Patents

Literature

1029 results about "Trimethylamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Trimethylamine (TMA) is an organic compound with the formula N(CH₃)₃. It is a colorless, hygroscopic, and flammable tertiary amine. It is a gas at room temperature but is usually sold in pressurized gas cylinders or as a 40% solution in water. TMA is a nitrogenous base and can be readily protonated to give trimethylammonium cation. Trimethylammonium chloride is a hygroscopic colorless solid prepared from hydrochloric acid. Trimethylamine is a good nucleophile, and this reaction is the basis of most of its applications. It has a strong "fishy" odor in low concentrations and an ammonia-like odor at higher concentrations. It is a toxic compound which causes corrosion and necrosis after contact with mucous membranes.

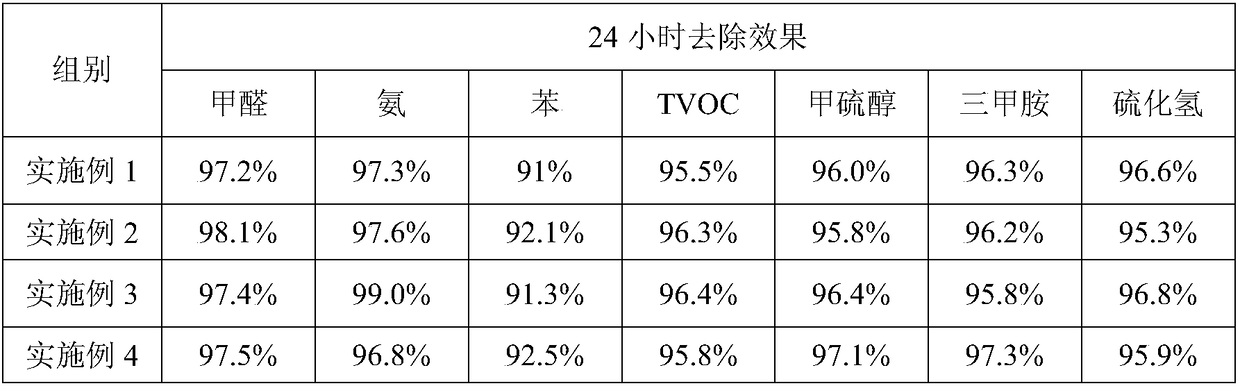

Preparation method of composite functional fabric with antimicrobial, anti-ultraviolet, deodorization and self-cleaning functions

ActiveCN104294583ASimple methodGood antibacterial, anti-ultraviolet and deodorizing propertiesLight resistant fibresWrinkle resistant fibresStaphylococcusHydrogen

The invention discloses a preparation method of a composite functional fabric with antimicrobial, anti-ultraviolet, deodorization and self-cleaning functions. The preparation method comprises the steps of preparing an activated modified treatment liquid, preparing a nano-titania dispersion liquid, processing fabrics by virtue of the activated modified treatment liquid, processing the fabrics by virtue of the nano-titania dispersion liquid, and the like. After the composite functional fabric is processed, the UPF value is more than 100, the deodorization rate is more than 95%, the photocatalysis self-cleaning fading rate of the composite functional fabric to chili oil is 96.7%, and the antibacterial rate (to staphylococcus) is 98.6%; after the composite functional fabric is washed for ten times in families, the UPF value is more than 50, the deodorization rate of the composite functional fabric to substances (including ammonia gas, formaldehyde, acetaldehyde, sulfureted hydrogen, nicotine and trimethylamine) is more than 90%, the photocatalysis self-cleaning fading rate of the composite functional fabric to chili oil is 93.9%, and the antibacterial rate (to staphylococcus) is 95.8%.

Owner:江苏巧雅纺织科技有限公司

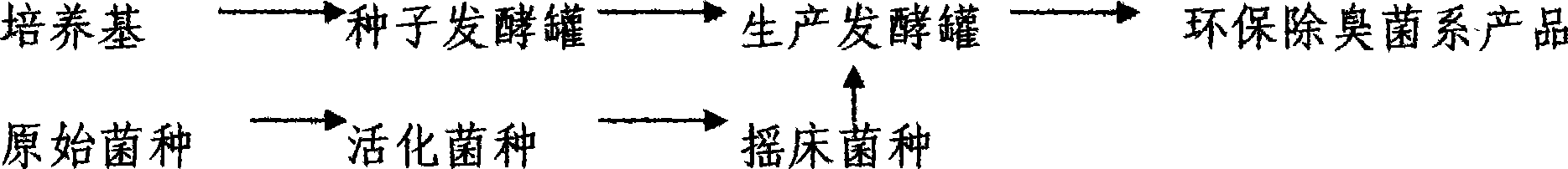

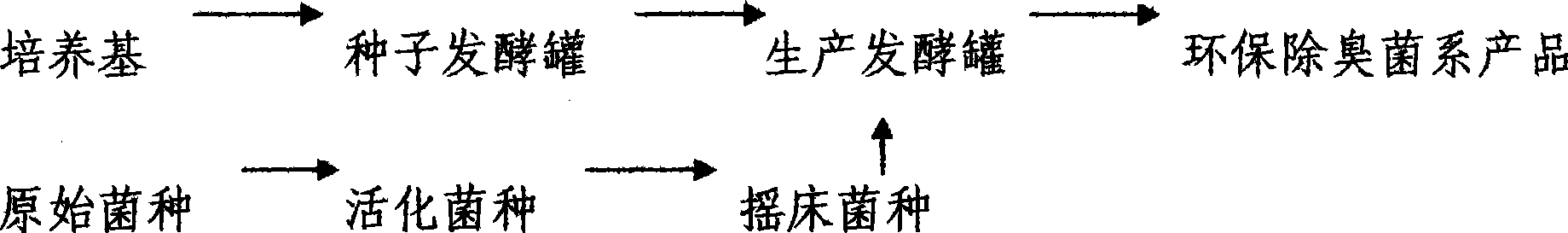

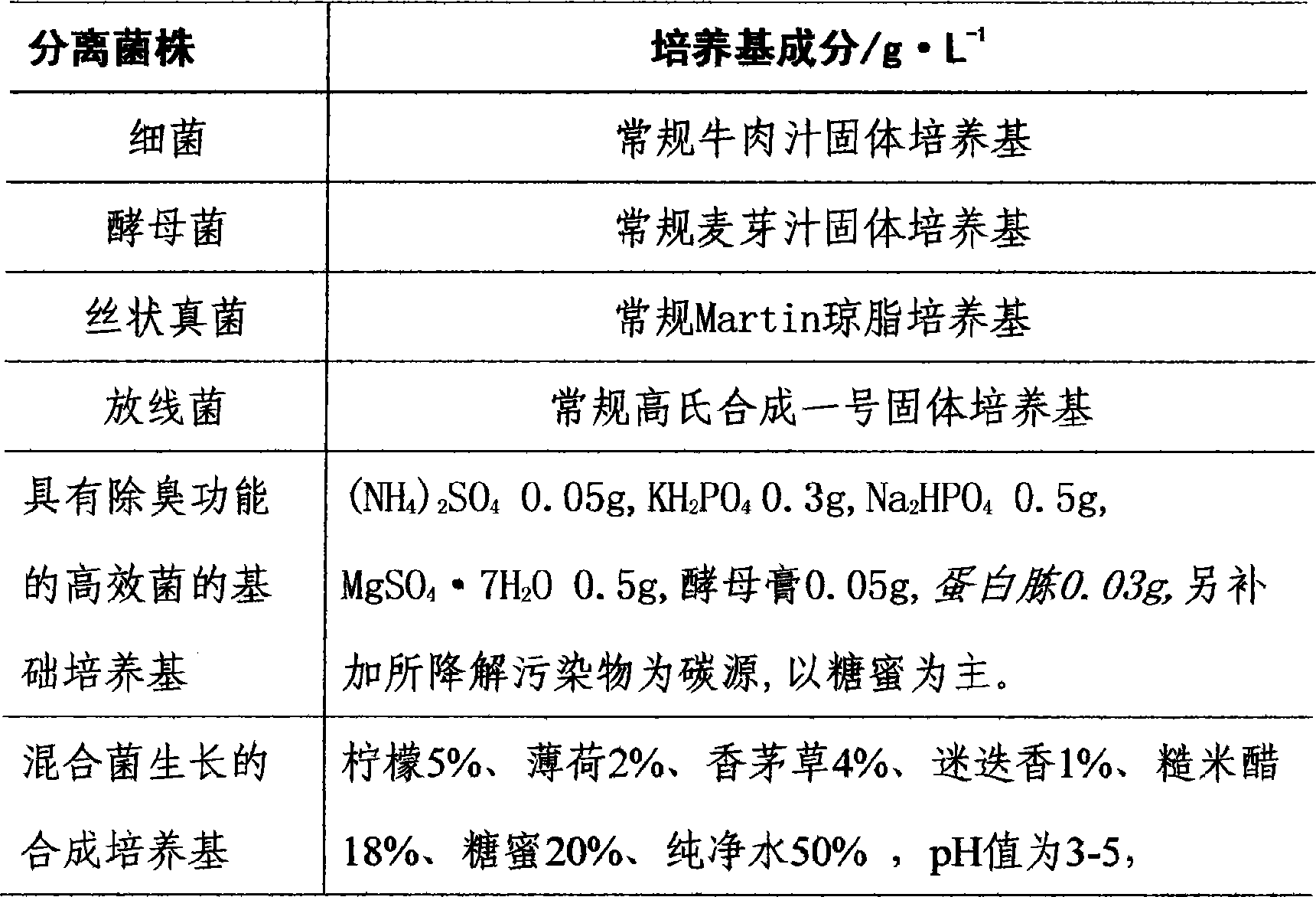

Antibacterial and environment-friendly deodorant of microorganism strains

The invention relates to an antibacterial and environment-friendly deodorant of microorganism strains and a preparation method thereof. The traditional method for removing odor generally uses essence to cover up the odor or pumping odor physically or uses ozone to oxidize and degrade the odor or uses a chemical method. The methods also can alleviate the odor to a certain extent, but finally the problem can not be solved really and fundamentally and the essence and chemical deodorization also have secondary pollution. The microbial deodorization technology utilizes the effects of high-efficient absorption, absorption and metabolism of particular microorganism strains which can convert or degrade odorant, to purify the odorous gases of amyl mercaptan, benzene methanethiol, methyl sulfide, ethanethiol, hydrogen sulfide, sulfur dioxide, p-benzyl mercaptan, ammonia, dimethylamine, trimethylamine and carbon disulfide and the like which are emitted from human life areas, domestic sewage and domestic garbage and the like and to convert the odorous components of amyl mercaptan, benzene methanethiol, methyl sulfide, ethanethiol, hydrogen sulfide, sulfur dioxide, p-benzyl mercaptan, ammonia, dimethylamine, trimethylamine and carbon disulfide and the like into matters without harm and odor, thus achieving the purpose of thoroughly improving air quality and protecting health of people. The preparation method utilizes a fermentation method of microorganism strains to prepare deodorant products.

Owner:王峰

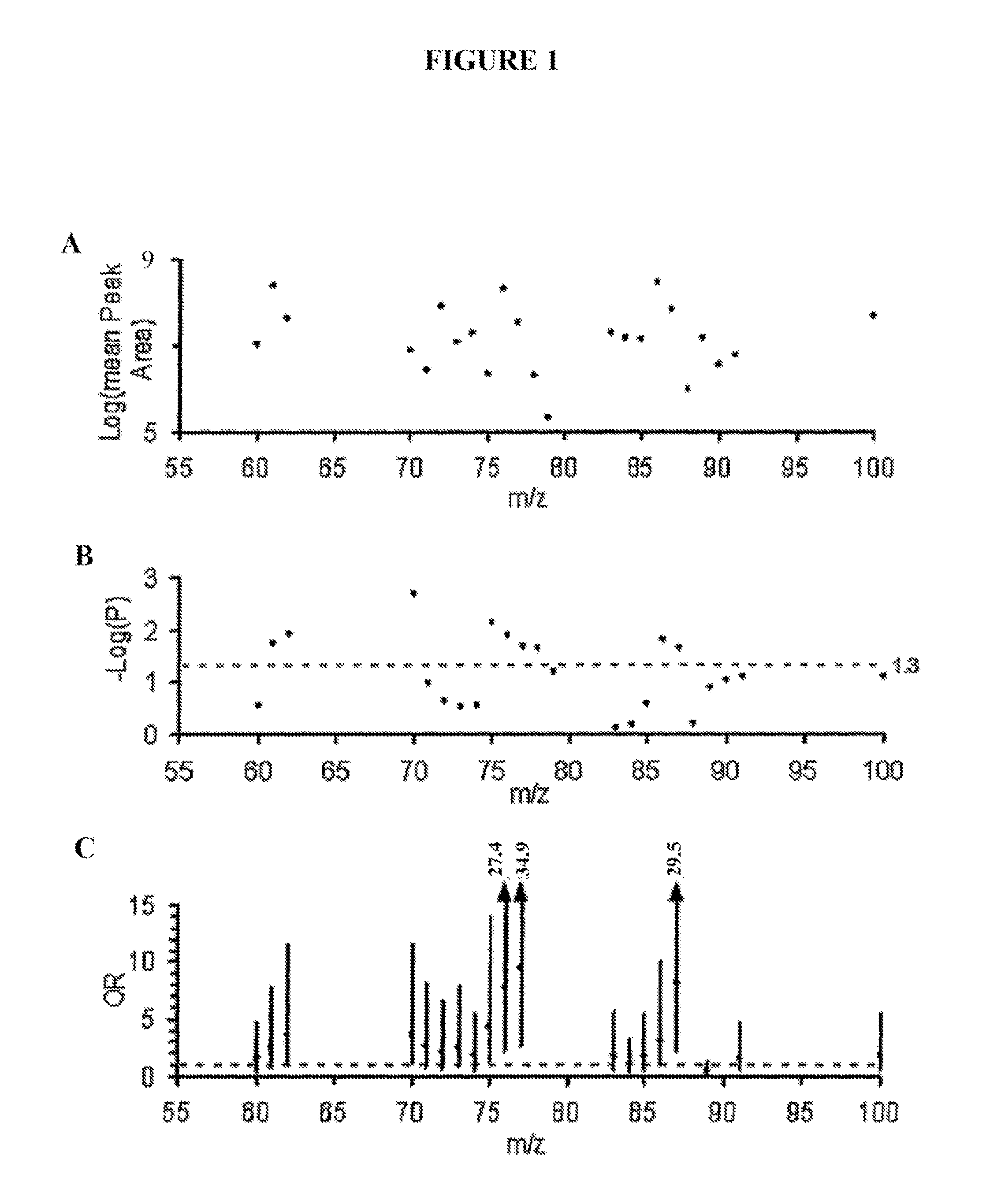

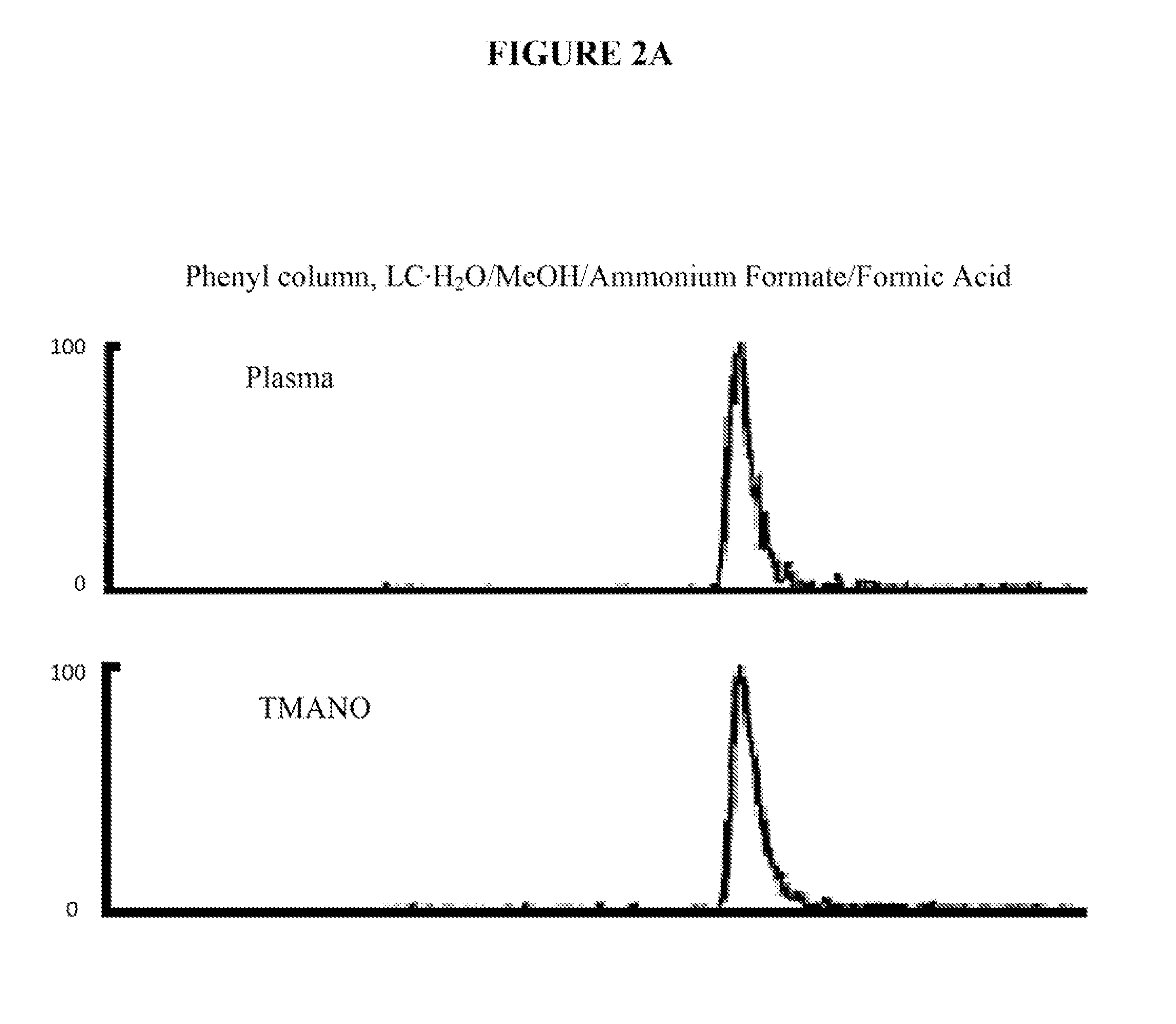

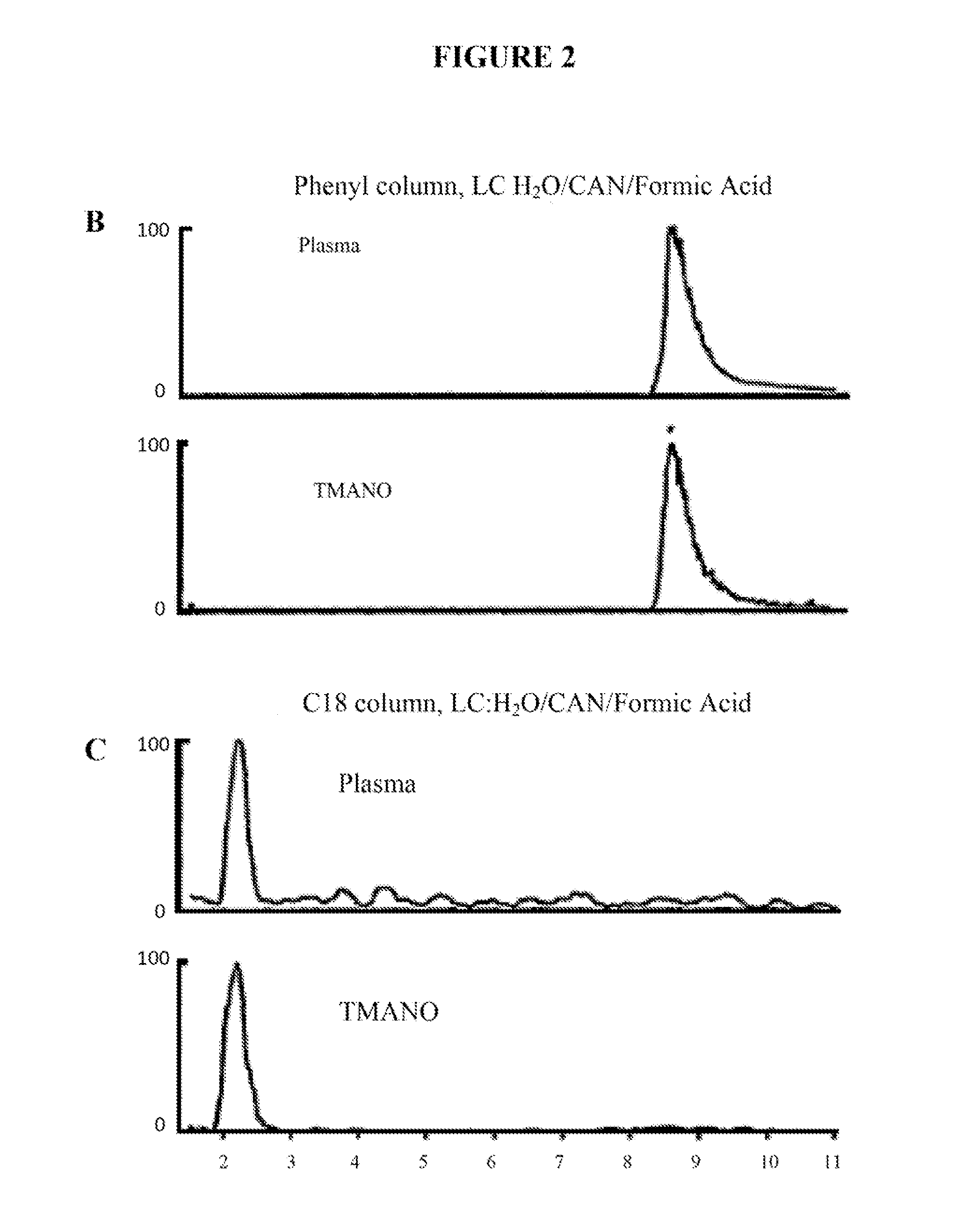

Trimethylamine-containing compounds for diagnosis and prediction of disease

The present invention provides markers and methods for determining whether a subject, particularly a human subject, has or is at risk of developing, a disease such as cardiovascular disease, diabetes mellitus, insulin resistance, metabolic syndrome, NAFLD (Nonalcoholic Fatty Liver Disease) or NASH (Nonalcoholic Steatohepatitis) (e.g., within the ensuing year, two years, and / or three years). The present application also relates to the use of such markers and methods for monitoring the status of such diseases in a subject or the effects of therapeutic agents on subjects with such diseases.

Owner:THE CLEVELAND CLINIC FOUND

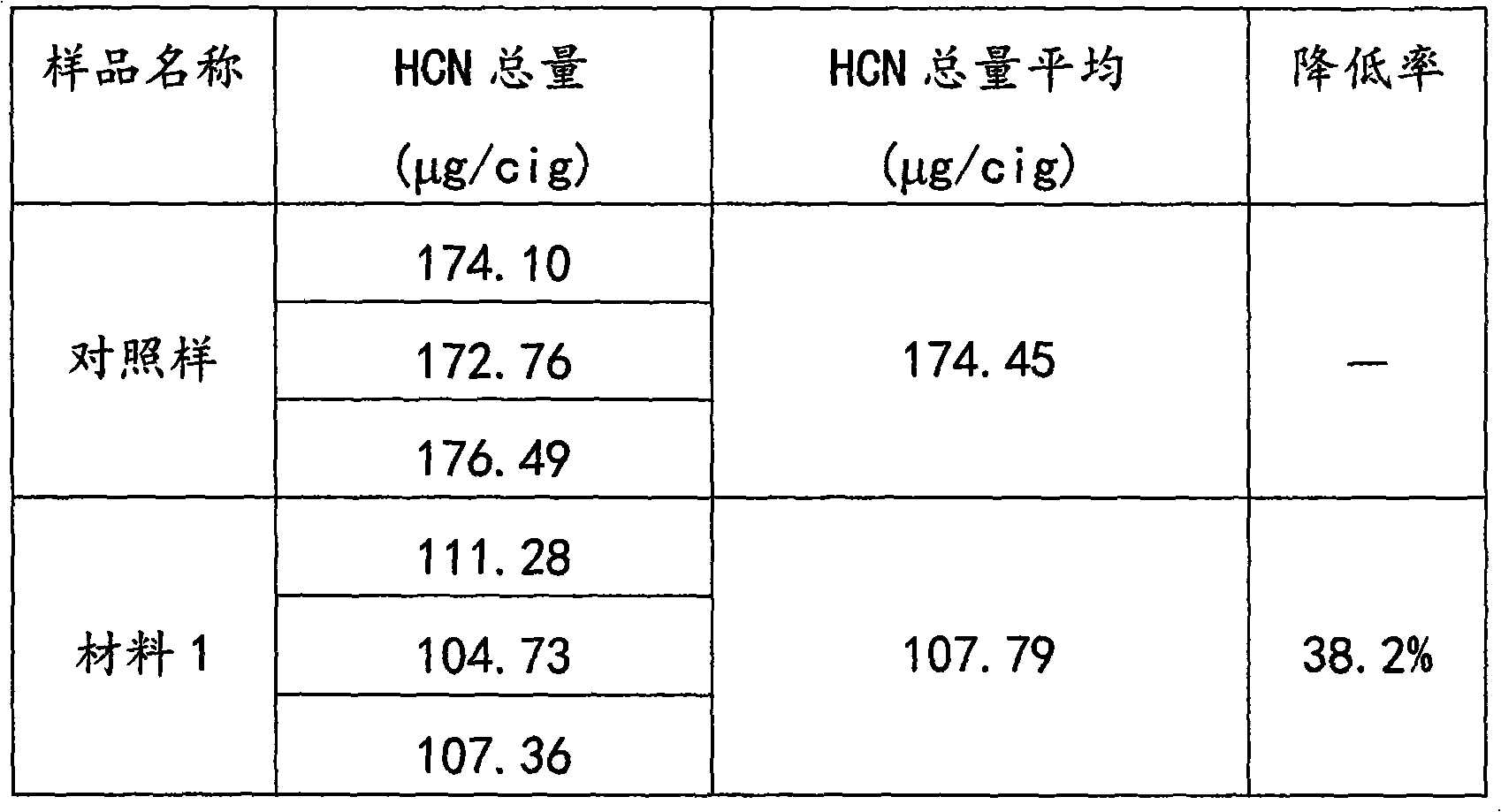

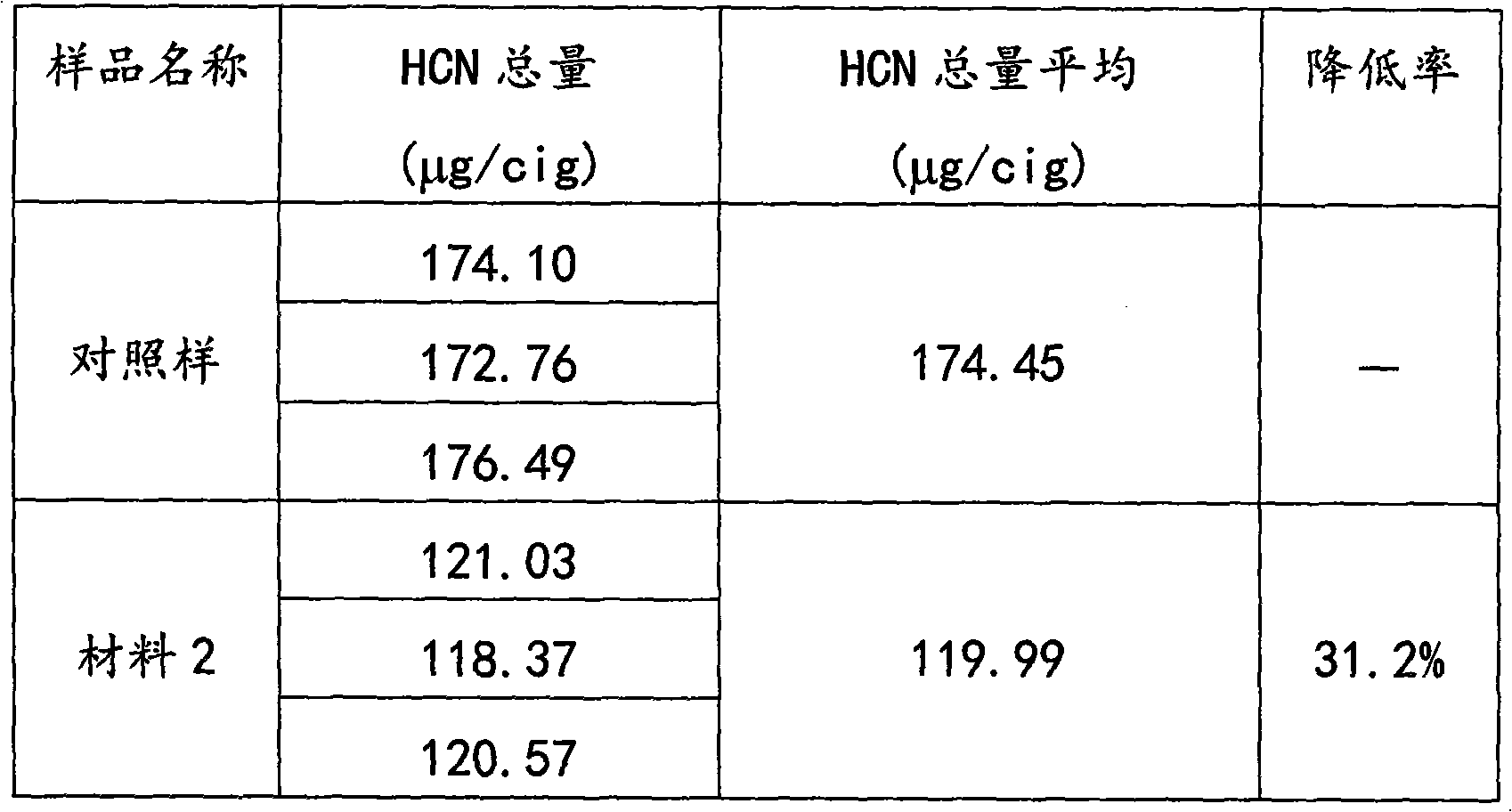

Filter additive material for selectively reducing hydrocyanic acid emission amount in mainstream smoke of cigarette and preparation method thereof

ActiveCN101669678AEffective contactImprove adsorption efficiencyTobacco smoke filtersSodium hydroxideCigarette filter

The invention relates to a filter additive material for selectively reducing the hydrocyanic acid emission amount in the mainstream smoke of cigarettes and a preparation method thereof. The filter additive material for selectively reducing the hydrocyanic acid emission amount in the mainstream smoke of cigarettes is characterized in that the filter additive material is a novel material that can effectively absorb acidic gas and is obtained by chemically modifying a porous material and introducing different alkali groups. The preparation method of the filter additive material comprises the following steps: respectively carrying out surface chemical modification on the selected porous carrier material with trimethylamine chloride acethydrazide or (2-bromomethyl)trimethyl ammonium bromide, soaking with sodium hydroxide solution, washing with water and drying to obtain the modified porous material containing ammonium hydroxide group. Adding the material in a cigarette filter rod can reducethe hydrocyanic acid content in the mainstream smoke of cigarette by more than 30%, and no negative influence is caused on the taste quality of cigarette, thus achieving the purpose of selectively reducing harm.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

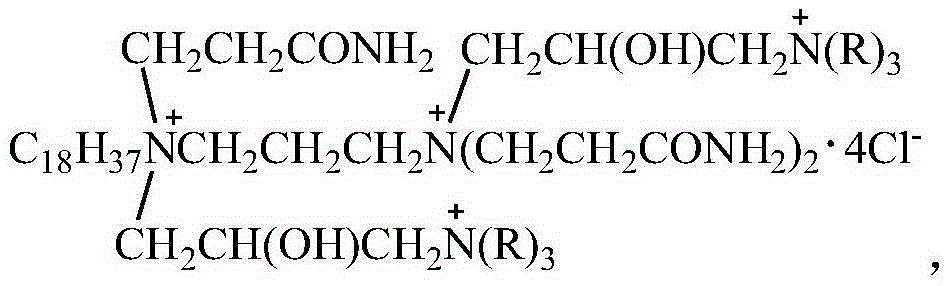

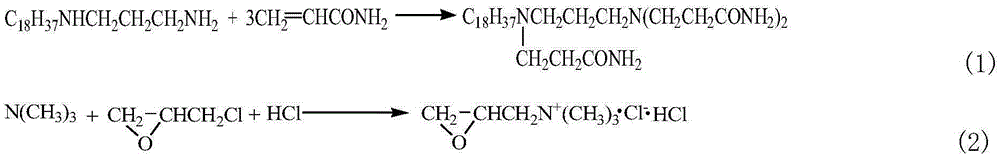

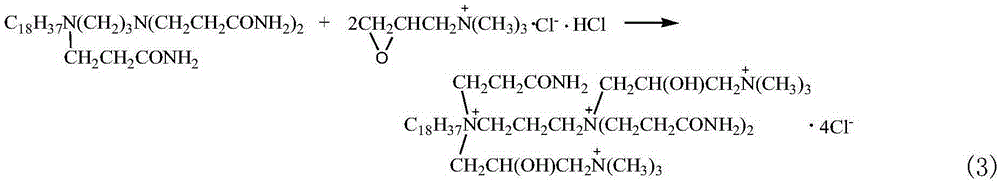

Multi-positive-ion amide-type asphalt emulsifier and preparation method thereof

InactiveCN105399645AGood emulsifying effectImprove hydrophilicityOrganic compound preparationCarboxylic acid amides preparationSolventHigh heat

The present invention discloses a multi-positive-ion amide-type asphalt emulsifier and a preparation method thereof, and the asphalt emulsifier is prepared from raw materials of N-hydrogenated tallow-1,3-propylene diamine, an alcohol solvent, acrylamide, a low-carbon tertiary amine, industrial hydrochloride and epichlorohydrin in the molar ratio of N-hydrogenated tallow-1,3-propylene diamine to alcohol solvent to acrylamide to low-carbon tertiary amine to industrial hydrochloride to epichlorohydrin of 1mol: (5.00-11.00) mol: (3.00-3.10) mol: (2.02-2.10) mol: (2.02-2.10) mol: (2.02-2.08) mol. The alcohol solvent is ethanol, methanol or isopropanol. The low-carbon tertiary amine is a trimethylamine aqueous solution, triethylamine or triethanolamine. The asphalt emulsifier synthetic raw materials are readily available, production cost is low, a process is simple, and a high temperature reaction is not required. The asphalt emulsifier can emulsify a variety of different types of asphalt, the prepared emulsified asphalt is fine, uniform, and good in storage stability, and positive-ion-type emulsified asphalt can be prepared.

Owner:SHANDONG UNIV

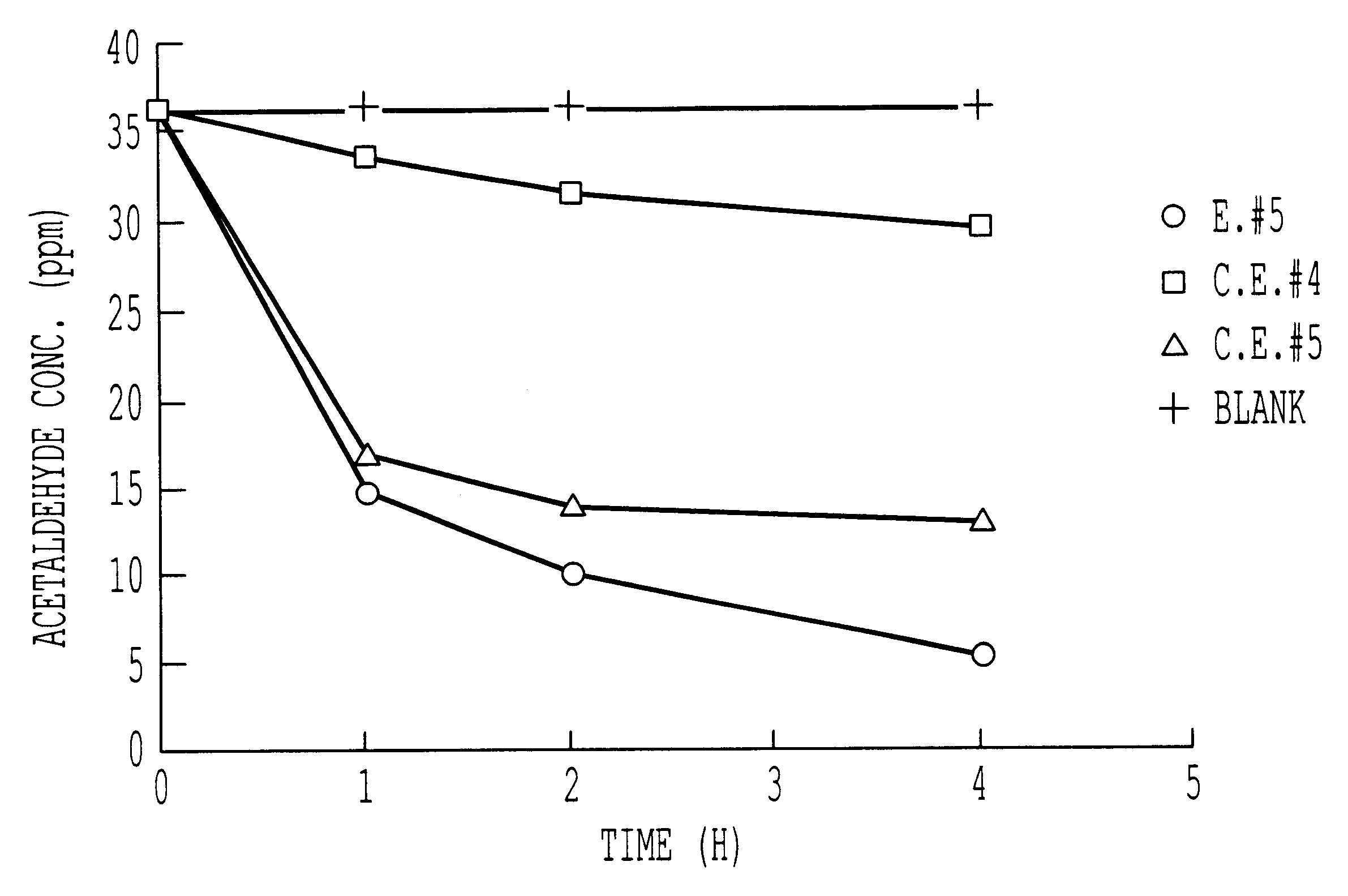

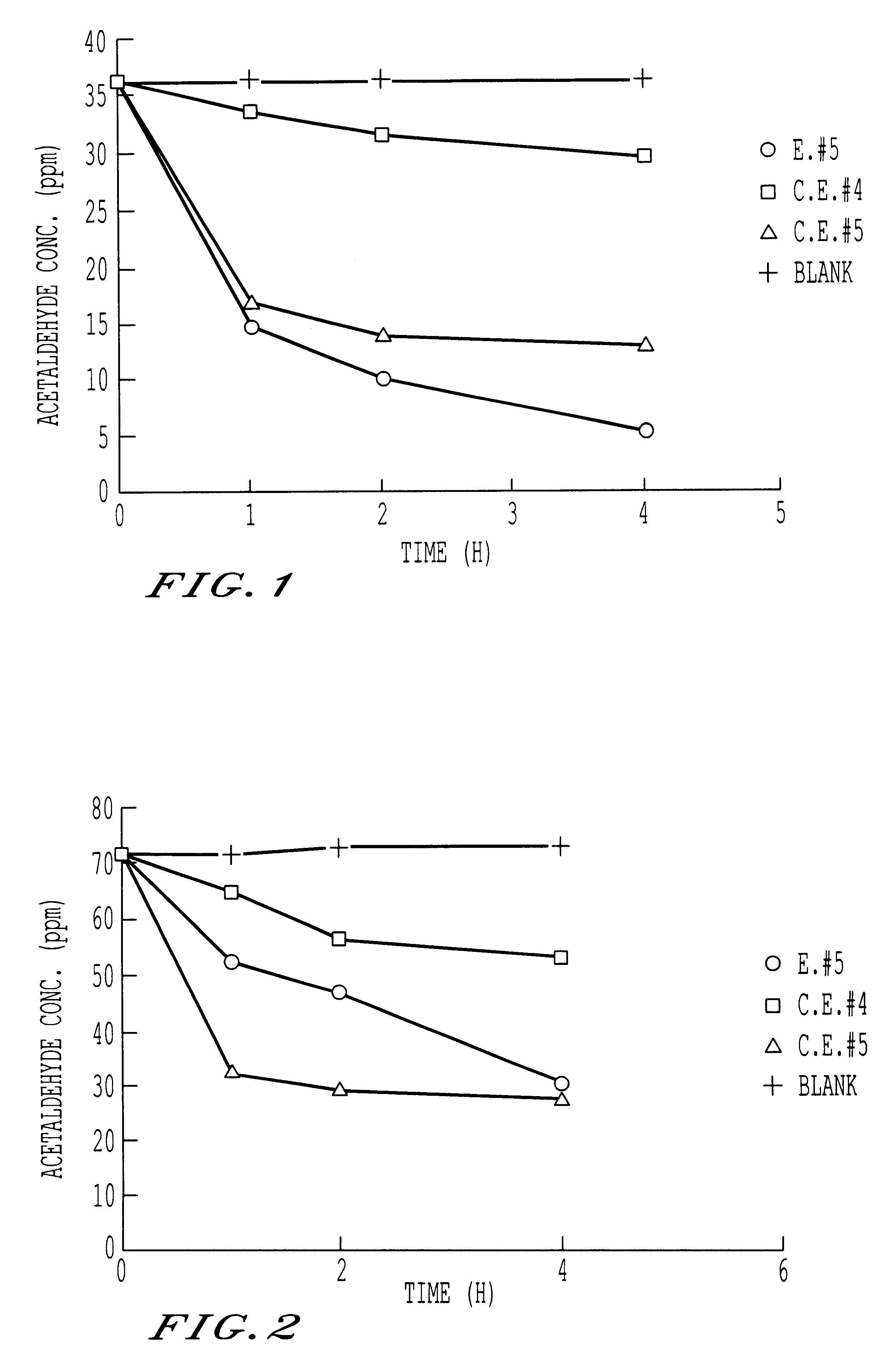

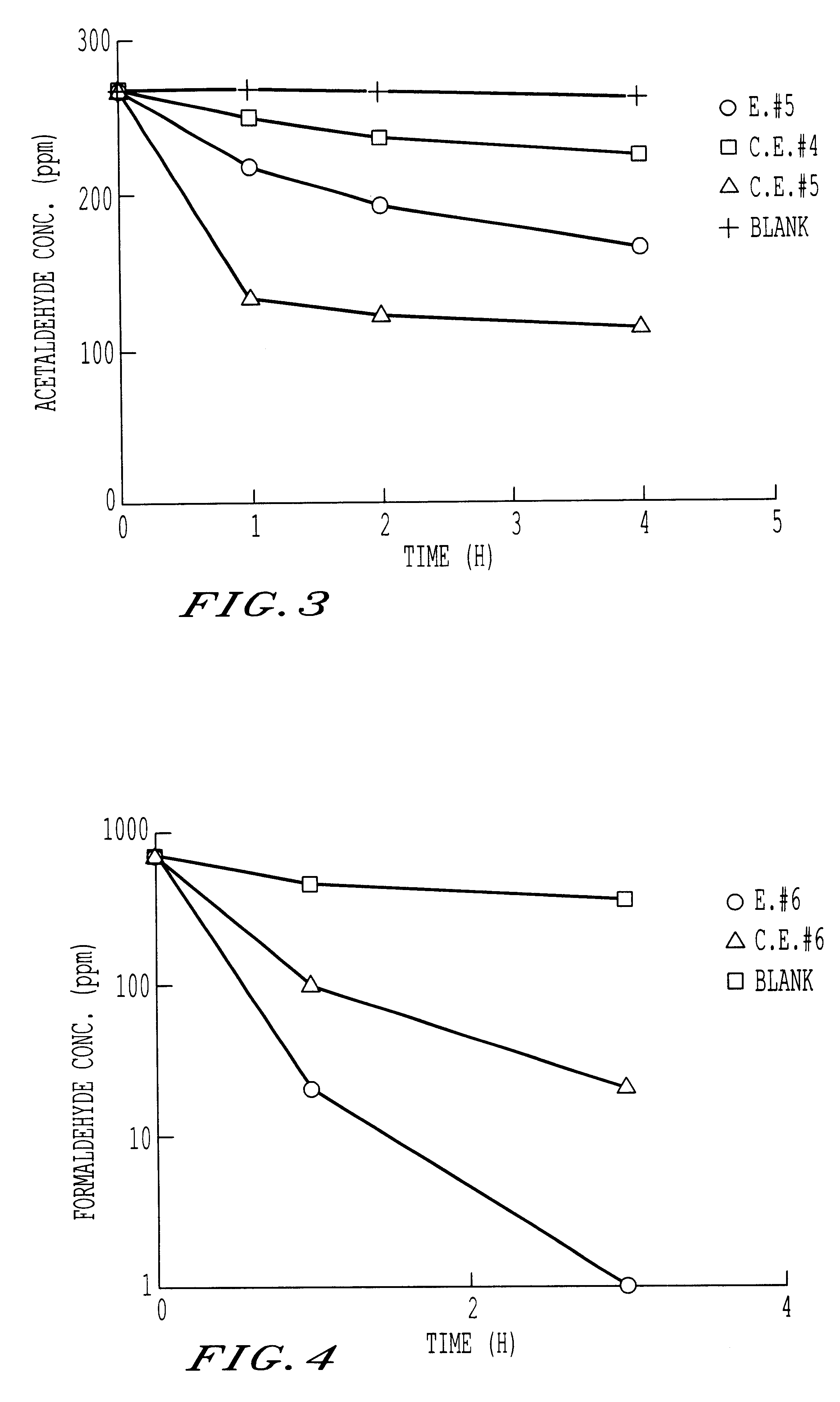

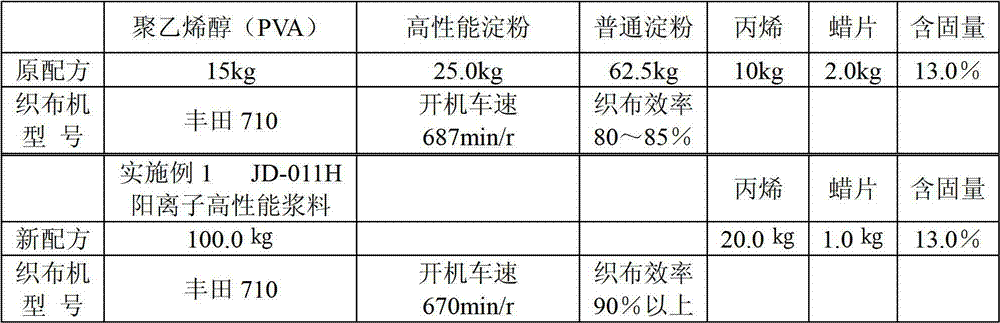

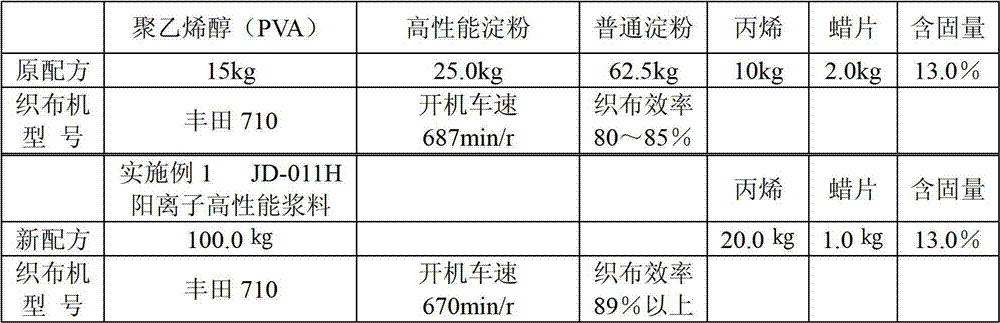

Ordinary-temperature purifying catalyst

An ordinary-temperature purifying catalyst includes an oxide having an oxygen defect introduced by a reduction treatment, and a noble metal loaded on the oxide. For example, the oxide can be at least one oxide selected from the group consisting of cerium oxides and zirconium oxides, at least a part of which has an oxygen defect. The catalyst can purify an environmental loading material, such as carbon monoxide, a nitrogen oxide, ethylene, formaldehyde, trimethylamine, methyl mercaptan and acetaldehyde, in air at an ordinary temperature. A method for how to use the catalyst is also disclosed.

Owner:TOYOTA CENT RES & DEV LAB INC

Cation high performance slurry

The invention discloses cation high performance slurry. The slurry is formed by commixture reaction of raw materials including corn starch, sodium hydroxide, trimethylamine hydrochloride and persulfate with the following quality content: 80-95% of the corn starch, 1-10% of the sodium hydroxide, 1-15% of the trimethylamine hydrochloride, and 0.1-15% of persulfate. The cation high performance slurry has the advantages of strong adhesive force, good film formation property, tenacious chorion and good elasticity, the flexibility (anti-fatigue property) is improved by 3-4 times compared with common modified starch slurry, the cation high performance slurry has good wear-resisting property and ageing resistance, and a serous fluid has good liquidity and stable viscosity under an I normal temperature condition; and the slurry contains no polyvinyl alcohol, when a spinning purified cotton yarn is subjected to a sizing process, a variety with 60 yarns with common compactness can be processed without polyvinyl alcohol, when sash cotton or purified cotton yarn with more than 60 yarns is subjected to sizing process, little polyvinyl alcohol or no polyvinyl alcohol is used, desizing is easy, waste water of serous fluid is easy to process, pollution of the waste water to the environment is small, and zero-pollution discharge in the production process is realized.

Owner:YIXING JUNDA SLURRY TECH

Cation high-performance size

The invention discloses cation high-performance size which is made from the following raw materials: corn starch, hydroxides, trimethylamine hydrochloride and persulfate through a hybrid reaction, wherein corn starch accounts for 80%-95% by weight, calcium hydroxide and / or magnesium hydroxide account(s) for 1%-10% by weight, trimethylamine hydrochloride accounts for 1%-15% by weight, and persulfate accounts for 0.1%-15% by weight. The cation high-performance size has the advantages of strong adhesive ability, good film forming property, tough size film, and excellent elasticity; the flexibility (fatigue endurance) is improved by 3-4 times in comparison with common modified starch size; the cation high-performance size is excellent in wear-resisting and anti-aging properties; and the size has good flowability under the condition of normal temperature, and is stable in viscosity. Polyvinyl alcohol is not used. When pure cotton yarns are sized during spinning, 60-count yarns of common tightness do not need polyvinyl alcohol, and when polyester or pure cotton yarns higher than 60-count are sized, no polyvinyl alcohol is needed or only a small amount of polyvinyl alcohol is needed, so that desizing is easy, the size waste is easy to process and causes small pollution to the environment; and zero pollution emission is realized in a production process.

Owner:YIXING JUNDA SLURRY TECH

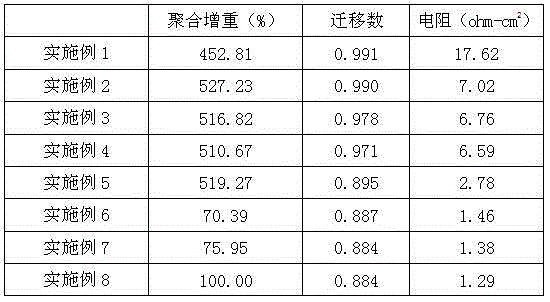

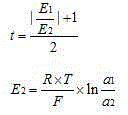

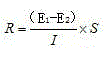

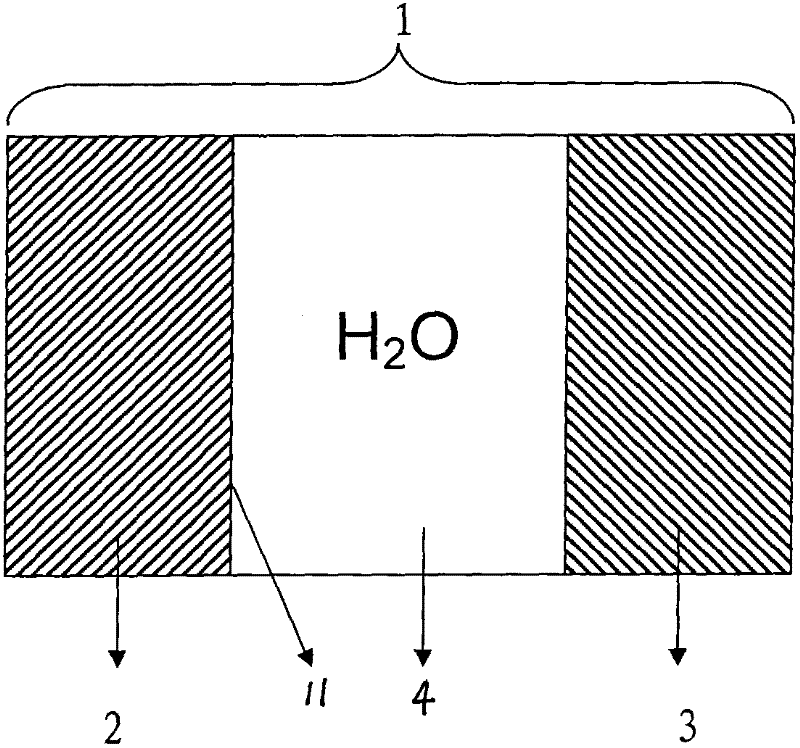

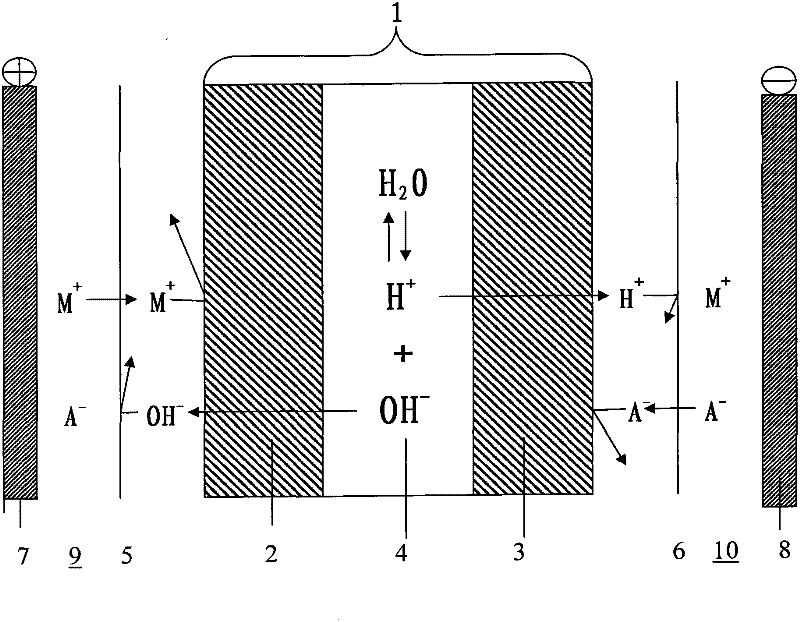

Method for manufacturing homogeneous ion exchange membrane

The invention discloses a method for manufacturing a homogeneous ion exchange membrane, which comprises the following steps: impregnating a polyethylene and ethylene-octylene copolymer elastomer blended alloy membrane or a polyethylene, ethylene-octylene copolymer elastomer, and polyisobutylene rubber blended alloy membrane, which serves as a substrate membrane, with solution of styrene, divinyl benzene and benzoyl peroxide, pressurizing and heating the impregnated membrane for polymerization to obtain a base membrane; and chloromethylating the base membrane in chloromethyl ether solution containing anhydrous stannic chloride to obtain a chloromethyl membrane, and quaternizing the chloromethyl membrane in aqueous solution of trimethylamine to obtain the ion exchange membrane. The method has the advantages of greatly reducing an impregnation temperature, and reusing solution of styrene and divinyl benzene. The capacity of the manufactured ion exchange membrane is up to 2.2 milligram equivalent per gram of dry membrane, and the sheet resistance of the manufactured ion exchange membrane is about 6 omega m<2>.

Owner:福建省延润膜环保科技有限公司

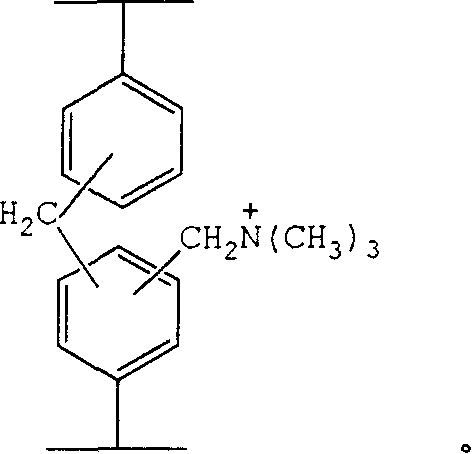

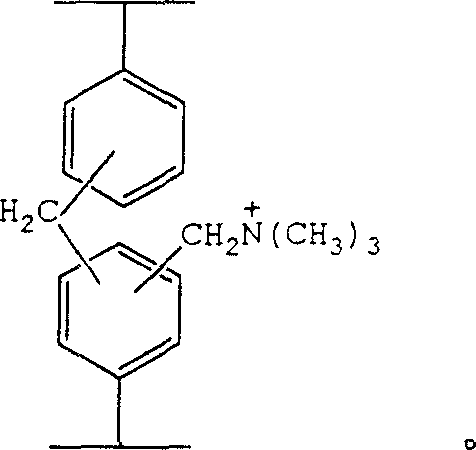

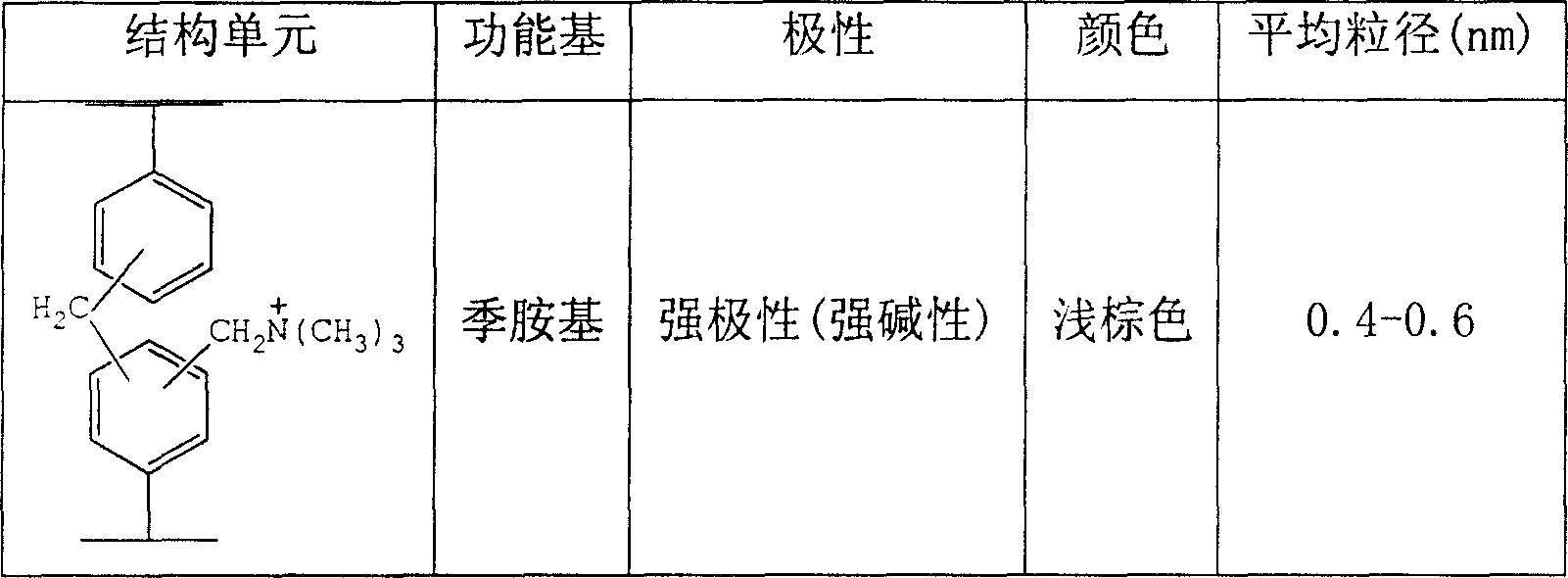

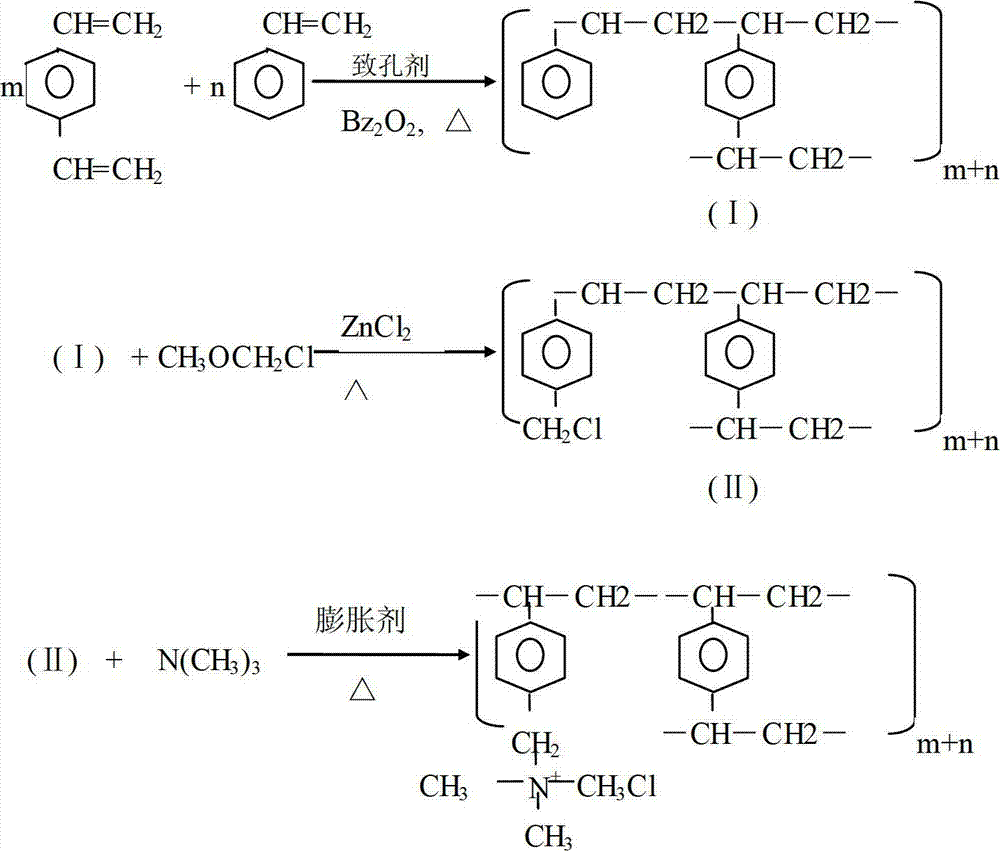

Composite functional super high cross-linked adsorption resin containing quaternary amine group, and its preparation method

ActiveCN1865302AHighlight hydrogen bondsProminent electrostatic effectOther chemical processesDibenzoyl PeroxideDisperser

The invention discloses a super high cross-linking adsorption resin with quaternary amines base composite function and making method, which comprises the following steps: utilizing phenylethene as monomer, diphenyl ethylene as cross linking agent, liquid wax as hole-sealing agent, magnesium carbonate as disperser, benzoyl peroxide as initiator; adopting nitrobenzene, substituted nitrobenzene, dichloroethanes or orthodichlorobenzene as swelling agent in the cross-linking reaction course of chloromethylation low cross-linking large-hole polyphenylacetylene; using zinc chloride, ferric chloride or tin tetrachloride as catalyst to produce different cross linking composite functional resin priority in the preset time and temperature condition; adding trimethylamine to aminate to produce the product. The resin possesses double functions of adsorption and ion exchanging, which can be applied in drug separation, little polluted water source and organic chemical waste water harnessing.

Owner:NANJING UNIV +1

Functional systems with reduced odor cationic polygalactomannan

InactiveUS20060046943A1Reduce body malodorCosmetic preparationsHair cosmeticsPersonal careLower limit

A reduced odor composition is composed of a functional system such as household care, personal care or pet care products and at least one cationic polygalactomannan or a derivative of cationic polygalactomannan having a cationic degree of substitution (DS) lower limit of about 0.01 and an upper limit of about 3.0 and weight average molecular weight (Mw) having a lower limit of 200,000 and an upper limit of 2,000,000 a concentration with a lower limit of 0.005 wt % and an upper limit of 10 wt %, and a trimethylamine content of less than 25 ppm, wherein the composition, at an alkaline pH, has no discernible amine odor.

Owner:HERCULES INC

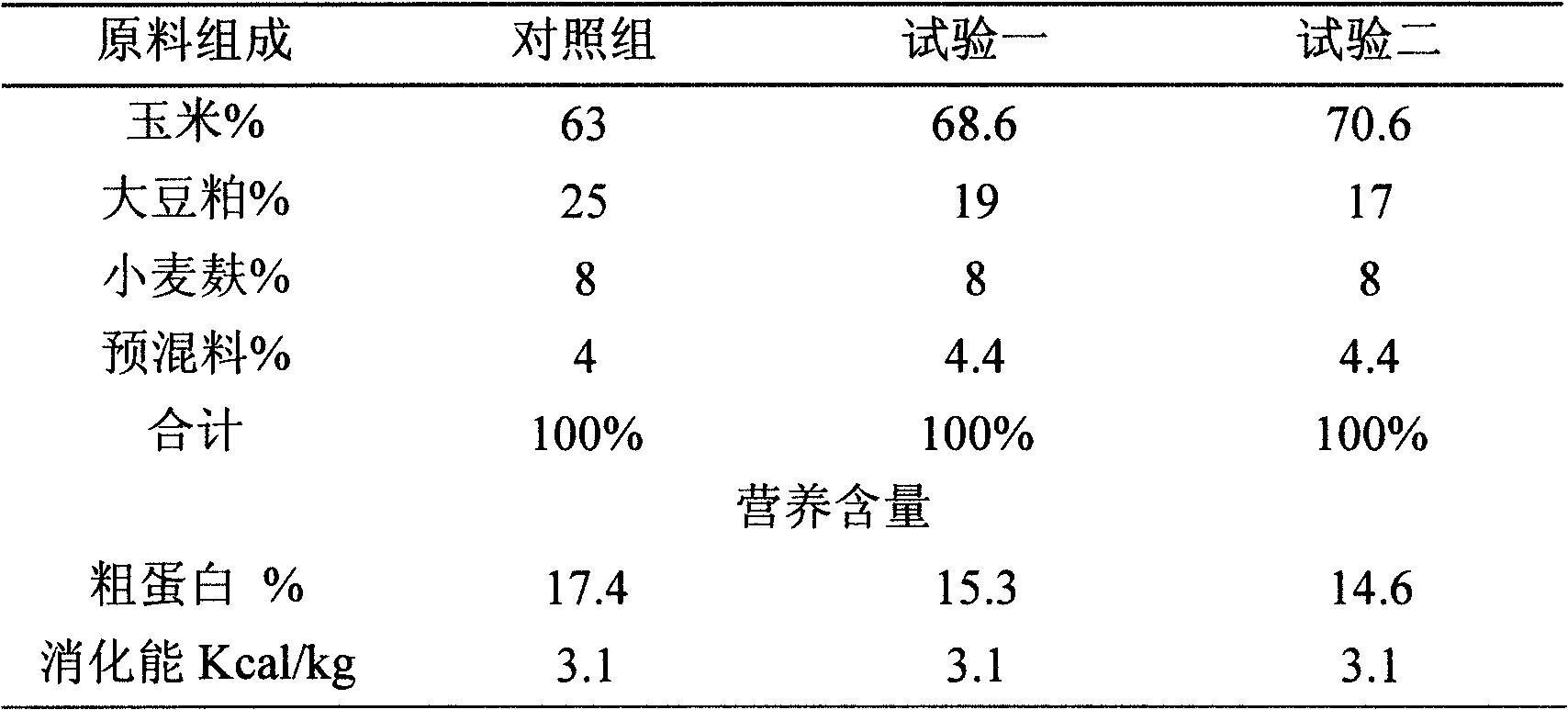

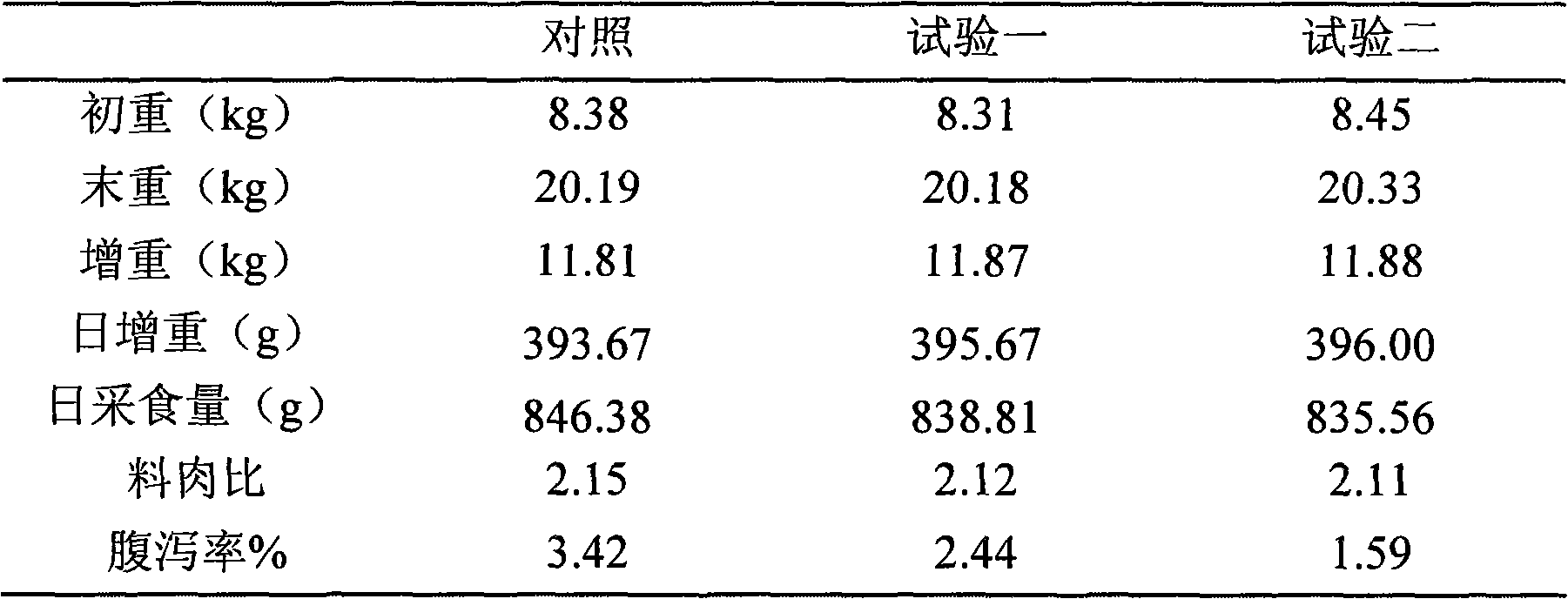

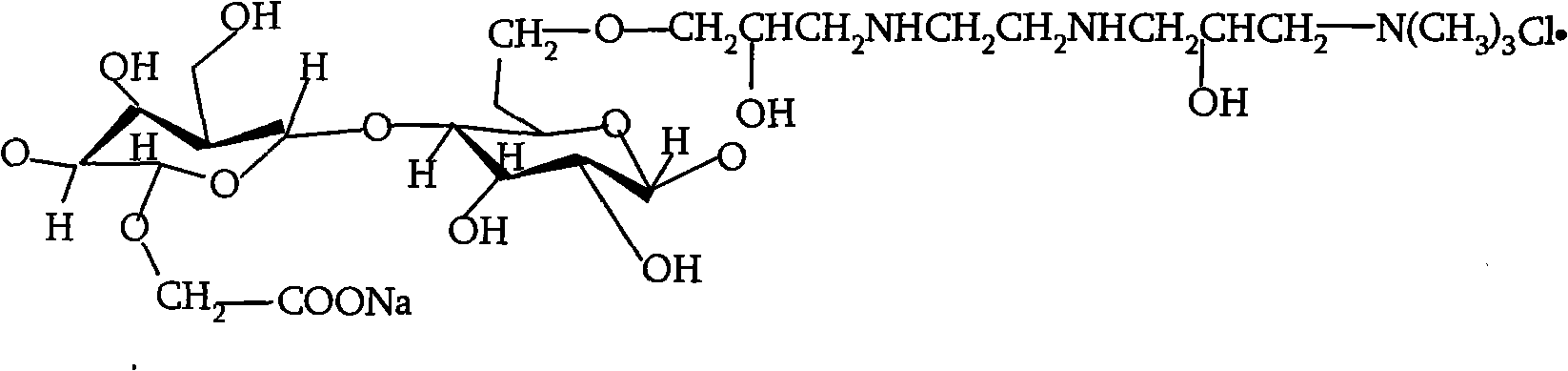

Low-protein amino acid balance daily ration, preparation method and application thereof

ActiveCN101658237AGuarantee product qualityImprove utilization efficiencyAnimal feeding stuffPhytaseData information

The invention discloses a low-protein amino acid balance daily ration, a preparation method and the application thereof. The daily ration comprises the components based on parts by weight: 68-80 partsof corn, 3-20 parts of bean pulp, 6-20 parts of wheat bran and 4-5 parts of pre-mixed material, wherein the pre-mixed material comprises the following components: pig multi-vitamin, pig compound trace element, lysine, methionine, threonine, tryptophan, choline chloride, calcium carbonate, calcium hydrogen phosphate, phytase, common salt, ethoxy quinoline, trimethylamine B lactone, sodium glutamate and zeolite powder. Based on summary of the existing experimental data, the low-protein daily ration combines the actual conditions of China, utilizes the latest data information of raw materials made in China, fully takes the organic combination of the pre-mixed material and the main raw materials into account, and adopts a net energy system structure and a new nutrition model, thus developingthe utilization rate of feed to the utmost extent on the premise of ensuring the quality of animal products.

Owner:北京挑战牧业科技有限公司

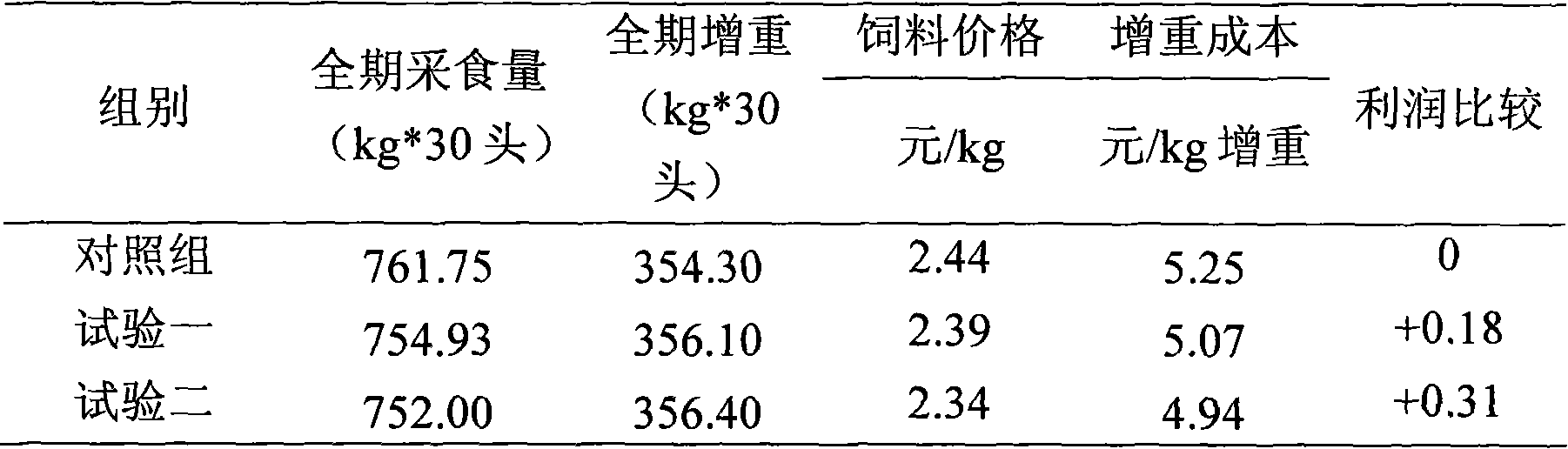

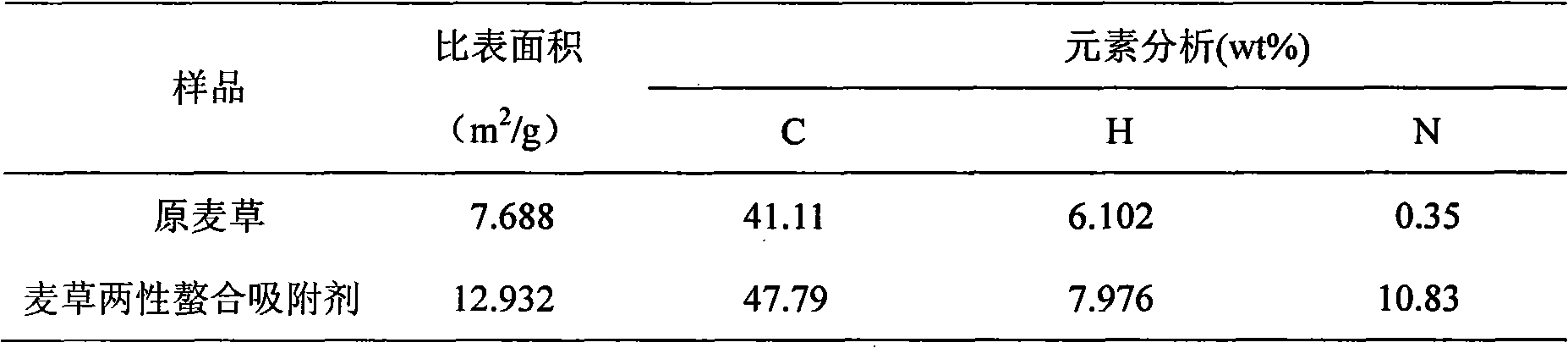

Preparation method and application of amphoteric chelate sorbent containing agricultural straw

InactiveCN101862642AEasy to handleSimple production processOther chemical processesWater contaminantsCross-linkEthylenediamine

The invention relates to a preparation method and application of an amphoteric chelate sorbent containing agricultural straw. The sorbent is brownish-yellow solid powder, the nitrogen content is 10.83wt%, and the specific surface area is 12.93m<2> / g. The sorbent is prepared by taking agricultural straw, epoxy chloropropane and monochloroacetic acid as raw materials, taking trimethylamine or triethylamine as a grafting reaction agent and taking ethylenediamine, diethylenetriamine or triethylenetetramine as a cross-linking agent. The method of the invention has the advantages of simple production processes, economy, practicability, reproducibility and the like and can be suitable for large-scale production. The sorbent prepared by the invention has the characteristics of good stability, good adsorption effect, wide application range and the like, can be widely applied to treatment of waste water containing heavy metal ions, and has better treatment effect.

Owner:SHANDONG UNIV

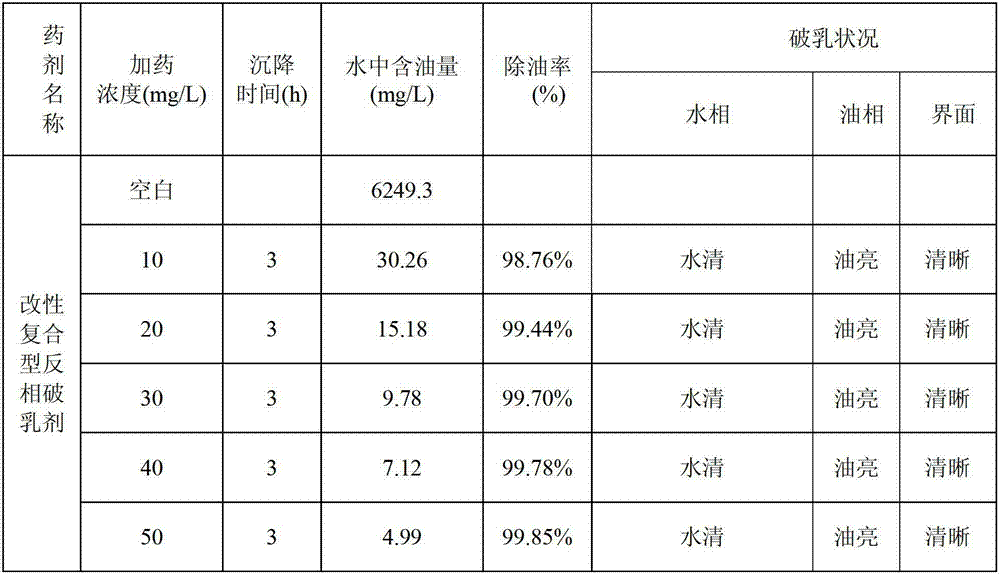

High-temperature sewage treatment reverse demulsifier of ultra-heavy oil

InactiveCN103086472ASimple technical routeMild reaction conditionsFatty/oily/floating substances removal devicesNon-miscible liquid separationCross-linkPotassium hydroxide

The invention discloses a high-temperature sewage treatment reverse demulsifier of ultra-heavy oil. The method comprises the following steps of preparing chlorinated polyether by taking propanetriol and epichlorohydrin as materials and boron trifluoride ether solution as an initiator; preparing cationic poly ether by placing the chlorinated polyether and trimethylamine in a high-pressure reactor; by taking carbinol as a solvent, and boron trifluoride diethyl etherate as the initiator, repeatedly and alternatively carrying out Michael addition reaction and amidation by ethanediamine, methyl acrylate and the like to prepare 3.0-generation dendritic macromolecule polyamide-amine; by taking polyethylene glycol and poly propylene glycol as materials, and potassium hydroxide powder as a catalyst, adding polypropylene glycol to prepare non-ionic polyether after the polyethylene glycol reacts a period of time; finally by taking 3.0-generation polyamide-amine as a cross-linking agent, preparing the modified composite polyamide-amine-polyether high-temperature sewage treatment reverse demulsifier of the ultra-heavy oil by compounding cationic polyether and non-ionic polyether.

Owner:KARAMAY SANDA NEW TECH +1

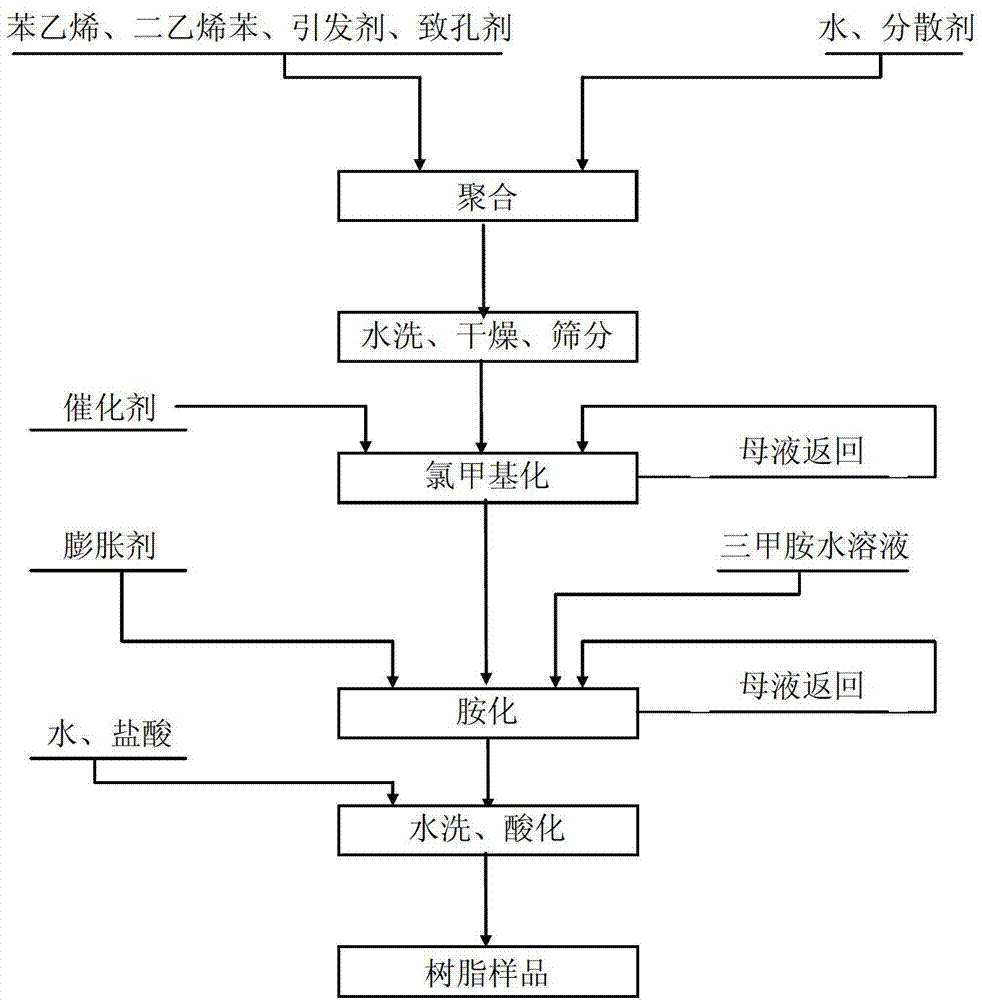

Preparation method of ion exchange resin

InactiveCN102898569AReduce consumptionGood rinse effectAnion exchangersChloromethyl EtherIon exchange

The invention provides a preparation method of an ion exchange resin, which comprises the following steps: (1) mixing a dispersant solution and an organic phase, and gradually heating to carry out polymerization reaction; (2) adding chloromethyl ether into the obtained white ball, and adding a catalyst zinc chloride to carry out chloromethylation reaction; and (3) adding methanol into the obtained chlorine ball, dropwisely adding a trimethylamine water solution, adding a 10% sodium chloride solution, adding hydrochloric acid for neutralization, and washing with water to obtain the resin. The ion exchange resin provided by the invention has the advantages of favorable selectivity, high uranium adsorption capacity and high exchange speed.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

Method for preparing homogeneous phase ion exchange membrane

InactiveCN104610558AImprove surface propertiesImprove hydrophilicitySemi-permeable membranesCation exchanger materialsCross-linkFunctional monomer

The invention discloses a method for preparing a homogeneous phase ion exchange membrane. The method comprises the following steps: (1) blending a functional monomer, a cross-linking agent and an initiator into a uniform solution, thereby obtaining a membrane liquid; (2) soaking a substrate into the membrane liquid to impregnate, taking out the substrate, and clamping between two thin clamps, thereby forming a composite body; (3) enabling the initiator to initialize polymerization reaction on the composite body at 60-120 DEG C, and peeling off the two thin clamps, thereby obtaining a polymerized membrane; (4) putting the polymerized membrane into a chlorosulfonic acid chloroform solution for sulfonation treatment, after the sulfonation treatment, soaking in a NaCl solution, after being soaked, washing with water, and drying, thereby obtaining a Na type cation exchange membrane, or putting the polymerized membrane into a trimethylamine solution, performing amination treatment at 20-40 DEG C, after the amination treatment, soaking in the NaCl solution, after being soaked, washing with water, and drying, thereby obtaining a Cl type anion exchange membrane. The cation exchange membrane prepared by using the method is low in surface resistance, high in transference number and relatively high in selectivity.

Owner:SHANDONG TIANWEI MEMBRANE TECH

Superheavy oil crude oil reverse-phase demulsifier preparation method

InactiveCN104479731AGood demulsification effectLow costDewatering/demulsification with chemical meansEthylenediamineEpoxy

The invention provides a superheavy oil crude oil reverse-phase demulsifier preparation method characterized in that: epoxy chloropropane, glycerol and trimethylamine and the like are used as raw materials for preparation of multi segment poly quaternary ammonium salt, methyl acrylate and ethylenediamine are used as raw materials for preparation of 3.0 generation polyamidoamine-amine, and a water-soluble solution, namely a composite type reverse-phase demulsifier is prepared from the poly quaternary ammonium salt, the 3.0 generation polyamidoamine-amine, polymeric aluminium and a solvent according to the mass fraction ratio of (10-30): (10-40): (1-20): (100-500). The reverse-phase demulsifier prepared by the method has good demulsification effect on crude oil exploited from an oil field, and is a reverse-phase demulsifier suitable for chemical flooding produced liquid, and the preparation method provided by the invention has the advantages of simple operation, low requirement on equipment, wide application range and reduces the cost of crude oil exploitation.

Owner:TIANJIN DAGANG OILFIELD BINGANG GRP BOHONG PETROLEUM CHEM

Preparation method of bagasse active carbon/ferric oxide

InactiveCN101757892ASimple processReduce manufacturing costOther chemical processesWater/sewage treatment by sorptionOxide compositeChemistry

The invention discloses a preparation method of bagasse active carbon / ferric oxide, which comprises the following steps of: adding 800ml of distilled water into a 2L beaker, adding 100ml of 0.01-0.1mol / L hexadecyl trimethylamine bromide into the 2L beaker, heating and boiling; slowly dropwise adding 100ml of 0.5-2.5mol / L ferric chloride solution in stirring to obtain a brownish red colloid; adding 20-60g of bagasse into the brownish red colloid, stirring and standing for 24 hours; slowly adding ammonia water with the volume ratio of 1.0-10.0 percent into the 2L beaker under stirring by using an automatic titrimeter and regulating pH to 7.4 to obtain water solution of a bagasse / iron hydroxide mixed suspended matter; filtering the water solution of the bagasse / iron hydroxide mixed suspended matter and drying 105-110 DEG C to obtain a bagasse / iron hydroxide mixture; respectively carbonizing the bagasse / iron hydroxide mixture at 400-600 DEG C to obtain an active carbon / ferric oxide composite; and grinding the active carbon / ferric oxide composite with over 60 meshes. The preparation method has the advantages of simple process and low cost, and the prepared product can be widely applied to dephosphorization production procedures in city town sewage treatment plants.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

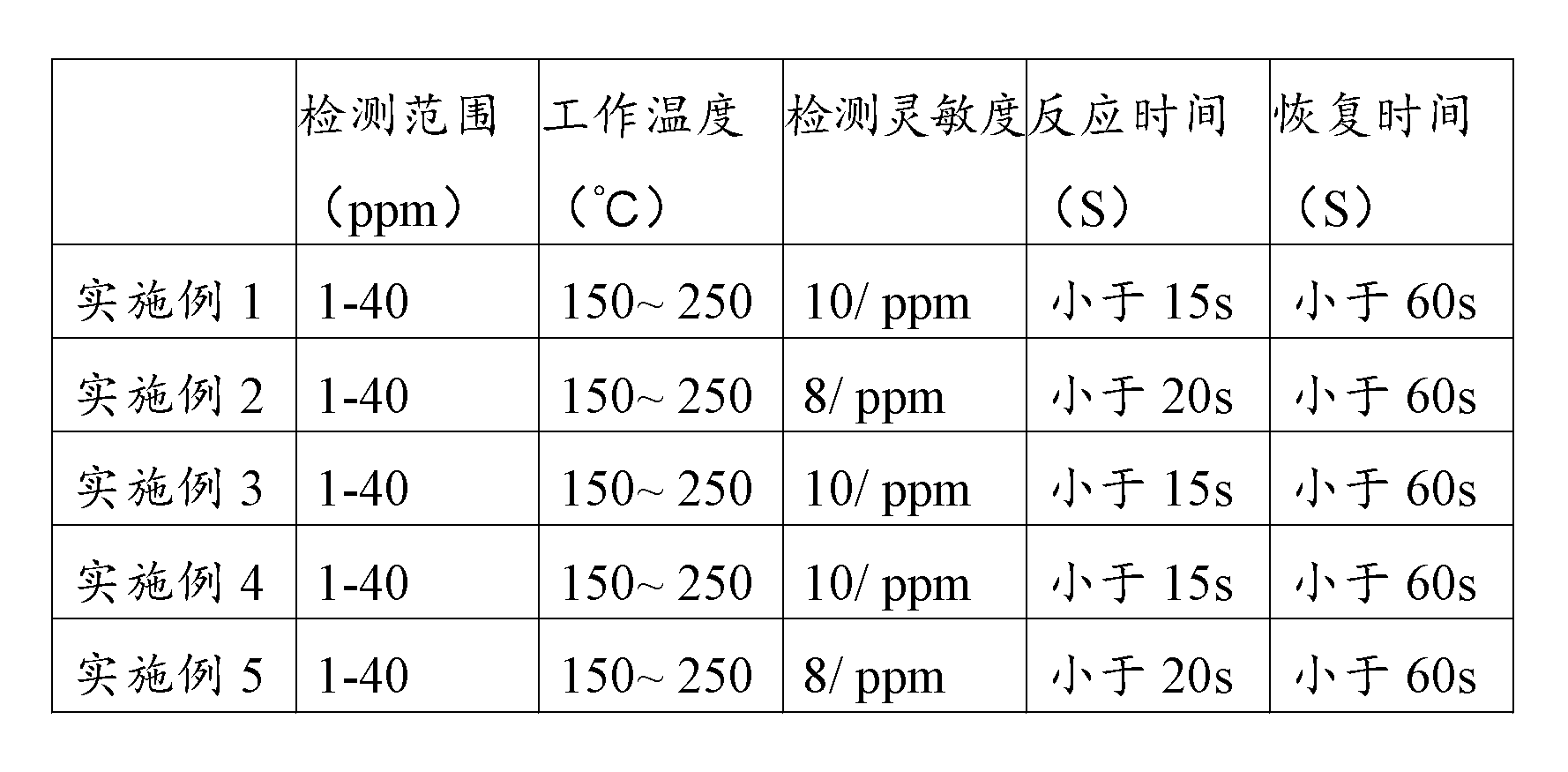

Trimethylamine gas sensor and preparation method thereof

InactiveCN103063705AWith quantum effectSelf-catalytic activityMaterial analysis by electric/magnetic meansAutocatalysisImage resolution

The invention discloses a trimethylamine gas sensor which comprises a gas sensing electrode tube, wherein an AI2O3 ceramic tube is as a carrier of the gas sensing electrode tube, nanometer SnO2 is as gas sensitive materials, and Eu3+ or La3+ which accounts for 0.5-5% of SnO2 molar mass is contained in the gas sensitive materials. The invention also discloses a preparation method of the trimethylamine gas sensor. The preparation method of the trimethylamine gas sensor includes steps of preparation of coralloid nanometer SnO2, preparation of the gas sensitive materials, preparation of the gas sensing electrode tube and the like. The gas sensitive material prepared in the trimethylamine gas sensor has the characteristics of nanometer materials of quantum effect, autocatalysis activity, surface effect and the like. The trimethylamine gas sensor which is made of the gas sensitive materials has the advantages of being high in sensitivity, good in anti-interference, short in response and recovery time, low in working temperature and the like when trimethylamine gas is detected. The trimethylamine gas sensor can be used for detecting trimethylamine gas pollution.

Owner:HUAZHONG AGRI UNIV

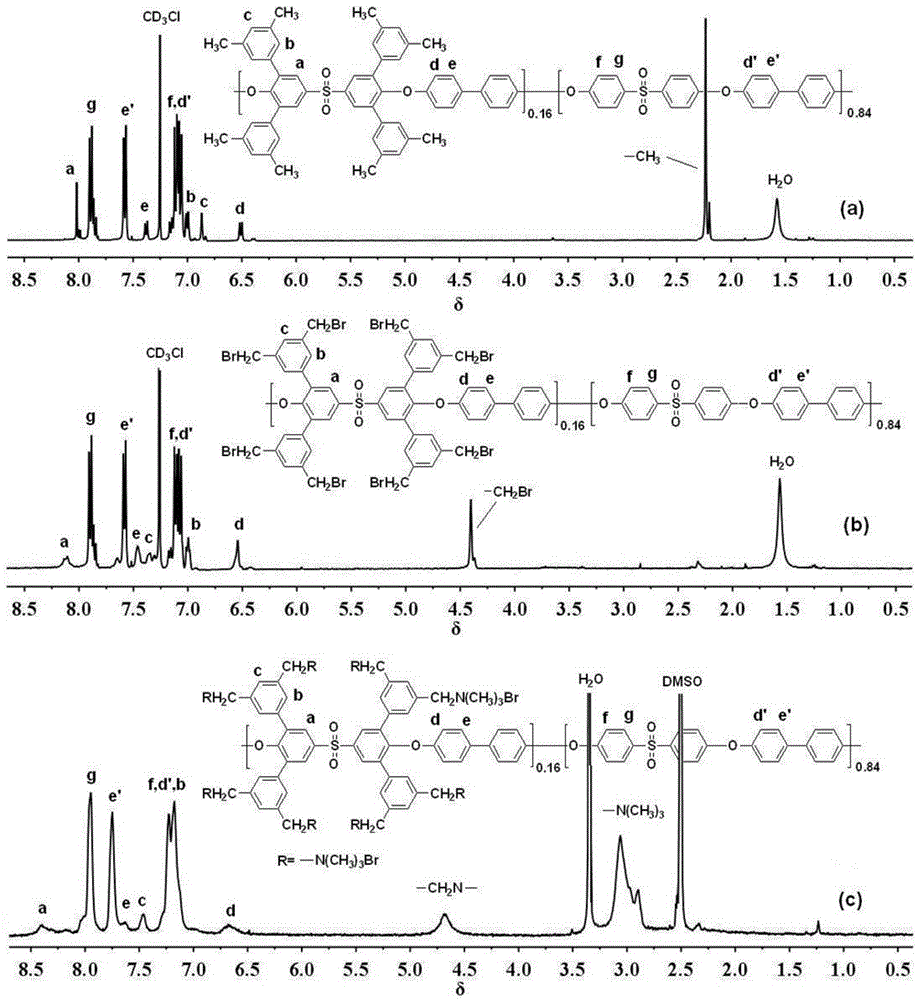

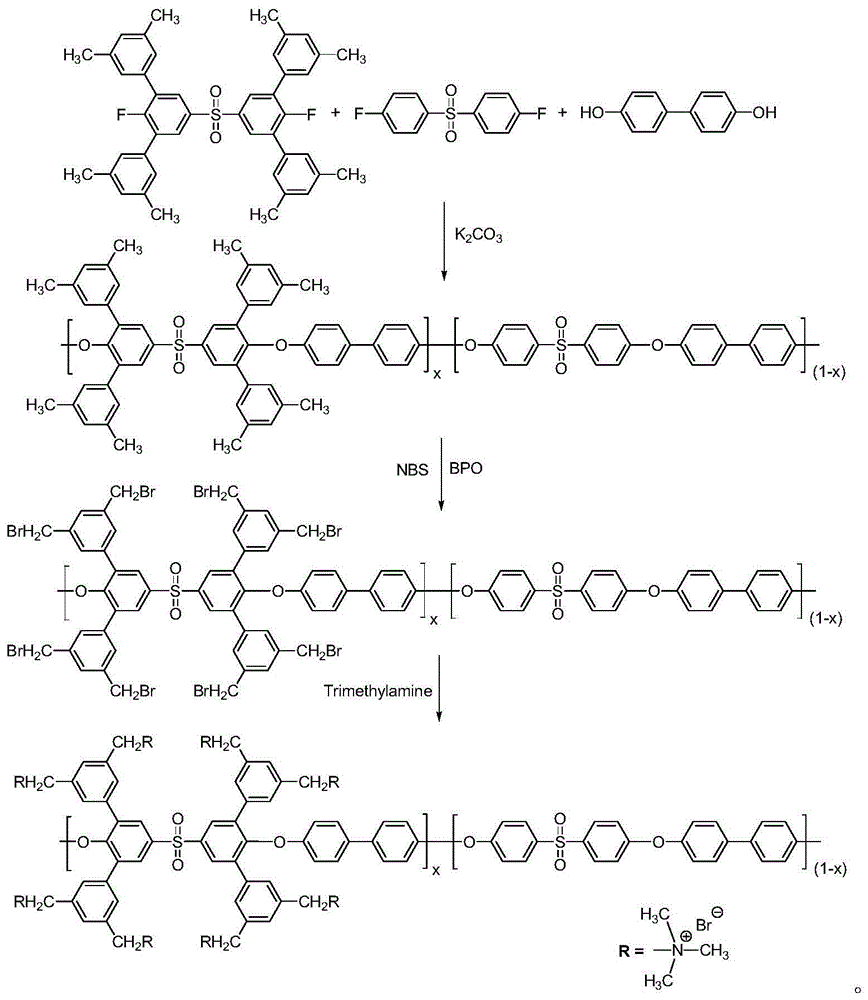

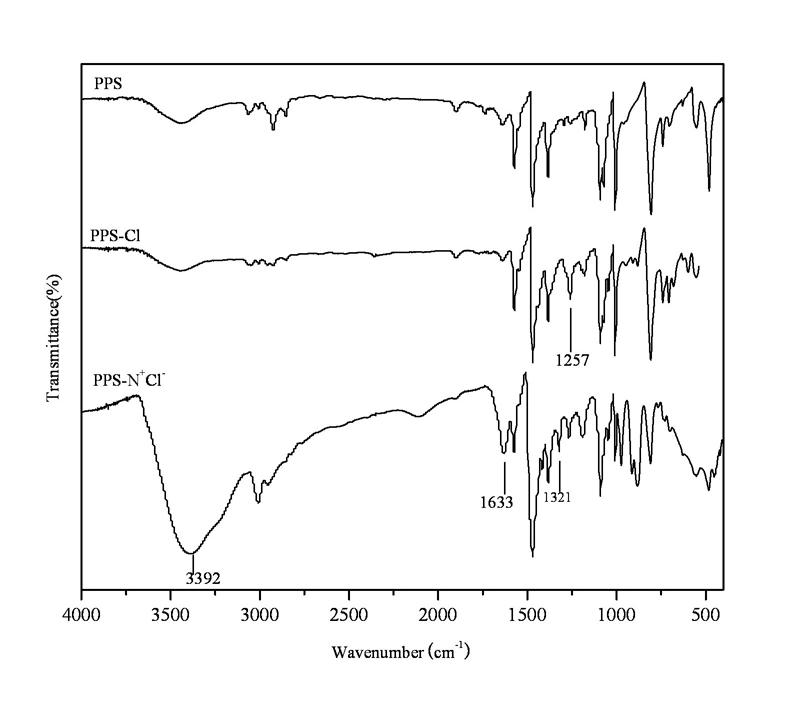

Polyether sulphone containing plurality of quaternary ammonium salt phenyl side group structures and preparation method for polyether sulphone

The invention provides polyether sulphone containing a plurality of quaternary ammonium salt phenyl side group structures. The preparation method for polyether sulphone comprises the following steps: firstly, producing copolycondensation of an active difluorosulphone monomer containing the polymethyl structure, 4,4'-difluorodiphenyl sulfone and biphenol to prepare polyether sulphone containing a polymethyl structure; secondly, converting prepared polyether sulphone containing the polymethyl structure into a polymer containing a bromomethyl structure by utilizing a bromination reaction; finally, by utilizing a nucleophilic substitution reaction, reacting the polymer containing the bromomethyl structure with trimethylamine to obtain polyether sulphone containing the plurality of quaternary ammonium salt phenyl side group structures. Polyether sulphone has good film-forming property; a prepared polymer thin film has good alkali resistance, relatively high ionic conductivity and excellent size stability, and can serve as an anion exchange membrane material for alkaline fuel cells.

Owner:CHANGZHOU UNIV

Method for preparing polyphenylene sulfide-based strong basic ion exchange fibers

InactiveCN102051811AEasy to operateEasy to prepareIon-exchange process apparatusOrganic anion exchangersFiberIndustrial effluent

The invention discloses a method for preparing polyphenylene sulfide-based strong basic ion exchange fibers, which comprises the following steps of: first swelling raw polyphenylene sulfide fibers in a solvent, adding a raw material polyphenylene sulfide and a catalyst after the raw polyphenylene sulfide fibers are swelled, heating the mixture for chloromethylation and crosslinking reaction, and obtaining chloromethylated crosslinked polyphenylene sulfide fibers after the reaction is finished; then swelling the obtained chloromethylated crosslinked polyphenylene sulfide fibers in the solvent, adding trimethylamine solution after the chloromethylated crosslinked polyphenylene sulfide fibers are swelled, heating the reaction solution for quaternization reaction, and obtaining the polyphenylene sulfide-based strong basic ion exchange fiber products after the quaternization reaction is finished; and finally washing the products, and performing extraction, brine-washing and drying. The method for preparing the polyphenylene sulfide-based strong basic ion exchange fibers is simple and easy to industrially popularize and apply, and ensures relatively lower production cost. The products prepared by the method can be applied in the fields of treatment of industrial wastewater, air purification, preparation of ultrapure water, separation and extraction of medicinal chemicals, and the like.

Owner:ZHENGZHOU UNIV +1

Method for producing fermented fish paste

The invention discloses a method for producing fermented fish paste. The method for producing the fermented fish paste mainly comprises the steps of low-value fish raw materials, pretreatment (removal of scales, head, tails, internal organs and vertebras), soaking in salt vinegar water, draining, soaking in ozone water, draining, defibrination, salt addition, in-jar fermentation, seasoning, mixedhomogeneity and obtaining of finished products. The method adopts a salt vinegar water soaking method to remove fishy-smell substance, is scientific, easy to operate and good in effect. The salt vinegar water is used for soaking fish slices, and acetic acid promotes solubility of the fishy-smell substance (trimethylamine oxide and dimethylamine oxide) in water with the assist of the salt water and enables the fishy-smell substance to be solved in the water, thereby achieving the removal purpose. Ozone solution produced by an electrolysis type ozone generator is used for soaking and disinfection, sundry fungus pollution and usage of preservatives are reduced, and the requirement for green production is met. Self enzyme of fishes is utilized to perform natural fermentation, thereby ensuringgood taste and special flavor of the fish paste.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

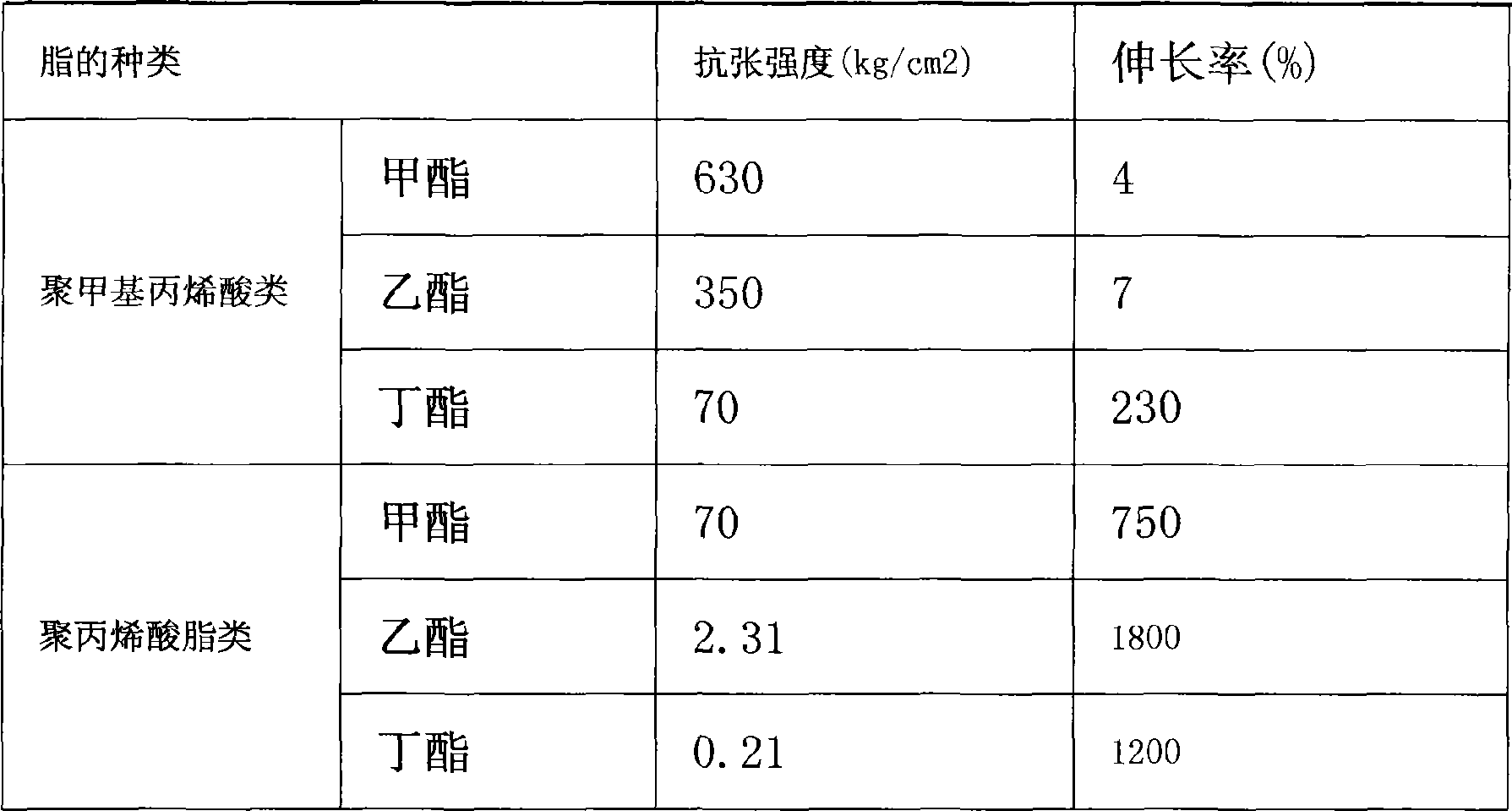

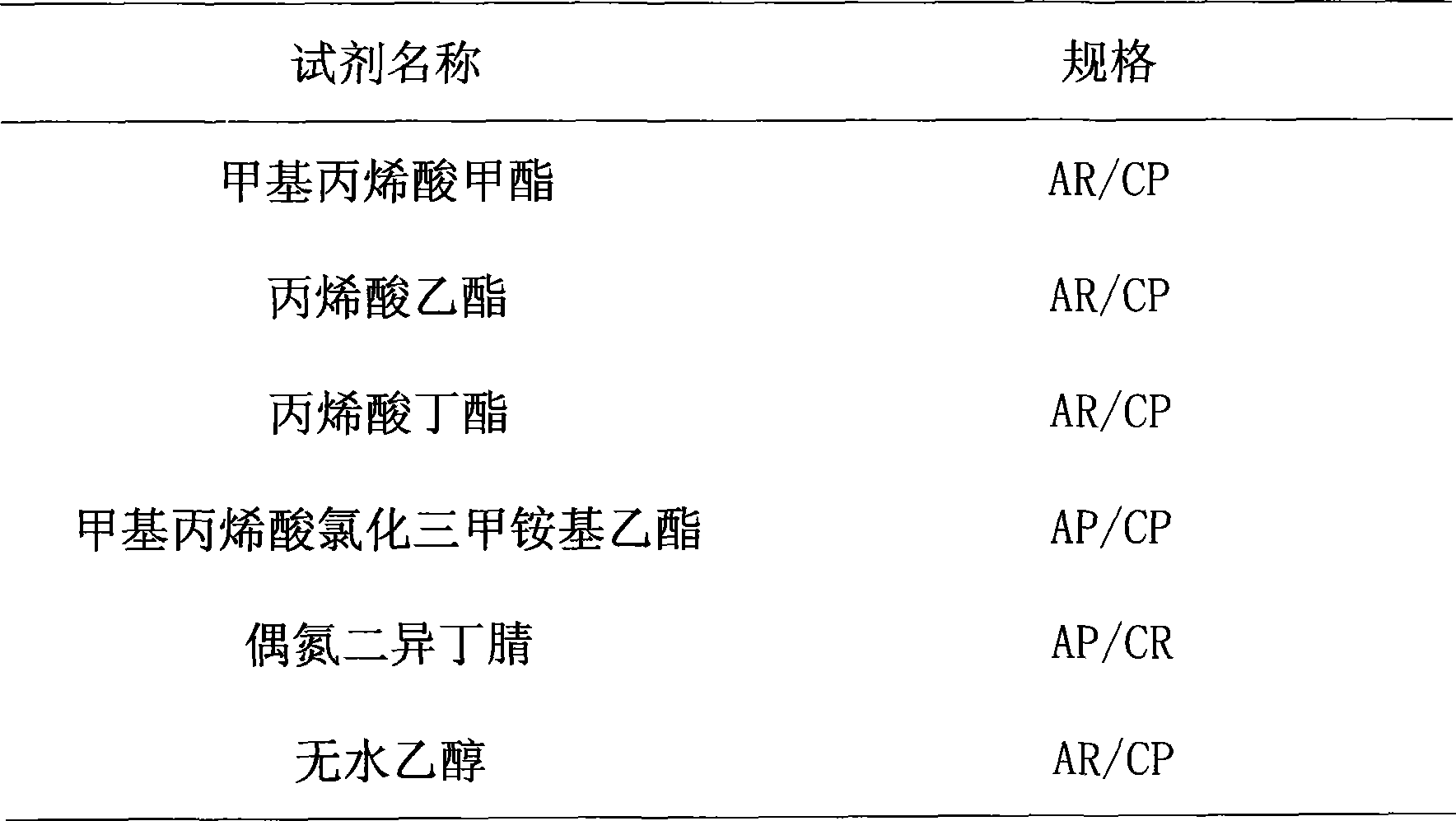

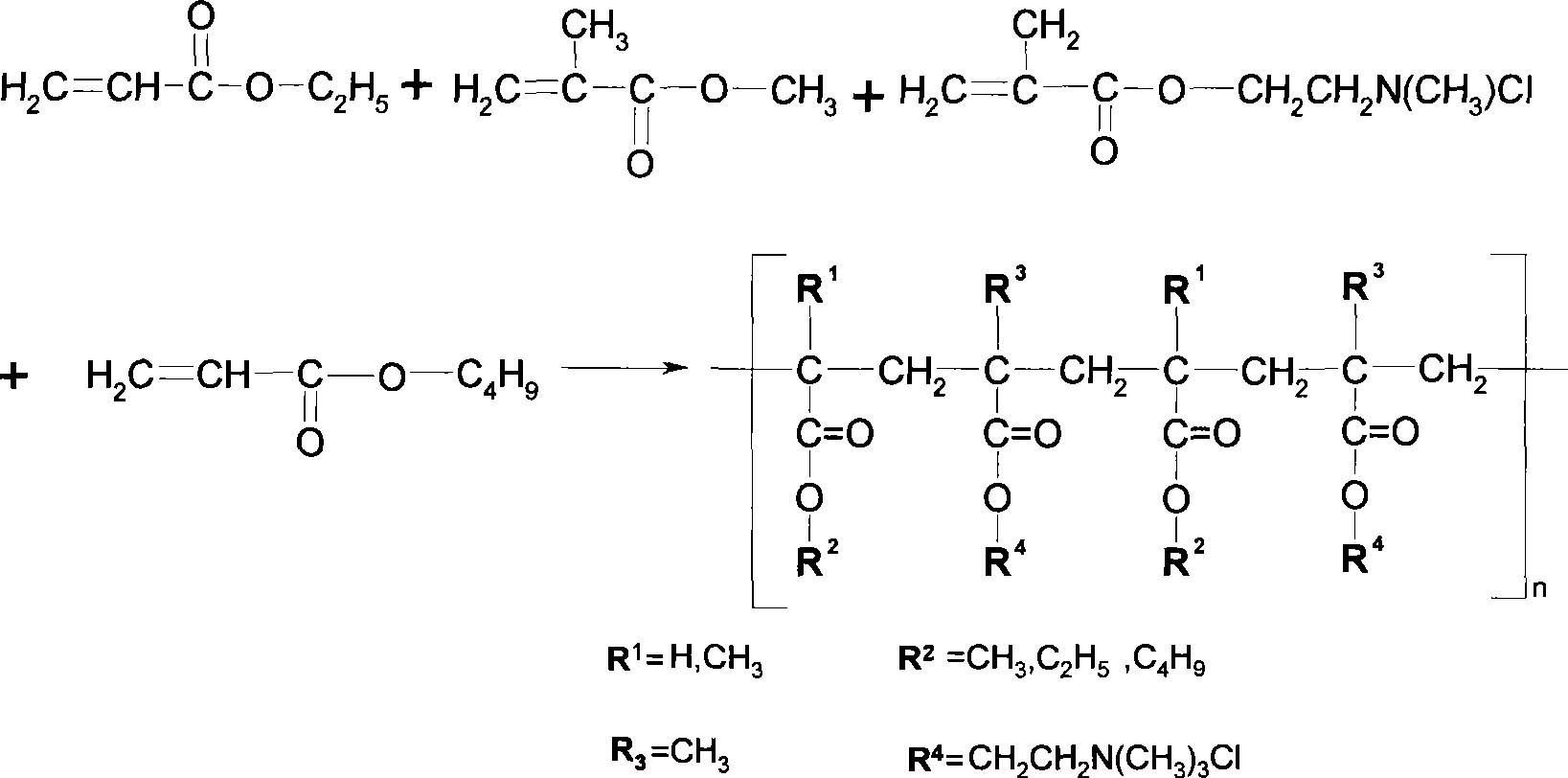

Preparation of medicinal poly(methyl acrylamide) with low film forming temperature and medium permeability

InactiveCN101475662ALow costEasy to operatePharmaceutical non-active ingredientsSynthesis methodsWater soluble drug

The invention relates to a synthesis method for a low MFT moderate permeability polymethyl acrylamide ester for drug use and application thereof, which belongs to the technical field of sustained release coating material for drug use. The synthesis method comprises the following steps: adopting the body-solution polymerization, introducing a butyl acrylate monomer to obtain the low MFT polymethyl acrylamide ester, and carrying out coating and film forming without adding a plasticizer; regulating the proportion of methylacrylic acid chlorinated trimethylamine ethyl ester in the polymer monomer to obtain the polyacrylic acid resin with moderate permeability. The polymer is mainly applied to the water soluble drug sustained release coating, and can reach a satisfied sustained release effect by adding a few insoluble components or pore-forming agents.

Owner:广州华博生物制药研究所

Method for manufacturing monolithic bipolar membrane

ActiveCN102061004BIncrease elasticityImprove flexibilitySemi-permeable membranesElastomerBenzoyl peroxide

The invention relates to a method for manufacturing a monolithic bipolar membrane, which comprises the following steps of: immersing a substrate membrane in a solution containing styrene, divinybenzene and benzoyl peroxide, pressurizing the immersed membrane, wherein the substrate membrane is a thin alloy membrane formed by two-element blending of polyethylene and ethylene-octylene copolymer elastomer or by three-element blending of polyethylene, ethylene-octylene copolymer elastomer and polyisobutylene rubber; and pressurizing the membrane immersed in the solution and polymerizing under the condition of heating to obtain a base membrane; sulfonating one side face of the base membrane by heating in concentrated sulfuric acid; performing chloromethylation reaction of the membrane with one sulfonated side face in chloromethyl ether containing anhydrous stannic chloride so that the other side face of the membrane is chloromethyl; and immersing the membrane in a trimethylamine aqueous solution or a trimethylamine aqueous solution containing dimethylamine to carry out an aimination or quaterisation reaction to obtain the monolithic bipolar membrane. The method has the advantages that the immersing temperature is greatly reduced, the styrene and divinybenzene solution can be repeatedly used, and the electric resistance of the bipolar membrane is low. The bipolar membrane has a catalytic layer for accelerating water decomposition, the method is simple and convenient and is easy for large-scale industrialized production.

Owner:福建省延润膜环保科技有限公司

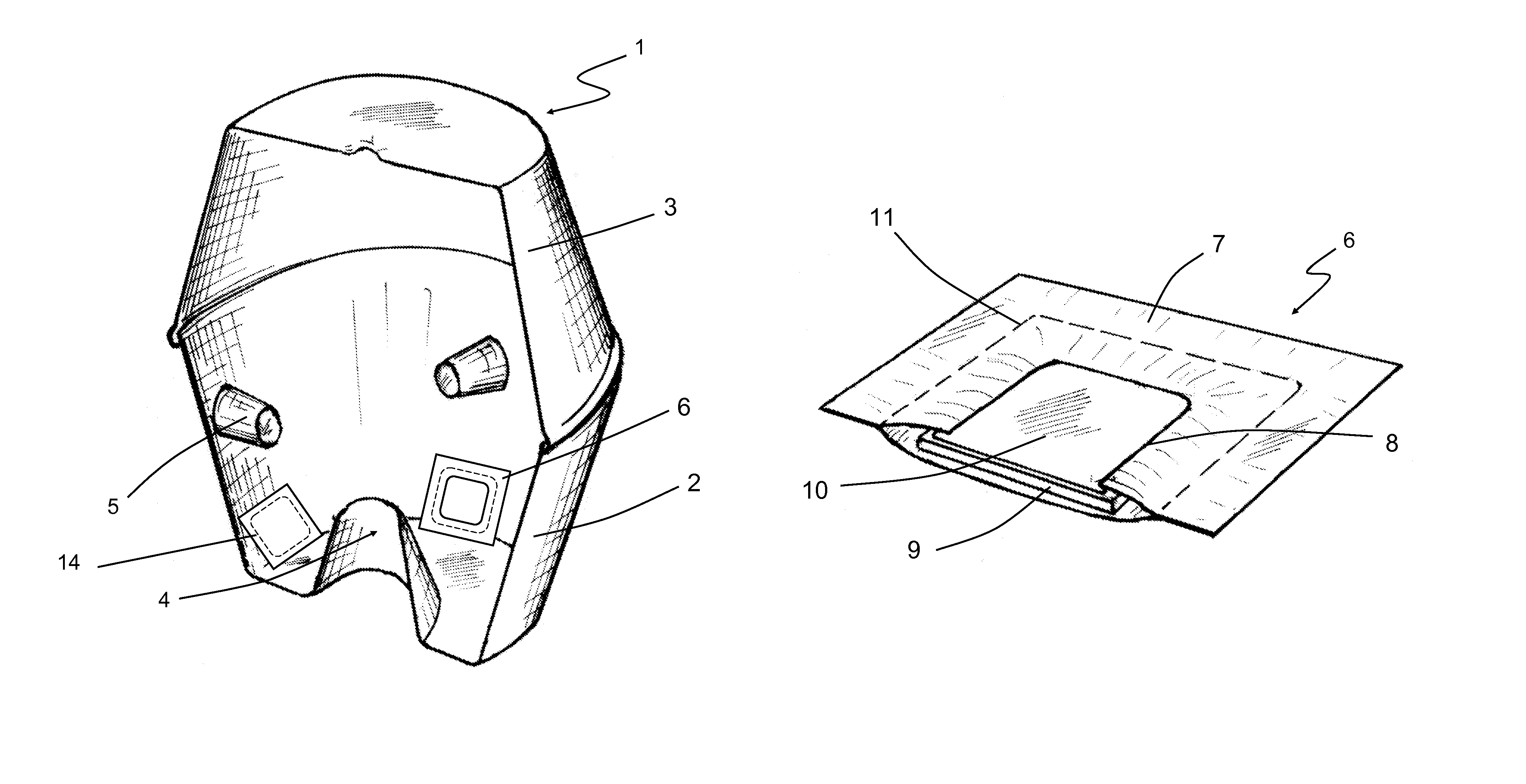

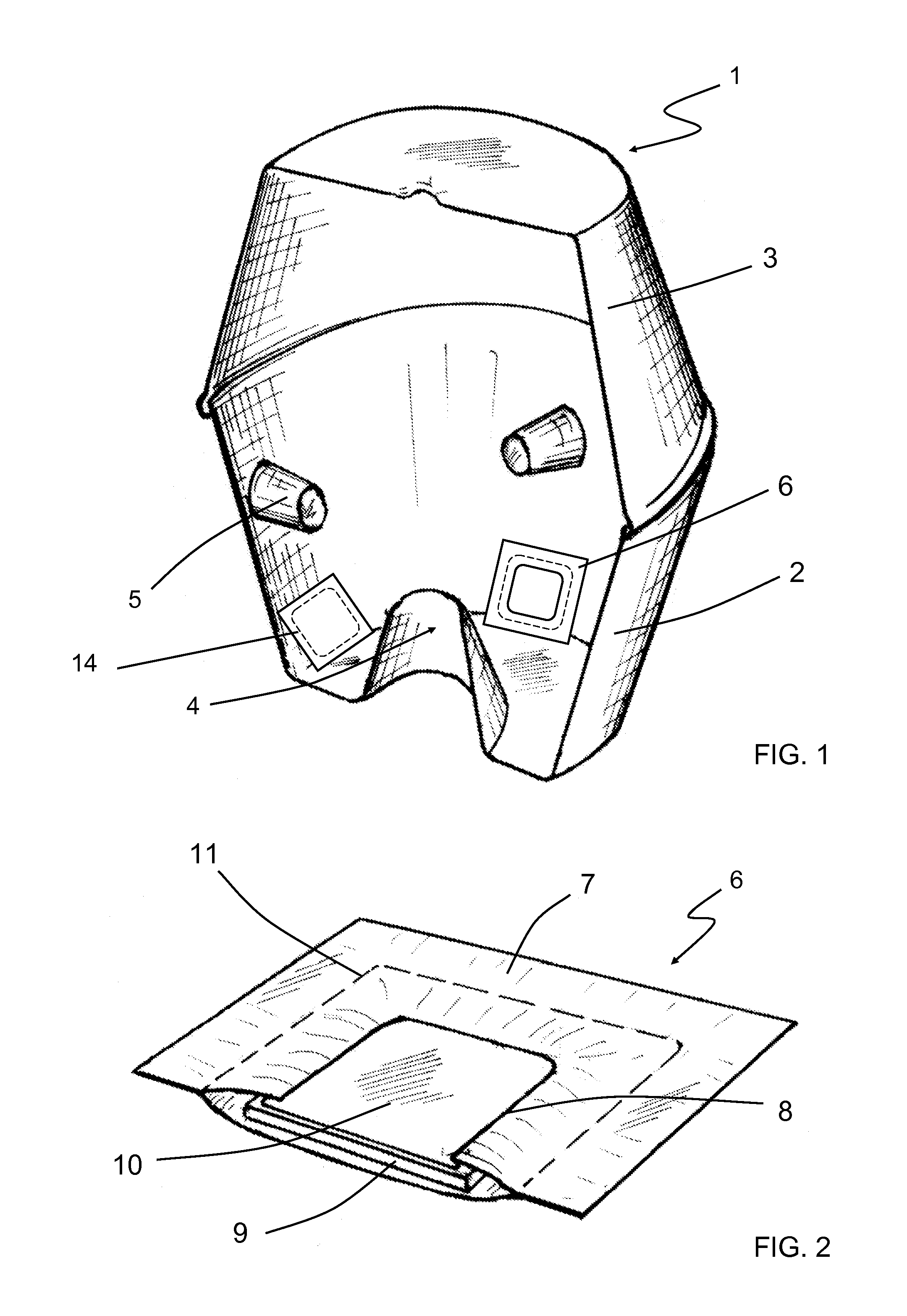

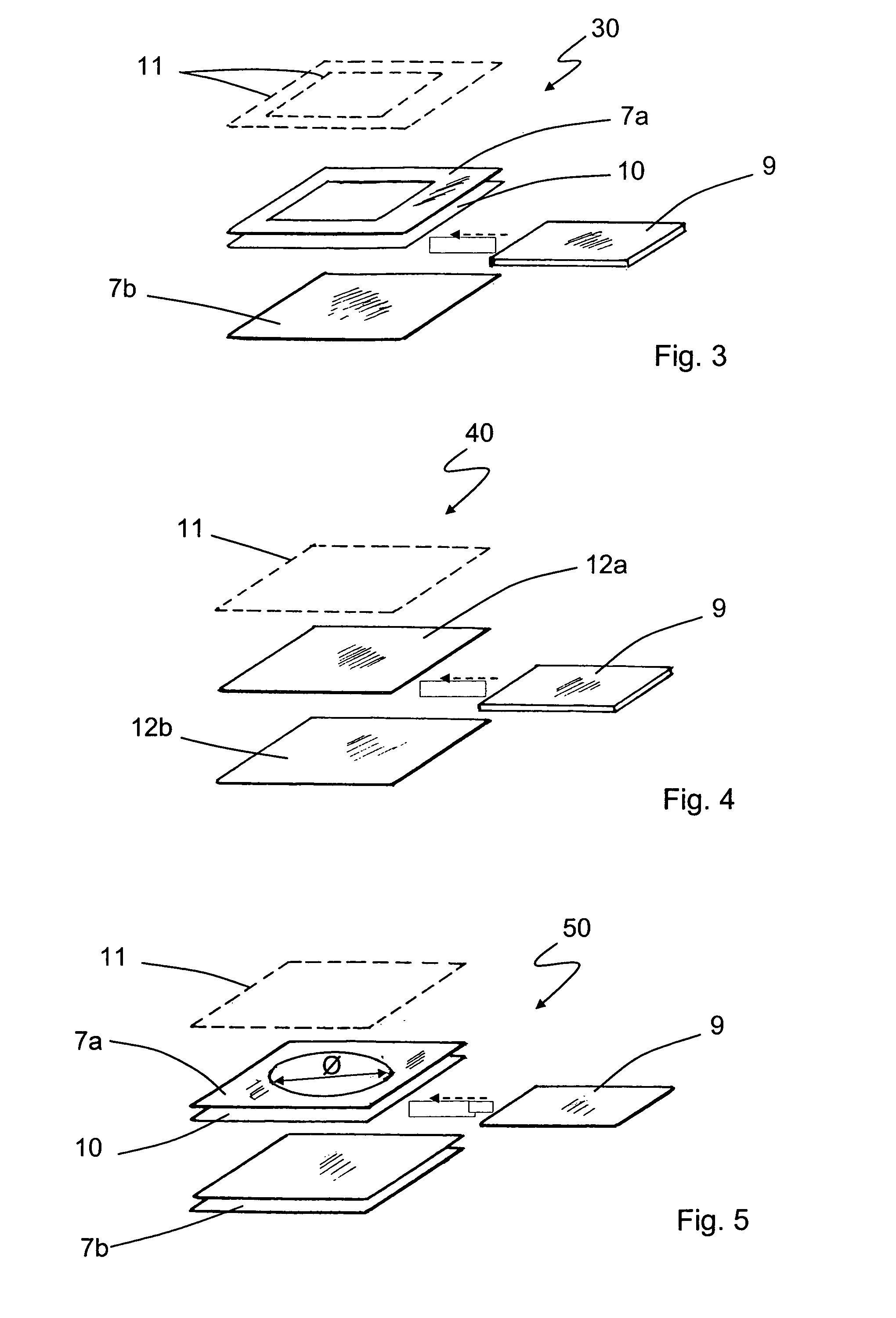

Trapping device for frugivorous insects

Trapping device for frugivorous insects. The device comprises trapping means and a single diffuser of attractant means arranged inside the trapping means. The diffuser is made up of a container containing inside a support material. This support material, which is of the porous type, is impregnated with a solution comprising a diaminoalkane, ammonium acetate and trimethylamine.

Owner:SEDQ HEALTHY CROPS SL

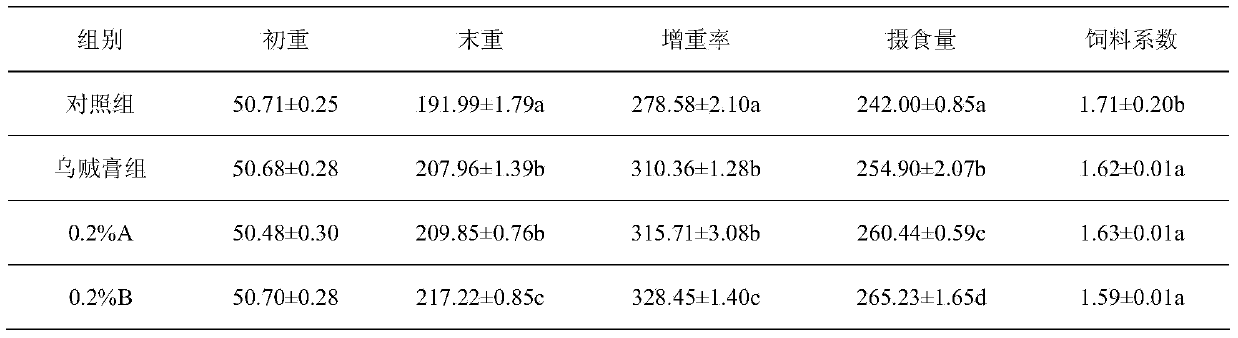

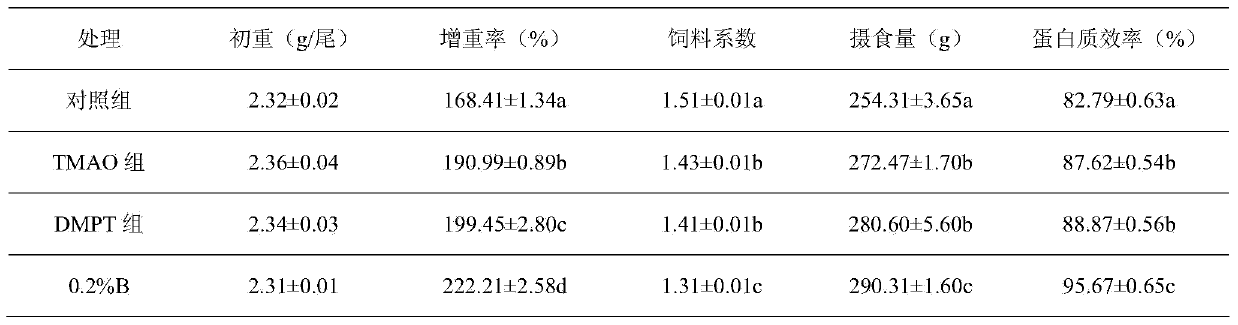

Feed inducing agent for aquatic feed

ActiveCN103734530AIncrease appetitePromote digestionFood processingAnimal feeding stuffHazardous substanceAquatic animal

The invention provides a feed inducing agent for aquatic feed. The feed inducing agent comprises the following materials in percentage by total mass: 40-50% of yeast extract, 5-10% of DMPT (dimethyl-dimethylpropiothetin), 20-30% of TMAO (trimethylamine oxide), 5-10% of bile salt and 10-20% of filler. The feed inducing agent provided by the invention compounds multiple single feed inducing agents and the bile salt with functions of promoting digestion, protecting liver and benefiting to the gallbladder, and has good feed-inducing effect and digestion promoting effect to aquatic animals; the feed inducing agent for aquatic feed is added into the aquatic feed, and due to the contained bile salt, the digestion and the absorption of the feed can be effectively promoted; the safety is high, no toxic and harmful substances are contained, the added amount is low, the quality of the selected materials is stable and controllable, and the application range of the product is wide.

Owner:FOSHAN XINTUN BIOLOGICAL SCI & TECH

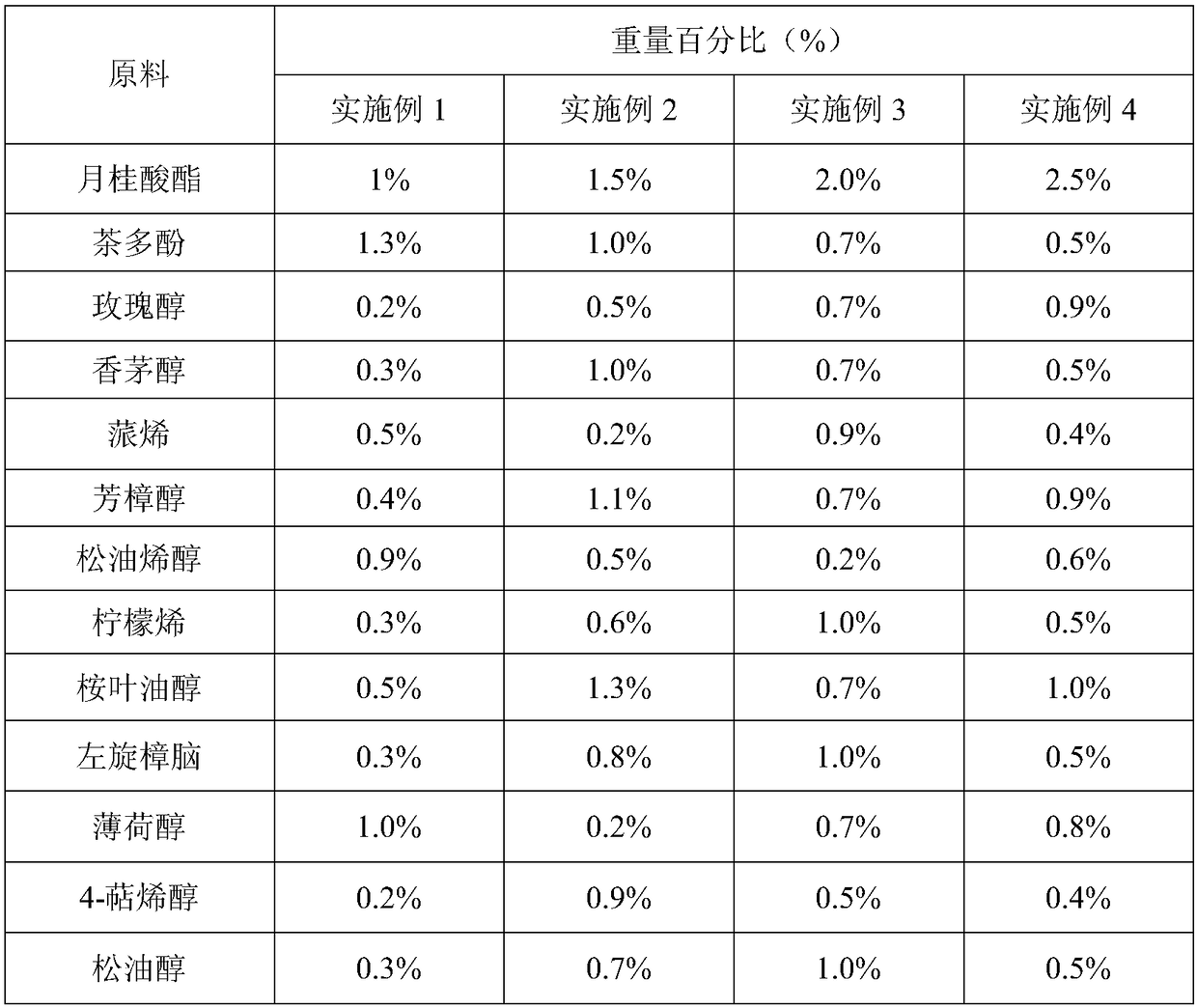

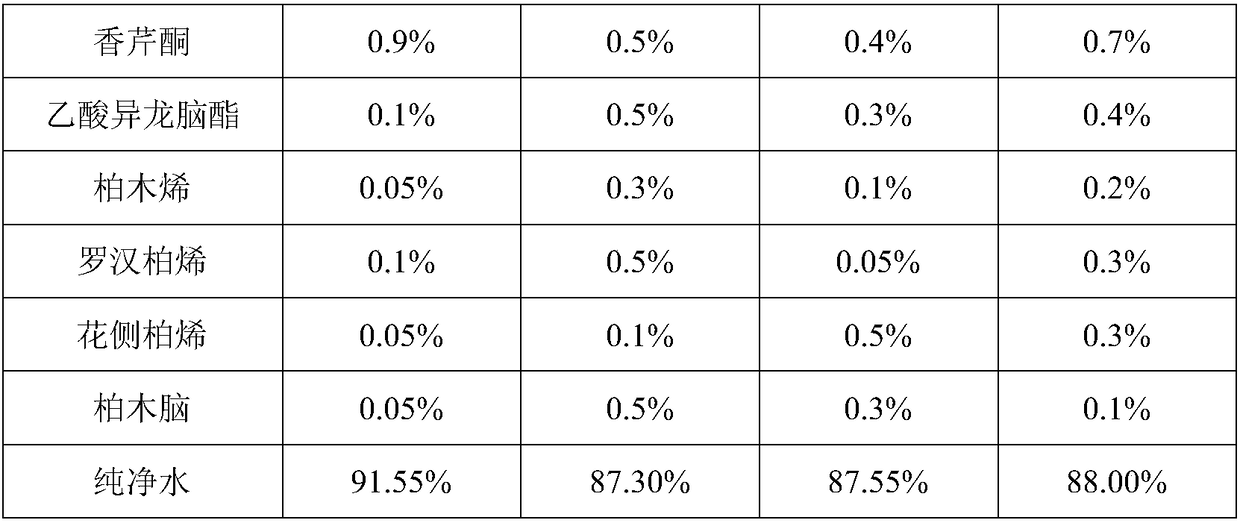

Deodorant based on plant essence extracting solution and preparation method of deodorant

InactiveCN108465121AHigh purityAvoid residueBiocideGas treatmentEscherichia coliStaphylococcus aureus

The invention relates to a deodorant based on a plant essence extracting solution and a preparation method of the deodorant. The deodorant is prepared from raw material as follows: laurate, tea polyphenol, rhodinol, citronellol, pinene, linalool, terpinenol, limonene, eudesmol, L(-)-camphor, menthol, terpinen-4-ol, terpilenol, carvone, isobornyl acetate, cedrene, thujopsene, cuparene, cedrol and purified water. With the adoption of a supercritical CO2 extraction technology, effective constituents are extracted from plants including Moroccan laurel, Australian tea trees, pelargonium graveolens,lavender, sabina pingii, mint, pine needle, cinnamomum camphora, eucalyptus, myristica fragrans, dill seeds and the like, the purity of the extracting solution is high, and organic solvent residues in a traditional process are avoided; the pure plant essence extracting solution is adopted, so that the deodorant is harmless to a human body and pollution-free for the environment, and no secondary pollution is produced. The deodorant has a more thorough effect, can remarkably remove formaldehyde, ammonia, methyl mercaptan, trimethylamine, hydrogen sulfide, benzene, TVOC and odorous hydrocarbon gas, and can also inhibit common escherichia coli and staphylococcus aureus.

Owner:上海澳克林新材料科技有限公司

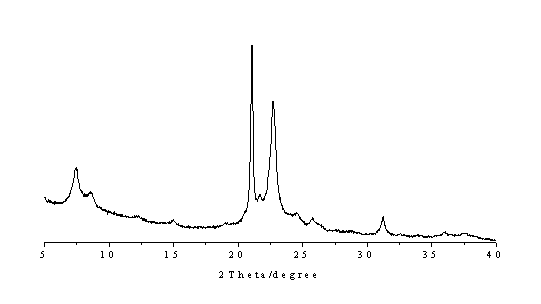

Preparation method for ZSM-48 molecular sieve

ActiveCN102910642ALower synthesis costEase of industrial productionCrystalline aluminosilicate zeolitesMolecular sieveSilicon

The invention relates to a preparation method for a ZSM-48 molecular sieve. The method comprises the steps of mixing silicon source, aluminium source, alkali, water and template uniformly; crystallizing, filtering, washing, drying and roasting to obtain the ZSM-48 molecular sieve, wherein the template is dibromohexane (DBH), trimethylamine (TMA) and ethanol (ETA); and properly adjusting the amount of the reaction mixture, and thus the ZSM-48 molecular sieve is obtained. Compared with a molecular sieve prepared by a conventional technology, the ZSM-48 molecular sieve synthesized by the method has the characteristics of low synthetic cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

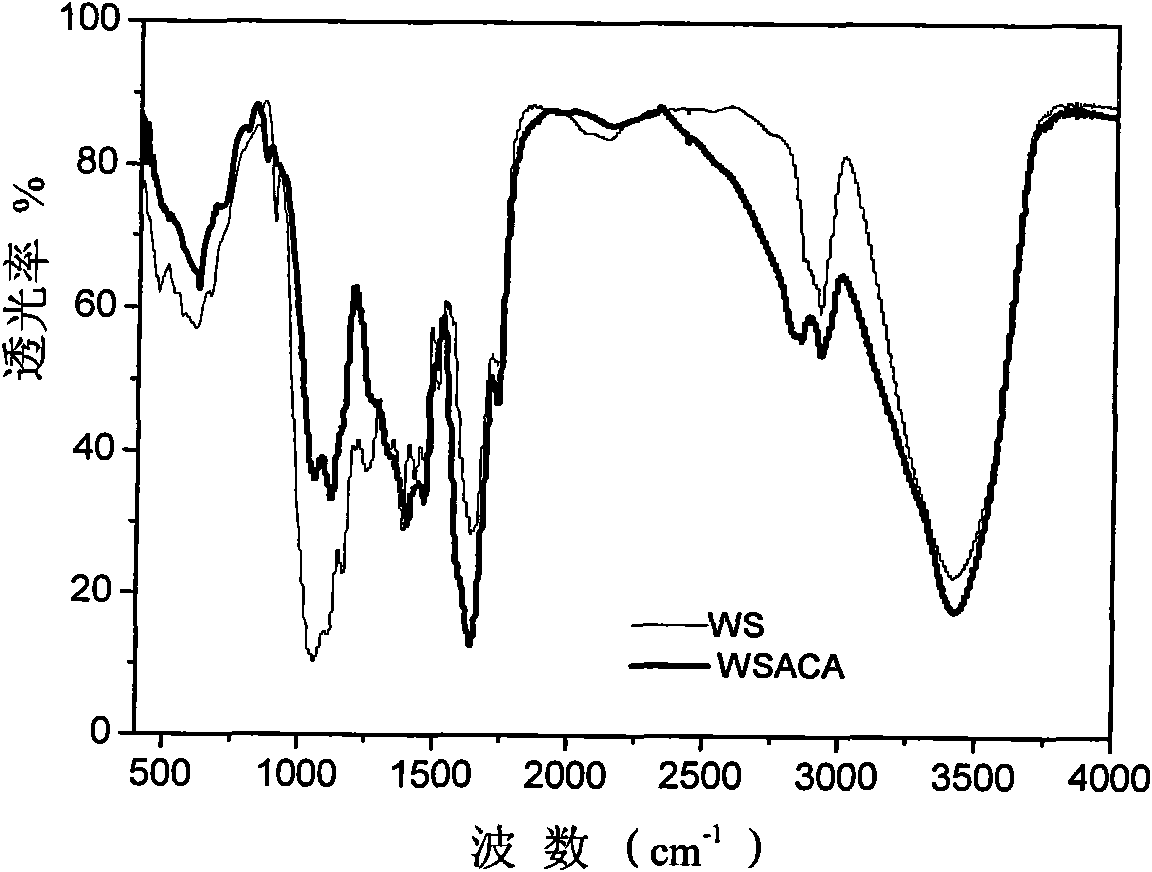

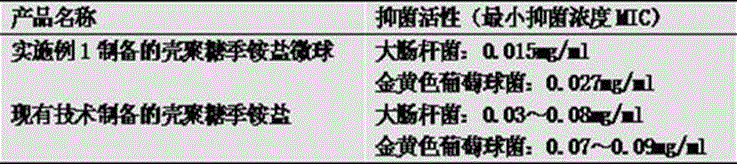

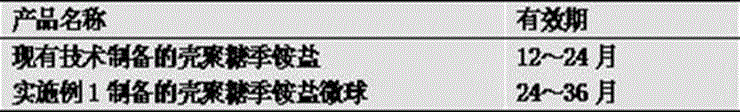

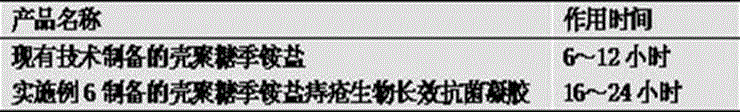

Chitosan quaternary ammonium salt product and preparation method thereof

The invention discloses a chitosan quaternary ammonium salt microsphere with antibacterial activity. The chitosan quaternary ammonium salt microsphere is characterized by being prepared from the following raw materials epichlorohydrin, trimethylamine hydrochlorate and chitosan, and generating the chitosan quaternary ammonium salt microsphere with 0.93 substitution degree under specific conditions according to specific ratio. The chitosan quaternary ammonium salt microsphere is enhanced in antibacterial activity, good in stability, excellent in effect, the treatment effect is apparently improved, and a good effect can be achieved.

Owner:JILIN JUNTONGXING BIOTECH

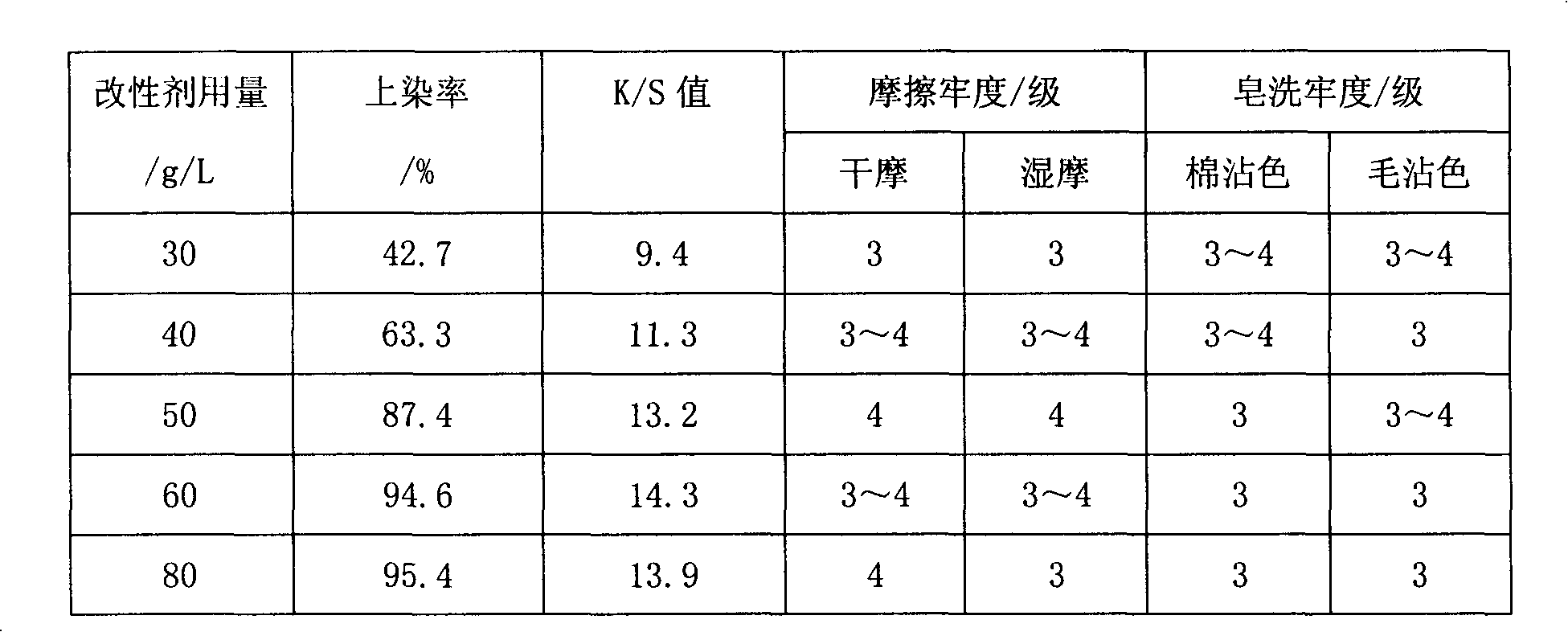

Cellulose fiber cation modifier, preparing method and usage thereof

InactiveCN101914853AImprove dyeing effectOrganic compound preparationDyeing processCellulose fiberSolvent

Owner:JIANGSU GEMEIGAO DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com