Silicon dioxide hollow nano-structure and preparation method thereof

A hollow nano and silicon dioxide technology is applied in the field of nano materials to achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

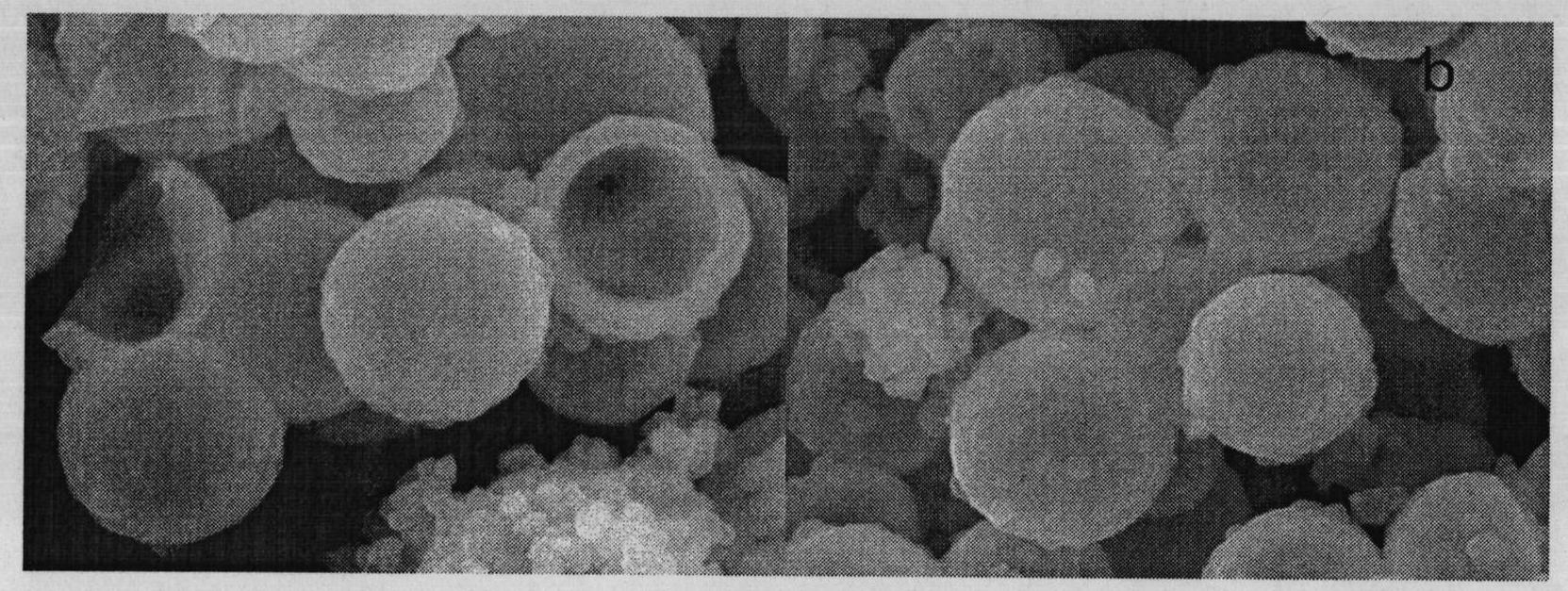

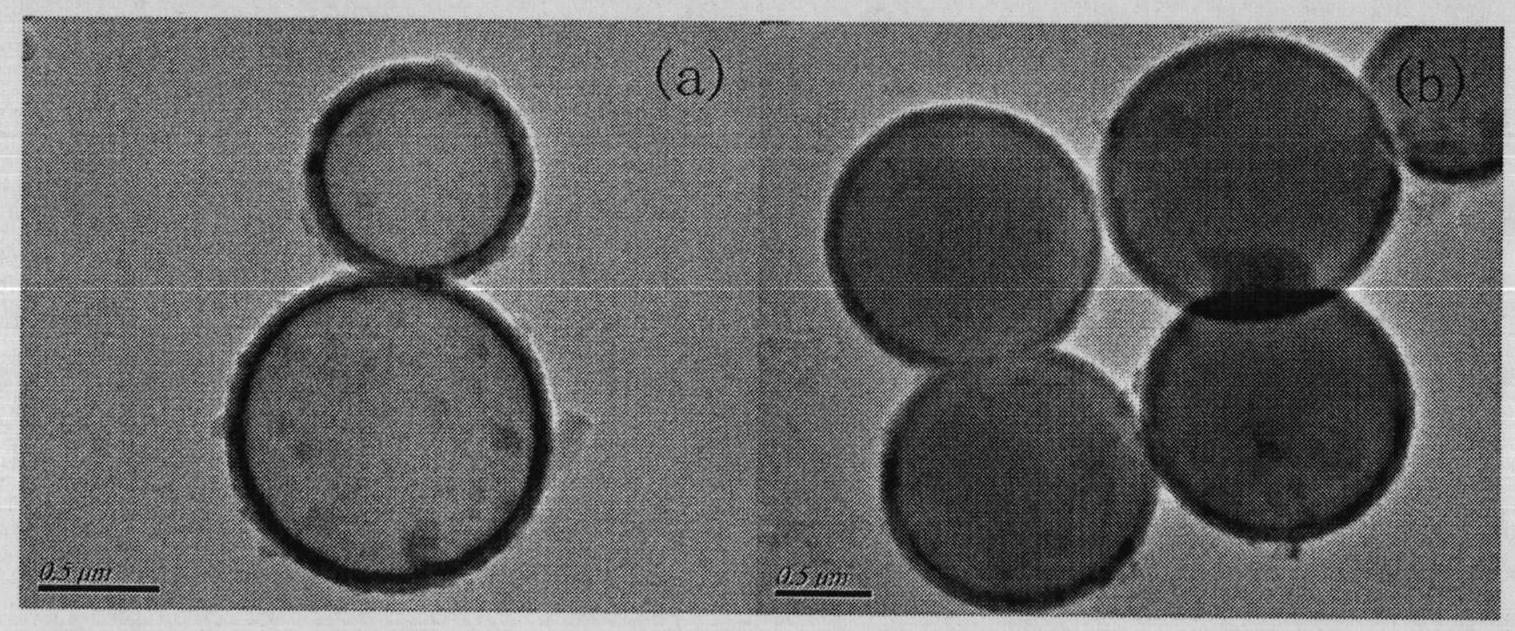

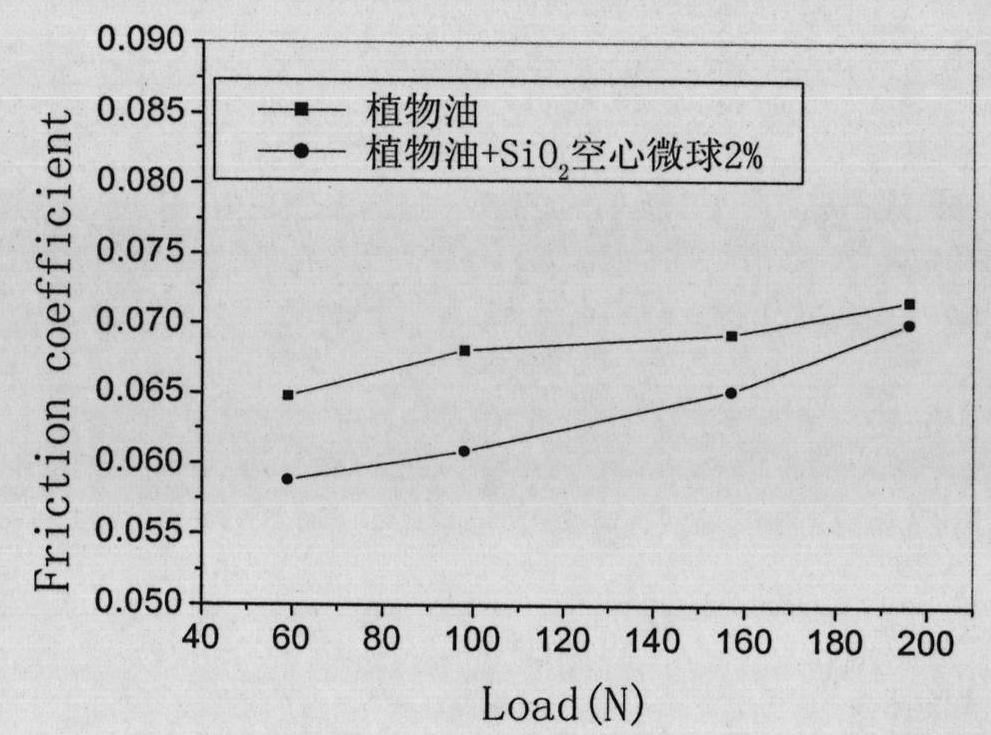

Image

Examples

Embodiment 1

[0017] (1) Styrene and chlorinated 2-methacryloyloxyethyltrimethylamine (MTC) with a mass ratio of 25:1 are used as raw materials, through dispersion polymerization (using absolute ethanol as a reaction solvent, poly Vinylpyrrolidone is a dispersant, azobisisobutyronitrile is an initiator), and a PS / MTC copolymerized microsphere template with uniform size distribution is prepared;

[0018] (2) Take 5 g of PS / MTC copolymerized microsphere templates and disperse them in 30 g of absolute ethanol, add 3 g of ammonia water (NH3·H 2 0), ultrasonic dispersion 30min gets dispersion liquid;

[0019] (3) Disperse 1.5ml TEOS in 30ml of absolute ethanol, and add it dropwise to the dispersion in step (2) at 25°C under magnetic stirring;

[0020] (4) At a temperature of 25°C, stir magnetically for 6-8 hours, and collect a milky white spherical product by filtration;

[0021] (5) Vacuum drying the spherical product at a temperature of 60° C. for 10 hours;

[0022] (6) Put the dried produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com