Patents

Literature

1762results about How to "Improve mildew resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zeolite colored coating powder having air-purifying function

InactiveCN105272114ASolving difficult-to-disperse reunionsImprove the bactericidal effectPorosityPyrophosphate

The invention discloses zeolite colored coating powder having an air-purifying function. According to the technical scheme, the zeolite colored coating powder having the air-purifying function is characterized in that ingredients include attapulgite pottery clay powder having the air-purifying function, acidified zeolite particles, colored portland cement, Paris plaster, white carbon black, calcium chloride, aerosil, expanded perlite, nanometer silver-loaded antibacterial powder, nanometer titanium dioxide, sodium pyrophosphate and powder defoaming agents. The ingredients of the zeolite colored coating powder having the air-purifying function are input three times into a stirring machine to be stirred evenly and packaged into the finished product. By the adoption of the colored coating, in indoor wall decoration, an artistic emboss effect of various embossed three-dimensional colored patterns can be achieved through spraying and manufacturing, after spraying, a coating is hard, the porosity is high, the specific surface area is large, adhesion is strong, indoor formaldehyde, ammonia nitrogen, benzene and other harmful substances can be adsorbed and decomposed, and the functions of automatic humidification, mould prevention, sterilization, deodorization and air purification are achieved.

Owner:蒋文兰

Nano-silica sol-modified outer wall paint and preparation method thereof

The invention discloses nano-silica sol-modified outer wall paint and a preparation method thereof. The nano-silica sol-modified outer wall paint comprises, by weight, 10-25% of nano-silica sol, 0.1-0.2% of a coupling agent, 0.2-2.0% of a neutralizer, 10-30% of an acrylic emulsion or a styrene-acrylic emulsion, 10-15% of a pigment, 10-20% of a filler, 0.2-0.4% of a dispersant, 0.2-0.4% of a wetting agent, 0.3-2.0% of a thickening agent, 0.2-0.4% of an antifoaming agent, 0.4-0.6% of a mildew-resistant antiseptic, 0.6-1.4% of an antifreezing agent, 0.4-1.2% of a film forming assistant and 20-30% of deionized water. The invention also provides the preparation method of the nano-silica sol-modified outer wall paint. The nano-silica sol-modified outer wall paint has good storage stability and can form a paint film which does not effloresce and fall off easily, has good permeability, does not mildew easily, and has excellent water resistance and alkali resistance.

Owner:CHANGSHA UNIVERSITY

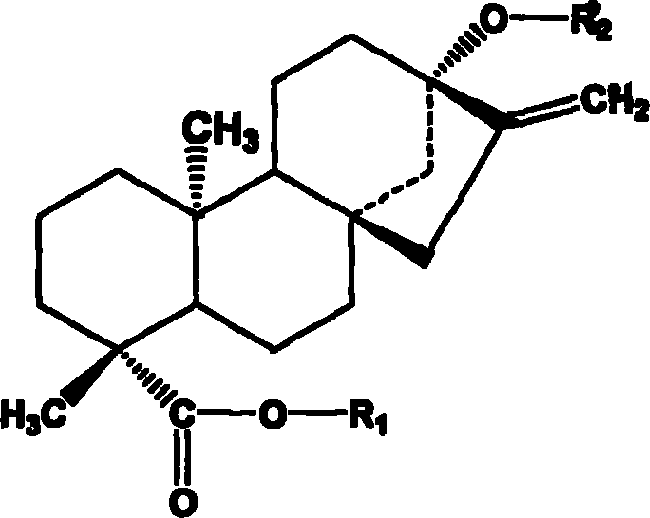

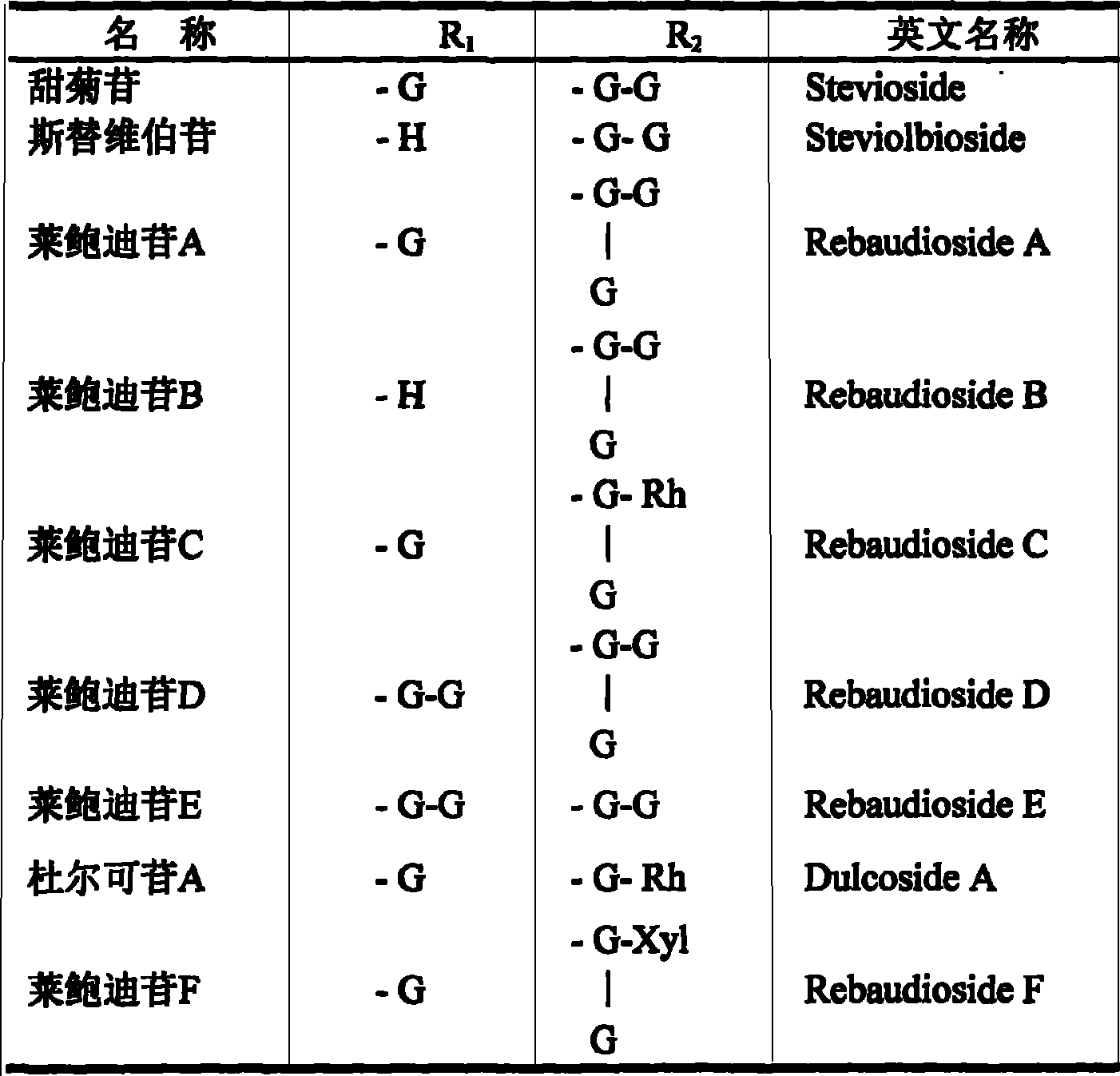

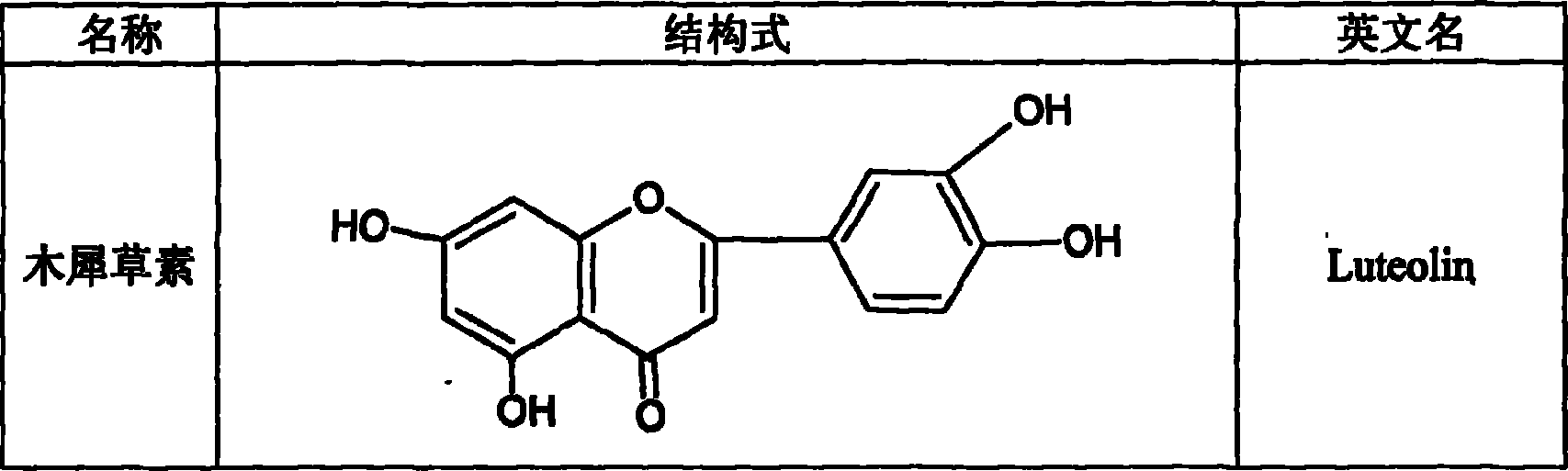

Method for preparing stevia whole stevioside and stevia whole flavone at the same time

ActiveCN101062077AImprove mildew resistanceConducive to food preservationSugar derivativesMetabolism disorderLuteolinGlucoside

The invention discloses a preparing method of total sweet chrysanthemum glycosides and total chromocor in sweet leaf chrysanthemum, which is characterized by the following: comprising sweet chrysanthemum glycosides, stevi primary glycosides, labroid glycosides A, B, C, D, E, F, duacl glycosides A and so on in total sweet chrysanthemum glycosides; comprising cyanidenon, meletin, cyanidenon-7-0-beta-D glycosides, celery element-7-0-beta-D-glycosides, quercetin, meletin-3-0-beta-D-arabinoside, meletin-3-0-[4-0-trans-coffe acyl-alpha-L-isodulcitol-(1-6)-beta-D-arabinoside] and so on; choosing one or several methods from solvent extraction, solvent extraction process, macroreticular absorption resin method, column chromatography, supercritical fluid chromatography, liquid-liquid counter-current partition chromatography and so on; extracting the total chromocor; setting content of sweet chrysanthemum glycosides element in total sweet chrysanthemum glycosides at 5-100%; counting 5-100% of all sweet chrysanthemum glycosides content with sweet chrysanthemum glycosides and labroid glycosides; counting 5-100% of chromocor element in sweet leaf chrysanthemum total chromocor; counting 5-100% of all total chromocor content with cyanidenon-7-0-beta-D glycosides, quercetin and meletin-3-0-[4-0-trans-coffe acyl-alpha-L-isodulcitol-(1-6)-beta-D-arabinoside].

Owner:石任兵 +1

Preparation method of heat-not-burn reconstituted tobacco through roll-in method and application thereof

InactiveCN108065448AIncrease contentHigh in fiberTobacco preparationCigar manufactureFiberFood grade

The invention discloses a preparation method of heat-not-burn reconstituted tobacco through a roll-in method and application thereof. On the basis of a roll-in method technology, a technical method isimproved, the heat-not-burn reconstituted tobacco is prepared, the problem of high-proportion addition of a fogging agent is solved, and a food-grade adhesive is used for evenly dispersing and solidifying the fogging agent into a tobacco material; the content of the fogging agent of the prepared heat-not-burn reconstituted tobacco is increased, the heat-not-burn reconstituted tobacco is evenly distributed at the same time, the surface is not sticky, the fiber content is increased, the tensile strength is improved, the machining resistance is good, smoke is evenly released during smoking, thesensory effect is good, and the simulated feeling of cigarette smoking is good.

Owner:HUBEI CHINA TOBACCO IND

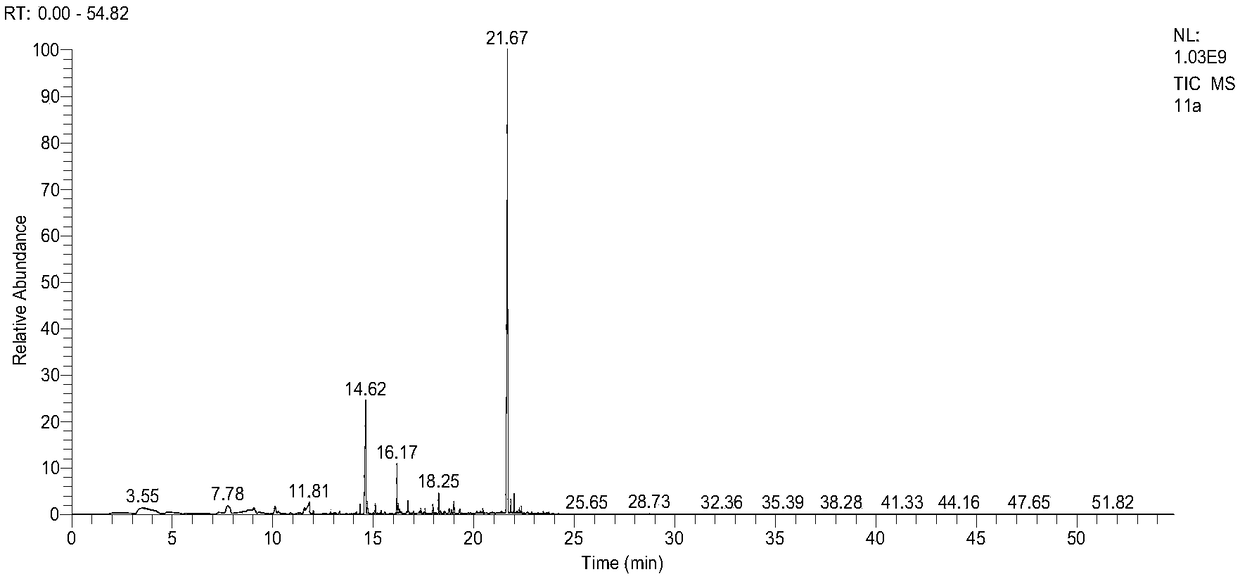

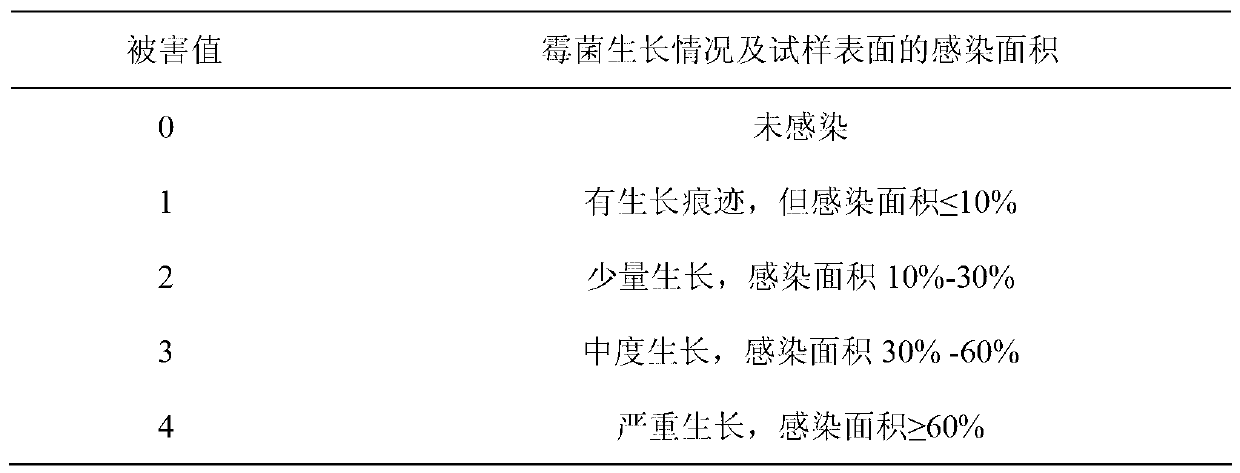

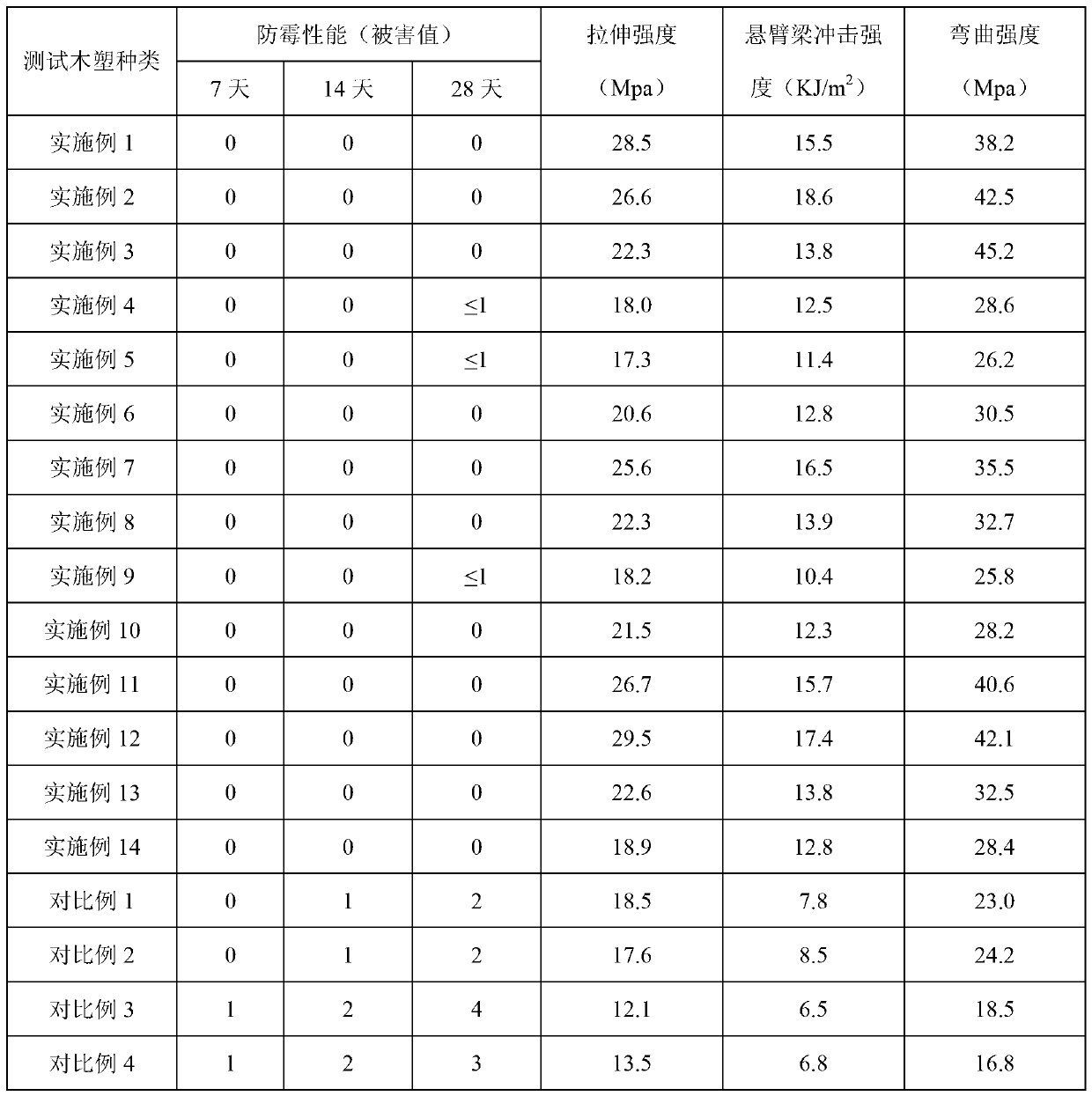

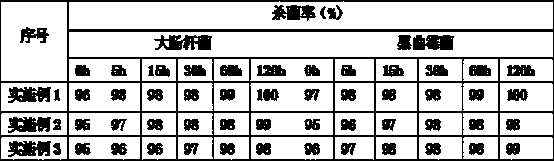

Environmentally-friendly mould-proofing wood-plastic composite material and preparation method thereof

ActiveCN103102591AImprove mildew resistanceImprove compatibility and interface affinityRevolutions per minuteCalcium carbonate

The invention discloses an environmentally-friendly mould-proofing wood-plastic composite material and a preparation method thereof. The preparation method comprises the following steps: mixing a plastic substrate, modified wood fiber powder, calcium carbonate, a lubricant, a light stabilizer, a toner and other components in parts by mass; adding the mixture to a high-speed mixer; uniformly stirring; mixing for 6 to 15 minutes at a high speed and at a temperature of 100-120 DEG C and a revolving speed of 700 to 100 revolutions per minute; cooling; discharging to obtain a premix; adding the premix to a parallel twin-screw machine to granulate and extrude, wherein the temperature is controlled to 150-185 DEG C, and screws are at a revolving speed of 280 to 320 revolutions per minute during granulating, the temperature is controlled to 155-190 DEG C, and the screws are at a revolving speed of 10 to 15 revolutions per minute during extruding; thus obtaining the environmentally-friendly mould-proofing wood-plastic composite material. The environmentally-friendly mould-proofing wood-plastic composite material is high in mould proofing performance and mechanical performance, and is environmentally-friendly.

Owner:GUANGDONG INST OF MICROBIOLOGY GUANGDONG DETECTION CENT OF MICROBIOLOGY

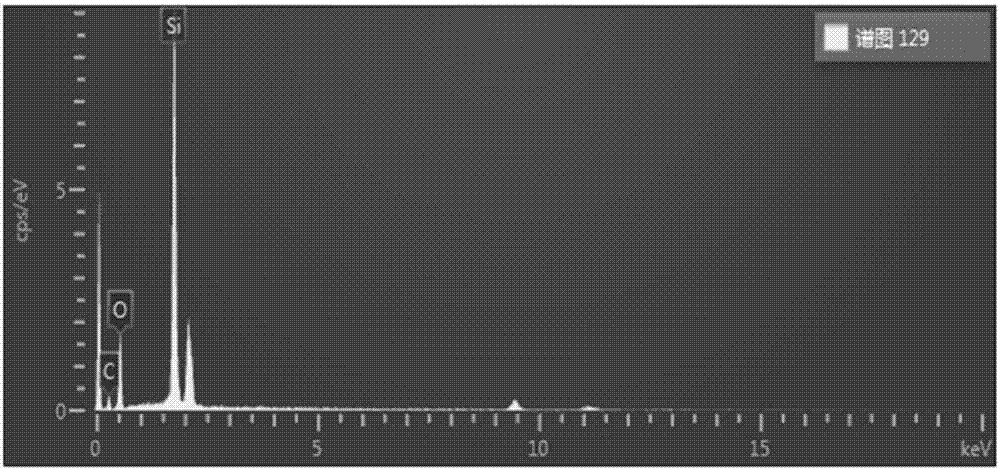

Environment-friendly water-based nano coating material used for concrete protection, and preparation method thereof

ActiveCN103275616AStable performanceGood environmental stabilityAntifouling/underwater paintsPaints with biocidesSilane couplingOrganosilicon

The invention provides an environment-friendly water-based nano coating material used for concrete protection, and a preparation method thereof. The environment-friendly water-based nano coating material comprises 15%-65% of an organic silane coupling agent, 0.5-10% of nano silica, 0.5-5% of nano titanium dioxide, 0.4%-4% of an organosilicon oligomer, 0.3%-3% of an emulsifier, 0.1%-0.6% of a bactericidal anti-algae agent, 0.01%-0.1% of a regulator, and the balance being deionized water. The environment-friendly water-based nano coating material used for the concrete protection takes advantages of a nanometer effect of nanoparticles and a hydrophobic effect of long-chain organosilicone coupling agent. The prepared environment-friendly water-based nano coating material used for the concrete protection has excellent protection performance.

Owner:江苏道成不锈钢管业有限公司

Antibacterial down feather and manufacturing method thereof

InactiveCN101611938APrevent mildew and insectsHigh antibacterial rateFibre treatmentDry-cleaning apparatus for textilesAntibacterial agentInflammation

The invention relates to an antibacterial down feather and a manufacturing method thereof. The manufacturing method comprises the steps of raw material stem removal, dust and sand removal, precise separation, washing, dehydration, drying, cooling and package, wherein an antibacterial agent comprises the following components in portion by weight: 6 to 10 portions of quaternary ammonium salt A, 1 to 2 portions of modified chitosan, 0.2 to 0.5 portion of silane coupling agent, 0.1 to 0.5 portion of solubilizing agent, and 0.3 to 0.6 portion of dispersing agent. The antibacterial down feather can effectively prevent mildew and attack of insects of the down feather in storage, transportation and use, and particularly when the antibacterial down feather serves as a filling material and is manufactured into articles for daily use, because of the antibacterial and bacteriostatic functions, the corresponding products have obvious functions of resisting bacteria, diminishing inflammation, deodorizing, resisting mildew, relieving itching and converging, and have no stimulation to skins, and the antibacterial rate of the obtained down feather to staphylococcus aureus bacteria reaches up to 99 percent, and after 10 times of washing, the antibacterial rate still reaches 92 percent.

Owner:凌颖

High strong adhesive and method for preparing same

The powerful adhesive includes neoprene, grafting monomer, thickener, dispersant, adhesion promoter, catalyst, antioxidant, solvent, stuffing, etc. The present invention also discloses the preparation process of the adhesive, and the preparation includes introducing grafting monomer to neoprene molecule chain to raise the adhesion strength, selecting proper adhesion promoting resin to increase the initial adhesion force, and adopting mixed solvent to form high adhering performance. The adhesive has high solid content and excellent environment protecting performance, and has also excellent antiageing performance, high resistance to heat, oil, chemical and corrosion, high weather resistance, good mildew-proof performance, antibiotic performance, etc. and may be used for adhering timber, concrete, rubber, metal, gypsum board, brick and other building material.

Owner:GUANGZHOU GLORYSTAR CHEM

Multifunctional green environmental protection type nanometer paint

The multifunctional green nano paint consists of mainly: quaternary methacrylic acid-butyl acrylate-styrene-methyl methacrylate copolymer emulsion 20-65 wt%; nano titania 0.3-5 wt%; nano zinc oxide 0.2-3 wt%; silica 0.3-3 wt%; nano calcium carbonate 0.5-5 wt%; deionized water 3-12 wt%; superfine talcum powder 1-3 wt%; superfine calcium carbonate 3-15 wt%; titanium white3-25 wt%; and assistants including dispersant, wetter, rheologic agent, thickener, color paste, defoaming agent, etc. 2-12 wt%. The paint of the present invention features no toxicity, no pollution, wash resistance, scratching resistance, ultraviolet resistance, ageing resistance, waterproofing and mould proofing as well as self-cleaning function, so that the paint may be used wide in the decoration of inner and outer walls and the anticorrosive treatment of metal material surface.

Owner:王崇高

Inorganic silicate coating, preparation method thereof and application of coating

InactiveCN109575659AImprove mildew resistanceNever fall offFireproof paintsAntifouling/underwater paintsCelluloseEmulsion

The invention relates to the technical field of coatings for inner walls and outer walls of buildings, in particular to an inorganic silicate coating, a preparation method thereof and an application of the coating. The inorganic silicate coating is prepared from, by weight, 18-30 parts of deionized water, 0.1-0.8 part of cellulose, 0.5-1.5 parts of dispersing agents, 0.01-1.0 part of wetting agents, 0.01-1.0 part of defoaming agents, 10-20 parts of titanium dioxide, 10-20 parts of ground calcium carbonate, 10-20 parts of talcum powder, 5-10 parts of emulsion, 20-30 parts of modified potassiumsilicate, 0.01-5 parts of stabilizing agents and 0.01-5 parts of hydrophobic agents. The modified potassium silicate is selected from one or more of VB-2837 and INOCOT 955 or K-2837, and the emulsionis selected form one or more of styrene-acrylic ester and pure acrylic emulsion. The coating reaches the standard without a detected VOC (volatile organic compound) and good in fungus resistant and falling-off prevention performances.

Owner:北京莱恩斯新材料科技有限公司

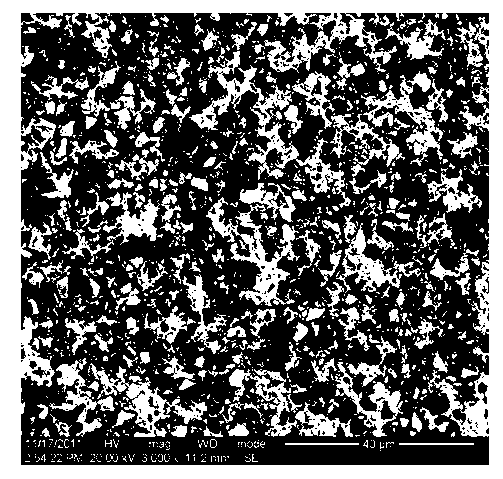

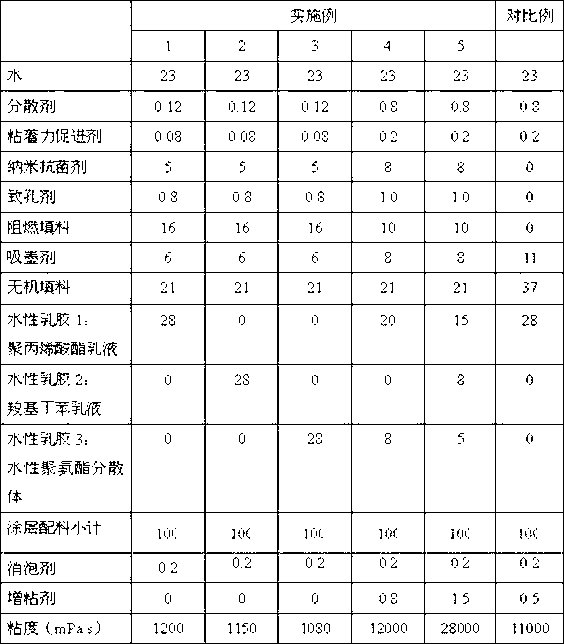

Method for preparing novel environment-friendly wallpaper based on high-filling synthetic paper

InactiveCN103015655ABreathableImprove mildew resistanceCovering/liningsAntifouling/underwater paintsPlasticizerVolatile substance

The invention relates to a method for preparing a piece of novel environment-friendly wallpaper by a high-filling synthetic paper. The high-filling composite paper (also known as a replaceable plant fiber paper) is used as a base material, a coating material is coated on the base material to form a transparent coating, the coating material contains a water emulsion, a nano antibacterial, a pore-foaming agent, a flame retardant filler, an ink absorbing agent and the like, and a novel environment-friendly wallpaper with the waterproof, ventilating, mildewproof and flame retardant performances is manufactured by rotary screen, flat screen and gravure printing methods. Compared with the PVC (polyvinyl chloride) wallpaper, the novel environment-friendly wallpaper has the advantage that the coating and the printing are carried out at low temperature, the temperature is lower than 100 DEG C, and the temperature of the PVC wallpaper reaches to 220 DEG C during foaming and drying, so the energy-saving effect is favorably realized. Compared with the existing wallpaper, the novel environment-friendly wallpaper has the advantage that heavy metals, formaldehyde, plasticizers, VOC (volatile organic compounds) and the PVC are not contained, so the environment-friendly, ecological and health effects are realized.

Owner:宋旭

Environment-friendly multifunctional diatom ooze and preparation method thereof

InactiveCN105565705AExcellent mildew resistanceExcellent scrub resistanceHydroxypropylmethyl celluloseCalcite

The invention discloses environment-friendly multifunctional diatom ooze. The diatom ooze is prepared from, by mass, 20% to 45% of kieselguhr, 5% to 20% of kaolin, 1% to 5% of bentonite, 3% to 7% of attapulgite, 5% to 15% of sepiolite powder, 1% to 15% of white carbon black, 3% to 10% of anion powder, 5% to 20% of titanium dioxide, 3% to 10% of imidoketone, 5% to 25% of calcite powder, 5% to 25% of sierozem, 5% to 25% of redispersible powder, 0.2% to 0.5% of powder antifoaming agent, 0.2% to 0.5% of powder wetting agent, 0.2% to 0.5% of powder mildew preventive, 0.2% to 0.5% of hydroxypropyl methyl cellulose and 0.5% to 3% of wood fiber powder. The diatom ooze has the functions of purifying and freshening indoor air, is excellent in cracking resisting performance, mould preventing performance and scrubbing-tolerant performance, and is an indoor decoration wall material with excellent comprehensive performance of functionality, practicality and decoration performance.

Owner:FUZHOU BIMITER ENVIRONMENT FRIENDLY PROD

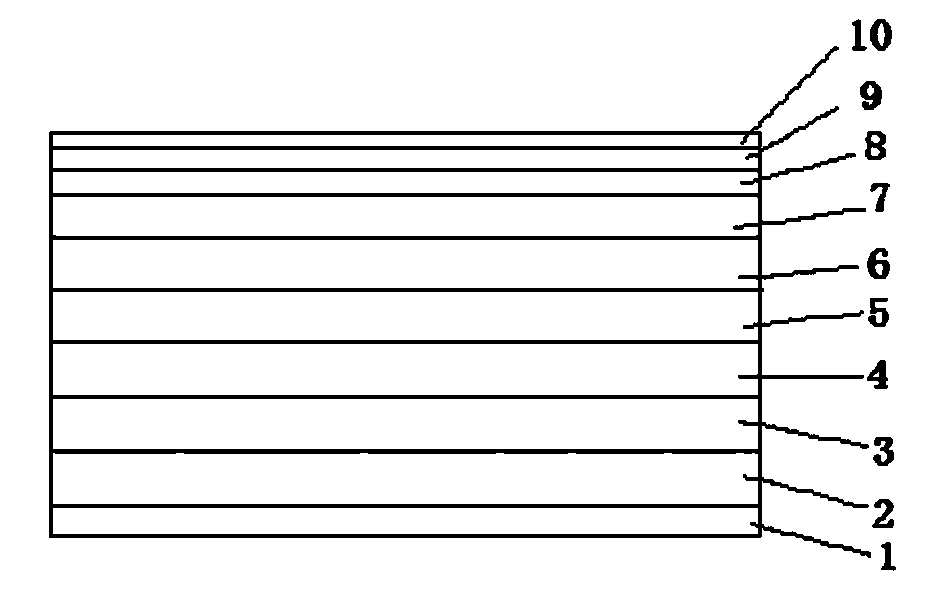

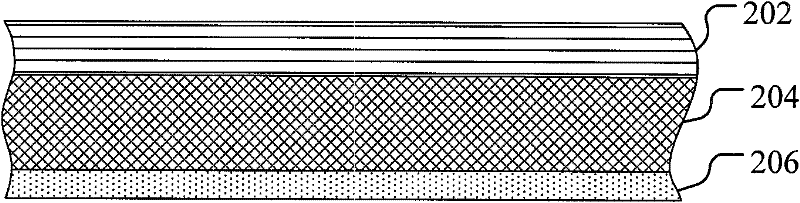

Environment-friendly antibacterial and mildew-proof wallpaper

ActiveCN104074099AHas antibacterial propertiesGood antibacterialCovering/liningsSpecial paperAnti bacteriaAntibacterial property

The invention provides environment-friendly antibacterial and mildew-proof wallpaper. The environment-friendly antibacterial and mildew-proof wallpaper comprises a base layer, wherein the back face of the base layer is provided with a waterproof coating; a coating layer is arranged on the base layer; a bamboo charcoal fiber layer is arranged on the coating layer; an antibacterial layer is arranged on the bamboo charcoal fiber layer; a diatomite adsorption layer is arranged on the antibacterial layer; a printing embossing layer is arranged on the diatomite adsorption layer and is coated with a mildew resisting coating; a polytetrafluoroethylene layer is arranged on the mildew resisting coating and is provided with a film coating layer. The wallpaper is provided with the coating layer, the antibacterial layer and the bamboo charcoal fiber layer, and the triple effect enables the wallpaper to have a good antibacterial property; the coating layer and the mildew resisting coating are arranged so that the wallpaper is good in mildew resistance; furthermore, the diatomite adsorption layer is arranged so as to further enhance the deodorization capability of the wallpaper; finally, the wallpaper provided by the invention has good antibacterial, mildew-proof and deodorization performance.

Owner:苏州苏尔达包装科技有限公司

Attapulgite colored coating powder having air-purifying function

The invention discloses attapulgite colored coating powder having an air-purifying function. According to the technical scheme, the attapulgite colored coating powder is characterized in that ingredients include attapulgite pottery clay powder having the air-purifying function, acidified attapulgite clay particles, acidified zeolite particles, colored portland cement, Paris plaster, white carbon black, calcium chloride, aerosil, expanded perlite, nanometer silver-loaded antibacterial powder, nanometer titanium dioxide, sodium pyrophosphate and powder defoaming agents. The ingredients of the attapulgite colored coating powder having the air-purifying function are input three times into a stirring machine to be stirred evenly and packaged into the finished product. By the adoption of the colored coating, in indoor wall decoration, an artistic emboss effect of various embossed three-dimensional colored patterns can be achieved through spraying and manufacturing, grain composition inside a wall spraying layer is good, the porosity is high, the specific surface area is large, indoor formaldehyde, ammonia nitrogen, benzene and other harmful substances can be adsorbed and decomposed, and the functions of automatic humidification, mould prevention, sterilization, deodorization and air purification are achieved.

Owner:蒋文兰

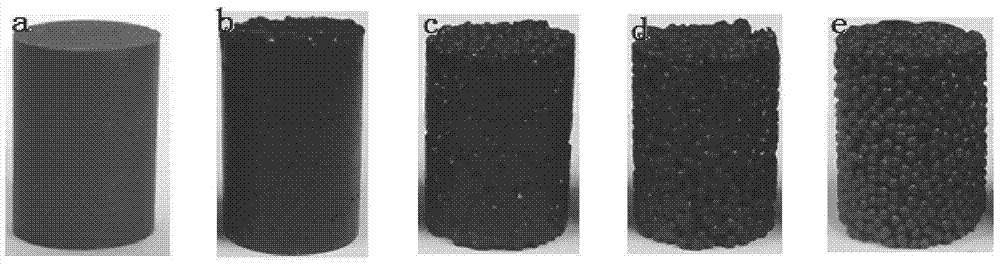

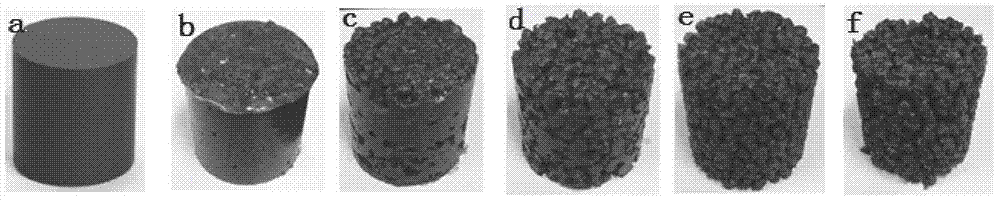

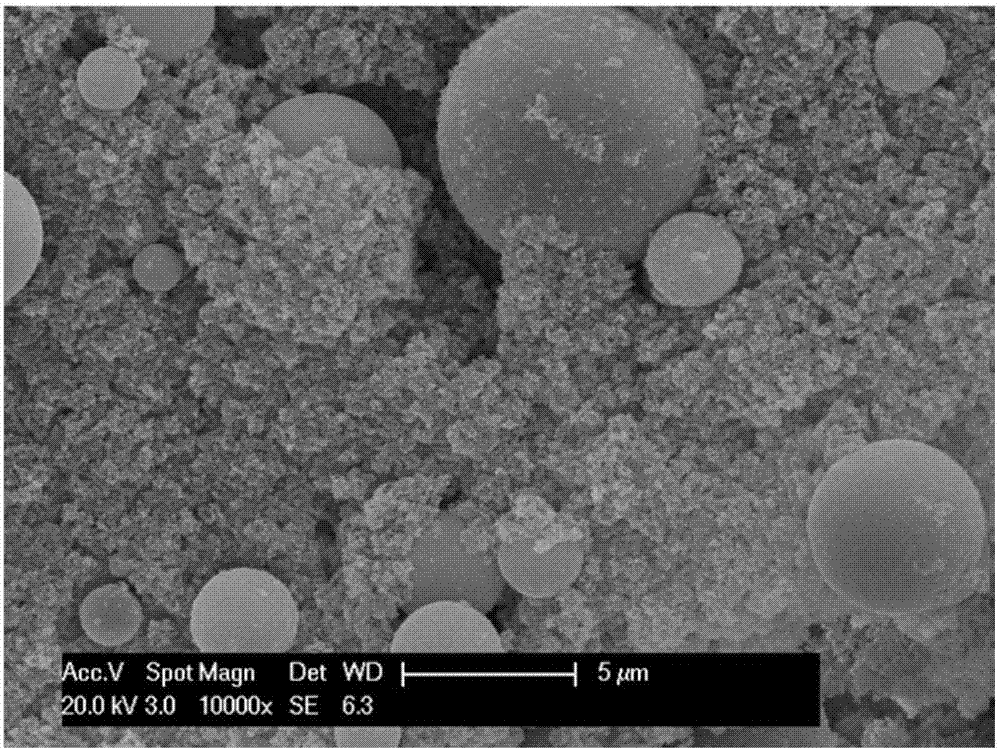

Epoxy resin based neutron and gamma ray shielding composite material, as well as preparation method and application thereof

The invention relates to an epoxy resin based neutron and gamma ray shielding composite material, as well as a preparation method and an application thereof, belonging to the technical field of shielding materials, used for solving the following technical problems that the shielding property of a shielding material in the prior art is difficultly combined with other physical and mechanical properties; requirements of application flexibility and construction diversity cannot be satisfied; and furthermore, the preparation process is complex. The epoxy resin based neutron and gamma ray shielding composite material is composed of the following components in parts by weight: 5-15 parts of epoxy resin, 2-9 parts of a curing agent, 1-10 parts of a fast neutron moderator, 2-20 parts of a thermal neutron absorber, 65-85 parts of a gamma ray shielding agent, 0-3 parts of an inert diluent, 0-3 parts of an active diluent, 0-2 parts of an accelerant, and 0.5-5 parts of auxiliaries. The epoxy resin based neutron and gamma ray shielding composite material has excellent neutron and gamma ray mixing-field shielding property; furthermore, the epoxy resin based neutron and gamma ray shielding composite material is low in toxicity, free from smell, simple in preparation process and convenient to construct; and thus, the epoxy resin based neutron and gamma ray shielding composite material can be widely applied in various fields of strict radiation-resistant requirements.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

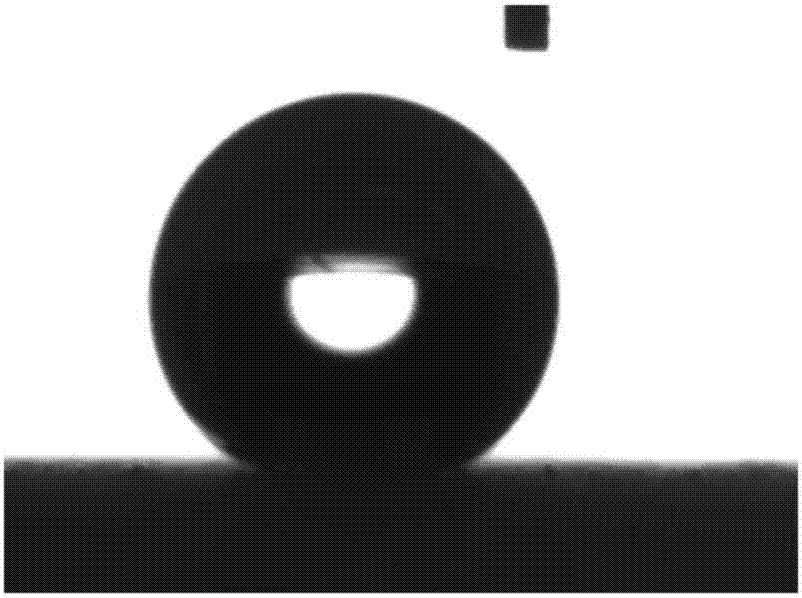

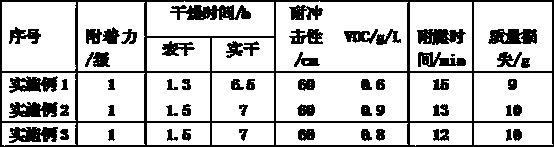

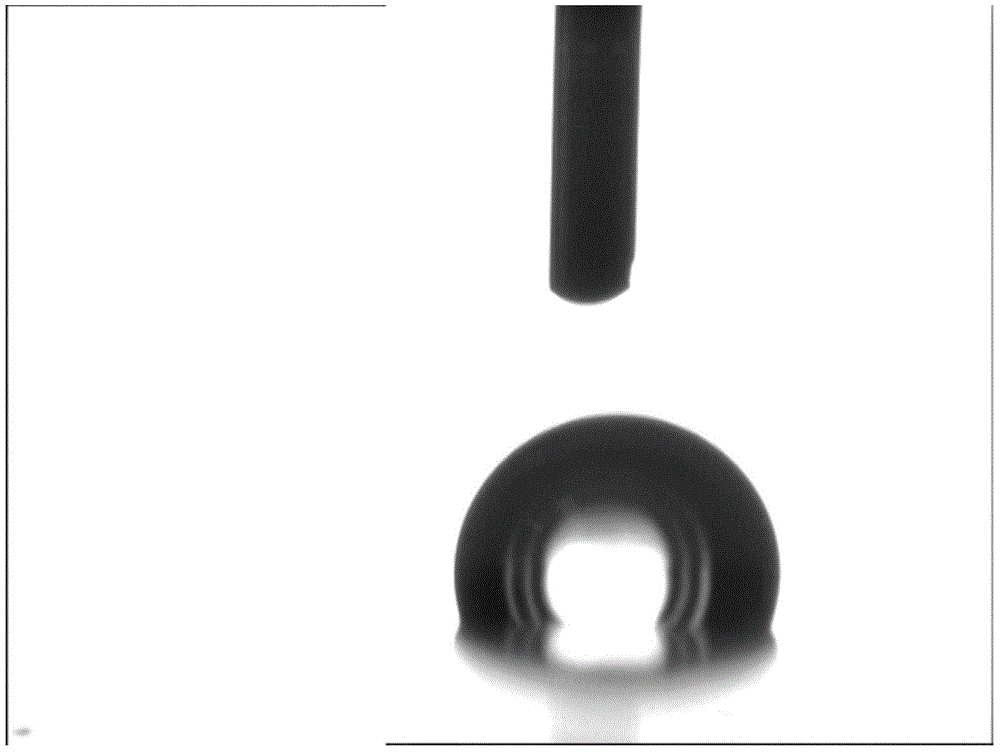

Aqueous transparent super-hydrophobic paint and preparation method thereof

The invention provides aqueous transparent super-hydrophobic paint and a preparation method thereof. The preparation method comprises the steps that firstly, deionized water is added into a reaction still, and the pH value is adjusted; secondly, aqueous colloidal silica is added under the conditions of water-bath heating and stirring, then micro composite SiO2 powder is added, tetraethyl orthosilicate, siloxane and aqueous organosilicone or silicone-modified resin are added, and the aqueous super-hydrophobic paint can be obtained after mechanical stirring is conducted for a certain time. In the preparation and use processes of the paint, no fluorine-containing substance is involved, the solvent is water, and the paint is green and environmentally friendly, free of toxins and harmless. The paint is widely used in the aspects of self-cleaning, corrosion prevention, mould prevention, condensation resistance, freezing resistance, oil water separation and the like.

Owner:SOUTHEAST UNIV

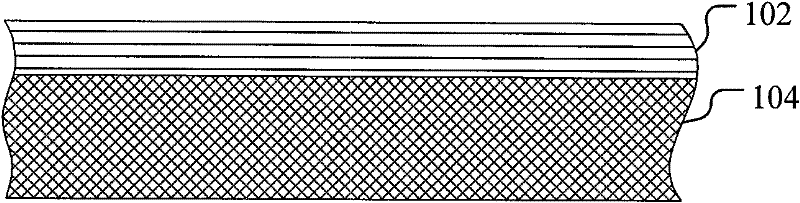

Building sheet material and its manufacture method

InactiveCN102337770AMoisture-proofImprove mildew resistanceConstruction materialCovering/liningsEcological environmentMoisture resistance

The invention provides a building sheet material and a manufacture method for solving the problems of the current building sheet materials which are easy to be wetted, corroded and deformed. According to an enforcement of the present invention, the building sheet material comprises a cement plate layer and a magnesium oxide plate layer. The building sheet material of the present invention employs a composite structure of a cement plate and a magnesium oxide plate or a wood plate, which has the advantages of moisture resistance, mildew resistance, fire resistance, corrosion resistance, sound insulation effect and difficult deformation. The building sheet material of the present invention uses a firm cement plate layer as an exposed surface, and has good durable performance. In addition, because the usage of wood material is reduced, the building sheet material influence on ecological environment can be effectively reduced.

Owner:上海亮世国际贸易有限公司

Treatment method of bamboo skin for wickerwork

InactiveCN104029262AImprove pest controlImprove mildew resistanceReed/straw treatmentWood impregnation detailsMedicineToughness

The invention relates to a treatment method of bamboo skin for wickerwork. Firstly, traditional Chinese medicines are used to prepare soak solution; and then, the stewed bamboo skin is fed in the soak solution for dipping. The treatment method of the bamboo skin, provided by the invention, stews the bamboo skin firstly to kill bacteria and parasites on the bamboo skin and to remove redundant water in the bamboo skin, and then feeds the bamboo skin in the soak solution for dipping to increase the amount of the soak solution of the bamboo skin; and the treatment method intensifies insect-preventing and mould-preventing effects of the bamboo skin, and can improve the toughness of the bamboo skin to conveniently perform the wickerwork.

Owner:阜南腾强工艺品有限公司

Mite and mosquito-bite preventing underwear, sleepwear and home wear

InactiveCN102251412AHeat-clearing and damp-dryingAnti-miteHeating/cooling textile fabricsDyeing processFiberDisease

The invention relates to the technical field of fibers, in particular to a mite and mosquito-bite preventing underwear, sleepwear and home wear which is characterized by comprising the following processing steps of: preparing medical liquid; carrying out dyeing and printing and other pre-treatments on cottons or cotton blended fabrics; preparing bleaching and dyeing liquid; dyeing cloth; carrying out high temperature tentering; and processing so as to prepare the underwear, the sleepwear and the home wear. According to the invention, the fabrics provided by the invention have the obvious effects of mite preventing, mosquito preventing, anti-bacterium, deodorization, rot resistance, itching relieving, blood circulation invigoration and meridians activation and the like; the repellent rate of dust mite is as high as 99 percent; the repellent rate of mosquito is 95 percent; the repellent rate of termite is 95 percent; fabric-touching pathogens such as staphylococcus aureus, staphylococcus epidermidis, gonococcus and esherichia coli and the like can be completely killed; all efficacies of the fabrics still reach to over 97 percent after the fabrics are washed for 50 times; and the fabrics have the advantages of no irritation to skin, no anaphylactic reaction, no toxicity to the human body, comfort for wearing and can effectively prevent the infection of asthma and other diseases.

Owner:王建波

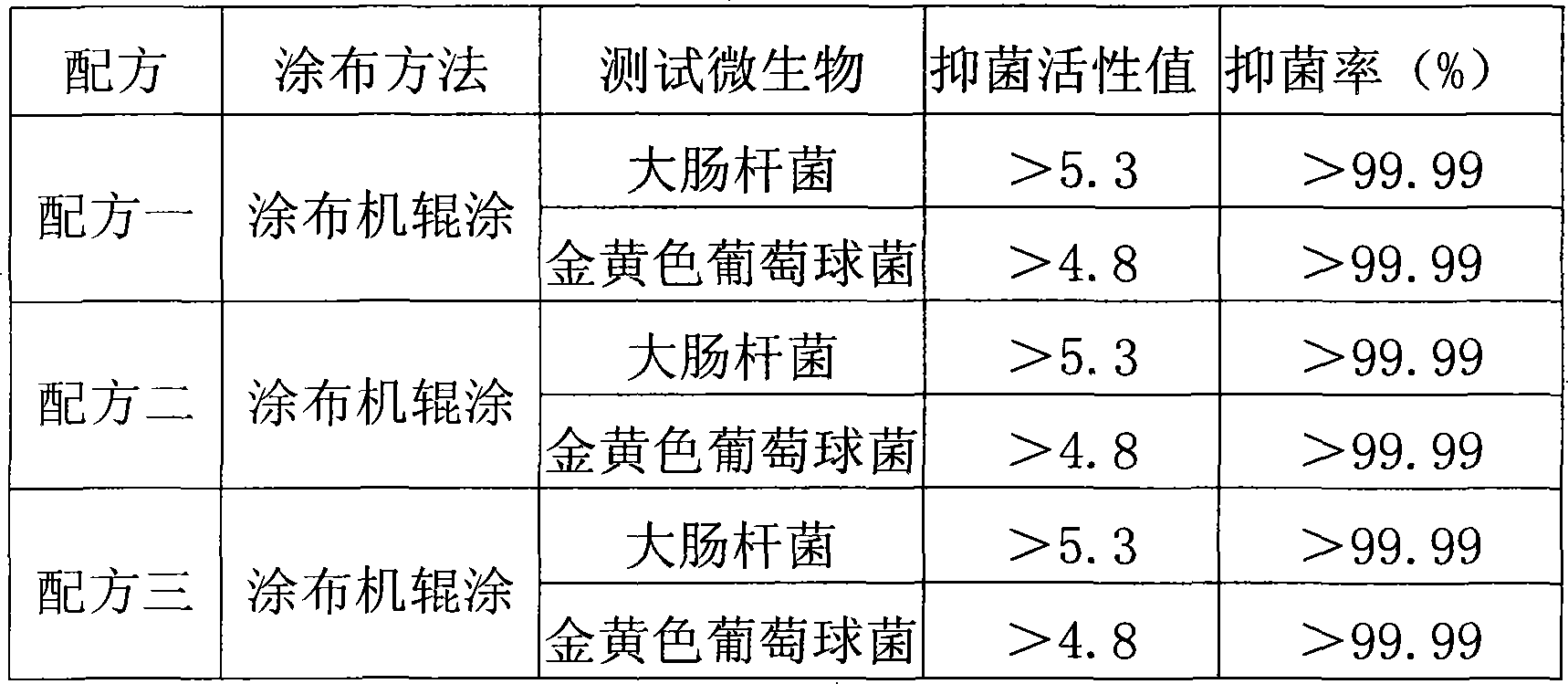

Antibiotic paint and method for preparing the same

ActiveCN101250344AImprove mildew resistanceGood antibacterial effectAntifouling/underwater paintsPaints with biocidesFungicideTriclosan

The invention relates to antibacterial paint and a production process, which comprises raw materials with following parts by weight of 1-10 parts of antibacterial agent. 2-30 parts of organic silicate, 10-40 parts of silane coupling agent and 40-90 parts of water, wherein antibacterial agent is triclosan and pyridine thione. The preparation process comprises adding water with required quantity in a liquid mixing container, adding organic silicate with required quantity into water, adding silane coupling agent after evenly agitated, continuing to agitate to make solution evenly mix, adding anti-bacterial agent of triclosan and pyridine thione, and continuing to agitate for 20 minutes. The invention solves the technical problem that fungicide and addition agent which are adopted by current anti-bacterial paint can affect environment and the health of persons, and has significant mildew proof, anti-bacterial and bacterial inhibiting property. And anti-bacterial material which is adopted belongs to no toxic material, has no harmful affect to environment and human health, and can realize anti-bacterial effect with long-term and high efficiency.

Owner:CHINA BANKNOTE PRINTING & MINTING

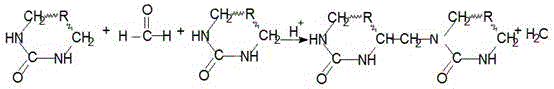

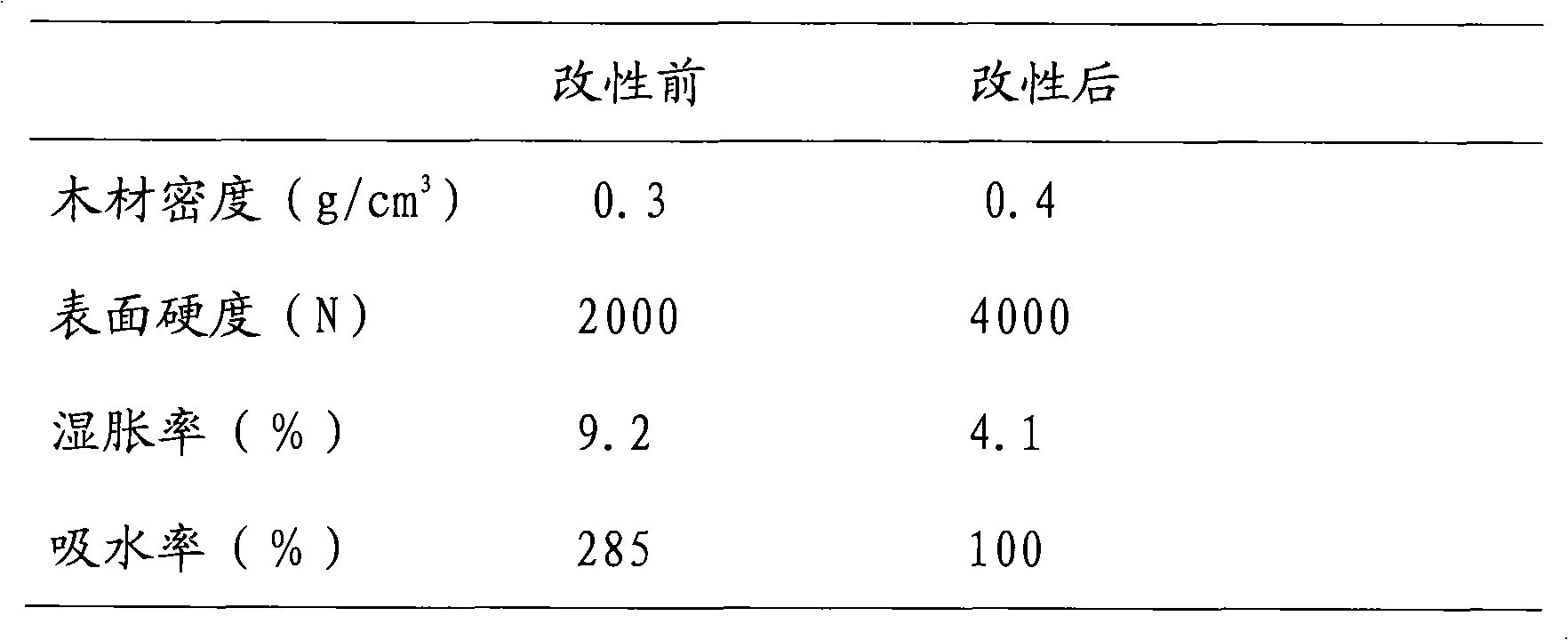

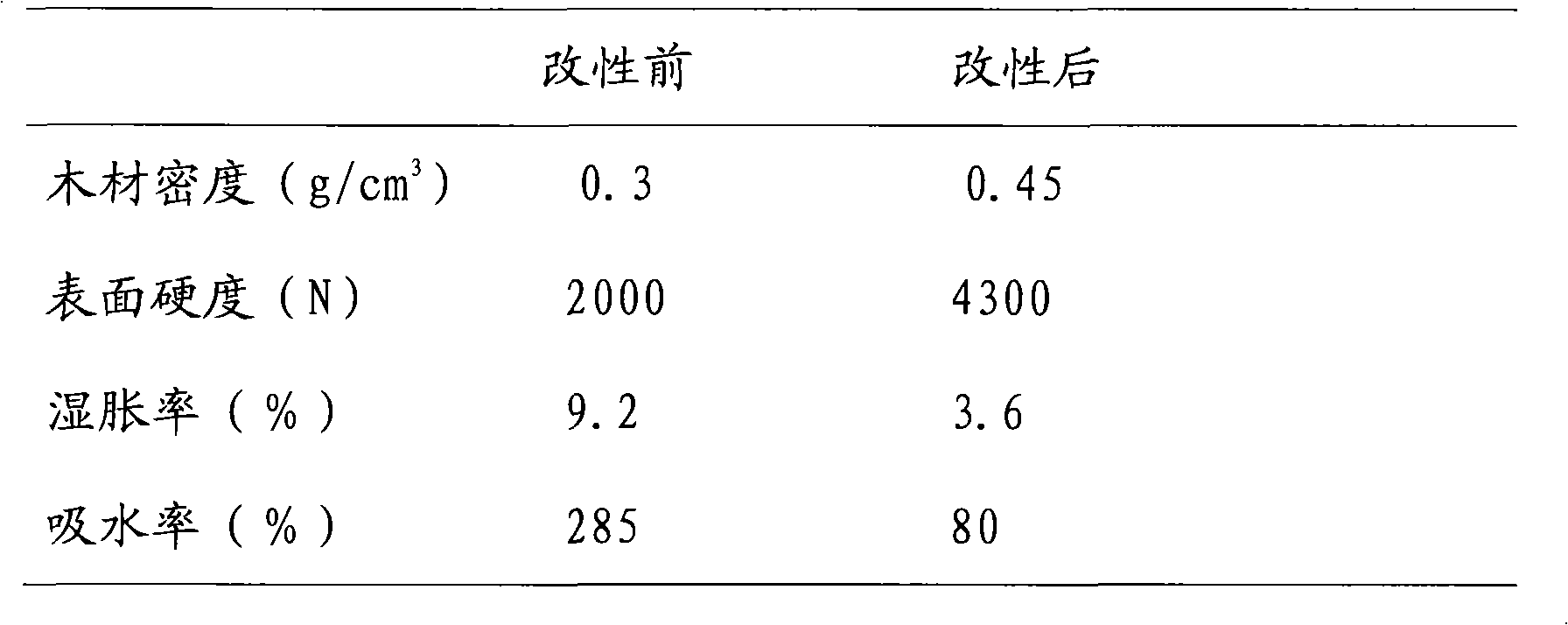

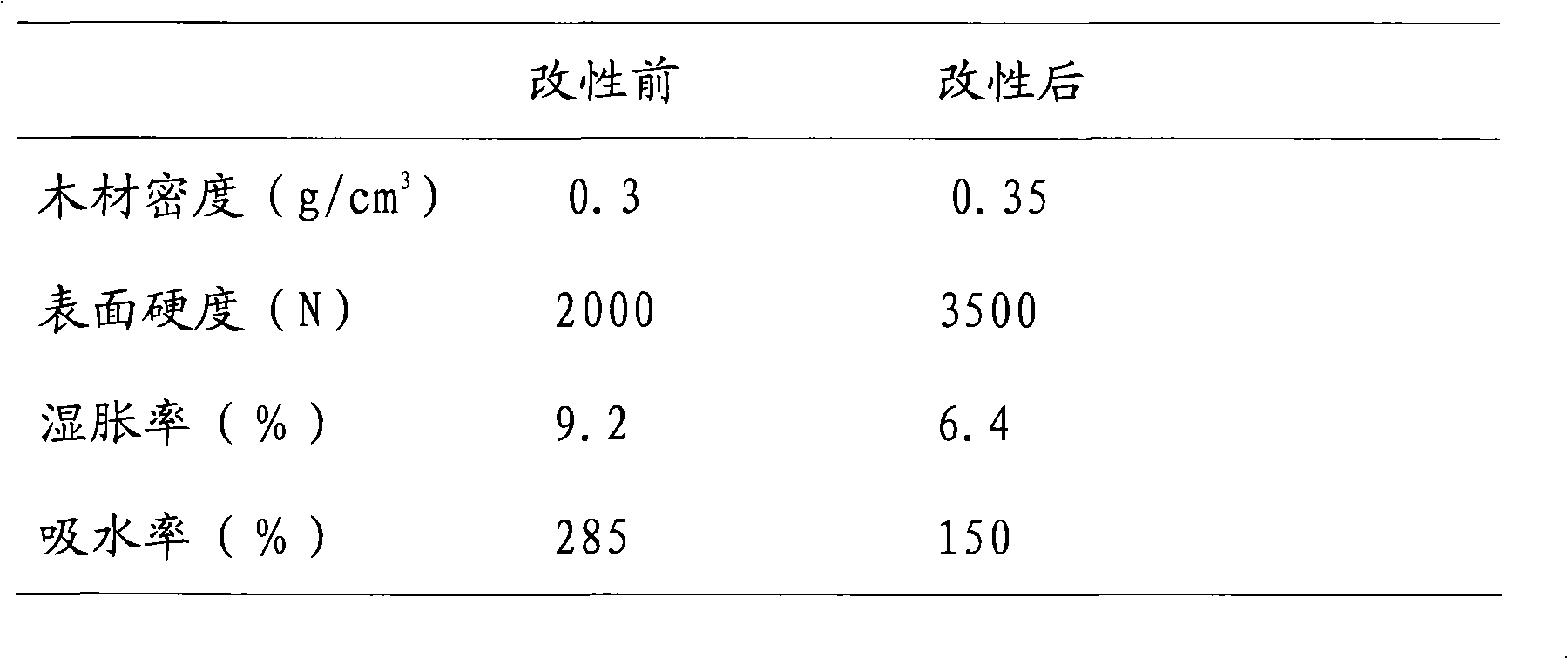

Modified wood composition and its manufacturing method and application

InactiveCN101549507AHigh strengthEasy to usePressure impregnationWood impregnation detailsSolubilityChemical industry

The invention discloses a kind of modified wood composition and its preparation method and application, which is part of the forest chemical industry. This invention of modified wood composition consists of low molecular urea-formaldehyde resin and methylol urea mixture; the described methylol urea mixture mainly consists of monomethylurea and dimethylolurea. The modified wood composition of this invention featuring low viscosity, water-solubility and good storage stability is suitable for the use of vacuum pressure impregnation of a variety of tree species, especially suitable for increasing the density of low-end plantation, function, etc. After the modification of plantation timber by the modified wood composition, the invention may significantly increase the timber size stability, overcome the cracking and deformation defects before the application, and significantly improve the physical and mechanical properties. The modified wood composition, if working with the functional reagents with good water-solubility as the flame retardant, preservative and so on, may improve the timber performance as fire-retardation, moth proofing, mildew proofing and antisepsis properties.

Owner:EVERFIRST WISEFUND TECH BEIJING

Water-based coating

ActiveCN104017445AImprove defoaming abilityWell mixedFireproof paintsAntifouling/underwater paintsExtensibilityWater based

The invention discloses a water-based coating which is characterized by comprising the following components by weight parts: 20-30 parts of water, 20-25 parts of an acrylic emulsion, 0.3-0.5 part of a wetting agent, 0.1-0.3 part of a de-foaming agent, 15-20 parts of titanium dioxide, 10-15 parts of talcum powder, 0.3-0.5 part of a fireproof agent and 0.2-0.4 part of an antibacterial agent. The coating disclosed by the invention is reasonable in composition, low in cost, good in compatibility among the components, environment-friendly, mildew-proof and flame-retardant, and has excellent application values; a natural antibacterial agent and an inorganic antibacterial agent are mixed for use, so that the problems of poor stability due to single use of the natural antibacterial agent or pollution caused by single use of an organic antibacterial agent and high cost due to single use of the inorganic antibacterial agent are solved; due to combined use, the mildew-proof effect is more lasting; the film-forming drying time is short, the hardness is good, and the extensibility and the heat resistance are good.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Process for repairing ancient books, paintings and calligraphy and paper literatures by using paper pulp

ActiveCN1844574AFast patchingEasy to operateNon-fibrous pulp additionPaper/cardboardFiberPulp and paper industry

The invention relates to a pulp repair method of ancient book, painting and calligraphy, which comprises: 1, according to the material of repaired book, painting and calligraphy, selecting pulp material, and adding the raw paper of selected pulp material into mixer, adding water and suspending agent, to mix and break uniformly; the mass ratios between raw paper, suspending agent, and water are: raw paper in 5-20; suspending agent in 5-15; and water in 500-1000, while the mixing time is 30-90s, then getting out the pulp; 2, spreading the book, painting and calligraphy on the repair support that made from paper shade; filling prepared pulp into repair pen to repair them that dropping pulp into the damaged part to use the combine force generated when the pulp becomes paper, the interlace force of fiber, and the adhesive function of suspending agent to complete said process; 3, removing repaired book, painting and calligraphy from the repair support, to be laid on the water-adsorption paper, to be dried.

Owner:邱晓刚

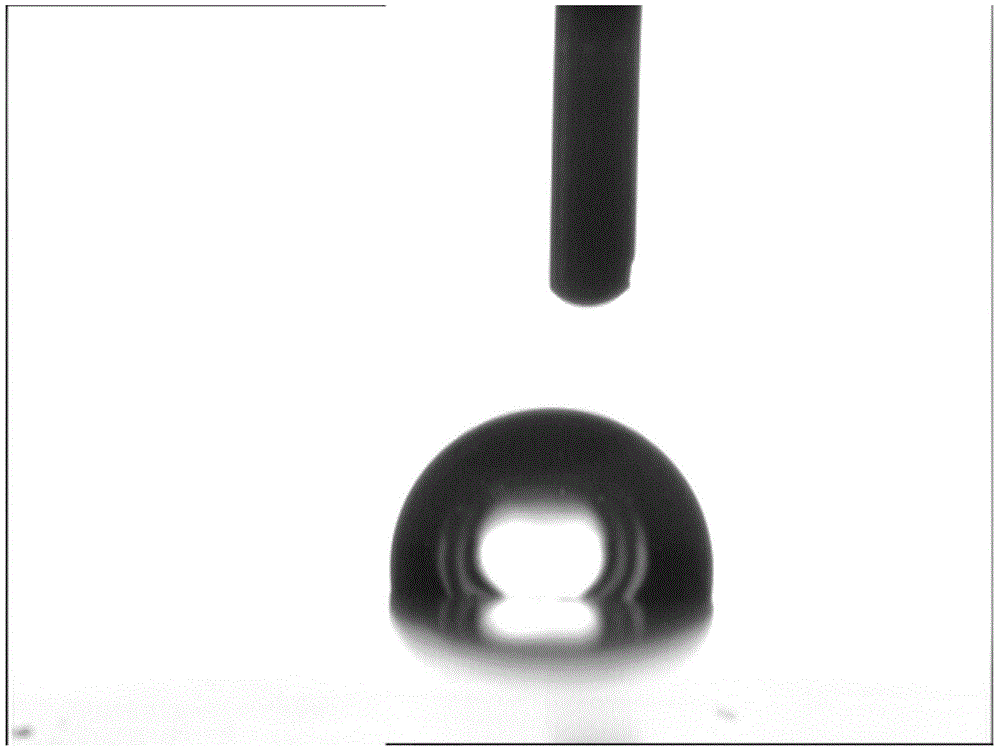

High-performance environment-friendly water-based ship inner cabin coating

ActiveCN104559635AHigh water contact angleGood surface mobilityAntifouling/underwater paintsPaints with biocidesWater basedEpoxy

The invention discloses a preparation method and an application of a high-performance environment-friendly water-based ship inner cabin coating. According to the high-performance environment-friendly water-based ship inner cabin coating, a two-component modified epoxide resin emulsion coating system containing fluoroalkyl side chains is adopted, wherein a component A is a mixture taking a structure modified epoxide resin emulsion containing fluoroalkyl side chains as a base material, and a component B is a water-based amine curing agent consisting of epoxy-terminated polyether compounds and an amine addition product; the component A and the component B are proportionally and uniformly prepared for coating; the limited quantity of hazardous substances in a cured paint film meets the environmental protection standard of VOC (volatile organic compound) content smaller than or equal to 120 g / L, the water contact angle of the paint film is larger than 100 degrees and kept stable, recoating is easy, and the coating has excellent mould-proof, contamination-resisting and corrosion-resisting properties and is suitable for protective decoration of a ship inner cabin.

Owner:MARINE CHEM RES INST

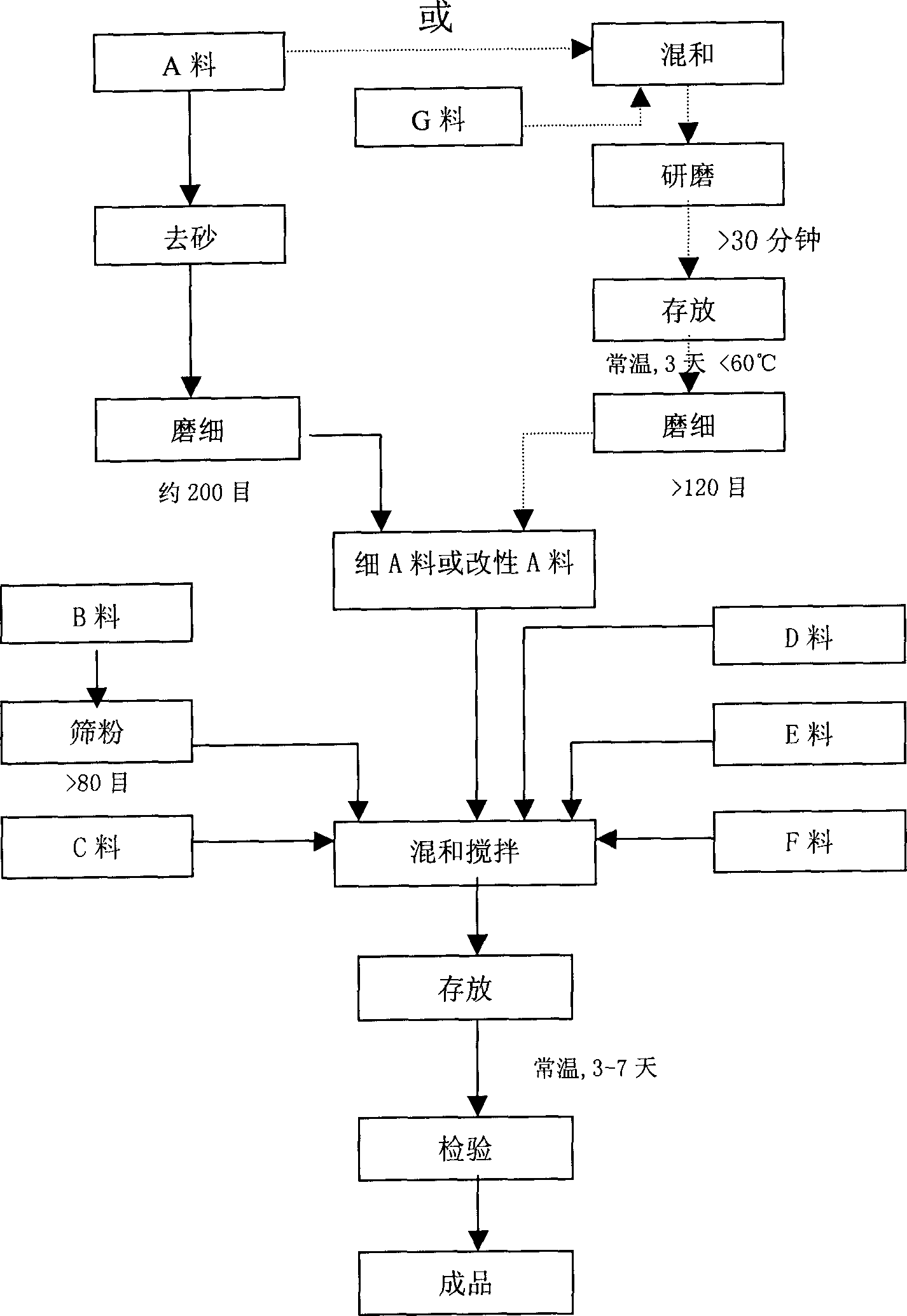

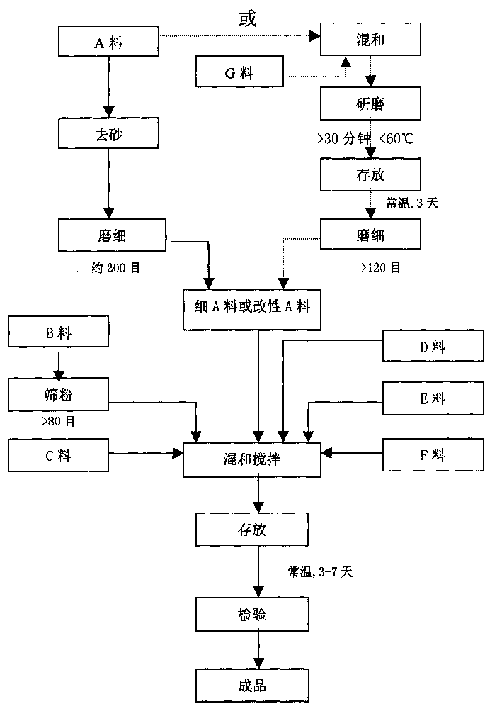

Multifunctional carpentery stuffing and its compounding process

InactiveCN1506427AImproved preload performanceImproved cold bond fastnessMacromolecular adhesive additivesUreaMultiple function

The multifunctional carpentery stuffing consists of component A of one selected from bentonite, attapulgite and kaolin in 45-80 wt%; component B comprising one of wood powder, corn cob powder and stalk powder in 15-40 wt%, densifier in 2-15 wt%, melamine in 0-2 wt%, urea in 0-3 wt%, and acidity regulator in 0-4; and G component sodium salt in 0-3 wt%. The compounding process includes ore dressing, eliminating sand and grinding to obtain component A; mixing component A and component G, grinding, storing, sodium modifying and fine grinding; high speed shearing and mixing all the materials in a high speed rotary no-gravity mixer. The plywood with the said stuffing has less formaldehyde releasing amount, improved waterproof, antiaging, flexibility and other performances and low production cost. The stuffing may be used in replacing available stuffing.

Owner:江苏众诚新材料科技有限公司

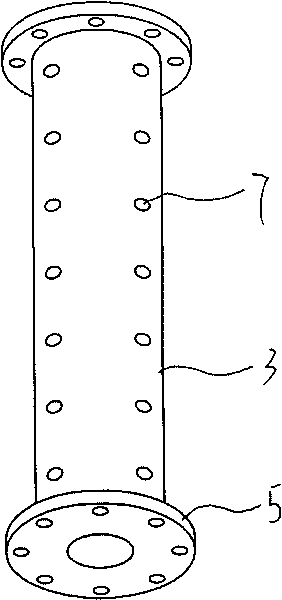

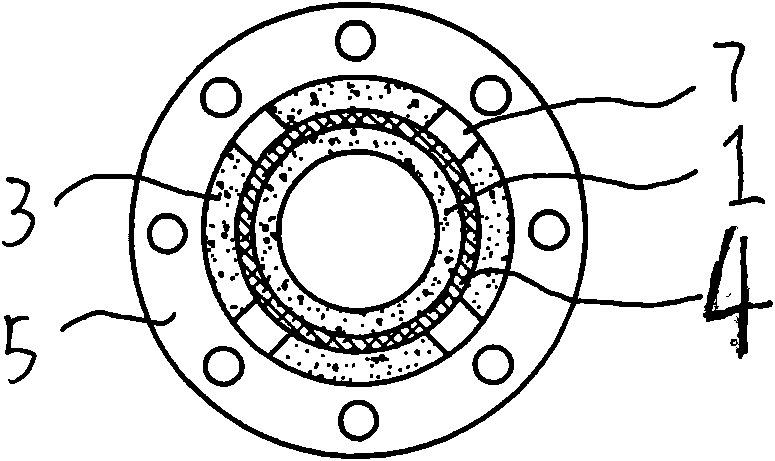

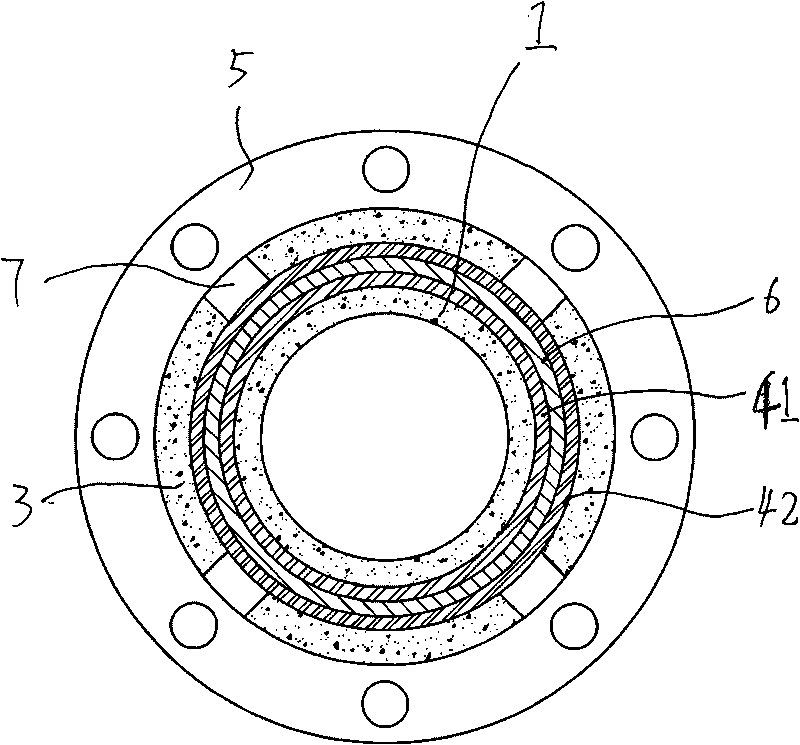

Over-pressure over-temperature environment-friendly silica gel composite pipe and preparation method thereof

The invention belongs to the technical field of silica gel pipes and preparation methods thereof, and discloses an over-pressure over-temperature environment-friendly silica gel composite pipe and a preparation method thereof. The over-pressure over-temperature environment-friendly silica gel composite pipe is mainly and technically characterized by comprising an inner rubber layer and an outer rubber layer which are made of silicon rubber, wherein a strengthening layer is arranged between the inner rubber layer and the outer rubber layer. The inner rubber layer 1 and the outer rubber layer 3 comprise the following materials in parts by weight: 100 parts of silicon rubber SR, 40-55 parts of fume colloidal silica, 0.4-1 part of vulcanizing agent double-25DBPMH, 1-5 parts of ferric oxide, 0-5 parts of colorant, 5-8 parts of environment-friendly tasteless adhesive AS-88 and 5-8 parts of inorganic flame retardant aluminium hydroxide or zinc borate. The silicon rubber composite pipe is prepared by adopting the following steps of: freezing an inner rubber tyre to harden, winding the strengthening layer and vulcanizing, thus, the pressure resistance and the high temperature resistance of the common silicon rubber pipe are improved, the service life of the common silicon rubber pipe is prolonged, and the abrasion resistance is improved.

Owner:河北东劲液压橡塑制品有限公司

Fiberboard with formaldehyde self-absorbing function and manufacturing method thereof

InactiveCN101585204AAnti-corrosionMoisture-proofWood working apparatusFlat articlesActivated carbonFiber

The present invention provides a fiberboard with formaldehyde self-absorbing function and a manufacturing method thereof. The fiberboard of the invention adopts the wood fiber, aldehyde adhesive and active carbon as main raw materials. The dosage of the adhesive is 9%-12% of that of the wood fiber mass, and the dosage of the active carbon is 2%-30% of that of the wood fiber mass. The invention provides the novel fiberboard which is added with a certain amount of active carbon component with the absorbing function in the manufacturing process of the board so that the fiberboard has the function of free formaldehyde (harmful gas) self-absorbing function in the board for a long time. The releasing of the formaldehyde in the board can be reduced for reducing the formaldehyde pollution to the environment. Simultaneously the fiberboard has the functions of corrosion resistance, moisture resistance, deodorization and fungus resistance. Furthermore the fiberboard has the advantages of high absorbing efficiency, excellent absorbing effect, low cost, no toxicity, no side effect, etc.

Owner:NORTHEAST FORESTRY UNIVERSITY +3

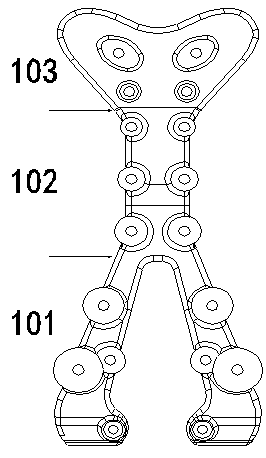

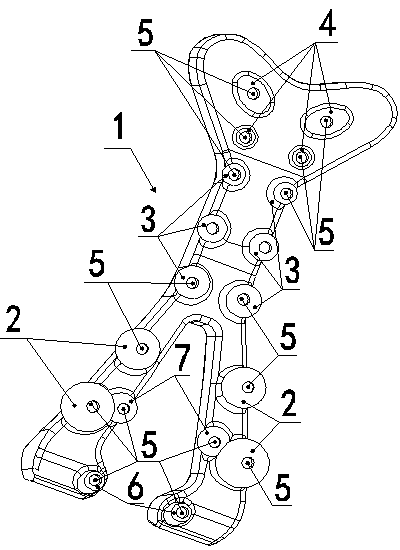

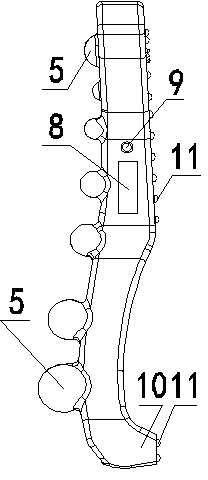

Touch pressing self-regulated type massaging backrest and massaging method

InactiveCN104069003AAvoid breedingAccurate and effective massageDevices for pressing relfex pointsChiropractic devicesMedicineSwitching signal

The invention relates to a touch pressing self-regulated type massaging backrest capable of automatically regulating the back massaging frequency and strength according to back pressure and a massaging method. The touch pressing self-regulated type massaging backrest comprises a battery, a base body of the massaging backrest is a Y-shaped base body and made of latex, multiple latex massaging heads independent of a herringbone base body are respectively arranged on a V-shaped head, the spine back and a heart-shaped spine tail back face of the Y-shaped base body and connected with a vibration head of a vibration source, pressure sensors are respectively embedded into the centers of the latex massaging heads, heads of the pressure sensors are balls, the signal output ends of the pressure sensors are connected with the signal input end of a vibration source controller, and the signal output end of the vibration source controller is respectively connected with the switch signal input ends of the V-shaped head, the spine back and the vibration source in the heart-shaped spine tail backrest through electronic switches.

Owner:HANGZHOU CHANGMING LATEX SPONGE

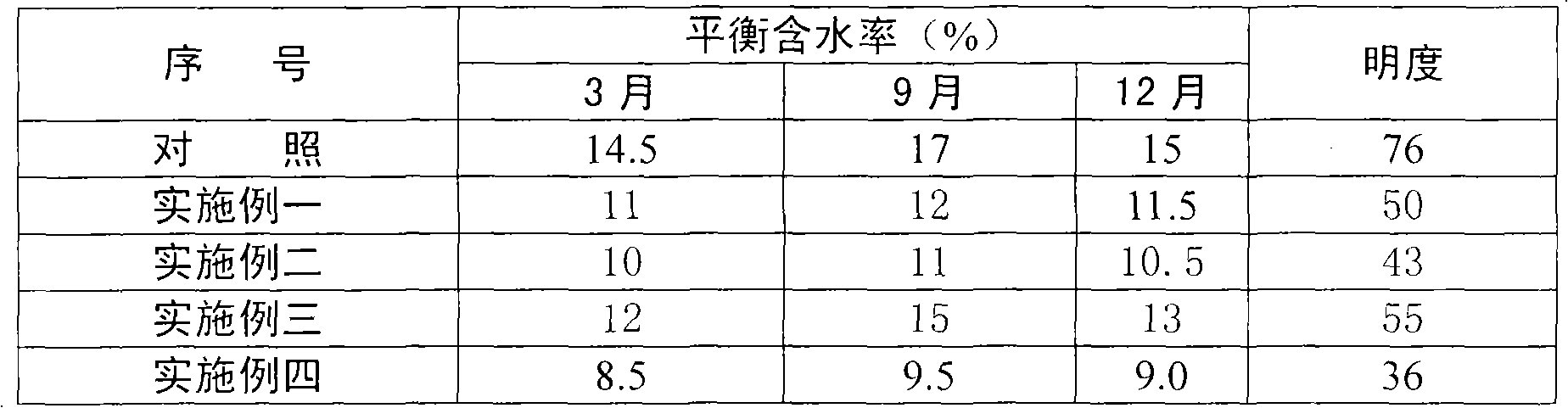

Production method for indoor integrated carbonized rubberwood

InactiveCN102581902AGood dimensional stabilityIncreased durabilityPressure impregnationWood charring/burningCarbonizationEquilibrium moisture content

The invention relates to a production method for indoor integrated carbonized rubberwood, which includes: sawing rubberwood log into specified wood, and subjecting the specified wood to termite proofing treatment, stacking, air drying and carbonizing; and subjecting the carbonized specified wood to tenoning, finger jointing, polishing, paneling and sanding to obtain the indoor integrated carbonized rubberwood. By means of combination of high-temperature carbonization and termite proofing treatment, the strength, moth and termite resistance, durability and mould proofing performance of the integrated rubberwood can be effectively improved, the integrated carbonized rubberwood has the coffee appearance, has the advantages of low variation of equilibrium moisture content, stable size, high corrosion resistance and the like, and is widely applicable to indoor furniture, floors, stair boards, decoration, fitment and the like.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

Method for making surface-carbonized bamboo-wood products

InactiveCN101024292AGood electrical conductivityPrevent static electricityWood treatment detailsWood charring/burningWood productMetal

The invention discloses a surface charring bamboo and wood products manufacturing method. It includes the following steps: using bamboo or wood as raw material; putting it into metal melting furnace to char; surface polishing. The charcoal has good damp proof, mold proof, sterilizing effect which is good for health. Besides, it is green without using chemical coating. The surface charred products have good conductivity to prevent static electricity, can anti moth by high temperature charring.

Owner:林智勇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com