Patents

Literature

110results about How to "Little change in performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

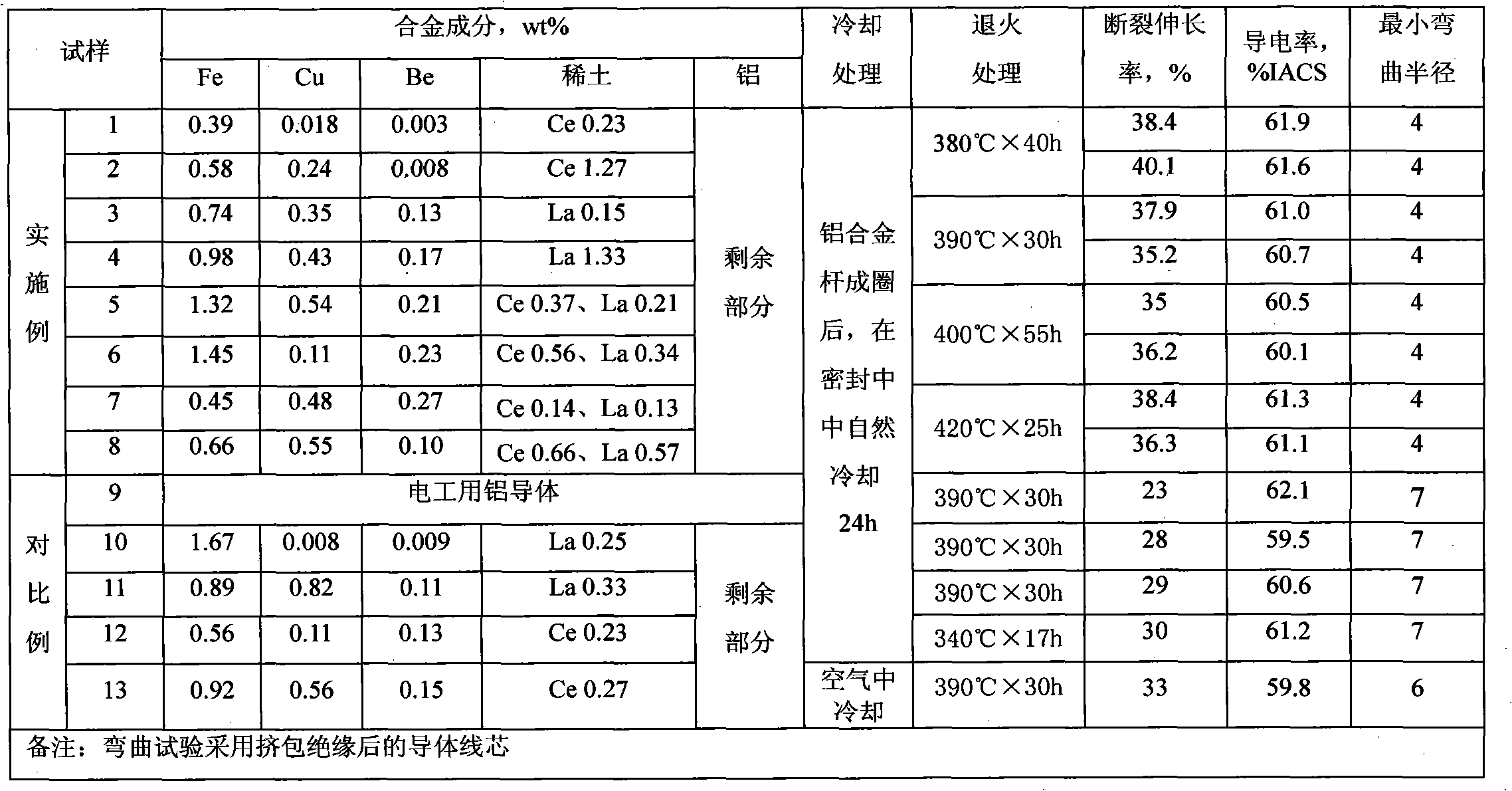

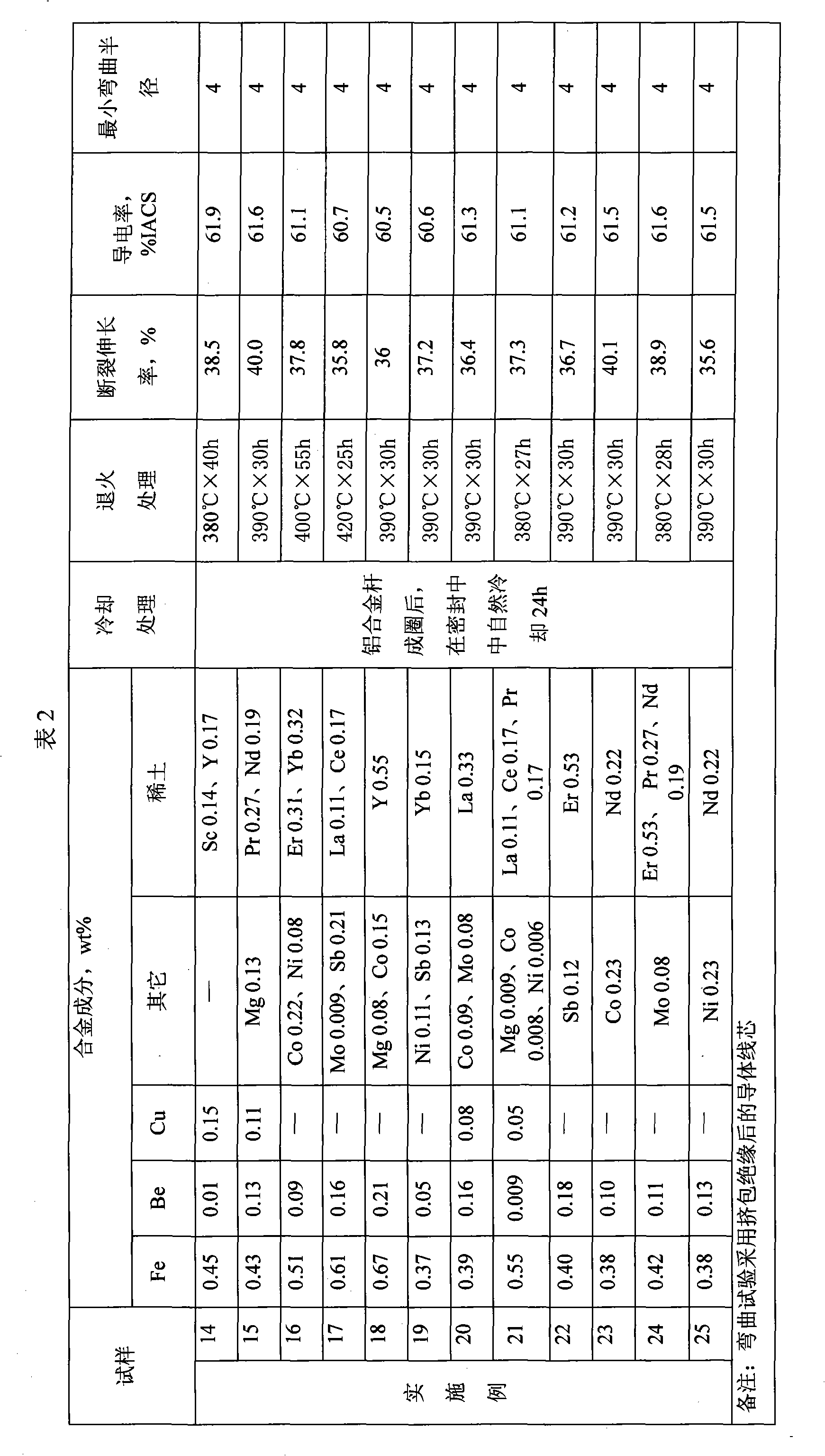

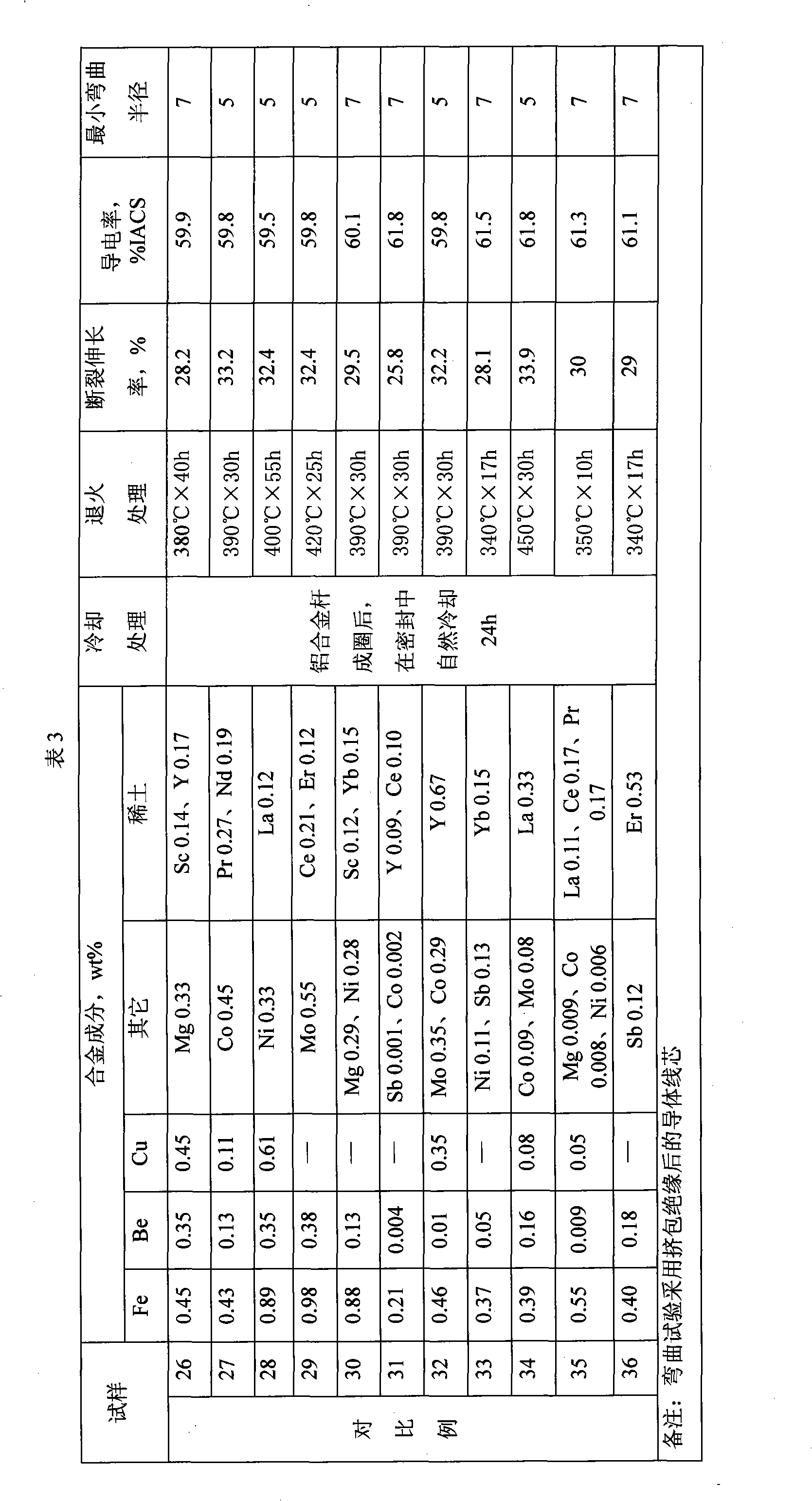

Super-soft aluminum alloy conductor and preparation method thereof

The invention provides a super-soft aluminum alloy conductor and a preparation method thereof. The aluminum alloy conductor comprises the following materials in percentage by weight: 0.3 to 1.5 percent of Fe, 0.001 to 0.3 percent of Be, 0.005 to 0.6 percent of Cu, 0.1 to 1.5 percent of rare earth, less than or equal to 0.08 percent of Si, less than or equal to 0.15 percent of total inevitable impurities, and the balance of aluminum. The aluminum alloy is drawn into an aluminum alloy wire by melting, continuous casting and continuous rolling, and the aluminum alloy wire is put into an annealing furnace and annealed for 20 to 40 hours at the temperature of between 380 and 420 DEG C to form the aluminum alloy conductor, wherein the annealing is performed in a sealed heat insulation device under the protection of nitrogen. The aluminum alloy has extremely good toughness and elongation performance, the coefficient of elongation reaches or exceeds 35 percent and even can reach 40 percent, and the electric conductivity can reach 60 percent IACS.

Owner:ANHUI JOY SENSE CABLE

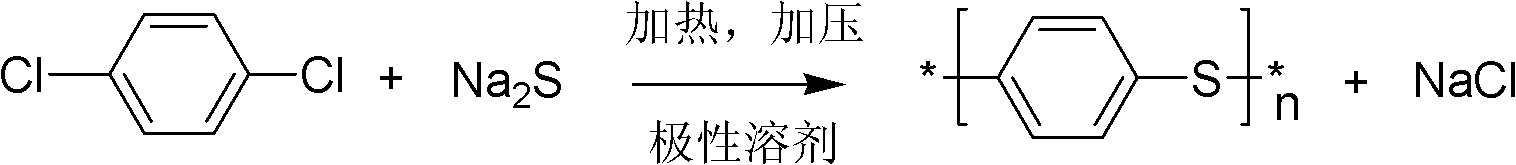

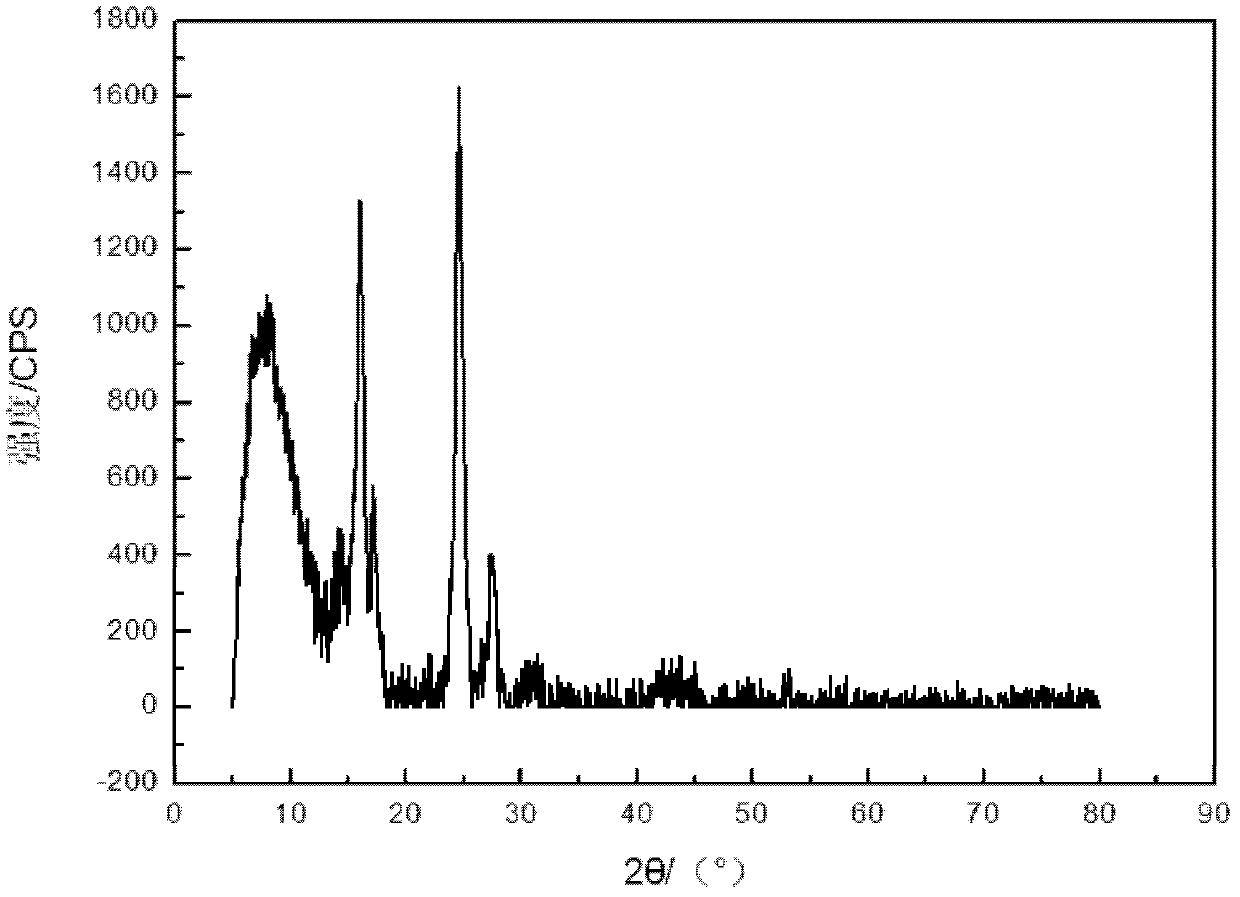

Method for synthesizing low-color high-purity fiber-grade polyphenylene sulfide resin

ActiveCN103073720AThe average molecular weight is largeMolecular distribution index is smallMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention discloses a method for synthesizing low-color high-purity fiber-grade polyphenylene sulfide resin. According to the invention, sodium sulfide and p-dichlorobenzene are adopted as raw materials; N-methyl pyrrolidone, N,N-dimethyl acetamide, and the like are adopted as solvents; under the existence of a basic salt, through a four-step method comprising pre-polymerization, polymerization, chain extension and end-capping, the high-purity low-color fiber-grade polyphenylene sulfide resin is synthesized. By adjusting process parameters, polyphenylene sulfide average molecular weight and distribution index can be effectively controlled. Also, purification process can be simplified, and metal ion embedding can be reduced. Resin slice color is reduced, resin processing stability is improved, and resin performance is improved.

Owner:CHINA PETROLEUM & CHEM CORP

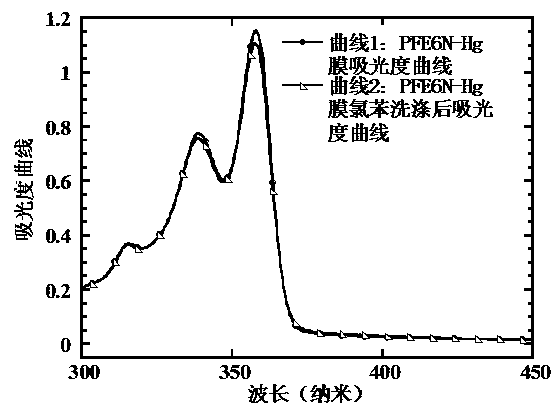

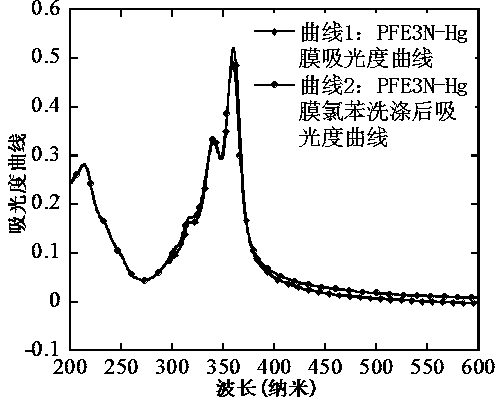

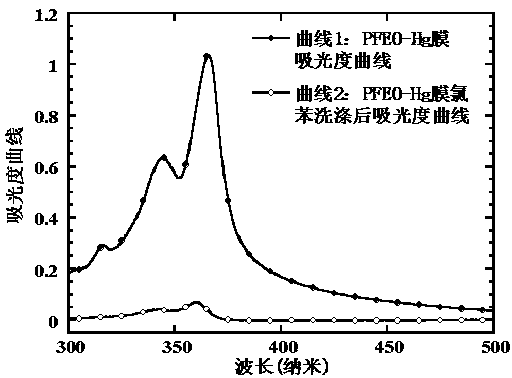

Conjugated metal polymer photoelectric material with functionalized polarity side-chain radicals and application thereof

ActiveCN103360604AGood water and alcohol solubilityImprove migration propertiesSolid-state devicesSemiconductor/solid-state device manufacturingSolubilityFiltration

The invention provides a conjugated metal polymer photoelectric material with functionalized polarity side-chain radicals and an application thereof. The material has conjugated main chains and functionalized polarity side-chain radicals, wherein the conjugated main chains contain Hg metal atoms; the functionalized polarity side-chain radicals comprise a high-polarity radical A with water-alcohol solubility. Due to the existence of the metal atoms in the conjugated main chains, the conjugated polymer material has the mutual metal-metal supermolecule function, and has a good current-carrier transferring characteristic; due to the existence of the radical A, the conjugated polymer material can be prepared by using a high-polarity solvent such as alcohol, can remarkably decrease the work function of a stable metal electrode, has good functions of suction filtration, injection and the like on enhanced high work function metal electrode electrons, and is applicable to manufacturing of complex multi-layer organic / polymer photoelectric devices. The conjugated metal polymer with the functionalized polarity side-chain radicals can be used as an electronic suction filtration / transferring layer to be applied to photovoltaic, light-emitting organic / polymer photoelectric devices to improve the properties of the devices.

Owner:SOUTH CHINA UNIV OF TECH

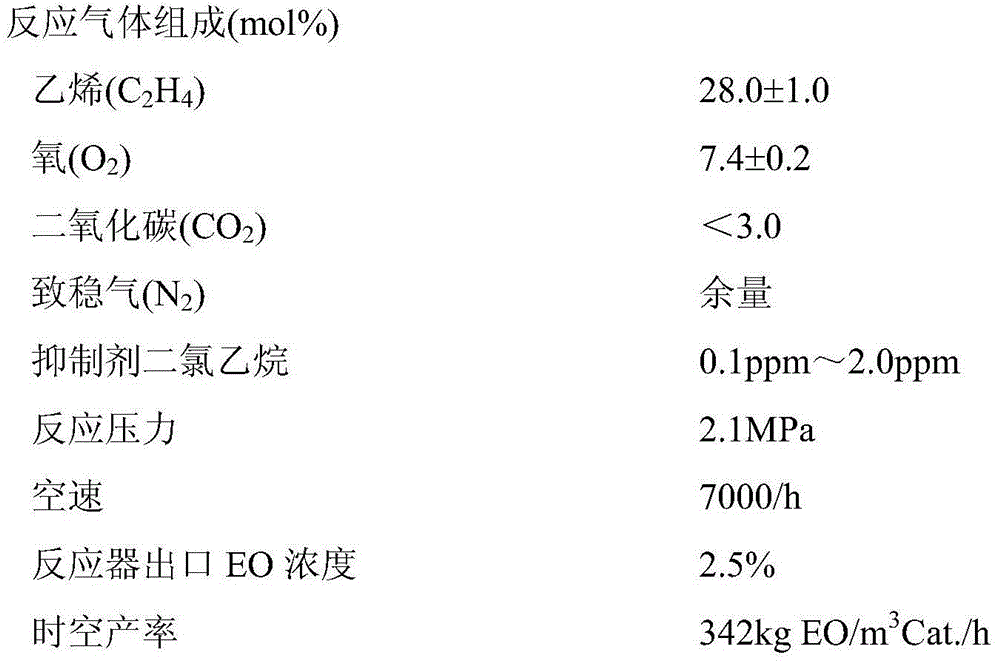

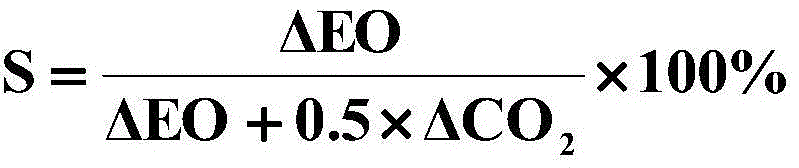

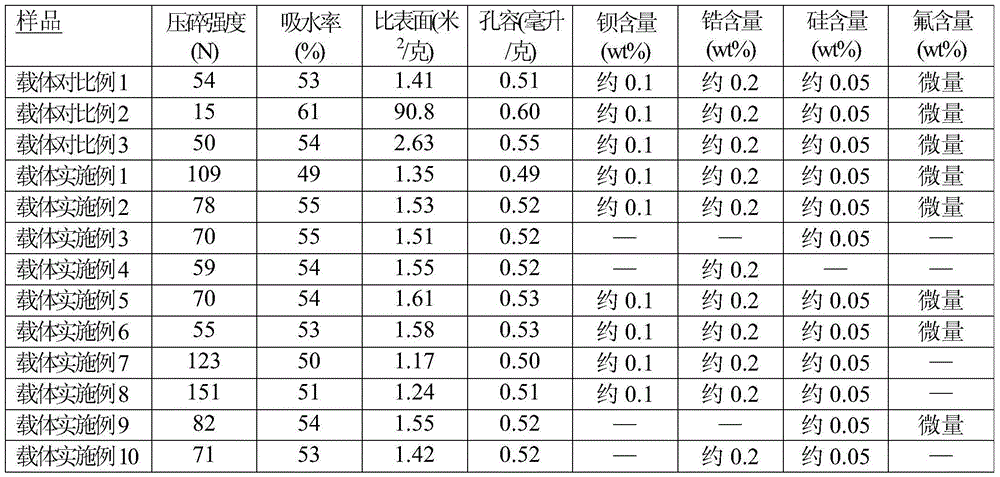

Preparation method and application of alumina carrier

ActiveCN105080617AHigh activityImprove performanceCatalyst carriersOrganic chemistryPolymer scienceAdhesive

The invention relates to a method for preparing an alumina carrier. The method comprises the following steps: (I) preparing a mixture including alpha-Al2O3 trihydrate, pseudo-Al2O3 monohydrate and auxiliaries; (II) adding an adhesive into the mixture obtained in the step (I); (III) uniformly kneading the mixture obtained in the step (II), extruding and molding; (IV) drying the product obtained in the step (III), and roasting for the first time to obtain a carrier semi-finished product; (V) soaking the product obtained in the step (IV) with an auxiliary solvent, and drying; (VI) roasting the product obtained in the step (V) for the second time. The invention further relates to the alumina carrier prepared by the method, a silver catalyst prepared by the carrier and application of the silver catalyst. The silver catalyst is used for producing ethylene oxide by ethylene oxidation, and has excellent activity and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

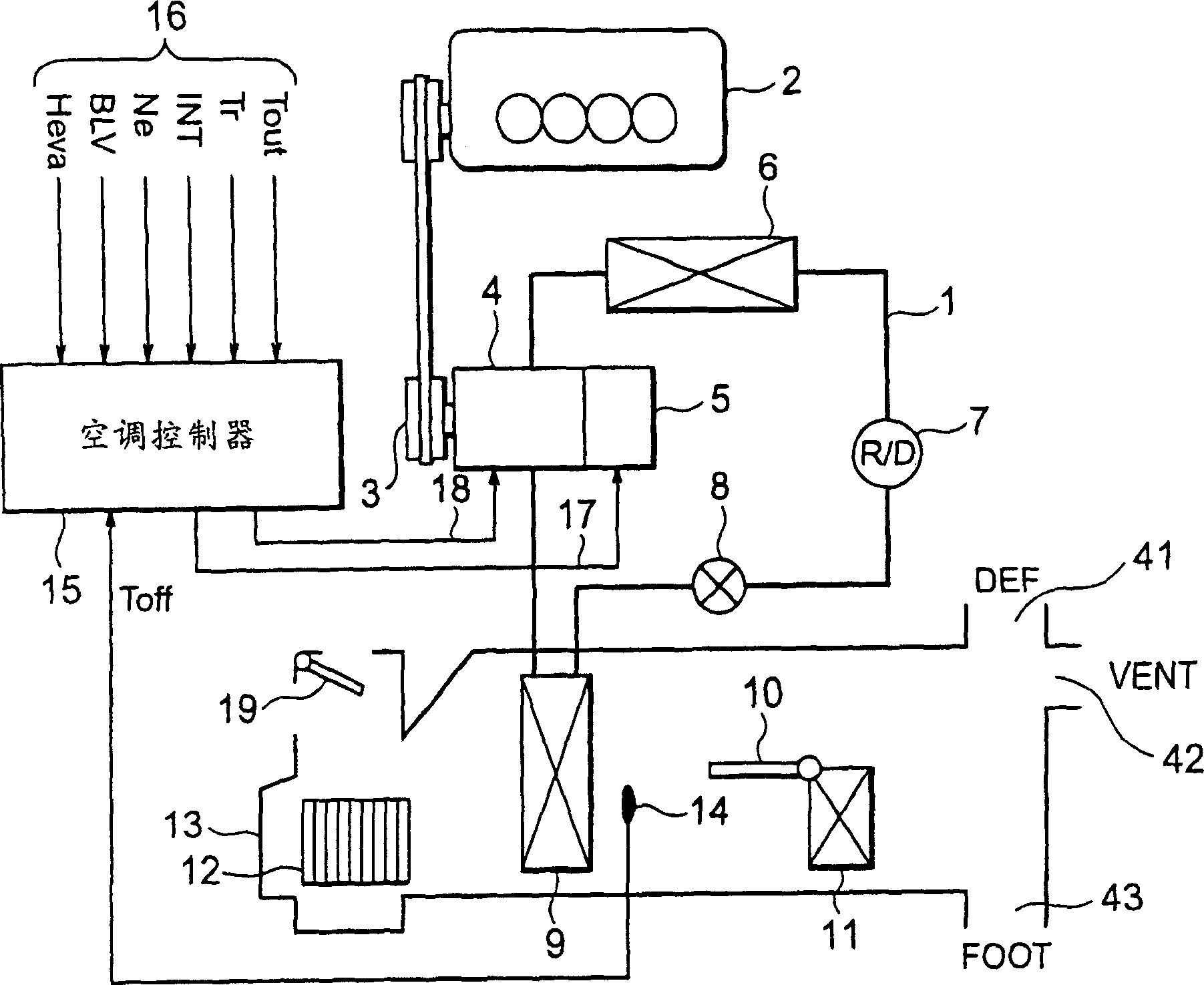

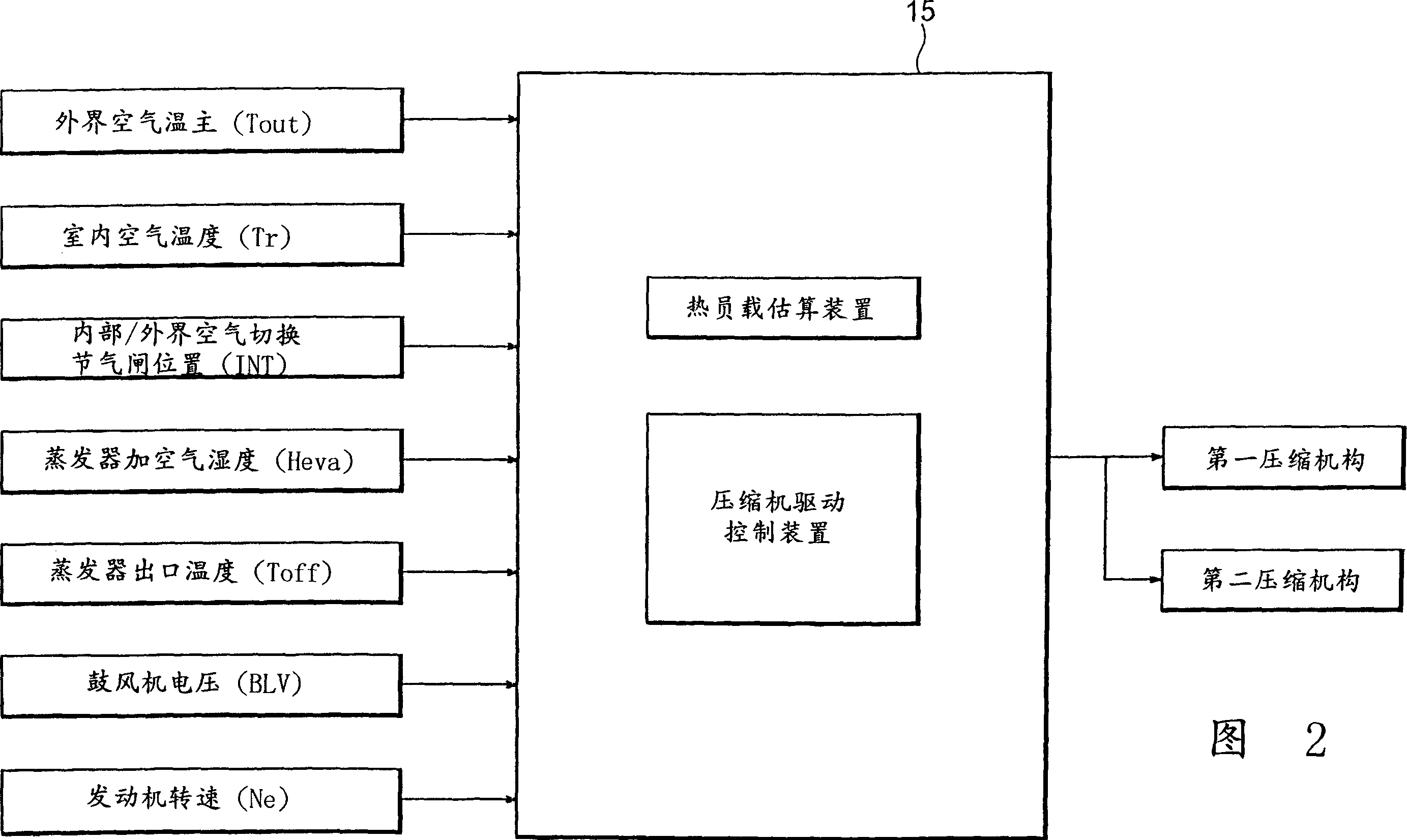

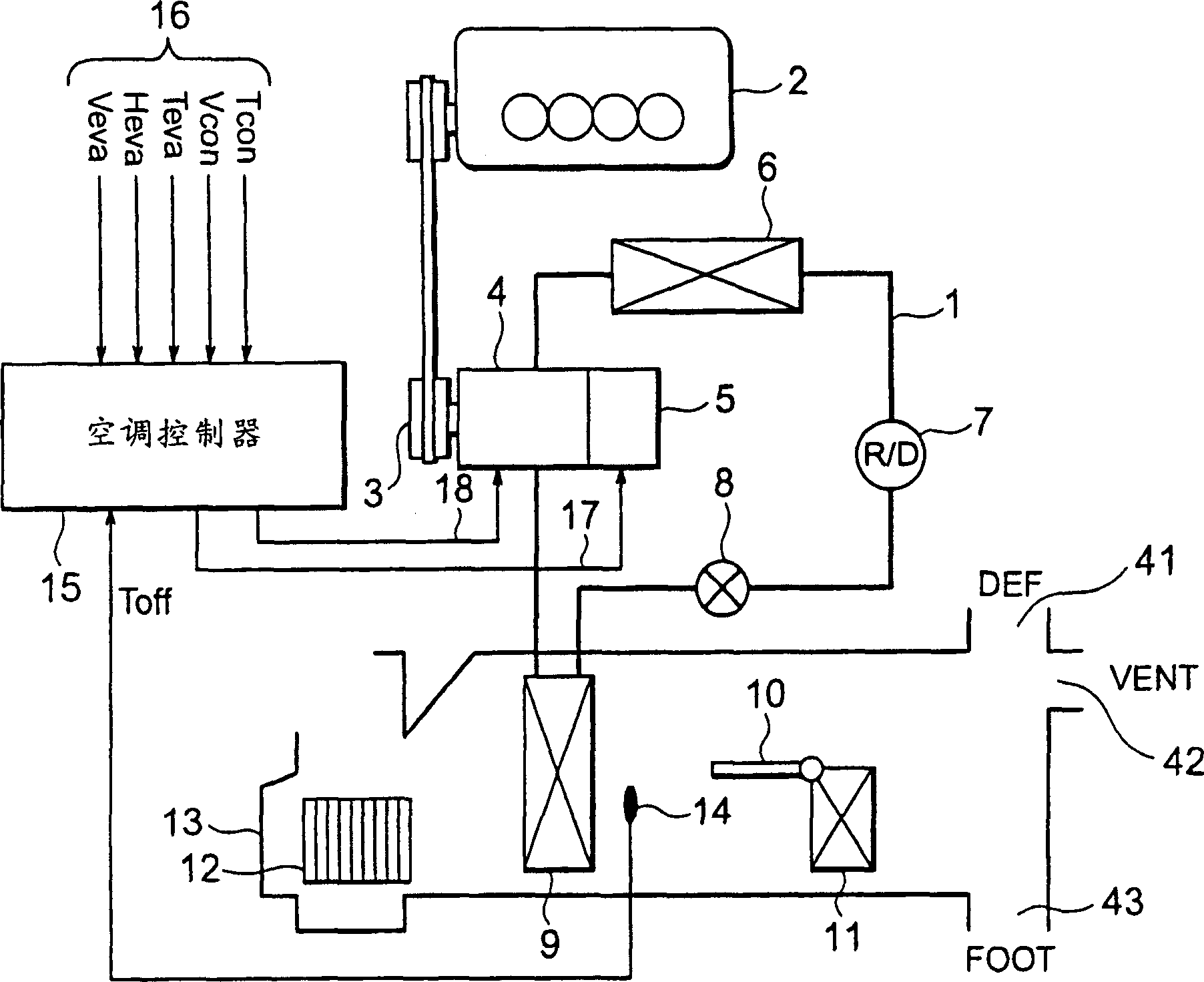

Motor-vehicle airconditioner using mixed compressor

InactiveCN1438133AImprove air conditioning performanceImprove abilitiesAir-treating devicesRotary piston pumpsOperation modeControl mode

An air conditioner for a vehicle uses a hybrid compressor (4) including a first compression mechanism driven by a first drive source (2) and a second compression mechanism driven by a second drive source (5), and a single discharge port connected to the first and the second compression mechanisms. The operation of the hybrid compressor is controlled by a controller (15) in accordance with a control mode. The controller has a first operation mode in which the first compression mechanism alone is driven, a second operation mode in which the second compression mechanism alone is driven, a third operation mode in which the first and the second compression mechanisms are simultaneously driven, and a fourth operation mode in which the first and the second compression mechanisms are simultaneously stopped. Depending upon various conditions, the controller selects, as the control mode, one of the first, the second, the third, and the fourth operation modes.

Owner:SANDEN CORP

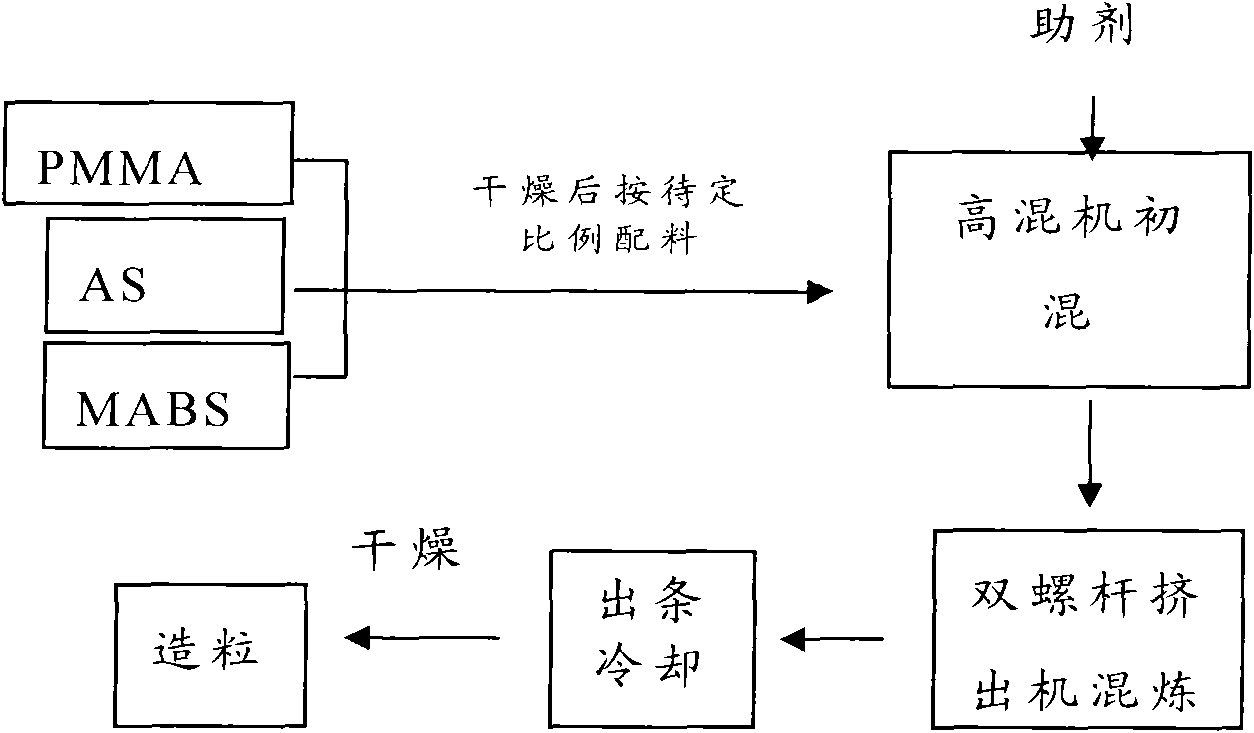

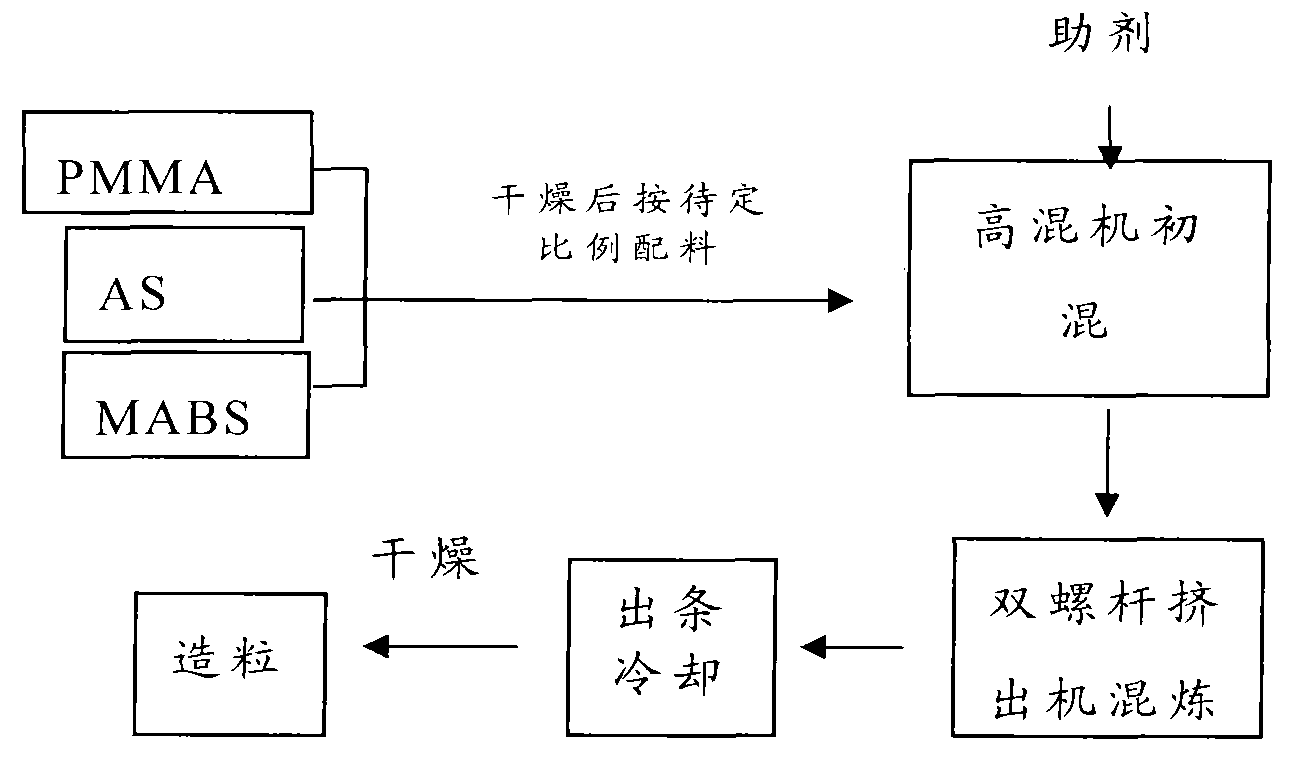

High-transparence composite and manufacturing method thereof

The invention provides a high-transparence composite and a manufacturing method thereof, which can solve the problems that the transparence effect needs to be further improved, the production cost is high and the like in the prior art. The invention has a technical proposal that the material comprises the following component in parts by weight: 35-50 parts of polymethyl methacrylate, 35-40 parts of acrylonitrile-styrene, 20-30 parts of methyl methacrylate-acrylonitrile-butadiene-styrene, 0.2-0.8 part of polyvinyl alcohol, 0.1-0.2 part of dispersant, 2-6 parts of n-dodecyl mercaptan and 0.5-1.0 part of plasticizer. The experimental data indicates that the light transmittance of the invention is 75-88, thereby being greatly superior to the prior art.

Owner:青岛国恩复合材料有限公司

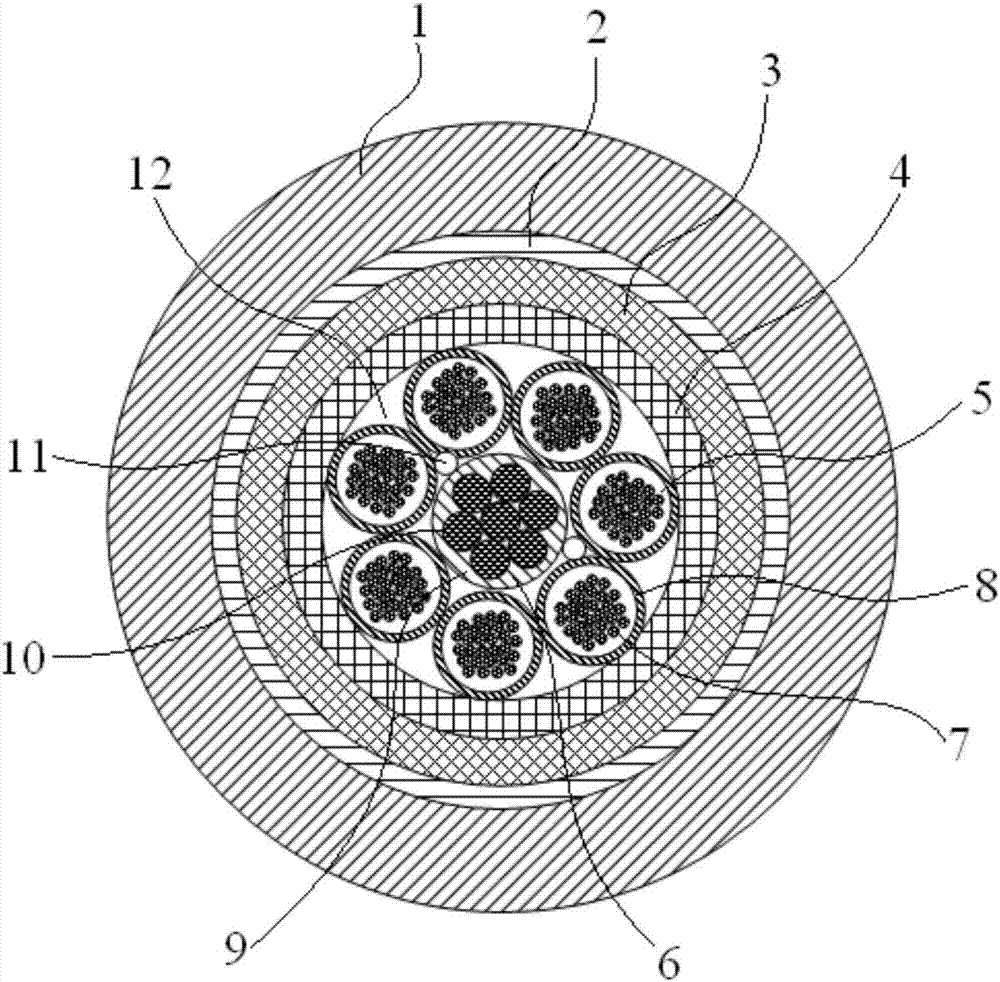

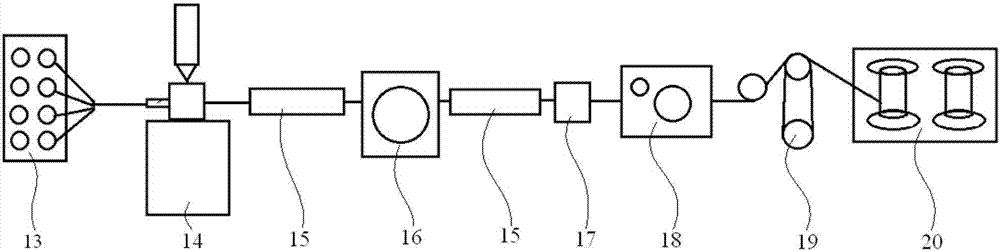

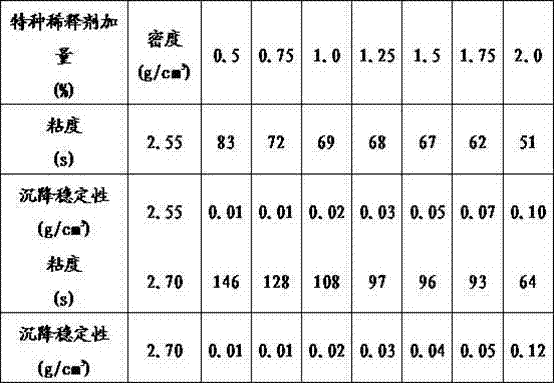

Ultra-soft temperature-resistant bulletproof optical cable and production method thereof

ActiveCN107422435AIngenious structural designImprove flexibilityFibre mechanical structuresThermal insulationPliability

The invention relates to an ultra-soft temperature-resistant bulletproof optical cable and a production method thereof. The optical cable comprises a cable core, a plastic foaming layer, a bulletproof armored layer and an outer sheath layer, the surface of the cable core is provided with the plastic foaming layer, the outside of the plastic foaming layer is provided with the bulletproof armored layer, the outside of the bulletproof armored layer is provided with the outer sheath layer, the cable core comprises optical fiber units and a central reinforcing element which are twisted in an SZ twisting manner, each optical fiber unit comprises coated optical fibers and a buffer tube, the external parts of the coated optical fibers are wrapped by the buffer tube, the central reinforcing element comprises flexible reinforcing members and a PE sheath layer wrapping the external parts of the flexible reinforcing members, and the outer sheath layer is a bellows sheath. According to the optical cable, good thermal insulation performance is achieved by employing the plastic foaming layer structure, the impact force of the exterior on the optical cable can be effectively buffered, the optical fiber has good flexibility and good bulletproof performance by employing the bulletproof armored layer, the overall bending resistance of the optical fiber can be effectively improved by employing the bellows outer sheath, and the bending recovery toughness can be improved.

Owner:NANJING WASIN FUJIKURA OPTICAL COMM LTD

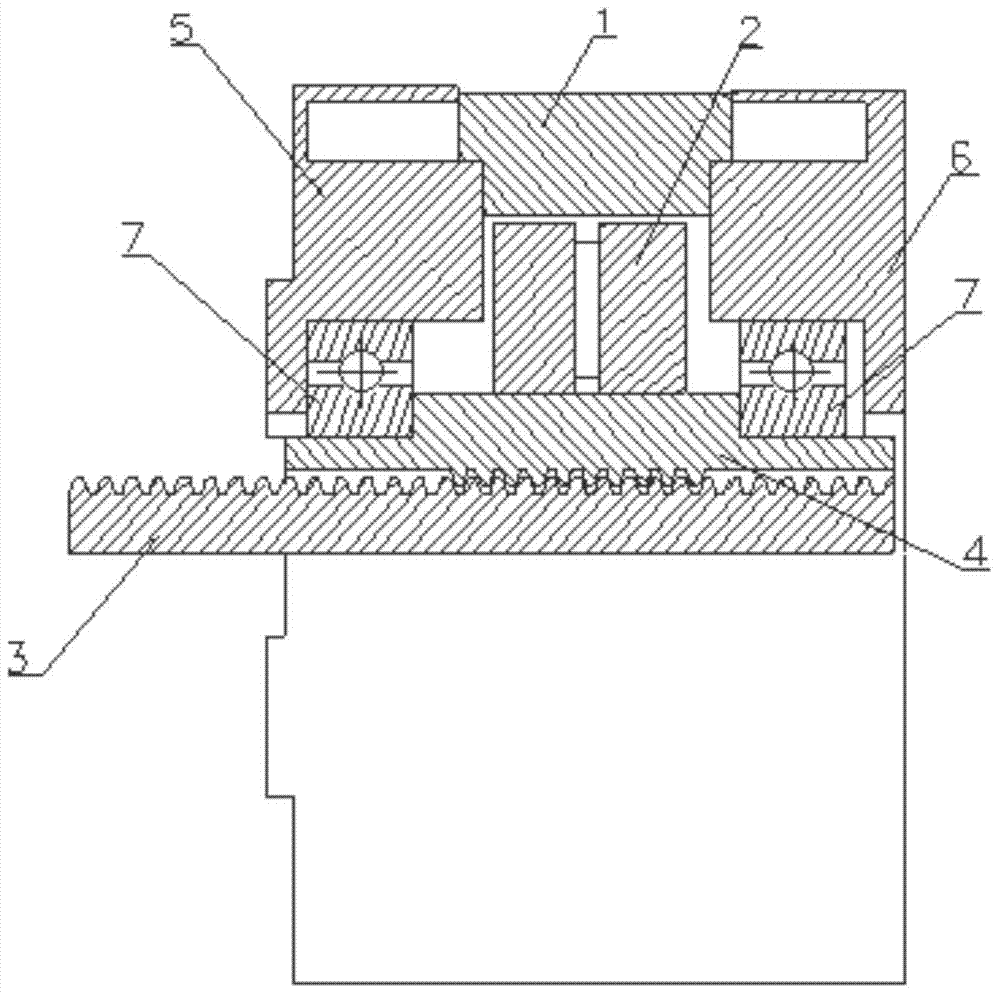

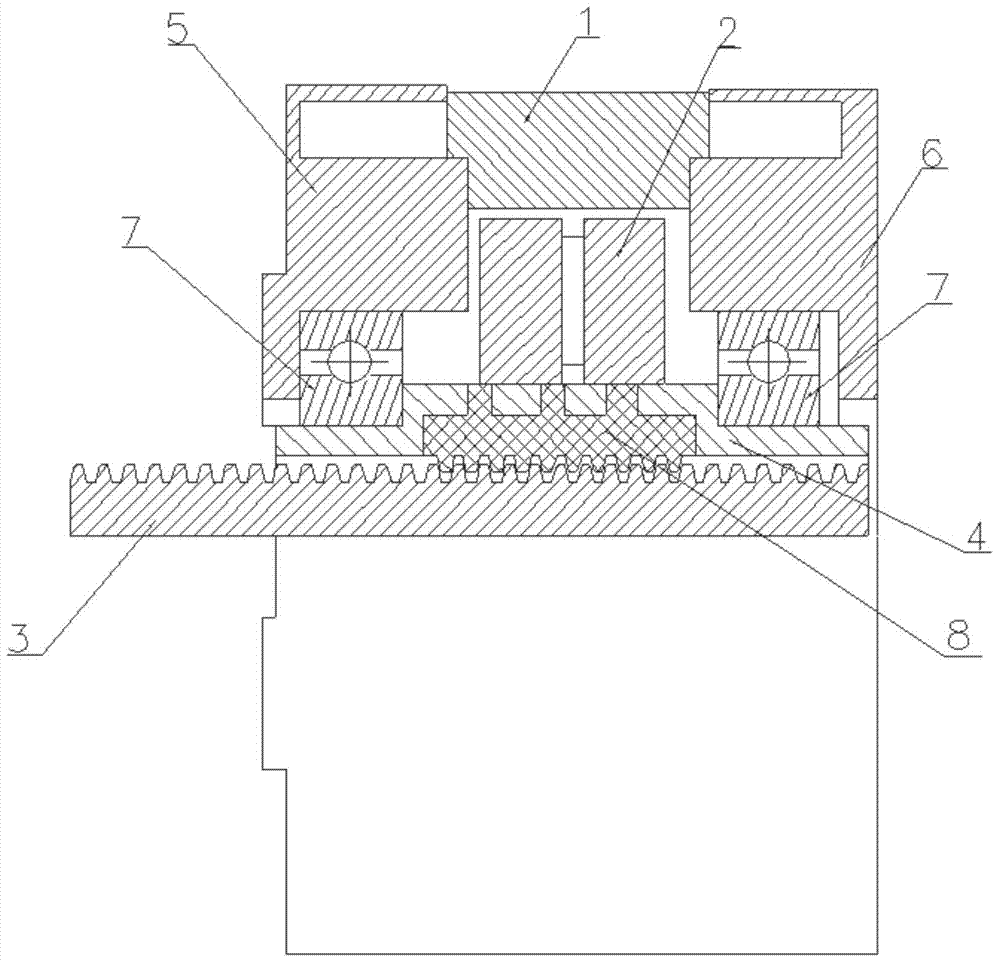

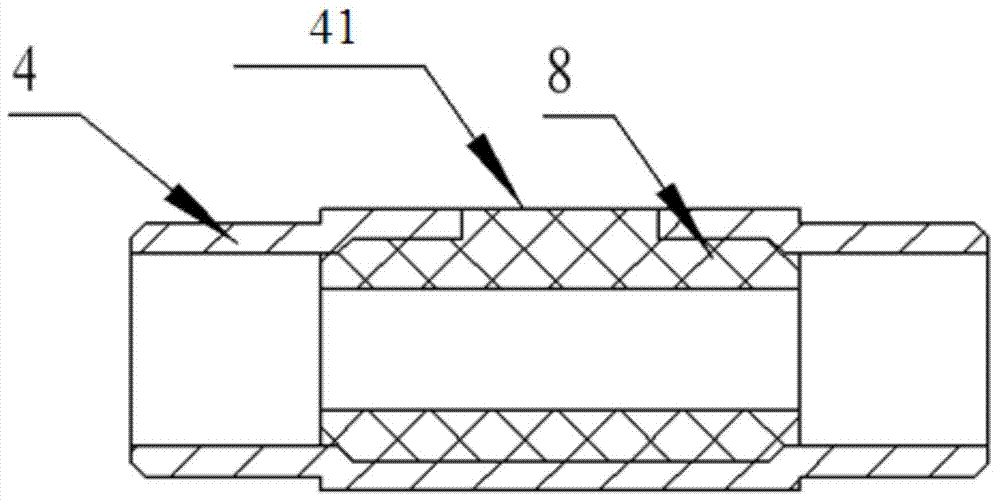

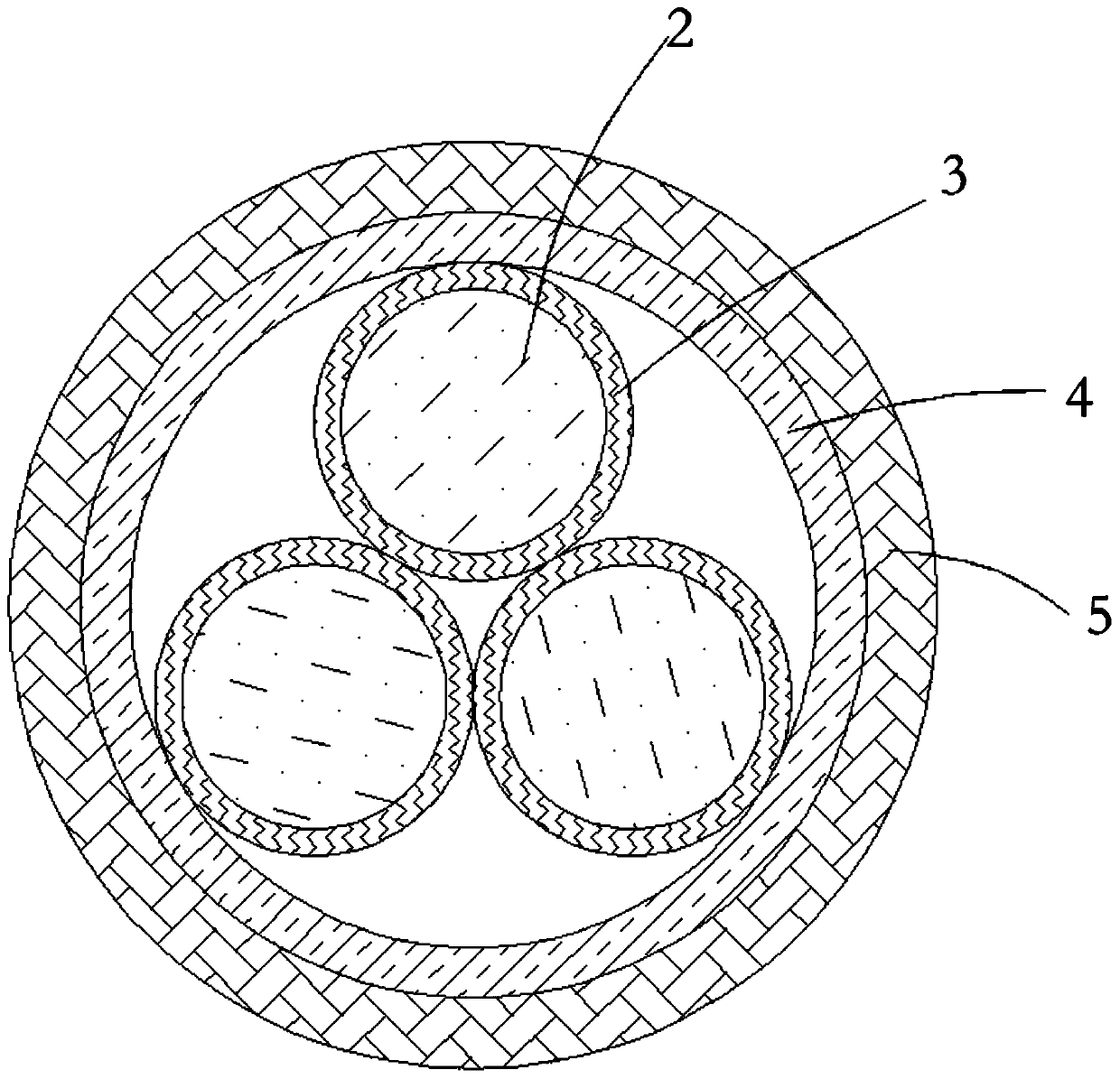

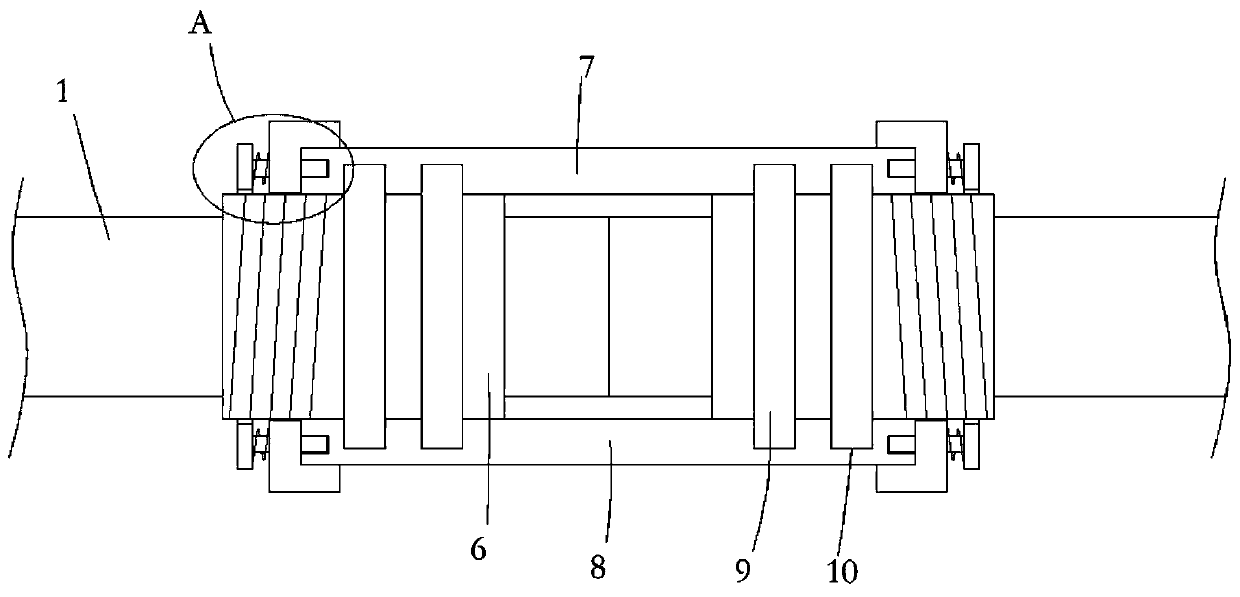

Stepping linear motor

InactiveCN104333194ALittle change in performanceHigh precisionMechanical energy handlingPropulsion systemsEngineeringLinear motor

The invention relates to a stepping linear motor which comprises a stator (1), a rotor (2), a screw (3), a rotor shaft (4), a left end cover (5), a right end cover (6), bearings (7) and a plastic nut (8). The screw (3) is in transmission connection with the rotor shaft (4), the rotor shaft (4) is in transmission connection with the rotor (2), the bearings (7) are arranged at two ends of the rotor shaft (4), the left end cover (5) and the right end cover (6) are arranged at two ends of the stator (1) respectively and then enclose the rotor (2), the rotor shaft (4) is of a hollow structure, the plastic nut (8) is provided with a thread matched with the screw (3), and the screw (3) is connected with the plastic nut (8) and then extends into the rotor shaft (4). Compared with the prior art, the stepping linear motor has the advantages of high precision, fine concentricity, fine universality and the like.

Owner:SHANGHAI MOONS ELECTRICAL APPLIANCE

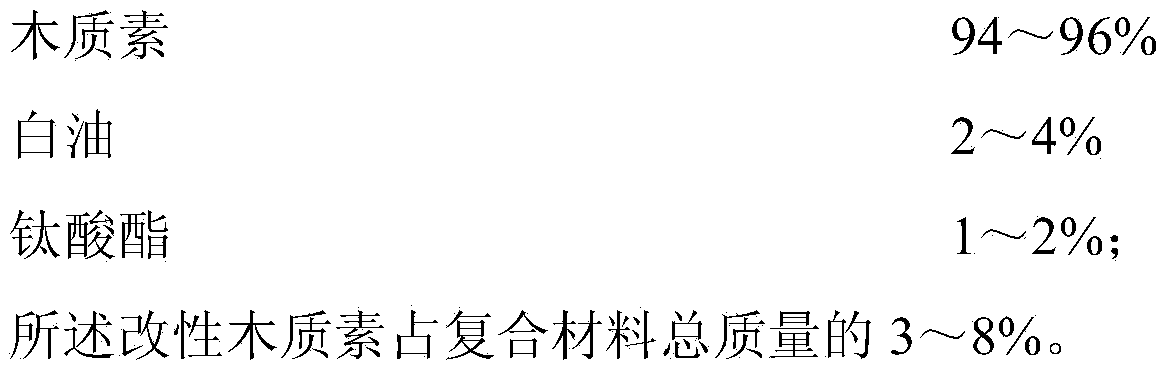

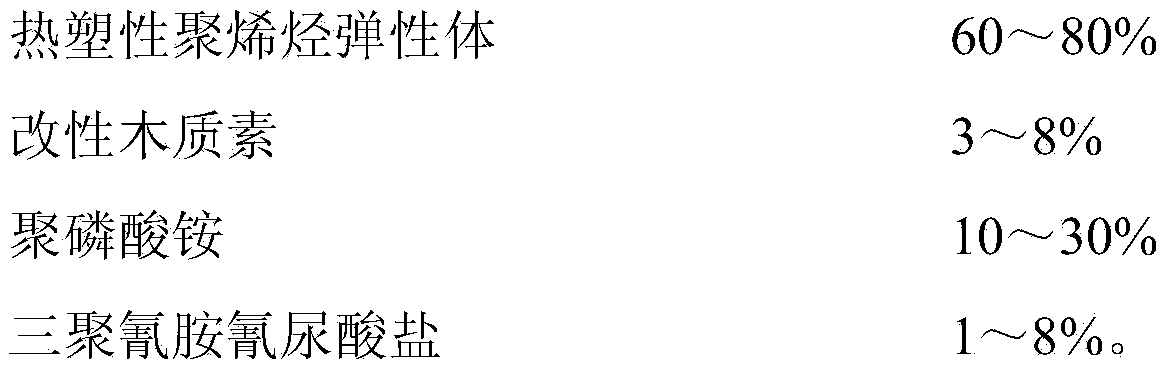

Modified lignin intumescent flame retardant TPO composite material as well as preparation method and application of composite material

InactiveCN103834107APromote environmental protectionHigh char formation ratePolyolefinAging resistance

The invention relates to a modified lignin intumescent flame retardant thermoplastic polyolefin (TPO) composite material as well as a preparation method and an application of the composite material. The composite material contains modified lignin, wherein the modified lignin consists of the following components in percentage by mass: 94-96% of lignin, 2-4% of white oil and 1-2% of titanate; and the modified lignin accounts for 3-8% in terms of total mass of the composite material. The prepared modified lignin intumescent flame retardant TPO composite material disclosed by the invention has the beneficial effects of being high in tensile strength at break, high in elongation at break, low in heating expansion amount, good in low temperature flexibility, good in penetration resistance and strong in chemical corrosion resistance; and the composite material is excellent in weather aging resistance, applicable to damp, hot and cold natural environments in a long term, and low in performance change.

Owner:DALIAN POLYTECHNIC UNIVERSITY

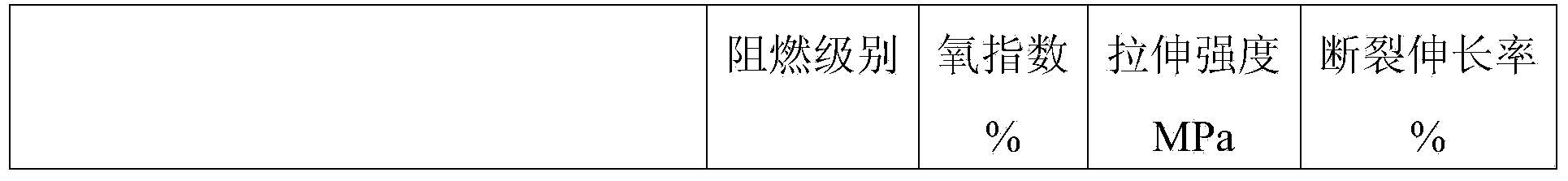

Positive photosensitive resin composition

ActiveCN1820228AEasy to shapeExcellent removalSemiconductor/solid-state device manufacturingPhotosensitive materials for photomechanical apparatusBenzenePolyamide

Owner:ASAHI KASEI KK

Preparation method for anti-pollution PVDF (polyvinylidene fluoride) separation film

InactiveCN104174304ALittle change in performanceImprove anti-pollution performanceSemi-permeable membranesHydrophilizationPolyvinylidene difluoride

The invention discloses a preparation method for an anti-pollution PVDF (polyvinylidene fluoride) separation film, belongs to the technical field of films, and in particular relates to an anti-pollution macromolecular film technology. The invention provides a preparation method for a hydrophilization and anti-pollution PVDF separation film in order to solve the technical problem. The preparation method is characterized in that chitosan which is strong in hydrophilicity and pollution-resistant is added to PVDF. No special equipment is needed during product preparation; industrial implementation is easy, and the technology is simple in general. The separation film product has an extremely good anti-adsorption effect on bovine serum albumin; the flux recovery rate of the separation film in which the mass ratio of PVDF to chitosan is 1 to 0.1 and which is filtered by a bovine serum albumin solution is over 95 percent. The anti-pollution PVDF separation film prepared by the preparation method disclosed by the invention integrates the advantages of the PVDF separation film and the anti-pollution performance and the hydrophilicity of chitosan, so that the physical performance of the film is stable, and the pure water flux is increased.

Owner:TIANJIN POLYTECHNIC UNIV

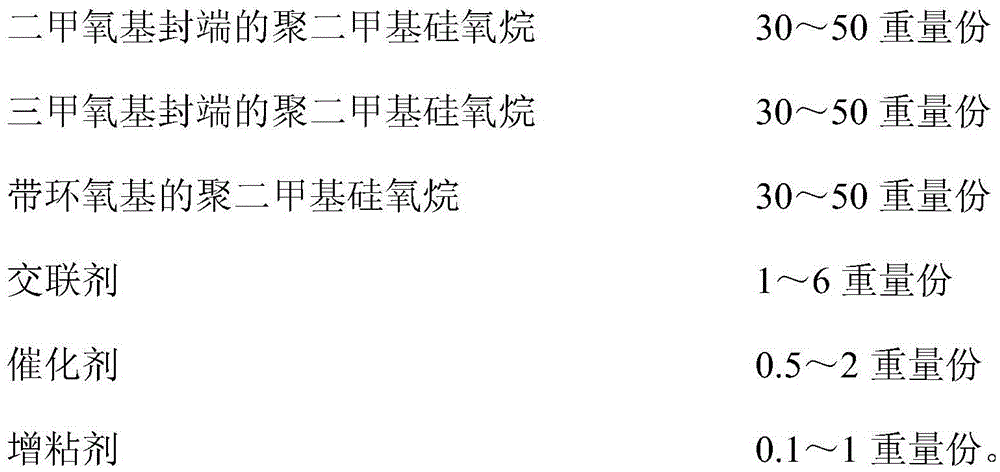

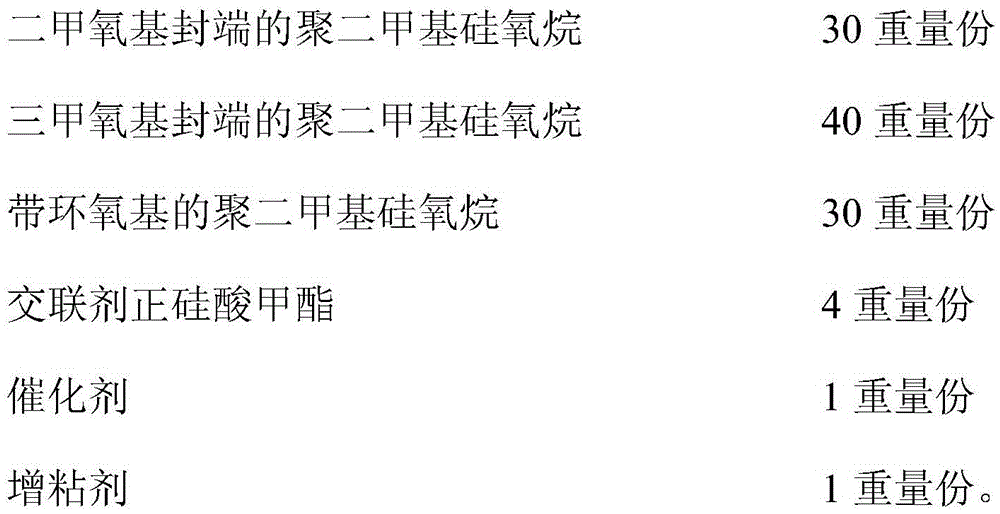

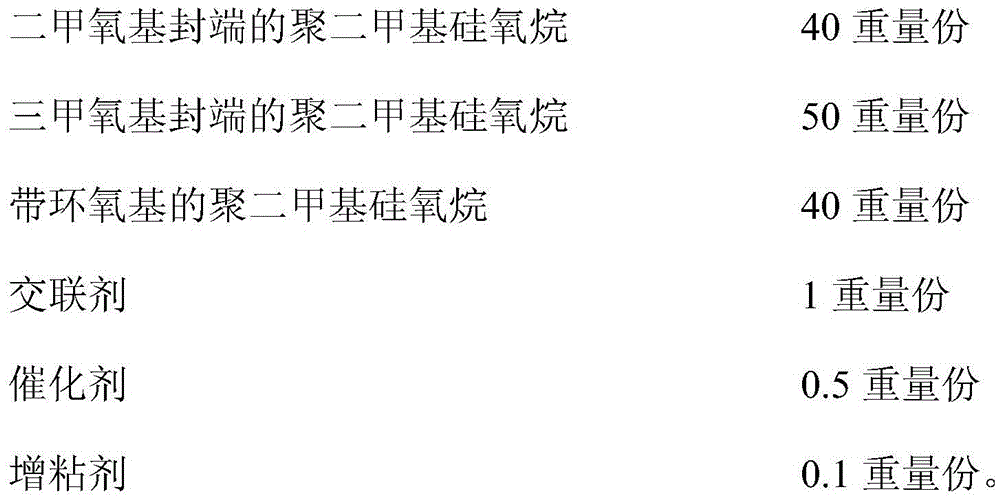

Organic silicone coated adhesive and preparation method and application thereof

The invention provides organic silicone coated adhesive and a preparation method and application thereof. The organic silicone coated adhesive is prepared from, by weight, 30-50 parts of dimethoxy terminated polydimethylsiloxane, 30-50 parts of triethoxy terminated polydimethylsiloxane, 30-50 parts of polydimethylsiloxane with an epoxy group, 1-6 parts of a cross-linking agent, 0.5-2 parts of a catalyst and 0.1-1 part of tackifier. The organic silicone coated adhesive has excellent comprehensive performance, viscosity is low (500-1000 dpas), the preparation process is free of peak viscosity, the organic silicone coated adhesive is resistant to a high temperature and a low temperature, can be used at the temperature ranging from minus 60 DEG C to 200 DEG C and can be heated and solidified, is high in solidification speed (surface drying time is less than 5 minutes at the temperature of 80 DEG C) and has high stability, and all properties scarcely change after the organic silicone coated adhesive is stored at the room temperature for one year.

Owner:兆舜科技(广东)有限公司

Silicon carbide and silicon particle reinforced aluminum-copper based composite material and preparation method thereof

Owner:有研金属复材技术有限公司

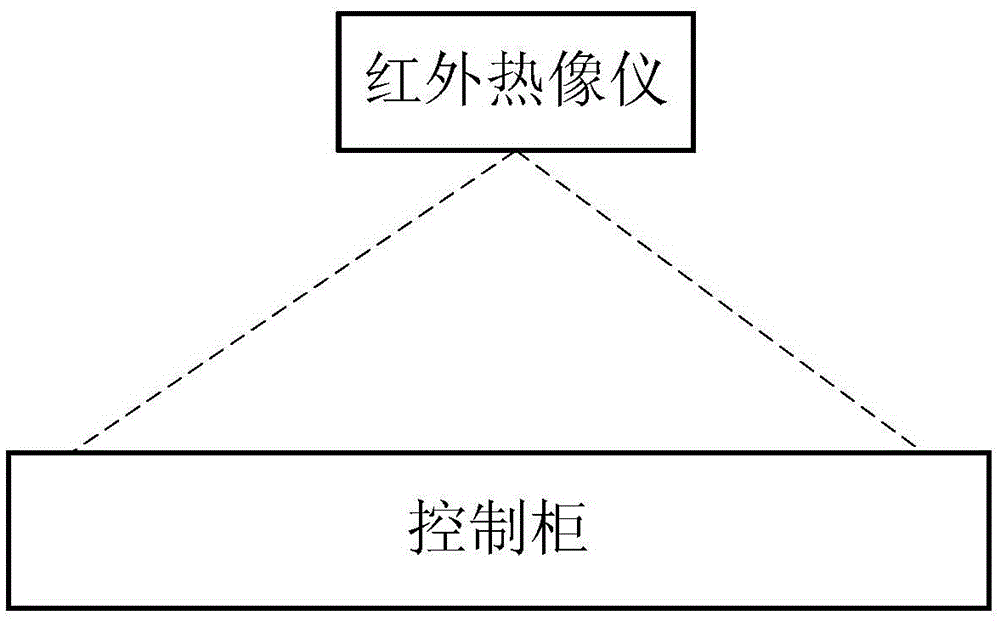

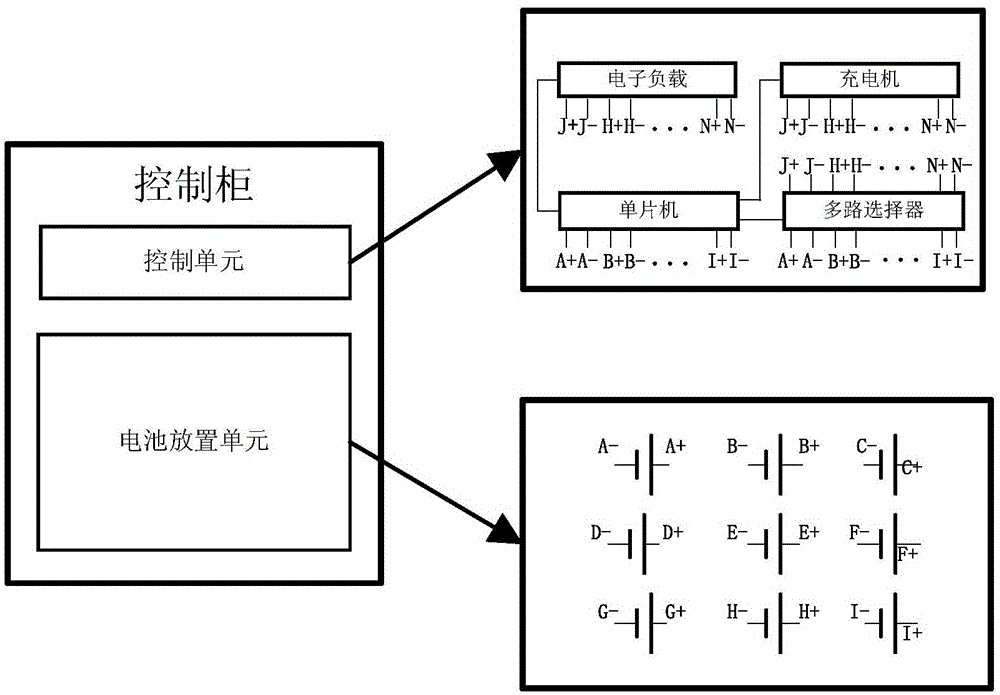

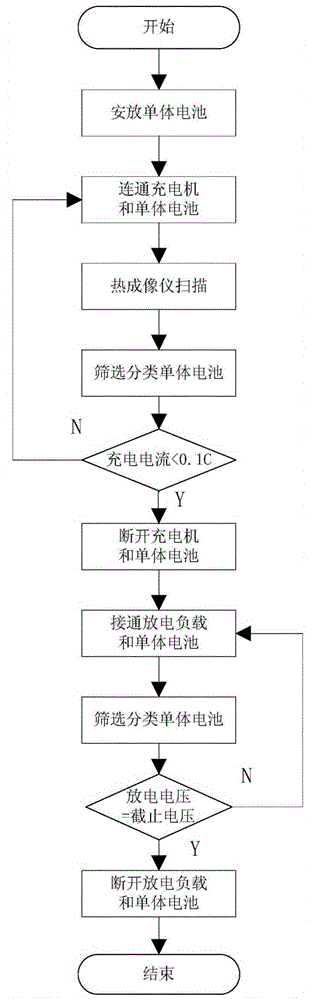

Battery consistency detection classification method and device

ActiveCN105116342AFeasible and efficientLittle change in performanceElectrical testingMicrocontrollerInfrared

The invention provides a battery consistency detection classification method and device, which belongs to battery detection methods and devices. The detection device comprises an infrared thermal imager and a control cabinet. The infrared thermal imager is placed above the control cabinet. The infrared thermal imager receives infrared reflected by a detected object, converts the infrared into corresponding gray, and acquires the temperature and the thermal image of the object according to the gray value. The control cabinet comprises a control unit and a battery placement unit. The battery placement unit is connected with the control unit through a wire. The control unit comprises an electronic load, a charger, a microcontroller and a multiplexer. The charger and the electronic load have multiple channels. The microcontroller is sequentially connected with the electronic load, the charger and the multiplexer. The multiplexer is sequentially connected with the electronic load and the charger. The detection device has the advantages of simple and feasible application and easy control. Mass heat consistency screening test can be carried out. The possibility of battery pack performance variations caused by heat inconsistency in actual use is reduced. Soaking management of a battery management system is reduced.

Owner:XUZHOU LIREN MONORAIL TRANSPORTATION EQUIP CO LTD

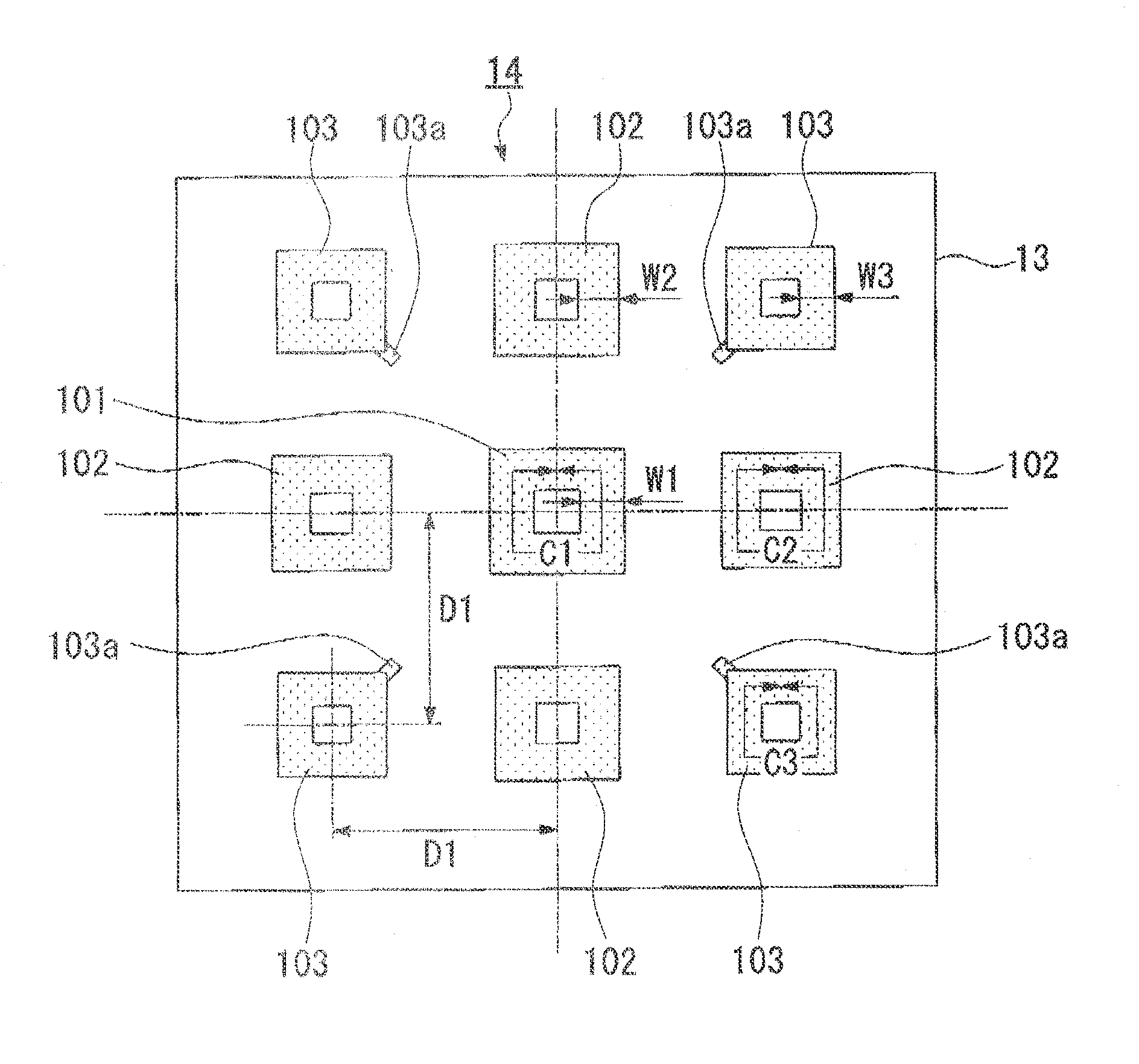

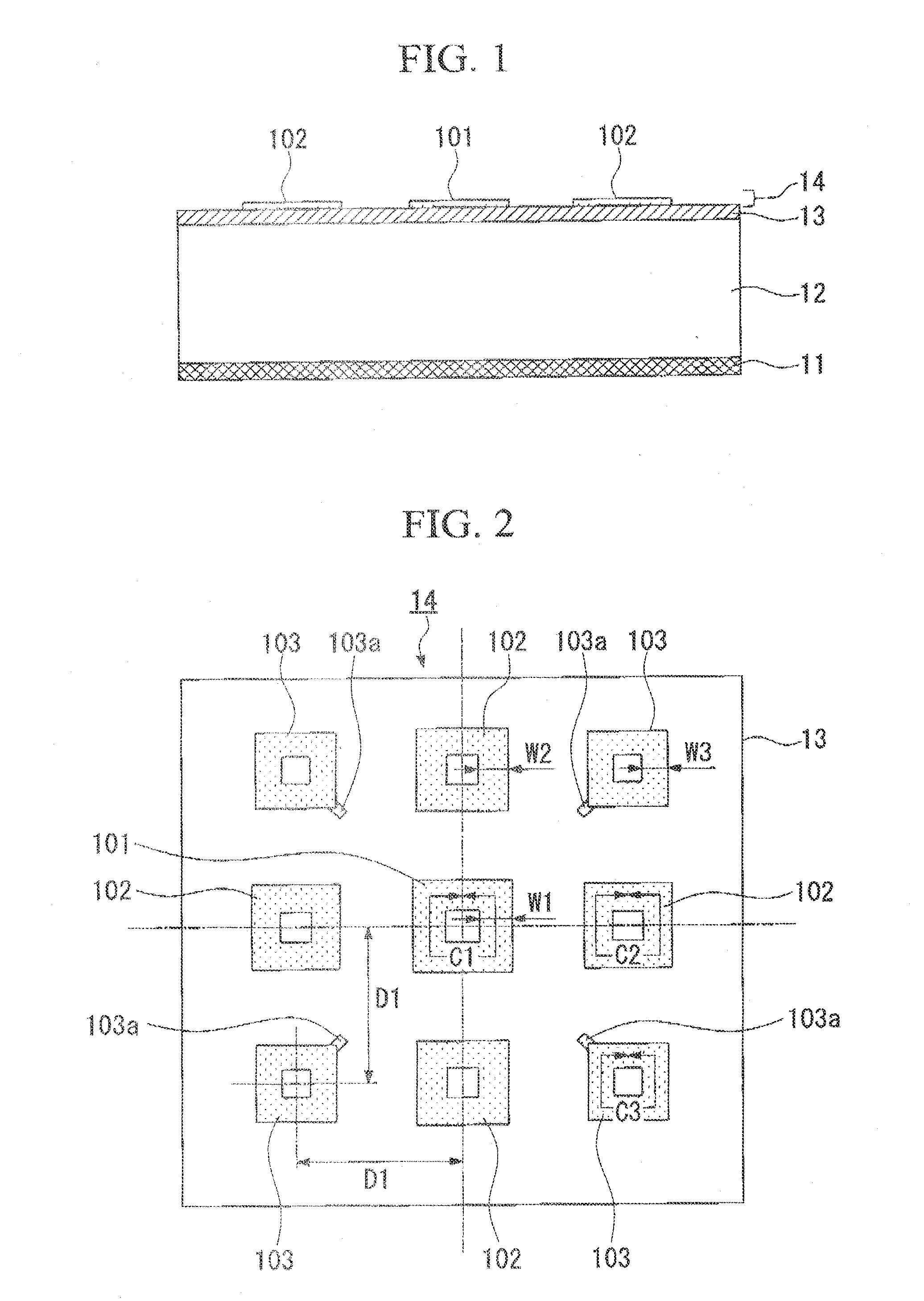

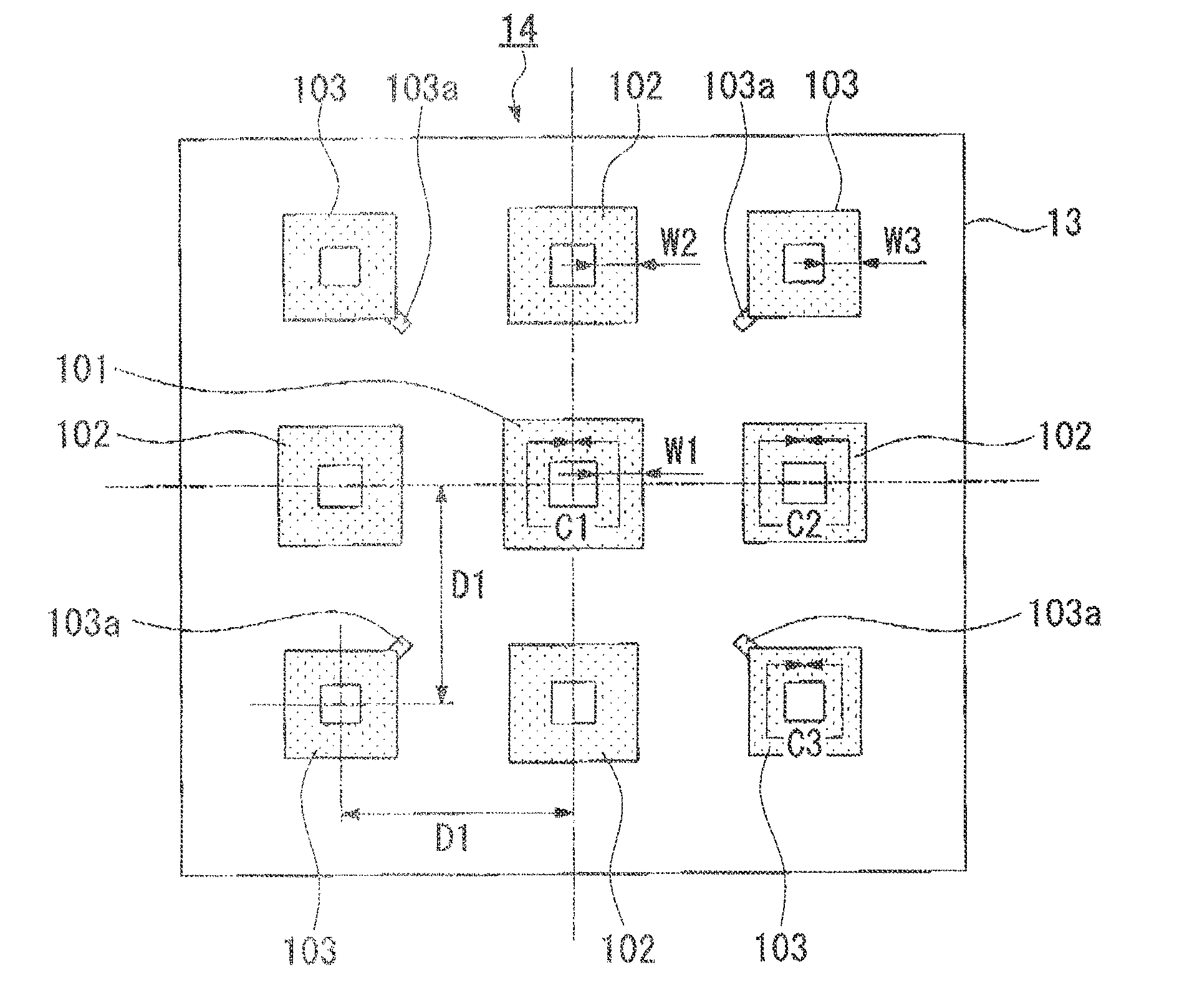

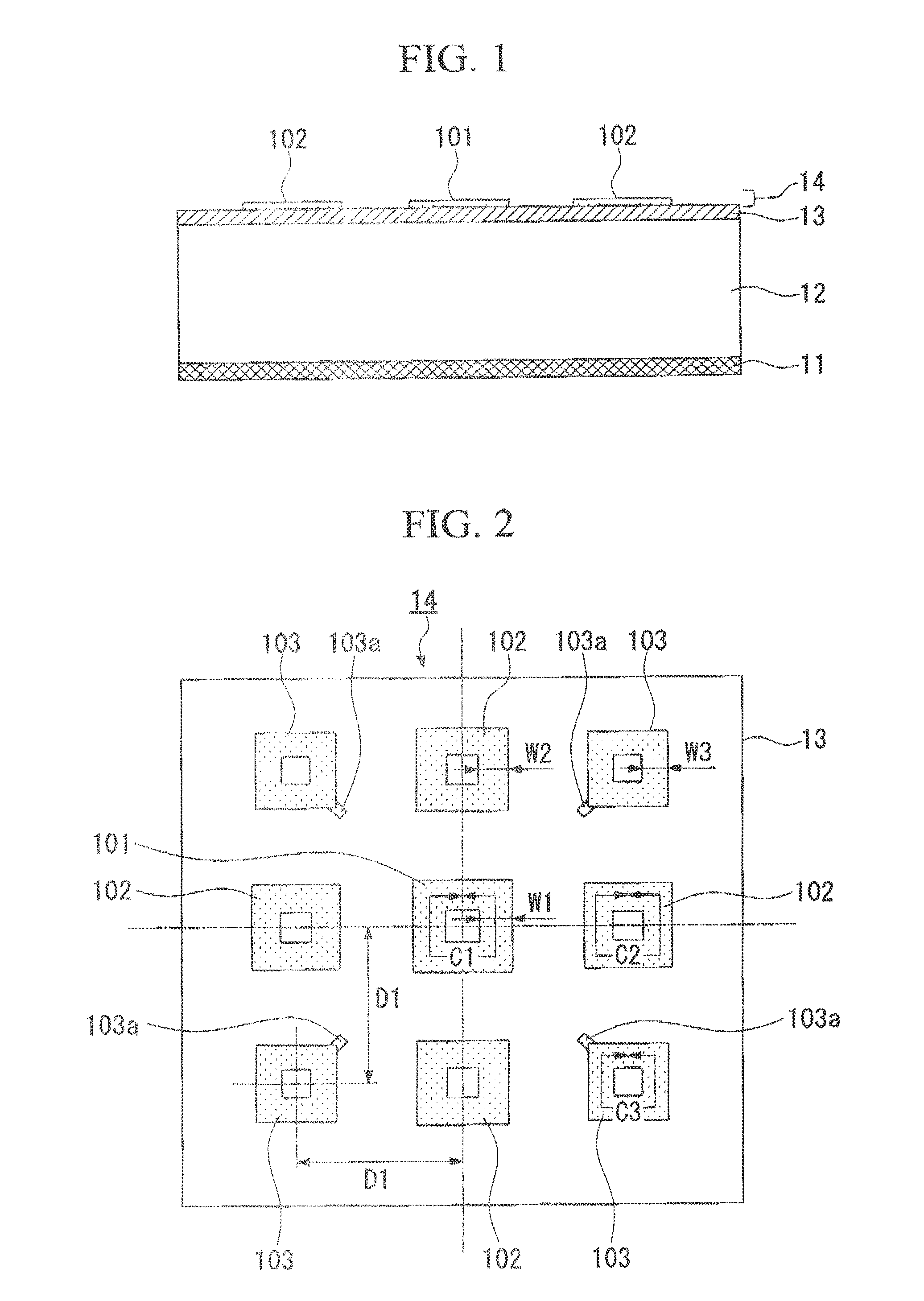

Wave Absorber

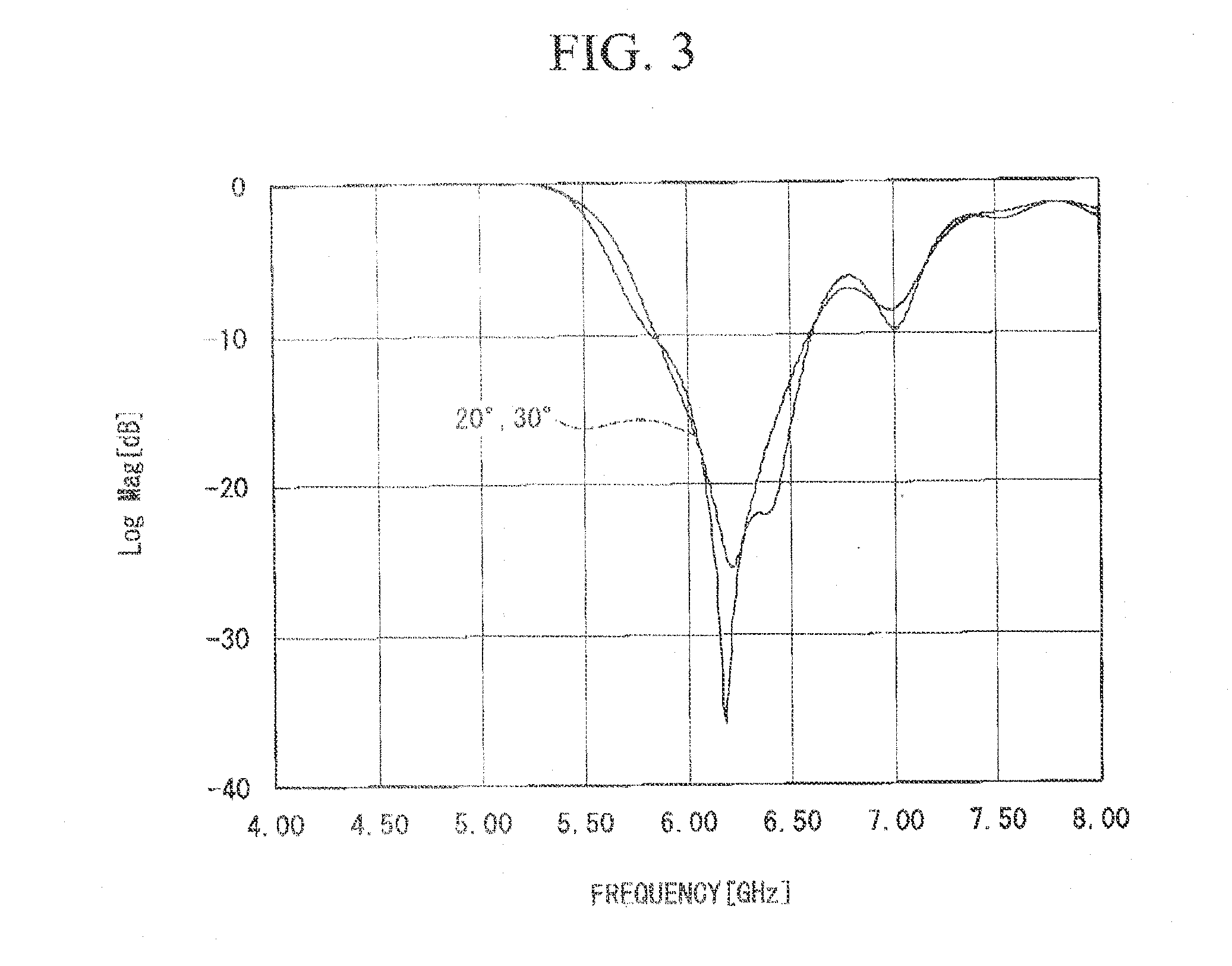

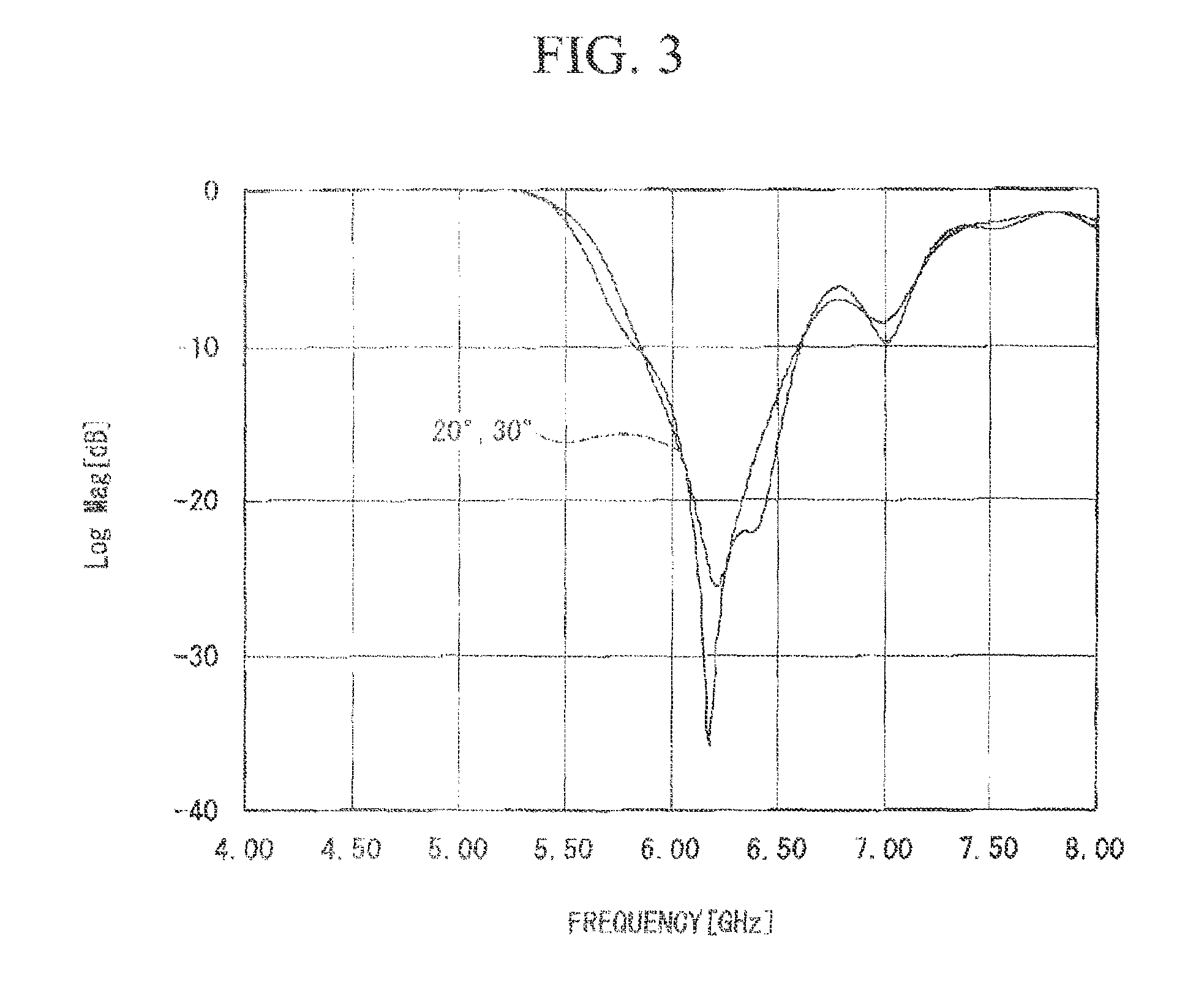

InactiveUS20070247349A1Thin thicknessReduce weightMagnetic/electric field screeningIndividually energised antenna arraysUltrasound attenuationOptoelectronics

A wave absorber of the present invention includes a sequentially laminated structure including an conductor layer (11) made of a conductive material; a first dielectric layer (polycarbonate substrate (12) and bismaleimide-triazine substrate (13)) made of one layer or a multilayer of a dielectric material; and a patterned layer (14) including a plurality of a pattern made of the conductive material, wherein the conductor layer, the first dielectric layer, and the patterned layer are laminated sequentially, and each pattern in the patterned layer (14) is different from other adjacent patterns with respect to at least one of size and shape. Therefore, the wave absorber has sufficient reflection-attenuating capability to prevent communication failure caused by a reflection of a radio wave and so on, can be thin-sized and reduced in weight, and has a wide-band attenuation property.

Owner:MITSUBISHI GAS CHEM CO INC

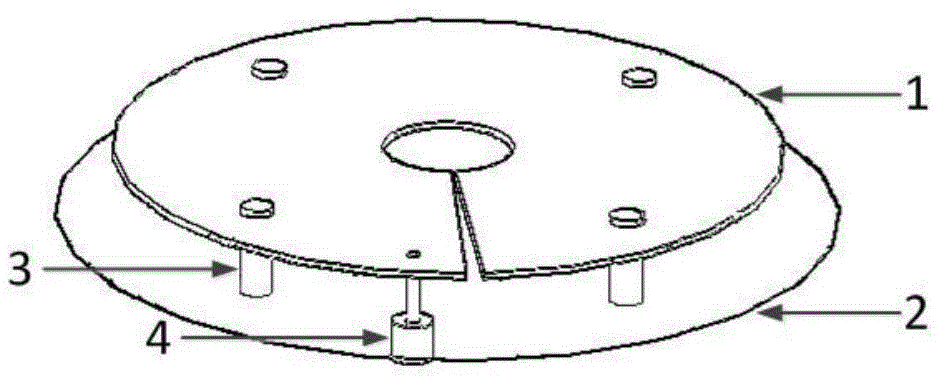

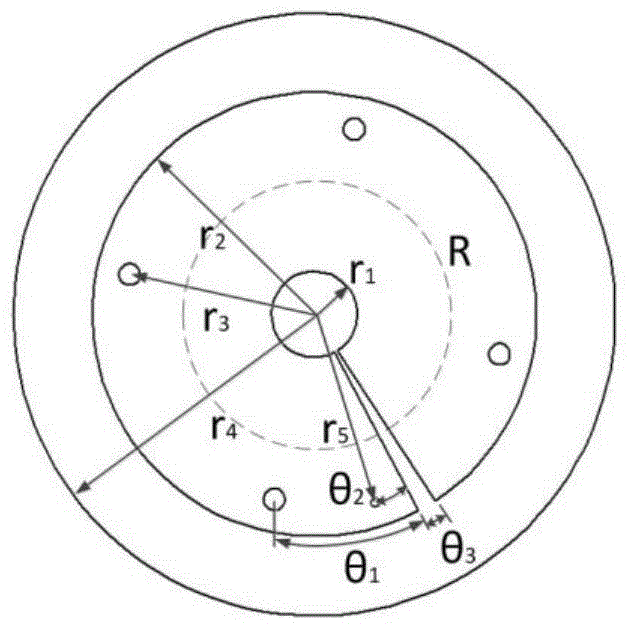

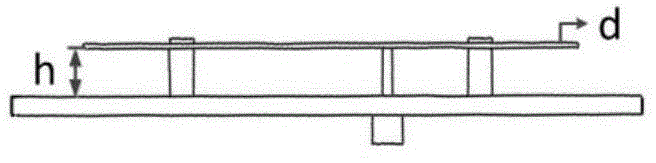

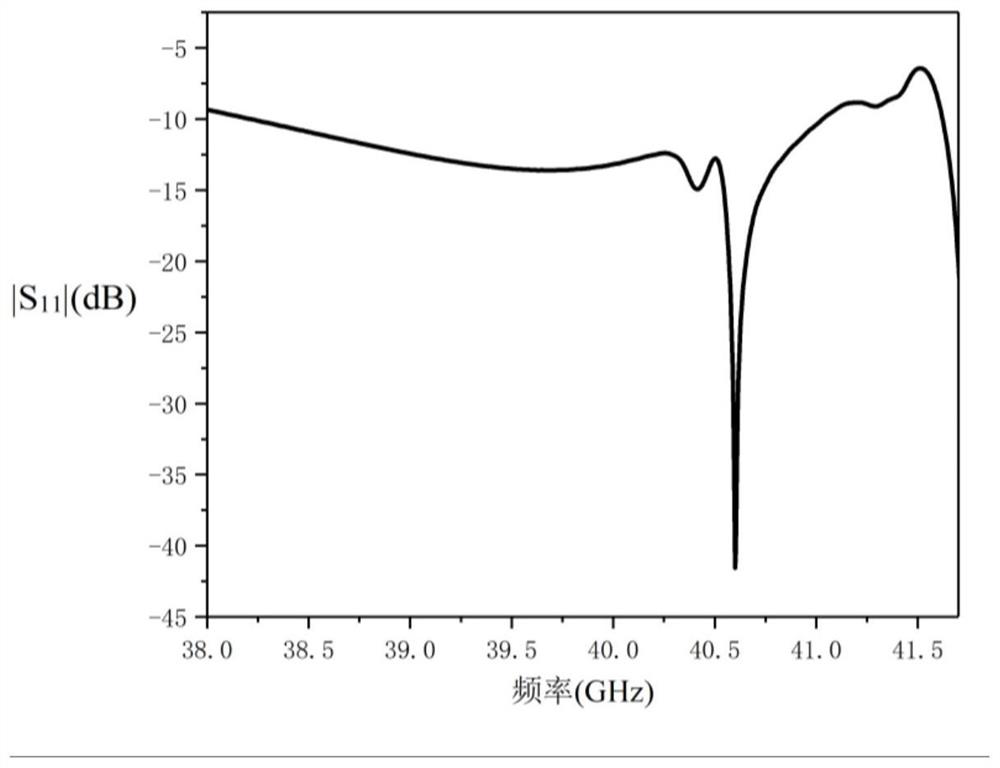

Notched jade ring type circular polarized antenna

InactiveCN104659474ASimple structureLittle change in performanceRadiating elements structural formsAntennas earthing switches associationDielectricCircularly polarized antenna

The invention provides a notched jade ring type circular polarized antenna. The circular polarized antenna comprises an antenna unit and an earth plate, and is characterized in that the antenna unit conducts single feeding through a coaxial feeder; a sector is cut in the surface of the annular antenna unit; the center of the sector and the center of the antenna unit are at a same position; the radius of the sector is equal to the outer diameter of the antenna unit; air dielectric is arranged between the antenna unit and the earth plate. The circular polarized antenna has the advantages that the circular polarized antenna is simple in feeding manner, relatively low in influence of change of feeding point position to aerial performance, and relatively wide in band frequency.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

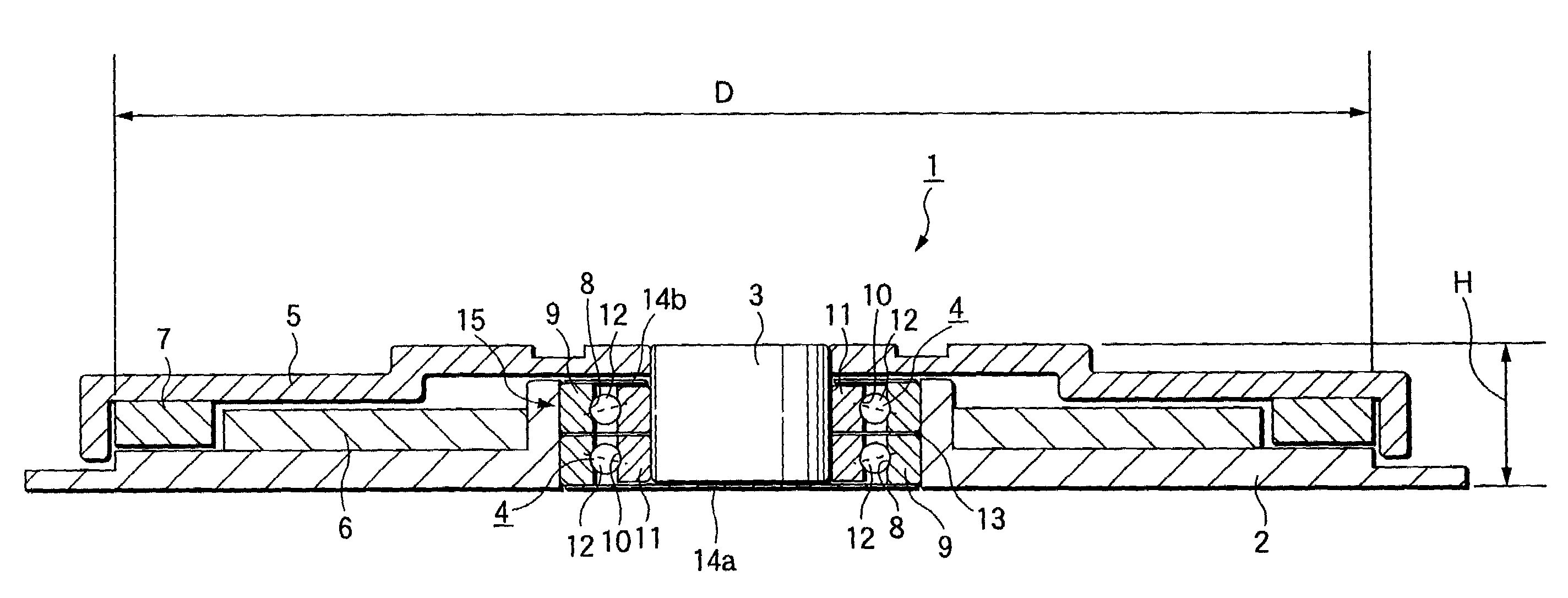

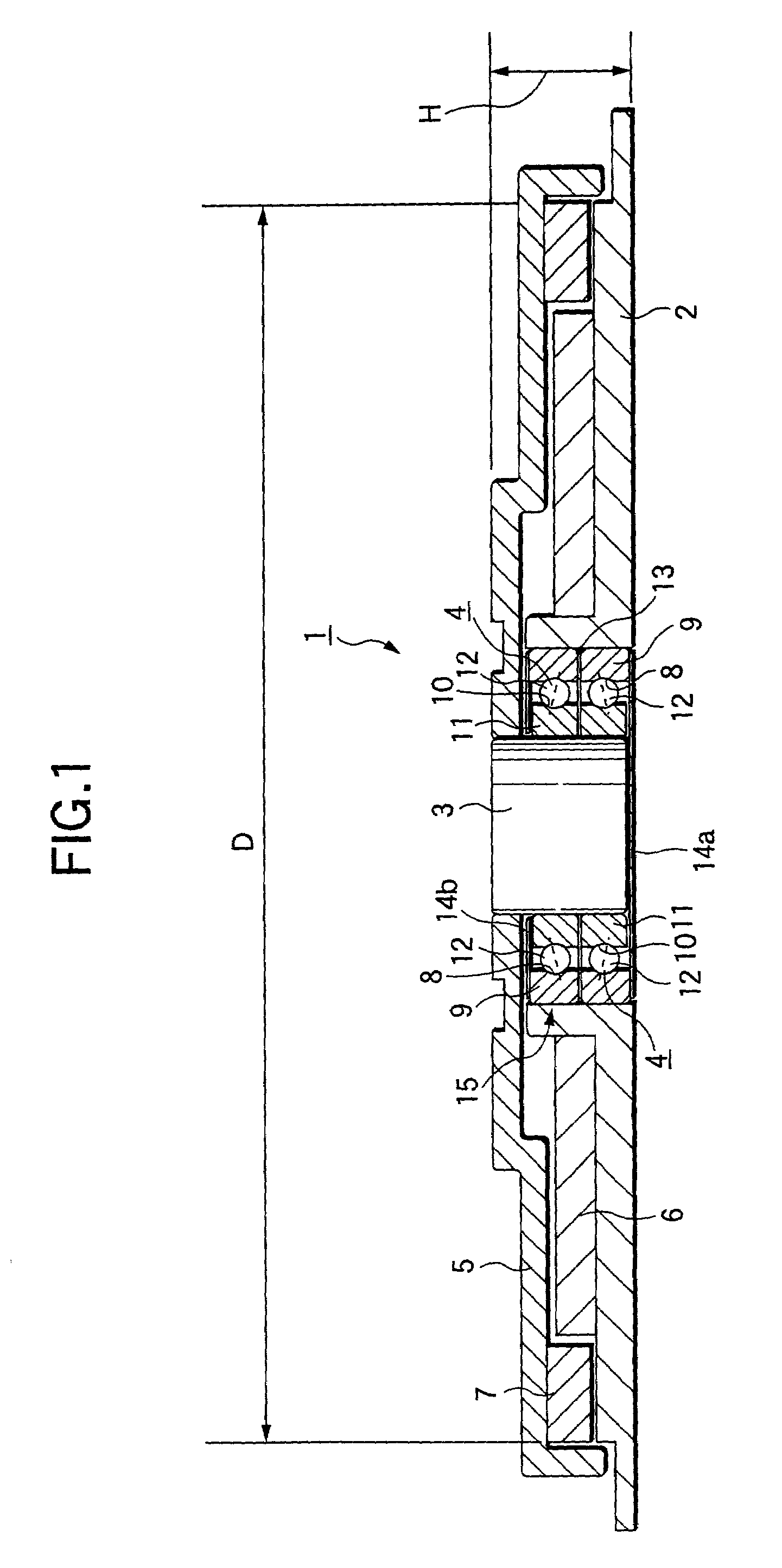

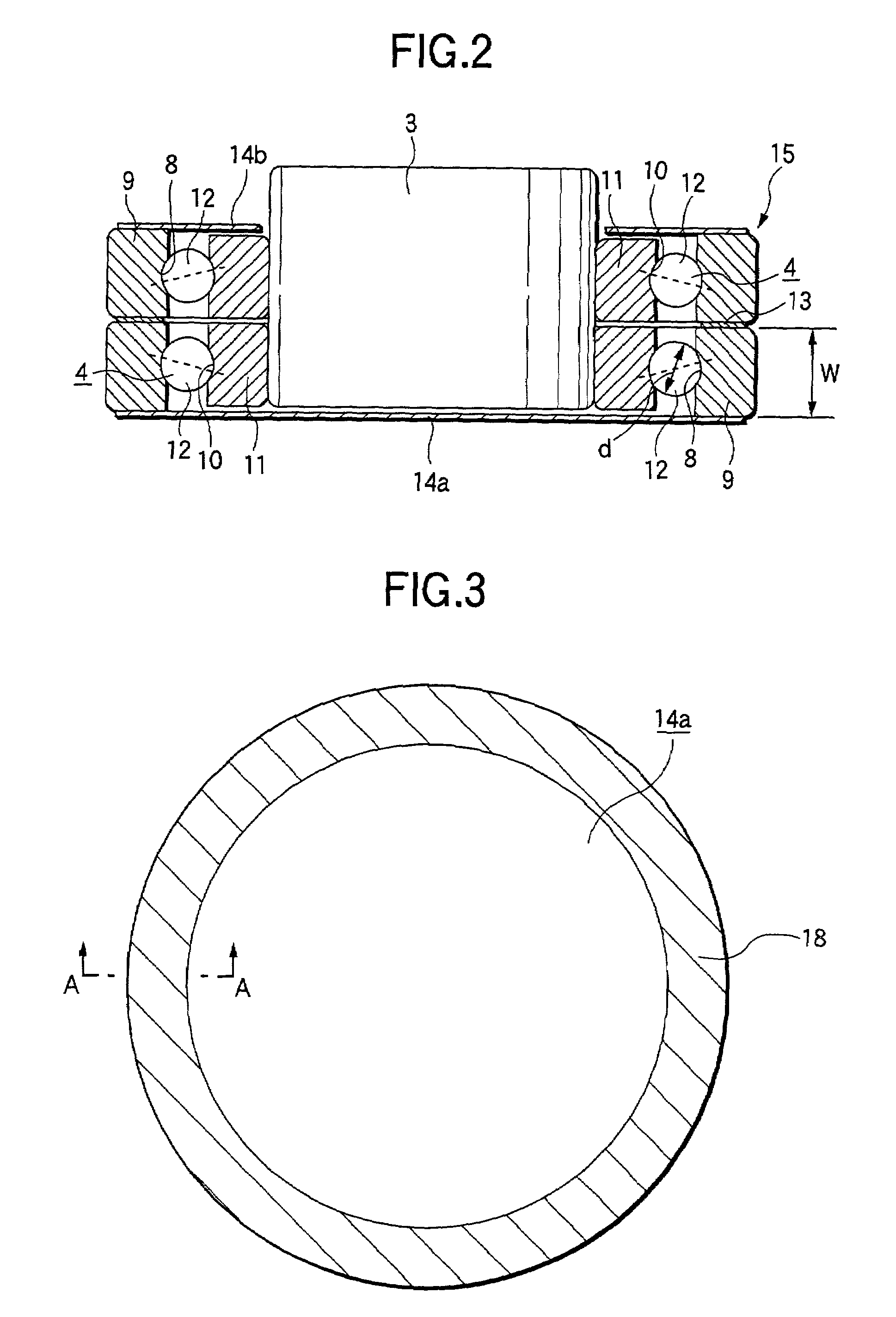

Sealing member, rolling bearing, thin motor, and bearing device

InactiveUS7031106B2Easy to peelReduce the binding forceEngine sealsBearing assemblyRolling-element bearingEngineering

The sealing members (14a, 14b) comprise a film member produced by forming an aluminum or alumina deposition film on at least one side surface of a film-like core material. One side surface outer circumferential rim part of the sealing members is bonded and fixed on the outer end surface of outer rings (9, 9) constituting the rolling bearings (4, 4).

Owner:NSK LTD

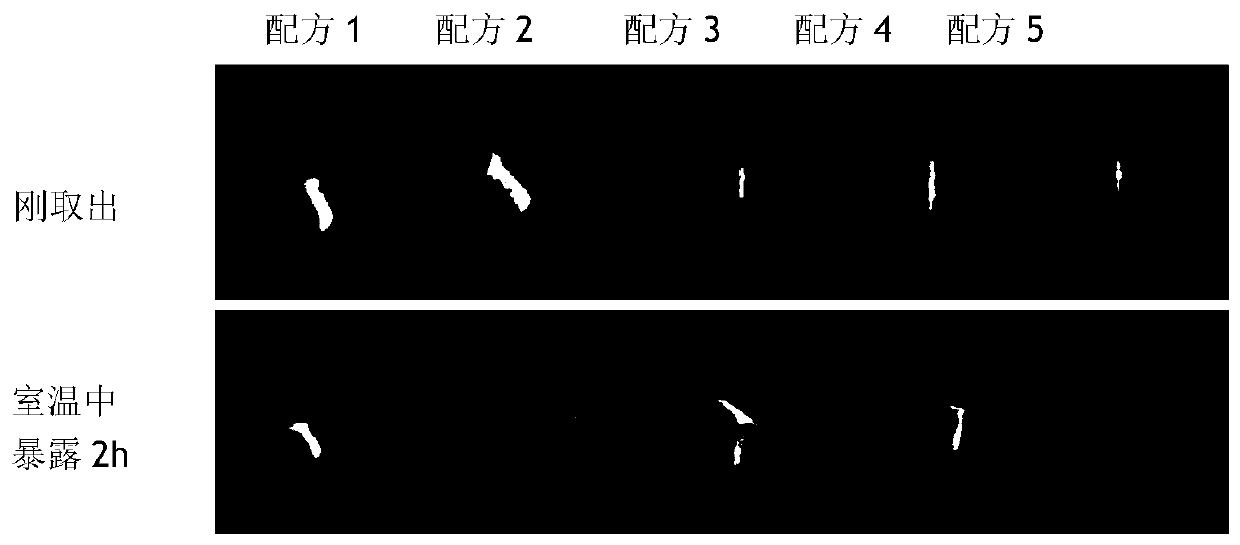

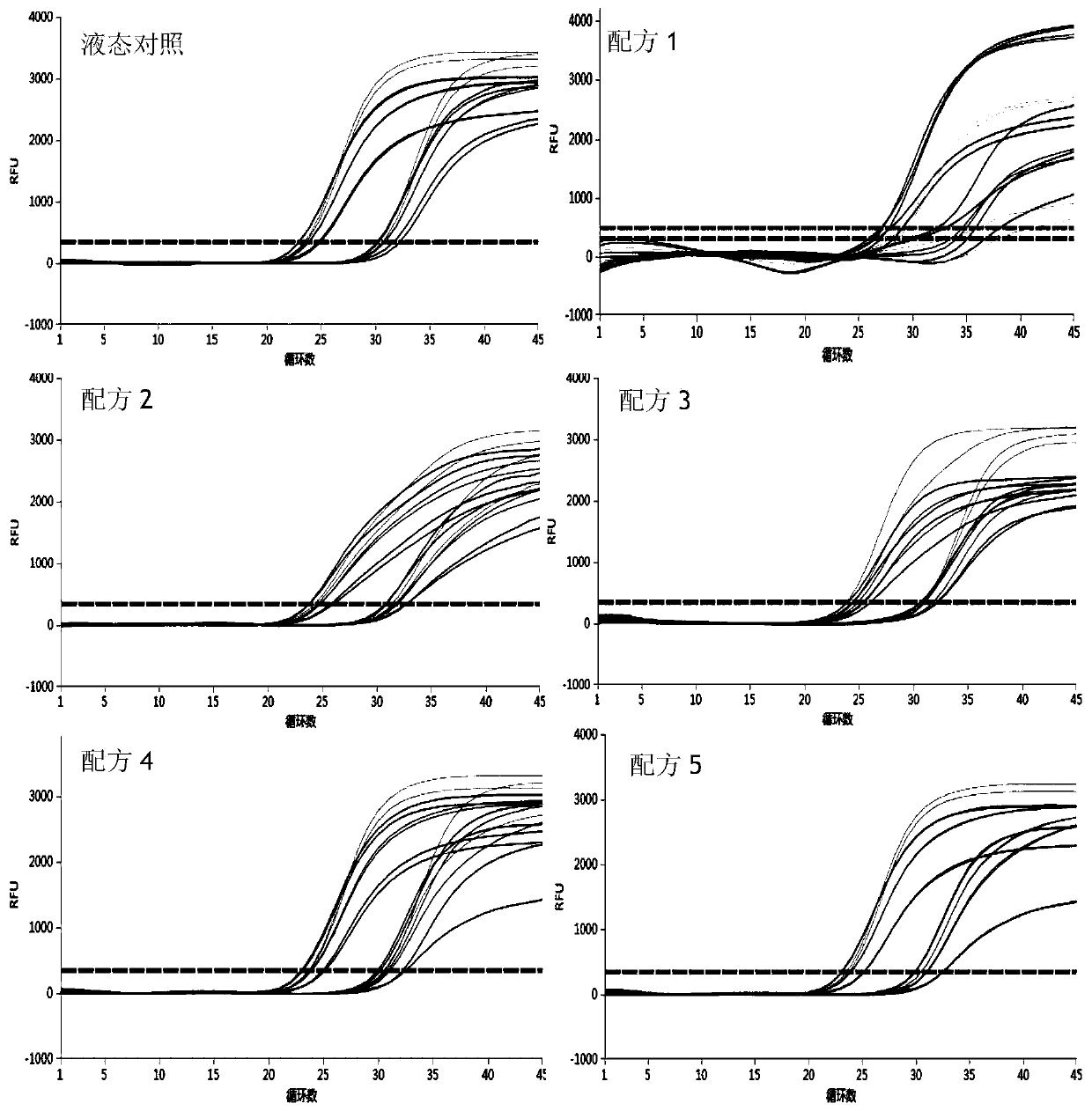

Multiplex fluorescent PCR universal freeze-drying protective agent and application thereof

PendingCN110923303ASimple ingredientsDoes not affect the amplification reactionMicrobiological testing/measurementFreeze-dryingPolyethylene glycol

The invention discloses a multiplex fluorescent PCR universal freeze-drying protective agent and an application thereof. The freeze-drying protective agent consists of 0.3-0.6M of trehalose, 0.001-0.004M of polyethylene glycol 8000, 0.02-0.08M of mannitol and the balance of purified water. The multiplex PCR universal freeze-drying protective agent disclosed by the invention can exert effects of aprotective agent and an excipient in a freeze-drying process of a multiplex PCR reagent, and the added protective agent has simple components and does not influence an amplification reaction of the multiplex PCR. After the freeze-drying protective agent is used for freeze-drying, appearance is smooth, hygroscopic performance is low, performance change of the multiplex PCR reagent before and afterfreeze-drying is small, and stability of a freeze-dried product is good. A preferred freeze-drying procedure has high adaptability and can be applied to various glycerol-free enzyme reaction systems under adoption of the freeze-drying protective agent provided by the invention.

Owner:苏州天隆生物科技有限公司

Wave absorber

InactiveUS7777664B2Little change in performanceAvoid failureMagnetic/electric field screeningIndividually energised antenna arraysUltrasound attenuationTriazine

A wave absorber of the present invention includes a sequentially laminated structure including an conductor layer (11) made of a conductive material; a first dielectric layer (polycarbonate substrate (12) and bismaleimide-triazine substrate (13)) made of one layer or a multilayer of a dielectric material; and a patterned layer (14) including a plurality of a pattern made of the conductive material, wherein the conductor layer, the first dielectric layer, and the patterned layer are laminated sequentially, and each pattern in the patterned layer (14) is different from other adjacent patterns with respect to at least one of size and shape. Therefore, the wave absorber has sufficient reflection-attenuating capability to prevent communication failure caused by a reflection of a radio wave and so on, can be thin-sized and reduced in weight, and has a wide-band attenuation property.

Owner:MITSUBISHI GAS CHEM CO INC

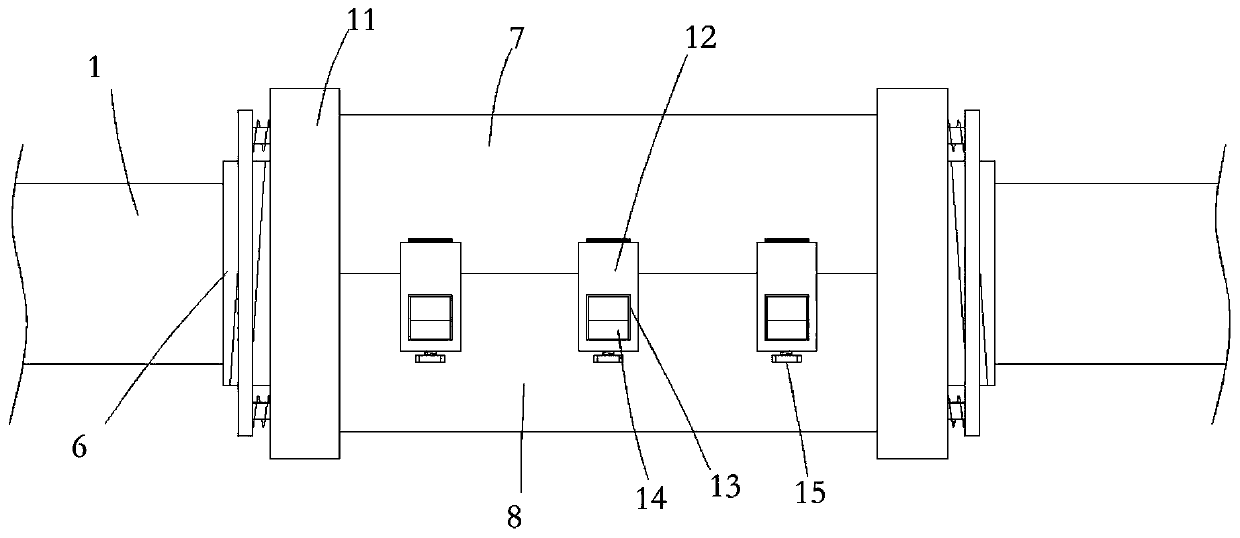

Flame-retardant cable

InactiveCN103886980AImprove fire resistanceImprove stabilityInsulated cablesPower cablesElectrical conductorEngineering

The invention relates to a flame-retardant cable which comprises conductors and insulating layers. The insulating layers are wrapped outside the conductors to form wire cores. The space outside the wire cores and the space between the wire cores are filled with filling layers, and the filling layers and the wire cores are twisted to form a cable core; an inner protective sleeve is arranged outside the cable core in an extruded mode; a first flame-retardant layer, a first armor layer, a second flame-retardant layer, a second armor layer and an outer protective sleeve are sequentially wrapped outside the inner protective sleeve from inside to outside. The flame-retardant cable has the advantages of being reasonable in structural design, good in flame retardance and the like; arrangement is achieved according to an alternate structure, the first flame-retardant layer is protected by the first armor layer, the second flame-retardant layer is protected by the first armor layer and the second armor layer, and therefore the internal structure of the cable can be effectively prevented from damage in the actual transportation and cable erection process, the use performance of the first flame-retardant layer and the second flame-retardant layer is ensured, the flame retardance characteristic of the cable itself can be ensured, and the service life of the cable is prolonged.

Owner:ANHUI XINGFU ELECTRIC APPLIANCES & CABLES

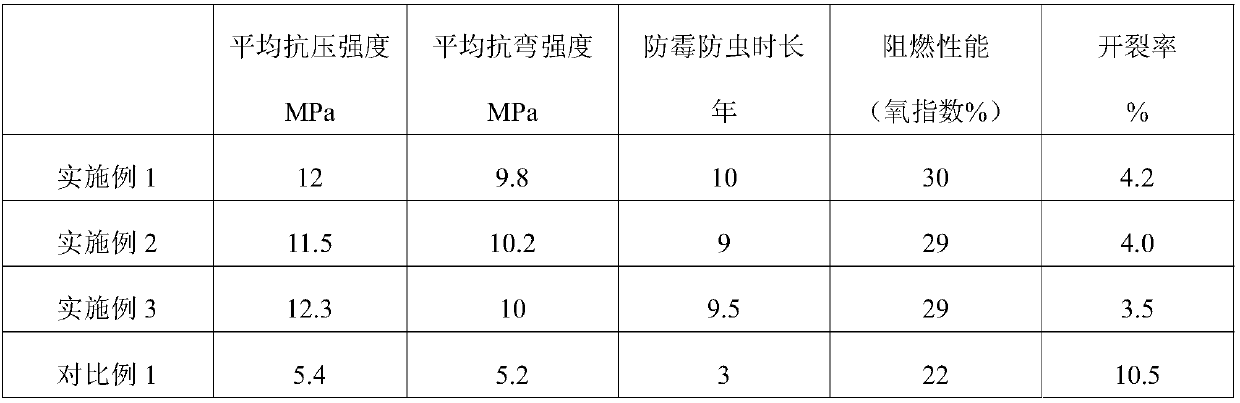

Treatment method of rattan for rattan-woven product

InactiveCN107932671AImprove toughnessEasy to manufactureWood treatment detailsReed/straw treatmentDisinfectantMedicine

The invention provides a treatment method of rattan for a rattan-woven product, and relates to the technical field of rattan-woven product processing. The treatment method comprises the following steps of pretreatment, disinfection treatment, fermentation treatment, toughening treatment, moistureproof and flame-retardant treatment and drying. According to the treatment method of the rattan for therattan-woven product, special pretreatment liquid, a disinfectant, a toughener and a moistureproof agent are adopted to carry out the pretreatment, the disinfection treatment, the toughening treatment and the moistureproof treatment on the rattan correspondingly, so that the prepared rattan is good in toughness and is able to be used to manufacture the rattan-woven product better, and the prepared rattan-woven product has excellent mothproof, moldproof and flame-retardant effects.

Owner:荔浦庆祥竹木有限公司

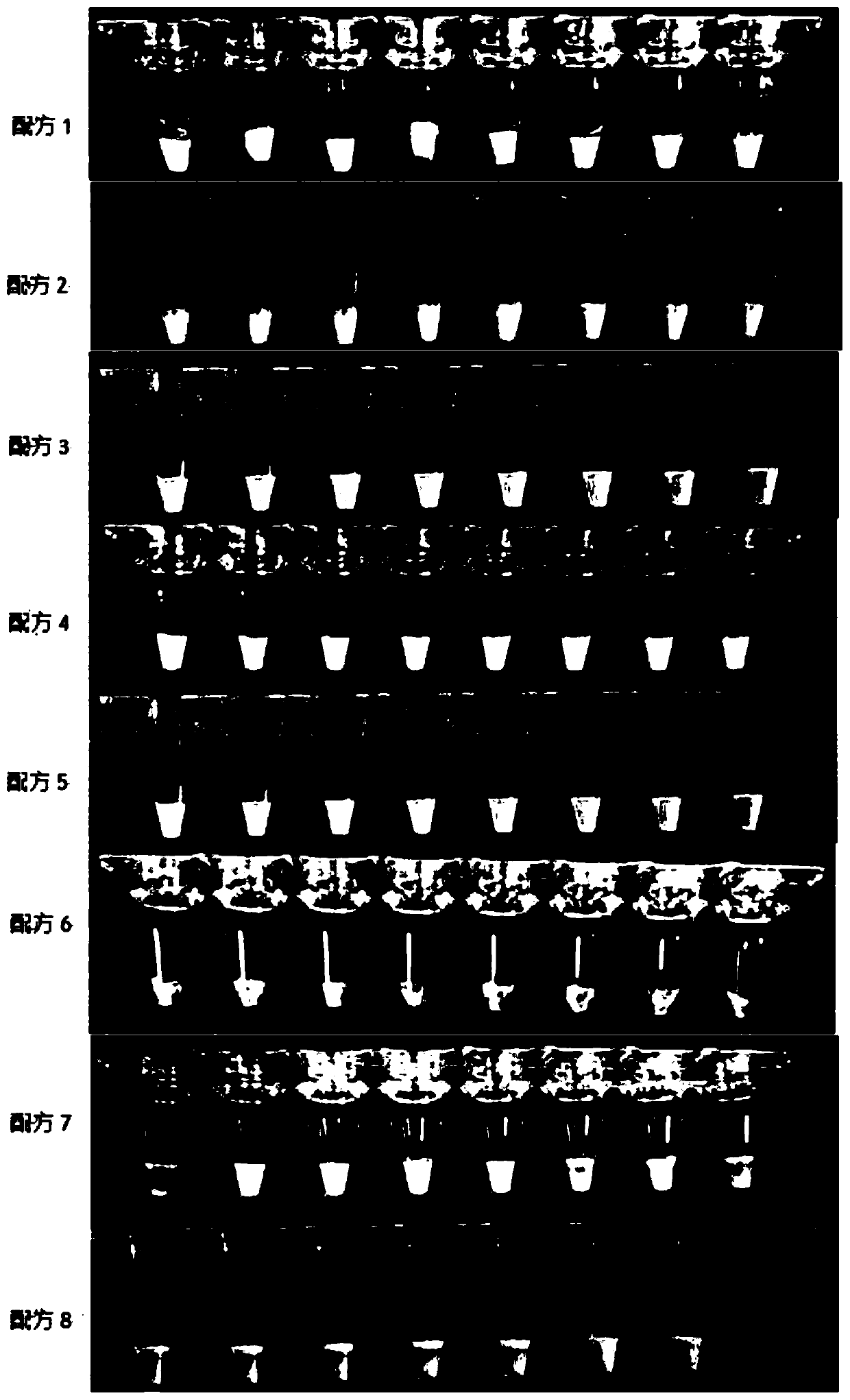

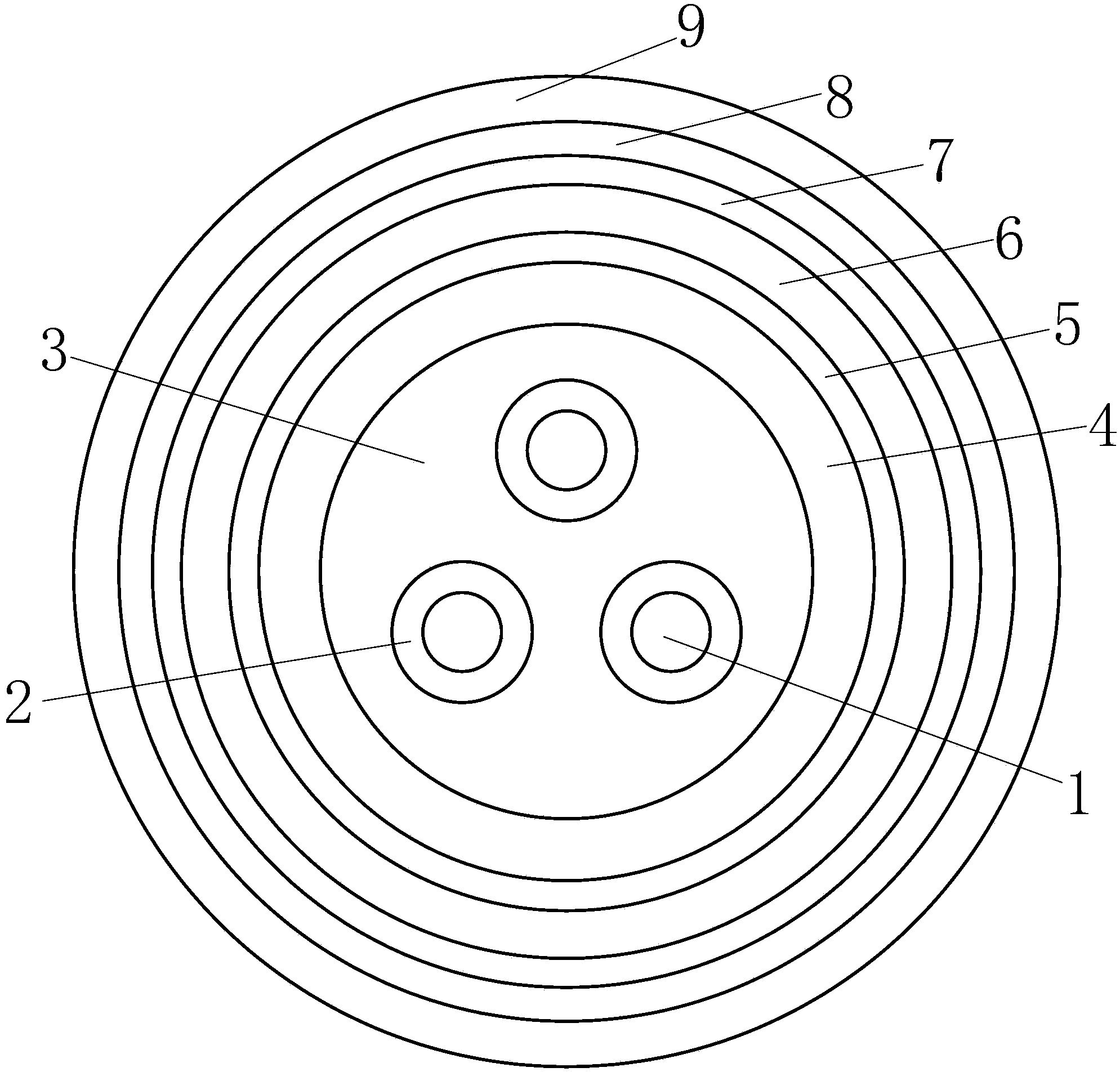

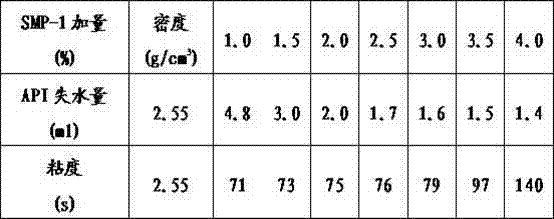

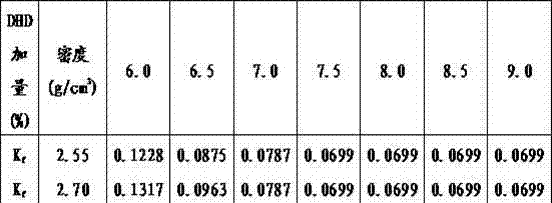

Ultrahigh-density water-base drilling fluid and preparation method thereof

InactiveCN102516955AIncrease the capacity limit of the solid phaseHigh densityDrilling compositionComposite electrolytePhysical chemistry

The invention discloses ultrahigh-density water-base drilling fluid and a preparation method thereof. The preparation method of the ultrahigh-density water-base drilling fluid comprises the following steps that: (1) conventional barite is adopted as an exclusive weight material, so the density of the ultrahigh-density water-base drilling fluid reaches 2.55 to 2.70g / cm<3>, and the ultrahigh-density water-base drilling fluid comprises the following ingredients: clean water, humic acid fluid loss additive RSTF, sulfonated bitumen lubricant DHD, sulfonated phenolic resin fluod loss additive SMP-1, ferrochrome special thinner, sodium hydroxide (NaOH) and composite electrolyte; (2) basic formula of ultrahigh-density water-base drilling fluid with the density of 2.55 to 2.70g / cm<3> is determined through experiment; and (3) by changing the addition quantity of one processing agent in the basic formula, the influence of different addition quantity on the ultrahigh-density water-base drilling fluid performance is researched, so a best addition quantity range of the processing agent is obtained, and an achievement formula is finally obtained.

Owner:中国石油集团川庆钻探工程有限公司川西钻探公司

High-flame-retardant cable for oil platform

ActiveCN111540507AImprove flame retardant performanceIncrease ampacityCommunication cablesInsulated cablesThermodynamicsElectrical conductor

The invention relates to the technical field of cables, and discloses a high-flame-retardant petroleum platform cable. The cable comprises a cable body, and is characterized in that the cable body comprises conductors located in the middle, a wrapping layer is connected outside each conductor in a wrapping manner, an insulating layer is coated outside a plurality of conductors, and an outer sheathis coated outside the insulating layer. The high-flame-retardant cable for the oil platform has the advantages that the whole cable is environmentally friendly, high in flame retardance, high in mechanical performance, and resistant to mud, oil and cold.

Owner:ANHUI CABLE

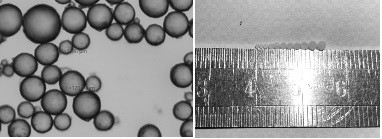

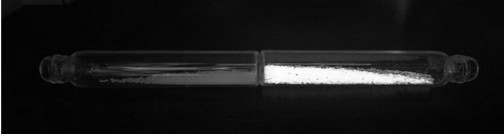

Plastic scintillator microsphere, preparation method and application

PendingCN113671555AShort decay timeImprove physical stabilityX/gamma/cosmic radiation measurmentMicroballoon preparationMeth-Microsphere

The invention discloses a plastic scintillator microsphere applicable to the field of nuclear detection, and a preparation method and application thereof. The scintillator resin components comprise a matrix material, a scintillating substance and a wave shifter, the particle size of the plastic scintillator microsphere is smaller than or equal to 1mm, and more specifically, the matrix material of the plastic scintillator microsphere is formed by polymerizing an unsaturated matrix monomer containing an active group, and the matrix monomer is styrene or vinyl toluene. The scintillating substance is 2, 5-diphenyl oxazole, and the wave shifter is 1, 4-bis (5-phenyl oxazole) benzene or-bis-(sigma-methyl styryl) benzene. The microspheres disclosed by the invention have very good physical and chemical stability, and have the advantages of low raw material price, wide raw material source, simple and convenient preparation method and the like. The plastic scintillator provided by the invention can be applied to continuous monitoring of radioactivity of a solution, or can be applied to preparation of a liquid scintillation spectrometer.

Owner:LANZHOU UNIVERSITY

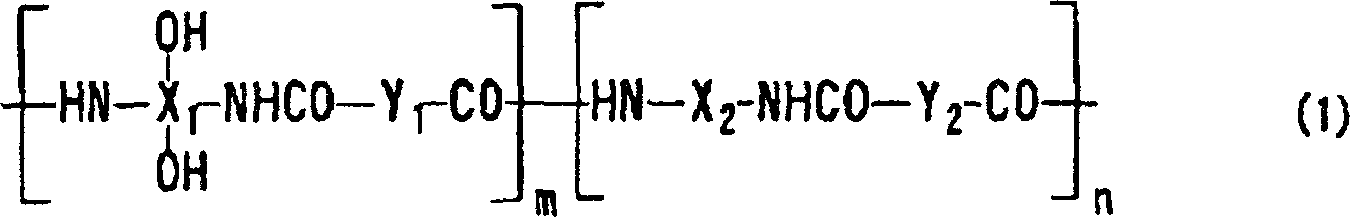

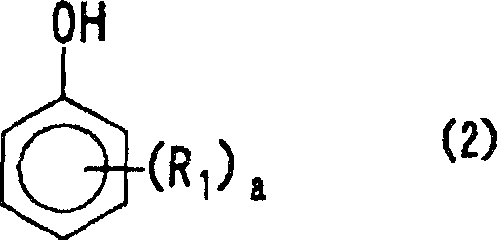

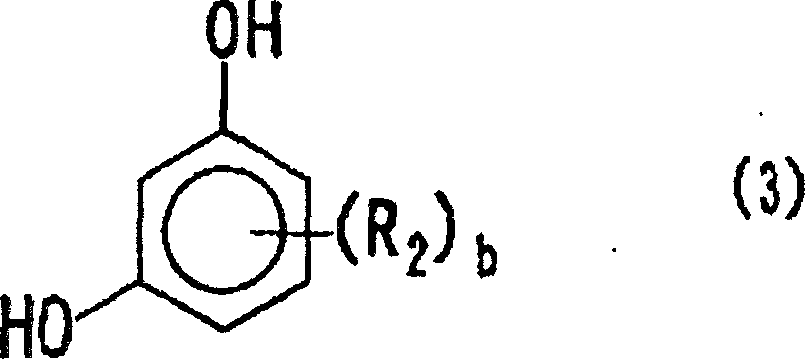

Novel phosphorus-containing thermotropic liquid crystal copolyester and preparation method and application thereof

InactiveCN102585188ALittle change in performanceSimple methodLiquid crystal compositionsSide chainPhenol

Phosphorus-containing thermotropic liquid crystal copolyester is formed by polycondensation synthesis of composite binary chloride and phosphorus-containing phenols monomers in solution by using an acyl chloride method. A main chain of the phosphorus-containing thermotropic liquid crystal copolyester is provided with a mesomorphic unit, and a side chain comprises an antiflaming element phosphorus. The novel aromatic thermotropic liquid crystal copolyester does not only have excellent performance of thermotropic liquid crystals, but also has a certain antiflaming effect simultaneously. The phosphorus-containing thermotropic liquid crystal copolyester can be applied to acrylonitrile butadiene styrene (ABS) resin to prepare ABS-enhanced composite materials of phosphorus-containing thermotropic liquid crystal copolyester. The composite materials have good mechanical properties, thermal stability properties and antiflaming effects.

Owner:DALIAN POLYTECHNIC UNIVERSITY

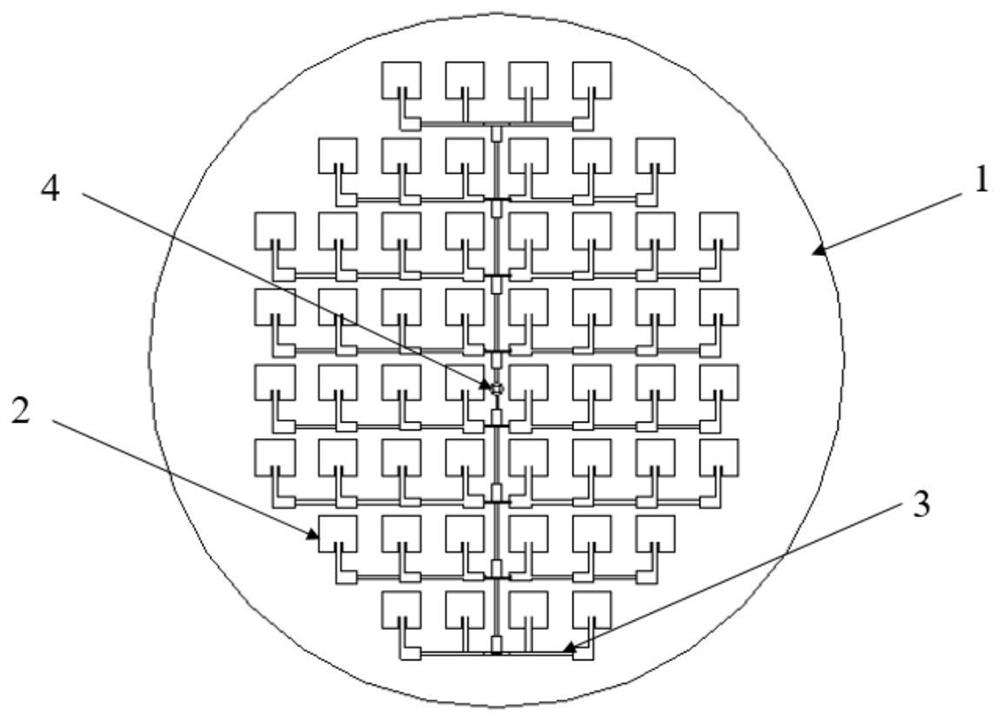

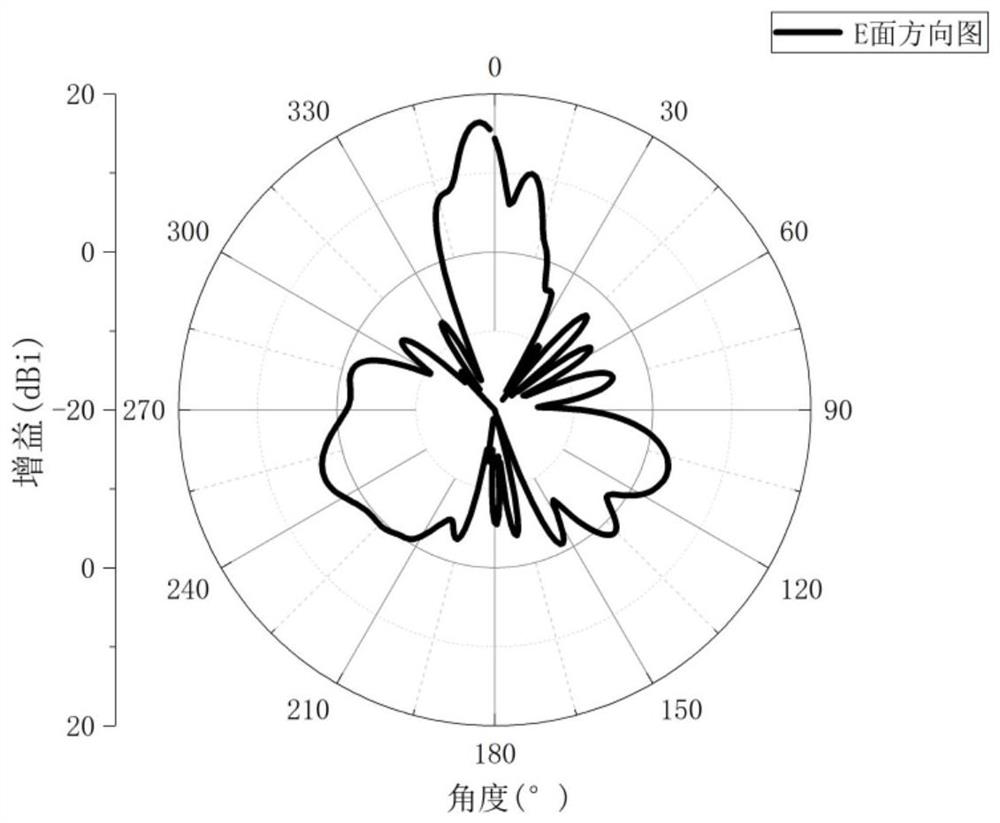

Millimeter wave flexible circular antenna array

PendingCN112467398ALittle change in performanceImprove performanceIndividually energised antenna arraysDielectric substrateEngineering

The invention discloses a millimeter wave flexible circular antenna array, and the antenna array comprises a flexible dielectric substrate; an antenna array is arranged on the flexible dielectric substrate, the antenna array comprises a plurality of antenna units, the antenna units are connected through microstrip lines, the antenna array is symmetrically arranged along the axis of the flexible dielectric substrate, and a metal circular hole is formed in the center of the antenna array. The millimeter wave flexible circular antenna array structure is light in weight and small in size, the bendability of the antenna is improved on the premise of ensuring the performance of the antenna array, and the conformality between the antenna and equipment is good.

Owner:NANJING UNIV OF POSTS & TELECOMM

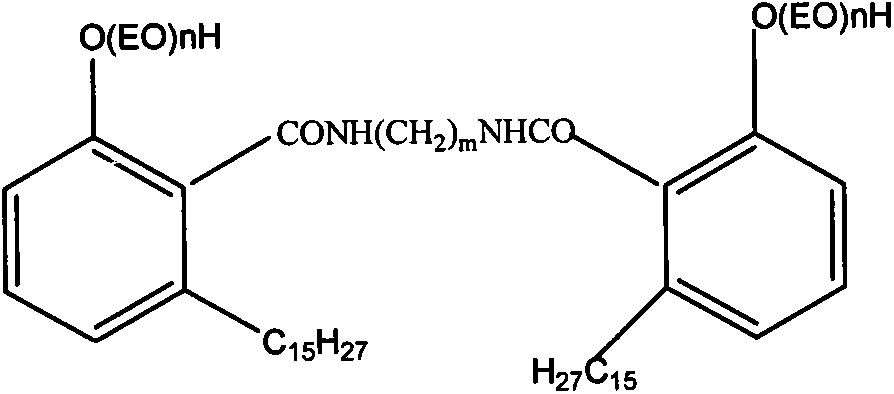

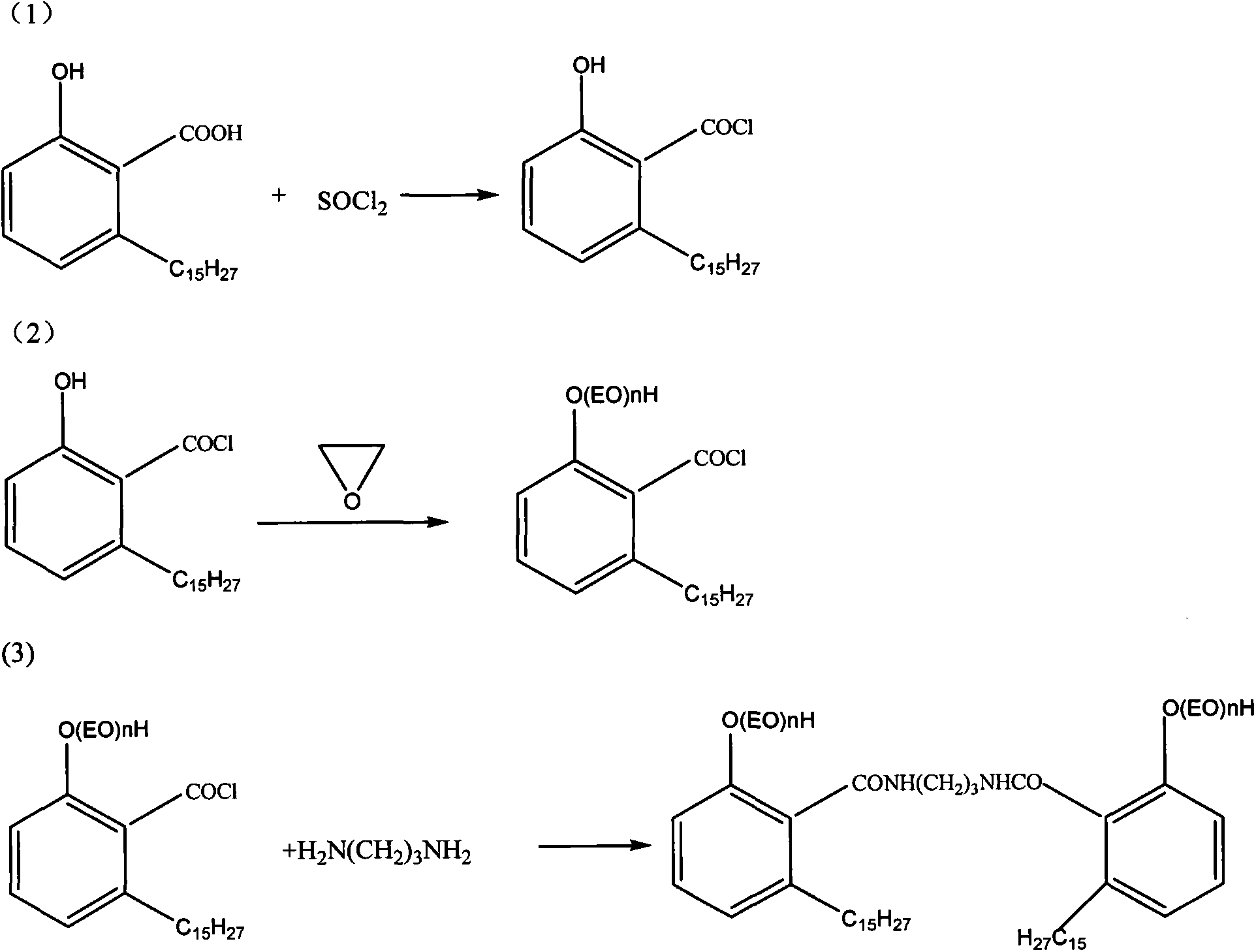

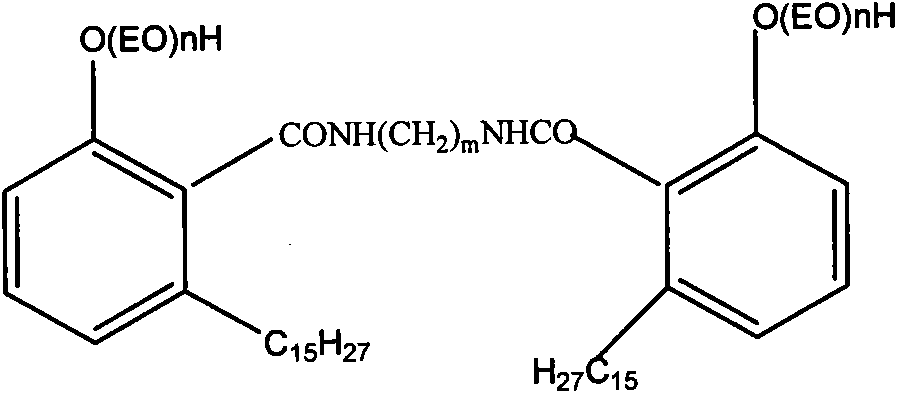

Cashew nut based amide surfactant and preparation method thereof

InactiveCN103752209AReduce surface tensionNo cloud pointOrganic compound preparationTransportation and packagingDiamineChemistry

The invention discloses a cashew nut based amide surfactant and a preparation method thereof. The cashew nut based amide surfactant is prepared by the following steps: (1) carrying out reaction on cashew nut acid and an acylation agent to obtain (2-hydroxy-5-pentadecyl) benzoyl chloride; (2) carrying out reaction on the (2-hydroxy-5-pentadecyl) benzoyl chloride and ethylene oxide, and introducing an ethylene oxide hydrophilic group on hydroxyl to obtain (2-hydroxy ether-5-pentadecyl) benzoyl chloride; and (3) carrying out reaction on the product obtained in the step (2) and diamine to obtain the cashew nut based amide surfactant. The cashew nut based amide surfactant has the action of well lowering the surface tension of a water phase system, does not have cloud points, is excellent in salt resistance, emulsifying performance and detergency ability and can be widely applied to the industry and daily use chemical fields as a detergent, an emulsifier and the like. The preparation method disclosed by the invention is simple in the process, high in the yield and easy to operate.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

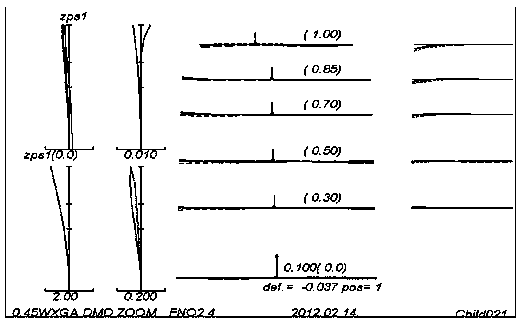

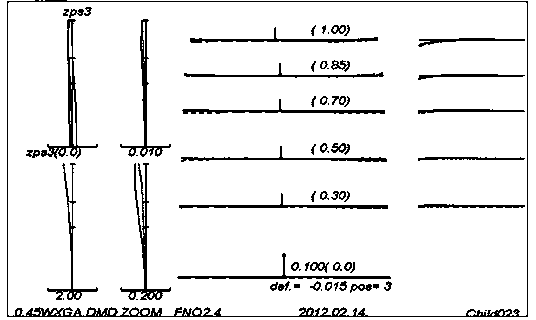

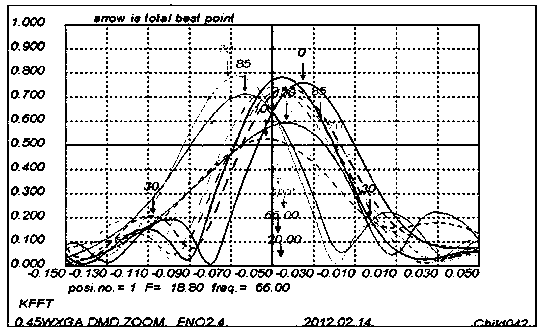

Zoom projection lens

InactiveCN103454756AReduce chromatic aberration of magnificationImprove image qualityLensCamera lensImaging quality

The invention discloses a zoom projection lens which is used for a digital light processing (DLP) projector. The zoom projection lens comprises a first lens group arranged on the object side and a second lens group arranged on the image side. The first lens group comprises a first lens, a second lens and a third lens. The second lens group comprises a fourth lens, a fifth lens, a sixth lens, a seventh lens, an eighth lens, a ninth lens and a tenth lens. The ten lenses are sequentially arranged from the object side to the image side and are all spherical lenses made of glass materials. The zoom projection lens is high in imaging quality, low in cost, small in size, small in performance change along with temperature, simple in structure, low in sensitivity and high in mass production.

Owner:SUZHOU CHINONTEC IND INC

Curing production process of ultracrystalline iron core for current transformer

InactiveCN112151257ALittle change in performanceHigh hardnessTransformersInductancesFirming agentPolymer chemistry

The invention discloses a curing production process of an ultracrystalline iron core for a current transformer, and relates to the technical field of curing production of the ultracrystalline iron core for the current transformer. The curing production process of the ultracrystalline iron core for the current transformer comprises the following steps of S1, mixing and configuring; S2, processing the ultracrystalline iron core; S3, drying, curing and forming; and S4, carrying out secondary curing. According to the curing production process of the ultracrystalline iron core for the current transformer, a production process is cured, epoxy resin pouring sealant is used as a raw material, the epoxy resin pouring sealant is uniformly stirred after being mixed in proportion, a mixed glue solution is obtained, the ultracrystalline iron core subjected to heat treatment and paint dipping is brushed, the iron core is placed in a constant-temperature drying box to be heated for curing and shaping, and a silicone grease transparent curing agent is used for secondary curing so that the hardness of the iron core is obviously improved, a performance change of a mutual inductor after pouring is reduced, the installation of a protection box is replaced, and the cost is reduced.

Owner:南通巨升非晶科技股份有限公司

A kind of silicon carbide and silicon particle reinforced aluminum-copper matrix composite material and preparation method thereof

The invention relates to a silicon carbide and silicon particle reinforced aluminum-copper based composite material and a preparation method thereof, and belongs to the field of the particle reinforced metal based composite material. The composite material is composed of the components by the weight percentage: 15-25 wt.% of silicon carbide, 45-50 wt.% of silicon and 25-40wt.% of an aluminum-copper alloy; the silicon carbide and silicon particles as a reinforcement phase are uniformly distributed in the aluminum-copper alloy matrix, and the aluminum-copper alloy matrix forms a three-dimensional reticular structure. A powder metallurgy method is used for preparation. The obtained aluminum based composite material has uniform structure, is fully dense, has the comprehensive performance of light weight, low expansion, high modulus, high strength, resistance to space radiation environment, easy processing and the like, is suitable for use in space environments, and can be used as related component materials in the aviation and aerospace fields.

Owner:有研金属复材技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com