Patents

Literature

5096 results about "Energy conversion efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Energy conversion efficiency (η) is the ratio between the useful output of an energy conversion machine and the input, in energy terms. The input, as well as the useful output may be chemical, electric power, mechanical work, light (radiation), or heat.

Organic photovoltaic devices

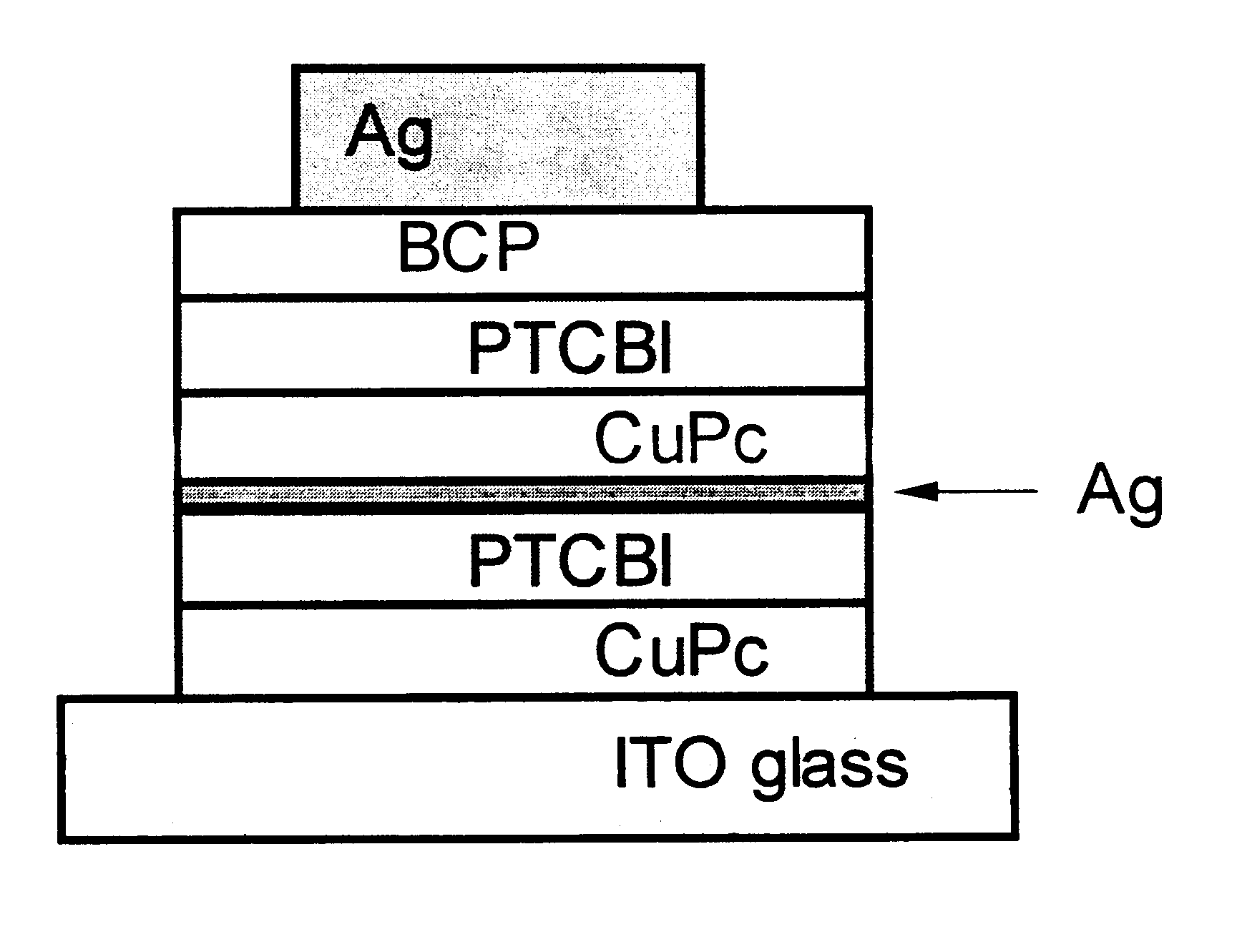

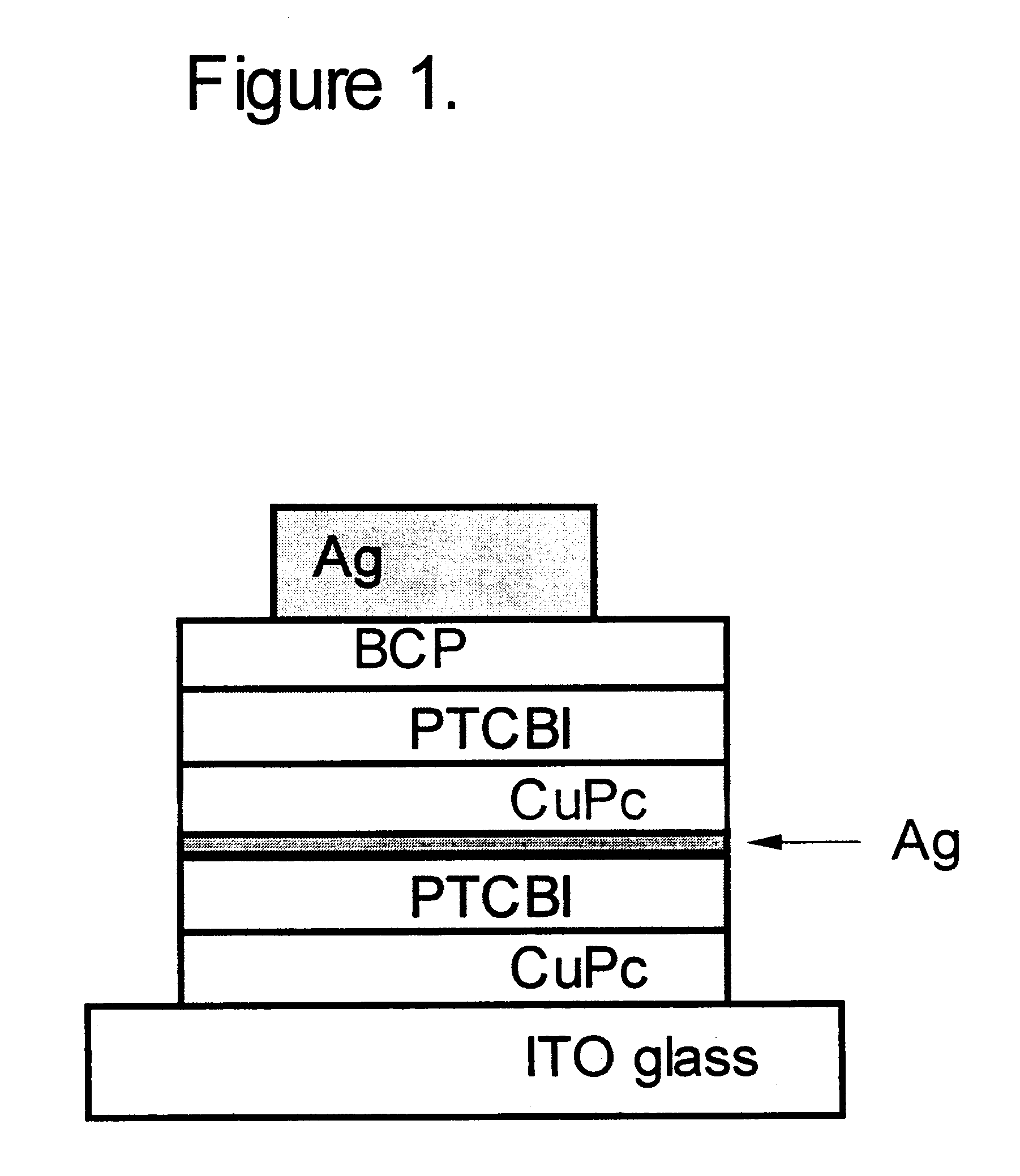

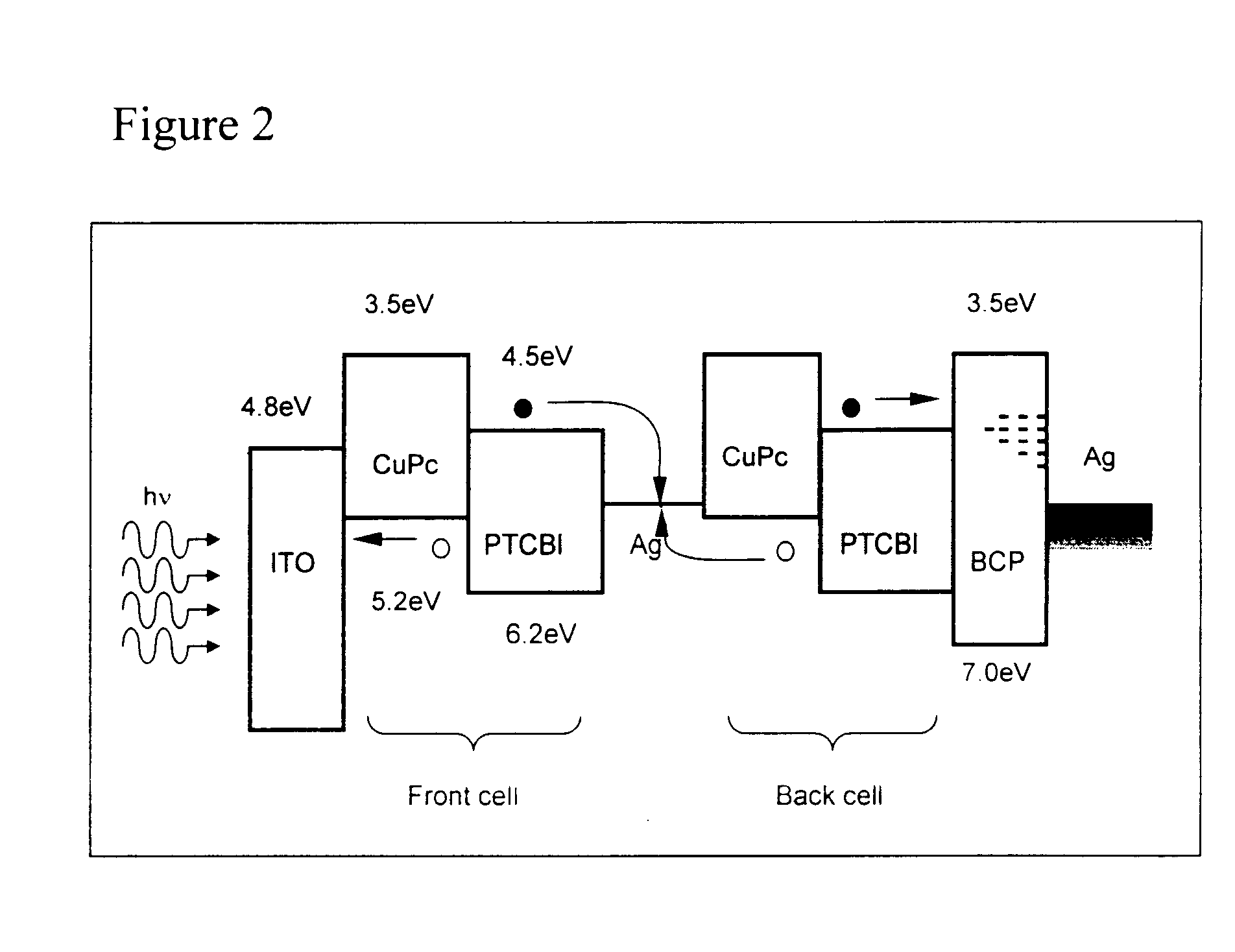

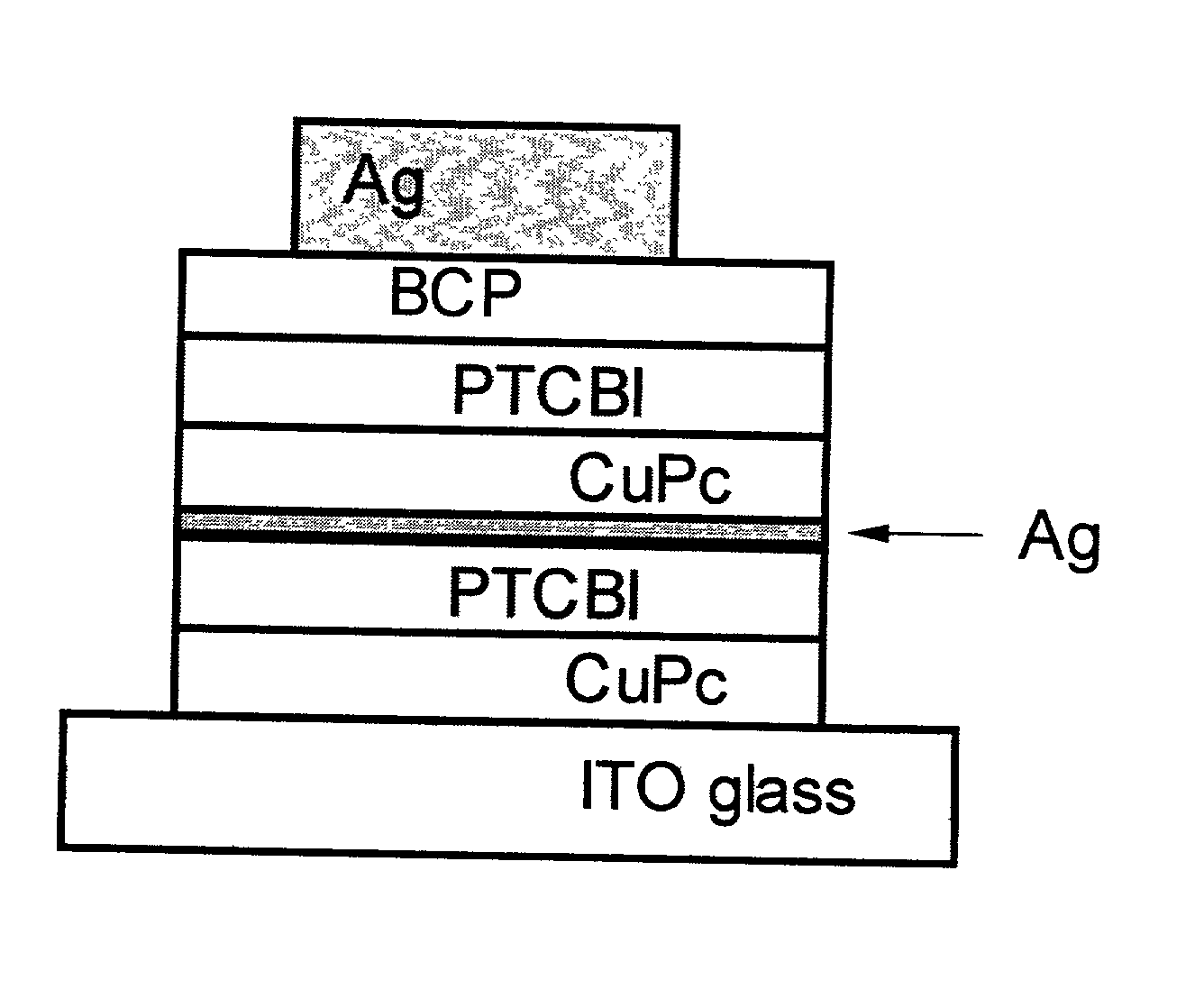

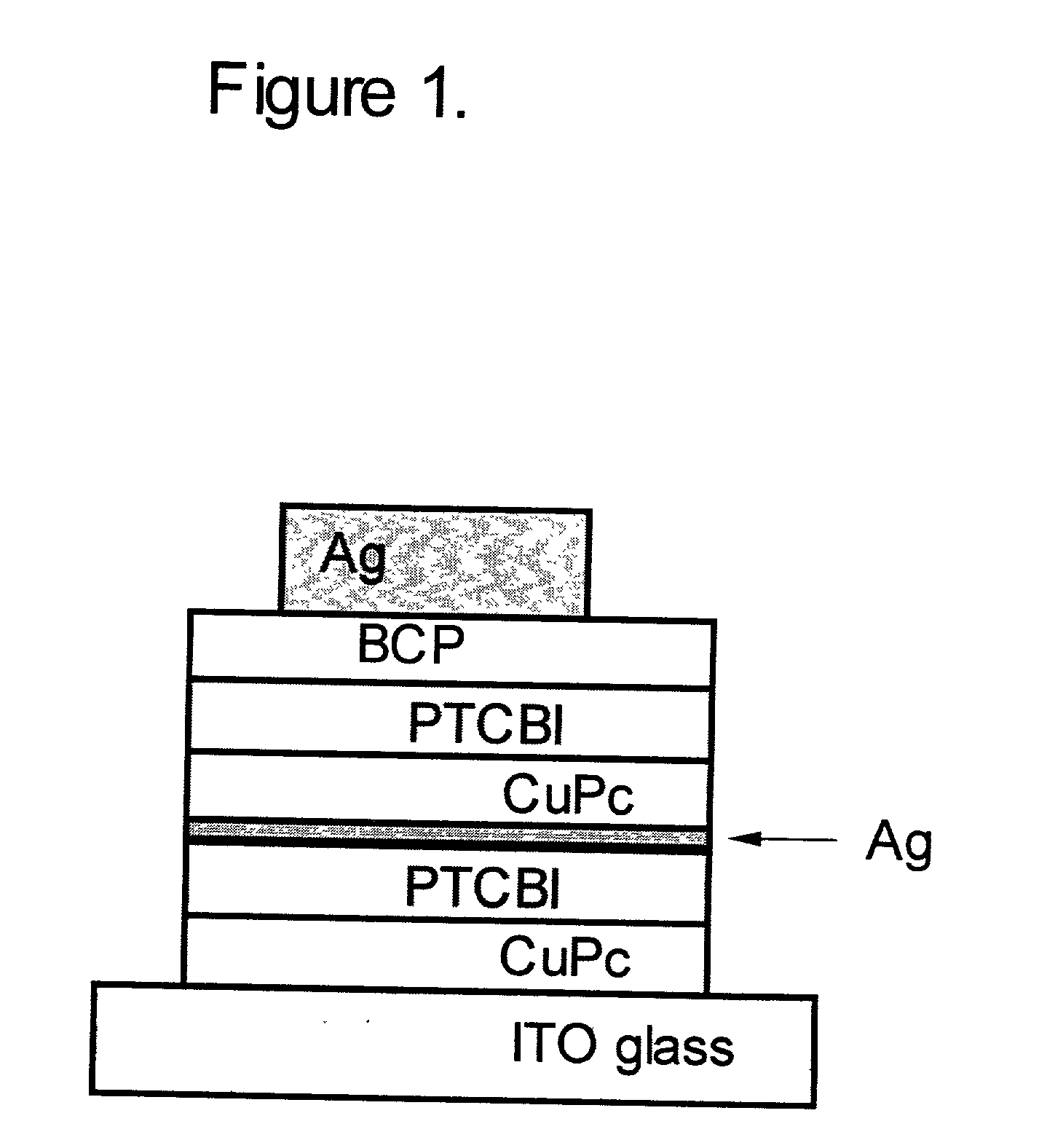

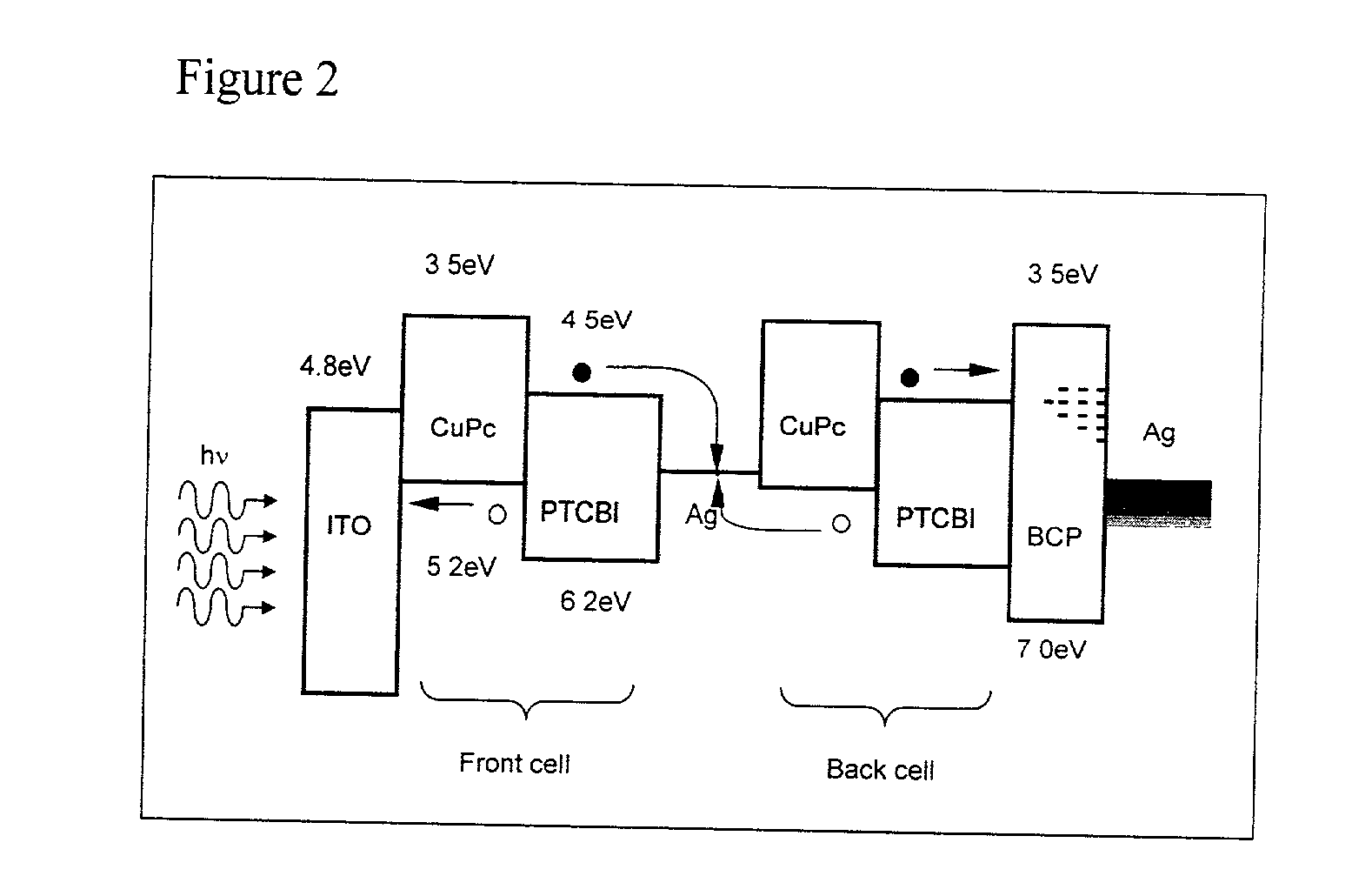

InactiveUS6657378B2Improve efficiencyImprove equipment efficiencyDischarge tube luminescnet screensLamp detailsOrganic solar cellElectron blocking layer

The present invention generally relates to organic photosensitive optoelectronic devices. More specifically, it is directed to organic photovoltaic devices, e.g., organic solar cells. Further, it is directed to an optimized organic solar cell comprising multiple stacked subcells in series. High power conversion efficiency are achieved by fabrication of a photovoltaic cell comprising multiple stacked subcells with thickness optimization and employing an electron blocking layer.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Electromagnetic linear generator and shock absorber

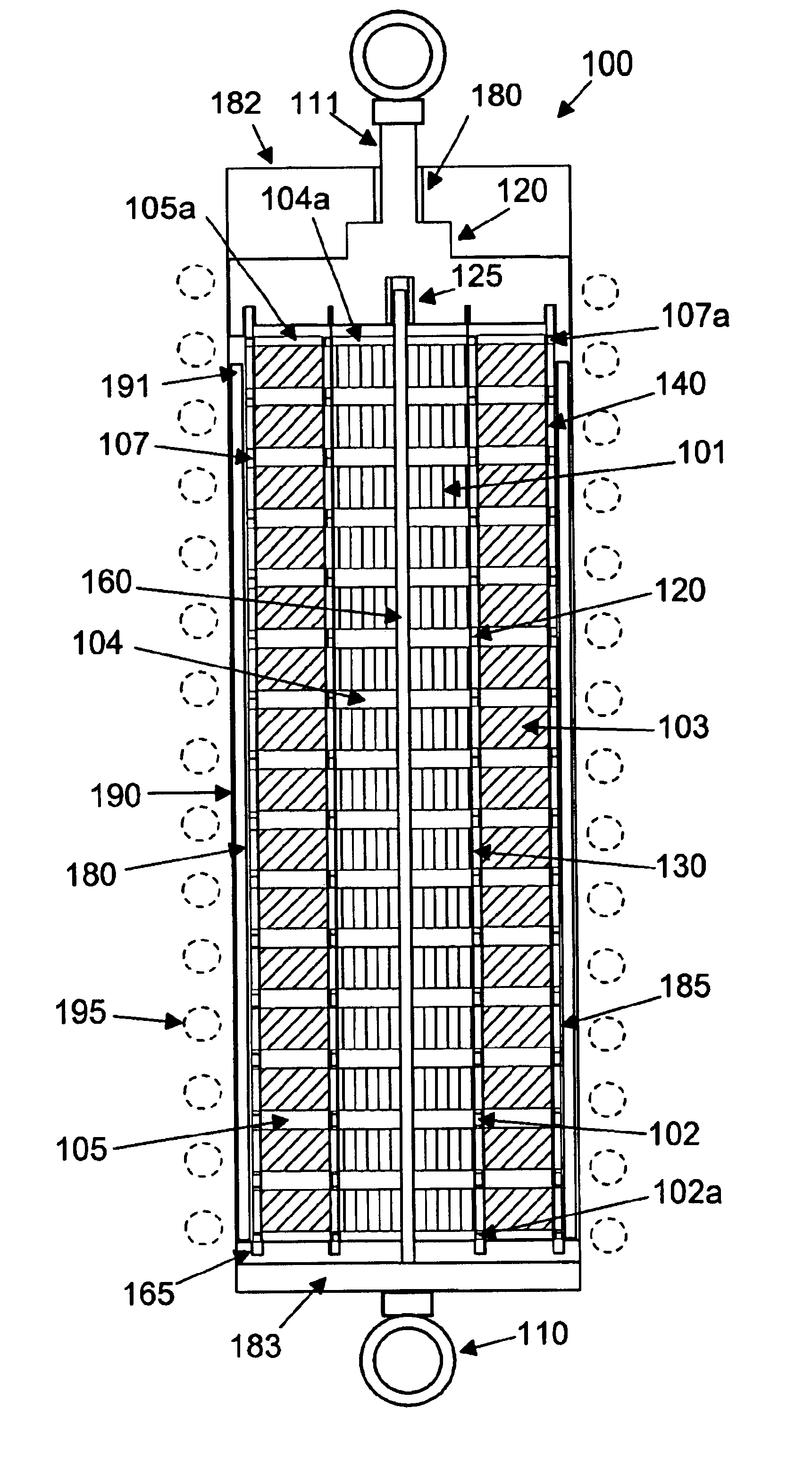

InactiveUS6952060B2Maximizing magnetic flux densityMaximize power generationNon-rotating vibration suppressionMechanical energy handlingElectromagnetic generatorFuel efficiency

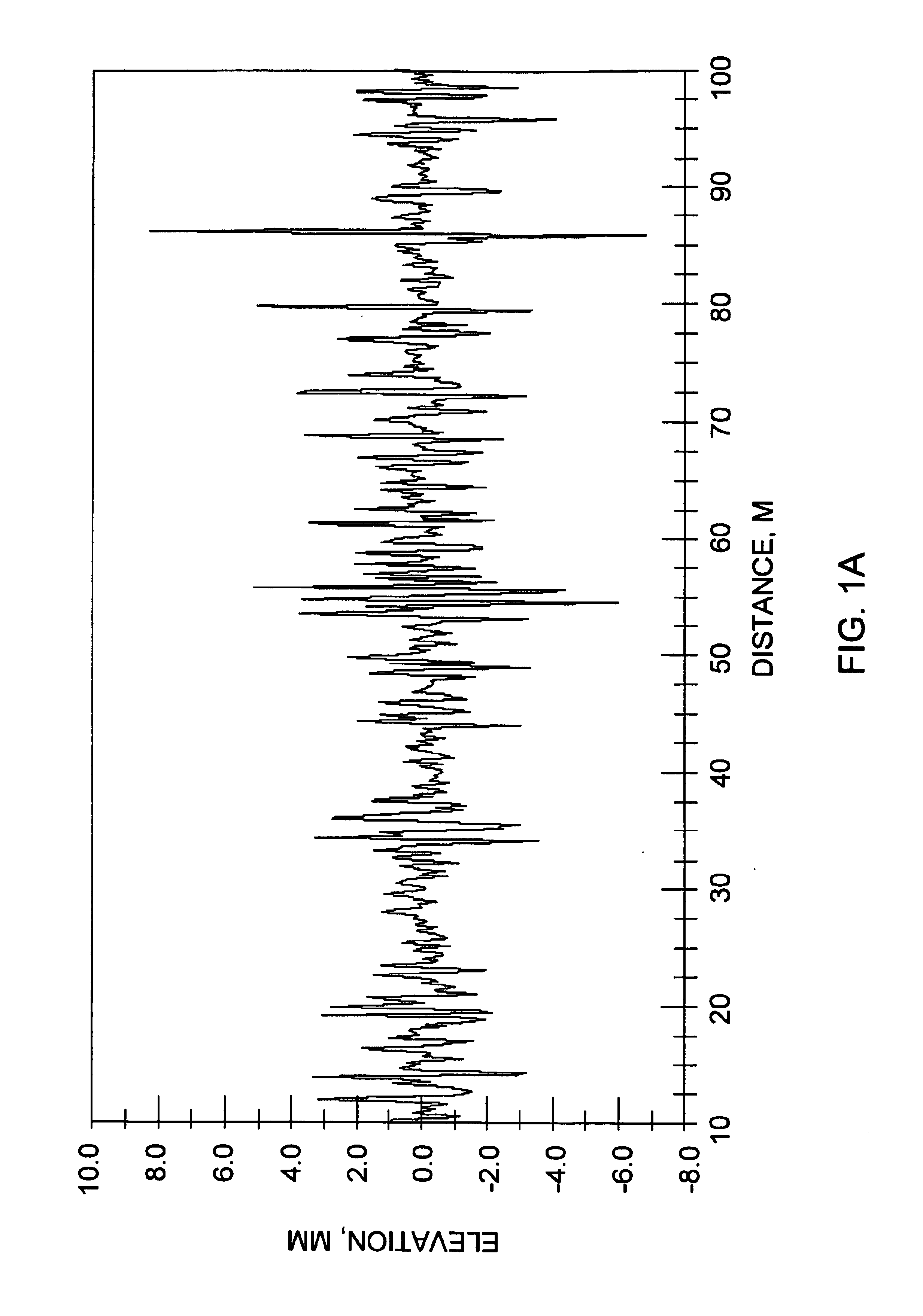

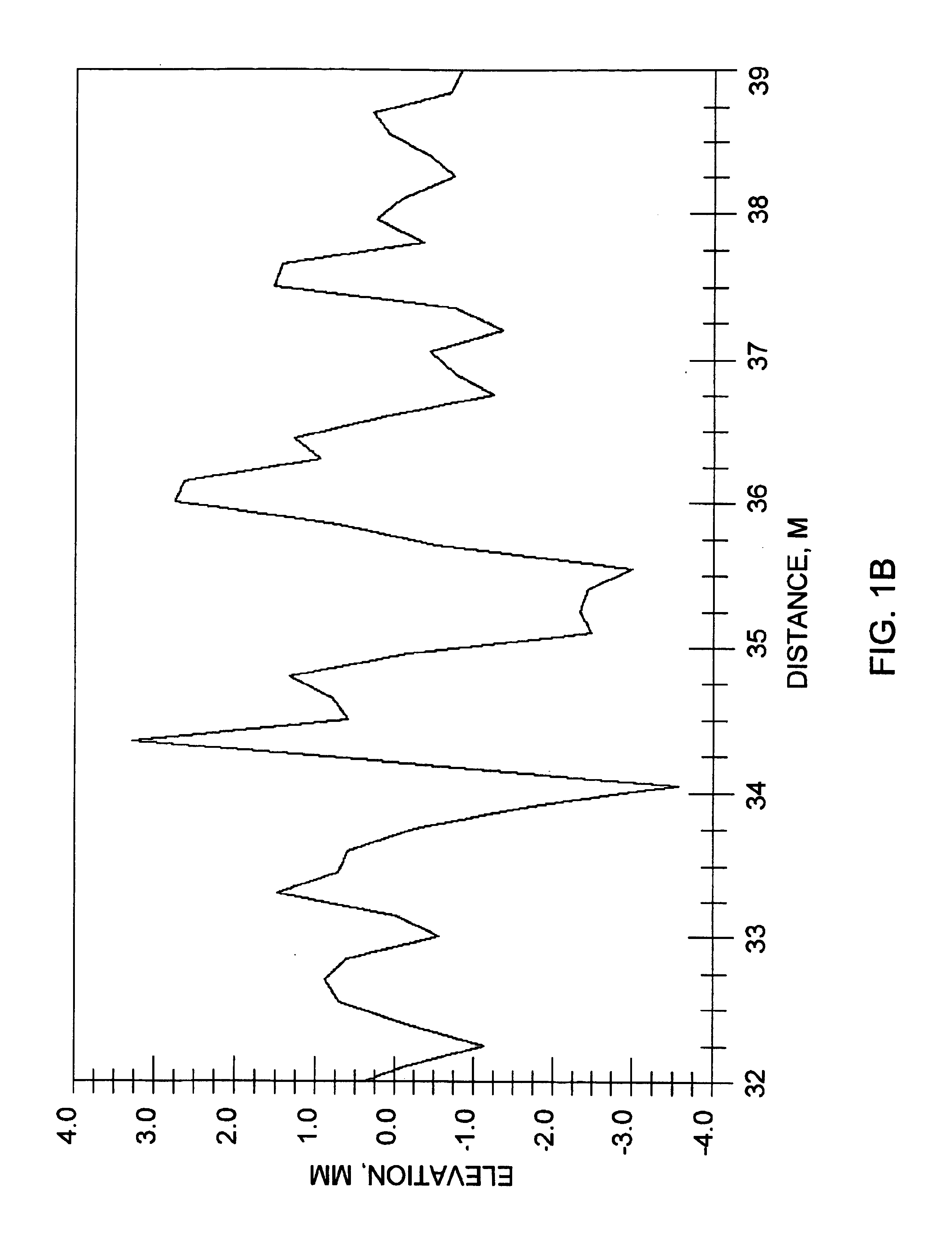

An electromagnetic linear generator and regenerative electromagnetic shock absorber is disclosed which converts variable frequency, repetitive intermittent linear displacement motion to useful electrical power. The innovative device provides for superposition of radial components of the magnetic flux density from a plurality of adjacent magnets to produce a maximum average radial magnetic flux density within a coil winding array. Due to the vector superposition of the magnetic fields and magnetic flux from a plurality of magnets, a nearly four-fold increase in magnetic flux density is achieved over conventional electromagnetic generator designs with a potential sixteen-fold increase in power generating capacity. As a regenerative shock absorber, the disclosed device is capable of converting parasitic displacement motion and vibrations encountered under normal urban driving conditions to a useful electrical energy for powering vehicles and accessories or charging batteries in electric and fossil fuel powered vehicles. The disclosed device is capable of high power generation capacity and energy conversion efficiency with minimal weight penalty for improved fuel efficiency.

Owner:TRUSTEES OF TUFTS COLLEGE TUFTS UNIV

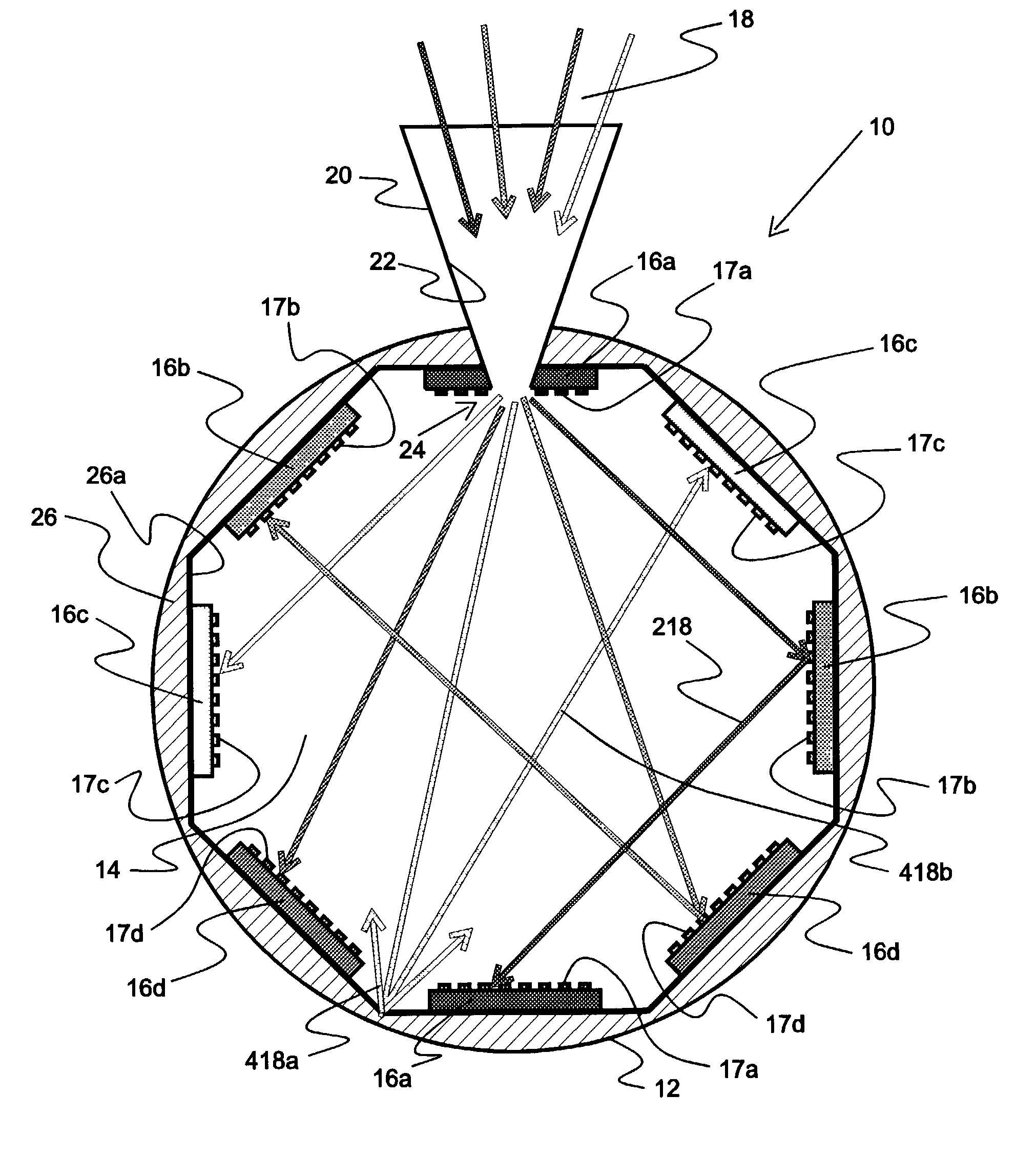

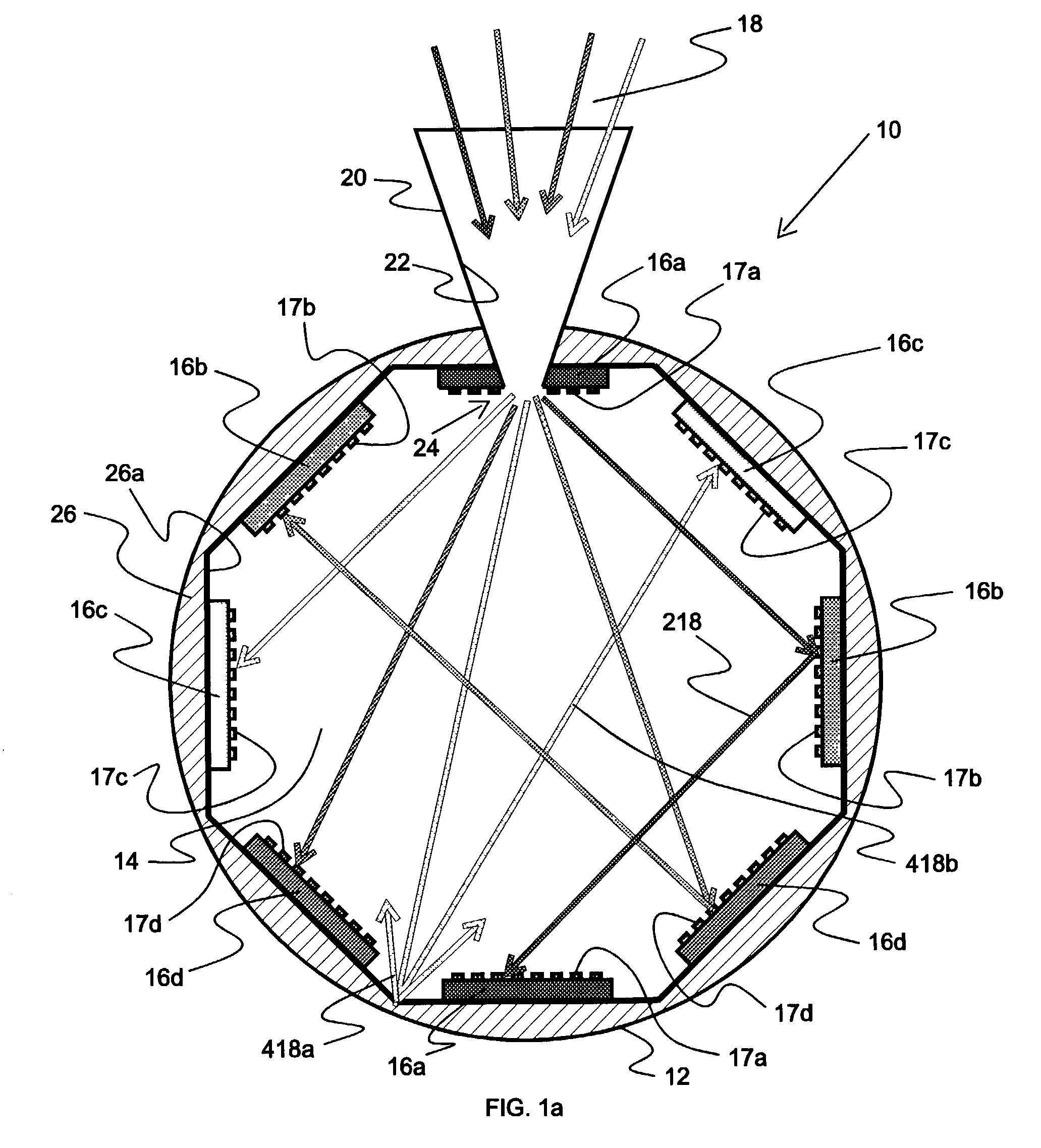

Concentrating photovoltaic cavity converters for extreme solar-to-electric conversion efficiencies

InactiveUS6689949B2Maximize utilizationAuxillary drivesFrom solar energyEngineeringEnergy conversion efficiency

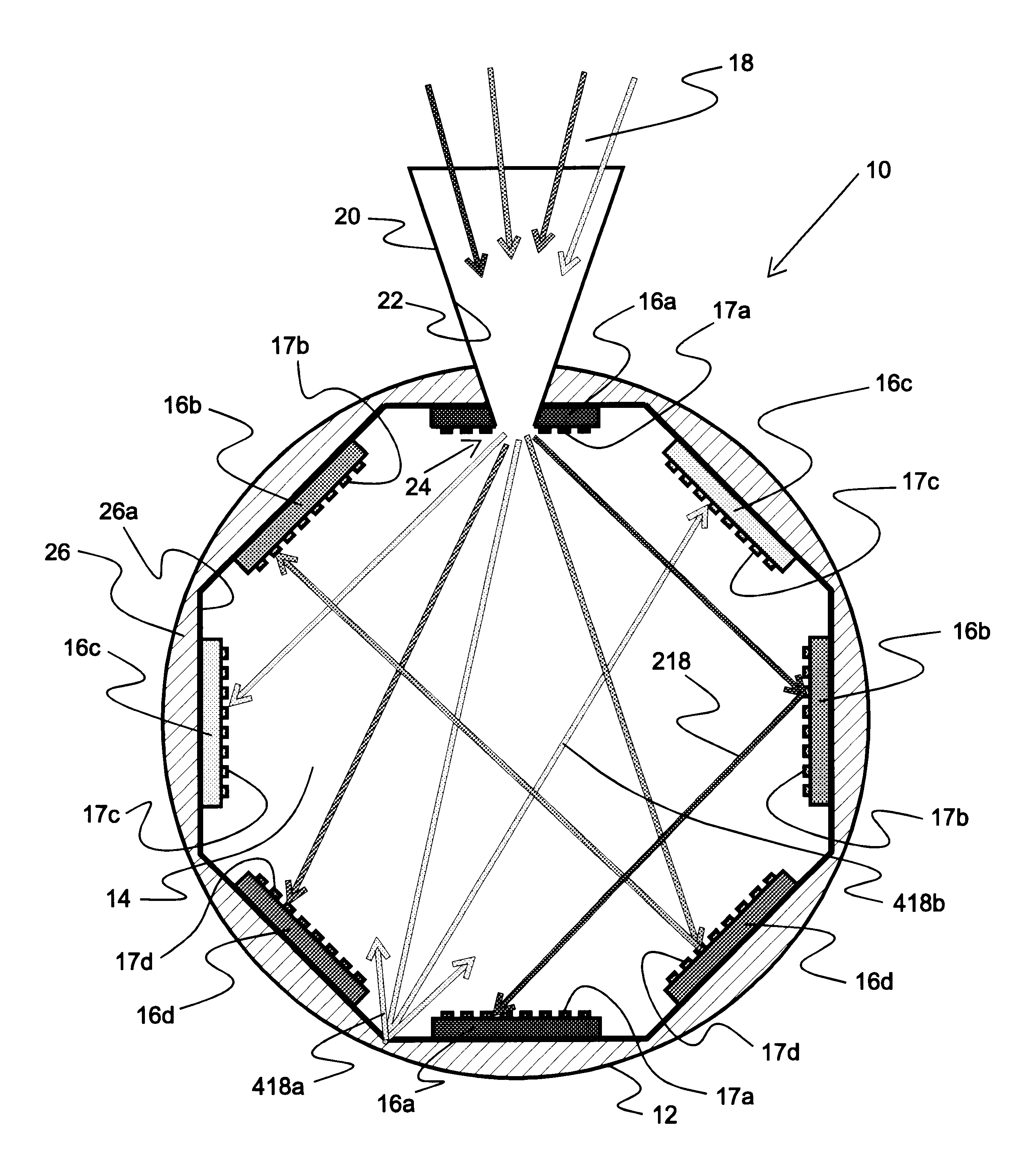

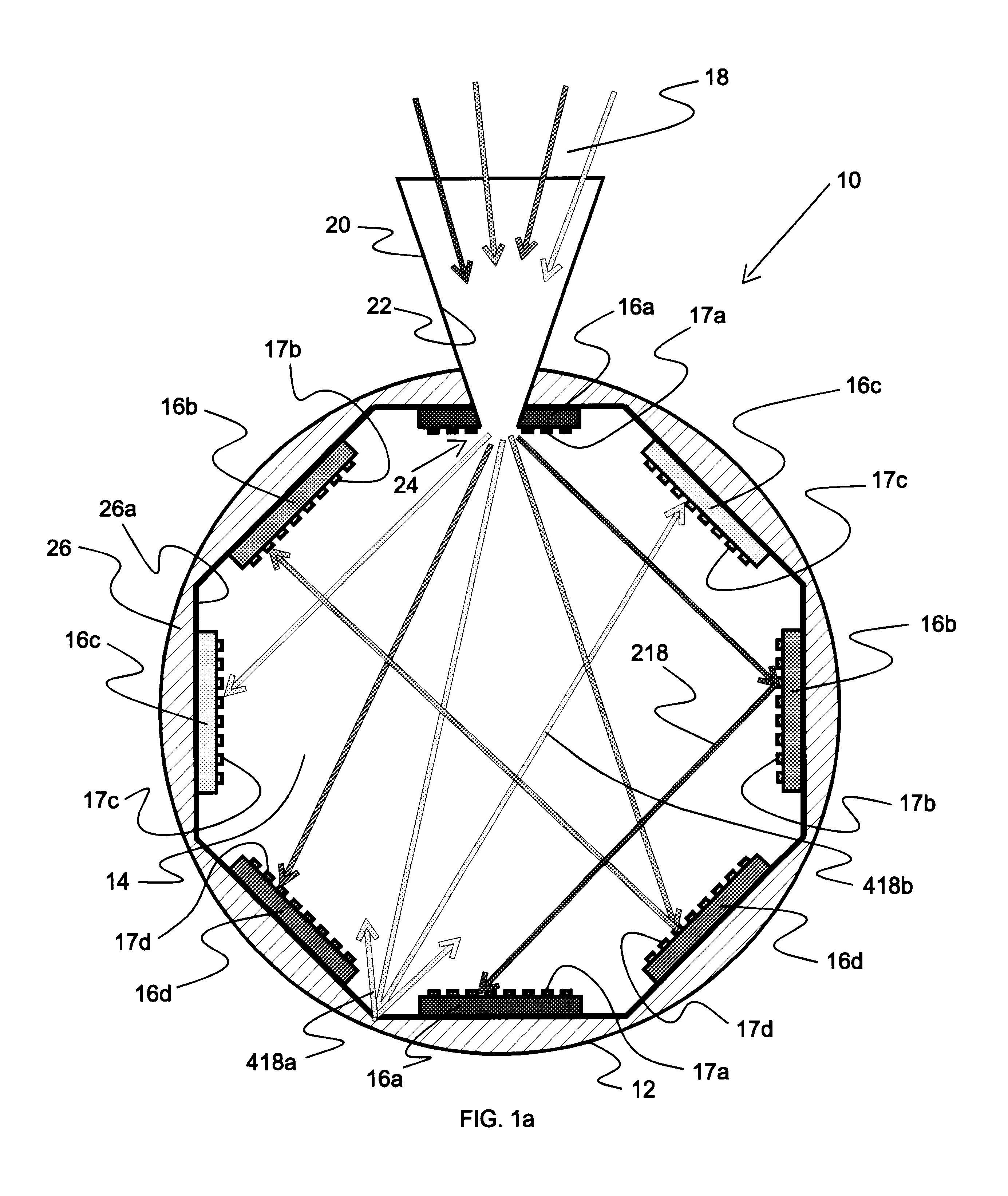

A concentrating photovoltaic module is provided which provides a concentration in the range of about 500 to over 1,000 suns and a power range of a few kW to 50 kW. A plurality of such modules may be combined to form a power plant capable of generating over several hundred megaWatts. The concentrating photovoltaic module is based on a Photovoltaic Cavity Converter (PVCC) as an enabling technology for very high solar-to-electricity conversions. The use of a cavity containing a plurality of single junction solar cells of different energy bandgaps and simultaneous spectral splitting of the solar spectrum employs a lateral geometry in the spherical cavity (where the cell strings made of the single junction cells operate next to each other without mutual interference). The purpose of the cavity with a small aperture for the pre-focused solar radiation is to confine (trap) the photons so that they can be recycled effectively and used by the proper cells. Passive or active cooling mechanisms may be employed to cool the solar cells.

Owner:UNITED INNOVATIONS

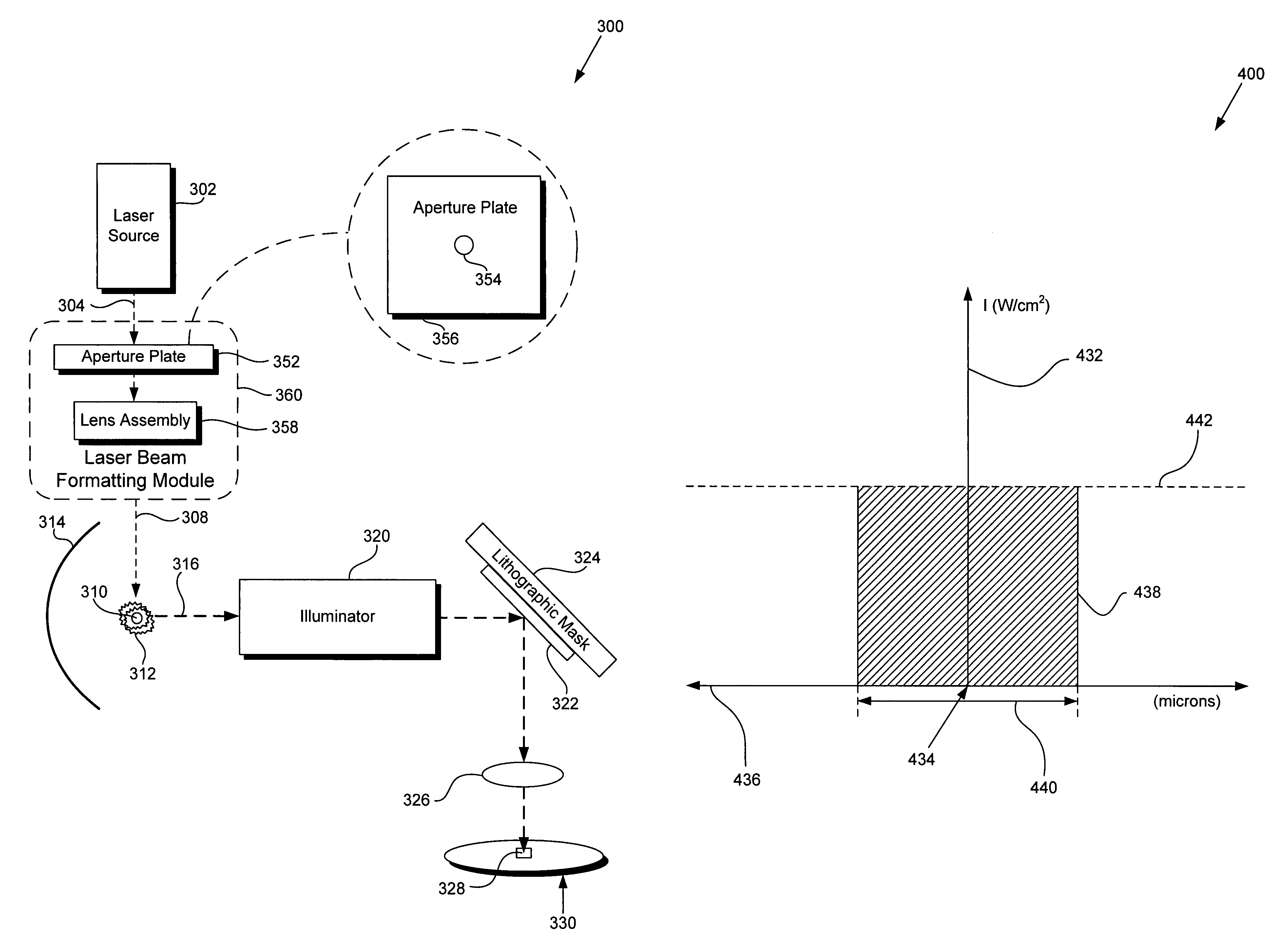

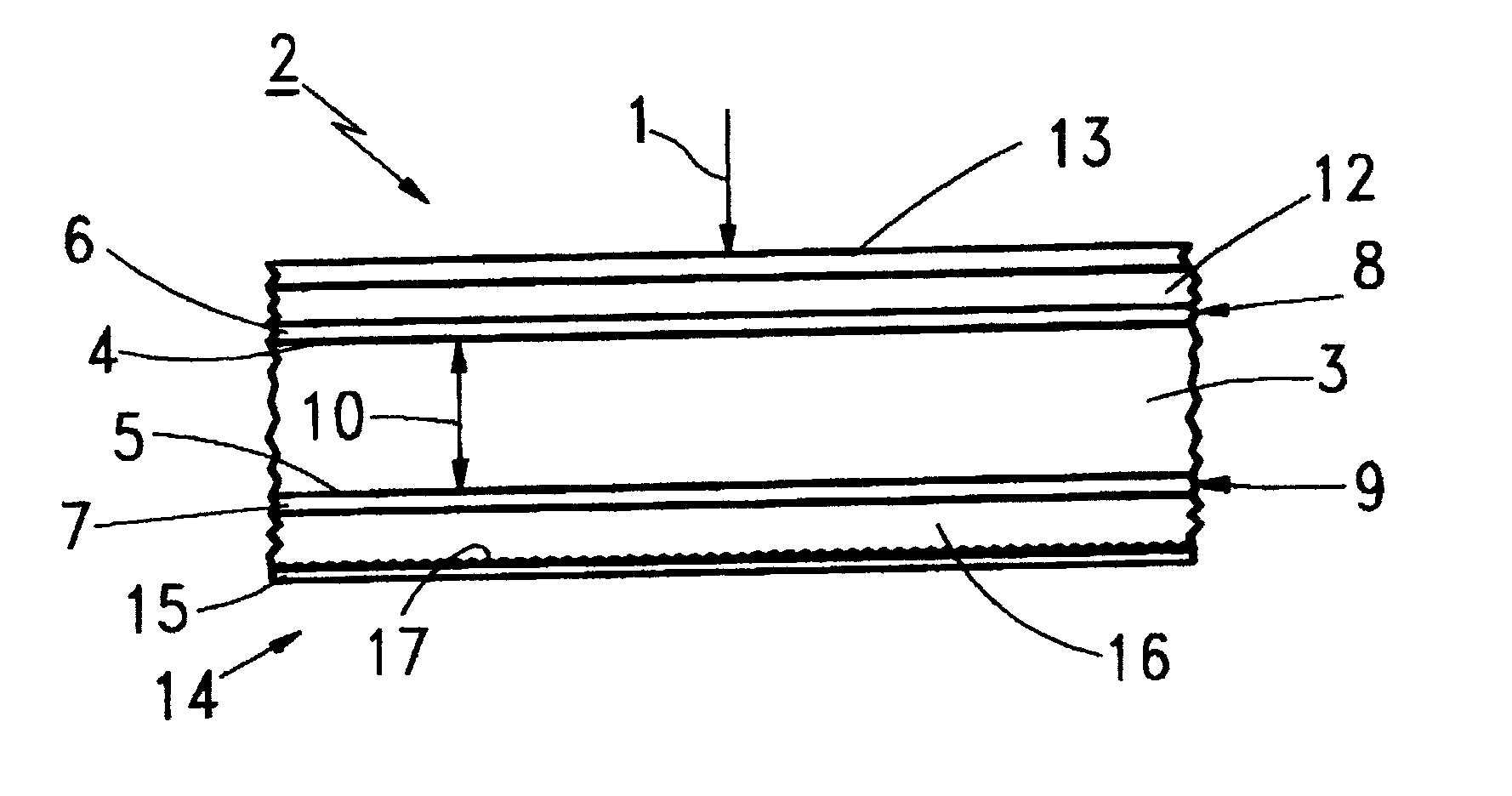

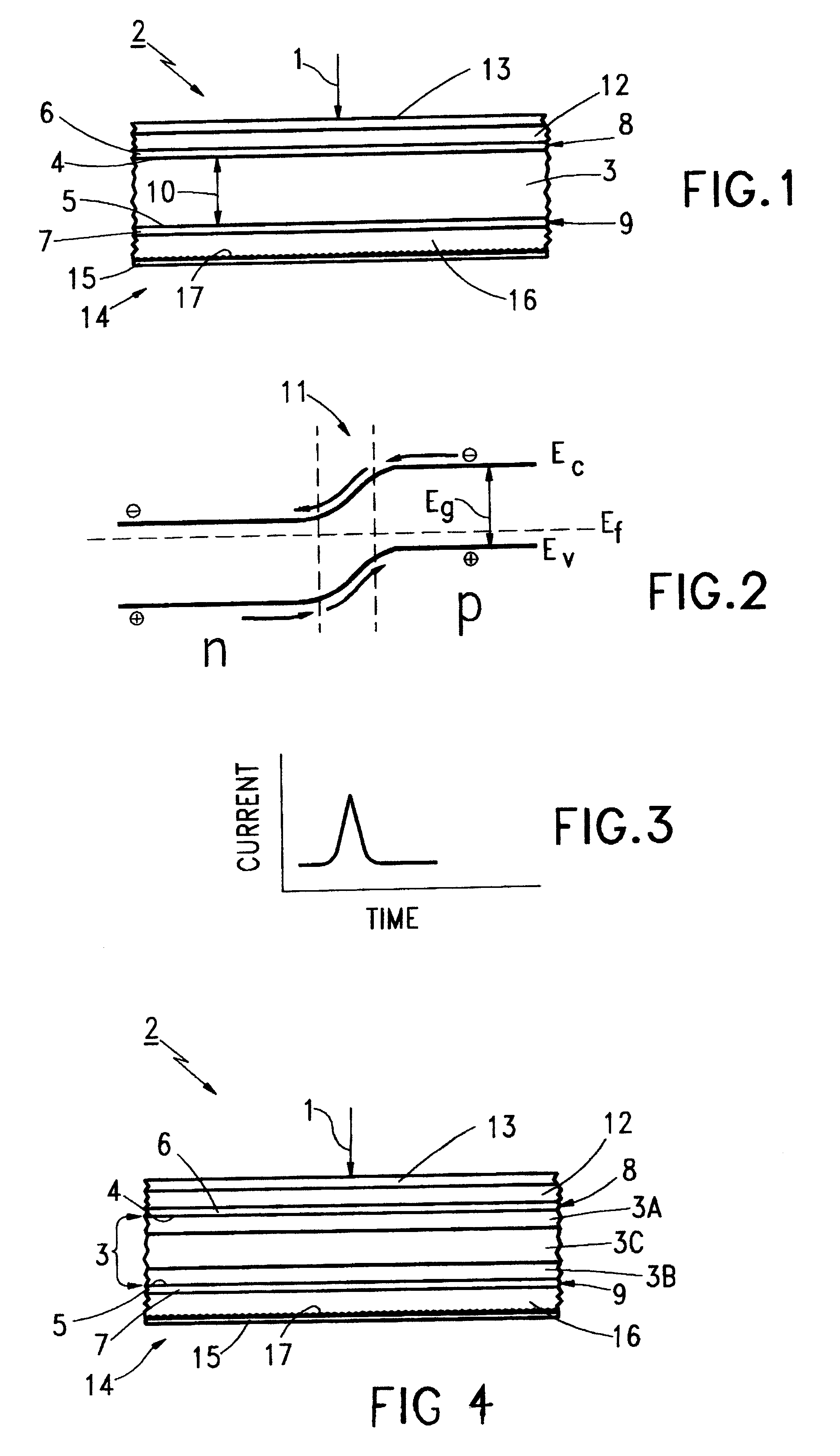

Method for forming crystalline semiconductor layers, a method for fabricating thin film transistors, and method for fabricating solar cells and active matrix liquid crystal devices

InactiveUS6066516AGreat fabricationImprove mobilityTransistorFinal product manufactureActive matrixSolar cell

PCT No. PCT / JP96 / 01775 Sec. 371 Date Jan. 31, 1997 Sec. 102(e) Date Jan. 31, 1997 PCT Filed Jun. 26, 1996 PCT Pub. No. WO97 / 01863 PCT Pub. Date Jan. 16, 1997A crystalline semiconductor layer can be formed by forming a semiconductor film on an inexpensive conventional substrate. Next, perform a first annealing process in which nearly the entire surface of the semiconductor film is exposed to laser irradiation or other forms of irradiation, and then perform a second annealing process consisting of rapid thermal annealing. This enables the formation of a high quality crystalline semiconductor film with high throughput but without subjecting the substrate to undue thermal stress. When this invention is applied to thin film transistors, good transistors having high performance are easily fabricated. When this invention is applied to solar cells, energy conversion efficiency is increased.

Owner:SEIKO EPSON CORP

Organic photovoltaic devices

InactiveUS20030042846A1Improve efficiencyImprove photovoltaic performanceDischarge tube luminescnet screensLamp detailsOrganic solar cellElectron blocking layer

The present invention generally relates to organic photosensitive optoelectronic devices. More specifically, it is directed to organic photovoltaic devices, e.g., organic solar cells. Further, it is directed to an optimized organic solar cell comprising multiple stacked subcells in series. High power conversion efficiency are achieved by fabrication of a photovoltaic cell comprising multiple stacked subcells with thickness optimization and employing an electron blocking layer.

Owner:THE TRUSTEES FOR PRINCETON UNIV

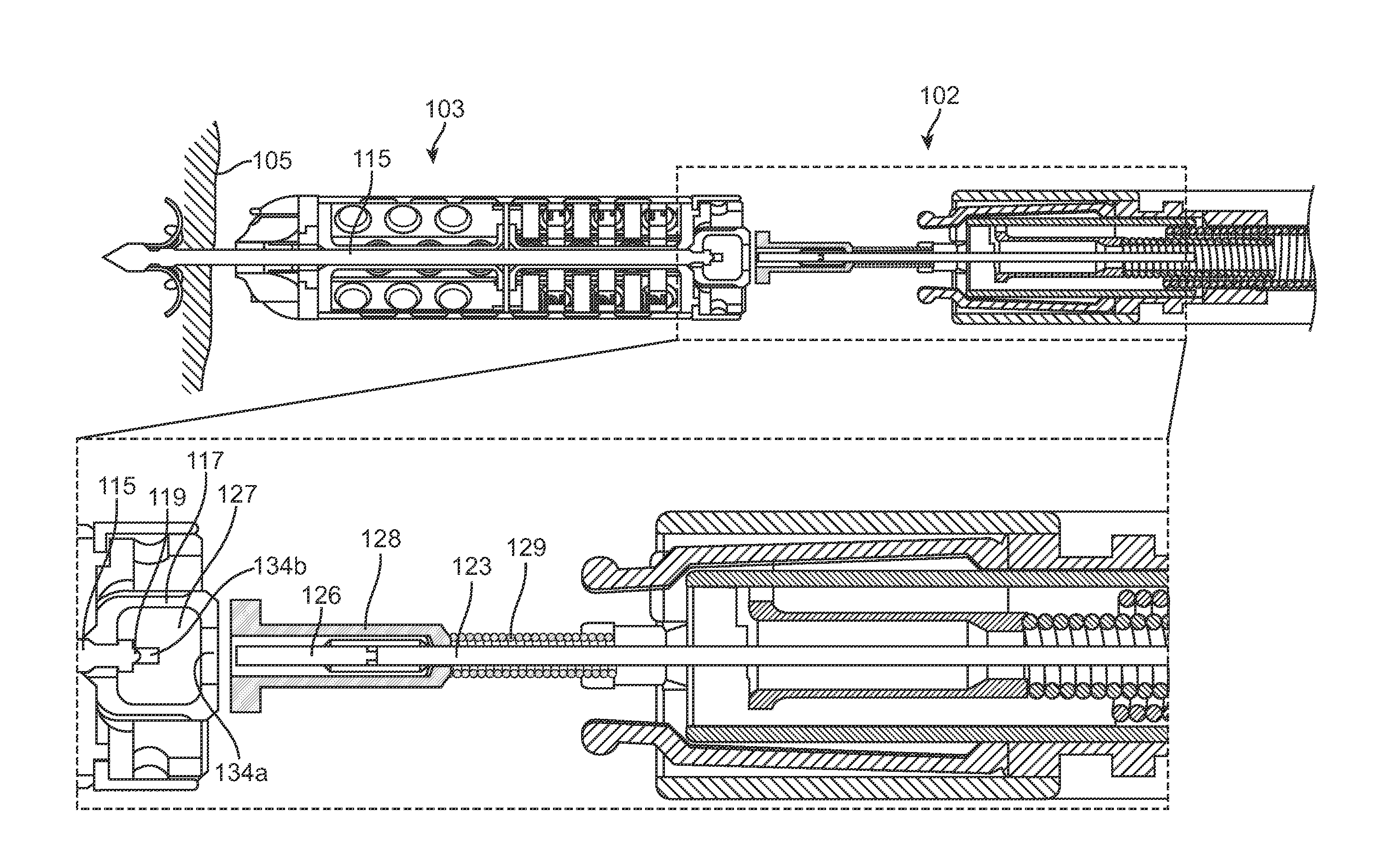

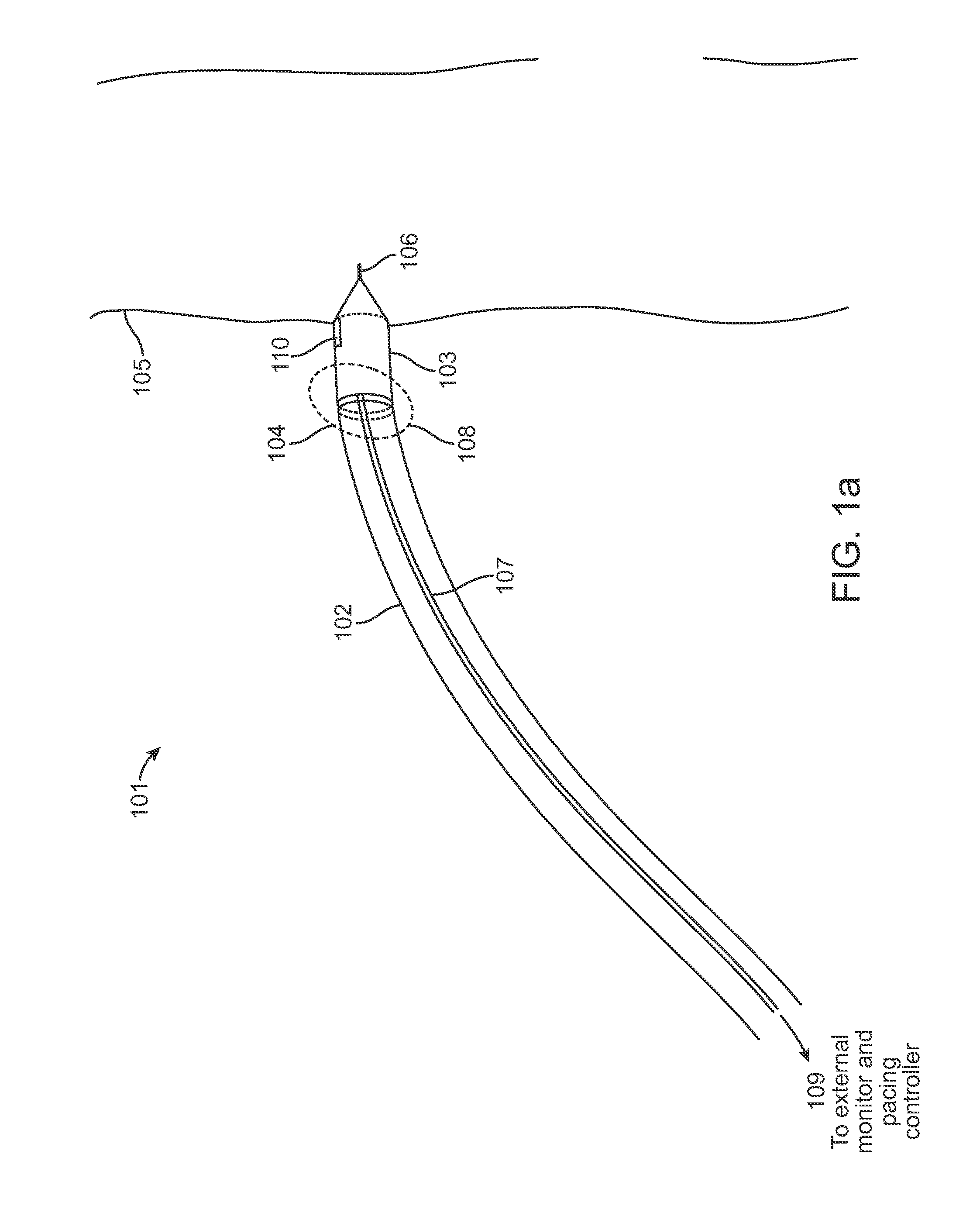

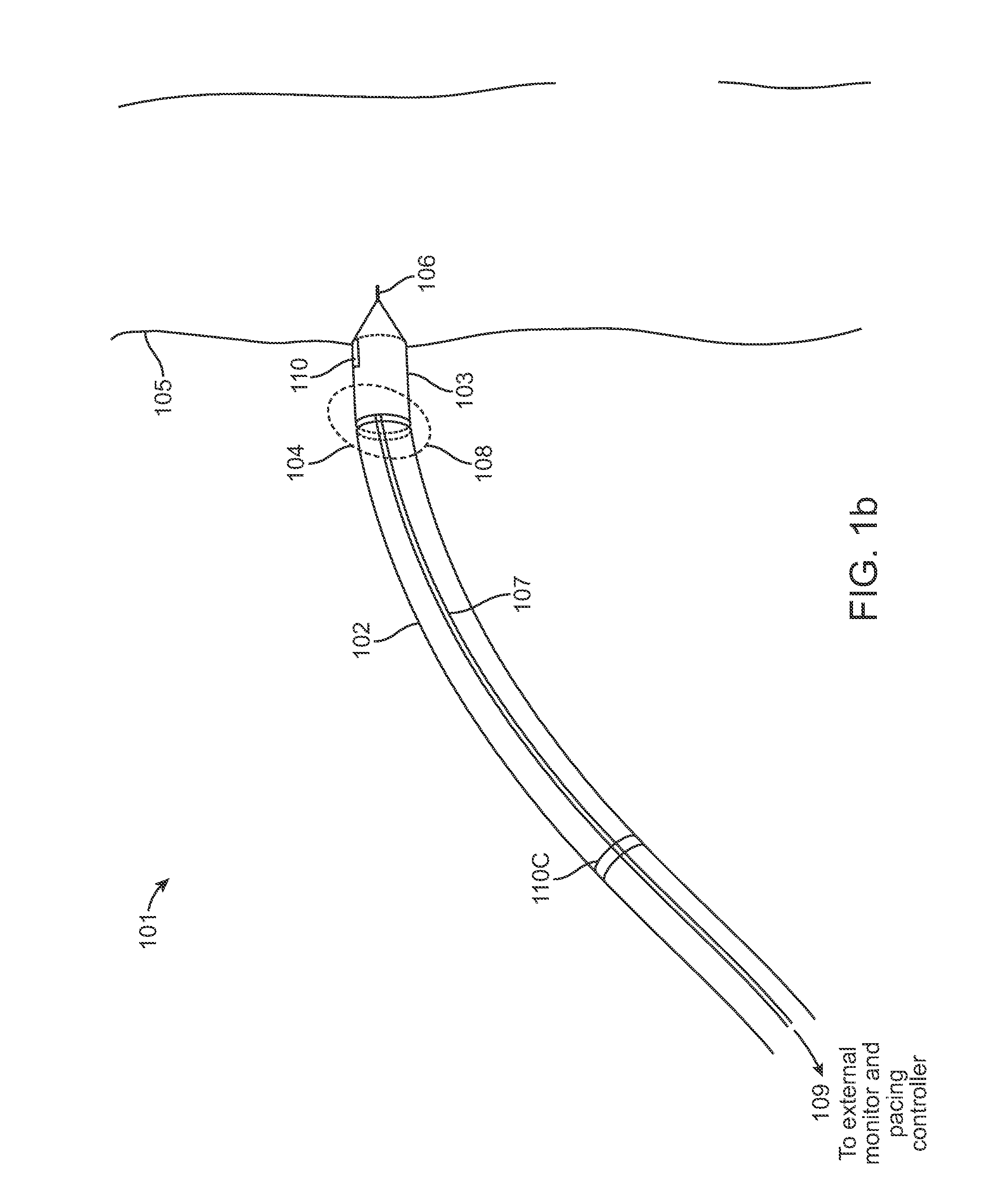

Temporary electrode connection for wireless pacing systems

Delivery of an implantable wireless receiver-stimulator (R-S) into the heart using delivery catheter is described. R-S comprises a cathode and an anode and wirelessly receives and converts energy, such as acoustic ultrasound energy, to electrical energy to stimulate the heart. Conductive wires routed through the delivery system temporarily connect R-S electrodes to external monitor and pacing controller. R-S comprises a first temporary electrical connection from the catheter to the cathode, and a second temporary electrical connection from the catheter to the anode. Temporary electrical connections allow external monitoring of heart's electrical activity as sensed by R-S electrodes to determine tissue viability for excitation as well as to assess energy conversion efficiency.

Owner:EBR SYST

Concentrating photovoltaic cavity converters for extreme solar-to-electric conversion efficiencies

InactiveUS20030213514A1Improve conversion efficiencyMaximize utilizationAuxillary drivesFrom solar energyElectricityPower station

A concentrating photovoltaic module is provided which provides a concentration in the range of about 500 to over 1,000 suns and a power range of a few kW to 50 kW. A plurality of such modules may be combined to form a power plant capable of generating over several hundred megawatts. The concentrating photovoltaic module is based on a Photovoltaic Cavity Converter (PVCC) as an enabling technology for very high solar-to-electricity conversions. The use of a cavity containing a plurality of single junction solar cells of different energy bandgaps and simultaneous spectral splitting of the solar spectrum employs a lateral geometry in the spherical cavity (where the cell strings made of the single junction cells operate next to each other without mutual interference). The purpose of the cavity with a small aperture for the pre-focused solar radiation is to confine (trap) the photons so that they can be recycled effectively and used by the proper cells. Passive or active cooling mechanisms may be employed to cool the solar cells.

Owner:UNITED INNOVATIONS

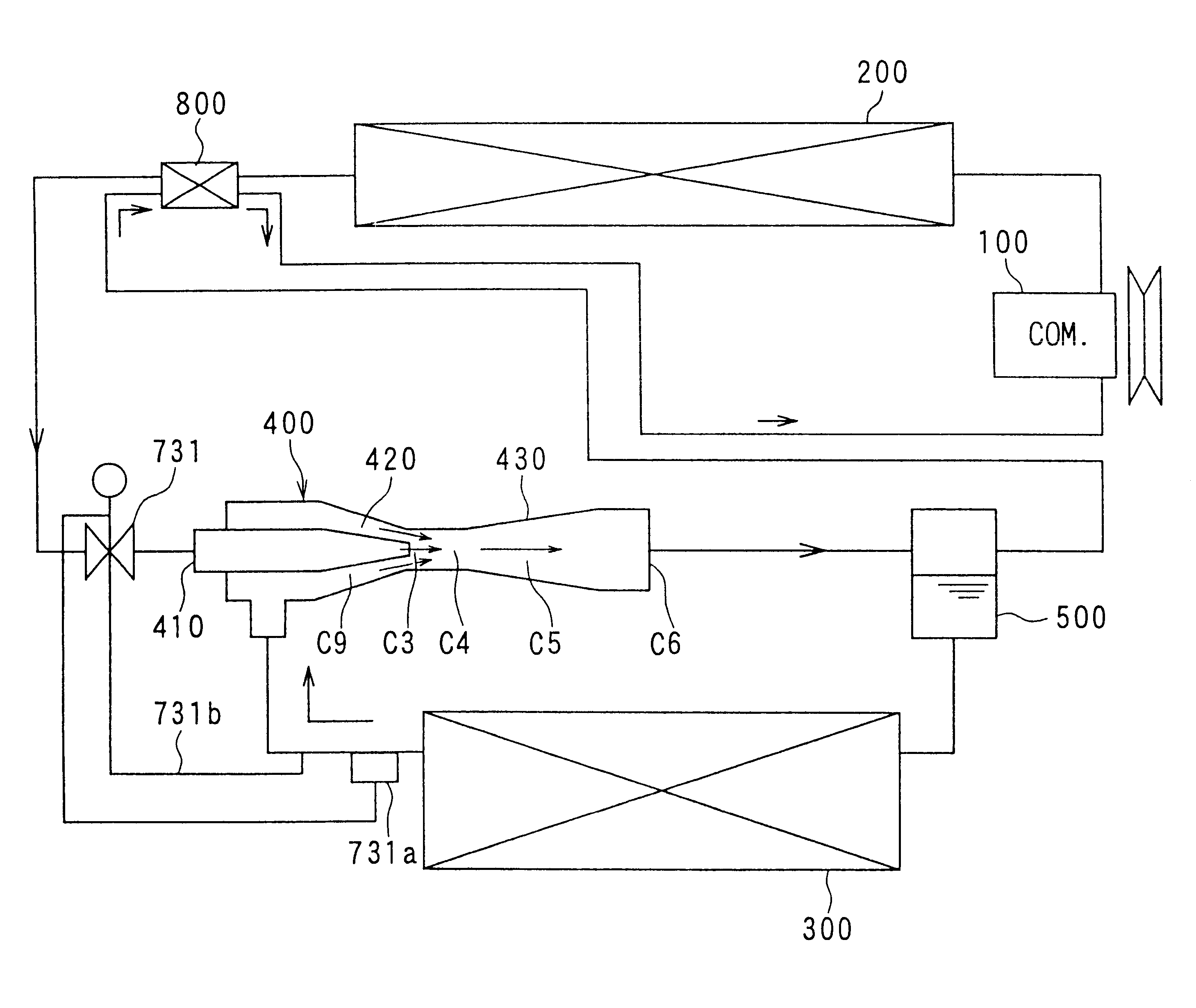

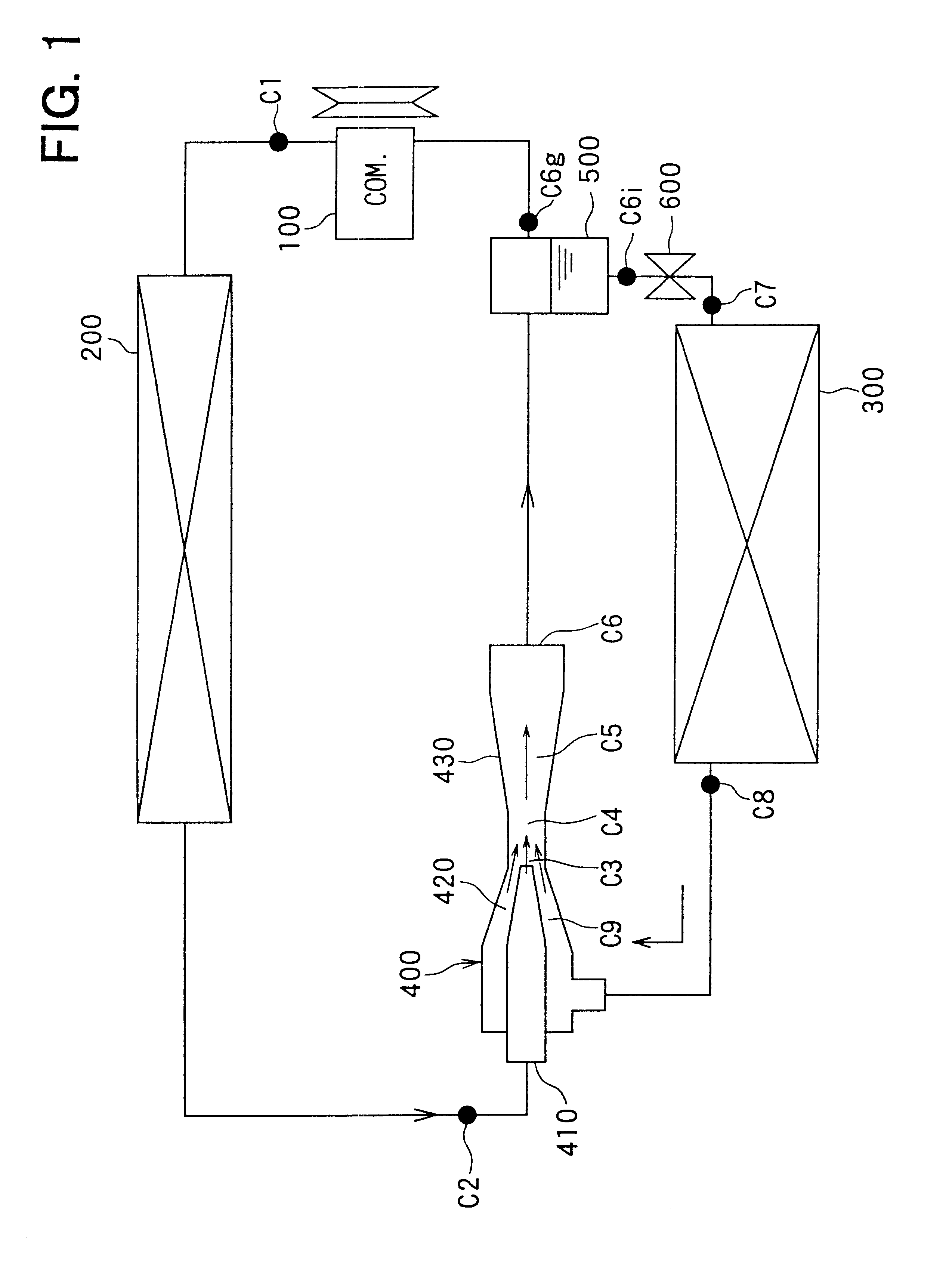

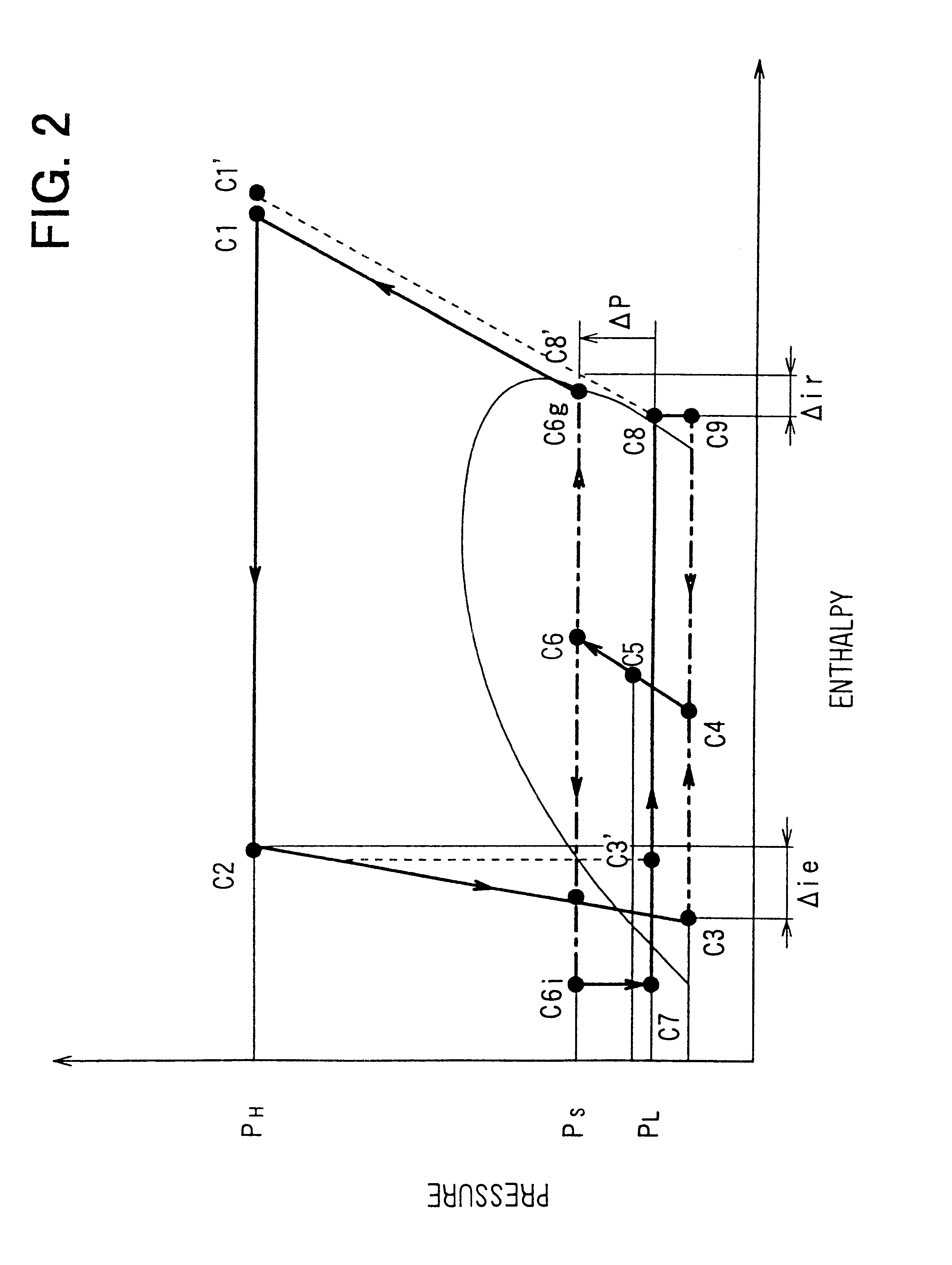

Ejector cycle system with critical refrigerant pressure

InactiveUS6477857B2Recover energyReduce power consumptionCompression machines with non-reversible cycleEvaporators/condensersEngineeringPressure difference

Owner:DENSO CORP

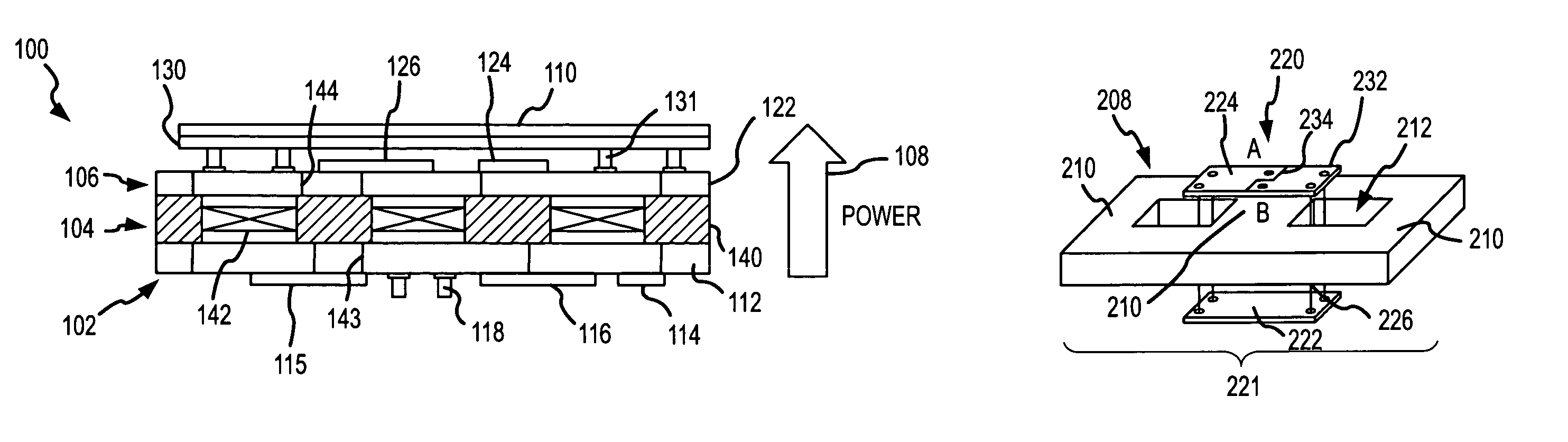

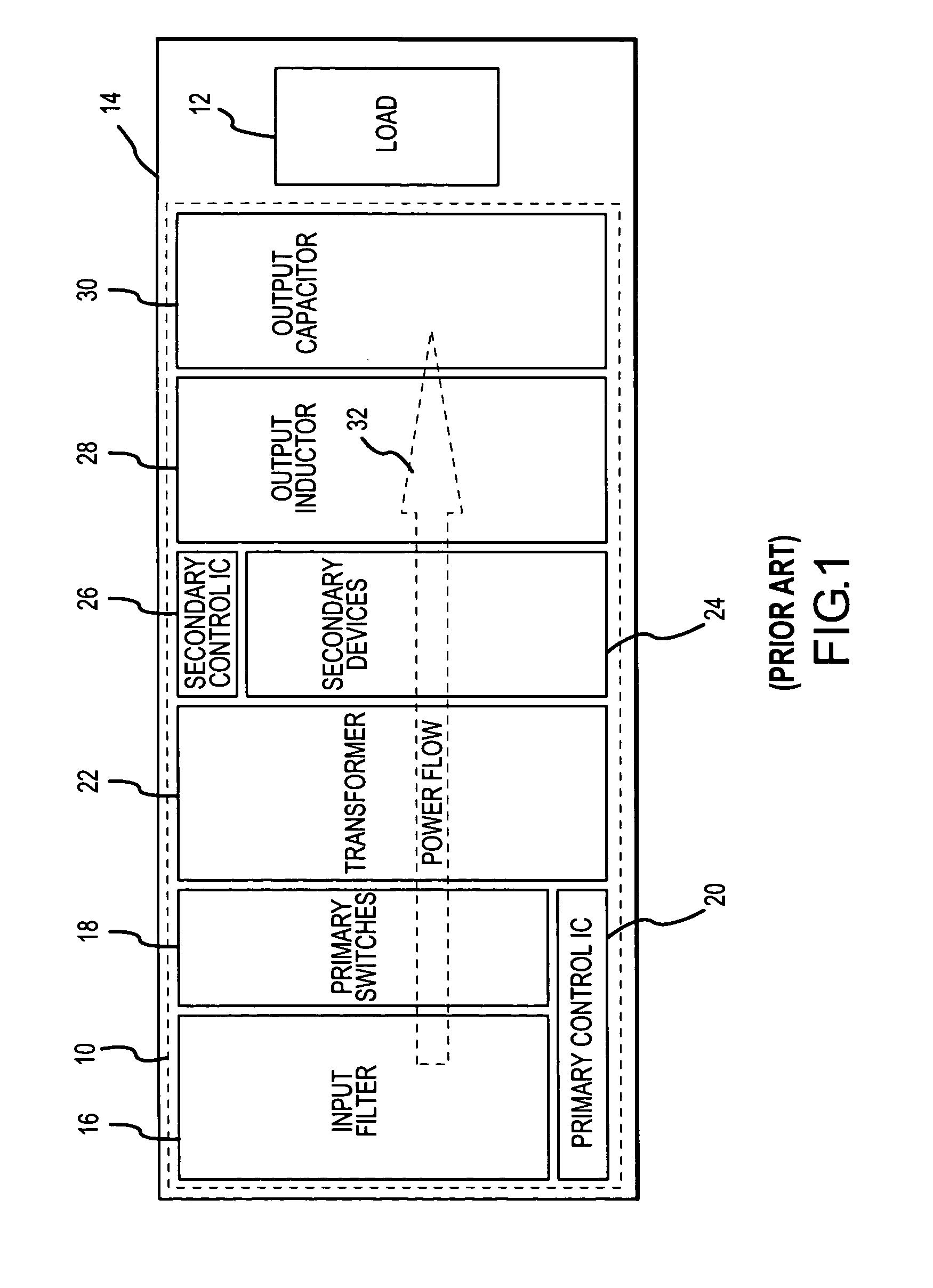

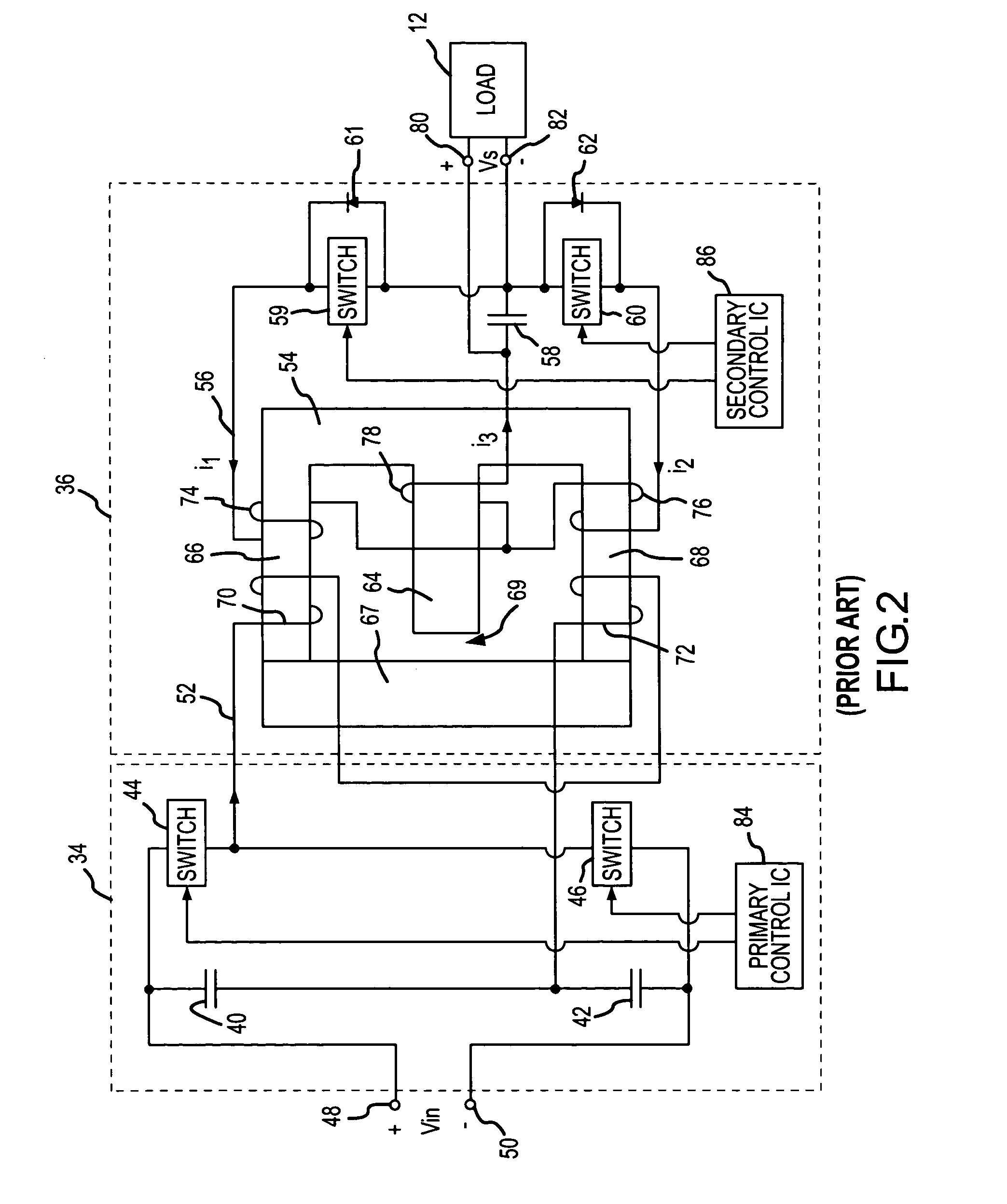

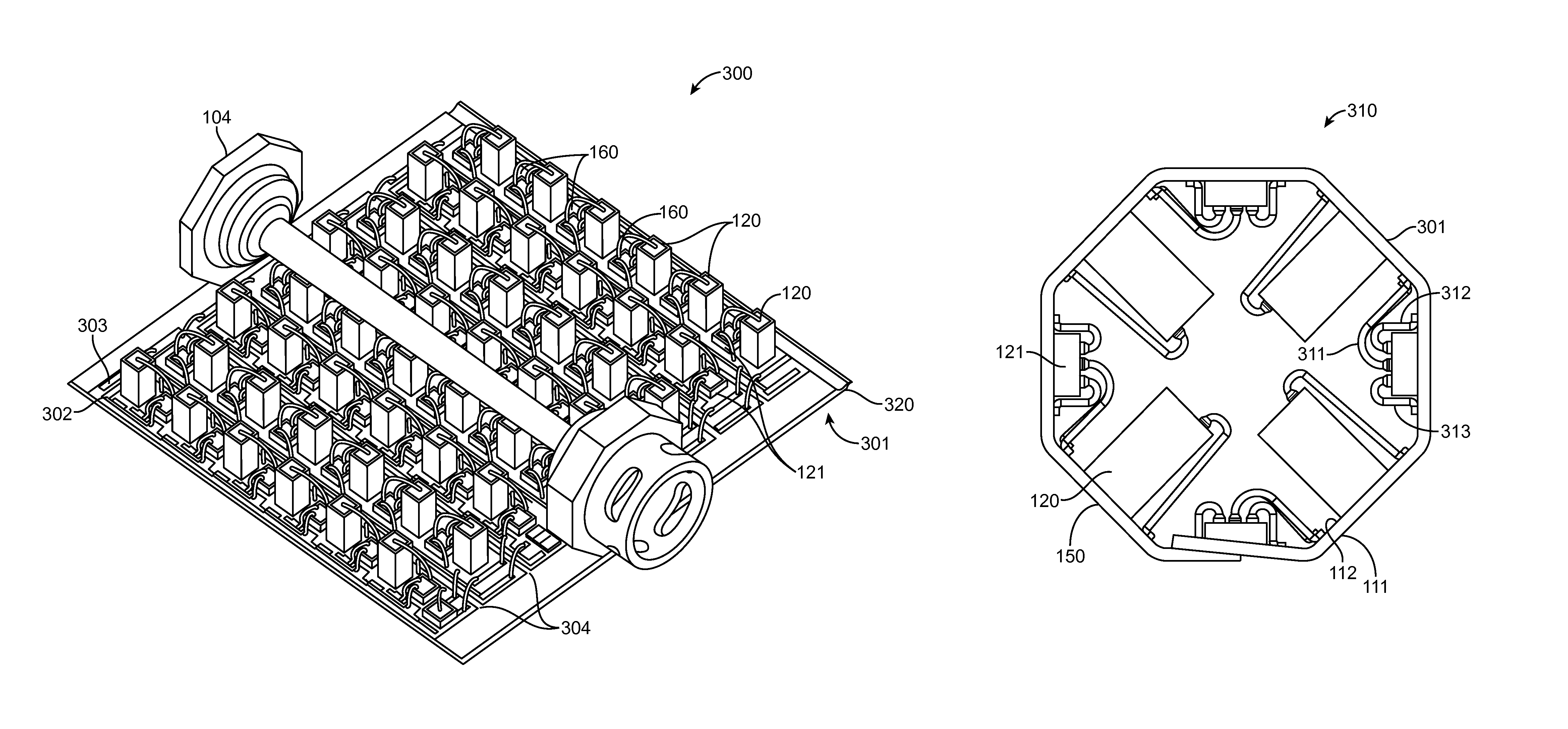

Vertically packaged switched-mode power converter

ActiveUS7012414B1Tight regulationFast transient responseTransformersConversion constructional detailsElectrical resistance and conductanceCellular architecture

A vertically packaged cellular power converter solves the problems associated with conventional designs and paves the way for a cellular circuit architecture with ultra-low interconnect resistance and inductance. The vertical packaging results in a power flow in the vertical direction (from the bottom to the top) with very short internal interconnects, thereby minimizing the associated conduction losses and permitting high conversion efficiency at high currents. The cellular architecture is ideally suited for generating multiple supply voltages.

Owner:MYPAQ HLDG LTD

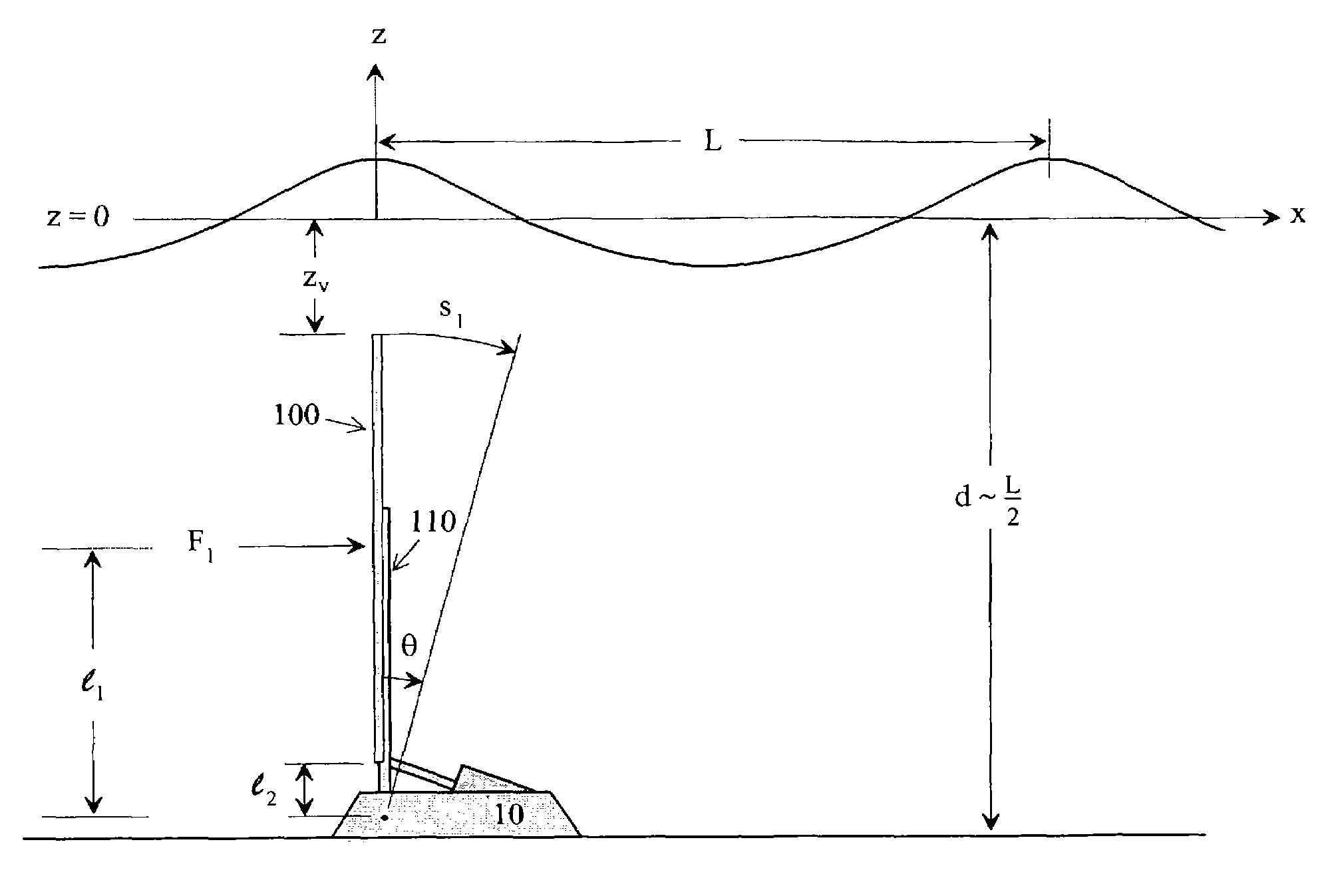

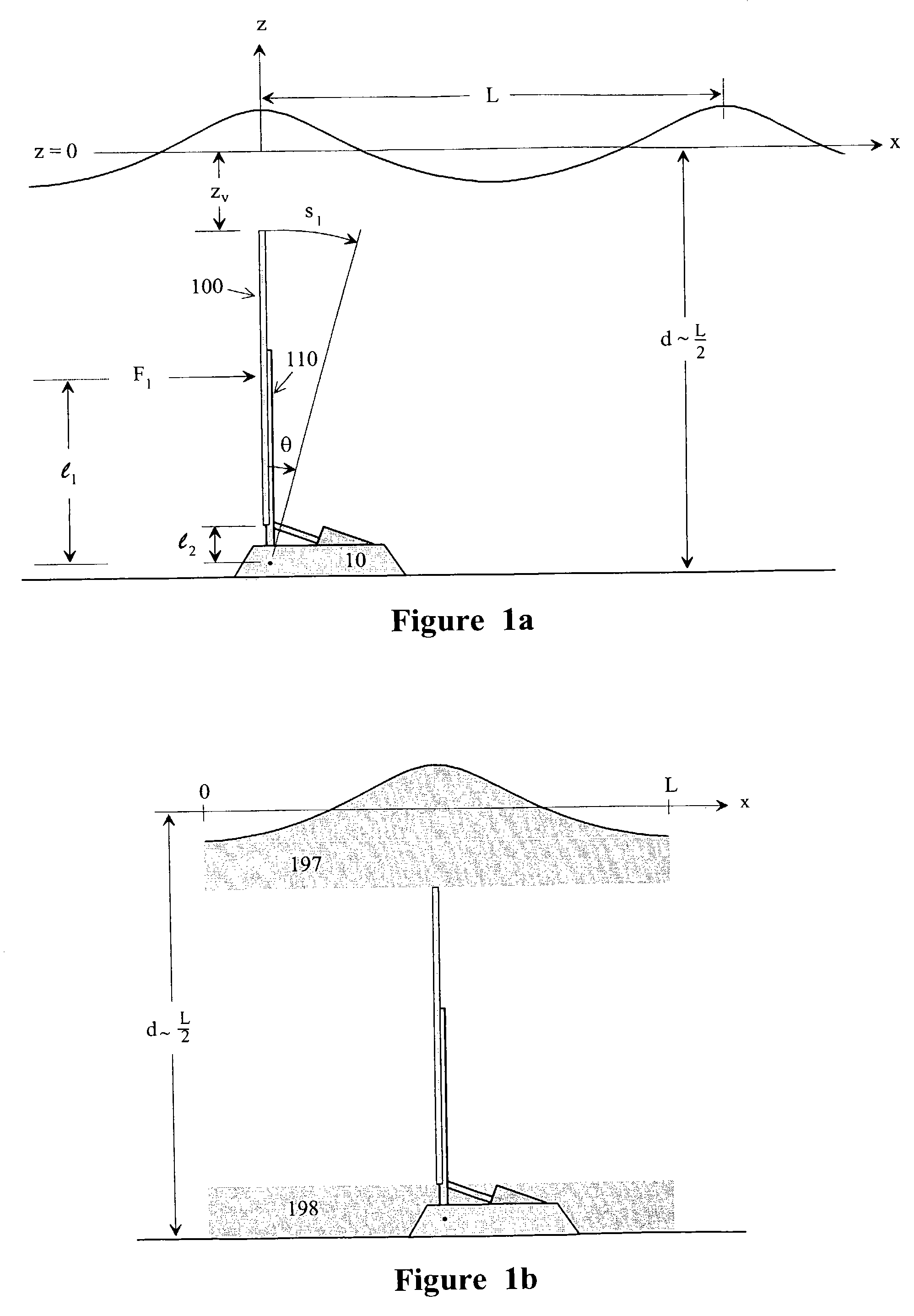

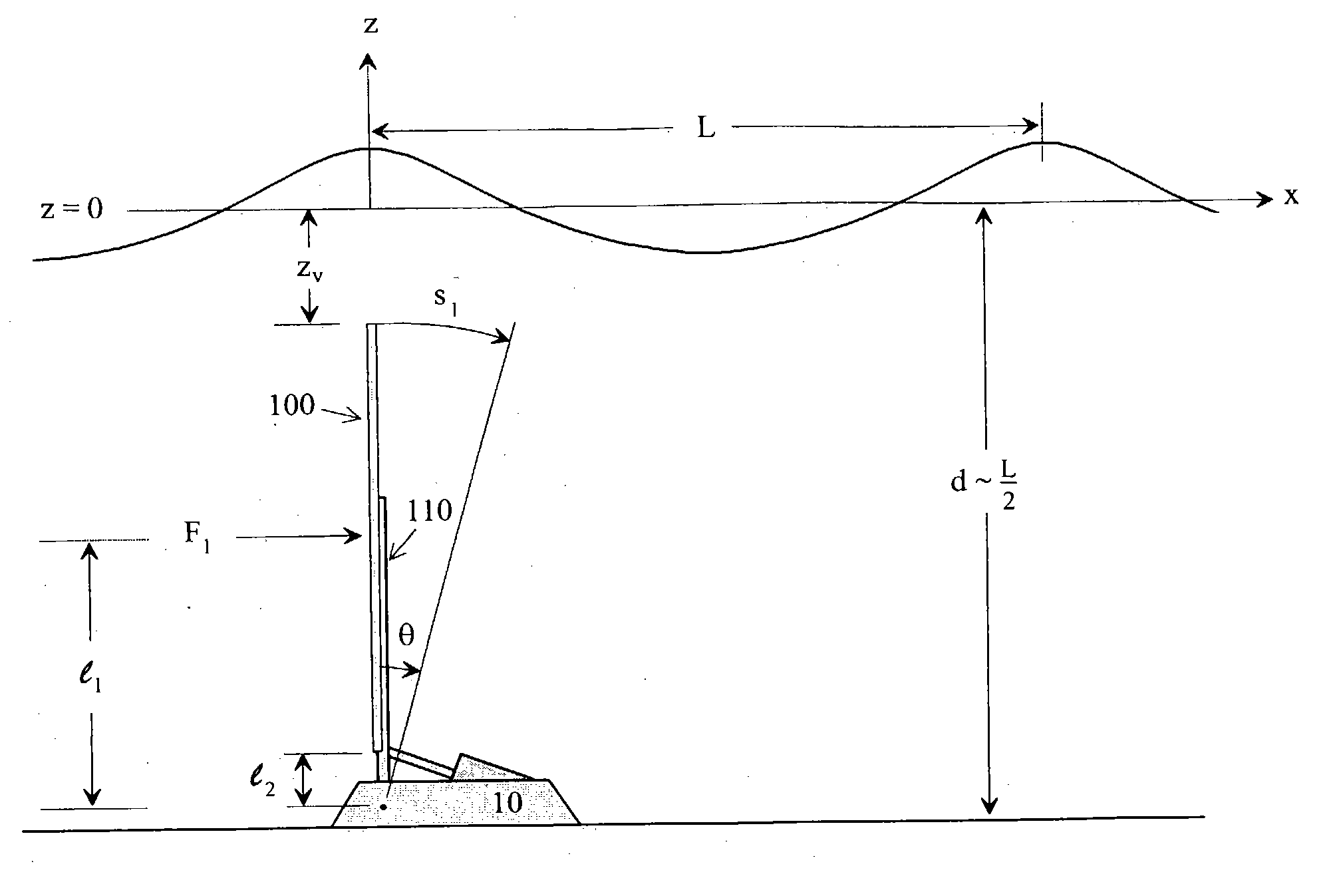

Wave energy conversion device for desalination, ETC

InactiveUS7023104B2Improve efficiencyEasy to operateWind motor controlGeneral water supply conservationWater qualityEngineering

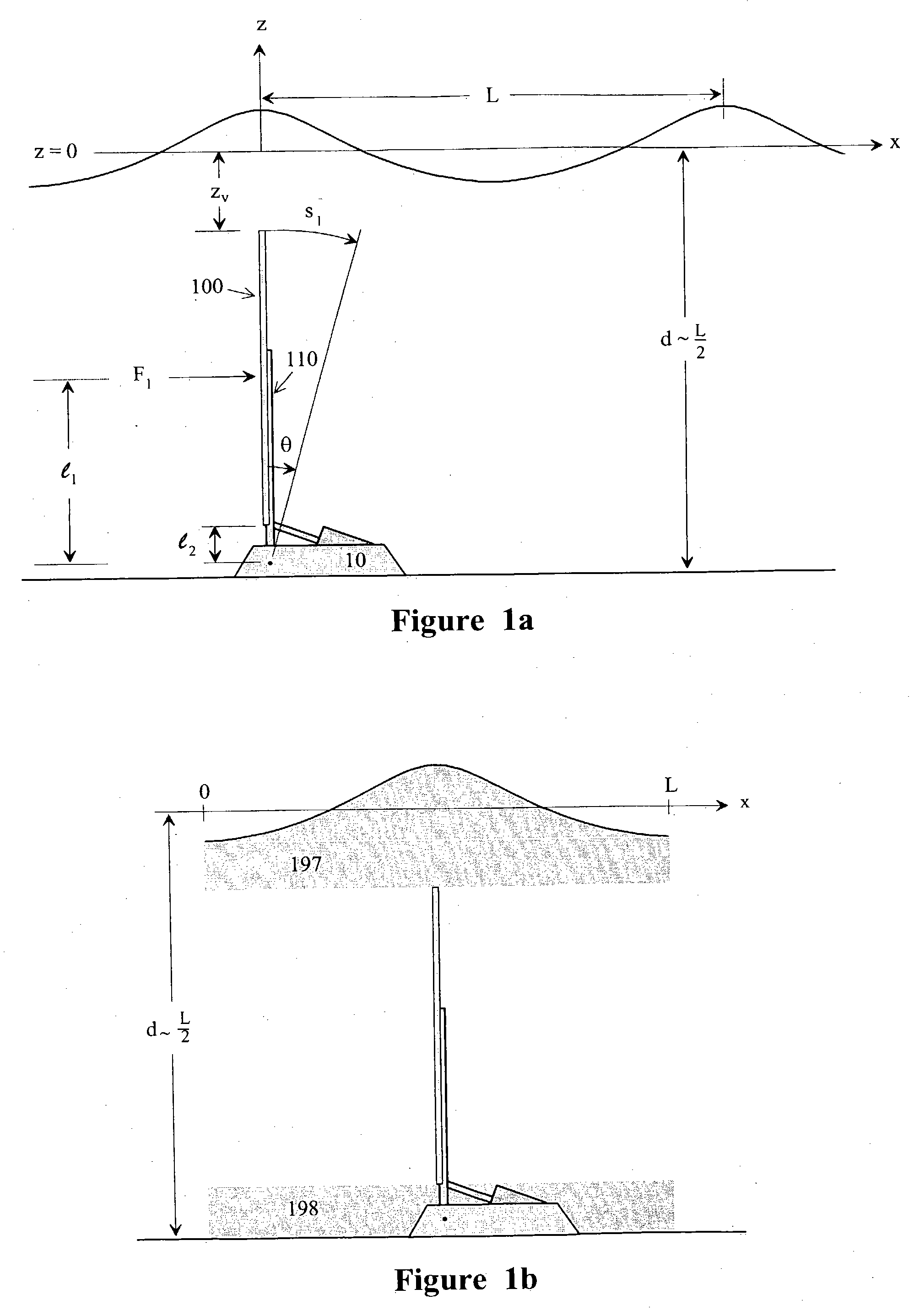

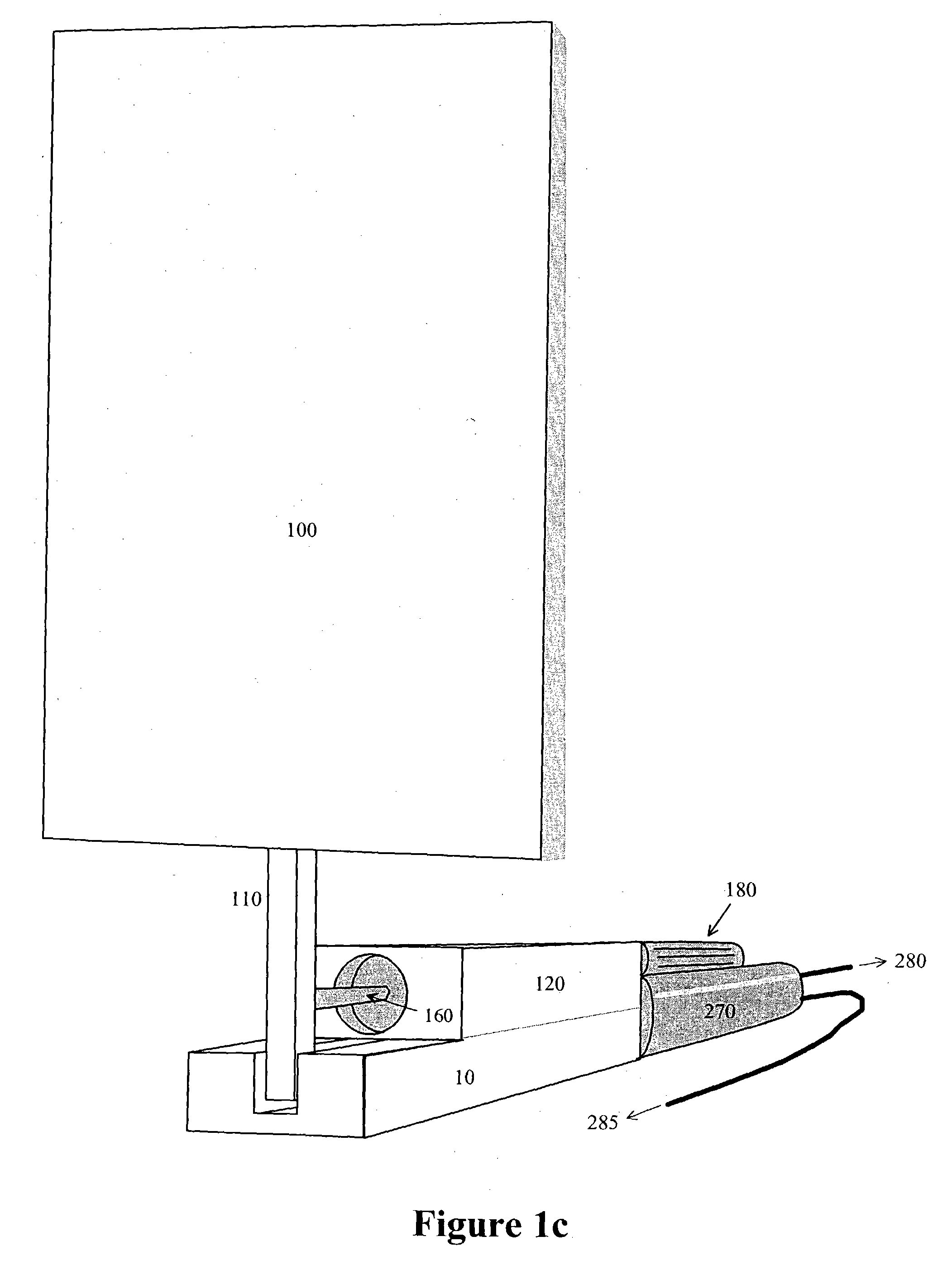

An impulse-type “wave motor” employs a seabed-mounted or supported structure mounting a wave energy absorbing panel on a hinged lever arm for reciprocation motion to obtain optimal absorption of wave energy from wave motion in the sea. For deepwater wavelengths of L, the panel is optimally positioned in a region within L / 2 depth from the sea surface. The panel motion is coupled by a connecting rod to a fluid pump which generates a high-pressure fluid output that may be used to drive a reverse osmosis desalination unit or to produce other useful work. Seawater or brackish water may be desalinated through reverse osmosis membranes to produce water quality for consumption, agricultural, or other uses. The submerged operating environment of the device in a region of one-half the design wavelength provides the maximum available energy flux and forced oscillations. The pump may be of the positive-displacement piston type, plunger type, or multi-staging driver type, or a variable volume pump.

Owner:KOBASHIKAWA ALVIN +1

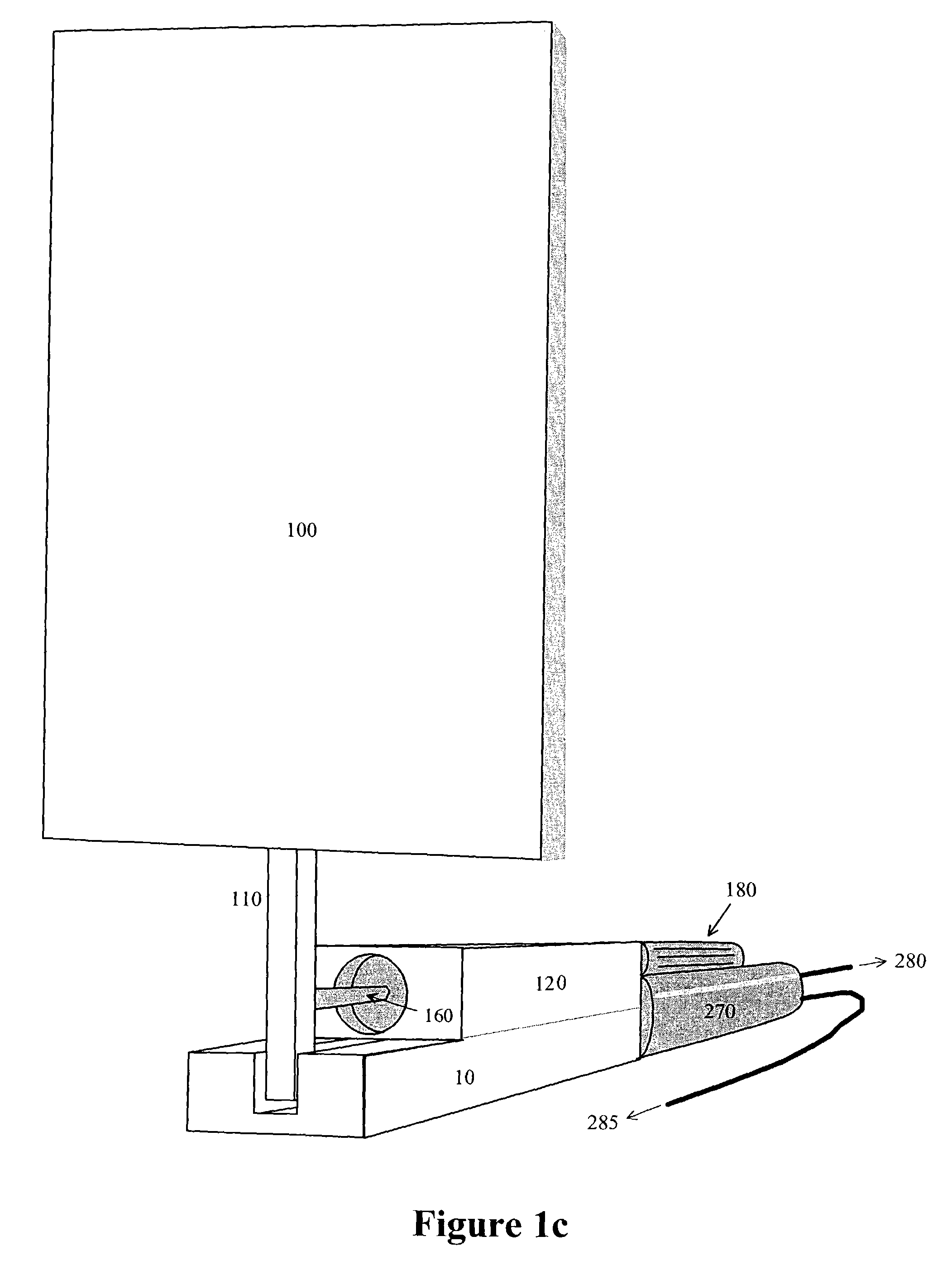

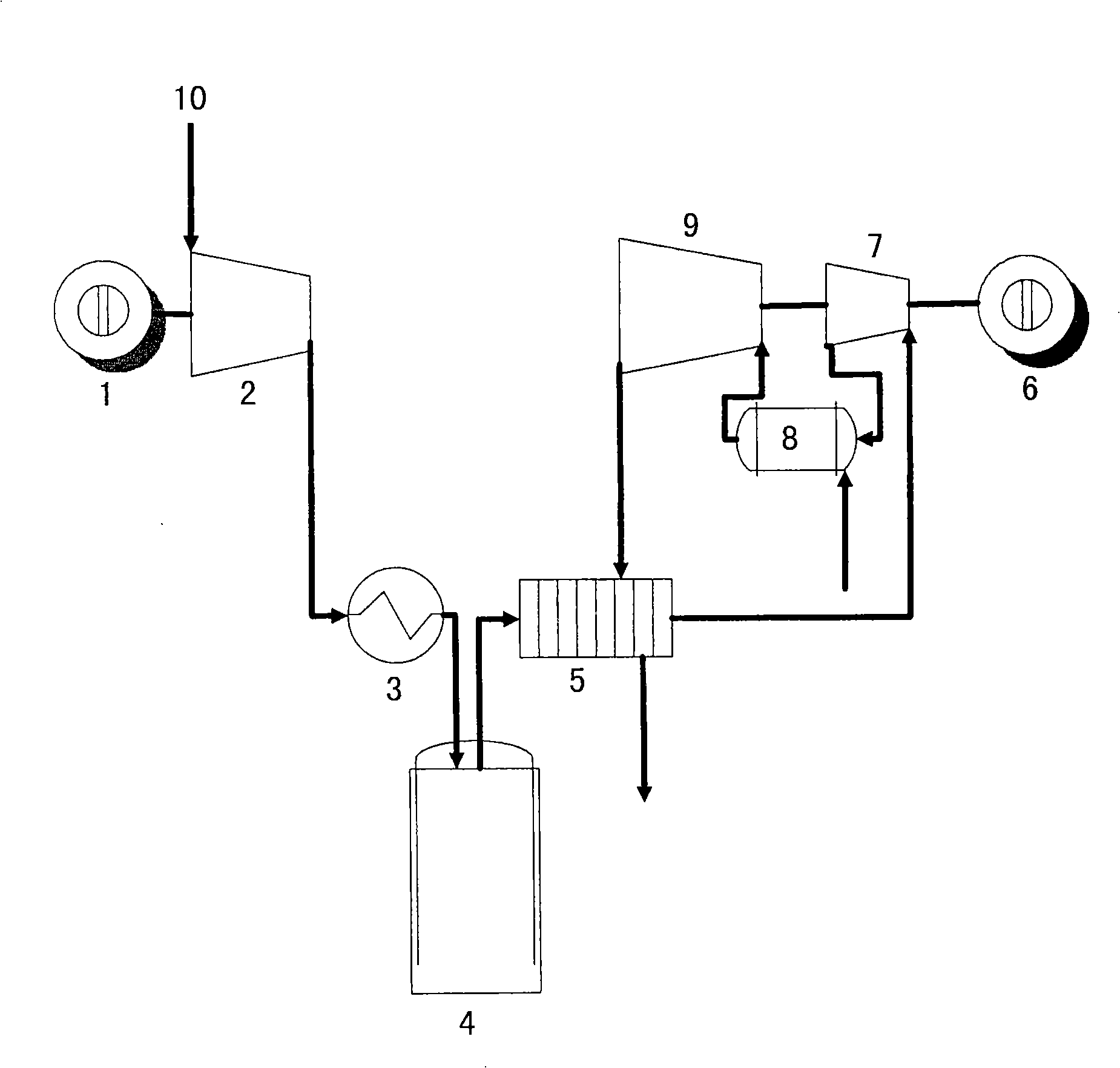

Compressed-air energy-storage system

The invention discloses a compressed air energy storage system, in particular to a compressed air energy storage system for an electric power system. The compressed air energy storage system disclosed by the invention has reasonable structure, flexible layout, high energy conversion efficiency, good economical efficiency and peakload regulation performance, rapid startup, safety and reliability. The compressed air energy storage system applying the invention can be used for despicking and valley filling of the electric power system, energy storage of renewable energy source and power supply when the renewable energy source is in supply intermission or in shortage in an electric network, and can be used as an emergency power station, an energy accumulator of distributed energy resource and other equipment for electric power energy storage.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

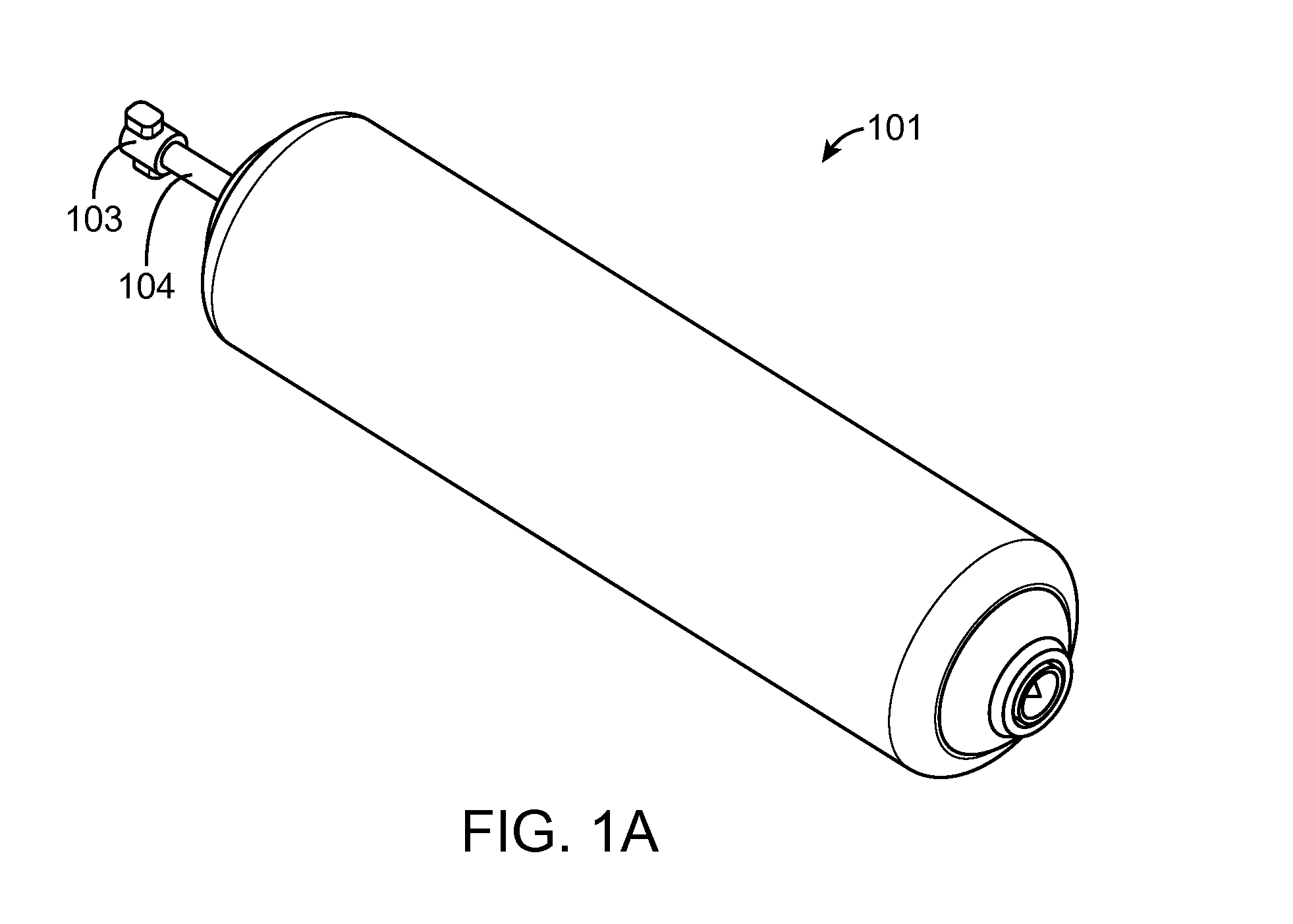

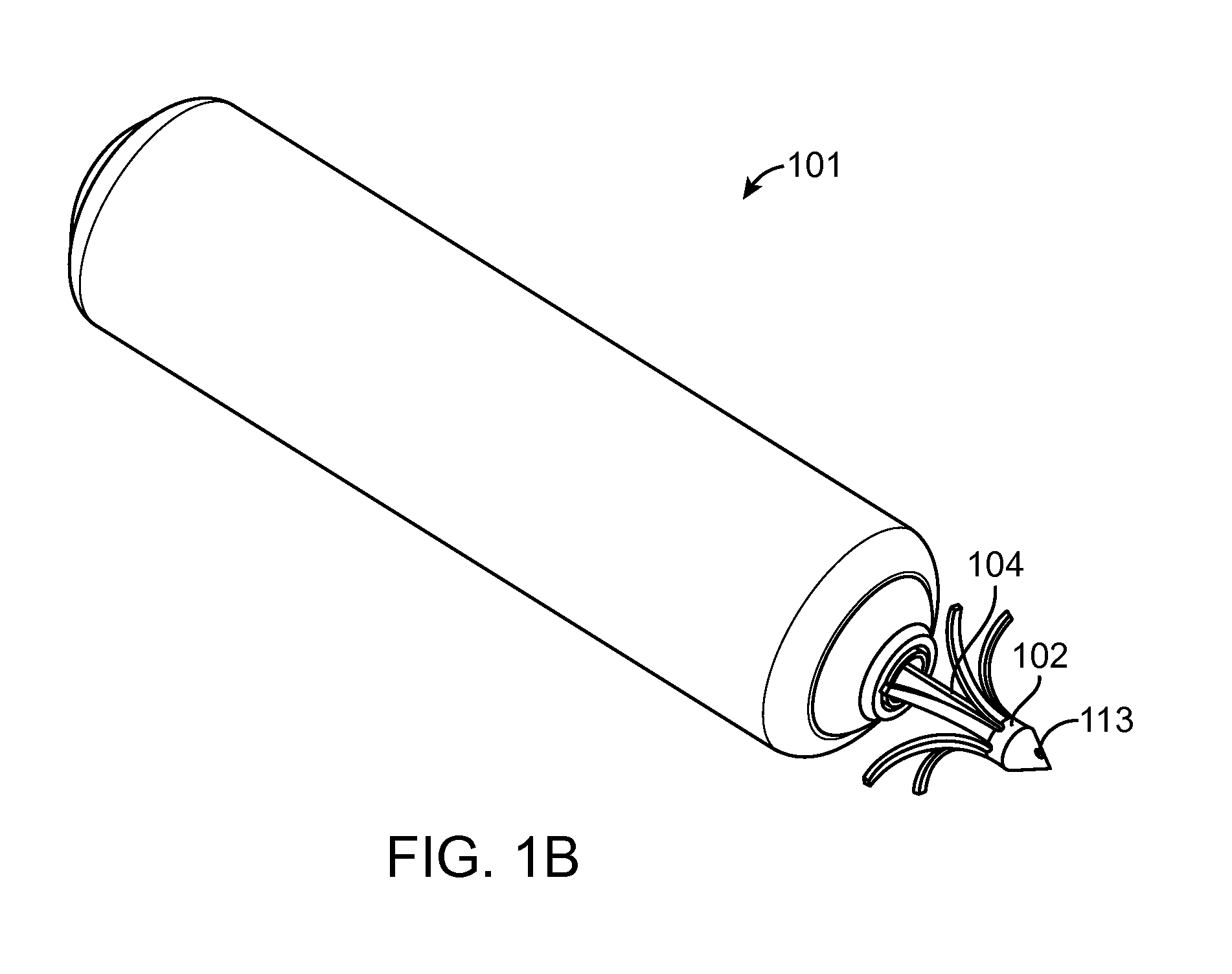

Implantable wireless accoustic stimulators with high energy conversion efficiencies

ActiveUS8588926B2Efficient HarvestingImprove isotropyPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectricityAcoustic energy

Receiver-stimulator with folded or rolled up assembly of piezoelectric components, causing the receiver-stimulator to operate with a high degree of isotropy are disclosed. The receiver-stimulator comprises piezoelectric components, rectifier circuitry, and at least two stimulation electrodes. Isotropy allows the receiver-stimulator to be implanted with less concern regarding the orientation relative the transmitted acoustic field from an acoustic energy source.

Owner:EBR SYST

Wave energy conversion device for desalination, ETC

InactiveUS20040007881A1Minimize exposureLow profileWind motor controlGeneral water supply conservationWater qualityWave motor

An impulse-type "wave motor" employs a seabed-mounted or supported structure mounting a wave energy absorbing panel on a hinged lever arm for reciprocation motion to obtain optimal absorption of wave energy from wave motion in the sea. For deepwater wavelengths of L, the panel is optimally positioned in a region within L / 2 depth from the sea surface. The panel motion is coupled by a connecting rod to a fluid pump which generates a high-pressure fluid output that may be used to drive a reverse osmosis desalination unit or to produce other useful work. Seawater or brackish water may be desalinated through reverse osmosis membranes to produce water quality for consumption, agricultural, or other uses. The submerged operating environment of the device in a region of one-half the design wavelength provides the maximum available energy flux and forced oscillations. The pump may be of the positive-displacement piston type, plunger type, or multi-staging driver type, or a variable volume pump.

Owner:KOBASHIKAWA ALVIN +1

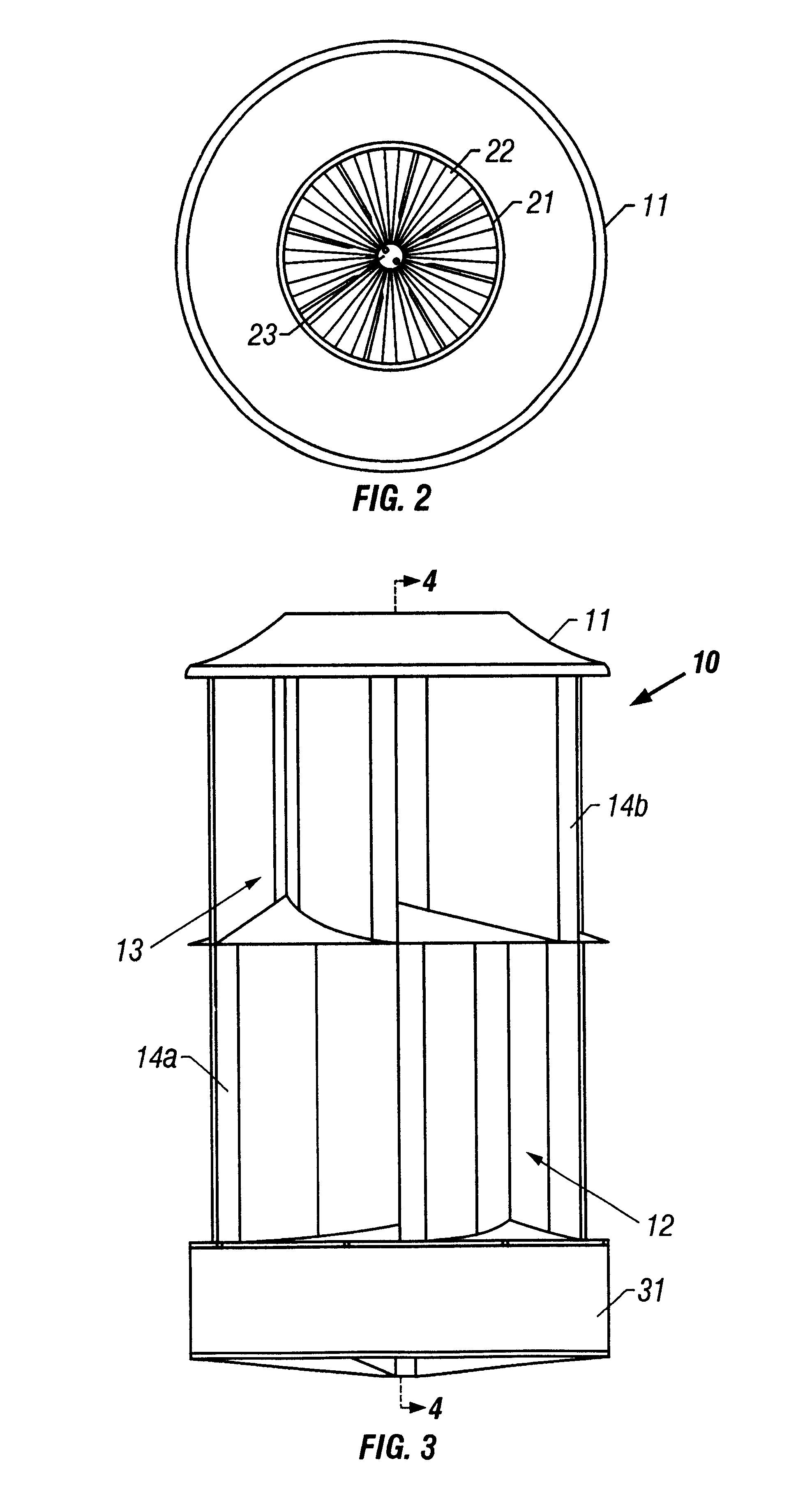

Fluid-powered energy conversion device

InactiveUS6518680B2Velocity increasesReducing start-up inertiaWind motor controlWind energy with kinetic energyMomentumTurbine blade

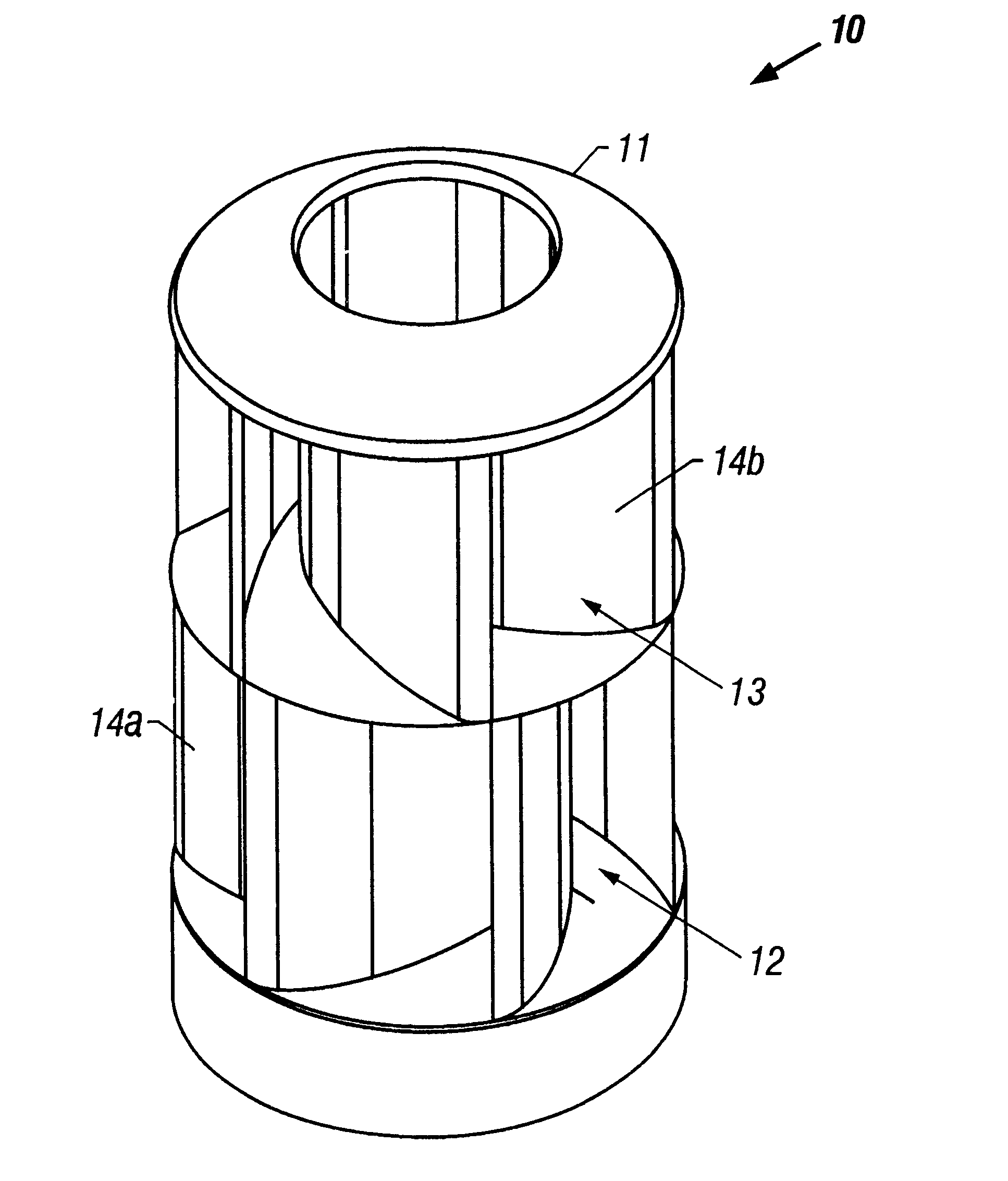

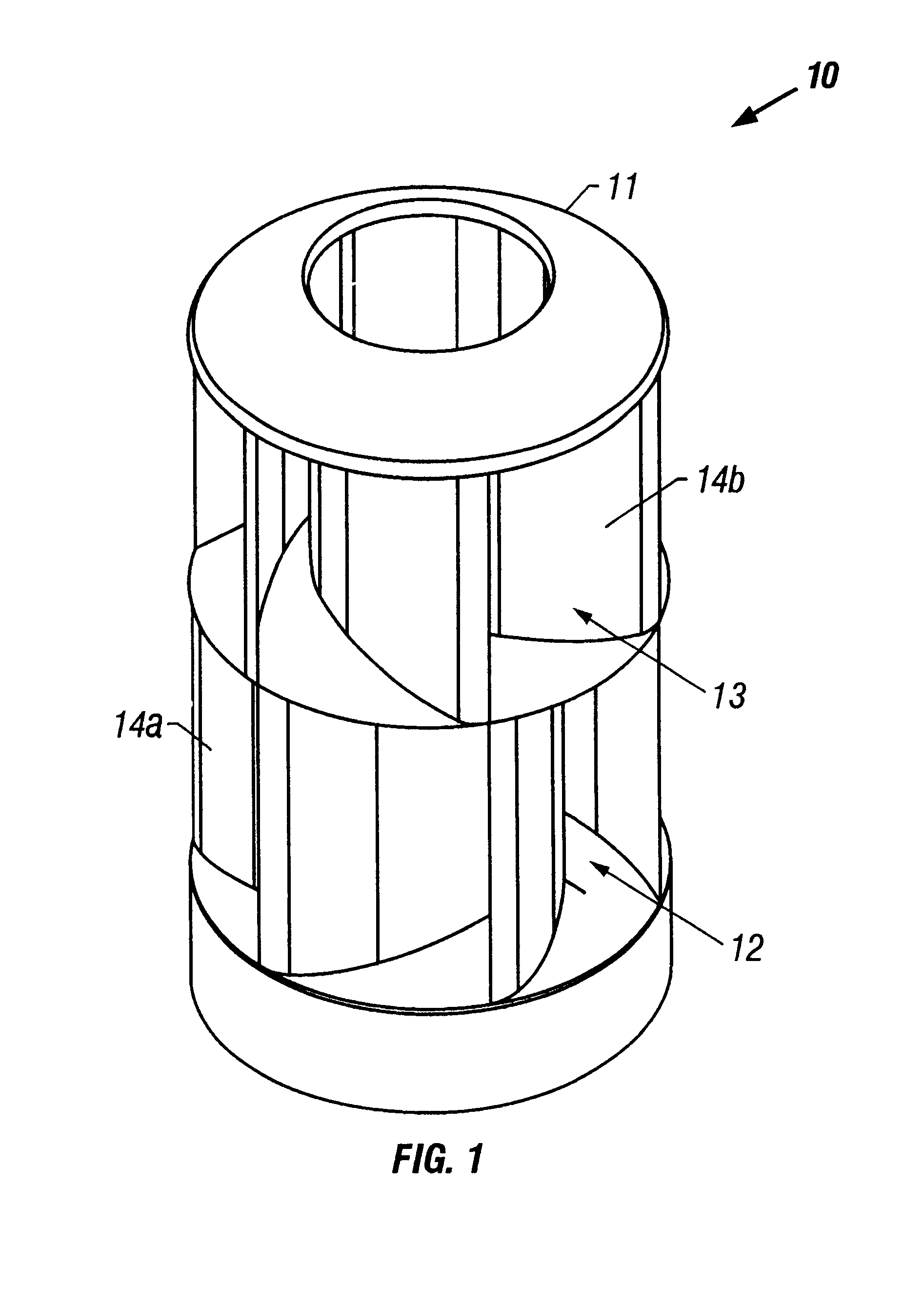

A fluid-powered energy conversion device for converting energy in a moving fluid such as air into mechanical energy. A rigid cylindrical frame includes an upstream annular chamber and a downstream annular chamber, each of the chambers having sides that are open to allow entry of the wind. A plurality of longitudinal baffles form a toroidal pattern that creates an upstream drive vortex in the upstream chamber, and a downstream extraction vortex rotating in the opposite direction in the downstream chamber. The drive vortex rises and changes direction as it passes through a turbine mounted on a longitudinal drive shaft in a central aperture between the chambers. The turbine is rotated by the rotational momentum of the drive vortex, by lift that is generated by each turbine blade, and by additional momentum that is created by the vortex reversal.

Owner:MCDAVID JR WILLIAM K

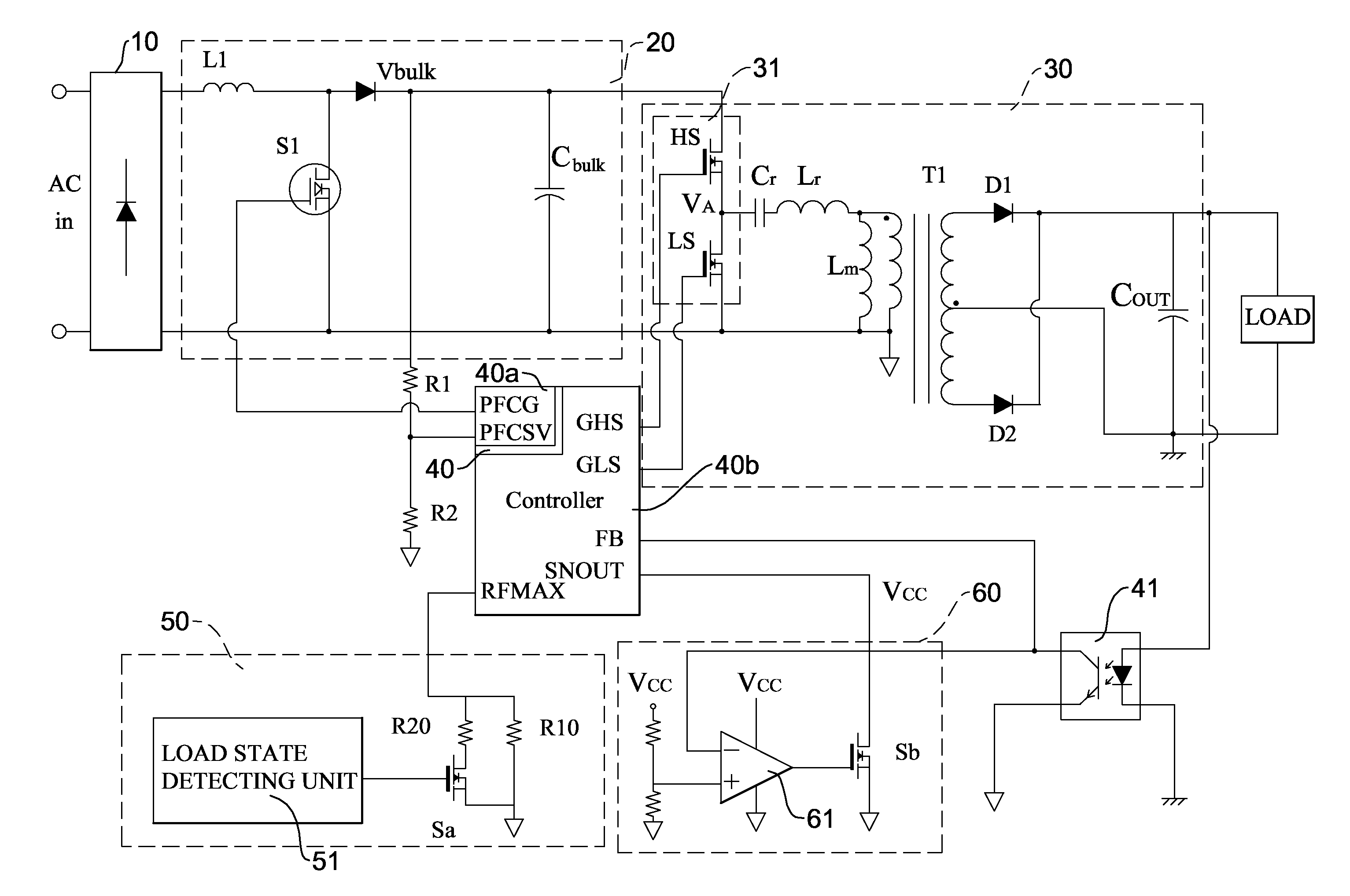

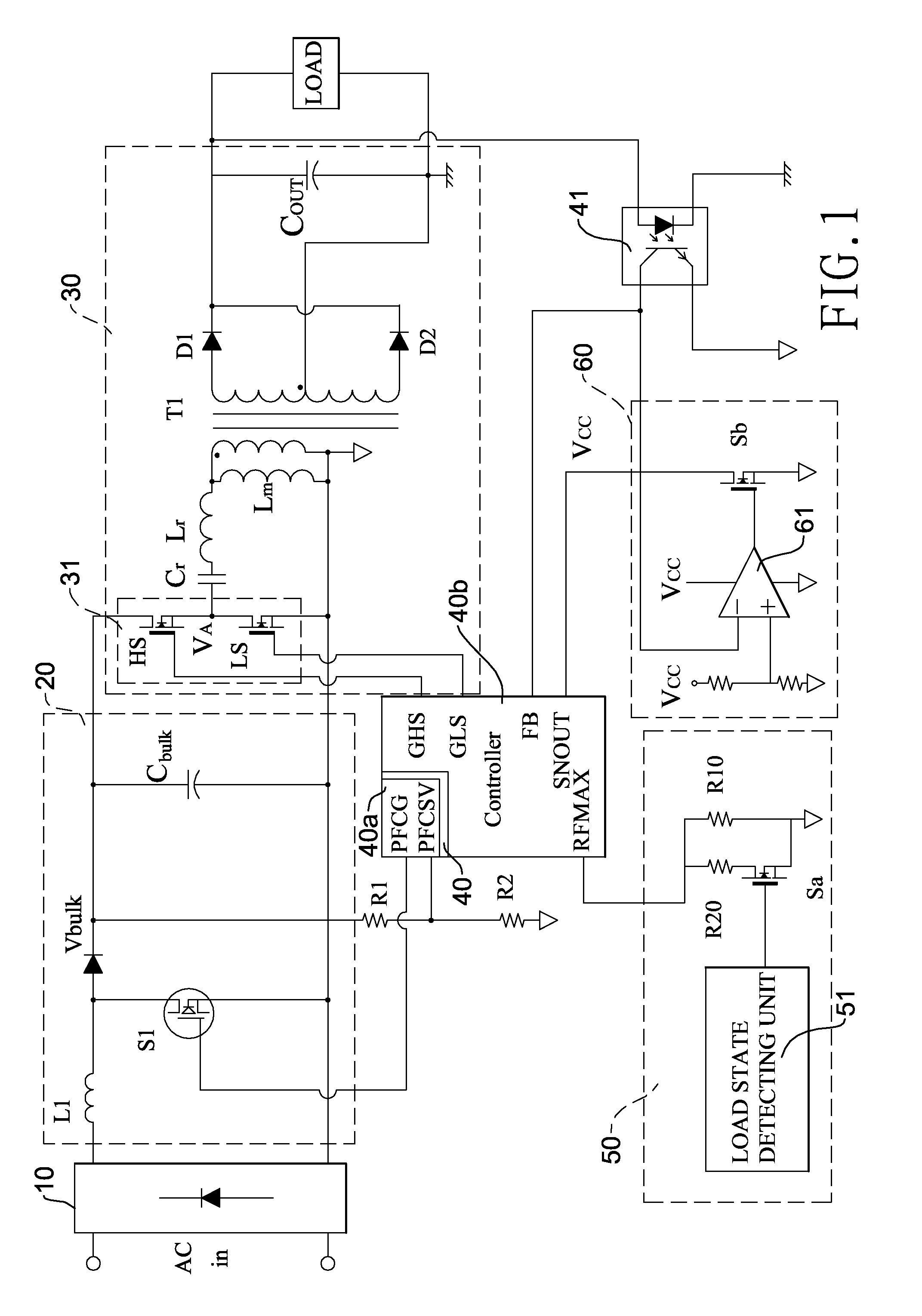

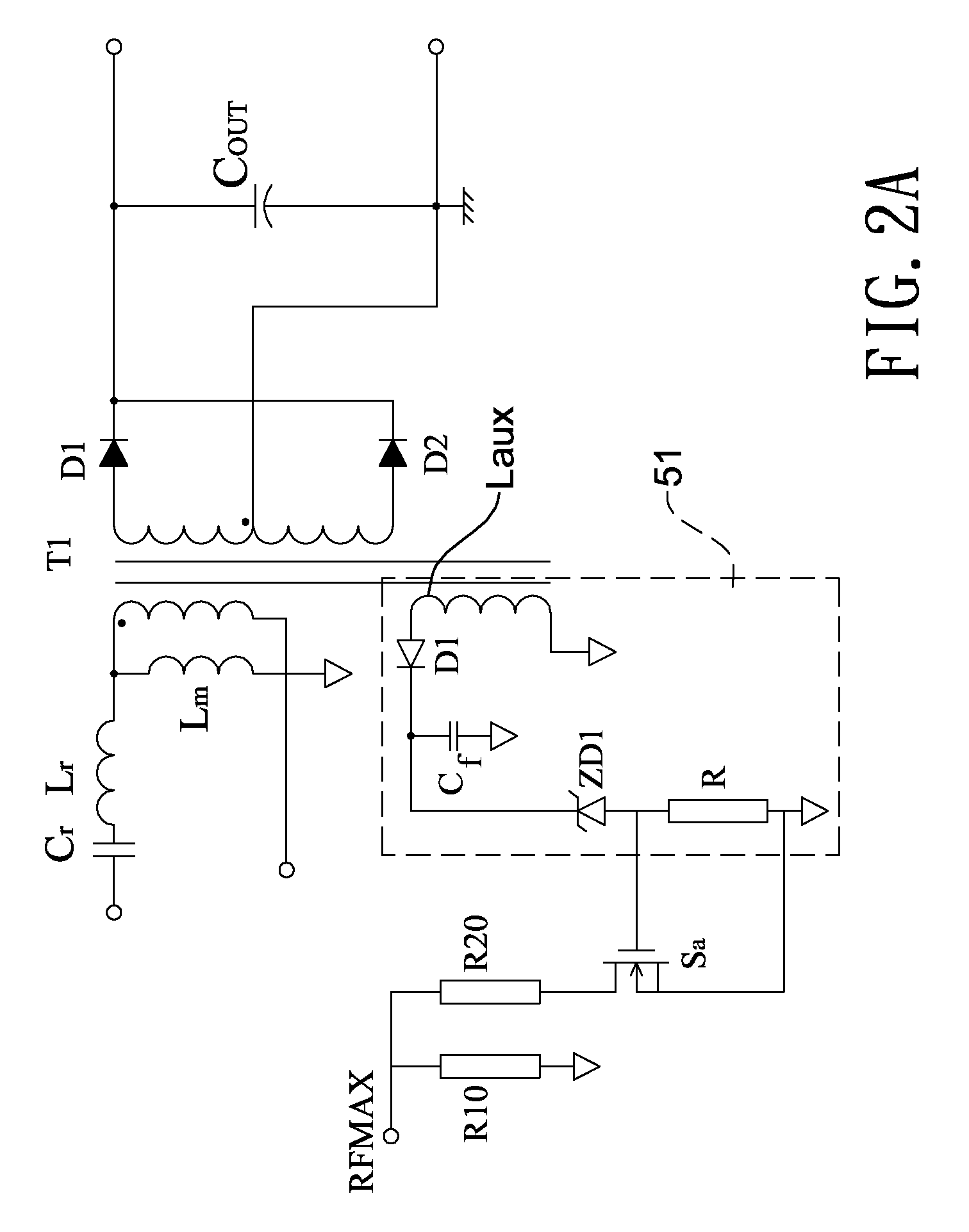

Burst mode resonant power converter with high conversion efficiency

InactiveUS20110085354A1Improve conversion efficiencyLowering maximum switch frequencyEfficient power electronics conversionDc-dc conversionTransformerResonant power converters

A burst mode resonant power converter with high conversion efficiency has a rectifier, a power factor correction circuit, a resonant circuit, a controller, and a burst mode triggering unit. The maximum frequency switching end of the controller is connected to a maximum frequency variable circuit. When the load is medium or heavy, the maximum frequency variable circuit increases the maximum switch frequency of the controller. When the load is in the no-load or the light conditions, it reduces the maximum switch frequency thereof. Therefore, the controller reduces the number of times that the resonant circuit switches the bridge switch circuit. The conduction cycle of the 50% pulse signal output to the bridge switch circuit becomes longer. Larger energy can be transmitted at a time to the secondary coil of the transformer. This increases the overall efficiency.

Owner:ACBEL POLYTECH INC

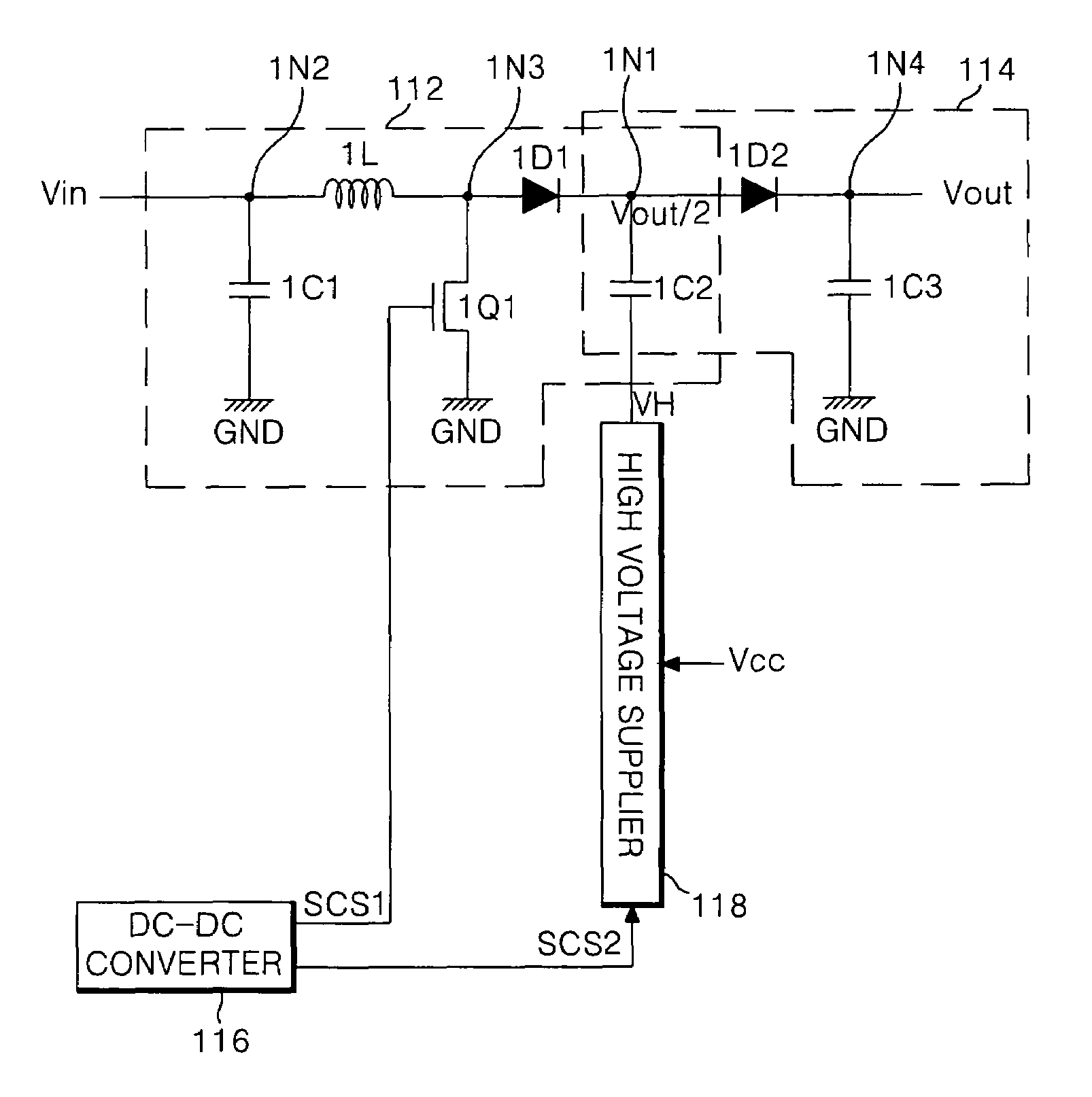

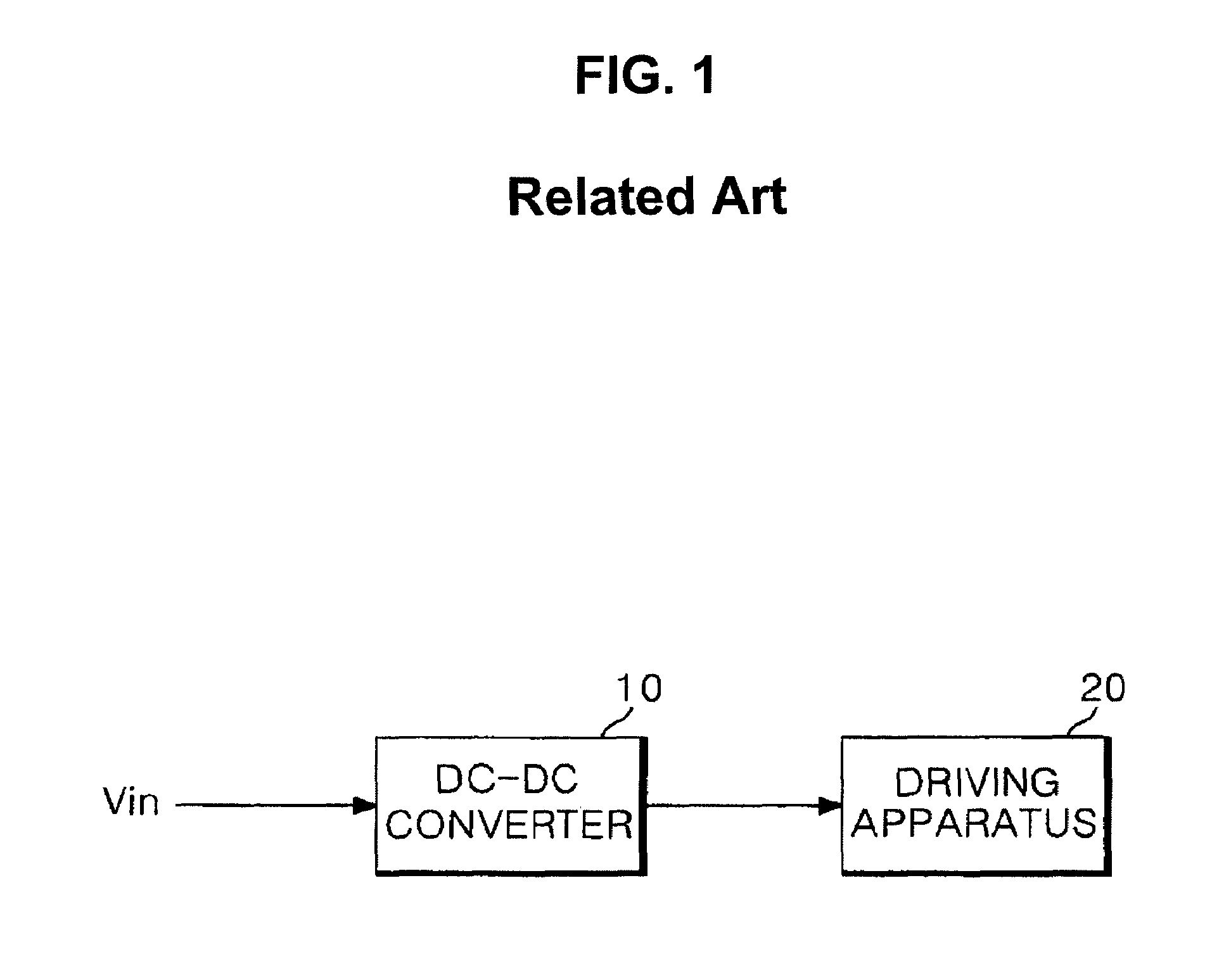

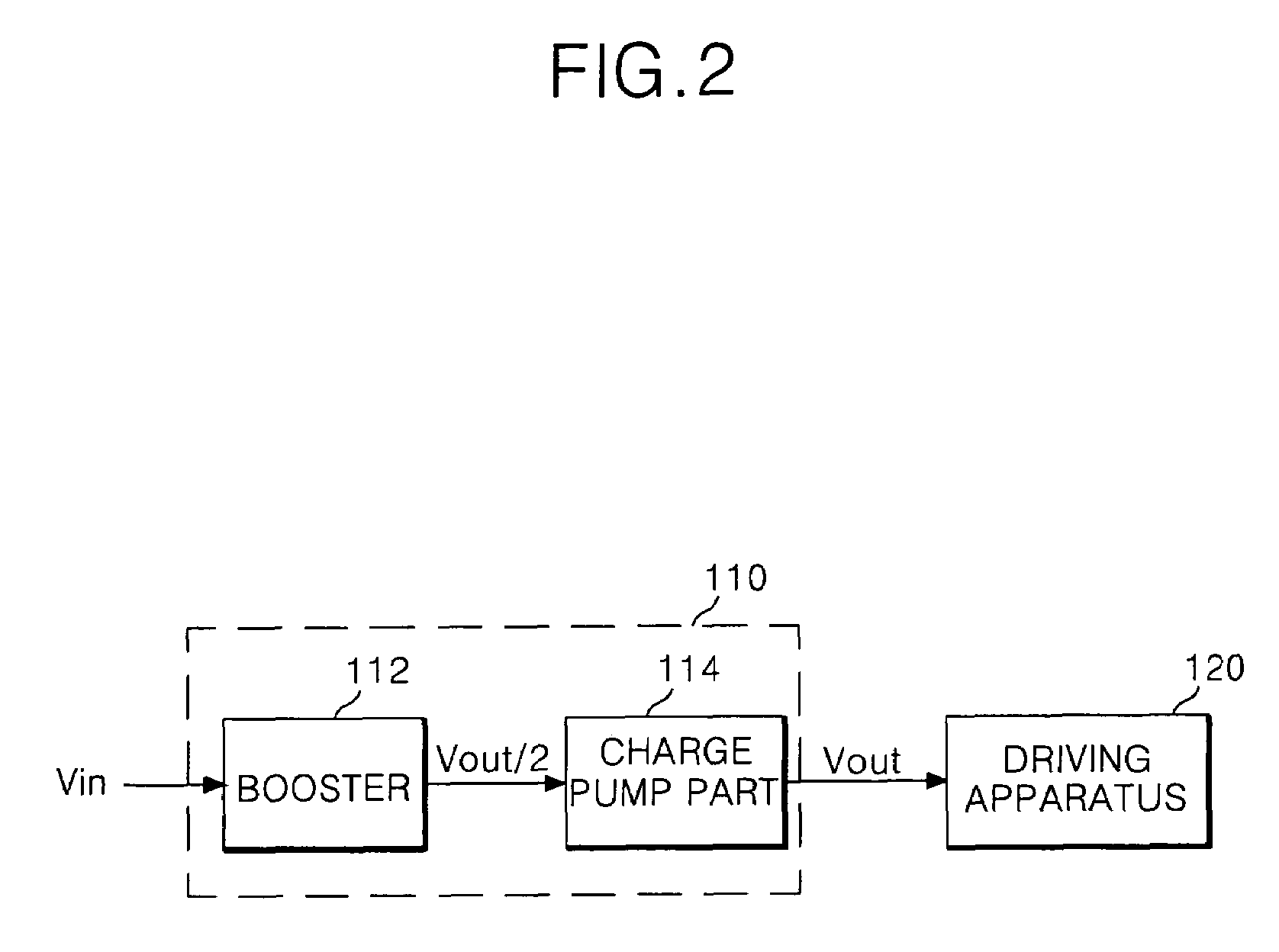

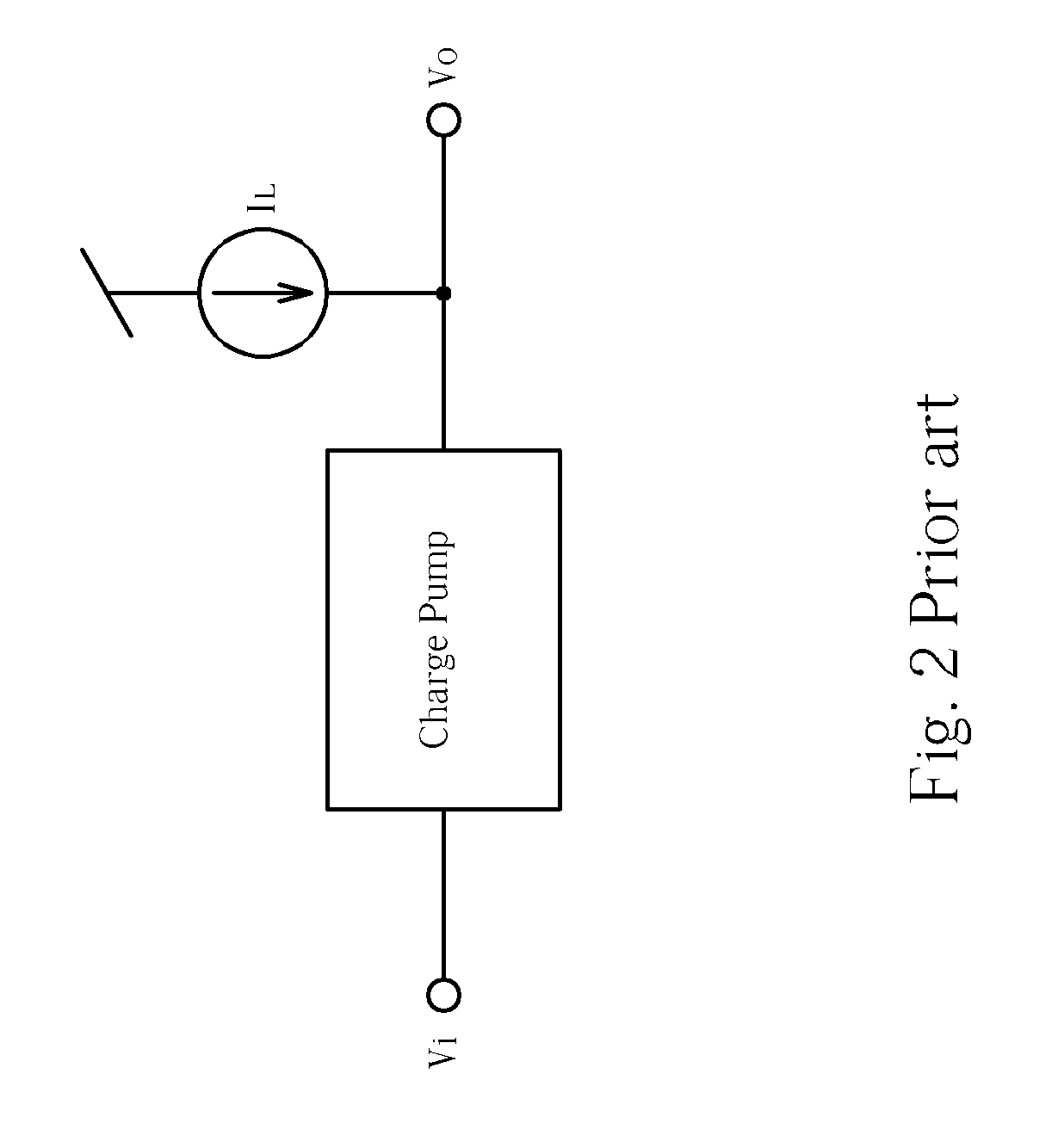

Power supply and driving method thereof and apparatus and method for driving electro-luminescence display device using the same

InactiveUS7528807B2Improve energy conversion efficiencyElectroluminescent light sourcesSolid-state devicesDc dc converterDisplay device

The present invention relates to a power supply that is adaptive for improving energy conversion efficiency and a driving method thereof and an apparatus and method for driving an electroluminescence display device using the same. A power supply that supplies a driving power to drive a driving apparatus according to an embodiment of the present invention includes a power source to supply DC power; and a DC-DC converter to convert the DC power from the power source to a level of 1 / N (provided that N is a positive integer of not less than 2) times the driving power, and then to convert the converted DC power of 1 / N times to a level of the driving power.

Owner:LG ELECTRONICS INC

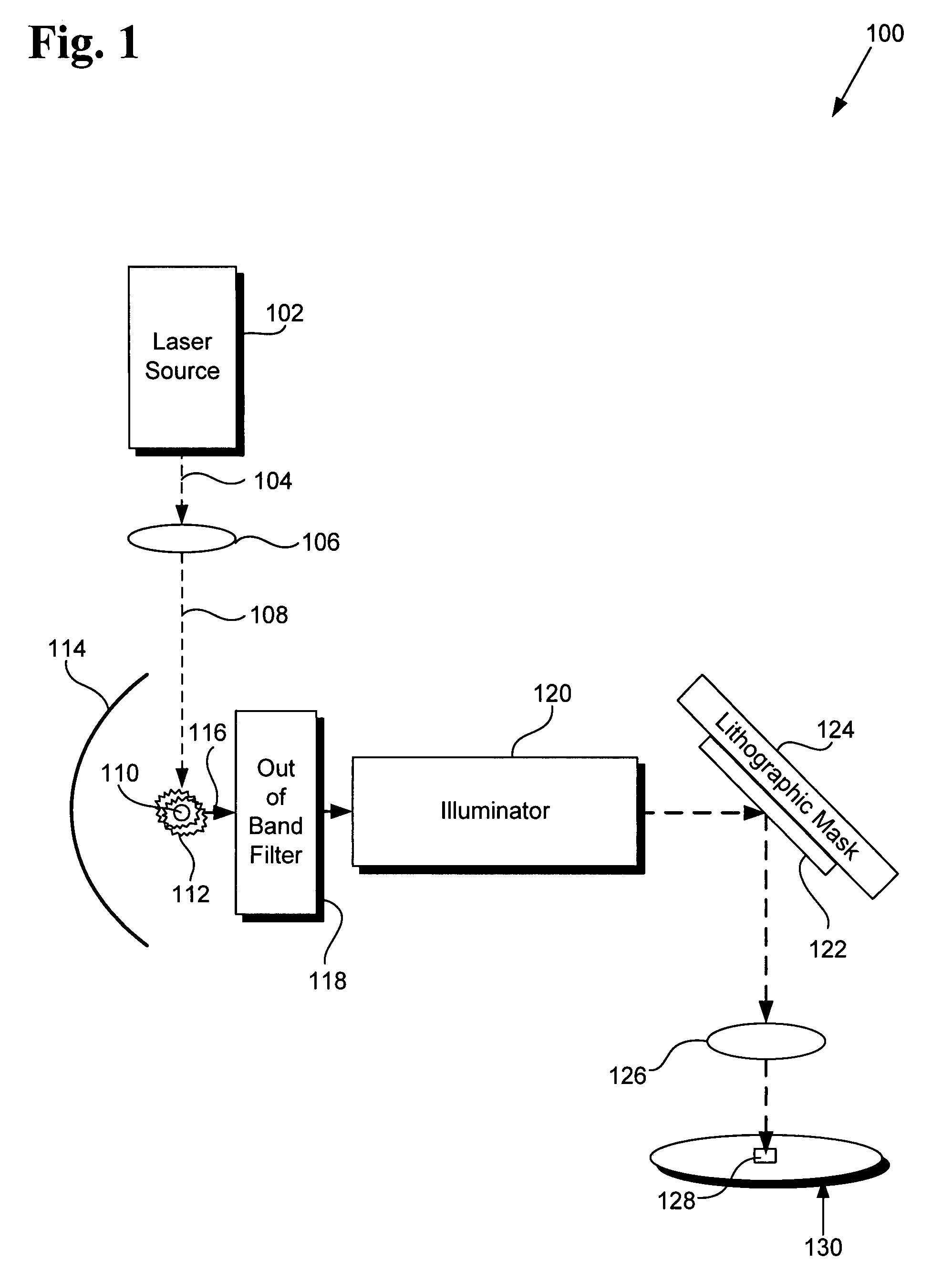

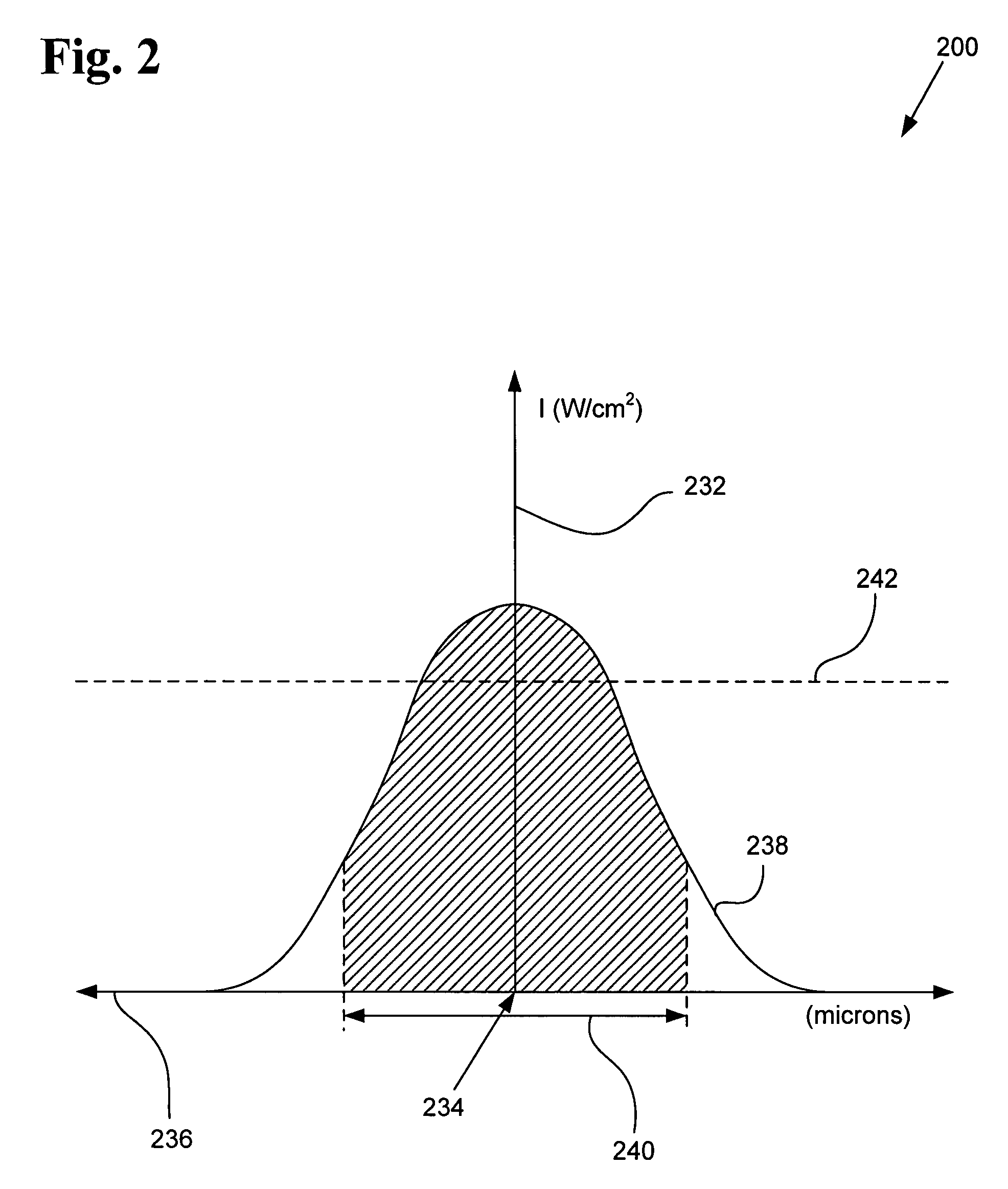

Laser beam formatting module and method for fabricating semiconductor dies using same

Owner:GLOBALFOUNDRIES U S INC

Fabrication of single absorber layer radiated energy conversion device

InactiveUS6180432B1Semiconductor/solid-state device manufacturingPhotovoltaic energy generationDiffusionSemiconductor materials

Owner:INTERFACE STUDIES

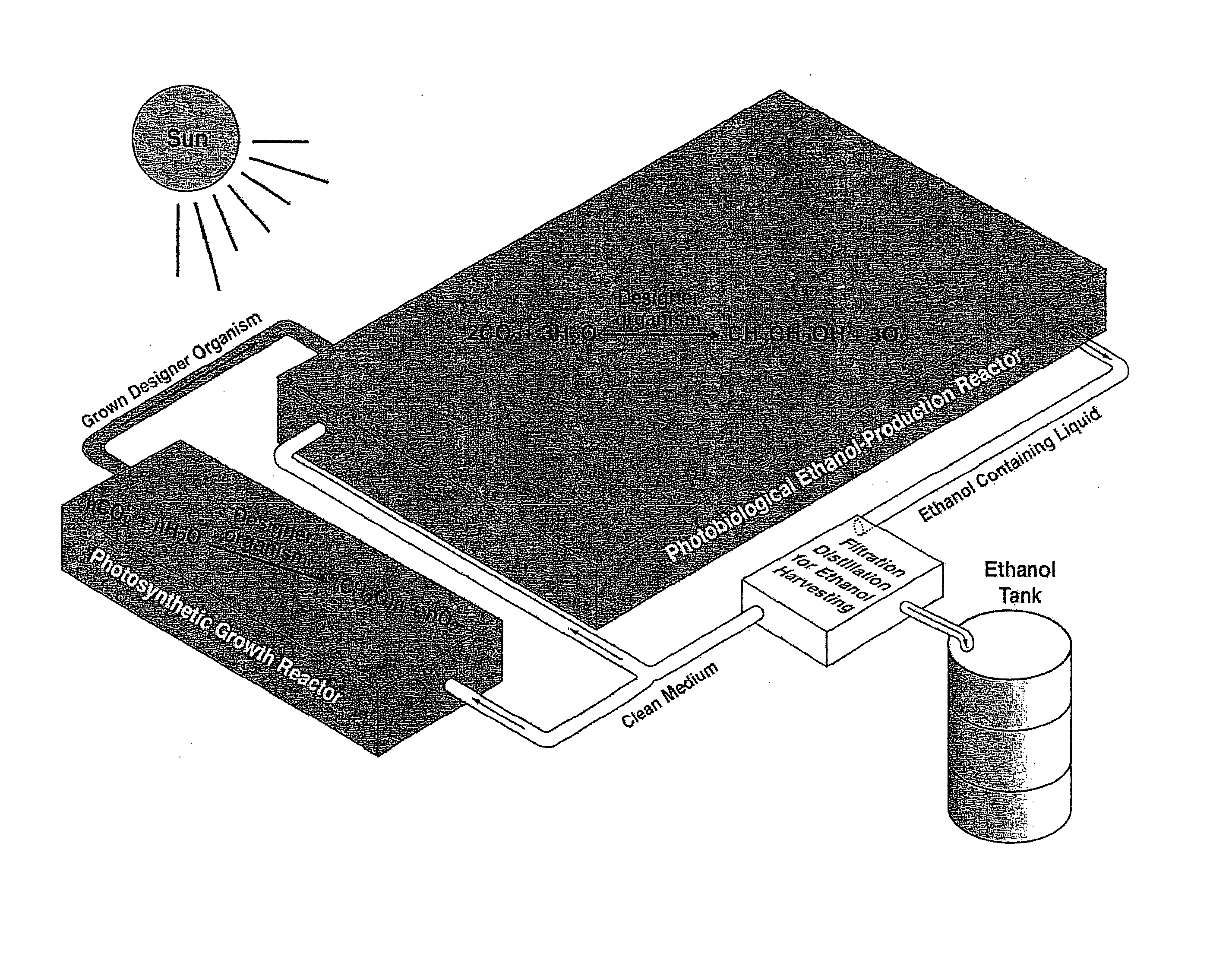

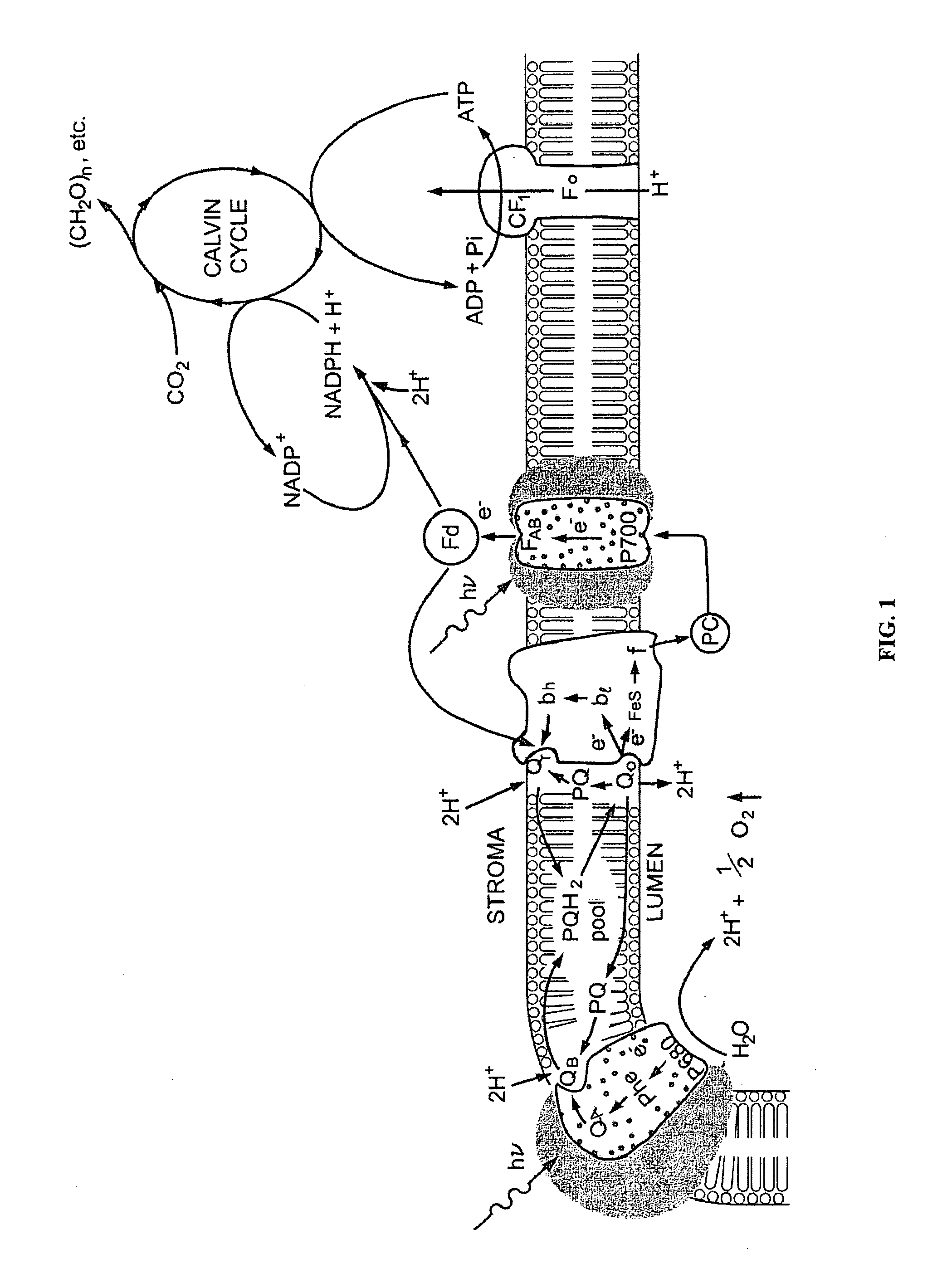

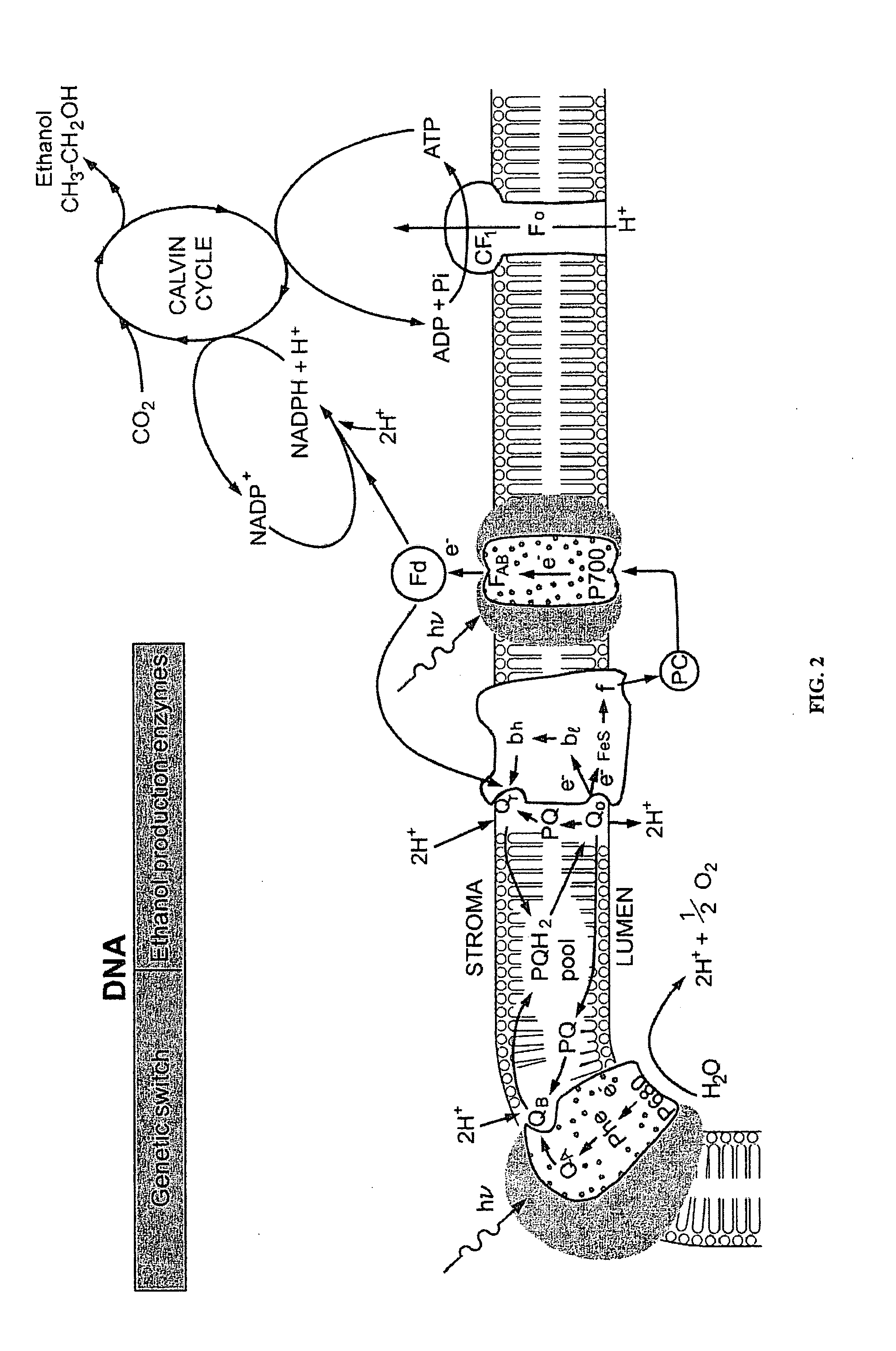

Designer Organisms for photosynthetic production of ethanol from carbon dioxide and water

The present invention provides a revolutionary photosynthetic ethanol production technology based on designer transgenic plants, algae, or plant cells. The designer plants, designer algae, and designer plant cells are created such that the endogenous photosynthesis regulation mechanism is tamed, and the reducing power (NADPH) and energy (ATP) acquired from the photosynthetic water splitting and proton gradient-coupled electron transport process are used for immediate synthesis of ethanol (CH3CH2OH) directly from carbon dioxide (CO2) and water (H2O). The ethanol production methods of the present invention completely eliminate the problem of recalcitrant lignocellulosics by bypassing the bottleneck problem of the biomass technology. The photosynthetic ethanol-production technology of the present invention is expected to have a much higher solar-to-ethanol energy-conversion efficiency than the current technology and could also help protect the Earth's environment from the dangerous accumulation of CO2 in the atmosphere.

Owner:UT BATTELLE LLC

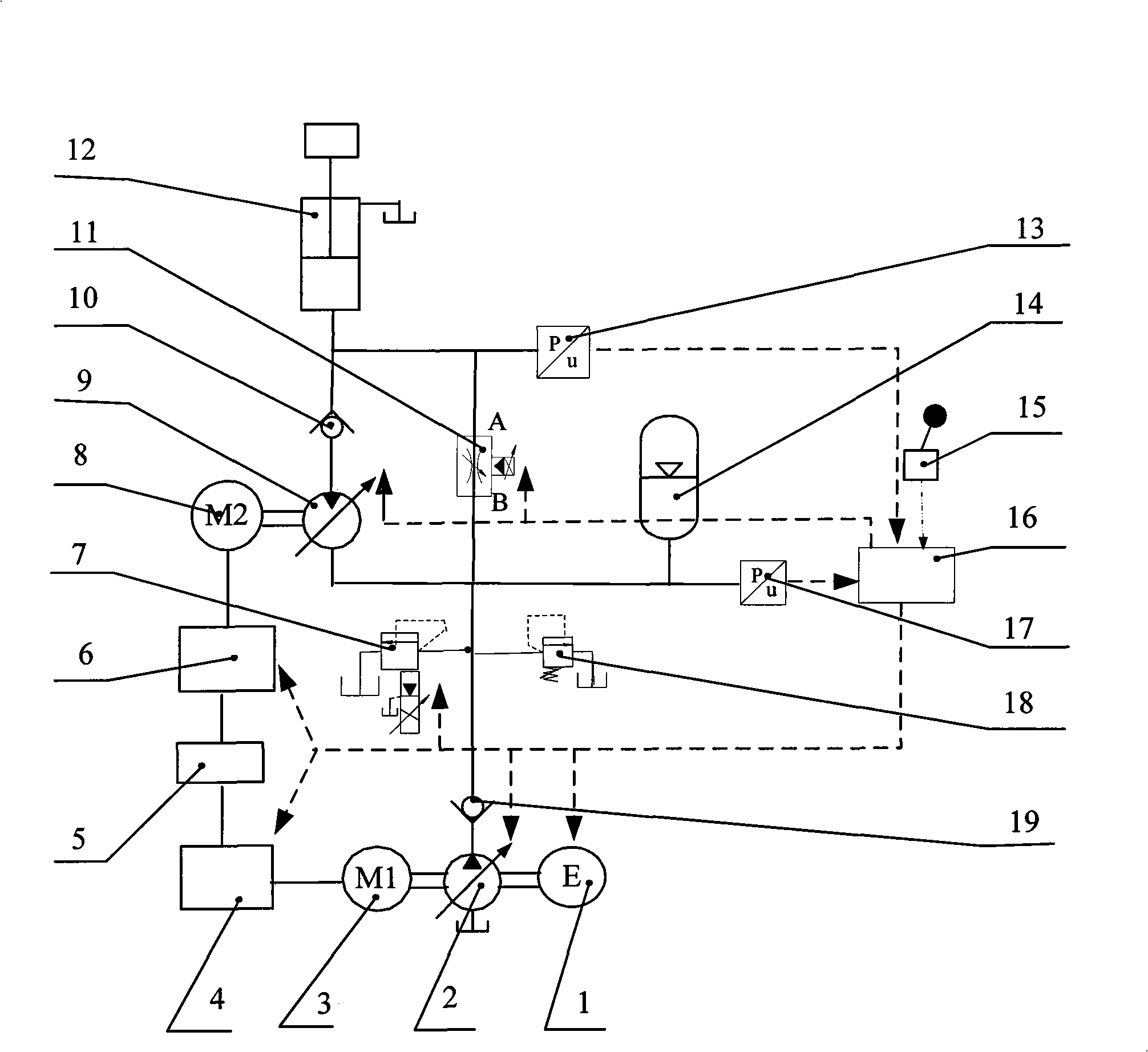

Energy recovery system of hybrid power engineering machinery energy accumulator-hydraulic motor

InactiveCN101408213AHigh specific powerFast absorptionAccumulator installationsGas pressure propulsion mountingHydraulic motorEnergy recovery

The invention discloses a hybrid power engineering mechanical accumulator-hydraulic motor energy recovery system. The system mainly comprises an engine, a variable pump, variable frequency motors, a variable motor, a signal control unit, an accumulator and a hydraulic implementation element, and the like. In the system, the variable motor is coaxially connected with a variable frequency motor M2 and forms a composite energy recovery system with the accumulator so as to recover the gravitational potential energy and braking energy in the lowering process of an implementation mechanism. The variable pump, the engine and a variable frequency motor M1 are coaxially connected; a hybrid power system which consists of the engine and the variable frequency motor M1 drives the hydraulic implementation mechanism to rise and lift heavy objects together with the accumulator. The system overcomes the defects that the variable motor-power generator energy recovery system responds slowly and the specific energy of the accumulator is low, enhances the dynamic response performance of the energy recovery system, improves the working conditions of power generation of an electric generator, and simultaneously can directly recover part of potential energy by the accumulator, thus raising the energy recovery efficiency of the system.

Owner:ZHEJIANG UNIV

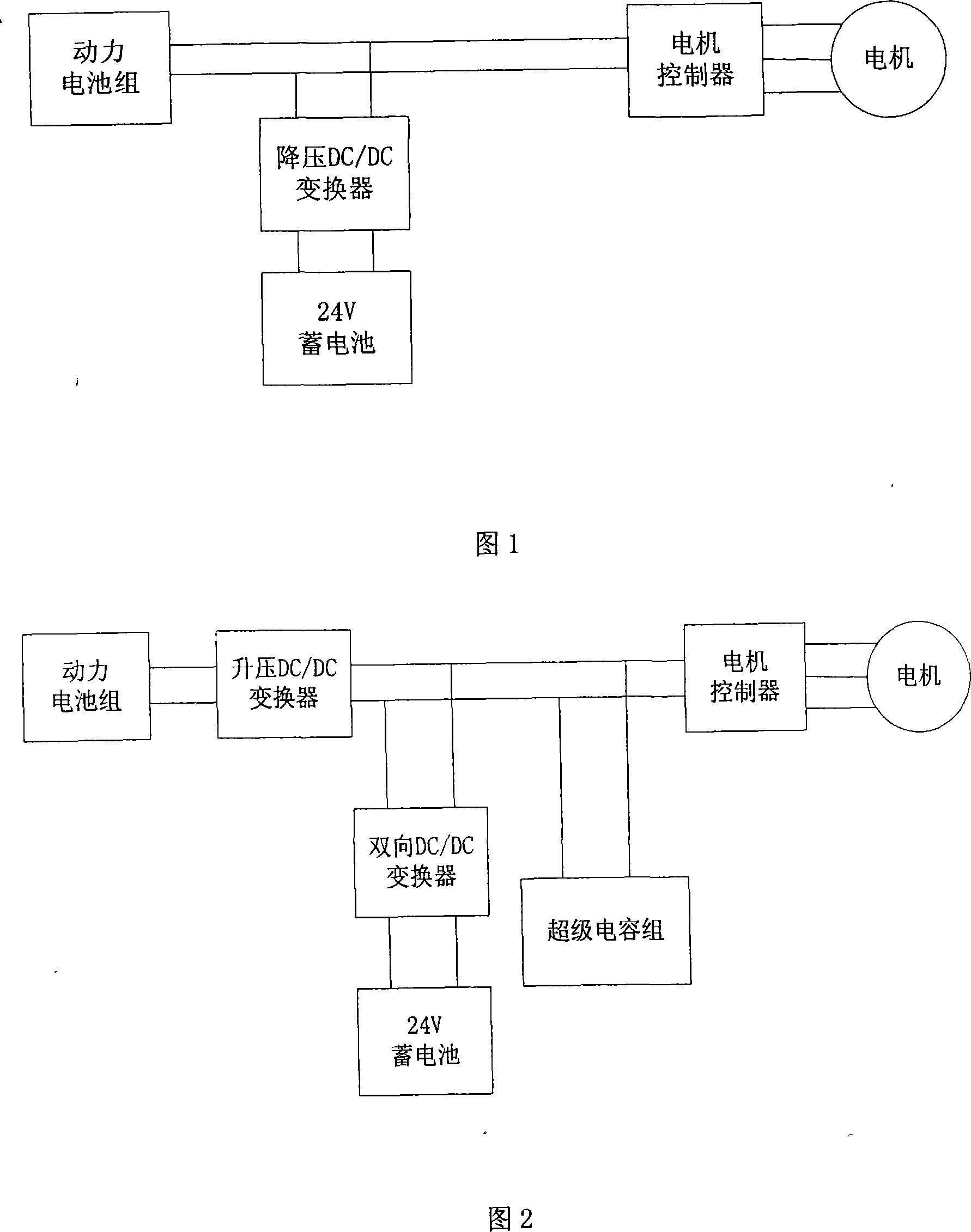

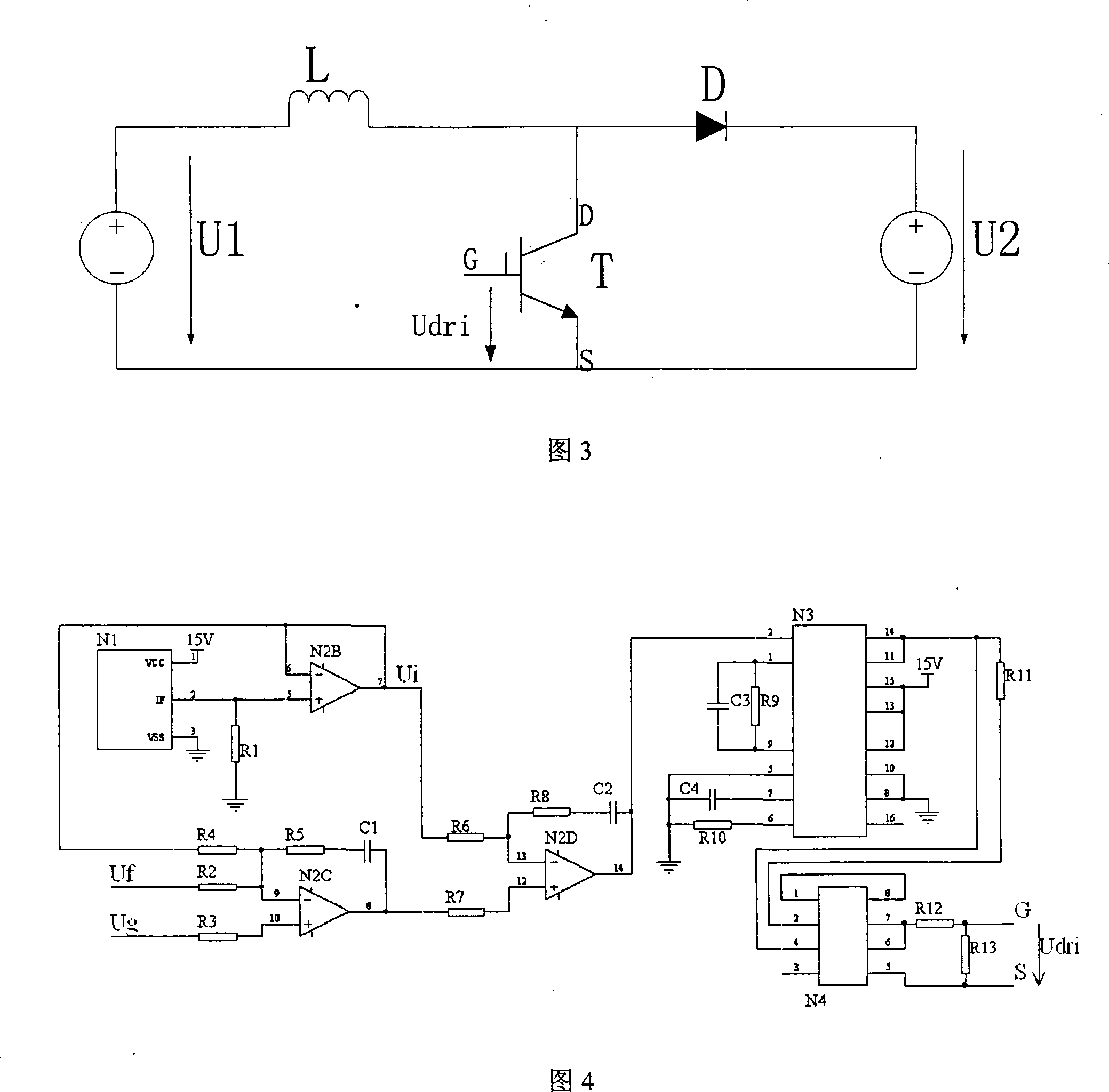

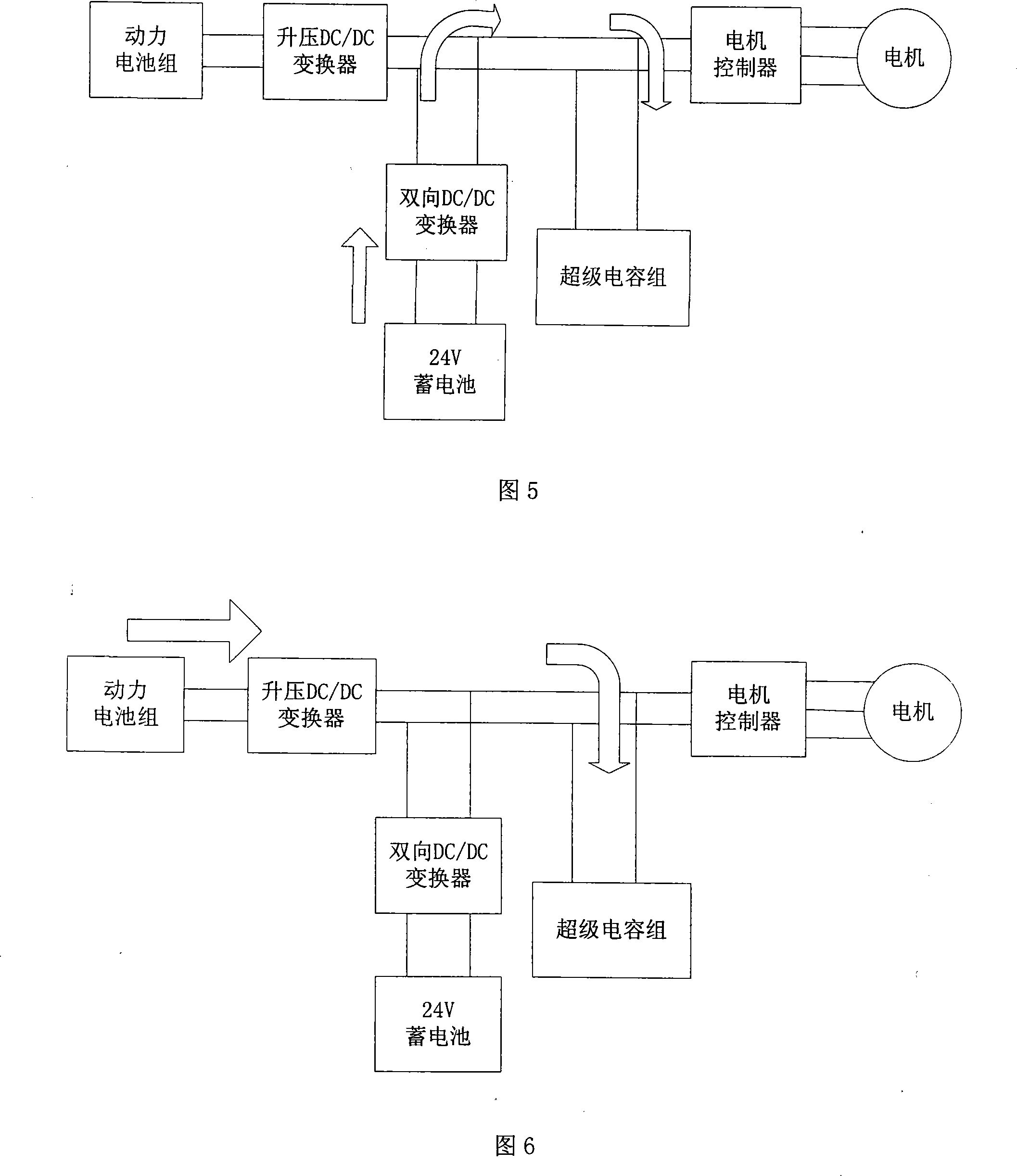

Dynamics battery-super capacitance mixed dynamic system for electric car

InactiveCN101237154AReduce peak discharge currentImprove energy efficiencyElectrical storage systemBatteries circuit arrangementsDischarge efficiencyCapacitance

The invention relates to a power battery-super capacitor hybrid power system for electric automobiles, belonging to the electric automobile technical field. The power battery-super capacitor hybrid power system for the electric automobiles comprises a power battery pack, a motor controller and a 24V storage battery, a boost DC / DC converter, a bi-directional DC / DC converter and a super capacitance group, wherein, the low voltage end of the boost DC / DC converter is connected with the output end of the power battery pack, the high voltage end of the boost DC / DC converter is connected with the motor controller; the super capacitance group and the high voltage end of the bi-directional DC / DC converter are directly hitched with the high voltage end of the boost DC / DC converter, and the low voltage end of the bi-directional DC / DC converter is connected with the 24V storage battery. The power battery of the power battery-super capacitor hybrid power system for the electric automobiles has smooth output current, small peak current, high discharge efficiency and long service life; when the battery pack SOC is lower, the hybrid system still ensures the normal power output capability; and the super capacitance can directly absorb the braking feedback energy and has high energy conversion efficiency.

Owner:TSINGHUA UNIV

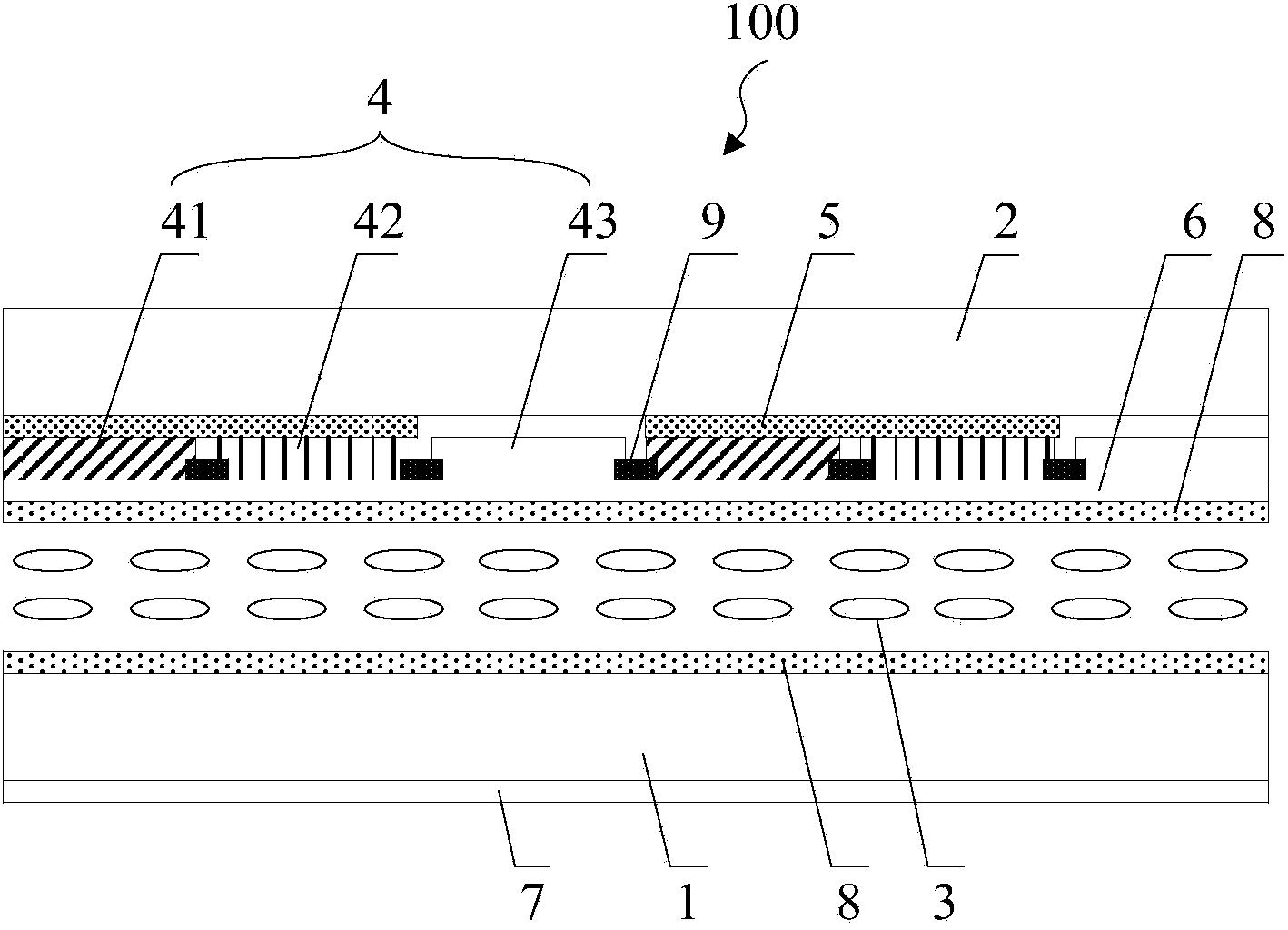

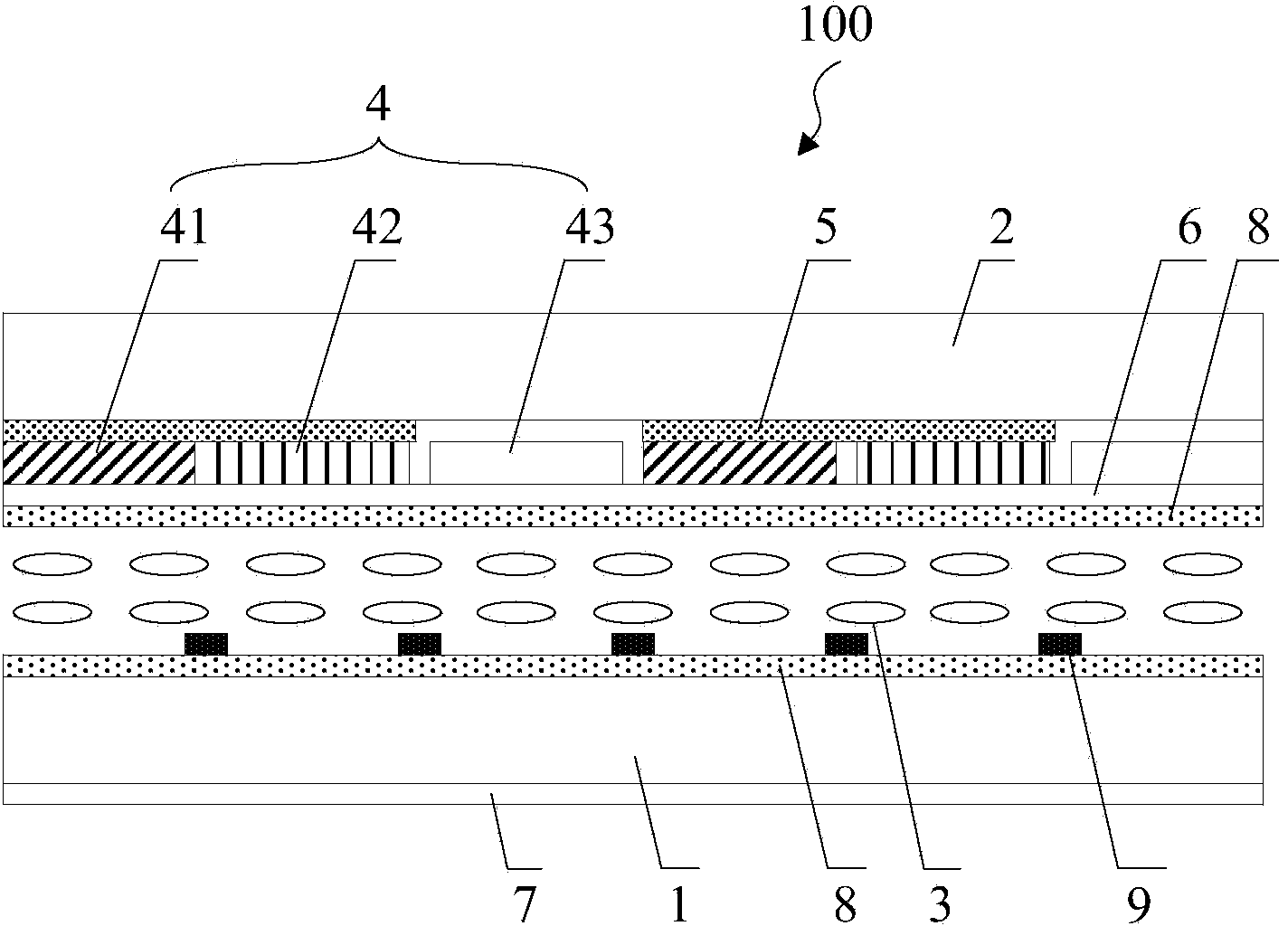

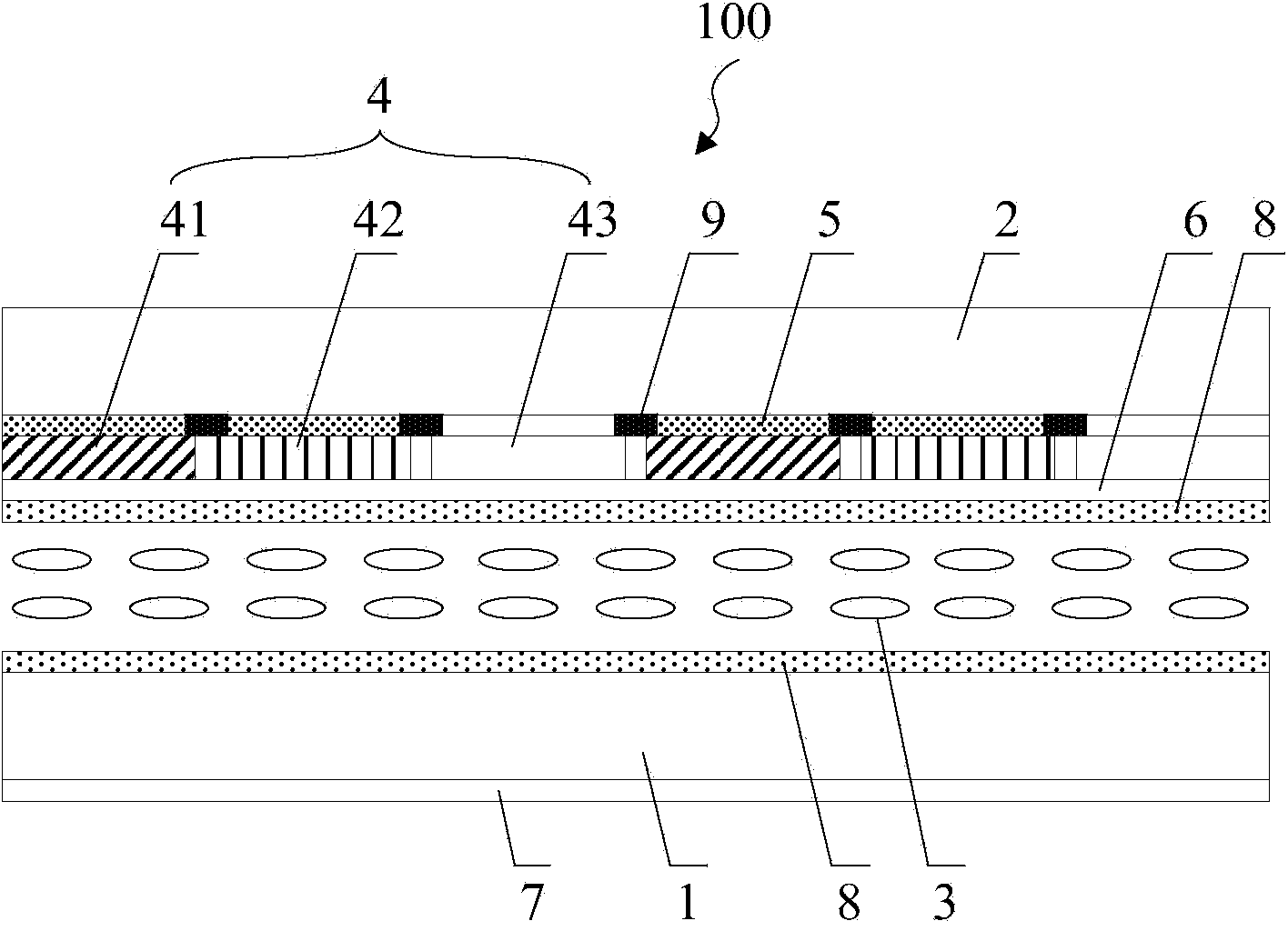

Display panel and display device

InactiveCN104330918AHigh light conversion efficiencyNon-linear opticsLiquid-crystal displayDisplay device

The invention discloses a display panel and a display device, capable of improving light conversion efficiency of the display panel. The display panel comprises an array substrate and a color film substrate which are oppositely arranged as well as a liquid crystal layer between the array substrate and the color film substrate, wherein a quantum dot excitation layer is arranged on the color film substrate; an upper polarizing layer is arranged between the color film substrate and the liquid crystal layer; a lower polarizing layer is arranged on one surface, not adjacent to the liquid crystal layer, of the array substrate; and through the upper polarizing layer, linearly polarized light transmitted from the lower polarizing layer can reach the quantum dot excitation layer by keeping the state of the linearly polarized light.

Owner:BOE TECH GRP CO LTD

Oxide semiconductor electrode, dye-sensitized solar cell, and, method of producing the same

InactiveUS20060219294A1Improve adhesion stabilityImprove productivityLight-sensitive devicesPhotovoltaic energy generationSemiconductor electrodeSilanes

Owner:DAI NIPPON PRINTING CO LTD

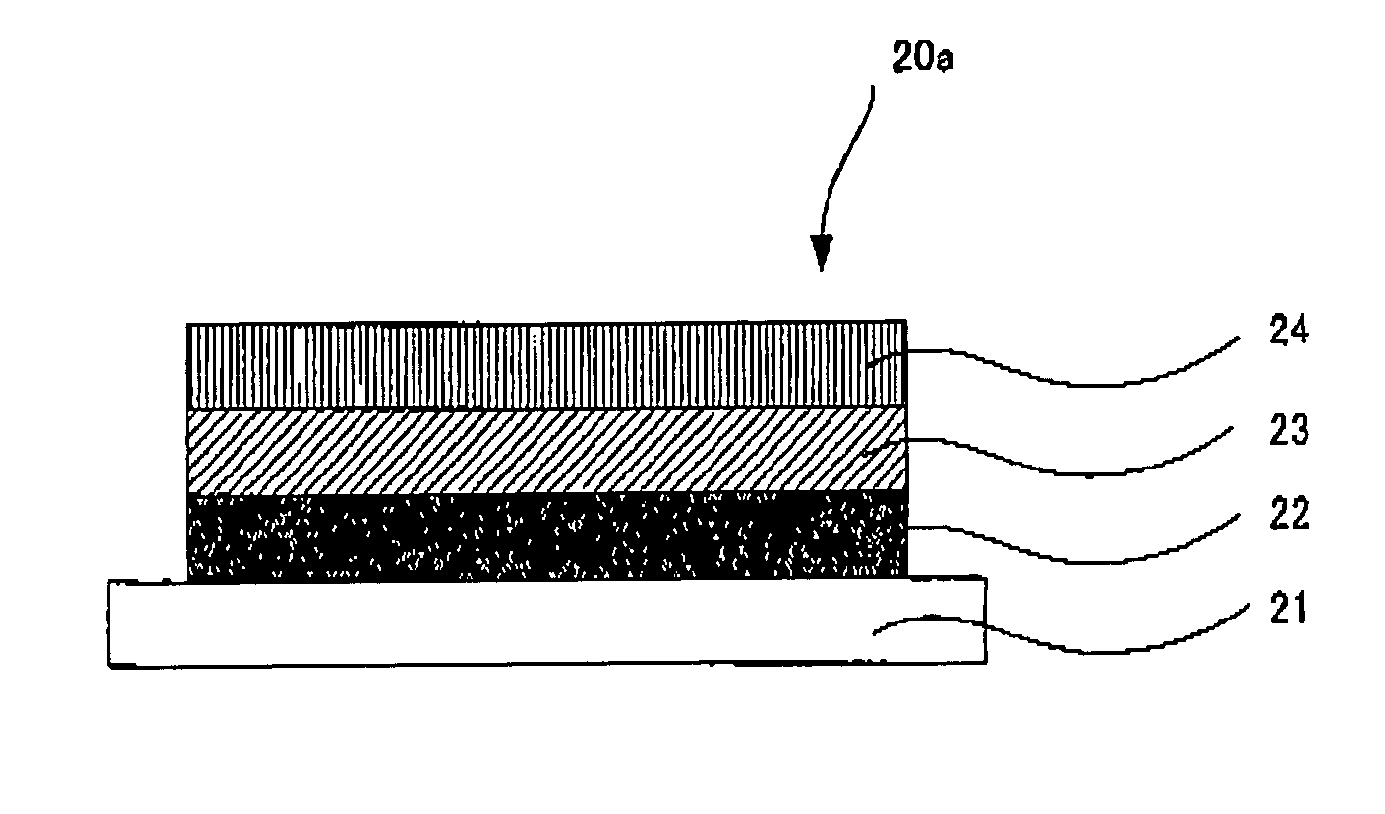

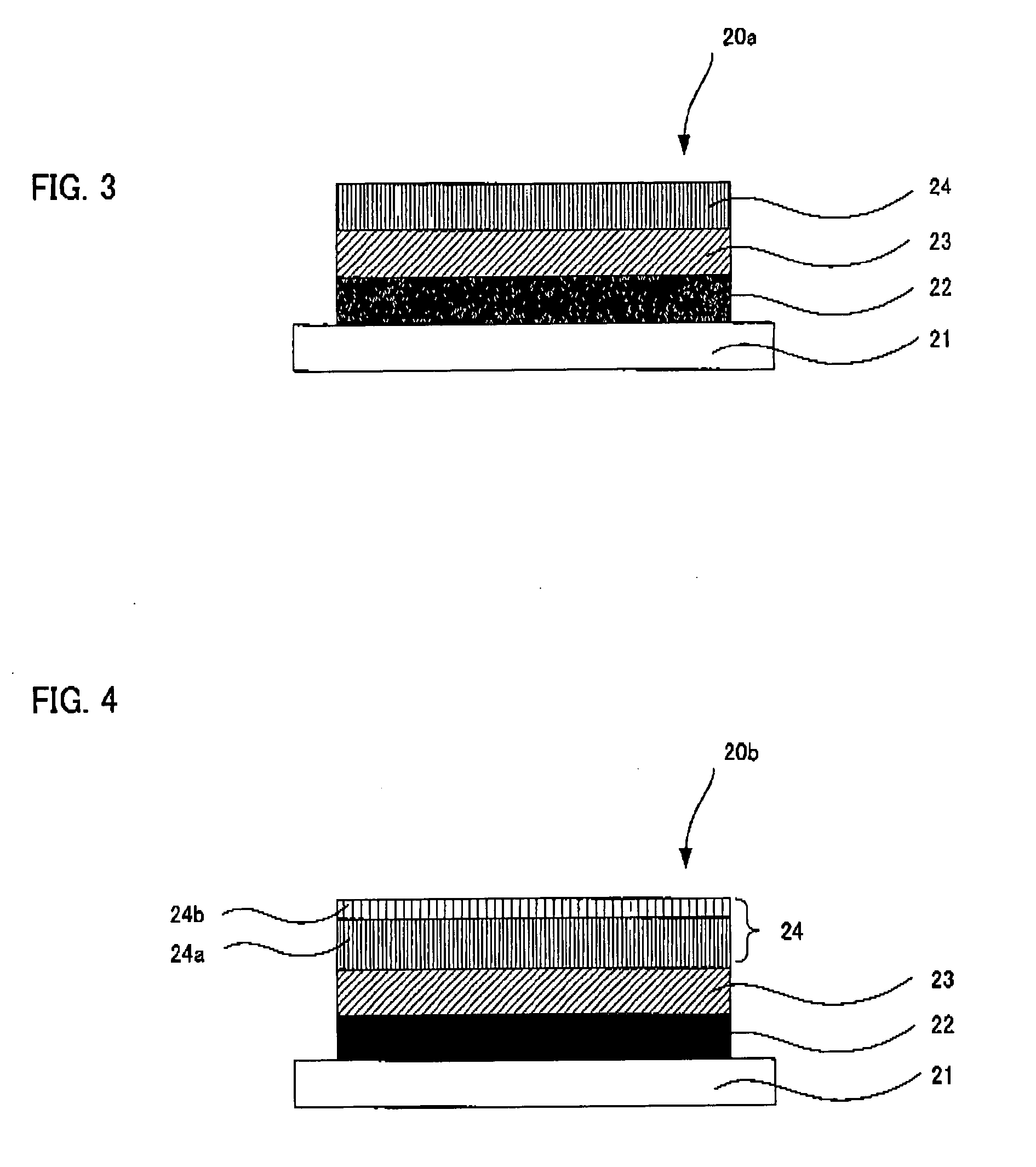

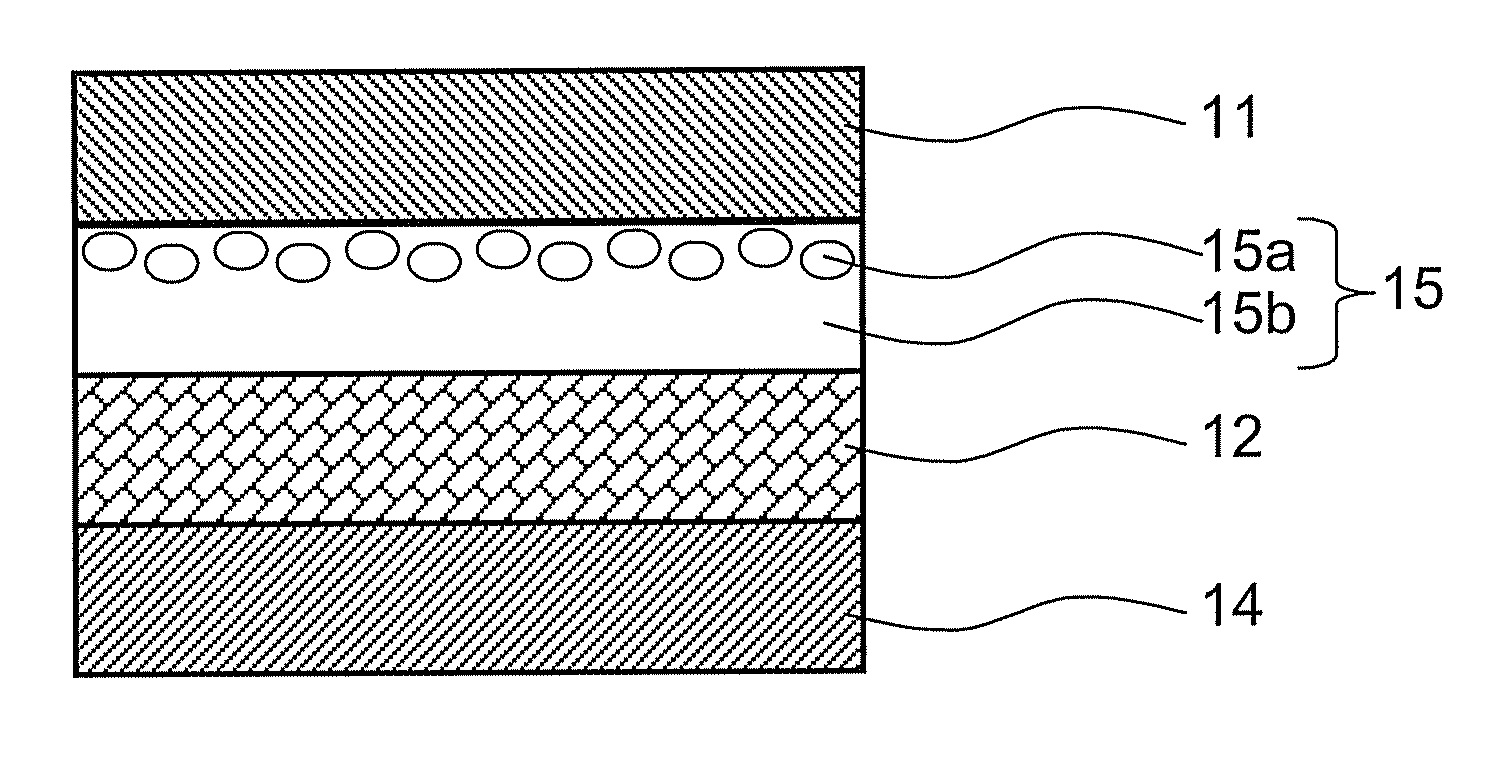

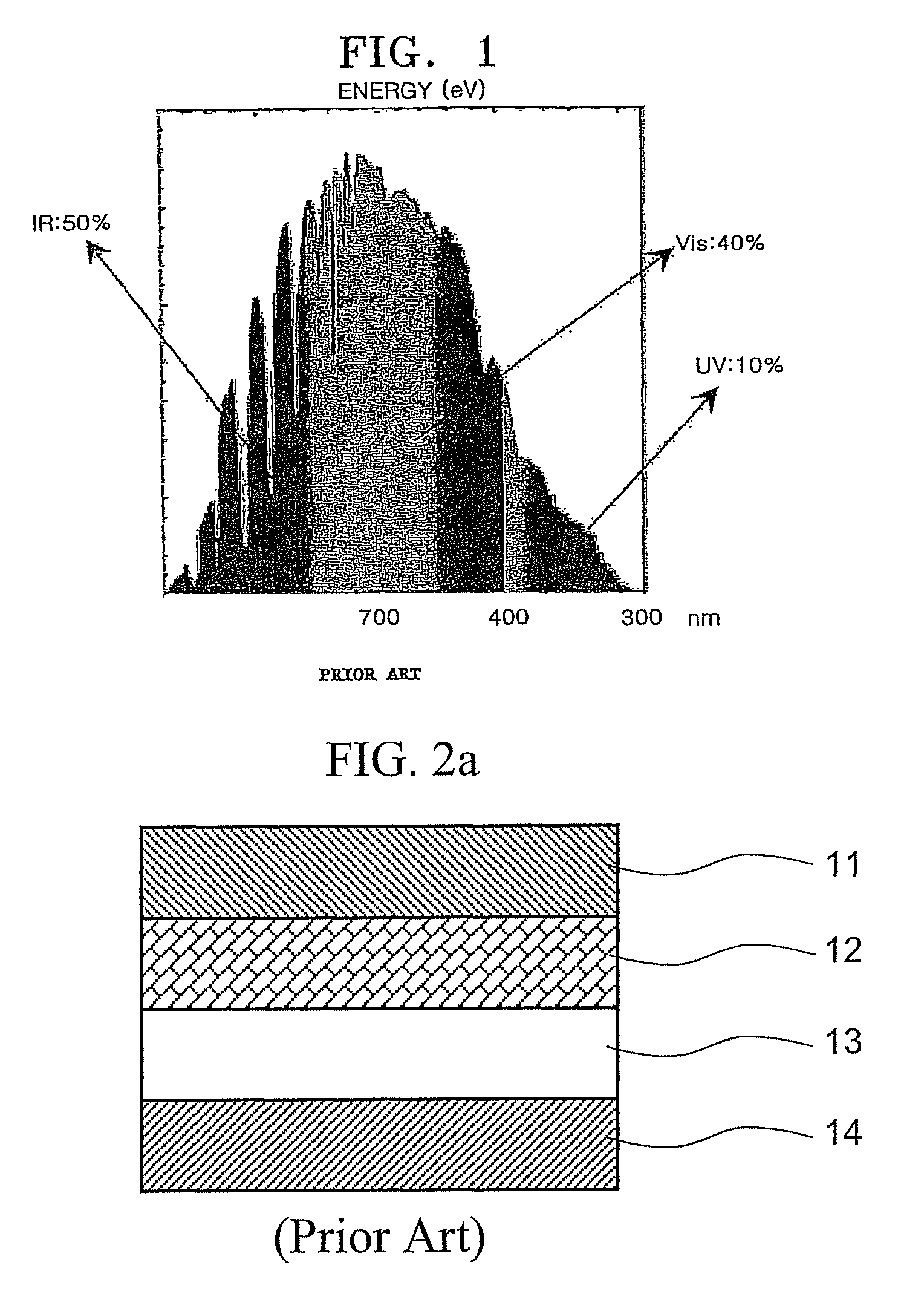

Energy conversion film and quantum dot film comprising quantum dot compound, energy conversion layer including the quantum dot film, and solar cell including the energy conversion layer

ActiveUS7791157B2Improve energy efficiencyHigh solar efficiencyElectrolytic capacitorsFinal product manufactureHigh energySpectral responsivity

An energy conversion film and a quantum dot film which contain a quantum dot compound, an energy conversion layer including the quantum dot film, and a solar cell including the energy conversion layer. The films act as cut-off filters blocking light of a particular energy level using the light absorption and emission effects of quantum dots and can convert high energy light to low energy light. The efficiency of a solar cell may be improved by providing the cell with a film that converts light above the spectrum-responsive region to light in the cell's spectrum-responsive region. The absorption wavelength region of the films can be broadened by providing the quantum dot compound in a variety of average particle sizes, for example, by providing a mixture of a first quantum dot compound having a first average particle size and a first quantum dot compound having a second average particle size.

Owner:SAMSUNG ELECTRONICS CO LTD

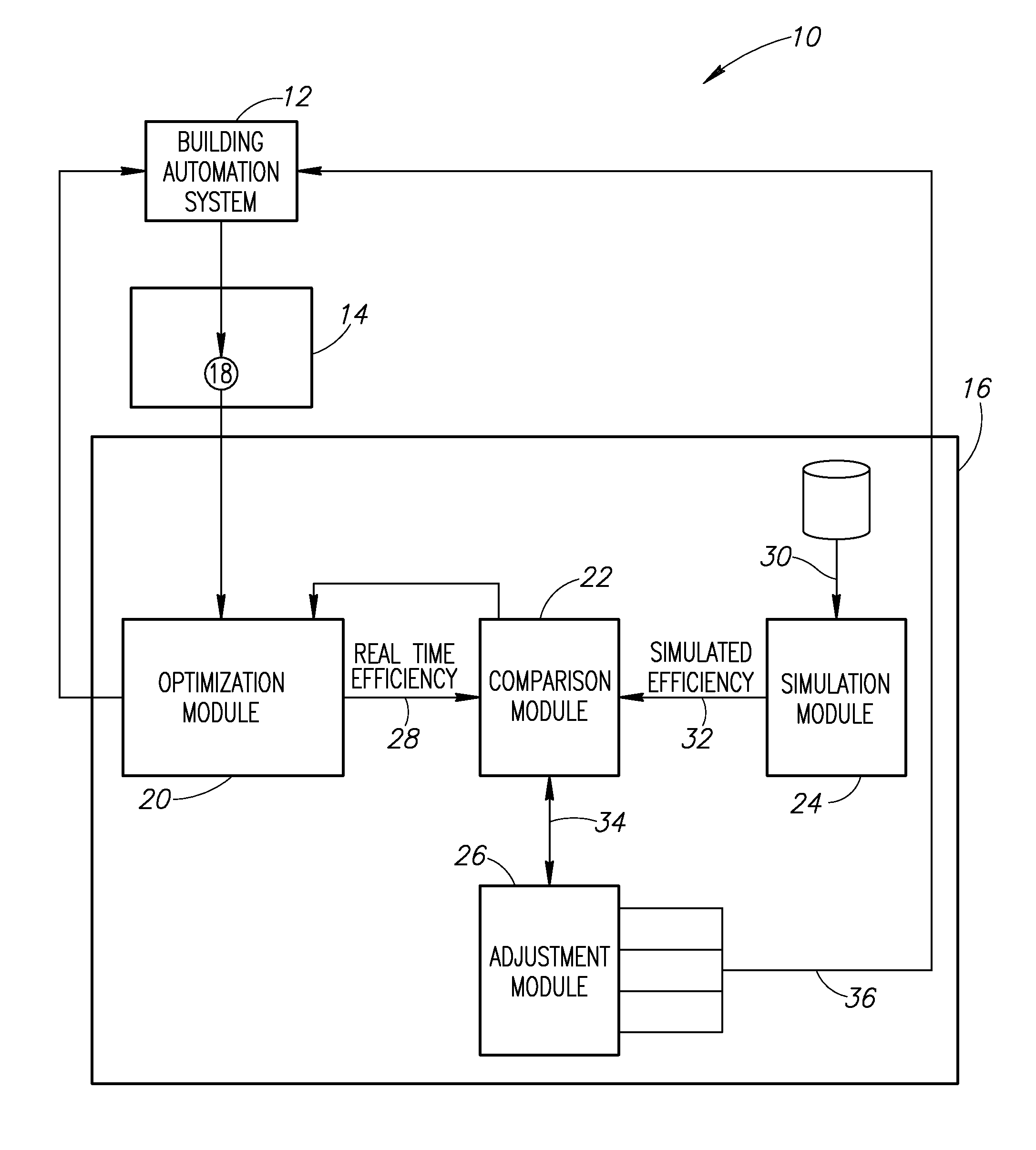

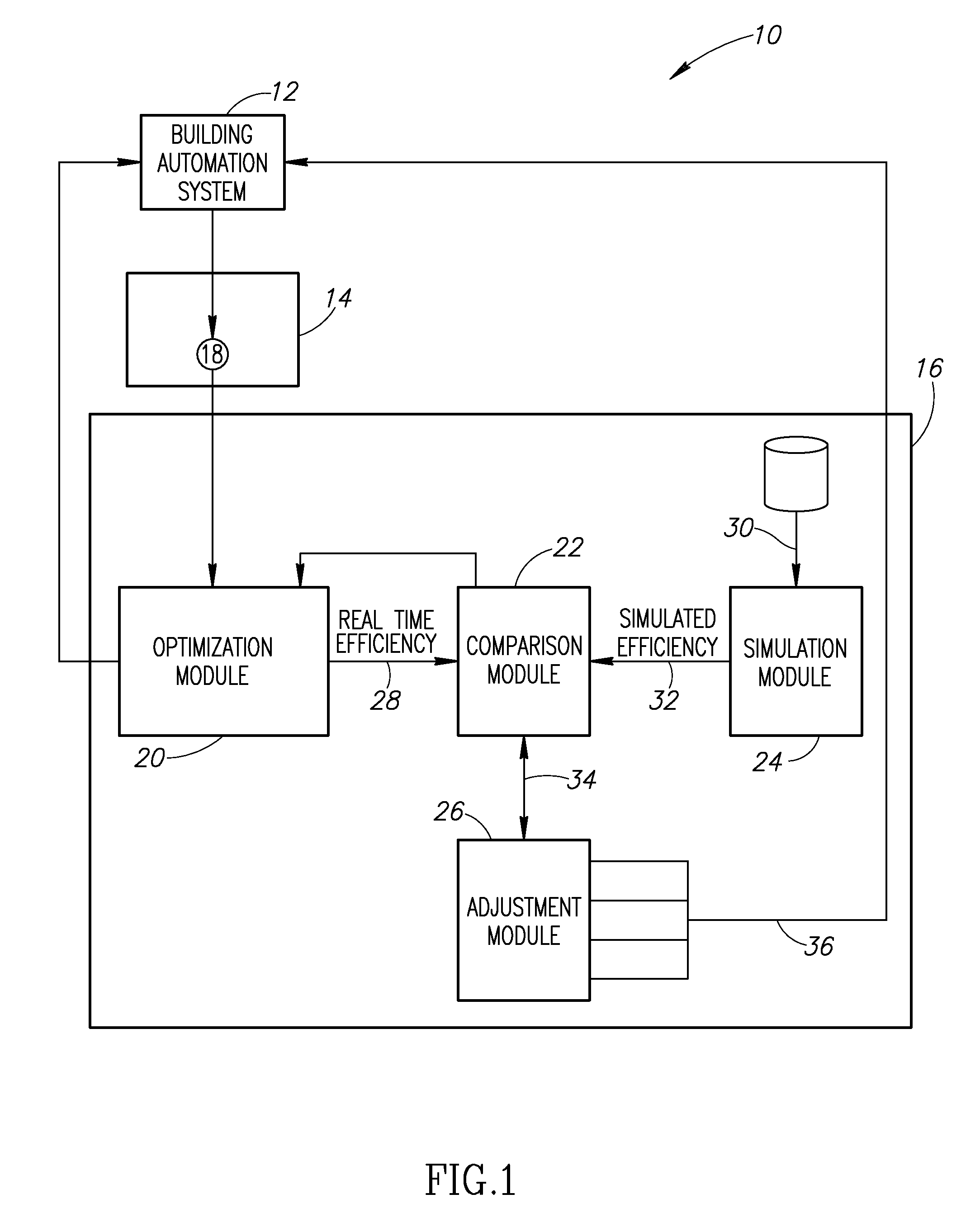

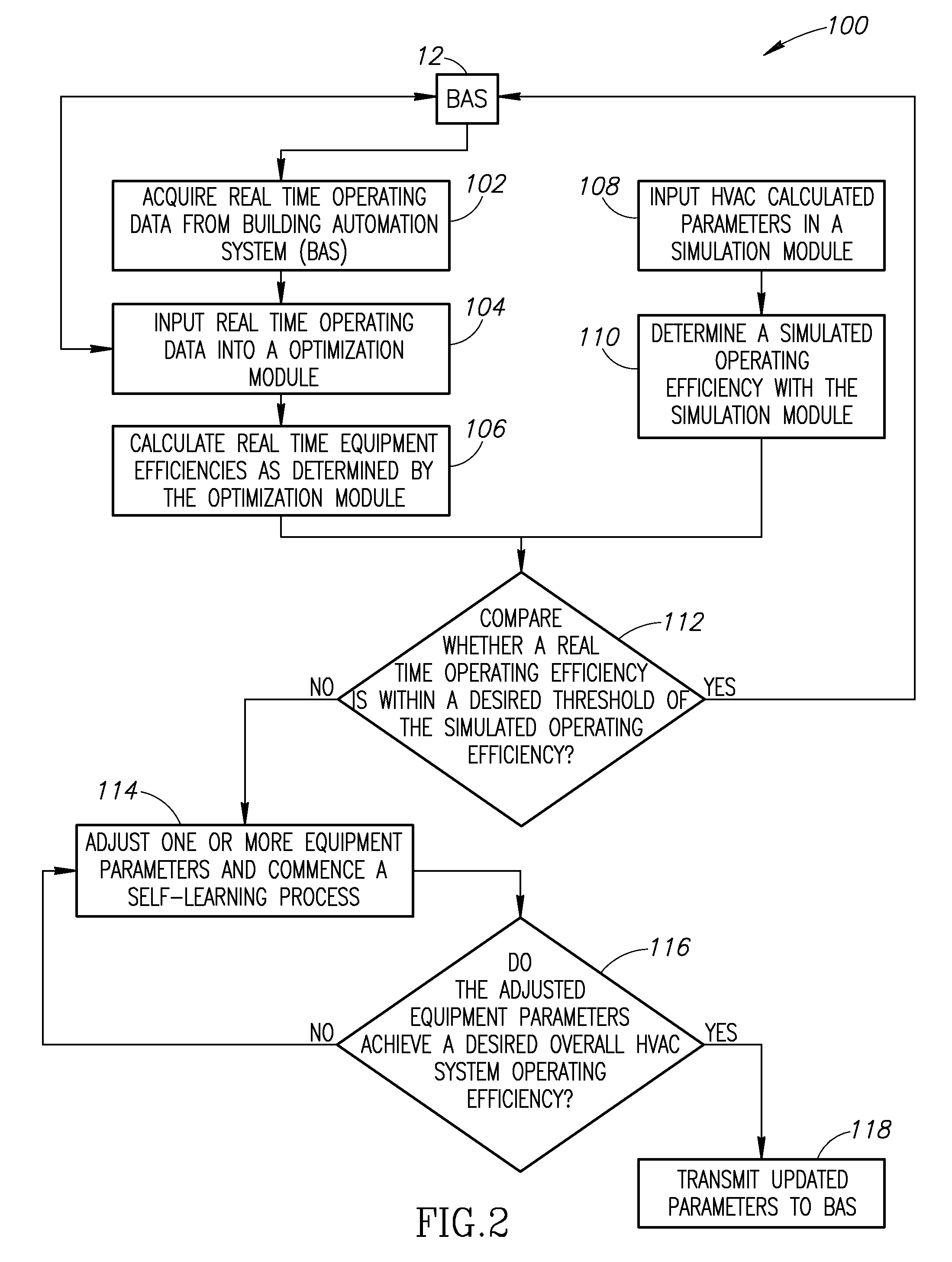

Systems and methods to control energy consumption efficiency

ActiveUS8219250B2Minimization needsMinimum energy wastageProgramme controlSampled-variable control systemsSimulationComputer module

A controller is configured to exchange information with a building automation system and includes various executable programs for determining a real time operating efficiency, simulating a predicted or theoretical operating efficiency, comparing the same, and then adjusting one or more operating parameters on equipment utilized by a building's HVAC system. The controller operates to adjust an operating efficiency of the HVAC system. An adjustment module utilized by the controller may modify the HVAC equipment parameters based on the likelihood that various HVAC equipment operates in parallel and on-line near its natural operating curve. In addition, the adjustment module may include a self-learning aspect that permits the controller to more efficiently make similar, future adjustments as needed.

Owner:OPTIMUM ENERGY

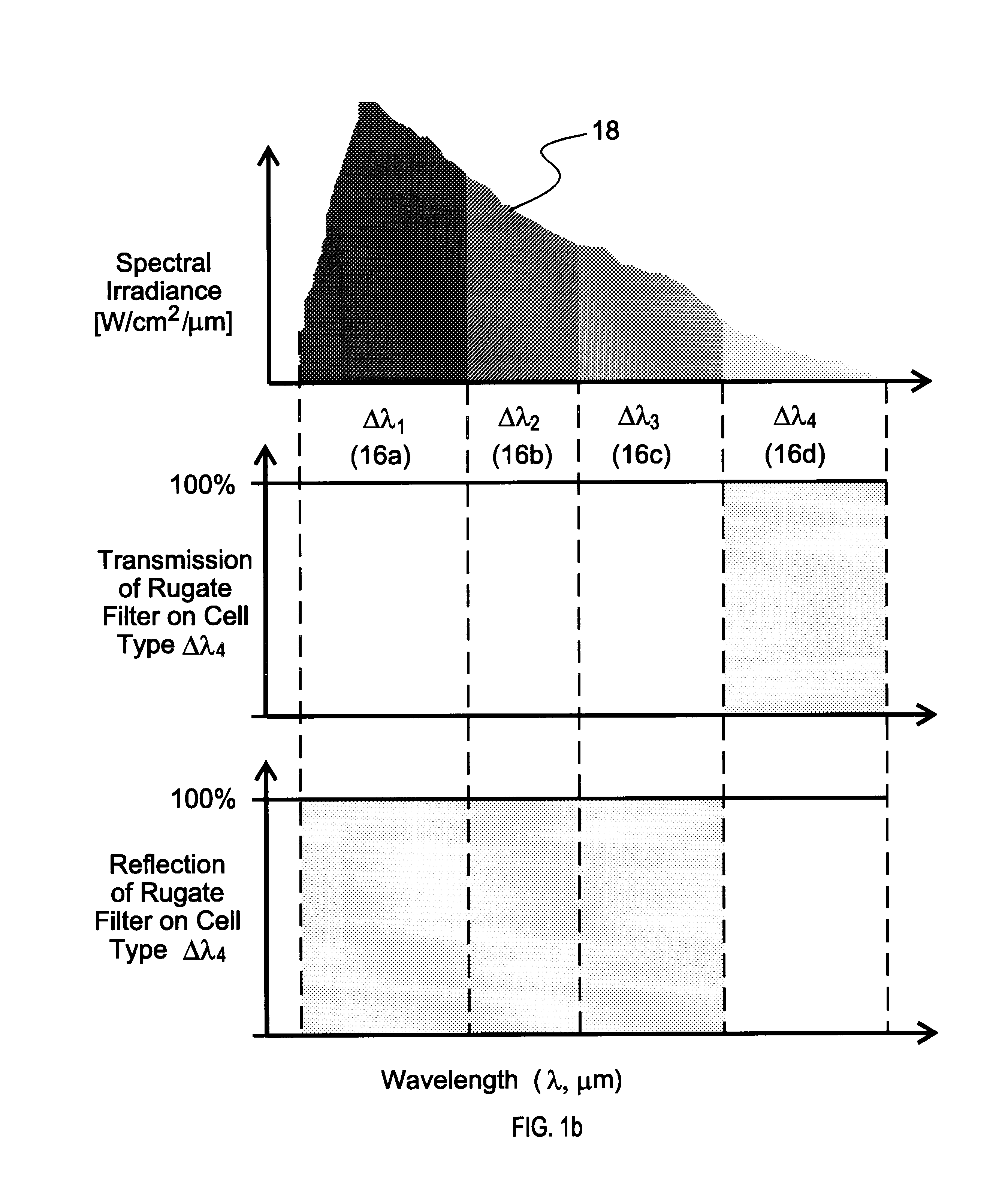

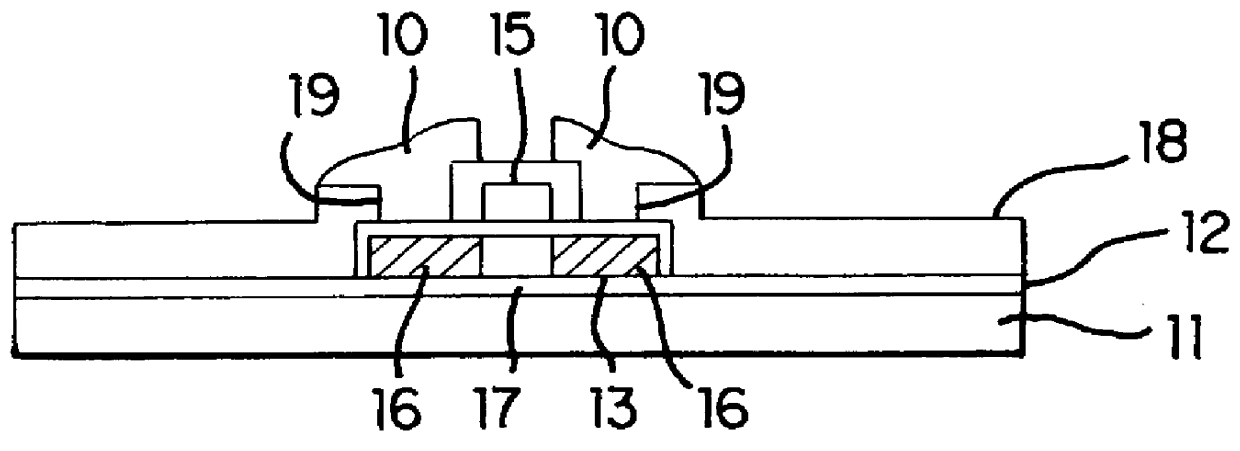

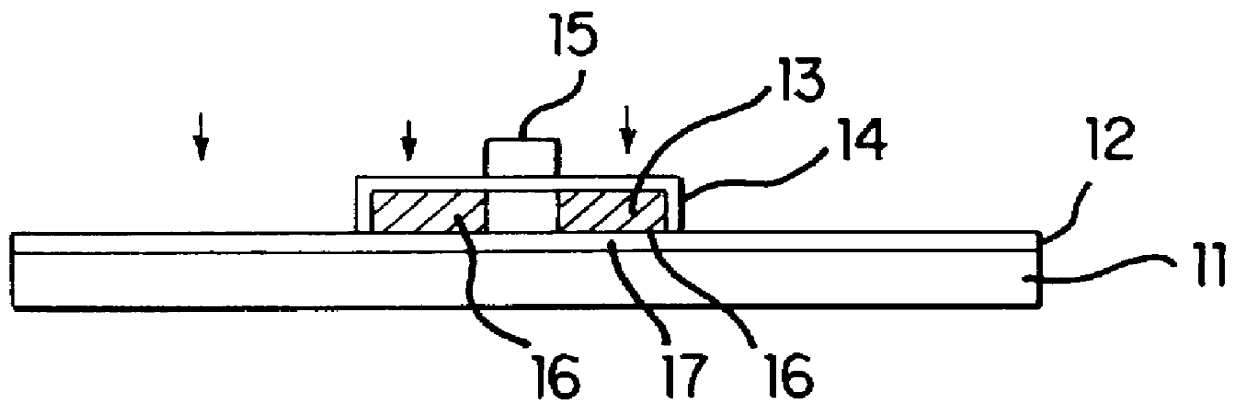

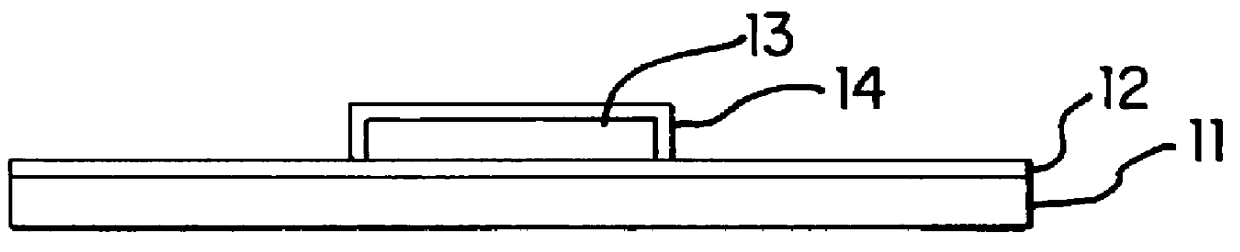

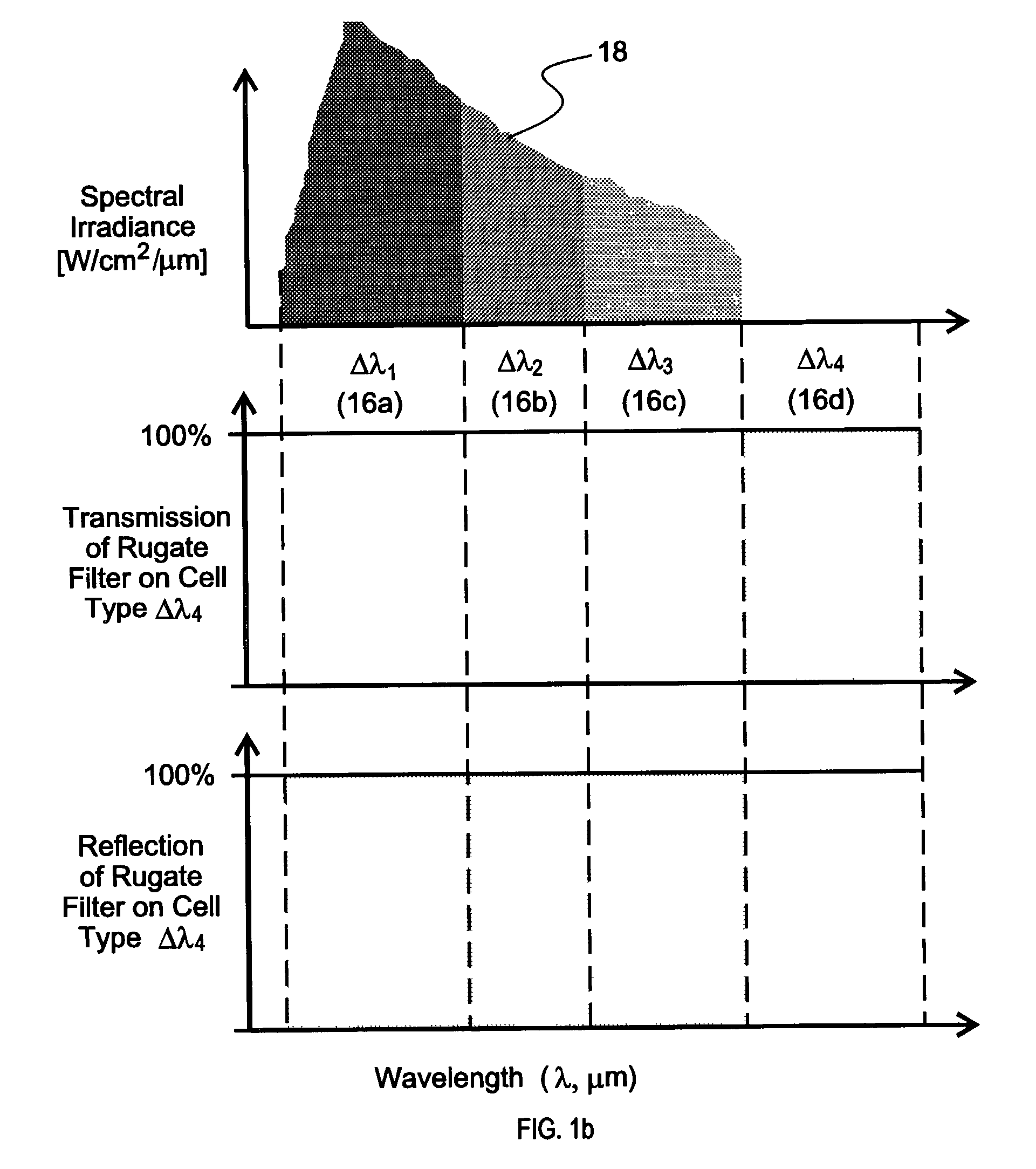

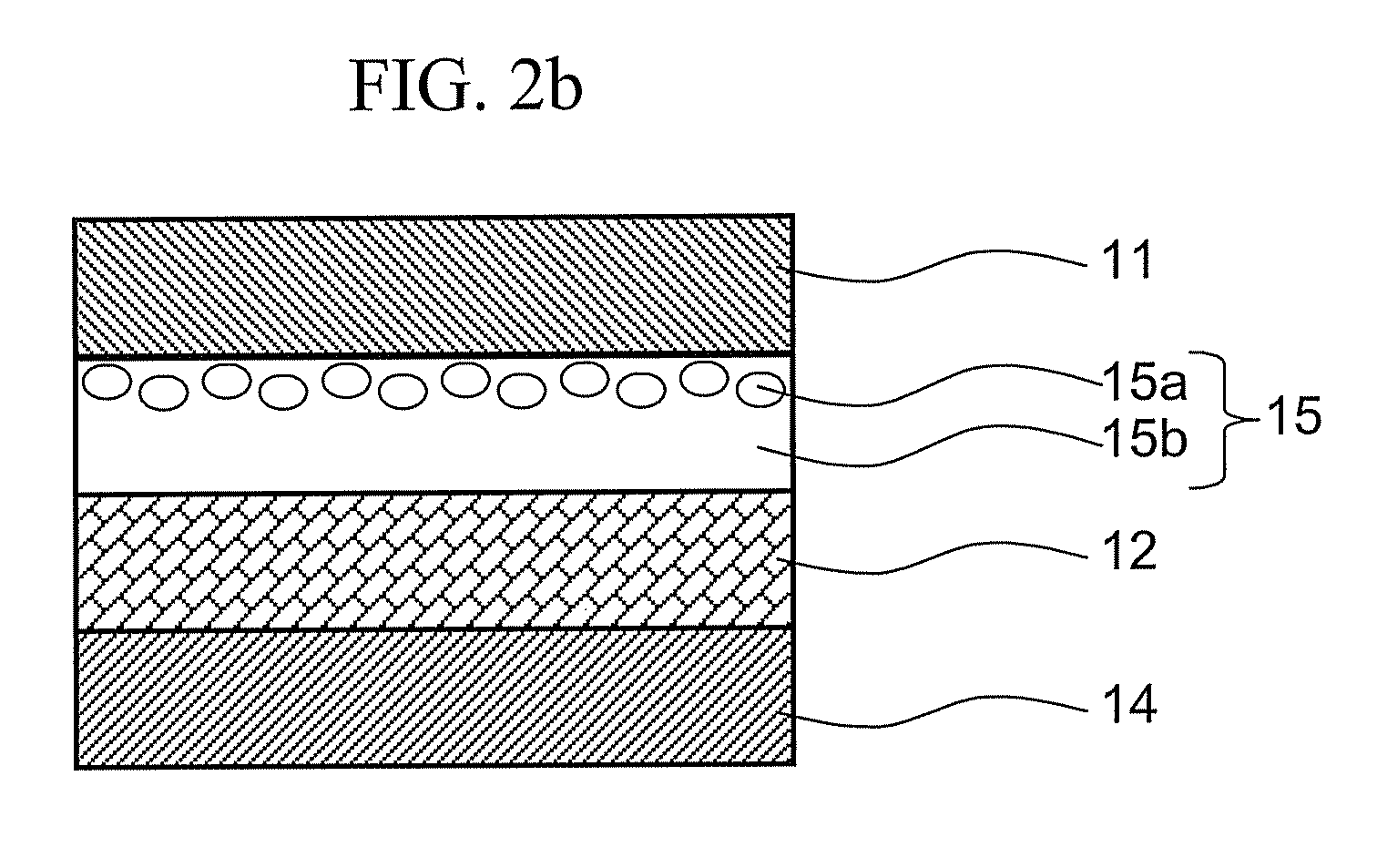

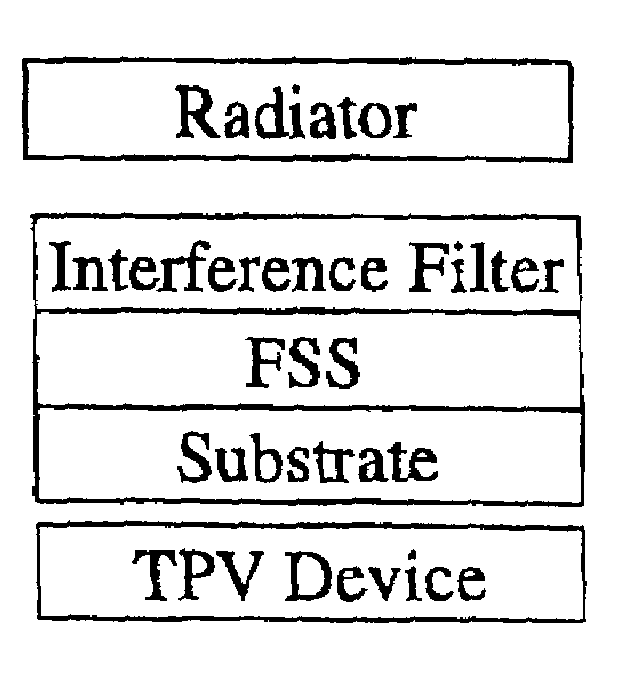

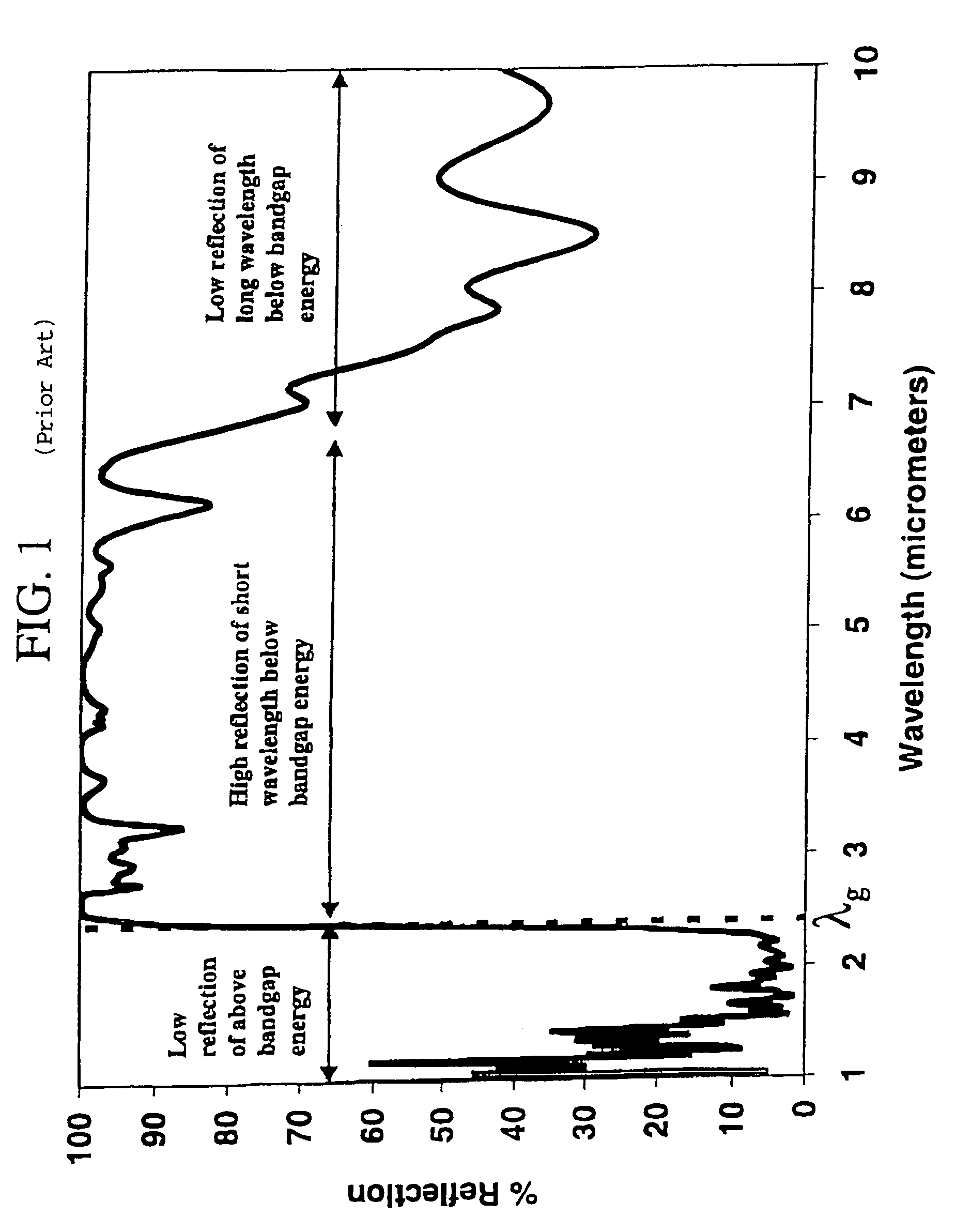

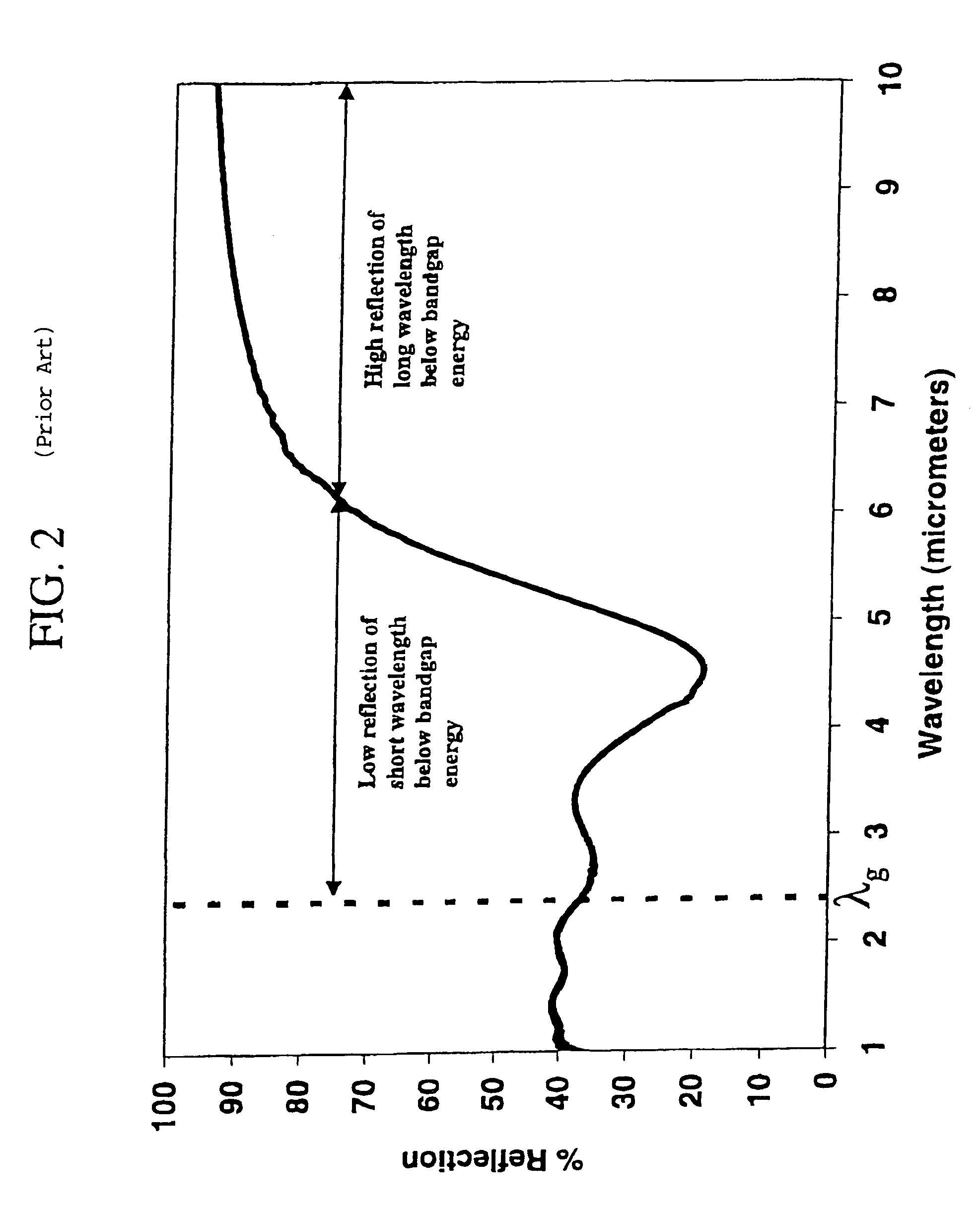

Tandem filters using frequency selective surfaces for enhanced conversion efficiency in a thermophotovoltaic energy conversion system

InactiveUS7166797B1High bandgap energyImprove reflectivityMirrorsBeam/ray focussing/reflecting arrangementsTransmittanceLength wave

This invention relates to the field of thermophotovoltaic (TPV) direct energy conversion. In particular, TPV systems use filters to minimize parasitic absorption of below bandgap energy. This invention constitutes a novel combination of front surface filters to increase TPV conversion efficiency by reflecting useless below bandgap energy while transmitting a very high percentage of the useful above bandgap energy. In particular, a frequency selective surface is used in combination with an interference filter. The frequency selective surface provides high transmission of above bandgap energy and high reflection of long wavelength below bandgap energy. The interference filter maintains high transmission of above bandgap energy and provides high reflection of short wavelength below bandgap energy and a sharp transition from high transmission to high reflection.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

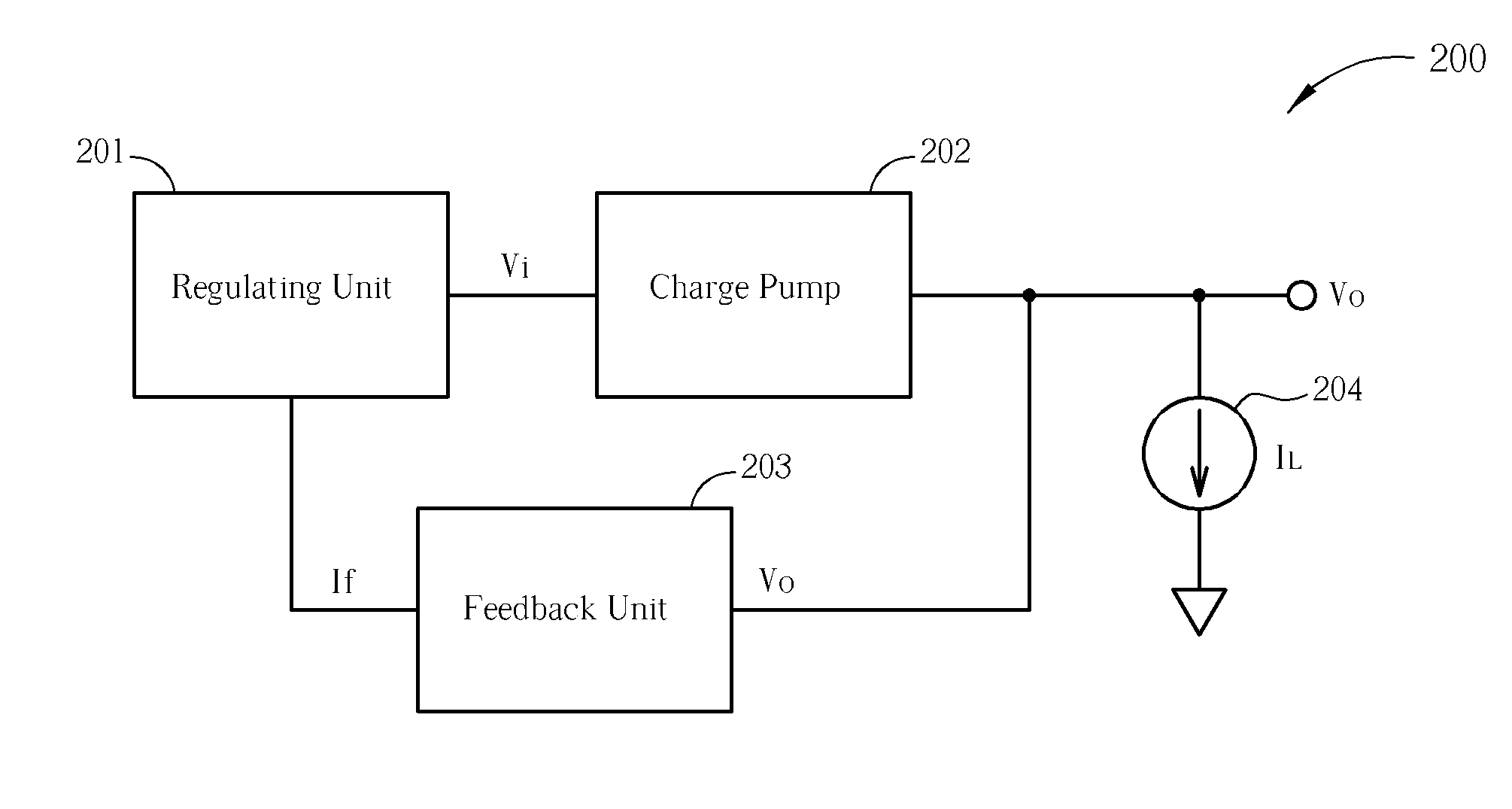

Voltage conversion device capable of enhancing conversion efficiency

ActiveUS8111054B2Improve conversion efficiencyAc-dc conversionApparatus without intermediate ac conversionLinearityControl theory

A voltage conversion device capable of enhancing conversion efficiency includes a charge pump for generating output voltage linear to input voltage according to the input voltage, a feedback unit for generating a feedback signal according to the output voltage generated by the charge pump, and a regulating unit for outputting and adjusting the input voltage according to the feedback signal provided by the feedback unit, so as to keep the output voltage unchanged.

Owner:NOVATEK MICROELECTRONICS CORP

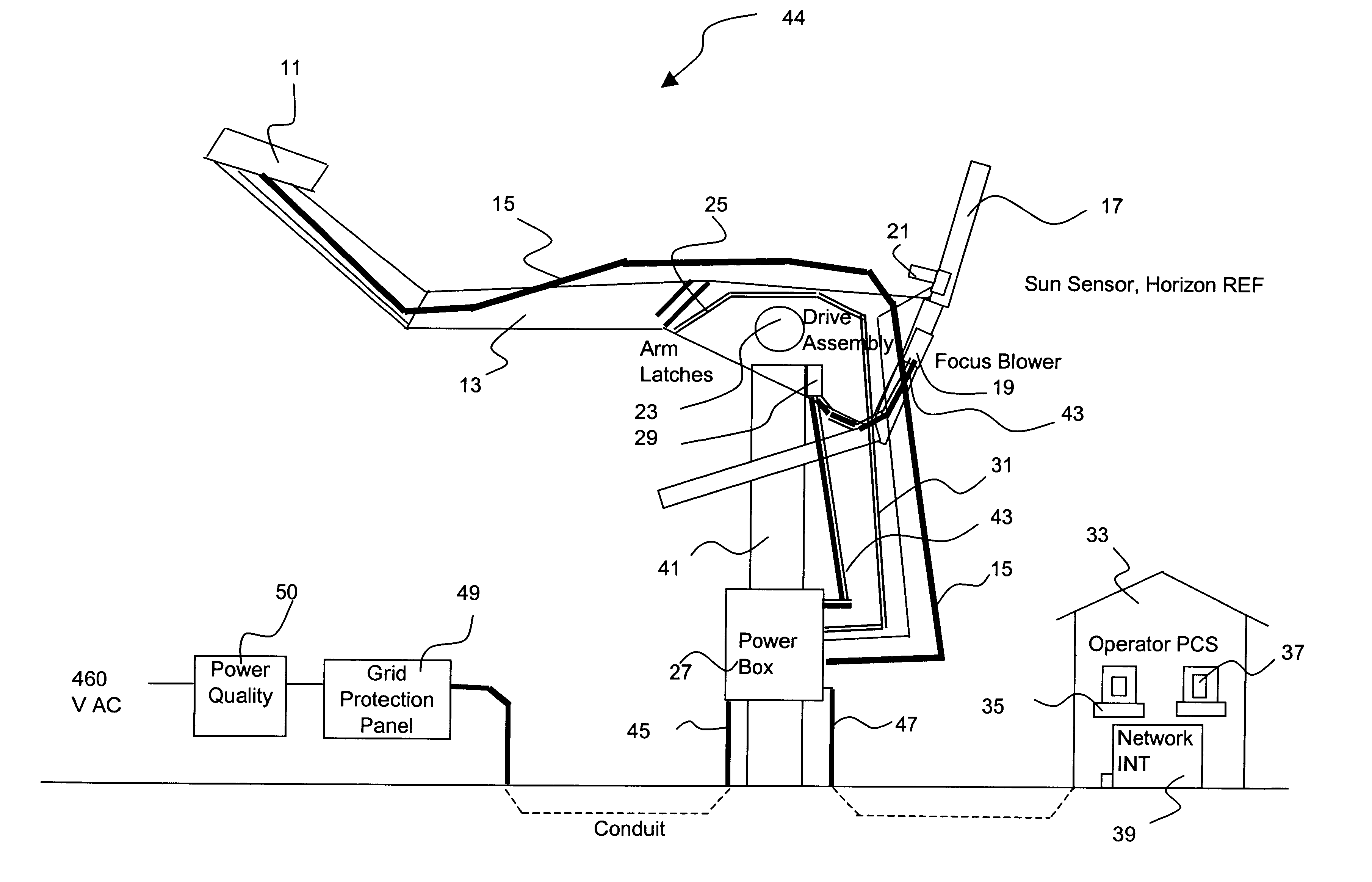

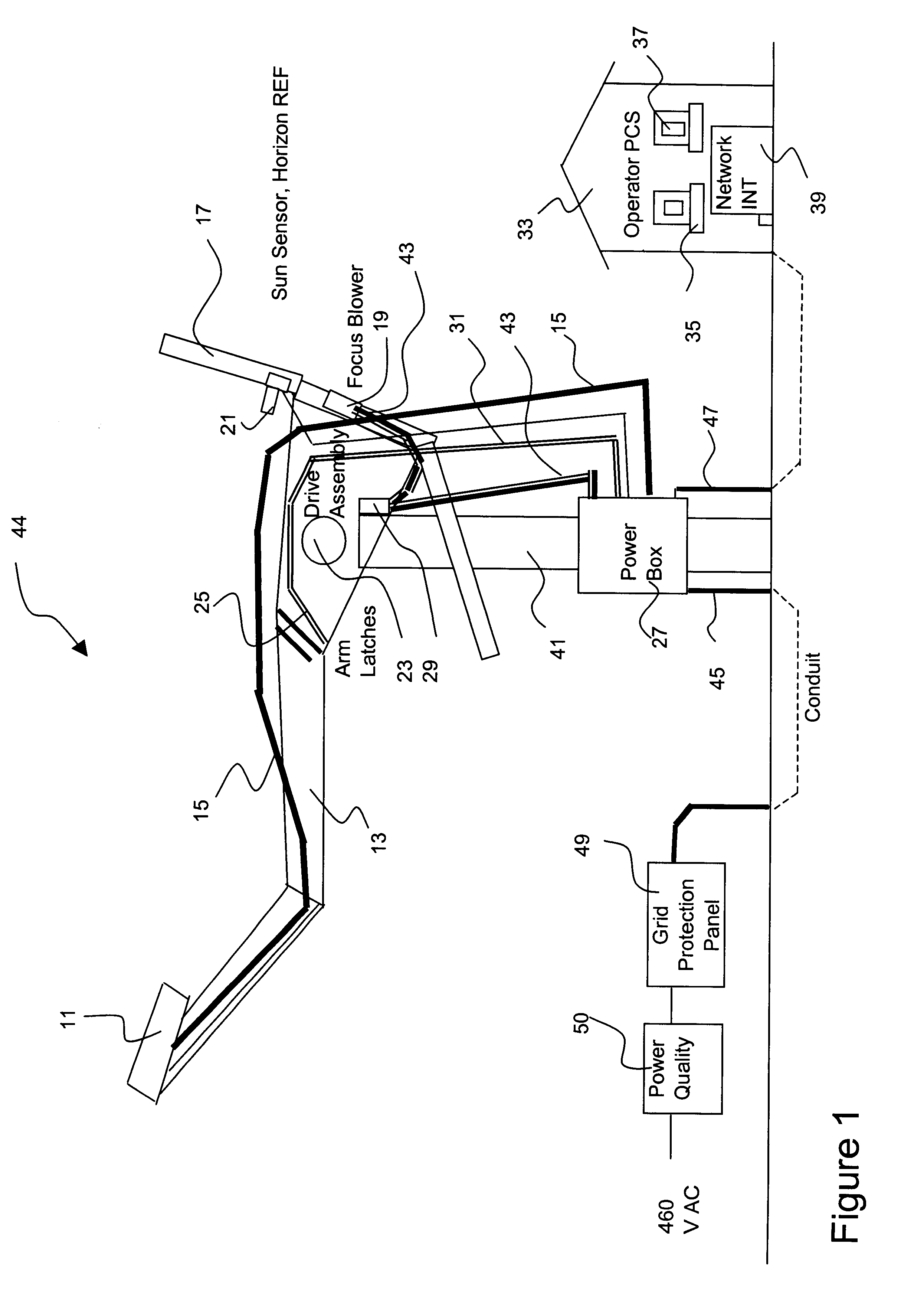

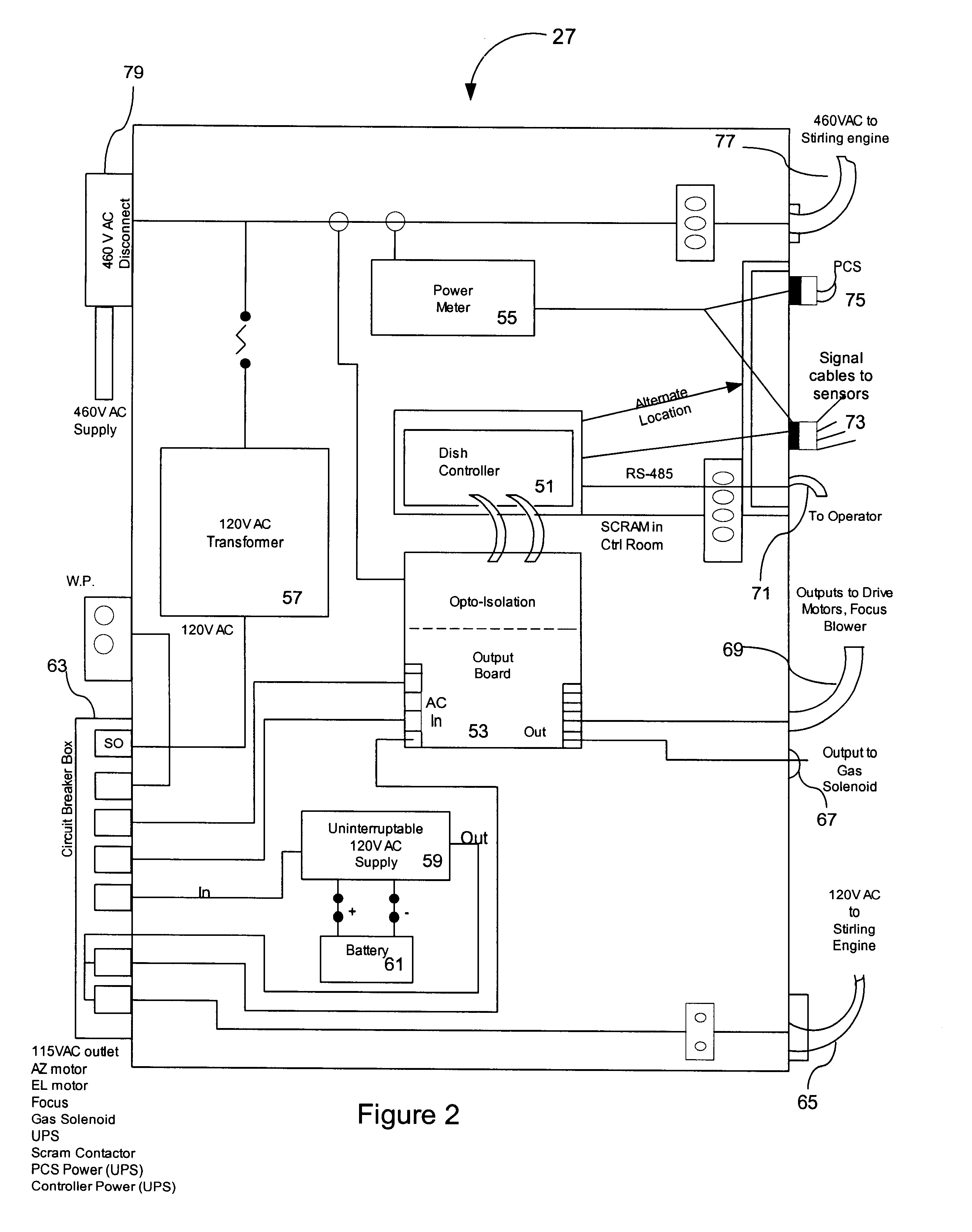

Method and system for controlling operation of an energy conversion device

A method and system is described for controlling a solar collector. A microprocessor receives inputs from one or more sensors in the system and determines the level of operation of an energy conversion device. If the level of operation reaches a predetermined setpoint below a maximum level at which the device is to operate, a variable focus solar concentrator is defocused to reduce energy input into the energy conversion device. When the system cools down and operates at a second predetermined level, lower than the first predetermined level, the concentrator is then refocused to increase the power input to the energy conversion device.

Owner:LEIDOS

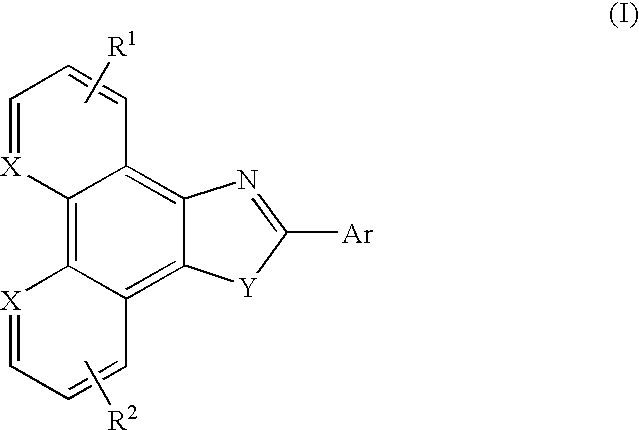

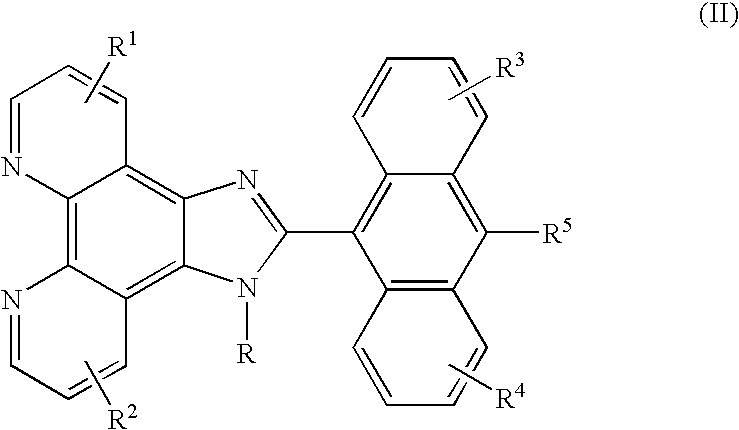

Organic light emitting devices

ActiveUS20040209117A1Improve efficiencyEnhanced operational lifetimeOrganic chemistryDischarge tube luminescnet screensElectron injectionDisplay device

The present invention is an organic light emitting device (OLED) comprising an anode, a cathode and a luminescent region provided between the anode and the cathode. The luminescent region comprises an electron injection and transporting zone and at least one of a hole injection and transporting zone and a mixed charge transport layer. One or both of the electron injection and transporting zone and the mixed charge transporting layer comprises an azole compound represented by formula I and / or II. The provision of the novel azole compounds of the invention as electron transport materials within an organic electroluminescent device advantageously reduces power consumption and increases power conversion efficiency within the device and as such, are suitable for a variety of display applications.

Owner:LG DISPLAY CO LTD

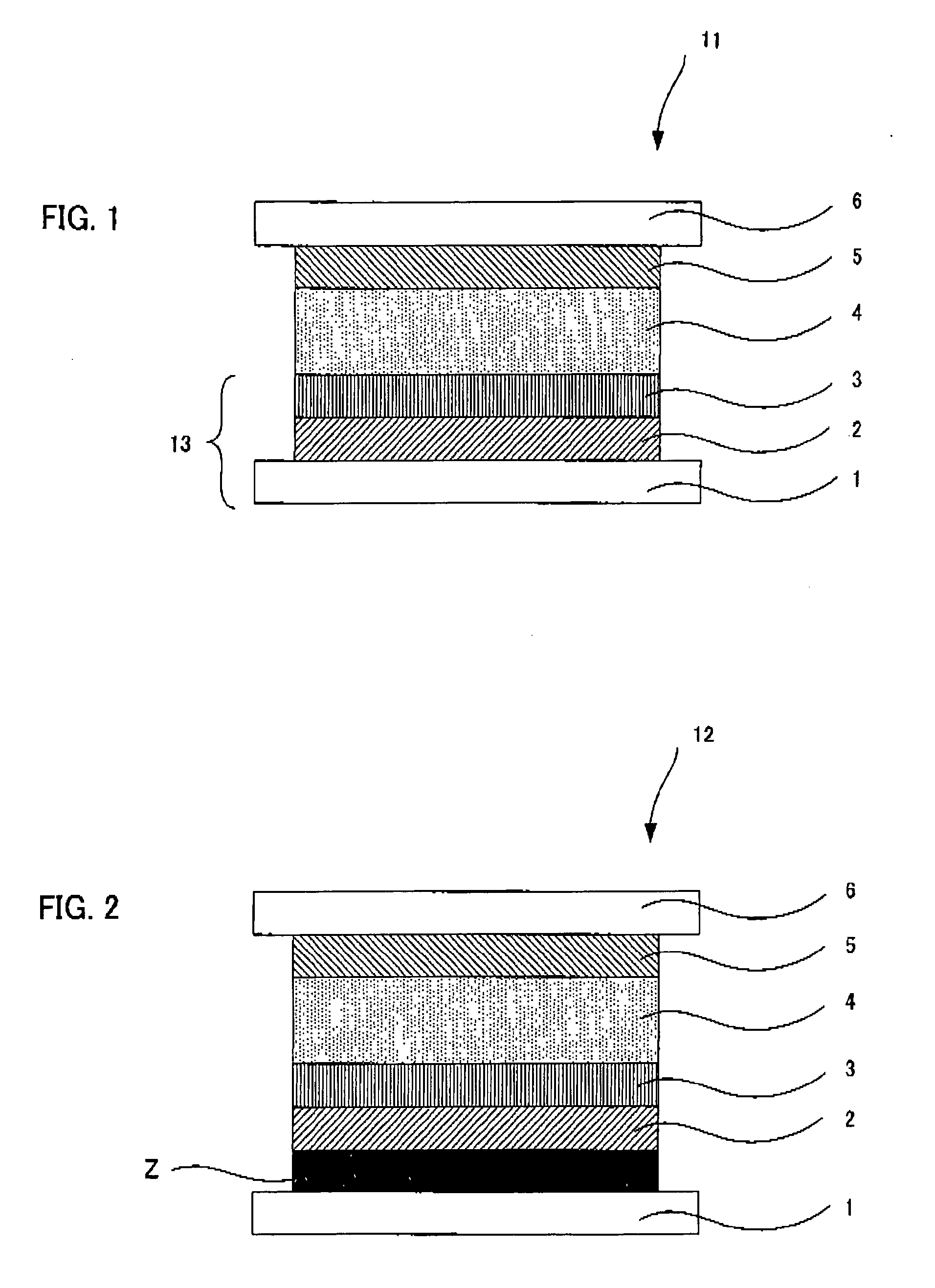

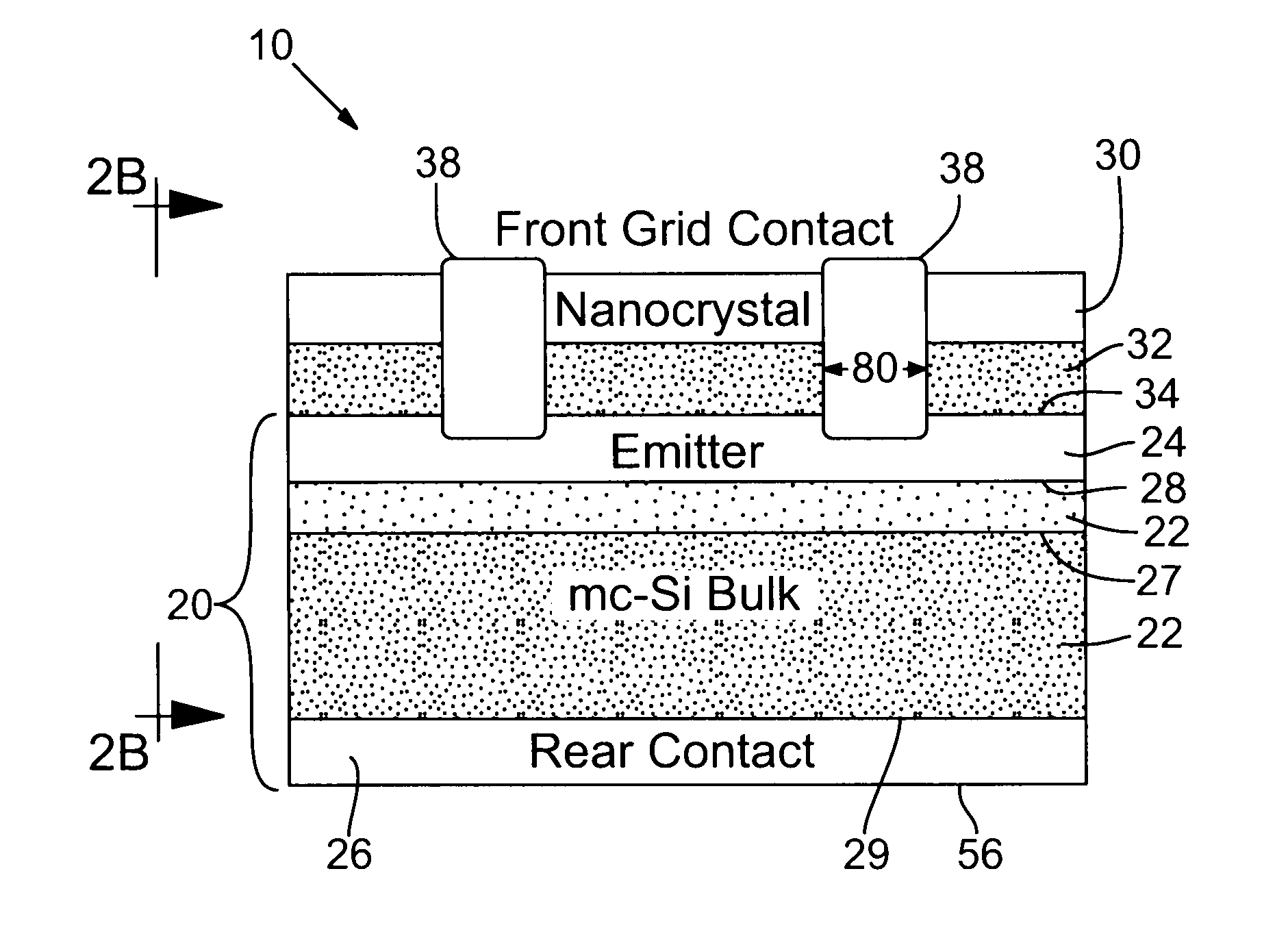

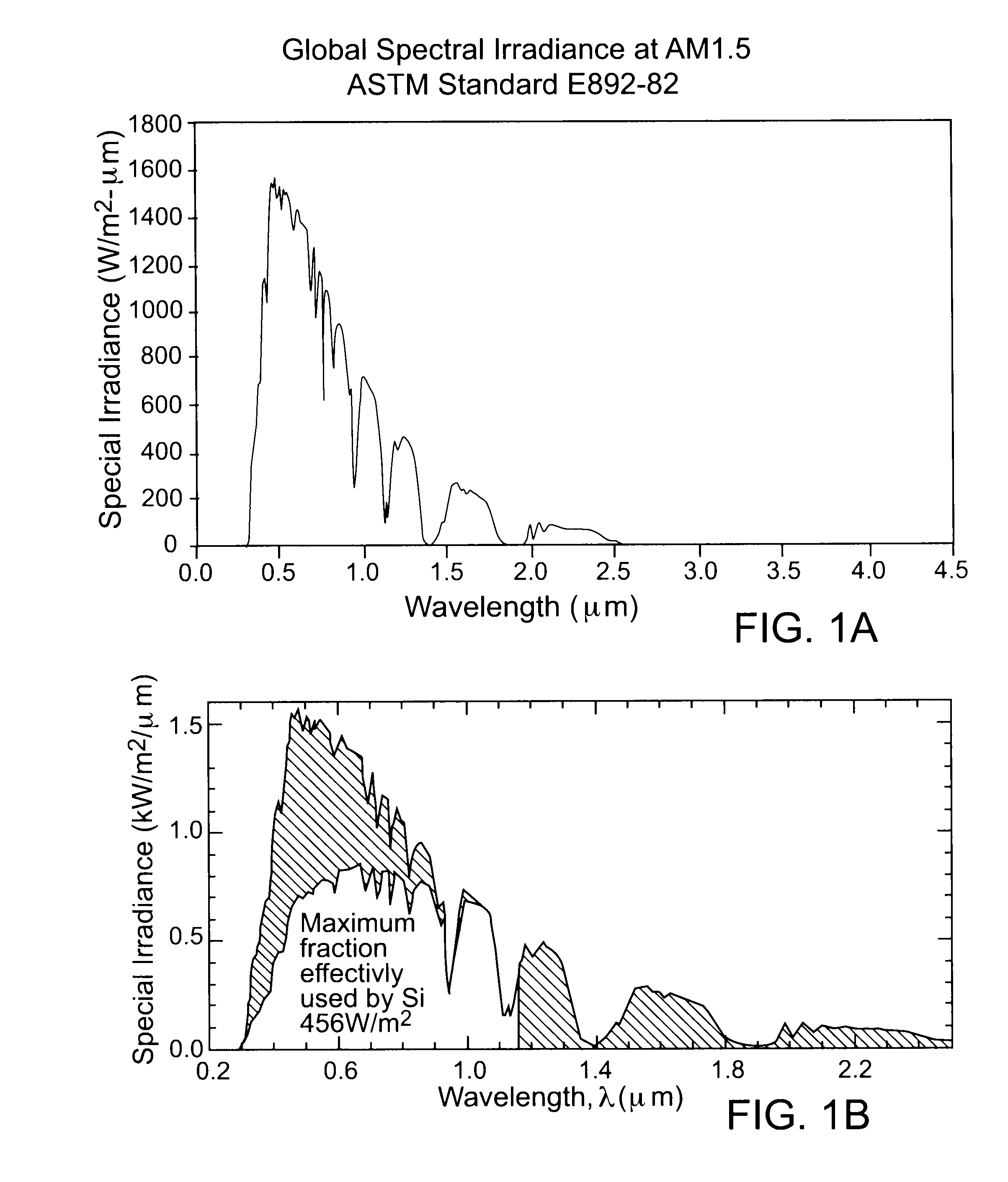

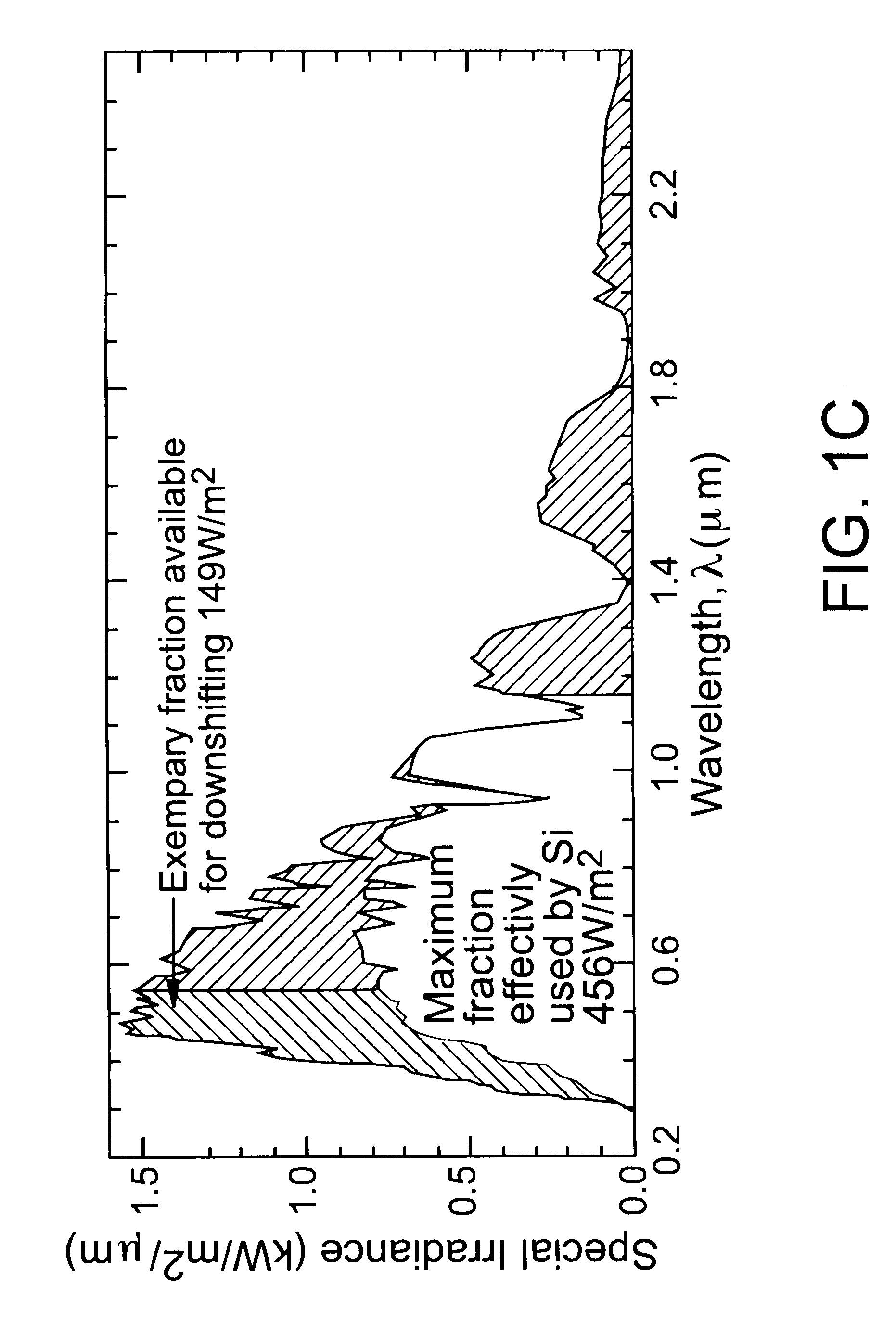

Light conversion efficiency-enhanced solar cell fabricated with downshifting nanomaterial

InactiveUS20110220194A1Convenient lightingEnhance collection and absorptionLuminescent compositionsPhotovoltaic energy generationCost effectivenessQuantum dot

The light conversion efficiency of a solar cell (10) is enhanced by using an optical downshifting layer (30) in cooperation with a photovoltaic material (22). The optical downshifting layer converts photons (50) having wavelengths in a supplemental light absorption spectrum into photons (52) having a wavelength in the primary light absorption spectrum of the photovoltaic material. The cost effectiveness and efficiency of solar cells platforms (20) can be increased by relaxing the range of the primary light absorption spectrum of the photovoltaic material. The optical downshifting layer can be applied as a low cost solution processed film composed of highly absorbing and emissive quantum dot heterostructure nanomaterial embedded in an inert matrix to improve the short wavelength response of the photovoltaic material. The enhanced efficiency provided by the optical downshifting layer permits advantageous modifications to the solar cell platform that enhances its efficiency as well.

Owner:PACIFIC LIGHT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com