Patents

Literature

607results about How to "Pouring evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

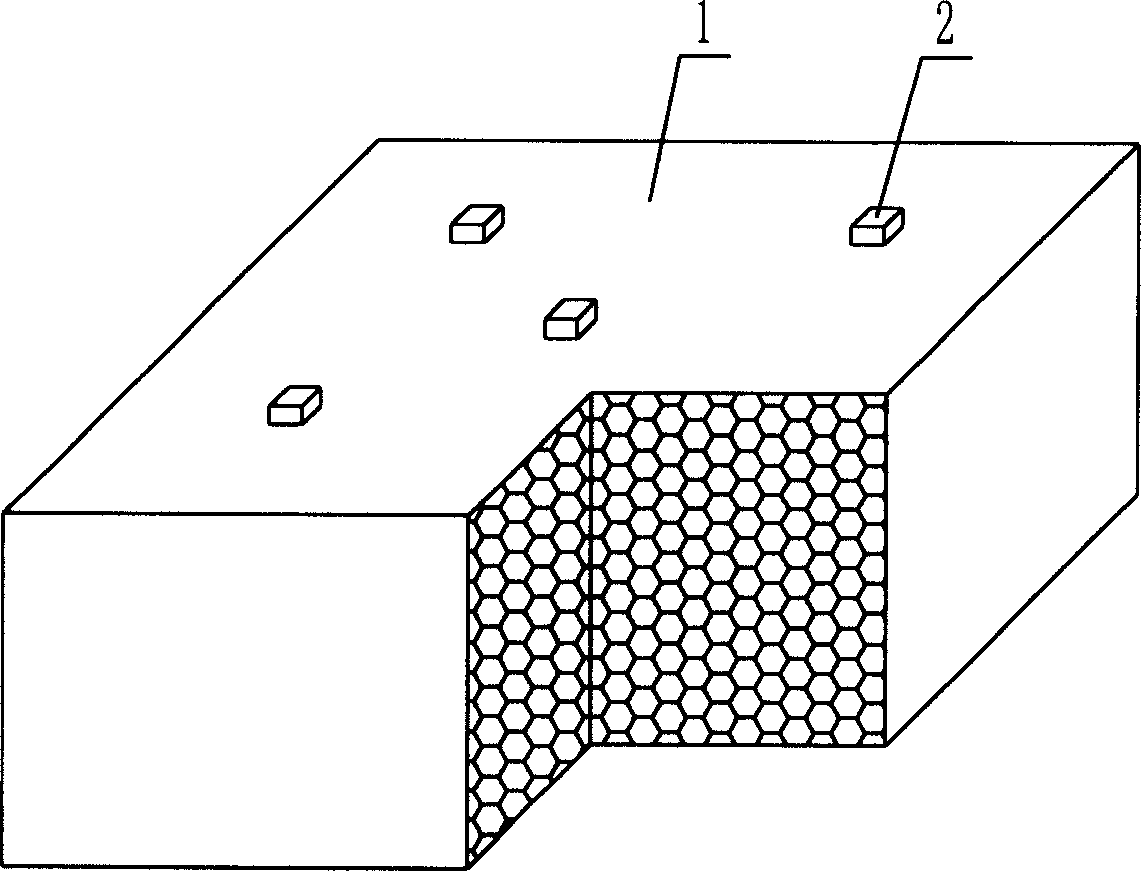

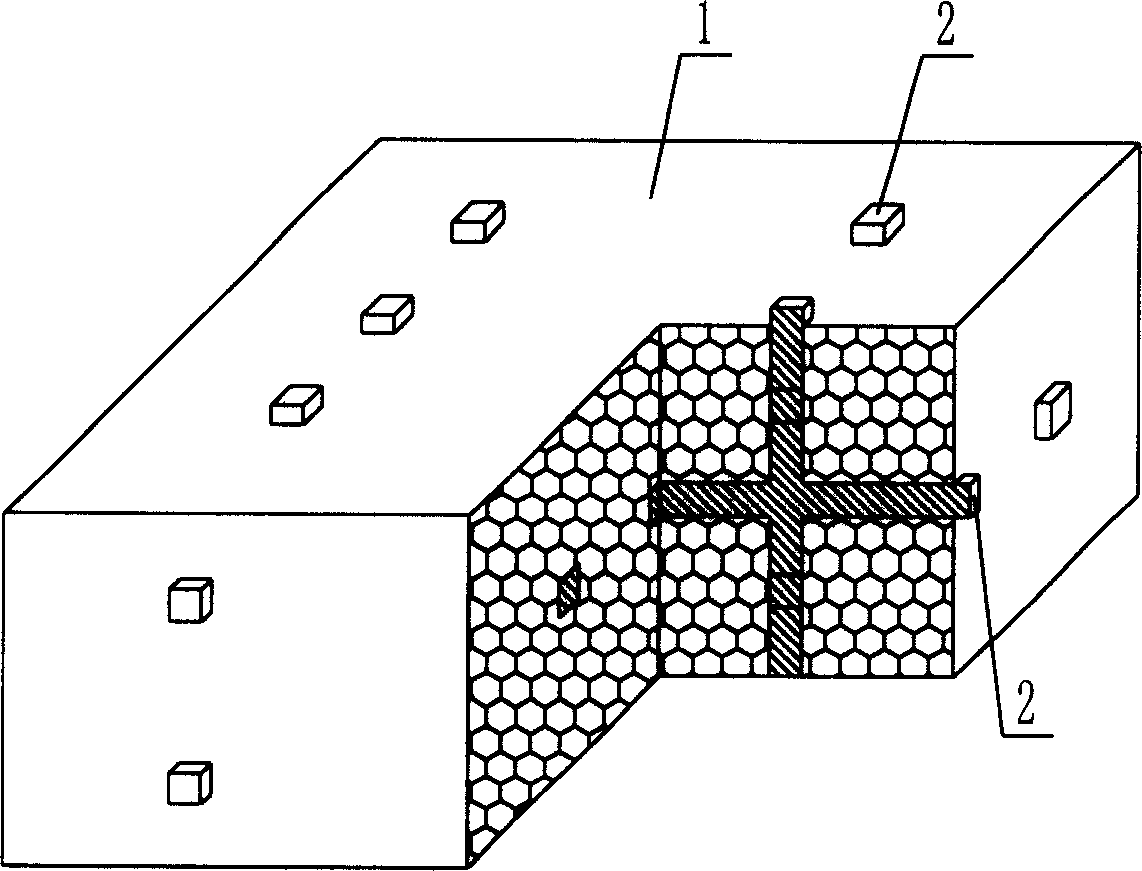

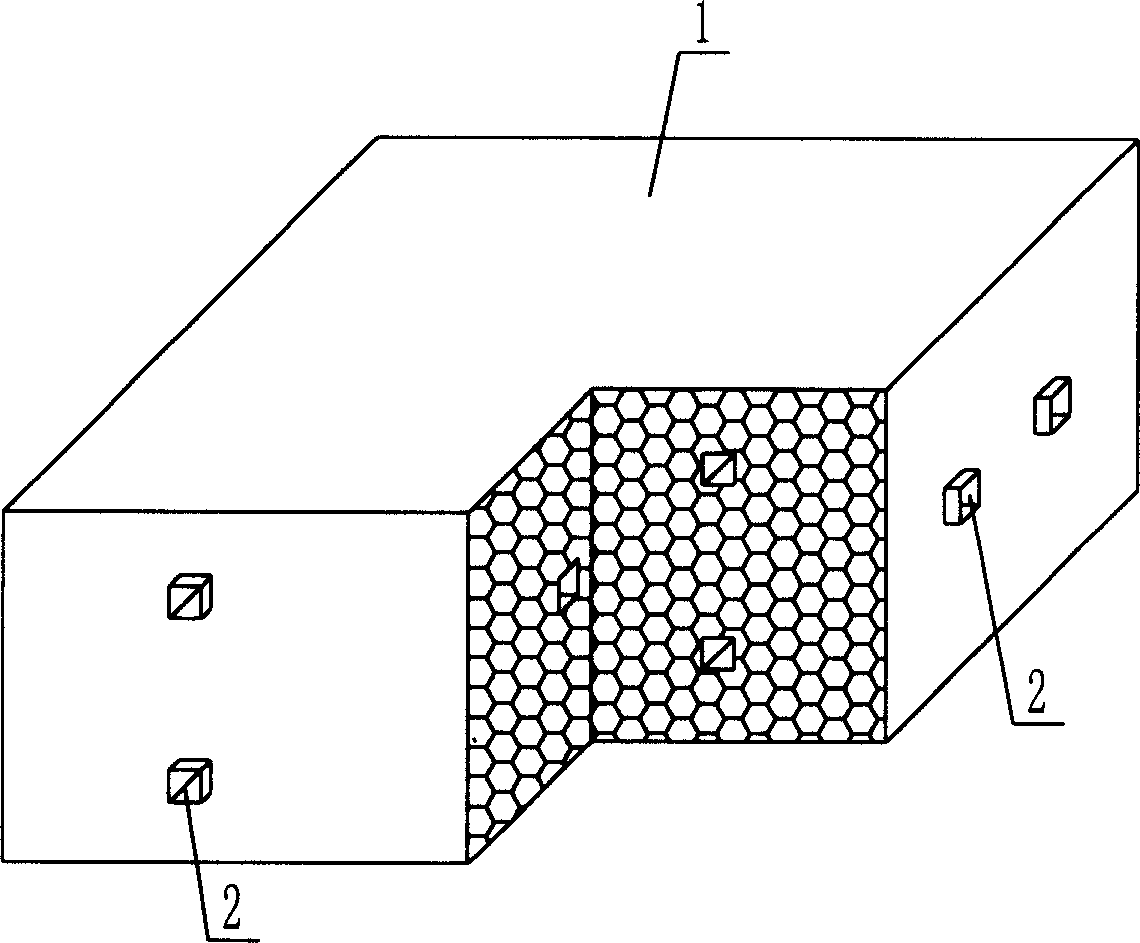

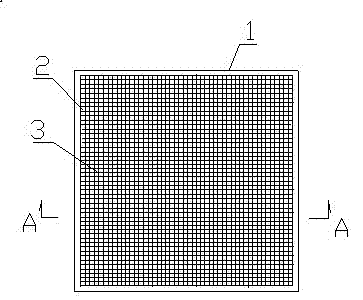

Component of light stuffing mould for concrete poured-in-situ

InactiveCN1598205AIt is convenient to obtain materials nearbyReduce manufacturing costFloorsSolid lightPre stress

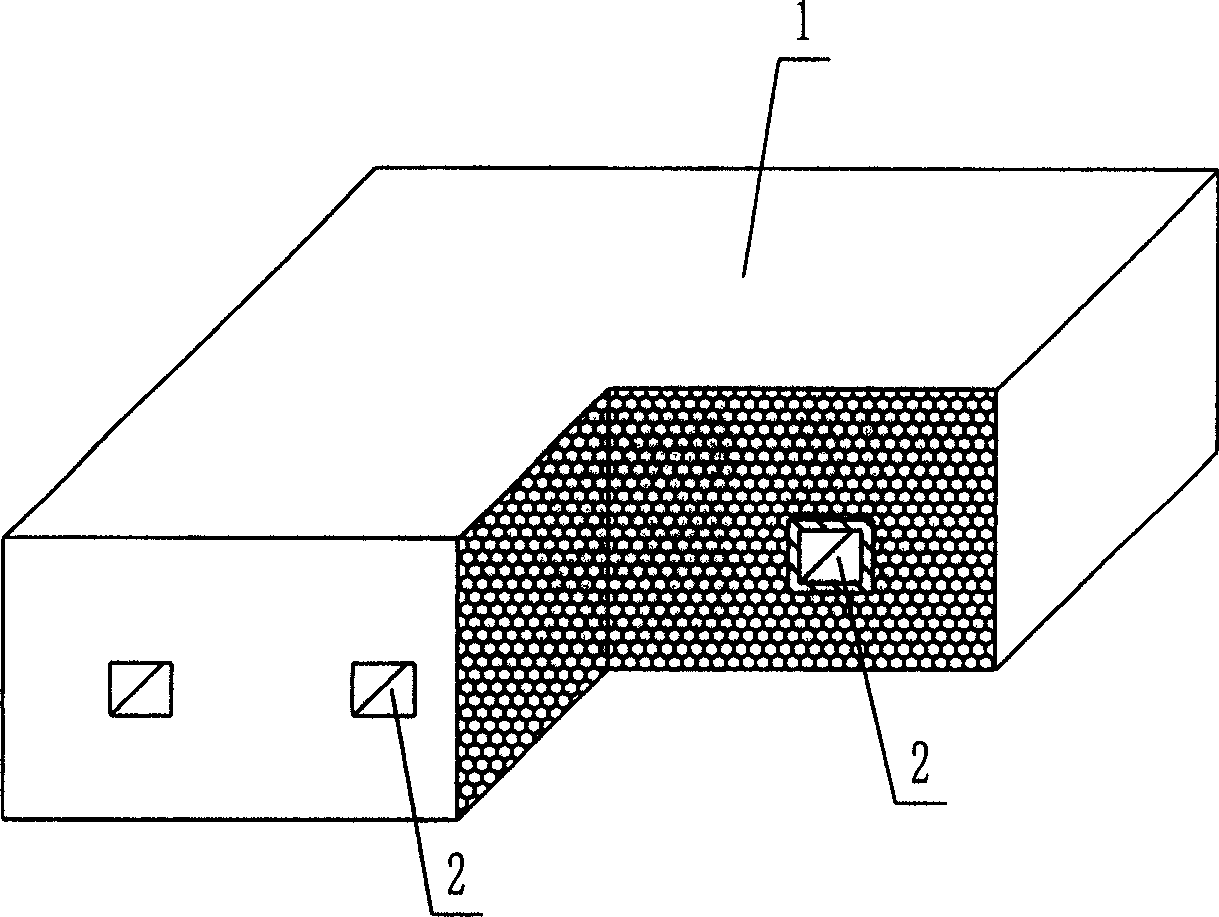

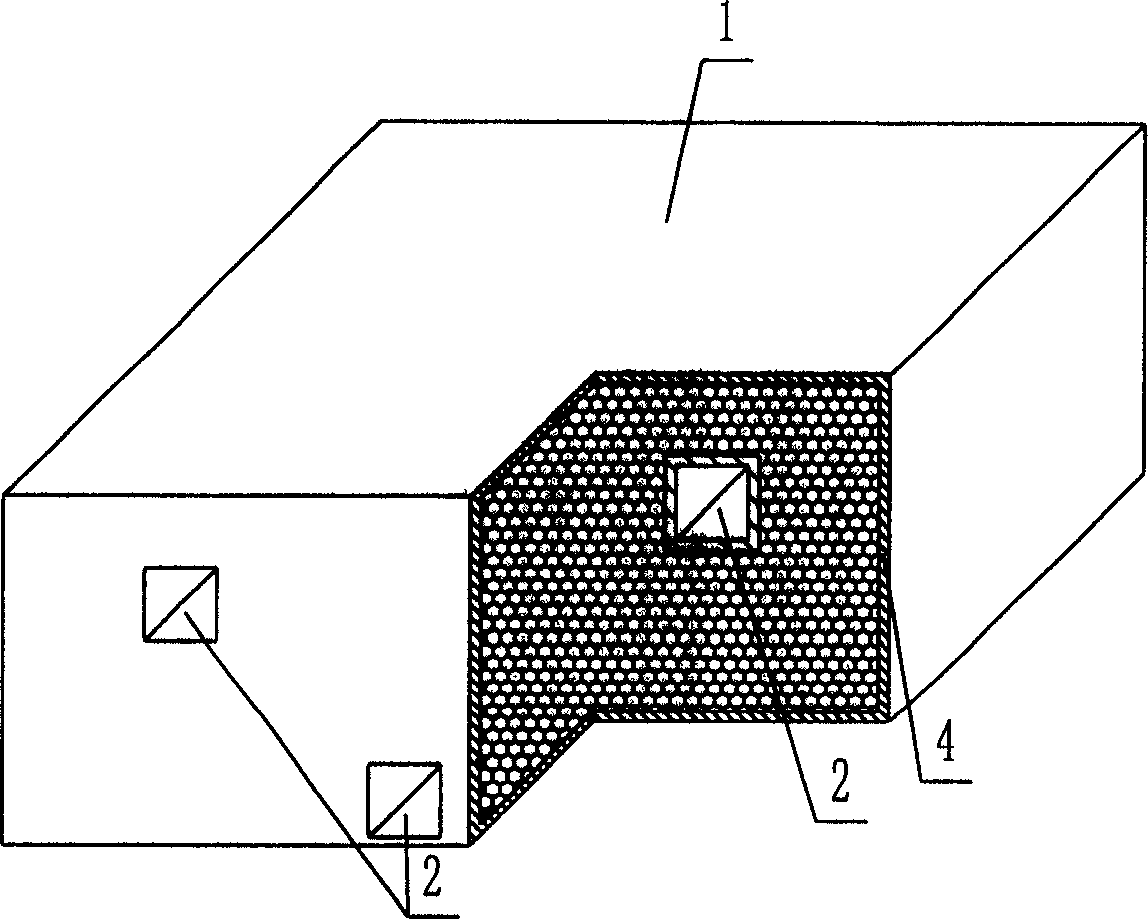

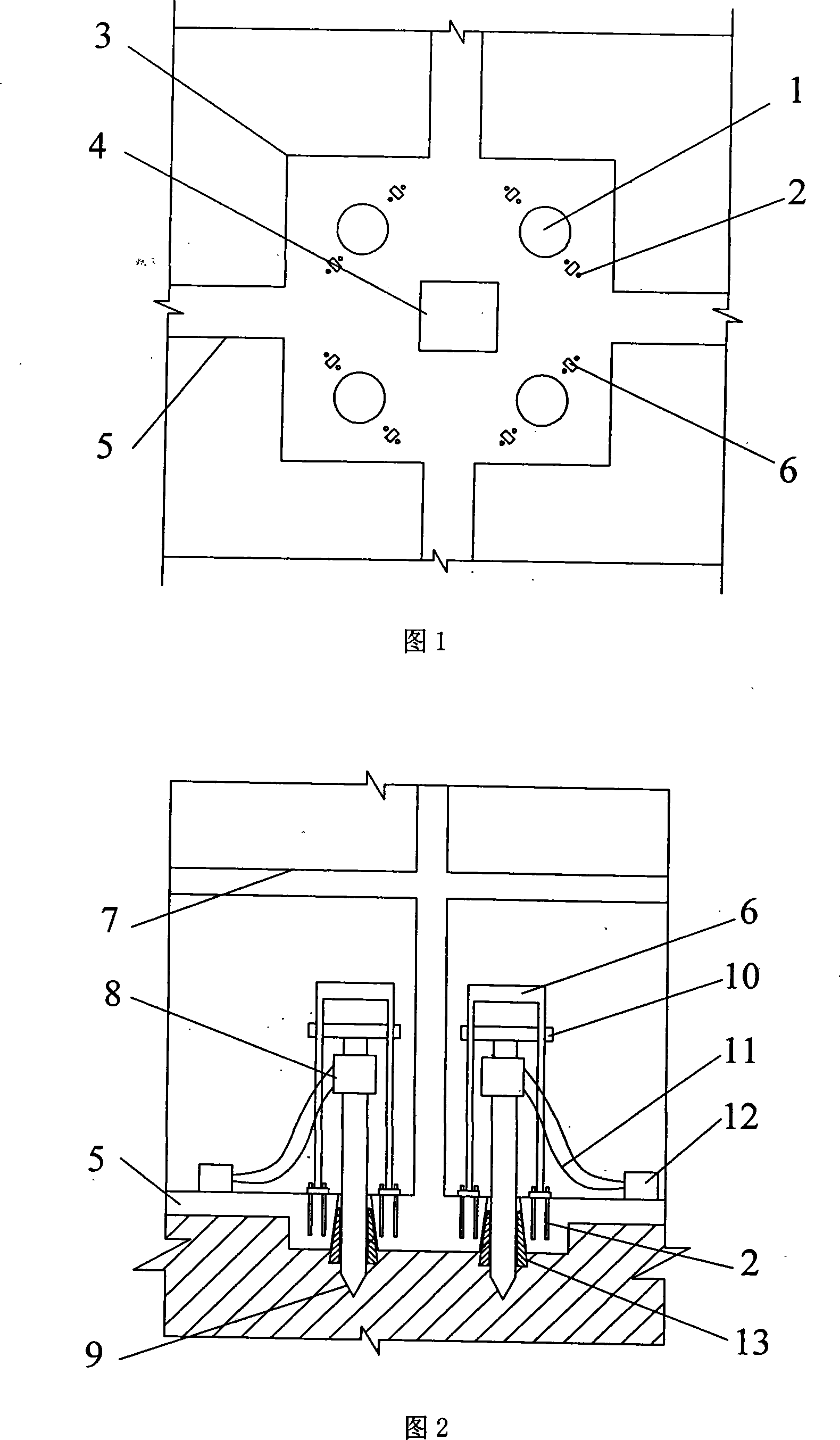

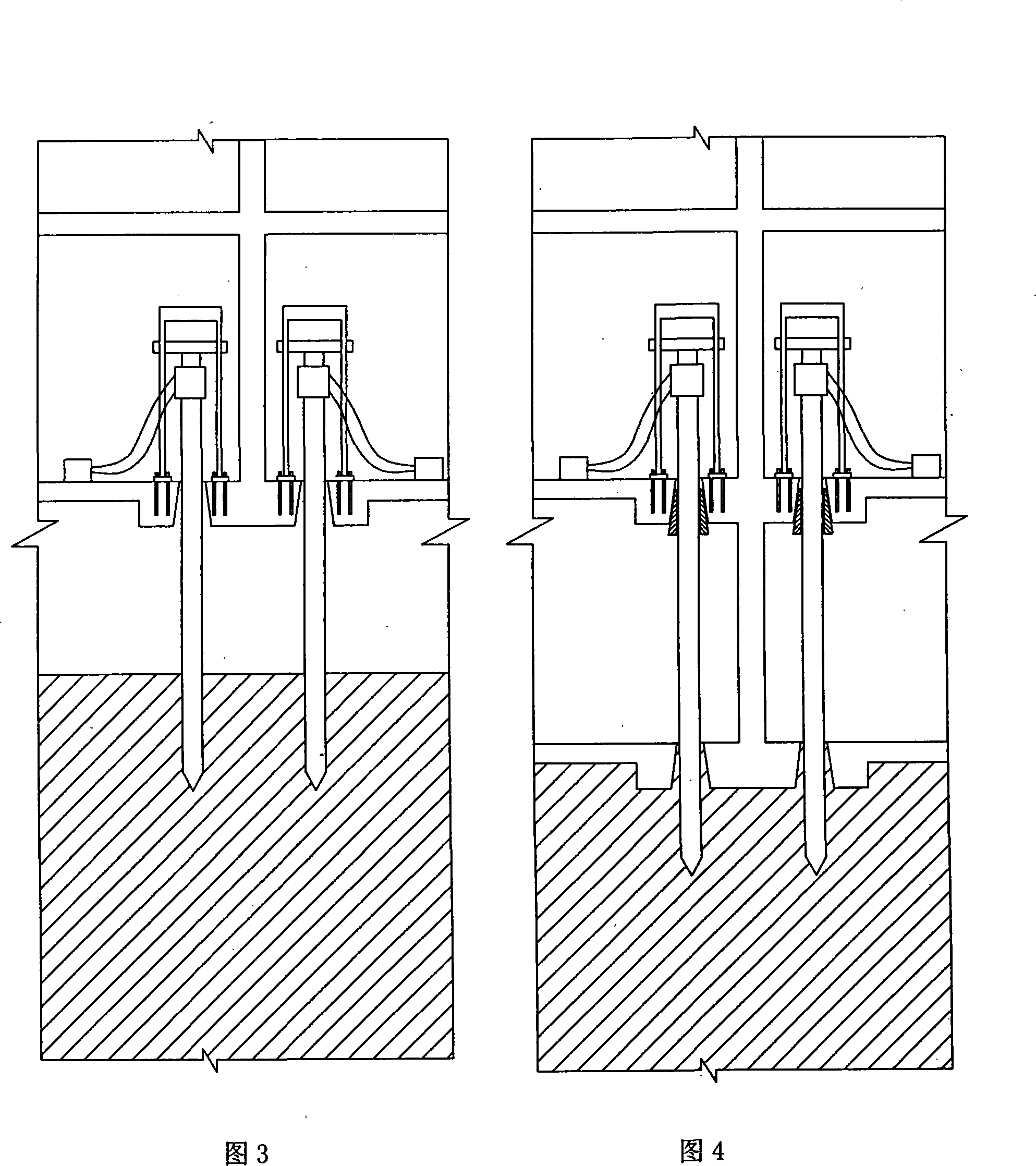

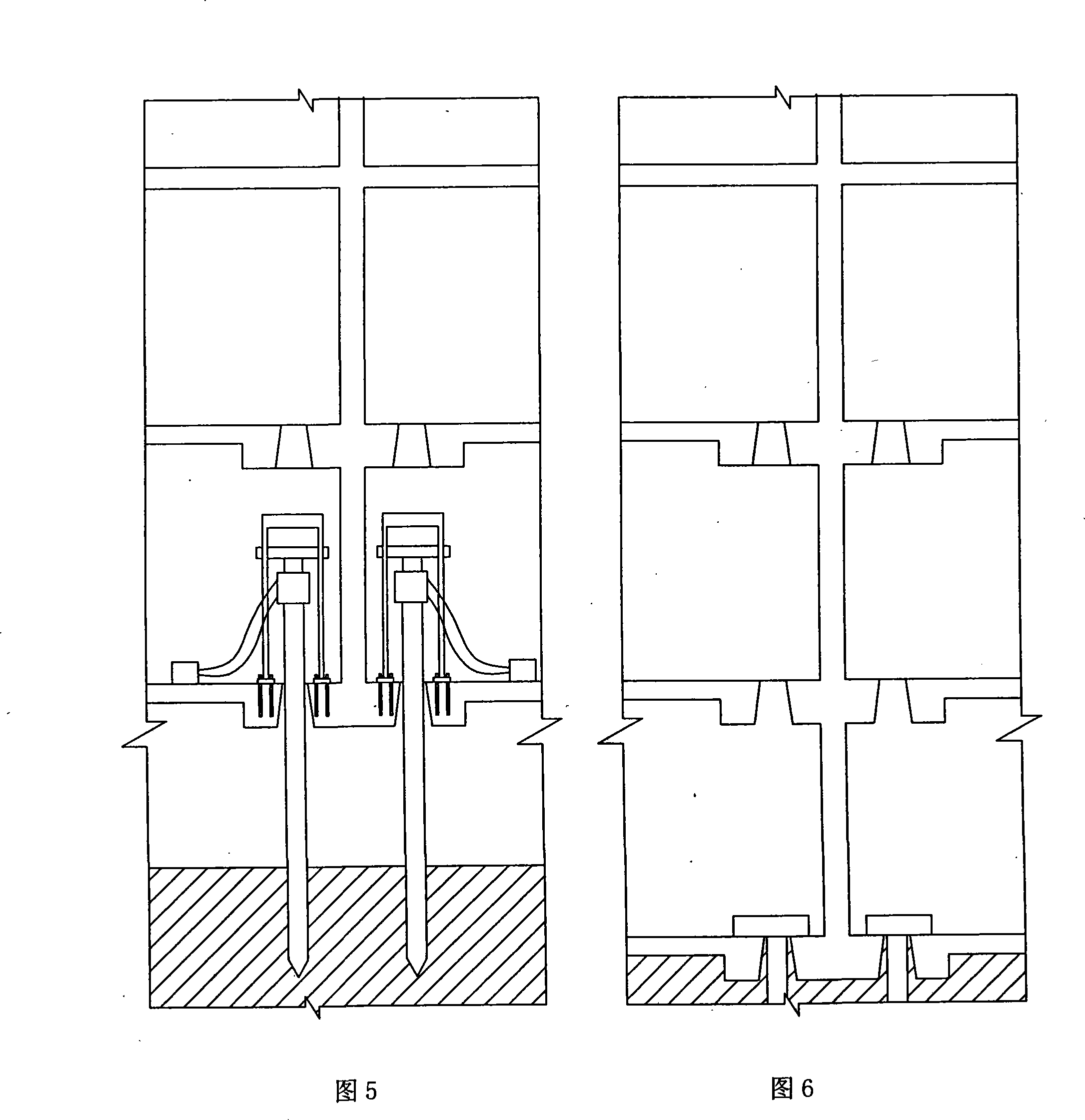

A light mould component for concreting, which includes a polyhedron solid light material component, its character lies in: the mentioned polyhedron solid light material component contains at least one strengthening pole. Because of the strengthening pole, the intensity of the component is high, the rigidity is large, and it is not apt to be damaged; additionally, it has characters of simple structure, high intensity, deformation and vibration resisting, easy producing, low cost, and convenient construction. And the applications of the component are wide.

Owner:湖南邱则有专利战略策划有限公司

Component of light stuffing mould for concrete poured-in-situ

A light mould component for concreting which includes a polyhedron solid light weight material component, its character lies in: the polyhedron solid light weight material component is arranged with at least one transverse aperture penetrating the surface of the component. When it is applied to the construction, because that the apertures penetrates the around side surfaces of the component, and the concrete is poured into the aperture cavities, after they are solidified, there forms concreting poles, thus a stressing and bearing component is formed in the light weight tire matrix component, the mechanical performance is upgraded greatly; at the same time, the light weight tire matrix component has characters of low cost, convenient construction and quick.

Owner:湖南邱则有专利战略策划有限公司

Plastic package material of AC permanent magnet submersible motor, plastic package technique and application

InactiveCN1958706AImprove plastic sealing efficiencyMolding time shortenedOther chemical processesManufacturing dynamo-electric machinesEpoxyTransformer

This invention provides a plastic sealant for AC permanent magnetic submersible motor, its sealing process and application. The plastic sealant is composed of: epoxy resin, diluent, curing agent, and silicon micropowder. The process comprises: (1) preparing the plastic sealant; (2) placing the motor stator in the stator sealing mold, locating, and placing the rotor in the rotor sealing mold; (3) sealing; (4) curing. This invention can be used for sealing AC permanent magnetic submersible motor, permanent magnetic wind power generator, electrical appliance, capacitor, transformer and inducer. This invention can largely shorten the sealing time, and can improve the sealing efficiency of diving motor. The plastic sealant has such advantages as low viscosity, smooth pouring, simple process, high product smoothness, good heat conductivity, good insulation, good waterproof property, no pollution during production and usage, and no toxicity to human bodies, thus is suitable for mass production.

Owner:SUN YAT SEN UNIV

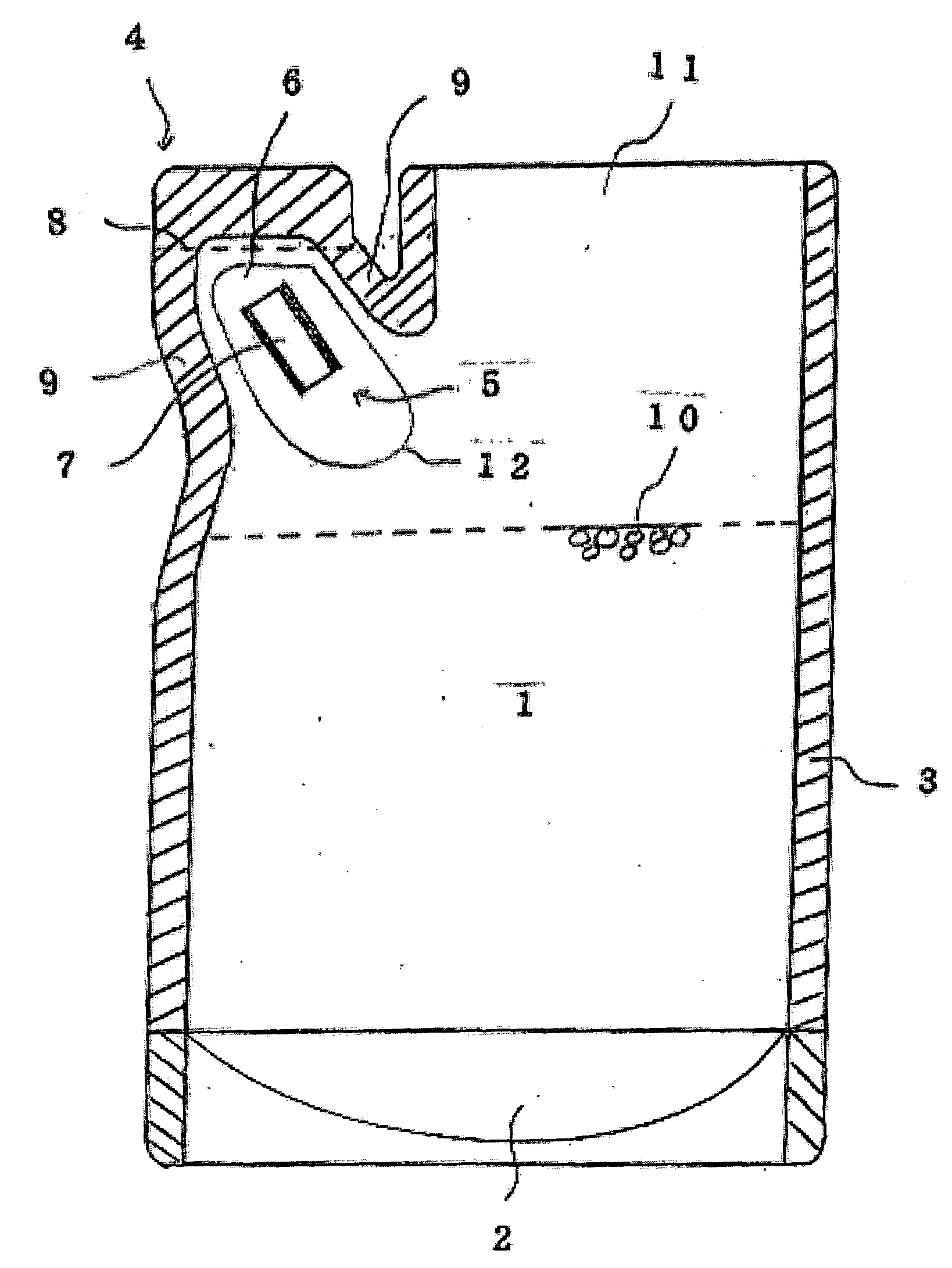

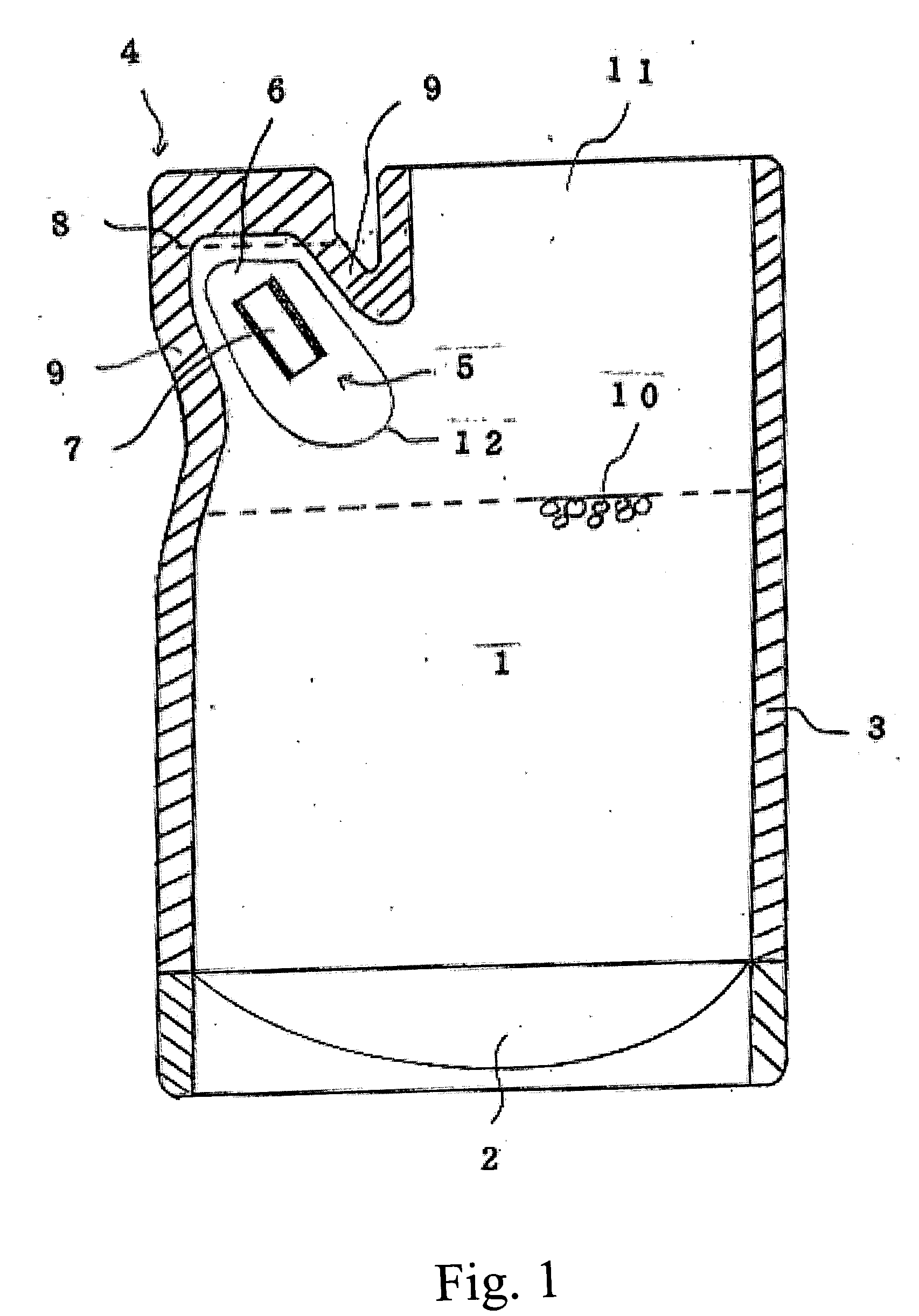

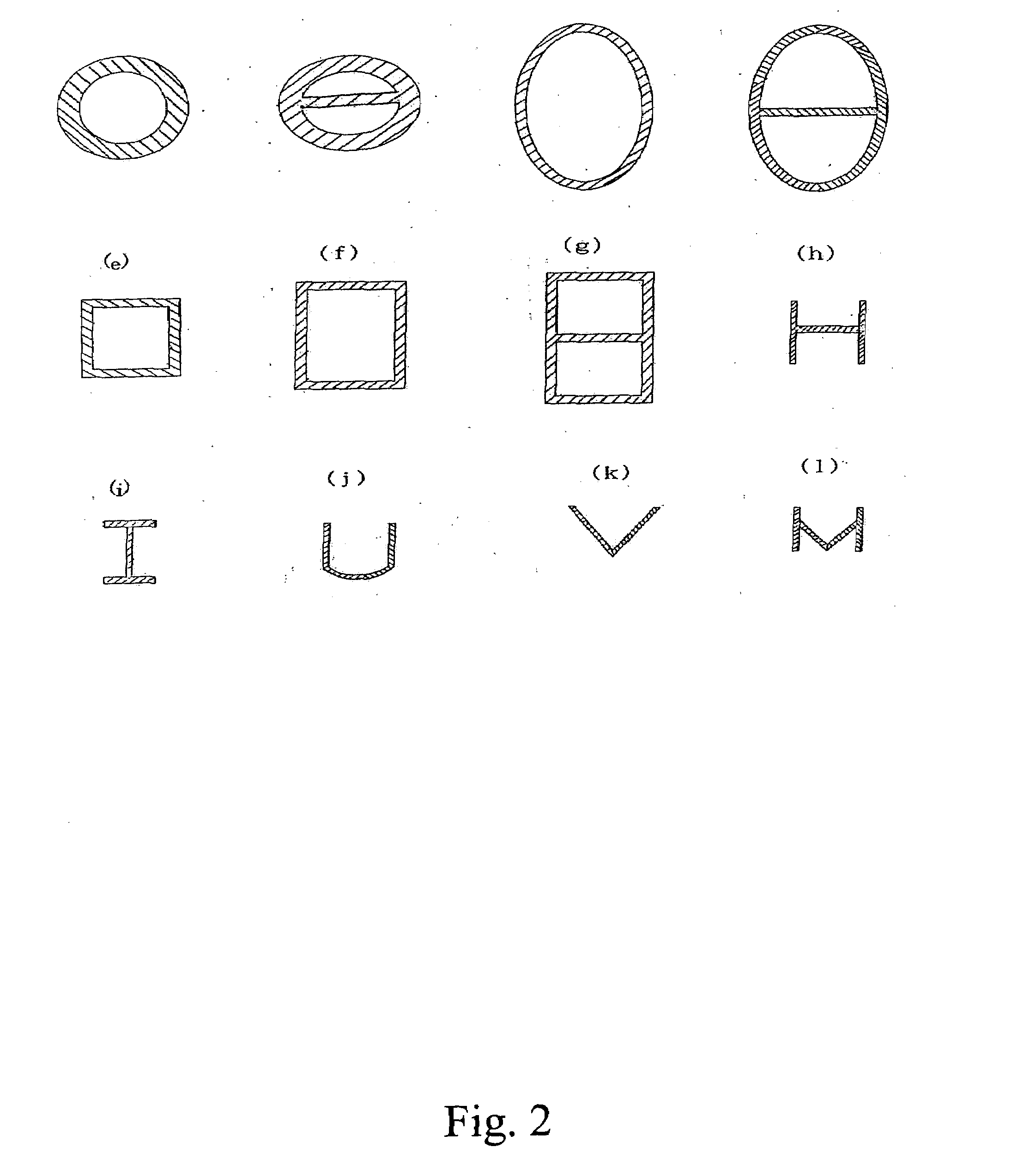

Pouch for storing granules

InactiveUS20070175920A1Increase in sizePouring evenlyPowdered material dispensingFlexible containersMedicineSynthetic resin

To provide a pouch for storing granules which can smoothly pour out the granular content even when filled with various granules.A pouch for storing granules where the perimeter of a front and back pair of synthetic resin film are sealed, wherein:a pouring spout with an easily opened port is formed to protrude out from the top perimeter region of the pouch, and opening support member is placed at the pour spout, and the front and back pair of synthetic resin film are prevented from mutually contacting by the opening support member in the region where the opening support member is established and surrounding regions thereof, so that the opening of the pour spout is always maintained in an open condition.

Owner:THE PROCTER & GAMBLE COMPANY

Static pressure pile process for construction of existing building basement

The present invention provides a static pressure pile technique for the construction of the basements of the existing building. The present invention includes eight steps: (1) a bearing platform and connecting beams are constructed, and pile-driving holes are arranged on the bearing platform; (2) anchor rods are embedded and reaction frames are installed; (3) precast piles are hoisted and jacks are installed; (4) the precast piles are driven to a designed elevation one by one, clamped and fixed; (5) earth is excavated layer by layer till the elevation of the bottom of the lower floor slab of the newly constructed basement; (6) the vertical force-bearing components, such as posts, walls, etc., are lengthened, and the bearing platform and the connecting beams of the next layer are casted; (7) the precast piles are driven to the next floor, and the reaction frames and the jacks are moved to the next floor; (8) the steps are repeated, and after the construction of the basement of each layer is finished, the reaction frames are disassembled. Applying the construction technique with the anchor rods and the static pressure piles to construct the basements of the existing building, the present invention has the advantages of shockproofness, noiselessness, no pollution, etc., thus furthest reducing the affection on the life of people in the building.

Owner:SHANDONG JIANZHU UNIV

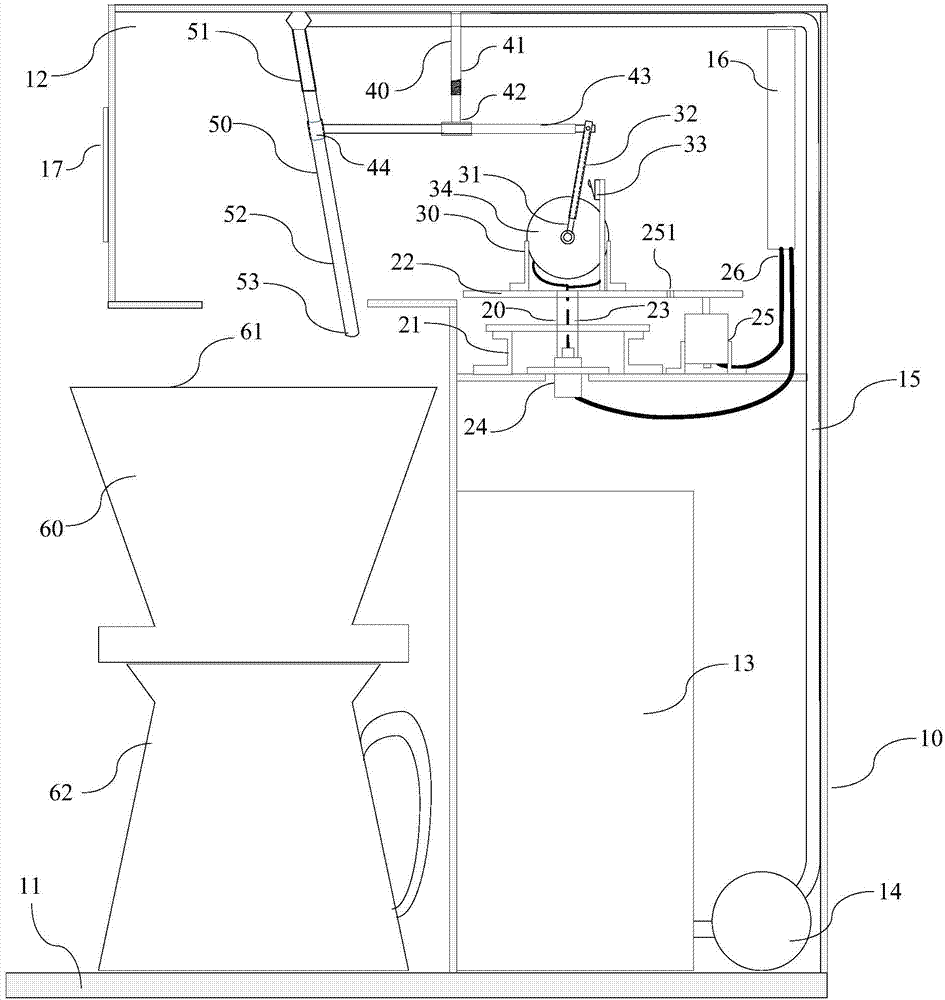

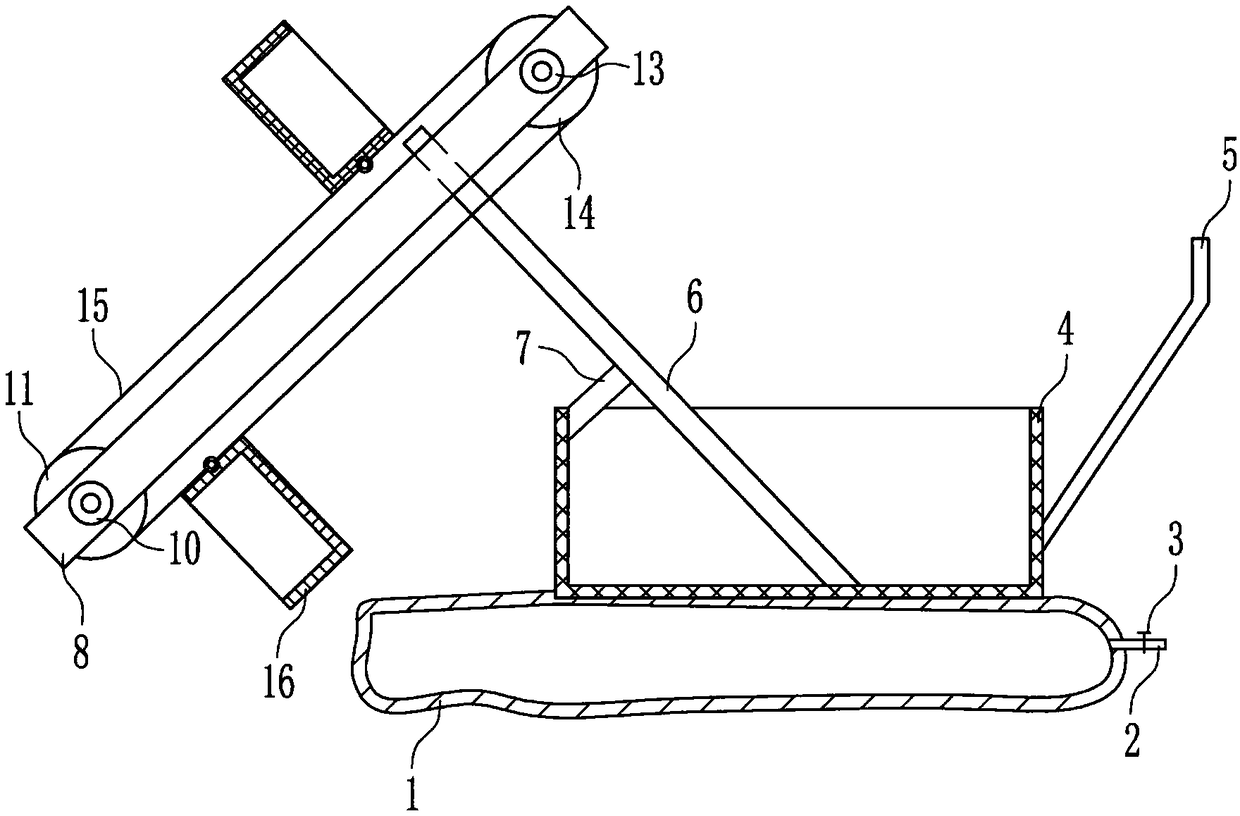

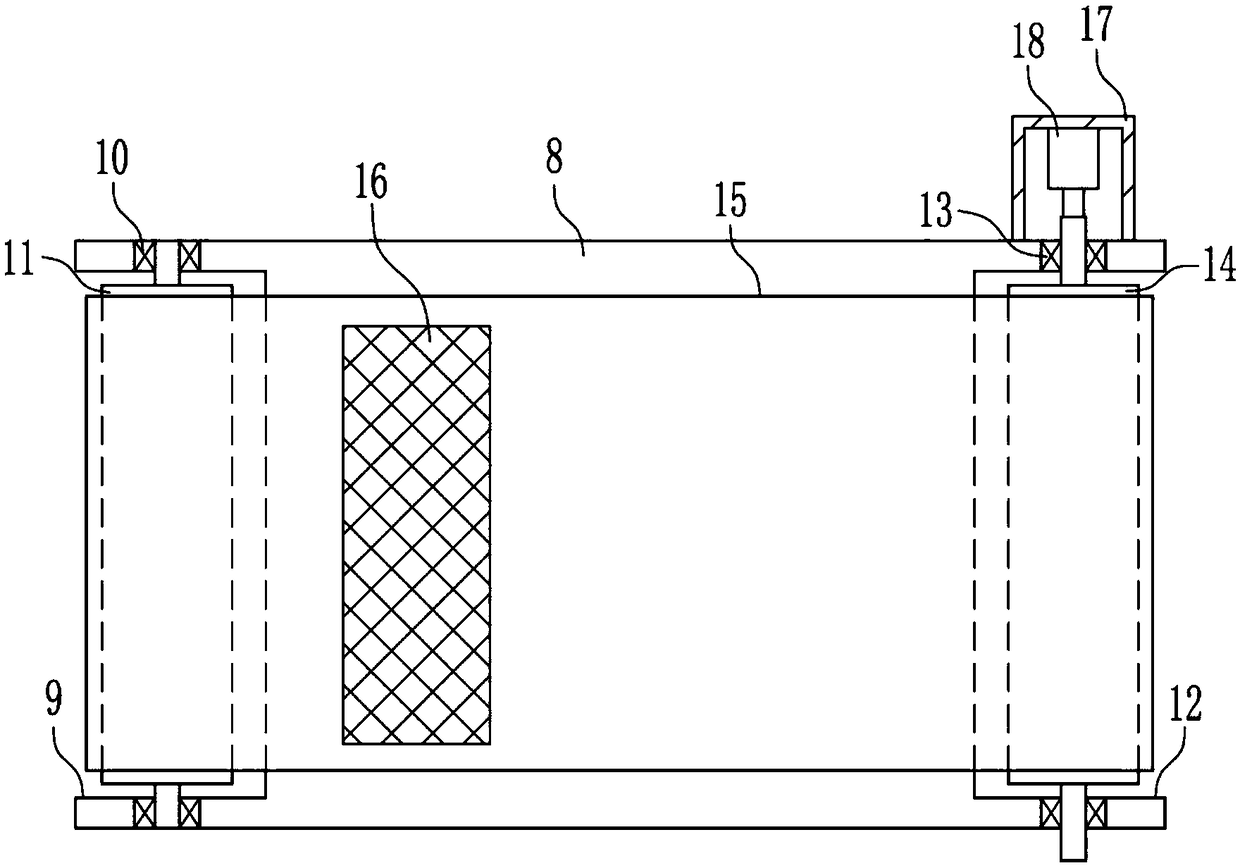

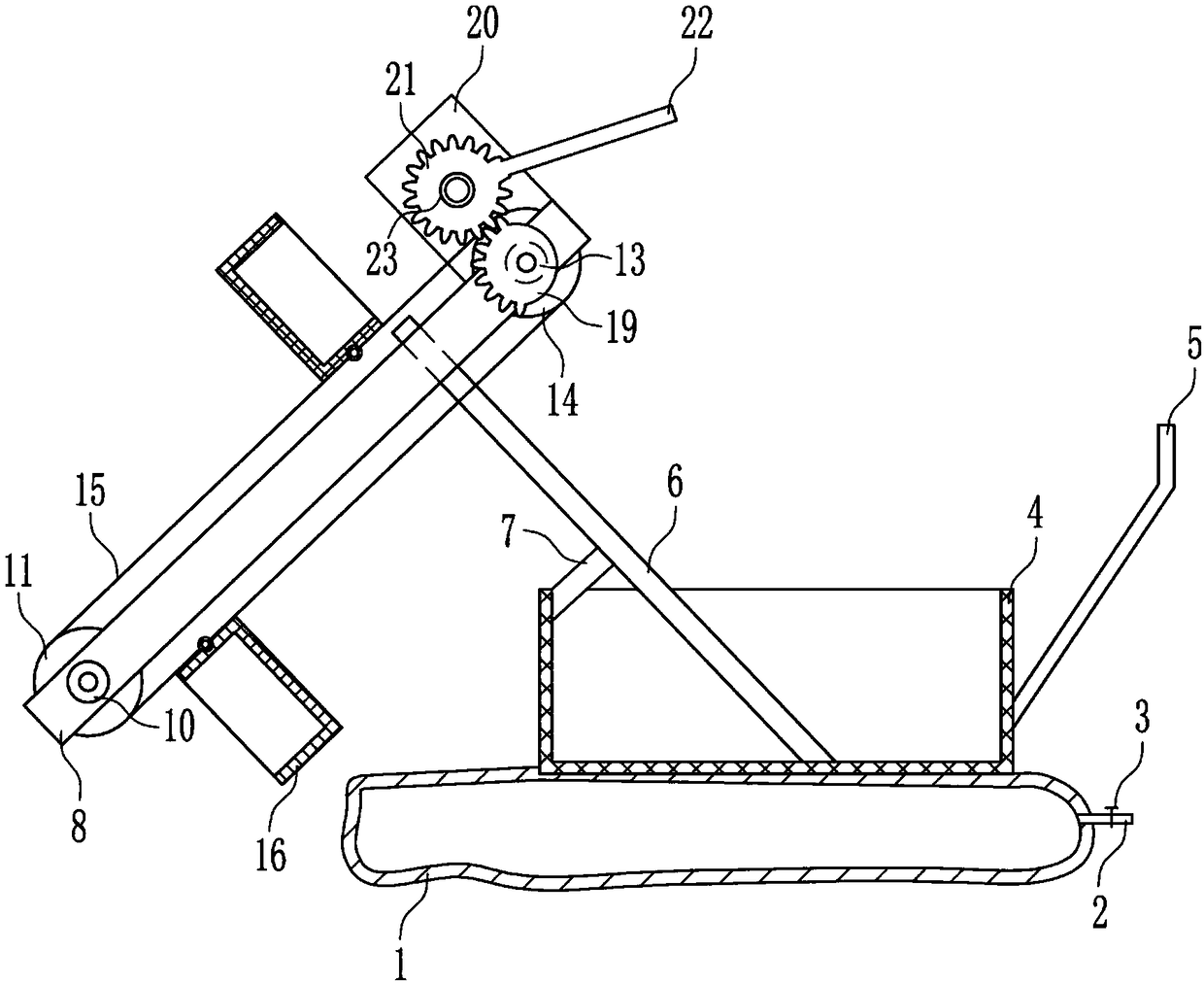

Drip filter coffee maker with helical inspection

The disclosure provides a drip filter coffee maker with helical inspection, comprising a rotating machine seat set, a tilting rod set, a connecting rod set and a water injection pipe set. The rotation machine seat set comprises a rotating seat and a machine seat motor, wherein the rotating seat is driven by the machine seat motor to rotate. The tilting rod set is arranged on the rotating seat and comprises a tilting motor and a tilting rod; the tilting rod motor drives the tilting rod to repeatedly swing within a predetermined angle range, and a top end of the tilting rod performs helical rotation. The connecting rod set has a connecting rod driven by the tilting rod. The water injecting pipe set has a water injecting pipe driven by the connecting rod. By the connecting rod, the helical rotation of the top end of the tilting rod is transferred to the water injecting pipe, and the water injecting pipe performs helical water injection. Hot water is poured repeatedly and uniformly onto the coffee powder along a helical path. Therefore, the coffee powder is uniformly mixed with the water, and coffee with a more mellow taste is obtained.

Owner:黄永政

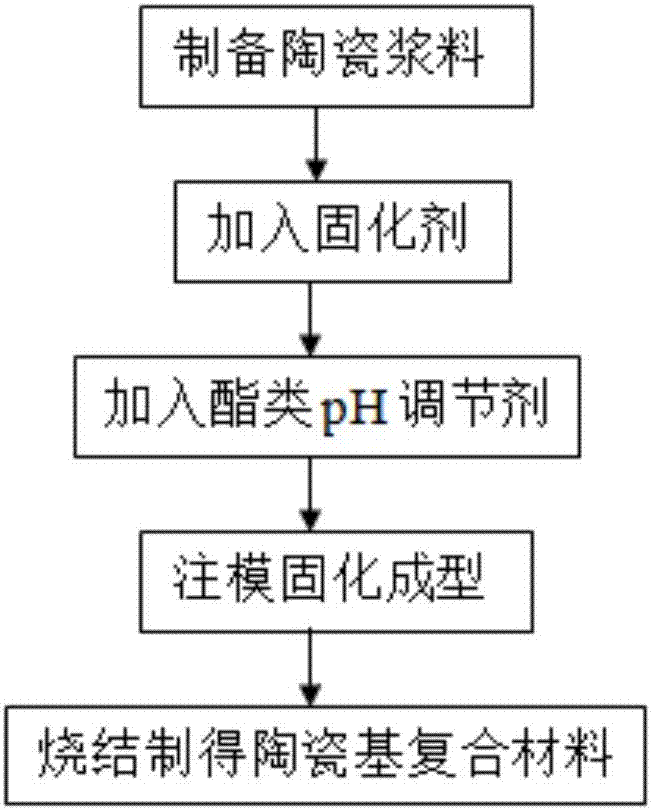

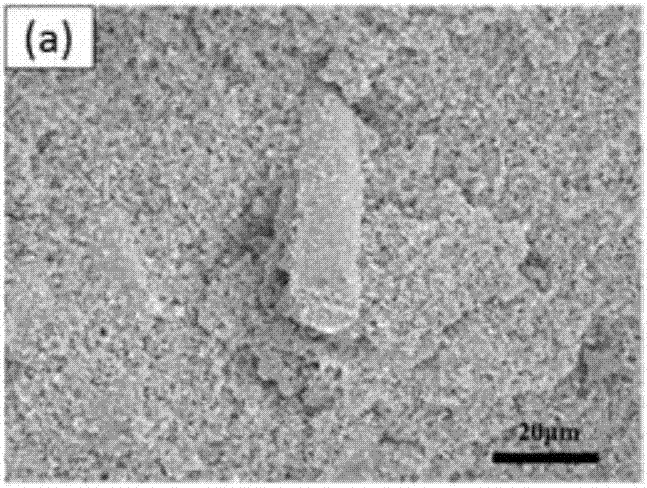

Method for rapidly preparing inorganic fiber-enhanced ceramic composite material

The invention belongs to the technical field of inorganic non metal, and concretely relates to a method for rapidly preparing an inorganic fiber-enhanced ceramic composite material. The method comprises the following steps: ceramic powder, inorganic fiber, a dispersant and deionized water are uniformly mixed through ball milling, the uniform ceramic slurry with negative electricity is on the surface of ceramic powder particles; a curing agent containing high-valence counter ions is added and is subjected to ball milling; an esters pH conditioning agent is added in the obtained slurry; then the material is stirred under vacuum condition and is degassed, the material is slowly injected into a nonporous die, then is demoulded through water-bath heating to obtain a wet blank, the wet blank is dried to the dried blank; and the ceramic composite material is obtained through sintering. According to the prepared inorganic fiber-enhanced ceramic composite material, compared with the ceramic without inorganic fiber, the bending strength at room temperature is increased by about 30%, the ceramic composite material is uniform and consistent, the time required by the method is short, an organic matter is not required for being added, rubber discharge is not required, and the ceramic composite material having complex shape is obtained.

Owner:HUAZHONG UNIV OF SCI & TECH +2

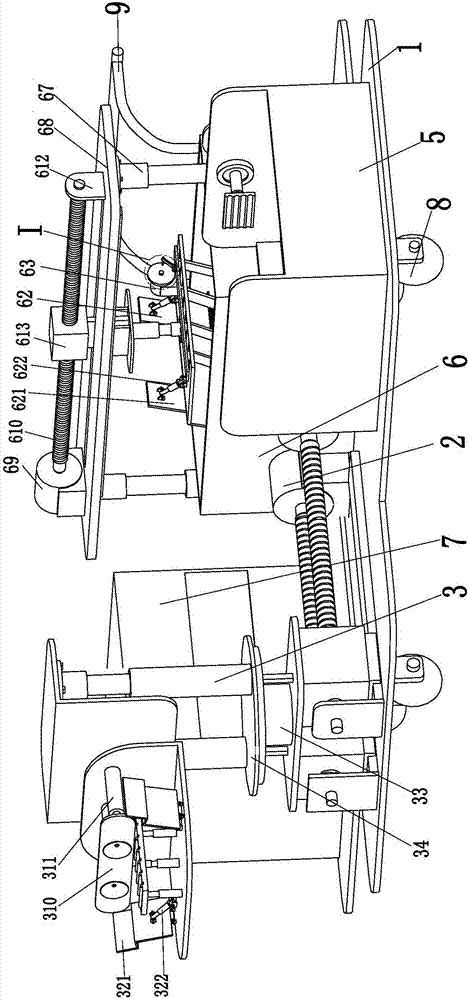

Silkworm rearing tool integrated treatment device specially used for silkworm rearing

InactiveCN106912454ASmooth movementNo manual operationHollow article cleaningDrying gas arrangementsUltimate tensile strengthLateral movement

The invention relates to a silkworm rearing tool integrated treatment device specially used for silkworm rearing. The device comprises a bottom plate. The lower end of the bottom plate is symmetrically provided with four universal wheels. The bottom plate is symmetrically provided with two lateral movement mechanisms on left and right. The upper ends of the two lateral movement mechanisms are provided with a push mechanism. The left side of the bottom plate is provided with a collection mechanism. The rear side of the bottom plate is provided with a cleaning mechanism. The right side of the bottom plate is provided with a drying mechanism. The drying mechanism can rapidly dry a silkworm rearing tool. The push mechanism, the two lateral movement mechanisms, the collection mechanism, the cleaning mechanism, and the drying mechanism are cooperated to complete an integrated treatment process of the silkworm rearing tool. The device solves problems that manual silkworm rearing tool pulling and placing, manual silkworm excrement collection, manual silkworm rearing tool cleaning and disinfection, and manual airing and air drying of the cleaned silkworm rearing tool are needed in an existing silkworm rearing tool treatment process, and operation is complex, labor intensity is high, and working efficiency is low, and the device can realize pushing and placing, cleaning, and drying integrated automatic treatment functions of the silkworm rearing tool.

Owner:谢秋晨

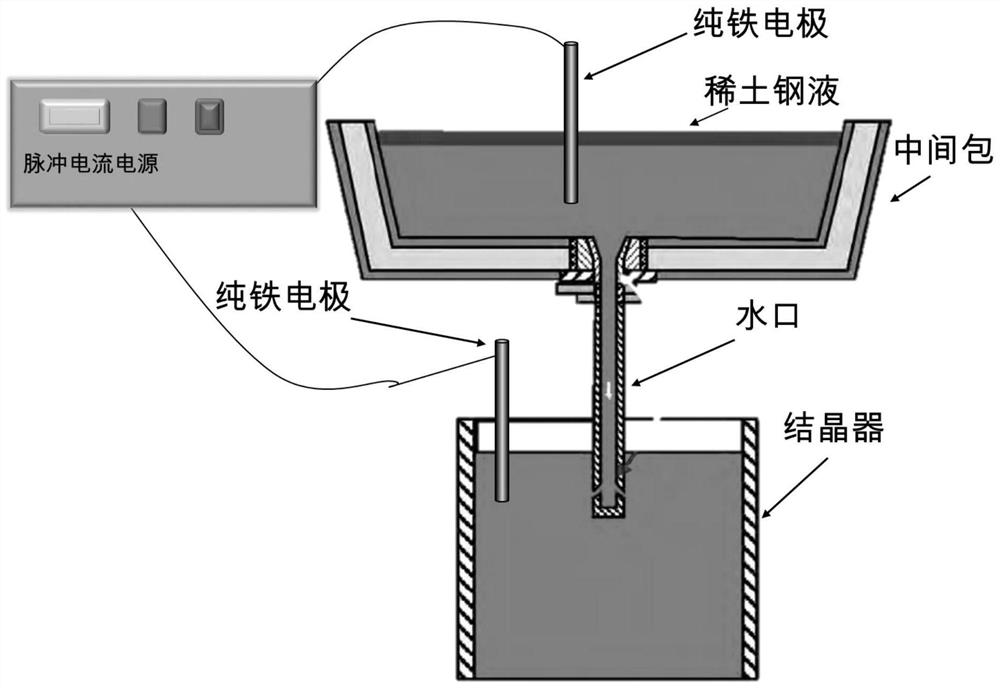

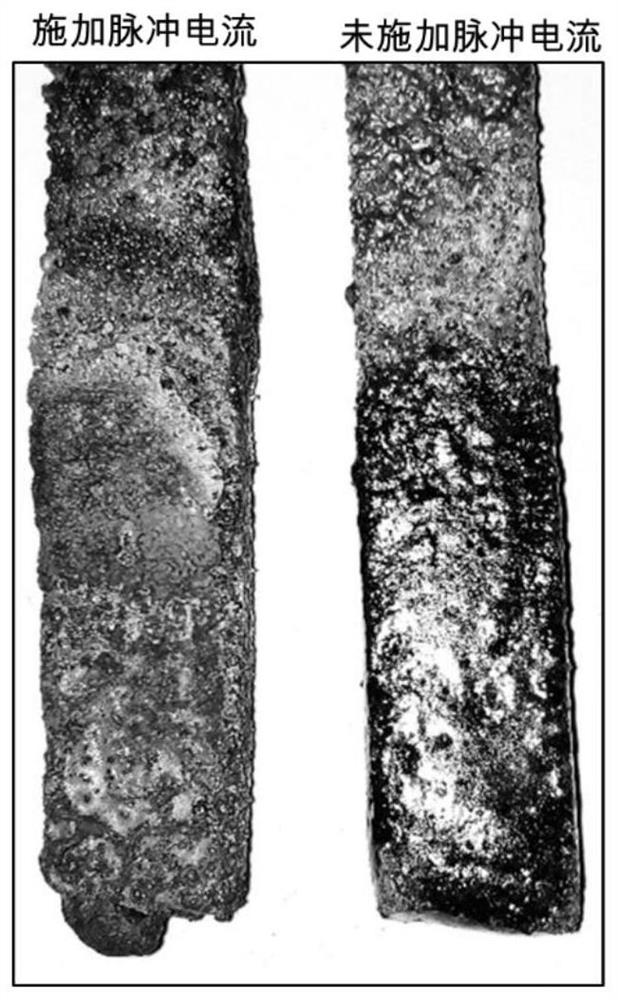

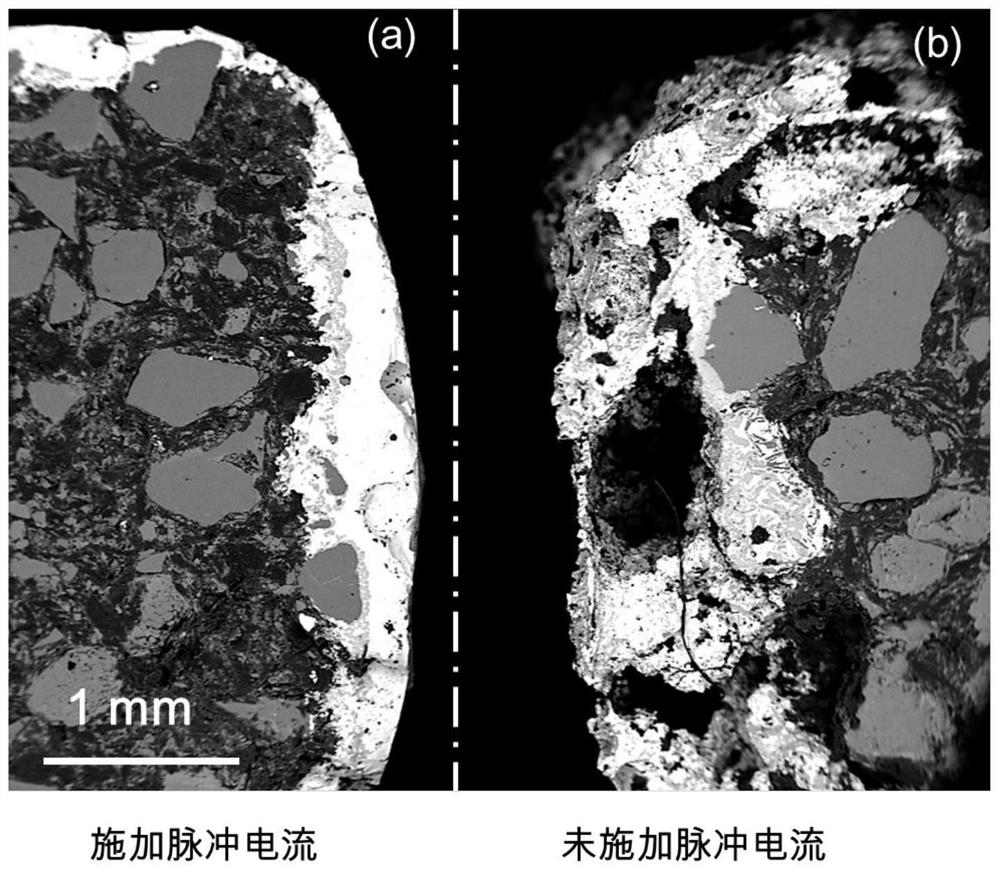

Method for inhibiting blockage of rare earth molten steel pouring nozzle through pulse currents

ActiveCN111906266AChemically activeAccelerated decarbonizationMelt-holding vesselsMischmetalEngineering

The method includes the steps that an electrode is inserted into rare earth molten steel, the pulse currents are applied to the electrode through a power supply device, the erosion reaction between the inner wall of the nozzle and an interface of the rare earth molten steel is intervened through the pulse currents, the rare earth molten steel corrosion resistance of the inner wall of the nozzle isimproved, and inclusions in the molten steel are further prevented from adhering to the inner wall of the nozzle. The method for inhibiting blockage of the rare earth molten steel pouring nozzle through the pulse currents is provided in order to solve the problems that rare earth metal elements in the molten steel erode the nozzle and rare earth inclusions adhere to the nozzle to cause nodulationand blockage of the nozzle in rare earth steel smelting and pouring, so that a rare earth steel smelting and continuous casting process is stabilized, and the quality of continuous casting billets isimproved. The invention discloses a method for inhibiting blockage of a rare earth molten steel pouring nozzle through pulse currents, and relates to the field of rare earth steel smelting and casting.

Owner:UNIV OF SCI & TECH BEIJING

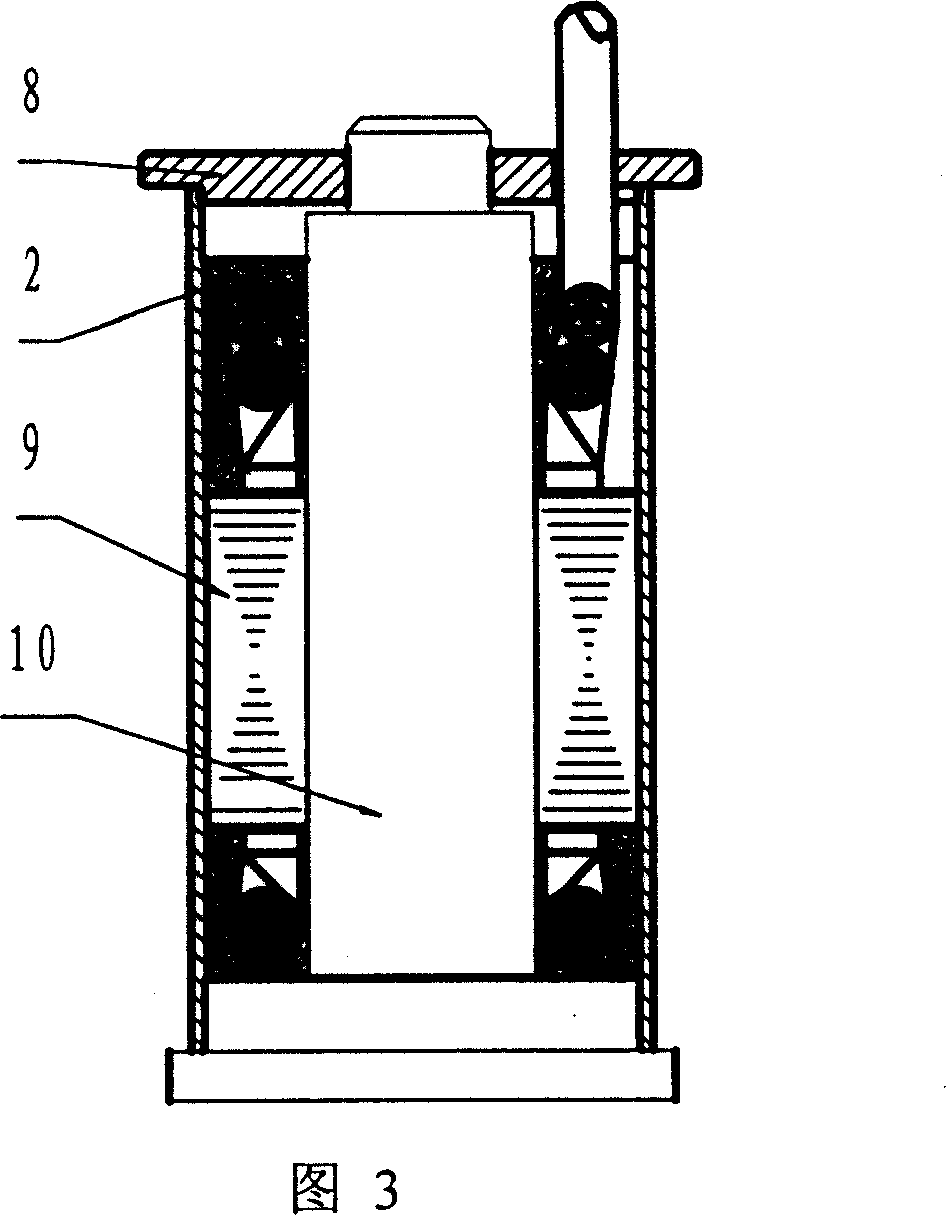

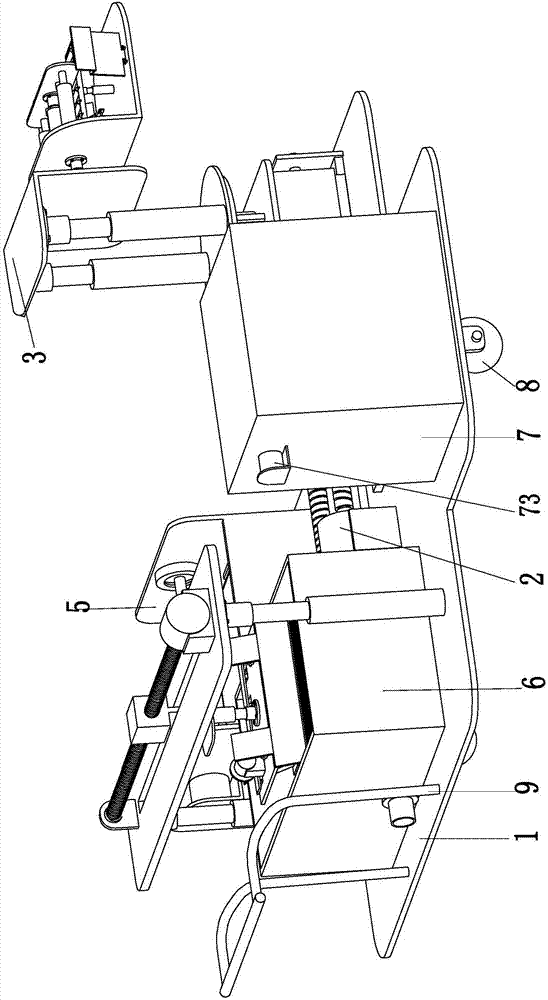

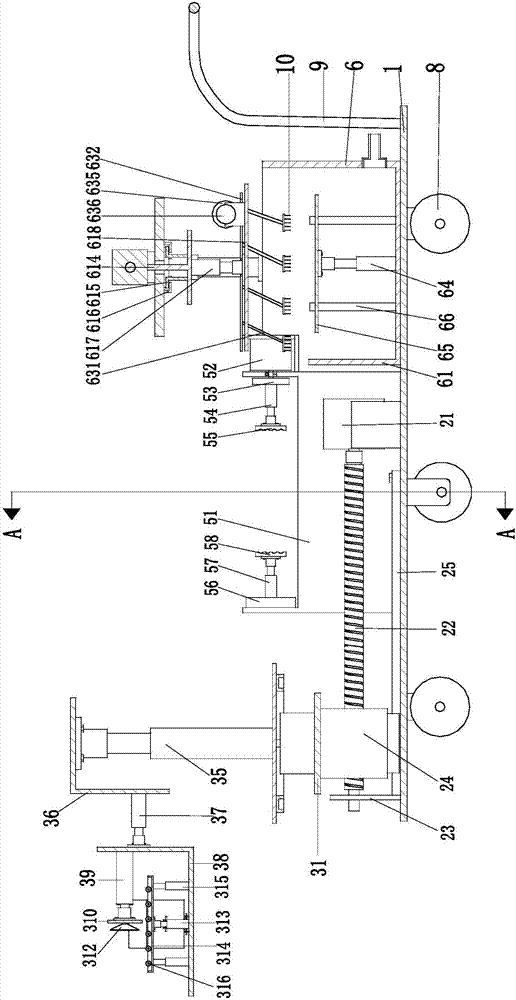

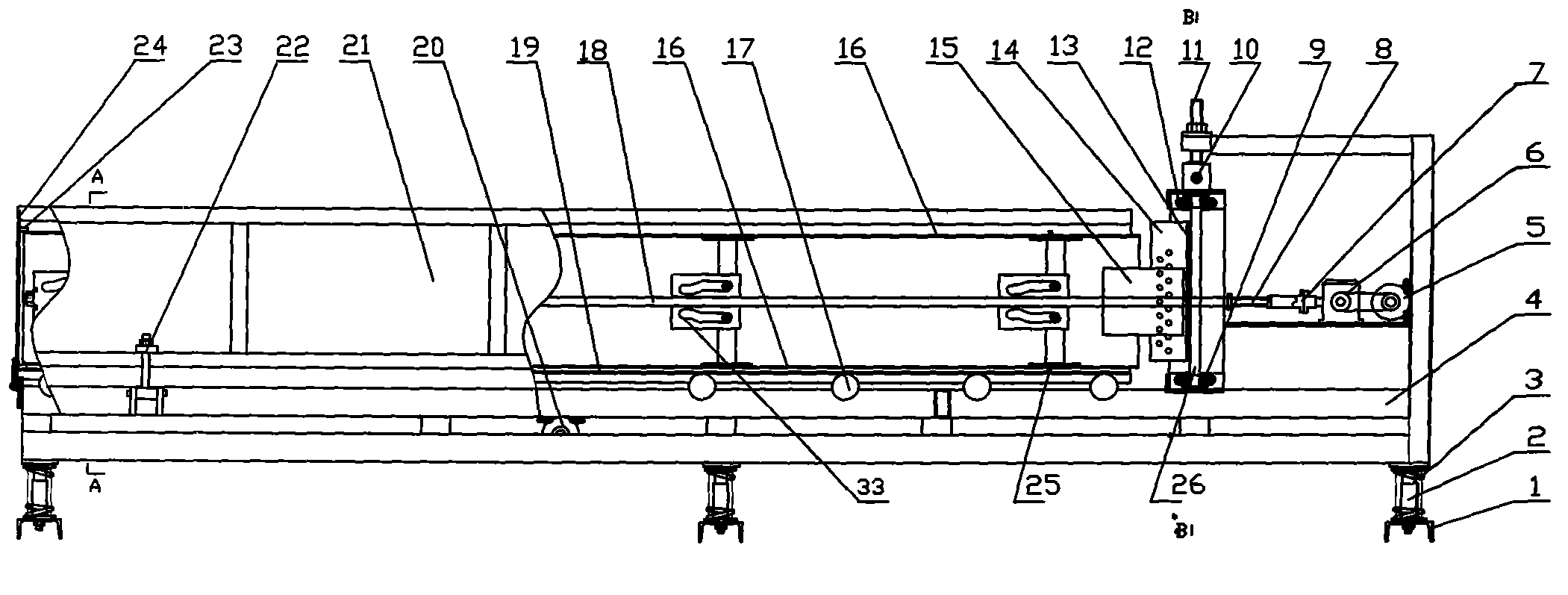

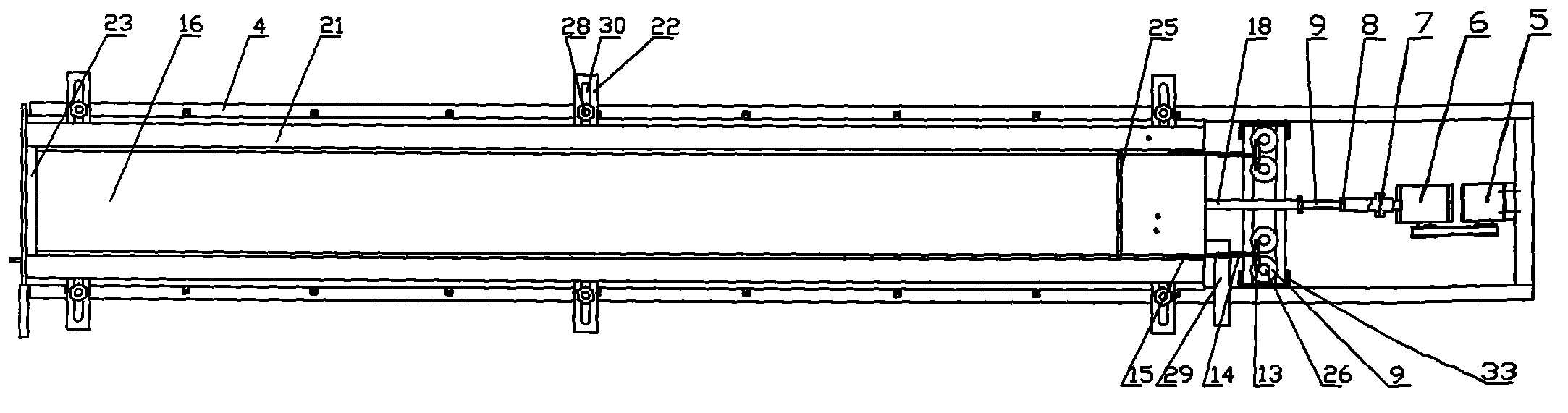

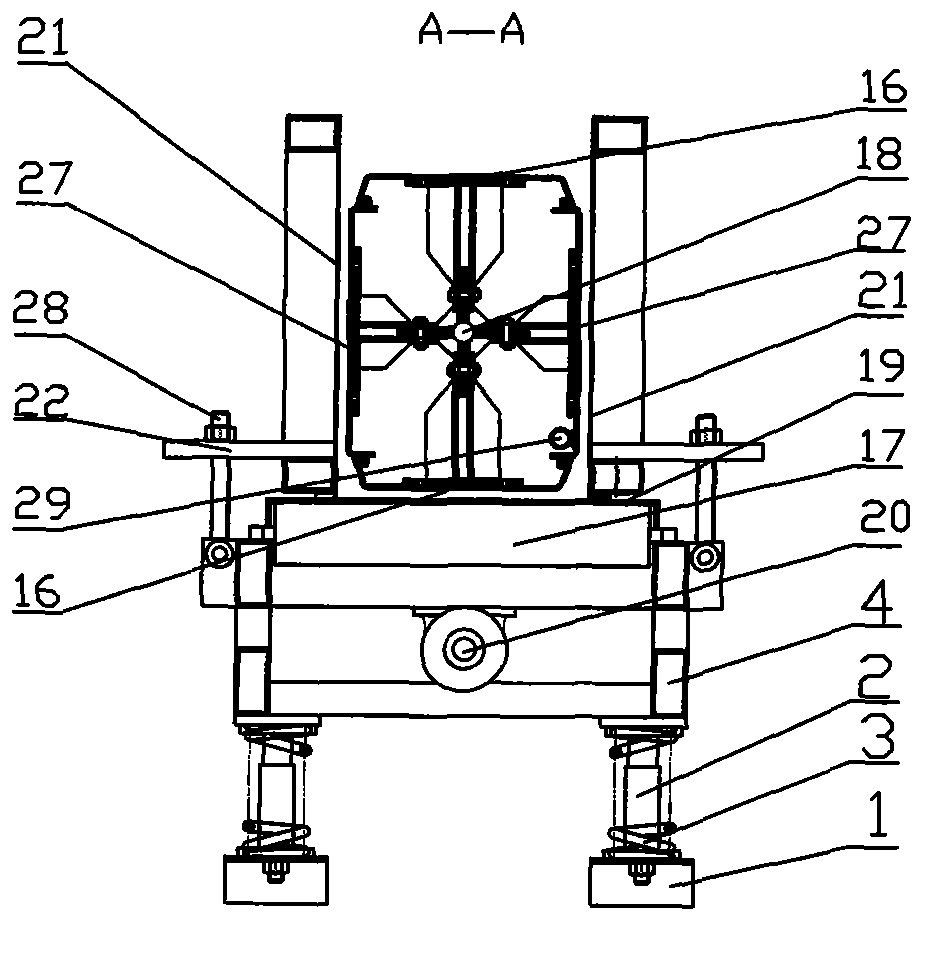

Molding equipment capable of manufacturing cement flues with various sizes

InactiveCN103252831AProlong clotting timeShorten production timeDischarging arrangementMouldsEngineeringMechanical engineering

The invention discloses molding equipment capable of manufacturing cement flues with various sizes. The molding equipment comprises a base; a framework is connected onto the base by an elastic support device, a plurality of rollers are transversely uniformly distributed on the upper surface of the framework, a bottom mold plate capable of transversely sliding along the rollers is supported on the rollers, outer-side mold plates are respectively hinged on two sides of the framework, and outer-side mold plate width adjusting devices are arranged on the outer-side mold plates; and an inner mold height adjusting device is arranged in the front of the framework, the bottom mold plate, the outer-side mold plates and an inner mold form a cement flue molding cavity with a top opening, a front mold frame and a rear mold frame are movably connected to the front end and the rear end of the inner mold, and the shape of the front mold frame and the shape of the rear mold frame are identical to the shape of the cement flue molding cavity. The molding equipment has the advantage that the width of each outer-side mold plate, the size of the inner mold and the height of the inner mold are adjusted according to requirements of users, so that the cement flues with the various sizes can be manufactured.

Owner:临颍县东方建筑机械厂

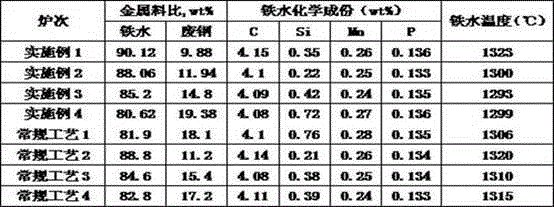

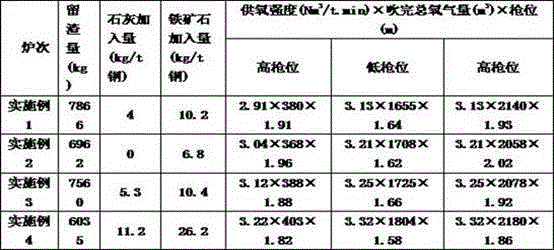

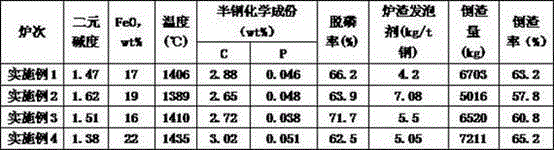

Converter less slag smelting early stage deslagging control method

ActiveCN105132612ASteady pourPouring evenlyManufacturing convertersProcess efficiency improvementFoaming agentSlag

The invention discloses a converter less slag smelting early stage deslagging control method in order to mainly solve the technical problems of difficult pour-out of early stage slag of a double slag + residual slag smelting technology and large deslagging rate fluctuation in the prior art. The converter less slag smelting early stage deslagging control method comprises the following steps: adding scrap steel, and adding molten iron; carrying out converter blowing desiliconization and dephosphorization; adding a slag foaming agent; pouring out early stage slag; carrying out converter blowing decarburization; carrying out converter tapping; and remaining slag. The converter blowing desiliconization, the lance position in the dephosphorization stage, the oxygen supply intensity and the lime and iron ore addition amount are controlled in the invention in order to make the dephosphorization rate of the converter early stage slag reach 60% or more; and the pour-out amount of the early stage slag in the double slag + residual slag smelting technology is accurately controlled through using the slag foaming agent and a weighing device arranged on a slag tank, and the converter slag accounts for 50-70% of the weight of total slag, so the converter double slag + residual slag smelting technology is realized.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Low temperature decrease steel ladle pouring method

InactiveCN1640579AReduce consumptionOvercome defects such as loose segregationMelt-holding vesselsRefractoryMaterial consumption

The present invention relates to a two temperature drop ladle pouring method. It is characterized by that in the ladel pouring process said invention utilizes gas to heat molten steel by means of high-effective nozzle mounted on the ladel cover, and utilizes bottom blowing argon to stir the molten steel. Said method can stabilize pouring basket temperature and can implement stable low overheat molten steel pouring operation.

Owner:SHOUGANG CORPORATION

Material used for dry power transformer and its use method

InactiveCN101499369ASmall expansion coefficientImprove thermal conductivityPlastic/resin/waxes insulatorsTransformers/inductances coils/windings/connectionsThermal conductivityConductor Coil

The invention discloses a material used for a dry-type power transformer and a using method thereof; the material comprises epoxy resin, curing agent, toughening agent, promoter, colorant, and filler; the using method thereof includes coil winding process, coil drying process, coil casting process, coil demoulding process, and coil curing process; compared with the prior art, the invention adds quartz powder in the epoxy resin, reduces the expansion coefficient of the resin system, improves the thermal conductivity of the resin, leads the casting material to be uniformly cast on the outer periphery of the coil and causes the cracking rate of an insulating layer after the transformer is used for two years to be 0.1-0.2% by optimizing the casting process, and thus improving the short-circuit resistance strength of the dry-type power transformer.

Owner:WUHU JINNIU ELECTRIC

Method for producing duplex stainless steel

The invention discloses a method for producing duplex stainless steel. The method comprises the steps that 1, molten iron is desiliconized and dephosphorized, alloy is molten in an intermediate frequency furnace, the treated molten iron and the molten alloy are mixed into a refining furnace for decarbonization, reduction, nitrogen discharging and deep desulfurization, and after the mass fraction of components of molten steel meets the preset requirement, the molten steel is tapped to a steel ladle; 2, the refining furnace is pulled in, argon blowing is carried out after the refining furnace is pulled in, after electrochemical residues are fed, a pure calcium line is added, lime and fluorite are added, power is transmitted to heat the molten steel, aluminum particles are added according to the residue color condition to adjust the residue color to be white, and after the mass fraction of the molten steel meets the preset requirement, argon flow is adjusted, ferroboron is added, and steel tapping is carried out soft blowing; 3, after the molten steel stands still, pouring is carried out, and duplex stainless steel blanks are produced.

Owner:SHANDONG TAISHAN STEEL GROUP

Novel process for manufacturing dark-red enameled teapot

The invention belongs to the field of manufacturing of porcelain, and relates to a novel process for manufacturing a dark-red enameled teapot. The process comprises the following steps of: manufacturing a teapot blank, manufacturing an accessory blank, installing the teapot blank and sintering the teapot, wherein before the teapot blank is sintered, the teapot is put into a drying room to be dried at the indoor temperature of 50 DEG C for 3 to 4 hours; in the step of sintering the teapot, the teapot blank is conveyed to a kiln to be heated to the temperature of between 100 and 120 DEG C; after the constant temperature is kept for 1 to 1.5 hours, the teapot blank is heated gradually, and the highest temperature is controlled to be between 1,170 and 1,200 DEG C; and the temperature is reduced gradually and is kept for 1 hour when reduced to 100 DEG C, and the teapot is taken out when the temperature is reduced to be between 55 and 45 DEG C. By improving the conventional process for manufacturing the dark-red enameled teapot, the dark-red enameled teapot is more practical and attractive, and the phenomenon of low yield of the dark-red enameled teapot due to poor mastering of mud properties or moisture and temperature is avoided simultaneously.

Owner:YIXING MEITAOYUAN CERAMICS

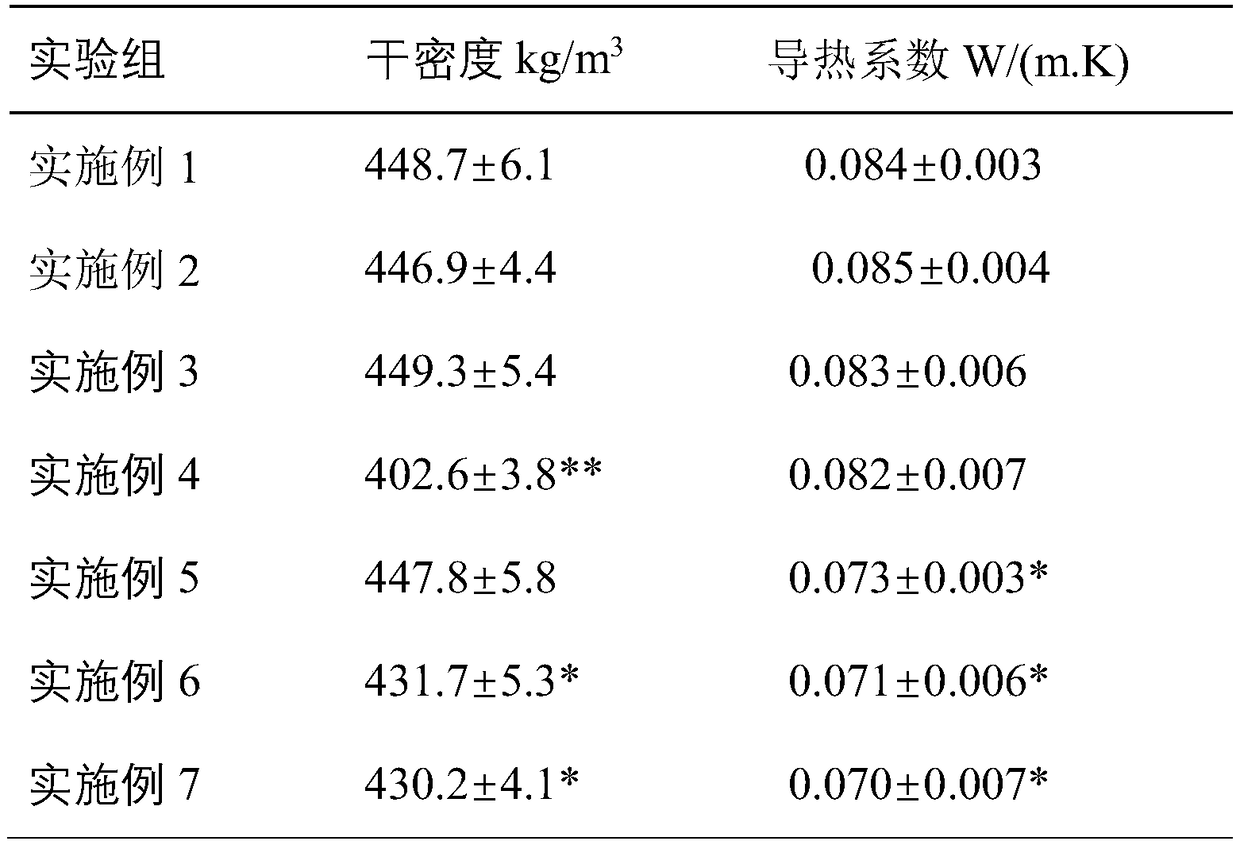

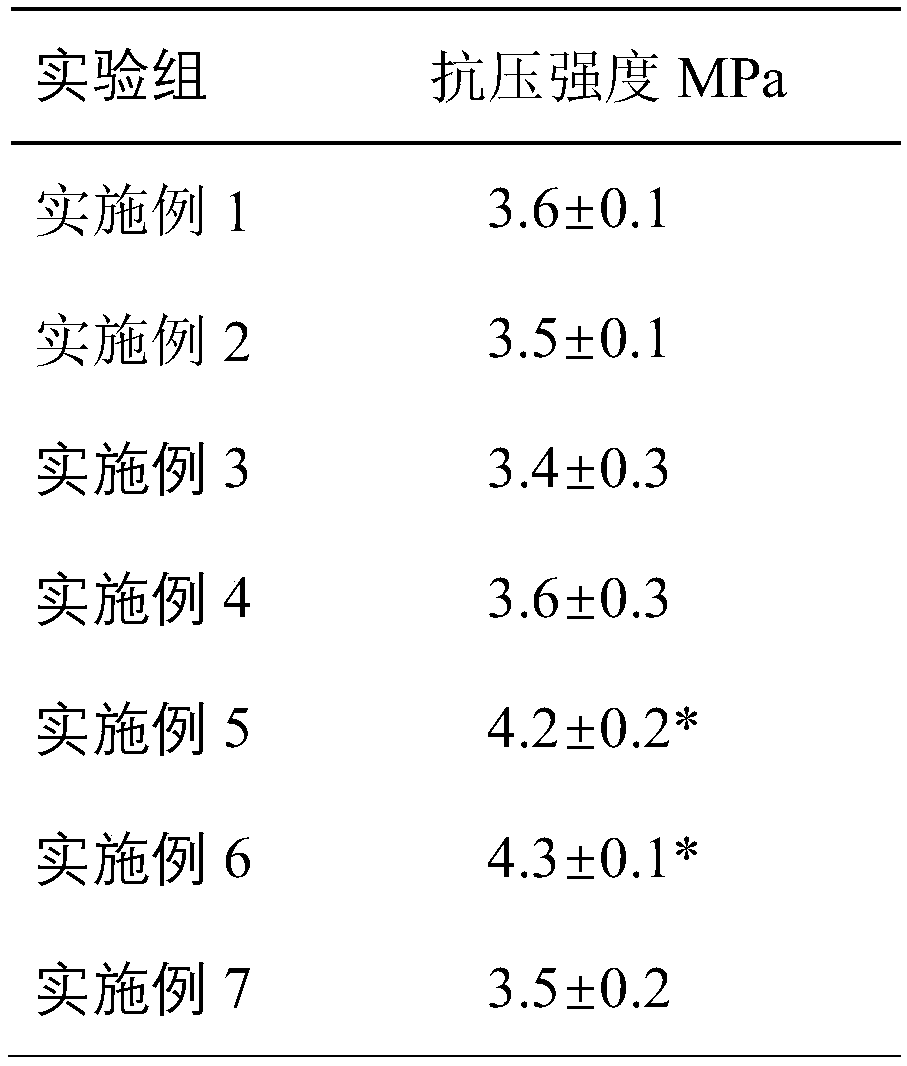

Autoclaved ceramic powder aerated concrete self-insulating block

The invention discloses an autoclaved ceramic powder aerated concrete self-insulating block. The self-insulating block is prepared from the following raw materials in parts by weight: 45-66 parts of ceramic slag powder, 10-15 parts of quick lime, 6-10 parts of cement, 3-5 parts of gypsum, 2-5 parts of aluminum powder, 3-6 parts of ferrosilicon powder, 15-25 parts of waste slurry, 0.3-0.6 part of an additive and 50-120 parts of water. An ultrafine powder slurry aeration molding method is established, the bottleneck of an ultrafine powder application problem in the field of aerated concrete thatthe size of a silicon material is always considered to not be less than 180-200 meshes can be overcome by utilizing multiple additives, and the problems of fine size of ceramic slag powder, large specific surface area, high water absorption rate, dispersing difficulty, large viscosity and poor slurry pouring stability can be effectively solved.

Owner:山东和悦生态新材料科技有限责任公司

Cast production technology for shell

InactiveCN101875092AImprove mechanical propertiesImprove shrinkageFoundry mouldsFoundry coresCooling effectVolumetric Mass Density

The invention discloses cast production technology for a shell. The technology sequentially comprises the steps of: manufacturing a mould, namely manufacturing an external metal mould, wherein the lower part of the external metal mould is provided with a molten iron inlet; manufacturing a sand mould, namely manufacturing a foaming mould, coating cast steel paint on the surface of the foaming mould, filling resin sands into the mould and hardening the sand mould by air blowing; setting a core, namely assembling the sand mould and the external metal mould, wherein a high temperature resistant material is coated on the core; pouring at the temperature of between 1,380 and 1,420 DEG C for 4 to 8 seconds and preserving the heat for 100 to 150 minutes, wherein a product yield reaches 50 to 70 percent; and performing subsequent operation, namely opening the mould to take the cast out, and cleaning and grinding the cast to obtain the required shell. The technology has the advantages of high sand mould quality, difficult cracking, good cooling effect and uniform internal density of the cast.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

Production process for casting spherical end cover

ActiveCN101890478AQuality improvementIncrease success rateFoundry mouldsFoundry coresMass ratioCasting mold

The invention relates to a production process for casting a spherical end cover, which sequentially comprises the following steps of: mold manufacturing, namely manufacturing an upper formwork, a lower formwork and a mold sleeve according to the shape of the spherical end cover; core manufacturing; core setting; pouring, namely preheating a casting mold formed by the core setting, spraying a heat-resisting material on the internal surface of the preheated casting mold, preserving the heat of the sprayed casting mold, pouring casting liquid at the tapping temperature of between 1,500 and 1,550 DEG C into a cavity for 5 to 15 seconds at the pouring temperature of between 1,380 and 1,440 DEG C, and preserving the heat of a casting for 60 to 100 minutes, wherein the process yield is 45 to 60 percent, and the heat-resisting material is quartz powder and diatomite in a mass ratio of 6:1-9:1; and mold opening. The process has the advantages of simpleness, capability of improving the quality of the casting, and high processing efficiency.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

Garbage cleaning device for domestic wastewater

The invention relates to a cleaning device, in particular to a garbage cleaning device for domestic wastewater. The garbage cleaning device for domestic wastewater provided by the invention takes relatively little labor amount and is convenient to clean. According to the technical scheme, the garbage cleaning device for domestic wastewater comprises an air bag, an air inlet pipe, a valve, a collection frame, a push hand, supporting rods, a reinforcing rib, an installing plate, a first bearing pedestal, a first chain roller, a second bearing pedestal, a second chain roller and the like, whereinthe right side of the airbag is connected to the air inlet pipe; the valve is arranged on the air inlet pipe; the collection frame is arranged on the top of the air bag and is netted; the lower partof the right side of the collection frame is connected to the push hand; and the front side and rear side of the interior of the collection frame are slantwise connected to the supporting rods. According to the garbage cleaning device for domestic wastewater, a fishing frame can be driven to rotate forwards through the forward rotation of a motor to fish up garbage floating on the water surface and dump the garbage into the collection frame; and an L-shaped rod is used for beating the fishing frame, so that the fished garbage is successful dumped into the collection frame, thus achieving the effects of consumption of relatively little labor amount and convenience to clean.

Owner:南京艾芬豆信息科技有限公司

Light stuffing mould component for concrete poured-in-situs

A light mold component that is cast-in-place concrete. It includes polyhedron solid light material component. Its feature is that at least two polyhedrons solid light material component alternated arranged with each other, and forms inner pleura cavity. At least one alternated interval support and pull component alternated combined with each other by opposite or consecutive polyhedron solid light material component in the pleura cavity. It is suited for kinds of active pouring concrete or pre-stressing force reinforcing steel bar for building casing, wall, basis bottom board and bridge, especially suited for girderless building casing.

Owner:湖南邱则有专利战略策划有限公司

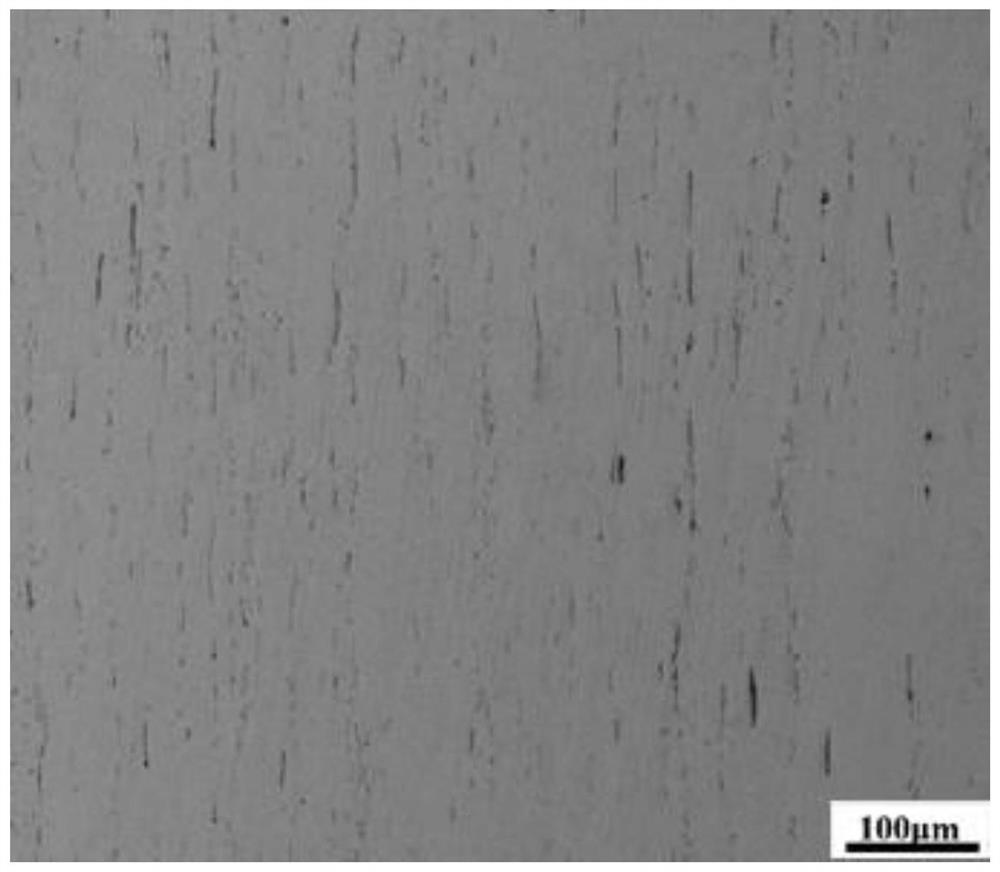

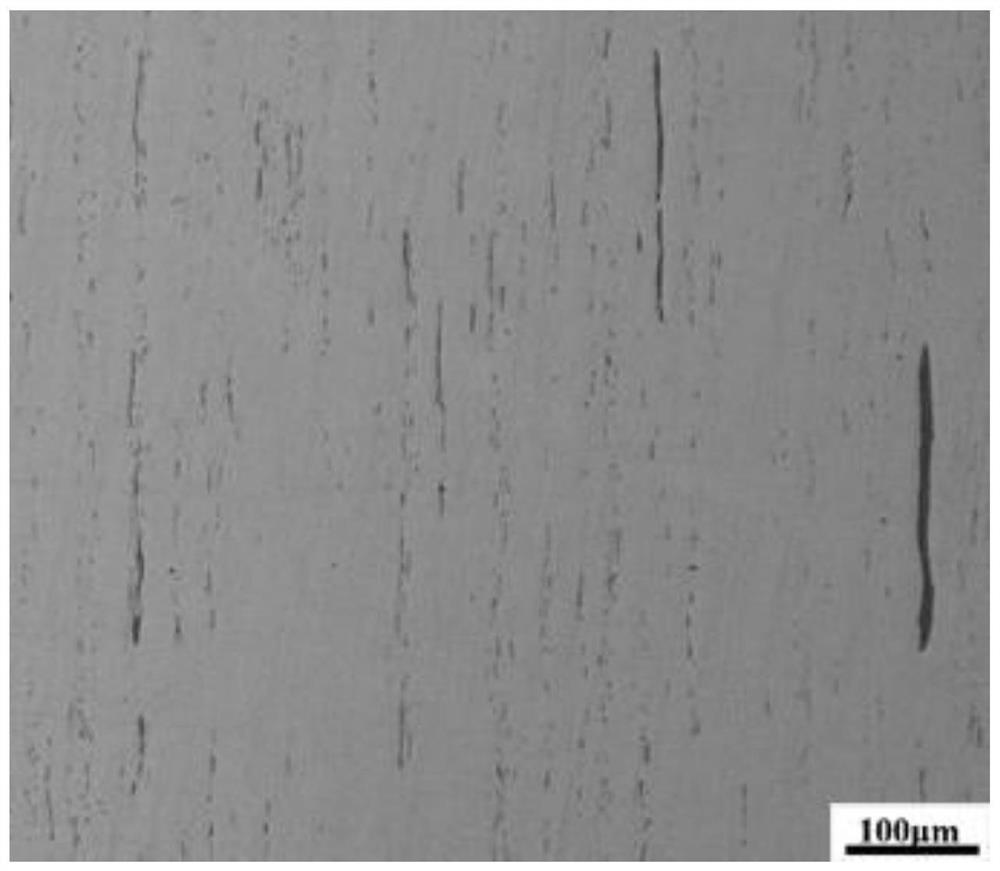

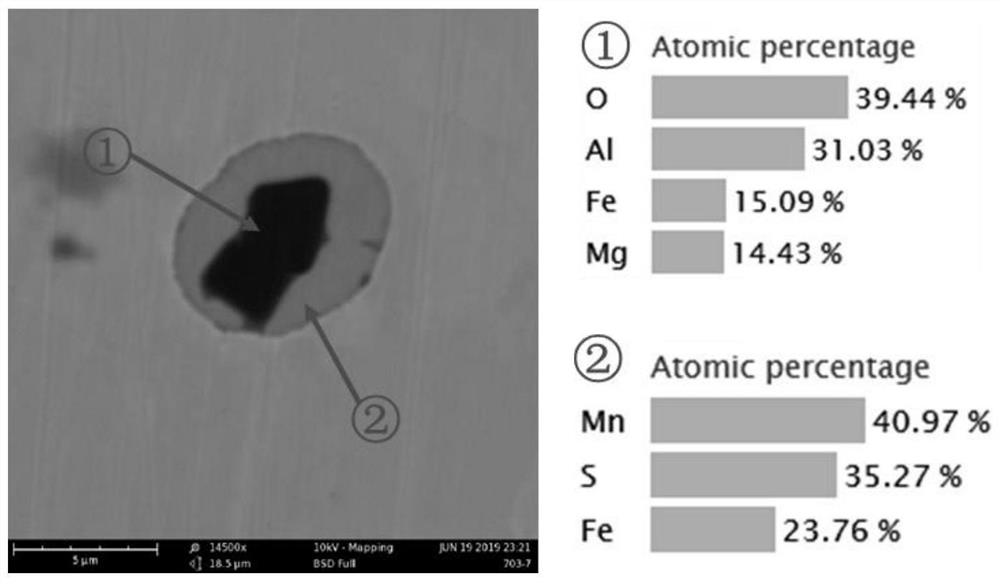

Preparation method of magnesium-based high-sulfur free-cutting steel

PendingCN112063916AEasy to shapeImprove chip breaking abilityManufacturing convertersProcess efficiency improvementMachinabilityContinuous casting

The invention discloses a preparation method of magnesium-based high-sulfur free-cutting steel. The magnesium-based high-sulfur free-cutting steel comprises the following chemical components in percentage by mass: 0.05-0.50% of C, less than or equal to 0.40% of Si, 1.0-1.7% of Mn, less than or equal to 0.08% of P, 0.15-0.35% of S, 0.0003-0.0020% of Mg, less than 0.0030% of O and the balance of iron and inevitable impurities. A production process comprises the steps of converter or electric furnace smelting, LF refining, continuous casting and rolling, magnesium-containing cored wires are addedat the final stage of refining, the degree of superheat is controlled before wire feeding, the total oxygen content is not higher than 30 ppm, and an intermittent feeding method is adopted. The wirefeeding process is stable, violent splashing is avoided, and the yield of the magnesium element is higher. The product prepared by the preparation method has excellent cutting performance and remarkably improved cutting breaking performance and the abrasion resistance of cutters. The cost of each ton of steel is increased by not more than 10 yuan, and the price advantage is obvious.

Owner:SHANGHAI UNIV

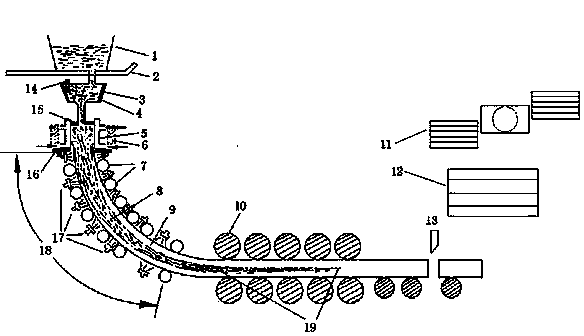

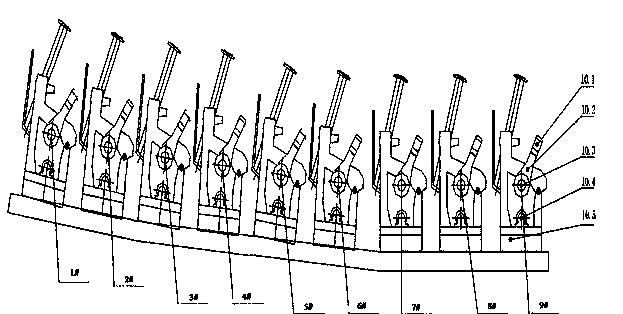

Continuous casting system and process producing large-specification elliptical billets

The invention relates to a continuous casting system producing large-specification elliptical billets. The continuous casting system comprises a tundish, a crystallizer, an aftercooling area and a straightening mechanism, a continuous temperature measuring device matched with an inductive heating device is arranged in the tundish, an electromagnetic stirring device stirring molten steel is arranged in the crystallizer, the aftercooling area comprises an arc-shaped guide section and atomizing water nozzles arranged on two sides of the arc-shaped guide section, the straightening mechanism comprises a plurality of straighteners capable of continuously straightening the elliptical billets, and the straighteners are distributed along the progressing direction of the elliptical billets on a declining curve, and a cutting machine, a burial pit and a shot blasting machine are sequentially arranged at the tail end of the straighteners. The invention further provides a continuous casting process on the basis of the continuous casting system. The continuous casting process has the advantages of short procedures and low cost, the elliptical billets have excellent surface quality, macro quality of the cross section reaches the primary standard of the country, and yield of the elliptical billets is up to 96% which is at least 10% higher than a die casting process.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

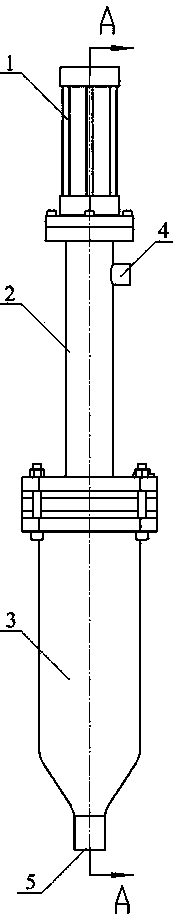

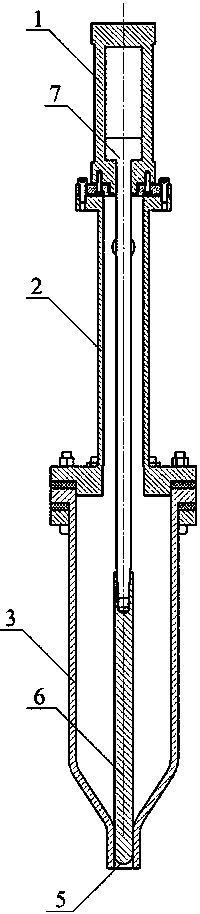

Vacuum quantifying tank

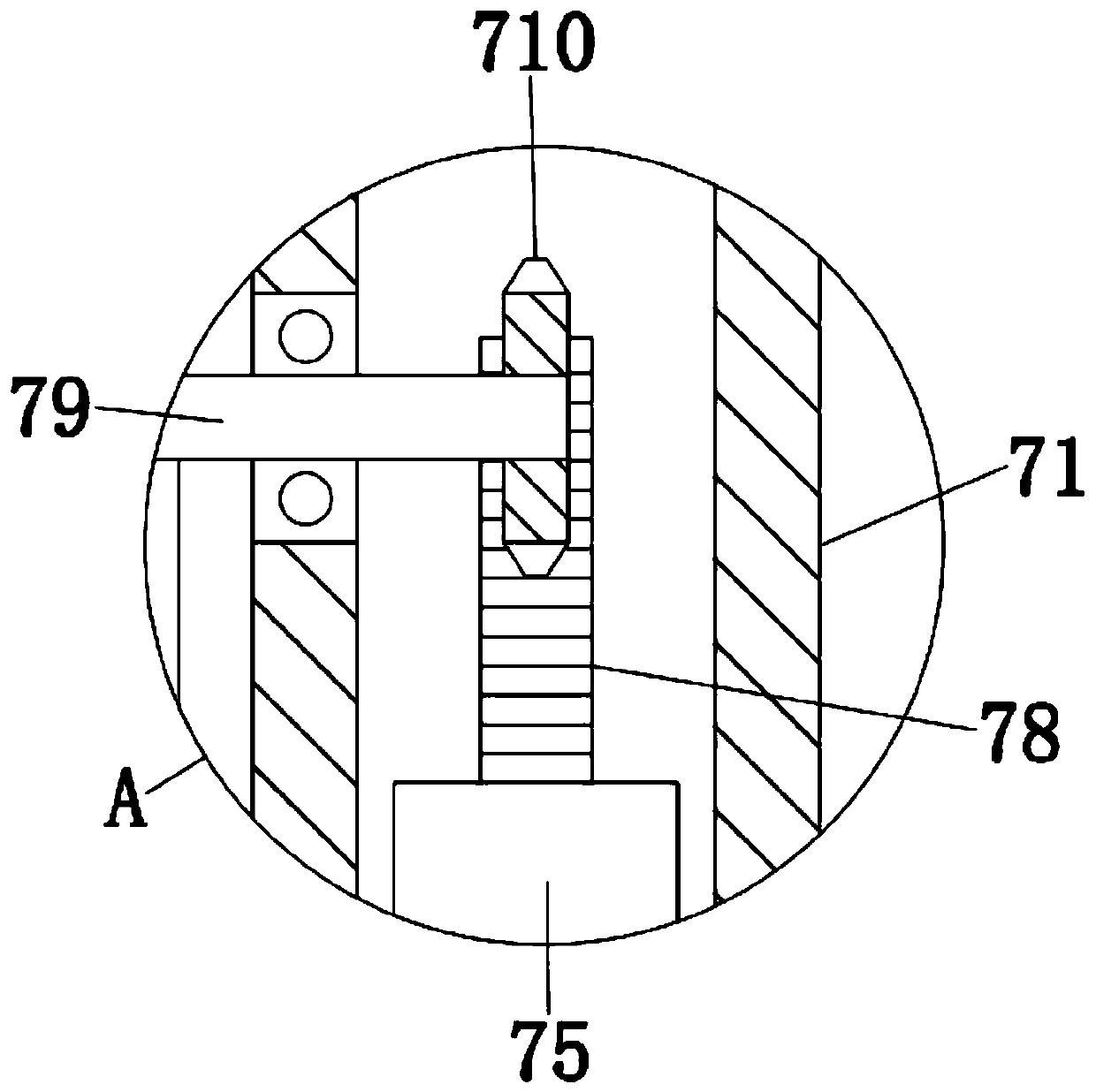

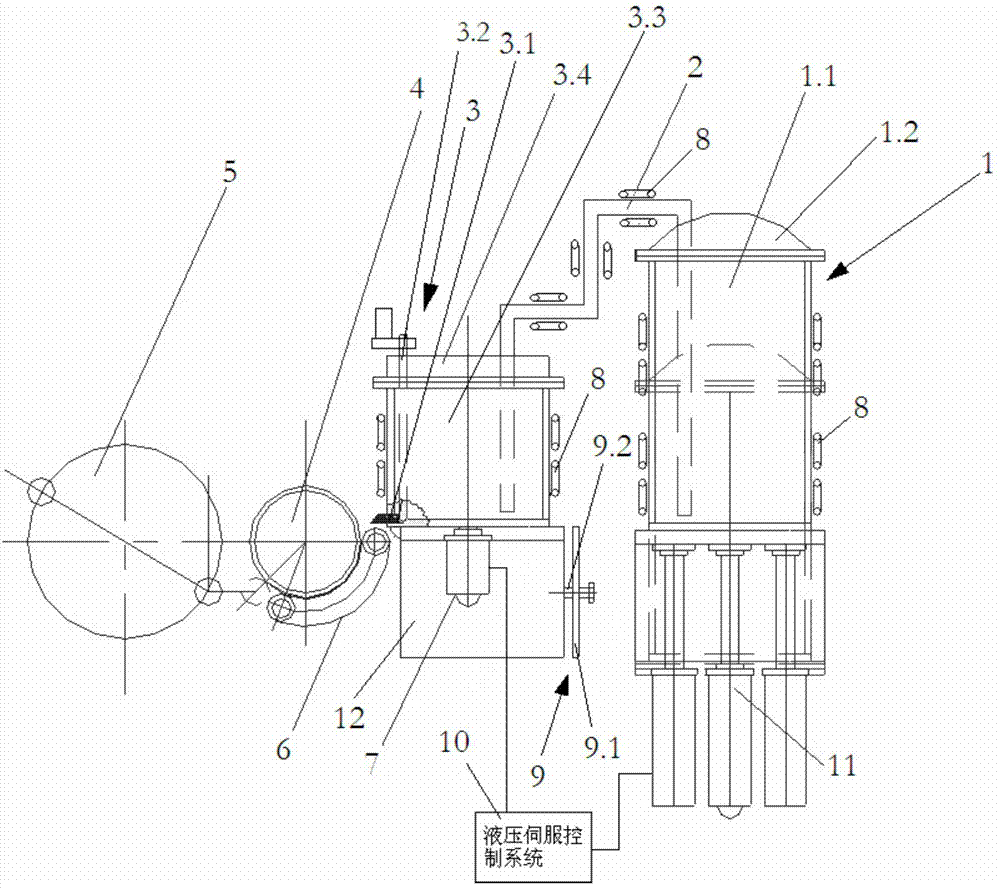

ActiveCN104353811ARealize opening and closingRealize automatic extractionEngineeringMechanical engineering

The invention discloses a vacuum quantifying tank which comprises a cylinder, a bearing seat and a tank body which are sequentially connected in series in a sealed manner, wherein the cavities of the bearing seat and the tank body are communicated to form a vacuum cavity; a vacuum port connector is arranged on the bearing seat, so that the vacuum degree of the vacuum cavity is controlled; a tank hole is formed in the bottom of the tank body; a valve core for sealing the tank hole is arranged inside the cavity of the tank body; the piston rod inside the cylinder is connected with the valve core; the piston rod drives the valve core to move upwards and downwards so as to control the tank hole to be opened and closed. By adopting the vacuum quantifying tank, automatic sucking and automatic pouring of stoste are achieved by controlling the vacuum degree of the vacuum cavity and the working state of the cylinder in the vacuum quantifying tank, the stoste can be conveyed in a sealed manner, the cleanliness degree is high, and the stoste is effectively prevented from being oxidized.

Owner:ANHUI OURUIDA ELECTRICAL APPLIANCE TECH

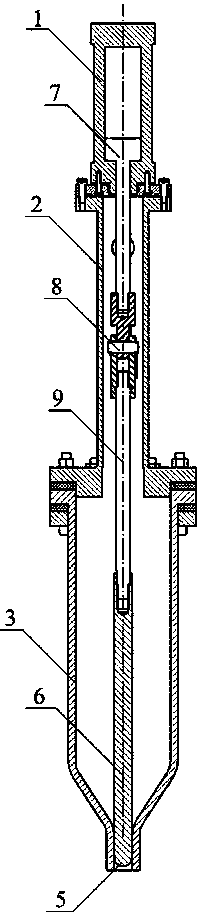

Autoclaved sand aerated concrete plate device and preparation method

ActiveCN111452186AShorten movement timeIncrease productivityFeeding arrangmentsAutoclaved aerated concreteEnvironmental geology

The invention discloses an autoclaved sand aerated concrete plate device and a preparation method. The device comprises a base, and further comprises two guide rails fixedly connected to the front side and the rear side of the top of the base respectively, a die slidably connected to inner cavities of the guide rails, a baffle detachably arranged at the top of the rear side of the die, a pouring tank detachably arranged on the outer side of the top of the base, a guide pipe fixedly connected to the center position of the bottom of the pouring tank, a driving mechanism detachably arranged in the middle of the rear side of the top of the base and detachably connected to the guide pipe, and a dispersing component detachably arranged at the bottom end of the guide pipe. According to the device, the quantitative pouring of the die in an advancing process can be realized, the moving time of the die is saved, the production efficiency is improved, a purpose of uniform pouring is achieved, thequality and the size of the autoclaved aerated concrete plate are consistent, the machining quality is guaranteed, and the requirements for autoclaved aerated concrete plate production are met.

Owner:江苏美利美新型建材科技有限公司

Equipment and process for manufacturing belt in quenching mode

The invention discloses equipment for manufacturing a belt in a quenching mode. The equipment comprises a first hydraulic cylinder, a siphon, a magnetic reeling machine, a cooling roller, a cooling track matched with the cooling roller, a liftable tundish ascending and descending through the hydraulic cylinder, a nozzle package communicated with the liftable tundish through the siphon, a base arranged at the bottom of the nozzle package and a second hydraulic cylinder which is arranged between the nozzle package and the base and can drive the nozzle package to ascend and descend, a cooling channel is formed between the cooling roller and the cooling track, a nozzle of the nozzle package corresponds to an inlet of the cooling channel, the magnetic winding drum of the magnetic reeling machine corresponds to an outlet of the cooling channel, and the length of the cooling channel is larger than one fourth of the perimeter of the cooling roller and smaller than one half of the perimeter of the cooling roller. The nozzle of the nozzle package is arranged above the central line of the cooling roller. A lifting blocking plate capable of controlling the speed of metal liquid flowing out of the nozzle is arranged in the nozzle package. According to the equipment and process, steel belts of different thicknesses can be produced conveniently, the cooling effect is good, and the final performance of materials is easy to control.

Owner:武汉钢铁有限公司

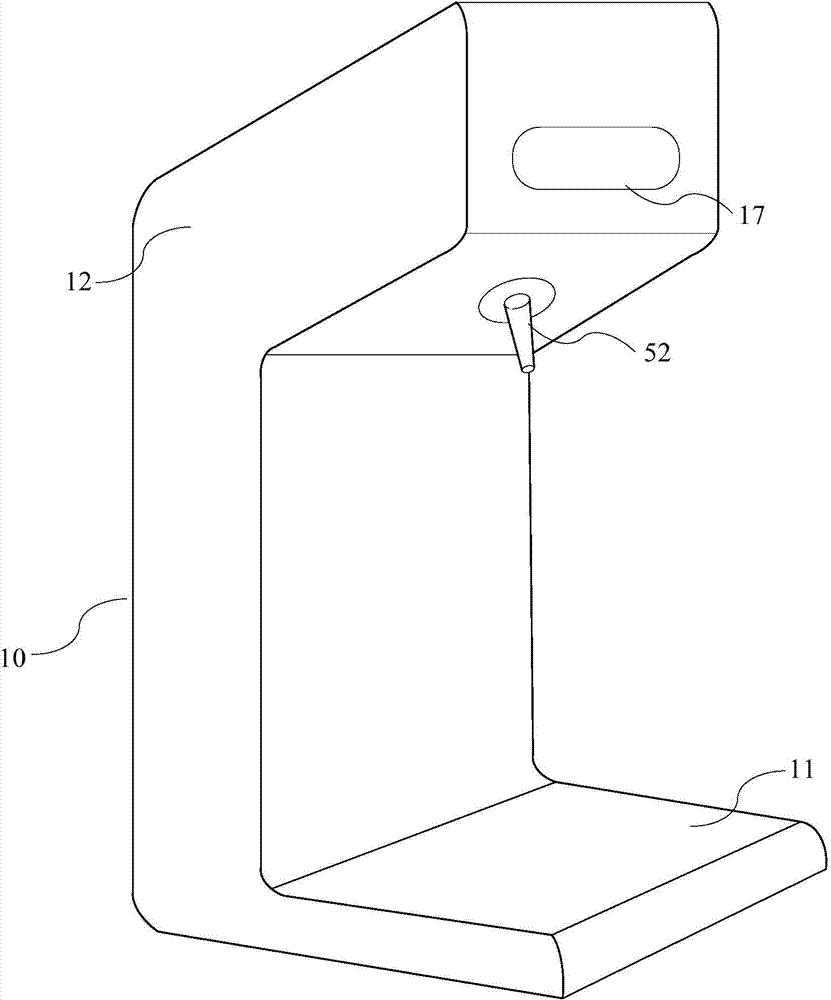

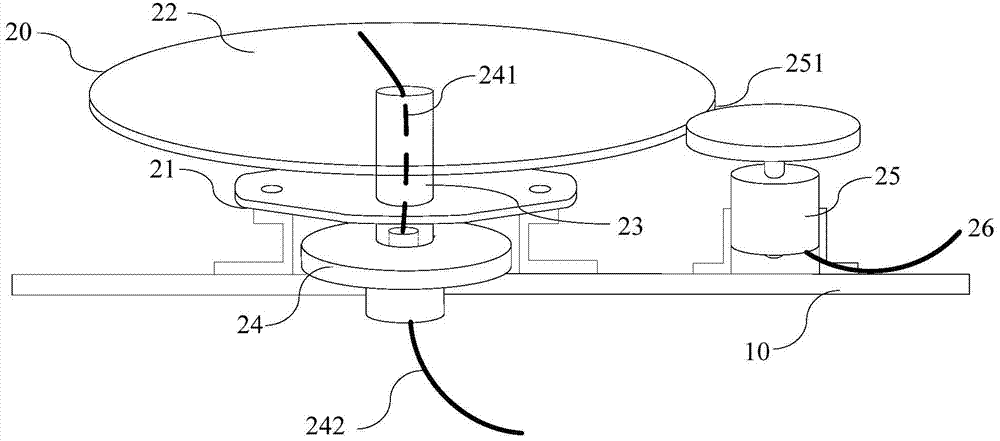

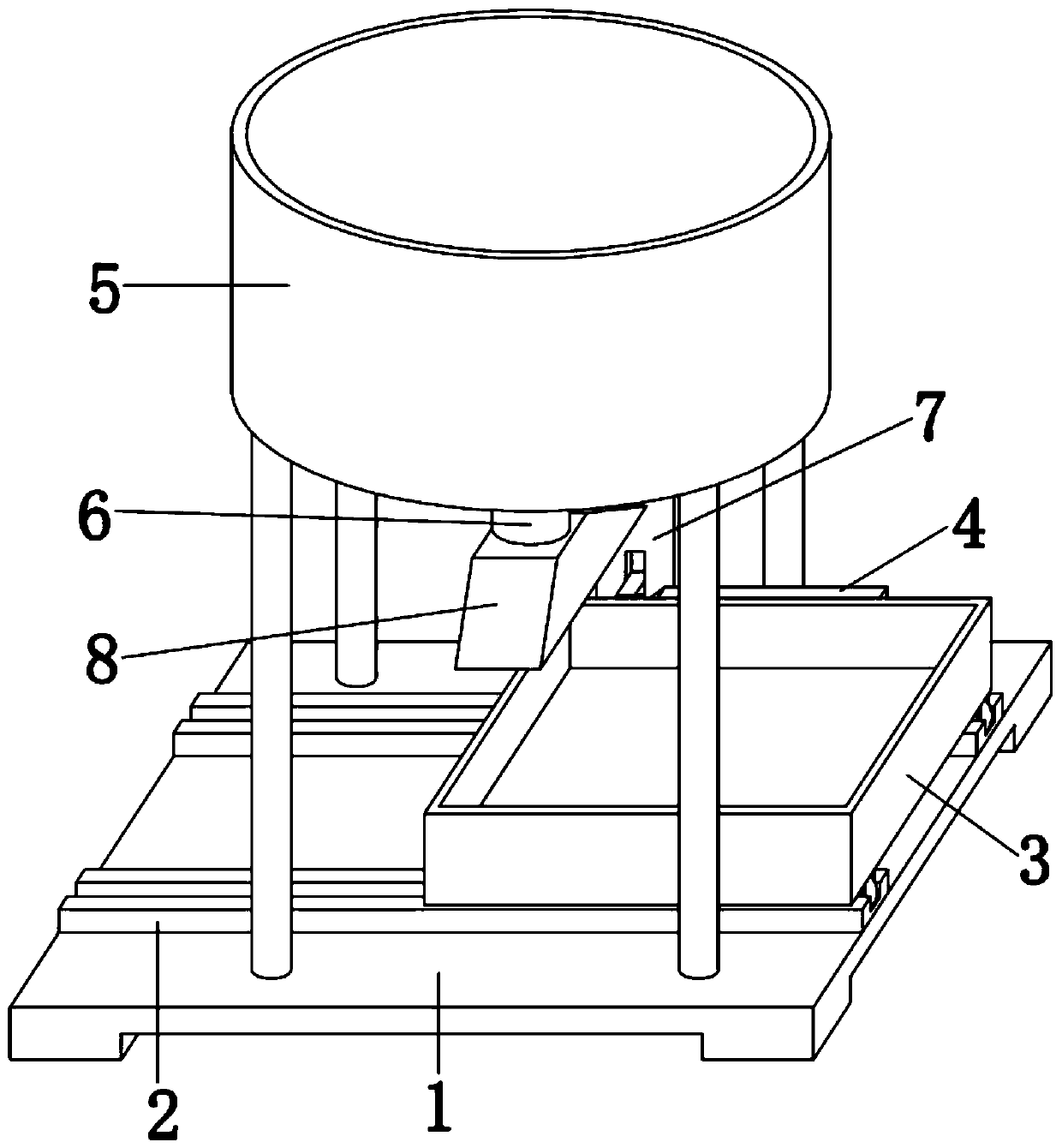

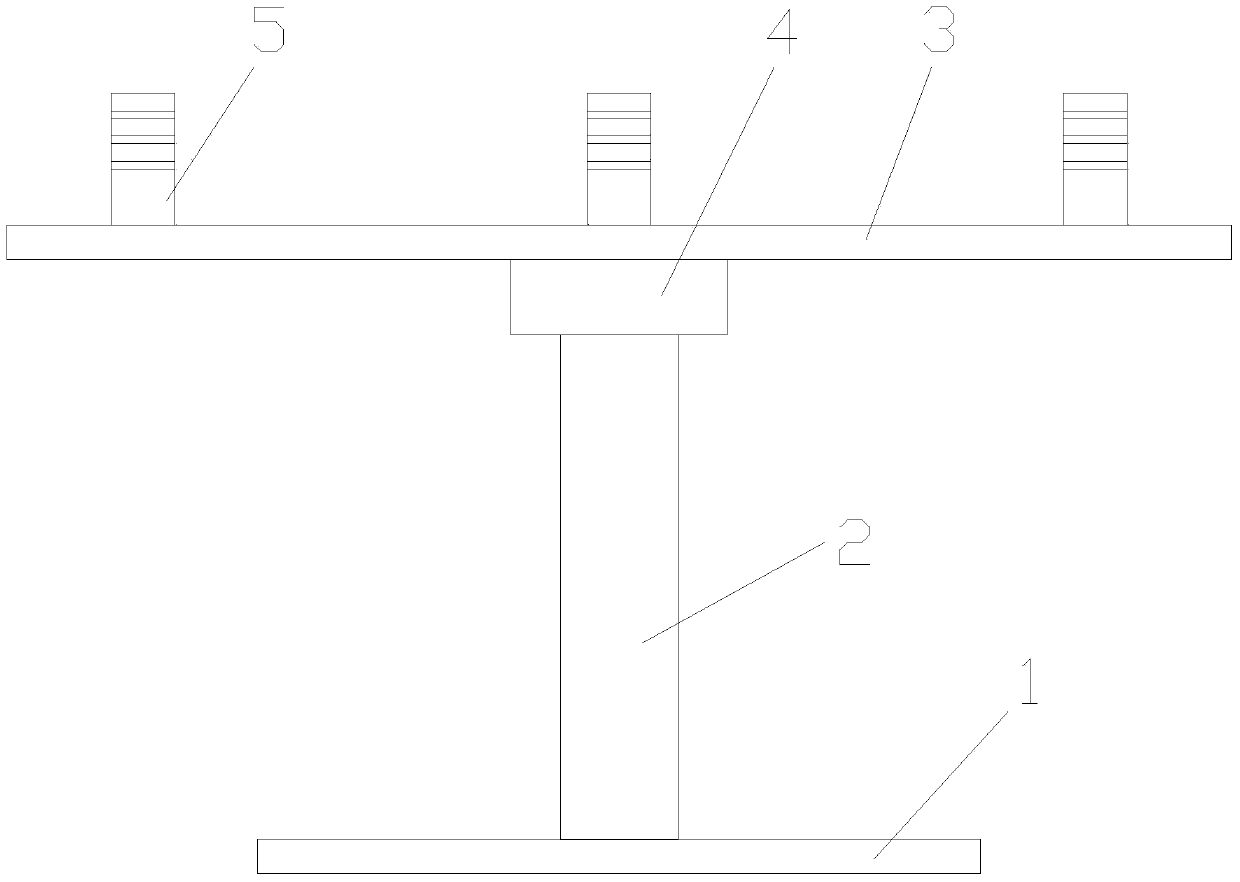

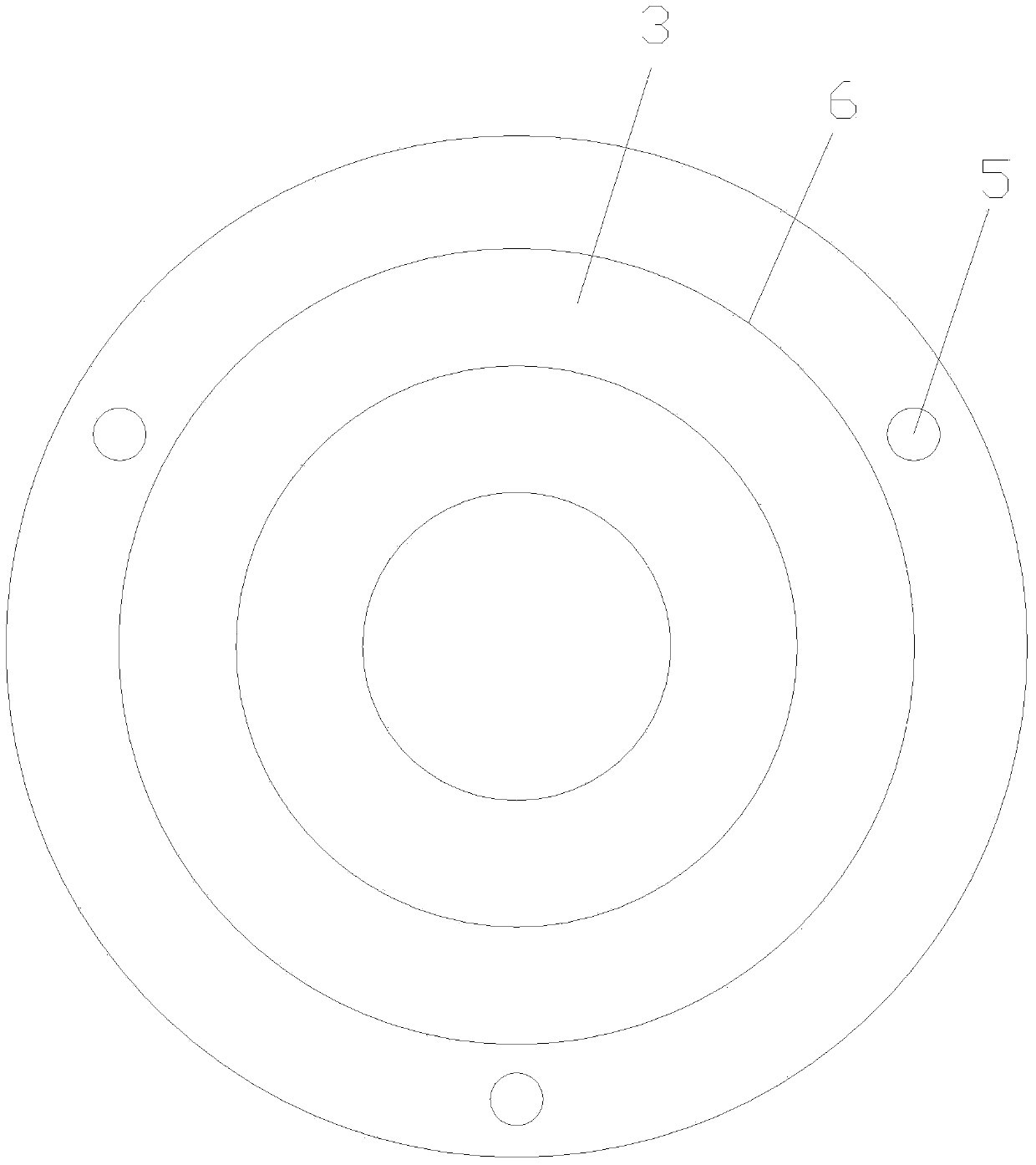

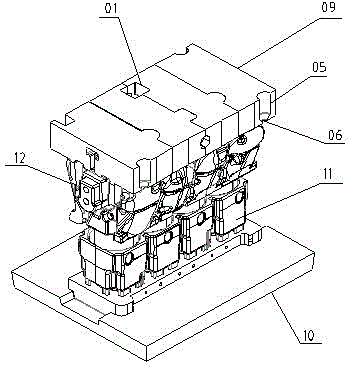

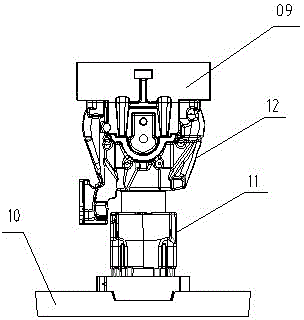

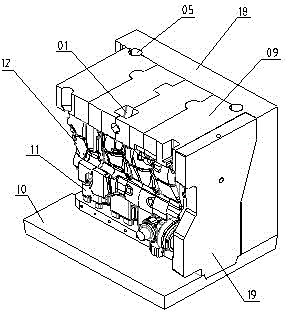

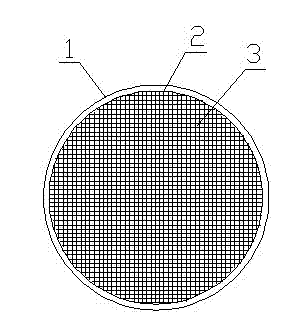

Rubber injection turntable

InactiveCN103464346APouring evenlySimple structureLiquid surface applicatorsCoatingsControl theoryMechanical engineering

A rubber injection turntable relates to the field of filter production equipment and comprises a round base plate and a round turntable, wherein the base plate and the turntable are connected through a vertically arranged support shaft, the upper end of the support shaft is connected with the turntable through a bearing, the lower end of the support shaft is fixedly connected with the base plate, and three cylindrical limit blocks are arranged at the upper end of the turntable. The rubber injection turntable is simple in structure, low in manufacturing cost and simple and convenient to use, a filter element end cover is limited through a movable magnetic block, the rubber injection turntable is applicable to different specifications of the filter element end covers, a scale mark is arranged on the turntable, so that the position of the limit block is arranged according to the size of the filter element end cover, the rubber can be uniformly poured in the rotating process of the filter element end cover, and the pouring efficiency is improved.

Owner:BENGBU HONGWEI FILTER

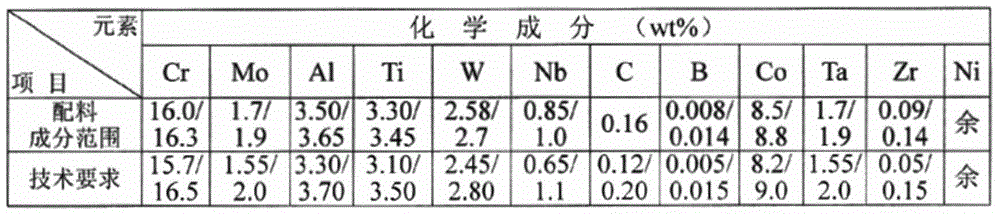

Method for preparing K438 alloy by adopting K438 alloy return material

InactiveCN103556004AIncrease profitReduce wasteIncreasing energy efficiencyChemical compositionIngot

The invention relates to a method for preparing a K438 alloy by adopting a K438 alloy return material. The technical scheme is as follows: the preparation method comprises the following steps of carrying out purifying treatment on the K438 alloy return material; smelting the K438 alloy return material into a return material charge bar; regulating the chemical components of the return material charge bar; smelting the return material charge bar into a finished product K438 alloy ingot. The method disclosed by the invention can be used for producing the K438 alloy which meets the requirement for usage of a product, increases the utilization ratio of materials and reduces the waste of precious metal resources.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Casting process for crankshaft

InactiveCN105081229AOvercome the problems of many processes and heavy workloadIncrease profitFoundry mouldsFoundry coresManganeseMolten steel

The invention relates to a casting process for a crankshaft. The casting process comprises the following steps: step S01: producing a sand mould according to the design dimension requirements of the crankshaft, horizontally arranging the axis line of the sand mould, forming a direct gate and an inner gate in the sand mould, connecting the direct gate with the inner gate through a transversal channel, roasting the sand mould for 20 minutes at a high temperature of 750-900 DEG C, and then cooling to 400 DEG C; step S02: smelting a steel material in a circuit, after a temperature rises to 1400-1500 DEG C, adding a refining agent and refining for 20min to obtain molten steel in which a carbon content is 0.1-0.14%, a silicon content is 0.15-0.19%, a nickel content is 0.36-0.45% and a manganese content is 0.46-0.55%; step S03: pouring the molten steel in the step S02 into the direct gate and the inner gate of the sand mould in the step S01, controlling a pouring temperature to be 1560-1660 DEG C and controlling a pouring time to be 40s, and after the pouring is finished, insulating for 30min; and step S04: cooling to normal temperature, talking out the formed crankshaft, cleaning the surface of the crankshaft, and then polishing to obtain the crankshaft.

Owner:GUILIN CHANGXIN MACHINERY MFG

Composite casting system of crank shaft box

InactiveCN102873278AEasy to manufactureImprove production efficiencyFoundry mouldsFoundry coresSlagCrankshaft

The invention discloses a composite casting system of a crank shaft box. The composite casting system comprises a base plate core, a jacket core, a main core, an end face core, an outer cast core and a pouring system. The base plate core, the jacket core, the main core and the pouring system are sequentially overlapped from the bottom layer to the high layer to form a crank shaft box sand mould structure. The pouring system comprises two rows of pouring openings evenly arranged and gates located outside the two rows of pouring openings. The two rows of pouring openings are communicated with a pouring opening cup through a flow division pouring gate and a pouring gate cup. The gates comprise hole-shaped gates located at four corners and strip gates located between the hole-shaped gates and outside the two rows of pouring gates. The composite casting system adopts a rain type pouring system in the middle of a cast piece to conduct liquid feeding pouring from a plurality of positions of a shaft seat and reduces impact of pouring to casts, floating impurities cannot be easily adhered to the cast wall or the cast core, and the pouring system is good in slag blocking effect. The main core is arranged on the upper portion of a sand mould and on the shaft seat, and the two strip gates and the four hole-shaped gates are utilized to discharge air completely. The composite casting system does not require core drying and is stable in cast piece pouring.

Owner:SICHUAN XIANGYE MASCH CASTING CO LTD

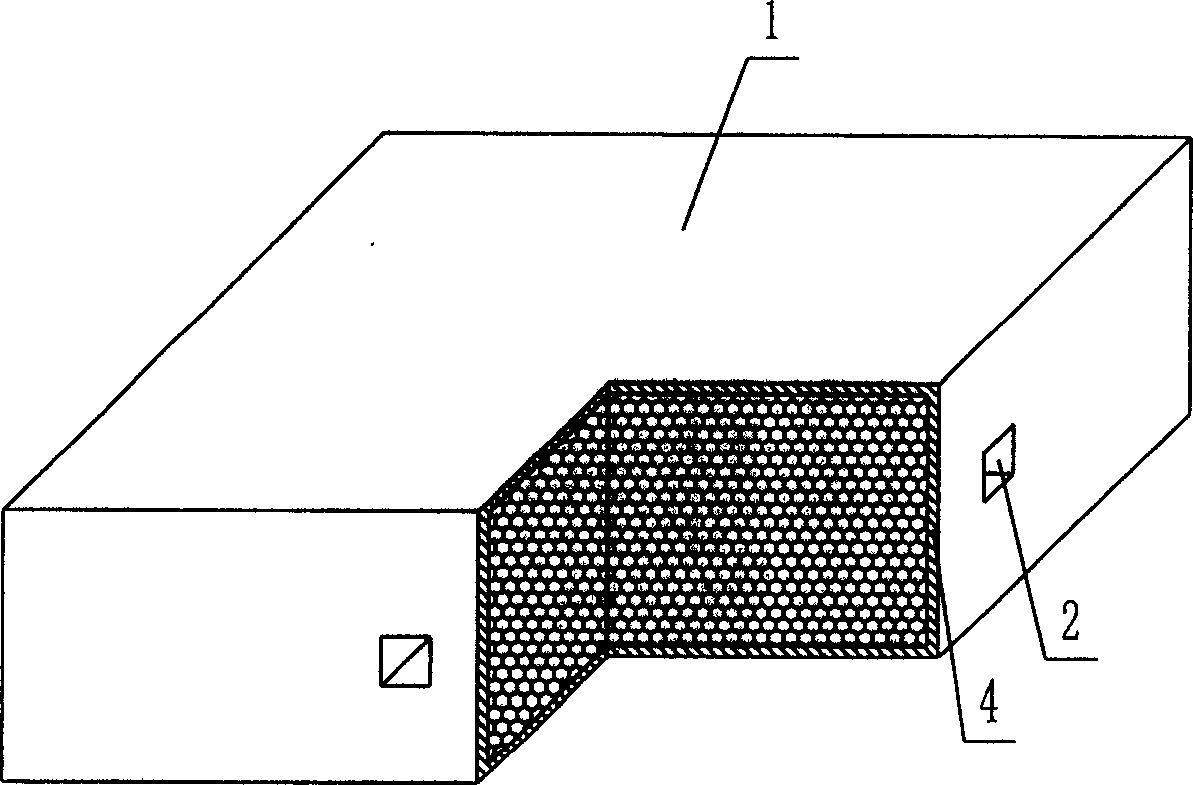

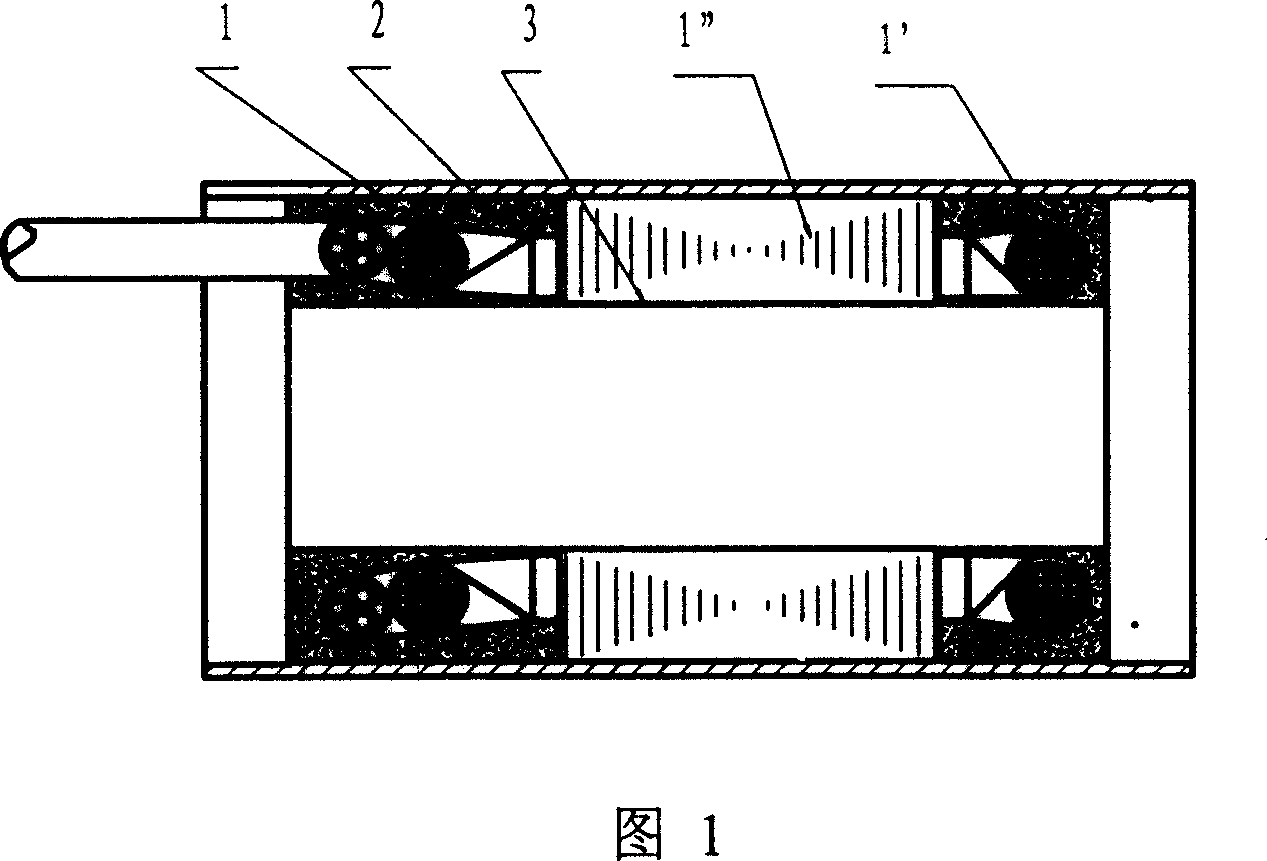

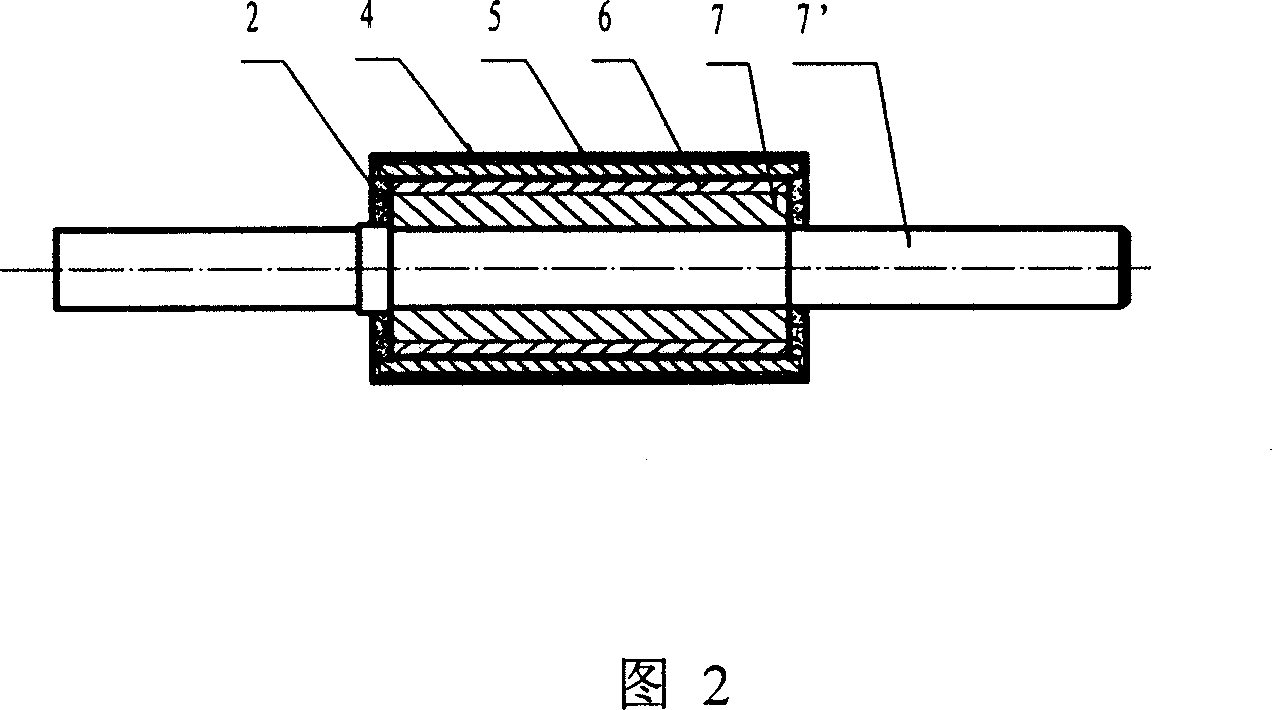

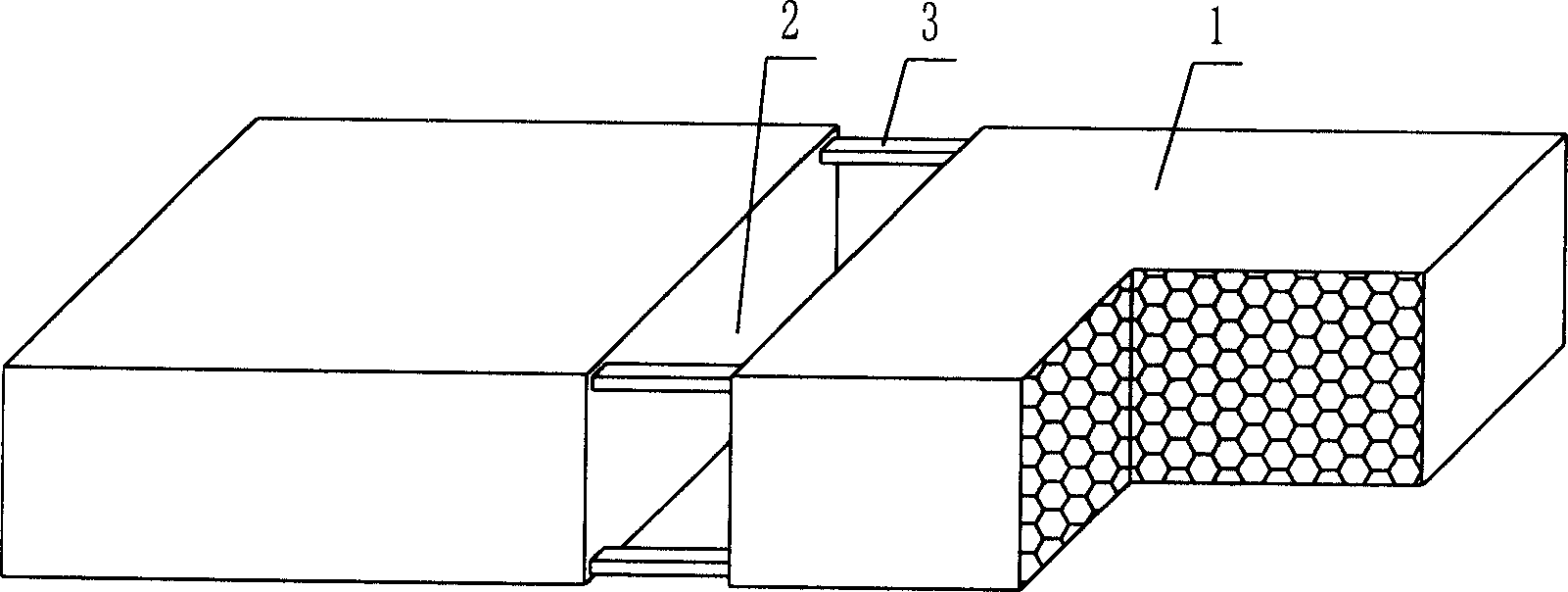

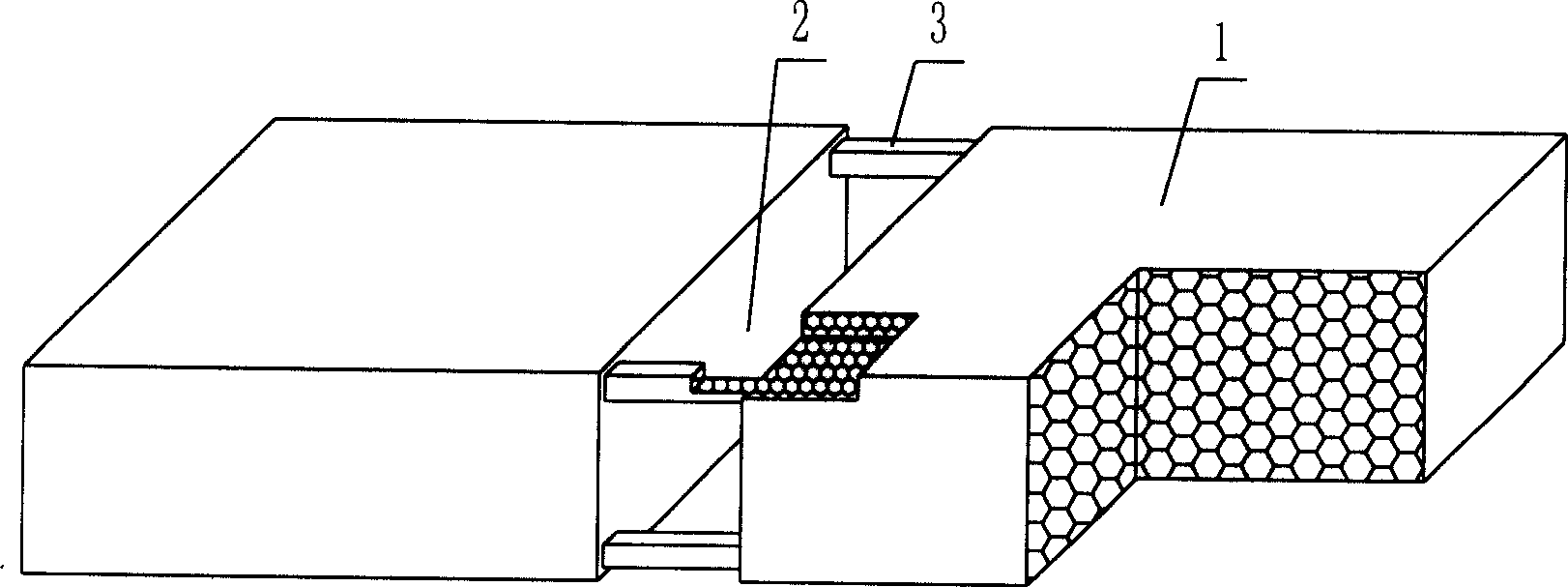

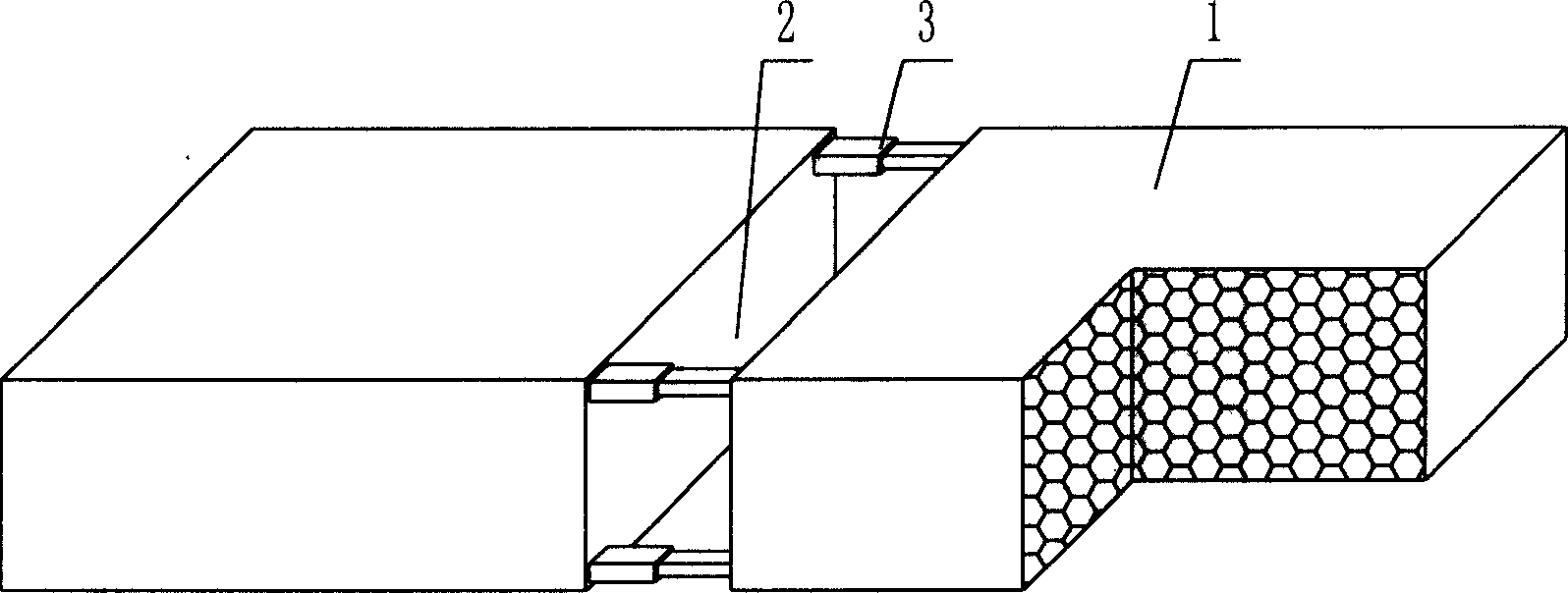

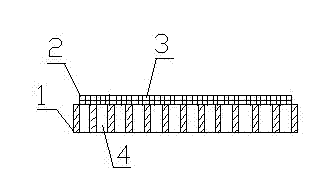

Multilayer casting filter

ActiveCN102350134AShort flow distanceLow flow resistanceFiltration separationPore diameterHoneycomb like

The invention discloses a multilayer casting filter, comprising a support layer (1) made of a ceramic material and a filtering layer (2) made of a ceramic material and arranged on the support layer. The filtering layer contains alveolate filtering holes (3); the support layer contains grid liquid flow holes (4); a hole density of the filtering layer is larger than that of the support layer; an aperture of a filtering hole is smaller than that of a liquid flow hole; a porosity of the support layer is larger than that of the filtering layer (2); and a thickness of the filtering layer is smaller than that of the support layer. The invention can simplify a pouring system, increase produce rate of a cast technology, reduce cast costs, enhance flow velocity and continuity of pouring, facilitate cast mold filling, improve high temperature impact resistance and high temperature bearing capacity of the filter, ensure integrity of the filter in the whole pouring process, facilitate filtering purification of metal liquid and improve inner quality and comprehensive performances of a cast product, and is suitable for pouring of multiple-part mold and large and medium size cast.

Owner:JIANGXI BAOAN NEW MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com