Patents

Literature

163 results about "Expanded PTFE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

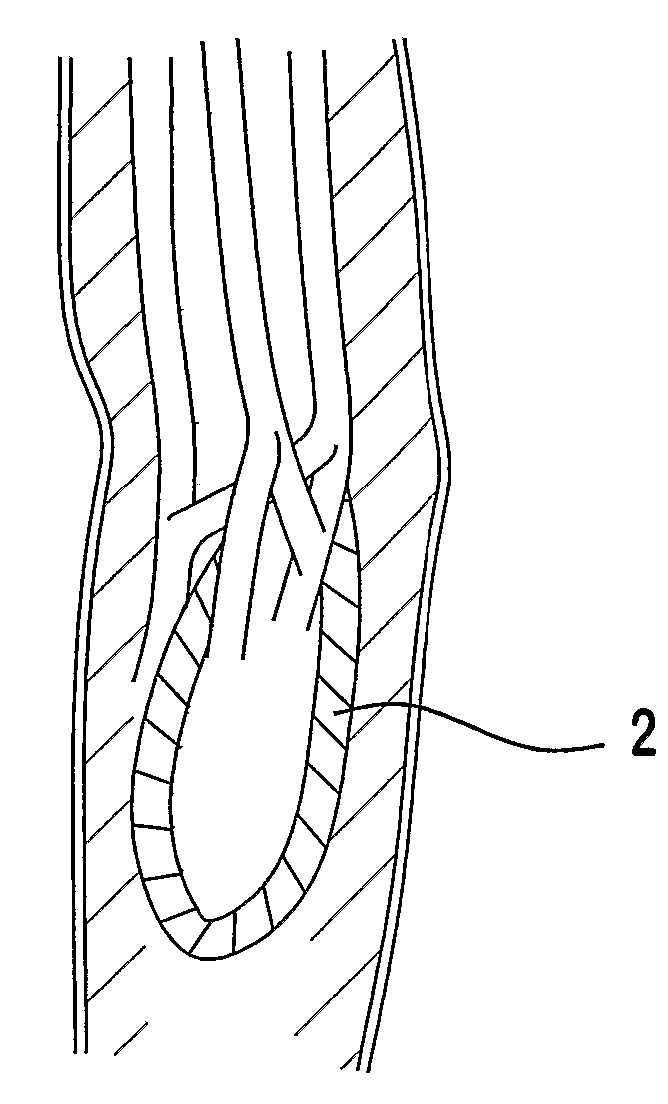

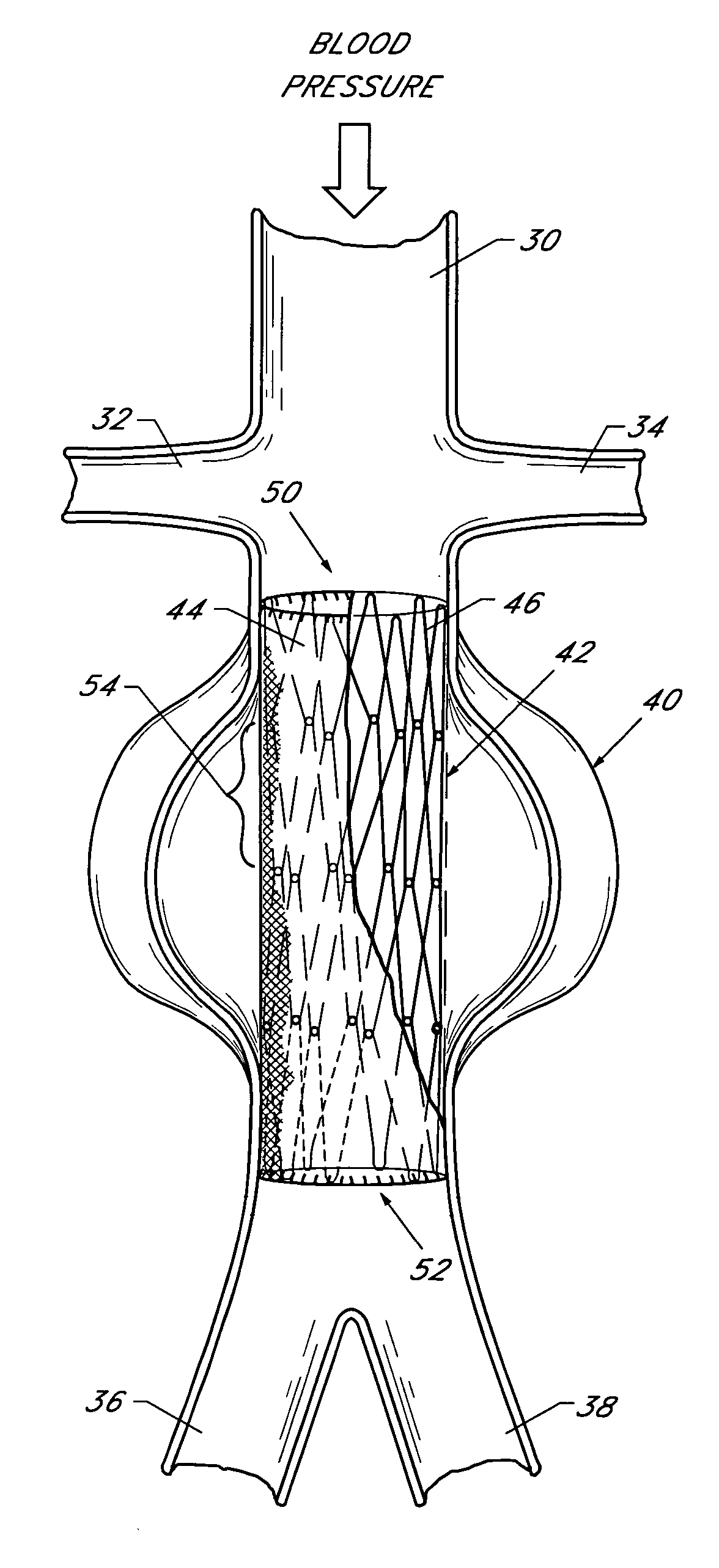

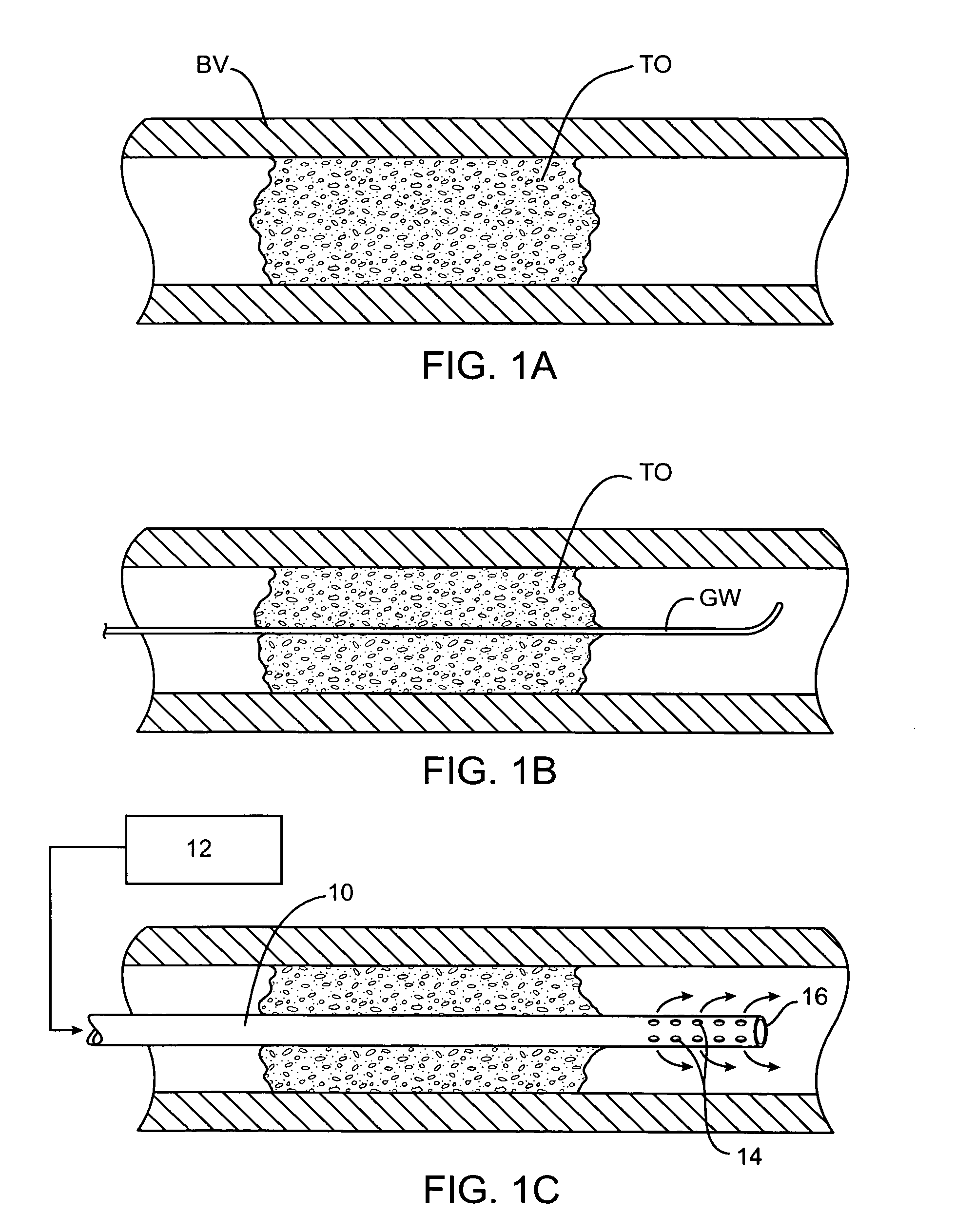

Self-sealing residual compressive stress graft for dialysis

InactiveUS20070167901A1Easy accessInhibit swellingMedical devicesBlood vesselsVeinHaemodialysis machine

Vascular access systems for performing hemodialysis are disclosed. Some embodiments relate to vascular access grafts comprising an instant access or self-sealing material reinforced with expanded PTFE to resist stretching of the instant access material and thereby resist leakage associated with stretching or bending. The graft may comprise two end segments comprising ePTFE without the instant access material to allow easier anastomosis of the graft to veins and arteries. The graft may have a unibody design or have modular components that may be joined together to create a graft with customized length or other features. One or more sections of the graft may also be cut or trimmed to a custom length.

Owner:HEMOSPHERE

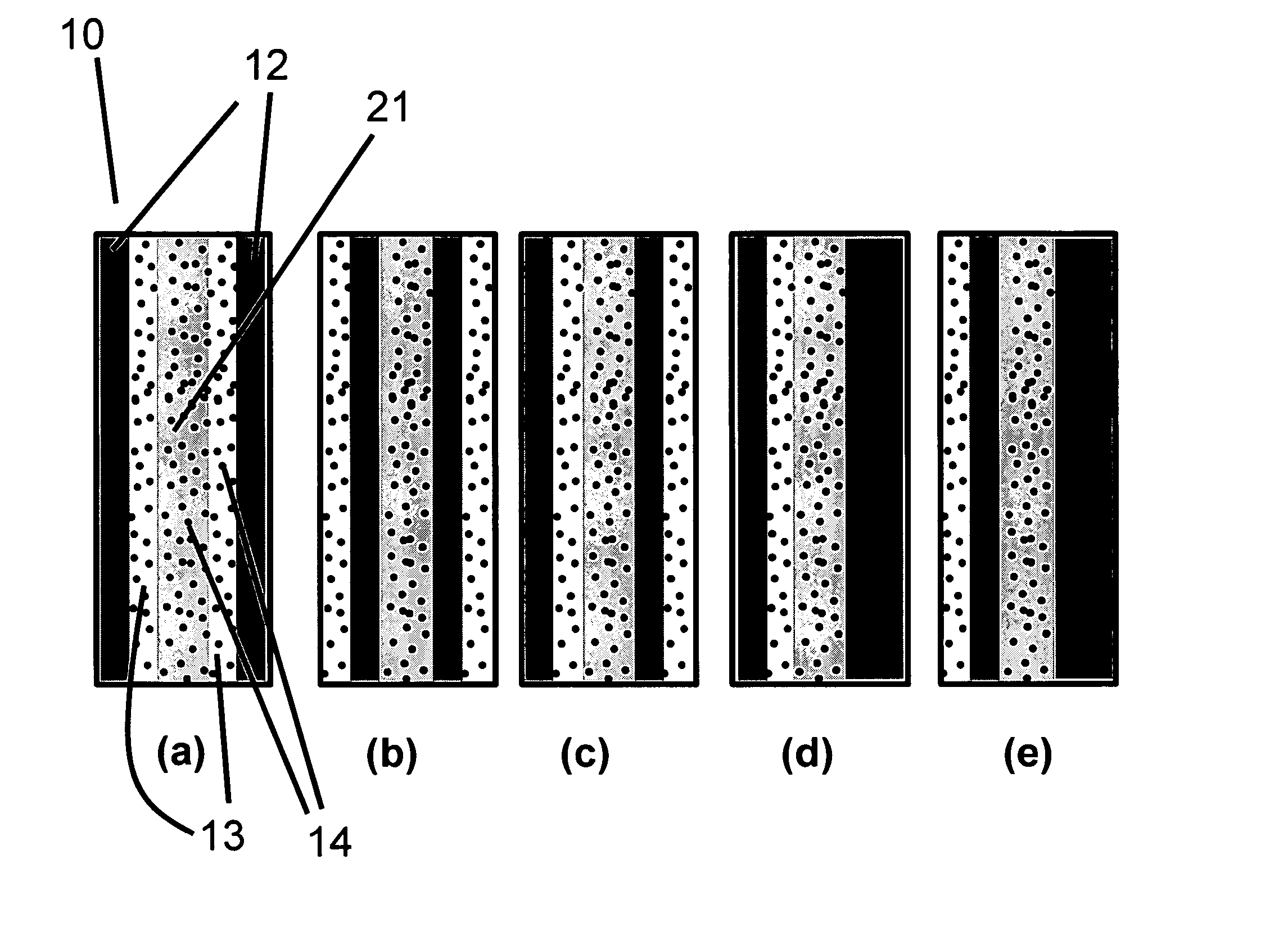

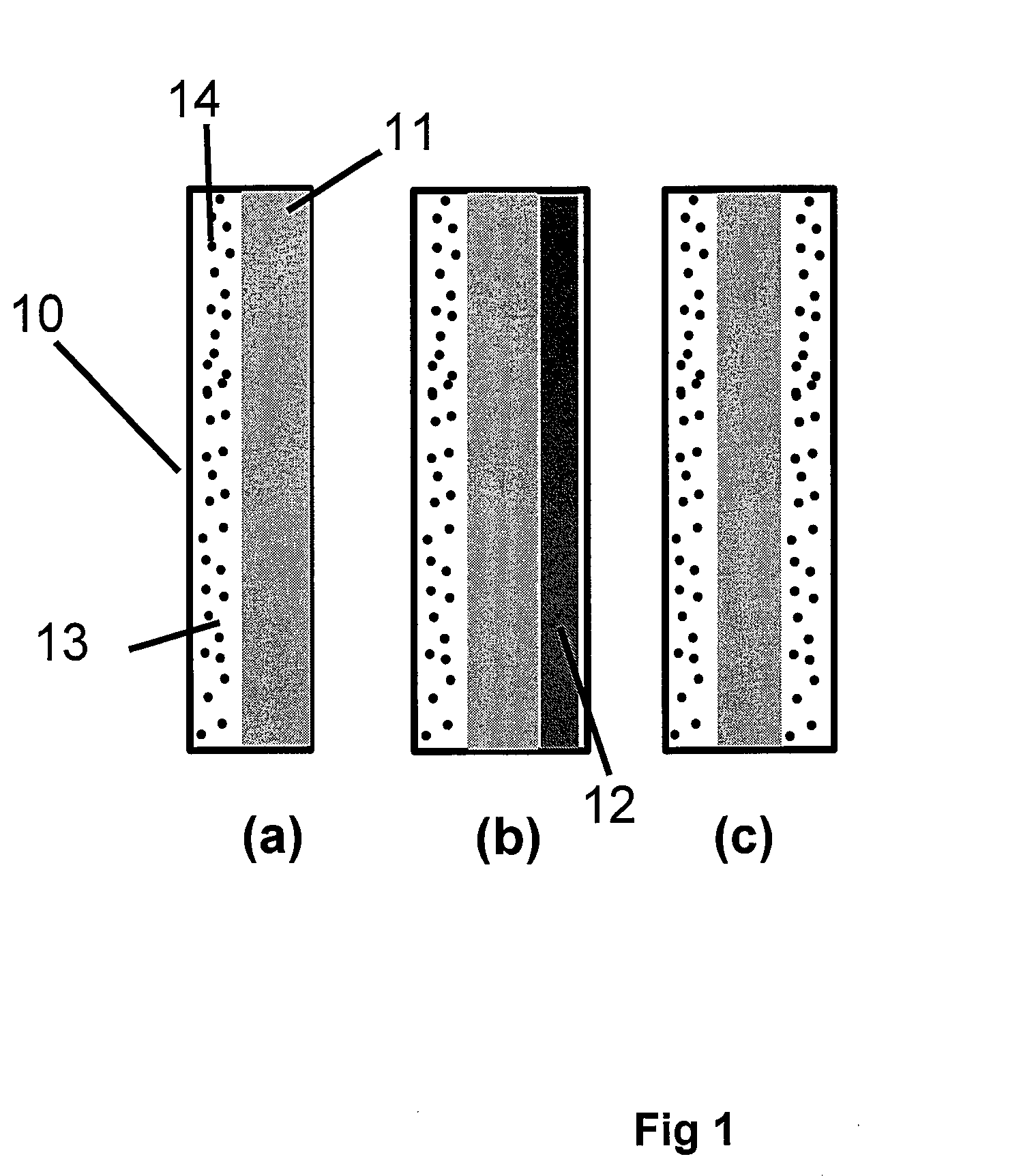

Solid polymer electrolyte and process for making same

ActiveUS20070072036A1Enhanced release propertiesIon-exchanger regenerationFinal product manufactureFiberIon exchange

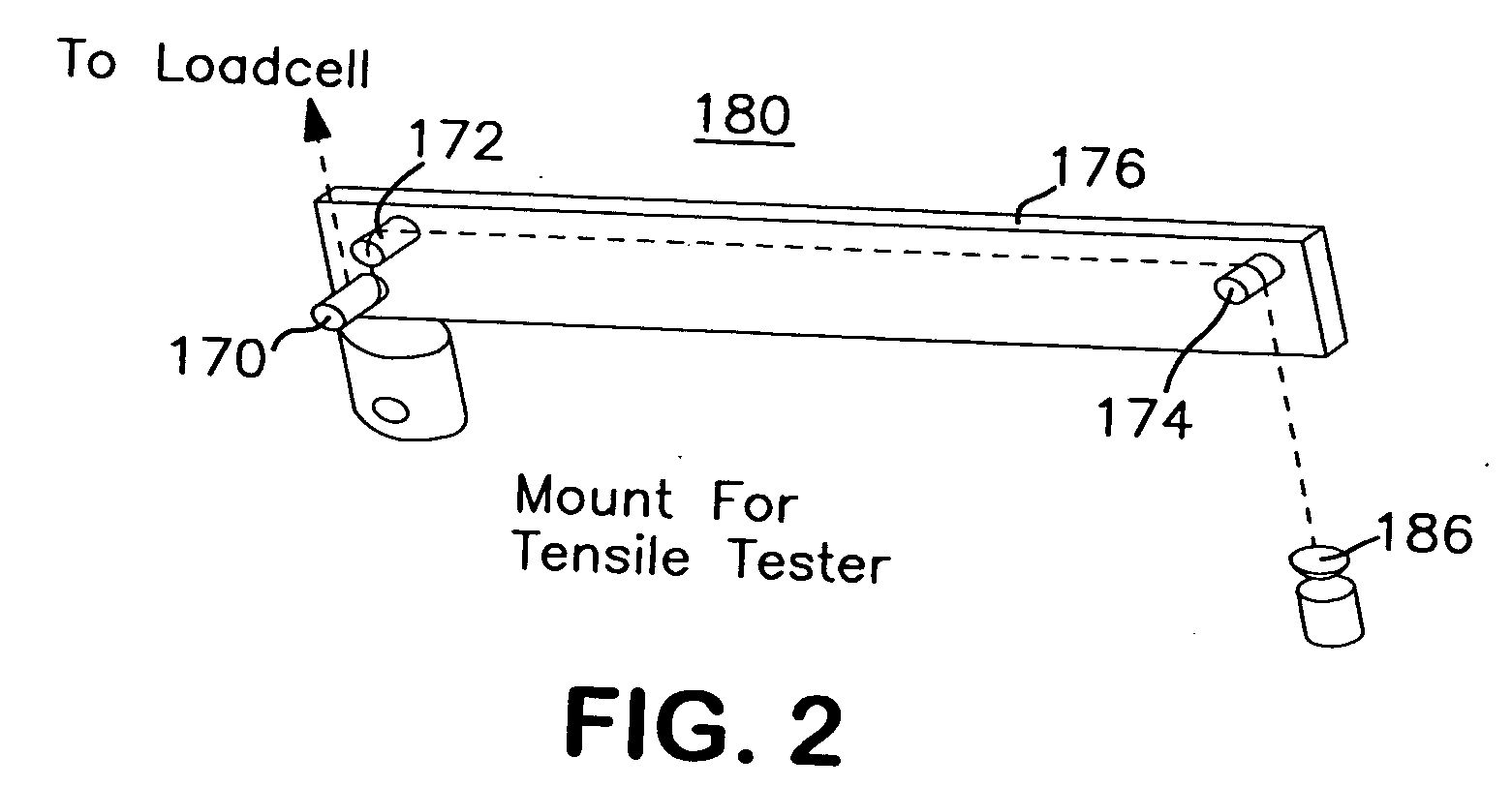

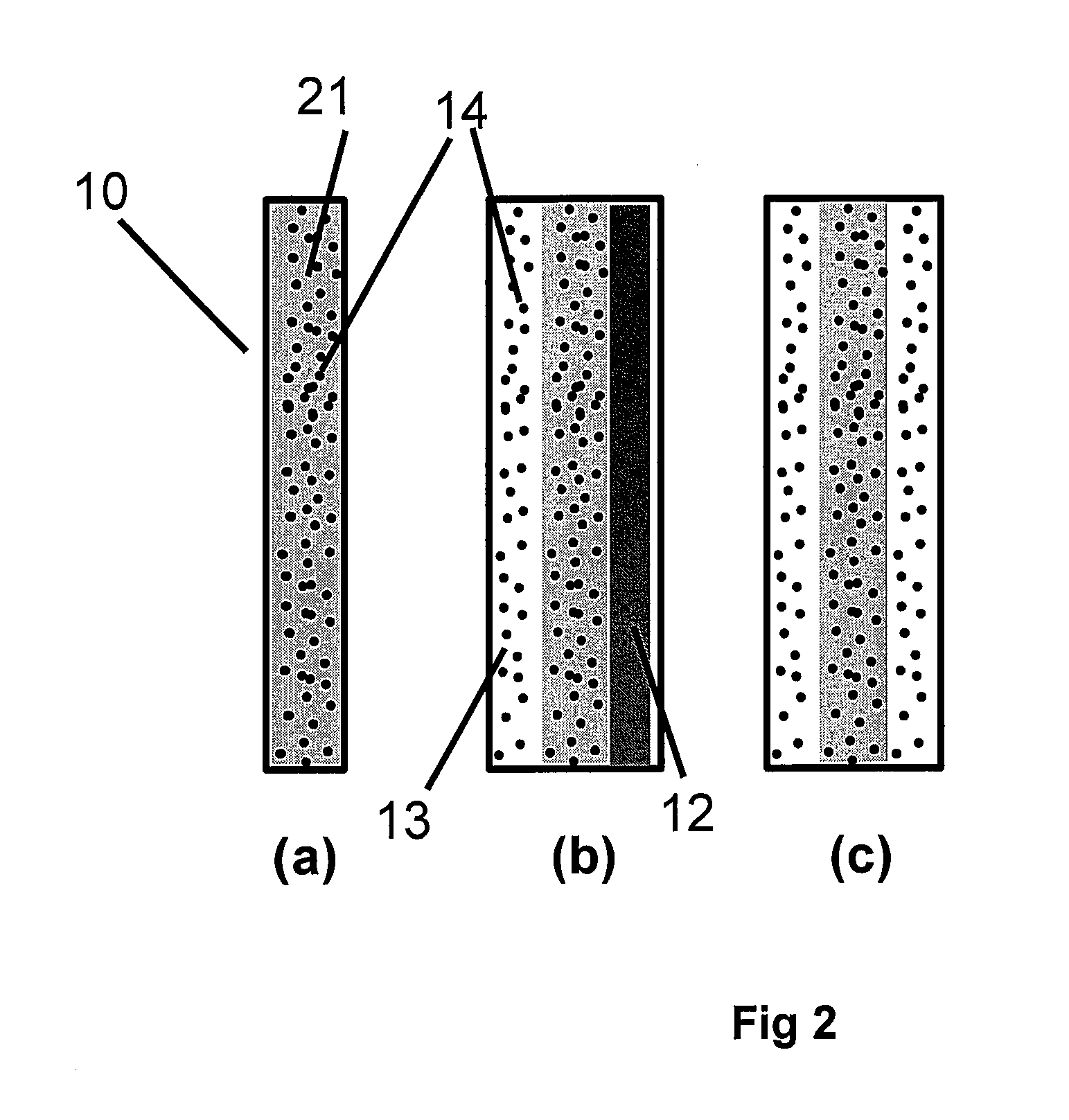

A solid polymer electrolyte membrane having a first surface and a second surface opposite the first surface, where the solid polymer electrolyte membrane has a failure force greater than about 115 grams and comprises a composite membrane consisting essentially of (a) at least one expanded PTFE membrane having a porous microstructure of polymeric fibrils, and (b) at least one ion exchange material impregnated throughout the porous microstructure of the expanded PTFE membrane so as to render an interior volume of the expanded PTFE membrane substantially occlusive; (c) at least one substantially occlusive, electronically insulating first composite layer interposed between the expanded PTFE membrane and the first surface, the first composite layer comprising a plurality of first carbon particles supporting a catalyst comprising platinum and an ion exchange material, wherein a plurality of the first carbon particles has a particle size less than about 75 nm, or less than about 50 nm, or less than about 25 nm.

Owner:WL GORE & ASSOC INC

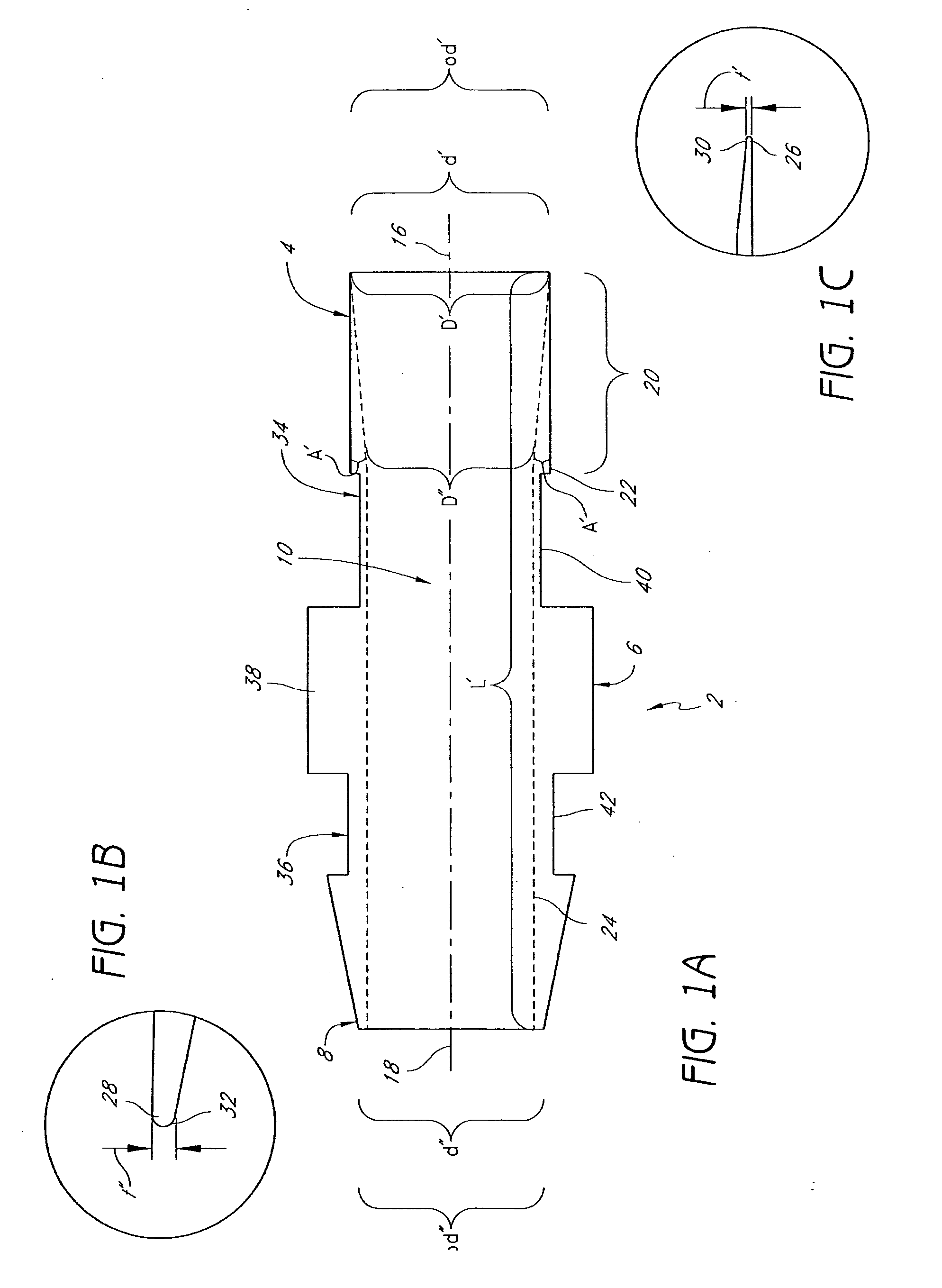

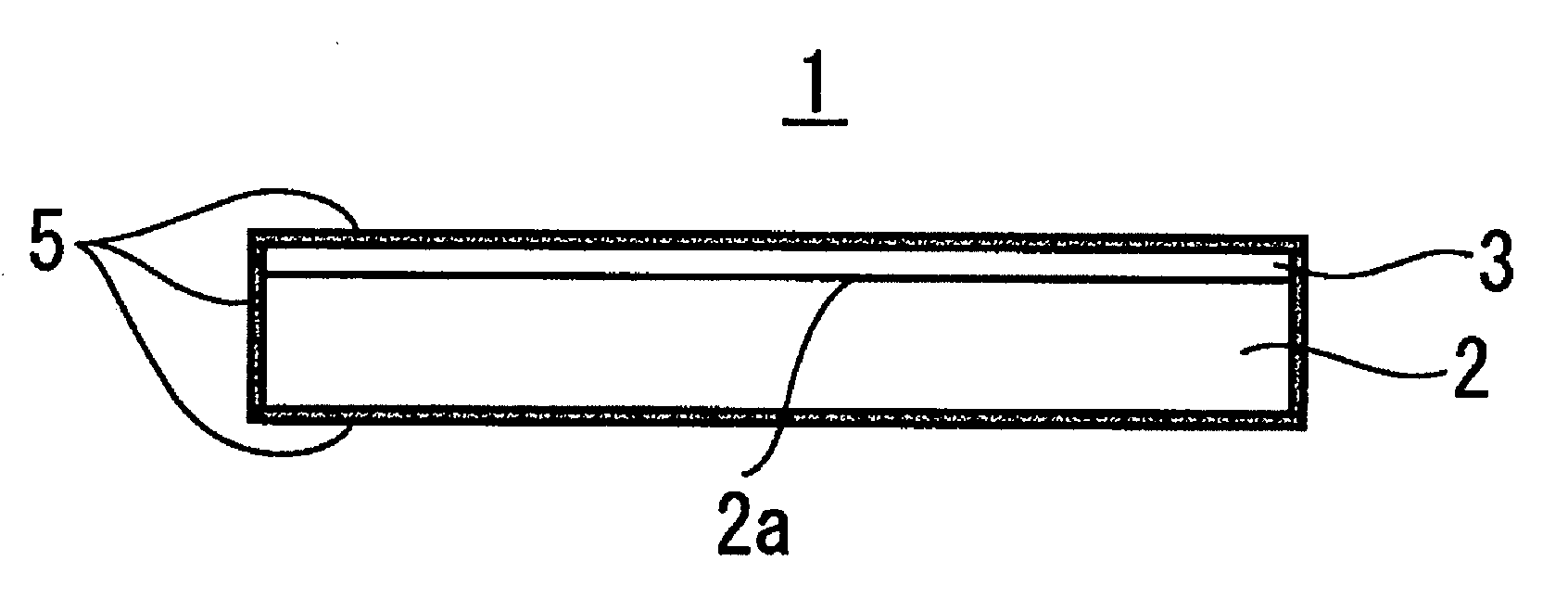

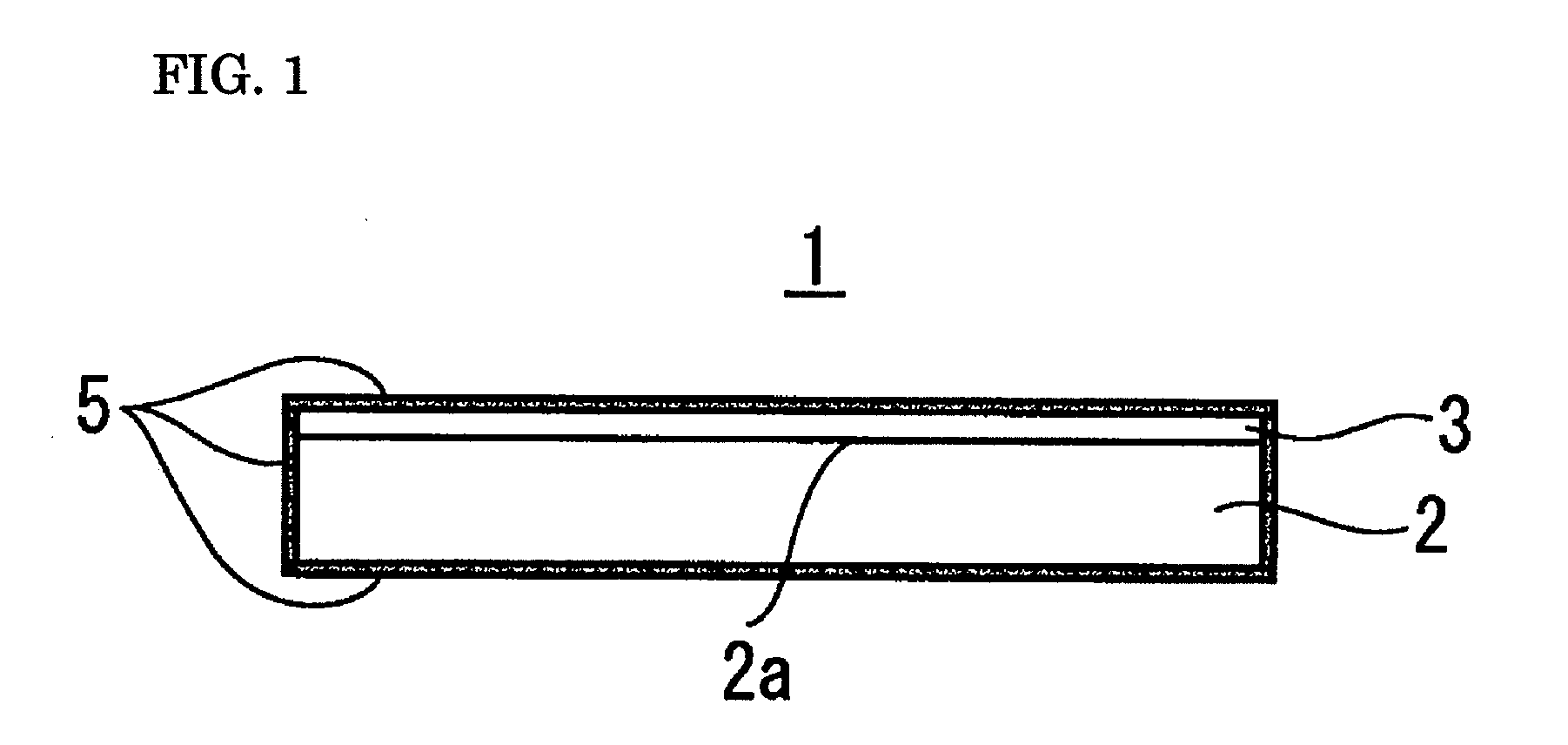

Thin-wall polytetrafluoroethylene tube

A thin-wall PTFE (polytetrafluoroethylene) tube in the form of a tube of porous expanded PTFE film wherein the porous PTFE film has a microstructure containing a multiplicity of fibrils. The thin-wall tube is used in a non-porous embodiment as the balloon portion of a balloon catheter. The thin-wall tube is not elastomeric; however, because of the thinness, strength and flexibility of the tube, it may be inserted into a body conduit in a collapsed state and then deployed from a catheter and inflated up to the maximum diameter of the thin-wall tube. The porous PTFE film is provided with a continuous layer of adhesive to provide the non-porous tube; the adhesive is preferably a thermoplastic and more preferably a thermoplastic fluoropolymer such as fluorinated ethylene propylene.

Owner:GORE ENTERPRISE HLDG INC

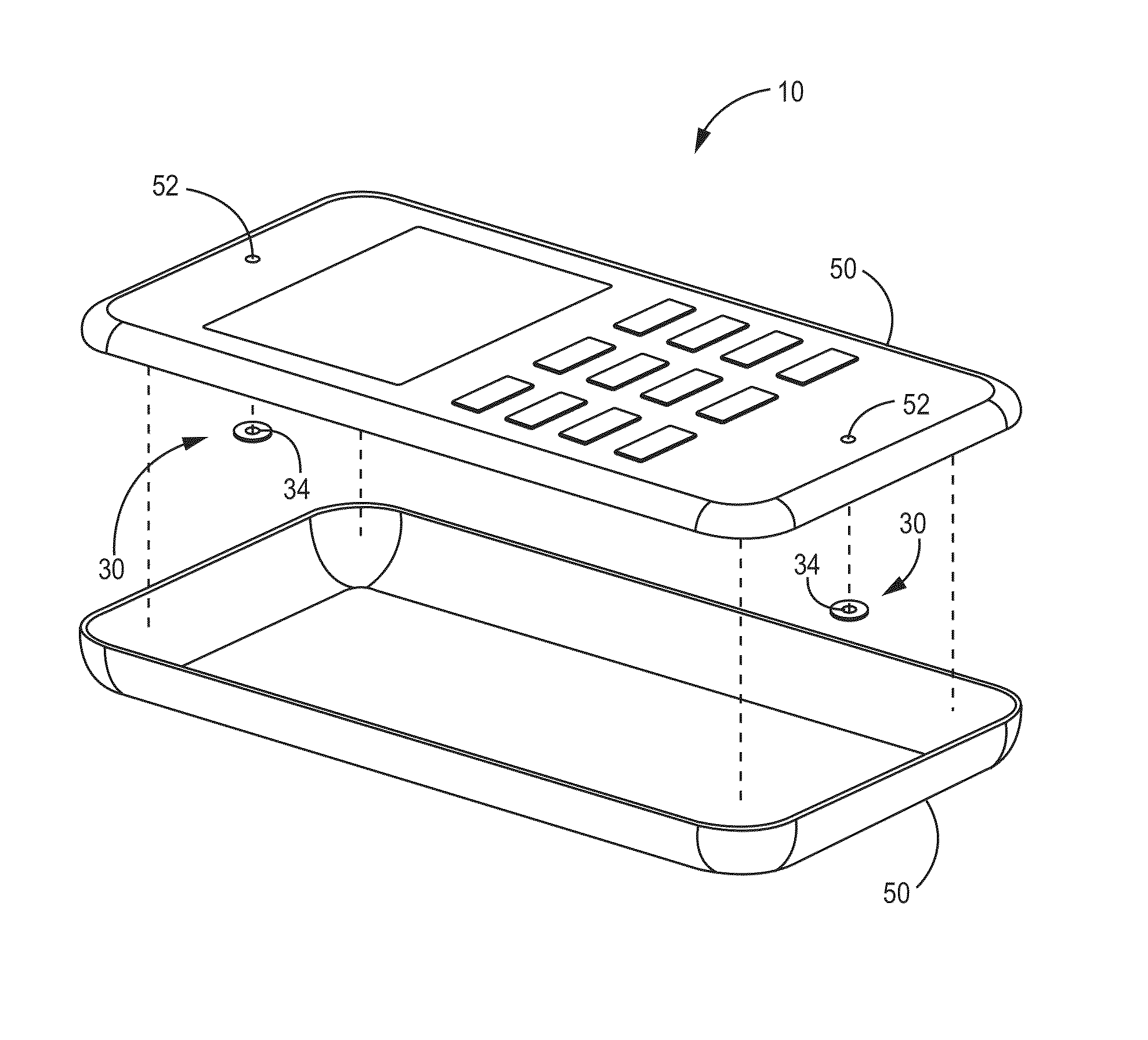

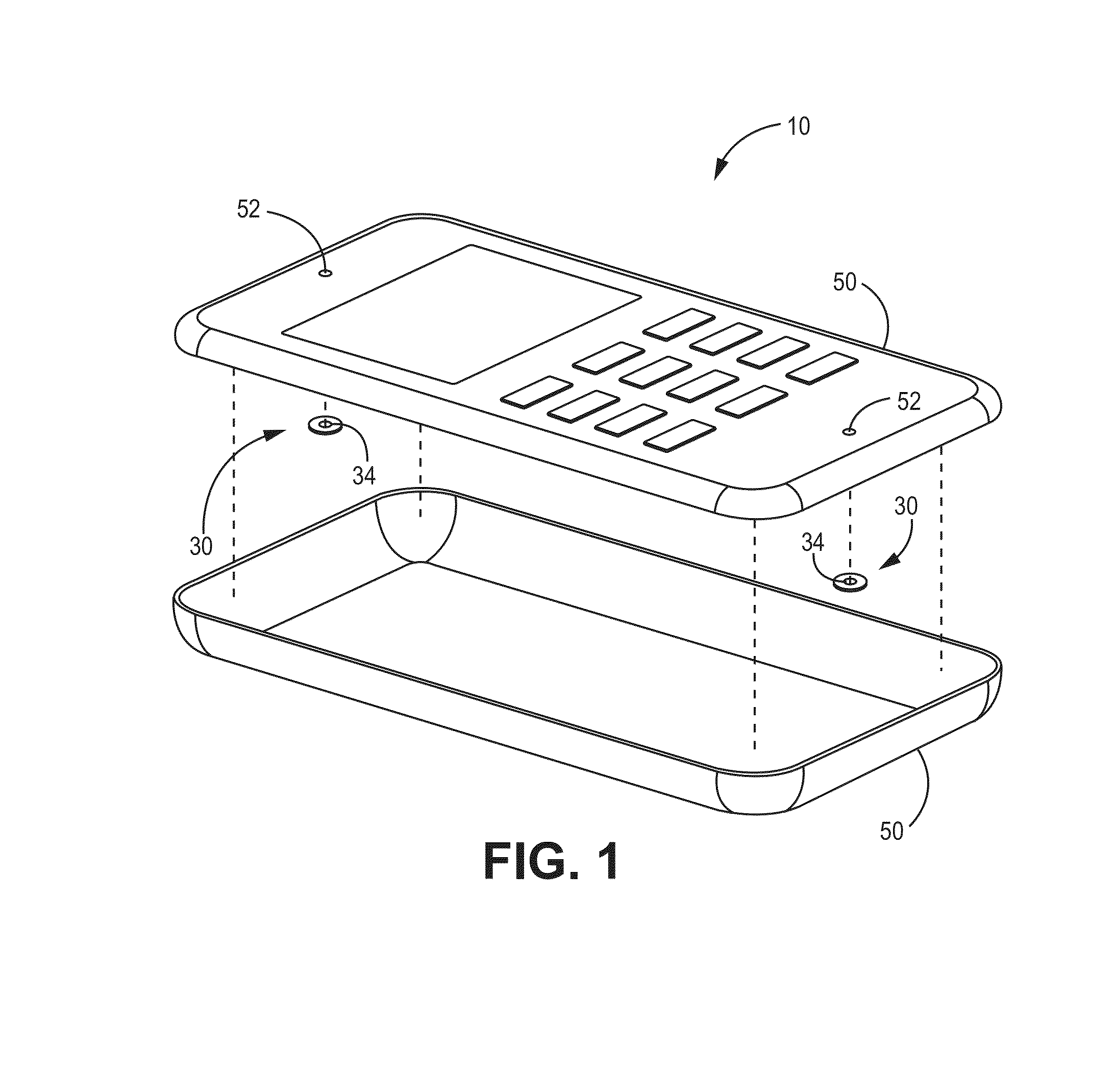

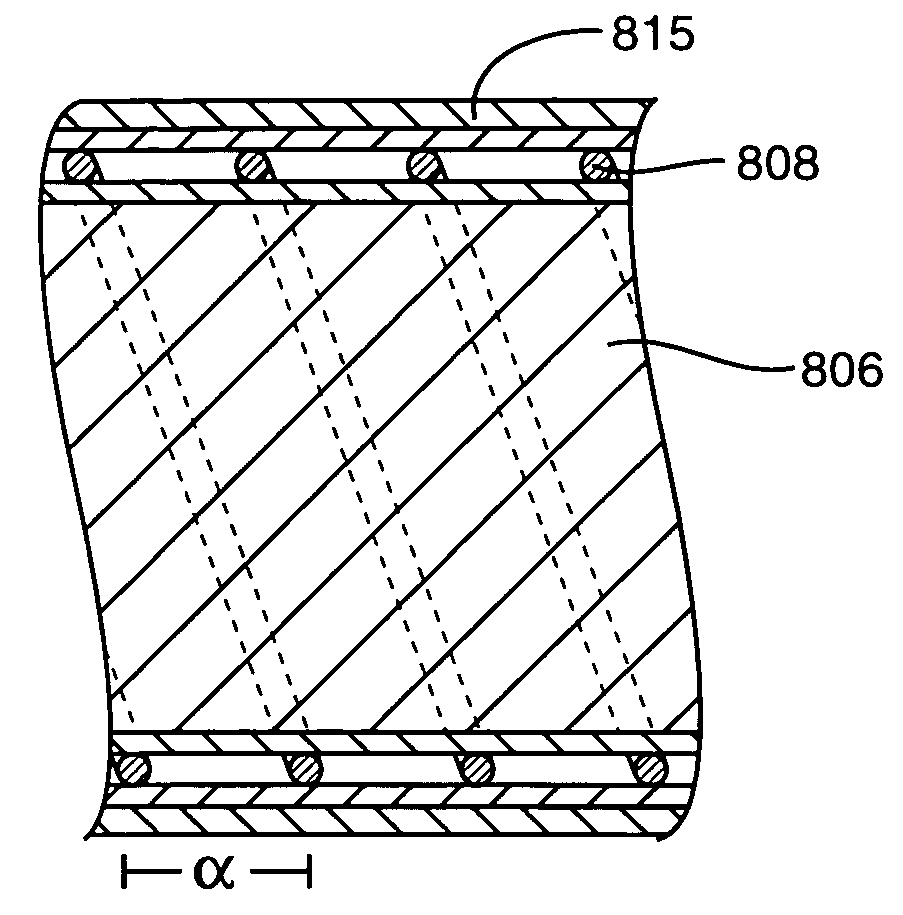

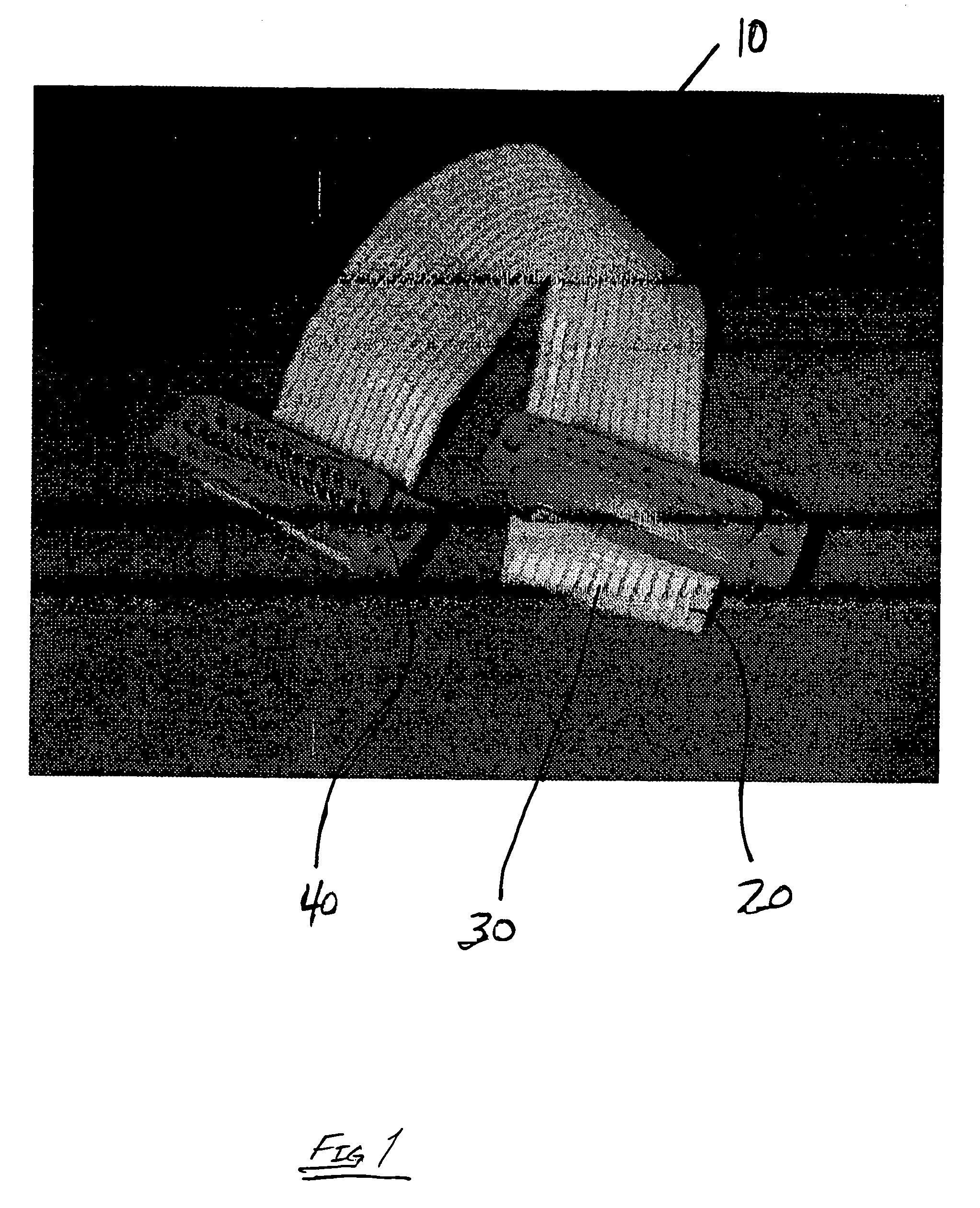

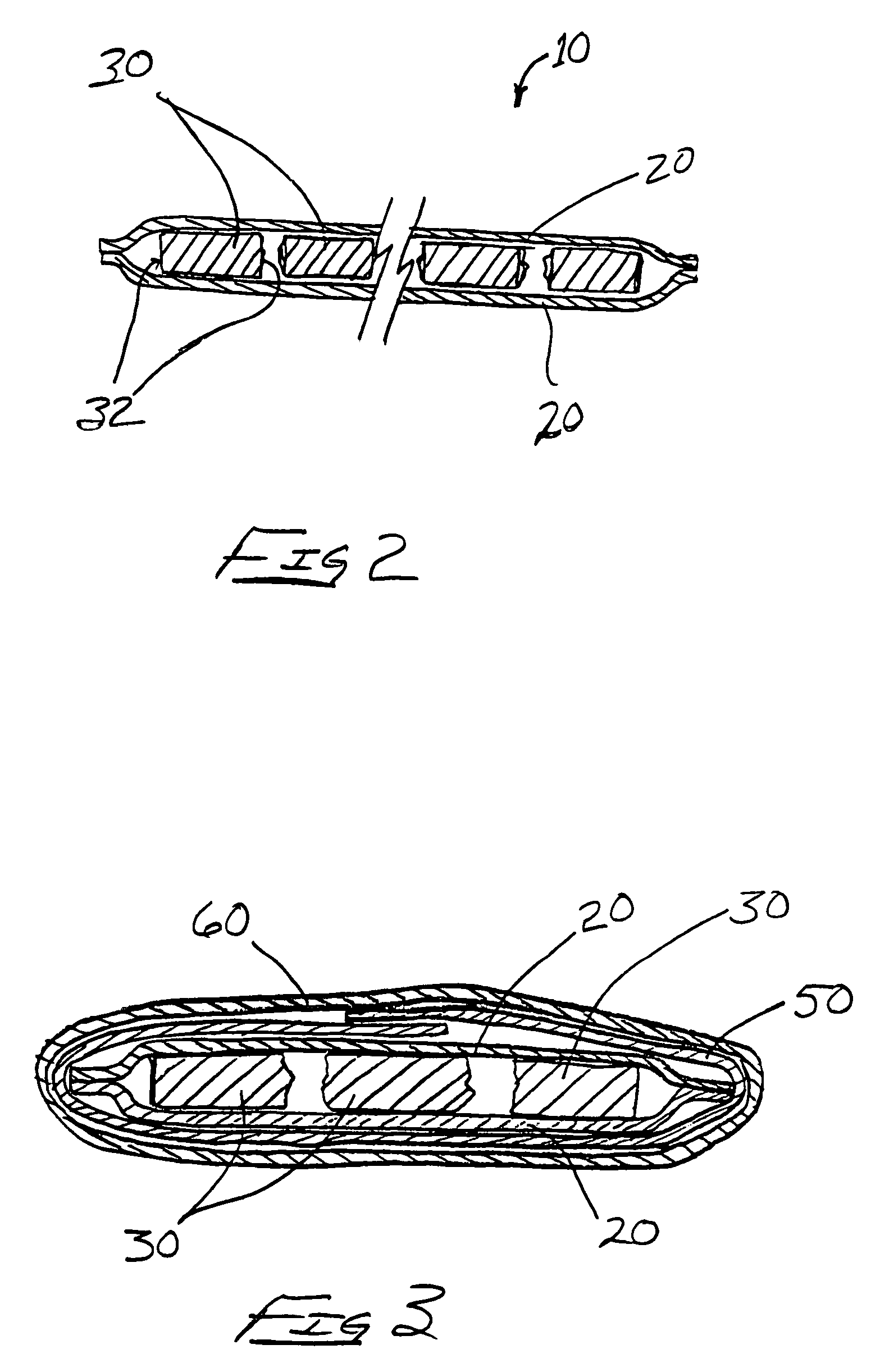

Self-Sealing Ptfe Graft with Kink Resistance

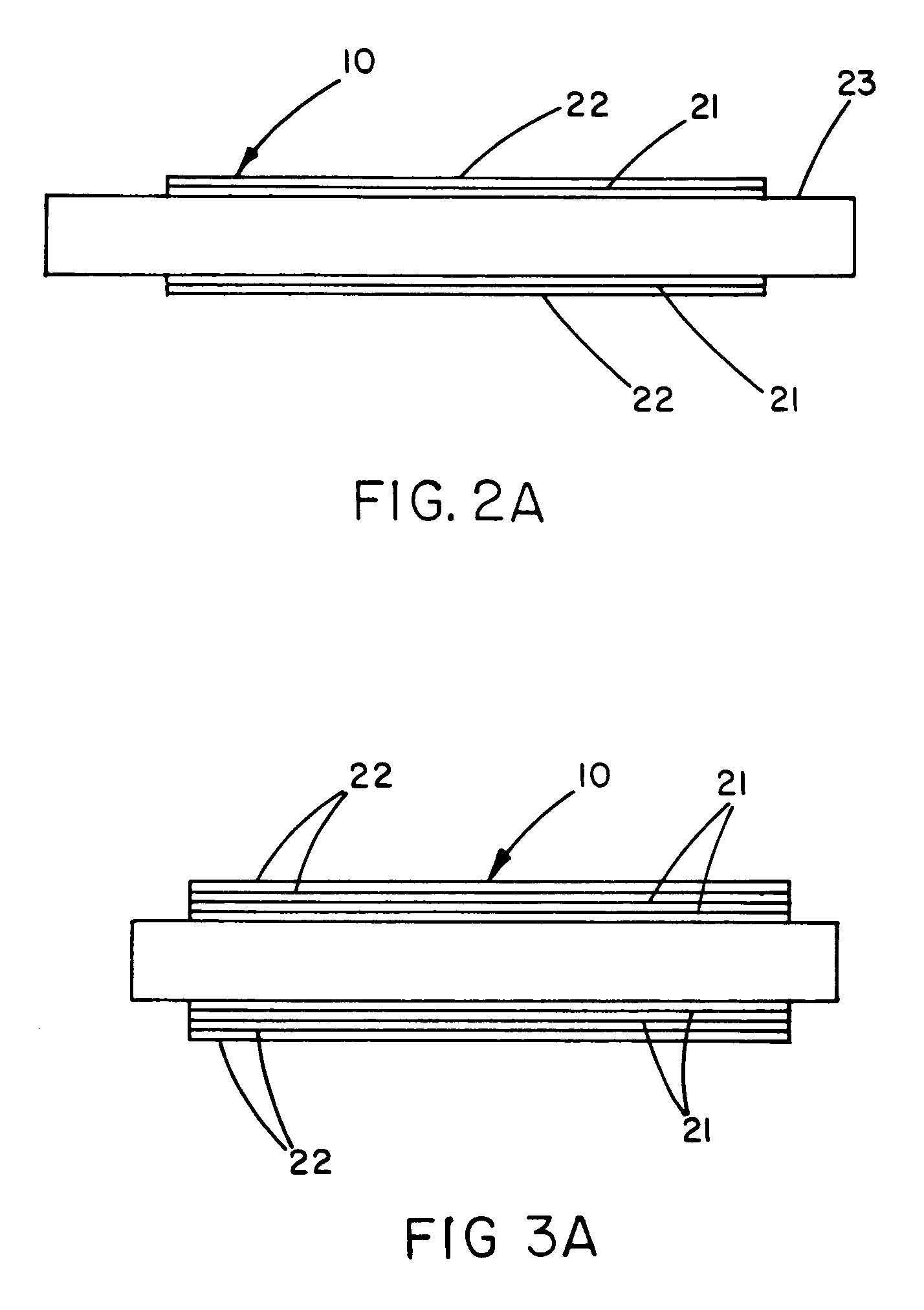

InactiveUS20080027534A1High porosityMaintain good propertiesStentsIntravenous devicesMedicineVascular graft

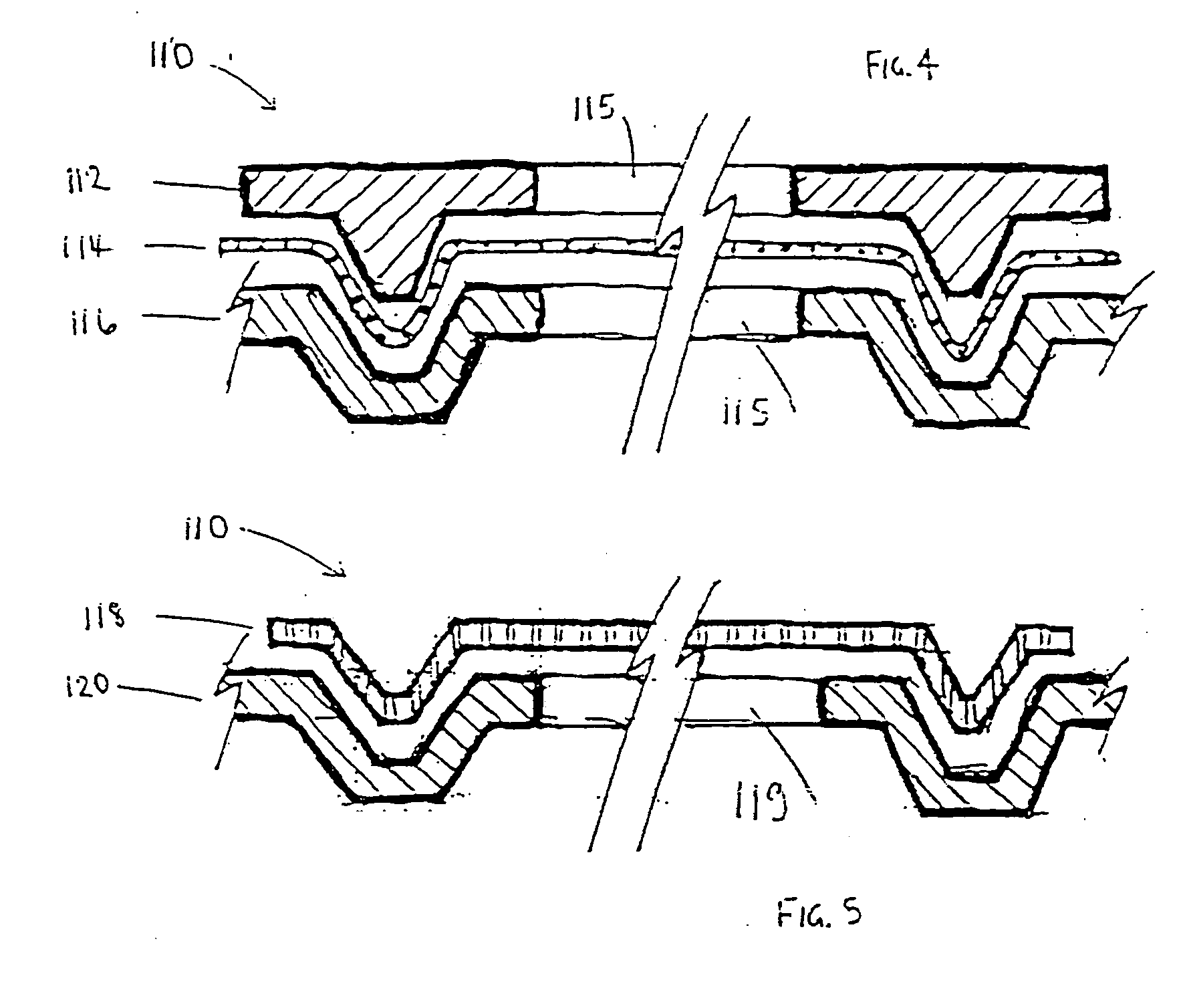

A self-sealing vascular graft, including a substrate with a sealant layer and several optional additional layers, is described. The substrate can be ePTFE and the material used for the sealant and additional layers can be polyurethane. The sealant layer and additional layers may include one or more base layers, one or more foam layers, beading of different sizes and shapes, and ePTFE tape. A flared cuff may be integral to one or both ends of the substrate or may be attached to one or both ends. Various methods of making a self-sealing vascular graft are also described, including methods of disposition, methods of forming, methods of bonding and methods of attaching.

Owner:CR BARD INC

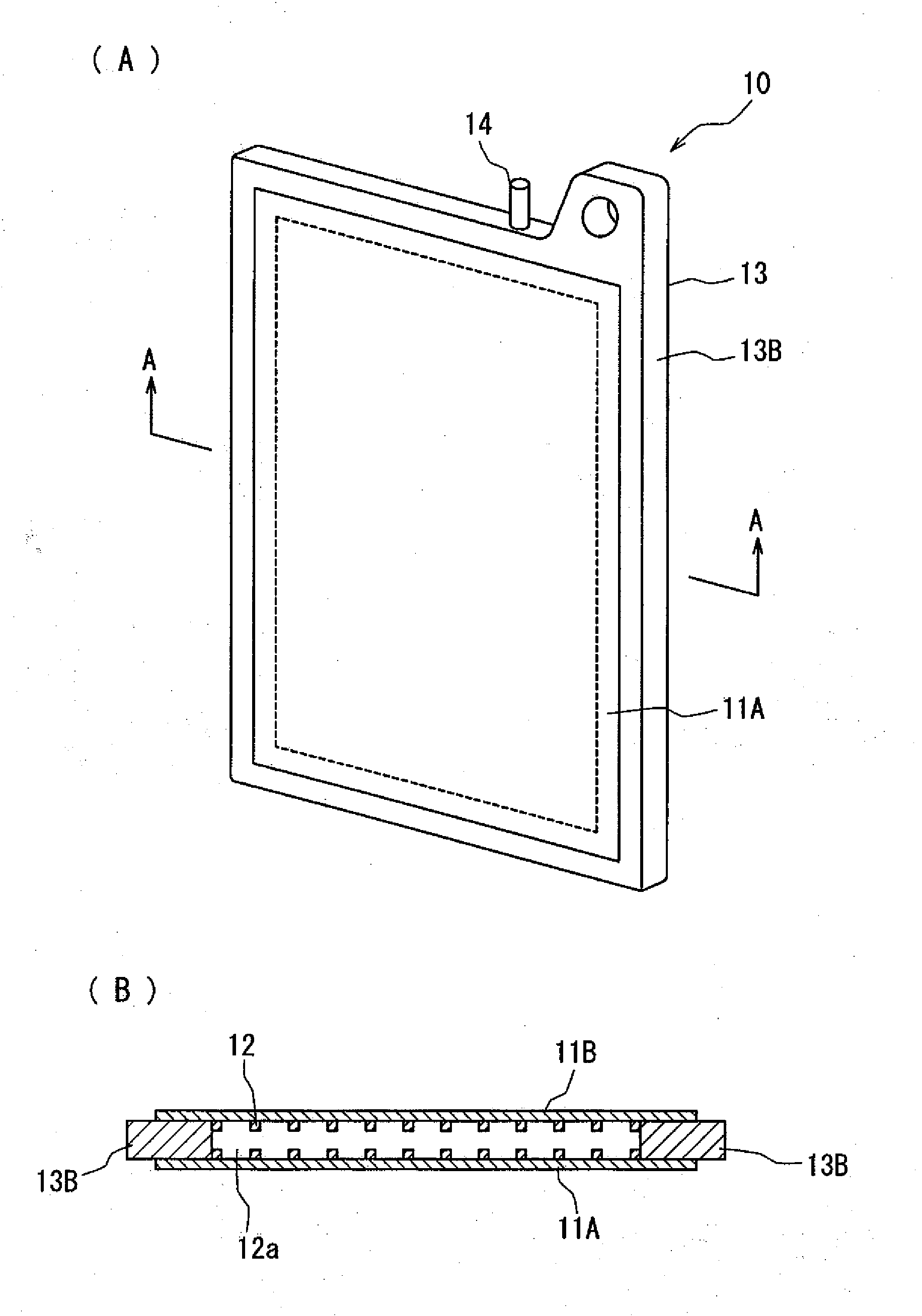

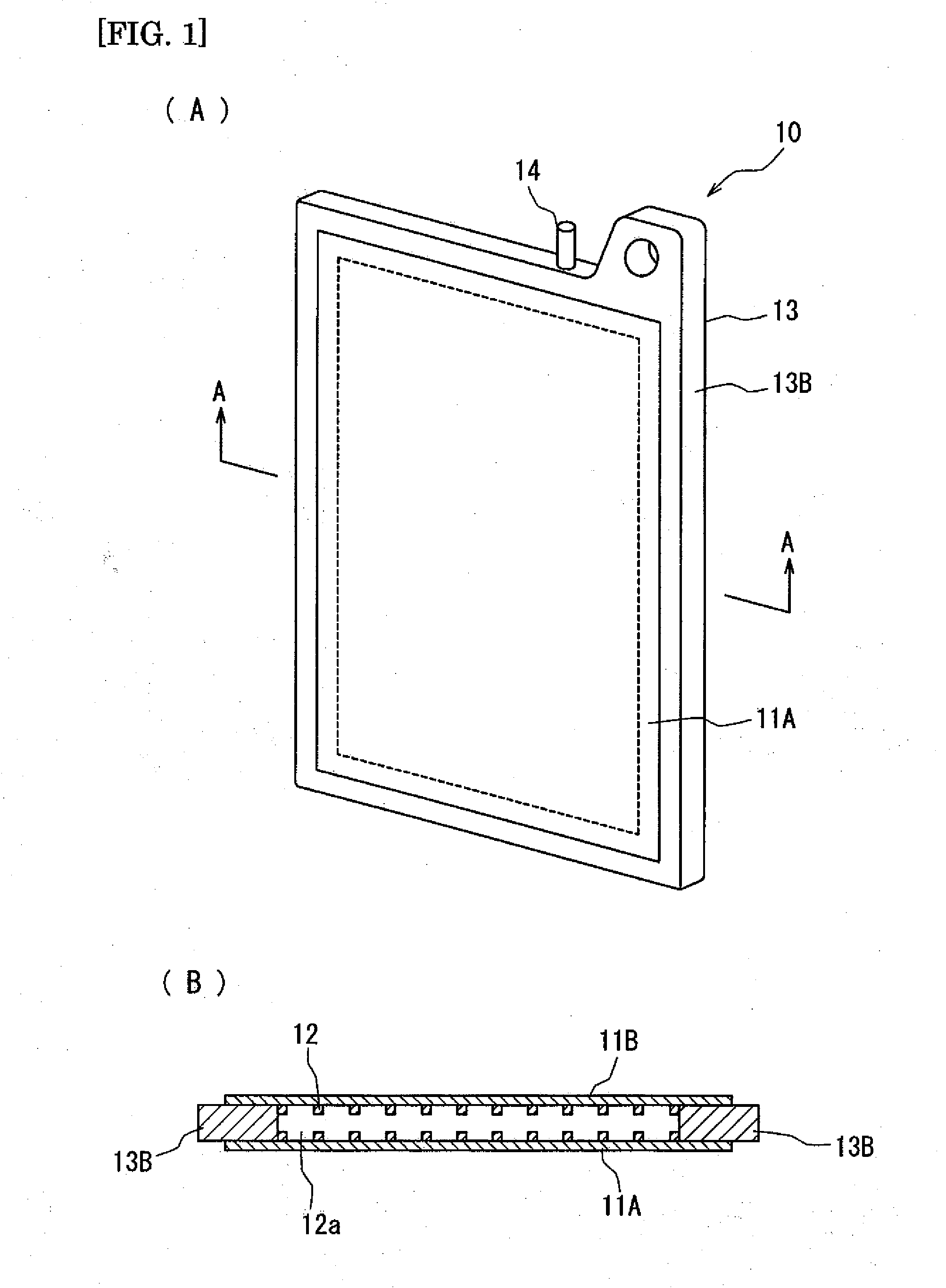

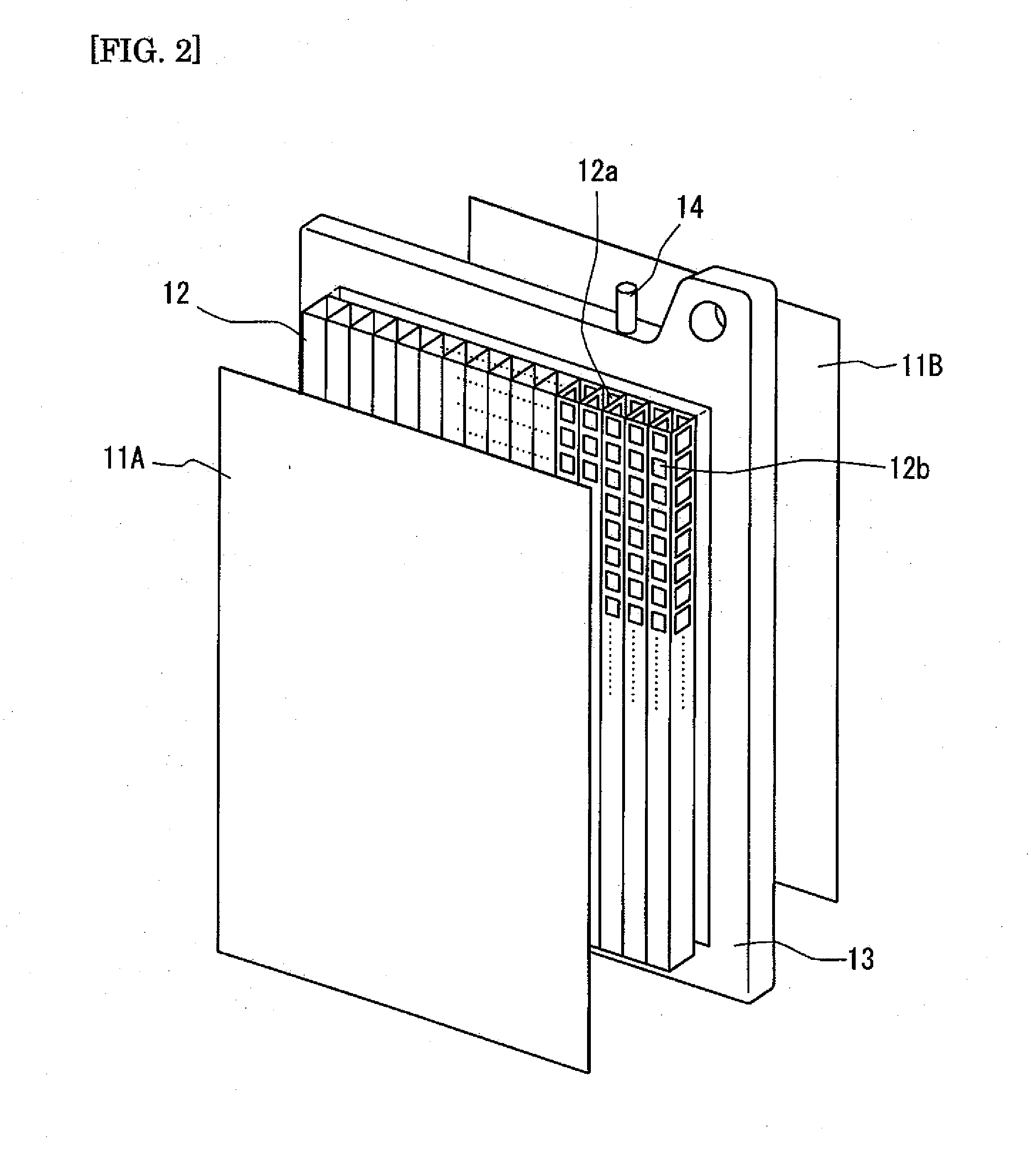

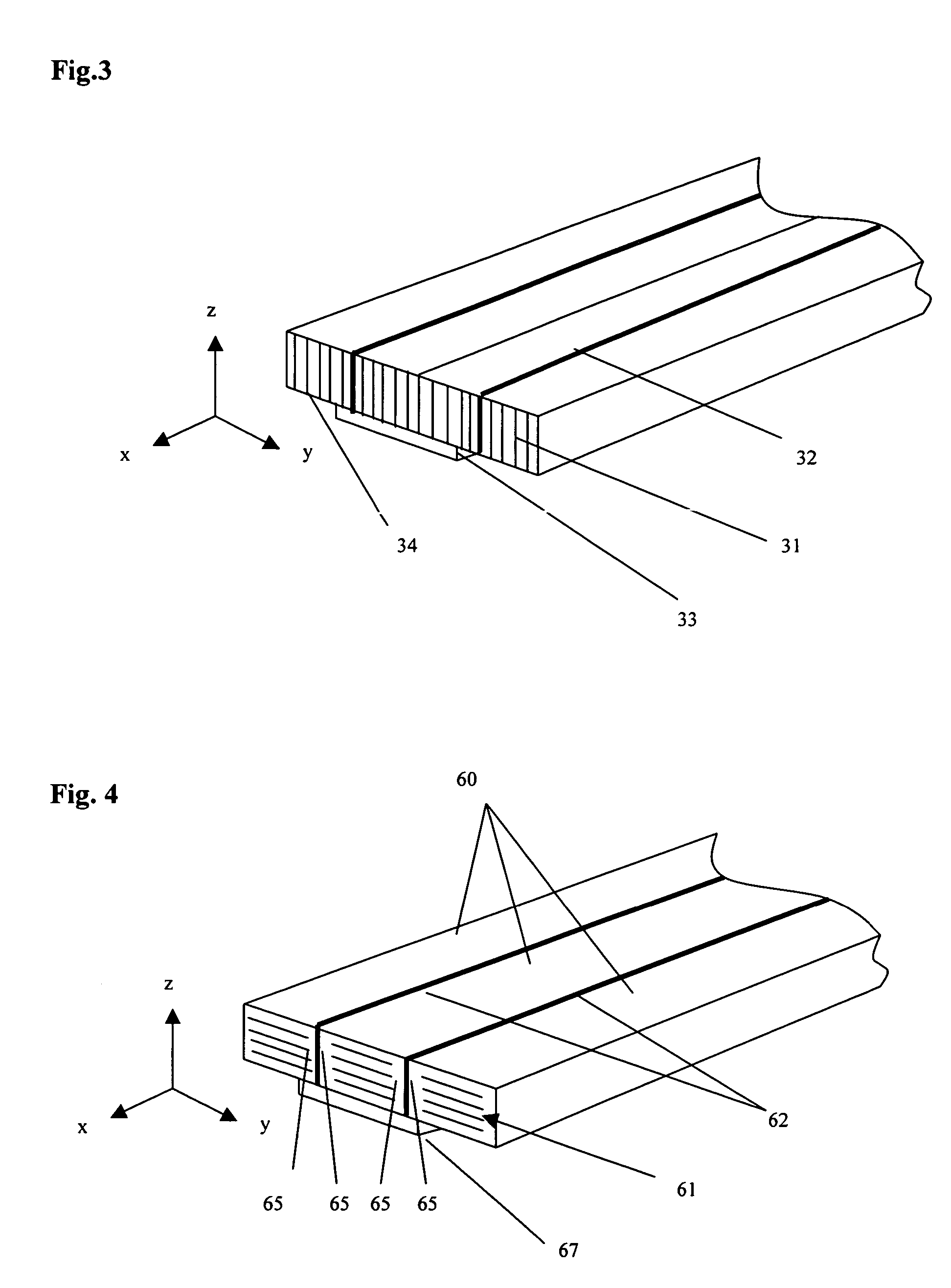

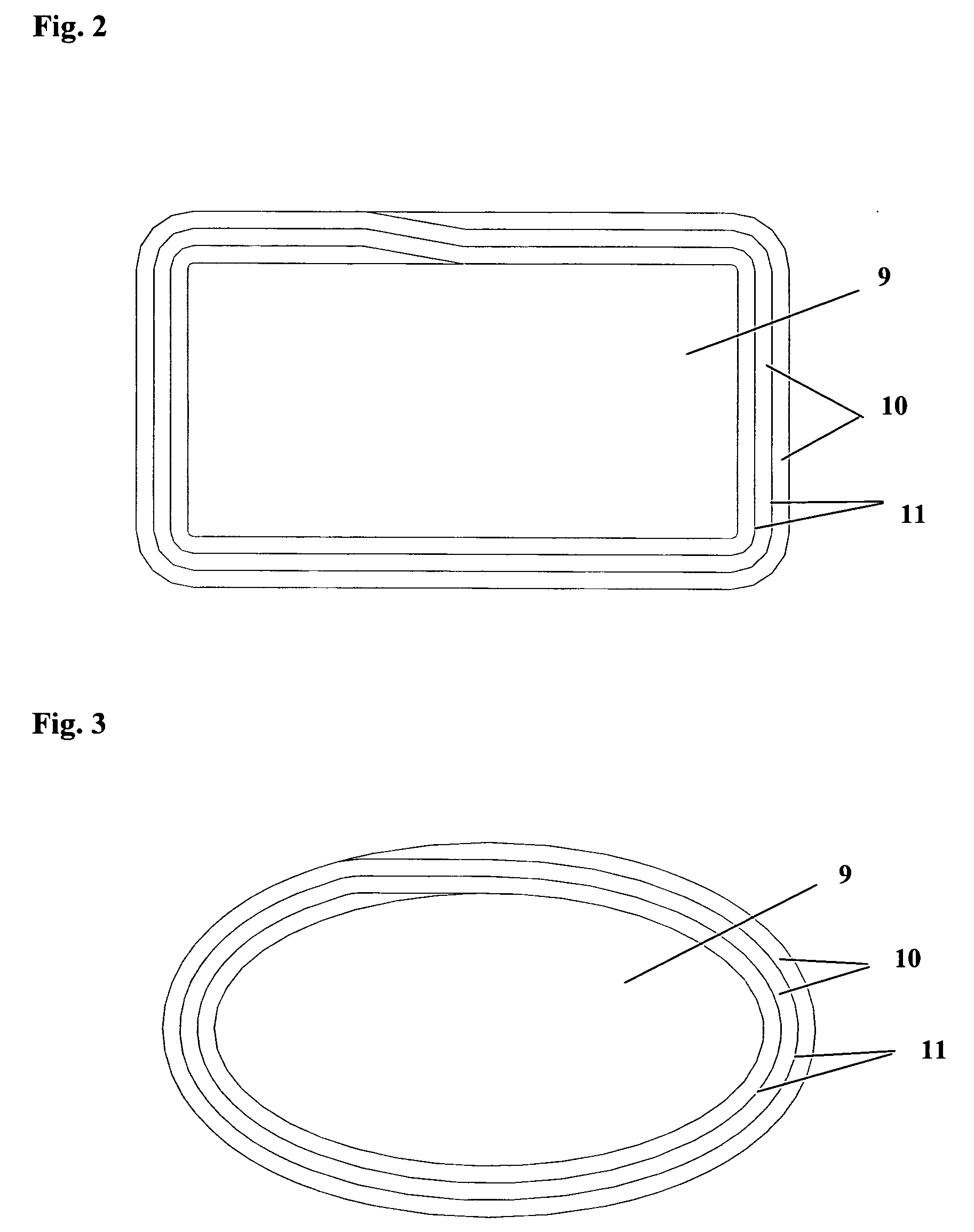

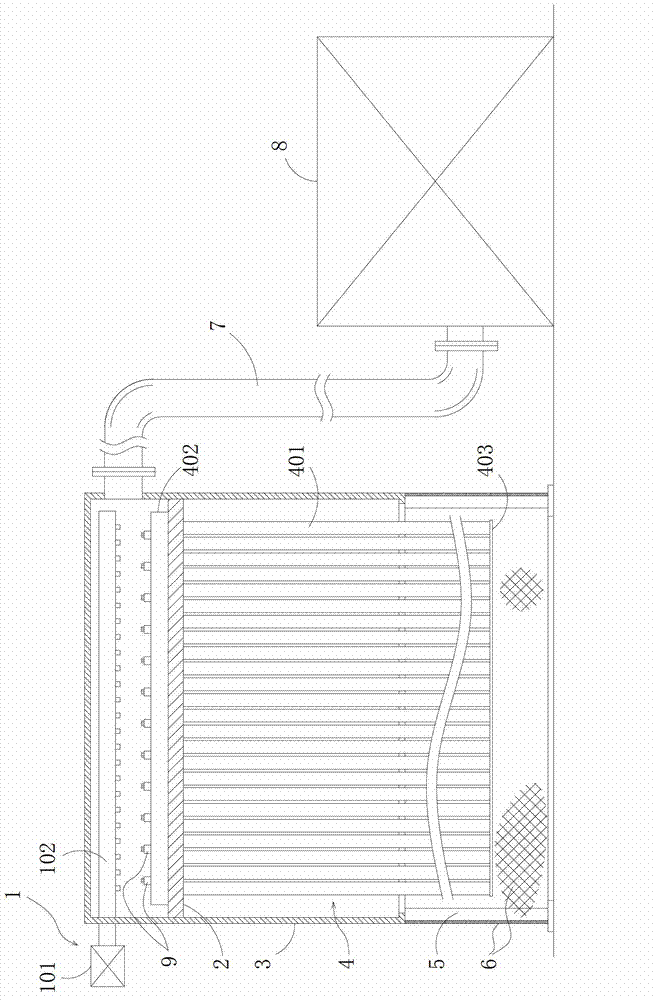

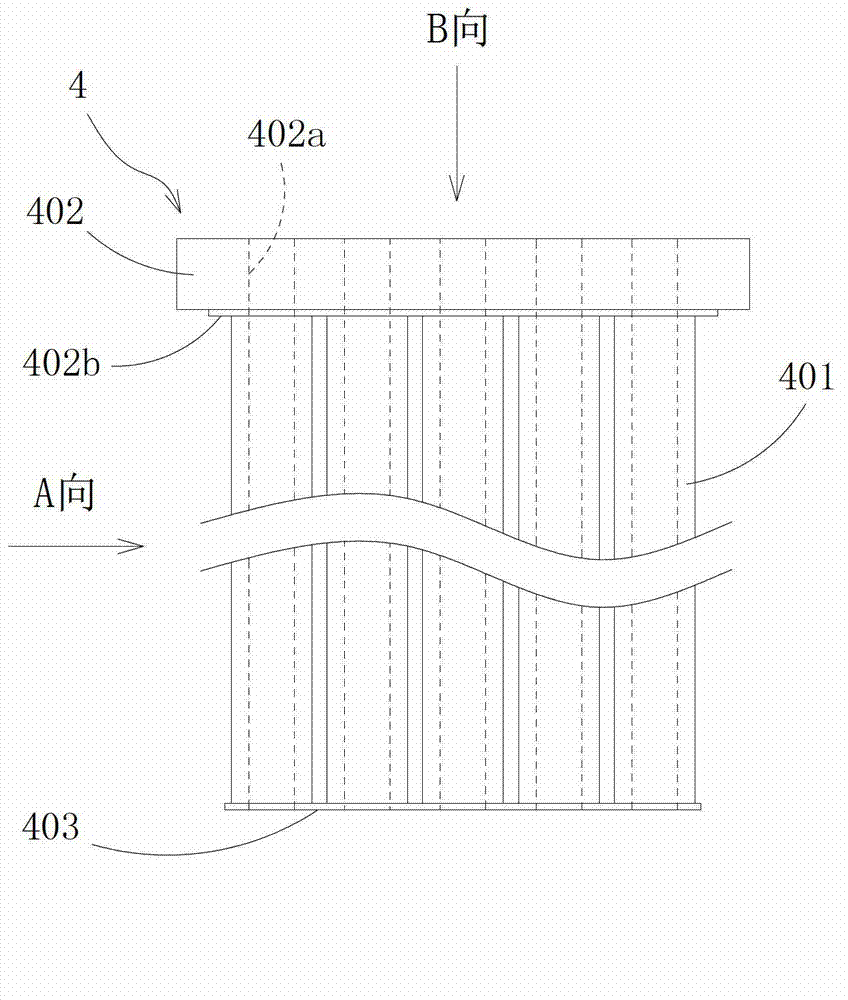

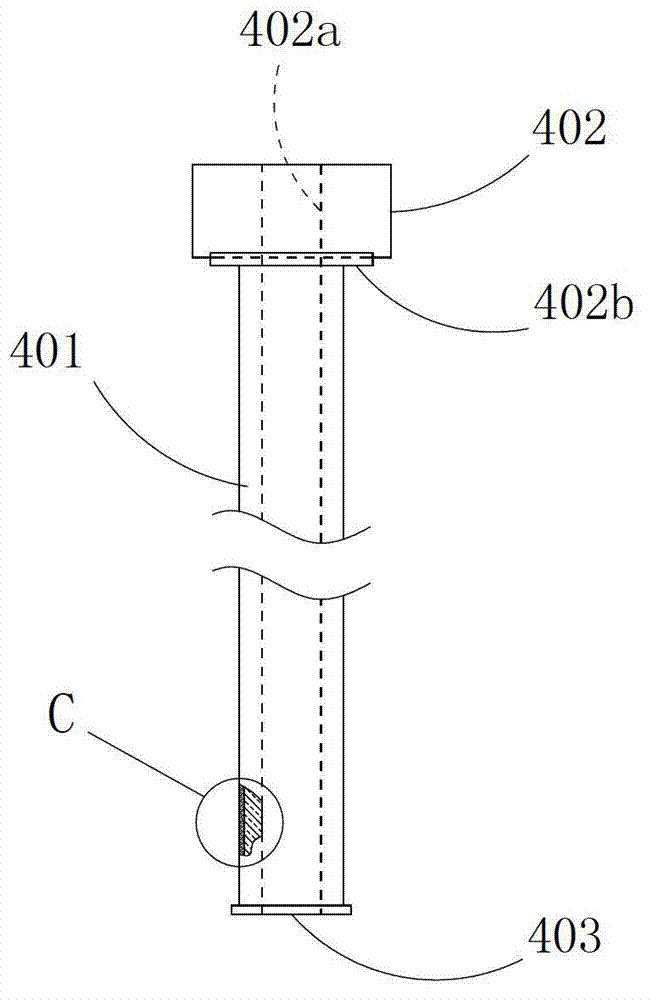

Flat sheet membrane element for filtration and flat sheet membrane filtration module

InactiveUS20100096317A1Improve performanceStable permeation flow rateMembranesUltrafiltrationFiltration membranePorous membrane

A flat sheet membrane element for performing solid-liquid separation by immersion in a liquid to be treated which contains a suspended component includes sheet-shaped filtration membranes disposed opposite to each other with a space for a treated liquid flow path, a support portion for securing the space for the treated liquid flow path, and a peripheral sealing portion for sealing the peripheral edges of the filtration membranes arranged opposite to each other so as to form at least one treated liquid outlet, the filtration membranes including at least expanded PTFE (polytetrafluoroethylene) porous membranes.

Owner:SUMITOMO ELECTRIC IND LTD

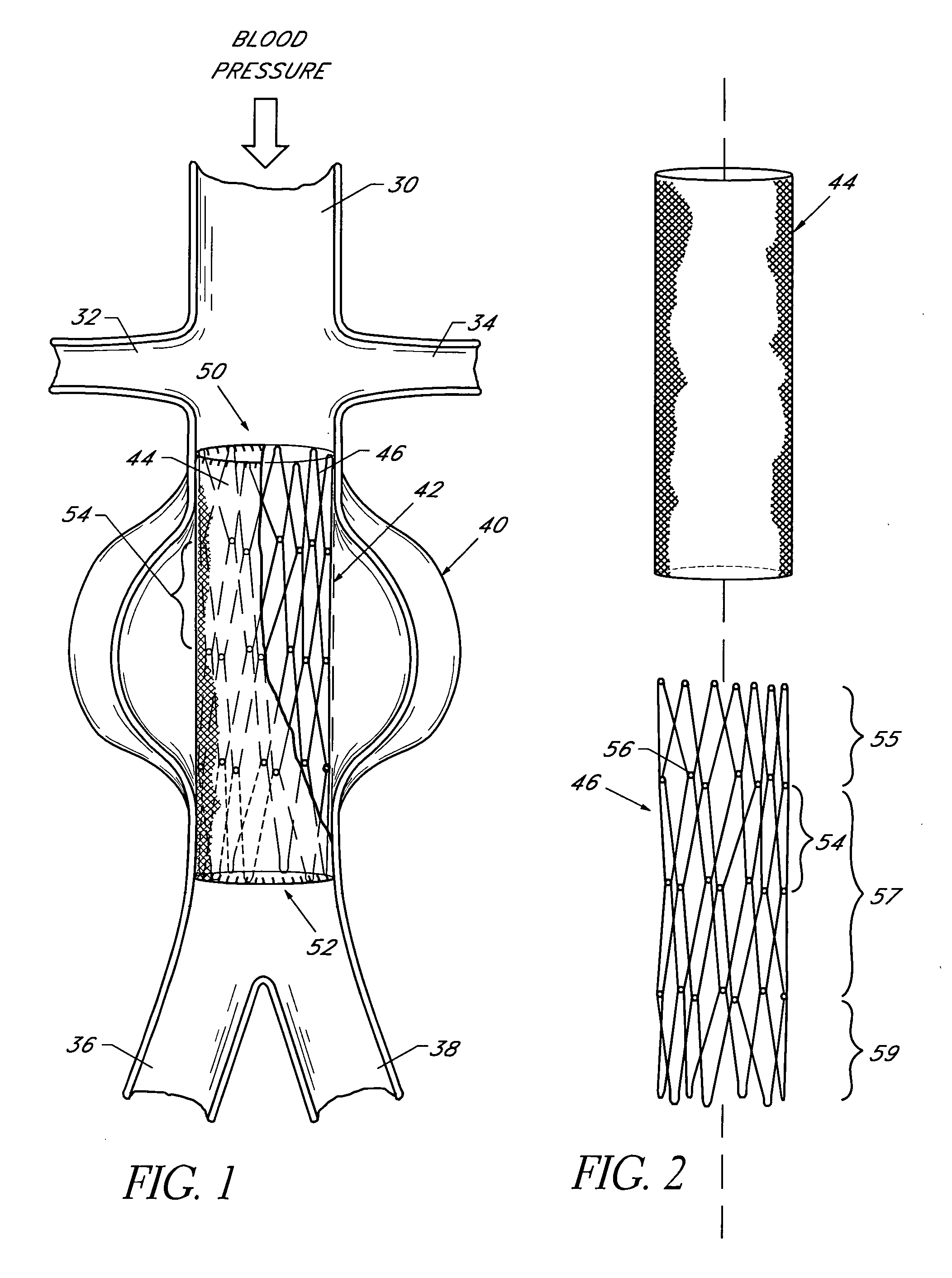

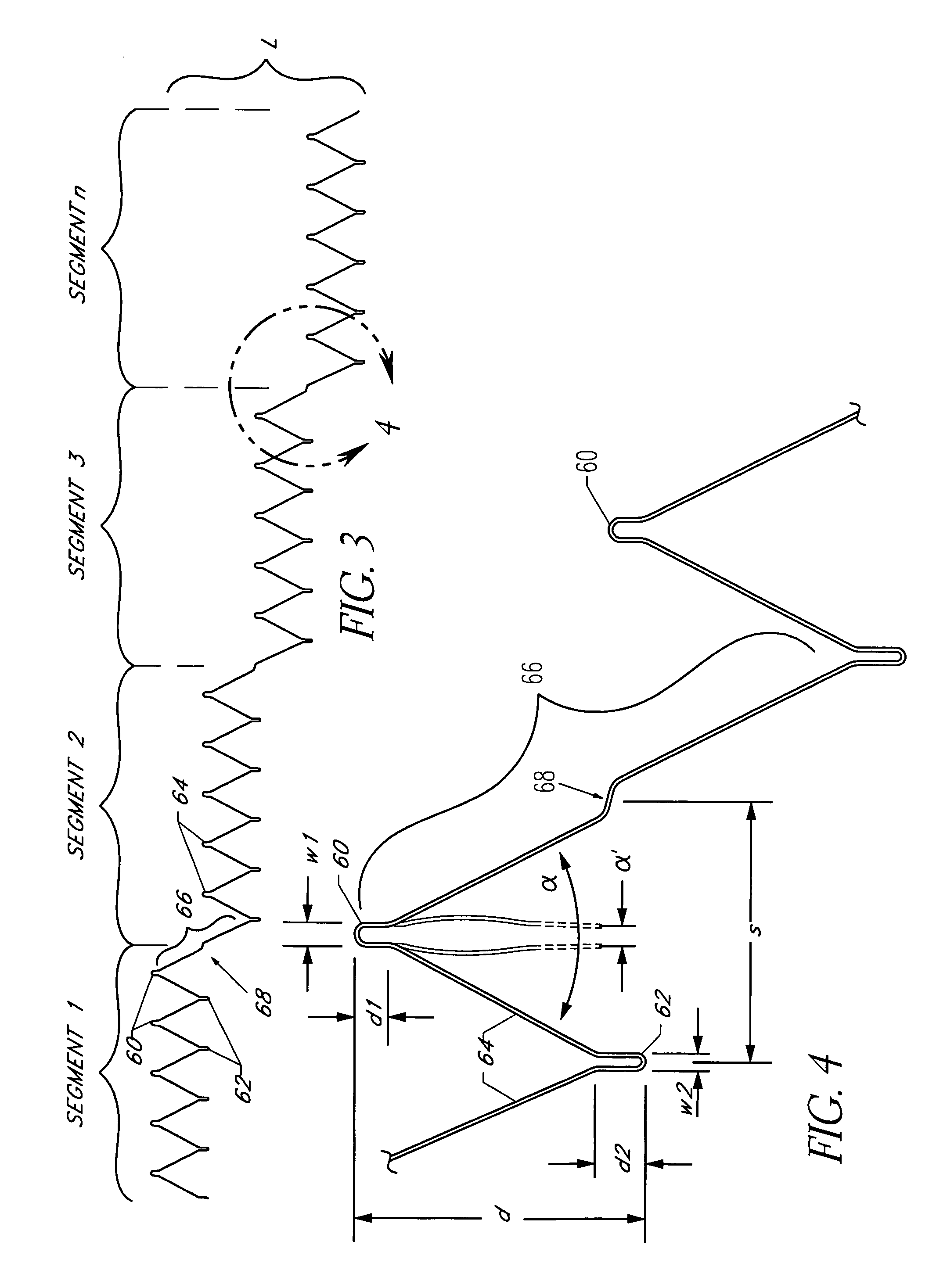

Endolumenal vascular prosthesis with neointima inhibiting polymeric sleeve

ActiveUS20050228480A1Improve physical propertiesInhibition formationStentsBlood vesselsNeointimaTunica intima

The present invention is related to a low profile endolumenal prosthesis. The prosthesis comprises a radially expandable tubular wire support and an expanded PTFE membrane. The density, wall thickness and intranodal distance of the ePTFE are selected to inhibit the formation and nourishment of a viable neointima on the inner surface of the prosthesis, through the ePTFE membrane.

Owner:ENDOLOGIX LLC

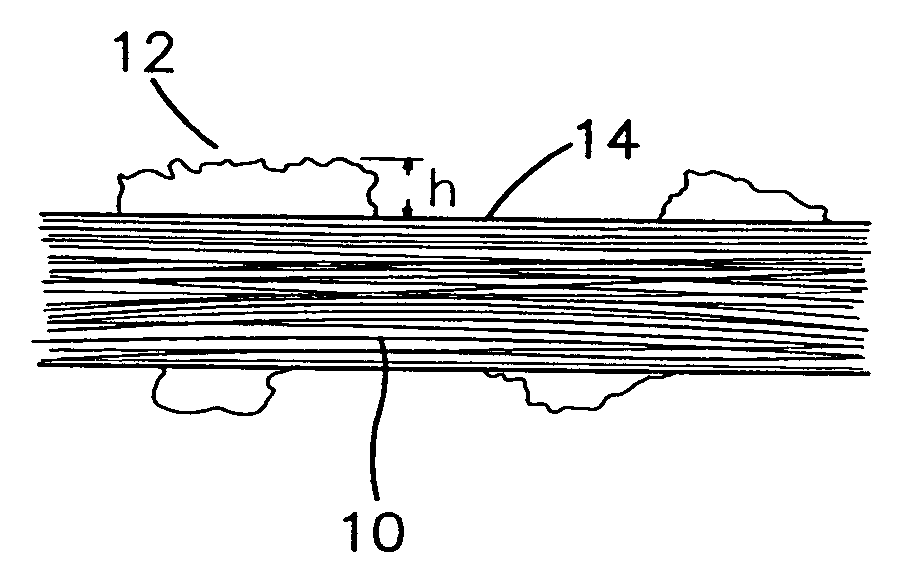

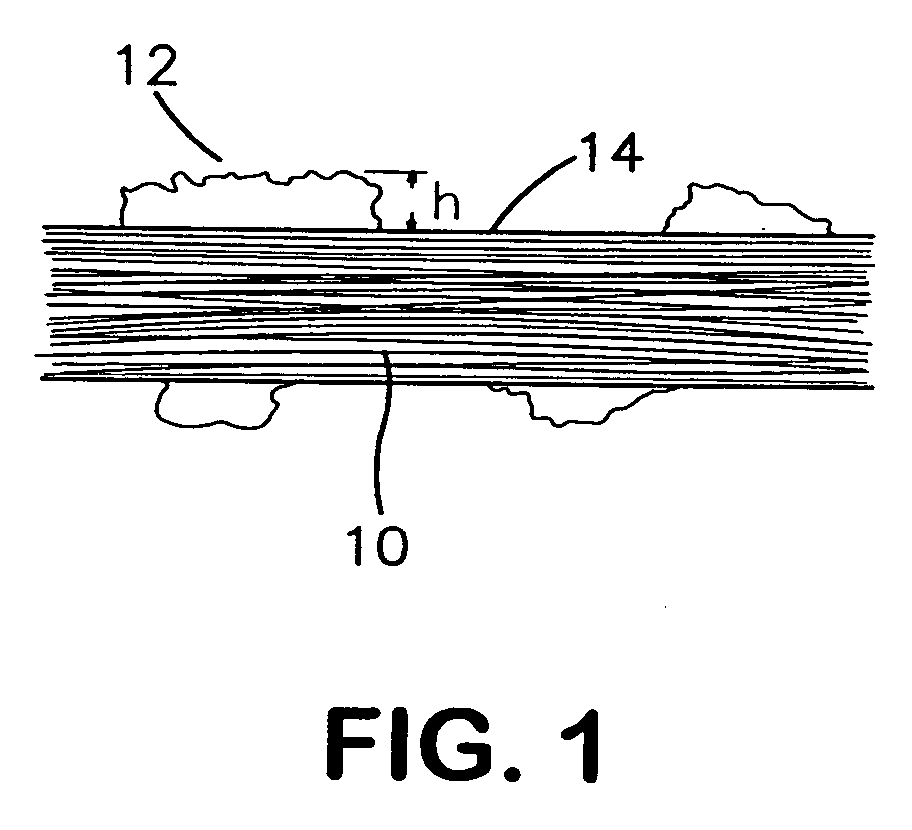

Expanded PTFE articles and method of making same

Unique PTFE structures comprising islands of PTFE attached to an underlying expanded polytetrafluoroethylene (ePTFE) structure and to methods of making such structures is disclosed. The ePTFE material may or may not have been exposed to amorphous locking temperatures. These unique structures exhibit islands of PTFE attached to and raised above the expanded PTFE structures.

Owner:WL GORE & ASSOC INC

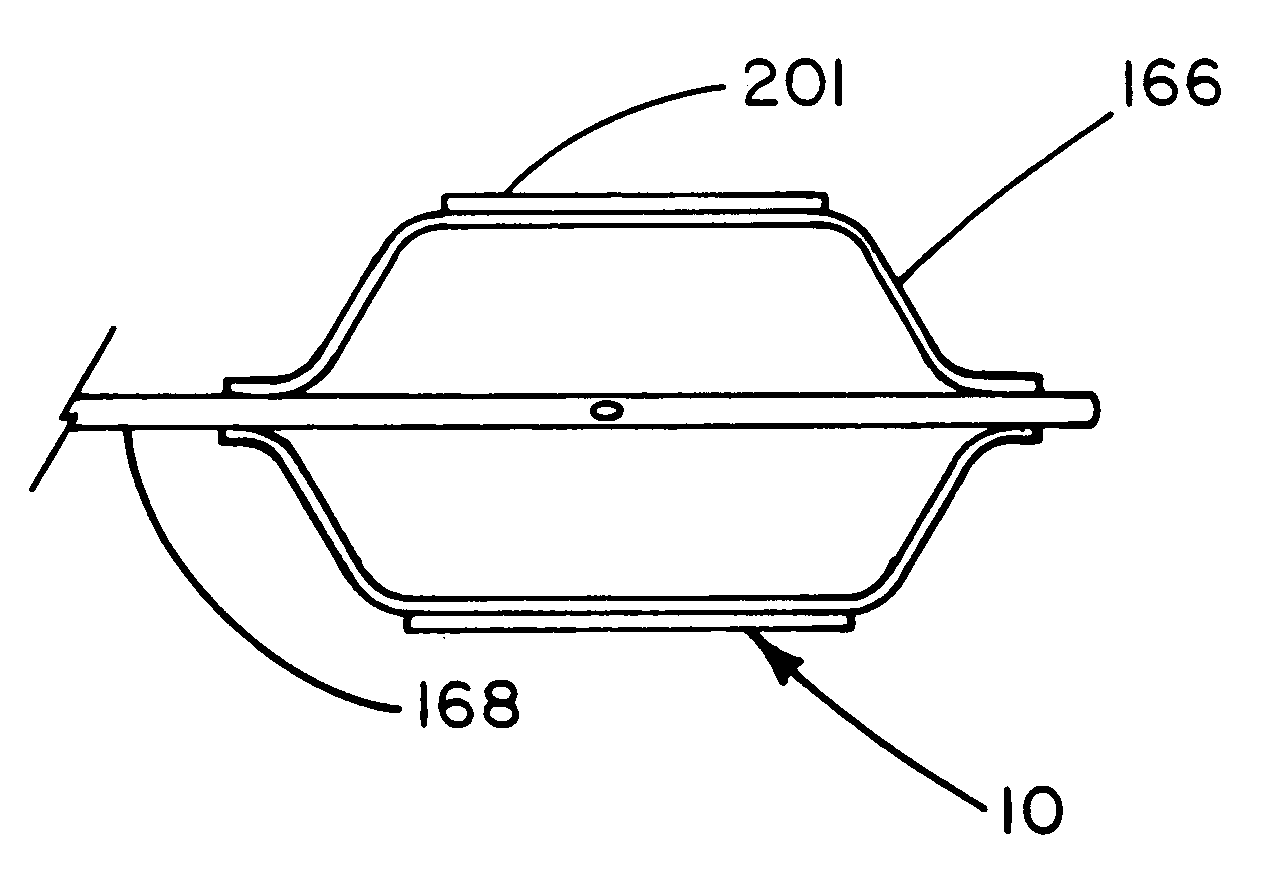

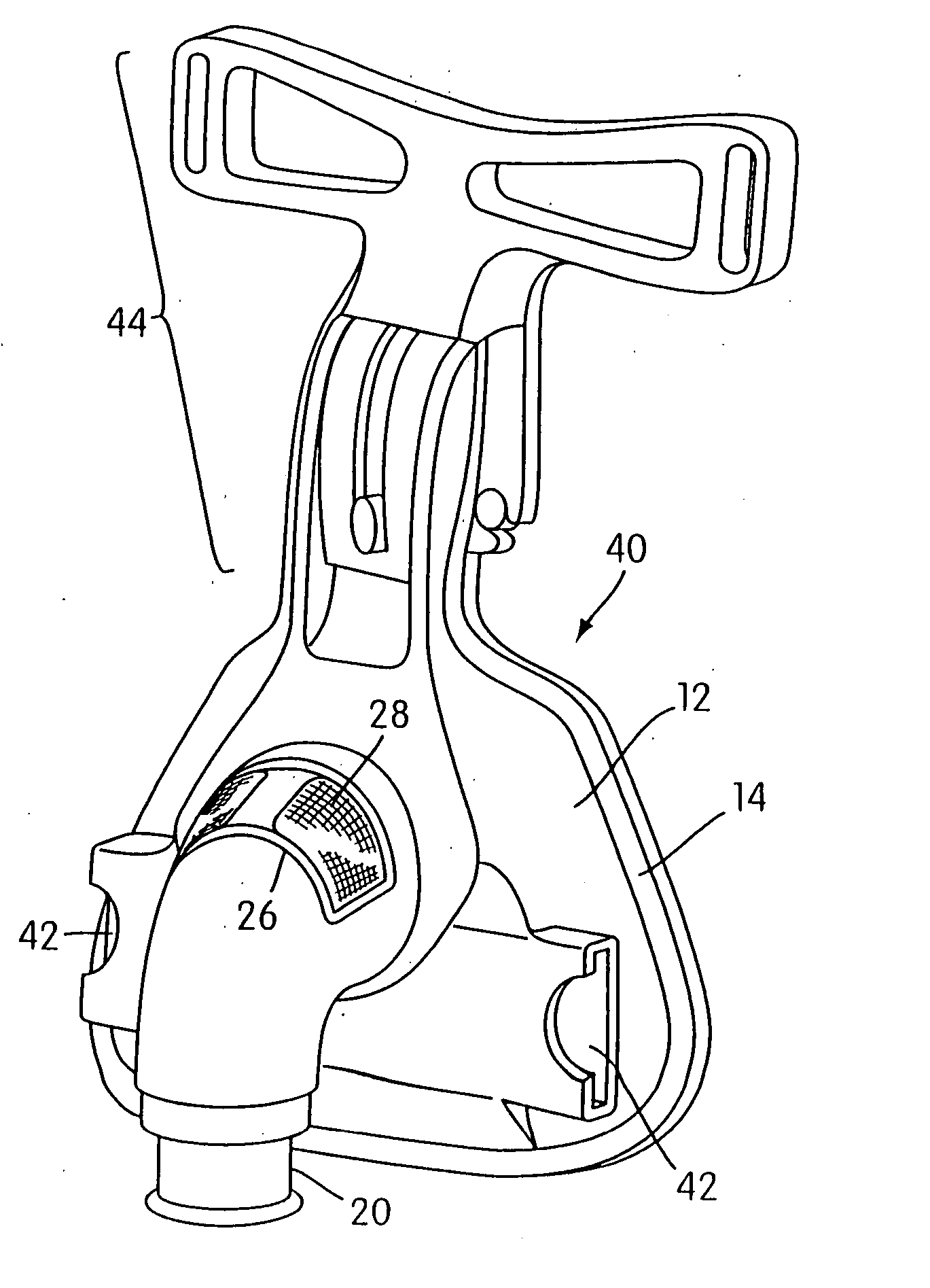

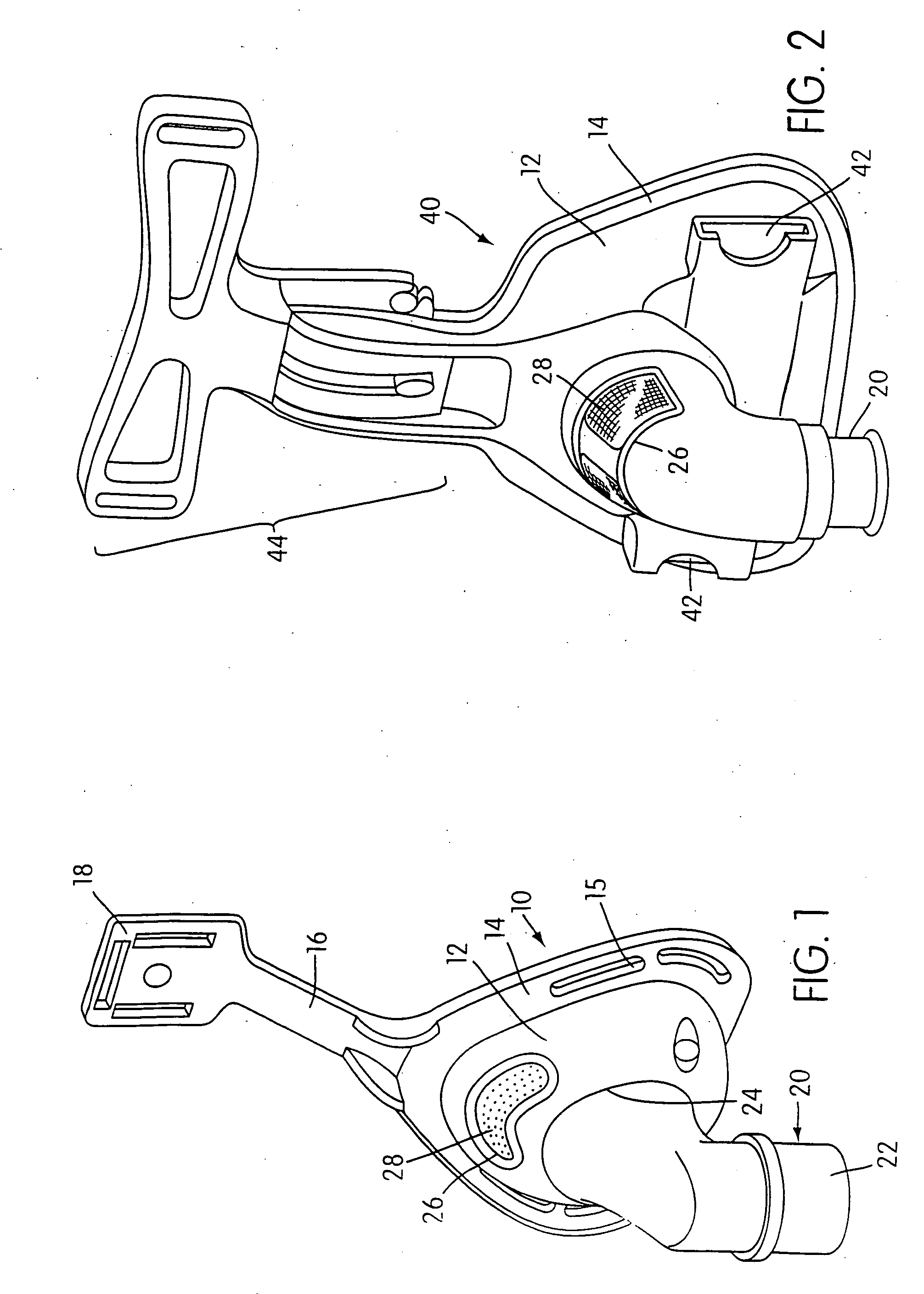

Respiratory mask having gas washout vent and gas washout vent assembly for respiratory mask

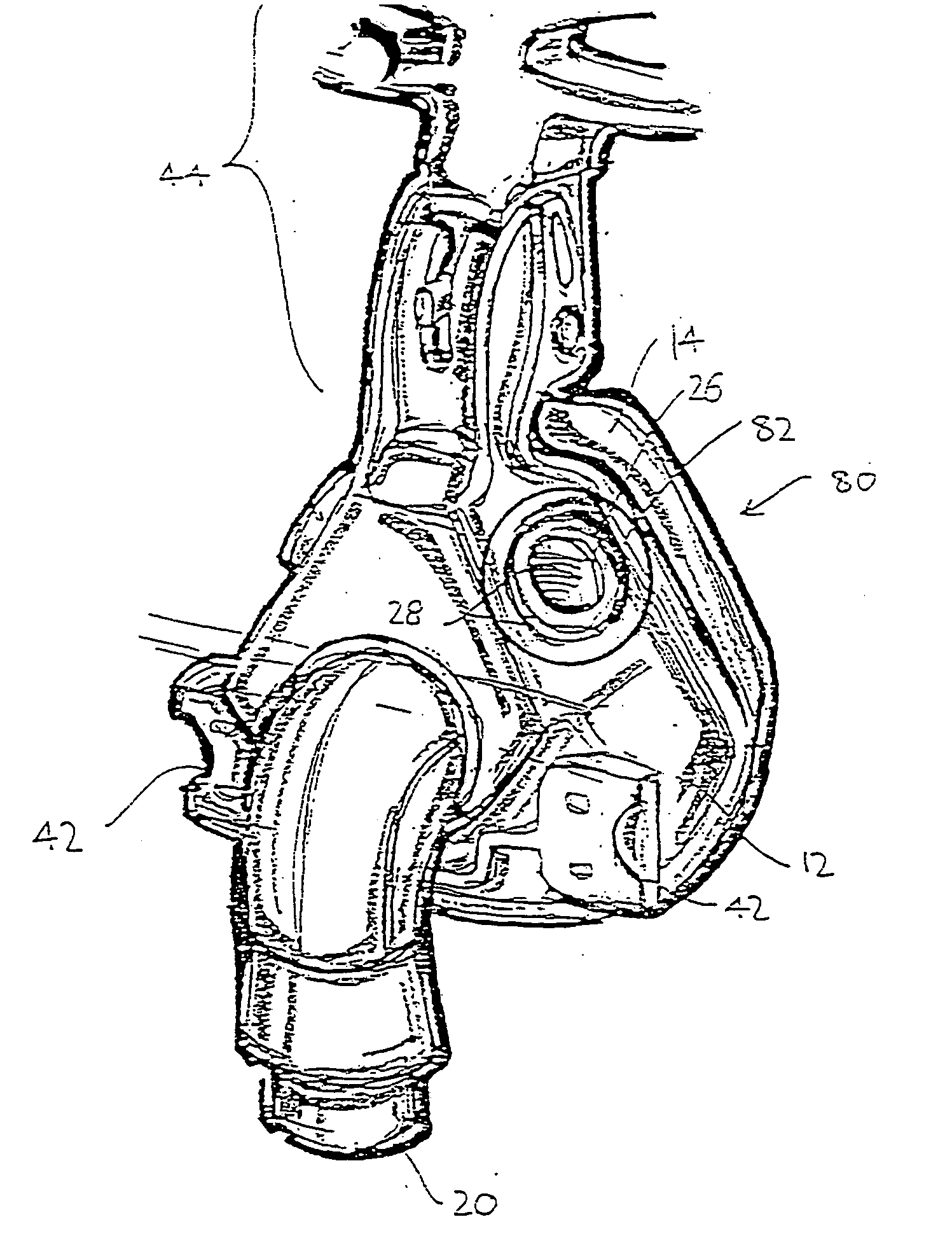

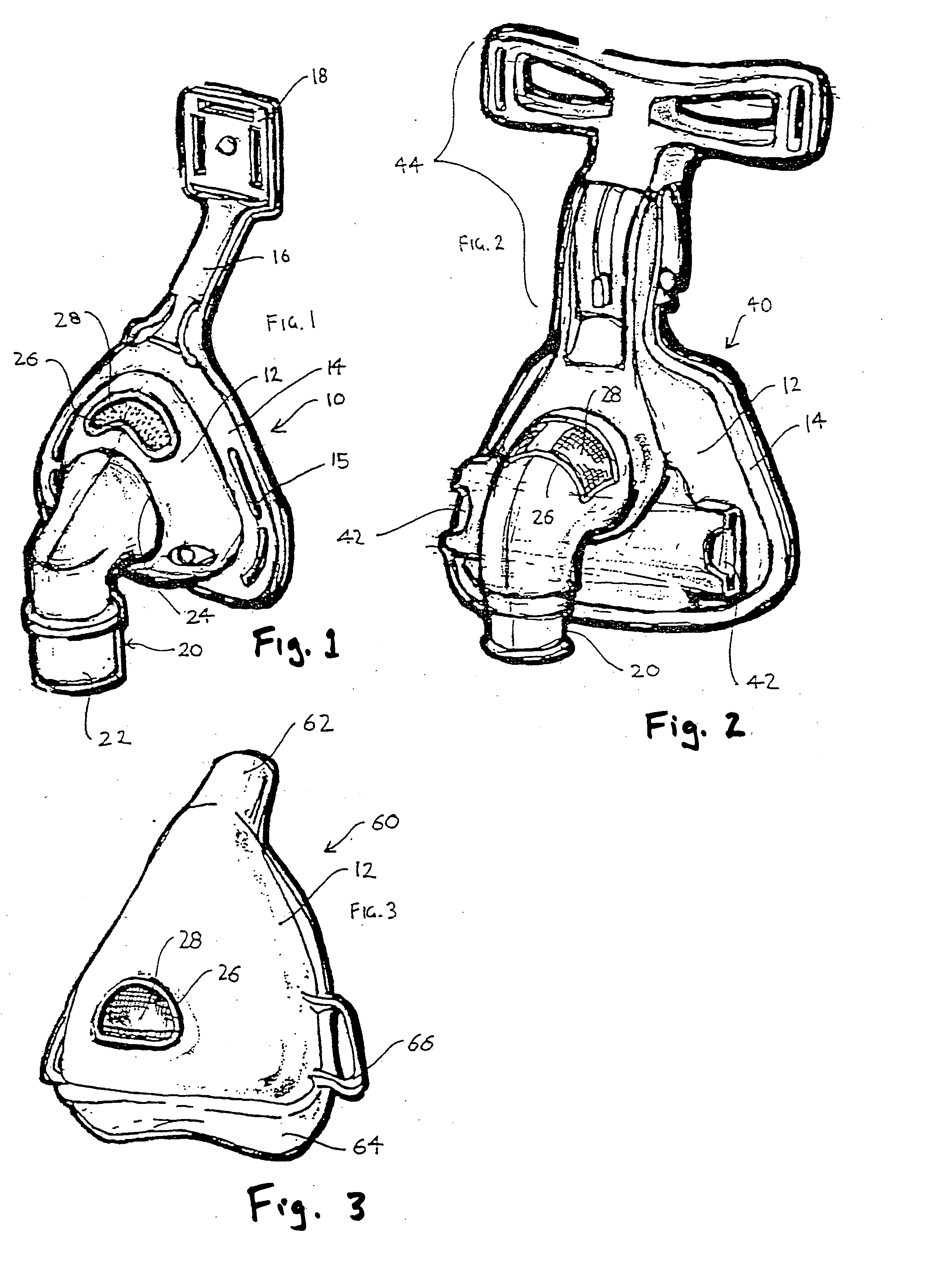

The present invention provides a vent assembly suitable for use with a respiratory mask of the type used in CPAP treatment. In one embodiment the vent is made of a thin air permeable membrane. Generally, the membrane is thinner than 0.5 mm. The membrane can be made of a hydrophobic material such as polytetrafluoroethylene (PTFE). The membrane can also be fabricated from expanded PTFE. The expanded PTFE membrane is mounted on a polypropylene scrim. The pores of the membrane have a reference pore size of 10 to 15 microns. In an alternative embodiment, the vent assembly includes a vent constructed from stainless steel. In another embodiment the membrane has a superficial cross-sectional area of approximately 500 mm2. In another embodiment the vent assembly comprises a membrane attached to a vent frame, the vent assembly forming an insert which can be removeably attached to a mask fame.

Owner:RESMED LTD

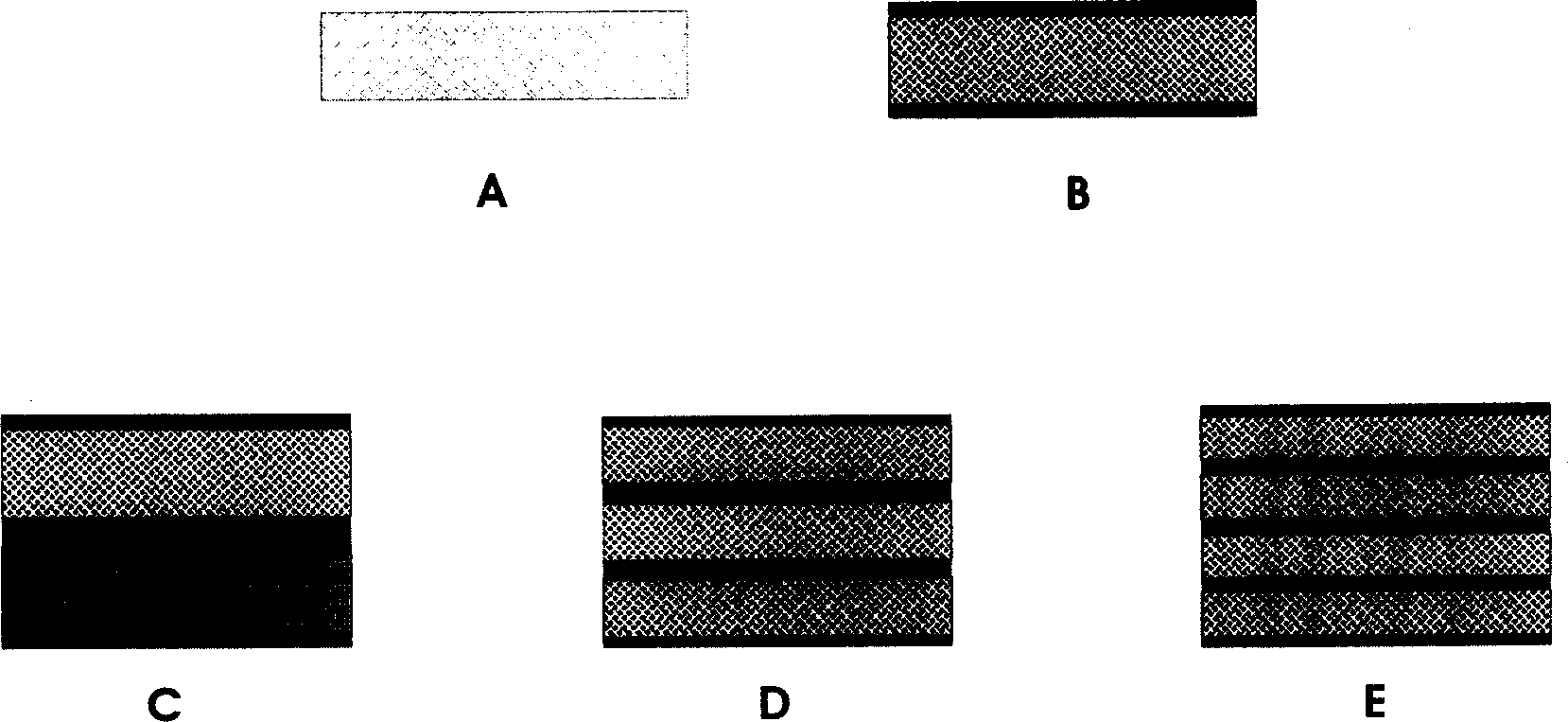

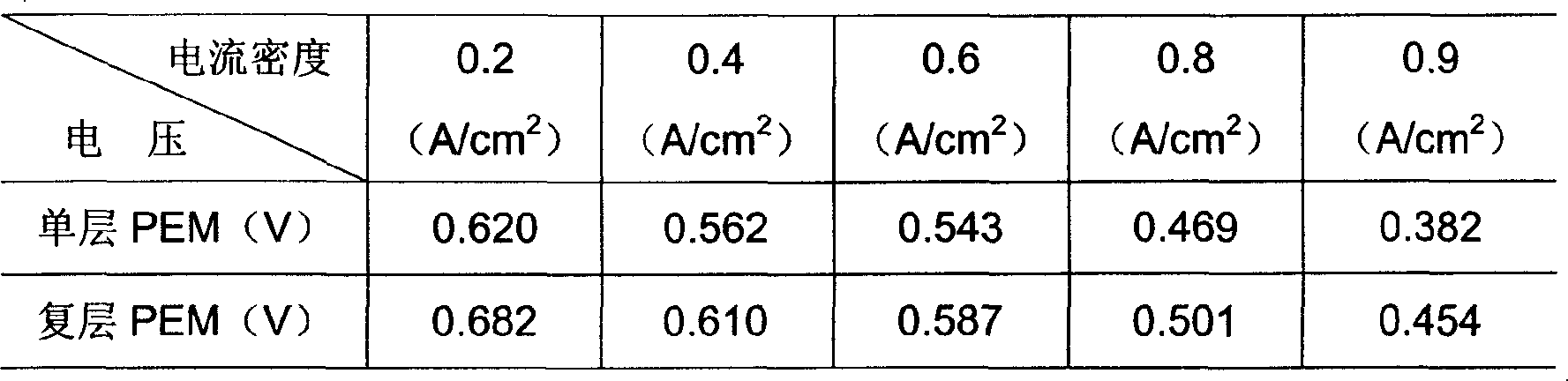

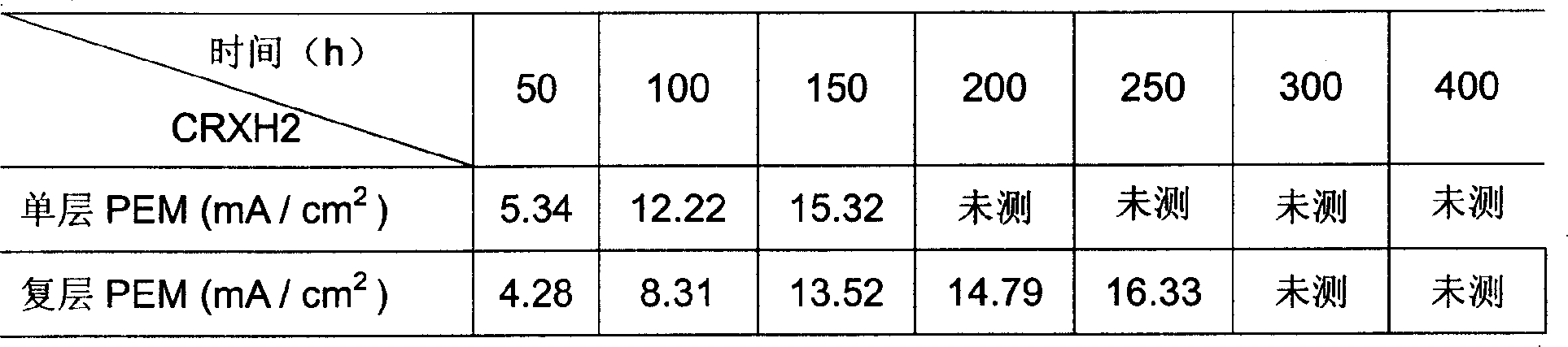

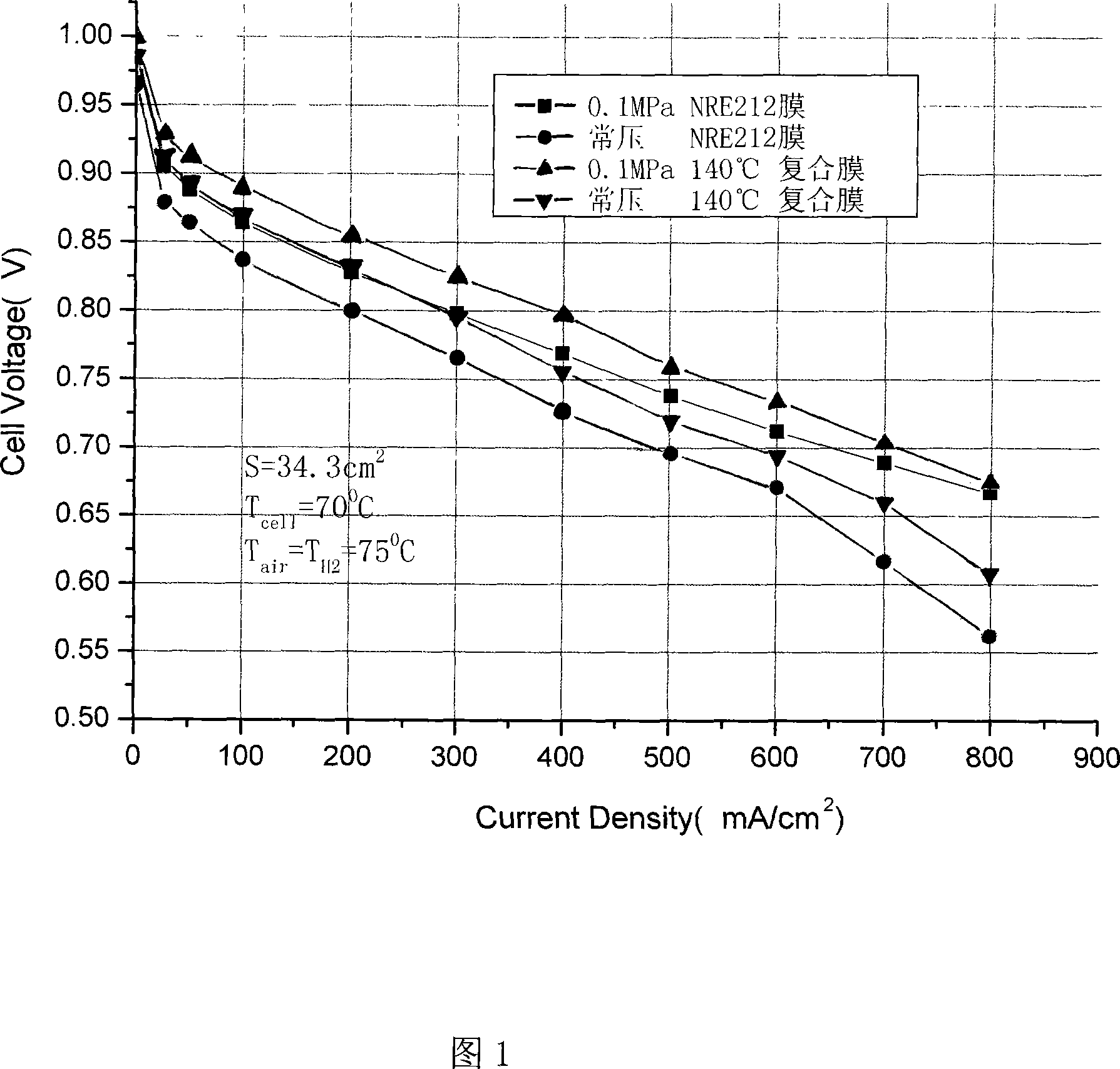

Composite proton exchange membrane for high-temp proton exchange membrane fuel cell and preparation method

InactiveCN1694290AImprove mechanical propertiesGood water retention at high temperatureCell component detailsSolid electrolyte fuel cellsProtonPre treatment

This invention relates to a compound proton exchange film of a high temperature proton exchange film fuel battery, characterizing that said film is a multiplayer proton exchange film composite by multiplayer multi-hole polymer intensified compound proton exchange films. The multi-hole polymer is a buck Teflon micro-hole film, which makes up of the multi-hole polymer enhanced compound proton exchange film together with the inorganic nm particles and solid poly-electrolyte fillers. The preparation method of the exchange film is: a micro- pore film is pre-processed and fastened filled by inorganic nm particles and solid poly electrolytes to be rolled to single layer multi-hole polymer intensified proton exchange film to be laminated and hot-pressed to form a multiplayer proton exchange film.

Owner:WUHAN UNIV OF TECH

Ballistic Resistant Composite Fabric

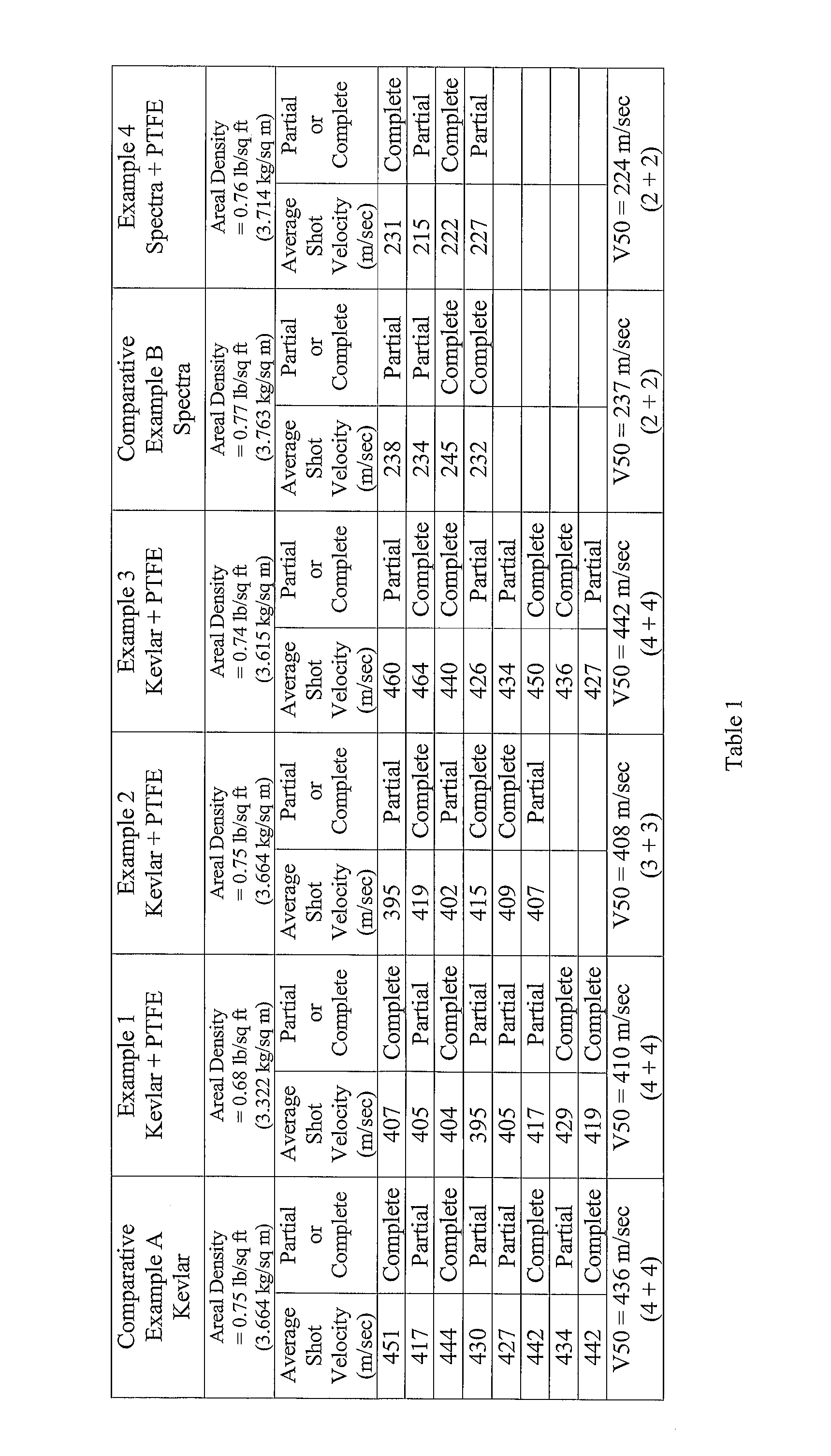

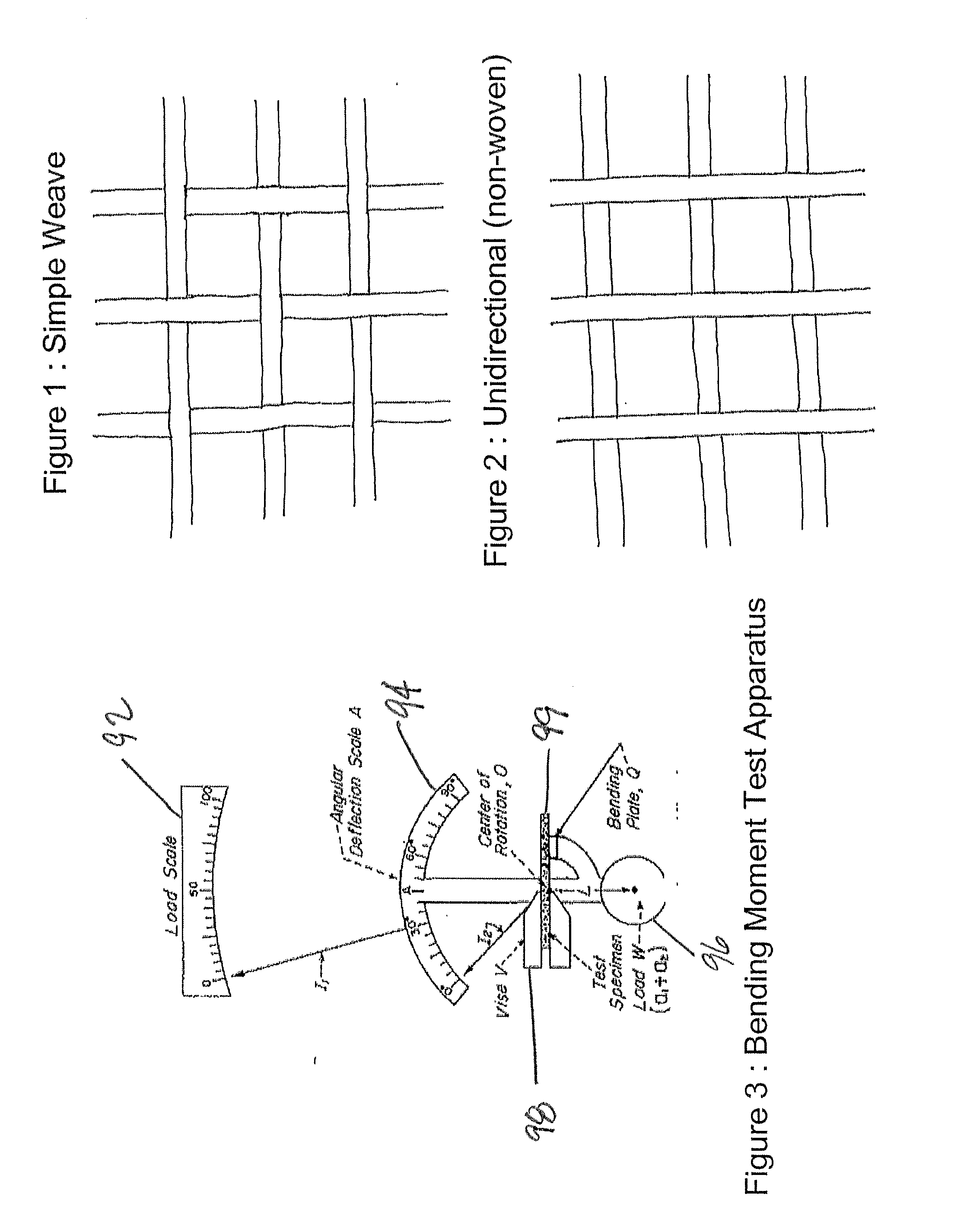

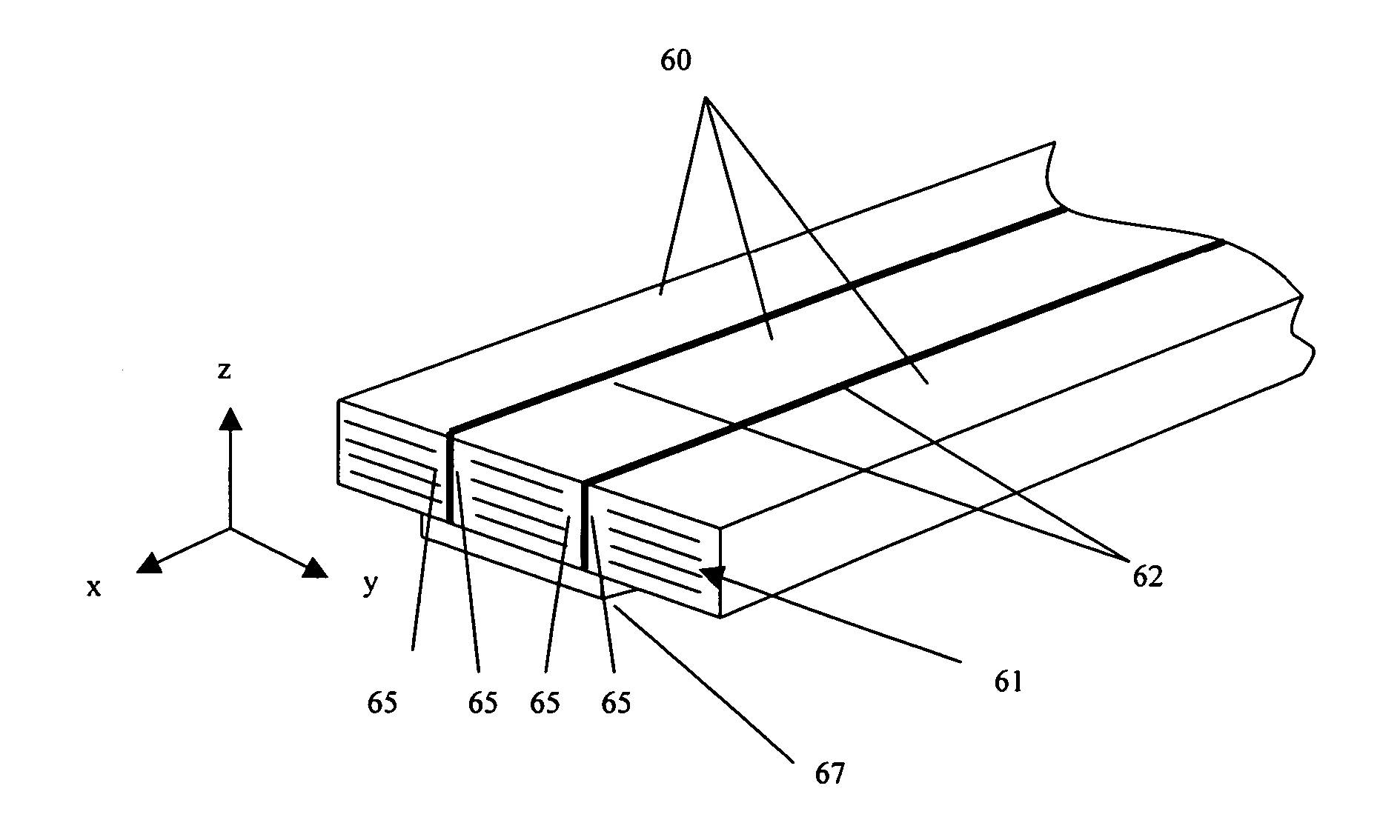

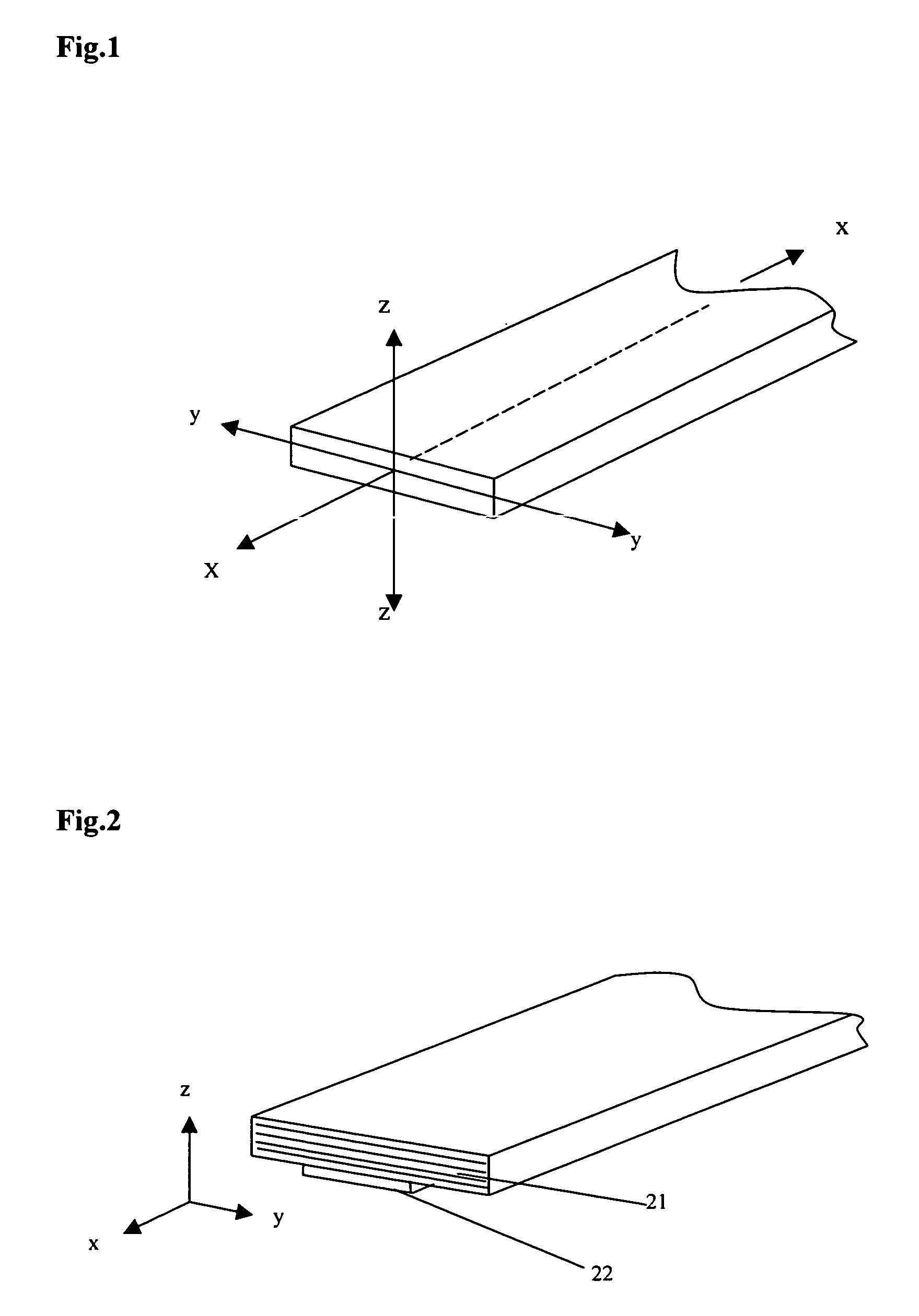

A ballistic resistant article comprising high strength Kevlar fibers and expanded PTFE fibers, wherein the article is a fabric further comprising a V50 of greater than about 1420 ft / s (433 m / s) at a fabric weight of about 0.75 lb / ft2 (3.7 kg / sq m) and a bending moment at room temperature of less than about 0.0008 N-m. A ballistic resistant article comprising high strength Spectra fibers and expanded PTFE fibers, wherein the article is a fabric further comprising a V50 of greater than about 735 ft / s (224 m / s) at a fabric weight of about 0.75 lb / ft2 (3.7 kg / sq m) and a bending moment at room temperature of less than about 0.0007 N-m.

Owner:WL GORE & ASSOC INC

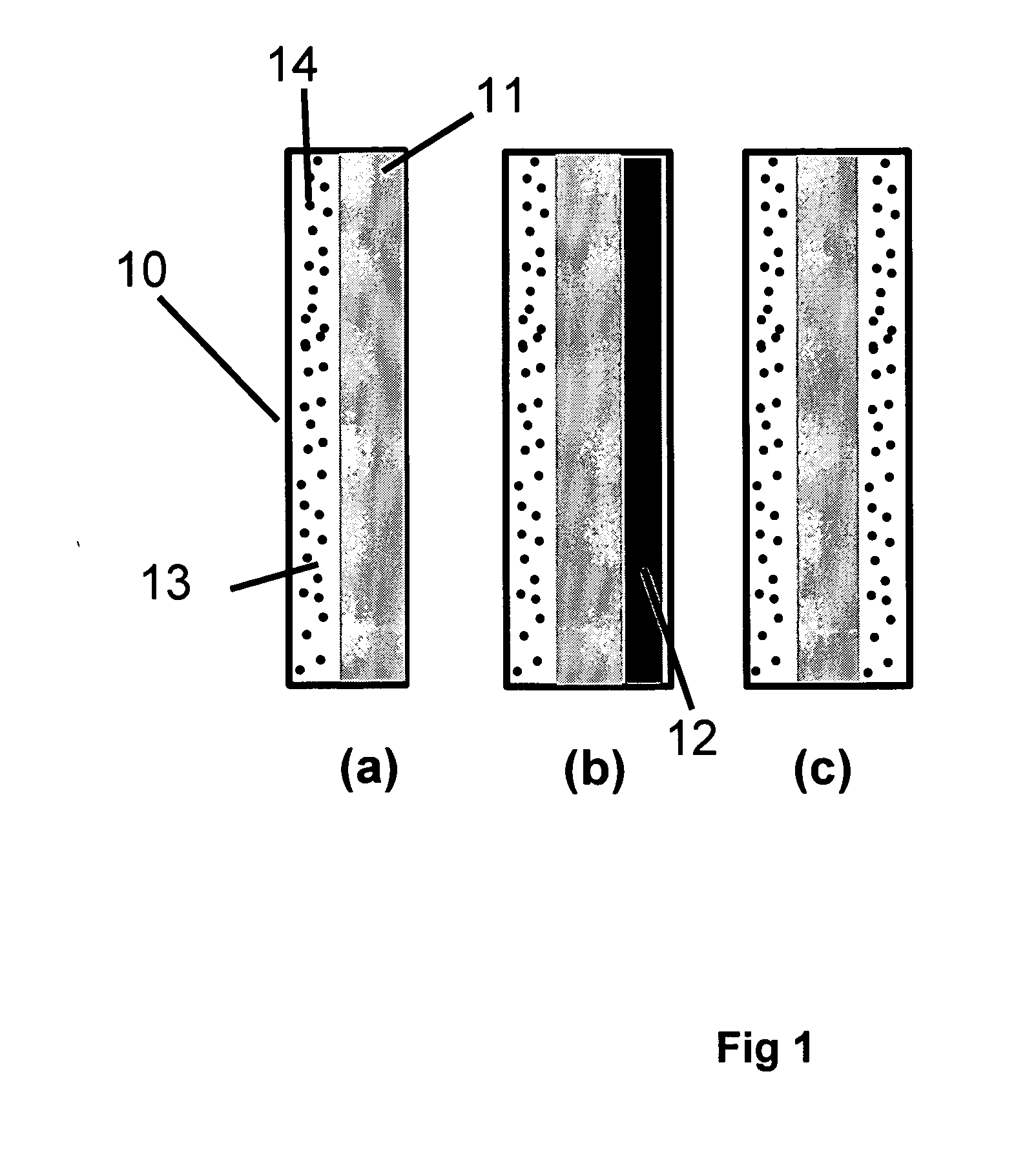

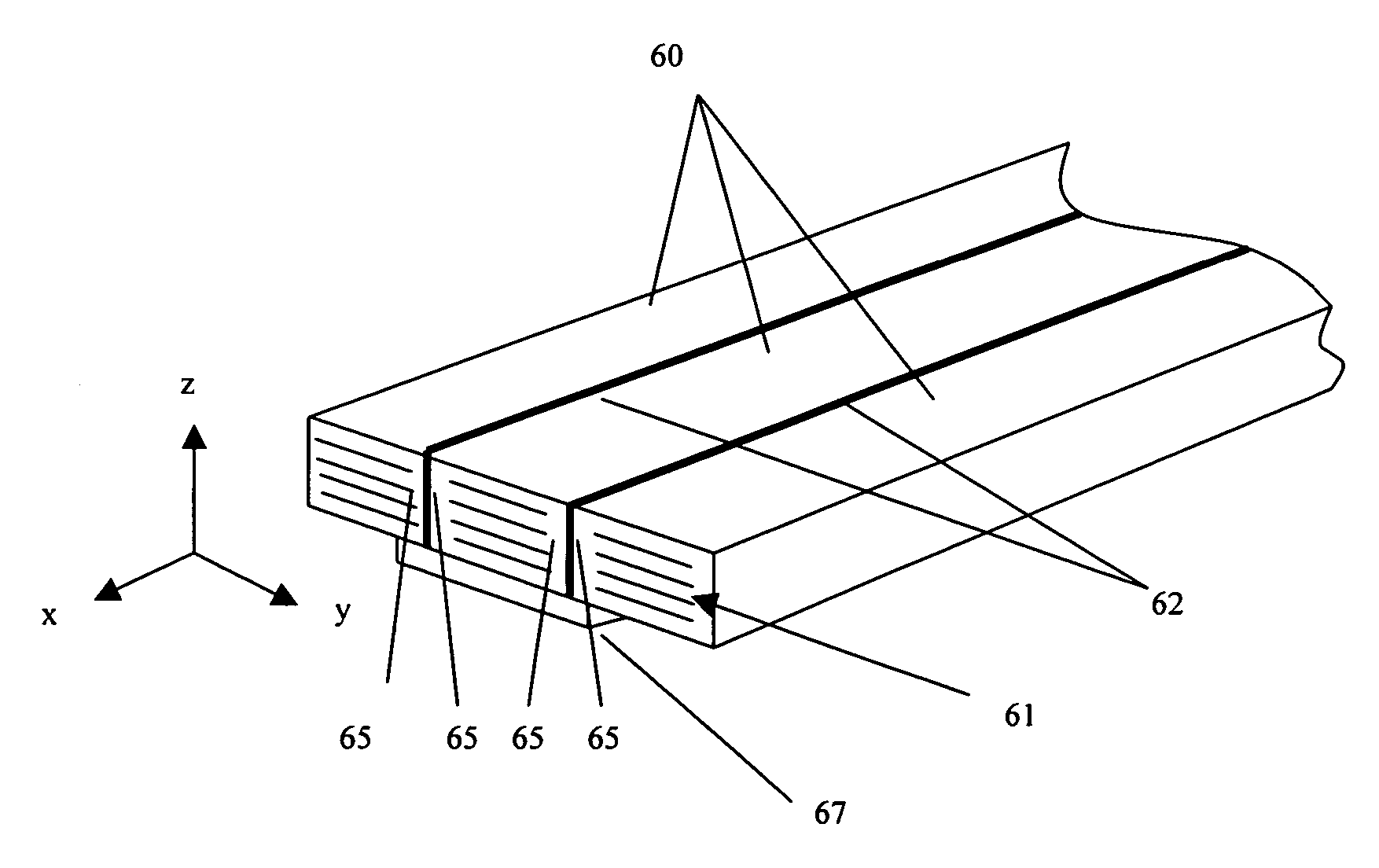

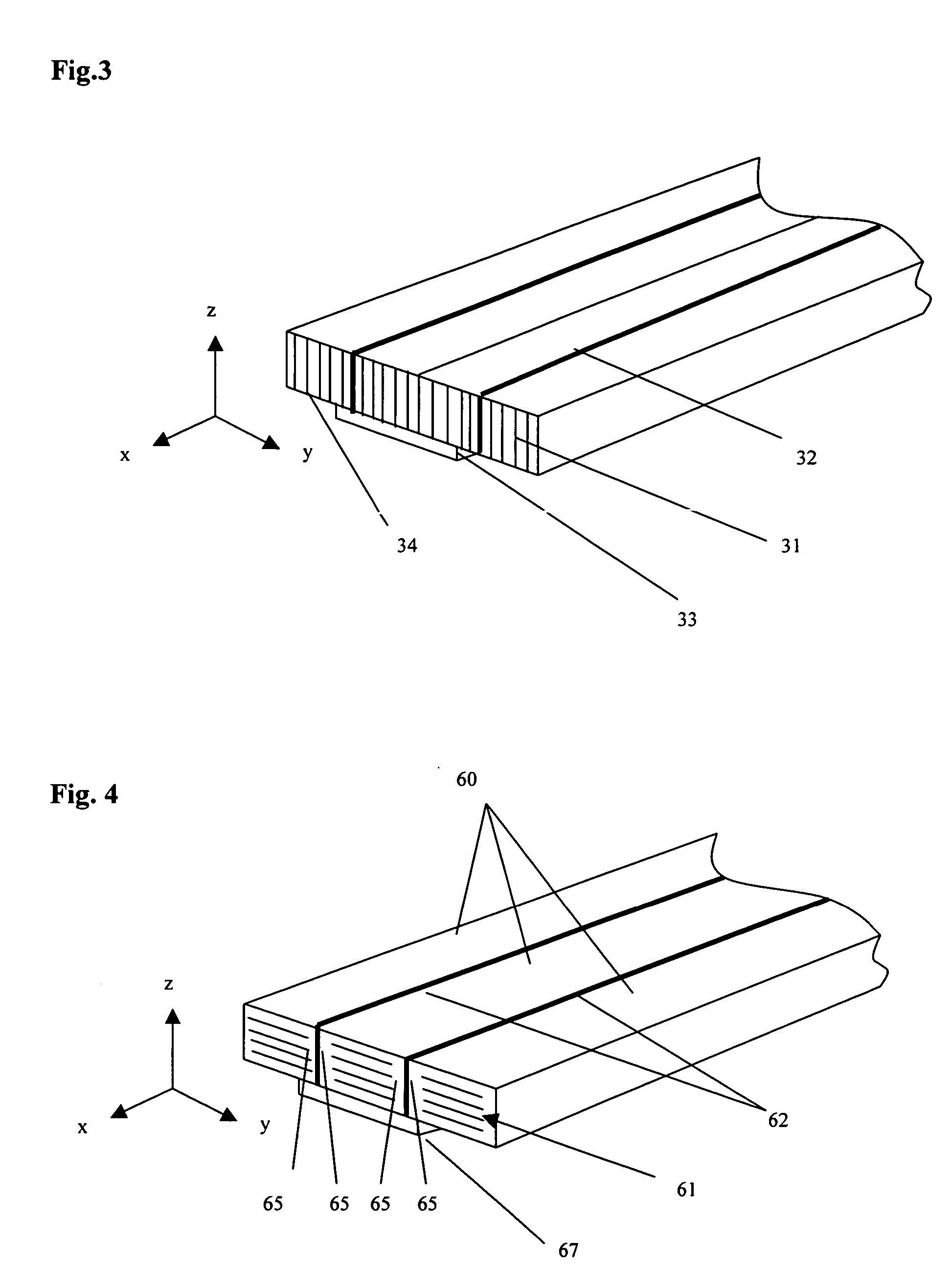

Low stress to seal expanded PTFE gasket tape

ActiveUS7179525B2Reduce loadReduce stressDomestic sealsEngine sealsUltimate tensile strengthExpanded PTFE

A low stress to seal, unitary gasket tape is provided that is particularly suited for use in form-in-place gaskets. The gasket tape preferably comprises at least two joined porous expanded polytetrafluoroethylene (ePTFE) tapes aligned along tape side surfaces and a substantially air impermeable layer there between. The plane of expansion of the ePTFE is substantially parallel to the flange surface providing longitudinal and transverse strength. The substantially air impermeable layer prevents fluid from permeating through the gasket in the radial direction.

Owner:WL GORE & ASSOC INC

Respiratory mask having gas washout vent & gas washout vent assembly for a respiratory mask

The present invention provides a vent assembly suitable for use with a respiratory mask of the type used in CPAP treatment. In one embodiment the vent is made of a thin air permeable membrane. Generally, the membrane is thinner than 0.5 mm. The membrane can be made of a hydrophobic material such as polytetrafluoroethylene (PTFE). The membrane can also be fabricated from expanded PTFE. The expanded PTFE membrane is mounted on a polypropylene scrim. The pores of the membrane have a reference pore size of 10 to 15 microns. In an alternative embodiment, the vent assembly includes a vent constructed from stainless steel. In another embodiment the membrane has a superficial cross-sectional area of approximately 500 mm2. In another embodiment the vent assembly comprises a membrane attached to a vent frame, the vent assembly forming an insert which can be removeably attached to a mask fame.

Owner:RESMED LTD

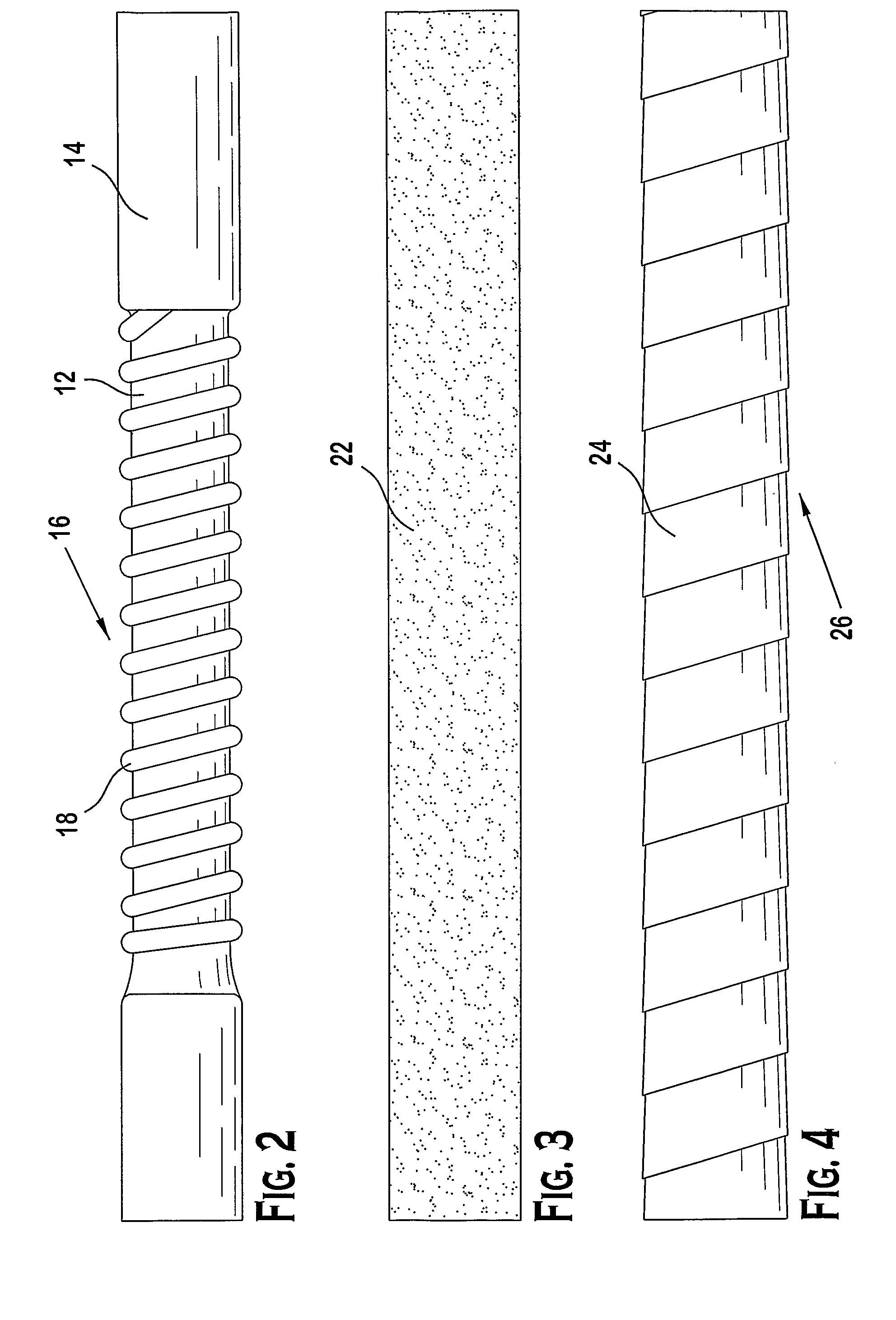

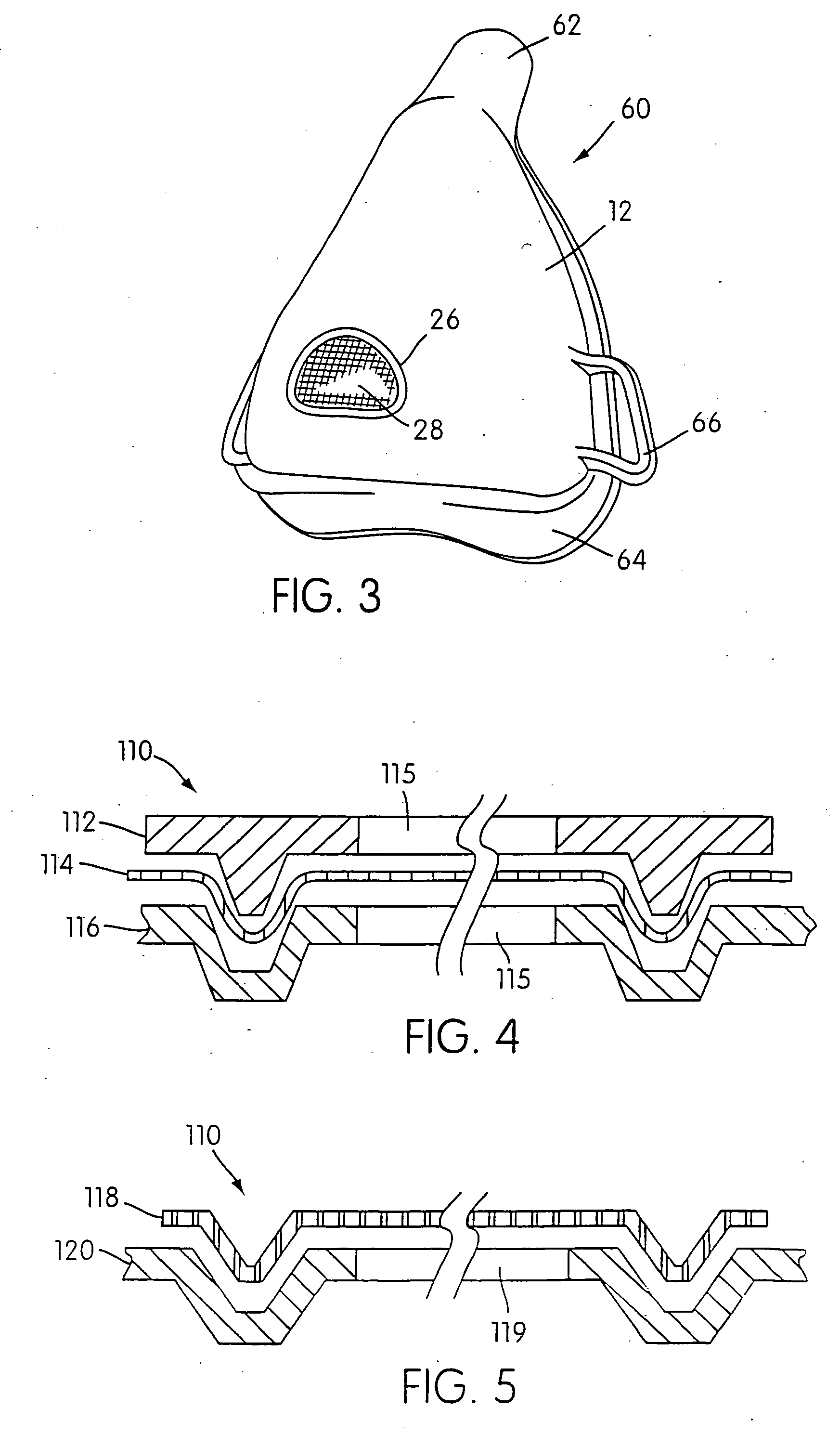

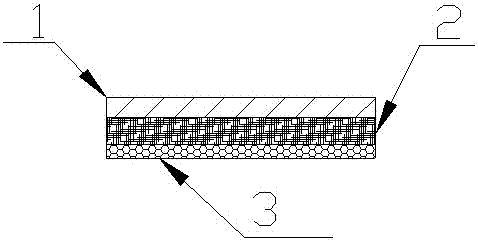

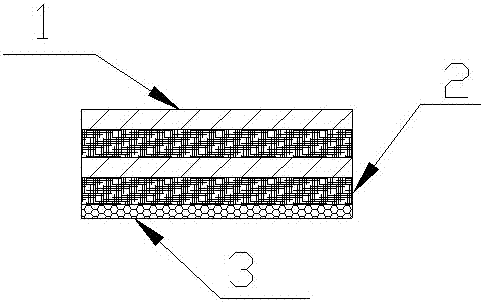

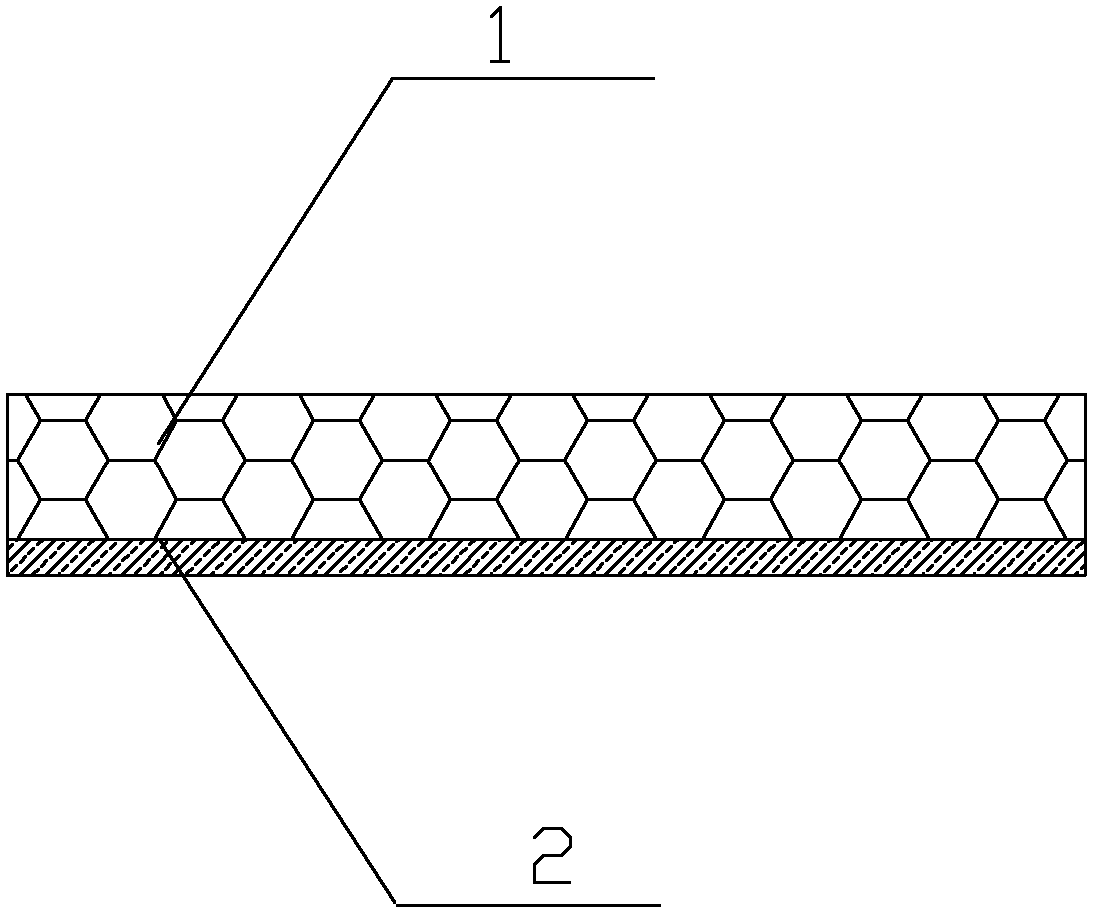

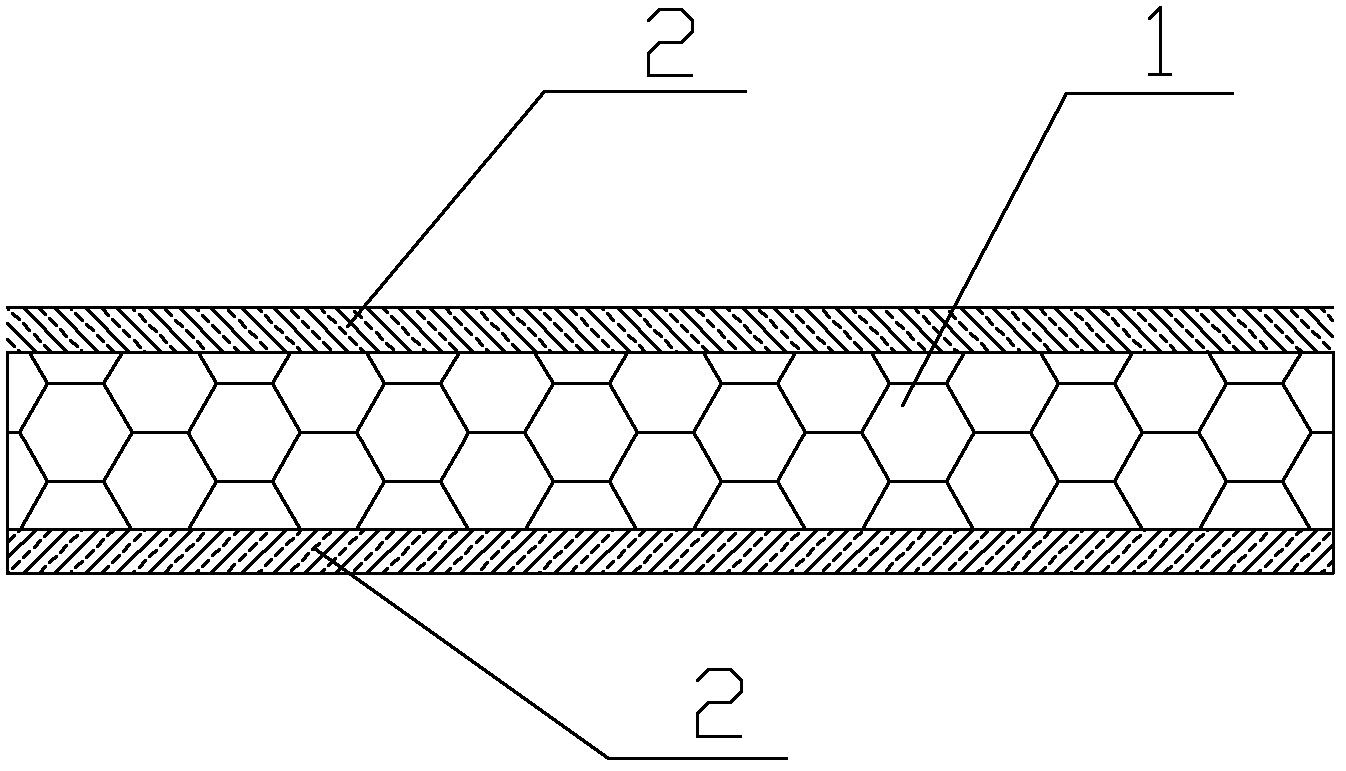

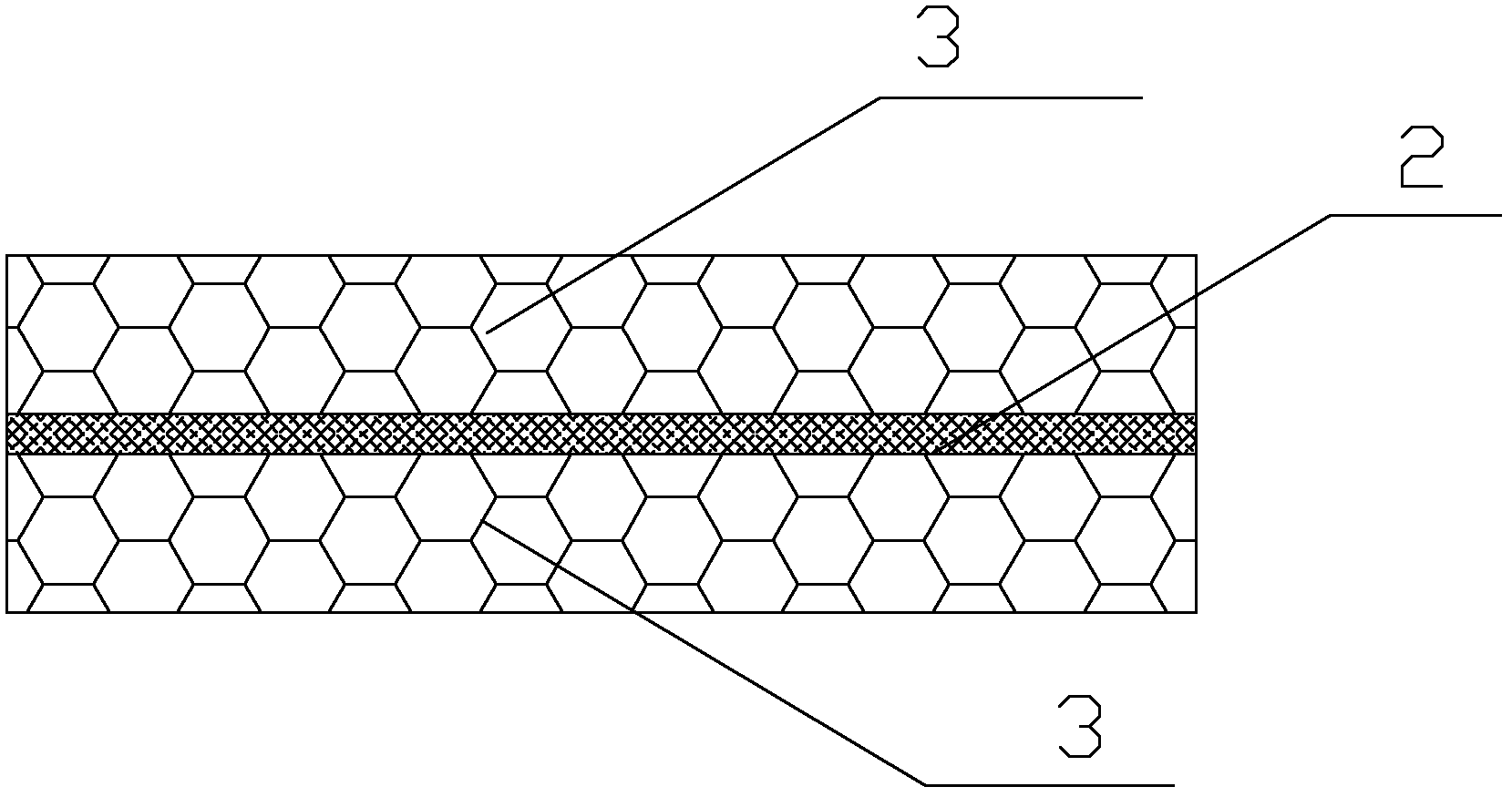

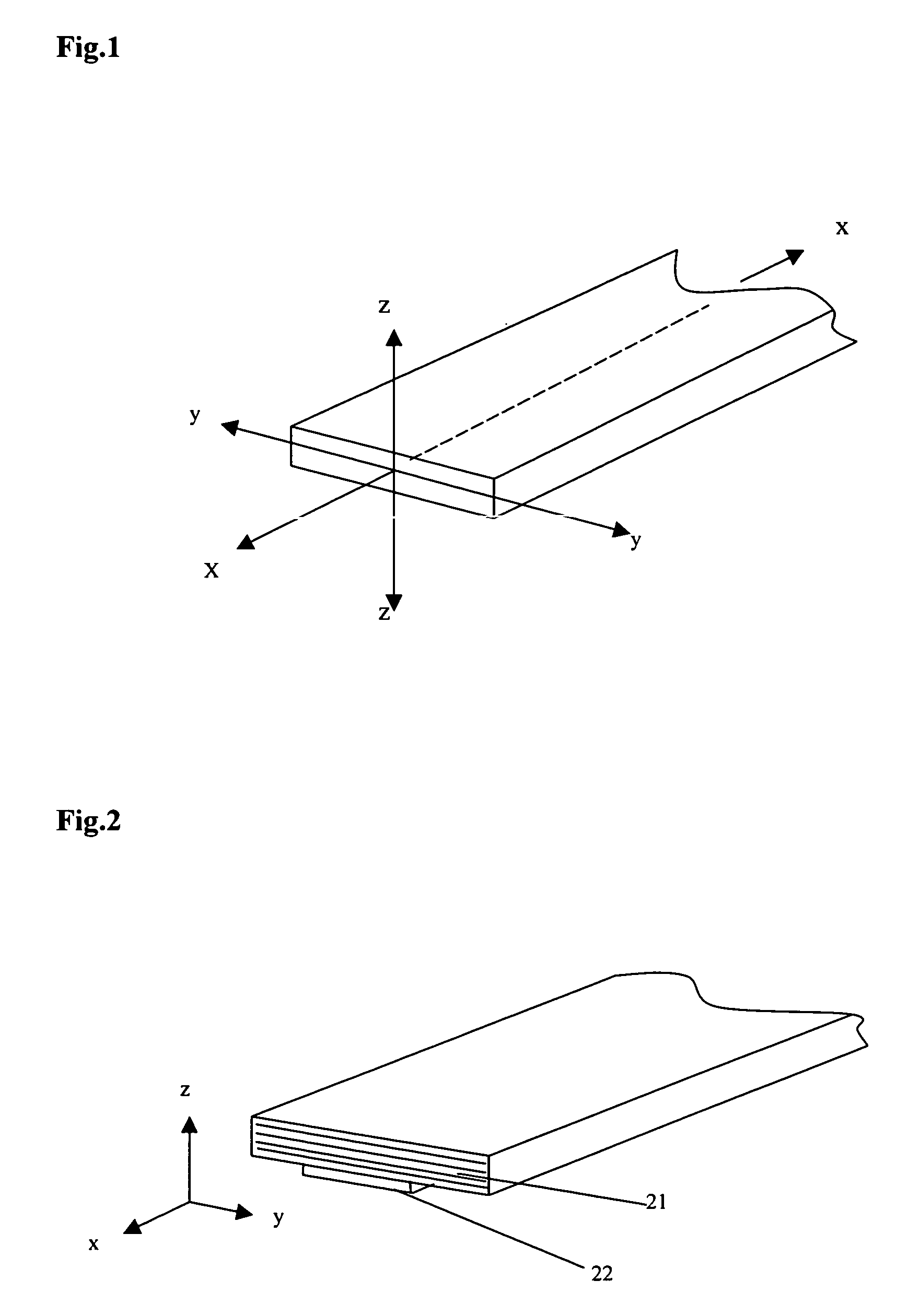

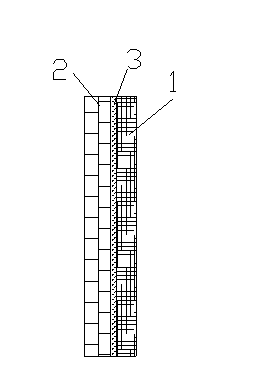

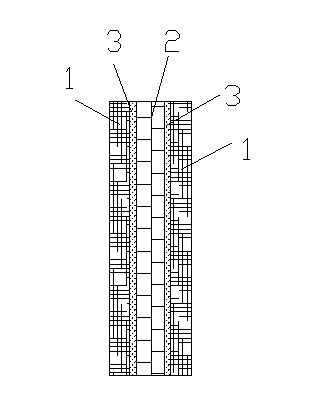

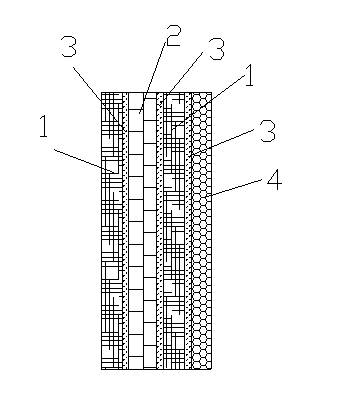

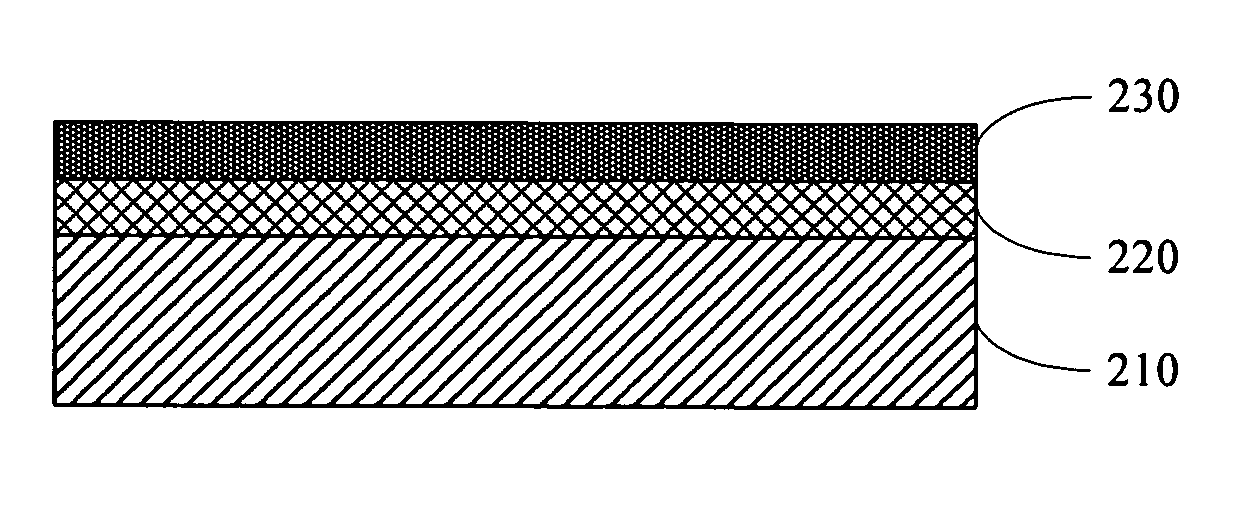

Porous multilayer filter and method for producing same

InactiveUS20110052900A1Large poresReduce thicknessMembranesSemi-permeable membranesFiberHydrophilization

Provided is a porous multilayer filter which can trap ultrafme particles and in which permeability is high and treatment can be performed at a high flow rate. A porous multilayer filter is characterized by including a support layer 2 composed of a porous expanded PTFE sheet, and a filtration layer 3 composed of a porous expanded PTFE sheet which is different from that of the support layer 2, wherein at least a liquid-to-be-treated inflow surface of the filtration layer 3 is subjected to hydrophilization treatment, the filtration layer 3 and the support layer 2 are fusion-bonded to each other at a boundary therebetween to form a multilayer structure, pores of the support layer 2 three-dimensionally communicate with pores of the filtration layer 3, and pores surrounded by a fibril skeleton of the filtration layer 3 are smaller than pores of the support layer 2.

Owner:SUMITOMO ELECTRIC FINE POLYMER INC

Expanded polytetrafluoroethylene film coating composite material with functions like heat conduction, heat insulation, electric conduction and electromagnetic shielding and preparation method thereof

PendingCN107513168AFix stability issuesThe overall thickness is thinSynthetic resin layered productsPolyurea/polyurethane coatingsElectromagnetic shieldingGraphite

The invention discloses an expanded polytetrafluoroethylene film coating composite material with functions like heat conduction, heat insulation, electric conduction and electromagnetic shielding and a preparation method thereof. The composite material comprises at least one expanded polytetrafluoroethylene film layer, a graphene electric-conductive and heat-transfer coating and a silica aerogel coating, wherein the surface of one side of the at least one expanded polytetrafluoroethylene film layer is compounded with the graphene electric-conductive and heat-transfer coating; and the surface of the other side of the at least one expanded polytetrafluoroethylene film layer is compounded with the silica aerogel coating. Thus, the problems of attachment compactness and fastness of the graphene electric-conductive and heat-transfer coating and the heat-insulating silica aerogel coating can be solved; the expanded polytetrafluoroethylene film coating composite material with functions like heat conduction, heat insulation, electric conduction and electromagnetic shielding has the advantages of good softness and bonding properties, strong coating tensile resistance, no cracking, small material thickness and environmental aging resistance; meanwhile, the coating-free surface of the expanded polytetrafluoroethylene has the functions of insulation and isolation.

Owner:PAN ASIAN MICROVENT TECH JIANGSU CORP

Microporous membrane and fine-fiber laminate

InactiveUS20140060330A1Loudspeaker screensDigital data processing detailsPolymer sciencePolymer solution

Taught herein is a venting media laminate having a microporous membrane layer, a fine fiber layer directly coupled to the microporous membrane layer, and a colorant disposed in the fine fiber layer. Also described is an acoustic venting assembly with a microporous membrane layer and a fine fiber layer having an average insertion loss no more than 100% more than the average insertion loss of the microporous membrane layer alone in the frequency range from 300 to 4000 Hz. Methods of manufacturing venting media is also described, where a colorant is added to the polymer solution which is spun to form a fine fiber layer. The fine fiber layer is laminated to an expanded PTFE membrane.

Owner:DONALDSON CO INC

Modified material film of micropore film composite nonwoven fabric for waterproof dustproof acoustically transparent expanded polytetrafluoroethylene (PTFE) and preparation method thereof

ActiveCN102248715ASo as not to damageHigh strengthSynthetic resin layered productsReady to useNonwoven fabric

The invention relates to a modified material film of a micropore film composite nonwoven fabric for waterproof dustproof acoustically transparent expanded polytetrafluoroethylene (PTFE) and a preparation method thereof. The modified material film comprises a micropore film layer of an expanded PTFE, one or more layers of nonwoven fabrics compounded and connected with the micropore film layer surface of the expanded PTFE; the modified material film can protect a loud speaker, a microphone, an alarm and the like while keeping the tonal quality of an apparatus, further prevents common liquids such as beverage, beer, coffee and the like, and can tolerate the water soaking; the protection level can achieve IP67; the dewing phenomenon in the loud speaker, the microphone and the alarm can be eliminated; the capability of tolerating the environment temperature change is improved, the shell design difficulty and the manufacturing cost are reduced, the cold flow property of the micropore film of the expanded PTFE is solved, and the processability is improved; the modified material film can be manufactured as dustproof waterproof venting acoustically transparent bolts, pasters and other ready-to-use components with a series of standard venting product sizes for the loud speaker, the microphone, the alarm and the like; and therefore, the design application is convenient.

Owner:PAN ASIAN MICROVENT TECH JIANGSU CORP

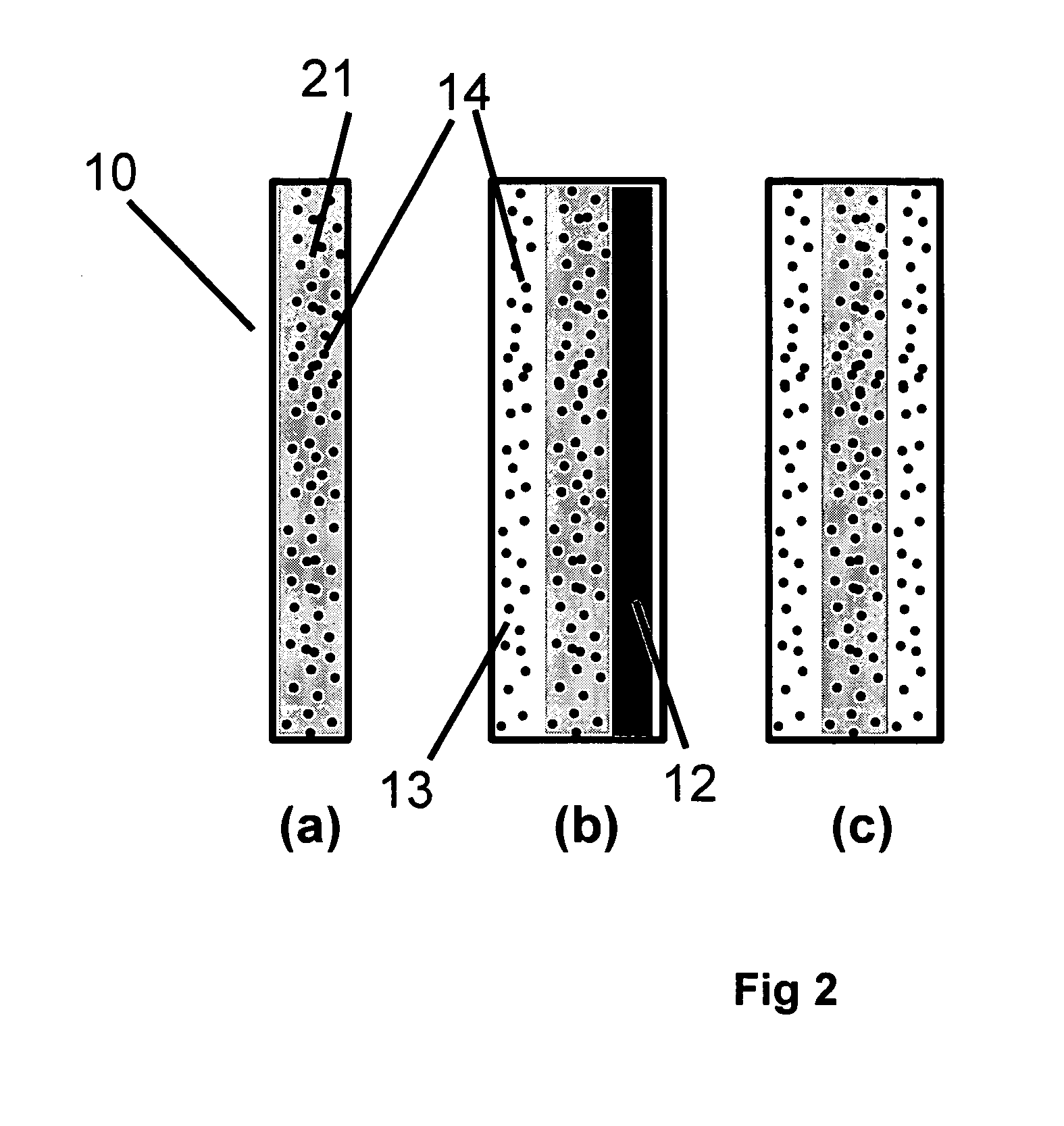

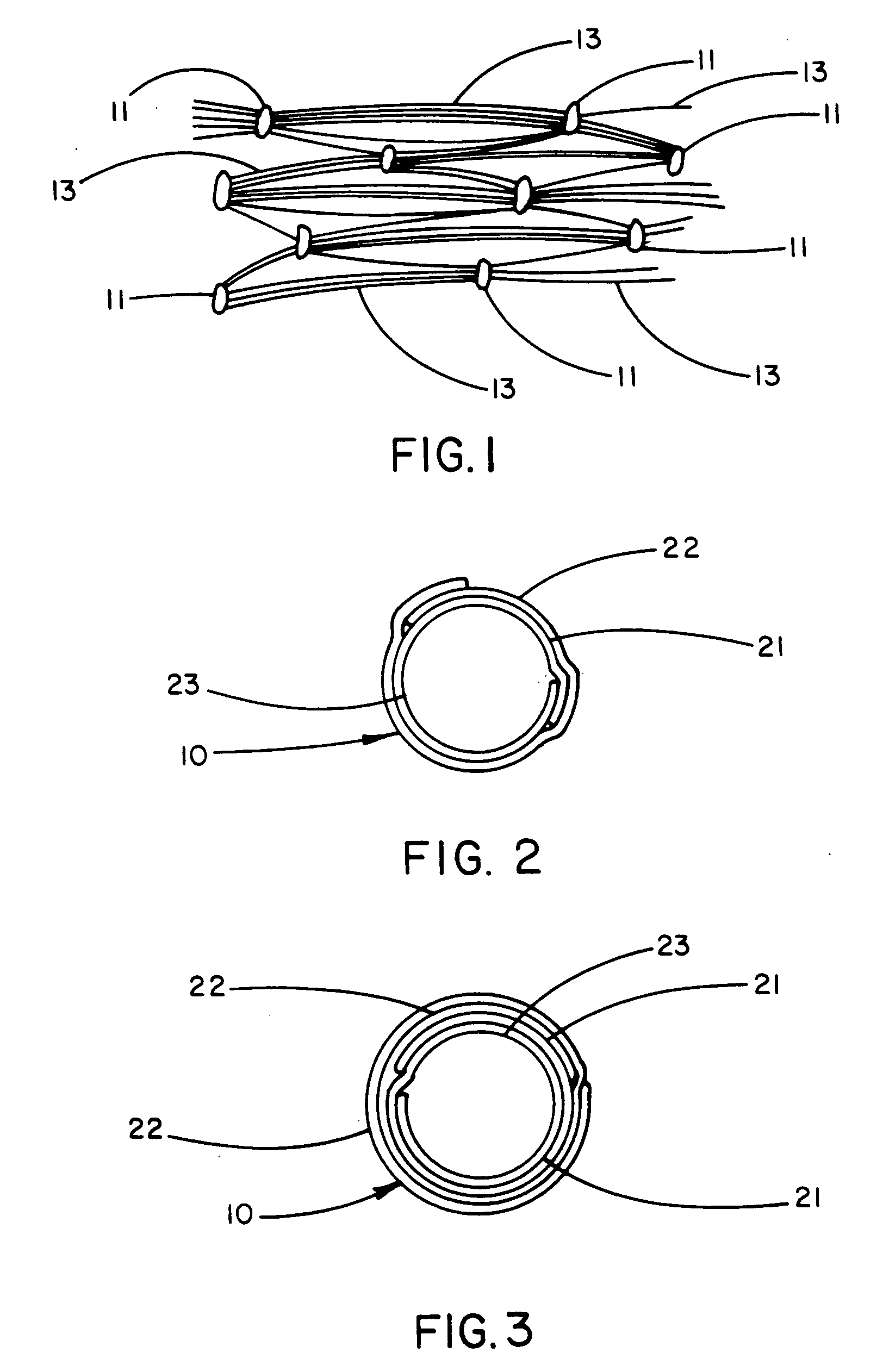

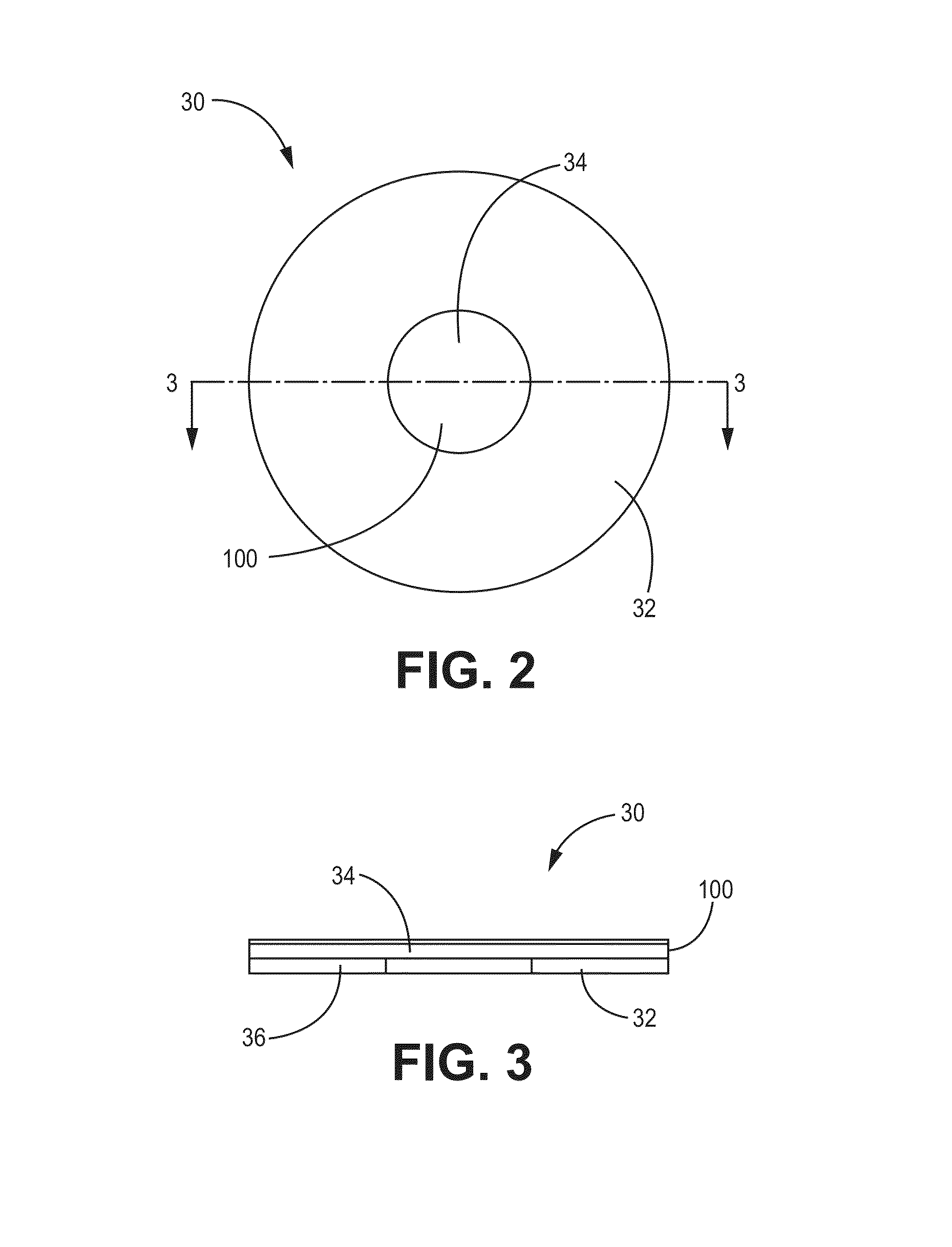

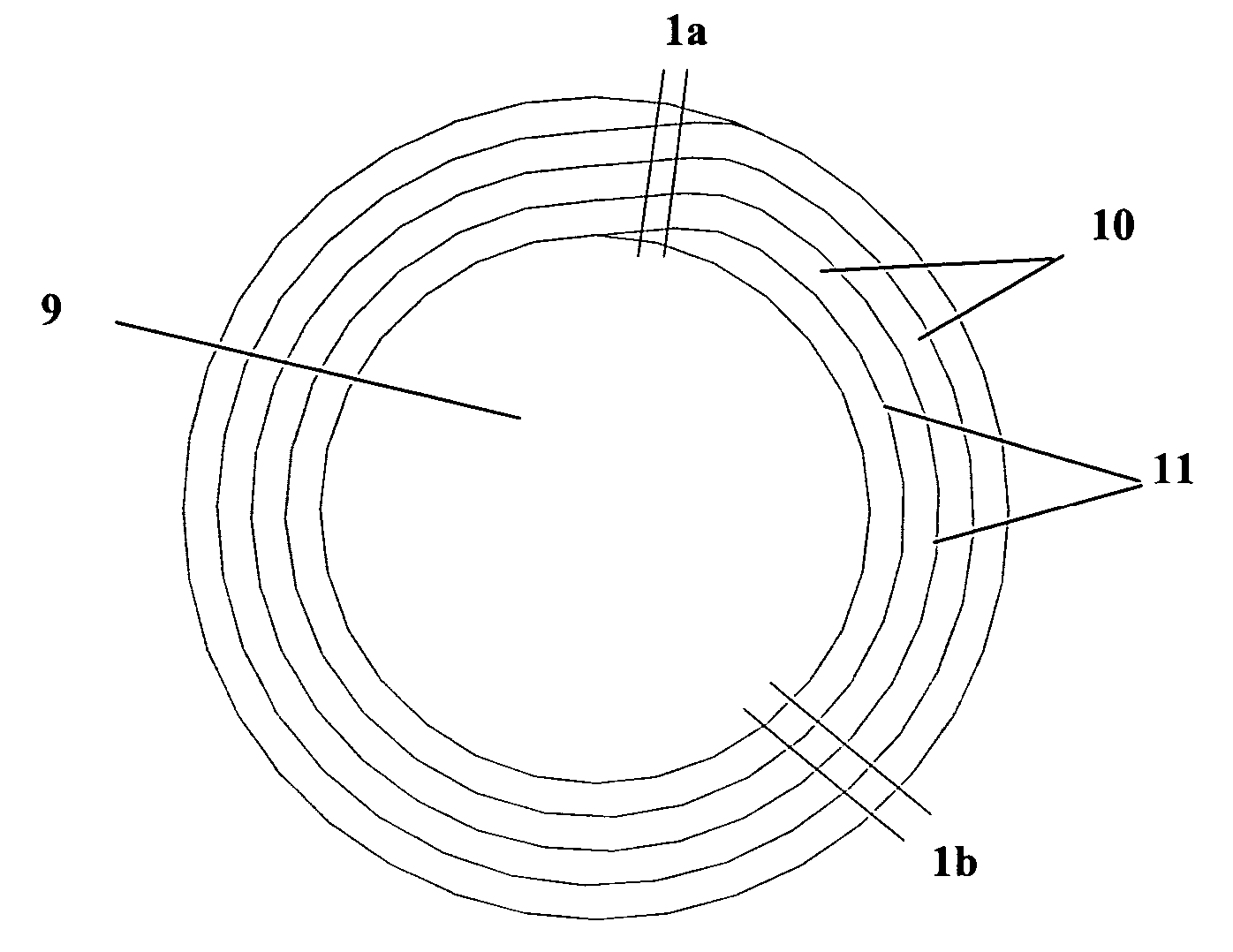

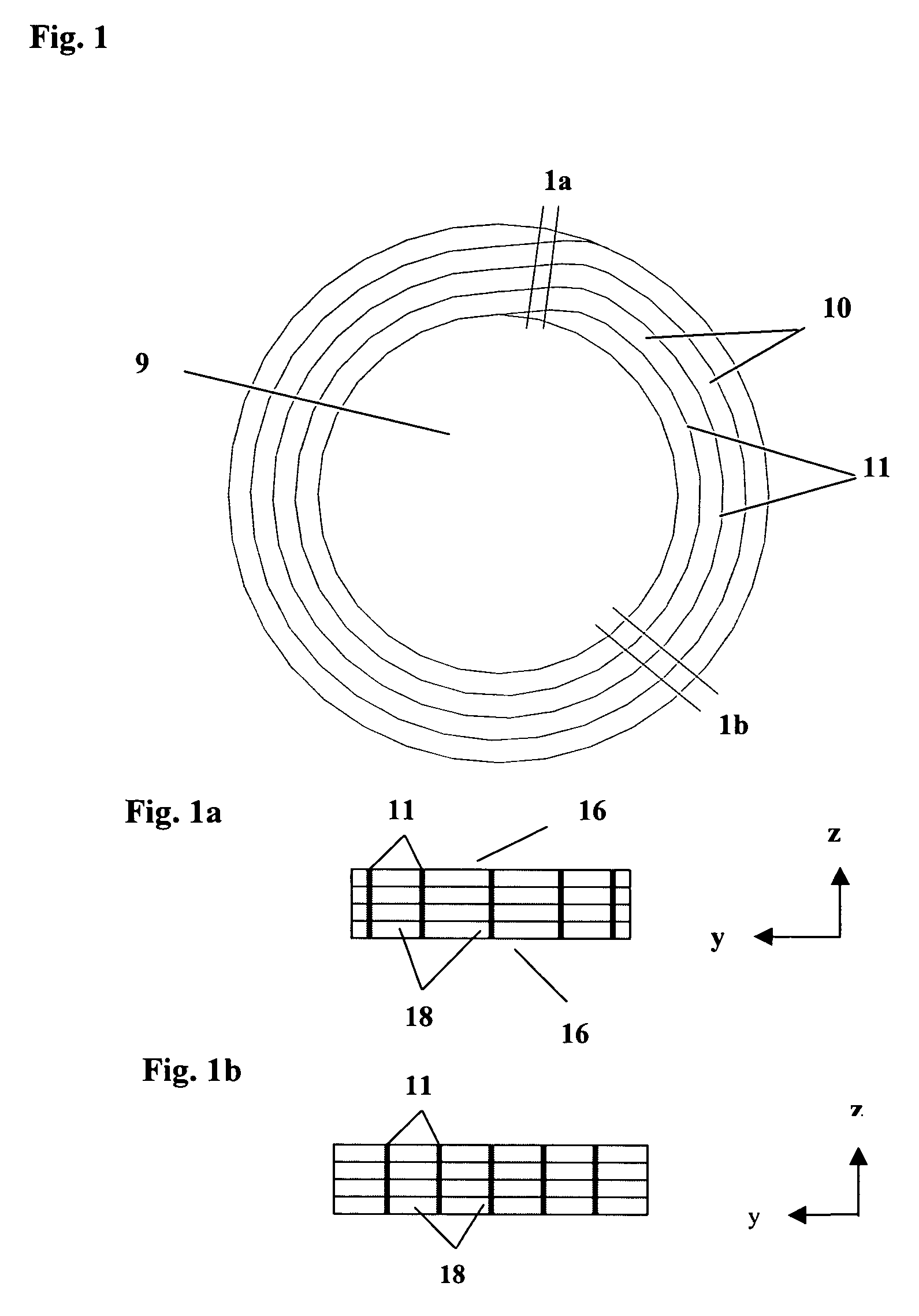

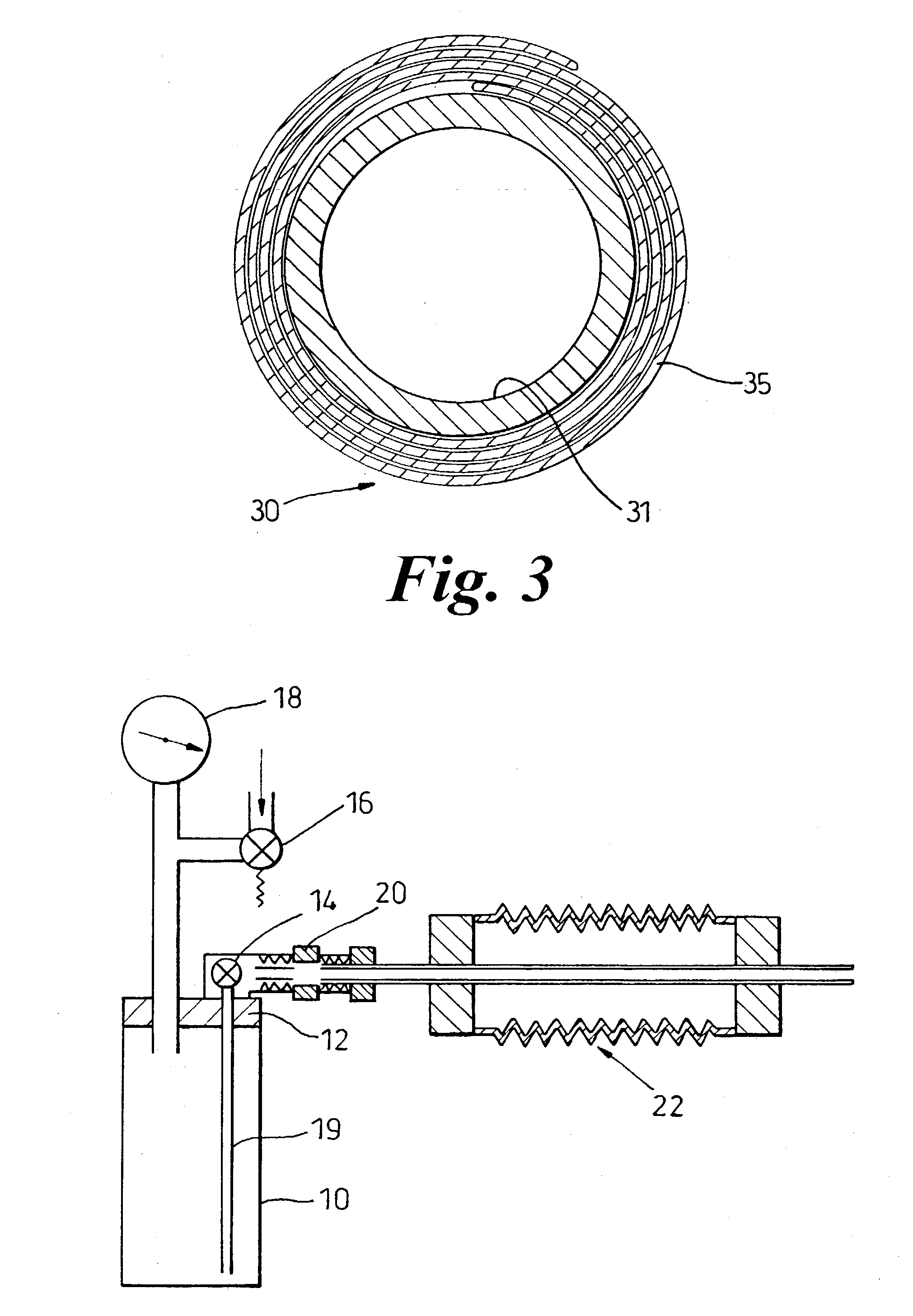

Coil gasket

InactiveUS20050225037A1Reduce leak rateEngine sealsFluid pressure sealed jointsEngineeringExpanded PTFE

A low stress to seal, unitary gasket is provided that is particularly suited for applications requiring large gaskets. Gaskets of the present invention preferably comprise at least two windings of expanded PTFE tape wound at an increasing distance around a gasket inner periphery, wherein a substantially air impermeable layer is interposed between the tape windings. Preferably, the plane of the expansion of the ePTFE is substantially parallel to the flange surface, providing longitudinal and transverse strength. The substantially air impermeable layer prevents fluid from permeating through the gasket in the radial direction.

Owner:WL GORE & ASSOC INC

Technique for molding new type proton exchange membrane

ActiveCN101050285ASimple process routeFacilitate large-scale productionHigh concentrationSilicon dioxide

This invention discloses a process for shaping a novel composite proton exchange membrane. The process comprises: dissolving perfluorosulfonic acid in aqueous solution of low-boiling-point organic alcohol, adding high-boiling-point organic solvent and silica sol to obtain membrane-forming solution, dragging base membrane-expanded PTFE microporous membrane on the carry roller of a membrane-forming machine, soaking the base membrane in the low-concentration resin solution, drying at 40-100 deg.C, soaking in the high-concentration resin solution, drying at 40-100 deg.C, soaking and drying repeatedly until the thickness of the composite membrane reaches the predetermined value, and shaping the composite membrane in a drier at 120-200 deg.C. The process is simple, and suitable for mass production. The obtained composite proton exchange membrane has such advantages as high self-water-generating and water-retaining ability, high environmental adaptability, high strength and size stability, and long service life.

Owner:SUNRISE POWER CO LTD

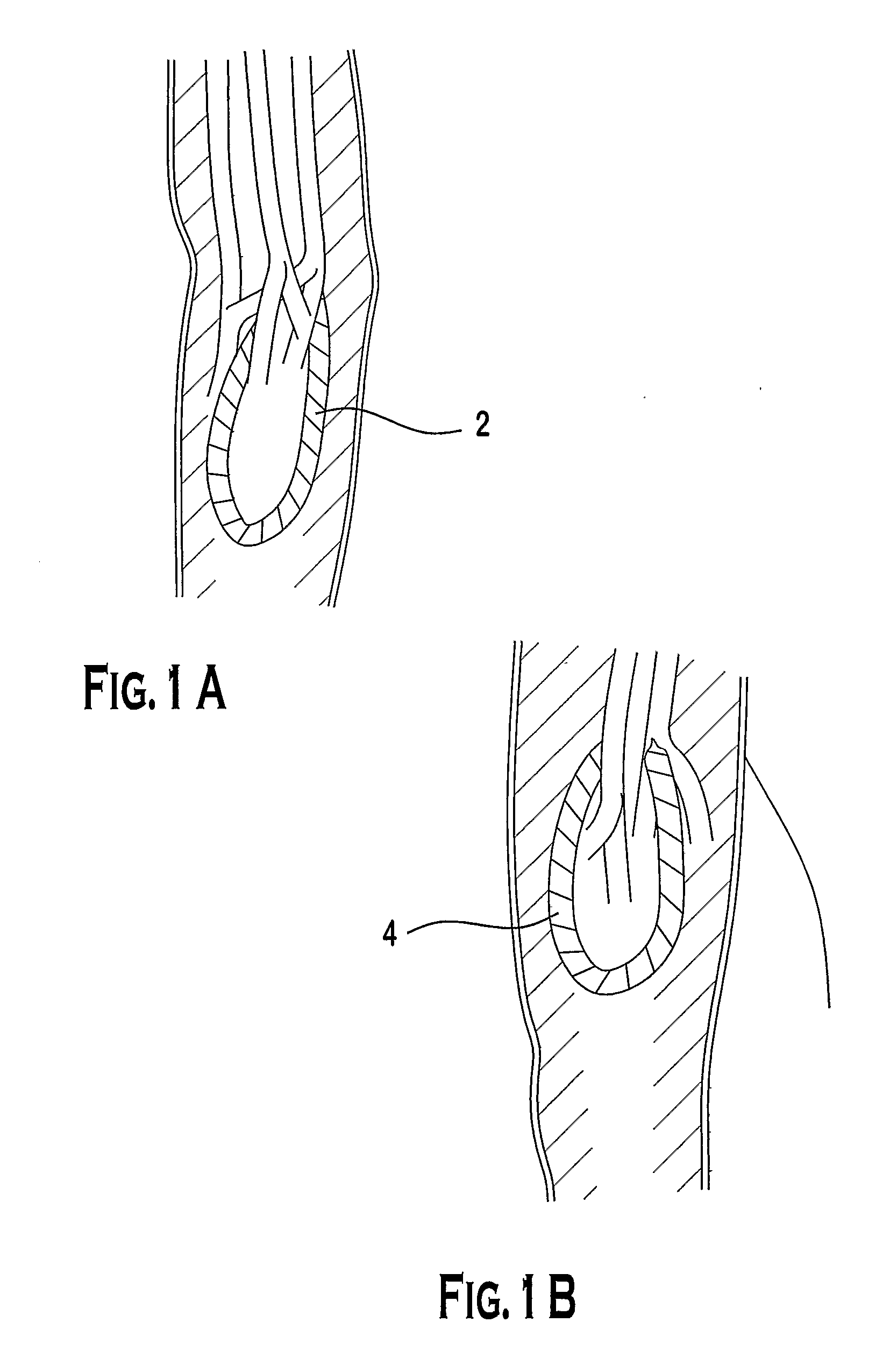

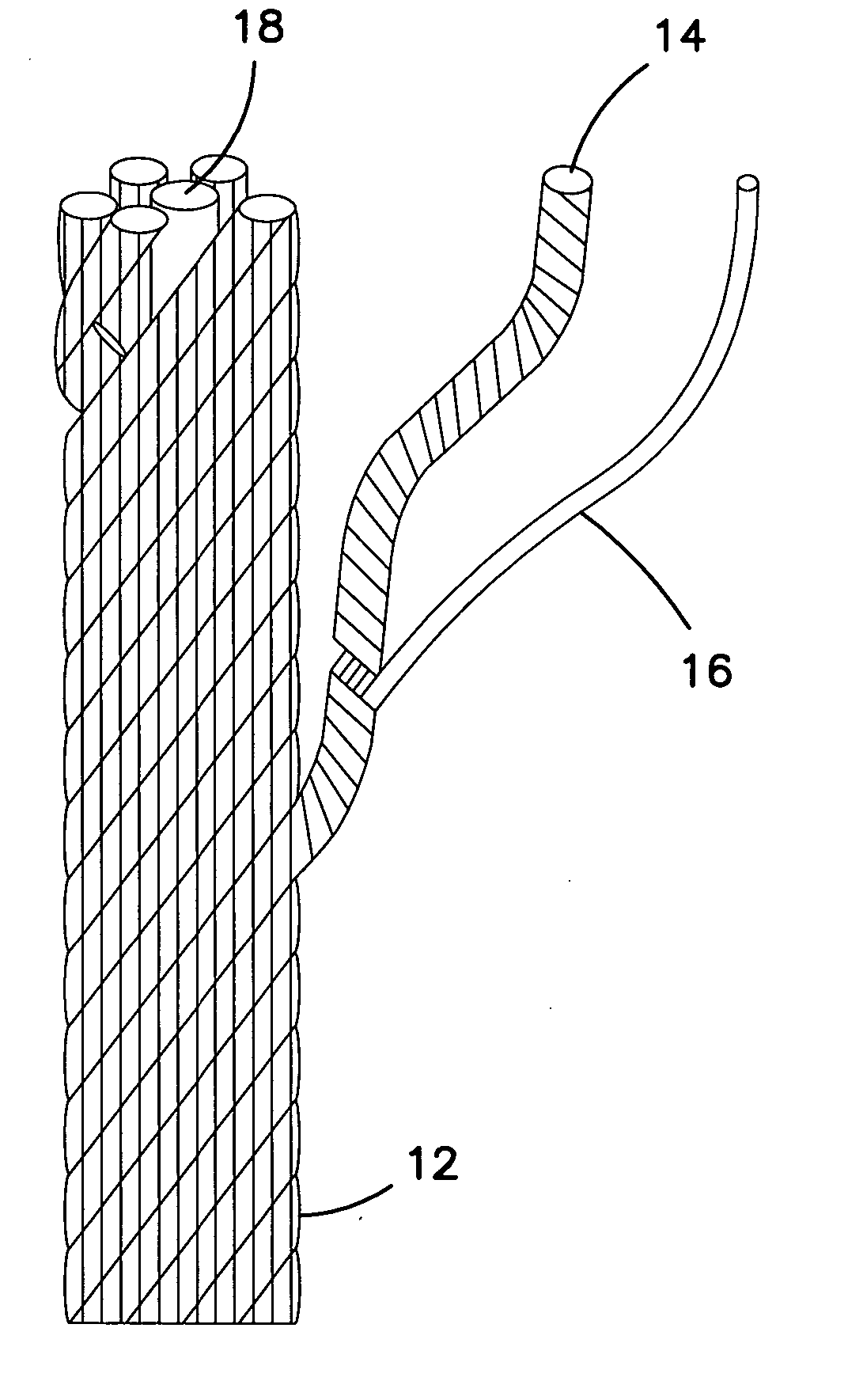

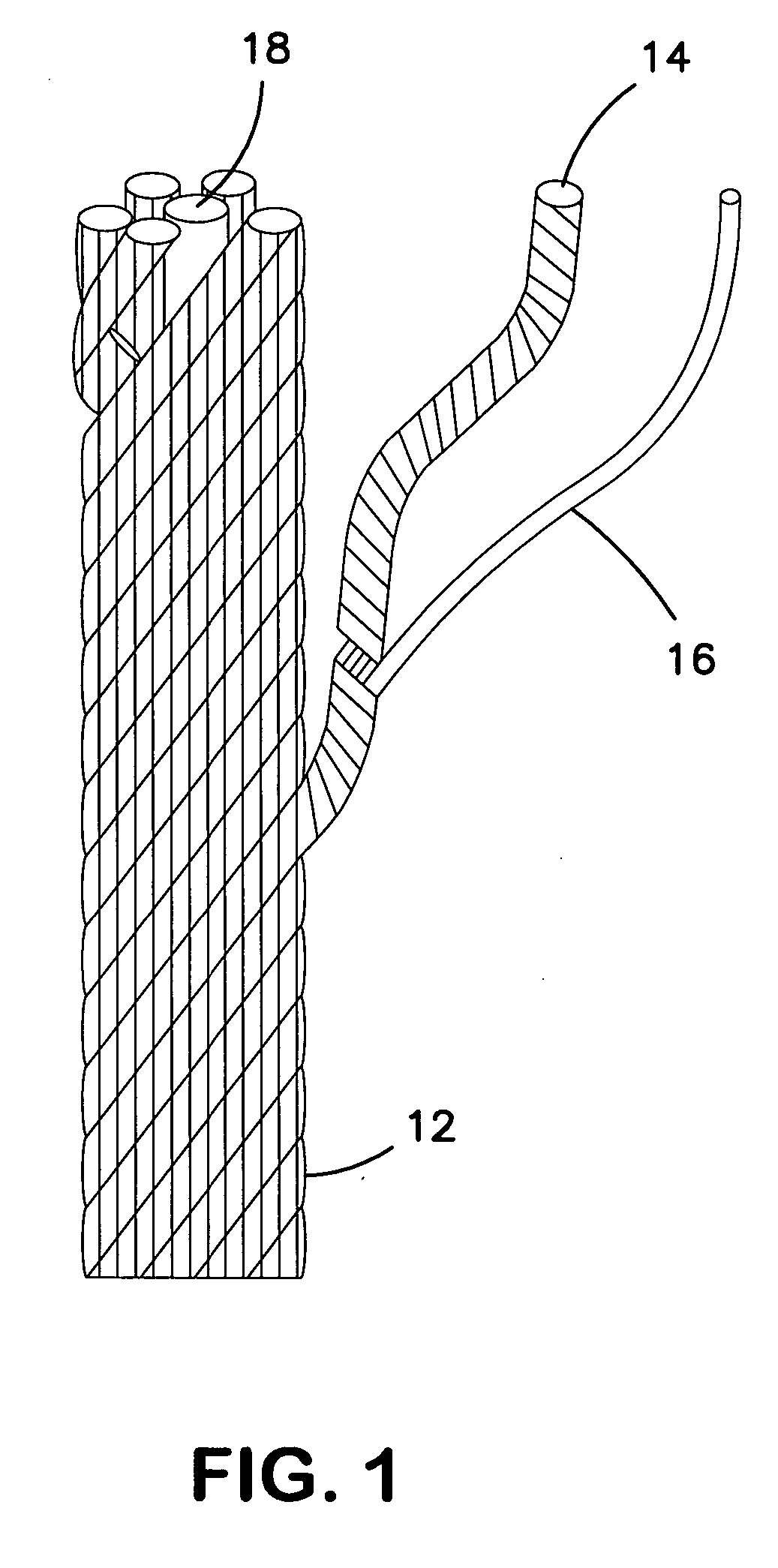

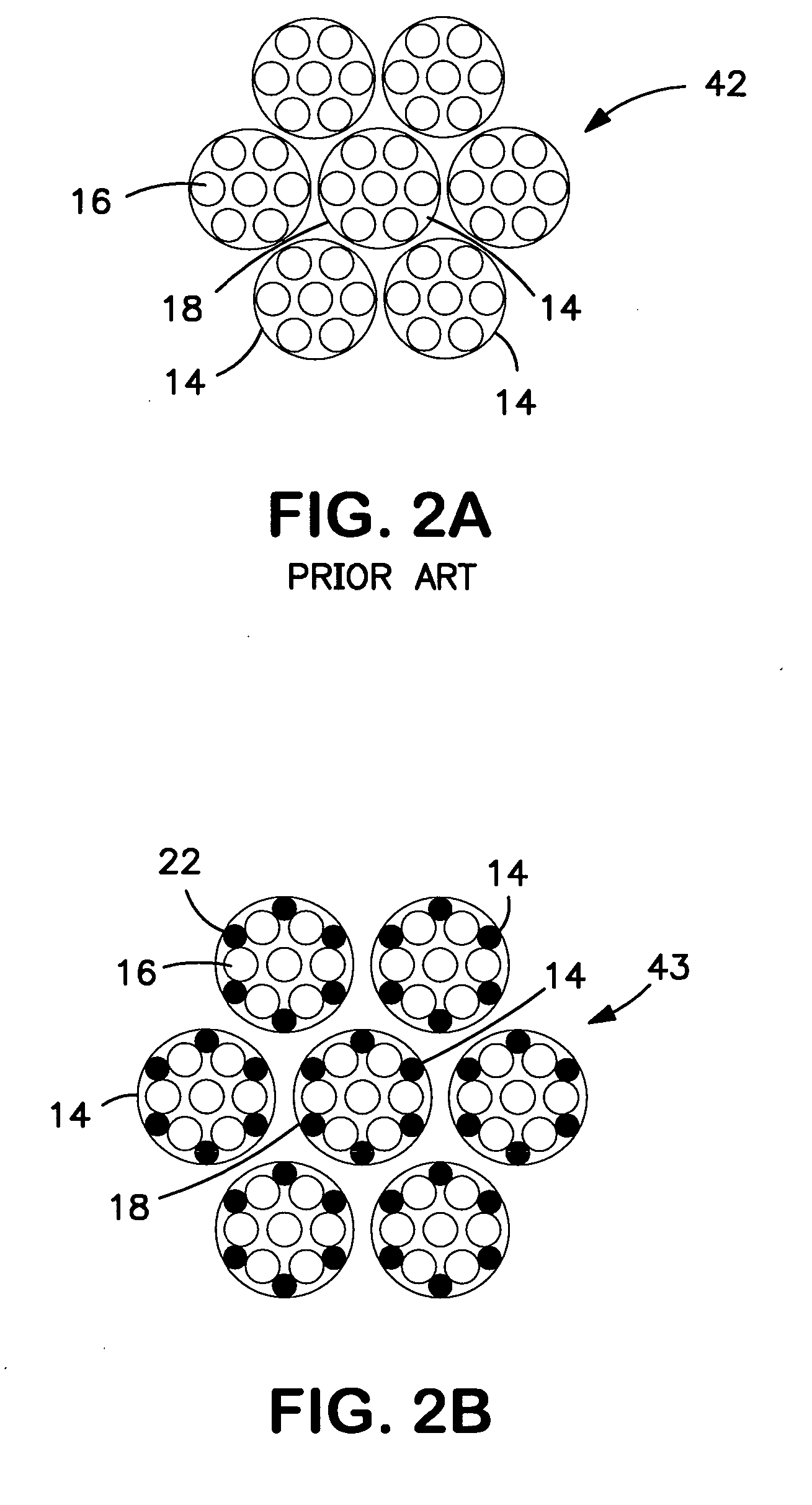

Wire rope incorporating fluoropolymer fiber

A wire rope including at least one metal wire and at least one fluoropolymer fiber. Preferably, the fluoropolymer fiber is present in an amount less than about 25 weight %, and in alternative embodiments less than 20 weight %, 15 weight %, 10 weight %, and 5 weight %. The fluoropolymer fiber is preferably PTFE, and most preferably expanded polytetrafluoroethylene (ePTFE). The wire rope is useful in tensioned and bending applications.

Owner:WL GORE & ASSOC INC

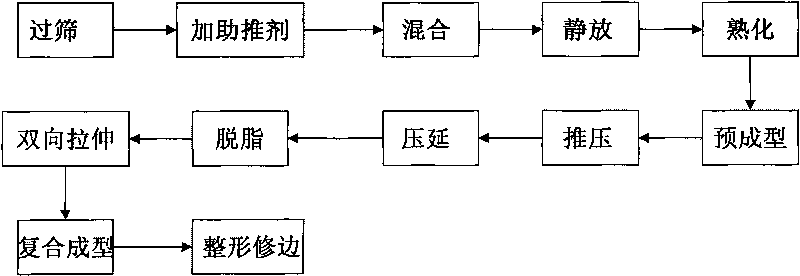

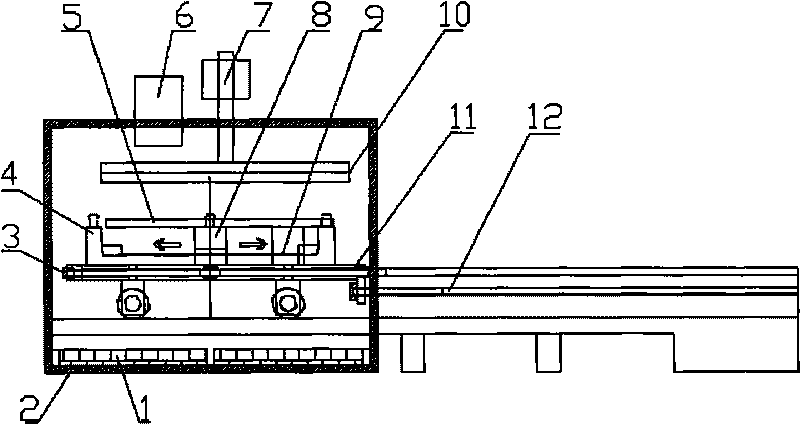

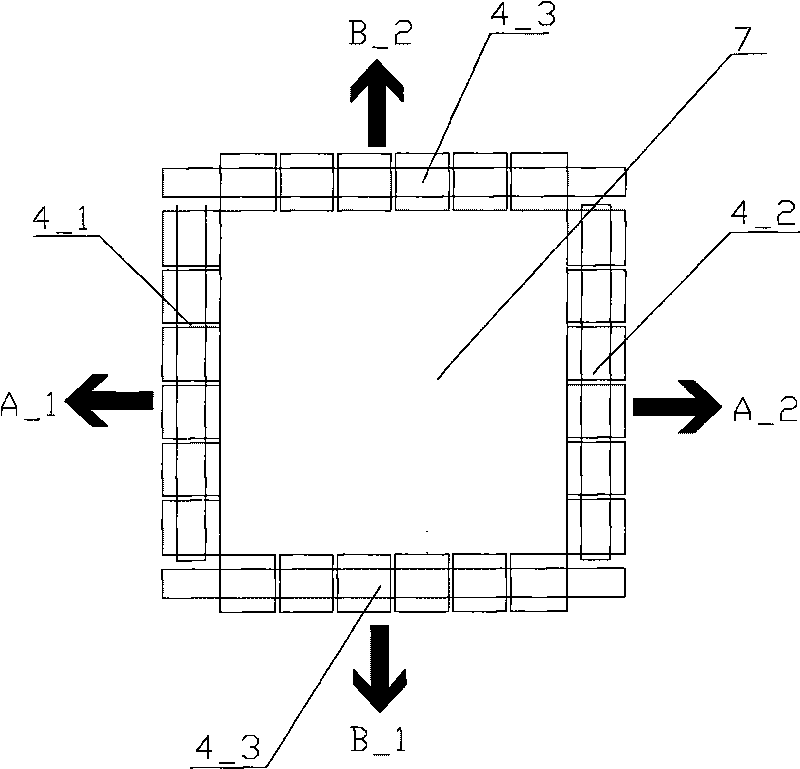

Method for manufacturing expanded polytetrafluoroethylene plate

A method for manufacturing an expanded polytetrafluoroethylene (PTFE) plate comprises the following steps: sieving PTFE dispersion resins, adding a propellant and mixing the two materials, placing the mixed materials for 24h and then carrying out aging treatment, then carrying out pre-press shaping and extruding blanks, carrying out calendaring with two rollers, removing the propellant, carrying out composite shaping after biaxial tension and carrying out reshaping and trimming to finally manufacture the expanded PTFE plate. The expanded PTFE plate is a great breakthrough in the manufacturingprocess of molded plates and turning plates. The compression resilience, the tensile strength and the low stress relaxation rate of the expanded PTFE plate are obviously increased and the expanded PTFE plate obviously improves the performance defects of the fluoroplastics, thus meeting the demand of the use functions of the sealing elements and propelling the fluoroplastics to be one of the substitutes of the asbestos materials widely used at present in the sealing material field.

Owner:四会市生料带厂有限公司

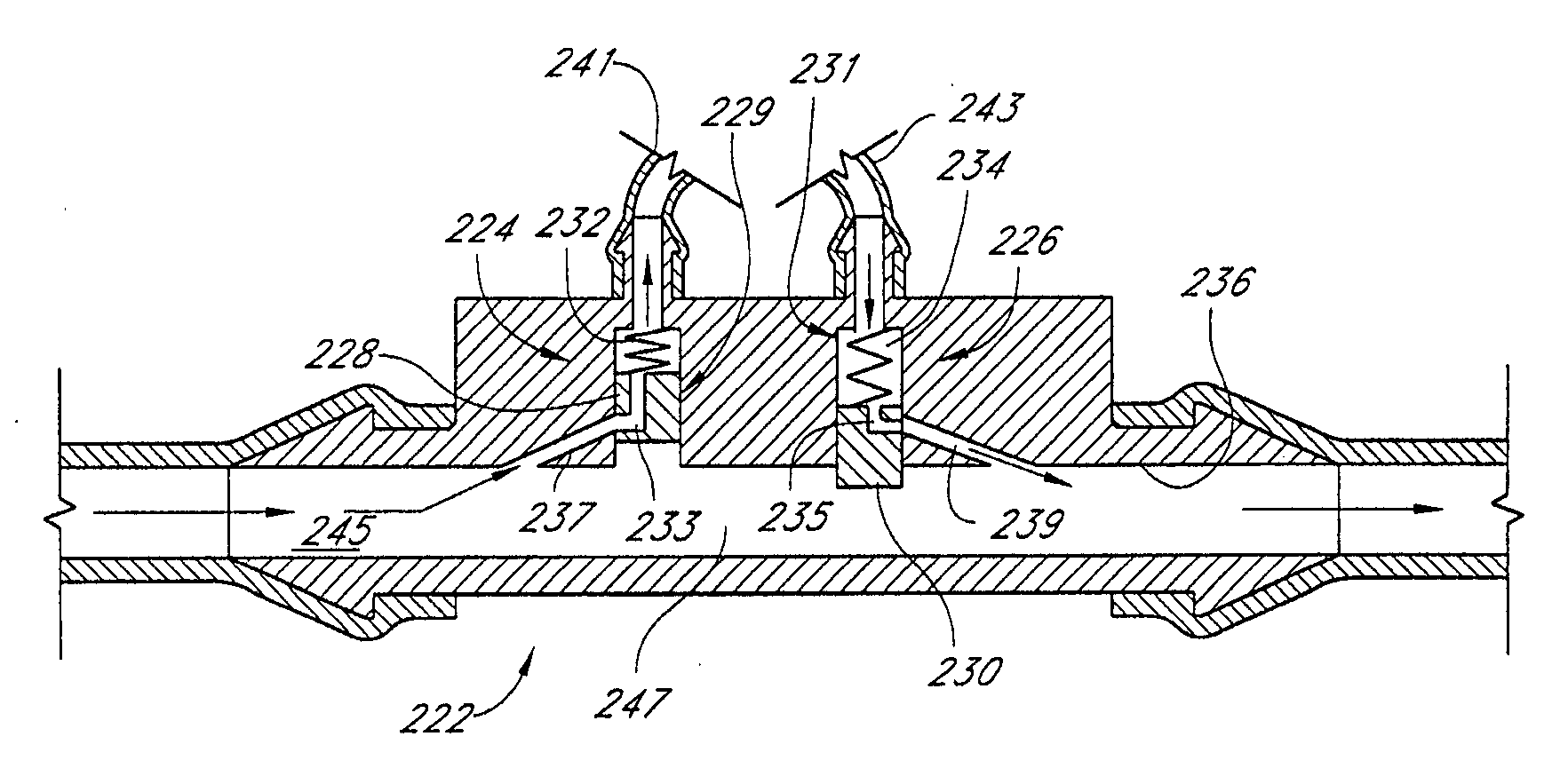

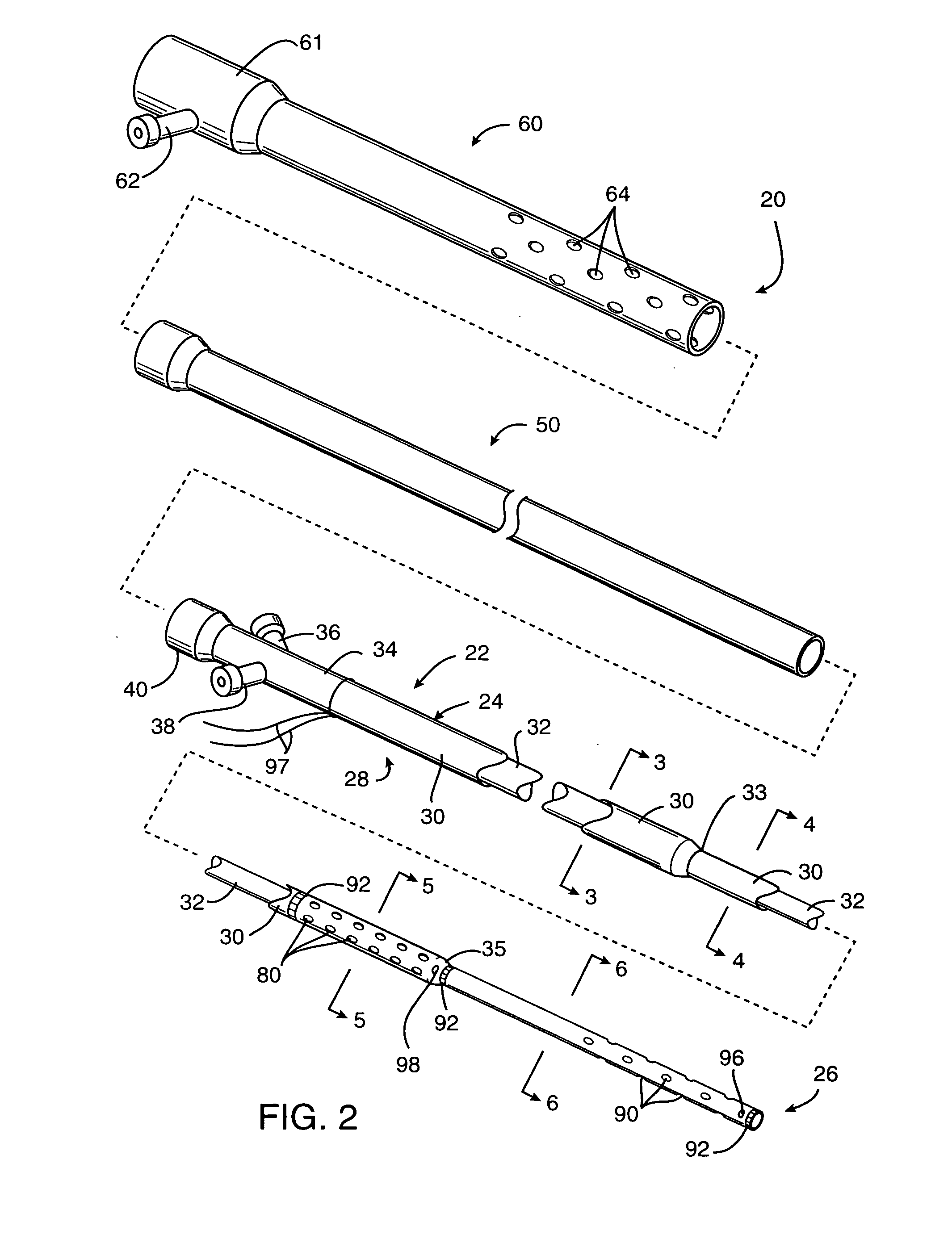

Intravascular device and method of manufacture and use

InactiveUS20050245897A1Lessen and eliminate reperfusion injuryRapid infusionGuide needlesStentsDistal portionExpanded PTFE

An intravascular device and method of constructing an intravascular device. The device has a proximal portion which is stiffer than a distal portion. The device of the present invention may also be advanced through small vessels without the aid of a guidewire although a guidewire may be used when necessary. The device may be manufactured in a number of different ways and a preferred method is to use an expanded PTFE liner at the distal portion and an etched PTFE liner along the proximal portion. The device also has a number of different jacket sections, preferably at least four, with increasing durometer towards the proximal end and a braided section with varying pic along the length.

Owner:SALIENT INTERVENTIONAL SYST

Full-frequency sound absorbing cotton

ActiveCN103177719AReduce stressExtended service lifeLayered productsSound producing devicesFiberEngineering

The invention relates to full-frequency sound absorbing cotton which is provided with a double-layer structure or three-layer structure. The full-frequency sound absorbing cotton of the double-layer structure is composed of a melt-blow high polymer fiber layer and a varicosity polytetrafluoroethylene layer. The full-frequency sound absorbing cotton of the three-layer structure is composed of a melt-blow high polymer fiber layer with double faces compounded with the varicosity polytetrafluoroethylene layer or the varicosity polytetrafluoroethylene layer with double faces compounded with the melt-blow high polymer fiber layer. A high-performance composite micropore thin layer new material has better full-frequency sound absorbing capacity; is environment-friendly, non-toxic and free of peculiar smell, volatile gas, pollution or carcinogenic substances; and is free of stimulation caused by operating similar glass fiber on the skin, can be machined in punching mode, and does not generate dust or scraps and the like. The sound absorbing cotton made of the two materials of the melt-blow high polymer fiber layer and the varicosity polytetrafluoroethylene layer has good thermal resistance, and a sound absorbing effect cannot be affected by high-humidity climate and water.

Owner:PAN ASIAN MICROVENT TECH JIANGSU CORP

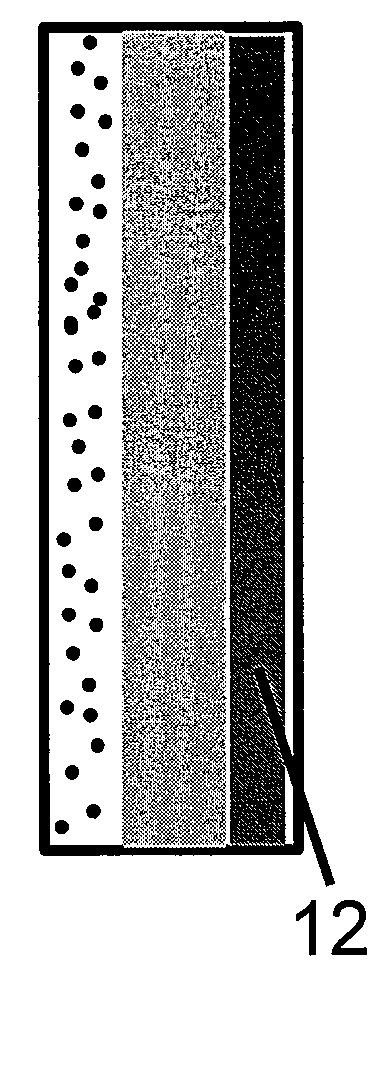

Solid Polymer Electrolyte and Process for Making Same

A solid polymer electrolyte membrane having a first surface and a second surface opposite the first surface, where the solid polymer electrolyte membrane has a failure force greater than about 115 grams and comprises a composite membrane consisting essentially of (a) at least one expanded PTFE membrane having a porous microstructure of polymeric fibrils, and (b) at least one ion exchange material impregnated throughout the porous microstructure of the expanded PTFE membrane so as to render an interior volume of the expanded PTFE membrane substantially occlusive; (c) at least one substantially occlusive, electronically insulating first composite layer interposed between the expanded PTFE membrane and the first surface, the first composite layer comprising a plurality of first carbon particles supporting a catalyst comprising platinum and an ion exchange material, wherein a plurality of the first carbon particles has a particle size less than about 75 nm, or less than about 50 nm, or less than about 25 nm.

Owner:WL GORE & ASSOC INC

Low stress to seal expanded PTFE gasket tape

ActiveUS20050202233A1Low tensile strengthHigh bonding strengthEngine sealsDomestic sealsUltimate tensile strengthExpanded PTFE

A low stress to seal, unitary gasket tape is provided that is particularly suited for use in form-in-place gaskets. The gasket tape preferably comprises at least two joined porous expanded polytetrafluoroethylene (ePTFE) tapes aligned along tape side surfaces and a substantially air impermeable layer there between. The plane of expansion of the ePTFE is substantially parallel to the flange surface providing longitudinal and transverse strength. The substantially air impermeable layer prevents fluid from permeating through the gasket in the radial direction.

Owner:WL GORE & ASSOC INC

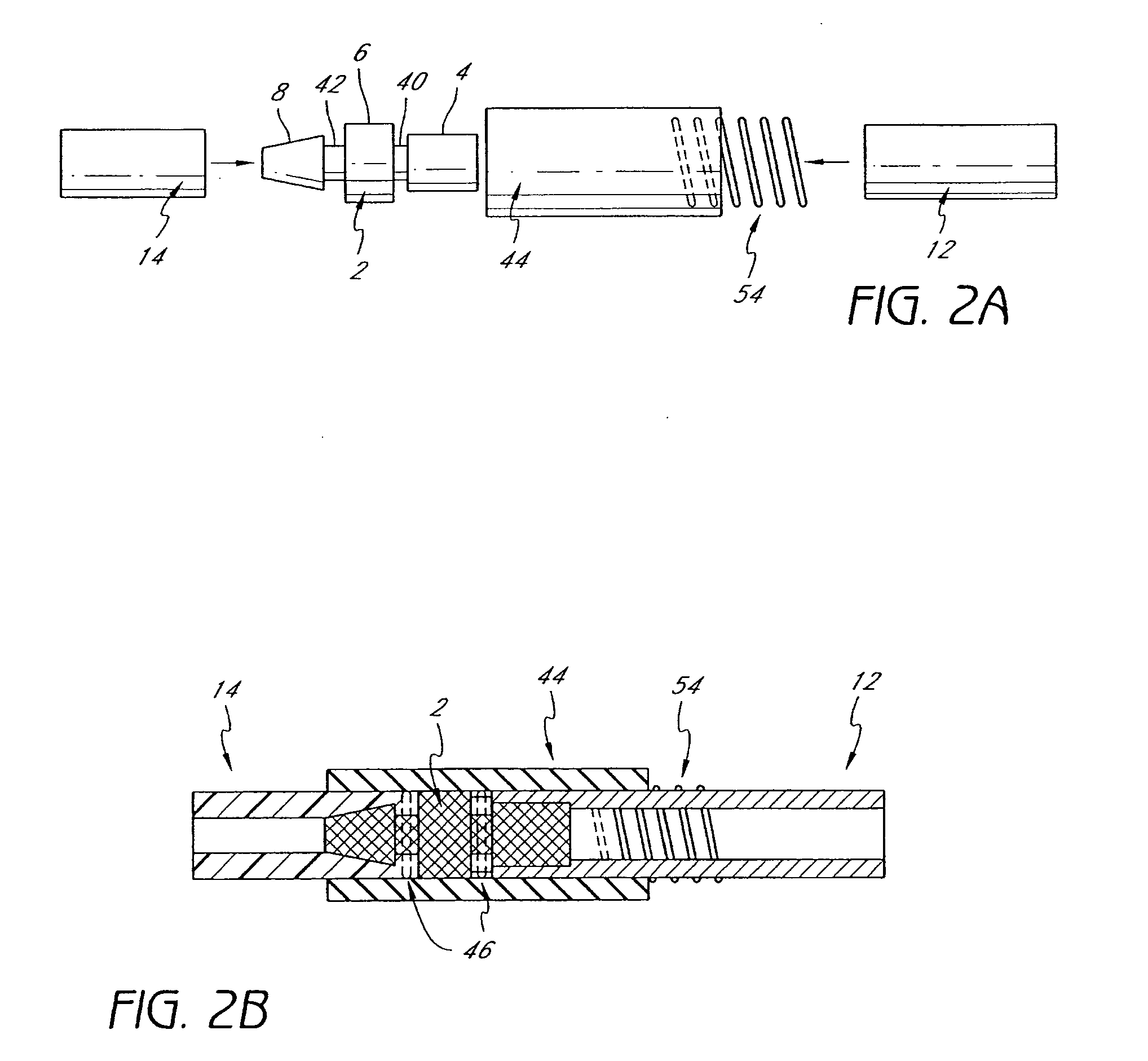

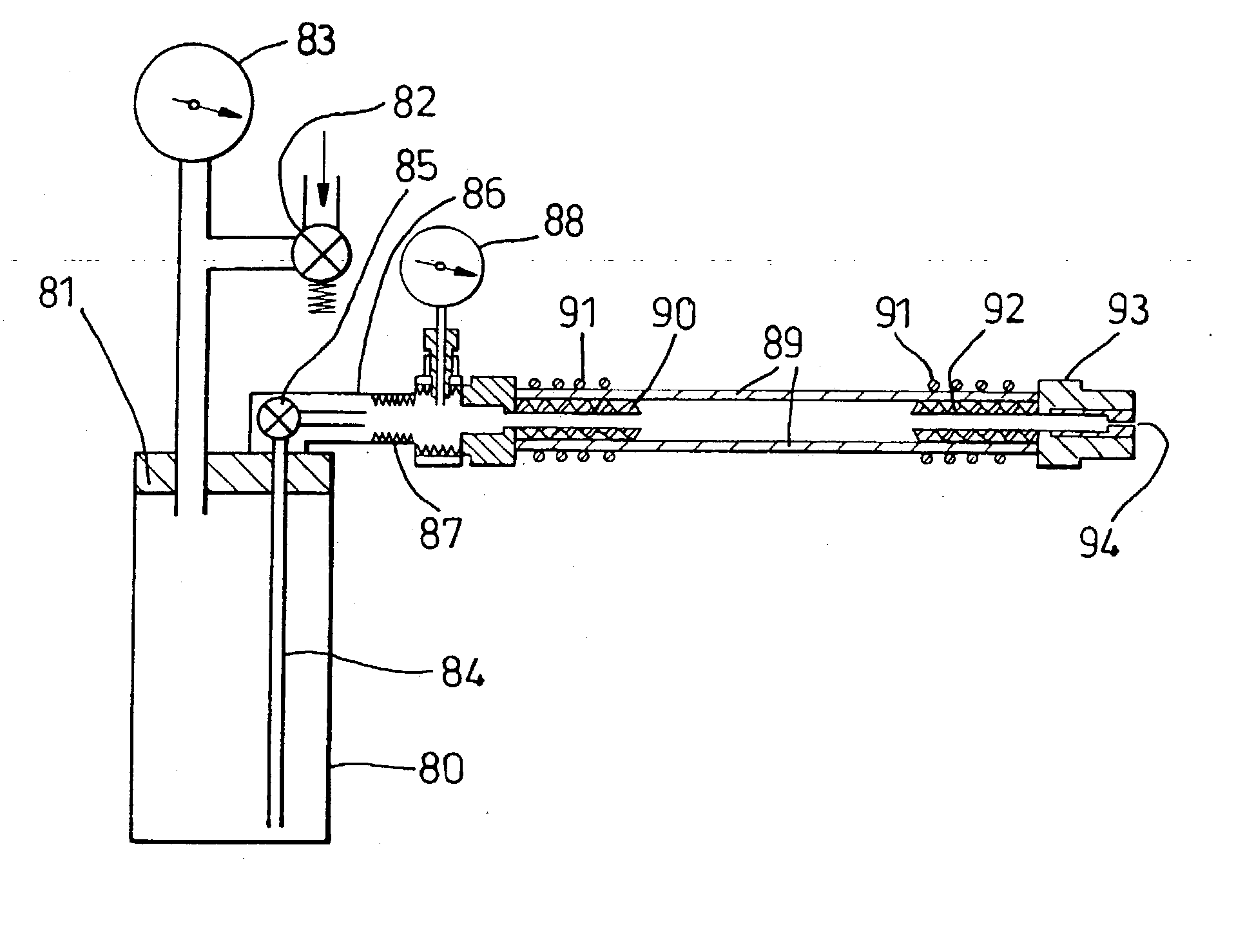

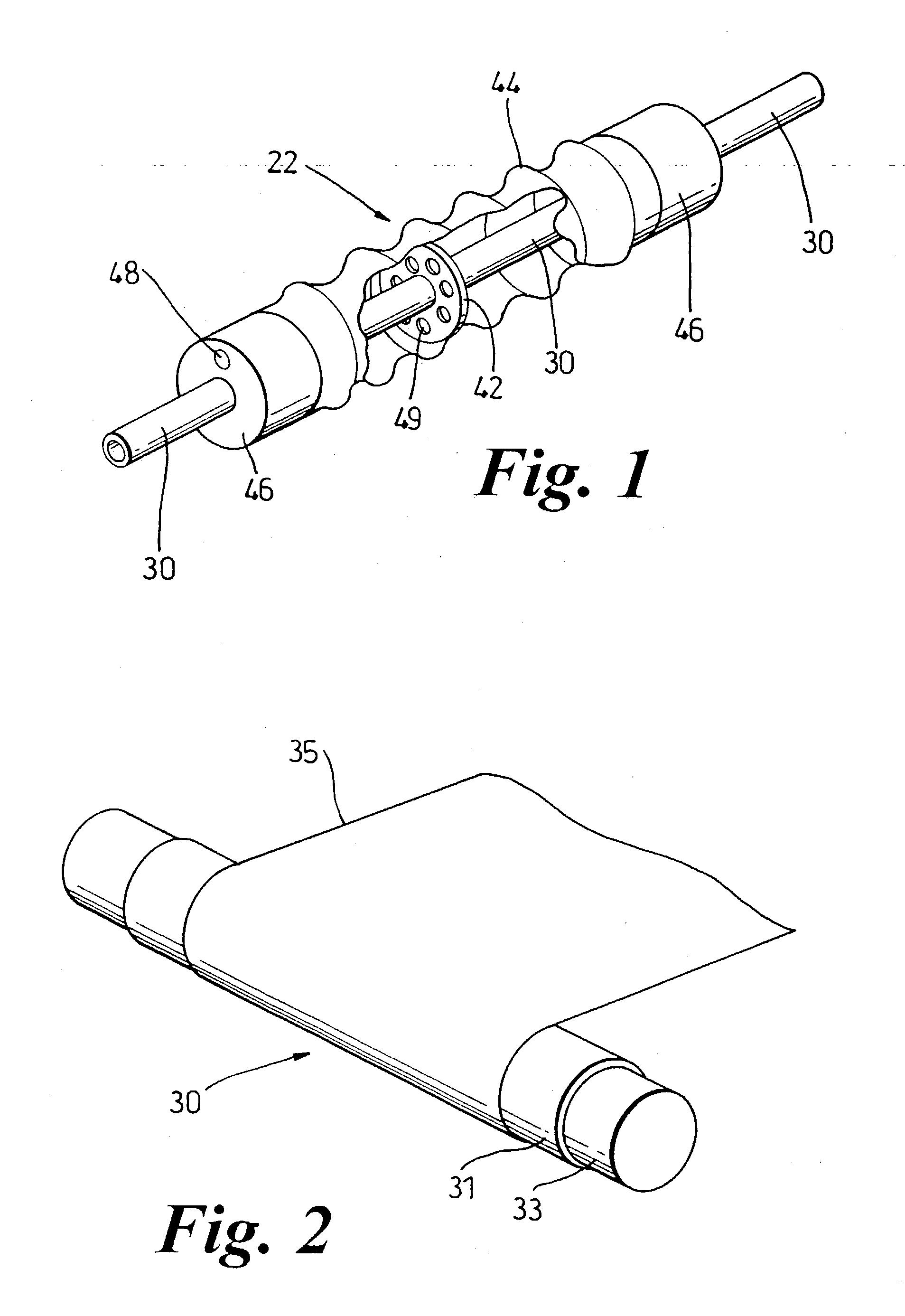

Cryogenic fluid transfer tube

InactiveUS20030106325A1Maximise fluid deliveryFast deliveryThermal insulationContainer filling methodsTetrafluoroethyleneFluoropolymer

The present invention is an improved tube for the effective transfer of cryogenic fluids and the like. The transfer tube (22) comprises at least two tubes, an inner tube (30) coaxially housed within an outer tube (44) with a defined gap therebetween. The inner tube is sufficiently permeable to gaseous cryogenic fluid that it allows release of limited amounts of gaseous fluid into the defined gap. The outer tube is essentially impermeable so as to contain the gaseous fluid within the gap. Preferably both tubes are constructed from flexible and cold temperature resistant polymer materials, such as fluoropolymer materials and especially expanded polytetrafluoroethylene (PTFE) and / or fluorinated ethylene propylene (FEP). The transfer tube of the present invention is highly effective at cryogenic fluid transfer while being lighter, more flexible, and more efficient than currently available transfer tubes.

Owner:W L GORE & ASSOCS UK

Electrical cable

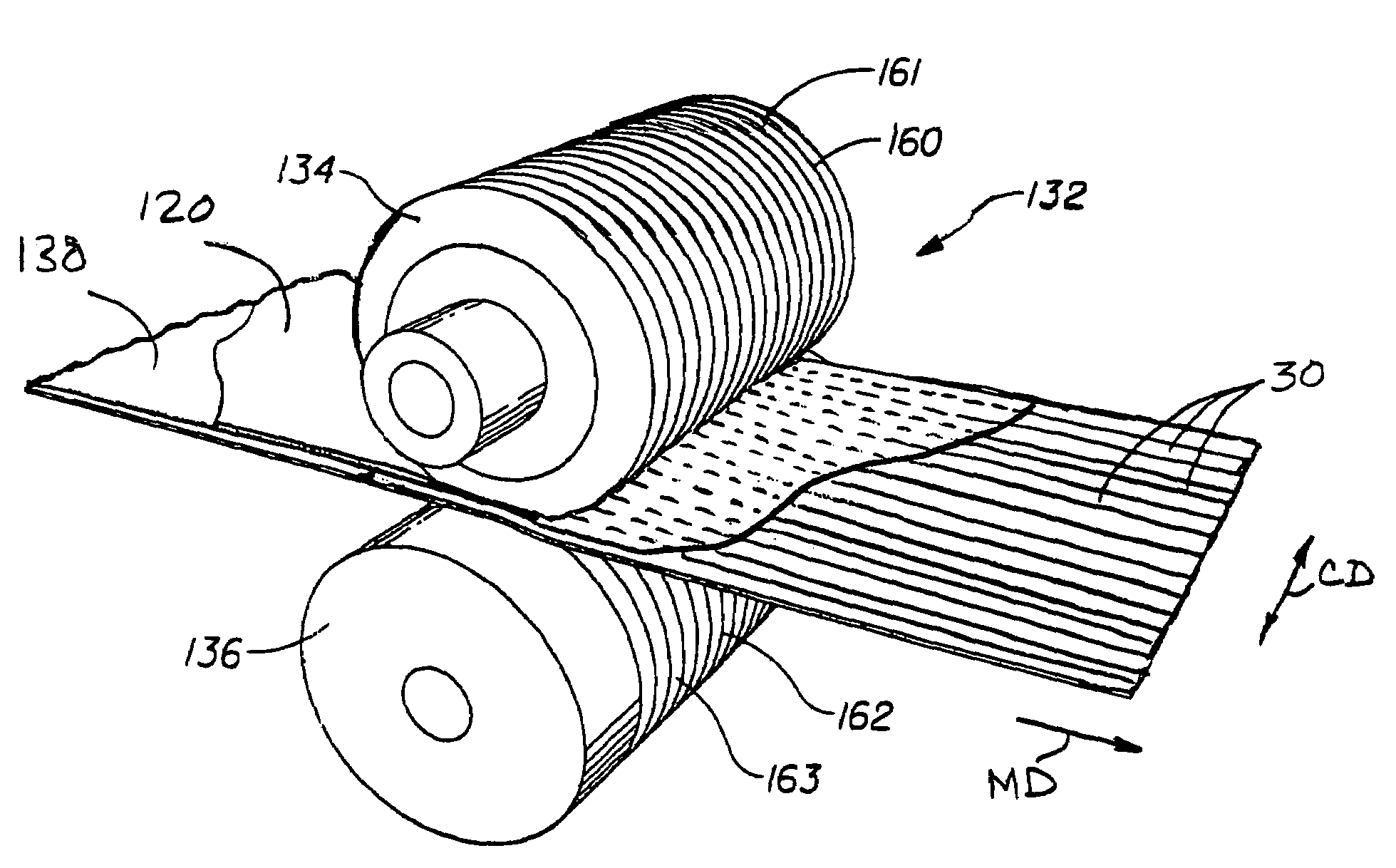

An electrical cable of the present invention comprises a plurality of spaced, parallel flat conductors. Each of the plurality of flat conductors was previously integral with each immediately adjacent flat conductor. A dielectric material is holds the conductors in the spaced, parallel relationship. The dielectric material can be a polymer film, a nonwoven, or other polymer materials such as PTFE, or expanded PTFE. The cable of the present invention is made by providing first and second webs of dielectric materials and a third sheet of conductive material. The first and second web materials are bonded to the third sheet of conductive material in a face-to-face layered relationship thereby forming a bonded laminate. The bonded laminate is then incrementally stretched to separate the sheet of conductive material in to spaced, parallel flat conductors.

Owner:THE PROCTER & GAMBLE COMPANY

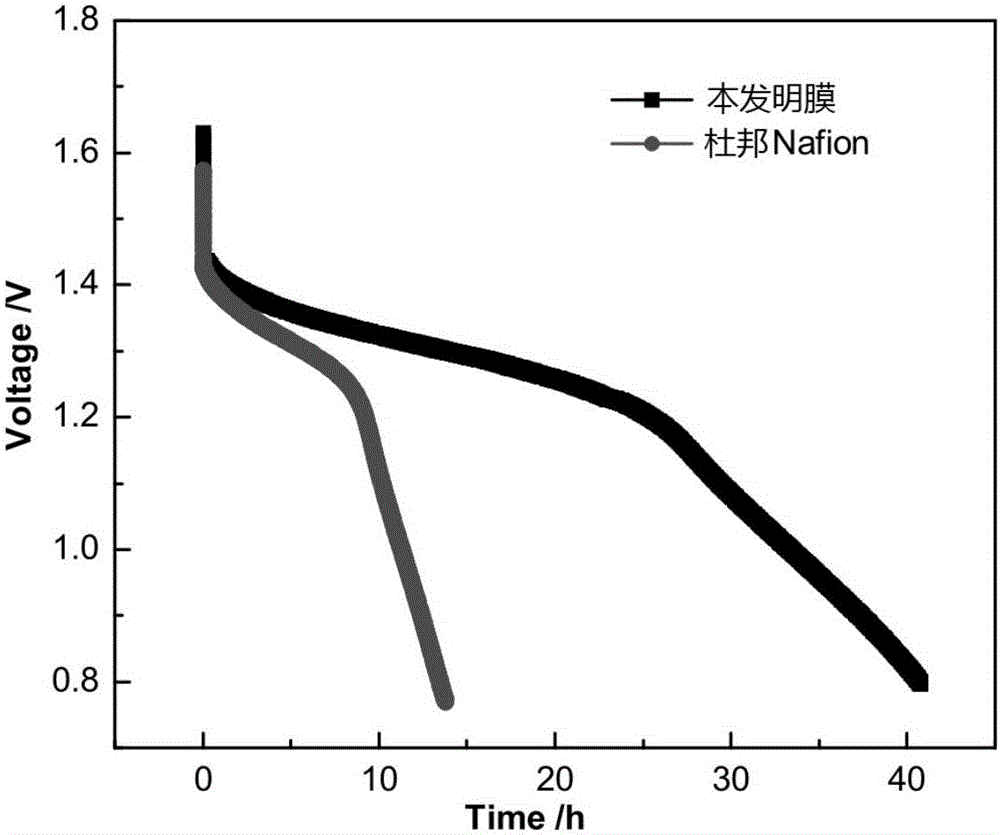

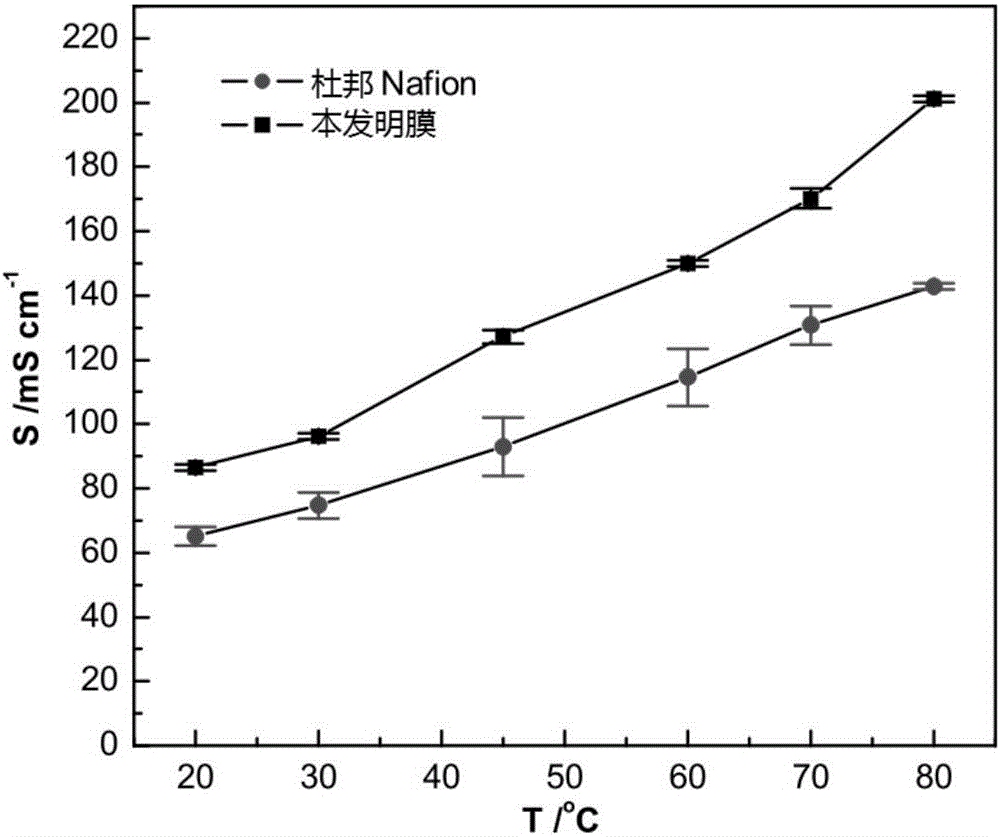

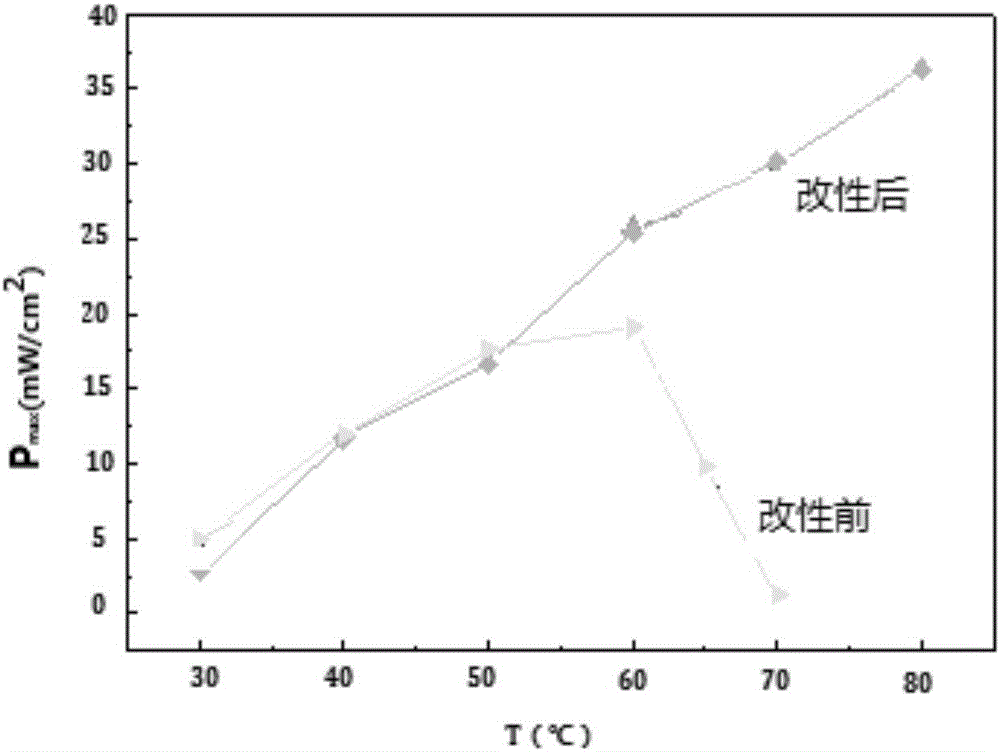

Sulfonated graphene modified perfluorosulfonate ion composite membrane and preparation method thereof

ActiveCN106589443ASimple process routeFacilitate large-scale productionFuel cellsPermeationNafion membrane

The invention provides a preparation method of a sulfonated graphene modified perfluorosulfonate ion composite membrane. According to the ion composite membrane, an expanded PTFE microporous membrane serves as a base membrane. The method comprises the step that the base membrane is soaked in a sulfonated graphene perfluorosulfonate resin solution. Compared with the prior art, through doping of sulfonated graphene, self-discharge caused by permeation of vanadium ions is effectively prevented; meanwhile, the conductivity of the composite membrane is greatly improved compared with a Nafion membrane, and the improvement effect is more remarkable along with raise of temperature. Compared with a proton exchange membrane before sulfonated graphene modification, the maximum power of the composite membrane is increased by 80%.

Owner:THINKRE MEMBRANE MATERIAL

Expanded polytetrafluoroethylene-based thermal insulation moisture permeable garment material and preparation method thereof

InactiveCN103009687AEliminate the feeling of stuffiness and discomfort in the human bodySoft touchSynthetic resin layered productsLaminationSolventThermal insulation

The invention discloses an expanded polytetrafluoroethylene-based thermal insulation moisture permeable garment material and a preparation method thereof. At least a fabric layer is connected on a microporous thin layer of the expanded polytetrafluoroethylene of the garment material through a bonding layer; the preparation method of the bonding layer being a chemical bonding layer comprises the steps that the bonding layer is applied on one side or two sides of the microporous thin layer of the expanded polytetrafluoroethylene and the fabric layer is composited on a chemical bonding layer, a multi-layer material is laminated through a roller, solvent is removed through drying and baking and solidification; and the preparation method of the bonding layer being a hot melting bonding layer comprises the steps that hot melting non-woven fabric is laid on one side or two sides of the microporous thin layer of the expanded polytetrafluoroethylene, a fabric layer is composited on the hot melting bonding layer, and air cooling shaping is carried out after laminated bonding through hot melt. By adopting the method, the expanded polytetrafluoroethylene-based thermal insulation breathable garment material has the characteristics of being soft, moisture permeable and beautiful, and keeping warm; and the fabric has breathable, moisture permeable and thermal insulation performances, thus eliminating uncomfortable wet feeling caused by wet gas.

Owner:PAN ASIAN MICROVENT TECH JIANGSU CORP

Turbine type gas compressor front end dust remover and filter element thereof

ActiveCN103089714AHigh filtration precisionImprove foulingPump componentsPumpsGas compressorMicrometer

The invention discloses a turbine type gas compressor front end dust remover and a filter element of the turbine type gas compressor front end dust remover. By means of the turbine type gas compressor front end dust remover and the filter element of the turbine type gas compressor front end dust remover, the phenomenon that a turbine type gas compressor is subjected to scaling after being used for a long time can be effectively improved. The front end dust remover comprises an outer shell, the filter element mounted in the outer shell, and a back-blowing dust cleaning device which acts on the filter element. The outer shell is connected with the filter element through a pore plate and forms a first space and a second space which are separated. Transmission of gas to be filtered happens in the first space, and the transmission of filtered gas happens in the second space. The filter element is provided with a filter material which is composed of a porous high-density polyethylene support body and an expanded polytetrafluoroethylene (PTFE) filter film, wherein the expanded PTFE filter film is closely attached to the surface of the porous high-density polyethylene support body. The removal rate of dust with a grain diameter of greater than or equal to 0.5 micrometer in the gas to be filtered by the expanded PTFE filter film is more than 99%. According to the turbine type gas compressor front end dust remover and the filter element of the turbine type gas compressor front end dust remover, the filter material can maintain stable and high filter precision for a long time, and therefore the phenomenon that the turbine type gas compressor is subjected to the scaling after being used for a long time can be effectively improved.

Owner:CHENGDU RUIKELIN ENG TECH

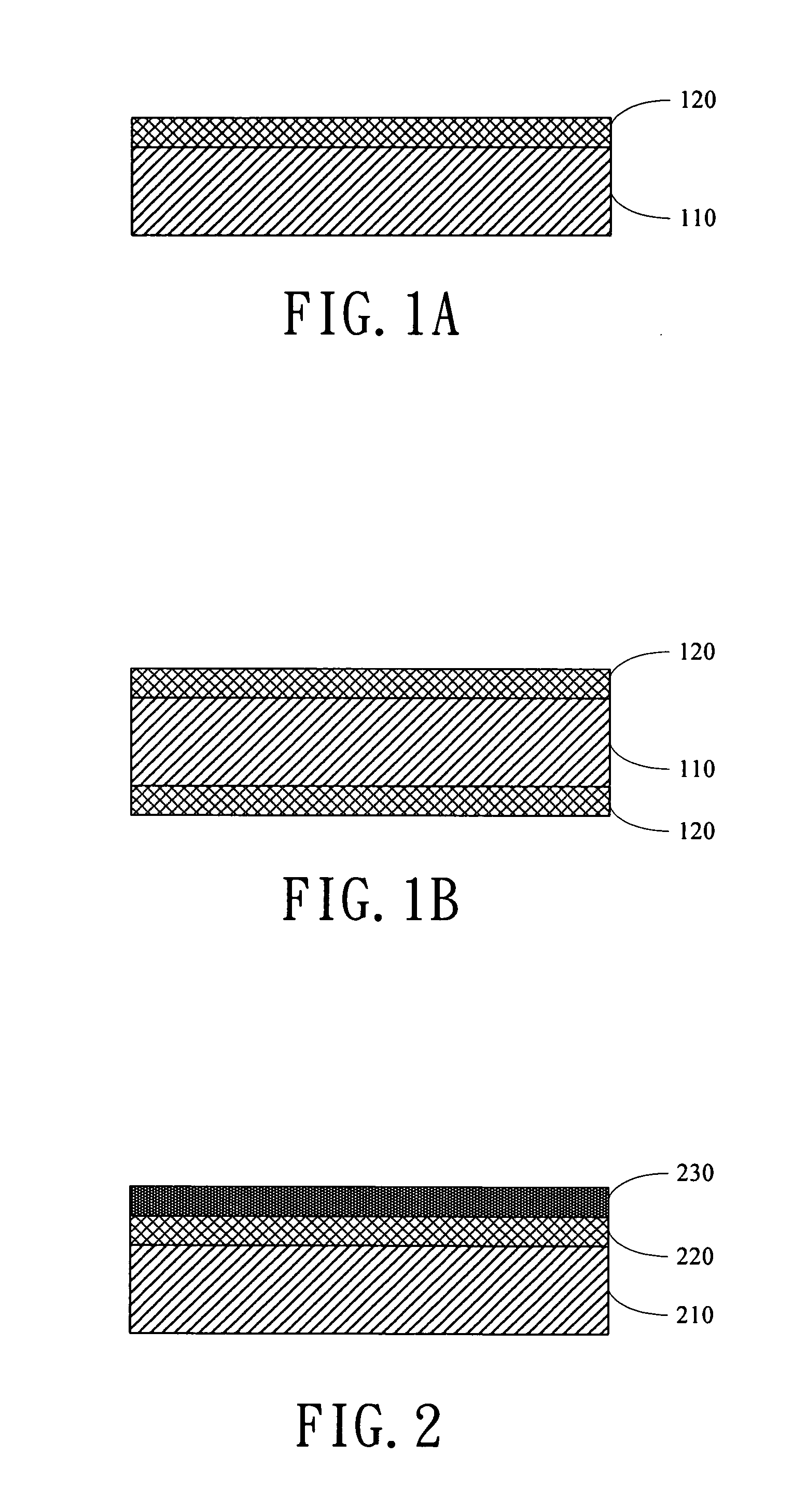

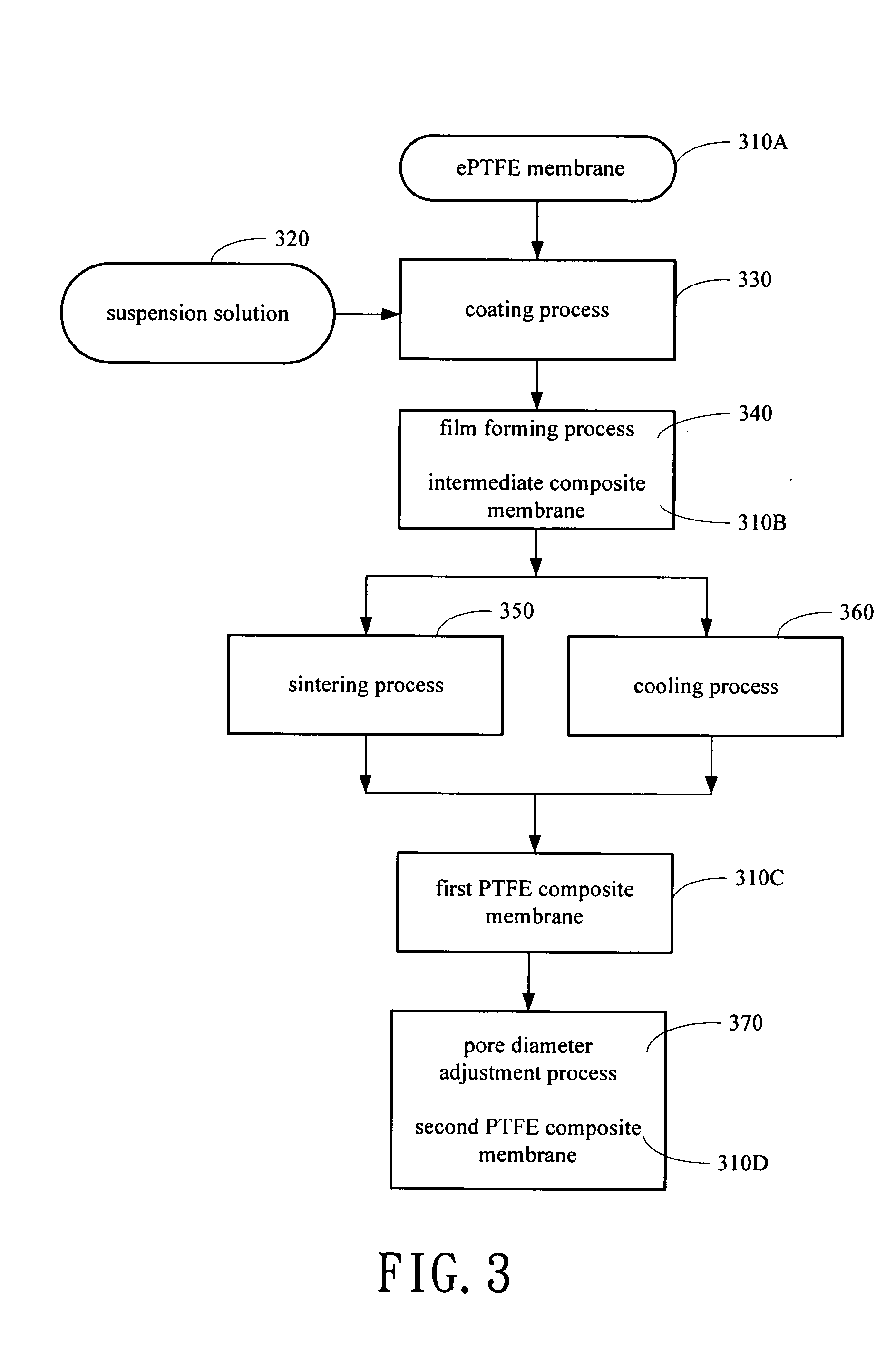

Composite membrane and method for forming the same

ActiveUS20060269735A1Shorten the sintering timeBroaden applicationMembranesSemi-permeable membranesExpanded PTFEMembrane configuration

The present invention discloses discloses a composite PTFE membrane comprising an expanded PTFE membrane as substrate and a sintered porous PTFE membrane on top of it. The porous PTFE membrane on top has porous structure with interconnected channels formed with a sintering process that fuses the PTFE fine powders coated on the ePTFE membrane. Furthermore, the present invention discloses a method for forming the composite PTFE membrane.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com