Patents

Literature

1044 results about "Tension stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stress | tension |. is that stress is (countable|physics) the internal distribution of force per unit area (pressure) within a body reacting to applied forces which causes strain or deformation and is typically symbolised by while tension is condition of being held in a state between two or more forces, which are acting in opposition to each other.

Thermocouple

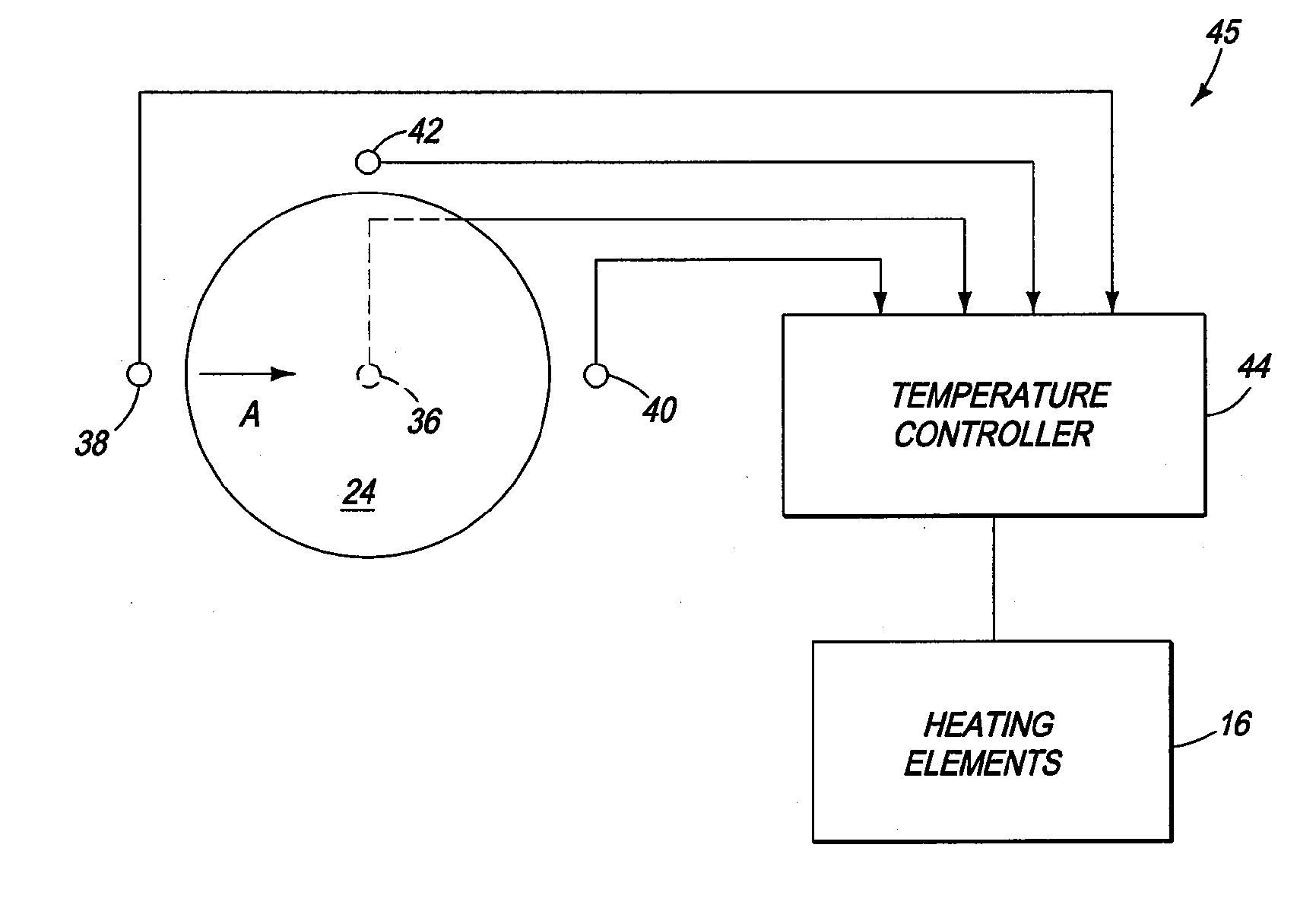

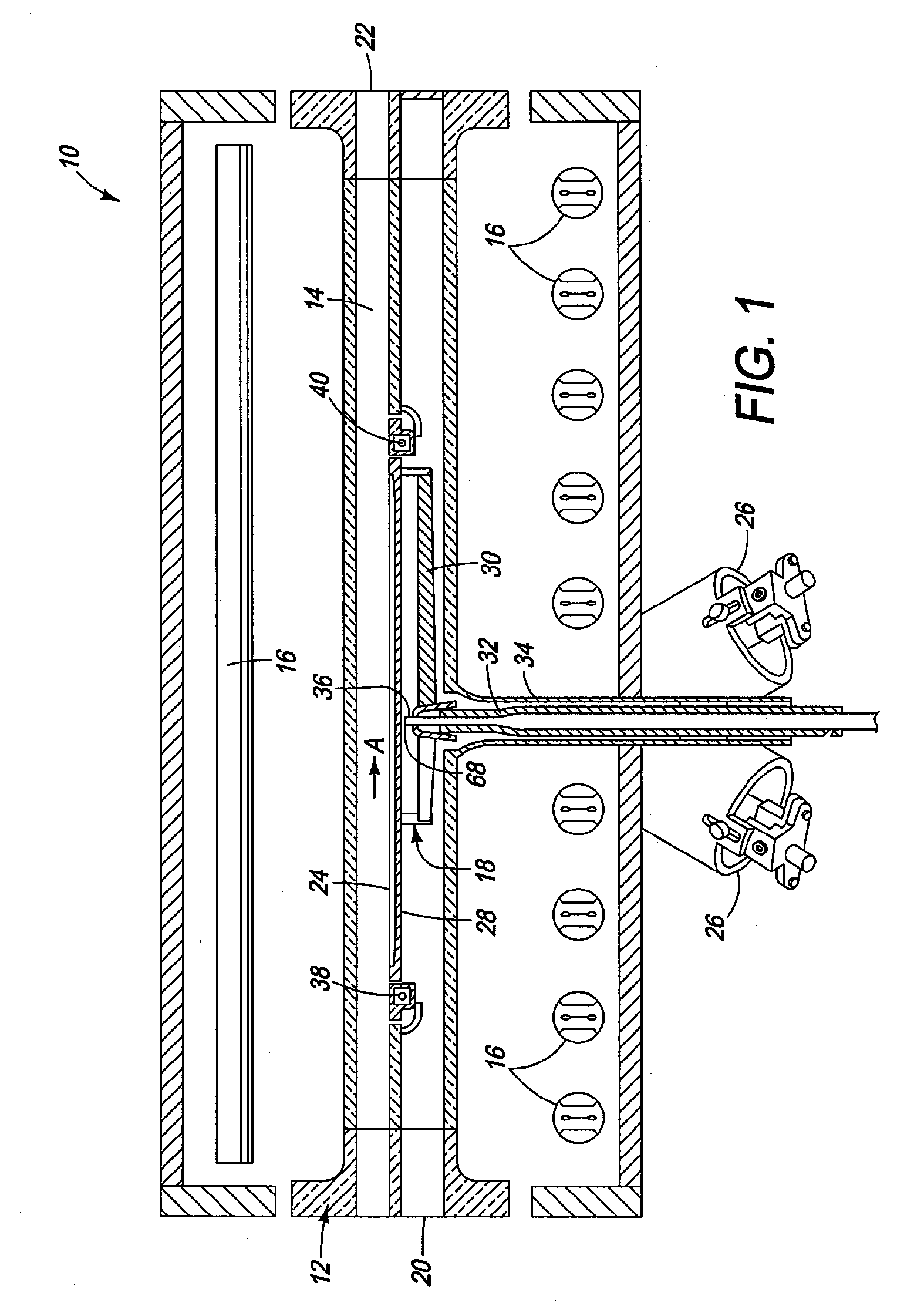

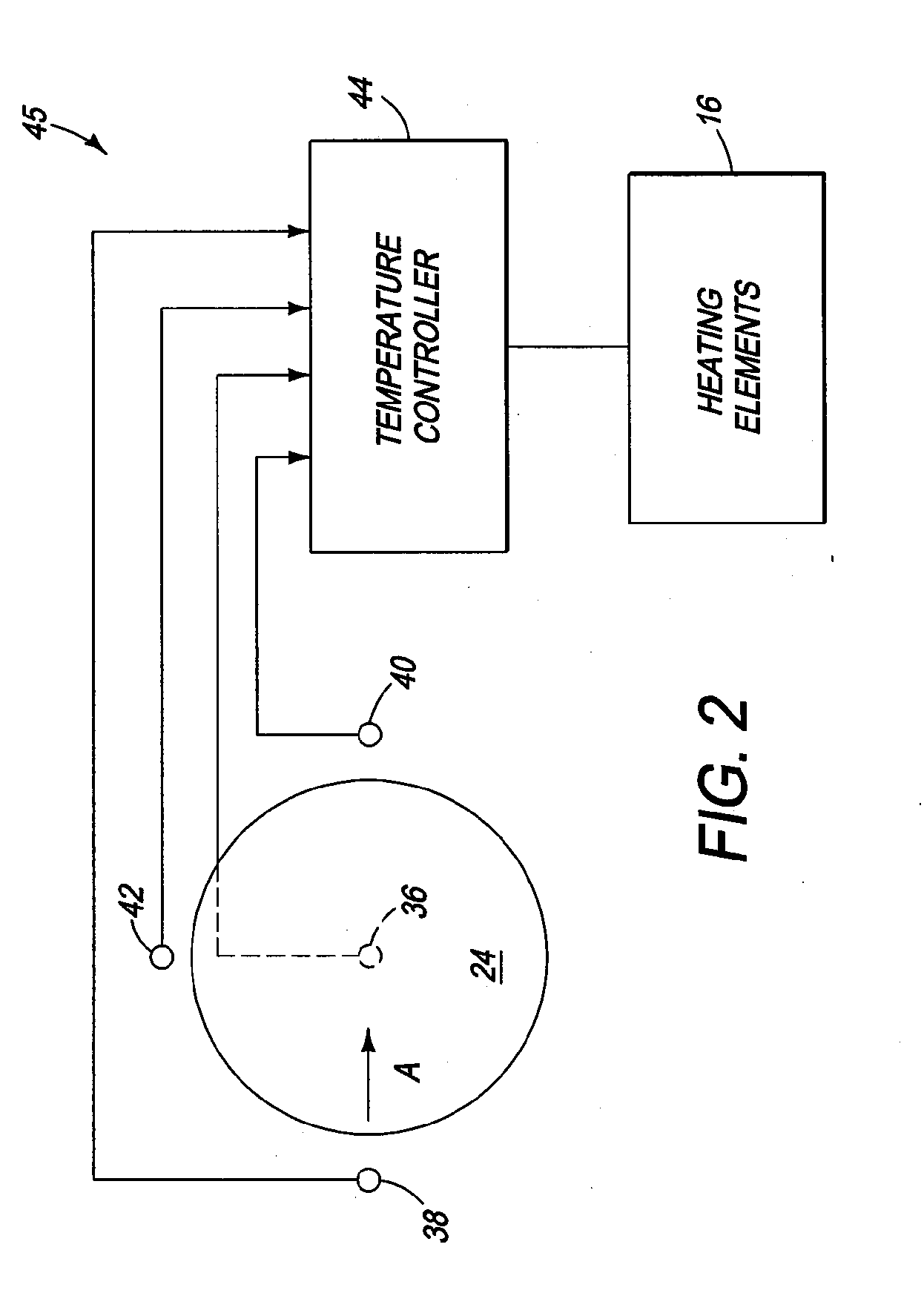

A thermocouple for use in a semiconductor processing reaction is described. The thermocouple includes a sheath having a measuring tip and an opening at the opposing end. A support member that receives a portion of a first wire and a second wire is received within the sheath. The first and second wires form a junction that contacts the inner surface of the sheath at the measuring tip. A spacing member is secured at the opening of the sheath and receives the support member. The spacing member allows the support member, first wire, and second wire to freely thermally expand relative to each other without introducing compression or tension stresses therein.

Owner:ASM IP HLDG BV

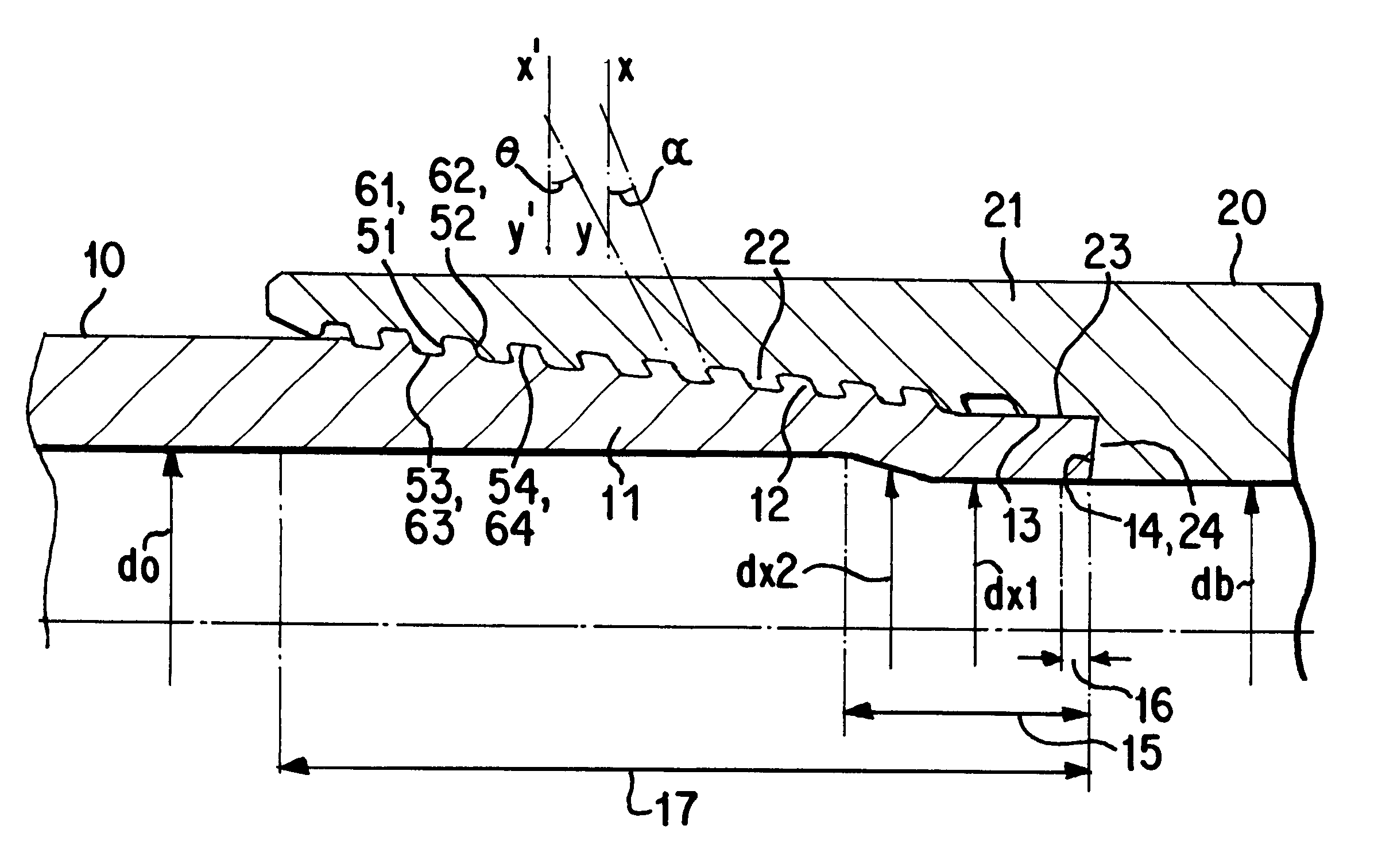

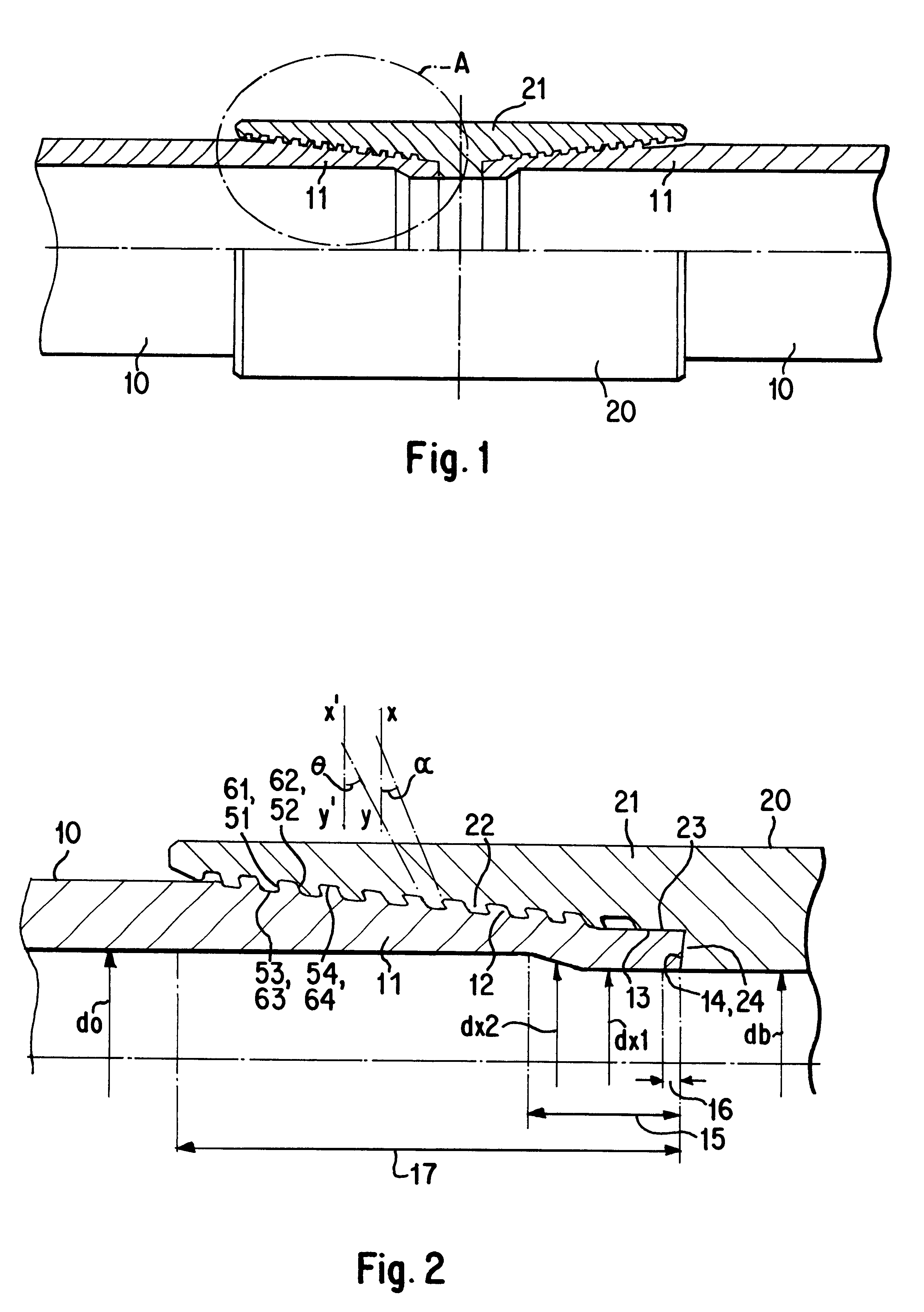

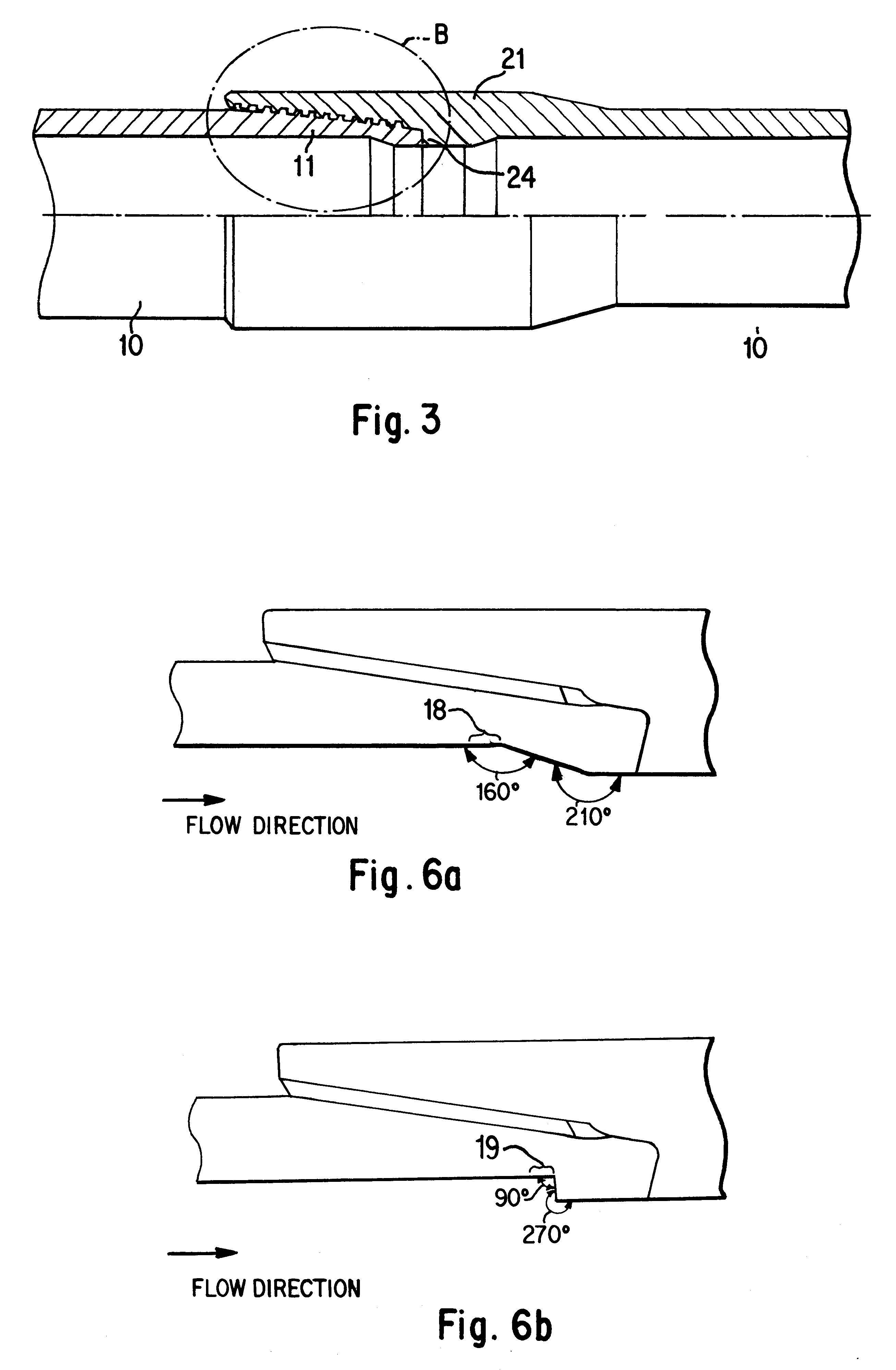

Threaded connection for oil country tubular goods and its method of manufacturing

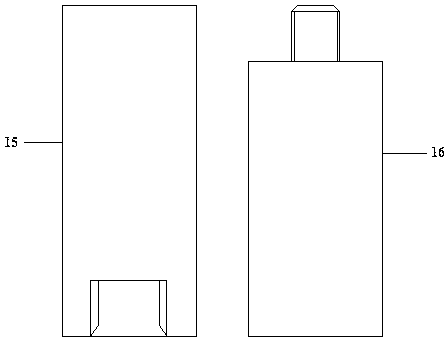

[Purpose]To provide a threaded connection capable of preventing deterioration of gas tightness from occurring when a tensile stress acts thereon after a compressive force in the direction of the axis of a pipe is applied.[Means of Solving Problems](1) A threaded connection for oil country tubular goods wherein a length (15) of a thick walled portion with a diameter defined in the formula (1), is longer than the length (16) from seal contact to the extremist of the pin section, shorter than a half of the length (17) of the pin section, the rest of inside diameter is equal to the inside diameter of pipe proper, having smooth tapered inner wall between thick walled portion and pipe proper. The inside diameter of the box section of torque shoulder section is the same as inside diameter of thick wall.Where dx(mm)=inside diameter of the thick walled portion of the pin section, and d0(mm)=inside diameter of the pipe proper.

Owner:SUMITOMO METAL IND LTD +1

Method for increasing compression stress or reducing internal tension stress of a CVD, PCVD or PVD layer and cutting insert for machining

InactiveUS6884496B2Prolong lifeIncrease resistance to crack formation and corrosion resistance and wear resistanceVacuum evaporation coatingSputtering coatingMaximum diameterTension stress

A method of increasing the compressive stress or of reducing the tensile residual stress of a CVD layer, a PCVD layer or PVD layer and a cutting insert for machining.The invention relates to a method of increasing the compressive residual stress or of reducing the tensile residual stress of a hard material outer layer or a hard material outermost layer in which the coated substrate after coating is subjected to a dry blast treatment using a granular blast agent that, according to the invention, has a maximum diameter of 150 μm.

Owner:WIDIA

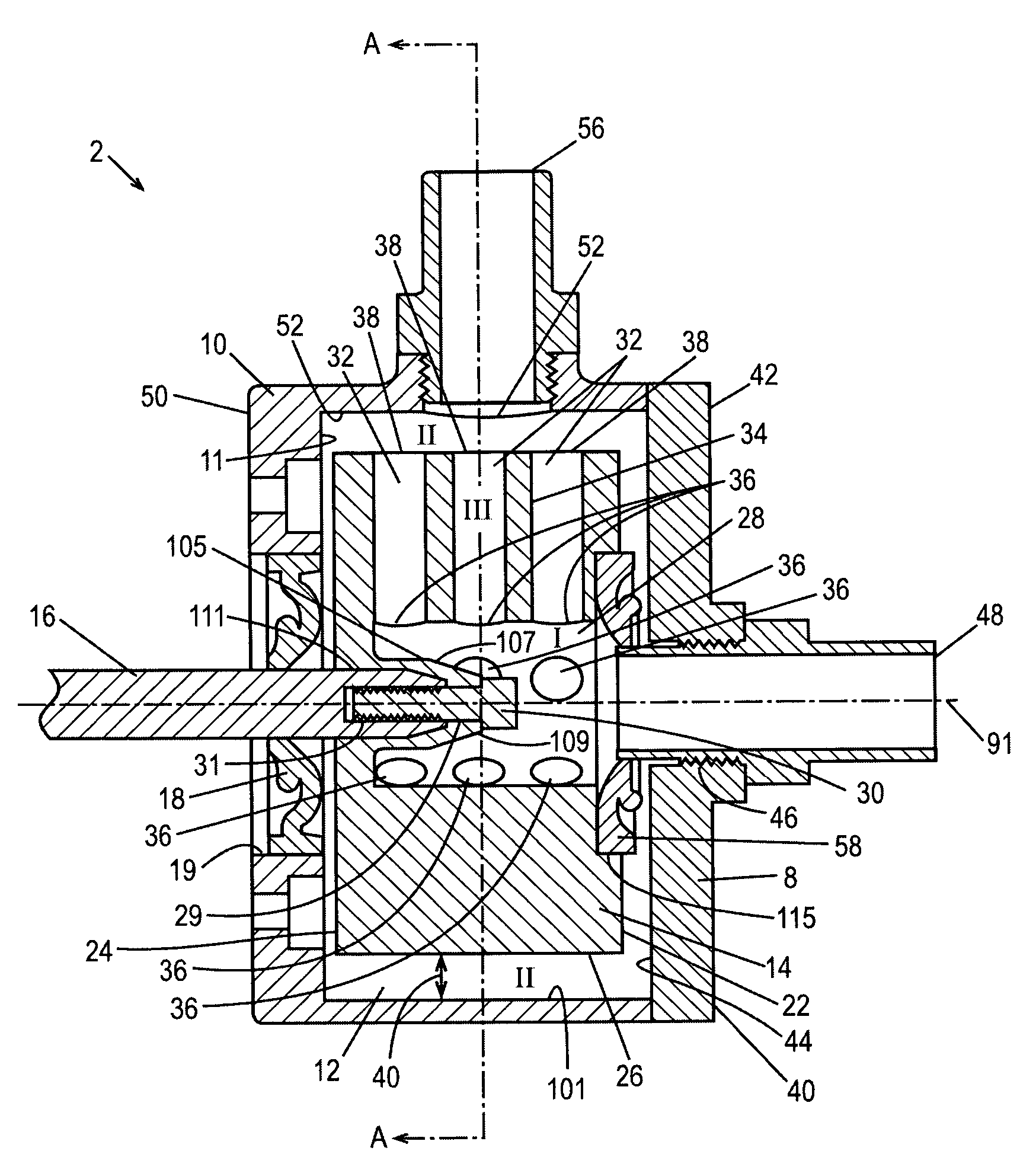

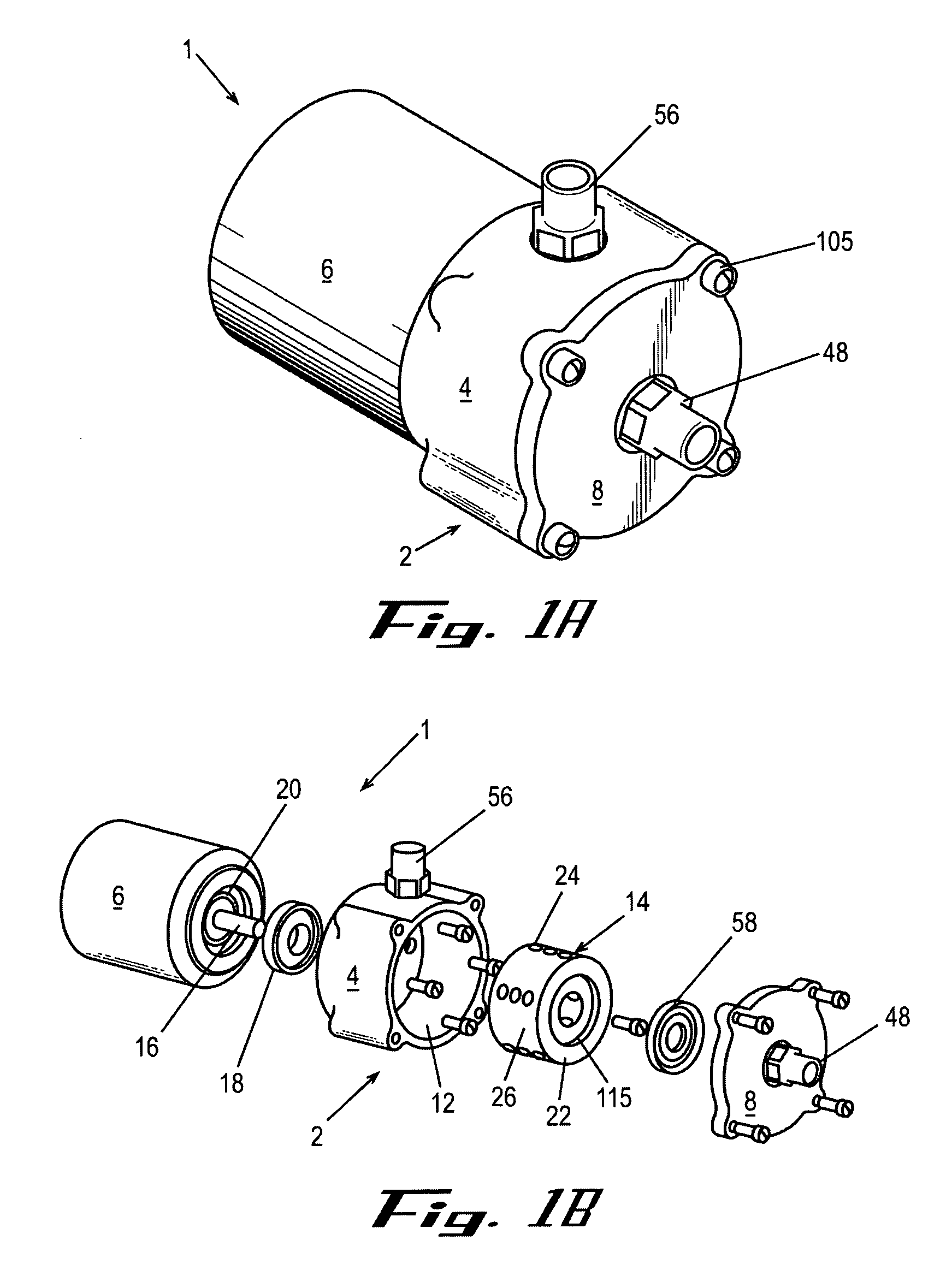

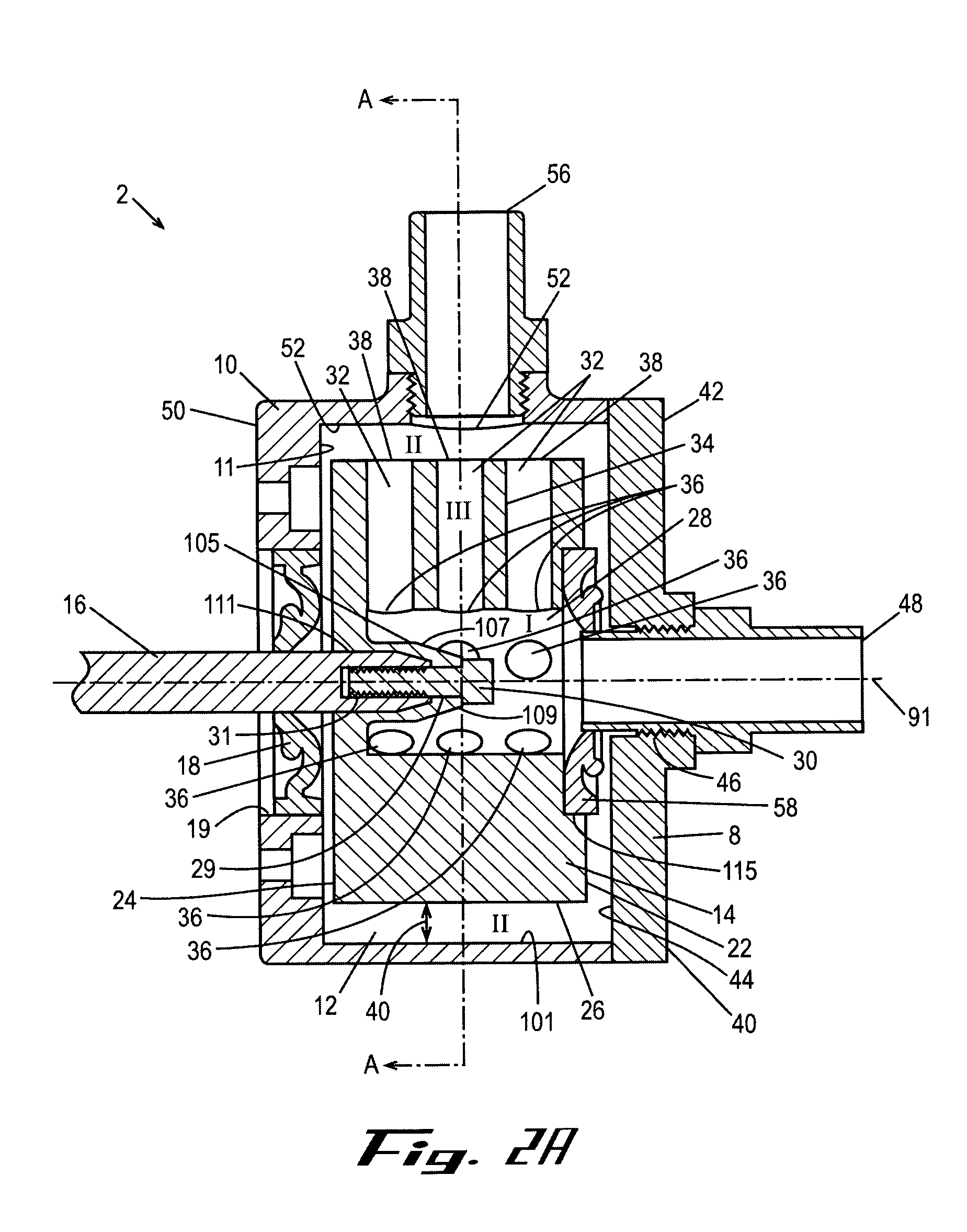

Roto-dynamic fluidic systems

An apparatus and method for generating cavitation in fluids is disclosed. The apparatus includes a housing for receiving a rotor, which is driven by a motive force. Multiple embodiments of the rotors are disclosed including, but not limited to, centrally feed, centrally drained, face feed, and face drained rotors. In one preferred embodiment, cavitation is enhanced by inducing tensile stress in the fluid by subjecting the fluid centrifugal force or centripital force depending upon the flow of the fluid.

Owner:GARRETT III NORMAN H

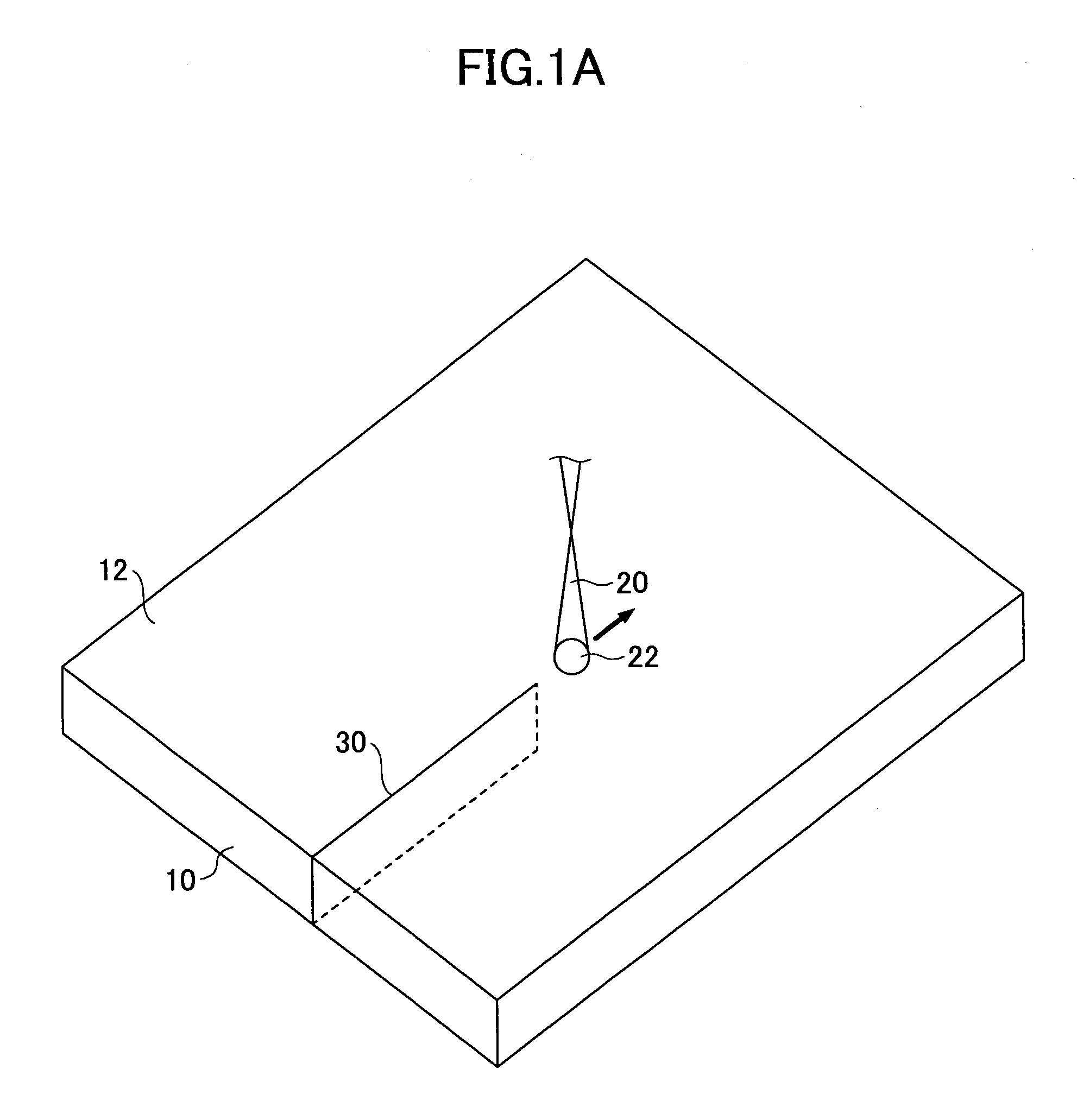

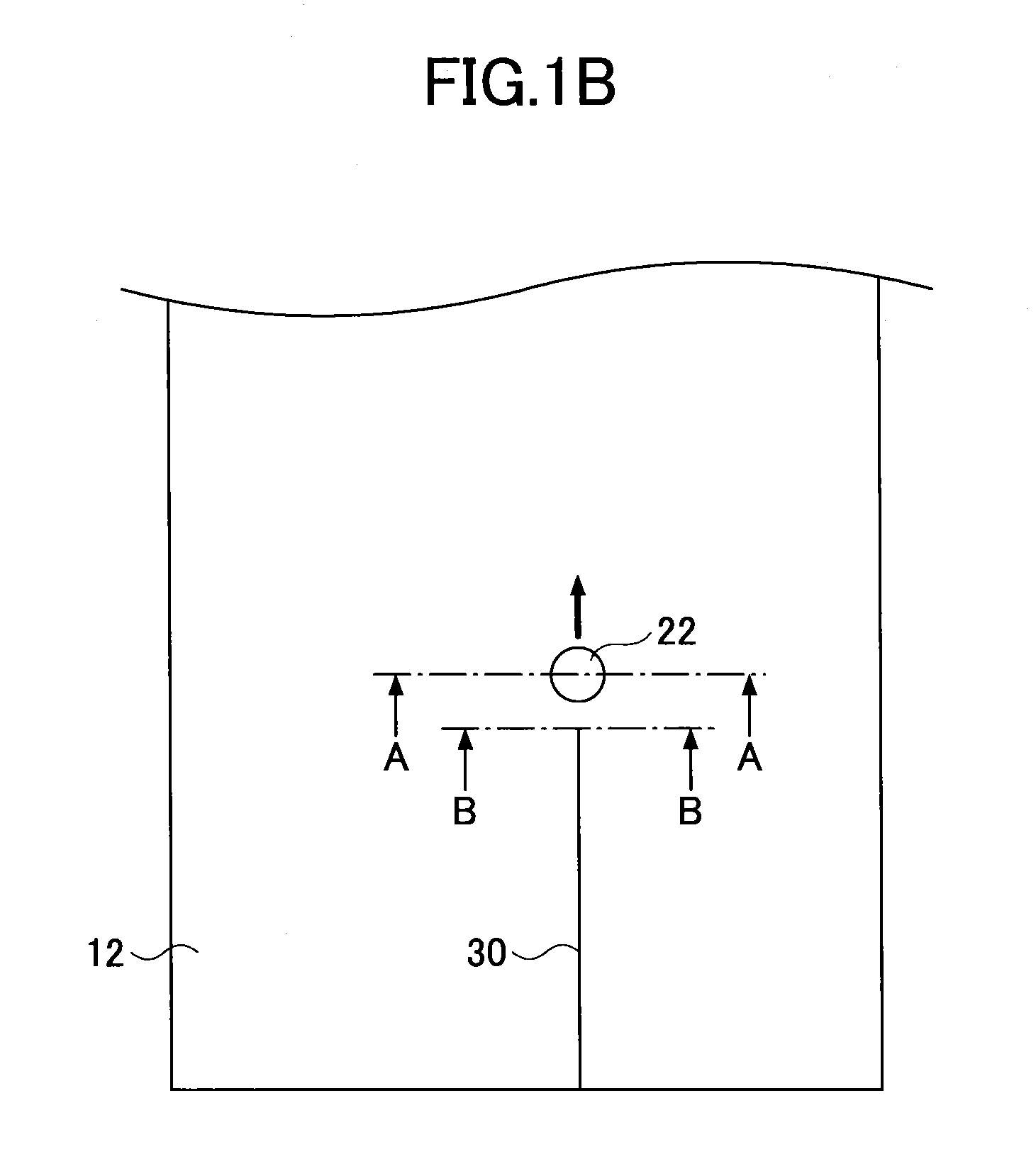

Method of cutting strengthened glass plate

InactiveUS20130291598A1Improve accuracyEasy to trackFine working devicesVehicle componentsSurface layerTension stress

A method of cutting a strengthened glass including, a front surface layer and a back surface layer each having a remaining compression stress, respectively, and an intermediate layer formed between the front surface layer and the back surface layer, having an internal remaining tensile stress, the method includes heating the intermediate layer at an irradiation area of a laser beam at a temperature less than or equal to an annealing point to generate a tensile stress less than a value of the internal remaining tensile stress of the intermediate layer or a compression stress at the center of the irradiation area for suppressing the propagation of the crack.

Owner:ASAHI GLASS CO LTD

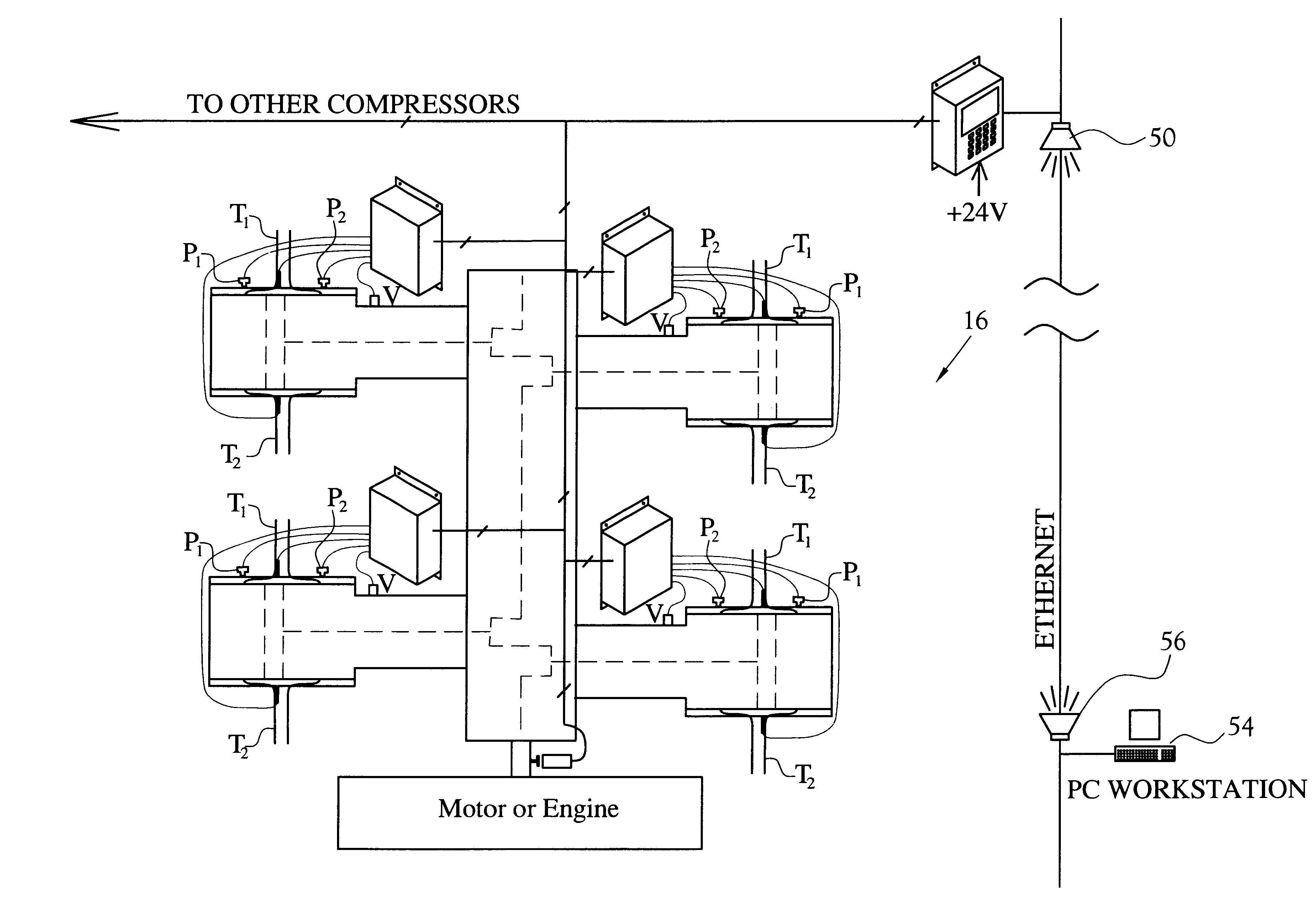

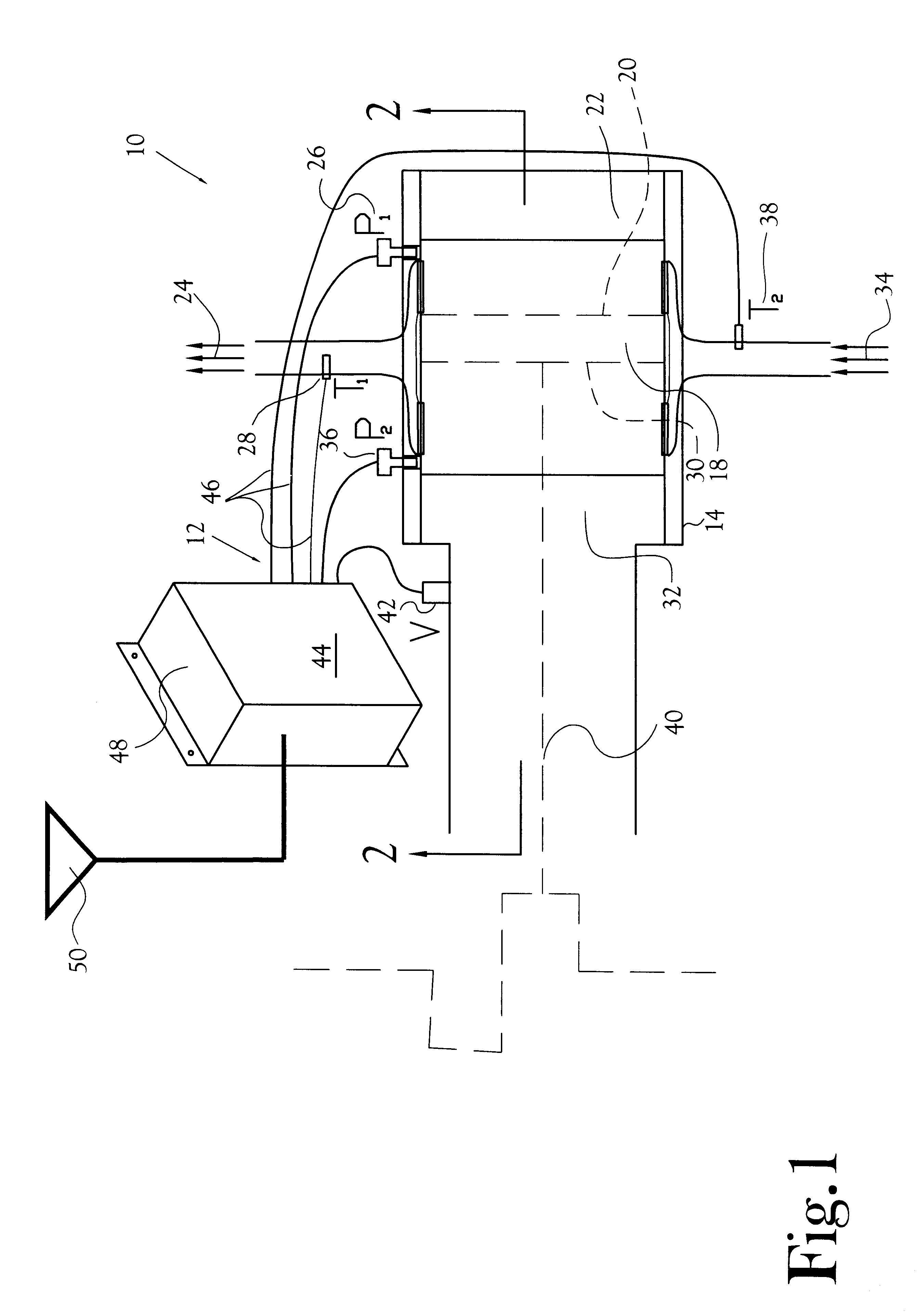

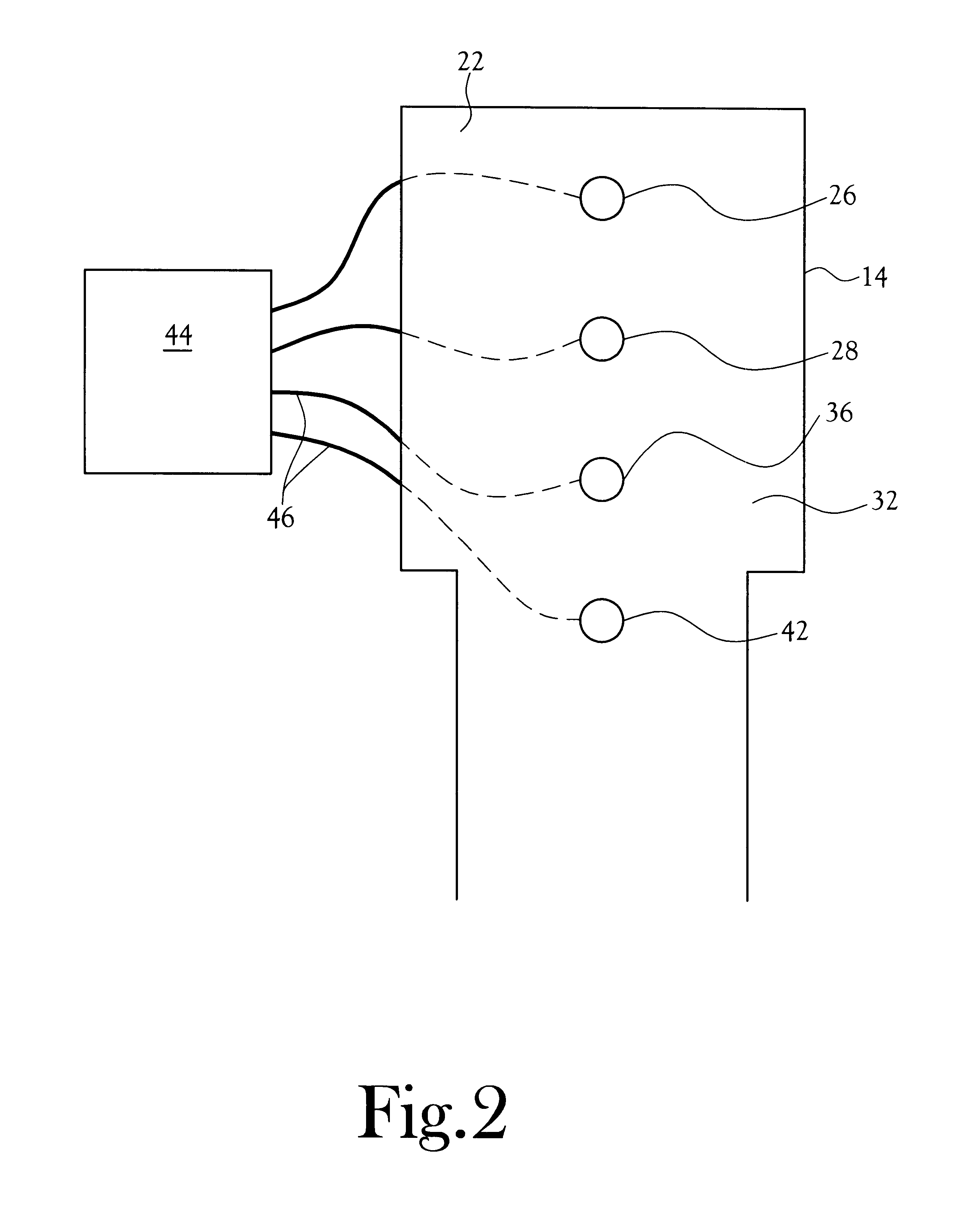

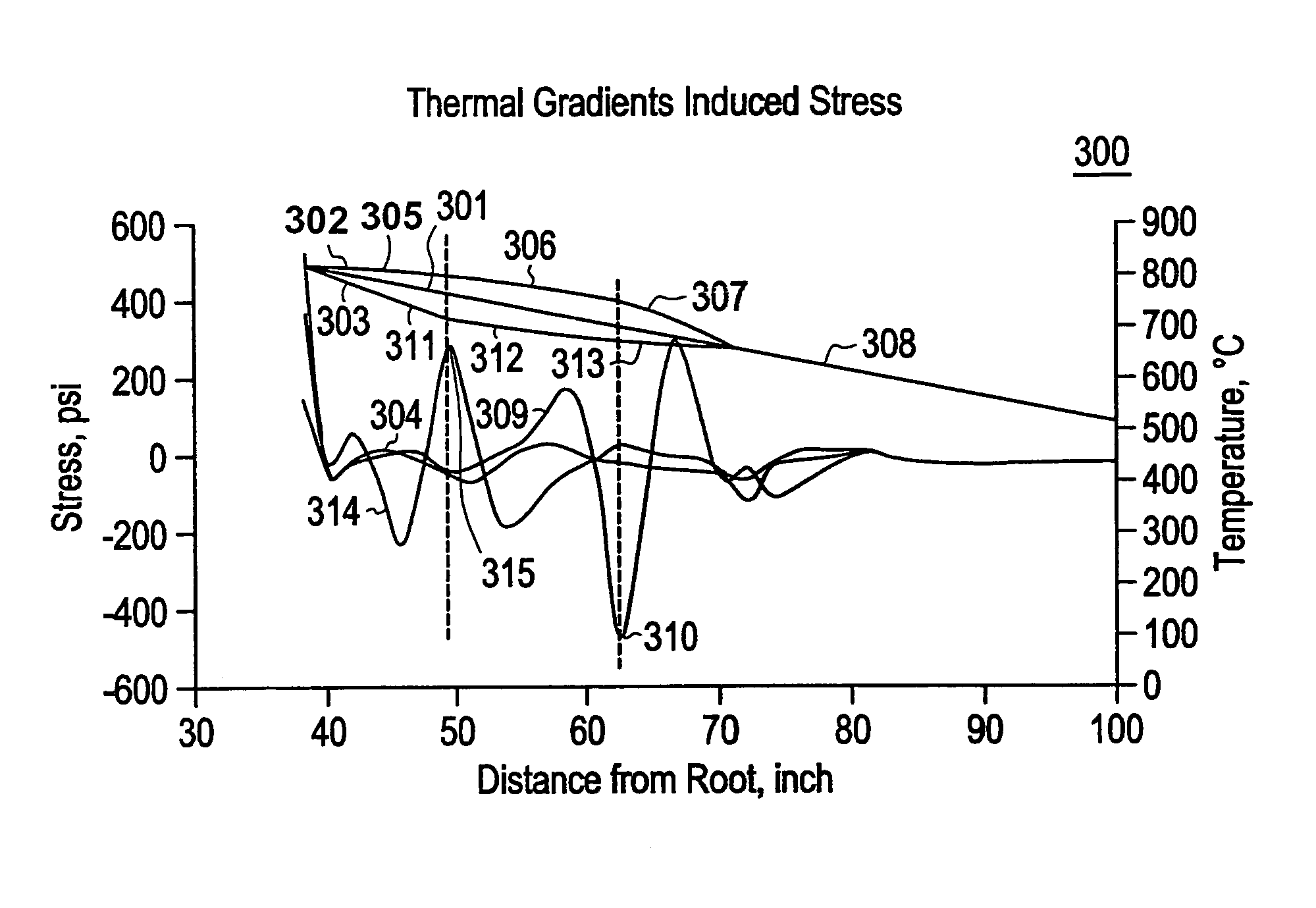

Method and apparatus for continuously monitoring parameters of reciprocating compressor cylinders

InactiveUS6292757B1Continuous monitoringAnalogue computers for vehiclesInternal-combustion engine testingEngineeringVolume Curve

An apparatus and method for continuously monitoring selected parameters of reciprocating compressor cylinders is disclosed, the apparatus includes a plurality of sensors positioned to monitor selected parameters within the cylinder on either side of the piston, with the selected parameters including pressures on each side of the piston for each cycle, temperatures of the gas entering and exiting the cylinder, and vibrations of components such as a piston shaft within the cylinder. A calculator means in close proximity to the cylinder receives the signals from the sensors and analyzes the signals for each cycle of the piston. Output signals proportional to the monitored signals are transmitted to a remotely located computer. The output signals include pressure versus volume curves for each cylinder volume, horsepower consumed by the cylinder, inlet suction and outlet discharge gas temperatures of the gases moved through the cylinder, and compression and tension stress on the piston rod. Computer analyses compare monitored signals to pre-selected ranges of operating parameters to provide alarm signals to alert operators of the performance and mechanical conditions within the monitored reciprocating compressor cylinder. A method of operation for continuously monitoring selected parameters of reciprocating compressor cylinders is also disclosed.

Owner:WINDROCK

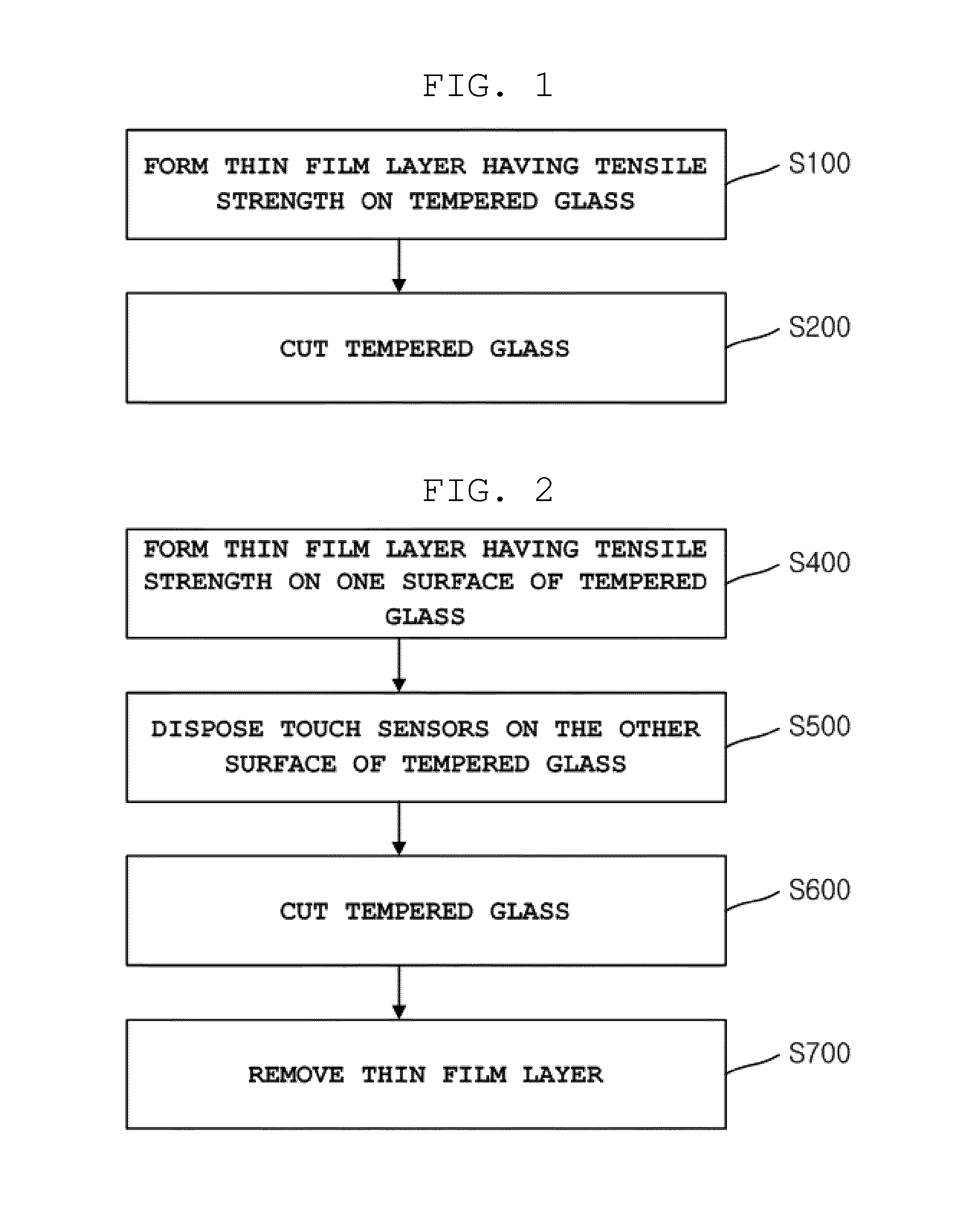

Method of cutting tempered glass and method of fabricating touchscreen using the same

InactiveUS20130149434A1Maintain strengthImprove productivityPretreated surfacesCoatingsOptoelectronicsTouchscreen

A method of cutting a piece of tempered glass in which the piece of tempered glass is cut after a thin film having a tensile stress is formed a method of fabricating a touchscreen using the same. The method includes a step of forming a thin film layer having a tensile stress on the piece of tempered glass and a step of cutting the piece of tempered glass.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

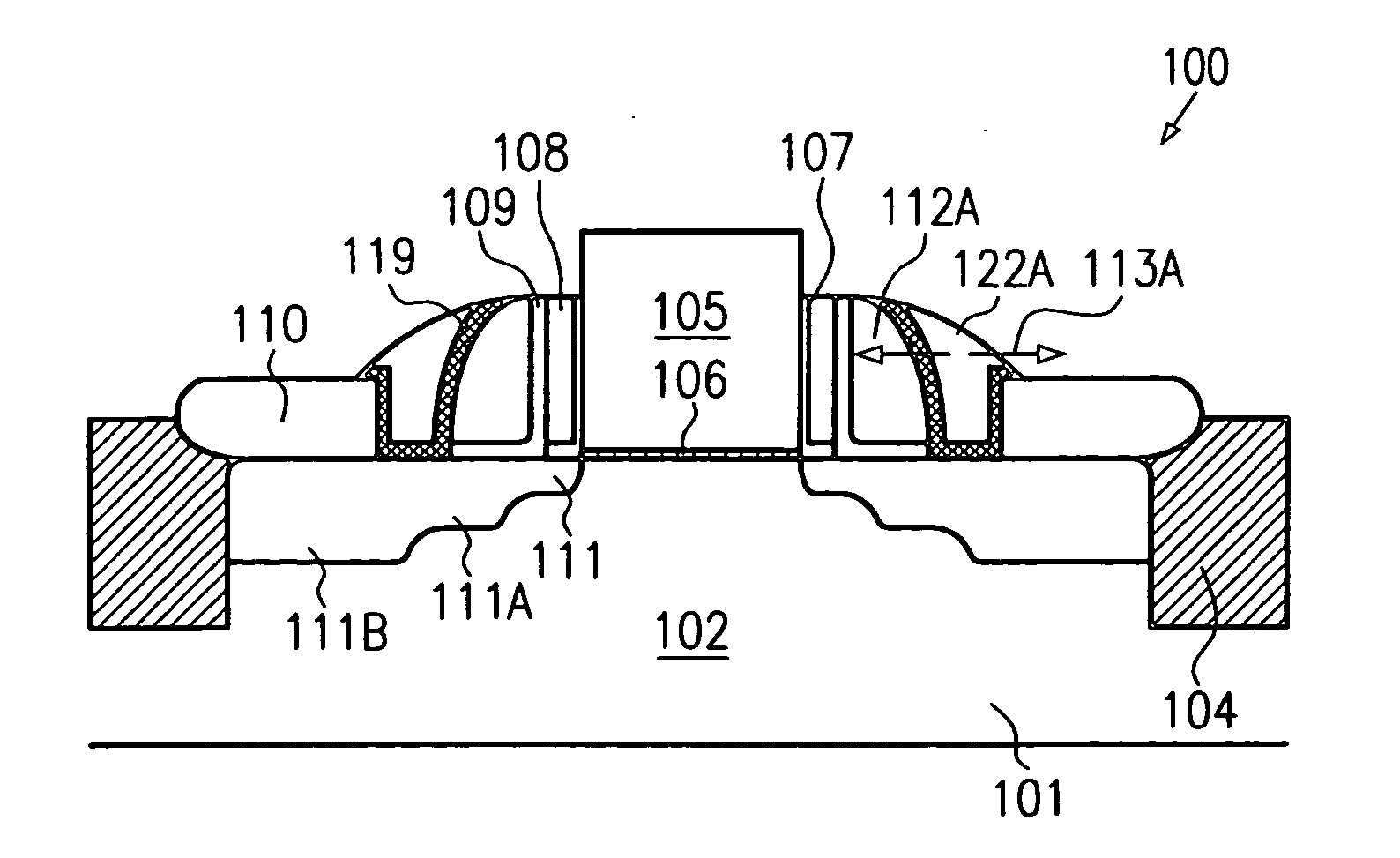

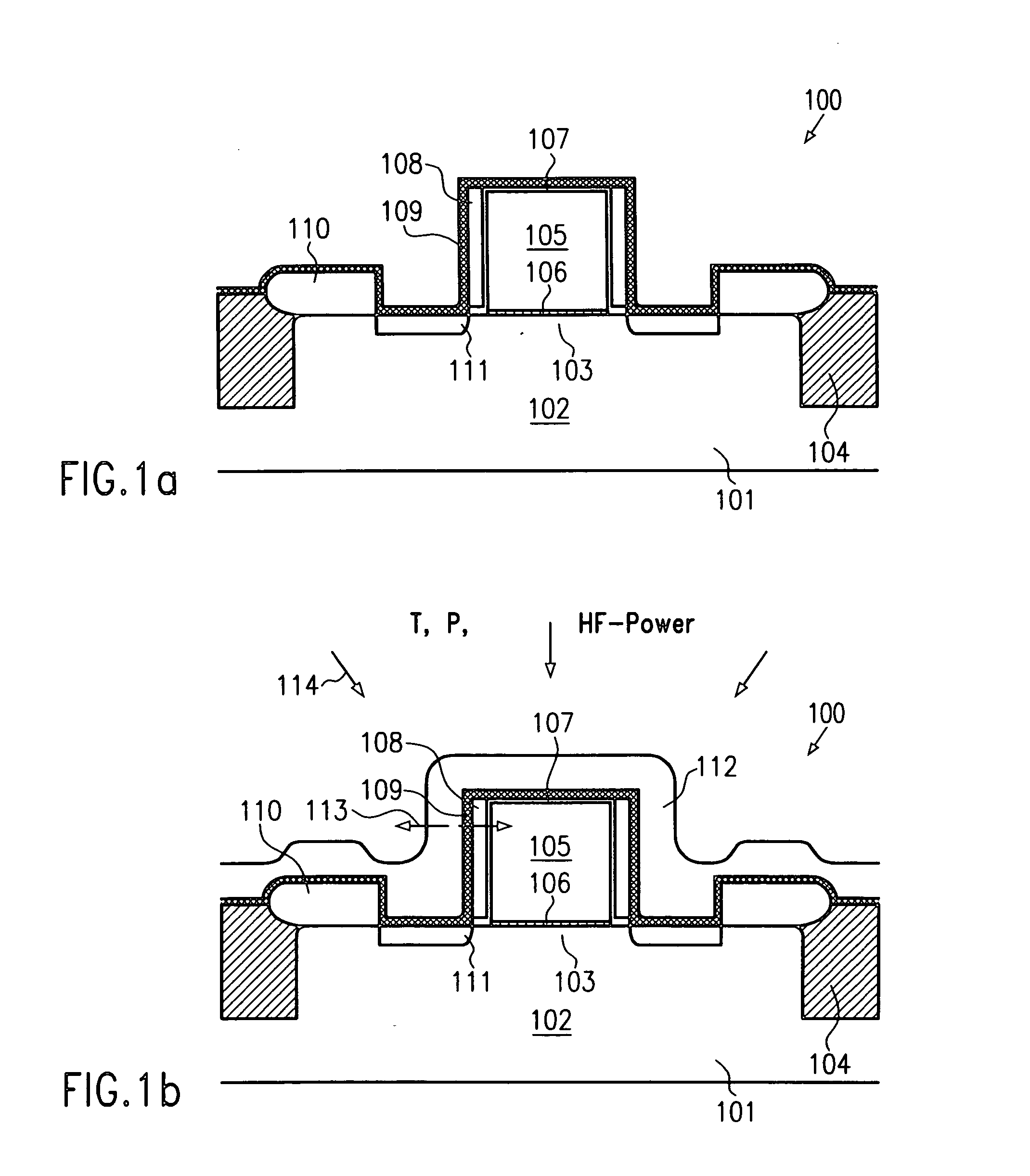

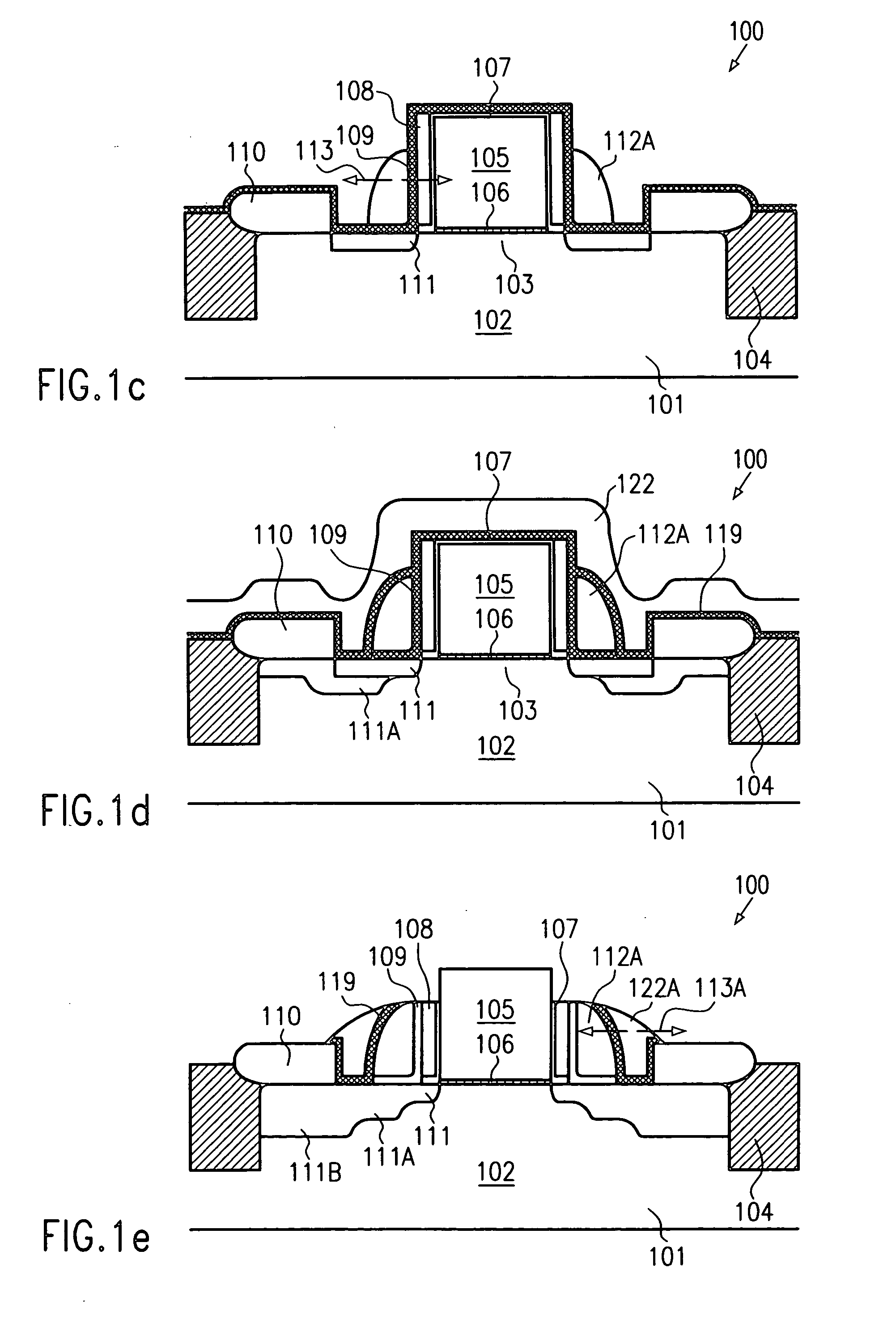

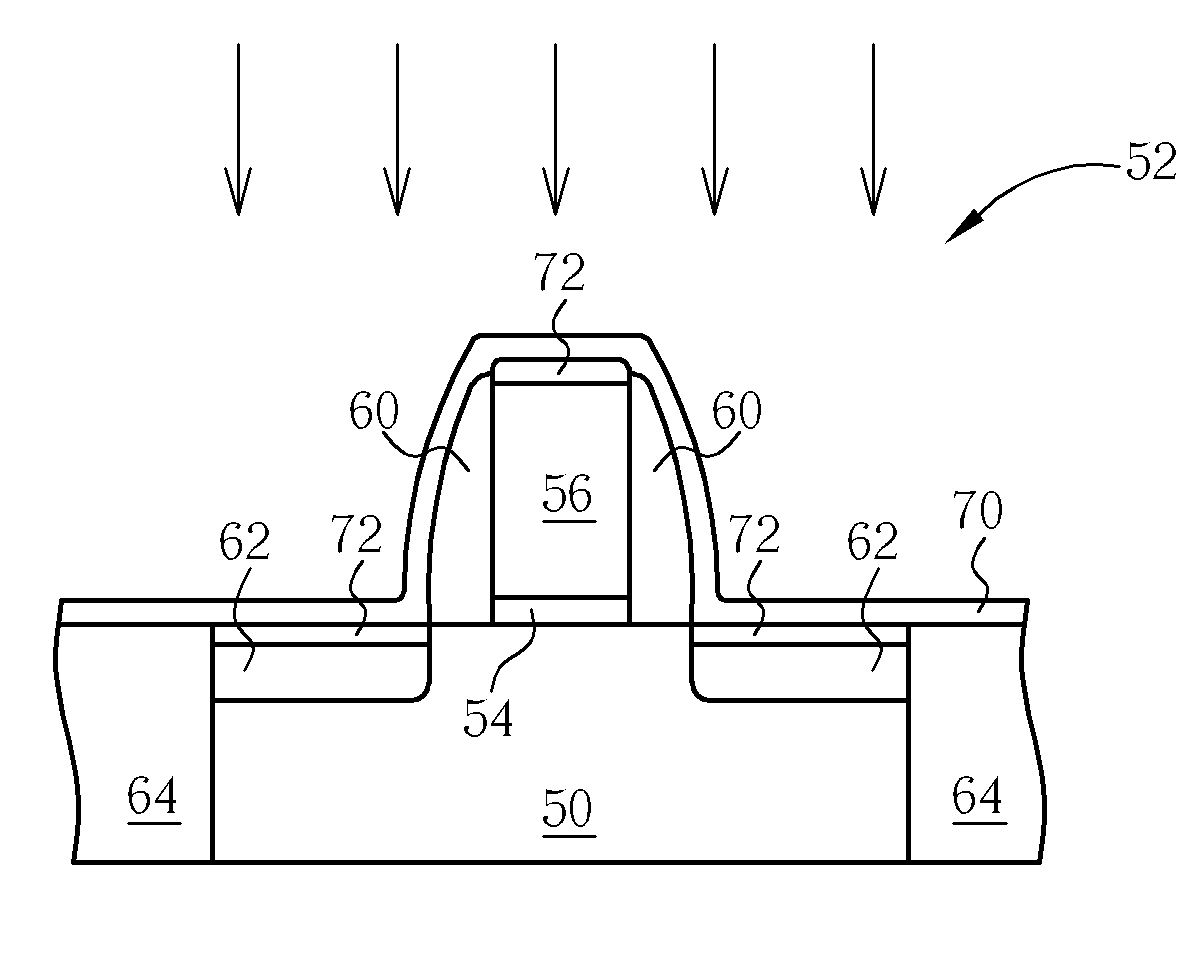

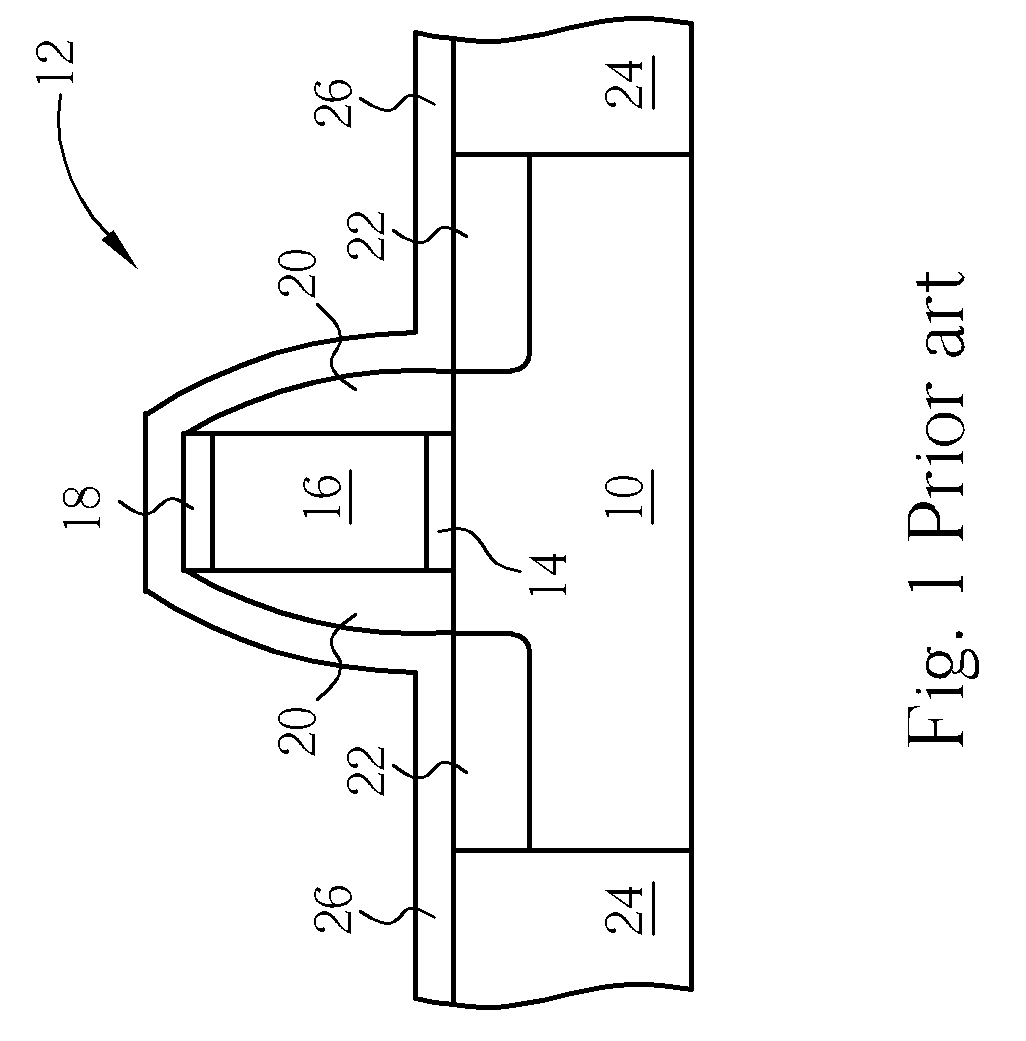

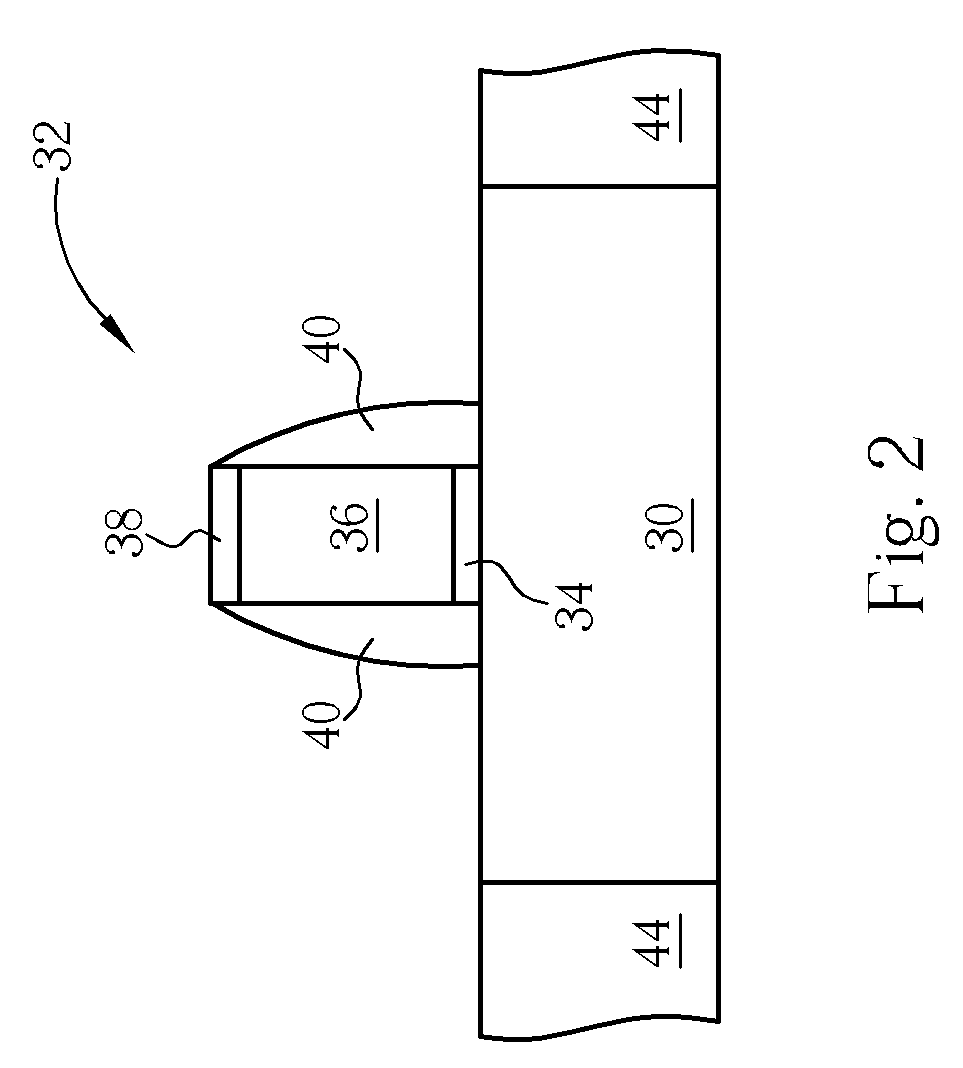

Spacer for a gate electrode having tensile stress and a method of forming the same

ActiveUS20050136606A1Affect carrier mobilityTransistorSemiconductor/solid-state device testing/measurementCharge carrier mobilityField-effect transistor

By reducing a deposition rate and maintaining a low bias power in a plasma atmosphere, a spacer layer, for example a silicon nitride layer, may be deposited that exhibits tensile stress. The amount of tensile stress is controllable within a wide range, thereby providing the potential for forming sidewall spacer elements that modify the charge carrier mobility and thus the conductivity of the channel region of a field effect transistor.

Owner:GLOBALFOUNDRIES US INC

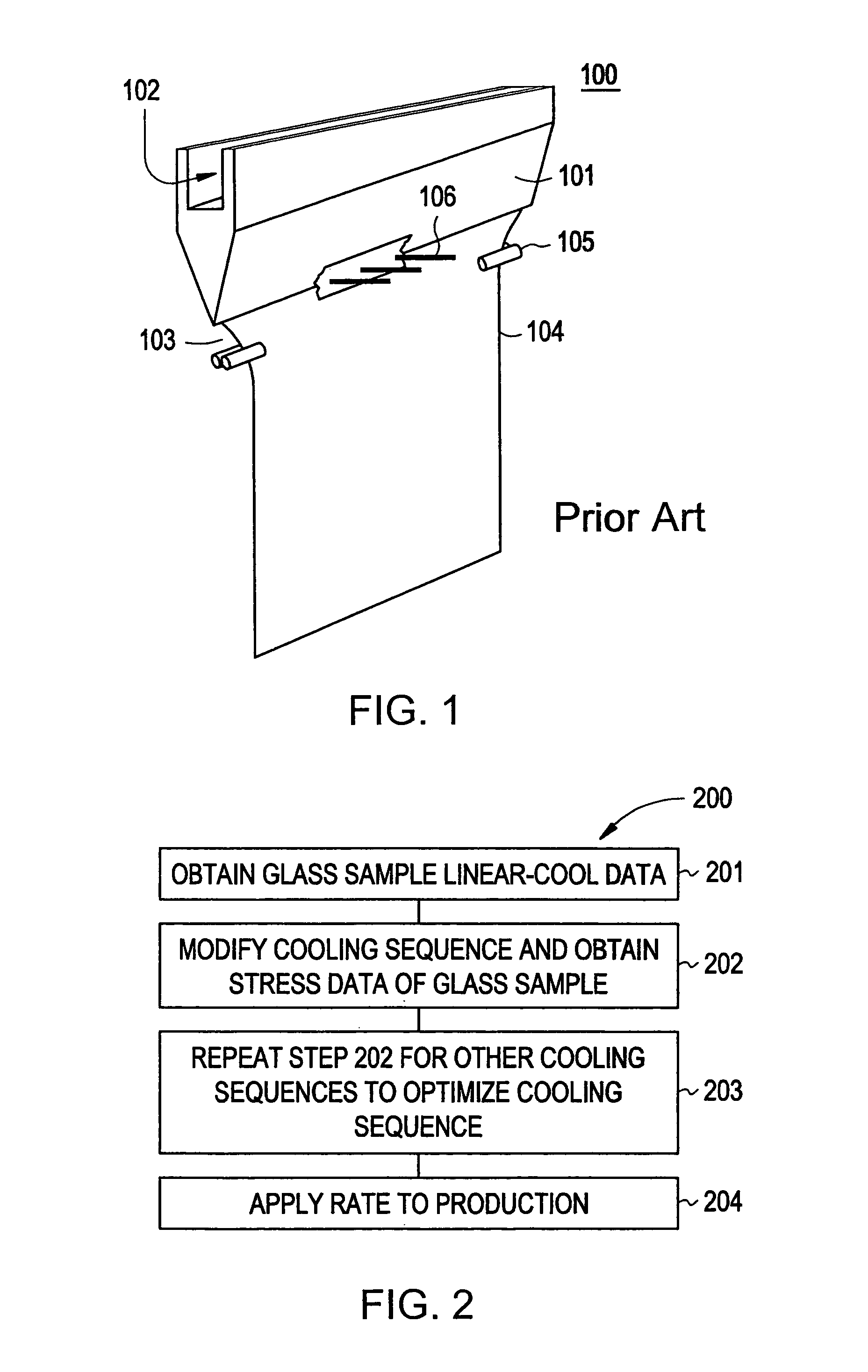

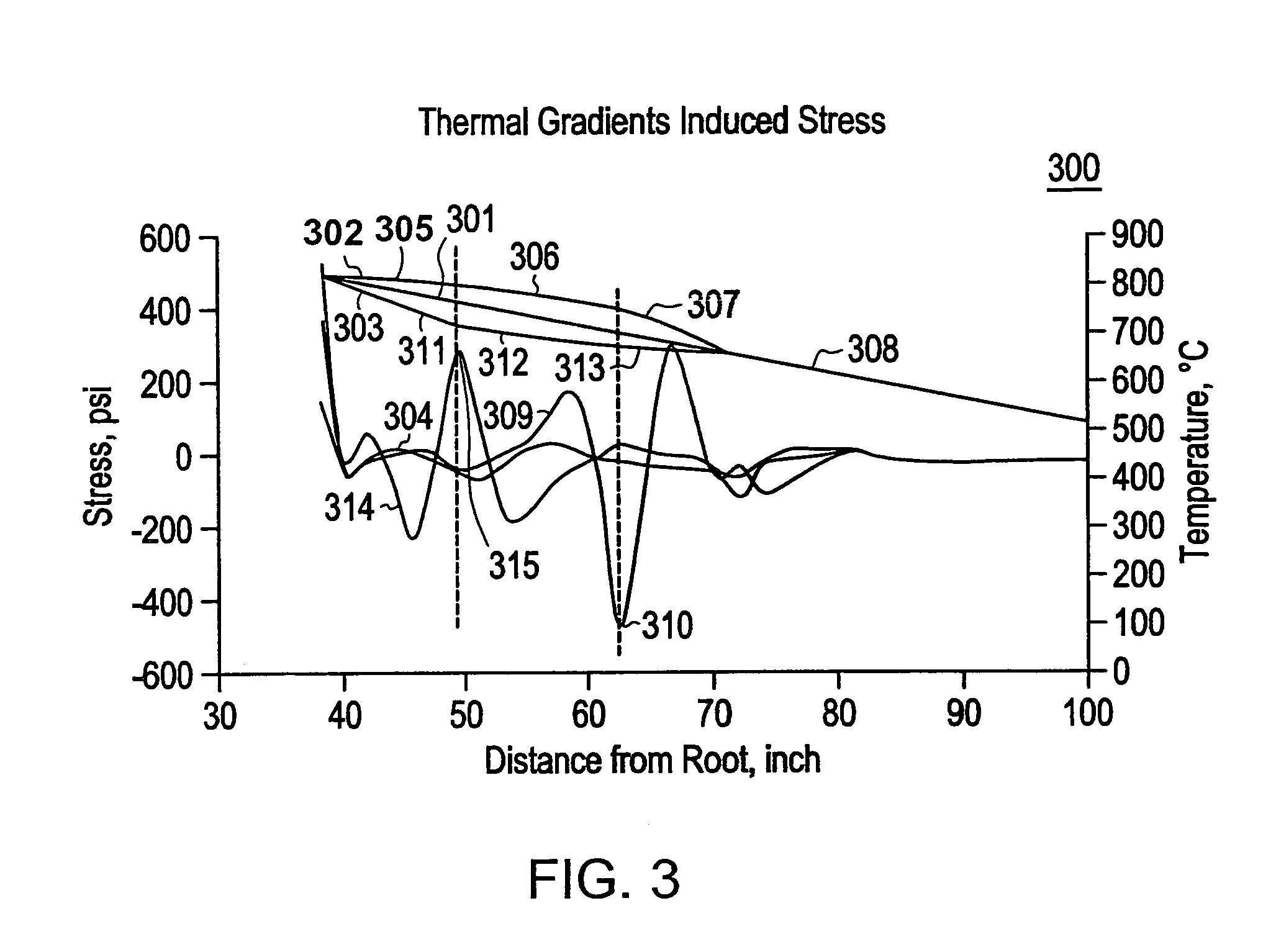

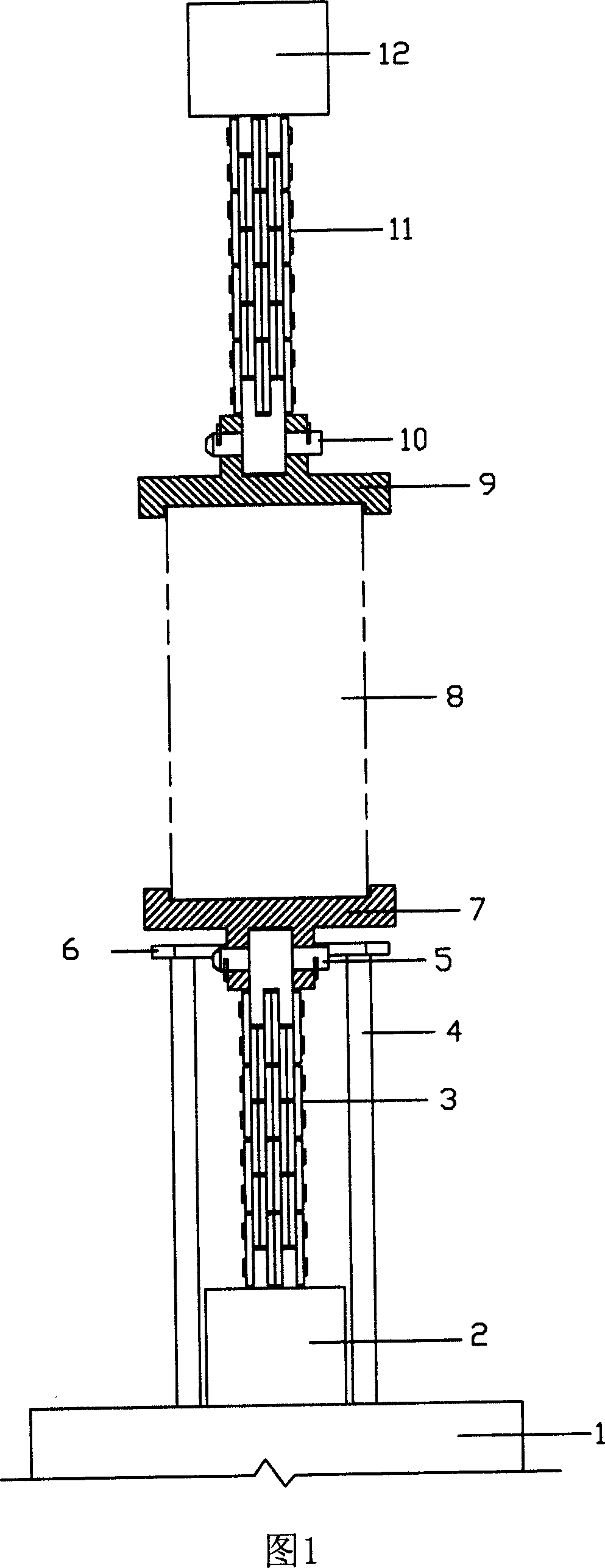

Method of fabricating low-warp flat glass

A method of fabricating a glass sheet comprises modifying the thermal stress in the glass such that it is a tensile stress or substantially zero stress in a particular temperature zone of the glass, with that zone selected such that the glass sheet is formed substantially free of warping. In an example embodiment, the modifying of the thermal stress is effected by non-uniform cooling of the glass across the glass transition temperature range. This non-uniform cooling may be applied in cooling segments that are linear and at least two of the segments have differing slope.

Owner:CORNING INC

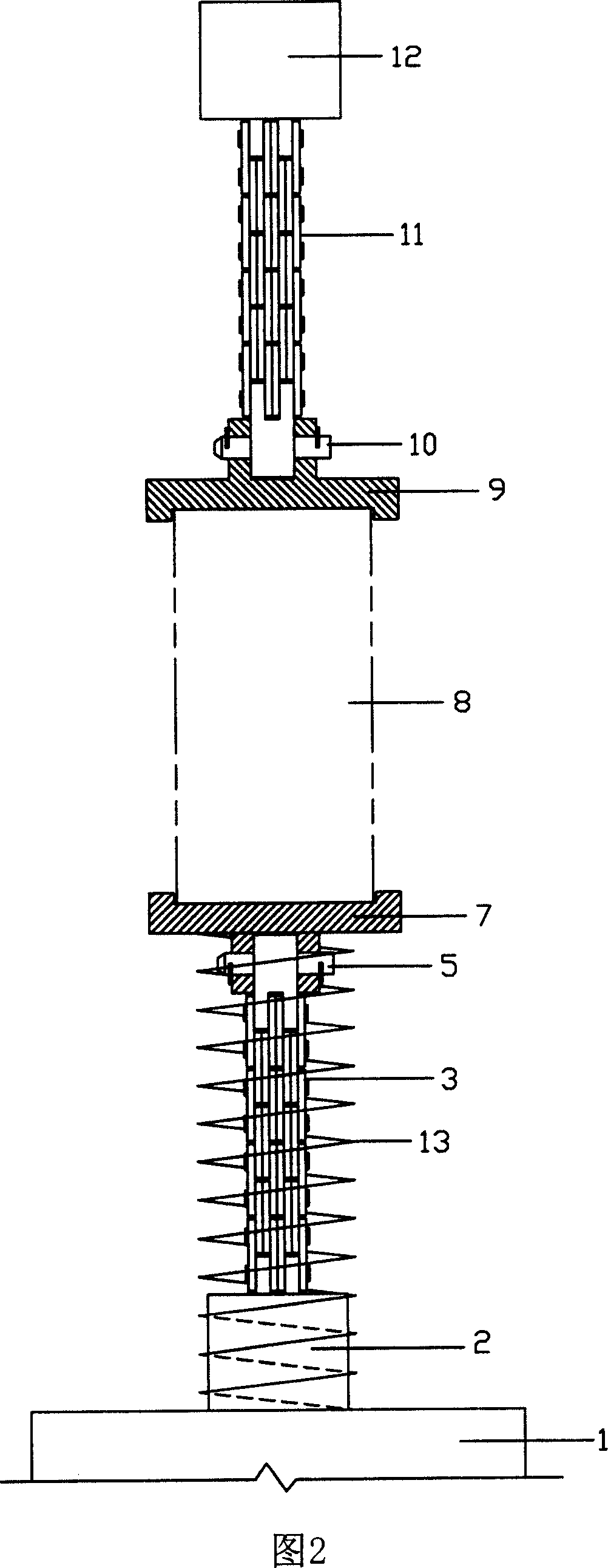

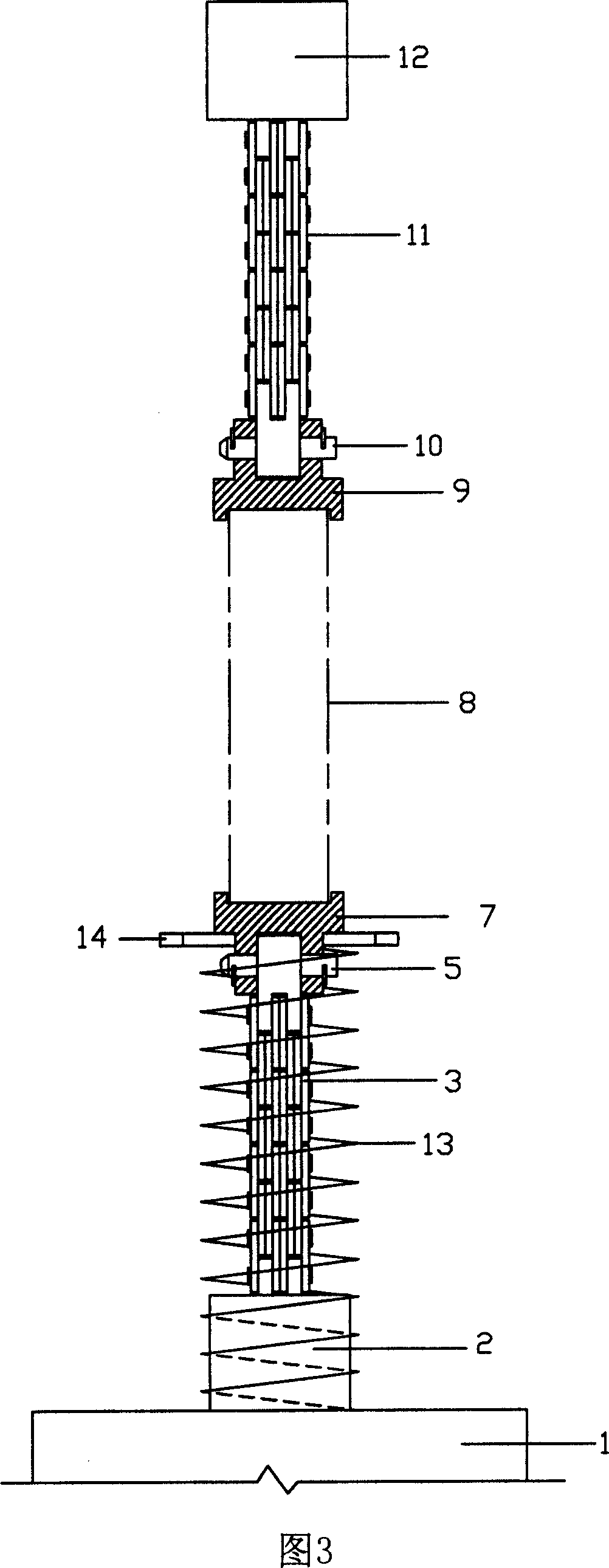

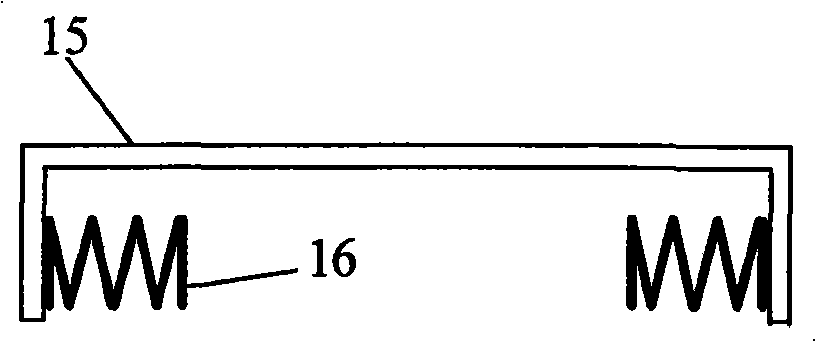

Spring thrust down clamp of direct tensile test

InactiveCN1952643AAvoid sudden destructionSimple structureMaterial strength using tensile/compressive forcesEngineeringTensile testing

Owner:SICHUAN UNIV

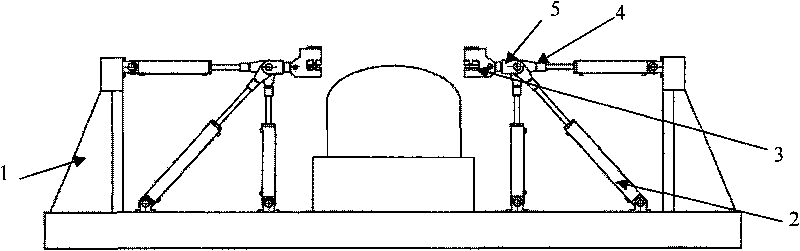

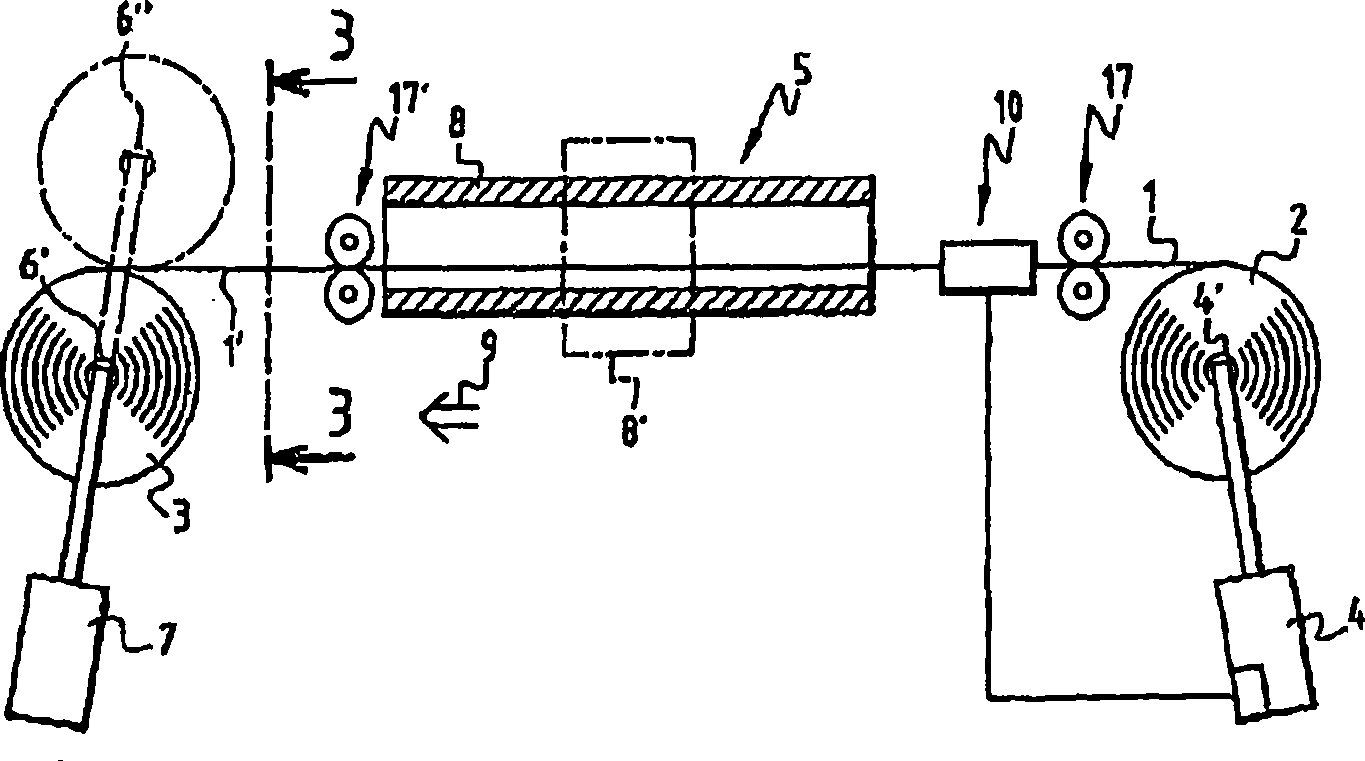

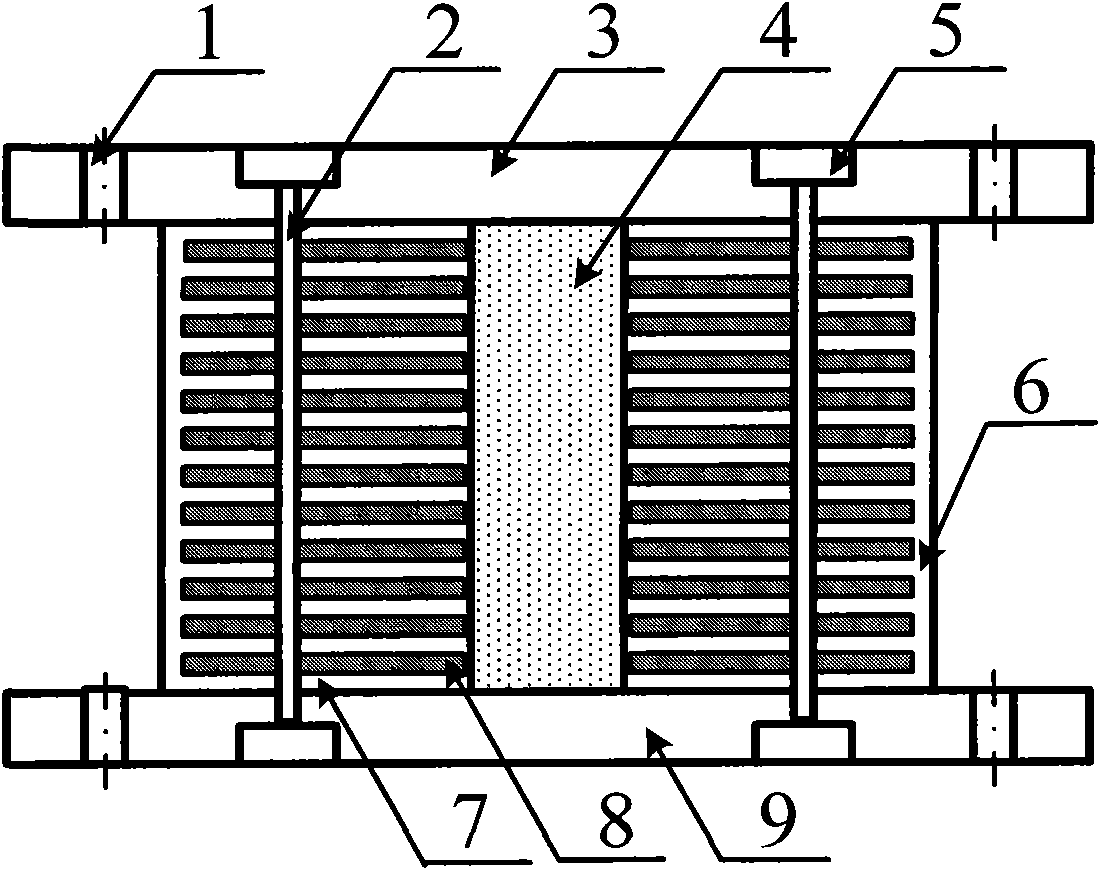

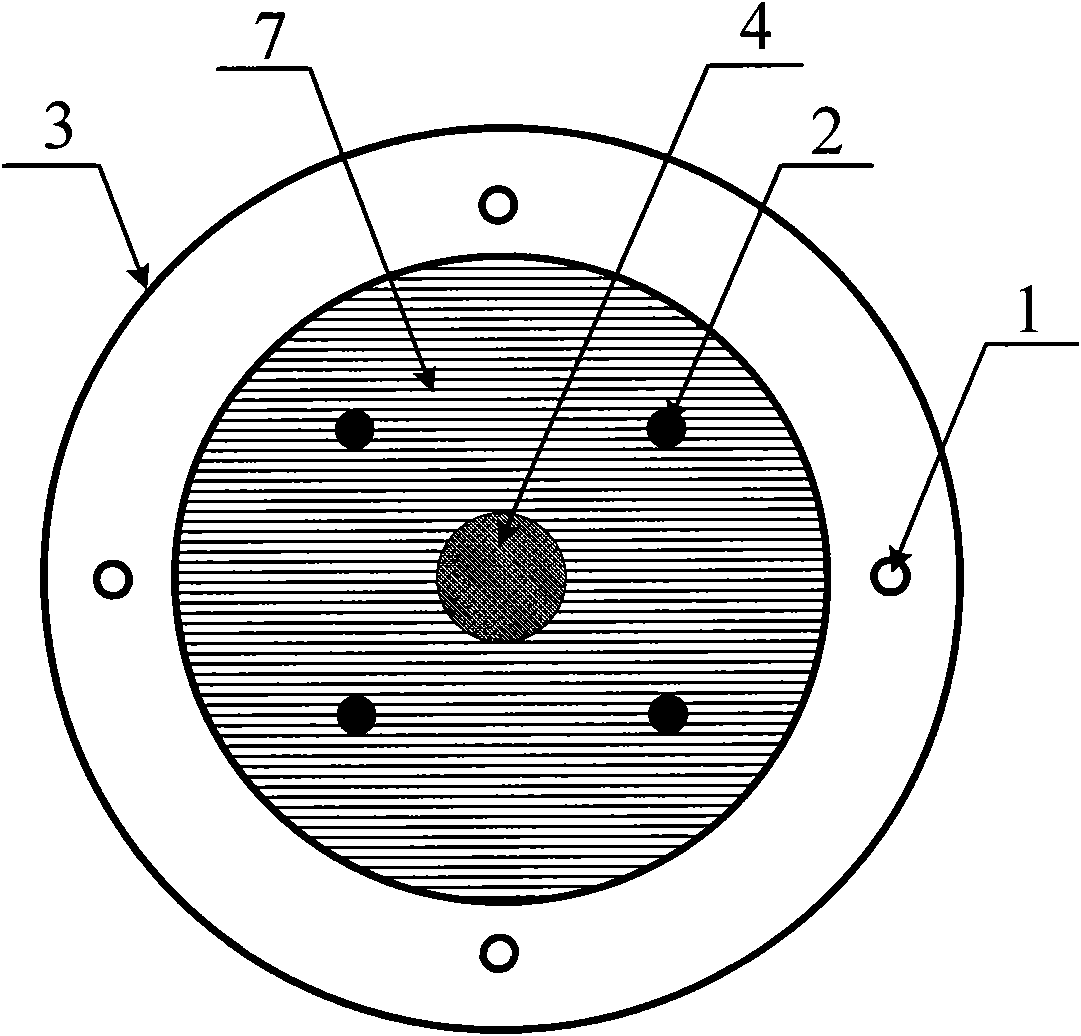

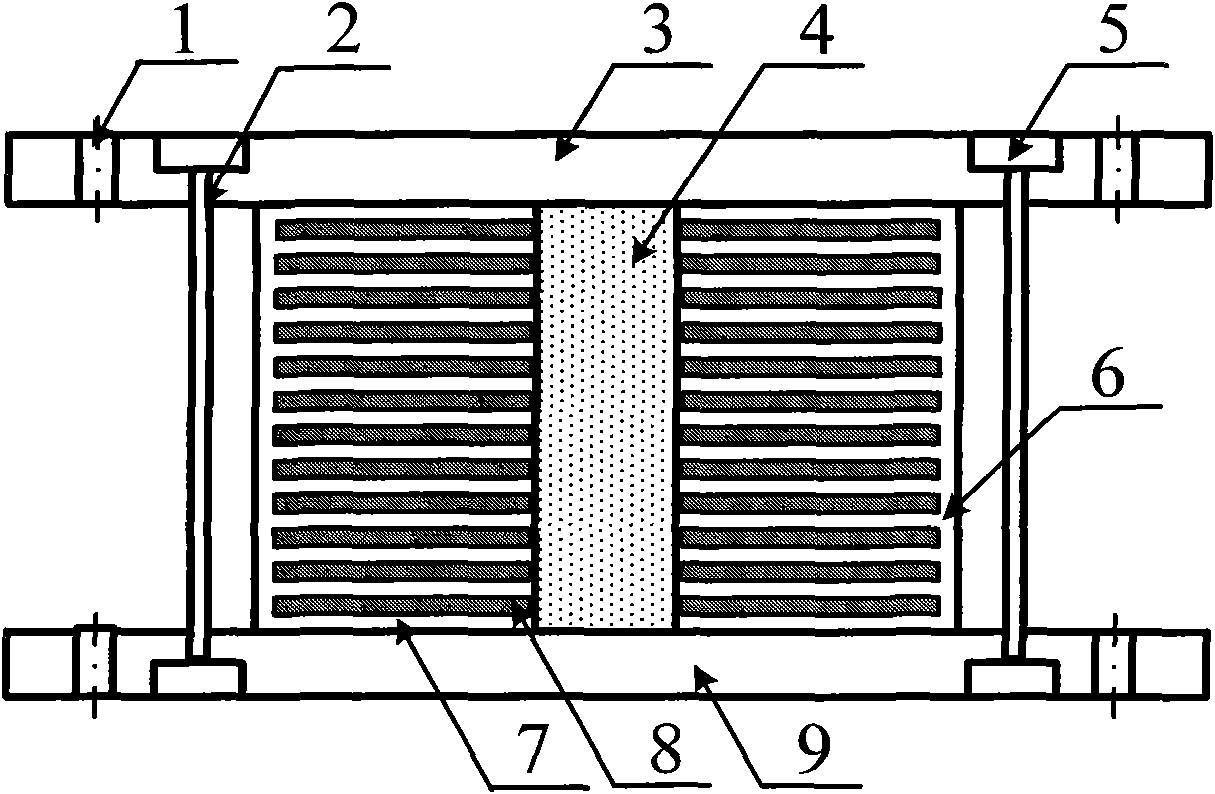

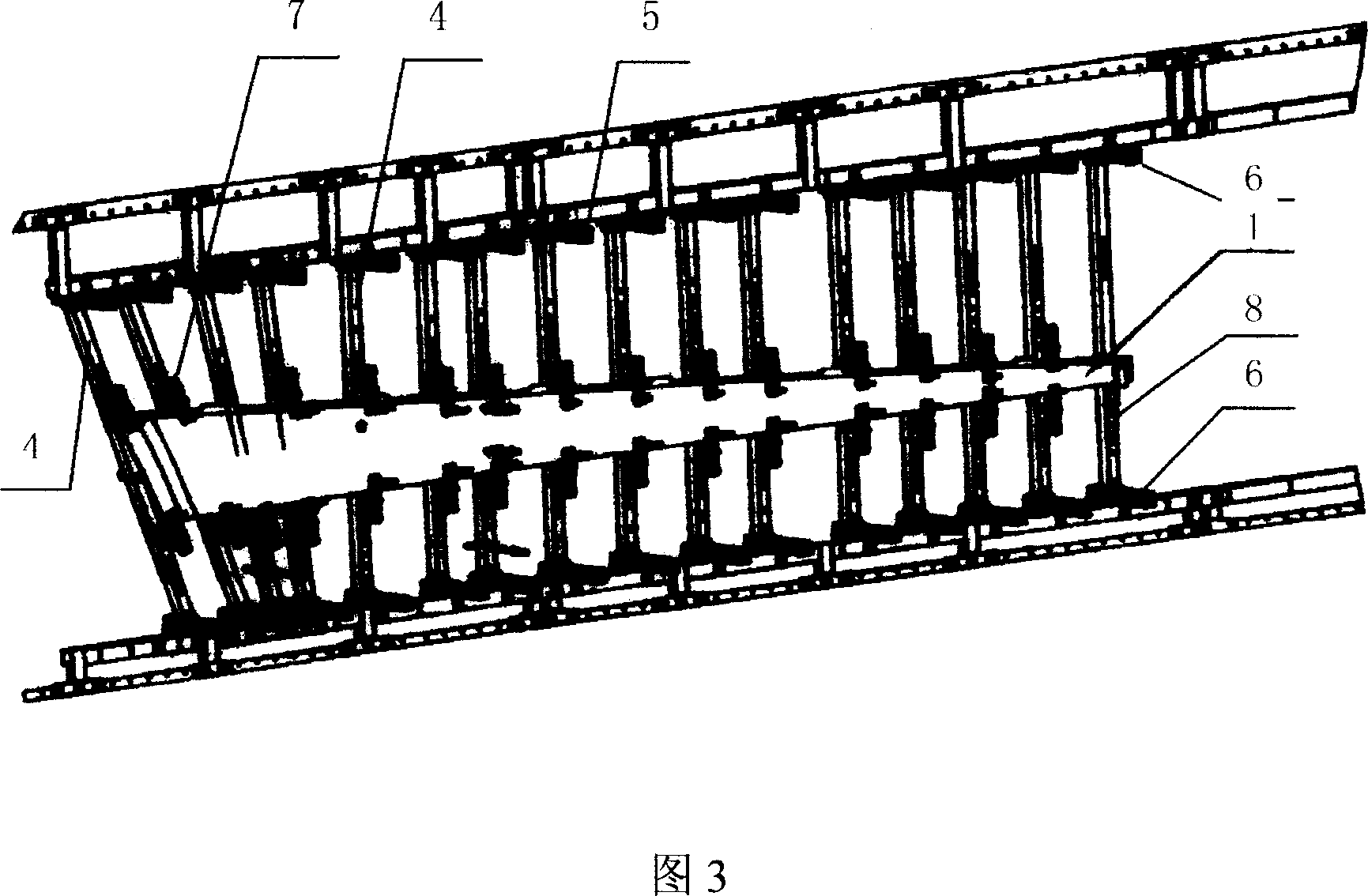

High-flexibility multi-head stretching machine

The invention discloses a high-flexibility multi-head stretching machine, which relates to plastic processing equipment for three-dimensional curved surface forming of sheet parts and belongs to the field of mechanical engineering. The machine aims to make the distribution of the pulling stress and the tension strain of stretched parts more trend to be uniform, improve the stretching quality and the utilization rate of materials, and realize the stretching of curvature parts with larger transverse curvature or certain wave. The machine mainly comprises a main frame (1), material pulling mechanisms, material clamping mechanisms (3) and universal mechanisms (5), wherein a row of a plurality of the material pulling mechanisms, the material clamping mechanisms (3) and the universal mechanisms (5) are arranged on both sides of the main frame (1) respectively; the material pulling mechanisms consist of three hydraulic cylinders (2) respectively, one of the hydraulic cylinders (2) is horizontally arranged, the other hydraulic cylinder (2) is vertically arranged, and the third hydraulic cylinder (2) are slantways arranged; and one end of each of the three hydraulic cylinders (2) is hinged with the main frame (1) respectively, while the other end is jointly connected with the universal mechanism (5) and the material clamping mechanism (3) through a hydraulic cylinder connection body (4) respectively.

Owner:JILIN UNIV

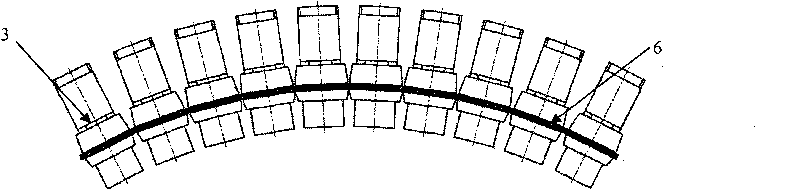

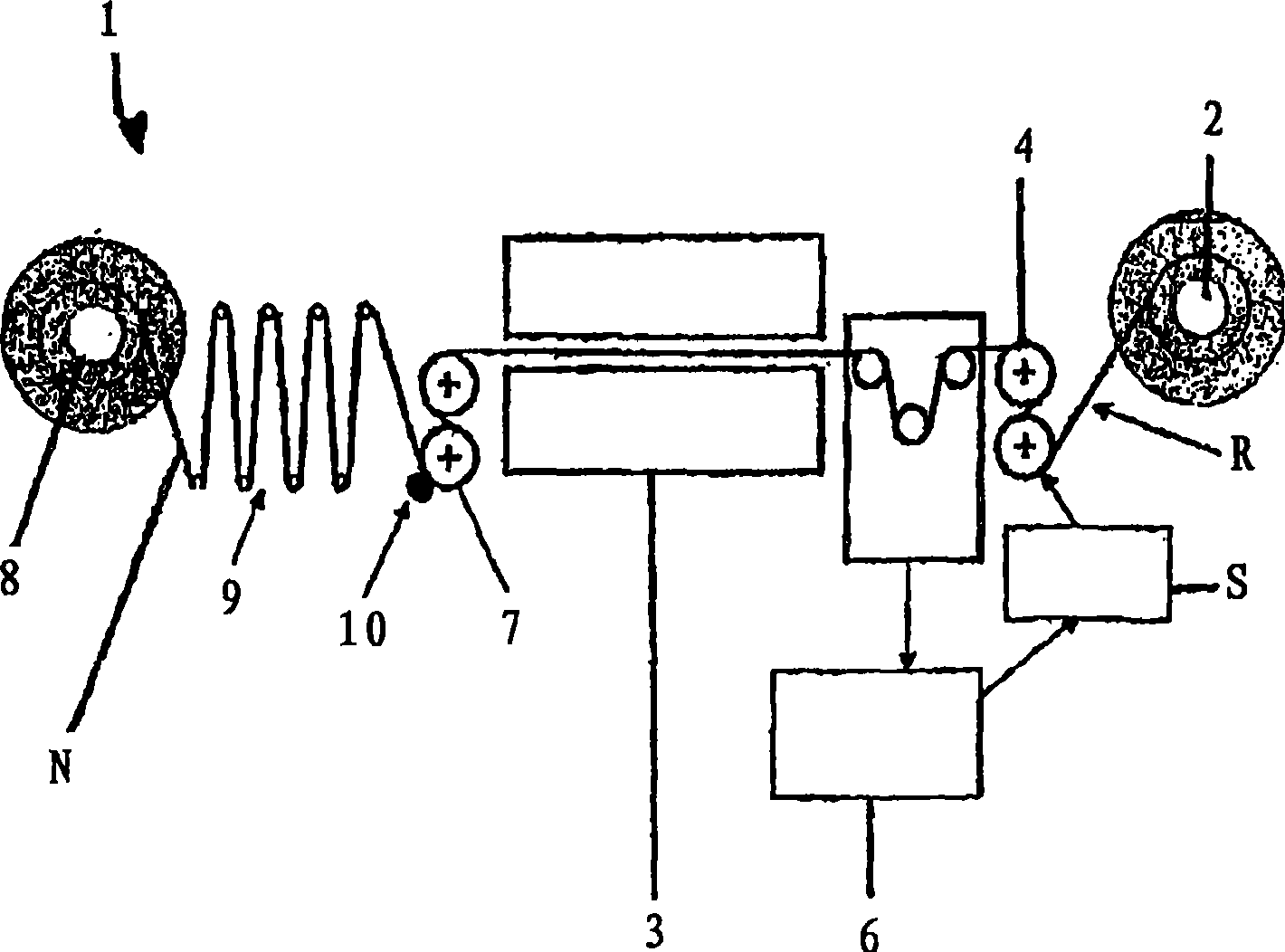

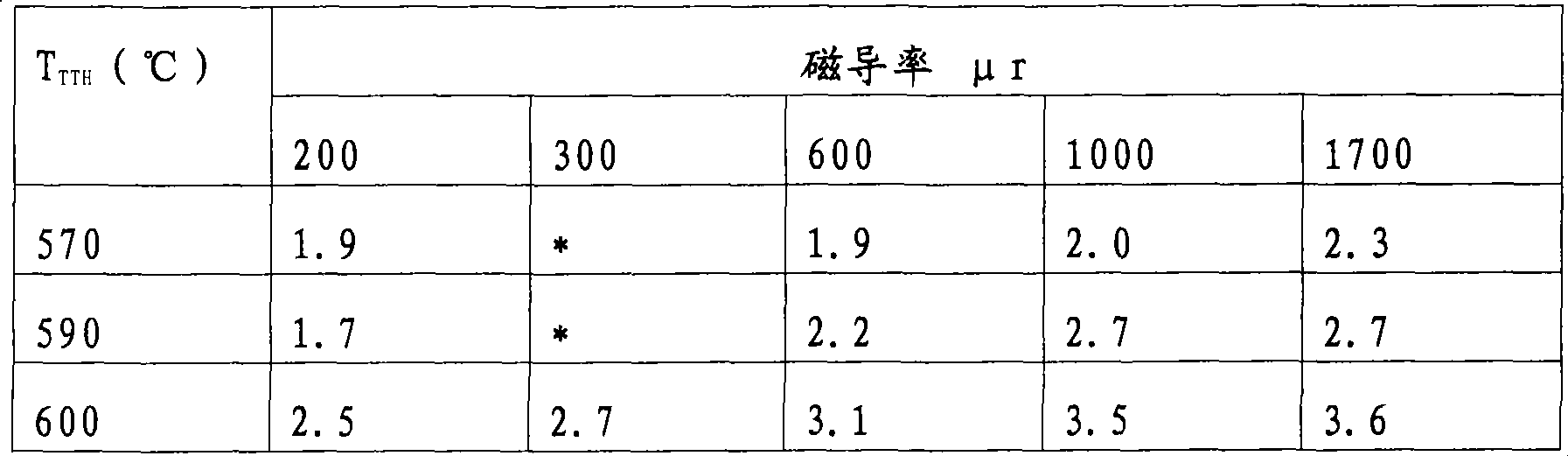

Method of producing a strip of nanocrystalline material and device for producing a wound core from said strip

The invention relates to a method of producing a strip of nanocrystalline material which is obtained from a wound ribbon that is cast in an amorphous state, having atomic composition [Fe1-a-bCoaNib]100-x-y-2-alpha-beta-gamma Cu<x>Si<y>BzNbalphaM'betaM''gamma, M' being at least one of elements V, Cr, Al and Zn, and M being at least one of elements C, Ge, P, Ga, Sb, In and Be, with: a <= 0.07 and b = 0.1, 0.5 <= x <=1.5 and 2 <= a <= 5, 10 <= y <= 16.9 and 5 <= z <= 8, beta <= 2 and gamma <= 2. According to the invention, the amorphous ribbon is subjected to crystallisation annealing, in which the ribbon undergoes annealing in the unwound state, passing through at least two S-shaped blocks under voltage along an essentially longitudinal axial direction of the ribbon, such that the ribbon is maintained at an annealing temperature of between 530 DEG C and 700 DEG C for between 5 and 120 seconds and under axial tensile stress of between 2 and 1000 Mpa. The tensile stress applied to the amorphous ribbon, the displacement speed of the ribbon during annealing and the annealing time and temperature are all selected such that the cross-section profile of the strip is not in the form of Omega and the maximum deflection of the cross-section of the strip is less than 3% of the width of the strip and preferably less than 1% of the width. The invention also relates to the strip and the core thus obtained and to the device used to implement the method.

Owner:IMPHY ALLOYS

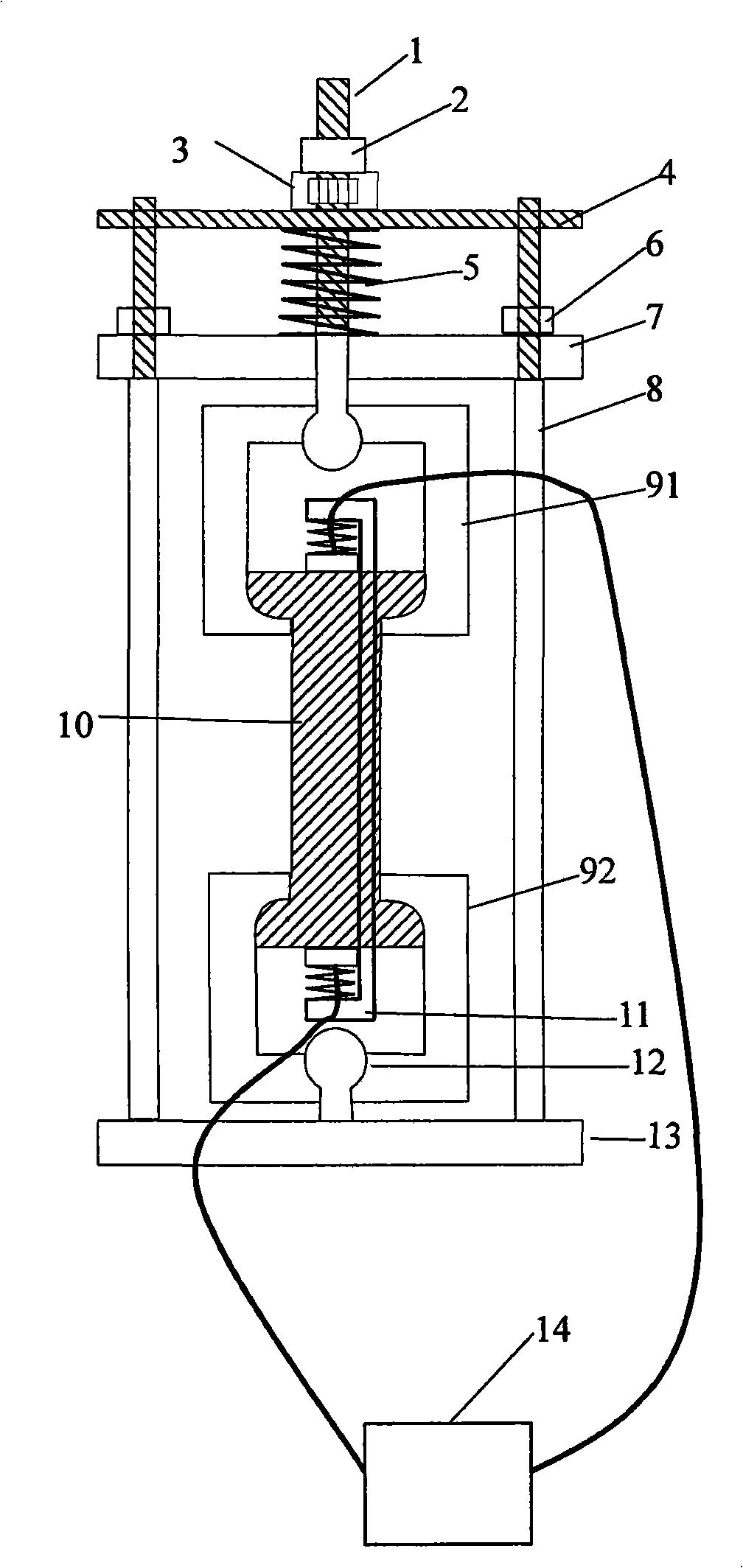

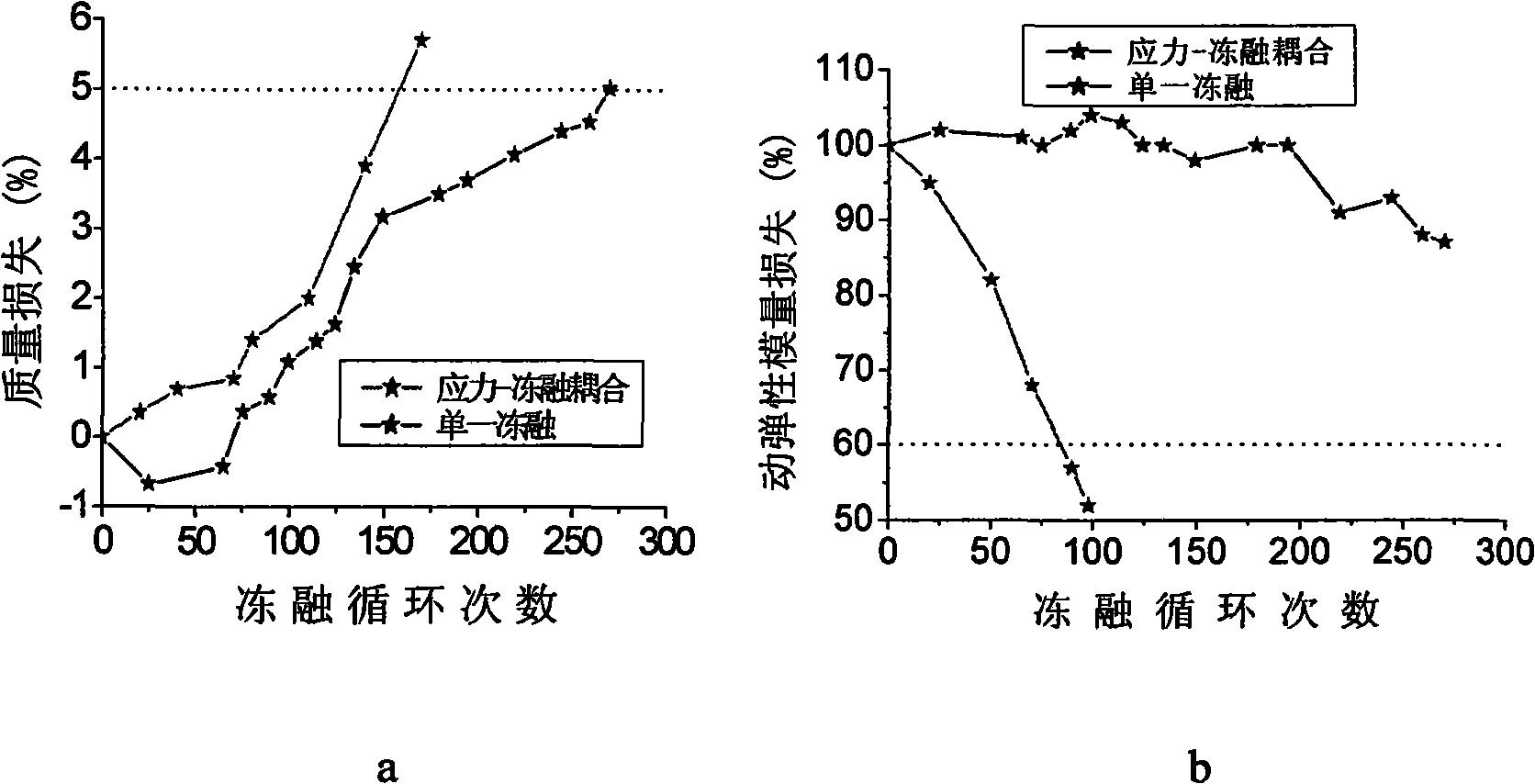

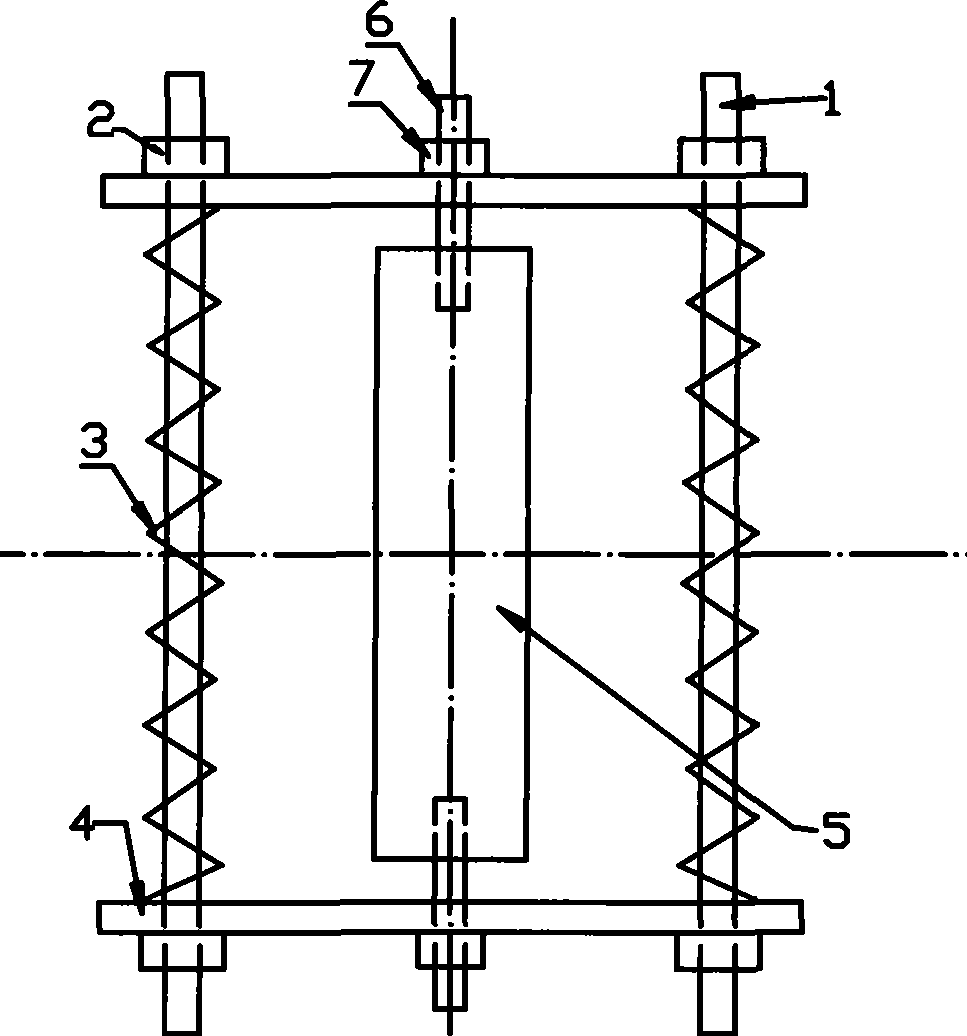

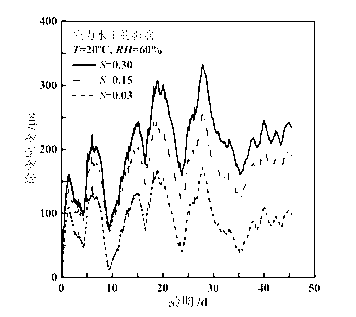

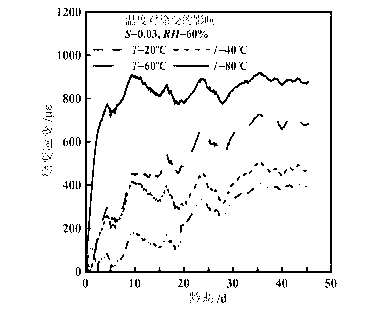

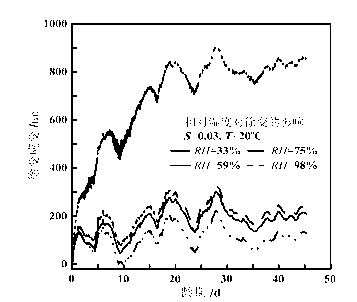

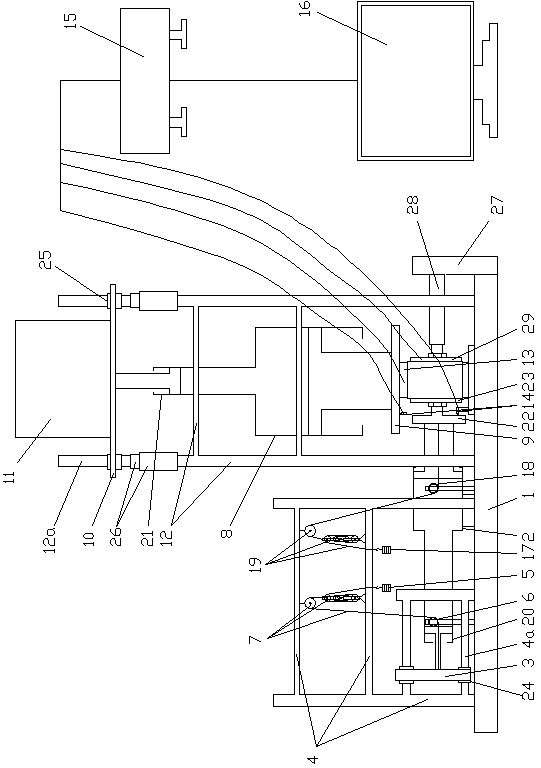

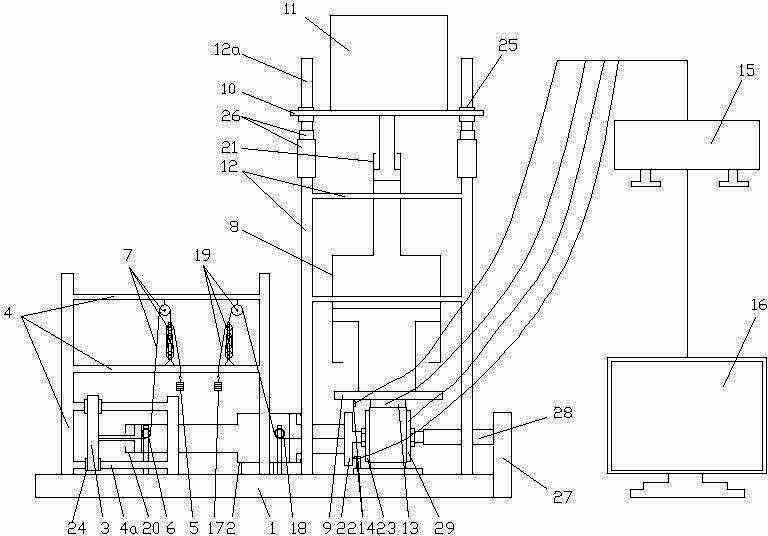

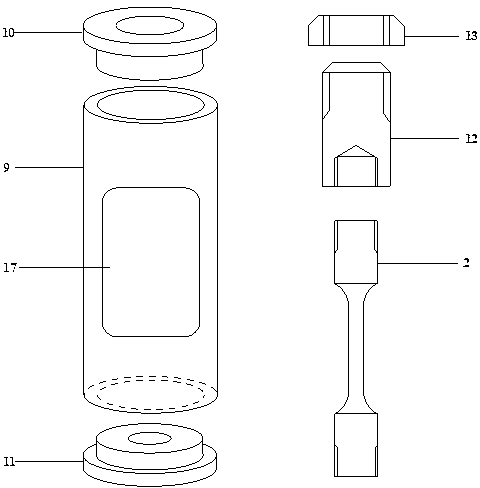

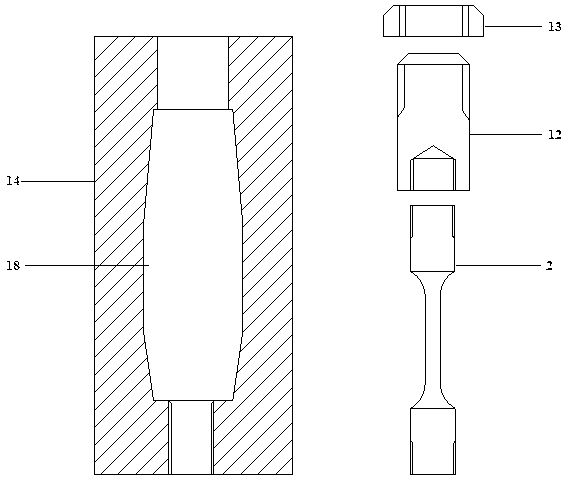

Experimental device for concrete multifactor permanent stability under co-action of pulling stress and surroundings

InactiveCN101271103AGeometrically accurateEasy to processMaterial testing goodsStrength propertiesConstant forceUltrasonic testing

The invention relates to a concrete multi-factor durability test device under the common effect of tensile stress and environment, wherein, the lower part of a pull rod (8) is connected with a lower pull plate (13), the upper part of the pull rod (8) penetrates an upper pull plate (7) and a limit plate (4), the upper pull plate (7) is penetrated on the pull rod (8) to be fixed by a lock nut (6), a screw cap (2) presses a stress sensor (3) on the limit plate by a spherical screw rod (1), a spring (5) is sheathed on the spherical screw rod (1) and is positioned between the limit plate and the upper pull plate, an upper stretching chuck (91) and a lower stretching chuck (92) are arranged between the upper pull plate and the lower pull plate (13), the upper stretching chuck (91) is connected with the spherical head part of the spherical screw rod (1), the lower stretching chuck (92) is connected with the spherical head part of a spherical pull rod (12), a dumbbell-shaped concrete sample (10) is positioned between the upper stretching chuck (91) and the lower stretching chuck (92), the dumbbell-shaped concrete sample is held by the stretching chucks, both sides of the dumbbell-shaped concrete sample (10) are provided with constant force holding instruments (11), and the constant force holding instruments are connected with a non-metallic ultrasonic testing instrument (14).

Owner:SOUTHEAST UNIV

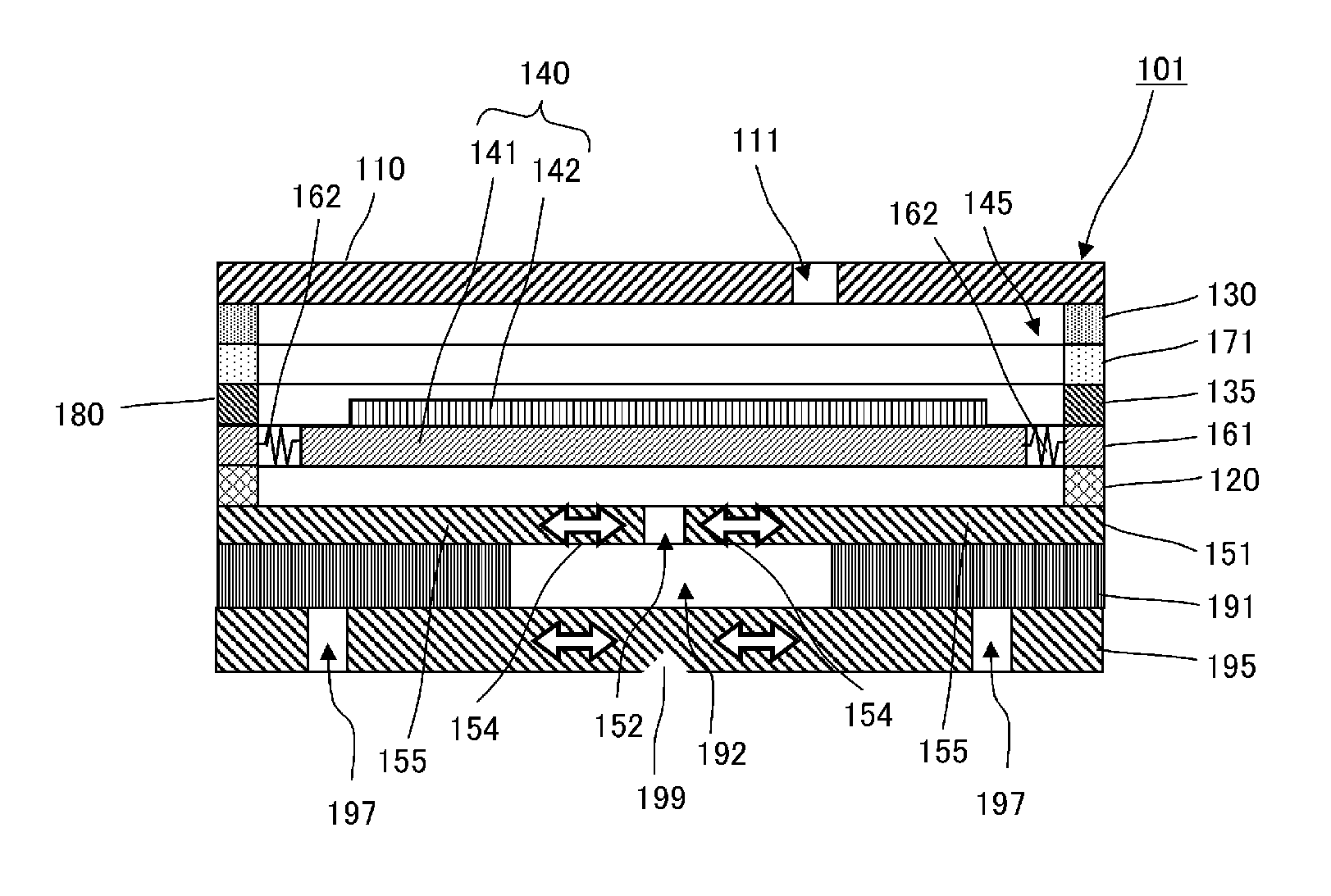

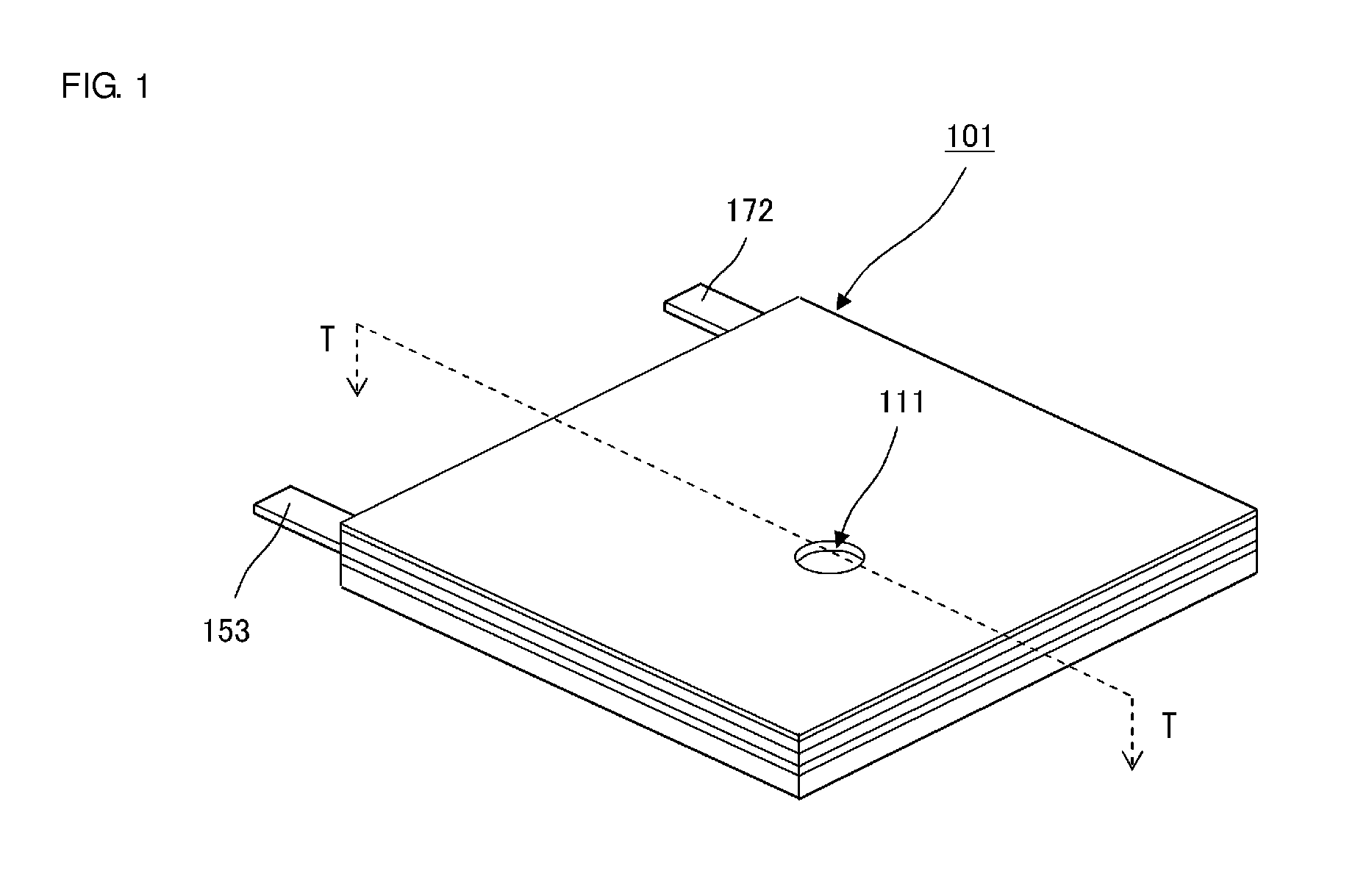

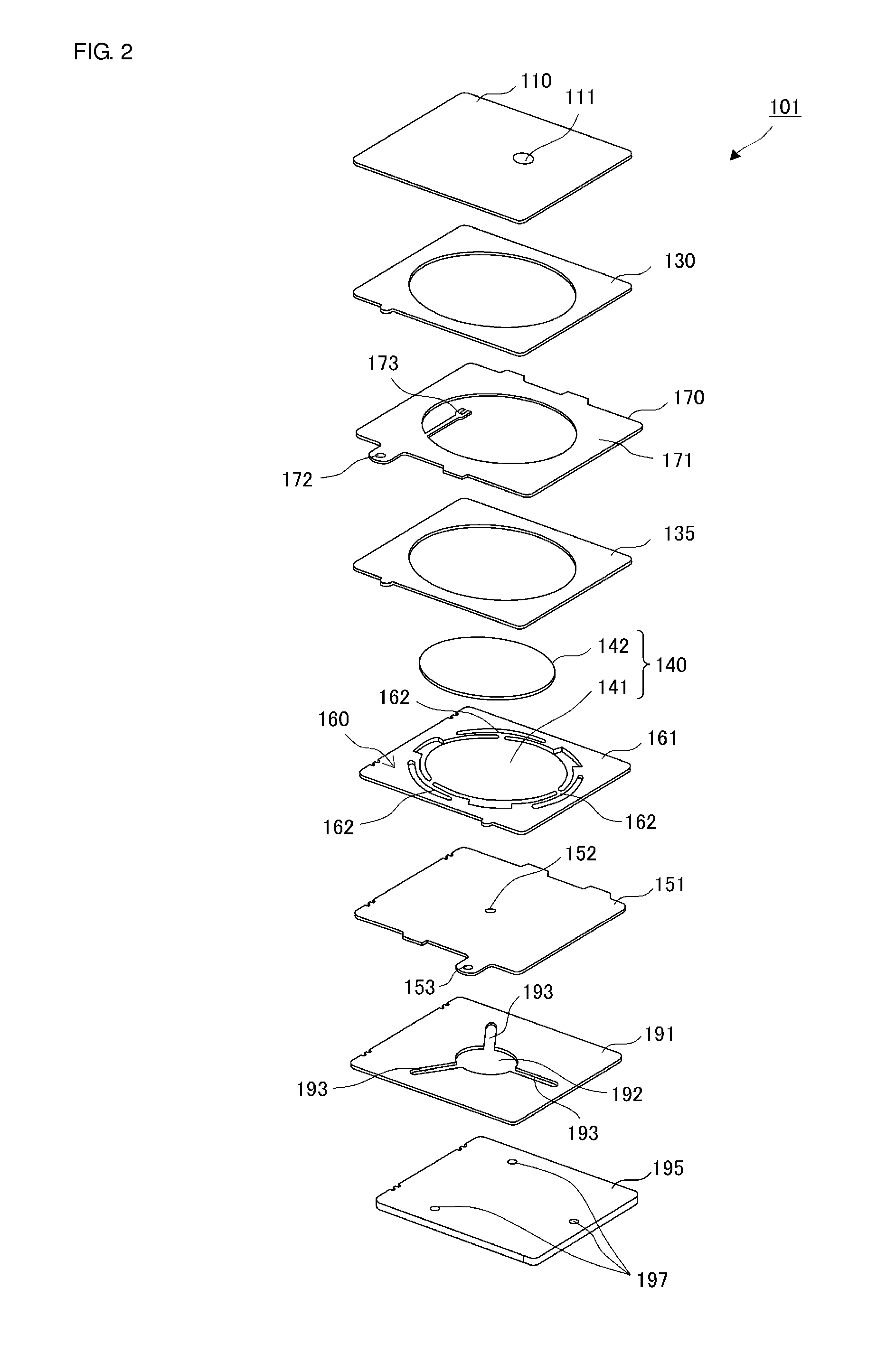

Fluid control apparatus and method for adjusting fluid control apparatus

ActiveUS20130323085A1Increase valueFlexible member pumpsPositive-displacement liquid enginesFluid controlEngineering

In a method for adjusting a fluid control apparatus, in a pressing step, a piezoelectric pump is placed on a stage with a cover plate facing upward, the stage is moved up, and a center portion of a principal surface of the cover plate on a side opposite to a diaphragm is pressed with a pressing pin. As a result, the cover plate and the base plate are shaped so as to warp convexly toward the diaphragm side, and a portion joined to a flexible plate is pulled, such that the flexible plate is caused to warp convexly toward the diaphragm side. Thus, residual tensile stress occurs in a movable portion of the flexible plate. Therefore, due to the residual tensile stress, the tensile stress of the movable portion of the flexible plate is increased.

Owner:MURATA MFG CO LTD

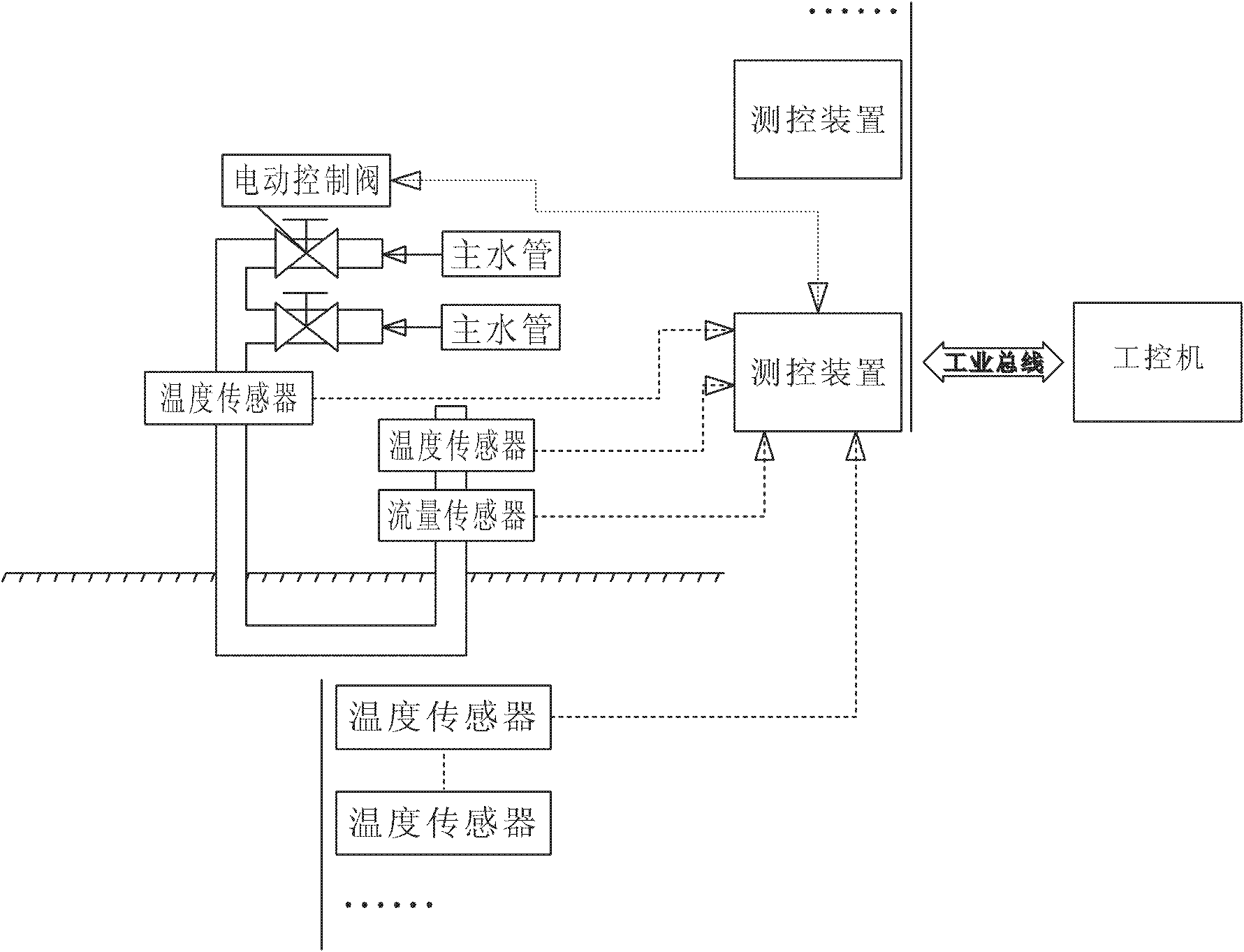

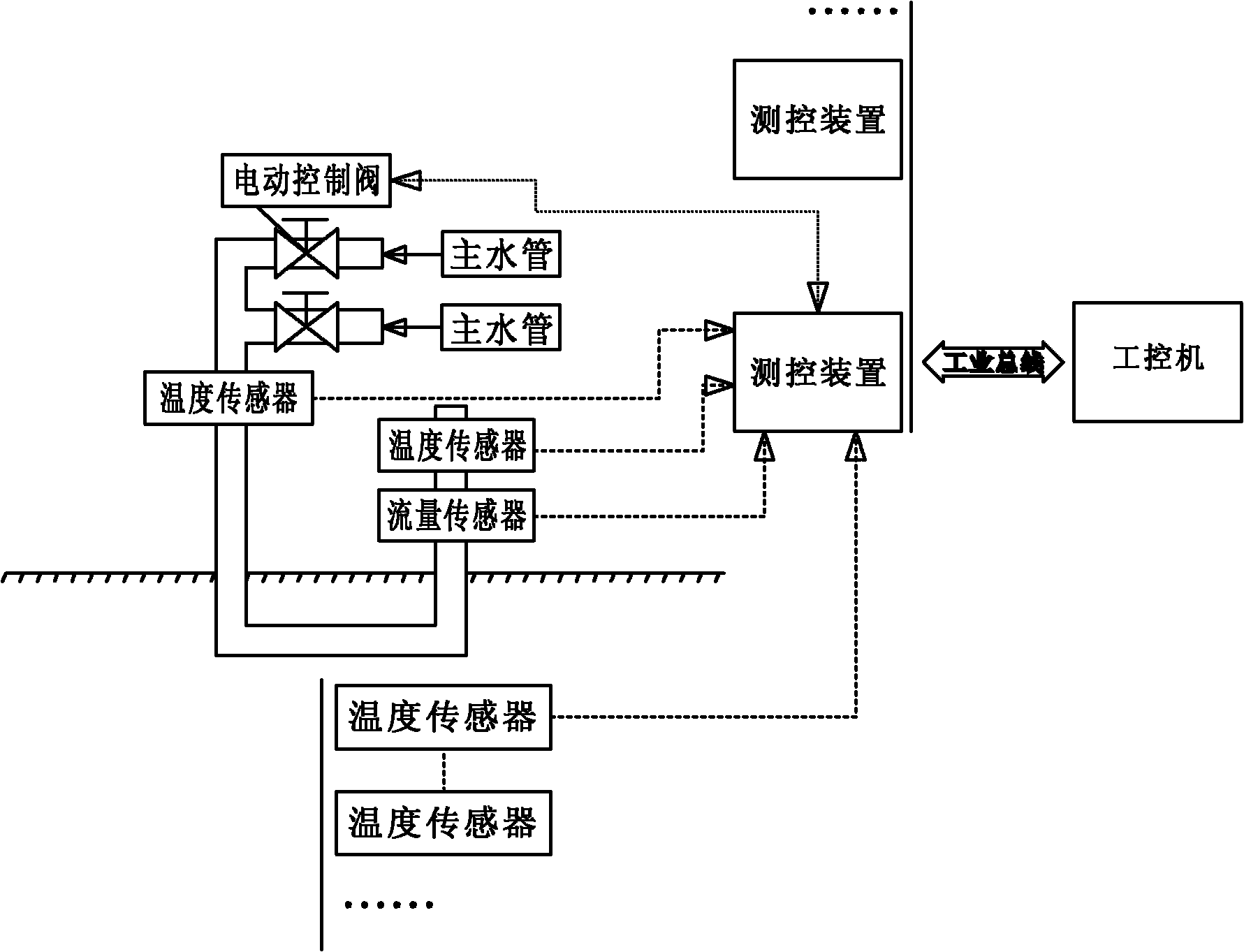

Intelligent cooling water passage system for concrete

The invention relates to an intelligent cooling water passage system for concrete, which is characterized in that (1) a temperature sensor is installed in the concrete and is used for measuring the temperature of the concrete; (2) a flow sensor, a temperature sensor and an electric control valve are installed on a cooling water pipe; (3) measurement and control devices are installed near the electric control valve and are connected with the sensors and the electric control valve through cables; (4) a plurality of the measurement and control devices are connected with an industrial control computer through an industrial bus; and (5) according to temperature, flow signals and opening information acquired by the measurement and control devices, a program in the industrial control computer sends control signals for controlling the electric control valve, and the measurement and control devices control the opening of the electric control valve and regulate the water passage flow and the water passage temperature, thereby realizing the purpose of reducing the temperature gradient to the maximum, reducing the tension stress of the temperature of the concrete, and achieving the effect on preventing cracks from occurring on the concrete.

Owner:HUBEI GEZHOUBA TESTING

High intensity variable section spring piece under high stress and method for producing the same

ActiveCN101397629AAddress fatigue performance on surfacesAddresses significantly increased susceptibility to internal defectsFurnace typesProcess efficiency improvementTemperature controlHigh intensity

The invention relates to a high-strength variable cross-section reed which can bear high-stress, comprising the components with mass mixture ratios as follows: 0.46 to0.62 percent of C, 0.20 to 2.00 percent of Si, 0.30 to 0.90 percent of Mn, 0.8 to 1.20 percent of Cr, 0.10 to 0.20 percent of V, 0.005 to 0.1 percent of Al, and the rest of Fe and impurity. The manufacturing method of the reed is that: temperature control and variable cross-section rolling is carried out to a spring flat steel which has the components and mass mixture ratios under 700 DEG C to 950 DEG C to form the variable cross-section reed which is then heated to 86 DEG C to 950 DEG C for quenching, tempering is carried out at temperature of 380 DEG C to 450 DEG C, and then stress shot blasting is carried out to the pulled stress surface by adopting the steel shot with diameter from 0.8 mm to1.0 mm at the speed of 50 to 90mm / s under the bending stress of 800MPa to 1600MPa. The high-strength variable cross-section reed effectively solves the problem that fatigue property on the surface and the inside defect sensibility is significantly increased under the high stress condition after the strength is improved, the tensile strength is more than1800MPa, and the performance thereof is much better than the performance level of domestic spring and achieves the international leading level.

Owner:NANJING NAVECO AUTOMOBILE CO LTD

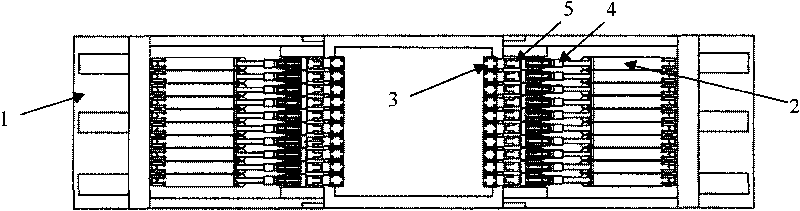

Uniaxial tension loading unit for testing concrete carbonizing performance under tensile stress and testing method

InactiveCN101387634AContinuous uniaxial tensionAchieve carbonization resistance durabilityMaterial testing goodsStrength propertiesSheet steelEngineering

The invention discloses a single shaft tension loading device for testing the carbonation property of the concrete under tensile stress and a test method, wherein the hex nuts pre-embedded at the axis of two ends of the tested element connect the cylinder or rectangle tested element between two parallel steel plates, four same compressed springs are sheathed on four steel columns of the diameters smaller than the inner diameter of the springs, the two steel plates can parallel move between the four steel columns, the material parameters and the compressed quantity of the springs can be used to calculate the axial tensile load on the tested element, the tested element is axially patched with three stress sheets to find the actual tensile stress at different parts. The characteristic parameters of the springs can be changed to obtain the carbonation test parameters under different tensile stresses.

Owner:SOUTHEAST UNIV

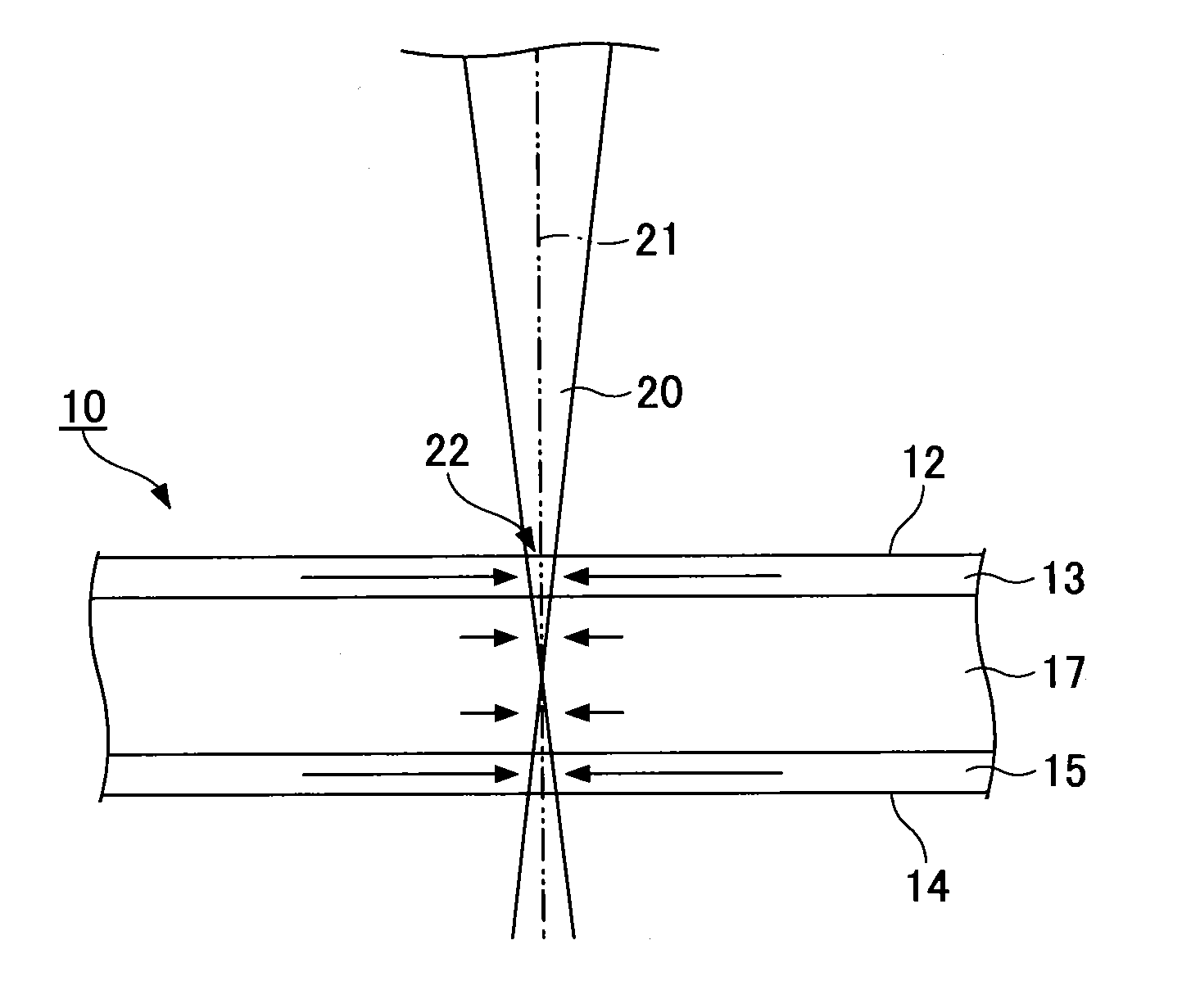

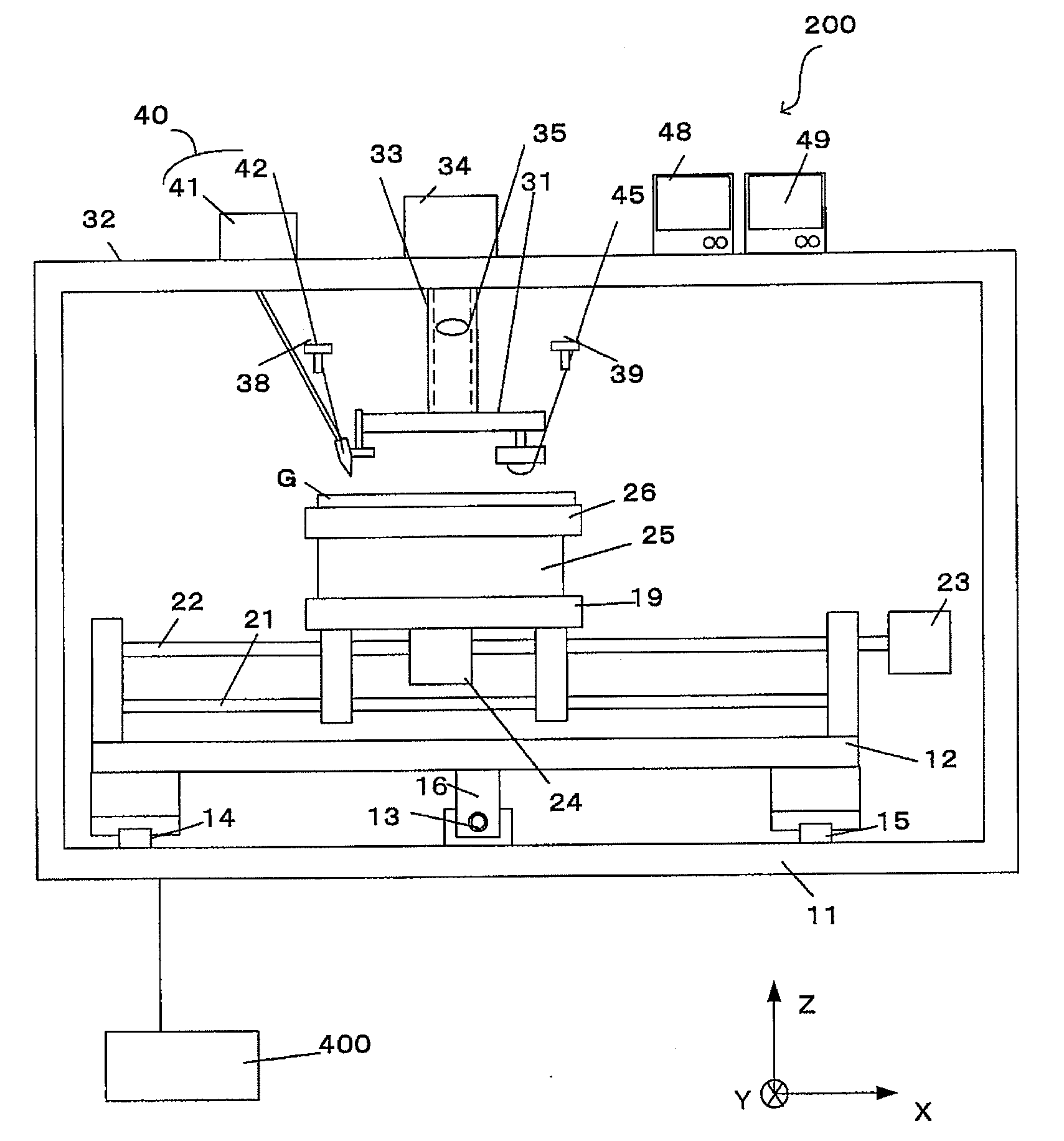

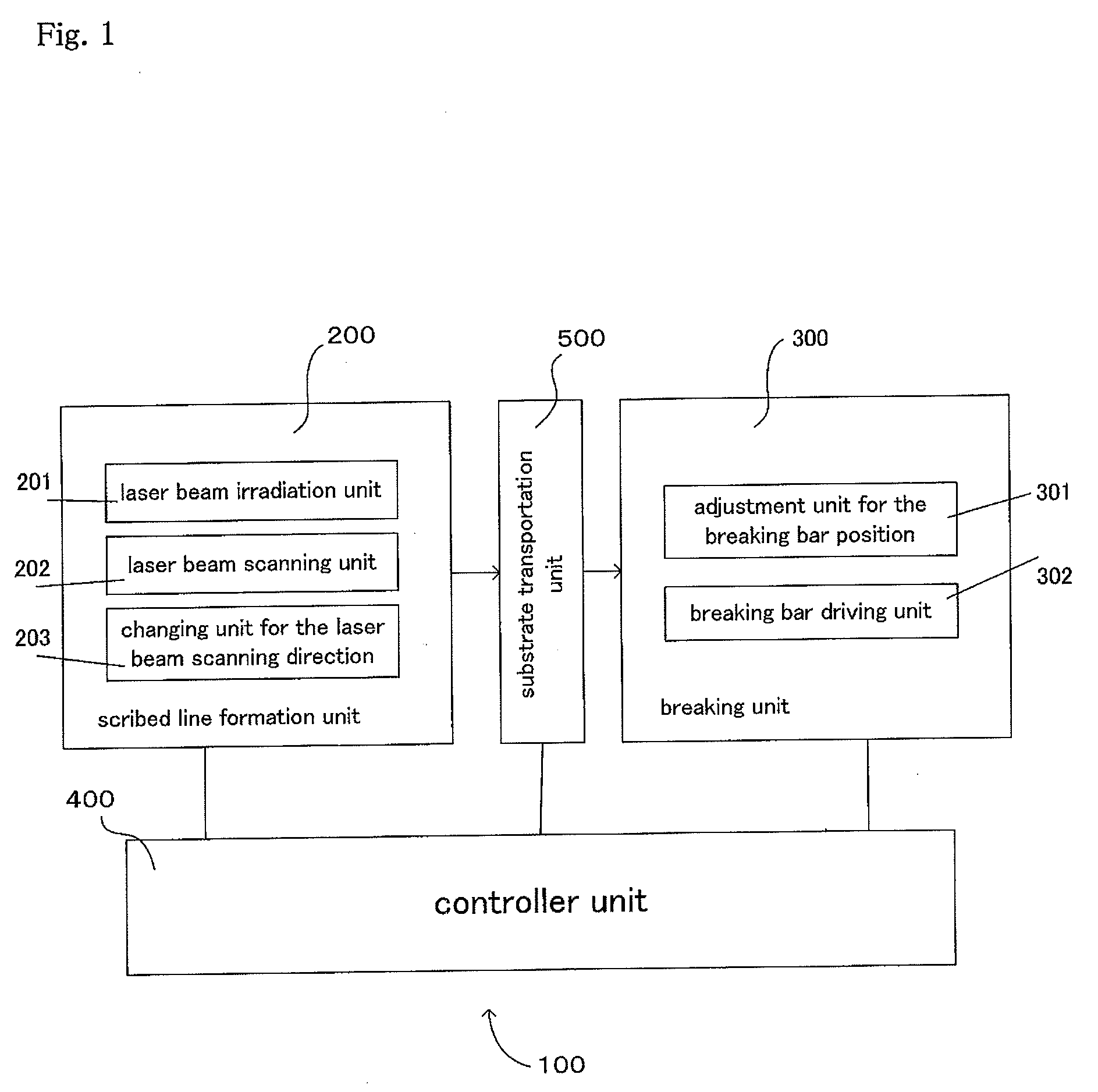

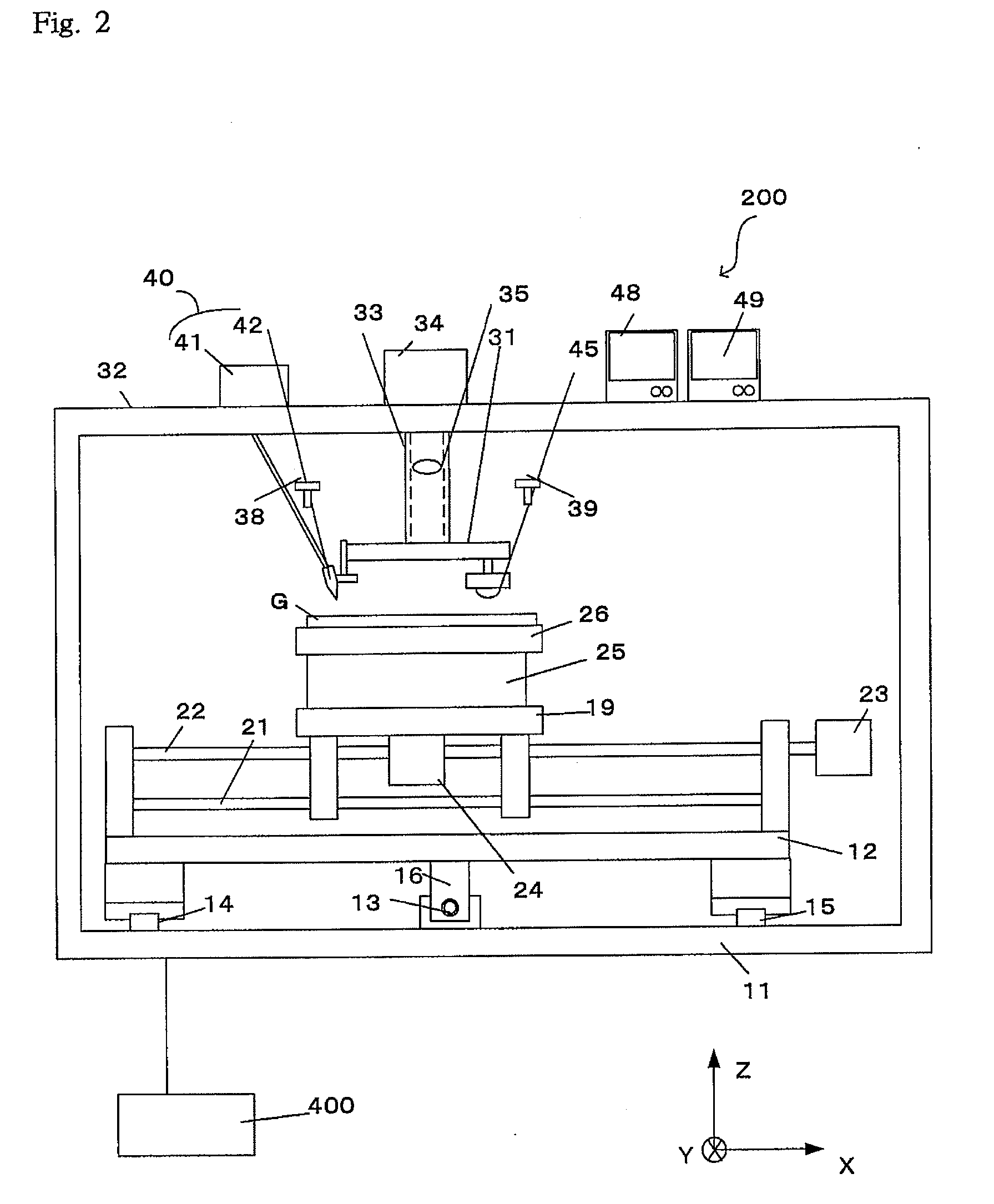

Method of Scribing and Breaking Substrate Made of a Brittle Material and System for Scribing and Breaking Substrate

InactiveUS20080305615A1Inhibition effectBreaking after breaking is remarkably loweredConveyorsPrinted circuit aspectsTension stressLaser beams

An object of the present invention is to provide a method of scribing and breaking a substrate made of a brittle material by which good-quality cutting surface of the substrate can be obtained without any defects such as chippings on the substrate.The method comprises (a) the first scribing step in the first direction by controlling the relative moving velocity and output power of the laser beam so that local volume shrinkage and local tensile stress can be generated in the vicinity of the formed first scribed line, (b) the second scribing step in the second direction of forming locally trigger cracks, which use tensile stress in the vicinity of the first scribed line and work as a starting point in the second direction, in the vicinity of the intersection of a scribed line in the first direction with a scribed line in the second direction, (c) the first breaking step of breaking the substrate along the first scribed line in the first direction, and (d) the second breaking step of breaking the substrate along the second scribed line in the second direction after the first breaking step and performing the breaking from the trigger that works as a starting point of breaking.

Owner:MITSUBOSHI DIAMOND IND CO LTD

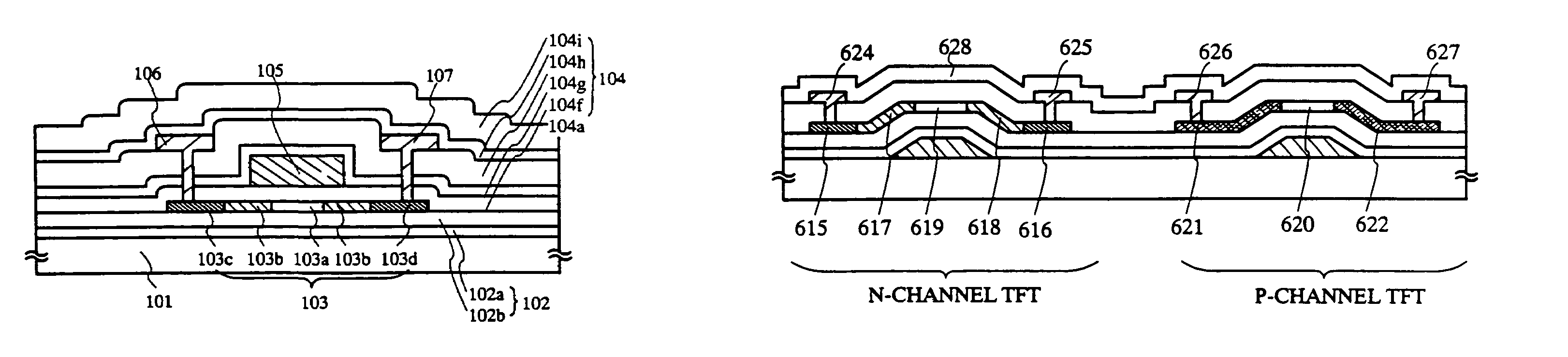

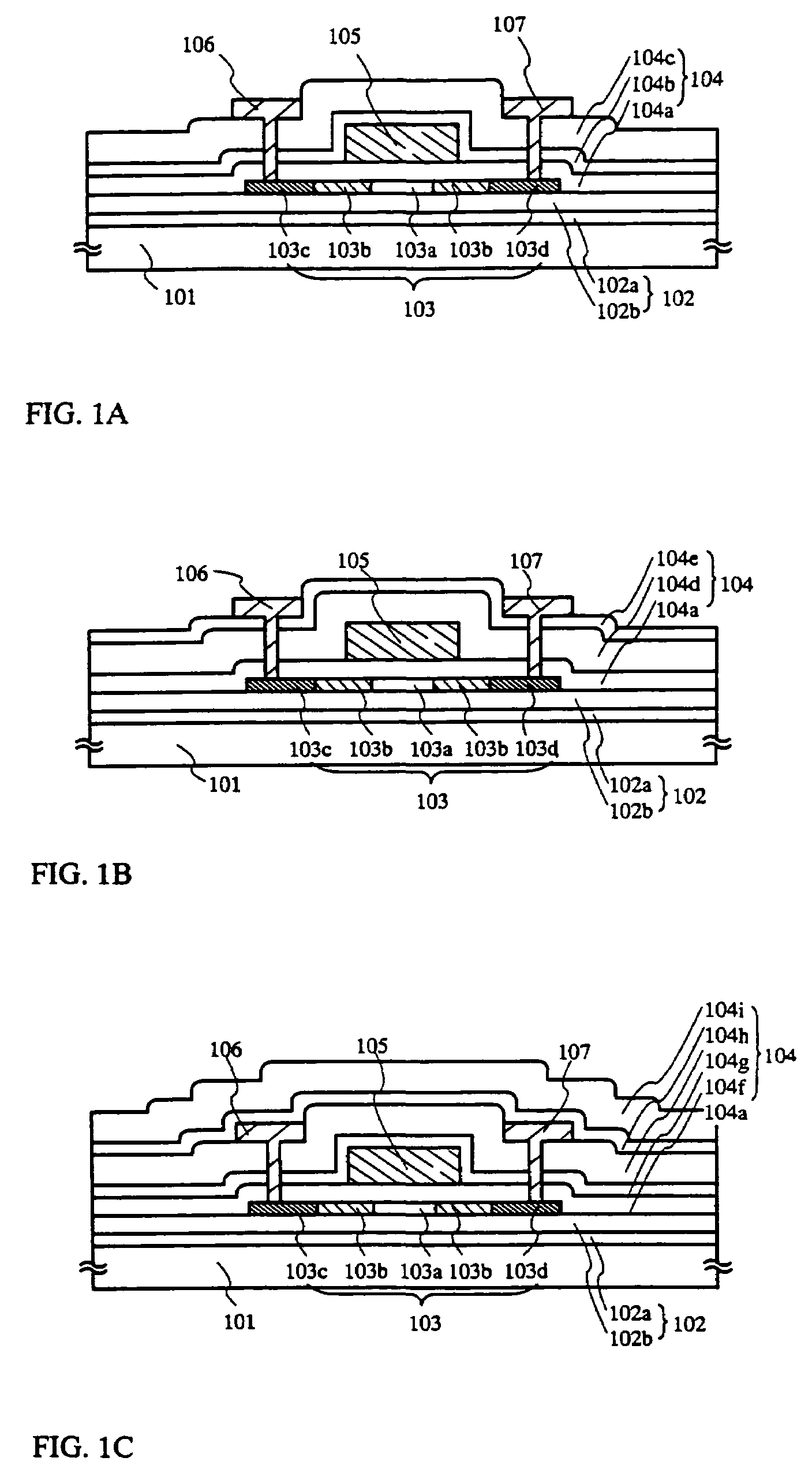

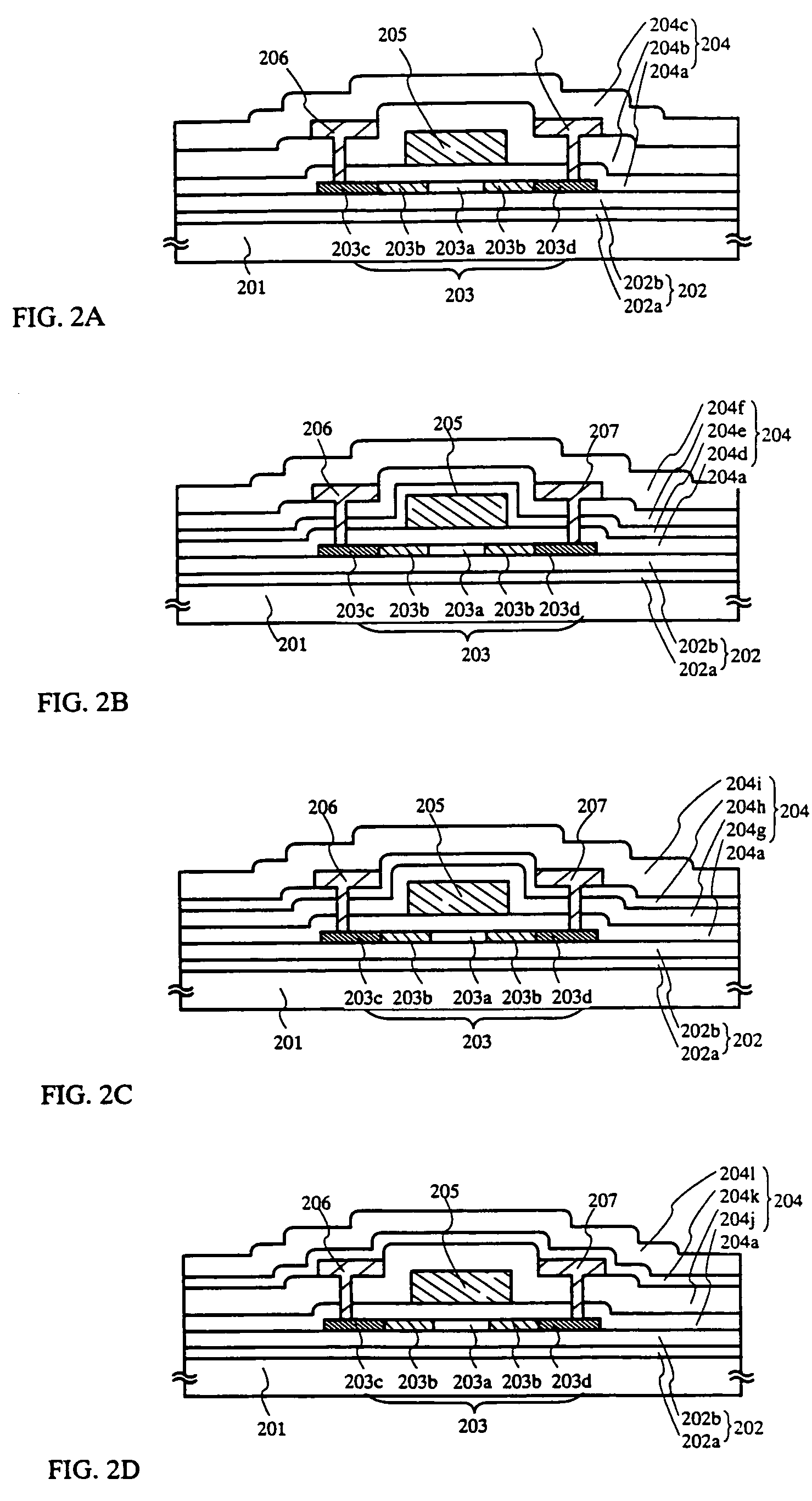

Semiconductor device and method of fabricating the same

InactiveUS7015505B2Bulk defect density interface defect densityReduce defect densityTransistorSolid-state devicesActive layerTension stress

In a semiconductor device including a laminate of a first insulating layer, a crystalline semiconductor layer, and a second insulating layer, characteristics of the device are improved by determining its structure in view of stress balance. In the semiconductor device including an active layer of the crystalline semiconductor layer having tensile stress on a substrate, tensile stress is given to the first insulating layer formed to be in close contact with a surface of the semiconductor layer at a substrate side, and compressive stress is given to the second insulating layer formed to be in close contact with a surface of the semiconductor layer at a side opposite to the substrate side.

Owner:SEMICON ENERGY LAB CO LTD

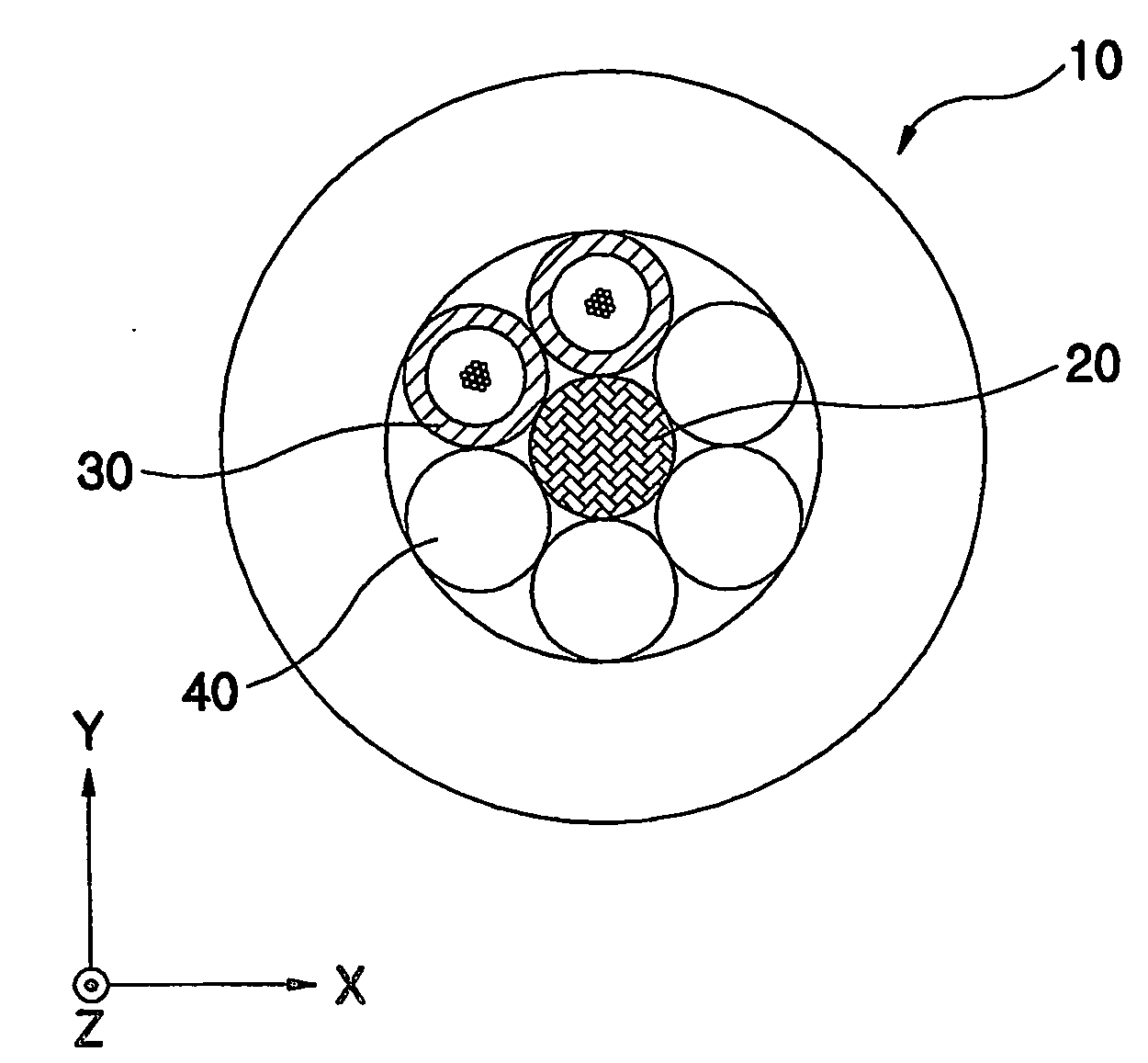

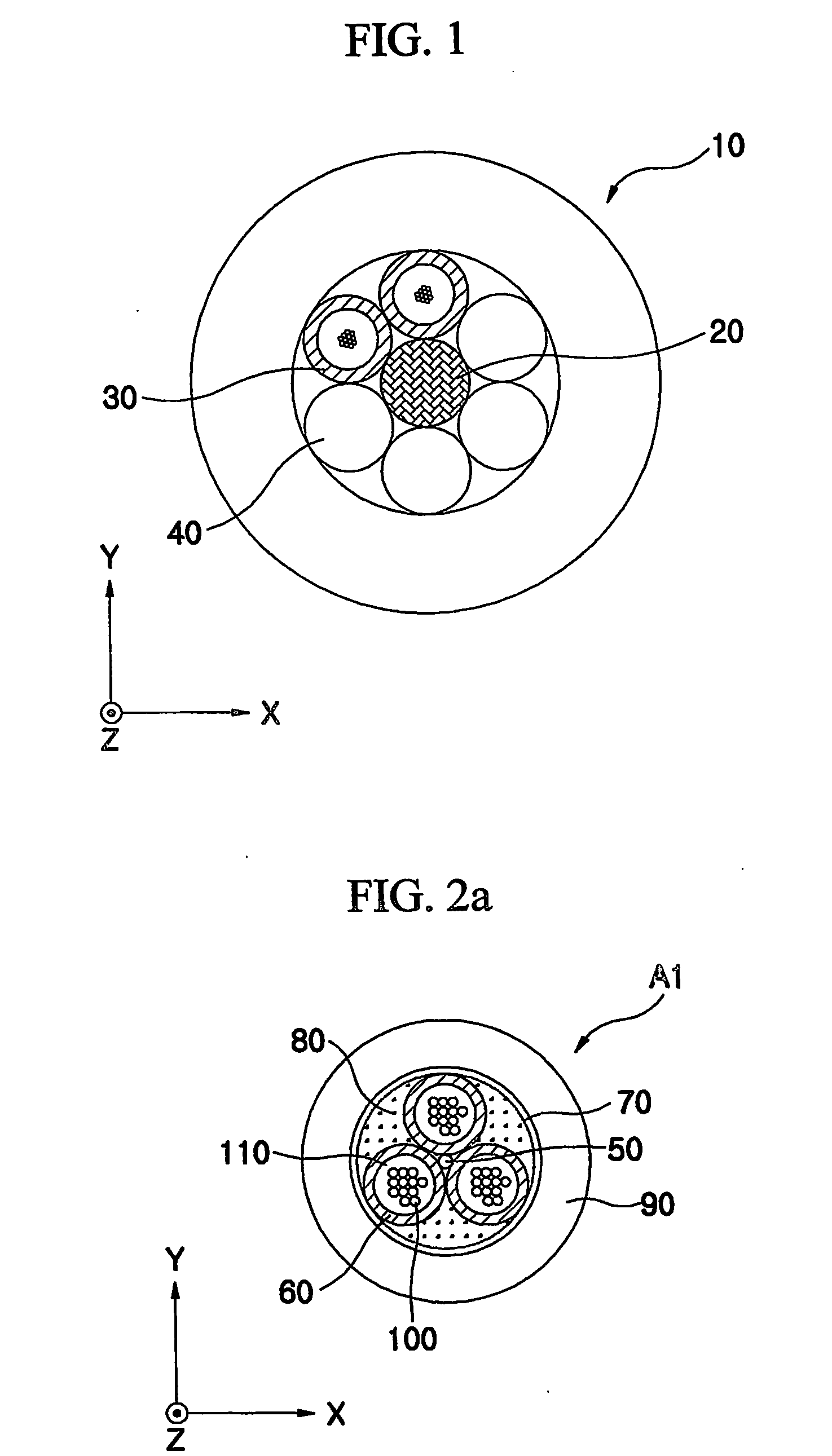

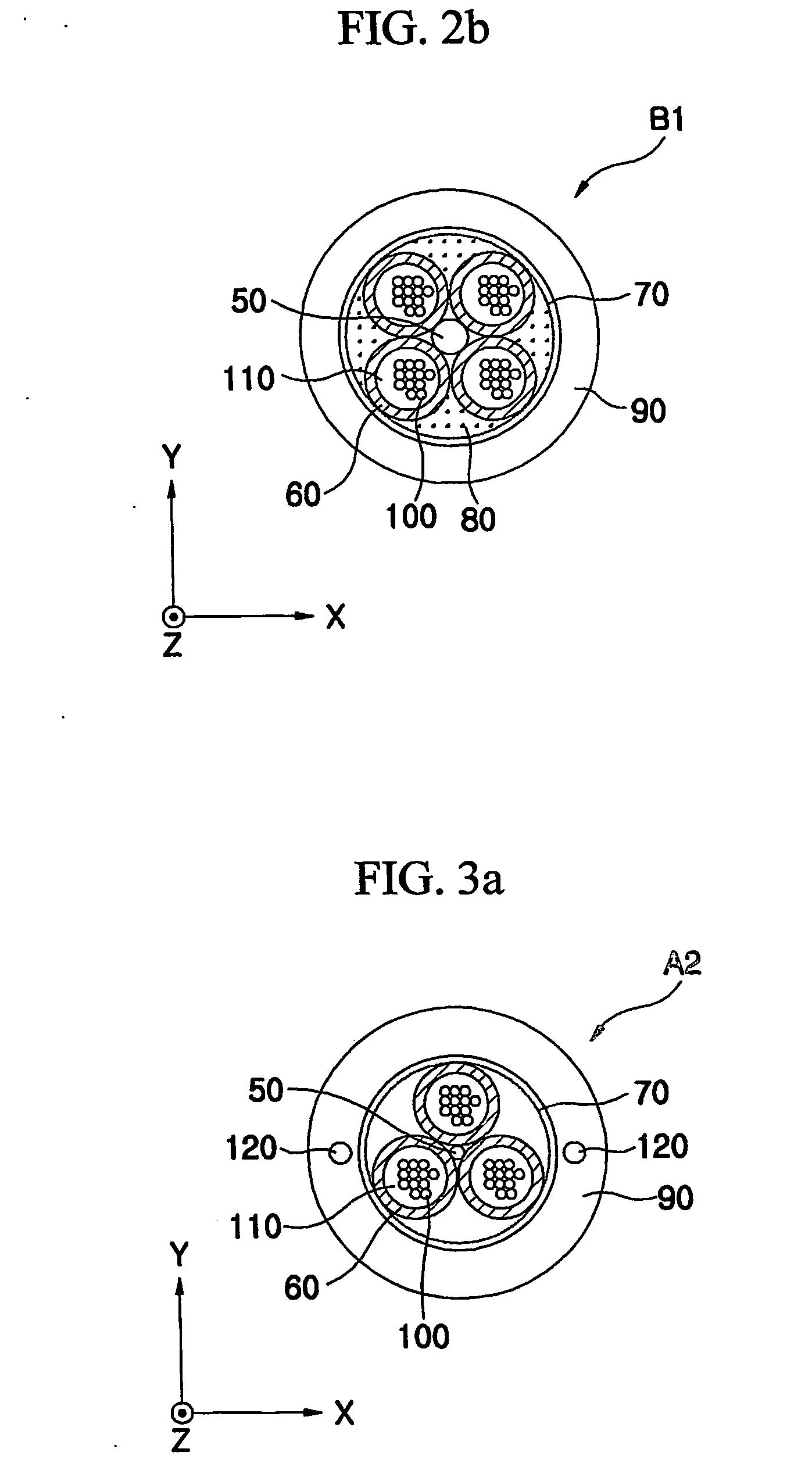

Loose tube optical cable

InactiveUS20060072886A1Reduced optical cable diameterReduce weightFibre mechanical structuresBundled fibre light guideEngineeringTension stress

Disclosed is a loose tube optical cable, which includes at most four cable aggregation units longitudinally twisted in contact with a central tensile member and having a loose tube optical fiber unit or inclusion, a cable coating for longitudinally surrounding a cable core aggregation having the central tensile member and the cable aggregation units, and one selected from the group consisting of a fibered tension-reinforcing member for surrounding the cable core aggregation, a wired tension-reinforcing member and a ring-shaped tension-reinforcing member formed in the cable coating. This loose tube optical cable has a compact structure by excluding unnecessary inclusion, thereby decreasing the outer diameter and the weight thereof. In addition, since the central tensile member and the tension-reinforcing member are not twisted with the cable aggregation units, tensile stress may be minimized in the optical cable.

Owner:LG CABLE INC

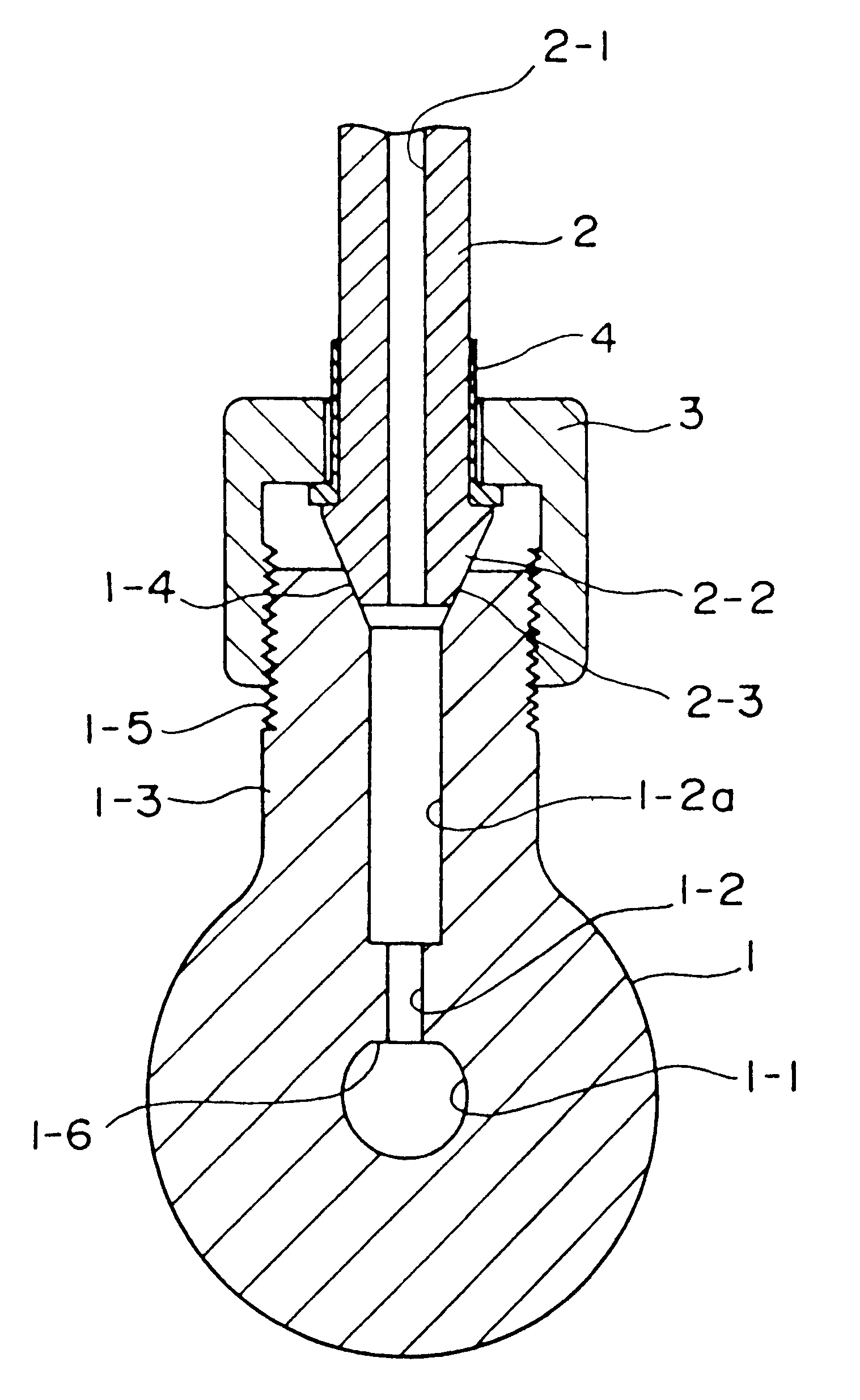

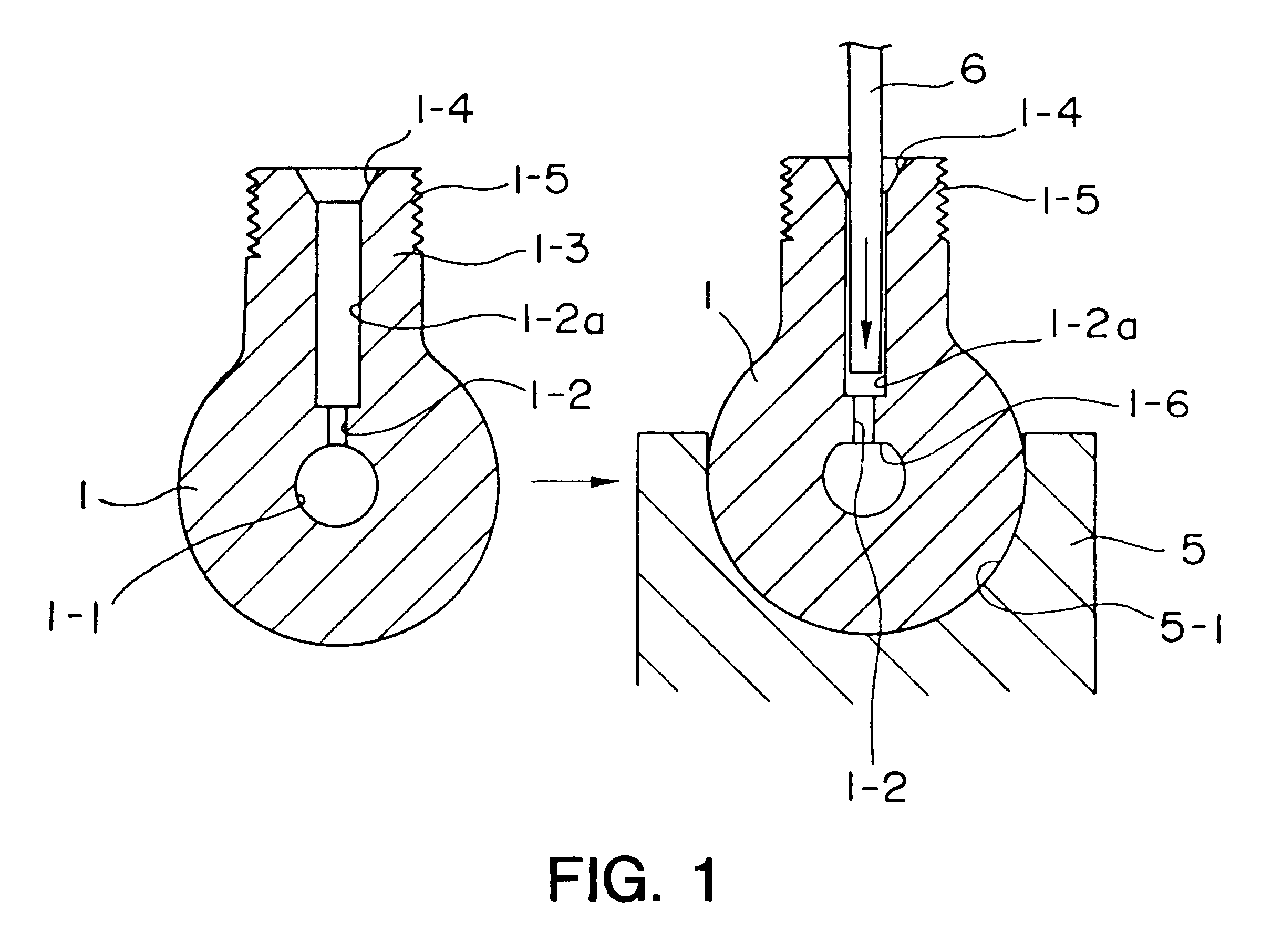

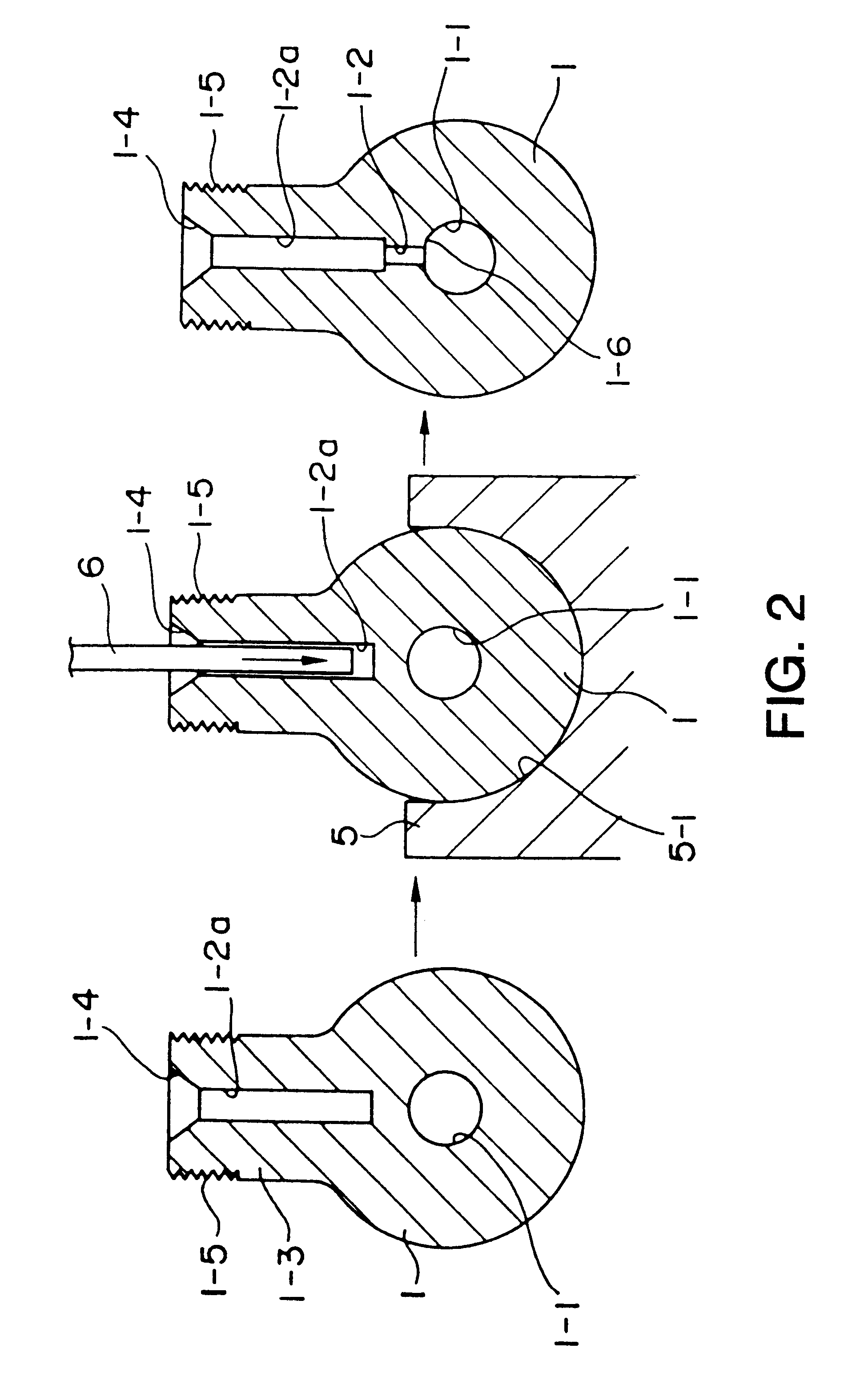

Device and method for testing material creep under coupling action of tensile stress and environment

InactiveCN103267682AUniform stressUniform stress distributionMaterial strength using tensile/compressive forcesTemperature controlInorganic salts

The invention discloses a device for testing material creep under the coupling action of tensile stress and the environment. The device comprises a support, a weight, a heating jacket, a container containing a saturated inorganic salt solution, a strain demodulator, a power supply, a temperature controller, a strain sensor and a test piece, wherein the support comprises a positioning plate, an upper spherical hinge, an upper clamping head, a supporting rod, a bearing plate, a base plate, a lower clamping head and a lower spherical hinge; the supporting rod is connected with the bearing plate through a sliding bearing; the test piece is embedded in a groove in the upper clamping head and a groove in the lower clamping head; the weight is positioned on the bearing plate; the heating jacket covers on the outer side of the support; the container is positioned between the support and the heating jacket; the strain sensor is adhered to the outer wall surface of the test piece; and the temperature controller is connected with the ring-shaped heating jacket. By adopting the device, the reliability of the test process can be improved, and the accuracy of results is ensured. Meanwhile, the invention also discloses a test method for the test device. The method is simple and easy to operate, and can keep that the test piece does not generate stress relaxation in the process of long-term load application, and the stress is uniformly distributed.

Owner:SOUTHEAST UNIV

Common rail and method of manufacturing the same

A common rail is provided for promoting inner pressure fatigue strength at location in proximity to a branch pipe. The common rail includes a main pipe rail with a main flow path. At least one boss in provided on the peripheral wall and includes a branch hole communicating the main flow path. The branch pipe is provided with a connecting head that has a pressing face at and end of the branch pipe. The pressing face of the branch pipe is urged into a pressure receiving seat of the boss. A compressive residual stress is provided at location in the peripheral wall where the main flow path of the main pipe rail communicates with the branch hole. The compressive residual stress increases the pressure fatigue strength by substantially canceling tensile stress.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

Tensile prestress rubber earthquake isolation support

InactiveCN101806097ASimple structureSeismic isolation mechanism is clearBridge structural detailsShock proofingVulcanizationStressed state

The invention relates to a prestress rubber earthquake isolation support and belongs to the field of structural earthquake isolation control. The tensile prestress rubber earthquake isolation support consists of upper and lower connecting steel plates, an internal thin steel plate, an internal rubber layer, a prestress steel strand and an anchorage device. The internal thin steel plate and the internal rubber layer are alternately overlapped; and the internal thin steel plate, the internal rubber layer and an external rubber protective layer are connected with the upper and lower connecting steel plates by high-temperature and high-pressure vulcanization, and the internal prestress steel stand is connected with the upper and lower connecting plates by the anchorage device. In the prestress rubber support, the insufficient tensile strength is compensated by the large tensile pressure bearing capacity of the rubber support; and before the support bears a service load, a pressure stress is applied in advanced, so that the support, in high-level earthquake, maintains a pressed or low-tensile stress state for ensuring the safety of a earthquake isolation structure system. The support has a simple structure, applies a clear earthquake isolation mechanism and is suitable for earthquake isolation control of large structures with high earthquake-resistance requirements, such as high-rise buildings, tower structures and large-span bridges.

Owner:BEIJING UNIV OF TECH

Method and apparatus for fabricating high tensile stress film

ActiveUS20080305600A1Simple processElectric discharge tubesSemiconductor/solid-state device manufacturingUltravioletTension stress

A method and an apparatus for fabricating a high tensile stress film includes providing a substrate, forming a poly stressor on the substrate, and performing an ultra violet rapid thermal process (UVRTP) for curing the poly stressor and adjusting its tensile stress status, thus the poly stressor serves as a high tensile stress film. Due to a combination of energy from photons and heat, the tensile stress status of the high tensile stress film is adjusted in a relatively shorter process period or under a relatively lower temperature.

Owner:UNITED MICROELECTRONICS CORP

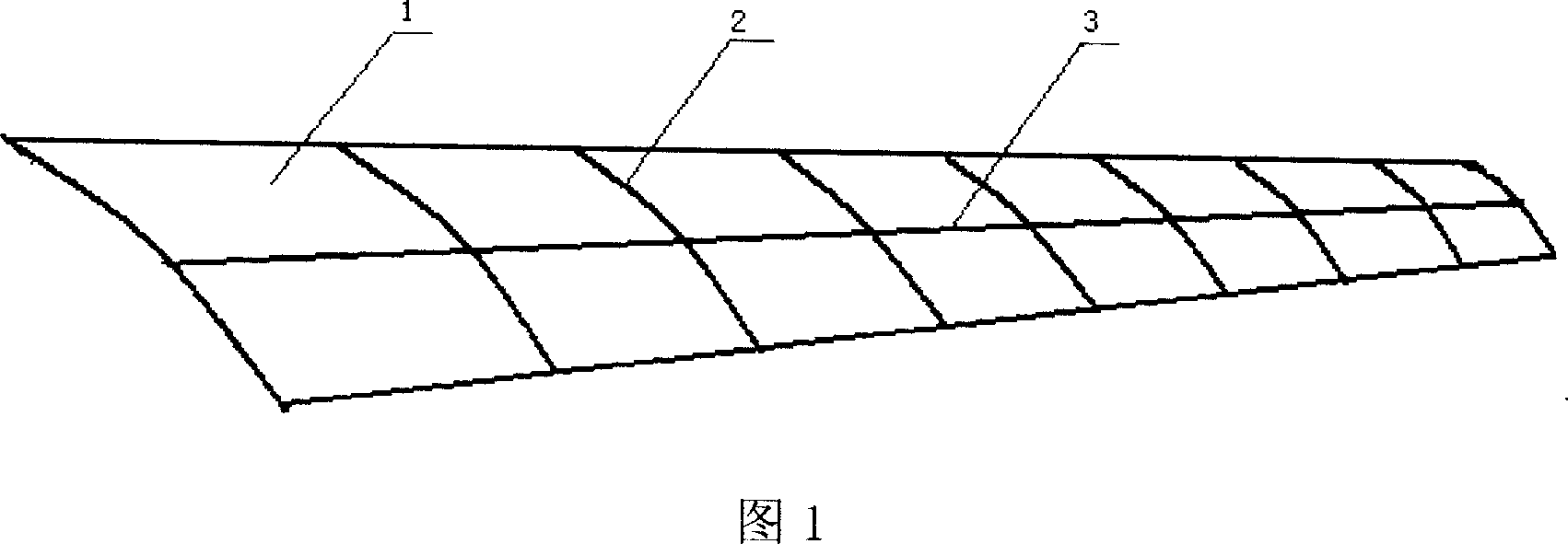

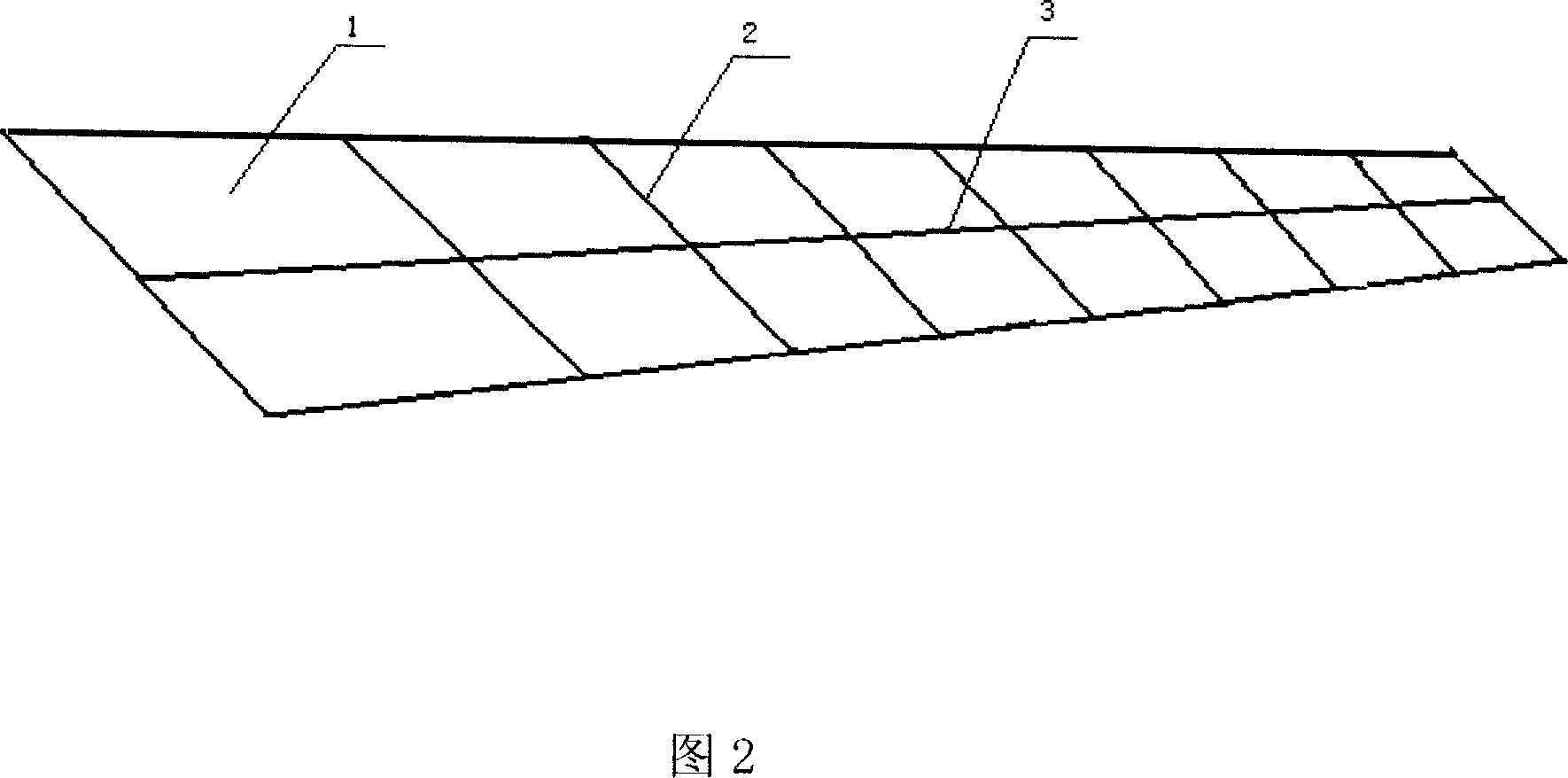

Prestressing shot-blasting formation technique for double-curved wallboard

A pre-stressing and grit-blasting technique for shaping a double-curvature plate wall used as the thick jacket of large airplane features that a pre-stressing fixture unit is used to pre-bend a plate longitudinally and transversely and fix it for applying a pre-stress to it while the grits are blasted onto said plate for obtaining a needed shape.

Owner:XIAN AIRCRAFT IND GROUP

Multifunctional true triaxial rock creepmeter

InactiveCN102621012AMany experimental functionsPracticalInvestigating material ductilityConstant loadStress path

The invention discloses a multifunctional true triaxial rock creepmeter, comprising a base, a test piece mounting base arranged on the base, two groups of horizontal direction stress loading systems with the same structure, a vertical direction stress loading system and a creep data measuring system. The multifunctional true triaxial rock creepmeter disclosed by the invention can carry out a single-axis pulling and pressing creep test and also can carry out a true triaxial compression, pulling and pressing combined creep and unloading-creep test which simulates three-dimensional stress state and loading and unloading stress path of a natural geological rock mass and an engineering rock mass and maintain tension stress states in one or two directions unloaded to the rock; and test function is more comprehensive, practicability is stronger, and a pulling and pressing combined creep and stable pressing and pulling stress conversion unloading-creep test is realized; a pull pressure loading system can provide a pressure which is high enough to meet creep test requirements of most rock materials, and a long-term constant load can be provided; and the multifunctional true triaxial rock creepmeter disclosed by the invention has the characteristics of having a simpler structure, hardly consuming energy source in a test process and having low test cost.

Owner:CHONGQING UNIV

Petroleum casing pipe with high-strength and high ductility as well as manufacturing method thereof

ActiveCN101250671AImprove mechanical propertiesImprove performanceFurnace typesMetal rolling arrangementsAlloyHigh intensity

The invention provides a steel grade of a bergol cannula with high intensity and high toughness, wherein the propositions of composition elements are that C 0.22-0.4%, Si 0.17-0.35%, Mn 0.45-0.60%, Cr 0.95-1.10%, Mo 0.70-0.80%, Al 0.015-0.040%, Ni<0.20%, Cu<0.20%, V 0.070-0.100%, Ca>0.0015%, P<0.010%, S<0.003% and the allowance is iron. The invention also provides a method for rolling the bergol cannula, which comprises the following steps: firstly, smelting batching, secondly, continuously casting and rolling, thirdly, processing a pipe. The method has the advantages of embodying steel grade with higher alloy content is adopted through the method, excellent mechanical property and lower production cost, the making of perforation and rolling techniques are reasonable, mechanical property of cannual is maximally improved, the selection of heat treatment process technique and thermal straightening temperature are reasonable, grain fineness numbers of tissues are refined, residual tension stress of the cannula is greatly lowered, geometric precision control range is strictly planned, and the property of the cannula is improved under the circumstance of reasonable production cost.

Owner:TIANJIN PIPE GROUP CORP

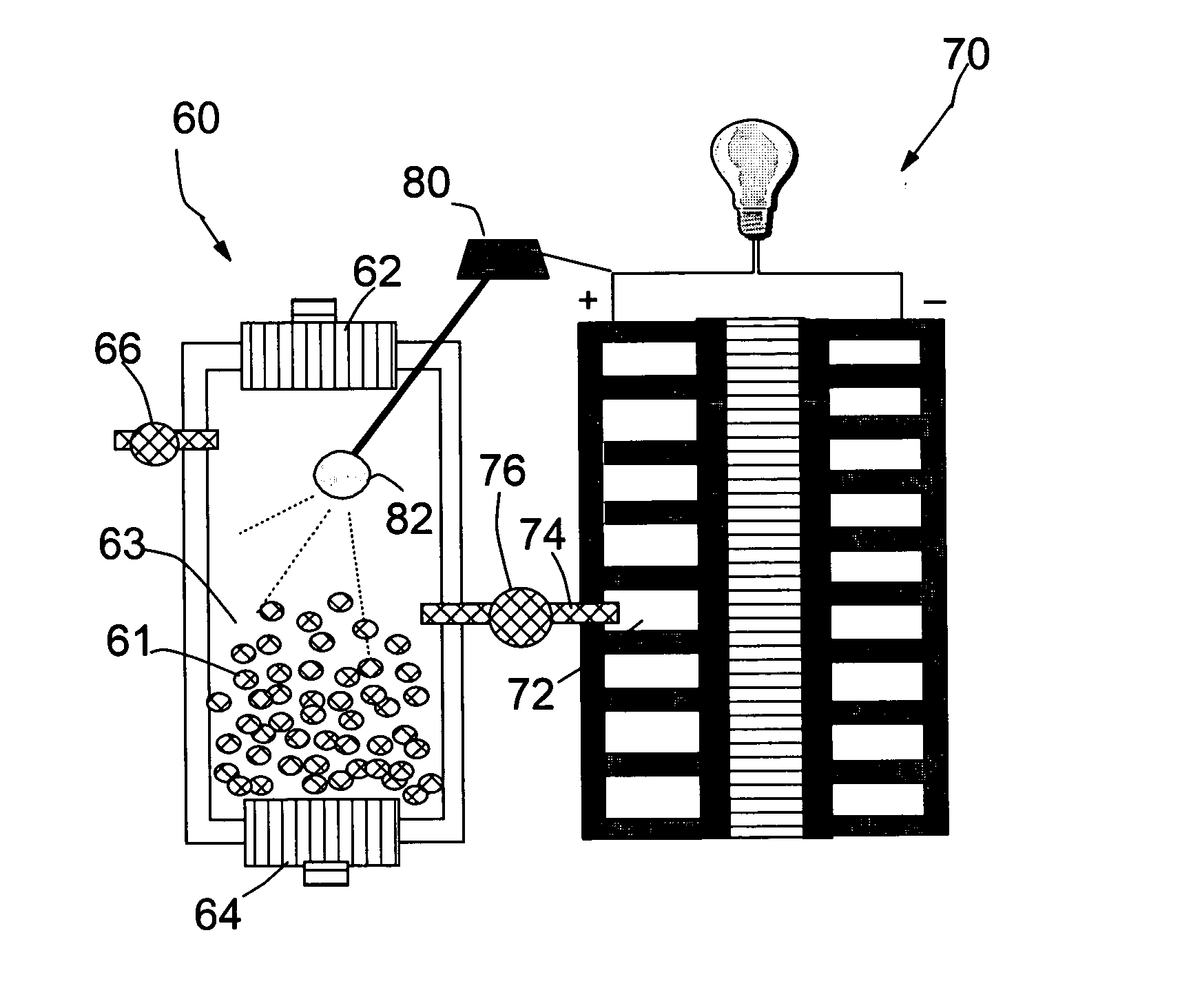

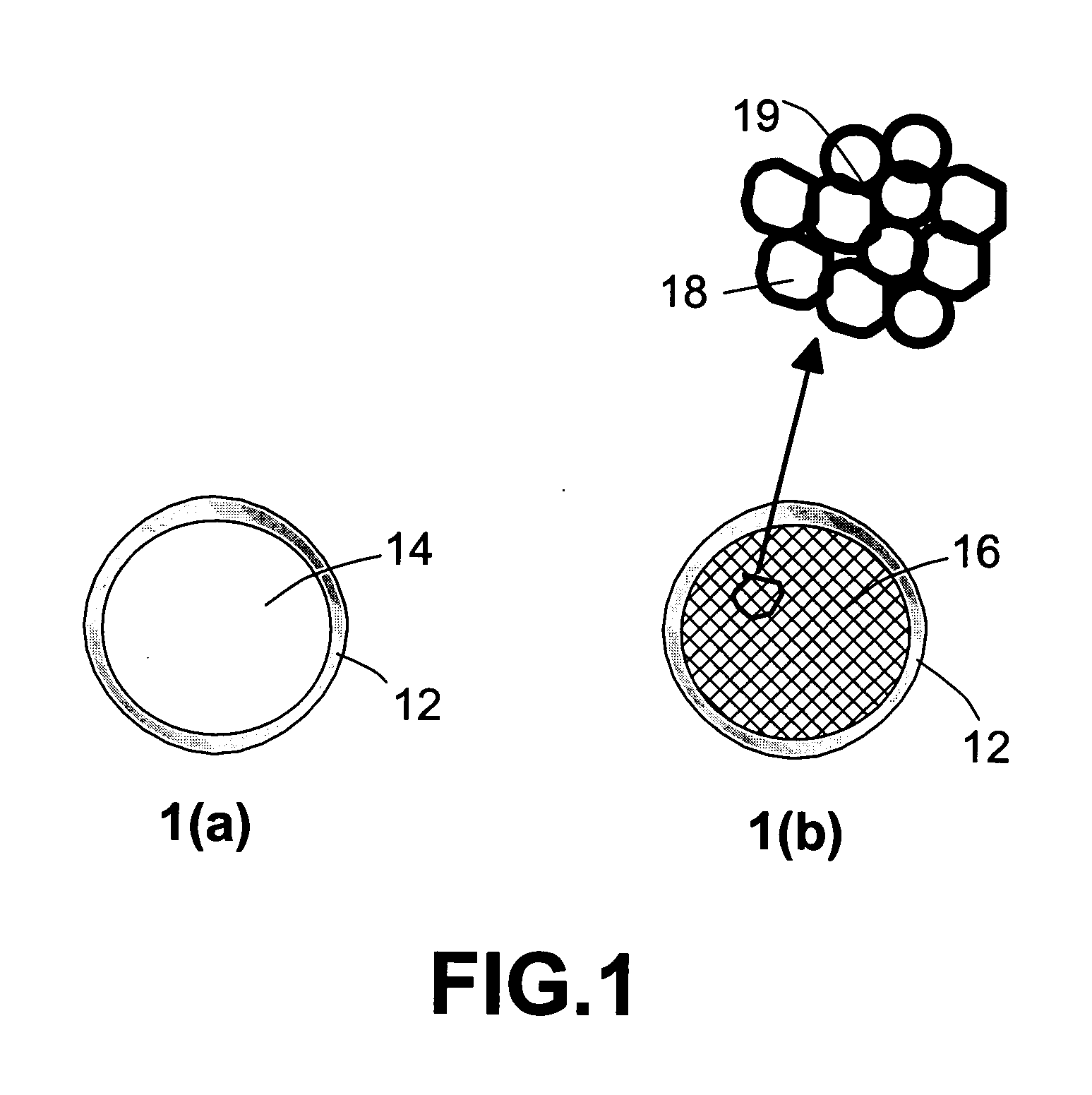

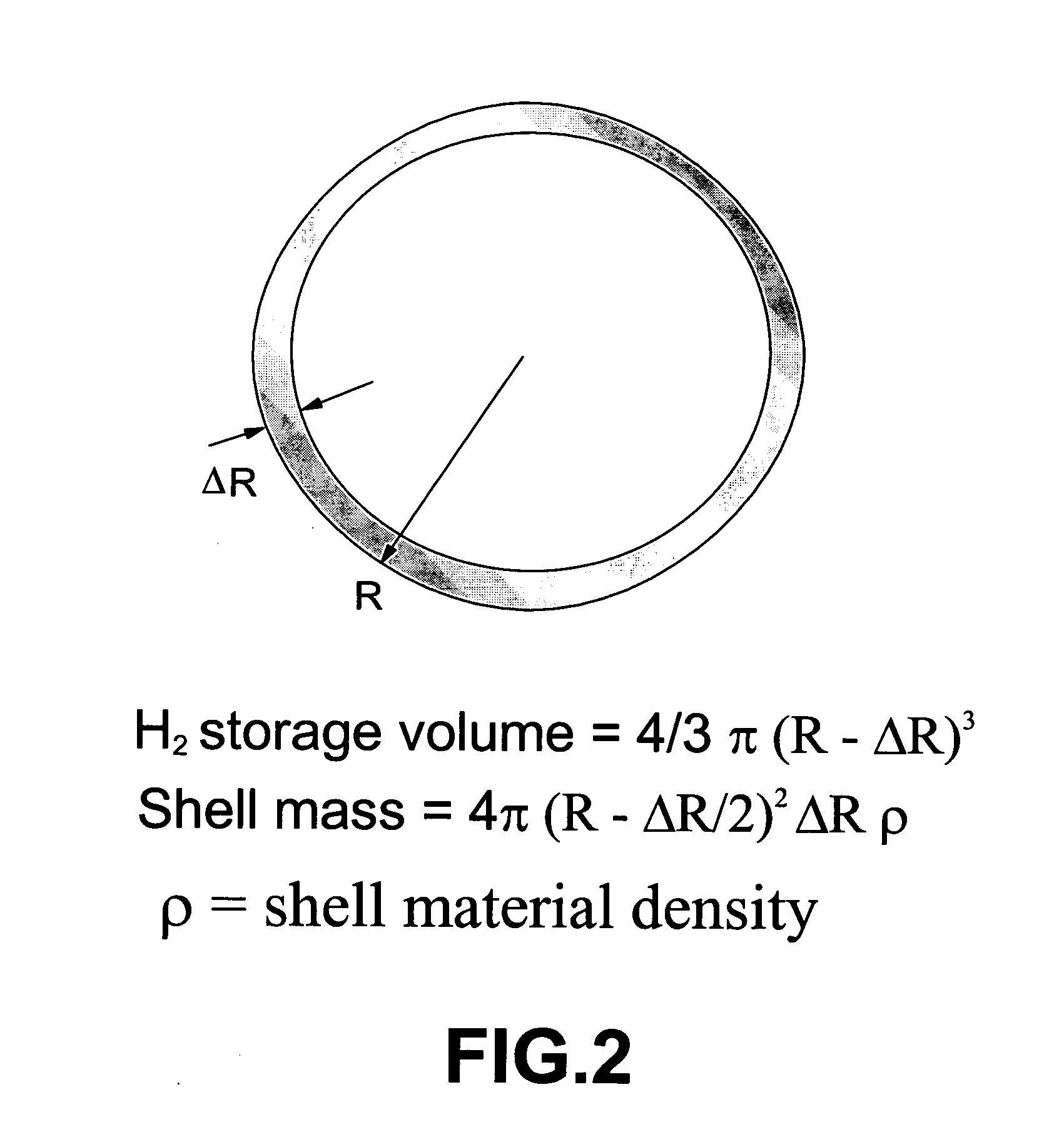

Method for storing and delivering hydrogen to fuel cells

InactiveUS20060026900A1Reduce shell tensile strengthEfficient releaseReactant parameters controlReversible hydrogen uptakeEngineeringGlass transition

A hydrogen gas storage and supply method including: (a) providing a chamber and, contained therein, a plurality of shell-core micro-spheres, each comprising a shell and a hollow or porous core, filled with pressurized hydrogen gas at an internal pressure P; and (b) heating the micro-spheres to a temperature T to reduce the shell tensile strength σt to an extent that a tensile stress σ experienced by a shell of the micro-spheres meets the condition of σ≧ασt, causing hydrogen to diffuse out of the micro-spheres to provide hydrogen fuel from the chamber to a hydrogen-consuming device, where the material-specific parameter α has a value between 0.3 and 0.7. The shell stress scales with the internal hydrogen gas pressure and the tensile strength σt decreases with increasing micro-sphere temperature. For instance, this condition is met when the micro-spheres are heated to a temperature within the range of [Tg−25° C.] to [Tg+25° C.] for an amorphous polymer (Tg=glass transition temperature or softening point) or withing the range of [Tm−25° C.] to [Tm+10° C.] for a crystalline polymer (Tm=melting point). This method is useful for feeding hydrogen to a fuel cell used in a portable microelectronic device, automobile, and unmanned aerial vehicle where light weight is an important factor.

Owner:JANG BOR Z

High-temperature high-pressure constant load stress corrosion experiment method and device

InactiveCN102706750ARealistic simulation of mechanical damageStability test methodWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesMetallic materialsStressed state

The invention discloses a high-temperature high-pressure constant load stress corrosion experiment method and device. The technical scheme are that constant load stress corrosion experiment of metal materials can be conducted in certain stress state under the combined action of high-temperature high-pressure gaseous phase and liquid phase corrosion media, and subjected to combined action of the constant stress, and high-temperature high-pressure gaseous phase and liquid phase corrosion media in experiment process, and evaluation and research on the applicability and action mechanism of the metal material can be conducted under high-temperature high-pressure corrosive environment and tension stress state according to the experiment results. Damage to strength, plasticity and flexibility of the metal materials can be determined in high-temperature high-pressure gaseous phase and liquid phase corrosive environments under the action of any load by utilizing the experiment method and device, the mechanical property damage degree of the metal materials can be obtained in certain stress state and special corrosion environment according to the test result, thus conducting preference of the metal materials and applicability evaluation.

Owner:SOUTHWEST PETROLEUM UNIV

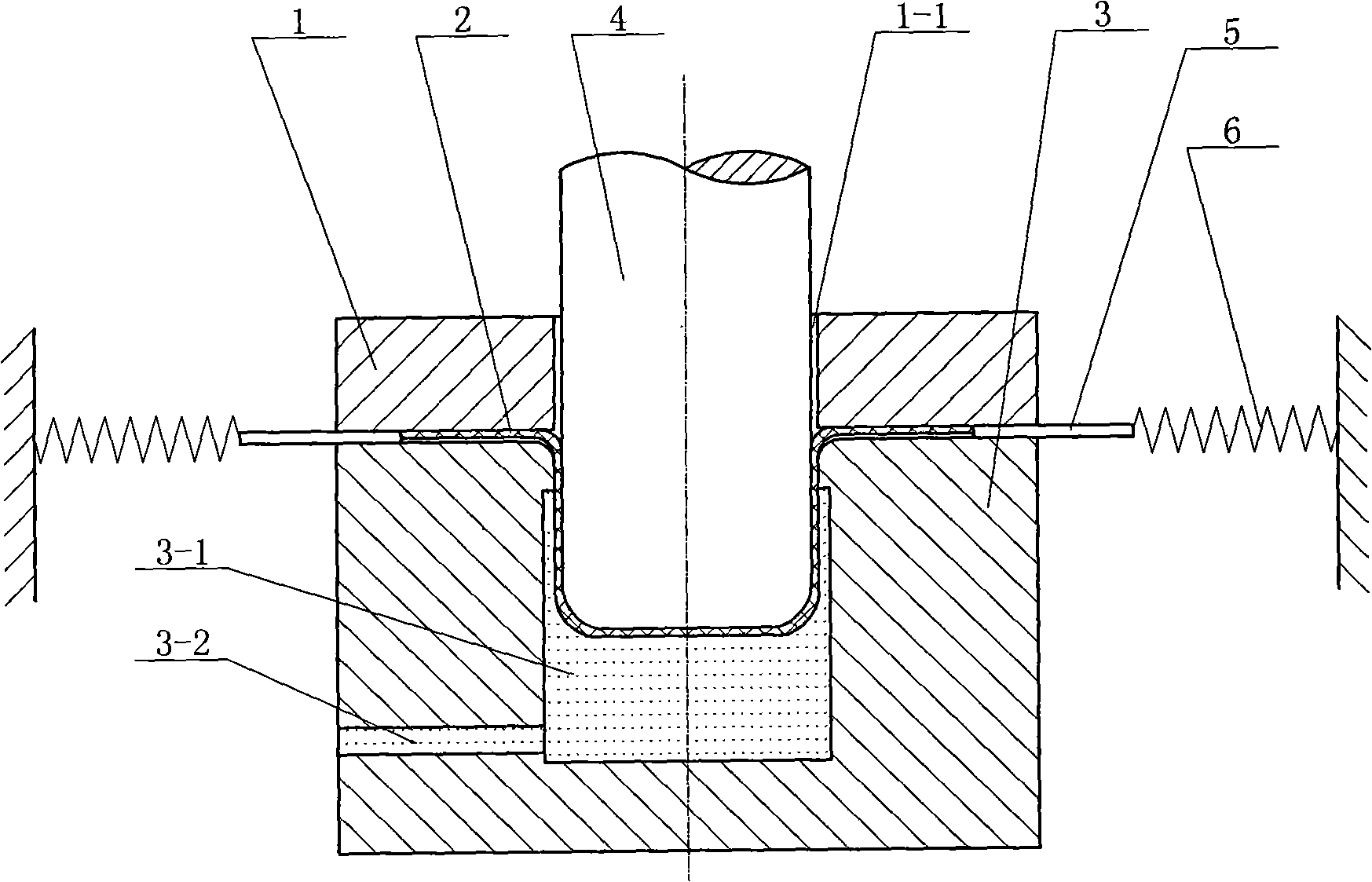

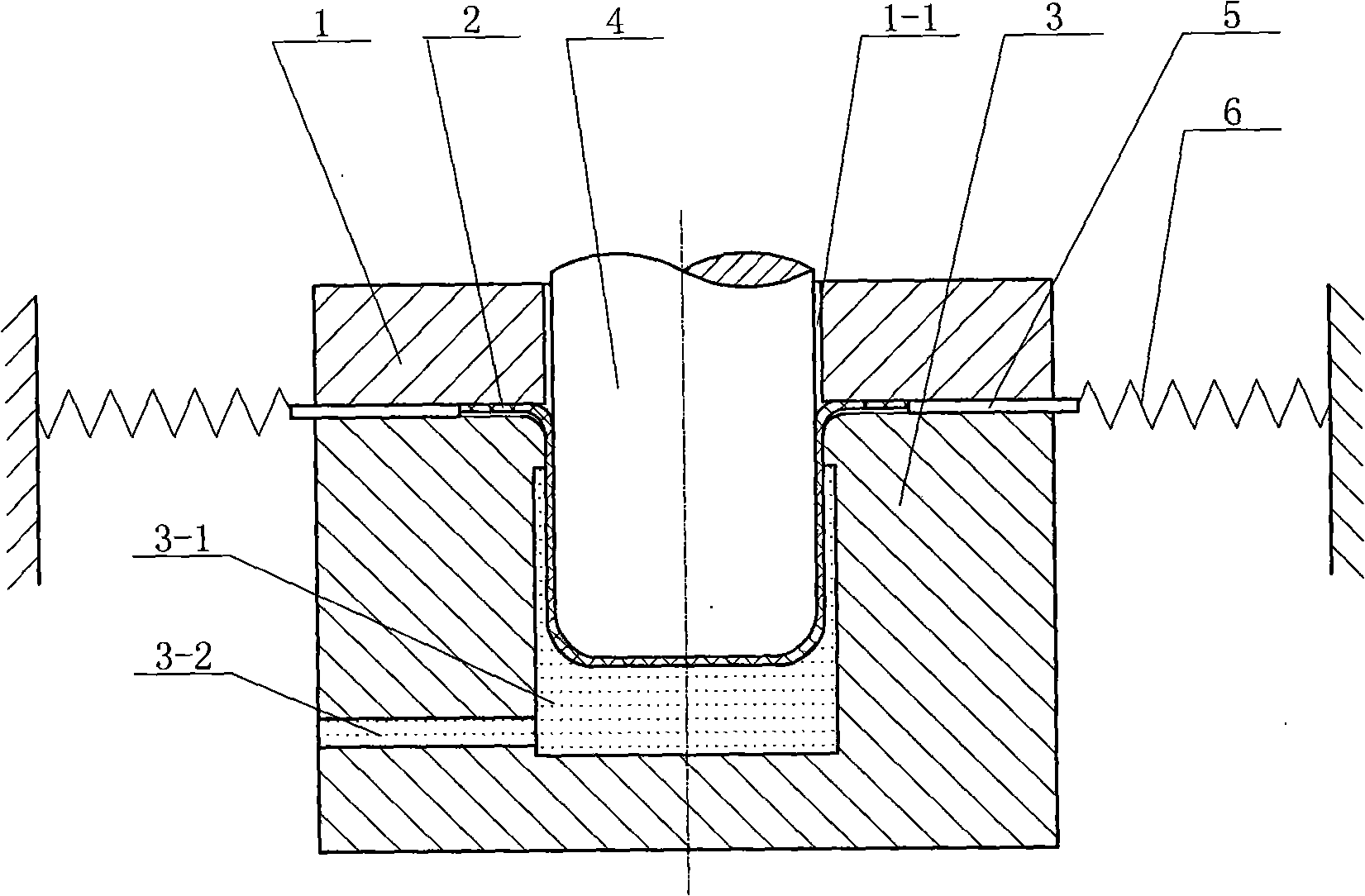

Device for improving forming limit in hydromechanical deep drawing of sheet material and method thereof

The invention discloses a device and a method for improving the limit of hydraulic deep drawing molding of plank stuff, which relates to a hydraulic deep drawing molding device of metal plank stuff and a method thereof, and solves the problem that as the deep drawing plate parts such as the plate parts made of magaluma have large deep drawing rate and deformed plank flange parts, the bottom of the deep drawing plate parts is easy to fracture and has limitation to the molding limit due to overlarge pulling stress. A stamping ring (1) is arranged at the upper part of a cavity die (3), a die space (1-1) of the stamping ring (1) has the same shaft and the same pore diameter with a die space (3-1) of the cavity die (3), one end of a male die (4) is arranged in the die space (1-1), one end of a dowel steel (5) is arranged between the stamping ring (1) and the cavity die (3), and the other end of the dowel steel (5) is fixedly connected with a spring (6). The device and the method for improving the limit of the hydraulic deep drawing molding of plank stuff realize the radial pressure exertion and controllability at a position of a deformed region at the outer side of the plate parts, are favorable for the deep drawing molding of the plate parts with complicated shapes, have simplicity, reliability, lower cost and easy implementation, and can remarkably improve the limit of the deep drawing molding of the plate parts.

Owner:HARBIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com