A production process for rolling double-zero aluminum foil

A production process, double zero aluminum foil technology, applied in metal rolling, profile control and other directions, can solve the problems of poor mechanical properties, damage to the elongation rate of aluminum foil, etc., to reduce friction coefficient, surface flatness and uniformity, eliminate Stiffening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

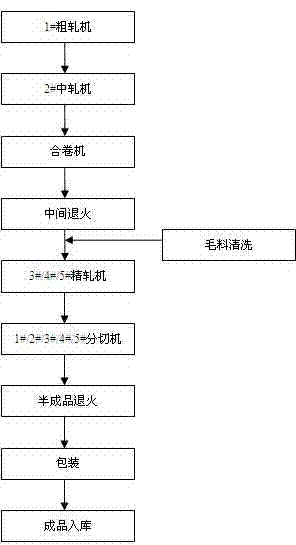

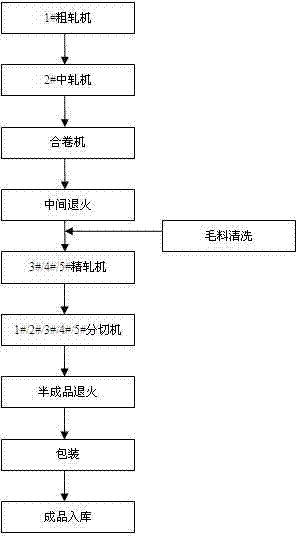

Image

Examples

Embodiment

[0009] The first step is rough rolling. The aluminum billet coil is put into the rough rolling mill and lubricated with rolling oil. The rough rolling pass is 0.3mm→0.14mm→0.07mm→0.038mm m, and the pass reduction rate is in order 53%, 51%, 55.8%, control parameters: first pass, 800-1000m / min, rolling pressure 1100-1500kN, pre-tension stress 30N / mm 2 , the post-tension stress is 25-45N / mm 2 , the oil temperature is 30-40°C, the oil pressure is 5.5-6.0Pa; the second pass, 1100-1200m / min, the rolling pressure is 1300-1700kN, and the pre-tension stress is 30N / mm 2 , the post-tension stress is 25-45 / mm 2 , the oil temperature and oil pressure remain unchanged, the third pass, the rolling speed is 1300-1400m / min, the rolling pressure is 1300-1700kN, and the pre-tension stress is 35N / mm 2 , the post-tension stress is 40-50N / mm 2 , the oil temperature and oil pressure remain unchanged.

[0010] The second step is intermediate rolling. The rough-rolled aluminum foil wool is interme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com