Patents

Literature

2004 results about "P-Phenylenediamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

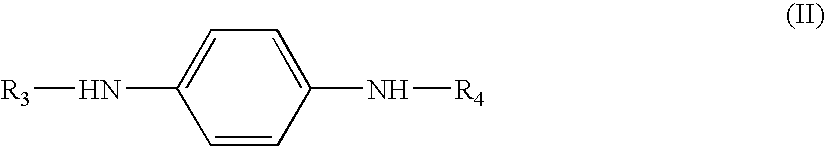

P-Phenylenediamine (PPD) is an organic compound with the formula C₆H₄(NH₂)₂. This derivative of aniline is a white solid, but samples can darken due to air oxidation. It is mainly used as a component of engineering polymers and composites like kevlar. It is also an ingredient in hair dyes and is occasionally used as a substitute for henna.

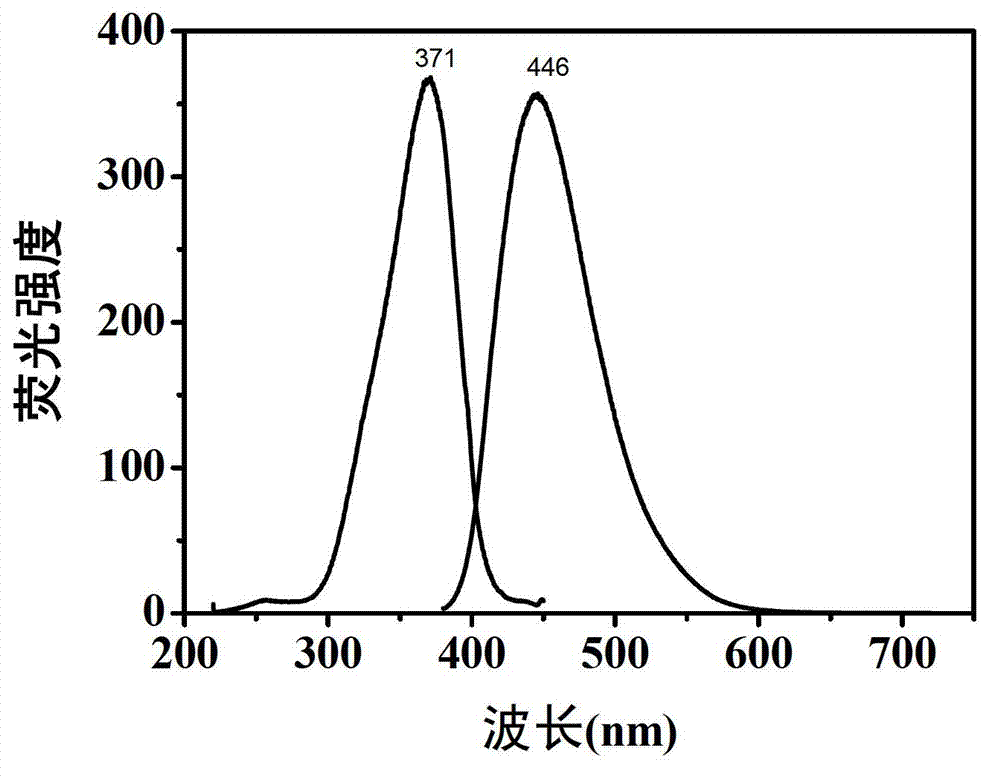

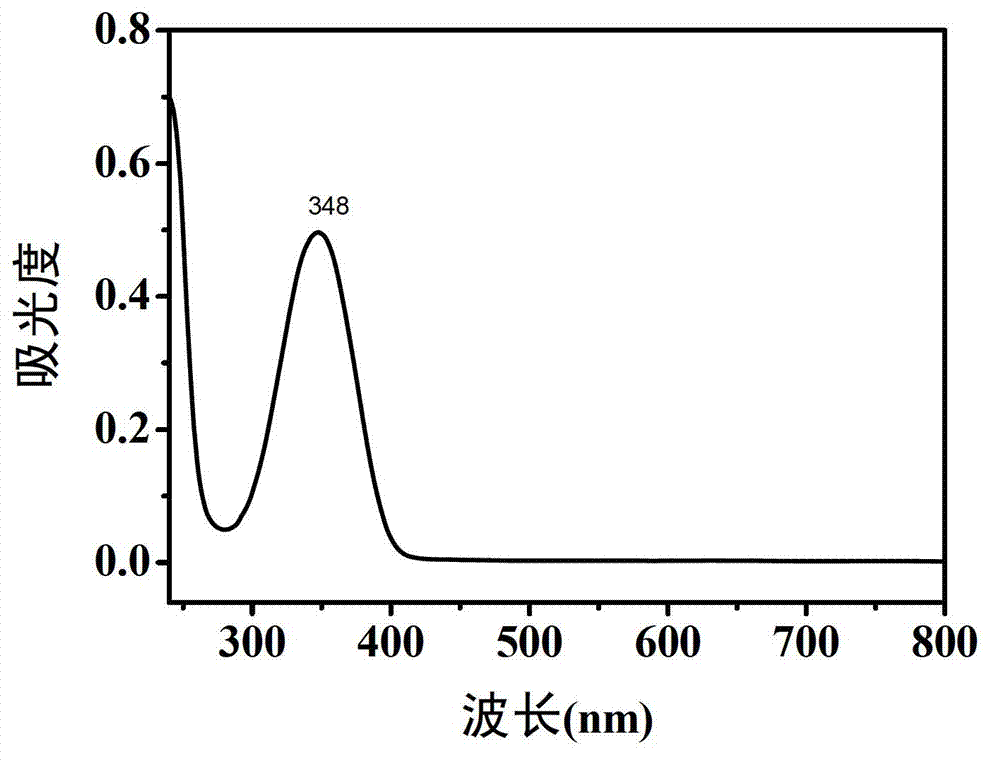

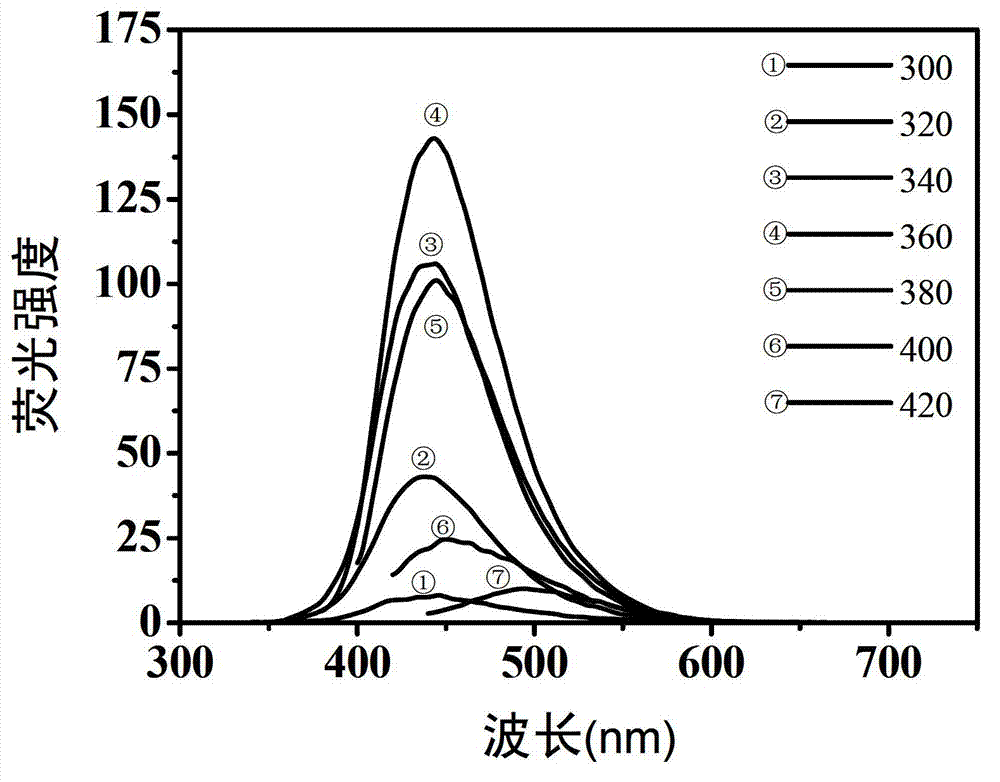

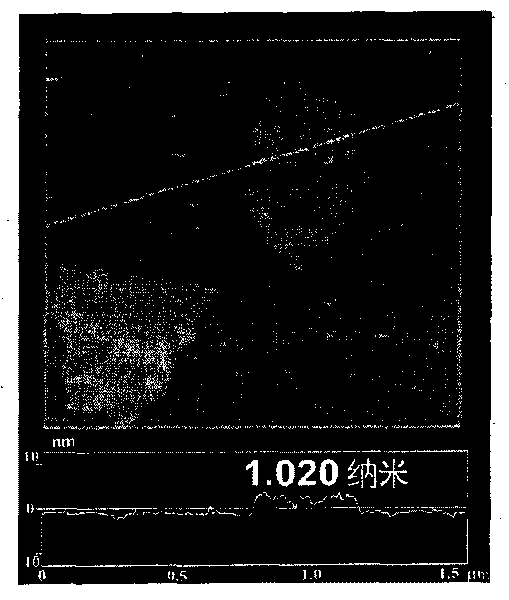

Preparation method of carbon dot having high fluorescent quantum yield

The invention belongs to the technical field of preparation of a carbon nano material, and particularly relates to a method for preparing a carbon dot having a high fluorescent quantum yield from citric acid and different nitrogen-containing molecules. The method comprises the following steps: weighing 1-10 mmol of solid citric acid, and dissolving in 10 ml of deionized water; weighing 1-10 mmol of ethylenediamine, ethylamine, propylamine, butanediamine, n-hexylamine, p-phenylene diamine or urea, adding into the citric acid solution, and uniformly stirring; transferring the solution into a hydrothermal or high-pressure microwave reaction kettle, reacting under hydrothermal or microwave conditions, and naturally cooling the reaction kettle to room temperature, thus obtaining a yellow or brown carbon dot water solution; and finally, purifying the carbon dot water solution, evaporating, and drying to obtain pure carbon dot solid powder. The carbon dot solution can send out bright blue fluorescence under the irradiation of a handheld ultraviolet lamp. The invention has wide application prospects in the fields of biological imaging, fluorescent printing and the like.

Owner:JILIN UNIV

Tire with low hydrocarbon emission rubber combination of tread and sidewall components with compositional limitations

InactiveUS7214731B2Eliminate emissionsEmission reductionSpecial tyresInflatable tyresElastomerHydrophobic silica

The invention relates to a tire of a structural combination of tire tread and sidewall components with compositional limitations containing minimal, if any, of in situ formed alcohol and methyl isobutyl ketone byproducts. The tread component rubber composition contains pre-hydrophobated silica reinforcement. The sidewall component contains low unsaturation EPDM or brominated copolymer of isobutylene and p-methylstyrene and may contain pre-hydrophobated silica reinforcement. The silica reinforcement for said tread and sidewall components is a pre-hydrophobated precipitated silica. The pre-hydrophobated silica is prepared, prior to mixing with the elastomer(s), by reacting hydroxyl groups (e.g. silanol groups) contained on the surface of a precipitated silica with an alkoxyorganomercaptosilane or a combination of an alkoxyorganomercaptosilane and a substituted alkylsilane or with a bis-3(trialkoxysilylalkyl) polysulfide which contains an average of from 2 to 4 connecting sulfur atoms in its polysulfidic bridge to form a composite thereof. The alcohol byproduct therefrom is removed from the composite prior to its introduction into the rubber composition(s). In another aspect of the invention, the connecting sidewall rubber composition, and optionally the tread composition is free of N-(1,3-dimethylbutyl)-N′-phenyl-p-phenylenediamine antidegradant (referred herein to as 6PPD) in order to prevent in situ formation of methyl isobutyl ketone byproduct from the reaction of 6PPD with atmospheric oxygen and / or ozone.

Owner:THE GOODYEAR TIRE & RUBBER CO

Lubricant compositions stabilized with multiple antioxidants

InactiveUS20060128574A1Prevent oxidationPromote oxidationLiquid carbonaceous fuelsAdditivesAntioxidantOxidation stability

A lubricant composition is disclosed that comprises lubricating oil and a mixture of at least two antioxidants, the first antioxidant being a secondary diarylamine and the second antioxidant being a substituted para-phenylenediamine. Also disclosed is a method of increasing the oxidation stability of a lubricating oil comprising adding thereto at least two antioxidants, the first antioxidant being a secondary diarylamine and the second antioxidant being a substituted para-phenylenediamine.

Owner:LANXESS SOLUTIONS US INC

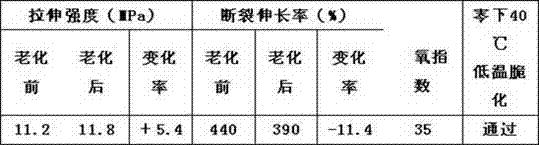

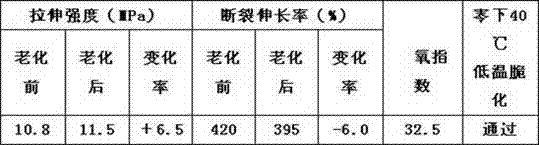

Cold-resistant rubber cable sheath material and preparation method

ActiveCN102399397AImprove low temperature performanceImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesParaffin waxActive agent

The invention discloses a cold-resistant rubber cable sheath material and a preparation method. The material comprises chlorinated polyethylene, ethylene-propylene-diene monomer (EPDM) rubber, lead oxide, calcium carbonate, N-isopropyl benzene-N'-phenyl p-phenylenediamine serving as an anti-aging agent, antimonous oxide, magnesium oxide, paraffin hydrocarbon oil, chlorinated paraffin, paraffin, carbon black, settled white carbon black, talc powder, gamma-aminopropyl triethoxysilane serving as a surfactant, dicumyl peroxide serving as a vulcanizing agent and triallyl isocyanurate serving as a co-vulcanizing agent. The low temperature performance of the material is improved by blending the chlorinated polyethylene and the EPDM rubber, and meanwhile, the flame-retardant performance of the rubber sheath material is improved by synergy of the antimonous oxide serving as a flame retardant and the chlorinated paraffin; experiments show that the rubber sheath material can pass low-temperature embrittlement test of 40 DEG C below zero, has excellent low-temperature resistance, has the oxygen index of more than 32 and has good flame-retardant performance; and the preparation method is simple and strong in operability.

Owner:JIANGSU HENGTONG POWER CABLE

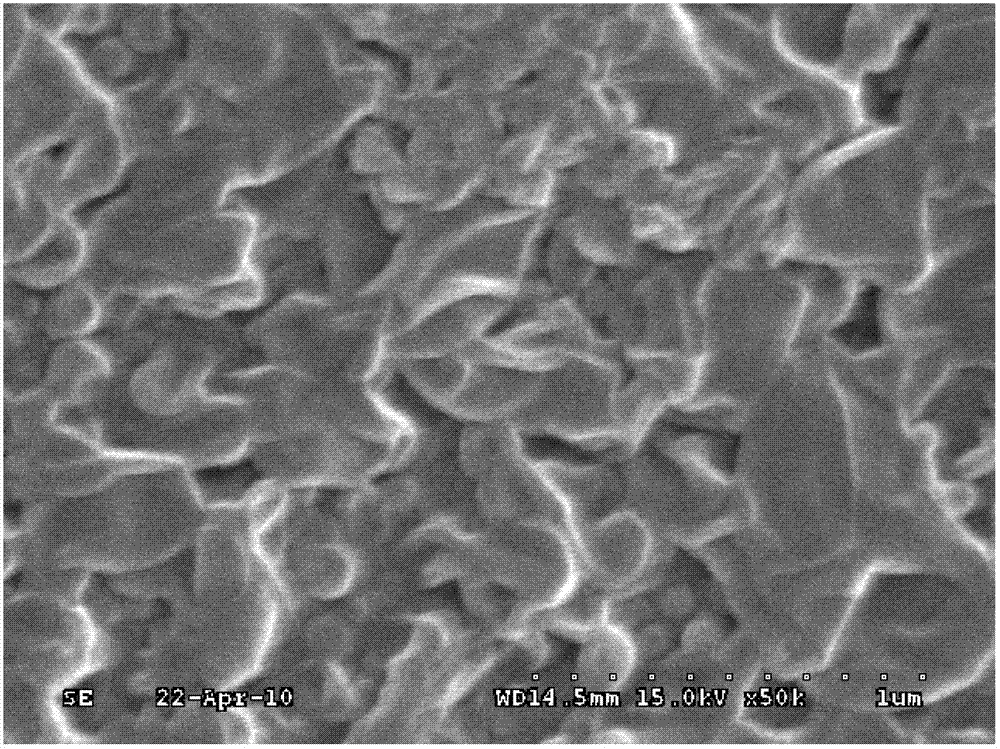

Compound reverse osmosis membrane with interpenetrating network desalting layer and preparation method of membrane

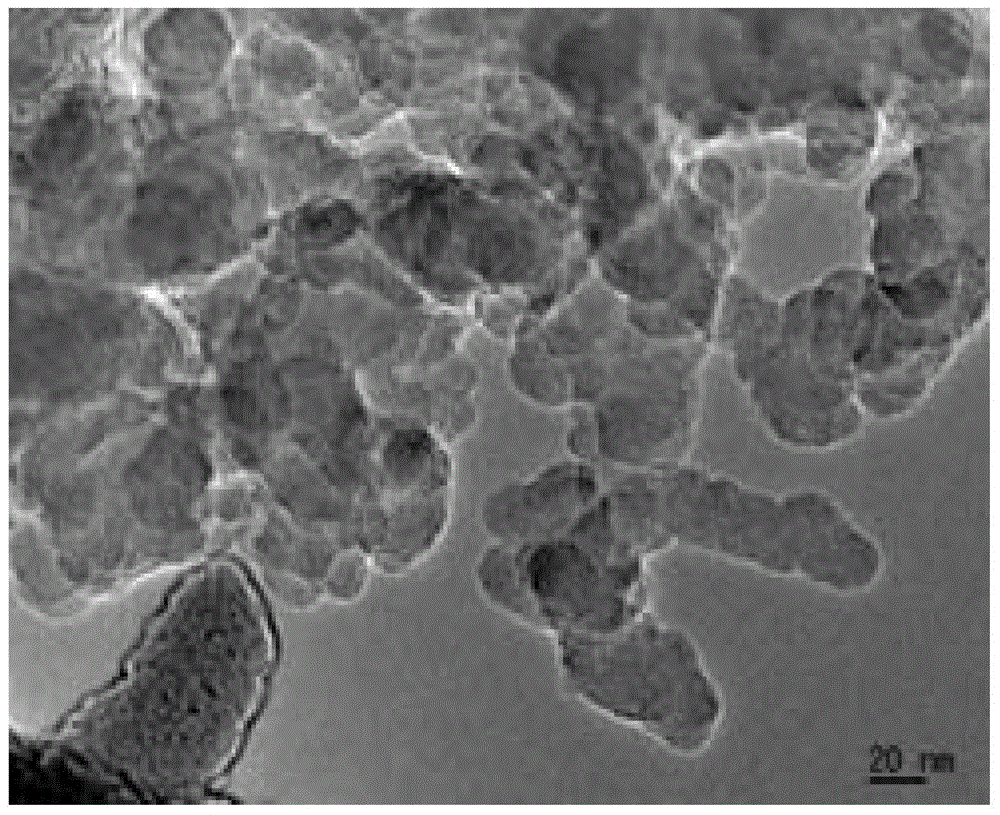

ActiveCN102921314AImprove throughputHigh desalinationSemi-permeable membranesPolyamideReverse osmosis

The invention discloses a compound reverse osmosis membrane with interpenetrating network desalting layer and a preparation method of the membrane. The desalting layer consists of a stereoscopic network which is formed by interpenetrating macromolecule nanogel and polyamide. The preparation method comprises the following steps of: pre-adding hydrophilic and / or oleophylic macromolecule nanogel with good dispersion into a solvent of solution A and / or B, preparing a water phase A solution containing m-phenylenediamine and / or p-phenylenediamine, preparing an organic phase B solution containing trimesoyl chloride, enabling the solution A and the solution B to fully contact on a porous support carrier for interface reaction, rinsing by using deionized water, carrying out moisturizing treatment by using glycerol, and drying. The compound reverse osmosis membrane disclosed by the invention has a sodium chloride removal rate of not less than 99% and a flux of not less than 25GFD (Geophysical Fluid Dynamics) under a pressure of 225psi; the microstructure and the charge property of the desalting layer can be regulated and controlled through the macromolecule nanogel so that the reverse osmosis membrane with high anti-pollution capability is prepared; and the compound reverse osmosis membrane can further be used for developing novel low-pollution reverse osmosis membranes.

Owner:VONTRON TECH CO LTD

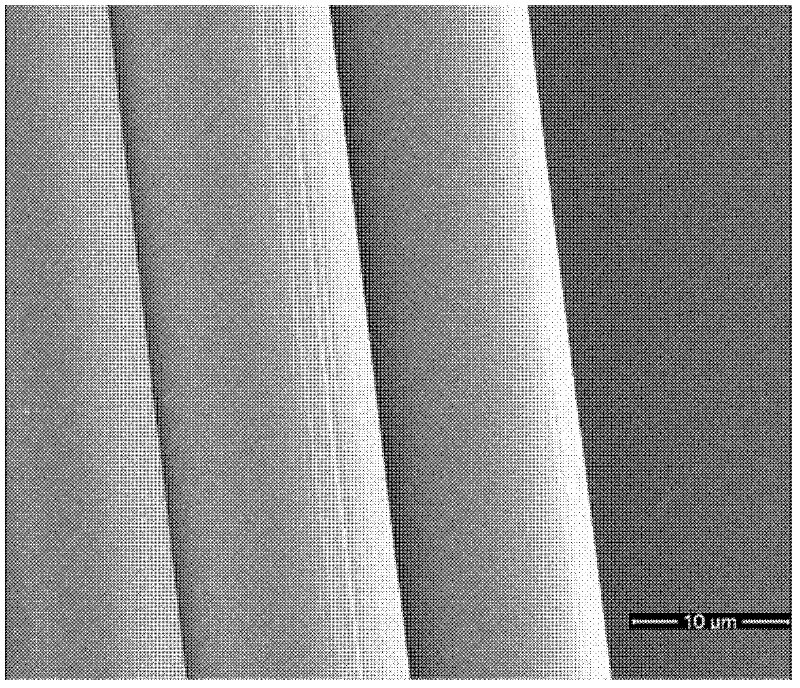

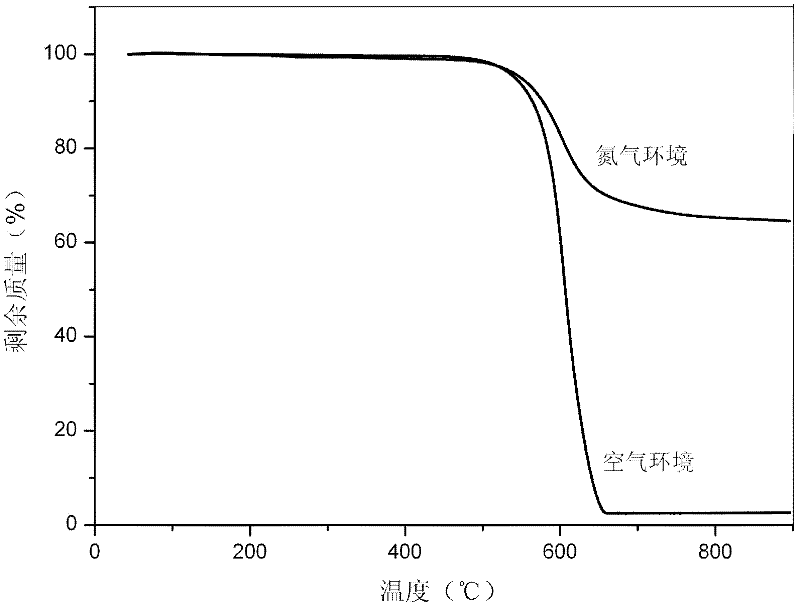

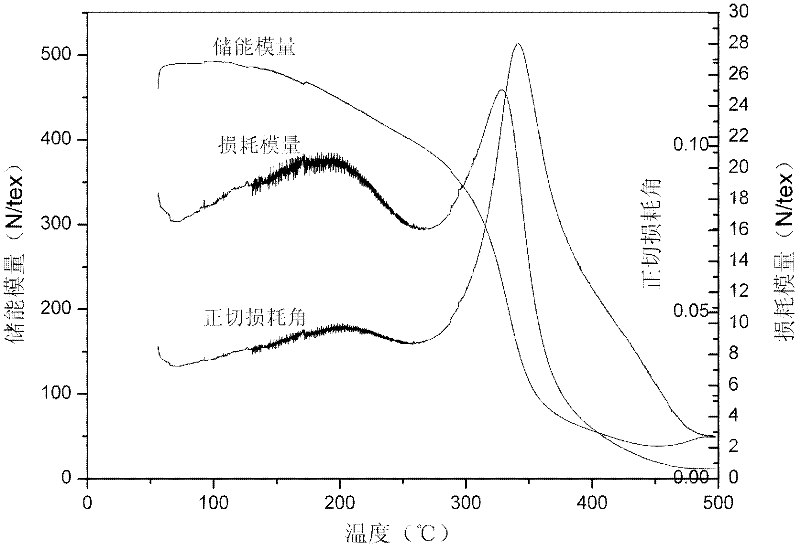

High-strength high modulus polyimide fiber and preparation method thereof

ActiveCN102345177AImprove performanceReasonable molecular structureArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention relates to high-strength high modulus polyimide fiber and a preparation method thereof, which belongs to the high performance organic fiber technical field. The fiber comprises the polyimide fiber which is prepared by biphenyltetracarboxylic dianhydride (BPDA), para-phenylene diamine (pPDA) and 2-(4-aminophenyl)-5-aminobenzimidazoles (BIA), wherein the mol ratio of pPDA to BIA is 1:10-3:1, other di-amine and di-anhydride monomers are added in the synthesis process, a gradient temperature reaction method and a one step continuous preparation method are used in the preparation process, so that the difficulties for synthesizing and processing due to the content increase of 2-(4-aminophenyl)-5-aminobenzimidazoles are solved, the problems of poor homogeneity and stability of thefiber performance can be solved, and the high-strength high modulus polyimide fiber can be obtained, the strength can reach 4.5GPa, the modulus can reach 201GPa, and the raw material source is wide, the spinning process can be continuously performed, the method has low cost and high efficiency which is capable of realizing the industrial production.

Owner:JIANGSU XIANNUO NEW MATERIAL TECH

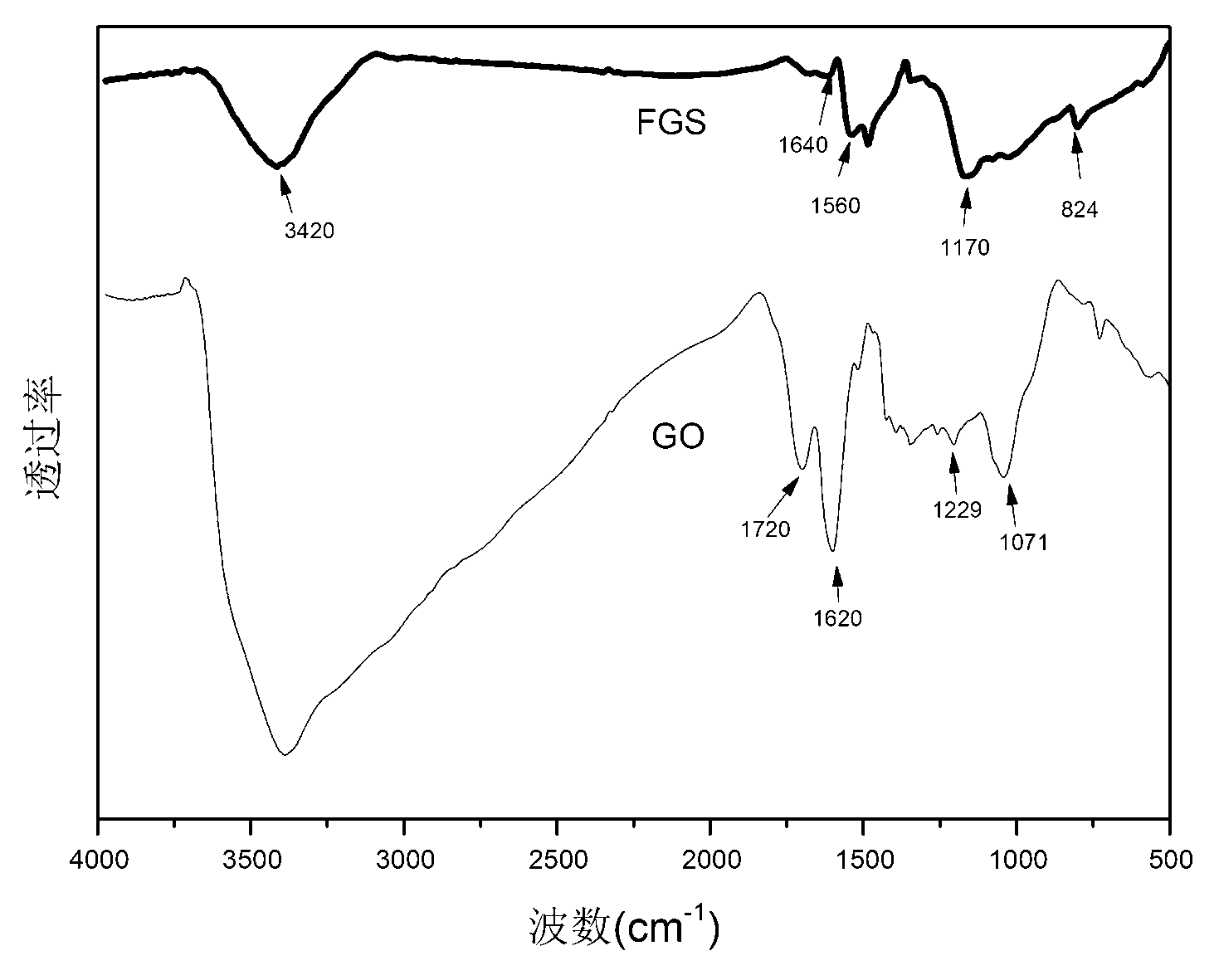

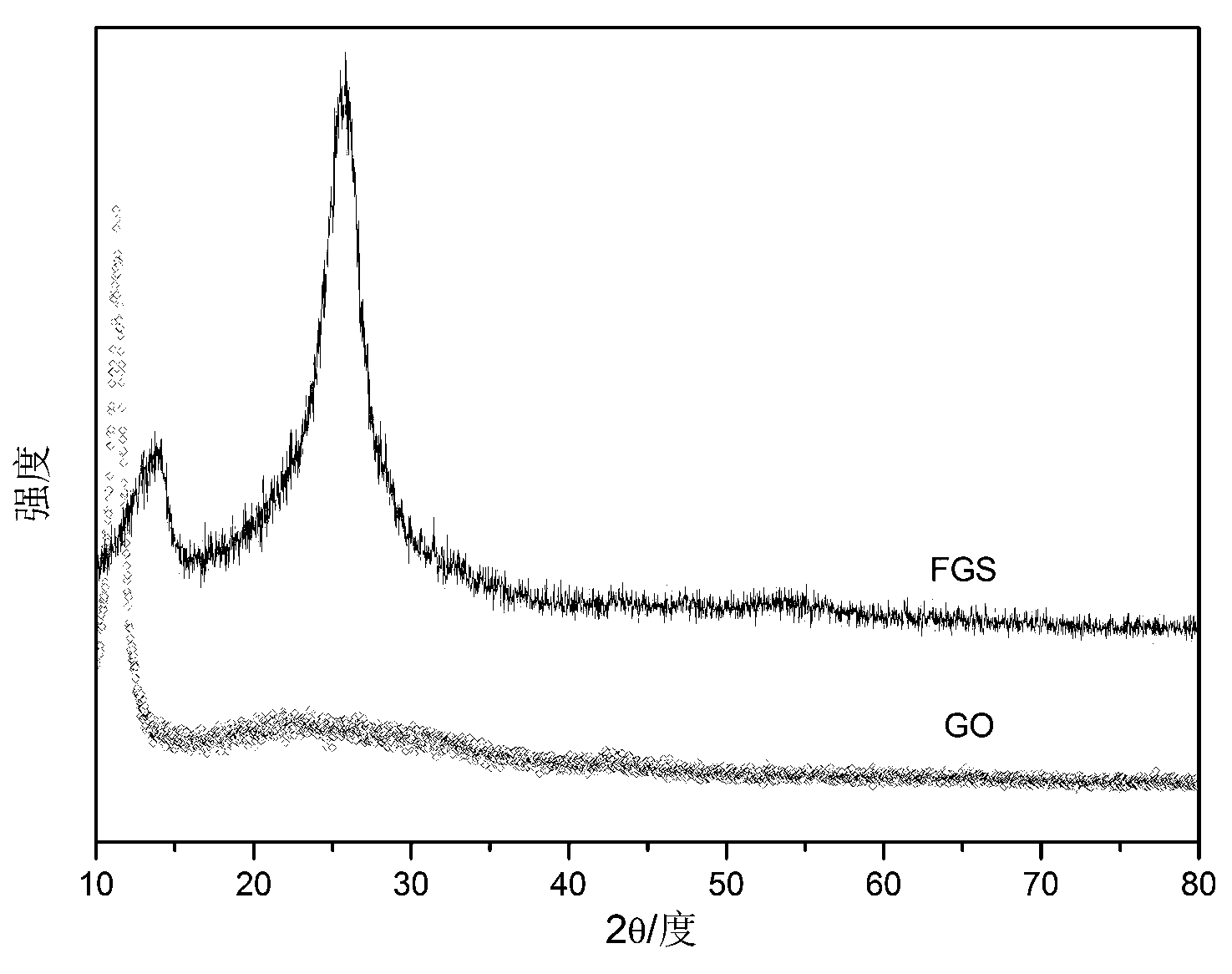

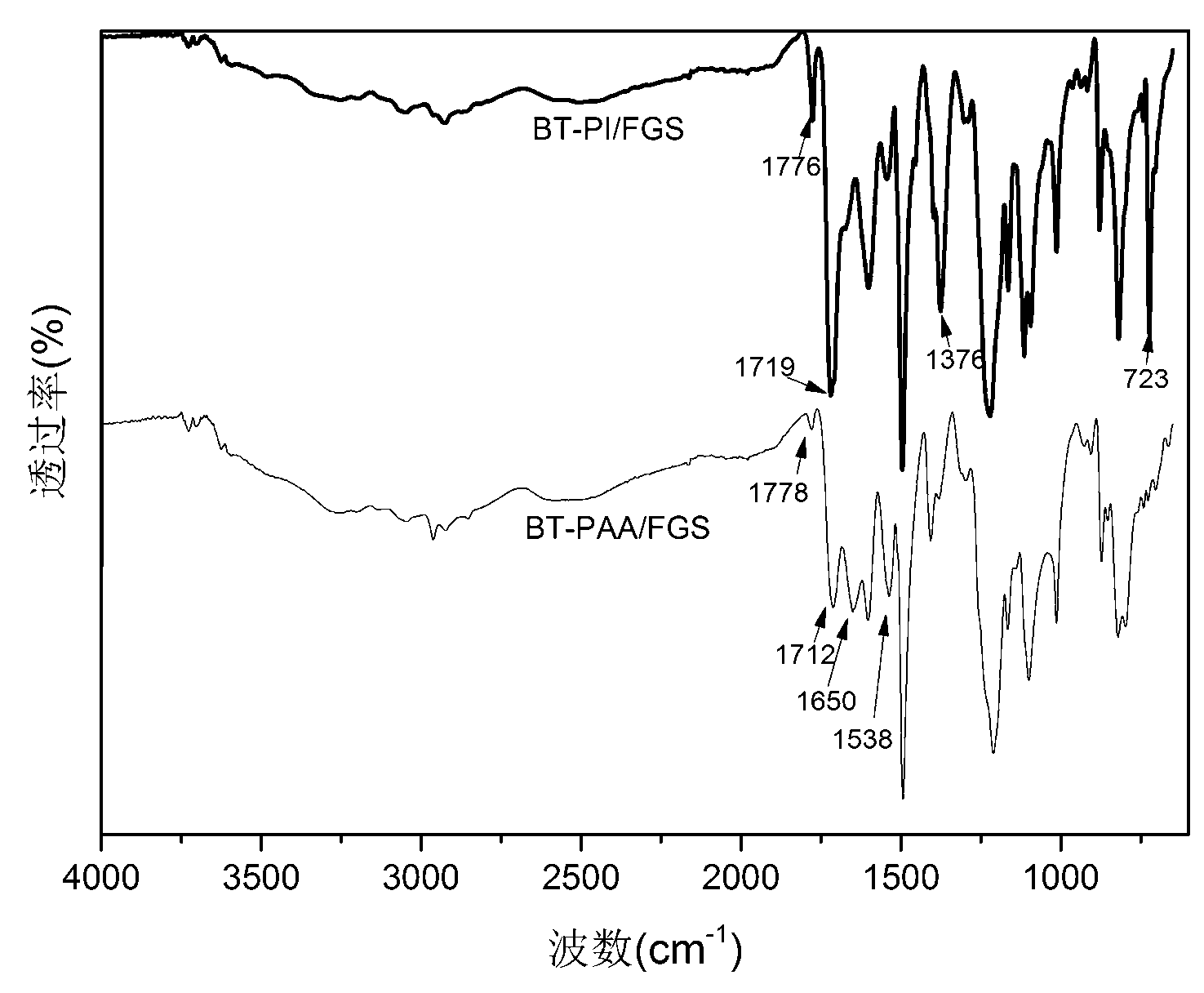

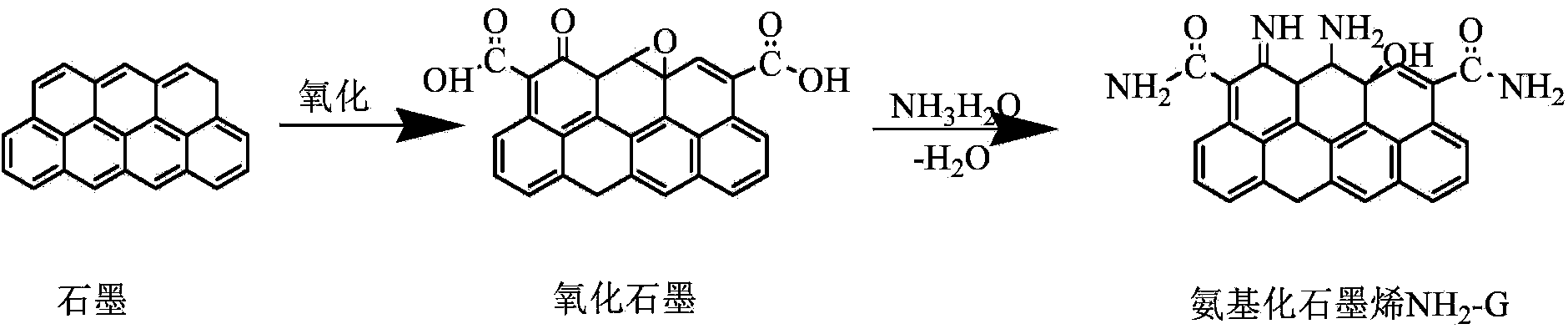

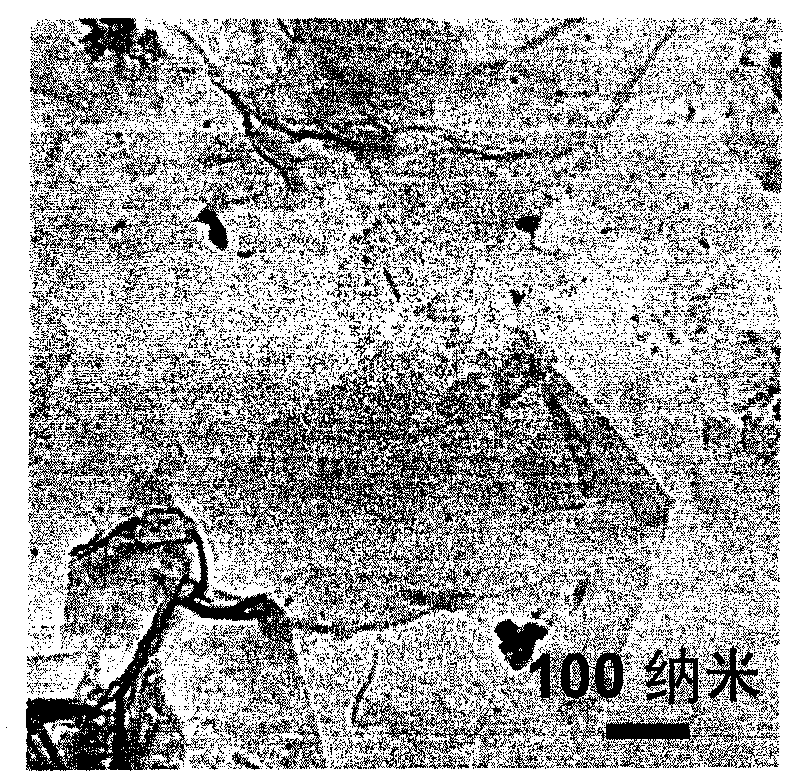

Polyimide high dielectric composite material and preparation method thereof

The present invention relates to a polyimide high dielectric composite material, wherein polyimide is adopted as a matrix phase, modified graphene and nanometer barium titanate are adopted as inorganic phases, components comprise, by mass, 0.5-3.0 w% of modified graphene, 9.6-29.8 w% of nanometer barium titanate, and 69.7-87.4 w% of polyimide, the modified graphene is p-phenylenediamine graft modified graphene, and the surface of the modified graphene contains chemically grafted polyimide. The preparation method comprises the following steps: (1) graphene oxide modification, (2) polyamic acid prepolymer preparation, and (3) composite material thermal cross-linking. According to the preparation method, the functionalized graphene and the polyimide molecules can be combined through a covalent bond form, electric conductivity of the graphene can directly affect dielectric property of the composite material, and a volume fraction of the barium titanate can be effectively reduced. In addition, the conventional solution blending technology is adopted, the preparation process is simple, operation is easy, and the method can be widely promoted and applied.

Owner:EAST CHINA UNIV OF SCI & TECH

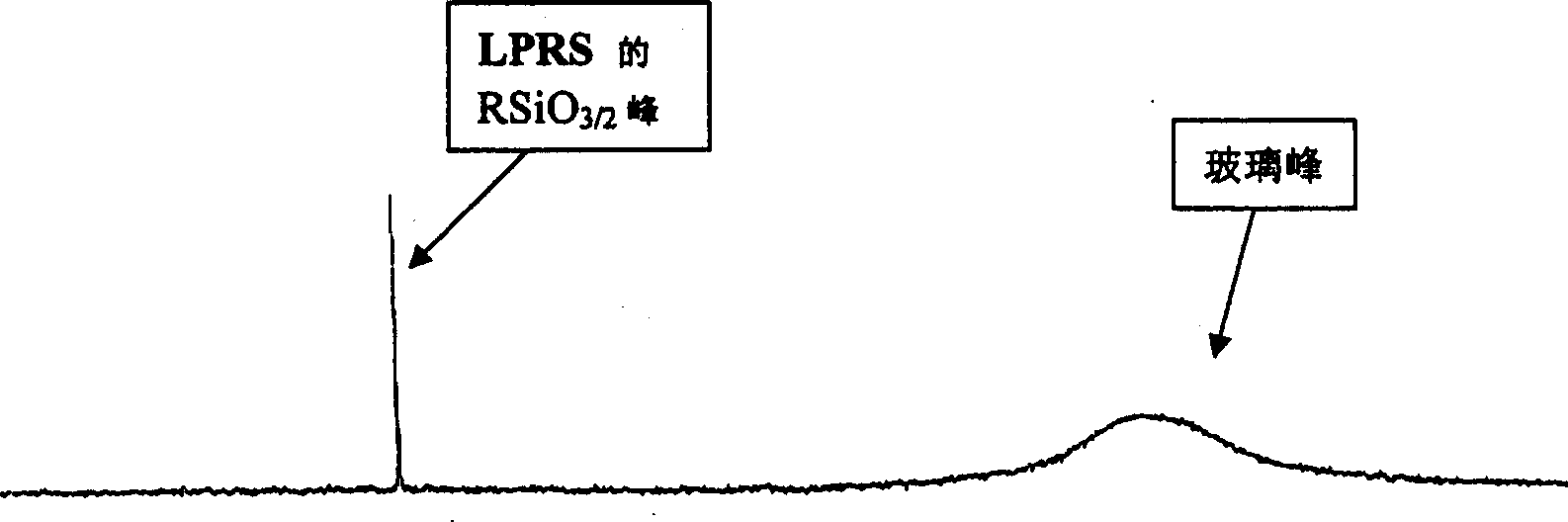

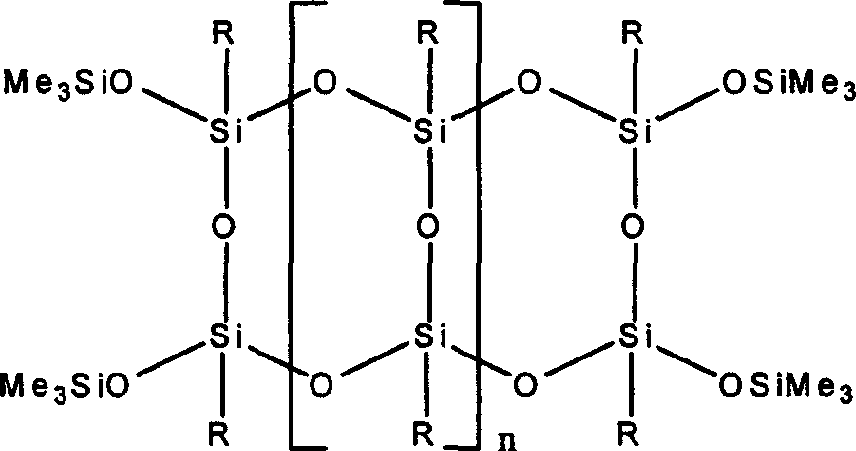

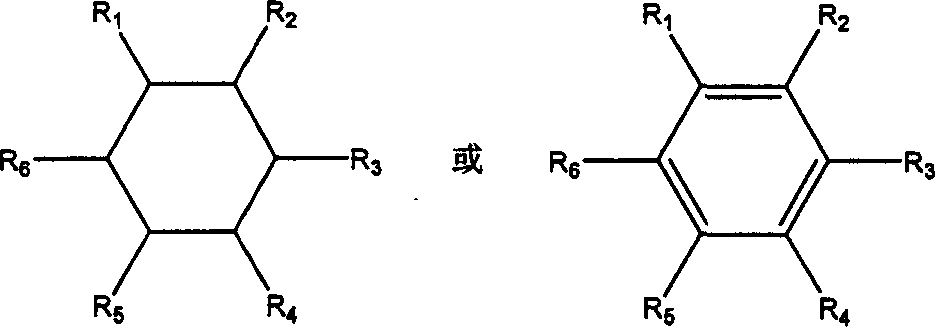

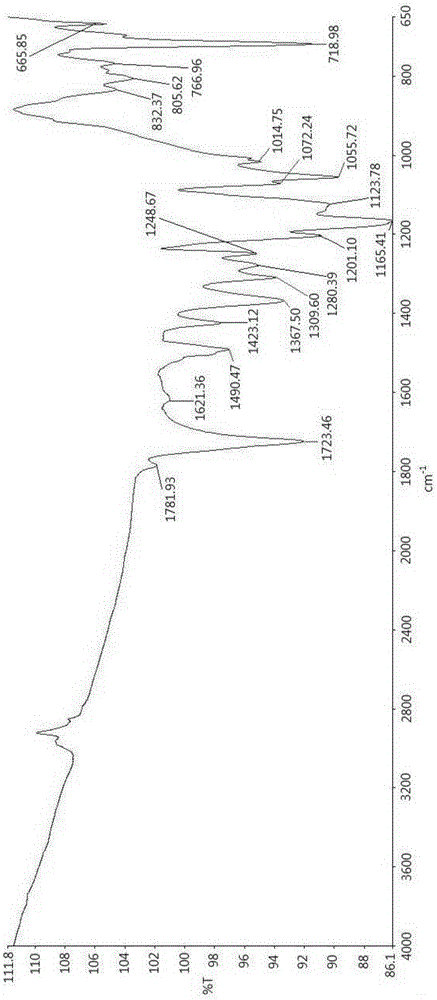

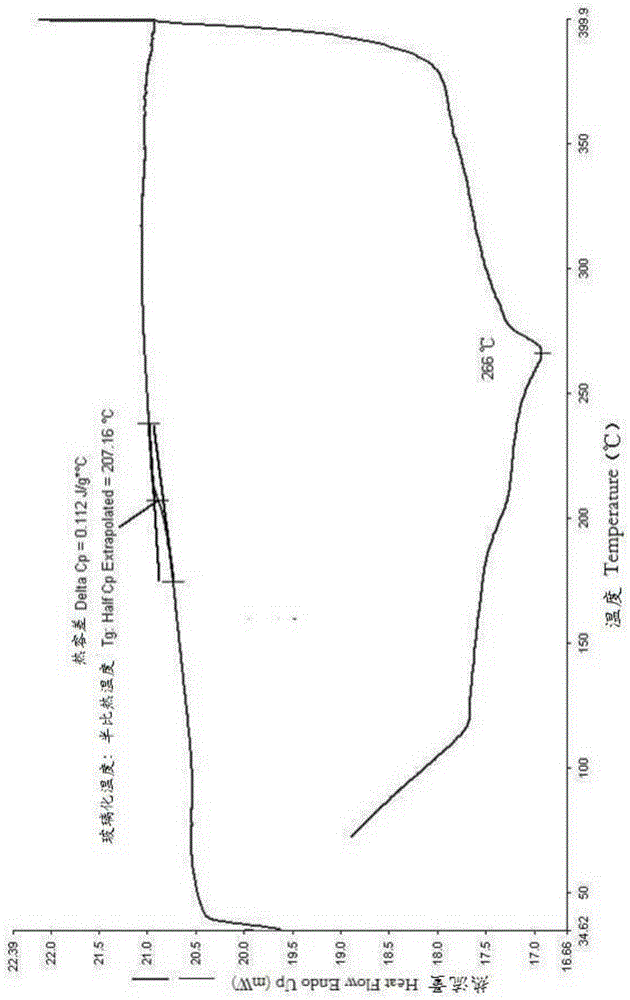

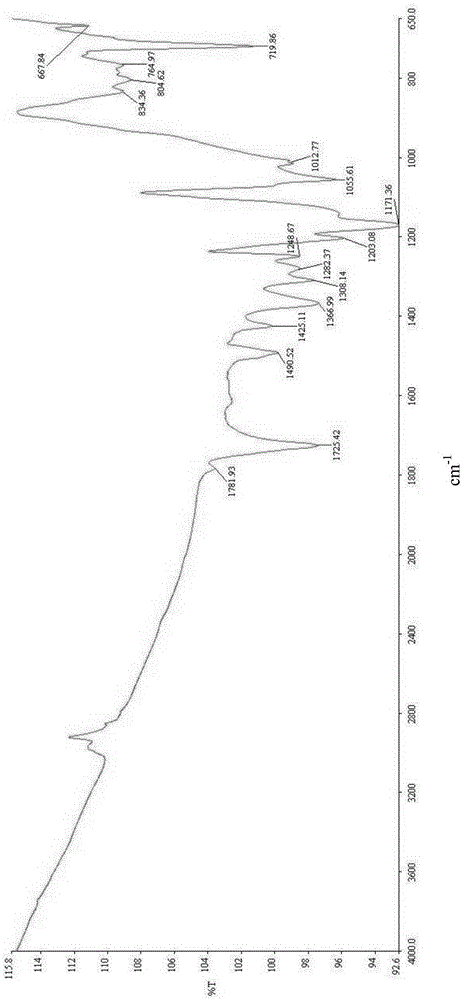

Trapezoidal organic poly sesquisiloxane and preparation method

A preparation method for highly tactic ladder-like polysilsequioxane with solubility, high molecular weight and different organic side groups is introduced in this invention. Trichlorosilicane with different substituents reacts with template-1, 4-dianiline or its derivatives with ladder-brace template method to produce conjugate precursor containing four silicon-chlorine bonds, which self-assembles into ladder polymers by hydrogen bond template function of p-dianiline and transforms into silanol end-capping organic bridging siloxane polymers after hemihydration-hydrolysis-condensation. Such a compound is then end-capped with trimethylsiloxyl and hydrolyzed to remove p-dianiline, and ladder-like polysilsequioxane can be obtained after further condensation. Or tetrafunctional disiloxane monomers with template-function side groups self-assemble into ladder-like polymers, which are then condensation-polymerized and end-capped with trimethylsiloxyl to obtain ladder-like polysilsequioxane.

Owner:INST OF CHEM CHINESE ACAD OF SCI

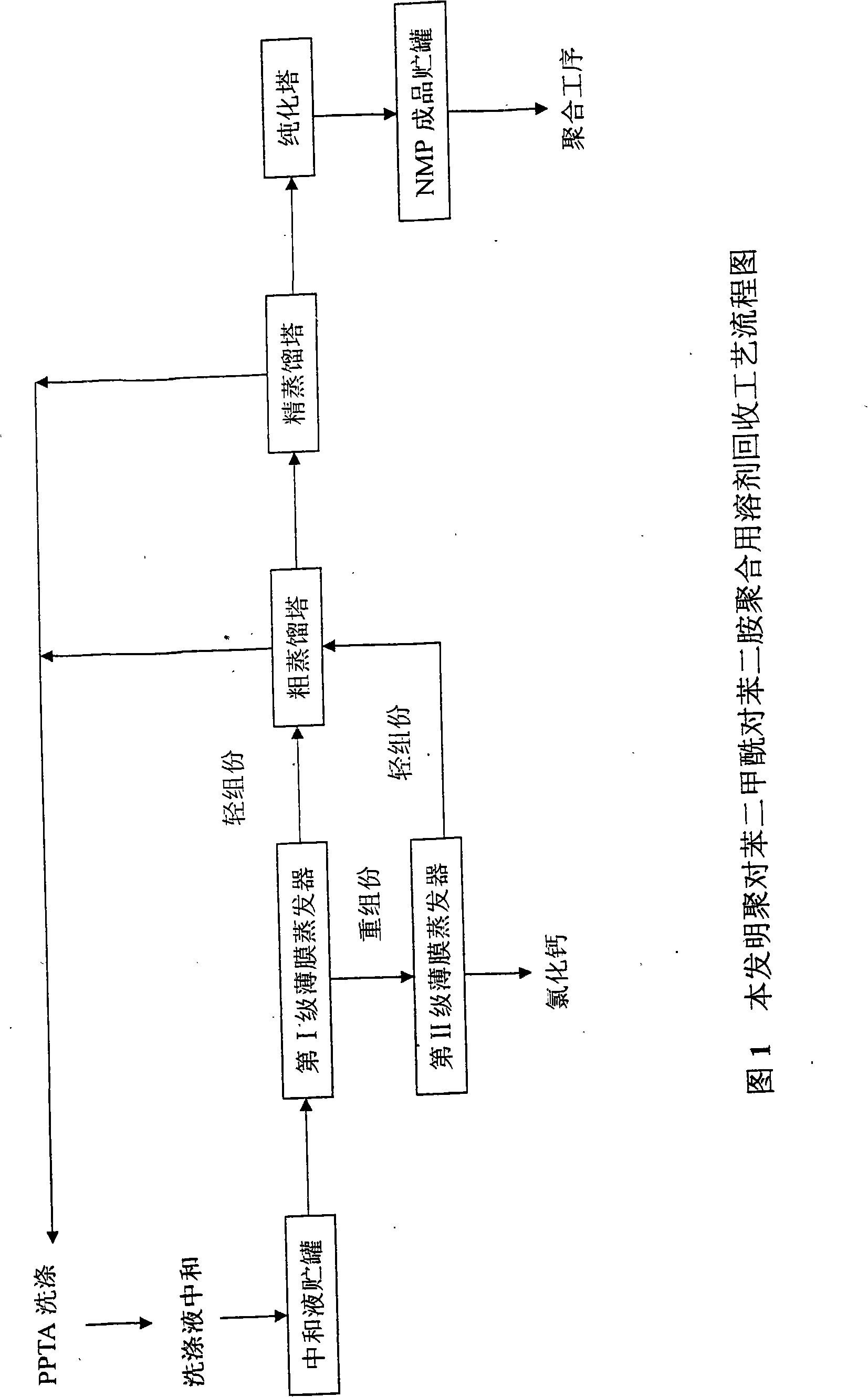

Novel method for recovering solvent for polymerization of poly(p-phenytene terephthalamide)

The invention relates to a novel method for recycling a solvent used for polymerizing the poly (p-phenylene terephthalamide) which has a shortened form of para-aramid or PPTA. The method comprises the following steps that: the PPTA polymer made by the low-temperature solution polycondensation contains a large amount of solution N-Methyl pyrrolidine which has a shortened form of NMP and certain amount of calcium chloride (CaCl2), the PPTA polymer is washed by deionized water for a plurality of times, the PPTA polymer is collected to enter a drying system, a scrub solution is neutralized and enters a neutralizing liquid storage tank of a solvent recycling system; the neutralizing fluid is processed by a two-stage film evaporator to remove the CaCl2 added to the polyreaction and generated by the neutralizing reaction, the hydration NMP enters the middle part of a topping still from the top of the film evaporator in a state of mixed gas to remove most of water by the distillation process, the purity quotient of NMP is improved further and the minim water inside the NMP is lowered by the rectification and purification processes, the obtained NMP has a purity quotient higher than 99.5 percent, a water content lower than 100ppm, thereby completely satisfying the requirement of PPTA polymerization. The technique is used for recycling the solvent for PPTA polymerization; the recycling rate of the NMP is higher than 96 percent, thereby lowering the cost further and providing reliable guarantee for the industrialization of the para-aramid.

Owner:SINOCHEM HIGH PERFORMANCE FIBER MATERIALS CO LTD

Polyimide film, and method for production thereof

InactiveUS20090197068A1Increase production capacityImprove productivitySynthetic resin layered productsPrinted circuit aspectsToluenediamineCarboxylic acid

Disclosed is a polyimide film prepared from an aromatic tetracarboxylic acid component consisting essentially of 3,3′,4,4′-biphenyltetracarboxylic dianhydride and an aromatic diamine component consisting essentially of not less than 65 mol phenylenediamine % but less than 97 mol % of p-phenylenediamine and not less than 3 mol % but less than 35 mol % of 2,4-toluenediamine.

Owner:UBE IND LTD

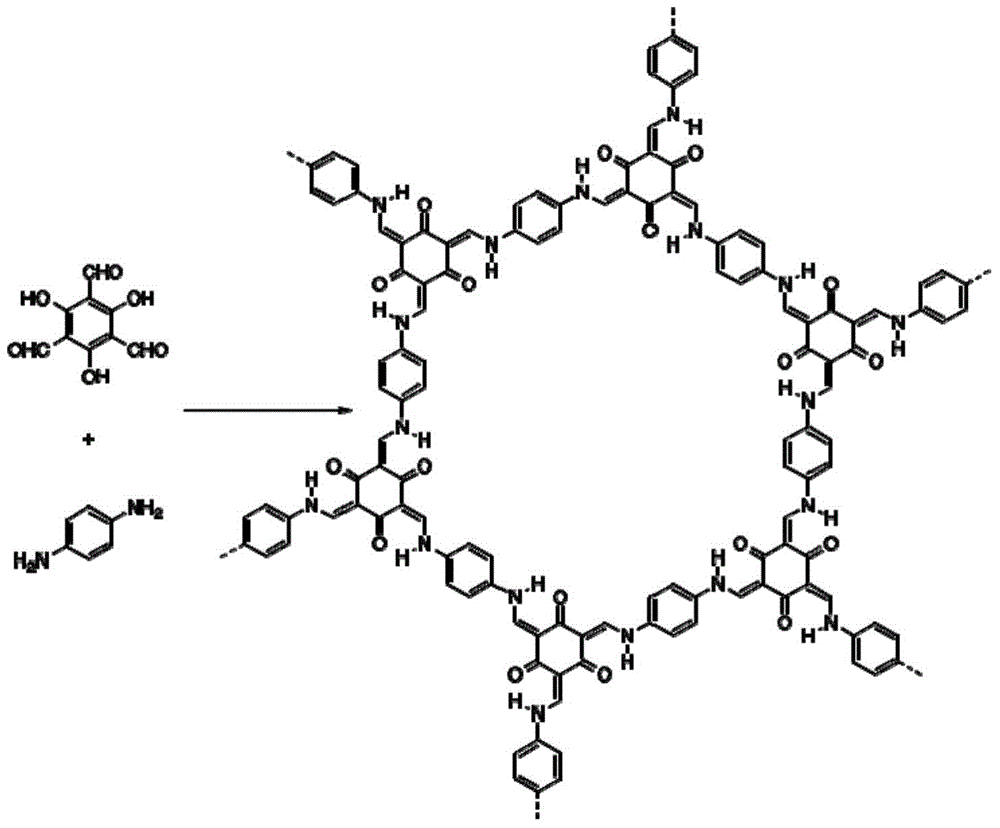

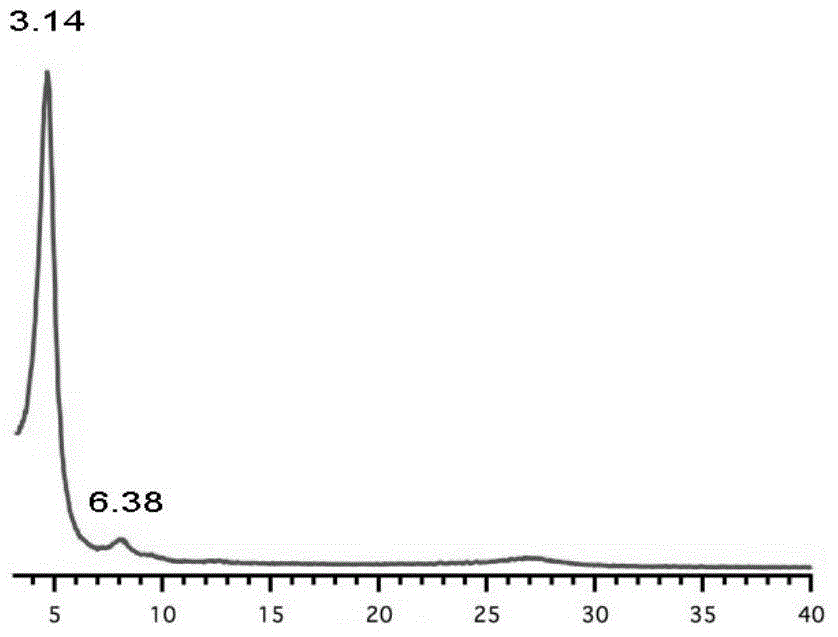

Microwave auxiliary preparation method of keto-enamine covalently linked organic framework

ActiveCN104927048ALarge specific surface areaHigh crystallinityOther chemical processesMicrowaveEnamine

The invention discloses a microwave auxiliary preparation method of a keto-enamine covalently linked organic framework. The method comprises the following steps: charging 1 , 3 , 5-triformylphloroglucinol and p-phenylenediamine into solvent, and ultrasonically dispersing to form suspension; the solvent is mixed solvent of sym-trimethylbenzene, dioxane and acetum; freezing, by liquid nitrogen, vacuumizing and degassing the suspension for at least three times, then sealing, carrying out the thermal reaction for 1 hour under the assistance of microwaves at the temperature of 100 DEG C, and obtaining a crude product; and centrifuging the crude product, collecting insoluble matters, washing the insoluble matters sequentially by sym-trimethylbenzene and acetone to obtain the keto-enamine covalently linked organic framework, and obtaining the keto-enamine covalently linked organic framework. The method is pollution-free, the reaction condition is moderate and simple, the requirement on equipment is simple, and the method is suitable for the industrialized mass production.

Owner:芩洋科技(上海)有限公司

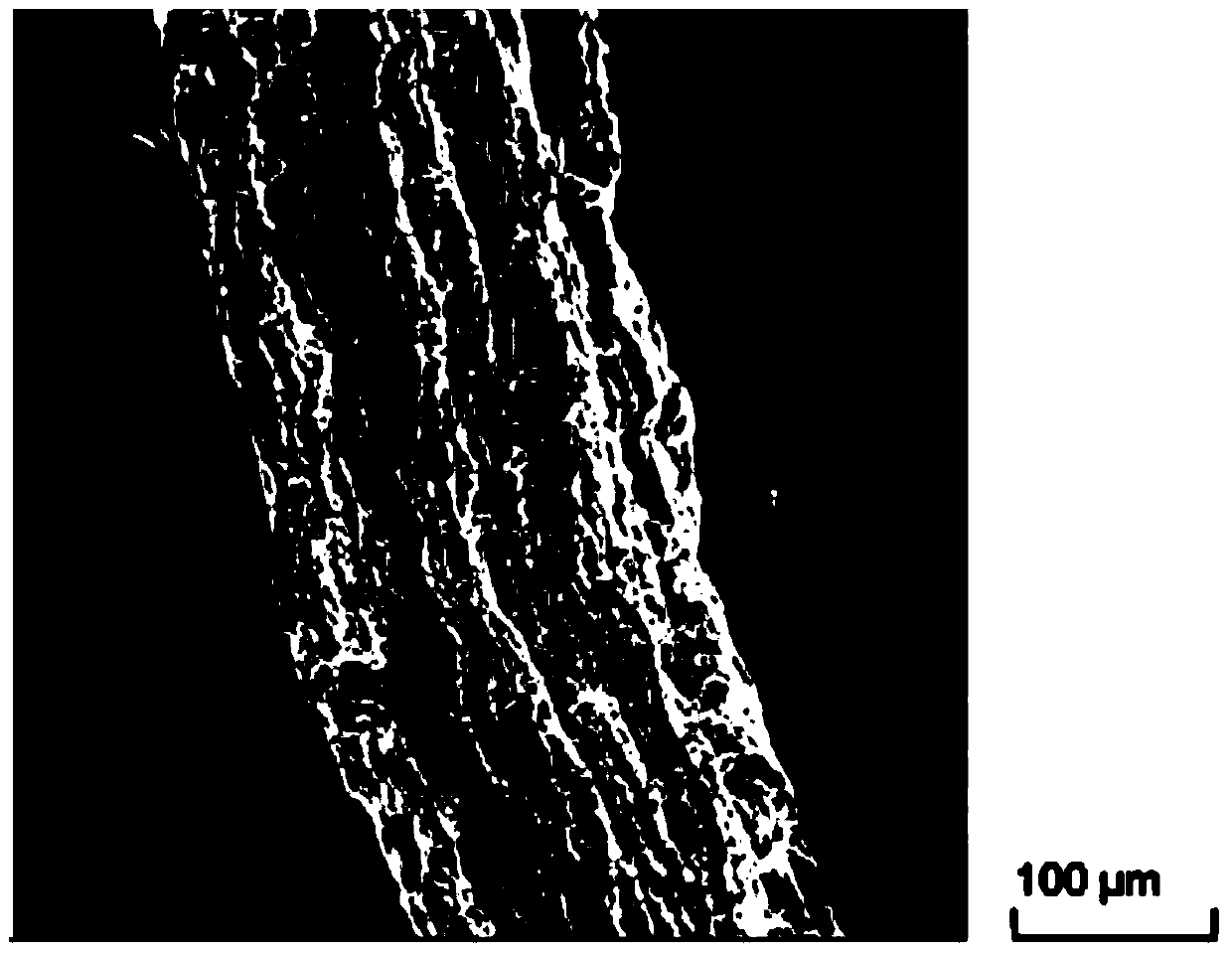

Preparation method of graphene fibers

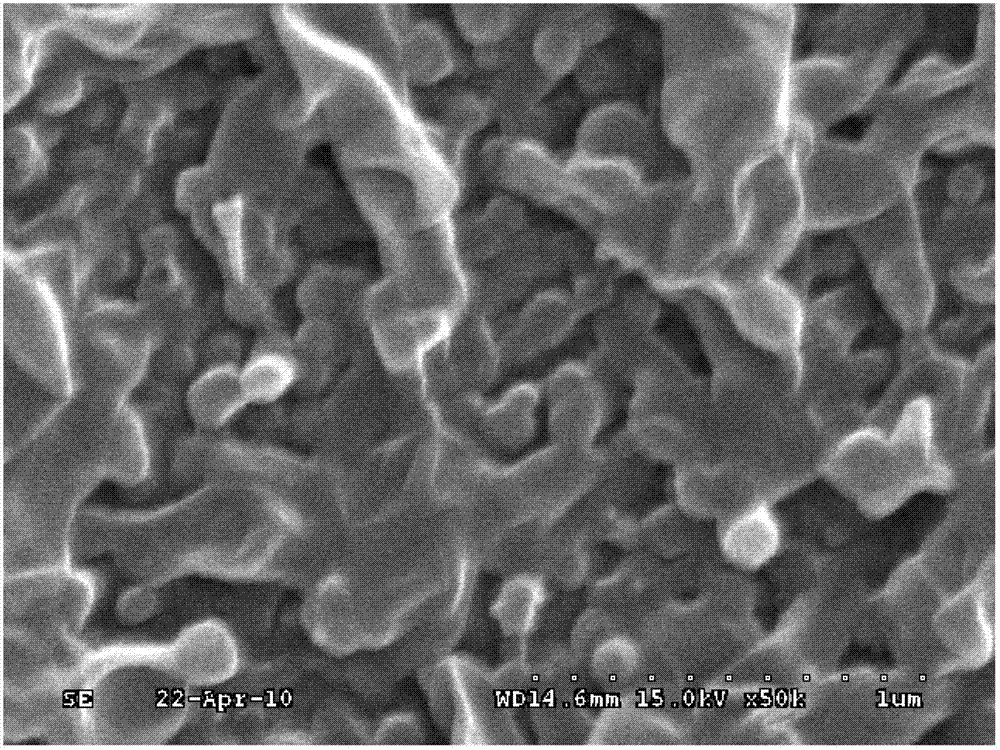

ActiveCN103966699ALow reaction temperatureEasy to operateArtificial filament chemical after-treatmentEthylenediamineFiber

The invention discloses a preparation method of graphene fibers. The preparation method comprises the following steps: (1), a mixture of a graphene oxide solution and a water-soluble reducing agent is added into a tubular reactor, wherein the water-soluble reducing agent is one or more of ascorbic acid, sodium ascorbate, sodium citrate, HI, HBr, NaHSO3, Na2S, ethylenediamine, p-phenylenediamine and hydroquinone; (2), the tubular reactor in the step (1) is heated, and graphene oxide is reduced and assembled to aqueous graphene gel fibers, and the heating temperature is 60-95 DEG C; and (3), the aqueous graphene gel fibers obtained in the step (2) is dried to obtain the graphene fibers. The preparation method is simple to operate, mild in conditions and low in raw material cost; and the graphene fibers obtained with the preparation method are uniform in structure, excellent in mechanical property and easiness in functionalization.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

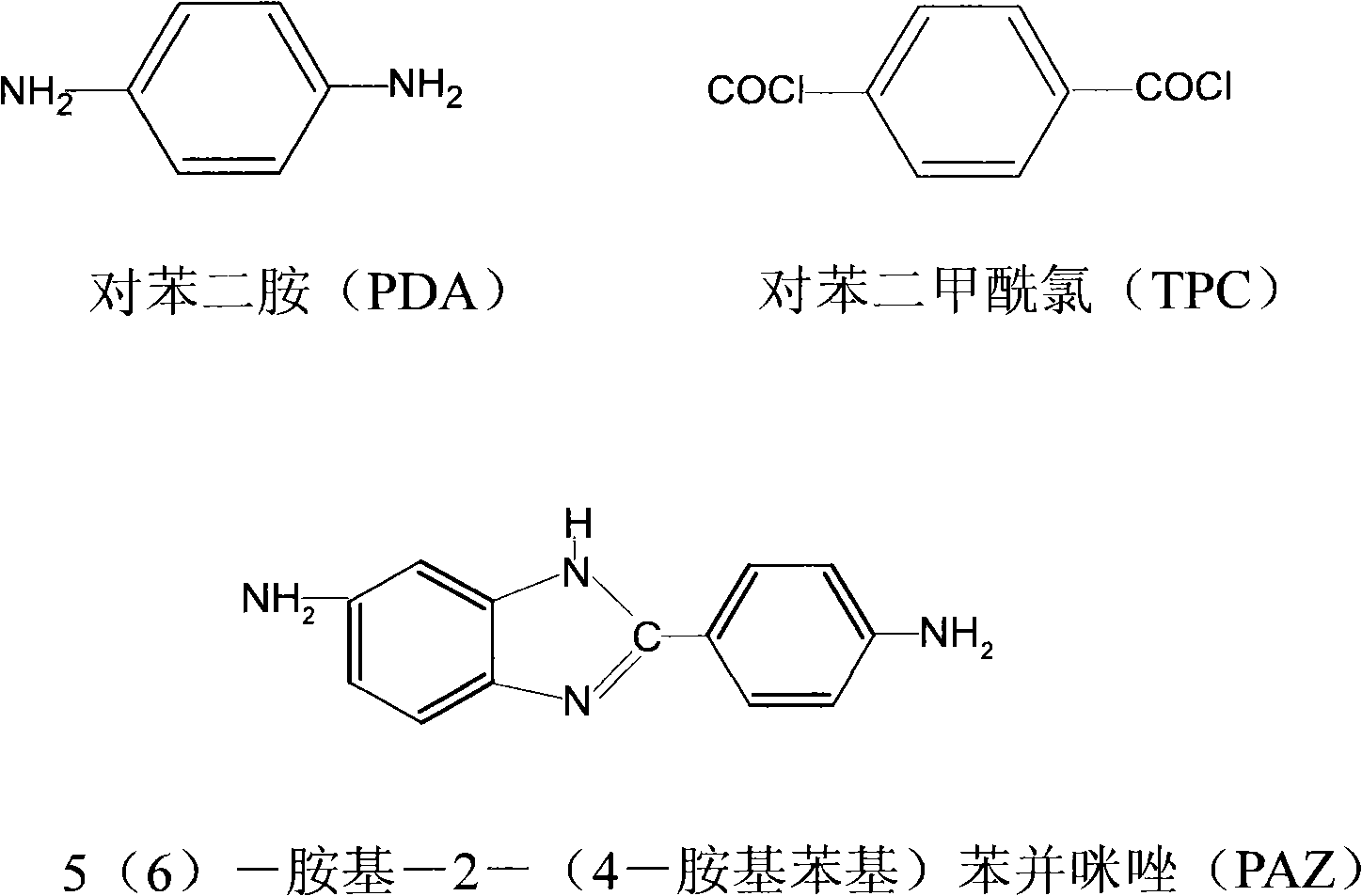

Method for preparing aramid IIII fiber

InactiveCN101851809AImprove spinning efficiencyLow investment costMonocomponent copolyamides artificial filamentDry spinning methodsYarnLithium chloride

The invention relates to a method for preparing an aramid IIII fiber, which comprises the following steps of: (1) synthesizing a spinning stock solution, carrying out low-temperature copolymerization by adopting three monomers of p-phenylenediamine, paraphthaloyl chloride and 5(6)-amido-2-(4-amidophenyl)benzimidazole as raw materials and adopting dimethylacetylamide / lithium chloride as a solvent; (2) spinning by adopting a dry method spinning process, i.e. leading the spinning stock solution obtained in the previous step to pass through a spinneret and directly enter a hot inert gas channel and evaporating and removing the solvent in the spinning stock solution by utilizing a hot inert gas to obtain cured raw yarn; and (3) carrying out water washing and heat treatment on the raw yarn and winding to obtain the aramid IIII fiber. The method has high solid content of the spinning stock solution, high spinning speed, great improvement of spinning efficiency, obvious reduction of fiber manufacturing cost, improved mechanical performance of the manufactured aramid IIII fiber and wide application prospect.

Owner:SINOSELEN HI TECH

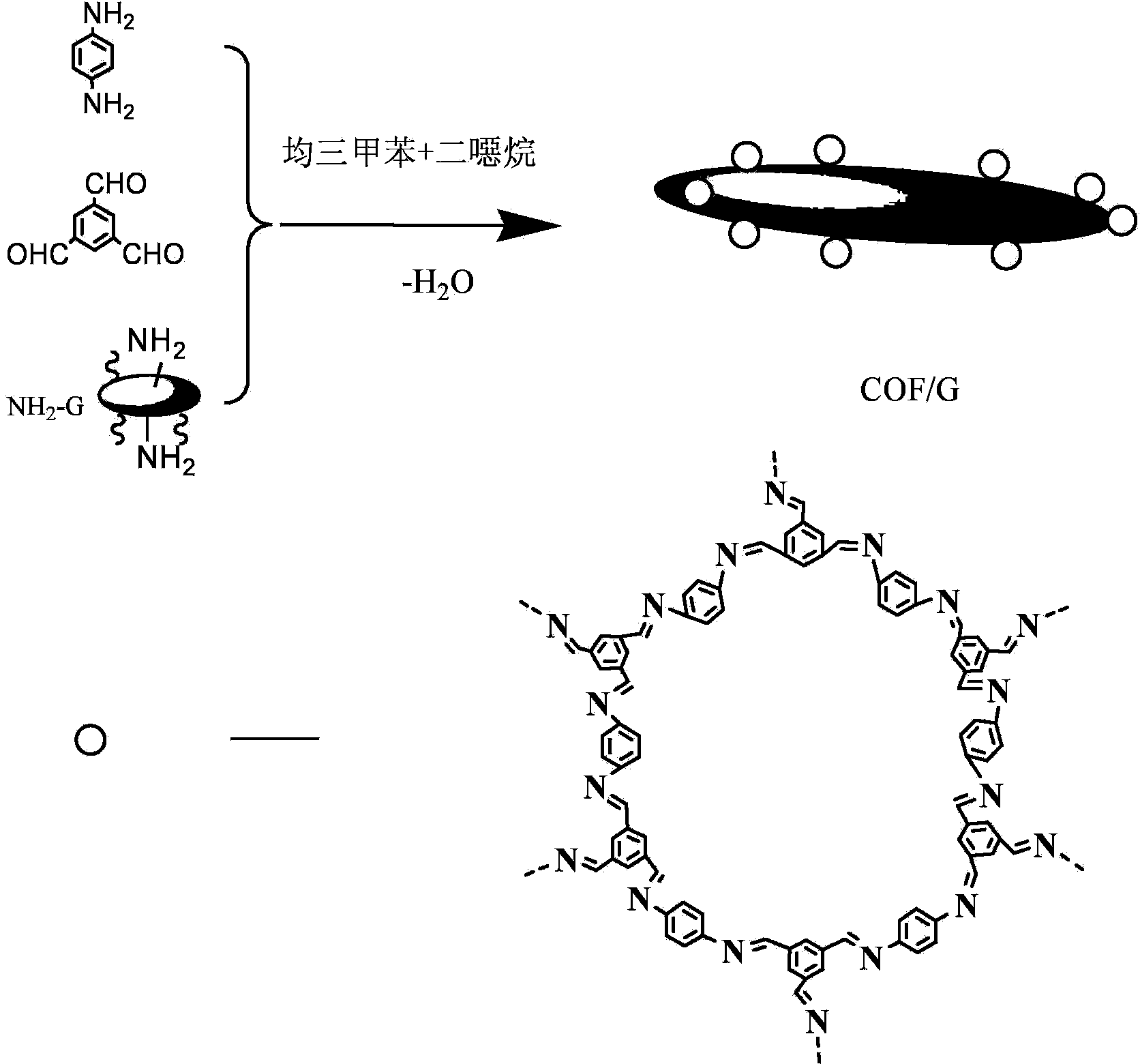

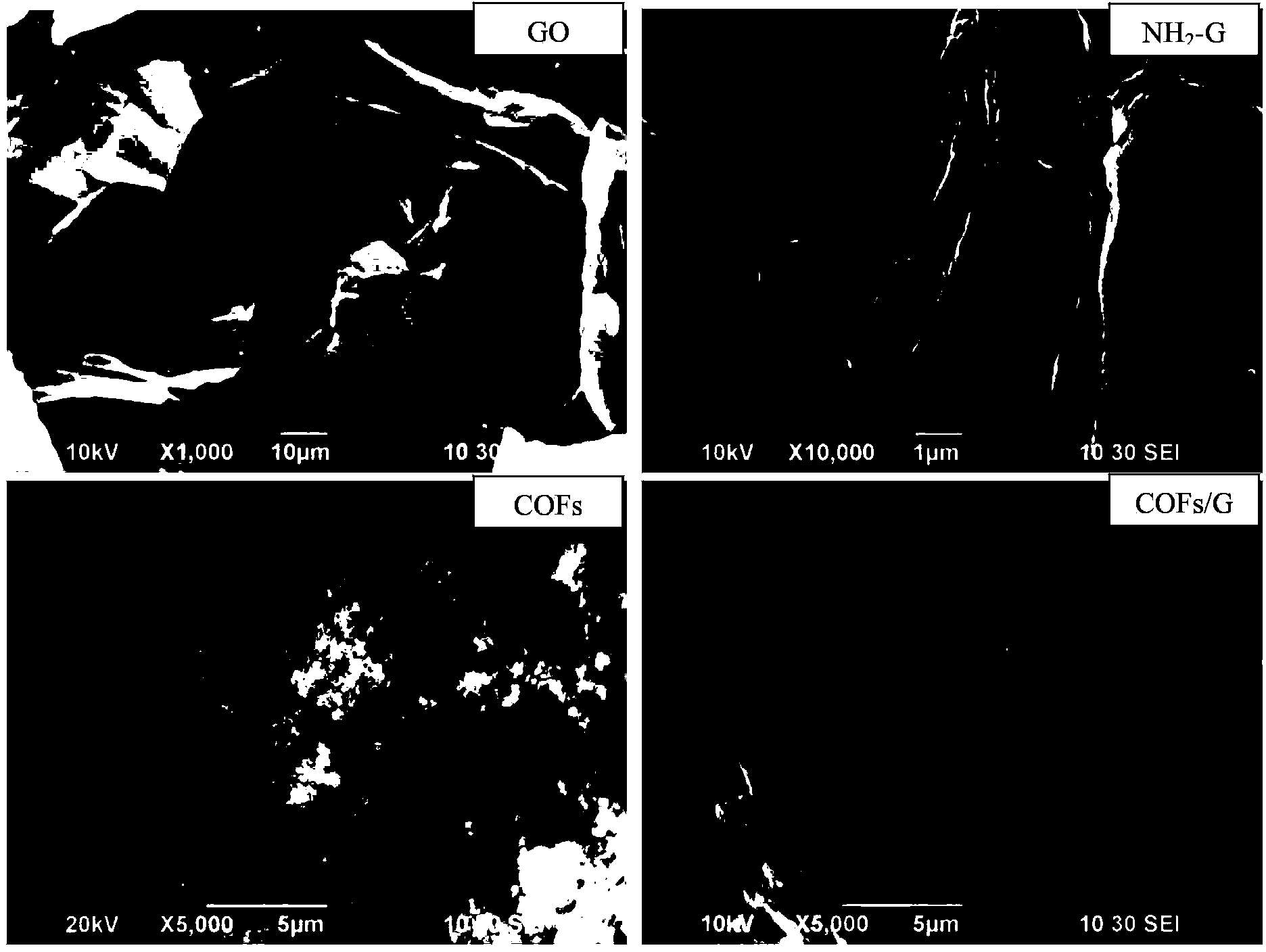

Covalence organic frame/graphene composite materials, preparing method and application

InactiveCN104319107AImprove Capacitive PerformanceImprove cycle stabilityHybrid capacitor electrodesHybrid/EDL manufactureAcetic acidCapacitance

The invention relates to covalence organic frame / graphene composite materials and a preparing method. According to the materials, amination graphene is used as a base body, 1,3,5-benzenetricarboxaldehyde, p-phenylenediamine and catalyst acetic acid are added into graphene turbid liquid according to a certain ratio for stirring, the liquid is placed in a reactor to be heated for certain time, and the covalence organic frame / graphene composite materials can be obtained. The technology is simple, the prepared composite materials have the advantages of being high in specific capacitance and stable in performance, and the materials can be used as electrode materials of a novel energy storing system used by an electric car.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

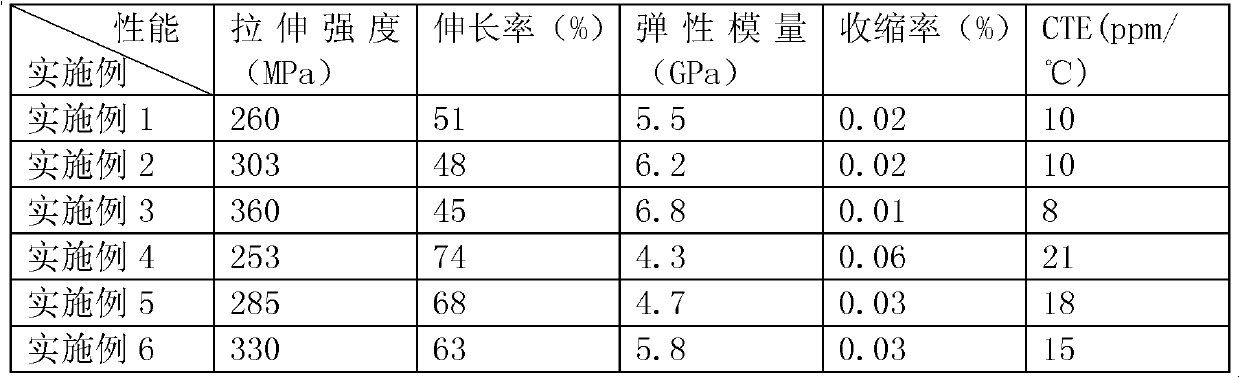

Dimensionally-stable polyimide film and preparation method thereof

ActiveCN102558860ALow heat shrinkageSmall coefficient of thermal expansionDiaminodiphenyl etherPolymer science

The invention discloses a dimensionally-stable polyimide film and a preparation method thereof. According to the weight percentage, the polyimide film is manufactured by evenly mixing 40 to 80 percent of component A, 0 to 60 percent of component B and 0 to 60 percent of component C and then conducting slobbering and imidization according to a conventional process, wherein the component A is polyamide acid resin solutions obtained after 2-(4-aminophenyl)-5-amido-benzimidazole reacts with pyromellitic dianhydride (PMDA) or biphenyltetracarboxylic acid dianhydride (BPDA); the component B is polyamide acid resin solutions obtained after p-phenylenediamine (PDA) reacts with the PMDA; and the component C is polyamide acid resin solutions obtained after 4,4'-diaminodiphenyl ether (ODA) reacts with the BPDA and the PMDA. The polyimide film provided by the invention has the advantages of lower thermal shrinkage rate, lower thermal expansion coefficient, higher elastic modulus and higher tensile strength and reflects better dimensional stability. The whole preparation method is simple and is easy to operate.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

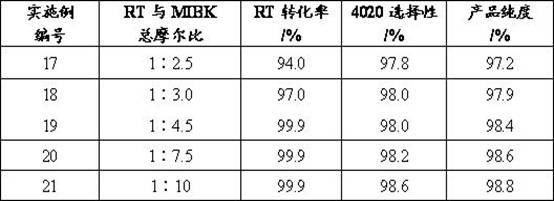

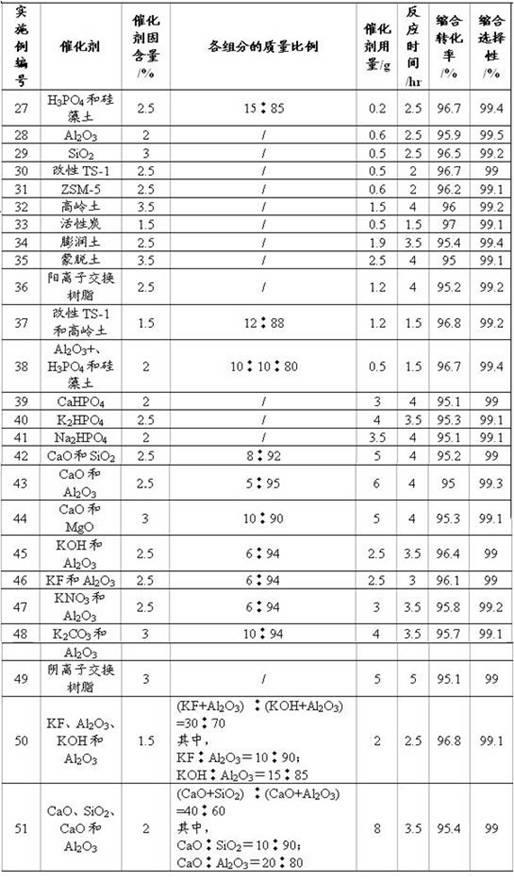

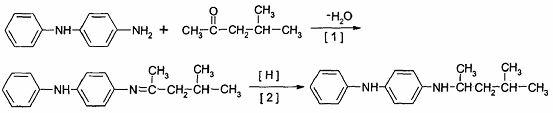

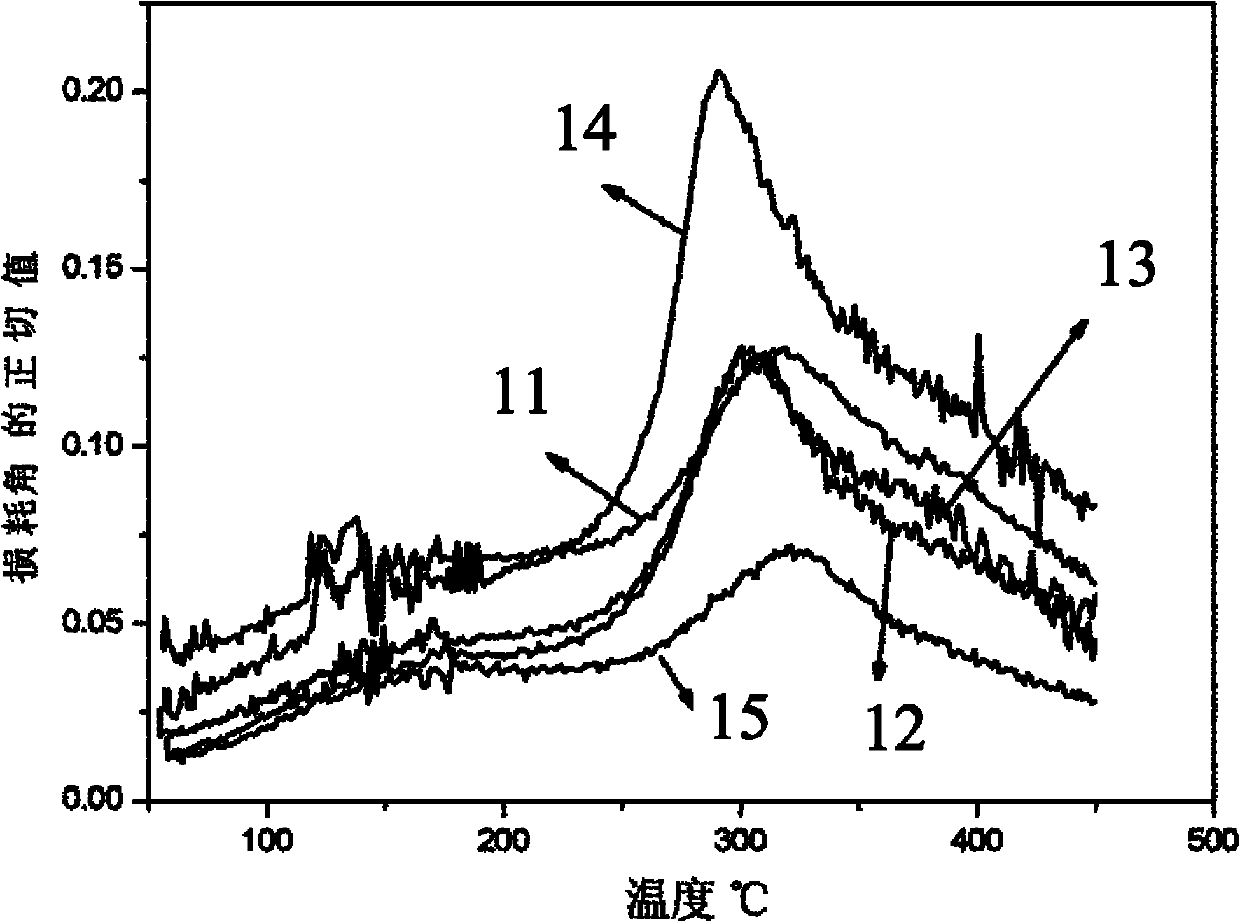

Method for preparing p-phenylenediamine rubber aging inhibitor

InactiveCN102146042ALow costReduce consumptionOrganic compound preparationAmino compound preparationChemical synthesisPtru catalyst

The invention discloses a method for preparing a p-phenylenediamine rubber aging inhibitor, and relates to the technical field of chemical synthesis. The method comprises the following steps of: adding 4-aminodiphenylamine and partial methyl isobutyl ketone into a condensation reaction kettle, performing condensation reaction at a certain temperature under certain pressure, removing water generated by the reaction, and obtaining a condensation solution; adding the condensation solution, a hydrogenation catalyst and replenished methyl isobutyl ketone into the reaction kettle, performing hydrogenation reaction at a certain temperature under certain pressure, and obtaining a hydrogenation solution; and performing post treatment on the hydrogenation solution to obtain the p-phenylenediamine rubber aging inhibitor 4020, wherein the hydrogenation catalyst is a nickel, palladium or platinum catalyst. From the practice of industrial production, the rubber aging inhibitor 4020 is synthesized by adopting two-step reaction of condensation and hydrogenation; the difficulty of the hydrogenation reaction is reduced; and the requirement on the catalyst is reduced. The method has mild reaction conditions, high product quality and simple flow and no pollution, and is easy to realize industrialization.

Owner:JIANGSU YANGNONG CHEM GROUP +2

Polyimide fiber and preparation method thereof

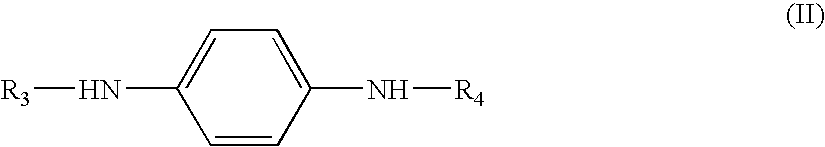

ActiveCN102041577AImprove mechanical propertiesGood mechanical propertiesArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentFiberOrganic solvent

The invention provides a polyimide fiber comprising a polymer with a structure shown in a formula (I) in the specification, wherein m is the proportion of a repeat unit with a structure shown in a formula (II), in the structure of the polymer, and is more than and equal to 0.8 and less than and equal to 0.95. The invention also provides a preparation method of the polyimide fiber, comprising the following steps of: mixing p-phenylenediamine, 4,4'-diaminodiphenyl ether and 3,3',4,4-biphenyltetracarboxylic dianhydride in an organic solvent to carry out condensation polymerization so as to obtain a polyamic acid spinning solution, wherein proportion of the mole number of the p-phenylenediamine to the total mole number of the p-phenylenediamine and the 4,4'-diaminodiphenyl ether is 0.8-0.95; spinning to obtain polyamic acid protofilaments by using the polyamic acid spinning solution; carrying out imidization processing on the polyamic acid protofilaments to obtain polyimide nascent fibers; and carrying out hot stretching processing on the polyimide nascent fibers to obtain the polyimide fiber.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

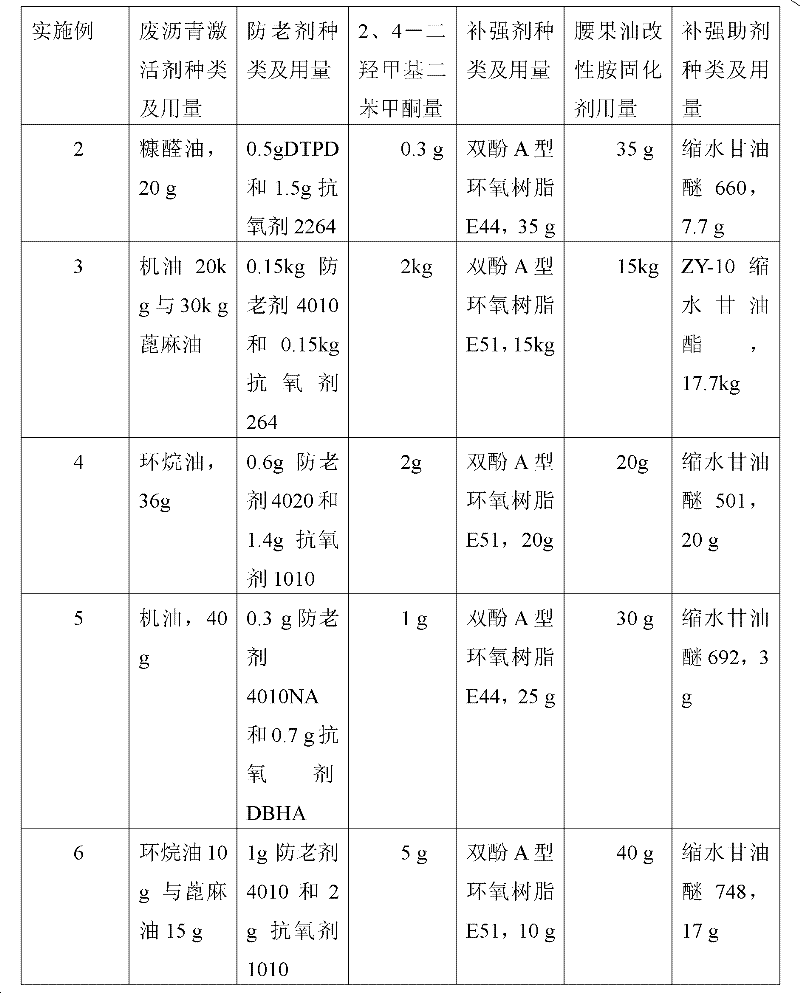

Asphalt cold recycling agent and preparation method thereof

ActiveCN102174267ANo pollution in the processImprove recycling ratesSolid waste managementBuilding insulationsCrack resistanceAntioxidant

The invention relates to an asphalt cold recycling agent, which is characterized by being prepared from a waste asphalt activator, an anti-aging agent, an ultraviolet absorbent, a reinforcing agent, a reinforcing curing agent and a reinforcing auxiliary agent serving as raw materials, wherein the waste asphalt activator consists of any one or more of engine oil, castor oil, naphthenic oil, aromatic hydrocarbon oil and furfural oil; the anti-aging agent is a mixture of an antioxidant and a p-phenylenediamine anti-aging agent; the ultraviolet absorbent is 2,4-dihydroxymethyl benzophenone; the reinforcing agent is bisphenol A epoxy resin E44 or E51; the reinforcing curing agent is a cashew nut oil modified amine curing agent; and the reinforcing auxiliary agent is a glycidyl ester epoxy active diluent. An asphalt recycled mixture prepared by adding the asphalt cold recycling agent into waste asphalt has high comprehensive performance, namely high bonding strength, high-temperature performance, low-temperature crack resistance and rheological performance, the actual service life of 8 years, and high aging resistance and weather resistance.

Owner:重庆市智翔铺道技术工程有限公司

Tyre tread rubber composition used in hard mine area and production method of tyre tread rubber composition in hard mine area

ActiveCN102634089AGood dispersionImprove puncture resistanceSpecial tyresMicrocrystalline waxVulcanization

The invention relates to the technical field of rubber, in particular to a tyre tread rubber composition used in a hard mine area and a production method of the tread rubber composition in the hard mine area. The tyre tread rubber composition comprises the following materials by weight: 50-90 parts of styrene butadiene rubber, 10-50 parts of natural rubber, 45-55 parts of carbon black, 15-25 parts of white carbon black, 2-5 parts of zinc oxide, 1-3 parts of stearic acid, 2-4.5 parts of silane coupling agent, 2-5 parts of cutting resistant resin, 10-20 parts of aromatic oil, 1-3 parts of antioxidant N-(1,3-dimethylbutyl)-N'-phenyl p-phenylenediamine, 1-2 parts of antioxidant 2, 2, 4-trimethyl-1,2-dihydroquinoline polymer, 1-3.5 parts of microcrystalline wax, 1-2 parts of sulfur, 1.0-2.0 parts of vulcanization accelerant N-tertiary butyl-2-benzothiazole sulfonamide, 0.5-1.0 parts of vulcanization accelerant N,N-diphenylguanidine and 0.1-0.3 parts of scorch retarder. The tyre tread rubber composition used in a hard mine area and the production method provided by the invention can obviously improve puncture resistant property, the chipping resistant property, the safety and the service life of a tyre in the hard mine area.

Owner:TRIANGLE TIRE

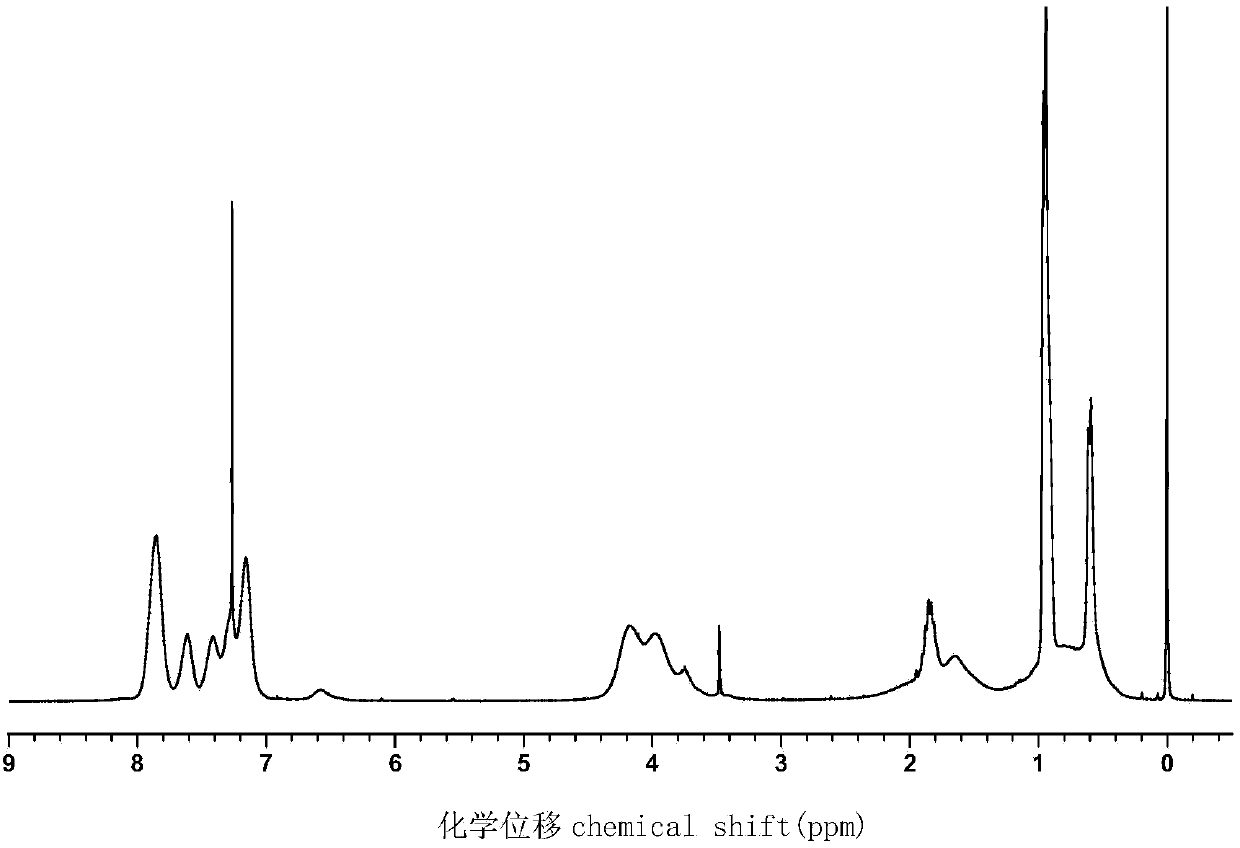

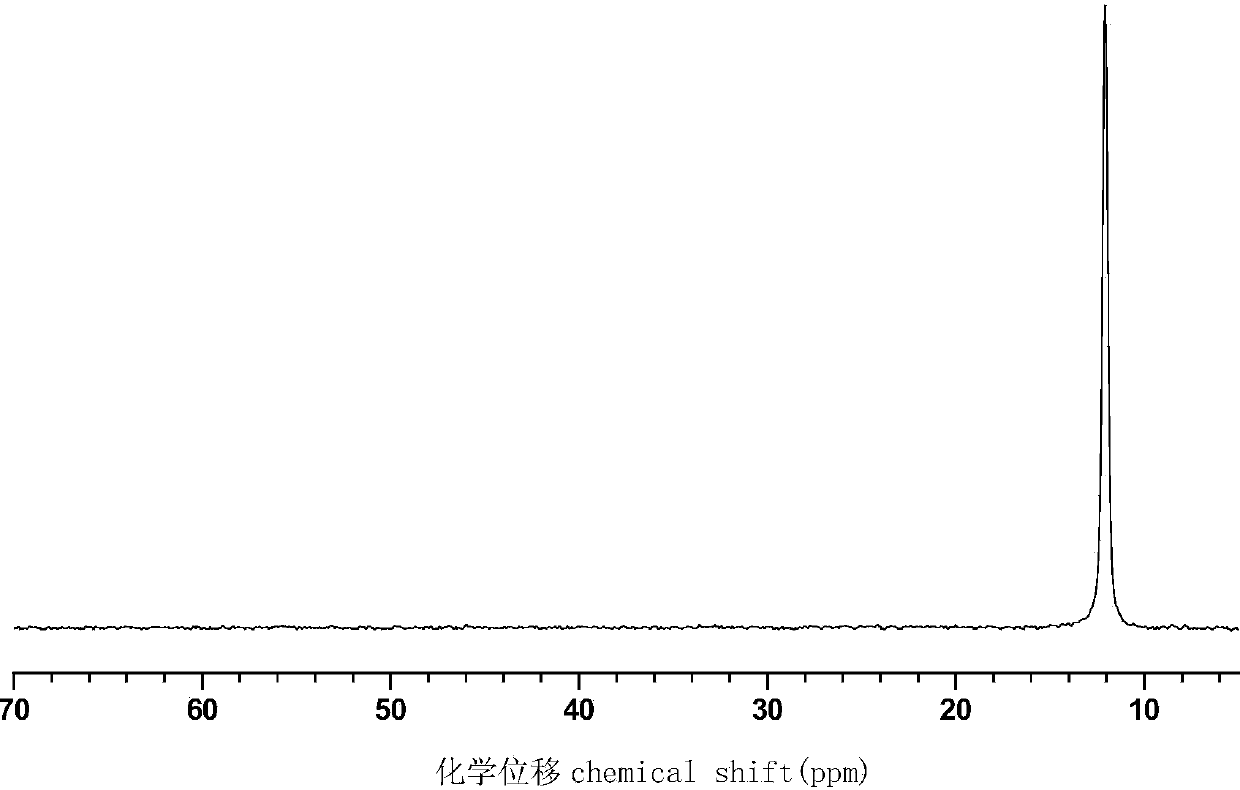

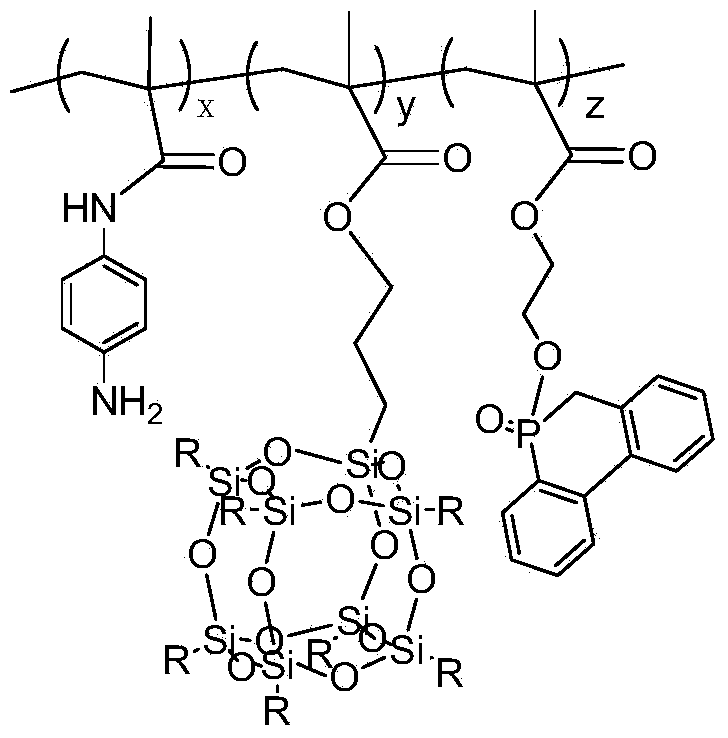

Phosphorus/silicon-containing reactive high-molecular flame retardant, and preparation method and application thereof

The invention provides a phosphorus / silicon-containing reactive high-molecular flame retardant, and a preparation method and application thereof, relating to flame retardants. The preparation method comprises the following steps: reacting methacryloyl chloride and p-phenylenediamine in the presence of a solvent and an acid-binding agent, carrying out vacuum filtration to remove the acid-binding agent salt generated by the reaction, and purifying the crude product by water washing, rotary evaporation and drying to obtain 4-methacrylamidoaniline; reacting hydroxyethyl methacrylate and 9,10-dihydro-9-oxa-10-phosphaphenanthryl-10-oxide in the presence of carbon tetrachloride, a solvent and an acid-binding agent, carrying out vacuum filtration to remove the acid-binding agent salt generated by the reaction, and purifying the crude product by water washing, rotary evaporation and drying to obtain a phosphorus-containing monomer; and carrying out free-radical polymerization on the 4-methacrylamidoaniline, phosphorus-containing monomer and methylacryloyloxypropyl heptaisobutyl POSS (polyhedral oligomeric silsesquioxane) under the initiation conditions of a solvent and an initiator to obtain the phosphorus / silicon-containing reactive high-molecular flame retardant. The phosphorus / silicon-containing reactive high-molecular flame retardant can be used for preparing a flame-retardant epoxy resin.

Owner:XIAMEN UNIV

Ultrahigh-sensitivity fluorescent probe for detecting nitrogen monoxide

InactiveCN102617467AHigh selectivityHigh sensitivityGroup 5/15 element organic compoundsMicrobiological testing/measurementSolubilitySide effect

The invention relates to an ultrahigh-sensitivity fluorescent probe for detecting nitrogen monoxide. The ultrahigh-sensitivity fluorescent probe has the structural general formula in the original text. During preparation, firstly, 4-bromine-1, 8-anhydride naphthalene and o-nitro p-phenylenediamine with equal molar weights are used as raw materials, dissolved in ethylene glycol monomethyl ether and heated for reaction to obtain light yellow solid. Secondly, the light yellow solid is dissolved in anhydrous DMSO, primary amine is added into the anhydrous DMSO, the anhydrous DMSO is heated and refluxed, and reaction liquid is filtered in a sucking manner, depressurized and dried to obtain yellow solid. The yellow solid is dissolved in mixed liquid of tetrahydrofuran and methanol, and a yellow probe is obtained under catalysis of hydrogen and catalysts. Probe molecules have fine chemical and optical stability, good solubility and biological compatibility and high nitric oxide selectivity, and are free of interference of other active oxygen, active nitrogen and the like. Laser confocal imaging experiments indicate that the probe has fine cellular permeability, has no toxic and side effects on cells and organisms, and can be used for detecting protogenetic nitrogen monoxide in a high-sensitivity manner.

Owner:DALIAN UNIV OF TECH

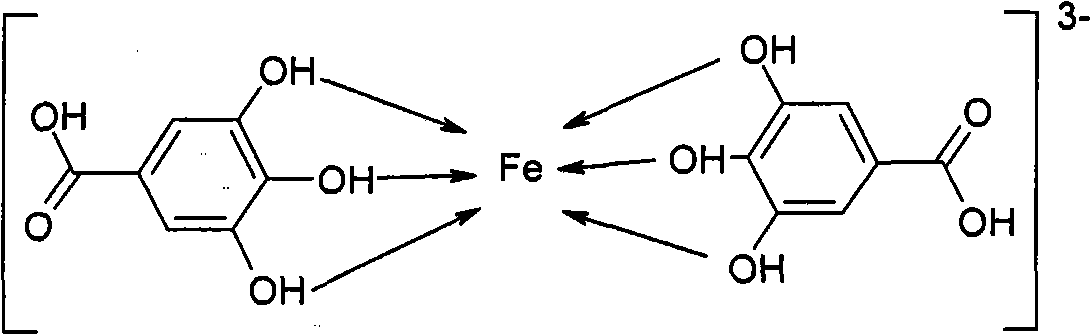

Mordant and hair dyeing product containing same

ActiveCN101812246ANo carcinogenic potentialGuaranteed stabilityCosmetic preparationsHair cosmeticsAcetic acidHair dyes

The invention relates to a mordant for a hair dyeing product and the hair dyeing product containing the same. The mordant comprises effective amounts of ferrite, antioxygen and water; and the hair dyeing product of the invention comprises three parts, i.e. softener, dye solvent and mordant. The mordant and the hair dyeing product containing the same, provided by the invention, do not contain mercaptoacetic acid, aromatic amine compounds, such as p-phenylenediamine and the like as well as hydrogen peroxide, so that the mordant and the hair dyeing product containing the same are safe and have no stimulation. The hair dyeing product of the invention has favorable hair dyeing chroma, firmness, product stability and using convenience.

Owner:NATURAL MEDICINE INST OF ZHEJIANG YANGSHENGTANG

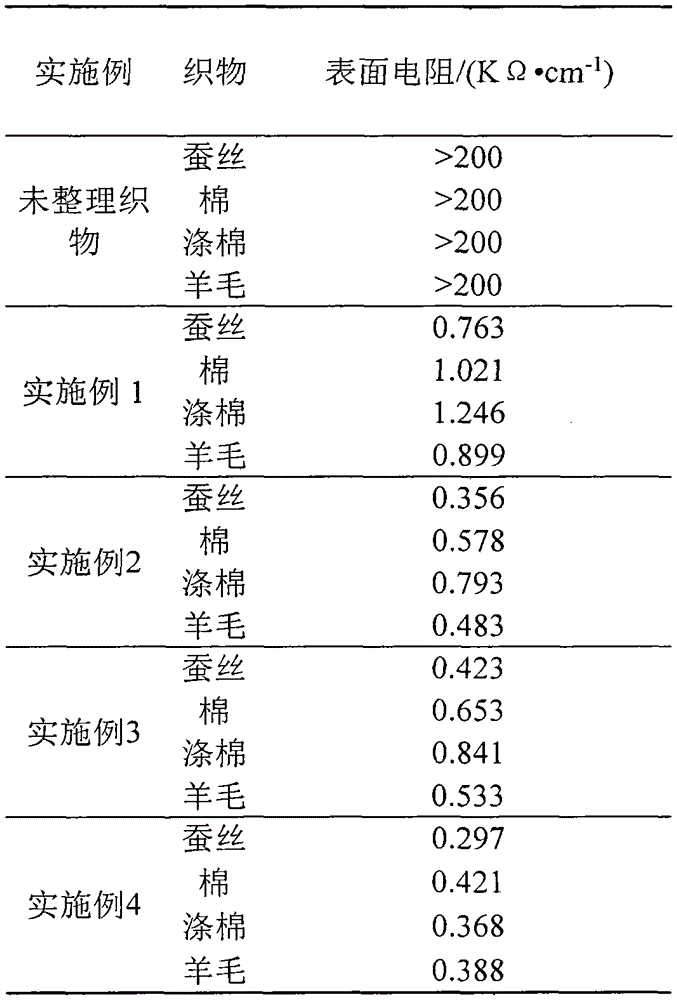

Preparation method of graphene/polyaniline covalent binding conductive fabric

ActiveCN104313872AEasy to operateVegetal fibresAnimal fibresGraphene derivativesIn situ polymerization

The invention discloses a preparation method of a graphene / polyaniline covalent binding conductive fabric, which belongs to the technical field of textile chemistry. The preparation method comprises the steps of applying oxidized graphene or oxidized graphene derivative and a reaction product of p-phenylenediamine onto the fabric to be reduced, enabling the fabric to adsorb the polyaniline monomer, enabling the in-situ polymerization of the polyaniline monomer on the fabric to form polyaniline, and enabling the polyaniline to form covalent key combination with the graphene. According to the method, a conductive layer formed by covalently combining the graphene and polyaniline can be acquired on the surface of the fabric, so that the stability of the conductive layer is improved, and the conductive fabric with excellent effect can be acquired. The method is applicable to conventional fabrics such as natural fibers including cotton, wool, silk and the like, synthesized fibers including terylene, chinlon, acrylic fibers and the like and blending of fabric or conductive arrangement of intertexture, and the prepared functional fabric can be applied to the fields of medical healthcare, intelligent sensors, mobile power generation, military and the like.

Owner:JIANGNAN UNIV

Rare earth complex modified butadiene styrene rubber cable sheath material

The invention discloses a rare earth complex modified butadiene styrene rubber cable sheath material which comprises the following raw materials in parts by weight: 60-80 parts of butadiene styrene rubber, 10-20 parts of chlorosulphonated polyethylene, 10-20 parts of silicone rubber, 3-10 parts of coupling agent, 15-30 parts of carbon nano tube / silica composite material, 5-10 parts of modified white mica, 3-8 parts of modified quartz, 5-15 parts of modified kaolin, 3-15 parts of rare earth complex, 3-15 parts of modified starch, 5-20 parts of hemp stem core powder, 2-7 parts of benzoyl peroxide, 3-9 parts of magnesium oxide, 2-4 parts of epoxy resin, 1-4 parts of p-phenylenediamine, 1-5 parts of stearic acid, 1-3 parts of accelerant and 3-8 parts of anti-aging agent. The rare earth complex modified butadiene styrene rubber cable sheath material disclosed by the invention is high in aging resistance and high in strength, and the manufactured cable sheath is good in comprehensive performance and long in service life.

Owner:安徽华峰电缆集团有限公司

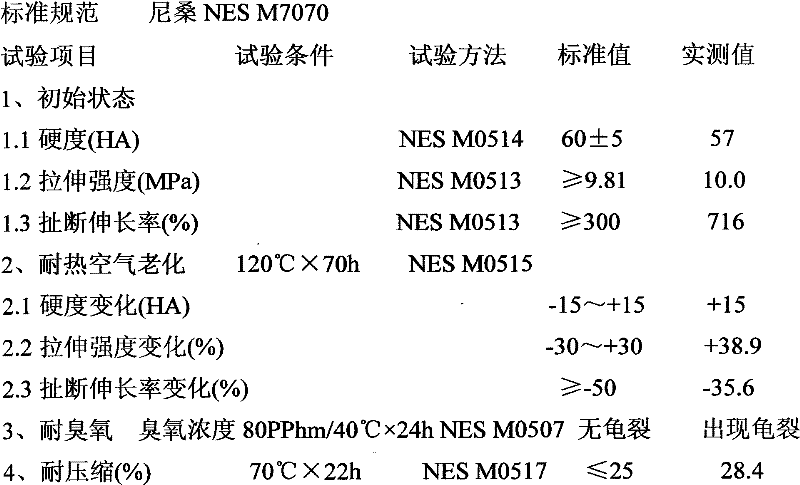

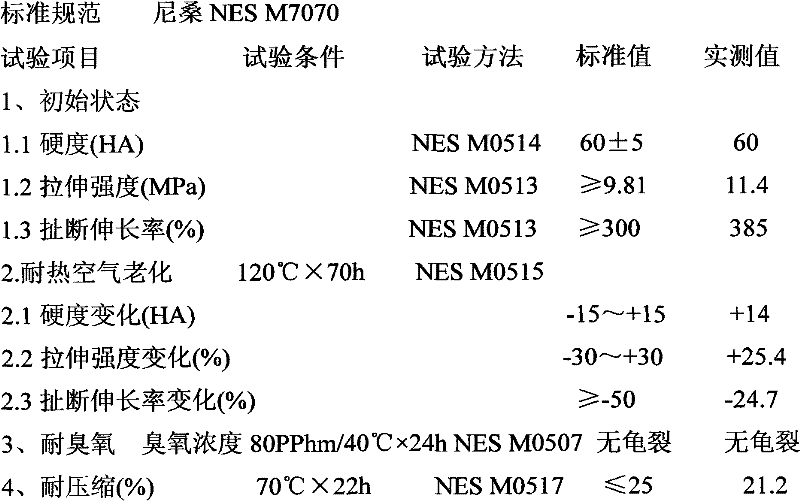

Preparation method of heat/ozone/compressive deformation resistant rubber material for automobile sealing element

The invention discloses a preparation method of a heat / ozone / compressive deformation resistant rubber material for an automobile sealing element, and the method comprises a formula and a preparation process. In the invention, nitrile rubber / polyvinyl chloride resin and rubber are adopted; in the formula, a vulcanizing system of dicumyl peroxide and N,N'-m-phenylene dimaleimide is adopted, the anti-aging agents of 2,2,4-trimethyl-1,2-dihyaroquinoline polymer and 2-mercaptobenzimidazole are added, the anti-aging agent of N-isopropyl-N'-phenyl-p-phenylenediamine and a paraffin lubricating agent with ozone resistance are added, and the technical scheme of the corresponding preparation process is provided, thus the problems and defects of low temperature / ozone / permanent compressive deformation resistances in the prior art are overcome, and through the heat / ozone / compressive deformation resistant rubber material prepared by the method, the manufactured rubber article of an automobile oil tank pumping hole sealing element achieves the purpose of improving the heat / ozone / compressive deformation resistances to conform to the Nissan NES M707 standard.

Owner:宁波市天普橡胶科技股份有限公司

Polymide resin, method for manufacturing the same and thin film thereof

The invention discloses a polymide resin, a method for manufacturing the same and thin film thereof. The polyimide resin is derived from at least two dianhydrides and at least two diamines. The dianhyride is selected from a group consisting of p-phenylenebis (trimellitate anhydride), 4,4'-(hexafluoroisopropylidene)-diphthalic anhydride, and 4,4'-(4,4' -isopropylidenediphenoxy)bis(phthalic anhydride). One of the diamine monomers is 2,2' -bis(trifluoromethyl)benzidine, and the molar ratio of the 2,2'-bis(trifluoromethyl)benzidine to the diamine monomers is between 70% and 90%; and the other diamine monomers are selected from a group consisting of 4,4'-diaminobenzanilide, 4,4'-methylenedianiline, 2,2-bis[4-(4-aminophenoxy)phenyl, 4,4'-diaminodiphenyl-sulfone, 1,3-bis(4-aminophenoxy)benzene, 4,4'-oxydianiline, p-phenylenediamine, 4,4'-diamino-2,2'-dimethyl-1,1'-biphenyl and 2,2-bis[4-(4-aminophenoxy)phenyl]-1,1,1,3,3,3-hexafluoropropane.

Owner:MICROCOSM TECH

Method for removing hexavalent chromium from water by using polyaniline-modified palygouskite

InactiveCN102350322AImprove adsorption capacityEasy to operateOther chemical processesWater contaminantsWater bathsIce water

The invention discloses a method for removing hexavalent chromium from water by using polyaniline-modified palygouskite. The method comprises the following steps of: dissolving aniline and p-phenylenediamine in a 1 mol / L hydrochloric acid solution under the condition of ice water bath, adding palygouskite, and uniformly stirring; then dissolving ammonium persulfate in another 1 mol / L hydrochloric acid solution; and performing polymerization reaction on solutions obtained in the previous steps, standing at room temperature, filtering, washing, drying to obtain polyaniline-modified palygouskite composite particles, and mixing the obtained polyaniline-modified palygouskite composite particles and water from which hexavalent chromium is to be removed in a mass ratio of 1:(800-5,000) to effectively remove hexavalent chromium from wastewater of which hexavalent chromium initial concentration is 2.5 to 35mg / L. The method overcomes defects of low adsorption capacity, rate and efficiency of adsorbent in the conventional adsorption method; and by the method, pollution and damage of hexavalent chromium to water are effectively controlled.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing composite material of graphene and graphene poly-p-phenylenediamine

The invention relates to a method for preparing a composite material of graphene and graphene poly-p-phenylenediamine, which comprises the following steps of: dissolving p-phenylenediamine in N,N-dimethylformamide, and then adding the mixture into an oxidized graphite colloid treated by ultrasonic de-bonding; treating the mixture in an oil bath, and filtering an obtained colloid; washing the colloid with acetone, and then dispersing the obtained wet powder into ethanol, glycol, N-methyl pyrrolidone and the N,N-dimethylformamide to obtain a stable graphene colloid; adding a K2S2O8 hydrochloric acid aqueous solution into the unfiltered and unwashed graphene colloid; treating the mixture in an ice bath; and washing the mixture with acetone, hydrochloric acid and water to obtain graphene poly-p-phenylenediamine composite powder. The composite material of the graphene colloid and the graphene poly-p-phenylenediamine prepared by the method has good dispersity and simple preparation process.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Polyimide Film

InactiveUS20090078453A1Cause of the mounting inferiority can be avoided effectivelyPrinted circuit aspectsThin material handlingBulk resistanceThermal expansion

The present invention relates to polyimide film for insulating material etc. prepared by reacting a mixture of 4,4-oxydiphthalic anhydride and at least one monomer of aromatic or aliphatic tetracarboxylic dianhydride with a mixture of p-phenylenediamine and at least one monomer of flexible diamines, and having excellent electric properties such as a coefficient of thermal expansion, an elongation, a intensity, a dielectric strength and a bulk resistance etc, a TAB tape applying the polyimide film, and flexible printed wiring board.

Owner:KOLON IND INC

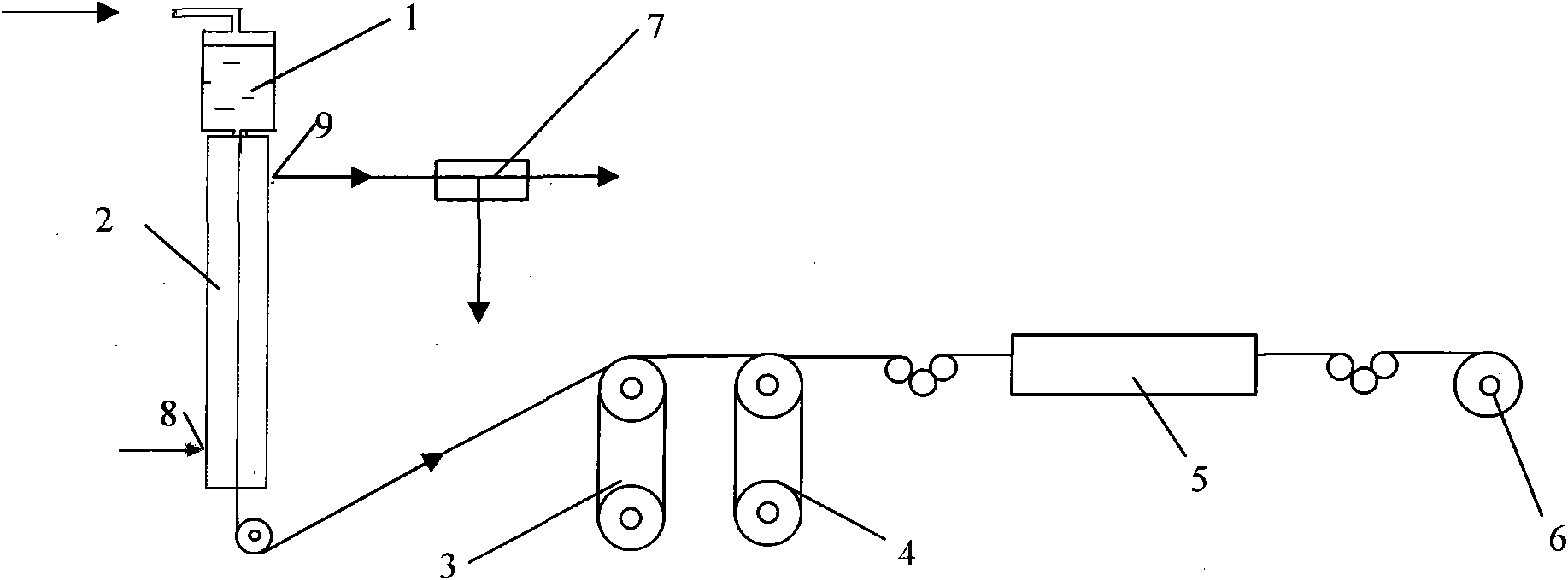

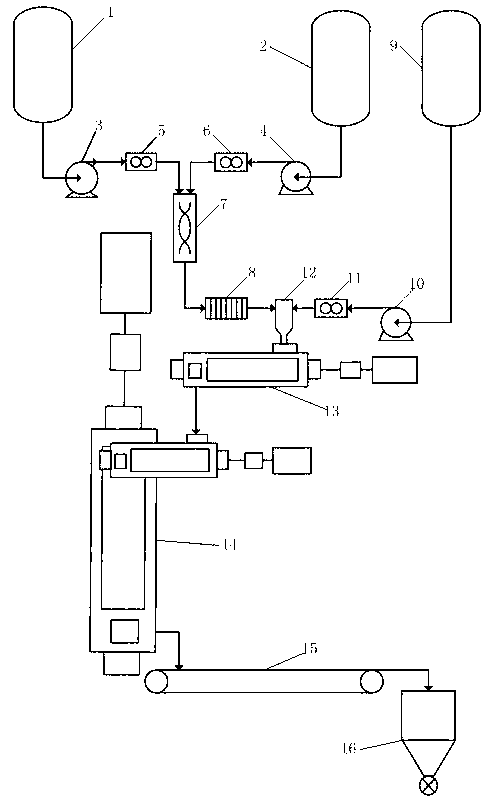

Continuous production device for poly-p-phenylene terephthamide resin

ActiveCN102838744AReduce continuous metering errorsQuality improvementContinuous measurementPolymer science

The invention provides a continuous production device for a poly-p-phenylene terephthamide resin, which belongs to the field of high molecular materials and relates to a high molecular material manufacturing technology. The continuous production device is characterized by comprising a p-phenylenediamine melt and solvent mixing and cooling device, a pre-polycondensation double-screw reactor, a combined second-order polycondensation double-screw reactor and a water washing device. After the continuous production device provided by the invention is used, the p-phenylenediamine and paraphthaloyl chloride are both fed as melts, so that continuous measurement errors are reduced and degrees of influences of flow fluctuation and solvent concentration on the mol ratio of the p-phenylenediamine and the paraphthaloyl chloride are reduced; and the obtained poly-p-phenylene terephthamide resin has the advantages of stable mass, narrow molecular weight distribution and low ash content and is suitable for industrially and continuously preparing the poly-p-phenylene terephthamide resin on a large-scale.

Owner:SHANGHAI HUIBO NEW MATERIAL SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com