Aviation tire reinforcing layer adhesive of high adhesive strength

A technology for aviation tires and bonding strength, which is applied in the field of rubber for the reinforcement layer of aviation tires, can solve the problems of reduced use safety and service life, prone to delamination, insufficient strength, etc., and can prevent tire delamination and process performance. Good, high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

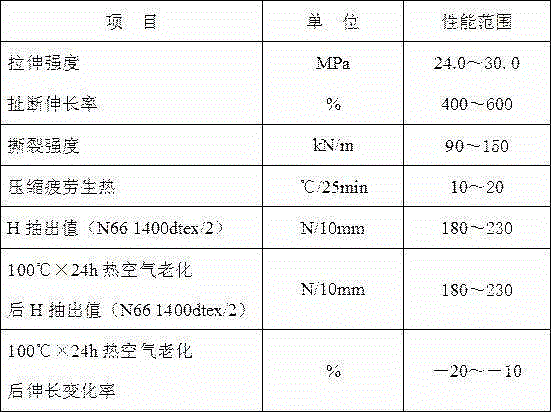

[0028] In the embodiment, each component raw material consumption is weight portion, see Table 2.

[0029] Table 2

[0030] Raw material name Example 1 Example 2 1 # smoked sheet glue 80 90 SBR 1500 20 10 New process high structure and high wear resistance carbon black 30 40 Silica 15 5 Silane coupling agent KH-560 1 3 Adhesion Promoter AIR-201 2 3 Adhesion Promoter AIR-1 5 3 Adhesive SL-3090 3 3 Adhesive A 2 2 Zinc oxide 5 5 Stearic acid 3 3 p-phenylenediamine antioxidant 2 2 Anti-aging agent RD 1.5 1.5 Anti-aging agent BLE 2 2 insoluble sulfur 2 1.7 Sulfenamide accelerators 1.5 2 Anti-scorch agent CTP 0.3 0.3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com