Patents

Literature

539results about How to "Avoid bulging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electroless nickel-phosphorus plating process for Nd-Fe-Bo permanent magnet material

InactiveCN1807682AAvoid bulgingPrevent peelingLiquid/solution decomposition chemical coatingCleaning using liquidsElectroless nickelPhosphor

The invention discloses a chemical plating nickel plating method of neodymium-iron- boron permanent magnet material, which is characterized by the following: adopting plugging chemical plating to plug neodymium-iron-boron and thick and block-up neutral chemical plating; carrying on chemical plating nickel phosphor method of acidic high-phosphorus chemical plating, wherein the method comprises the following steps: tumbling; chamfering; degreasing; derusting; activating; plugging chemical plating; neutering chemical plating; acidifying high-phosphorus chemical plating; inactivating. The invention simplifies the application of industry, which reduces cost of production.

Owner:鲁国强

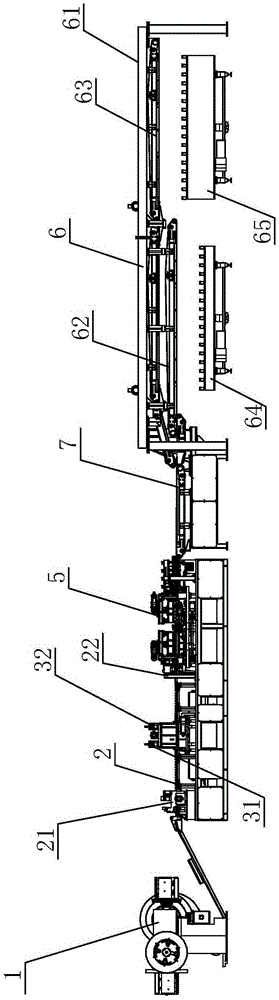

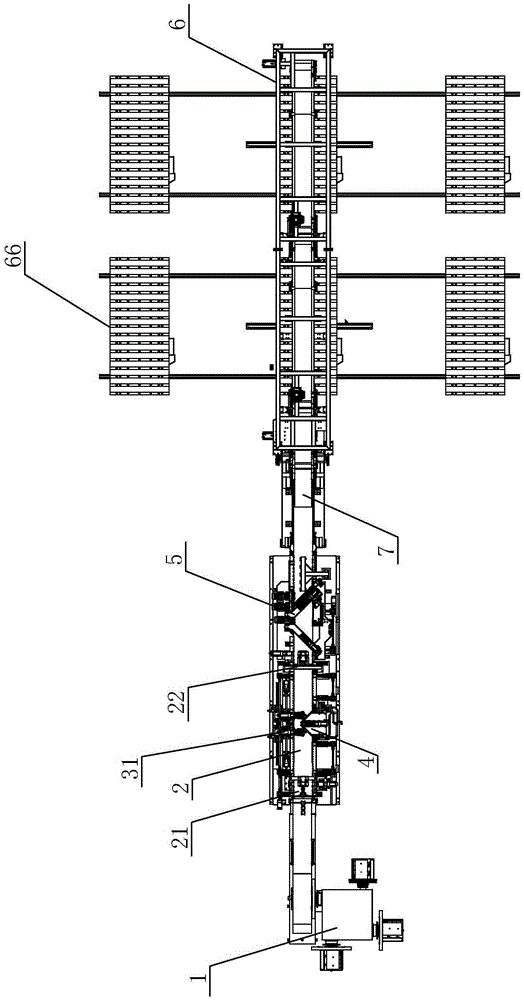

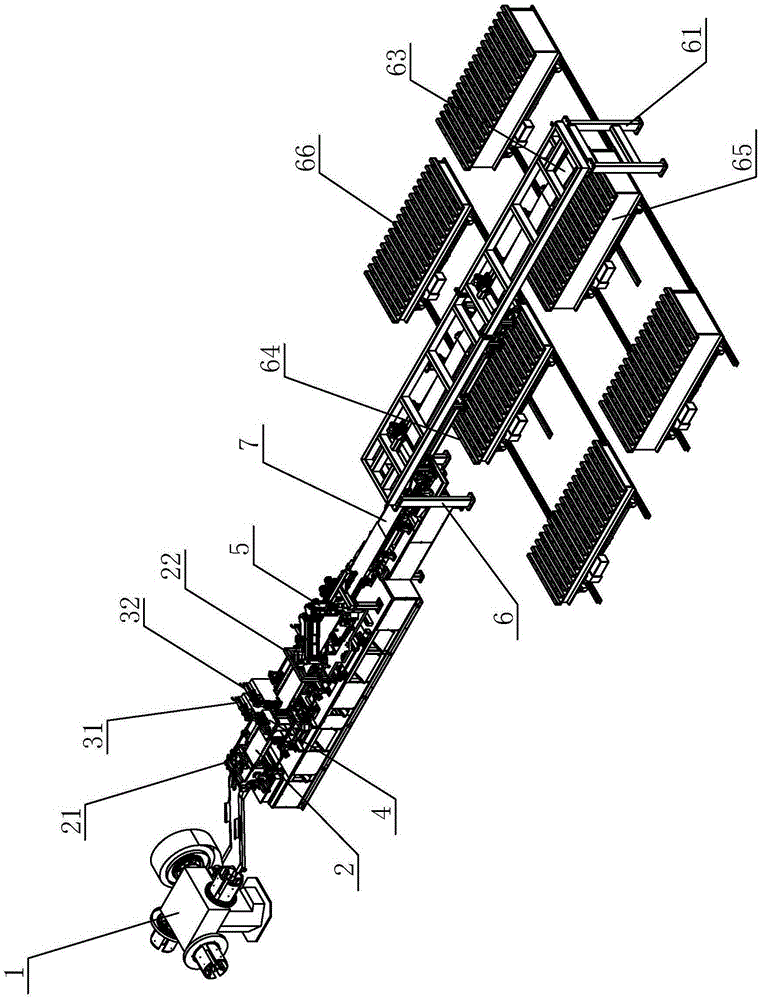

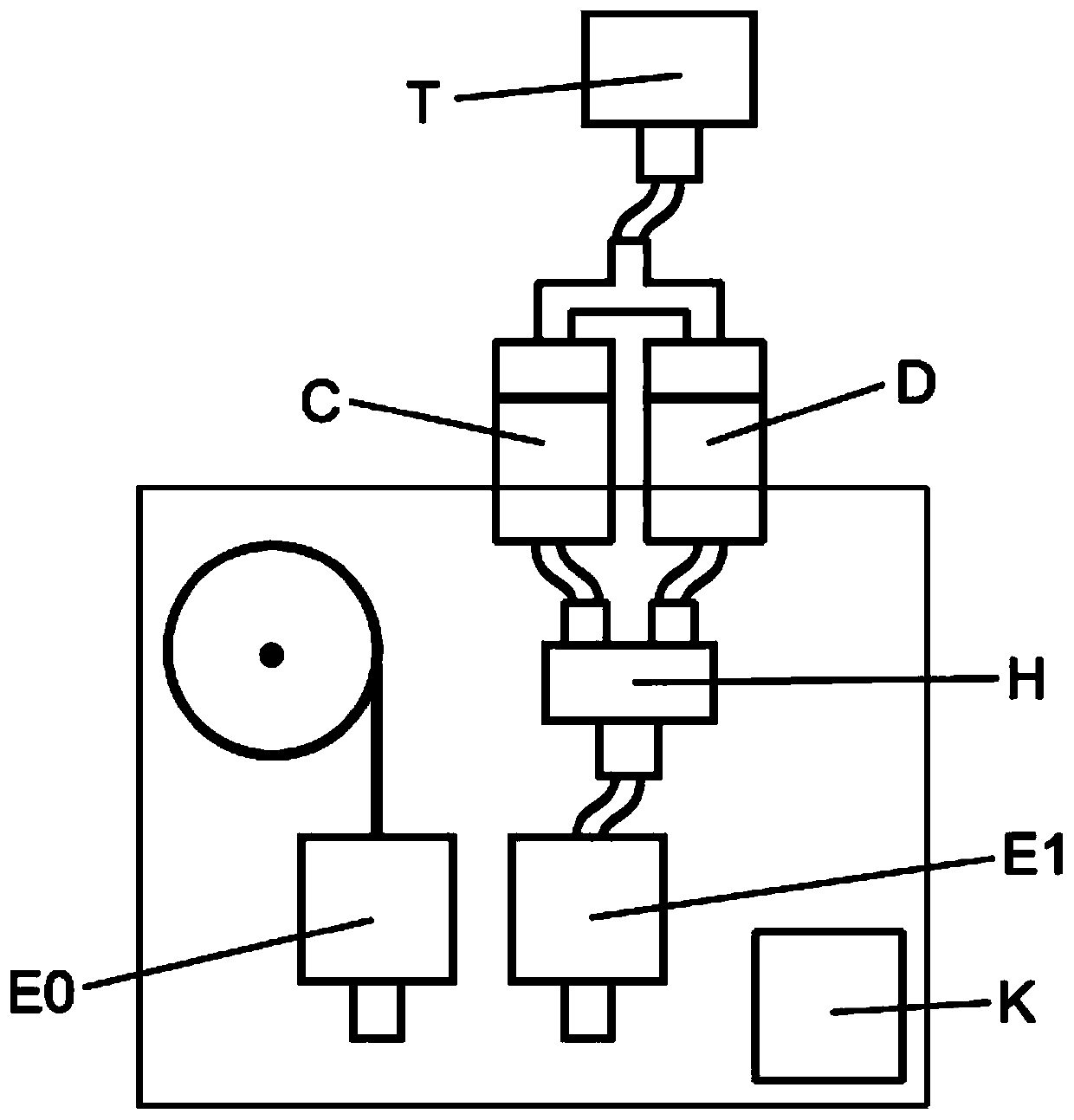

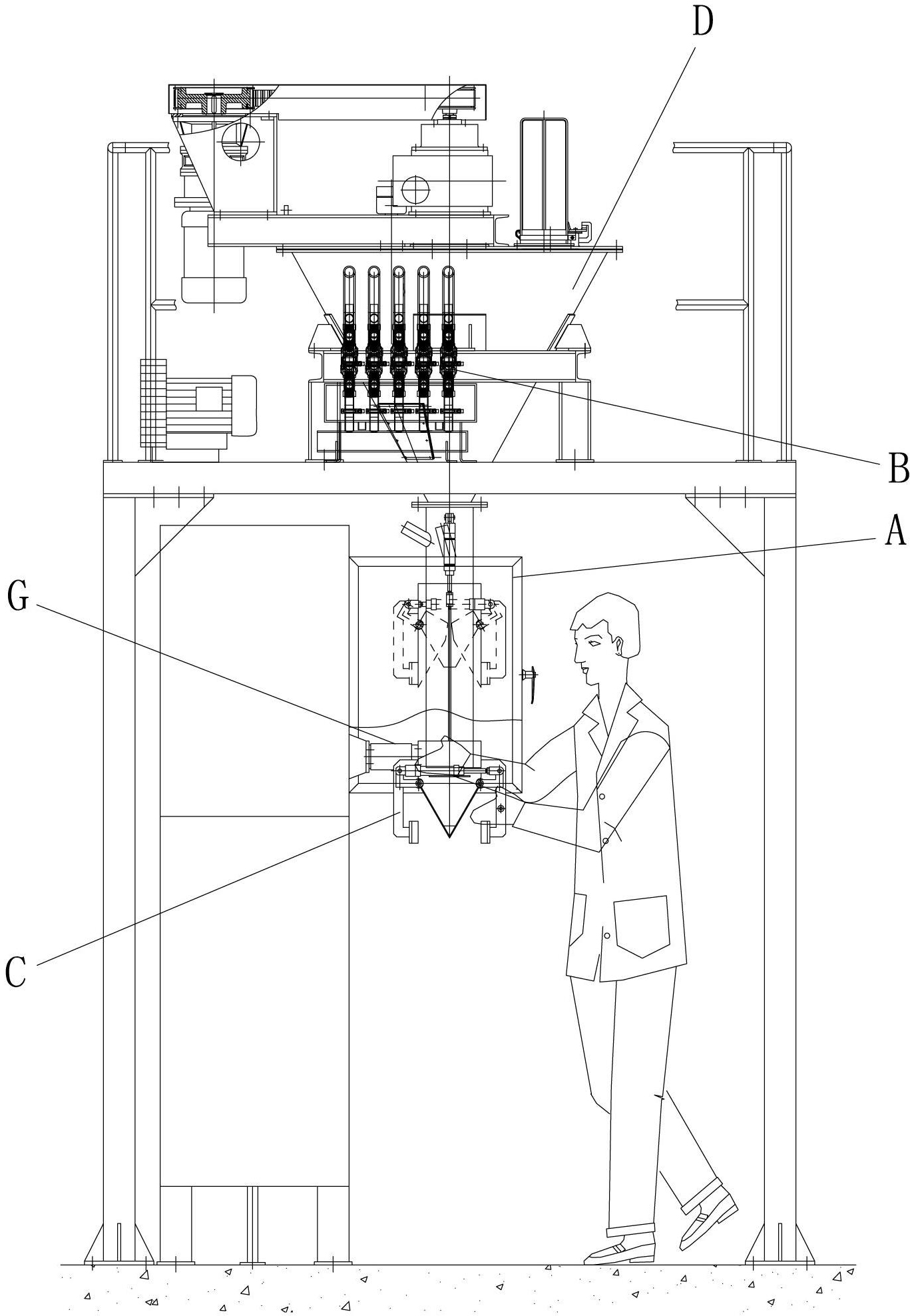

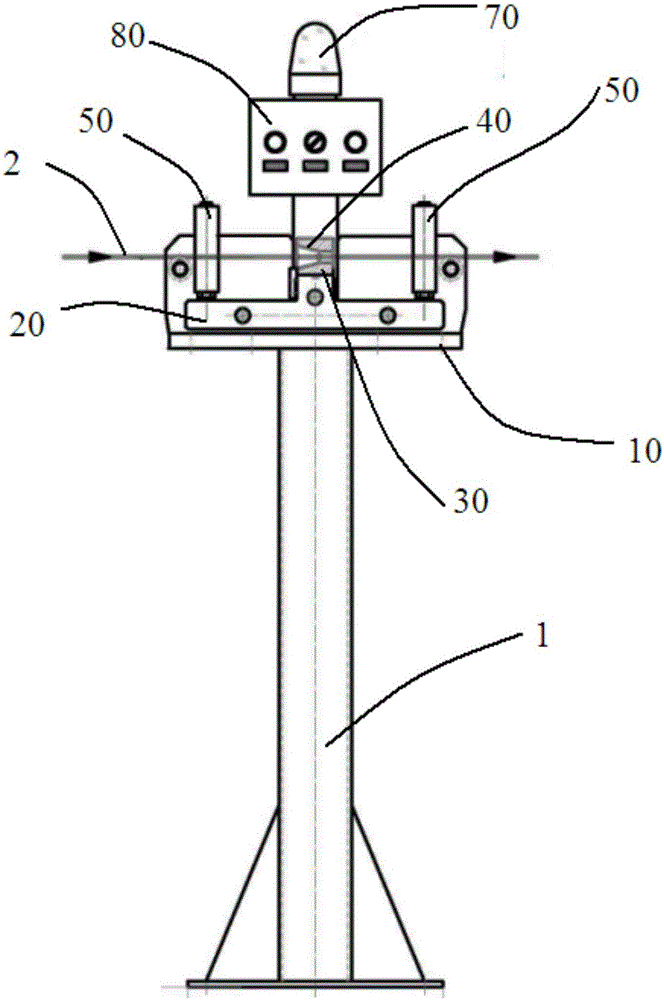

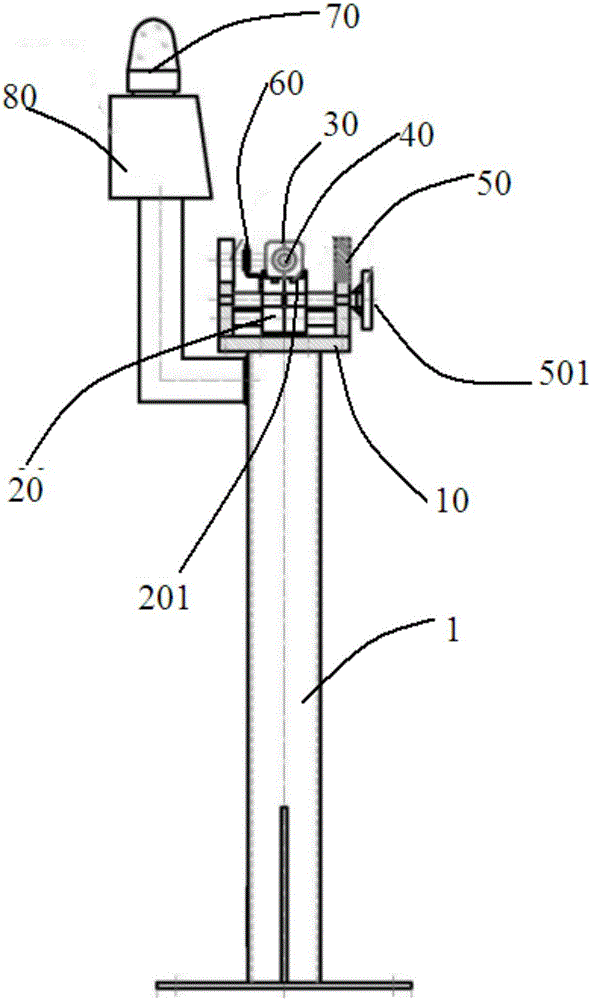

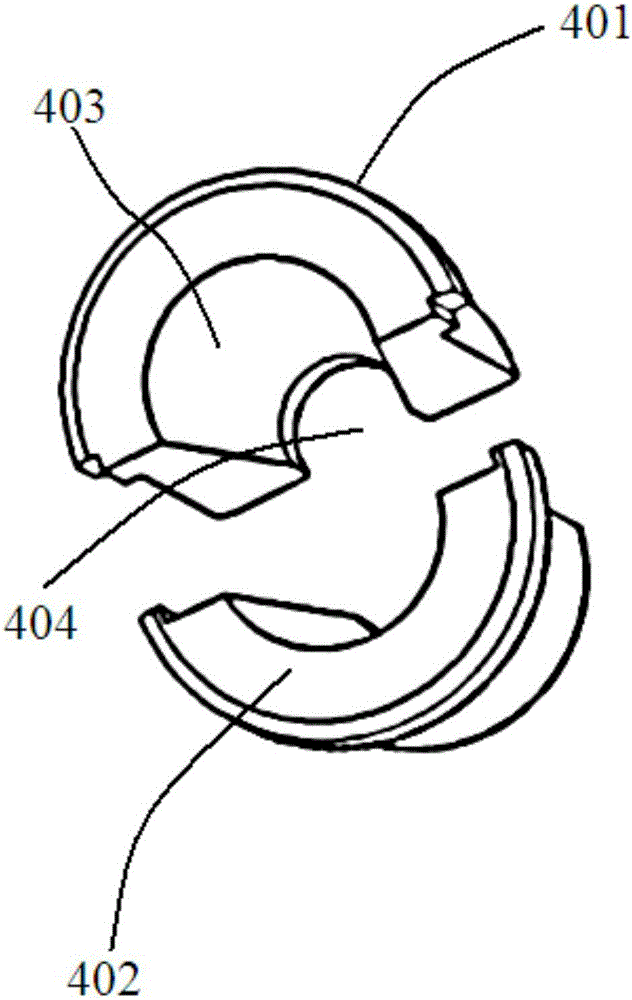

Novel numerical control silicon steel sheet transverse shearing line device

ActiveCN105397495AReduce distanceShorten the lengthOther manufacturing equipments/toolsShearing machine accessoriesNumerical controlPunching

The invention discloses a novel numerical control silicon steel sheet transverse shearing line device. The novel numerical control silicon steel sheet transverse shearing line device comprises a control center, a discharging device and a feeding channel. The feeding channel is sequentially provided with a front feeding device, a first punching device, a V-shaped opening shearing device, a second punching device, a rear feeding device, a swing shearing device and a discharging table. A material collecting device is arranged behind the discharging table. The material collecting device comprises a magnetic conveying belt and a sheet stacking table. The numerical control silicon steel sheet transverse shearing line device has the beneficial effects that the front feeding device and the rear feeding device are arranged, waste of sheets is reduced, and the shearing precision is improved; twisting and bulging of silicon steel sheets are avoided, and high-speed conveying of the silicon steel sheets is achieved; the first punching device and the second punching device are symmetrically distributed on the front side and the rear side of the V-shaped opening shearing device, one-step punching is achieved, time is saved, and the production efficiency is improved; and according to the material collecting device, the magnetic conveying belt is matched with the sheet stacking table, shorn silicon steel sheets are automatically stacked in order, operation of workers is reduced, human resources are saved, and efficiency is improved.

Owner:CANWIN AUTOMATIC EQUIP CO LTD

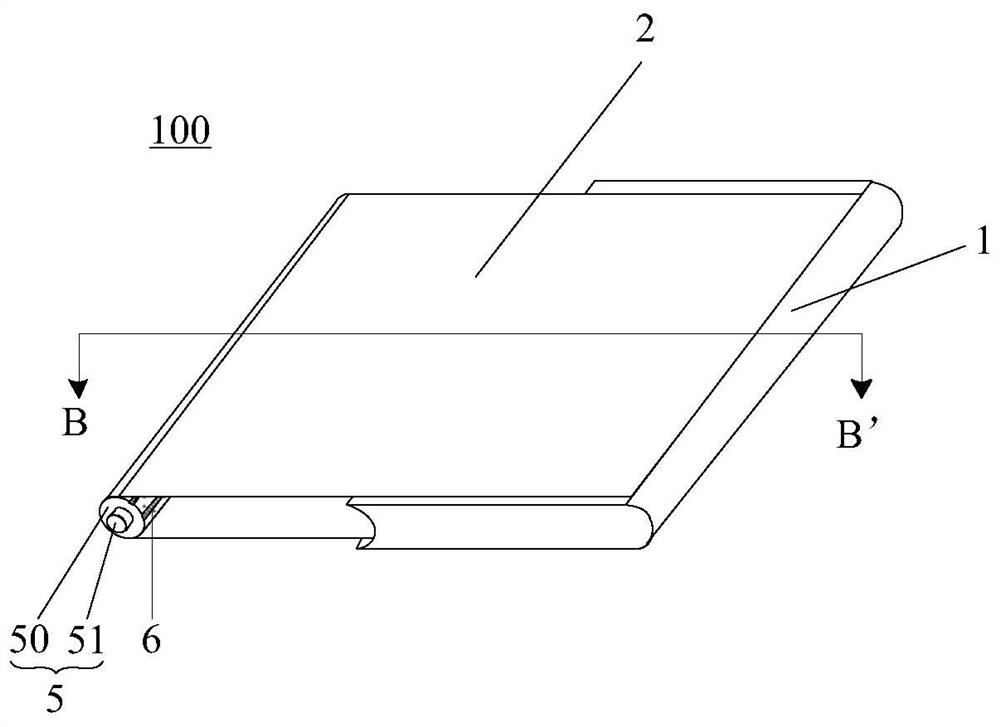

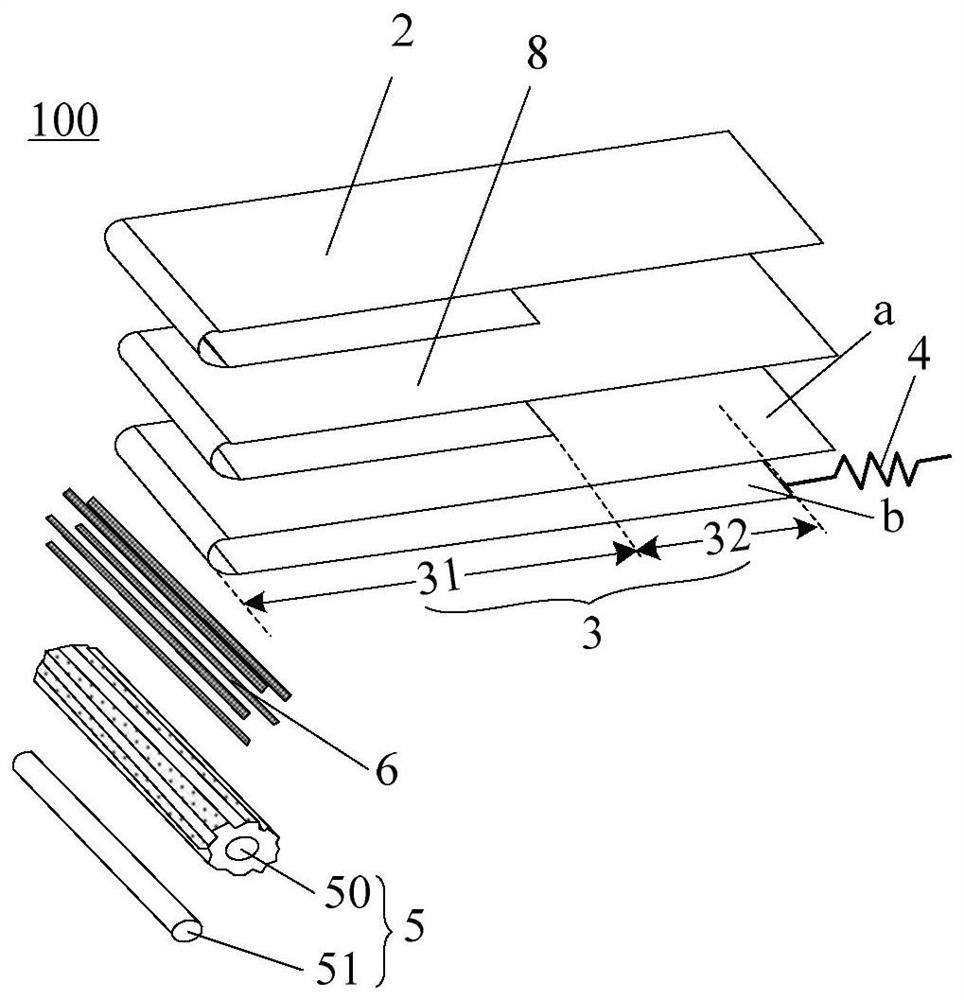

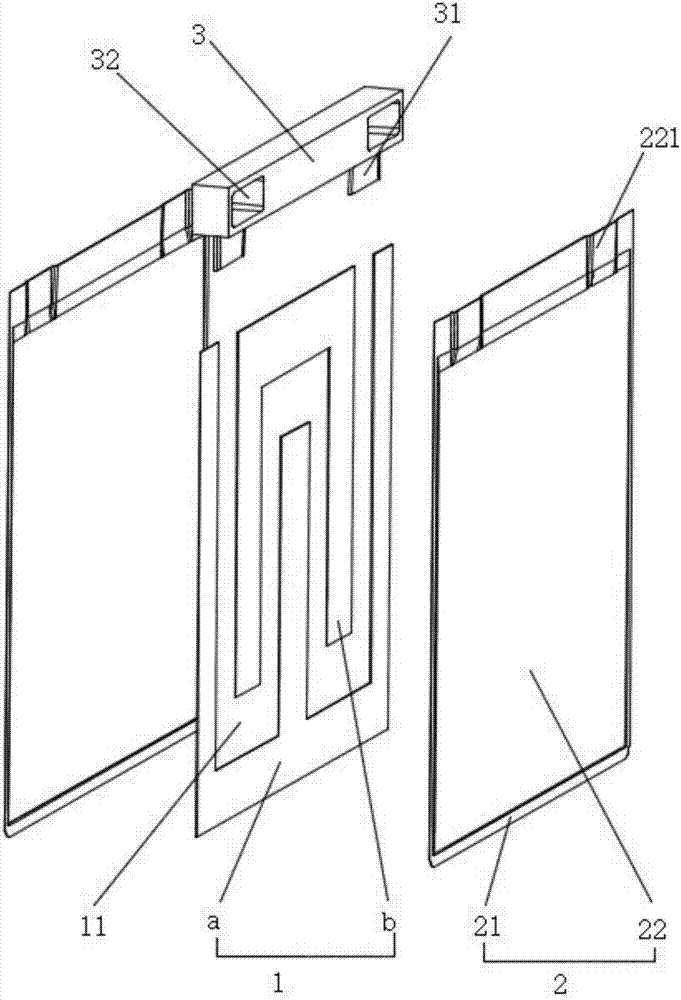

Display device

The embodiment of the invention provides a display device, relates to the technical field of the display, and can solve the problems that a flexible display screen is bulged to be damaged and slippingand idling occur between a reel and a flexible metal supporting layer, and the display device comprises a first shell which is provided with a first supporting surface, at least one part of the flexible display screen covers the first supporting surface; the flexible metal supporting layer is arranged on the side, close to the first supporting face, of the flexible display screen and connected with the flexible display screen. The first end of the flexible metal supporting layer covers the first supporting surface and is connected with the first supporting surface; the elastic element is located in the first shell and connected with the first shell and the second end of the flexible metal supporting layer. The reel is arranged on the side, away from the flexible display screen, of the flexible metal supporting layer. The flexible display screen and the flexible metal layer are wound on the scroll; the magnetic element is located between the reel and the flexible metal supporting layer, connected with the reel and magnetically attracted to the flexible metal supporting layer.

Owner:BOE TECH GRP CO LTD

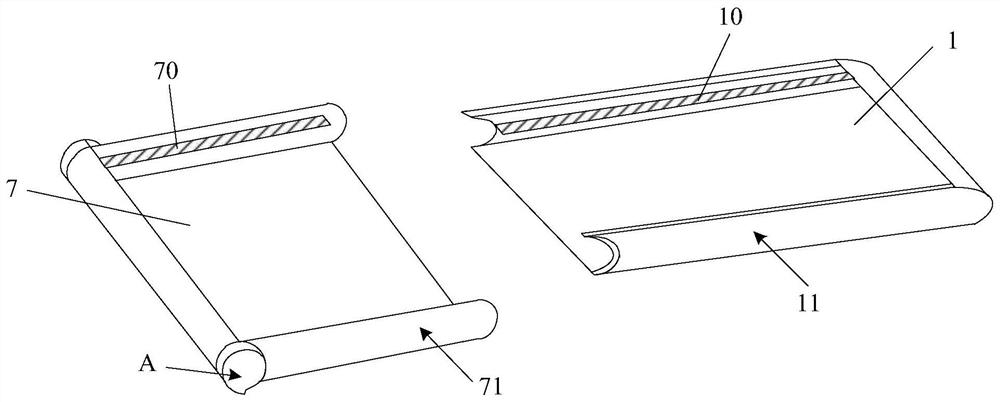

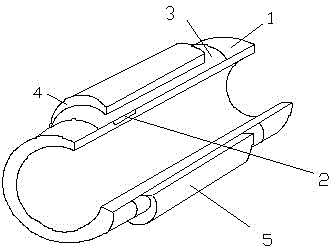

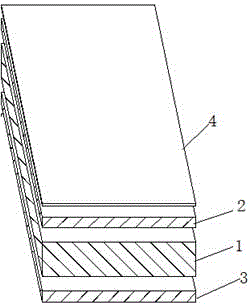

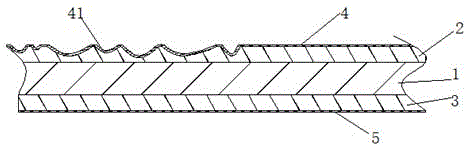

Over-pressure over-temperature environment-friendly silica gel composite pipe and preparation method thereof

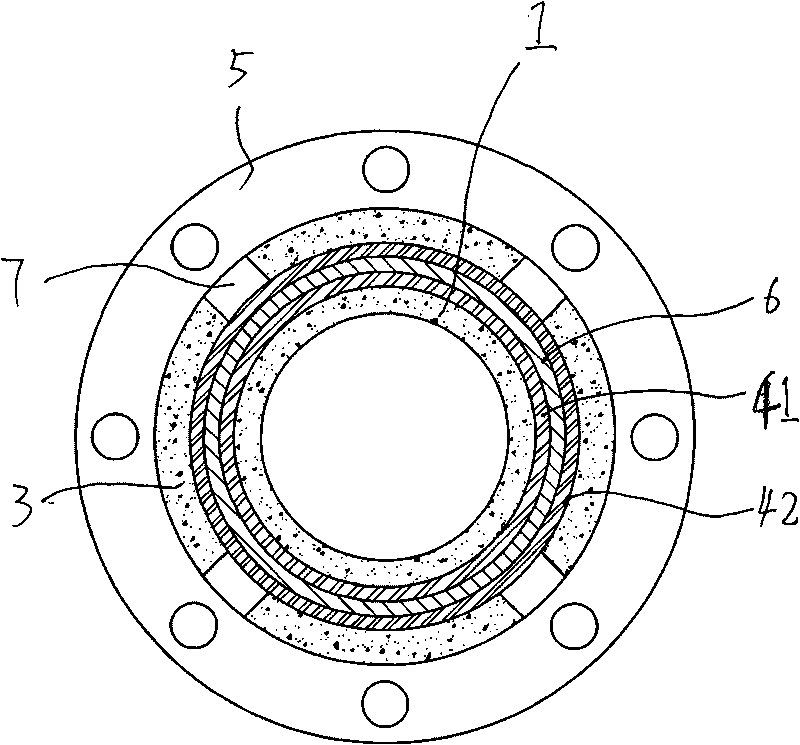

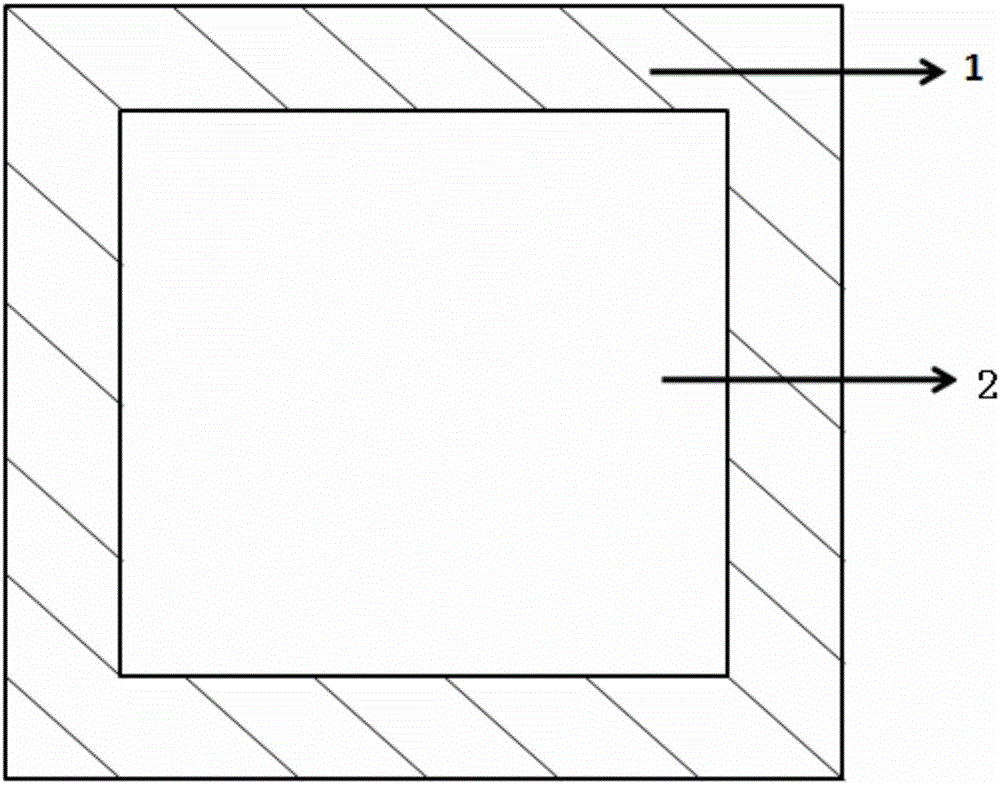

The invention belongs to the technical field of silica gel pipes and preparation methods thereof, and discloses an over-pressure over-temperature environment-friendly silica gel composite pipe and a preparation method thereof. The over-pressure over-temperature environment-friendly silica gel composite pipe is mainly and technically characterized by comprising an inner rubber layer and an outer rubber layer which are made of silicon rubber, wherein a strengthening layer is arranged between the inner rubber layer and the outer rubber layer. The inner rubber layer 1 and the outer rubber layer 3 comprise the following materials in parts by weight: 100 parts of silicon rubber SR, 40-55 parts of fume colloidal silica, 0.4-1 part of vulcanizing agent double-25DBPMH, 1-5 parts of ferric oxide, 0-5 parts of colorant, 5-8 parts of environment-friendly tasteless adhesive AS-88 and 5-8 parts of inorganic flame retardant aluminium hydroxide or zinc borate. The silicon rubber composite pipe is prepared by adopting the following steps of: freezing an inner rubber tyre to harden, winding the strengthening layer and vulcanizing, thus, the pressure resistance and the high temperature resistance of the common silicon rubber pipe are improved, the service life of the common silicon rubber pipe is prolonged, and the abrasion resistance is improved.

Owner:河北东劲液压橡塑制品有限公司

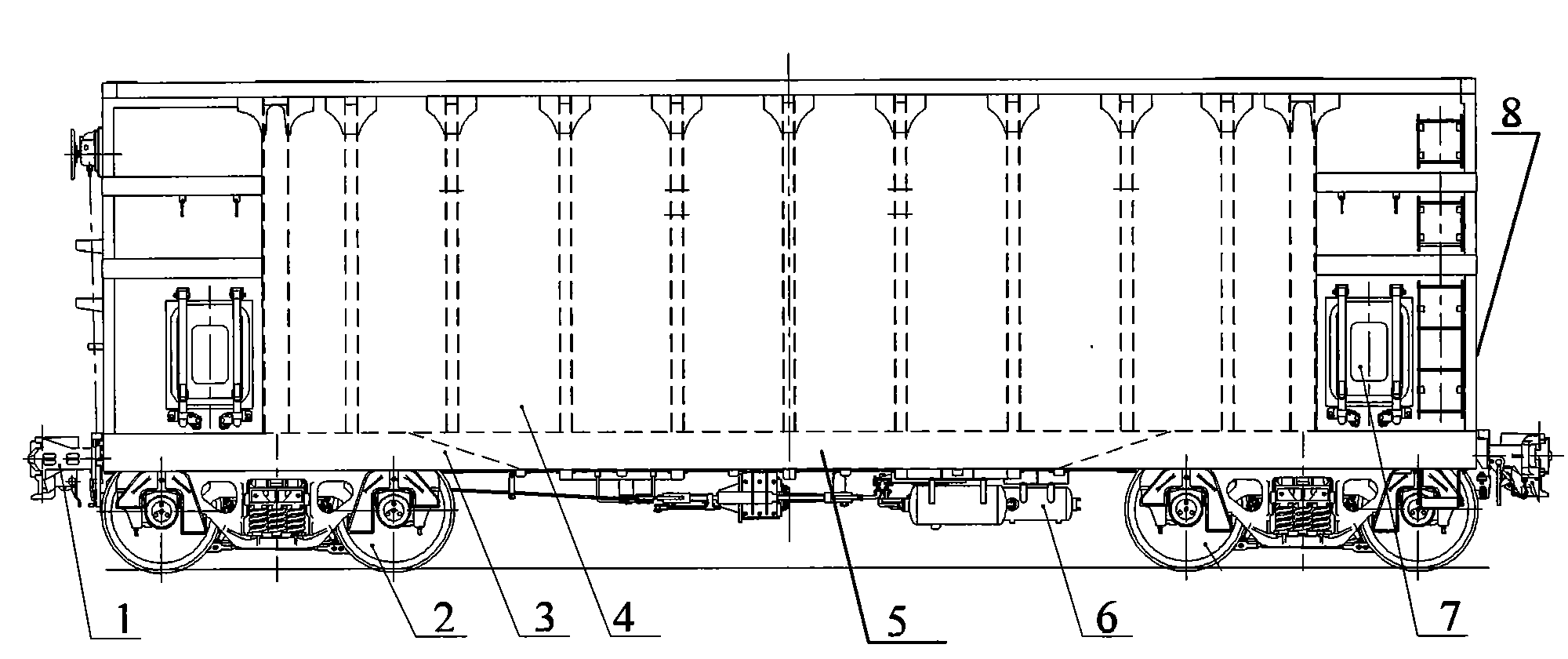

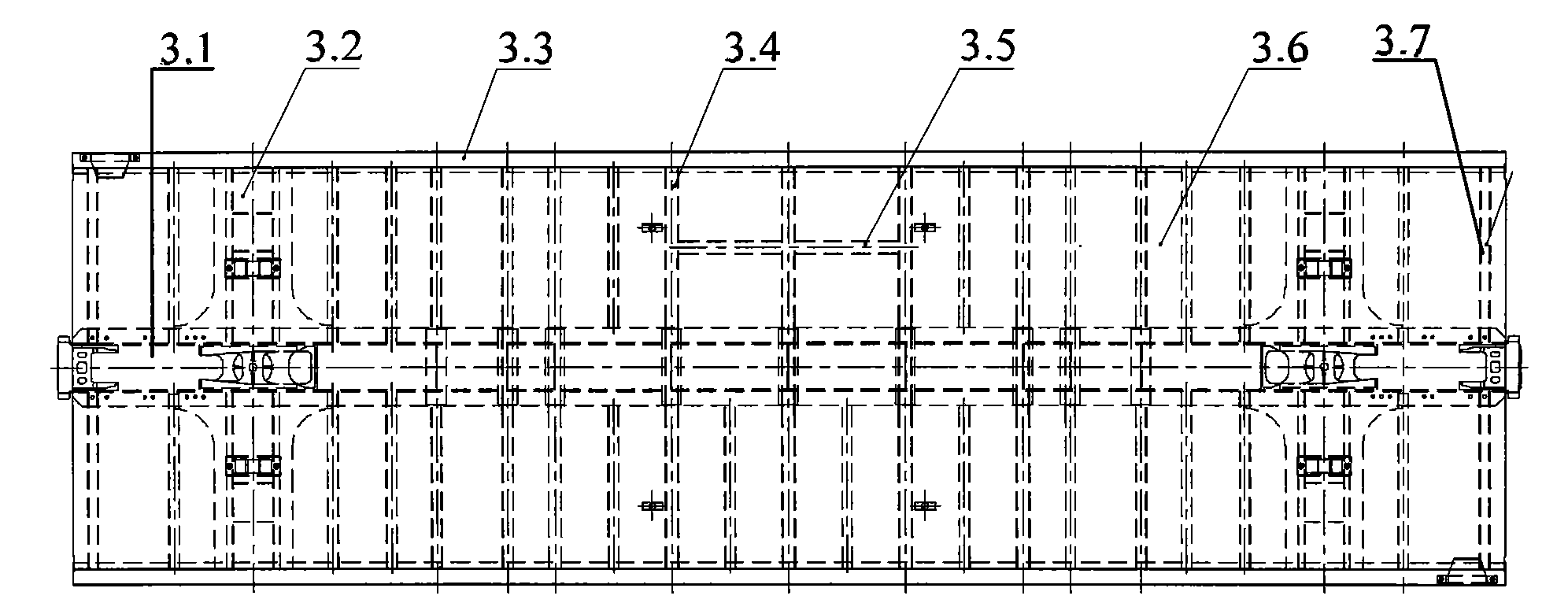

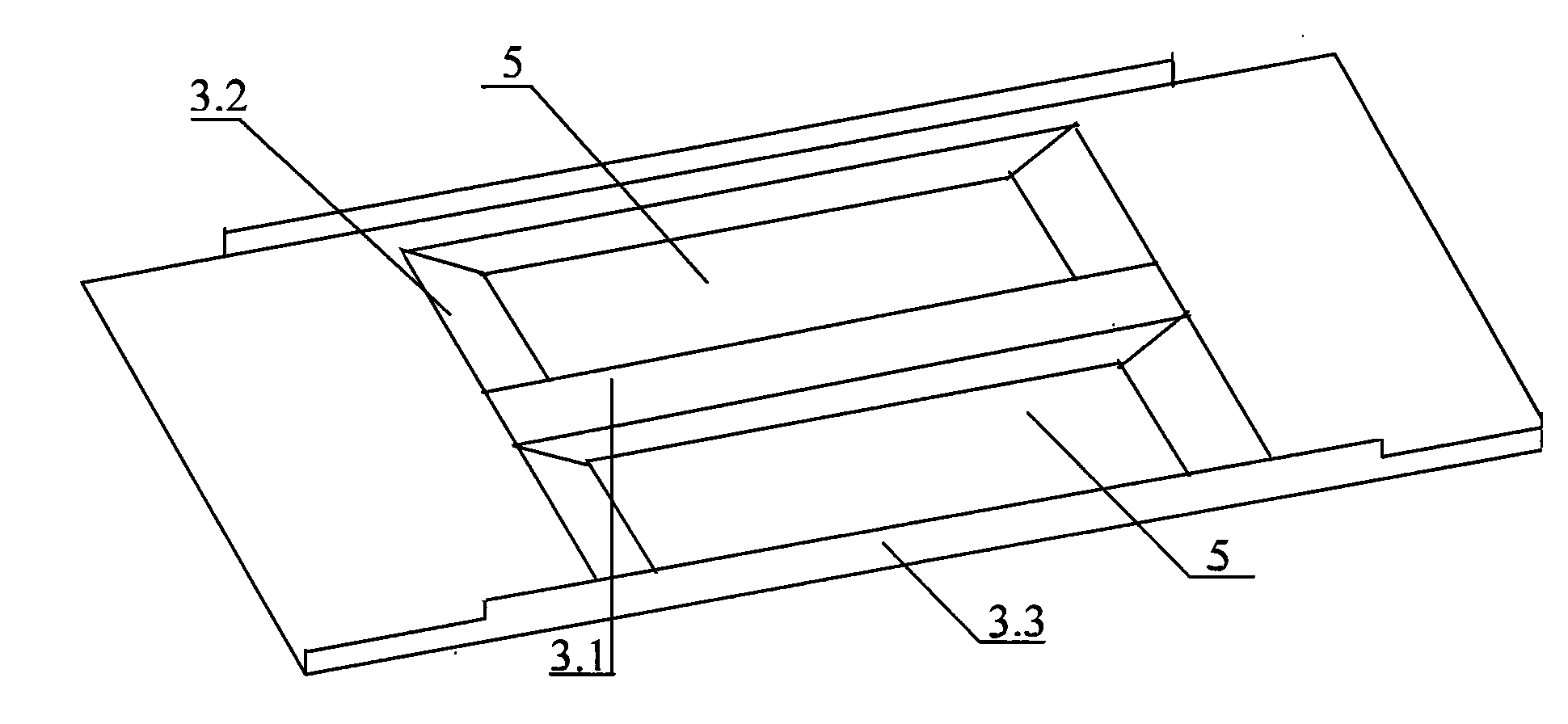

Special gondola vehicle with a shallow concave bottom for coal transportation

ActiveCN101585364ALower center of gravityEasy maintenance and repairRailway transportAxle-box lubricationBogieEngineering

A special gondola vehicle with a shallow concave bottom for coal transportation belongs to the transportation facilities, in particular to a railway truck gondola vehicle. The gondola vehicle comprises a vehicle body, a vehicle coupler buffer device, a braking device and a bogie. The vehicle body comprises a chassis, a side wall and an end wall. The key technique is that the chassis comprises a centre sill, a sleeper beam, a lower side beam and an end beam, two downwards concave shallow concave bottoms are arranged between the two sides of the centre sill and between the lower side beam and the sleeper beam in the middle of the side wall, the depths of the shallow concave bottoms are aligned with the lower plane of the centre sill, the side wall comprises a side wall board and a side post, the two ends of the side wall are end door panels which are inwards concave with respect to the side wall board to form stages, so as to form the end door plate with a concave structure. The invention not only effectively increases the vehicle body volume, but also decreases vehicle height of center of gravity, and improves vehicle riding quality.

Owner:CRRC MEISHAN

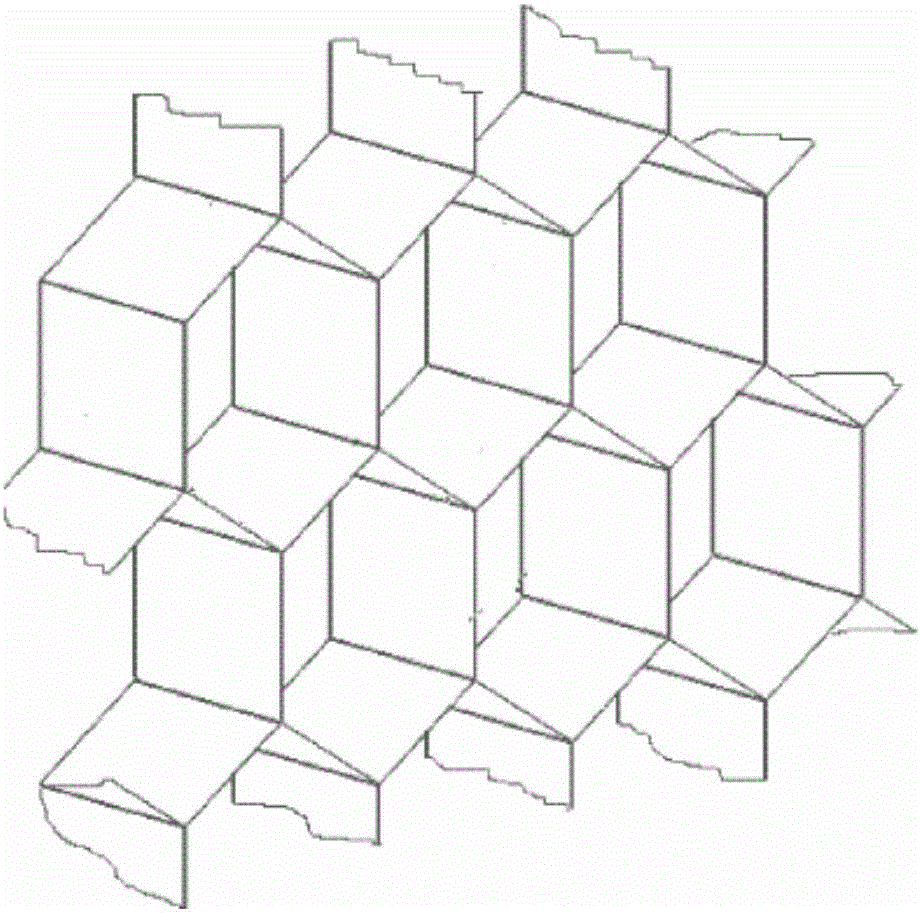

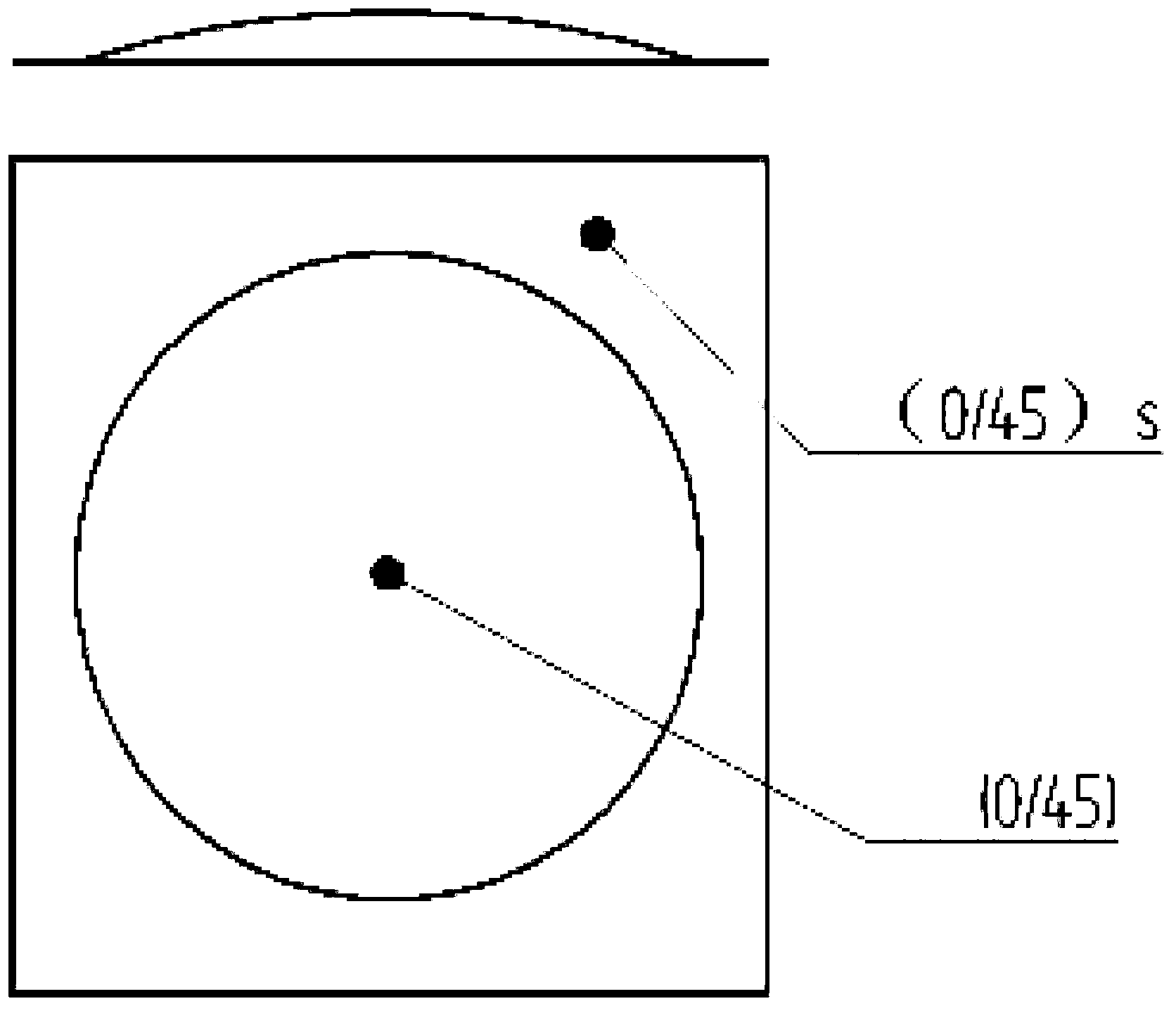

Integrated molding method for high-temperature-resistant heat-insulation wave-transmissive radome with honeycomb interlayer C

The invention discloses an integrated molding method for a high-temperature-resistant heat-insulation wave-transmissive radome with a honeycomb interlayer C and relates to the field of composite structure molding processes. The integrated molding method is realized through the steps of preparing a high-temperature-resistant polyimide honeycomb core; filling honeycomb core girds with aerogel; precuring a quartz / polyimide composite flanged connection frame; molding a quartz / polyimide skin; assembling through bonding by using a high-temperature-resistant glue film; coating; curing; machining and the like. The schematic diagram of the radome is as shown in figure 1; one-step integrated molding is realized by using an autoclave molding process and a stepwise preparation way of the core, the skin and a connecting flange, so that the problem that the high-temperature-resistant radome with the honeycomb interlayer structure has no multifunctional integration is solved, and the radome is enabled to be high-temperature-resistant and also meets the design requirements of heat insulation and wave transmission; and meanwhile, a flanged connection structure, shaped like a Chinese character Hui, of the radome is artfully and integrally molded together with a radome body, so that the connection process is simplified, the assembling quality is improved, and the assembling period is shortened.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

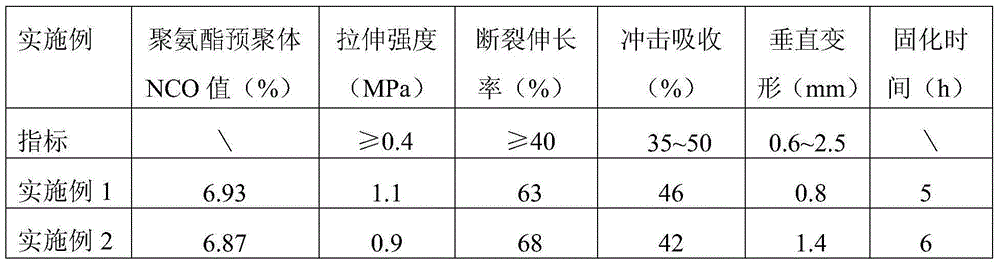

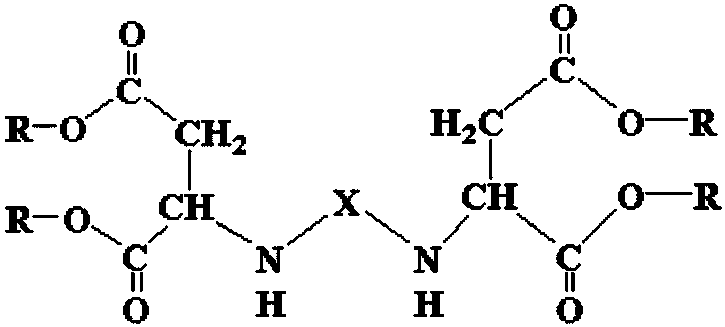

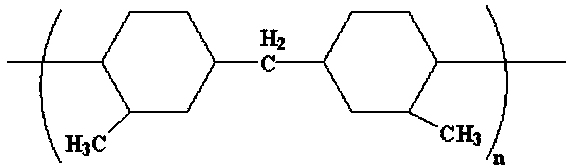

Method for preparing environment-friendly polyurethane adhesive for plastic track

InactiveCN105038684AWell formedImprove quality scoreNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane adhesiveChlorinated paraffins

The invention discloses a method for preparing an environment-friendly polyurethane adhesive for a plastic track. According to the method, polyether polyol and aromatic diisocyanate serve as raw materials, chlorinated paraffins and dibutyl phthalate serve as auxiliaries, white carbon black serves as packing, organotin serves as a catalyst, and the environment-friendly high-performance polyurethane adhesive for the plastic track is prepared through a prepolymer method. The prepared adhesive is moderate in system viscosity in the preparation process, the temperature can be controlled easily, and the adhesive is good in product quality, stable in performance and high in yield and room temperature bonding strength. After the adhesive is evenly mixed with rubber particles according to a certain proportion and compressed, a sample is very excellent in mechanical property, and the surface drying time and curing time are short. The adhesive is low in volatility, non-toxic and free of pungent smell, does not cause damage to constructors and users, is good in breathability and conforms to the environmental protection and construction requirements.

Owner:YANCHENG INST OF TECH

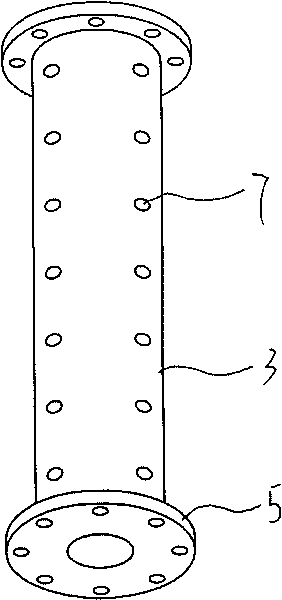

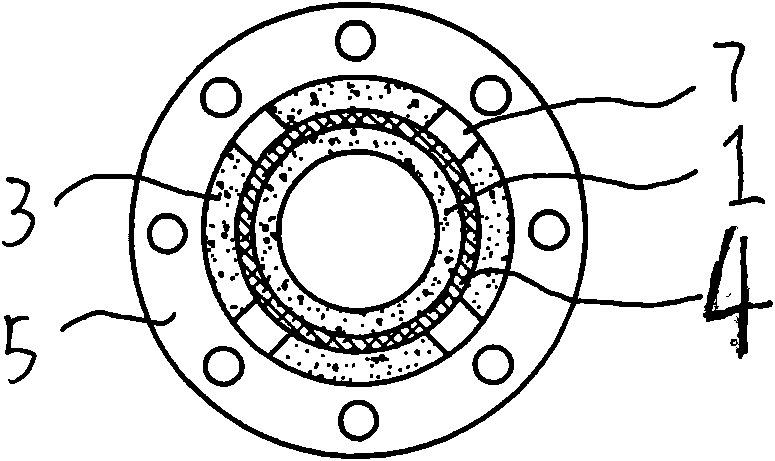

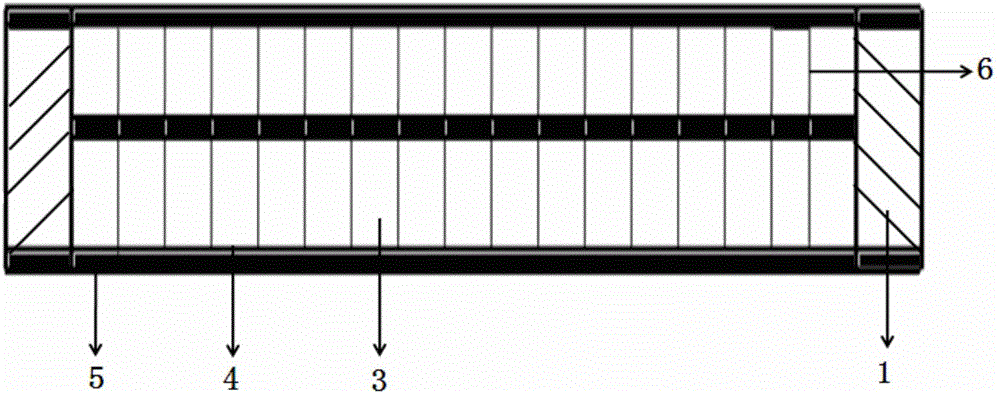

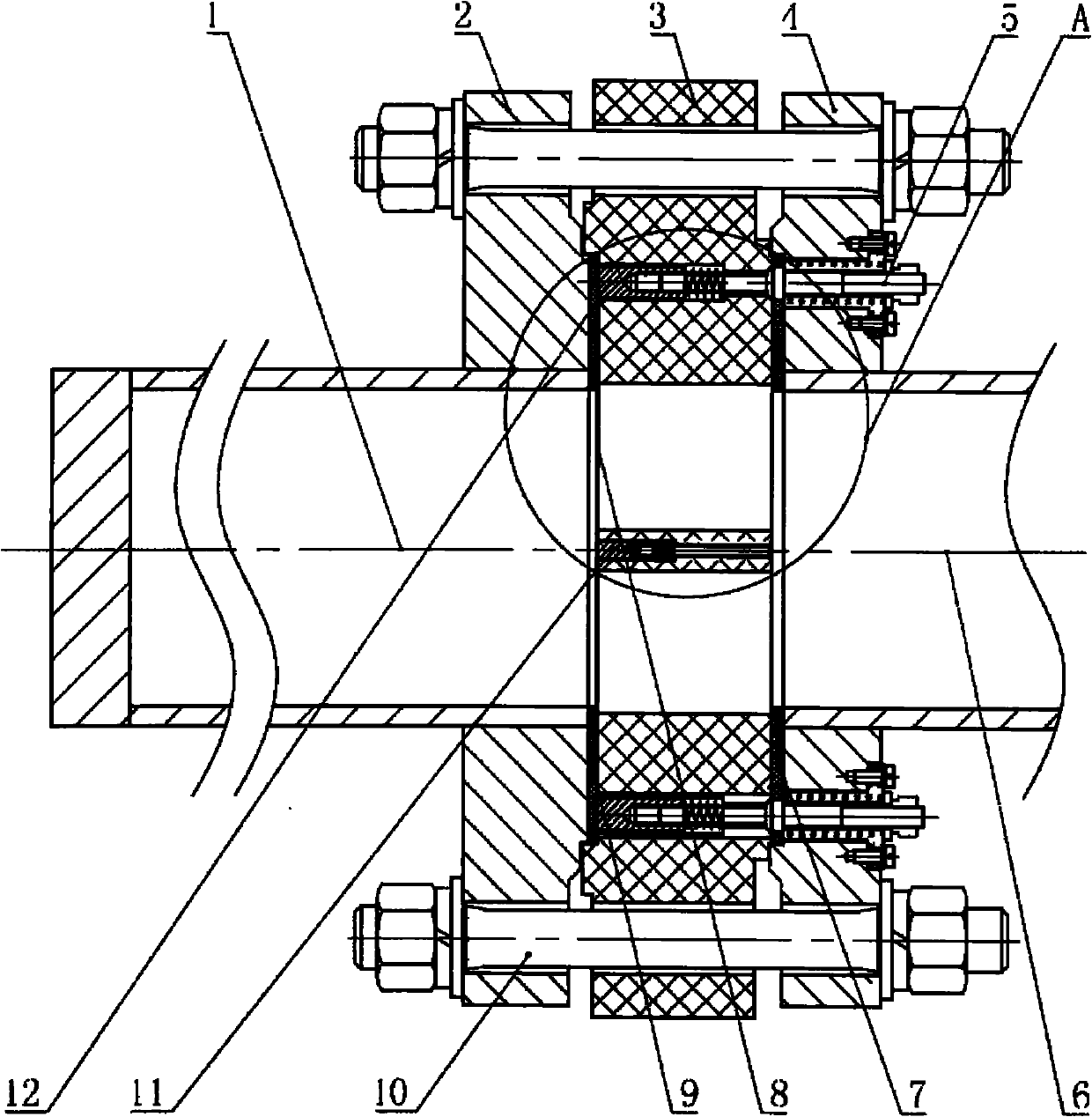

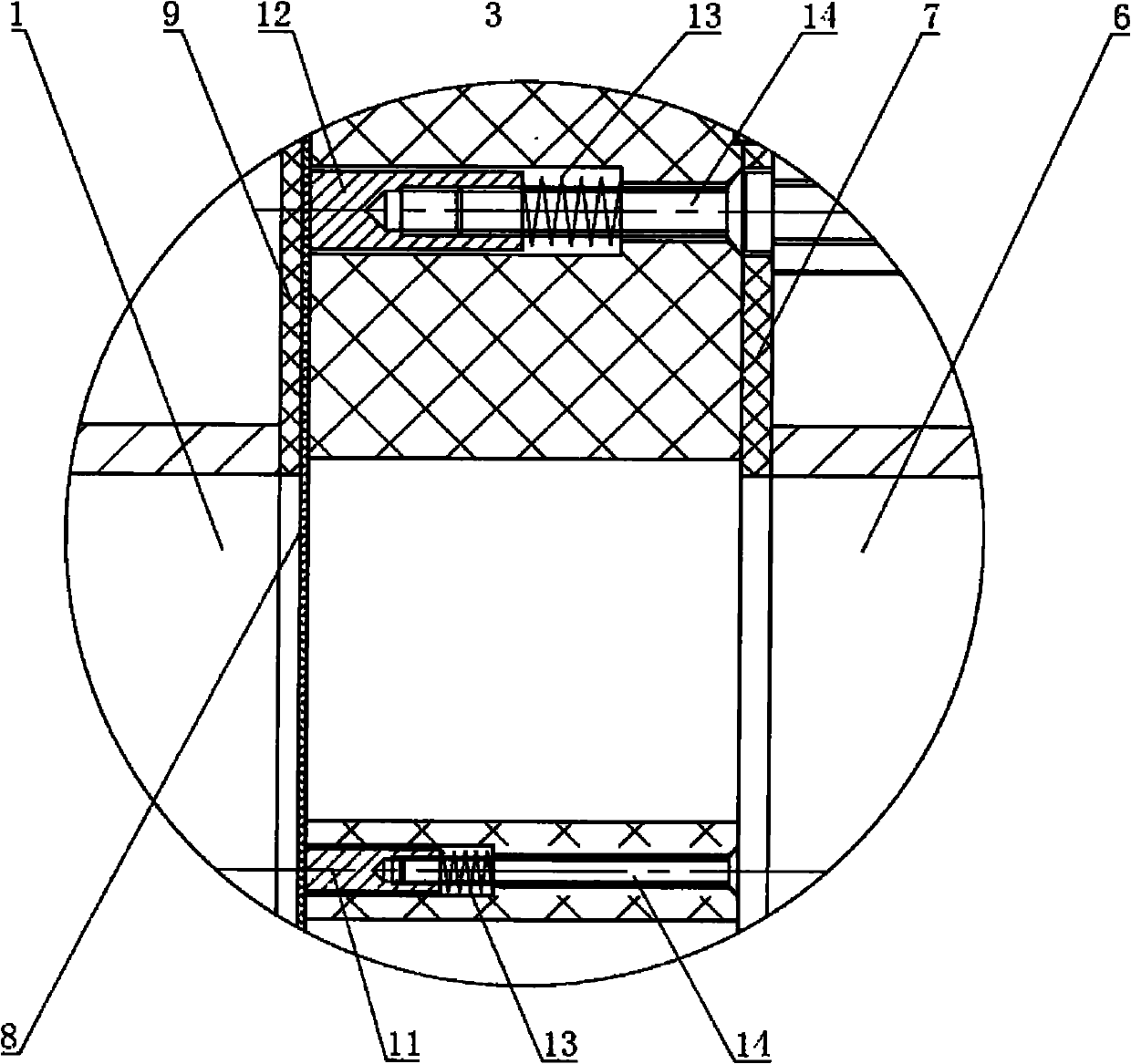

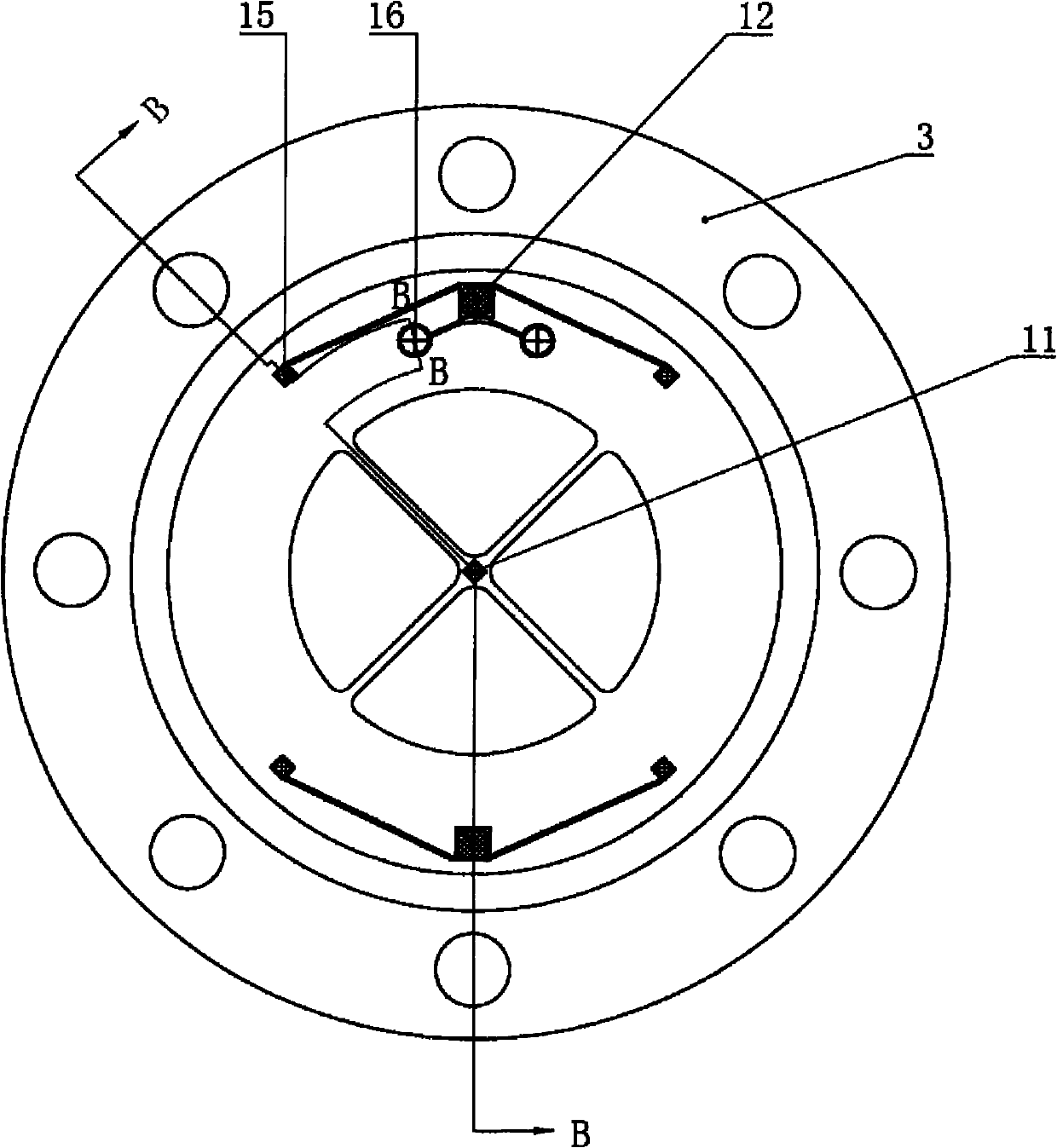

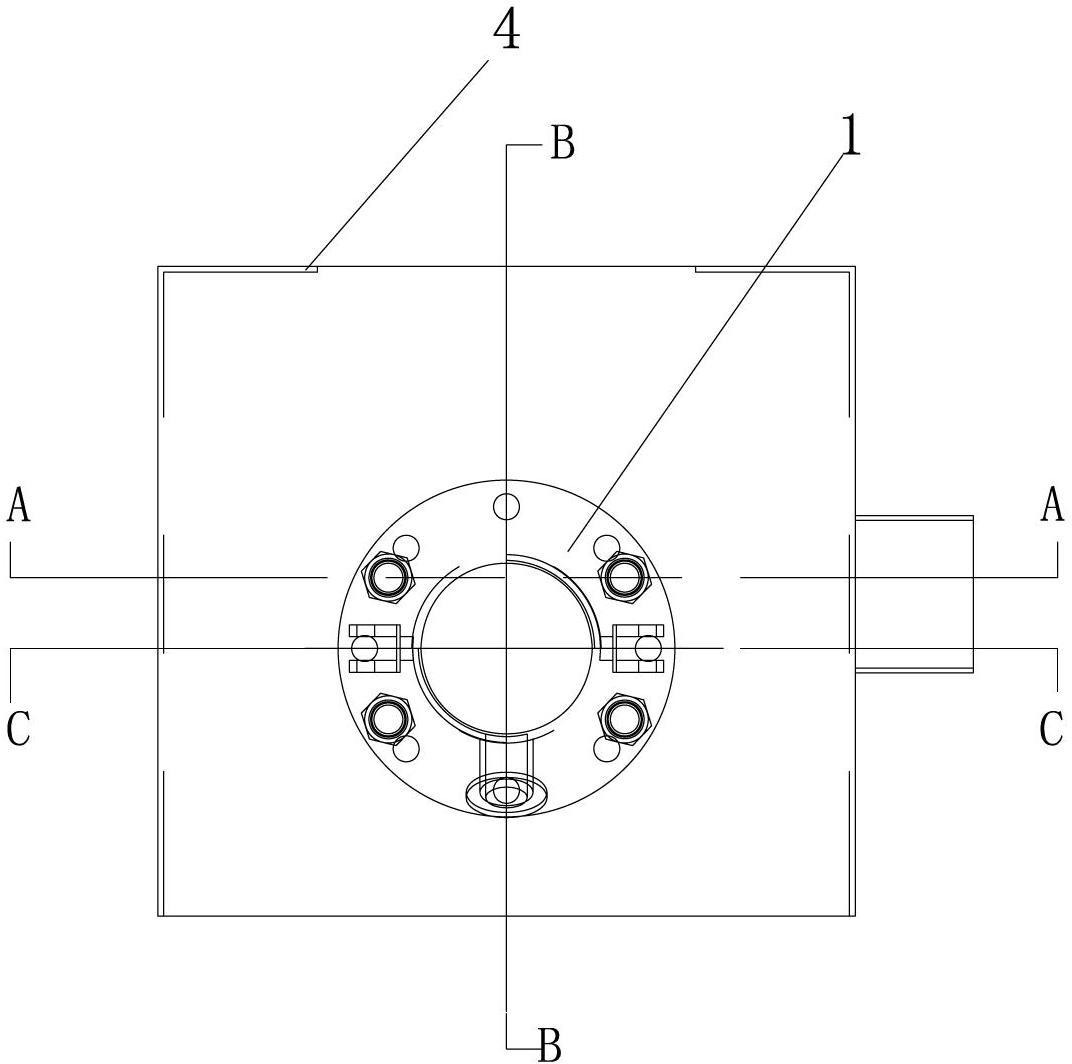

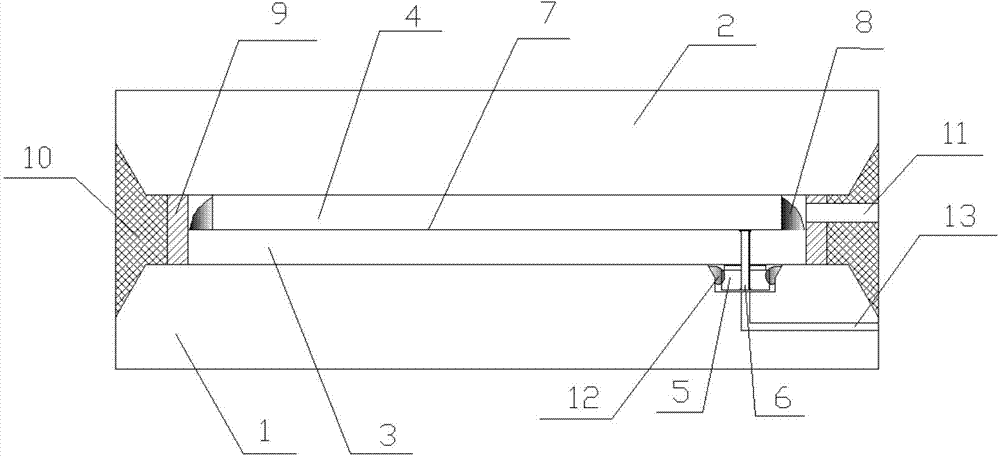

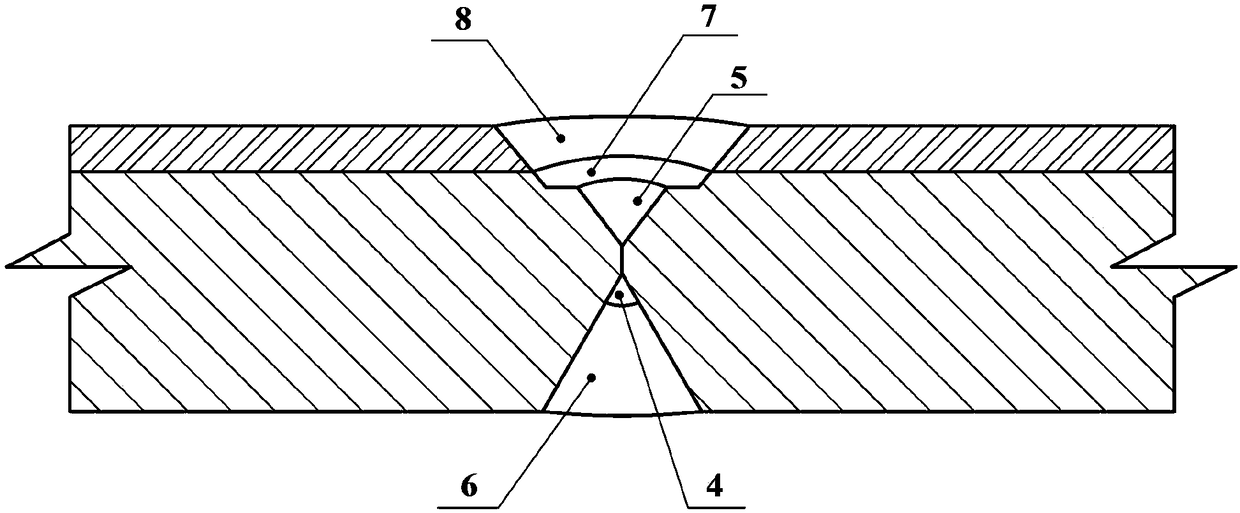

Film-breaking device of electric film-breaking shock tube

InactiveCN101975654AGood break symmetryAvoid bulgingHydrodynamic testingElectrical resistance and conductanceShock wave

The invention relates to a film-breaking device of an electric film-breaking shock tube, which comprises a high-pressure section (1) and a low-pressure section (6) that are connected through a bolt (10), wherein a film-breaking device is arranged between the high-pressure section (1) and the low-pressure section (6). The film-breaking device is characterized by being a circular baffle plate (3), the periphery of which is an annular plate, wherein the center of the circular baffle plate (3) is provided with a center column, ribs are uniformly distributed between the center column and the annular plate, a fan cavity is formed between every two ribs; the annular plate is provided with a power supply binding post (5); a center conducting column (11) is arranged on the center column; a wire fixing post (15) is arranged on the annular plate; a resistor wire (17) is wound between the wire fixing post (15) and the center conducting column (11), each rib forms a bridge frame of the resistor wire (17), the resistor wire (17) is connected through an electric connecting member to form a power supply loop; and an easily-melting film (8) is adhered on the circular baffle plate (3); and the back surface of the easily-melting film (8) is tightly attached to the resistor wire (17) on the bridge frame.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

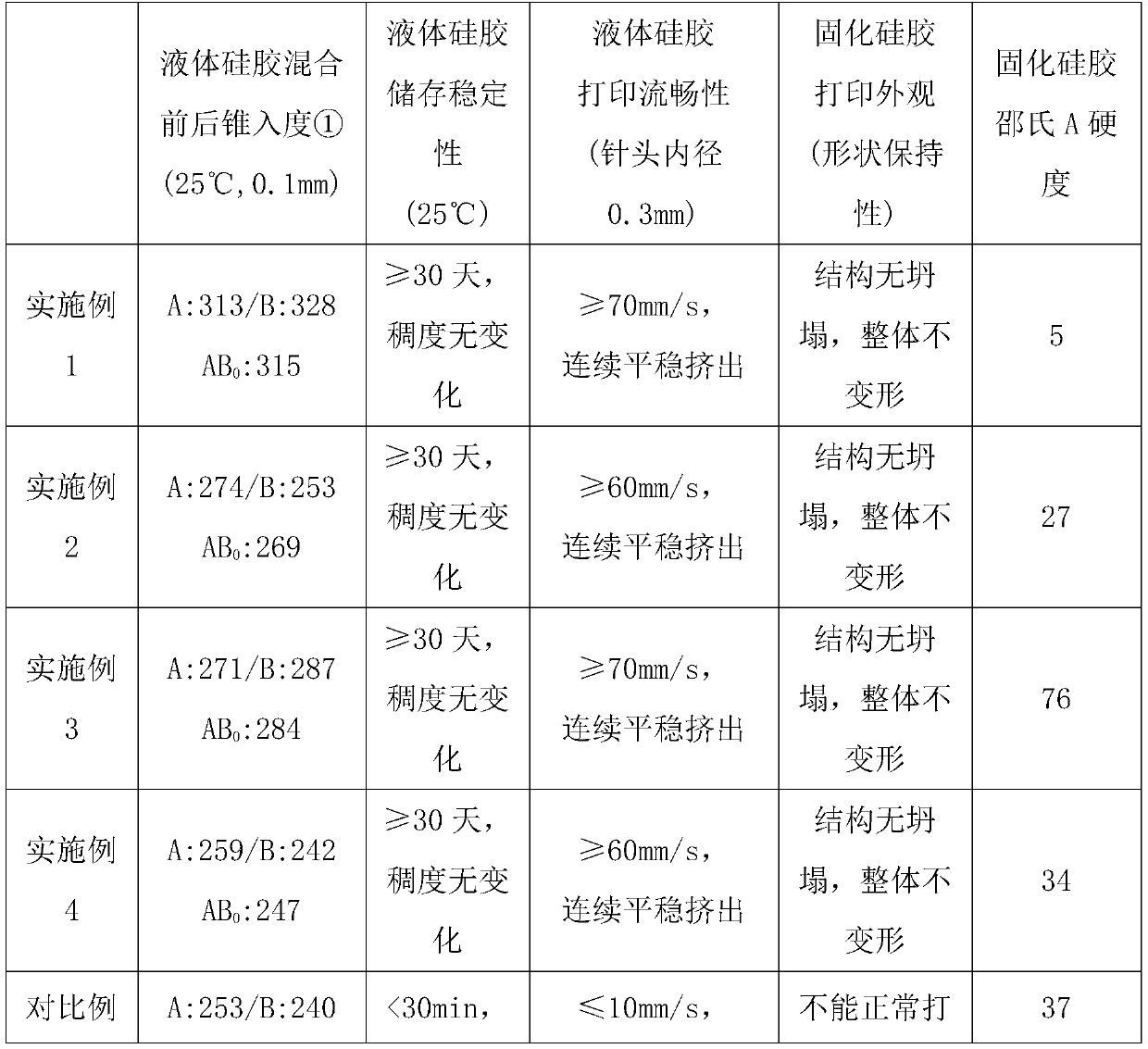

Dual component liquid silica gel for 3D printing and printing method thereof

ActiveCN110128833ASolve problems that are difficult to 3D printIncrease elasticityAdditive manufacturing apparatus3D object support structuresOrganic solventPolyol

The invention discloses a dual component liquid silica gel for 3D printing and a printing method thereof. The liquid silica gel comprises a component A and a component B. The component A comprises following components in parts by weight: 100 parts of vinyl polysiloxane, 0.01 to 5 parts of a hydrosilylation catalyst, 1 to 10 parts of polyether polyol, and 1 to 10 parts of fumed silica. The component B comprises following components in parts by weight: 100 parts of vinyl polysiloxane, 1 to 50 parts of hydrogen containing polysiloxane, 0.01 to 5 parts of a hydrosilylation inhibitor, 1 to 10 partsof polyether polyol, and 1 to 10 parts of fumed silica. During the printing process, the thickness of the liquid silica gel does not change, the structure is not deformed, an onsite heat treatment isnot needed, only post sectioned thermosetting moulding is needed, the printing technology is simplified, and the printing cost is reduced. The liquid silica gel does not contain any organic solvent or photosensitive component, is very safe and nontoxic, and 3D products prepared from the liquid silica gel can be applied to fields, which have high safety requirements, such as children toys, food, medicines, and the like.

Owner:SOUTH CHINA UNIV OF TECH

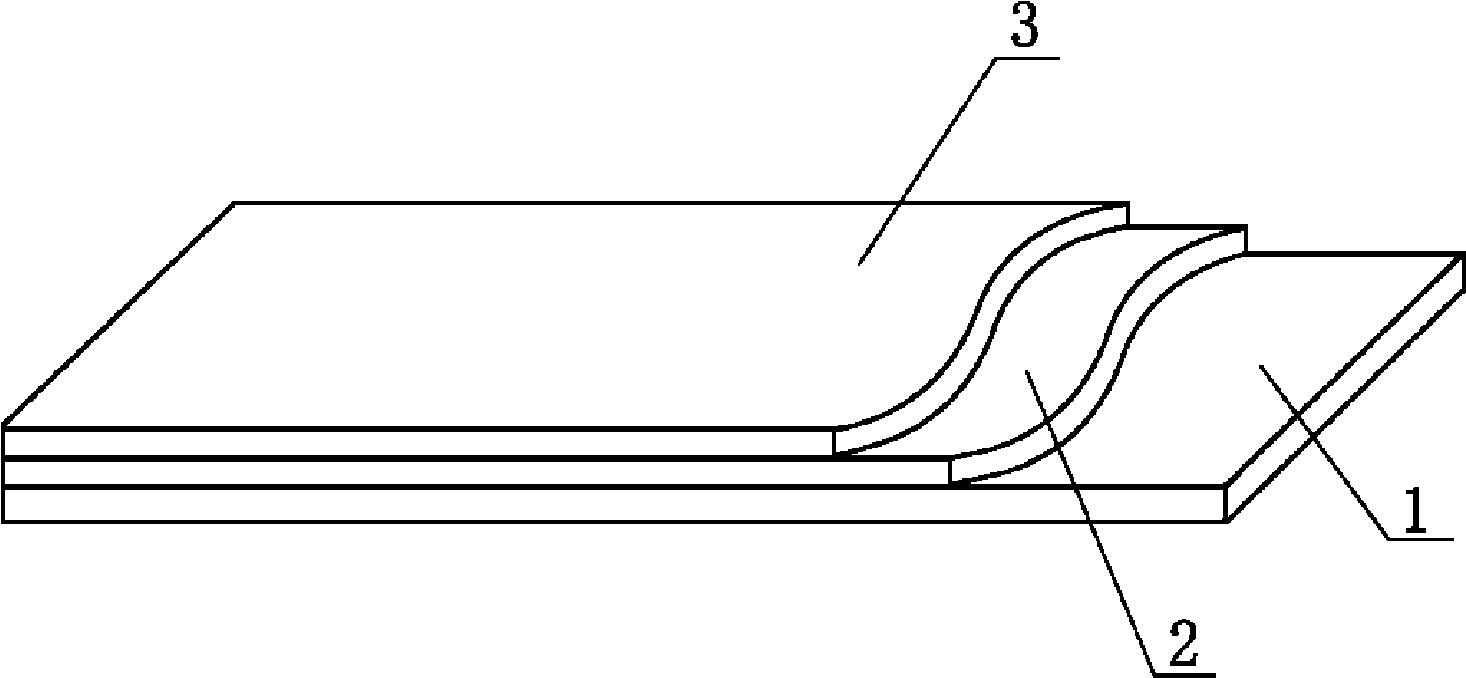

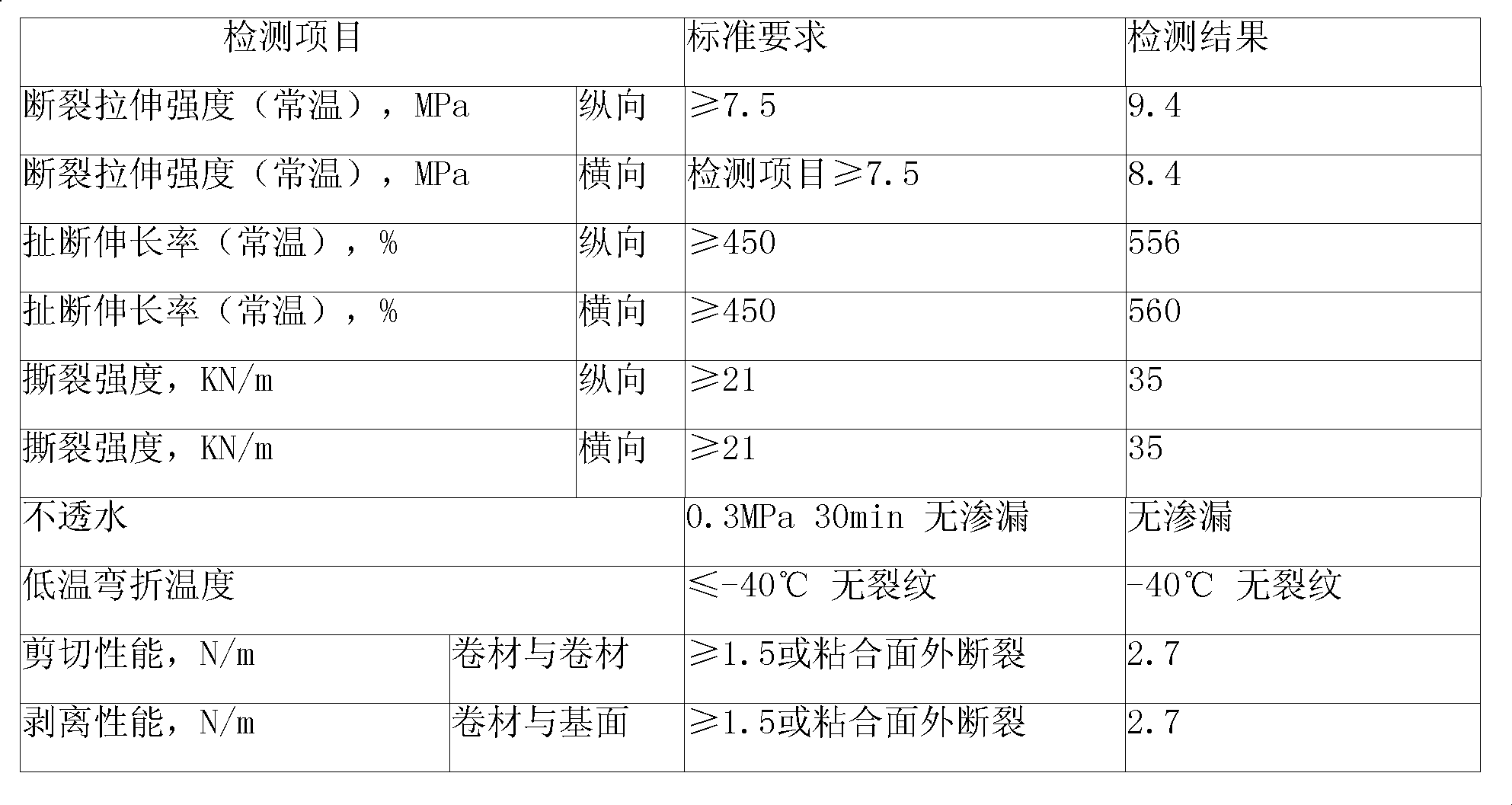

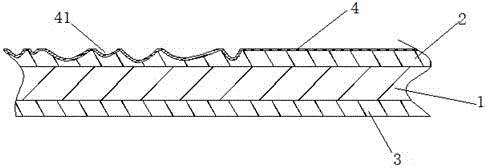

Self-adhering rubber water-proof coiled material and method for preparing same

InactiveCN101545285AUnique "self-locking water" functionSolve the problem of water leakageProtective foundationMarine site engineeringGlass fiberEngineering

A self-adhering rubber water-proof coiled material and a method for preparing the same composed of a rubber water-proof coiled material basal layer, a glue spreading reinforcement layer and a self-adhering rubber waterproof layer on the glue spreading reinforcement layer. The glue spreading reinforcement layer is glue spreaded nonwoven cloth or glue spreaded glass-fiber cloth. The self-adhering rubber waterproof layer is produced by mixing the following materials in proportion by weight: 60-70 portions of ethylene propylene terpolymer (PET); 10-26 portions of butyl rubber; 4-25 portions of chloroprene rubber; 50-70 portions of black carbon; 50-70 portions of fine particle calcium carbonate; 2-7 portions of coumarone; 10-20 portions of naphthenic oil; 5-10 portions of zinc oxide and 0.7-1.2 portions of stearic acid. The construction art is simple and fast. Because the self-adhering base material contains hydrophilic material, the basal layer can be in wet lay up if the basal layer has no water. The method has no glue brushing and glue shining process so as to save time limit for a project and the cost, effectively avoid hollow casing and burst phenomenon and form a whole a complete waterproof sealing system.

Owner:北京立高科技股份有限公司

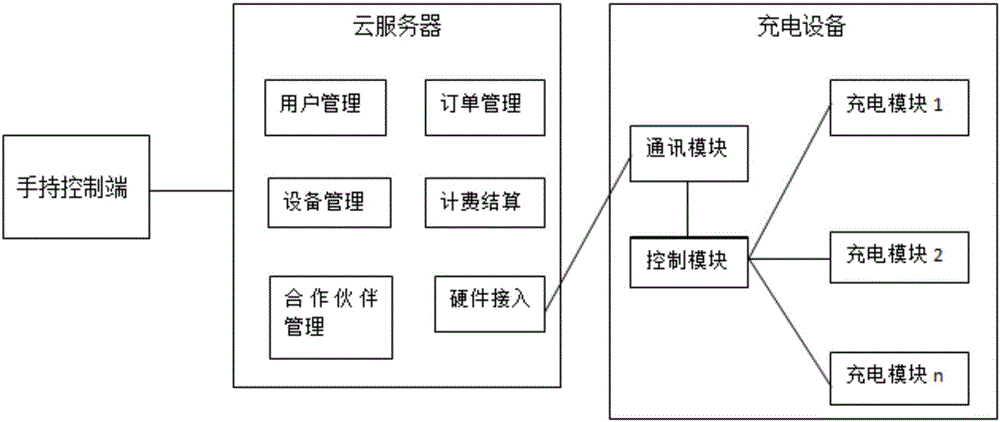

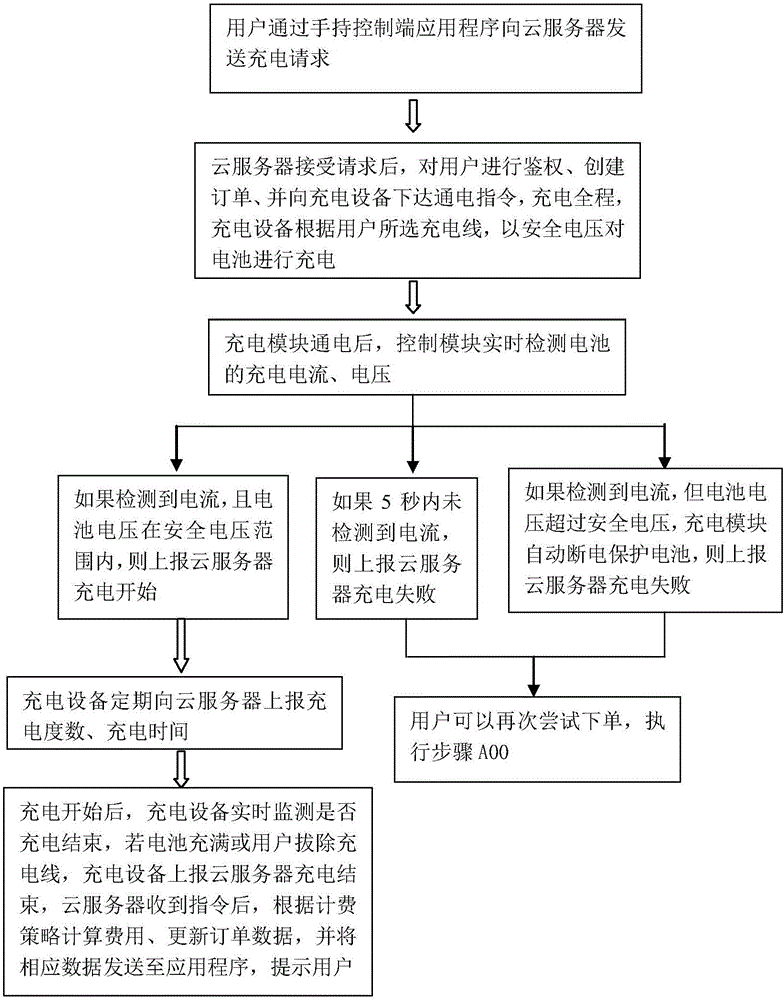

Electric bicycle self-service charging system and method

InactiveCN106230039AImprove securityMeet the use requirementsCharging stationsElectric powerHand heldTime cost

Owner:深圳市绿色星球互联新能源科技有限公司

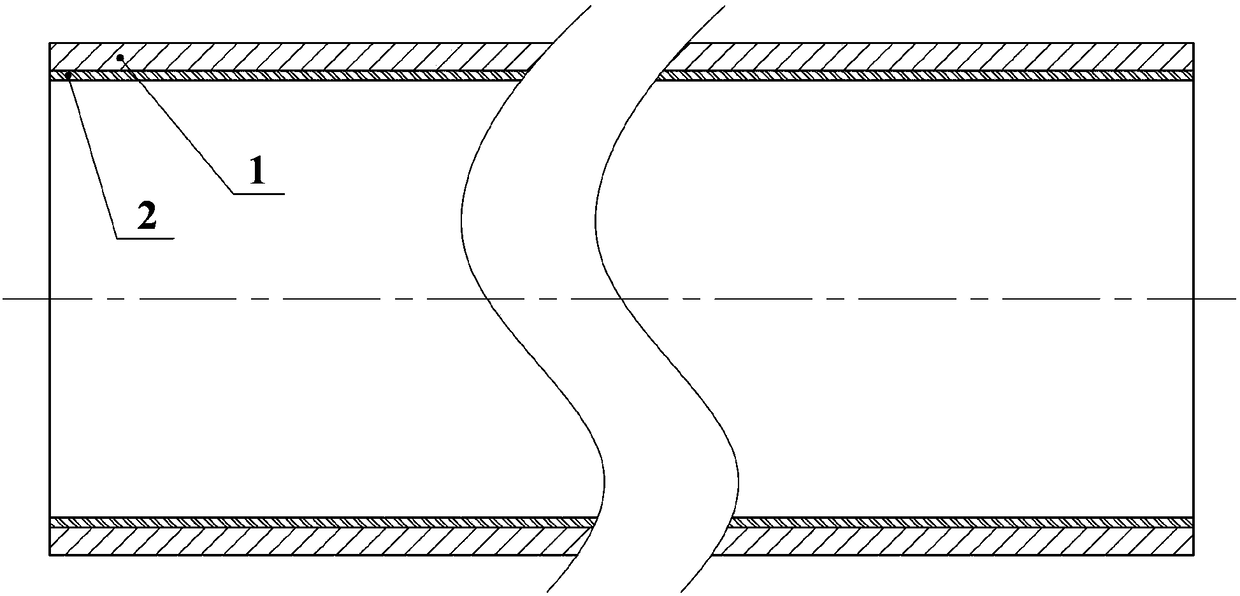

Gas pipe corrosion defect under-pressure repair method

The invention discloses a gas pipe corrosion defect under-pressure repair method. The gas pipe corrosion defect under-pressure repair method comprises performing surface cleaning on the pipe repair position; filling the pipe perforation leakage position or the outer surface corrosion position with a repairing agent; brushing the epoxy resin primer at the pipe surface position which needs to be wrapped, wherein the thickness of the epoxy resin primer is not less than 0.2 mm; enabling a carbon fiber band to wind the epoxy resin primer brushed pipe surface in a spiral mode, wherein the carbon fiber band winds the first to third layer, a special adhesive is bonded between the layers, and the drum rolling is adopted in the process of winding of the carbon fiber band to avoid the interlayer bulge; brushing the anticorrosive paint at the carbon fiber band wrapping position of the pipe surface. According to the gas pipe corrosion defect under-pressure repair method, the defects of the traditional repair method are overcome; the pipe corrosion and perforation defects are repaired in the running state of a gas pipe, the stress state of the pipe is not changed, the flame operation is not required, and accordingly the potential safety hazard is avoided and the service life is long; the stop operation is not required and accordingly the continuous production is ensured.

Owner:SHANGHAI JINYI INSPECTION TECH

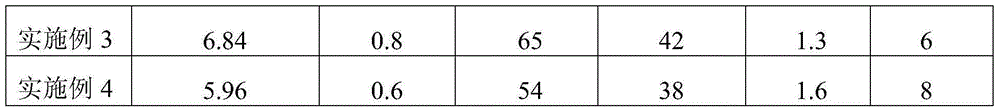

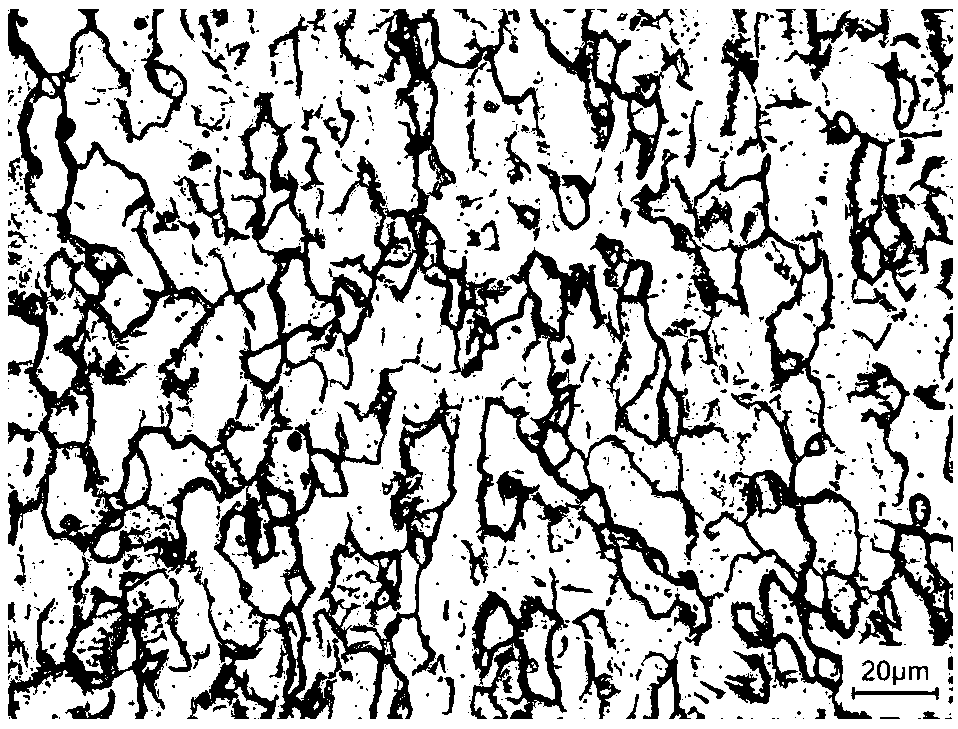

Quick and thinning stamping processing new energy automobile battery shell steel and method for producing same

InactiveCN109136444AComposition is stableImprove cleanlinessJackets/cases materialsFurnace typesSteelmakingChemical composition

The invention discloses quick and thinning stamping processing new energy automobile battery shell steel and a method for producing the same. The quick and thinning stamping processing new energy automobile battery shell steel comprises chemical components including, by weight, 0.0030-0.0060% of C, 0.10-0.20% of Mn, less than or equal to 0.03% of Si, 0.050-0.090% of Als, 0.050-0.070% of Ti, less than or equal to 0.015% of P, less than or equal to 0.012% of S, less than or equal to 0.0040% of N, the balance Fe and inevitable impurities. The method includes steelmaking, continuous casting, hot rolling, reeling, cold rolling, continuous annealing and flattening working procedures. The quick and thinning stamping processing new energy automobile battery shell steel and the method have the advantages that the quick and thinning stamping processing new energy automobile battery shell steel produced by the aid of the method can adapt to quick stamping and thinning stamping processing requirements, and the problem of poor forming properties of low-carbon battery shell steel can be solved by the aid of the quick and thinning stamping processing new energy automobile battery shell steel andthe method; control points of technologies for producing the quick and thinning stamping processing new energy automobile battery shell steel are clear and definite, and the quick and thinning stamping processing new energy automobile battery shell steel and the method are good in implementation and low in production cost.

Owner:TANGSHAN IRON & STEEL GROUP +1

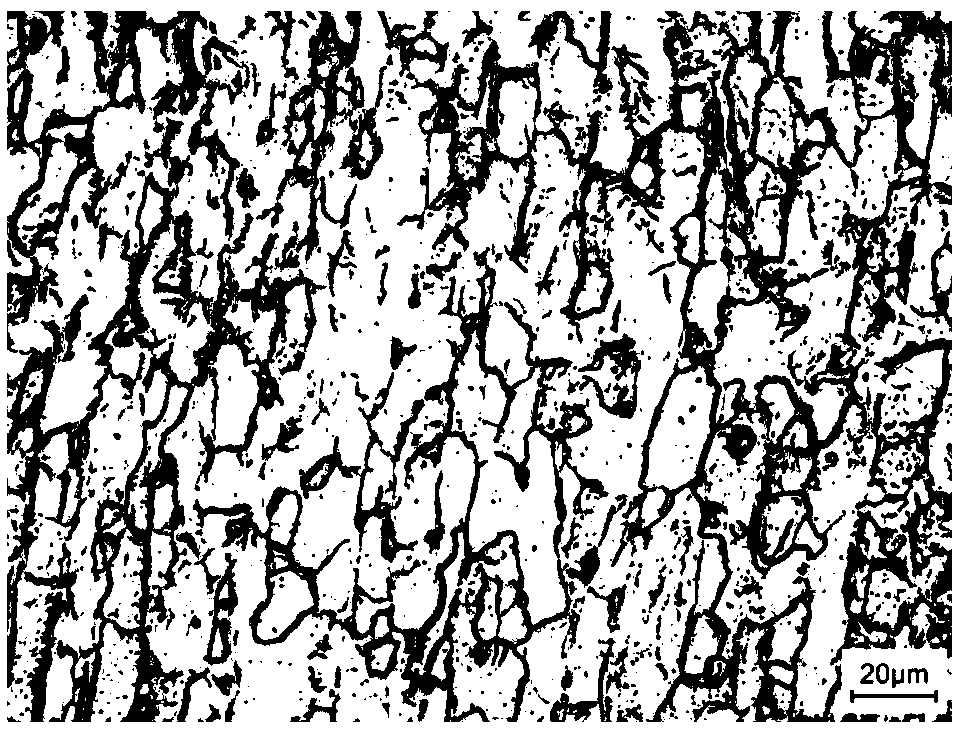

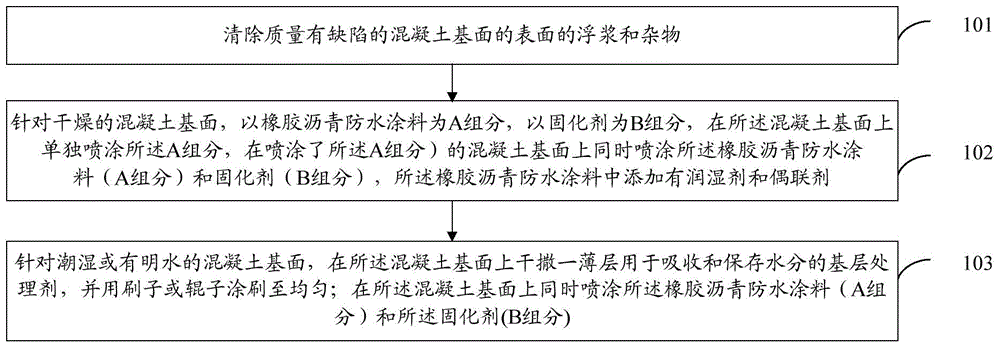

Method of preparing and constructing rubber asphalt waterproof paint without bulge defect

ActiveCN104817959AImprove physical strengthAnti-alkaliLiquid surface applicatorsConjugated diene hydrocarbon coatingsOpen waterThin layer

The invention provides a method of preparing and constructing a rubber asphalt waterproof paint without a bulge defect. The method comprises the steps of removing laitance and sundries on the surface of a concrete base surface with a quality defect; aiming at the dried concrete base surface, taking the rubber asphalt waterproof paint as a component A, taking a curing agent as a component B, and separately spraying the component A to the concrete base surface; spraying the component A and the component B when the concrete base surface of the component A is sprayed, and adding a wetting agent and a coupling agent into rubber asphalt waterproof paint; aiming at humid concrete base surface or the concrete base surface with open water, taking the rubber asphalt waterproof paint as the component A, taking a curing agent as the component B, spreading a thin layer of base layer processing agent used for absorbing and storing moisture on the concrete base surface, and brushing until the base layer processing agent is uniform by either a brush or a roller; and simultaneously spraying the component A and the component B on the concrete base surface.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +5

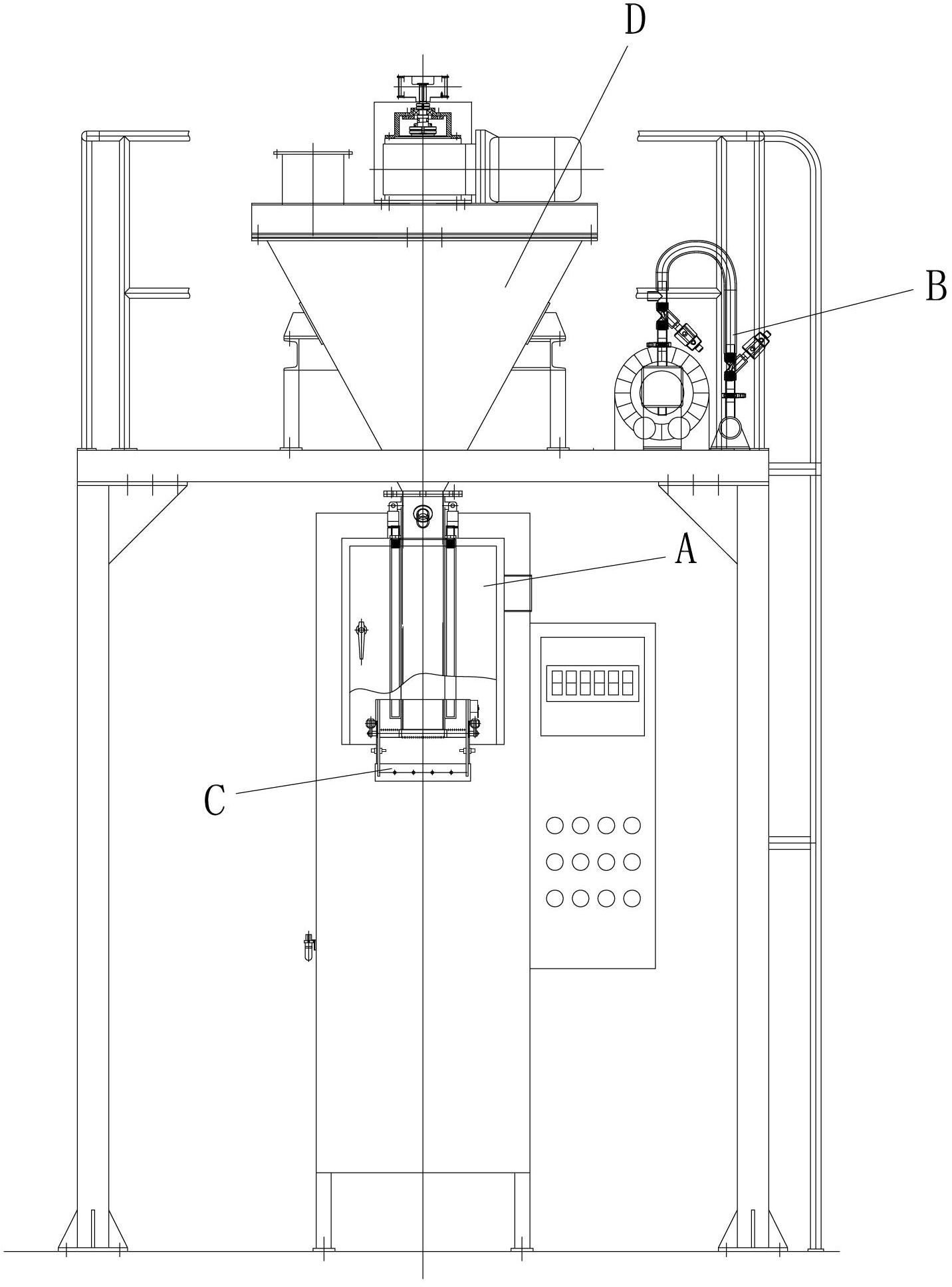

Operating method of powder material packing scale

The invention relates to an operating method of a powder material packing scale, which is suitable to solve the problems that the packaging bag is unable to be vertically placed and the rated quantity of materials are difficultly put into the bag within a normal time when powder materials with high gas contents enter a packaging bag; and the dust is easy to fly everywhere, after the packaging equipment is used, a better effect is obtained, and the efficiency is improved. The packaging scale comprises a degassing blanking device which is arranged on an outlet at the bottom of a hopper, an air suction blowing combination valve group and a vacuum pump which are used for degassing, blowing and blockage removing and are connected with the degassing blanking device, and a pneumatic bag-clamping lifting mechanism which is arranged at the bottom of the degassing blanking device; and the degassing blanking device comprises a blanking barrel, integrated microporous filter elements are arranged at both the inner wall and the outer wall of the blanking barrel, and the pore diameters of the filter elements can be set according to the sizes of material particles, and can range between 50 mum and 1mum. Ports which are communicated with a clearance between the inner wall of the blanking barrel and the inner filter elements are arranged in the outer wall of the blanking barrel; and the ports are connected with air suction blowing combination valves.

Owner:CHANGZHOU CHANGHENG DEYU POWDER INTEGRATIVE SYST

Manufacturing method for satellite borne antenna reflecting surface

The invention relates to a manufacturing method for a satellite borne antenna reflecting surface, particularly relates to a manufacturing method for a high-precision satellite borne antenna reflecting surface adopting a carbon fiber composite panel aluminium honeycomb sandwich structure, and belongs to the technical field of satellite communication and deep space detection. The reflecting surface is shaped like a 'cap with a brim', the periphery of a panel adopts a symmetrical laying layer, and is enabled to form a local thickened symmetrical laying layer, the maintenance of the shape surface precision during the panel forming process and the follow-up operation is facilitated, and the condition that the inboard shrinkage produced due to the differential pressure change during the honeycomb sandwich structure forming process influences the precision of the center reflecting area is prevented.

Owner:BEIJING SATELLITE MFG FACTORY

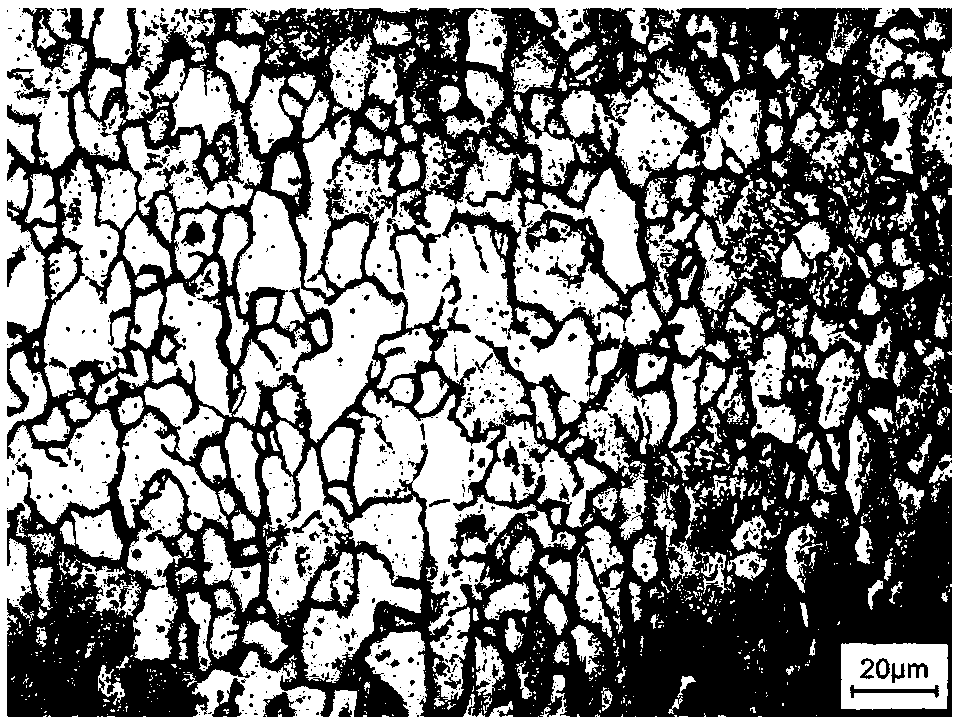

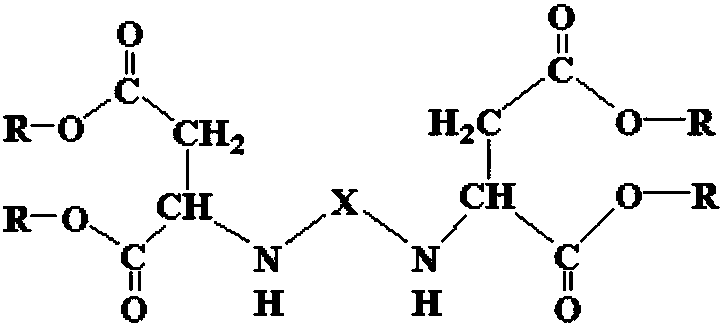

Construction method of spray polyurea protection system for concrete base surface

ActiveCN108331279AFast curing rateAvoid bulgingCovering/liningsProtective foundationPolyolProtection system

The invention provides a construction method of a spray polyurea protection system for a concrete base surface. The construction method comprises the steps that a first primer layer, a first repair putty layer, a first polyurea spray layer, a second repair putty layer and a second polyurea spray layer coat the concrete base surface in sequence, wherein the first repair putty layer is formed by curing single-component polyurethane putty, and the single-component polyurethane putty is obtained by adding a latent curing agent for stirring and mixing when the content of isocyanate is up to 10%-15%by the reaction of polyols, isocyanate and a catalyst; and the surface defects of the first polyurea spray layer are repaired by the second repair putty layer, the second repair putty layer is formedby curing two-component polyurethane putty, the two-component polyurethane putty is composed of a component A and a component B, the component A is the single-component polyurethane putty, and the component B comprises 90.5-97.8 parts of polyaspartic acid ester.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

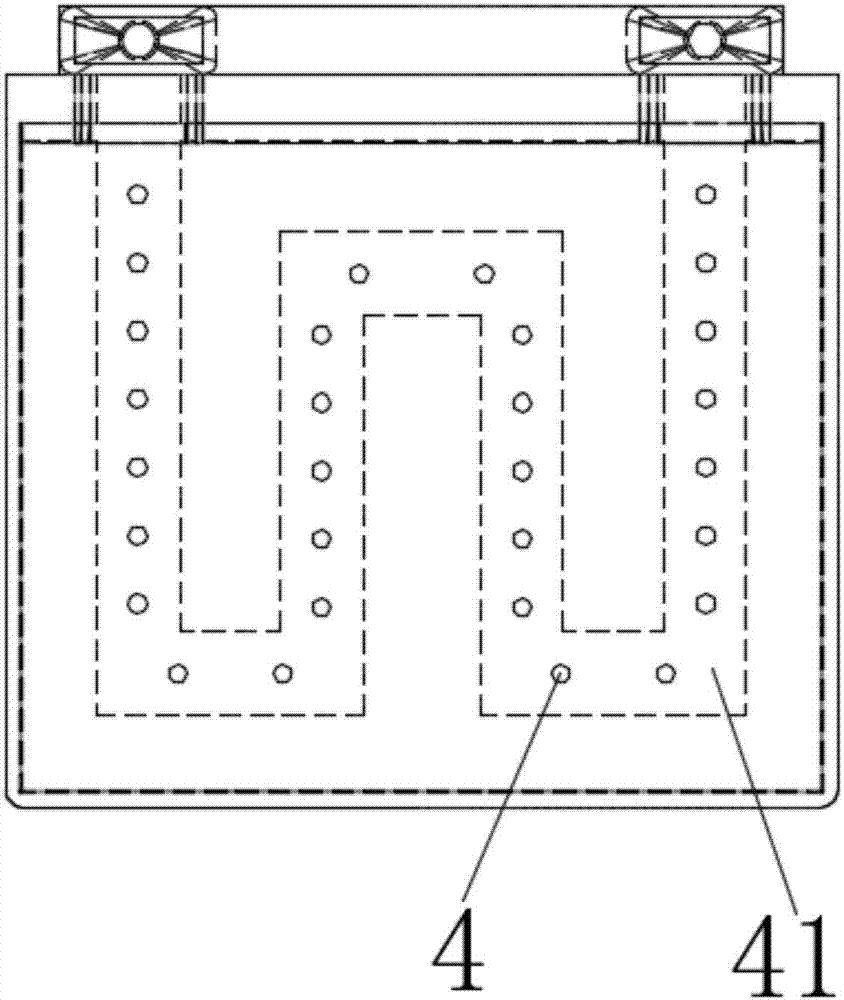

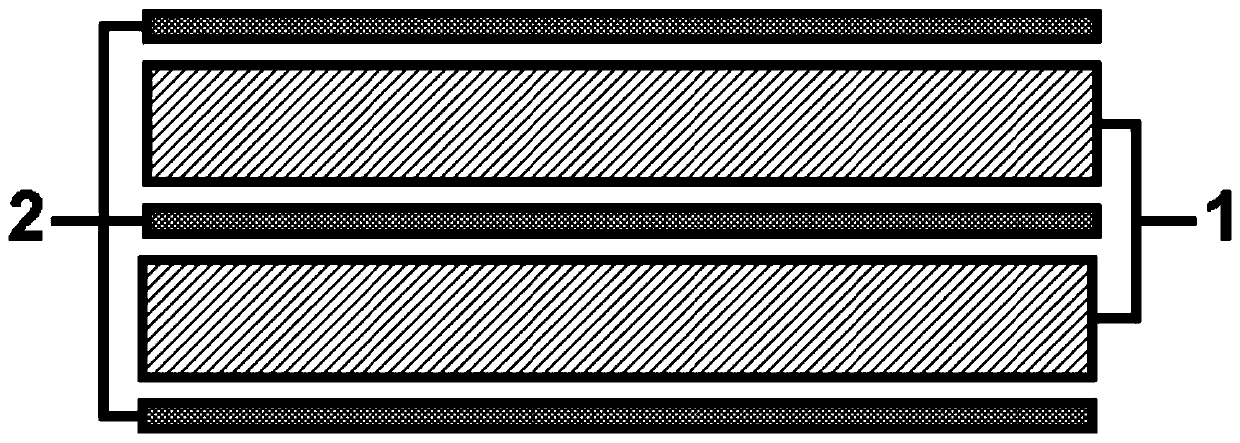

Liquid cooling system and liquid cooling bag thereof

ActiveCN107331915AControl thicknessQuality is not affectedSecondary cellsBatteriesLiquid cooling systemBattery cell

The invention provides a liquid cooling system and a liquid cooling bag thereof. The liquid cooling bag comprises two sealing membranes and an internal structural member clamped between the two sealing membranes, wherein the internal structural member comprises at least two flat parts, and a gap is reserved between opposite edge sides of the adjacent flat parts; the two sealing membranes are fixedly connected with front and back surfaces of the internal structural member respectively, so that the gap forms a flow channel allowing a refrigerant to circulate; each sealing membrane is prepared from a metal plastic composite and comprises a metal layer for heat conduction and a plastic layer used for fixed connection with the internal structural member. The liquid cooling bag and the liquid cooling system comprising the same are used for liquid cooling of a battery module, a battery cell is directly cooled or heated under the condition that space use is basically not increased, and the efficiency is high.

Owner:TIANJIN ENERGIES

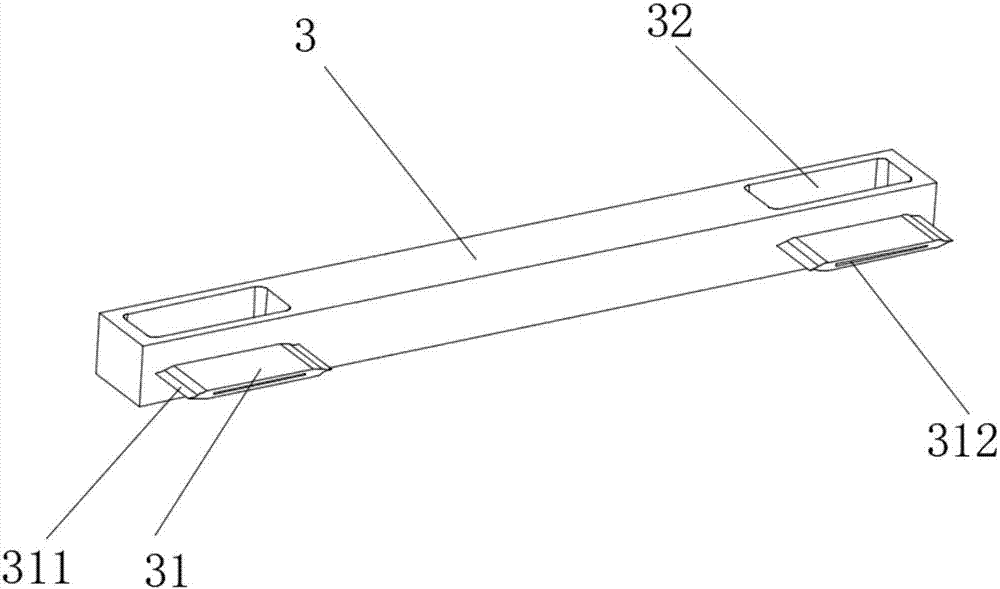

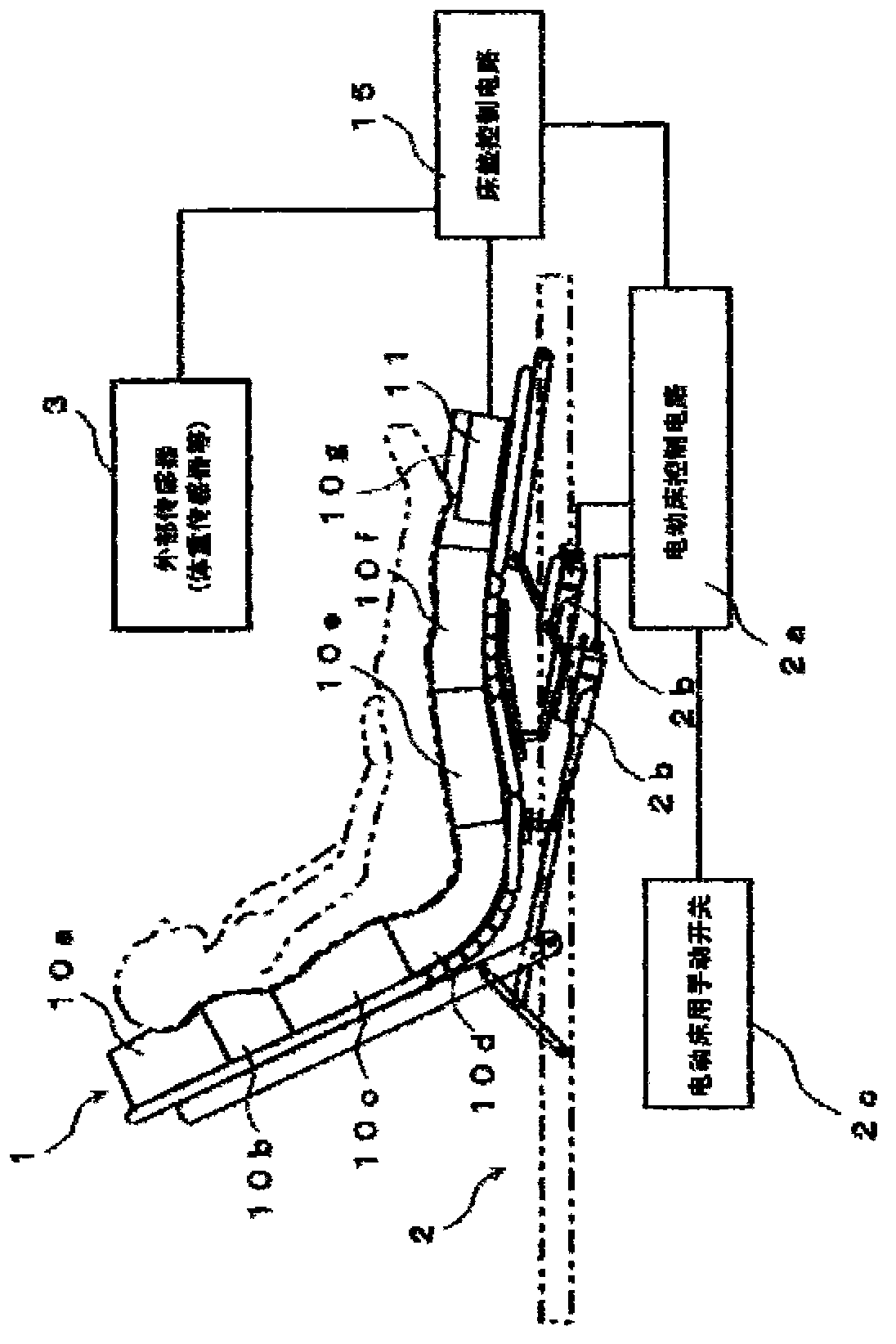

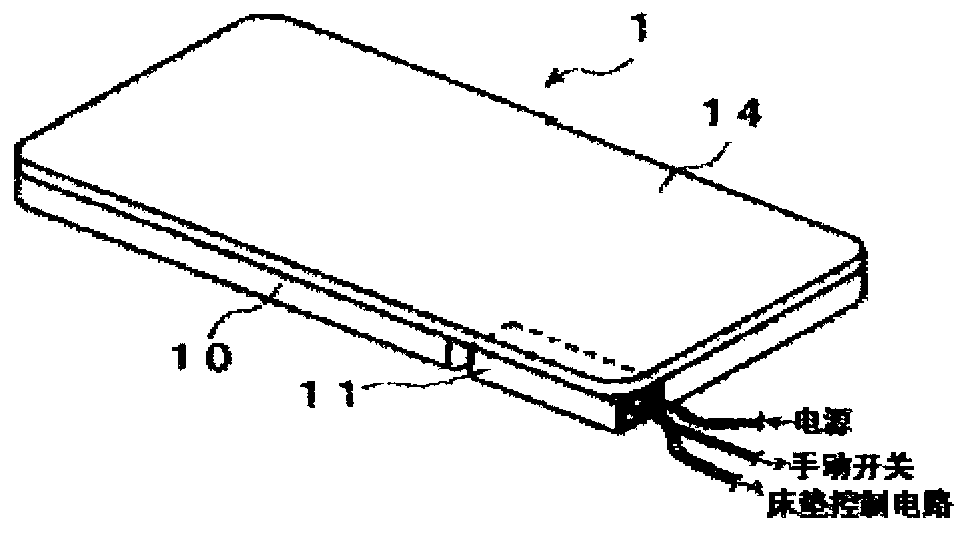

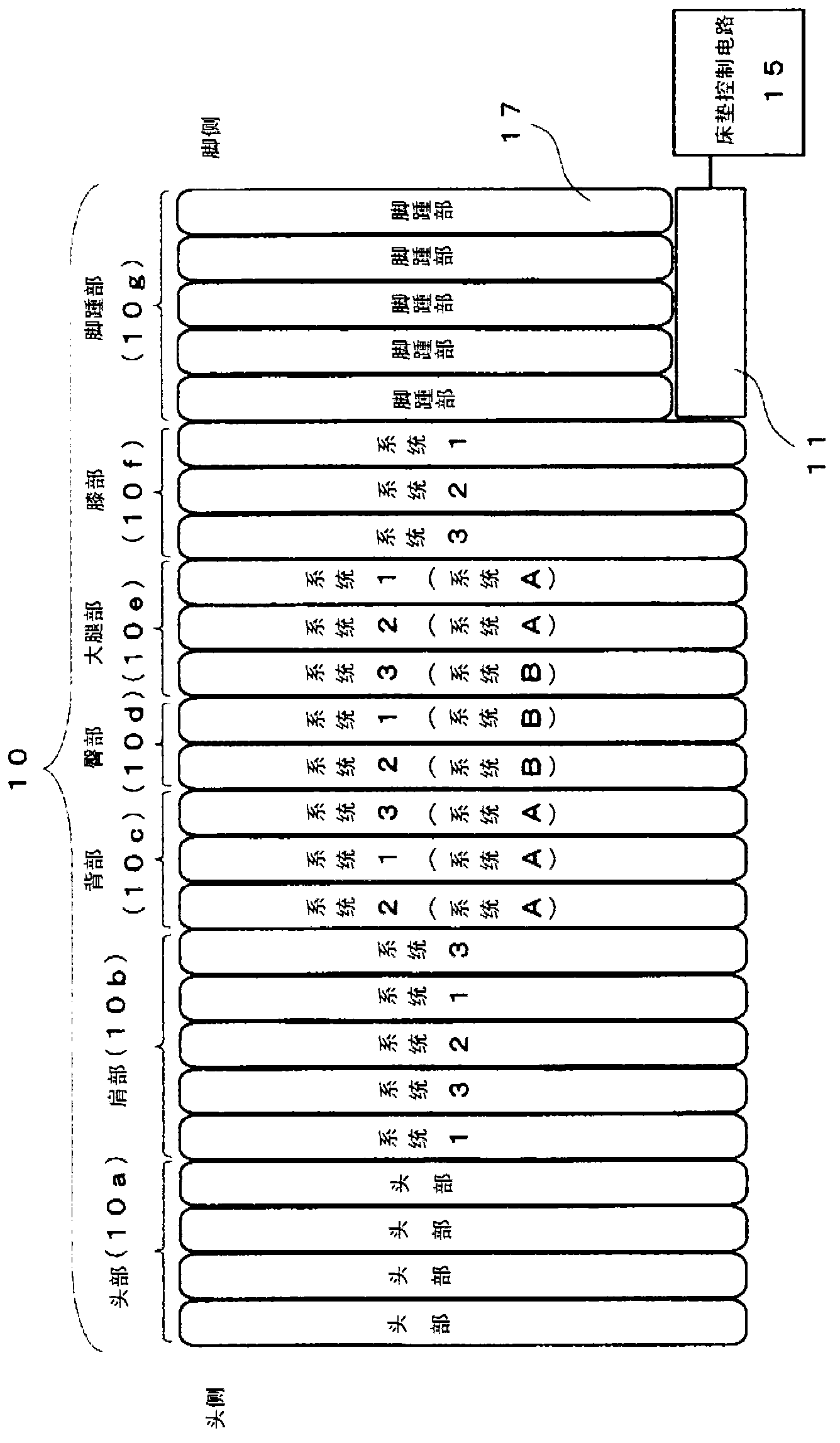

Air mattress

ActiveCN102821655ADistribute pressureAvoid bulgingFluid mattressesNursing bedsInternal pressureAir cell

Provided is an air mattress in which internal pressure can be controlled according to the movements of a bed. The air mattress is provided with a plurality of air cell groups lined up in the lengthwise direction of the air mattress, each of which groups is made from a plurality of bladder-shaped cells; an air supply / release pump; and an air tube connecting the air cell groups and the air supply / release pump in an independent system for each air cell group of two or more air cell groups out of said air cell groups. Air supply / release by the air supply / release pump to each of the air cell groups is controlled by a controller, at least a part of information needed to control the bed is received from an external sensor for detecting such information, and air supply / release by the air supply / release pump for each of the air cell groups is controlled on the basis of the received information.

Owner:PARAMOUNT BED CO LTD

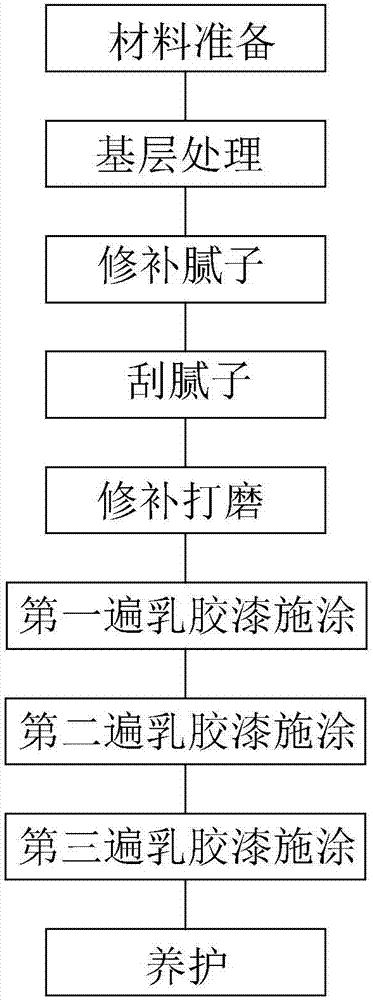

Concrete plastering surface emulsion paint coating technique

InactiveCN107044196AGuaranteed smoothGuaranteed flatnessCovering/liningsMaterials preparationEmulsion

Owner:北京广佳建设股份有限公司

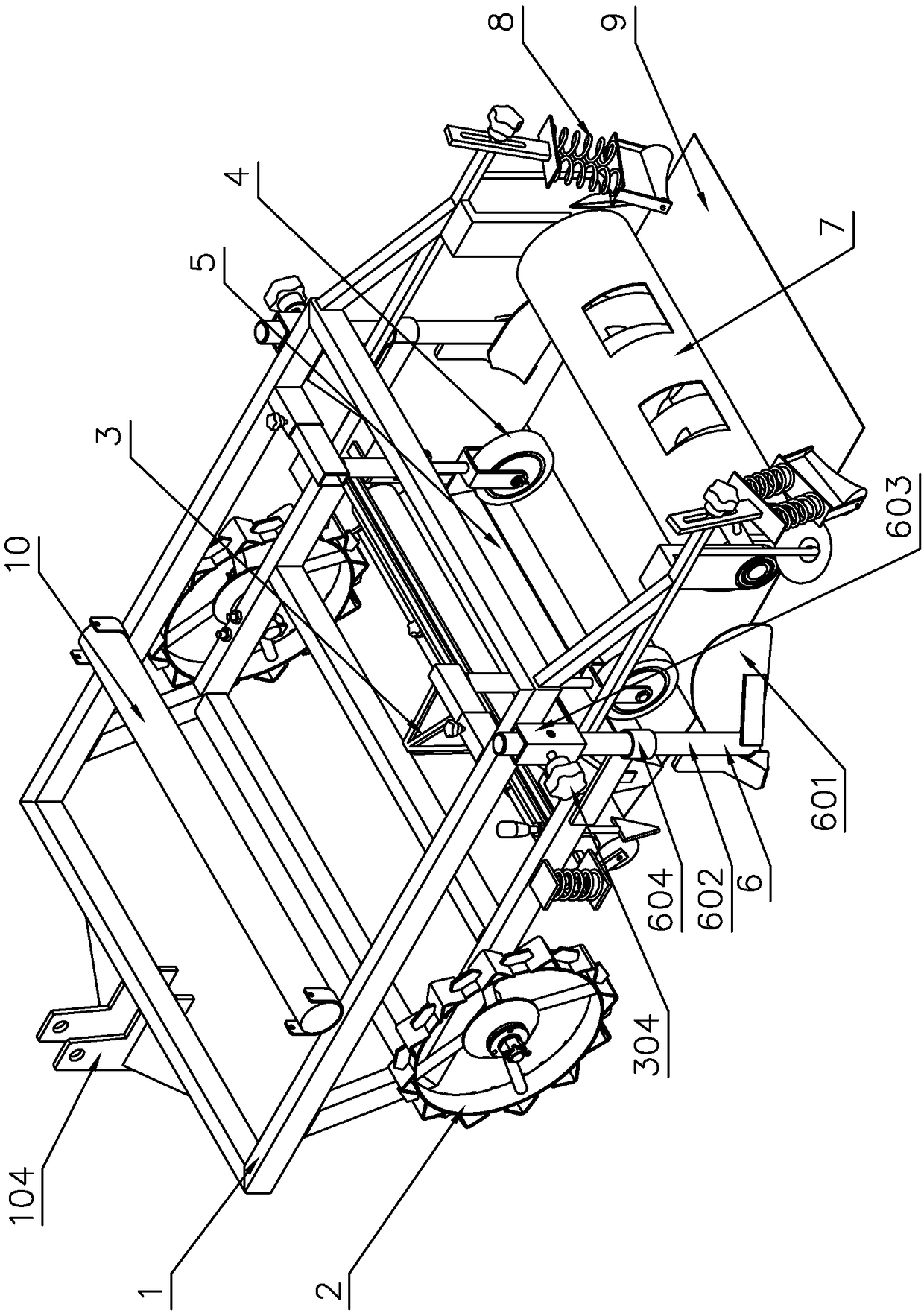

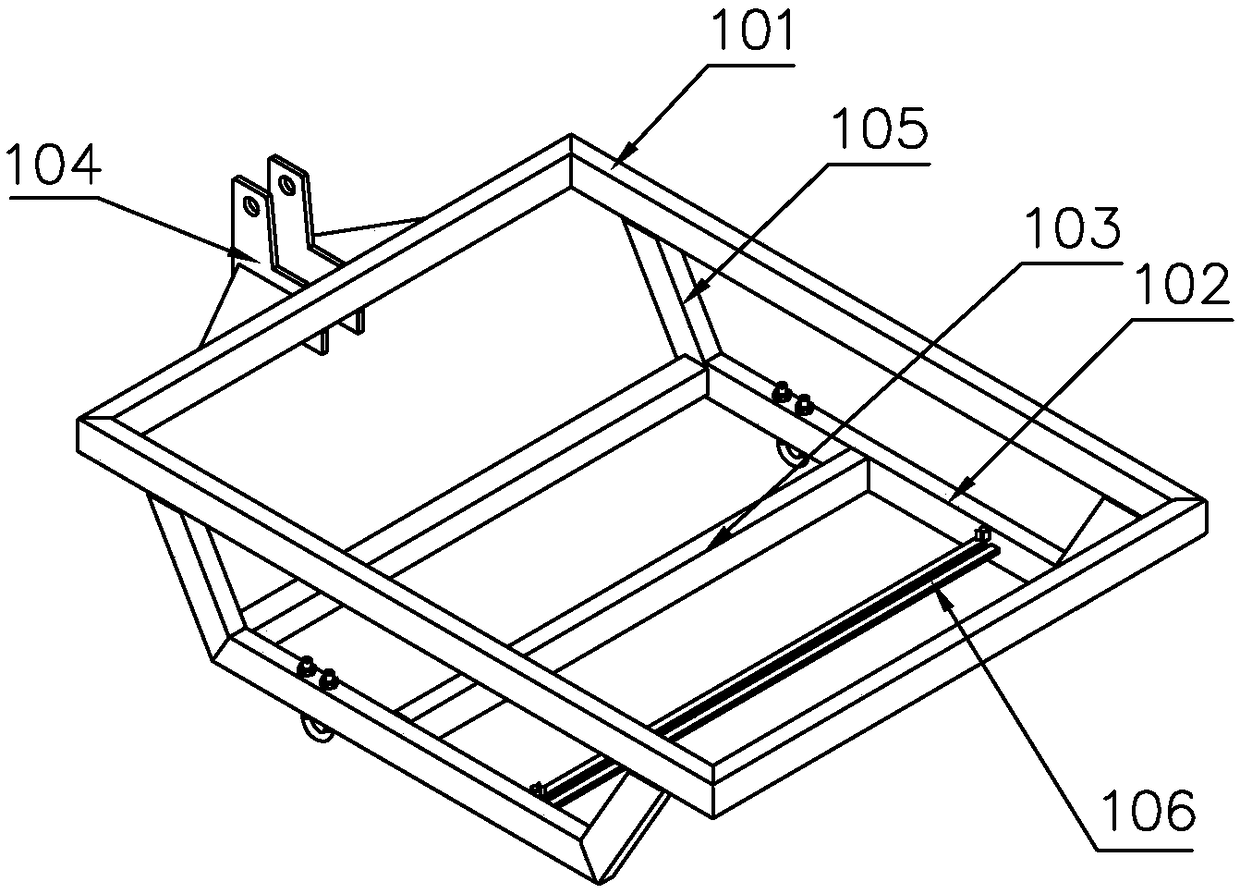

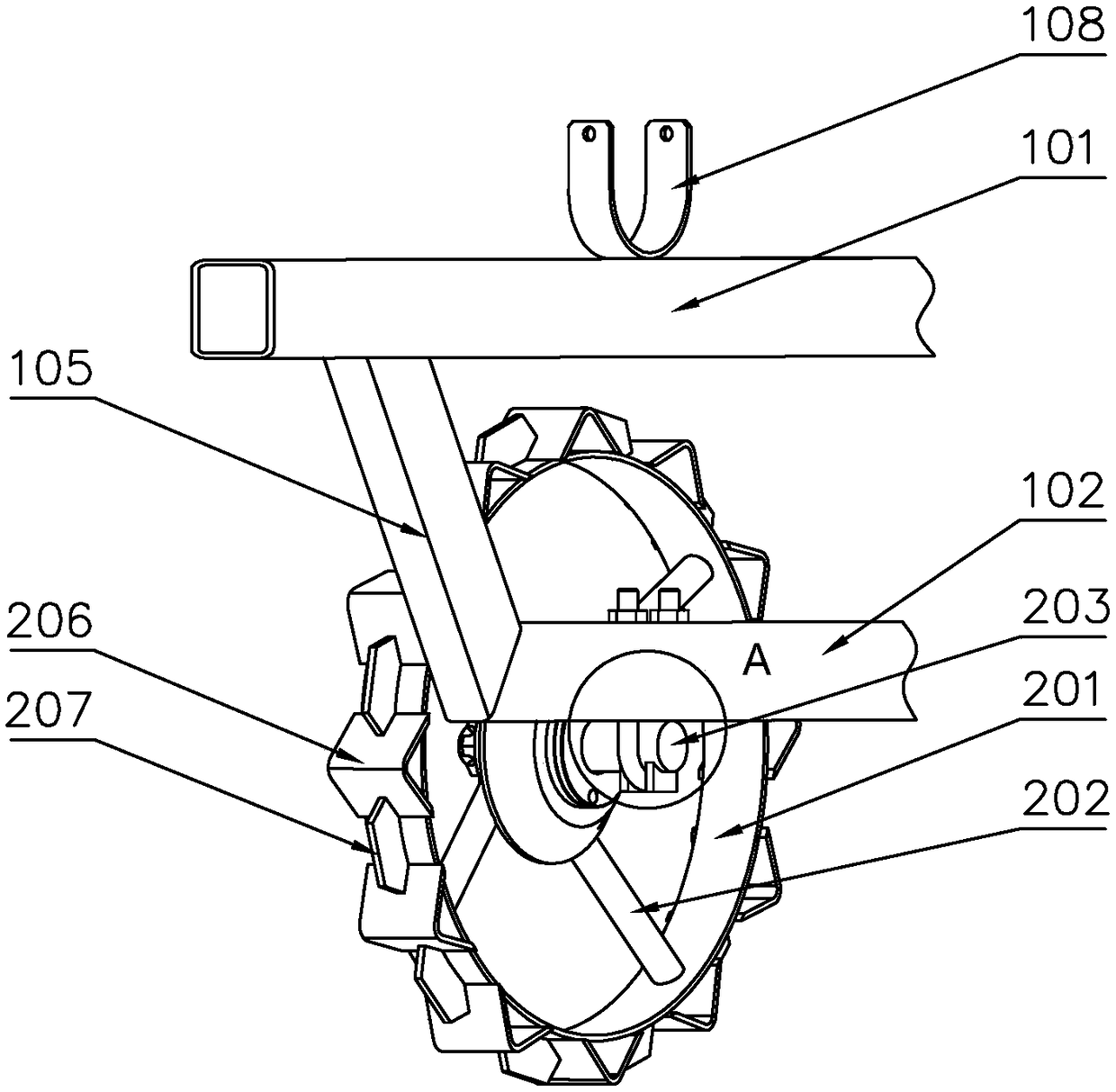

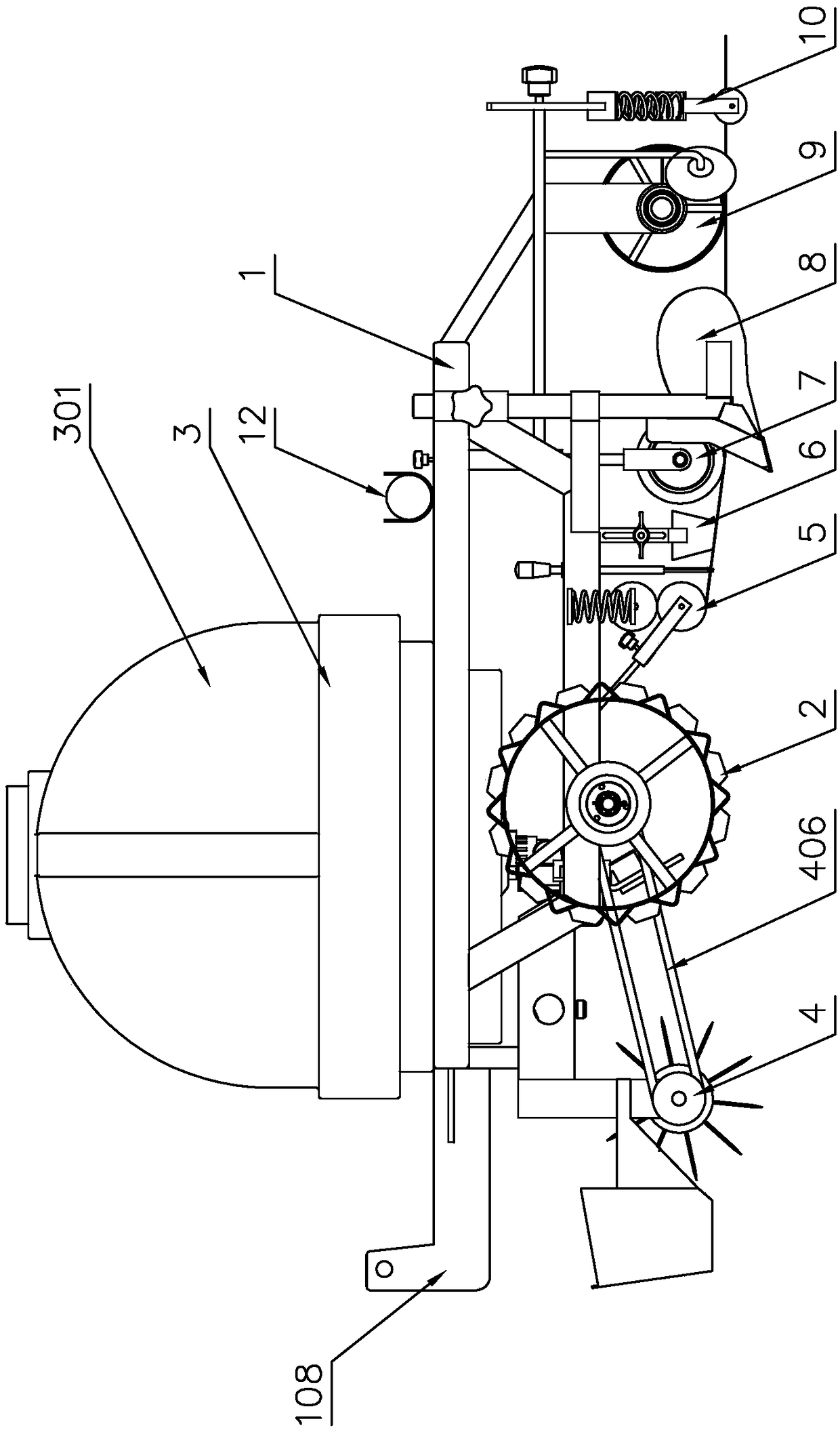

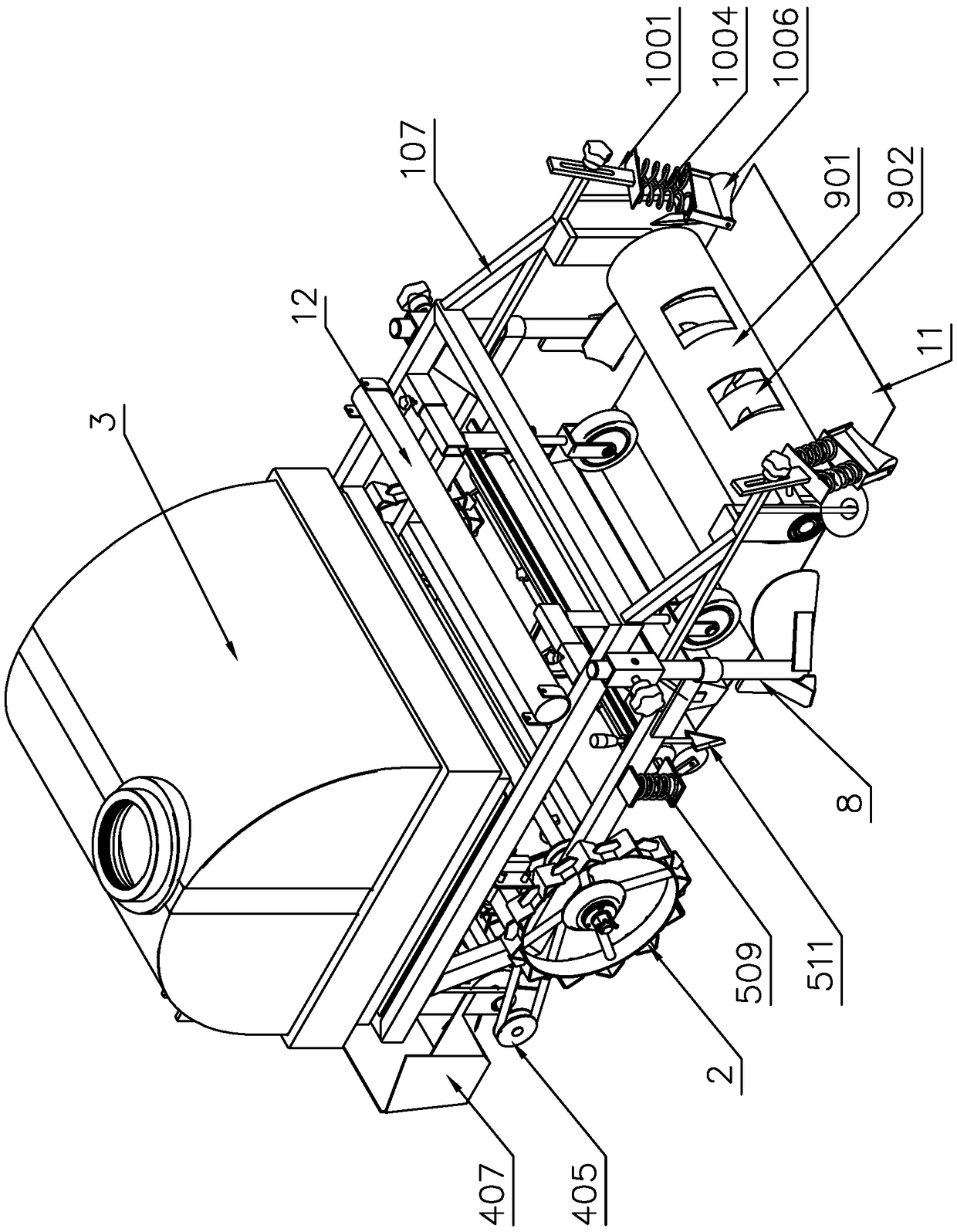

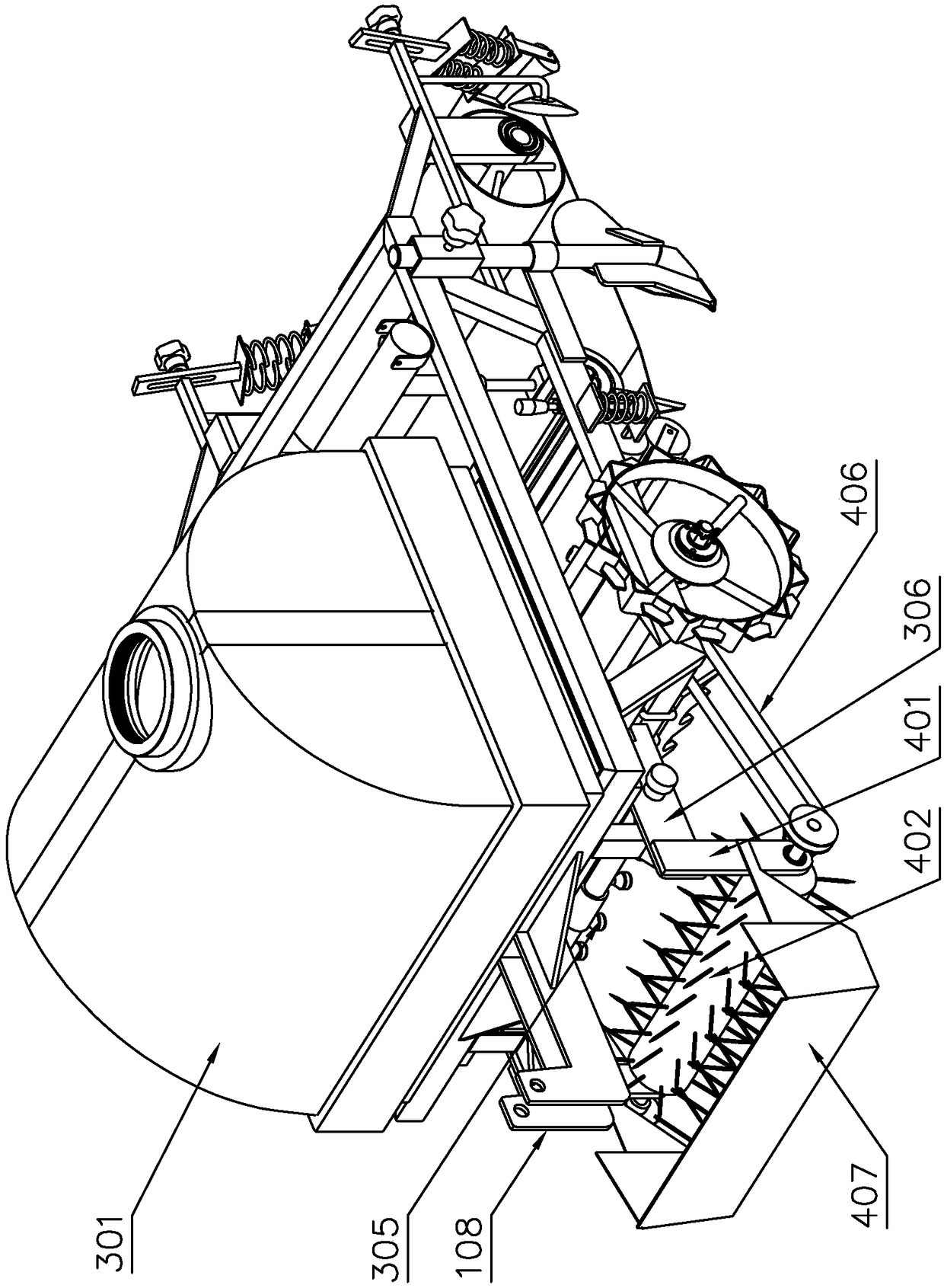

Furrow ridge film mulching device for agricultural use

ActiveCN109220426AImprove work efficiencyGuaranteed effectPlant protective coveringsVehicle frameAgricultural engineering

The invention discloses a furrow ridge film mulching device for agricultural use. The device comprises a vehicle frame, rolling wheels, a film placing mechanism, film pressing mechanisms, a soil storage box, soil covering mechanisms and soil pressing mechanisms; the rolling wheels are arranged on both sides of a lower frame, the film placing mechanism is arranged on one side of the lower frame, the soil storage box is arranged on one side of the film placing mechanism, the film pressing mechanisms are symmetrically arranged on one side of the soil storage box, the soil covering mechanisms aresymmetrically arranged on one sides of the film pressing mechanisms, and each soil pressing mechanism is arranged on one side of the corresponding soil covering mechanism. The soil storage box is arranged on the lower frame; when film mulching of one furrow ridge is completed, a film is cut by a cutter, and soil in the soil storage box drops down under the action of gravity to press the tail end of the film, so that manual soil pressing is avoided, and the work efficiency of film mulching is improved; meanwhile, the soil pressing mechanisms are arranged at the tail part of the vehicle frame tocompact the soil on both sides of the film, so that the film mulching effect is ensured, and the situation that wind enters from the sides of the film and blows the film upward is avoided.

Owner:众智机械(临沂)有限公司

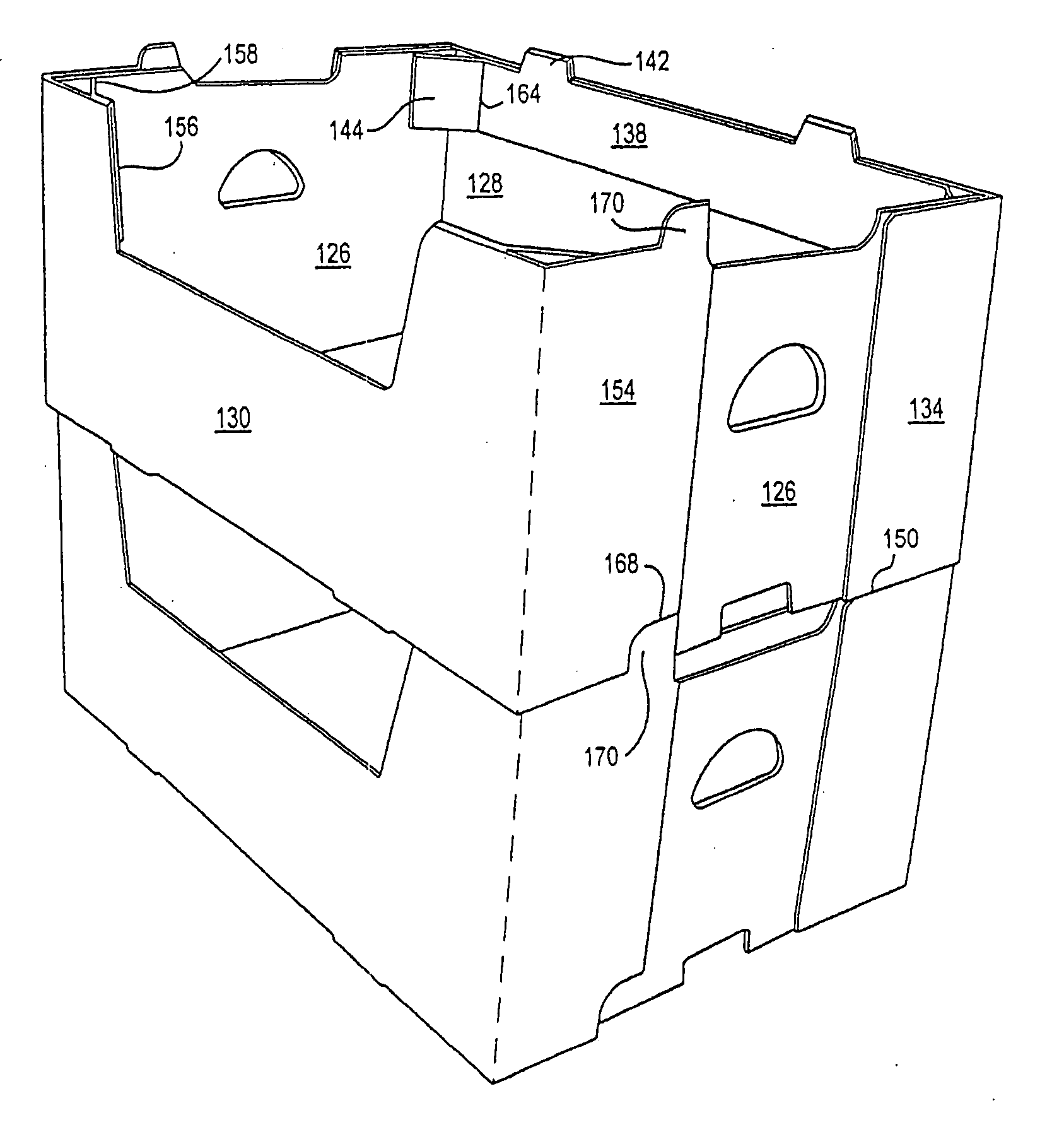

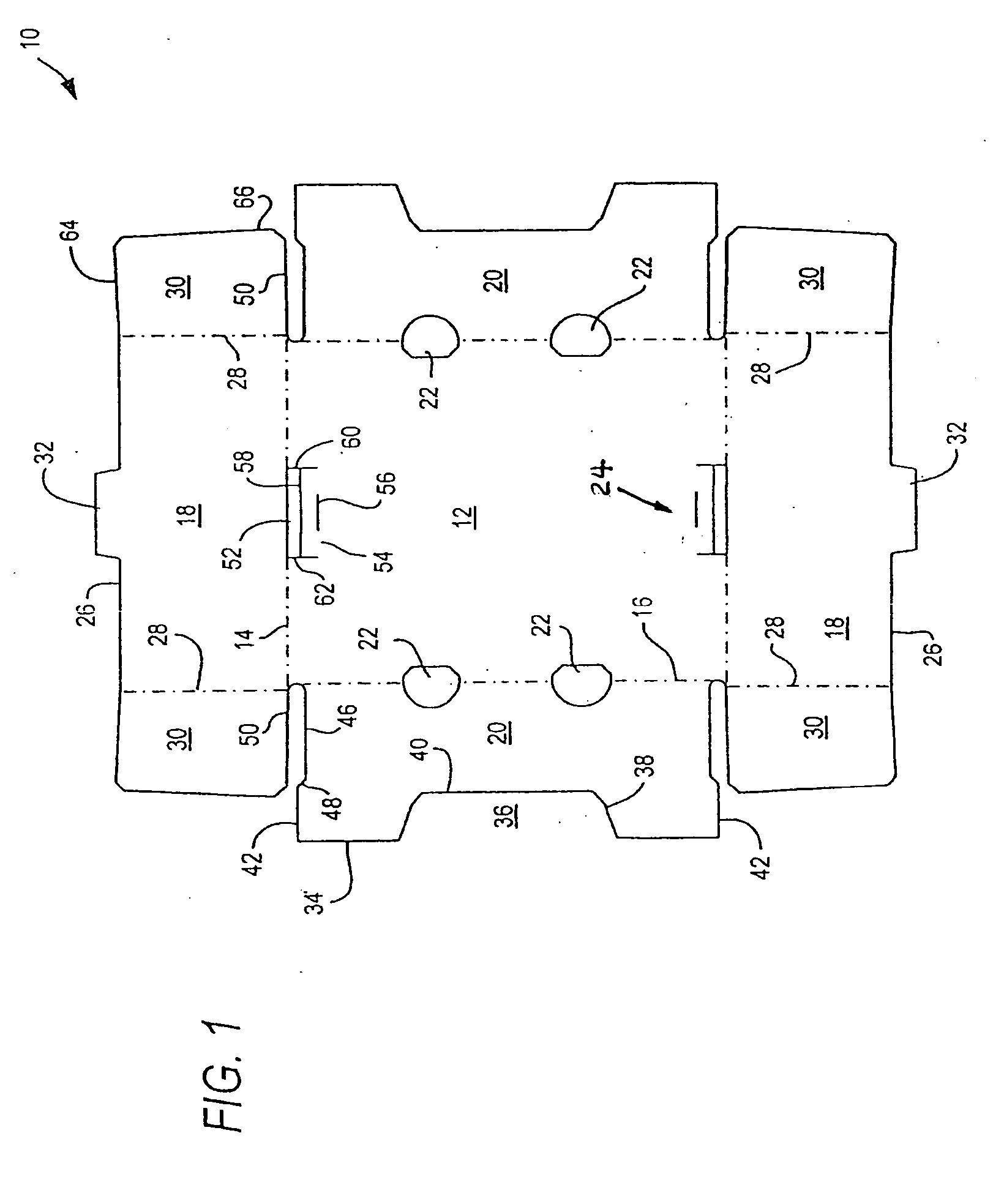

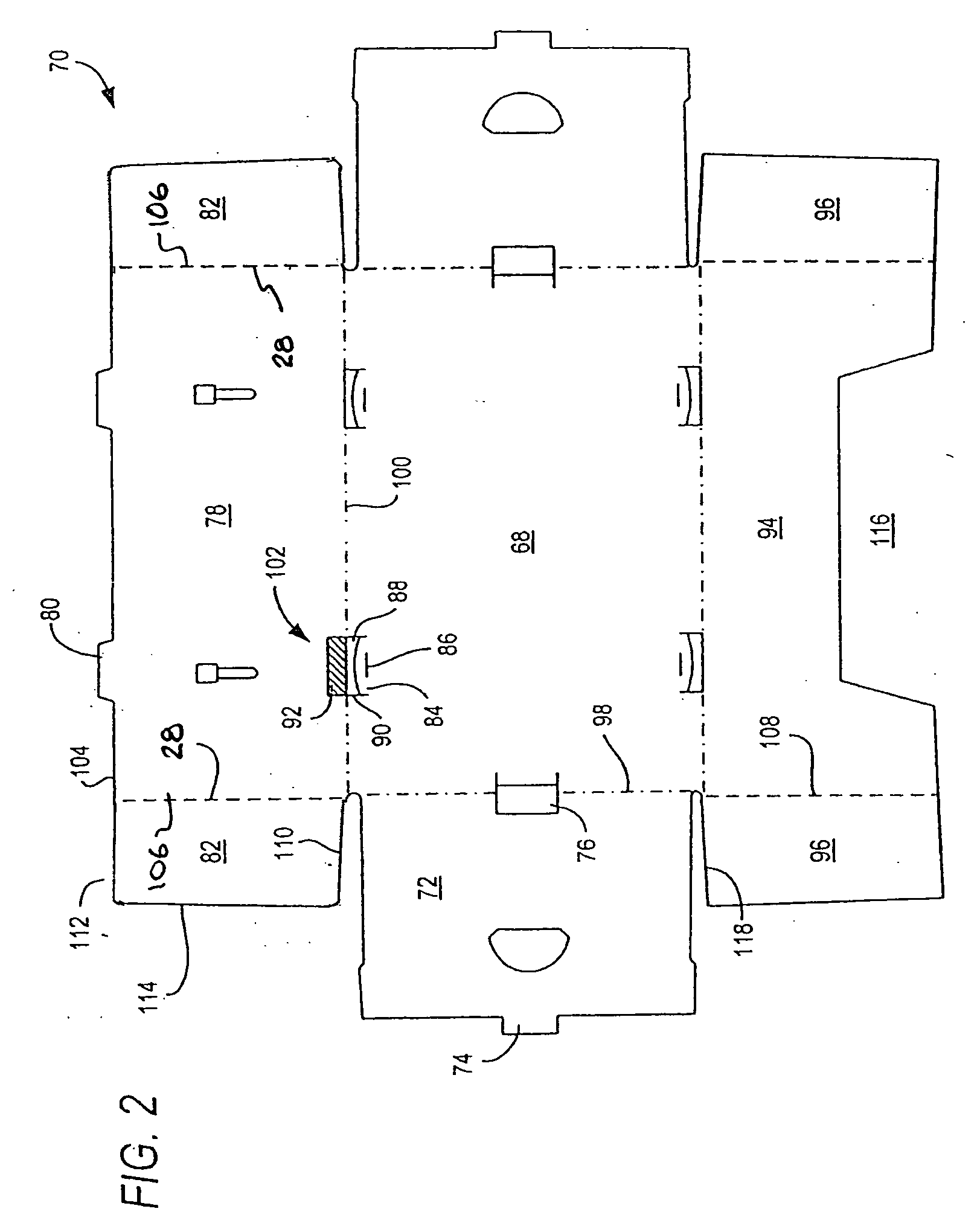

Containers with tapered sidewalls and stacking tabs

InactiveUS20060091194A1Avoid bulgingIncreasing thicknessPaper/cardboardRigid containersEngineeringMechanical engineering

A stackable container has a bottom panel, upstanding sidewalls, upstanding end walls, and an open top. According to one aspect of the invention, narrow reinforcing flaps are attached to the upper edge of at least one of the side and end walls, defining a stacking ledge and reinforcing the walls against outward bulge. The reinforcing flaps extend over only a small portion of the height of the side or end wall, and corner post flaps extend from opposite ends of the reinforcing flaps, extending diagonally across interior corners of the container. According to another aspect, the side and / or end walls lean inwardly, defining a narrower footprint at the top of the container than at the bottom. In a specific embodiment one of the walls leans in more than the other. According to a further aspect, an indexing and aligning tab extends upwardly from an upper edge of the container, and a complementary notch is formed in a lower edge for receiving the tab when the containers are stacked. According to a still further aspect, stacking tabs extend upwardly from the upper edge of the container, and slots are formed in the bottom panel for receiving the tabs when containers are stacked. Locking flaps extend into the slots to frictionally engage and hold the tabs.

Owner:INT PAPER CO

Agricultural ditch and ridge pesticide spraying and film laminating integrated device

ActiveCN109041603AGuaranteed effectImprove planting efficiencySpadesPloughsAgricultural engineeringUltimate tensile strength

The invention discloses an agricultural ditch and ridge pesticide spraying and film laminating integrated device which comprises a machine frame, wheels, a pesticide spraying device, a film pick-up device, a film put-down mechanism, a film pressing mechanism, a soil covering mechanism and a soil pressing mechanism. The pesticide spraying device is arranged on one side of the upper portion of the machine frame. The wheels are arranged on one side of the lower portion of the lower frame. The film pick-up device is arranged on one side of the wheels. The film put-down mechanism is arranged on oneside of the film pick-up device. The film pressing mechanism is arranged on one side of the film put-down mechanism. The soil covering mechanism is arranged on one side of the film pressing mechanism. The soil pressing mechanism is arranged on one side of the soil covering mechanism. By means of the integrated device, pesticide spraying and film laminating are integrated, pesticide spraying and film laminating can be completed at the same time through one time of operation, and the ditch and ridge film laminating planting efficiency is improved; by arranging the soil pressing mechanism, the film laminating effect is ensured; in addition, by arranging the film pick-up device, residual films on ditches and ridges are automatically picked up, and the labor intensity of farmers is relieved.

Owner:众智机械(临沂)有限公司

High-structural-strength three-dimensional solid wood composite board and forming method thereof

The invention discloses a high-structural-strength three-dimensional solid wood composite board which comprises a hard base layer and further comprises a first capacity layer group, a second capacity layer group and a surface layer, wherein the first capacity layer group and the second capacity layer group are arranged on the two sides of the base layer, wherein each of the first capacity layer group and the second capacity layer group is provided with at least one flexible capacity layer; the surface layer is arranged on the surface of the first capacity layer; a decoration groove is formed in the surface layer; and the bottom of the decoration groove is embedded into the first capacity layer group. The hard base layer can provide enough mechanical strength for the whole board and support the capacity layers and the surface layer in the board, so as to prevent the board from deforming in the process of making the decoration groove under high pressure. The solid wood composite board provided by the invention has a brand-new structure different from that of a conventional board, has the characteristics of stereoscopic vision, high mechanical strength and long service life, further has the advantages of low formaldehyde release amount and environment friendliness in use and can be widely applied to the fields of home decoration, artwork processing, commercial place decoration and municipal construction.

Owner:SHENZHEN SONGBOYU TIMBERING

Production method for vacuum-rolling layered metal composite board

The invention provides a production method for a vacuum-rolling layered metal composite board. The high-performance layered composite board is obtained through the steps of blanking of a base plate and a cover plate, drilling a blind hole and a through hole on the base plate, welding a transmission joint, welding a breather pipe, assembling the cover plate, painting separant, sealing welding the periphery of the cover plate, sealing welding the periphery of a billet, drilling a vacuum hole, vacuumizing, rolling and the like. The space in a compound billet is divided into two spaces through the method of the transmission joint, one space is communicated with the outside world, the high-temperature separant is in the space, so that the gas generated by the separant when the compound billet is heated is exhausted to avoid bulging, and the quality of the surface of a covering layer is improved; the other space is a vacuum space, a face to be compounded is in the space, and the face to be compounded is in a vacuum space alone, so that the face to be compounded is not prone to be polluted during the heating and rolling process, and the generation of unbinding at the edge of the face to be compounded is avoided. According to the production method, heating is not needed, high efficiency, energy consumption and environmental protection are possessed, and the layered composite board with high bonding intensity can be produced.

Owner:JIANGSU RUNBANG NEW MATERIAL GRP CO LTD

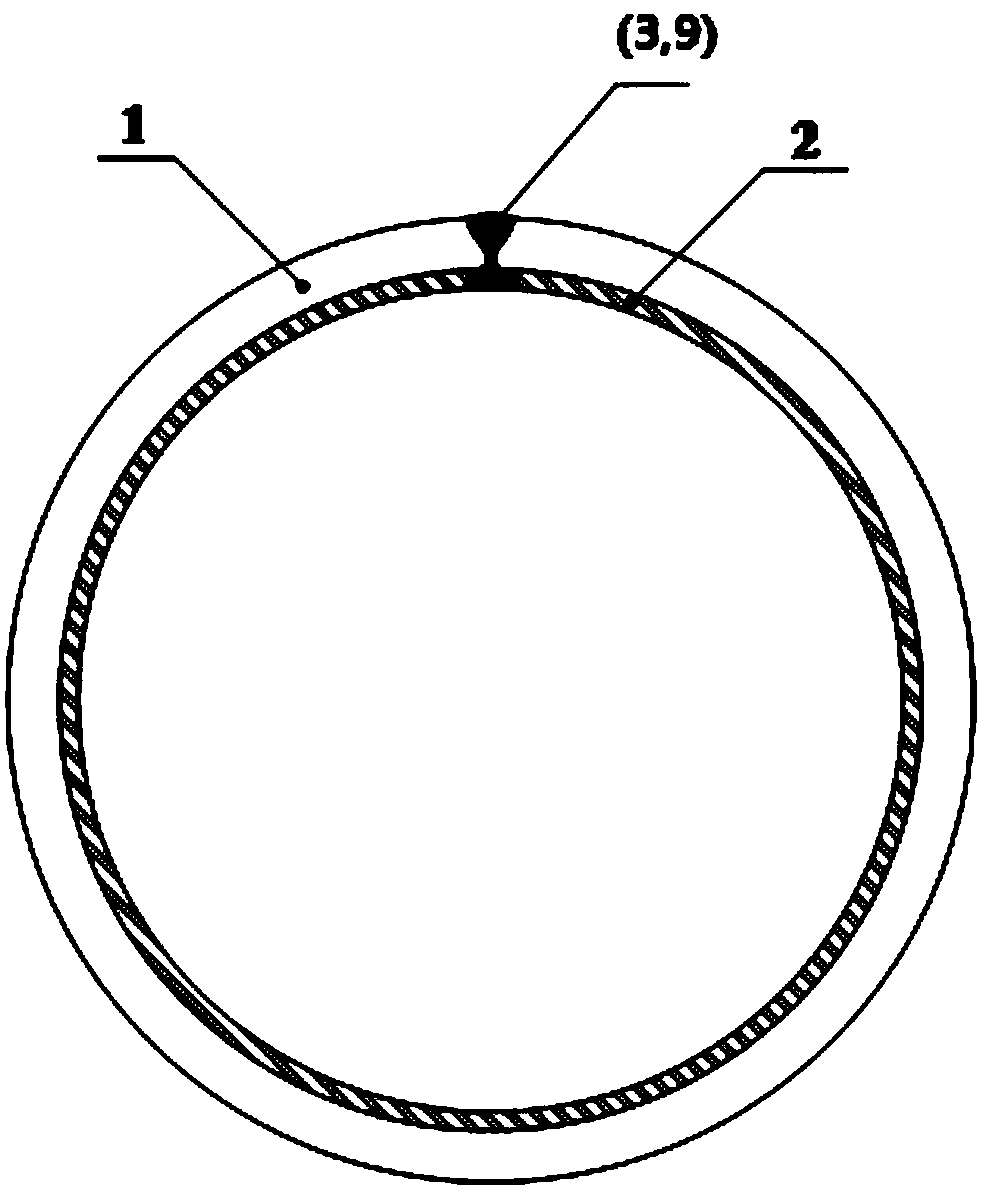

Bimetal metallurgy composite straight seam welding pipe and manufacturing method thereof

InactiveCN108568462AHigh bonding strengthReduce use costWorkpiece edge portionsSheet steelComposite plate

The invention discloses a bimetal metallurgy composite straight seam welding pipe and a manufacturing method thereof. The manufacturing method comprises: 1, preparing a metallurgical composite plate from a base layer steel plate and an inner cladding layer steel plate through an explosive welding method; 2, carrying out JCO molding on the composite plate to obtain a composite pipe; 3, carrying outvertical welding seam double Y-shaped composite groove processing on the composite pipe; 4, carrying out base layer centering pre-welding on the composite pipe groove by using a GMAW method, whereinthe welding material is CHW-60C; 5, welding the base layers on the inner side and the outer side of the groove of the composite pipe by using a SAW method, wherein the welding material is JW-9 / 995N; 6, welding the composite pipe groove transition layer by using GTAW, wherein the welding material is GMS-309MoL; and 7, welding the composite pipe groove inner cladding layer by using GTAW, wherein thewelding material is GMS-316L. According to the present invention, the problem of poor corrosion resistance of the existing submarine pipeline can be solved.

Owner:CNOOC ENERGY TECH & SERVICES +2

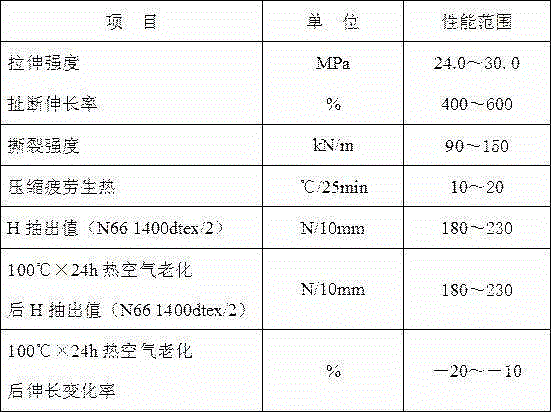

Aviation tire reinforcing layer adhesive of high adhesive strength

The invention discloses an aviation tire reinforcing layer adhesive of high adhesive strength, prepared through two-stage mixing performed by a mixer by using main materials: 80-90% of ribbed smoked sheet 1#, 10-20% of styrene butadiene rubber 1500, 30-40% of new process high structural and high wear resistant carbon black, 5-10% of silica, and silane coupling agent KH-560, adhesion promoter AIR-201, adhesive SL-3090, p-phenylenediamine antioxidant 4010NA, antioxidant RD, sulfenamide accelerator and scorch retarder CTP, . The invention has properties of high initial adhesive strength, high adhesive after aging, high tensile strength, high tensile modulus and low heat production, and can meet property requirements of high speed and high load of future new model tires; and the adhesive strength between rubber before and after aging and nylon cord is high, has high hardness and tensile, low heat production, and can improve the dynamic property of tires, thereby preventing tires from delaminating, blowing up and rejecting of tread, and improving the safety performance of aviation tires.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

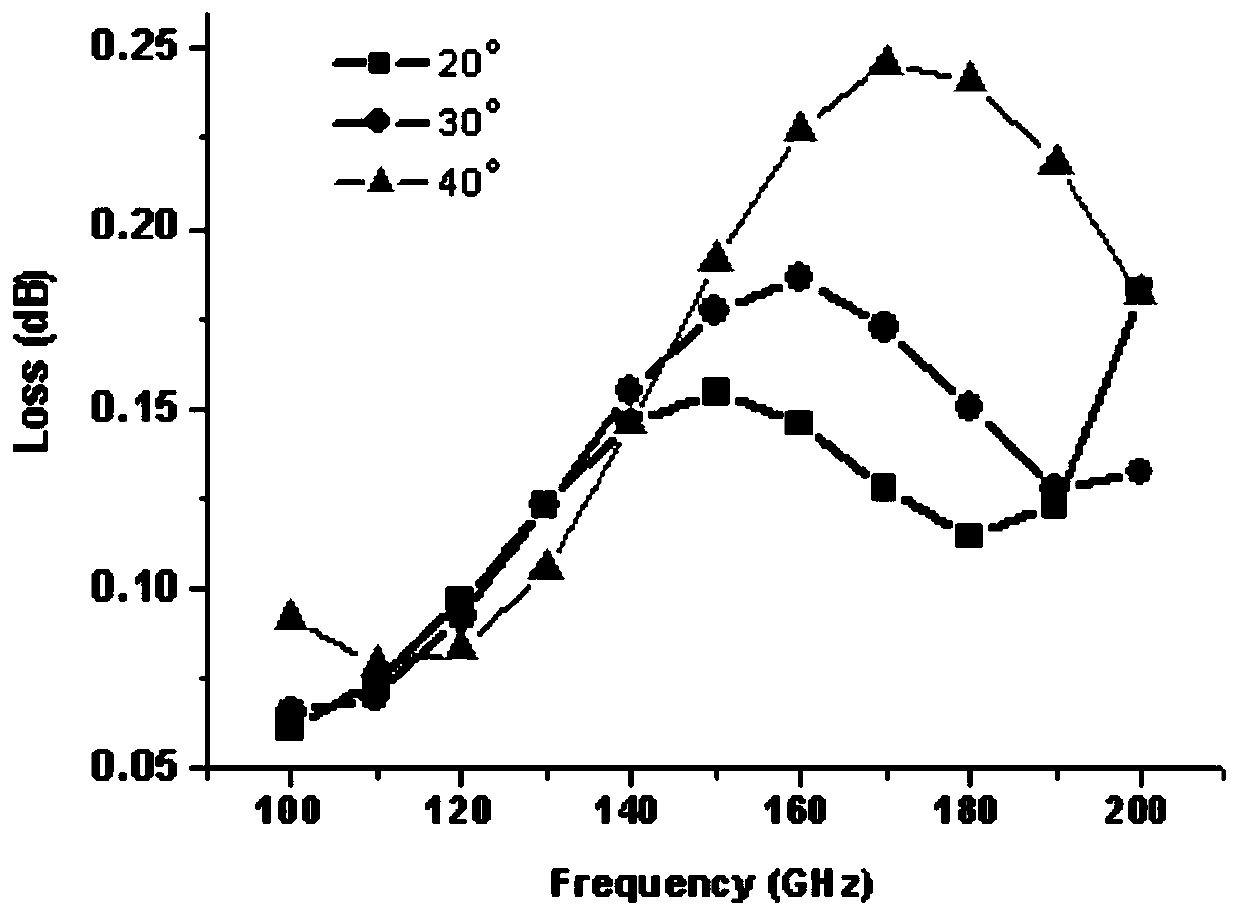

6G radome suitable for terahertz antenna and preparation method thereof

ActiveCN110350317AImprove temperature resistanceLightweightRadiating element housingsMaxillary gingivaBisphenol

The invention relates to a 6G radome suitable for a terahertz antenna and a preparation method thereof. The radome comprises an outer skin, a foam core layer, a middle skin, a foam core layer and an inner skin. The 6G radome is characterized in that the prepreg formed by combination of fiber reinforcement and resin is used as the skin material. As for the prpreg, the resin is polyphenylene ether modified bisphenol M cyanate ester resin and has the following dielectric properties: dielectric constant is less than or equal to 2. 6 and the loss factor is less than or equal to 0. 004. The fiber reinforcement is quartz fiber braid. The prepreg gum content is 30wt%-44wt%. The hot-pressing pot forming technology is used. The radome has high wave transmittance within the range of 100-200GHz and can meet the transmission performance requirements of the 6G antenna network within the terahertz band.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

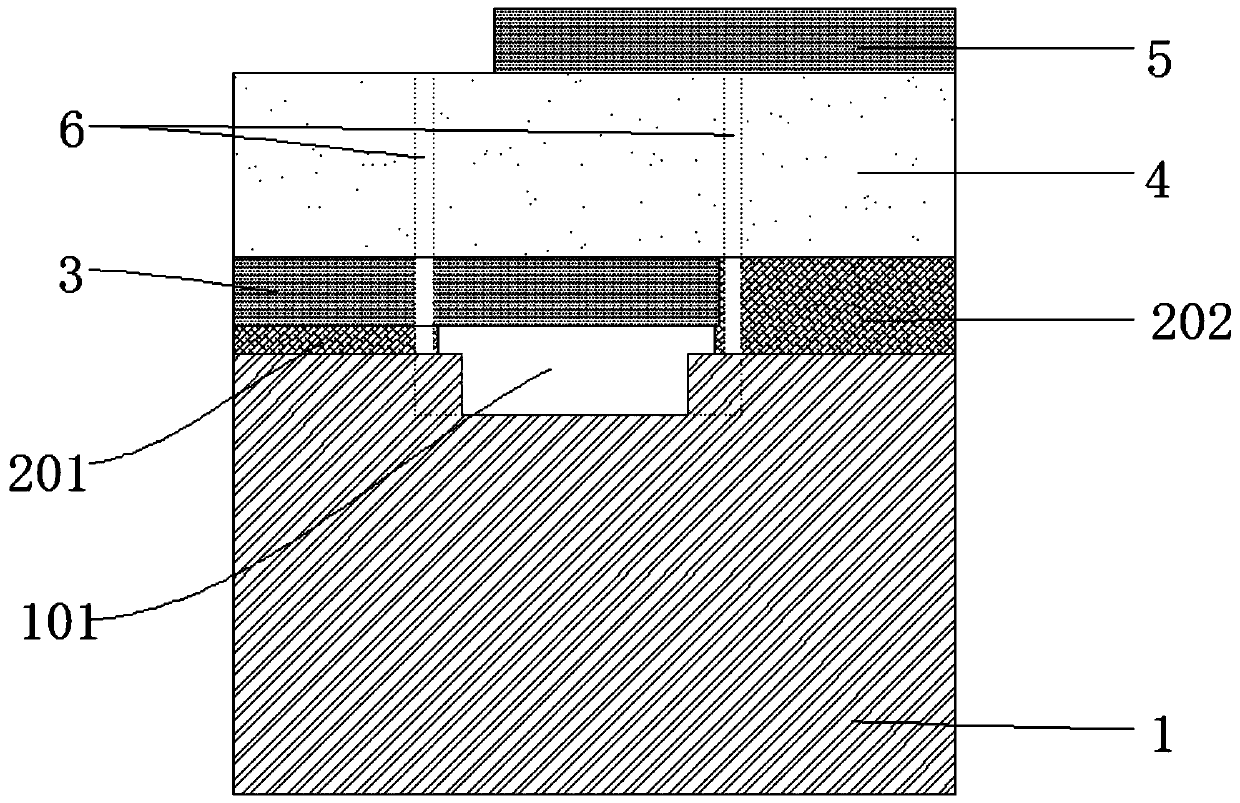

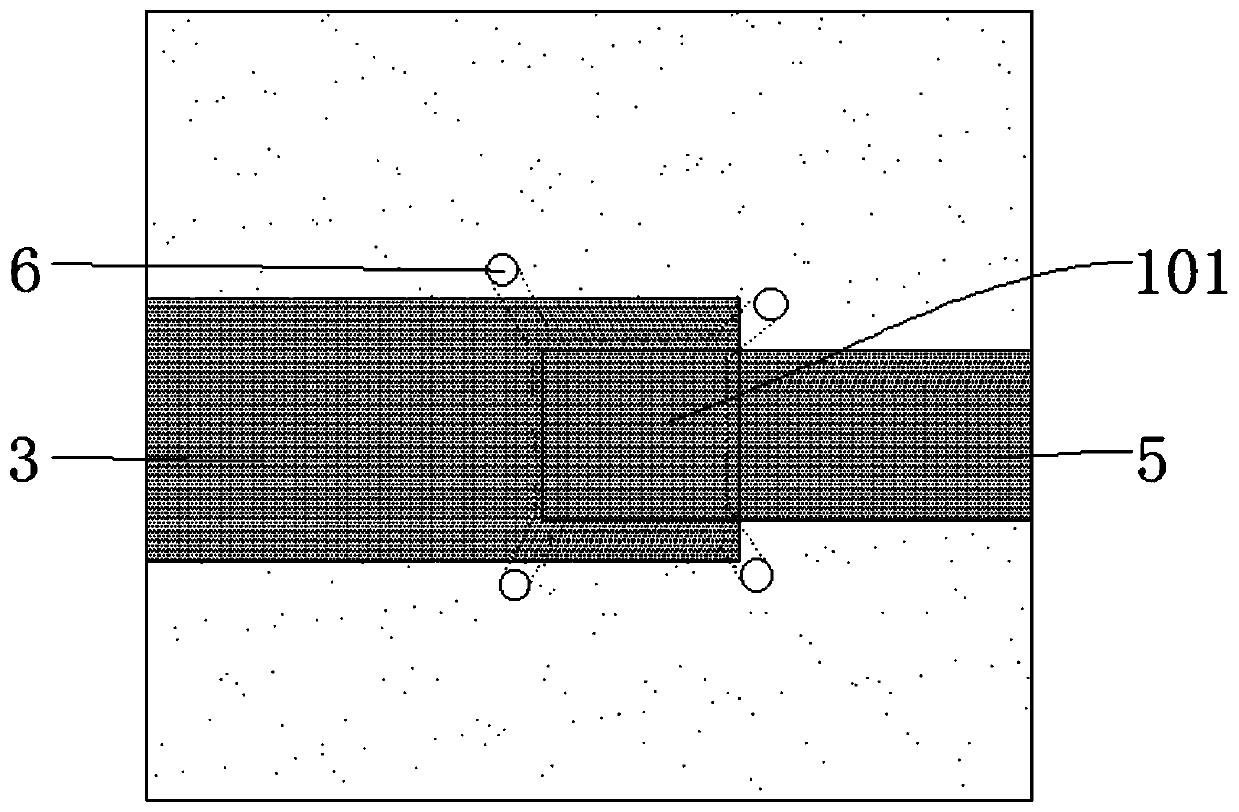

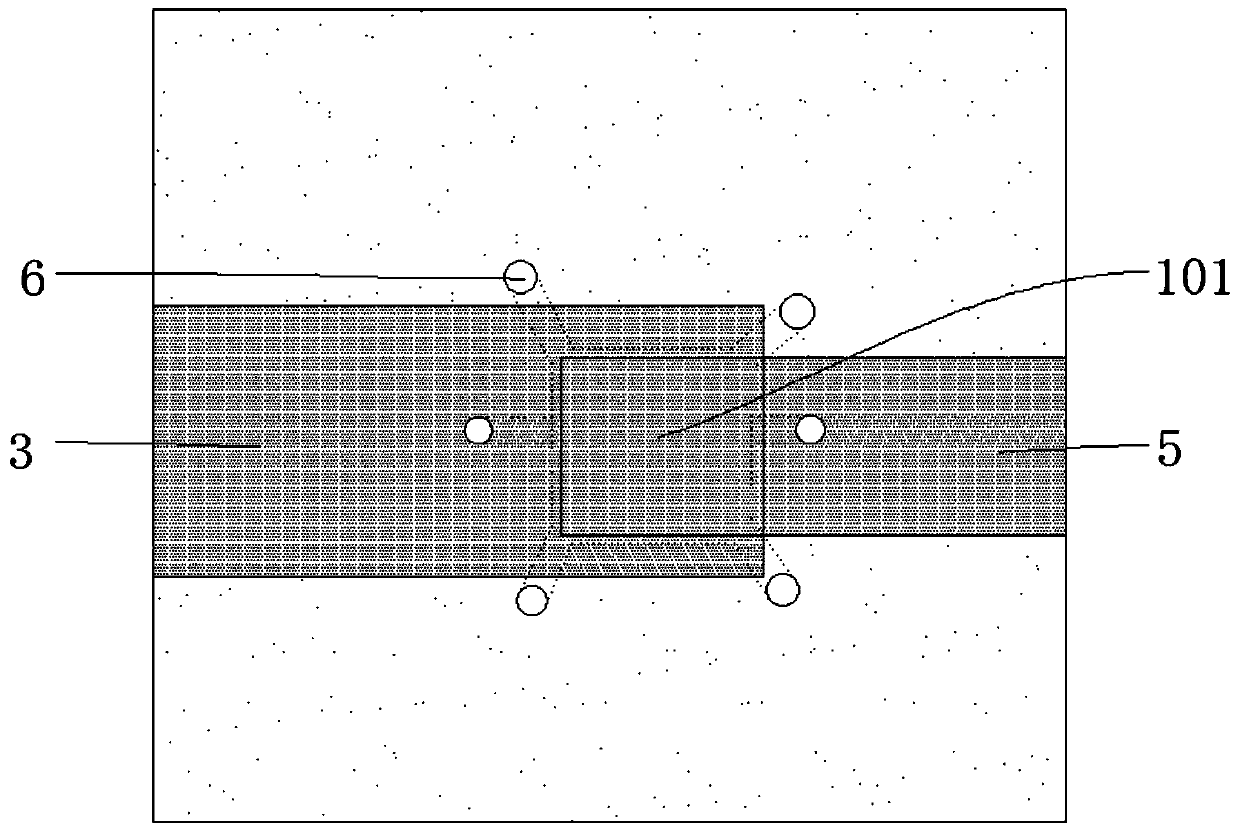

Film bulk acoustic resonator and preparation method thereof

The invention discloses a film bulk acoustic resonator and a preparation method thereof, and the resonator comprises a substrate which is provided with a cavity; a bonding layer which comprises a first bonding layer and a second bonding layer which are arranged on the upper surface of the substrate outside the cavity, wherein the thickness of the first bonding layer is less than that of the secondbonding layer; a bottom electrode layer which is arranged on the upper surface of the first bonding layer and completely covers the cavity, so the bottom electrode layer is flush with the second bonding layer; a piezoelectric layer which is arranged on the upper surfaces of the bottom electrode layer and the second bonding layer, wherein a through hole is formed in the piezoelectric layer and penetrates through the piezoelectric layer, and the bottom electrode layer and the bonding layer to be communicated with the cavity; a top electrode layer which is arranged on the upper surface of the piezoelectric layer, wherein the orthographic projections of the top electrode layer and the bottom electrode layer on the horizontal plane only coincide at the positions corresponding to the cavities.According to the preparation method, before silicon is completely removed, the cavity is communicated with the outside, and the difference between the interior of the cavity and the atmospheric pressure is solved under the condition that silicon binding force with enough strength exists.

Owner:广州市艾佛光通科技有限公司

Sheathed line swelling detecting device and method

PendingCN106019515AEasy assemblyEasy to operateMechanical diameter measurementsFibre mechanical structuresMagnetStatistical analysis

The invention discloses a sheathed line swelling detecting device which comprises a die base. A half die is placed in the die base. A magnet is placed below the die and attracts the die. The inner diameter of the die is slightly larger than the outer diameter of an optical cable sheath. Guide rods are designed on the two sides of the die base to stabilize an optical cable and prevent the optical cable from shaking. In normal production, the optical cable can smoothly pass through the half die, once the surface of the sheath swells, friction force can drive the half die out of the die base, at the moment, a proximity switch is switched on and an alarm is given, an operator is likely to process the swelling defect in time, record the quality and conduct rectifying and reforming by counting and analyzing the defect conditions, less rejected products are produced and unexpectedly flow to customers, the device is simple, practical, efficient and economical, and expected aims can be achieved.

Owner:JIANGSU ETERN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com