Organic solar cell with high work function graphene derivative as intermediate layer and preparation

A solar cell and graphene technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of high preparation cost and low work function, and achieve the effects of low cost, simple and convenient method, and improved photoelectric conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Graphene oxide is configured into a 2 mg / ml aqueous solution by means of ultrasound and centrifugation, and it is spin-coated on the surface of ITO glass to form a uniform graphene oxide film with a thickness of 2-3 nanometers on the surface of ITO glass. Using the plasma treatment process, the ITO glass spin-coated with graphene oxide was placed in a vacuum chamber, the flow rate of 30sccm oxygen was introduced, the power of the power supply was set at 30W, and the post-glow treatment was 10s. XPS analysis was done with the graphene oxide films before and after treatment. It was found by XPS analysis that the amount of C=O of the graphene oxide film after oxygen plasma treatment increased by 7%, and the amount of C-C bonds decreased by 5%. It shows that oxygen atoms with higher electronegativity and carbon atoms form more C=O after oxygen plasma treatment. The work function of graphene oxide film before and after oxygen plasma treatment was tested by Kelvin probe atom...

Embodiment 2

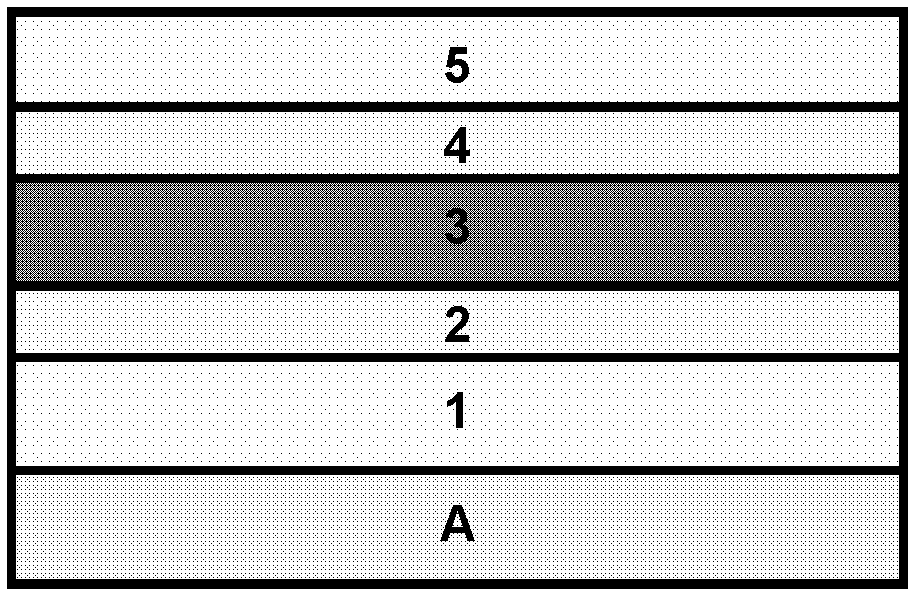

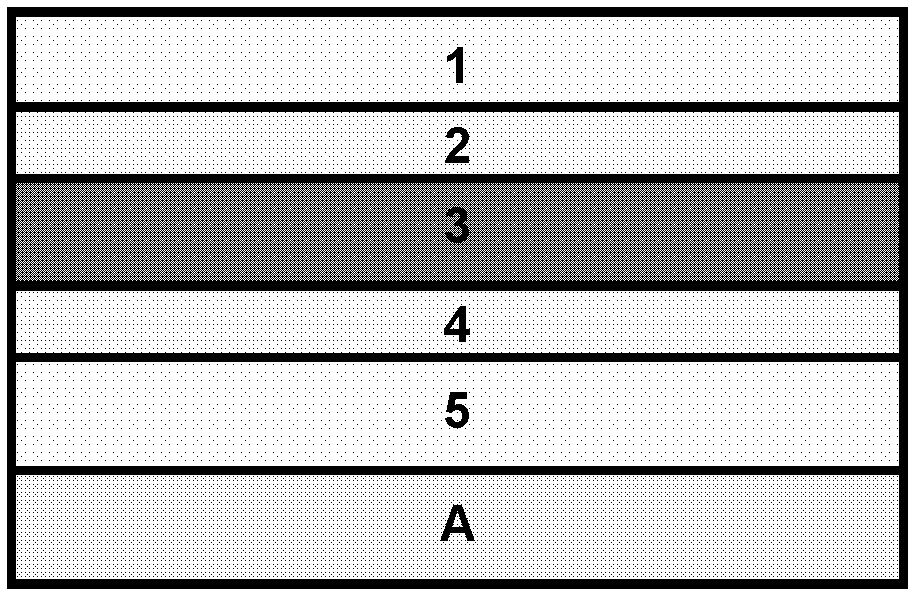

[0028] Prepare the thin film of 2-3 nanometer graphene oxide on ITO conductive glass, on the graphene oxide thin film before and after oxygen plasma treatment, the P3HT of PCBM thin film that spin-coats 140nm thick composition ratio is 1: 1, then at 160 ℃ for 30 minutes, transferred to the thermal evaporation system to evaporate the metal electrode preparation as figure 1 The organic solar cell structure shown.

[0029] Prepare an anode on the upper surface of the substrate, spin-coat the solution prepared by graphene or graphene oxide on the surface of the anode to form a uniform film with a thickness ranging from 0.1 nm to 100 nm; then chemically treat the graphene or graphene oxide, Then prepare a photosensitive layer on the modified graphene or graphene oxide film with high work function, and then prepare a cathode intermediate layer 4 and a cathode 5 on the other side of the photosensitive layer away from the anode to prepare an organic solar cell;

[0030] Or, prepare a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Short circuit current | aaaaa | aaaaa |

| Short circuit current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com