Patents

Literature

1820results about How to "Dense tissue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Various grains nutritious vermicelli produced with dual-extrusion pressing and compound steam combined method

InactiveCN101366479AImprove qualityGreat tasteDough extruding machinesFood preparationCombined methodThermal stability

The invention relates to flour food, in particular to a minor cereal nutrient dried noodle produced by a double extrusion and secondary steaming combination method and a preparation method thereof. The invention is characterized in that the minor cereal nutrient dried noodle is prepared through the following steps: five cereals are taken as main raw materials, cucurbits, vegetables and potatoes are added or are not added, an auxiliary material capable of improving and enhancing the quality of a product and a complex quality improvement liquid are added, and processes such as raw material pretreatment, mixing and stirring, noodle-making molding by the double extrusion and secondary steaming combination method, drying, cutting, packing and so on, are performed. The reasonable formula design and the noodle-making molding process by the double extrusion and secondary steaming combination method, namely a process of steaming and cooking once again after two-stage extrusion molding, assure the balanced nutrition and the strong health care function of the product, and the minor cereal nutrient dried noodle has the advantages of long storage period, steady quality, no turbid soup during the cooking, boiling fastness, good thermal stability, smooth appearance, and chewy taste, and can be eaten as staple food like ordinary dried noodles.

Owner:奥生平 +1

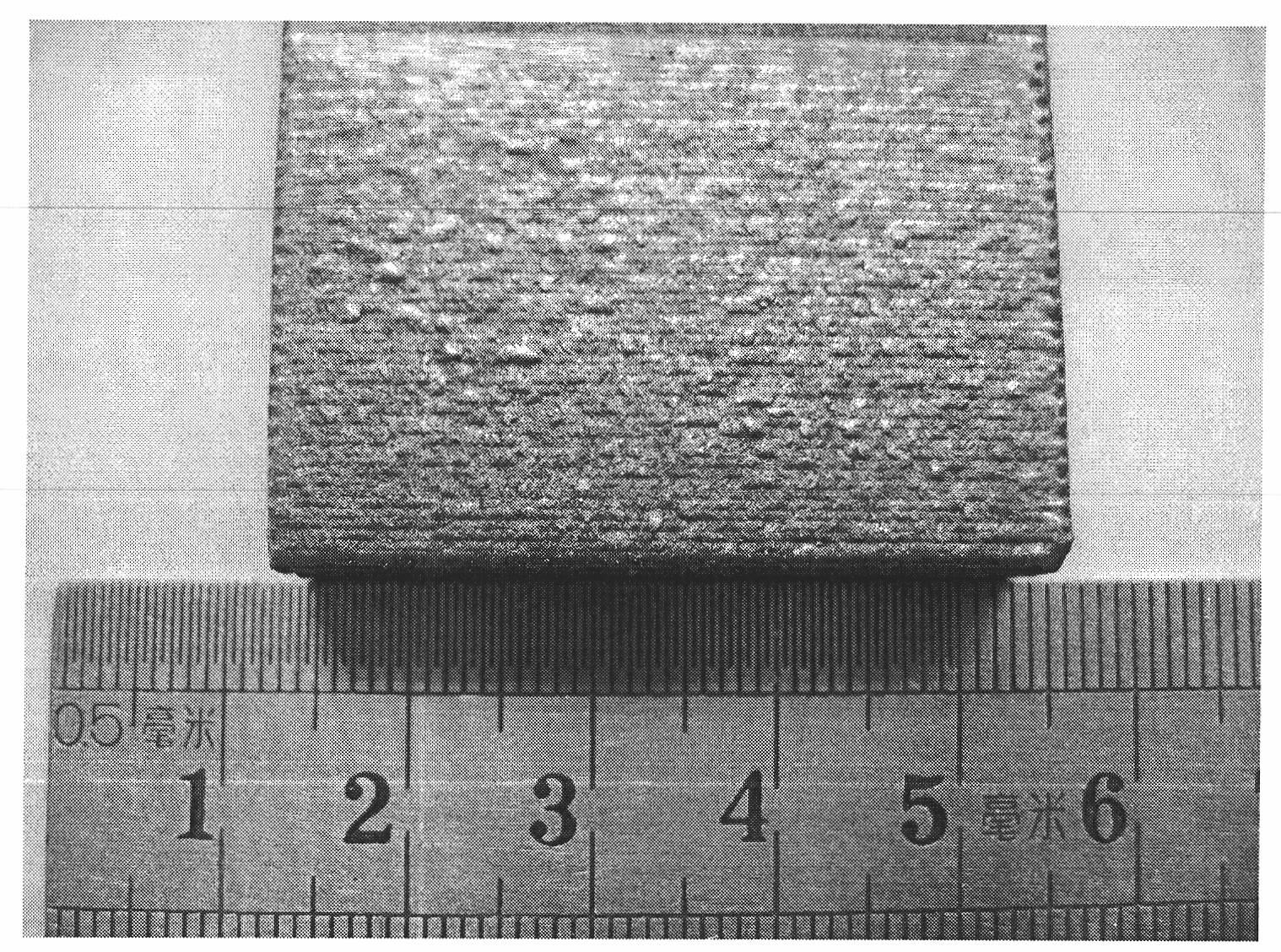

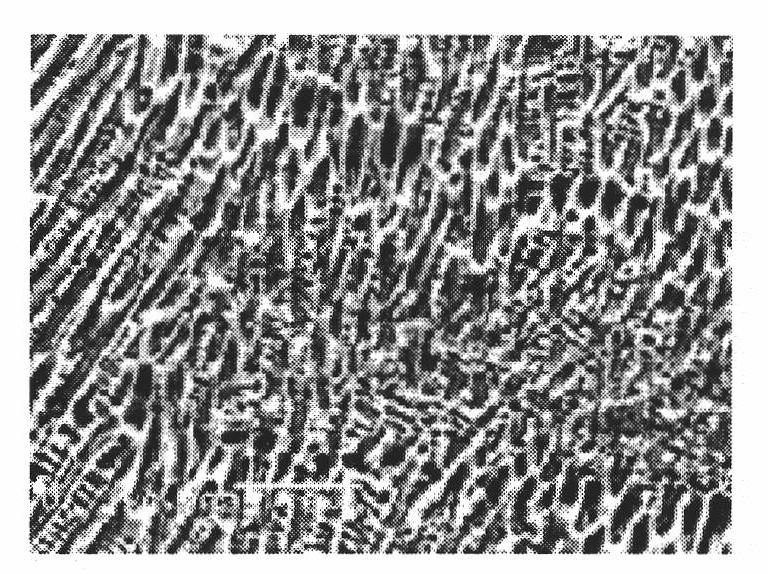

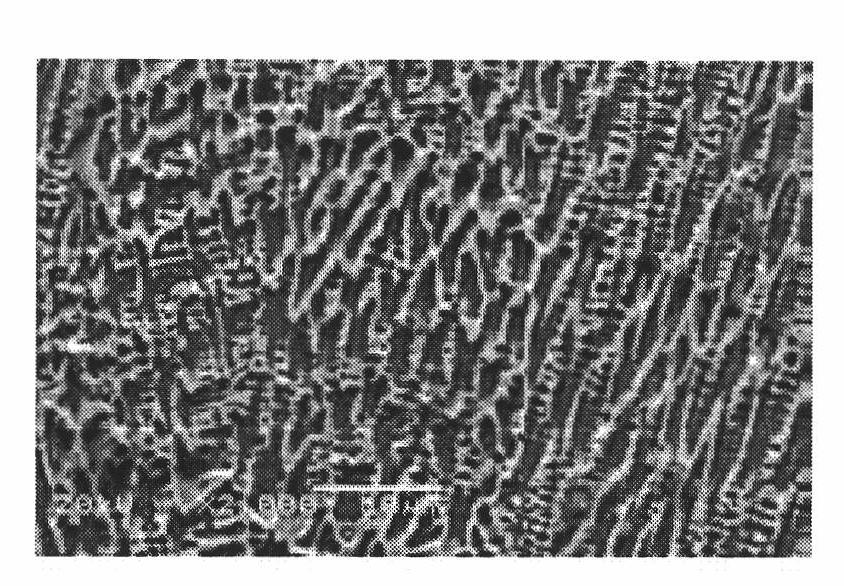

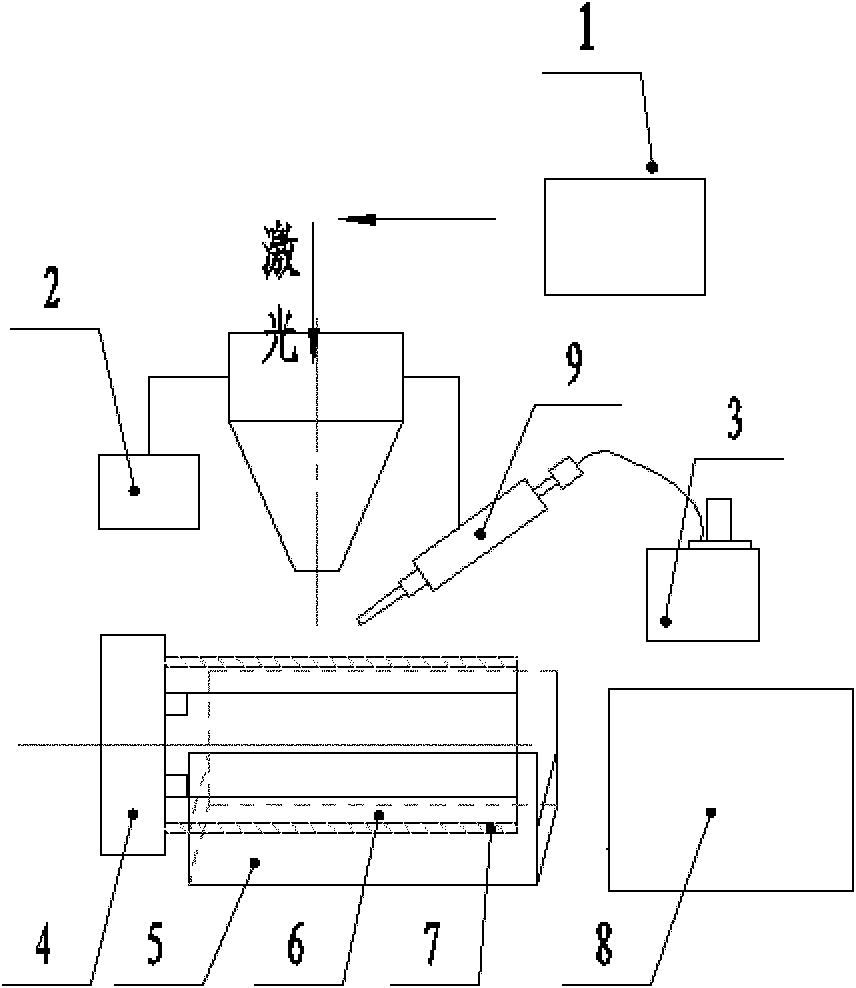

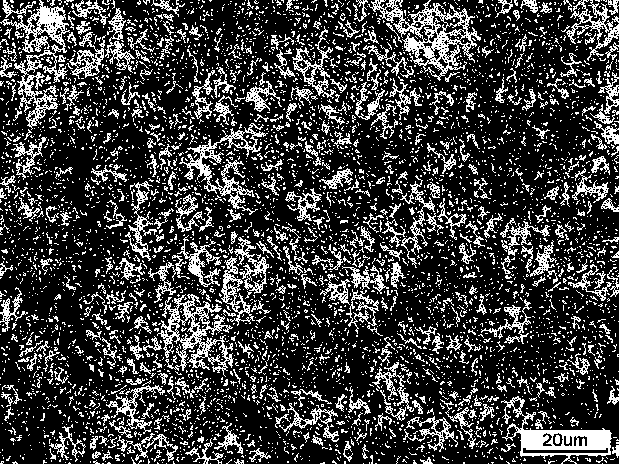

Laser-cladded composite wear-resisting layer on surfaces of copper and copper alloys and preparation method

InactiveCN102041503ADense tissueReduce energy consumptionMetallic material coating processesCobalt based alloyCopper alloy

The invention relates to a laser-cladded composite wear-resisting layer on the surfaces of copper and copper alloys and a preparation method. The composite wearing layer is a multi-layered laser cladding layer comprising at least two or more than two layers, wherein the coating connected with a substrate is the first layer, which is also called as a transition layer and is a copper-based alloy prepared from the following components in percentage by weight: 20.0-30.0 percent of Cu, 6.0-8.0 percent of Al, 0.3-0.6 percent of Si, 1.7-2.4 percent of Zr and the balance of Ni; and the rest layer is a cobalt-based alloy prepared from the following components in percentage by weight: 1.0-1.5 percent of C, 25-30 percent of Cr, 2-4 percent of Fe, 10-15 percent of W, 0.8-1.2 percent of Si, 3-4 percent of B, 8-12 percent of Ti, 10-12 percent of Ni and the balance of Co. The composite wear-resisting layer provided by the invention has compact tissues without cracks or pores and forms favorable metallurgy combination with the surfaces of copper and copper alloys. The preparation method provided by the invention can be used for accurately controlling the thickness of the composite wear-resisting layer and automatically controlling the whole process, and has the advantages of low energy consumption, no pollution, high efficiency and low cost.

Owner:HUAZHONG UNIV OF SCI & TECH

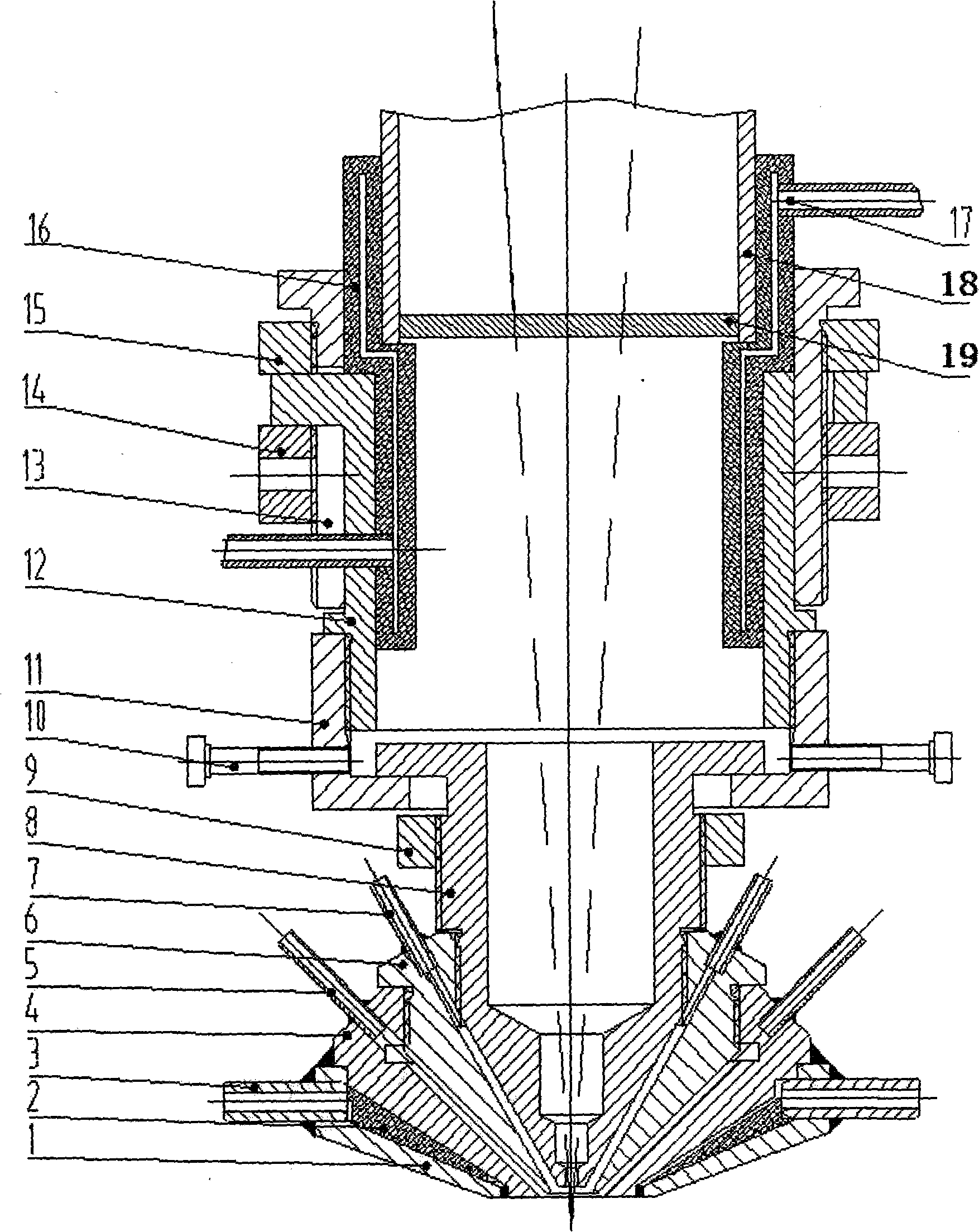

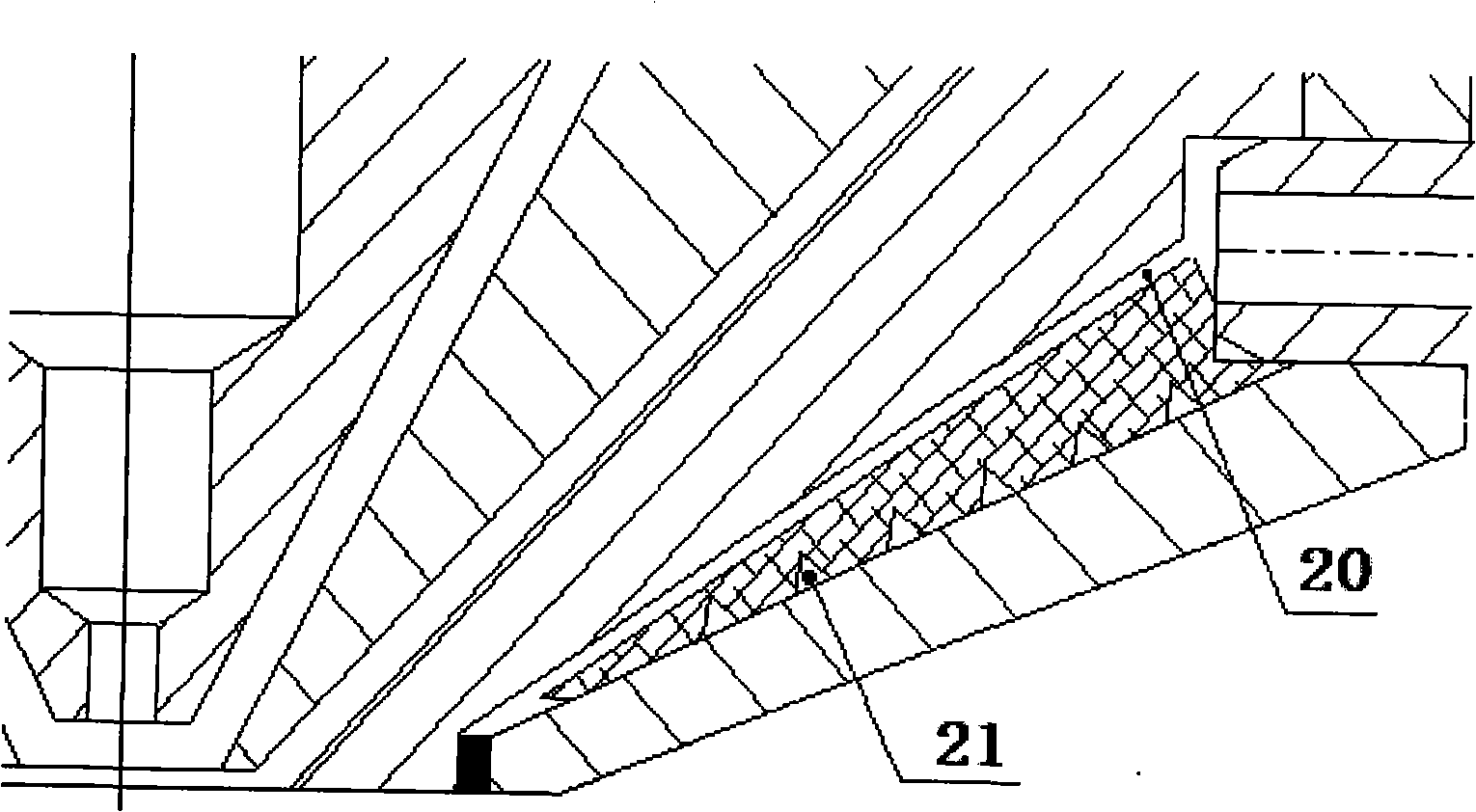

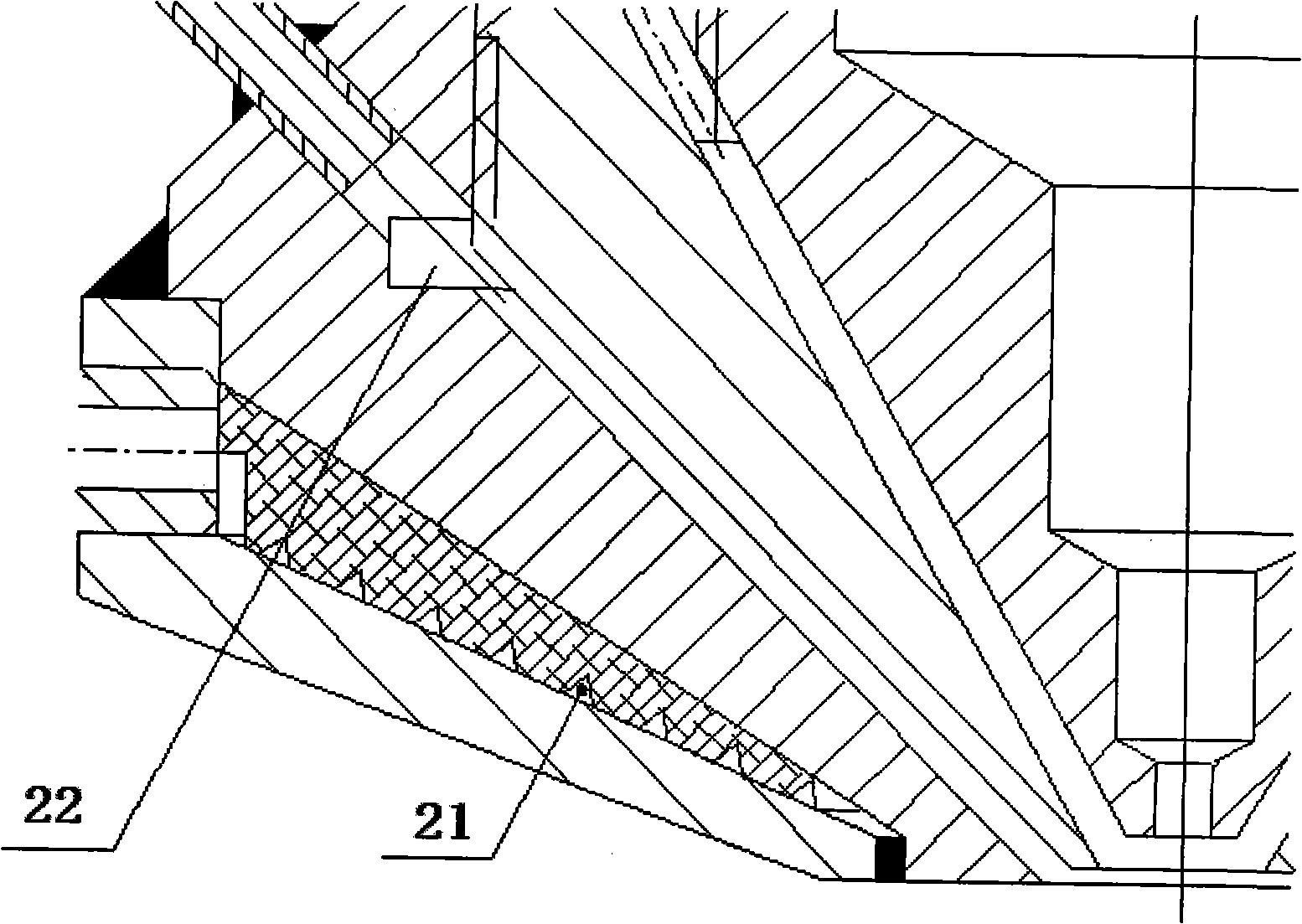

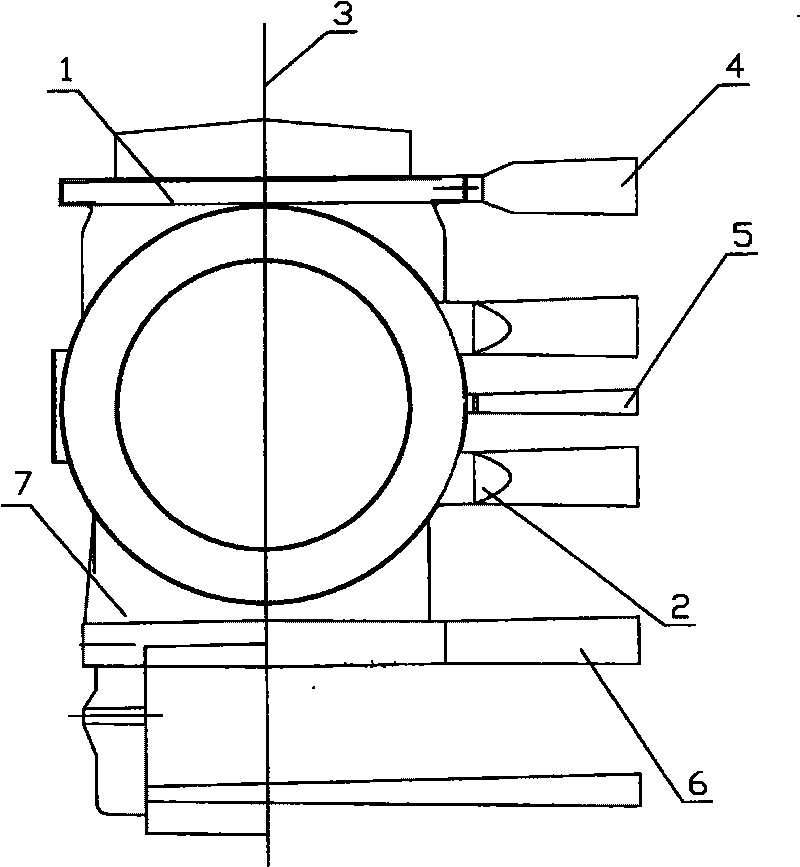

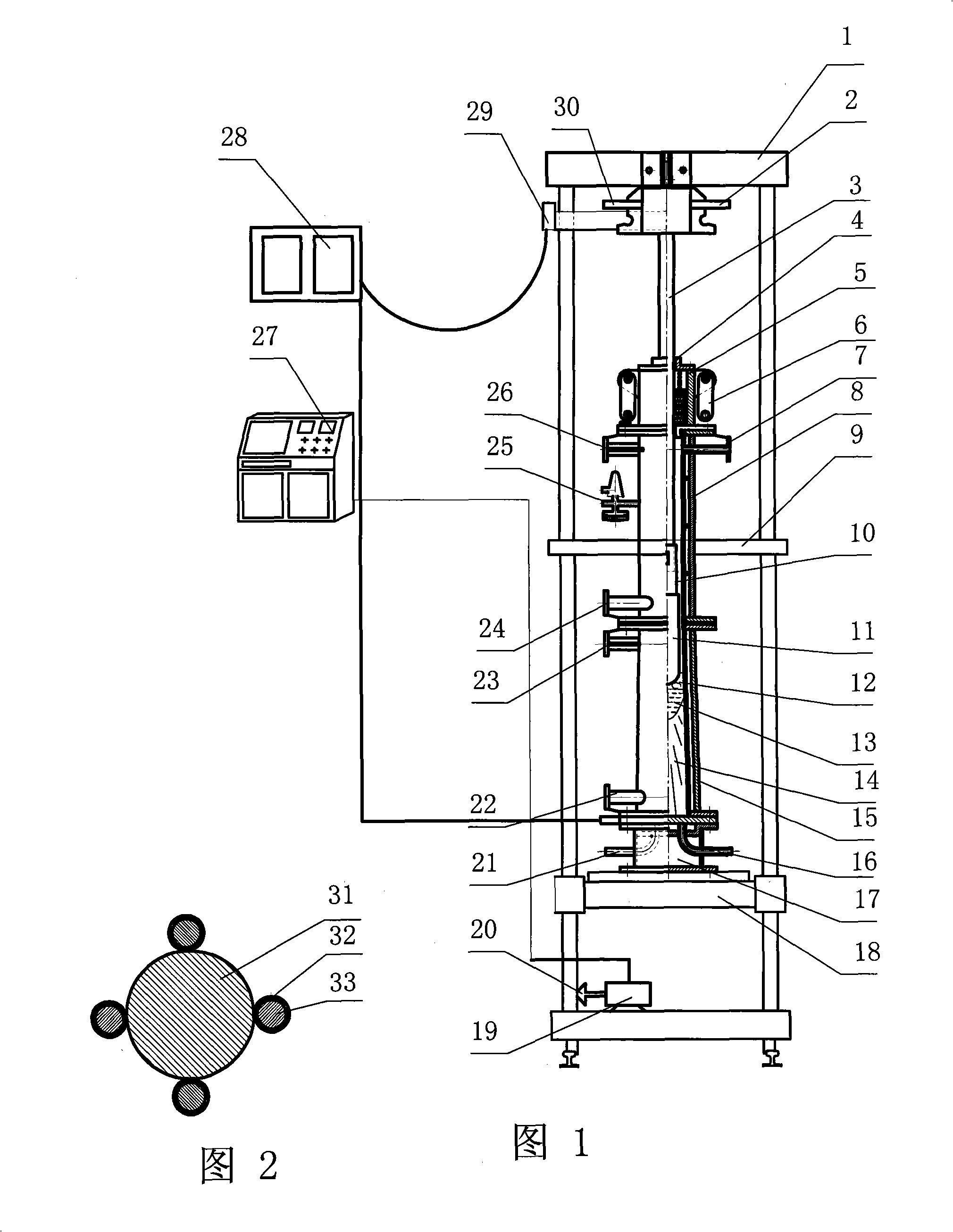

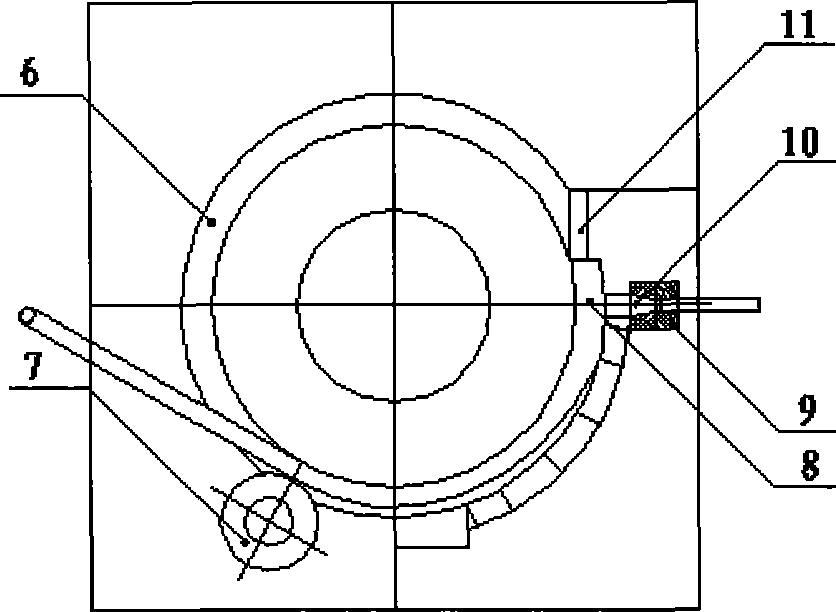

Adjustable laser coaxial powder feeding nozzle

The invention discloses an adjustable coaxial laser nozzle for sending powder, comprising a laser head, a protection lens, a water-cooling sleeve for the protection lens and a column laser cavity arranged on the upper part, a coaxial conical laser cavity which is formed by the inner layer of a laser sleeve and arranged in the middle part, wherein a powder cavity, a secondary external protective cavity and an external water-cooling cavity are arranged on the lower part of the external part of the laser sleeve; the powder cavity is formed between the laser sleeve and a power cavity sleeve screwed together; the secondary external protective cavity is formed between the powder cavity and a protective air casing screwed together; the powder cavity and the protective sir casing are screwed together and adjustable between 1mm to 3mm; 4 to 6 power transmitting pipes and 4 to 6 air tubes are respectively positioned around the top parts of the cones of the powder cavity and the protective air cavity. The adjustable coaxial laser nozzle for sending powder has the advantages that the focus length of the focus lamp fit for the coaxial powder-sending nozzle is between 100mm to 300mm, which ensures convenient assembly and disassembly, even velocity, flexible adjustment of the powder converge diameter, convenient changeable lower coaxial conical parts (the powder cavity, the air casing and the water cavity).

Owner:XI AN JIAOTONG UNIV

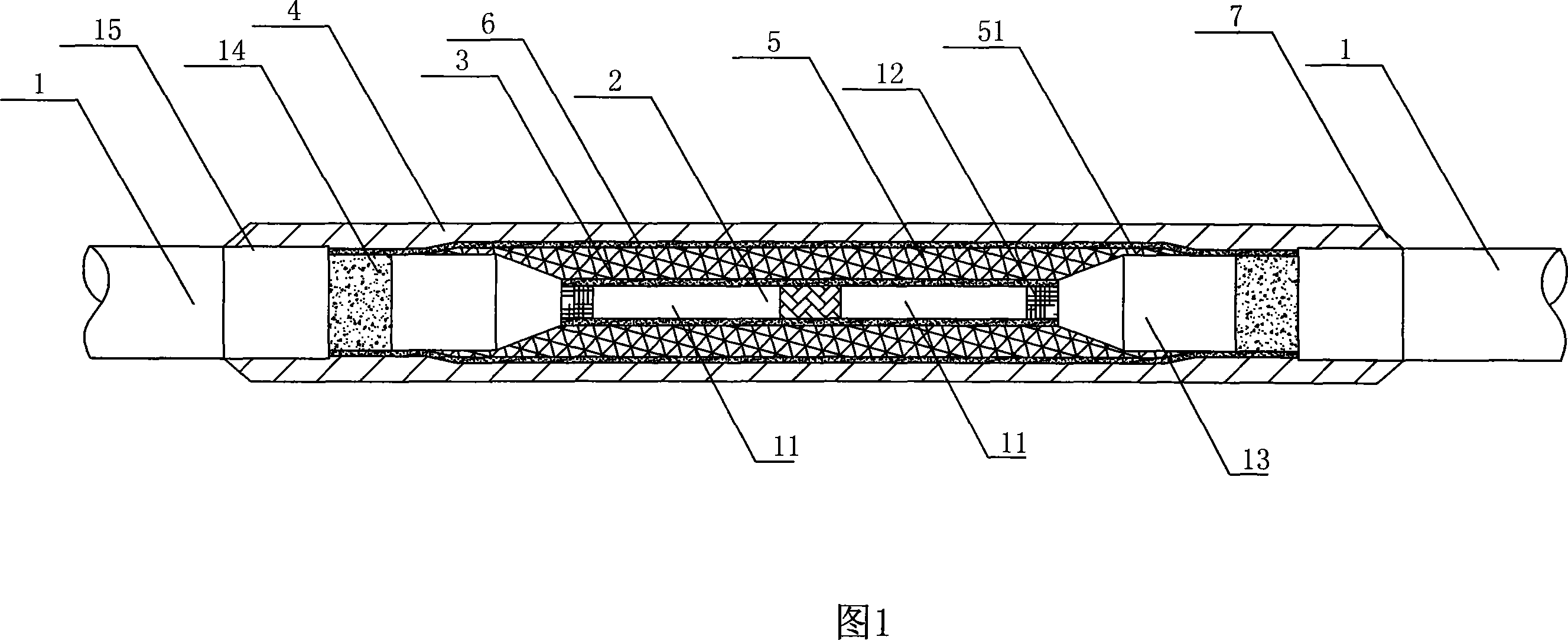

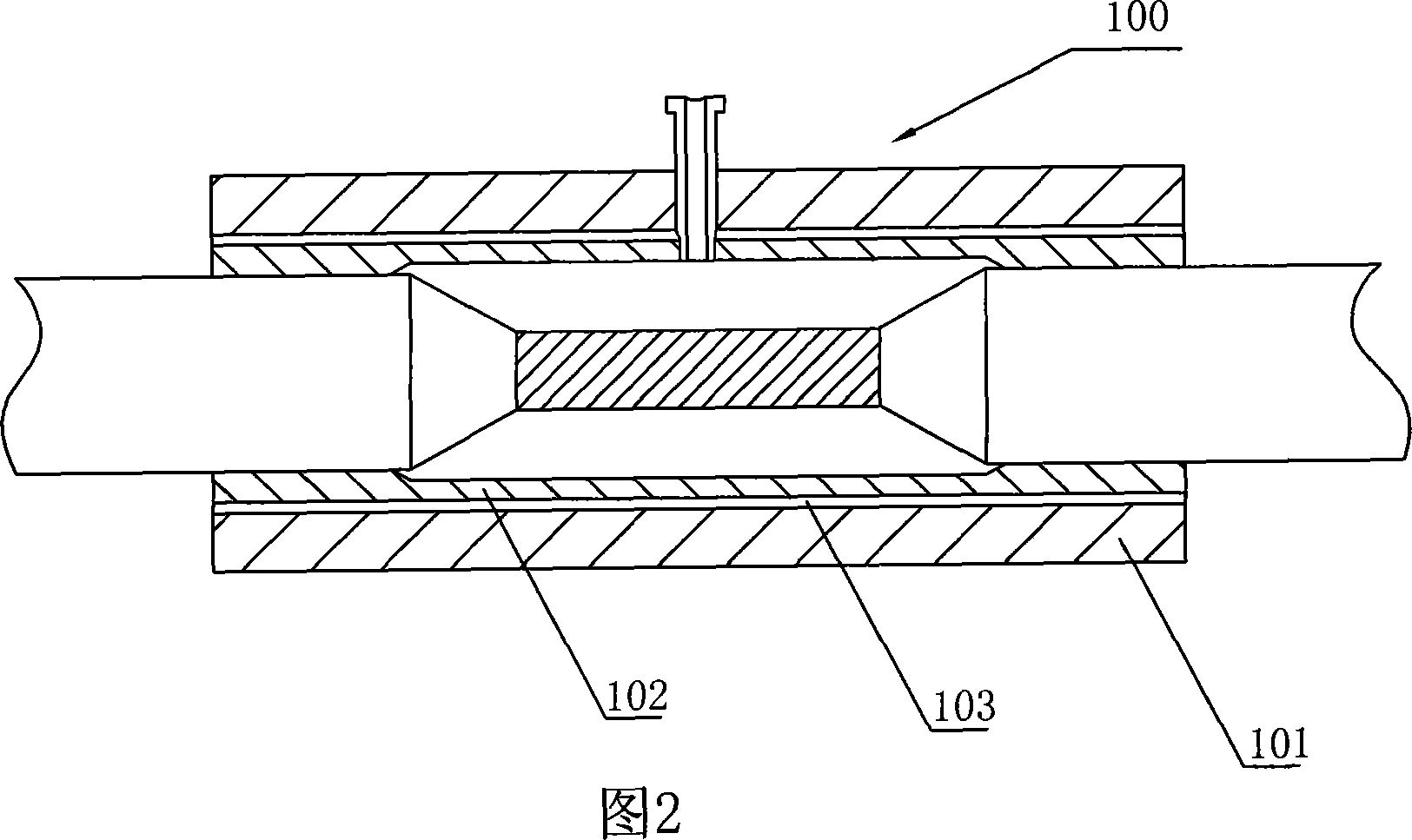

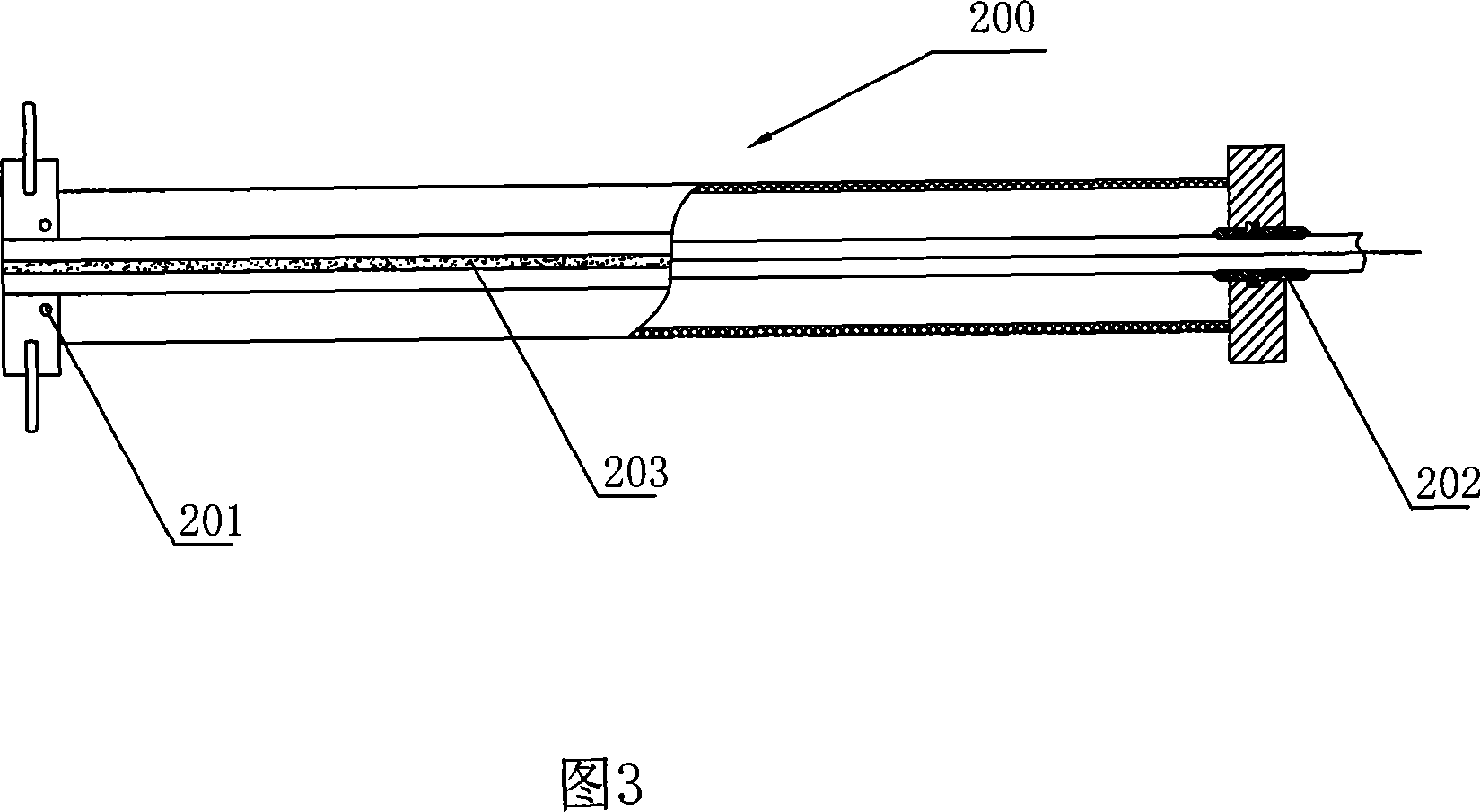

Soft joint for cross-linked polyethylene cable and producing method thereof

ActiveCN101068075AElectrical performance improvements and enhancementsEliminate void defectsCable junctionsApparatus for joining/termination cablesInsulation layerEngineering

This invention discloses a soft joint of a cross-linked polythene cable including an inner semiconductive layer and metal jacket sleeves, in which, two core leads between two cables are welded to form a core connection part, the inner semiconductive layer is combined with a preserved section of the inner screen layer of the cable characterizing in setting a polythene filled vulcanized insulation layer out of the inner semiconductive layer to be fused with the polythene insulation layer of the cable, and wrapping the polythene insulation of the cable with a transition connection section and an outer semiconductive layer combining with the preserved section of the outer screen of the cable is set out of the polythene filled vulcanized insulation layer, two ends of the metal jacket sleeve are welded with the out surfaces of lead protection pipe of the cable and set with slope connection sections.

Owner:宁波东方电缆股份有限公司

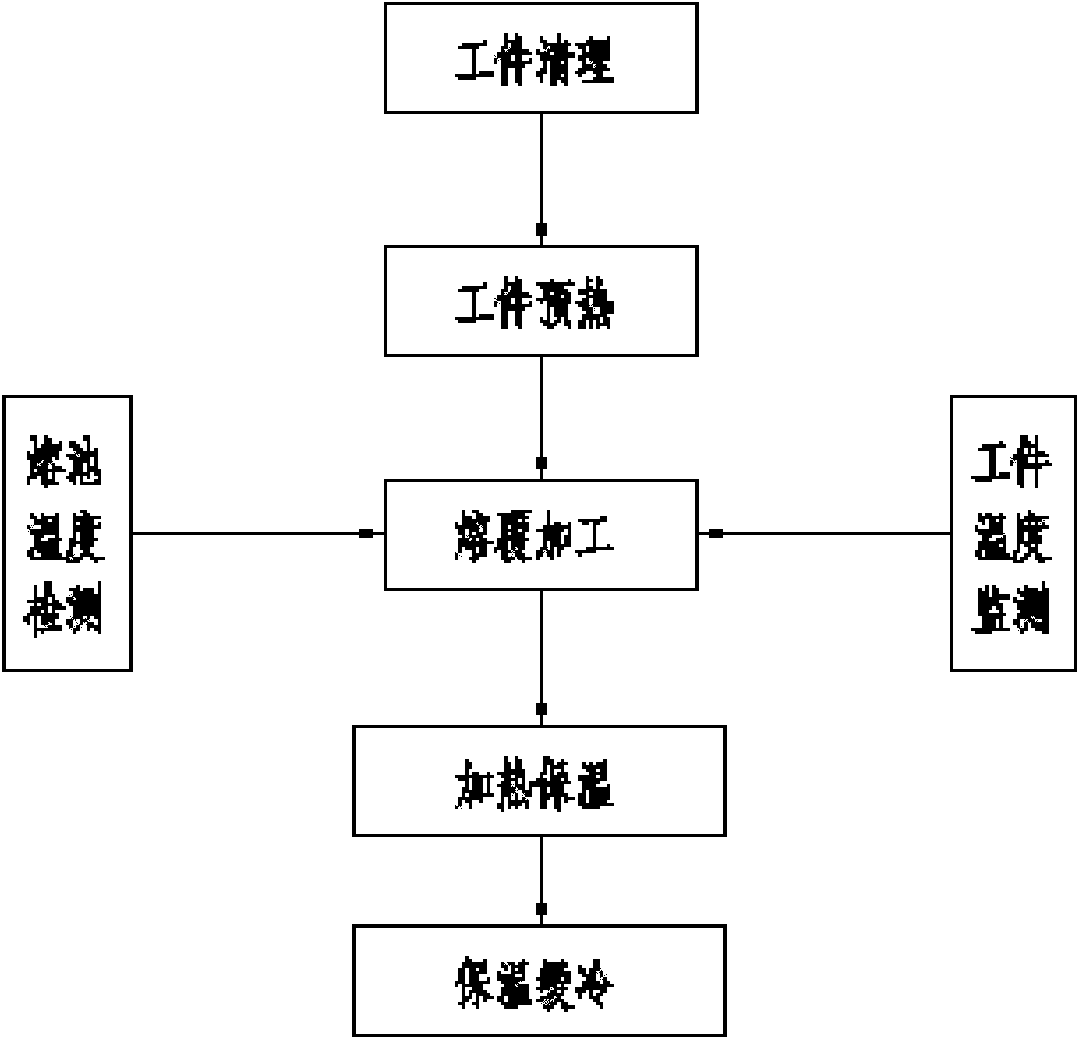

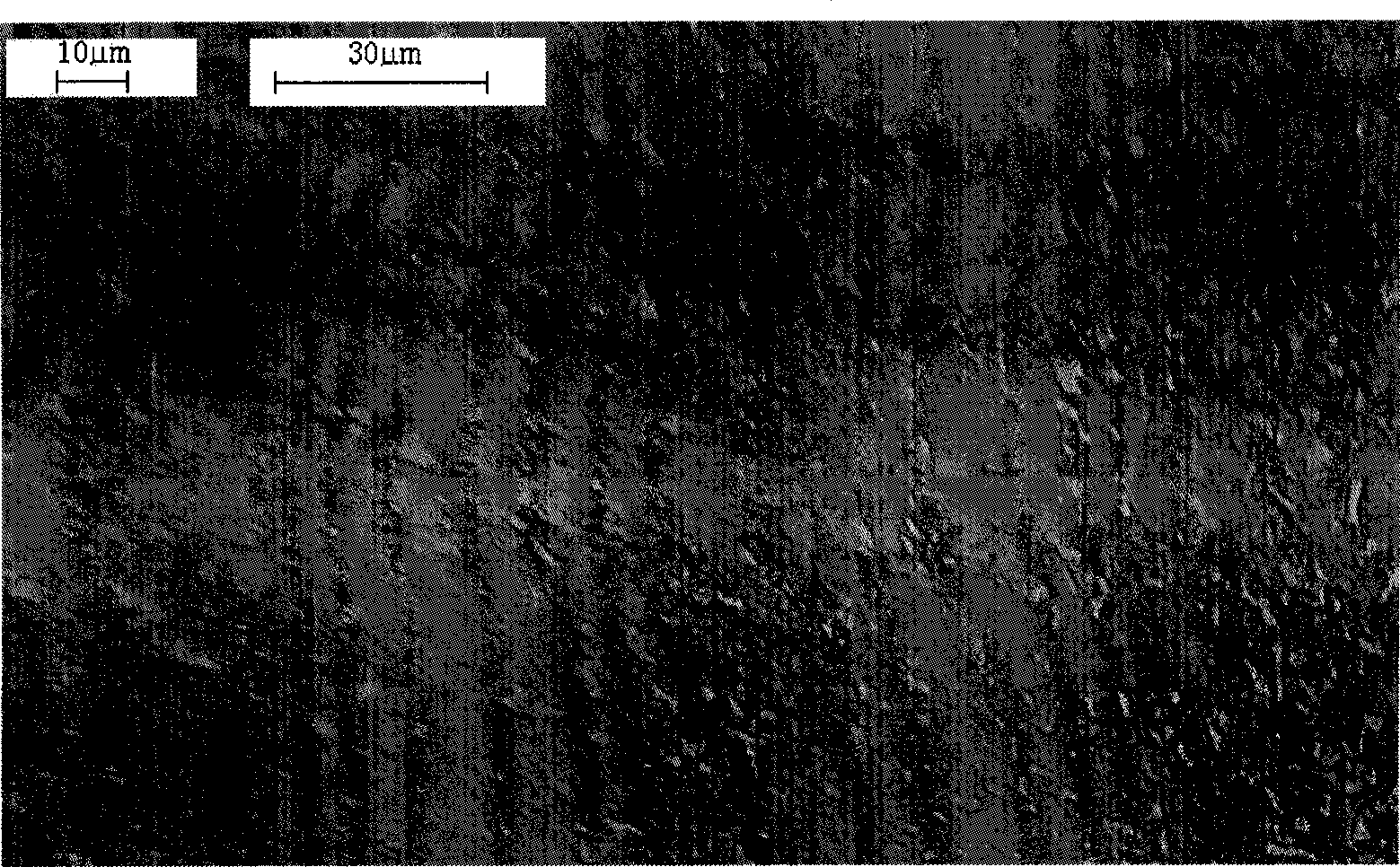

Method for carrying out laser-cladding on high-hardness nickel-based alloy material in large area

ActiveCN102465294AImprove wear and corrosion resistanceDense tissueMetallic material coating processesLaser beam welding apparatusSurface engineeringHeat-affected zone

The invention belongs to the field of material surface engineering and more particularly relates to a method for carrying out cladding on a high-hardness wear-resistant anti-corrosion nickel-based alloy material on a metal substrate E in a large area by applying a laser cladding technology, solving the problem of cracks generated in the laser cladding process of the high-hardness wear-resistant nickel-based alloy, in particular the cladding defects, such as cracks with the thickness of more than 1mm, pores and the like during large-area cladding. According to the invention, the high-hardness nickel-based alloy powder material is cladded on the surface of the metal substrate in the large area to form a high-hardness wear-resistant anti-corrosion nickel-based alloy coating by applying the laser cladding technology and adopting a scientific and reasonable process method. According to the method disclosed by the invention, stability and consistency of laser cladding are foundationally ensured, defects, such as cracks, pores, impurities can be prevented from generating, heat affected regions of the substrate are reduced, dilution rate is reduced, the high-wear-resistance anticorrosion nickel-based alloy coating with firm metallurgical bonding and fine and compact grains is obtained and has the hardness reaching 58-63HRC, and the service life of the processed workpiece can be prolonged by more than 1-2 times.

Owner:NINGBO SIASUN ROBOT TECH CO LTD

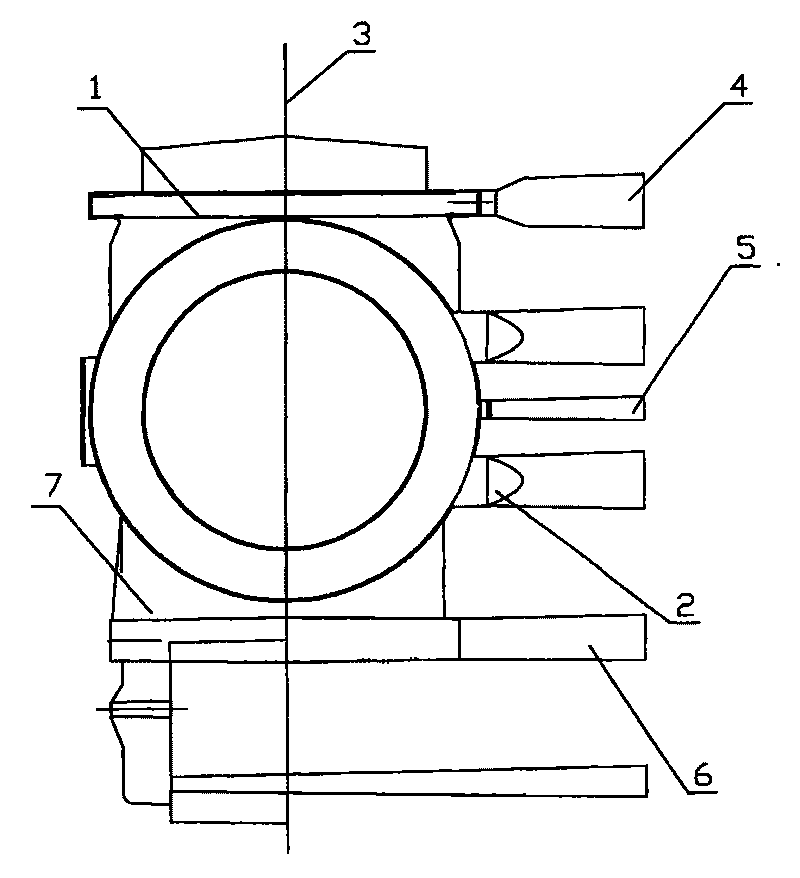

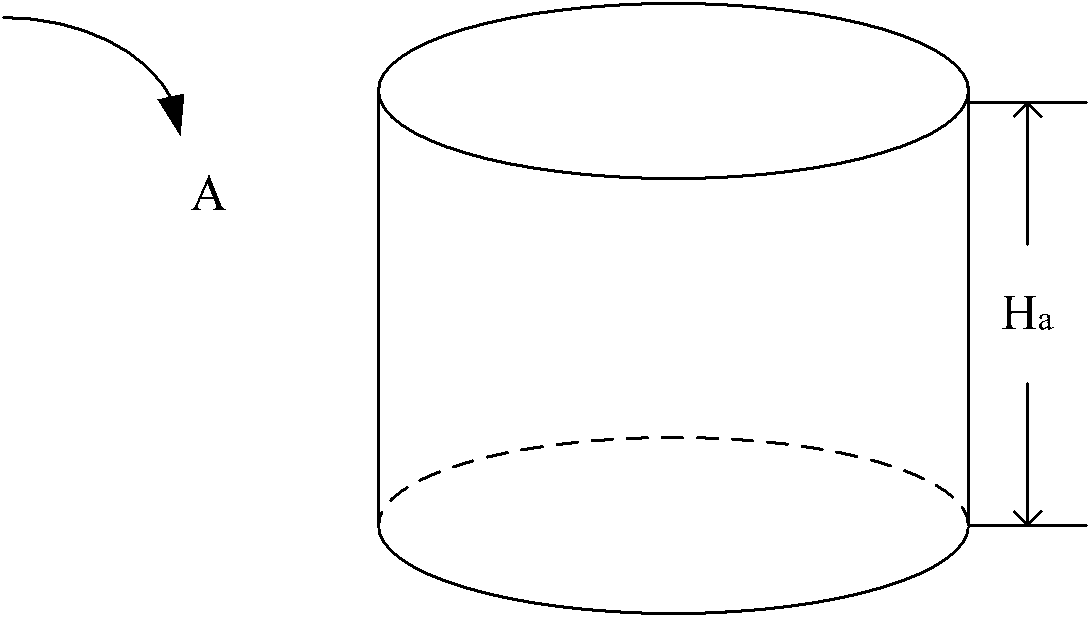

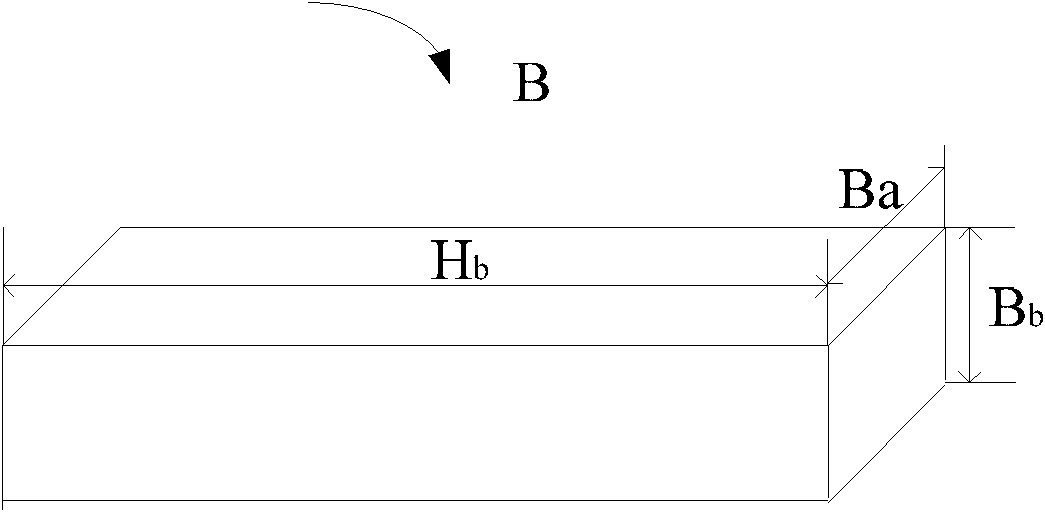

Method for producing voltage-bearing aluminum alloy tank body of ultra-high voltage switch by V-process

ActiveCN101693282AImprove mechanical propertiesImprove quality levelFoundry mouldsFoundry coresFoundryIntermediate frequency

The invention discloses a method for producing a voltage-bearing aluminum alloy tank body of an ultra-high voltage switch by a V-process, comprising the following steps: model making, thin film heating, thin film shaping (film absorbing), coating spraying, sandbox placing, ram-jolting by adding sand , back film covering, film loosening, core setting, box folding, pouring, removing box and shaking out. After the process is improved, an intermediate frequency furnace is utilized to melt and a crucible heat preserving furnace is utilized to modify and refine. When melting in the intermediate frequency furnace, microelements such as tombarthite and the like are replenished and a new non-stirring melting and refining technology is adopted so as to reduce oxide inclusion content in alloy liquid. Modification and refining treatment in the crucible heat preserving furnace ensures high purity degree and high component precision of aluminum liquid, and using pure aluminum alloy liquid can increase the ratio of acquiring qualified pressure-proof tank body foundry products.

Owner:NANYANG HUISEN PRECISION INSTR CASTING

Aluminum alloy and aluminum alloy extruded profile machining method

The invention discloses aluminum alloy and an aluminum alloy extruded profile machining method. The aluminum alloy comprises, by weight, 0.6-1.4% of Si, 0.7-1.3% of Mg, 0.1-1% of Cu, 0.1-1% of Mn, 0.01-0.15% of Ti, 0-0.2% of Zr, 0-0.5% of Cr, 0-0.4% of Fe, 0-0.25% of Zn and the balance Al. The aluminum alloy also meets the requirements that the weight percentage range of Mg+Si+Cu is 1.4-3.7%, themole ratio of Mg to Si is 0.7-1.5, and the weight percentage range of Mn+Cr+Zr is 0.1-1.5%. The machining method comprises the steps that (1) a cast ingot of the alloy is subjected to homogenization treatment; (2) the cast ingot is extruded into aluminum profile; (3) extrusion production is conducted; (4) on-line quenching is conducted; (5) tension leveling is conducted; and (6) artificial aging is adopted. According to the aluminum alloy and the aluminum alloy extruded profile machining method, the technology is simple, and the production cost is low.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

Composite roller for high vanadium high speed steel and its production process

The invention offers the high V super-speed steel complex roller and its producing craft. The roller includes roller heart and roller shell, the roller heart uses low metal alloy steel or middle carbon steel to produce, the shell uses high V super-speed steel, whose main element is : C: 1.8--3.5A%, V: 7--12%, Cr: 4--5%, Mo: 2--4%, Ni: 0.5--1.5%, other is Fe. The producing craft is: melt and cast the heart and shell by responding heat way. The roller in the invention has good whet feature, high rate of feature and price, using safely. Fine roller, high strength of combination, no crush in use; it can reduce the stop times. It efficiently increase the roller tenacity and whet feature, solve the problems in the heart leaving foundry, and solve the problems of complicated craft and high cost.

Owner:HENAN UNIV OF SCI & TECH +1

High abrasion-proof laser cladding nickel-base alloy powder and preparation method thereof

InactiveCN102943267AHigh hardnessImprove wear resistanceMetallic material coating processesCarbideAlloy

The invention relates to a high abrasion-proof laser cladding nickel-base alloy powder and a preparation method of the alloy powder. The high abrasion-proof laser cladding nickel-base alloy powder is characterized by comprising matrix alloy powder, hard carbide particles and a bonding agent; and the combined powder comprises 50-98% of matrix alloy powder, 1-45% of WC or TiC or mixed powder of WC and TiC, and 1-5% of bonding agent. The preparation method comprises the following steps of: preparing the matrix alloy powder, adding the carbide particles into the prepared matrix alloy powder, adding the bonding agent into the mixture, stirring, ball milling, combining the powder, drying, crushing and screening. The high abrasion-proof laser cladding nickel-base alloy powder not only is high in hardness, but also has excellent wear resistance and corrosion resistance, thus being especially suitable for laser cladding of alloy workpieces with high surface hardness and high wear resistance. Furthermore, the phenomenon of segregation caused by great differences among the specific gravities of all components in the processes of storage, transportation and using can be effectively prevented.

Owner:江苏新亚特钢锻造有限公司

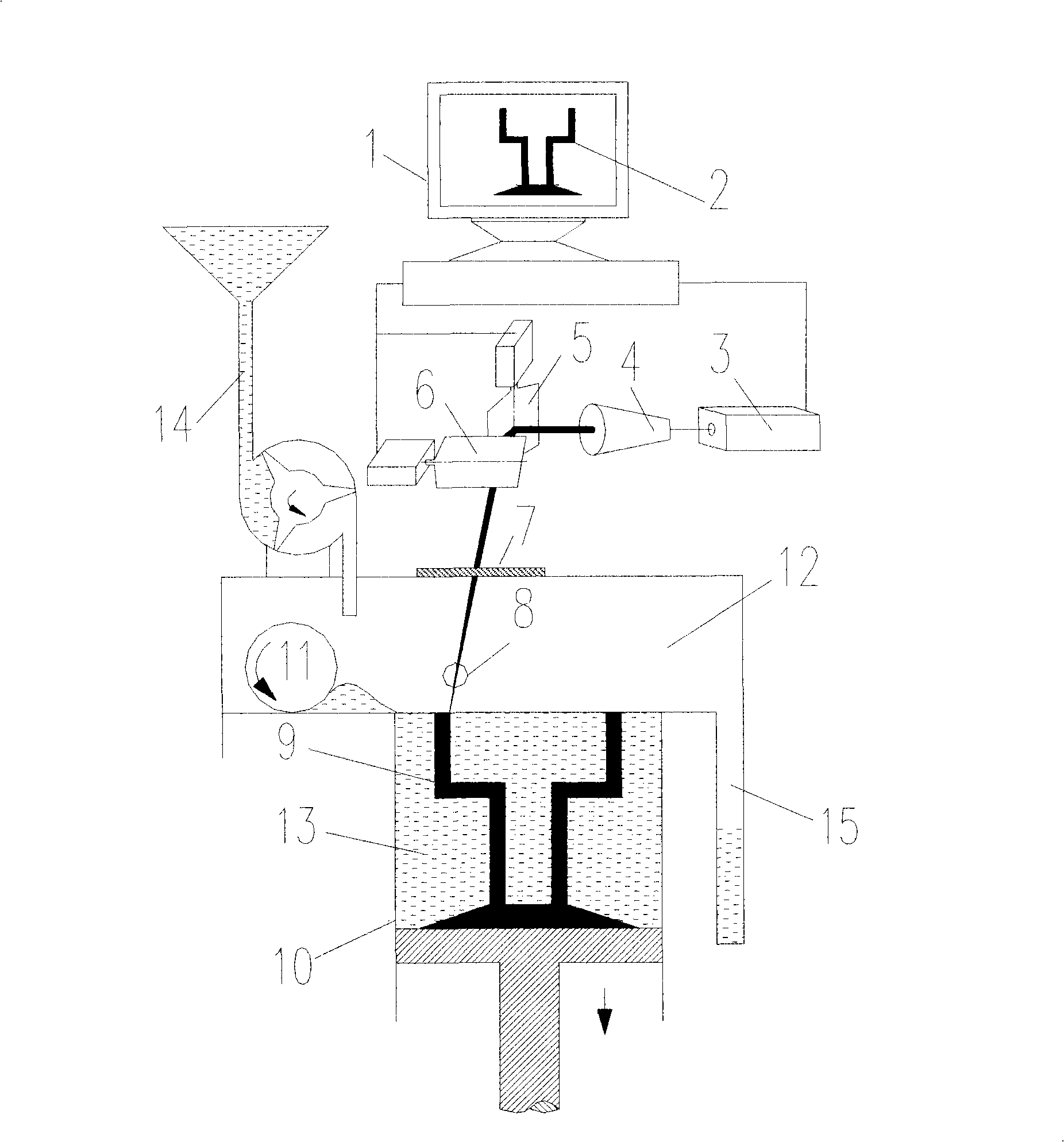

Precinct laser fusion rapid molding method and device of medical implantation material wax mould

InactiveCN101310964ADense tissueSimplify the manufacturing processComputerised tomographsTomographyWaxOriginal data

The invention provides a method for laser-melting and fast forming of a choosing area of a medical implant moulage, which refers to measuring an organ of a patient to obtain the original data for a medical implant; three-dimensional CAD software is adopted to transform the original data into a three-dimensional CAD model for secondary processing and then for slicing processing so as to obtain a multi-layer-slice two-dimensional CAD data model of the medical implant; scanning path planning is carried out to the two-dimensional CAD data model of each slice to obtain scanning path data which is guided into a host computer of a choosing area laser-melting and fast forming device, and a layer-to-layer fast scanning method is adopted to carry out the choosing area laser-melting and fast forming to paraffin powder so as to prepare and obtain the medical implant moulage; the medical implant moulage is taken out to clear redundant paraffin power on the surface. The slicing processing of the invention does not relate to STL format data; the formed moulage has dense tissue, thus no more processing is needed after infiltration of the paraffin, small scale forming equipment can be realized, equipment producing cost can be reduced and forming time is shortened.

Owner:SOUTH CHINA UNIV OF TECH

Permanent ferrite magnetic tile and preparation method thereof

InactiveCN101202138AIncrease solid solutionImprove performancePermanent magnetsInorganic material magnetismFiberSilicon oxide

The invention relates to a permanent ferrite magnetic arc and the manufacturing method thereof, belonging to a manufacturing field of a motor permanent ferrite. Weight proportions of main material components and additive components are as the following: main materials: 8.7 to 9.0 percent of strontium oxide; 86 to 87 percent of iron oxide red; additives: 0.6 to 1.0 percent of calcium carbonate; 0.6 to 1.0 percent of aluminum oxide; 0.4 to 0.8 percent of chrome oxide; 0.3 to 0.6 percent of boric acid; 0.3 to 0.5 percent of silicon oxide; 0.2 to 0.4 percent of cobalt oxide; 0.2 to 0.4 percent of lanthanum oxide and 0.1 to 0.3 percent of silicate fiber. The invention is provided with high surplus magnetic induction strength and high intrinsic coercivity so as to enhance a mechanical strength of the magnetic arc.

Owner:CHANGZHOU DIER MAGIC MATERIALS

Aluminium alloy for vehicle hub and preparation method thereof

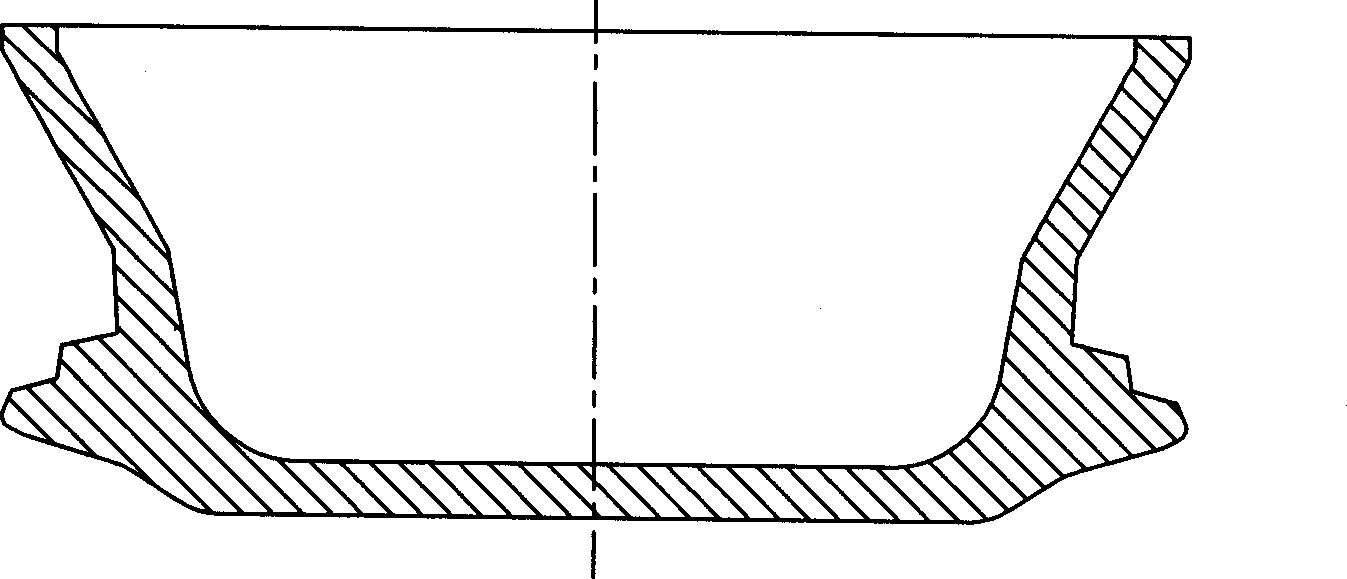

The invention provides an aluminium alloy for a vehicle hub and a preparation method thereof. The alloy comprises the following components by weight percent: 4.5-6.3% of Zn, 1.4-2.5% of Mg, 0.5-0.9% of Cu, 0.12-0.3% of Zr, 0.05-0.15% of Ti, 0.05-0.2% of Cr, 0.1-0.3% of Sc and the balance of Al. The preparation method of the aluminium alloy comprises the following steps: weighting raw materials, melting the raw materials except for magnesium blocks, adding a covering agent, then adding the preheated magnesium blocks, stirring, injecting nitrogen or argon to degas, filtering with a ported ceramic plate, reducing the temperature, standing for 20 minutes, and adopting a liquid forging mould and a liquid forging forming method to prepare the hub. The prepared vehicle hub has high strength, impact toughness and corrosion resistance; and the mechanical properties of the aluminium alloy hub can be ensured, the production cost can be reduced and the large-scale production of the hub is easy to perform.

Owner:ZHEJIANG GKO ALUMINUM

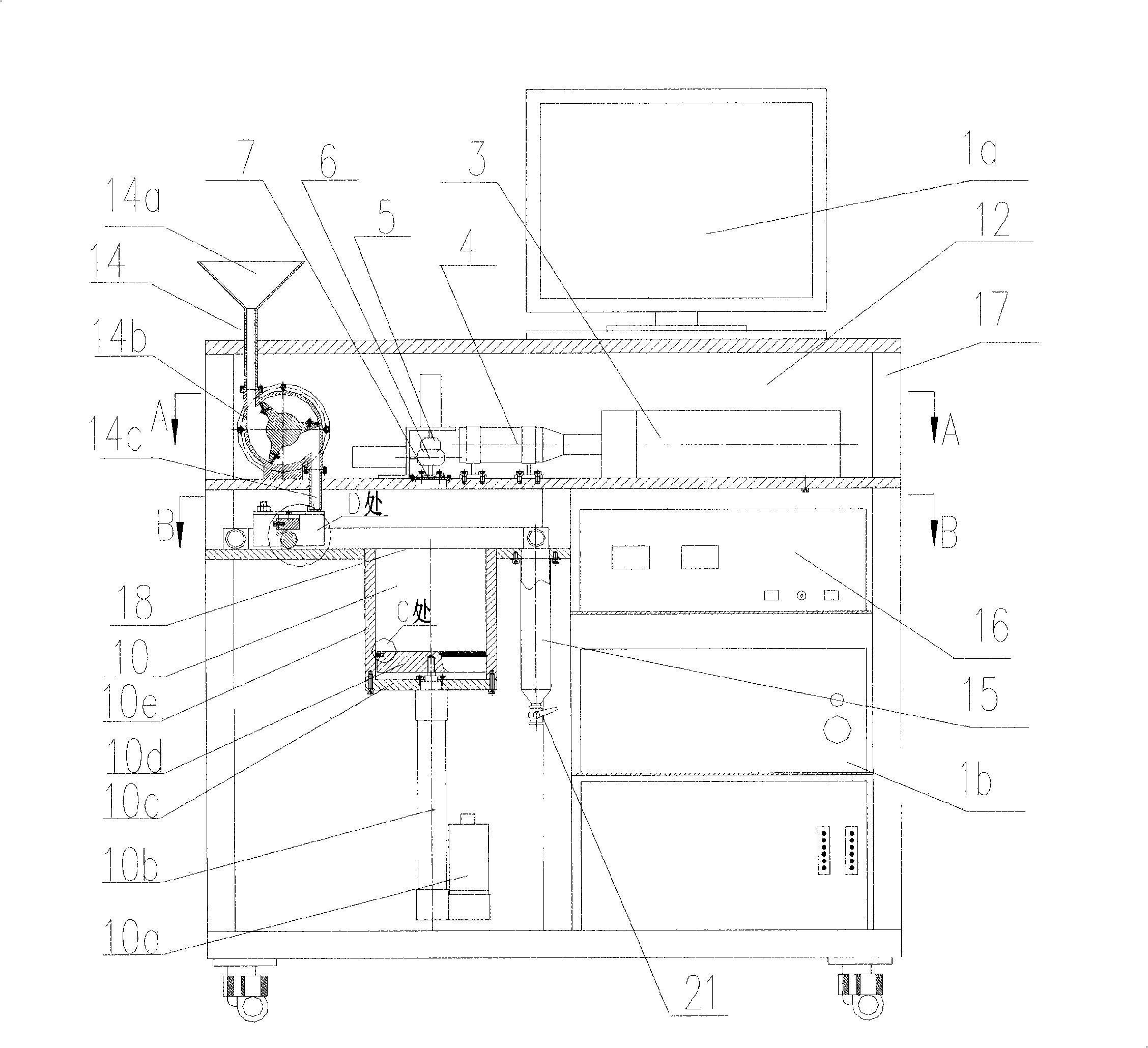

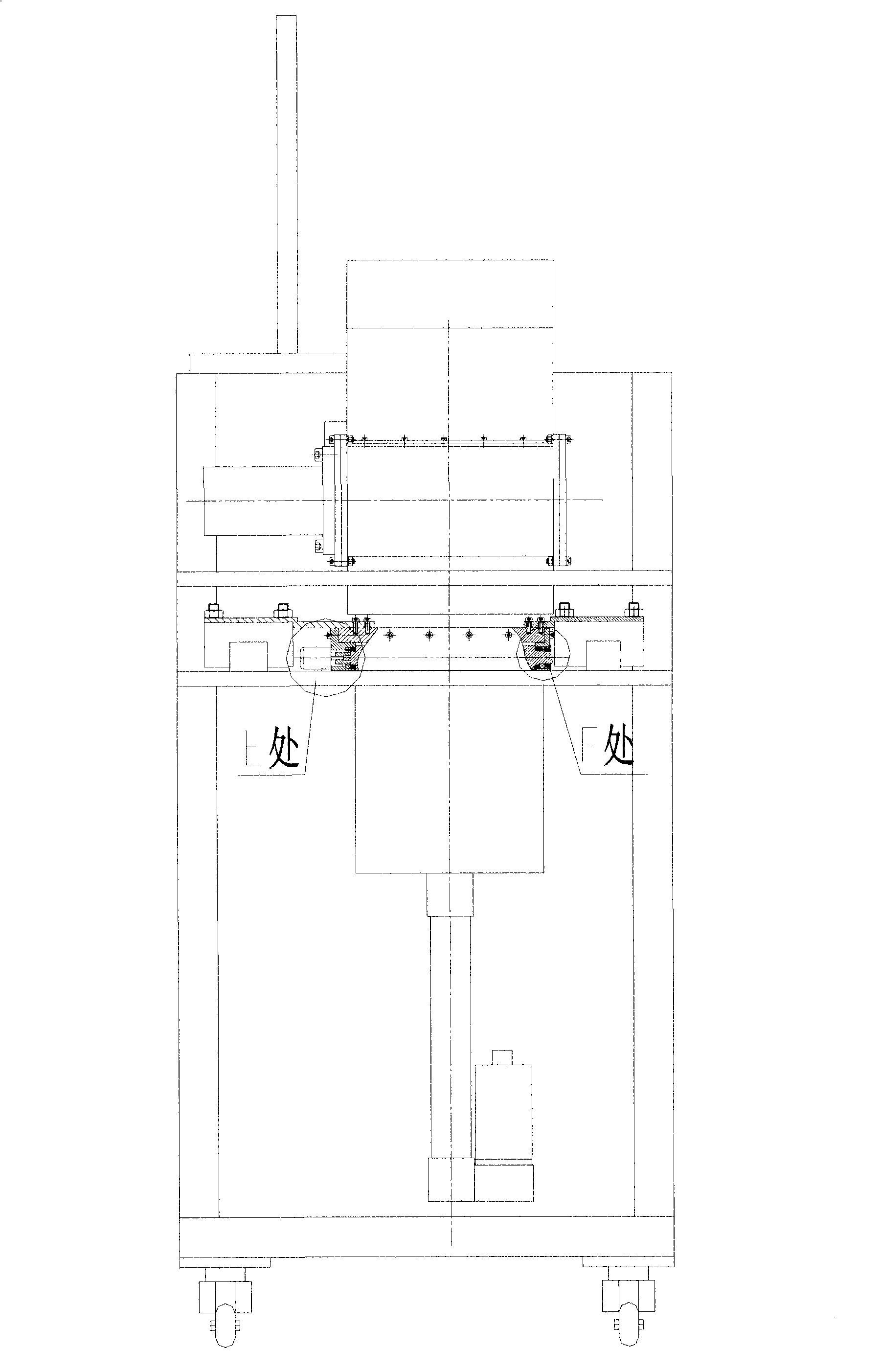

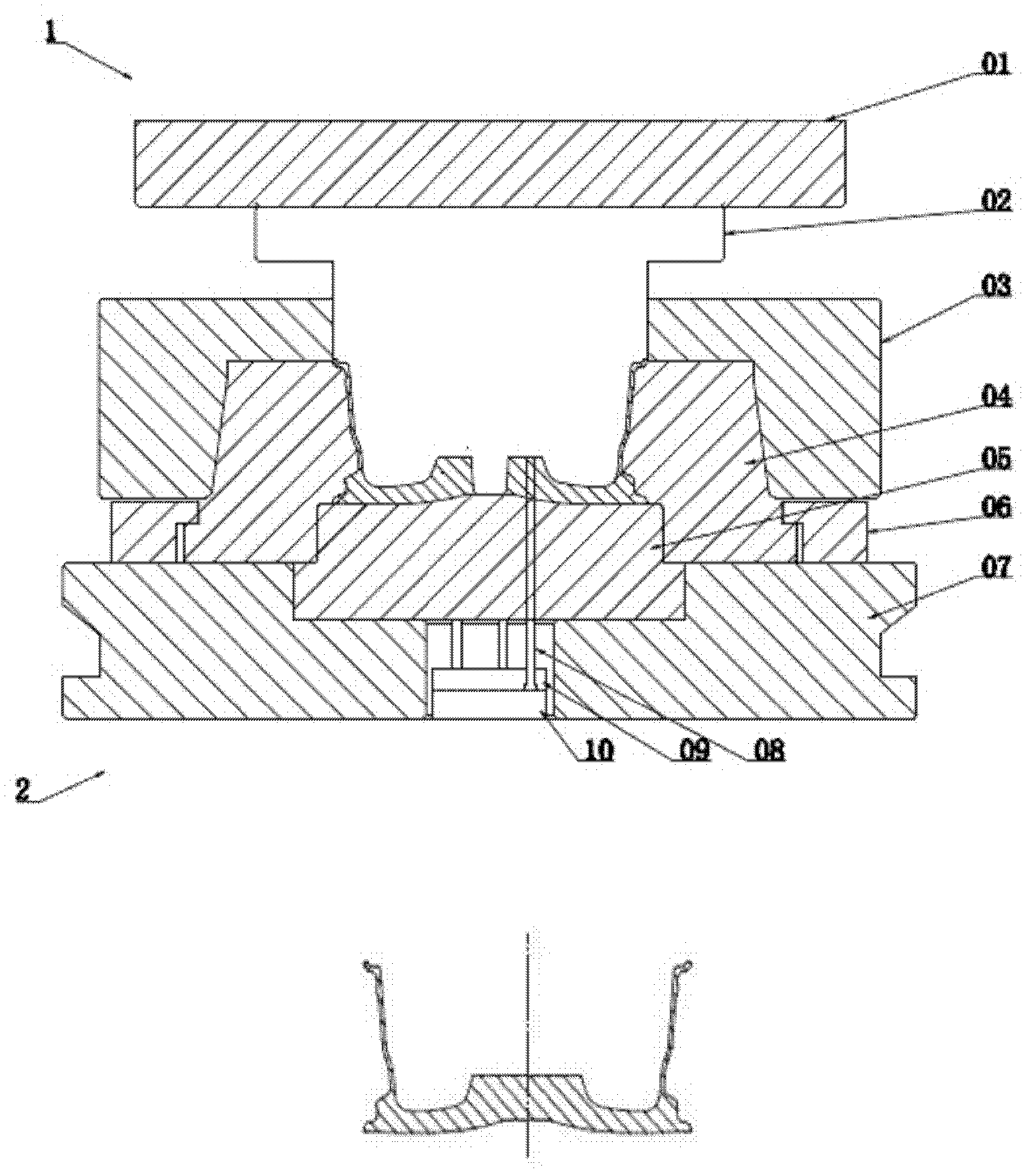

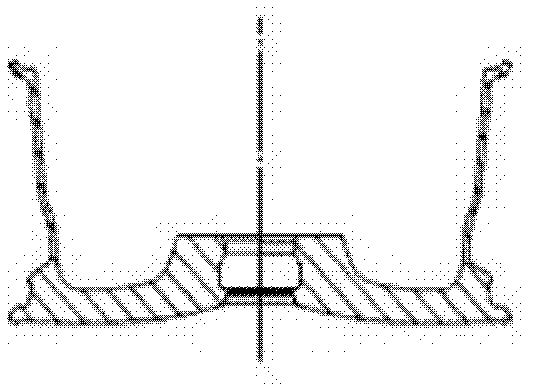

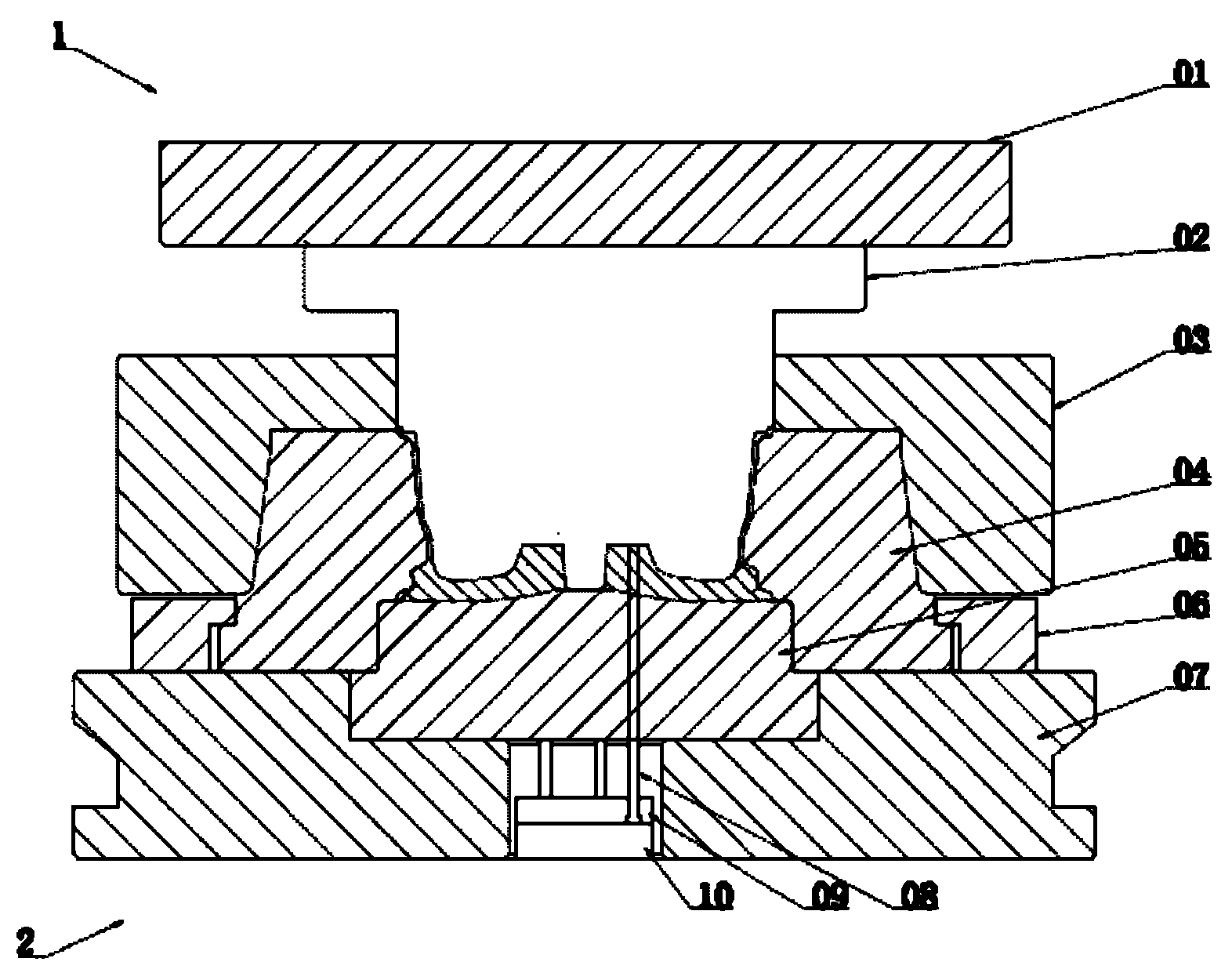

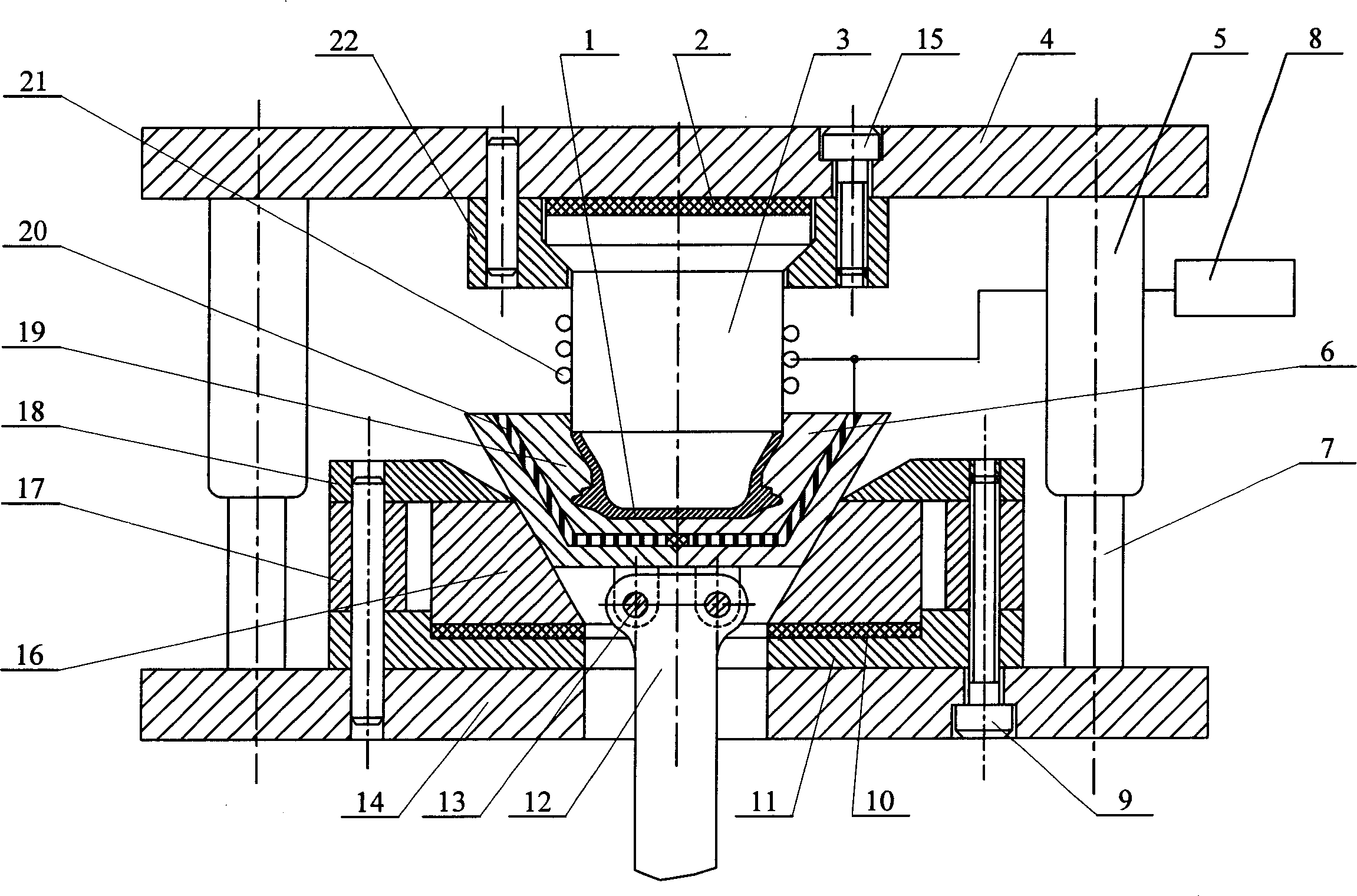

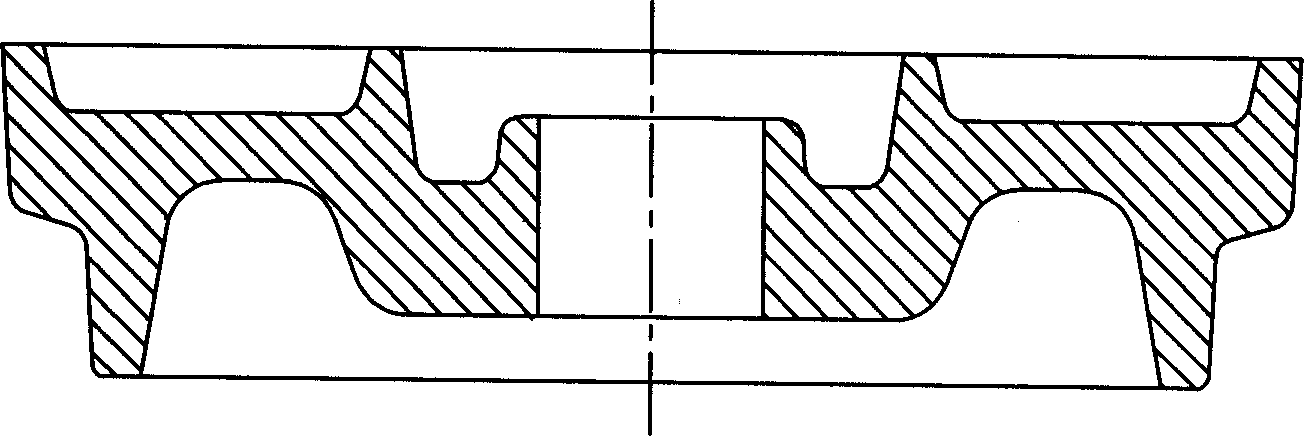

Shaping device of solid hot extrusion magnesium alloy wheel hub and shaping method thereof

A solid-state hot squeezing apparatus for shaping the Mg-alloy wheel hub is composed of upper die plate, male die and its heater, heat isolating plate between said upper die plate and male die, moulding cavity heater for left and right moulding cavities, heat isolating plate between female die and its die plate, push-out rod, and temp controller. Its shaping method includes such steps as blanking, heating, holding temp, preheating die set squeezing cutting, surface treating and ageing treating.

Owner:HARBIN INST OF TECH

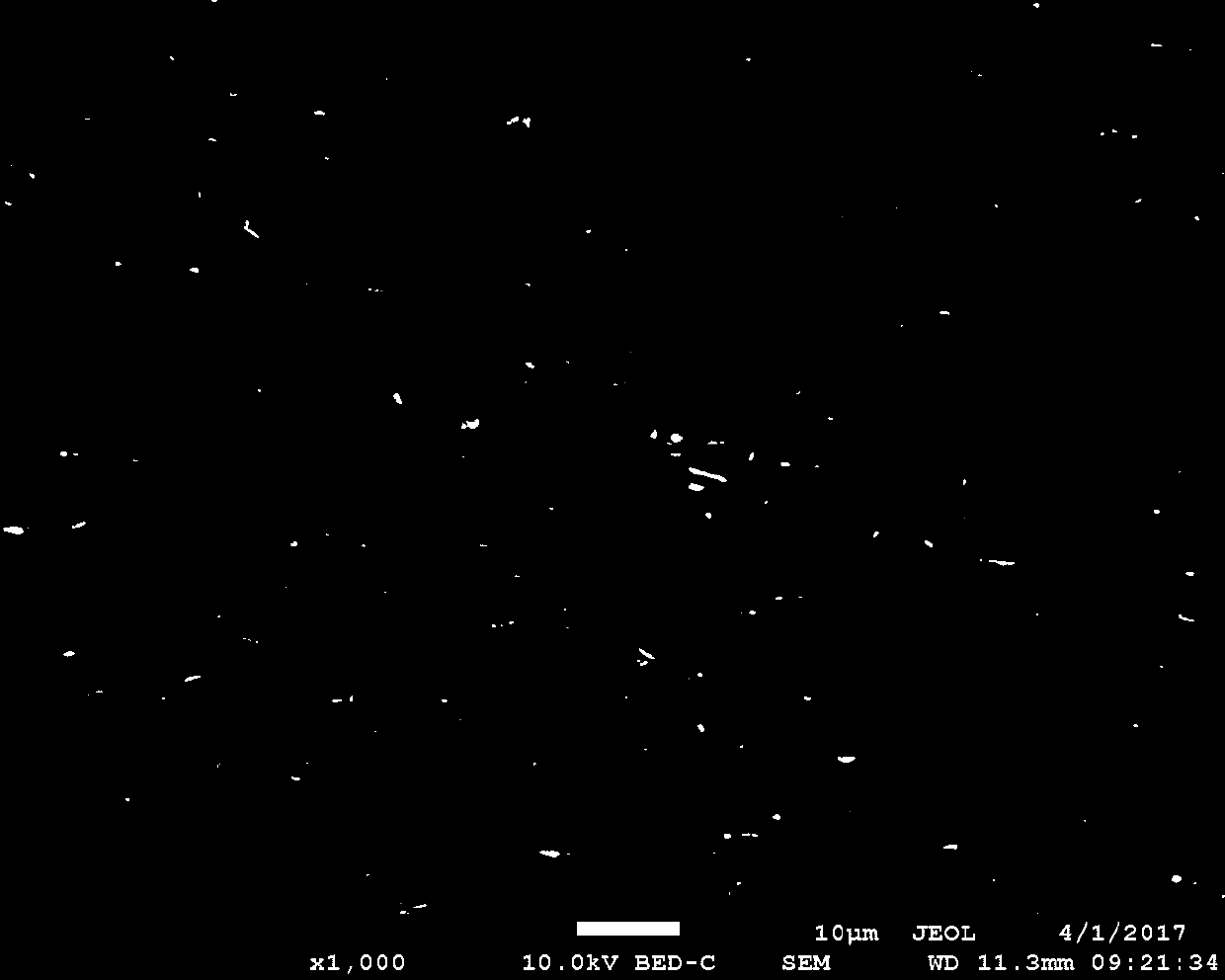

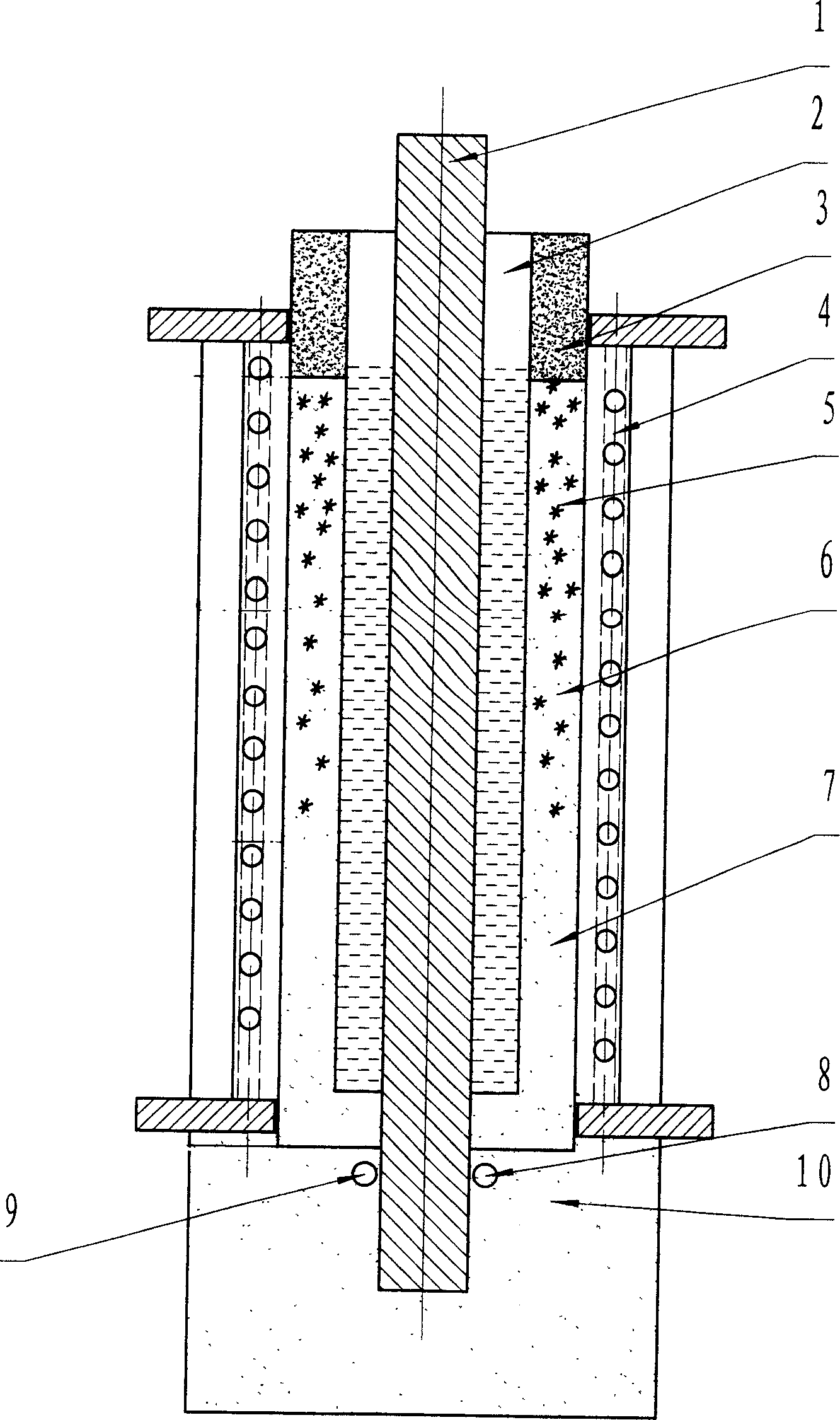

Method for preparing nano composite material by supercritical fluid electroforming

The invention discloses a method for preparing nano composite material by supercritical fluid electroforming, which comprises the following steps of: (1) adding metal salt solution, nano granules and composite additive into a reactor of an electroforming device, stirring uniformly, introducing carbon dioxide gas, and stirring at the temperature of between 35 and 50 DEG C under the pressure of 8 to 20MPa to generate supercritical fluid electroforming solution containing the nano granules; (2) setting pulse interval at 1 to 5 microseconds, setting the pulse width at 10 to 30 microseconds, setting the current density at 1 to 3A / dm<2>, switching on a direct-current power supply, and making the metal ions and the nano granules in the metal salt solution deposited on a cathode template togetherto obtain a nano composite electroforming layer; and (3) after the deposition is completed, obtaining the nano composite material by corresponding treatment. The method can electroform the nano composite material electroforming layer with uniform nano granule dispersion, flat surface, compact tissue, fine crystal grain and excellent performance.

Owner:临沂恩科开发建设有限公司

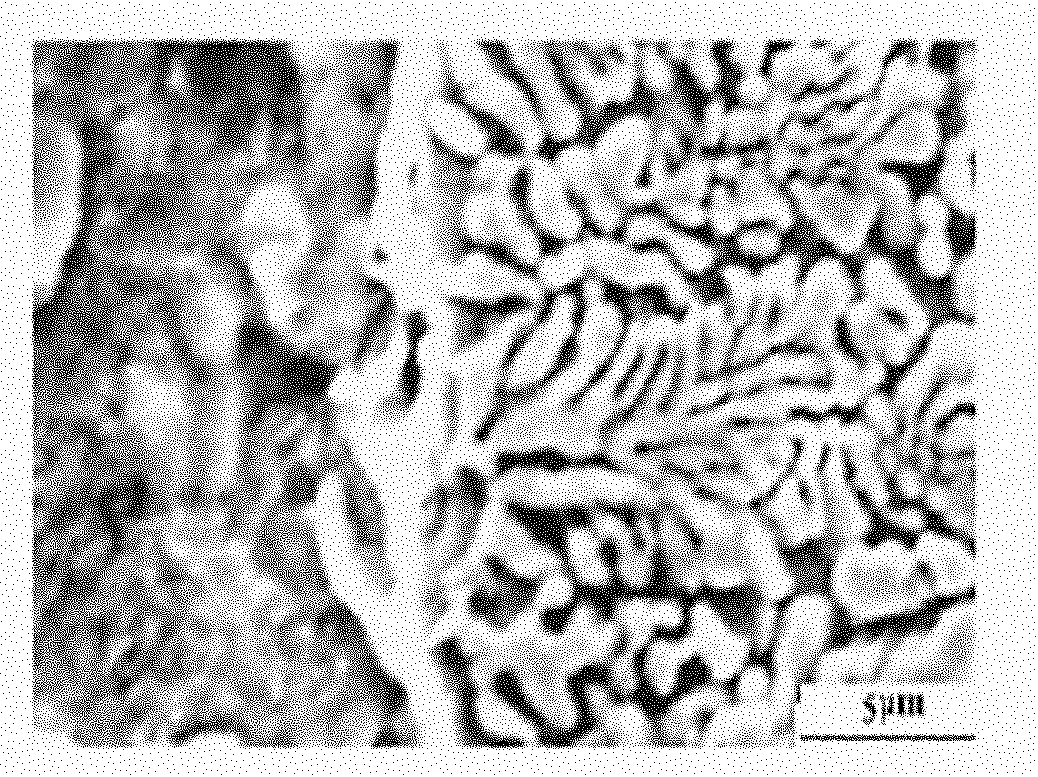

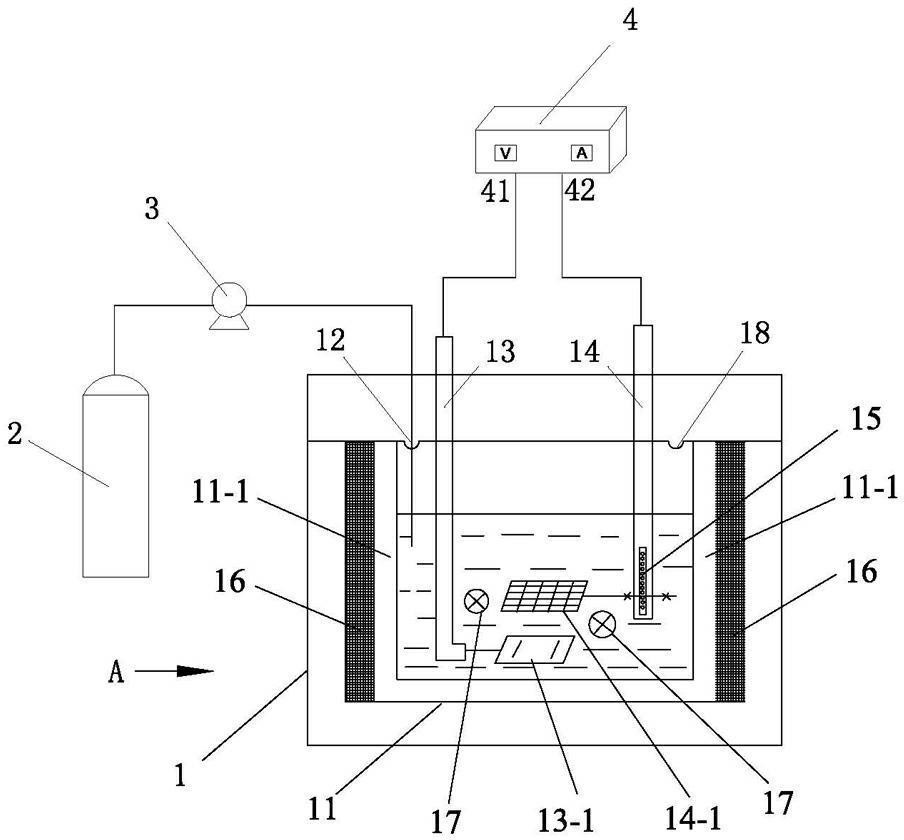

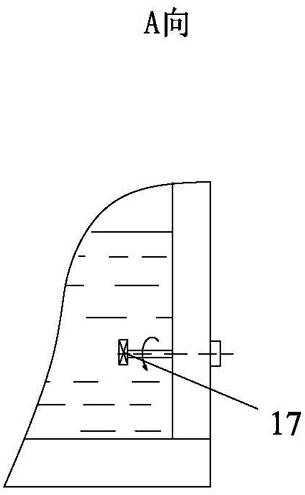

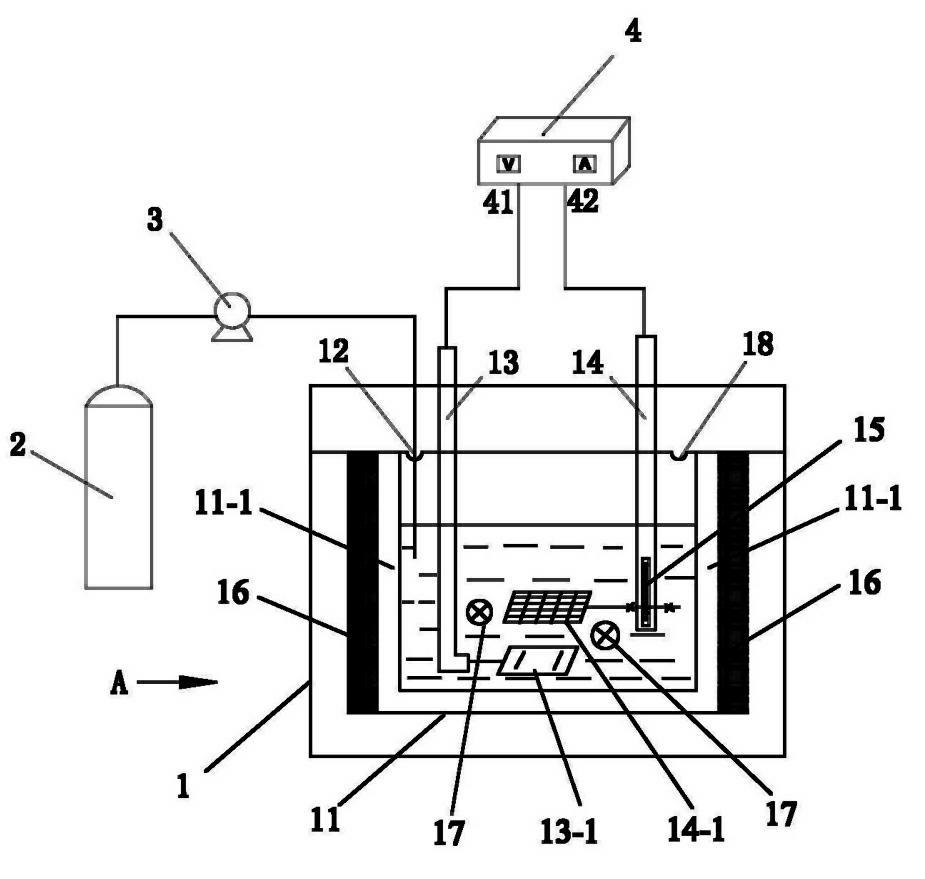

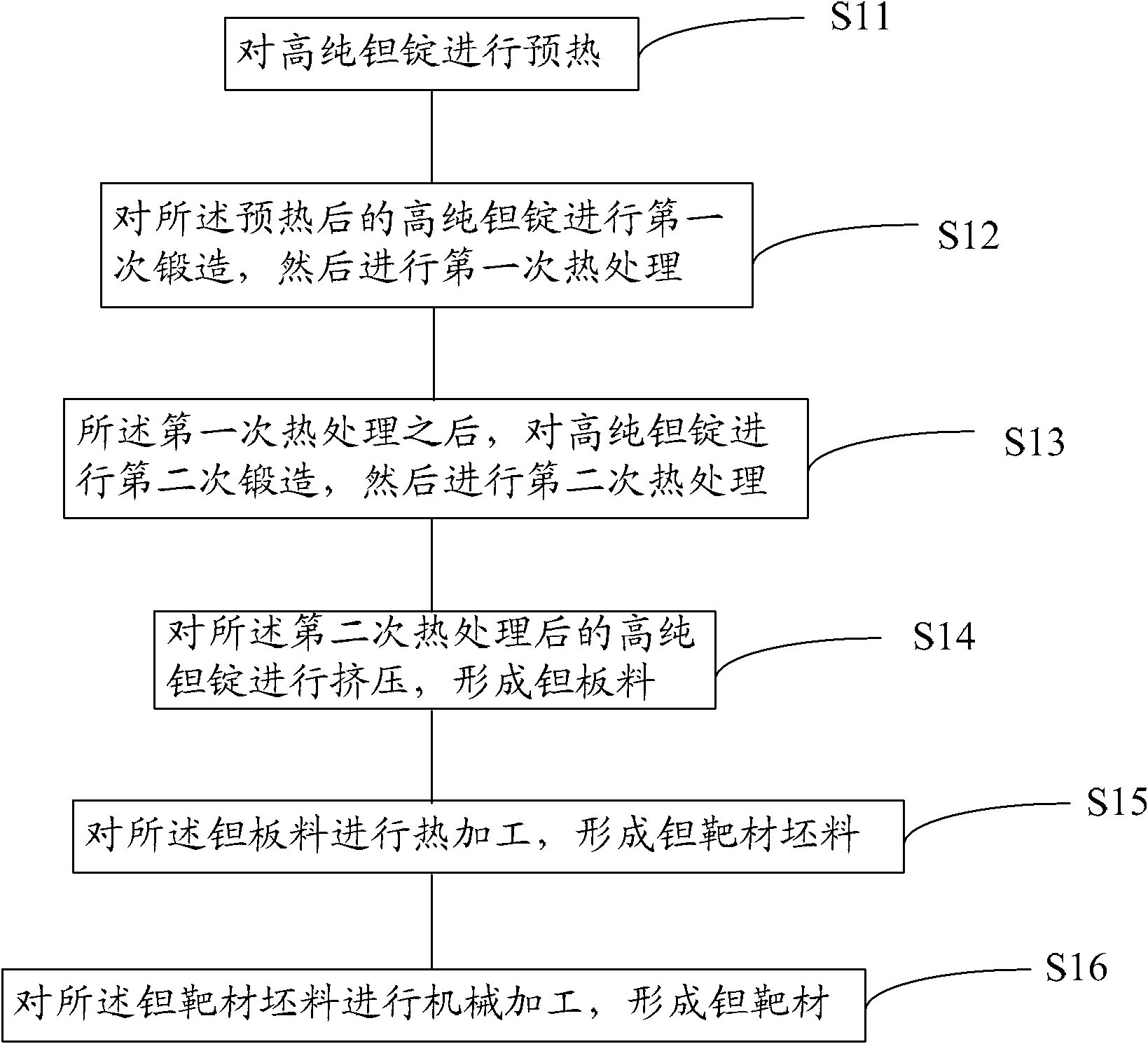

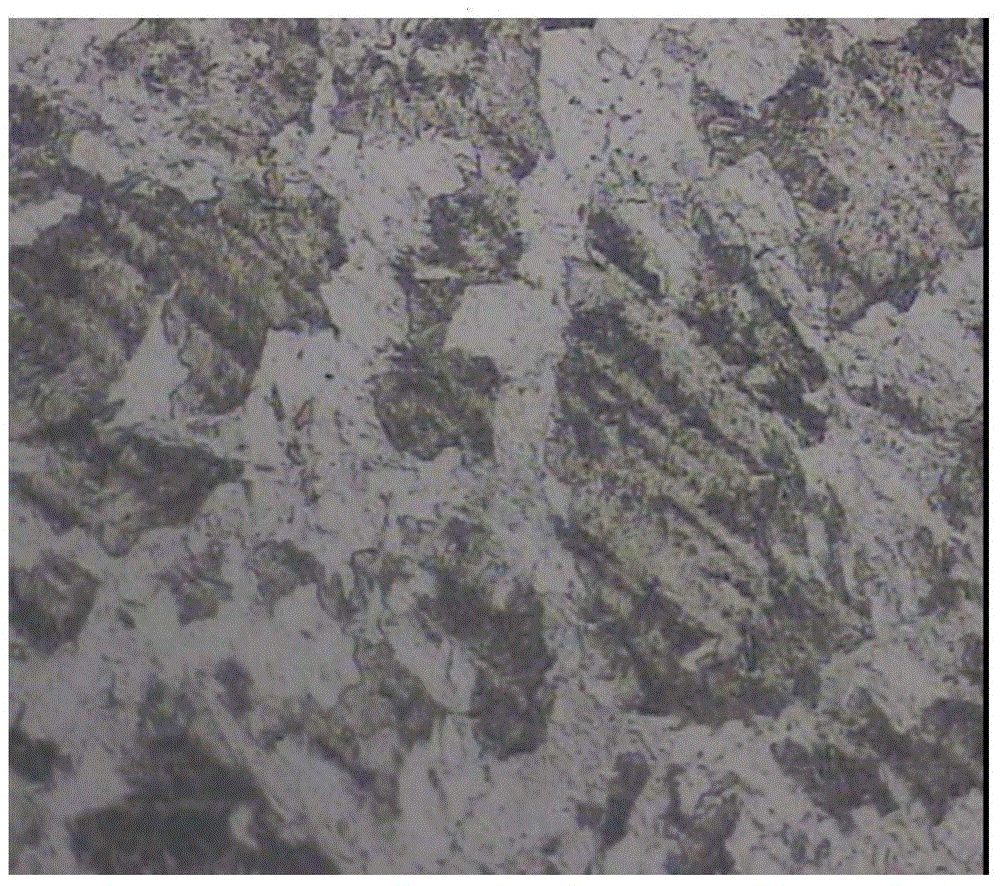

Method for preparing high-purity tantalum target

ActiveCN102517531ADense tissue structureFine and uniform grainVacuum evaporation coatingSputtering coatingSputteringCrystal orientation

A method for preparing a high-purity tantalum target comprises the following steps: preheating high-purity tantalum ingots; forging the preheated high-purity tantalum ingots by at least two times, wherein the high-purity tantalum ingots are heated after being forged each time; extruding the high-purity tantalum ingots after the high-purity tantalum ingots are heated for the last time, so as to obtain a tantalum board; heating the tantalum board to obtain a tantalum target blank; and machining the tantalum target blank to obtain the tantalum target. According to the process for preparing the tantalum target, the uniformity and the compactability of the tantalum target can be better, so as to meet the crystal particle requirements and the crystal orientation requirements of the tantalum target for semi-conductor sputtering.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Laser cladding nickel-based alloy powder and preparation method thereof

InactiveCN102912188AHigh hardnessNo crackMetallic material coating processesChemical compositionCrack free

The invention relates to laser cladding nickel-based alloy powder and a preparation method thereof. The laser cladding nickel-based alloy powder is characterized by comprising the following components by weight percent: 0.2-0.7% of C, 2-3.5% of Si, 1.5-3% of B, 1.0-1.5% of Mn, 3-10% of Cr, 2-5% of W, 3-5% of Mo, 0.5-1% of Nb, 0.5-2% of Co, less than 15% of Fe, 0.2-0.4% of Y, 0.2-0.5% of Ce and Ni and the balance of unavoidable impurity elements. A manufacturing process flow of the laser cladding nickel-based alloy powder is as follows: burdening, smelting, atomizing, drying and sieving. The alloy powder used for laser cladding provided by the invention is corrosion-resistant and also has higher hardness, and a treated laser cladding layer has the advantages of no crack, no pore, no impurity, compact structure and refined grain. A large-area thick crack-free laser cladding alloy layer can be obtained without preheating or follow-up heat treatment, and the cladding layer has the advantages of high strength, hardness and abrasion performance, good plasticity and toughness and low cost.

Owner:江苏新亚特钢锻造有限公司

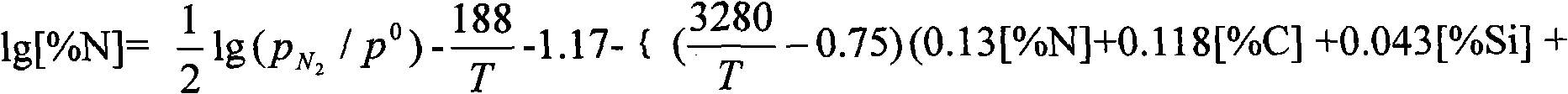

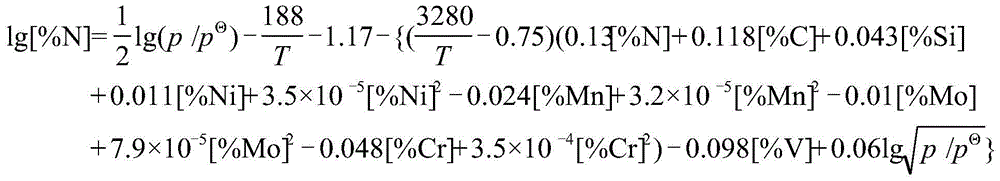

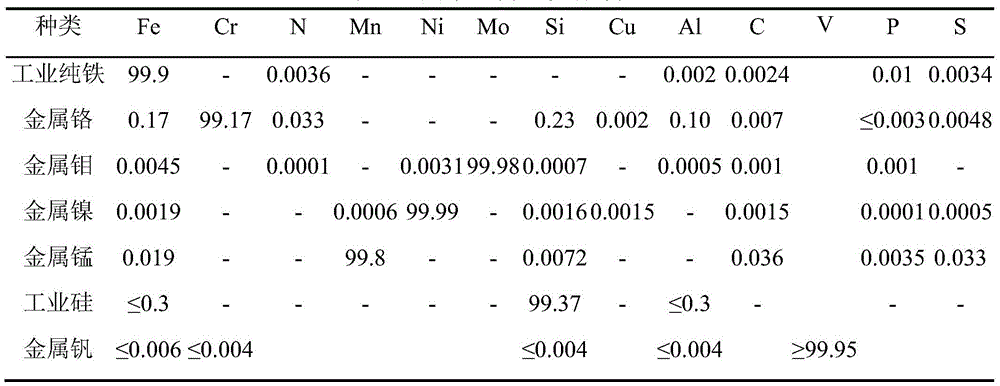

Method for smelting high-nitrogen steel by compression electroslag furnace

InactiveCN101260478ASolve the problem of uneven distribution of nitrogen contentAvoid secondary remeltingCurrent rangeSlag

The invention relates to a method for smelting the high-nitrogen steel by pressurizing an electroslag furnace. The method comprises the following steps that: the content and the weight percentage of each raw material of a self-consuming combined electrode parent metal are determined; the self-consuming electrode parent metal is smelted, an alloy pipe after charged with nitro-alloy particles and a deoxidizing agent is welded on the parent metal to produce the self-consuming combined electrode which is welded on a fake electrode and is clamped on the electrode; an arc starting agent is placed into a bottom water tank below the self-consuming electrode; the slag is dried for three to ten hours and is poured into a crystal device, a smelting chamber is sealed; under the condition of nitrogen, the slag is melted with a current ranging from 1000 to 2000A; afterwards, the pressure of the smelting chamber and the cooling water are increased to be 3 to 10 MPa, the smelting is performed with a current ranging from 2000 to 6000A; when the smelting current is reduced to 1000 A, the smelting is over. The method has the advantages that the solid state arc starting slagging way and the self-consuming combined electrode are adopted to perform the smelting in an over-normal pressure sealing smelting chamber, and the problem of the prior art of uneven distribution of nitrogen in the process of preparing high-nitrogen steel is solved, thereby avoiding the remelting and saving the production cost; moreover, the technique method is simple and the smelting effect is good.

Owner:NORTHEASTERN UNIV

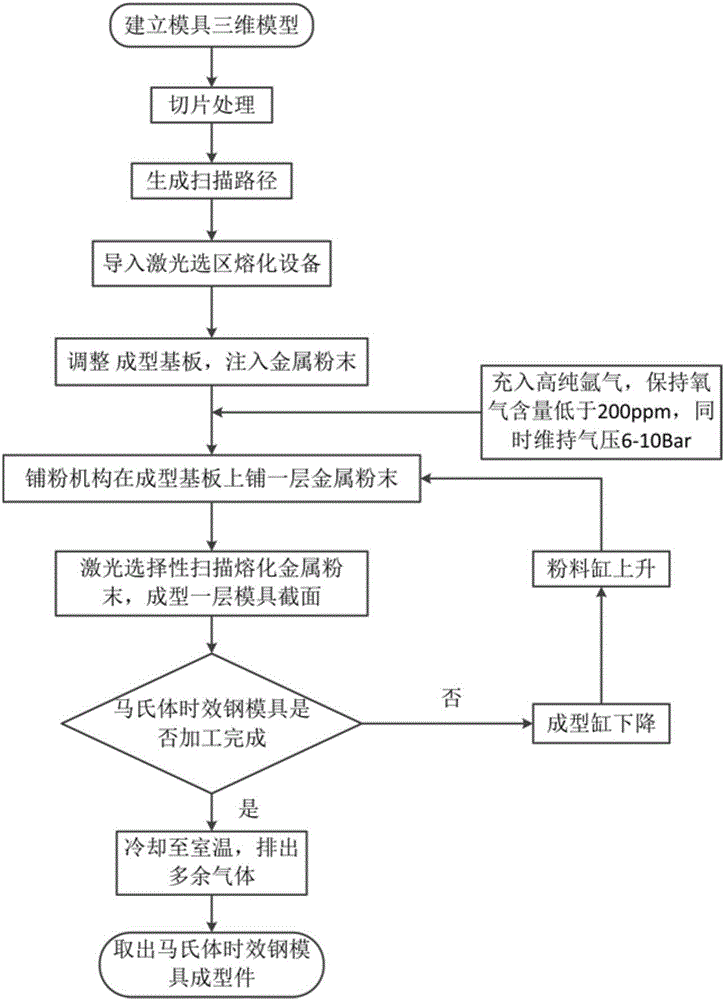

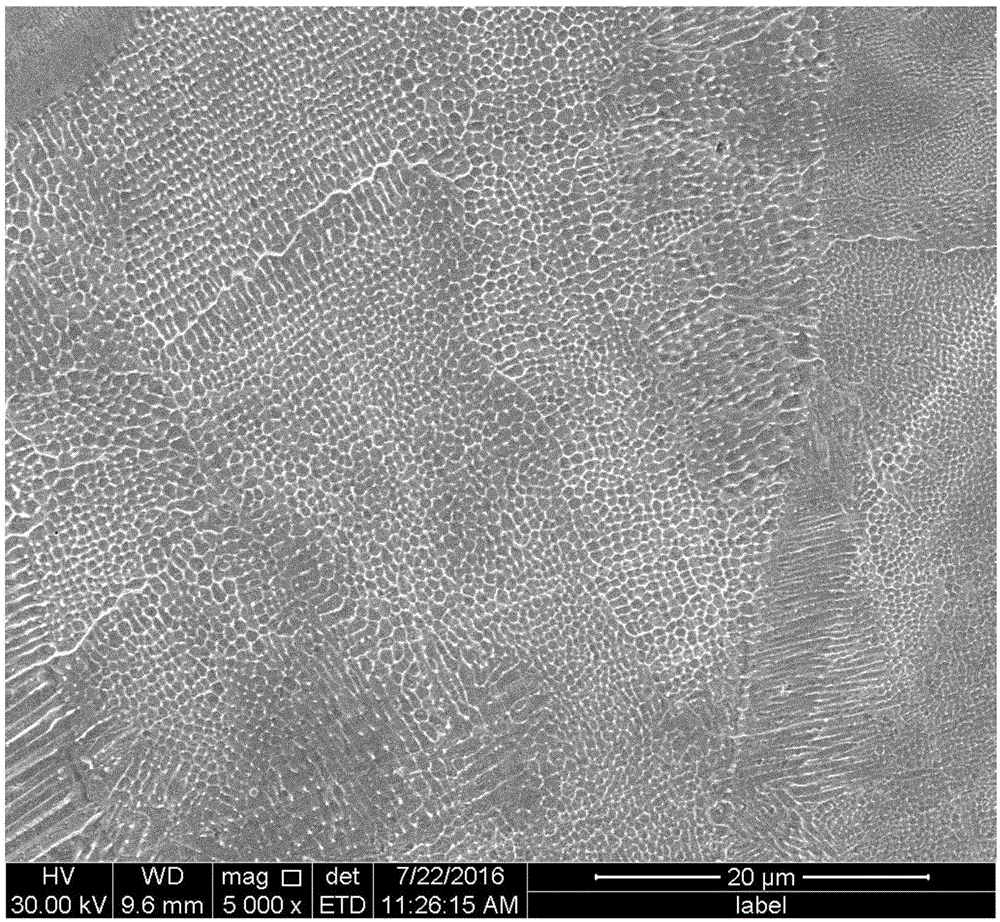

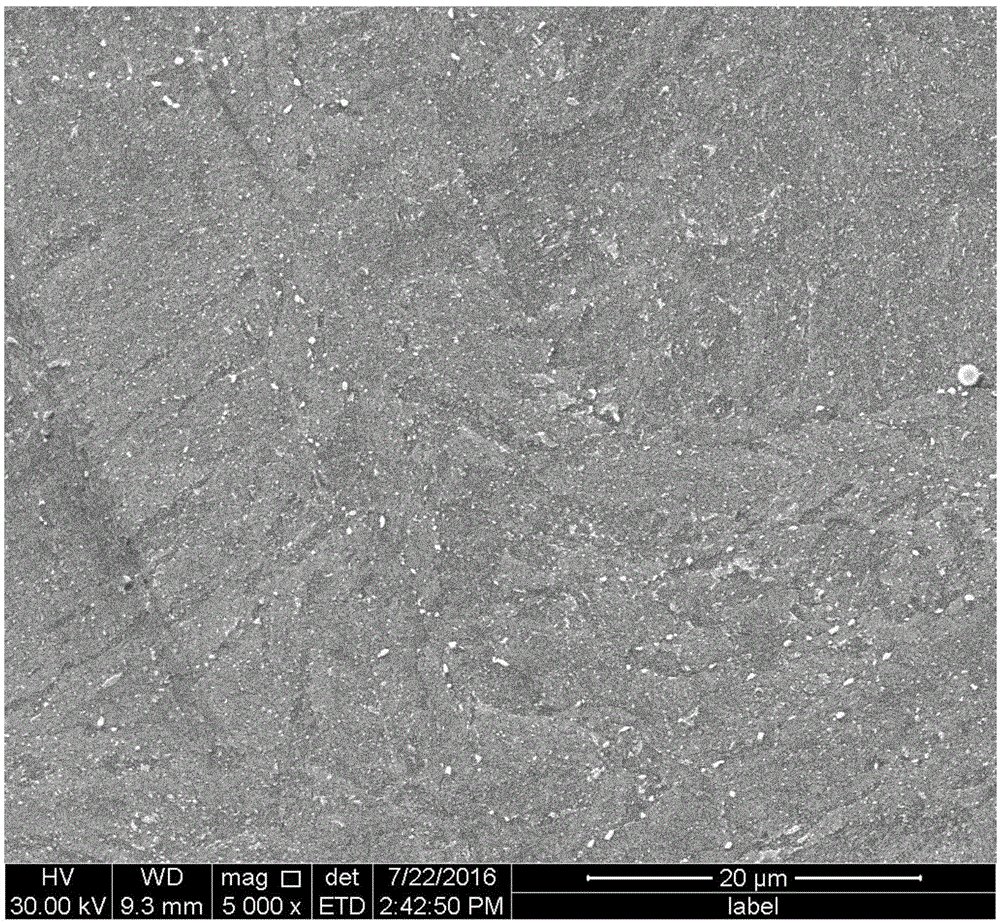

Forming method of maraging steel mold adopting selective laser melting

InactiveCN106825566AEasy to manufactureReduce pollutionAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingManufacturing cost reduction

The invention discloses a forming method of a maraging steel mold adopting selective laser melting. A three-dimensional structure of the mold is designed firstly by using three-dimensional design software such as Solidworks, ProE and Ug; and then the three-dimensional mold is subjected to slicing layering and route planning treatment, data are guided into a selective laser melting device, reasonable technical parameters are set, and the mold with a complex cooling channel is formed at a time. The mold formed by the method has the advantages of being high in compactness, few in internal defect, high in forming efficiency and high in free degree on the follow-up forming cooling channel. According to the forming method of the maraging steel mold adopting selective laser melting, the production period of the mold is effectively shortened, forming efficiency is high, external disturbance is small, the compressive property and production efficiency of the mold are remarkably improved, and meanwhile manufacturing cost is greatly reduced. After the directly-formed mold is subjected to solution and aging treatment, hardness and strength of the mold are remarkably improved, and the using requirements of the mold are met.

Owner:SOUTH CHINA UNIV OF TECH

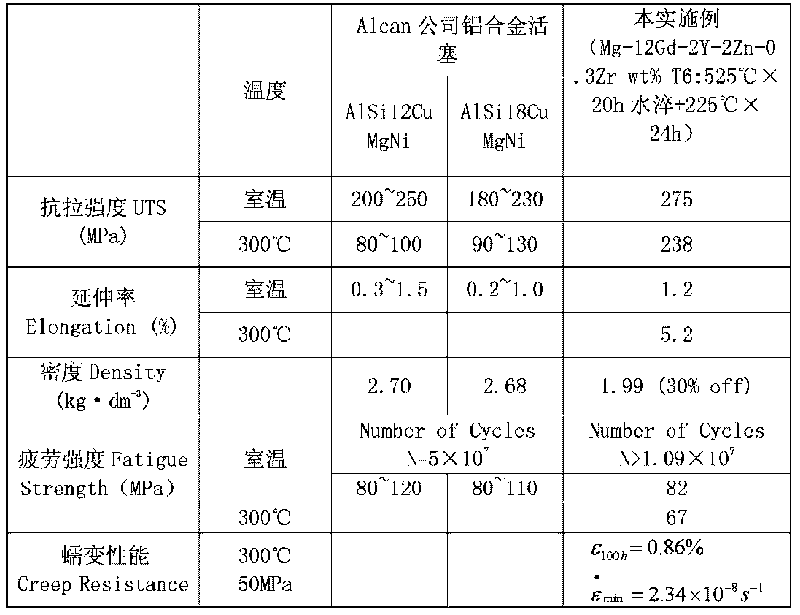

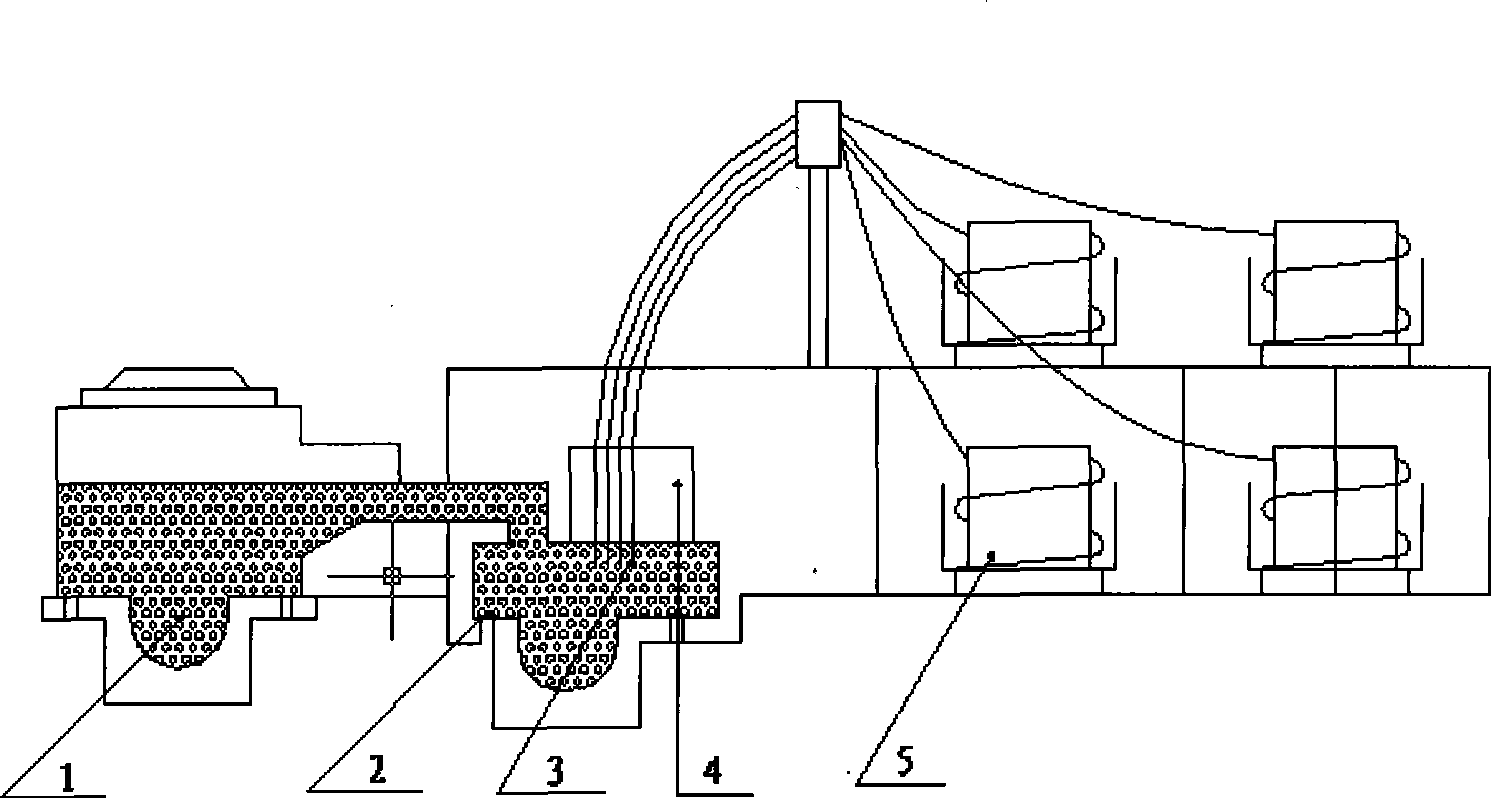

Low-pressure casting preparation method of heat resistant rare earth-magnesium alloy engine pistons

ActiveCN101693971AFine grainImprove creep resistanceMachines/enginesPistonsManufacturing technologyPressure casting

A low-pressure casting preparation method of heat resistant rare earth-magnesium alloy engine pistons in the field of the automobile manufacturing technology comprises preparing master alloy Mg-Y, Mg-Gd, Mg-Zr, industrial pure magnesium and industrial pure zinc, smelting alloy, obtaining magnesium alloy fused mass, squeezing and casting the magnesium alloy fused mass, obtaining the primary blank of a magnesium alloy piston, and obtaining a heat resistant tare earth-magnesium alloy engine piston through orderly carrying out the solid solution treatment, the cold treatment and the aging treatment. The method can prepare pistons with excellent high-temperature strength, fatigue strength and creep resistance performance through applying 0.2-0.8 atm pressure and selecting proper heat resistant rare earth-magnesium alloy, selecting proper low-pressure casting technical parameter and adjusting corresponding heat processing technology.

Owner:SHANGHAI JIAO TONG UNIV

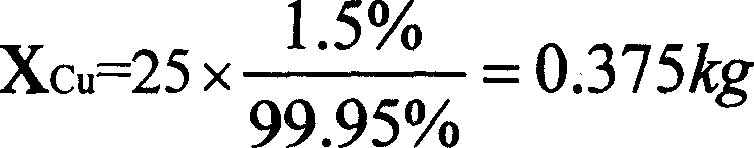

Shortened method for producing oxygen-free copper belt

InactiveCN101502872AUniform performanceEliminates effects on product surface qualityElectrolysisProduct gas

The invention provides a short process oxygen-free copper strip production method which is characterized in that the method comprises the following steps: an electrolytic copperplate is cleaned and dried, melted and insulated; after an upward continuous casting step, a copper rod is obtained; a continuous squeezing step is carried out on the copper rod to obtain a strip stock; after cold rolling, annealing and post treatment, the strip stock is made into a copper strip finished product. An upward casting rod is used by the invention to be continuously squeezed into the strip stock. The upward casting rod is directly made into the thickness of the finished product by cold rolling without surface milling and middle annealing. The continuous bright non-oxidation annealing is realized under the protection of air. Hot water degreasing is adopted for substituting the natron degreasing. The advantages of the up-draw process and the continuous squeezing method are combined. The product has the advantages of low oxygen content, pure tissue, small grain and perfect comprehensive performance. The short process oxygen-free copper strip production method has the advantages of brief process, energy saving, environment protection, pollution-free and the like.

Owner:SHANGHAI KANGCHENG COPPER GROUP +1

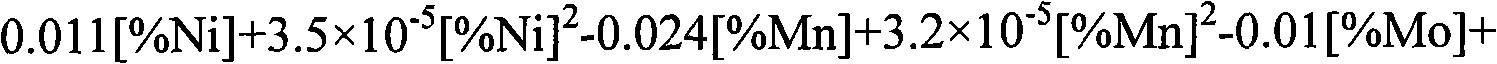

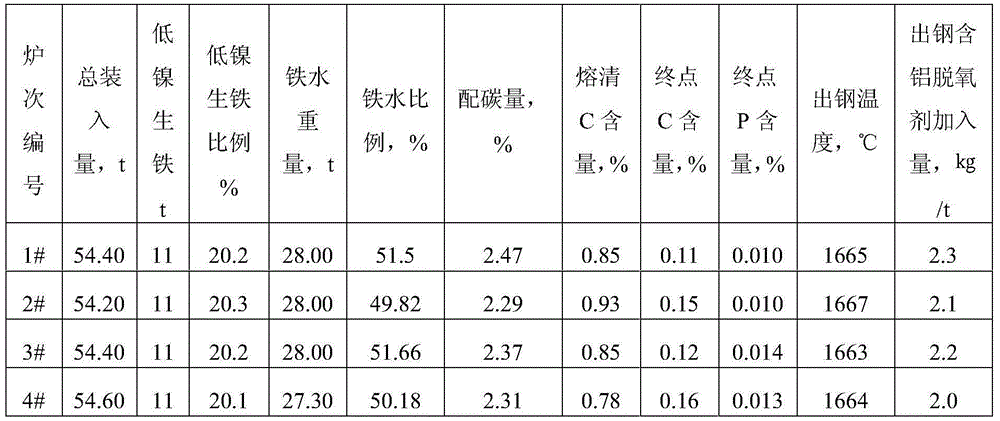

CrNiMo high-strength pinion steel and preparation method thereof

ActiveCN104372258AImprove heat treatment effectGuaranteed mechanical propertiesProcess efficiency improvementPinionUltimate tensile strength

The invention relates to a CrNiMo high-strength pinion steel and a preparation method thereof. The pinion steel comprises the following chemical components in percentage by mass: 0.19%-0.25% of C, 0.17%-0.37% of Si, 0.70%-1.00% of Mn, at most 0.030% of P, at most 0.030% of S, 0.85%-1.25% of Cr, 0.40%-0.70% of Ni, 0.30%-0.40% of Mo, 0.015%-0.050% of Al, at most 2.5*10<-4>% of H, 30*10<-4>%-80*10<-4>% of N, at most 15*10<-4>% of T.O, and the balance of Fe and inevitable impurities. The invention also provides a preparation method of the pinion steel. The nickel molybdenum alloy is added to improve the heat treatability of the material, thereby ensuring the mechanical properties of the material. The hardenability of the material is enhanced, and the material satisfies the performance requirements for large module pinions.

Owner:SHANDONG IRON & STEEL CO LTD

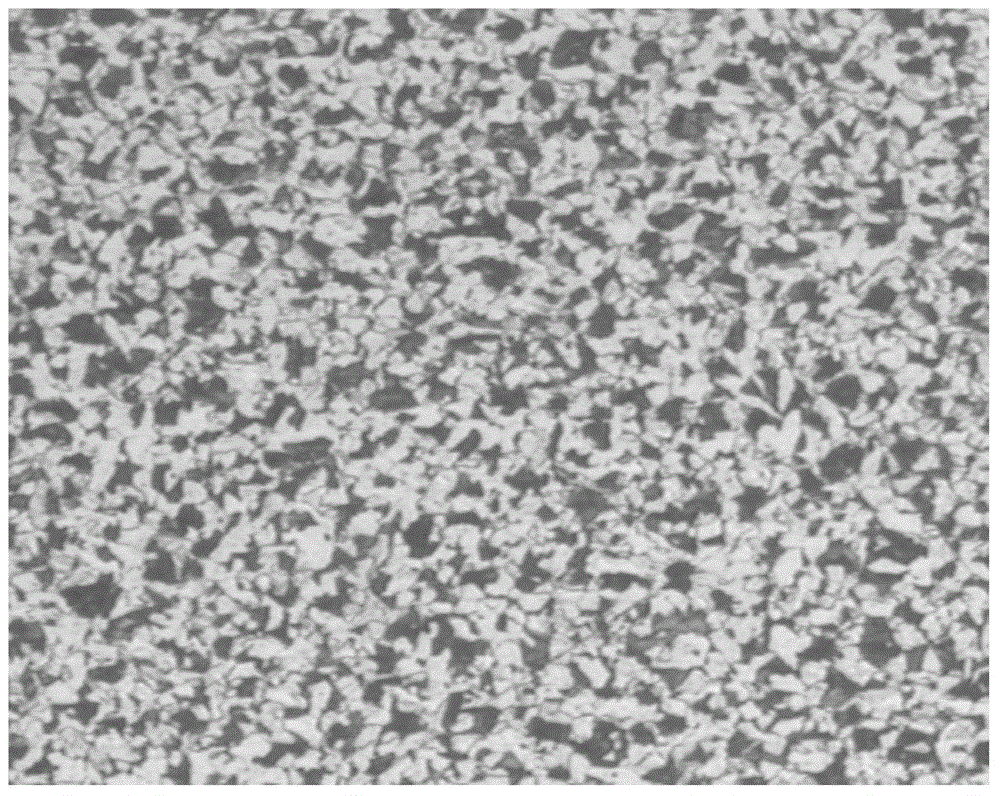

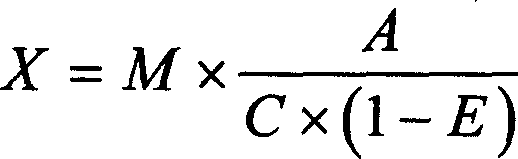

High silicon cast aluminium spectrum standard sample and its preparation method

InactiveCN1410572AUniform chemical compositionDense tissuePreparing sample for investigationAnalysis by material excitationChemical compositionStandard samples

The standard specimen contains chemical elements with following weight ratios in pure aluminium Si: 1.03-13.70, Fe: 0.147-1.50, Cu: 0.125-7.44, Mn: 0.090-1.05, Mg: 0.049-1.53, Zn: 0.052-1.05, Ti: 0.034-0.274 etc. Since the Al-Sr modification is adopted, thus the specimen provides the features of even chemical elements, compact structure, free of bulky initializing coarse grains as well as raised processability. The long-playing diffusion fusion technique adopted makes silicon diffuse to aluminium adequetely so as to increase uniformity of chemical elements in the specimen evidently.

Owner:SOUTHWEST ALUMINUM GRP

Alloy ingot for automotive hub and production method thereof

The invention discloses an alloy ingot for an automotive hub and a production method thereof. The alloy ingot comprises the following components: 6.8-7.2% of Si, 0.28-033% of Mg, 0.10-0.15% of Ti, 0.015-0.030% of Sr, less than or equal to 0.10% of Fe, less than or equal to 0.05% of Mn, less than 0.01% of zinc, less than 0.01% of Cu, less than 0.003% of Ca, less than 0.002% of P, less than 0.02% of other single impurity content, less than 0.1% of total impurity content and the balance of aluminum. The production method of the alloy ingot for the automotive hub comprises the following steps of: adding 3303 industrial metallic silicon and electrolytic aluminum liquid for batching, heating at an appropriate temperature and melting, spreading a covering agent so as to reduce oxidation slagging, stirring so that the industrial metallic silicon rapidly melts, keeping uniform temperature, slagging off, keeping melt clean, spraying powder and refining by adopting high-purity N2 and a refined powder spraying agent, controlling the temperature of a smelting furnace to 740-750 DEG C, adding Al-Sr alloy to aluminium water, carrying out secondary degassing and slagging-off by adopting a powder spraying refinement method, filtering to remove slag, and casting the alloy ingot in line with requirements. The alloy ingot obtained by the method has the advantages of stable and uniform components, compact structure and clean surface; and the production method is the best production method for producing the A356.2 alloy ingot for the low-iron high-end automotive hub.

Owner:河南省银湖铝业有限责任公司

Laser-cladding high-toughness high-hardness nickel-base alloy powder and preparation method thereof

InactiveCN102719708AHigh hardnessNo crackMetallic material coating processesChemical compositionRare earth

The invention discloses laser-cladding high-toughness high-hardness nickel-base alloy powder and a preparation method thereof. The nickel-base alloy powder is characterized by comprising the following chemical components in percentage by mass: 0.4-0.8% of C, 2-3% of Si, 1-3% of B, 12-18% of Cr, 6-8% of Cu, 0.5-1% of Sn, 10-15% of Fe, 0.2-0.5% of rare earth and the balance of Ni and inevitable impurity elements. The preparation process flow sequentially comprises: dosing, smelting, atomizing, drying and screening. The laser-cladding alloy powder disclosed by the invention has corrosion resistance and relatively high hardness; and the processed laser-cladding layer has the advantages of no crack, no air hole, no impurity, dense tissue, grain refinement and the like. Through the invention, a large-area great-thickness laser-cladding alloy layer without cracks can be obtained without preheating or follow-up thermal treatment, and the laser-cladding alloy layer has the advantages of high strength, hardness and abrasion resistance, good plasticity and toughness, low cost and the like.

Owner:丹阳市协昌合金有限公司

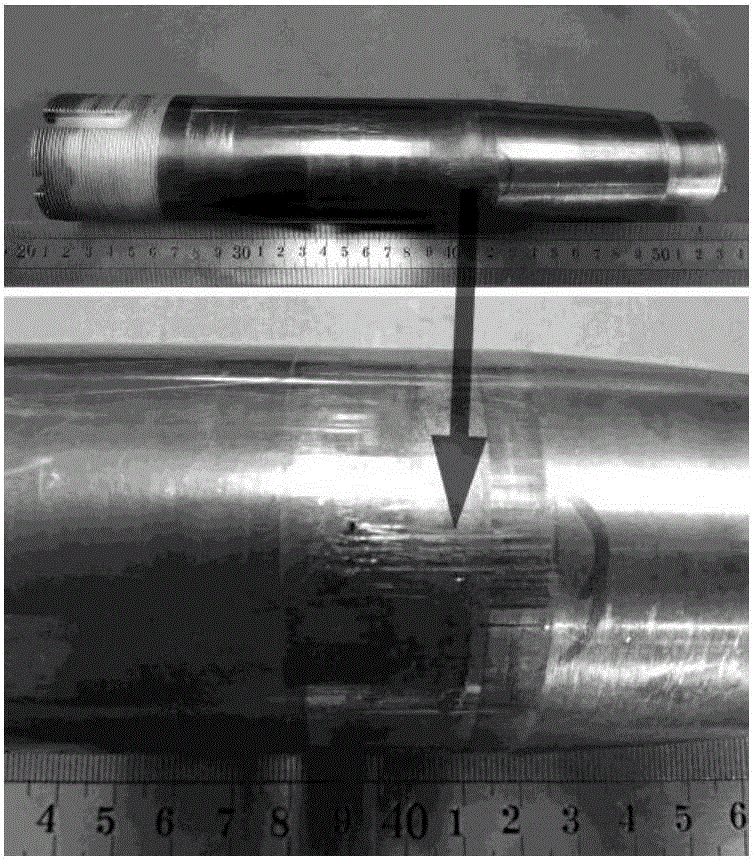

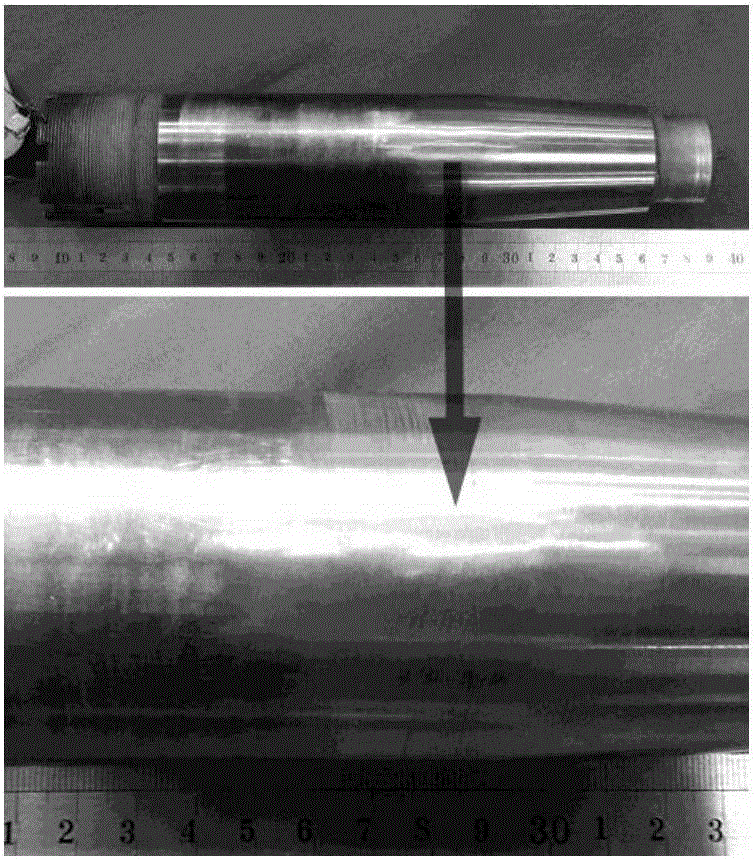

Laser cladding repairing method for aircraft end-journal part surface

InactiveCN105256249AShorten maintenance timeReduce maintenance costsMetallic material coating processesHeat-affected zoneSlag

The invention belongs to the technical field of laser cladding, relates to a laser cladding repairing method for aircraft end-journal part surface, particularly to a method for repairing the mechanical wear and scrape malfunction of an aircraft end-journal part after long-time service by adopting the laser fused deposition technology. The method aims at mechanical wear, scrape and other defects on the surface of the part, selects spherical precipitation to harden stainless steel metal dust, adopts reasonable laser cladding technological parameters, and removes residual stress of the part after cladding through the specific heat treatment technology to recover the performance of the aircraft end-journal and realize repairing of lengthening the service life. The repaired end-journal part hardly deforms, and the depth of a heat affected area is no more than 0.5mm; the repairing area does not have the defects of cracks, incomplete fusion and slag inclusion; the serviceability of the repaired end-journal is recovered.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Method for connection between composite type green low-melting solder glass and silicon carbide reinforced aluminum matrix composites

ActiveCN103894694AFirmly connectedSolve Wetting ProblemsWelding/cutting media/materialsWelding/soldering/cutting articlesWhiskersSoldering

The invention provides a method for connection between composite type green low-melting solder glass and silicon carbide reinforced aluminum matrix composites and relates to a method for connecting the silicon carbide reinforced aluminum matrix composites. The method aims at solving the problems that the silicon carbide reinforced aluminum matrix composites connected through an existing connection method are low in strength and the joint strength, and the surface of existing solder and the surface of the silicon carbide reinforced aluminum matrix composites are incompatible when the content of silicon carbide reinforced bodies in existing silicon carbide reinforced aluminum matrix composites is increased. The method includes the steps of classifying basis glass power, weighing, pretreating beta-SiC whiskers, preparing composite type lead-free low-temperature sealing glass powder, mixing, stirring, removing impurities, coating and assembling and welding test pieces. Through the method, the silicon carbide reinforced aluminum matrix composites can be connected in a low-temperature soldering mode.

Owner:HARBIN INST OF TECH

Method for manufacturing metal-based composite materials by aid of 3D (three-dimensional) printing space structures

The invention relates to a method for manufacturing metal-based composite materials by the aid of 3D (three-dimensional) printing space structures, and belongs to the technical field of metal-based composite materials. The method includes building stereoscopic models of the space structures by the aid of graphics software and printing the stereoscopic models by the aid of 3D printing machines to obtain plastic templates of the space structures; preparing slurry from ceramic particles and adhesion agents, and filling space structure gaps of the plastic templates with the slurry; drying and gradually heating the plastic templates, removing plastics, and sintering the templates to obtain ceramic particle prefabricated blanks with certain strength and complex space structures; manufacturing the metal-based composite materials by the aid of pressure impregnation technologies such as vacuum suction casting and squeezing casting technologies. The method has the advantages that the composite materials which can be accurately controlled, are varied within large ranges and have the complex space structures can be manufactured by the aid of the method, processes are simple, and mechanical and automatic batch production can be facilitated.

Owner:KUNMING UNIV OF SCI & TECH

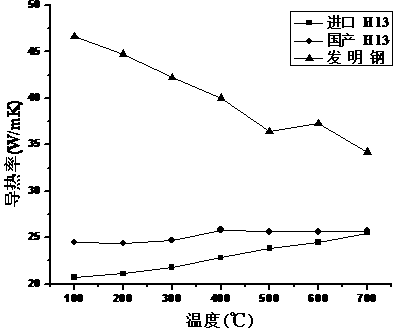

Ultrahigh thermal conductivity wear-resistant hot stamping die steel and manufacturing method thereof

Belonging to the technical field of alloy steel preparation processes, the invention relates to an ultrahigh thermal conductivity wear-resistant hot stamping die steel and a manufacturing method thereof. Current hot stamping die steel on the market is mainly various improved H13, H11 and other high alloy hot work die steel. The steel provided by the invention comprises the following components by mass percent: 0.33-0.40% of C; less than 0.30% of Si; less than 0.30% of Mn; 1.0-2.0% of W; 4.0-5.0% of Mo; less than 0.30% of Cr; 0.10-0.20% of V; and the balance Fe and inevitable impurities. And in the impurity elements, S is smaller than or equal to 0.01%; P is smaller than or equal to 0.01%; and O is smaller than or equal to 30ppm. The steel is characterized in that: simple C, Mo and W are adopted as the main elements to coordinate the ratio of carbides; low Mn, low Cr and low Si content are maintained; after electric furnace smelting, electroslag remelting, annealing, high temperature homogenization, forging and annealing, the material has good machining properties; and after heat treatment, the material has excellent impact toughness, tempering stability and thermal fatigue performance. With ultrahigh thermal conductivity, the steel can be more suitable for hot stamping.

Owner:SHANGHAI UNIV +1

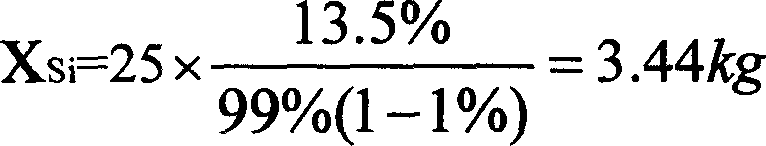

Aluminium-silicon-copper-magnesium pack alloy and its preparing process

The invention relates to an aluminium-silicon-copper-magnesium pack alloy and its preparing process, wherein the chemical constituents of the alloy include (by mass percent): silicon 13.0-15.0%, Cu 1.5-3.5%, Mg<=0.3%, Fe<=1.3%, Mn<=0.5%, impurity content <=0.15%, and balancing Al. The raw materials are prepared in a crucible furnace with a smelting temperature of 680-750 deg. C, after the pure aluminium and intermediate alloy are melt, silicon blocks and copper ingots are charged into the aluminium solution, magnesium blocks are charged in at 680-700 deg C, the pouring temperature is 660-720 deg C. The prepared alloy has a cast-state tensile strength of above 264 MPA, and a hardness of around HB95.

Owner:SHANDONG UNIV

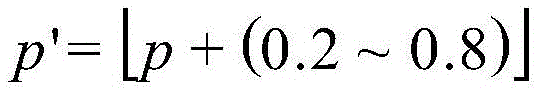

Method for smelting low-aluminum high-nitrogen martensitic stainless steel in pressurization and induction manner

The invention discloses a method for smelting low-aluminum high-nitrogen martensitic stainless steel in a pressurization and induction manner and belongs to the field of metallurgy, wherein the method is suitable for smelting. The low-aluminum high-nitrogen martensitic stainless steel comprises, 0.1%-0.6% of carbon, 0%-0.5% of manganese, 12%-24% of chromium, not larger than 1% of silicon, 0%-3% of molybdenum, 0.1%-0.6% of nitrogen, 0%-2% of nickel, 0%-1% of vanadium, not larger than 0.02% of aluminum, not large than 0.002% of sulfur and the balance iron and inevitable impurities. The method includes the specific steps of blending, material distribution, temperature increase after vacuumizing, high-pure argon filling after raw material melting-down, graphite adding for deoxygenation, industrial silicon adding for deoxygenation when the environment is vacuumized to 10 Pa, nitrogen filling and alloying, nickel magnesium alloy and rare earth adding for heat preservation for 5 min to 10 min, nitrogen charging and casting and the like.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com