Aluminium alloy for vehicle hub and preparation method thereof

A technology for an automobile wheel hub and a manufacturing method, which is applied in the metal field, can solve the problems of long production cycle, large equipment investment, complex process, etc., and achieves the effects of low production cost, reduction of unfavorable factors, and improvement of purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

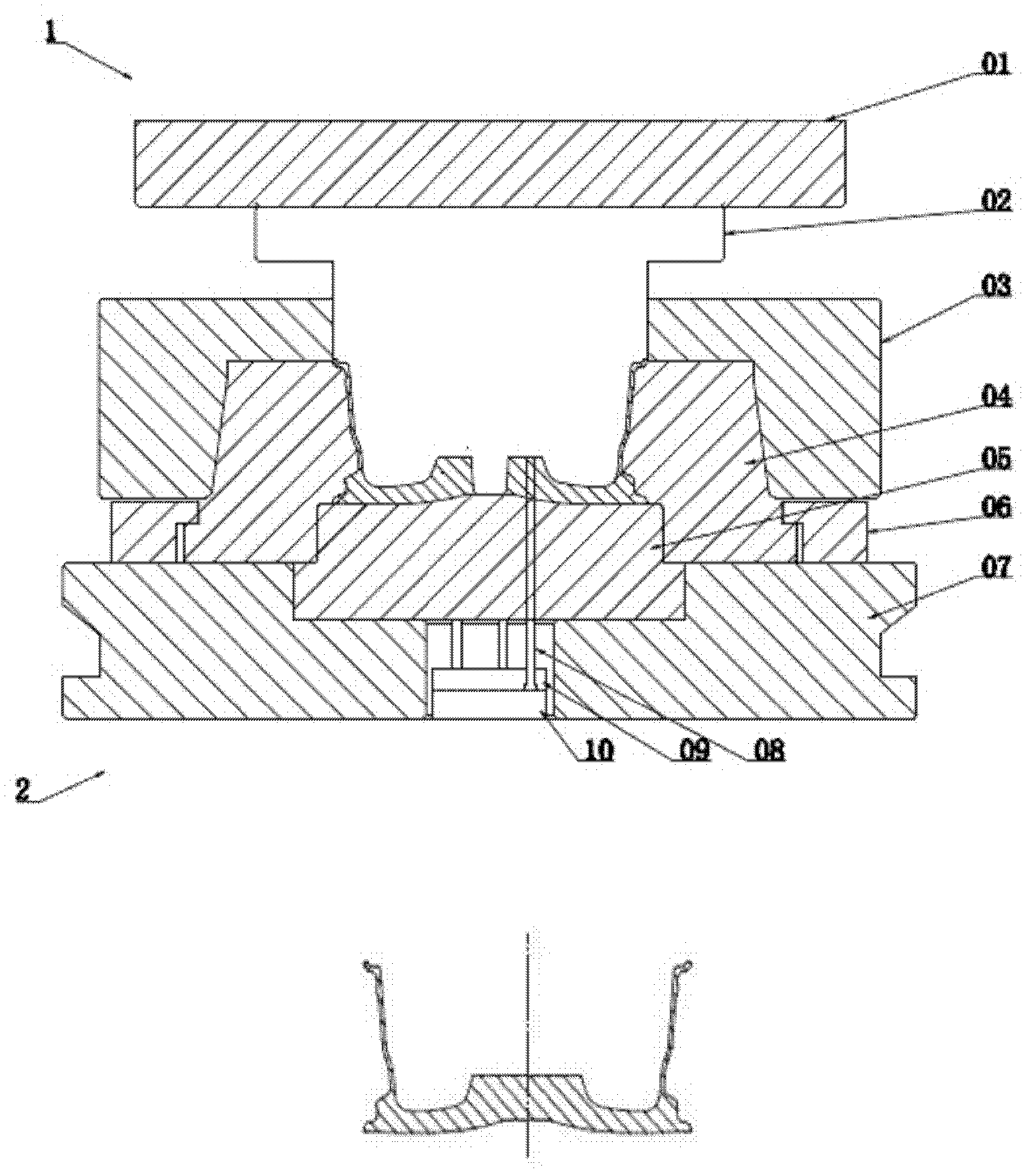

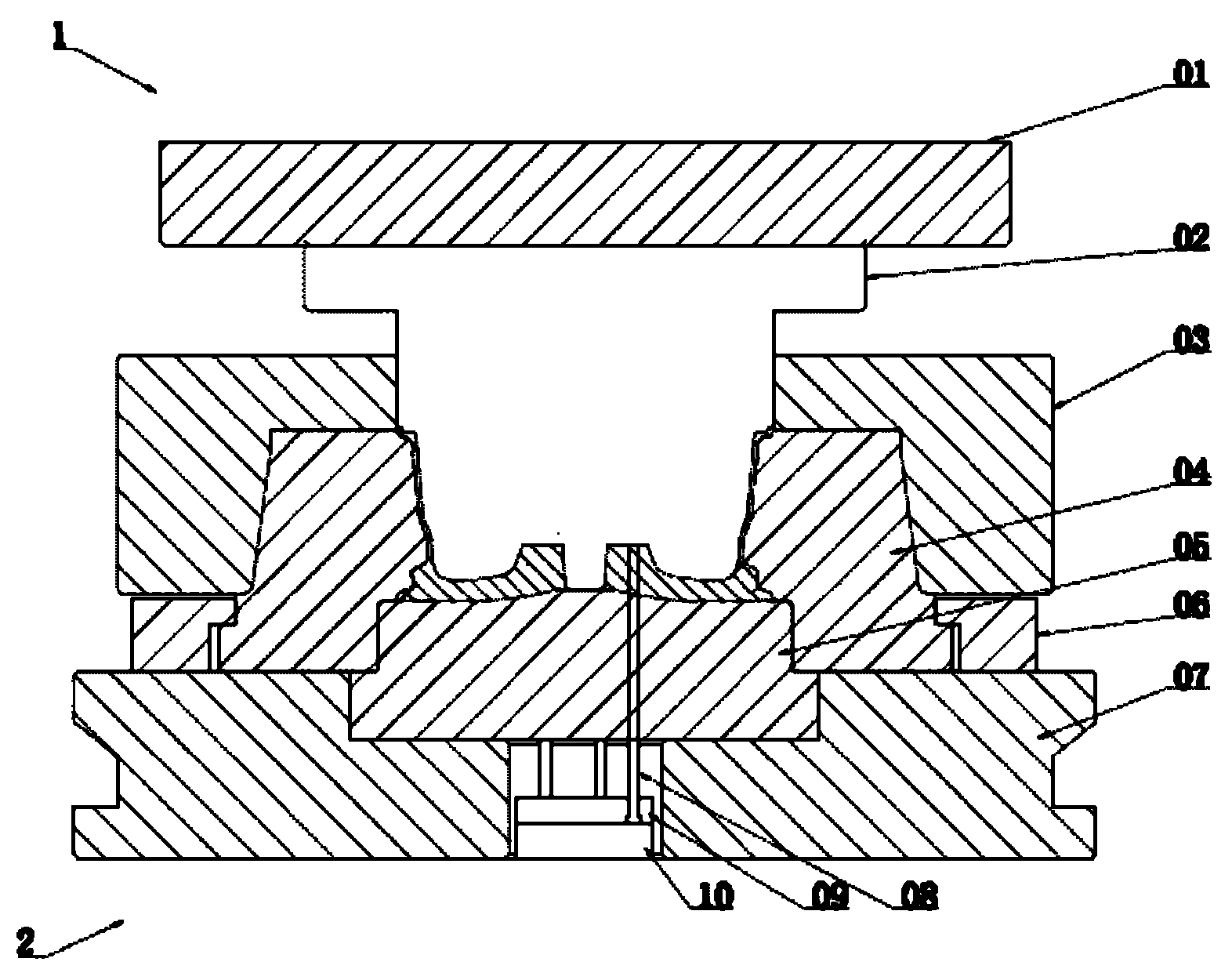

Image

Examples

Embodiment Construction

[0028] The mass percent of each component of an aluminum alloy for automobile wheel hub of the present invention is: Zn 4.5-6.3wt%, Mg 1.4-2.5wt%, Cu 0.5-0.9wt%, Zr 0.12-0.3%wt, Ti 0.05-0.15 wt%, Cr 0.05-0.2wt%, Sc 0.1-0.3wt%, the rest is Al. Each component of the alloy also contains impurity elements in a mass percentage of Si<0.1wt%, Fe<0.2wt%.

[0029] A kind of manufacture method of aluminum alloy for automobile wheel hub of the present invention is:

[0030] (1) First, according to pure Al 60-84%, industrial pure Mg 1.49-2.66%, industrial pure Zn 4.64-6.49%, AlCu50 master alloy 1.0-1.8%, AlZr15 master alloy 0.8-2.0%, AlTi5B1 master alloy 1.0-3.0 %, 2.5-10% of AlCr2 master alloy, and 5-15% of AlSc2 master alloy by weighing raw materials. Among them, the burning loss of the Mg element is relatively large, and the upper limit of the composition should be used as much as possible when weighing;

[0031] (2) Melt pure Al to 760-800°C in a smelting furnace, and then add indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com