Pouch for storing granules

a granule and pouch technology, applied in the field of pouches, can solve the problems of insufficient use of spouts for storing granules, difficulty in determining how wide of an opening to make when opening containers, and difficulty in determining the width of an opening by oneself, etc., and achieves convenient formation of pouring spouts, large volume, and smooth pouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]The present invention will be described below based on preferred embodiments while referring to the drawings.

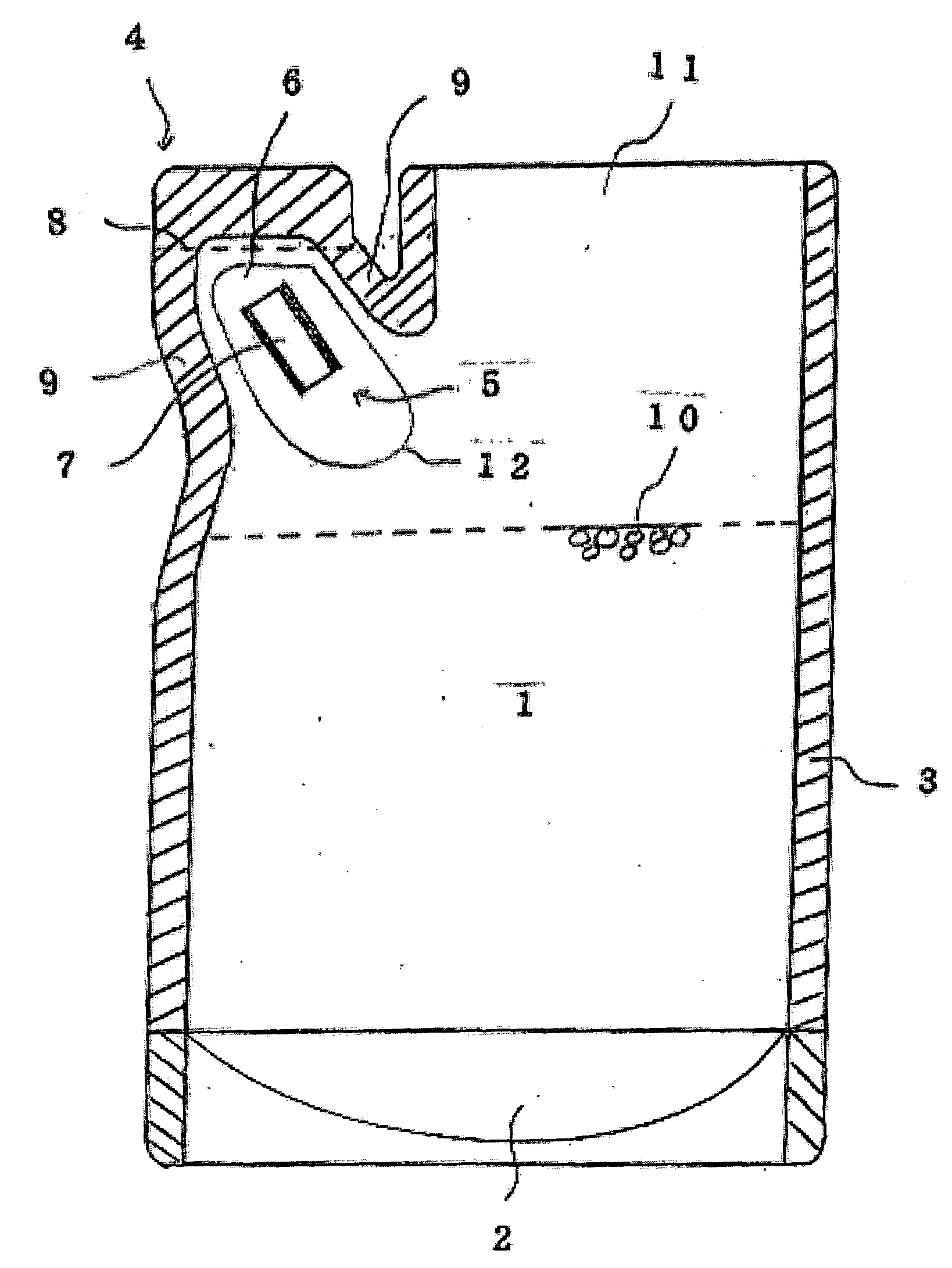

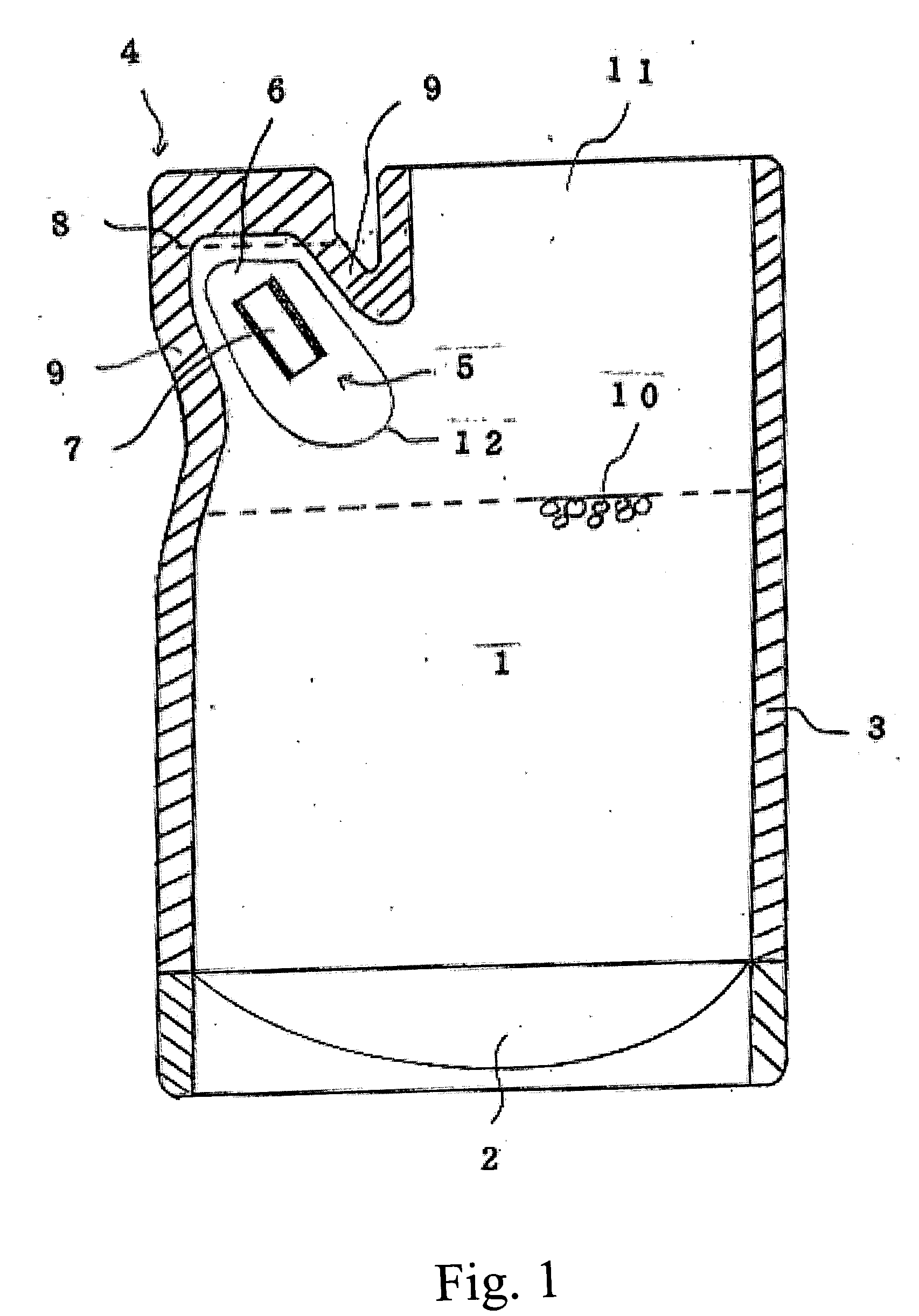

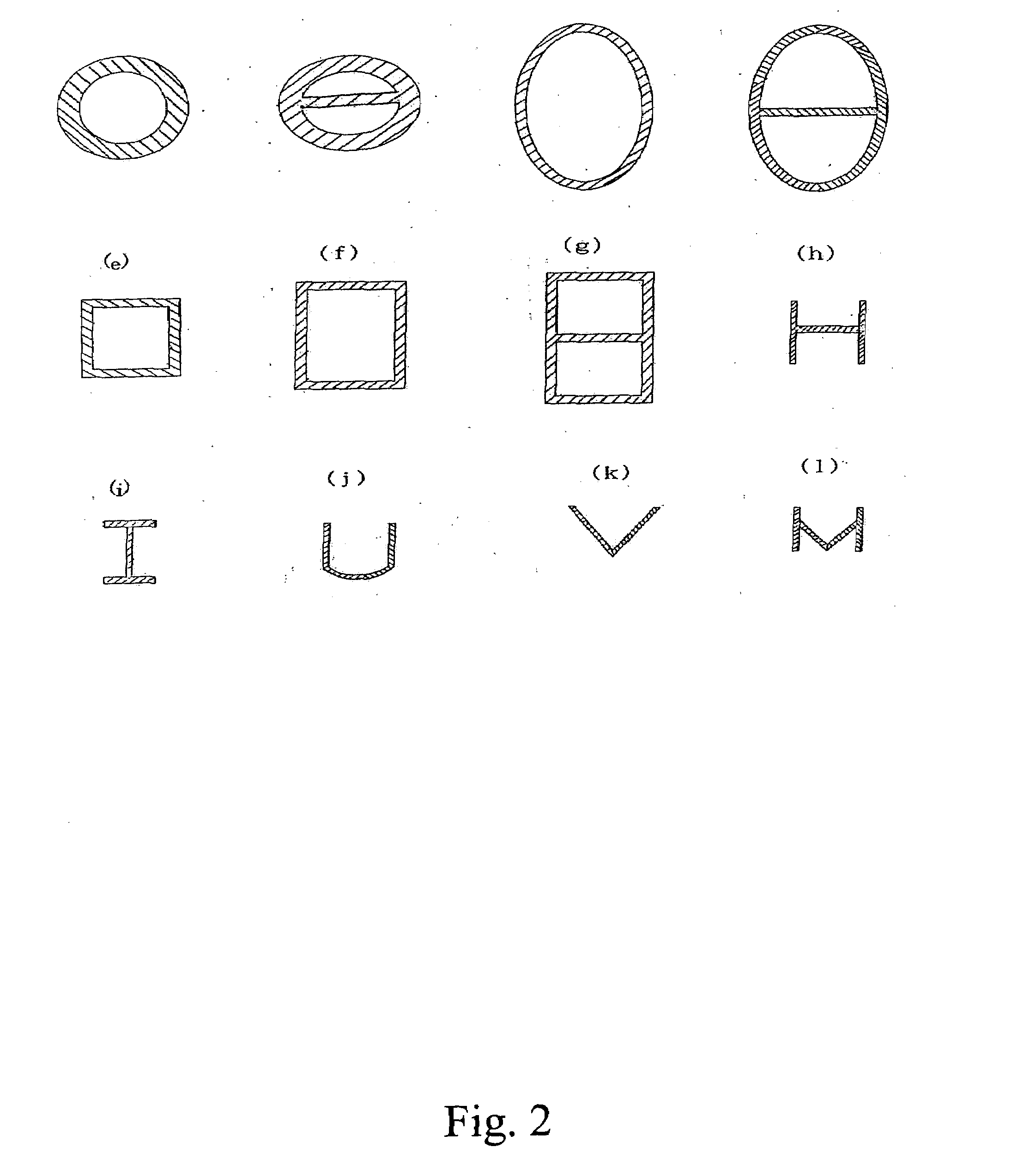

[0033]FIG. 1 through FIG. 4 are diagrams which show the first embodiment of the pouch for storing granules of the present invention, where FIG. 1 is a top view showing the components of the pouch for storing granules, FIG. 2 is a cross-section view showing an embodiment of the opening support member of the present invention, FIG. 3 shows an example of the divided flow path at the intake port of the opening region of the present invention (partial enlarged cross-section diagram along line A-A in FIG. 1), and FIG. 4 is a top view showing the condition where the pouch for storing granules of the present invention is inclined horizontally. FIG. 5 and FIG. 6 are diagrams showing the condition where a conventional liquid refilling pouch with an inserted cylinder is used for storing granules, where FIG. 5 is a top view drawing showing the condition where the pouch is inclined ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| outer diameter | aaaaa | aaaaa |

| outer diameter | aaaaa | aaaaa |

| resting angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com