Patents

Literature

165 results about "Graphene derivatives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

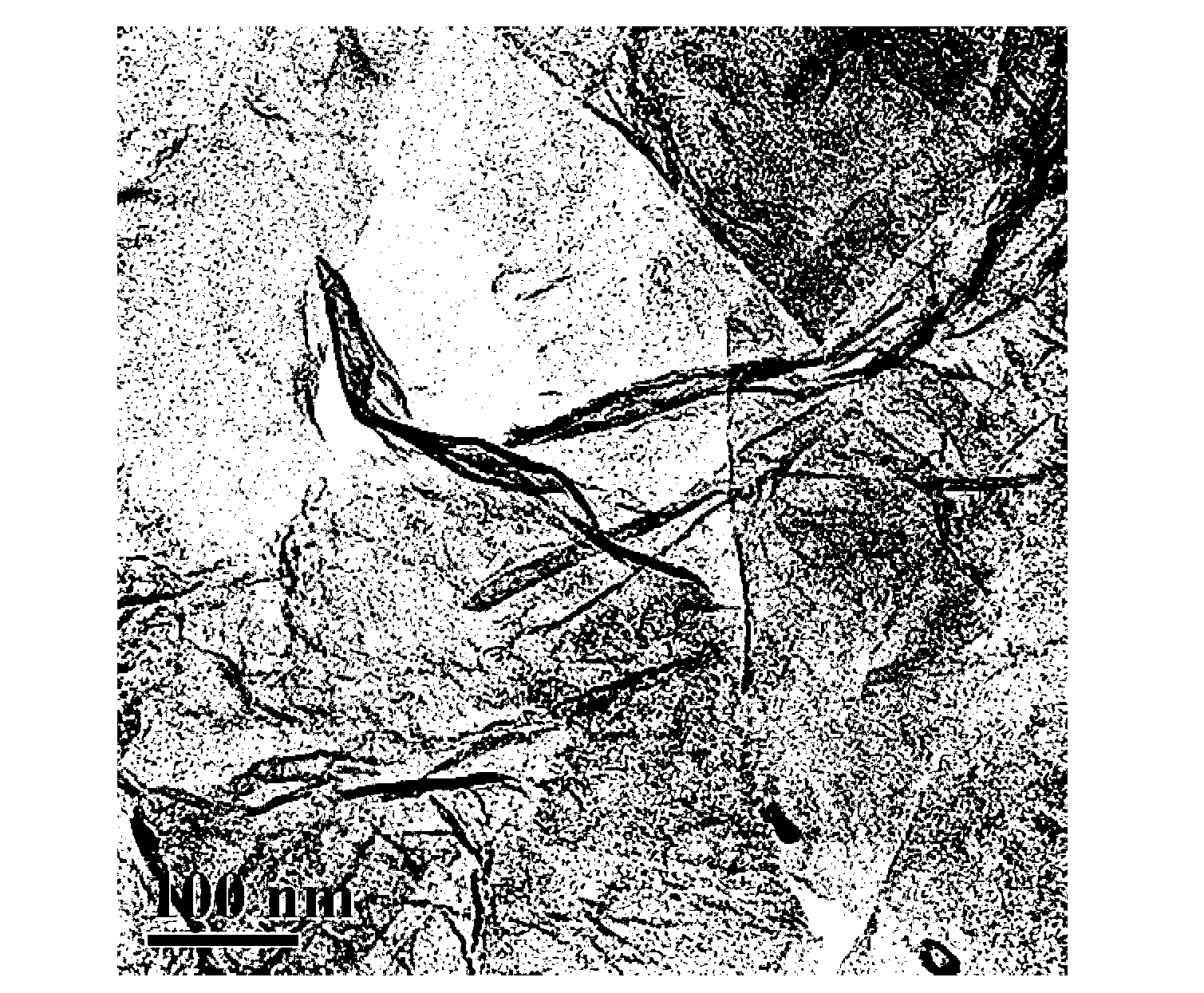

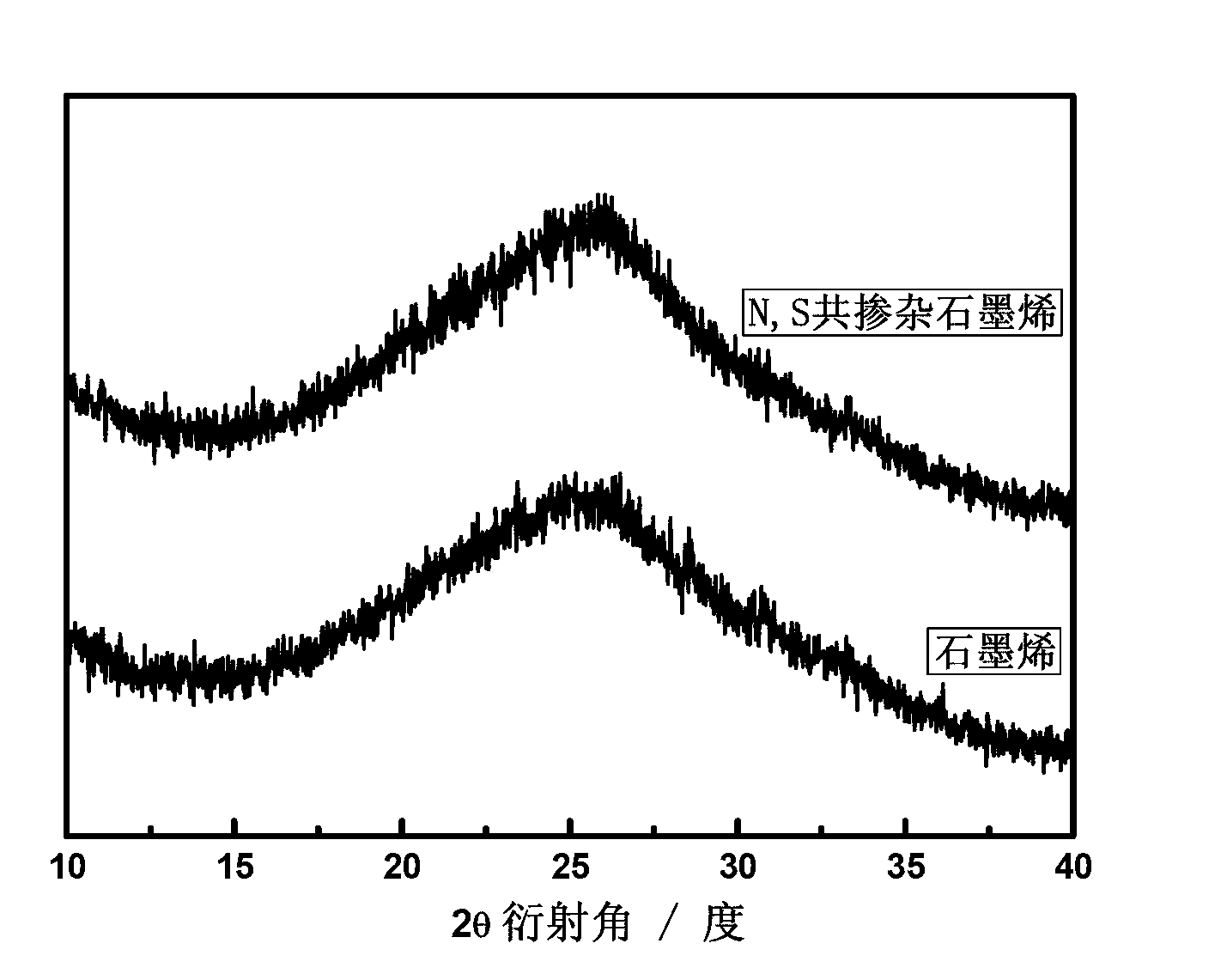

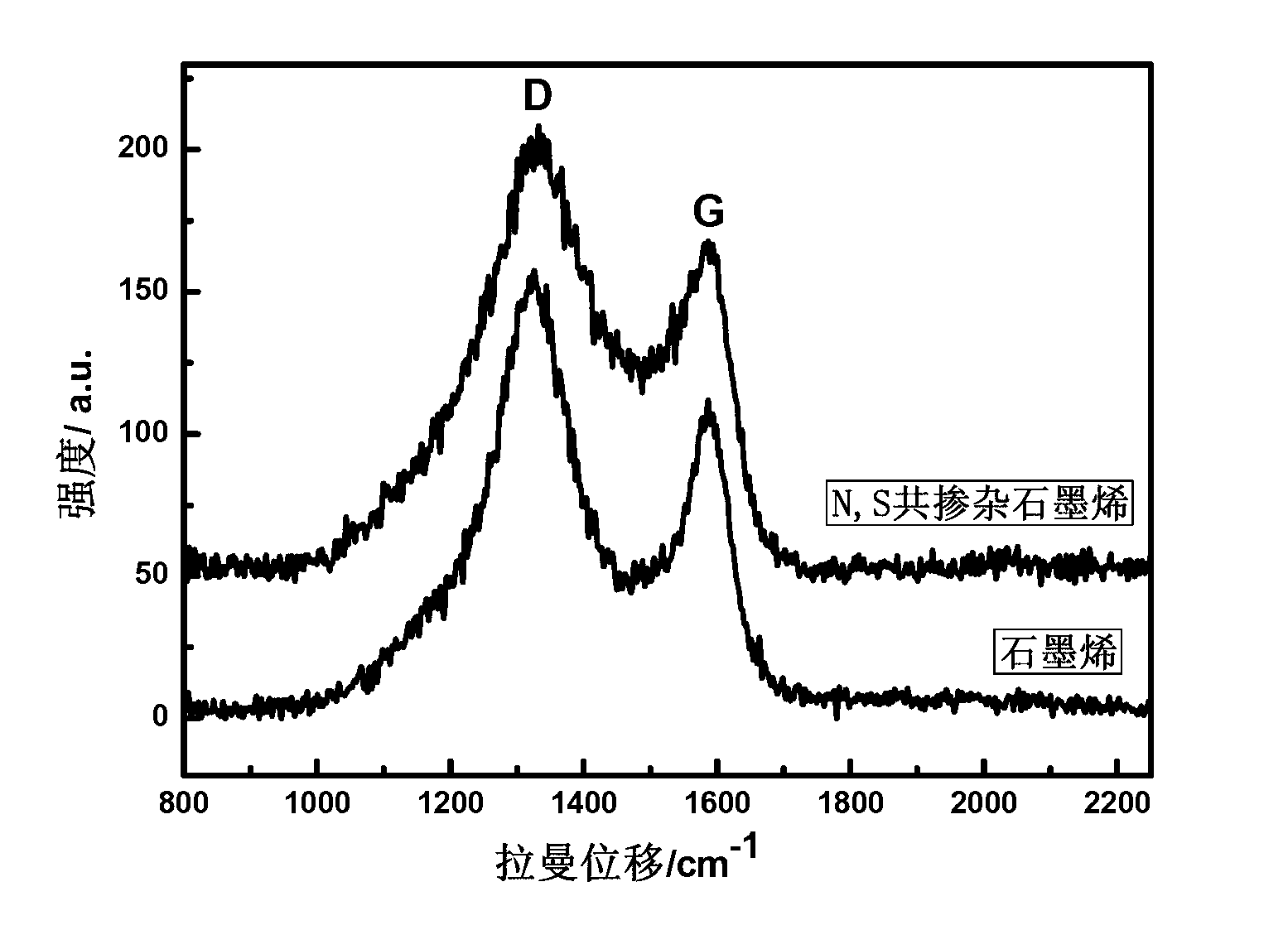

Preparation method of nitrogen and sulfur co-doped graphene

The invention discloses a nitrogen and sulfur co-doped graphene. The method comprises the following steps: grinding and uniformly mixing graphene or a graphene derivative, a nitrogen-containing compound and a sulfur-containing compound, carrying out thermal annealing under the protection of an inert gas at a temperature of 500-1000DEG C, maintaining the temperature for 1-5h, and cooling to room temperature to obtain the nitrogen and sulfur co-doped graphene, wherein content of the nitrogen element in the nitrogen and sulfur co-doped graphene is 1-10at.%, and the content of the sulfur element in the nitrogen and sulfur co-doped graphene is 0.5-2at.%. The method has the advantages of simple technology, low cost, easy control of the reaction process and the like, is suitable for the industrial large-scale production, and can be used in the super capacitor field, the sensor field, the catalytic field, the fuel battery field, the lithium air battery field and the like.

Owner:SOUTH CHINA UNIV OF TECH

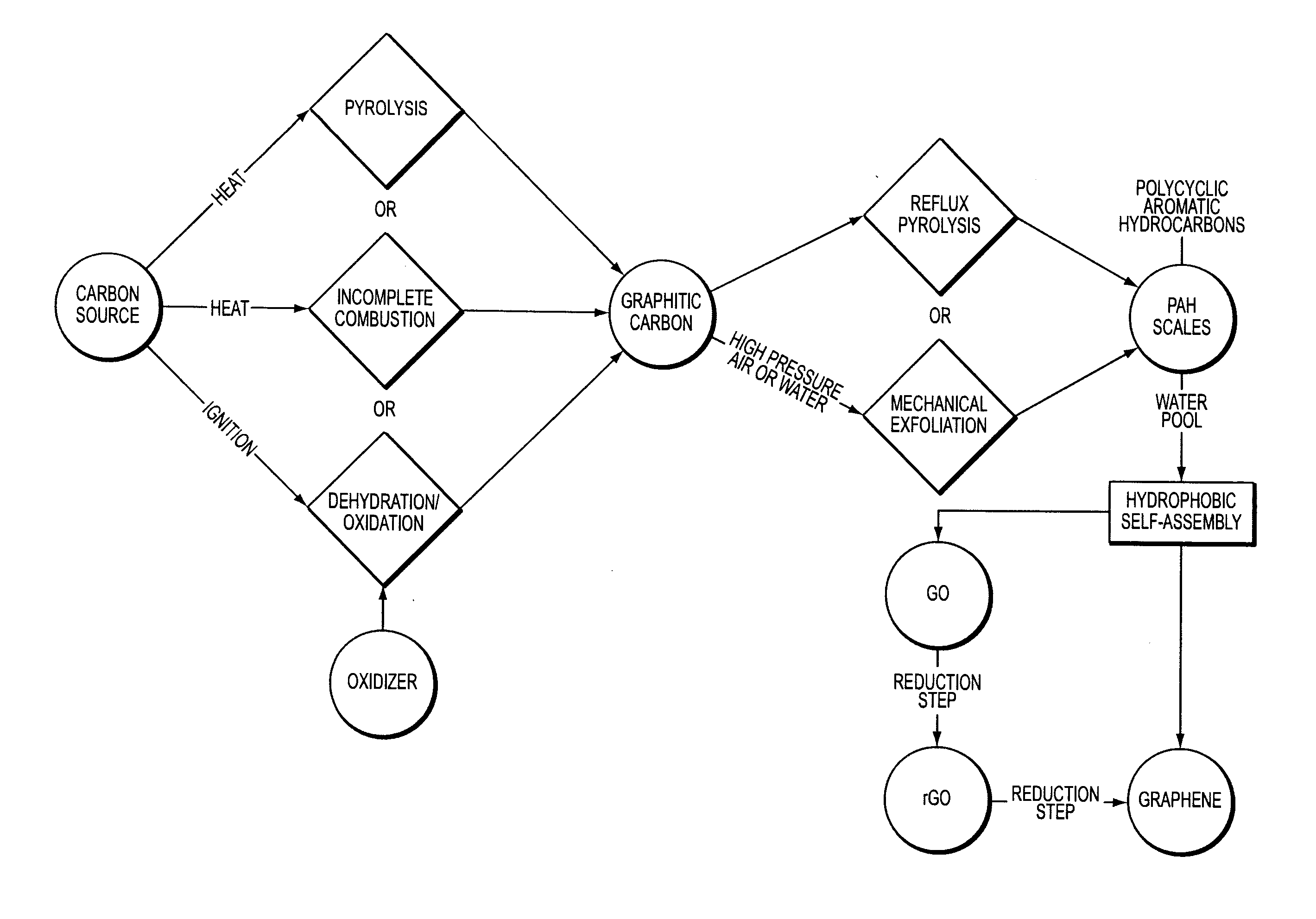

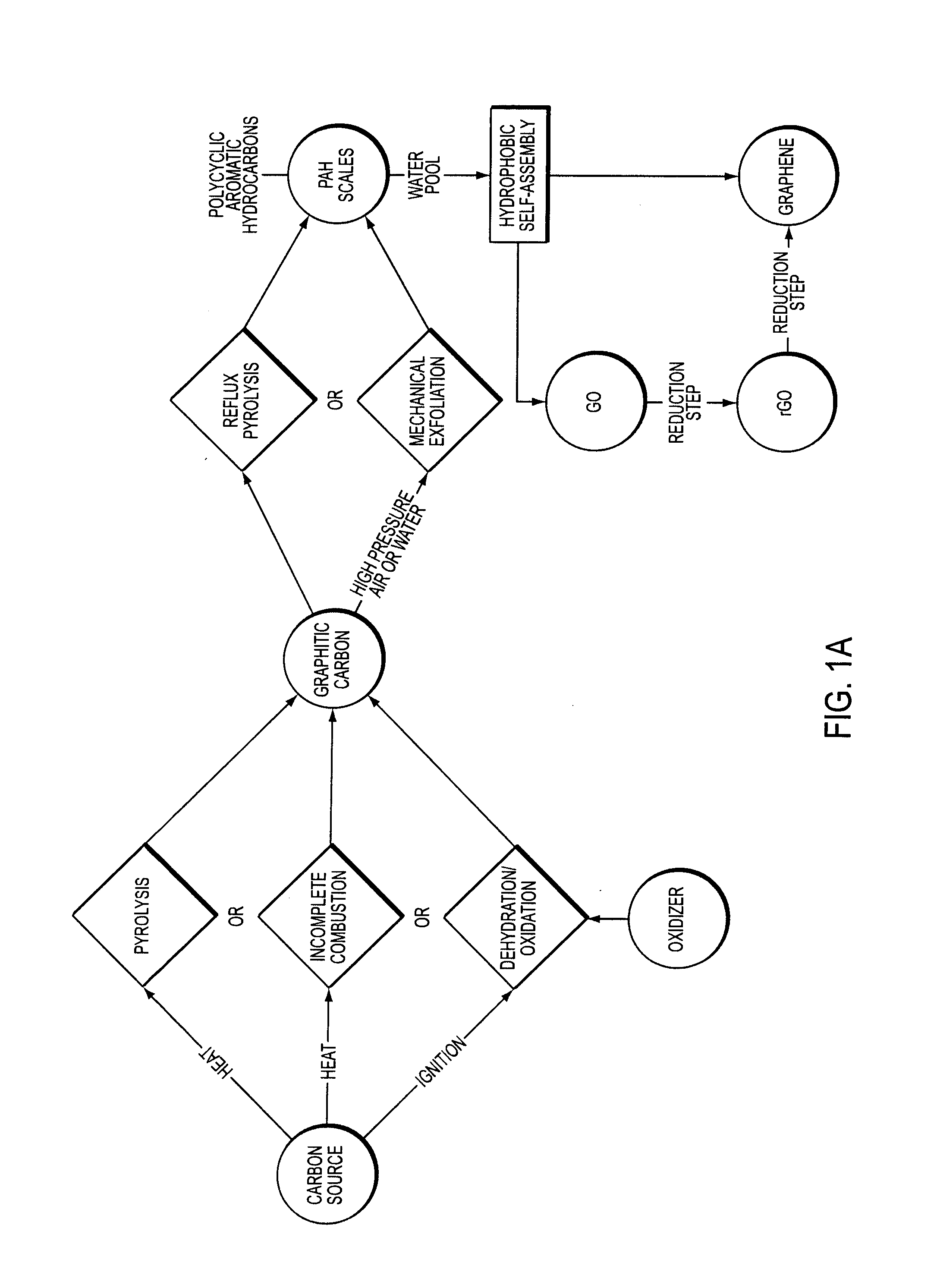

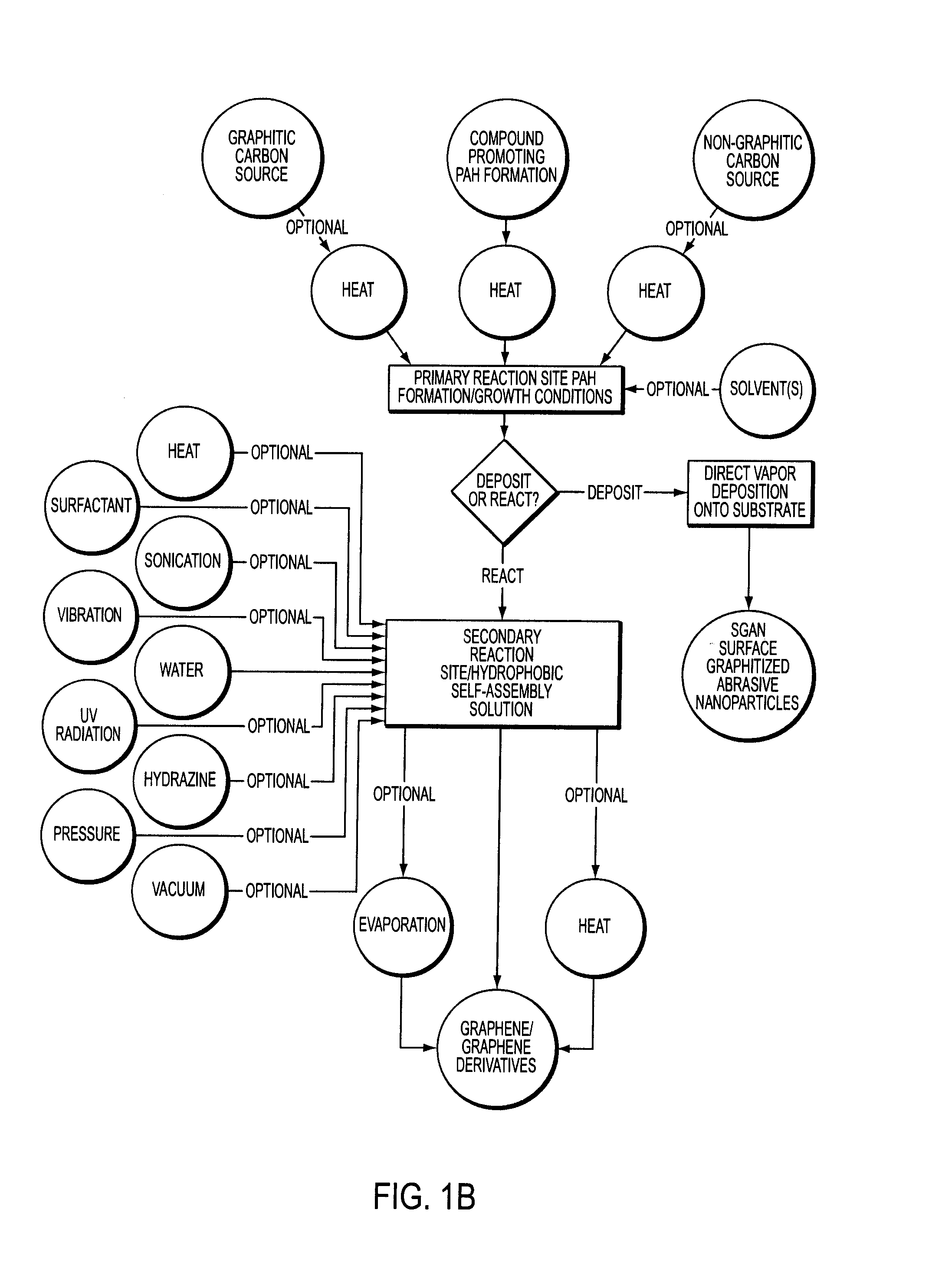

Facile synthesis of graphene, graphene derivatives and abrasive nanoparticles and their various uses, including as tribologically-beneficial lubricant additives

ActiveUS20140134092A1Reduce frictionImprove smoothnessMaterial nanotechnologyCosmetic preparationsNanoparticleGraphene derivatives

Owner:PEERLESS WORLDWIDE

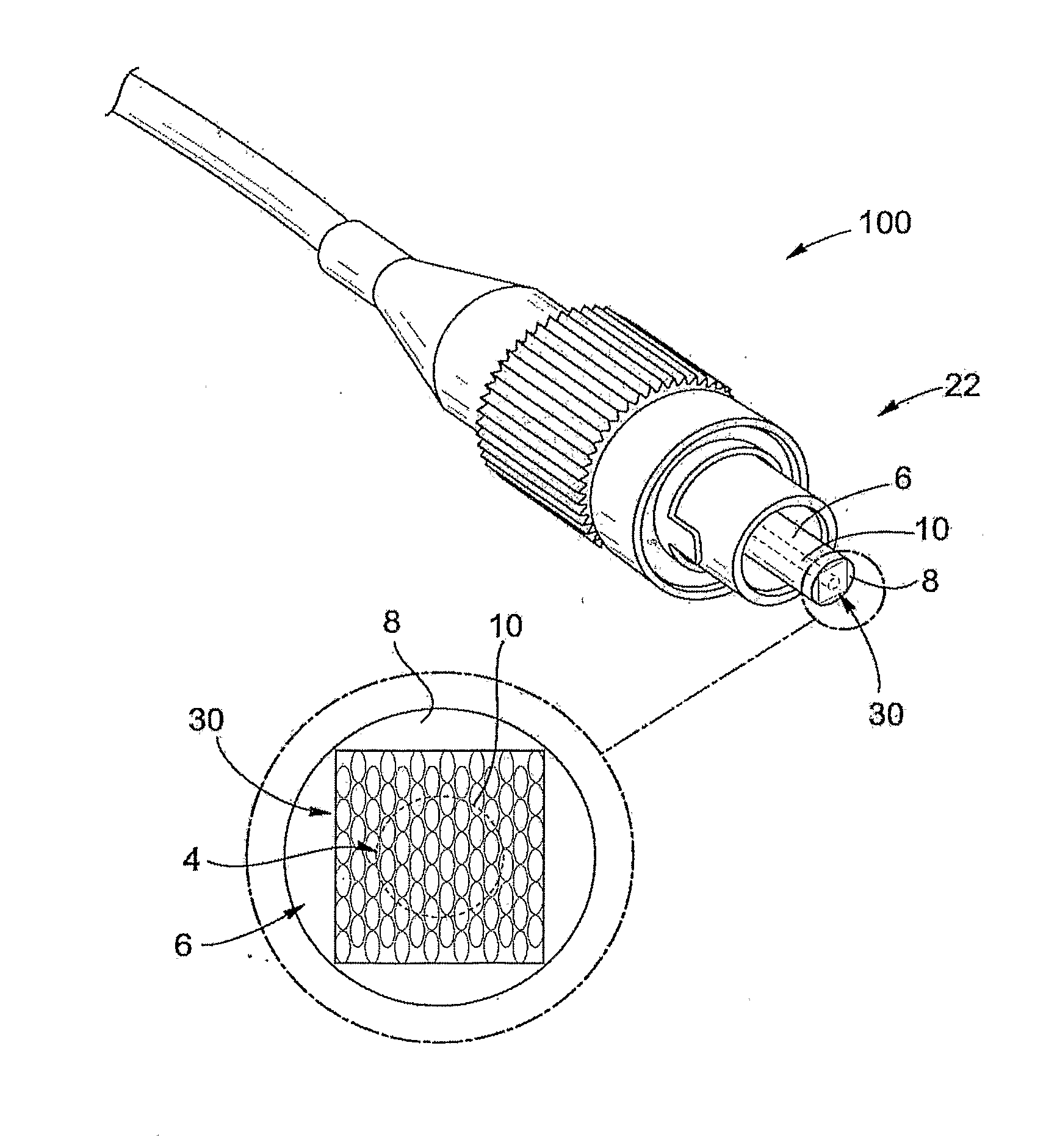

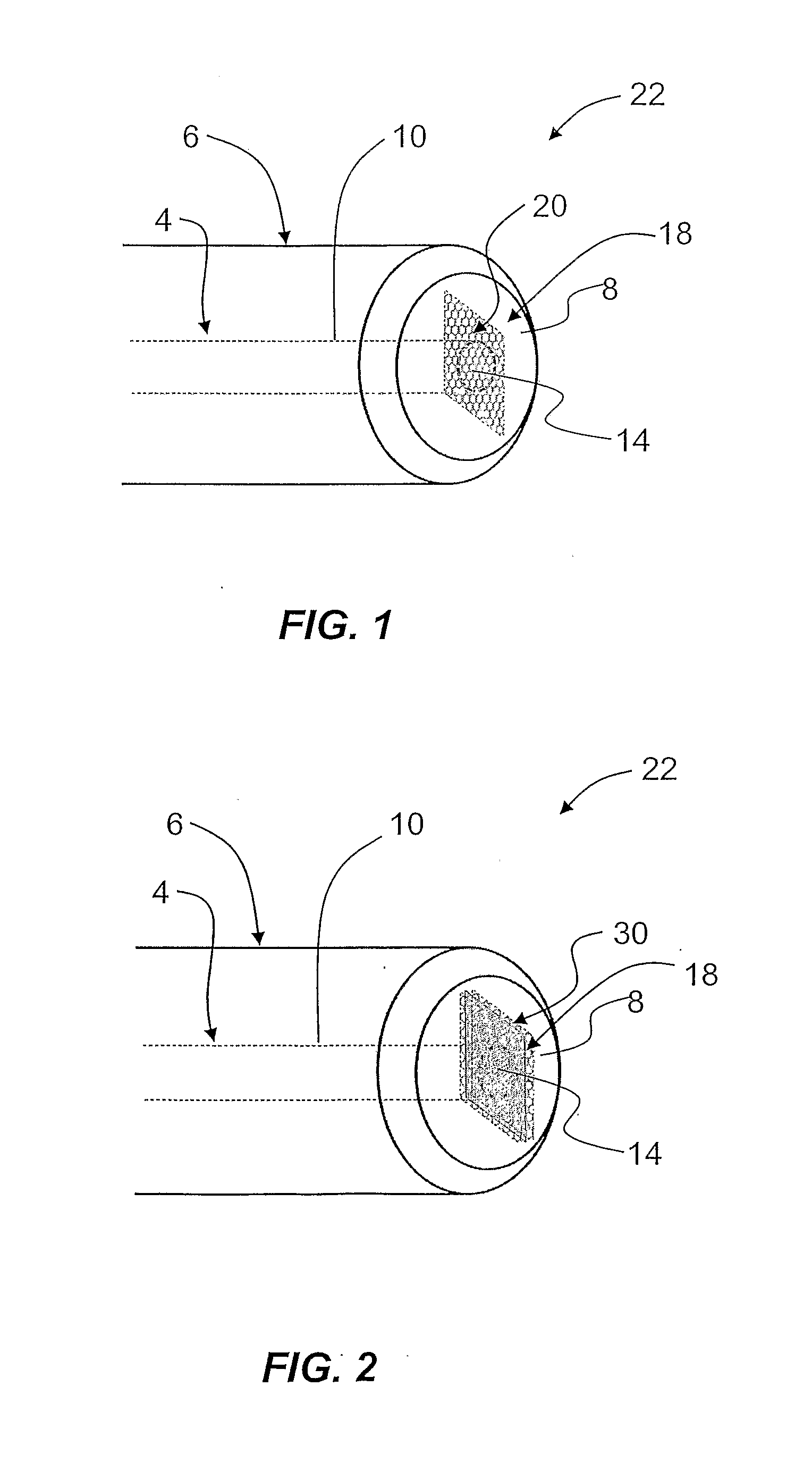

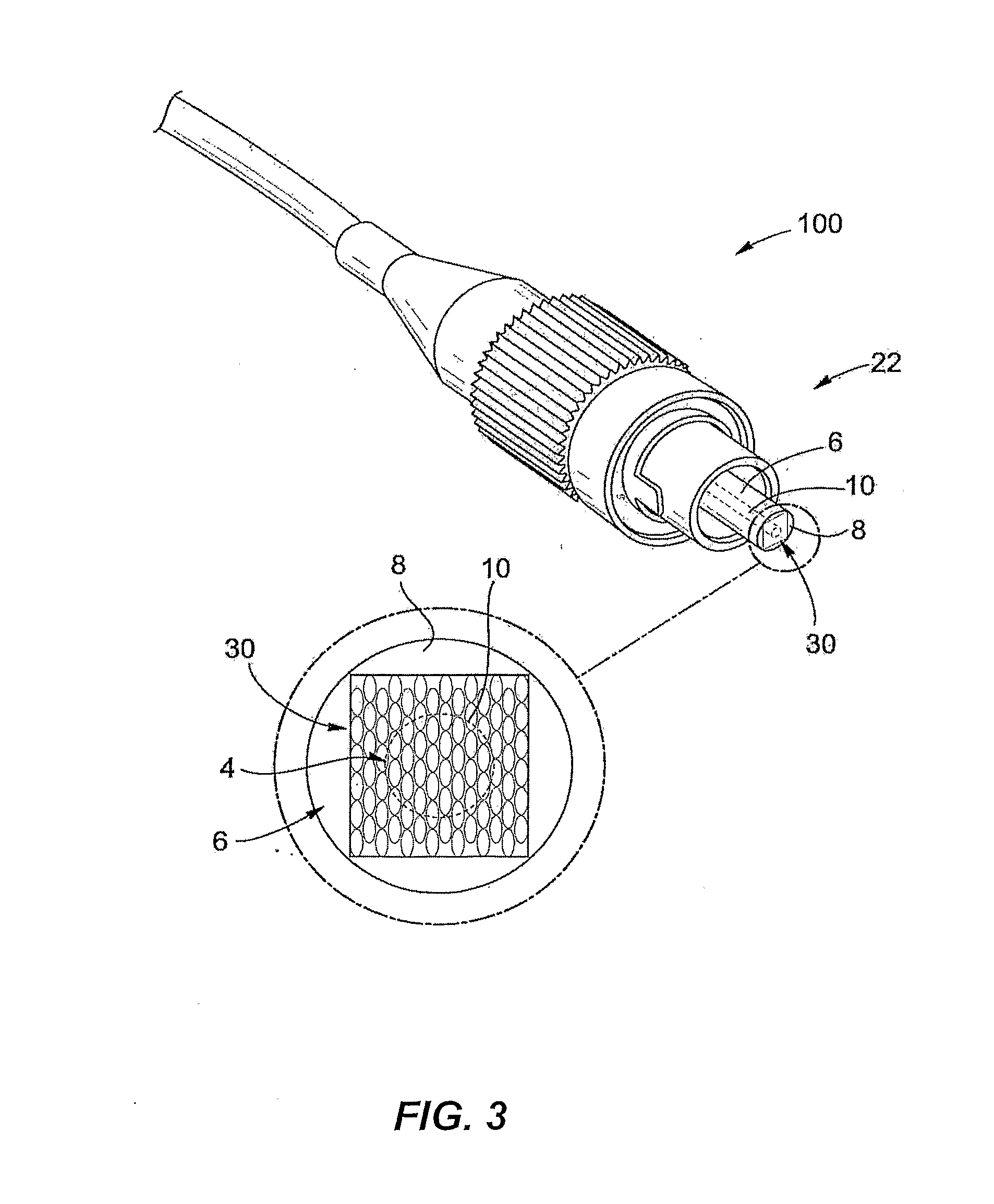

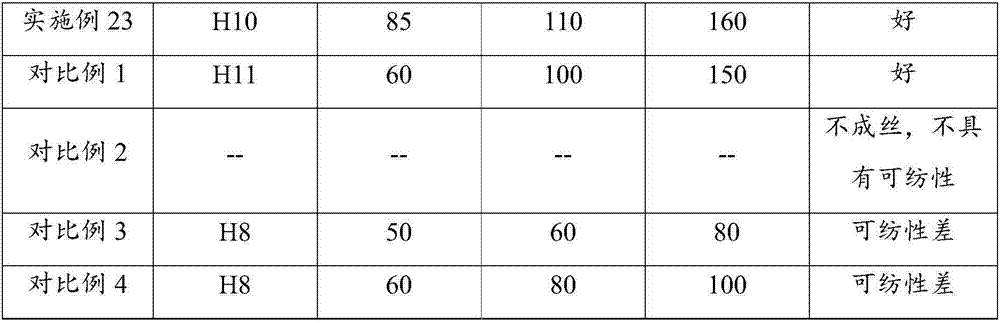

Graphene-based saturable absorber devices and methods

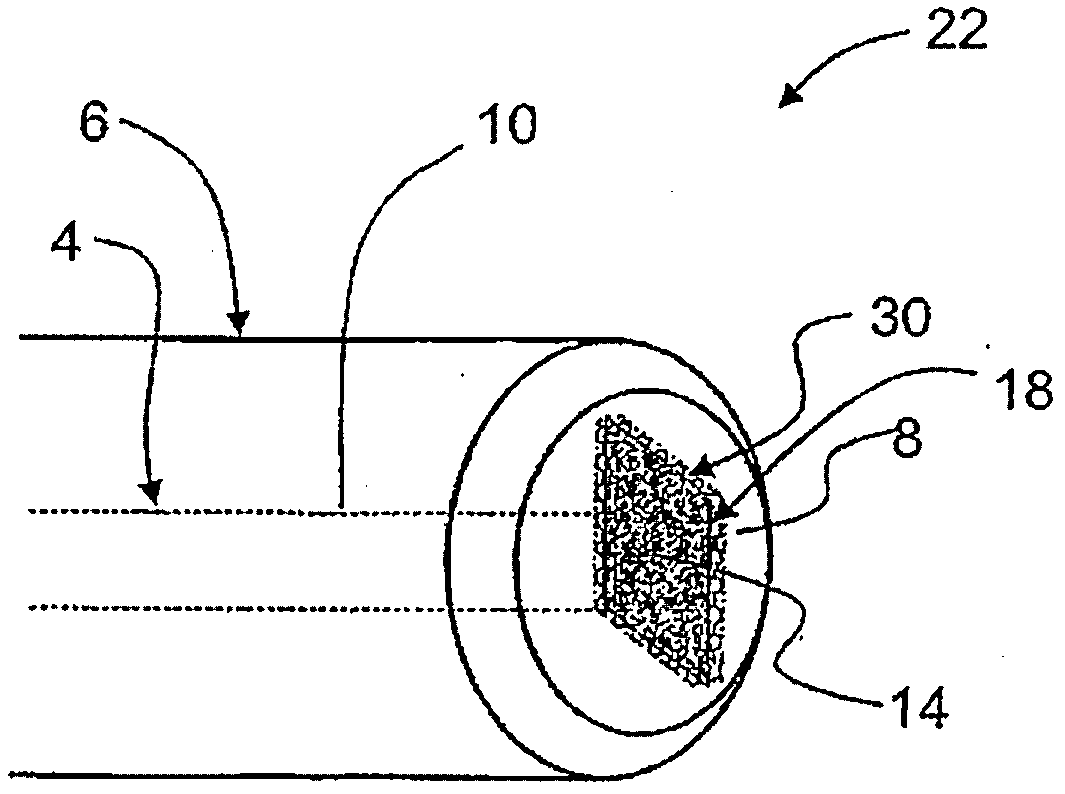

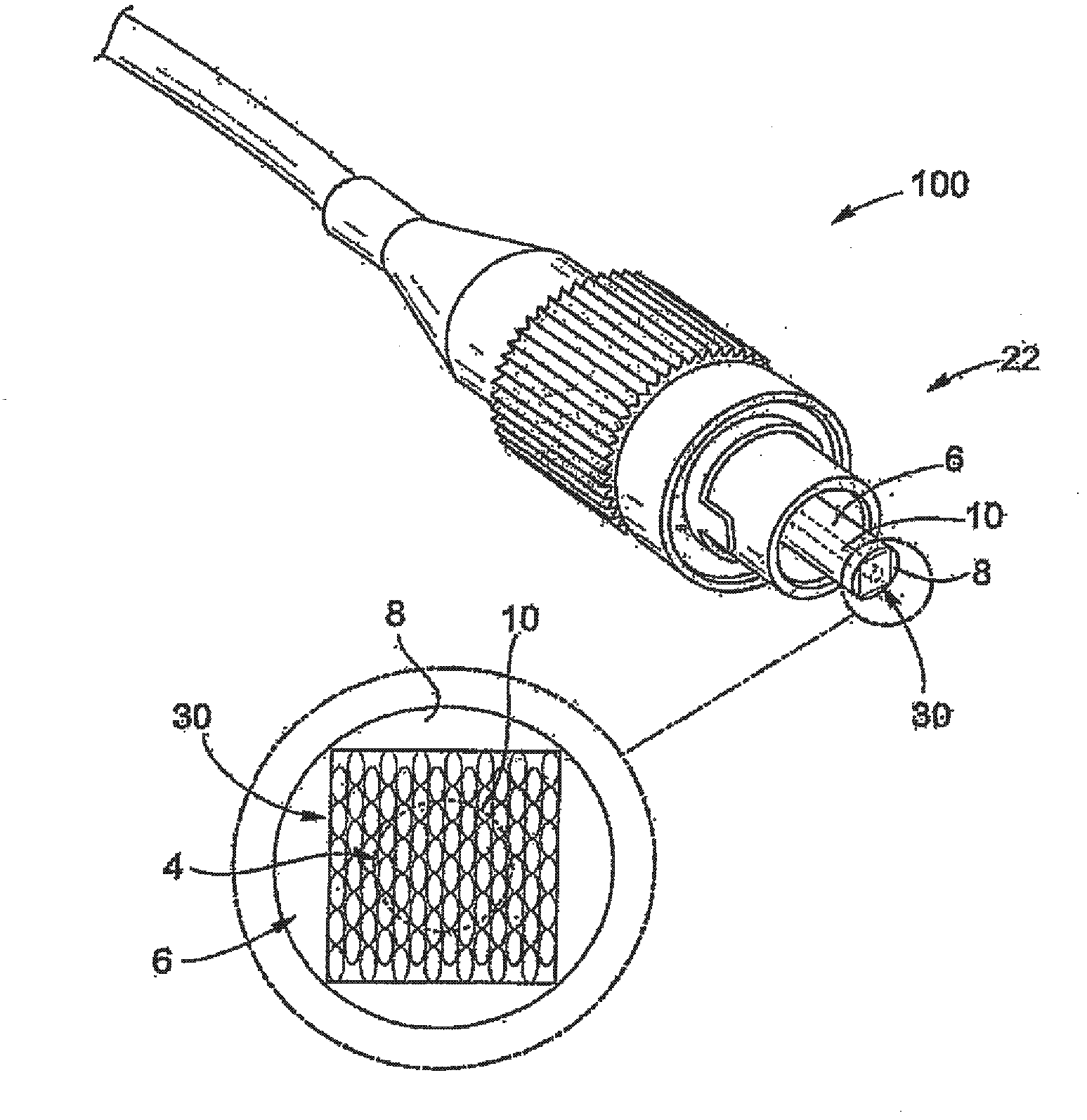

InactiveUS20120039344A1Improve performanceInexpensive to fabricateLaser using scattering effectsOptical resonator shape and constructionGraphene derivativesFacet

A graphene-based saturable absorber device suitable for use in a ring-cavity fiber laser or a linear-cavity fiber laser is disclosed. The saturable absorber device includes an optical element and a graphene-based saturable absorber material supported by the optical element and comprising at least one of graphene, a graphene derivative and functionalized graphene. An examplary optical element is an optical fiber having an end facet that supports the saturable absorber material. Various forms of the graphene-based saturable absorber materials and methods of forming same are also disclosed.

Owner:NAT UNIV OF SINGAPORE +1

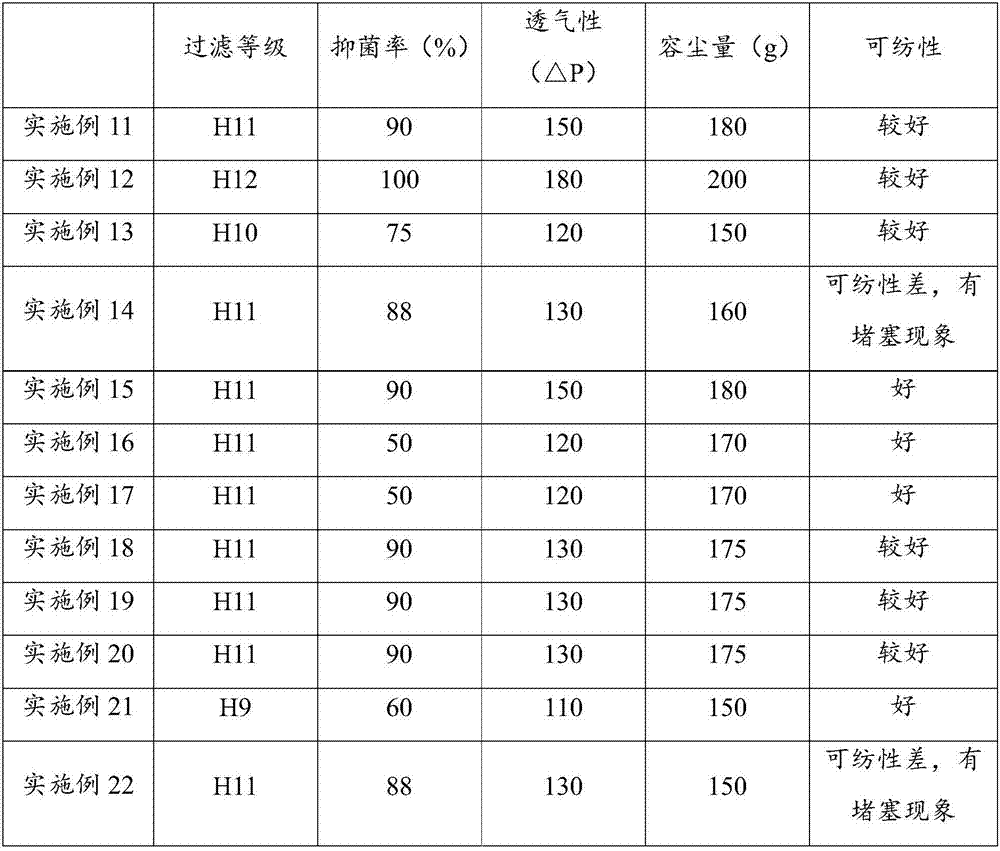

Modified polypropylene master batch, melt-blow cloth, preparation method and application thereof

InactiveCN107286473ALarge specific surface areaHigh conductivityFiltration separationNon-woven fabricsGraphene derivativesAntioxidant

The invention provides a modified polypropylene master batch, melt-blow cloth, a preparation method and an application thereof. The modified polypropylene master batch is mainly produced from, by weight, 77-90% of polypropylene, 5-20% of a graphene material and 1-5% of an additive. The graphene material includes any one or more of graphene, graphene oxide and graphene derivative. The additive includes any one or more of a coupling agent, a dispersant and an antioxidant and preferably includes the coupling agent, the dispersant and the antioxidant. The modified polypropylene master batch, when being used for manufacturing the melt-blow cloth, not only improves antibacterial and electrification property but also increases the filtering efficiency and dust capacity of the melt-blow cloth.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Graphene-based saturable absorber devices and methods

InactiveCN102439802AActive medium shape and constructionAdhesivesGraphene derivativesFunctionalized graphene

Owner:NAT UNIV OF SINGAPORE +1

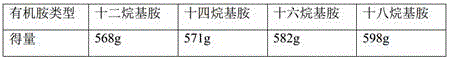

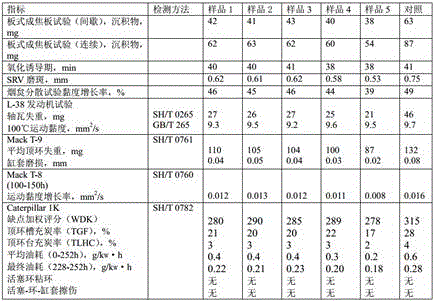

Modified graphene oxide, engine lubricating oil and application thereof

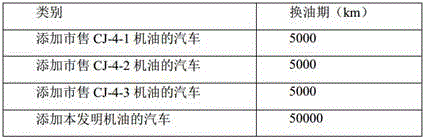

The invention discloses a graphene oxide modifying method and application thereof in engine lubricating oil. The method comprises the following steps: firstly preparing graphene oxide (GO) by adopting an improved Hummers process, and modifying the graphene oxide with long-chain fatty amine and organic silicon to obtain modified graphene derivative; and secondly, taking the modified graphene oxide as A), and compounding a friction modifier with a metal cleaning agent B), a metal corrosion inhibitor C), a complex antioxidant, an anti-foaming agent, a viscosity index improver, synthetic ester base oil and base oil, so that the engine lubricating oil added with the graphene oxide modifying agent is obtained. The method disclosed by the invention has the advantages that abrasion of an engine is greatly reduced by adding the graphene oxide modifying agent, so that oil draining period of automobile engine oil is prolonged to 50000 kilometers from 5000 kilometers, and fuel oil can be saved by 7-10% in the aspect of fuel economy.

Owner:江苏悦尔科技有限公司

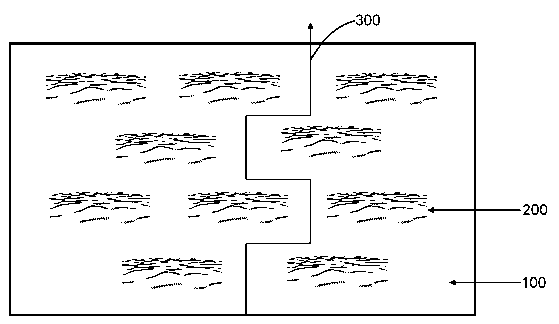

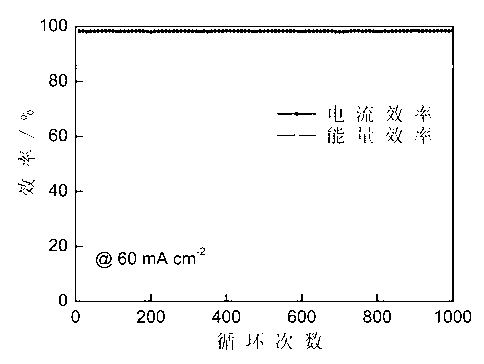

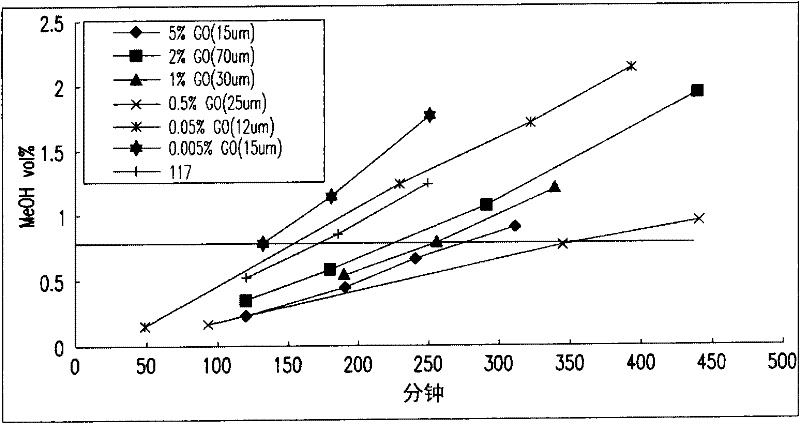

Composite graphene ion exchange membrane for flow battery and preparation method thereof

ActiveCN103219533AImprove stabilityHigh selectivityCell component detailsFuel cell detailsGraphene derivativesRedox

The invention discloses a composite graphene ion exchange membrane for a flow battery and a preparation method thereof. The composite graphene ion exchange membrane comprises a sulfonation polymer which serves as an ion exchange membrane matrix and graphene and / or graphene derivatives doped in the ion exchange membrane matrix. The preparation method is a method for preparing the composite graphene ion exchange membrane. Compared with the prior art, the graphene and / or graphene derivatives are introduced into the sulfonation polymer for modification, and the graphene with a two-dimensional lamellar structure and / or graphene derivatives can improve the stability of the composite ion exchange membrane through the interaction between the graphene and the polymer molecules, and can serve as an obstacle (barrier) of active substance penetration in the ion exchange membrane so as to improve the ion selectivity of the composite ion exchange membrane. The sulfonation polymer-composite graphene ion exchange membrane is applied to the flow battery, particularly an all vanadium redox flow battery, and high battery efficiency and stable battery performance can be obtained.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

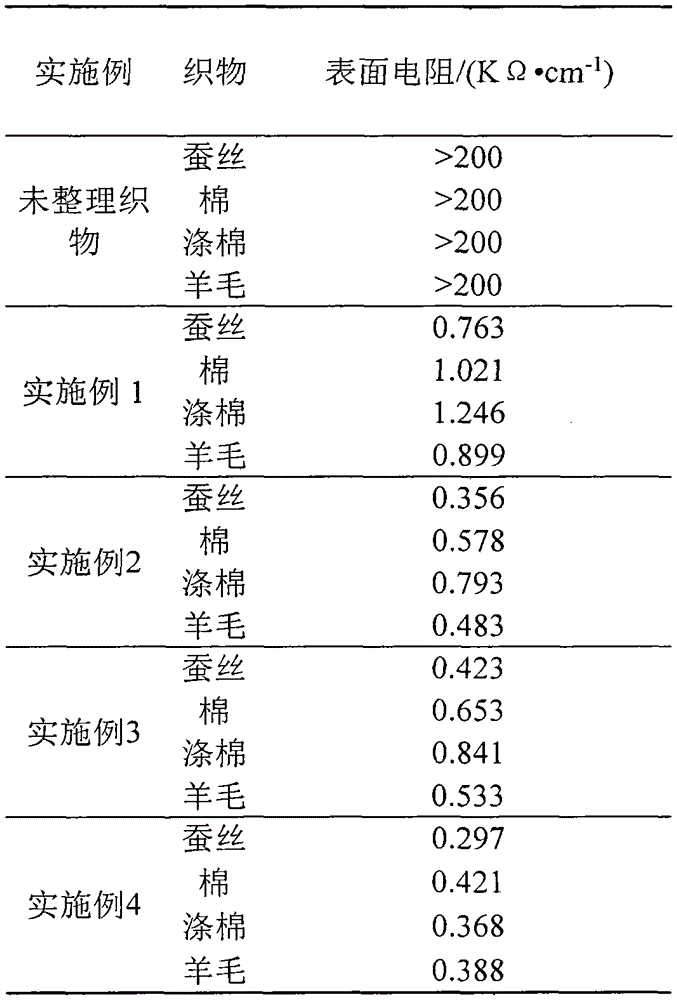

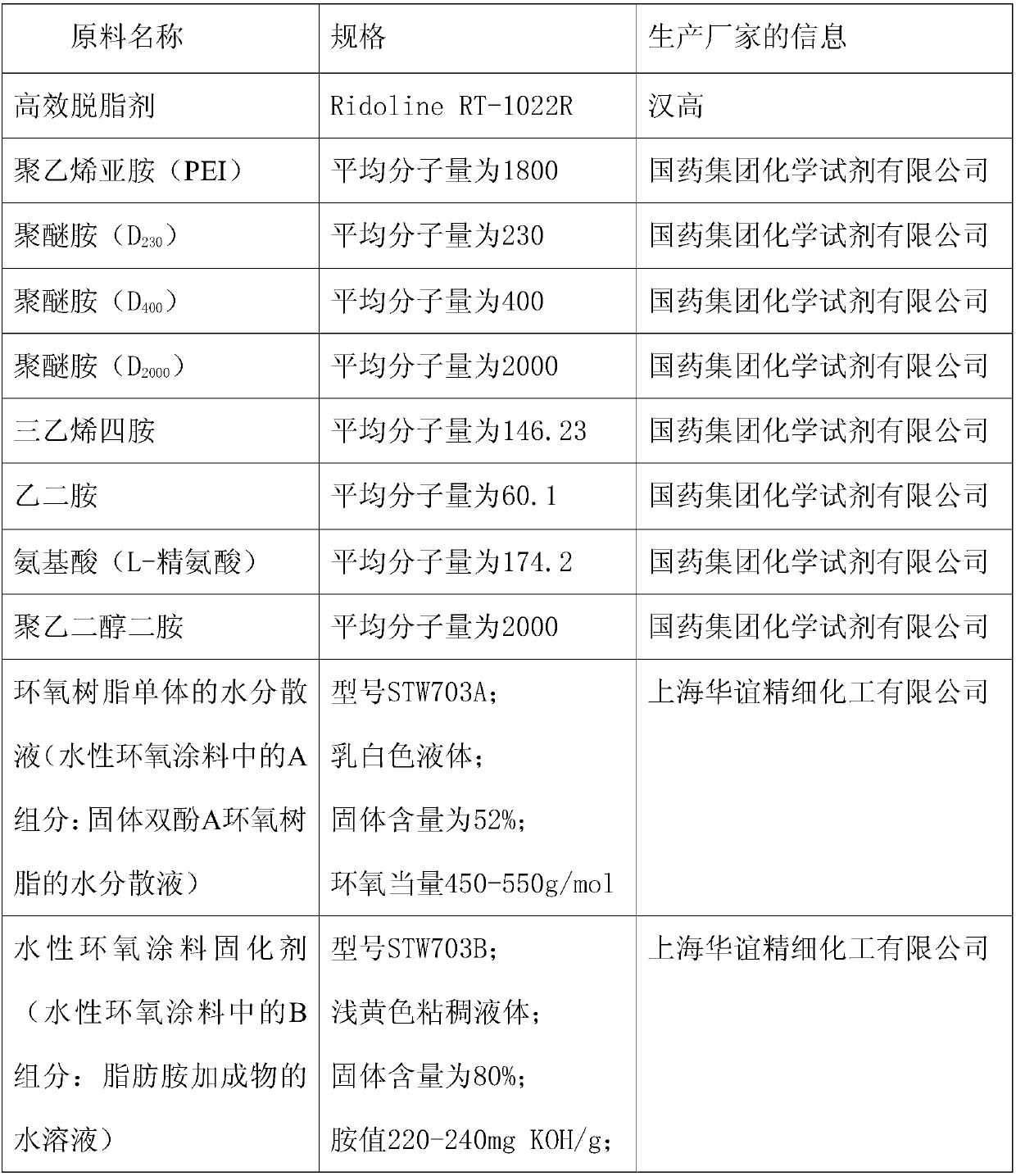

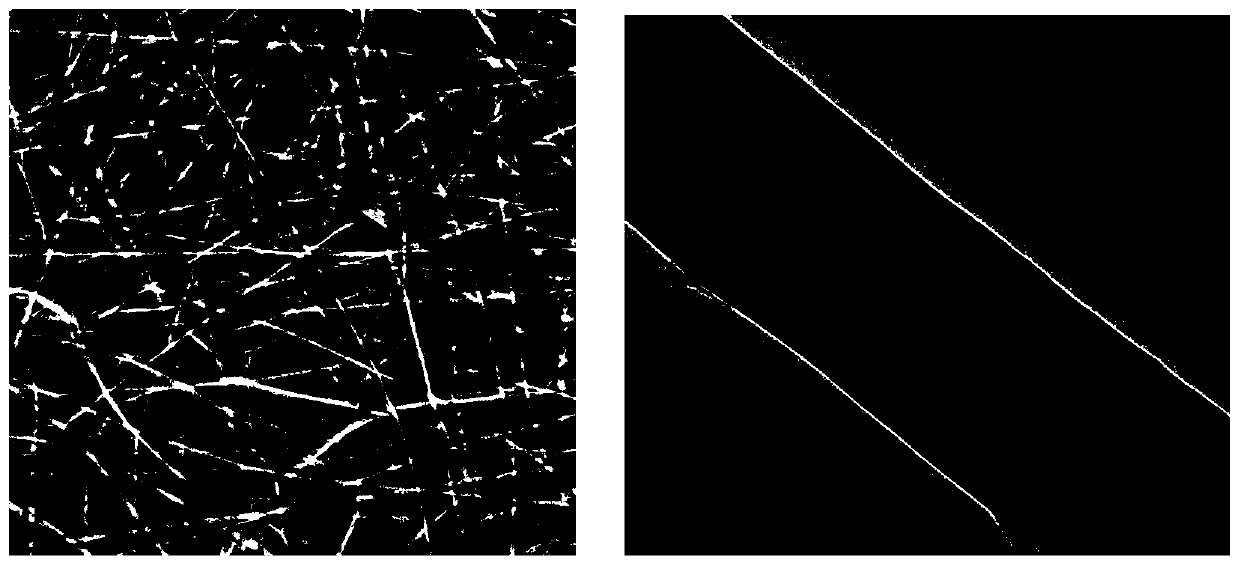

Preparation method of graphene/polyaniline covalent binding conductive fabric

ActiveCN104313872AEasy to operateVegetal fibresAnimal fibresGraphene derivativesIn situ polymerization

The invention discloses a preparation method of a graphene / polyaniline covalent binding conductive fabric, which belongs to the technical field of textile chemistry. The preparation method comprises the steps of applying oxidized graphene or oxidized graphene derivative and a reaction product of p-phenylenediamine onto the fabric to be reduced, enabling the fabric to adsorb the polyaniline monomer, enabling the in-situ polymerization of the polyaniline monomer on the fabric to form polyaniline, and enabling the polyaniline to form covalent key combination with the graphene. According to the method, a conductive layer formed by covalently combining the graphene and polyaniline can be acquired on the surface of the fabric, so that the stability of the conductive layer is improved, and the conductive fabric with excellent effect can be acquired. The method is applicable to conventional fabrics such as natural fibers including cotton, wool, silk and the like, synthesized fibers including terylene, chinlon, acrylic fibers and the like and blending of fabric or conductive arrangement of intertexture, and the prepared functional fabric can be applied to the fields of medical healthcare, intelligent sensors, mobile power generation, military and the like.

Owner:JIANGNAN UNIV

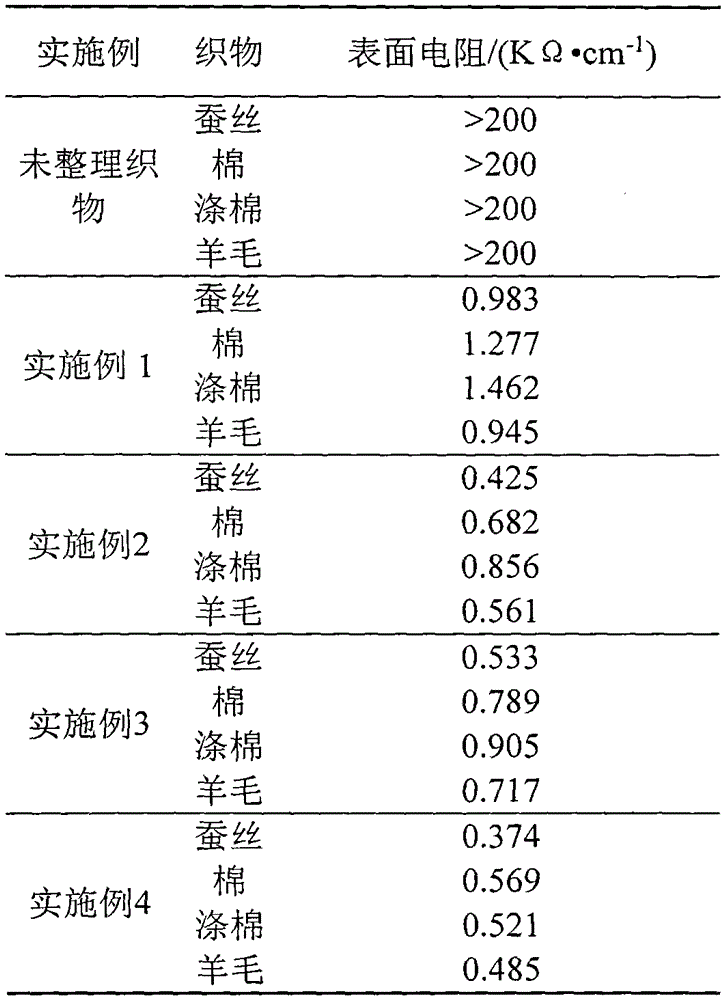

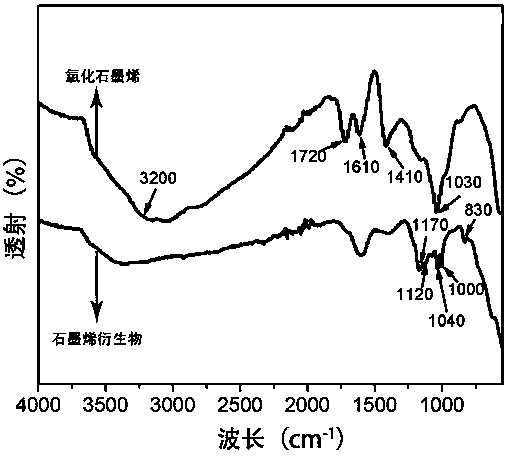

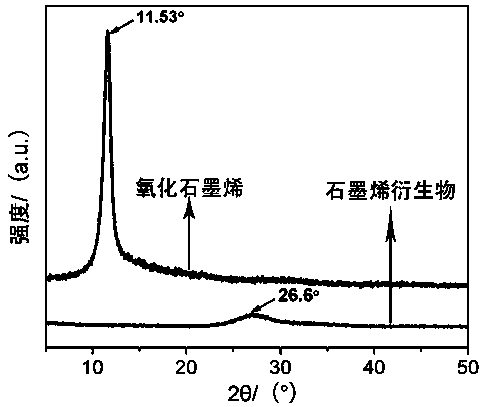

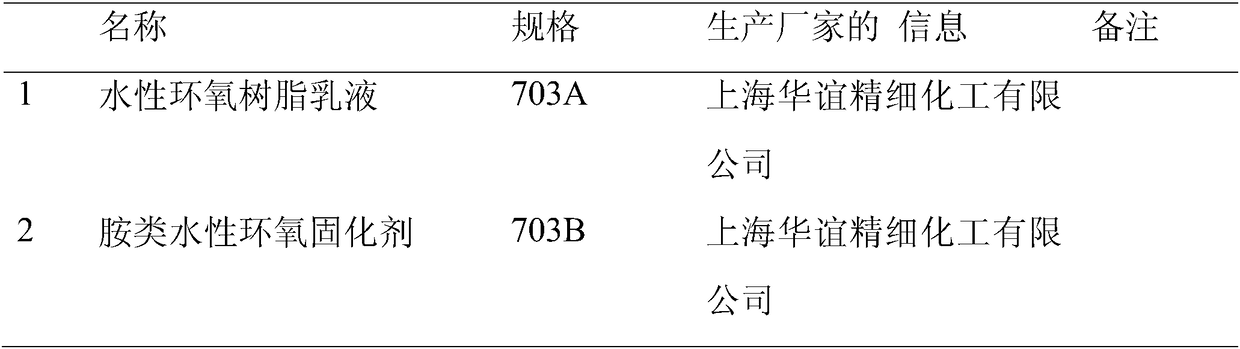

Graphene-modified waterborne epoxy coating curing agent as well as preparation method and application of curing agent

ActiveCN107815216AUniform and stable dispersionGood compatibilityAnti-corrosive paintsEpoxy resin coatingsEpoxyGraphene derivatives

The invention discloses a graphene-modified waterborne epoxy coating curing agent as well as a preparation method and application of the curing agent. The preparation method comprises the following steps: firstly dispersing graphene oxide prepared by virtue of an improved Hummers method into water, so as to obtain graphene oxide dispersion liquid; and adding a surfactant with amino end groups, uniformly mixing, carrying out microwave heating to enable graphene oxide to react with the surfactant, adding a graphene derivative water solution into a waterborne epoxy coating curing agent, and uniformly mixing, so as to obtain the graphene-modified waterborne epoxy coating curing agent. The graphene-modified waterborne epoxy coating curing agent is applied to the preparation of a bi-component waterborne epoxy coating, and the neutral salt spray test time of a formed anticorrosive coating can reach 185-252 hours.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Preparation method of graphene/polyaniline self-assembly flexible conductive fabric

ActiveCN104313873AEasy to operateVegetal fibresAnimal fibresIn situ polymerizationGraphene derivatives

The invention discloses a preparation method of a graphene / polyaniline self-assembly flexible conductive fabric, which belongs to the technical field of textile chemistry. The method comprises the steps of firstly covering the surface of the fabric with a layer of reduced oxidized graphene (rGO) or a derivative of the reduced oxidized graphene, carrying out in-situ polymerization after the fabric adsorb the polyaniline, covering the graphene arranged fabric with a layer of conductive macromolecular polymer, and repeating the steps to obtain the conductive fabric with excellent effect. By adopting the method, the weakness that the single graphene or graphene derivative arrangement fabric can obtain a good conductive effect only by adsorbing sufficient graphene and the single polyaniline arrangement fabric is poor in stability can be overcome, the prepared conductive fabric is high in conductivity and high in heat resisting stability, and the fabric can be applied to the fields such as medical healthcare, intelligent sensors, mobile power generation and military. The method is applicable to conventional fabrics such as natural fibers of cotton, wool, natural silk, synthesized fibers such as terylene, chinlon and acrylic fibers as well as the blended weaving of the fabric or the conductive arrangement of the intertexture.

Owner:绍兴衣佳科技有限公司

Novel nerve duct bracket and preparation method and application thereof

ActiveCN109847105ASimple manufacturing methodRaw material safetyFilament/thread formingNon-woven fabricsFiberCross-link

The invention relates to a novel nerve duct bracket and a preparation method and application thereof. Three-dimensional graphene or graphene derivative multichannel active nanofiber sponge is used asa stuffing inner core, and nanofibers in an axial direction are used as an outer pipe. The preparation method comprises the steps of performing ultrasonic dispersion on graphene or a graphene derivative into spinning liquid, performing electrostatic spinning, and performing drying so as to obtain a nanofiber film; performing shearing, and performing homogenization and crushing so as to obtain broken fiber mixed liquid; pouring the broken fiber mixed liquid into a multichannel mold, and performing freeze drying; performing cross-linked shaping; performing drying and shaping so as to obtain thethree-dimensional graphene or graphene derivative multichannel nanofiber sponge; and performing fixing in an axial direction spinning receiver, and performing axial direction spinning on an outer layer so as to obtain the novel nerve duct bracket. The novel nerve duct bracket is used for inducing repair and regeneration of nerve tissue. The novel nerve duct bracket disclosed by the invention is simple to operate and good in repeatability, and a new thinking is provided for repairing neurological deficits.

Owner:DONGHUA UNIV

Graphene Derivative Composite Membrane And Method For Fabricating The Same

InactiveUS20150053607A1Large apertureEfficient separationEnergy based wastewater treatmentDistillationGraphene derivativesTotal thickness

The invention provides a graphene derivative composite membrane and method for fabricating the same. The graphene derivative composite membrane comprises a support membrane made of porous polymer and a plurality of graphene derivative layers disposed on the support membrane wherein the distance between adjacent graphene derivative layers is about 0.3˜1.5 nm and the total thickness of the plurality of graphene derivative layers is more than 100 nm.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

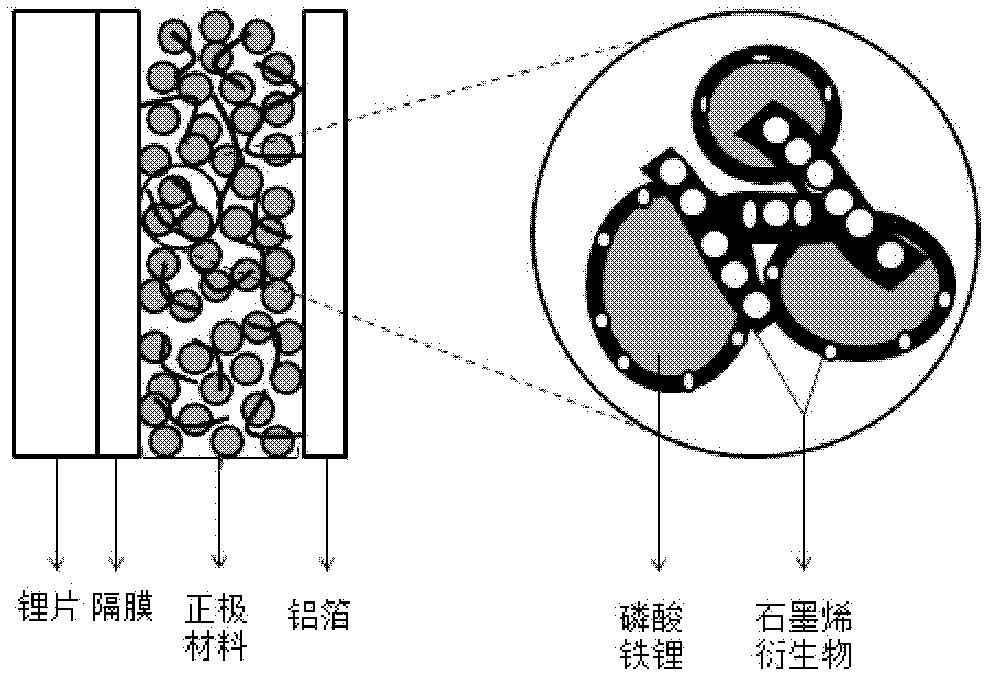

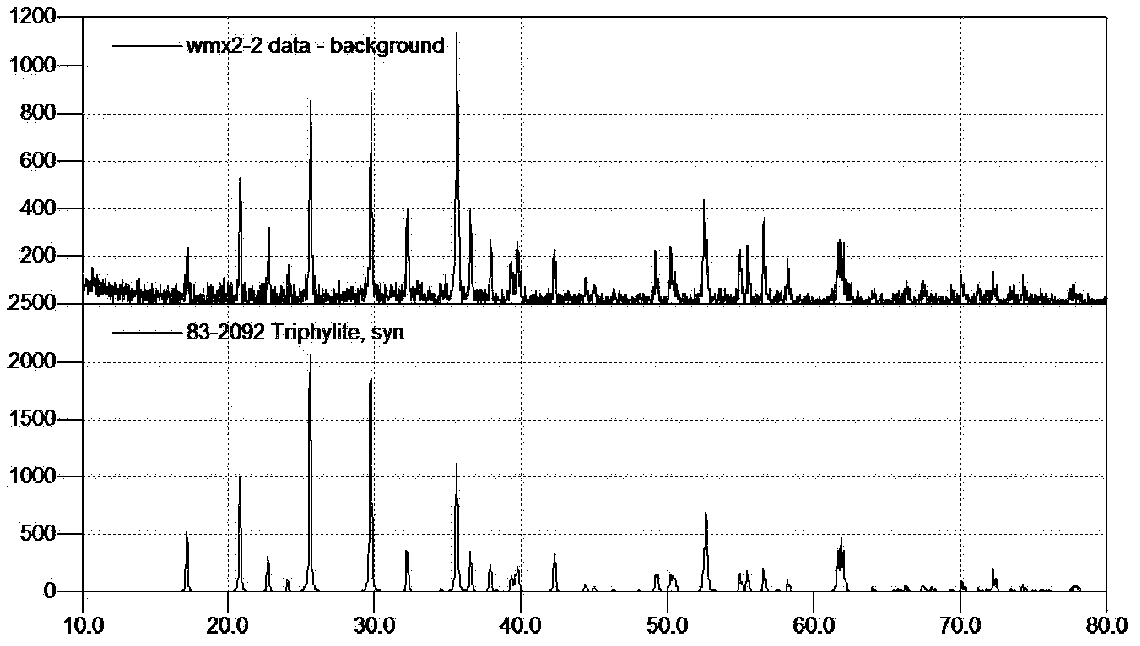

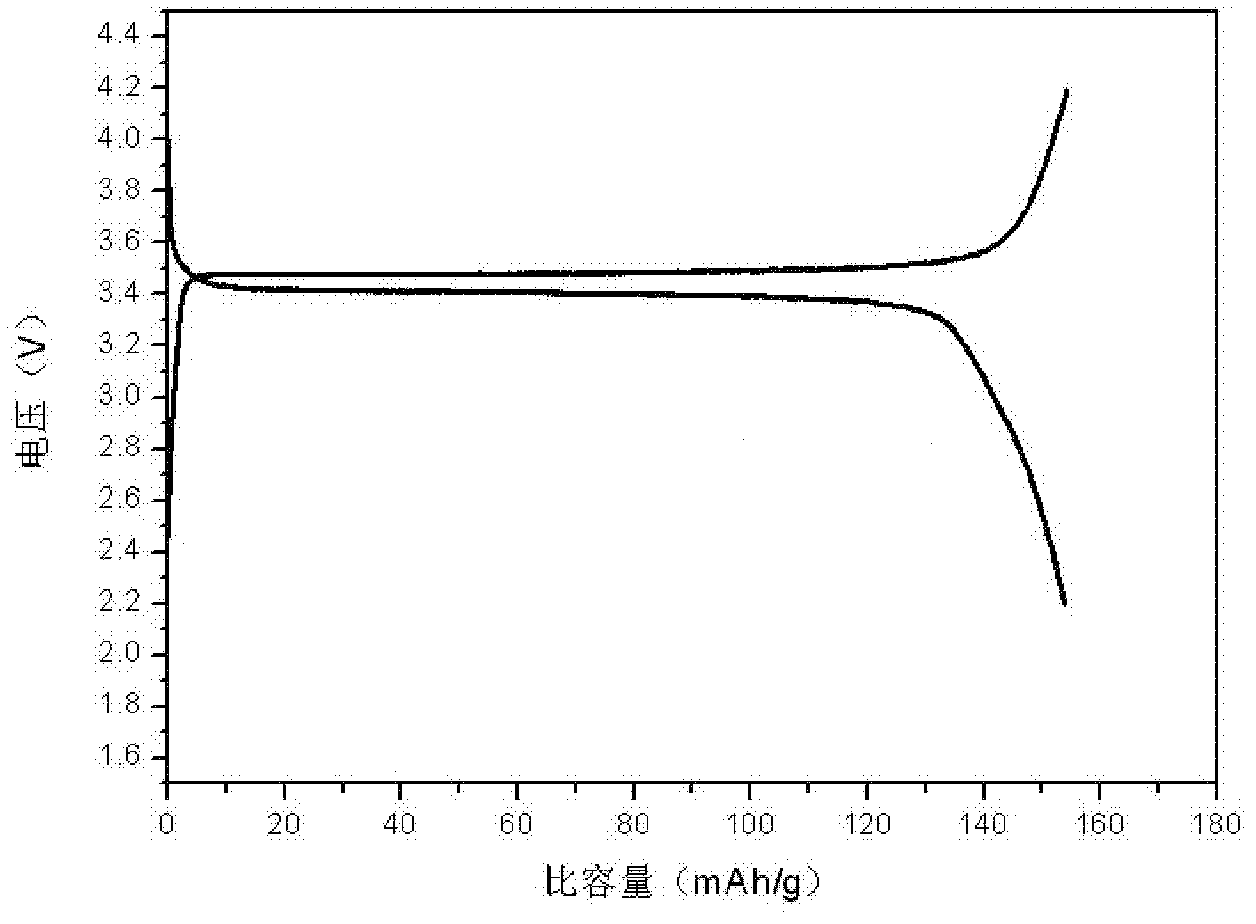

Graphene doped lithium iron phosphate positive electrode material and preparation method thereof

ActiveCN102544491APromote circulationLower internal resistanceCell electrodesSecondary cellsDoped grapheneInternal resistance

The invention relates to a graphene doped lithium iron phosphate positive electrode material and a preparation method thereof. The method comprises the following steps of: (1) mixing a soluble lithium compound, phosphate and a ferrous salt into a dispersing agent to obtain a dispersing solution a; (2) oxidizing a graphene derivative material to obtain an oxidized graphene derivative material, and performing ultrasonic dispersion to obtain a dispersing solution b; and (3) mixing the dispersing solution a and the dispersing solution b, stirring uniformly, spray-drying, and calcining to obtain the graphene doped lithium iron phosphate positive electrode material. A lithium iron secondary battery prepared from the graphene doped lithium iron phosphate positive electrode material has the advantages of high capacity, good circulating performance, large tap density, small internal resistance and long service life.

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

Methods for synthesis of graphene derivatives and functional materials from asphaltenes

ActiveUS20160039678A1Low costFrom normal temperature solutionsOrganic chemistryElectrophilic aromatic substitutionGraphene derivatives

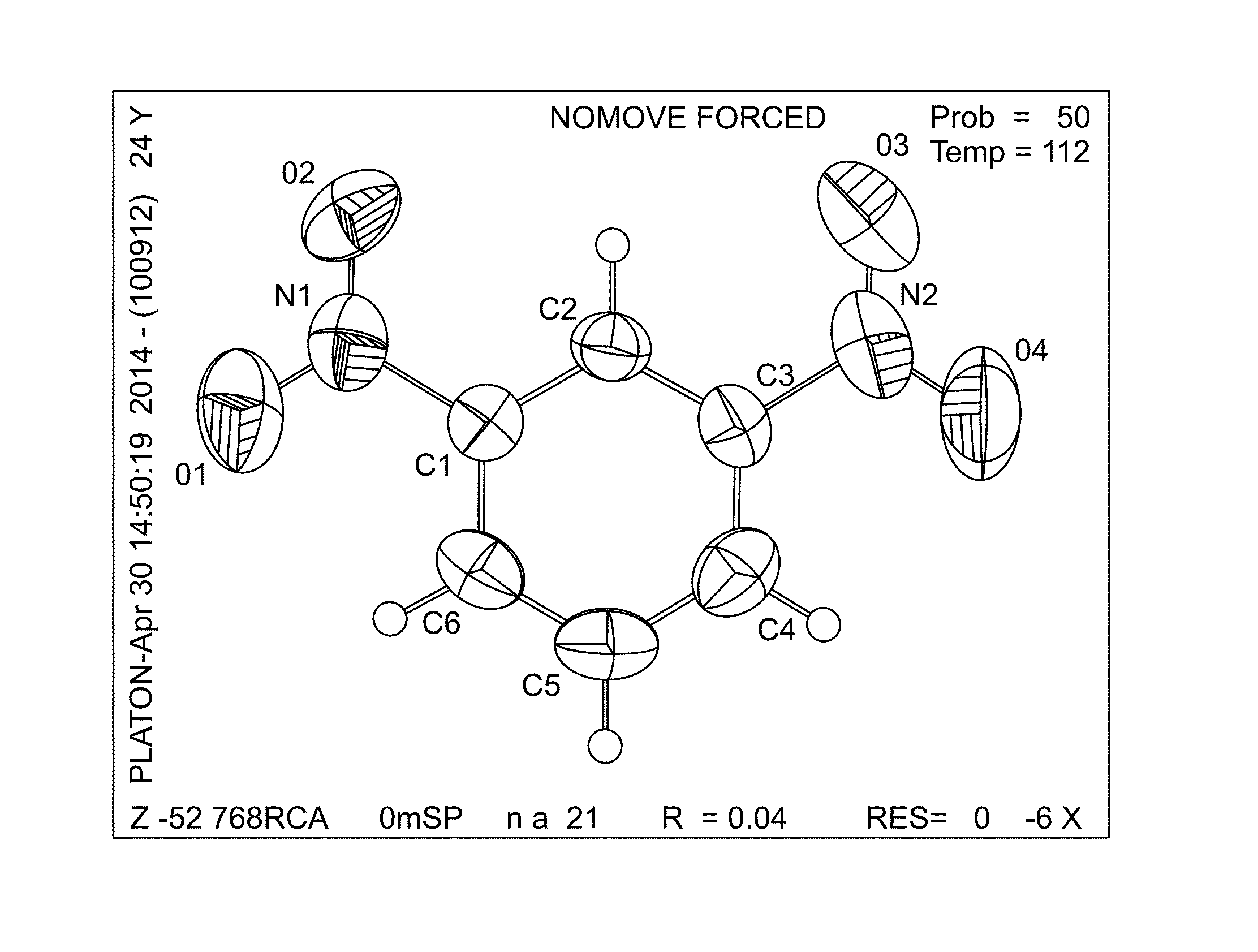

Embodiments described are directed to methods for the functionalization of asphaltene materials and to compositions made from functionalized asphaltenes. Disclosed is a method for synthesizing graphene derivatives, such as 2D single crystalline carbon allotropes of graphene and functional materials, such as sulfonic acid and its derivatives. Also disclosed is a method for the transformation of asphaltene into a source of graphene derivatives and functional materials, such as, 0D, 1D, 2D and combinations of 0D and 1D by utilizing chemical substitution reaction mechanism, such as, electrophilic aromatic substitution, nucleophilic aromatic substitution and Sandmeyer mechanism. Also disclosed are novel graphene materials comprising: acetylenic linkage and hydrogenated graphene. These novel materials, which may be produced by these methods, include, e.g.: 2D single crystalline carbon allotropes of graphene with asymmetric unit formulas C7H6N2O4, C6H4N2O4, C7H7O3S− H3O+, C7H7O3SH+, and a 2D single crystal with asymmetric unit formula (Na6O16S4)n.

Owner:TANIMOLA OLANREWAJU W

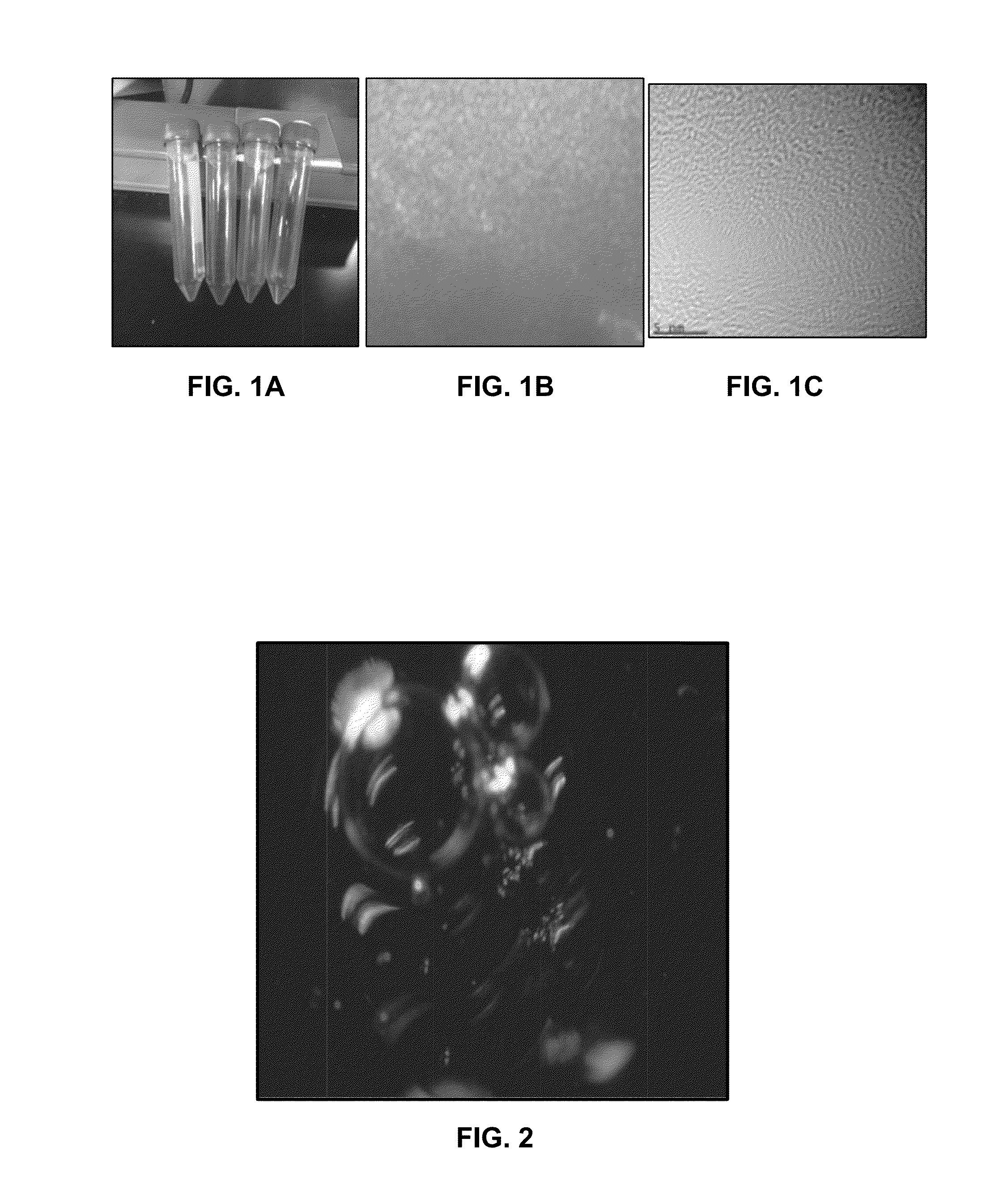

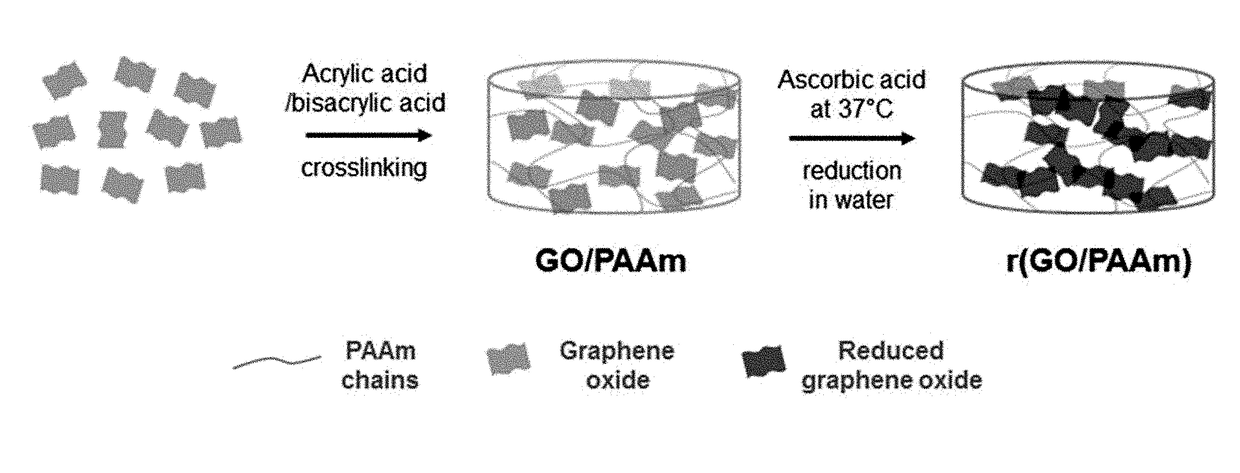

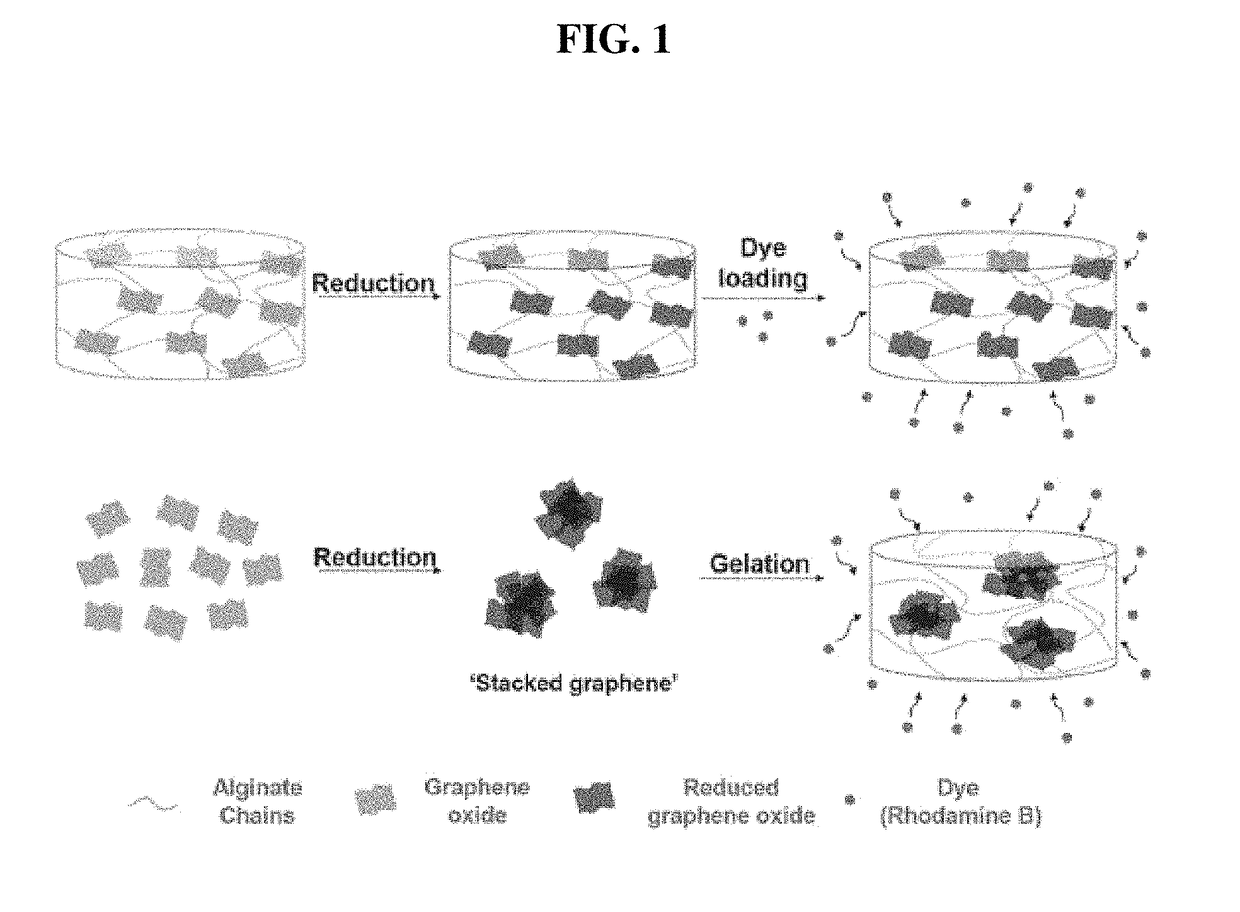

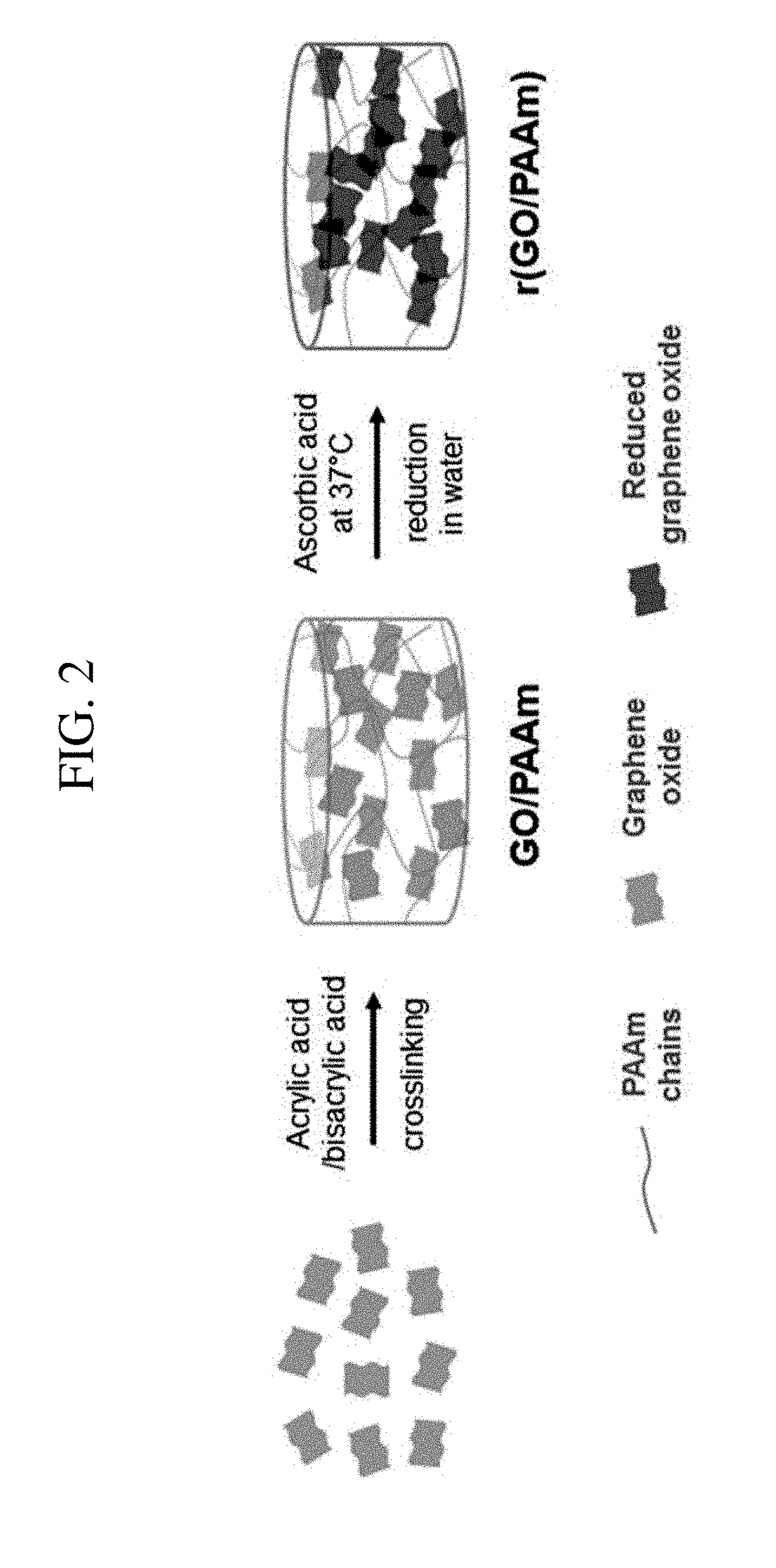

Method for preparing hydrogel containing reduced graphene oxide

InactiveUS20180193261A1Excellent dye adsorption capacityImprove adsorption capacityWater treatment compoundsAerosol deliveryGraphene derivativesPolyacrylamide Hydrogel

The present invention relates to a method for preparing a natural or synthetic polymer hydrogel loading graphene oxide or graphene, and to the selective and high-capacity adsorption and loading of the hydrogel with respect to a low-molecular weight material or a high-molecular weight material. More specifically, an alginate or polyacrylamide hydrogel loading graphene and a graphene derivative is prepared, wherein the hydrogel can be controlled to enable selective absorption according to the characteristics of an adsorbate by adjusting the reduction degree of graphene oxide, exhibits high adsorption capacity, and is easy to handle as a hydrate. These characteristics can significantly improve the adsorption efficiency with respect to a material in water or an organic phase material, compared with existing hydrogels.

Owner:AKROCELL BIOSCIENCES INC

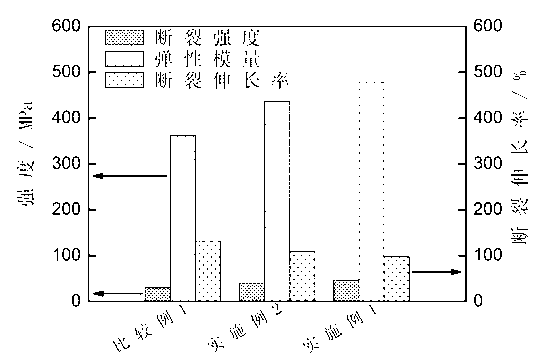

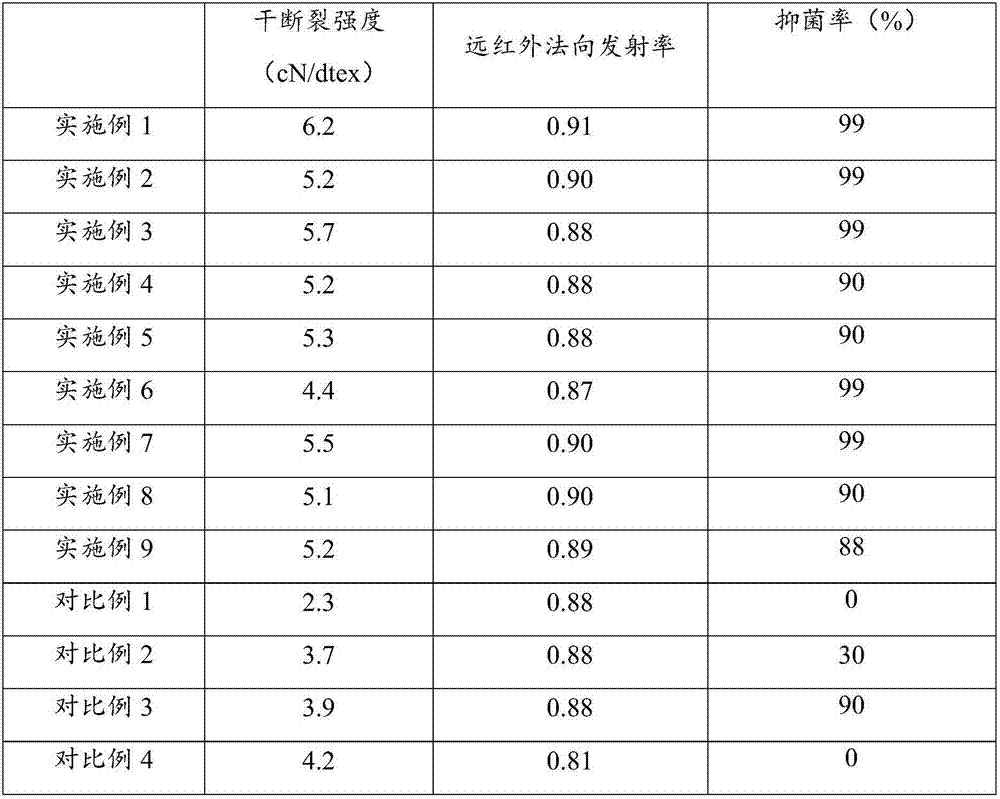

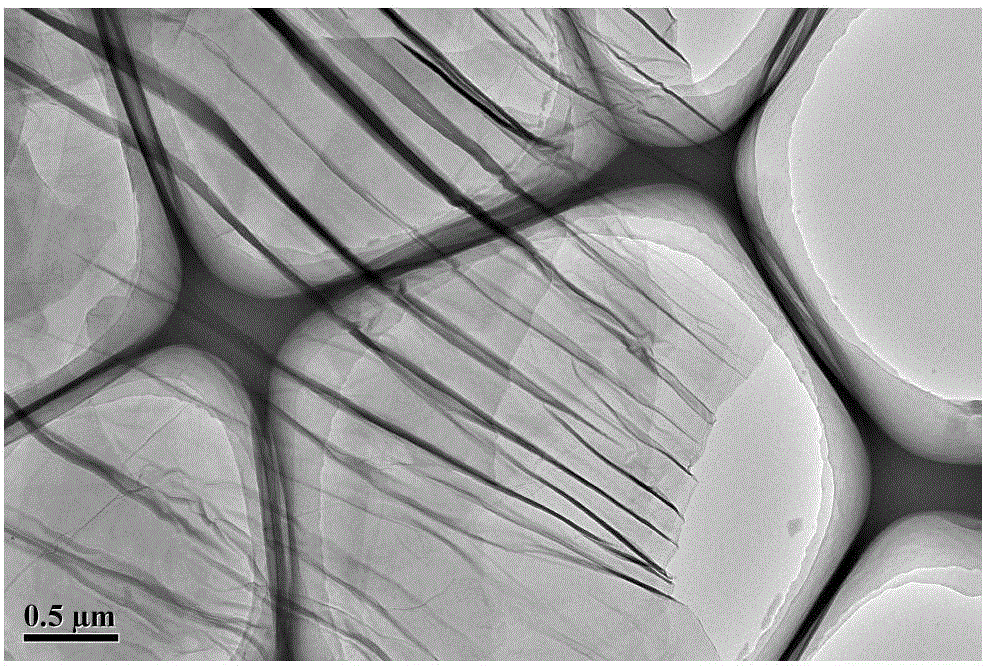

Stone needle complex fiber containing graphene as well as preparation method and application of stone needle complex fiber

ActiveCN107287682AHigh breaking strengthOutstanding far infrared functionMonocomponent polyesters artificial filamentArtifical filament manufactureFiberGraphene derivatives

The invention provides a stone needle complex fiber containing graphene as well as a preparation method and an application of the stone needle complex fiber. The stone needle complex fiber containing graphene is mainly prepared from components as follows: fiber carrier sections, stone needles and a graphene material, wherein the graphene material is of a graphene lamellar structure and comprises one or combination of at least two of graphene, graphene oxide and graphene derivatives. The graphene material is introduced into the complex fiber prepared from the stone needles and the fiber sections, so that dispersibility of the stone needles and the fiber is improved, and meanwhile, by means of multiple excellent characteristics of the graphene material, strength, far-infrared function, thermoelectric performance and stability of the fiber are improved.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Nano composite material as well as preparation method and application thereof to water treatment

ActiveCN106512943ASimple manufacturing methodEasy to operateOther chemical processesWater contaminantsNano compositesGraphene derivatives

The invention provides a nano composite material as well as a preparation method and application thereof to water treatment. The nano composite material provided by the invention comprises a matrix and nanoparticles loaded on the surface of the matrix, wherein the matrix comprises one or more of graphene and graphene derivatives; and the nanoparticles comprise Fe3O4 and Mg(OH)2. According to the nano composite material provided by the invention, a matrix material is used as the matrix, and the nanoparticle composite material has magnetism through loaded Fe3O4 magnetic nanoparticles and is easy to separate; and meanwhile, the saturation adsorbing capacity of the nano composite material is enlarged, and heavy metal ions are efficiently adsorbed through loaded Mg(OH)2 nanoparticles. According to the nano composite material provided by the invention, the removal rates of Pb<2+>, Cu<2+>, Ag<+> and Zn<2+> with the initial concentration of 50ppm within 90min can reach 99.9%, 99.9%, 88% and 85% respectively.

Owner:秦皇岛中科瀚祺科技有限公司

Preparation method of water-soluble magnetic targeting graphene oxide derivative and application thereof

The invention relates to a preparation method of a water-soluble magnetic targeting graphene oxide derivative and an application thereof. The problems of low curative effect and large side effects in the prior art can be effectively solved. The technical scheme for solving the problems is as follows: loading magnetic ferroferric oxide on graphene oxide through a chemical precipitation method, and then connecting with a hydrophilic group to get the water-soluble magnetic targeting graphene oxide derivative. In the graphene oxide derivative, the weight ratio of the ferroferric oxide to the graphene oxide is 1-11:1; and the graphene oxide is nano-scale graphene oxide. The water-soluble magnetic targeting graphene oxide derivative disclosed by the invention has the advantages of good physical and chemical stability, rich sources of raw materials, low cost, good biocompatibility, slow release and targeting property, and is of an innovation in anti-tumor medicaments.

Owner:ZHENGZHOU UNIV

Preparation method of graphene and macromolecule composite materials

The invention discloses a preparation method of a graphene and macromolecule composite material. The preparation method comprises the following steps: firstly dispersing a graphene derivative in a solvent, mixing a solid particulate matter to form a mixture, drying the mixture, performing heating treatment on the mixture through a microwave heating zone at a set speed in a set atmosphere to convert the graphene derivative in the mixture into grapheme, subsequently cooling to obtain a mixture of the grapheme and the solid particulate matter, and then compounding the mixture and macromolecules through methods of melting, bonding, forming and the like to obtain a grapheme-macromolecule compound. The preparation method disclosed by the invention solves the problems of difficult graphene dispersion and poor graphene derivative performance, can be used for conveniently and quickly producing the graphene and macromolecule composite material in batch and is expected to make a contribution to further development and application of the graphene and macromolecule material.

Owner:SOUTHEAST UNIV

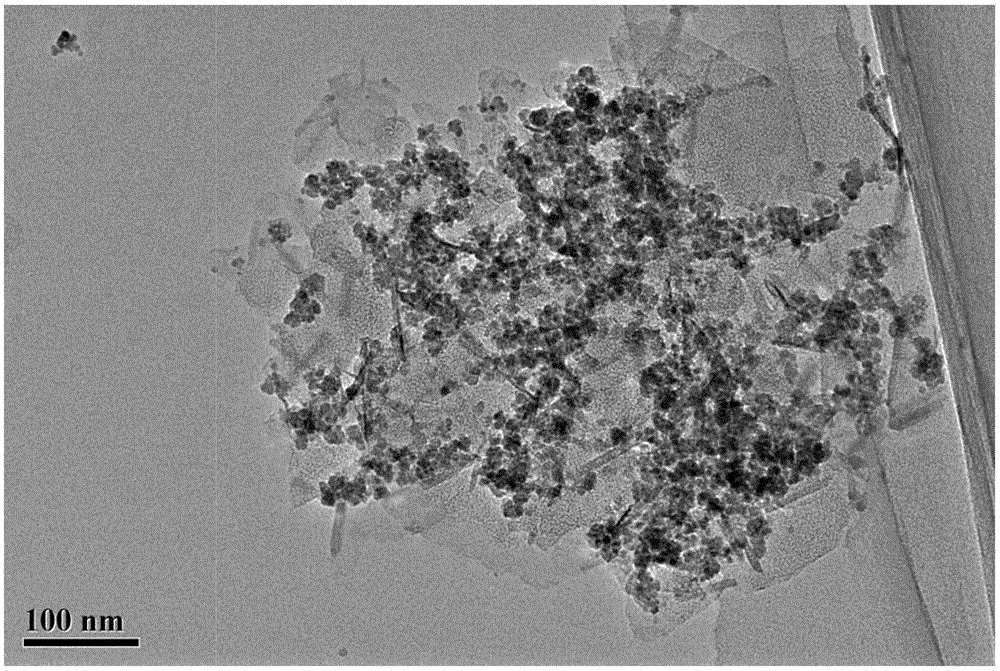

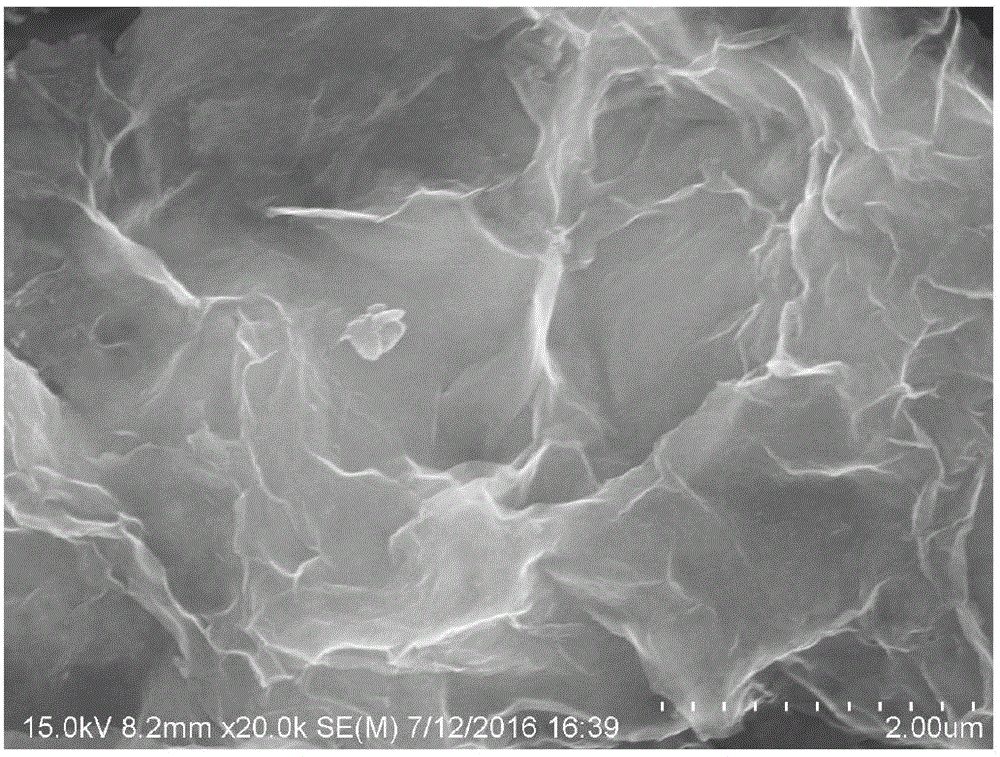

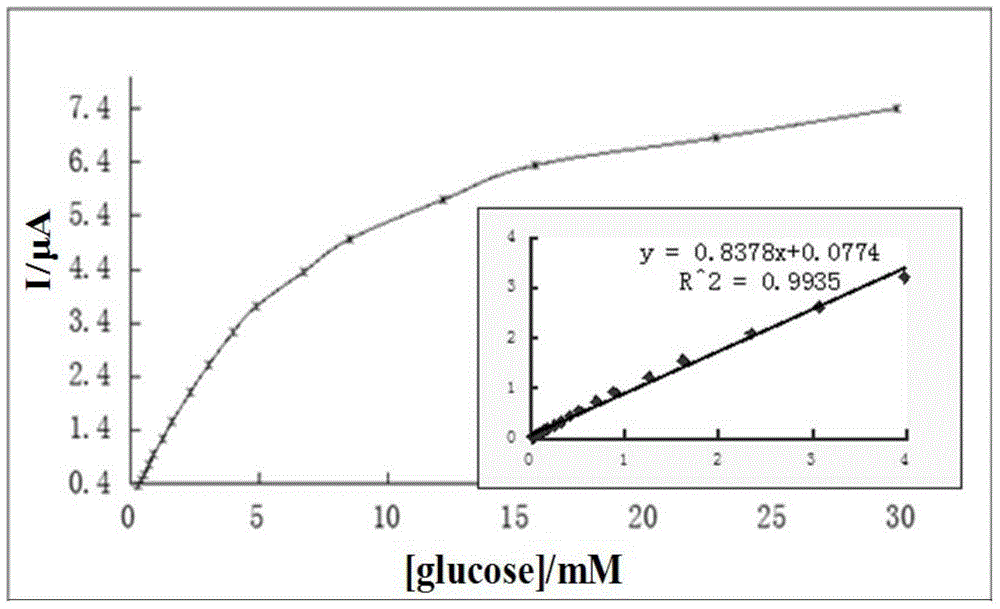

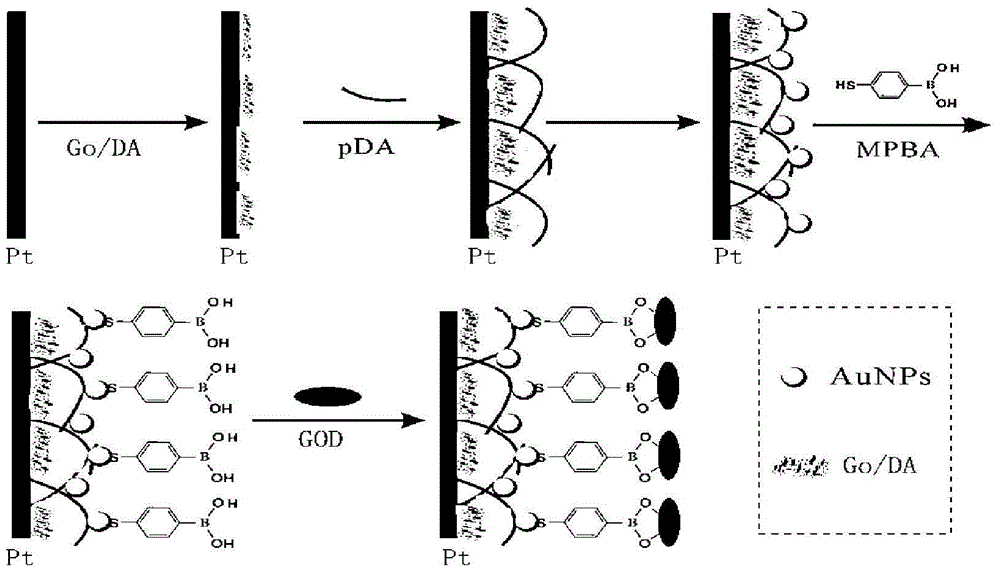

Graphene derivative based glucose oxidase electrode and preparation method thereof

InactiveCN105136888AImprove conductivityLow detection limitMaterial analysis by electric/magnetic meansGraphene derivativesBond strength

The invention discloses a graphene derivative based glucose oxidase electrode and a preparation method thereof. The electrode is sequentially composed of a conductive electrode substrate, a graphene derivative / dopamine composite layer, a polydopamine layer, a nanogold array, a 4-mercaptophenylboronic acid layer, and a glucose oxidase layer. According to the invention, dopamine is employed to reduce graphene oxide partially into reduced graphene oxide to form a graphene derivative / dopamine composite layer gathering on the surface of the conductive electrode substrate, also electropolymerization of a layer of polydopamine is carried out on the surface of the graphene derivative / dopamine composite layer, self-assembly of nanogold particles is performed on the platform, and then 4-mercaptophenylboronic acid is loaded to the nanogold array so as to fix glucose oxidase. The glucose oxidase electrode has the advantages of simple preparation method, low detection limit, high sensitivity and high enzyme bonding strength, and can realize sensitive detection of glucose.

Owner:NANJING UNIV OF SCI & TECH

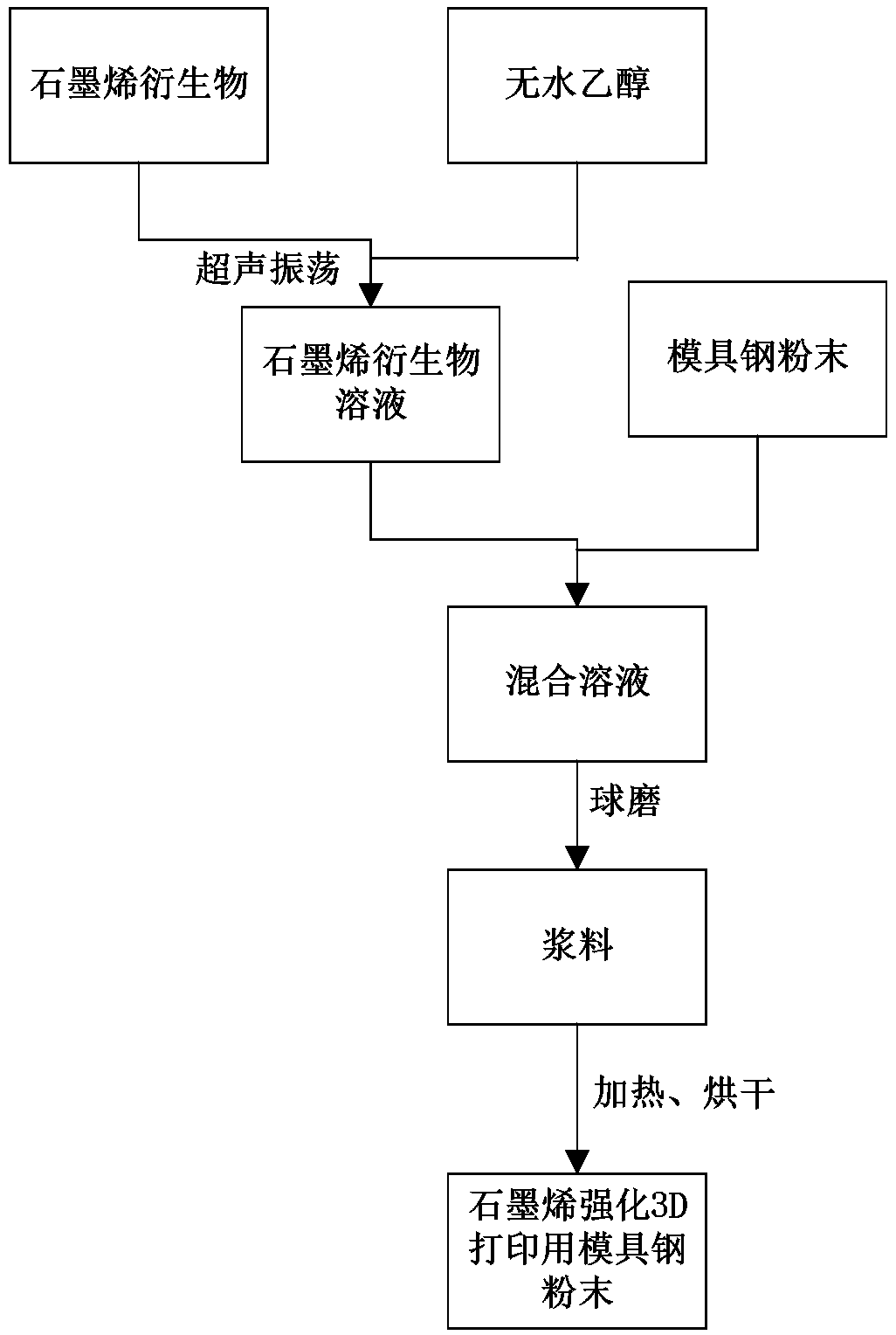

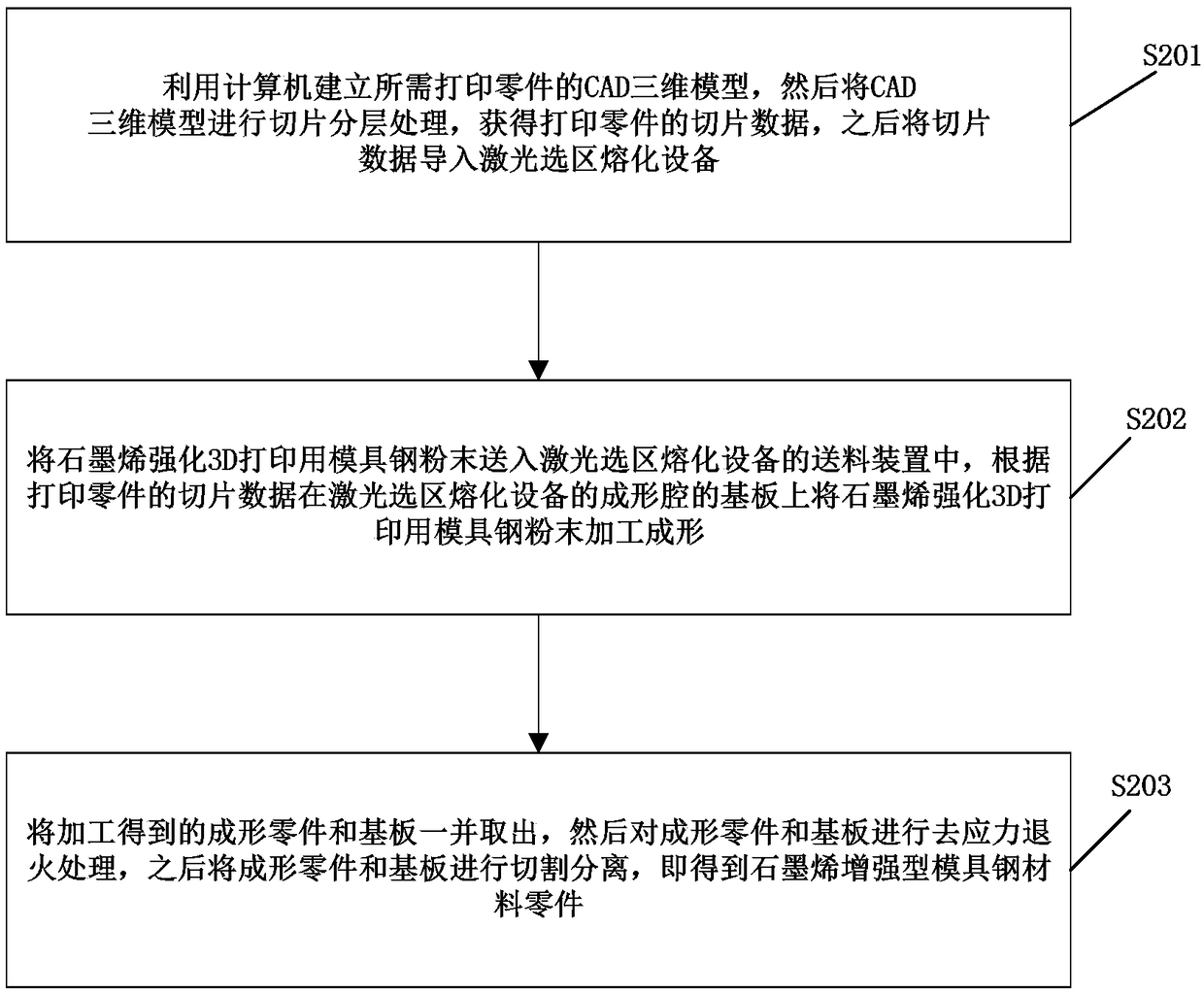

Graphene reinforced 3D printing mold steel powder and preparation method and application thereof

InactiveCN108941534AHigh hardnessExcellent thermal conductivityAdditive manufacturing apparatusIncreasing energy efficiencyAlcoholGraphene derivatives

The invention provides graphene reinforced 3D printing mold steel powder. The graphene reinforced 3D printing mold steel powder is prepared from raw materials which comprise 0.5%-2% of a graphene derivative and 98%-99.5% of mold steel powder according to the volume ratio. The invention further provides a preparation method of the graphene reinforced 3D printing mold steel powder. The preparation method comprises the following steps that the graphene derivative is dispersed into absolute ethyl alcohol, sonic oscillation is carried out, and a graphene derivative solution is obtained; the mold steel powder is added into the graphene derivative solution to obtain a mixed solution, and then the mixed solution is subjected to ball grinding to obtain slurry; the slurry is heated, and heating andstirring are carried out at the same time till the slurry is in a semi-dried state; and the semi-dried slurry is dried thoroughly, and the graphene reinforced 3D printing mold steel powder can be obtained. The two-step method of ethanol solution dispersing and ball grinding is adopted, the Van der Waals' force between agglomerated graphene can be effectively destroyed, an iron matrix of mold steelcannot be destroyed, and finally the graphene reinforced 3D printing mold steel powder which is uniform in mixing and forms a good bonding interface is obtained.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

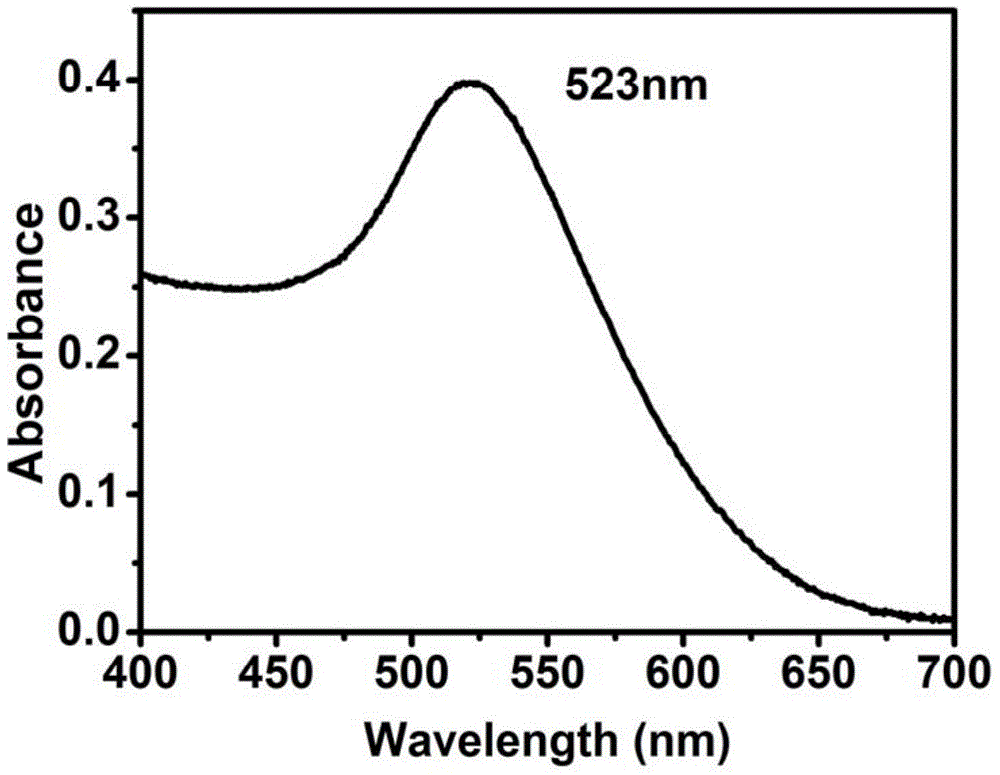

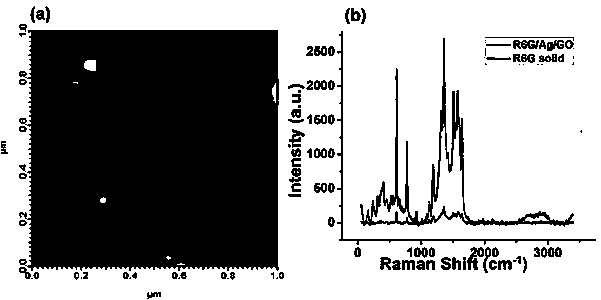

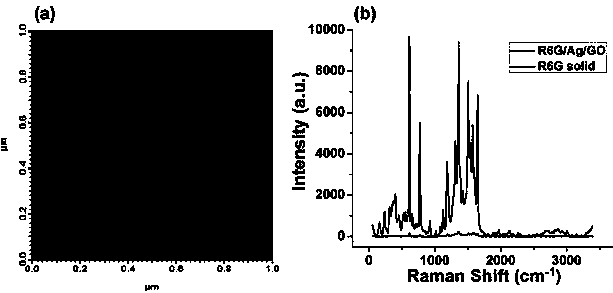

Preparation method of nano-silver/graphene derivative surface enhanced Raman substrate

ActiveCN104259475AControl thicknessExcellent fluorescence quenchingRaman scatteringNanotechnologyComposite filmGraphene derivatives

The invention discloses a preparation method of a nano-silver / graphene derivative surface enhanced Raman substrate. The preparation method is characterized by uniformly adsorbing a reducing agent such as glucose on the surface of a graphene derivative ultrathin film through the adsorption of the graphene derivative ultrathin film, and growing a nano-silver thin film on the surface of the graphene derivative ultrathin film through the silver mirror reaction. The growth of the nano-silver thin film and the particle size and distribution of nano-silver are regulated and controlled by controlling the number of layers of the graphene derivative thin film and the concentration of a silver ammonia solution. The surface Raman enhanced performance of a composite film is regulated and controlled through the number of layers of the graphene derivative thin film and the morphology of the nano-silver thin film. Finally, a technological parameter of the optimal Raman enhanced performance is obtained.

Owner:JIANGSU UNIV

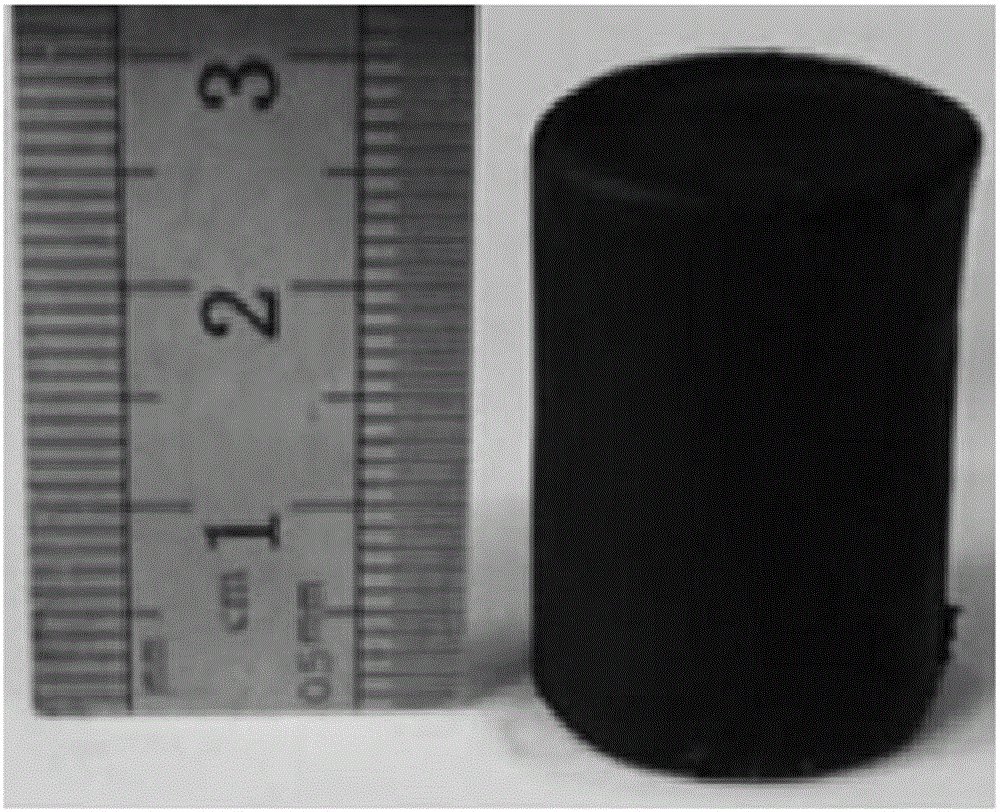

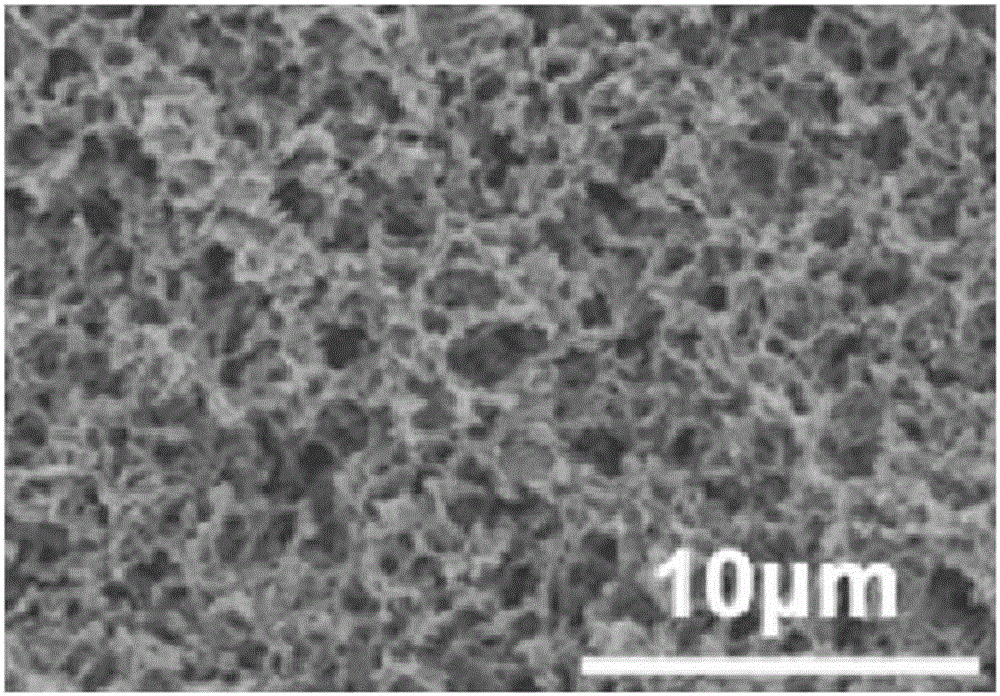

Graphene-based composite electrode material and preparation method thereof

InactiveCN105161310ACompact assemblyIncreasing the thicknessHybrid capacitor electrodesHybrid/EDL manufacturePorosityComposite electrode

The invention provides a graphene-based composite electrode material. The composite electrode material comprises a graphene base body and a polymer component. The graphene base body has a three-dimensional porous structure formed by self assembling of a laminated structure of a graphene derivative in an overlap joint, wherein the porosity is 10% to 95%. The porous structure of the graphene base body is filled with the polymer component and in-situ polymerization of the polymer component and the graphene base body is realized. In addition, the invention also provides a manufacturing method of the graphene-based composite electrode material.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Preparation method and application of sulfur-doped graphene and derivatives thereof

The invention relates to a preparation method of sulfur-doped graphene and derivatives thereof. The method includes the following steps: 1) uniformly mixing a solution of the graphene and the derivatives thereof with an sulfur-containing ionic group solution to prepare a suspension liquid; 2) freeze-drying the suspension liquid to obtain a solid mixture of the graphene and the derivatives thereof with the sulfur-containing ionic salt; 3) under protective atmosphere, calcining the solid mixture of the graphene and the derivatives thereof with the sulfur-containing ionic salt to obtain an intermediate of the sulfur-doped graphene and derivatives thereof; and 4) cooling, washing and drying the intermediate to obtain a finish product of the sulfur-doped graphene and derivatives thereof. The preparation method is simple in operation, employs common devices, is low in cost and achieves industrial production. The sulfur-doped graphene and derivatives thereof has very high specific surface area, has penetrated porous structure and has high pore capacity and high electric conductivity.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

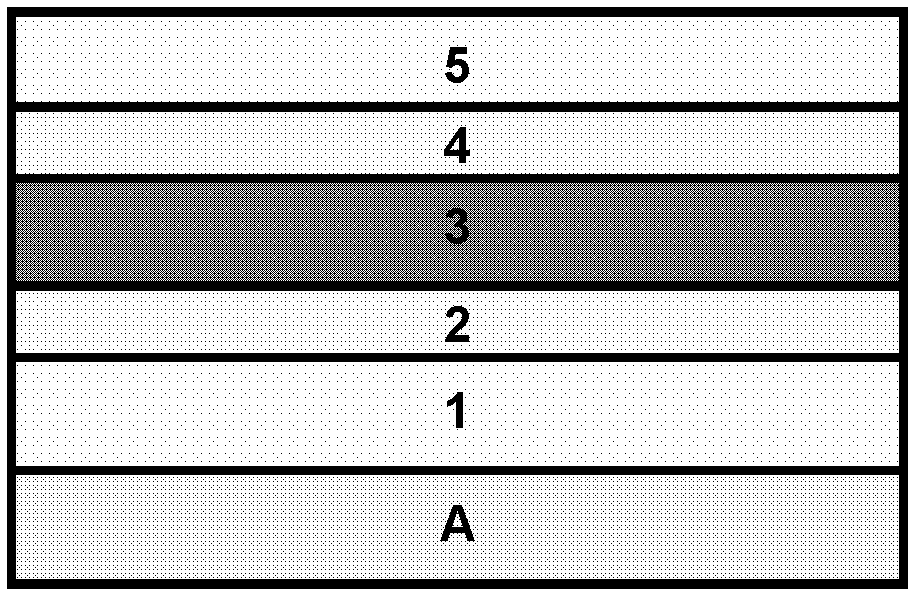

Organic solar cell with high work function graphene derivative as intermediate layer and preparation

InactiveCN103367641AImprove photoelectric conversion efficiencyThe modification method is simple and convenientSolid-state devicesSemiconductor/solid-state device manufacturingOrganic solar cellGraphene derivatives

The invention relates to an organic solar cell which is provided with a light-sensitive layer composed of two molecule compositions, i.e. an electron donor and an electron acceptor, and electrodes arranged on the two sides of the light-sensitive layer, i.e. an anode and a cathode. The organic solar cell is characterized in that a high work function graphene derivative is arranged between the anode and the light-sensitive layer so that the efficiency of the organic solar cell can be significantly enhanced.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Chemically modified graphene

ActiveCN103732533AIncrease load capacityEfficient separationMaterial nanotechnologyChromatographic cation exchangersGraphene derivativesMaterials science

Owner:RES FOUND THE CITY UNIV OF NEW YORK +1

Graphene modified waterborne epoxy resin coating material as well as preparation method and application thereof

InactiveCN108531045AImprove corrosion resistanceAct as a physical barrierFireproof paintsAntifouling/underwater paintsEpoxyOrganic solvent

The invention discloses a graphene modified waterborne epoxy resin coating material as well as a preparation method and application thereof. The graphene modified waterborne epoxy resin coating material is prepared from a component A' of which the solid content is 53 percent and a component B of which the solid content is 40 percent. The graphene modified waterborne epoxy resin coating material ofwhich the solid content is 33 percent is obtained by mixing the component A' with the component B according to a mass ratio of (1.5 to 4):1, adding deionized water, and uniformly mixing, wherein thecomponent A' is graphene modified waterborne epoxy resin emulsion and is obtained by adding 0.1 to 1 mass percent of graphene derivative in waterborne epoxy resin emulsion. The component A' is stablystored for a long term and has no precipitate after one-year storage. The obtained graphene modified waterborne epoxy resin coating material after the component A is applied is higher in corrosion resistance, conductivity and thermal stability, and the preparation method is safe and environmentally friendly, does not use heavy metal ions and volatile organic solvents and accords with the idea of environment-friendly protection.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +1

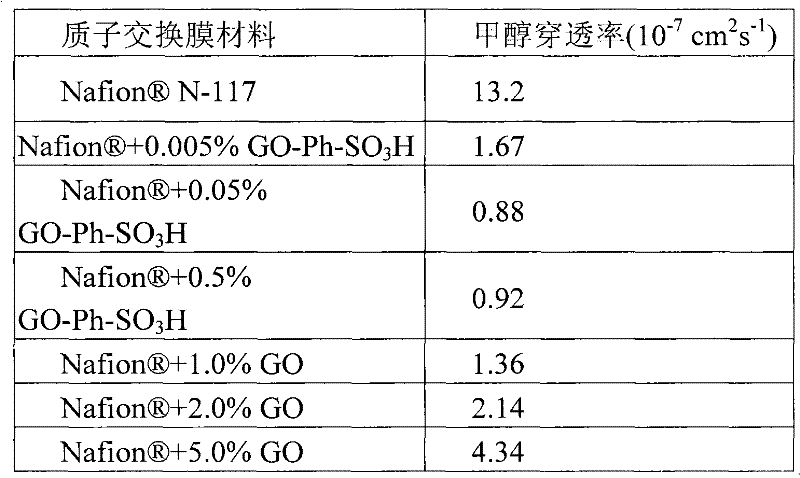

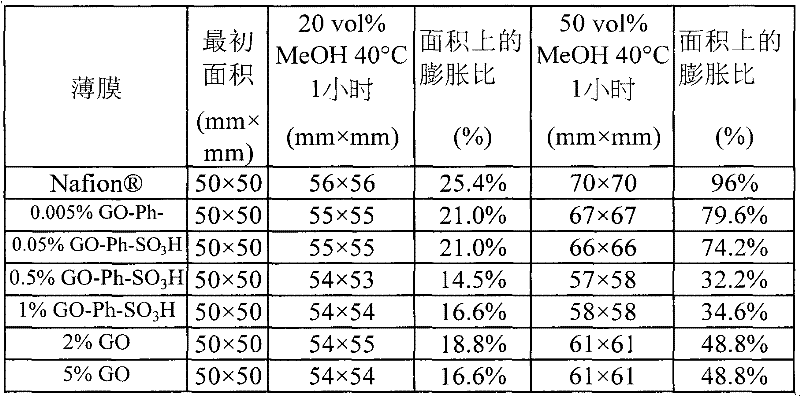

Low permeability composite proton exchange membrane including organic-inorganic hybrid

ActiveCN102544542AThe problem of blocking penetrationCell seperators/membranes/diaphragms/spacersFuel cell detailsGraphene derivativesProton

A composite proton exchange membrane is made up of dispersed organized graphene in ion conducting polymer as a fuel barrier material. The composite proton exchange membrane includes an inorganic material of 0.001-10 wt % and an organic material of 99.999-90 wt %. The inorganic material is a graphene derivative with two-dimensional structure. The organic material includes a polymer material with sulfonic acid group.

Owner:IND TECH RES INST

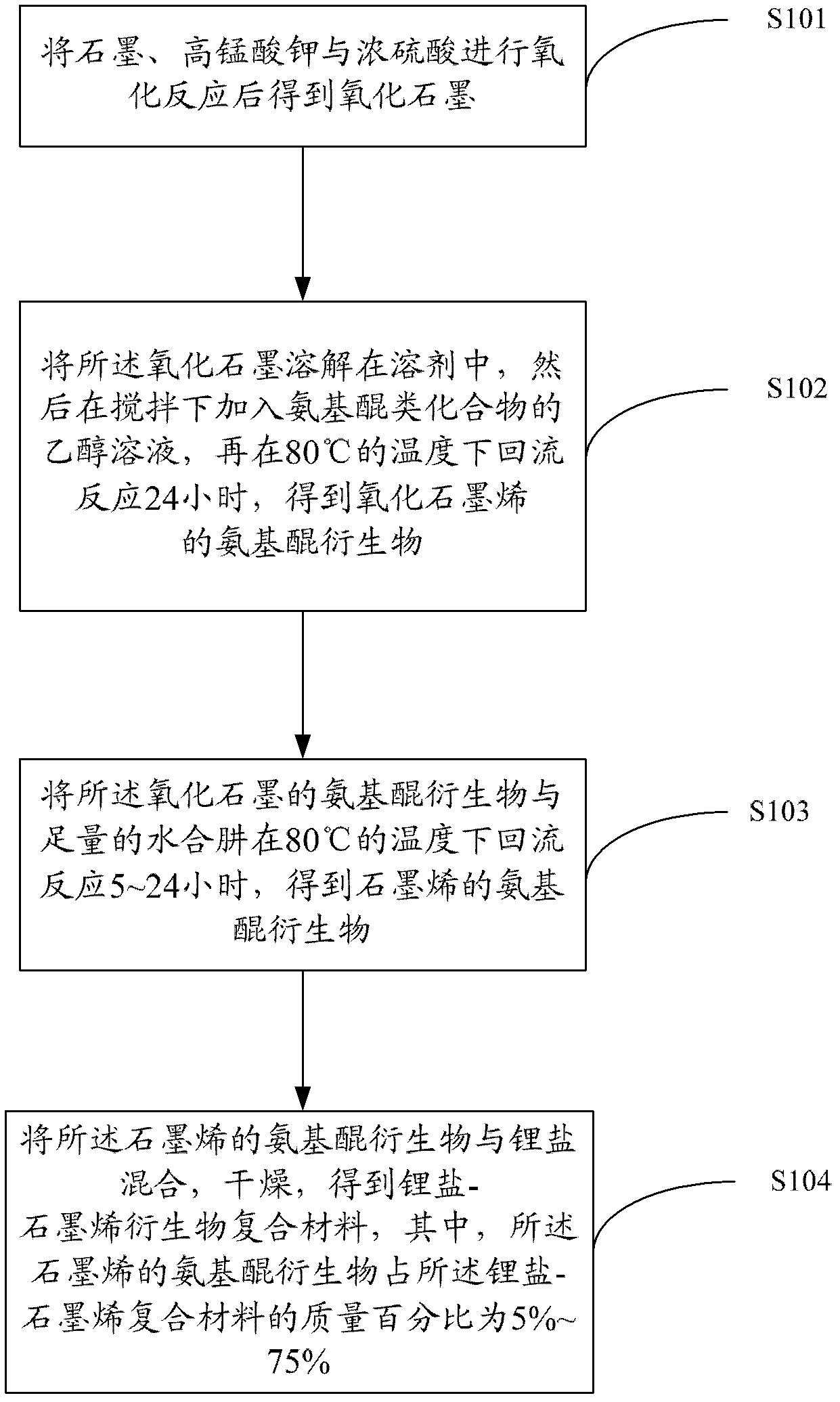

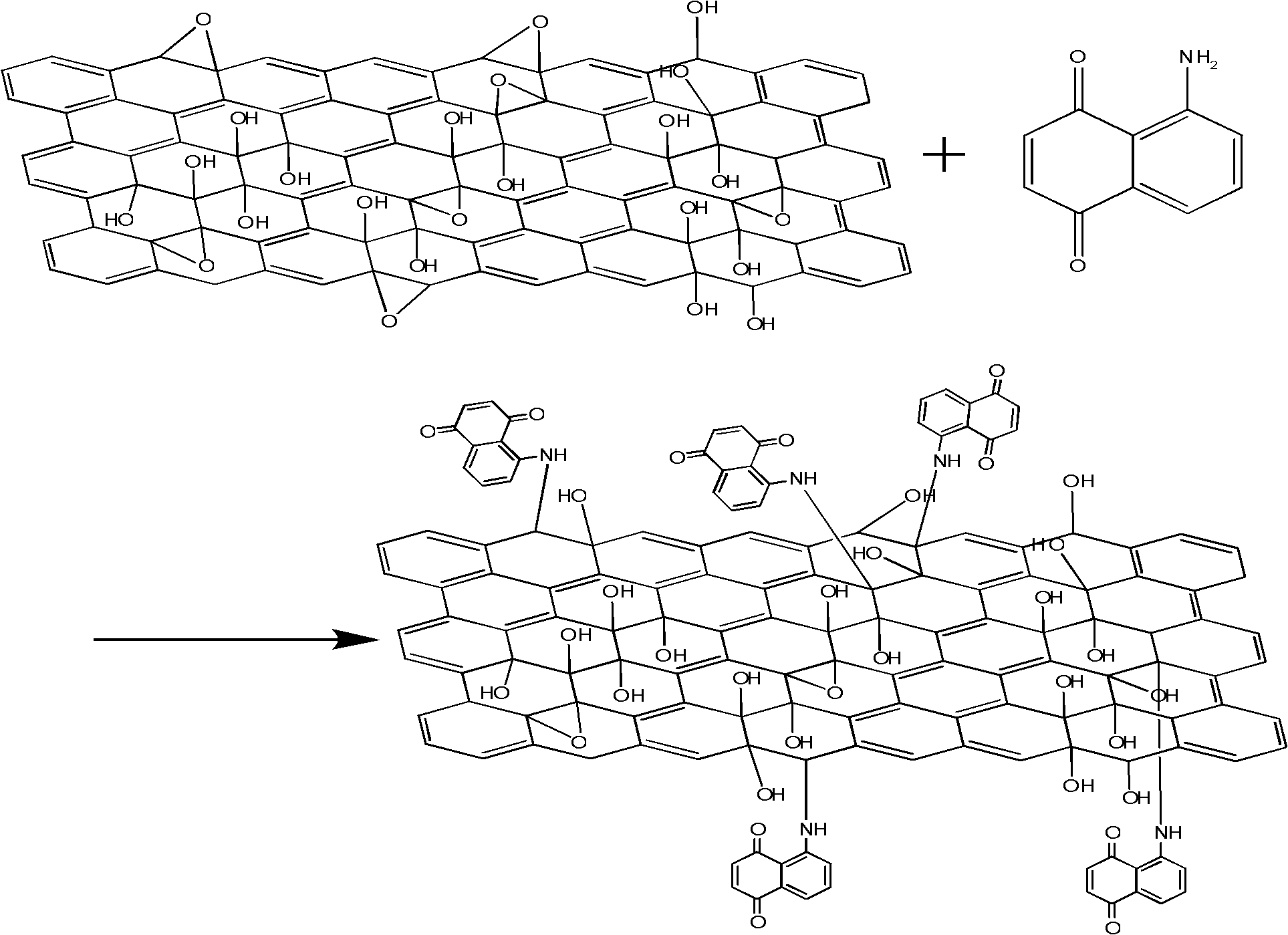

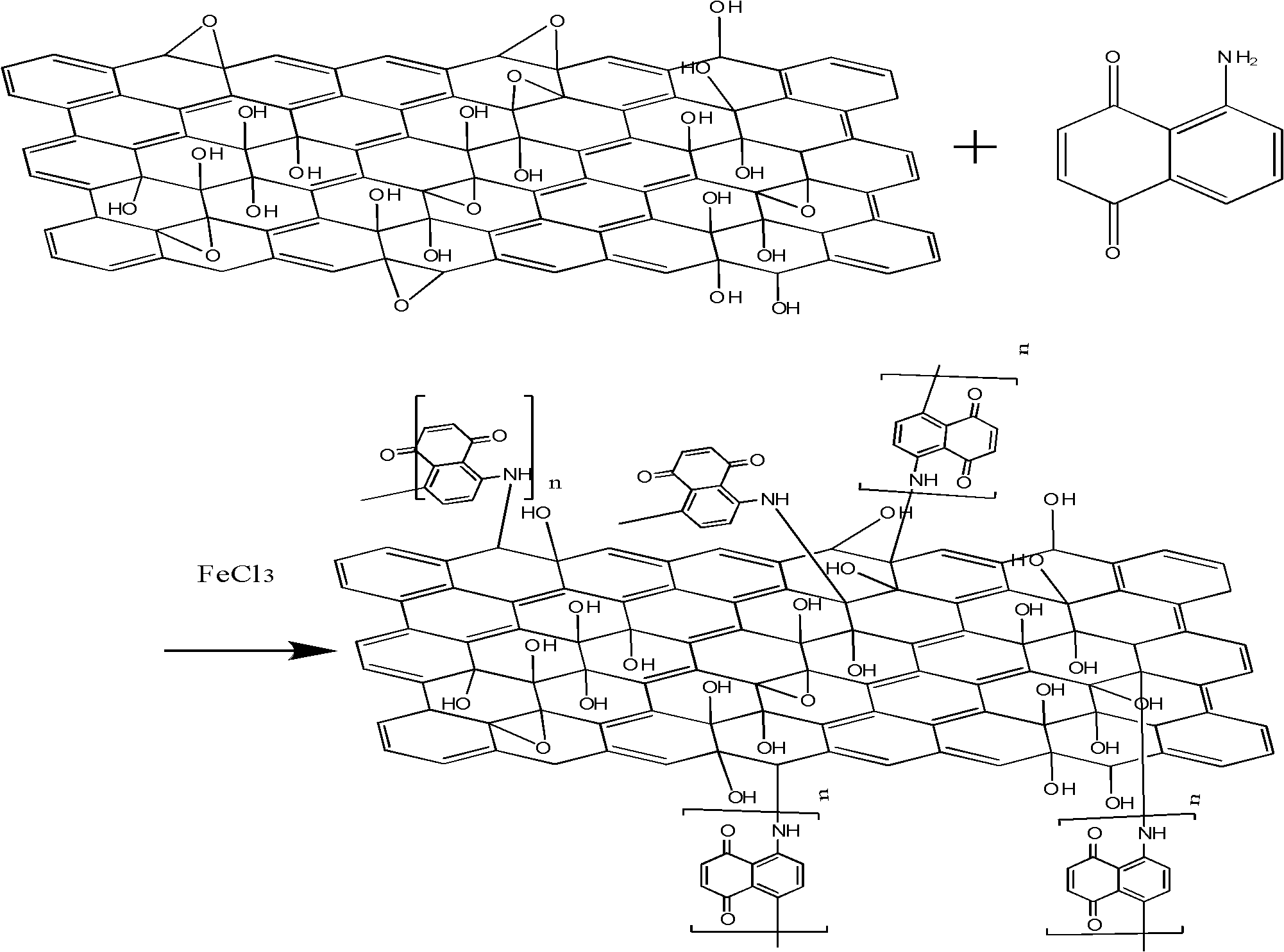

Lithium salt-graphene derivative composite material and preparation method and application thereof

The invention relates to a lithium salt-graphene derivative composite material, and a preparation method and the application of the lithium salt-graphene derivative composite material. The lithium salt-graphene derivative composite material is composed of lithium salt and amino quinone derivatives of graphene, wherein the mass percent of the amino quinone derivatives of the graphene in the lithium salt-graphene derivative composite material is 5-75%. According to the lithium salt-graphene derivative composite material, the amino quinone derivatives of the graphene and the lithium salt are crystallized in a composite mode, the lithium salt-graphene derivative composite material is enabled to be rich in hydroxyl lithium, and when the lithium salt-graphene derivative composite material is used as an electrode material, the maximum capacity can be up to 250mAh / g. Compared with traditional electrode materials, the lithium salt-graphene derivative composite material has the advantage of being high in specific capacity.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Preparation method of multi-element cathode material coated by graphene

InactiveCN104393282AImprove stabilityIncrease capacityPositive electrodesGraphene derivativesGraphite

The invention relates to a preparation method of multi-element cathode material coated by graphene. The active material of the multi-element cathode material comprises an inner layer and an outer layer, wherein the active material has the following chemical formula (1-a) LiNi1-xCoxO2.aLiMn0.3Al0.7O2, wherein a is equal to 0.3-0.35, and the x is equal to 0.25-0.45. The method comprises the following steps: (1) preparing the active material; (2) preparing graphene derivate materials; (3) coating the active material by the graphene derivate materials. The multi-element cathode material prepared by the method disclosed by the invention adopts a two-layer structures with various component matching ratios, the proportion of the nickel in the inner layer is the highest, so that the high capacity of the material is ensured; the outer layer has higher cobalt content, so that the cycling stability of the material is ensured; finally, another layer of graphene derivate material is adopted for coating the active material, so that the activity and the capacity of the material are further improved. Therefore, when the cathode materials are applied to lithium batteries, the specific capacity is higher, and the stability is good.

Owner:夏林美

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com