Device for improving forming limit in hydromechanical deep drawing of sheet material and method thereof

A liquid-filled deep drawing and forming limit technology, which is applied in the field of metal plate liquid-filled deep drawing forming devices, can solve the problems of large drawing ratio, cracking forming limit and limitation of the bottom of drawn parts, etc., and achieve low cost and improved deep drawing Forming limits, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

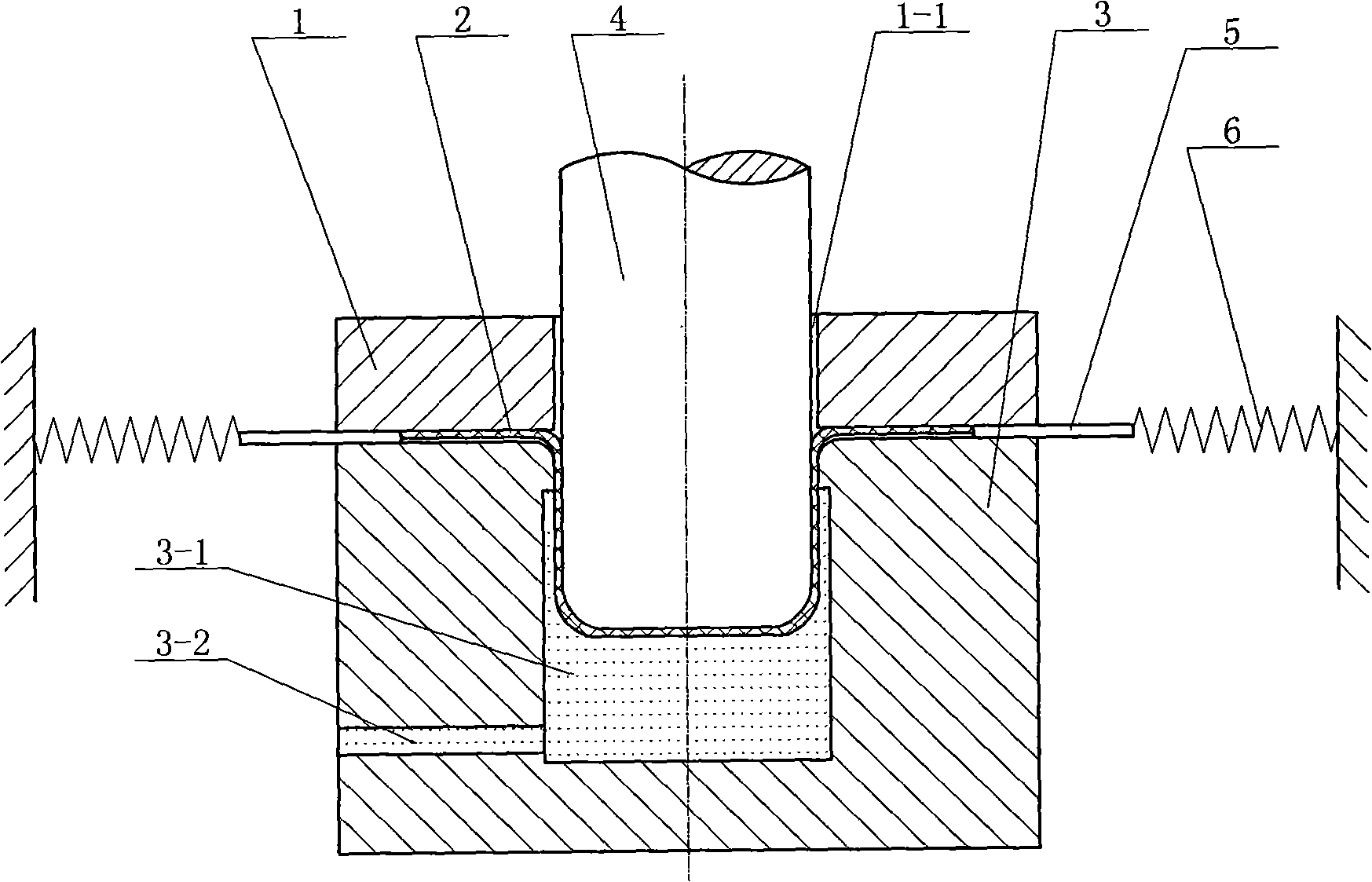

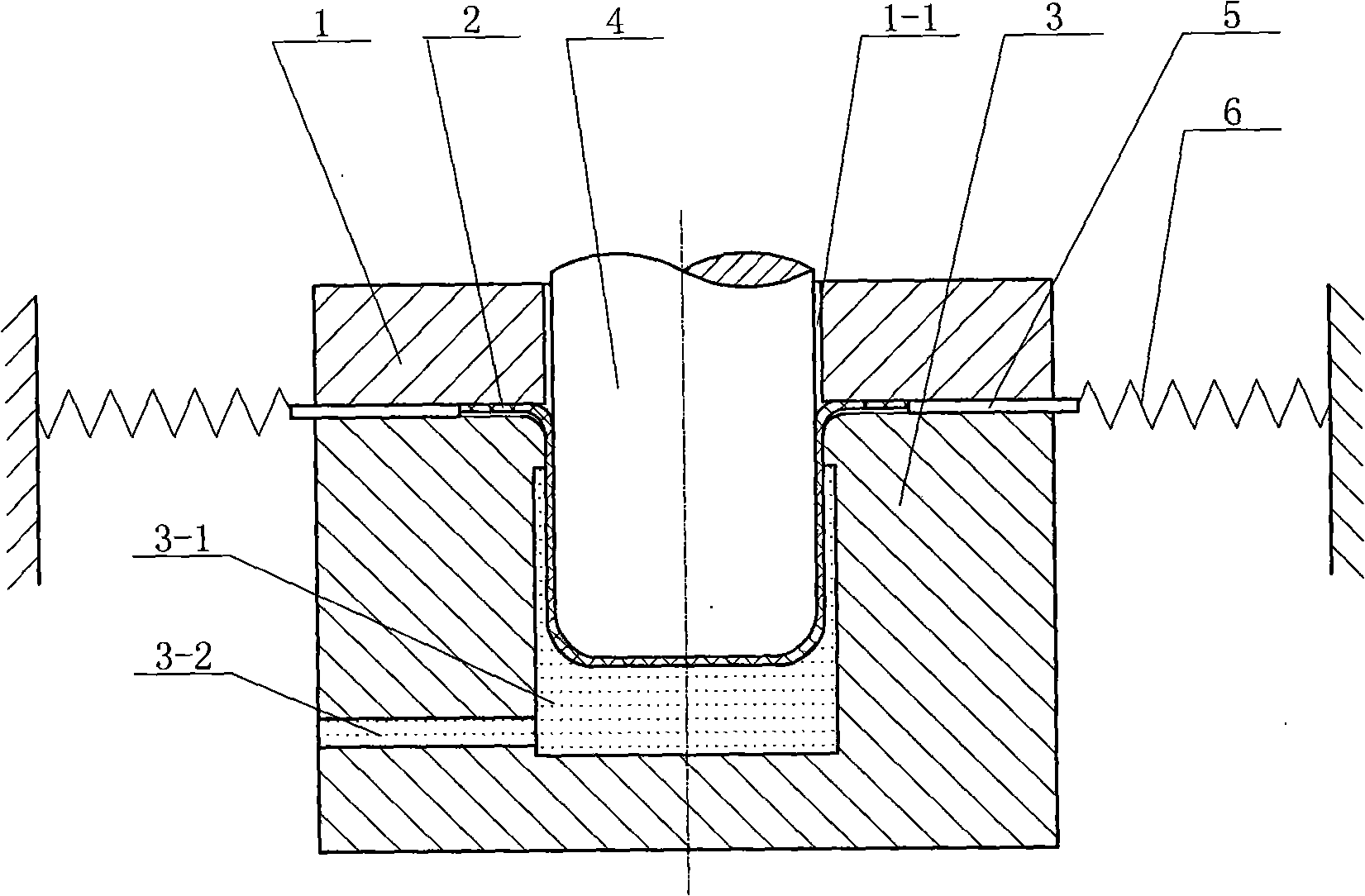

[0008] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, this embodiment is made up of blank holder 1, die 3, punch 4, dowel 5 and spring 6; 1-1 is coaxial with the concave mold cavity 3-1 of the concave mold 3 and has the same aperture, one end of the punch 4 is placed in the cavity 1-1, and one end of the dowel 5 is placed in the blank holder 1 and the concave mold 3 Between, the other end of dowel rod 5 is fixedly connected with spring 6. Place the sheet between the die and the blank holder, and connect the outer end of the sheet to the vertical rods. The dowels are arranged along the circumference of the sheet. The number of dowels can be adjusted according to the shape of the sheet. According to the specific material of the sheet metal, springs of different rigidity and length can be selected according to the different materials of the sheet metal forming, and radial pressure is applied to the surrounding area of the deformatio...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 and figure 2 This embodiment is described. In this embodiment, a liquid injection hole 3-2 is horizontally arranged on the die 3, and the liquid injection hole 3-2 communicates with the cavity 3-1 of the female die. The purpose of such setting is to inject liquid into the cavity of the concave mold to realize the liquid-filled deep drawing of the sheet.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 and figure 2 Describe this embodiment, this embodiment is completed by the following steps: 1. inject the liquid into the concave mold cavity 3-1; 2. place the blank 2 on the concave mold 3; 4. Place one end of the dowel bar 5 on the outer end of the sheet material 2; 5. Connect the other end of the dowel bar 5 to the spring 6; 6. The punch is 4-way Moving down, the sheet material 2 is deformed and flows into the concave mold cavity 3-1. At the initial drawing, the spring is in a compressed state, and the elastic force applied to the sheet is relatively large. As the drawing progresses, the spring gradually elongates, and the elastic force gradually decreases until the end of drawing, and the elastic force decreases to zero. This variation of elastic force is consistent with the variation of the radial tensile stress in the deformation zone of the sheet metal during the deep drawing process. In this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com