Patents

Literature

756 results about "Radial pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

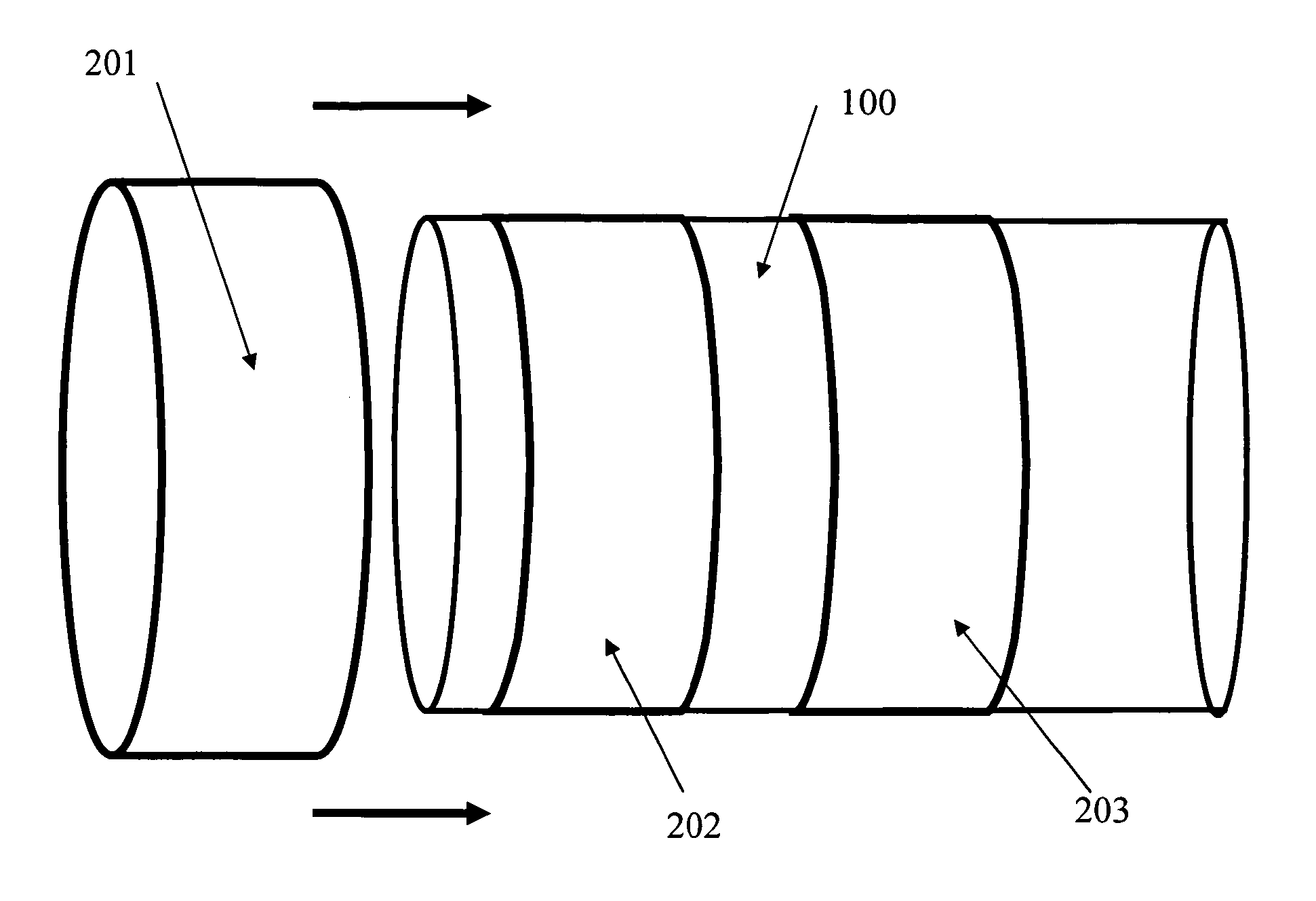

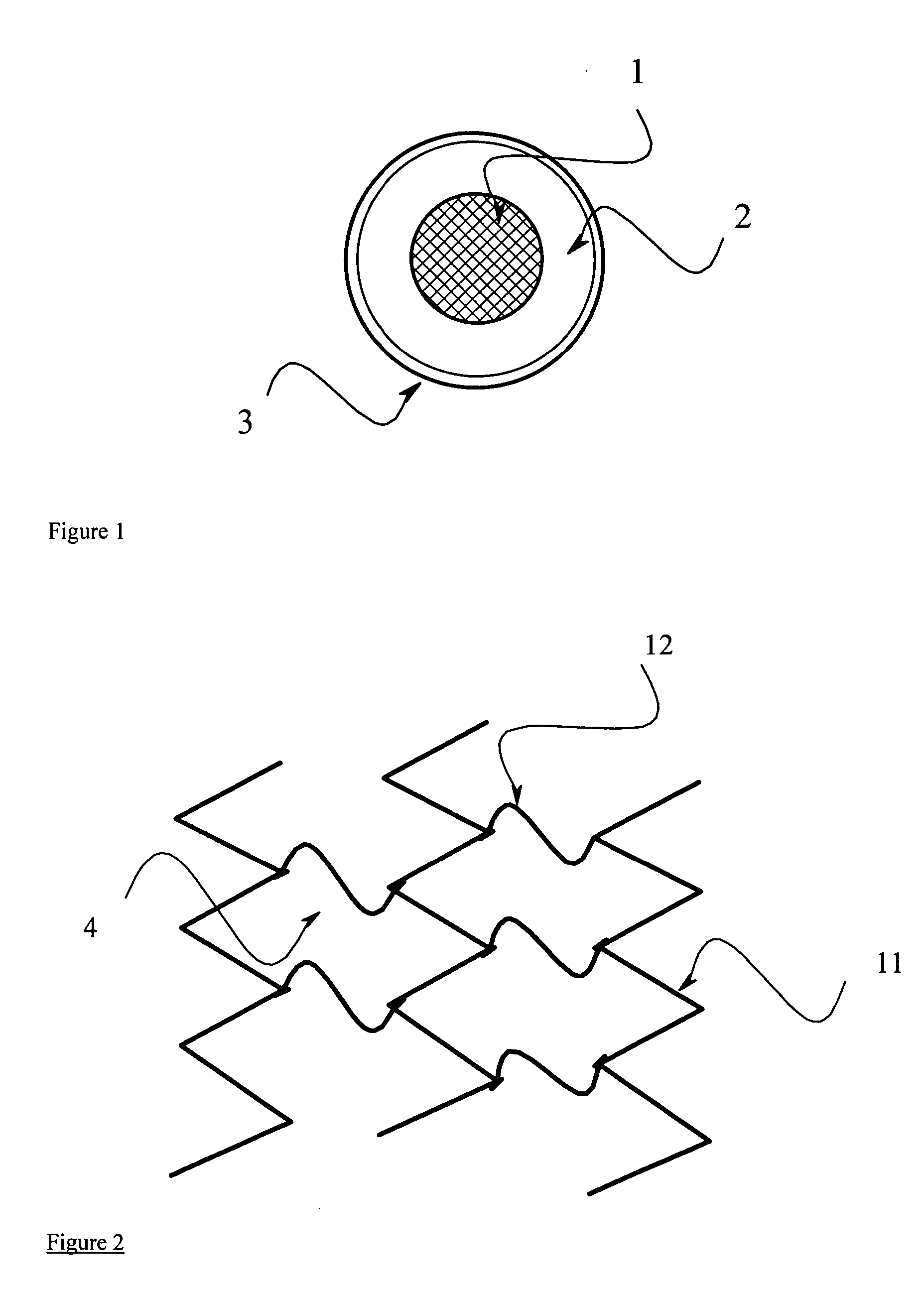

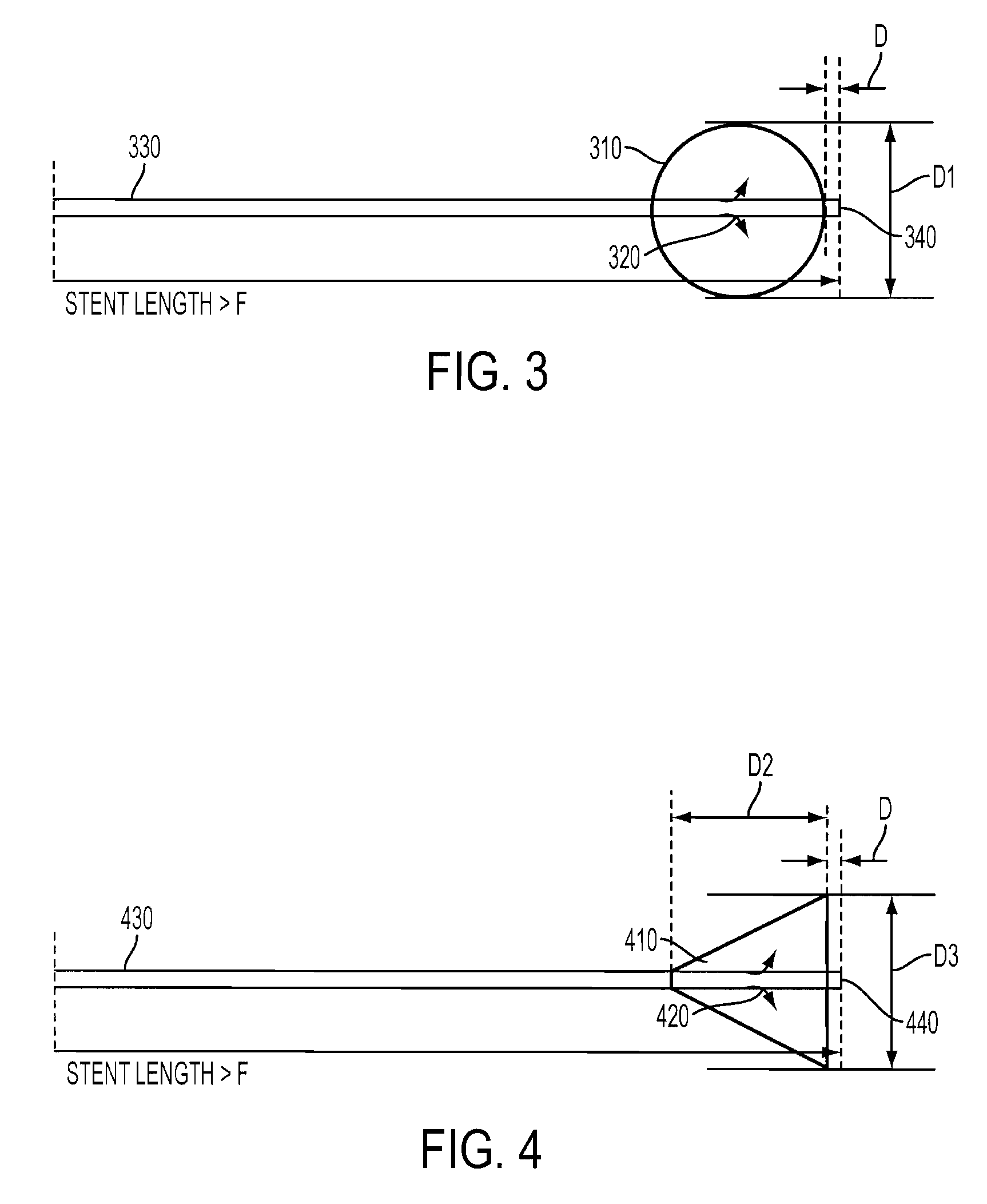

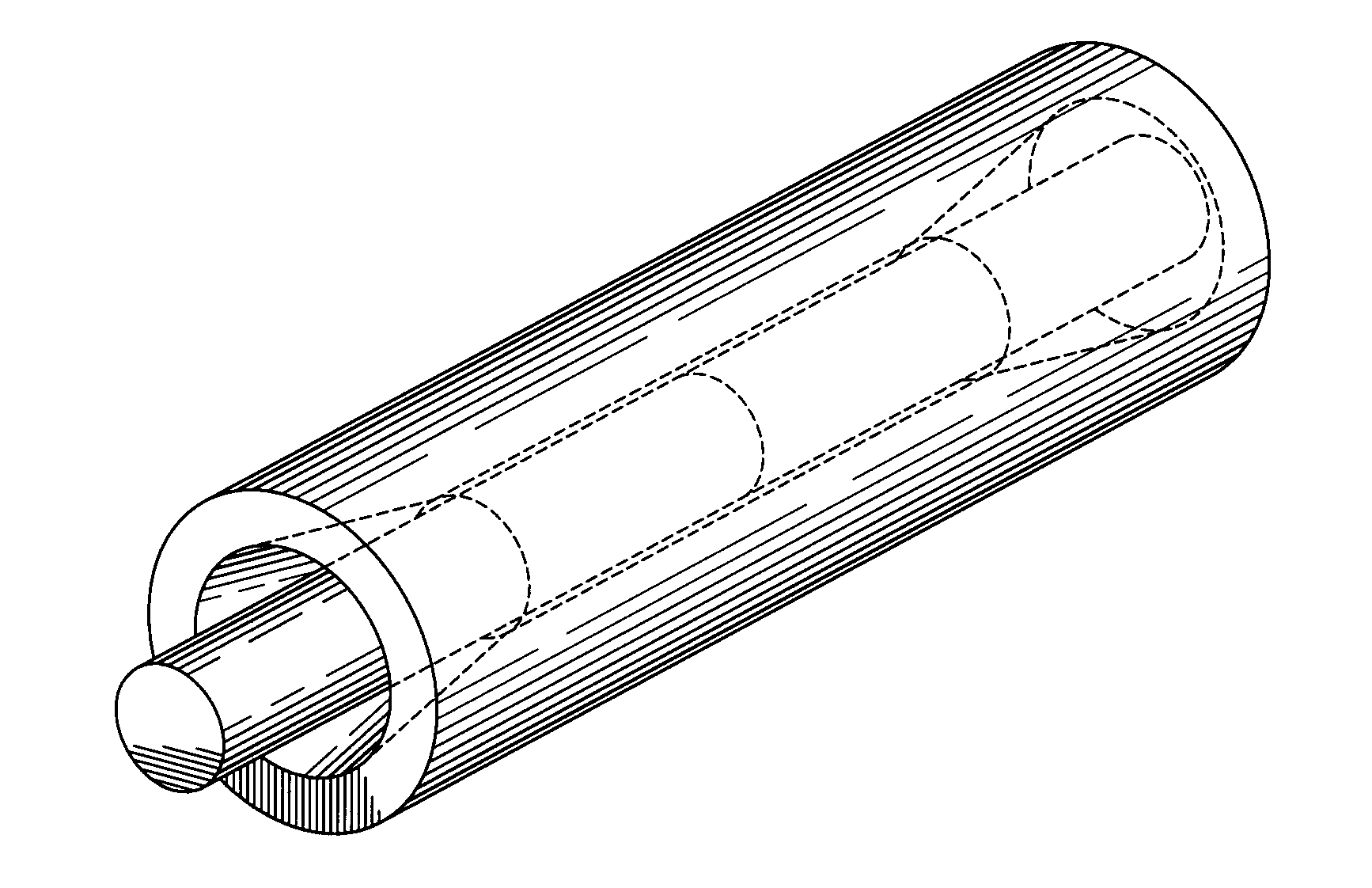

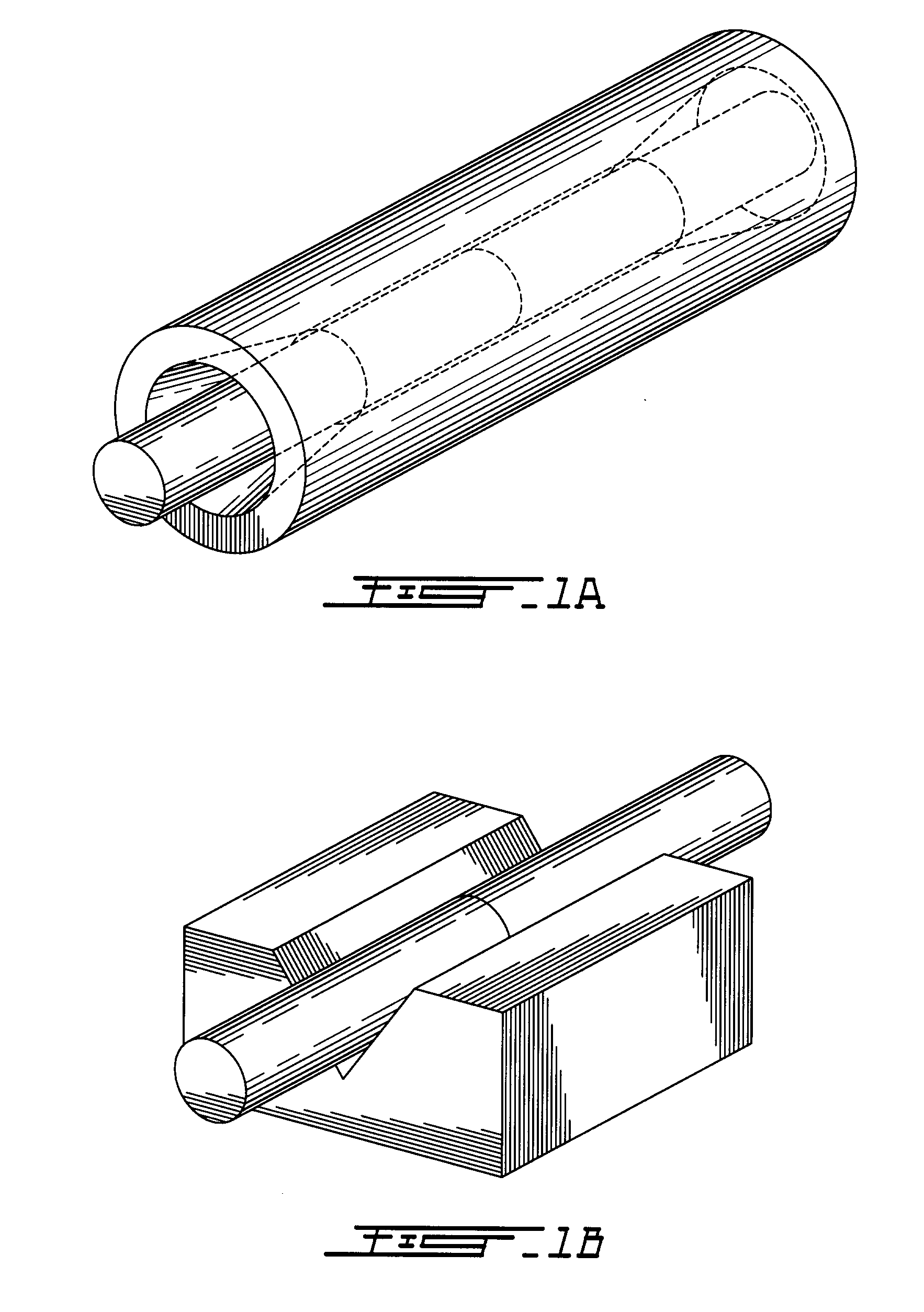

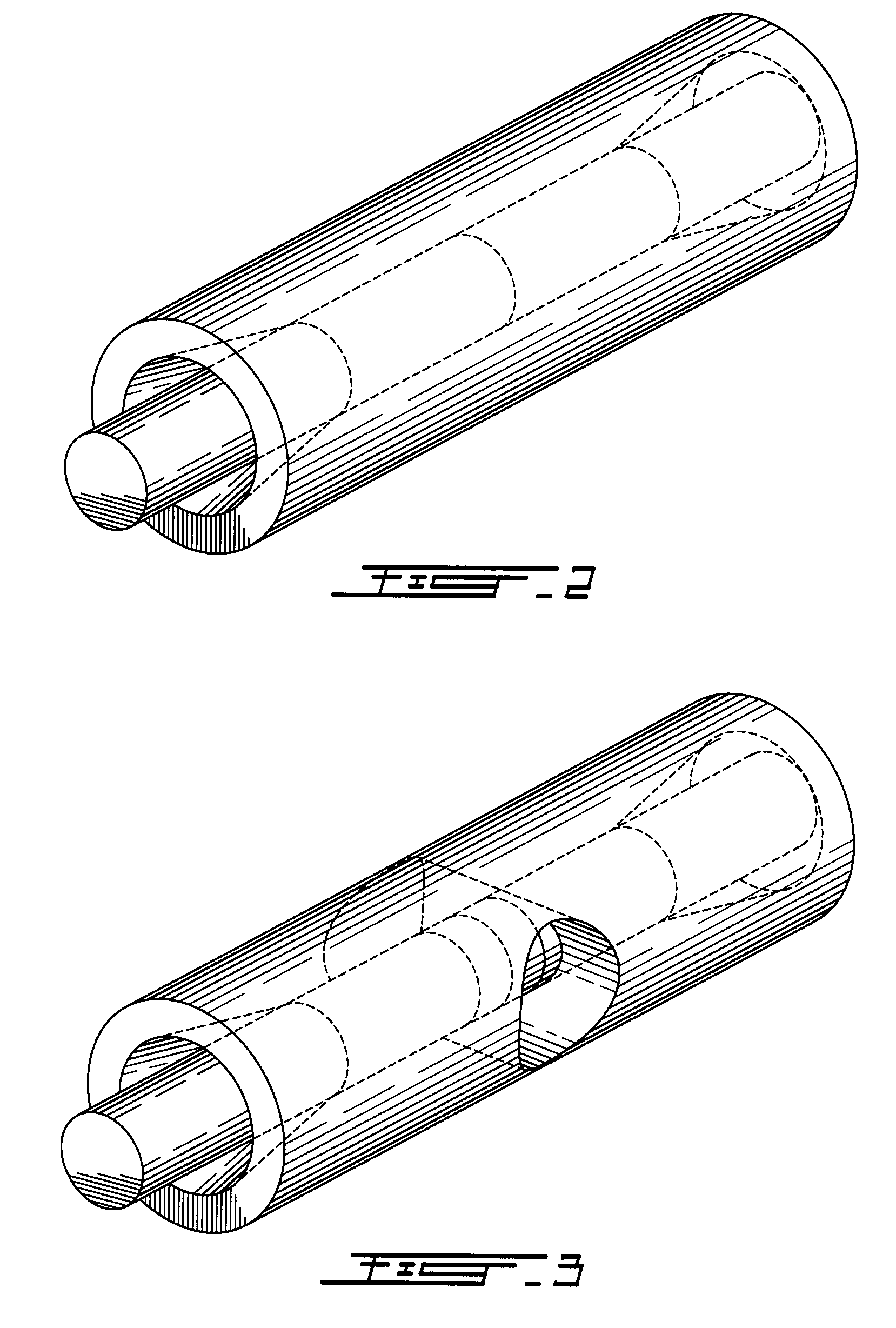

Stent with variable cross section braiding filament and method for making same

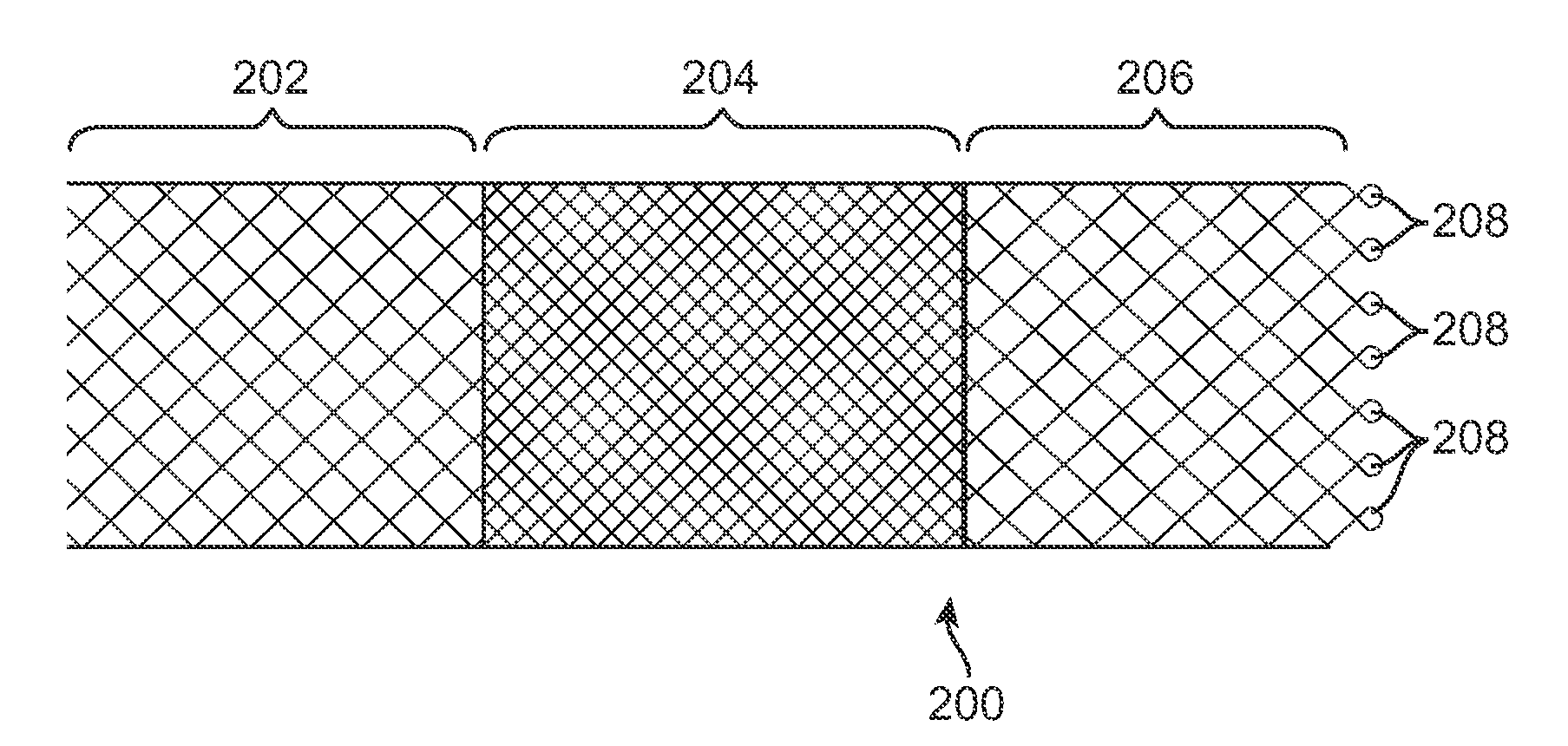

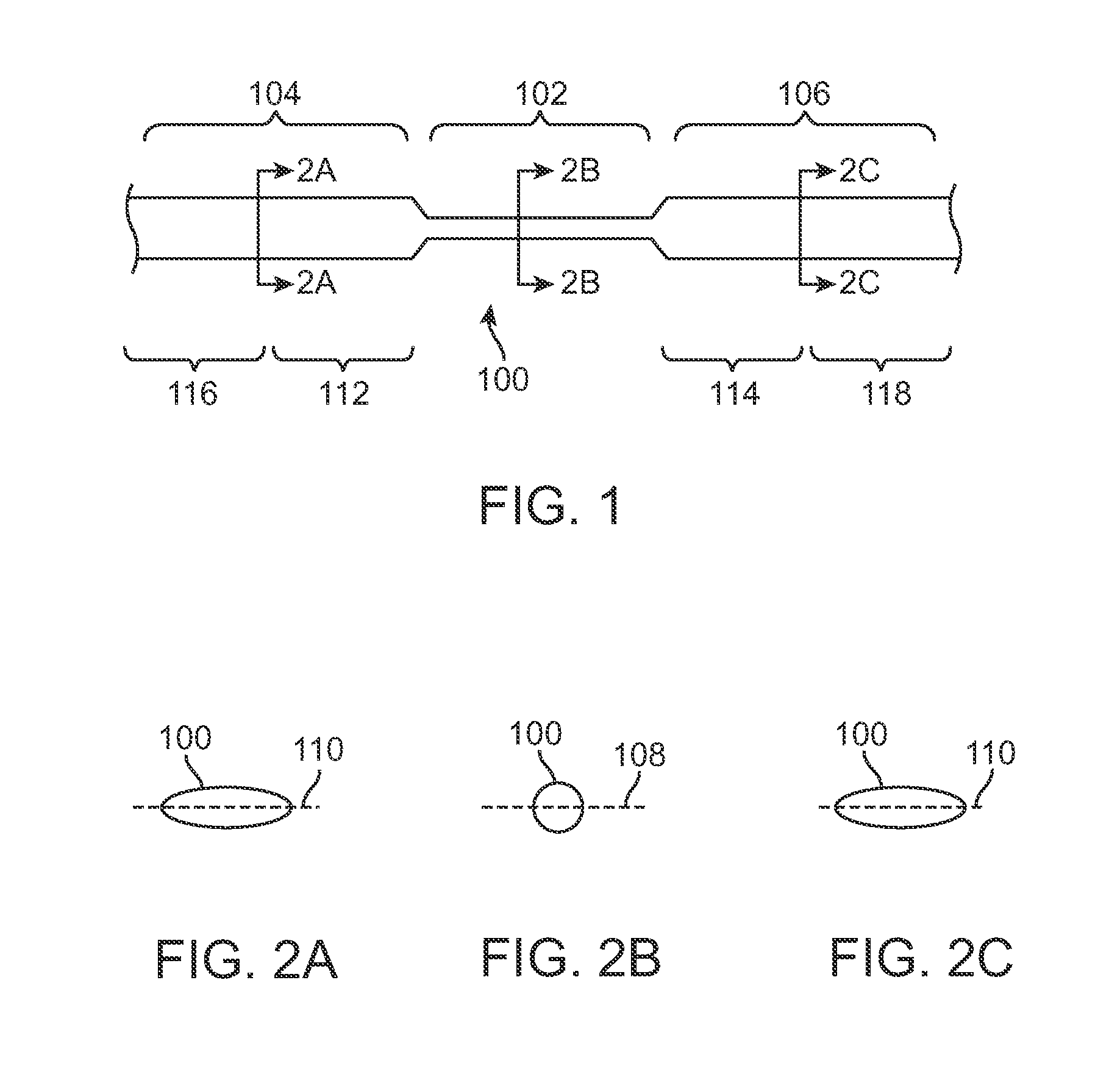

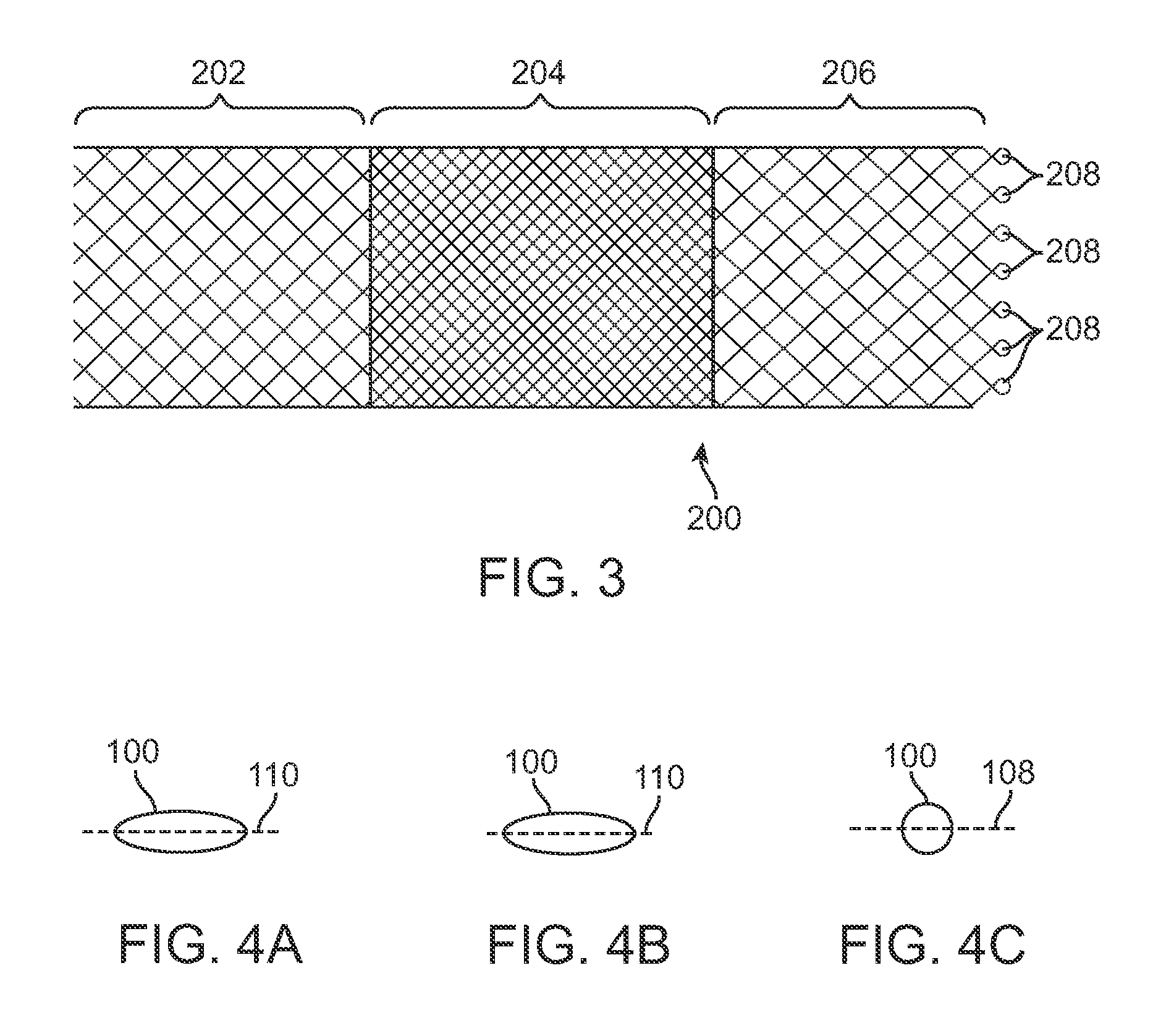

A braided stent comprises a filament having at least one circular zone and at least two non-circular zones. Embodiments of the braided stent have a proximal segment, a middle segment, and a distal segment, wherein a porosity of the middle segment is lower than, a respective porosity of the proximal and distal segments. In one embodiment, a radial pressure of the middle segment is separately controlled to be different from, e.g., less than, a radial pressure of the distal segment. In another embodiment, a stiffness of the middle segment is separately controlled to be different from, e.g., less than, a stiffness of the distal segment.

Owner:STRYKER EURO OPERATIONS HLDG LLC +1

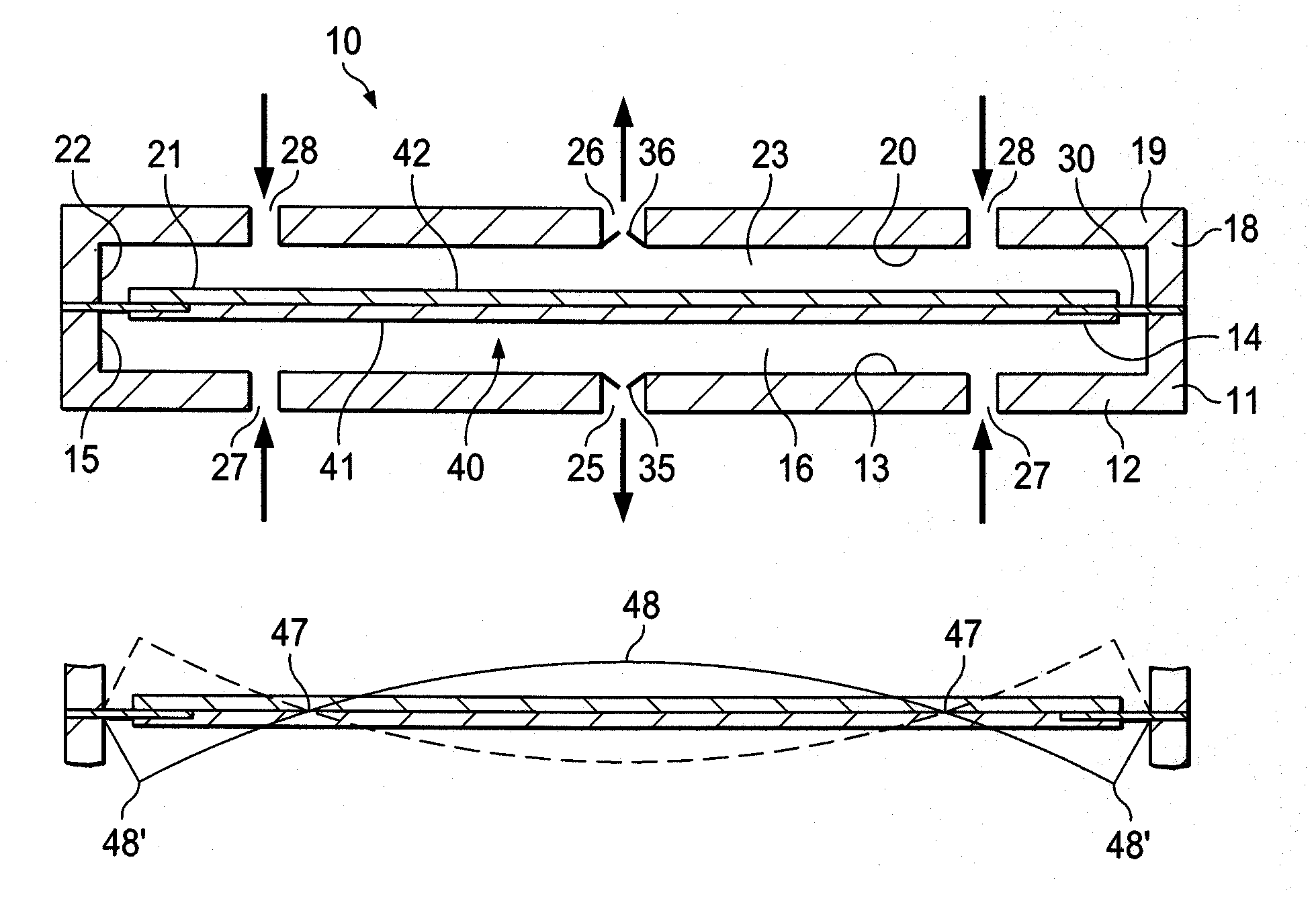

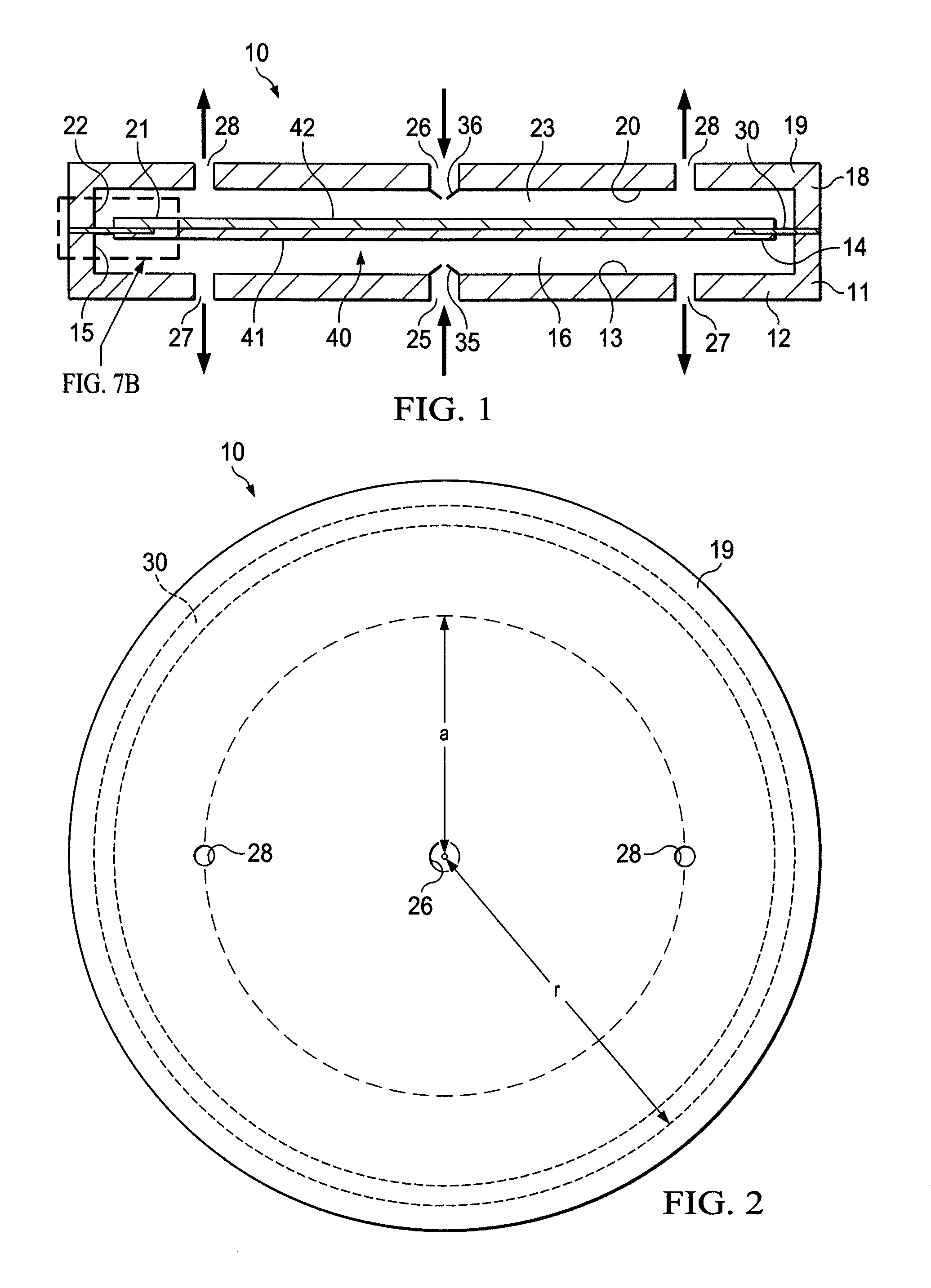

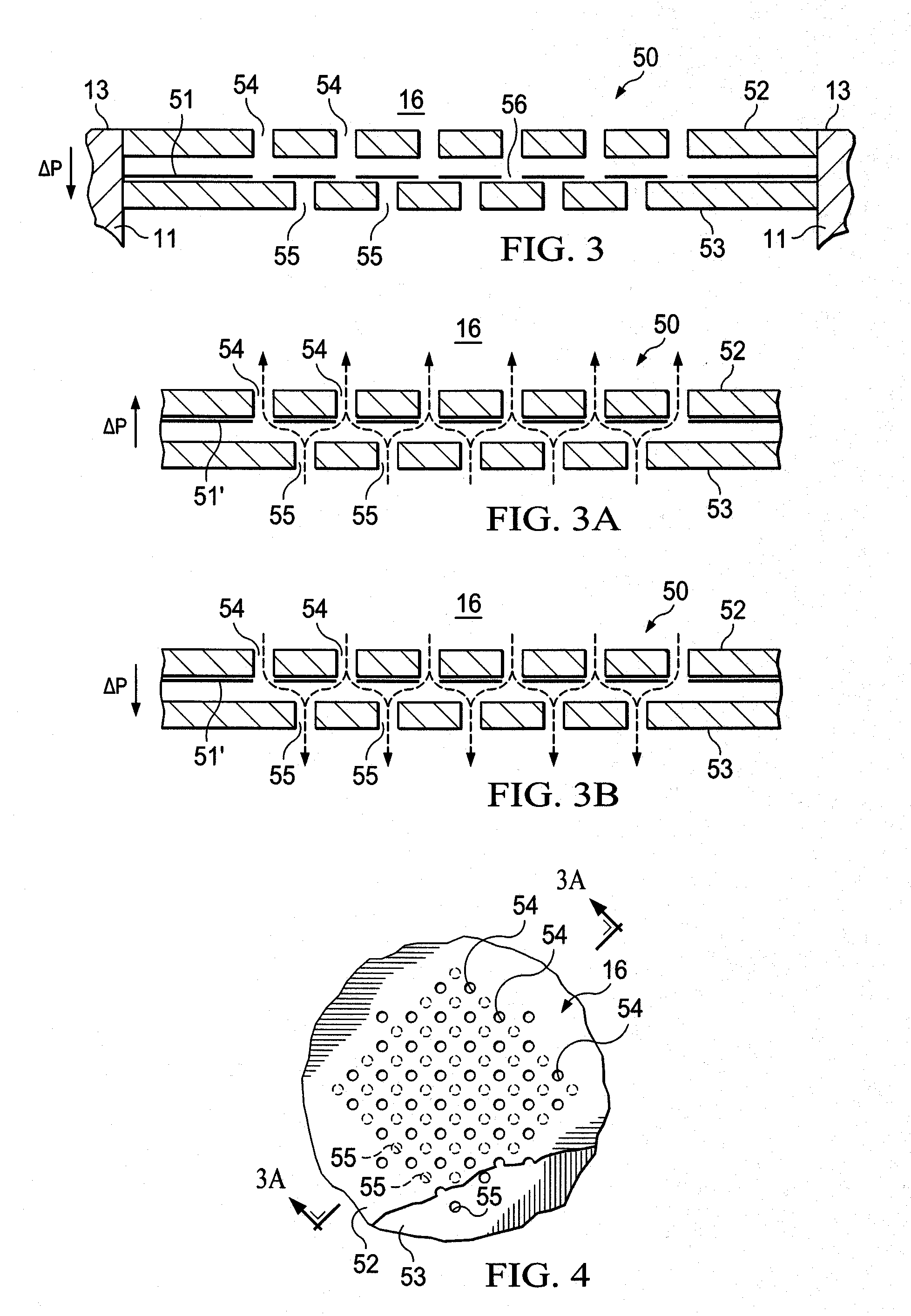

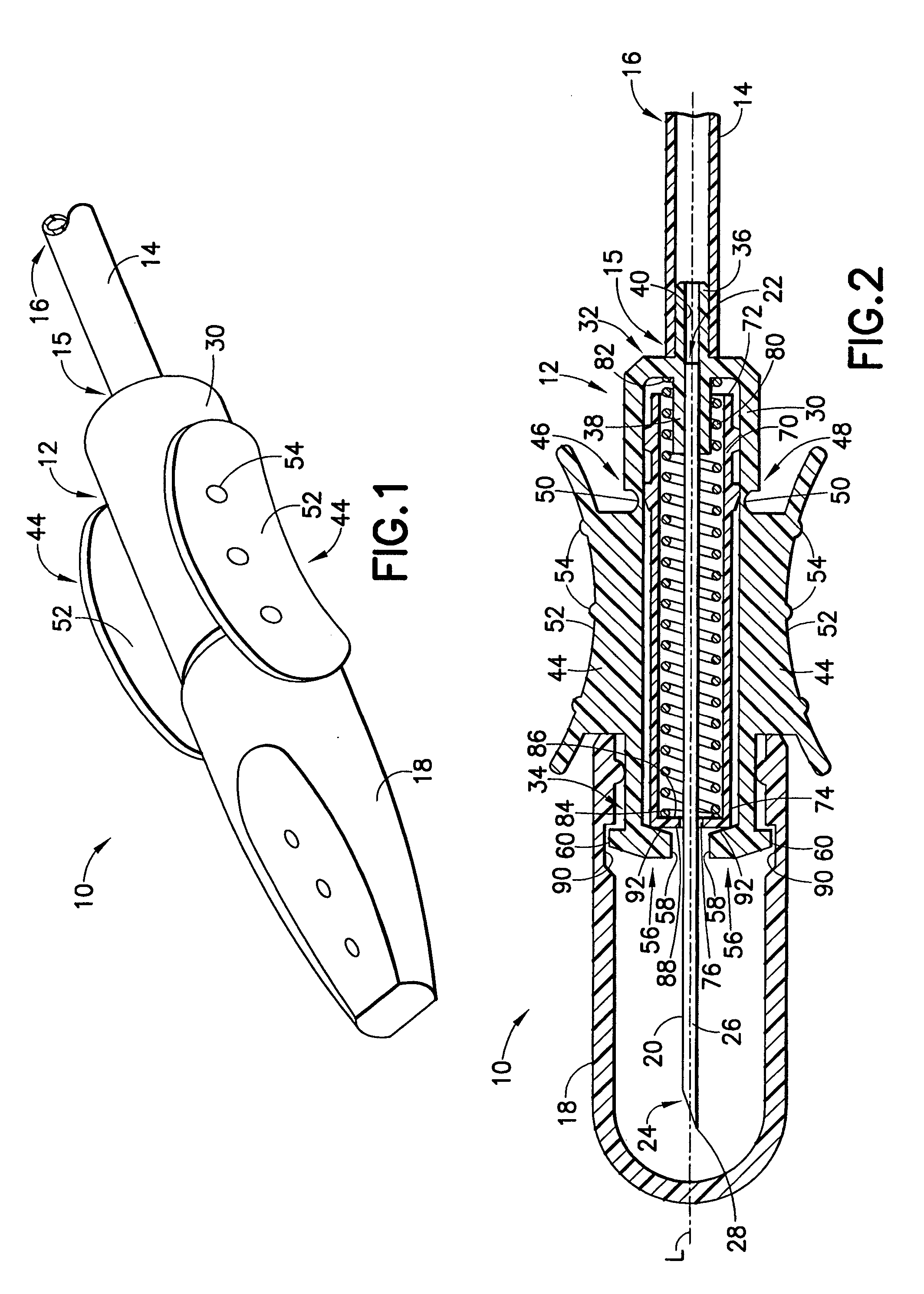

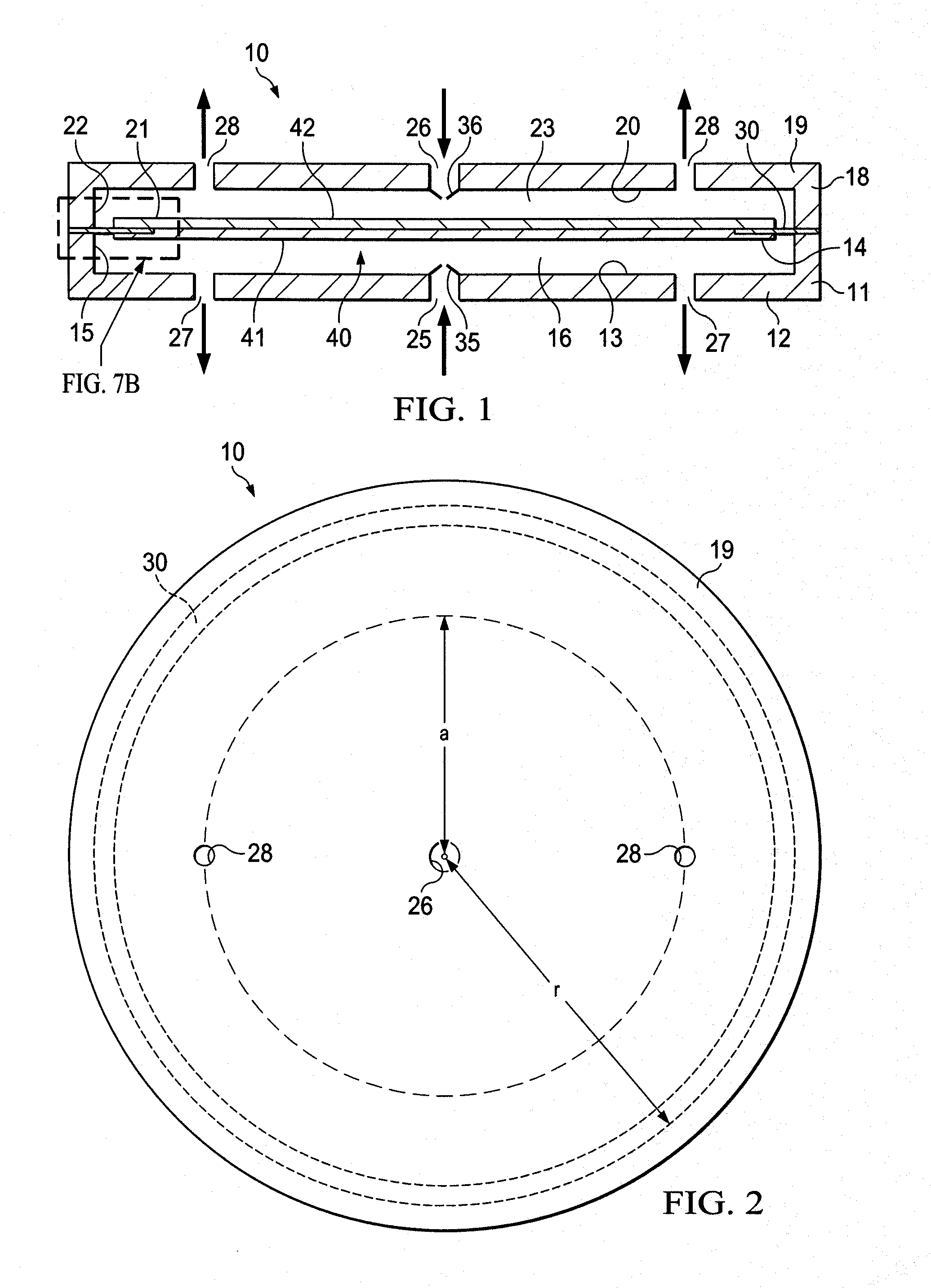

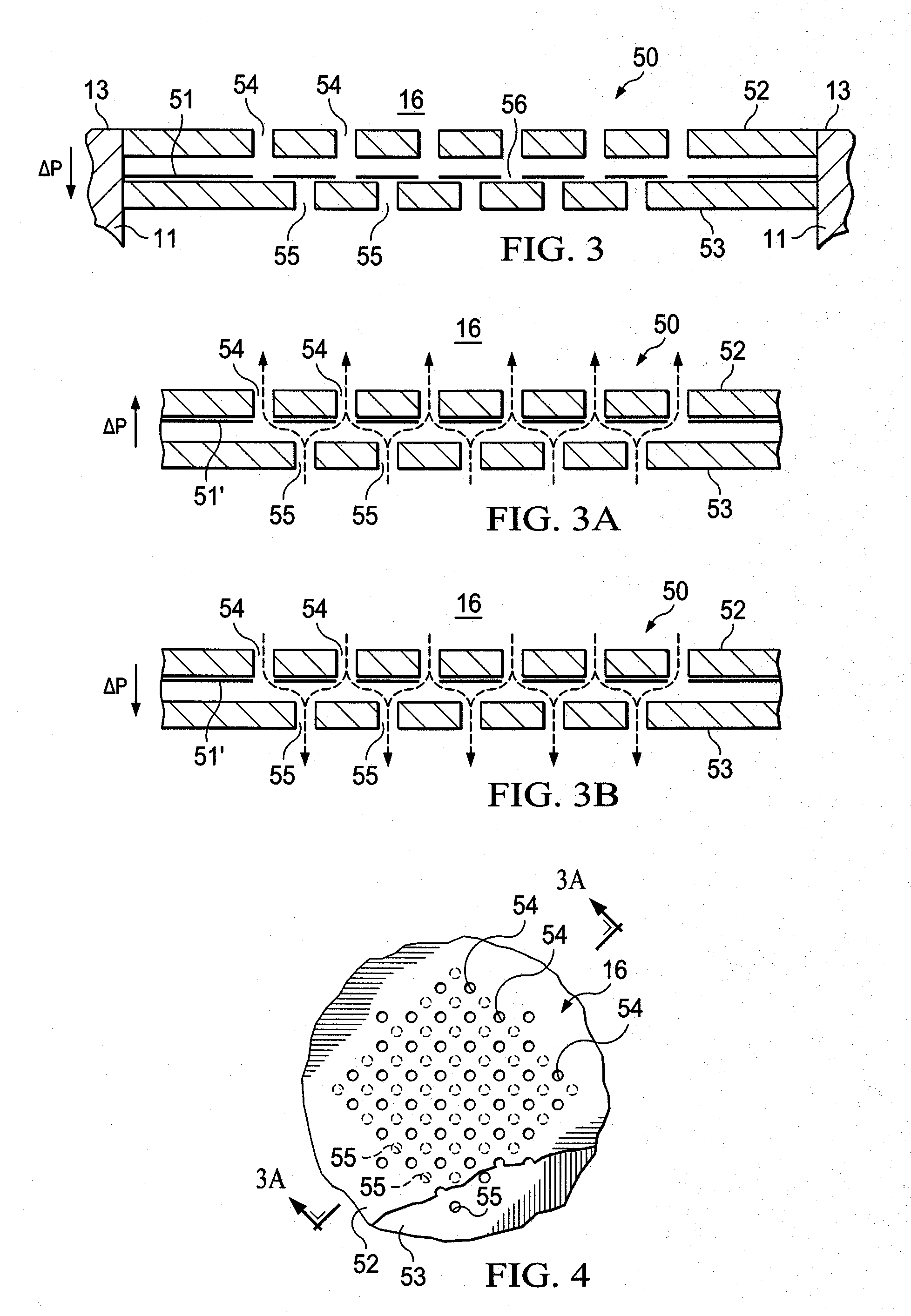

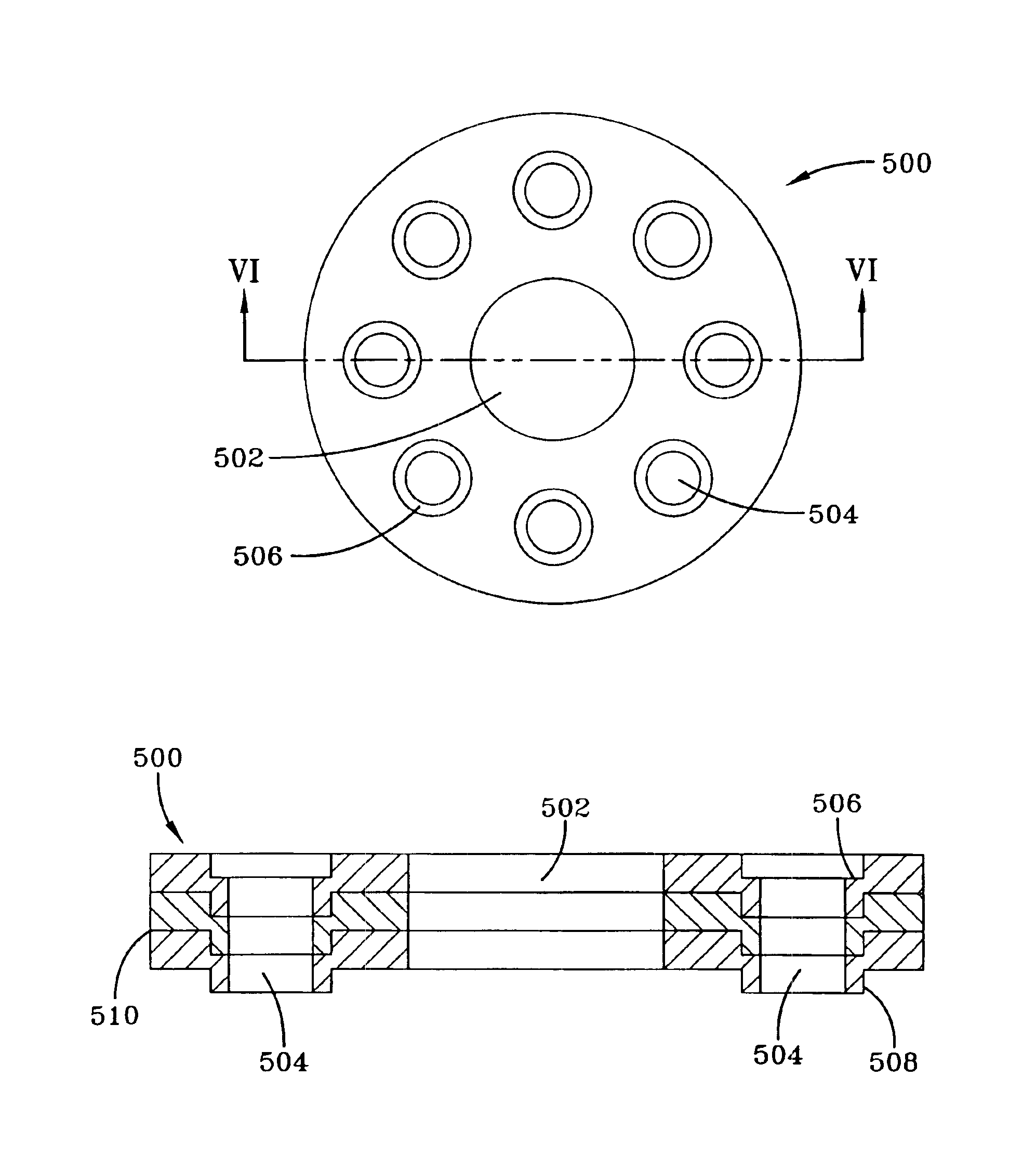

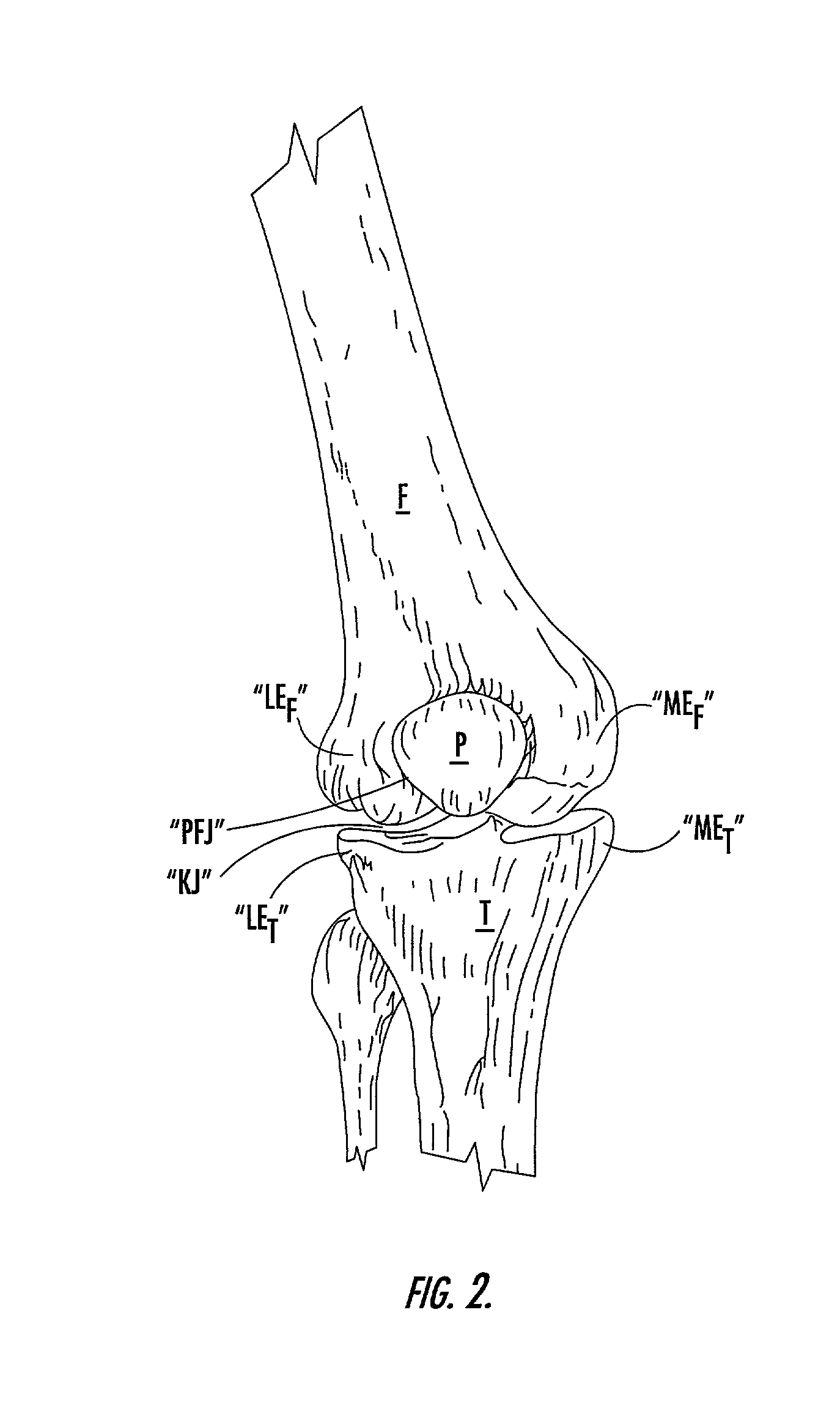

Disc pump with advanced actuator

A two-cavity pump having a single valve in one cavity and a bidirectional valve in another cavity is disclosed. The pump has a side wall closed by two end walls for containing a fluid. An actuator is disposed between the two end walls and functions as a portion of a common end wall of the two cavities. The actuator causes an oscillatory motion of the common end walls to generate radial pressure oscillations of the fluid within both cavities. An isolator flexibly supports the actuator. The first cavity includes the single valve disposed in one of a first and second aperture in the end wall to enable fluid flow in one direction. The second cavity includes the bidirectional valve disposed in one of a third and fourth aperture in the end wall to enable fluid flow in both directions.

Owner:3M INNOVATIVE PROPERTIES CO

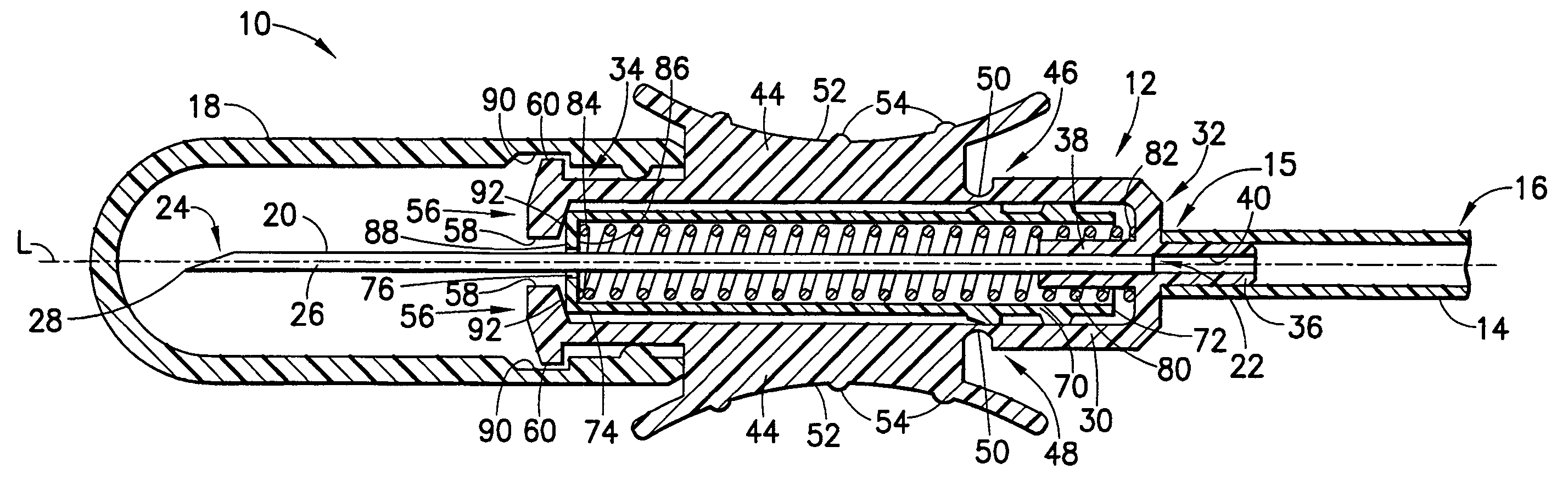

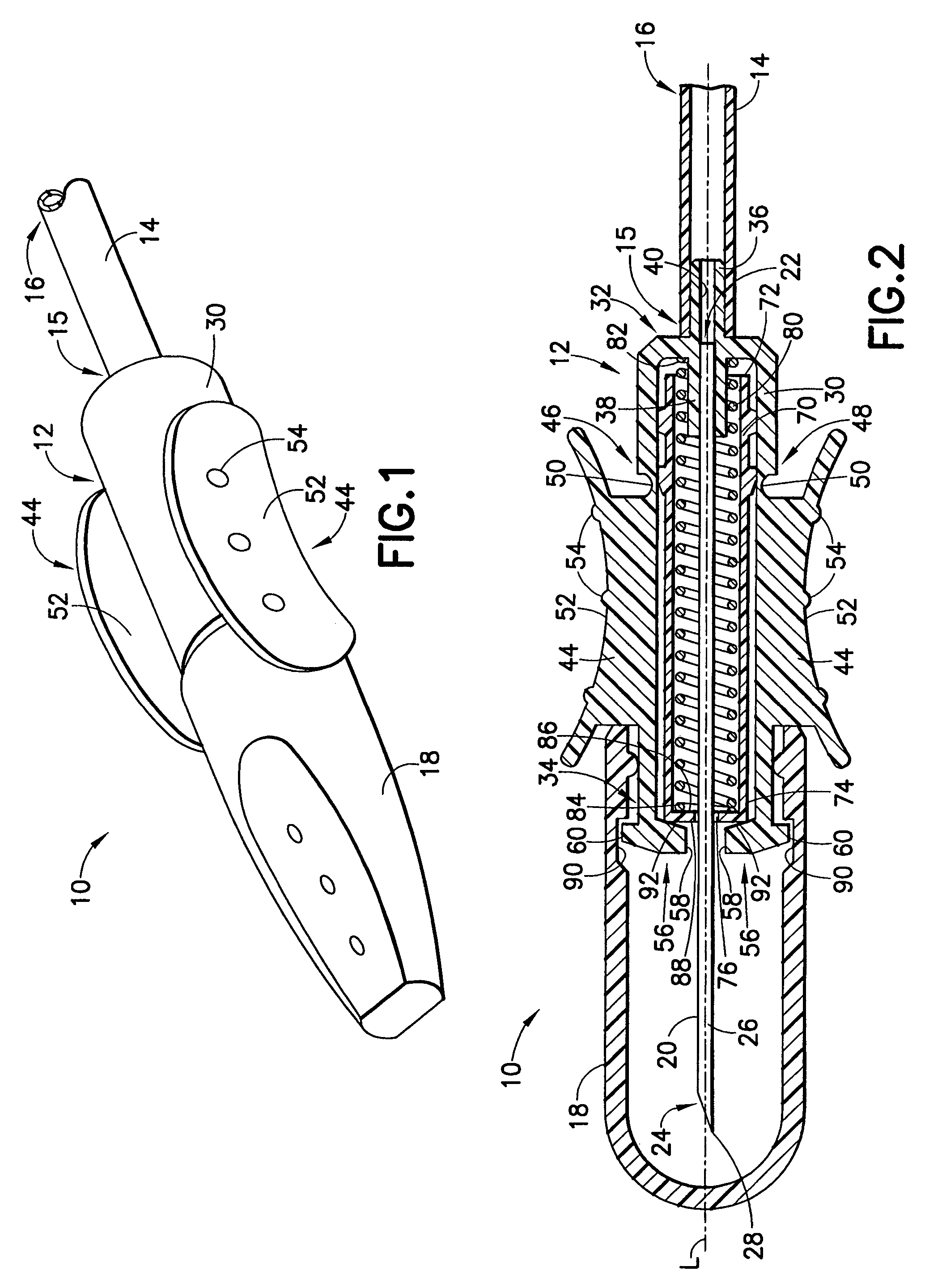

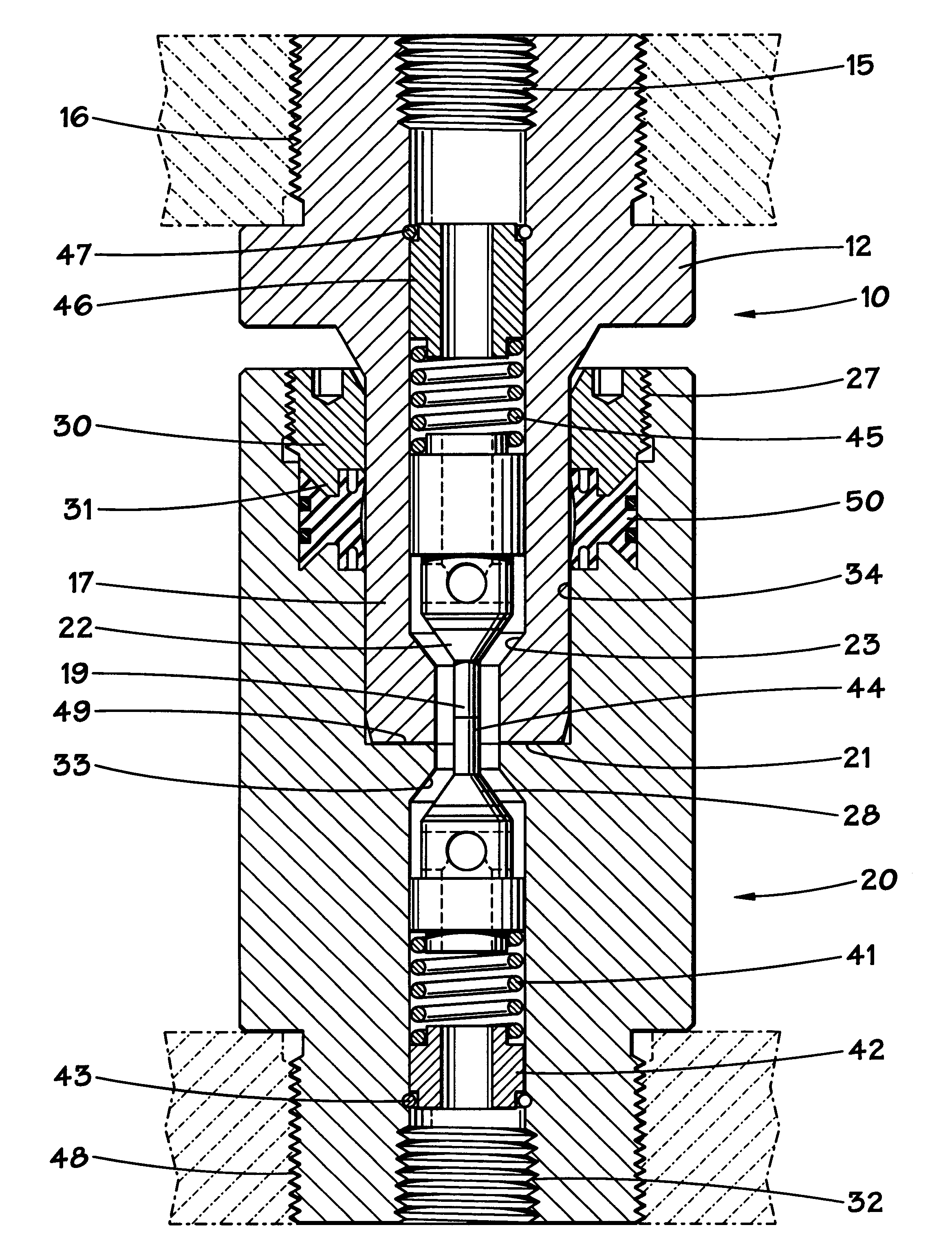

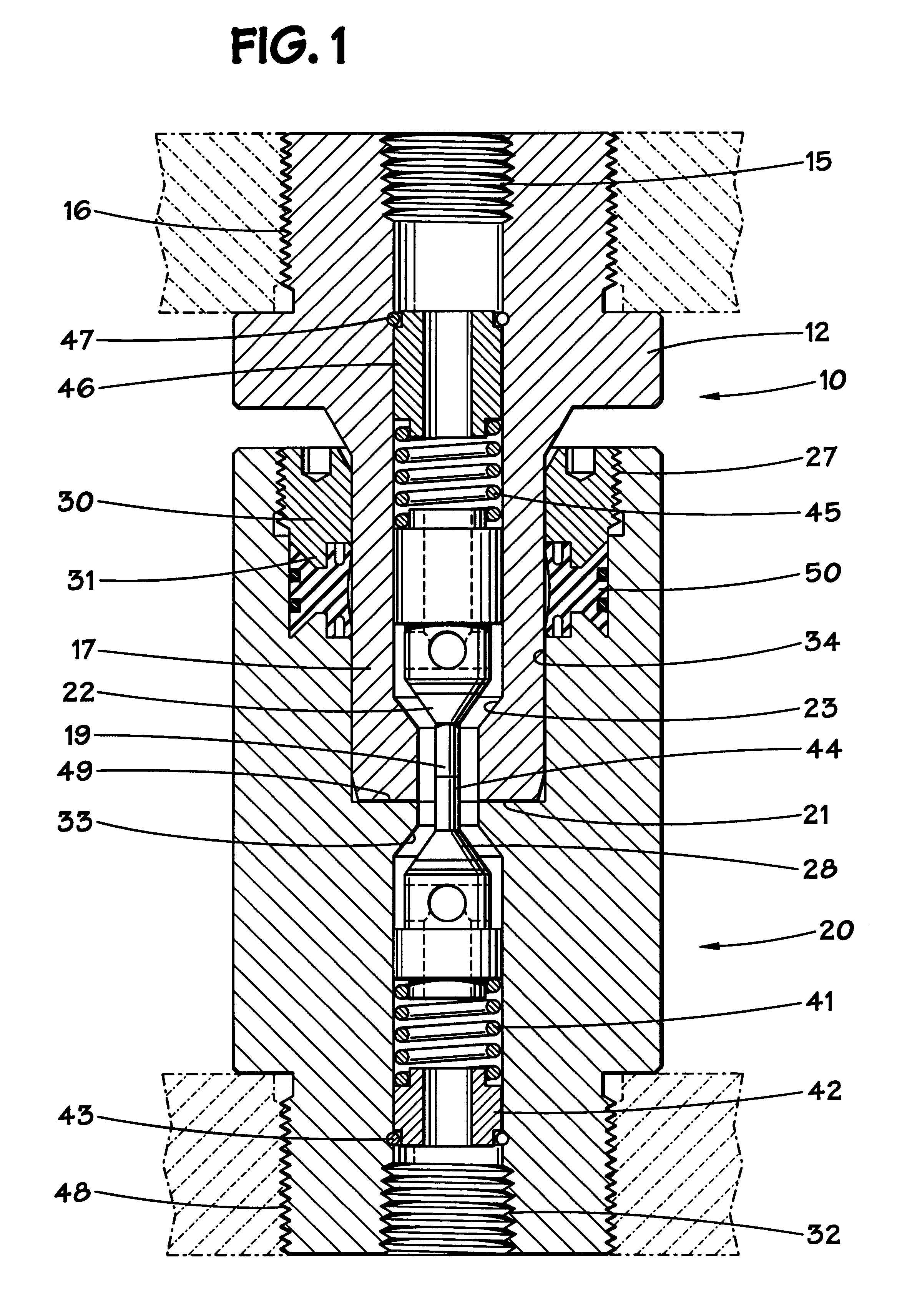

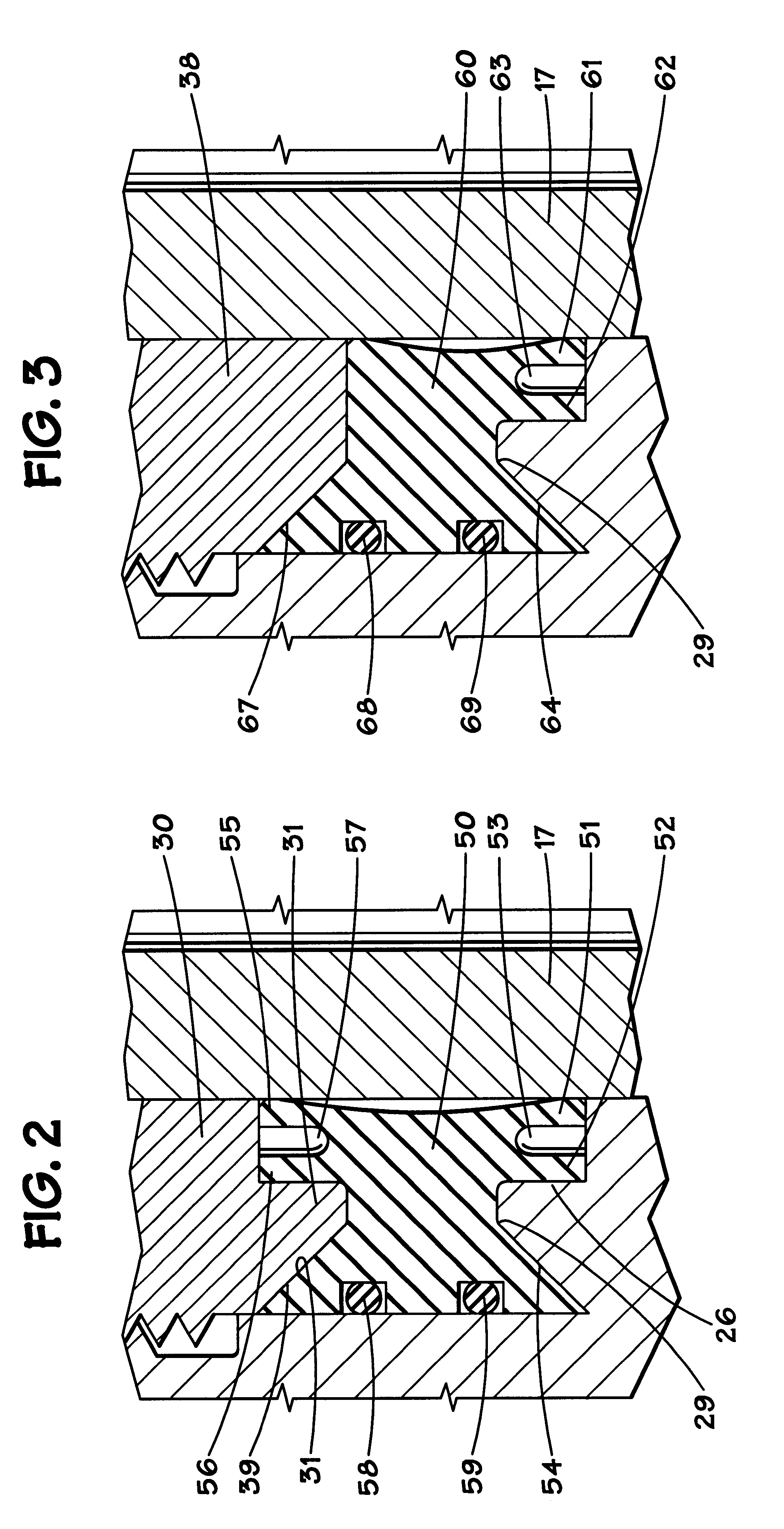

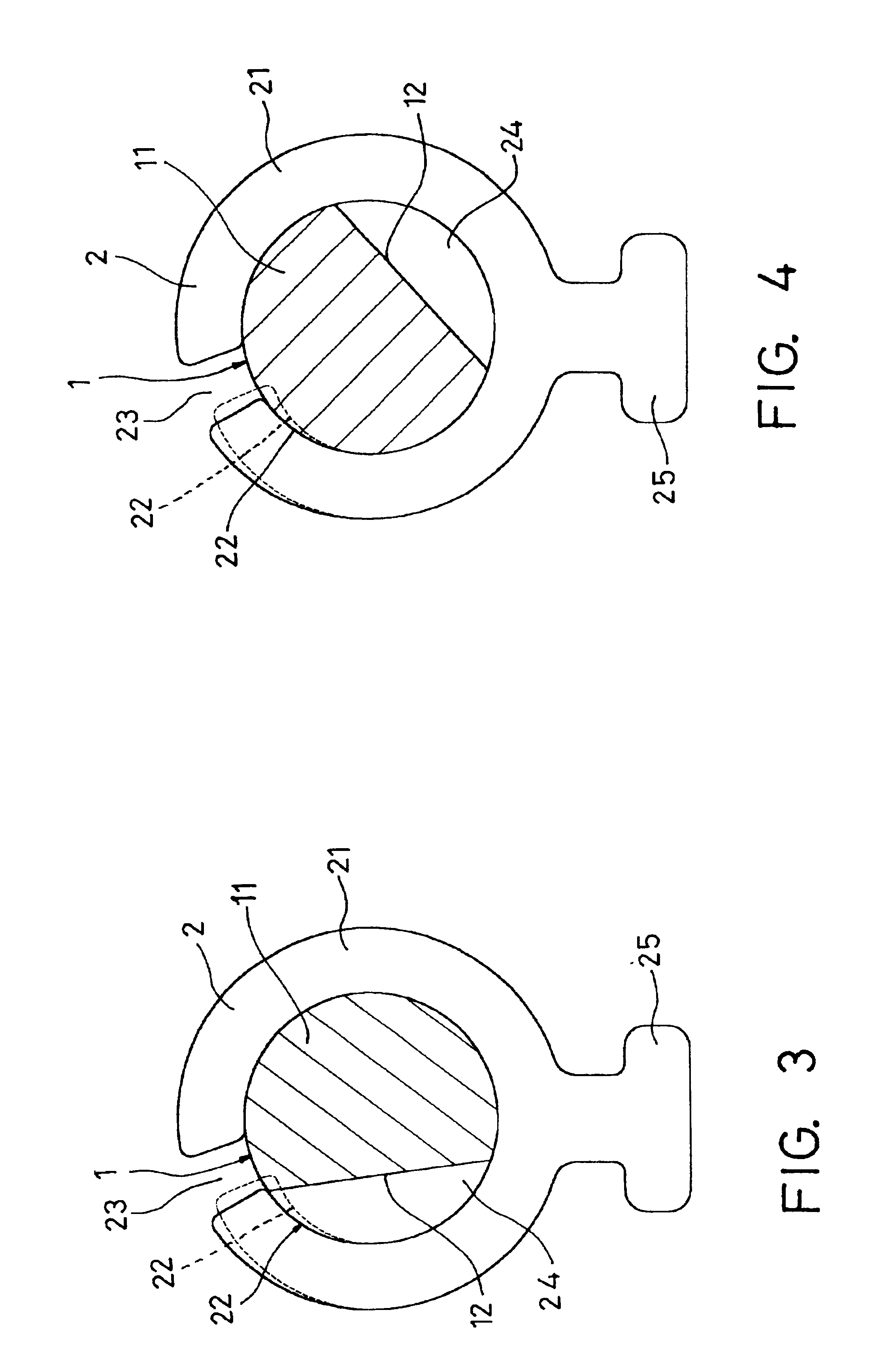

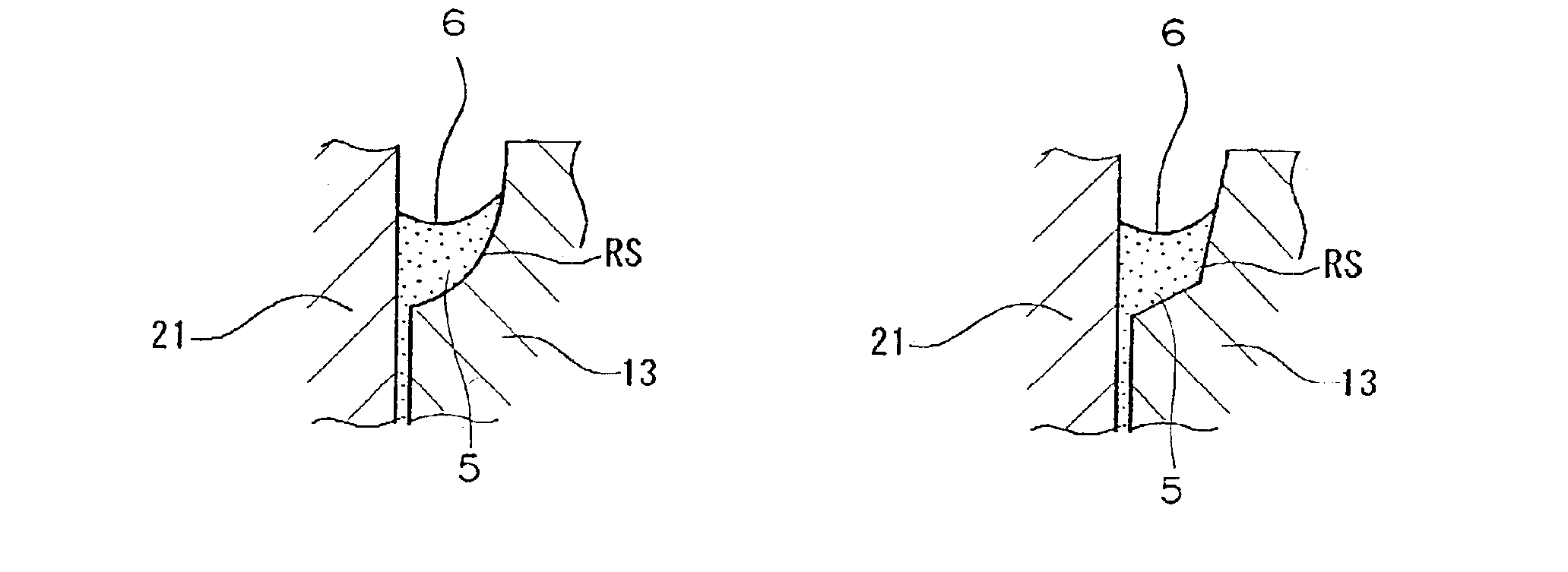

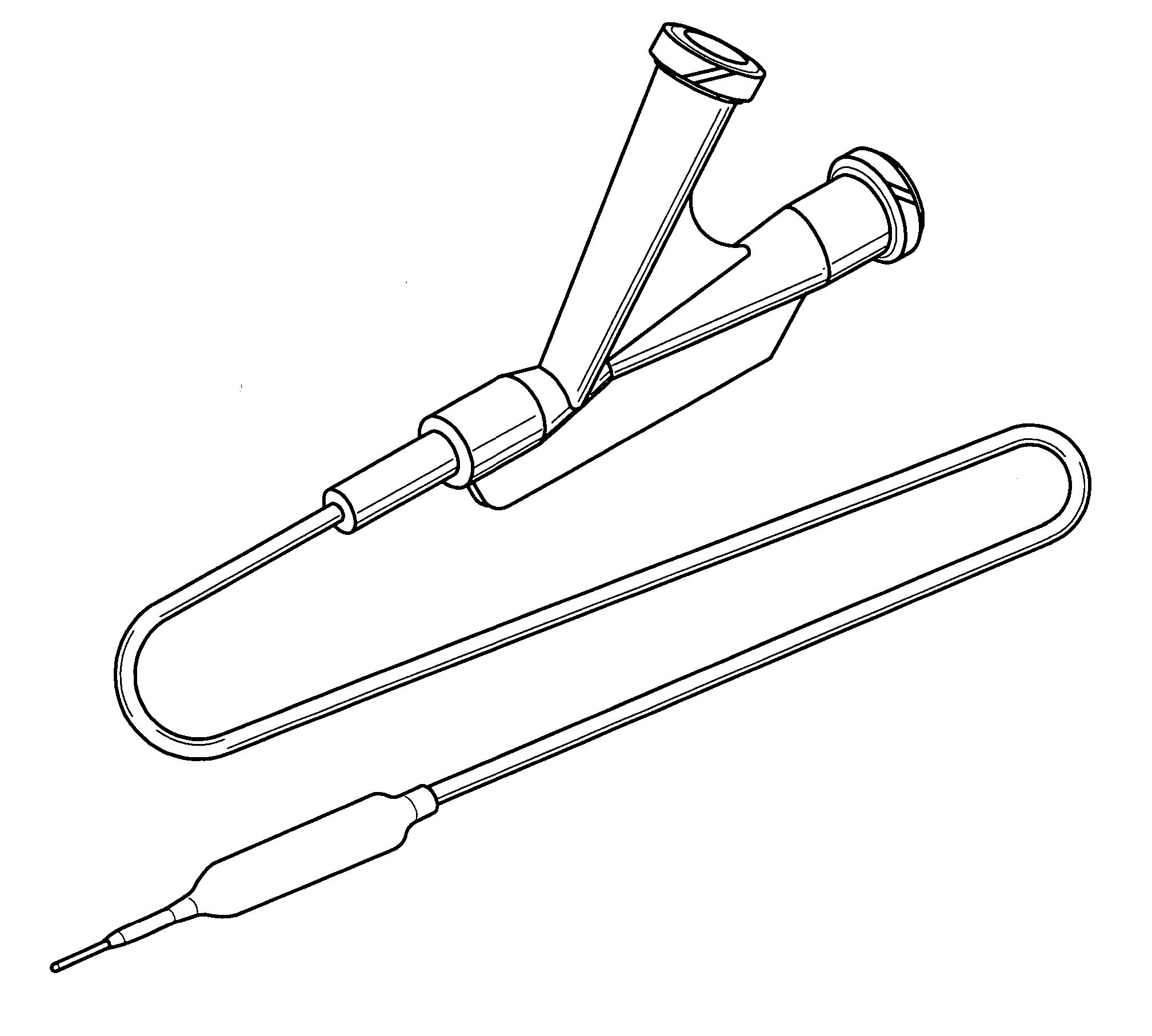

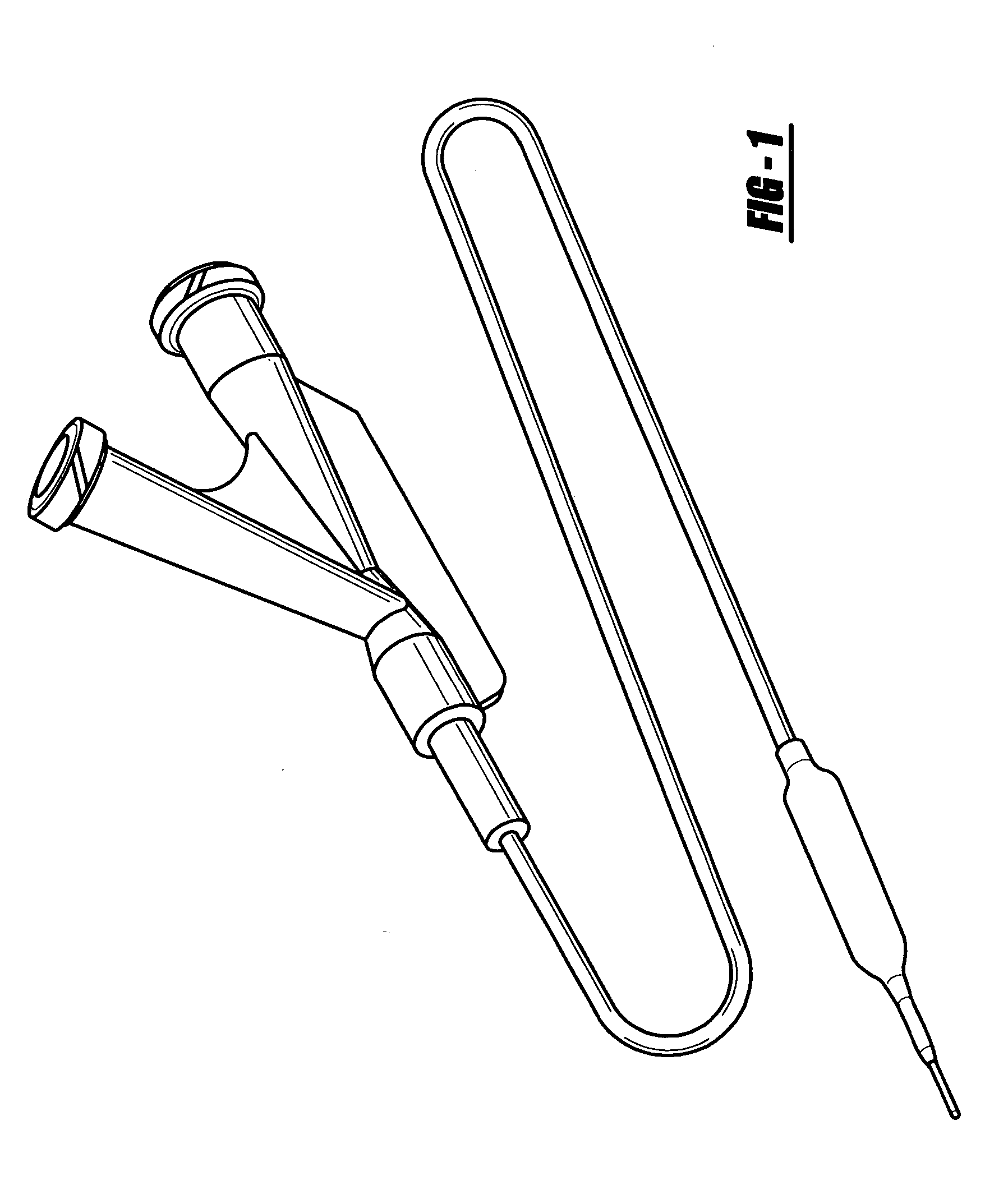

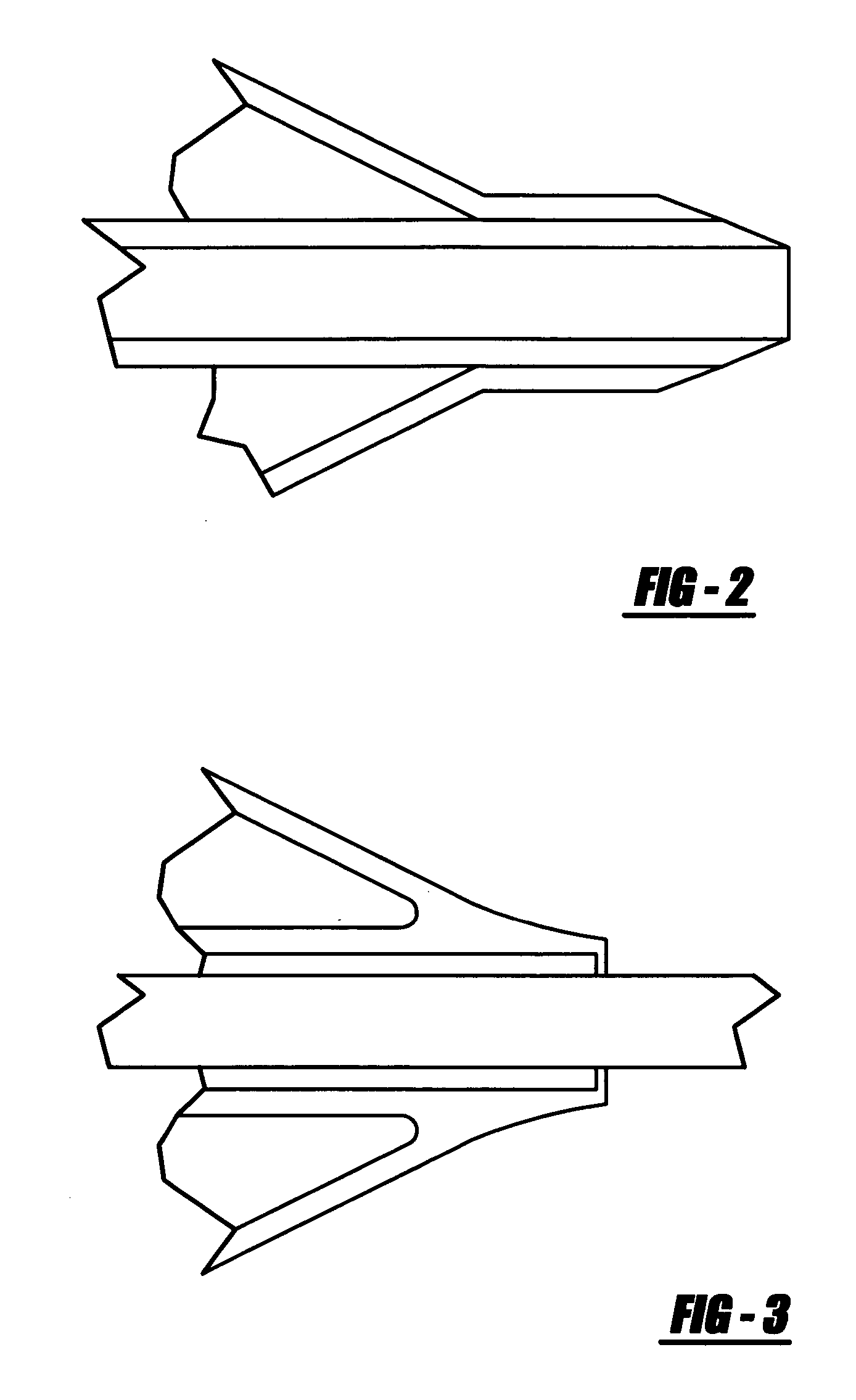

Forward-shielding blood collection set

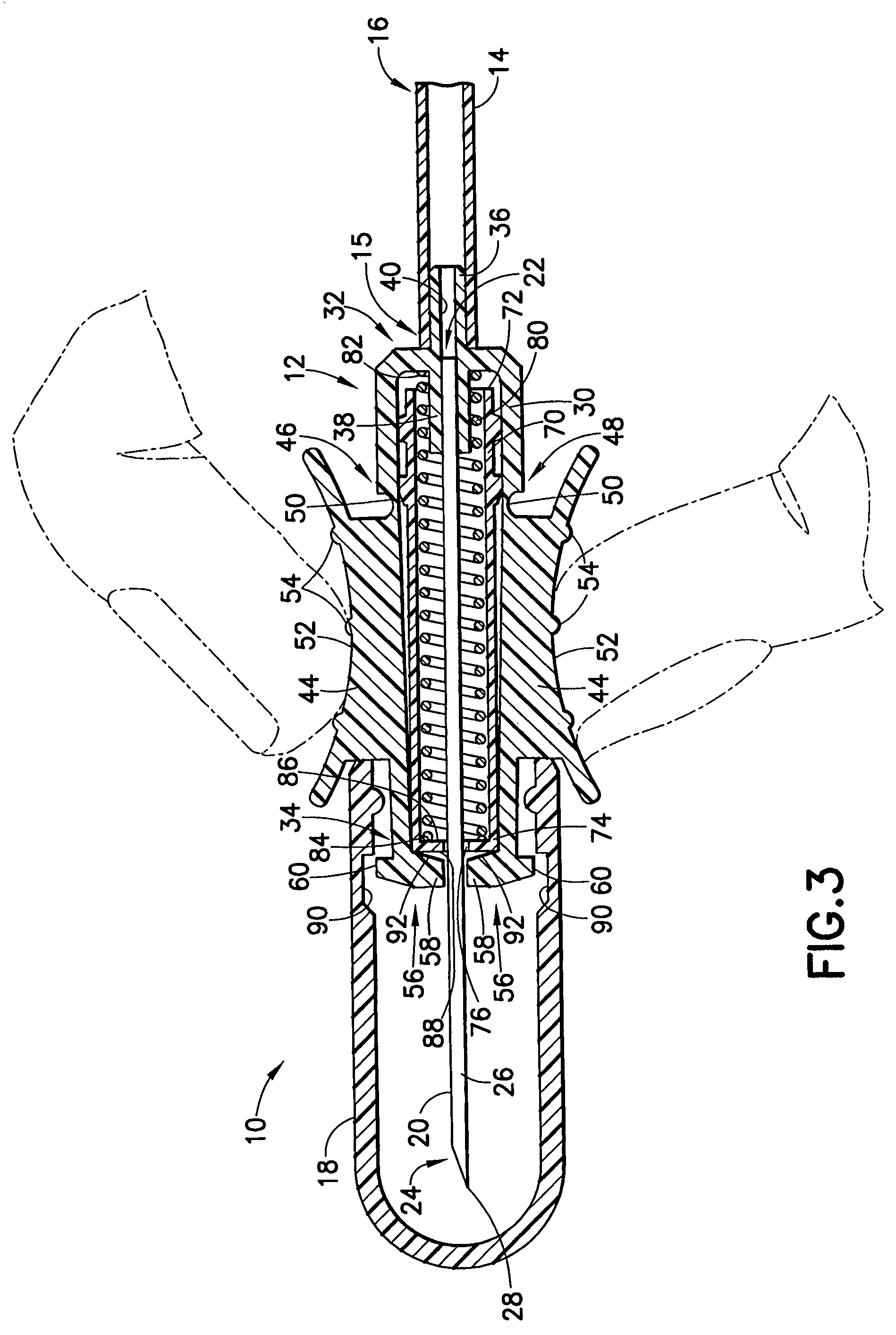

ActiveUS7201740B2Prevent removalCatheterDiagnostic recording/measuringBlood collectionBiomedical engineering

A blood collection set includes a needle having a puncture tip, a hub supporting the needle and including a release member, a safety shield, a drive member, and a packaging shield disposed on the hub. The safety shield is movable from a retracted position within the hub to an extended position shielding the puncture tip of the needle. The packaging shield encloses the puncture tip of the needle in the retracted position of the safety shield. The shielding feature of the blood collection set is activated by applying radial pressure to the release member, causing the release member to release the packaging shield from the hub, and maintain the safety shield in the retracted position. Upon sufficient or partial release of radial pressure, the drive member disengages the release member from the safety shield and moves the safety shield from the retracted position to the extended positions.

Owner:BECTON DICKINSON & CO

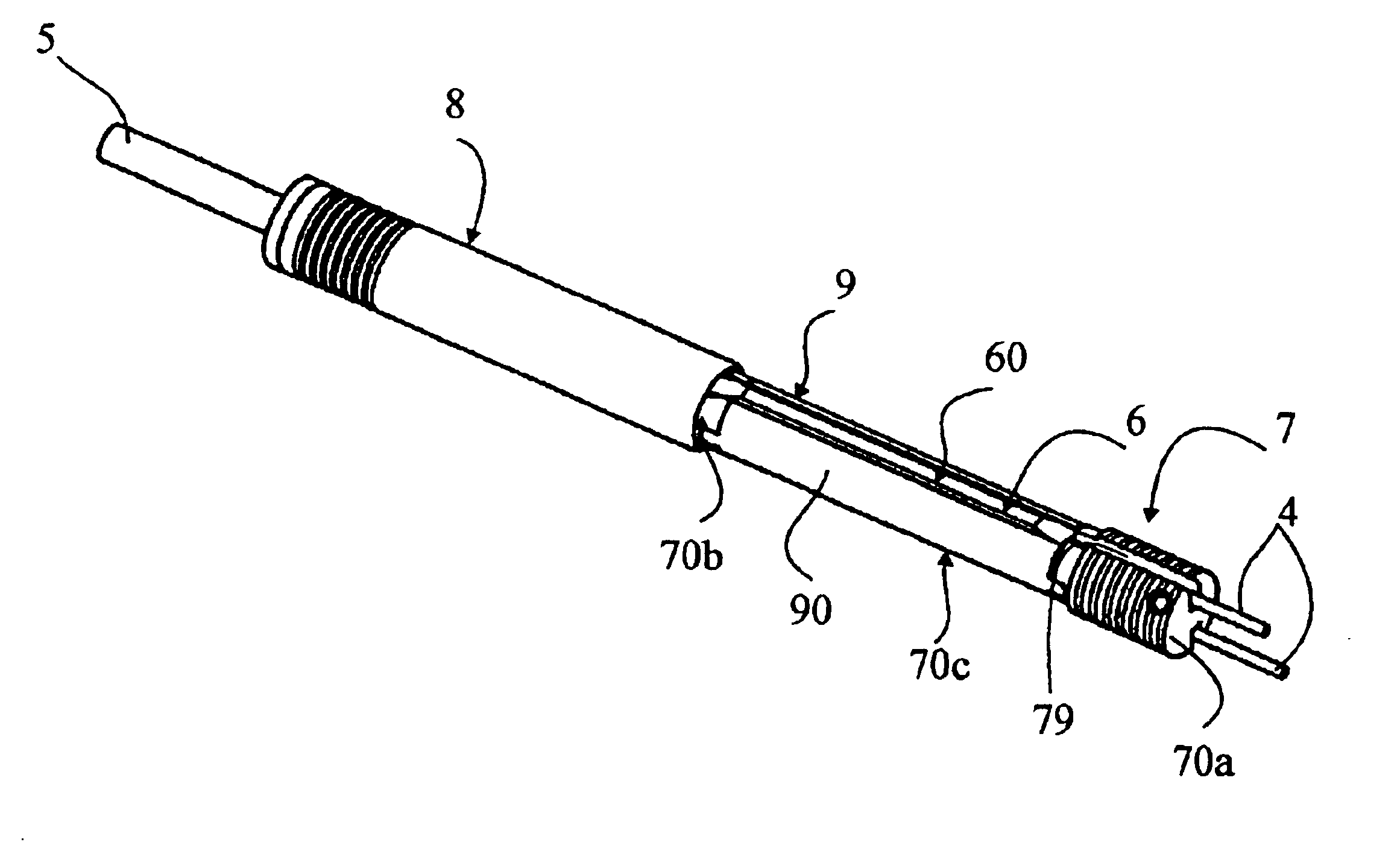

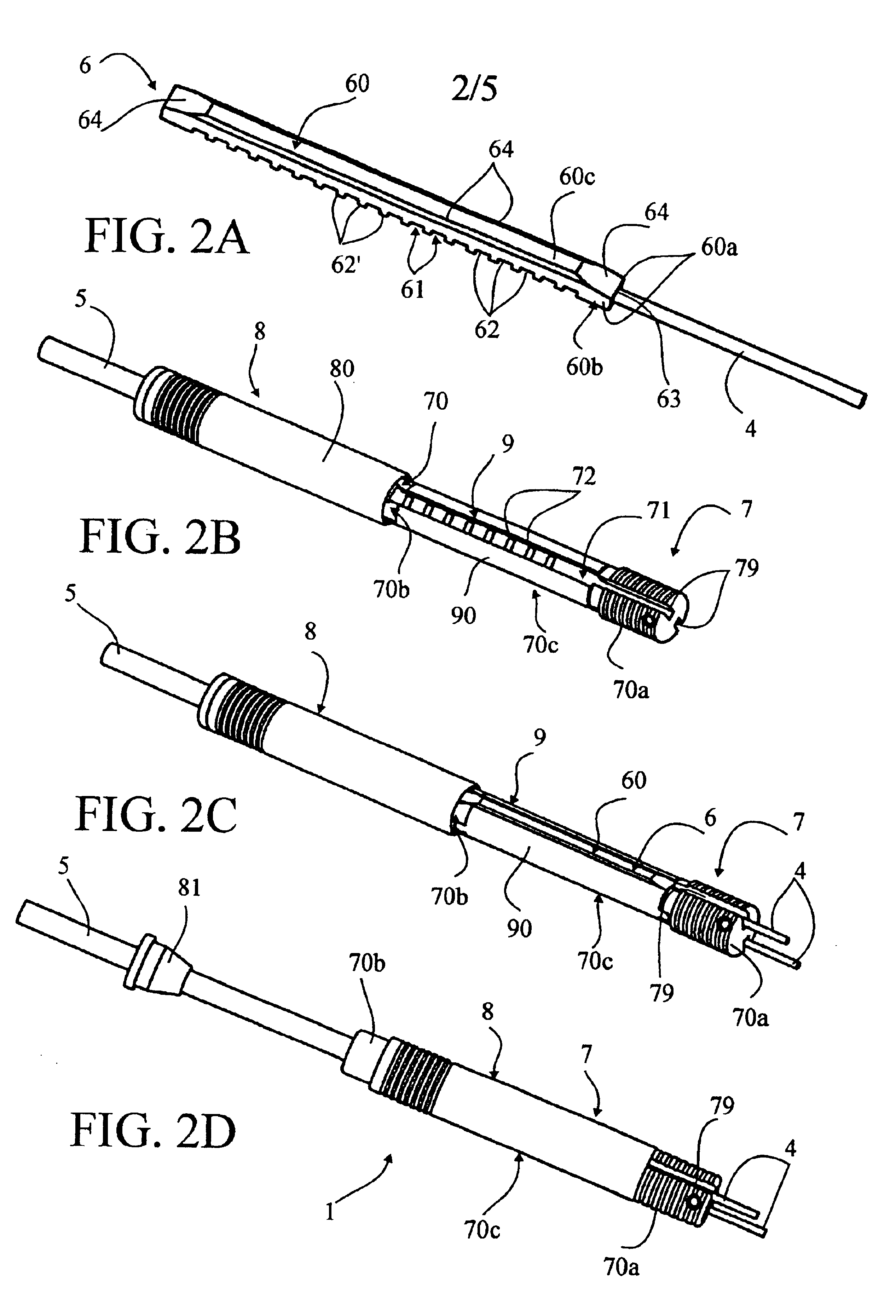

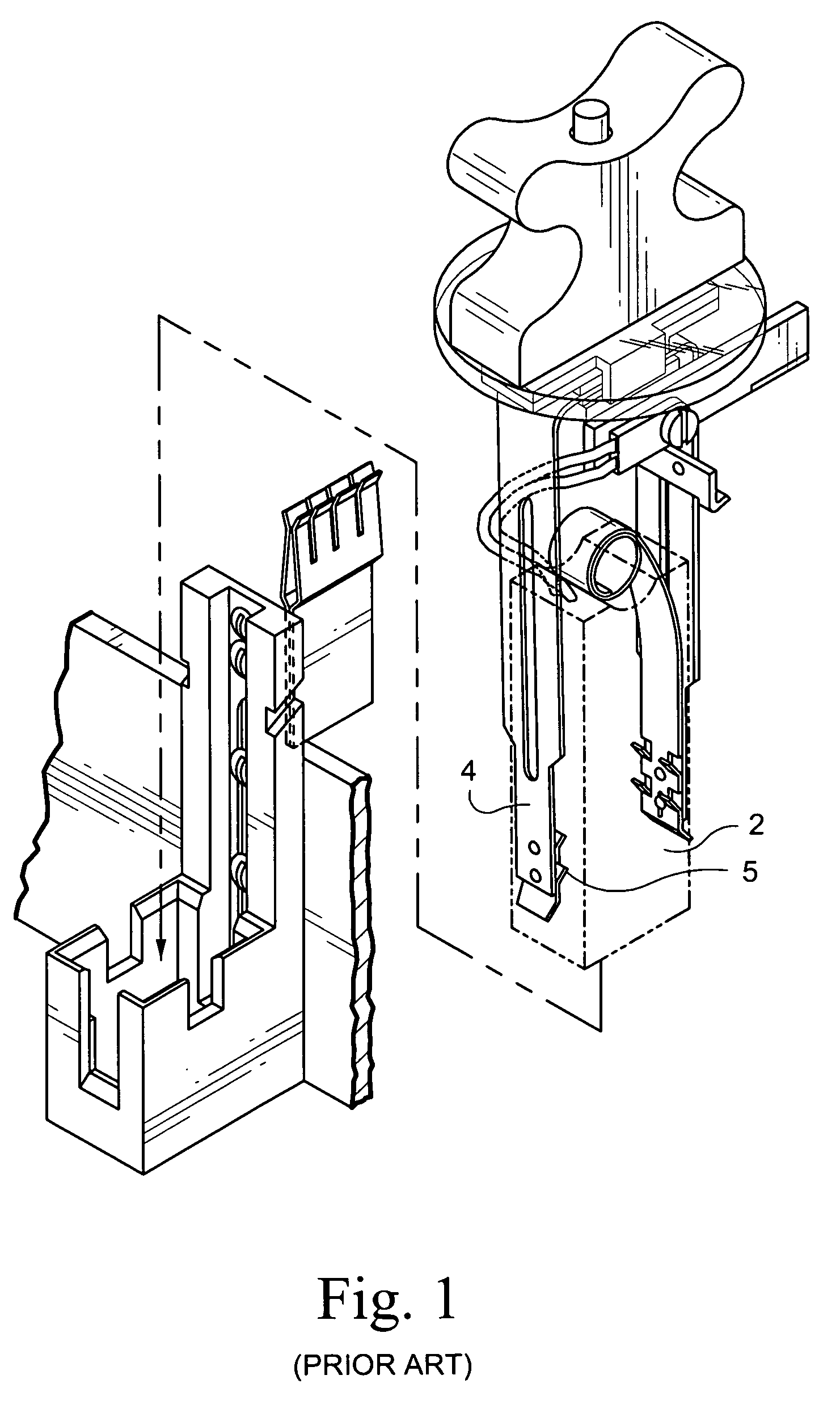

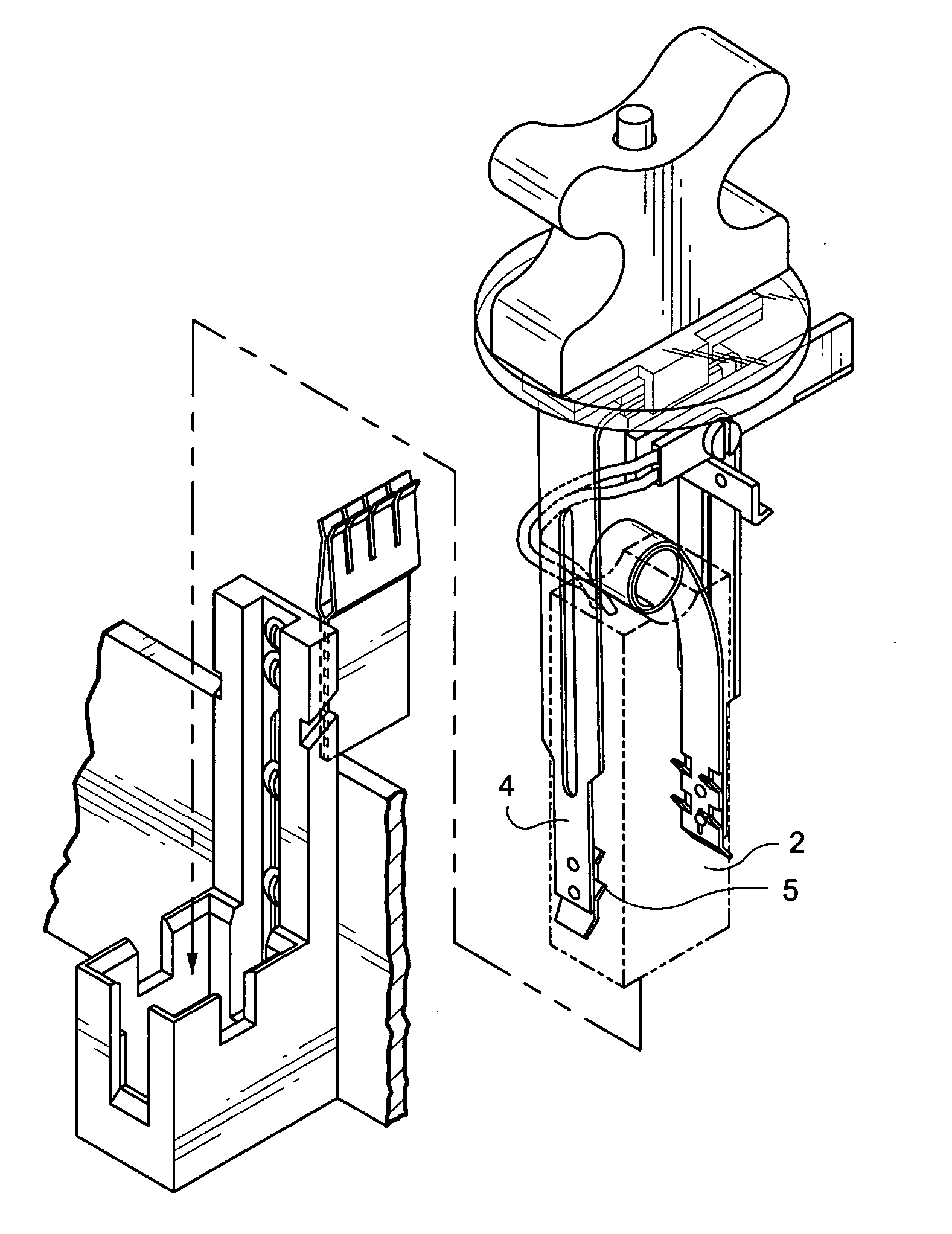

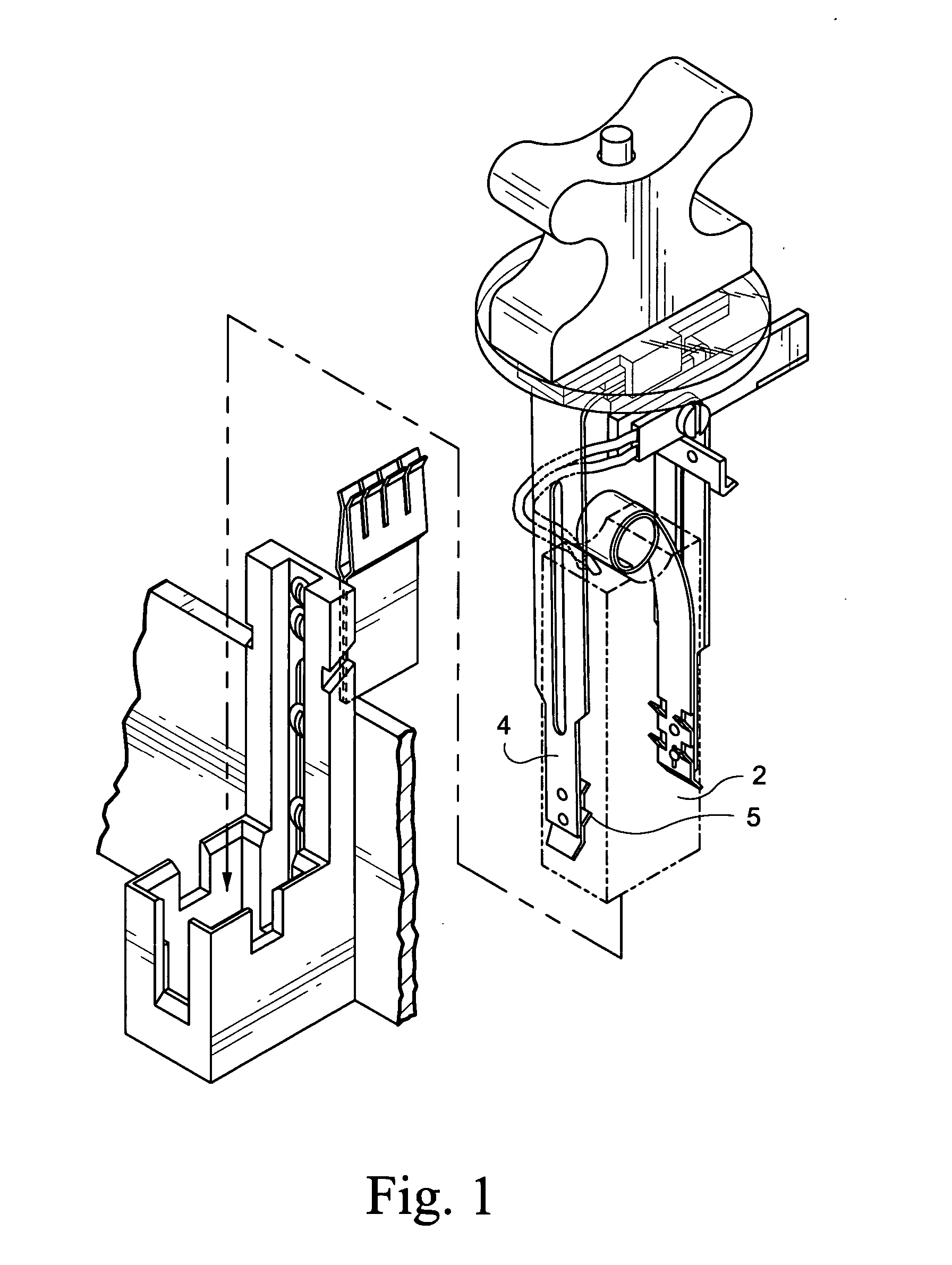

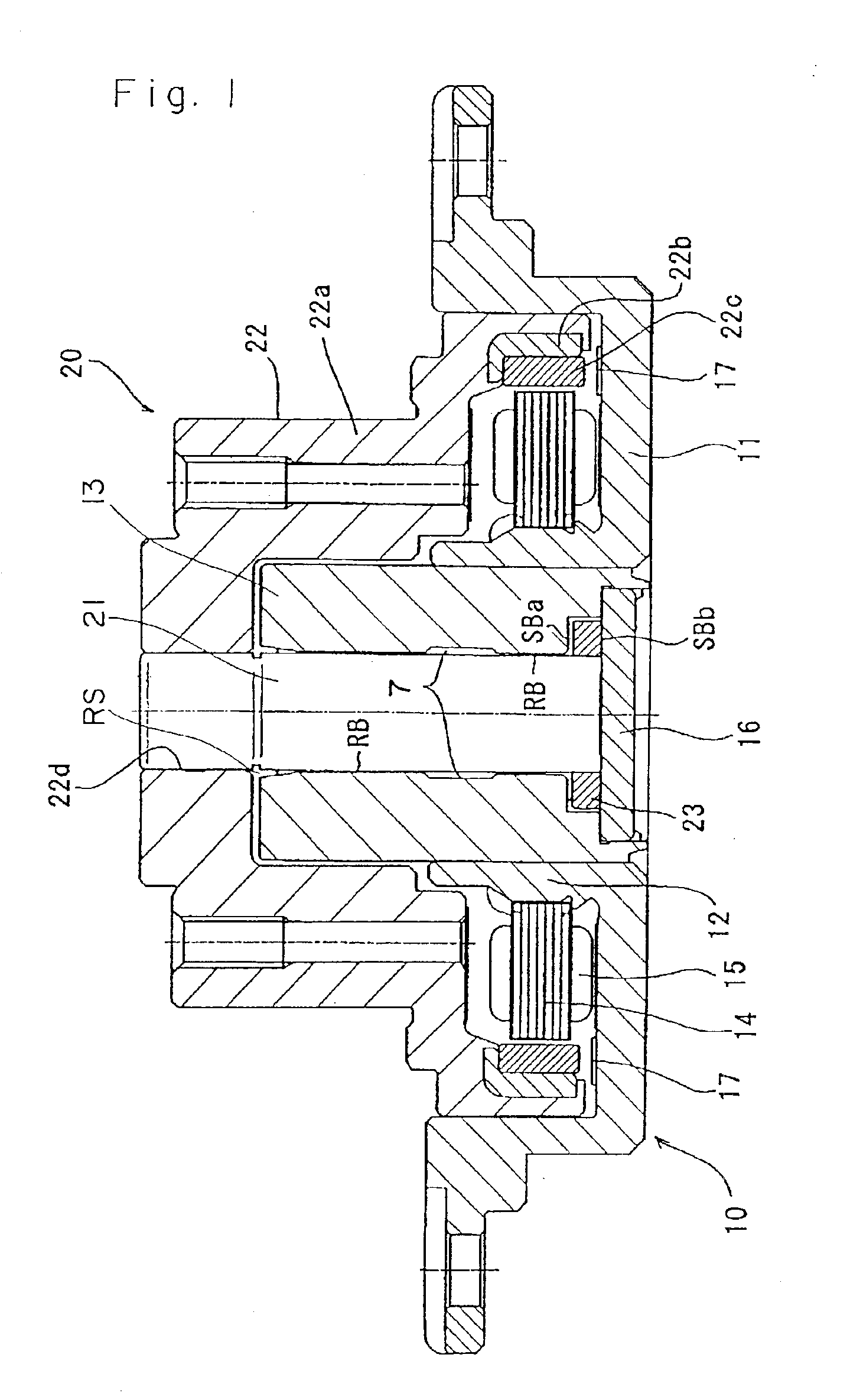

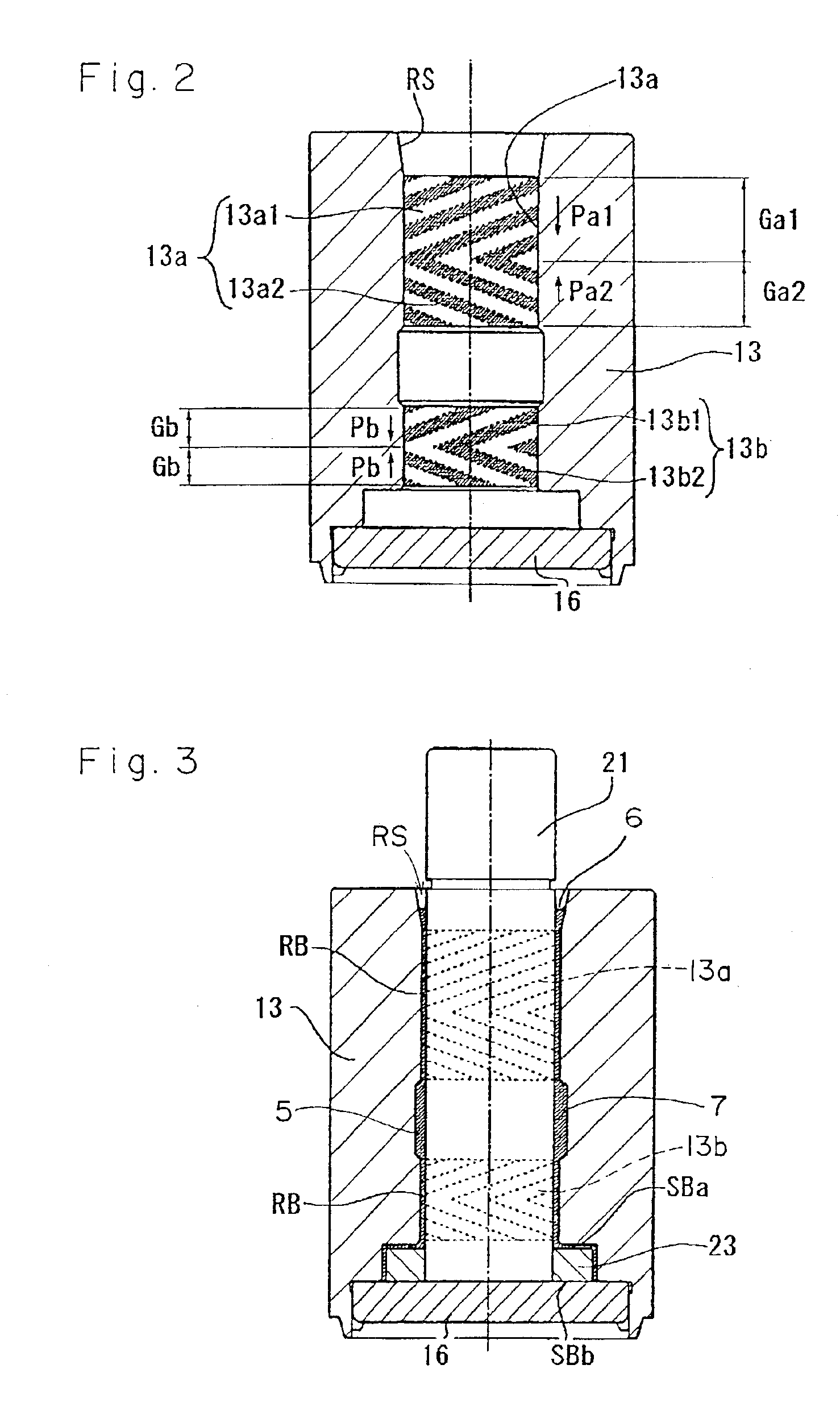

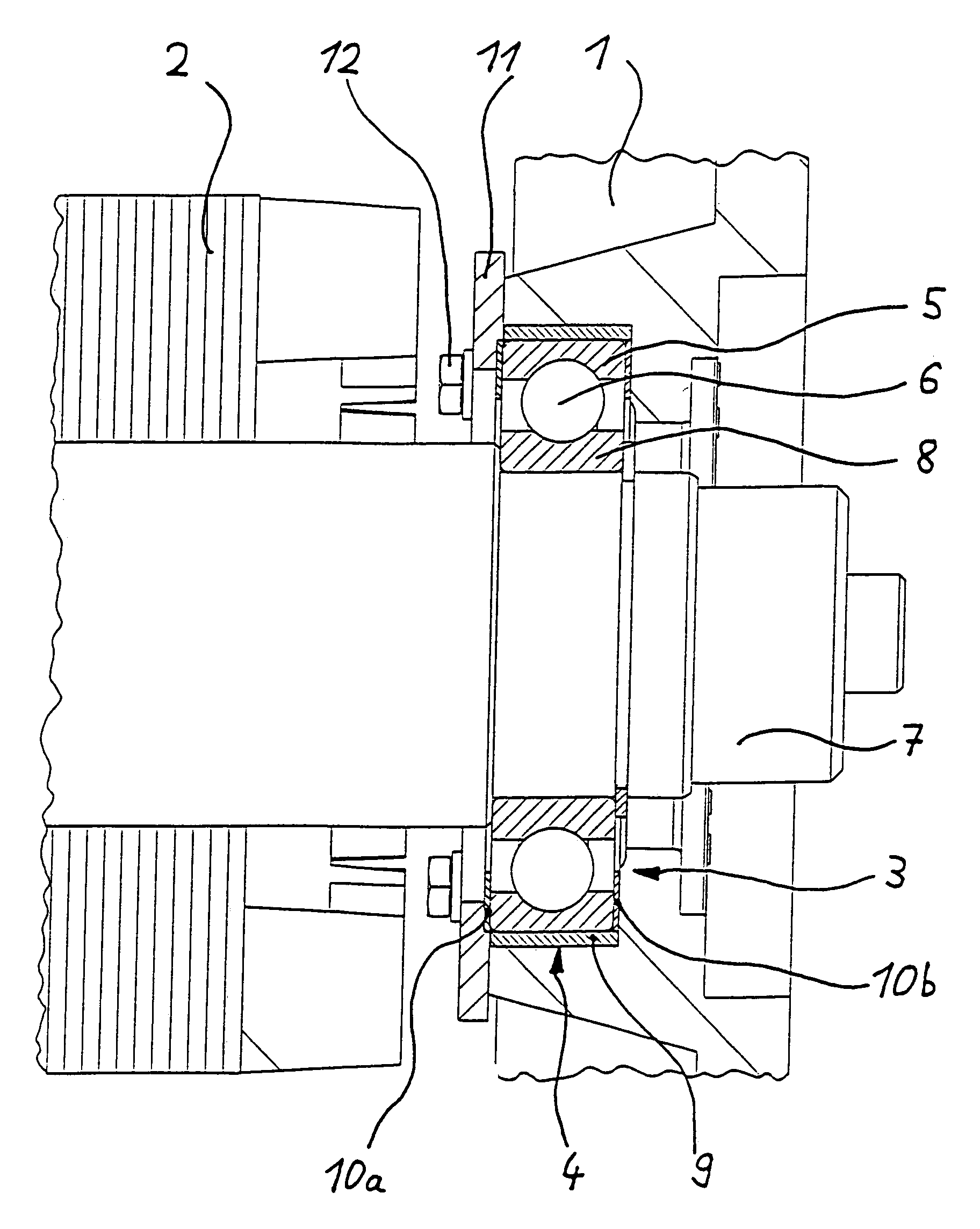

Multi-contact connector for electrode for example for medical use

InactiveUS6913478B2Reduce the space requiredReduce weightElectroencephalographyEngagement/disengagement of coupling partsElectrical connectionEngineering

Multiple contact connector for an electrode, for example, for medical use.The present invention relates to a multiple contact connector with reduced space requirement and weight regardless of the number of electrical contacts of the electrode, which can receive one or two electrodes, which guarantees a reliable and secured electrical connection with no risk of accidental disconnection and which is not a problem for a patient in whom the electrodes are implanted.This connector (1) consists of male plug (6) which has elongated support (60) provided on at least one of its sides with a number of contact zones (61) equal to the number of contacts of said electrode (2) and which are aligned parallel to the axis of first cable section (4), and female socket (7) having roughly cylindrical body (70) arranged in the extension of second cable section (5) and having at least one housing (71) provided with a number of contact elements (72) equivalent to the number of contact zones (61) of said male plug (6) and capable of receiving said support (60). This connector (1) is characterized in that it has tightening sleeve (8) arranged in order to maintain support (60) in housing (71) and to exert a radial pressure of contact zones (61) on contact elements (72) in such a way as to ensure the electrical connections.

Owner:DIXI MEDICAL

Hydraulic coupling with pressure-energized dovetail seal

An undersea hydraulic coupling having a radial pressure-energized seal with a dovetail interfit is disclosed. The seal has a pair of flexible sealing surfaces for sealing with the male and female coupling members, and a cavity therebetween that is exposed to fluid pressure in the coupling. The outer circumference of the seal has a dovetail interfit between inclined shoulders in the female member bore and on a seal retainer that holds the seal in the bore.

Owner:NAT COUPLING

Controlled release endoprosthetic device

InactiveUS20050192664A1Overcome problemsVascular smooth cell proliferation caused by stents can be reducedOrganic active ingredientsStentsBULK ACTIVE INGREDIENTPerfusion

The invention relates to improved drug-delivery endoprosthetic device for insertion at a vascular site via catheter placement at the site, comprising: (a) a structural member into the upper and / or lower surface of which one or more micro-deepenings are engraved and / or on which a polymer member is carried, for co-expansion with the polymer member from a contracted state to an expanded state when the device is exposed to said stimulus, (b) optionally a polymer member capable of expanding from a contracted to a stable, expanded state when the polymer member is exposed to a selected stimulus, wherein the device can be delivered from a catheter, with the structural and the optional polymer members in their contracted states, and is adapted to be held in a vessel at the vascular target site by radial pressure against the wall of the vessel, with the structural and the optional polymer members in their expanded states; and wherein the micro-deepenings of said structural member and / or said polymer member comprise a pharmaceutical composition containing one or more active ingredients selected from the group consisting of agents to inhibit or at least reduce excessive proliferation of vessel wall cells, agents to enhance the downstream perfusion of tissue, agents to promote and / or to enhance the neo-formation of capillaries, agents designed to modulate the amount or activity of coagulation factors, agents to reduce the amount of Thrombin- and / or Fibrin-formation, embedded therein for release from the member, with such in its expanded state.

Owner:BOEHRINGER INGELHEIM PHARM KG

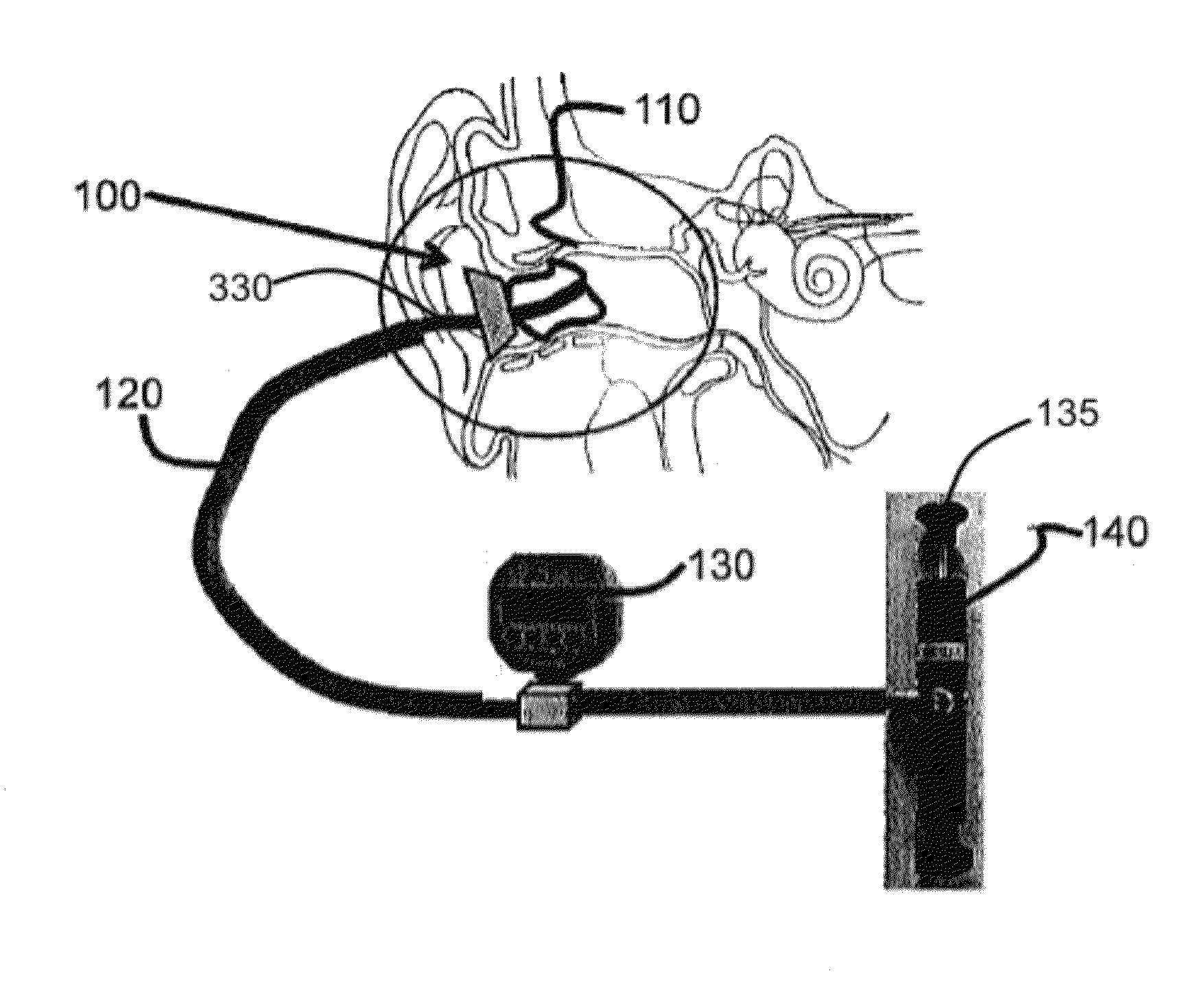

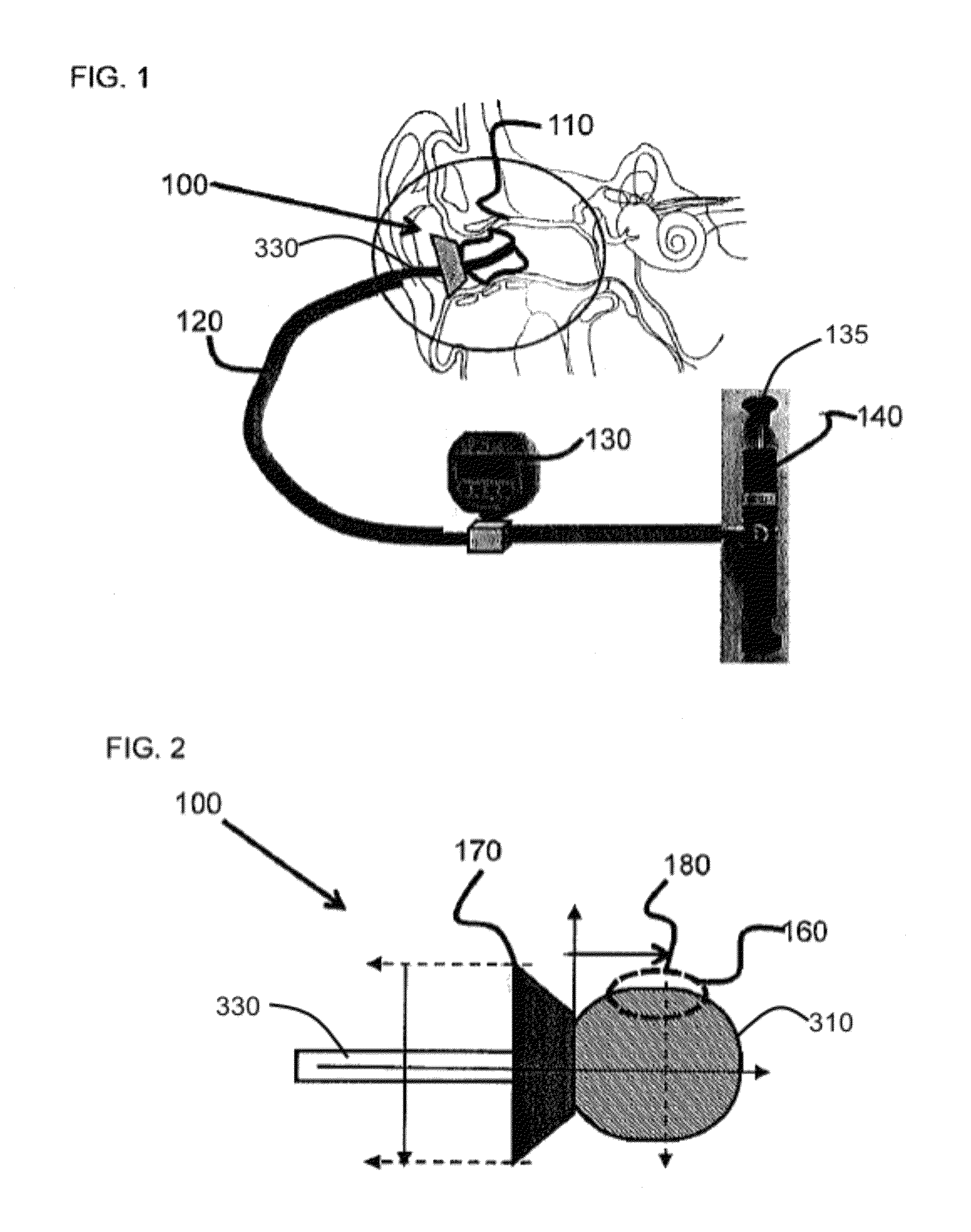

Device and method for radial pressure determination

Methods and apparatus for measuring ear canal wall pressure comfort level are provided. An expandable pressure exertion device is inserted into an orifice. The device is expanded inside the orifice in increments of pressure. A threshold level is saved where a user indicates that the pressure exerted against the walls of the orifice is becoming at least one of uncomfortable, painful, and noticeable.

Owner:STATON TECHIYA LLC

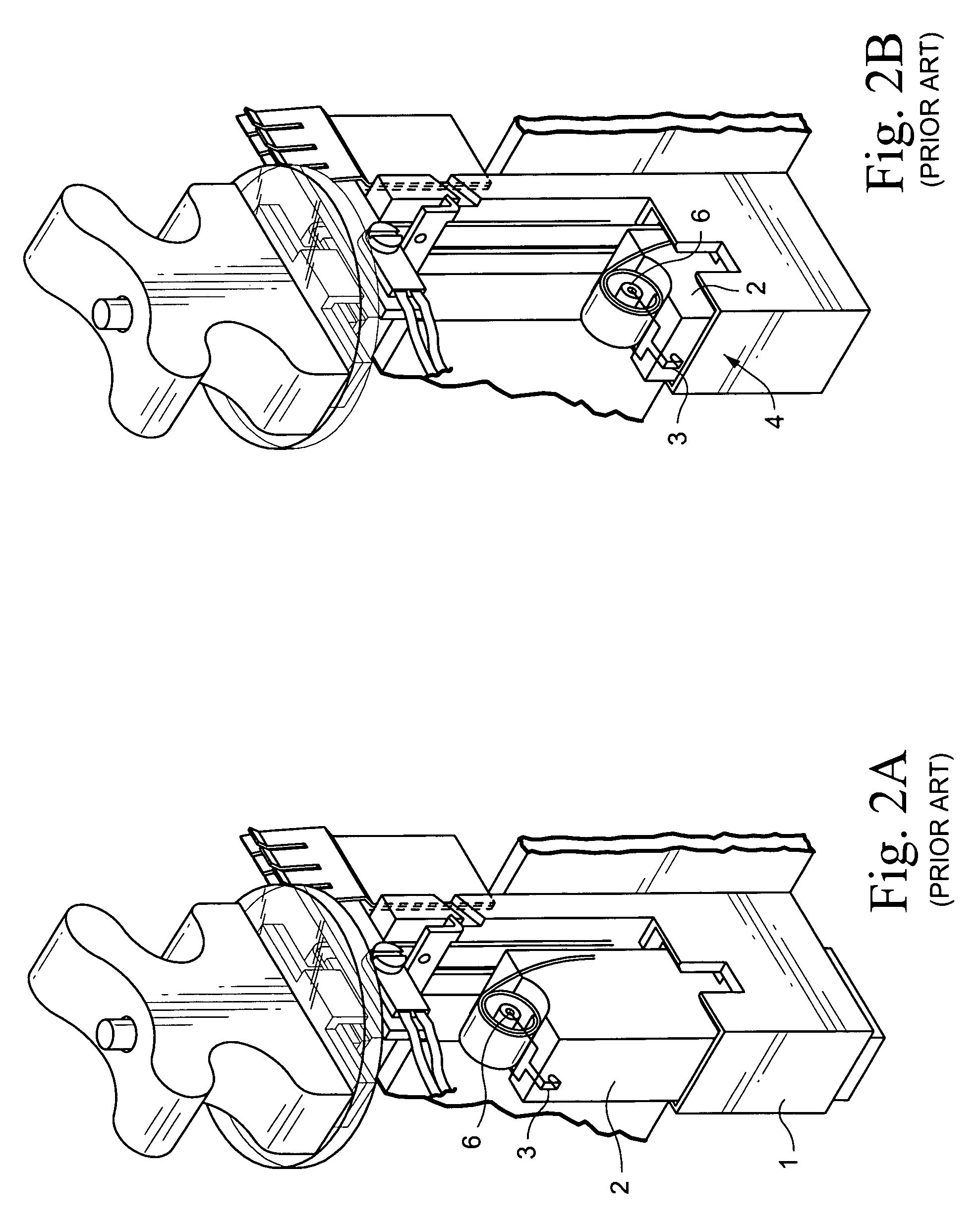

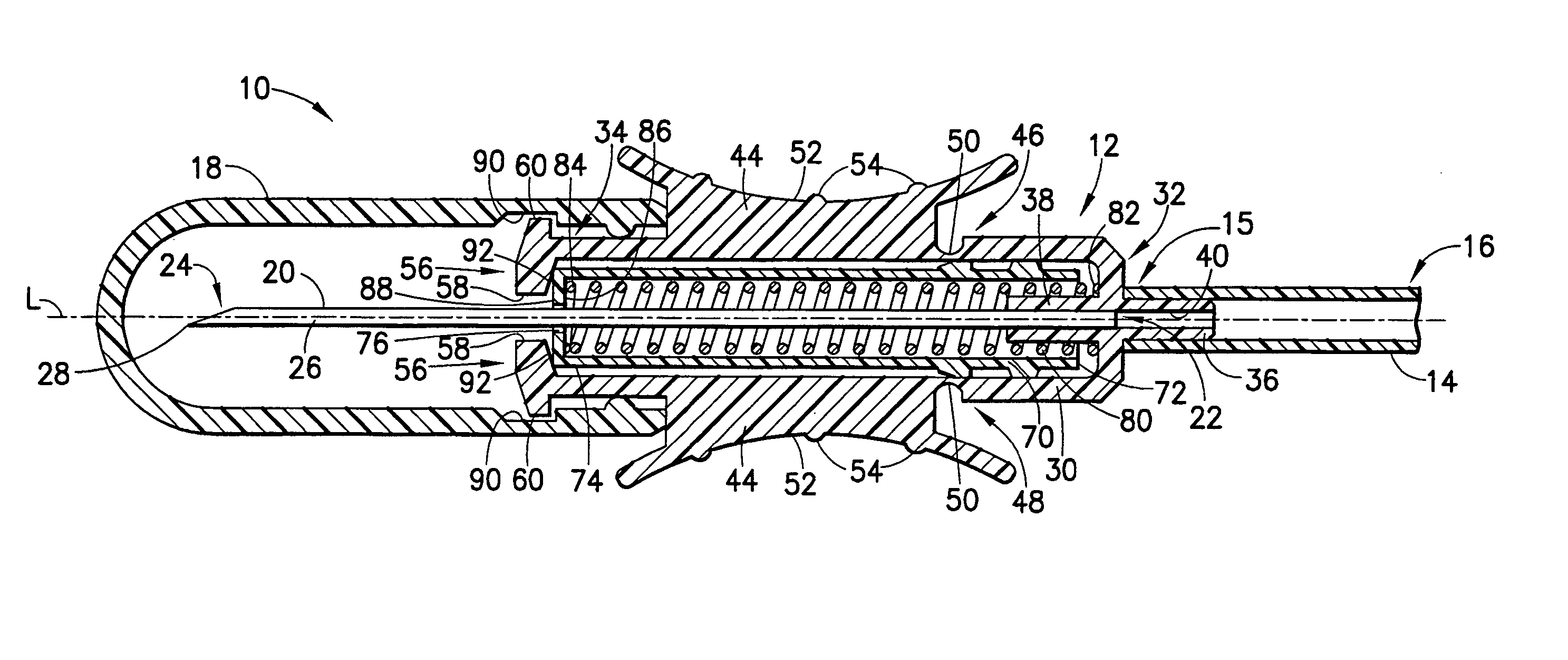

Brush holder assembly for dynamoelectric machines

ActiveUS7218028B2Safely released and retracted and replacedImprove securityRotary current collectorSupports/enclosures/casingsEngineeringMechanical engineering

A brush holder assembly that cannot be assembled incorrectly includes a brush inserted into a brush holder, a block attached to the top of the brush, a spring engaging the block that applies radial pressure to the block and brush, and a hook pin that holds the spring onto the block. The block includes a semicircular indentation that cradles a coiled portion of the spring and includes a slotted hole for receiving a portion of the hook pin as the block is glued to the top of the brush. The hook pin is a loop terminating at a first end that is a straight pin and terminating at a second end that is a hook-shaped loop in which the straight pin end is inserted. Alternatively, a U-shaped spool assembly can be used to engage the coiled portion of the spring to lock it in the indentation in the block.

Owner:GENERAL ELECTRIC CO

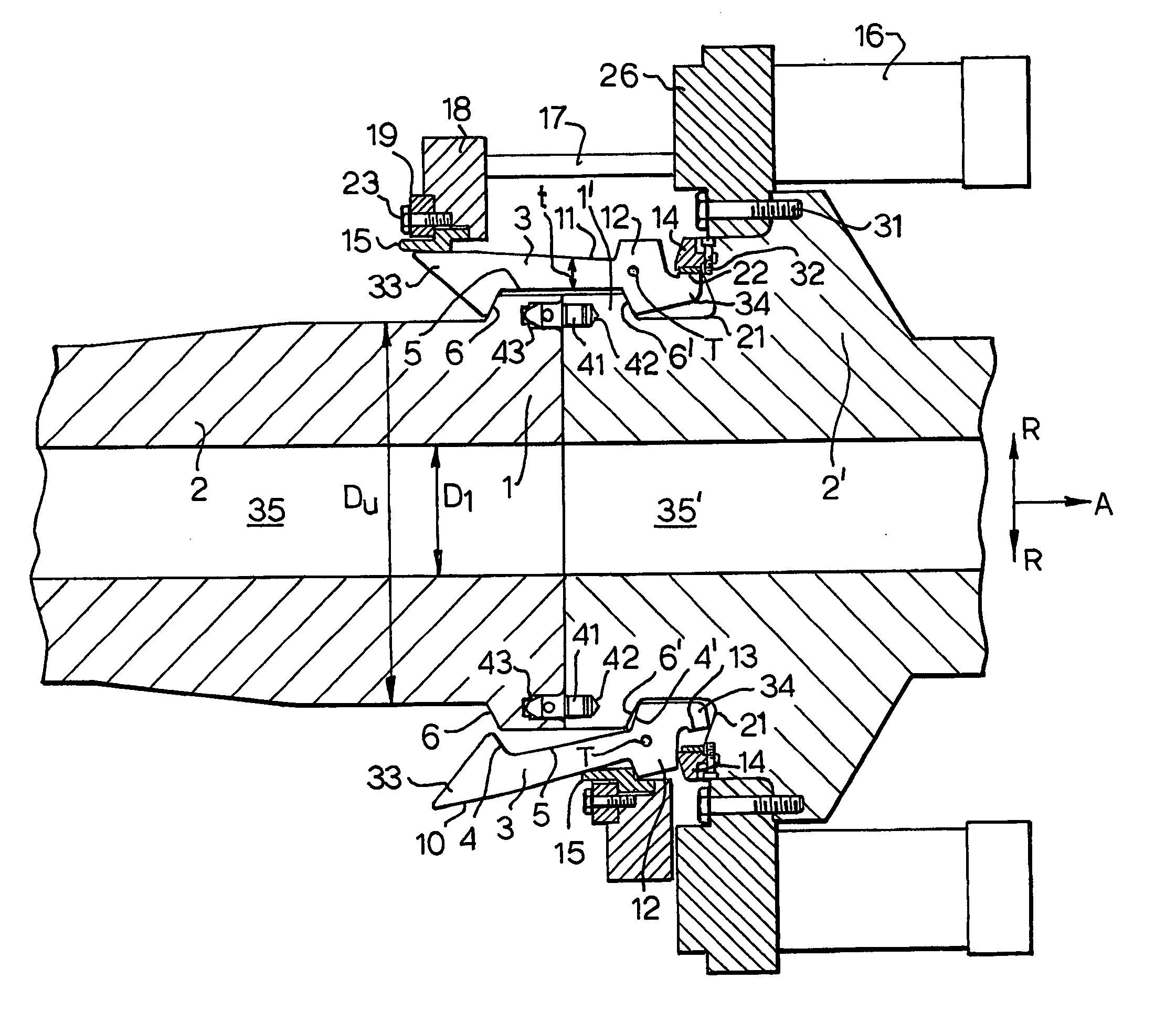

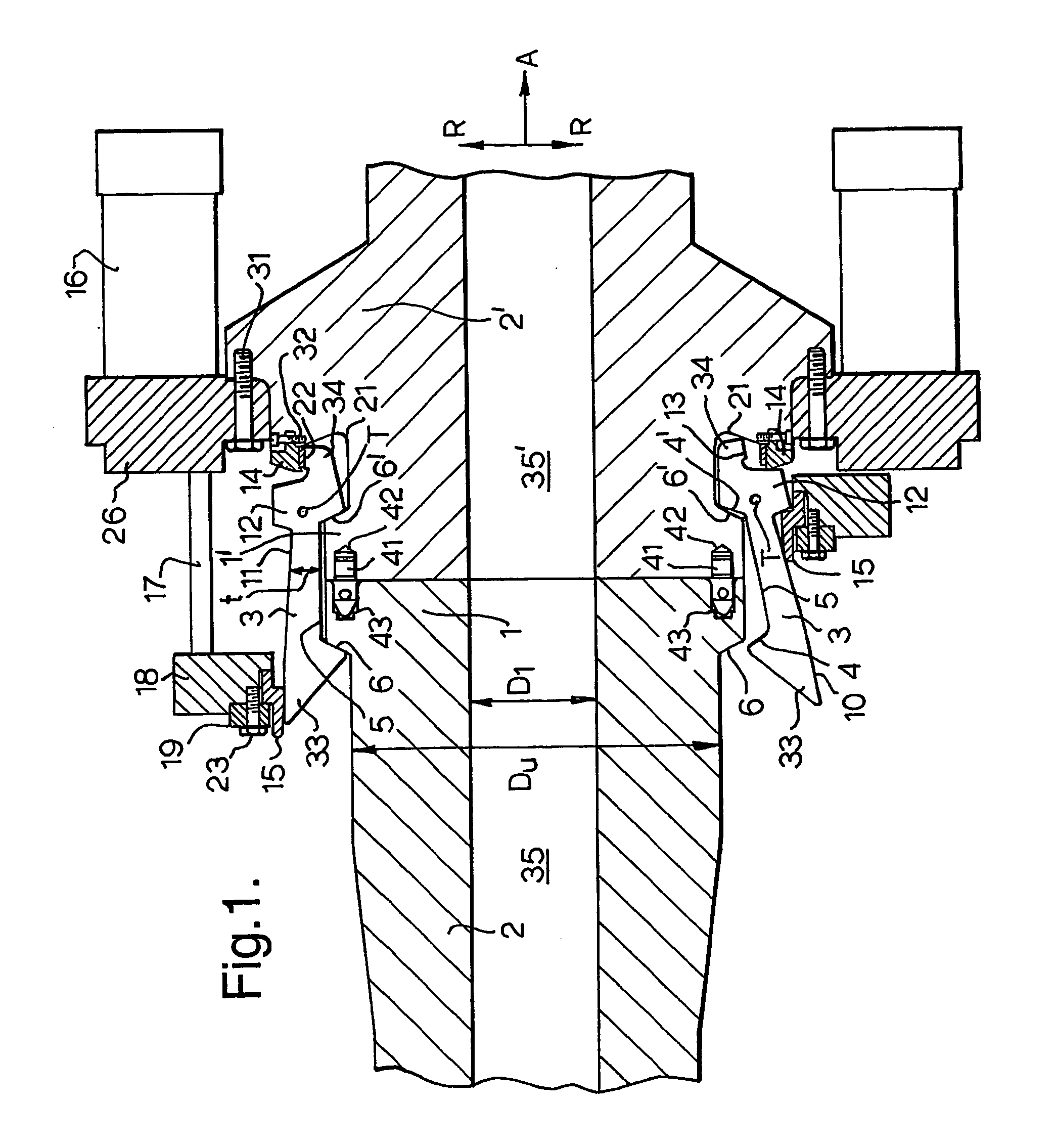

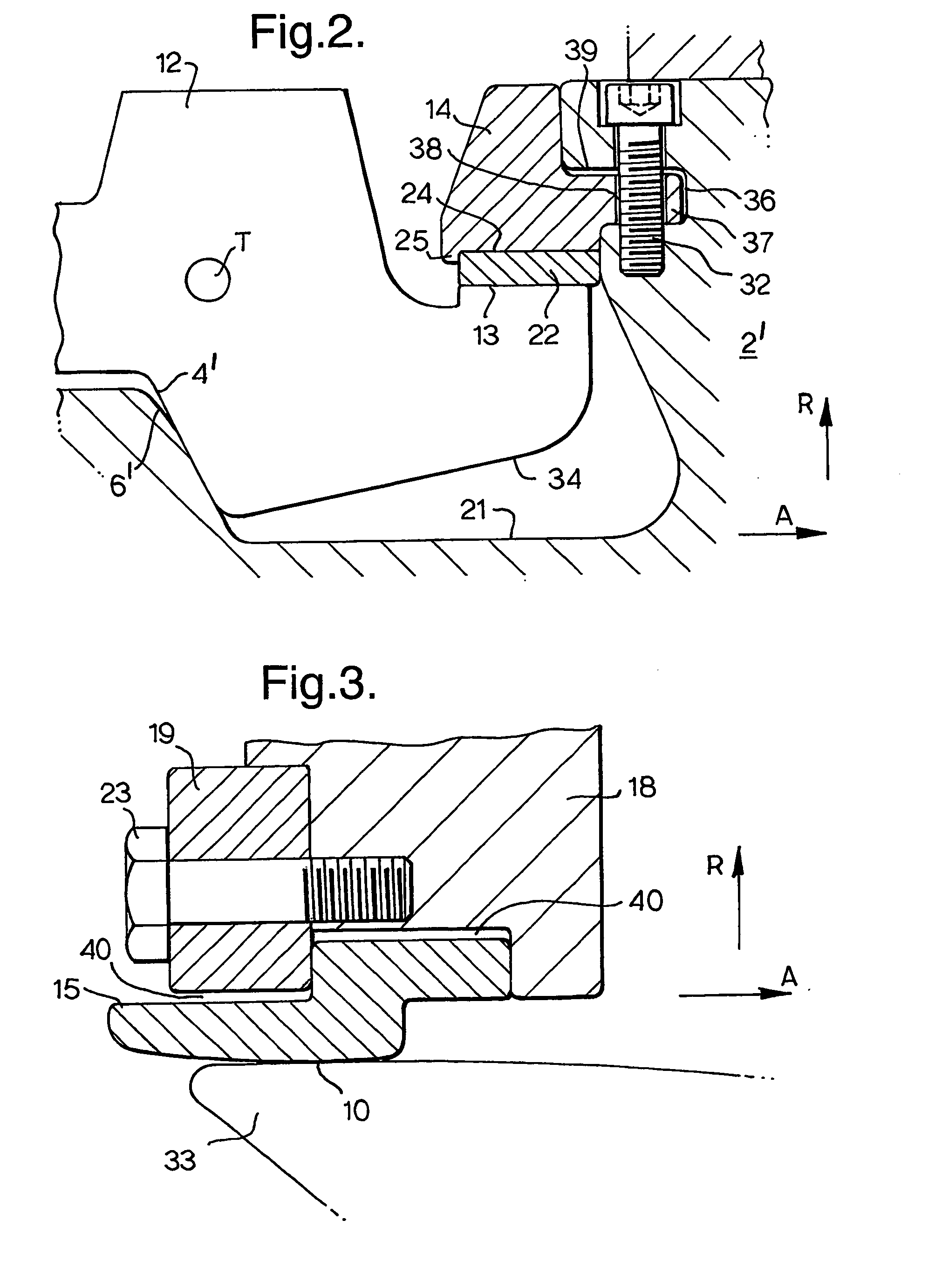

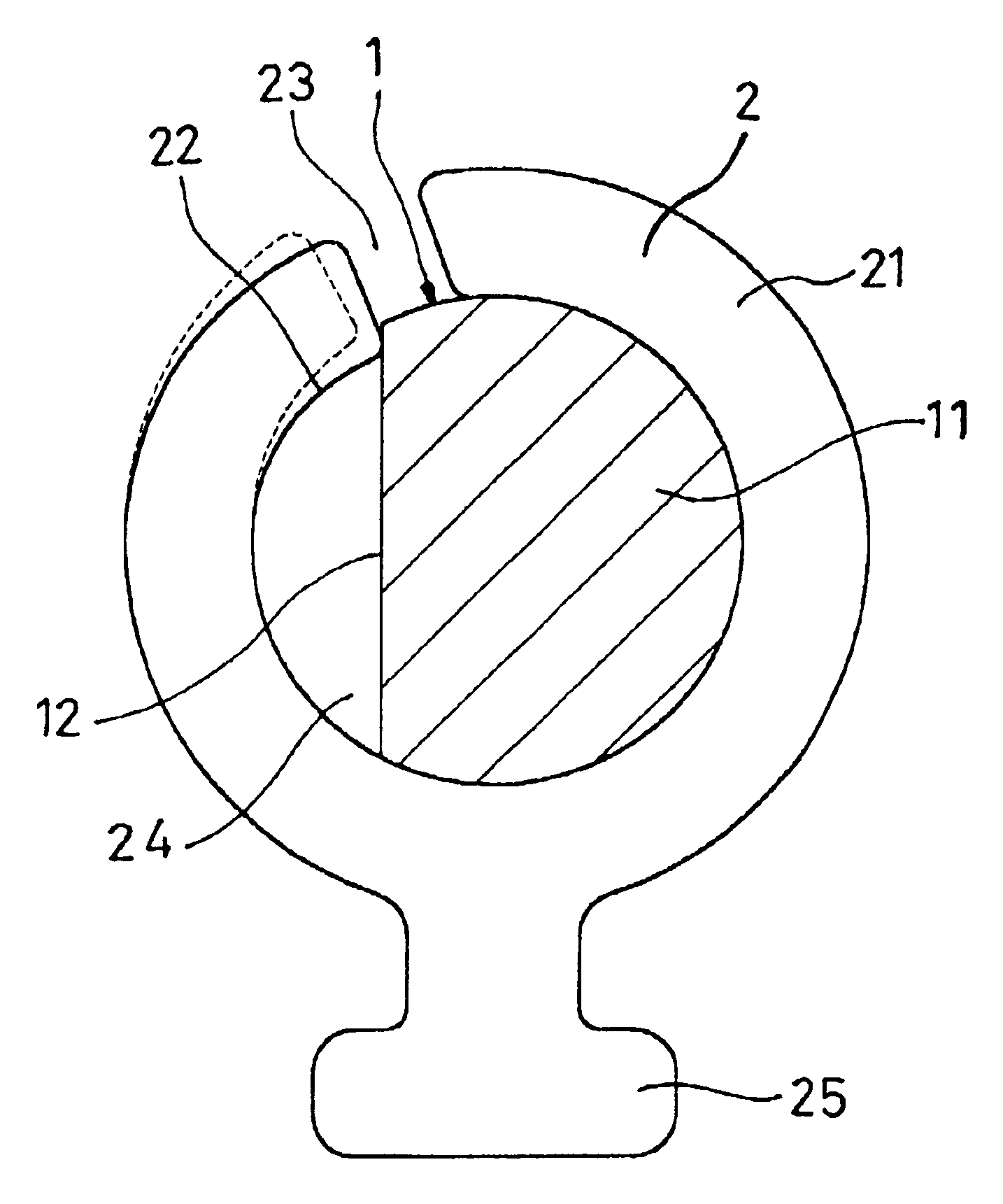

Mechanical joints for subsea equipment

InactiveUS20050146137A1Large dimensional toleranceExpand the scope of workSleeve/socket jointsPipe laying and repairJoint componentEngineering

A mechanical connector for oil and gas well apparatus applies a predetermined preload across the connection, the preload being adapted to accommodate relatively large dimensional tolerances in the loadpath of the connector preload by placing a component with a low modulus of elasticity within that load path. In one embodiment, the connector comprises fingers (3) of a pair of pipe flanges (1, 1′), a stationary retainer ring (14) against which a finger reaction surface (13) is pressed, a runner ring (15) located outside the fingers and movable lengthwise along the fingers by an actuator (16), the retainer ring and the runner ring having an elasticity that is so large that deviations in their elongation only have a small influence on the retainer ring and the runner ring radial pressure against the fingers and clamping forces of the fingers against the flanges. In a second embodiment, the connector comprises dogs (103, FIG. 4) located around the circumference of a first tubular joint component, a follower located outside the dogs (103) and movable axially of the dogs, the low elastic modulus component being a ring located in the loadpath below the dogs. In a third embodiment, the connector comprises a lockdown mechanism acting between nested components, the low elastic modulus component being an insert comprising a load shoulder transferring loads between the nested components.

Owner:FMC TECH INC

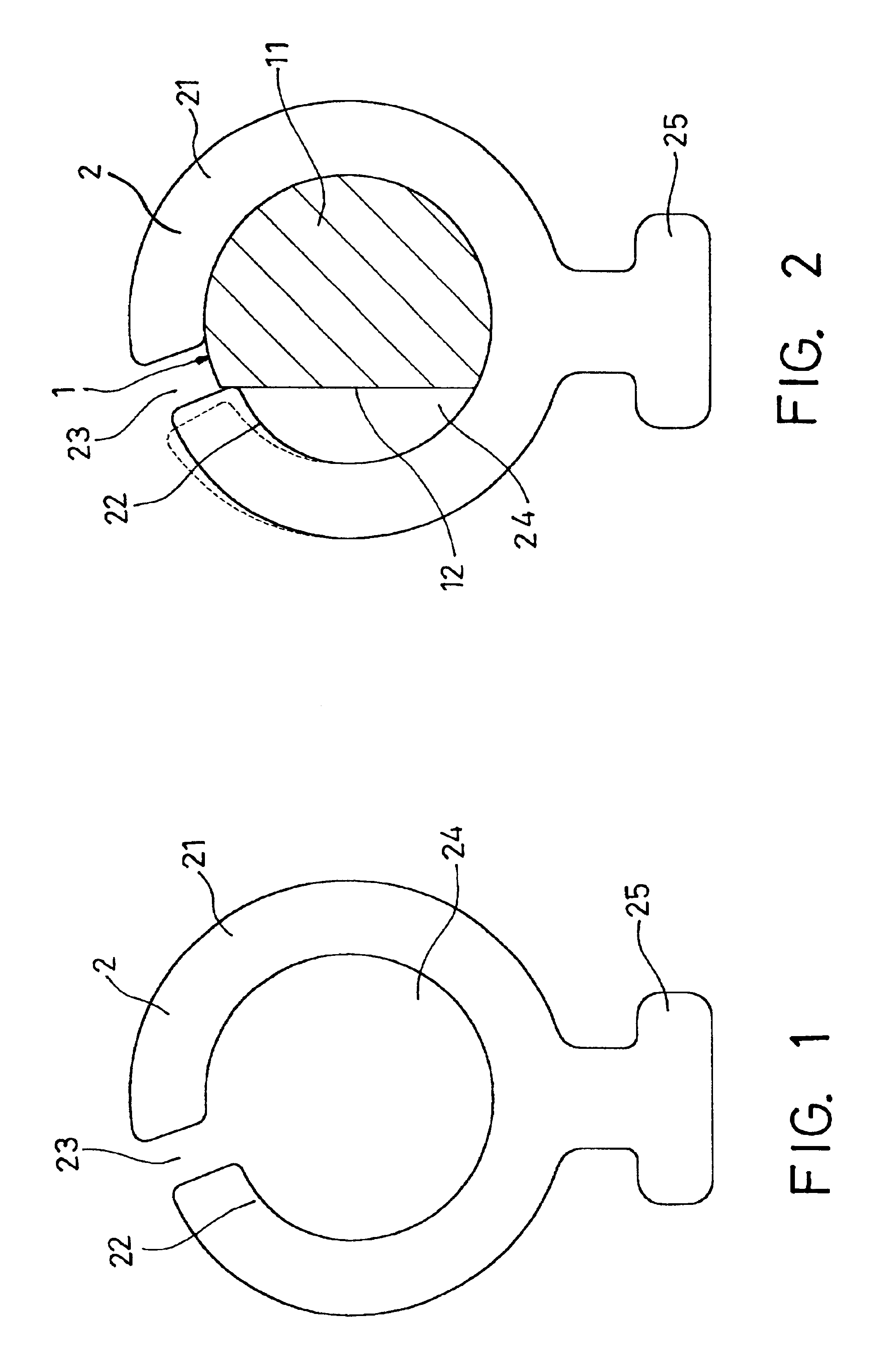

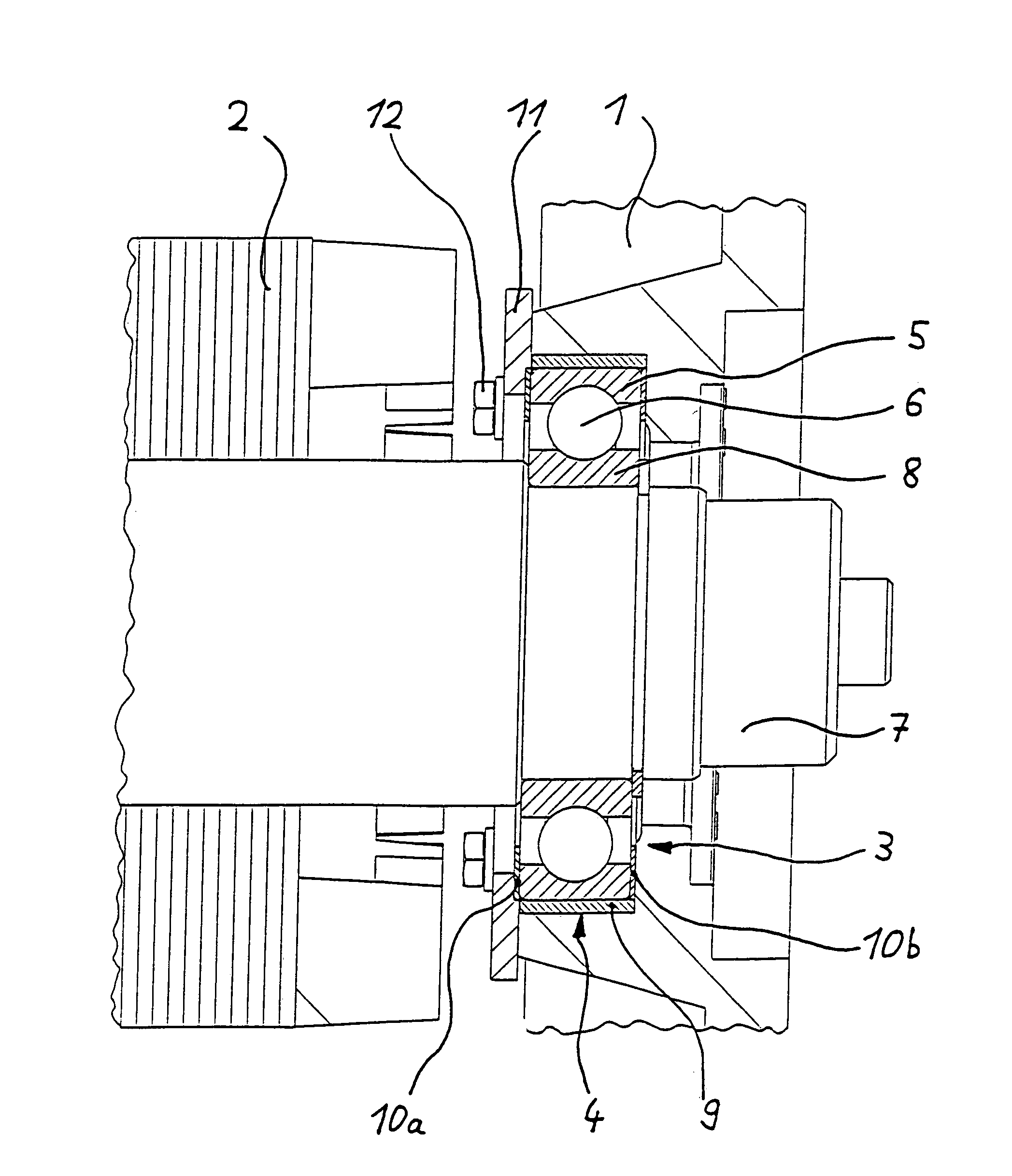

Rotating shaft with radial press device

InactiveUS6928700B2Wing fastenersDetails for portable computersMechanical engineeringRadial pressure

A rotating shaft with radial press device comprises a cylindrical rod and at least a friction part. The cylindrical rod extends from the rotating shaft and provides at least a milled face. The friction part is a ring piece composed of a circular section and an arched section and a gap is formed between the circular section and the arched section. An axial hole is surrounded by both of the circular section and the arched section for accommodating the cylindrical rod. Further, the arched section has a gradually reduced inner radius. As soon as the cylindrical rod is tightly pressed by the arched section, a position of standstill can be formed and when the milled face touches the free end of the arched section, the cylindrical rod can moves in a direction so that the milled face keeps contact with the free end of the arched section in a state of locking automatically.

Owner:JARLLYTEC CO LTD

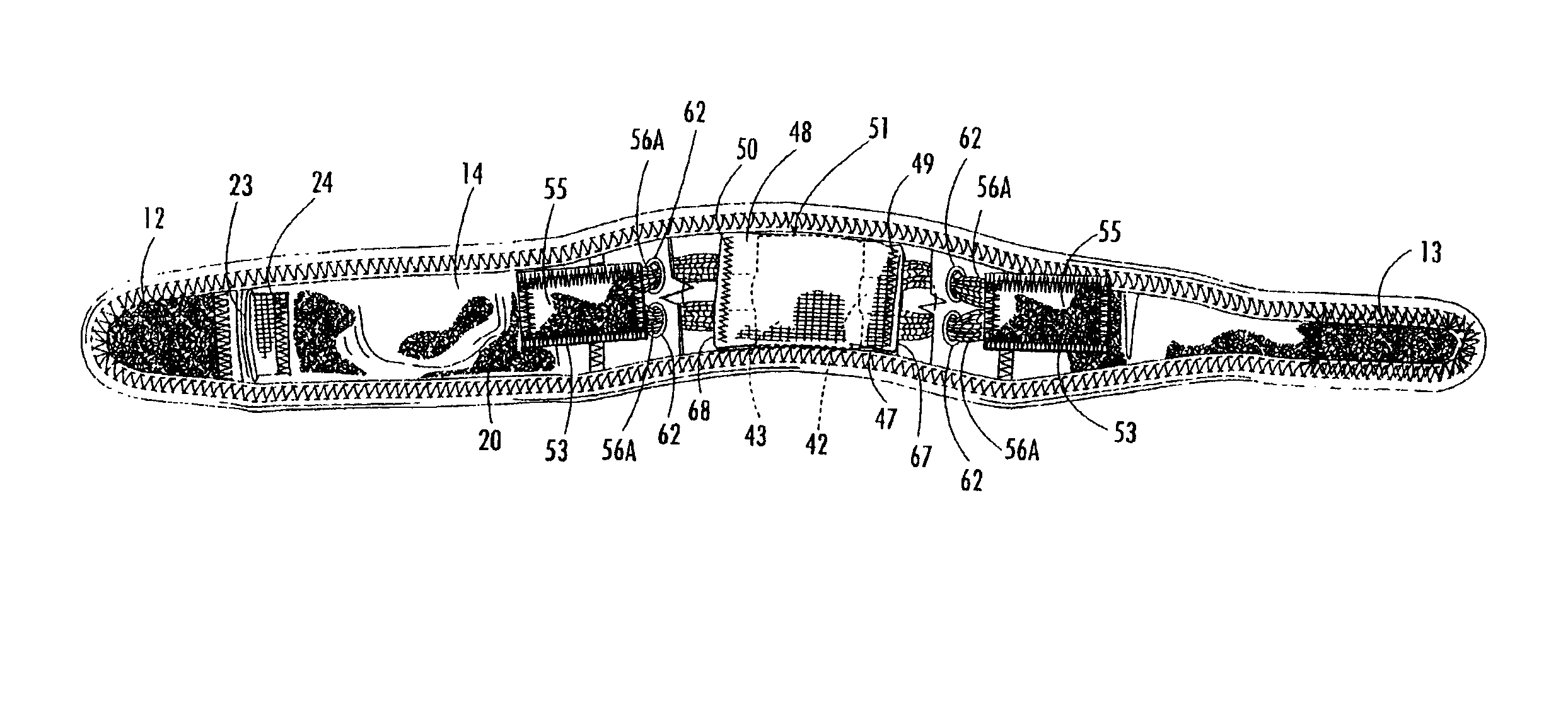

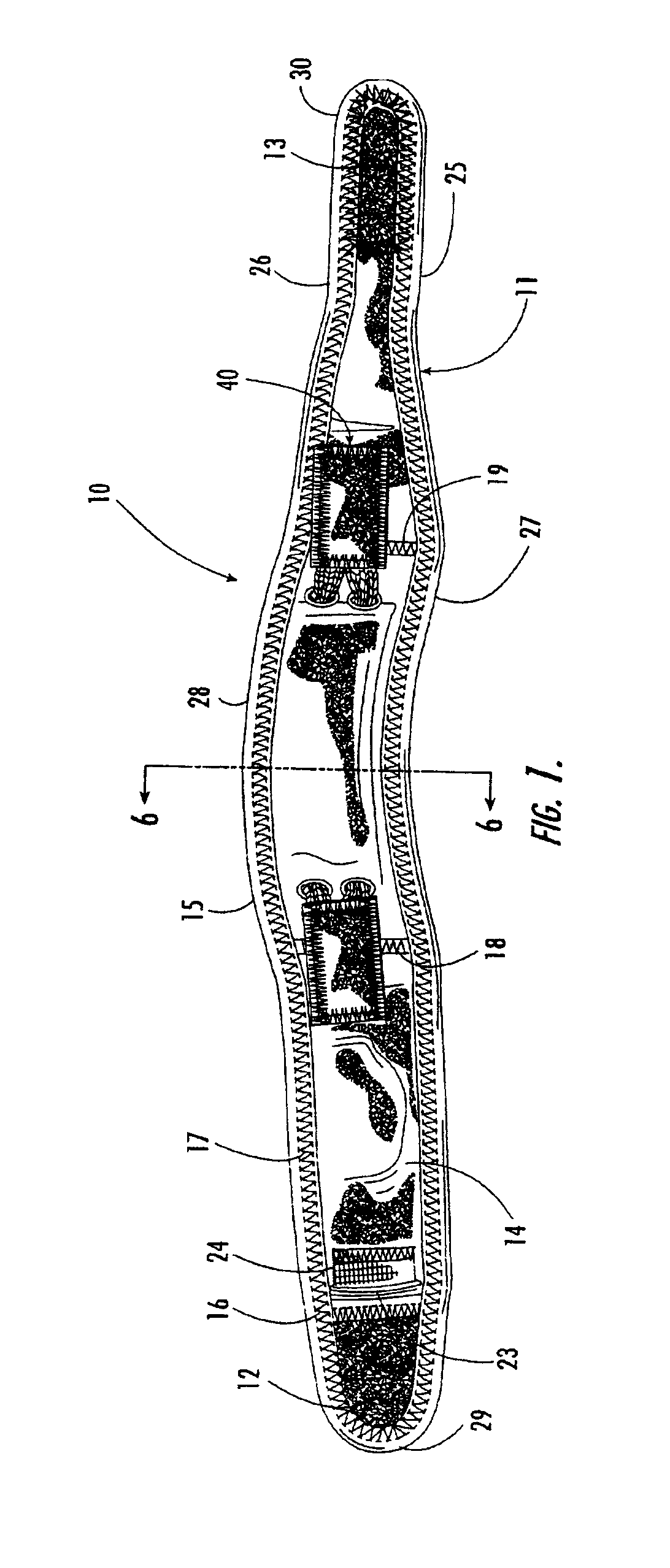

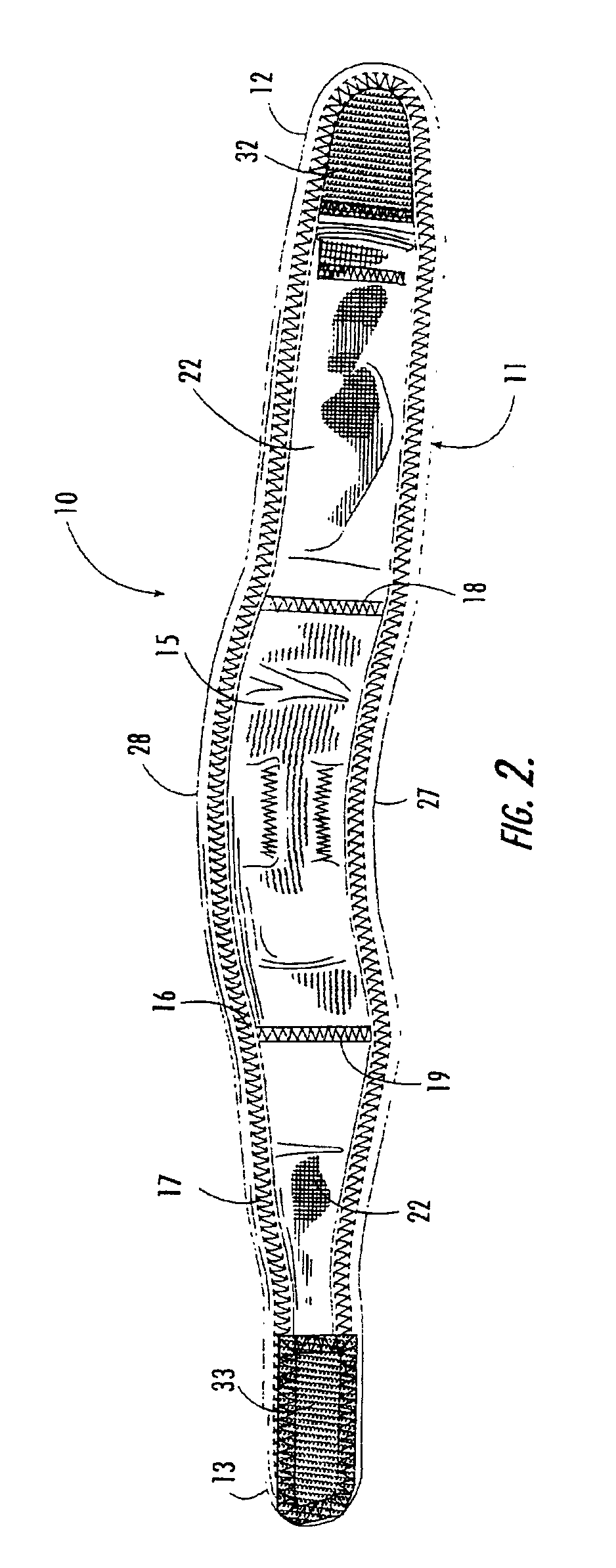

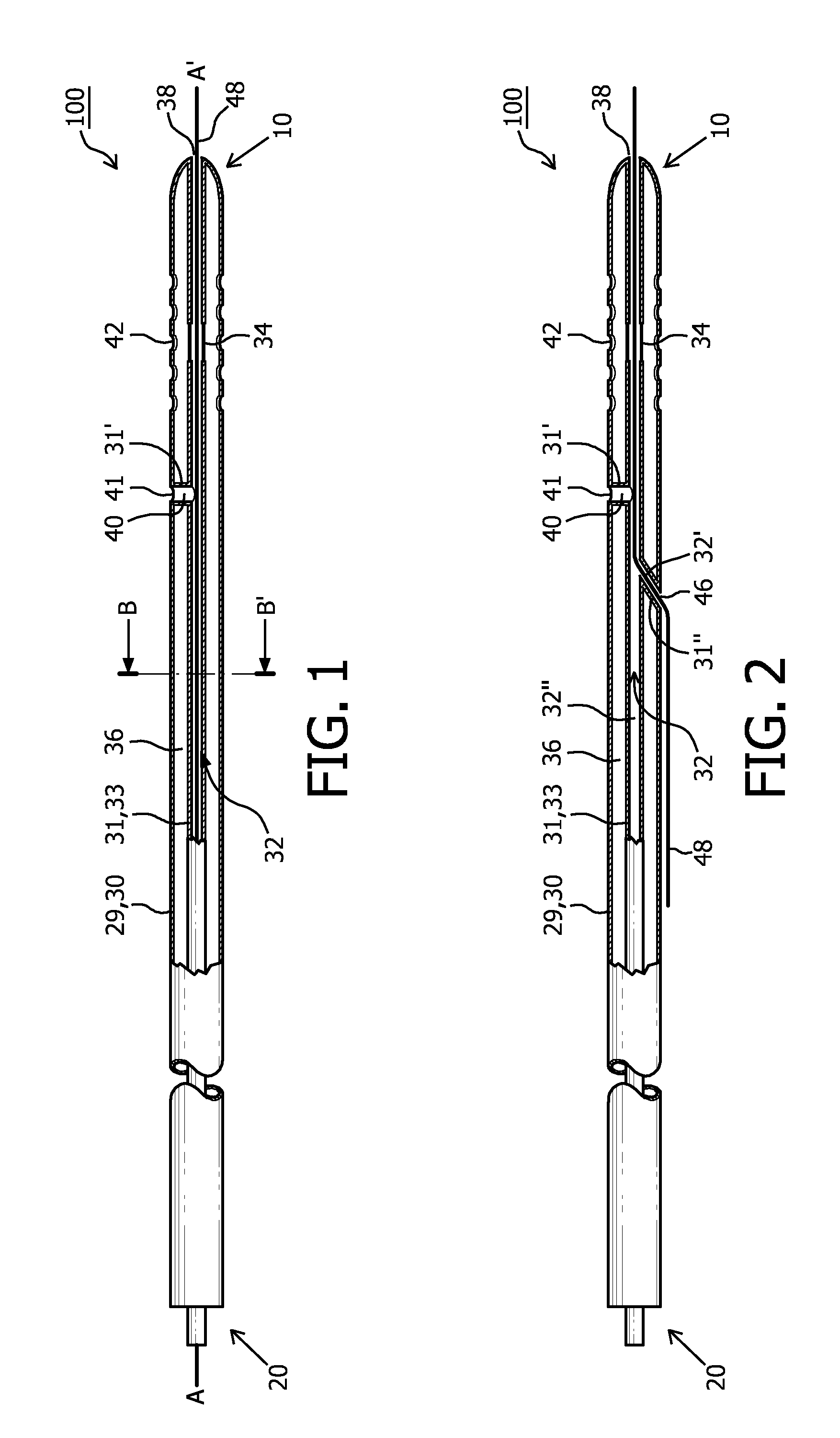

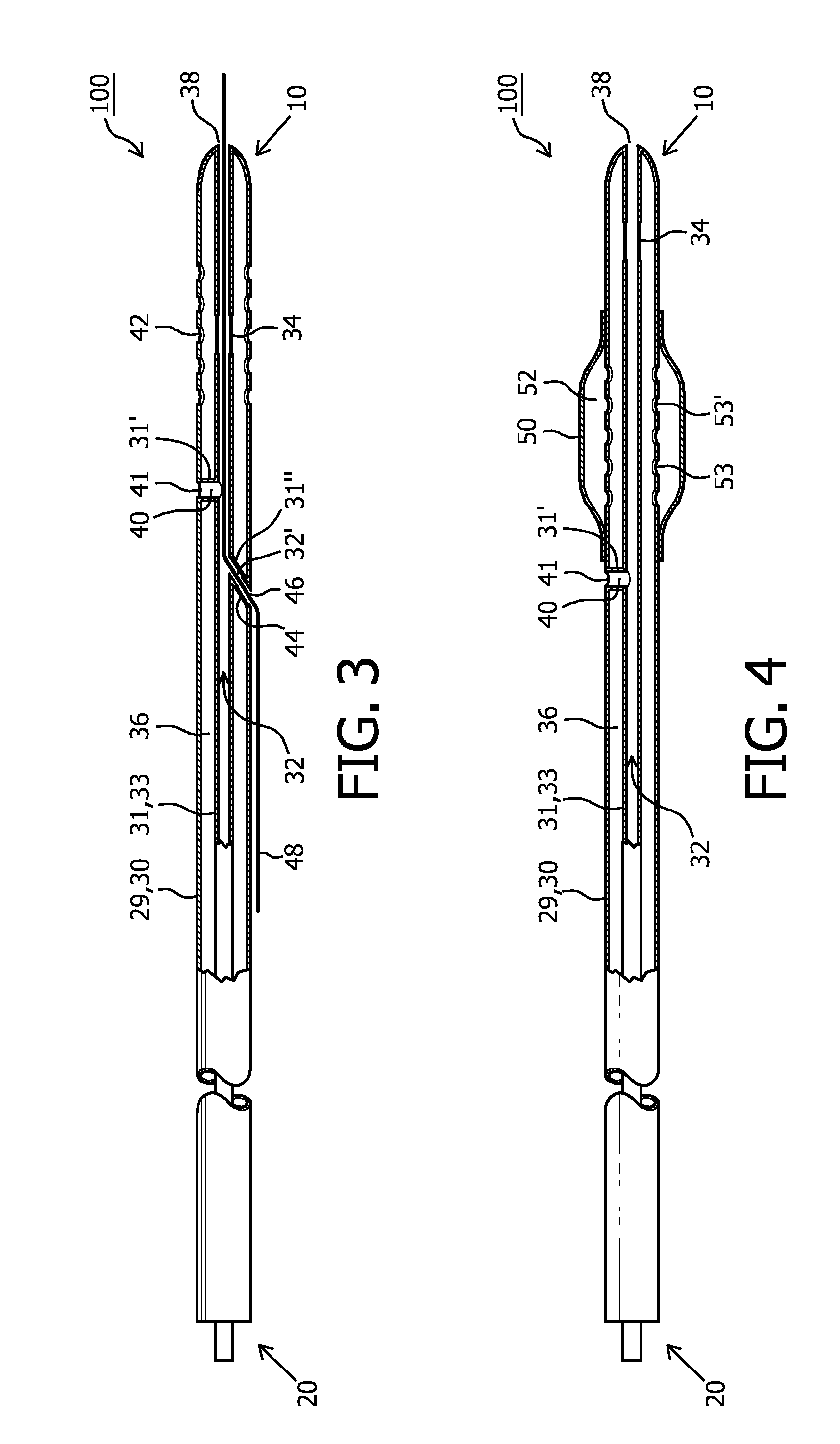

Forward-shielding blood collection set

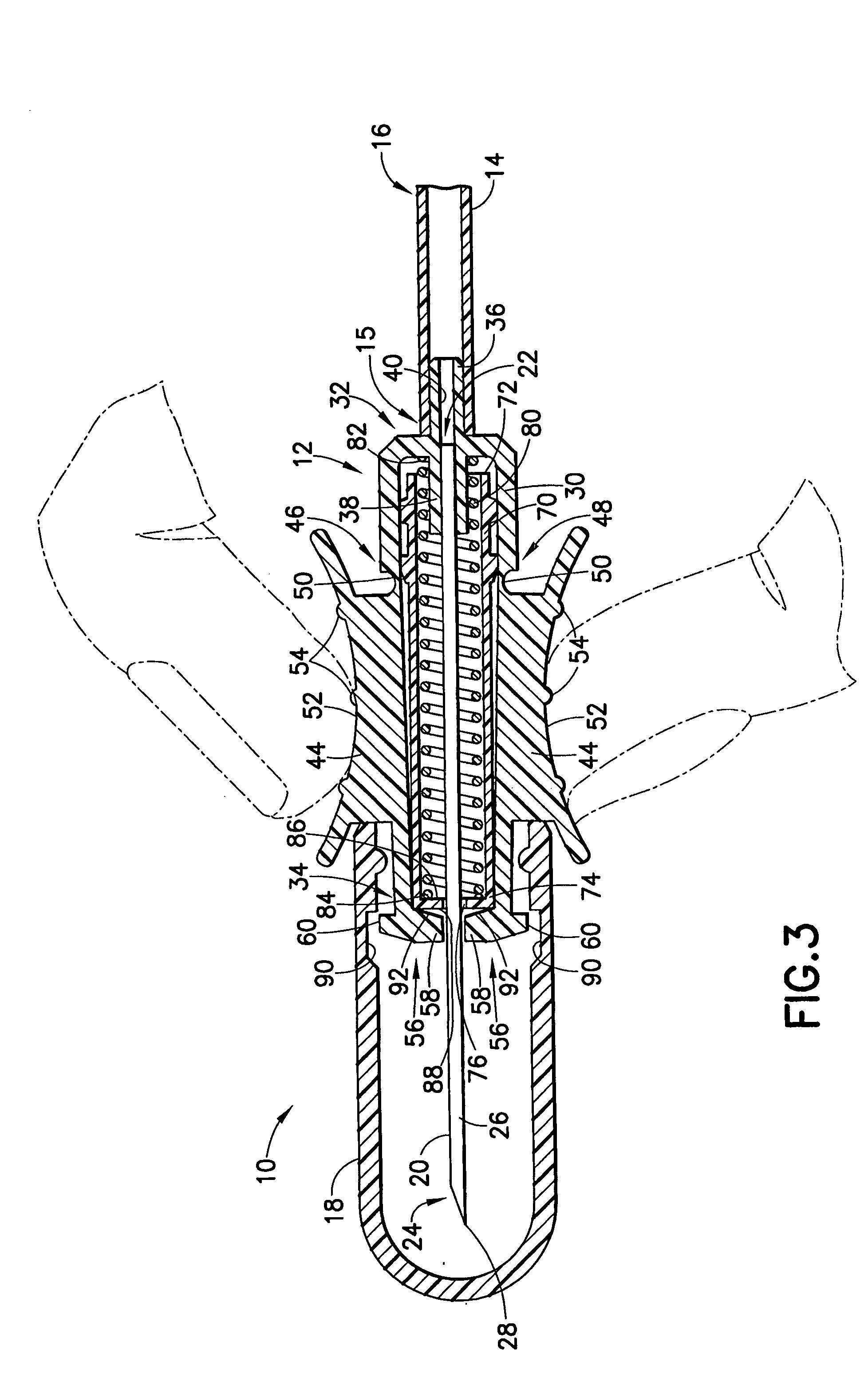

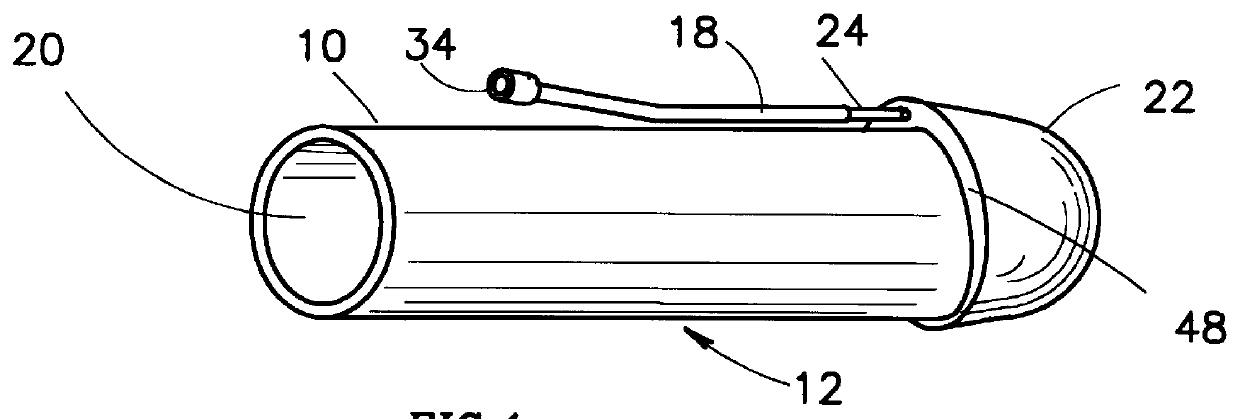

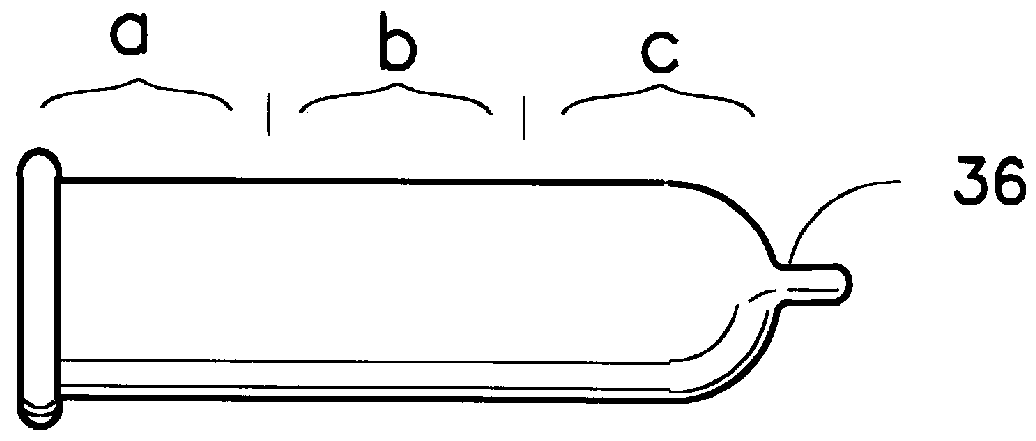

ActiveUS20060079847A1Prevent inadvertent removalPrevent removalCatheterDiagnostic recording/measuringBlood collectionBiomedical engineering

A blood collection set includes a needle having a puncture tip, a hub supporting the needle and including a release member, a safety shield, a drive member, and a packaging shield disposed on the hub. The safety shield is movable from a retracted position within the hub to an extended position shielding the puncture tip of the needle. The packaging shield encloses the puncture tip of the needle in the retracted position of the safety shield. The shielding feature of the blood collection set is activated by applying radial pressure to the release member, causing the release member to release the packaging shield from the hub, and maintain the safety shield in the retracted position. Upon sufficient or partial release of radial pressure, the drive member disengages the release member from the safety shield and moves the safety shield from the retracted position to the extended positions.

Owner:BECTON DICKINSON & CO

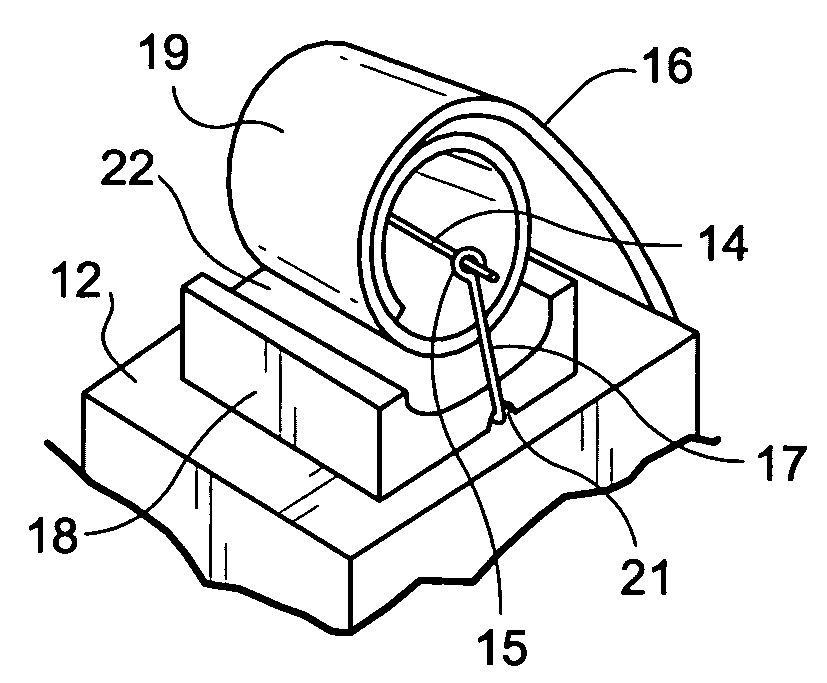

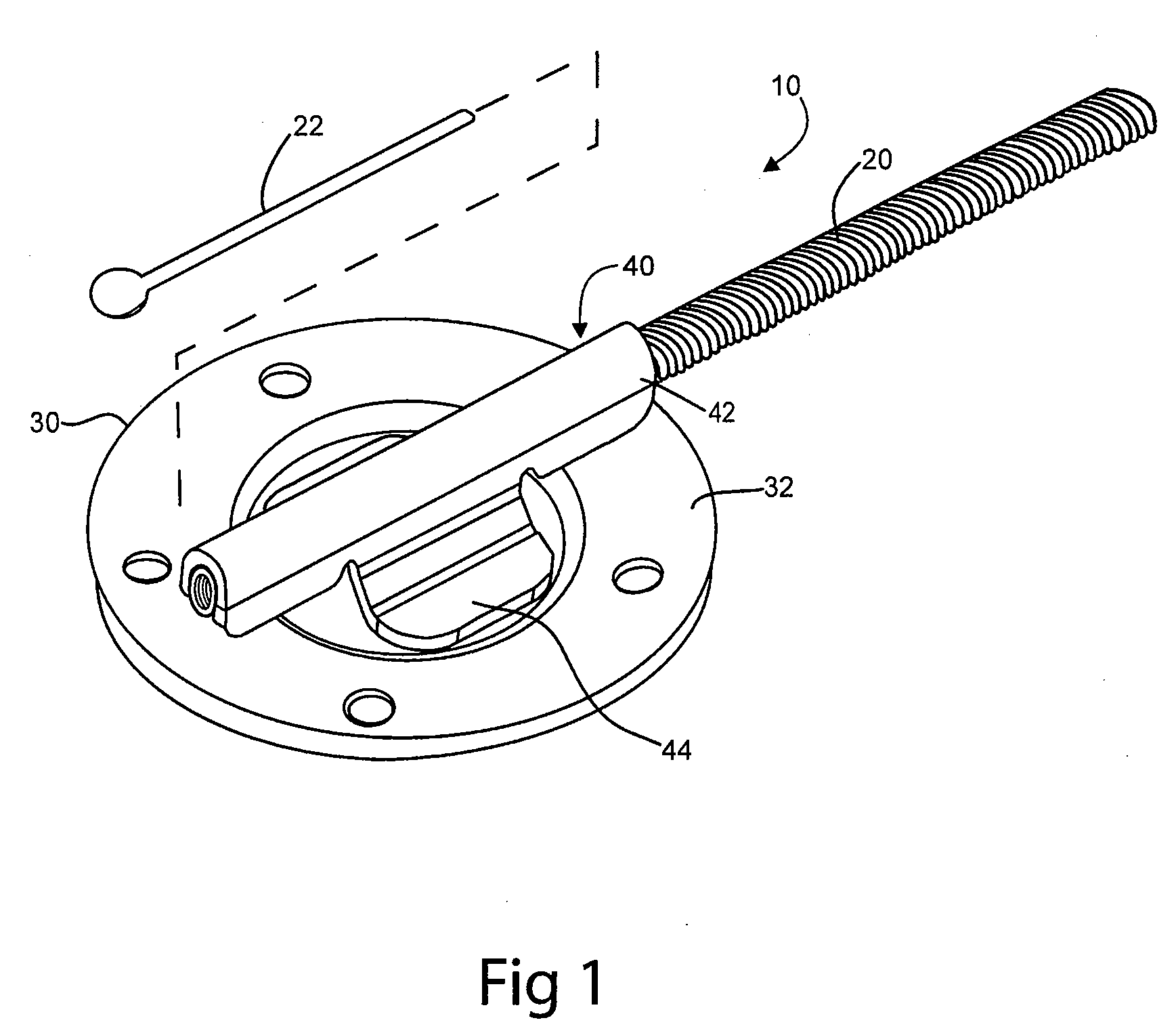

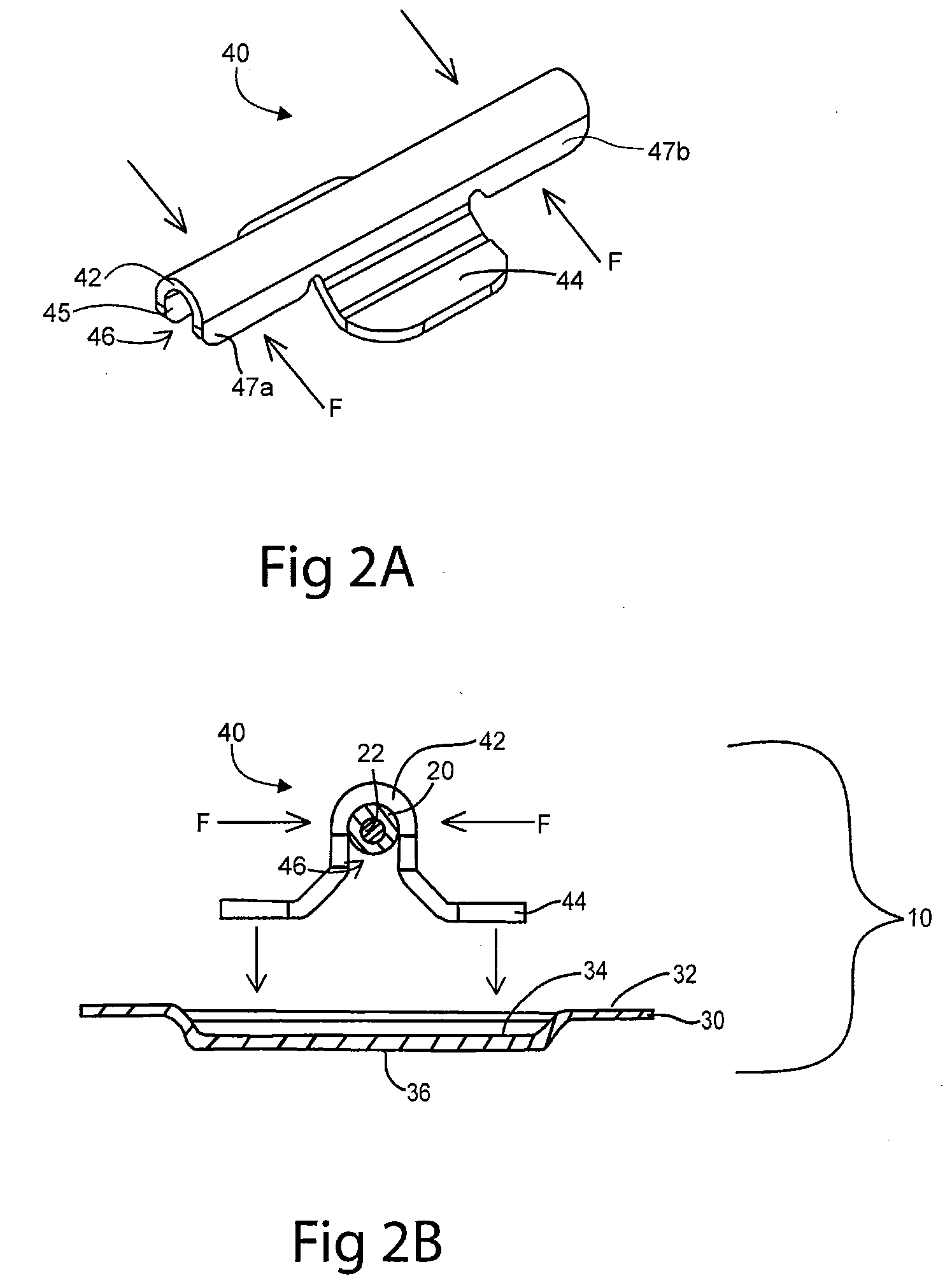

Erection control system

Erection control system of the invention overcomes known deficiencies of vacuum constriction devices, especially cumbersomness, technical difficulties and painfulness. A penis-shaped vacuum chamber (12) adapted for unnoticeable operation under user's cloth. Removably placed penile seal (14) and a baffle (16) are adjustable to the user's penile girth and provide attachment so that the vacuum chamber hangs on the user's penis without additional support. A ribbon-shaped constriction device (26) is wound with multiple turns over each other to form a cylindrical ring, retained by the belt (28) for exerting a prearranged inward radial pressure. A transferring device with the pulling loop (40) dislodges constriction device together with removably placed penile seal and baffle onto erect penis with simultaneous release of vacuum without additional mechanisms. The removably placed penile seal, the baffle, the belt are formed from segments of a condom. A method of vacuum erection treatment with a vacuum chamber, removable seal, a vacuum source and constriction device, in which forcible slip off of the constriction device onto erected penis causes slip off of the removable seal with simultaneous vacuum release in the vacuum chamber has been proposed.

Owner:ALTSHULER YAKOV

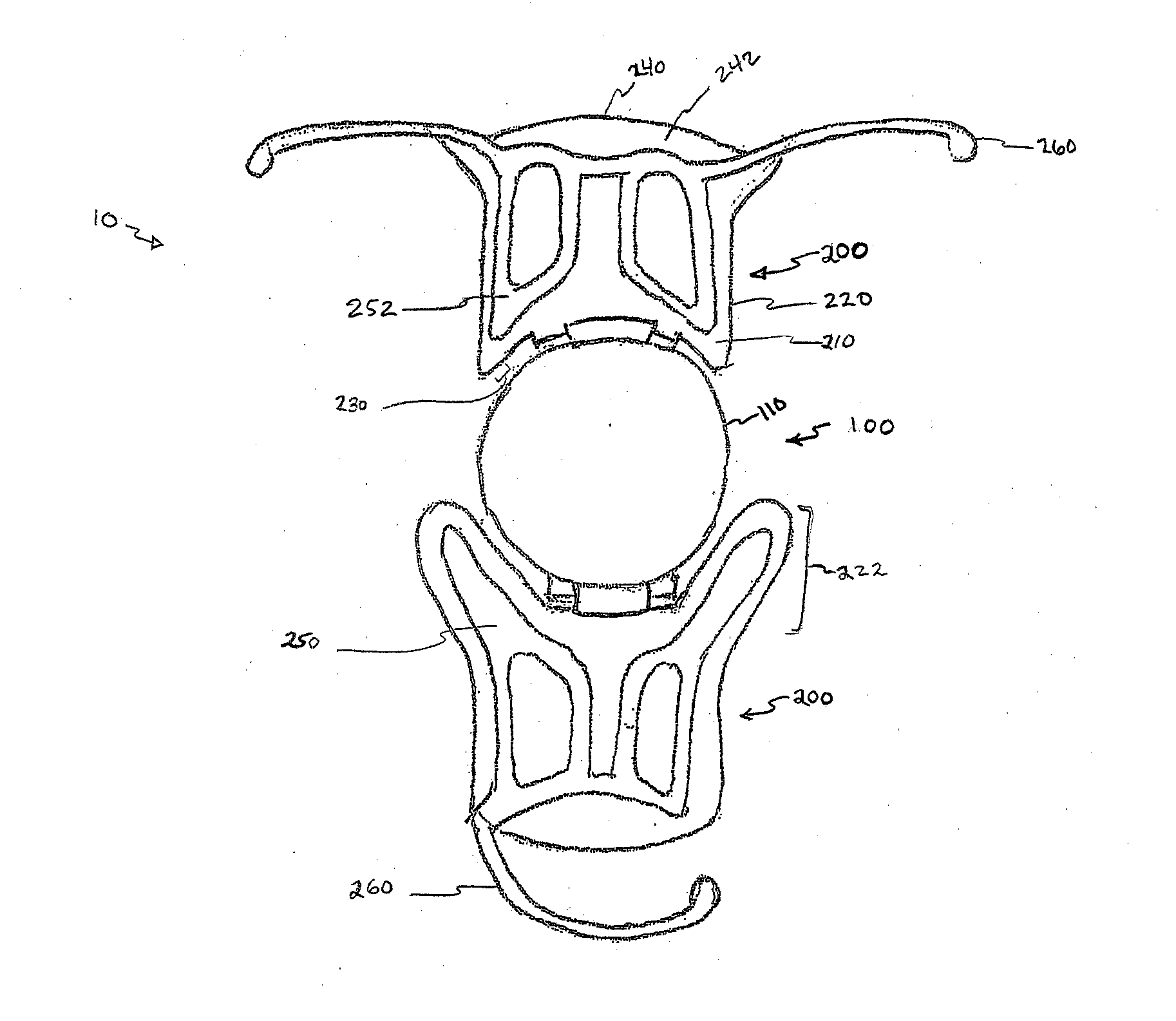

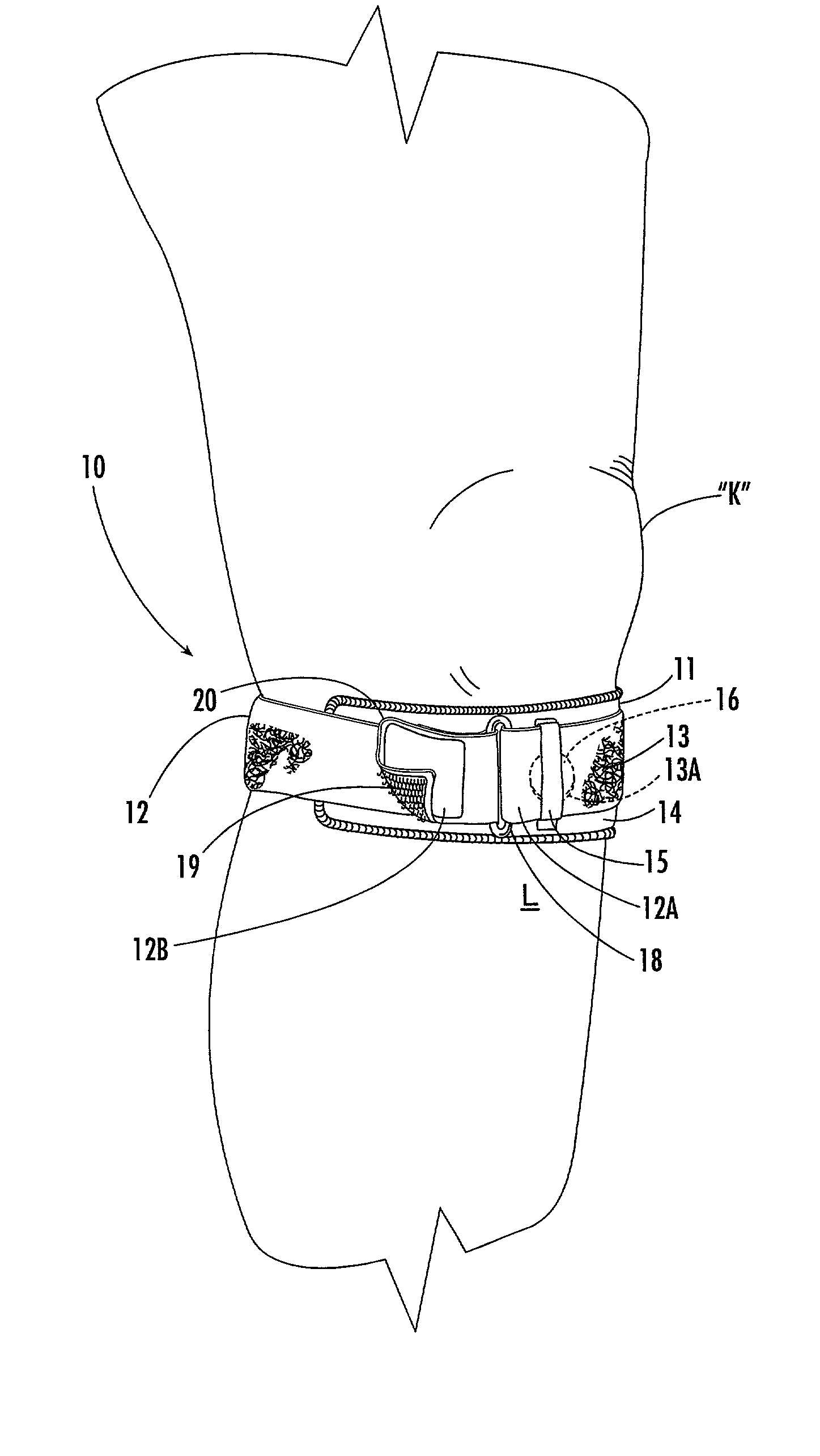

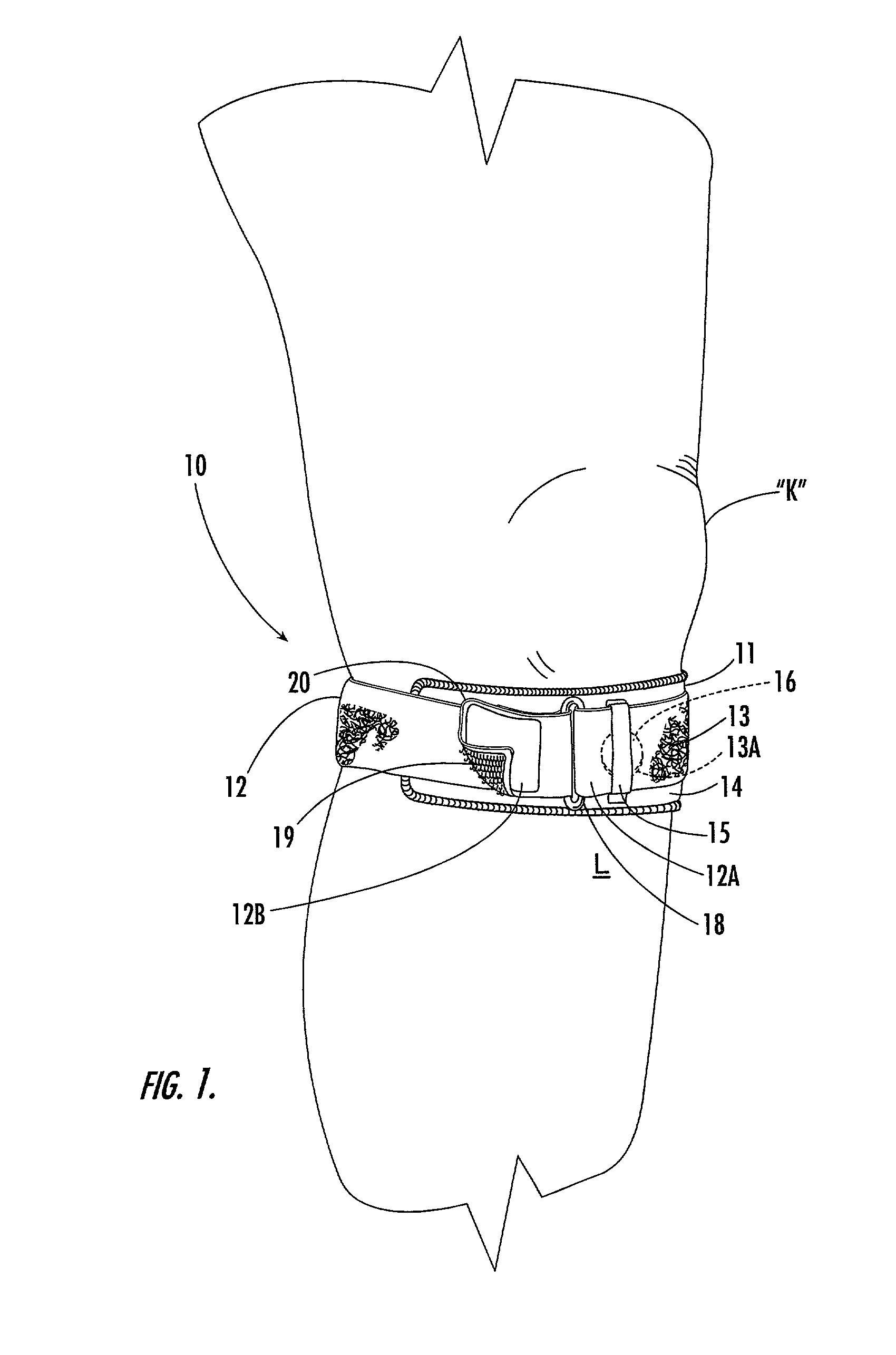

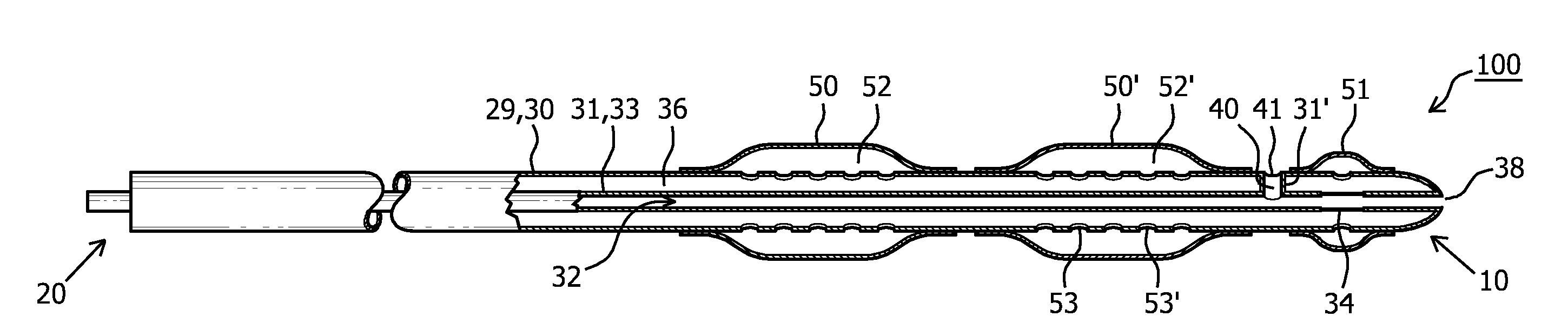

Knee support device for applying radial pressure

InactiveUS6852088B2Relieve symptomsAvoid lostFeet bandagesNon-surgical orthopedic devicesKnee supportKnee Joint

Owner:MEDICAL SPECIALTIES

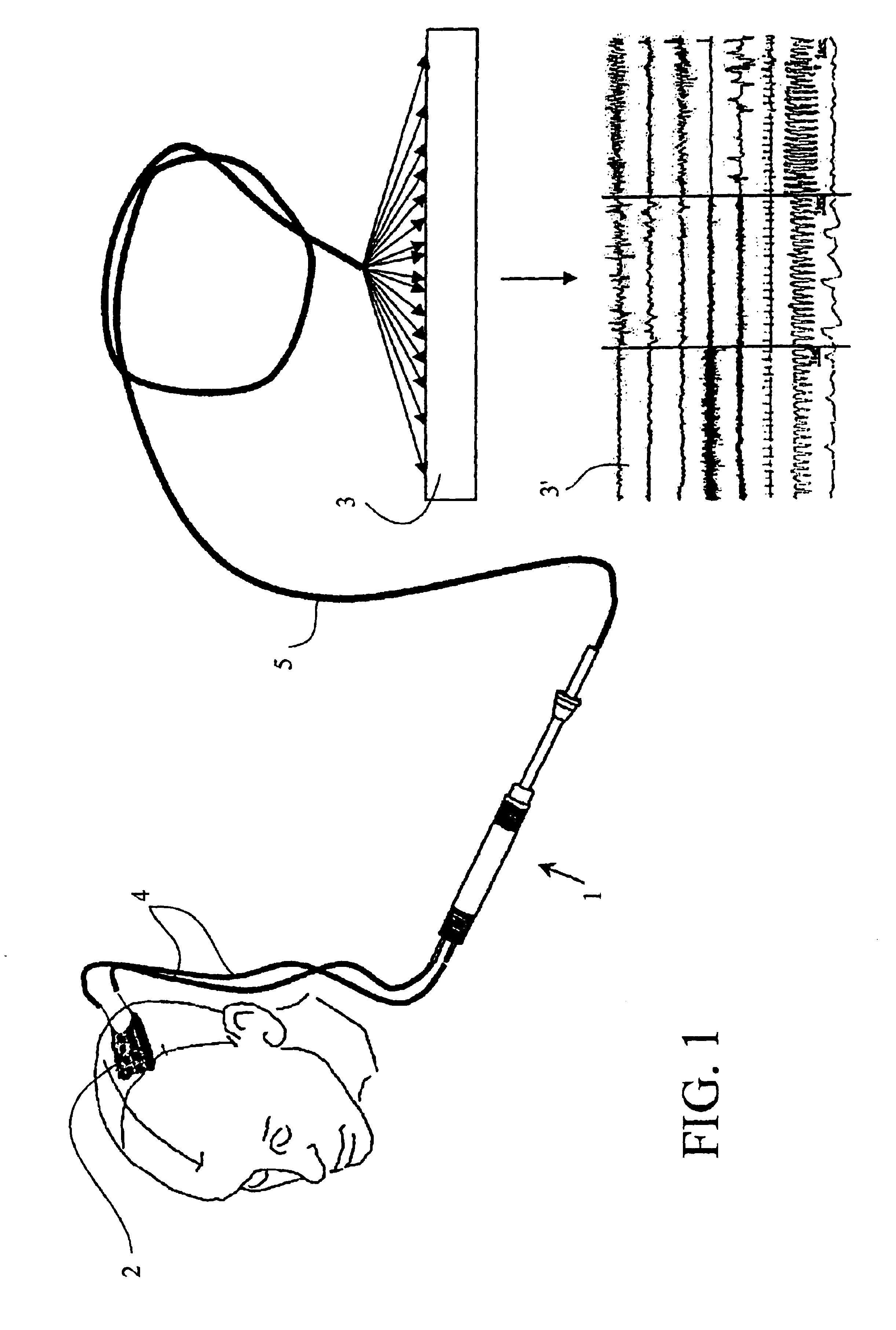

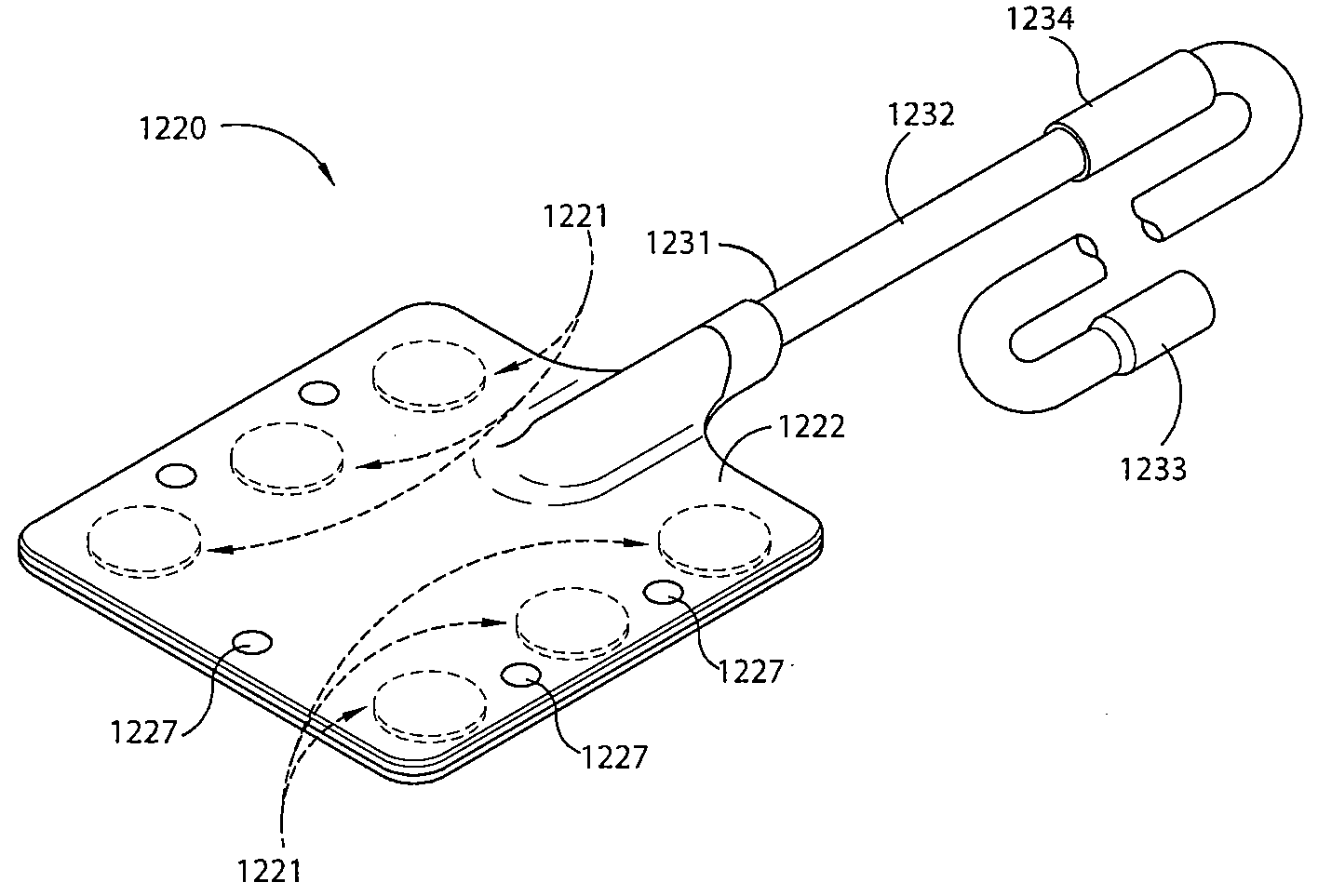

Methods and systems for securing electrode leads

Methods and systems for securing electrode leads are disclosed. An electrode system in accordance with one embodiment includes an electrode contact, a connector attached to the electrode contact, and an electrical lead. The electrical lead can be received in an opening of the contact, with an inner surface of the opening applying a generally uniform radial pressure around a circumference of the electrical lead. For example, the contact can have a tubular shape, optionally with an elongated slit, and can be crimped around the lead to apply the generally uniform radial pressure.

Owner:ADVANCED NEUROMODULATION SYST INC

Brush holder assembly for dynamoelectric machines

ActiveUS20060119211A1Improve securityReduce the number of partsRotary current collectorSupports/enclosures/casingsEngineeringMechanical engineering

A brush holder assembly that, by design, cannot be assembly incorrectly is disclosed. The brush holder assembly includes a brush inserted into a brush holder, a block attached to the top of the brush, a spring engaging the block so as to apply radial pressure to the block and brush, and a hook pin engaging the spring and the block so as to hold the spring onto the block. The block includes a semicircular indentation that cradles a coiled portion of the spring. The block also includes a slotted hole for receiving a portion of the hook pin as the block is glued to the top of the brush. The hook pin is preferably a loop terminating at a first end that is a substantially straight pin and terminating at a second end that is a hook-shaped loop in which the straight pin end is inserted. The hook pin is formed from a spring biased metal to facilitate insertion of the straight pin end and into the hook-shaped loop end. Alternatively, a spool assembly can be used to engage the coiled portion of the spring so as to lock it in the indentation in the block. The spool assembly is U-shaped with a first upright end that supports a first spool holder and a second upright end that supports a second spool holder, the first spool holder and second spool holder each engaging and supporting an end of the coiled portion.

Owner:GENERAL ELECTRIC CO

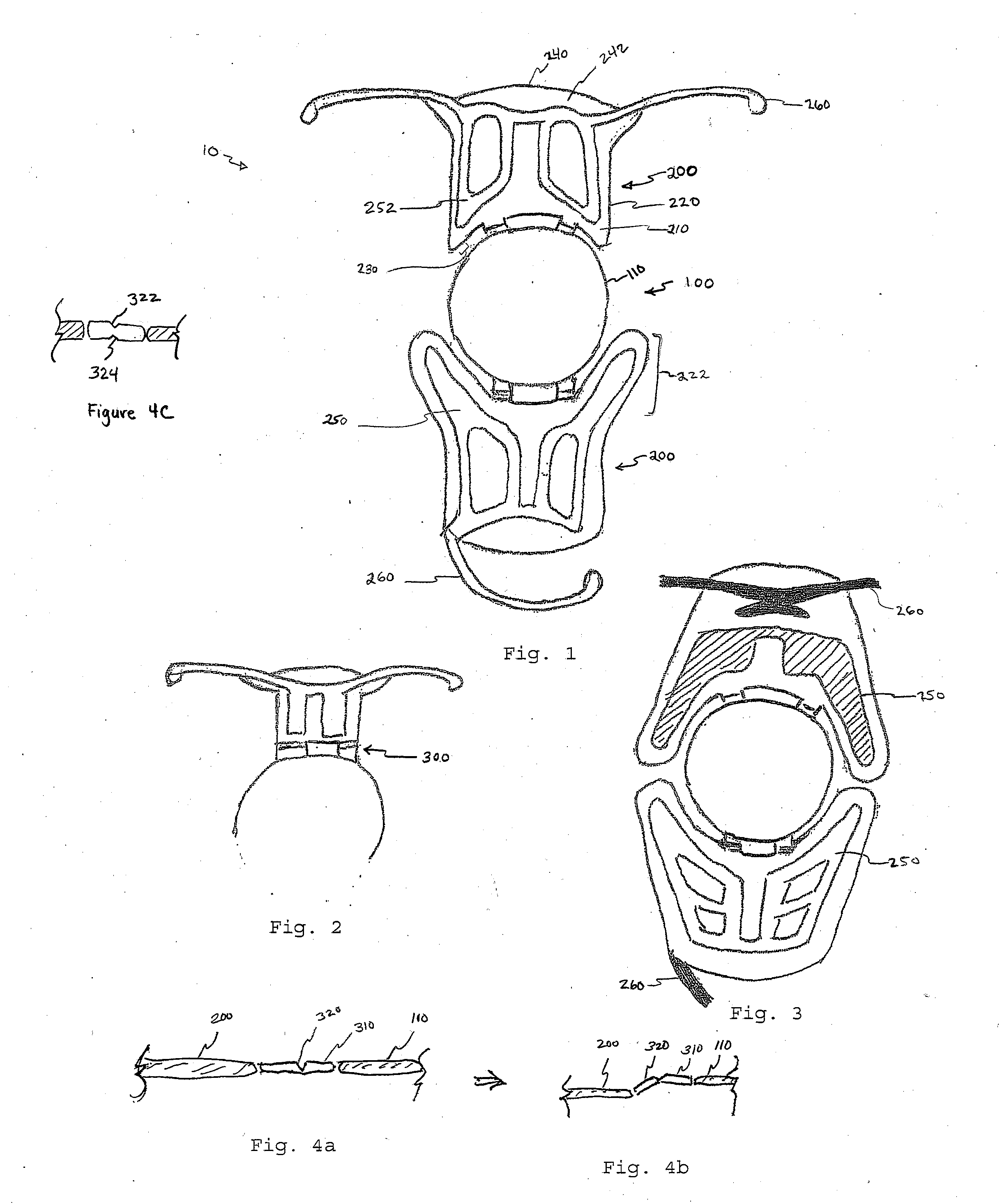

Accommodating Intraocular Lens

ActiveUS20110313519A1Reduce widthProcess stabilityIntraocular lensIntraocular lensMuscle contraction

An intraocular lens for insertion into a capsular bag of an eye comprises: an optic; and at least one plate haptic coupled to the optic by one or more flexible connecting members. The plate haptic with flexible finger extensions is designed to engage the periphery of the capsular bag. An increase in radial pressure upon constriction of the ciliary muscle causes the rigid posteriorly vaulted plate haptics to move centrally to further increase the vitreous cavity pressure with constriction of the ciliary muscle: the optic with its thin stretchable hinge across the connecting member is then displaced anteriorly along the axis of the eye. The haptic includes a longitudinally rigid frame to restrict deformation of the haptic in a longitudinal direction while permitting deformation in a transverse direction. Furthermore, the flexible connecting members include one or more hinged straps that extend radially and / or longitudinally from the optic. The optic can move forwards and backwards, relative to both the distal and proximal ends of the plate haptics, in response to ciliary muscle contraction and relaxation with an increase and decrease of vitreous cavity pressure. Finger-like projection extends from the plate haptic to engage the capsular bag to center and fixate the accommodating lens within the capsular bag.

Owner:CUMMING JAMES STUART

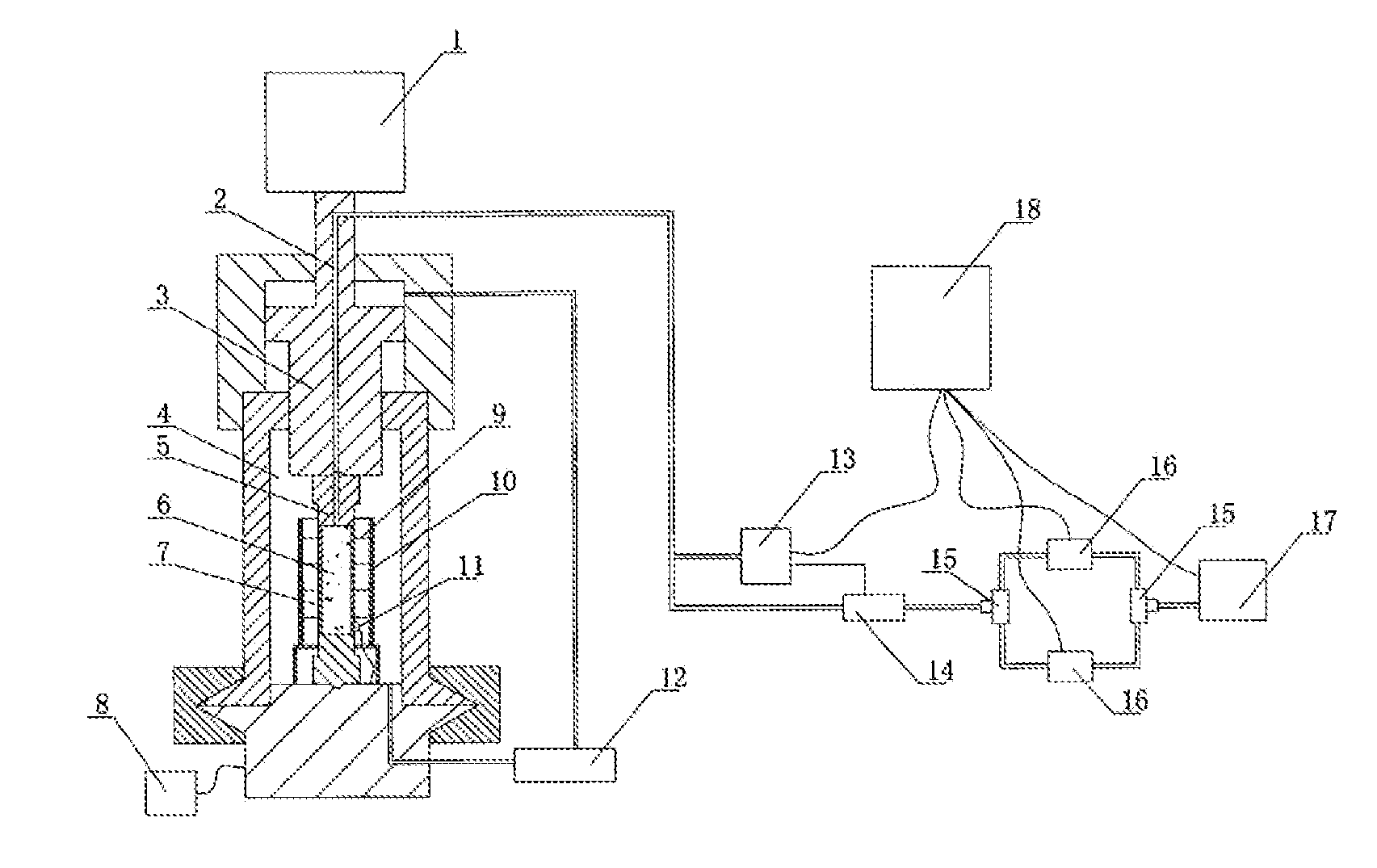

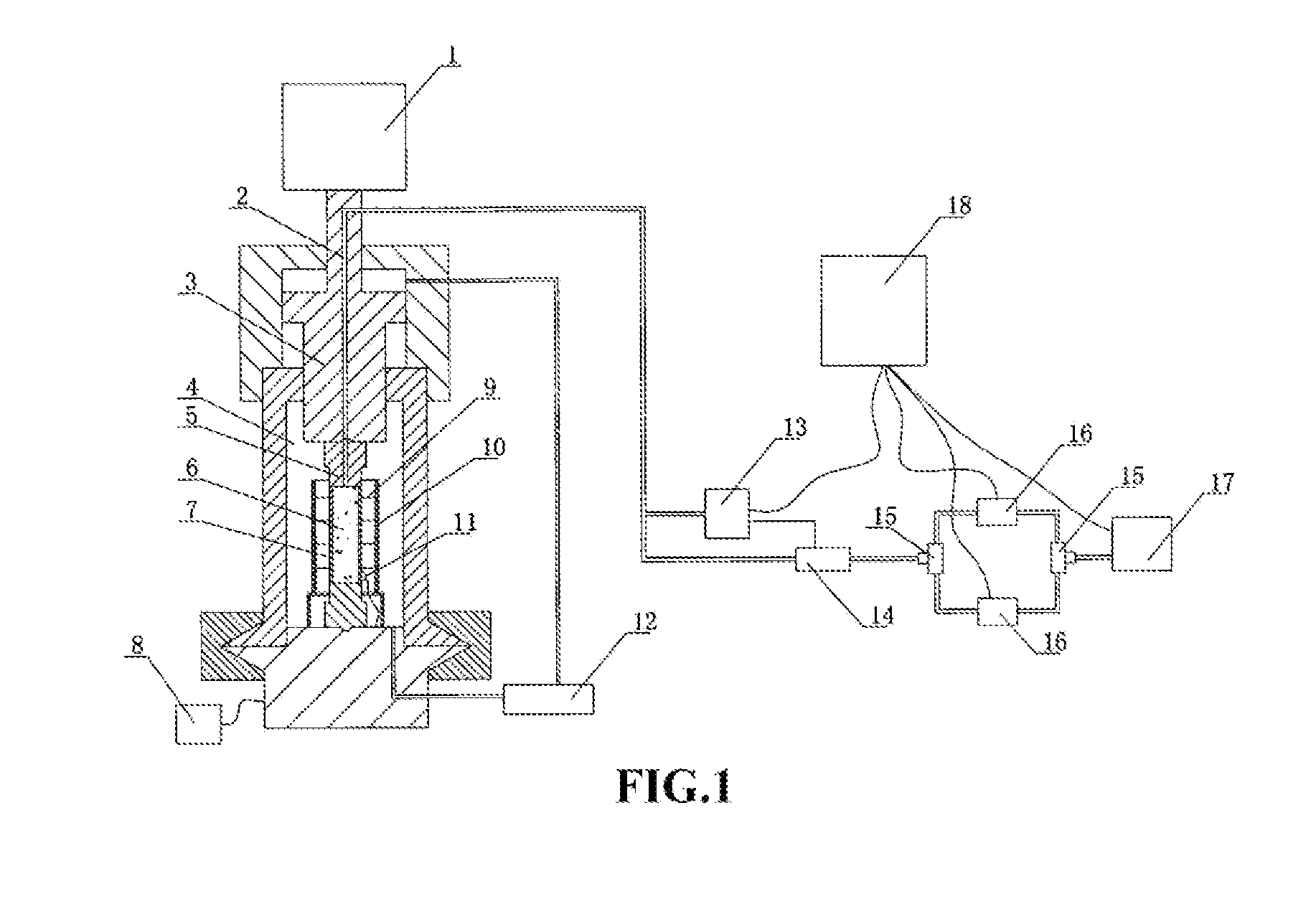

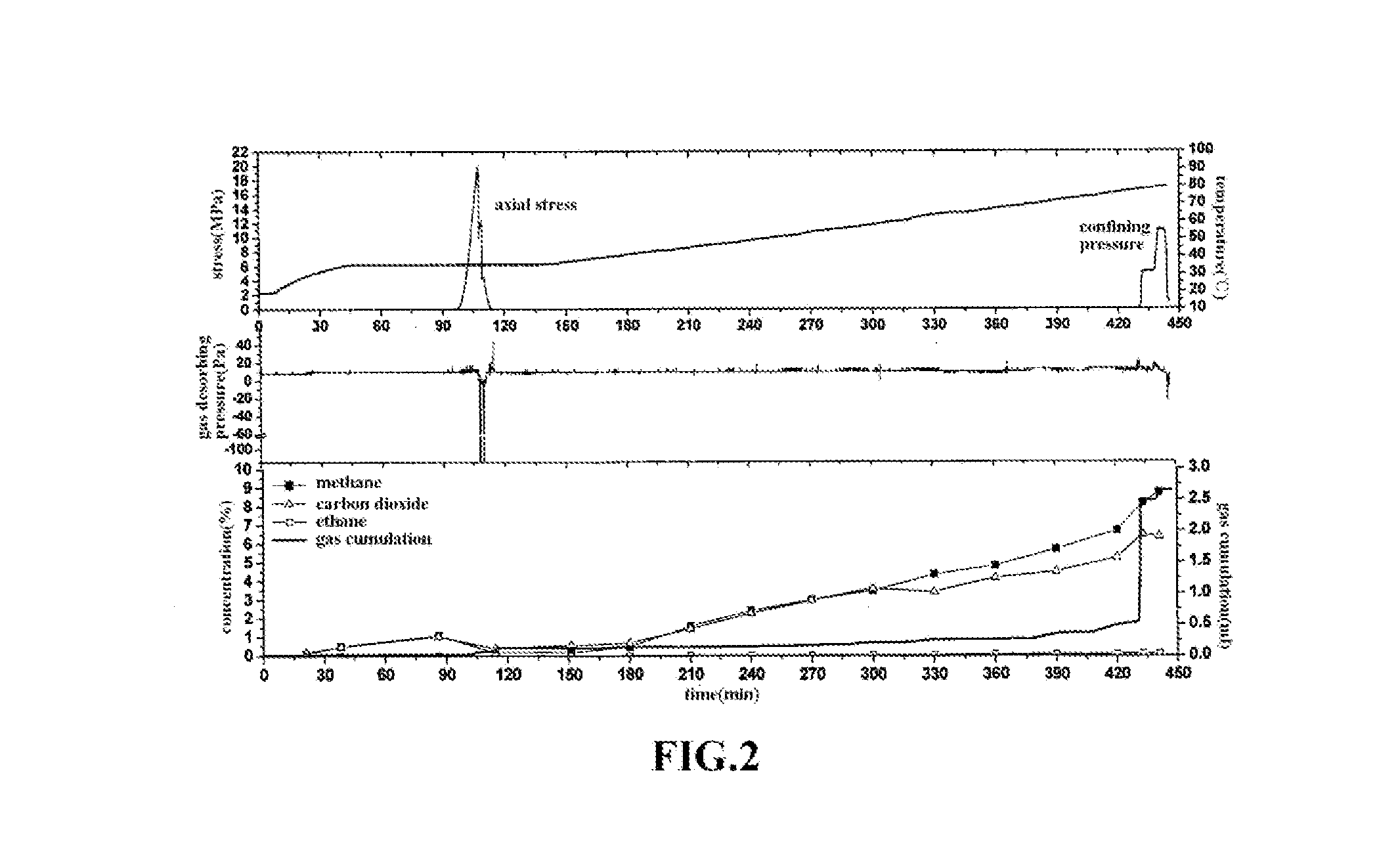

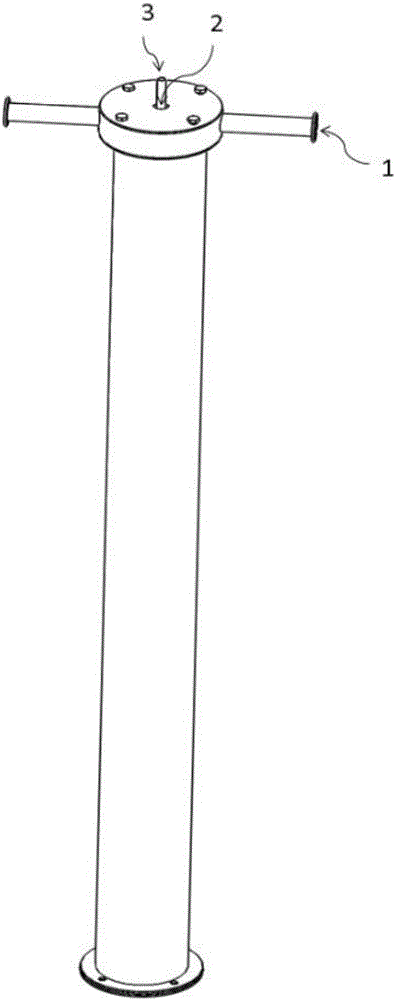

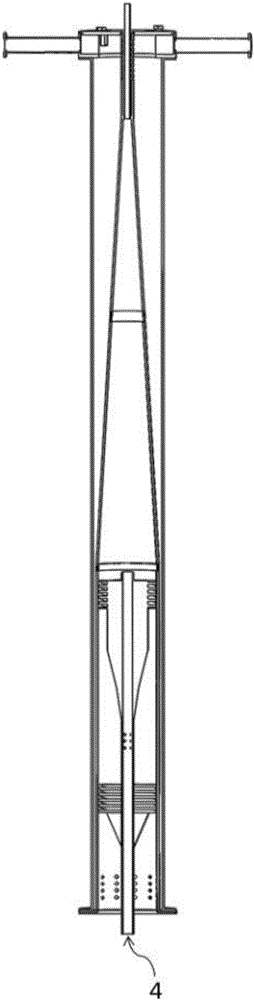

System and method for testing gas migration process in coal-rock mass

ActiveUS20120118041A1Accurate and reliable processPrevent penetrationComponent separationTesting waterStream flowGas composition

A system and method for testing gas migration process in the coal and rock mass are disclosed. The method includes the following steps: selecting a cylindrical coal sample, applying an axial pressure and a radial pressure to the coal sample under a sealing state, and / or increasing temperature, to desorb gas absorbed by the coal sample; guiding the gas desorbed from the coal sample by a guiding passage, detecting gas flow rate and pressure, analyzing gas composition and content, and achieving a data statistics. The method provides a theory and data basis for researching the forming and occurring process of gas outburst accident in coal mine. The system is simple and easy to use, and is suitable for migration research of the gas absorbed in the deep coal-rock mass.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

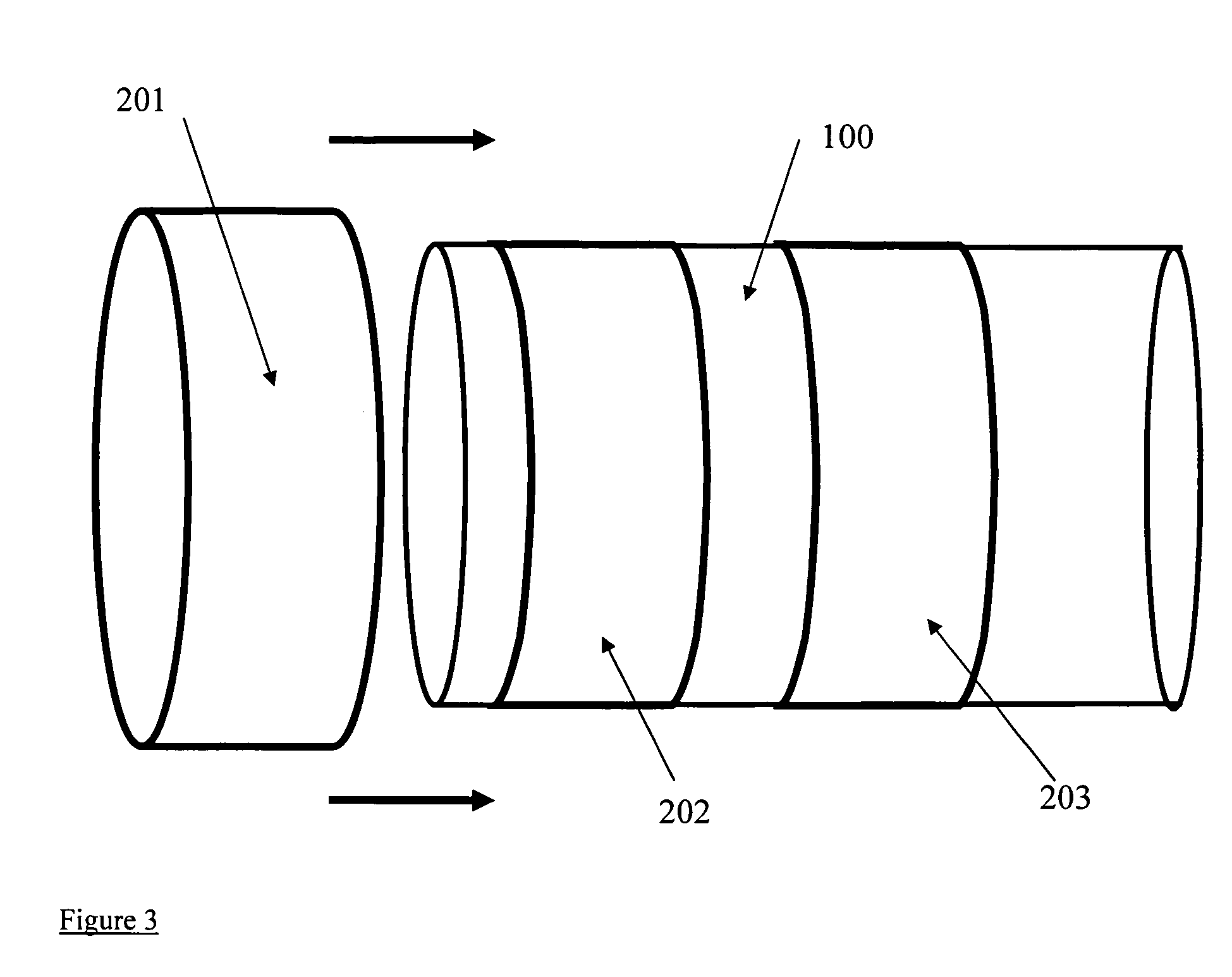

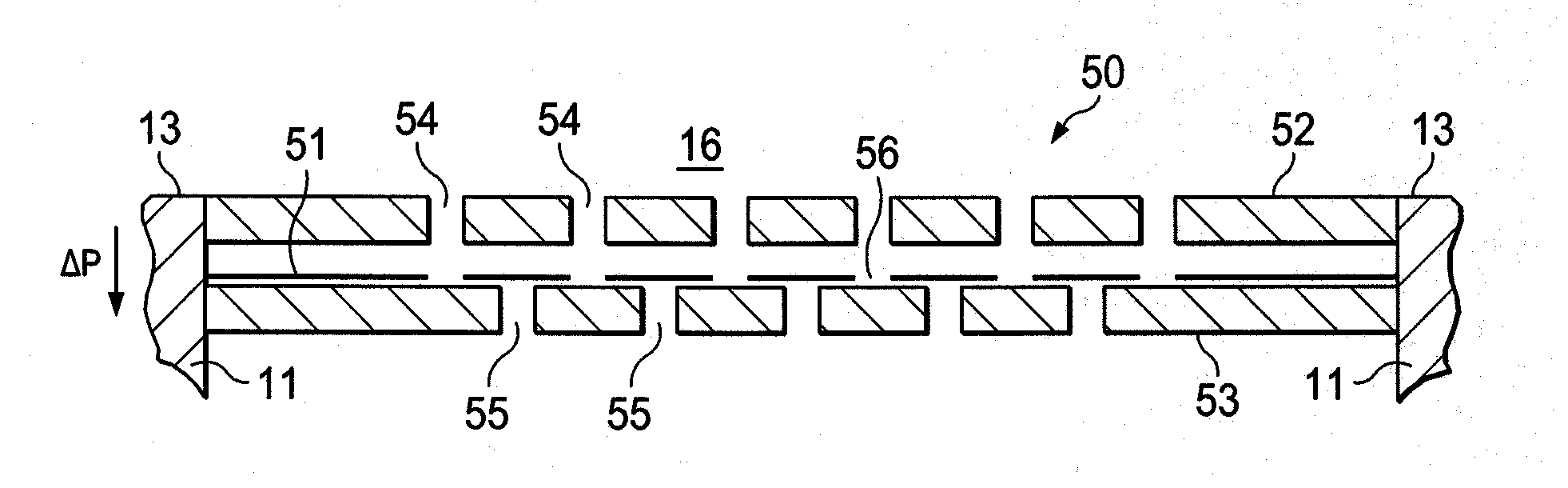

Disc pump with advanced actuator

ActiveUS20130236338A1High flow rateImprove pressure resistancePositive displacement pump componentsFlexible member pumpsActuatorRadial pressure

A two-cavity pump having a single valve in one cavity and a bidirectional valve in another cavity is disclosed. The pump has a side wall closed by two end walls for containing a fluid. An actuator is disposed between the two end walls and functions as a portion of a common end wall of the two cavities. The actuator causes an oscillatory motion of the common end walls to generate radial pressure oscillations of the fluid within both cavities. An isolator flexibly supports the actuator. The first cavity includes the single valve disposed in one of a first and second aperture in the end wall to enable fluid flow in one direction. The second cavity includes the bidirectional valve disposed in one of a third and fourth aperture in the end wall to enable fluid flow in both directions.

Owner:KCI LICENSING INC

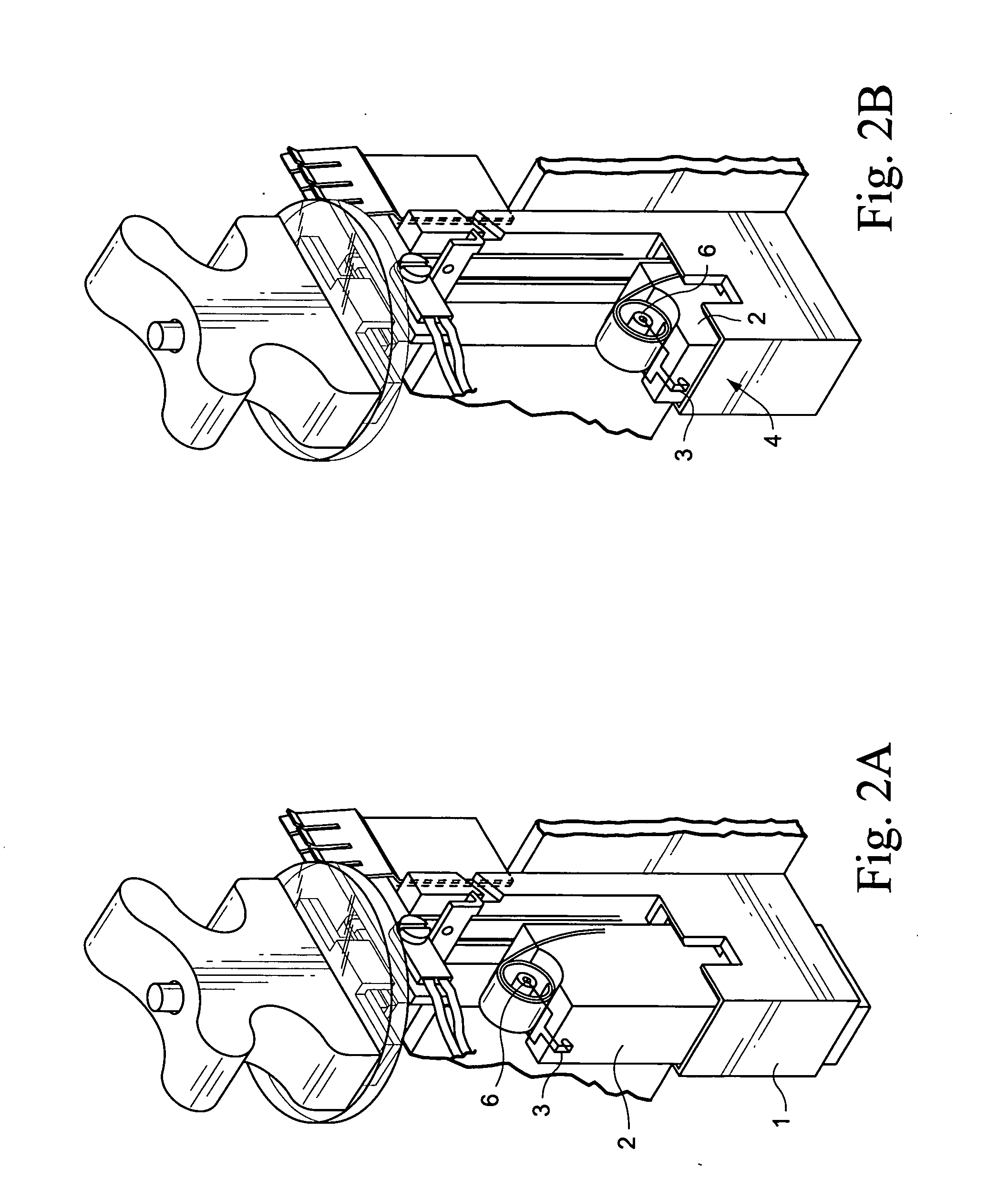

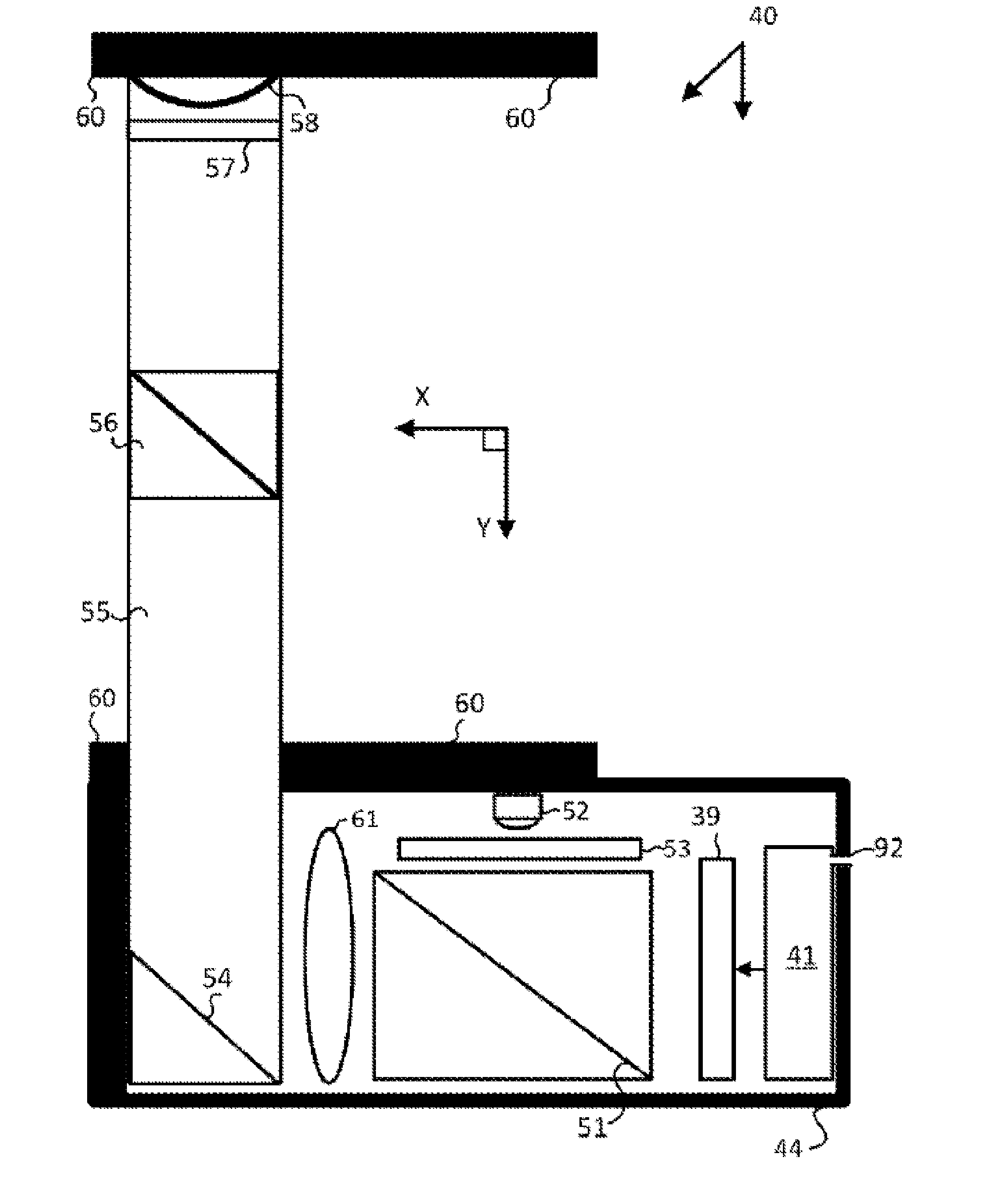

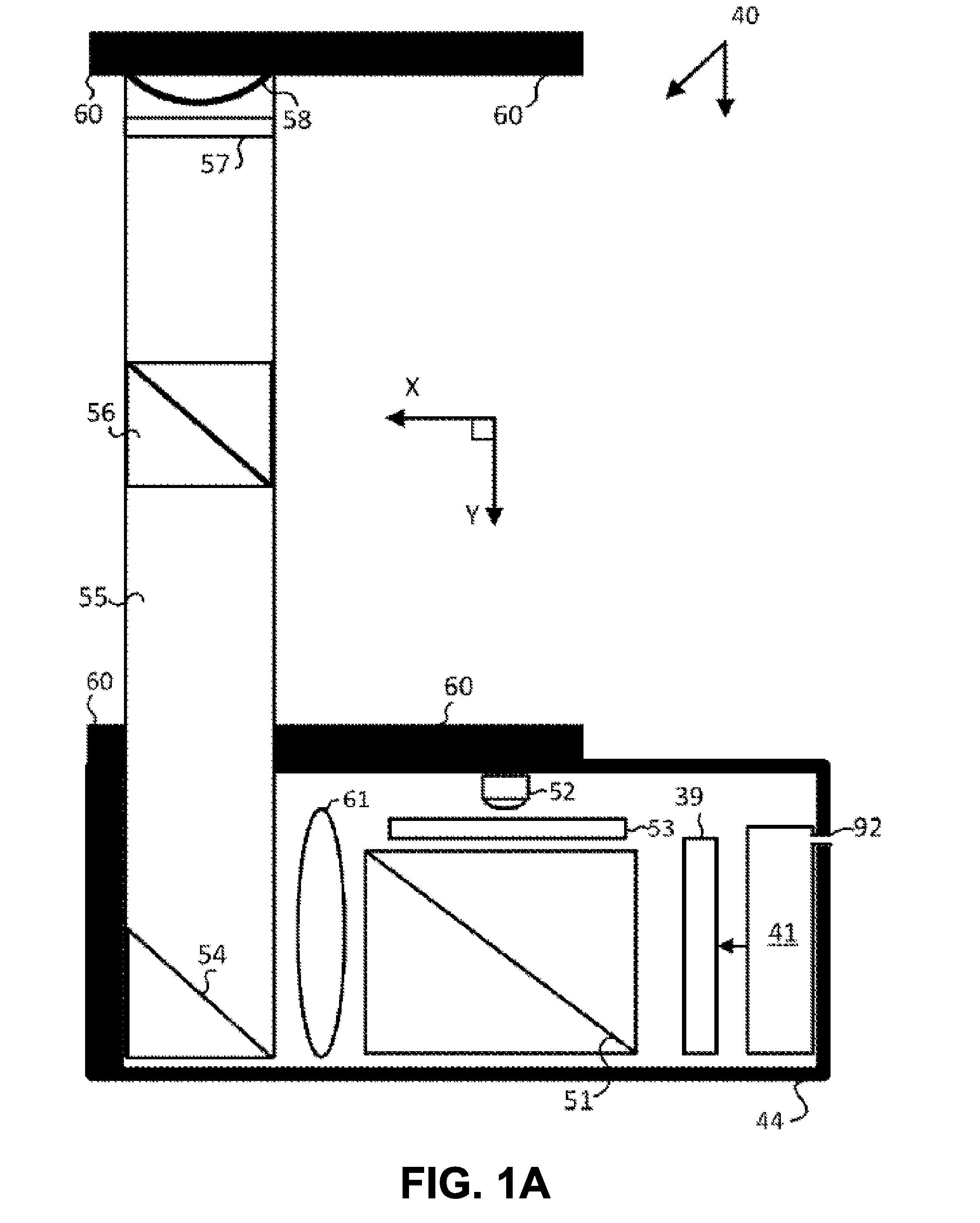

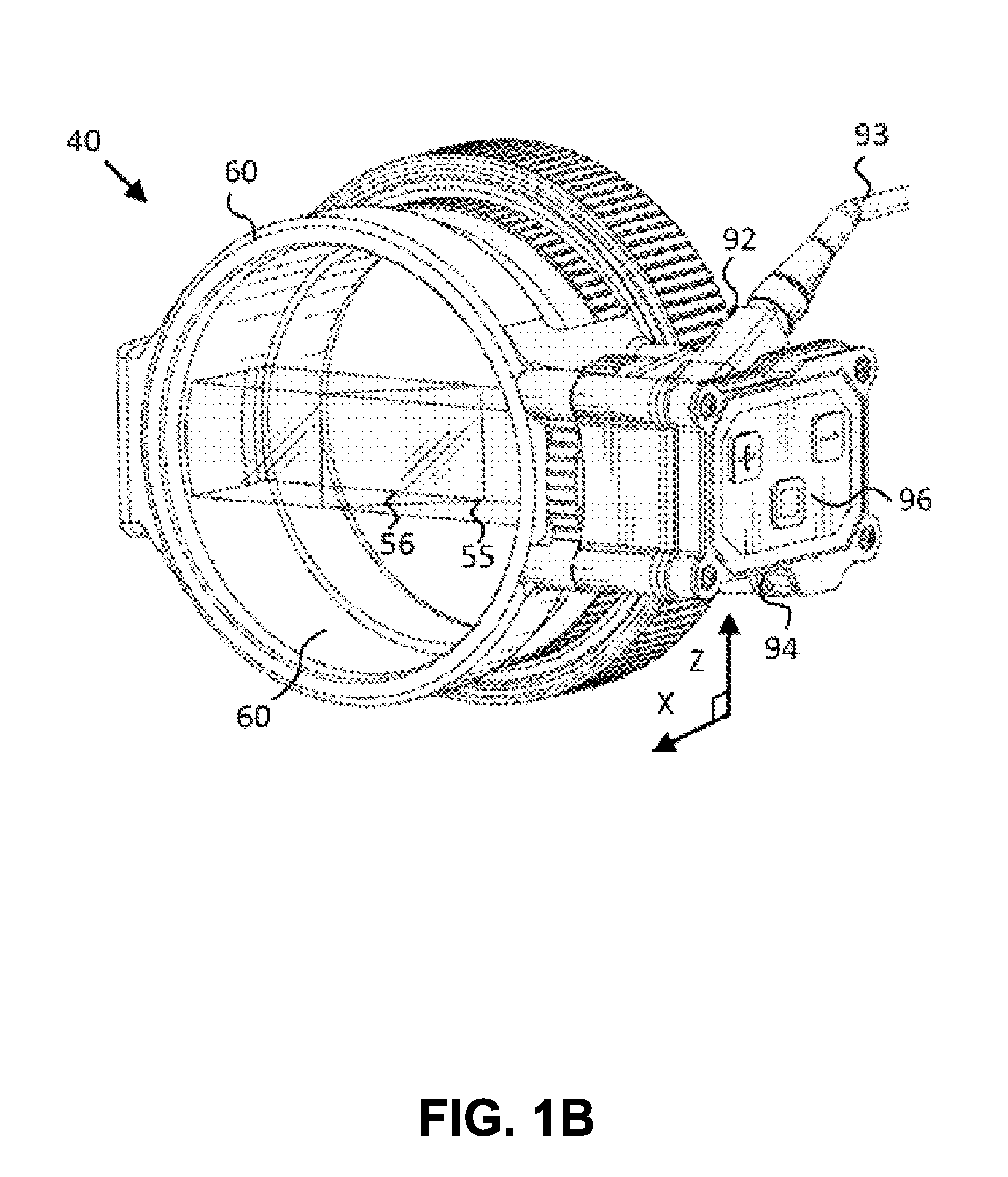

Rifle scope targeting display adapter mount

This disclosure describes a compact and lightweight rifle scope display adapter configured to be affixed in front of the objective lens of a rifle scope. The display adapter includes a receptacle that enables the adapter to be electrically connected to a ballistic computer, rangefinder or other targeting mechanism. The display adapter is configured to receive aimpoint information and project illuminated symbology that is brought into focus by the rifle scope optics in such a way that the symbology appears to overlay an image of a scene on which the rifle scope is focused. The adapter includes a mounting assembly that provides two attachment mechanisms. A first ring of the RDA can be screwed into the threads on the interior surface of the scope. Additionally, the scope can be inserted into a second ring of the RDA and provides compressive, radial pressure against the outside surface of the scope.

Owner:CUBIC CORPORATION

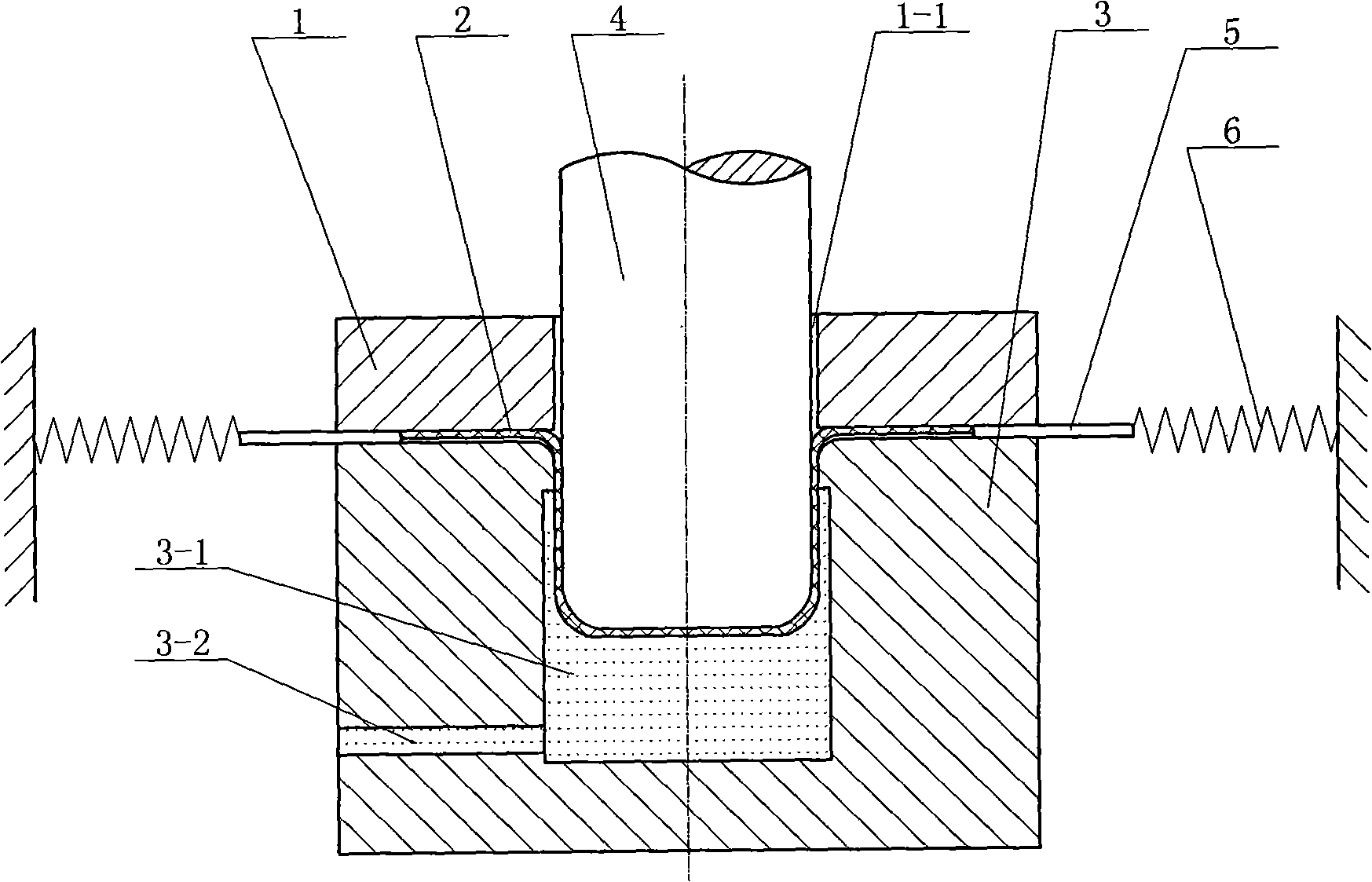

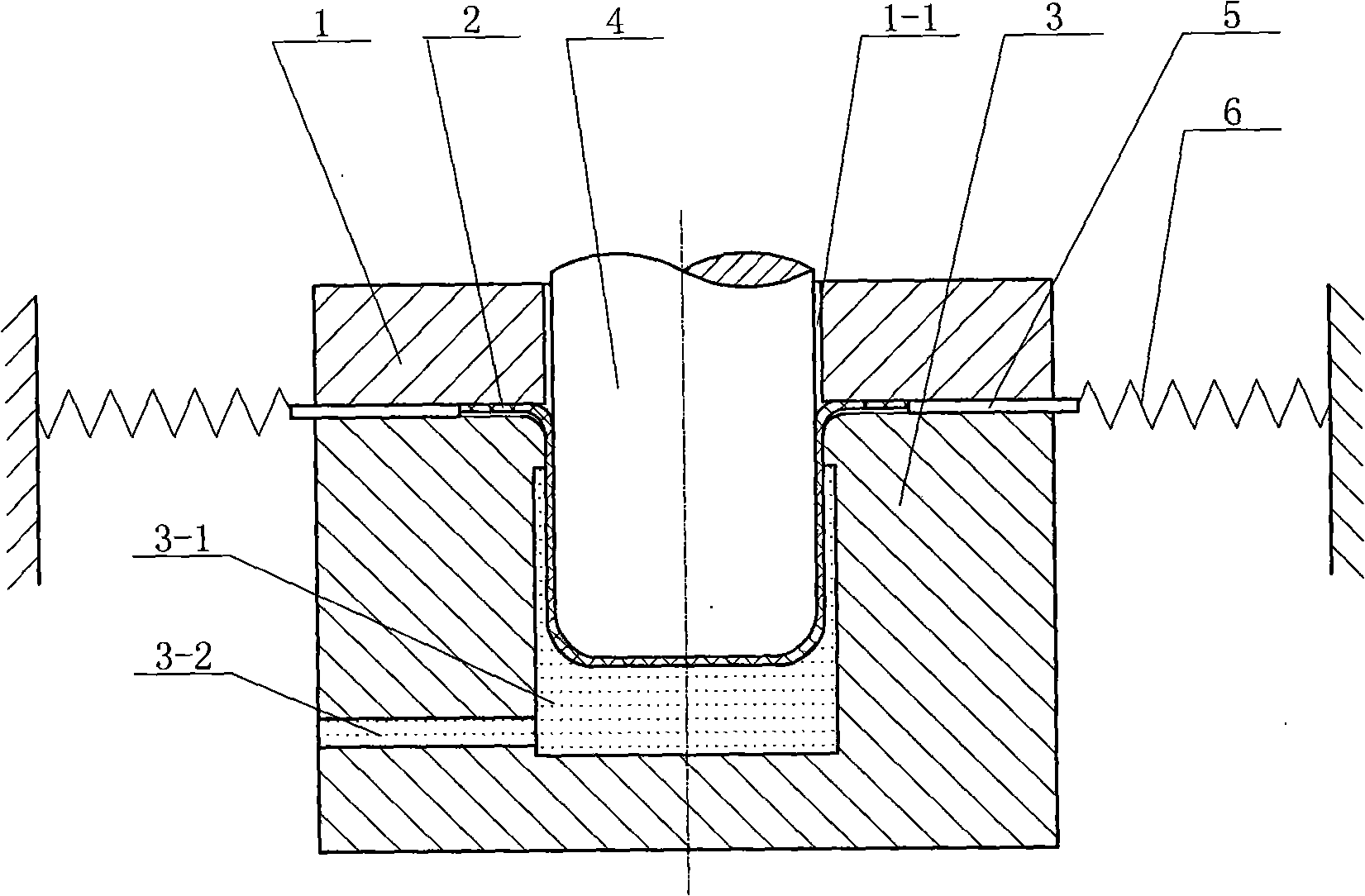

Device for improving forming limit in hydromechanical deep drawing of sheet material and method thereof

The invention discloses a device and a method for improving the limit of hydraulic deep drawing molding of plank stuff, which relates to a hydraulic deep drawing molding device of metal plank stuff and a method thereof, and solves the problem that as the deep drawing plate parts such as the plate parts made of magaluma have large deep drawing rate and deformed plank flange parts, the bottom of the deep drawing plate parts is easy to fracture and has limitation to the molding limit due to overlarge pulling stress. A stamping ring (1) is arranged at the upper part of a cavity die (3), a die space (1-1) of the stamping ring (1) has the same shaft and the same pore diameter with a die space (3-1) of the cavity die (3), one end of a male die (4) is arranged in the die space (1-1), one end of a dowel steel (5) is arranged between the stamping ring (1) and the cavity die (3), and the other end of the dowel steel (5) is fixedly connected with a spring (6). The device and the method for improving the limit of the hydraulic deep drawing molding of plank stuff realize the radial pressure exertion and controllability at a position of a deformed region at the outer side of the plate parts, are favorable for the deep drawing molding of the plate parts with complicated shapes, have simplicity, reliability, lower cost and easy implementation, and can remarkably improve the limit of the deep drawing molding of the plate parts.

Owner:HARBIN UNIV OF SCI & TECH

Method of fusing optical fibers within a splice package

InactiveUS20100101277A1Overcomes drawbackNot to damageGlass making apparatusOptical articlesFiberOptical fiber cable

The present invention relates to methods of connecting optical fibers. In a first aspect, the method proceeds by using a ferrule device having a passage adapted to apply radial pressure to optically align and hold in position opposed fiber ends, and fusing said fiber ends held by said ferrule device. In another aspect, the method of the present invention uses a ferrule device to optically align without mechanized adjustment and hold in position opposed fiber ends with a gap where said fiber ends meet, where the fibers have a temperature of fusion that is higher than a melting temperature of said ferrule device. The method then transmits radiation directly onto said fiber ends without significant direct transmission onto said ferrule device to generate heat in said fiber ends and fuse said fiber ends held by said ferrule device.

Owner:GONTHIER FRANCOIS +1

Hydrodynamic bearing device

InactiveUS6890104B2Excellently preventingSimple structureShaftsRecord information storageCapillaria obsignataFluid interface

A bearing has a thrust plate integrated with its shaft and a bearing member surrounds both. A radial pressure bearing portion and separate thrust portion generate pressure on a lubricating fluid in a gap between the shaft and bearing member. One end of the gap is closed while the other is open and has a capillary seal formed with an angle that is large at a boundary but smaller at increasing distance therefrom. The fluids fills the gap so that gas-fluid interface is where the angle is small and causes the thrust plate to float. A pressure mechanism forces the fluid from the open to the closed end and the quantity of fluid is set to fill the mechanism even if the gas-fluid interface moves.

Owner:SANKYO SEIKI MFG CO LTD +1

Methods of making balloon catheter tip

ActiveUS20060004399A1Increase inner diameter and cross-sectional areaPromote blood flowSurgeryDilatorsDistal portionBalloon catheter

A balloon catheter for medical treatment of a patient has an improved tip design and methods of making the tip. The balloon catheter has a flexible shaft with proximal and distal ends, a hub affixed to the proximal end, and a balloon affixed to the shaft near the distal end. At least a distal portion of the shaft includes a tubular inner body, and the balloon has a distal leg affixed to the inner body. A short, tubular tip member is placed in contact with the distal end of the inner body, and a shrink tube is placed around the point of contact. A wire mandrel is passed through a lumen defined by the inner body and tip member. While the shrink tube is heated, compressing the tip member and inner body, the mandrel is moved. This combination of heat, radial pressure, and mandrel movement causes a blending of the materials of the inner body and the tip member. The resulting joint of the tip member and inner body is both strong and flexible.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

Rolling bearing arrangement for an electromotor

InactiveUS6966701B2Reliable preventionPrevention is simpleRotary combination bearingsShaftsRolling-element bearingEngineering

The invention relates to a rolling bearing arrangement for an electromotor having a rotationally symmetrical rotor arranged rotatably inside a stator, there being provided for rotationally bearing the rotor. At least one standard rolling bearing that has an outer race which is arranged in a bearing seat in a fixed position relative to the stator and which cooperates via a rolling body arrangement with an inner race arranged on a shaft of the rotor. The bearing seat is lined with an insulation arrangement in order to avoid a flow of current between stator and rotor, the insulation arrangement having a thin, sheet-type semifinished product having insulation material resistant to the radial pressure force of the bearing.

Owner:REXROTH INDRAMAT

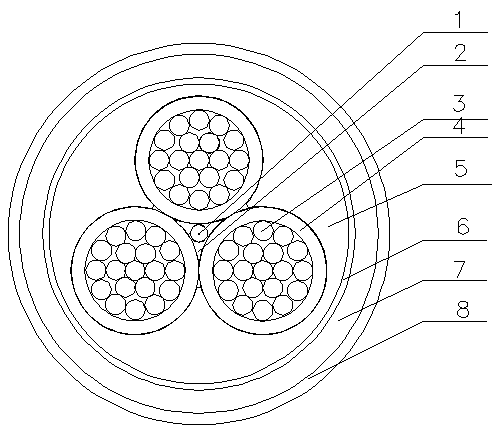

Load-bearing compression-resisting cable for moving occasions and manufacturing method thereof

InactiveCN102800390AHigh tensile strengthReduce weightFlexible cablesCable/conductor manufactureCopper wireNeoprene

The invention relates to a cable, in particular to a load-bearing compression-resisting cable for moving occasions and a manufacturing method thereof. When insulation wire cores of the cable are cabled and twisted, aramid tensile pieces consisting of bundled aramid and rubber thickening layers are arranged in the gaps; a liner layer made of butyronitrile rubber is extruded outside the cabled and twisted insulation wire cores; the outer side of the liner layer is coated with a shielding layer formed by braiding tin-plated copper wires; a sheath layer made of chloroprene rubber is extruded outside the shielding layer; and a layer of armoured layer which is armoured by means of metal bands in an internal interlocking manner is covered outside the sheath layer. The cable can ensure that the self weight of the cable and the weight of corollary equipment in specified range can be loaded under the condition of bending at high frequency, and the damage of external tension to the cable is reduced. Meanwhile, the load-bearing compression-resisting cable can prevent the damage of other external radial pressure to the inner side of the cable, has the advantages of super softness, high tensile, easy assembly, high physical compression resistance and simple production method, and facilitates large-scale industrial production.

Owner:唐山市海丰线缆有限公司

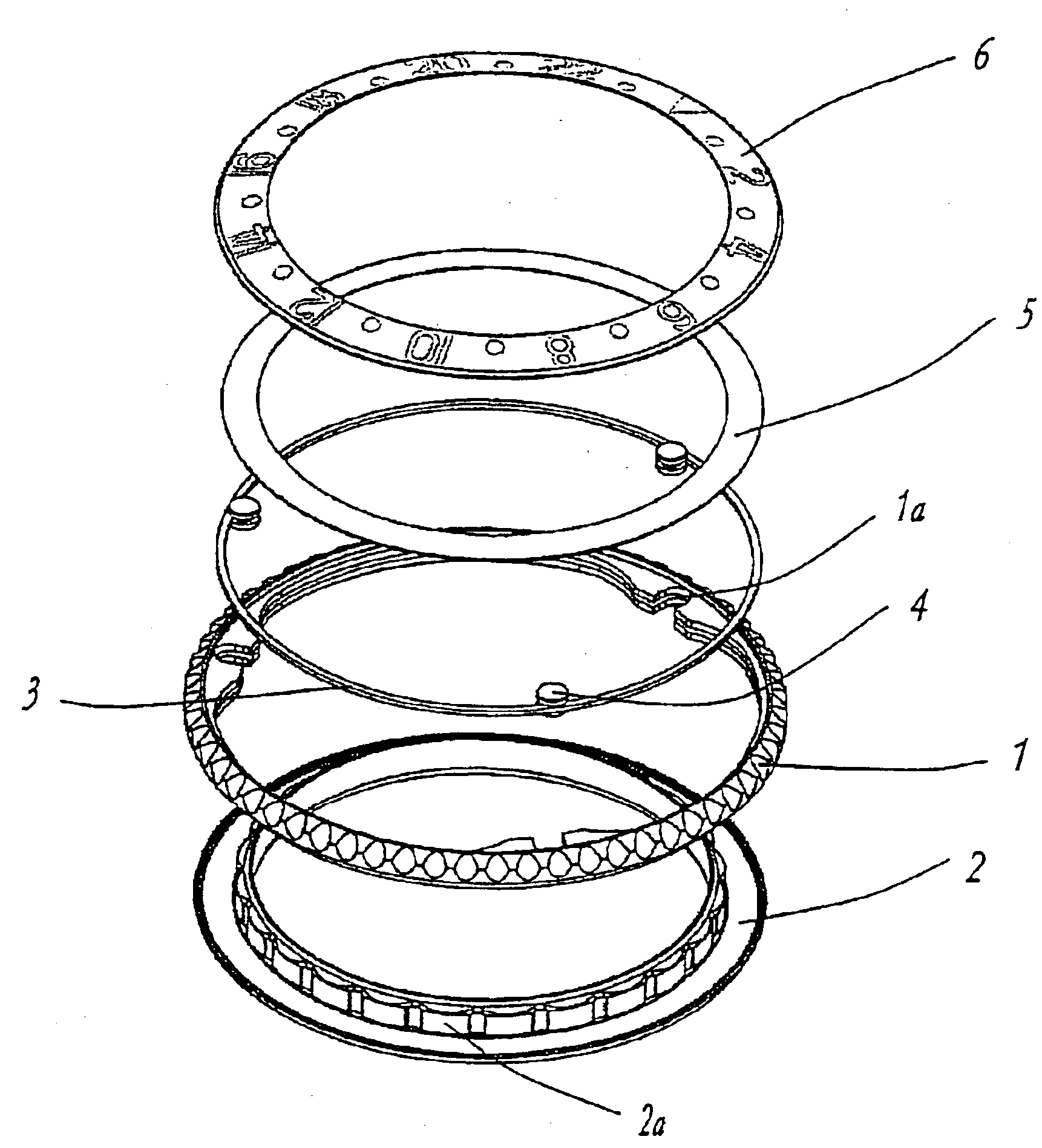

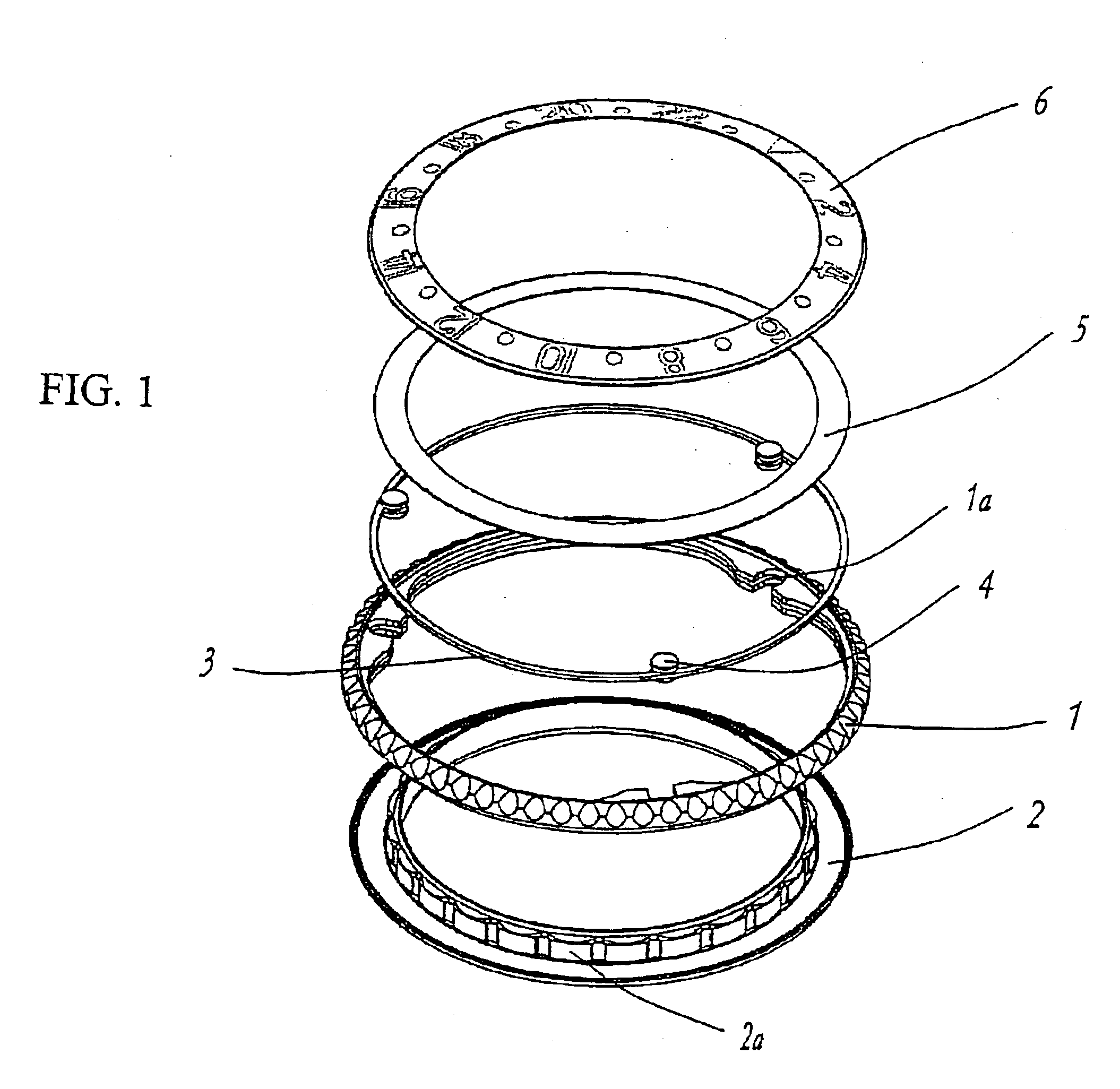

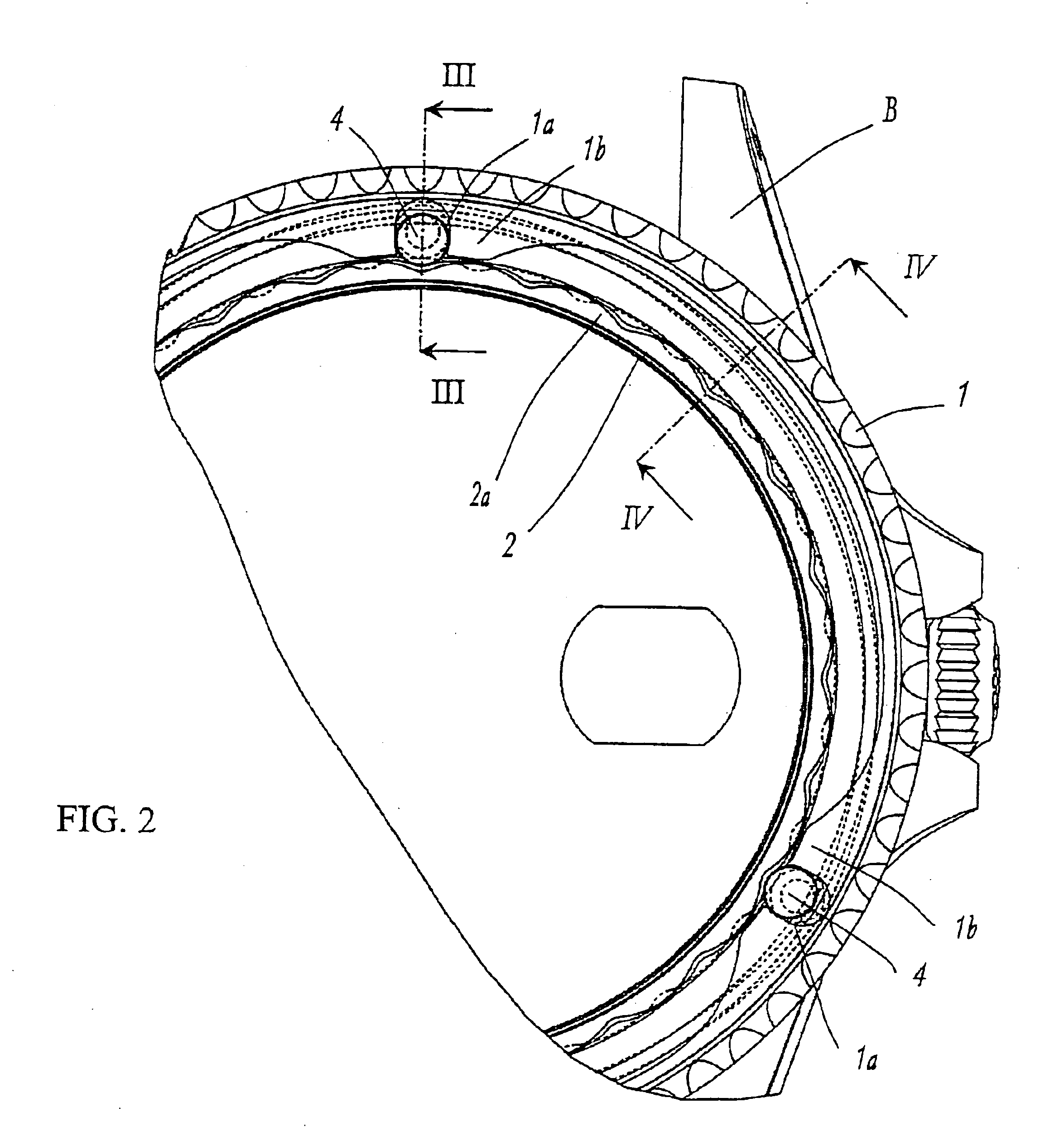

Watch case

ActiveUS6871997B2Little wearSimple and reliable processVisual indicationClockwork casesClosed loopEngineering

A watch case comprising a rotary bezel, first and second angular positioning markings, one set secured to the bezel and the other set to the case middle and elastic means in the form of a closed-loop spring tending to place the positioning markings into engagement with one another. These markings are distributed with numbers of spacings one of which is a multiple of the other and the outlines of which extend in a plane parallel to that of the bezel. Guide means are engaged with the markings having the smallest number of spacings, in order simultaneously to exert on these markings radial pressures directed toward the other markings.

Owner:ROLEX SA

Downhole degassing and oil removing cyclone separation device

ActiveCN106583068AImprove applicabilityWith continuous separationWaste water treatment from quariesWater/sewage treatment by centrifugal separationOil waterSeparation system

The invention discloses a downhole degassing and oil removing cyclone separation device and mainly aims to solve the problem that the downhole oil-water separation effect is limited due to existence of associated gas. The device is characterized in that the cyclone separation device adopts a twin-tangential inlet, so that the tangential and radial pressure required when a to-be-treated liquid is subjected to first-stage degassing separation is guaranteed, meanwhile, a first-stage degassing separation structure is separated from an oil removing separation structure through a barrel, and two stages of separation communicate with each other through hole opening in proper positions; the degassed treated liquid is pressurized and accelerated by a pressurizing part, and thus separation is conducted efficiently; and an oil-water separation structure adopts the two-stage pressurization and two-stage separation manners, and accordingly, the oil-water separation accuracy is improved. With the device, the downhole oil-water separation efficiency can be improved, and the feasibility and the applicability of the downhole oil-water separation system can be enhanced.

Owner:NORTHEAST GASOLINEEUM UNIV

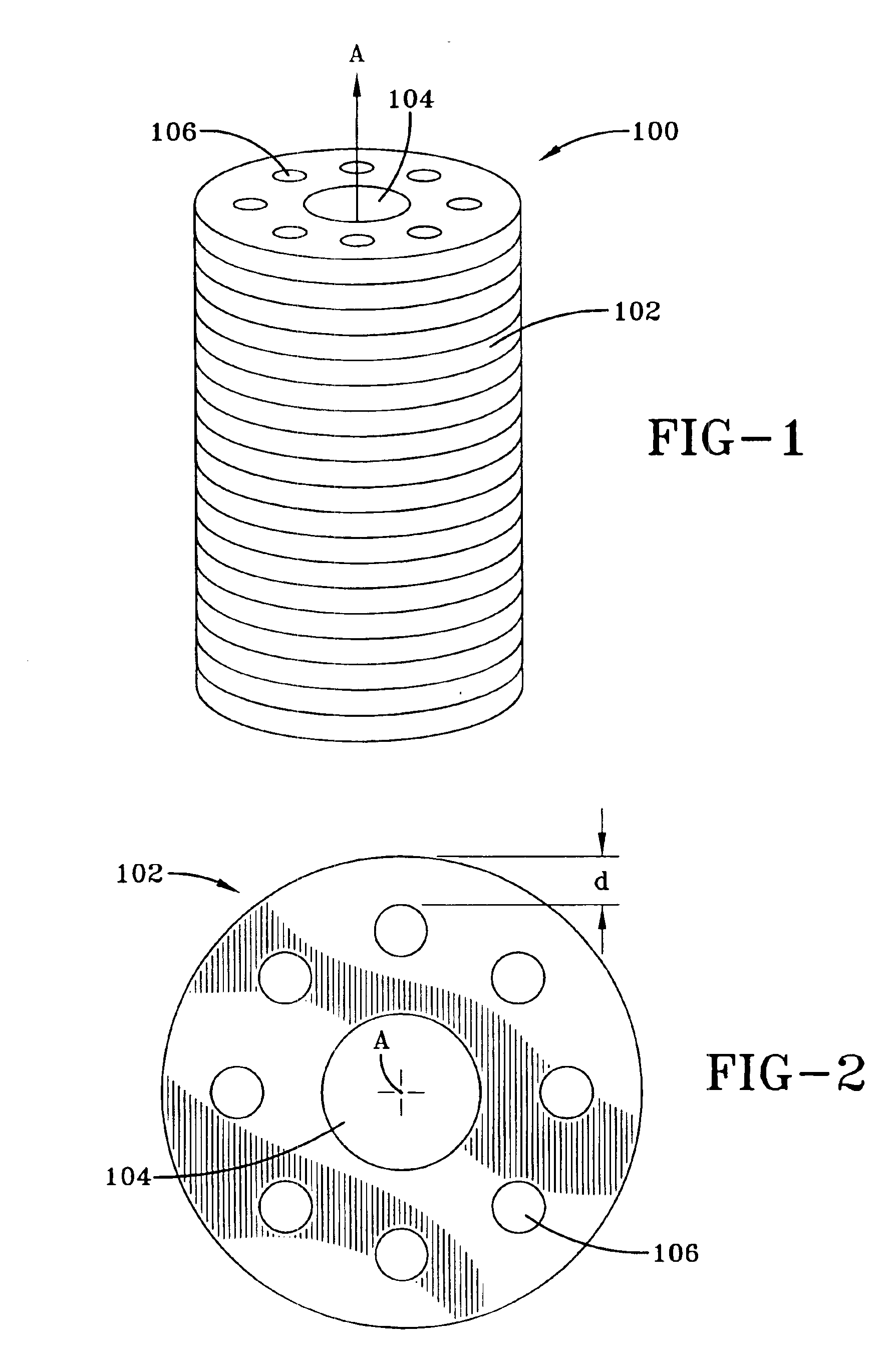

Rotor core lamination for a laminated rotor

InactiveUS6900573B2Rotor manufacturing process is more economical and efficientExpensive and laborious machining processes are eliminatedWindingsSynchronous motorsMechanical engineeringRadial pressure

A method of assembling and manufacturing a laminated rotor is provided which uses laminations having a thin bridge thickness. Different techniques are provided for preventing the molten material used in the casting or injection molding operation from leaking or seeping between the laminations during casting. In one technique, the laminations are stacked and oriented in the conventional way, and then both axial and radial pressures are applied to the stacked laminations to hold the laminations in position for the casting process. In another technique, the laminations are formed or extruded with a lip or collar portion that fit in a countersunk portion of an adjacent lamination and forms a wall or barrier between the laminations to prevent the leakage of the molten material during the casting or injection molding operation.

Owner:BRISTOL COMPRESSORS INT

Custom-moldable support for patellar tendinitis

InactiveUS20020147421A1Feet bandagesNon-surgical orthopedic devicesTibiaPhysical medicine and rehabilitation

A knee pad assembly for relieving the symptoms of patellartendinitis, including a pad adapted for being positioned against and molded onto a lower leg in the region of the knee for lying in closely-conforming relation against and applying radially-directed pressure to the attachment site of the patellar tendon to the patella, to the knee joint, and to at least one epicondyle of the tibia. The pad is hardened into a rigid structure for therapeutic use and includes an initially flexible inner substrate impregnated or coated with a reactive system. The system remains stable when maintained in substantially moisture-free conditions and hardens upon exposure to moisture to form a rigid, self-supporting structure having a shape conforming to the lower leg to which the pad is molded during curing. A flexible cover encloses the substrate, and cooperates with the pad for maintaining the pad in its closely-conforming position against the lower leg.

Owner:BSN MEDICAL INC

Narrow profile catheter with deformation-resistive guidewire lumen

The present disclosure relates to a catheter having a longitudinal guidewire lumen defined by a first tube configured for an over-the-wire or rapid-exchange mode of operation, the wall of the first tube provided with an expansion member that is a sub-region of the wall of the first tube provided with an expandable material. An inflation lumen extending from the proximal end towards the distal end of the shaft is in fluidic contact with the expansion member, the member being configured to expand or contract responsive to pressure in the inflation lumen. The wall of the first tube may be formed from a helically coiled wire or helically braided wire having a helix angle of 60 degrees or more which tubing is resistive to radial pressure applied in the inflation lumen.

Owner:ACROSTAK CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com