Patents

Literature

5444results about How to "The overall thickness is thin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

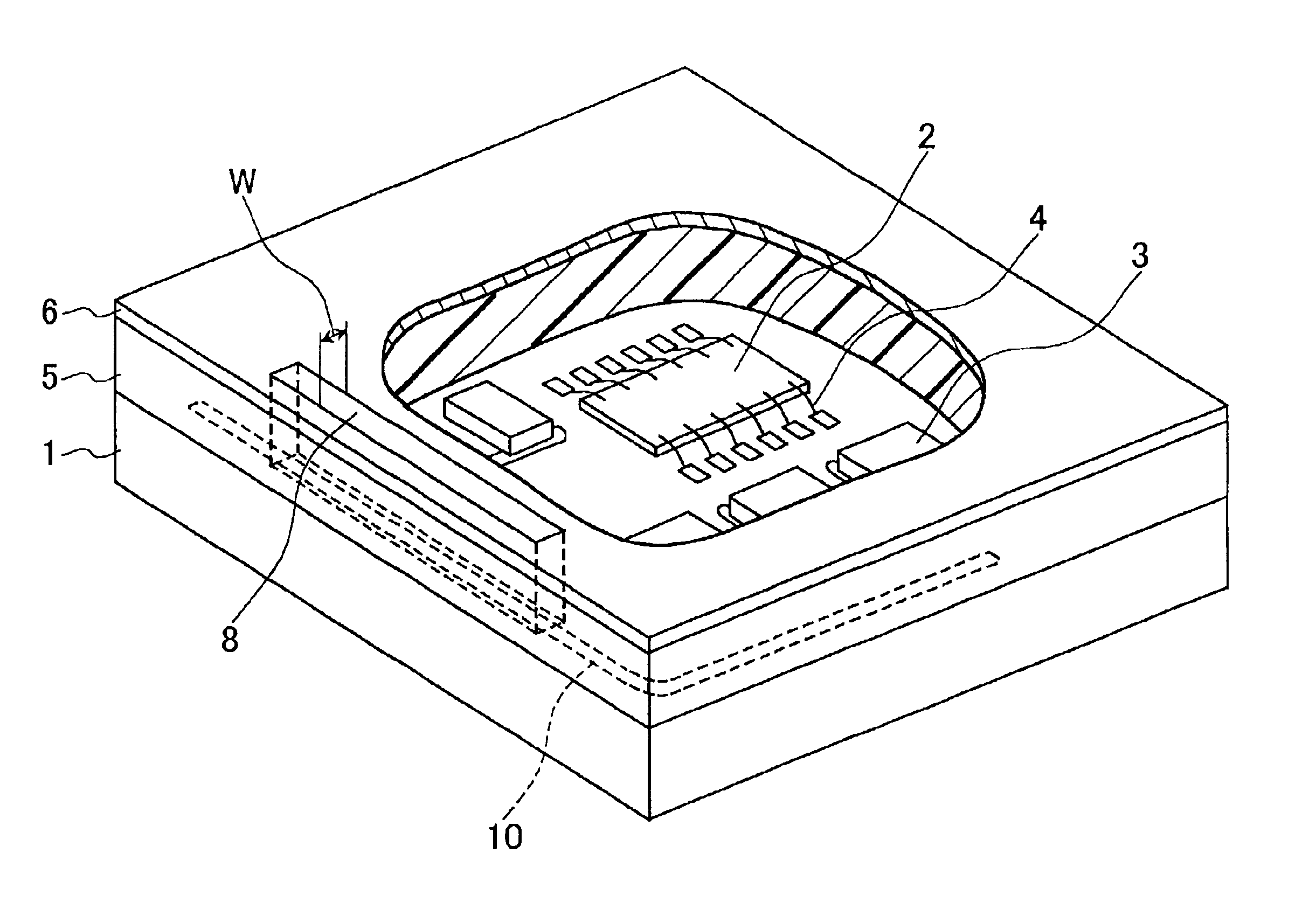

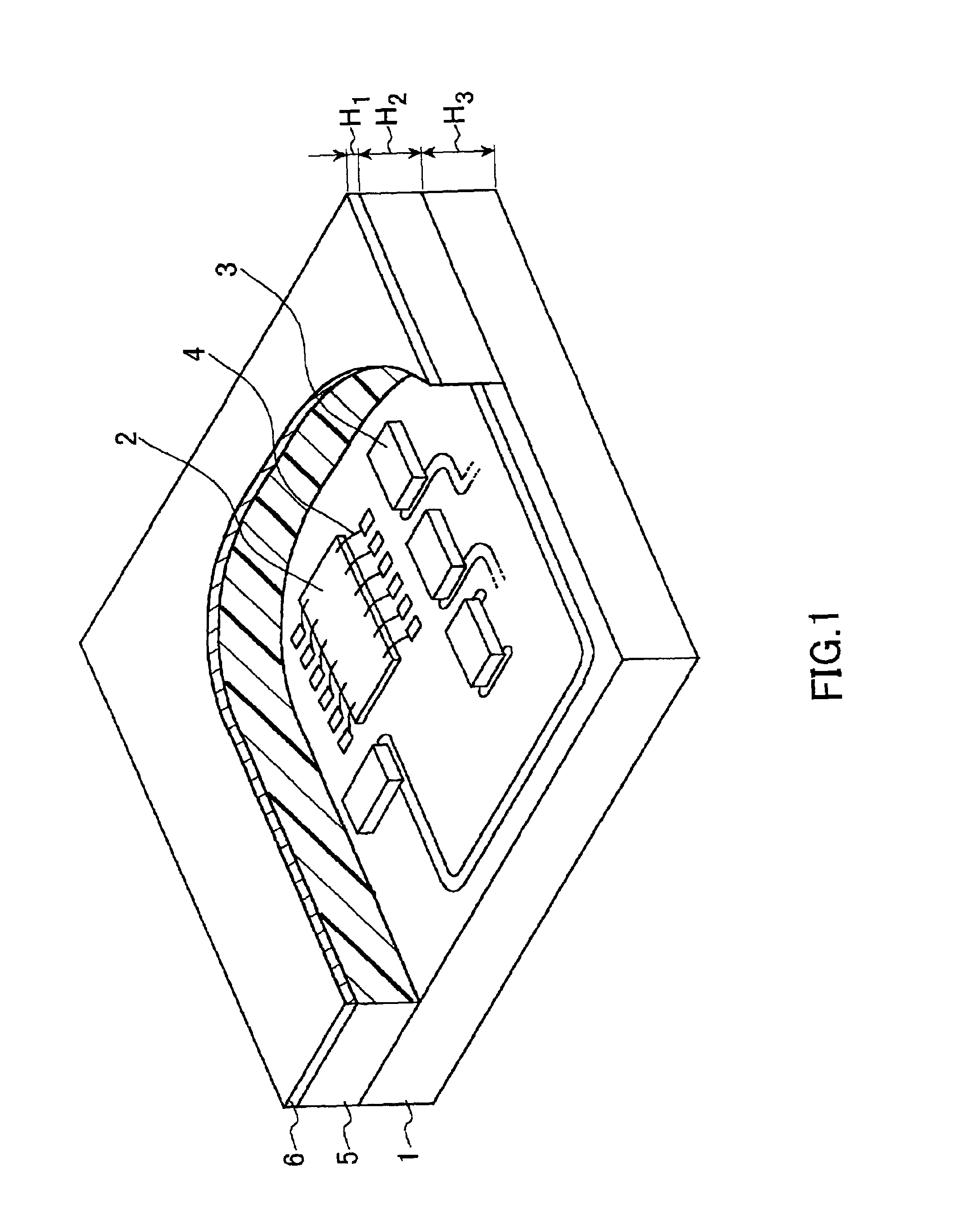

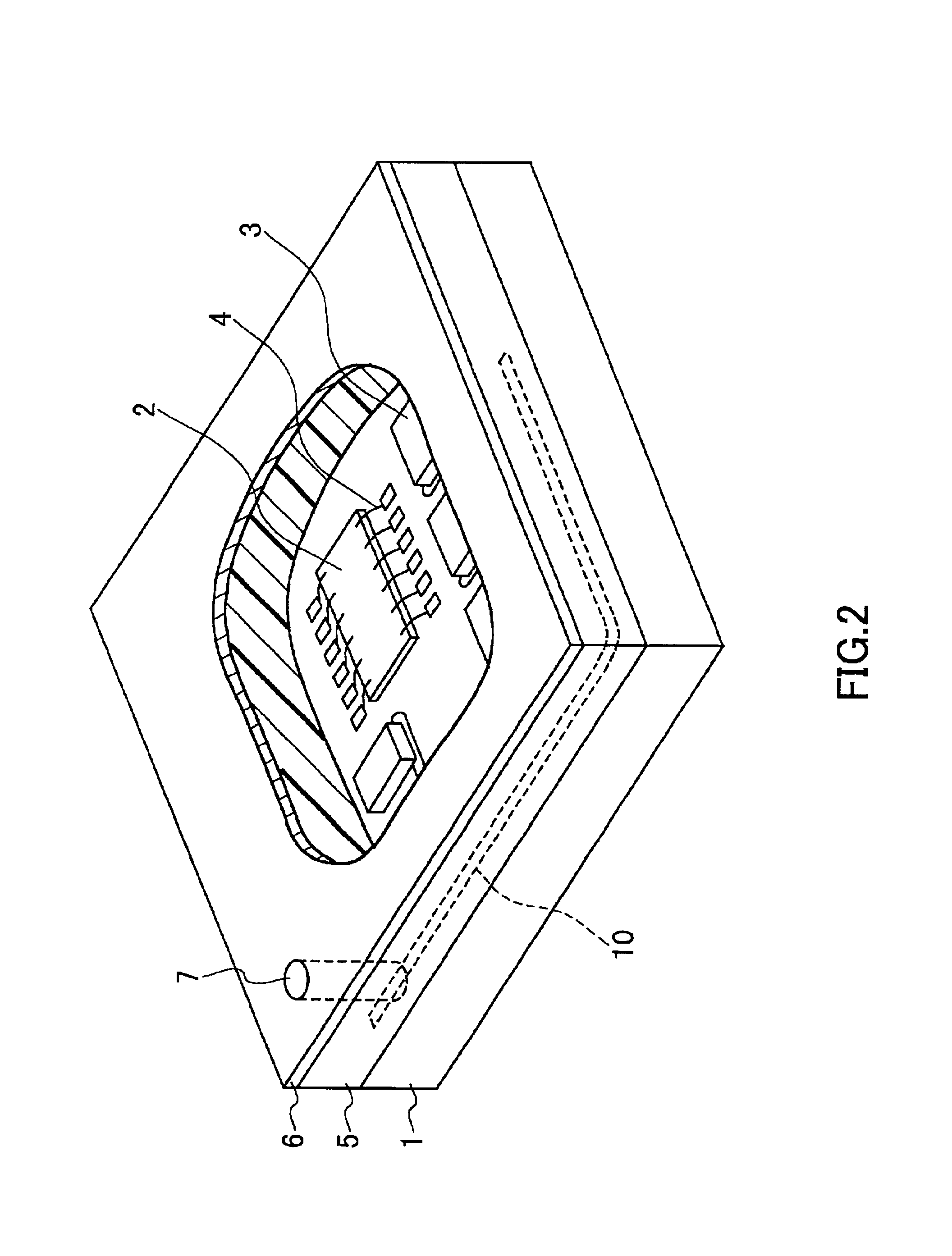

High-frequency module and method for manufacturing the same

InactiveUS7081661B2Reduce electromagnetic influencePliability problemMagnetic/electric field screeningSemiconductor/solid-state device detailsEngineeringElectronic component

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

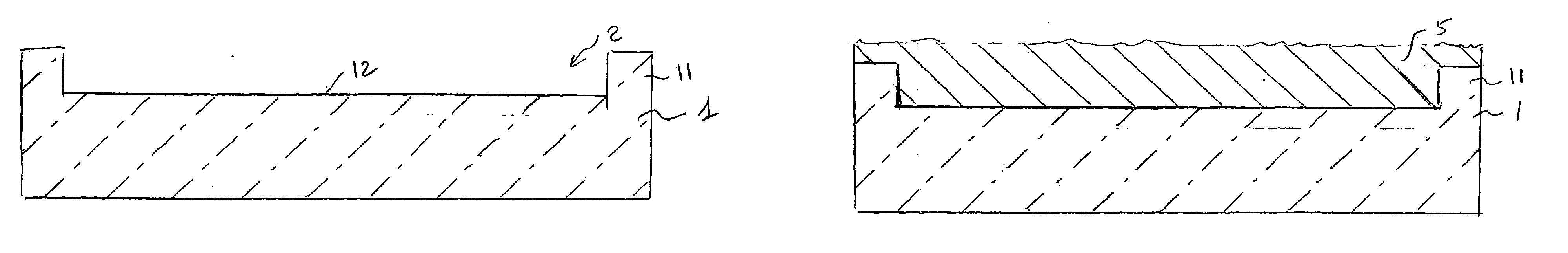

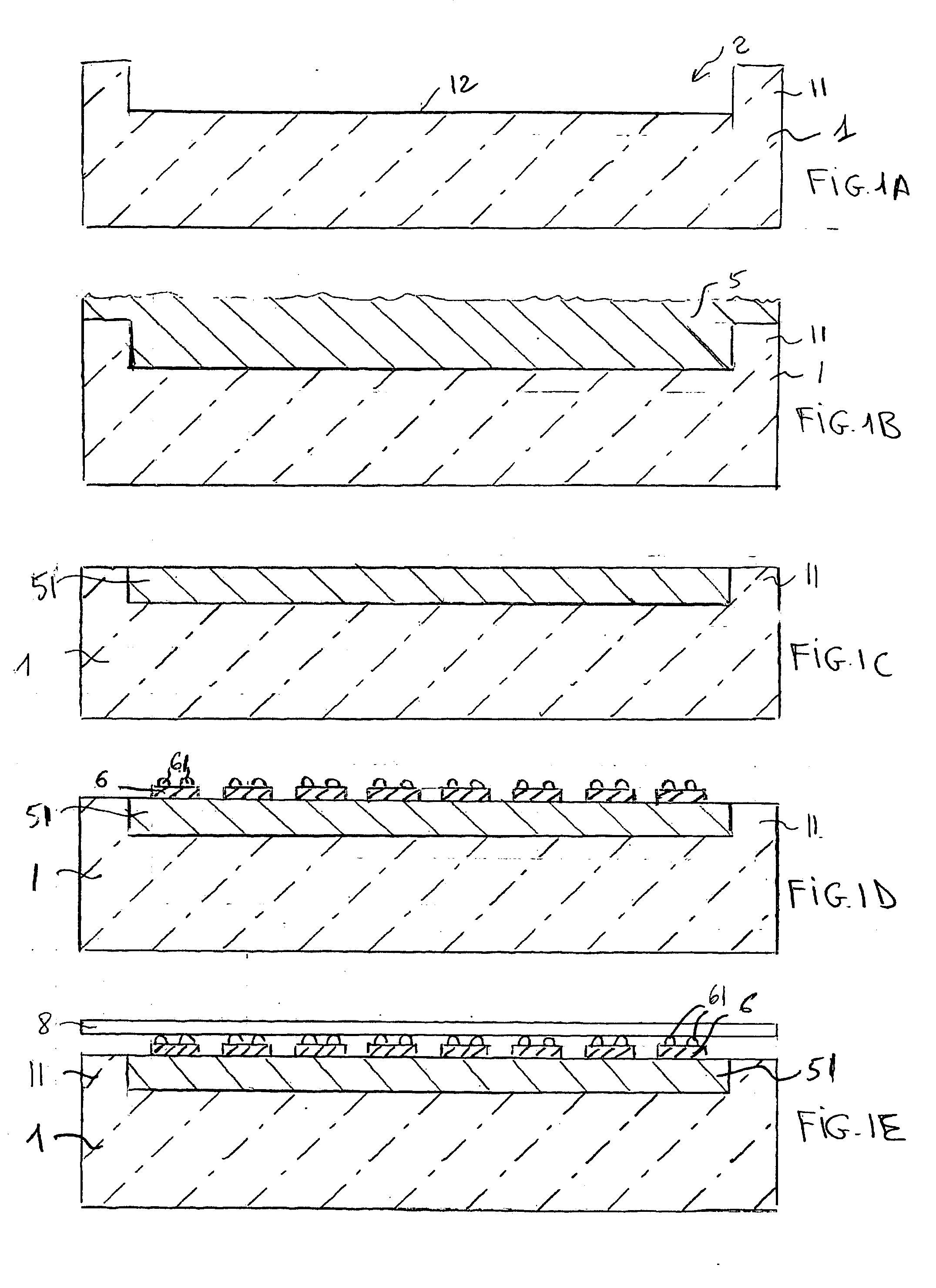

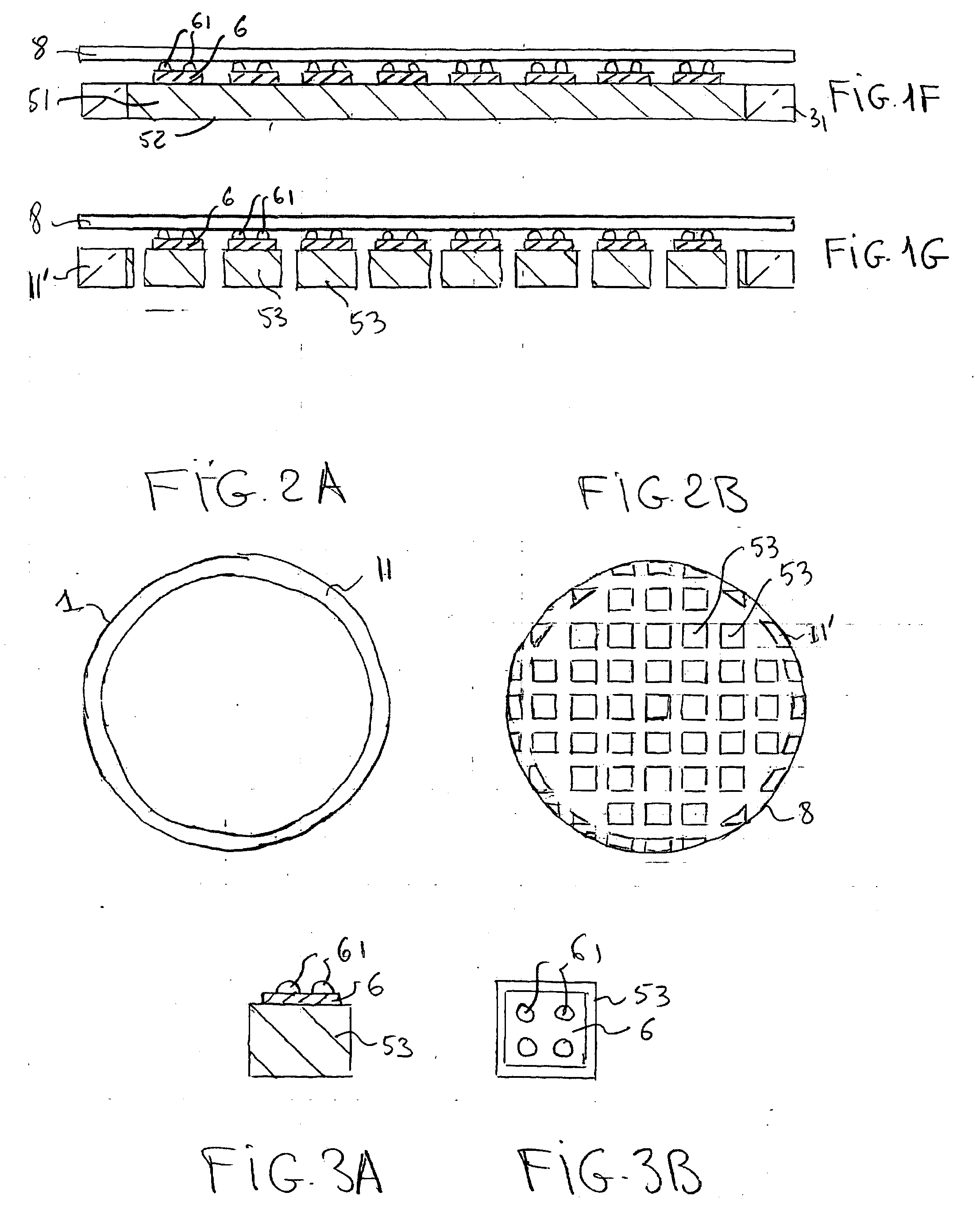

Thin glass chip for an electronic component and manufacturing method

ActiveUS20060057782A1Curb riskThe overall thickness is thinDecorative surface effectsSolid-state devicesElectronic componentThin glass

The manufacturing of electronic components on individual substrates made of an insulating material includes molding, in a silicon wafer, an insulating material with a thickness corresponding to the final thickness desired for the substrates, manufacturing the electronic components, and removing the silicon from the rear surface of the wafer after manufacturing of the components.

Owner:STMICROELECTRONICS SRL

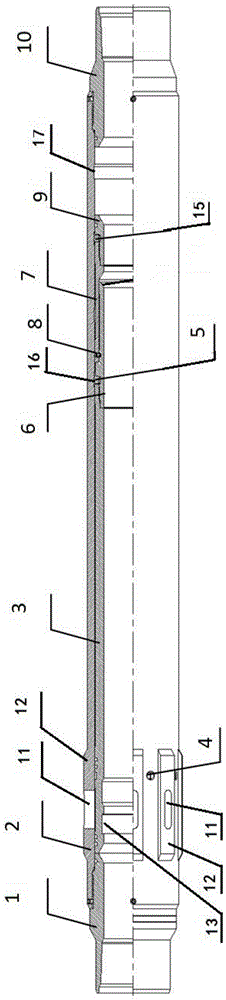

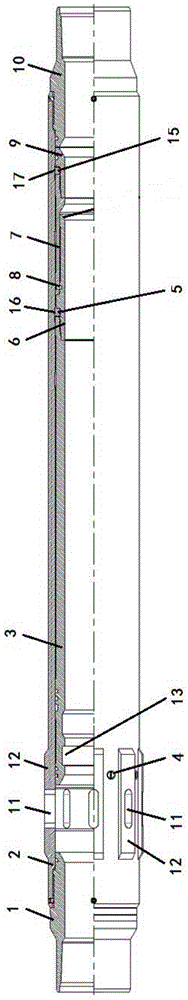

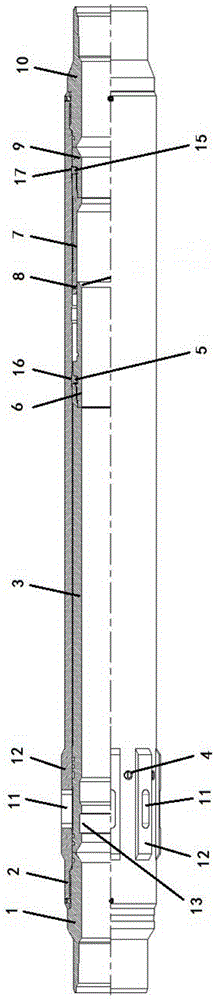

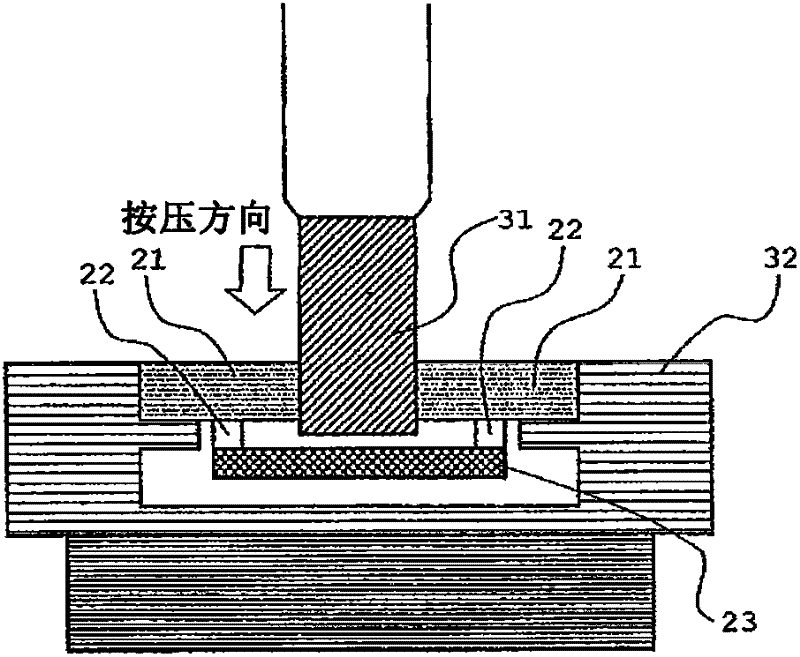

Switchable well cementation sliding sleeve based on fracturing of separate layers and construction method thereof

A switchable well cementation sliding sleeve based on fracturing of separate layers comprises an outer barrel, an upper joint and a lower joint are installed at the upper end and the lower end of the barrel respectively, a fracturing port is formed in the side wall of the upper portion of the outer barrel, and an upper center pipe, an upper connection sleeve, a lower center pipe and a lower connection sleeve are installed inside the outer barrel. The switchable well cementation sliding sleeve based on fracturing of the separate layers is not provided with a ball seat, so a full bore of the inner wall can be maintained, fracturing fluid can flow back in time, and the construction period is shortened. The well cementation sliding sleeve is set in the upper center pipe through a bottom packer, downward pushing force big enough can be generated in the process of annular or continuous tubing pressing, so the upper center pipe can overcome shearing force of corresponding shearing dowels and move downwards, and therefore the fracturing port of the well cementation sliding sleeve can be opened.

Owner:JEREH ENERGY SERVICES

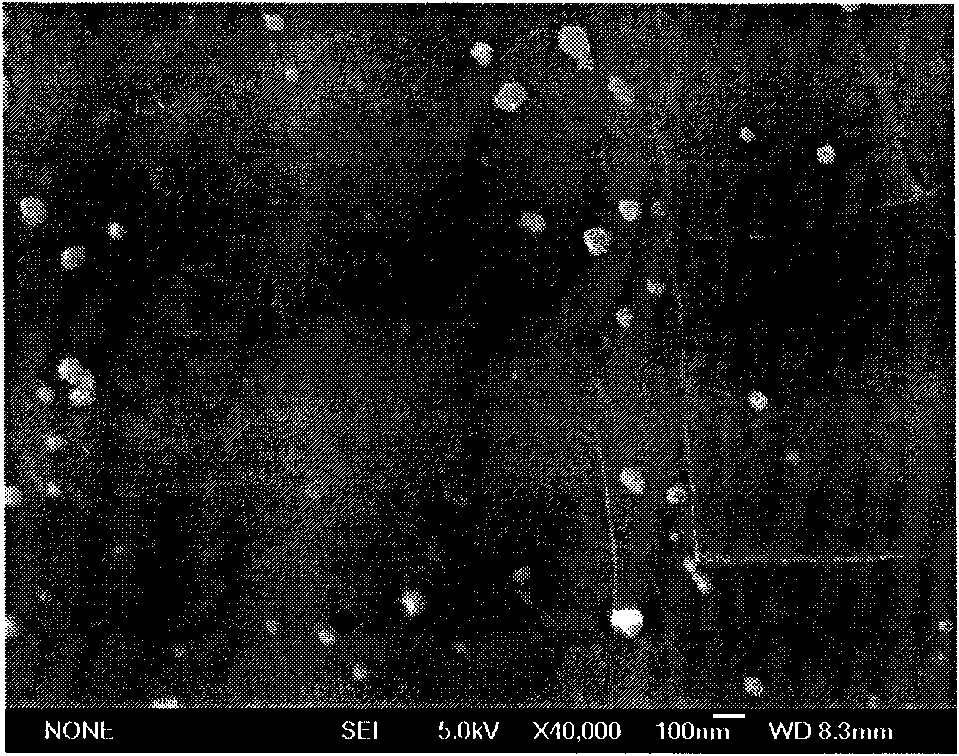

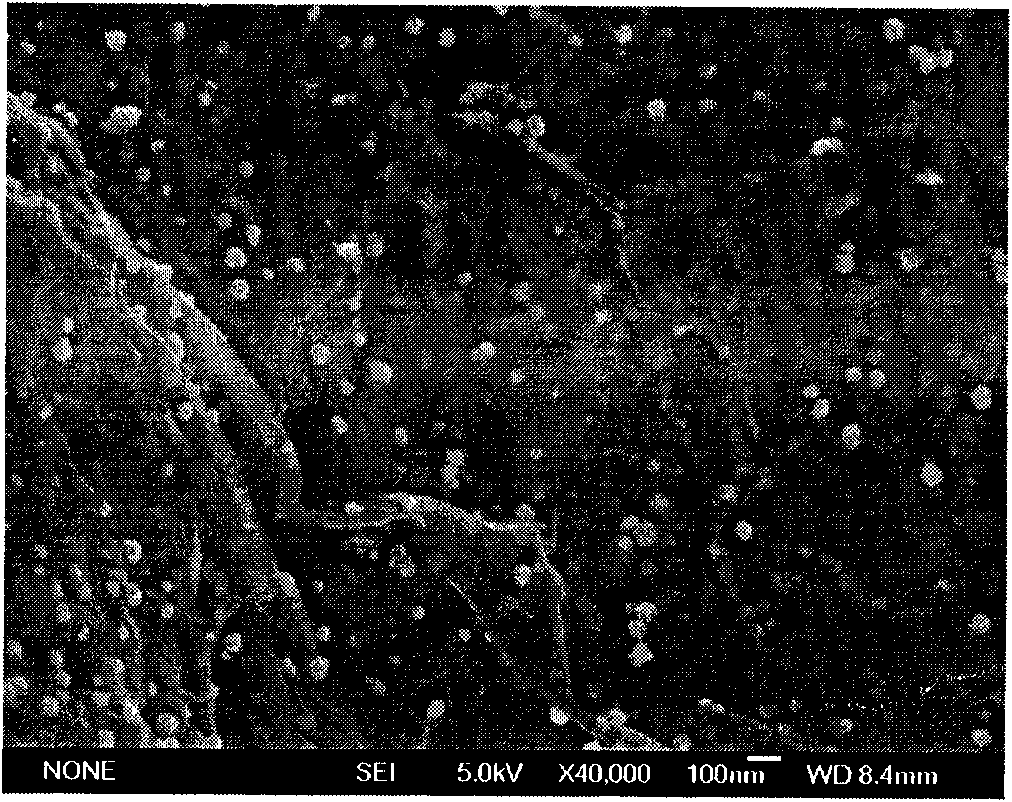

Nano-graphite alkenyl composite wave-absorbing material and method of preparing the same

The present invention provides a nano-graphite alkenyl composite wave-absorbing material and method of preparing the same. The wave-absorbing material includes graphite alkenyl and nanoparticle deposition material which is metal or metallic oxide; the weight percentage of the graphite alkenyl is 15-95%, the weight percentage of the nanoparticle deposition material is 5-85%, the metal or metallic oxide nanoparticle is deposited on the graphite alkenyl surface and between the layers, prepared by the metal salt and graphite alkenyl in the electrodeposition pattern. The nano-graphite alkenyl composite wave-absorbing material is provided with stable capability, thin thickness, low density, corrosion resistant, simple manufacture, good wave-absorbing capability and favourable application foreground.

Owner:HUNAN UNIV

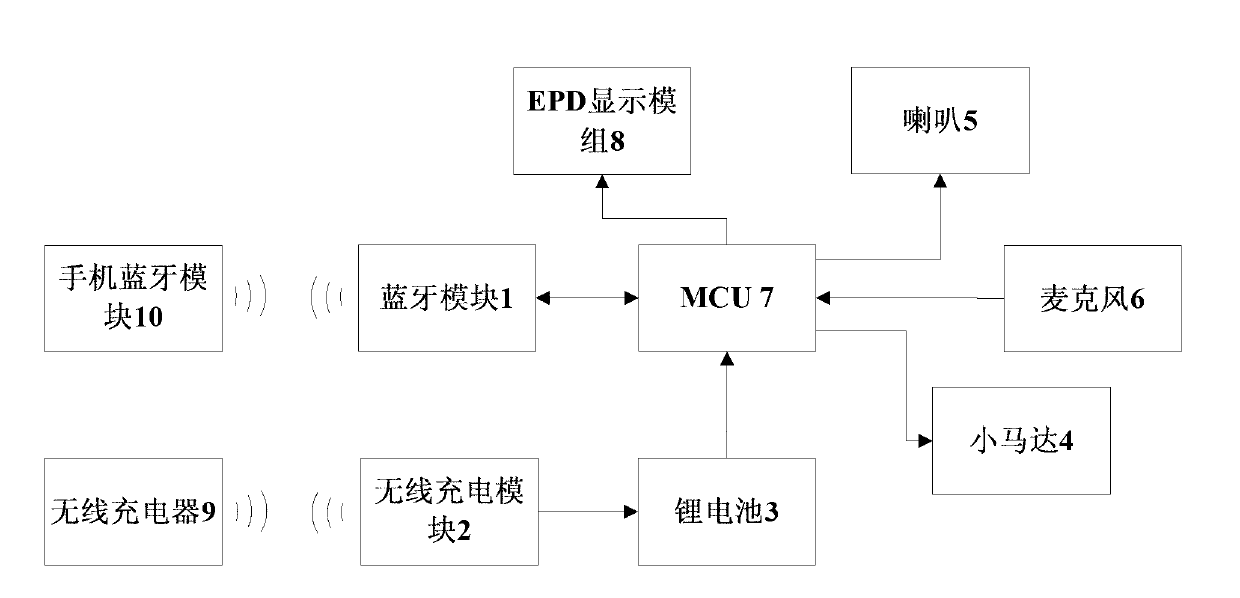

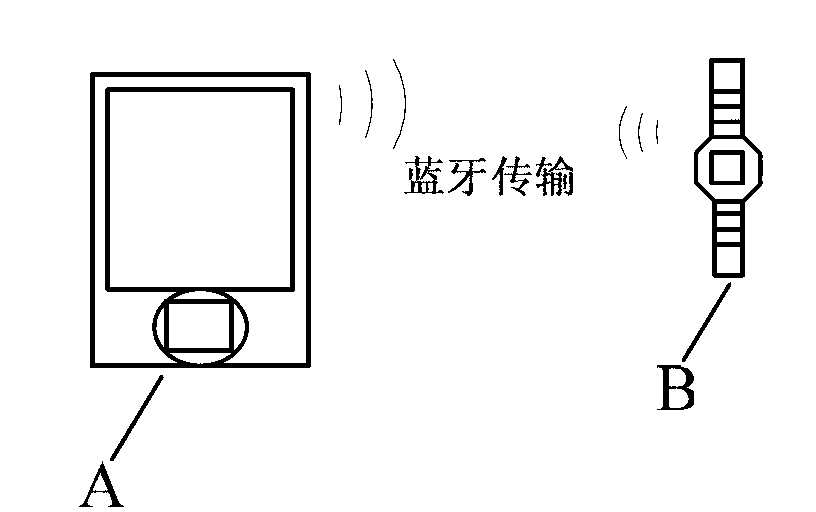

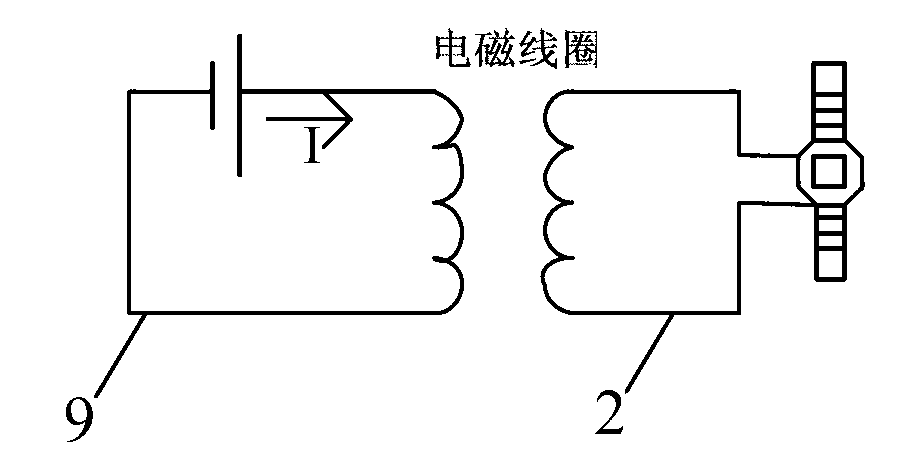

Bluetooth smart watch

ActiveCN103135440AThe overall thickness is thinShorten the timeNear-field transmissionVisual indicationsEngineeringBluetooth

The invention provides a Bluetooth smart watch which comprises a watch body and a wireless charger. A Bluetooth module, a wireless charging module, a lithium battery, a small motor, a horn, a microphone, a micro control unit (MCU) and an electrophoretic display (EPD) module are integrated inside the watch body. The wireless charging module is in connection with the lithium battery. The Bluetooth module, the lithium battery, the small motor, the horn, the microphone and the EPD module are respectively connected with the MCU. The wireless charger is connected with the wireless charging module inside the watch body through a wireless electric power transmission technology. A Bluetooth technology is adopted for data interaction between a mobile phone and the watch, a wireless charging technology is utilized for charging the watch, and the watch is small in thickness and multifunctional. Time for watching a message, weather forecast and communication is saved for people, and convenience is brought when the people are in occasions where a call is inconvenient to answer.

Owner:WUXI VISION PEAK TECH

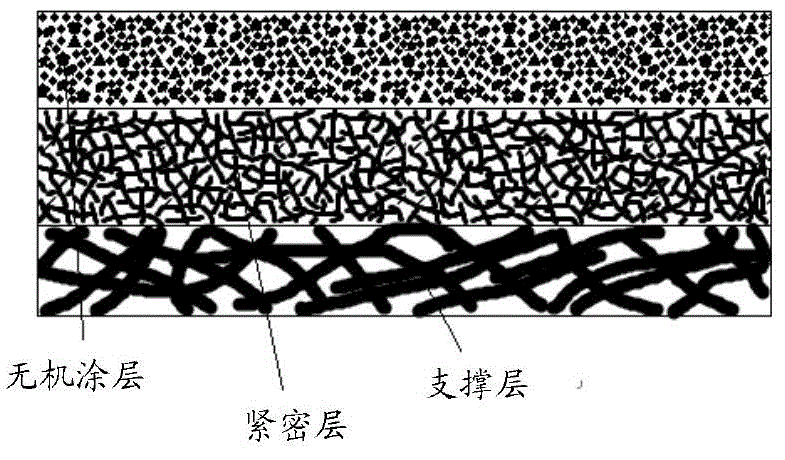

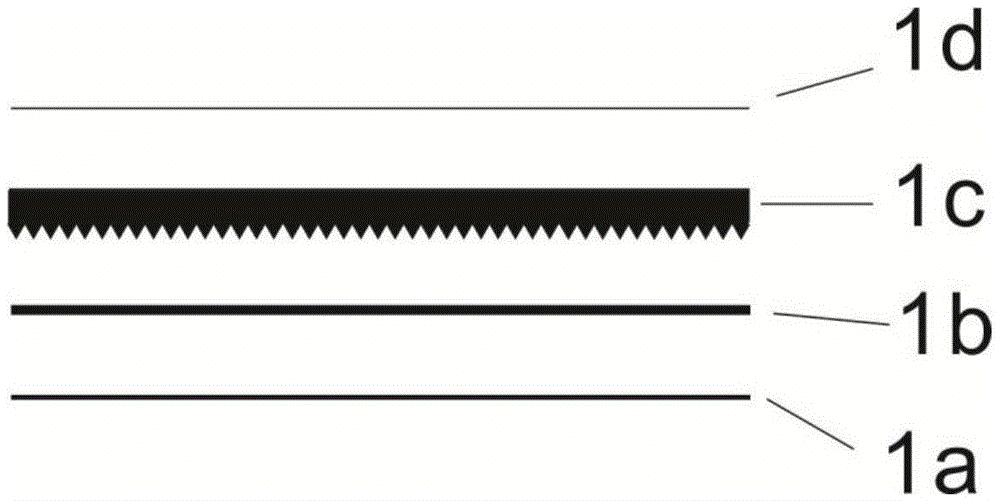

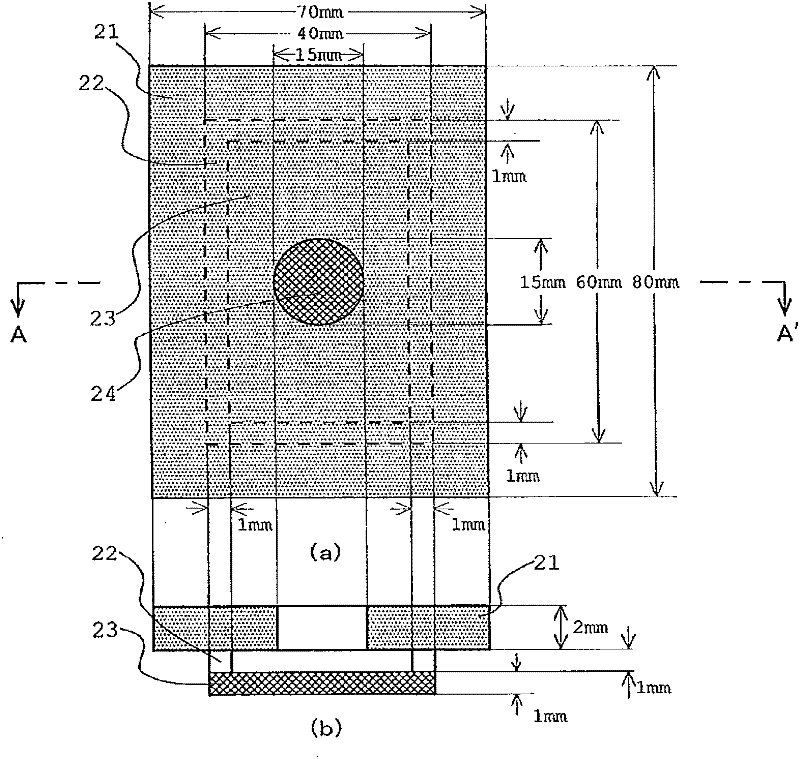

Lithium ion battery diaphragm, preparation method of lithium ion battery diaphragm and lithium ion battery

ActiveCN104157812ARequirements to ensure the strength of the diaphragmMeet the requirements of diaphragm strengthCell seperators/membranes/diaphragms/spacersSecondary cellsPorosityElectrical battery

The invention provides a lithium ion battery diaphragm, a preparation method of the lithium ion battery diaphragm and a lithium ion battery. The lithium ion battery diaphragm comprises a support layer, wherein either or both of a dense layer or an inorganic coating are compounded on the support layer; the average quantity of the lithium ion battery diaphragm is 8-25g / m<2>, the thickness is 15-60 mu m, the average aperture is 50-500nm, and the porosity is 78-82%. The lithium ion battery diaphragm provided by the invention is good in isolating property and excellent in electrolyte absorbing property, is further relatively high in tension strength, is capable of realizing high power capacity of a battery, and can meet the requirement of rapid large-current charge and discharge of the lithium ion battery.

Owner:SOUTH CHINA UNIV OF TECH

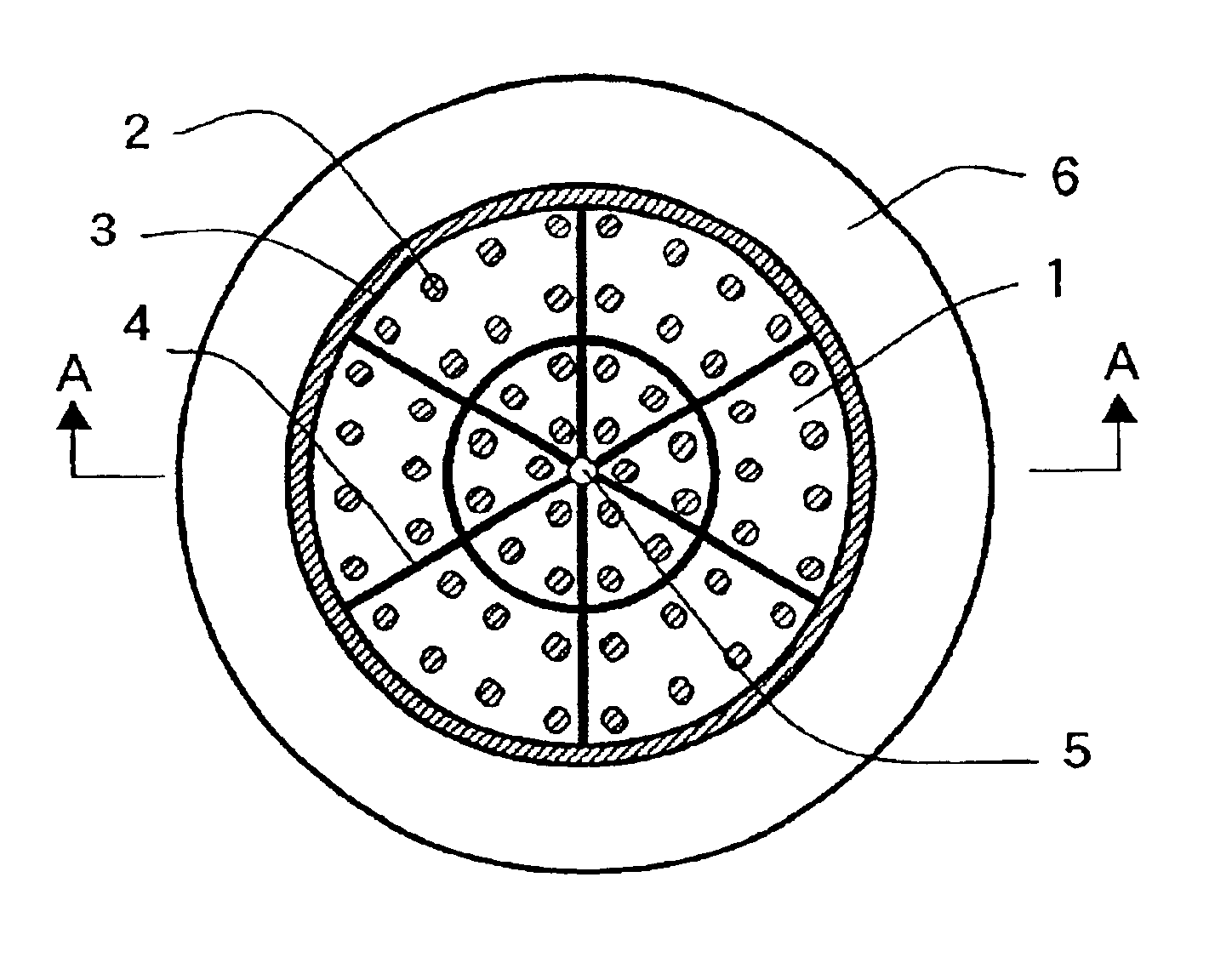

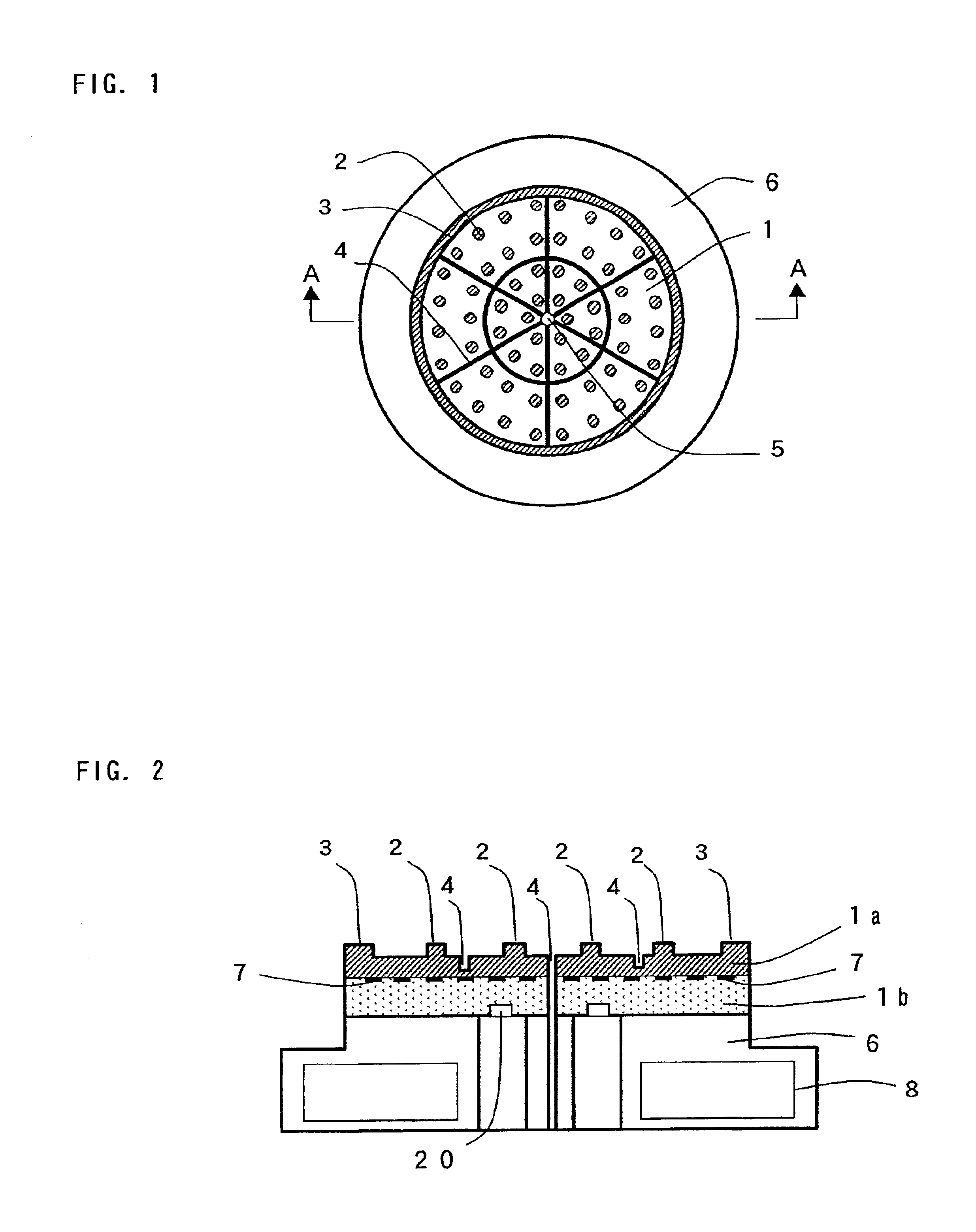

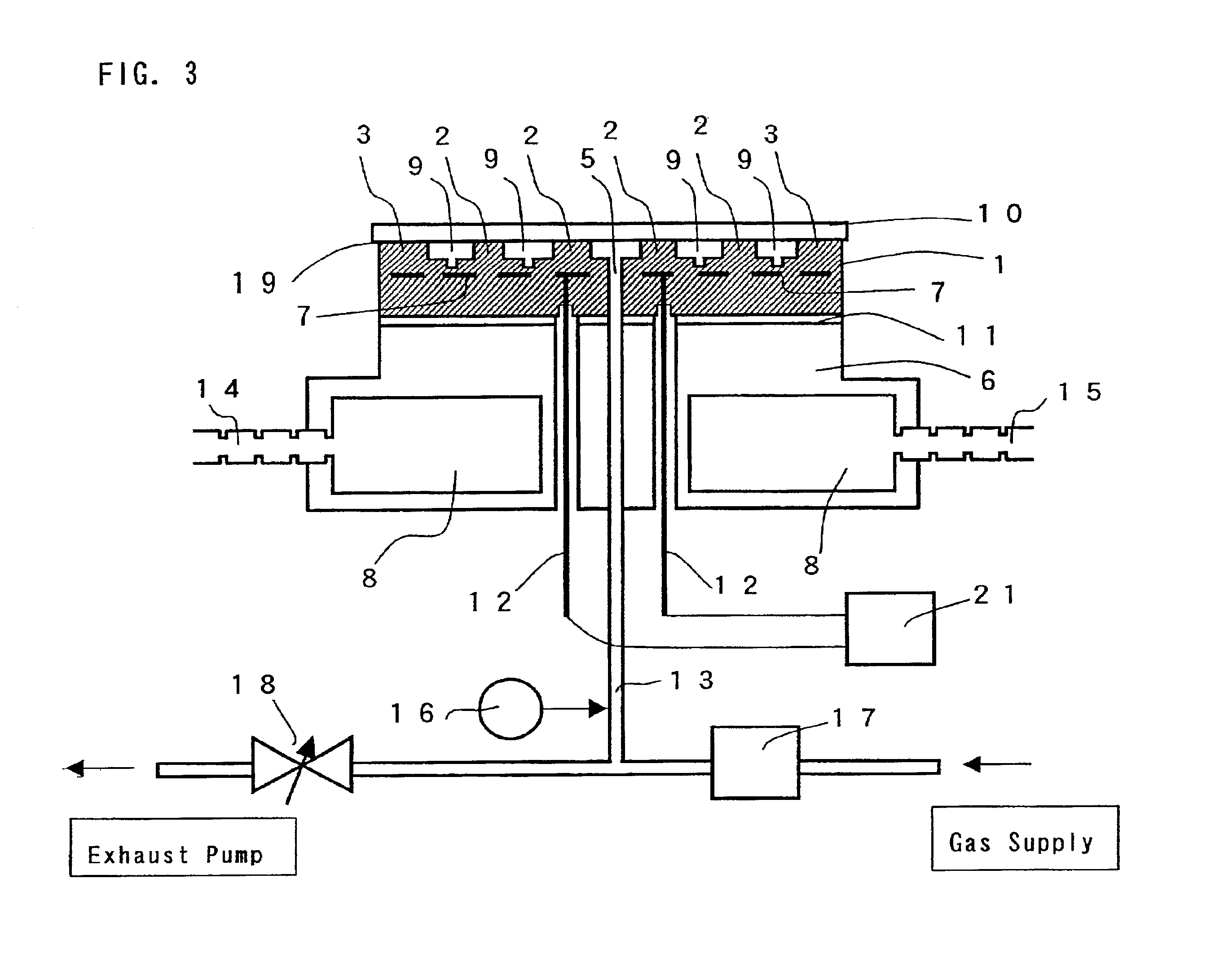

Electrostatic chuck and processing apparatus for insulative substrate

InactiveUS6768627B1The overall thickness is thinSmall distanceSemiconductor/solid-state device manufacturingPositioning apparatusElectrical connectionEngineering

An electrostatic chuck for attracting an insulative substrate, used under a vacuum atmosphere, comprises: a dielectric layer having a first surface which attracts an insulative substrate, and a second surface on which are provided a plurality of electrodes; an insulative support base plate fixing the dielectric layer thereon; a plurality of electrically conductive terminals provided on the insulative support base plate; and an electrical connection between the electrodes and the electrically conductive terminals.

Owner:ULVAC INC +1

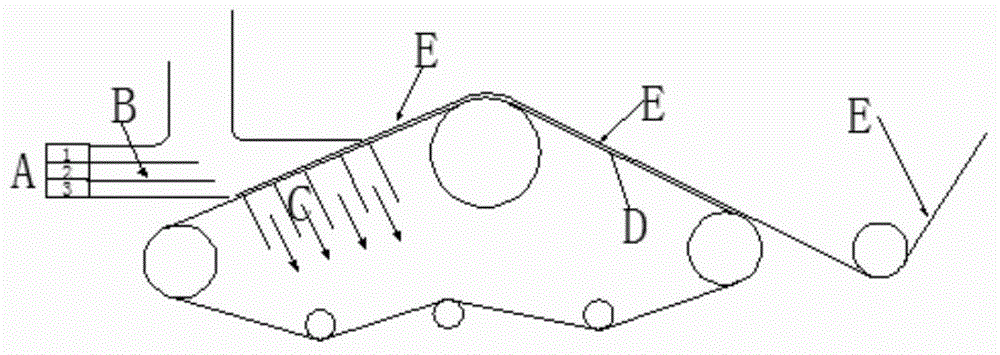

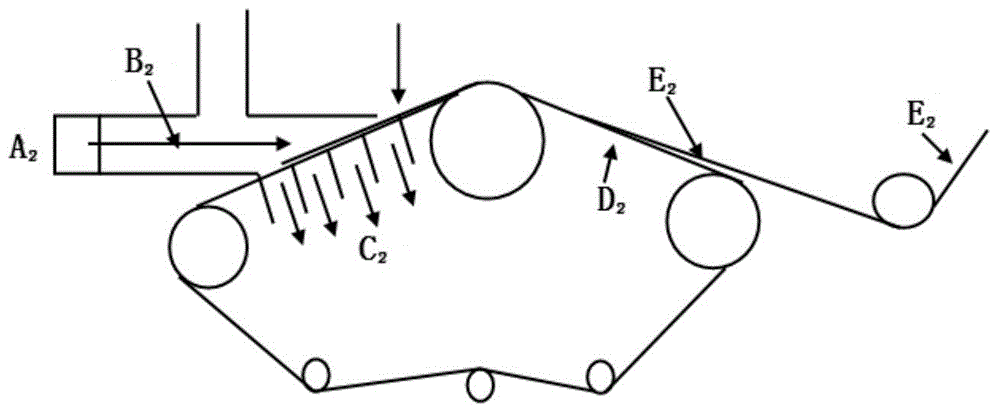

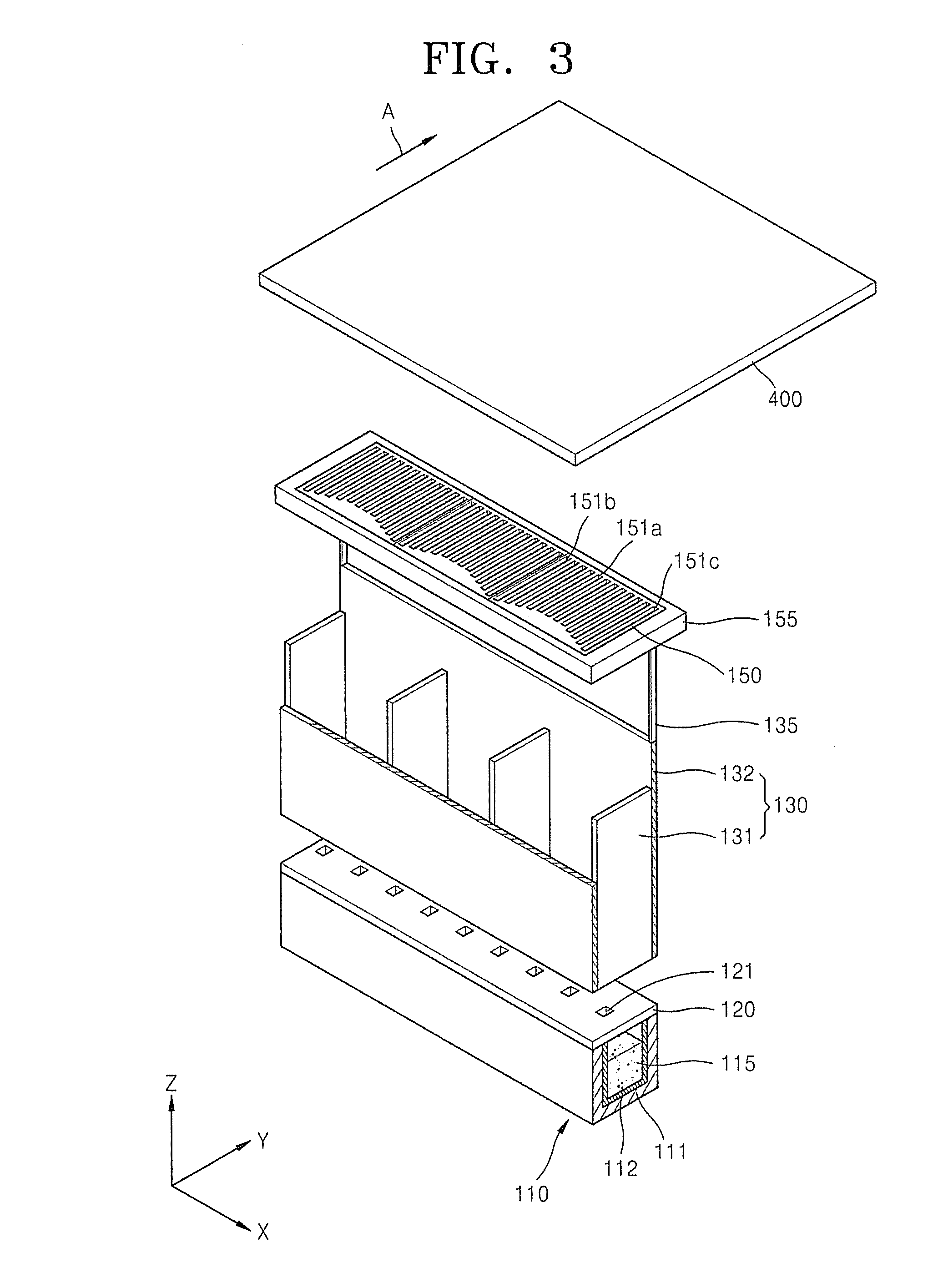

Thin film deposition apparatus and method of manufacturing organic light-emitting display device by using the same

InactiveUS20110053300A1Easy to manufactureIncrease depositionLiquid surface applicatorsVacuum evaporation coatingDisplay deviceEngineering

A thin film deposition apparatus that can be applied to manufacture large-sized display devices on a mass scale and that improves manufacturing yield, and a method of manufacturing an organic light-emitting display device by using the thin film deposition apparatus.

Owner:SAMSUNG DISPLAY CO LTD

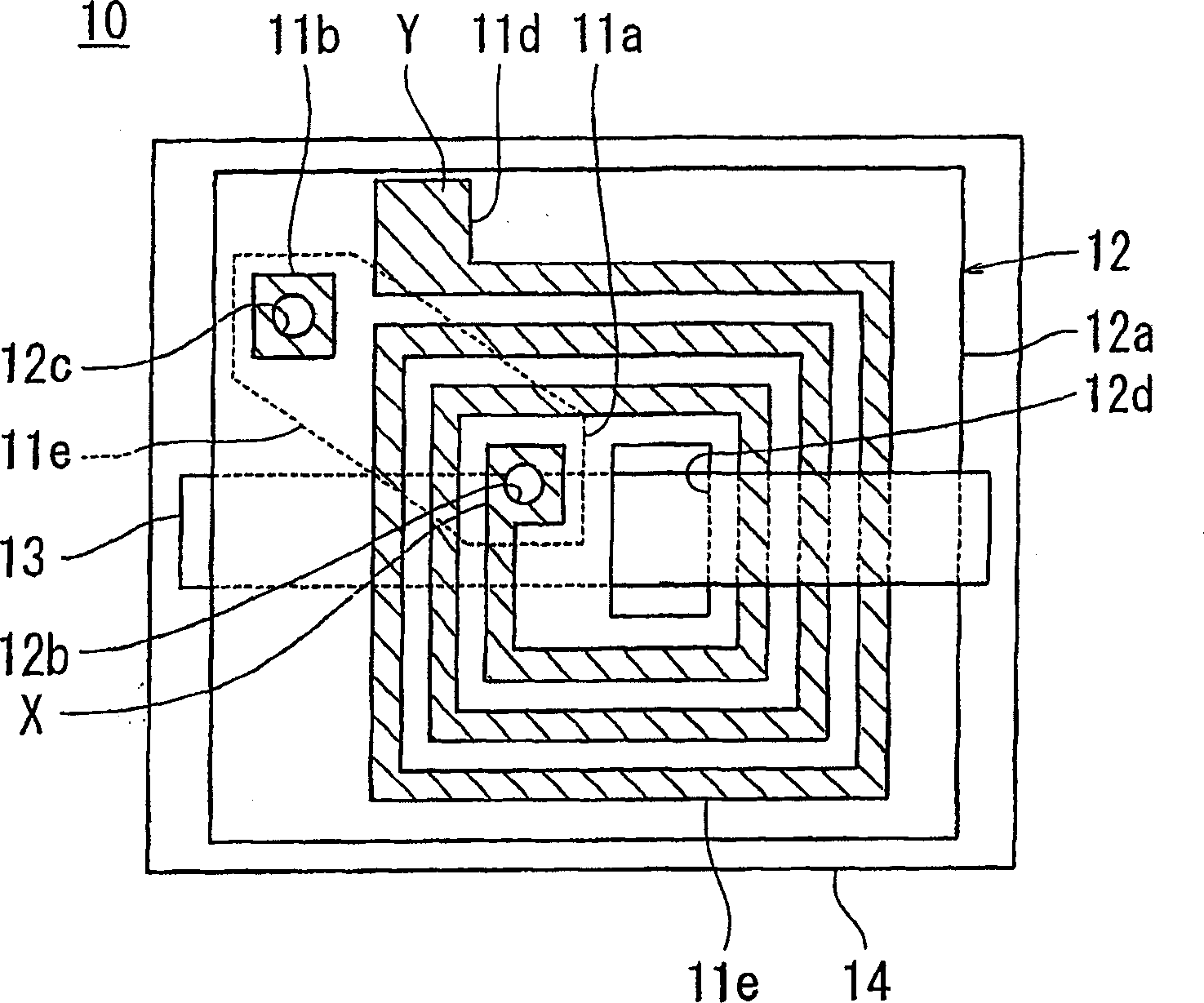

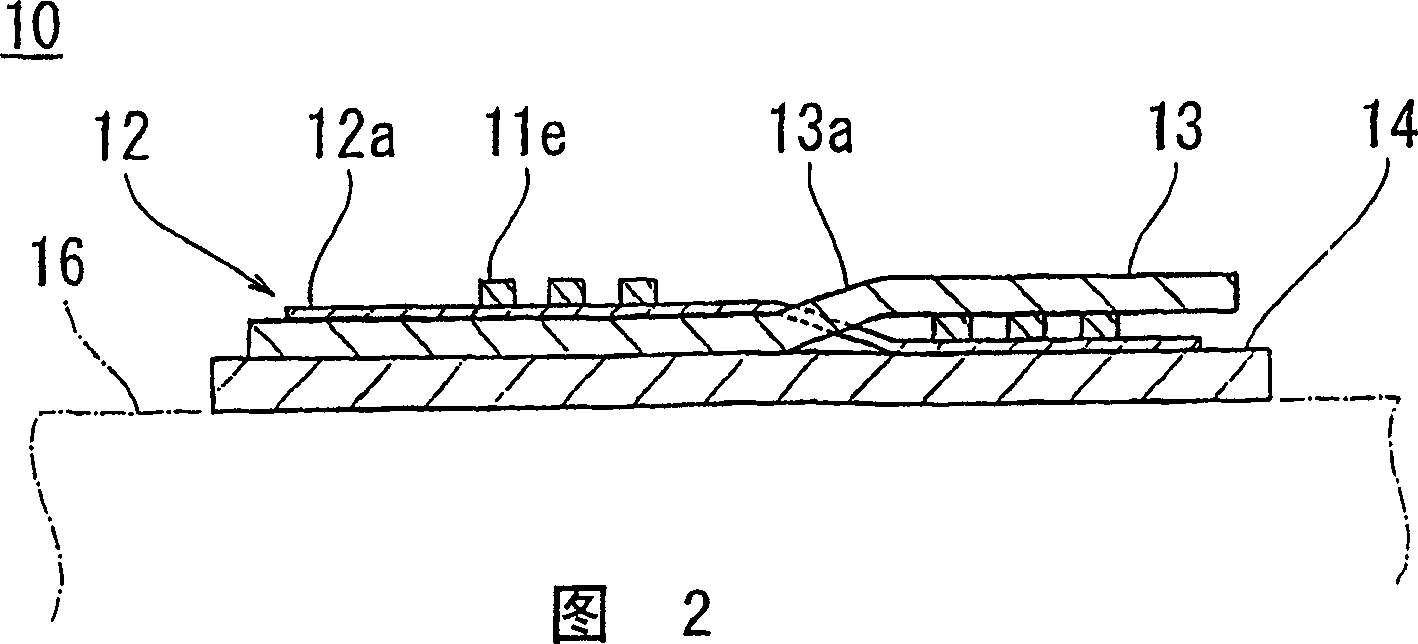

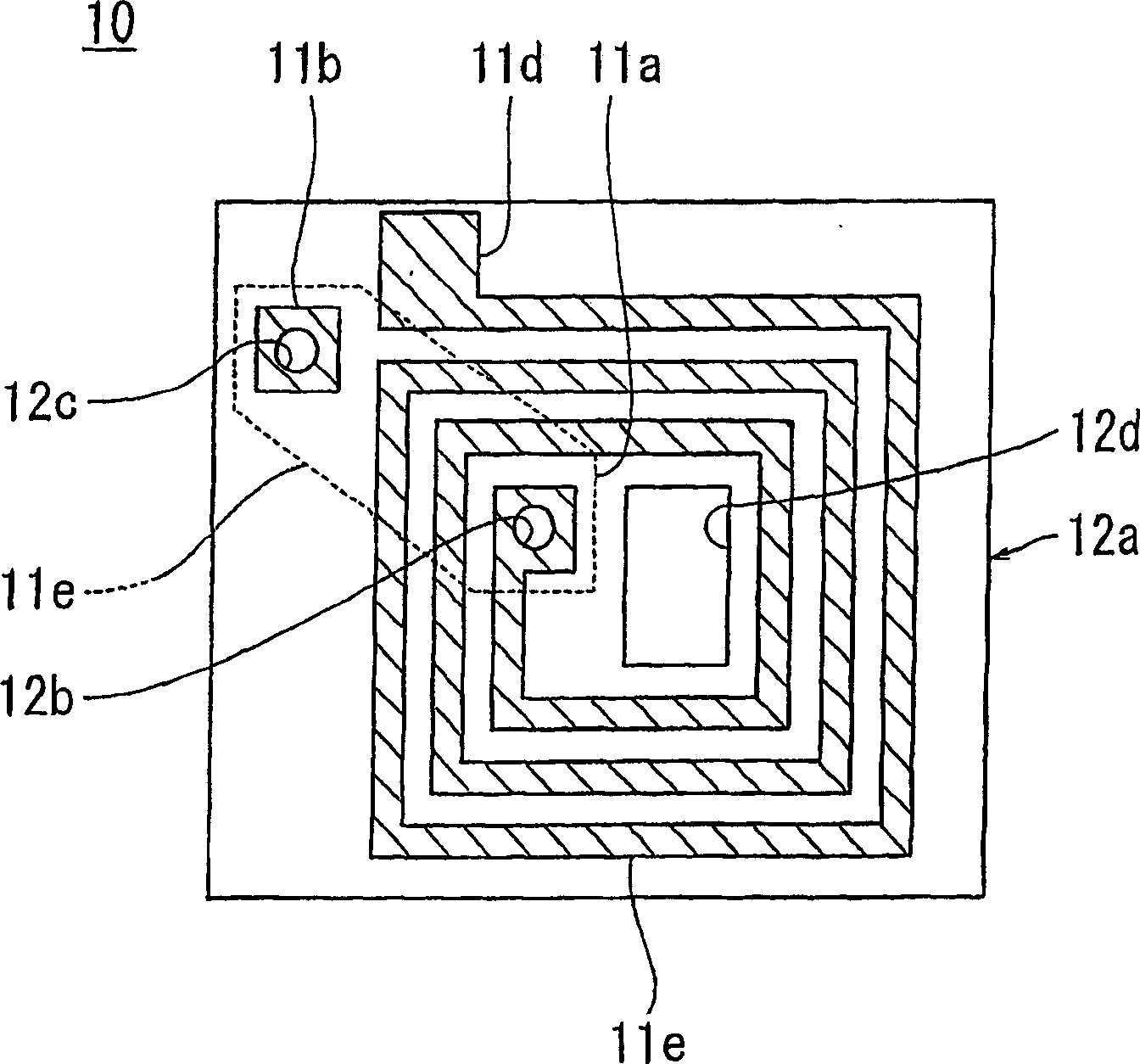

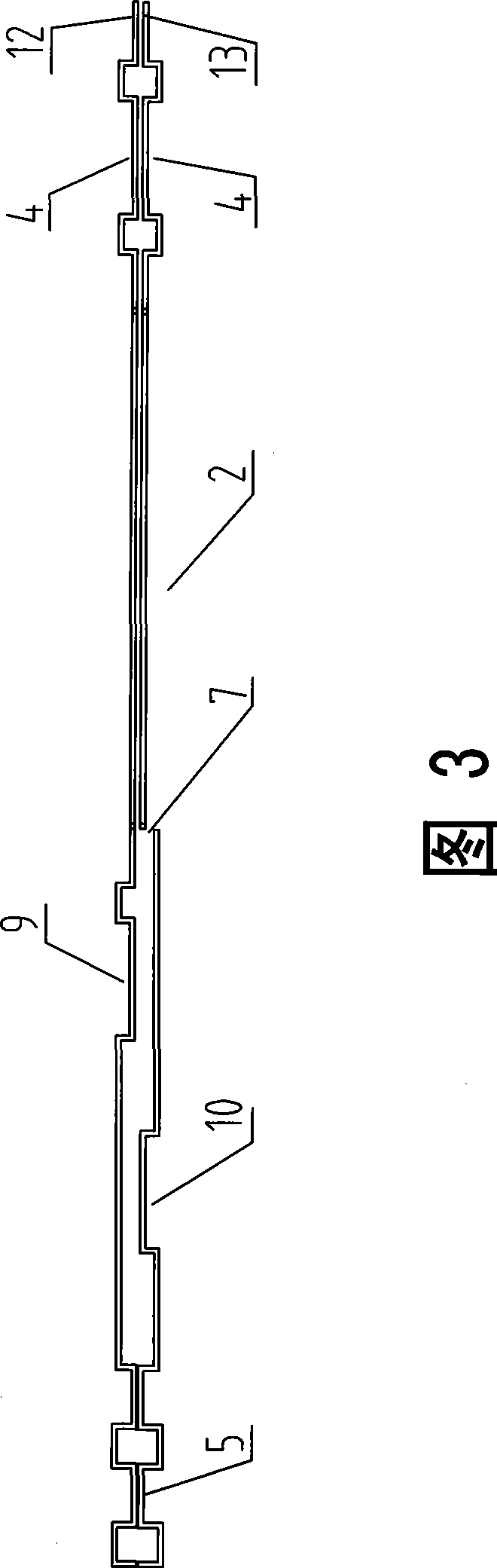

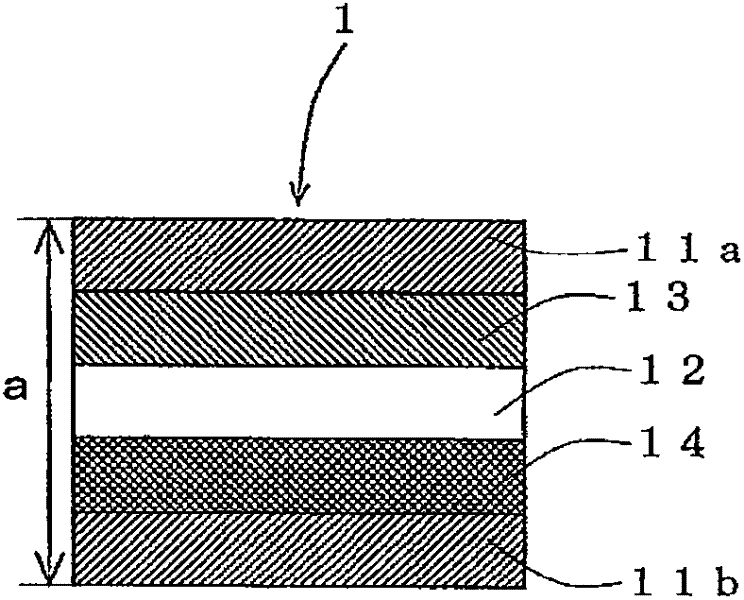

Antenna coil and RFID-use tag using it, transponder-use antenna

InactiveCN1871743AImprove rigidityEasy to useLoop antennas with ferromagnetic coreOther printing matterNon magneticRadio frequency

An antenna coil 10 comprises an air-core coil 12 which is wound helically in a plane and a plate magnetic core member 13 which is inserted in the air-core coil 12 so as to be approximately parallel with a plane of the air-core coil 12. The magnetic core member 13 is formed by a soft magnetic metal, an amorphous or ferrite, or a composite member of a powder, flake and plastic, or rubber. The magnetic core member 13 is formed by performing an injection molding operation or a compressing molding operation of the composite member. Alternatively, the magnetic core member 13 is a magnetic coating which is formed by applying and drying the composite member. A non-magnetic conductive plate 14 which has a conductivity is layered on a surface of the air-core coil 12 through which the magnetic core member 13 is inserted. The conductive plate 14 is made of a copper, a copper alloy, an aluminum or an aluminum alloy having 0.01 to 2 mm thickness. By doing this, it is operated by relatively high frequency while it is rigid relatively.

Owner:MITSUBISHI MATERIALS CORP

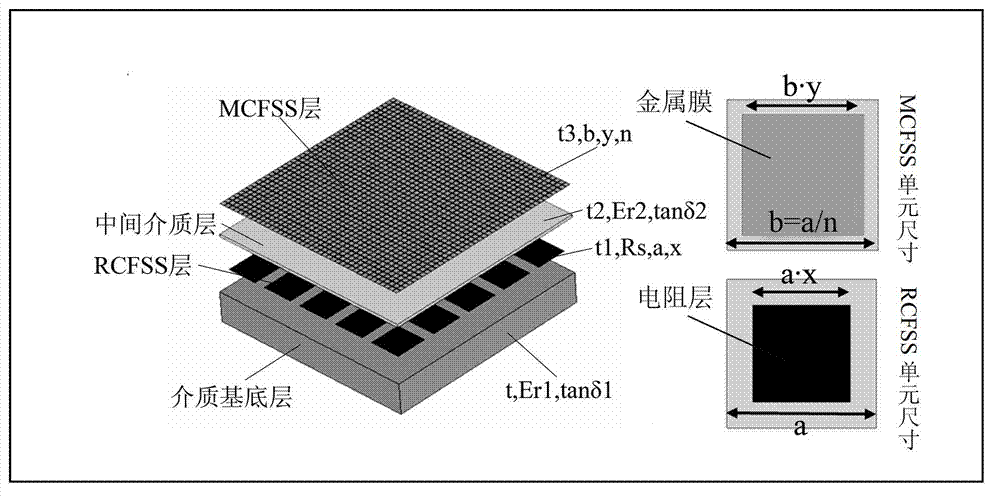

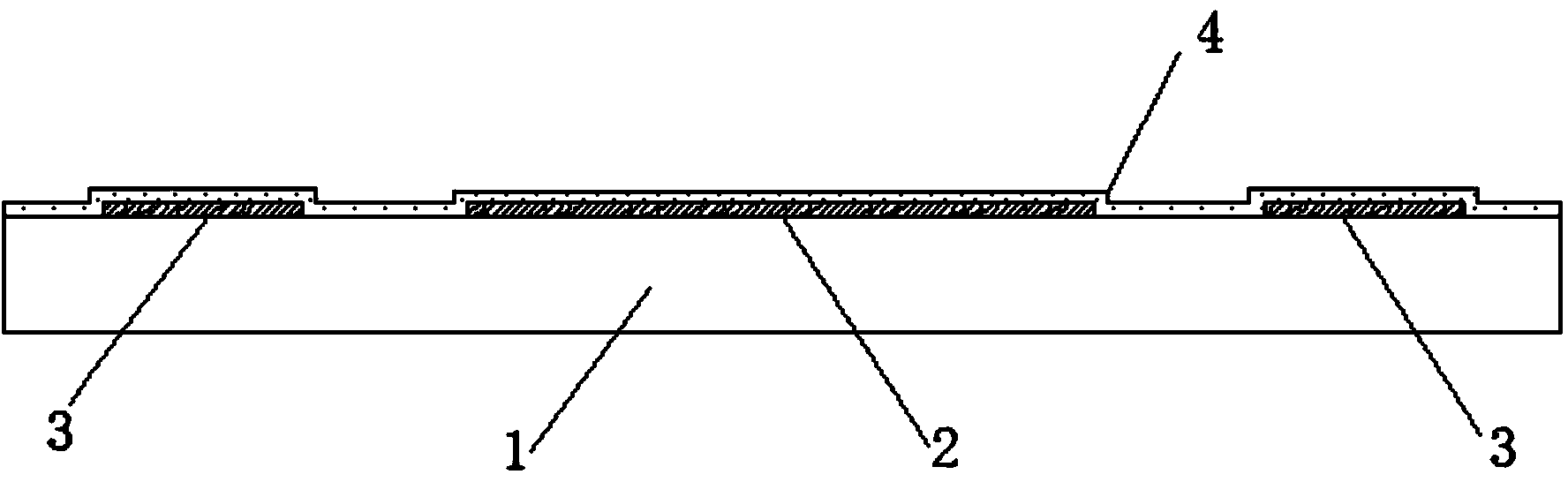

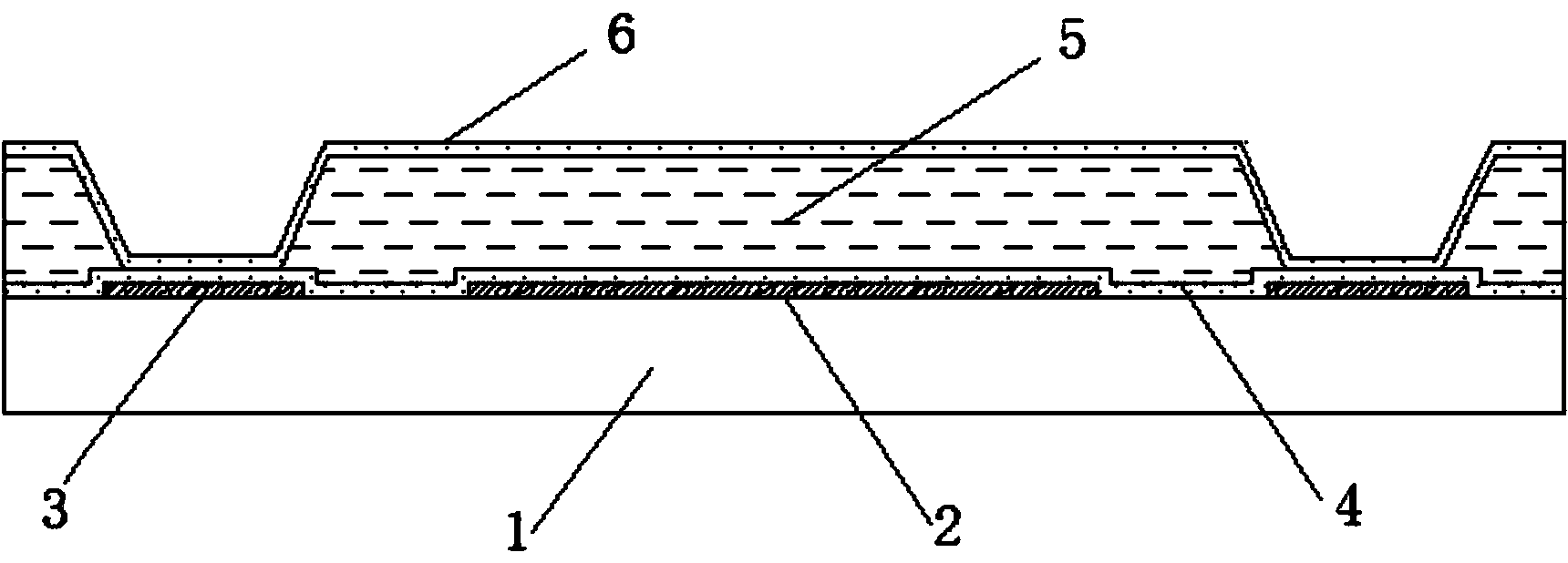

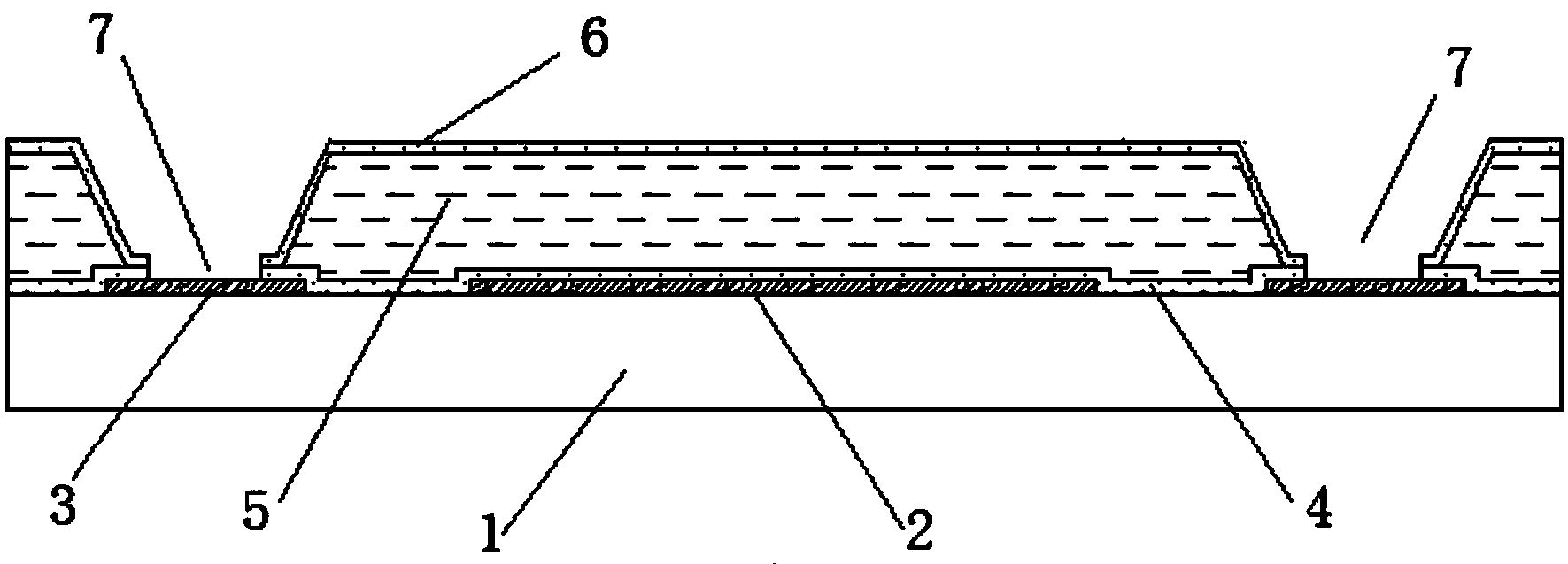

Radar-infrared combined stealth material and preparation method thereof

ActiveCN103158299ASimple structureThe overall thickness is thinLamination ancillary operationsLaminationElectricityScreen printing

The invention discloses a radar-infrared combined stealth material and a preparation method thereof. The radar-infrared combined stealth material orderly comprises a metal-type capacitive frequency selection surface layer, a middle medium layer, a resistance-type capacitive frequency selection surface layer and a medium base layer from top to bottom. The metal-type capacitive frequency selection surface layer and the resistance-type capacitive frequency selection surface layer have matrix structures. The metal-type capacitive frequency selection surface layer adopts metals having low infrared emissing ability. The middle medium layer and the medium base layer have dielectric constants of 3-10 and dielectric loss of 0.01 to 0.50. The preparation method comprises the following steps of preparing a metal film by screen printing processes, carrying out etching of the metal-type capacitive frequency selection surface layer on the metal film by a PCB technology, preparing the resistance-type capacitive frequency selection surface layer on the medium base layer by the screen printing processes, and binding the layers into an integral body by a binder by the vacuum bag molding process. The radar-infrared combined stealth material has a simple structure, is light and thin and has a good stealth effect.

Owner:NAT UNIV OF DEFENSE TECH

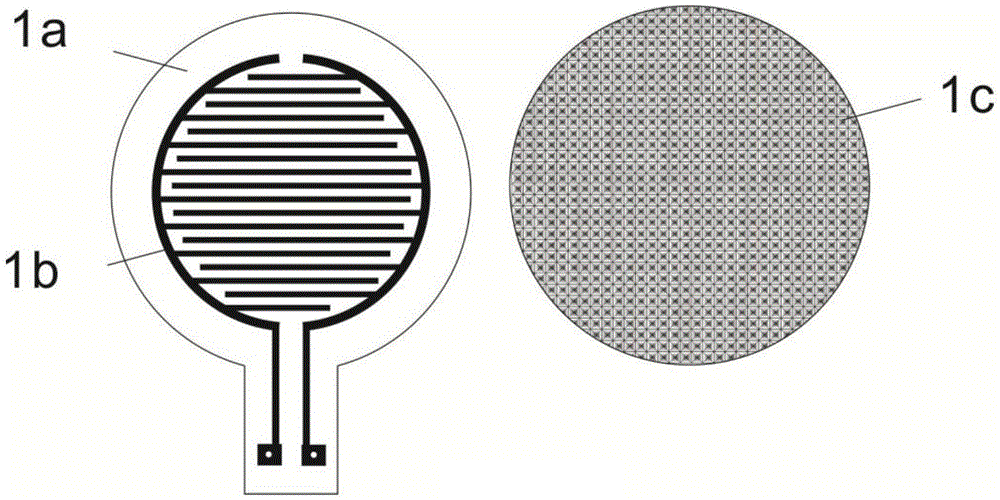

Wearable multi-information fusion gait analysis system and method thereof

InactiveCN105631195AFully flexibleThe overall thickness is thinHealth-index calculationTelemedicineGait analysisClient-side

The invention discloses a wearable multi-information fusion gait analysis system and a method thereof. The wearable multi-information fusion gait analysis system is characterized by comprising a flexible sensor module, a three-axis acceleration and gyro sensor, a microprocessor, a power supply module, a transmission module, a positioning module, a client side, a cloud server and the like. The flexible sensor is used for measuring the gait data of the bottoms of feet when a user walks, the gait data is sent to the cloud server after being analyzed through the microprocessor, and a gait situation is displayed on a user client side in real time. If the user is under an emergency situation, the guardian of the user can receive alarming information and position the position of the user in real time so as to rescue the user. The wearable multi-information fusion gait analysis system can cause the guardian to know the gait situation of a person under guardianship at any time, and receives the alarming information and the positioning information generated when the person under guardianship moves, so that support and help can be provided for the rehabilitation of a foot patient, the gait monitoring of the aged, walk learning of children and the like.

Owner:HEFEI UNIV OF TECH

Non-refrigeration infrared detector and preparation method thereof

ActiveCN103715307AReduce noiseThe overall thickness is thinFinal product manufacturePyrometry using electric radation detectorsImaging processingHeat sensitive

The invention provides a non-refrigeration infrared detection preparation method. The method comprises the steps of providing a semiconductor substrate with a reading circuit, sequentially depositing a metal reflection layer, an insulating medium layer, a sacrificial layer, a supporting layer, a metal electrode layer, and a silicon nitride medium layer on the semi-conductor substrate, etching away a part of the silicon nitride layer on the metal electrode layer to enable an metal electrode to be exposed and form a contact hole, depositing a temperature-sensitive film on the semiconductor substrate in which the contact hole is formed, conducting imaging processing on the temperature-sensitive film, depositing a silicon nitride passivation layer, and conducting passivation layer imaging and structure releasing. The invention further provides a non-refrigeration infrared detector structure, namely, the temperature-sensitive film covers the metal electrode so as to enable the infrared reflecting rate of the non-refrigeration infrared detector to be greatly reduced, and the infrared absorbing efficiency of the detector is improved.

Owner:YANTAI RAYTRON TECH

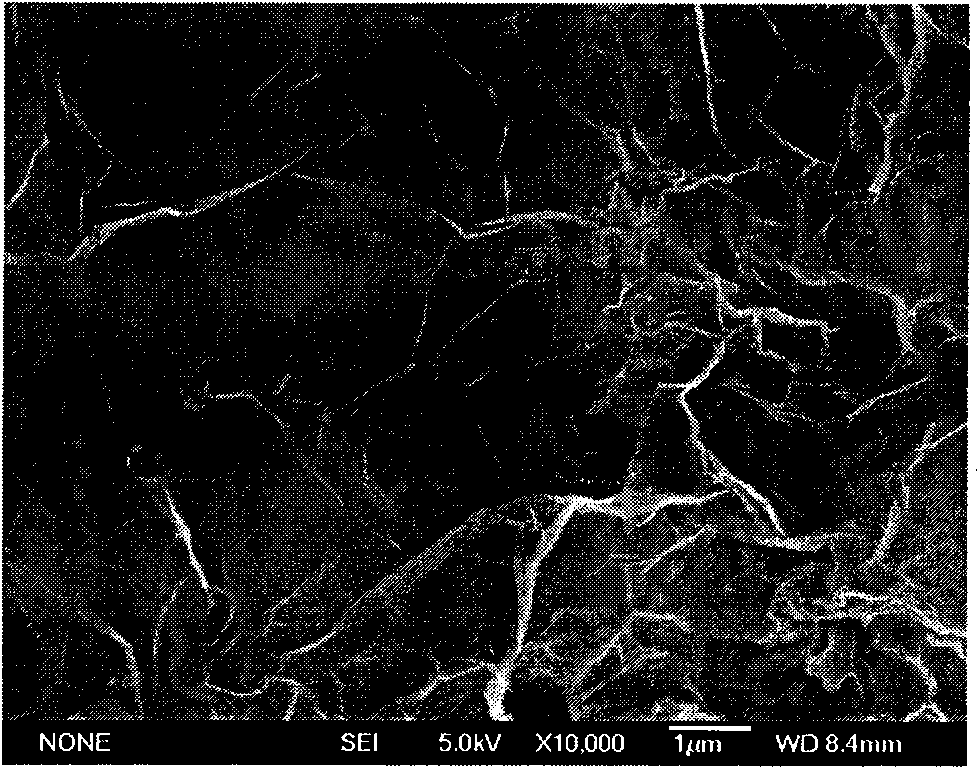

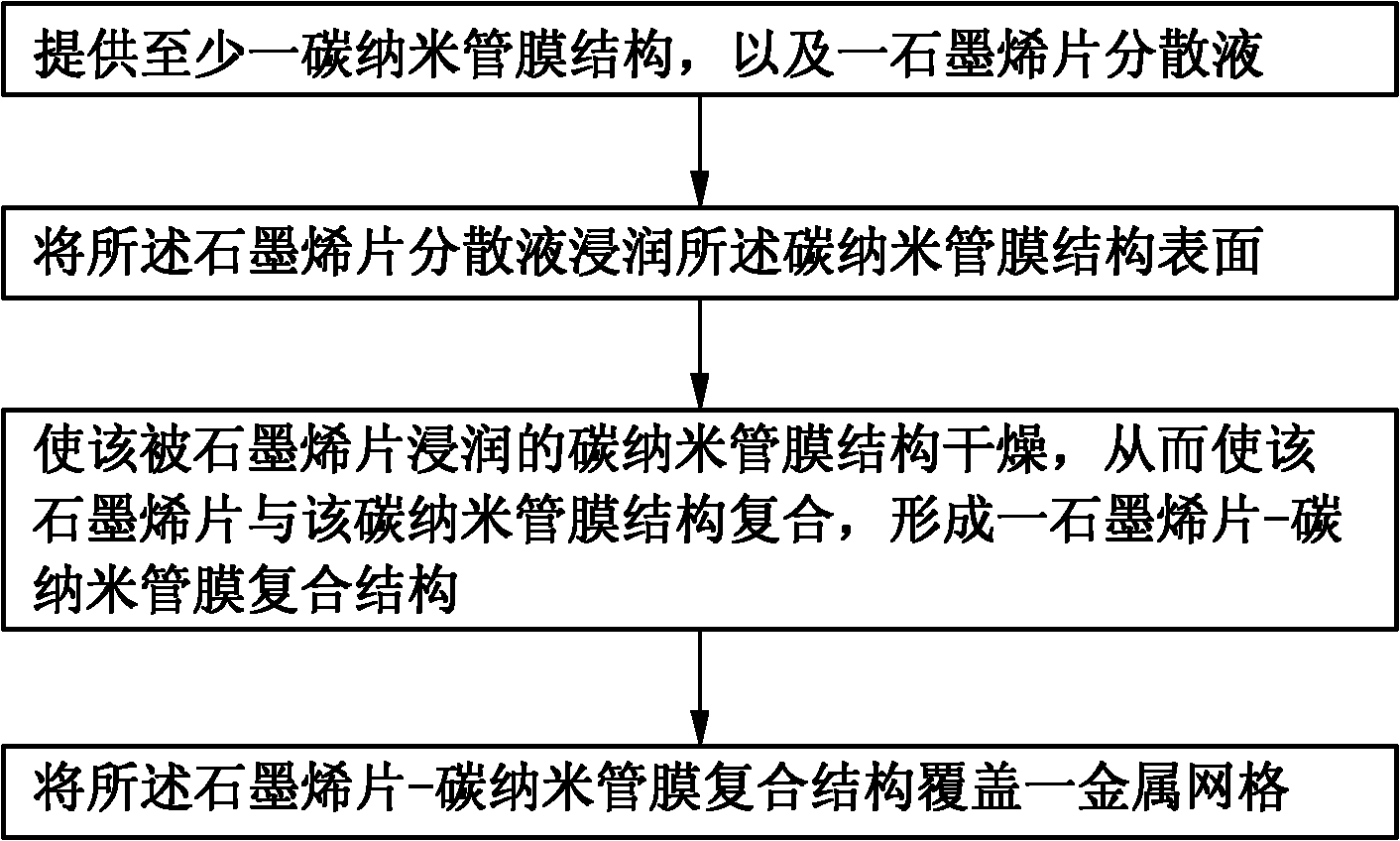

Graphene sheet-carbon nanotube film composite structure and preparation method thereof

ActiveCN101964292AImplement floating settingsThe overall thickness is thinElectric discharge tubesCold cathode manufactureCarbon nanotubeGraphene

The invention relates to a graphene sheet-carbon nanotube film composite structure which comprises at least one carbon nanotube film structure and a plurality of graphene sheets, wherein the carbon nanotube film structure comprises a plurality of micropores, wherein at least one micropore is covered by one graphene sheet. The invention also relates to a preparation method of the graphene sheet-carbon nanotube film composite structure.

Owner:TSINGHUA UNIV +1

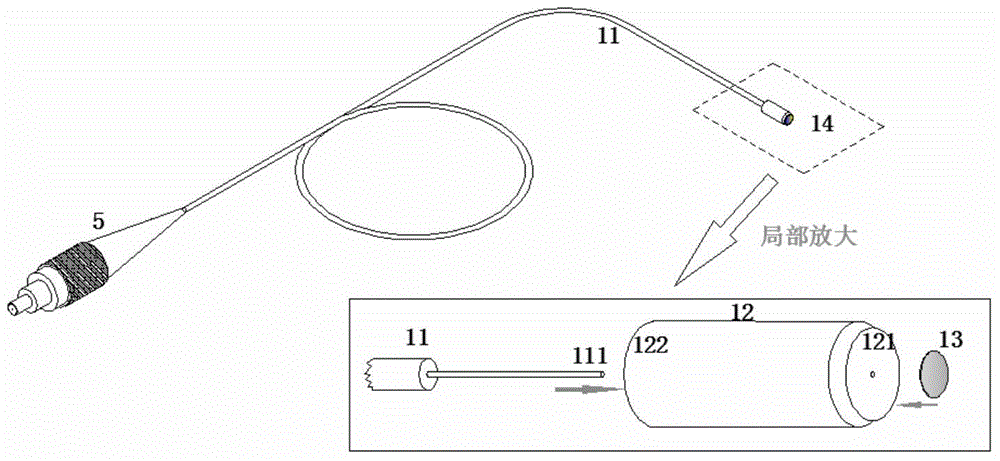

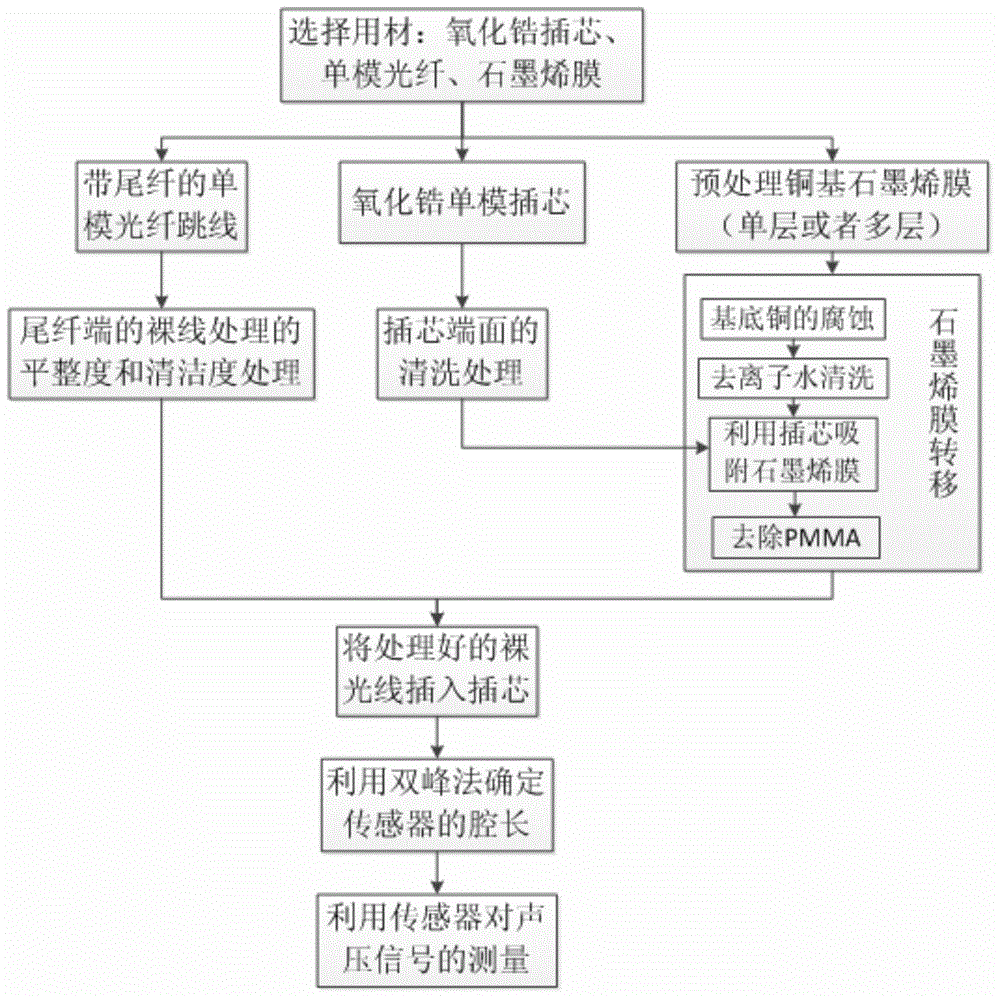

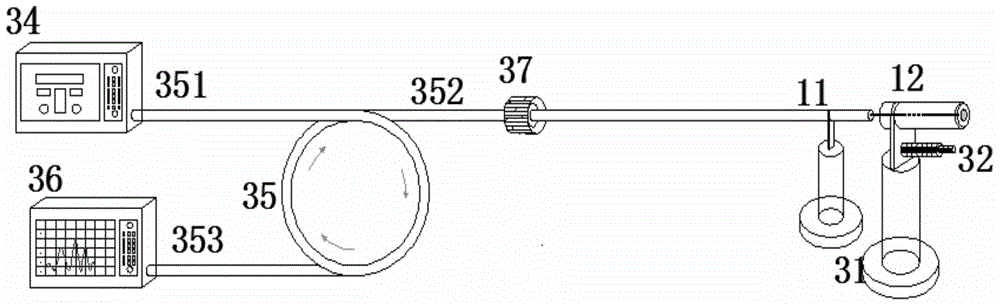

Optical fiber Fabry-Perot sound pressure sensor manufacturing method based on graphene membrane and measuring method and device thereof

ActiveCN103557929AThe overall thickness is thinExpand the measurement rangeSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansElectromagnetic interferenceSound pressure

The invention discloses an optical fiber Fabry-Perot sound pressure sensor manufacturing method based on a graphene membrane and a measuring method and device thereof. A sensor is manufactured based on the graphene membrane and the optical fiber Fabry-Perot interference optical principle. Firstly, a single mode fiber is rinsed and processed, the graphene membrane is transferred, and the graphene membrane is adsorbed to a zirconium oxide single mode inserting core; then, the zirconium oxide single mode inserting core is inserted into the processed single mode fiber from the other end. Therefore, two reflecting surfaces of Fabry-Perot interference are formed by the end face of the single mode fiber and the graphene membrane, an optical fiber-air-graphene membrane interference cavity is formed, an interference cavity length detecting device is set up, interference spectrum signals are demodulated by using a two-peak method, and the high sensitivity detection of weak sound pressure signals is achieved. The sensor has the advantages of being simple in manufacturing, high in sensitivity, small in size, resistant to electromagnetic interference and the like, the problem that a sensor is low in sensitivity due to the limitation of the reduction of the thickness of a membrane in the prior art is solved, the sensitivity of the membrane type sound pressure sensor is improved, and the sensor can be expected to be applied to the underwater sound field, the electroacoustic field, medical field, biomedical engineering filed and the like.

Owner:BEIHANG UNIV

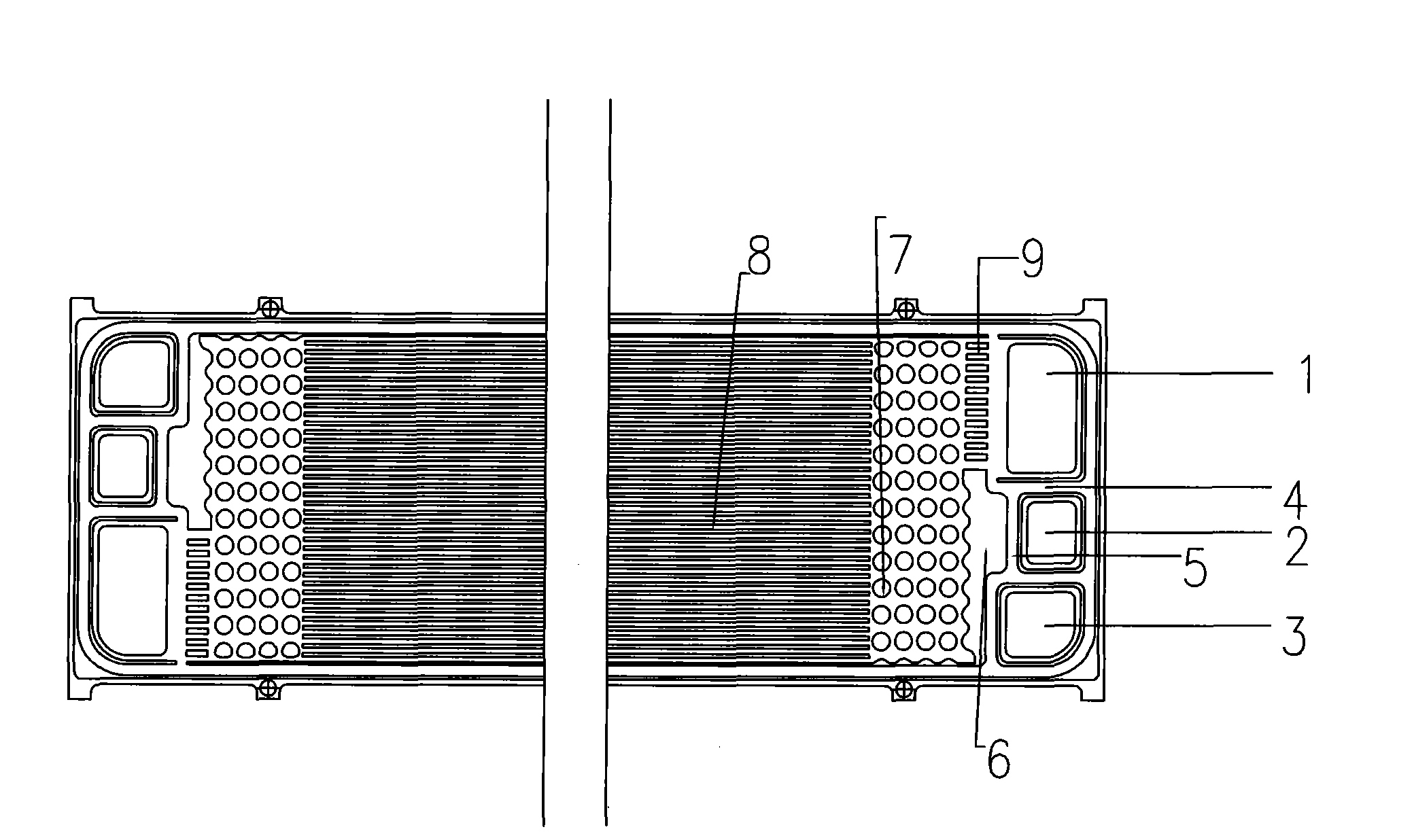

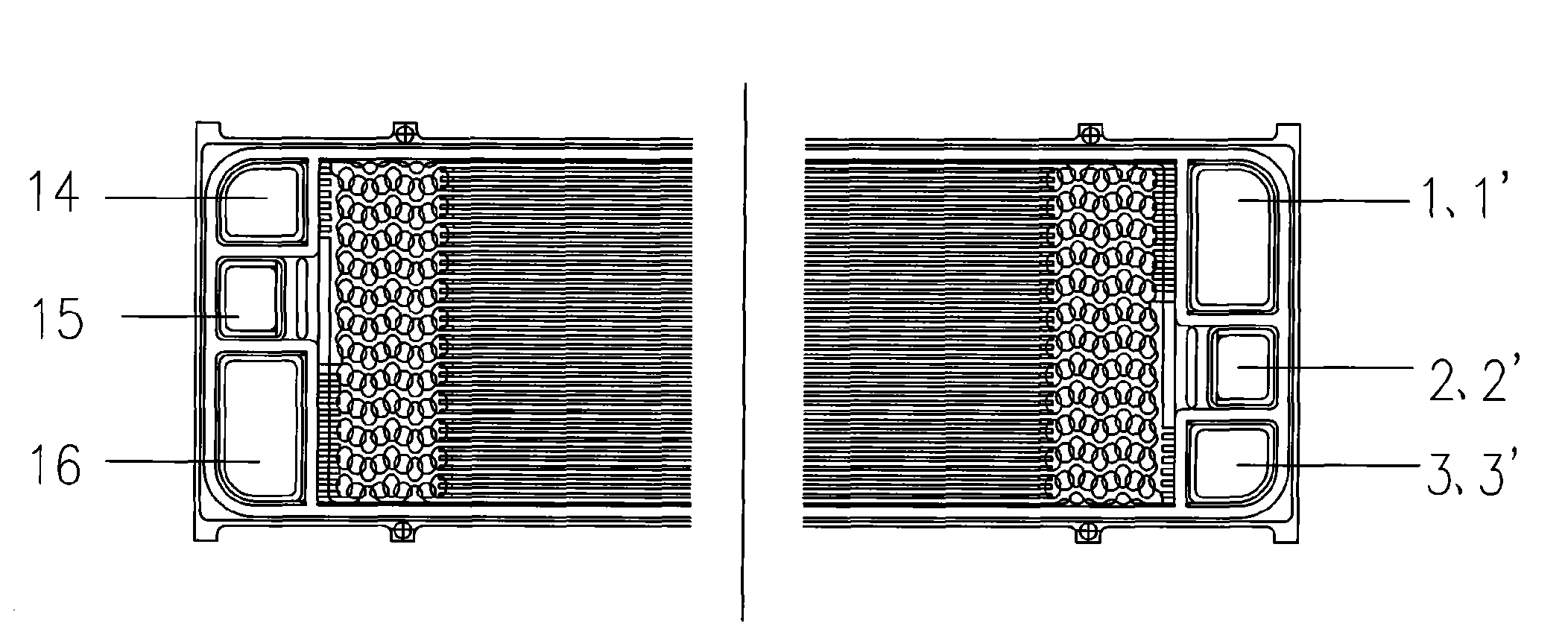

Metal bipolar plate for proton exchange membrane fuel cell

ActiveCN101420037AThe overall thickness is thinEasy to processCell electrodesFinal product manufactureProtonMembrane cell

The invention relates to a proton exchange membrane cell metal bipolar plate which is composed of a cathode chamber monopole plate and an anode chamber monopole plate which are made of metal sheets; the front surface of each of the monopole plates is respectively provided with a cathode chamber and an anode chamber, and cooling water chambers are arranged at the back surfaces of the cathode chamber monopole plate and the anode chamber monopole plate; flow passages composed of concavo convex grooves are arranged at the front and back surfaces of the monopole plates, the concavo convex grooves arranged on the front and back surfaces are corresponding to each other, the bumps on the front surfaces are the concave grooves on the back surfaces, and the concave grooves on the front surfaces are the bumps on the back surfaces; the concavo convex grooves on the front surfaces respectively form the flow passages of the cathode and anode chambers, and the concavo convex grooves on the back surfaces respectively form the flow passages of the cooling water chambers. The proton exchange membrane cell metal bipolar plate has the advantages that the manufactured bipolar plate is thin, the flow bodies are strictly separated, the flow body distribution is good, the weight is light, the processing is simple and the processing cost is low.

Owner:SUNRISE POWER CO LTD

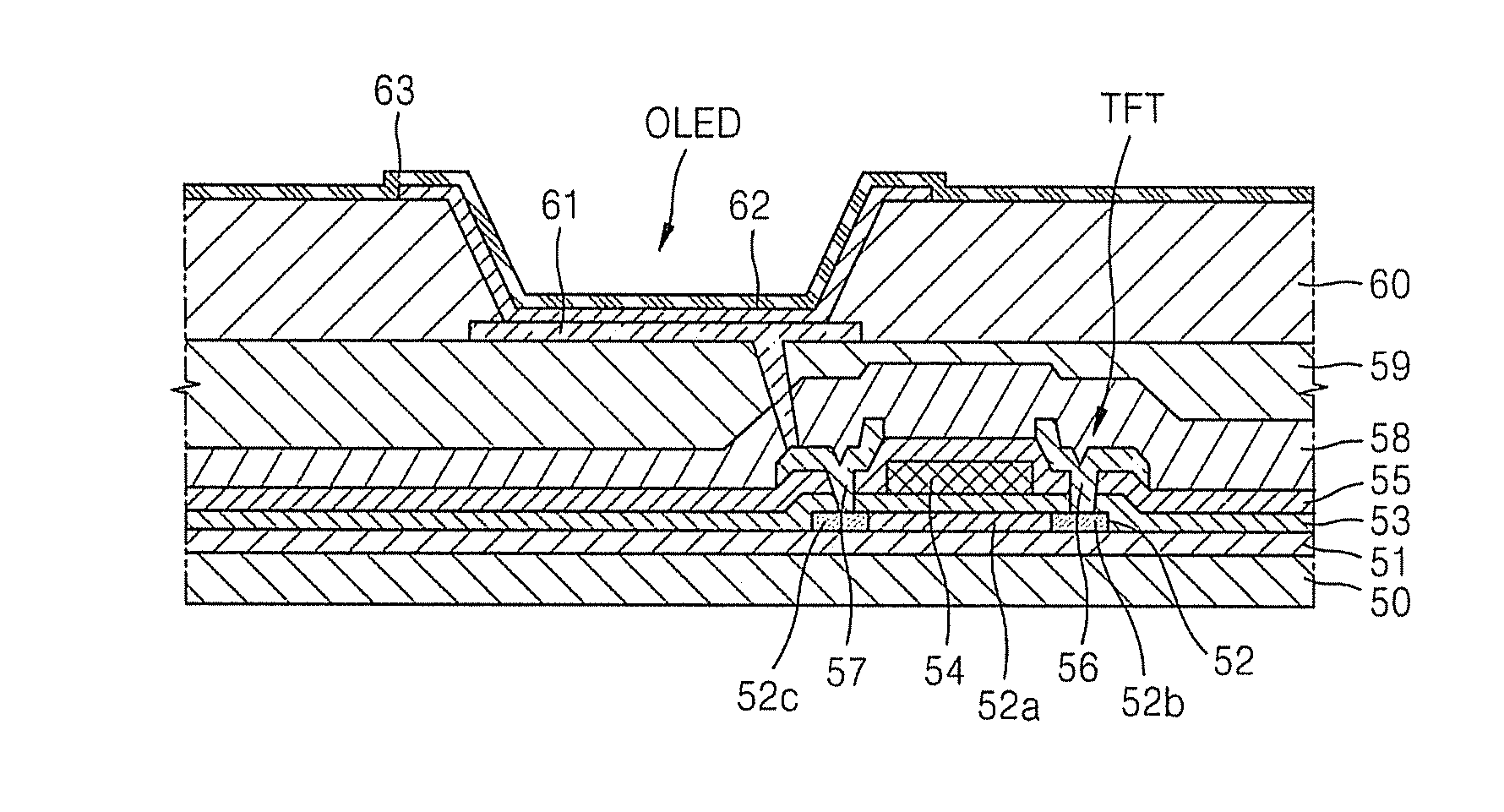

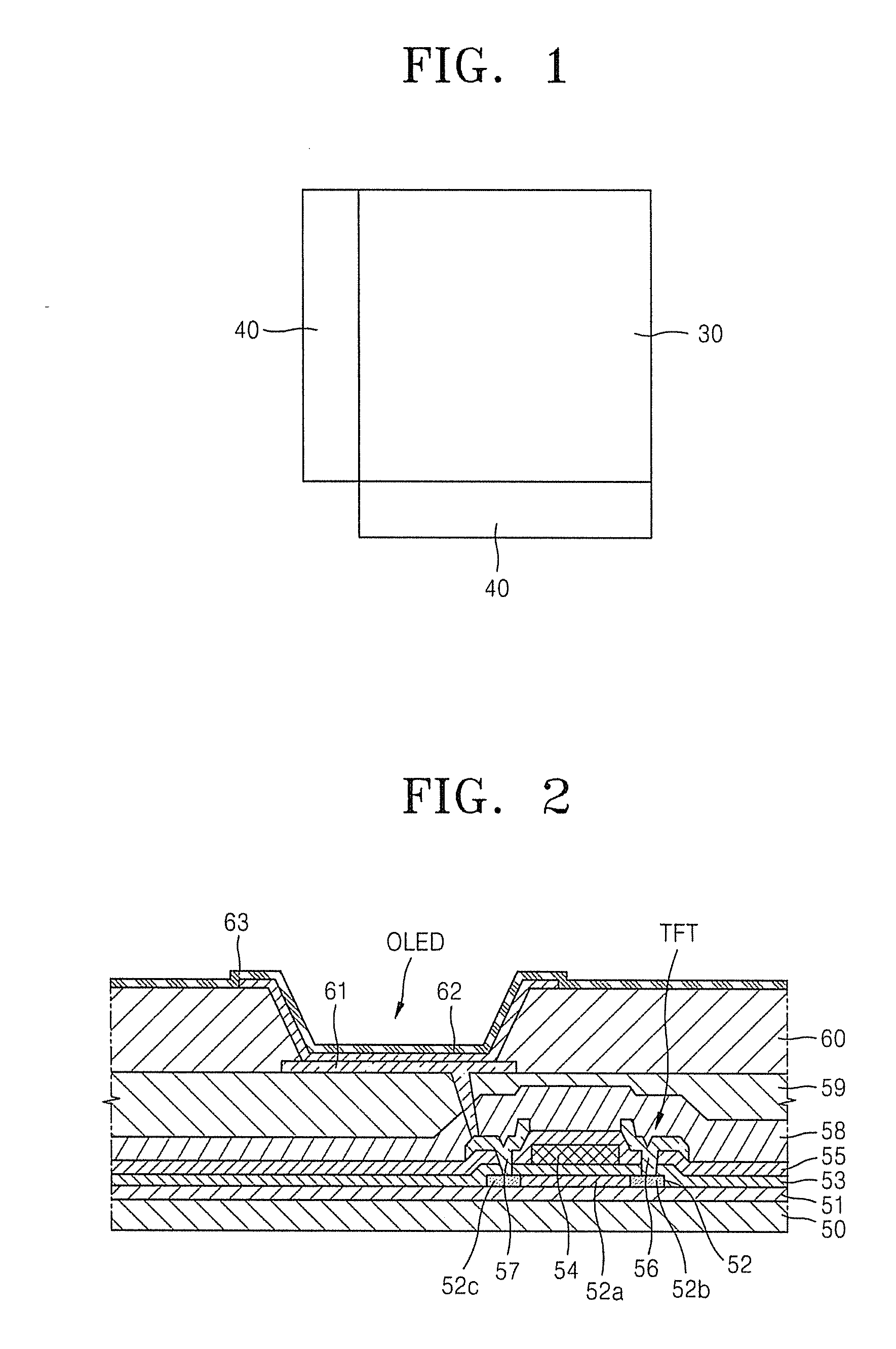

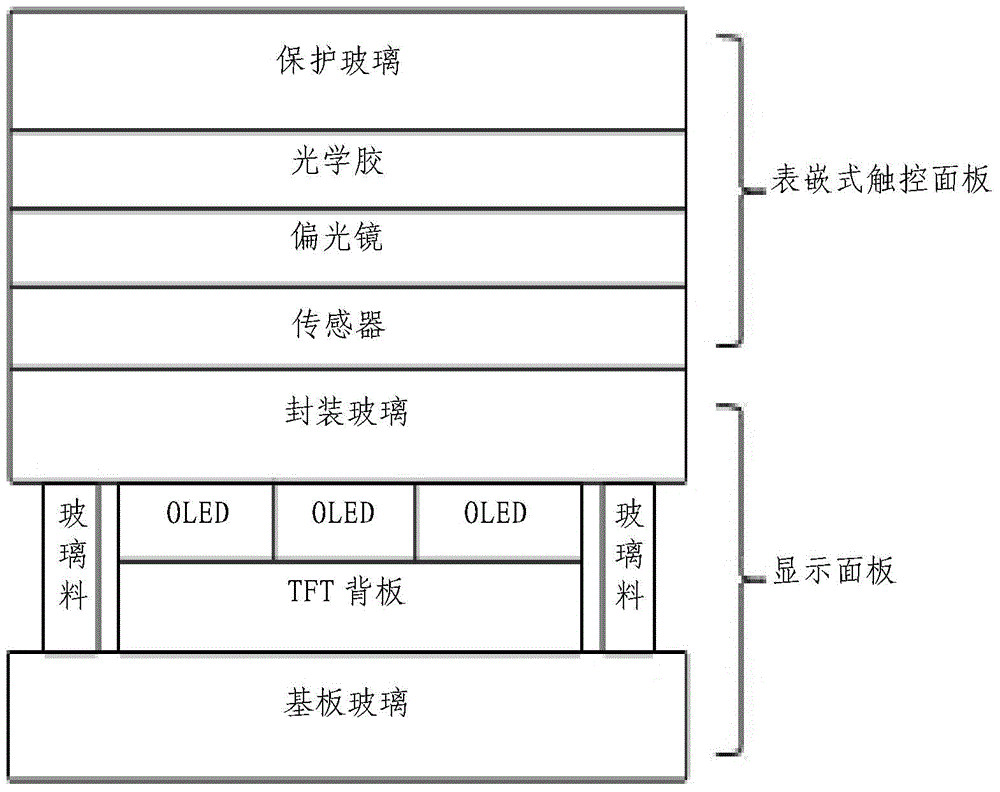

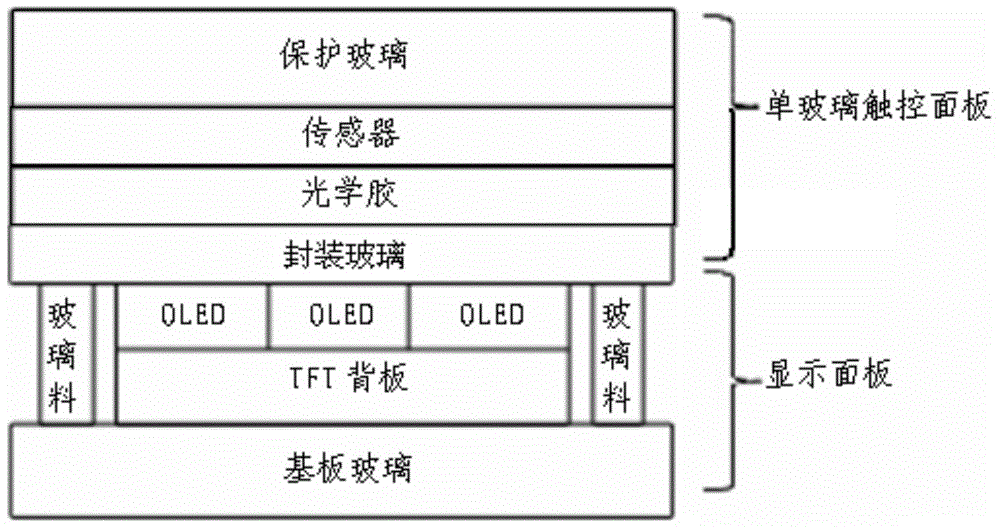

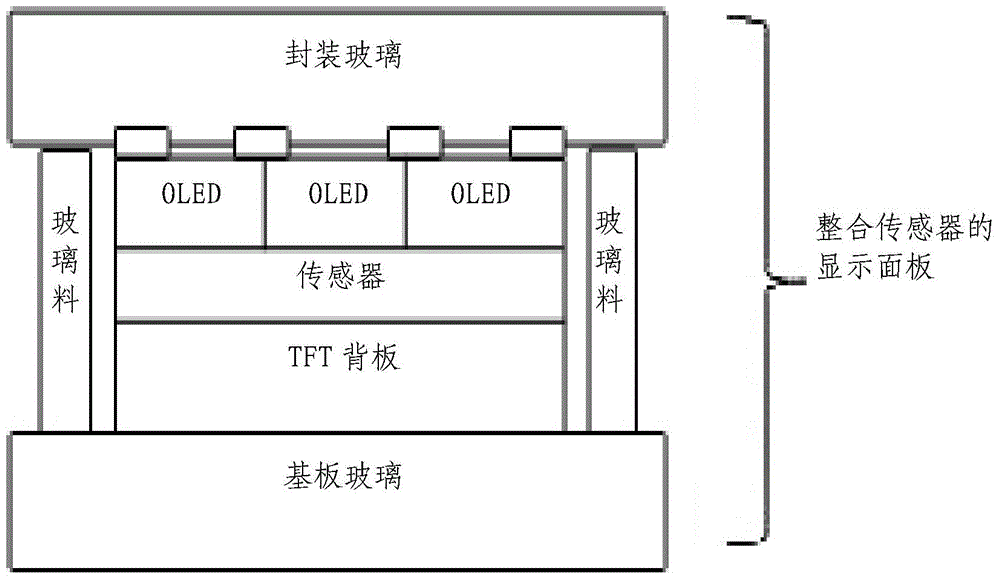

Embedded active matrix OLED (organic light emitting diode) touch panel

ActiveCN103984442ALow costStrong penetrating powerSemiconductor/solid-state device detailsSolid-state devicesSensor arrayRainbow

The invention relates to an embedded active matrix OLED touch panel and belongs to the technical field of display screens. According to the embedded active matrix OLED touch panel, an OLED board comprises a lower touch sensor layer and an upper touch sensor layer, the lower touch sensor layer comprises a lower touch sensor matrix, the upper touch sensor layer comprises an upper touch sensor array, the distribution direction of the lower touch sensor array is perpendicular to that of the upper touch sensor array, and the lower touch sensor array and the upper touch sensor array compose a mutual-capacitance touch sensing unit for sensing touch signals. Therefore, touch signal sensing elements can be integrated with the OLED board to form an embedded touch panel. The embedded active matrix OLED touch panel is simple structure, thinner in thickness, lower in cost and applicable to more light-weight, thinner and shorter electronic products, and meanwhile, can effectively improve the penetrating degree of the panel, reducing rainbow rings and greatly improve usage experience of users.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

Anticorrossion antiwear ceramic paint

InactiveCN1325931AHigh hardnessImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyGlass fiber

An anticorrosion and antiwear ceramic paint is prepared from epoxy resin (28.5-35 wt.portions), dibutyl phthalate (3.75-6), mixed solvent of xyrene and n-butyl ester (20-24), gas-phase SiO2 (0.5-1) and ceramic powder (38-45) which contains TiO2 (3-6.3), Al2O3 (11.7-20) and Si3N4 (16-20.45). The weight ratio of main component to slidifying agent is (14.5-17):1. It can be directly applied to the surfaces of metal, glass fibre, plastic, or concrete with the advantages of high antiwear performance and adhesion, and thin and compact coated layer.

Owner:BEIJING UNIV OF CHEM TECH

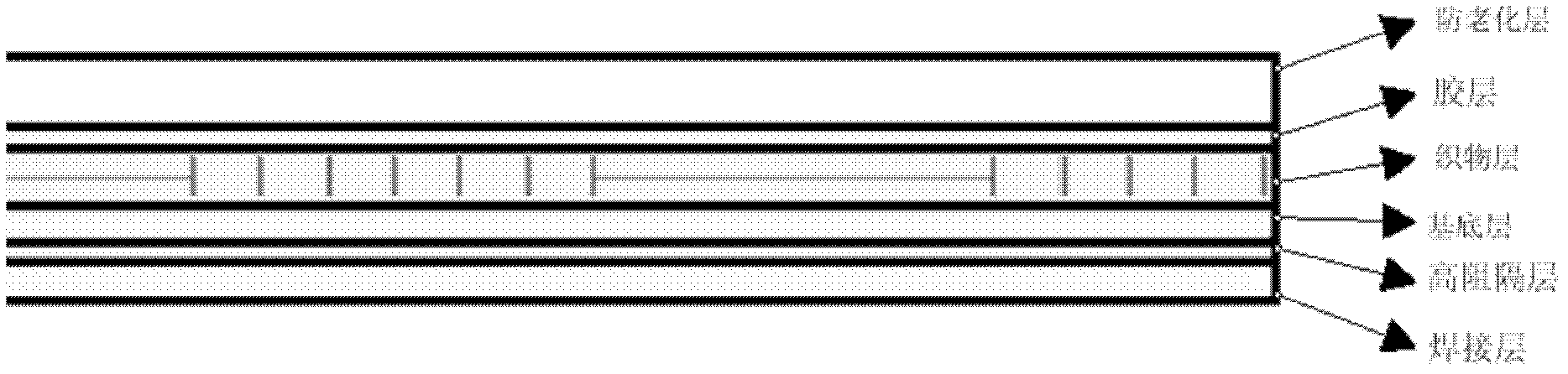

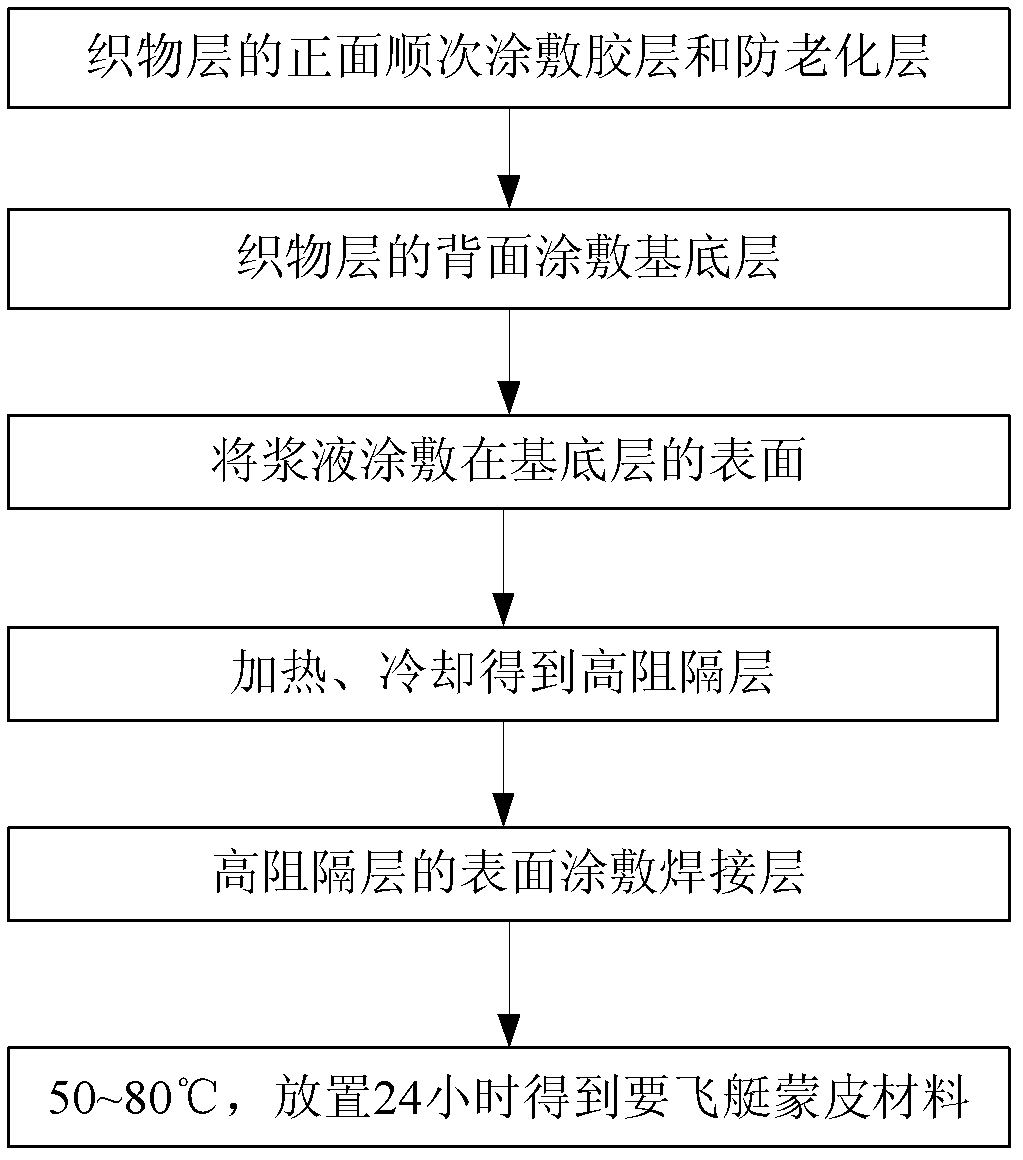

Airship sheath material and preparation method thereof

InactiveCN102416739AImprove barrier propertiesImprove rub resistanceSynthetic resin layered productsGas-bag arrangementsPolyvinyl alcoholNanoparticle

The invention provides an airship sheath material and a preparation method thereof. The sheath material comprises successively an anti-aging layer, a glue-line, a fabric layer, a basal layer, a high barrier layer and a weld layer. A material of the anti-aging layer is a thermoplastic polyurethane containing ZnO with a mass fraction of 1-3% and TiO2 with a mass fraction of 2.5-4% and having a thickness of 25-35 mum; a material of the high barrier layer is polyvinyl alcohol containing SiO2 nano particles with a mass fraction of 1.5-2.5%, a particle size of 20-70nm and a thickness of 1-3 mum. a material of the weld layer is thermoplastic polyurethane with a thickness of 20-30 mum. The high barrier layer of the airship sheath material is added with nano particles to gain a substantially enhanced obstruction effect and a helium permeation of 5-20ml / (m<2>.atm.24h). The preparation technology of the invention is simple; a coating technology and a simple applying technology are employed to realize a high obstruction effect.

Owner:BEIHANG UNIV

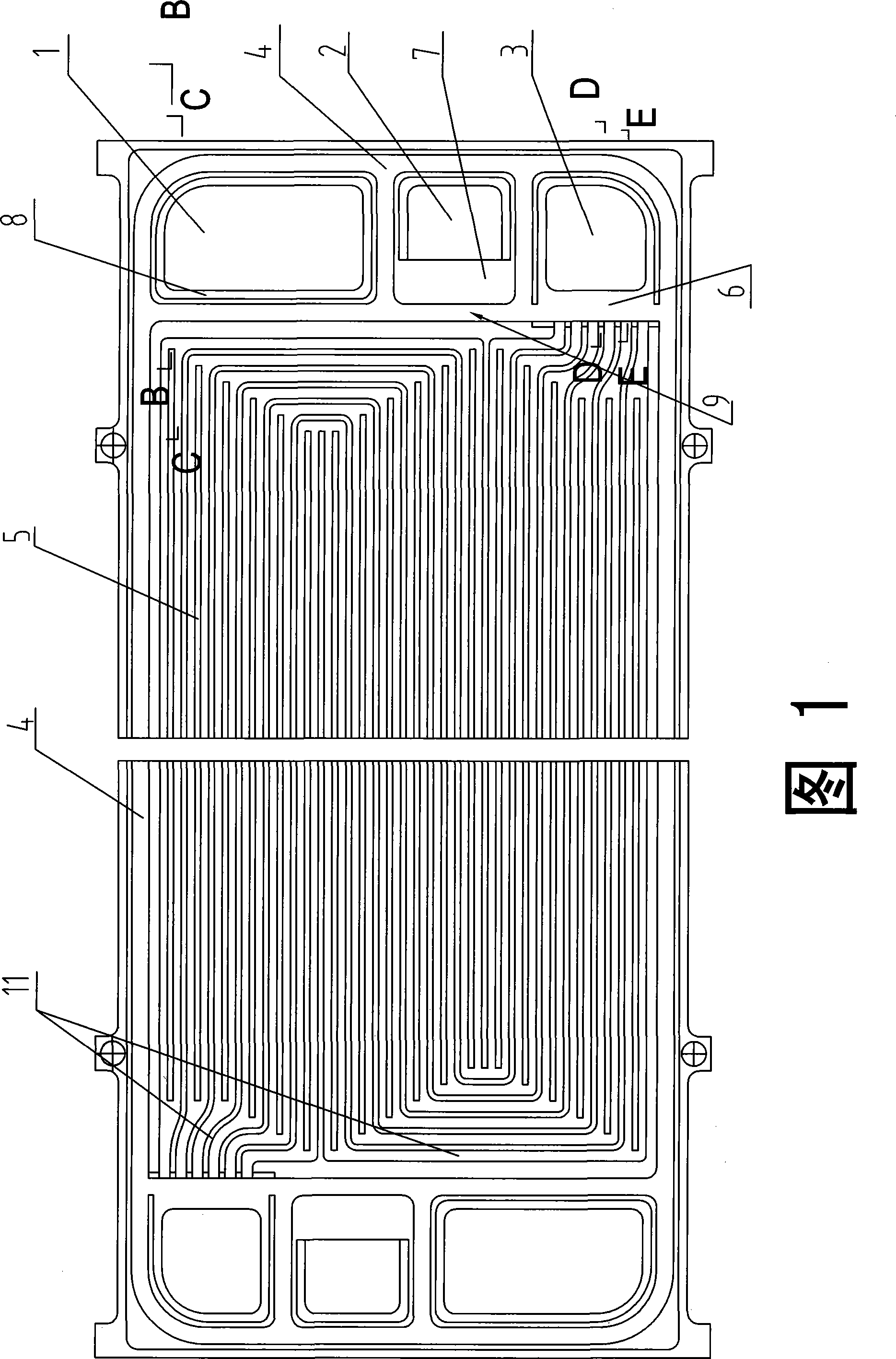

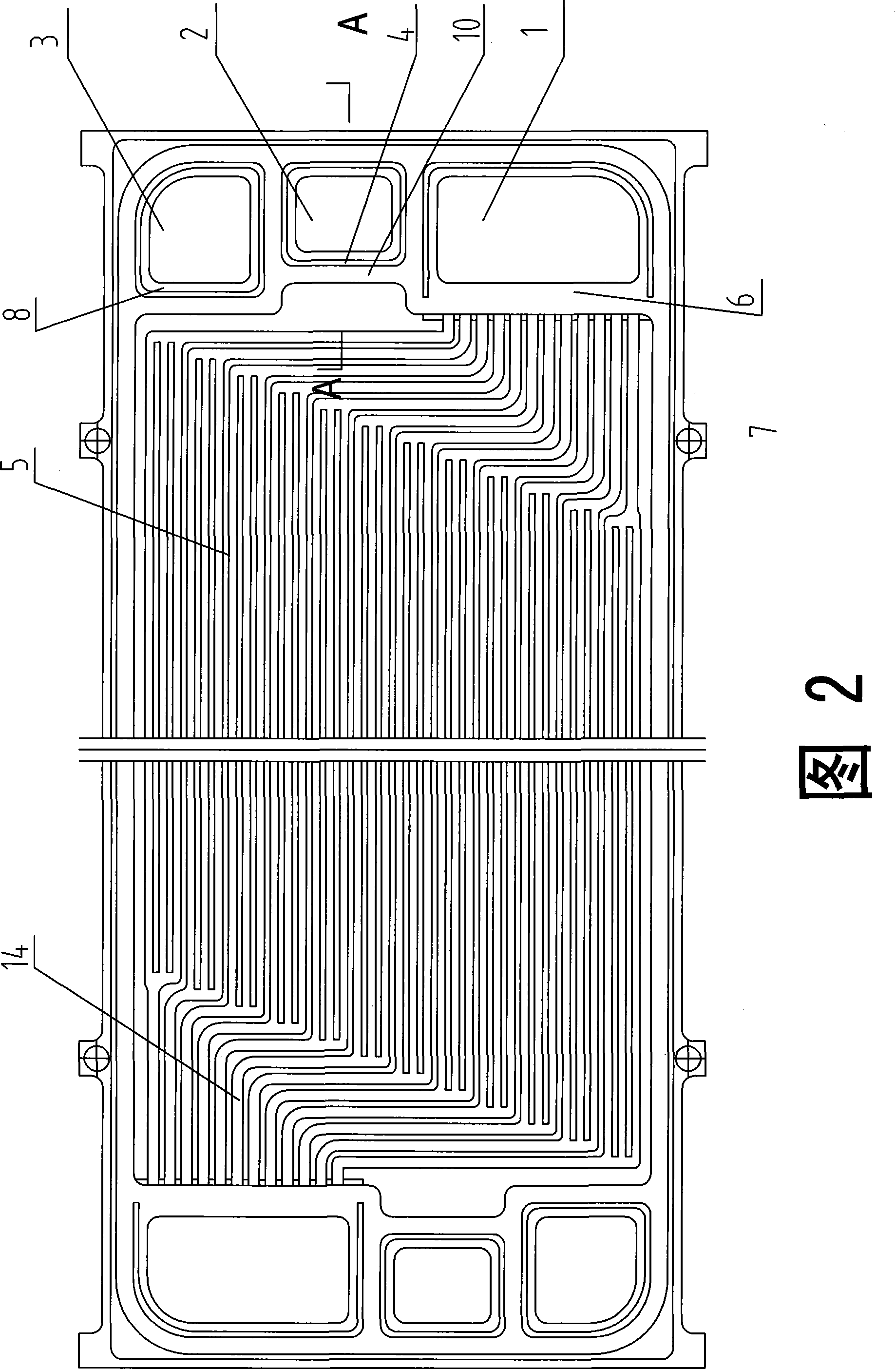

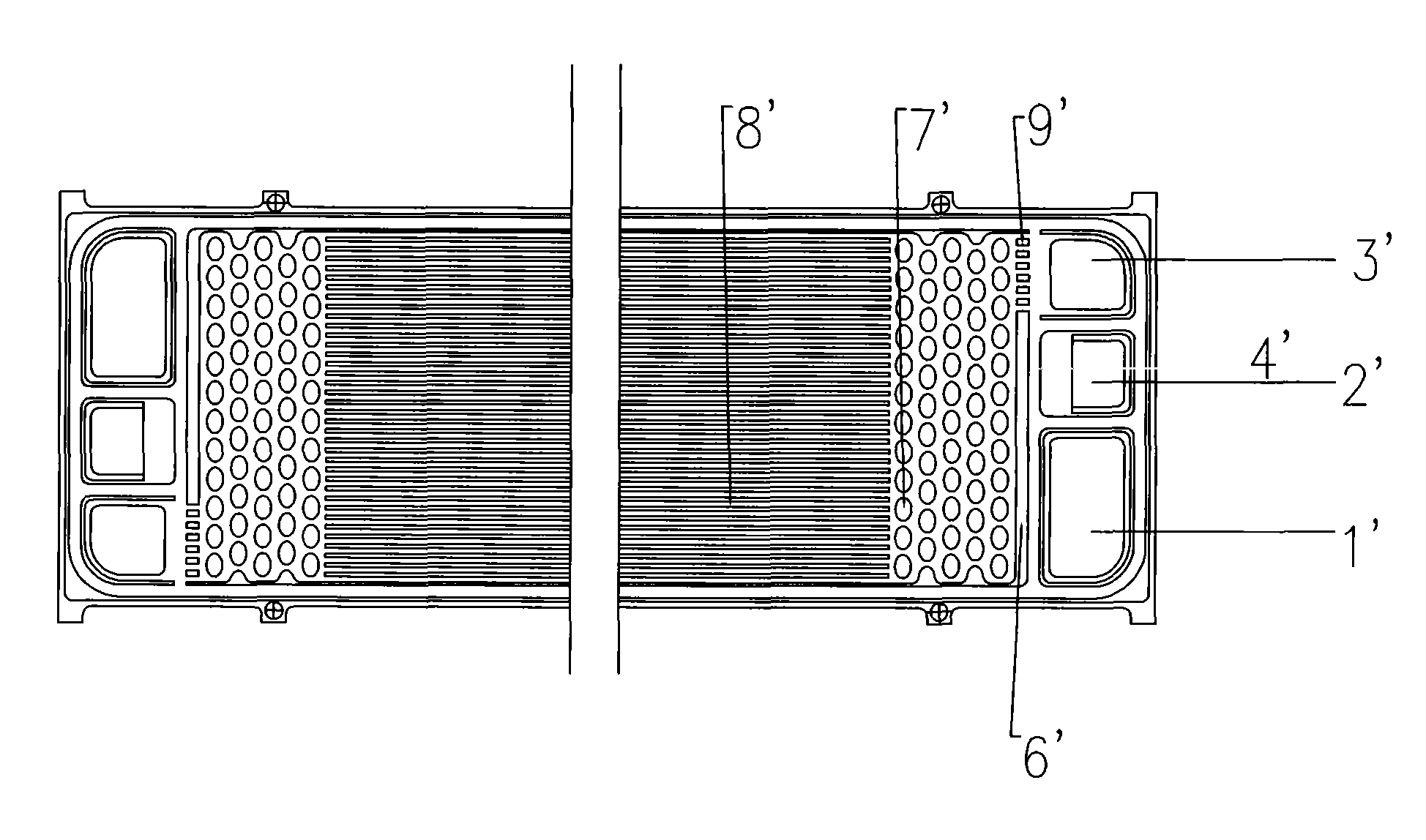

Proton exchange membrane fuel cell metal bipolar plate

ActiveCN101572318AThe overall thickness is thinReduce weightFinal product manufactureCell electrodesWater flowMetal sheet

The invention relates to a proton exchange membrane fuel cell metal bipolar plate, which consists of a cathode monopolar plate and an anode monopolar plate made of sheet metal, wherein a flow passage of the monopolar plates consists of a flow field flow passage, a distribution flow passage and an inlet-outlet passage, and the proton exchange membrane fuel cell metal bipolar plate is characterized in that the distribution flow passage is a point-like flow passage, the point-like flow passage consists of unconnected lug bosses raised towards the front side of the monopolar plates, the back sides of the lug bosses are provided with steel pits, the steel pit on the back side of the lug boss on the cathode monopolar plate is staggered with the steel pit on the back side of the lug boss on the anode monopolar plate, and the front part and the back part of the steel pits are overlapped relatively to form continuous water flow distribution flow passages which are connected in series. The proton exchange membrane fuel cell metal bipolar plate has the advantages of thin thickness for the manufactured bipolar plate, strict separation of fluid, good fluid distribution, light weight, simple processing and low processing cost; besides, the bipolar plate has high effective utilization area and good fluid resistance distribution evenness, and can satisfy the needs of different battery heat exchanges.

Owner:SUNRISE POWER CO LTD

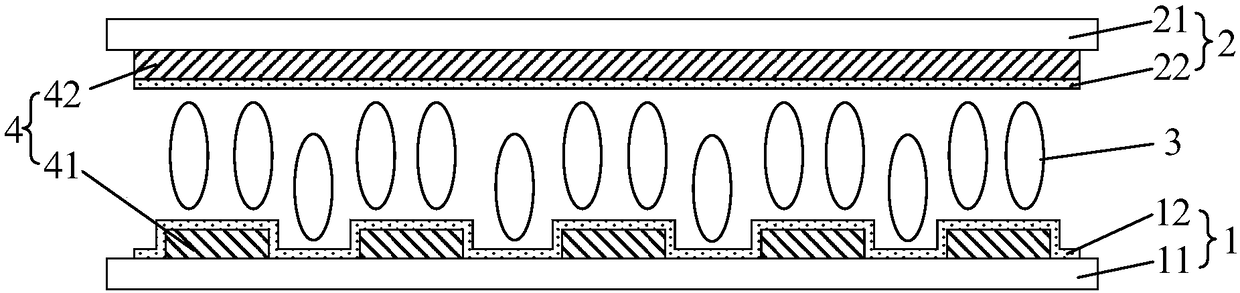

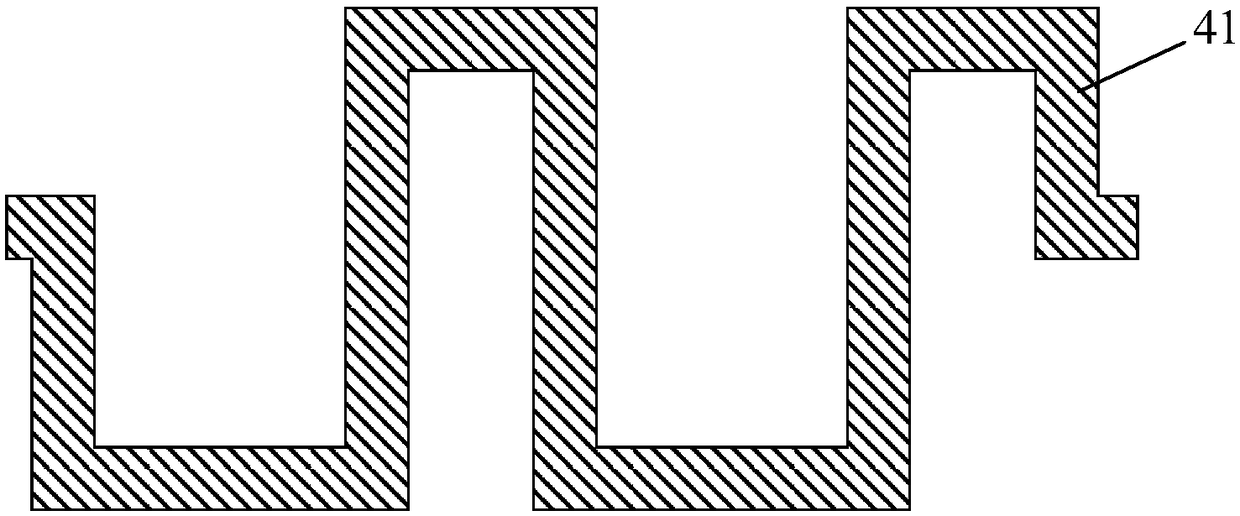

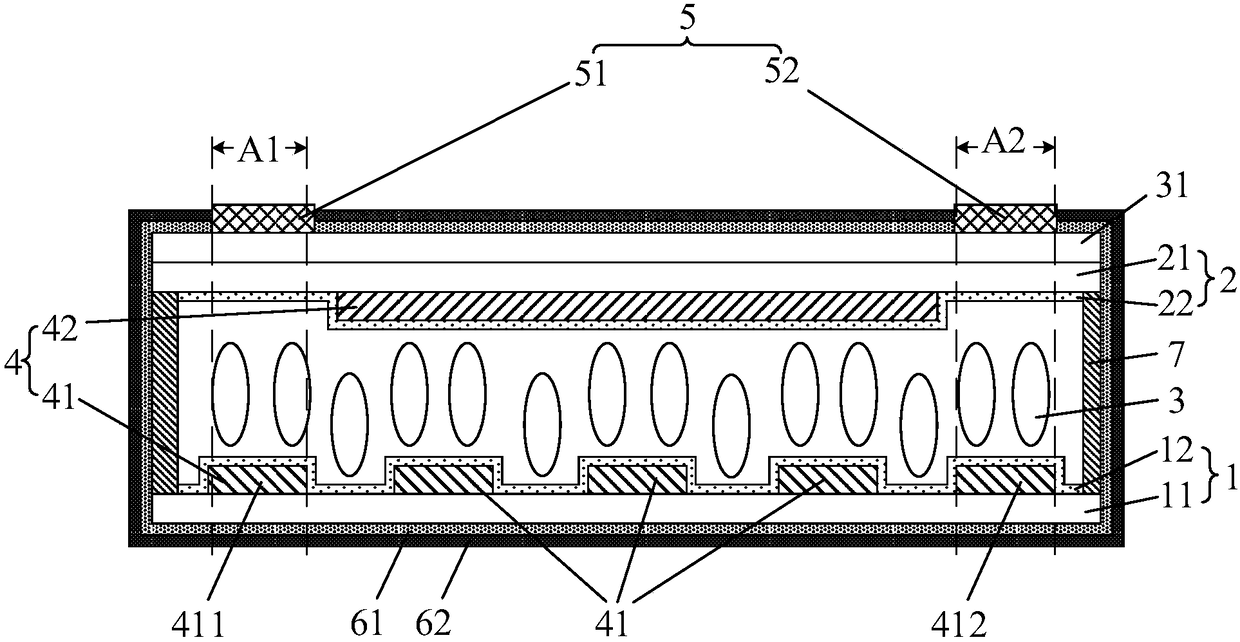

Liquid crystal phase shifter and antenna

ActiveCN108563050AReduce hardnessReduce thicknessStatic indicating devicesNon-linear opticsPhase controlLiquid crystal

An embodiment of the invention provides a liquid crystal phase shifter and an antenna, and relates to the technical field of electromagnetic waves. The liquid crystal phase shifter has a deformable feature, and can be applied to extensive scenes. The liquid crystal phase shifter comprises a first substrate, a second substrate, a liquid crystal layer and at least one phase shifting unit. The firstsubstrate is opposite to the second substrate. The liquid crystal layer is located between the first substrate and the second substrate. The first substrate comprises a first flexible substrate and afirst liquid crystal alignment layer. The first liquid crystal alignment layer is located on one side, close to the second substrate, of the first flexible substrate. The second substrate comprises asecond flexible substrate and a second liquid crystal alignment layer. The second liquid crystal alignment layer is located on one side, close to the first substrate, of the second flexible substrate.Each phase shifting unit comprises a microstrip line and a phase control electrode. The microstrip lines are located between the first flexible substrate and the first liquid crystal alignment layer.The phase control electrodes are located between the second flexible substrate and the second liquid crystal alignment layer.

Owner:CHENGDU TIANMA MICROELECTRONICS

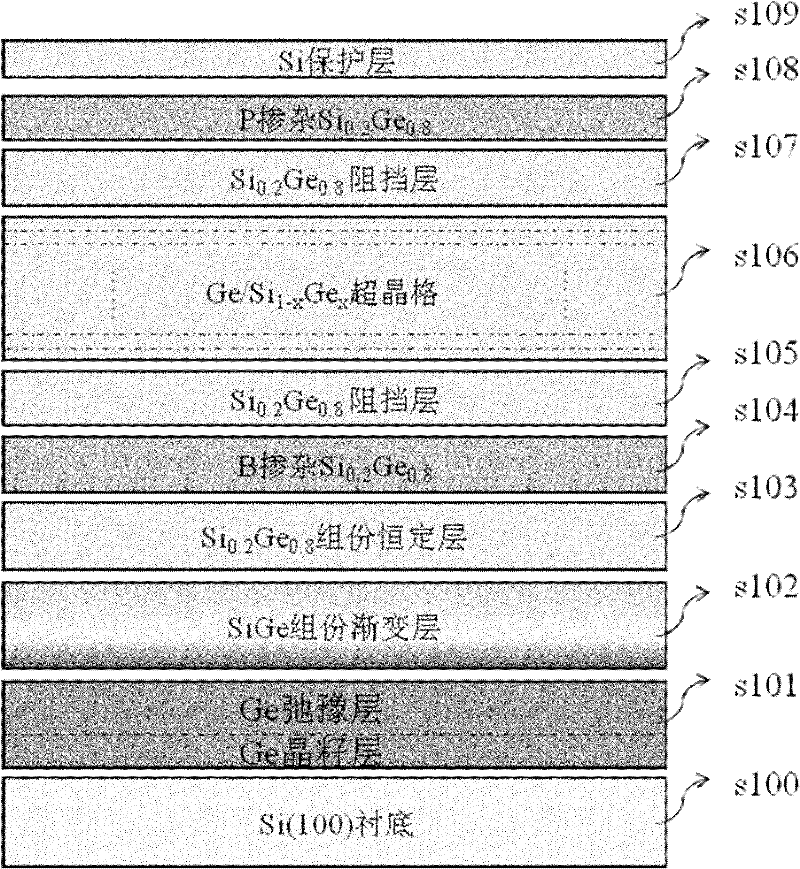

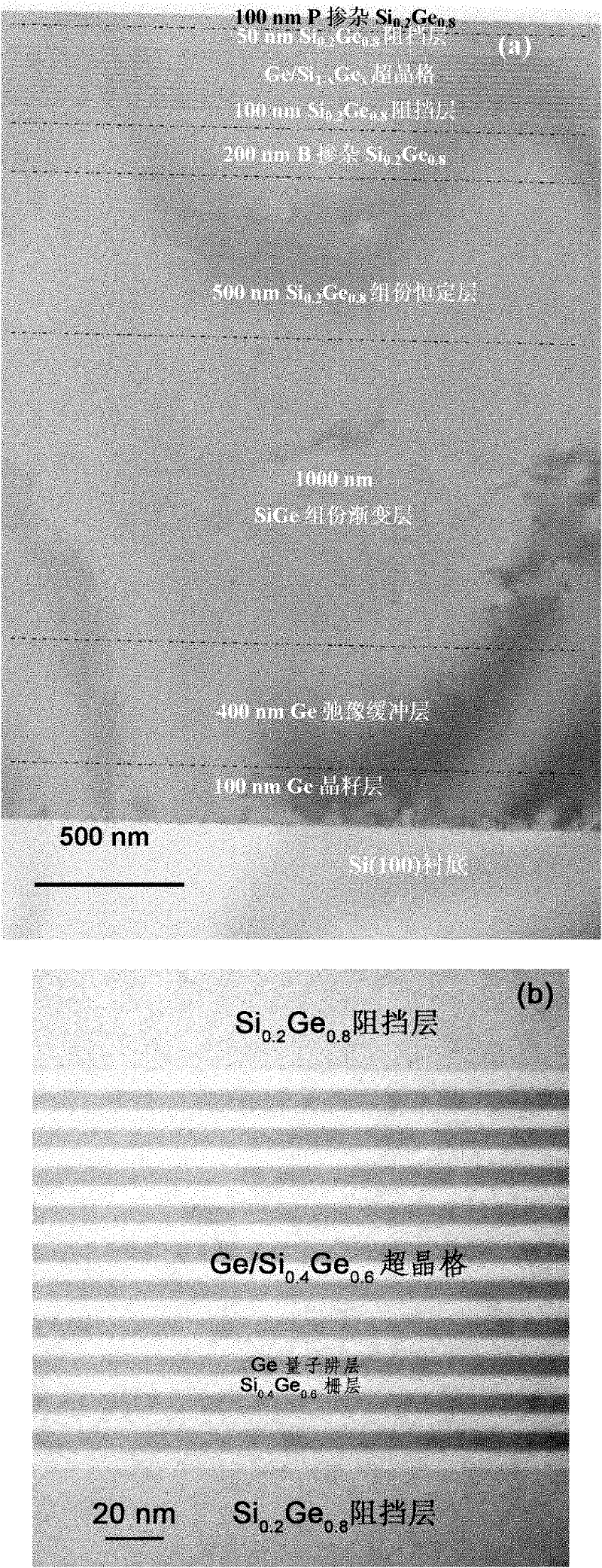

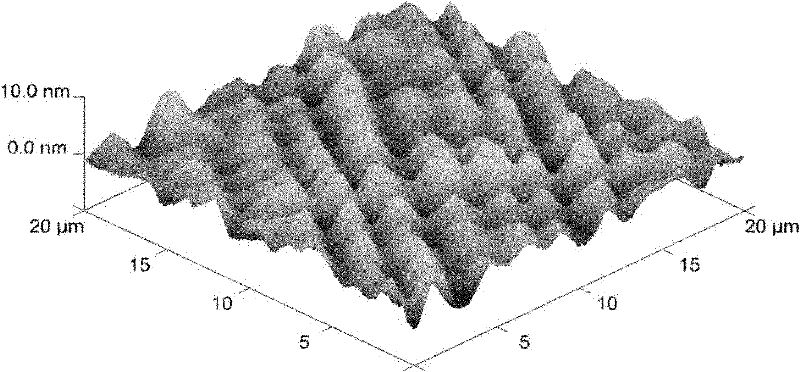

High quality strain Ge/SiGe super-lattice structure and preparation method thereof

InactiveCN102162137AHigh Ge contentReduce dislocation densityPolycrystalline material growthFrom chemically reactive gasesSemiconductor materialsReduced pressure chemical vapor deposition

The invention belongs to the technical field of semiconductor materials, and relates to a Ge / Si1-xGex super-lattice structure and preparation thereof. The high quality strain Ge / Si1-xGex super-lattice structure comprises a Si substrate, and a Si0.2Ge0.8 virtual substrate layer, a B-doped Si0.2Ge0.8 epitaxial layer, a Si0.2Ge0.8 blocking layer, a Ge / Si1-xGex super-lattice layer, a P-doped Si0.2Ge0.8 epitaxial layer, a Si0.2Ge0.8 blocking layer and a Si protective layer sequentially and epitaxially grown on the Si substrate, wherein x is more than or equal to 0.6 and less than or equal to 0.7. The epitaxial layers are sequentially grown on the Si substrate by adopting a reduced pressure chemical vapor deposition method; the obtained super-lattice structure has the properties of low dislocation defect density, low thickness and flat interface / surface, and the Ge / Si1-xGex super-lattice is in a strain state; and the super-lattice structure has high quality and is particularly suitable for manufacturing silicon-based laser devices and waveguide modulators.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

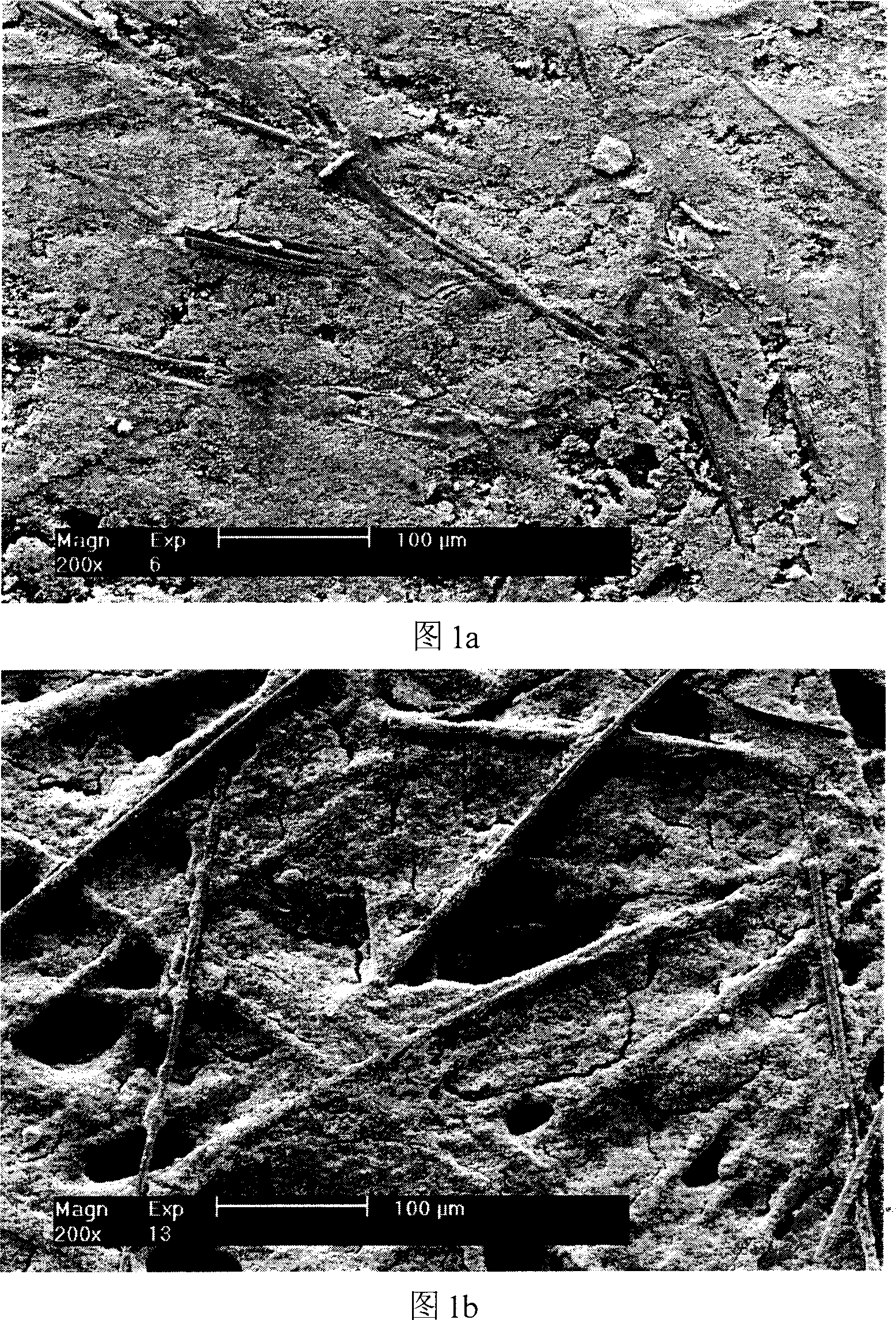

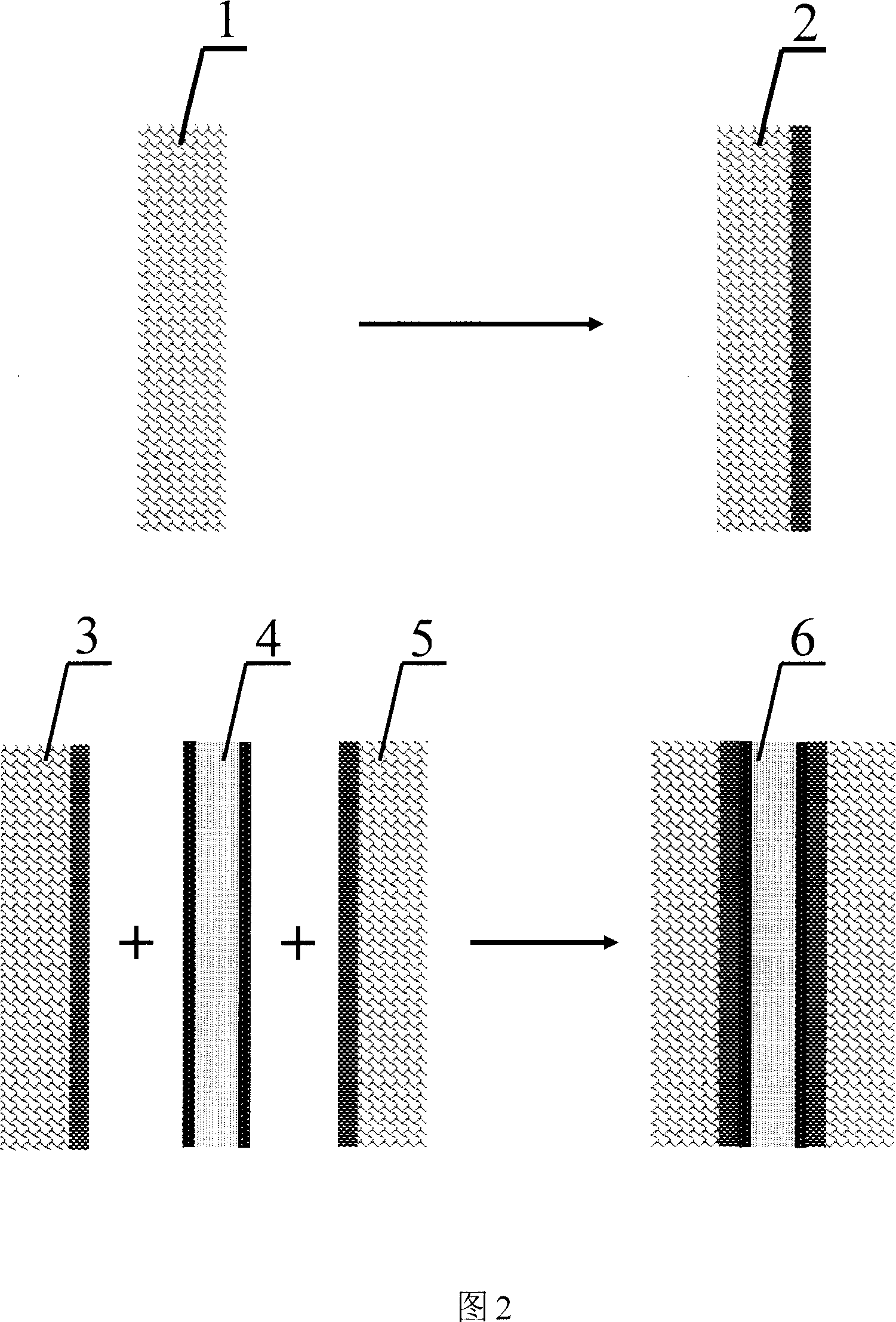

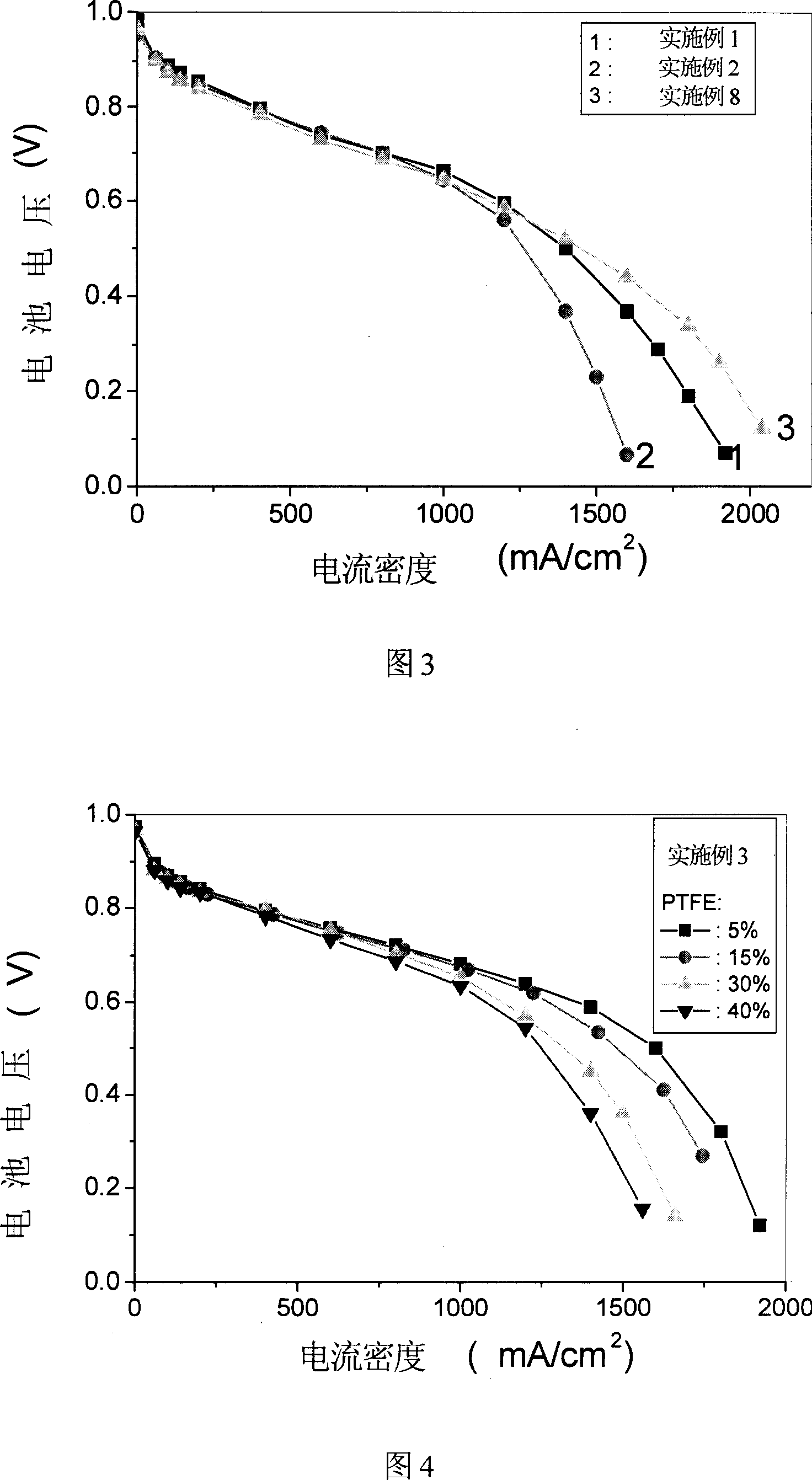

Gas diffusion layer for proton exchanging film fuel cell and its preparing method

InactiveCN1988225ALight weightUniform surfaceFinal product manufactureCell electrodesFiberHydrophile

This invention relates to a gas diffusion layer used in proton exchange film fuel cells and its preparation method, in which, the gas diffusion layer includes a multihole supporting layer and a microhole layer, the multihole supporting layer is a net and porous structure, the microhole layer is composited on the surface of the porous supporting layer closing to the catalyzed layer and covers the surface of the large hole and fiber dense region of the supporting layer uniformly but not penerates into the inside of the supporting layer, which applies a drying method to prepare a gas diffusion layer used in proton exchange membrane fuel cells, and polymr 1 and 2 containing FI is either a same kind or different, and the hydrophile / hydrophobic degree of the two layers is adjustable, so the gas diffusion layer structure is matched with the running condition of the fuel cell and discharges water more easily.

Owner:SUNRISE POWER CO LTD

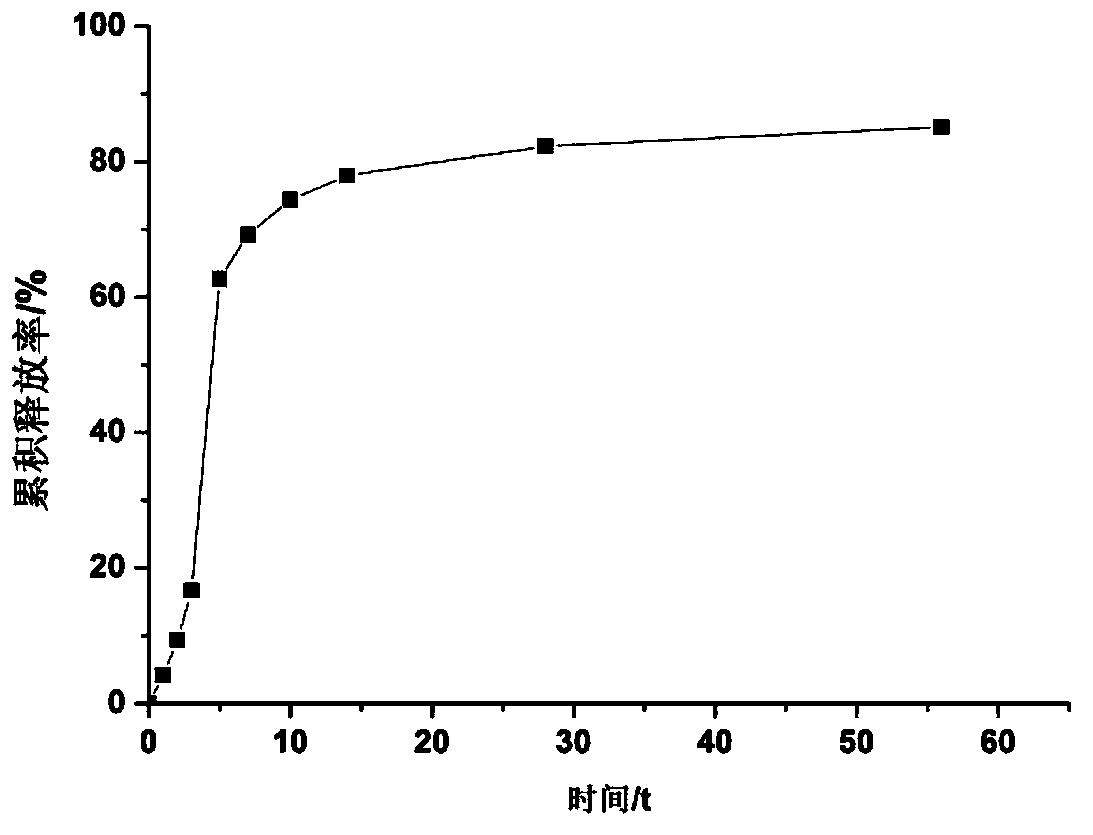

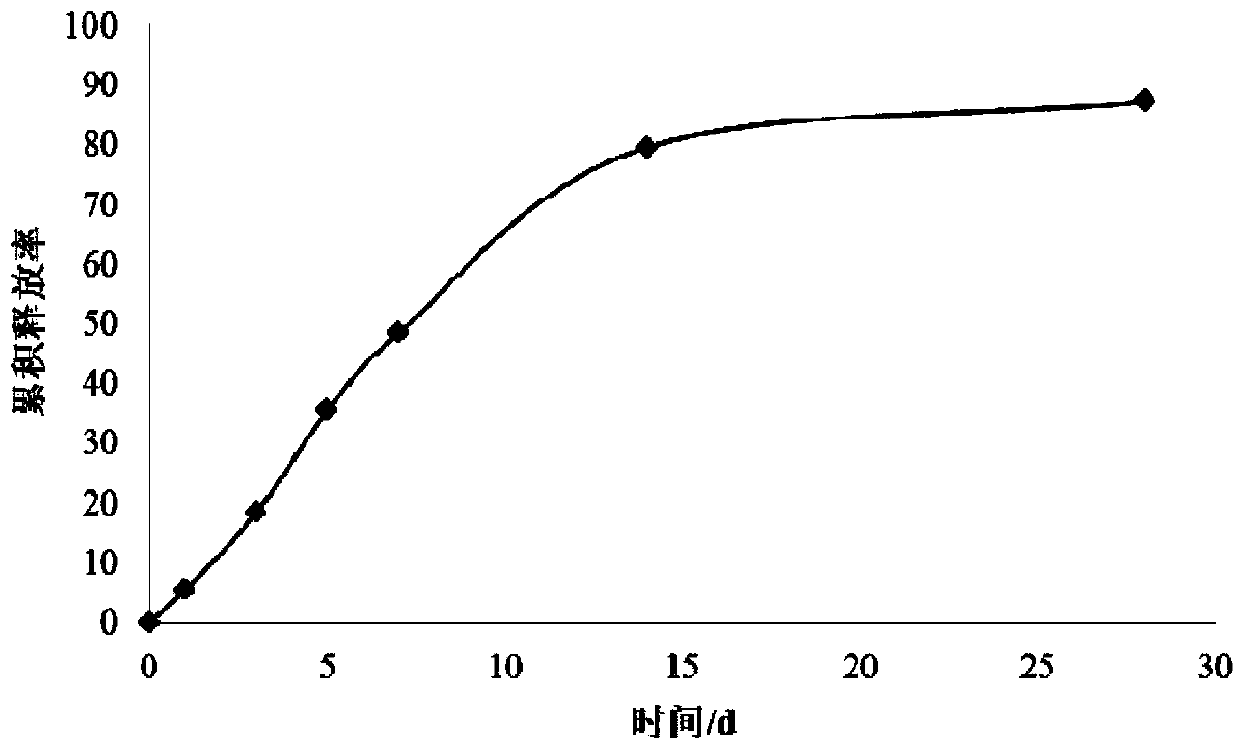

Polymer-coated controlled release pesticide granule and preparation method thereof

ActiveCN103387456AImprove water resistanceImprove targetingFertilizer mixturesWater basedPolyurethane membrane

The invention discloses a polymer-coated controlled release pesticide granule and a preparation method thereof. The polymer-coated controlled release pesticide granule comprises a pesticide granule and a polymer layer, wherein the pesticide granule is coated by the polymer layer; the pesticide granule contains one or more effective pesticide components; the polymer layer is a hydrophobic membrane layer and comprises a water-based polyacrylate membrane material or a polyurethane membrane material; the mass of the polymer layer accounts for 3%-15% of the weight of the polymer-coated controlled release pesticide granule. The effective pesticide components are acted on the peripheries of crop roots after the polymer-coated controlled release pesticide granule disclosed by the invention is applied along with a base fertilizer. The polymer-coated controlled release pesticide granule has good prevention and control effects on farmland weeds, soil insects and soil-borne diseases, and the coating material synthesis and preparation process is advanced and the polymer-coated controlled release pesticide granule has good controlled release property. The polymer-coated controlled release pesticide granule provided by the invention has the advantages of pesticide utilization ratio improvement, environment pollution reduction, sustainable development and wide application prospect.

Owner:BEIJING BOYICHENG SCI & TECH

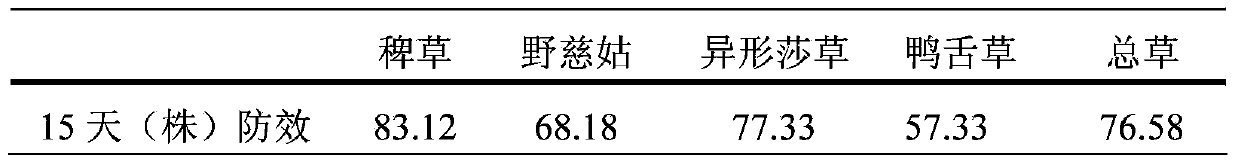

Method for preparing TiAl alloy clad plate by element powder

InactiveCN101011739AThe overall thickness is thinImprove mechanical propertiesFine structureTitanium alloy

The invention relates to the making of TIAl alloy compound plate using element powders, which mixes the element powders like Ti, Al and others in proportion evenly, getting the plate blank after cold rolling or compression, combining the blank and Ti alloy plate with certain thickness for heat compression or hot isostatic treatment to get the compound board. It makes the board with finer structure, thin board, with better comprehensive mechanic feature, being able to make high performance and big size compound board.

Owner:HARBIN INST OF TECH

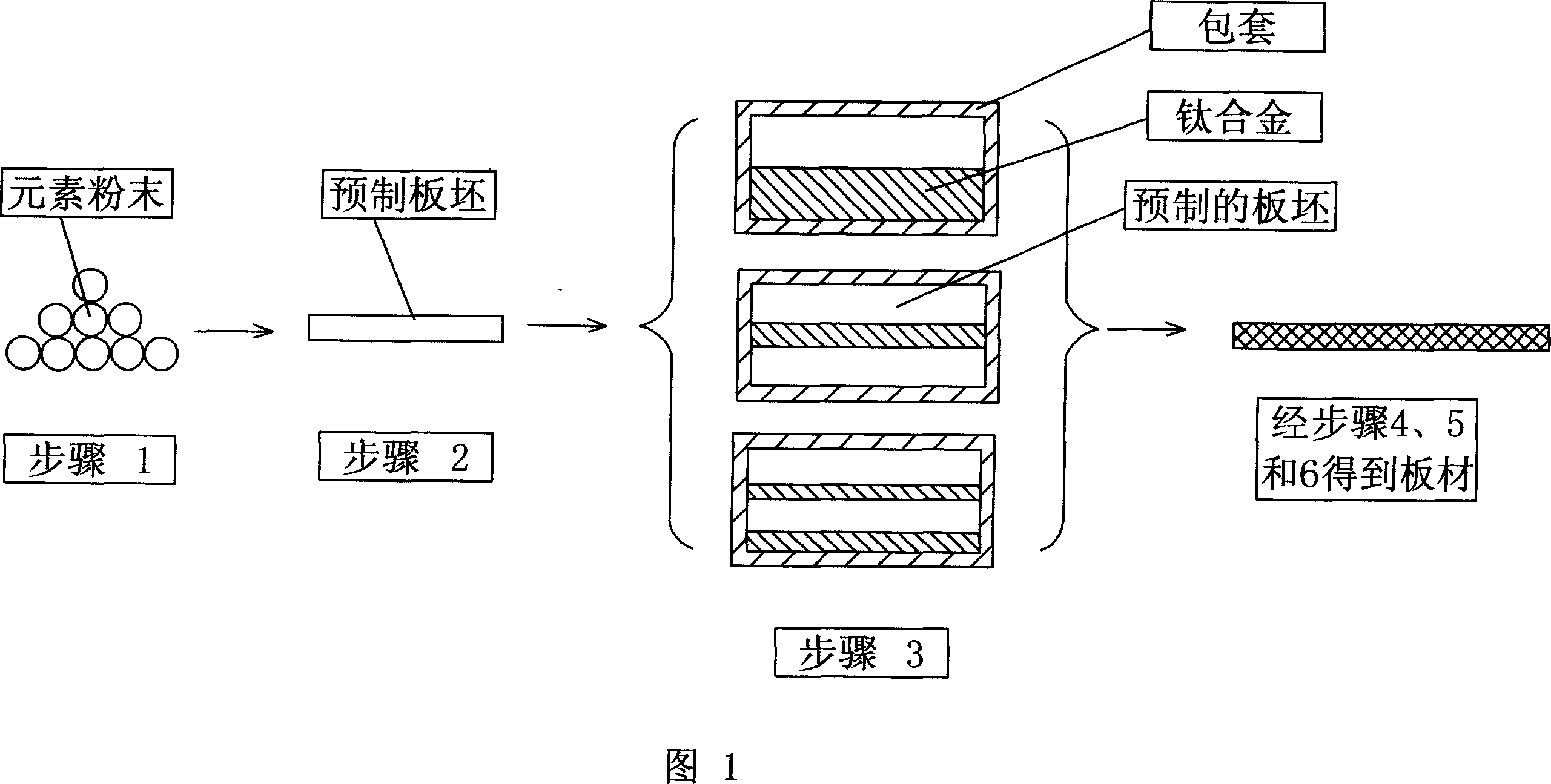

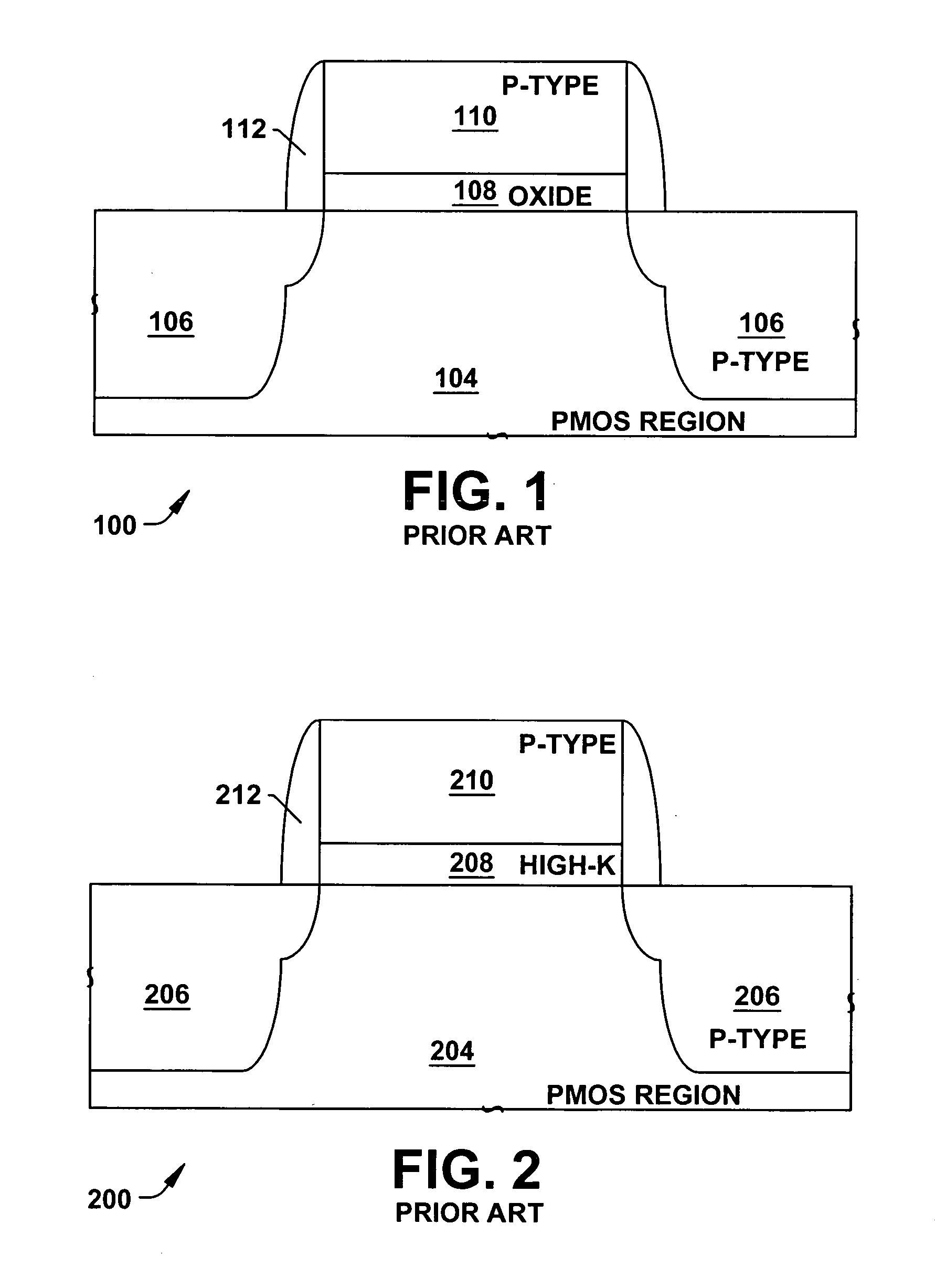

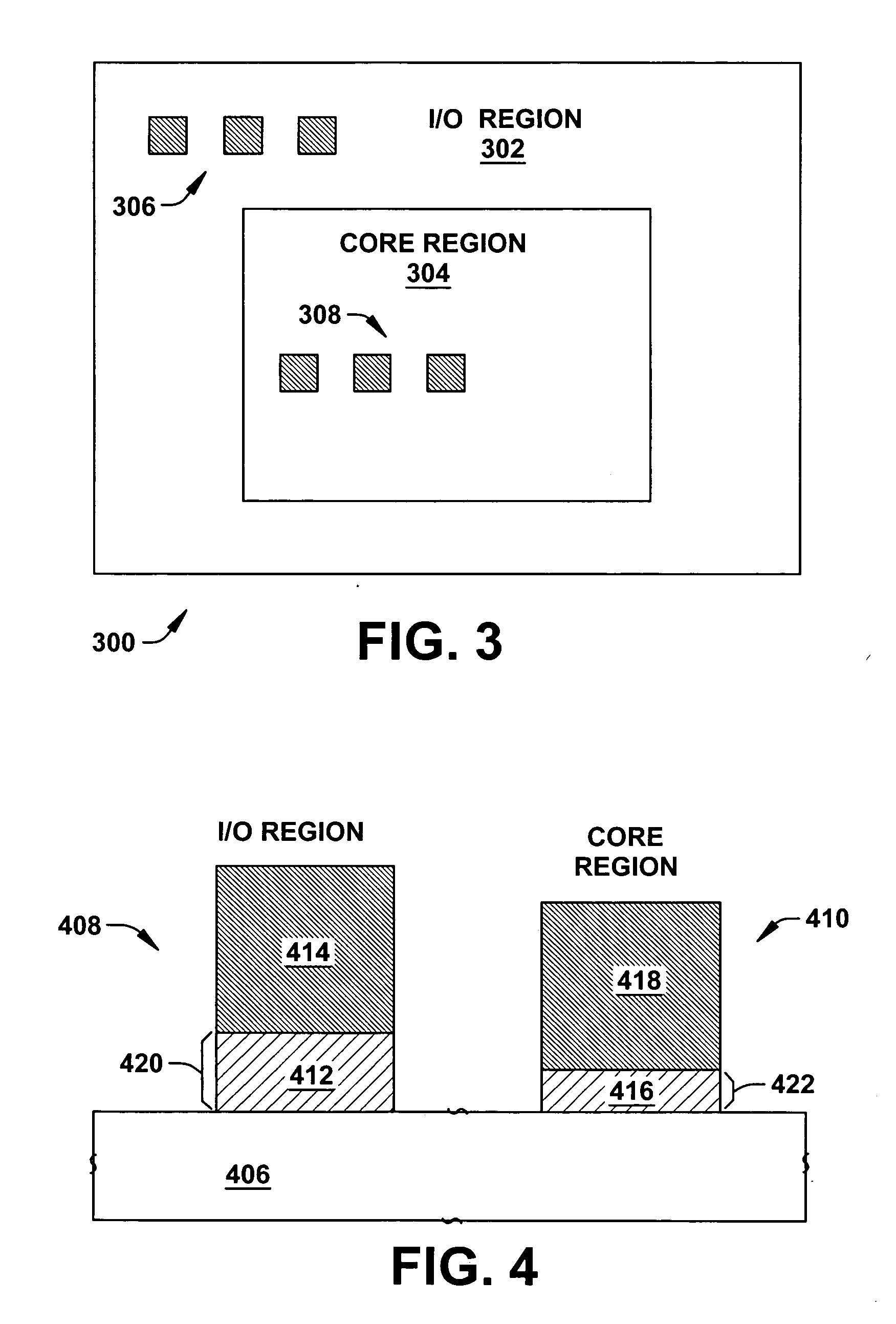

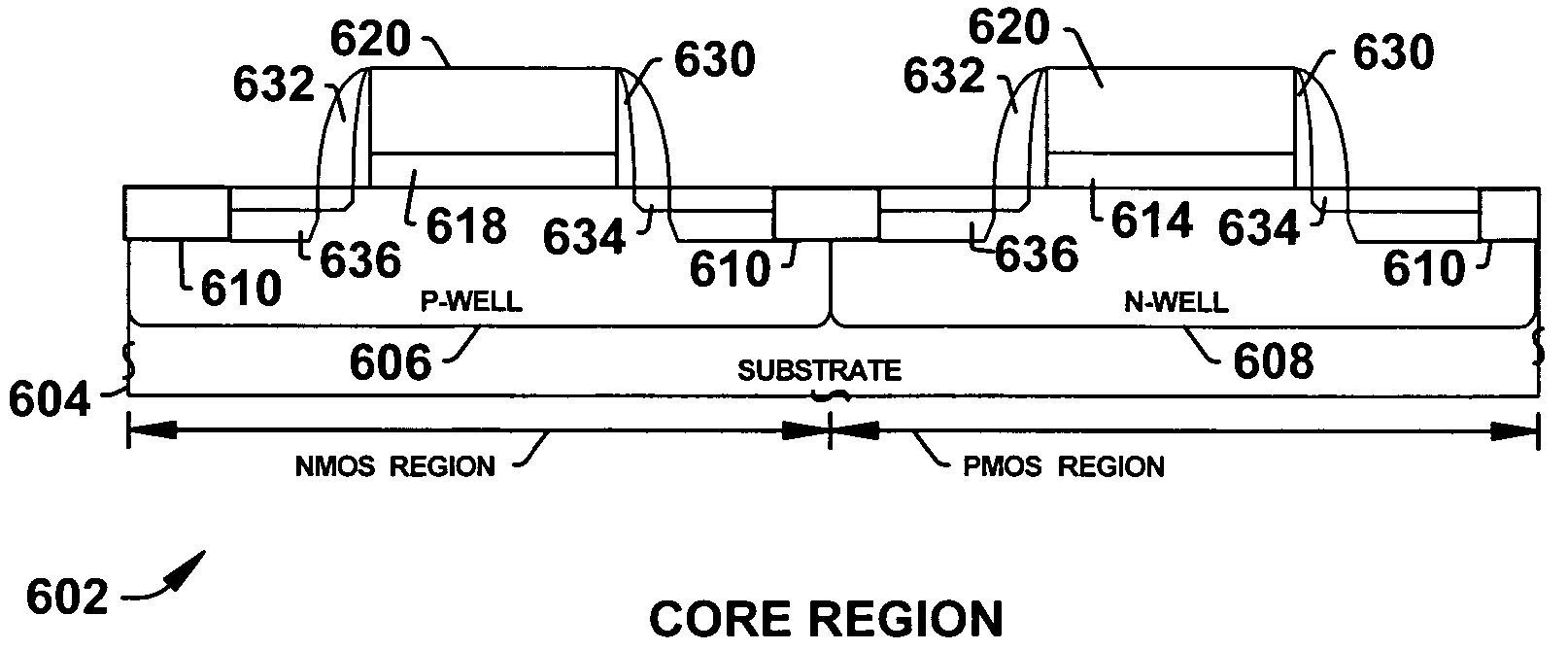

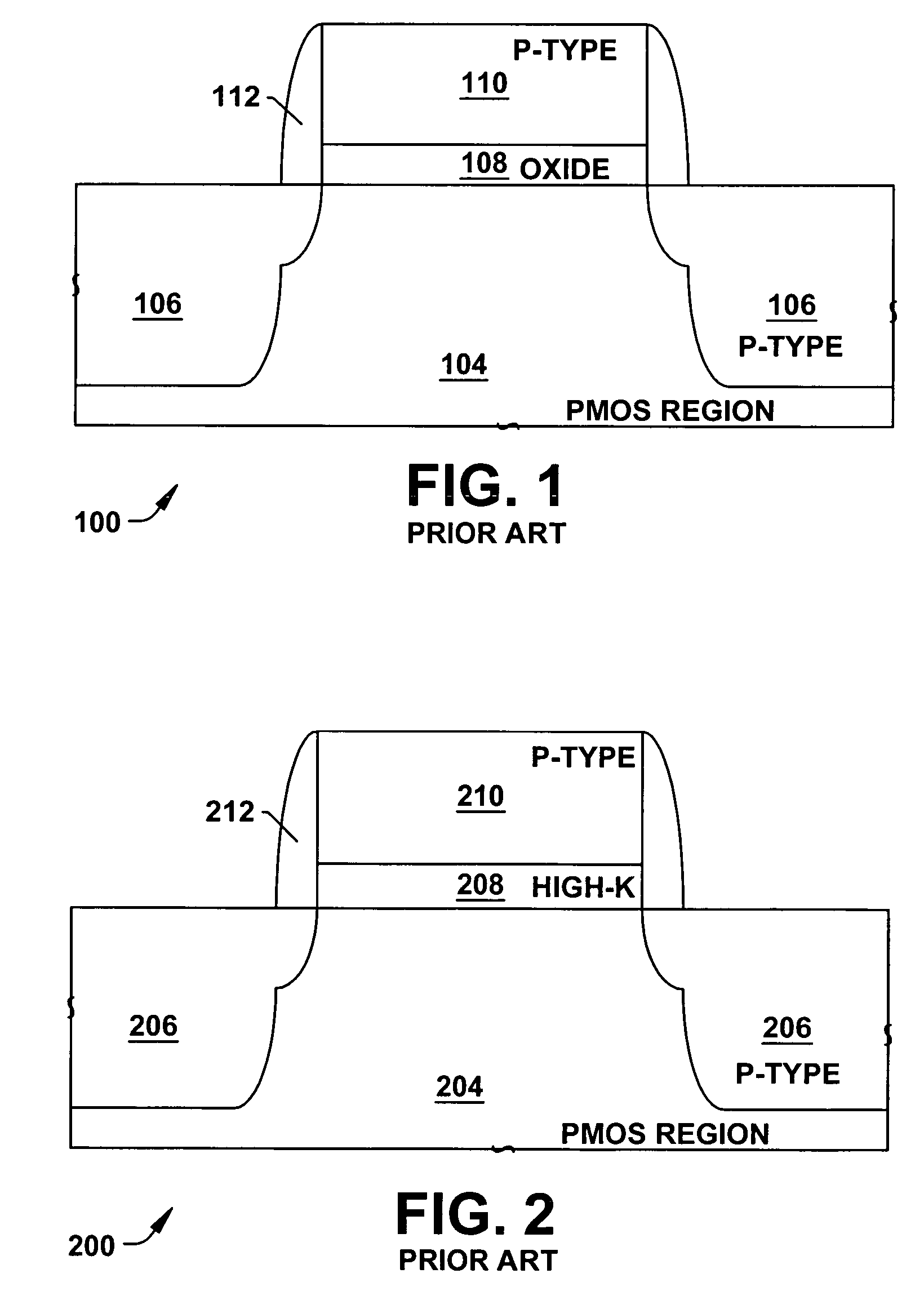

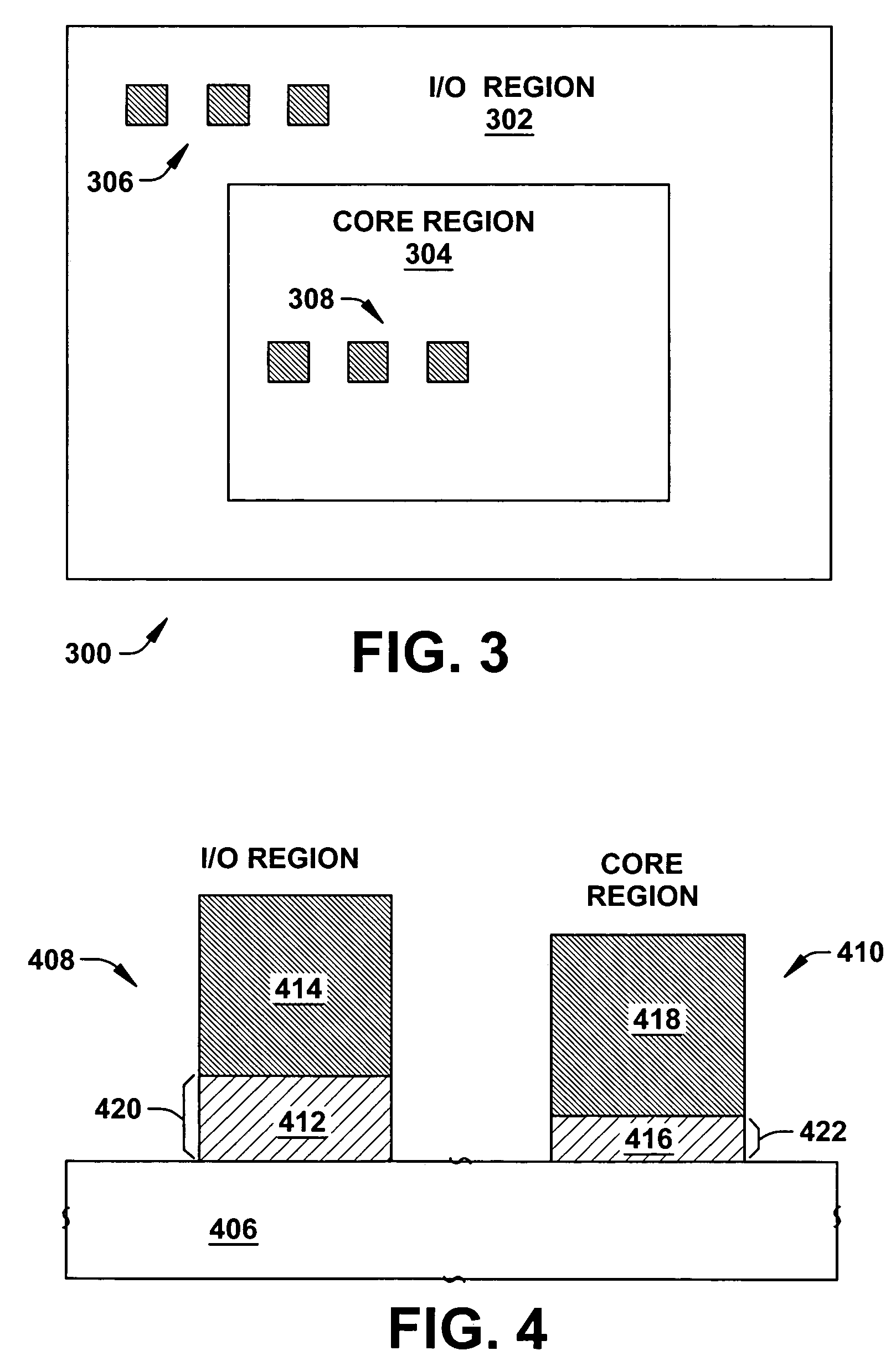

Semiconductor CMOS devices and methods with NMOS high-k dielectric present in core region that mitigate damage to dielectric materials

ActiveUS20060246651A1Facilitates semiconductor fabricationHigh operation voltage requirementSolid-state devicesSemiconductor/solid-state device manufacturingCMOSDevice material

The present invention facilitates semiconductor fabrication by providing methods of fabrication that selectively form high-k dielectric layers within NMOS regions. An I / O dielectric layer is formed in core and I / O regions of a semiconductor device (506). The I / O dielectric layer is removed (508) from the core region of the device. A core dielectric layer is formed in the core region (510). A barrier layer is deposited and patterned to expose the NMOS devices of the core region (512). The core dielectric layer is removed from the core NMOS devices (514). A high-k dielectric layer is formed (514) over the core and I / O regions. Then, the high-k dielectric layer is removed (512) from PMOS regions / devices of the core region and the NMOS and PMOS regions / devices of the I / O region.

Owner:TEXAS INSTR INC

Method for preparing TiAl alloy plate by argon atomization in powder metallurgy

ActiveCN102513537AThe overall thickness is thinImprove mechanical propertiesMetal rolling arrangementsMechanical propertyImpurity

The invention relates to a method for preparing a TiAl alloy plate by argon atomization in powder metallurgy. The method comprises the following steps of: reducing the content of inclusions in TiAl alloy powders by purity smelting in a cold-wall crucible and high-purity argon atomization; performing hot isostatic pressure compaction on the high-purity prealloy powder which is atomized by pure argon under such conditions that the temperature is 1100 to 1300 DEG C, the pressure is 140 to 200 MPa and the compaction time is 2 to 4 hours; removing coatings of the alloy blank after hot isostatic pressure compaction and then performing surface treatment and coating; heating alloy and rolling at a high temperature; and removing coatings to obtain a powder TiAl alloy plate. The plate has the advantages of uniform deformation, good surface quality, fine and uniform texture, low oxide and impurity contents, small thickness, good overall mechanical property and high quality and reliability. The method solves the key problems in development and application of TiAl alloy powder-metallurgy plates, and provides a technical support for innovation and progress of civil industry and aerospace industry.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

double sided adhesive tape

InactiveCN102268230AThe overall thickness is thinExcellent peelabilityEster polymer adhesivesFilm/foil adhesive release linersSurface layerAdhesive

Owner:NITTO DENKO CORP

Semiconductor CMOS devices and methods with NMOS high-k dielectric present in core region that mitigate damage to dielectric materials

ActiveUS7176076B2Operation voltage requirementThe overall thickness is thinSolid-state devicesSemiconductor/solid-state device manufacturingCMOSDielectric layer

The present invention facilitates semiconductor fabrication by providing methods of fabrication that selectively form high-k dielectric layers within NMOS regions. An I / O dielectric layer is formed in core and I / O regions of a semiconductor device (506). The I / O dielectric layer is removed (508) from the core region of the device. A core dielectric layer is formed in the core region (510). A barrier layer is deposited and patterned to expose the NMOS devices of the core region (512). The core dielectric layer is removed from the core NMOS devices (514). A high-k dielectric layer is formed (514) over the core and I / O regions. Then, the high-k dielectric layer is removed (512) from PMOS regions / devices of the core region and the NMOS and PMOS regions / devices of the I / O region.

Owner:TEXAS INSTR INC

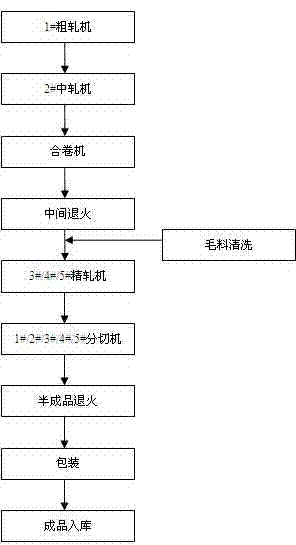

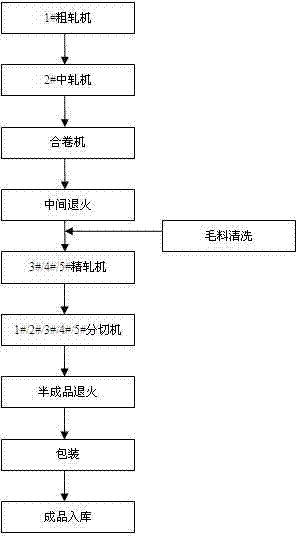

A production process for rolling double-zero aluminum foil

ActiveCN102284483AReduce the number of pinholesImprove mechanical propertiesMetal rolling arrangementsProfile control deviceSurface cleaningWork in process

The invention discloses a production process for rolling a light gauge aluminum foil, which comprises the following steps of: performing rough rolling, wherein the reduction per pass of the rough rolling is 0.3mm to 0.14mm to 0.07mm to 0.038mm; performing intermediate rolling, wherein the reduction per pass of the intermediate rolling is 0.038mm to 0.013mm; performing double rolling; performing intermediate annealing; cleaning a stock, namely performing surface cleaning on the aluminum foil stock by using rolling oil at a finish rolling inlet; performing finish rolling, wherein the reduction per pass of the finish rolling is 0.013mm to 0.005mm; slitting; annealing a semi-finished product; and packaging and warehousing. By adding the intermediate annealing and rolling oil cleaning processes for the aluminum foil, the mechanical property of the aluminum foil is improved while the thickness of the aluminum foil is reduced, and the breakage condition and a pinhole number in the rolling process are reduced.

Owner:JIANGSU ZHONGJI LAMINATION MATERIALS

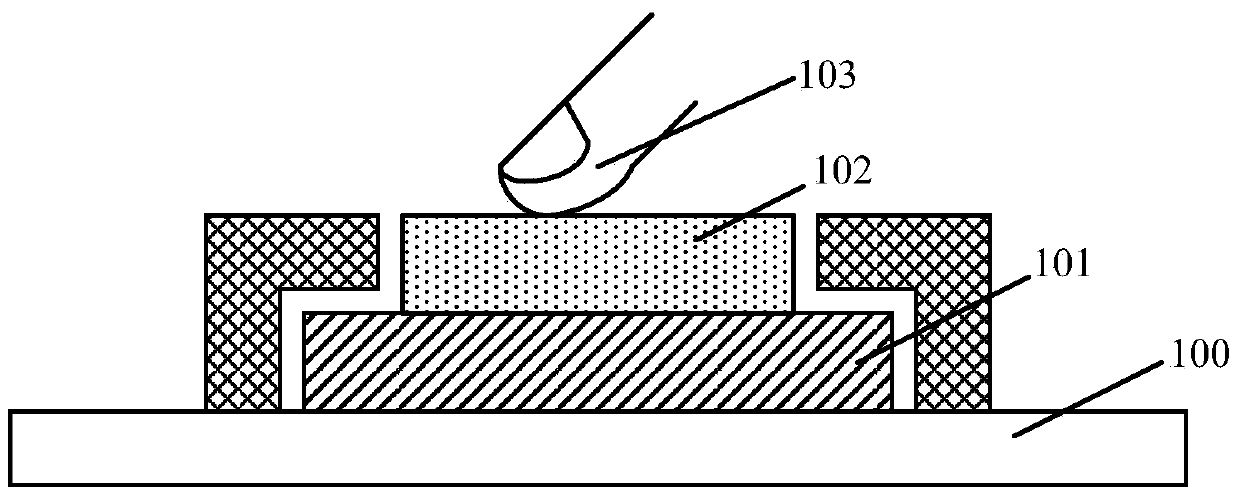

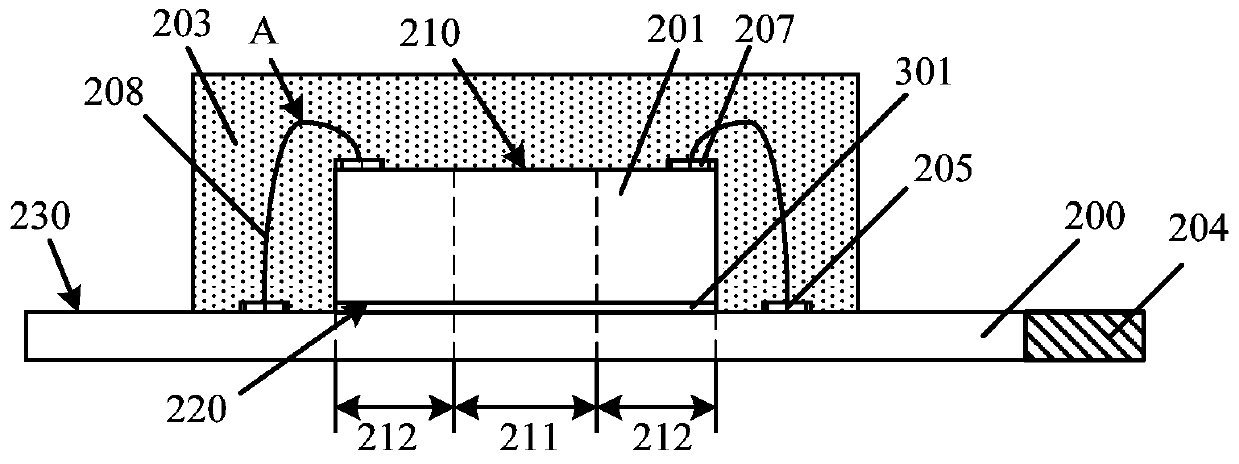

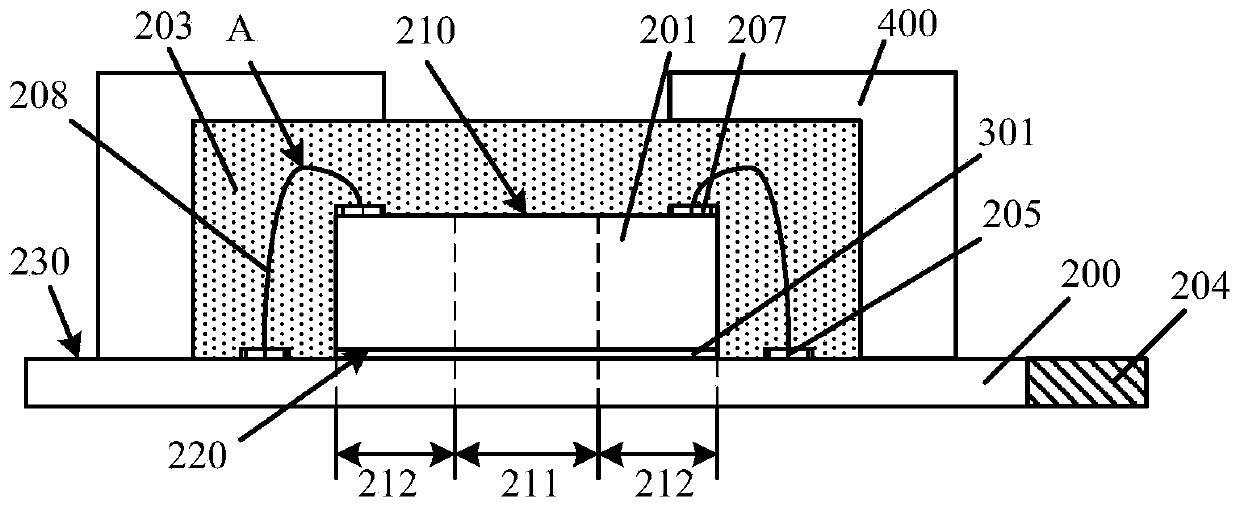

Packaging structure and packaging method for fingerprint recognition chip

InactiveCN104051367AReduce manufacturing costPackage structure is simpleSemiconductor/solid-state device detailsSolid-state devicesEngineeringFingerprint

The invention discloses a packaging structure and a packaging method for a fingerprint recognition chip. The packaging structure comprises a substrate, a sensing chip, a plurality of wires and a plastic package layer. The substrate is provided with a first surface, and the first surface of the substrate is provided with a first welding pad layer. The sensing chip is located on the first surface of the substrate and provided with a first surface and a second surface, the second surface of the sensing chip is located on the first surface of the substrate, the first surface of the sensing chip is provided with a sensing area and a peripheral area, and the surface of the portion, in the peripheral area, of the sensing chip is provided with a second welding pad layer. The two ends of the wires are electrically connected with the first welding pad layer and the second welding pad layer respectively, the wires have top points with the maximum distance to the surface of the substrate, and a first distance is reserved between the top points and the first surface of the sensing chip. The plastic package layer is located on the surface of the substrate and the surface of the sensing chip and surrounds the wires and the sensing chip, and a second distance is reserved between the surface of the plastic package layer and the first surface of the sensing chip and is larger than the first distance. According to the packaging structure, the requirement for the sensitivity of the sensing chip is lowered, and application is wider.

Owner:CHINA WAFER LEVEL CSP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com