Treatment method of rattan for rattan-woven product

A treatment method, rattan technology, applied in wood treatment, wood treatment details, reed/straw treatment, etc., can solve the problems of appearance impact, easy occurrence of moths, and influence on normal use, etc., to achieve enhanced anti-corrosion ability and good anti-mildew effect , good anti-moth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

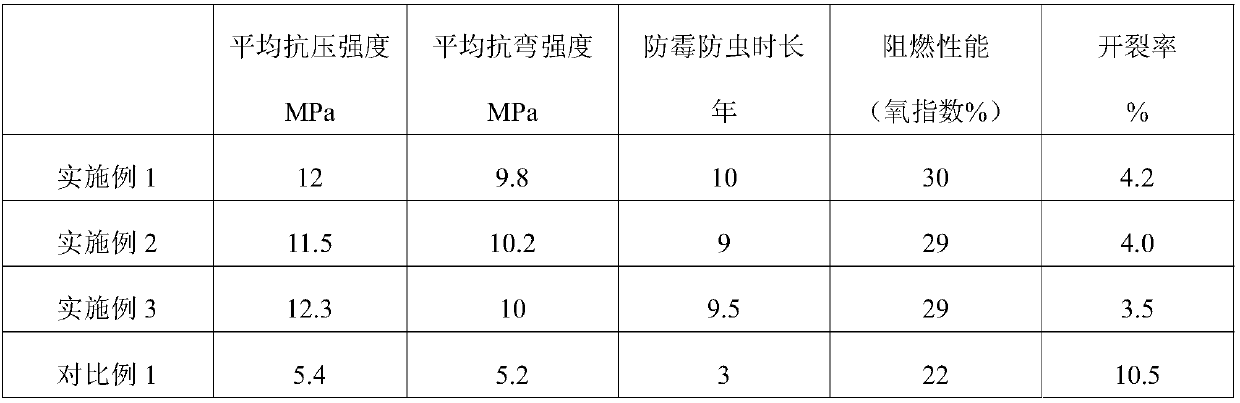

Examples

Embodiment 1

[0031] A processing method of rattan for rattan weaving, comprising the following steps:

[0032] S1. Pretreatment: Select rattans that are intact and free of moths, remove the leaves of the rattans, wash with water to remove impurities, then put them into the pretreatment solution, heat to 90-95°C and cook for 20 minutes, take them out and remove the rattans Skin, rinse with clean water and set aside.

[0033] The pretreatment liquid includes: citric acid 6%, potassium permanganate 1%, trisodium phosphate 2%, and the rest is water.

[0034] S2. Disinfection treatment: put the pretreated rattan into 10% salt water at a temperature of 30-40° C., soak for 2 hours, and then soak in disinfectant solution for 3 hours.

[0035] The disinfectant is prepared by boiling the following Chinese herbal medicines in parts by weight: 3 parts of Rosa rosae, 5 parts of clove, 5 parts of Hedyotis diffusa, 5 parts of Andrographis paniculata, 2 parts of Houttuynia cordata, 2 parts of wild chrysa...

Embodiment 2

[0044] A processing method of rattan for rattan weaving, comprising the following steps:

[0045] S1. Pretreatment: Select rattans that are intact and free of moths, remove the leaves of the rattans, wash with water to remove impurities, then put them into the pretreatment solution, heat to 90-95°C and cook for 15 minutes, take them out and remove the rattans Skin, rinse with clean water and set aside.

[0046] The pretreatment solution includes: 8% citric acid, 2% potassium permanganate, 1% trisodium phosphate, and the rest is water.

[0047] S2. Disinfection treatment: put the pretreated rattan into 12% salt water at a temperature of 30-40° C., soak for 1 hour, and then soak in disinfectant solution for 4 hours.

[0048] The disinfectant is prepared by boiling the following Chinese herbal medicines in parts by weight: 5 parts of Rosa laevigata, 1 part of clove, 5 parts of Hedyotis diffusa, 8 parts of Andrographis paniculata, 1 part of Houttuynia cordata, 5 parts of wild chr...

Embodiment 3

[0057] A processing method of rattan for rattan weaving, comprising the following steps:

[0058] S1. Pretreatment: Select rattans that are intact and free of moths, remove the leaves of the rattans, wash with water to remove impurities, then put them into the pretreatment solution, heat to 90-95°C and cook for 15 minutes, take them out and remove the rattans Skin, rinse with clean water and set aside.

[0059] The pretreatment solution includes: 5% citric acid, 3% potassium permanganate, 3% trisodium phosphate, and the rest is water.

[0060] S2. Disinfection treatment: put the pretreated rattan into 5% salt water at a temperature of 30-40° C., soak for 2 hours, and then soak in disinfectant solution for 2 hours.

[0061] The disinfectant is prepared by boiling the following Chinese herbal medicines in parts by weight: 2 parts of golden cherry, 2 parts of clove, 5 parts of Hedyotis diffusa, 5 parts of Andrographis paniculata, 2 parts of Houttuynia cordata, 3 parts of wild ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com