Patents

Literature

113results about How to "Improve longitudinal strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

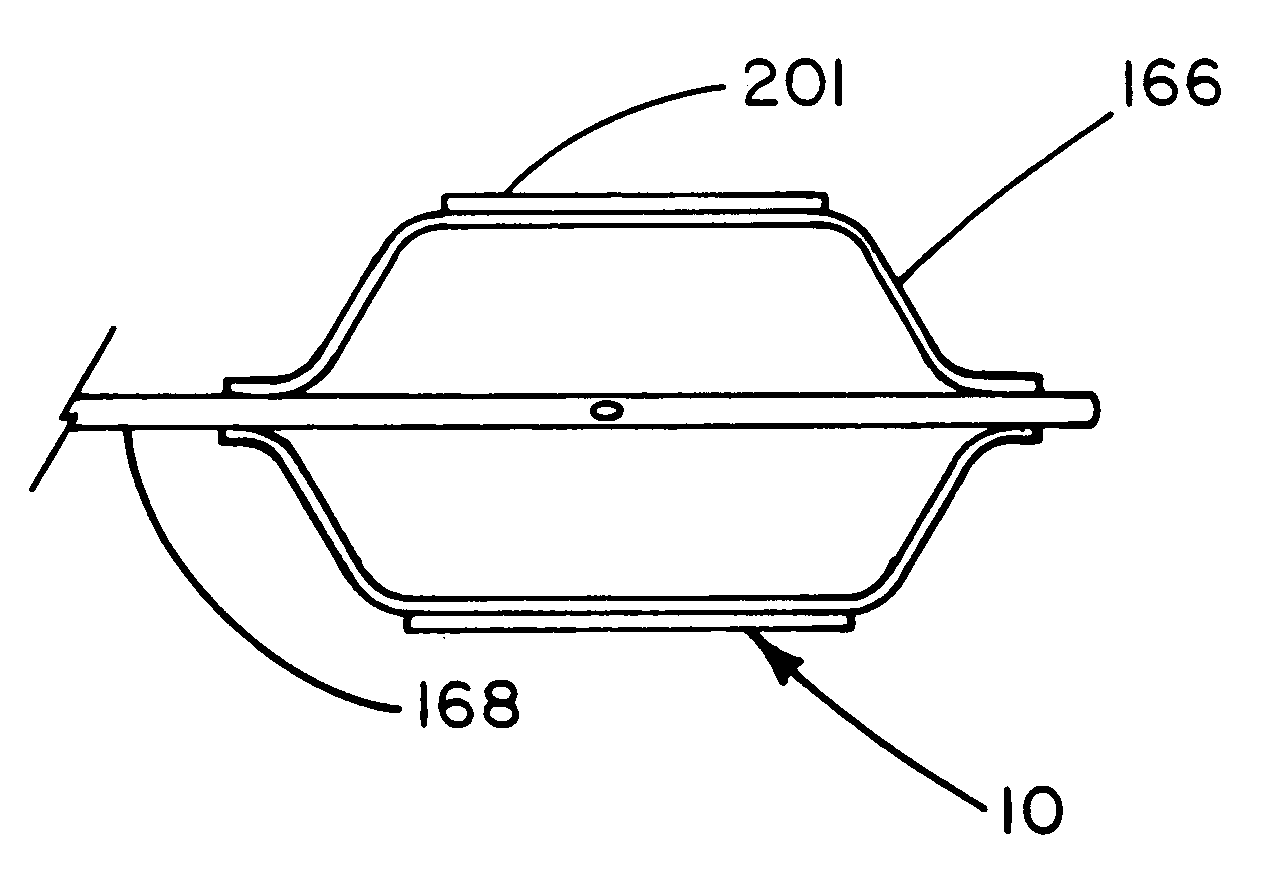

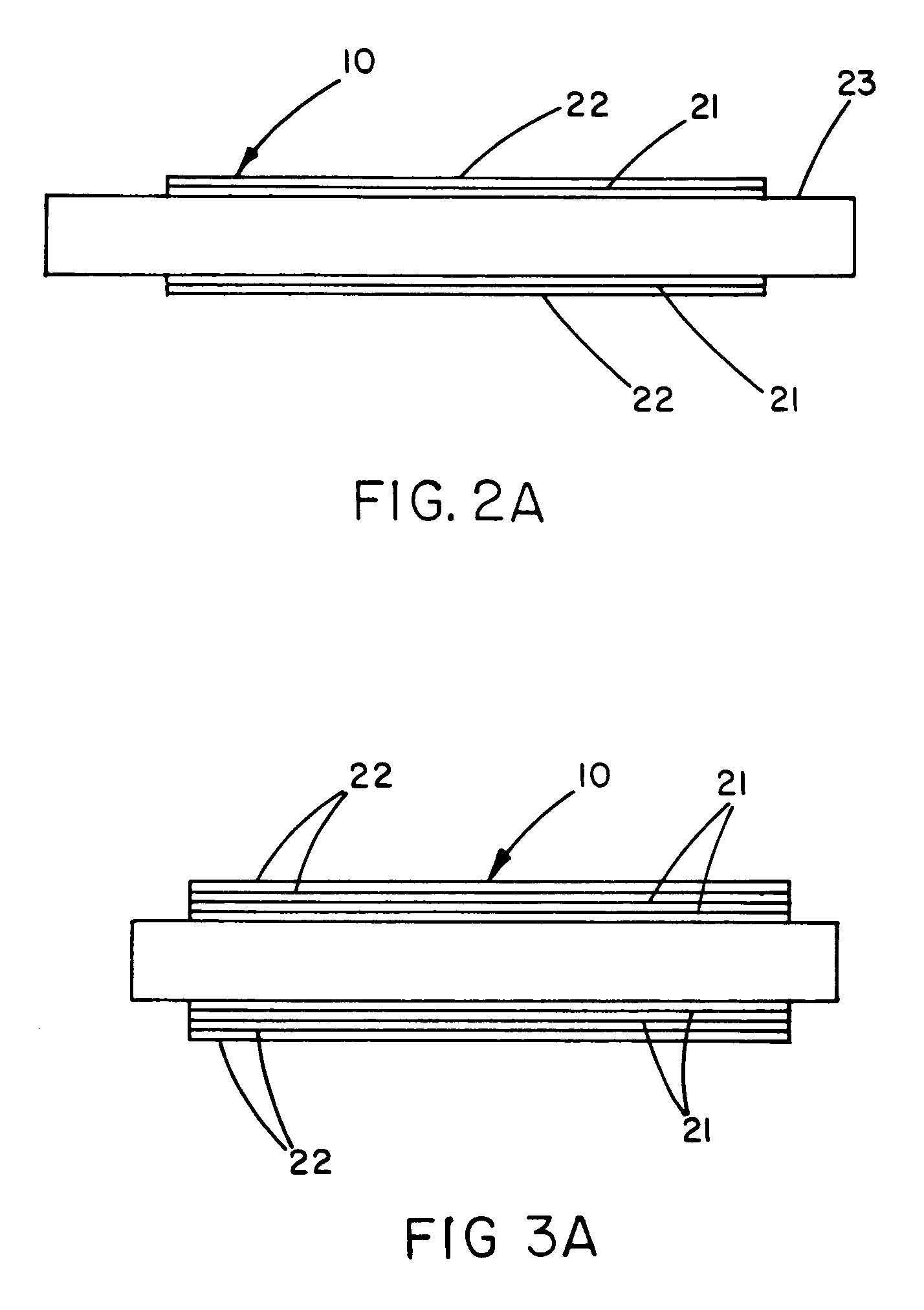

Thin-wall polytetrafluoroethylene tube

A thin-wall PTFE (polytetrafluoroethylene) tube in the form of a tube of porous expanded PTFE film wherein the porous PTFE film has a microstructure containing a multiplicity of fibrils. The thin-wall tube is used in a non-porous embodiment as the balloon portion of a balloon catheter. The thin-wall tube is not elastomeric; however, because of the thinness, strength and flexibility of the tube, it may be inserted into a body conduit in a collapsed state and then deployed from a catheter and inflated up to the maximum diameter of the thin-wall tube. The porous PTFE film is provided with a continuous layer of adhesive to provide the non-porous tube; the adhesive is preferably a thermoplastic and more preferably a thermoplastic fluoropolymer such as fluorinated ethylene propylene.

Owner:GORE ENTERPRISE HLDG INC

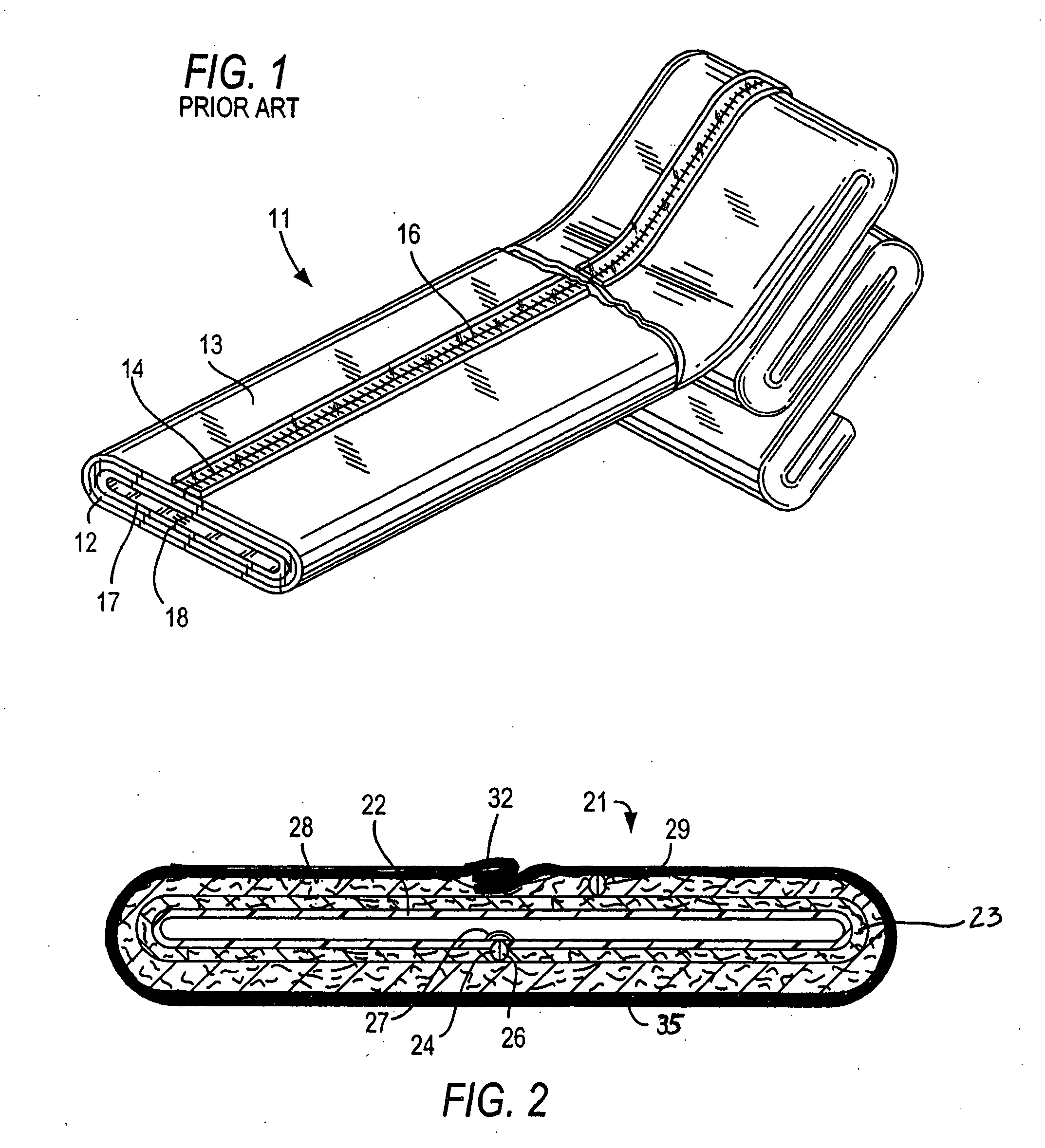

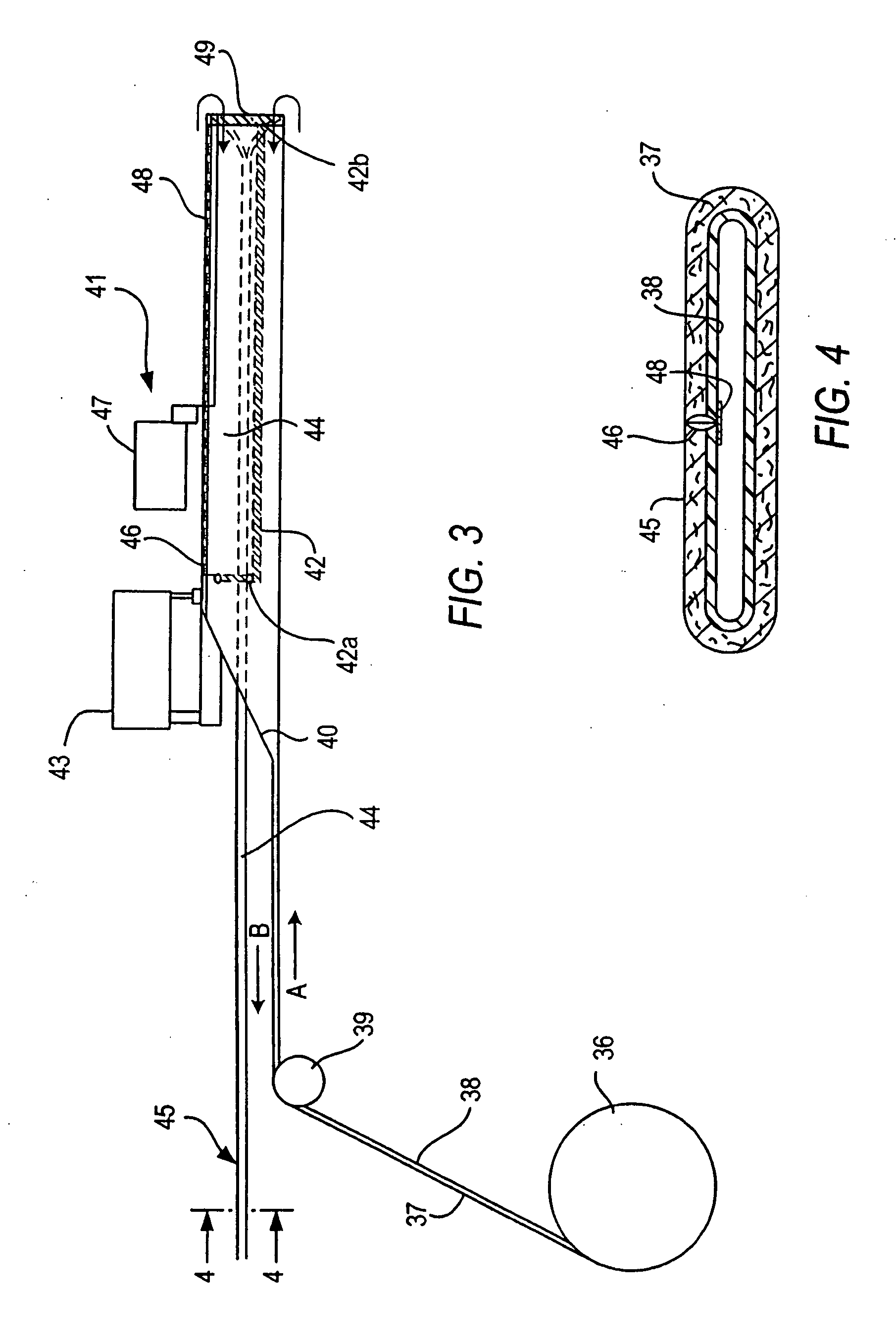

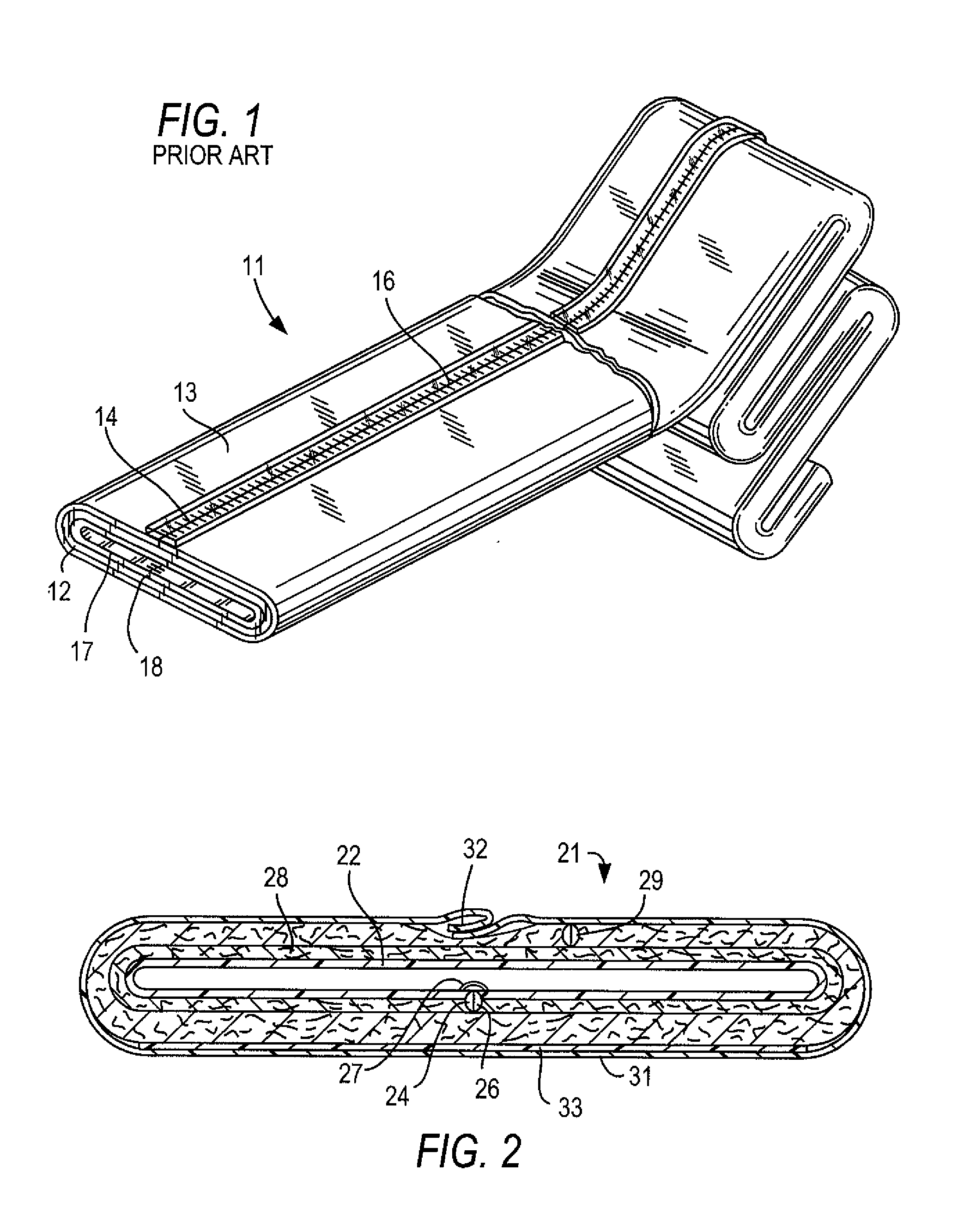

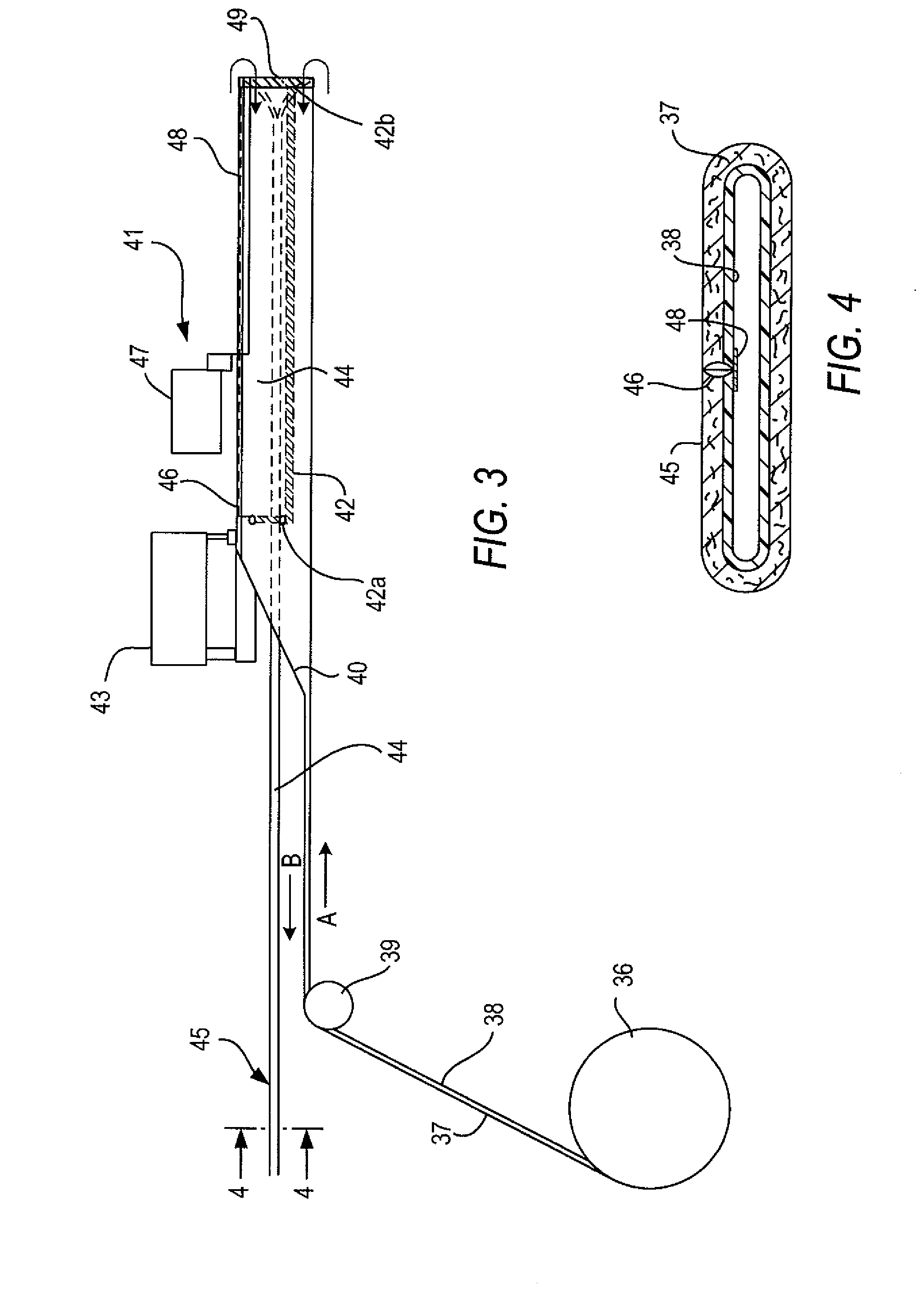

Longitudinally reinforced cured in place liner and reinforced coating

InactiveUS20070113971A1Increased longitudinal reinforcementReduce stretchLayered productsPipe elementsEngineeringUltimate tensile strength

Owner:INA ACQUISITION

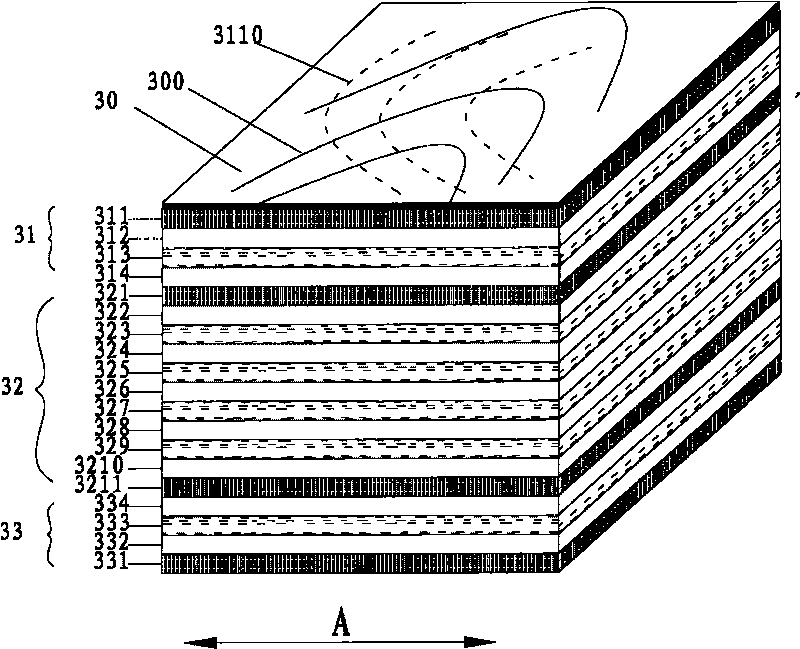

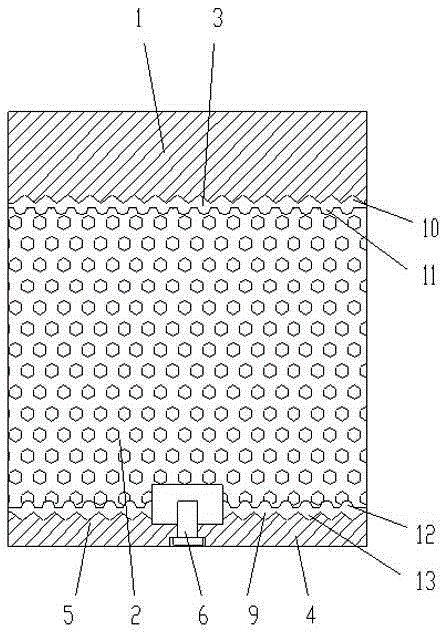

Preparation method for microporous diaphragm and microporous diaphragm

ActiveCN103633272AImprove longitudinal strengthUniform structureCell component detailsPolyolefinPolymer science

The invention relates to the field of the processing of lithium-ion battery diaphragms, and discloses a preparation method for a microporous diaphragm. The preparation method for the microporous diaphragm includes the following steps: 1) a principal polyolefin resin and an auxiliary additive are uniformly stirred through a stirring mixer to obtain a mixture I; 2) the obtained mixture I is added into an extruder to be uniformly melted and plasticized into a melt; 3) an intermediate diaphragm is prepared from a cast piece of the melt extruded from a die head; 4) annealing treatment is performed on the intermediate diaphragm under bi-directional micro-tension; 5) the annealed intermediate diaphragm is stretched longitudinally to prepare the diaphragm with a microporous structure. The invention further discloses the microporous diaphragm prepared through the method, which consists of the principal polyolefin resin with a weight percentage of 75 to 99.9 percent and the auxiliary additive with a weight percentage of 25 to 0.1 percent. The preparation method disclosed by the invention has the advantage that the lithium-ion battery diaphragm with a uniform structure, the specific microporous structure and high safety performance can be prepared.

Owner:SHENZHEN SENIOR TECH MATERIAL

Preparation method of hollow fabric with radial elastic shrinkage

ActiveCN102776649AHigh tensile strengthHigh temperature resistantWoven fabricsEngineeringWear resistance

The invention discloses a preparation method of a hollow fabric with radial elastic shrinkage and relates to the preparation method of the hollow fabric. The object of the invention is to solve the problem that elastic hollow fabric available in the market does not meet the requirement of thin diameter and longitudinal elasticity and very large radial elasticity when being used in a specific task, has poor strength of bearing accidental drawing and poor wearability, as well as poor dimensional stability, and especially poor radial elasticity. The method comprises the preparation work of warp yarns, which includes selecting fine denier 75-200D aramid fiber fibers, 100-300D PBO (p-phenylene-2,6- benzobisoxazazole fiber) fibers or aramid fibers and PBO combined filament yarns as warp yarns; preparation work of weft yarns; directly winding of the weft yarns to form a pirn with a size same as that of a shuttle of a shuttle loom; and a determining and weaving process of metric portie. The hollow fabric prepared by the preparation method provided by the invention has excellent radial elastic recovery, and also the characteristics of superstrong resistance to longitudinal stretching force and wear resistance and corrosion resistance. The method is used for preparing elastic hollow fabrics.

Owner:HARBIN INST OF TECH

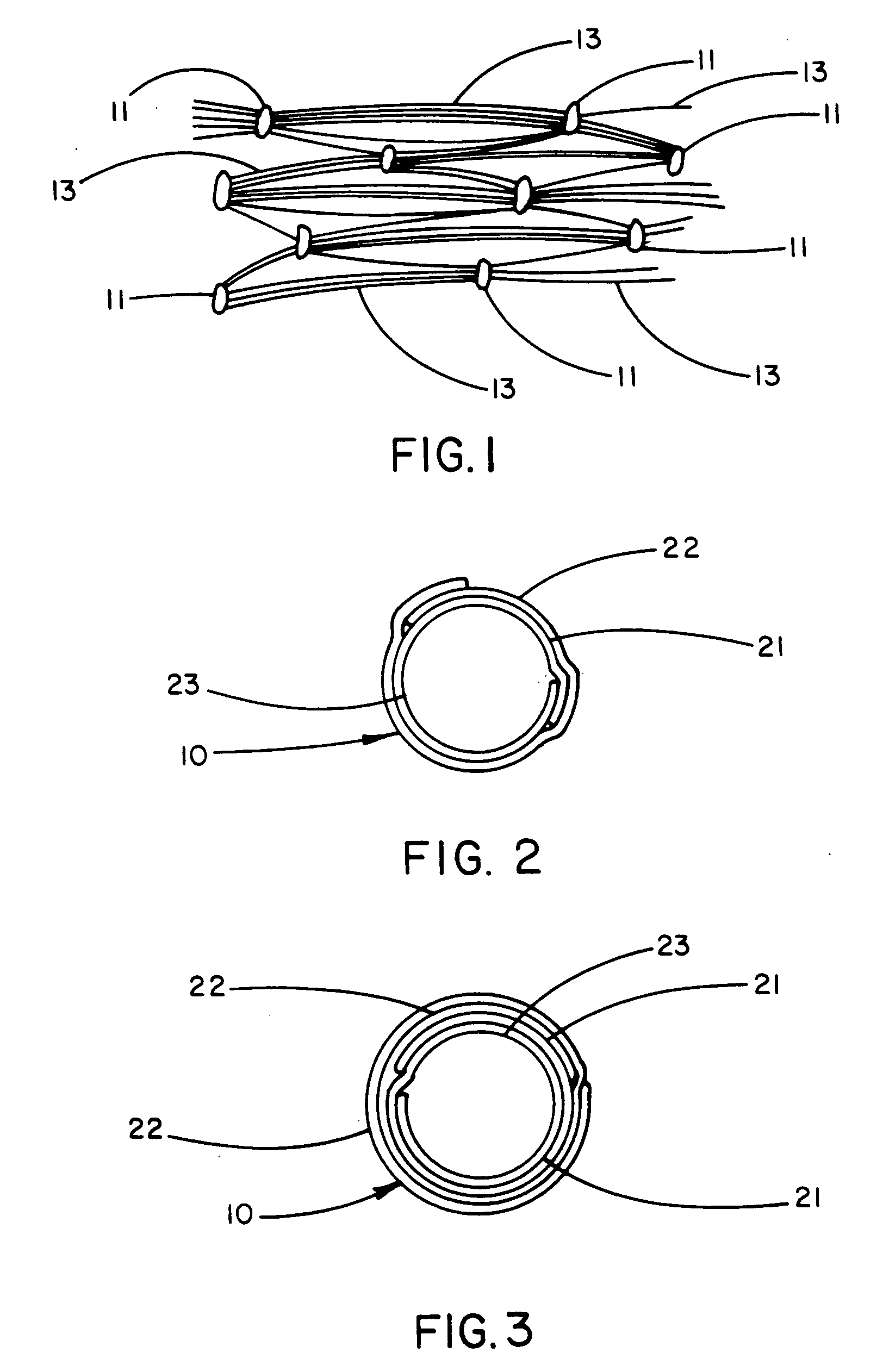

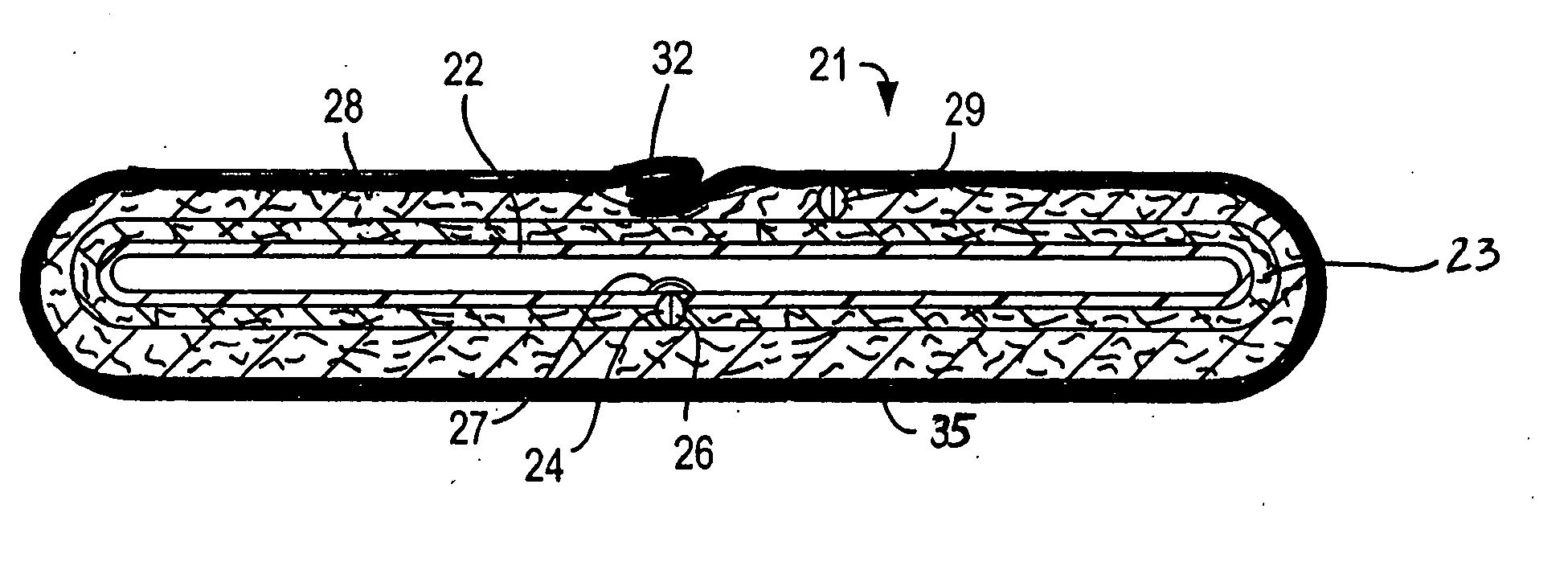

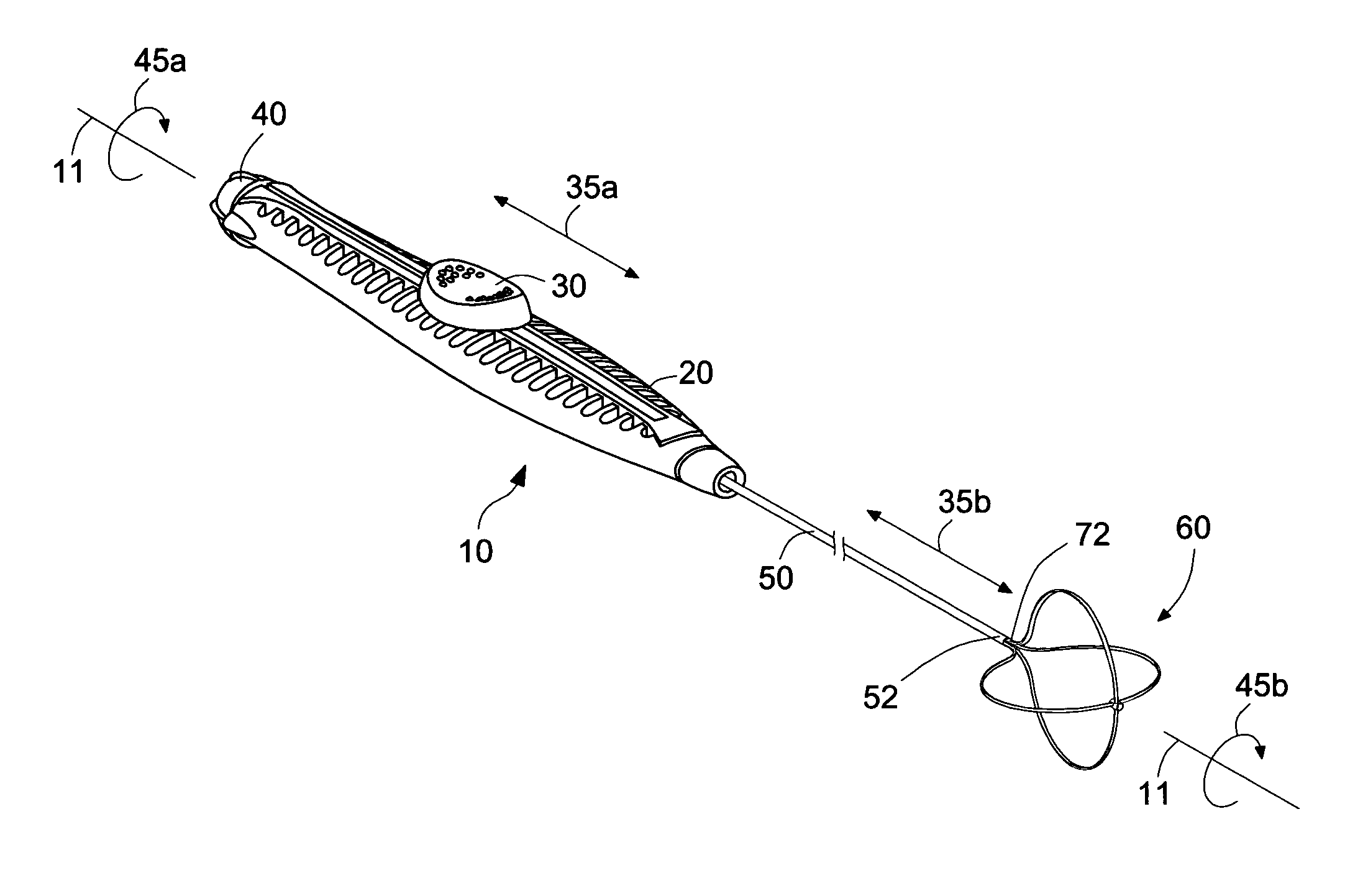

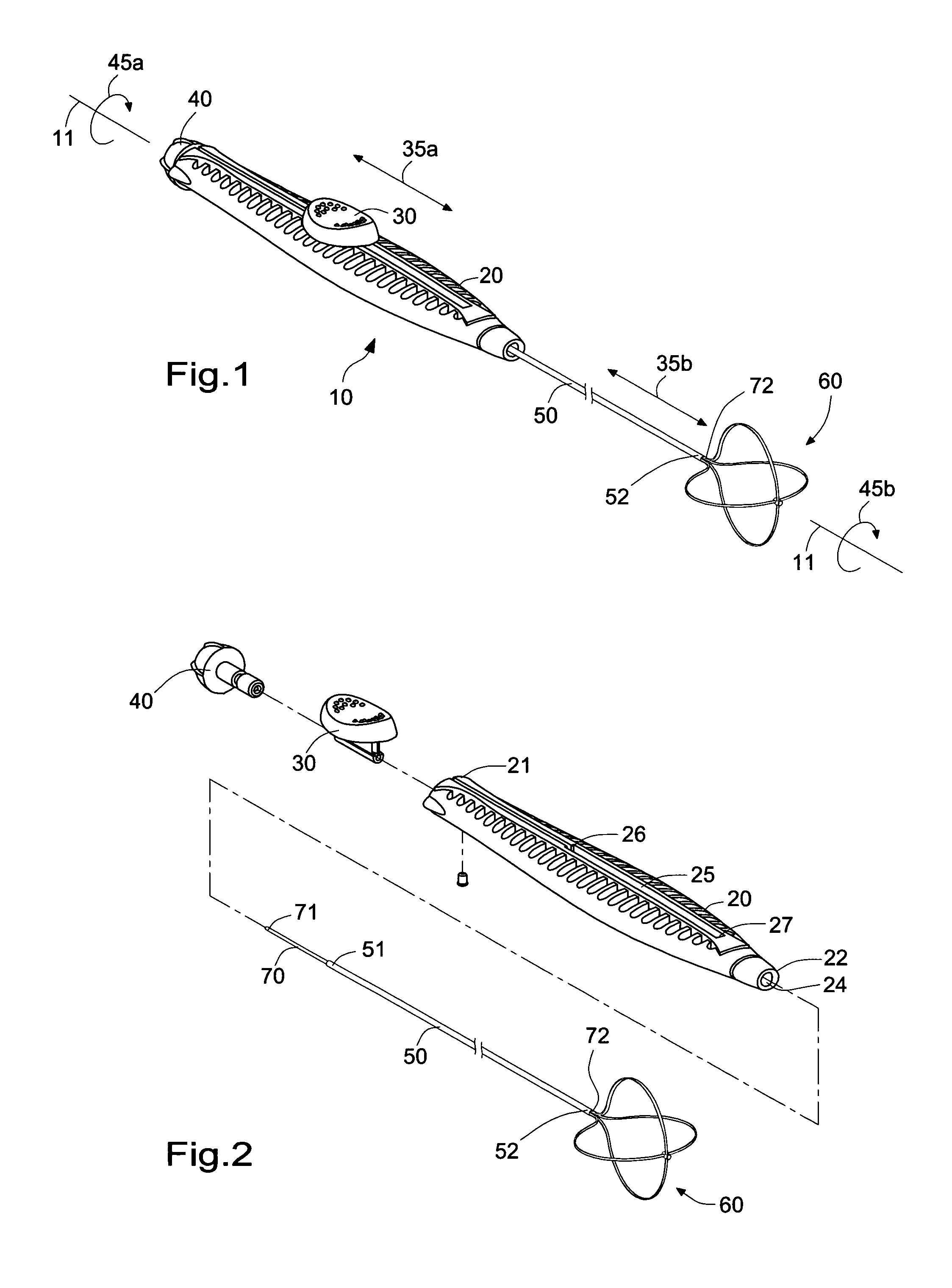

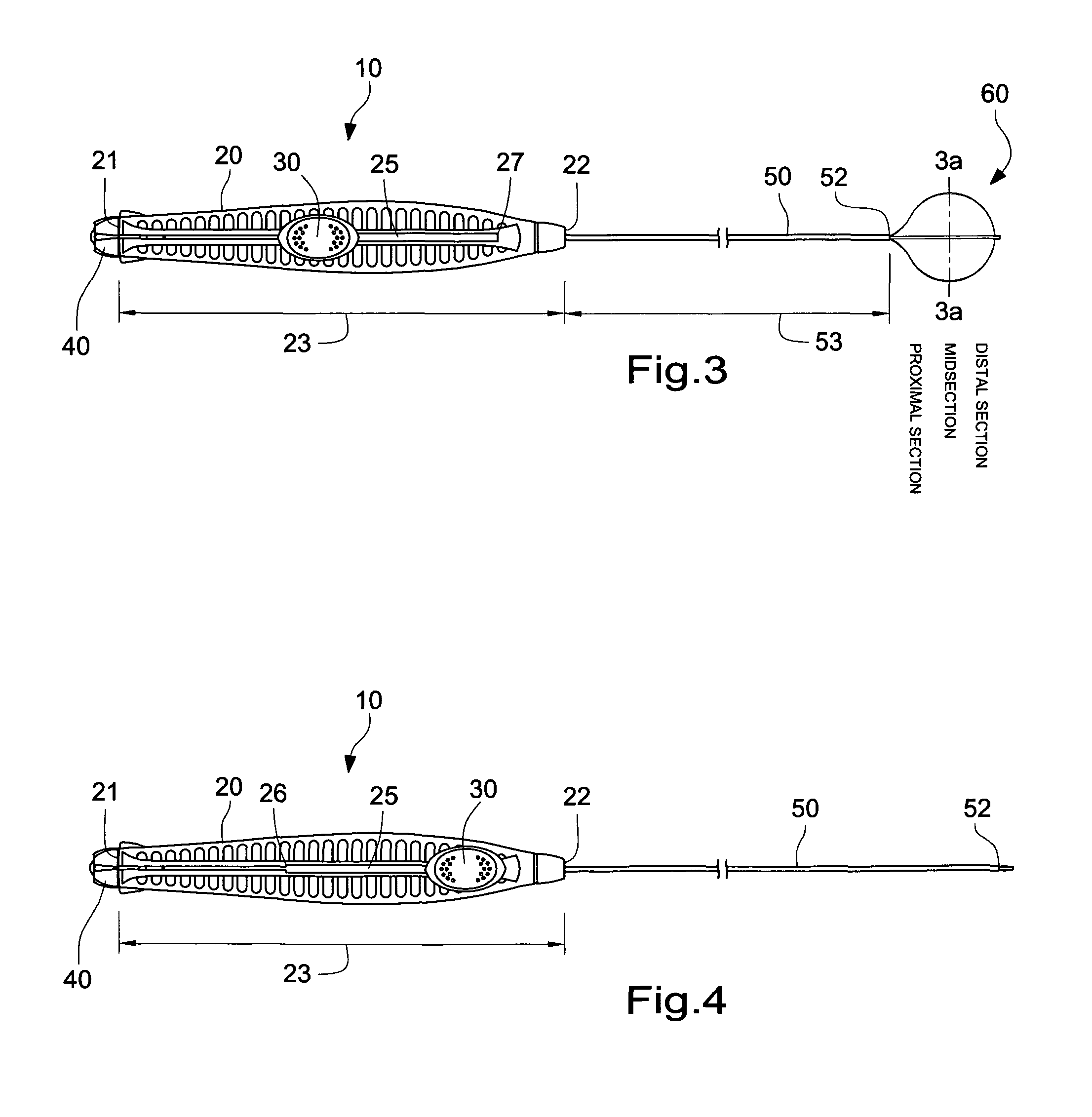

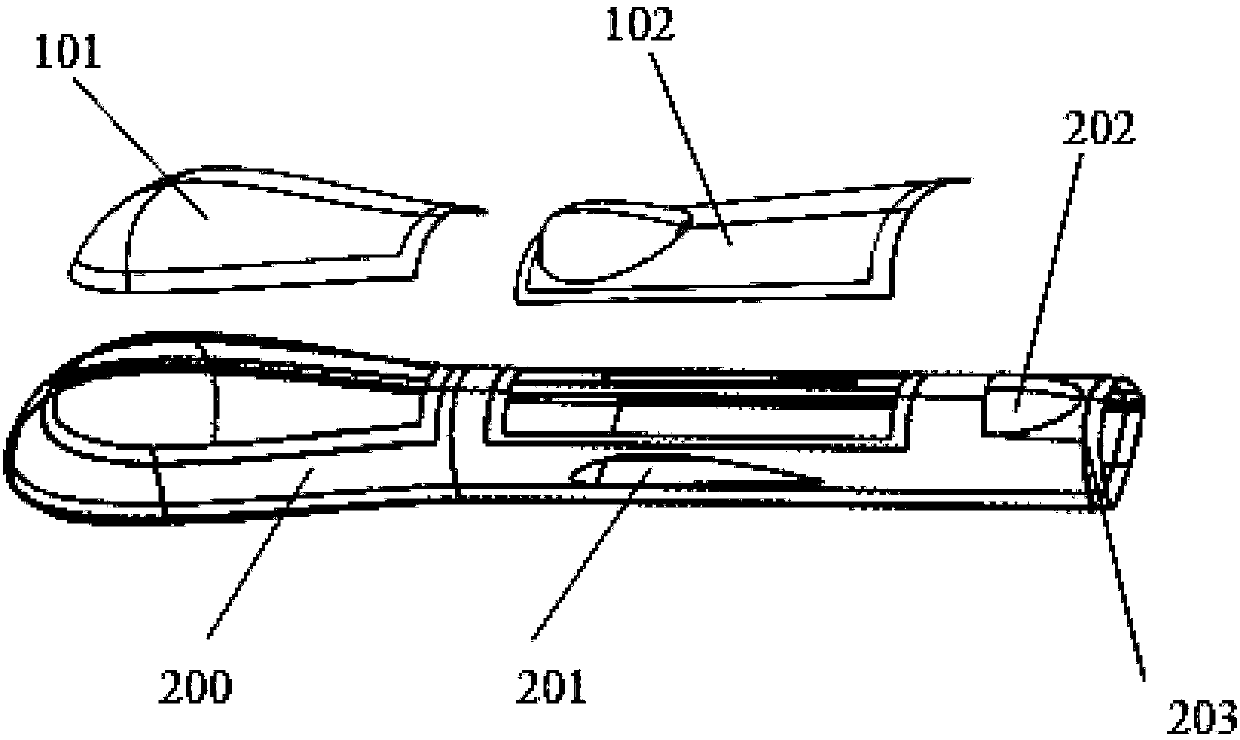

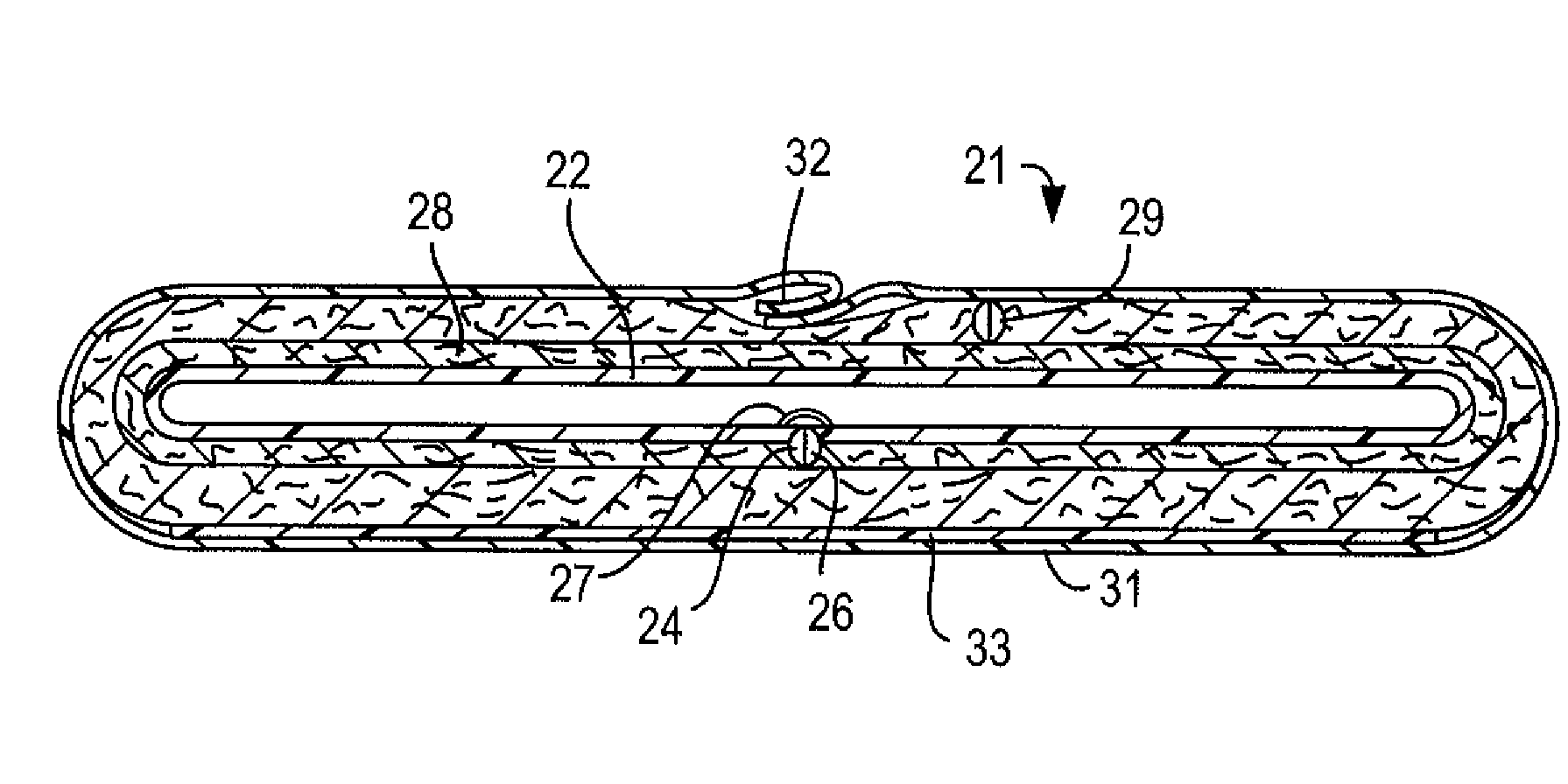

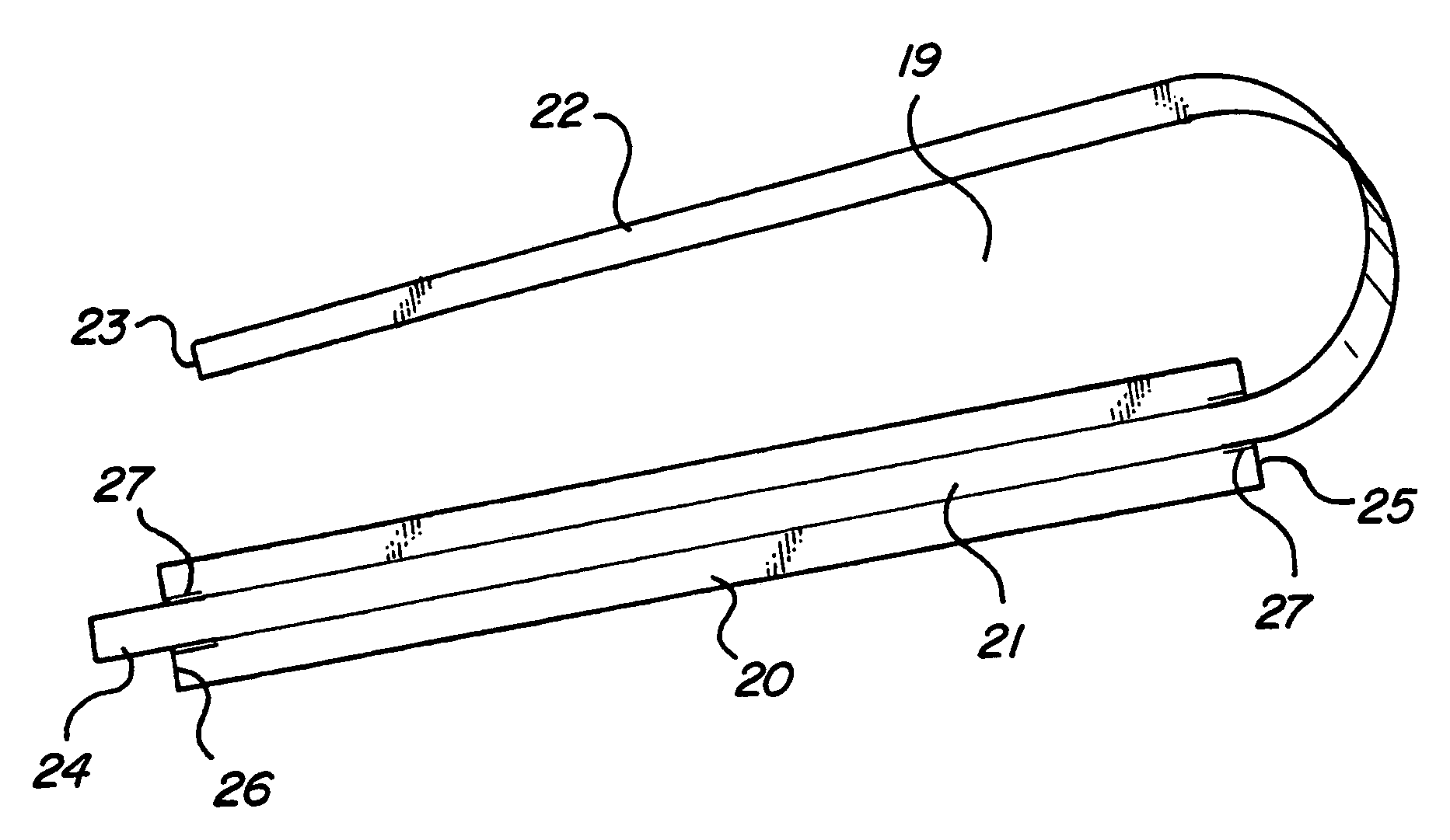

Stone retriever for flexible endoscopes having small diameter working channels

A medical retrieval device and method used in endoscopic procedures to retrieve stones has a shaft comprising a sheath with a lumen and a drive wire slidably disposed within the lumen for operating a stone entrapping mechanism on the distal end of the retrieval device. The shaft has an average outside diameter of less than 1.9 Fr. The shaft, sheath and drive wire each have proximal, intermediate and distal portions, and each of the corresponding portions are in generally similar locations along the longitudinal length of the device. The proximal portions of the shaft and the drive wire are preferably stiffer than the corresponding intermediate portions of the shaft and drive wire. The proximal and intermediate portions of the sheath have generally similar stiffnesses. The shaft reduces flow resistance within the working channel of an endoscope, increasing the flow of irrigation fluid in order to improve procedural visibility. The shaft varies in flexibility to match the requirements of a flexible endoscope and facilitate deflection of the endoscope.

Owner:ANNEX MEDICAL

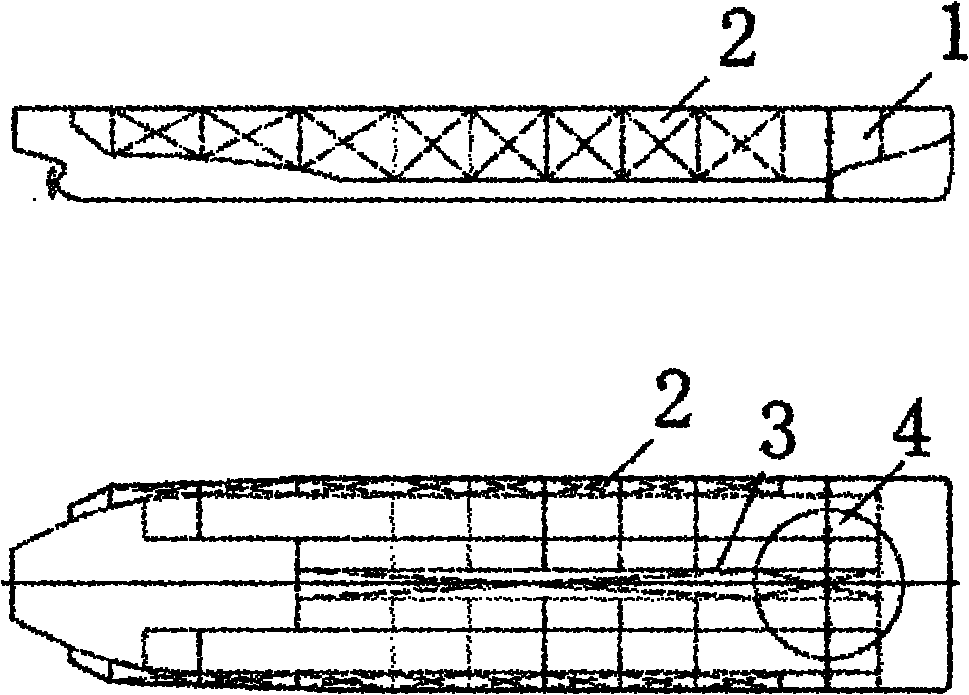

Unmanned aerial vehicle body integrated molding technology

InactiveCN107738457AImprove performanceImprove mobilityFuselage framesWeight reductionFiberCarbon fibers

The invention discloses an unmanned aerial vehicle body integrated molding technology. Carbon fiber prepreg and lightweight foam are used as raw materials, are paved on the inner wall of a double-female mold combination mold by adopting a prepreg lapping joint integral layering technology, and then are integrally solidified and molded by adopting an autoclave molding technology. The unmanned aerial vehicle body integrated molding technology has the beneficial effects that the technology is simple and is easy to operate; the molding time is short; the product size is accurate and controllable;and a manufactured unmanned aerial vehicle body has high strength, good rigidity, light dead weight and a smooth and fat surface, is easy to maintain routinely and is suitable for large batch production.

Owner:CGN JUNER NEW MATERIALS +1

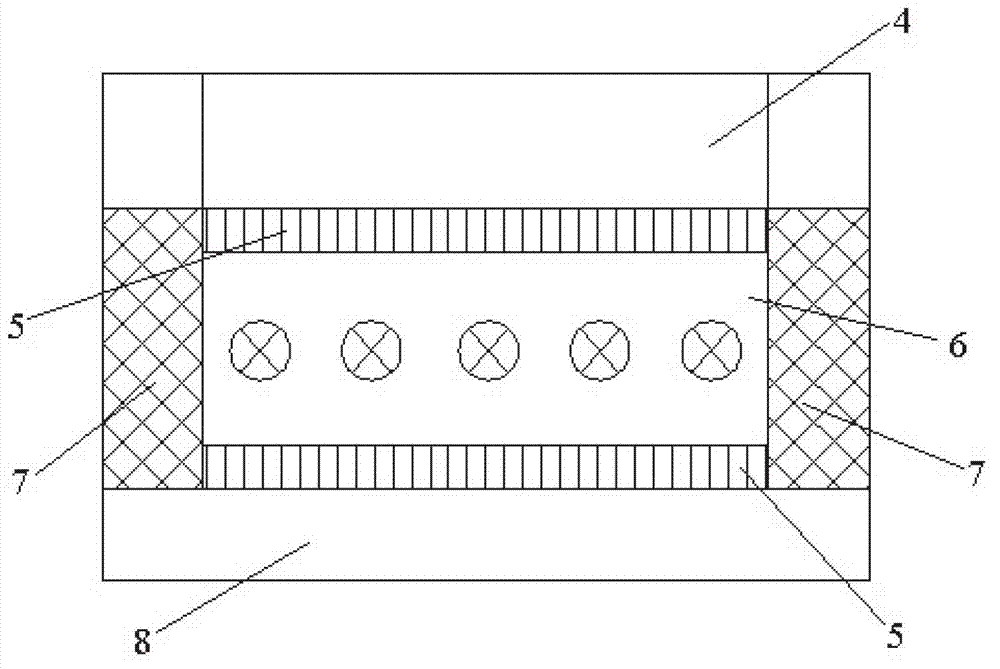

Lithium ion battery diaphragm and its production method

InactiveCN1514501AHigh crystallization conversion rateLow priceCell component detailsPorosityElectrical battery

Characters of the invention are that crystal-nucleating agent of amide family compound is added into polyolefine resin. The procedure of the method includes following steps. (1) Under computer full control, hoisting system adds polyolefine resin containing 0.001-3% crystal-nucleating agent to extruder. In temperature 130-280 deg.C, the material is melted and extruded out. Then, primal flat film is rolled and obtained by using cooling roller to treat the material at temperature 40-110 deg.C. (2) The said primal flat film is fed into vertical and horizontal biaxial stretcher for stretch formability. Finally, heat customization is carried out. The selected crystal-nucleating agent possesses high crystal transformation ratio, and abundant source. Battery diaphragm provides features of high porosity, shapely hole shape, good intensity in both directions, and low cost. The invention can be applied to lithium cell, secondary cell or other type batteries after hydrophilic treatment.

Owner:XINXIANG ZHONGKE SCI&TECH

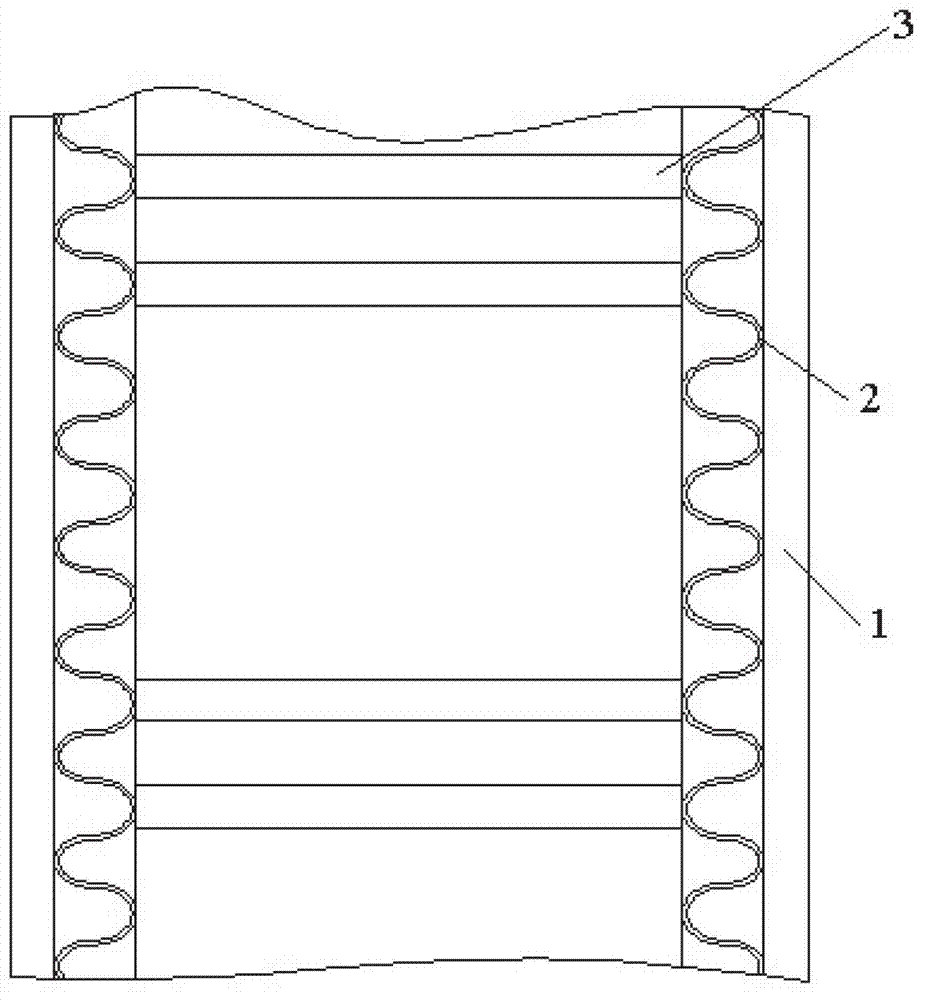

Large-inclination wavy-retaining-edge conveying belt and processing method thereof

InactiveCN102826330AImprove tear resistanceNot easy to tearConveyorsMetal layered productsVulcanizationMechanical engineering

The invention relates to a large-inclination wavy-retaining-edge conveying belt, which comprises a base belt, retaining edges and transverse baffles. The base belt is a composite rubber layer consisting of an upper covering rubber layer, a latitudinal steel cord anti-tearing layer, a steel chord skeleton layer, a side rubber layer and a lower covering rubber layer which are sequentially arranged from top to bottom, are bonded primarily and are vulcanized secondarily. A plurality of transversely and evenly arranged steel wires are embedded into the steel chord skeleton layer. The steel wires are embedded in the steel chord skeleton layer and are arranged in the same plane. The side rubber layer is arranged on the side of the steel chord skeleton layer. Wavy retaining edges which are fixedly arranged through a secondary vulcanization bonding method are symmetrically arranged on the two sides of the base belt. The number of the transverse baffles is multiple. The transverse baffles are vertically and fixedly arranged on the base belt at intervals through the secondary vulcanization bonding method and are arranged corresponding to the valleys of the wavy retaining edges. The large-inclination wavy-retaining-edge conveying belt has the advantages that the anti-tearing performance of the existing retaining edge conveying belt is mainly improved, the conveying belt is prevented from being longitudinally drawn, the requirement on large-inclination conveying is satisfied and the service life of the conveying belt is prolonged.

Owner:ZHANGJIAGANG HUASHEN INDAL RUBBER PRODS

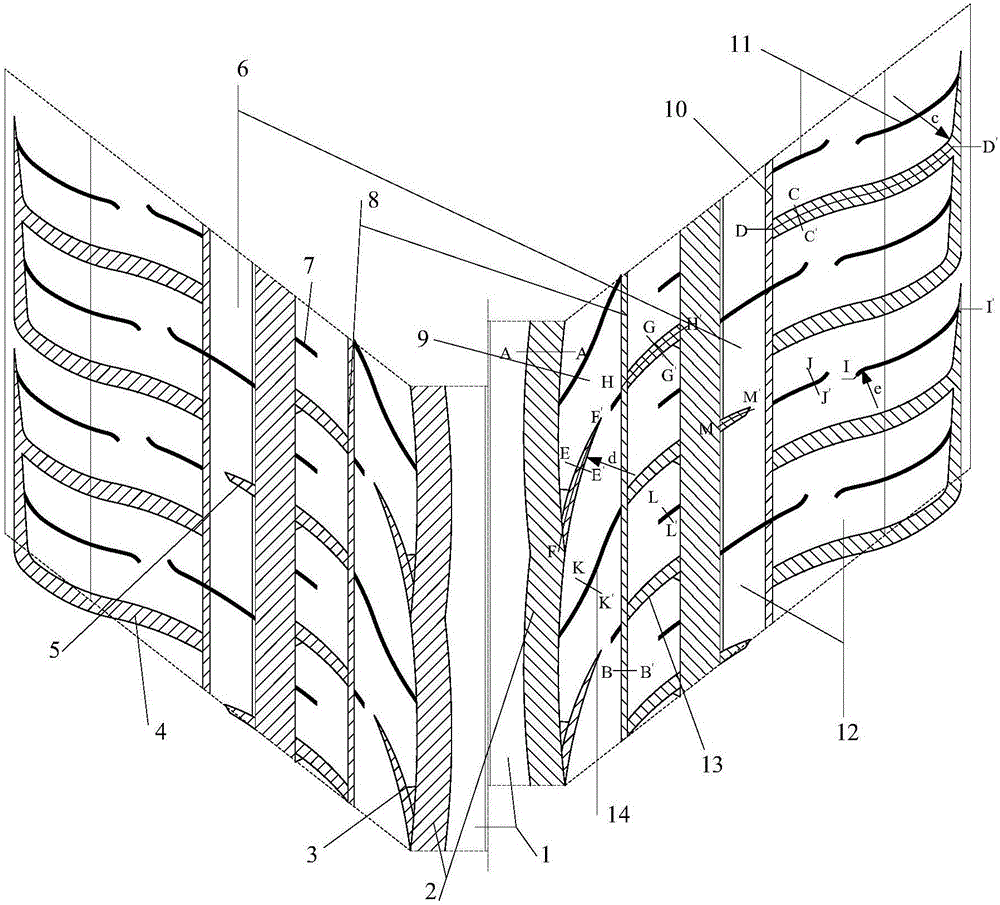

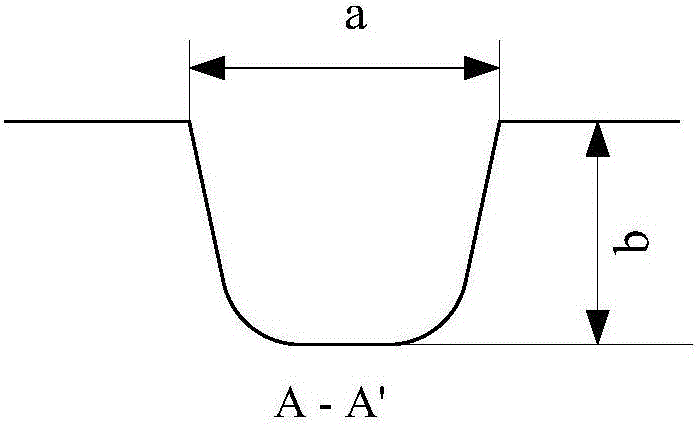

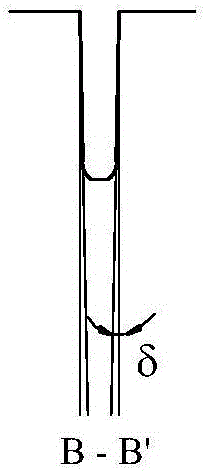

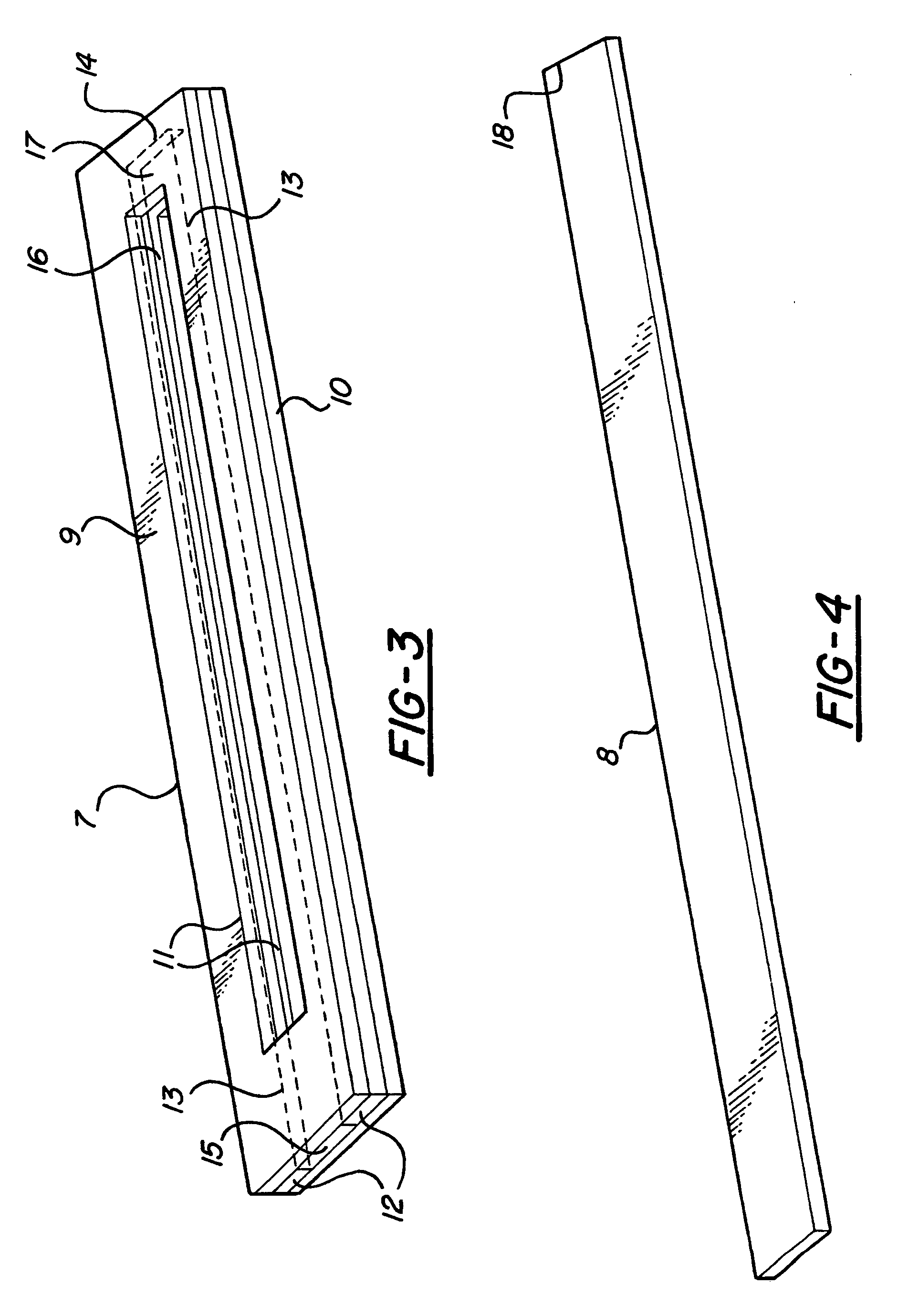

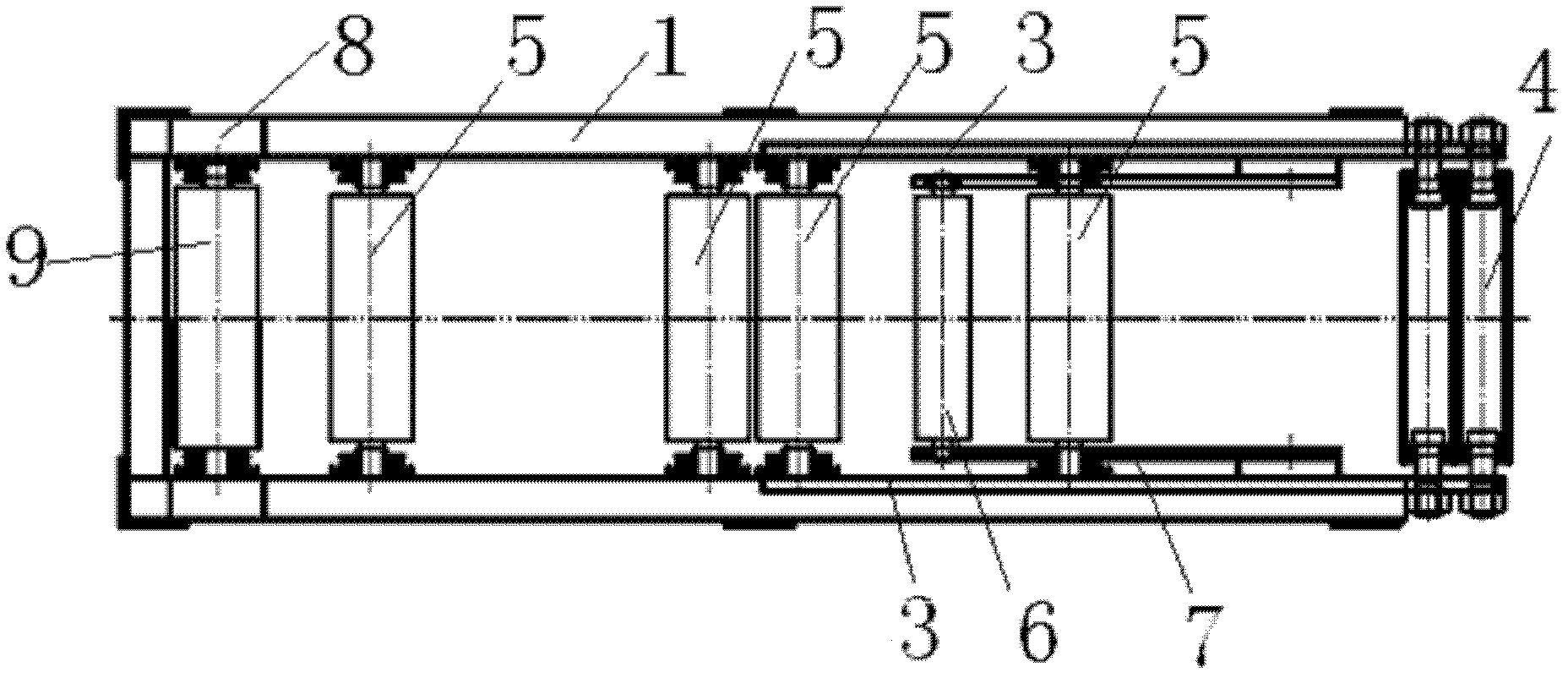

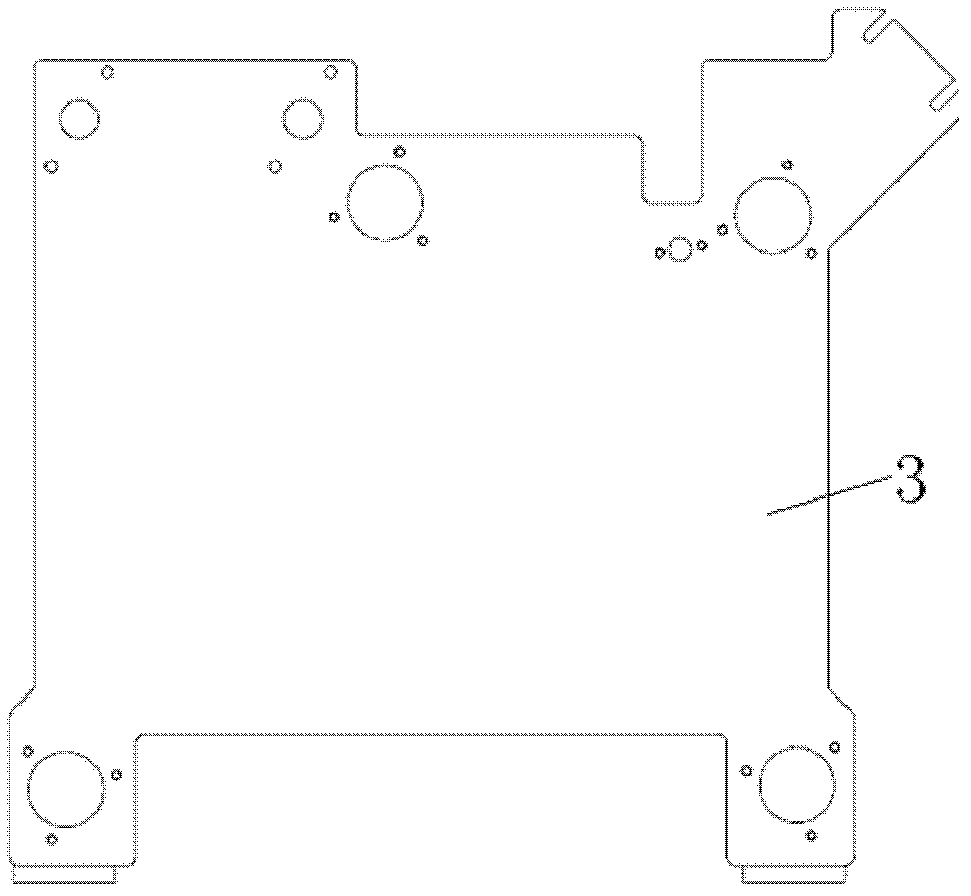

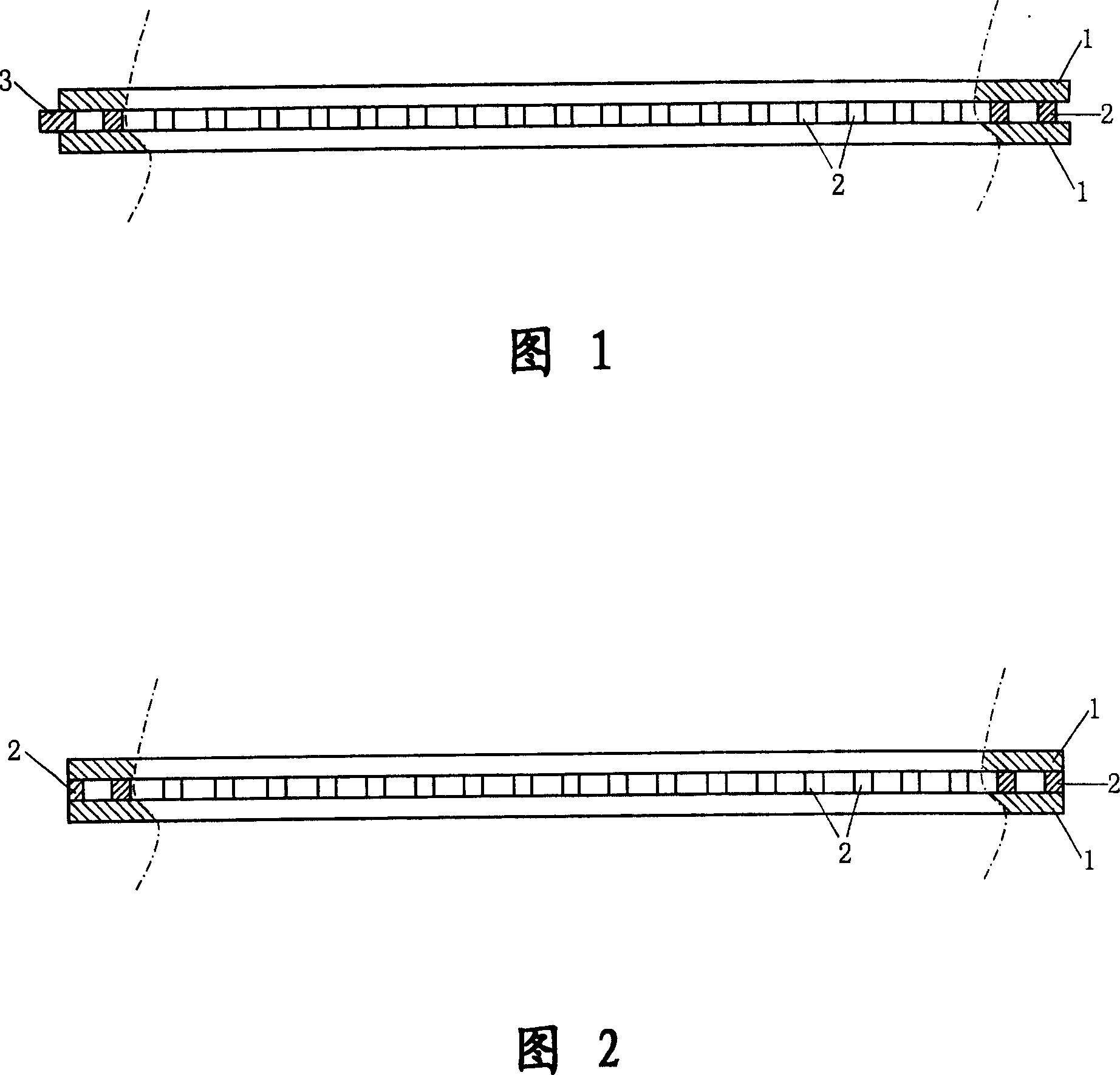

Longitudinally reinforced cured in place liner

InactiveUS20070209726A1Reduce stretchImprove longitudinal strengthPipe elementsTubular articlesUltimate tensile strengthMechanical engineering

Owner:INA ACQUISITION

Modification method of large-scale crane ship

InactiveCN101913412AIncrease the areaSatisfy the requirements of floating state controlHull decksSpecial purpose vesselsWork performanceHoneycomb like

The invention discloses a method in the technical field of shipping hoisting, in particular to a modification method of a large-scale crane ship based on a large-scale oil tanker with longer parallel middle body. The floating force is increased through assembling a modified ship bow and box-shaped floating bodies at the two sides of a ship body, and the modification of the large-scale crane ship is realized through replacing a main deck by a beamless flat deck, arranging a crane and reinforcing the interior of the ship body. The invention meets the requirement on controlling the floating state during the working of the large-scale crane ship, improves the total longitudinal strength of the shipping through the arrangement of a modified deck and a centerline bulkhead, and meets the requirement on local intensity through the design of a barrel-shaped honeycomb structure. Rapid dispensation of ballast water during working is realized through the optimized design of a ballast tank and the arrangement of a ballast water pump; the work performance and the control performance are improved through configuring an auxiliary machine, an anchoring machine, a winch and a bow thruster so as to realize that the large-scale oil tanker is modified into the large-scale crane ship on the basis of little modification, therefore, the time and the cost are saved; and the method has larger economic effect and finds a new way for developing old ships.

Owner:SHANGHAI JIAO TONG UNIV +1

Microporous film for power storage device separator and power storage device separator making use of the same

InactiveCN101292378AIncrease energy densityHigh output densityElectrolytic capacitorsLi-accumulatorsPhysicsElectrical and Electronics engineering

There are provided a microporous film for an electric storage device separator, which can increase energy density and power density when used in an electric storage device, and which is excellent in handling properties in a processing step to the electric storage device, as well as an electric storage device separator and an electric storage device, using the microporous film. Specifically, provided is a microporous film for an electric storage device separator, characterized by including a porosity of 70% or more, a strength of 40 MPa or more in a longitudinal direction, an average pore size of from 40 to 400 nm, anuclear pores, and exhibiting biaxial orientation.

Owner:TORAY IND INC

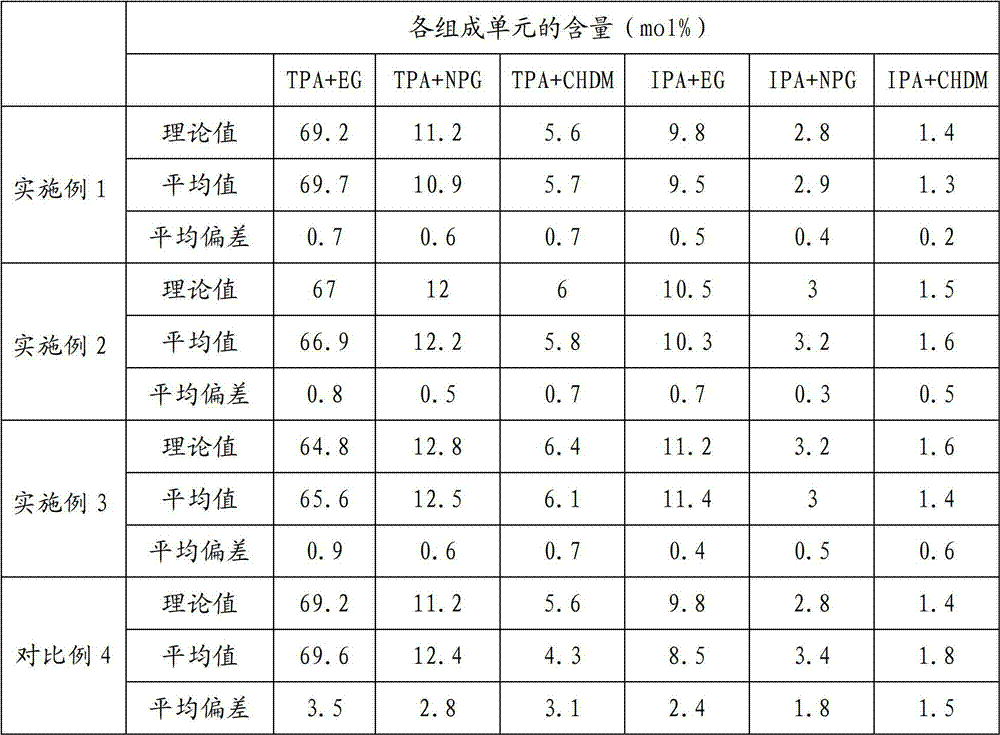

Thermoshrinkable polyester film and preparation method thereof

The invention discloses a thermoshrinkable polyester film and a preparation method thereof. The preparation method comprises steps as follows: various polyester raw materials subjected to dust removal respectively enter storage bins, are respectively metered by an agravic weigher according to the proportion, simultaneously enter an inlet of a double screw extruder, are subjected to melt extrusion by a sandwich layer double screw extruder and two surface layer double screw extruders, and form a casting piece through a three-layer co-extrusion die head; the casting piece is respectively subjected to longitudinal stretching and lateral stretching, wherein the longitudinal stretching comprises a preheating zone, a stretching zone, a thermal setting zone and a cooling zone, and the thermal setting zone of the lateral stretching is more than 15m long; and the casting piece is subjected to traction rolling to obtain the thermoshrinkable polyester film. By adopting the proportioning mode of directly feeding after accurate metering by people, the instantaneous addition error range of various materials is at most 1%; and the material is biaxially stretched, so that the produced film has the advantages of greatly higher density, strength and uniformity, lower longitudinal shrinkage and lateral low-temperature shrinkage, and especially higher ductility and thermoshrinkable uniformity.

Owner:SHANDONG SHENGHE PLASTIC DEV

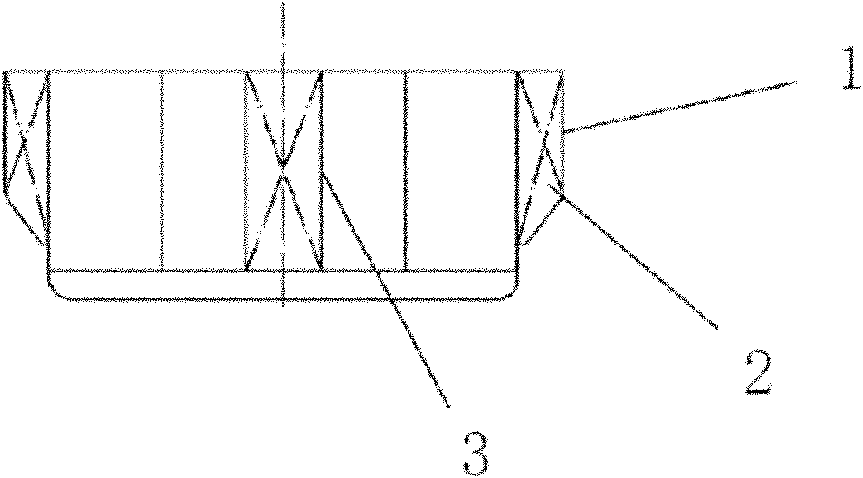

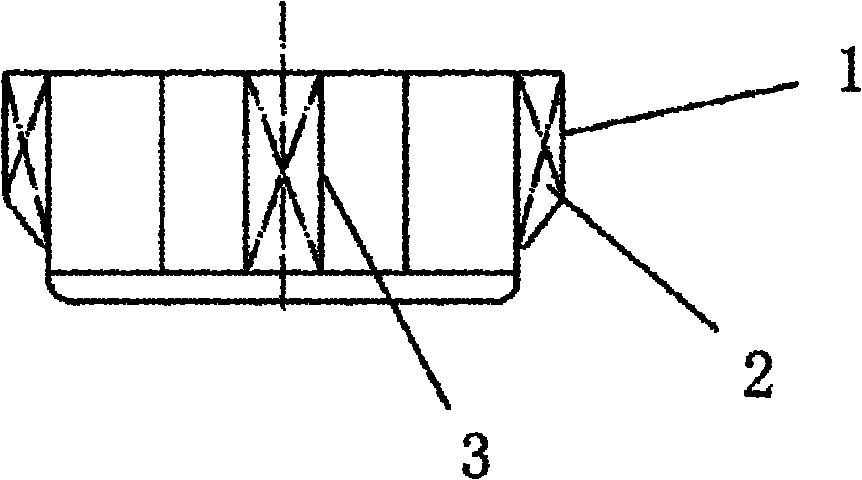

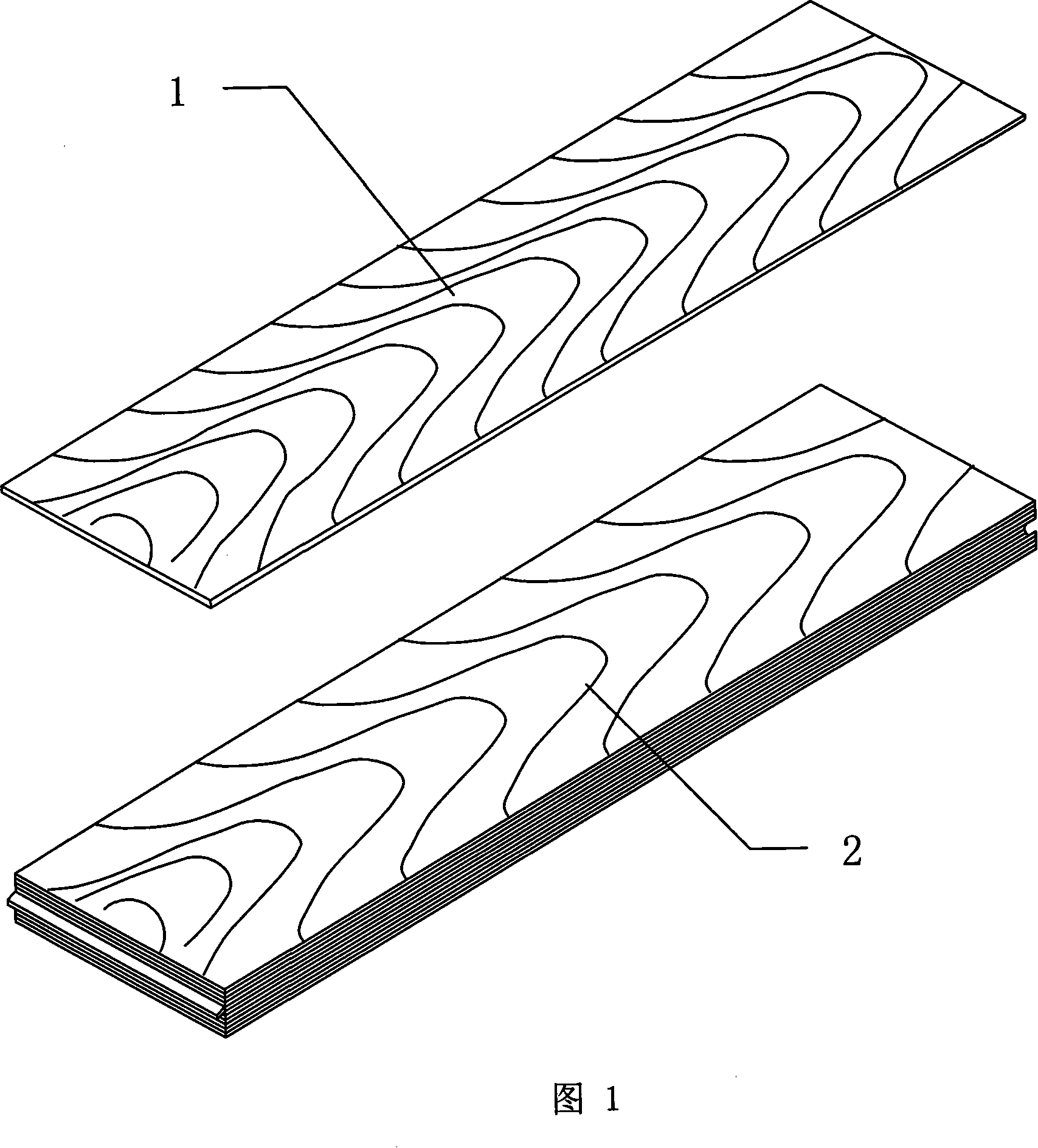

Veneer for container base plate

InactiveCN101549505AReasonable structureReasonable structural designWood veneer joiningWood layered productsMechanical engineeringLongitudinal strength

The invention relates to a veneer for a container base plate, belonging to the technical field of veneers. The veneer has reasonable structural design and enhances the horizontal and longitudinal strength of floors, thereby giving full play to the maximum performance of various materials and obtaining a more reasonable compounding floor structure; with the mixed structure, the veneer for the container base plate is ensured to meet the using requirement of the container base plate; materials used by the veneer for container base plate have extensive sources and lower cost, thus the production cost of the container base plate is reduced.

Owner:SHENGSHI CONTAINER MANAGEMENT SHANGHAI

Special patterned tire for high-speed car

ActiveCN106274299AImprove longitudinal strengthHigh strengthTyre tread bands/patternsNoise generationTransverse groove

The invention belongs to the technical field of rubber tire manufacturing and particularly relates to a special patterned tire for a high-speed car. A tire ground connection surface comprises a central rib, two main drainage channels, two side drainage channels, connecting block type bionic pattern blocks and closed type outer tire shoulders. The design of the central rib guarantees the optimum longitudinal rigidity of the tire and enables control force of the tire to be directly transferred onto the road surface from the tire. 3D grooves in the positions of curve grooves break airflow, generating noise, in longitudinal grooves and reduce tire noise. Transverse grooves and single guide patterns keep the same direction, and thus the traction property and drainage property of the tire are improved. The fluency design of the patterns improves the contact between the patterns and the ground and greatly increases ground holding force. Due to the design of the connecting block type bionic pattern blocks, the strength and appearance individuality of the pattern blocks are improved. Due to the design of the closed type outer tire shoulders, abrasion and noise of the tire are reduced, and meanwhile high traction force, a shorter braking distance and accurate turning performance of the tire are guaranteed.

Owner:山东新大陆橡胶科技有限公司

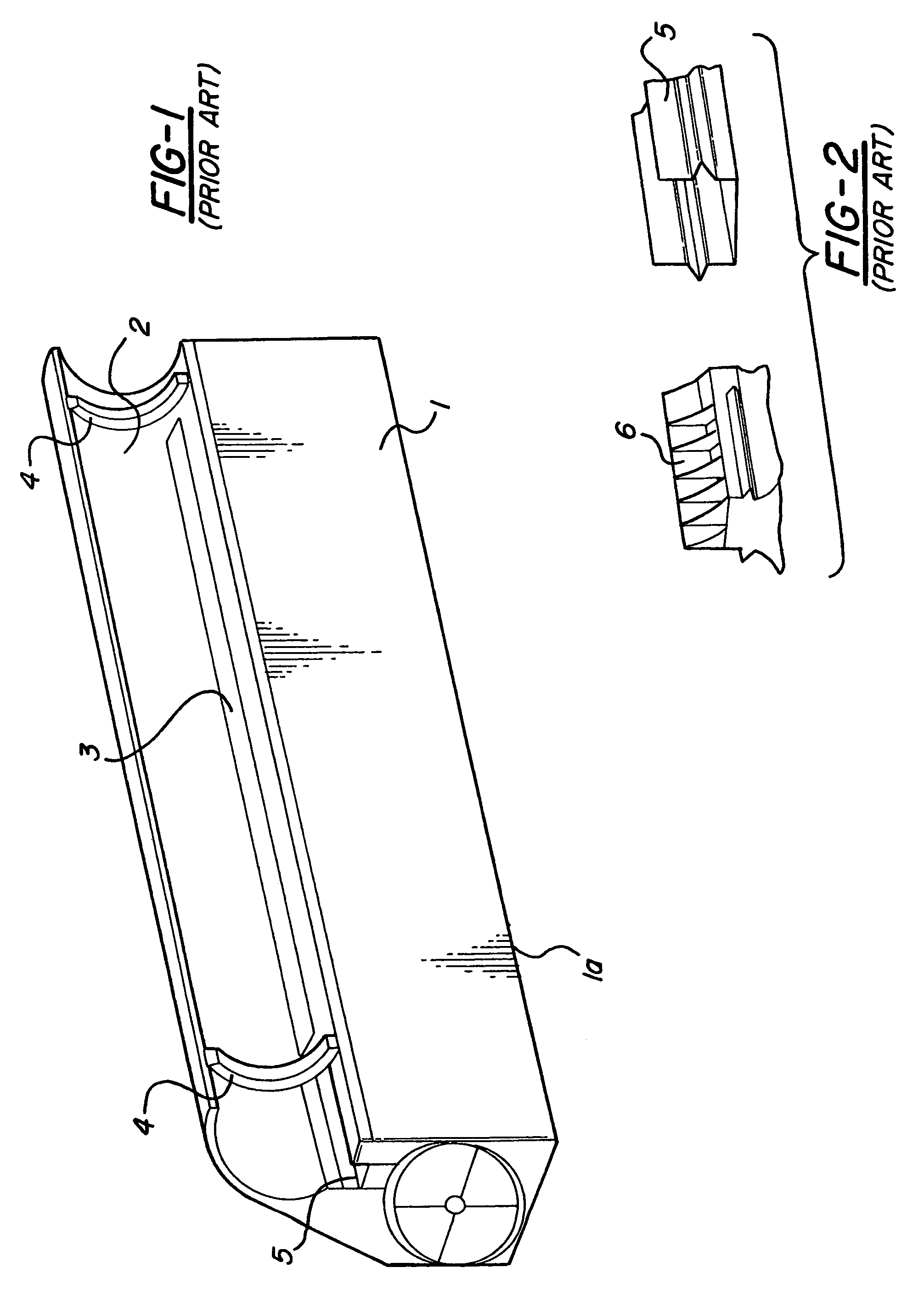

Tear-strip seal and tear-seal assembly using a pre-cut tear initialization and a toner hopper, toner cartridge and image forming apparatus using same and method of manufacturing same seal, toner hopper and toner cartridge assembly

InactiveUS7076186B1Maintain qualityAvoid hungerElectrographic process apparatusAdhesive beltConductive materials

An improved seal-insert and seal for a toner hopper as used in toner cartridge assemblies for printers, copiers and facsimile machines. In one embodiment, the seal has two slotted, rectangular outer pieces joined together with slot alignment and joined by an inner layer of two-sided tape. The two-sided tape is made with a long u-shape which does not interfere with the slots in the outer pieces. The open end of the u-shaped tape configuration allows a seal to be inserted or removed from between the outer pieces to close or open the slots. The seal-insert is applied over the passage from the toner hopper. The outer pieces are made from an antistatic and / or a conductive material, such as an aluminum laminate or plastic imprefnated with conductive particles. Alternately, the outer pieces may be made from plastic covered with an antistatic and / or conductive spray or coating. In another embodiment, a tear-seal is made from antistatic and / or conductive material, and is provided with a tear-guide secured to and under the tear-sheet. The tear-guide has a width smaller than the tear-sheet and slightly smaller than the slot of the seal-insert. When the tear-guide is pulled by the enduser, the tear-guide will rip the tear-sheet in a straight line, providing an opening with an even width that will not block toner flow.

Owner:STEVEN BRUCE MICHLIN +1

Three-floating-body type semi-submersible platform

A three-floating body type semi-submersible platform comprises an upper portion platform and lower floating bodies which extend along the upper portion platform longitudinally; vertical columns are connected between the upper portion platform and the lower floating bodies; the lower floating bodies are floating cylinders which are in slender shapes; three floating cylinders are horizontally arranged along the upper portion platform; the central line of the middle floating cylinder and the longitudinal section of the upper portion platform are in the same plane; the two outside floating cylinders are symmetrically arranged on bilateral sides of the middle floating cylinder; at least two vertical columns are connected between the upper portion platform and every floating cylinder; the vertical columns are arranged along the longitudinal direction of the floating cylinders in an interval mode; the middle floating cylinder and the two outside floating cylinder or the vertical columns on the middle floating cylinder and the vertical columns on the two outside floating cylinders are respectively connected through at least two horizontal supports. The three-floating body type semi-submersible platform has the advantages of being high in integral strength and rigidity, stable in stormy weaves and suitable for shallow water environment, enabling the integral strength and rigidity of the platform to be guaranteed and enabling platform stability in the stormy weaves when being a large sized platform with the size of several hundred meters to be guaranteed due to the fact of a three-floating-body type arrangement structure.

Owner:中国船舶重工集团公司第七〇二研究所

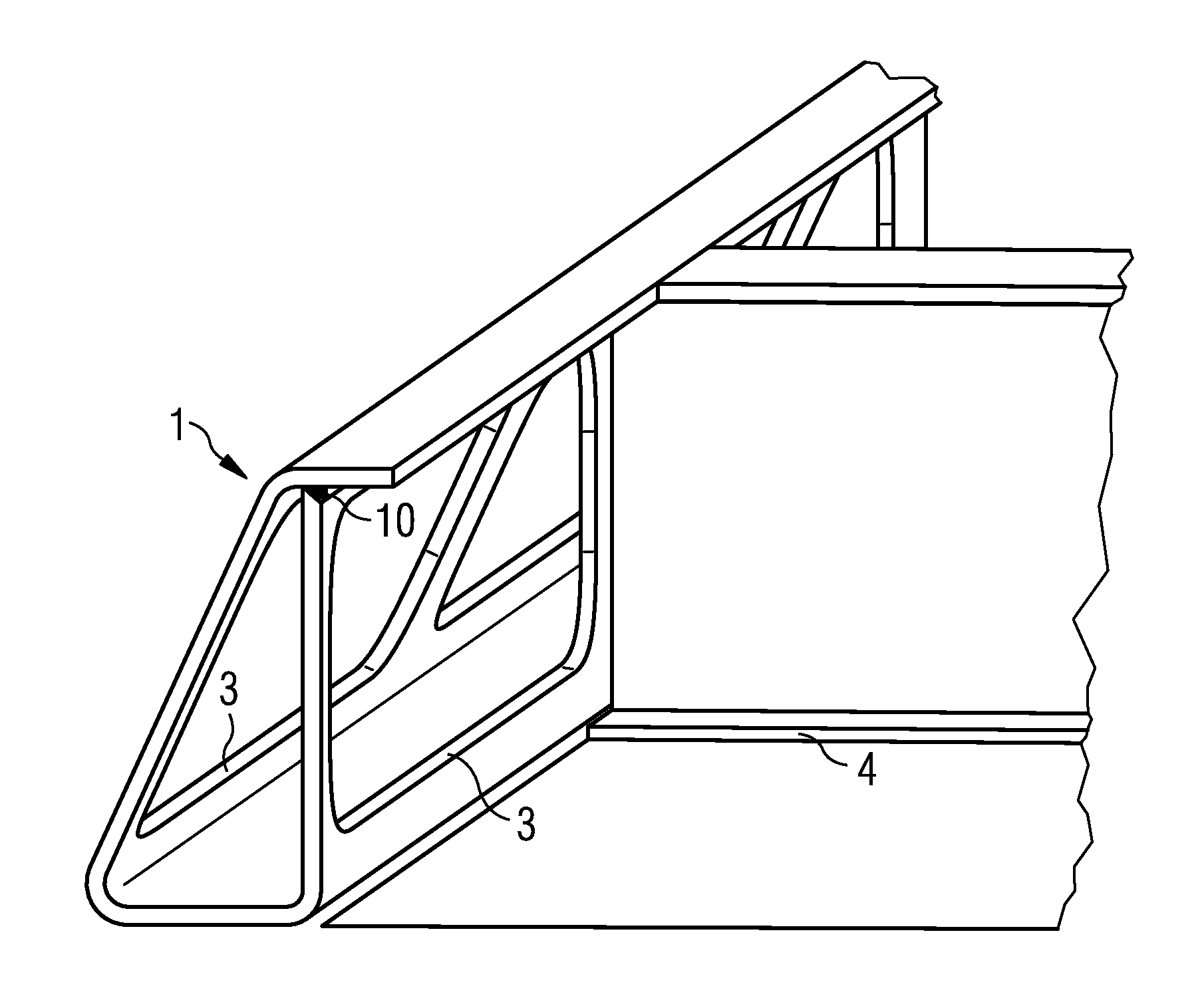

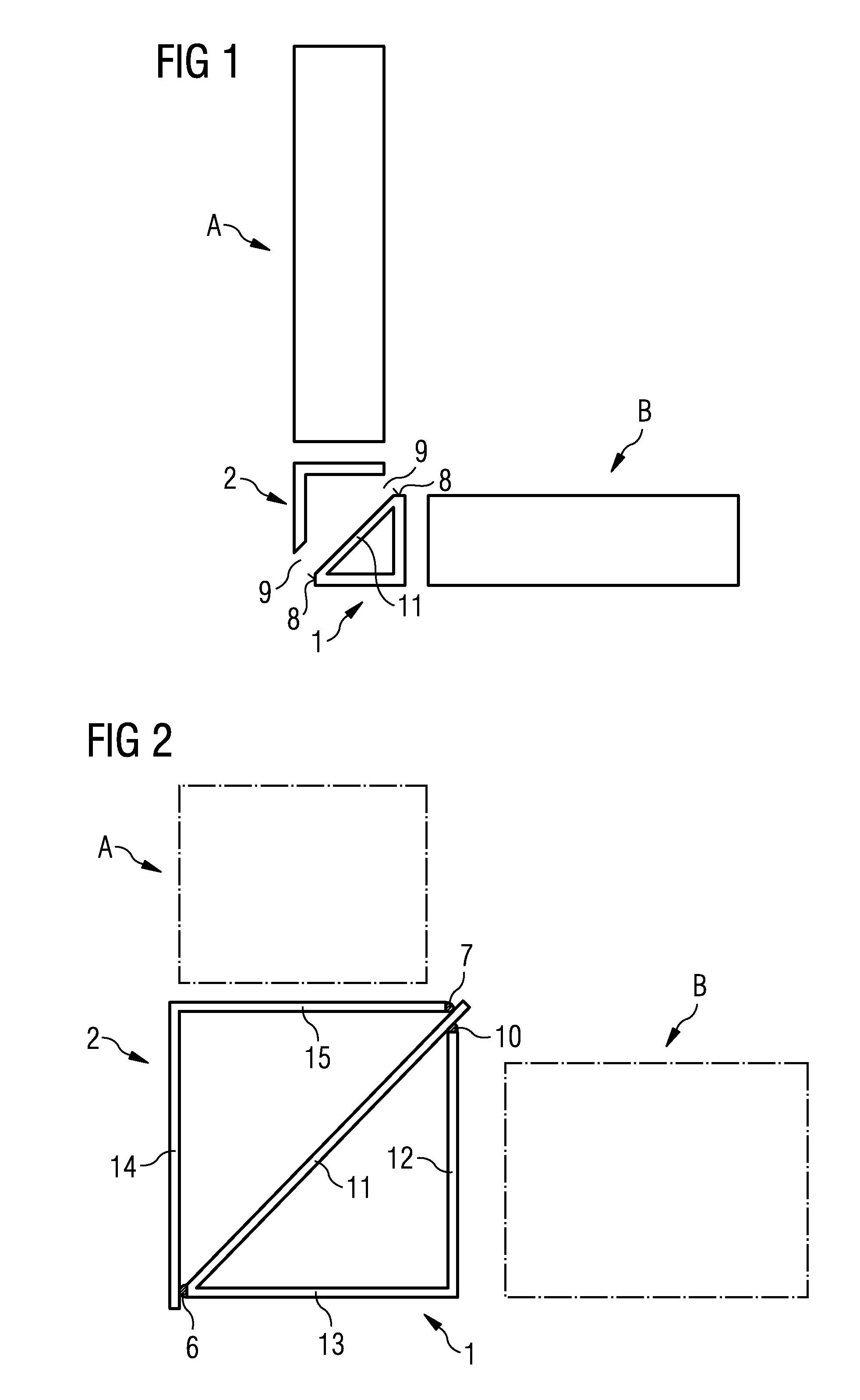

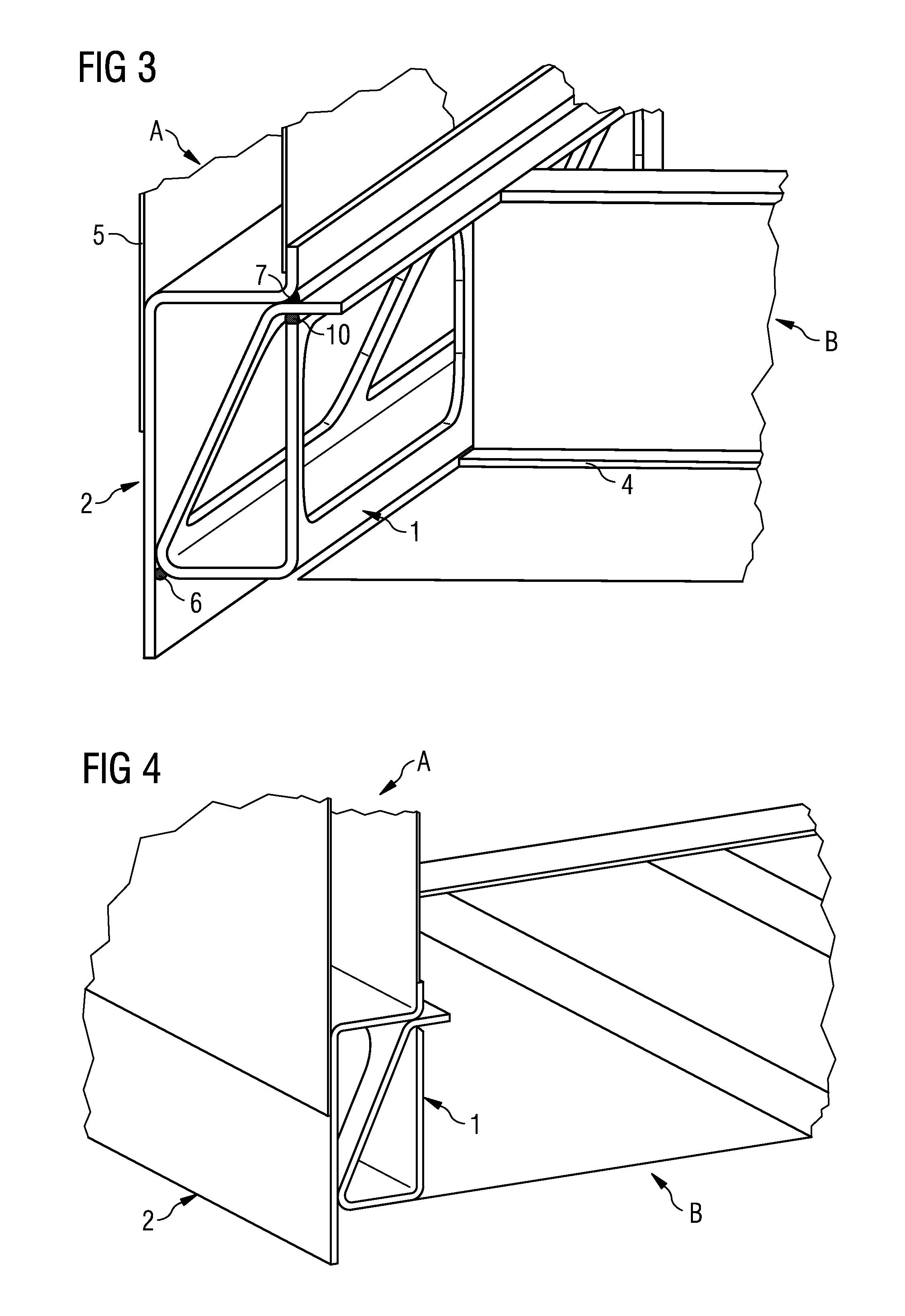

Reinforced longitudinal beam for a railway vehicle

InactiveUS20130036937A1Reduce penetrationImprove longitudinal strengthRailway roofsAxle-box lubricationEngineering

A reinforced longitudinal beam for railway vehicles includes a first partial beam and a second partial beam. The first partial beam is connected to a second assembly of the railway vehicle and the second partial beam is connected to a first assembly of the railway vehicle. Particular surfaces are provided on the first partial beam for forming a welded connection to the second partial beam, and particular surfaces are provided on the second partial beam for forming a welded connection to the first partial beam, wherein one of the partial beams comprises an end facing.

Owner:SIEMENS MOBILITY AUSTRIA GMBH

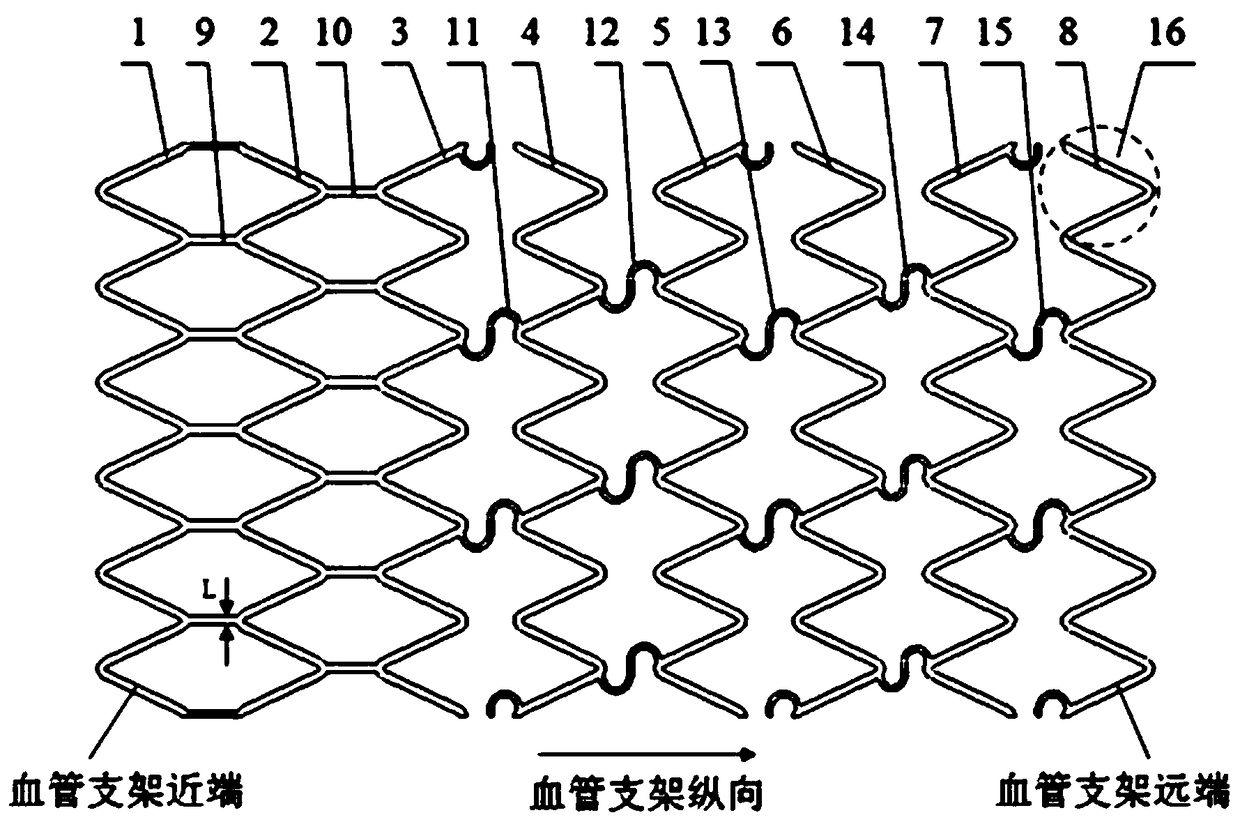

A vascular stent with anti-longitudinal deformation

InactiveCN105167881BIncreased deformation resistanceImprove flexibilityStentsBlood vesselsInsertion stentPercent Diameter Stenosis

The present invention provides a vascular stent with anti-longitudinal deformation. The vascular stent includes several groups of annular supports and connecting ribs connected between every adjacent two groups of the annular supports; the vascular stent is nearly The adjacent annular supports at the end are connected by straight-line connecting ribs, and the middle and distal ends of the vascular stent are connected by S-shaped connecting ribs, taking into account the longitudinal strength and flexibility of the vascular stent in the longitudinal direction; at the same time, Increase the number of circumferential linear connecting ribs at the proximal end of the vascular stent, further enhance the longitudinal strength of the proximal end of the vascular stent, and ensure the overall flexibility and transportability of the vascular stent so that it can reach the vascular lesion smoothly Moreover, the width of the straight-line connecting ribs at the proximal end of the vascular stent is increased to further ensure that the proximal end of the vascular stent has sufficient longitudinal strength, and at the same time increases its contact area with the plaque, which can reduce the In-stent restenosis.

Owner:JIANGSU UNIV

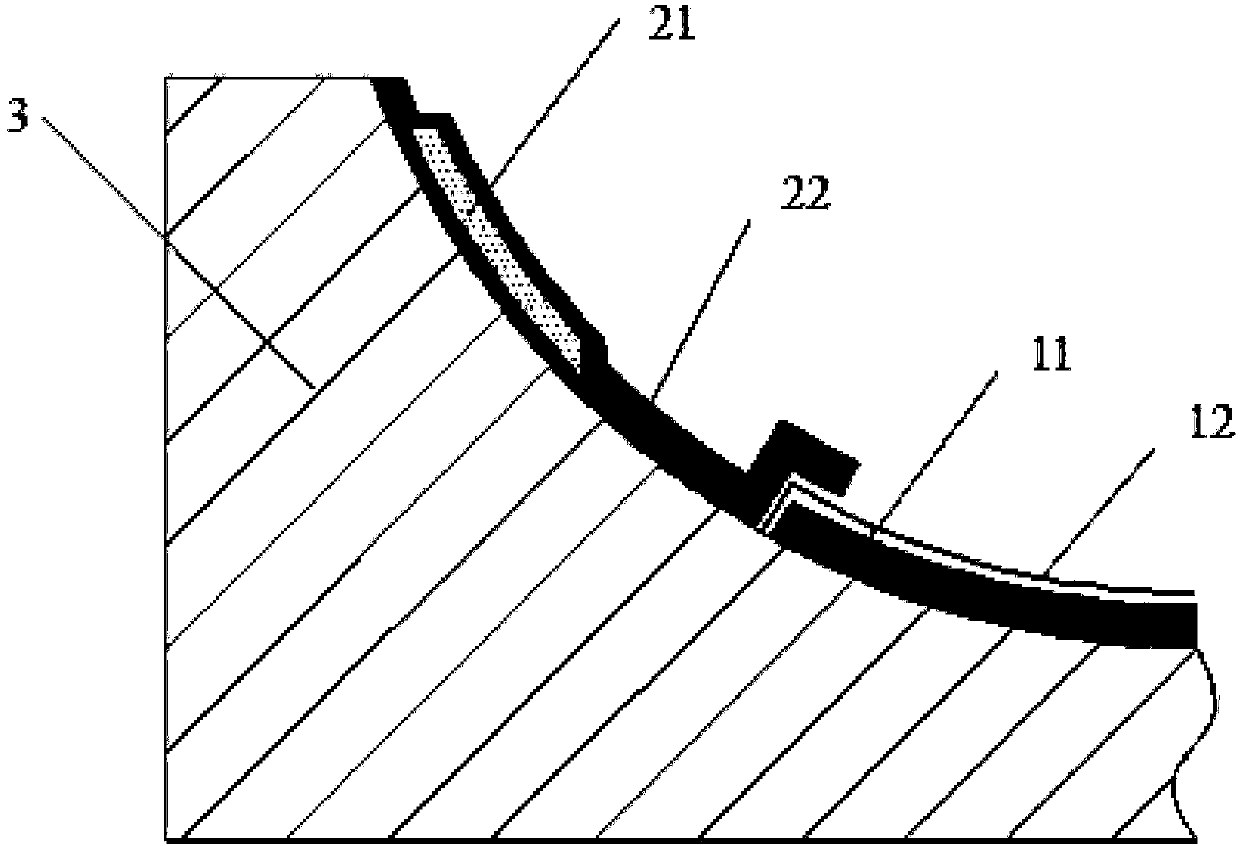

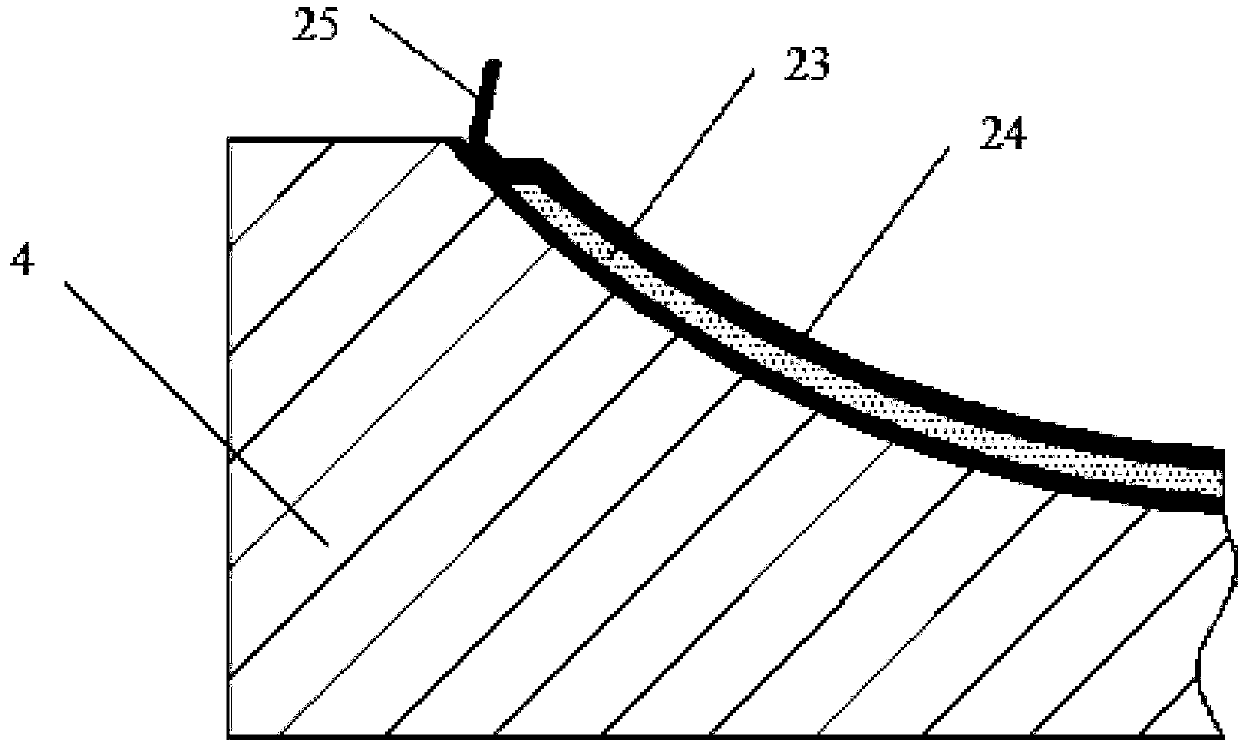

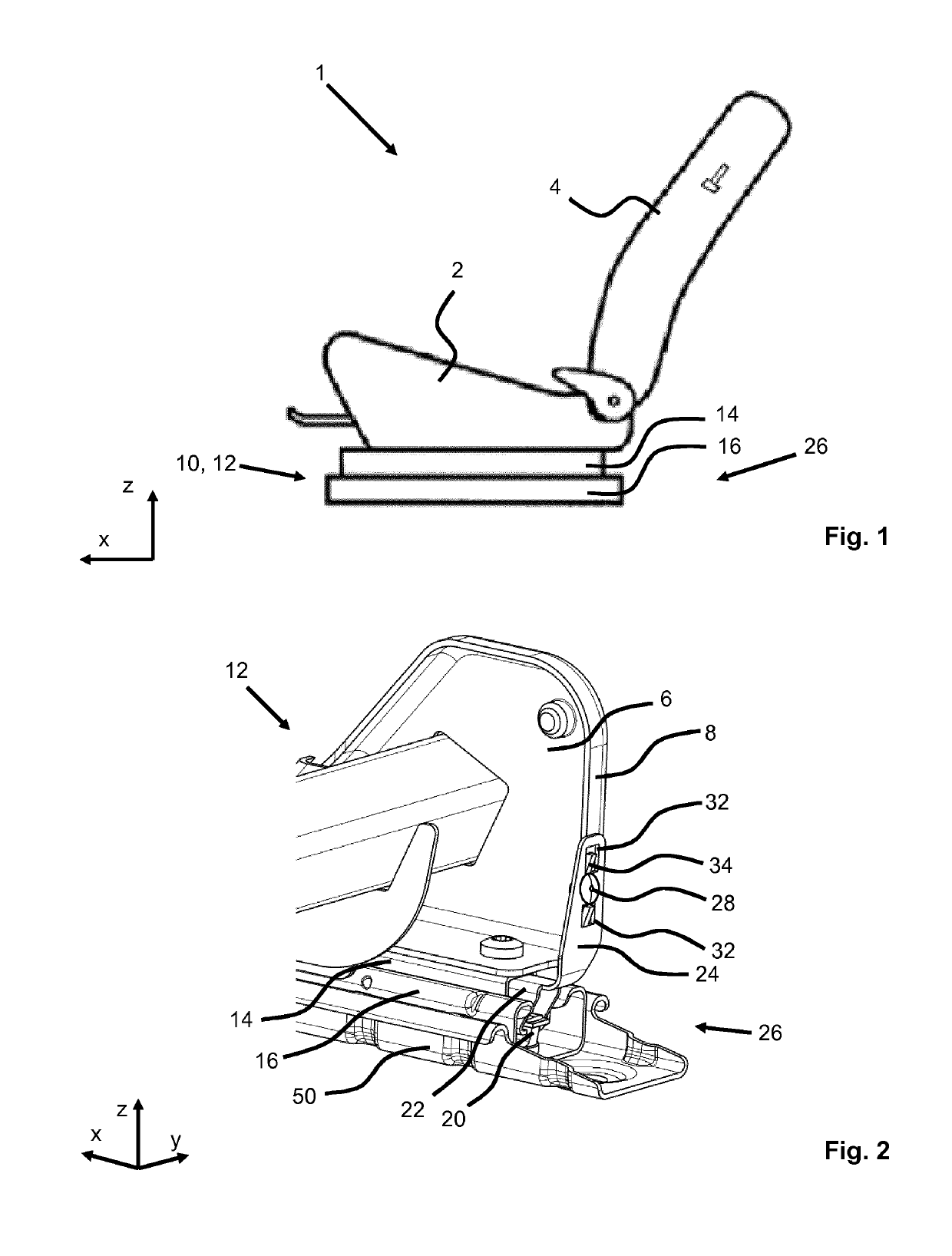

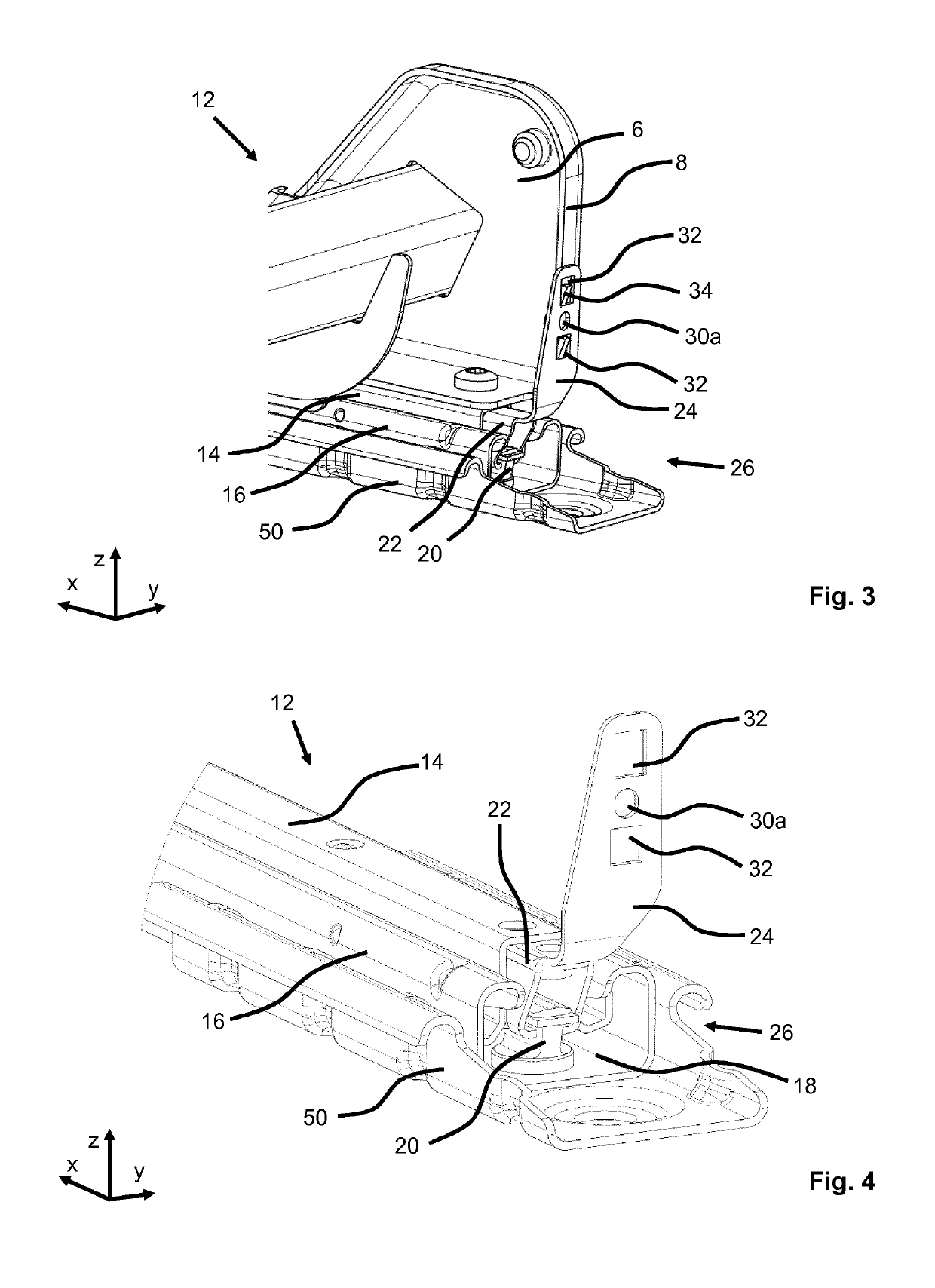

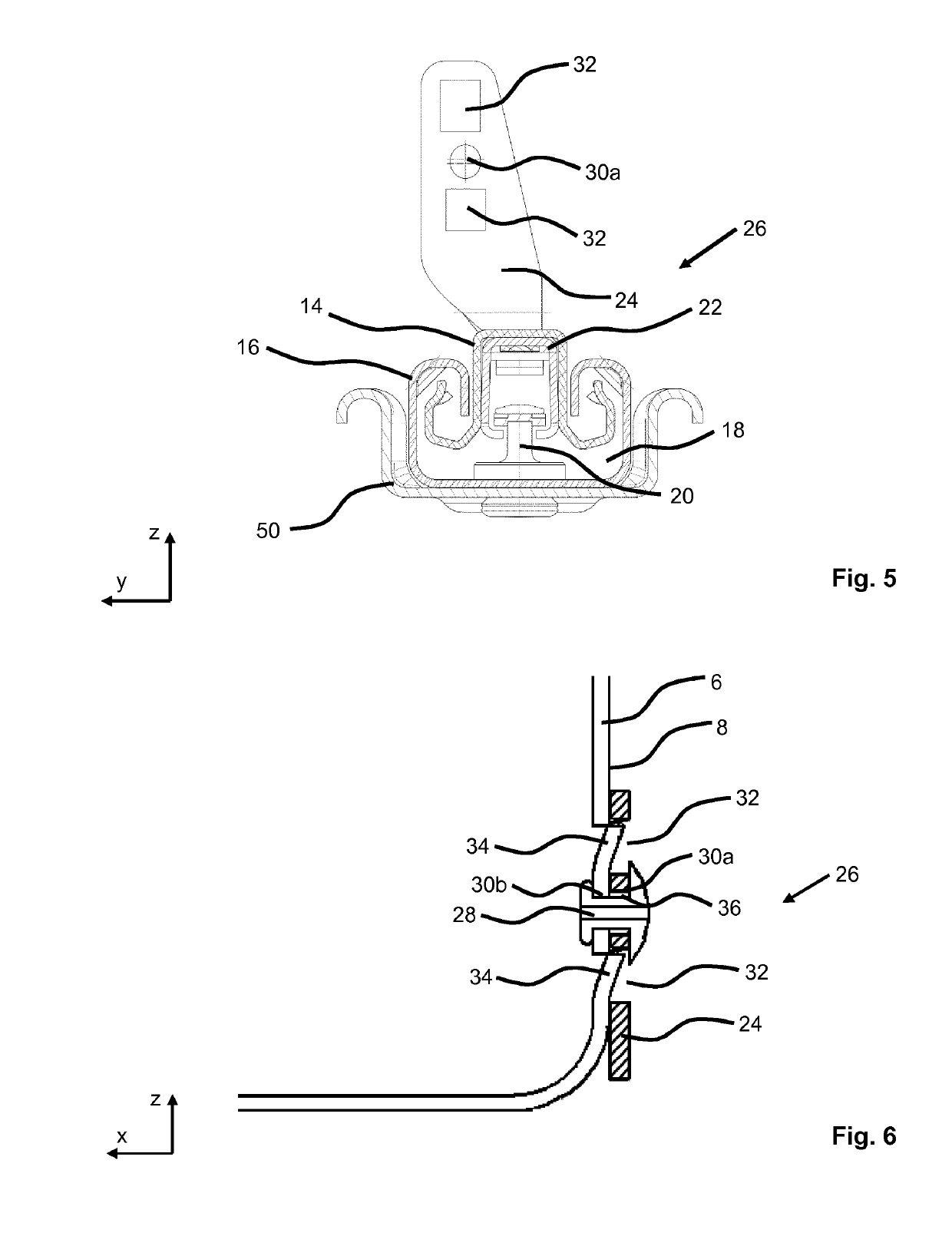

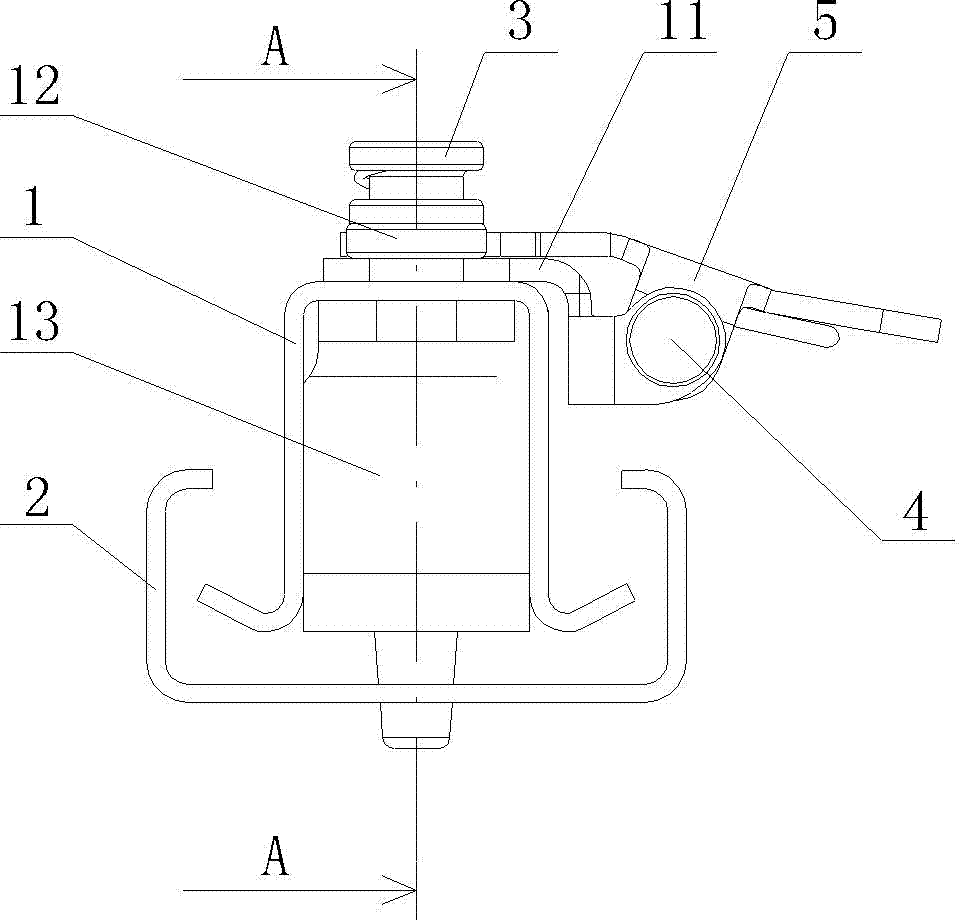

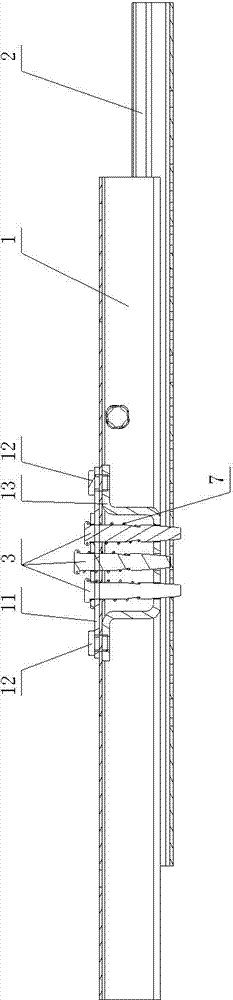

Longitudinal adjuster and vehicle seat

ActiveUS20190232833A1Reinforcement profileIncrease load capacityMovable seatsEngineeringMechanical engineering

A motor-vehicle seat longitudinal adjuster (10) includes a seat part seat rail (14) and a vehicle structure seat rail (16). The seat rails (14, 16) are slidable relative to each other in a longitudinal direction (x) and engage each other forming an inner channel (18). An anchor (20), fastened to the second seat rail (16), is arranged in the inner channel (18). A reinforcing profiled element (22), fastened to the first seat rail (14), is arranged in the inner channel (18). The reinforcing profiled element (22) and the anchor (20) are spaced apart from each other and engage with each other in response to a defined application of force (a crash). The reinforcing profiled element (22) has a connecting section (24) extending out of the inner channel (18) toward a rear for connection to a rear end surface (8) of a seat frame side part (6).

Owner:KEIPER SEATING MECHANISMS CO LTD

Production technology of plastic film

InactiveCN104290316ASimple production processReasonable production processProduction linePlasticulture

Owner:ANHUI MEIXIANG PLASTIC

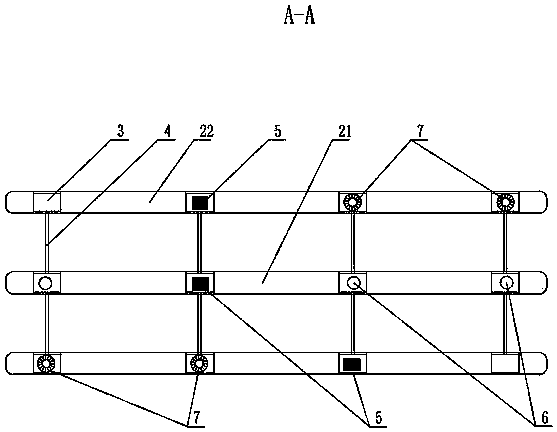

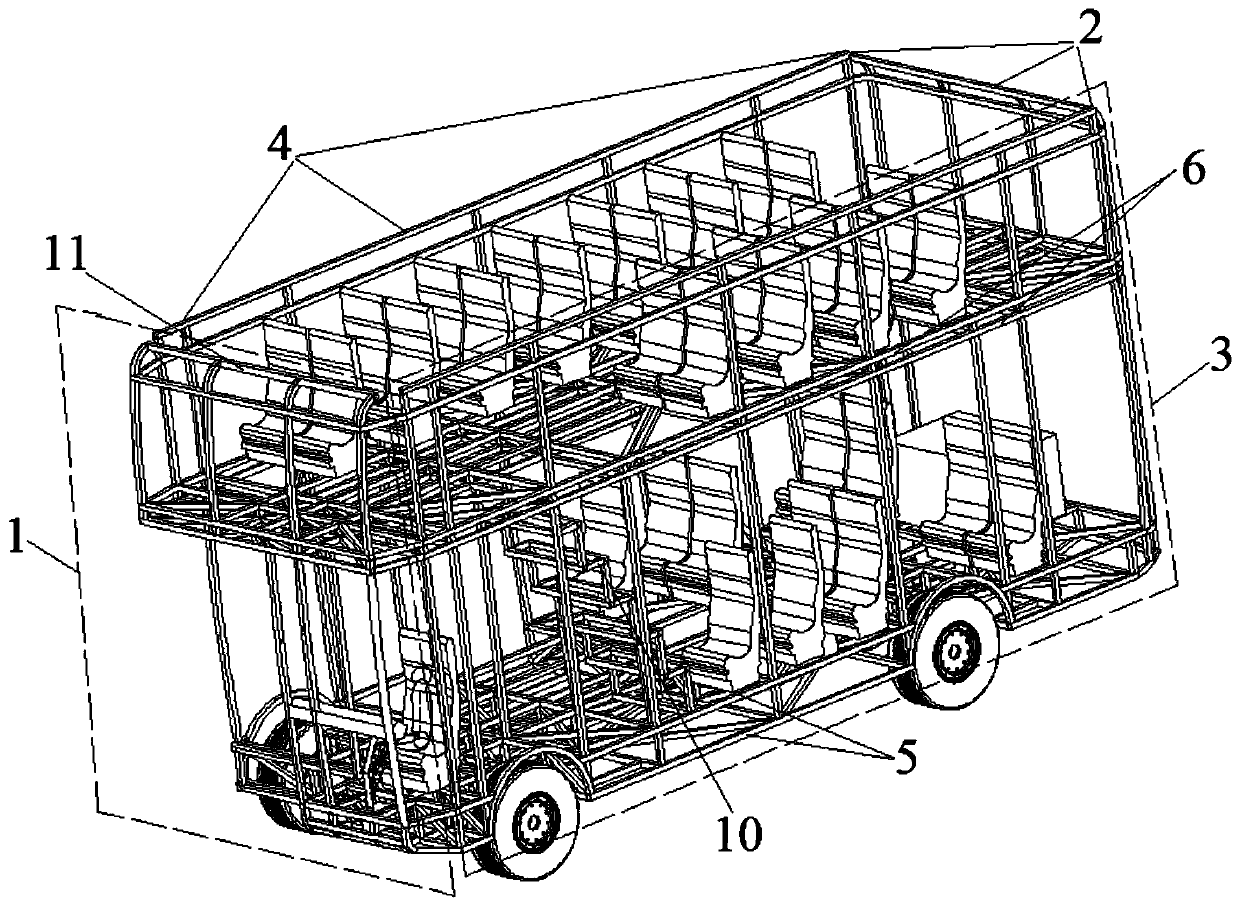

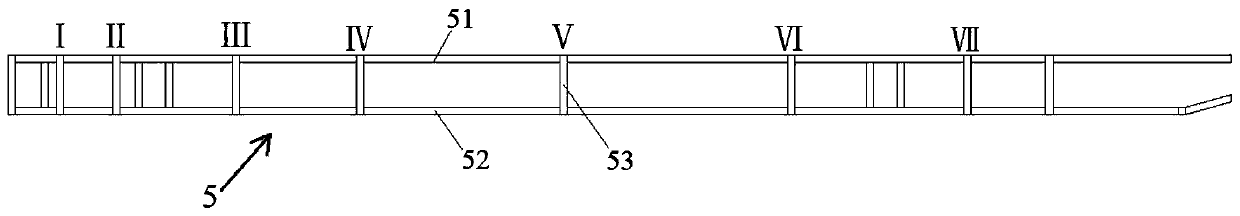

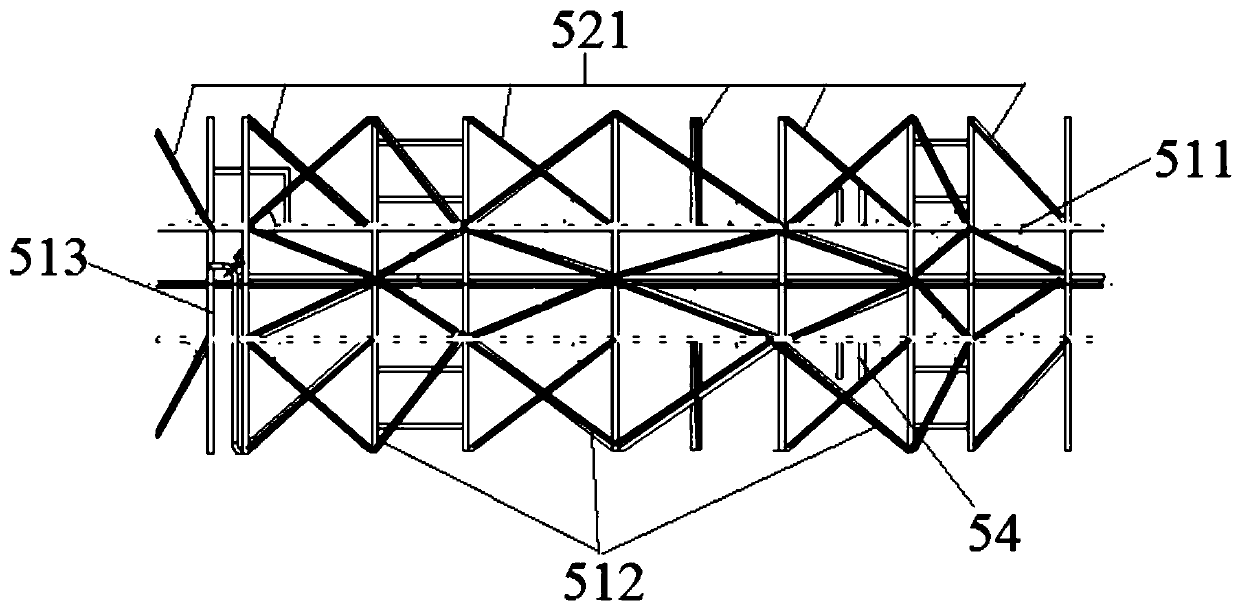

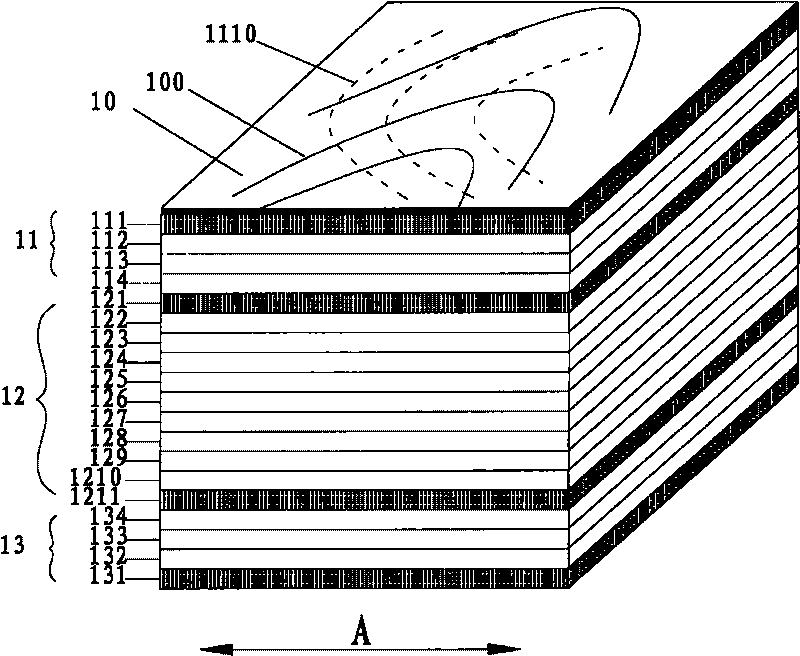

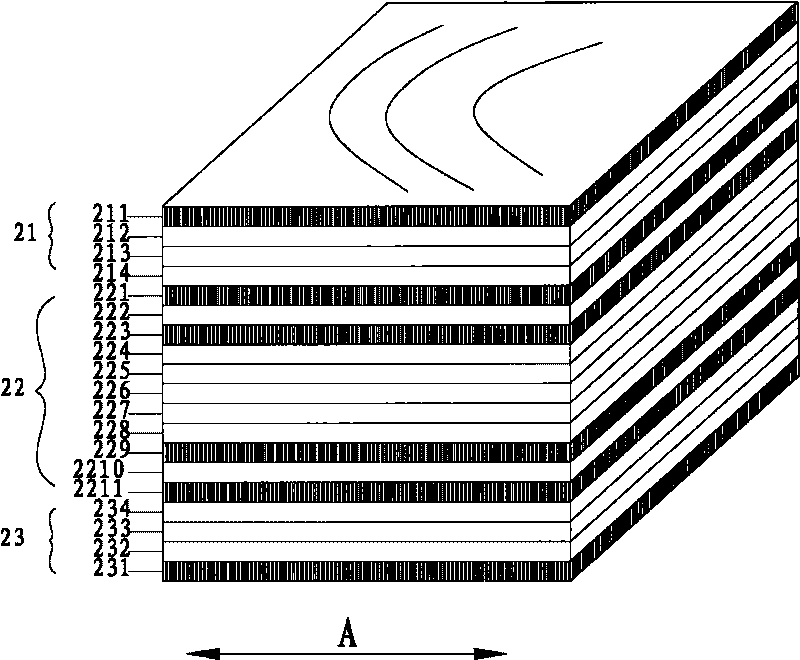

Triangular loop chain type bus body structure of full-load pure-electric double-layer tourist bus

InactiveCN111591356AImprove body structure lifeHigh longitudinal strength and stiffnessPassenger vehicle superstructuresCross overChain type

The invention discloses a triangular loop chain type bus body structure of a full-bearing pure-electric double-layer tourist bus, which is composed of six sub-assemblies, comprising a front wall, a rear wall, a left side wall, a right side wall, a first-layer underframe and a second-layer underframe, wherein each sub-assembly is of a space truss structure composed of small-section rod pieces; thefirst-layer bottom frame is composed of a first upper-layer framework, a first lower-layer framework and a first supporting piece. The first upper-layer framework is composed of a first upper rectangular supporting main frame, a triangular link chain A and a first upper auxiliary frame; a plurality of small upright posts are arranged at the crossed position of the triangular loop chain A and the first inclined strut group; the second-layer bottom frame is composed of a second upper-layer framework, a second lower-layer framework and a second supporting piece; the second upper-layer framework is composed of a second upper rectangular supporting main frame, a triangular link chain B and a second upper auxiliary frame. Through the design of the triangular loop chain type supporting frame, a force transmission chain in the driving direction is formed, the impact resistance is improved, and meanwhile the longitudinal bearing capacity is improved.

Owner:上海大荒纤维科技发展有限公司

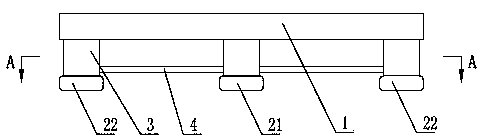

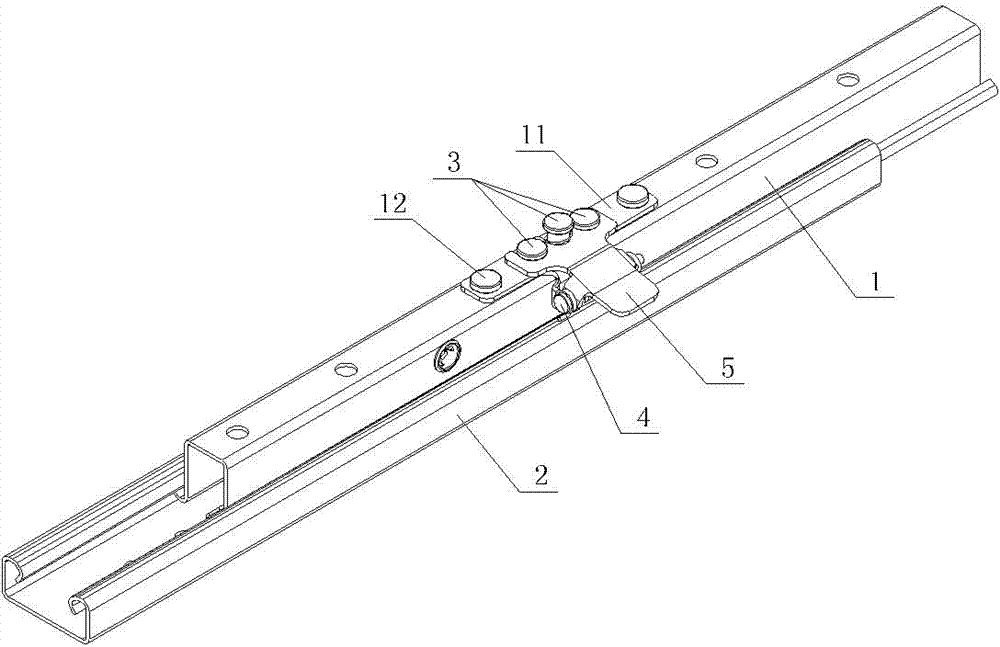

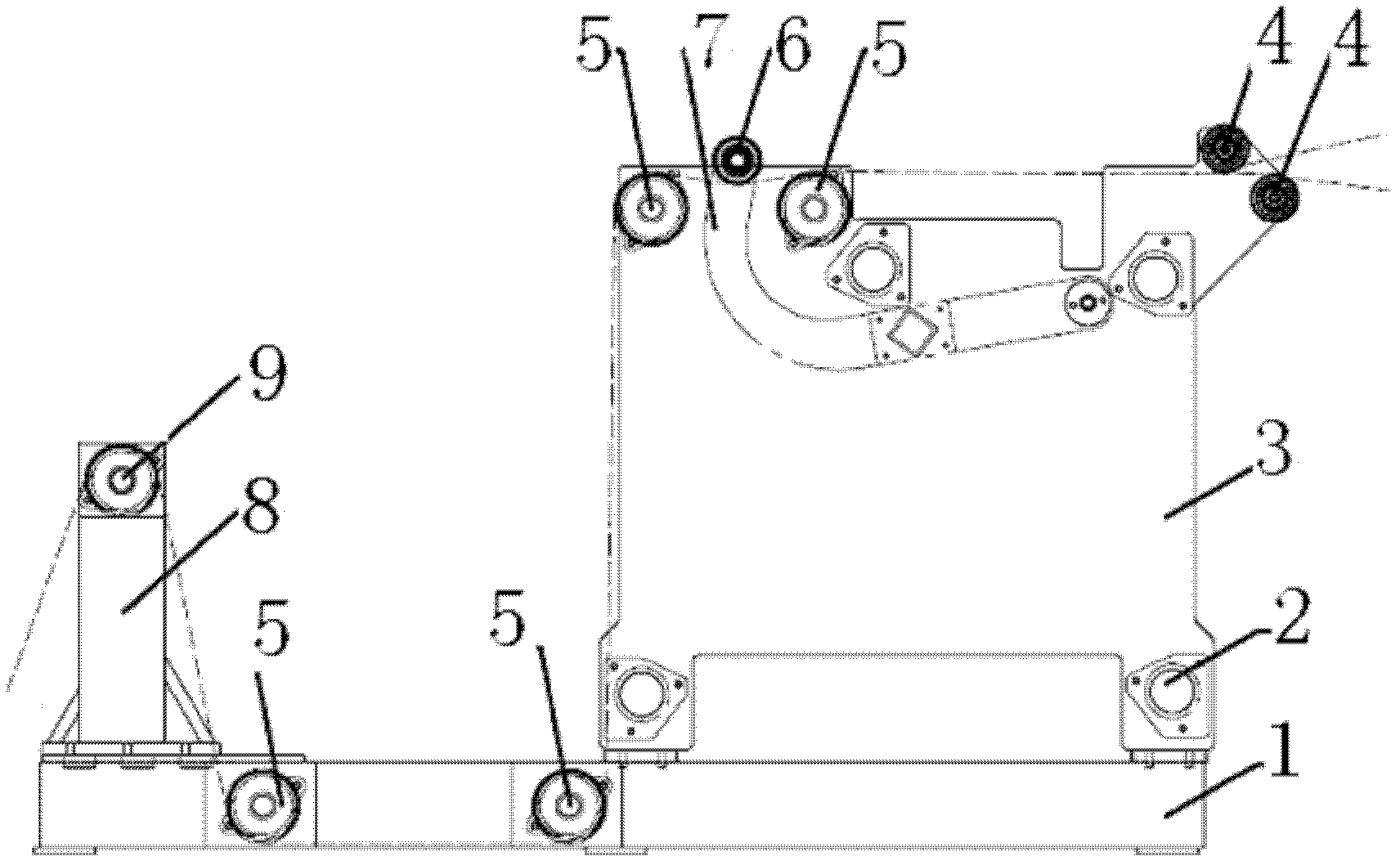

Locking structure of automobile seat sliding rail

ActiveCN103085685AImprove longitudinal strengthImprove space utilizationMovable seatsMechanical engineering

The invention provides a locking structure of an automobile seat sliding rail. The locking structure of the automobile seat sliding rail solves the problems that an existing locking structure is large in occupied space and high in cost, and improves utilization rate of a vertical space of a sliding rail. The locking structure of the automobile seat sliding rail comprises an upper sliding rail, a lower sliding rail, locking pins, a shaft pin and an unlocking driving plate, wherein the upper sliding rail is installed in the lower sliding rail and can move horizontally and frontward and backward in the lower sliding rail under unlocking condition, locking holes are formed in the lower sliding rail, a pin installing support is installed in the upper sliding rail, the locking pins penetrate through the upper sliding rail and the pin installing support from top to bottom, pin return springs are connected and installed on the periphery of the locking pins, the unlocking driving plate is installed on the shaft pin through an unlocking driving return spring, the shaft pin is installed on the upper sliding rail through a supporting plate, and a front end bayonet of the unlocking driving plate is connected with the locking pins in a clamped mode. The locking structure of the automobile seat sliding rail is characterized in that the supporting plate is fixedly installed on one side face of the upper sliding rail through a bolt.

Owner:WUXI HAIDAER PRECISION SLIDES CO LTD

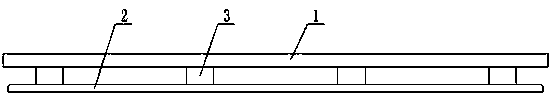

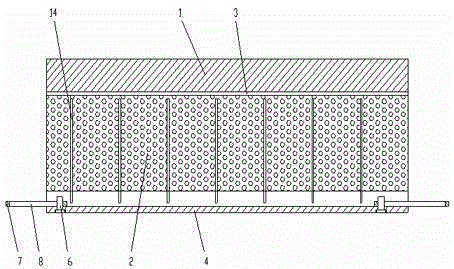

Composite bottom board for container

ActiveCN101712167AImprove lateral strengthImprove longitudinal strengthNatural patternsBio-packagingSurface layerEngineering

The invention discloses a composite bottom board for a container, which is formed by stacking and gluing a plurality of veneers; and the composite bottom board comprises an upper surface layer, a lower surface layer and a middle layer sandwiched between the upper surface layer and the lower surface layer. Through reasonable structural design, on the promise of ensuring that the performance of the bottom board can meet the usage requirement of the container, the log resources are better utilized so as to obtain high-quality face / bottom boards; and the laying-up mode of the traditional bottom boards for the container is changed, current log resources are more effectively utilized, the contradiction between the supply and requirement of the log resources is relieved, and the manufacturing cost of the bottom board for the container is reduced.

Owner:SHENGSHI CONTAINER MANAGEMENT SHANGHAI

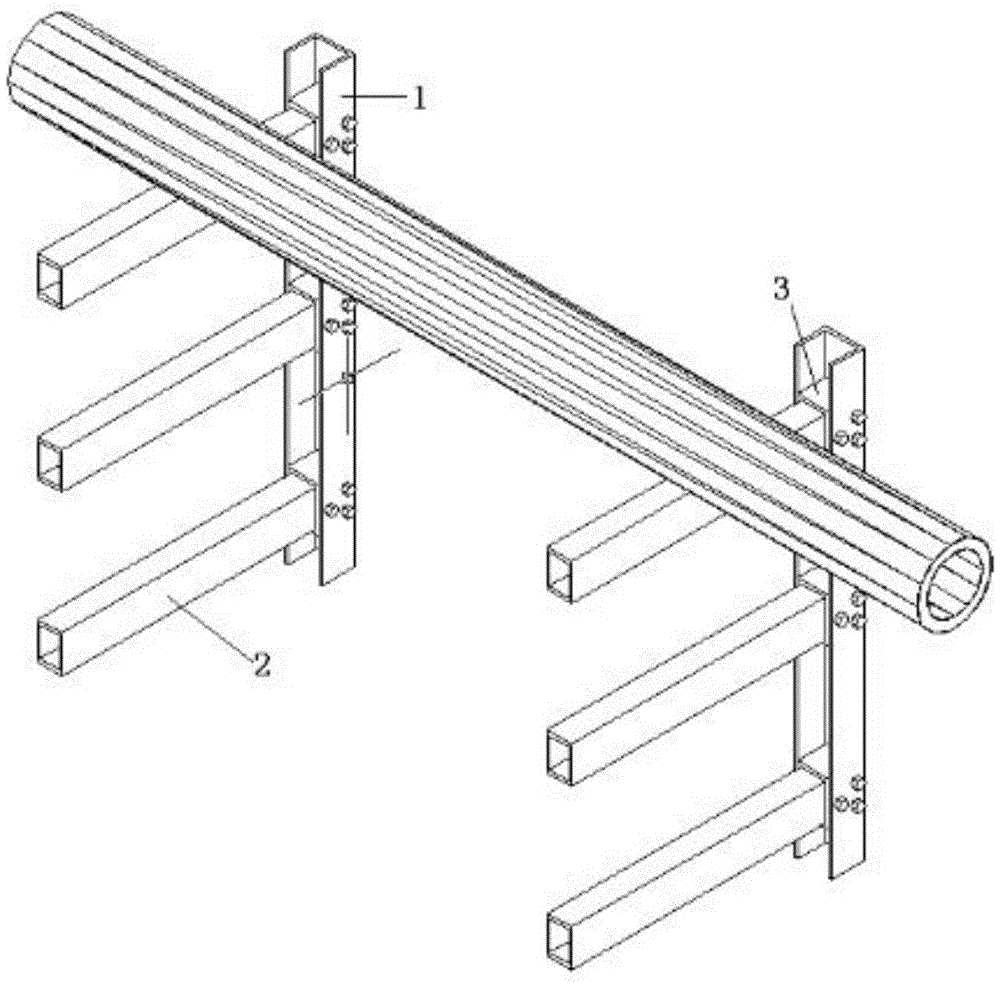

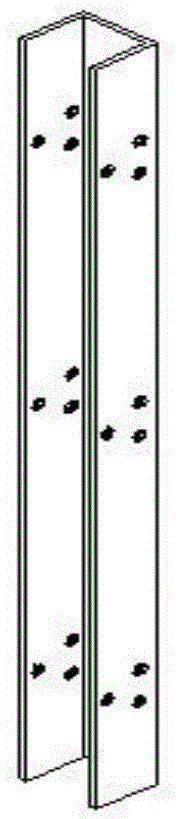

Combined type composite material bearing support

InactiveCN105626966AIncrease productivityHigh in fiberPipe supportsAging resistanceWorking environment

The invention discloses a combined type composite material bearing support. The combined type composite material bearing support comprises stand columns, connecting pieces and support arms; the support arms are connected to the stand columns through the connecting pieces; and the stand columns and the support arms are made of heat convertible resin and continuous fibers through a pultrusion process. The combined type composite material bearing support manufactured through the continuous long fiber reinforced heat convertible resin and the pultrusion process is disclosed, and the combined type composite material bearing support has the beneficial effects of being high in corrosion resistance, excellent in ageing resistance, high in strength, good in toughness, small in dead load, non-conducting, high in construction efficiency, environment-friendly and the like; in an actual work environment, working condition environmental requirements of high bearing loads, corrosion resistance, inflaming retarding, humidity resisting and the like are met, and the defects that a metal piece is prone to rusting and the later-period maintaining amount is large are overcome; and the structure of the combined type composite material bearing support is in a combined type, flexible disassembling and assembling can be achieved according to needs, and welding is not needed. According to the combined type composite material bearing support, all parts are produced through the pultrusion process; and the production efficiency of the pultrusion process is high, and the fiber content of the product is high and can be 80% or above.

Owner:南京海拓复合材料有限责任公司

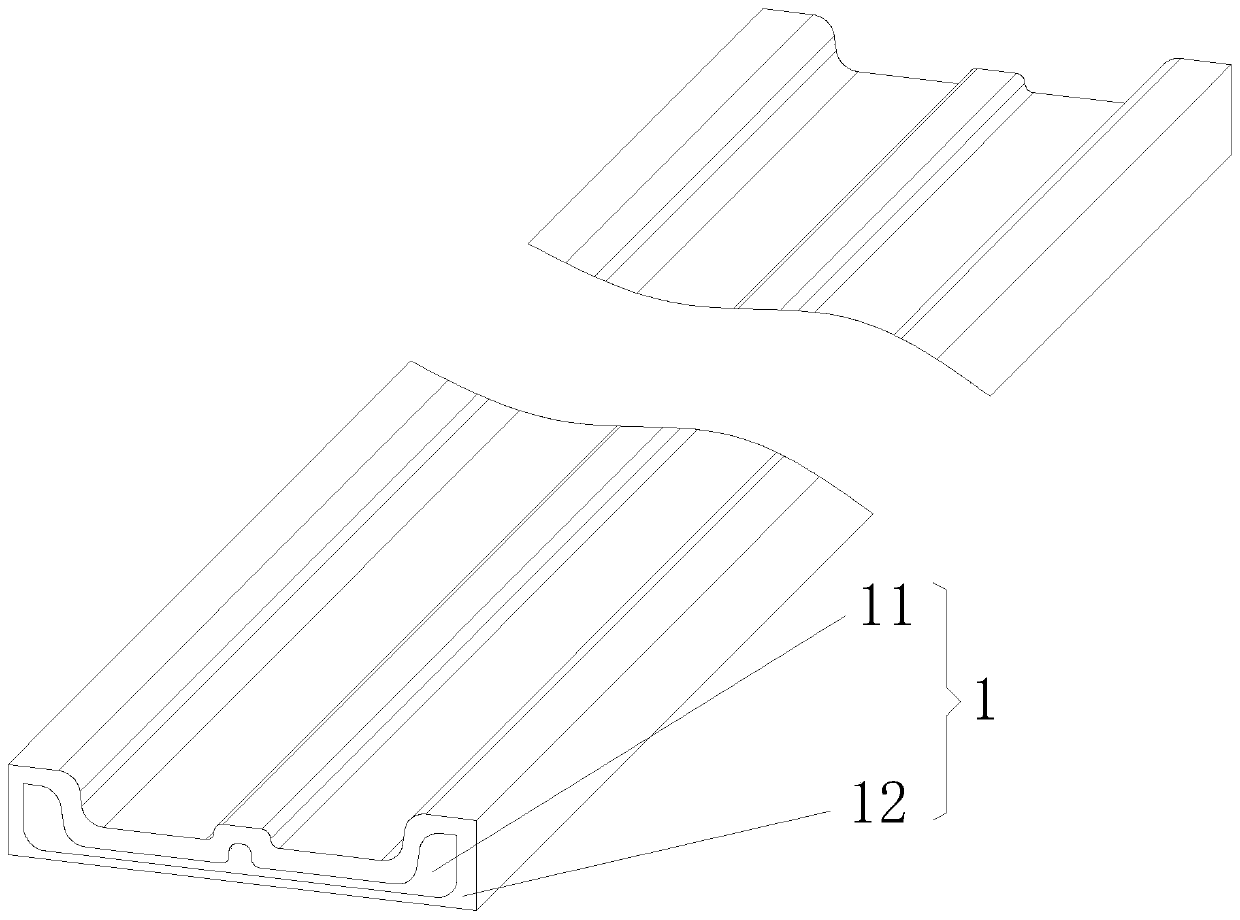

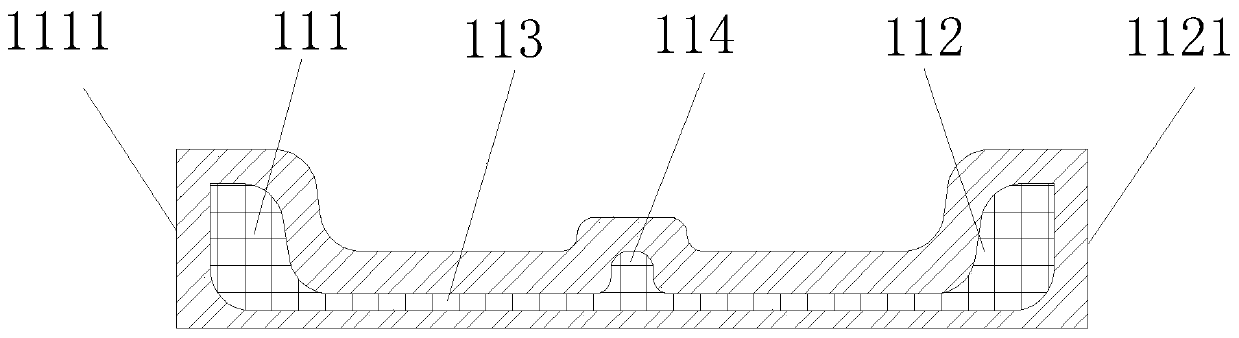

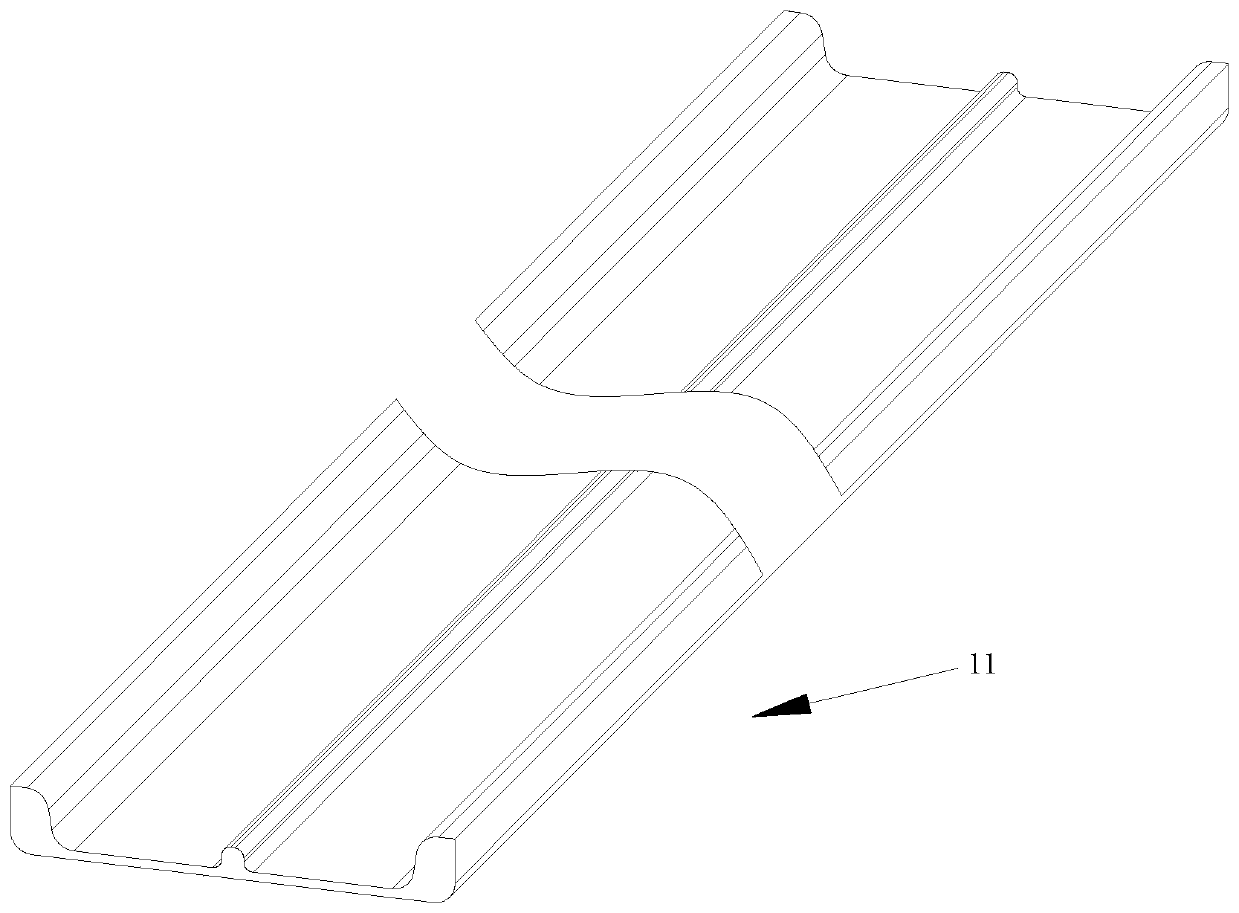

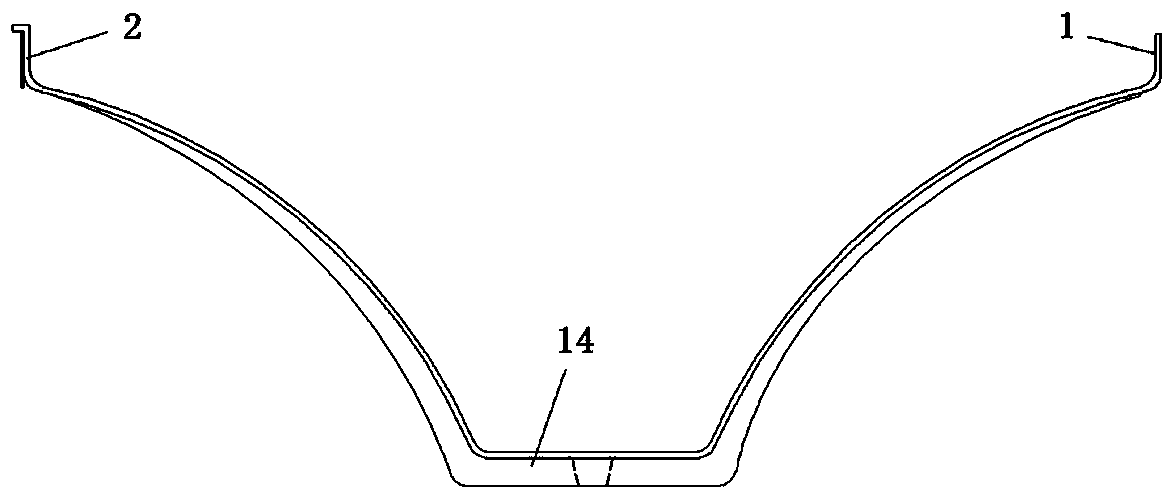

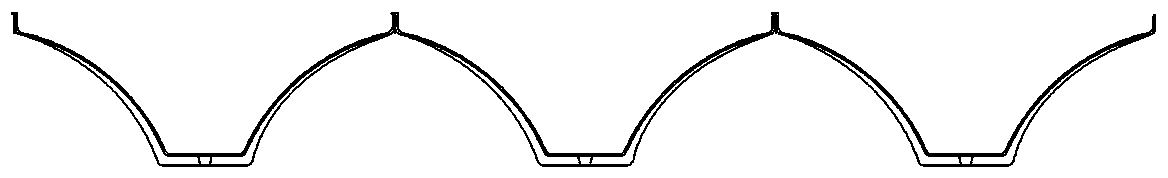

Hot winding solid corrugated pipe, sectional material thereof and manufacturing method thereof

PendingCN110588032AEasy to cool and formIncrease production speedRigid pipesTubular articlesSolid wallShock resistance

The invention relates to a hot winding solid corrugated pipe, and a sectional material and manufacturing method thereof. The sectional material of the hot winding solid corrugated pipe comprises a first sectional material and a second sectional material; the first sectional material comprises a supporting rib and a first hot coating layer; the first sectional material comprises a connecting strip,a first half wave crest strip and a second half wave crest strip; the second sectional material comprises a buckle plate and a second hot coating layer; a buckling groove is formed in the middle partof the second sectional material; and the shape and size of the buckling groove are matched with the shape and size of the outer wall of a small wave crest structure formed by splicing the first halfwave crest strip and the second half wave crest strip. The sectional material adopts the first sectional material and the second sectional material which are solid wall structures, and the sectionalmaterial can facilitate the cooling forming of a pipe, the production speed of the pipe is increased and the welding quality of the pipe can be improved. The solid corrugated pipe is of a solid wall structure, and is high in ring stiffness, good in impact resistance and destruction resistance, and excellent in ring flexibility. The manufacturing method of the corrugated pipe adopts hot winding tocompound all units together, the welding strength is high and the residual stress problem basically does not exist.

Owner:萍乡市大地新材料科技有限公司

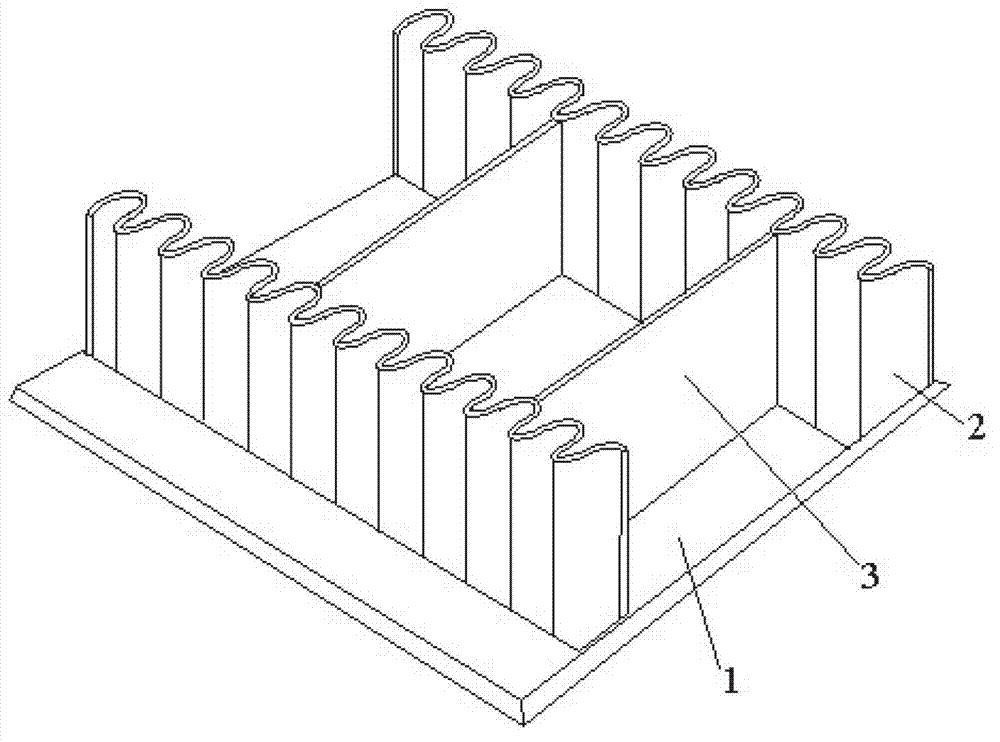

Tension device for weaving carbon fibers

InactiveCN102517764AGuaranteed Warp Tensile StrengthReduce end break rateLoomsWoven fabricsYarnBreaking strength

The invention relates to a tension device for weaving carbon fibers. A pair of rear yarn guide rollers is vertically arranged at one end of one wallboard and one end of the other wallboard, and an included angle is formed between the centers of the two yarn guide rollers; four middle yarn guide rollers are divided into two groups and respectively arranged on the wallboards and a support; a pair of swing arms is hinged to the wallboards; a tension roller is arranged at the tension roller mounting end of each swing arm through a bearing; when the mounting end of each swing arm moves to the upper surface of a support frame consisting of a pair of wallboards, the tension roller is positioned between a group of middle yarn guide rollers, and the lower circumferential surface of the tension roller and the upper circumferential surfaces of the group of middle yarn guide rollers are positioned on the same horizontal plane; and a pair of front support plates is fixed on the upper surface of one end of the support. The warp tension of the woven carbon fiber bidirectional cloth is uniform, platy macroscopic tension is 20 percent of breaking strength of a carbon fiber strand, an error is + / -2 percent, the warp texture fiber strength of the carbon fiber cloth is effectively improved, fatigue and damage tolerance is enhanced, cost is reduced, and the aim of reducing the whole weight is fulfilled.

Owner:XIAN KANGBEN MATERIAL

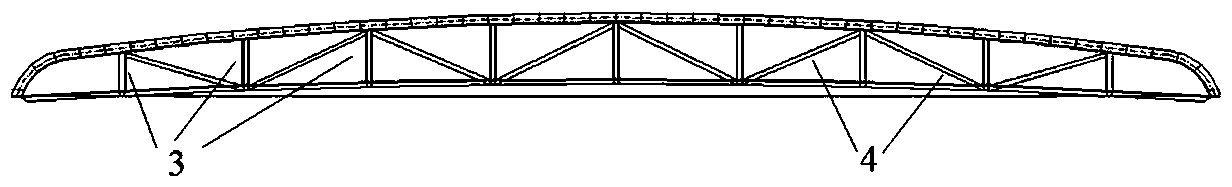

Super-large-span all-glass-fiber-reinforced-plastic deodorization cover plate and odor collection device

PendingCN108262325AIncrease spanImprove longitudinal strengthDirt cleaningGlass fiberMetal framework

The invention provides a super-large-span all-glass-fiber-reinforced-plastic deodorization cover plate. The cover plate is made of high-strength glass fiber reinforced plastic which is not supported by a metal framework, and is characterized in that the cross section of the cover plate is in a large-span arch shape, the longitudinal section of the cover plate is in a continuous small-span arch shape, the cover plate is formed by connecting a plurality of cover plate units, each cover plate unit comprises two semi-arch side wings positioned on the two sides, a pedestrian path is formed a sunkenpart between the two semi-arch side wings of each cover plate unit, the outer side ends of the two semi-arch side wings of each cover plate unit are provided with connecting flanges correspondingly,the connecting flanges are located at the tops of the semi-arch side wings, the two adjacent cover plate units are connected through the connecting flanges, and the connected flanges form a longitudinal reinforcing rib positioned outside the cover plate. A connecting position of the cover plate units of the cover plate is located at the top of each small-span arch shape, after the cover plate units are connected through the flanges, the flange edges form one longitudinal reinforcing rib located outside the cover plate, sealing is achieved, meanwhile, the longitudinal strength of the cover plate is further enhanced, and the span of the cover plate can be improved.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

High-density solid wood floor and producing method thereof

The high density wooden floor board is produced through the following steps: rotary cutting veneer, vertically cutting the facing board, defatting and drying, combining veneers in the same fiber direction to form base board blank, pressurizing to reach high density, and combining the facing board and the base board through adhesion in the same fiber direction. The high density wooden floor board includes one high density base board and one facing board combined integrally through adhering and pressing.

Owner:张征伟

Reliably adhered three-layer combined external wall insulation decorative board

The invention discloses a reliably adhered three-layer combined external wall insulation decorative board which comprises a decorative board, a thermal insulation layer, a bottom plate and a mounting connecting piece, wherein the mounting connecting piece comprises rivets and a connecting plate; a V-shaped groove I is formed in the decorative board; a pit I and a pit II are formed in the thermal insulation layer; and a V-shaped groove II is formed in the bottom plate. The rivets are arranged on the bottom plate, the connecting plate is inserted into a through hole and is connected with the rivets during installation, the connecting plate is connected with a keel mounted on the external wall in advance, namely the reliably adhered three-layer combined external wall insulation decorative board disclosed by the invention can be anchored on the external wall, the installation is convenient and rapid, and the appearance of the decorative board is not damaged during installation. Moreover, the V-shaped grooves and pits are respectively formed in the decorative board, the thermal insulation layer and the bottom plate, so that the contact area among the adhesion layer, the thermal insulation layer and the bottom plate is large; and therefore, the decorative board, the thermal insulation layer and the bottom plate can be reliably adhered by glue, and the bonding strength is high.

Owner:重庆固安捷启中建材有限公司

Floor slab for wooden structural building and producing method thereof

InactiveCN101021090AReduce the transmission of low frequency soundsLow thermal conductivityFloorsWood working apparatusFlueFloor slab

The present invention relates to a floor slab for wood structure building and its making method. Said method includes the following steps: cutting the wood raw material into wood lath or batten with defined size, applying glue to two sides of large wood lath or batten, splicing them into slab, cold pressing and forming so as to obtain wide slab, using said wide slab as upper and lower layers of said floor slab structure; applying flue to two sides of small wood lath or batten and splicing them to obtain narrow slab, using said narrow slab as intermediate layer of said floor slab structure, cold-pressing the above-mentioned upper, intermediate and lower three layers and making them be combined together so as to obtain the invented floor slab for wood structure building.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com