Patents

Literature

64 results about "Methanethiol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methanethiol /ˈmɛθeɪnˈθaɪɒl/ (also known as methyl mercaptan) is an organosulfur compound with the chemical formula CH₄S. It is a colorless gas with a distinctive putrid smell. It is a natural substance found in the blood and brain of humans and animals, as well as in plant tissues. It is disposed of through animal feces. It also occurs naturally in certain foods, such as some nuts and cheese. It is one of the main compounds responsible for bad breath and the smell of flatus. Methanethiol is classified as a thiol and is sometimes abbreviated as MeSH. It is very flammable.

Removal of methyl mercaptan from gas streams

InactiveUS20050287056A1Efficient productionGas treatmentDispersed particle separationHigh concentrationThiol

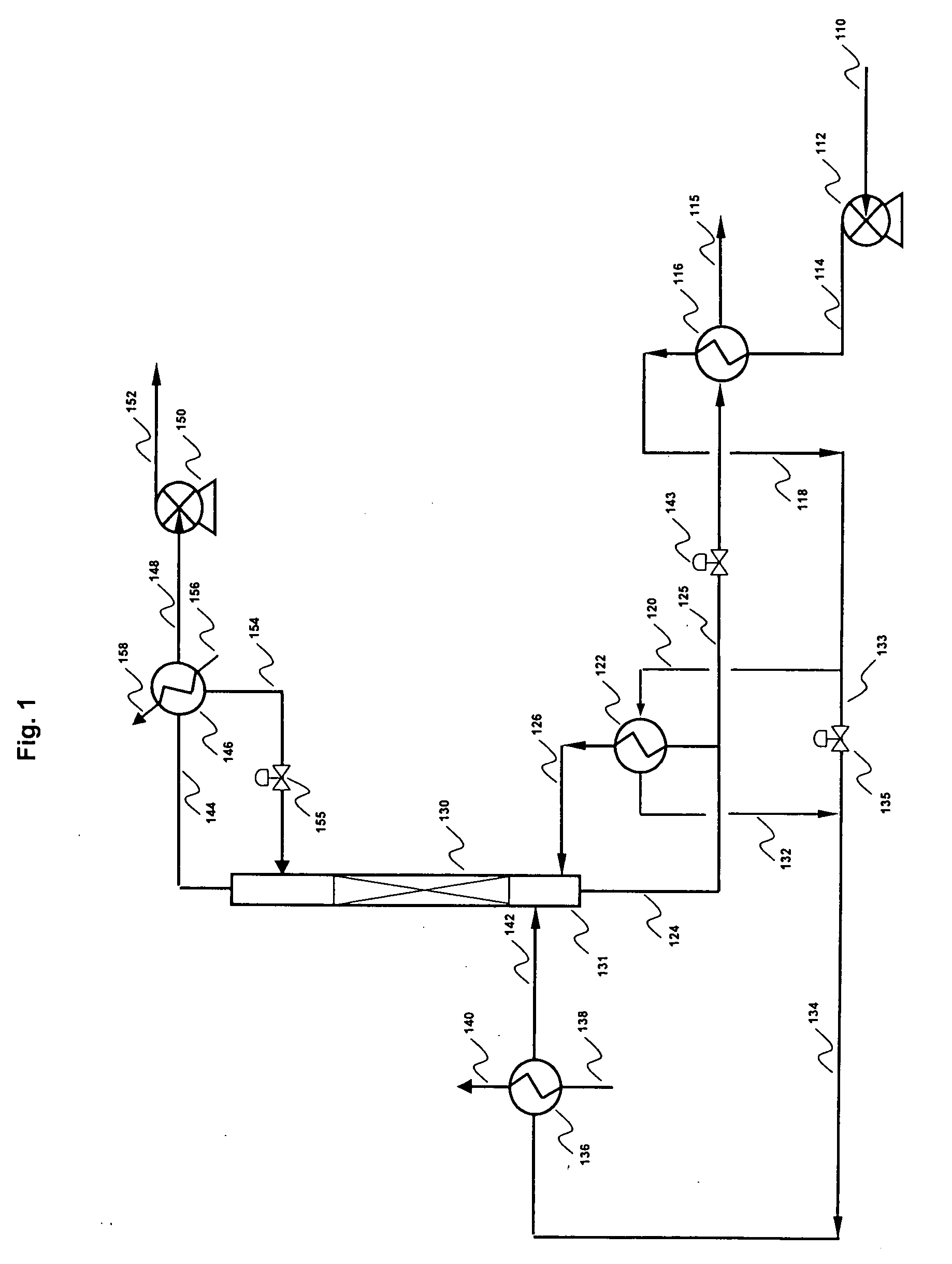

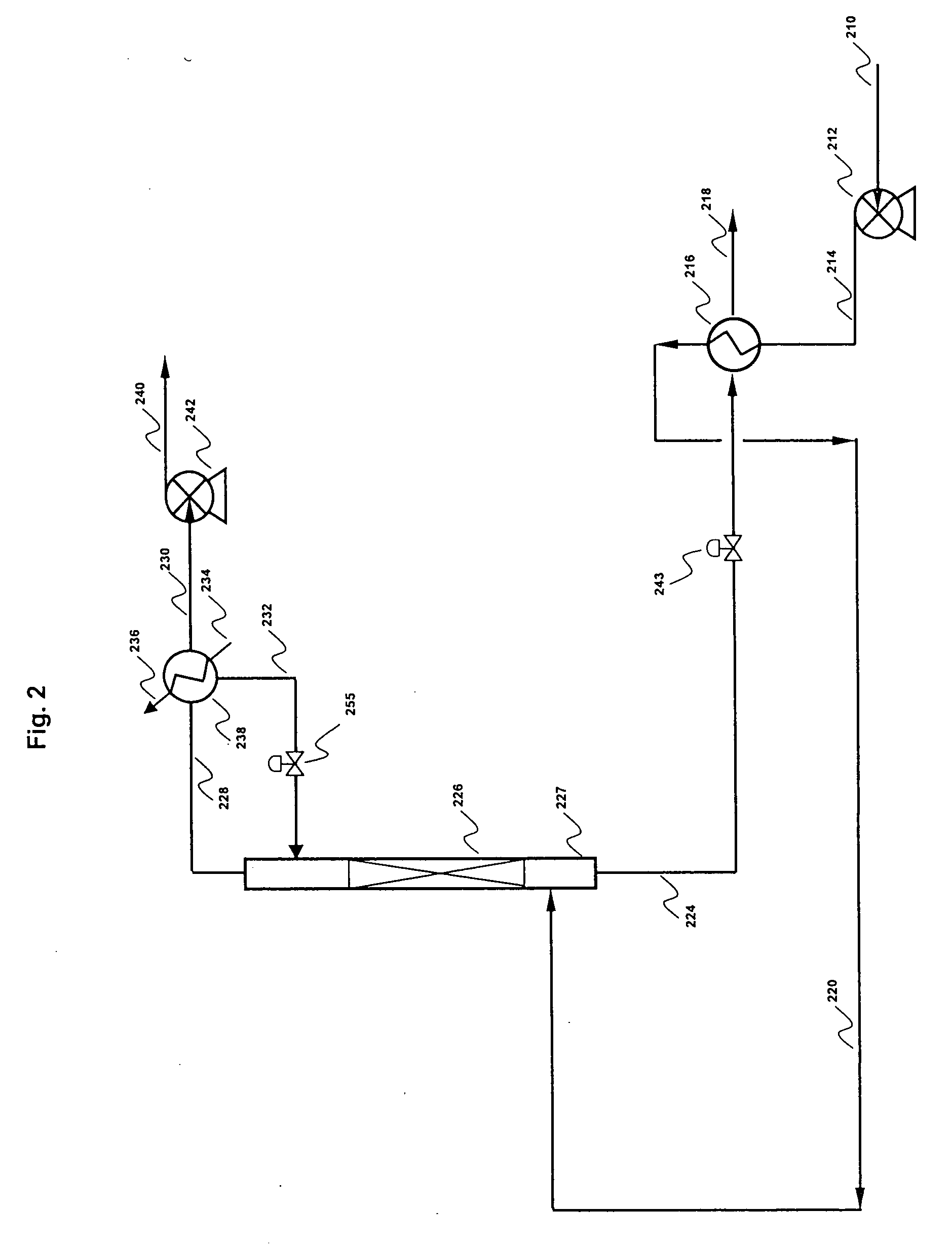

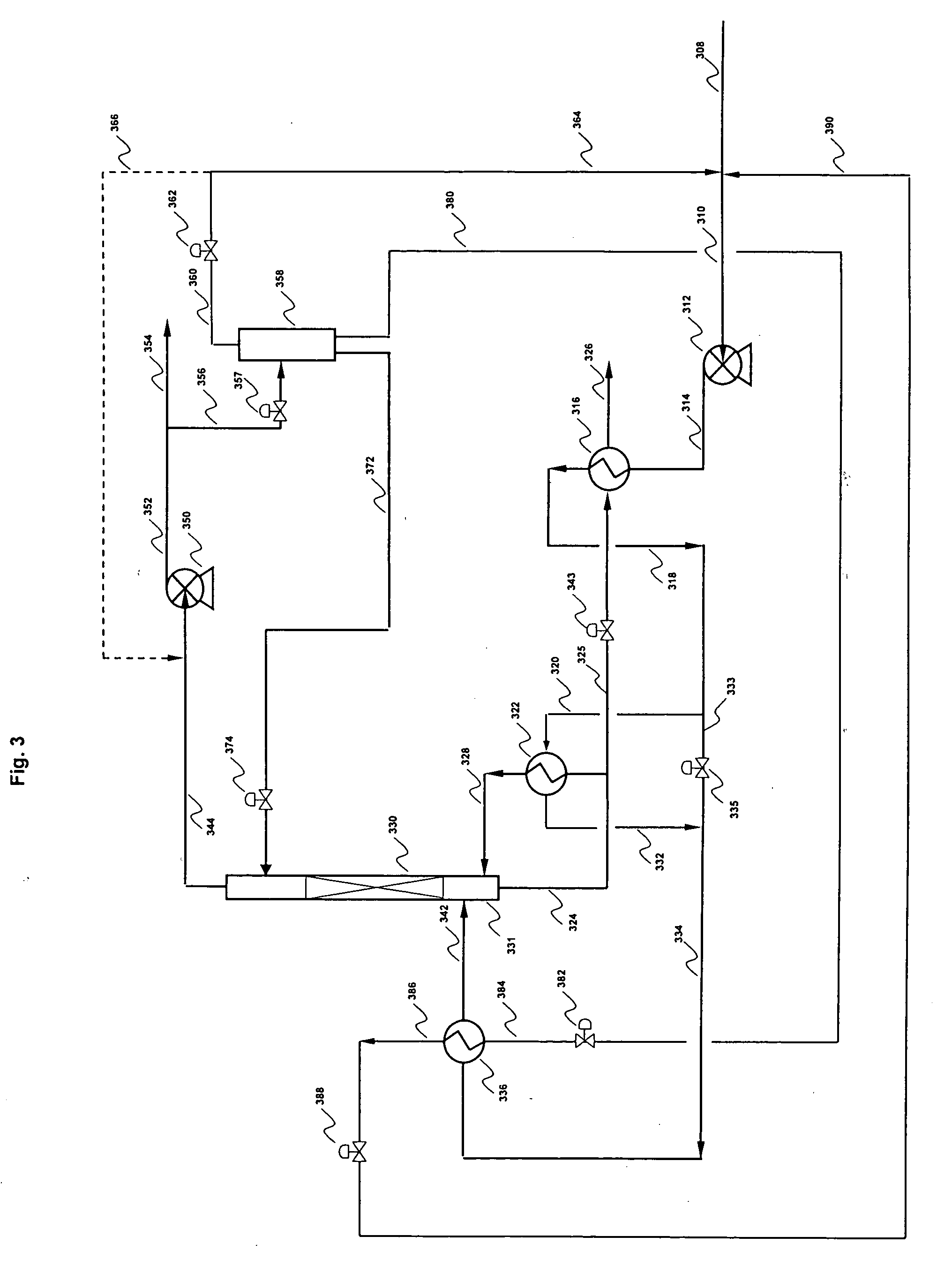

The invention described herein is a method for selectively removing mercaptans such as methyl mercaptan from dry gas mixtures containing high concentrations of carbon dioxide. In the method, the carbon dioxide-rich gas (sour gas) is passed through an absorption vessel or distillation column in which it is contacted with an absorbent such as liquid carbon dioxide in order to selectively absorb the mercaptans. The treated gas, which is now free of mercaptans, leaves the top of the vessel as a sales gas suitable for use in enhanced oil recovery applications. Preferably, a portion of the carbon dioxide in the sales gas is condensed and the liquid is returned to the absorber or distillation column as the scrubbing agent. At least part of this scrubbing agent leaves the bottom of the absorber or distillation column enriched in methyl mercaptan and other sulfur compounds. The stream from the absorption vessel containing the mercaptans can be incinerated or otherwise processed to utilize or dispose of the methyl mercaptan.

Owner:DAKOTA GASIFICATION COMPANY

Antibacterial and environment-friendly deodorant of microorganism strains

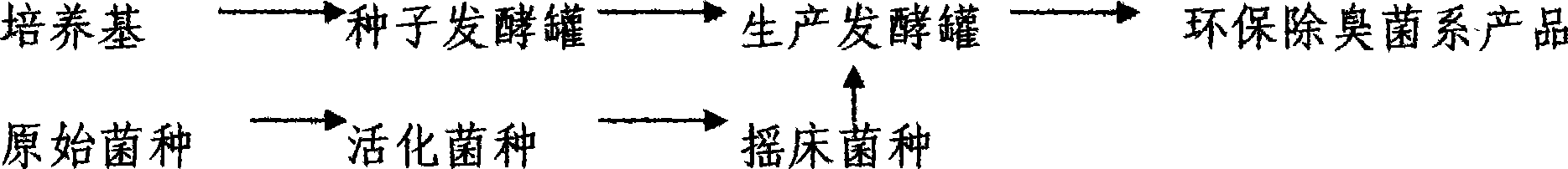

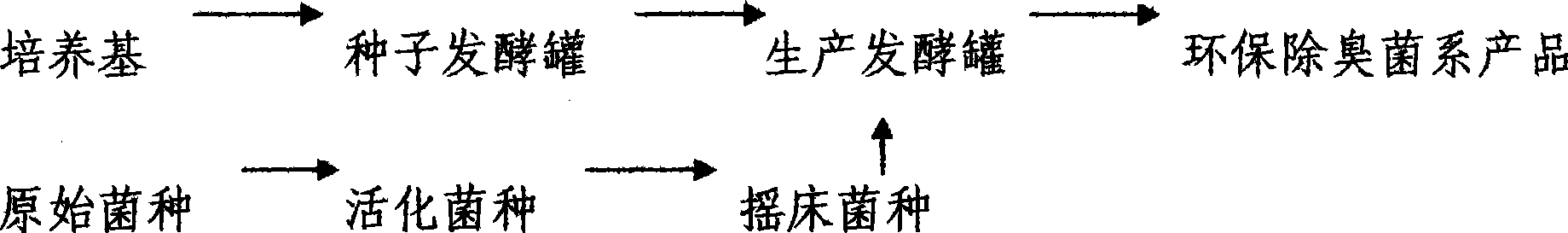

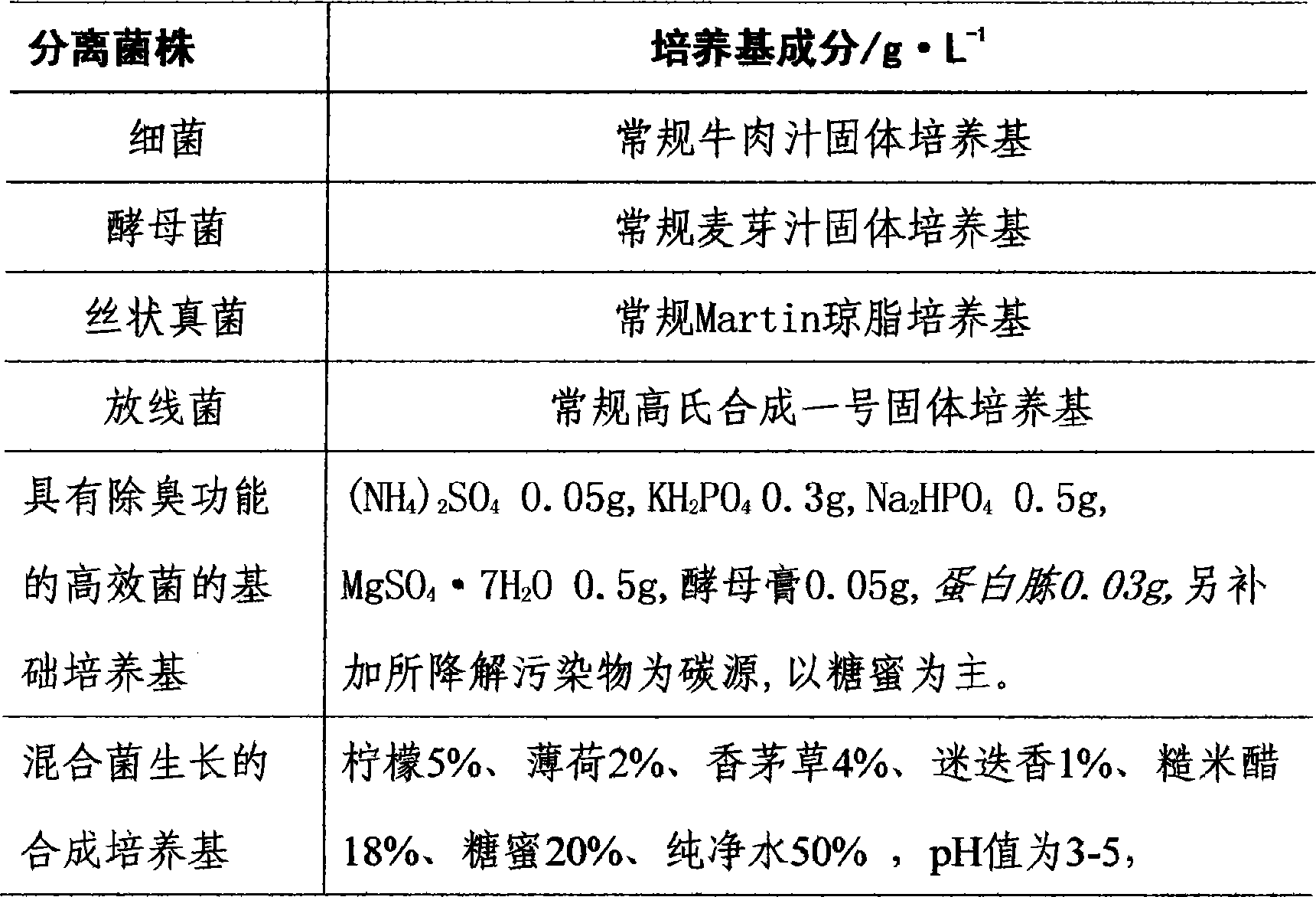

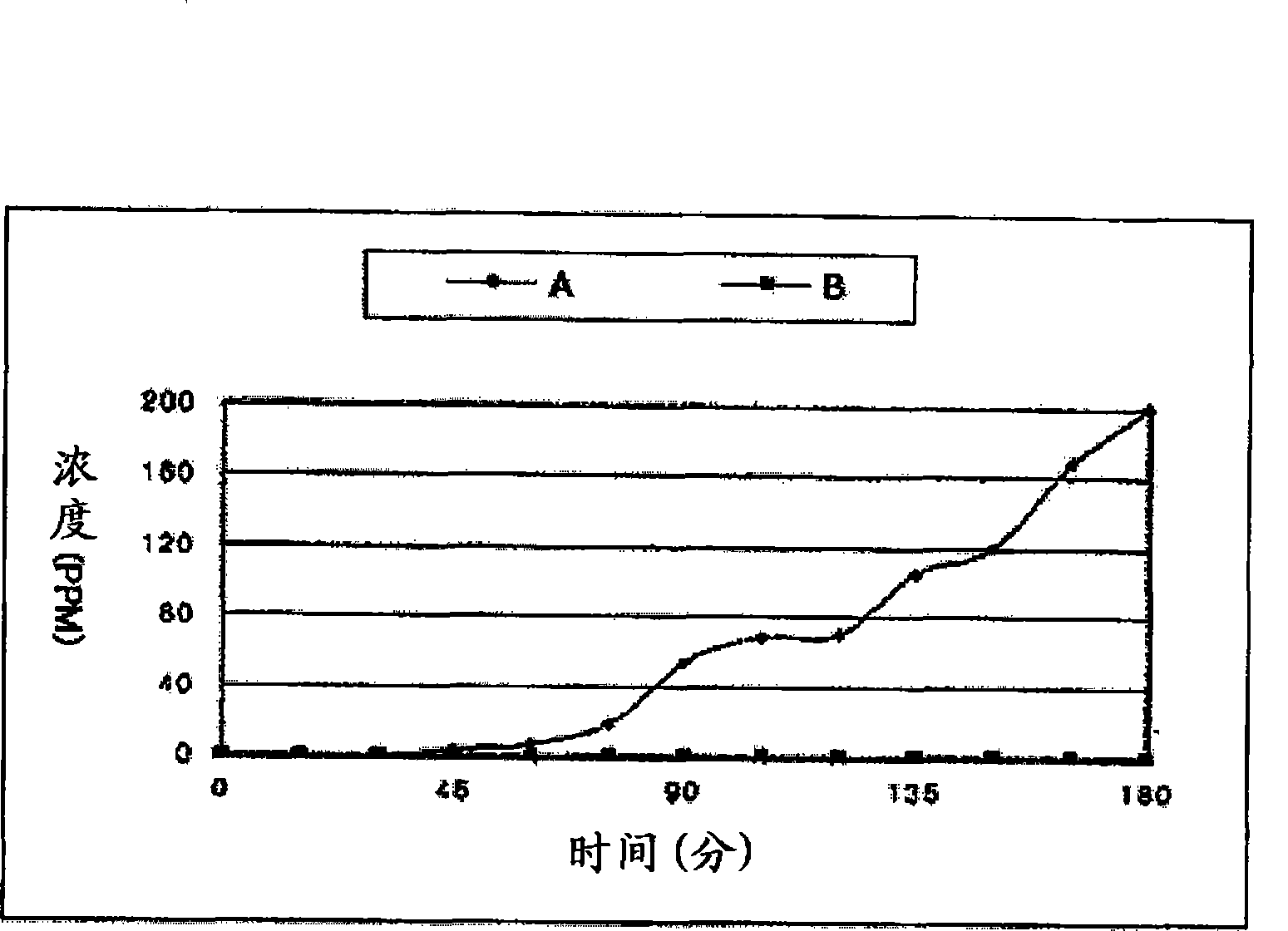

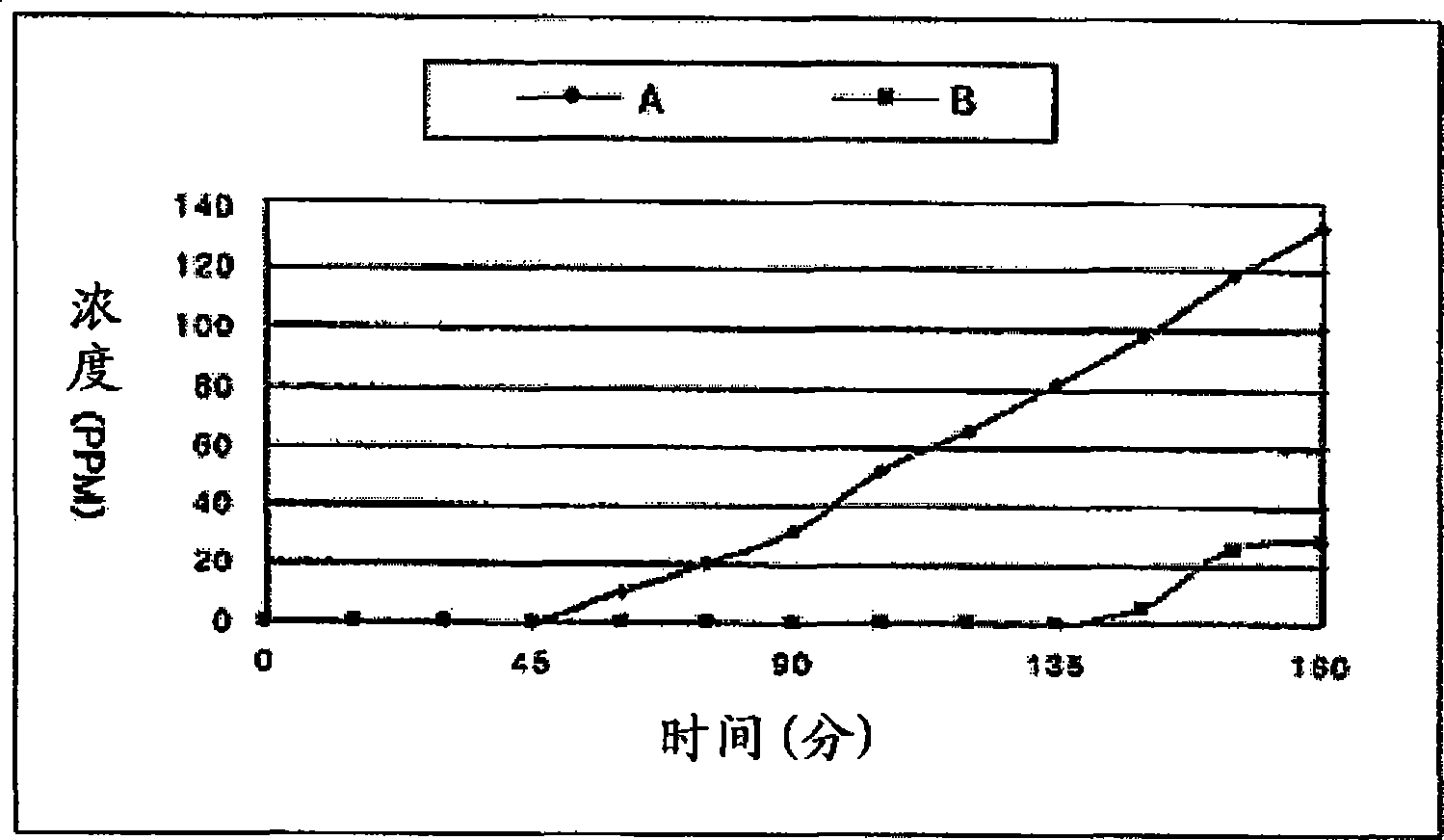

The invention relates to an antibacterial and environment-friendly deodorant of microorganism strains and a preparation method thereof. The traditional method for removing odor generally uses essence to cover up the odor or pumping odor physically or uses ozone to oxidize and degrade the odor or uses a chemical method. The methods also can alleviate the odor to a certain extent, but finally the problem can not be solved really and fundamentally and the essence and chemical deodorization also have secondary pollution. The microbial deodorization technology utilizes the effects of high-efficient absorption, absorption and metabolism of particular microorganism strains which can convert or degrade odorant, to purify the odorous gases of amyl mercaptan, benzene methanethiol, methyl sulfide, ethanethiol, hydrogen sulfide, sulfur dioxide, p-benzyl mercaptan, ammonia, dimethylamine, trimethylamine and carbon disulfide and the like which are emitted from human life areas, domestic sewage and domestic garbage and the like and to convert the odorous components of amyl mercaptan, benzene methanethiol, methyl sulfide, ethanethiol, hydrogen sulfide, sulfur dioxide, p-benzyl mercaptan, ammonia, dimethylamine, trimethylamine and carbon disulfide and the like into matters without harm and odor, thus achieving the purpose of thoroughly improving air quality and protecting health of people. The preparation method utilizes a fermentation method of microorganism strains to prepare deodorant products.

Owner:王峰

Titanate alloy steel anticorrosive coating and preparation method thereof

InactiveCN106147592AUniform particlesFine grainAnti-corrosive paintsEpoxy resin coatingsEpoxyPolyamide

The invention discloses a titanate alloy steel anticorrosive coating. The titanate alloy steel anticorrosive coating consists of the following raw materials in parts by weight: tetrabutyl titanate 4-6 parts, polysorbate 80 0.8-1 part, aniline 50-60 parts, pyrroles 30-40 parts, sulfosalicylic acid 7-9 parts, epoxy resin E51 3-4 parts, ammonium persulfate 1.3-2 parts, molybdic acid 4-6 parts, polyamide resin 3-5 parts, n-butyl alcohol 160-170 parts, butyl glycol ether 20-30 parts, polyadipate ethylene glycol 3-5 parts, zirconium ammonium carbonate 0.7-1 part, methyl stannum mercaptide 1-2 parts, kt101 titanate coupling agent 0.6-1 part, octyl and decyl glycerate 0.2-0.4 part, and aluminium triphosphate 1.6-2 parts. The titanate alloy steel anticorrosive coating is modified by the titanate coupling agent, and therefore, the surface hydrophobicity and the weather fastness of the finished coating are improved effectively.

Owner:TIANCHANG YINHU PAINT

Fiber toughened polyethylene wrapping film, and preparation method thereof

The invention discloses a fiber toughened polyethylene wrapping film. The fiber toughened polyethylene wrapping film is composed of, by weight, 1 to 2 parts of sodium diacetate, 100 to 110 parts of linear low density polyethylene, 1 to 2 parts of p-aminobenzene sulfonic acid, 7 to 10 parts of aluminium isopropoxide, 2 to 3 parts of cyanoethyl cellulose, 3 to 5 parts of isopropyl palmitate, 4 to 6 parts of cellulose phosphate, 0.7 to 2 parts of polybenzimidazole, 4 to 6 parts of oxidized polyethlene wax, 0.1 to 0.2 part of methyl stannum mercaptide, 3 to 4 parts of diacetone alcohol, 0.2 to 0.6 part of dialkyl hydroquinone, 1 to 2 parts of alkanolamide, 2 to 3 parts of antimonous oxide, 0.4 to 1 part of isothiazolinone, 1 to 2 parts of calcium propionate, and 10 to 13 parts of diatomite. According to a preparation method, a plurality of kinds of fiber are added, so that the strength and toughness of the fiber toughened polyethylene wrapping film are increased greatly, broken is not easily caused, the fiber toughened polyethylene wrapping film possesses both low temperature resistance and high temperature resistance, application effect is excellent, no pollution is caused, and cost is application is reduced.

Owner:宁波大名包装材料科技有限公司

Active alumina catalyst, and its preparation method and use

InactiveCN1579617AHigh purityLow impurity contentCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsAluminium hydroxideStone dust

The invention relates to a catalyst technology, concretely, an active alumina catalyst and its producing method. Components of the active alumina catalyst are: Na 0.8-0.1 percents, Fe<0.1 percent the others are alumina whose purity is over 99 percent. The producing approach is: using aluminium hydroxide powder or (and) bodhmite powder as material; evenly mixing aluminium hydroxide powder or (and) bodhmite with aqua fortis solution deployed by deionized water; forming, drying in 100-150deg.C for 2-8 hours, baking in 400-600deg.C for 3-20 hours, bolstering and getting production. Adopting the invention can improve selectivity and yield of compound alkyl sulfide and alkyl sulfhydrate, esp. dimethyl sulfide and methanethiol.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Deodorizing agent and method for manufacturing same and use thereof

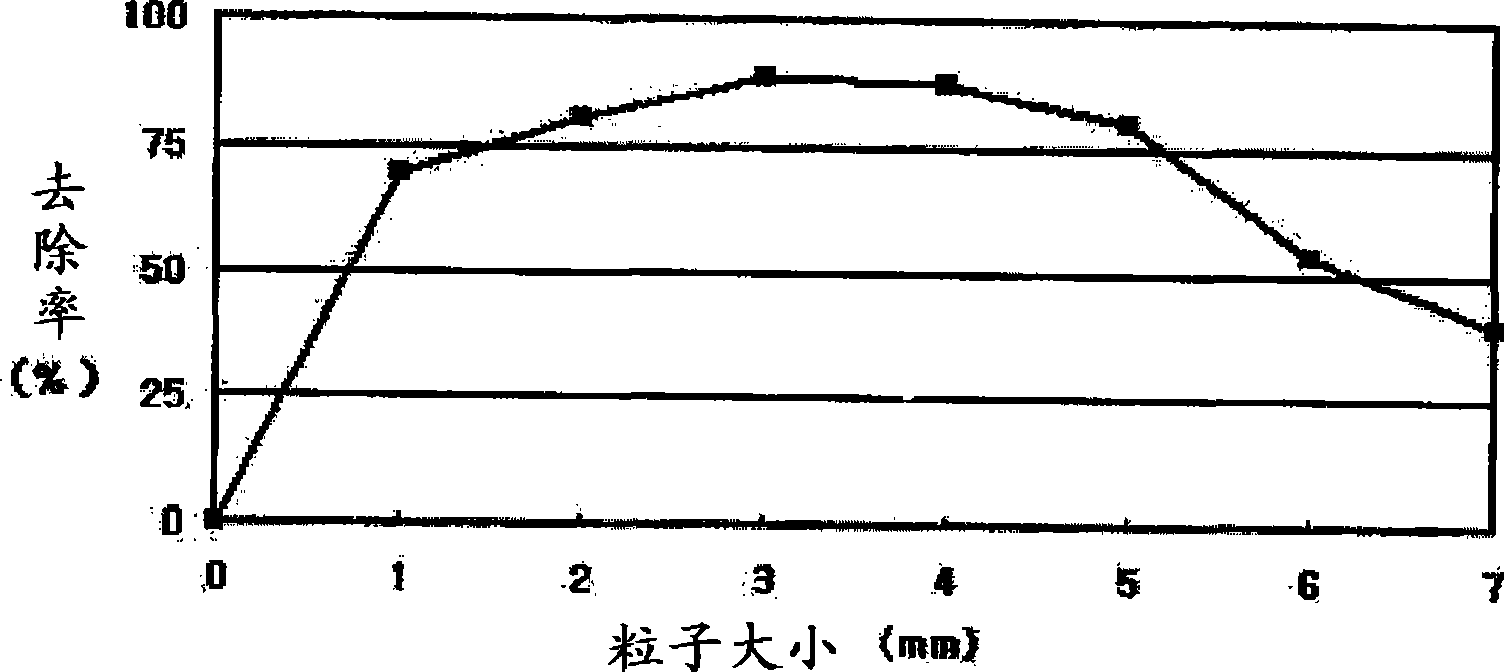

The invention relates to a deodorizing agent for removing mephitis source materials generated from food garbage treatment device, and manufacturing method and use thereof. The deodorizing agent is absorbed on surface of active carbon with 1-5mm average particle size and comprises adhesive of 0.1-10 wt% of copper compound and 0.05-8 wt % of manganese compound by using active carbon weight as standard. The deodorizing agent is especially adapted for absorbing and removing methanethiol, acetaldehyde, ammonia and acetic acid contained in mephitis generated from food garbage treatment device.

Owner:(株)亚洲NBC

Environment-friendly composite anti-rust oil

InactiveCN104450052AImprove coalescence performanceImprove stabilityAdditivesSodium metasilicate1-Propanol

The invention discloses environment-friendly composite anti-rust oil which comprises the following raw materials in parts by weight: 0.5-1 part of menthyl acetate, 30-40 parts of 500sn base oil, 1-2 parts of dicyclopentadiene resin, 30-40 parts of 25# machine oil, 1-2 parts of phenylethanolamine, 5-10 parts of acetylated lanolin, 1-2 parts of dimer acid, 1-2 parts of beta-sitosterol, 1-2 parts of sodium metasilicate, 2-4 parts of capric triglyceride, 12-20 parts of rare-earth film-forming hydraulic oil, 2-4 parts of camphor oil, 2-4 parts of octyl epoxy stearate, 2-4 parts of oleic acid and 0.5-1 part of methyl tin mercaptide. The rare-earth film-forming hydraulic oil is added into the antirust oil disclosed by the invention, and 3-phenoxy-1-propanol is added into a modified gelatin system of the antirust oil, so that the particles in the gelatin system are completely absorbed. Therefore, the coalescence performance and the stability of the system are improved, and the self-film-forming property is enhanced in the system. Moreover, the added rare earth ions can react with OH- generated on the surface of a metal base material in the oxygen absorption corrosion process so as to generate an insoluble complex, a corrosive electrode reaction is retarded, and an excellent slow release effect is achieved.

Owner:合肥宏图彩印有限公司

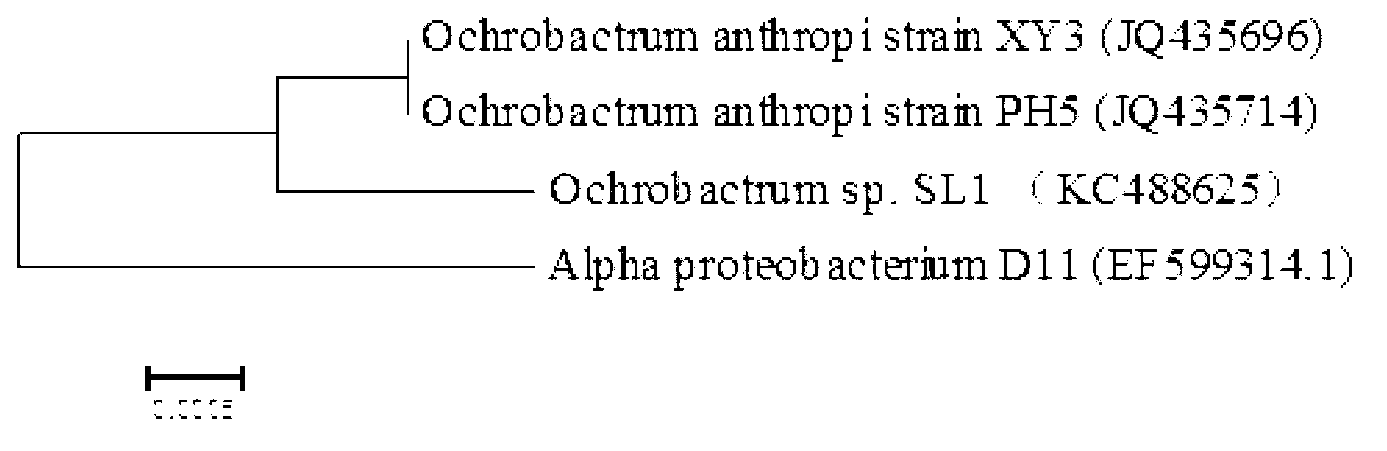

Ochrobactrum anthropi SL1 and application thereof to removal of repugnant substances containing sulfur

ActiveCN103266075AHigh efficiency of hydrogen sulfide degradationShort adaptation periodBacteriaDispersed particle separationSludgeEnvironmental studies

The invention discloses ochrobactrum anthropi SL1 and application thereof to removal of repugnant substances containing sulfur. Ochrobactrum anthropi SL1 is an isolate obtained from a reactor for treating repugnant substances containing H2S and the like in a water pollution control laboratory in Research Center for Eco-Environmental Sciences, Chinese Academy of Sciences. The strain is collected in China General Microbiological Culture Collection Center (CGMCC), with collection number of CGMCC No.7400. The strain can be used for preparing microbial active fillers, is used for purifying the repugnant substances containing sulfur and solving the problem of odor pollution produced in the processes of sewage, sludge and refuse treatment and composting, and has more than 90% of efficiency of degrading repugnant substances containing sulfur such as hydrogen sulfide, methanethiol, dimethyl sulfide and the like.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

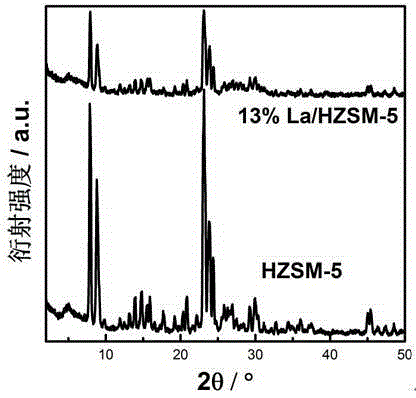

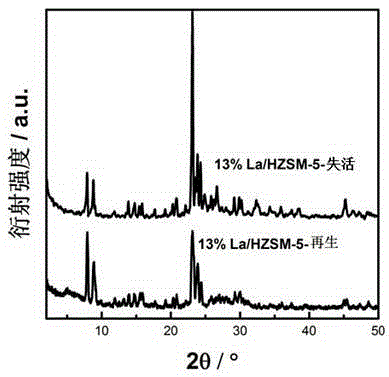

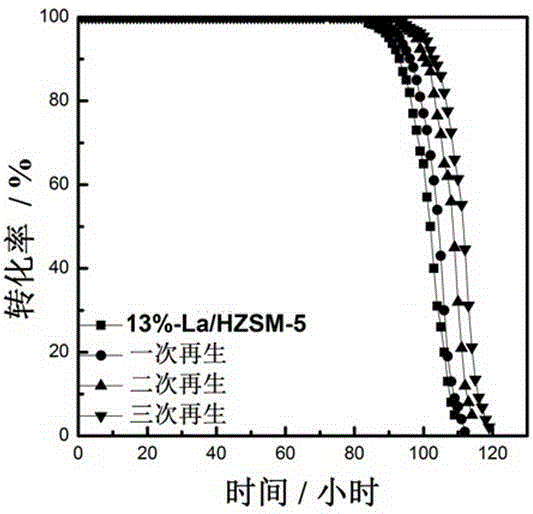

Method for regenerating (RE/HZSM-5) catalysts for resolving methanethiol gas

InactiveCN105233866AExtended service lifeEasy to operateMolecular sieve catalystsPtru catalystProcess engineering

The invention discloses a method for regenerating (RE / HZSM-5) catalysts for resolving methanethiol gas, which belongs to the treatment technical field of malodorous gas, wherein catalysts which are inactivated in normal pressure are regenerated, and are treated by using air, pure oxygen or inert gases containing water steam (1%-30%) to regenerate. The method for regenerating the RE / HZSM-5 catalysts for resolving methanethiol gas simply regenerates RE / HZSM-5 catalysts, can obtain excellent stability and activity, can obtain excellent stability for many times, and achieves the effects of excellent activity and stability. The method for regenerating the RE / HZSM-5 catalysts for resolving the methanethiol gas can recover regenerated catalysts to the decomposition performance of methyl mercaptan to the level of fresh catalysts, thereby enabling the regeneration process to have operability and repeatability. The method for regenerating the RE / HZSM-5 catalysts for resolving the methanethiol gas has excellent application prospect.

Owner:KUNMING UNIV OF SCI & TECH

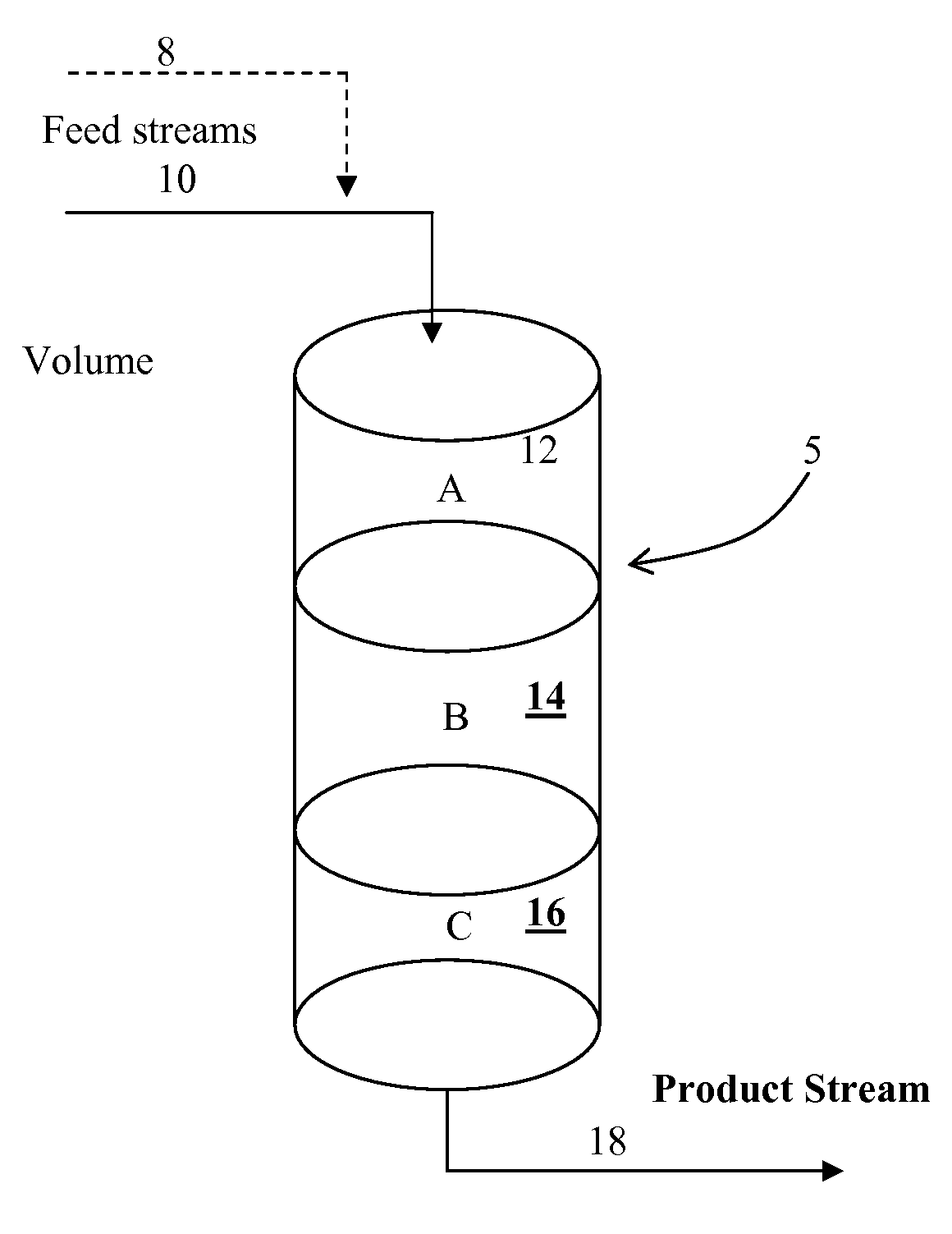

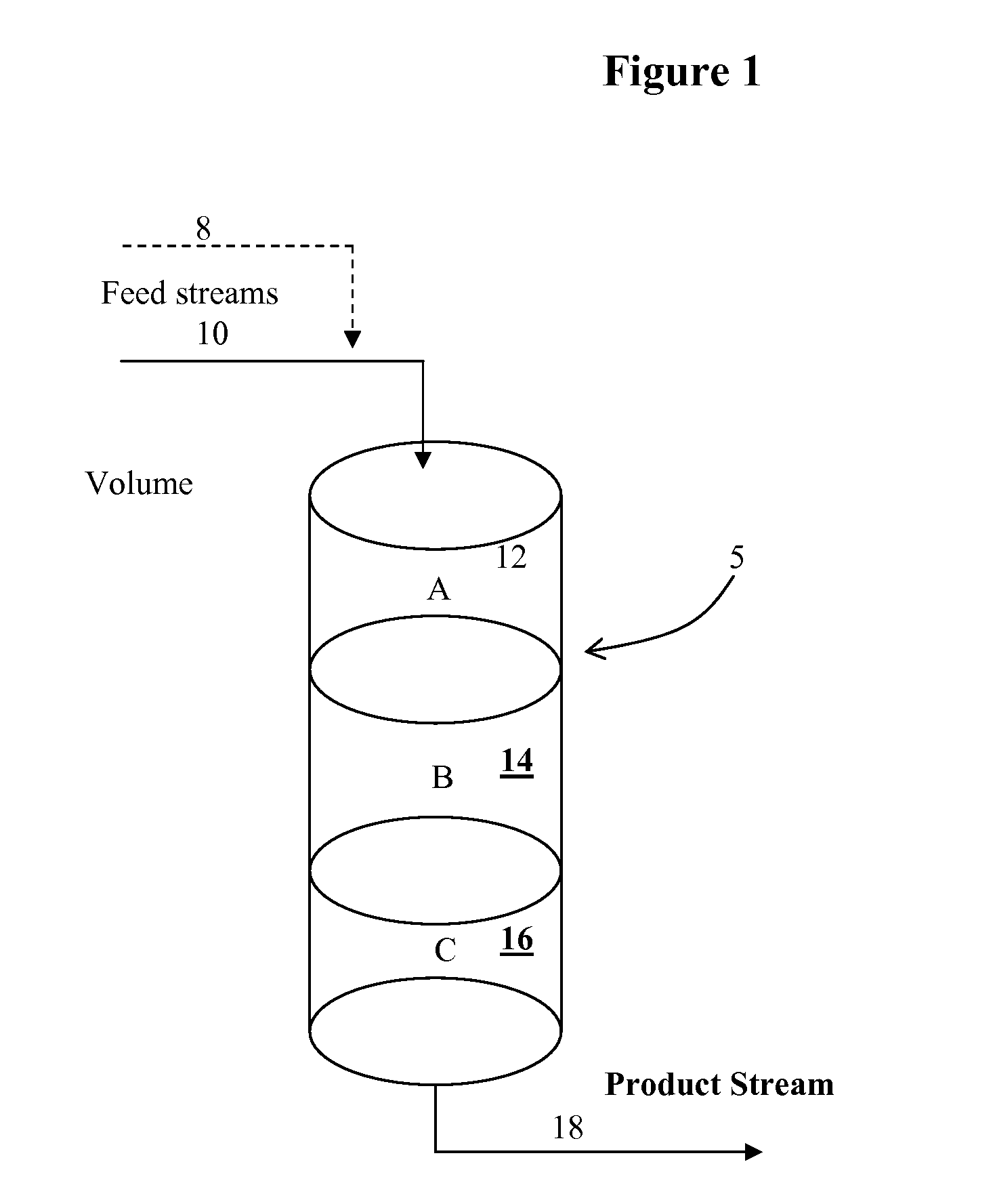

Graded Catalyst Bed for Methyl Mercaptan Synthesis

A process and graded catalyst bed for selectively producing methyl mercaptan from methanol. The methanol is reacted with hydrogen sulfide, in the presence of a graded catalyst bed containing at least three types of nickel or cobalt molybdenum alumina catalysts to convert the methanol to methyl mercaptan in one-pass. At least one of the hydrotreating catalysts can contain aluminium phosphate. Use of the graded catalyst bed prevents the formation of a hot spot within the graded catalyst bed. The methyl mercaptan having less than about 30 wt. % unreacted methanol contained therein.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Multi-enzyme complex microecological probiotic deodorant

InactiveCN107715686AReduce the content of malodorous substancesQuick to tasteFungiGas treatmentBiotechnologyActive enzyme

The invention discloses a multi-enzyme complex microecological probiotic deodorant, which is prepared from the following nine raw materials: a bacillus fermentation material, a yeast fermentation material, a lactic acid bacteria fermentation material, a photosynthetic bacteria fermentation material, protease, lipase, cellulase, spice and water. The multi-enzyme complex microecological probiotic deodorant has an efficient viable count of up to 5 billion / g, and the product is rich in bacillus, yeast, lactic acid bacteria, photosynthetic bacteria and protease, lipase, cellulase and other active enzymes to keep the air fresh, reduce the density of mosquitoes and flies, inhibit the growth of pathogenic microorganisms, and reduce the respiratory diseases of livestock, especially the respiratorydiseases prone to occur in animal breeding; the deodorant can quickly inhibit the growth of spoilage bacteria, effectively absorb and degrade ammonia nitrogen, hydrogen sulfide, methanethiol and othermalodorous harmful pollutants, has no harm to humans and animals and plants, no secondary pollution to the environment, and has the maximum removal rate of ammonia nitrogen of up to 95%, and the removal rate of hydrogen sulfide of up to 90%.

Owner:湖南山河美生物环保科技有限公司

Heat-resistant and waterproof building binder and preparation method thereof

ActiveCN105255395AEfficient water resistanceGood compatibilityNon-macromolecular adhesive additivesGraft polymer adhesivesSilanesAcetylated Lanolin

The invention discloses a heat-resistant and waterproof building binder. The heat-resistant and waterproof building binder comprises the following components in parts by weight: 160-170 parts of an ethylene-ethyl acrylate copolymer, 3-4 parts of palm wax, 1-2 parts of acetylated lanolin, 17-20 parts of a water-resistant aid, 0.7-1 part of methyltin mercaptide, 0.1-0.2 part of lithium laurate, 3-4 parts of bisphenol A phosphite and 0.1-0.3 part of 2,2'-ethylhexyl thioglycolate. The water-resistant aid prepared from maleic anhydride through graft modification is added into the raw materials, ethyl silicate is used as a precursor to prepare silica sol with excellent water resistance, and the aid with efficient water resistance is prepared from silica sol through fluorine-containing silane treatment. By utilizing palm wax and acetylated lanolin, the binding strength of the building binder can be improved, the consistency of the materials among copolymers can be further improved, and the overall performance is improved.

Owner:邵阳把兄弟新材料科技有限公司

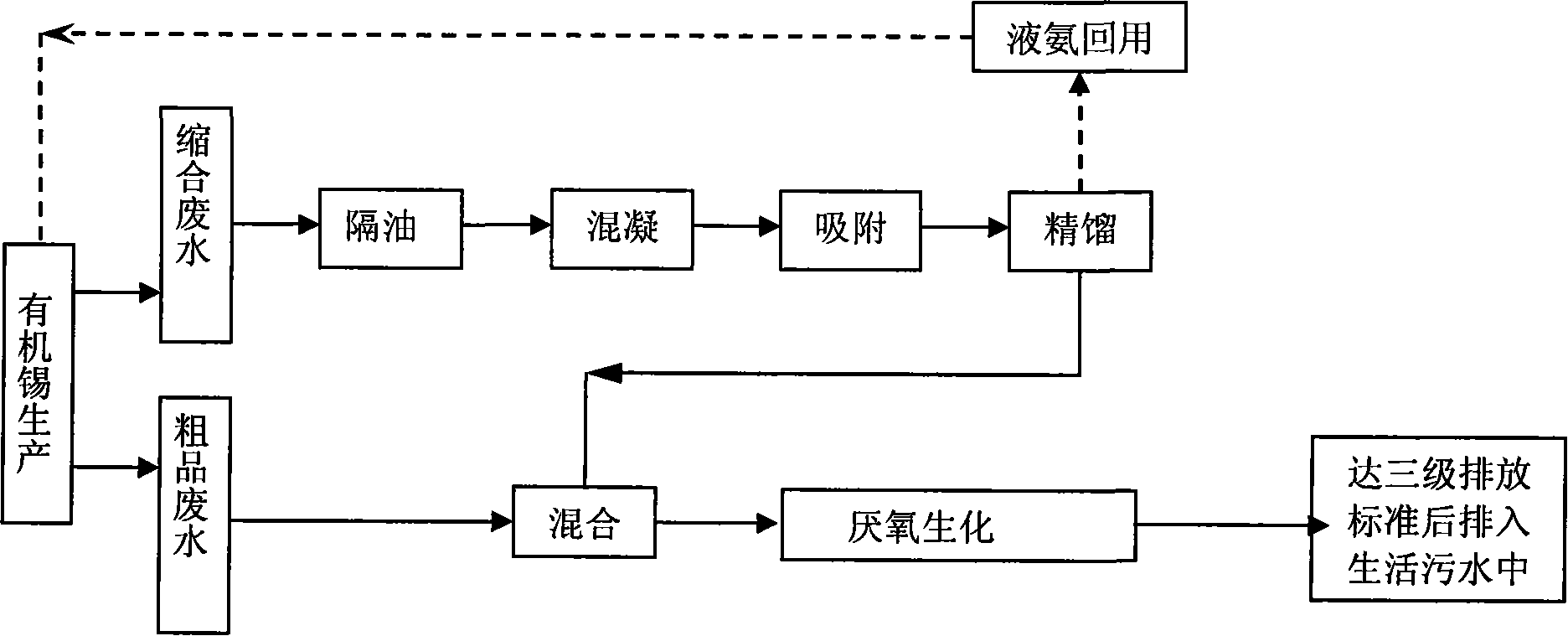

Purification technique for methyl stannum mercaptide industrial sewage

InactiveCN101250017ALess investmentLow running costFatty/oily/floating substances removal devicesTreatment with anaerobic digestion processesChemistryMethanethiol

The invention discloses a purification process of industrial wastewater of methyltin mercaptide, in which the condensation wastewater in the production of methyltin mercaptide is mixed with raw wastewater after sequentially via oil separating, coagulating, adsorbing and rectifying, further via anaerobic biological treatment, when COD in the water is lower than 500mg / L, mixture of the condensation wastewater and the raw wastewater is sent into domestic sewage via pipelines and purified with the domestic sewage. The invention purifies the industrial wastewater of methyltin mercaptide with the domestic sewage through classifying and preprocessing the industrial wastewater of methyltin mercaptide to the certain extent, then combining for biochemical treatment and meeting discharge requirement of class III, thereby not only saving investment and reducing operation costs, but also facilitating management.

Owner:ENG DESIGN & RES INST OF GENERAL ARMAMENTS DEPT

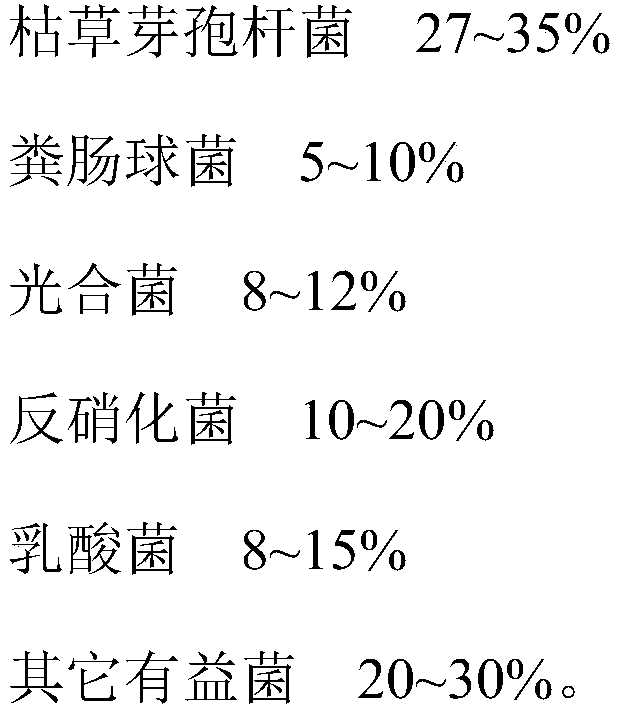

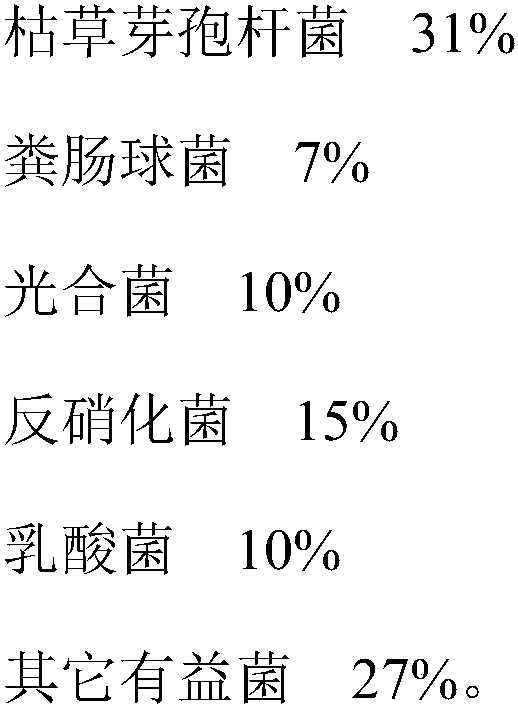

Microbial deodorant

InactiveCN109092048ANo secondary pollutionNo pungent odorSpecific water treatment objectivesDispersed particle separationAntioxidantCell membrane

The invention provides a microbial deodorant. The microbial deodorant comprises the raw materials of bacillus subtilis, enterococcus faecalis, photosynthetic bacteria, nitrifying bacteria and lactic acid bacteria. After the microbial deodorant is sprayed in wastewater or filth, microorganisms grow and multiply by exponential multiples, antioxidants such as NH3, H2S and NO2 are produced within a short period of time to resist the survival and reproduction of rot fungi, and a biodegradation layer is formed on the surface of the filth, so that gaseous NH3 is not escaped, furthermore, the microorganisms can also decompose harmful components such as NH3, H2S and methyl mercaptan to achieve the effect of quick deodorization, no pungent odors are produced during the use process, the microbial deodorant can be in contact with human bodies or animal skin and is non-toxic and harmless, and specially cleaning is not required; the microorganisms are decomposed into carbon dioxide, water and non-toxic cell residues after pollutants are eaten, so that secondary pollution is avoided. The deodorant forms microbial cell membranes on the pollutants such as bottom surfaces, objects and waterway equipments after being used for a long term to achieve a sustained and stable deodorization effect.

Owner:武汉邦奥生物技术有限公司

Hollow carbon tube array embedded with nano metal, preparation method and application thereof

ActiveCN110449150AImprove catalytic performanceEven and sufficient mass transferDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPlatinumChemical reaction

The invention discloses a preparation method of a hollow carbon tube array embedded with nano metal and an application thereof. The carrier of the catalyst of the present invention is a silanized hollow carbon tube array, and the supported metal is gold, platinum, silver or copper nanocluster. The catalyst of the invention has a unique micro reactor structure of a nano hollow carbon tube array. Byconstructing a long-range ordered hollow tube array structure carbon material, the chemical reaction rate can be remarkably increased, so as to improve the catalytic performance of the catalyst, thenano-cluster metals can catalyze ozone efficiently and quickly, improve the degradation efficiency of gaseous pollutants, the removal rate of methanethiol is 99.72%, silanizing treatment makes the surface of the hollow carbon tube array carry amino groups, and the metal nano-clusters are loaded on the surface of the hollow carbon tube array material through calcination reduction, so that the metalis uniformly distributed on the surface of the carbon material, and the utilization rate of the metal is improved, which can be widely used in the field of gas pollutant purification treatment.

Owner:SUN YAT SEN UNIV

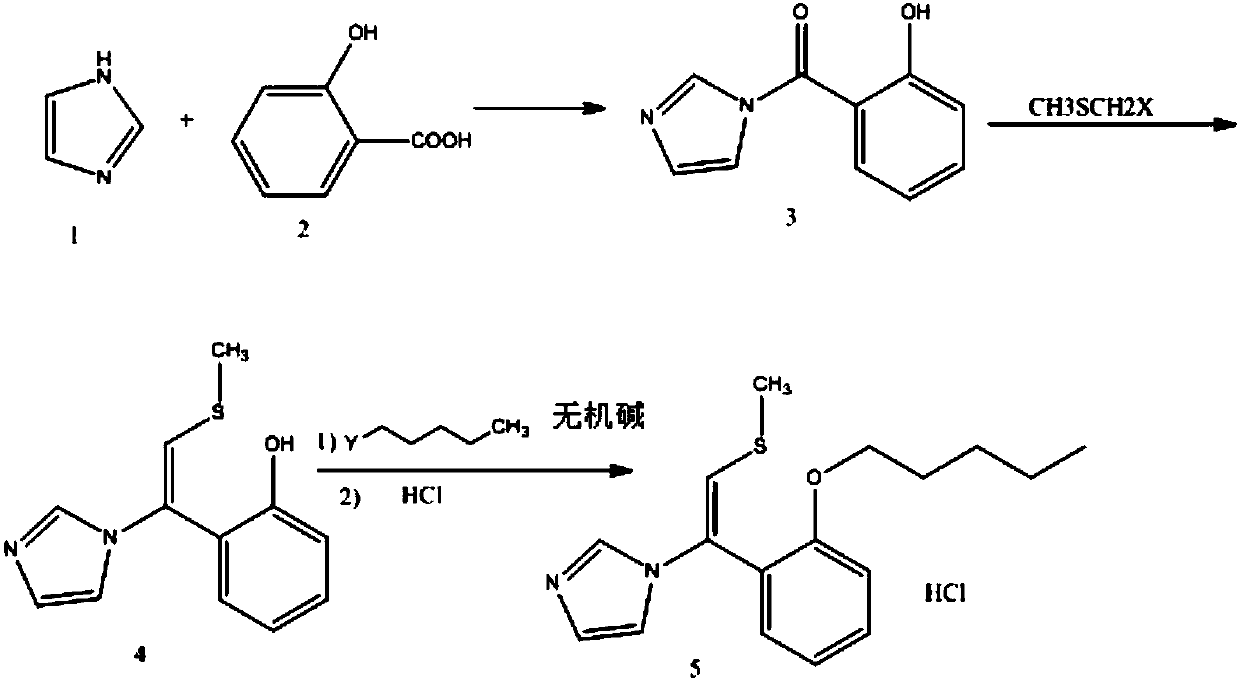

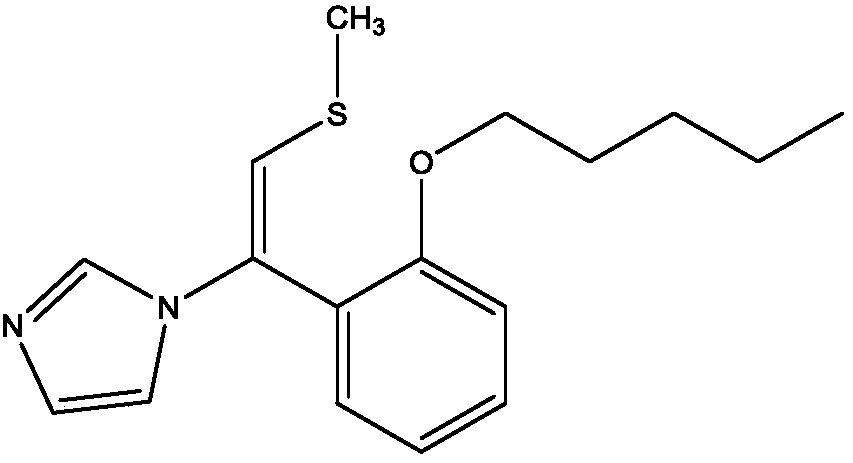

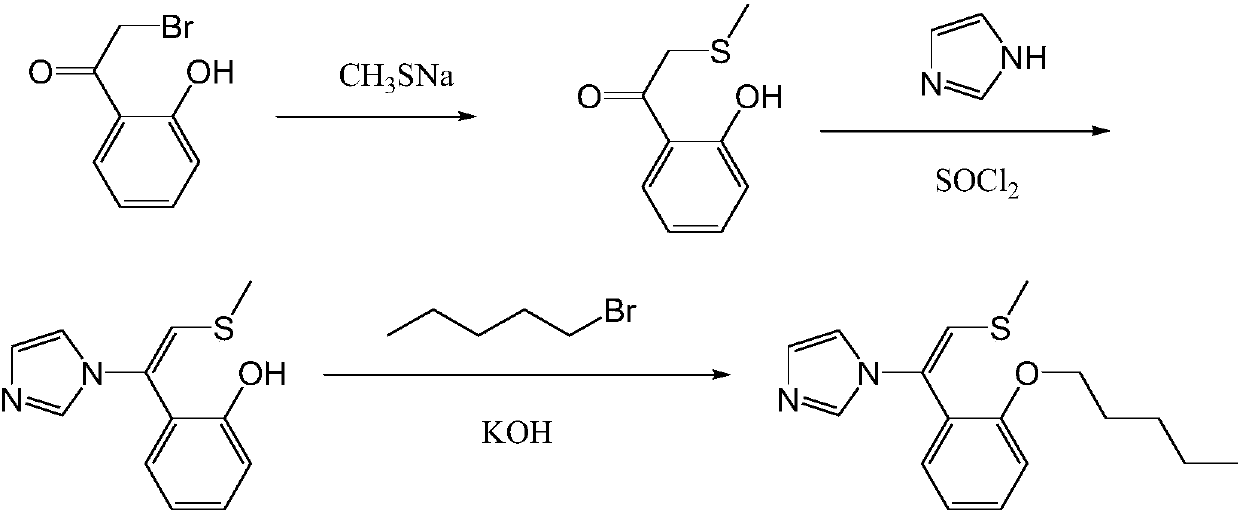

Neticonazole hydrochloride preparation method

The invention discloses a neticonazole hydrochloride preparation method, which comprises: carrying out an acylation reaction on imidazole and o-hydroxybenzoic acid, carrying out a wittig reaction on the product of the acylation reaction and 1-halogenated dimethyl sulfide, carrying out a reaction on the product of the wittig reaction and 1-halogenated pentane in an inorganic alkali, and salifying the product of the reaction and hydrochloric acid to obtain the neticonazole hydrochloride. According to the present invention, the method can avoid the use of the methanethiol and thionyl chloride, has characteristics of environmental protection, mild reaction condition, simple operation, simple post-treatment and high product purity, and is suitable for industrial production.

Owner:JIANGSU YUNYANG PHARMA GRP

Hydrogenated nitrile-butadiene rubber modified by rectorite and preparation method thereof

The invention provides hydrogenated nitrile-butadiene rubber modified by rectorite and a preparation method thereof, relating to hydrogenated nitrile-butadiene rubber and a preparation method thereof,and solving the problems of high cost and poor mechanical property when hydrogenated nitrile-butadiene rubber is solely adopted as a raw material to prepare a screw pump rubber stator in the prior art. The hydrogenated nitrile-butadiene rubber modified by rectorite is prepared from hydrogenated nitrile-butadiene rubber, organic rectorite, nano-zinc oxide, active magnesium oxide, sulfur, Naugard445, TMTD, N-cyclohexyl-2-benzothiazole sulfenamide CZ, methyl mercapto benzimidazole zinc Vulkenox ZMB-2 and poly-sebacic ester G-25. The preparation method comprises the following steps: firstly, weighing raw materials; secondly, when HNBR and Rectorite are melted and intercalated after being mixed, mixing, and mixing sequentially by adding residual raw materials; and thirdly, smelting in an overturning mode to obtain a film, and vulcanizing after the film is cooled in the air for 16h to obtain the hydrogenated nitrile-butadiene rubber modified by rectorite. The hydrogenated nitrile-butadienerubber modified by rectorite and the preparation method thereof have simple process, cost reduction and good mechanical property of the obtained material.

Owner:HARBIN INST OF TECH +1

Green methyl tin mercaptide compound

InactiveCN106008589AImprove stabilityFacilitate the subsequent synthesis reactionTin organic compoundsAlkaneDistillation

The invention relates to an organic tin substance, in particular to a green methyl tin mercaptide compound. The compound is prepared in steps as follows: (1) tinning: metal tin and a catalyst are placed into a reaction kettle, then chloromethane is introduced, the mixture is heated and mixed evenly at the temperature of 150-170 DEG C for a halogenating reaction for 0.2-0.4 h, then a redistribution agent is added, and the mixture is heated and pressurized for a tinning reaction; (2) synthesis: an obtained methyl tin chloride aqueous solution is added to isooctyl thioglycolate, a second catalyst, alkane diacid and a regulator are added, a reaction is conducted, the pH value is adjusted to range from 7 to 9, and then the mixture is heated to 60-70 DEG C for a reaction for 3-4 h and is left to stand, cooled and layered; the regulator is prepared from 6-9 parts of a first compound regulator by mass, 7-11 parts of a second compound regulator by mass and 8-14 parts of a third compound regulator by mass; (3) water washing; (4) distillation. The product has the yellowing resistance and volatile separation resistance, is good in heat stability and has the low tin content.

Owner:ANHUI SHENGHUA XINAOTE CHEM CO LTD

Improved antioxidant asphalt waterproof coiled material

InactiveCN104861666AIncrease the degree of cross-linkingImprove insulation performanceBuilding insulationsPolystyreneLanolin

The invention discloses an improved antioxidant asphalt waterproof coiled material, which comprises the following raw materials with parts by weight: asphalt 82-90, thiodipropionic acid 0.3-0.4, water-soluble lanolin 2-3, brominated polystyrene 6-8, methyl tin mercaptide 0.1-0.2, antioxygen 1010 0.8-2, scolecite 4-6, light calcium carbonate 20-26, dibutyl maleate 2-3, alkylated diphenylamine 0.1-0.2, 6% sodium hydroxide (NaOH) solution 30-40, alkali lignin 6-10, epichlorohydrin 2-3 and machine oil 21-30. The improved antioxidant asphalt waterproof coiled material epoxidizes the alkali lignin, improves degree of crosslinking of lignin molecules, can effectively improve insulativity, mechanical property, heat stability, adhesiveness and preservative effect by being added into a resin system, and can play the excellent role of high-temperature oxidation resistance by adding the alkylated diphenylamine into the machine oil.

Owner:胡刚

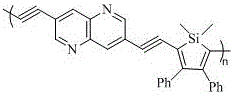

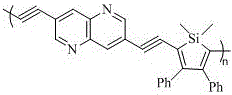

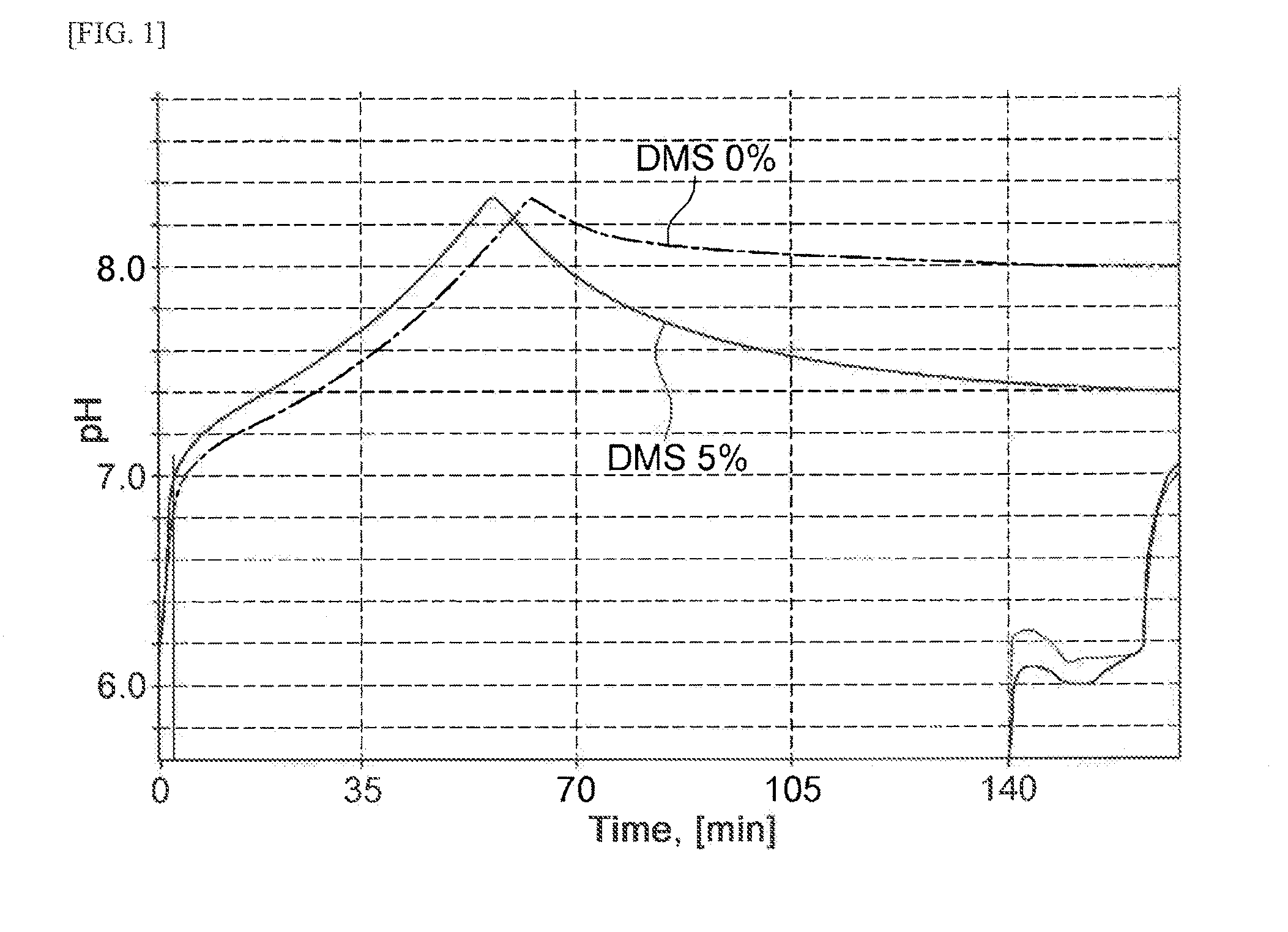

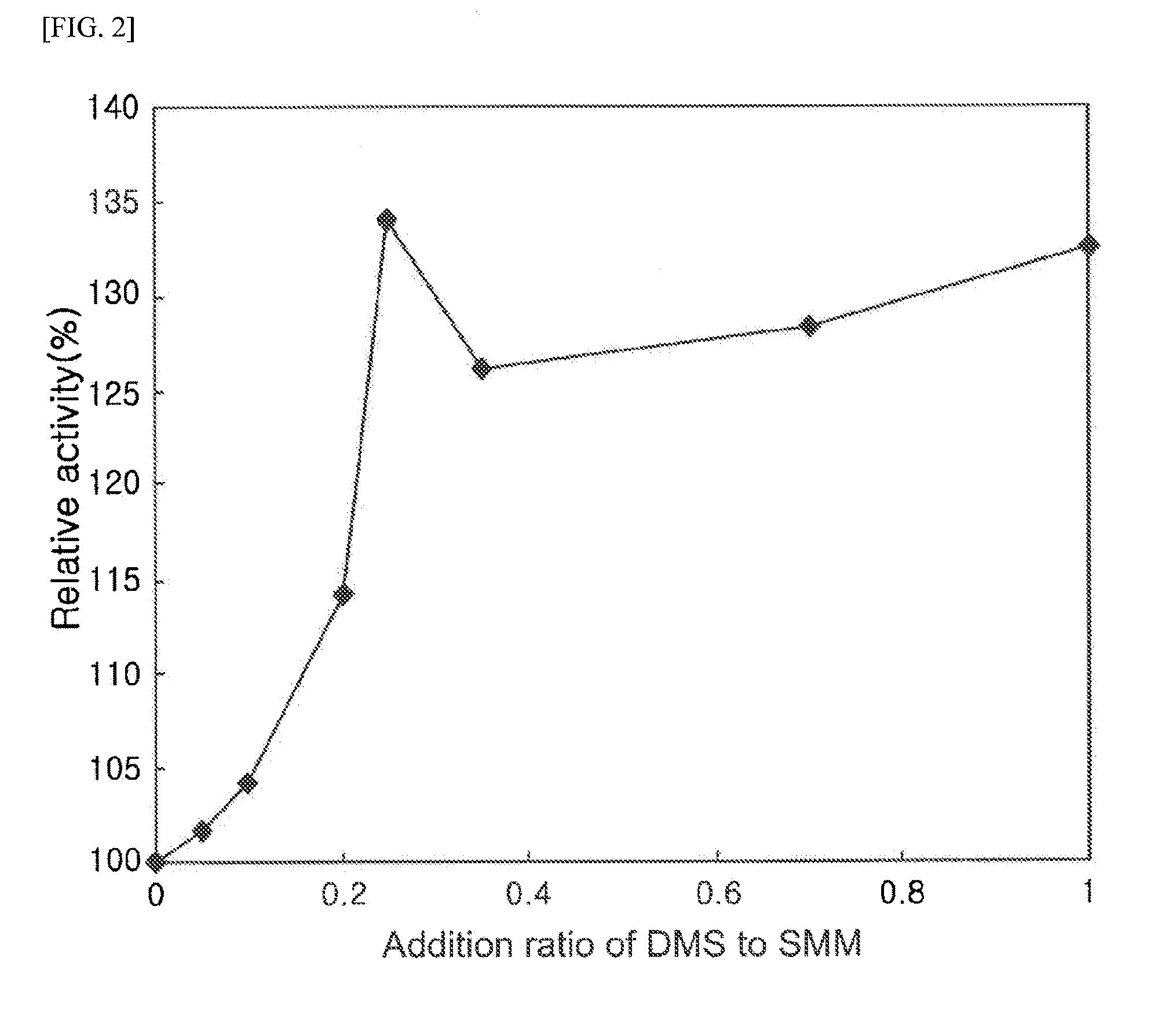

Method for Increasing Methionine Productivity Using a Mixture of Methyl Mercaptan and Dimethyl Sulfide

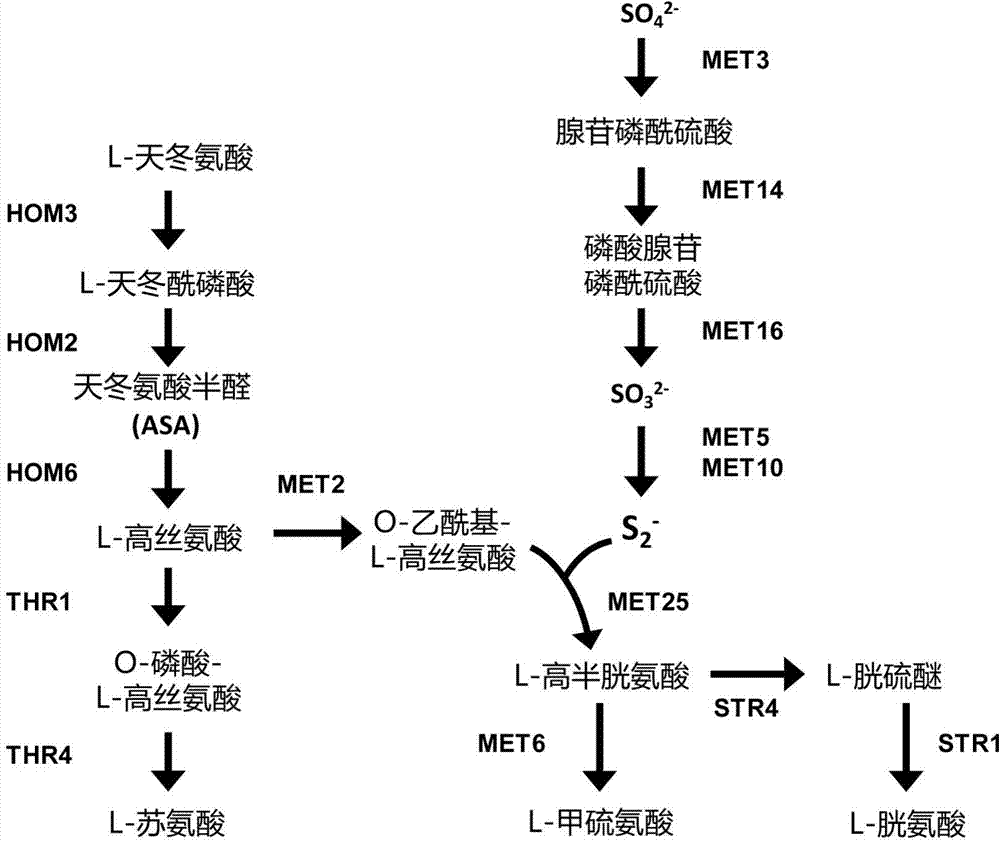

ActiveUS20120123158A1Low costImprove productivityOrganic chemistryFermentationHomoserineProduction rate

The present invention relates to a method for increasing L-methionine productivity and organic acid productivity. More particularly, the present invention relates to a method which involves adding a mixture containing methyl mercaptan and dimethyl sulfide at a appropriate ratio to O-acetyl homoserine or O-succinyl homoserine and to an enzyme having an activity of converting methionine precursor into L-methionine, so as to perform an enzyme reaction, to thereby improve the conversion rate of L-methionine and organic acid from the L-methionine precursor, and thus increasing L-methionine yield as compared to conventional method.

Owner:CJ CHEILJEDANG CORP

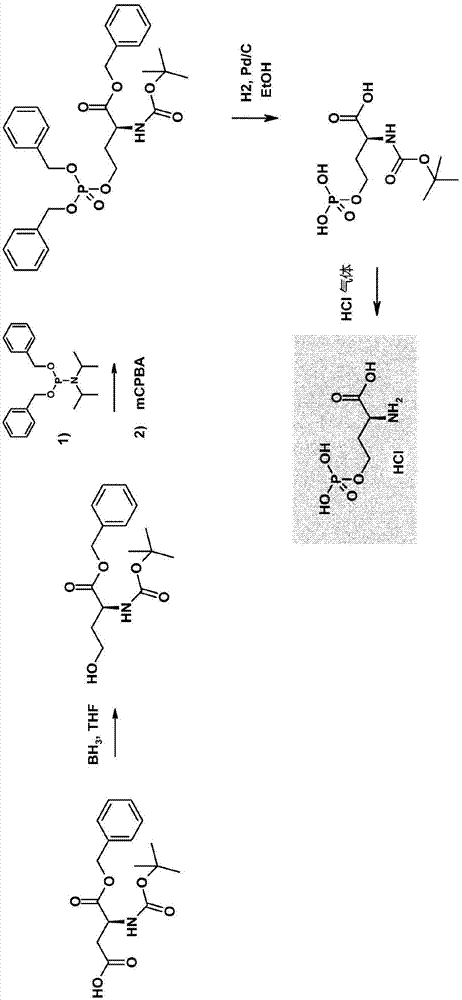

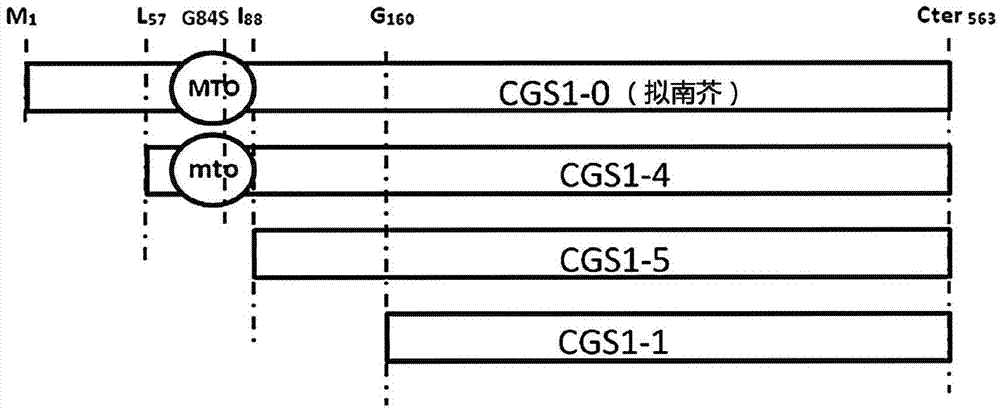

Process for producing L-methionine from O-phospho-L-homoserine and methanethiol employing a mutated cystathionine gamma-synthase

Provided is a method for producing L-methionine in which O-phospho-L-homoserine and methanethiol are enzymatically converted into L-methionine and H3P04. Such a conversion is achieved by an enzyme called O-phospho-L-homoserine (OHPS) dependent methionine synthase. Also described are O-phospho-L-homoserine (OHPS) dependent methionine synthases, i.e. proteins which are able to enzymatically convert O-phospho-L-homoserine and methanethiol into L-methionine and H3PO4 as well as microorganisms which have been genetically modified so as to be able to produce L-methionine from O-phospho-L-homoserine and methanethiol. Furthermore described are methods to screen for enzymes that catalyse the conversion of O-phospho-L-homoserine and methanethiol into L-methionine and H3PO4.

Owner:AVEATIS ANIMAL NUTRITION SA

Lamination adhesive sizing material for long-acting stable printing rubber roller and preparation method thereof

InactiveCN106188672AImprove wear resistanceImprove mechanical propertiesDiacetone alcoholCarbon fibers

The invention discloses a lamination adhesive sizing material for a long-acting stable printing rubber roller. The sizing material is prepared from the following raw materials in parts by weight: 0.3-1 part of methyl tin mercaptide, 2-4 parts of dodecenylsuccinic acid, 10-14 parts of graphene oxide, 6-7 parts of N-hydroxysuccinimide, 10-12 parts of 1-ethyl-3-(3-dimethylaminopropyl)carbodiimide hydrochloride, 7-9 parts of sulfanilic acid, 30-40 parts of styrene, 0.1-0.2 part of potassium peroxodisulfate, 0.3-0.4 part of lanthanum chloride, 2-3 parts of ethylene diamine tetraacetic acid, 1.7-2 parts of carbon fibers, 50-67 parts of ammonium hydroxide having a concentration of 20-25 percent, 1-2 parts of accelerant TL, 1-2 parts of an anti-aging agent DOD, 100-130 parts of natural rubber, 2-3 parts of calcium palmitate, 6-8 parts of dioctyl sebacate, 0.6-1 part of diacetone alcohol, 1-2 parts of aluminum dihydrogen phosphate, 0.4-1 part of diallylamine, 10-14 parts of sepiolite powder, 1-2 parts of ammonium molybdate and 0.8-1 part of sulphur. The lamination adhesive sizing material has the advantages of good stability, long service life, high comprehensive performance, acid and alkali resistance, ink proofing and strong humidity resistance.

Owner:TONGLING HONGZHENG NETWORK SCI & TECH CO LTD

Methionine production

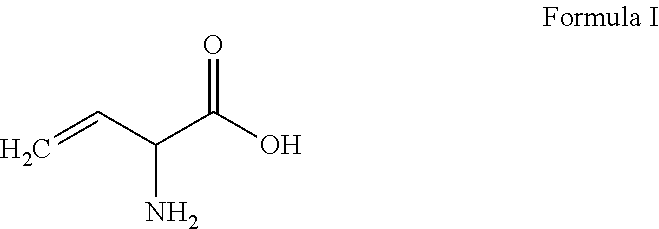

InactiveUS20190127321A1Produced economicallyIncrease conversion rateOxidoreductasesFermentationMethionine biosynthesisOrganic chemistry

There is provided a method of producing a method of producing methionine, the method comprisingcontacting vinylglycine or derivatives thereof with at least one free radical methyl mercaptan in a reaction medium.

Owner:EVONIK OPERATIONS GMBH

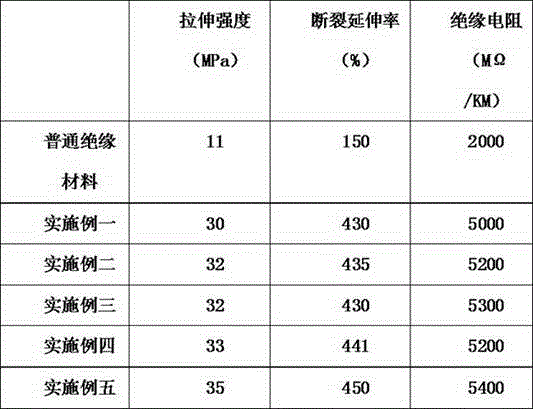

Insulating material for nuclear power plant and production technology thereof

InactiveCN106009102AGood acid and alkali resistanceImprove high temperature resistanceFiberPolyolefin

The invention discloses an insulating material for nuclear power plants and a production process thereof. The components of the insulating material include 30-50 parts of a rubber matrix, 15-30 parts of a flame retardant, 8-12 parts of a silane coupling agent, chlorinated 10‑20 parts of polyethylene, 1‑4 parts of UV absorber, 4‑10 parts of tin mercaptide, 5‑15 parts of toughening modifier, 15‑25 parts of polyolefin compound, 15 parts of polystyrene resin 30 parts, 8-15 parts of nano-scale silicon dioxide, 8-15 parts of cross-linked fluororesin, 10-15 parts of composite antioxidant and 10-30 parts of reinforcing fiber. The production process of the present invention is simple, and the production process is environmentally friendly and pollution-free , the prepared material has excellent acid and alkali resistance, high temperature resistance, flame retardancy, radiation resistance, long service life, and can be widely used as insulation material for nuclear power plant cables.

Owner:HENAN YAAN ELECTRICAL INSULATION MATERIAL PLANT CO LTD

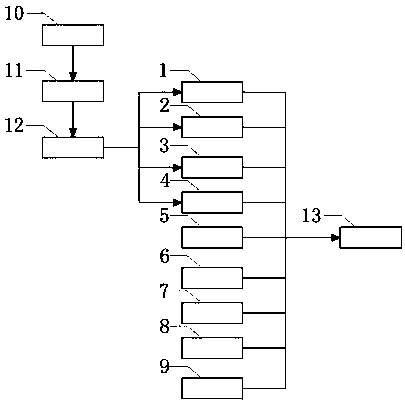

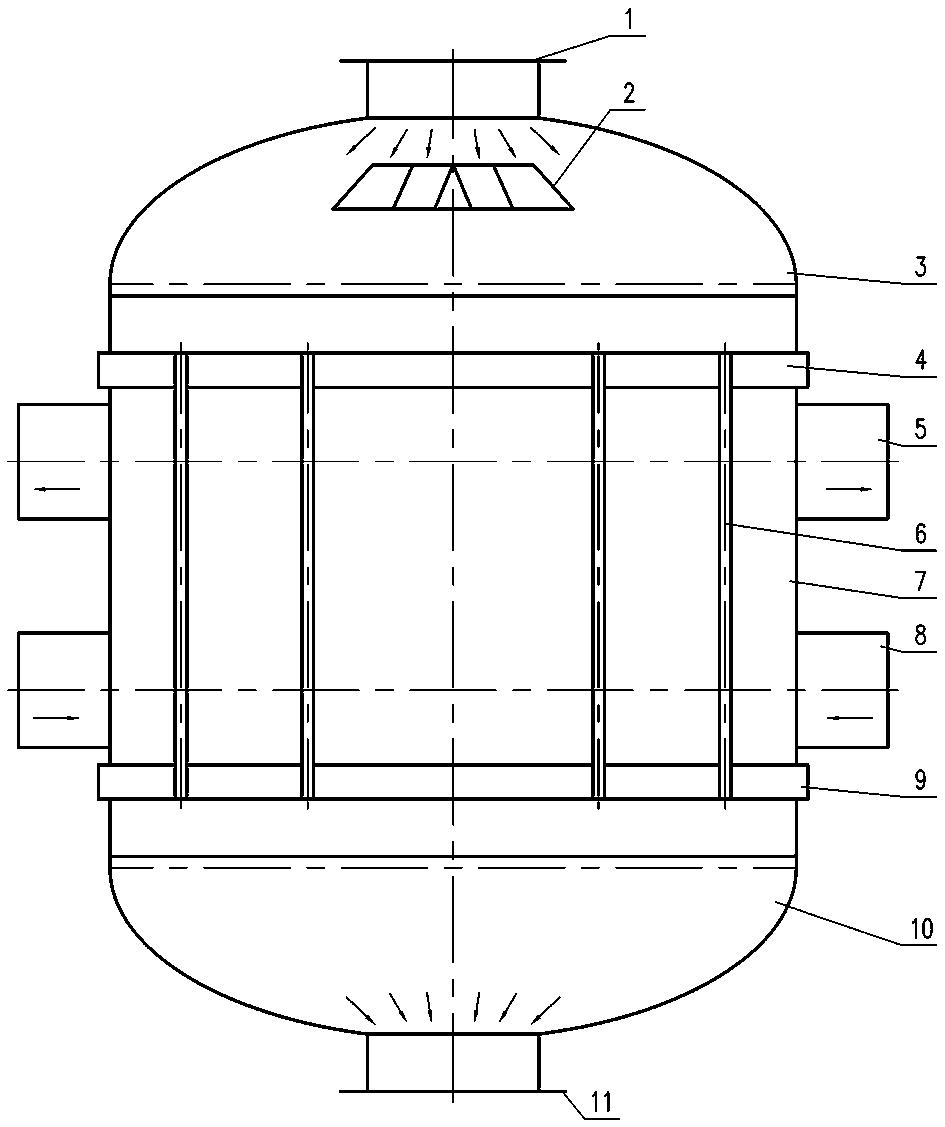

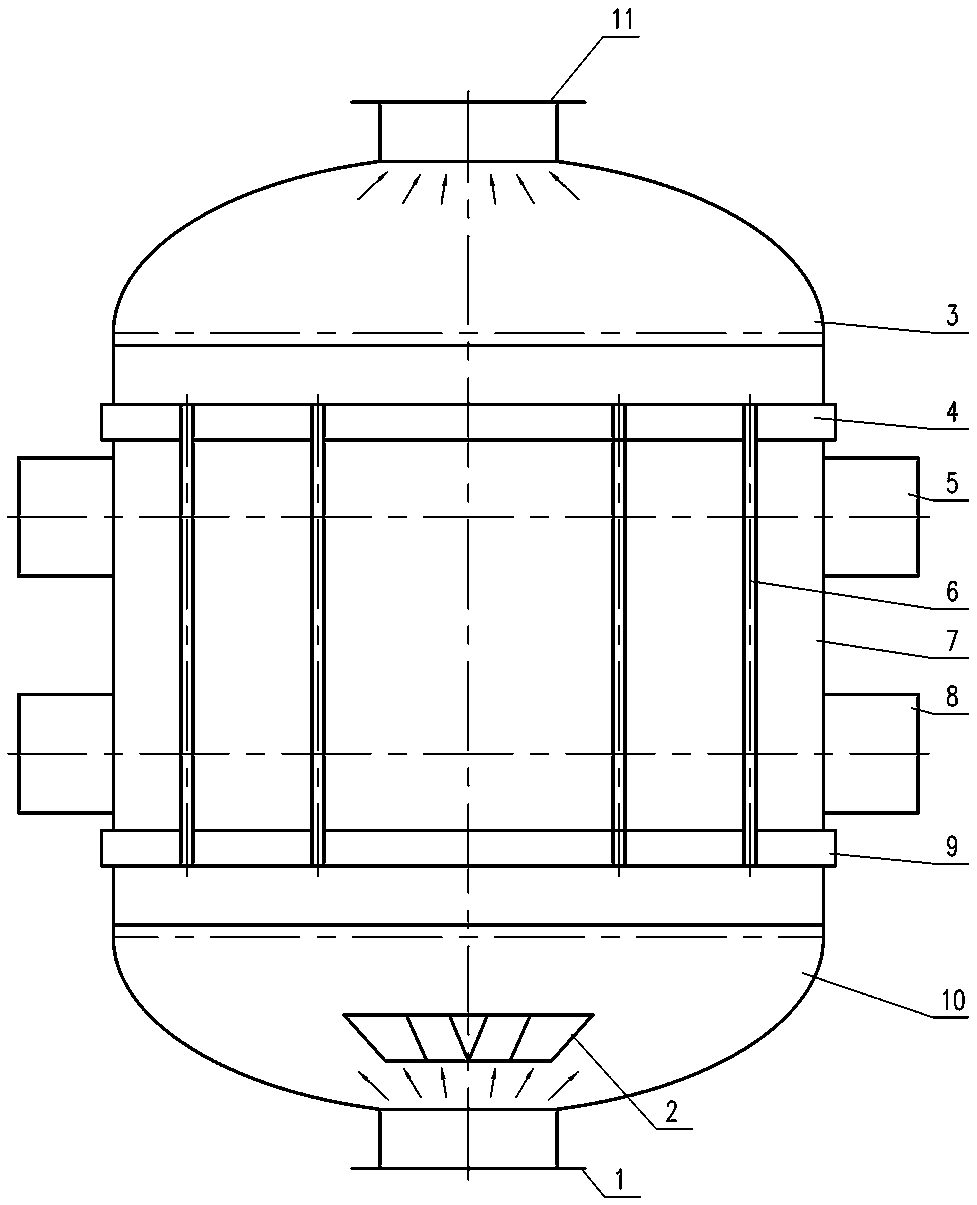

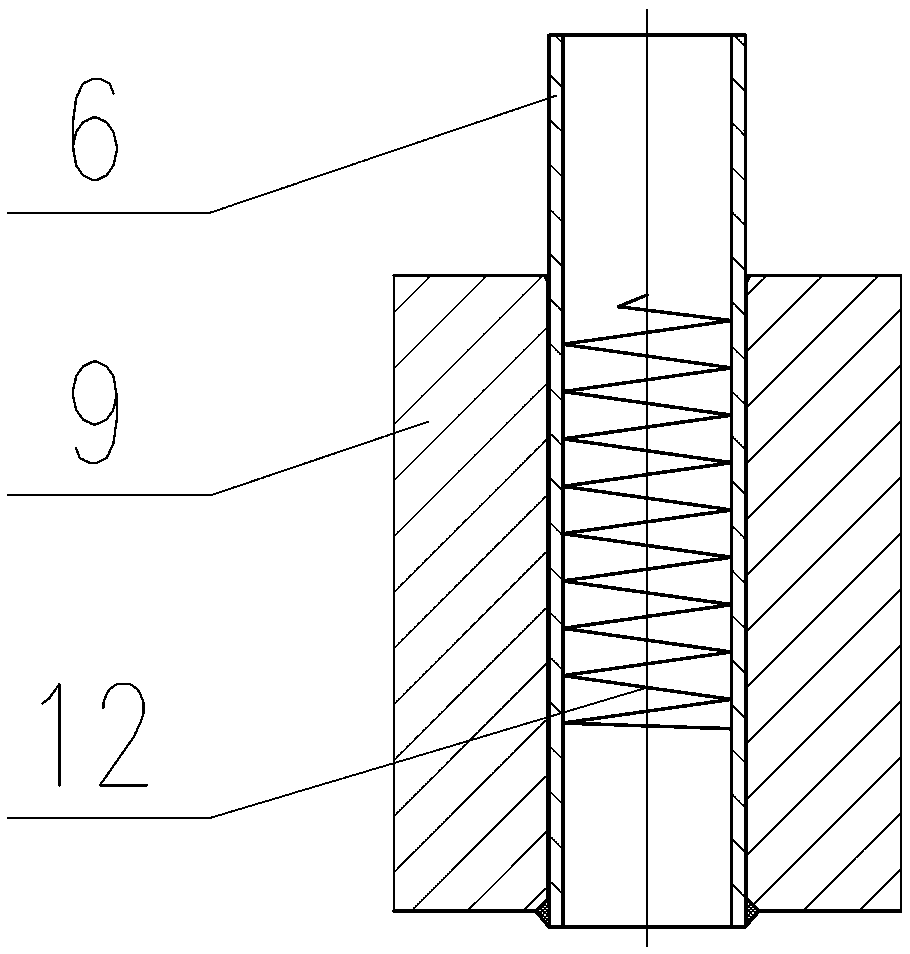

Tubular fixed bed reactor for methanethiol

The invention relates to a tubular fixed bed reactor for methanethiol. The reactor comprises an upper tube box, a shell pass cylinder body and a lower tube box from top to bottom, wherein the shell pass cylinder body is internally provided with an upper tube plate, reaction tubes and a lower tube plate, and two ends, i.e., an upper end and a lower end, of the reaction tube are respectively in sealing connection with the upper tube plate and the lower tube plate; a lower tube of the reaction tube is internally provided with a catalyst support spring. The reactor provided by the invention can conveniently be filled with a catalyst, when a single reaction tube leaks, the reaction tube can be directly blocked, the catalyst does not require to be completely dismantled, the equipment is convenient to maintain in a later period, and the maintenance cycle is shortened.

Owner:西安航天华威化工生物工程有限公司

Antistatic plastic formula

An antistatic plastic formula includes polyethylene, an additive, a plasticizer and a stabilizer; the stabilizer is methyl tin mercaptide, the additive is antimonous oxide, and the plasticizer is polyol benzoate. The formula comprises the following components by mass: 60% of polyethylene, 15% of antimonous oxide, 8% of polyol benzoate and 17% of methyl tin mercaptide. The advantages of the antistatic plastic formula are that: plastic products prepared from plastic which is produced according to the antistatic plastic formula can effectively avoid friction electrostatic generation, and are safer in using as electronic, dangerous goods, electric detonator and other product packaging.

Owner:TIANJIN GUANGQI PLASTIC PROD

Anti-static plastic

The invention discloses anti-plastic plastic which comprises raw materials in parts by weight as follows: 100-106 parts of APP (ammonium polyphosphate), 1.3-2 parts of glacial acetic acid, 1.3-2 parts of ethyl cellulose, 3-4 parts of TEOS (tetraethyl orthosilicate), 16-20 parts of dodecafluoroheptyl-propyl-trimethoxysilane, 30-34 parts of 90%-95% ethanol, 160-200 parts of a 0.5 mol / l aniline aqueous solution, 5-10 parts of sodium peroxide, 460-500 parts of PVC (polyvinyl chloride), 2-3 parts of aramid short fibers, 0.6-2 parts of methyl tin mercaptide, 1-2 parts of alkanolamide, 2-3 parts of alkyl sodium sulfonate, 3-4 parts of poly(1,2-propyleneglycol adipate), 12-17 parts of poly(butyl acrylate) and 6-10 parts of bentonite. The APP is firstly subjected to surface coating with a sol-gel treatment process, surface strength and water resistance are improved, then polyaniline coating is performed, flame resistance and thermolysis are improved, and dispersibility and compatibility of an additive in the plastic are effectively improved.

Owner:HEFEI JIKE NEW MATERIALS

Probiotic liquid for effectively eliminating animal feces and urine odor

InactiveCN108371227AReduce the content of malodorous substancesGood for healthFungiBacteriaBiotechnologyEcological environment

The present invention discloses probiotic liquid for efficiently eliminating animal feces and urine odor. The probiotic liquid is prepared from the ten raw materials of bacillus subtilis fermented materials, yeast fermented materials, aspergillus oryzae fermented materials, lactic acid bacterium fermented materials, xylooligosaccharide, protease, lipase, cellulase, spices and water. The probioticliquid product is rich in the bacillus, yeasts, lactic acid bacteria, aspergillus oryzae, protease, lipase, cellulase and other active enzymes, can reduce the content of odorous substances in the environment, inhibits reproduction of pathogenic microorganisms, reduces respiratory diseases of livestock and poultry, effectively absorbs and degrades harmful pollutants with putrid odors, including ammonia nitrogen, hydrogen sulfide, methyl mercaptan, etc., refreshes the air, can improve immunity of animals, improves oral and intestinal micro-ecological environment, and is conducive to digestion and absorption of nutrients by animals. At the same time, by using biological pathways to inhibit growth of harmful microorganisms in oral cavity and post-intestines, health conditions of the animals are improved and problems of animal oral cavity and feces odor are significantly solved.

Owner:刘德文

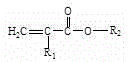

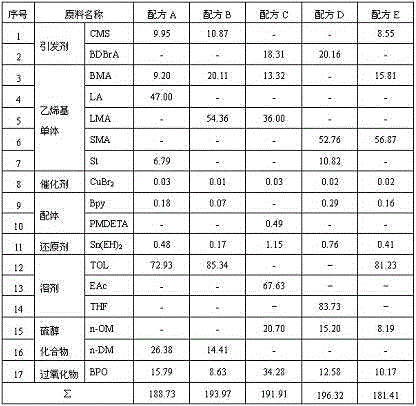

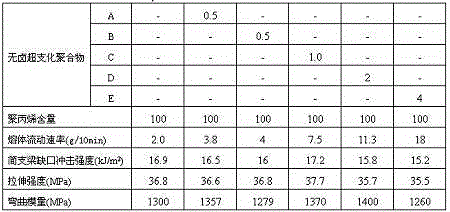

Halogen-free hyperbranched polymer and modified polypropylene containing same

The invention relates to a halogen-free hyperbranched polymer and modified polypropylene containing the same, applies to the fields of the automobile industry, the household appliance industry and other fields involving modified polypropylene materials. The halogen-free hyperbranched polymer is prepared with the preparation method comprising the following steps: an initiator halogen ester or hydrocarbon as well as a solvent is added to a reaction device under the condition of an inert gas, then a catalyst, a vinyl monomer, a reducing agent and a ligand are put into the device sequentially, and a thiol compound is added when a reaction endpoint is reached to modify an end group of the hyperbranched polymer to obtain the halogen-free hyperbranched polymer, wherein the thiol compound adopts methanethiol, ethanethiol, butyl mercaptan, 1-dodecanethiol, isooctyl thiol or tert-dodecylthiol. The halogen-free hyperbranched polymer and the modified polypropylene containing the same have the benefits as follows: the halogen-free hyperbranched polymer is taken as a flow modifier for polypropylene, the liquidity of polypropylene can be improved under the condition that the molecular weight and molecular weight distribution of polypropylene are not changed, the appearance of a product can be improved, energy consumption can be reduced, and the production cost can be reduced.

Owner:CHANGZHOU SITEEN AUTOMOTIVE TRIM SYST

Antistatic bismale-polyimide modified calcium carbonate filling

The invention relates to an antistatic bismale-polyimide modified calcium carbonate filling. The antistatic bismale-polyimide modified calcium carbonate filling is prepared from the following raw materials in parts by weight: 200 parts of calcium carbonate powder, 4-5 parts of glass fibers, 3-5 parts of glycerin monostearate, 1-2 parts of graphene, 80-100 parts of a hydrogen peroxide solution, 8-10 parts of peroxidase, 6-8 parts of polyethylene glycol octylphenol ether, 200-250 parts of dimethyl formamide, 1-2 parts of 5-hydroxylevulinic acid, 2-3 parts of 4,4-diphenylmethane bismaleimide, 2-3 parts of diethyl malonate, 0.5-1 part of a catalyst, 1-2 parts of cetyl trimethyl ammonium bromide, 1-2 parts of titanium dioxide, 2-3 parts of methyl tin mercaptide, 2-3 parts of alkyl sodium sulfonate, 2-3 parts of sodium lignosulfonate, 2-3 parts of hydroxyl silicone oil, an appropriate amount of acetone and an appropriate amount of deionized water. The filling disclosed by the invention is homogeneous in particle diameter and good in dispersibility, has good substantivity with organic high polymers, and has favorable stuffing properties.

Owner:凤台县泓瀚建筑防水材料厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com