Deodorizing agent and method for manufacturing same and use thereof

A manufacturing method and technology of deodorant, applied in the direction of deodorization, disinfection, etc., can solve the problems of no adsorption performance, etc., and achieve the effect of excellent physical and chemical adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

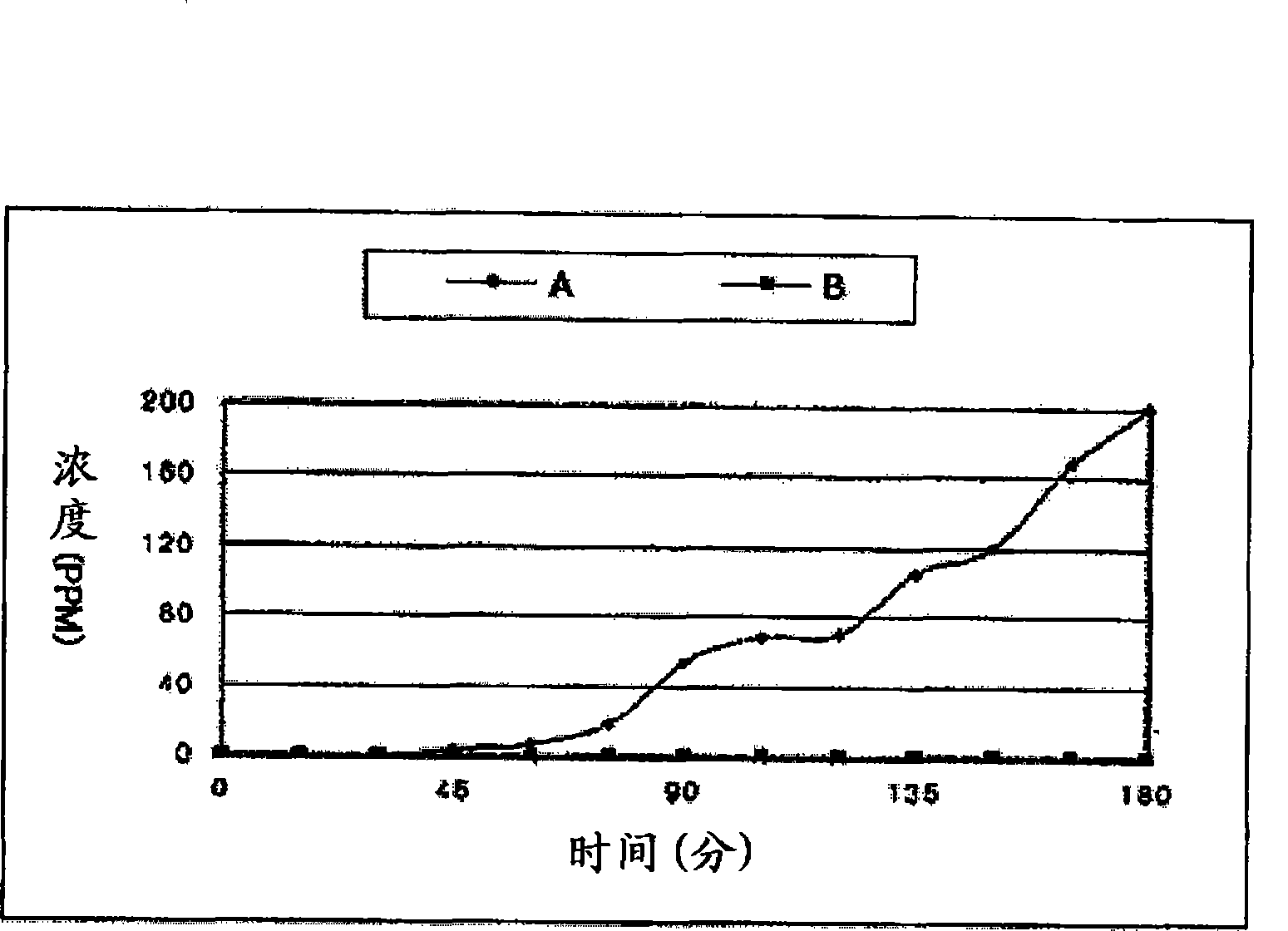

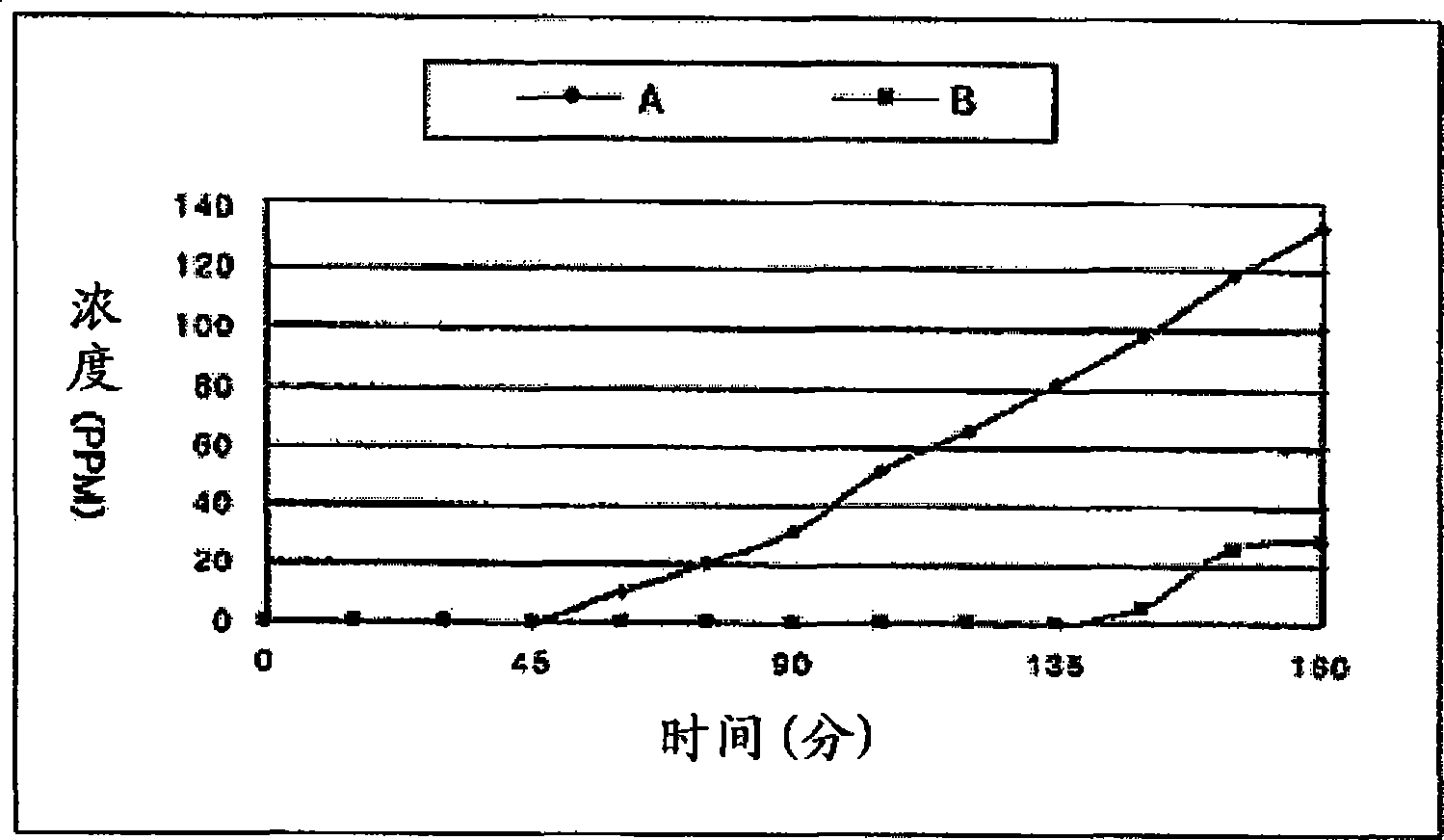

[0066] Structural activated carbon used in the present invention is different from activated carbon used in conventional deodorants. Comparison of odor removal efficiency

[0067] Structural activated carbon (particle diameter: 3mm, specific surface area: 1100m 2 / g, manufactured by Kuraray Corporation) and a conventional deodorant for air purifiers (particle size: 0.1mm, specific surface area: 1100m 2 / g, manufactured by Kuraray Corporation) and compared the odor removal efficiency of activated carbon of the component, the results are shown in Figure 1a and Figure 1b .

[0068] First, put 1 g of the structural activated carbon used in the manufacture of the deodorant of the present invention and 1 g of the activated carbon used in the conventional deodorant into a U-shaped reactor, and pass air through it to achieve a clean state without impurities. state.

[0069] Then, the sample gas whose flow rate and concentration are adjusted is injected into the MFC. The typ...

Embodiment 2

[0079] Manufacture of deodorant (a)

[0080] Drop into 40g copper compound (CuCl2) and 50g manganese compound (MnCl2) in 100ml water, and dissolve under stirring, in this aqueous solution, drop into 1000g and the same particle diameter of embodiment 1 is the structure active carbon of 3mm, and keep 0.5 hour Then take it out, and then dry it at 100°C for 8 hours. At this time, EDX (Energy Dispersive X-ray Spectroscopy) was used for analysis. As a result, when the weight of the structural activated carbon was used as a basis, the adhesion amounts of the copper compound and the manganese compound on the structural activated carbon were 5.5% by weight and 3.5% by weight, respectively. weight%.

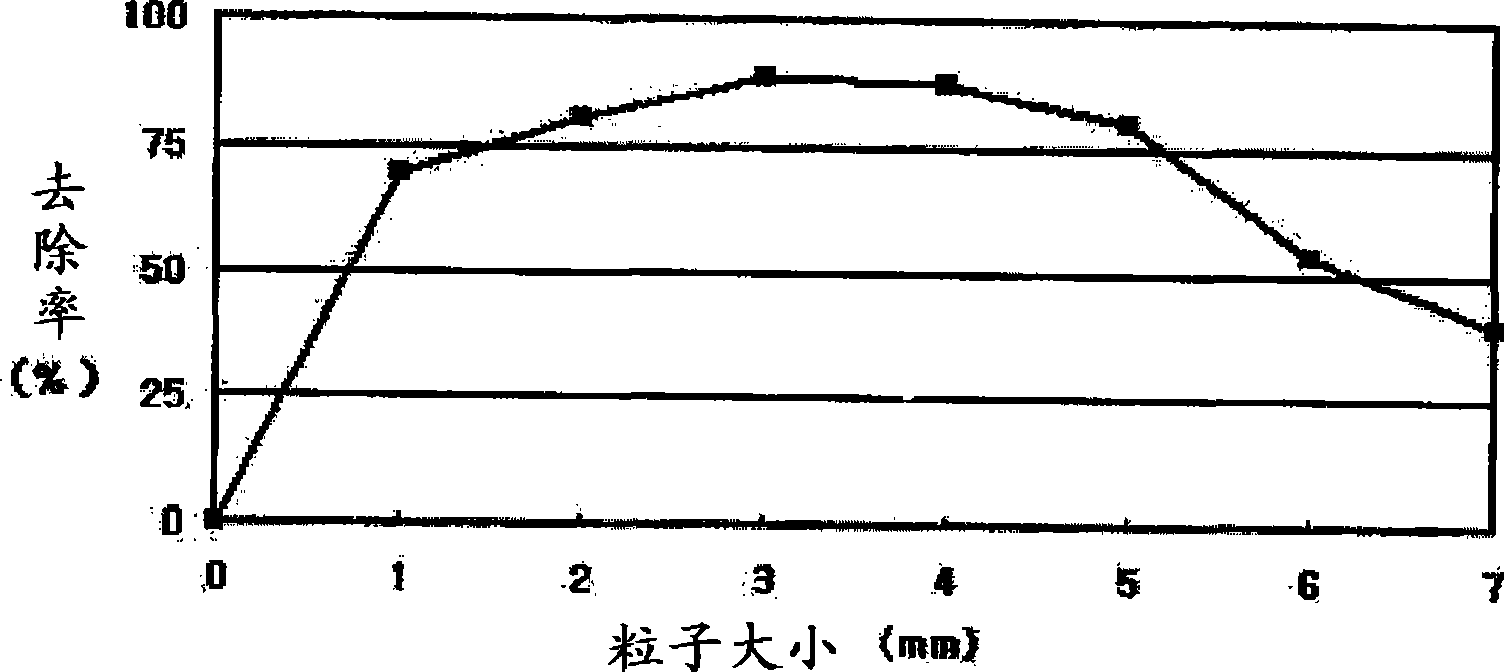

[0081] The adhesion process was adjusted so that the adhesion amount of the copper compound and the manganese compound was maintained at the above adhesion amount to produce a deodorant. At this time, the particle size of the structural activated carbon was changed to 1 mm unit.

[008...

Embodiment 3

[0091] Evaluation of Deodorizing Performance of Different Deodorants According to Compounds Adhering to Structural Activated Carbon

[0092] Manufacture of deodorants

[0093] Put 100g copper compound (CuCl 2 ) and 100g manganese compound (MnCl 2 ), dissolved under stirring, and in this aqueous solution, drop into 1000g the same particle diameter as Example 1 and be the structural activated carbon of 3mm, and take out after keeping 0.5 hour, then dry at 100 ℃ for 8 hours. At this time, EDX analysis showed that the adhered amounts of the copper compound and the manganese compound on the structured activated carbon were 8.2% by weight and 6.4% by weight, respectively, based on the weight of the structured activated carbon (1).

[0094] Deodorants (2 to 5) were manufactured as shown in Table 3 below by adjusting the type of metal compound to be adhered and / or the particle size of the structured activated carbon. At this time, the zinc (Zn) compound is Zn (NO 3 ) 2 . The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Particle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com