Load-bearing compression-resisting cable for moving occasions and manufacturing method thereof

A cable and occasion technology, applied in the field of load-bearing and pressure-resistant cables for mobile occasions and their production, can solve the problems of inability to meet safe use, the cable itself is cumbersome, and its softness is weakened, so as to facilitate large-scale industrial production and improve mechanical properties. Performance and flame retardant properties, excellent oil resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below in conjunction with embodiment.

[0019] This embodiment is a load-bearing and compression-resistant cable for mobile applications, with a specification of 3×10mm 2 , which is a circular structure with a diameter of 17.5mm as a whole.

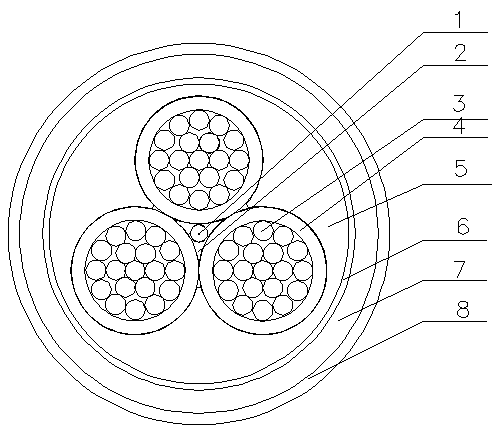

[0020] see figure 1 , the aramid tensile member 1 in the middle gap, the rubber thickened layer 2 wrapped in the outer layer of the aramid tensile member, 10mm 2 Tinned copper conductor core 3, the outer layer of the conductor core is wrapped with a layer of ethylene-propylene rubber insulation layer 4, and the inner layer of nitrile rubber tightly wrapped around the cabled stranded insulated core 5 is braided in the nitrile rubber Tinned copper wire braided shielding layer 6 outside the lining layer, neoprene sheath 7 evenly extruded on the braided shielding layer, aluminum alloy interlocking armoring layer 8 through an aluminum alloy corrugated inner interlocking armoring machine.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com