Patents

Literature

179results about How to "Improve isotropy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

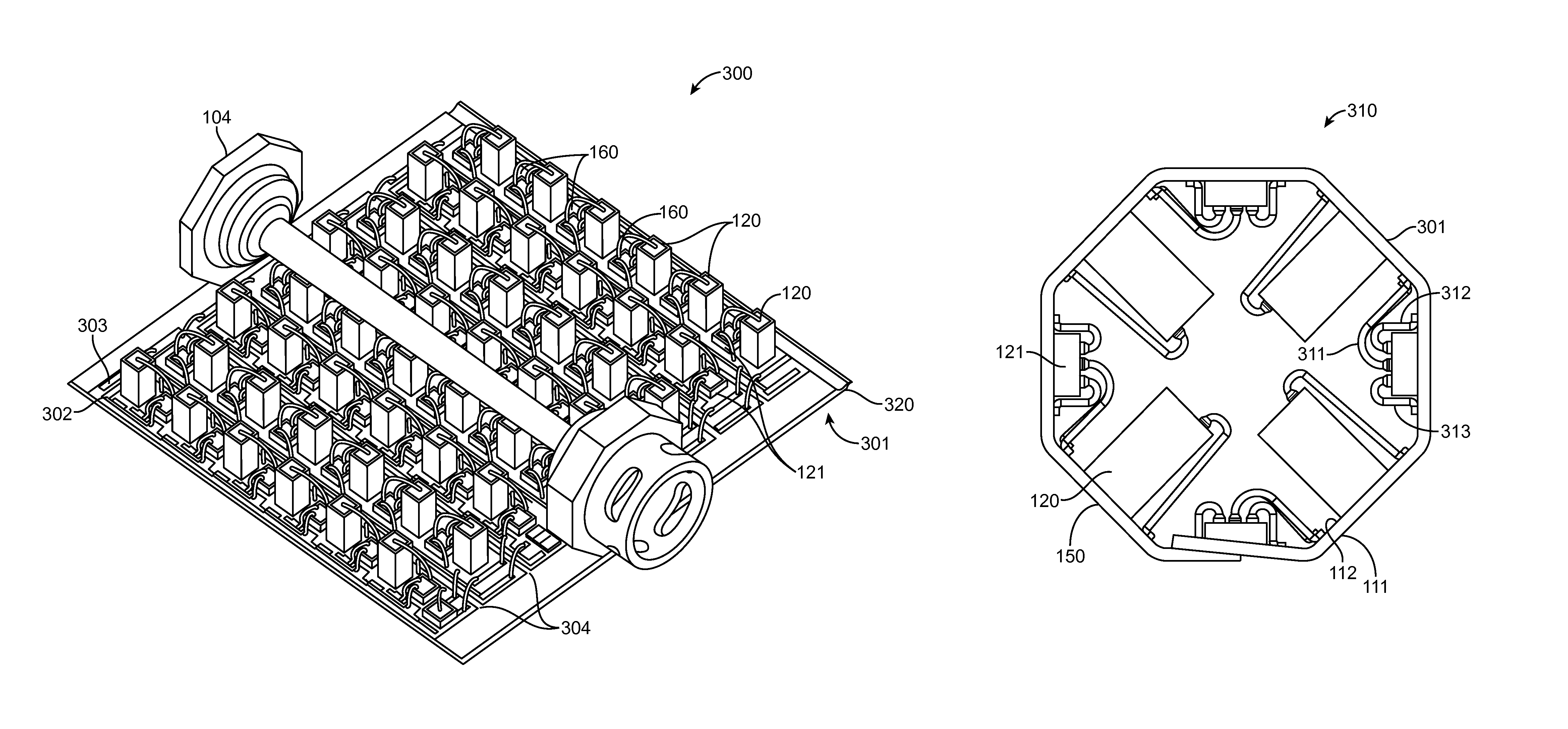

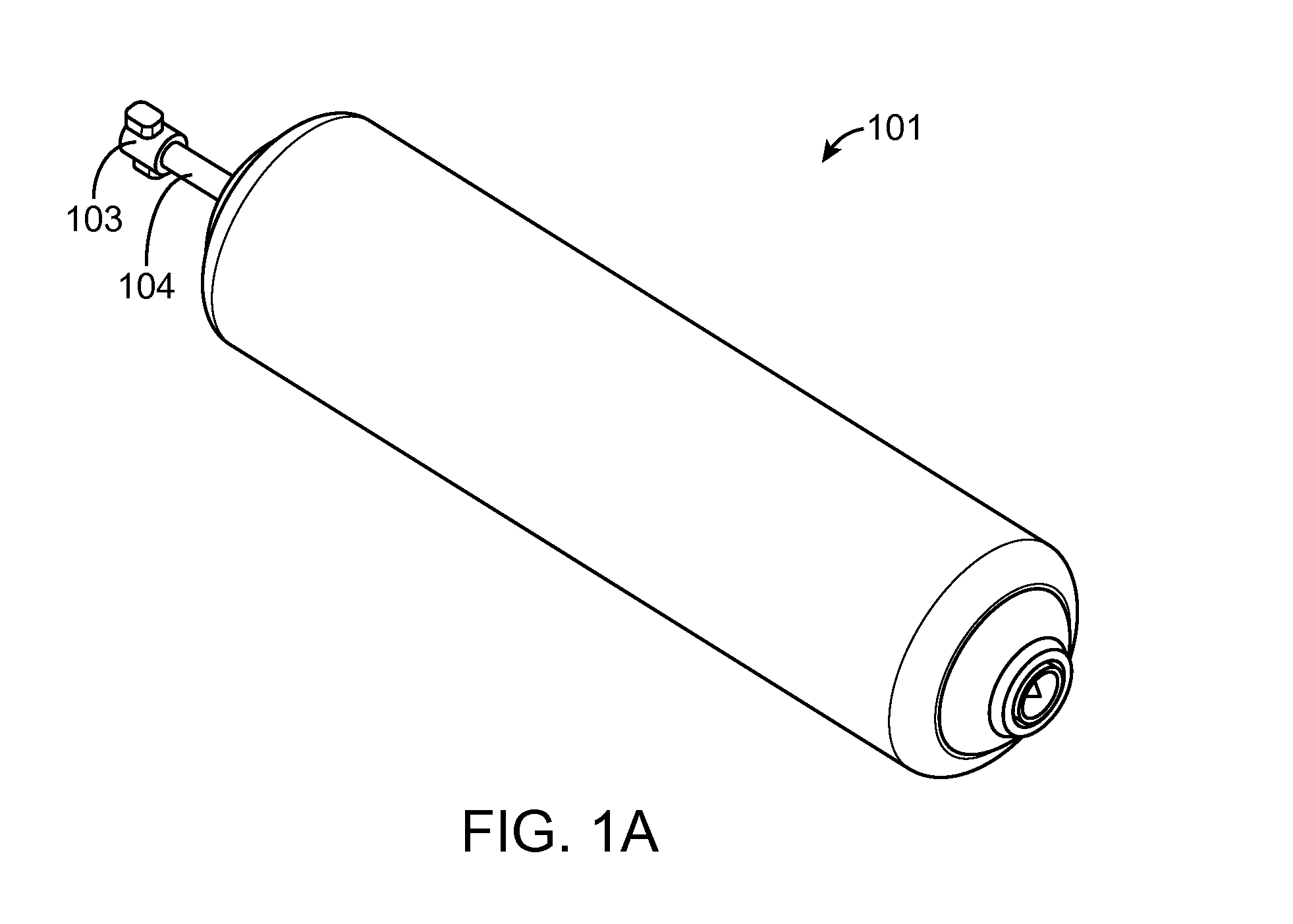

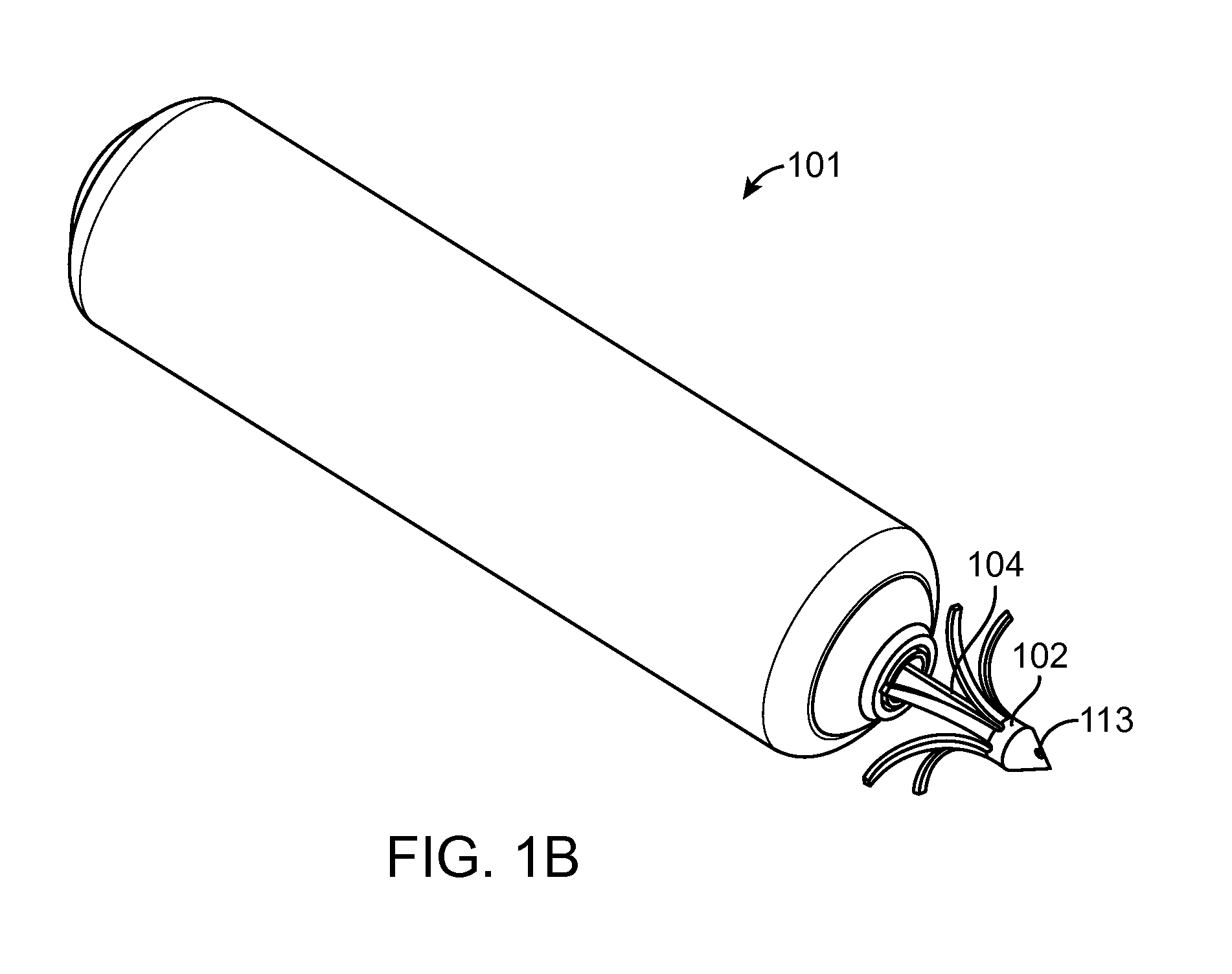

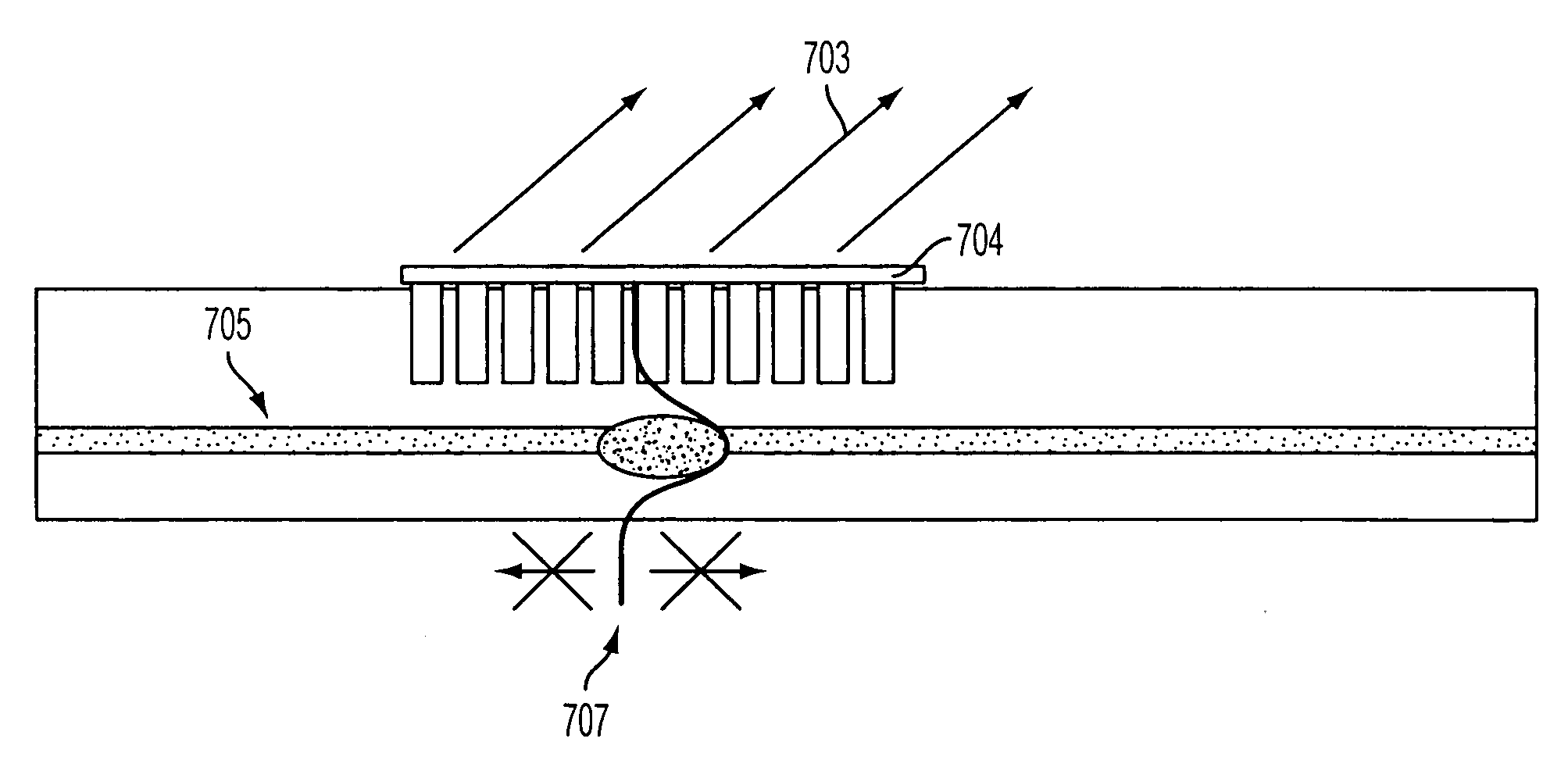

Implantable wireless accoustic stimulators with high energy conversion efficiencies

ActiveUS8588926B2Efficient HarvestingImprove isotropyPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectricityAcoustic energy

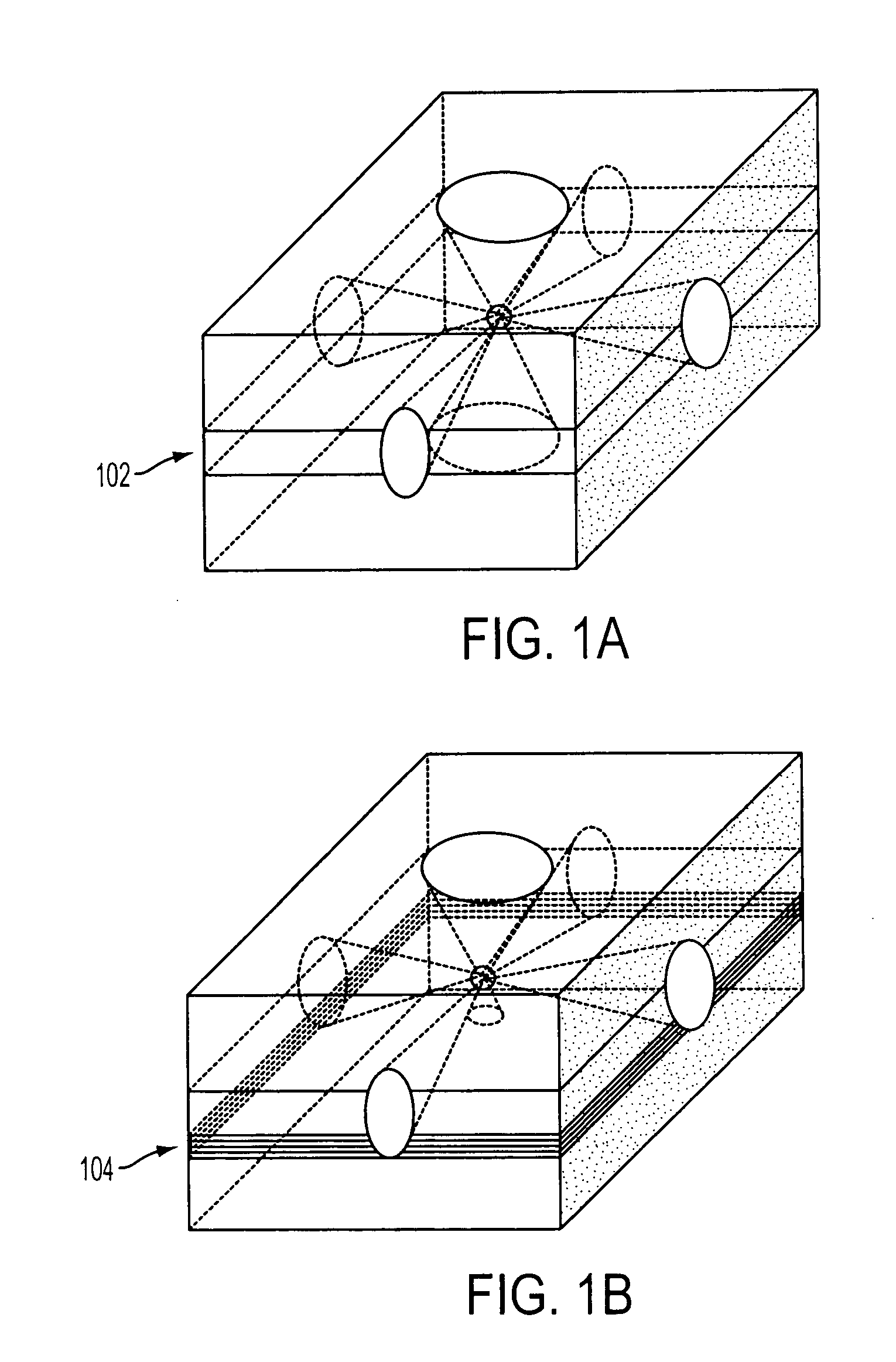

Receiver-stimulator with folded or rolled up assembly of piezoelectric components, causing the receiver-stimulator to operate with a high degree of isotropy are disclosed. The receiver-stimulator comprises piezoelectric components, rectifier circuitry, and at least two stimulation electrodes. Isotropy allows the receiver-stimulator to be implanted with less concern regarding the orientation relative the transmitted acoustic field from an acoustic energy source.

Owner:EBR SYST

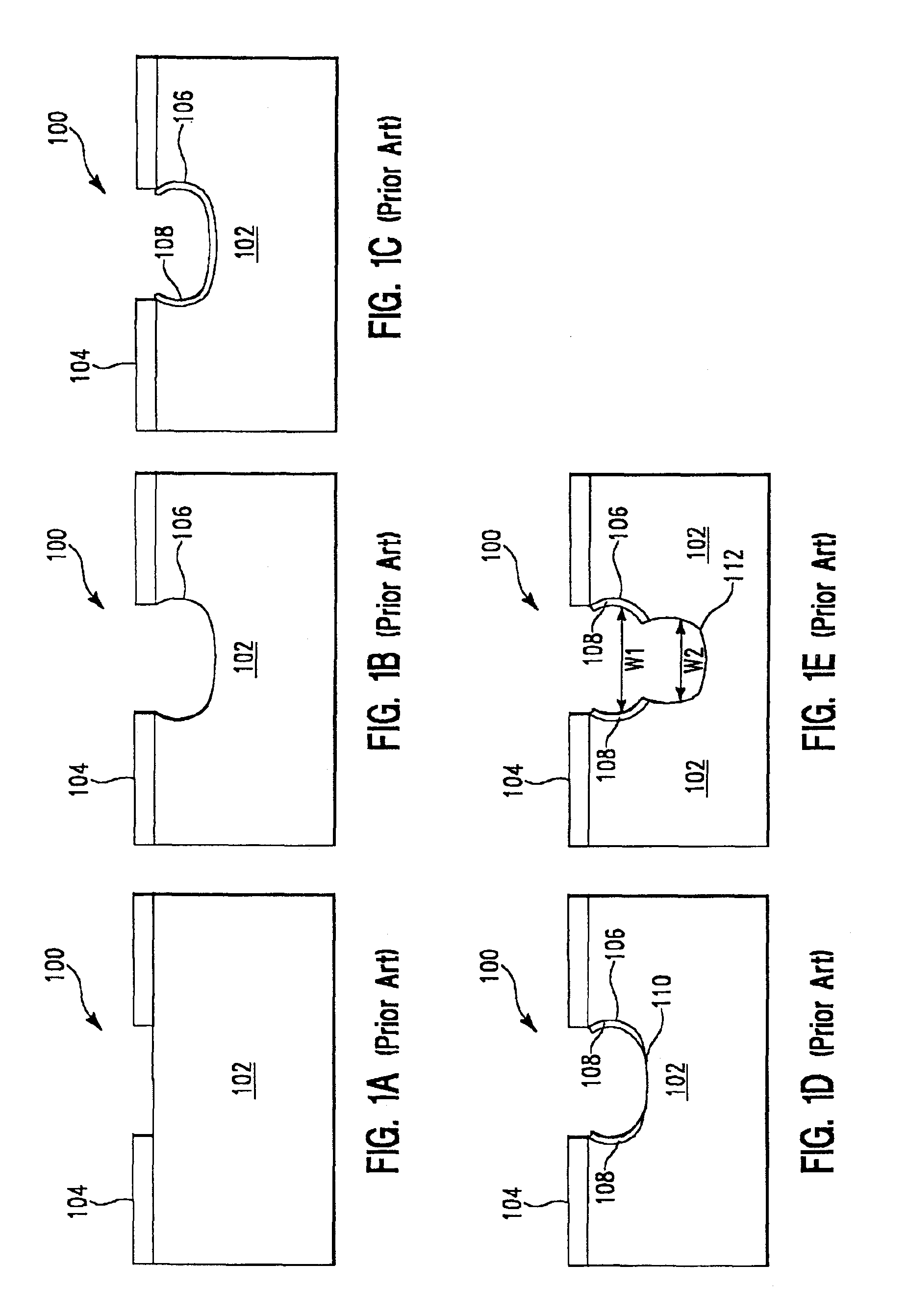

Light emitting diode structures

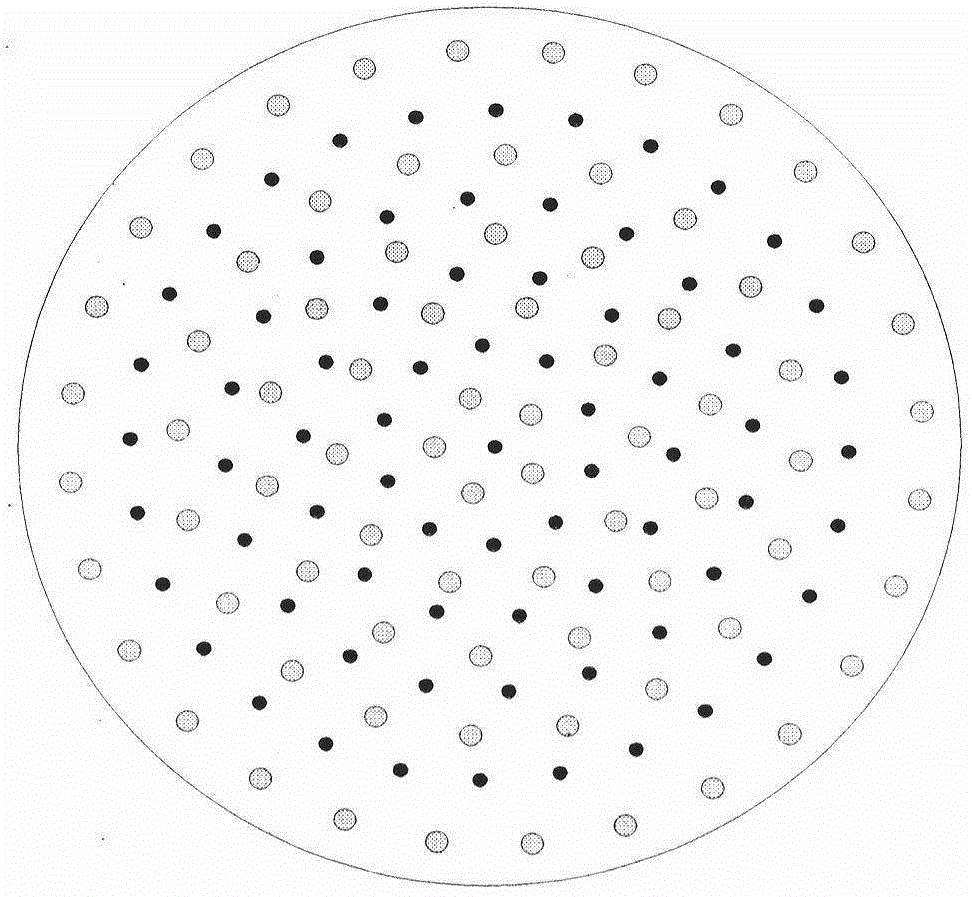

ActiveUS20060062540A1Improve isotropyImprove extraction efficiencySolid-state devicesNanoopticsRefractive indexPhotonics

According to one aspect of the present invention, a light emitting diode (LED) structure including an active core layer and at least one substrate layer having a first refractive index, comprises a 2-dimensional photonic quasicrystal in the structure, the photonic quasicrystal comprising an array of regions having a second refractive index, the array exhibiting long range order but short range disorder. The long range order is associated with diffractive properties of the structure and gives rise to uniform-far field diffraction patterns from the LED. The present invention enjoys the benefit of improved light extraction from LEDs without undesirable far field illumination patterns.

Owner:QUANTUM NIL LTD +1

Fiber-reinforced resin-based composite material core and preparation method thereof

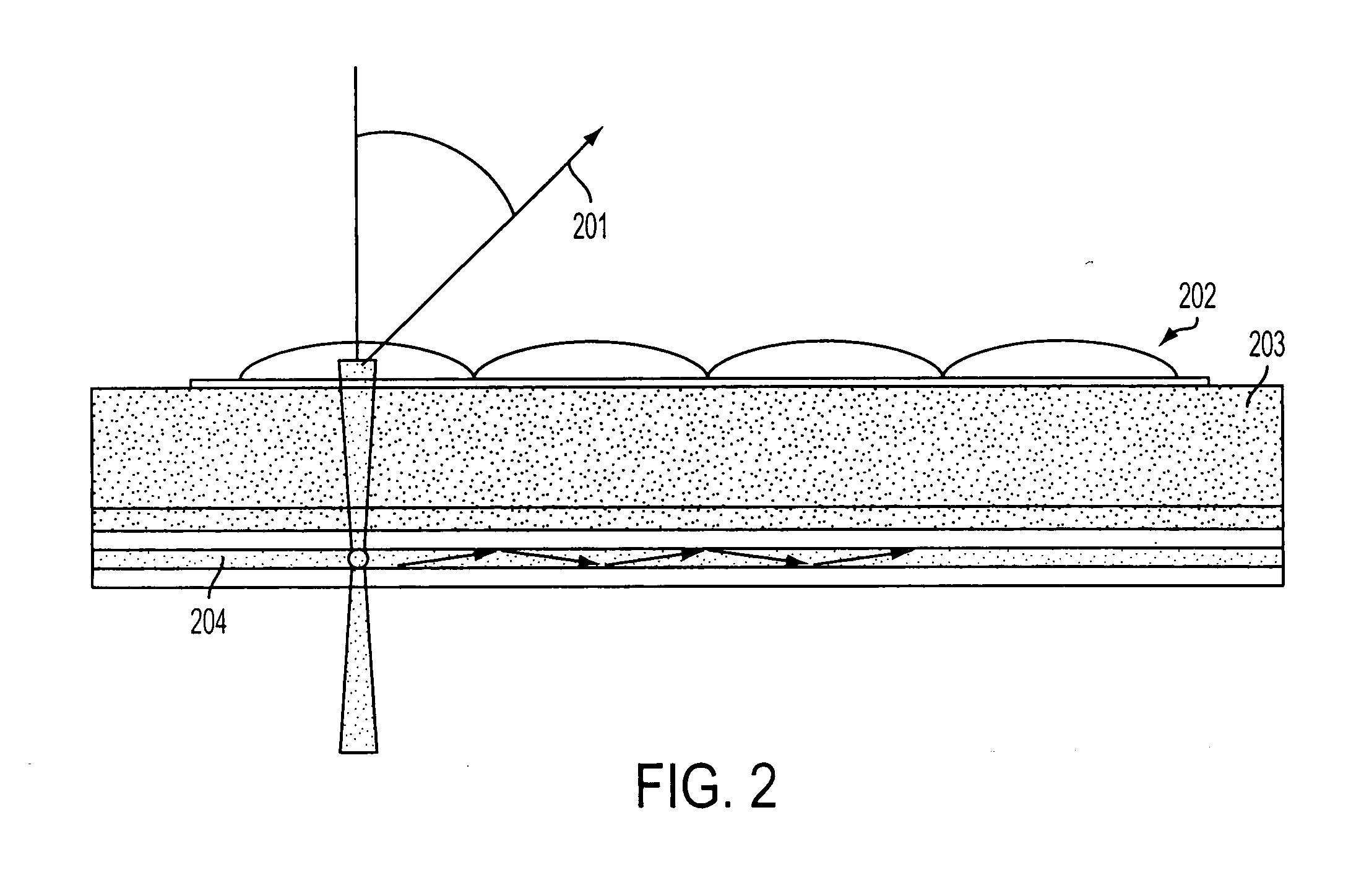

InactiveCN104672782AImprove promotion effectPromote the stability of the effectGlass fiberResin-Based Composite

The invention provides a fiber-reinforced resin-based composite material core. The composite material core is prepared from a fiber-reinforced composite material core in the inner part and an insulating layer on the outer layer, wherein the insulating layer is a glass fiber layer and has the thickness of 0.2-2mm. According to the fiber-reinforced resin-based composite material core, the internal structure is uniform, a layering phenomenon difficultly occurs, the strength is high, the toughness is high, and the cost is reduced.

Owner:STATE GRID CORP OF CHINA +3

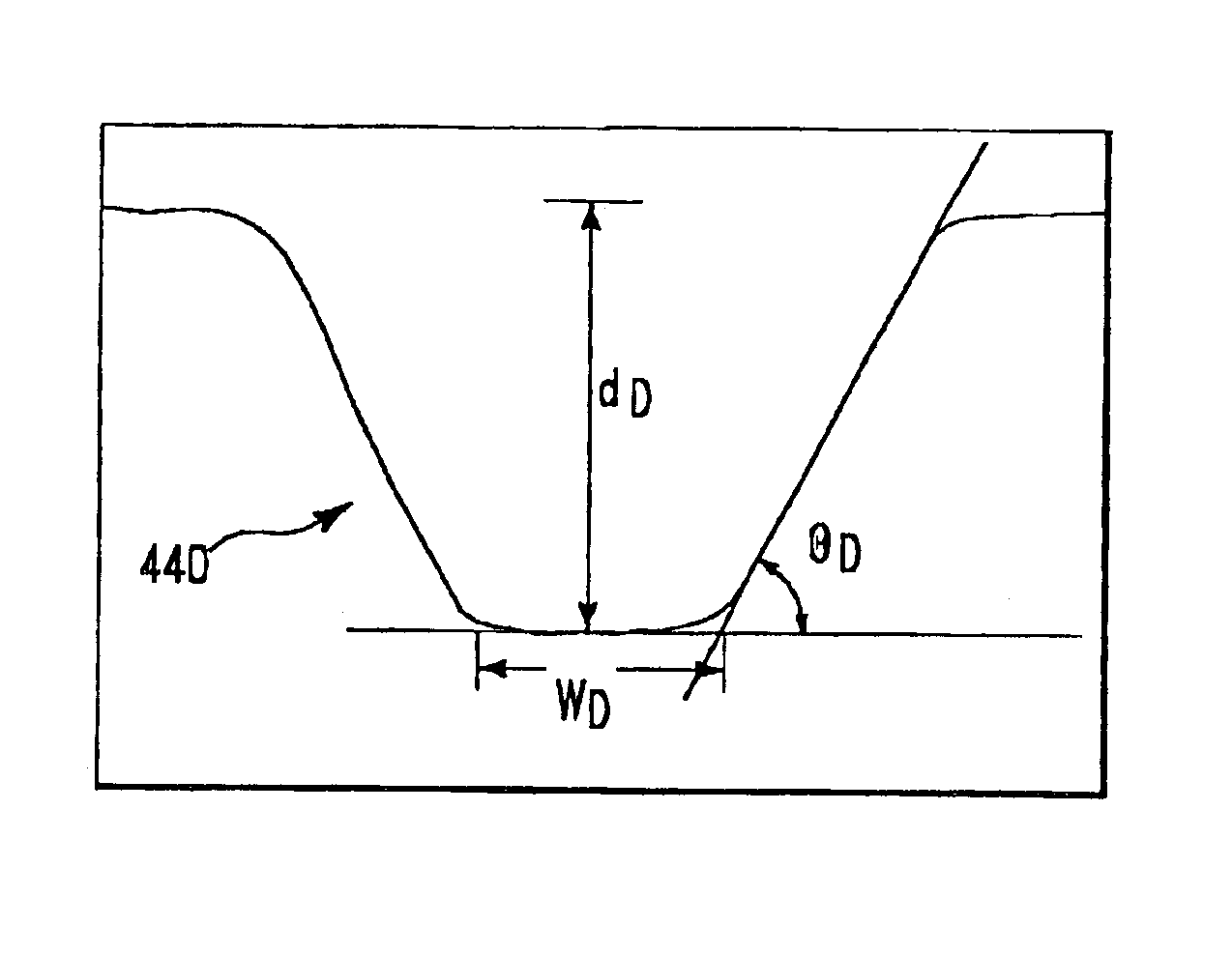

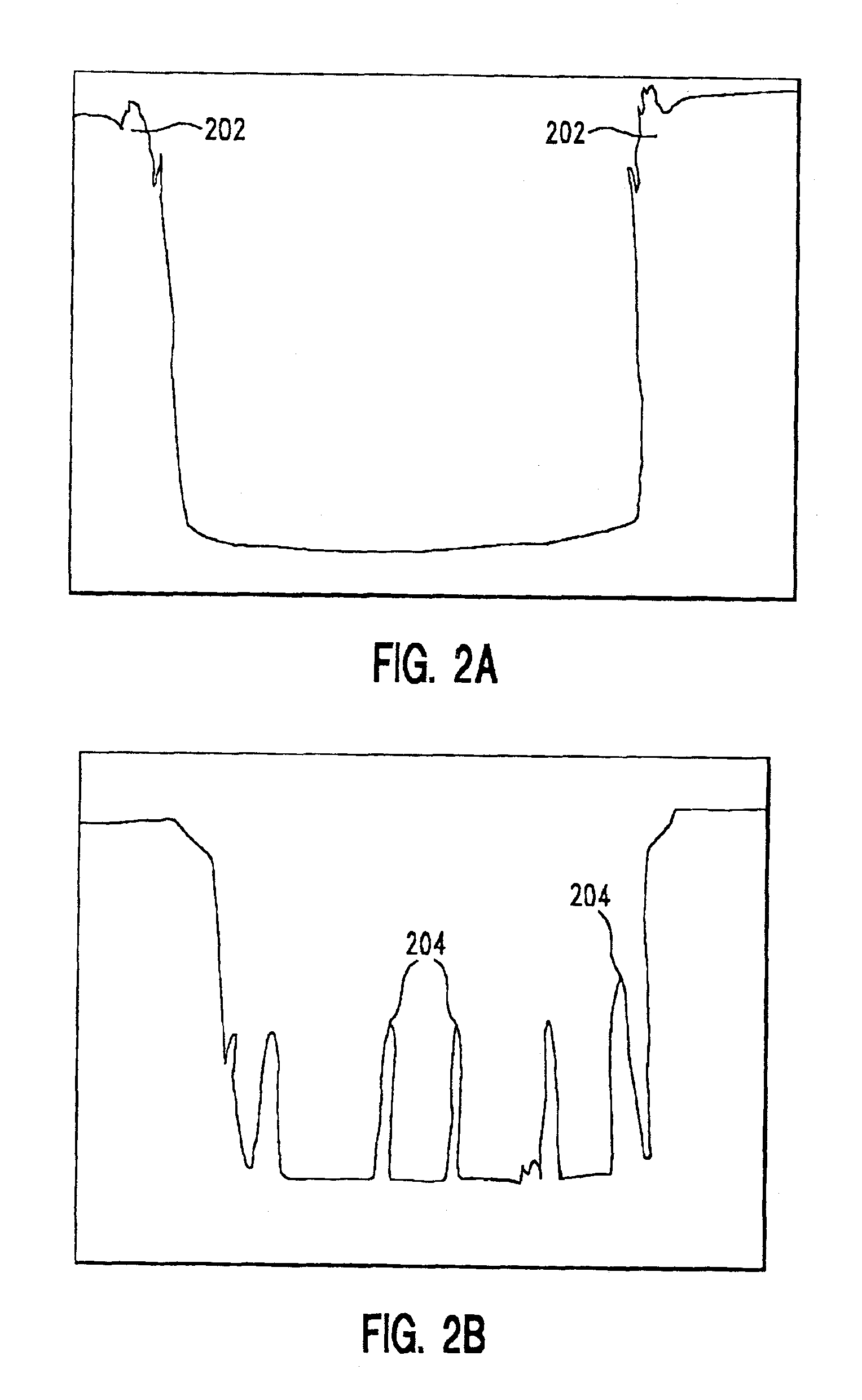

Method of etching a deep trench having a tapered profile in silicon

InactiveUS6849554B2Improve isotropyImprove pressure resistanceDecorative surface effectsSemiconductor/solid-state device manufacturingEtchingEngineering

Disclosed herein is a method of etching deep trenches in a substrate which utilizes the overlying mask structure to achieve a trench having a positive tapered sidewall angle of less than about 88°. The method employs the successive etching of a lateral undercut in the substrate beneath a masking material, while at the same time etching vertically downward beneath the mask. The coordinated widening of the lateral undercut at the top of the trench, while vertically extending the depth of the trench, is designed to provide the desired trench sidewall taper angle.

Owner:APPLIED MATERIALS INC

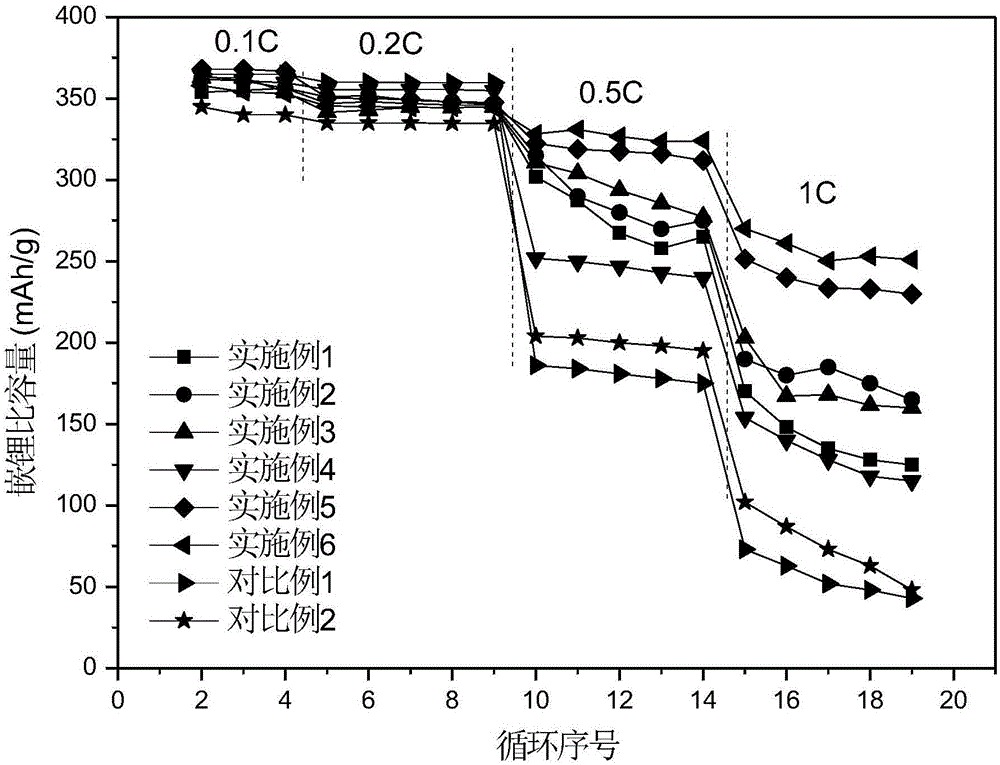

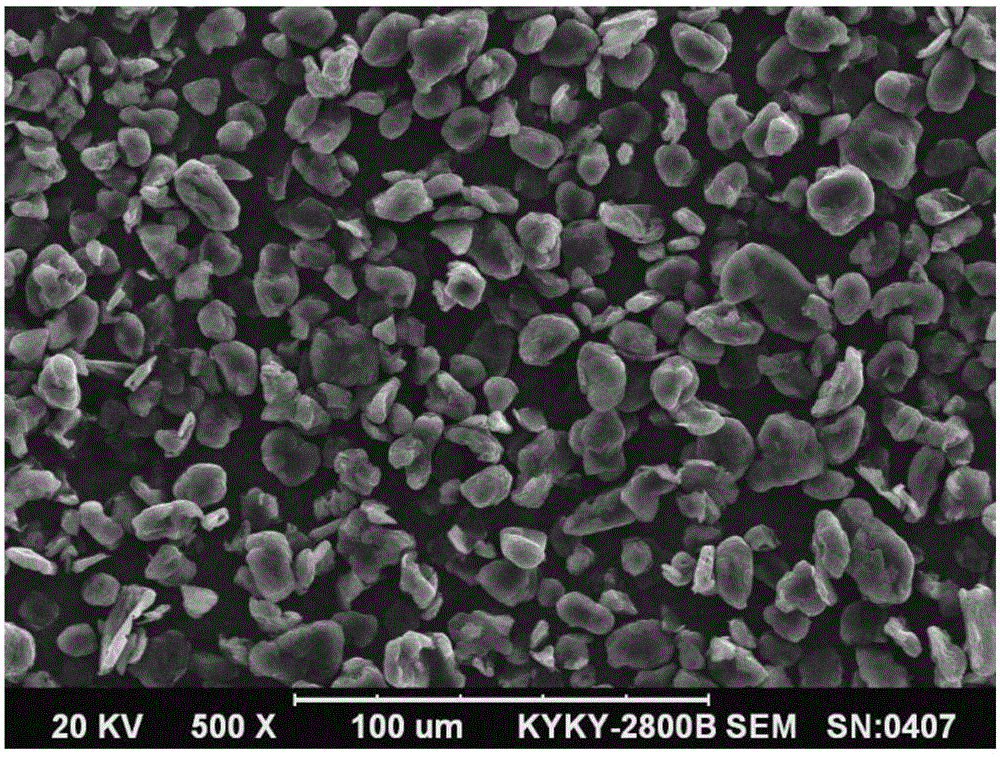

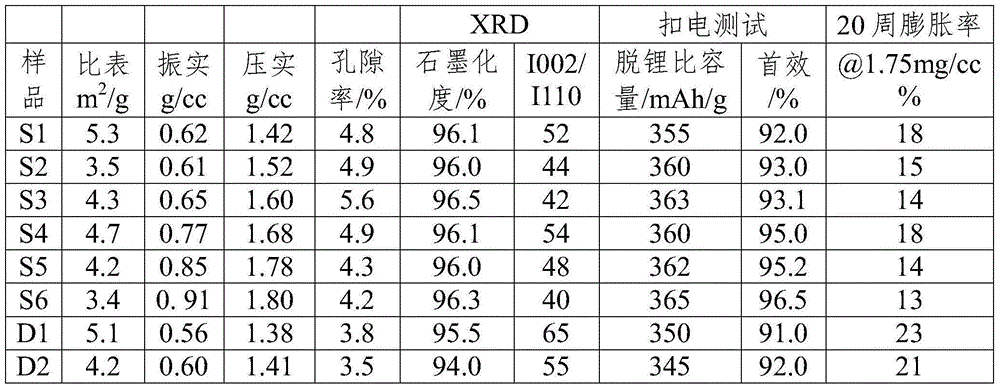

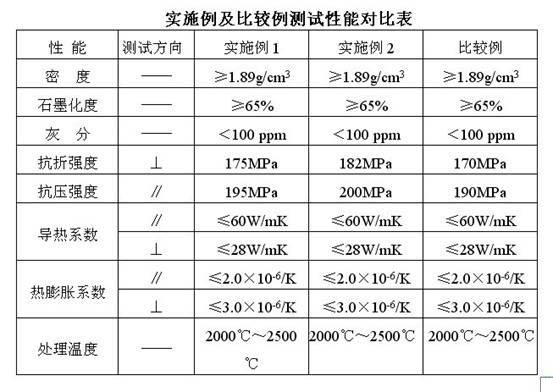

Preparation method of composite graphite, composite graphite and lithium ion battery

InactiveCN105098184ALow costHomogeneous catalytic effectCell electrodesSecondary cellsLithium electrodeGraphite

The invention provides a preparation method of composite graphite to overcome the problems that the composite graphite prepared by the method in the prior art is low in energy density, poor in high-rate charge and discharge properties and high in expansion rate in the charging and discharging processes. The preparation method comprises the following steps: (S1) providing ultrafine carbon powder, wherein the ultrafine carbon powder comprises green coke and / or mesophase carbon green microspheres; (S2) mixing the ultrafine carbon powder with a binder to obtain a mixture A, mixing the mixture A with a catalyst to obtain a mixture B, and then carrying out combined treatment on the mixture B to obtain a precursor; (S3) carrying out graphitizing treatment on the precursor to obtain a semi-finished product; and (S4) crushing, spheroidizing, wrapping and sieving the semi-finished product to obtain the composite graphite. Meanwhile, the invention further discloses the composite graphite prepared by the method and a lithium ion battery. The composite graphite provided by the invention is high in energy density, good in liquid absorption and retention properties, good in isotropic property, good in high-rate charge and discharge properties and low expansion rate in the charging and discharging processes.

Owner:BTR NEW MATERIAL GRP CO LTD

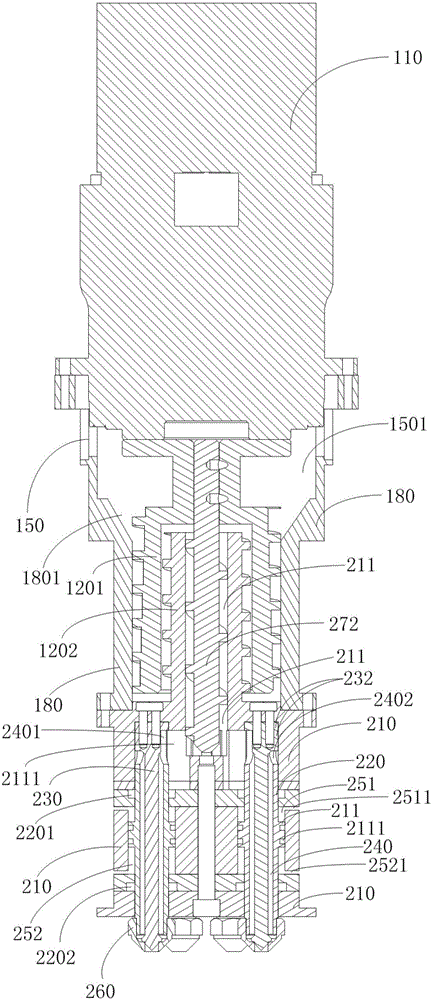

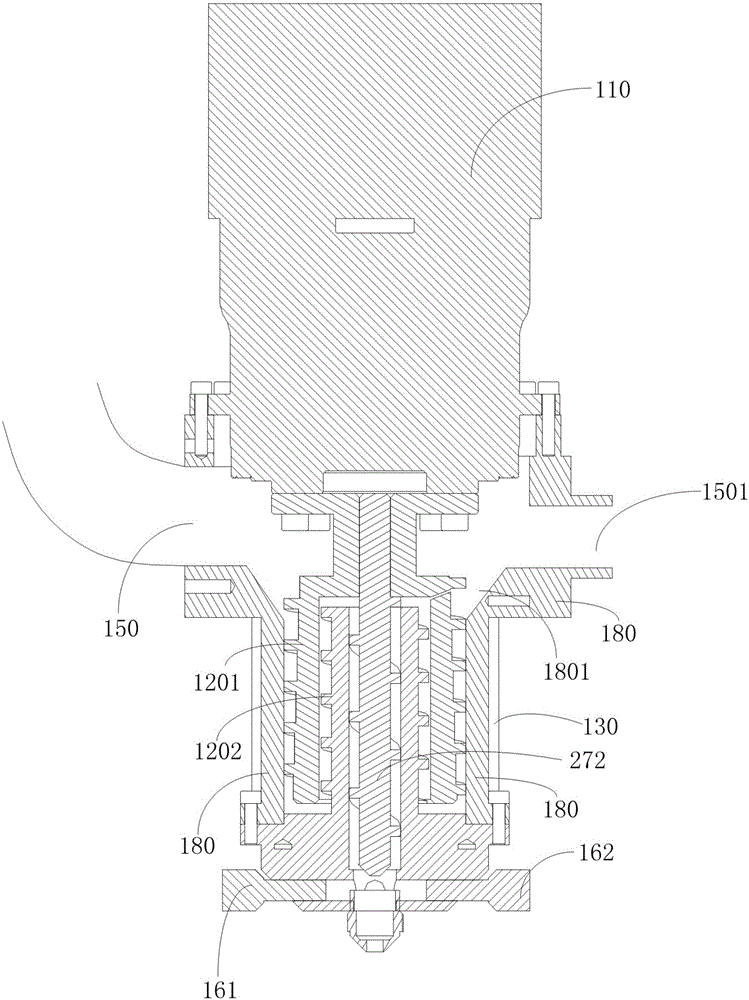

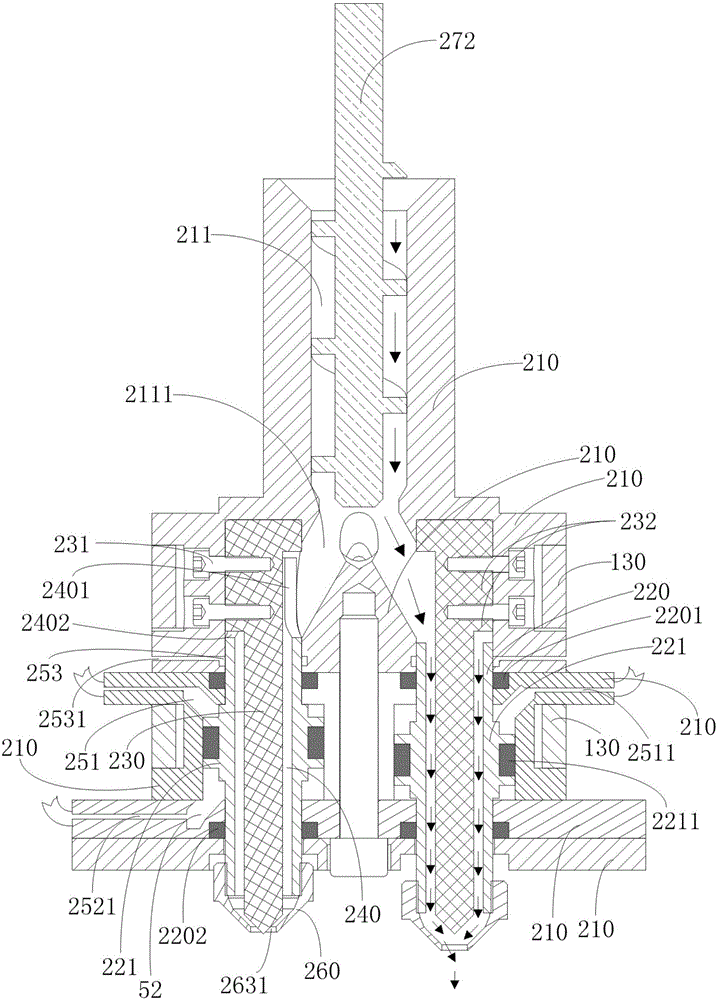

Printing head for 3D printing, control system, 3D printer and printing method

The invention discloses a printing head for 3D printing. The printing head comprises a machine shell, a screw extruding system, an installation seat, barrels, valve needles and spray nozzles. A drive system is arranged at one end of the machine shell. The screw extruding system is arranged in the machine shell and is composed of at least two screws which are embedded internally and externally, and at least one screw is driven by the drive system. The installation seat is mounted below the screw extruding system. One or more inner holes are distributed in the installation seat in the axial direction, and a discharge outlet is formed in the top or the side face of each inner hole. The barrels are mounted in all the inner holes of the installation seat correspondingly, the barrels extend out from one end of the installation seat, and barrel feeding openings are formed in the top ends of the barrels. Valve cavities are formed in the barrels. The valve needles penetrate through all the valve cavities of the barrels to be mounted on the installation seat, and the gaps between the valve needles and the valve cavities form discharging channels communicating with the feeding openings of the barrels. The spray nozzles are arranged at the tail ends of all the barrels. The printing head for 3D printing is light in weight, small in size, capable of achieving high printing precision and printing speed, novel in design, high in practicability and high in economic value.

Owner:浙江光镀智造科技有限公司

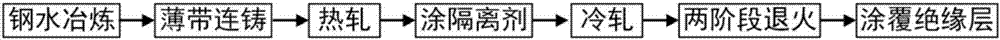

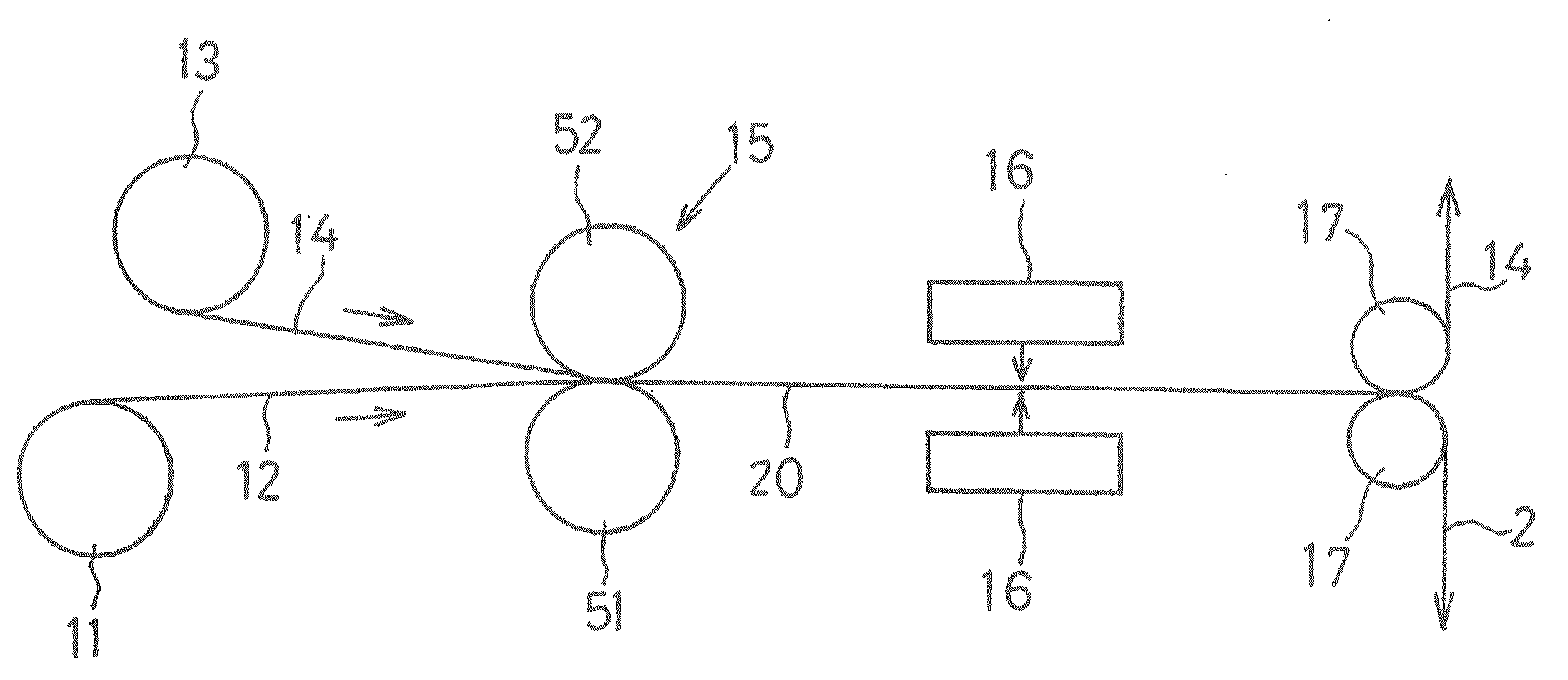

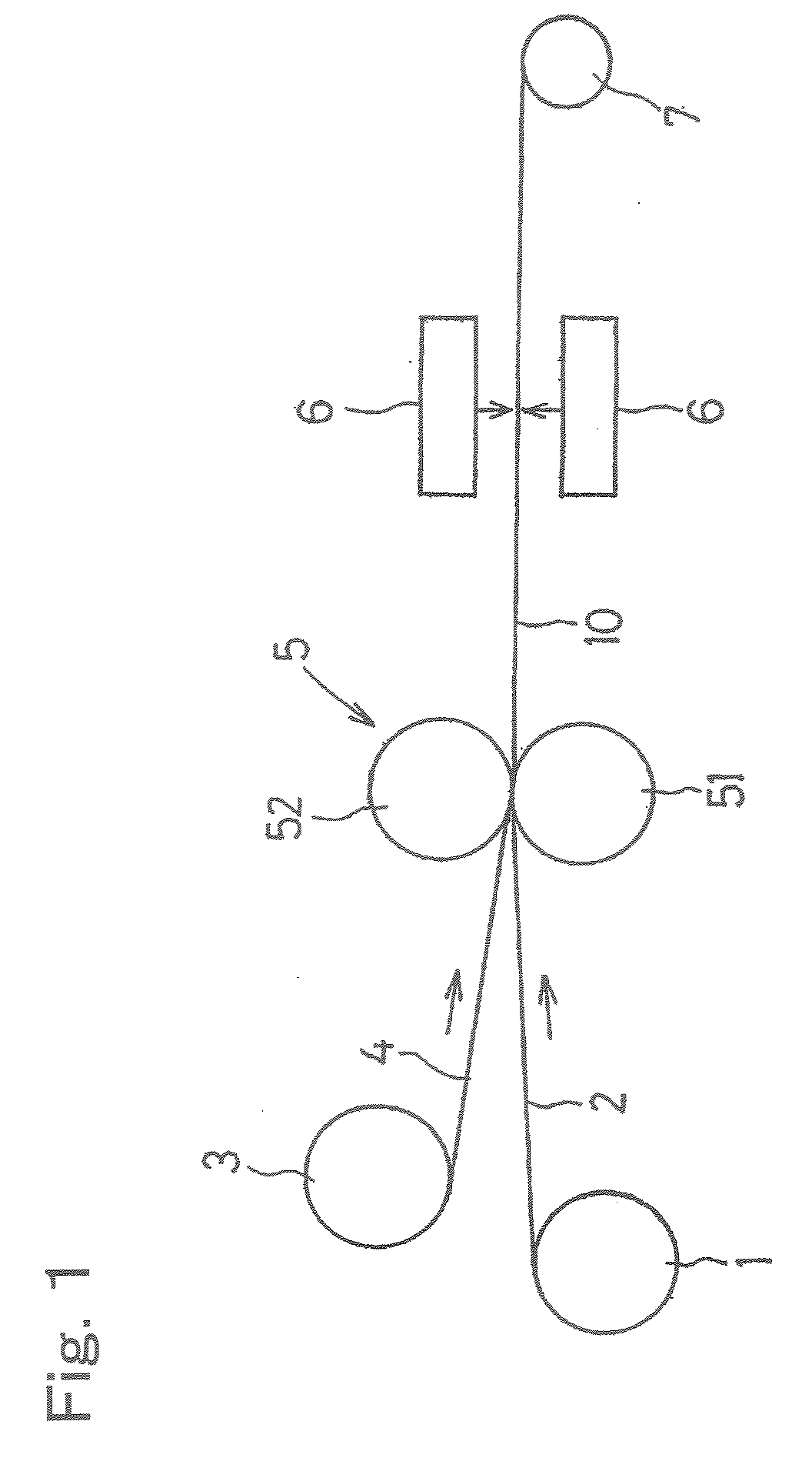

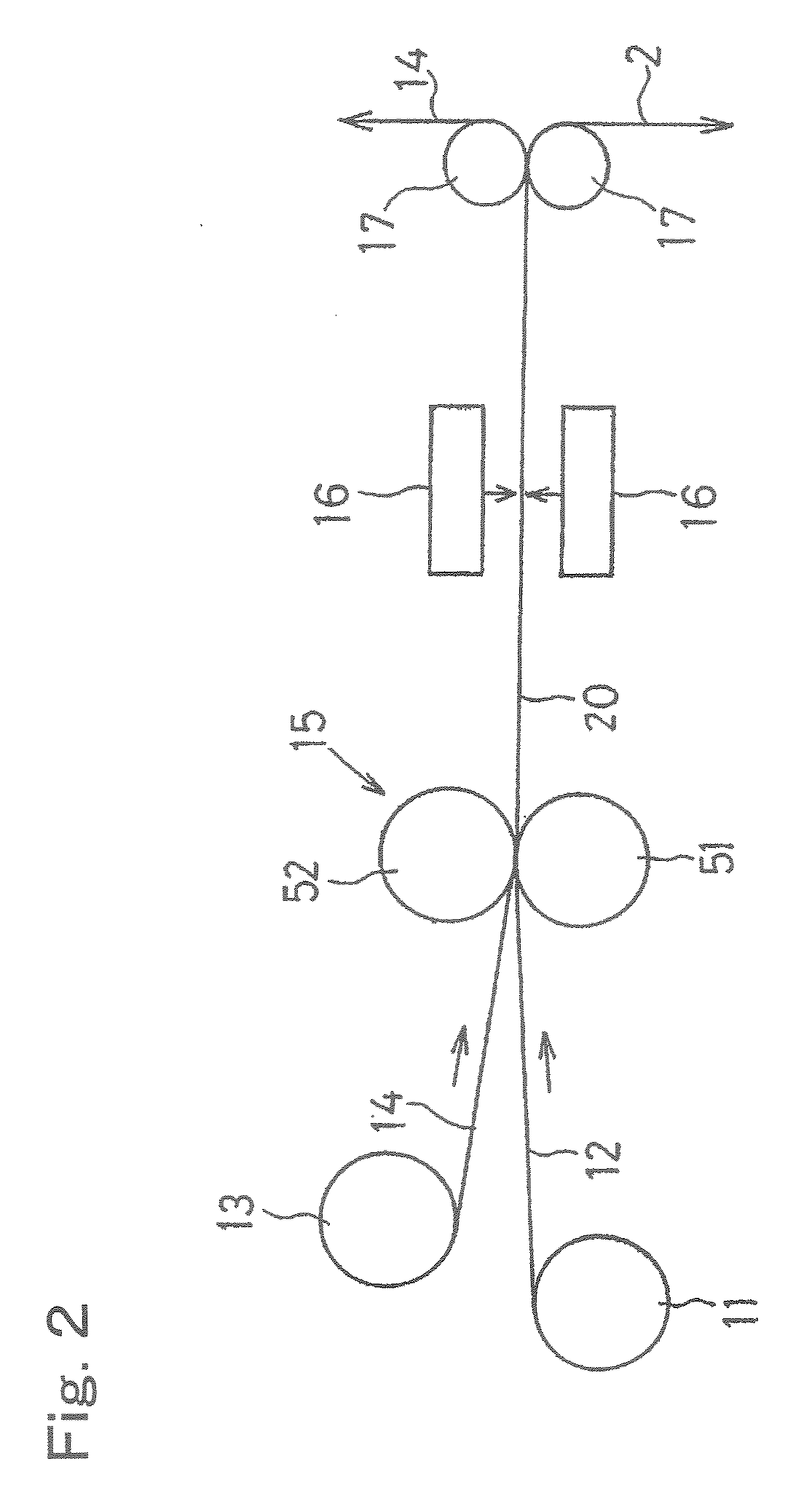

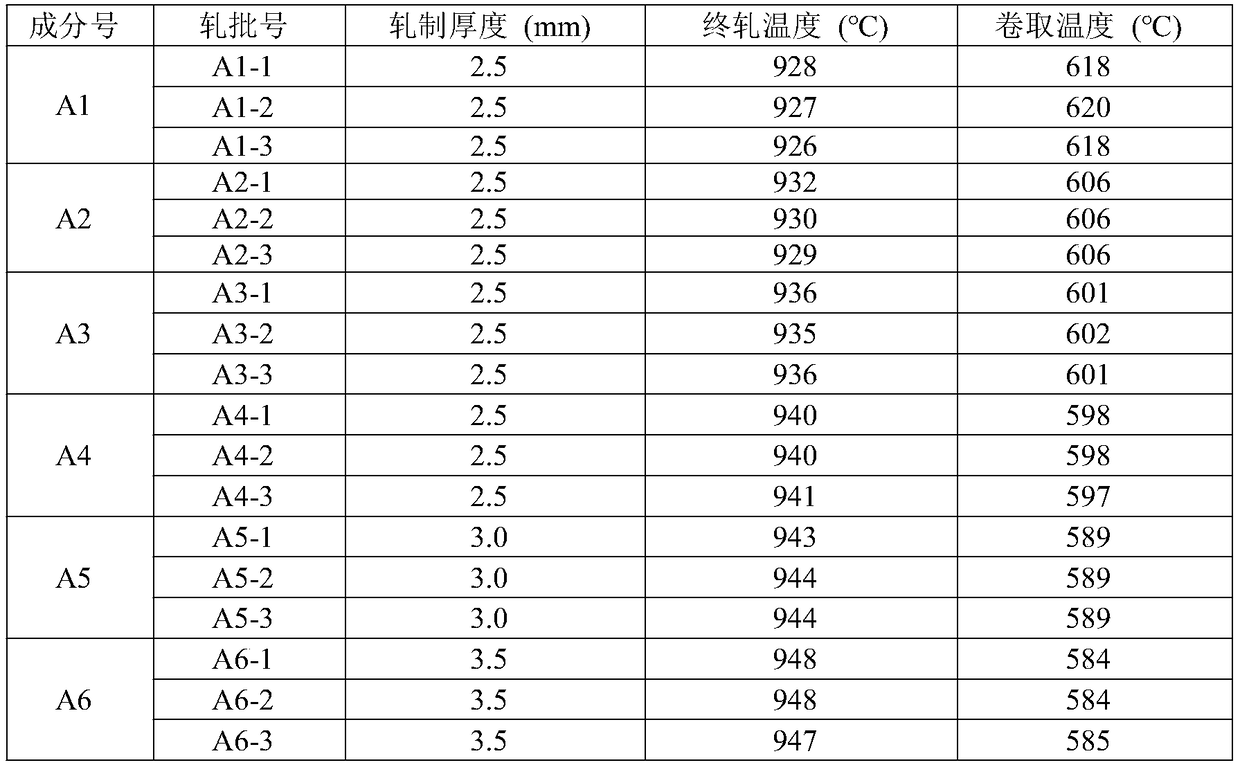

Method for preparing {100} surface developed-texture non-oriented silicon steel thin strip based on thin-strip continuous casting

The invention belongs to the technical field of metallurgy, in particular to a method for preparing a {100} surface developed-texture non-oriented silicon steel thin strip based on thin strip continuous casting. The method comprises the steps of smelting molten steel according to set components, wherein the set components comprise, by weight percentage, 0.002-0.005% of C, 2.2-3.5% of Si, 0.2-0.3% of Mn, less than or equal to 0.005% of Al, 0.08-0.20% of P, 0.002-0.005% of S and the balance Fe and inevitable impurities; (2) carrying out thin-strip continuous casting to form a cast strip with the thickness of 1.5-2.5mm; (3) carrying out one-pass hot rolling under an inert atmosphere condition; (4) carrying out single-stage multi-pass cold rolling on the hot rolled strip after clearing oxide skin of the hot rolled strip; (5) carrying out two-stage annealing on the cold rolled coil; and (6) applying an insulating layer to obtain a high-performance non-oriented silicon steel finished product. The method is based on the thin-strip continuous casting, the low-melting-point element P is added, the segregation characteristic of the P on the surface and the grain boundary is utilized, and therefore the intensity of {100} texture in the finished product plate can be enhanced. The method has the advantages that the technological process is short, the energy is saved, the consumption is reduced, and the anisotropy of the finished product plate can be obviously reduced.

Owner:NORTHEASTERN UNIV

Metal-Clad Laminate And Method For Production Thereof

ActiveUS20080107833A1Good dimensional stabilityImprove isotropyLiquid crystal compositionsAdhesive processesThermal expansionMetal sheet

A metal-clad laminate excellent in isotropy, appearance, bondability between a TLC polymer film and a metallic sheet, and dimensional stability is provided less costly with a first step of thermally compressing the film with the metallic sheet by passing them through a nipping region between heating rolls, and a second step of heat-treating the resultant metal-clad laminate at a temperature not higher than the melting point of the film, wherein the film has thermal expansion coefficient αL satisfying αL=βT+γ with thickness T, thickness coefficient β and anisotropy coefficient γ of the film; wherein the coefficient β is within the range of −0.08 to −0.01; the coefficient γ is within the range of αM+6≦γ≦αM+10 with thermal expansion coefficient αM of the metallic sheet; and thermal expansion coefficient αT of the film is within αM−2≦αT≦αM+3 with the coefficient αM.

Owner:KURARAY CO LTD

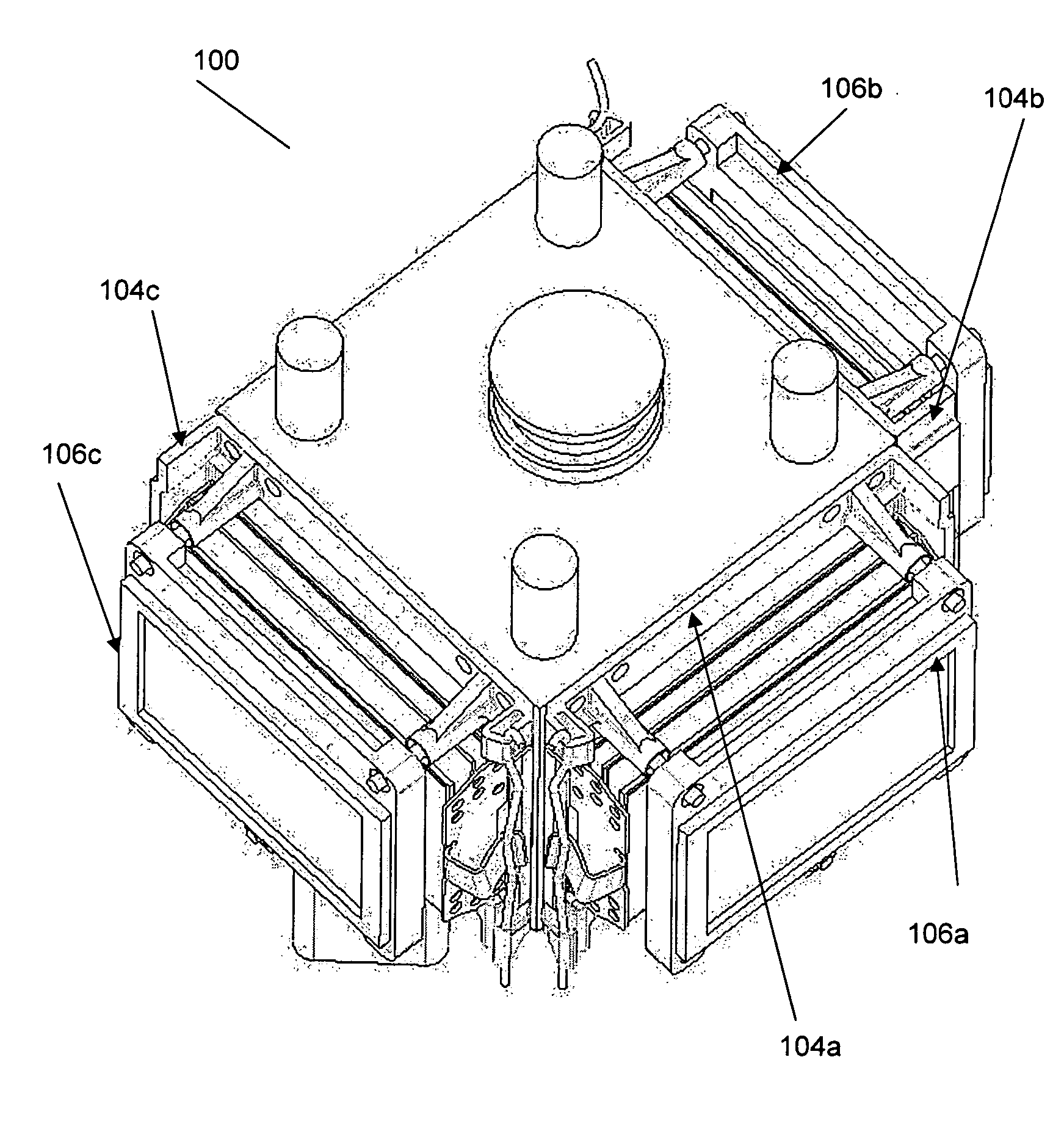

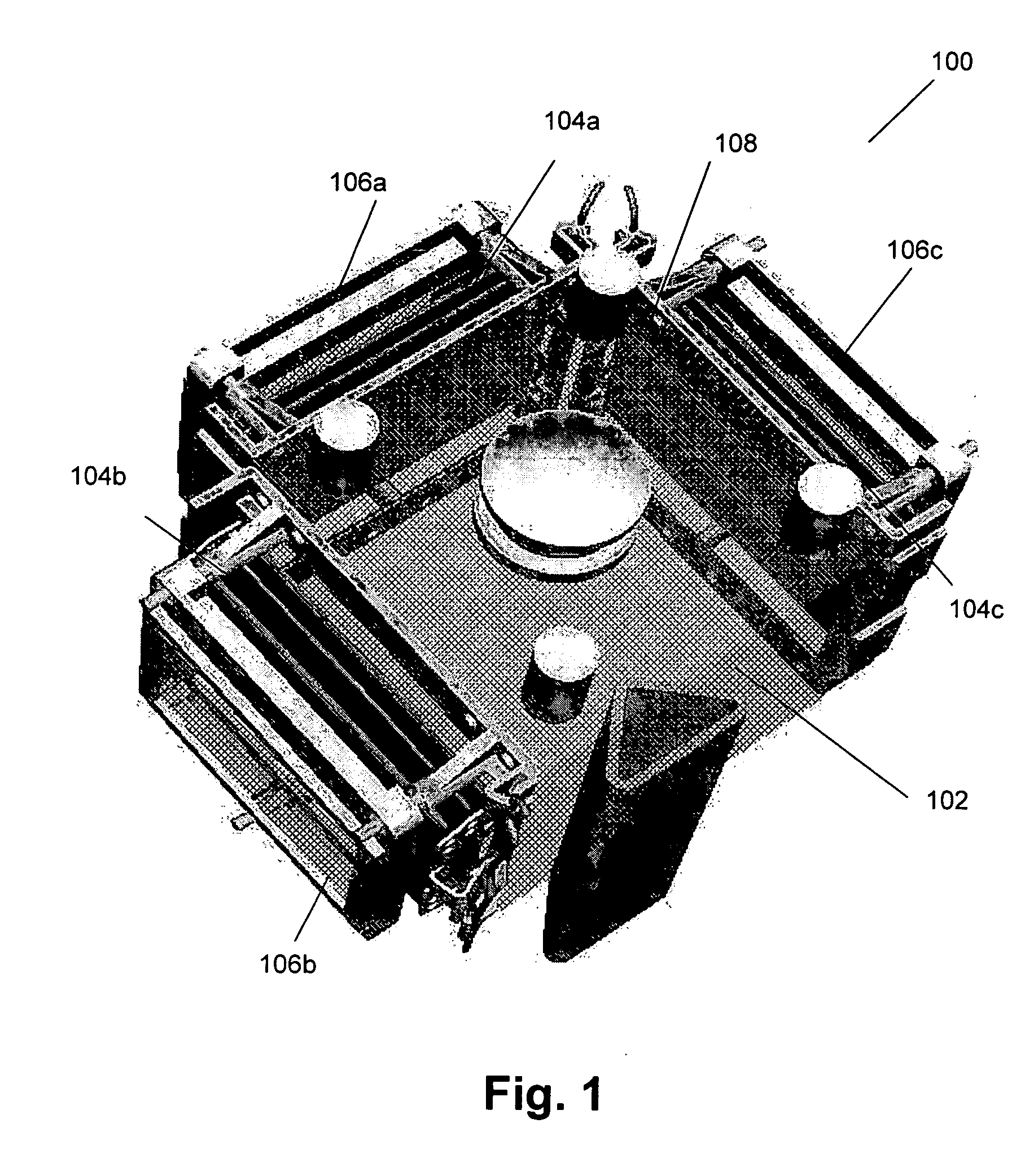

Convergence system for a projection display system

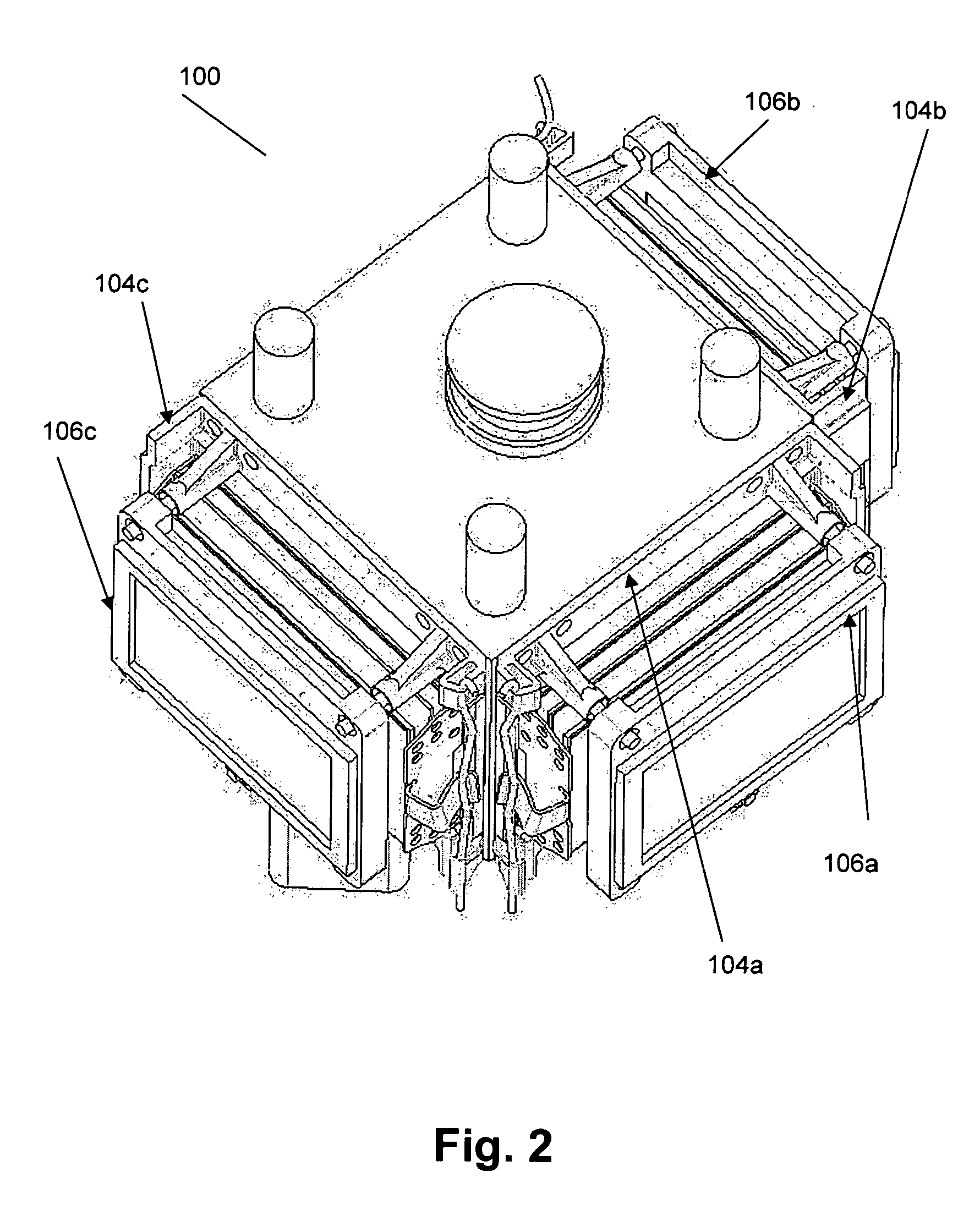

InactiveUS20050185145A1Highly isotropicResistance to humidityPicture reproducers using cathode ray tubesProjectorsEnvironmental effectEngineering

A convergence system 100 comprises a dichroic prism 102 for splitting and / or recombining light beams, intermediate parts 104a, 104b, 104c and a light modulator 106a, 106b, 106c for every color beam. The intermediate parts 104a, 104b, 104c are constructed such that the convergence system has an improved resistance for variations in environmental effects like temperature and humidity. The intermediate parts 104a, 104b, 104c are constructed such that the convergence system has a high stability, a large degree of monolithicy and a high movement isotropy. When used in a projection display system, the projection display system has a high degree of color uniformity.

Owner:BARCO NV

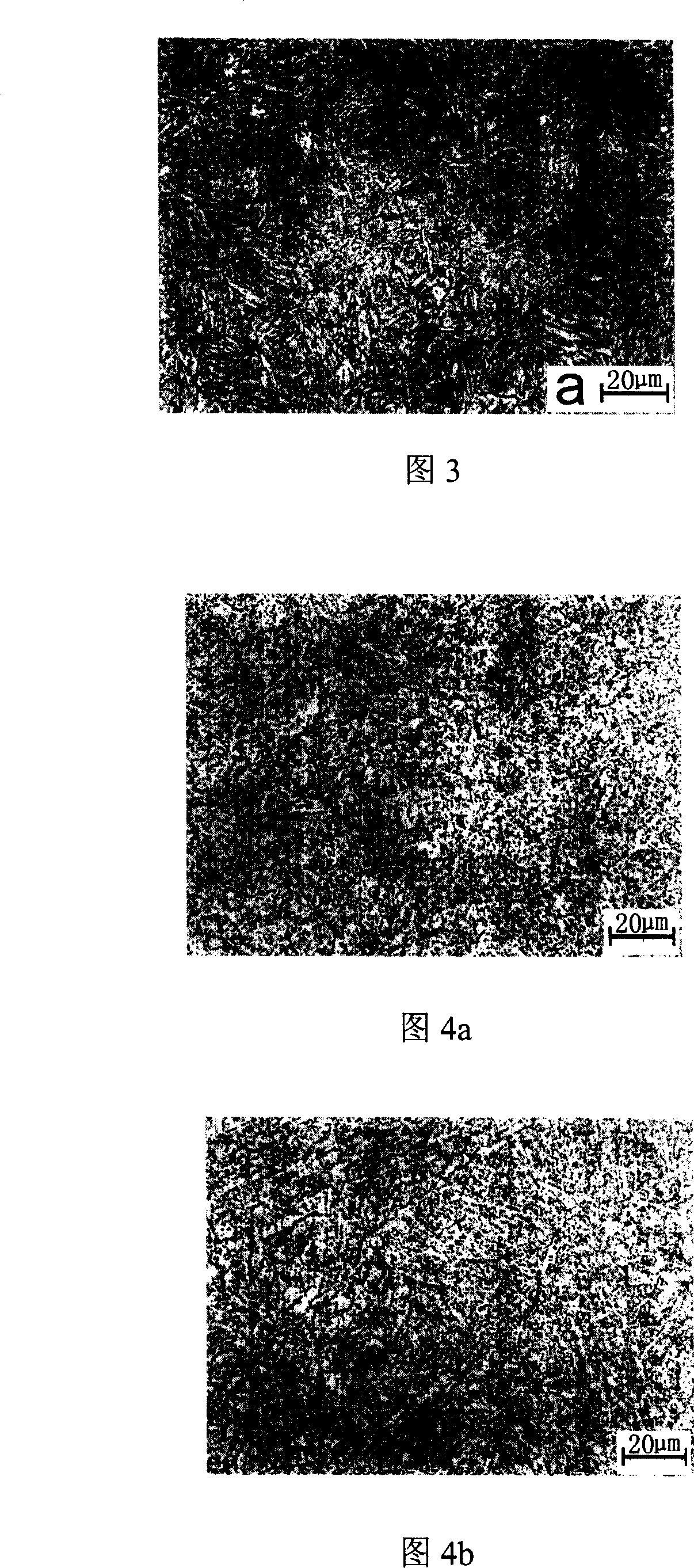

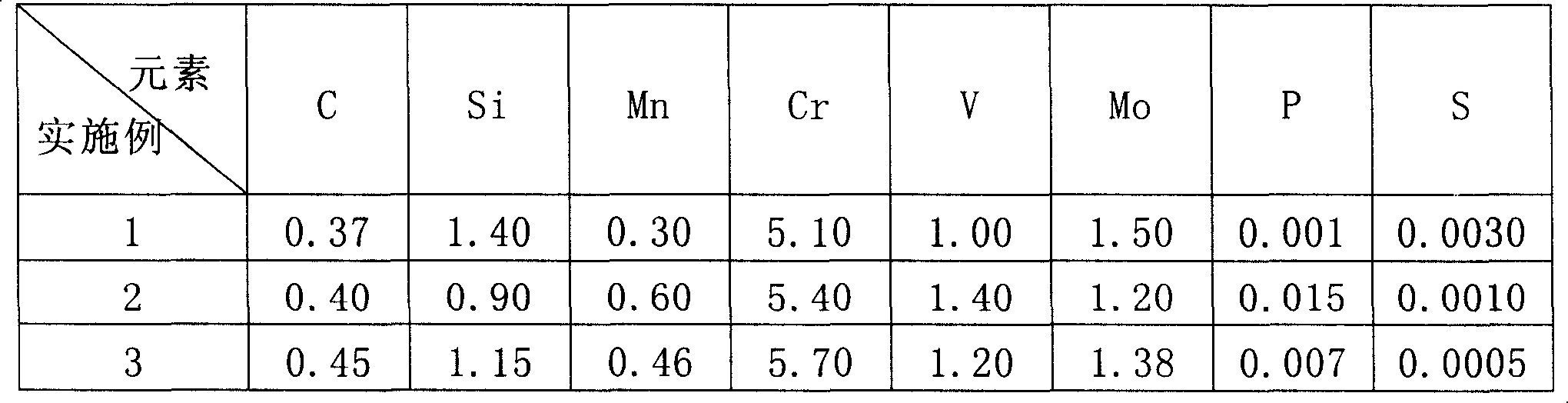

Process for producing H13 hot work die steel

The invention relates to a process for producing H13 hot work die steel, aiming to solve the problem that the present H13 hot work die steel universally has problems of 'good heat resistance and poor toughness or good toughness and poor heat resistance'. The chemical components of the 4Cr5MoSiV1(H13) hot work die steel are reasonably designed and adjusted to control the content of alloy elements such as Cr, Mo, V and Si and exert the interaction of the alloy elements, so that grains are thinned and distributed uniformly; meanwhile, by optimizing an electroslag remelting technology, a forging technology and a thermal treatment technology, the purity and compactness of the steel are improved, segregation is reduced, the mechanical property and isotropy of the steel are further improved, the heat uniformity of a forged part is ensured, a carbide ball structure with stable size and uniform distribution is obtained, and therefore the mechanical property and service life of a product are improved.

Owner:南平市双友金属有限公司

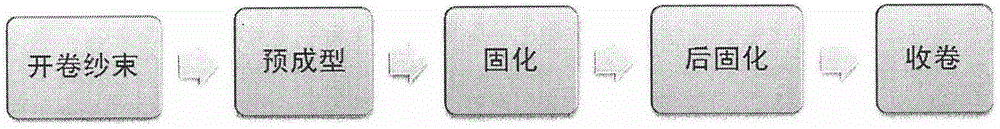

Method for preparing isotropical graphite

InactiveCN103011148AEasy to shapePromote sinteringCarbon compoundsManufacturing cost reductionMicrosphere

The invention discloses a method for preparing isotropical graphite, which is characterized by comprising the following steps: (1) mixing mesocarbon microbeads with asphalt to obtain a mixture; (2) carrying out thermal polymerization reaction to the mixture, and growing the mesocarbon microbeans for the second time to obtain intermediate phase raw material; (3) performing ball-milling treatment to the intermediate phase raw material to obtain ball-milled powder; (4) performing oxidization treatment to the ball-milled powder to obtain pre-treated powder; (5) performing iso-static compaction to the pre-treated powder; (6) sintering; and (7) graphitizing. The preparation method disclosed by the invention is short in process and easy to implement, and is beneficial for shortening the production cycle and reducing the manufacturing cost; in addition, the graphite material produced by the method disclosed by the invention has the characteristics of excellent homogeneity and high mechanical strength.

Owner:KAIFENG CARBON CO LTD OF CHINA PINGMEI SHENMA GRP

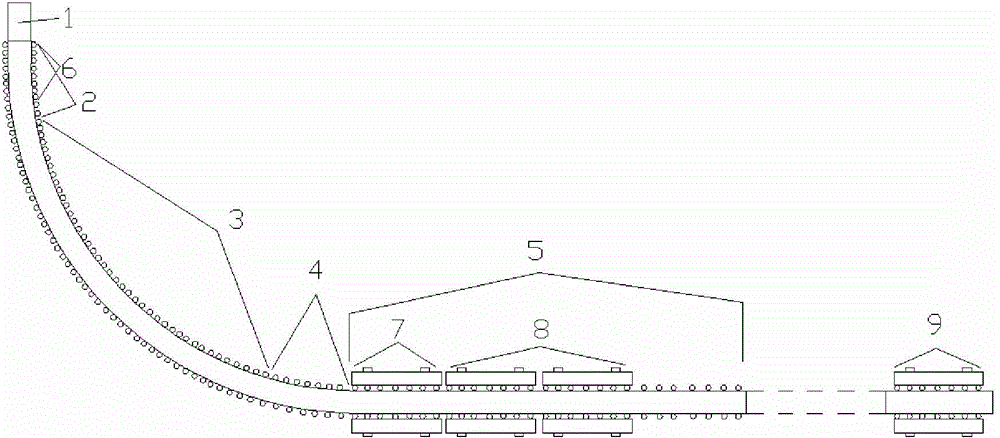

Method for producing ultra-thick plate continuous casting blank

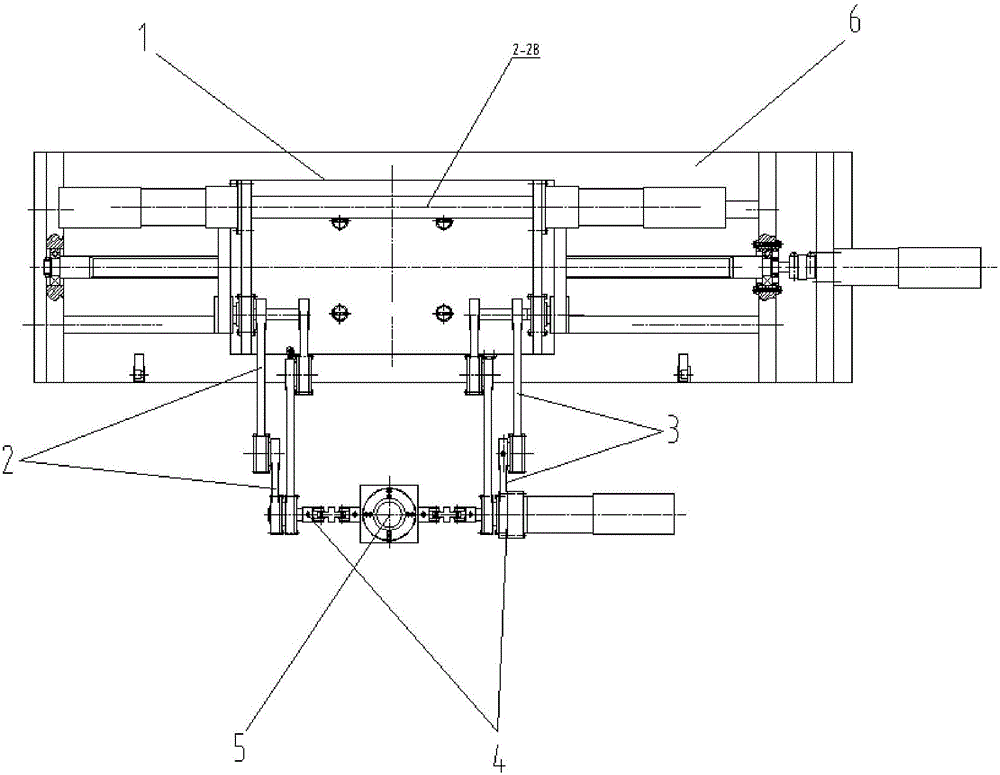

The invention relates to the field of metal continuous casting manufacturing, in particular to a method for producing an ultra-thick plate continuous casting blank by adopting fast cooling and unsymmetrical great pressing-down. According to the method, a continuous casting blank sequentially passes through a vertical section (2), an arc-shaped section (3), a straightening section (4) and a horizontal section (5) under a crystallizer (1), through the implementation of fast cooling and unsymmetrical great pressing-down in a secondary cooling region of a casting machine, the ferritiszation process of the casting blank surface layer is realized before the bending or straightening through the fast cooling process, in addition, the balanced separation of second-phase particles in crystals and at crystal boundaries is ensured, the surface layer tissues of the casting blank are improved, meanwhile, the deformation of a blank core part can be increased through the unsymmetrical great pressing-down process, the occurrence of surface cracks of medium and ultra-thick casting blanks in the bending and straightening process is prevented, and meanwhile, the center segregation and the center looseness of the ultra-thick casting blank is avoided. The method provided by the invention has the advantages that the surface quality and the center quality of the ultra-thick plate continuous casting plate can be better improved, so that the ultra-thick plate continuous casting blank can realize the rolling production of ultra-thick steel plates with the thickness being greater than 120mm at a low compression ratio.

Owner:ZHONG NAT ENG & RES CENT

Die steel

InactiveCN1940113AImprove isotropyImprove tissue uniformityFurnace typesHeat treatment process controlForge

The invention belongs to steel; it is a kind of die steel to be exact. The component of the die steel is composed of as follows: C, Mn, Si, S, P, Cr, M0, V, Ni, Cu, Nb, Fe margin. The die steel in this invention has these functions such as higher isotropism and the organization is uniform, it is able to endure heatproof strain, high temperature impact, polishing and burnish print, corrode, it is suitable to the forge hot mould and special mould that has strict request of polishing, figure, it can be apply to mechanical manufacture industry broadly.

Owner:沈阳市铸威特殊钢有限公司

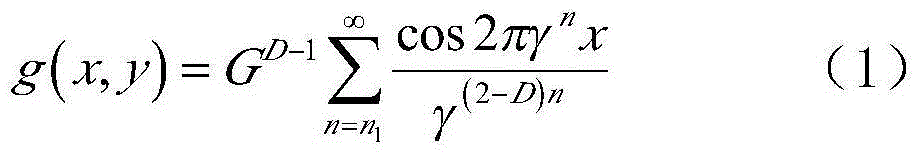

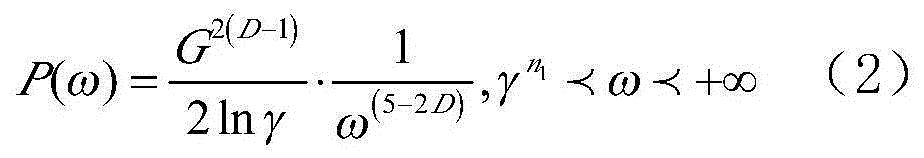

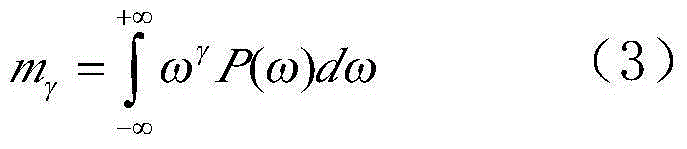

Selection method for suitable matching area of gravity-aided inertial navigation

ActiveCN105021182AImprove isotropyImprove matchNavigation instrumentsGravity anomalyComputer science

The invention provides a selection method for a suitable matching area of gravity-aided inertial navigation to overcome the technical problem that a traditional suitable matching area selection method neglects the directivity of a suitable matching area. According to the method, the navigation area of a carrier is divided into a plurality of subareas; classified statistic and analysis are carried out on gravity abnormal data in each subarea; a gravity abnormity three-dimensional curved surface isotropic coefficient, a gravity abnormity variation coefficient, a gravity abnormity skewness coefficient and a gravity abnormity kurtosis coefficient of each subarea are separately obtained; comprehensive characteristic parameter expression is constructed according to the relationship between each parameter and gravity abnormity probability distribution; thus, selection of the suitable matching area is realized.

Owner:BEIJING CNTEN SMART TECH CO LTD

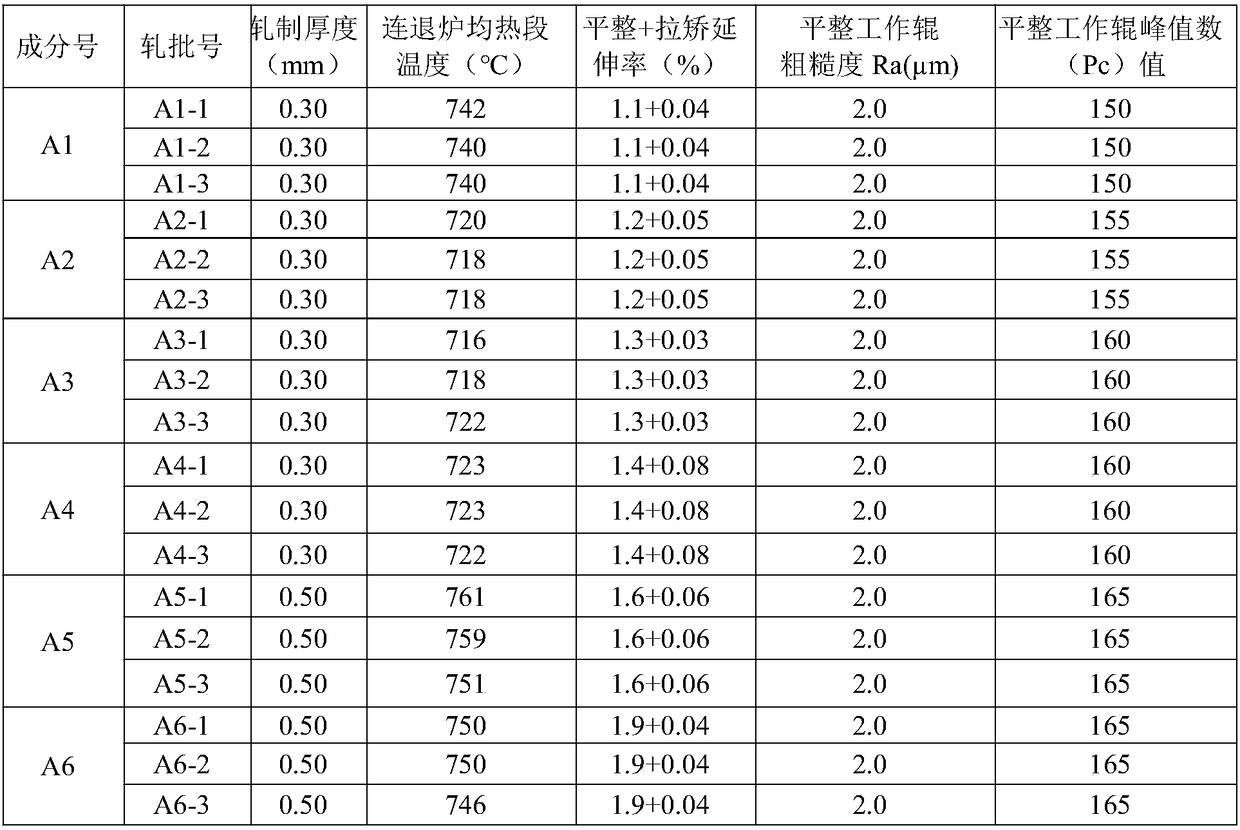

IF isotropic steel with stamping forming improved and manufacturing method thereof

The invention discloses IF isotropic steel with stamping forming improved and a manufacturing method of the IF isotropic steel. The IF isotropic steel is composed of, by weight percent, 0.0012% to 0.0026% of C, not larger than 0.026% of Si, 0.28% to 0.52% of Mn, not larger than 0.015% of P, not larger than 0.010% of S, 0.042% to 0.082% of Al, 0.046% to 0.066% of Ti, not larger than 0.0030% of N and the balance Fe and inevitable impurities. According to the IF isotropic steel, in the subsequent hot rolling, cold rolling, continuous annealing, flattening and bridging production processes, the rolling temperature is controlled to range from 580 DEG C to 620 DEG C, the cold rolling reduction rate is controlled to range from 85% to 95%, the annealing temperature is controlled to range from 708DEG C to 742 DEG C, the flattening ductility is controlled to range from 1.0% to 2.0%, and the bridging ductility is controlled to range from 0.03% to 0.10%; and according to the obtained IF isotropicsteel, the surface roughness Ra ranges from 0.36 micrometer to 0.56 micrometer, the peak concurrent Pc is larger than or equal to 126, the hardness ranges from 95 HV to 110 HV, the plastic strain ratio r90 value is larger than or equal to 1.8, the work-hardening exponent n90 value is larger than or equal to 0.18, and the delta r value is smaller than or equal to 0.20. The beneficial effect that when a round component is deeply stamped, no earing or galling defect is generated is achieved.

Owner:新余钢铁股份有限公司

Electrolytic membrane

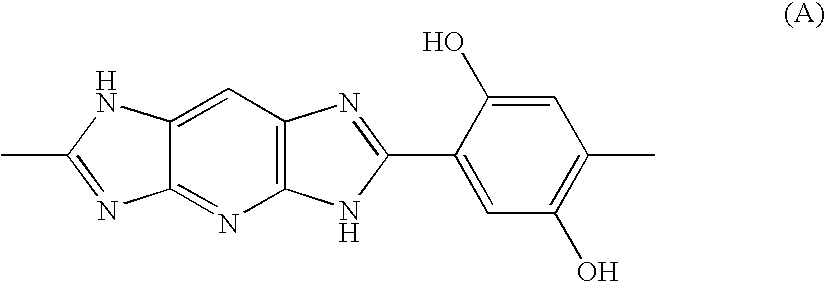

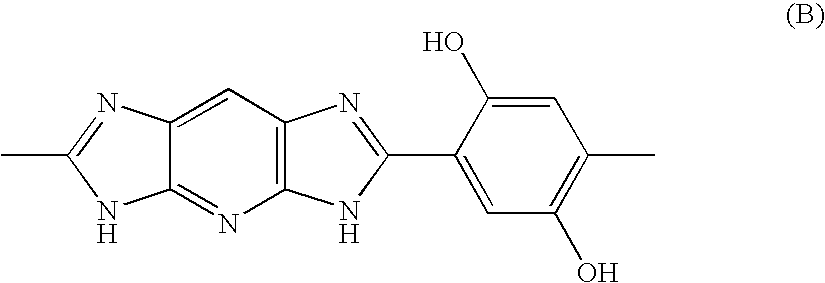

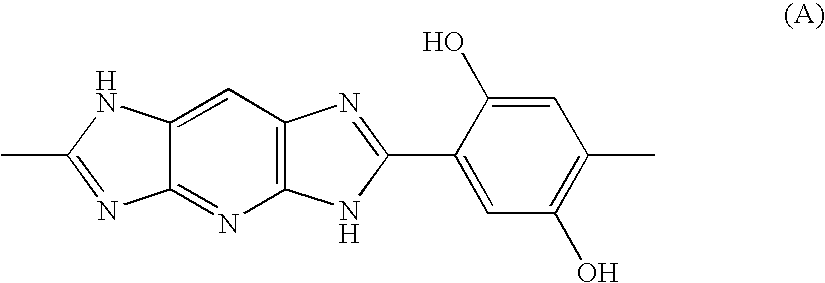

InactiveUS7833644B2Excellent in ion conductivity and oxidation resistanceImprove isotropic performanceNon-metal conductorsElectrolyte holding meansMethanesulfinic acidElectrolyte

An object of this invention is to provide an electrolytic membrane excellent in ion conductivity and oxidation resistance, and this invention is directed to an electrolytic membrane formed of a polymer comprising at least one recurring unit selected from the group consisting of a recurring unit of the following formula (A),and a recurring unit of the following formula (B),and having a reduced viscosity, measured in a methanesulfonic acid solution having a concentration of 0.5 g / 100 ml at 25° C., of 0.05 to 200 dl / g, and a process for the production thereof.

Owner:TEIJIN LTD

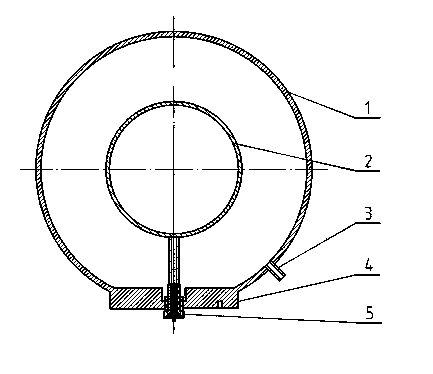

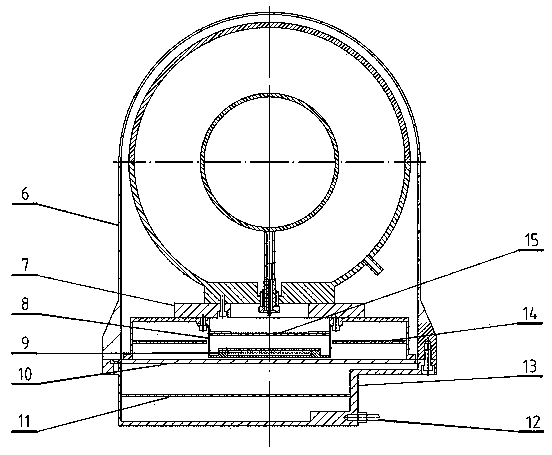

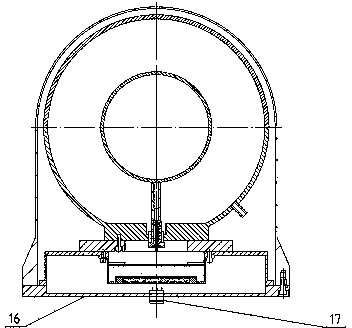

Detector for monitoring environmental radiation dose rate

The invention belongs to the field of radiation protection, and provides a detector for measuring the environmental level X ray and gamma ray radiation dose rate. The detector comprises a shell and a high atmospheric pressure ionization chamber. The outer wall of the high atmospheric pressure ionization chamber is of a spherical structure. An end cover through which the ionization chamber is conveniently connected with other parts inside the detector is arranged at the bottom of the outer wall. A spherical inner container which is concentric with the outer wall is arranged inside the ionization chamber. The inner container is connected with the end cover through an insulator. Except welding components of the insulator, the whole ionization chamber is made of aluminum or aluminum alloy. The detector is simple in structure and convenient to use, the problem that the high atmospheric pressure ionization chamber is high in energy lower limit in the environment monitoring process can be effectively solved, the sensitivity of the detector to lower-energy gamma rays is improved, energy response linearity and isotropy of the detector are improved, and credibility of the measuring result is improved.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

Pressure difference-based method and device for improving properties of carbon paper of quick CVI coating

InactiveCN101734940AQuick Surface Coating TreatmentUniform distribution of poresSynthetic cellulose/non-cellulose material pulp/paperFiberPorosity

The invention discloses a pressure difference-based method and a pressure difference-based device for improving properties of carbon paper of a quick CVI coating. The method comprises the following steps of: 1) preparation of a carbon fiber blank: using PAN-based carbon fiber serving as reinforcing materials and phenolic aldehyde or epoxy resin serving as a bonding agent to form the carbon fiber to prepare the carbon fiber blank by a the method papermaking method; and 2) deposition process: stacking the products, obtained by the step 1, placing the products in a reaction furnace for chemical vapor deposition. The device is a box-type reaction furnace in which two flat plate heating bodies are arranged, a deposition tank is placed between the two flat plate heating bodies which are parallel to each other, and the carbon paper or carbon paper blank is placed in the deposition tank; and one end and the other end of the reaction furnace are provided with an inlet and an outlet, which are used for flowing of the mixed gas of a carbon source and diluent gas, respectively. The method has the advantages that: the deposition is quick and the structure, density, porosity and the like are controllable; and the deposited carbon is evenly distributed on the surface of the carbon surface, and the prepared carbon paper material is low in resistivity, high in strength and good in isotropic degree.

Owner:CENT SOUTH UNIV

Base fabric for airbag, airbag and method for production of the same

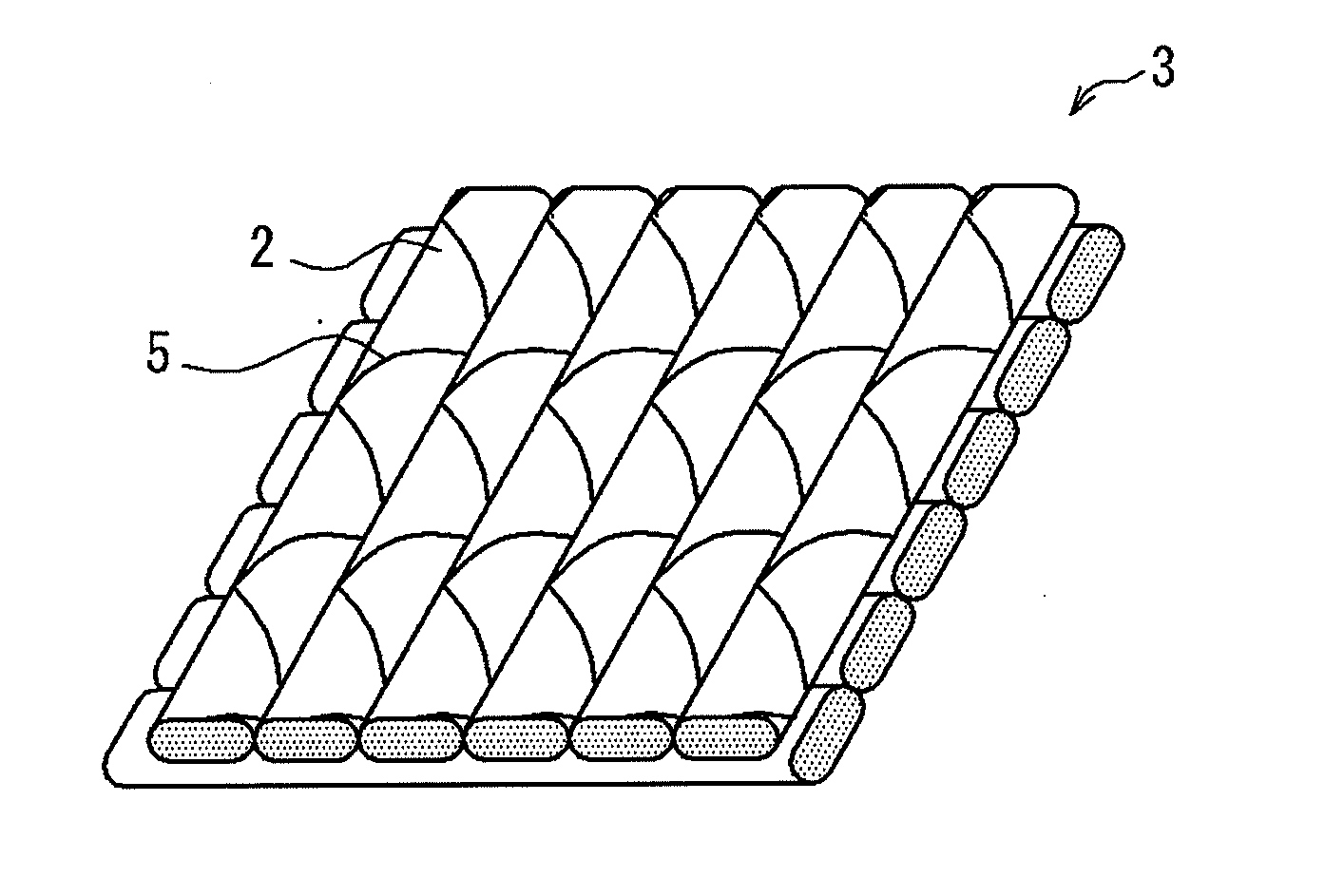

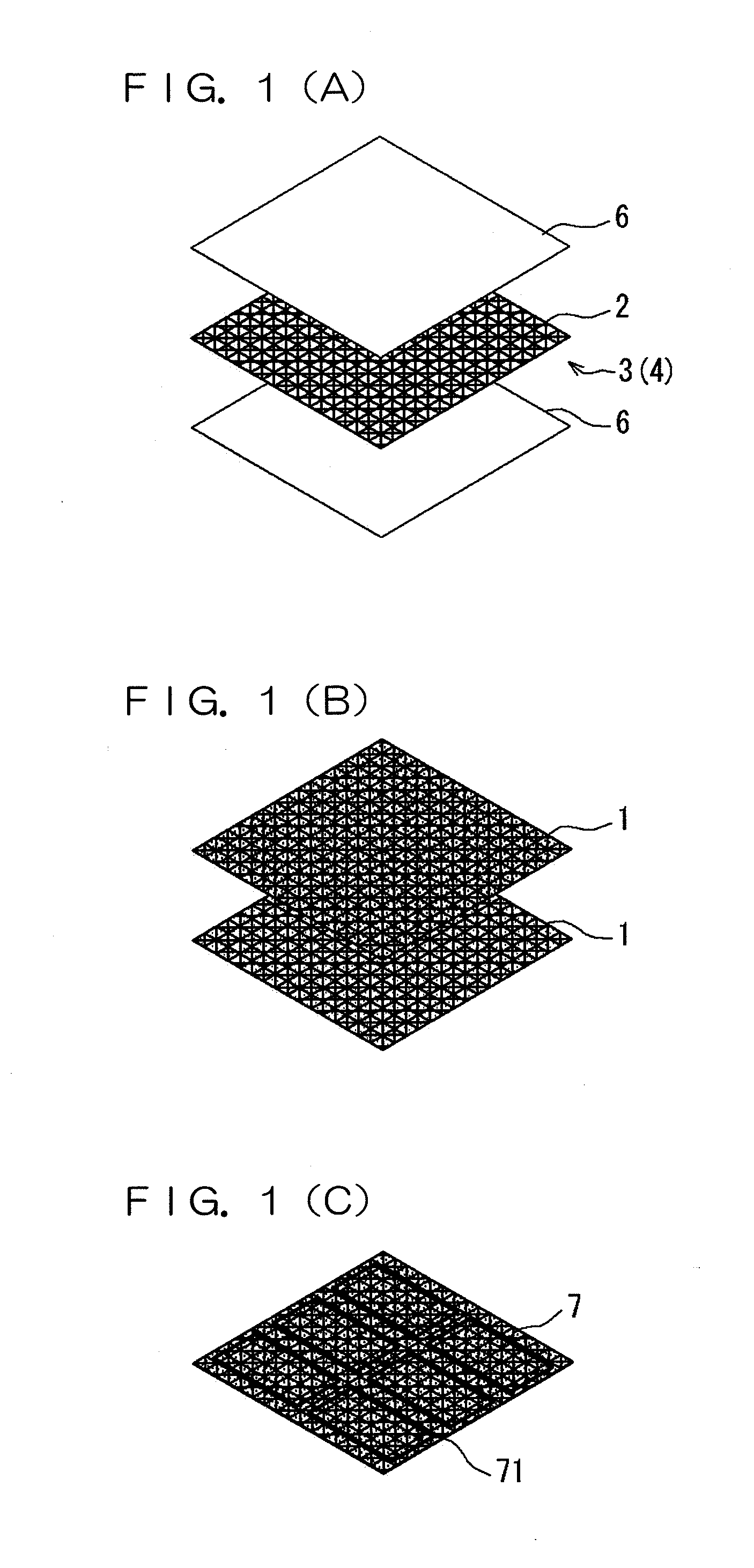

InactiveUS20100159189A1Improve isotropyHigh strengthPedestrian/occupant safety arrangementSynthetic resin layered productsFiberInterior space

The base fabric for an airbag of the present invention comprises a fibrous laminate in which plural fibrous bodies configured by fibers that are oriented in one direction are laminated, and an oriented direction of the fibers in one fibrous body out of two fibrous bodies that are adjacently laminated is different from an oriented direction of the fibers in the other fibrous body. The airbag of the present invention comprises the base fabric for an airbag and is obtained by a method including joining step for joining the plural base fabrics for an airbag so that an internal space having a predetermined shape is formed and cutting step for cutting along a joint section formed by the joining step.

Owner:TOYOTA BOSHOKU KK +1

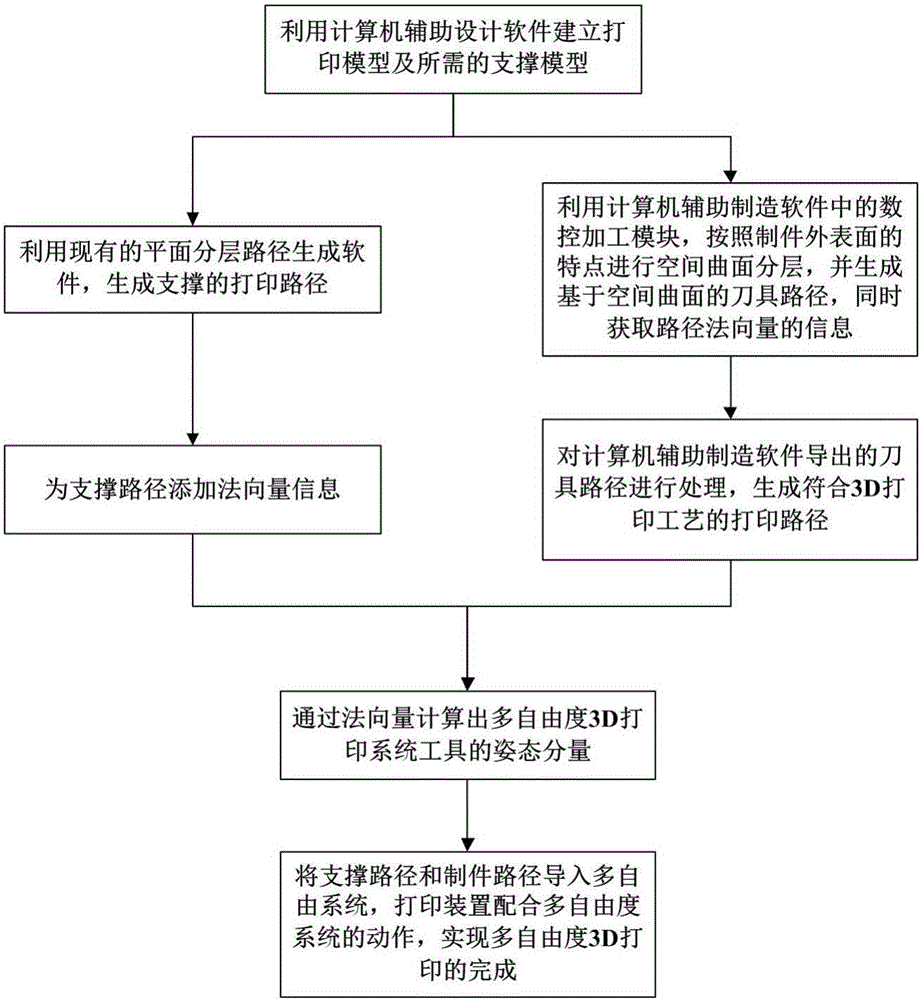

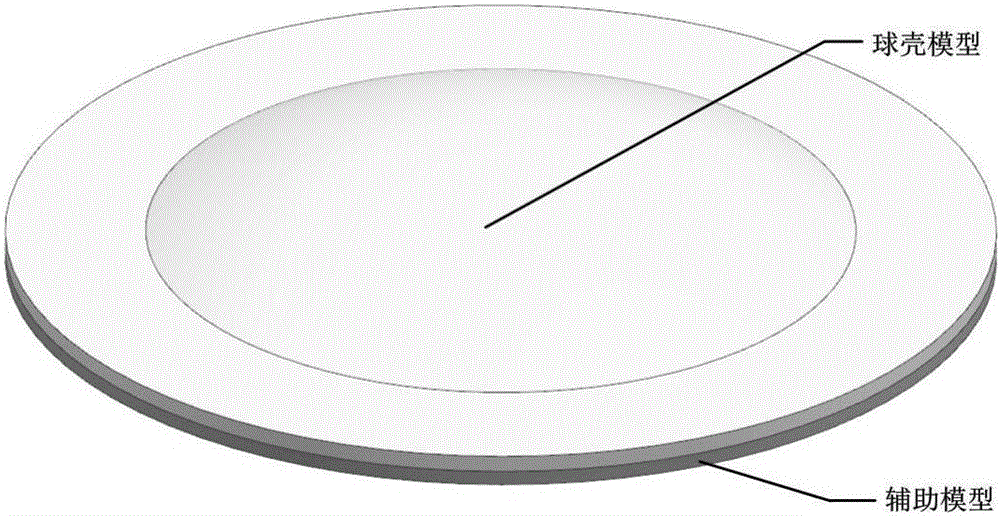

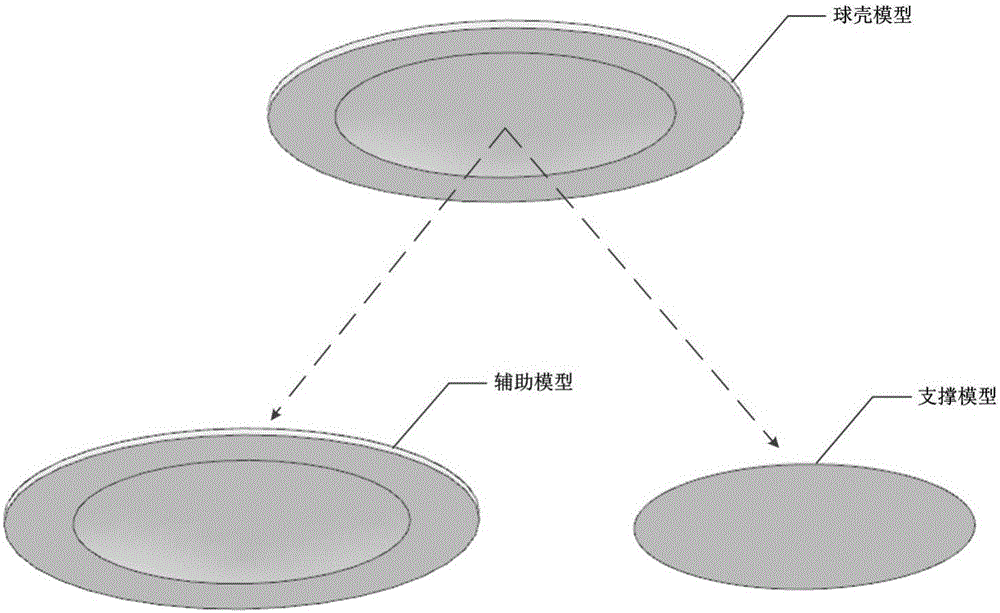

Space path generating methodorientedto multi-freedom-degree 3D printing

ActiveCN106202754AImprove mechanical propertiesImprove isotropyDesign optimisation/simulationSpecial data processing applicationsComputer Aided DesignDegrees of freedom

A space path generating methodorientedto multi-freedom-degree 3D printing comprises the steps that a three-dimensional part model is firstly established and an auxiliary model and a supporting model are generated by utilizing computer aided design (CAD) software, and then a part path is generated; then, the part path undergoes reverse ranking to generate a front-inside-to-outside 3D printing path, meanwhile printing action matching parameters required by a motion mechanism moving along the printing path are calculatedby adopting a 3D printing process; then the supporting model is introduced to the 3D printing path to generate software, and a supporting path is generated; normal vector information is added for the supporting path, and a posturecomponent of a printing head in a multi-freedom-degree 3D printing system is calculated through normal vectors; finally the generated supporting path and the part path are introduced to the multi-freedom-degree 3D printing system, and multi-freedom-degree 3D printing is completed. The space path generating method eliminates the step effect existing in an existing 3D printing technology, improves the mechanical properties of parts and increases the isotropy of the parts.

Owner:深圳协同创新高科技发展有限公司

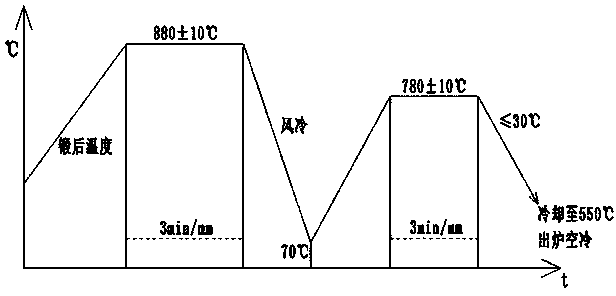

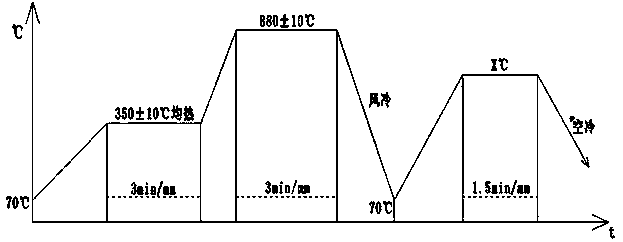

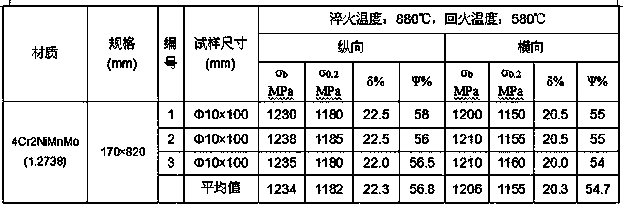

Pre-hardening plastic die steel

ActiveCN103774059AImprove corrosion resistanceImprove anti-corrosion performanceMetallurgyAir cooling

The invention relates to pre-hardening plastic die steel. The preparation method comprises the following steps: adding 0.05-0.15%V of microalloying elements into 4Cr2NiMnMo; after pleiotropic deformation, carrying out fine treatment and pre-hardening treatment, wherein the pleiotropic deformation comprises radial and axial forging deformation of the die steel and transverse and vertical pleiotropic deformation with the forging ratio greater than or equal to 8; the fine treatment comprises the following step: by taking the temperature of the forged die steel with the product thickness as a starting point, heating to 880+ / -10 DEG C; and after insulating at a speed of 3min / mm, discharging and air-cooling to 70 DEG C for spheroidizing annealing, wherein the specific process comprises the following steps: quickly heating to 780+ / -10 DEG C*3min / mm; and then cooling to 550 DEG C for discharging and air cooling at a speed less than or equal to 30 DEG C / h; the pre-hardening treatment comprises the following steps: heating the die steel with the product thickness from 70 DEG C to 350+ / -10 DEG C; insulating at the speed of 3min / mm; then heating to 880+ / -10 DEG C; then, insulating at the speed of 3min / mm; and then air-cooling to 70 DEG C and tempering.

Owner:胡财基

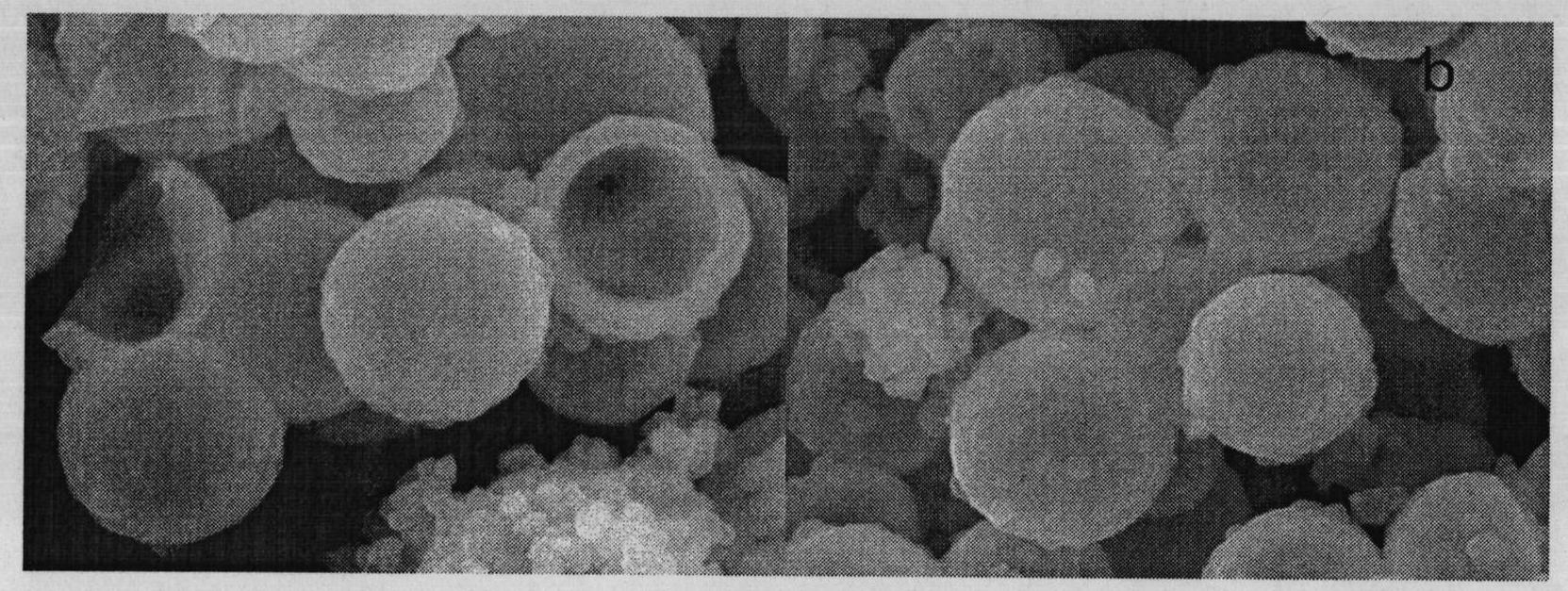

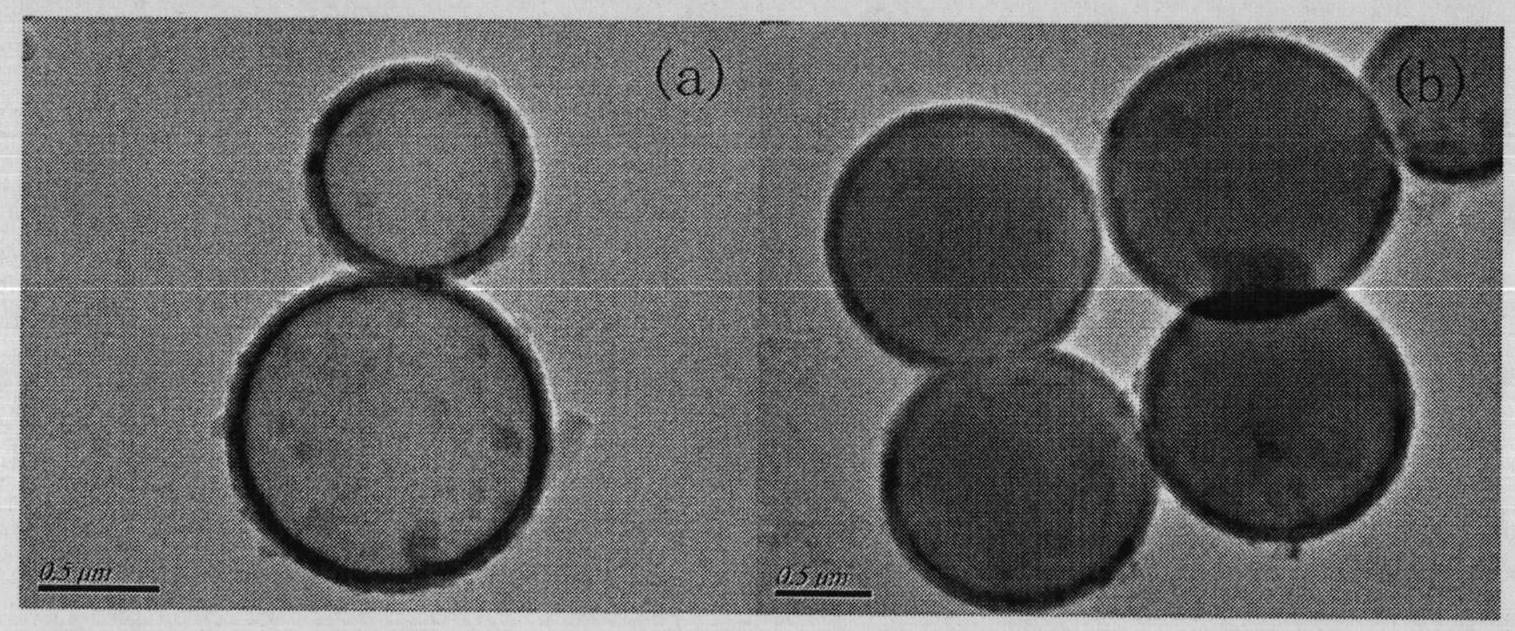

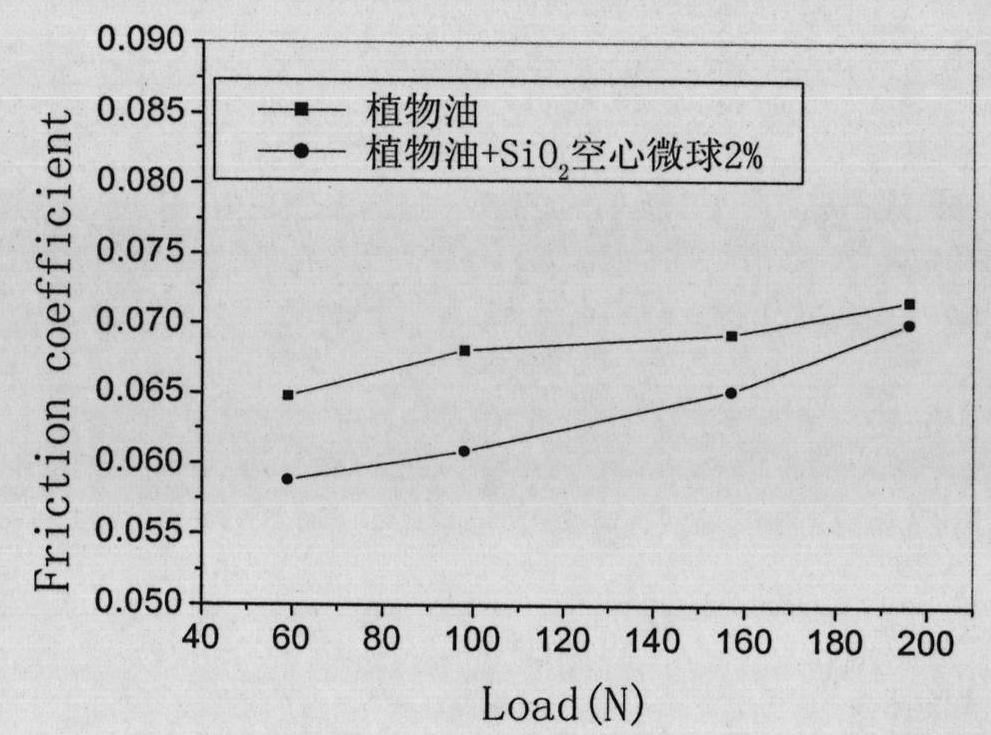

Silicon dioxide hollow nano-structure and preparation method thereof

The invention discloses a silicon dioxide hollow nano-structure and a preparation method thereof. Tetraethyl orthosilicate (TEOS) is taken as a precursor, polystyrene / 2-methacryloyloxyethyl trimethylamine chloride (PS / MTC) copolymer microspheres are taken as templates, and the shape of a product is controlled by the limiting function of spherical templates, so that the high-isotropy silicon dioxide hollow nano-structures of high-isotropy sizes can be synthesized in quantity at a relatively low temperature, and the problem of an overlarge dimension distributing range in the conventional process of synthesizing silicon dioxide is solved. The method is simple, has low cost and is suitable for large-scale industrial production, particularly for lubricating oil additives.

Owner:无锡润鹏复合新材料有限公司

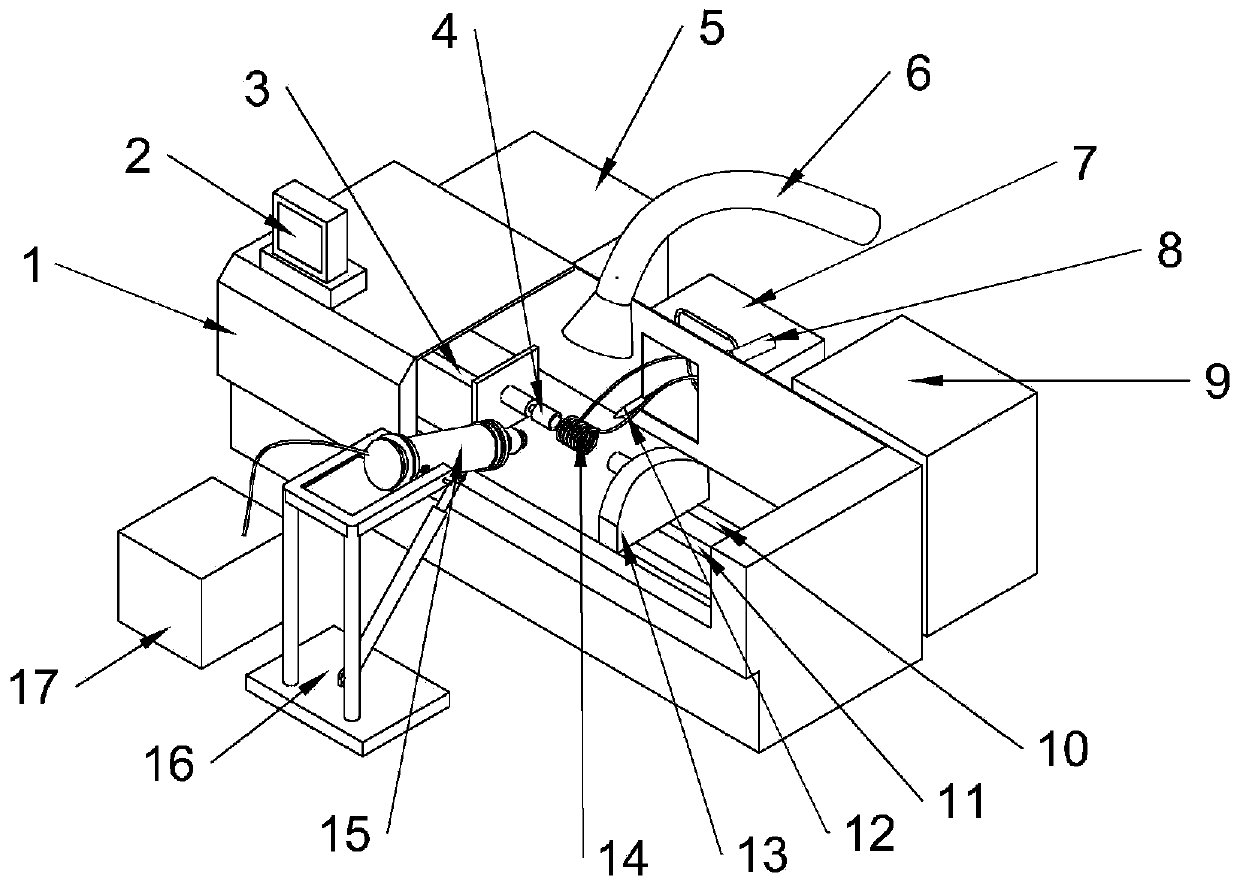

Device for high-frequency induction cladding with assistance with ultrasonic vibration and working method for device

PendingCN109811339AReduced crack susceptibilityImprove densification performanceMetallic material coating processesIncreasing energy efficiencyEngineeringUltrasonic generator

The invention relates to a device for high-frequency induction cladding with assistance with ultrasonic vibration and a working method for the device and particularly aims at surface treatment and reinforcement of a workpiece. The device comprises a horizontal machine tool, a PLC, a slide carriage tank, a triangular chuck, a power supply controller, a smoke removal system, an induction power supply, an infrared thermometer, an industrial water cooling circulation system, a guide rail, a ball screw, a nozzle, an ejector pin, an induction coil, an amplitude-change pole, a bracket and an ultrasonic generator. In the process of starting the induction coil for heating, and the PLC is used for controlling a motor to enable the workpiece to rotate at a certain speed (a specific speed value is obtained according to the fluidity of a molten pool in a state with assistance of ultrasonic vibration and the diameter of the workpiece), and unevenness in thickness of upper and lower cladding layers of the workpiece caused by the fact that the molten metal flows downwards due to gravity in the cladding process can be avoided. A gas protection device needs to be started before induction heating, sothat the workpiece is in an argon environment before being heated, injection of argon is stopped after the workpiece is thoroughly cooled, and the cladding layers and cladding layer influence regionscan be well prevented from being oxidized. By adding ultrasonic assistance equipment in the high-frequency induction cladding process, the quality of a bonding layer is improved to the maximum, generation of bubbles and cracks is reduced, the residual stress is eliminated, the comprehensive properties of the cladding layers are improved, the service life of the workpiece is prolonged, the production efficiency is improved, and the cost is lowered.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

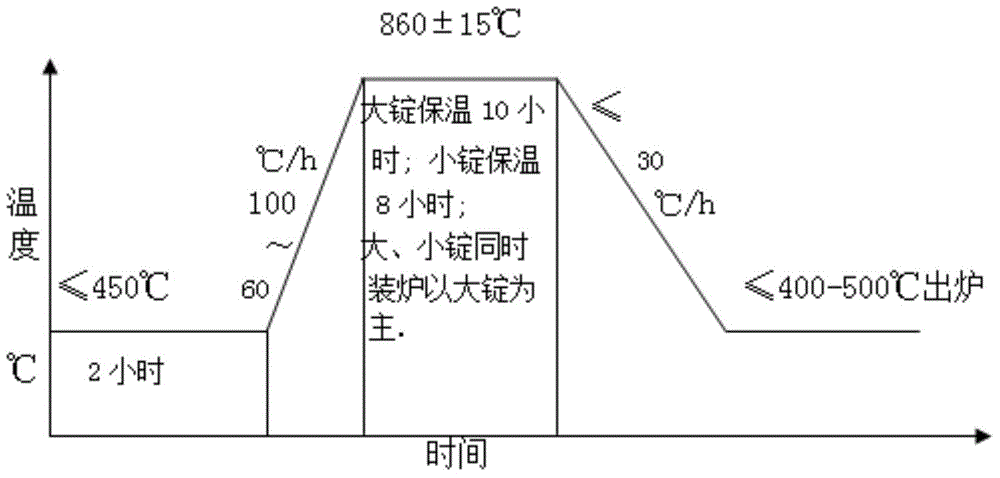

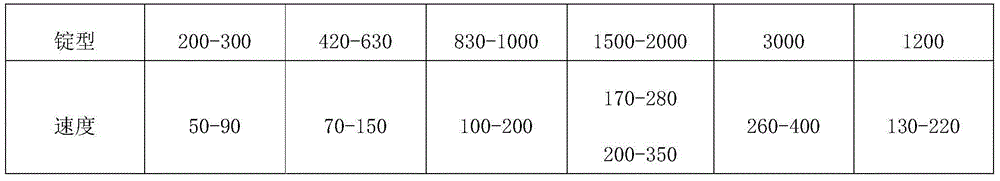

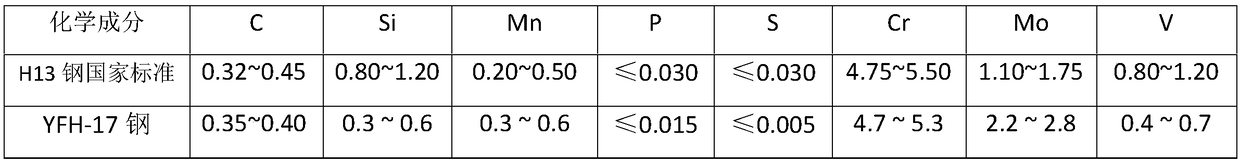

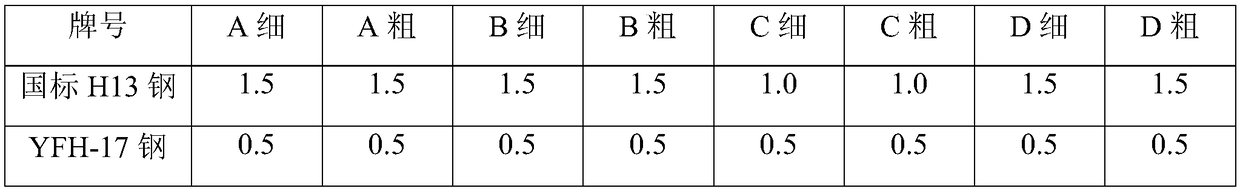

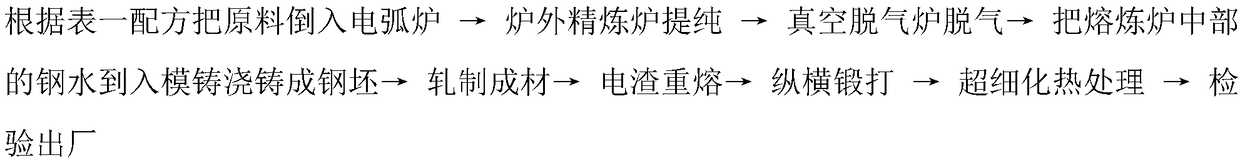

Optimization method and processing step of high-end hot work die steel

InactiveCN108265232AImprove thermal fatigue resistanceGood thermal strength and toughnessHot workCorrosion

The invention provides an optimization method and a processing step of high-end hot work die steel. On the basis of national standard die steel H13, an optimized raw material formula, an optimized melting process and an optimized heat treatment process are adopted, and the high stability of the H13 is combined, so that heat fatigue resistance and tempering resistance are further improved, better hot strength and toughness are realized, and the service life of a die is remarkably improved. The optimization method and the processing step of the high-end hot work die steel have the following characteristics and advantages of (1) high purity and prolonged fatigue life of the die; (2) high isotropy and excellent shock cracking resistance; (3) excellent toughness and excellent wear resistance; (4) excellent hardenability and dimension stability during high-temperature heat treatment; and (5) excellent hot flush corrosion resistance and excellent hot fracturing resistance.

Owner:浙江嵊州元丰模具有限公司

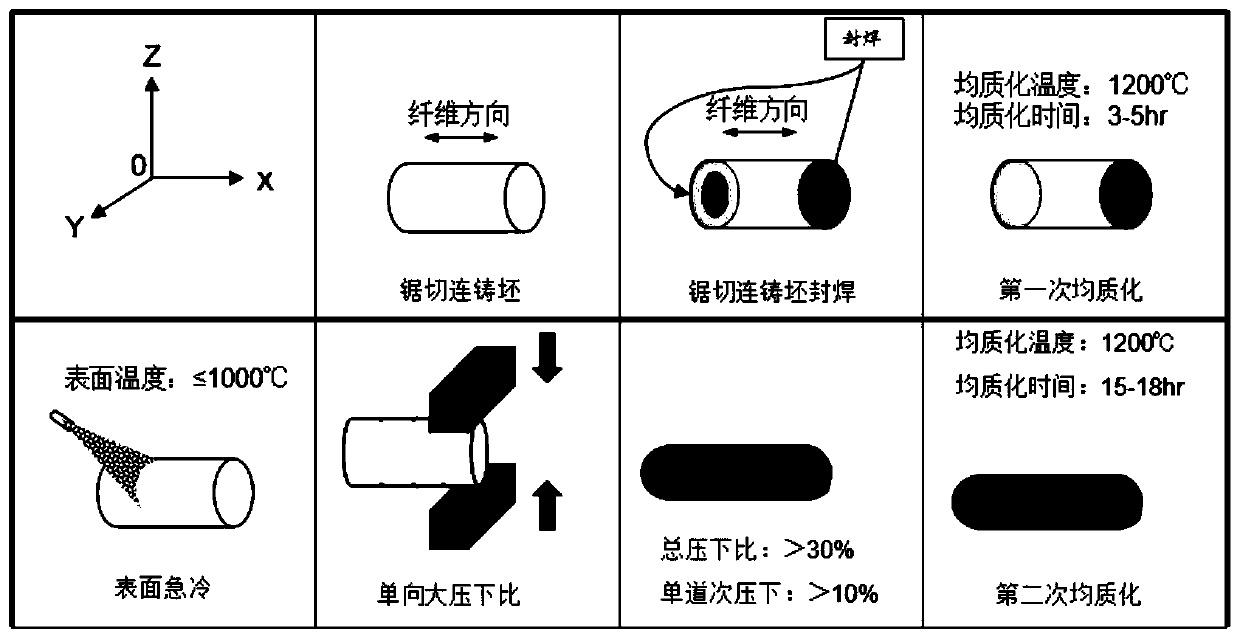

Long-life alloy die-casting module and manufacturing method thereof

ActiveCN101082110AReduce control contentReduce formationFurnace typesHeat treatment process controlDie castingIngot

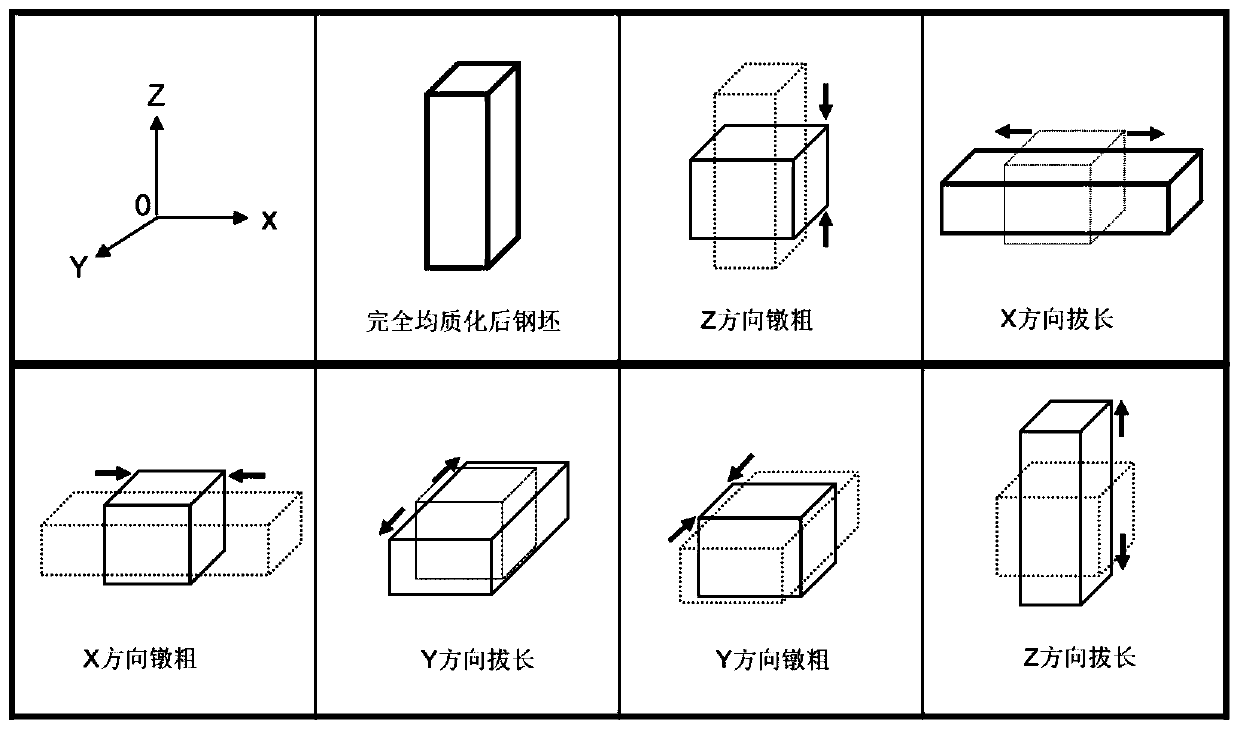

The present invention provides one kind of long service life module for aluminum alloy pressure casting die. The material for the module has the components including C 0.37-0.45 wt%, Si 0.90-1.40 wt%, Mn 0.30-0.60 wt%, Cr 5.10-5.70 wt%, V 1.00-1.40 wt%, Mo 1.20-1.50 wt%, S 0.0005-0.003 wt%, P 0.001-0.015 wt%, and Fe and inevitable impurities for the rest. The module is produced through the following steps: homogenizing electroslag ingot in a heating furnace at 1230-1290 deg.c for 15-20 hr, twice upsetting and stretching in the initial forging temperature of 1230-1250 deg.c and final forging temperature of 850-900 deg.c, and structure fining treatment of the hot forging in an annealing furnace at 860-950 deg.c. The module has over 3.5 times longer service life compared with that of available technology.

Owner:宝武特种冶金有限公司

Method for producing hot work mold steel adopting continuous casting billet direct forging

ActiveCN109894473AQuality improvementUniform qualityTemperature control deviceWork treatment devicesDecompositionCarbide

The invention provides a method for producing hot work mold steel adopting continuous casting billet direct forging. The method specifically comprises the steps that end face seal welding or overlaying is performed on a sawed and cut continuous casting billet, after that, first-time homogenization is performed, and the homogenization is performed for 3-6 h with the temperature being 1150-1320 DEGC; the surface of the continuous casting billet after the first-time homogenization is quenched to 1050 DEG C or below to perform one-way large press down ratio deformation, and second-time homogenization is performed for 10-20 h with the temperature being 1150-1320 DEG C; three-way forging is performed on the steel billet after the second-time homogenization; the initial forging temperature of the three-way forging is 1250 DEG C or below, and the final forging temperature is 800-950 DEG C; and a product is obtained through grain refining and annealing. According to the method for producing the hot work mold steel adopting the continuous casting billet direct forging, by means of organic combination of continuous casting billet special treatment, the two times of homogenization and two times of the forging, kinetic conditions favorable to diffusion of carbon and alloy elements are created, and continuous casting billet central continuity loose pores and other defects, decomposition liquid chromatography carbides and banded structures generated by dendritic segregation are completely eliminated.

Owner:江阴华润制钢有限公司

Magnesium alloy biological implant material and preparation method thereof

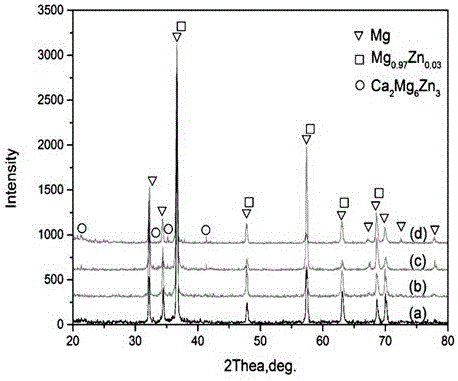

InactiveCN107435116AFacilitated DiffusionReduce thicknessSurgeryTissue regenerationIngotInterventional therapy

The invention discloses a magnesium alloy biological implant material and a preparation method thereof and belongs to the field of biomaterials. The magnesium alloy biological implant material is a magnesium alloy composed of Mg, Zn, Ca and Zr. The magnesium alloy biological implant material comprises the following chemical components in percentages by mass: 2.0-6.0% of Zn, 0.3-0.9% of Ca, 0.3-0.6% of Zr and the balance of Mg. The preparation method comprises the following steps of: manufacturing a cast ingot by means of a whole course gas shield resistance furnace smelting plus a rotating magnetic field and an ultrasonic external field compound treatment technology; and then performing homogenization treatment and thermal compressional deformation to obtain a second phase in dispersive distribution of uniform and fine Mg0.97Zn0.03 and Ca2Mg6Zn3 on a magnesium matrix so as to obtain the fully degradable biomedical magnesium alloy which is optimal in high toughness and corrosion resistant. The magnesium alloy biological implant material disclosed by the invention can be used in the medical fields of interventional therapy for cardiovascular diseases and endosteal implanting and the like.

Owner:TAIYUAN UNIV OF TECH

Orthopaedics operation robot

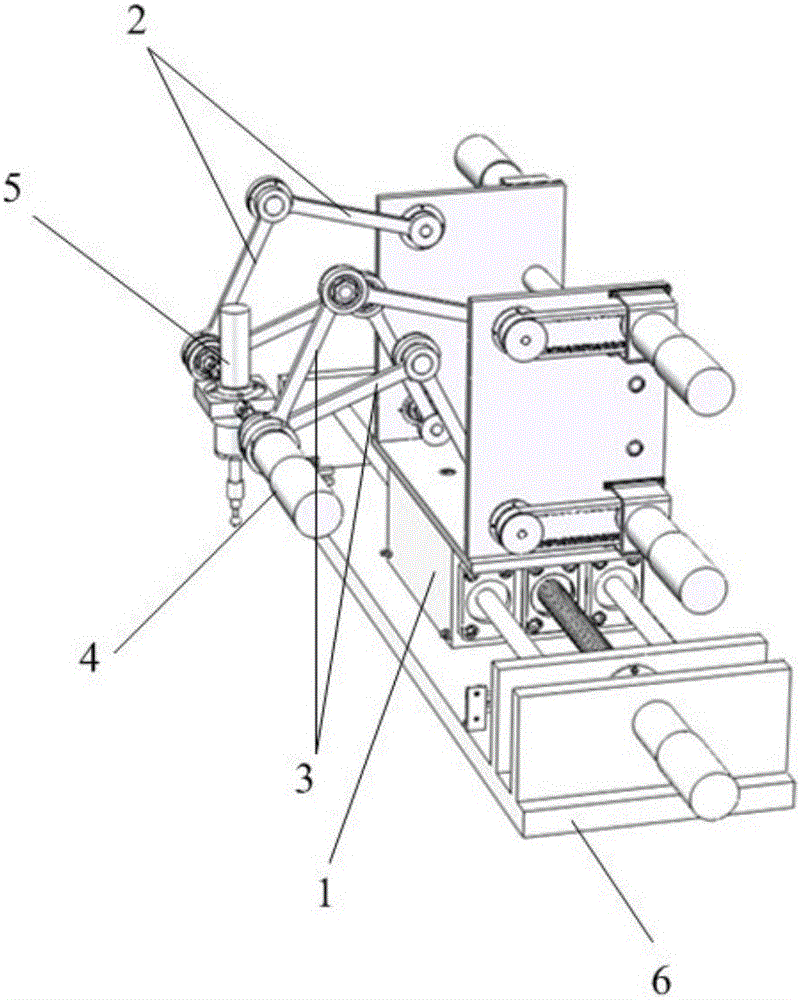

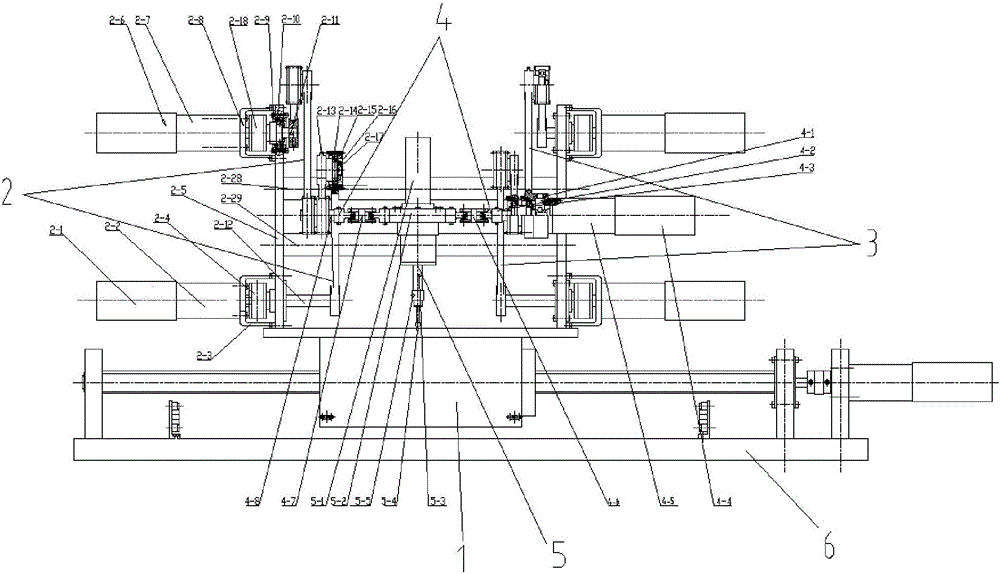

ActiveCN105662587ACompact structureGood dynamic responseSurgical robotsSurgical operationUniversal joint

The invention discloses an orthopaedics operation robot which structurally comprises six parts including a pedestal, a moving platform, two symmetrical five-linkage mechanisms, a polishing and drilling attitude adjustment mechanism and a polishing and drilling part, wherein the pedestal drives the moving platform to do rectilinear motion in the horizontal direction by virtue of a main component, that is, a screw sliding table; the two five-linkage mechanisms are connected in parallel with the polishing and drilling attitude adjustment mechanism; the polishing and drilling attitude adjustment mechanism and the polishing and drilling part are mounted on universal joints by virtue of a polishing and drilling fixed seat, are connected with the five-linkage mechanisms via shafts, and are driven by an independent EC motor, so that the polishing and drilling part has a front-and-back swing degree of freedom to meet the requirement of high-precision accurate execution of various complex actions. The orthopaedics operation robot is high in precision, flexible to operate, and high in isotropy, has no accumulative errors, and is especially suitable for drilling and polishing in a bone surgical operation.

Owner:SHANDONG UNIV OF SCI & TECH

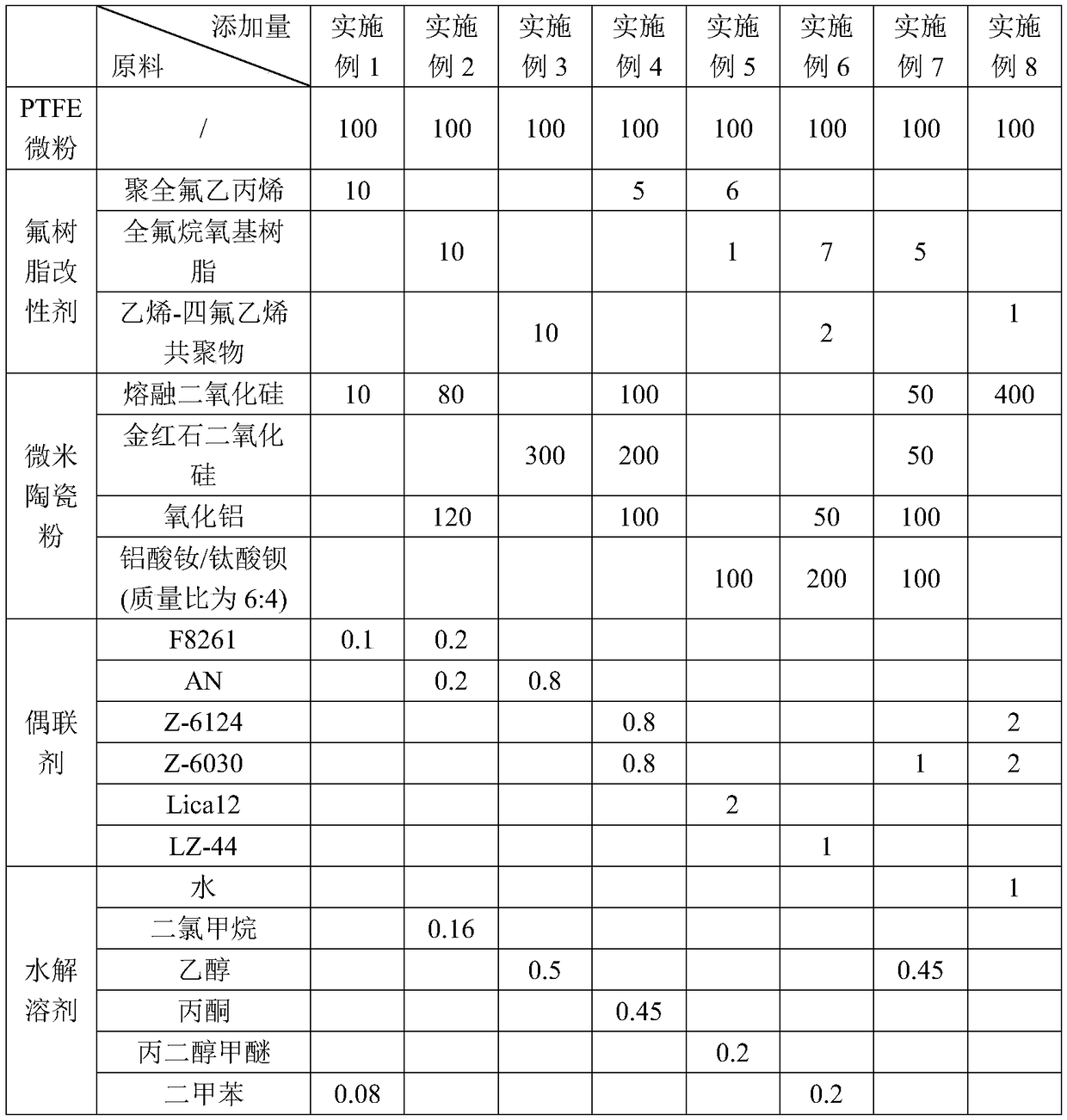

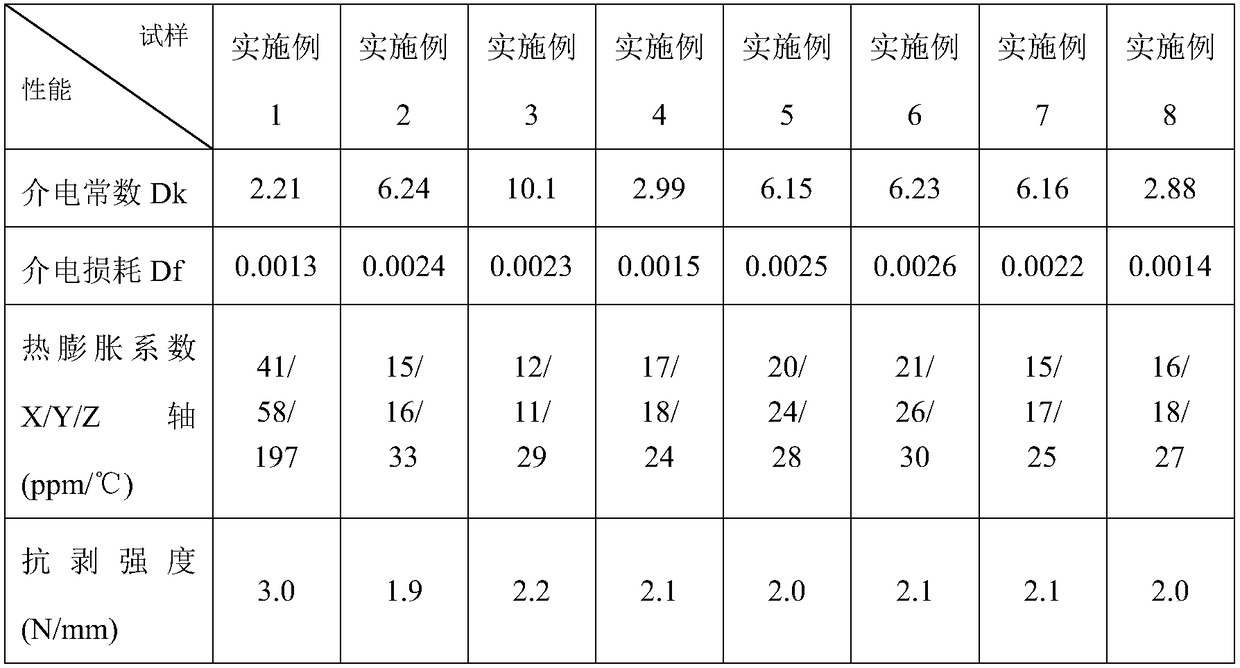

Preparation method of dry-method microwave composite medium board

ActiveCN108724900AReduce bloatImprove reliabilityLaminationLamination apparatusComposite mediaMicrowave

The invention relates to a preparation method of a dry-method microwave composite medium board. The method comprises the following operation steps that 1, a coupling agent, hydrolysis solvent and micron ceramic powder are mixed for ball-milling; 2, modified ceramic powder, teflon micropowder and a fluororesin modifying agent are evenly mixed, and drying and ball-milling are conducted; 3, a dry-method mixture is subjected to mould pressing through a mould to obtain a primary blank; 4, sintering is conducted to obtain a clavillose blank; 5, the clavillose blank is made into smooth even rectangular sheets with the thickness smaller than 0.1 mm through mechanical processing; 6, the front and back surfaces of the rectangular sheets are subjected to plasma activation treatment; 7, each activatedsheet and pure PTFE thin film are overlapped, matched and regarded as a layer of basic unit material, the multiple layers of basic unit materials are overlapped in sequence until the thickness required by the design is reached, then a composite basic board is obtained, metal foil is added to the two side surfaces respectively, and through high-temperature vacuum lamination, the PTFE-based microwave composite medium board is prepared. According to the method, in the preparation process, waste gas collection and treatment are not needed basically, so that the method is green and energy-saving,and the environment-friendly requirements are met.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Z direction continuous carbon fiber prefabricated body

The invention relates to an improvement on Z direction continuous carbon fiber prefabrication, which is characterized in that: a planar laminated carbon fiber fabric is weftless carbon fiber cloth formed by arranging long fibers in an interlaminar crossing way. A Z direction structure is stable, and basically undamaged continuous carbon fibers are arranged in the three-dimensional direction of the prefabricated body, so that the isotropy of the prefabricated body is enhanced, and a three-dimensional structural framework is formed. A chopped fiber web in which fibers are randomly distributed is introduced between adjacent layers, and a plurality of holes are distributed randomly, so that the introduction and uniform distribution of matrix carbon are facilitated. Due to the adoption of the weftless fabric, the needle threading resistance is reduced, the Z direction continuous fiber interval can be enlarged, and the Z direction continuous fiber introducing efficiency is improved; and large K-beam carbon fibers can be adopted, so that the cost can be lowered by 40-60 percent. The prefabricated body provided by the invention can be taken as a structural material, a functional material and a structural-functional material.

Owner:JIANGSU TIANNIAO HIGH TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com