Patents

Literature

19563results about How to "Avoid accumulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrosurgical instrument

InactiveUS7278994B2Lower impedanceReduced effectivenessCannulasDiagnosticsGynecologyPeritoneal cavity

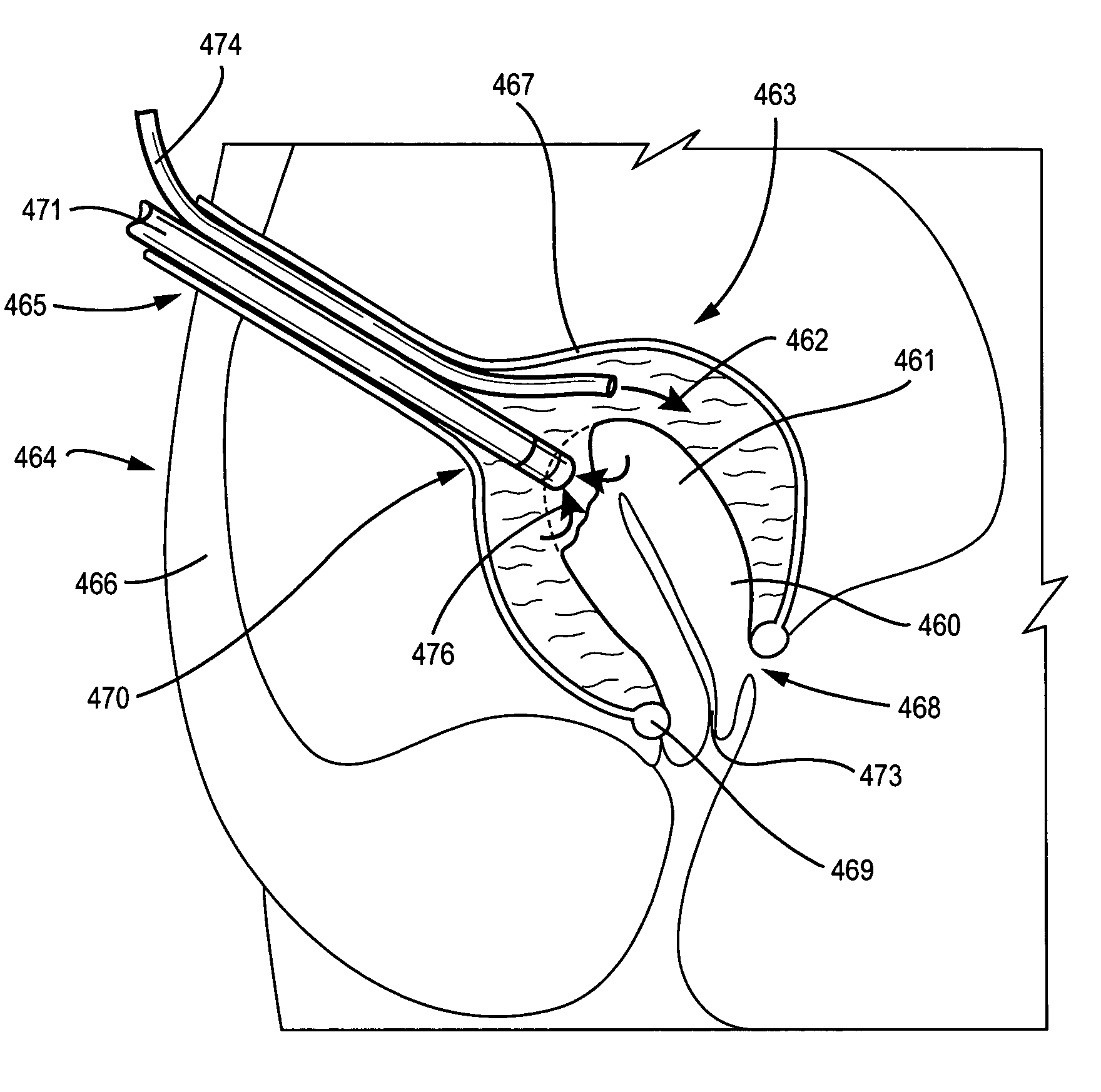

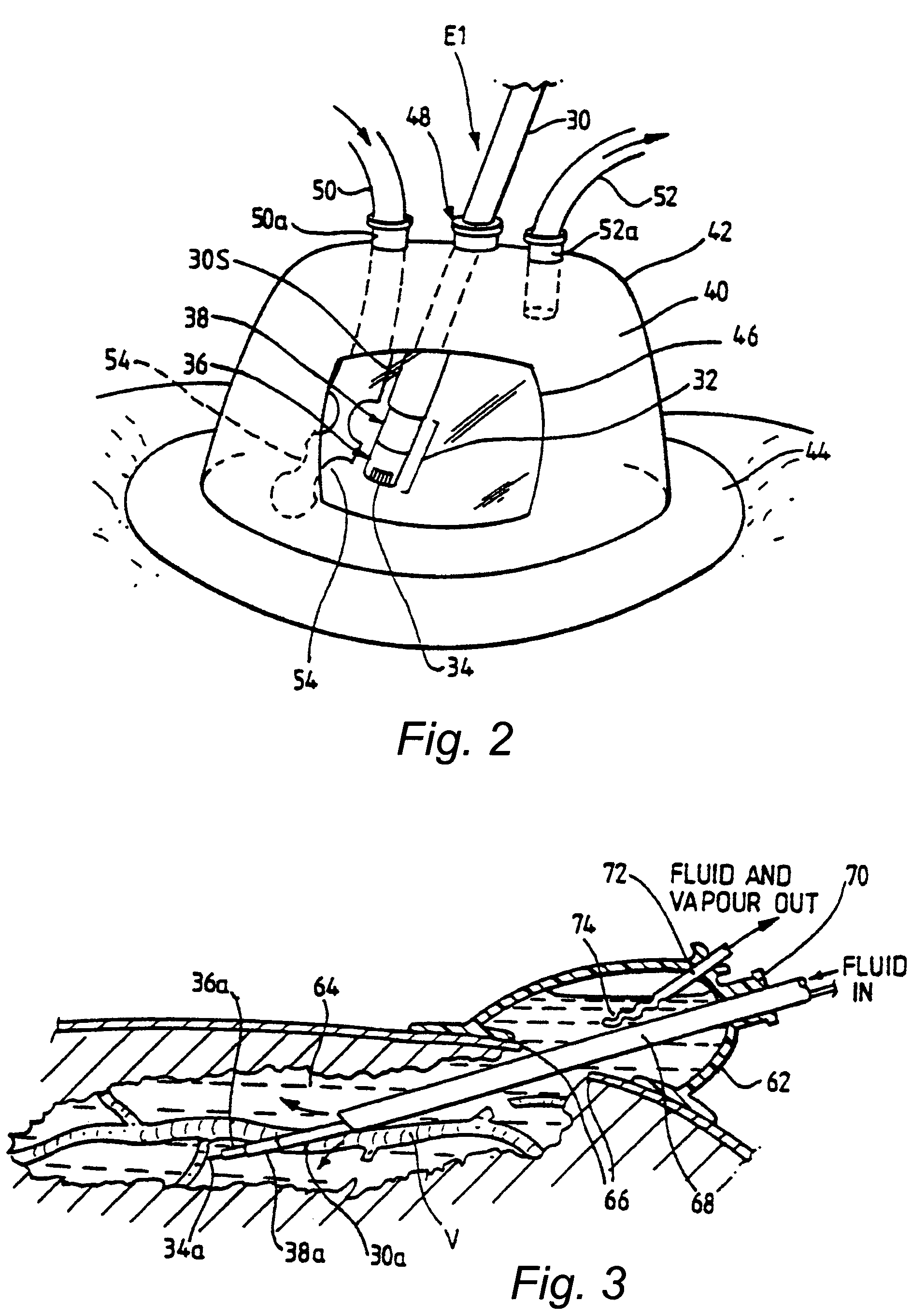

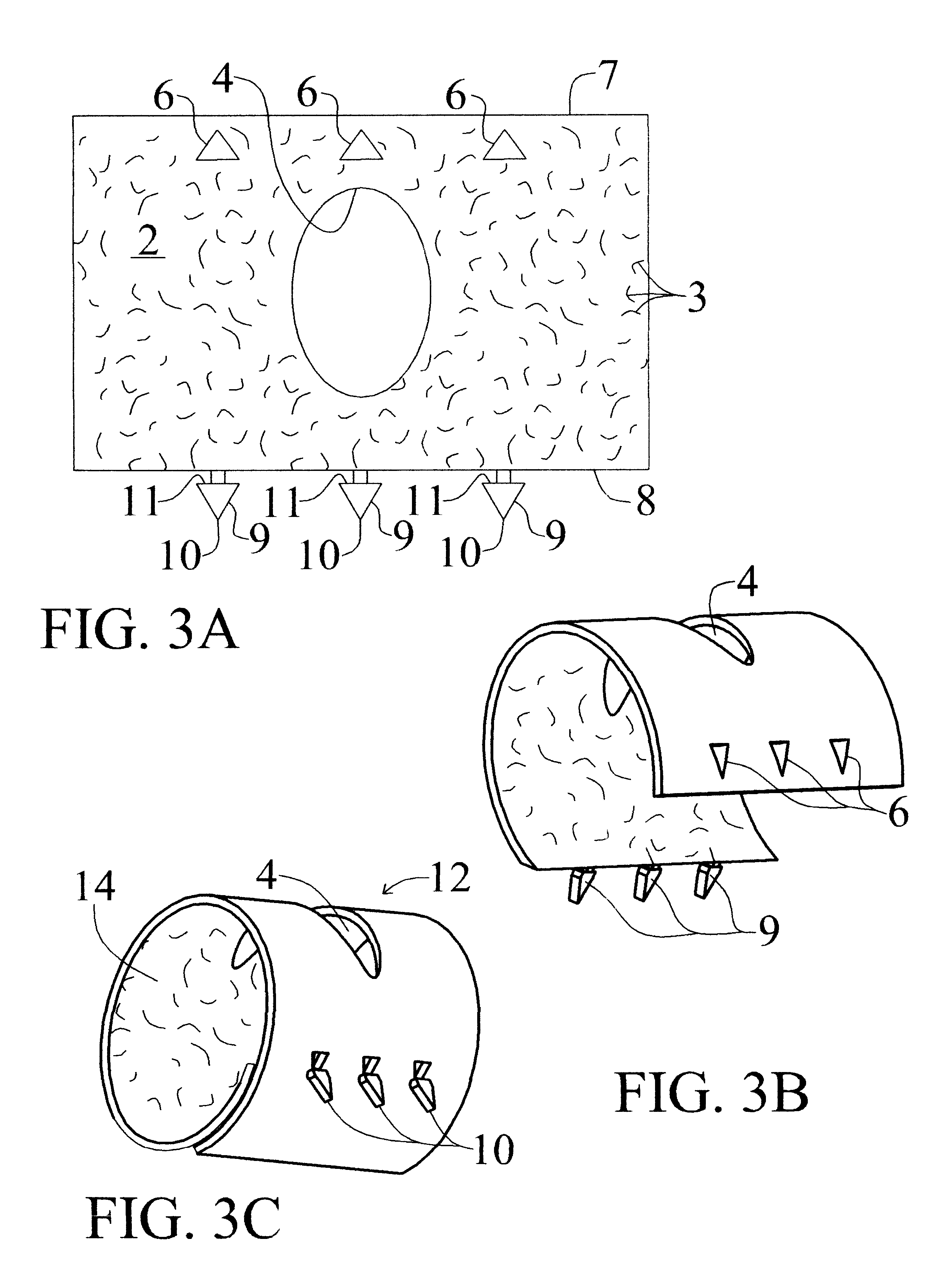

A system and method are disclosed for removing a uterus using a fluid enclosure inserted in the peritoneal cavity of a patient so as to enclose the uterus. The fluid enclosure includes a distal open end surrounded by an adjustable loop, that can be tightened, a first proximal opening for inserting an electrosurgical instrument into the fluid enclosure, and a second proximal opening for inserting an endoscope. The loop is either a resilient band extending around the edge of the distal open end or a drawstring type of arrangement that can be tightened and released. The fluid enclosure is partially inserted into the peritoneal cavity of a patient in a deflated condition and then manipulated within the peritoneal cavity over the body and fundus of the uterus to the level of the uterocervical junction. The loop is tightened around the uterocervical junction, after which the enclosure is inflated using a conductive fluid. The loop forms a pressure seal against the uterocervical junction to contain the conductive fluid used to fill the fluid enclosure. Endoscopically inserted into the fluid enclosure is an electrosurgical instrument that is manipulated to vaporize and morcellate the fundus and body of the uterus. The fundus and body tissue that is vaporized and morcellated is then removed from the fluid enclosure through the shaft of the instrument, which includes a hollow interior that is connected to a suction pump The fundus and body are removed after the uterus has been disconnected from the tissue surrounding uterus.

Owner:GYRUS MEDICAL LTD

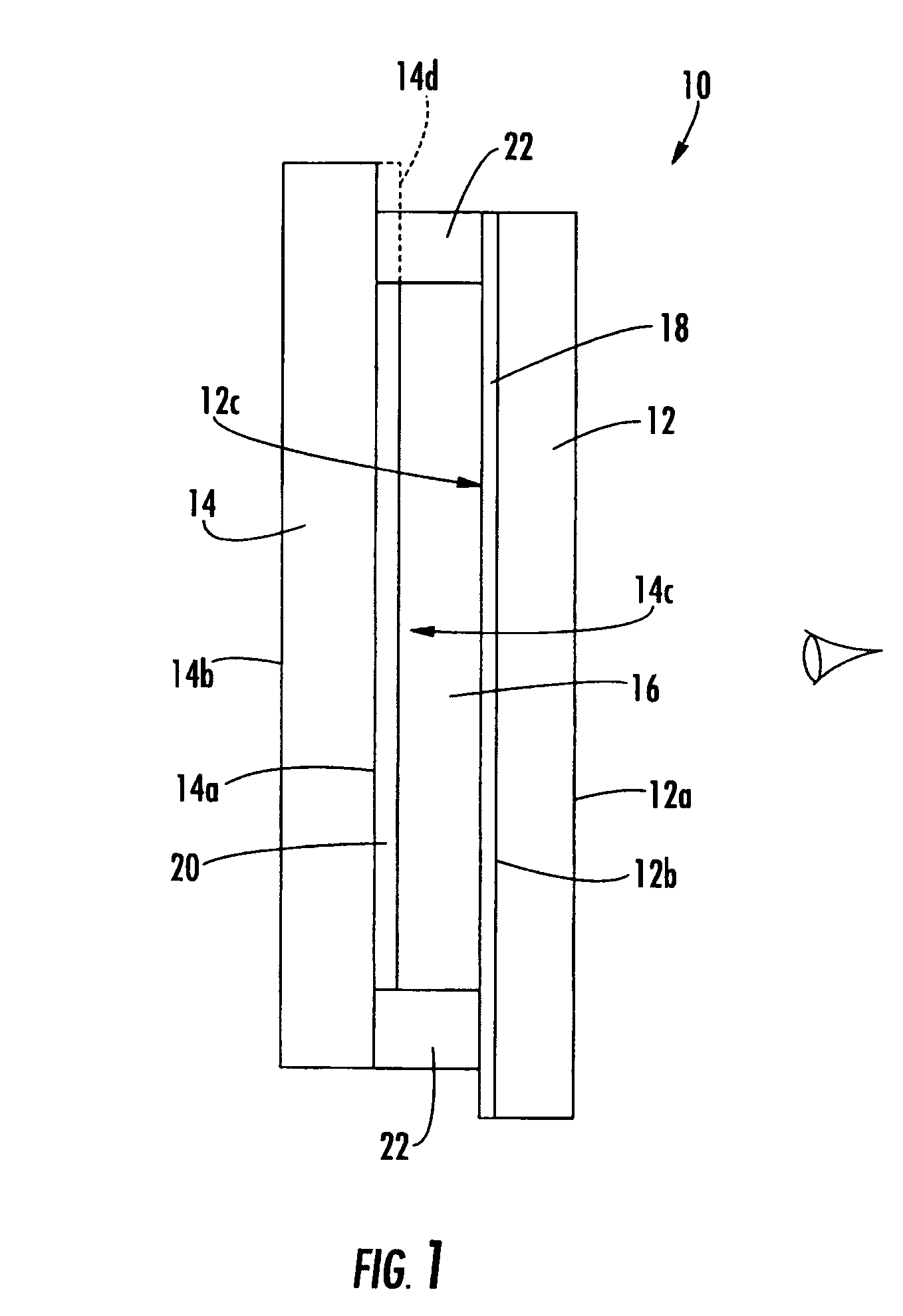

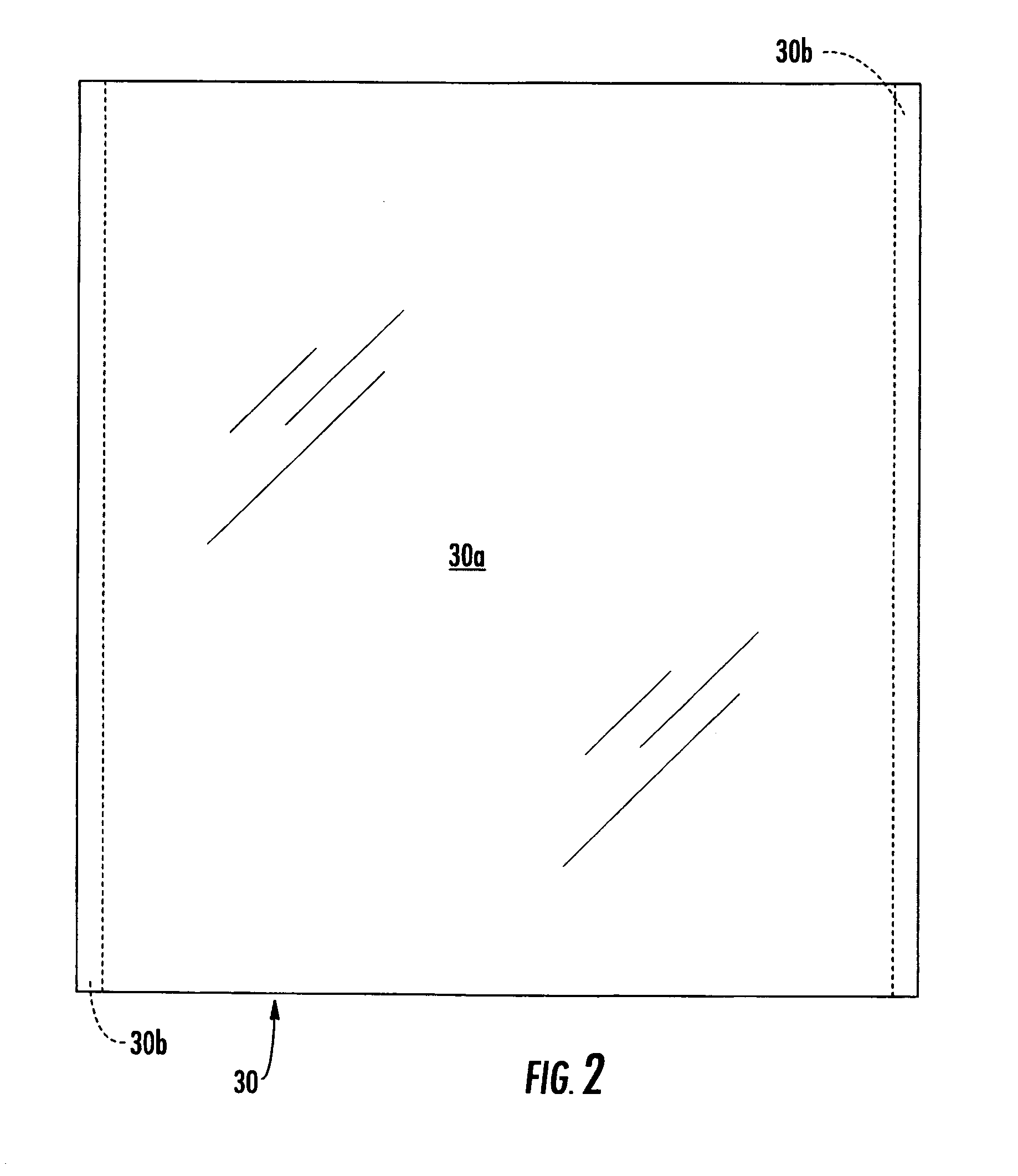

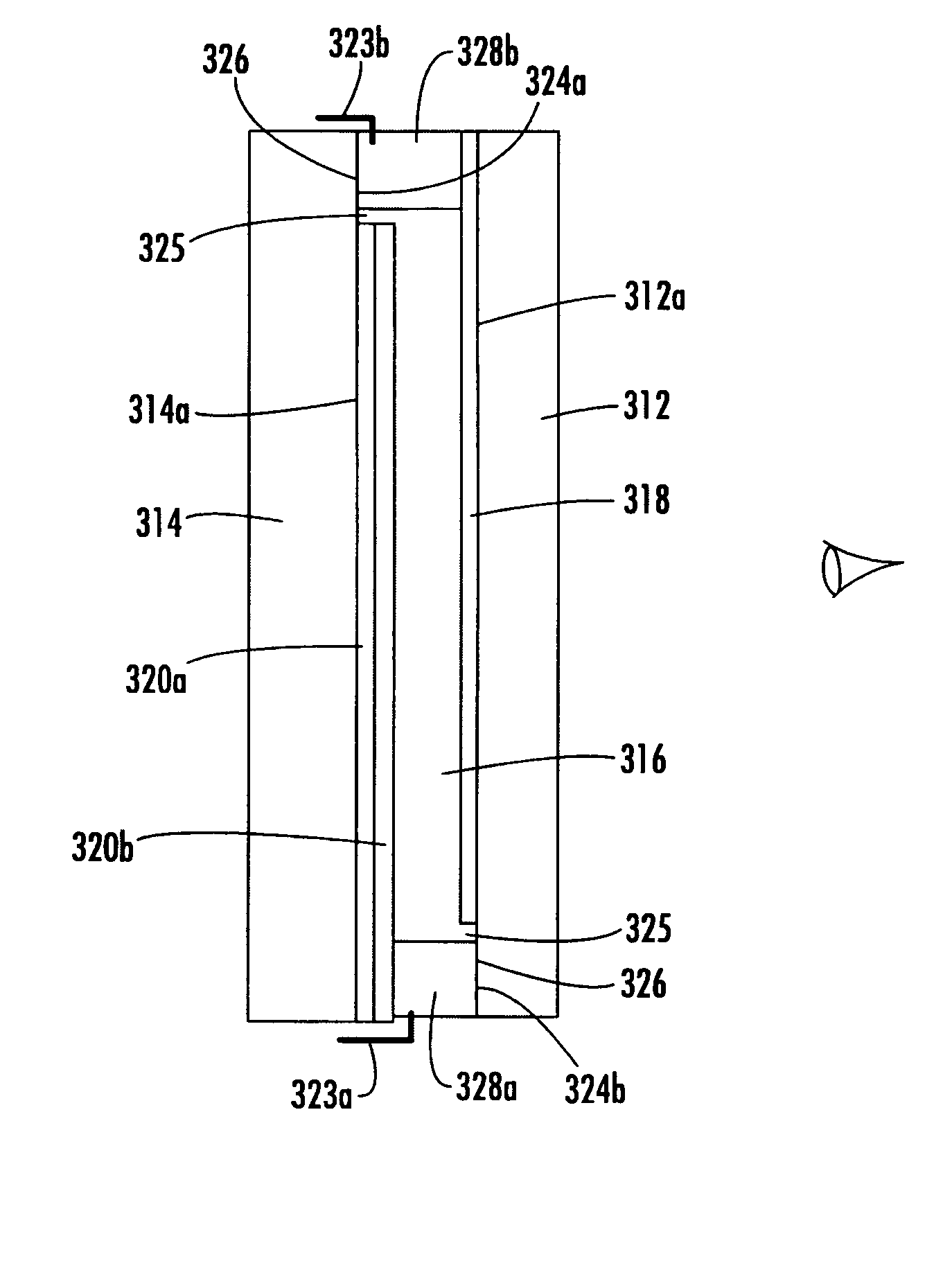

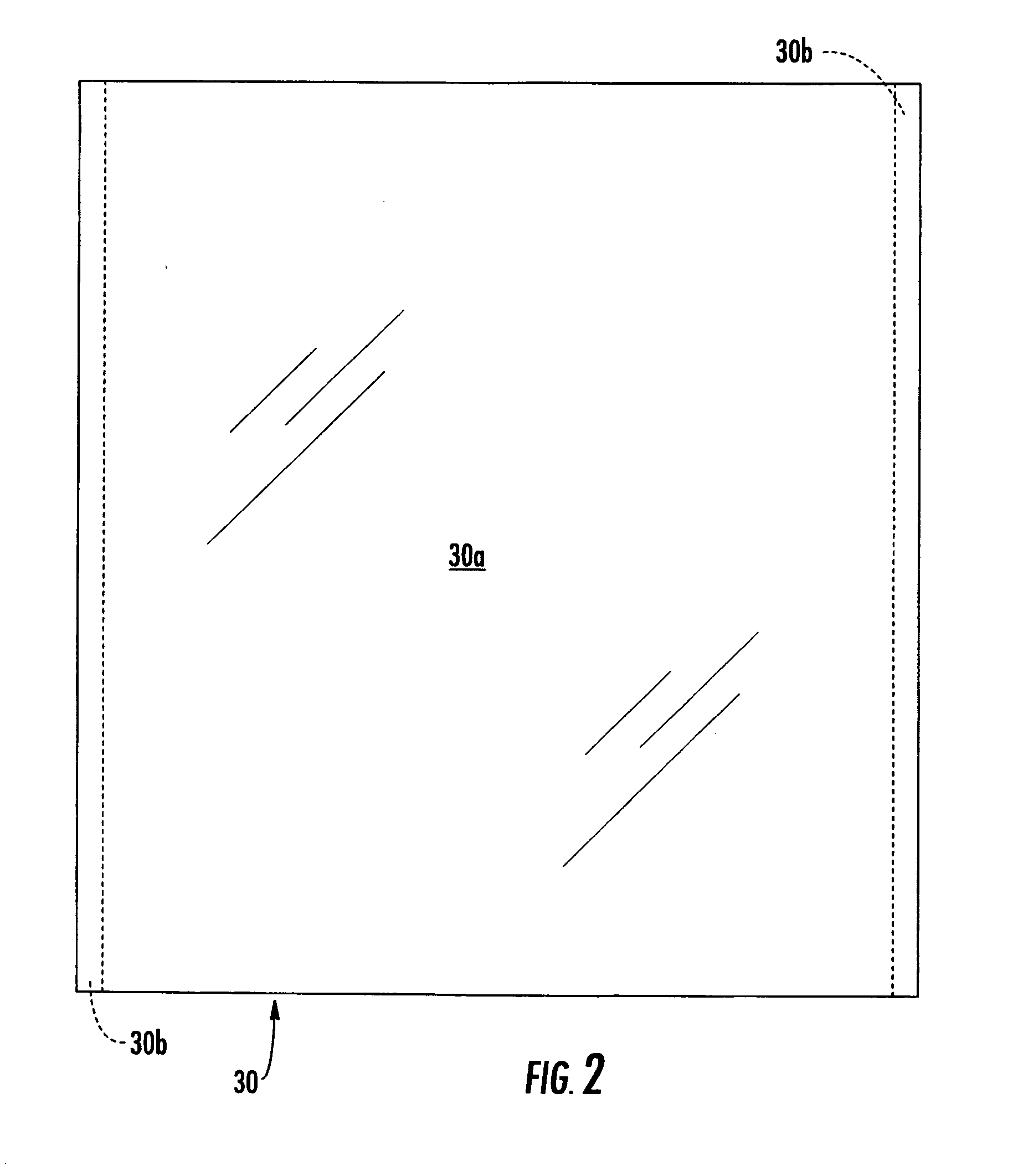

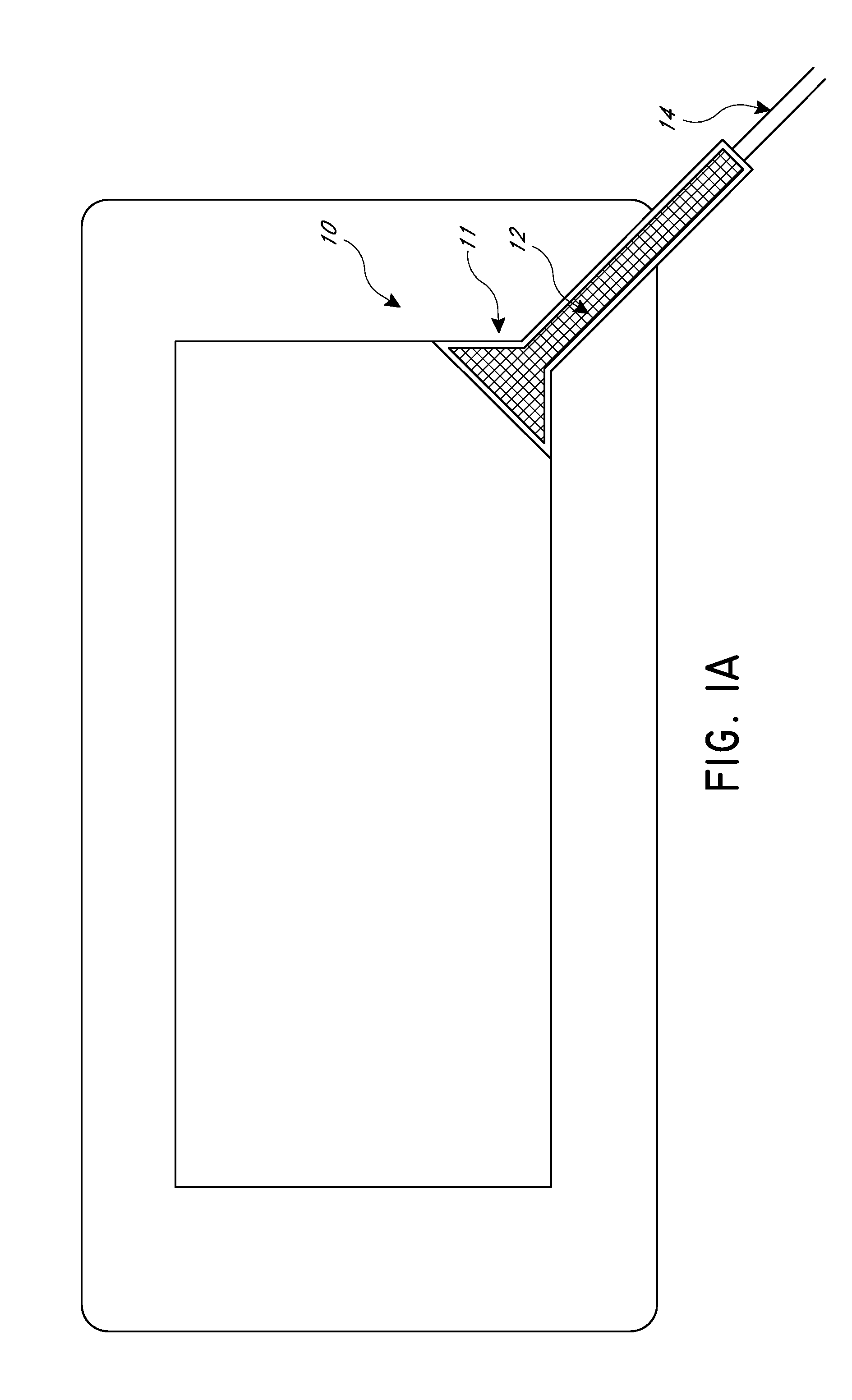

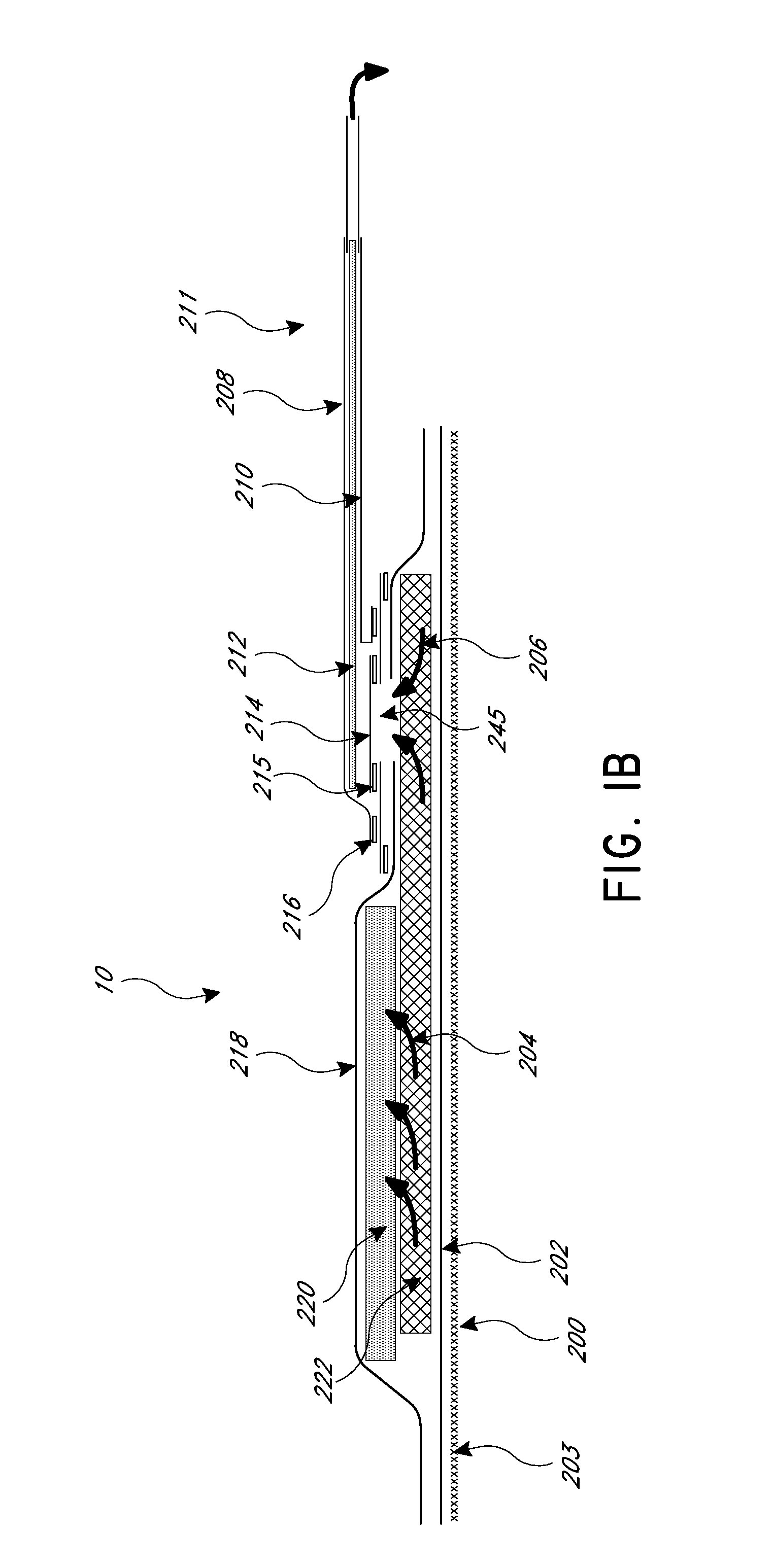

Electro-optic mirror cell

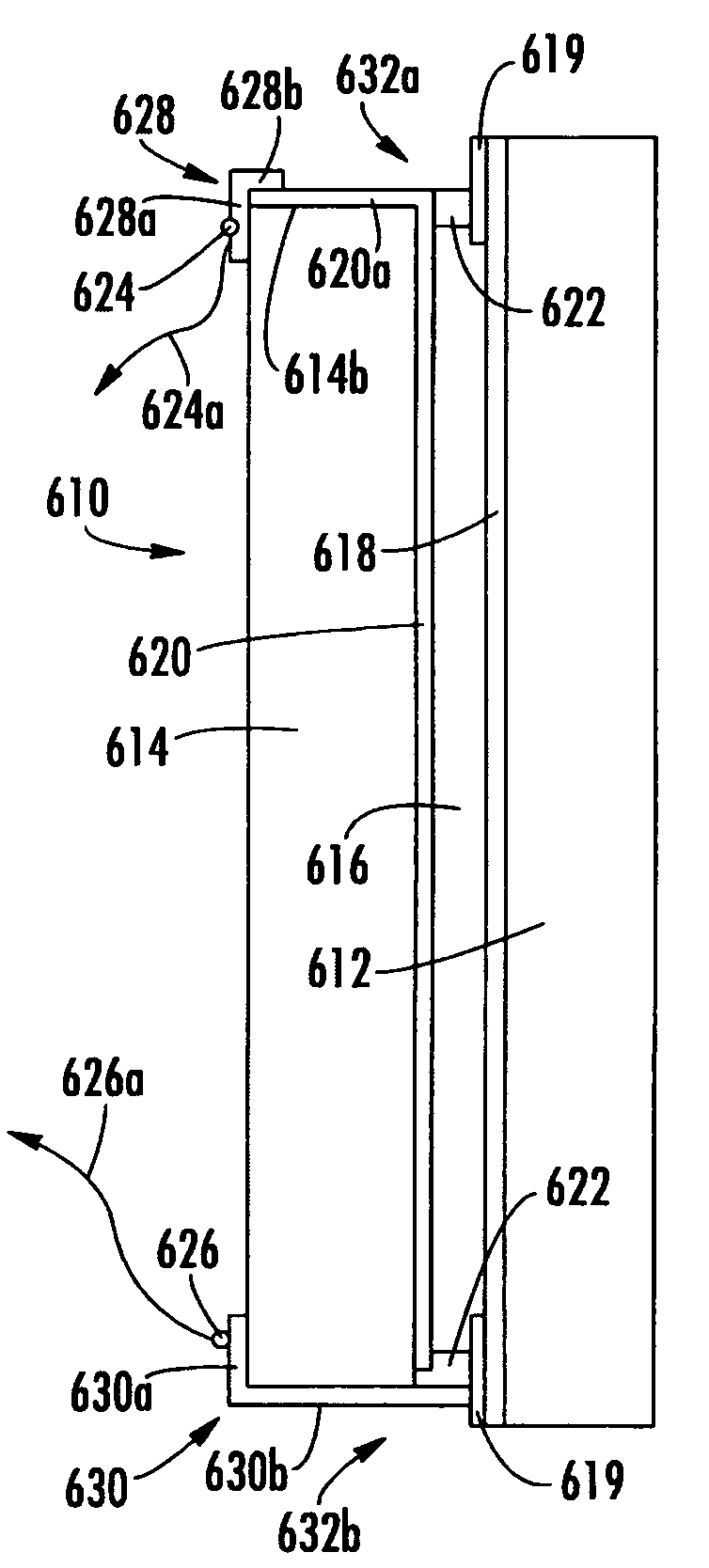

ActiveUS7255451B2Limit and substantially precludes touching and harmingSimple preparation processMirrorsThin material handlingElectricityConductive coating

A reflective element assembly for a variable reflectance vehicular mirror includes a front substrate having a transparent conductive coating disposed on a second surface, and a rear substrate having a third surface conductive coating disposed on its third surface and preferably, a fourth surface conductive coating disposed on its fourth surface. At least a portion of the third surface conductive coating may wrap around an edge portion of the rear substrate and at least a portion of the fourth surface conductive coating may wrap around at least a second portion of the perimeter edge so as to establish electrical continuity between the fourth surface conductive coating on the fourth surface and the third surface conductive coating on the third surface. The rear substrate may have a smaller dimension than the front substrate so as to provide an overhang region, preferably at the wraparound region.

Owner:DONNELLY CORP

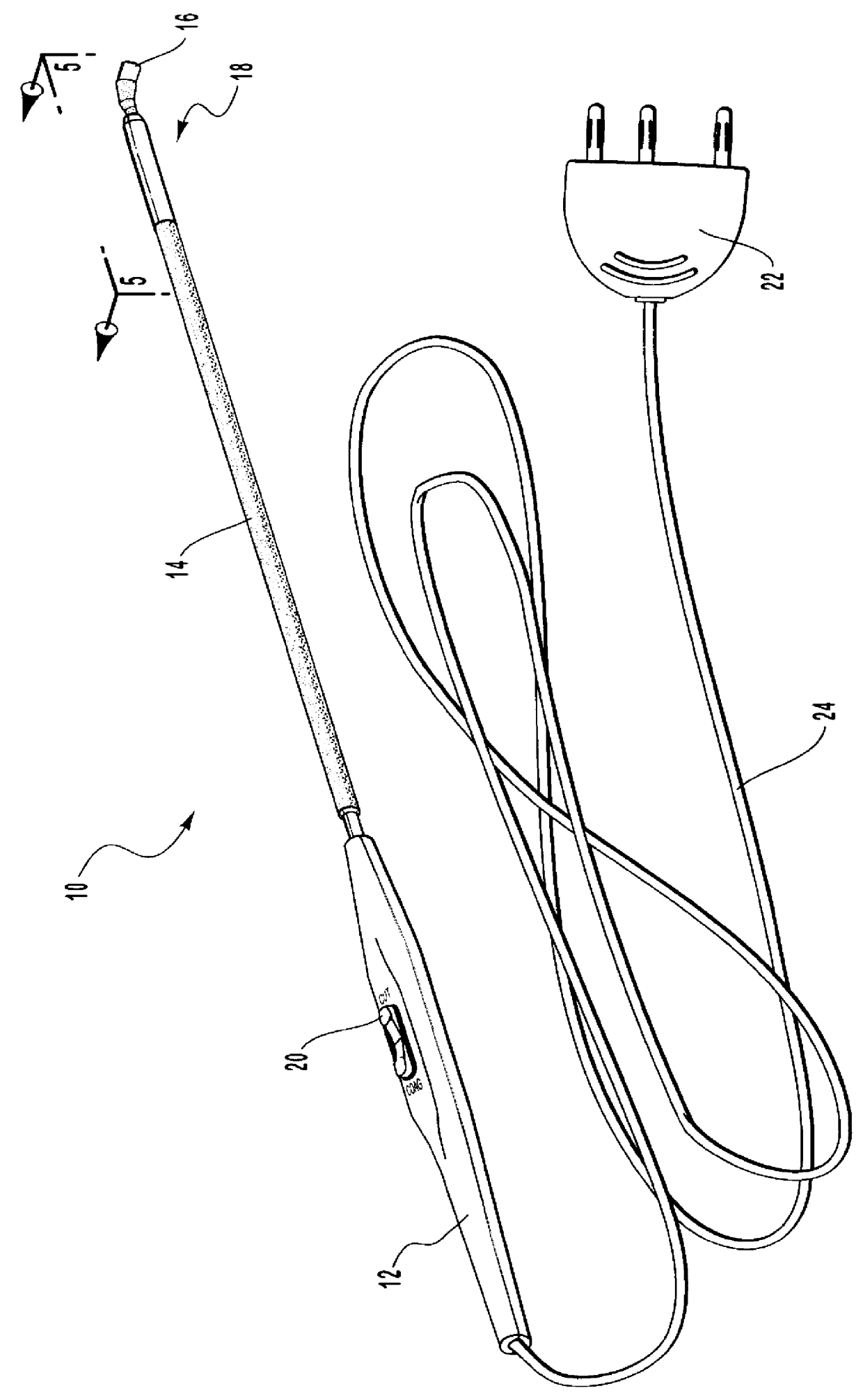

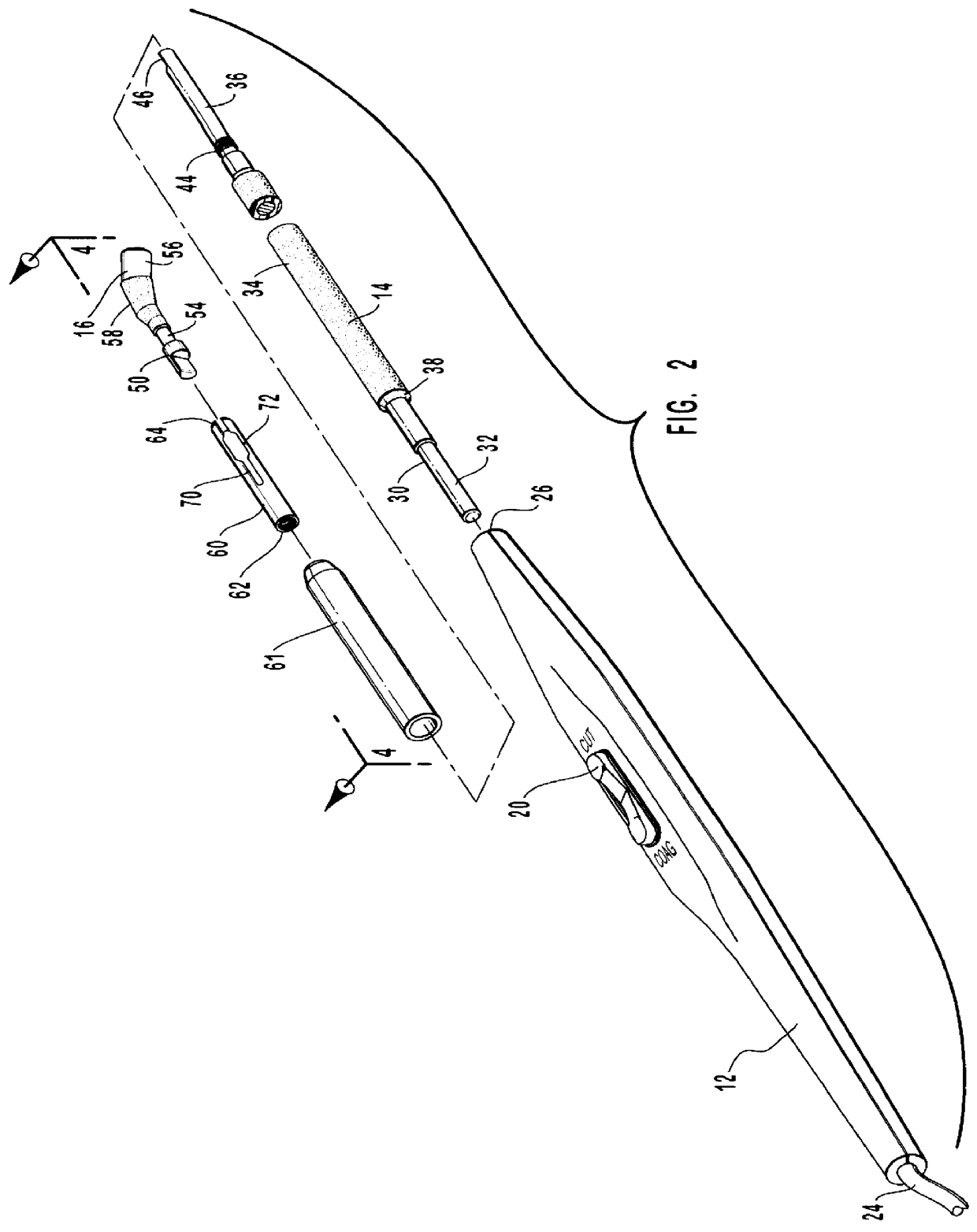

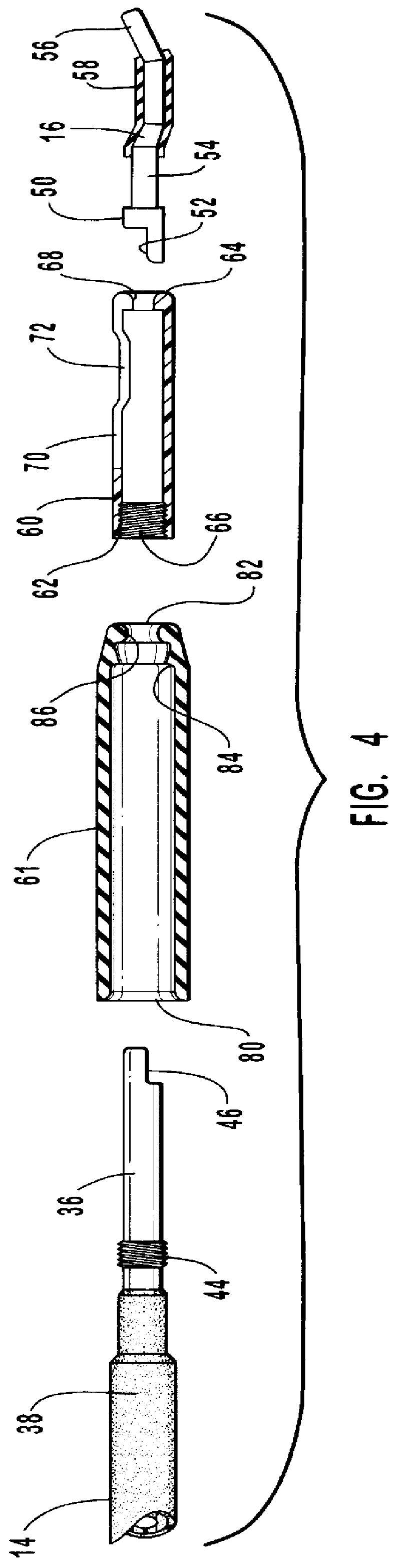

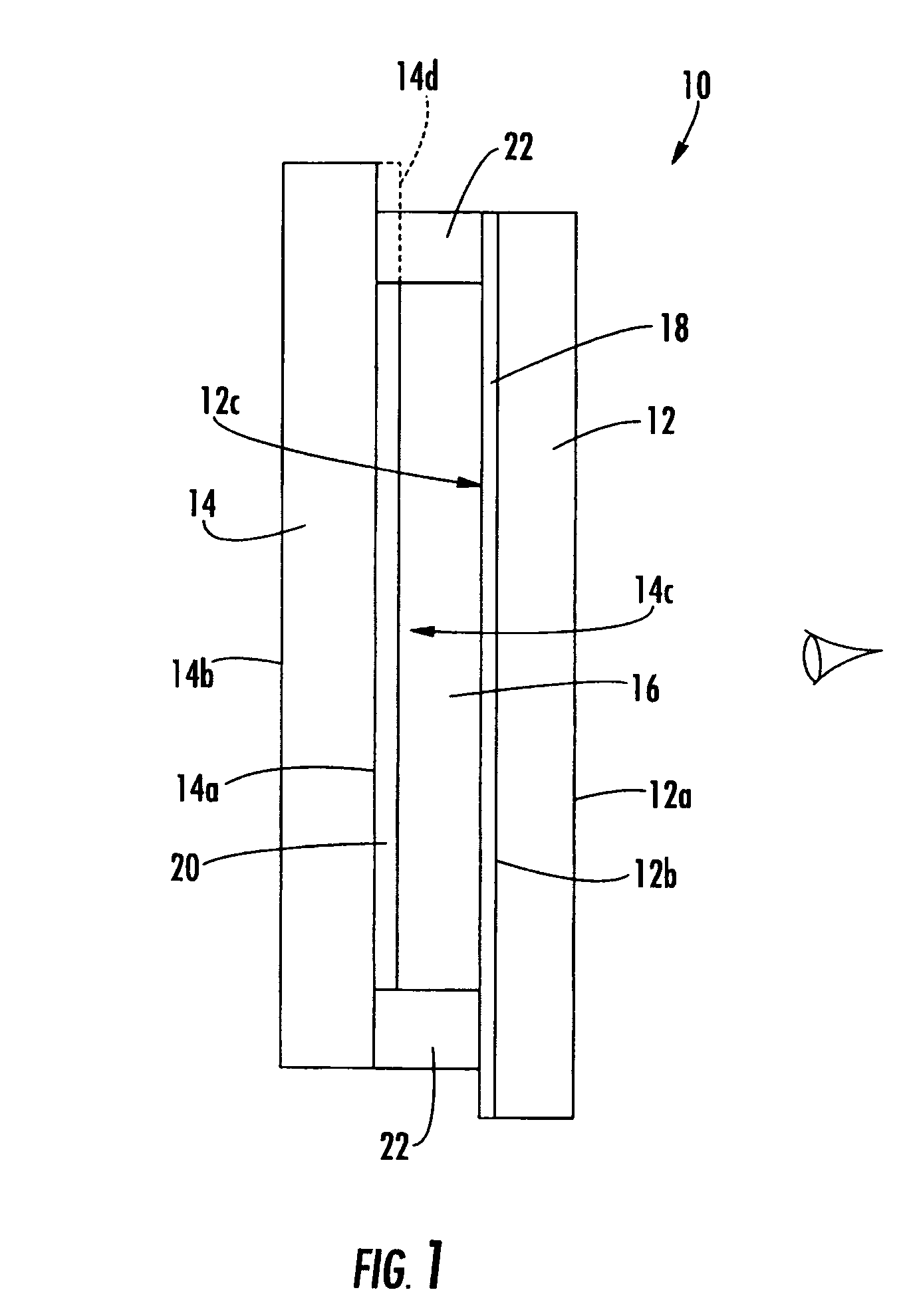

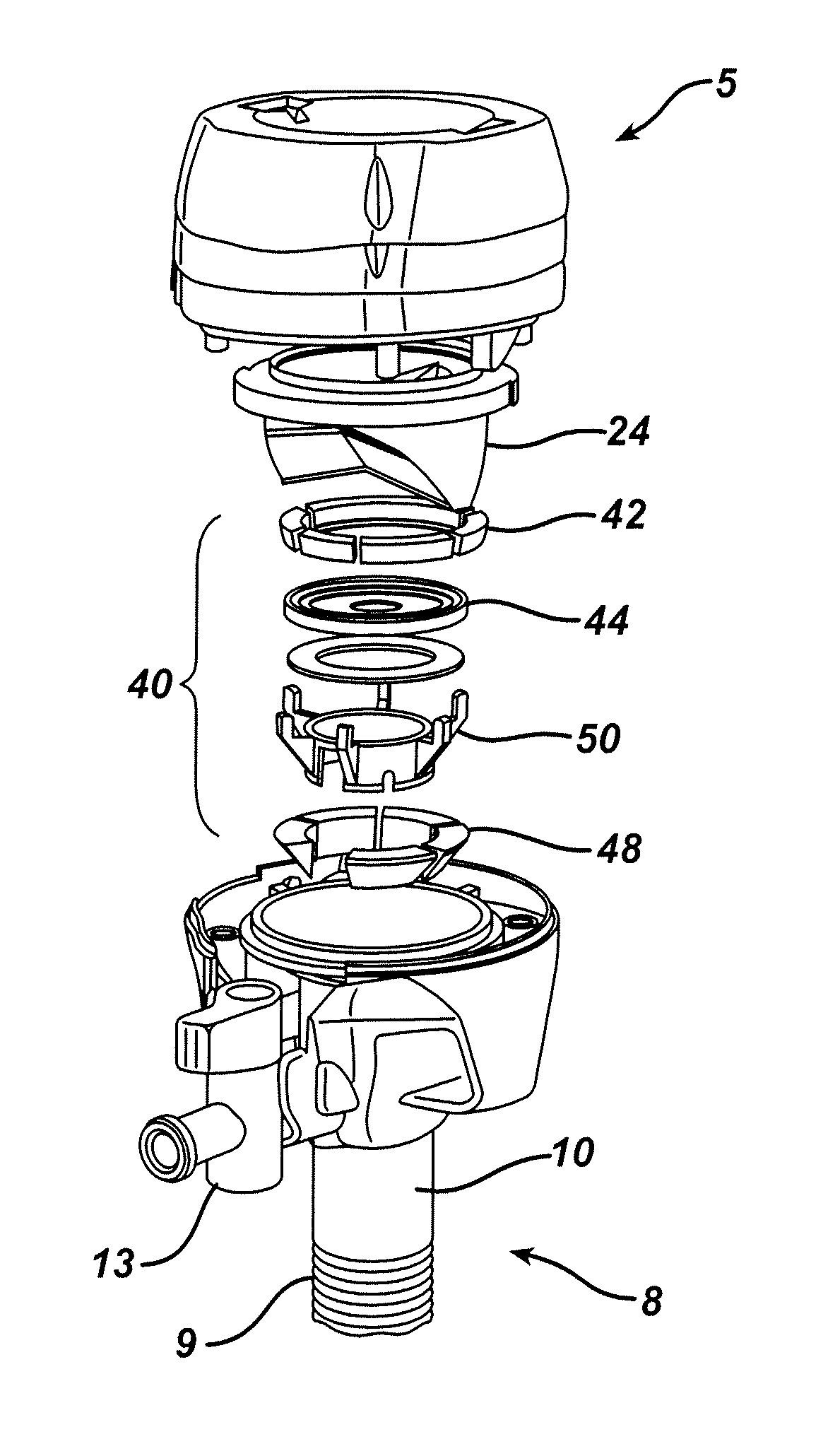

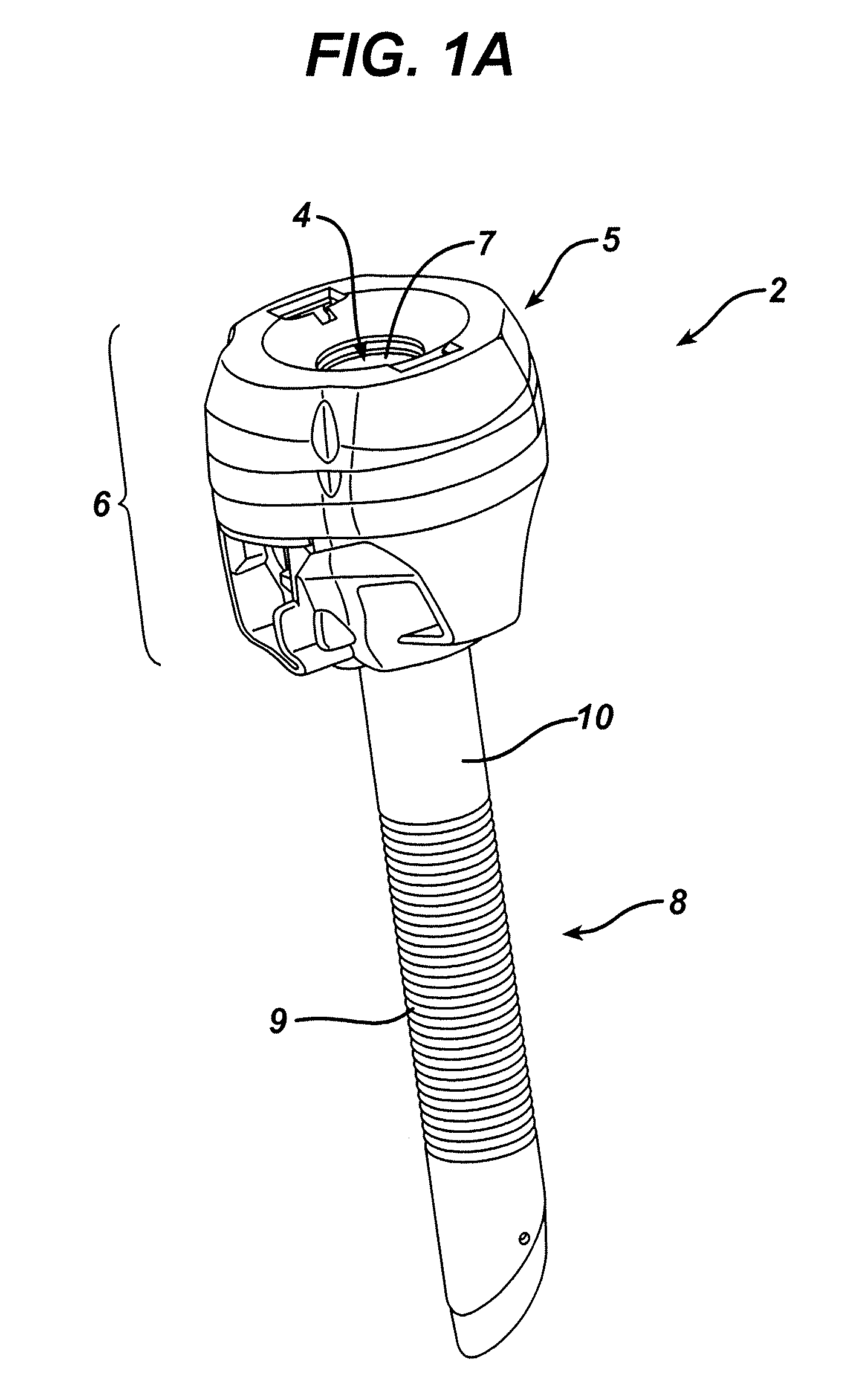

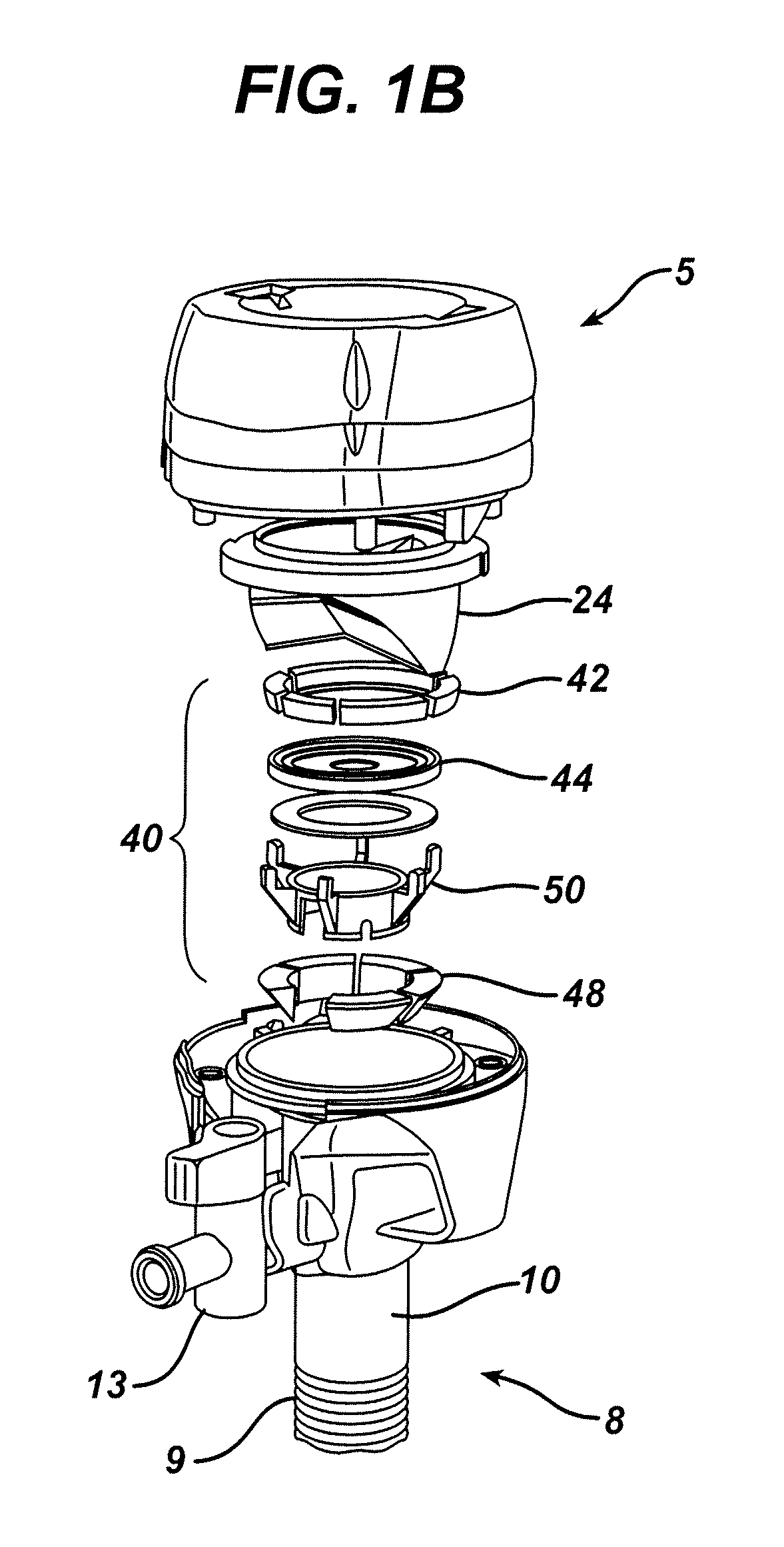

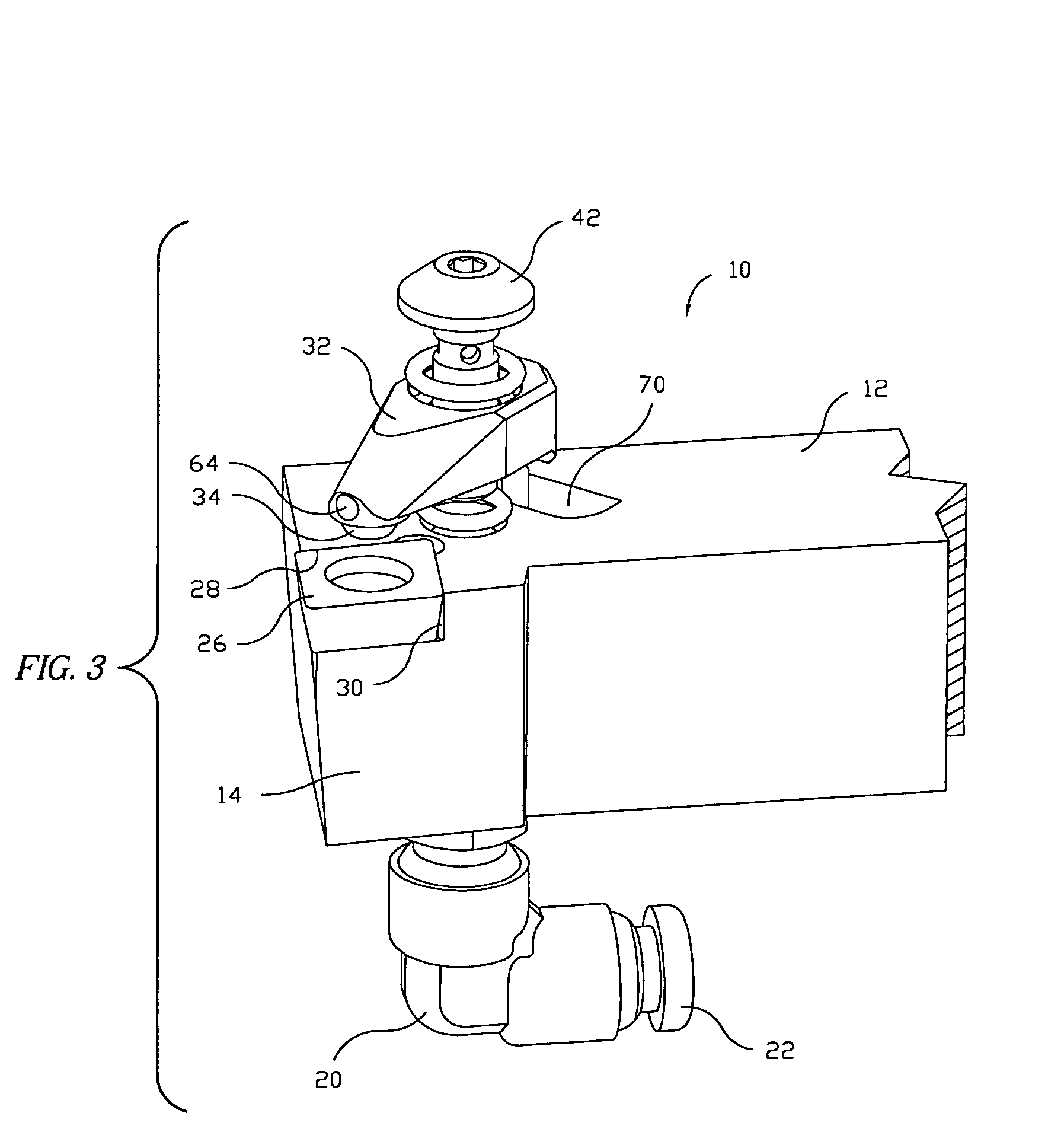

Resposable electrosurgical instrument

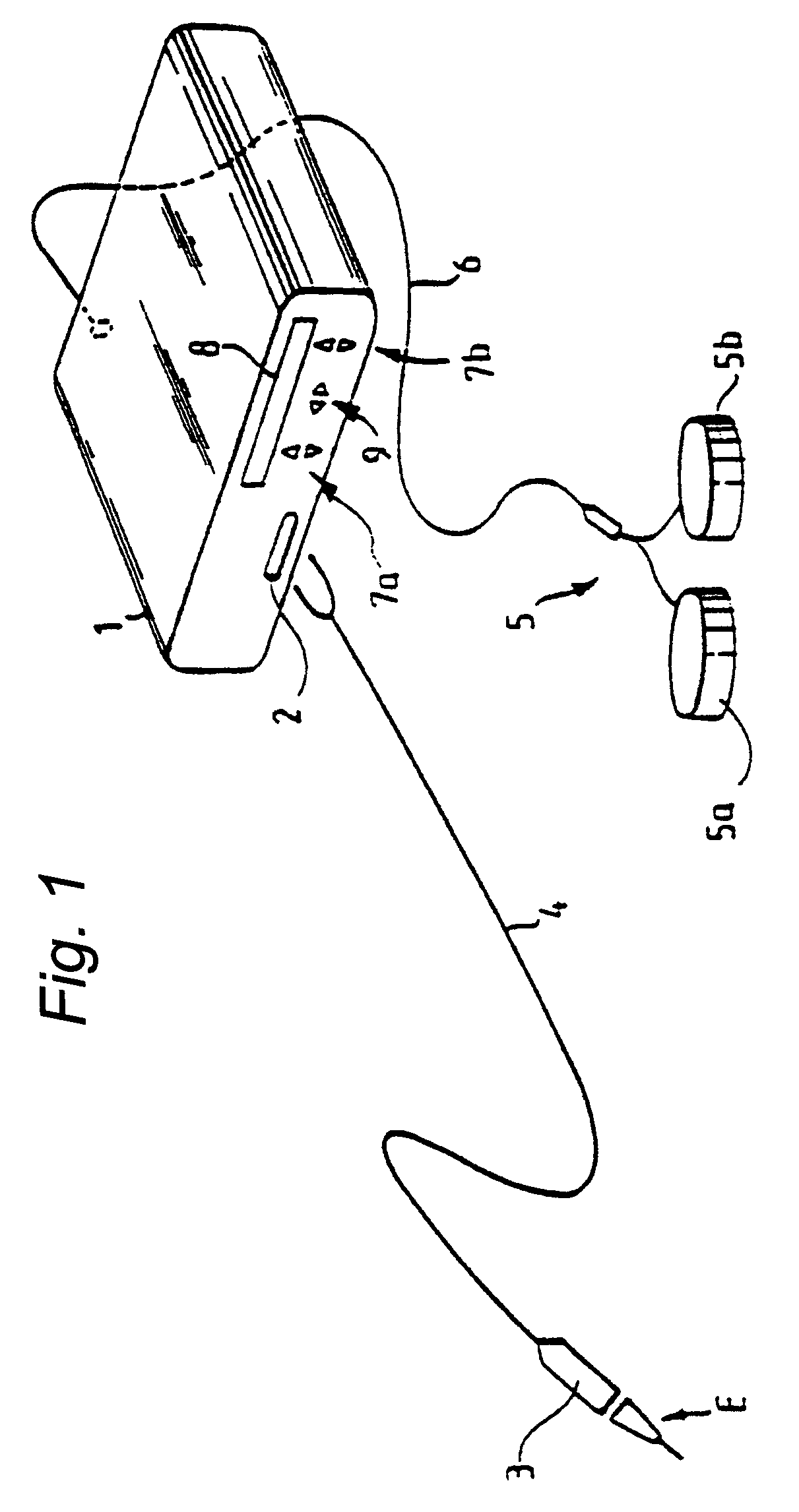

InactiveUS6090107AGuaranteed ease of connectionReliable electrical connectionSurgical instruments for heatingCouplingElectrical connection

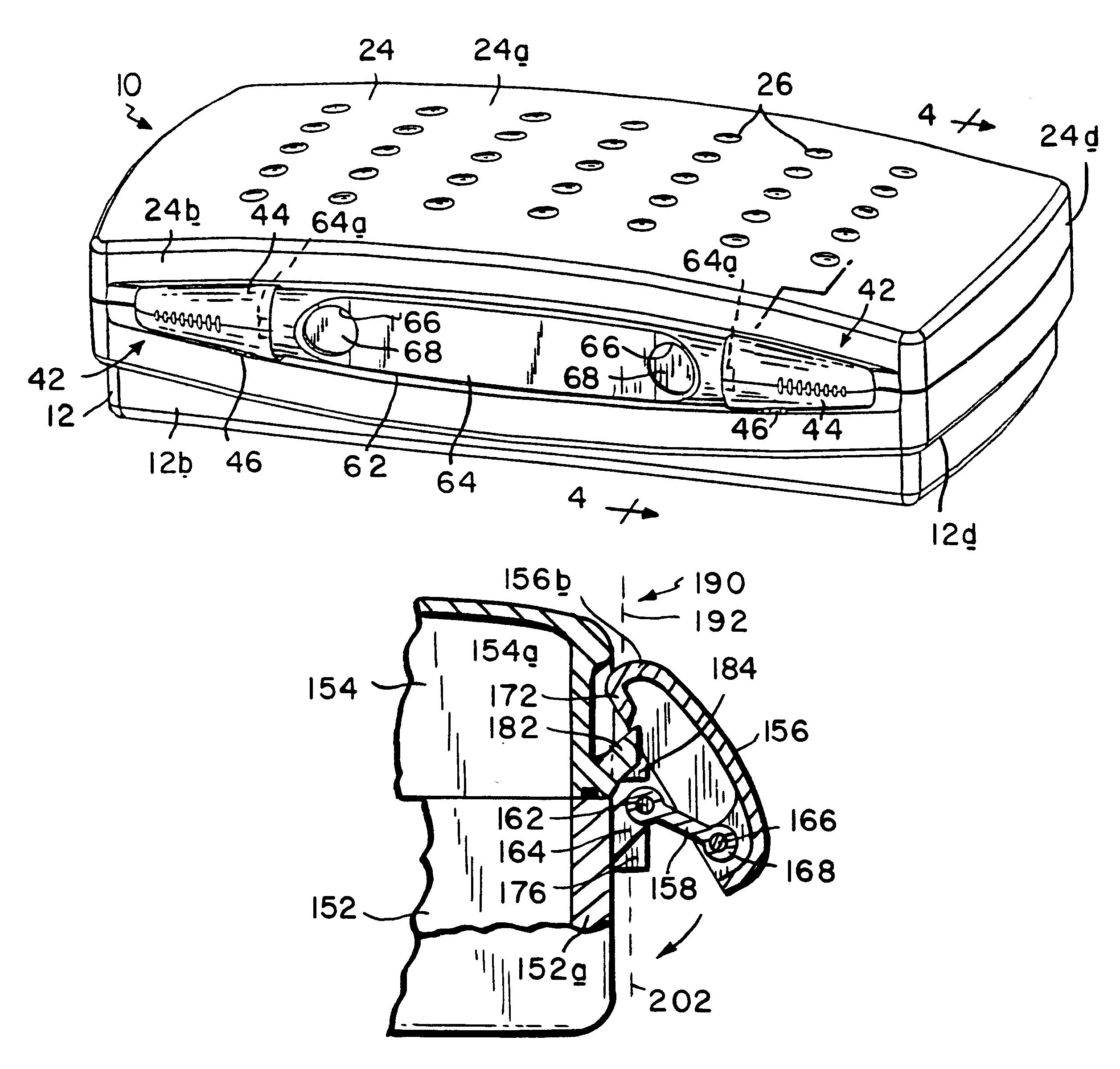

An improved electrosurgical instrument is disclosed and claims which includes a reusable electrode shaft, a disposable tip and a novel, insulated coupling for removably connecting the disposable tip to the electrode shaft. The present invention provides several advantages and features. The coupling provides ease in connecting the disposable tip to the reusable electrode shaft in an operating room environment. Once the tip is connected to the shaft, the coupling ensures a rigid and secure connection between the tip and the shaft, such that the coupled tip / shaft assembly feels to the surgeon like a single, unitary instrument. In addition, the coupling ensures a good electrical connection between the tip and the shaft, prevents the tip from inadvertently or accidentally becoming separated from the reusable electrode shaft, and maintains the position of the tip relative to the shaft by preventing the tip from rotating relative to the holder. The coupling also includes an insulating sheath that eliminates any conduction paths between the patient and the electrosurgical instrument other than the surgical tip.

Owner:MEGADYNE MED PROD INC US

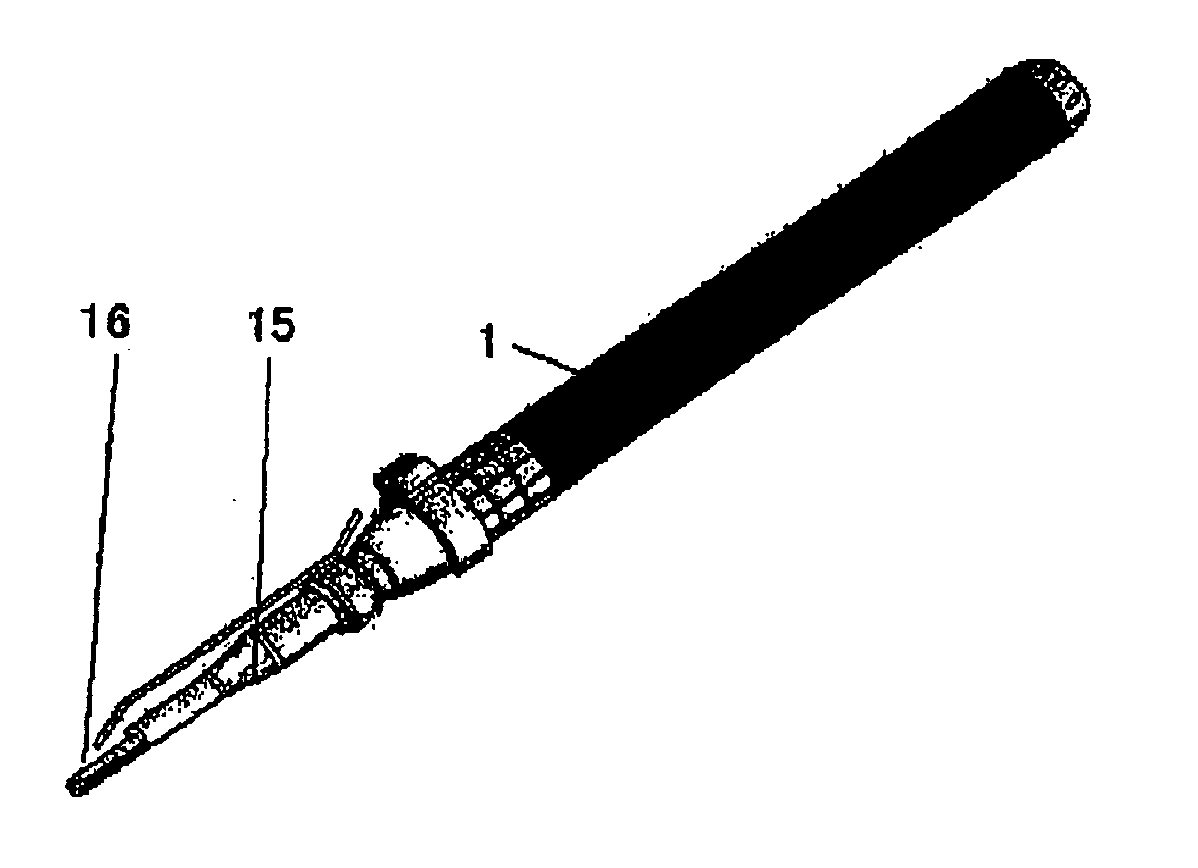

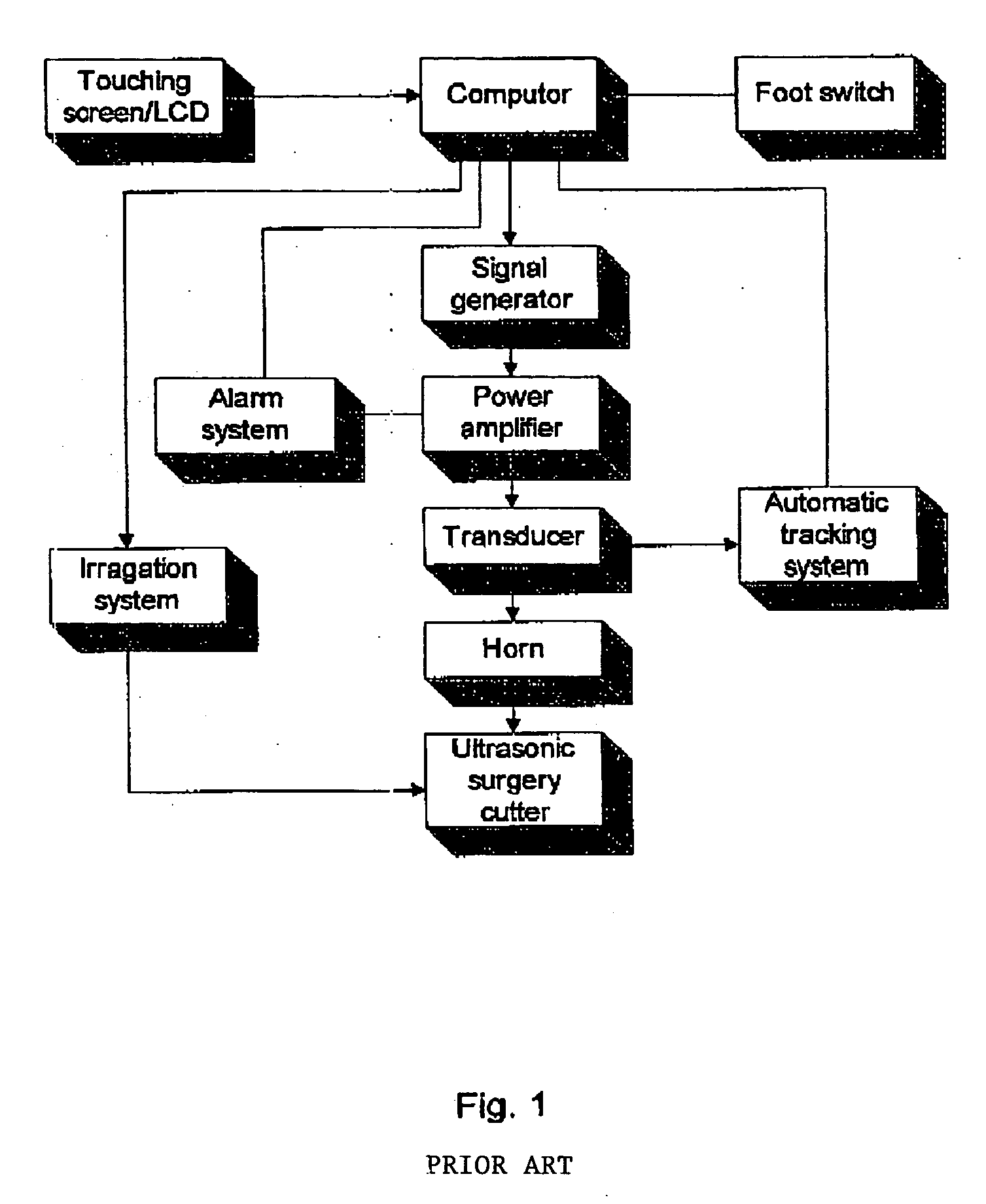

Ultrasonic orthopedic surgical device with compound ultrasound vibration

InactiveUS20060030797A1Improve cutting efficiencyAvoid local accumulationChiropractic devicesEye exercisersVibration amplitudeDrive motor

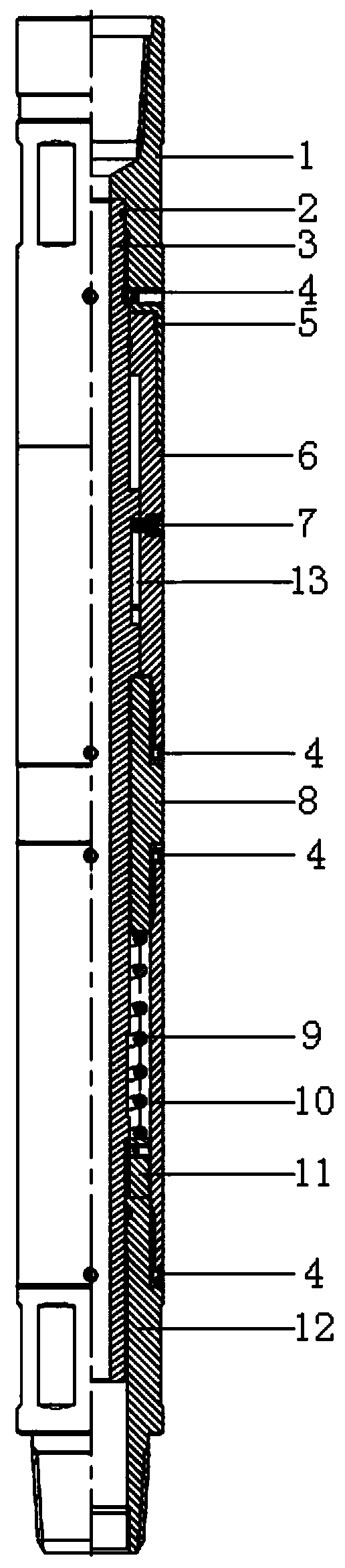

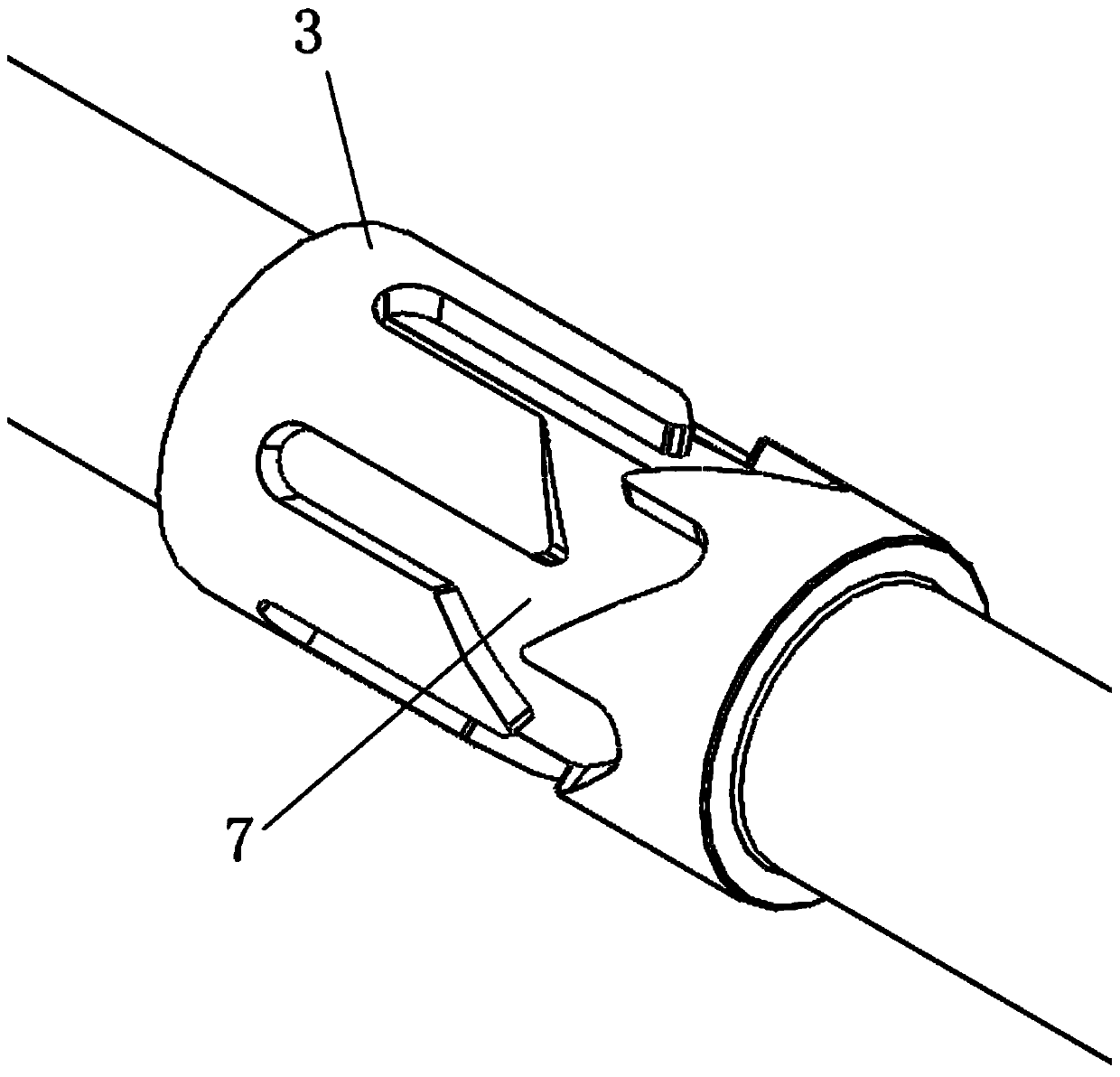

An orthopedic surgical device with compound ultrasound vibration that comprises a handpiece, a surgical cutter fixed on the anterior top of the handpiece, and an ultrasound signal generator. Inside the outer casing of said handpiece, there are provided: an ultrasound transducer for transforming the ultrasound signals from said ultrasound signal generator into ultrasound mechanical waves; a horn (or amplitude transformer) for amplifying vibration amplitude of ultrasound mechanical waves generated from said transducer and then transmitting the amplified ultrasound mechanical waves to said surgical cutter to lead to longitudinal vibration of the surgical cutter; a driving motor fixed in the back end of said handpiece for driving said ultrasound transducer and horn to accomplish the movement of swing and rotation; an adapter provided between said driving motor and said transducer for supplying ultrasonic electrical signals generated by said ultrasound signal generator to said ultrasound transducer.

Owner:ZHOU ZHAOYING +3

Deodorizing and sanitizing employing a wicking device

ActiveUS7285255B2Difficult to cleanAvoid accumulationLavatory sanitoryGaseous substancesCapillary actionChemistry

Owner:ECOLAB USA INC

Electro-optic mirror cell

ActiveUS20050195488A1Enhanced manufacturing processEconomy in coatingMirrorsThin material handlingConductive coatingReflectivity

A reflective element assembly for a variable reflectance vehicular mirror includes a front substrate having a transparent conductive coating disposed on a second surface, and a rear substrate having a third surface conductive coating disposed on its third surface and preferably, a fourth surface conductive coating disposed on its fourth surface. At least a portion of the third surface conductive coating may wrap around an edge portion of the rear substrate and at least a portion of the fourth surface conductive coating may wrap around at least a second portion of the perimeter edge so as to establish electrical continuity between the fourth surface conductive coating on the fourth surface and the third surface conductive coating on the third surface. The rear substrate may have a smaller dimension than the front substrate so as to provide an overhang region, preferably at the wraparound region.

Owner:DONNELLY CORP

Apparatus and methods for preventing or treating failure of hemodialysis vascular access and other vascular grafts

InactiveUS6726923B2Reduce calcificationInhibiting smooth muscle cell proliferationBiocideOrganic chemistryVascular graftBlood vessel

Owner:VASCULAR THERAPIES INC

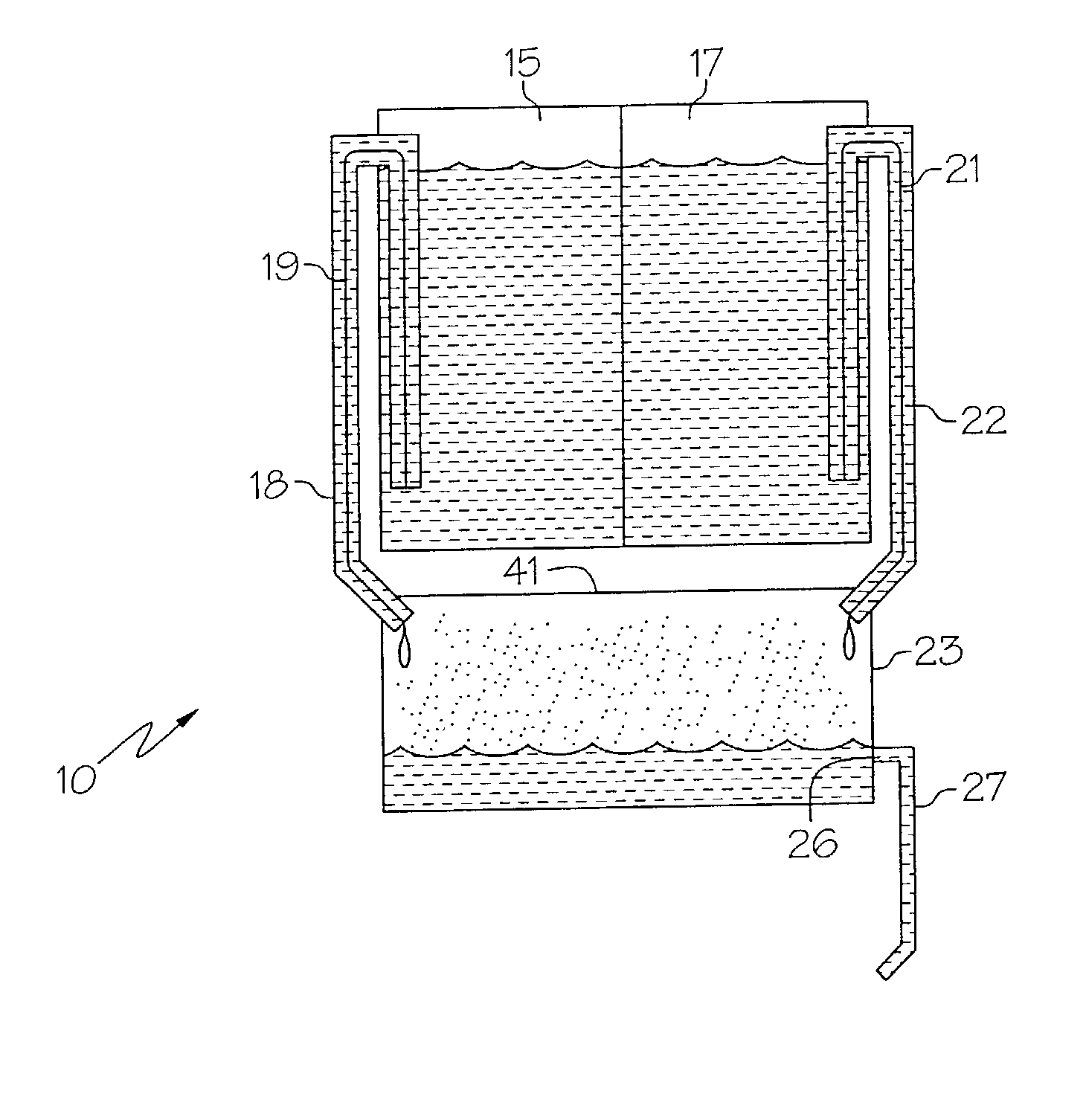

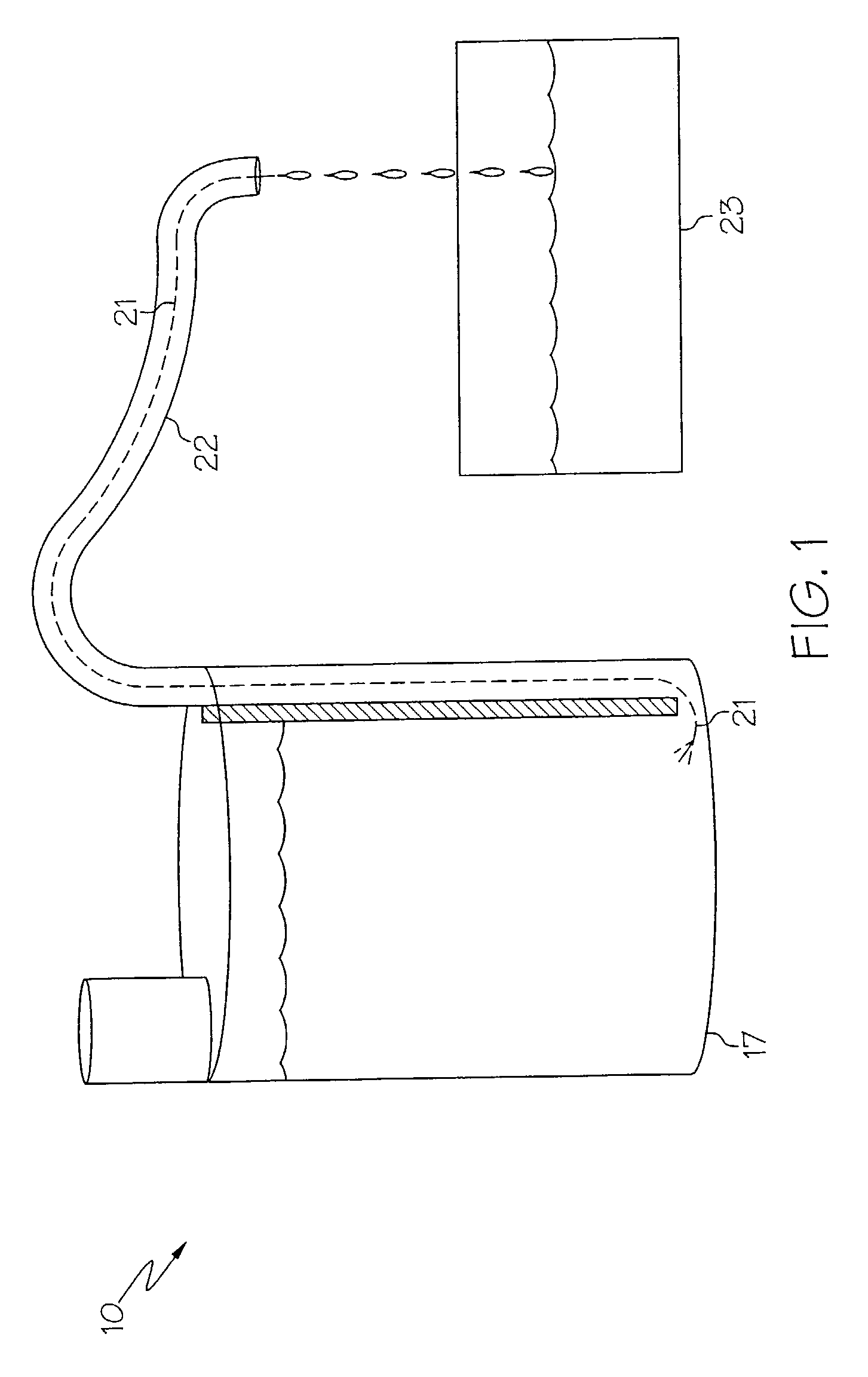

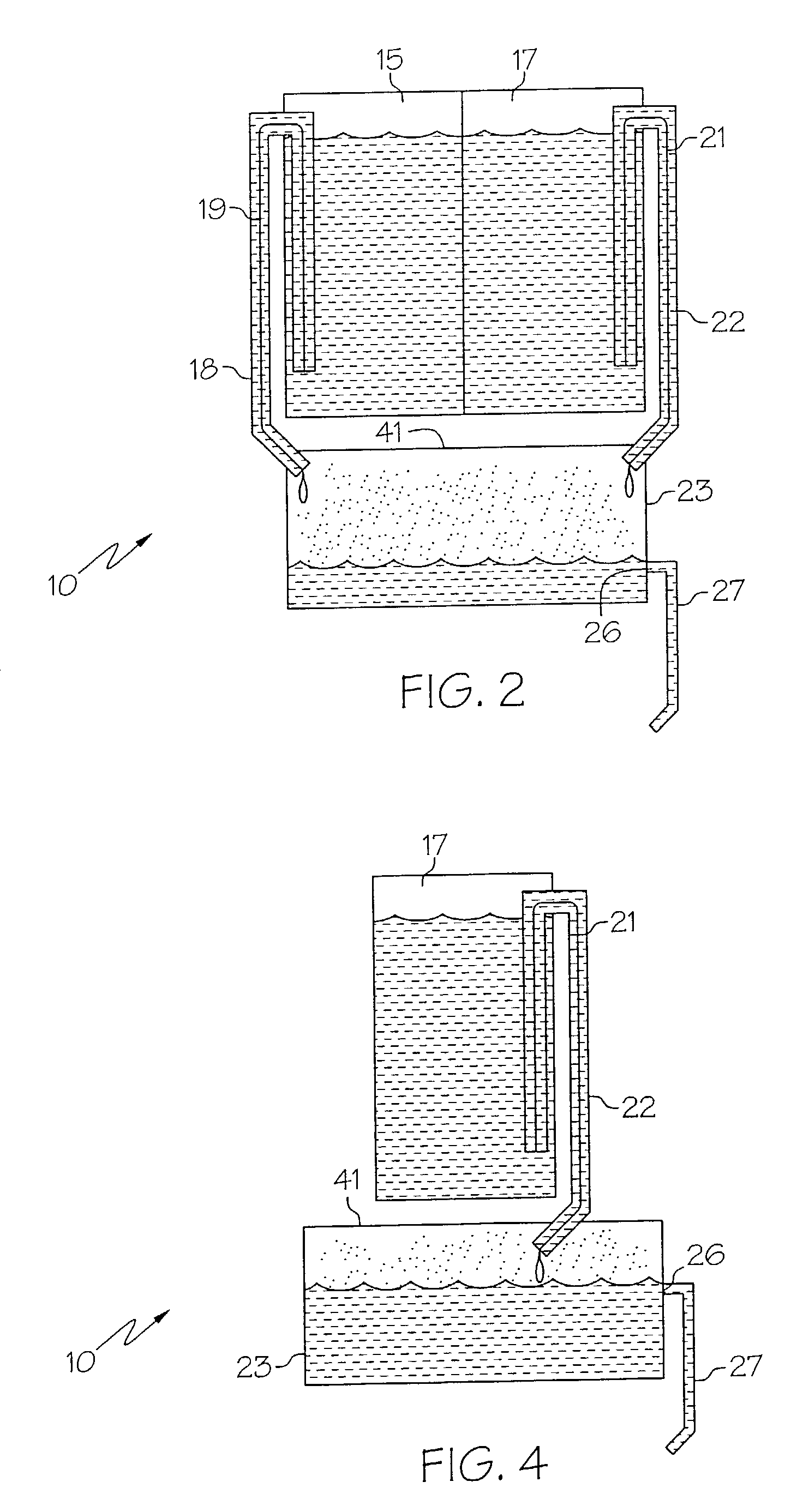

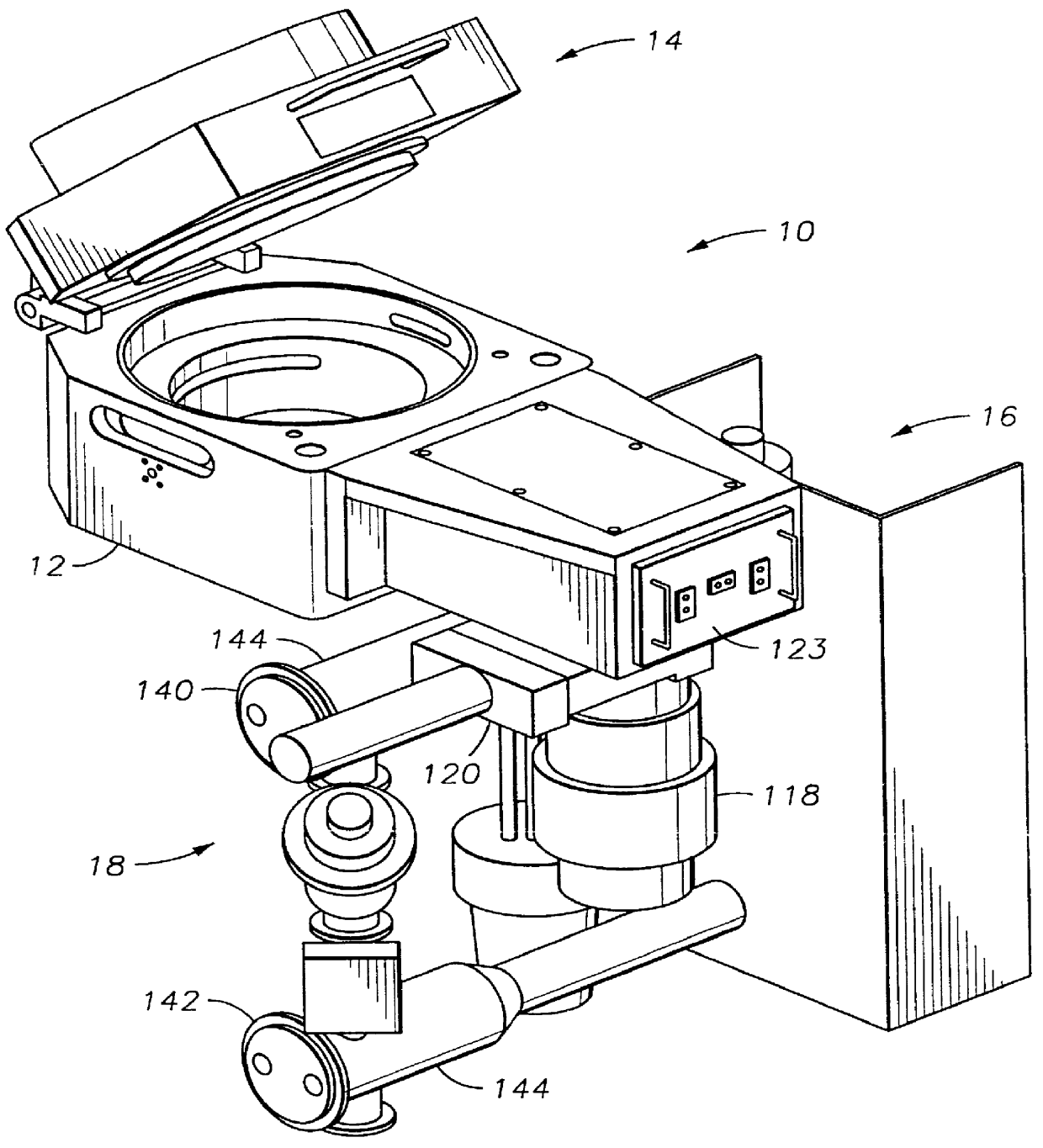

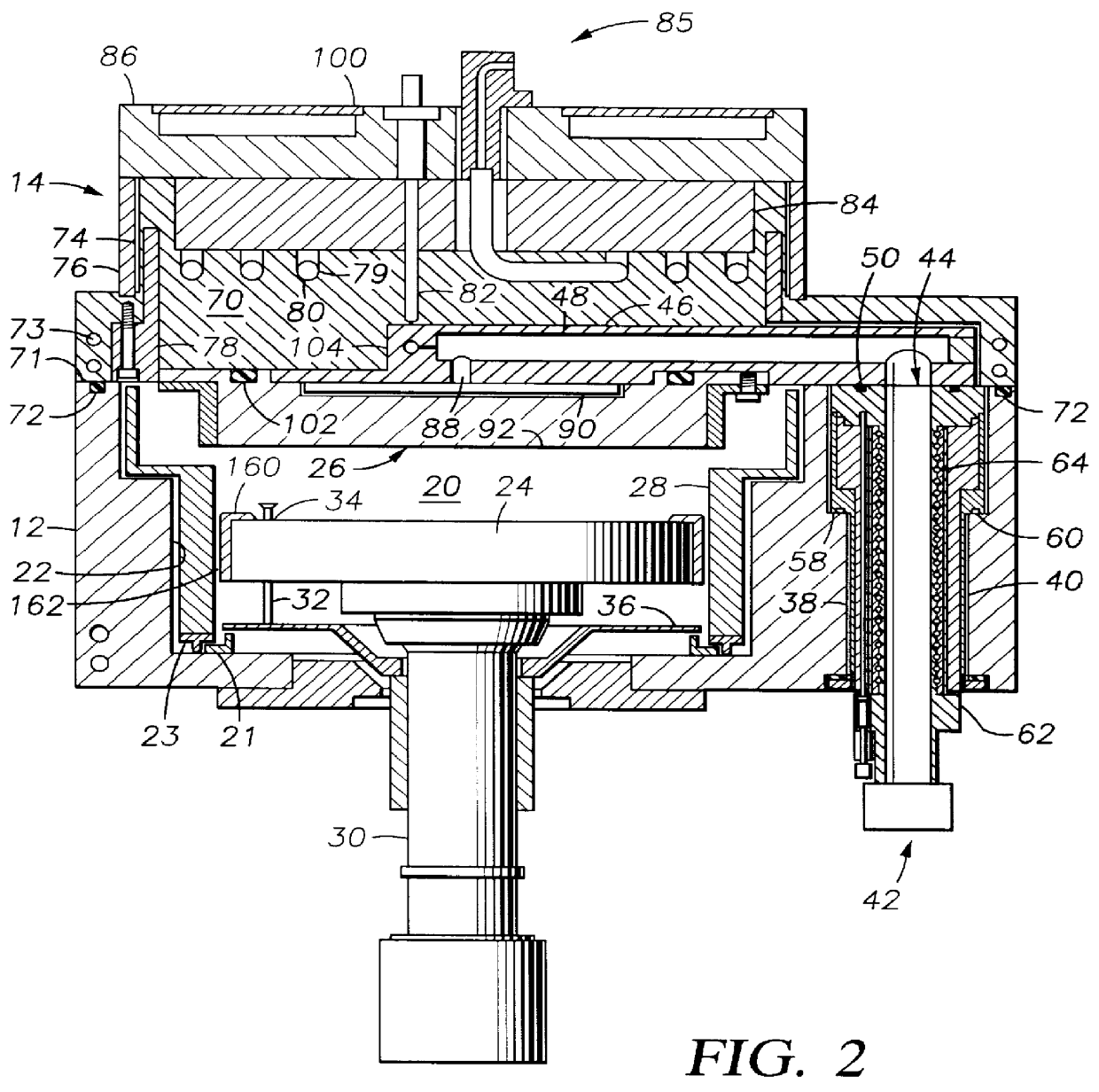

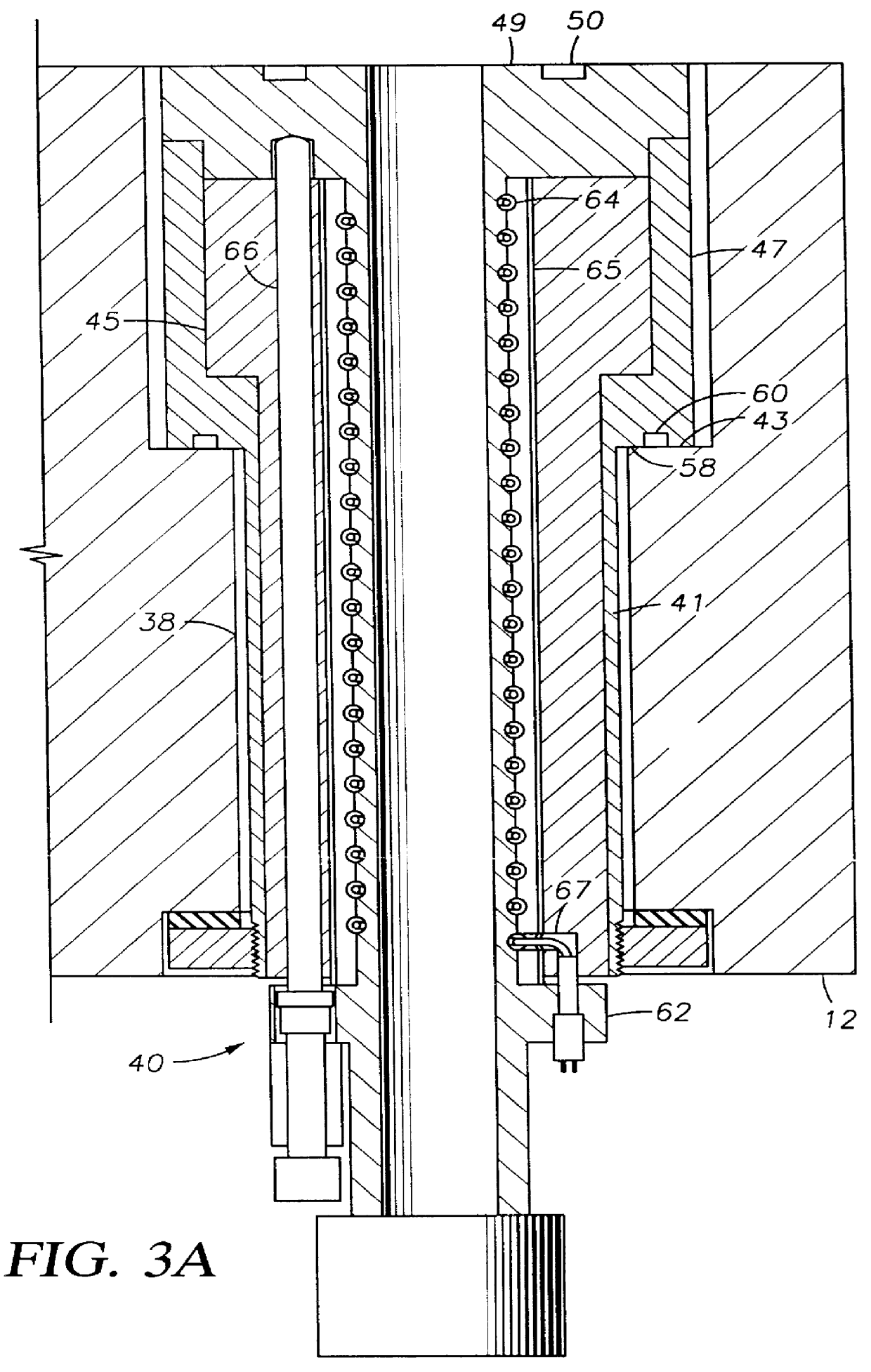

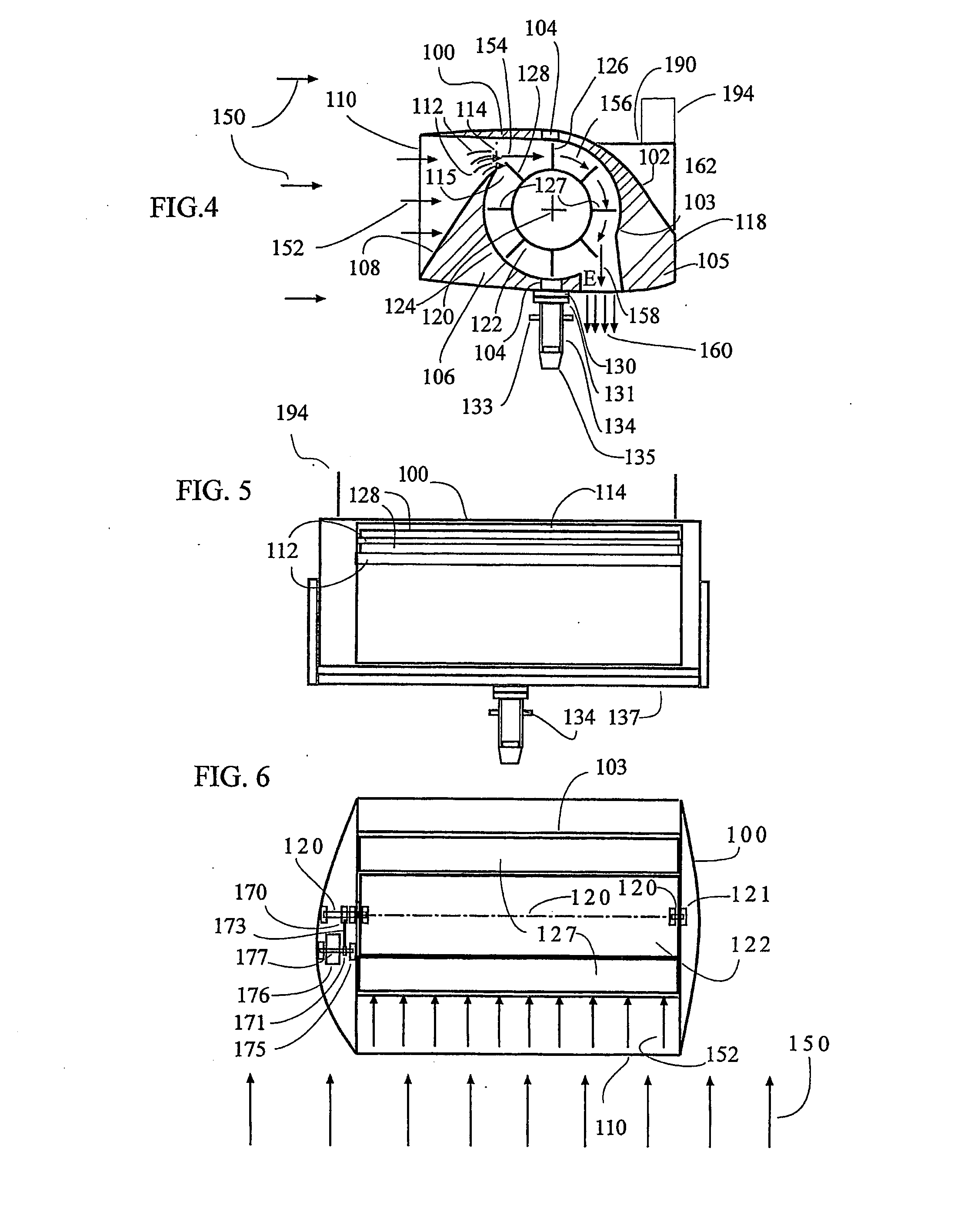

Sterilization container

InactiveUS6217835B1Improve sterilizationMinimum amount of timeCapsDispensing apparatusEngineeringMedical instruments

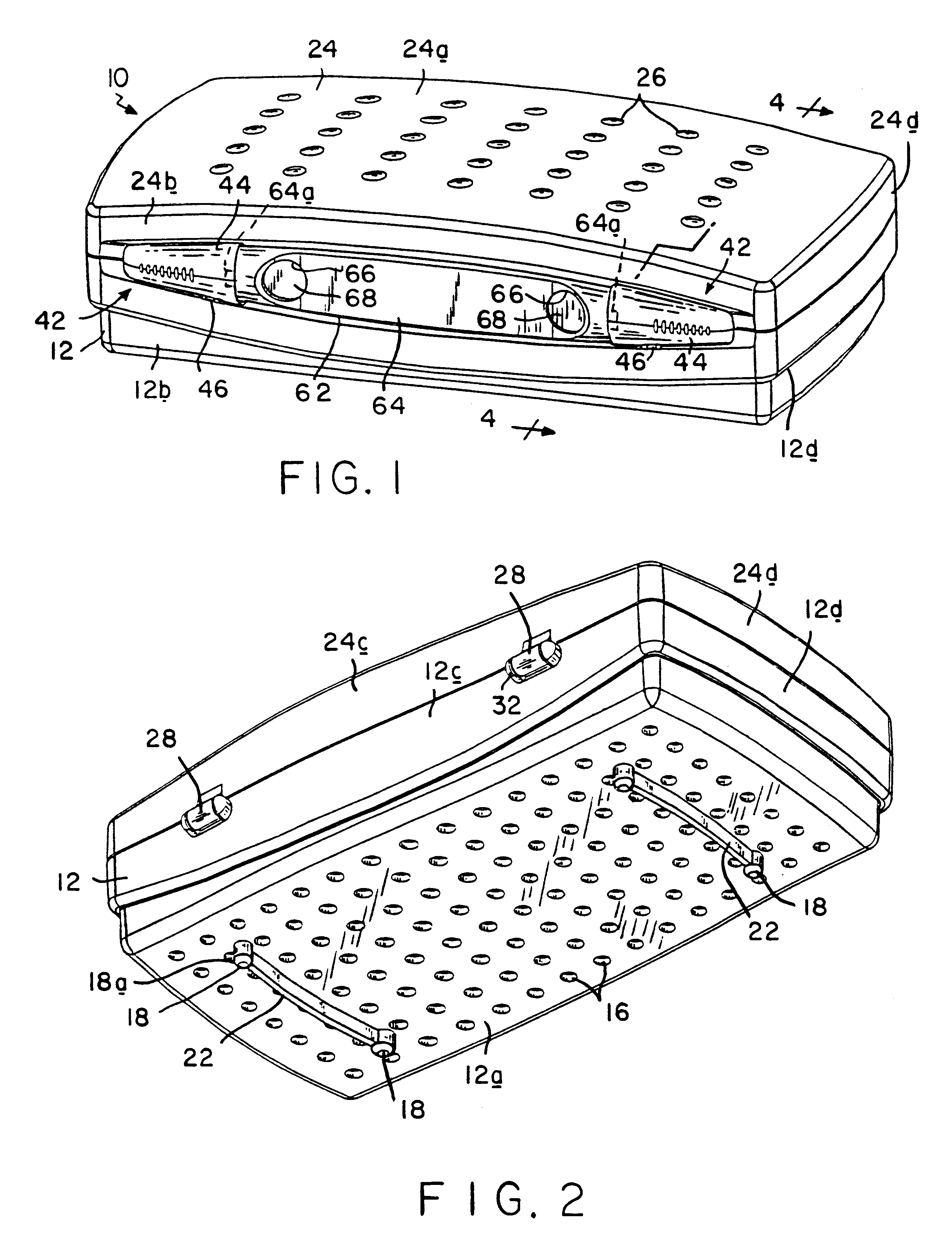

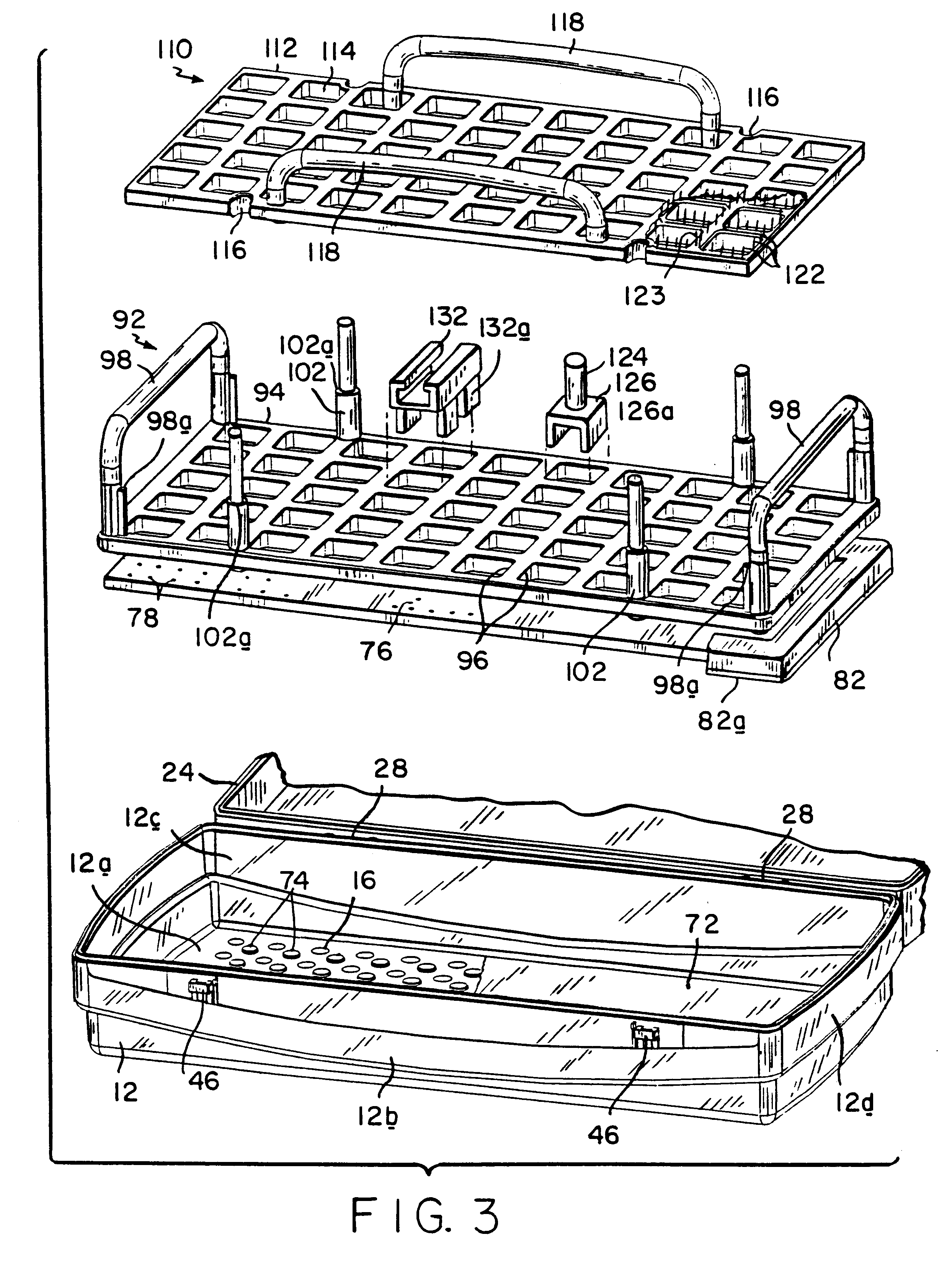

A sterilization container for medical instruments includes a receptacle with a bottom wall and an open top, there being a multiplicity of vent openings in the bottom wall. The receptacle has a cover movable between a closed position wherein the cover closes the open top of the receptacle and an open position wherein the cover is positioned to allow access to the interior of the receptacle. A filter sheet is positioned in the receptacle so as to cover the bottom wall and the vent openings therein and the receptacle contains one or more trays for supporting medical instruments above the filter sheet. A perforated highly thermally conductive plate is positioned between the trays and the filter sheet so that when steam enters the container through the vent openings during steam sterilization, it heats the plate to a temperature sufficient to revaporize steam condensate collecting on the plate. The internal structure of the container is also disclosed.

Owner:SYMMETRY MEDICAL MFG INC

Temperature controlled chamber liner

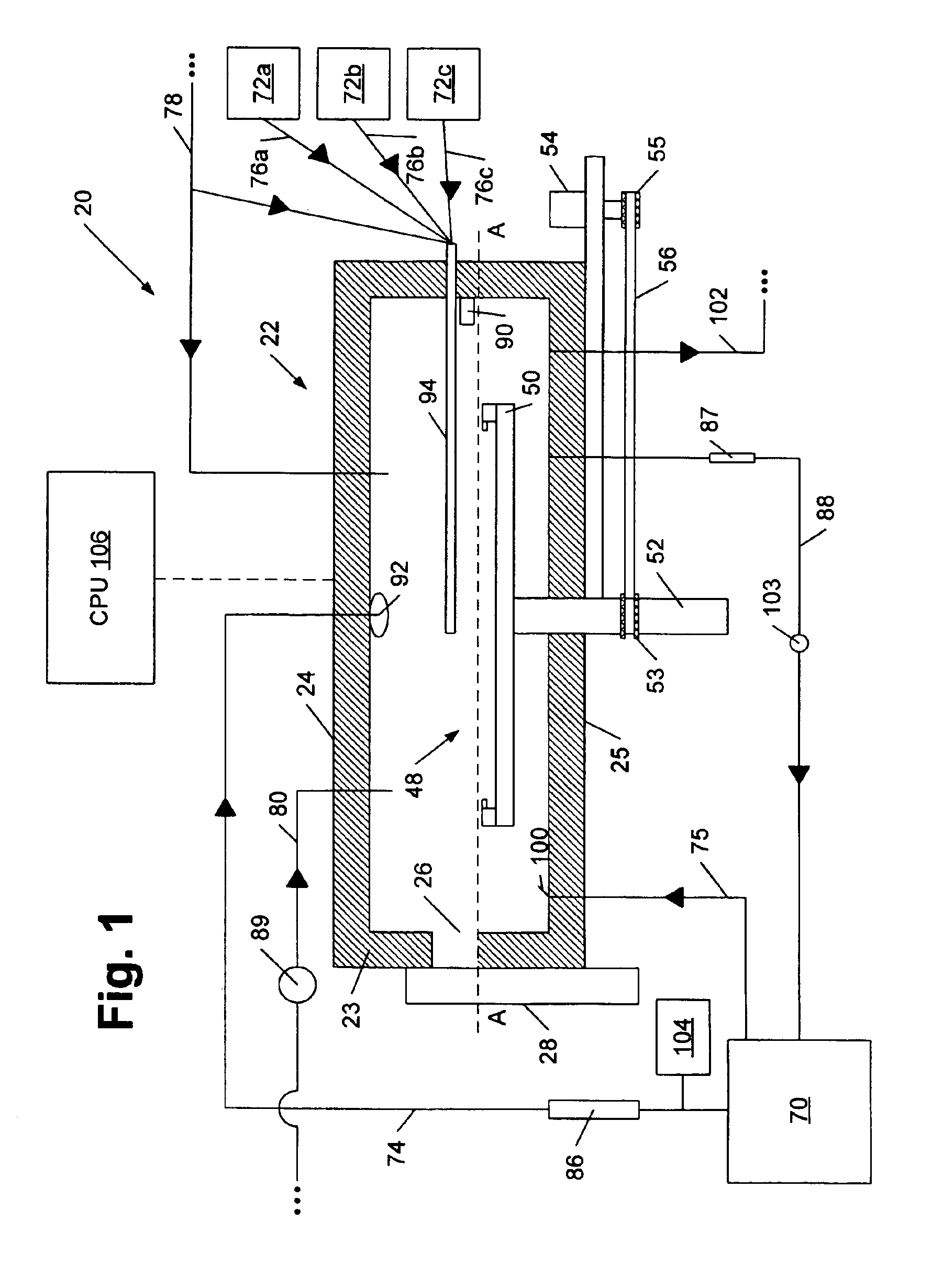

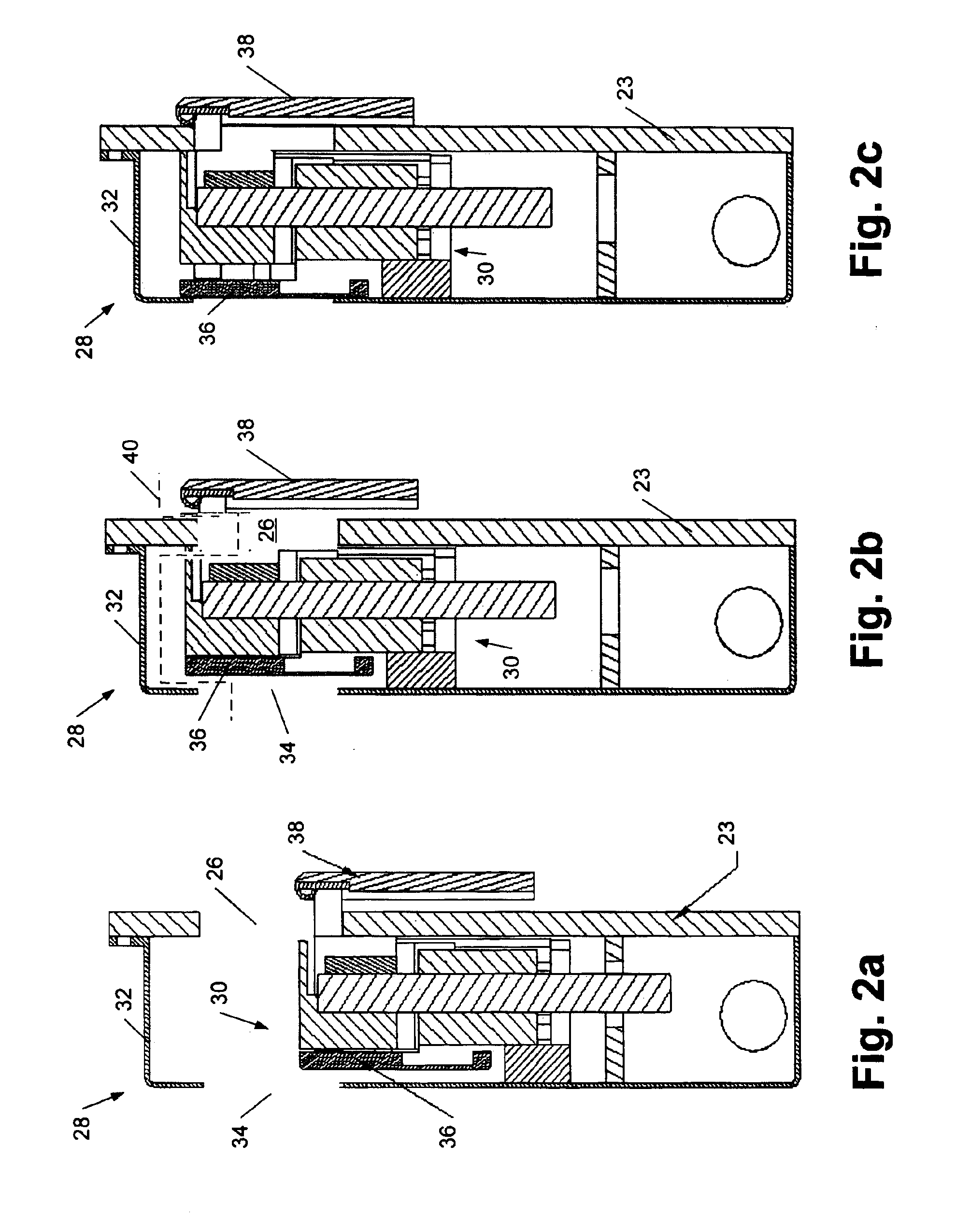

InactiveUS6099651APrevent unwanted condensationPrevent decomposition and condensationSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringTitanium oxide

The invention relates to an apparatus and process for the vaporization of liquid precursors and deposition of a film on a suitable substrate. Particularly contemplated is an apparatus and process for the deposition of a metal-oxide film, such as a barium, strontium, titanium oxide (BST) film, on a silicon wafer to make integrated circuit capacitors useful in high capacity dynamic memory modules.

Owner:APPLIED MATERIALS INC

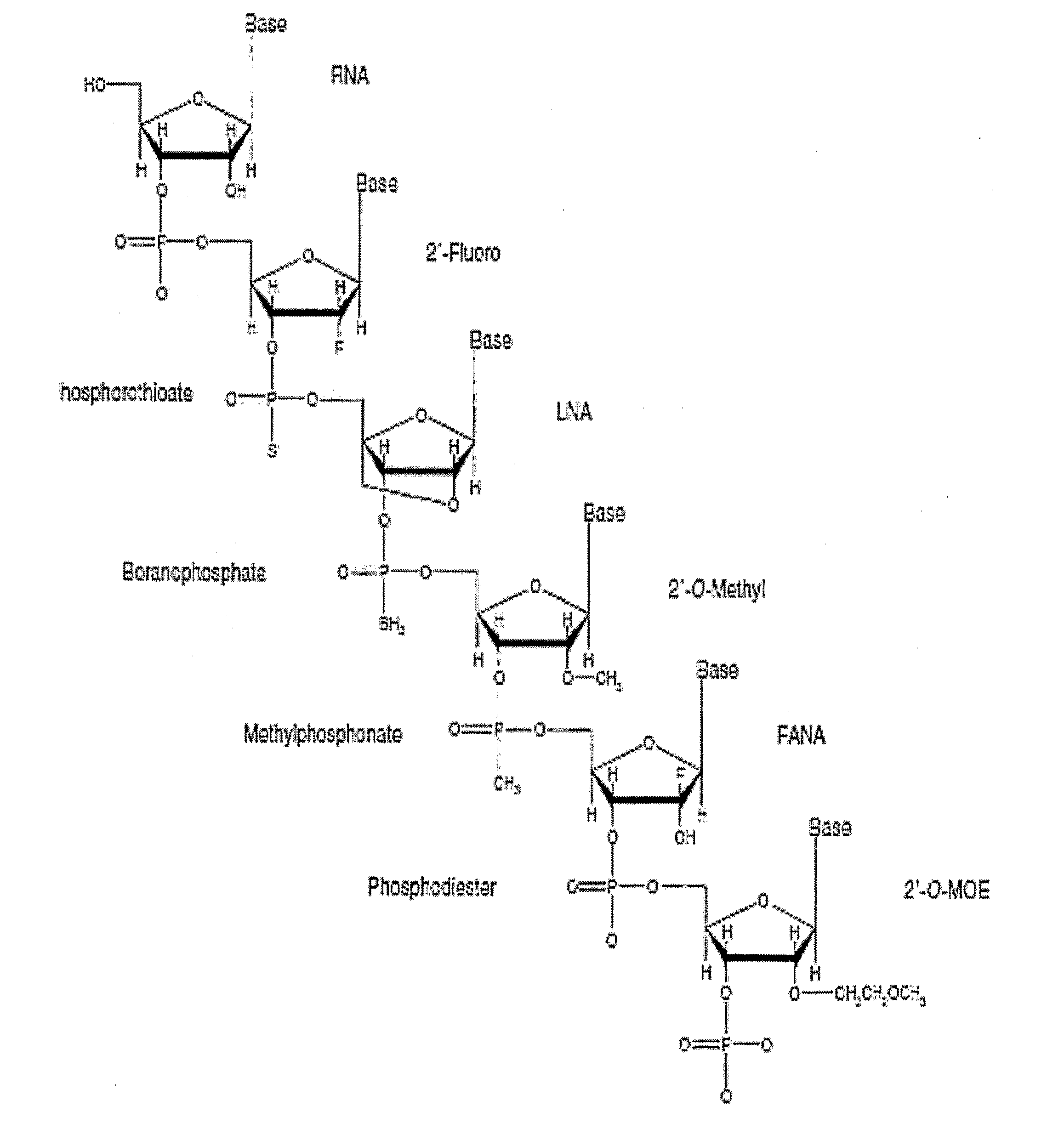

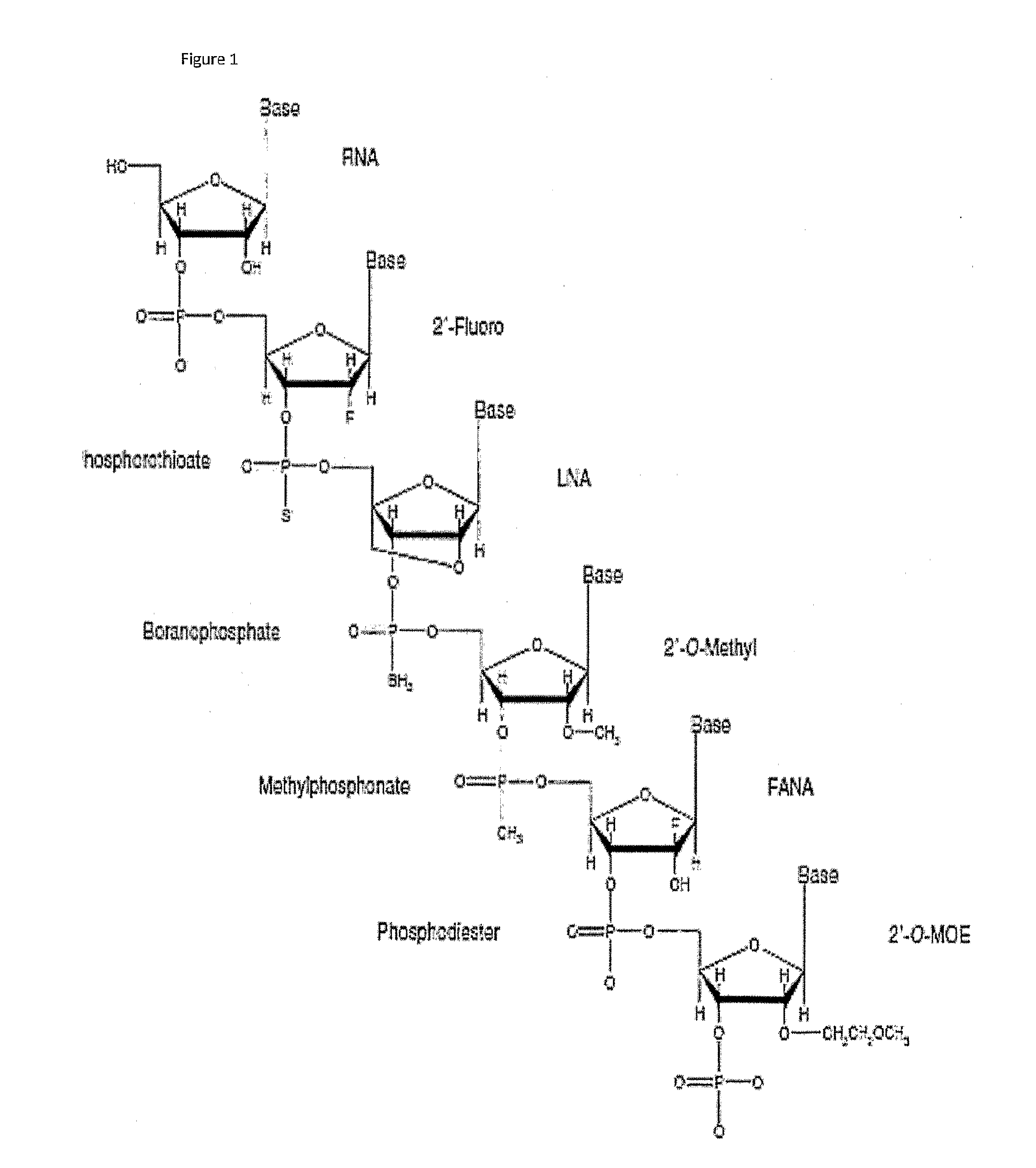

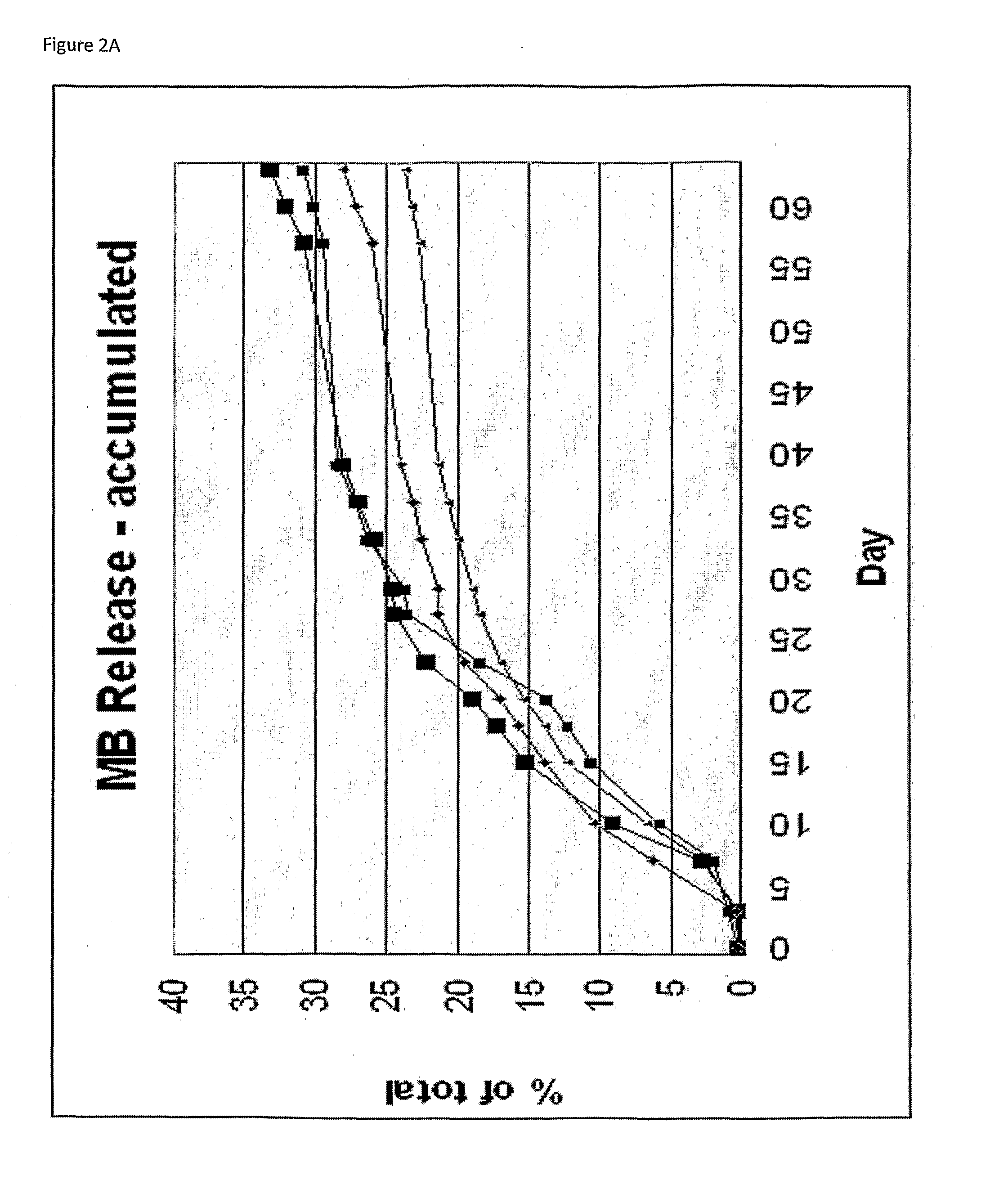

Methods, compositions and systems for local delivery of drugs

ActiveUS20110195123A1Reduce degradationImprove permeabilityBiocidePowder deliveryCell-Extracellular MatrixBrachytherapy

Implantable medical device eluting drug locally and in prolonged period is provided, including several types of such a device, the treatment modes of implementation and methods of implantation. The device comprising of polymeric substrate, such as a matrix for example, that is used as the device body, and drugs, and in some cases additional scaffolding materials, such as metals or additional polymers, and materials to enhance visibility and imaging. The selection of drug is based on the advantageous of releasing drug locally and in prolonged period, where drug is released directly to the extracellular matrix (ECM) of the diseased area such as tumor, inflammation, degeneration or for symptomatic objectives, or to injured smooth muscle cells, or for prevention. One kind of drug is the gene silencing drugs based on RNA interference (RNAi), including but not limited to si RNA, sh RNA, or antisense RNA / DNA, ribozyme and nucleoside analogs. The modes of implantation in some embodiments are existing implantation procedures that are developed and used today for other treatments, including brachytherapy and needle biopsy. In such cases the dimensions of the new implant described in this invention are similar to the original implant. Typically a few devices are implanted during the same treatment procedure.

Owner:SILENSEED LTD

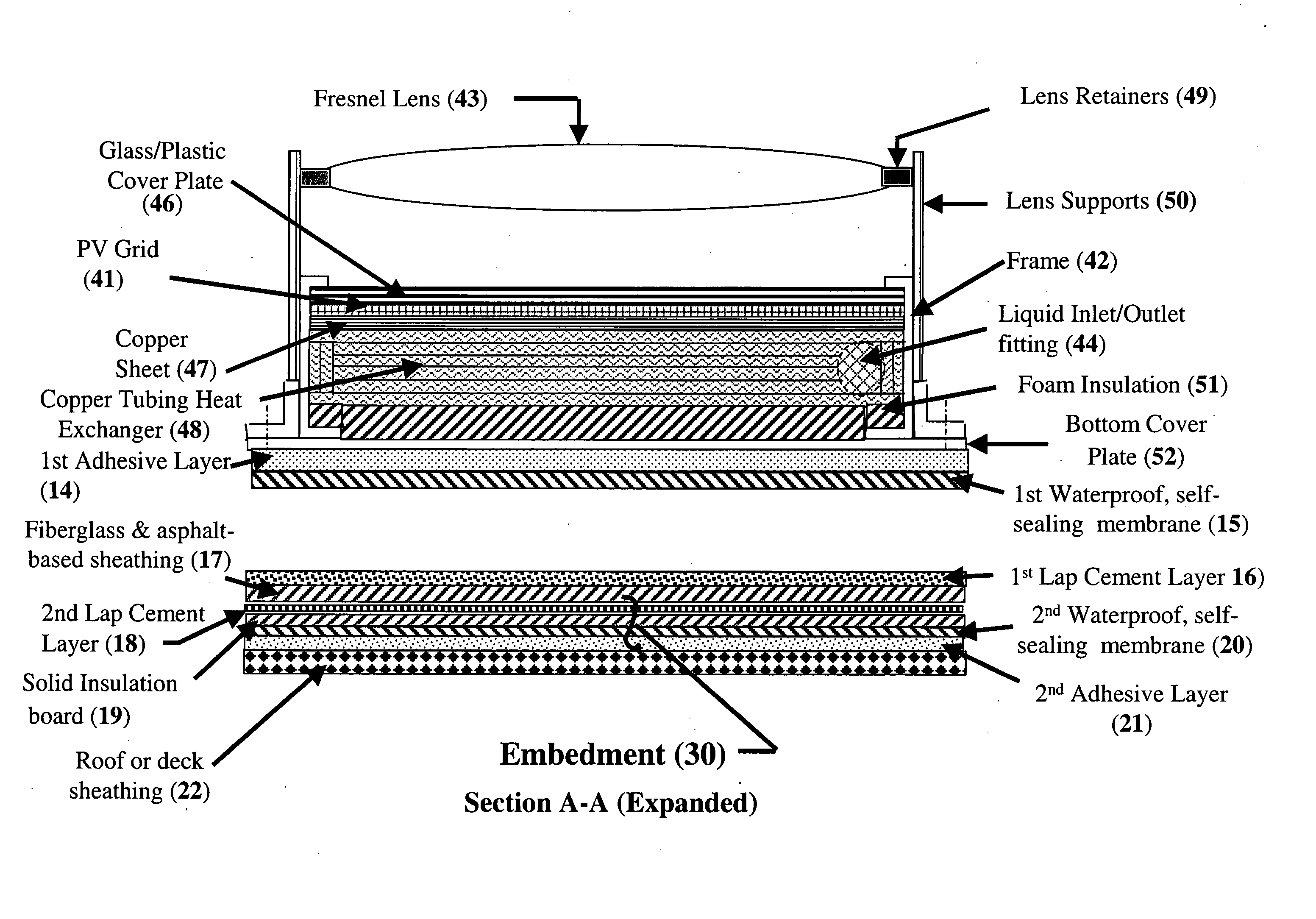

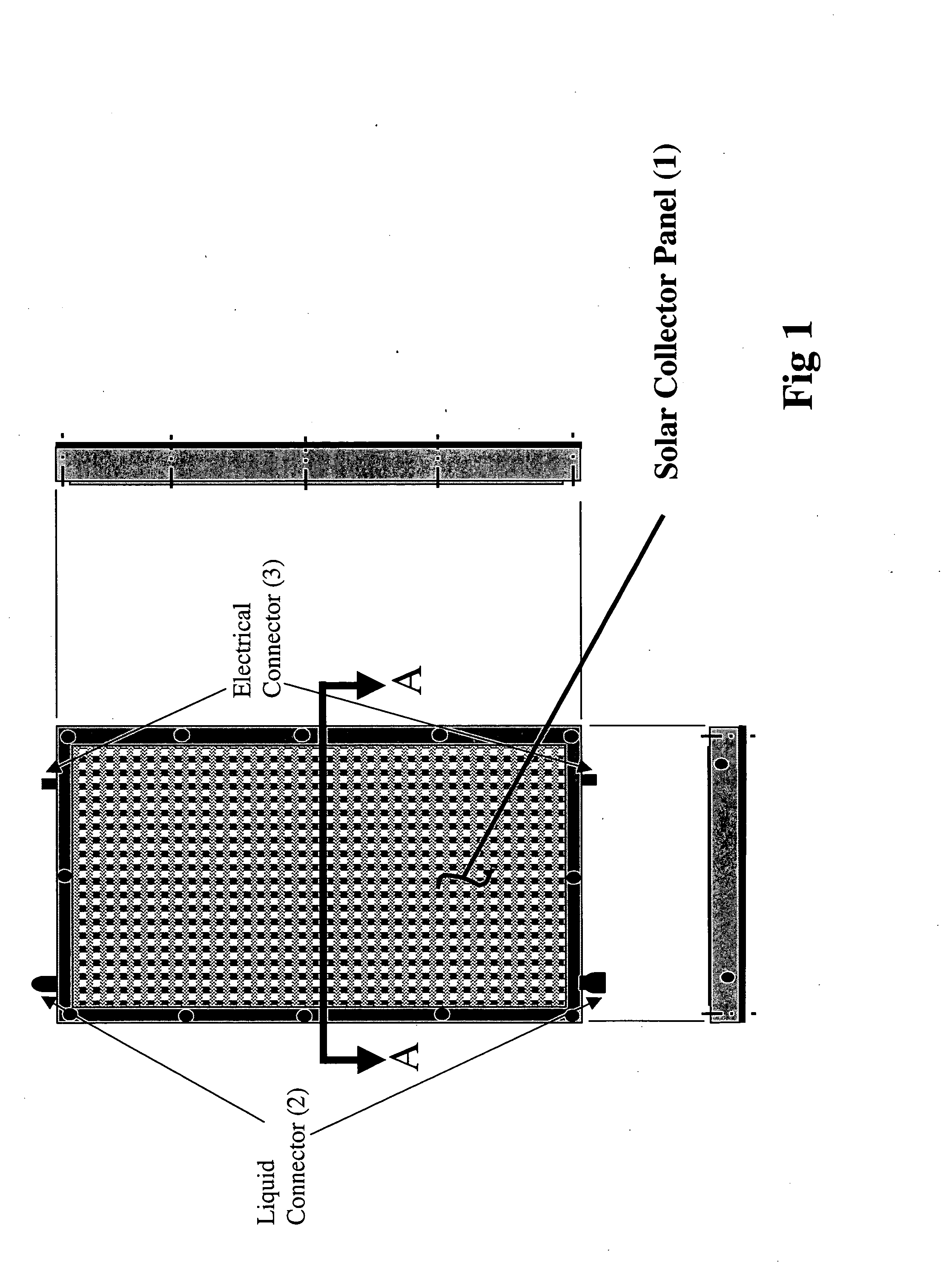

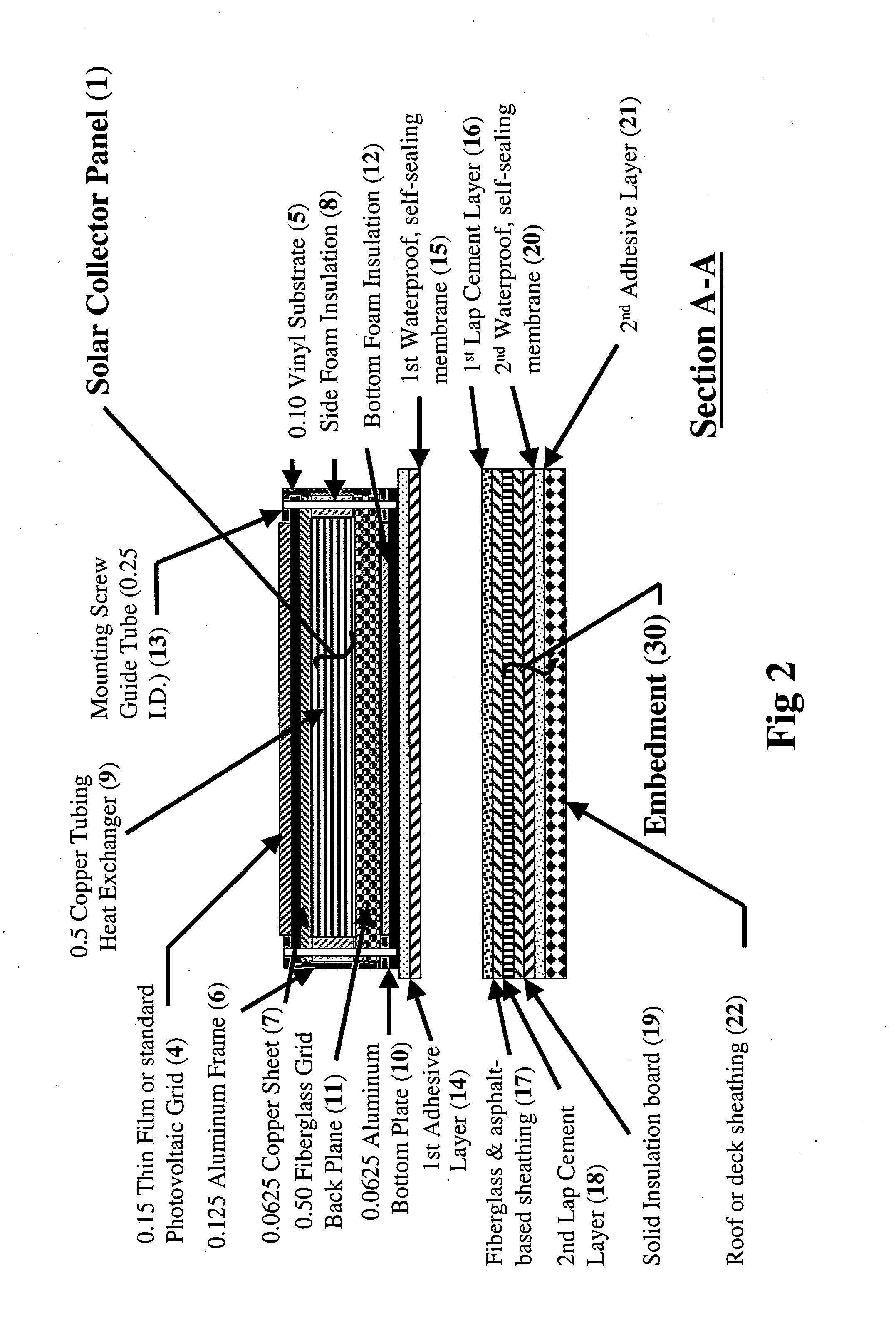

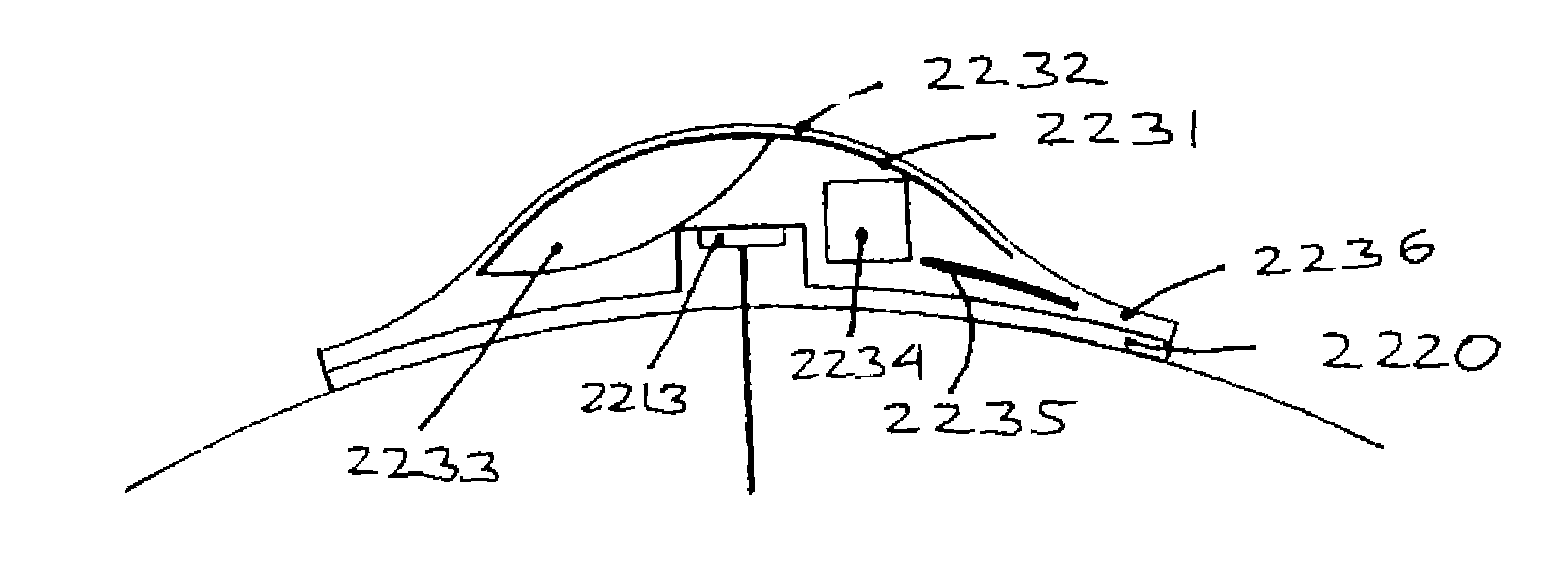

Integrated solar energy roofing construction panel

InactiveUS20050133082A1Reduce installation costsLabor savingSolar heating energySolar heat devicesThermal energyEngineering

A solar assembly comprising two components: a multi-functional solar collecting apparatus and a mounting embedment integrated with building construction material. The mounting embedment component is affixed to a building frame structure using standard construction techniques and receives the multi-functional solar collecting apparatus that is secured with fasteners. The multi-functional solar collecting apparatus converts solar energy to electrical energy using a photovoltaic grid mounted on a copper plate that provides even temperature dispersion across the plate and acts as a thermal radiator when the apparatus is used as a radiant cooler; and a plurality of interconnected heat transfer tubes located within the apparatus enclosure disposed on the plane below the copper plate but conductively coupled to the copper plate for converting the solar energy to thermal energy in a fluid disposed within the heat transfer tubes.

Owner:KONOLD ANNEMARIE HVISTENDAHL +1

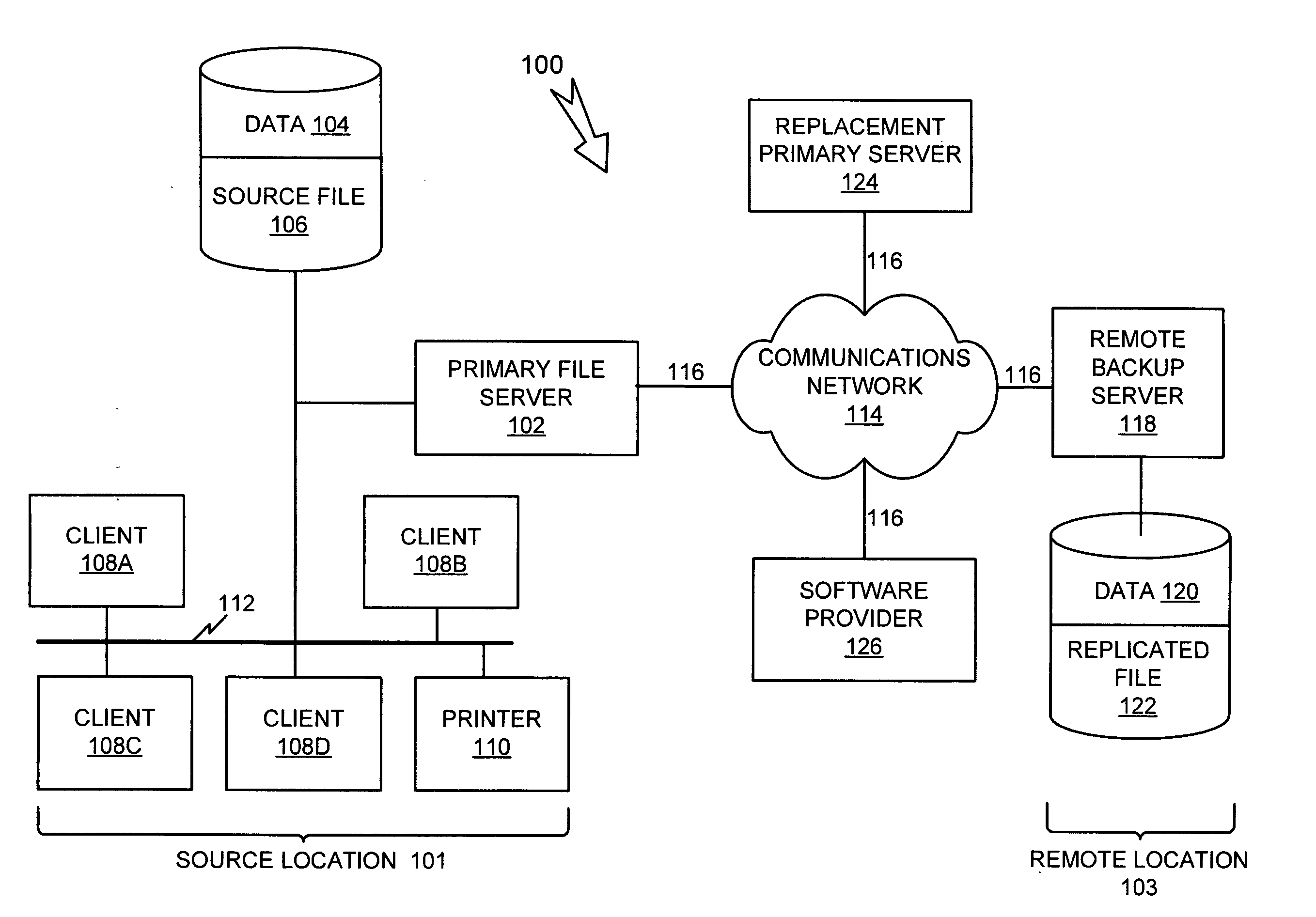

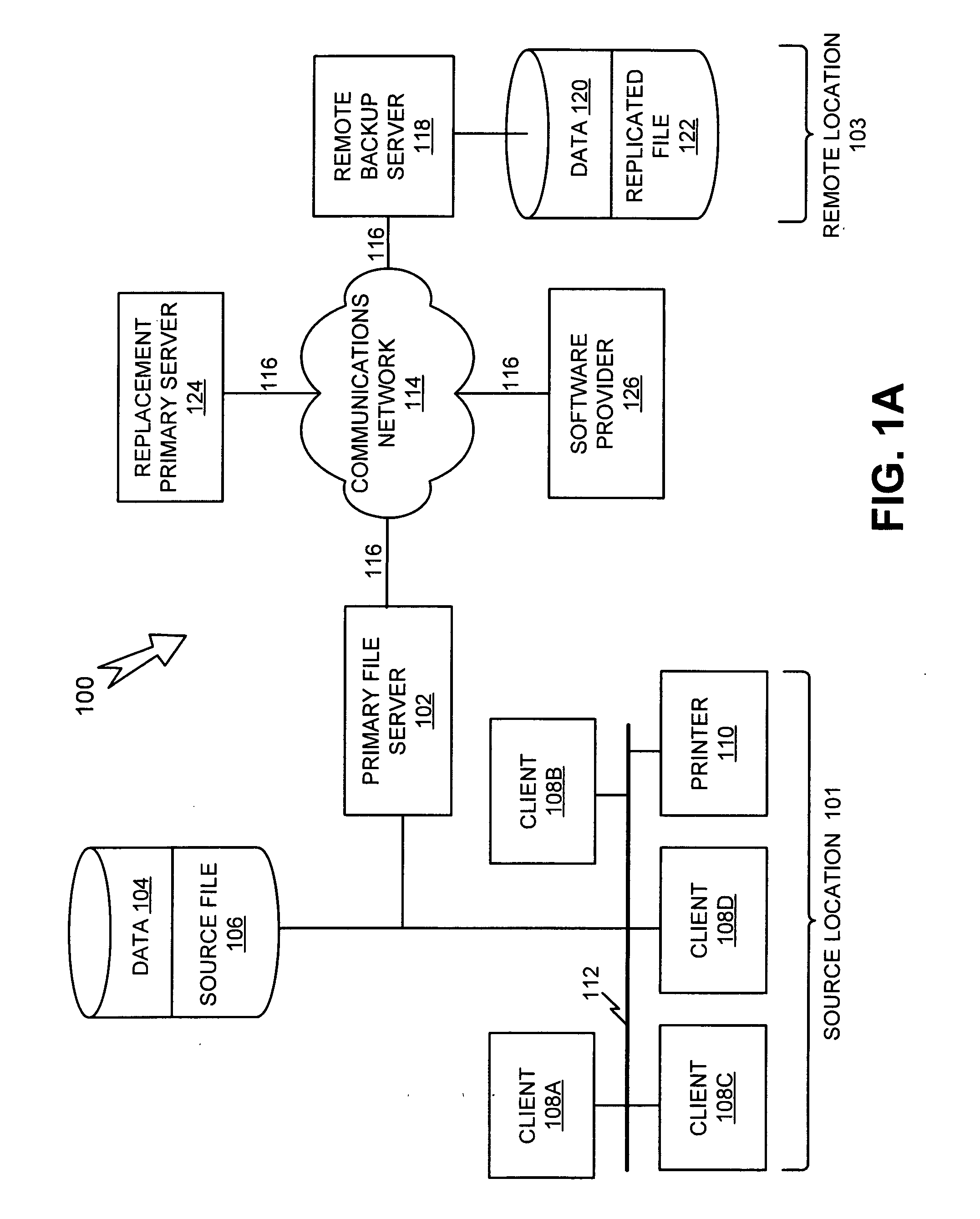

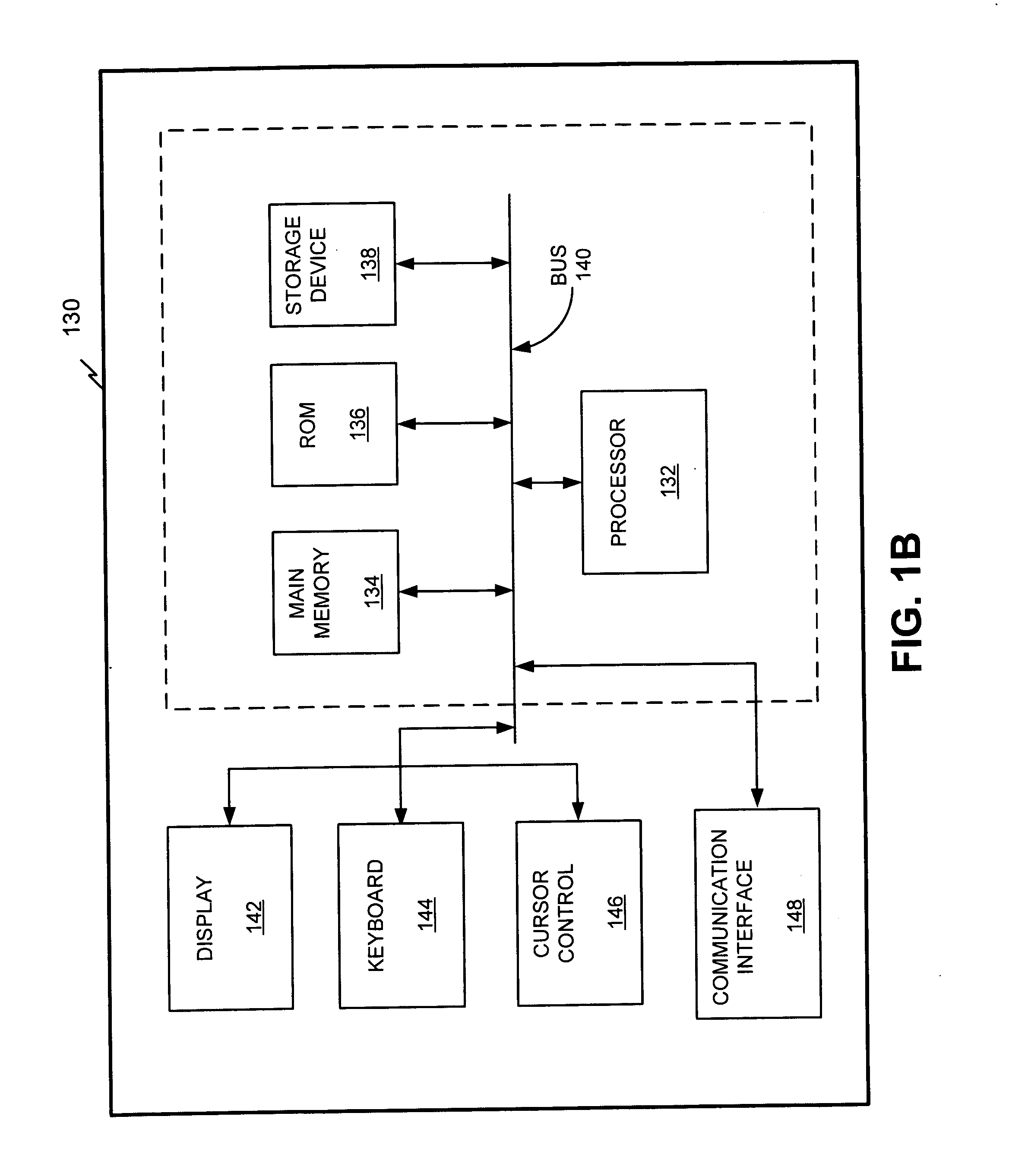

System and method for replicating files in a computer network

ActiveUS20050177603A1Facilitate substantially real-time synchronizationEfficient use ofError detection/correctionSpecial data processing applicationsReal-time dataTerm memory

A system and method for performing real-time replication of data across a network is provided. A mirroring engine receives a write request from a host application operating on a source computer. The mirroring engine compares data in the write request with corresponding data stored in memory. If data in the write request differs from stored data, the mirroring engine processes the write request. Processing involves computing a data signature across data in the write request and associating the signature with a transaction number and a status byte. The transaction number is used to uniquely identify the data signature and can be used to ensure that the signature is properly handled if it is received, for example, out of order. The status byte contains information used for handling the data signature and transaction number as well as information identifying how the data signature was computed. In an embodiment, the status byte may contain a bit for identifying if the data signature was computed across an entire block of data or if the signature was computed over only a portion of a data block, such as for example, only data bytes that have changed as compared with those in the stored data. Processing may further include compressing and encrypting the data signature, transaction number and status byte prior to transmission over a network. Embodiments may further employ a meta-file for storing data signatures, transaction numbers, status bytes, and other information useful for performing real-time data replication over a network.

Owner:GLOBALSCAPE

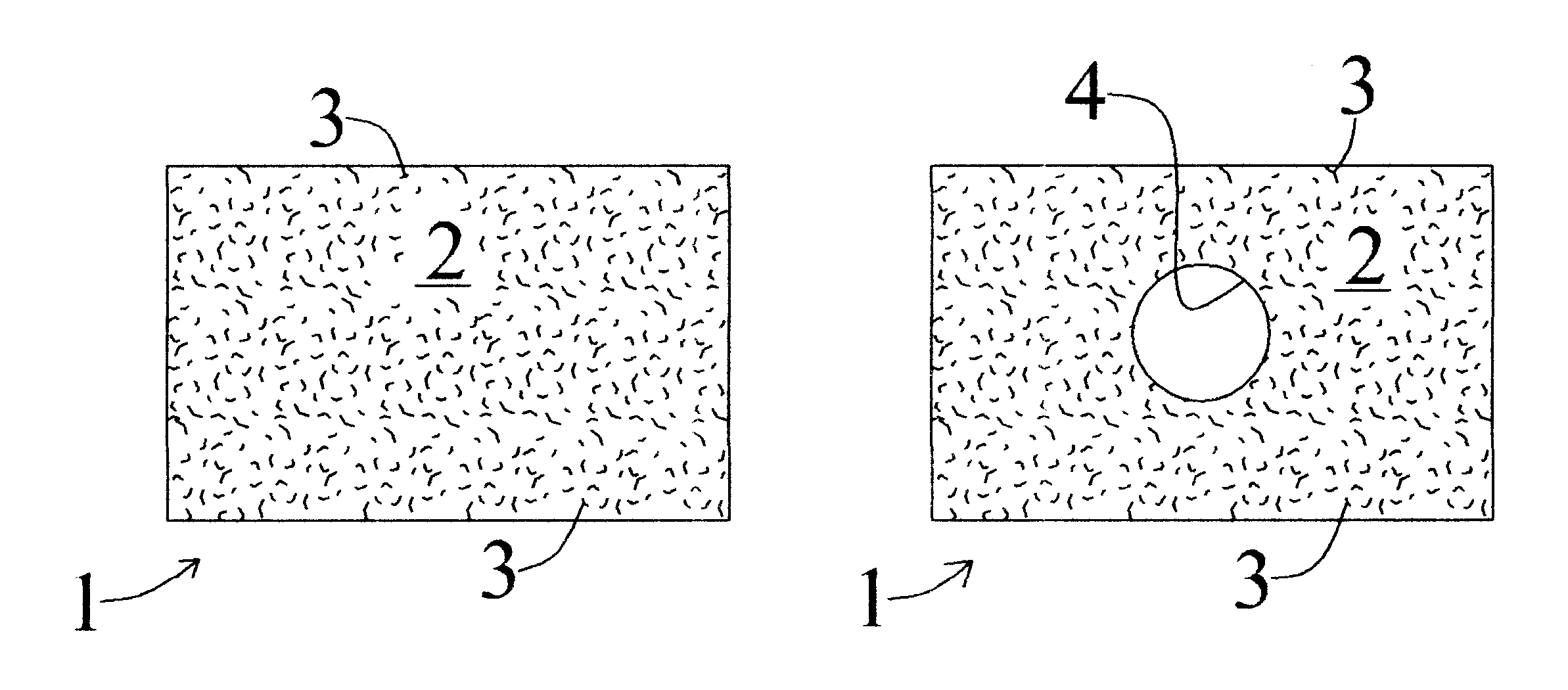

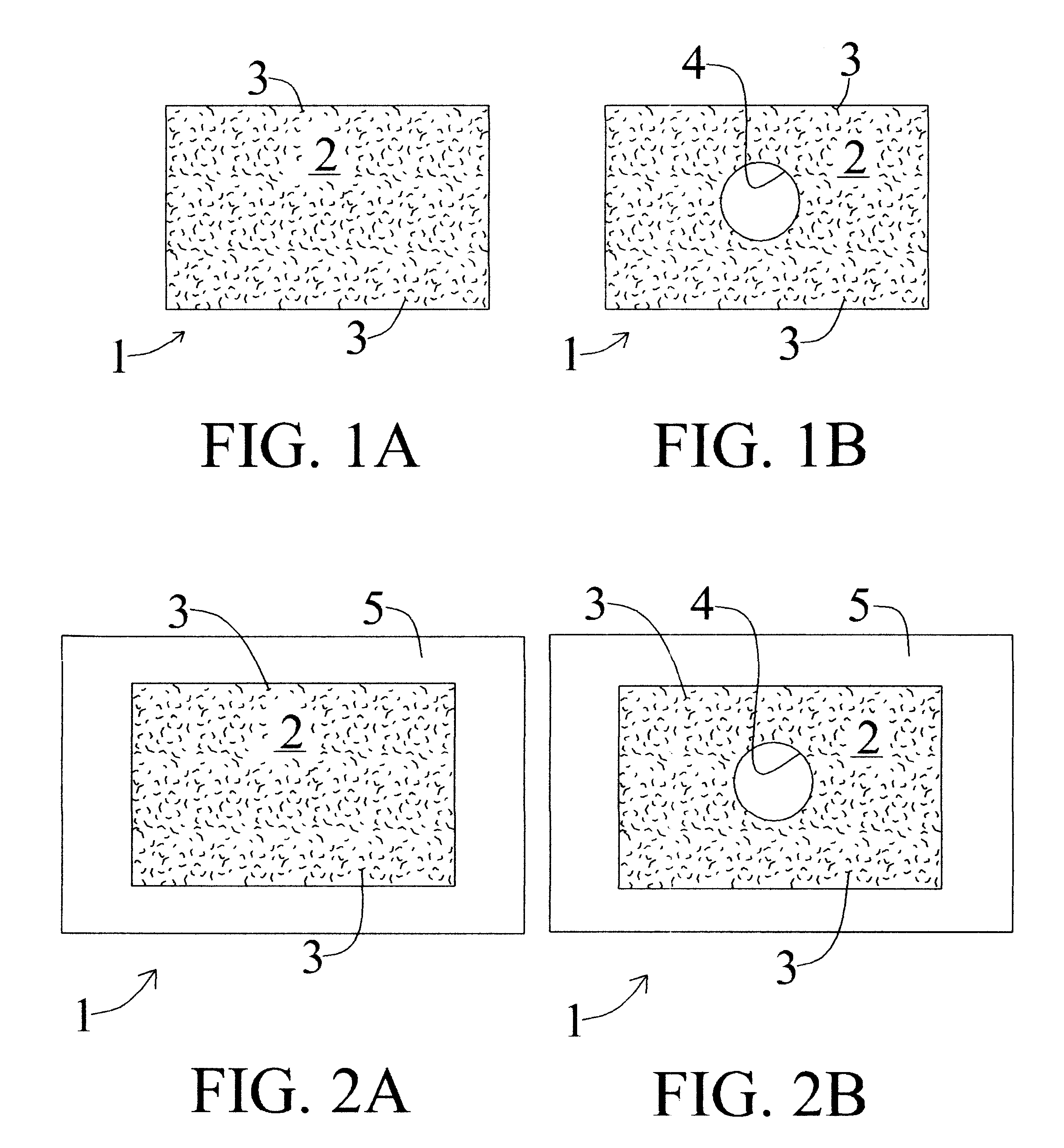

Nucleic acid analysis device

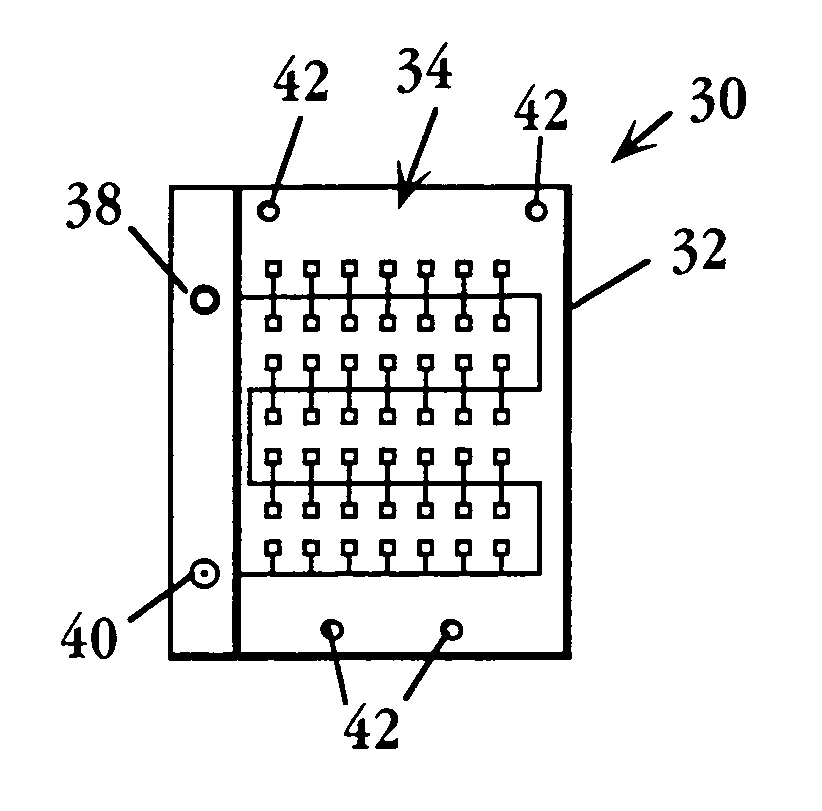

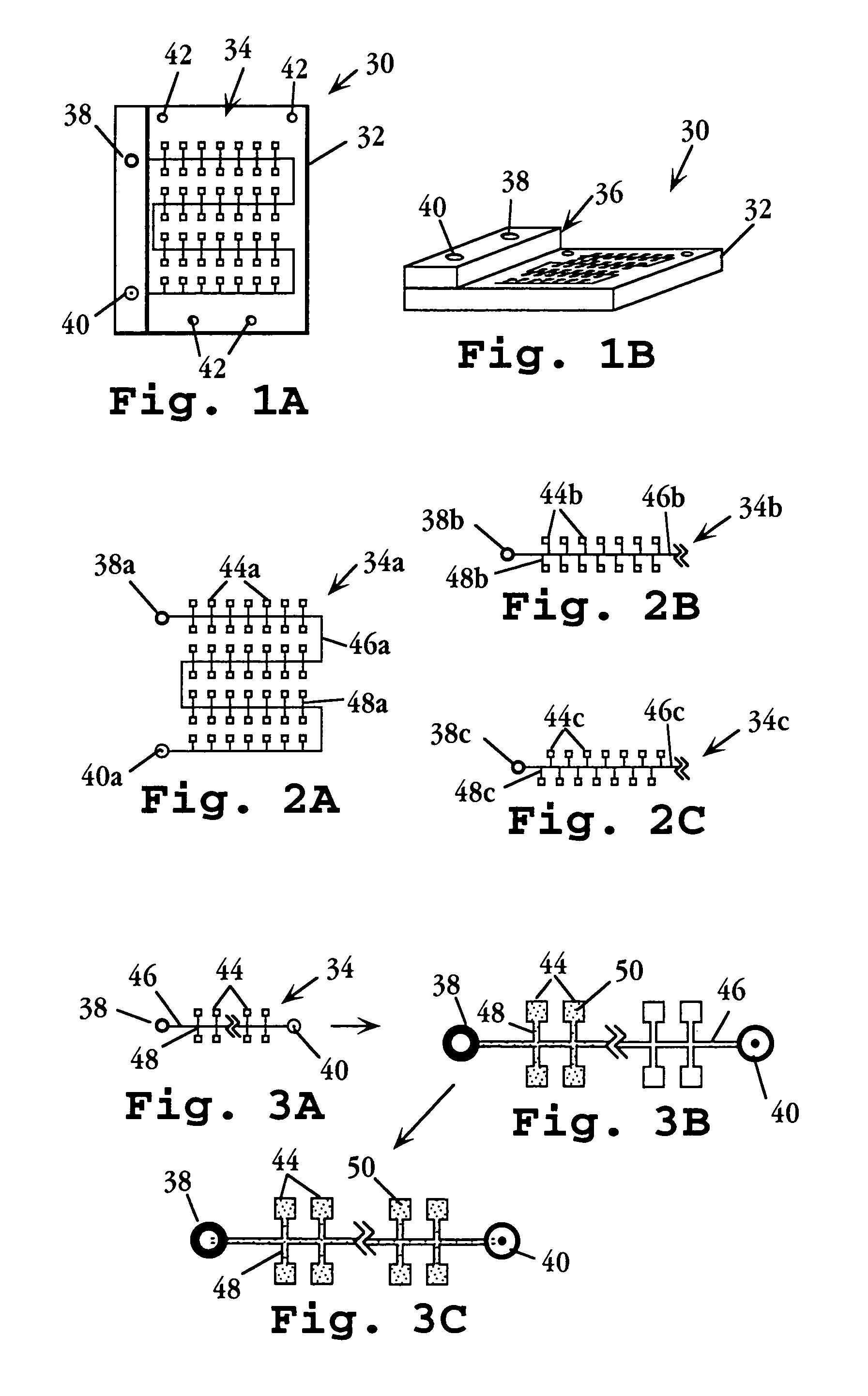

InactiveUS7235406B1Avoid accumulationEnough timeBioreactor/fermenter combinationsBiological substance pretreatmentsAnalyteAnalyte-specific reagent

The invention is directed to a method and device for simultaneously testing a sample for the presence, absence, and / or amounts of one or more a plurality of selected analytes. The invention includes, in one aspect, a device for detecting or quantitating a plurality of different analytes in a liquid sample. The device includes a substrate which defines a sample-distribution network having (i) a sample inlet, (ii) one or more detection chambers, and (iii) channel means providing a dead-end fluid connection between each of the chambers and the inlet. Each chamber may include an analyte-specific reagent effective to react with a selected analyte that may be present in the sample, and detection means for detecting the signal. Also disclosed are methods utilizing the device.

Owner:APPL BIOSYSTEMS INC

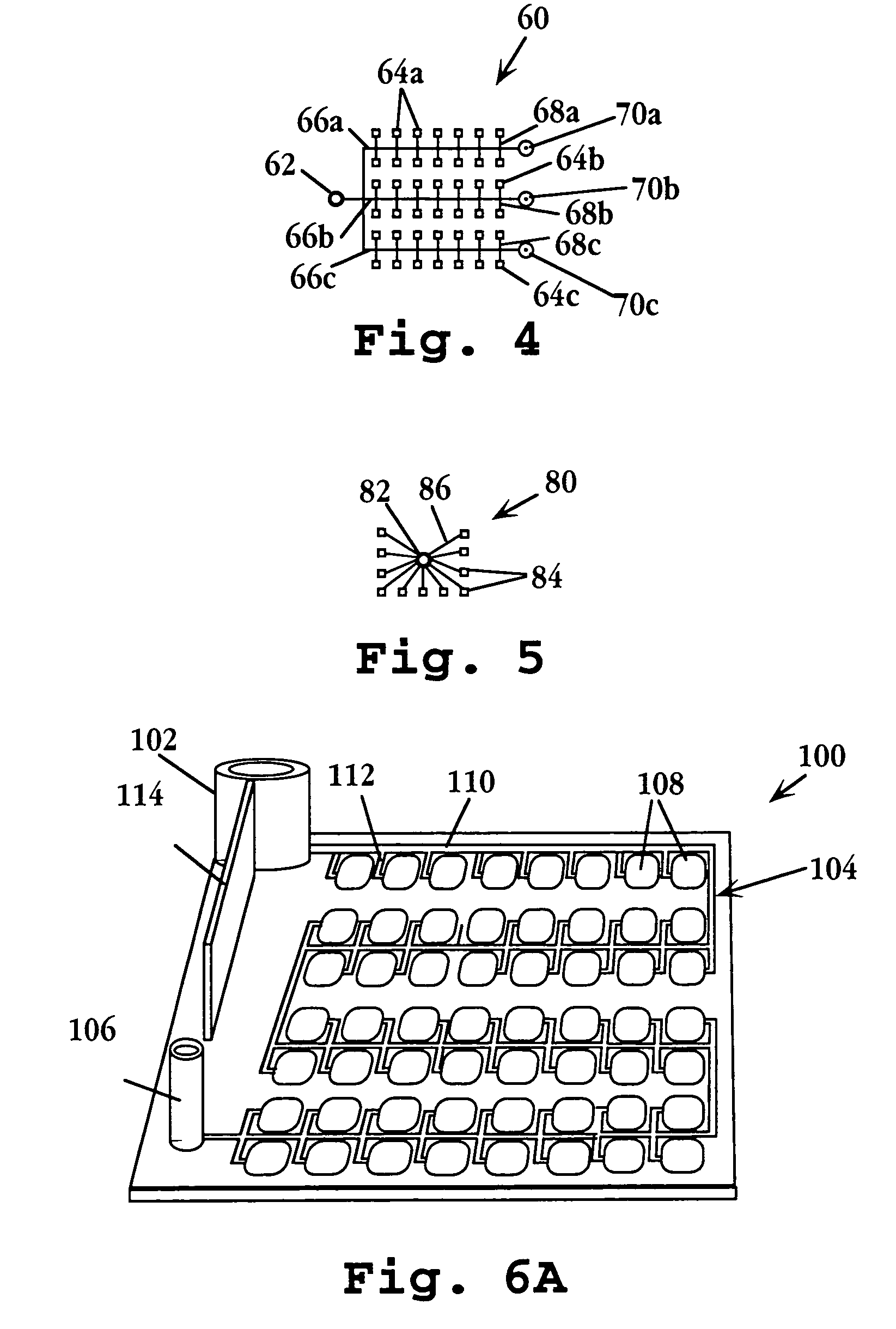

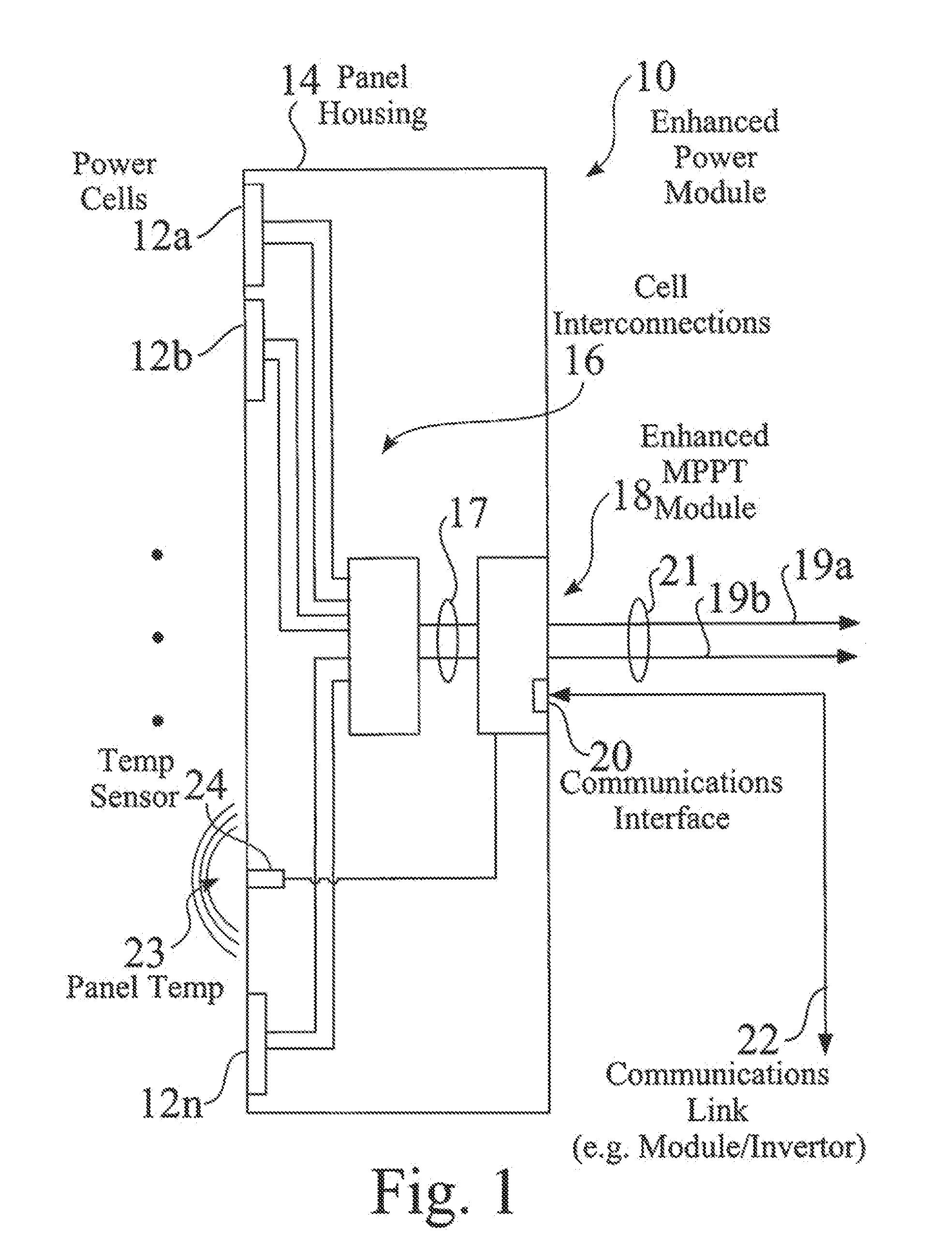

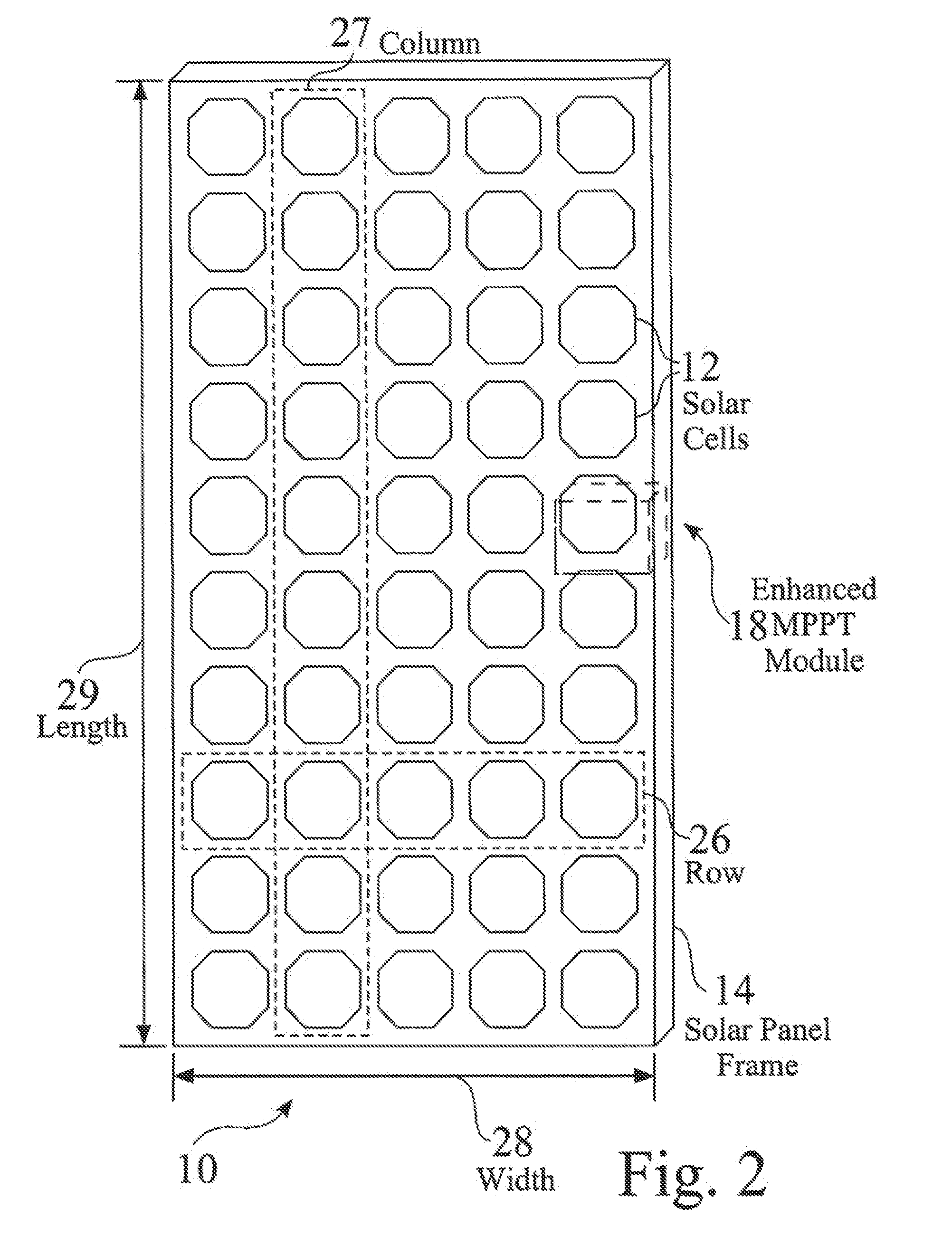

Enhanced solar panels, liquid delivery systems and associated processes for solar energy systems

ActiveUS20120138123A1Avoid accumulationReduce lossesSolar heating energyPhotovoltaic monitoringControl systemFiltration

Fluid delivery systems and related structures and processes are provided, such as for use with water, treated water, and / or a cleaning solution, for any of cleaning, cooling or any combination thereof, for one or more solar panels in a power generation environment. Enhanced coatings are provided for the incident surface of solar panels, such as to avoid build up of dirt, scale, or other contaminants, and / or to improve cleaning performance. Reclamation, filtration, and reuse structures are preferably provided for the delivered fluid, and seal structures may preferably be implemented between adjoining panels, to minimize loss of the delivered water or cleaning solution. The fluid delivery system may preferably be linked to an automated control system, such as but not limited to integrated DMPPT modules and related systems.

Owner:ACCURATE SOLAR POWER LLC

Semiconductor device and IC label, IC tag, and IC card having the same

ActiveUS20070285246A1Power shortageDeterioration over time of battery can be preventedNear-field transmissionBatteries circuit arrangementsEngineeringPower circuits

The present invention provides a power supply circuit provided with a battery as a power source for supplying power to an RFID, and the battery of the power supply circuit is charged with a wireless signal. Then, a switching circuit is provided in the power supply circuit that supplies power to a signal control circuit which transmits and receives individual information to and from the outside to intermittently control supply of power to the signal control circuit by a signal from a low-frequency signal generation circuit.

Owner:SEMICON ENERGY LAB CO LTD

Multilayer plastic composition having an electrically conductive inner layer

InactiveUS6090459AAvoid disadvantagesAvoid accumulationSynthetic resin layered productsCeramic shaping apparatusMobile vehicleFiber

A multilayer plastic composition having (I) an outer layer of a thermoplastic molding composition and (II) an inner layer of an electrically conductive thermoplastic molding composition containing graphite fibrils, which are useful for the transport of (petro)chemical materials and also in the motor vehicle sector for conveying brake, cooling and hydraulic fluid and also fuel.

Owner:EVONIK DEGUSSA GMBH

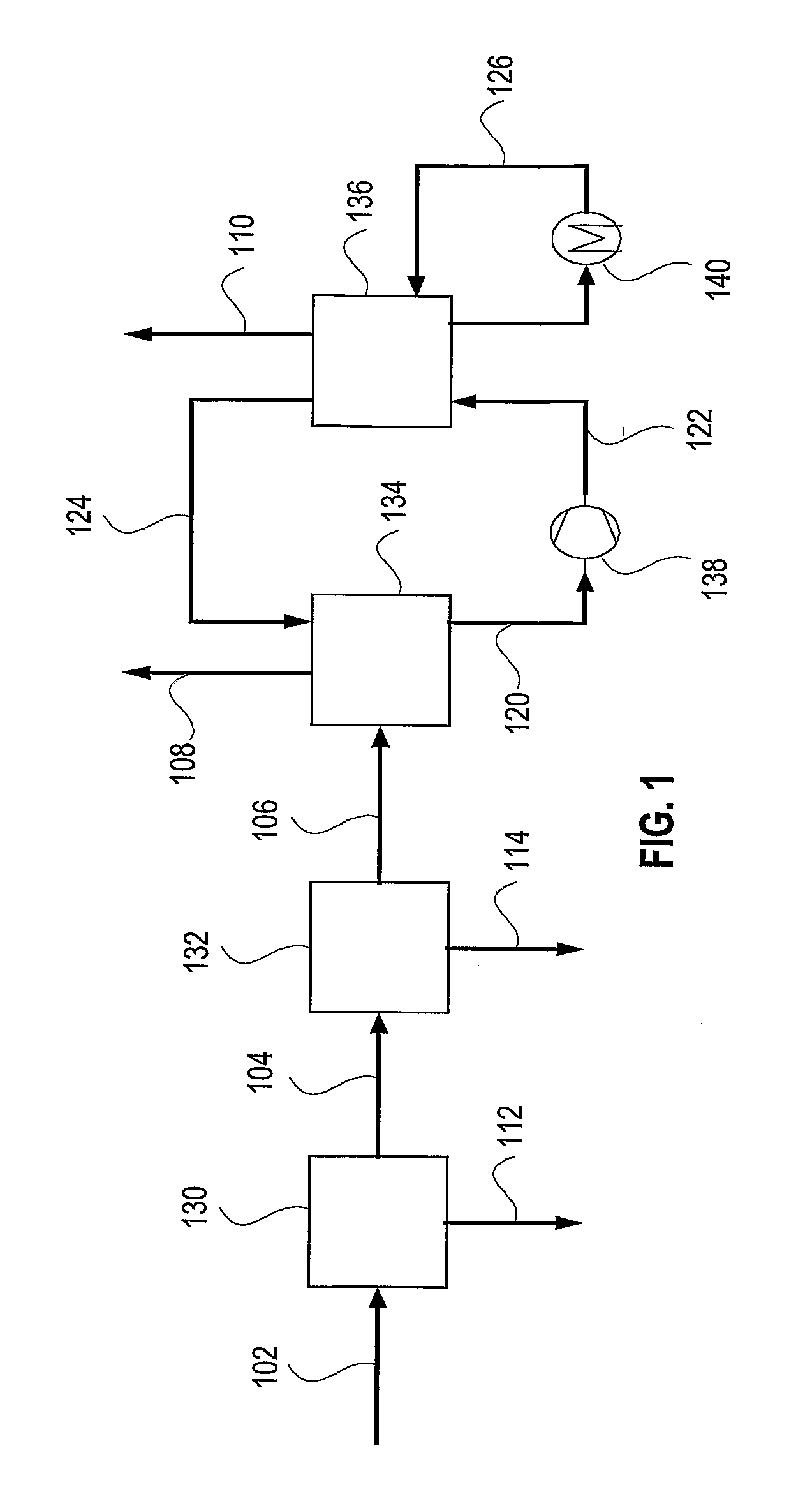

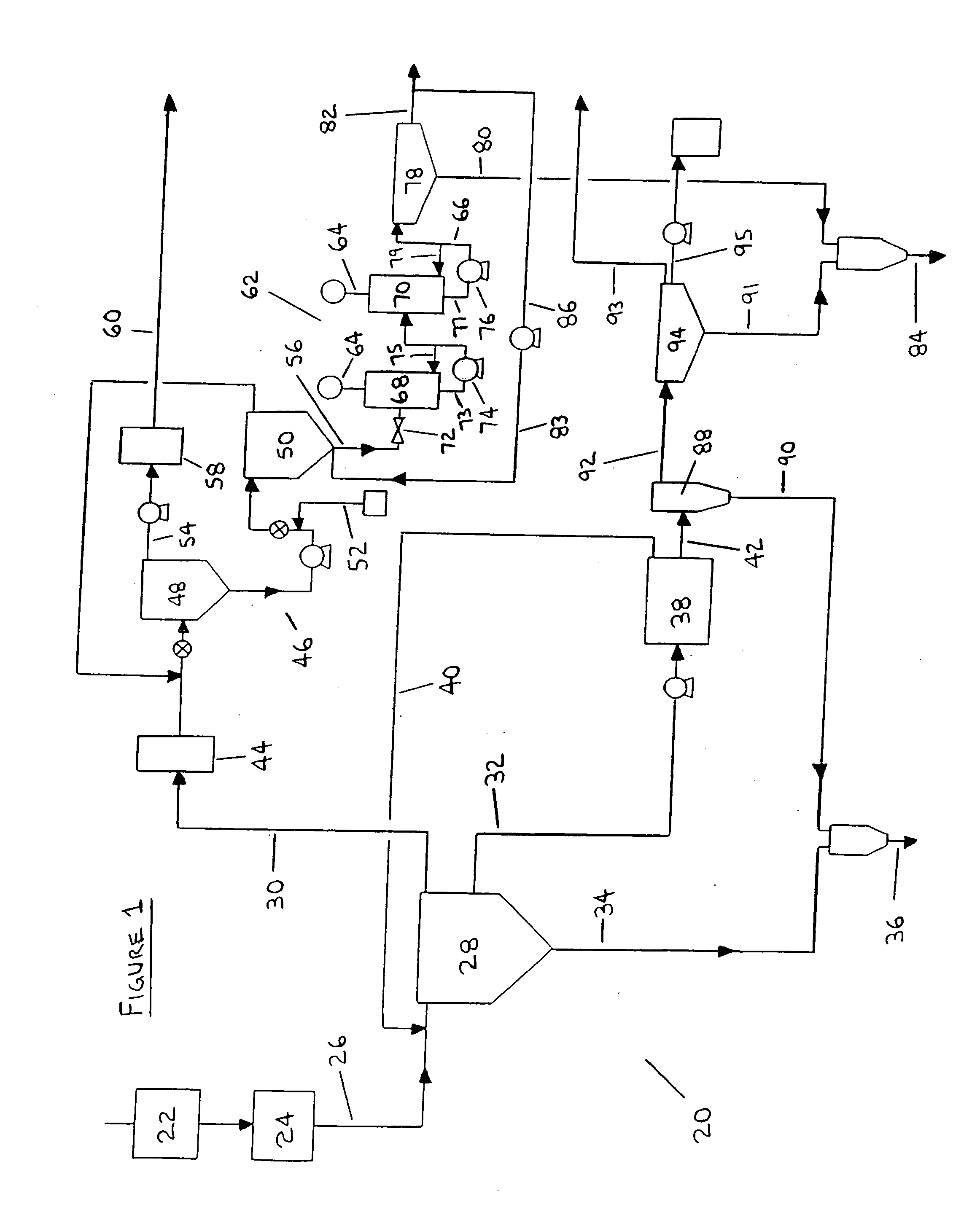

Ultra Cleaning of Combustion Gas Including the Removal of Co2

ActiveUS20080072762A1Reduce evaporationMinimize energy consumptionUsing liquid separation agentEmission preventionCo2 removalCombustion

Ultra cleaning of combustion gas to near zero concentration of residual contaminants followed by the capture of CO2 is provided. The high removal efficiency of residual contaminants is accomplished by direct contact cooling and scrubbing of the gas with cold water. The temperature of the combustion gas is reduced to 0-20 degrees Celsius to achieve maximum condensation and gas cleaning effect. The CO2 is captured from the cooled and clean flue gas in a CO2 absorber (134) utilizing an ammoniated solution or slurry in the NH3—CO2H2O system. The absorber operates at 0-20 degrees Celsius. Regeneration is accomplished by elevating the pressure and temperature of the CO2-rich solution from the absorber. The CO2 vapor pressure is high and a pressurized CO2 stream, with low concentration of NH3 and water vapor is generated. The high pressure CO2 stream is cooled and washed to recover the ammonia and moisture from the gas.

Owner:GENERAL ELECTRIC TECH GMBH

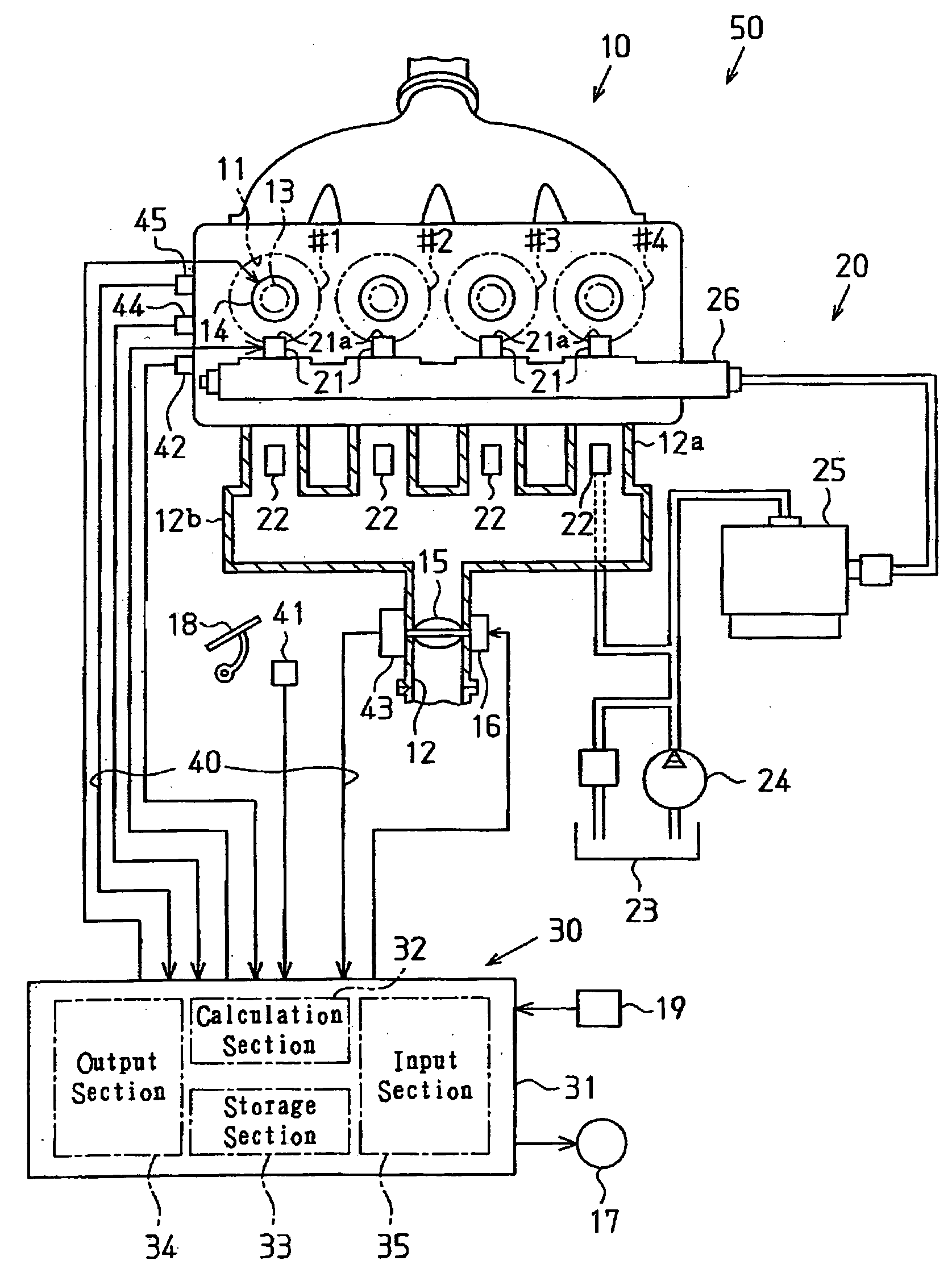

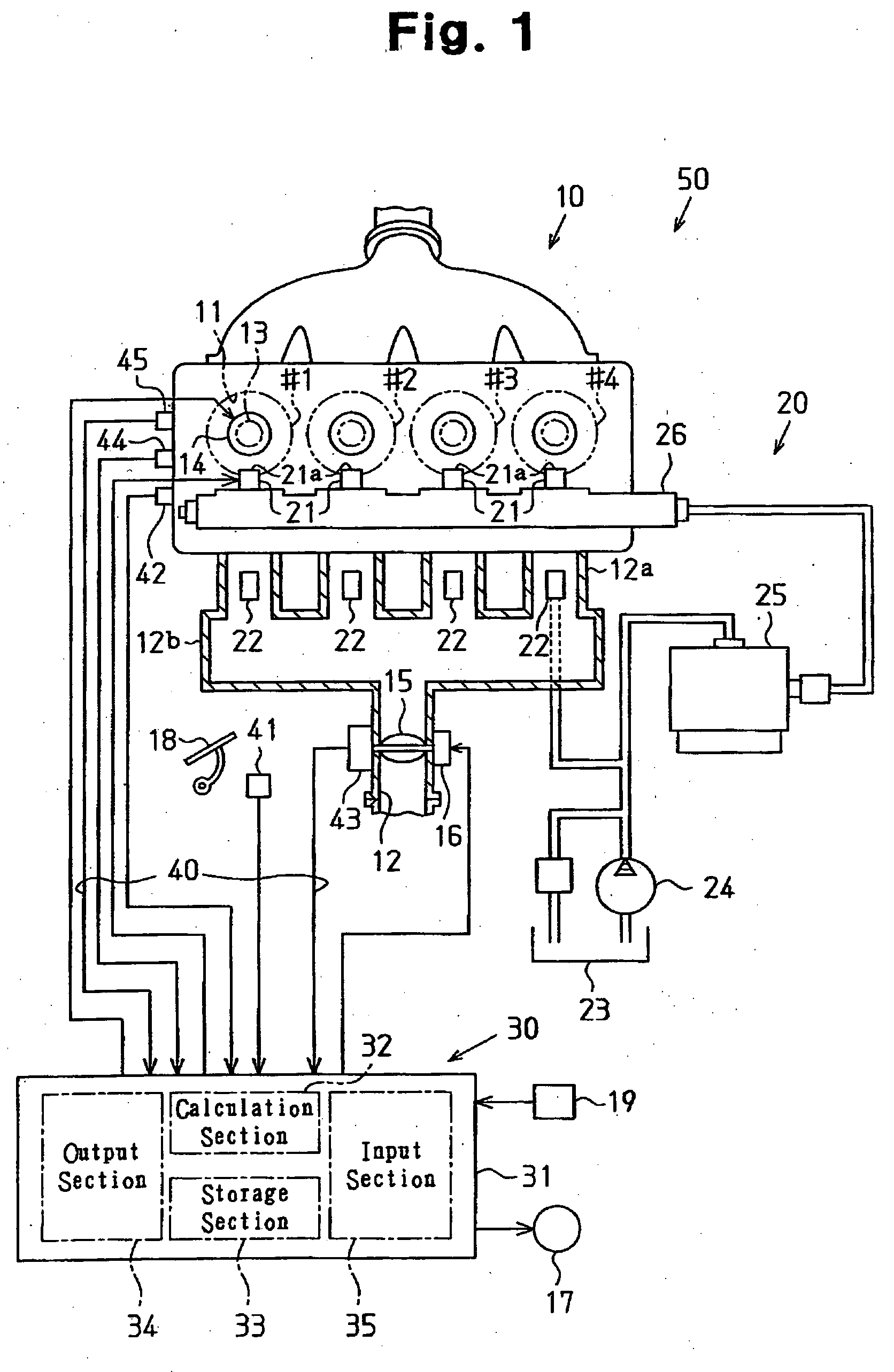

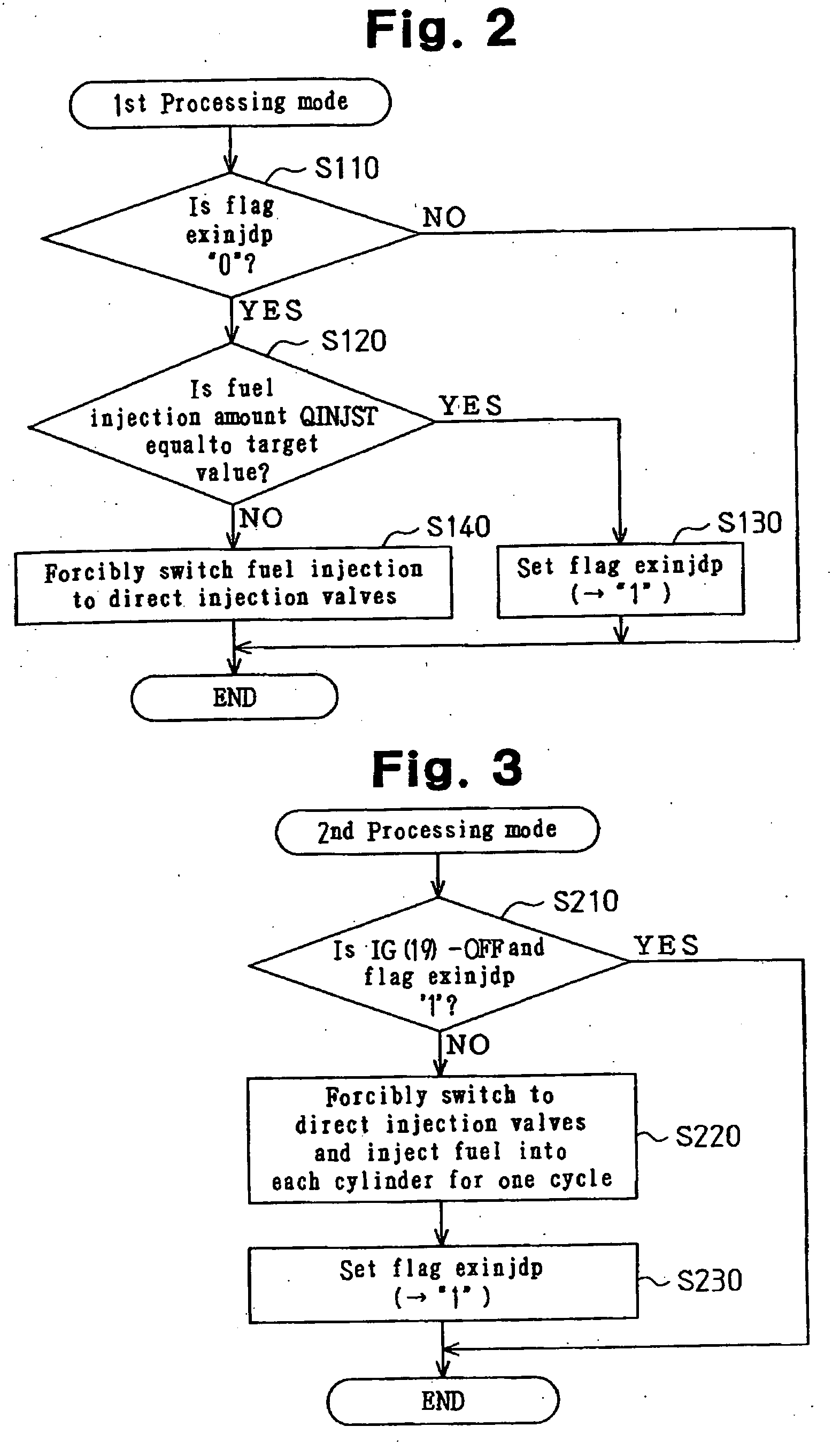

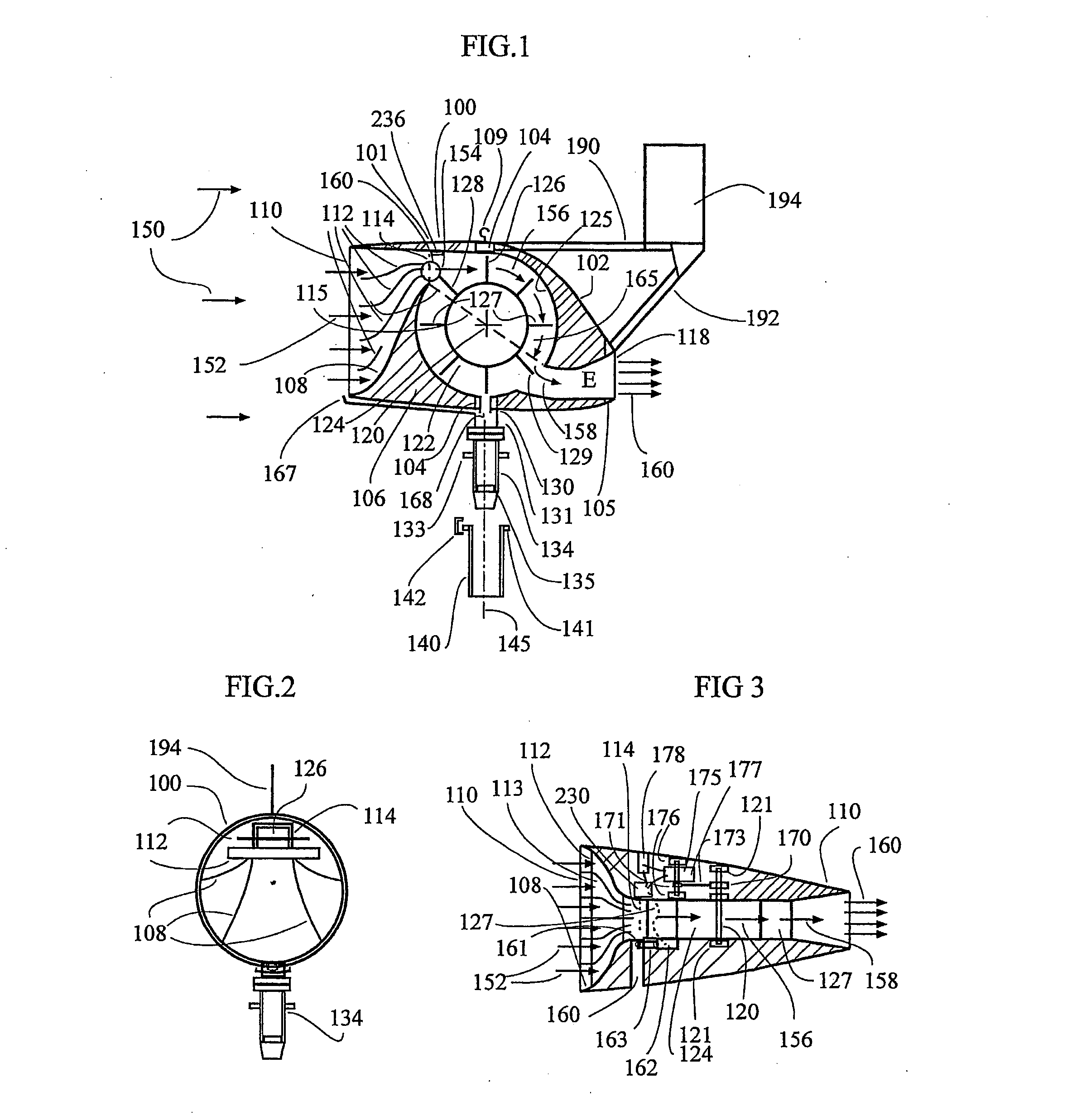

Injection controller for internal combustion engine

ActiveUS20050166896A1Avoid accumulationSuppresses accumulation of depositElectrical controlInternal combustion piston enginesInternal combustion engineVALVE PORT

An injection controller for an internal combustion engine that suppresses the accumulation of deposits on a nozzle hole of a direct injection valve. The injection controller includes the direct injection valve, which injects fuel into a cylinder, and an intake passage injection valve, which injects fuel into an intake passage. An ECU, which is connected to the direct injection and intake passage injection valves, executes a first fuel injection mode for injecting fuel with the direct injection valve and a second fuel injection mode for injecting fuel with the intake passage injection valve. The ECU switches fuel injection modes from the second fuel injection mode to the first fuel injection mode for a predetermined period when fuel is to be injected in the second fuel injection mode.

Owner:TOYOTA JIDOSHA KK

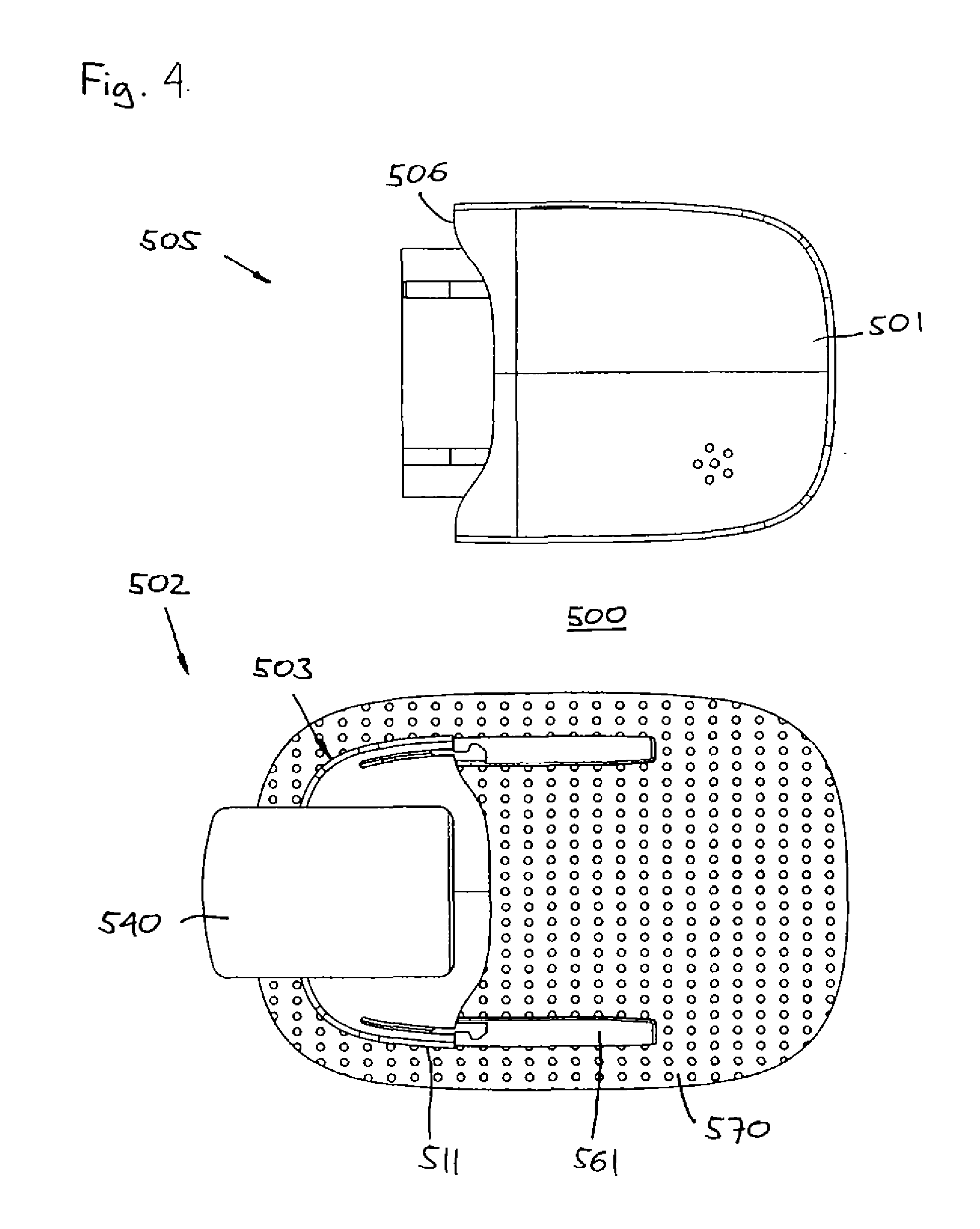

Apparatuses and methods for negative pressure wound therapy

ActiveUS20150141941A1Useful in treatmentReduce decreaseMedical devicesAdhesive dressingsWound dressingWound site

Disclosed herein are several embodiments of a negative pressure appliance and methods of using the same in the treatment of wounds. Some embodiments are directed towards wound dressings comprising a liquid and gas permeable transmission layer, an absorbent layer for absorbing wound exudate, the absorbent layer overlying the transmission layer, a gas impermeable cover layer overlying the absorbent layer and comprising a first orifice, wherein the cover layer is moisture vapor permeable. Some embodiments are directed to improved fluidic connectors or suction adapters for connecting to a wound site, for example using softer, kink-free conformable suction adapters.

Owner:SMITH & NEPHEW INC +1

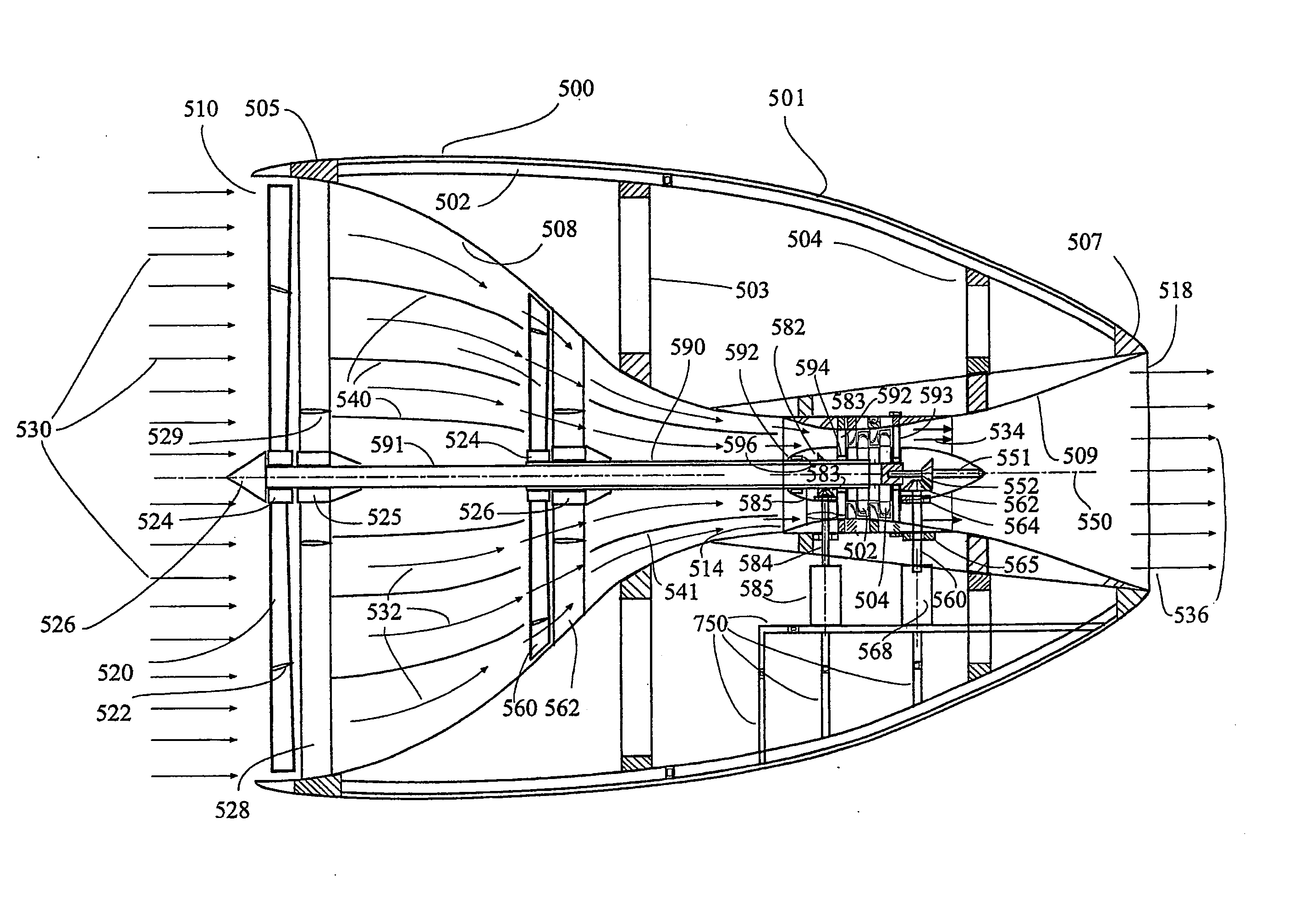

Use of Air Internal Energy and Devices

InactiveUS20080061559A1Increase static pressureAvoid accumulationCosmonautic vehiclesReaction enginesMoisture condensationLiquid water

A method of converting air internal energy into useful kinetic energy is based on air flowing through substantially convergent nozzle, which accelerates the air as the cross section of the nozzle decreases thus increasing the air kinetic energy. The increment of the kinetic energy equals to the decrement of air internal energy, i.e., air temperature. Within said nozzle a turbine is placed to convert airflow kinetic energy into mechanical energy that transformed into electrical energy or transferred into a gearbox to provide driving moment. Devices uses this method could use natural wind as airflow source or artificial airflow means. Devices, which incorporate means to create airflow artificially, can be used as engines for land, sea and flying vehicle. Since air temperature drops within the nozzle, moisture condensation exists and liquid water can be accumulated for further use.

Owner:HIRSHBERG ISRAEL

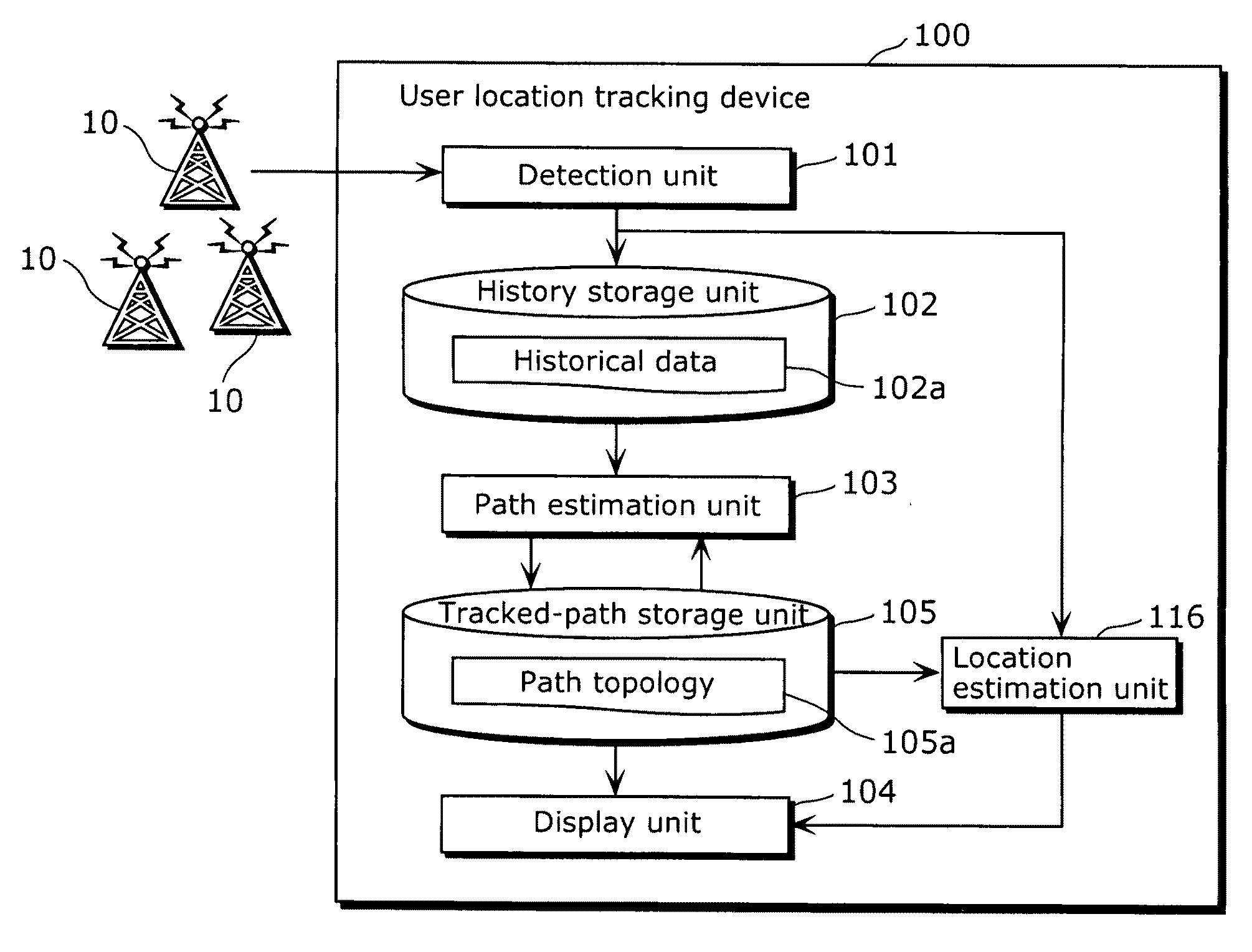

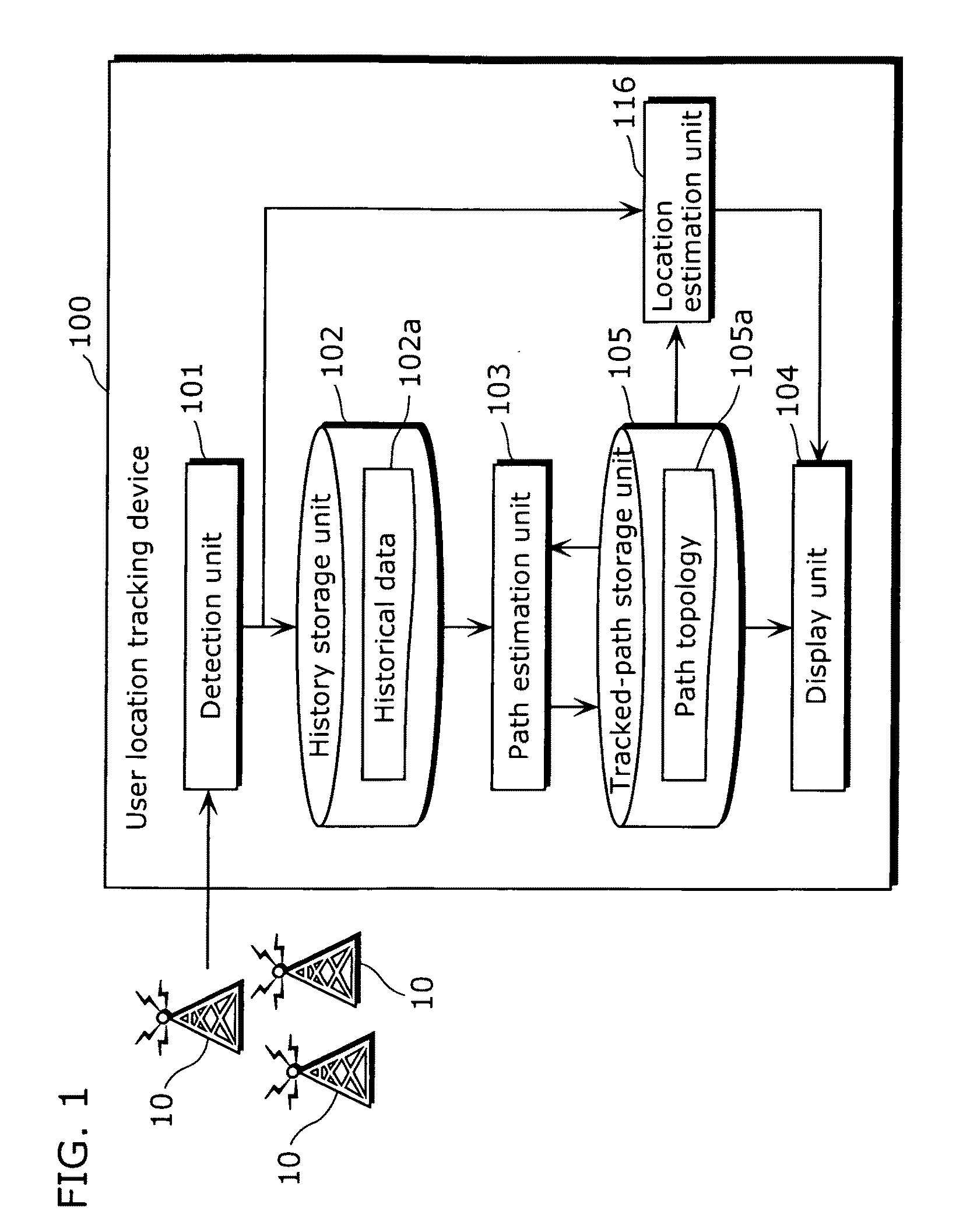

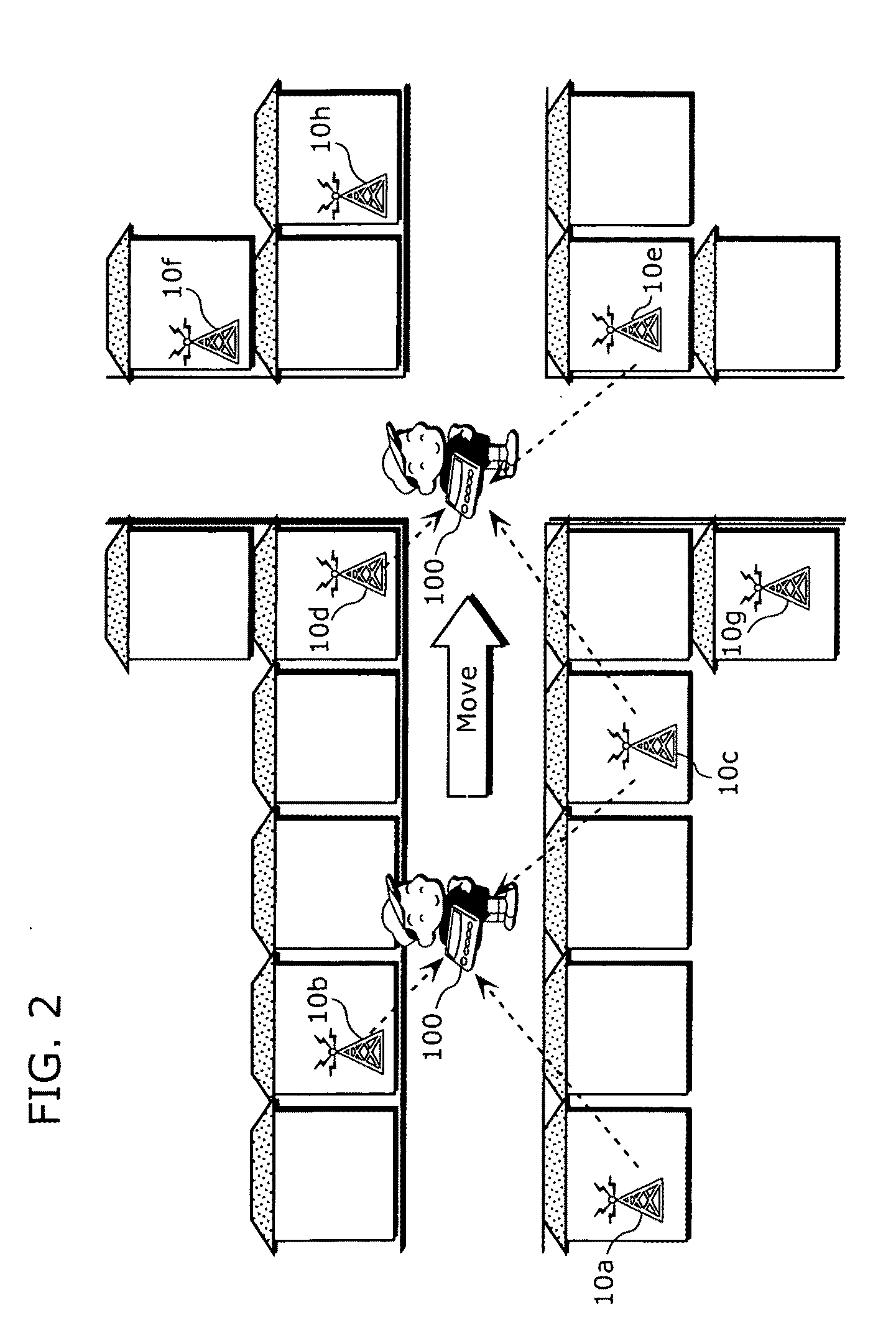

Mobility tracking method and user location tracking device

InactiveUS20090201149A1Sure easyAvoid accumulationNavigational calculation instrumentsNetwork topologiesLocation trackingComputer terminal

A user location tracking method allows a topology of a travel path taken by a user to be estimated without the use of location information such as GPS coordinates, so that a travel range of the user who only carries a small-sized terminal can be tracked at all times. The mobility tracking method is employed by a user location tracking device which uses radio waves sent from wireless devices distributed ubiquitously, the mobility tracking method including: detecting wireless device information identifying wireless devices out of the ubiquitously available wireless devices when the radio waves are received at a location where the user location tracking device is situated; storing the detected wireless device information as historical data; and estimating a topology, as the user location tracking device is moving, that shows a positional relation and a connection relation of a travel path taken by the user location tracking device, the estimation being performed on the basis that the location of the user location tracking device has deviated from a previously tracked path which has been traveled before by the user location tracking device and that the location of the user location tracking device has returned to the previously tracked path, using the stored historical data.

Owner:PANASONIC CORP

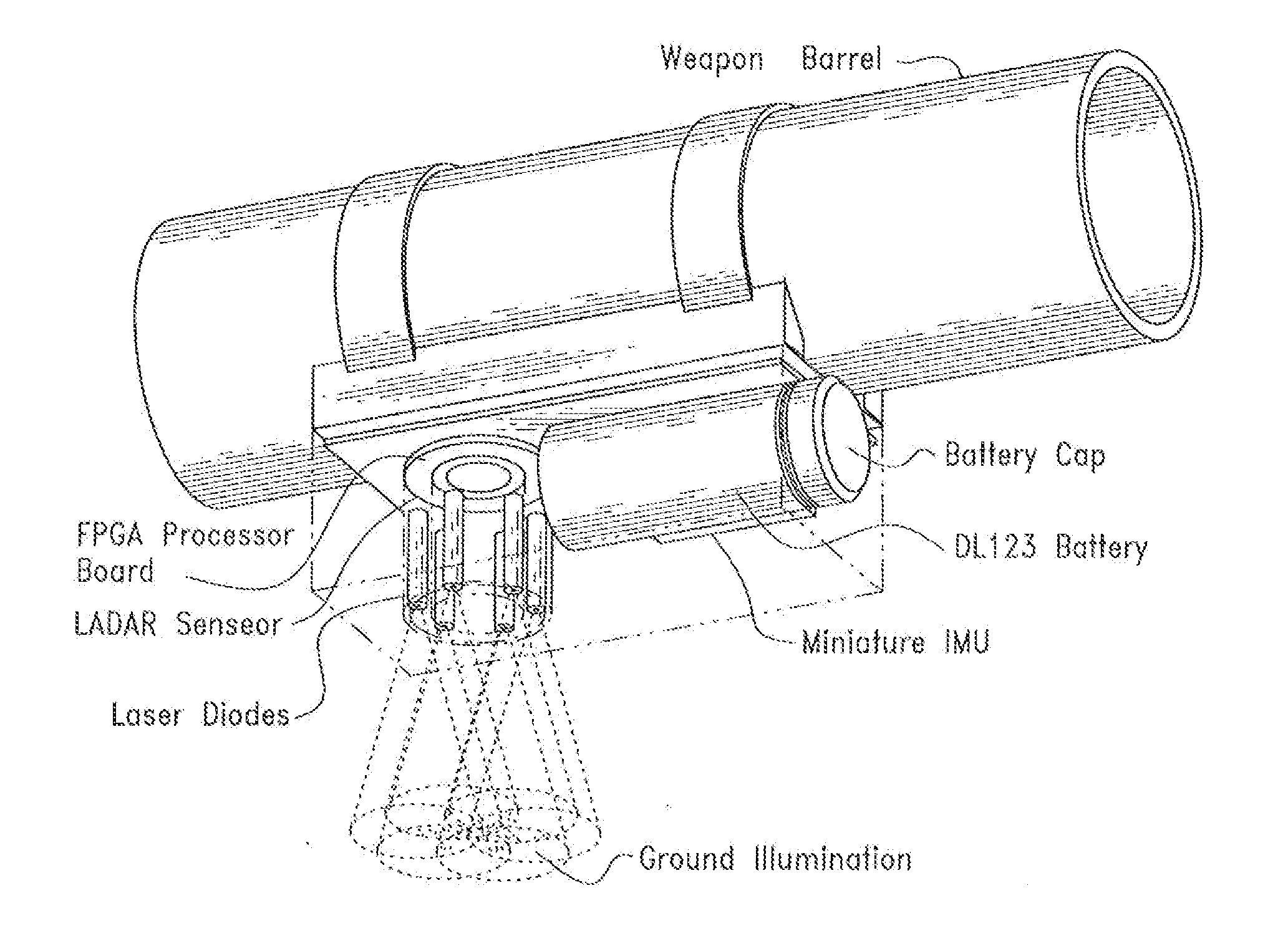

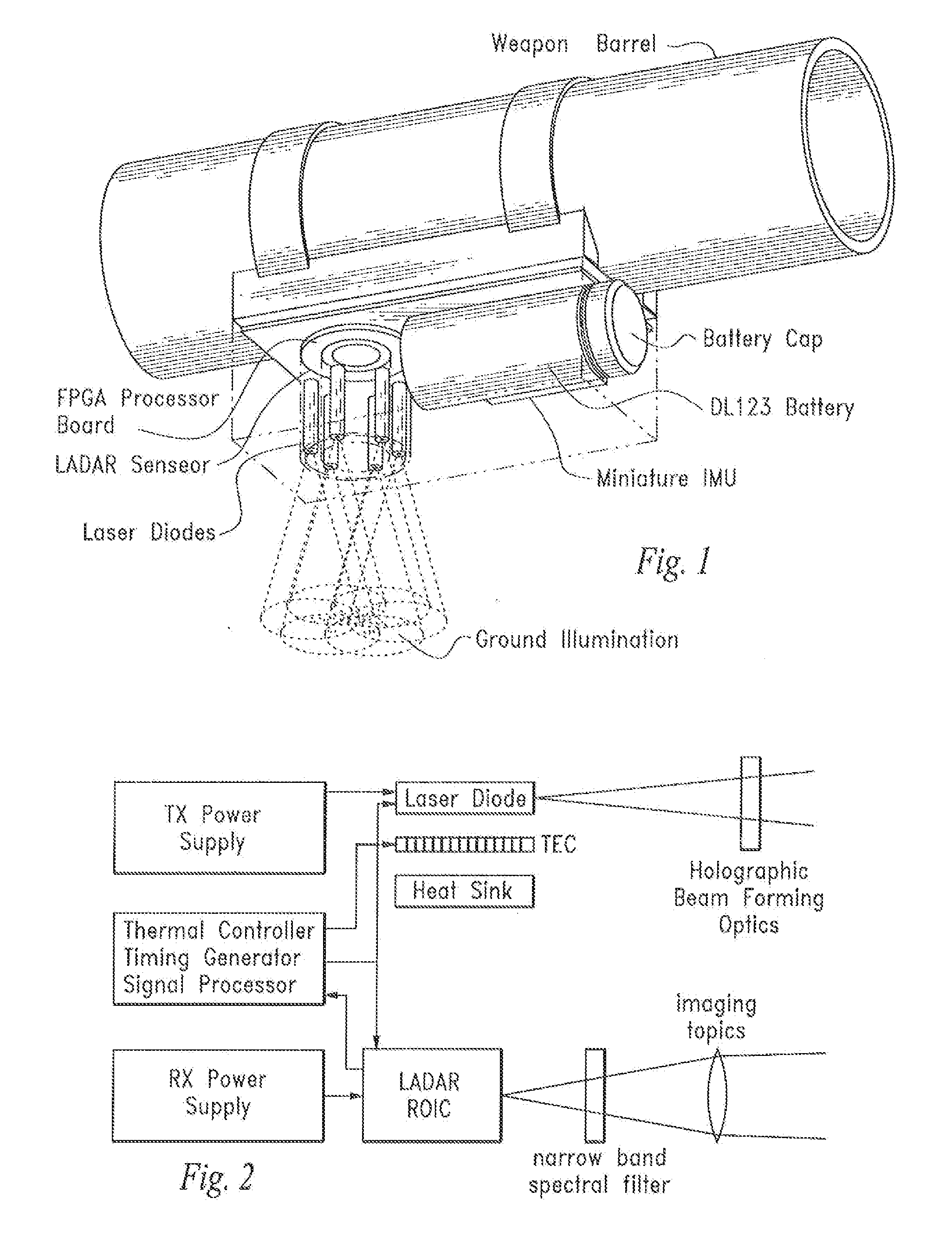

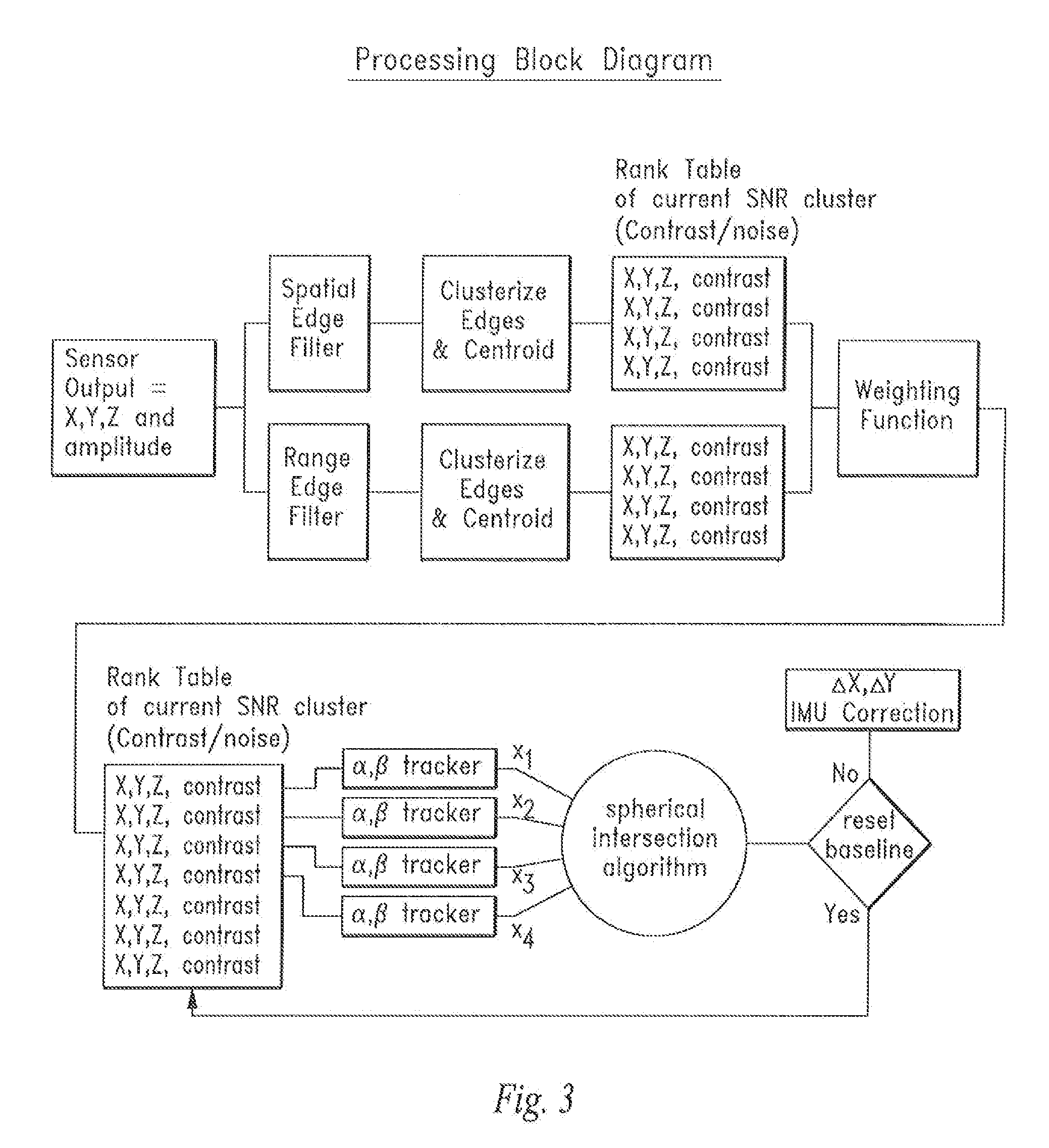

Local Alignment and Positioning Device and Method

InactiveUS20140293266A1Accurate measurement rangeAccurate measurementOptical rangefindersWeapon control systemsTerrainVoxel

A device and method that uses terrain features having one or more predetermined characteristics or weights in an electronic image date frame or set of frames such as a LIDAR voxel set of image data frames for use as system reference points which are, in turn, used in one or more trilateration calculations performed in electronic circuitry to determine a position or ego-motion of the device.

Owner:PFG IP

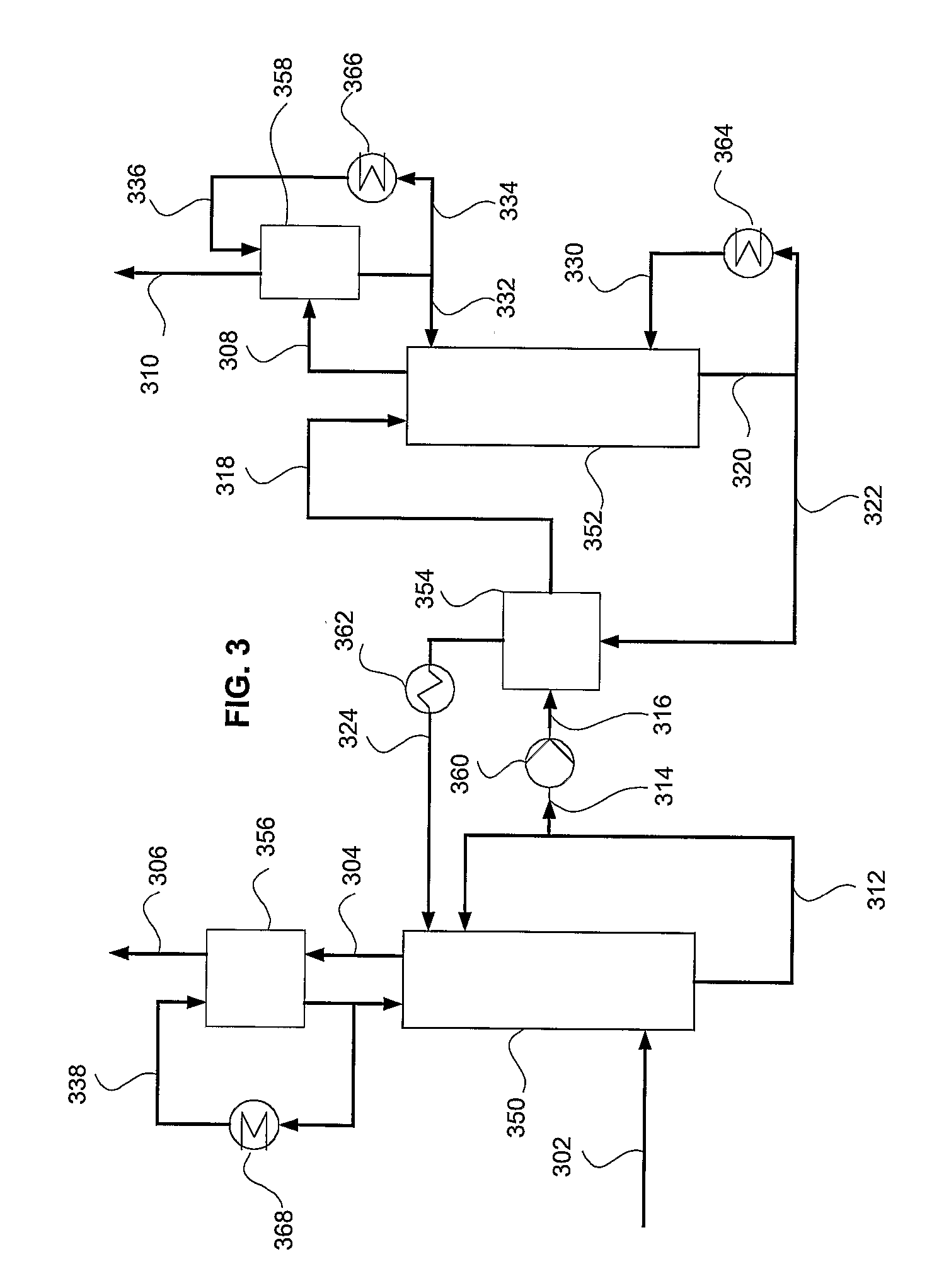

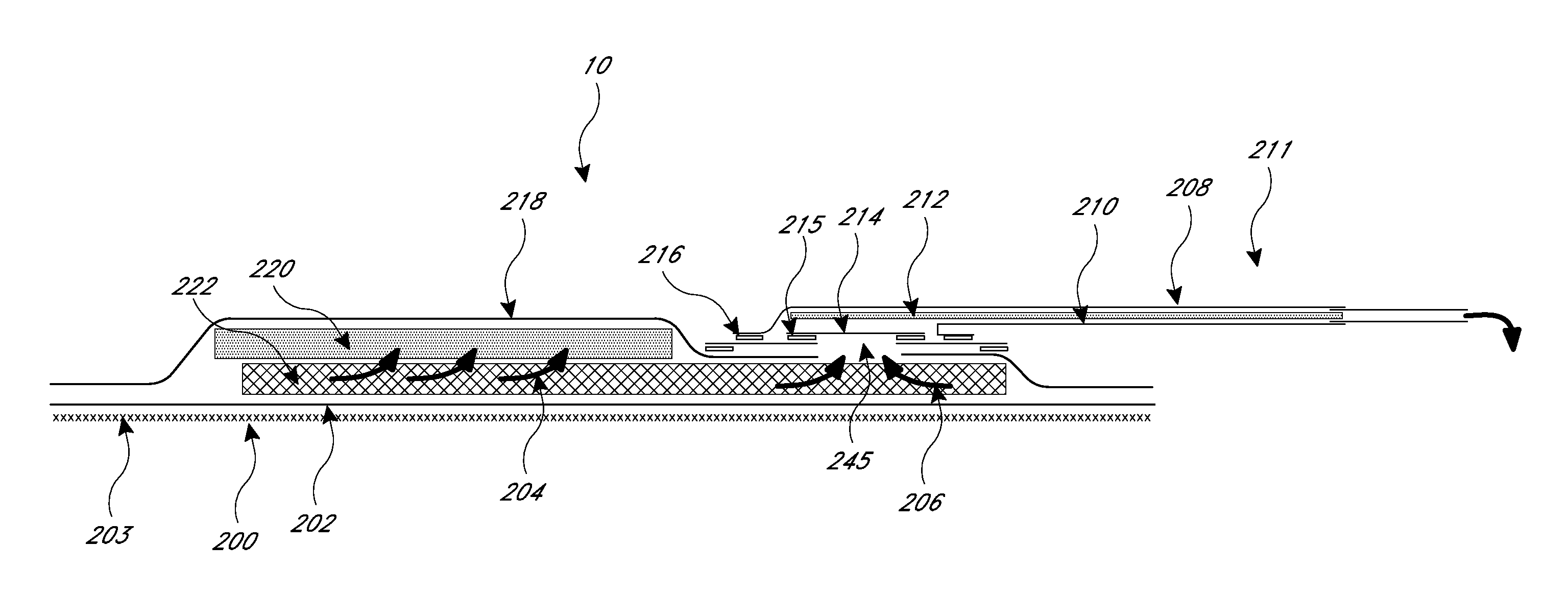

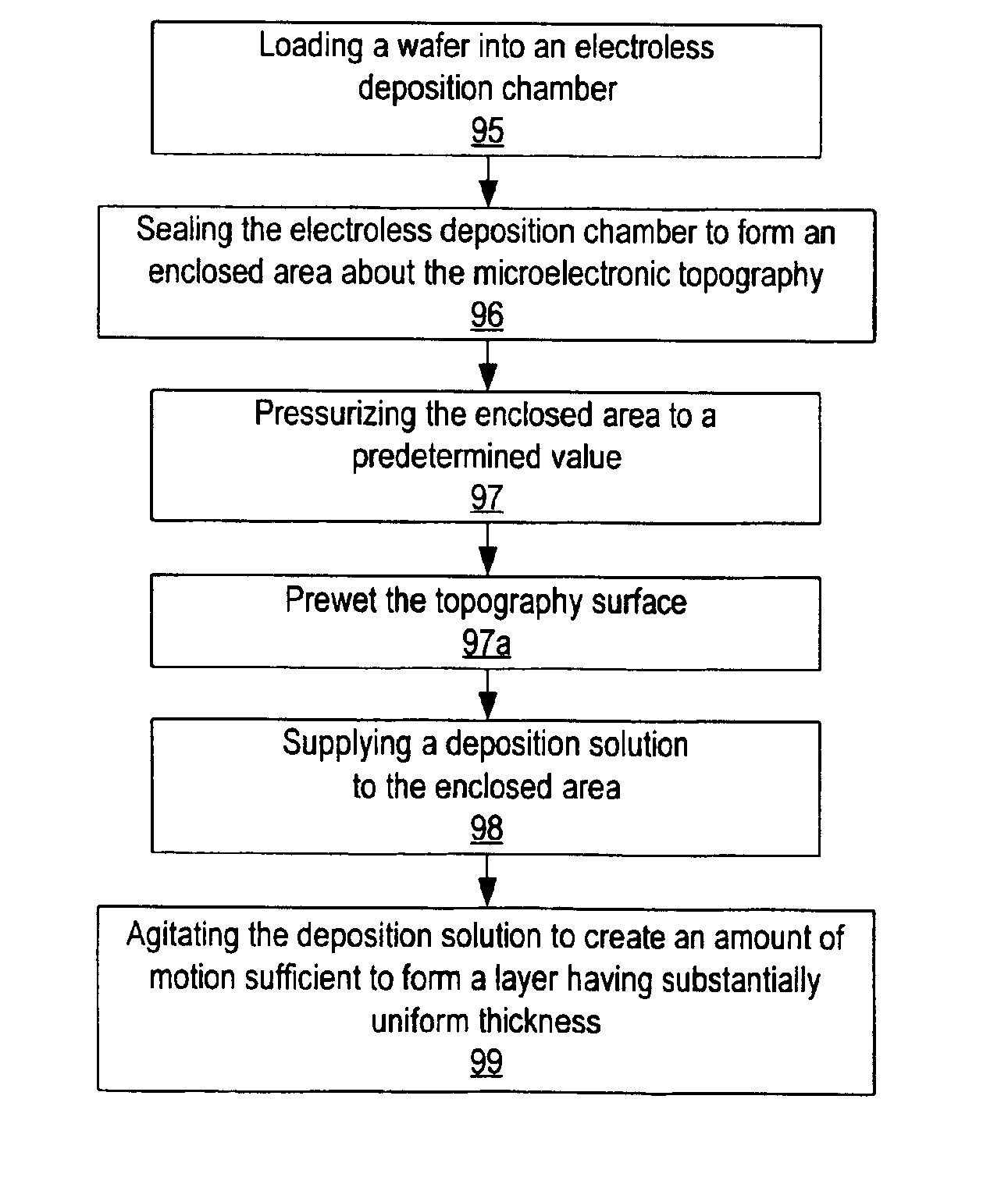

Methods and system for processing a microelectronic topography

InactiveUS6881437B2Avoid flowHigh boiling pointSemiconductor/solid-state device manufacturingPretreated surfacesElectroless depositionTopography

Methods and systems are provided which are adapted to process a microelectronic topography, particularly in association with an electroless deposition process. In general, the methods may include loading the topography into a chamber, closing the chamber to form an enclosed area, and supplying fluids to the enclosed area. In some embodiments, the fluids may fill the enclosed area. In addition or alternatively, a second enclosed area may be formed about the topography. As such, the provided system may be adapted to form different enclosed areas about a substrate holder. In some cases, the method may include agitating a solution to minimize the accumulation of bubbles upon a wafer during an electroless deposition process. As such, the system provided herein may include a means for agitating a solution in some embodiments. Such a means for agitation may be distinct from the inlet / s used to supply the solution to the chamber.

Owner:LAM RES CORP

Hydraulic reversing mechanism

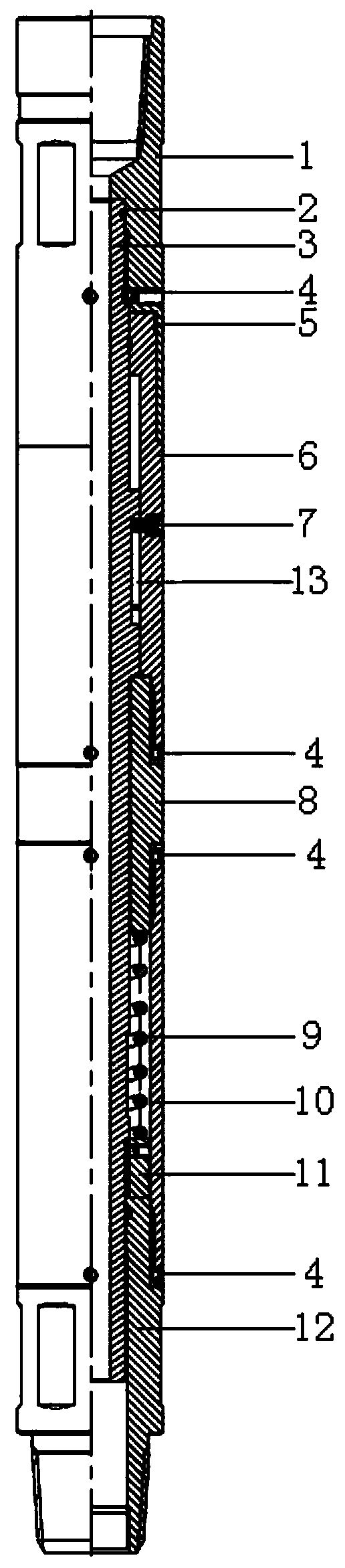

PendingCN111167769ASimple structureAchieve Rotary JettingFlushingCleaning using liquidsUpper jointEngineering

The invention discloses a hydraulic reversing mechanism. The hydraulic reversing mechanism comprises an upper joint, a center shaft, a guide ring, an upper shell, a guide pin, a connection nipple, a compression spring, a lower shell, a limiting sleeve and a lower joint, wherein the upper joint is connected with the center shaft, the guide ring is arranged between the upper joint and the upper shell, and the upper shell, the connection nipple, the lower shell and the lower joint can be slidably arranged on the outer side of the center shaft. The guide pin is arranged on the upper shell, a guidegroove is formed in the portion, corresponding to the guide pin, of the center shaft, the guide pin can rotate in the guide groove, a compression cavity is defined by the connection nipple, the lowershell, the lower joint and the center shaft, and the compression spring and the limiting sleeve are arranged in the compression cavity. The hydraulic reversing mechanism has the benefits that the hydraulic reversing mechanism can be used for rotational reversing of a sand washing tool, the washing operation is more sufficient, no atomization is generated, and the washing capacity is ensured. According to the hydraulic reversing mechanism, reversing is achieved under the hydraulic action, the structure is simple, and convenience is brought to installation, disassembly and maintenance. The large-discharge-capacity cleaning work can be met, and rotary jetting to the washing tool can be achieved.

Owner:JEREH ENERGY SERVICES

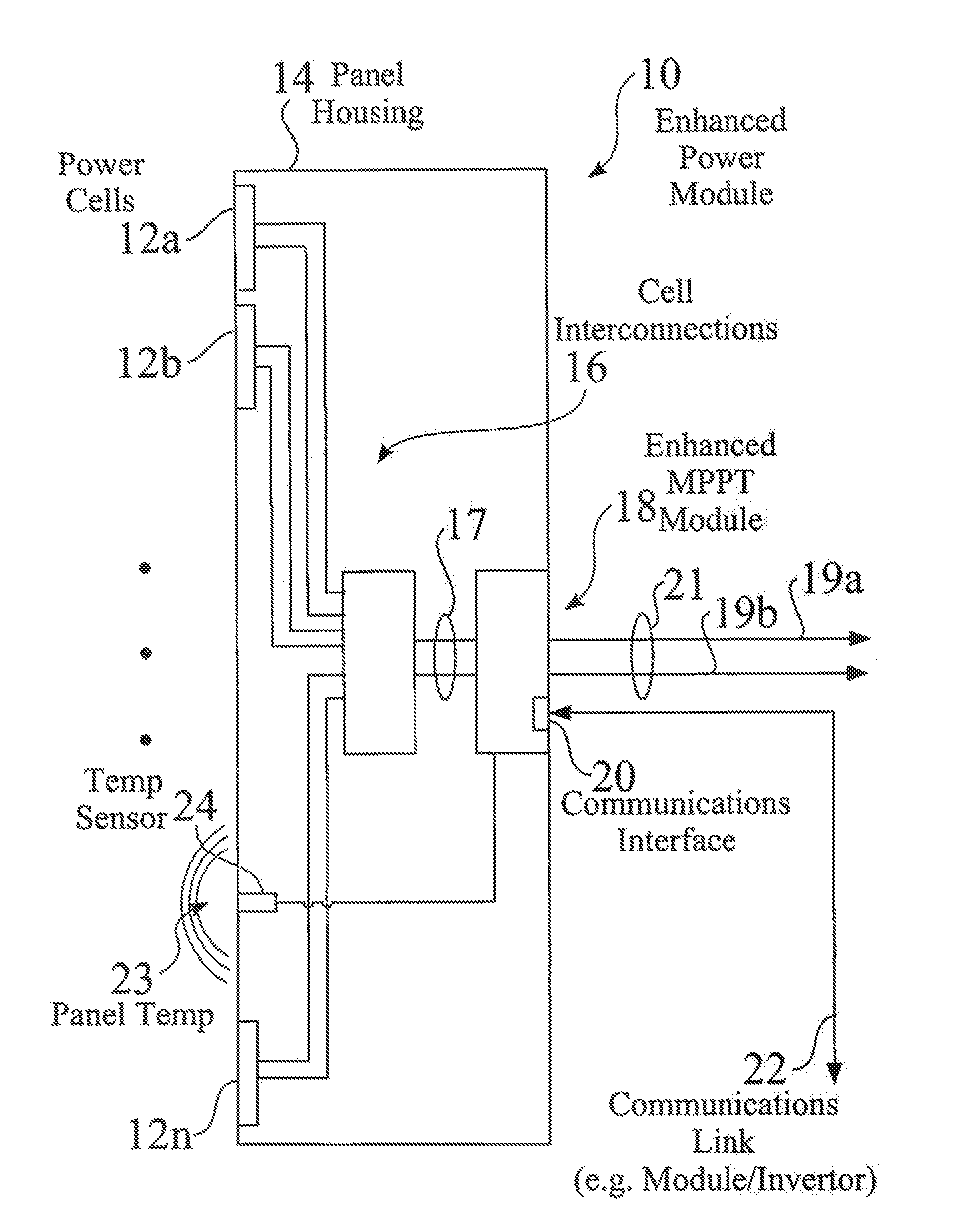

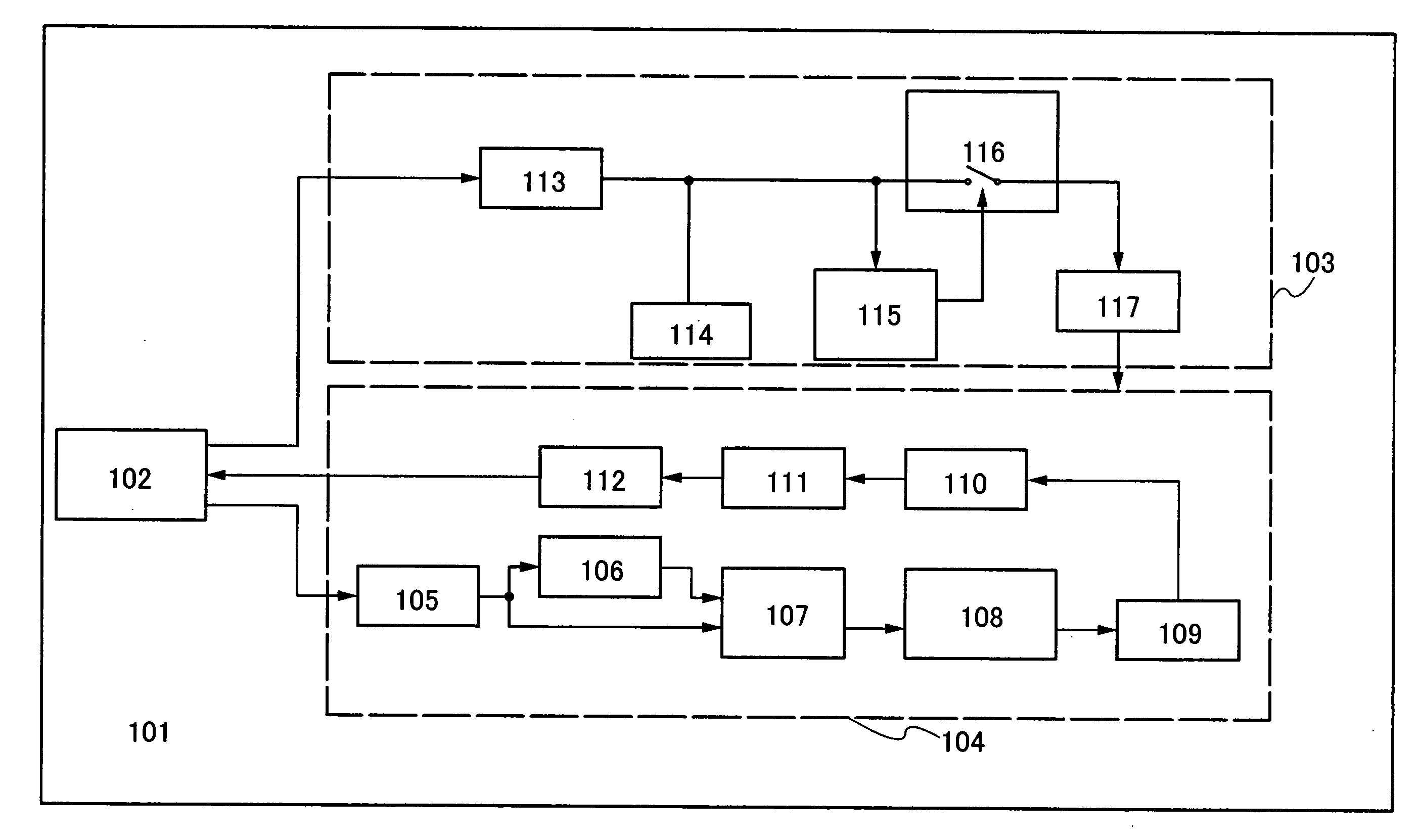

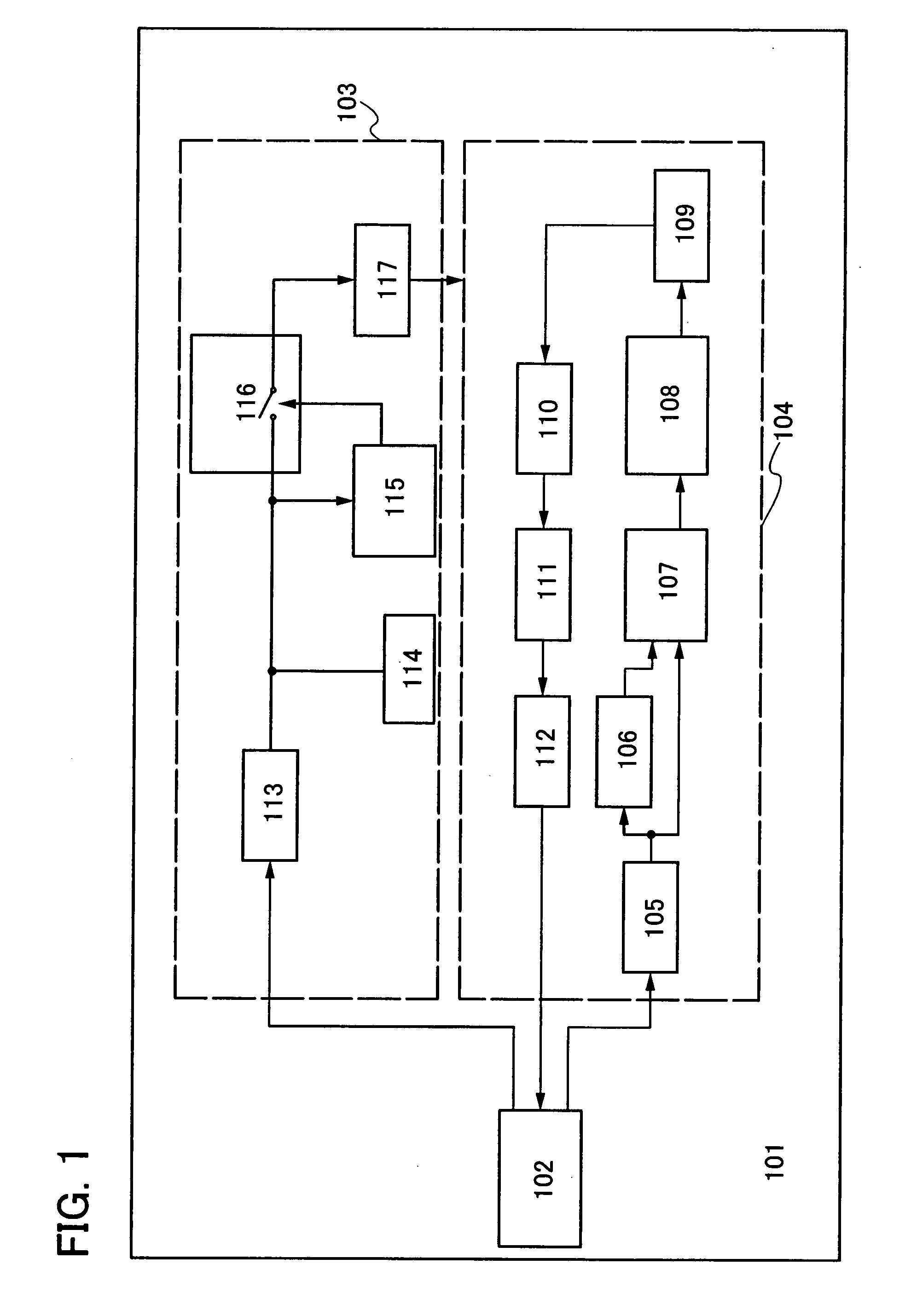

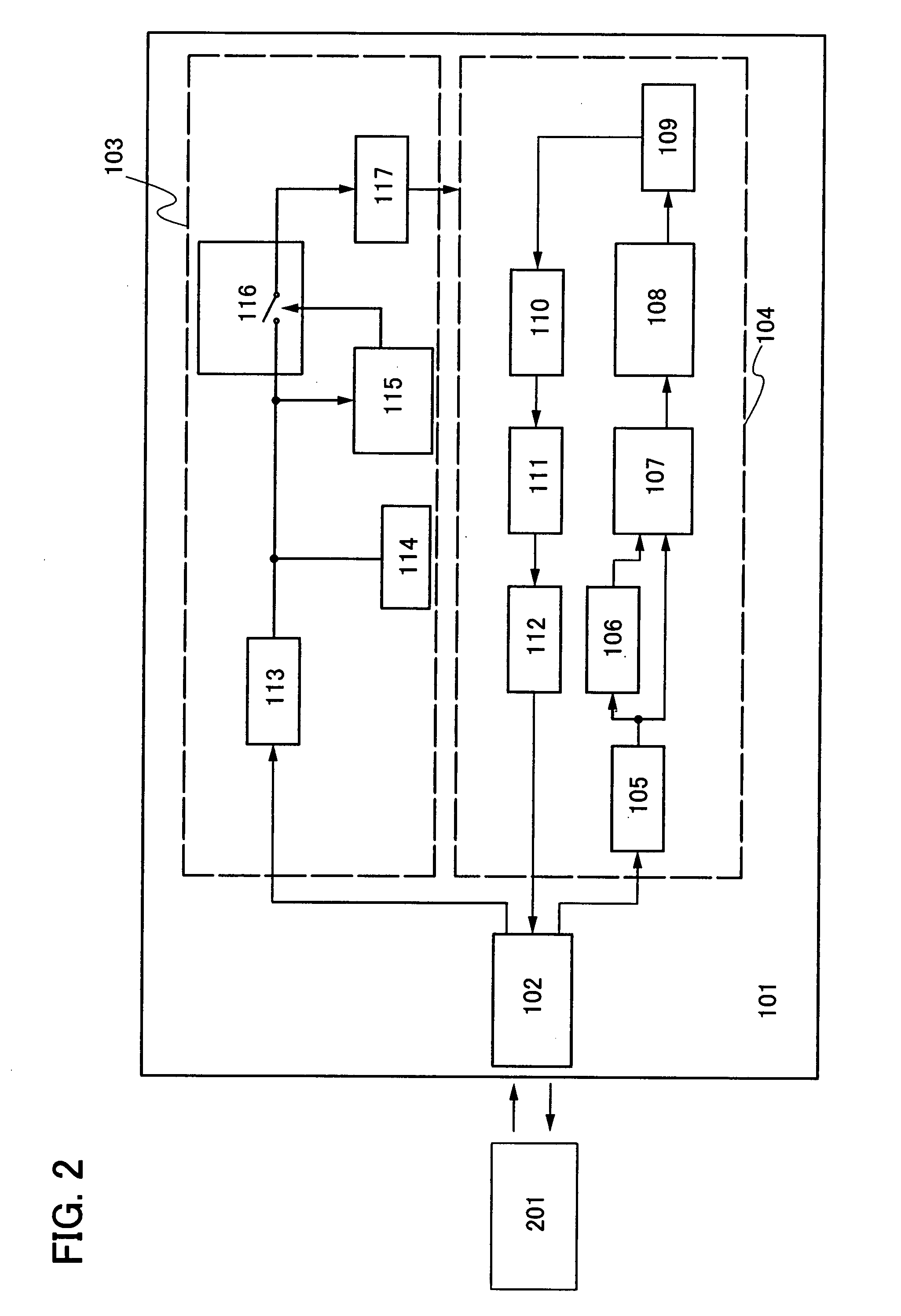

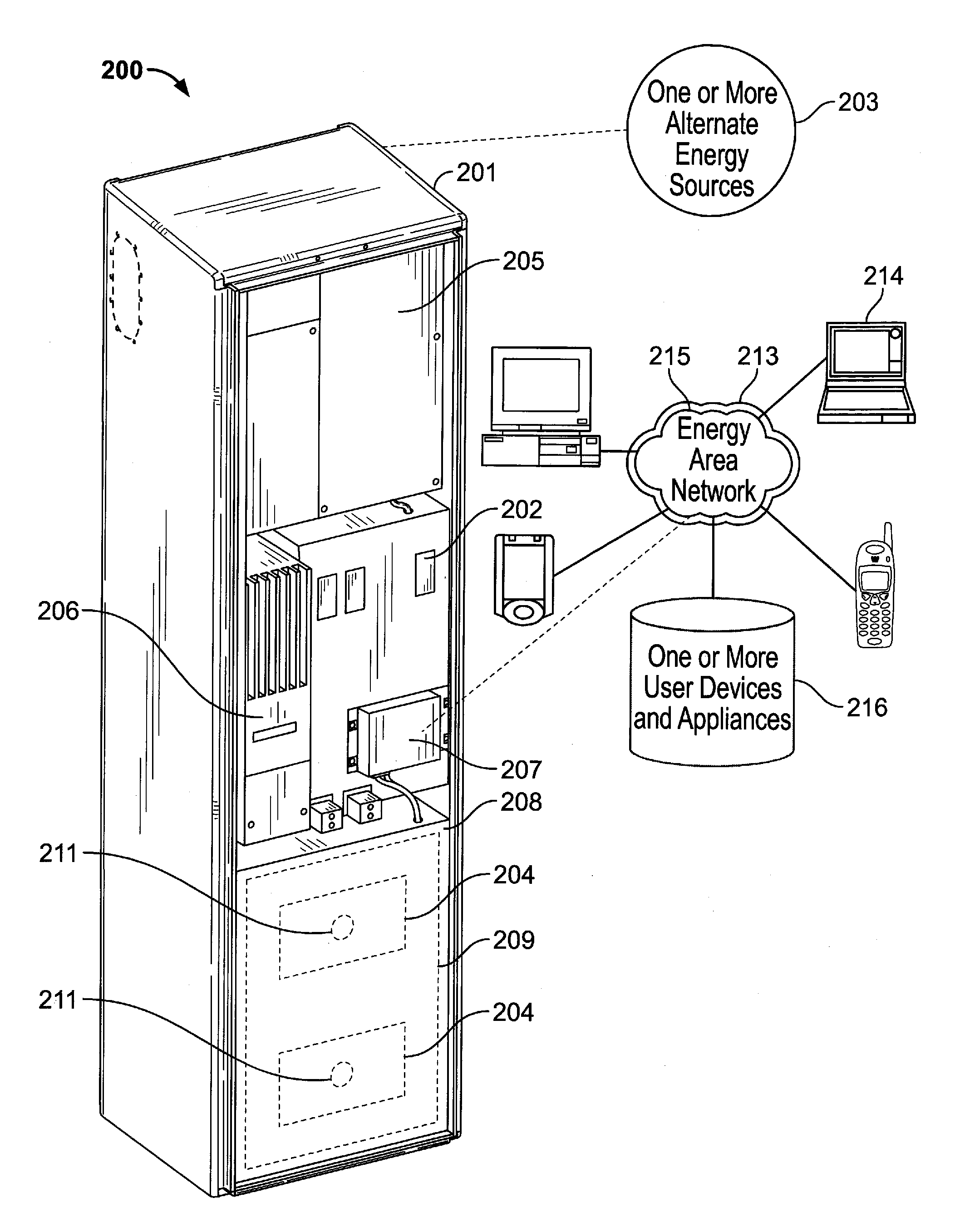

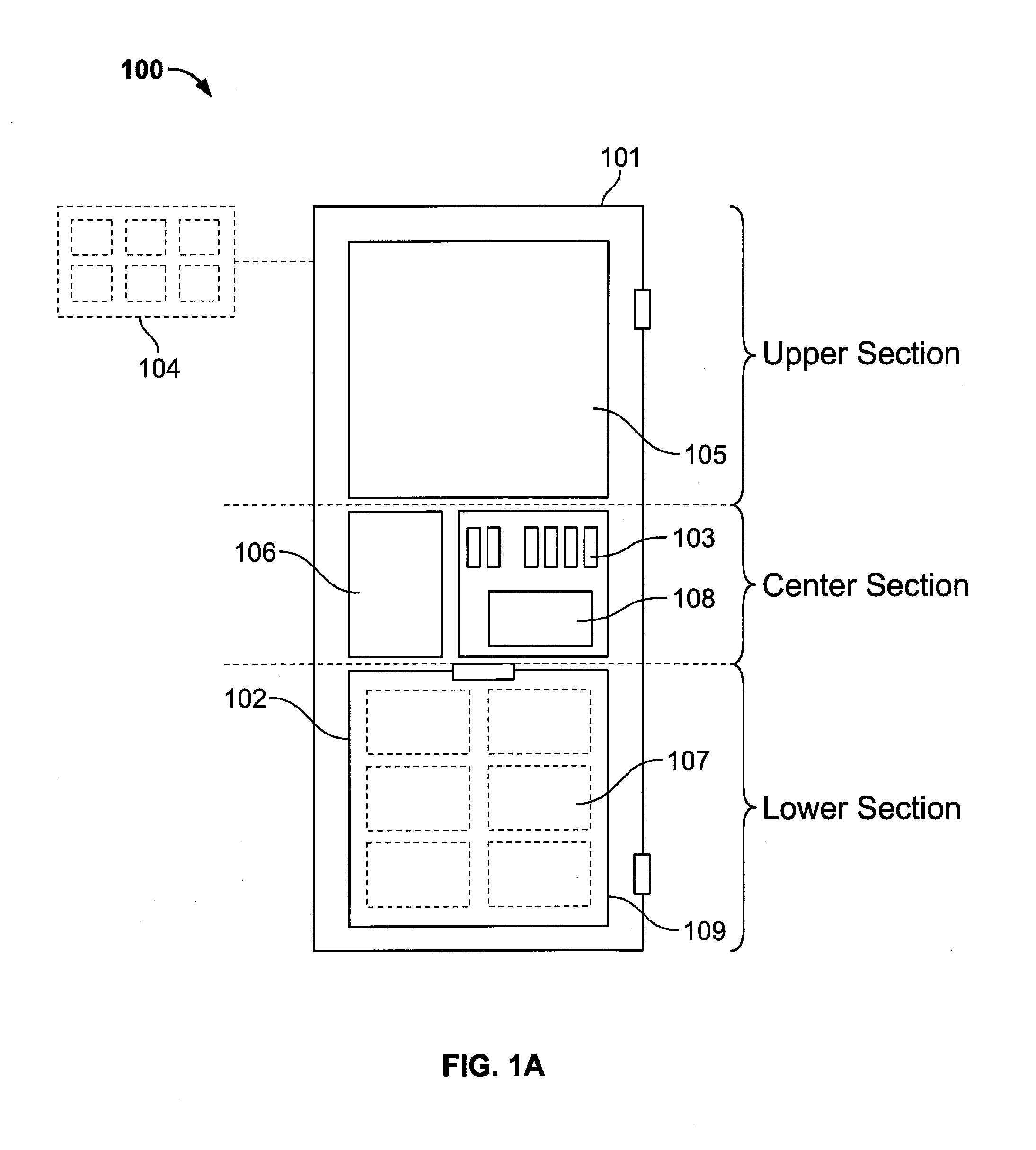

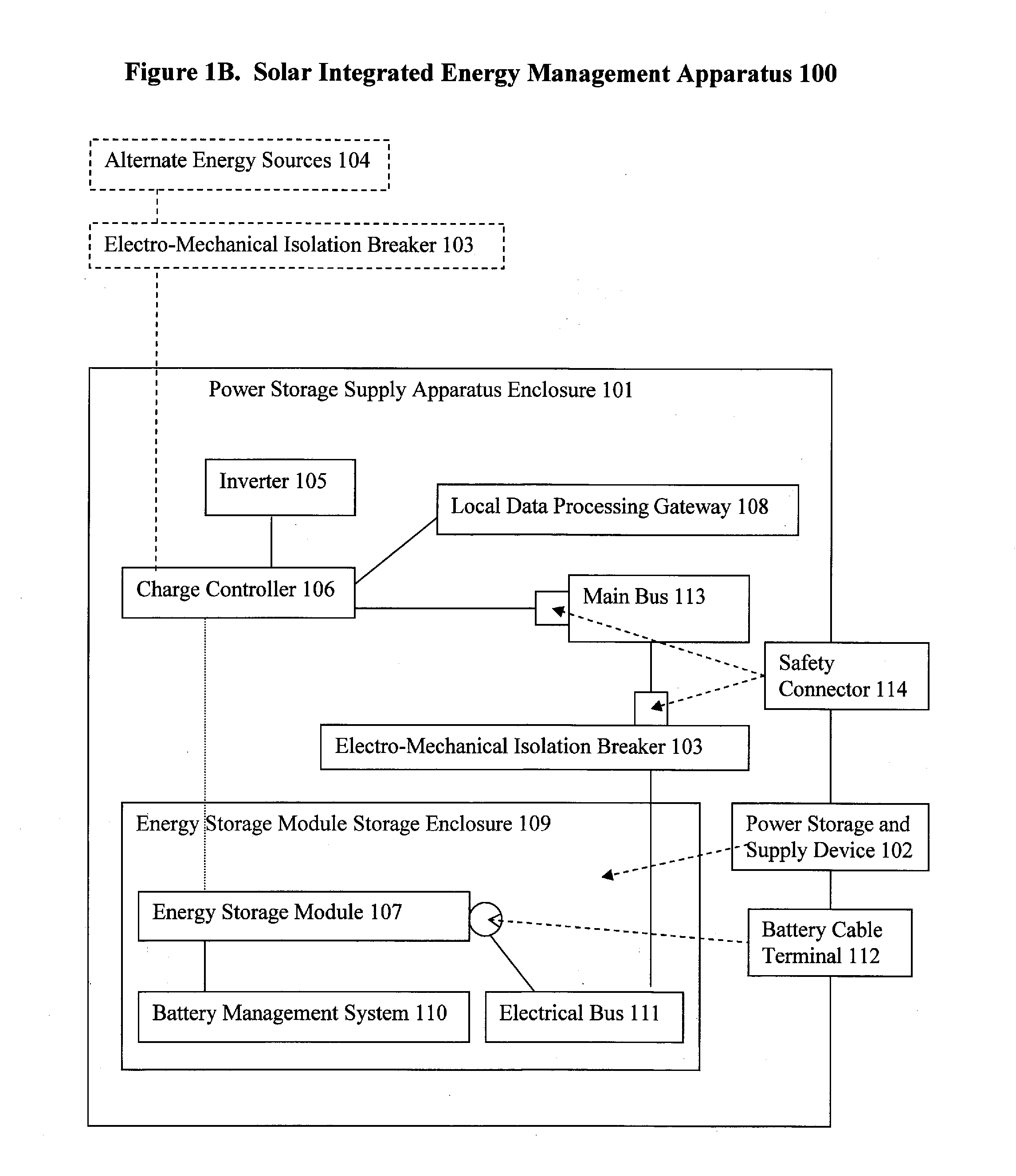

Systems, apparatus, and methods of a solar energy grid integrated system with energy storage appliance

ActiveUS20120197449A1Prevent tamperingIncrease contactPhotovoltaic supportsBatteries circuit arrangementsBalance of systemCharge controller

A system, method, and apparatus for integrating distributed energy sources, energy storage, and balance of system components into a single device with systems and control for monitoring, measuring, and conserving power generated on the premise. A data processing gateway, hybrid inverter / converter and charge controller provide flexibility in the multi-voltages, output capacities, and photovoltaic array sizes coupled to the apparatus and system. The system and apparatus may be used in various commercial and residential applications. A user may store energy provided by one or more alternate energy sources coupled to an energy storage module. The system provides a compact enclosure that fits within a utility workspace and enclosures that can be mechanically coupled together, placed in parallel or in a series. A method, computer implemented apparatus, computer readable medium, computer implemented method and a system for monitoring energy consumption, selling energy back to a utility company and peak shaving are also provided.

Owner:SUNVERGE ENERGY

Absorbing fluids in a surgical access device

Owner:CILAG GMBH INT

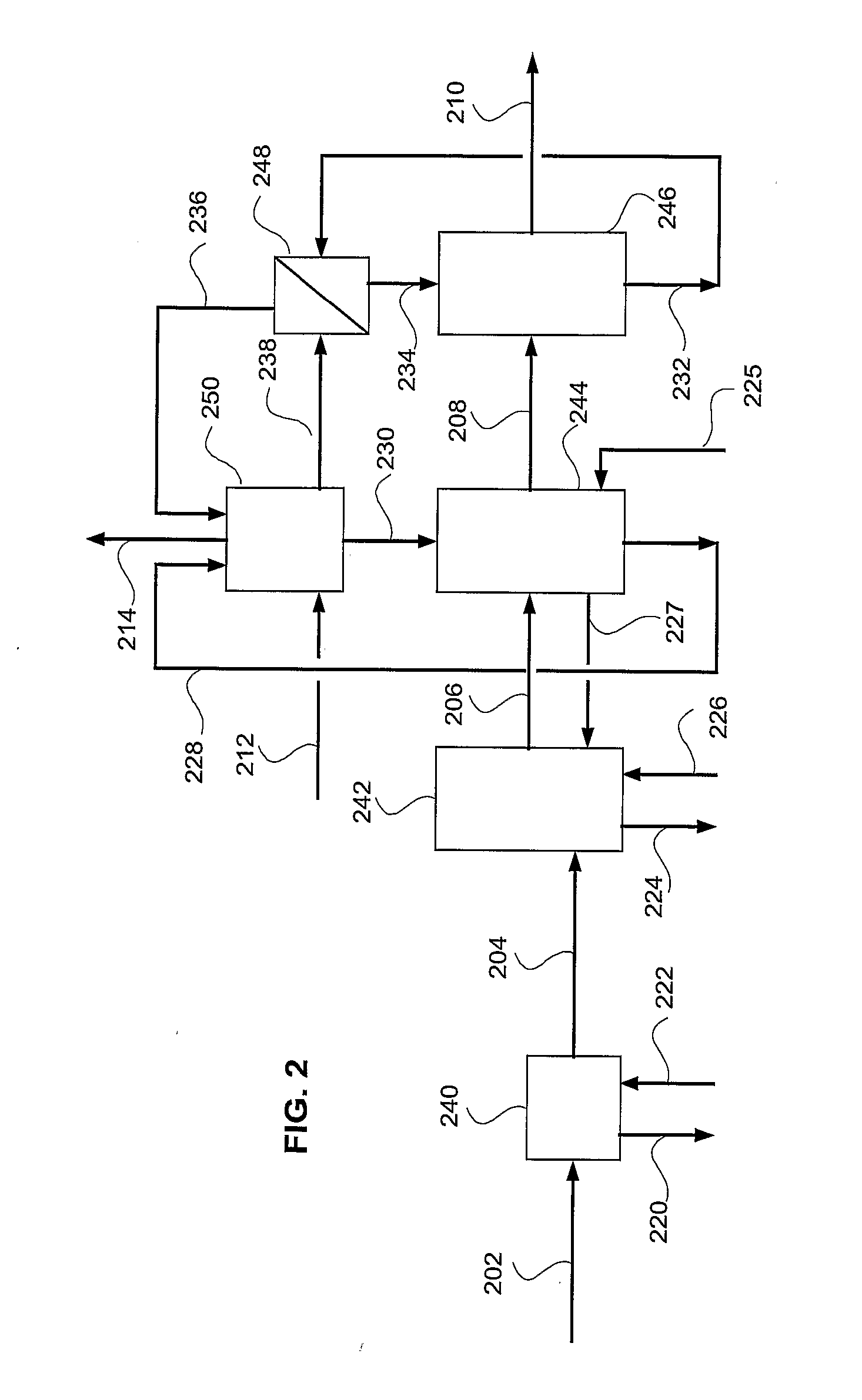

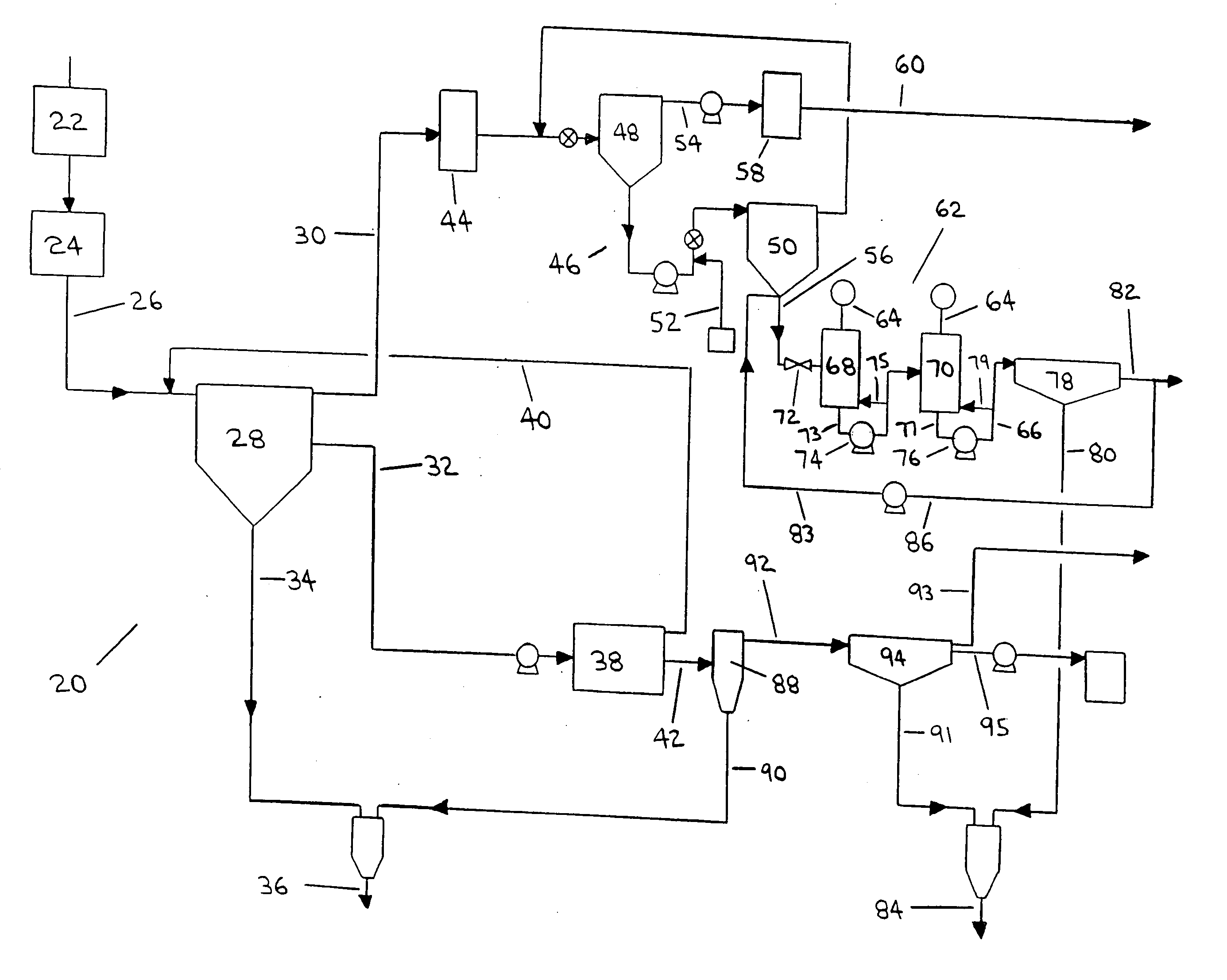

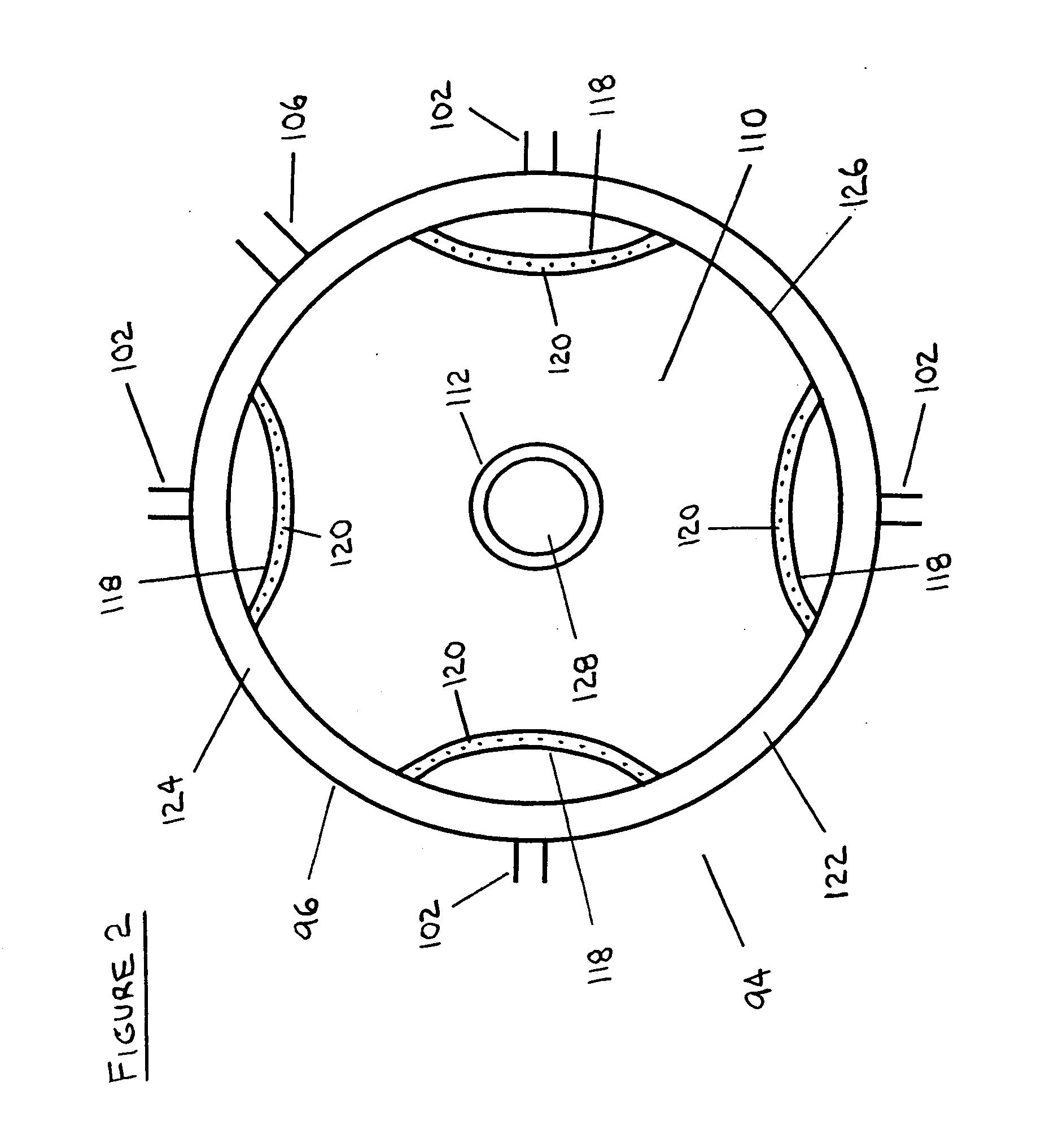

Process and apparatus for treating tailings

ActiveUS20050150844A1Easy to separateMaximize efficiencyWorking-up pitch/asphalt/bitumen by selective extractionSolid separationSolventOil sands

Processes and apparatus for the treatment of product streams from mineral processing operations, including the treatment of tailings which result from oil sand processing operations. The processes and apparatus relate to the recovery of a diluent solvent from bitumen froth tailings and to the thickening of tailings from a bitumen froth stream and a middlings stream resulting from an oil sand extraction process. In one aspect the processes and apparatus relate particularly to the recycling of product streams to maximize process efficiencies. In a second aspect the processes and apparatus relate particularly to the thickening of tailings to produce an underflow component, a clarified overflow component and an unclarified overflow component.

Owner:TRUENORTH ENERGY CORP

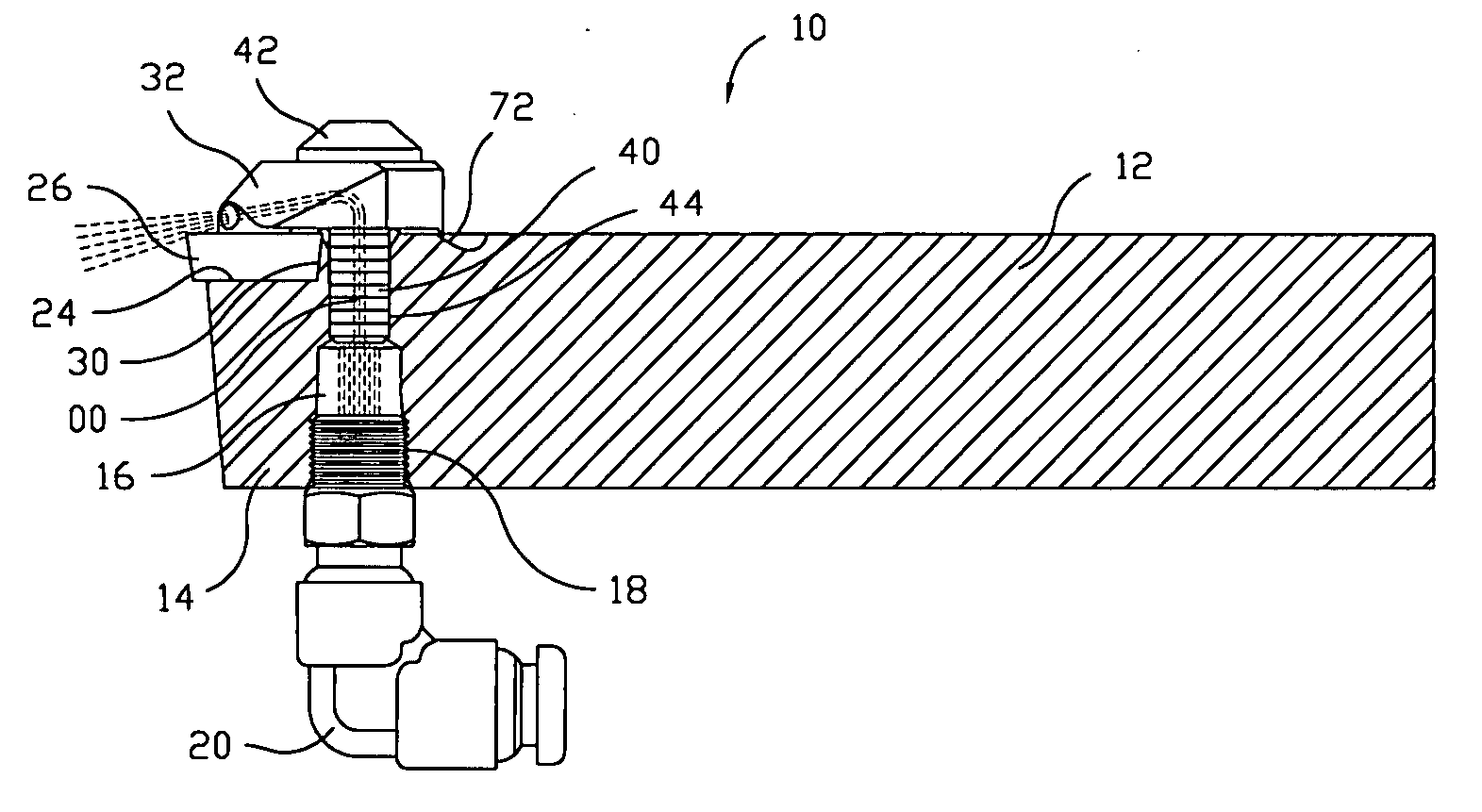

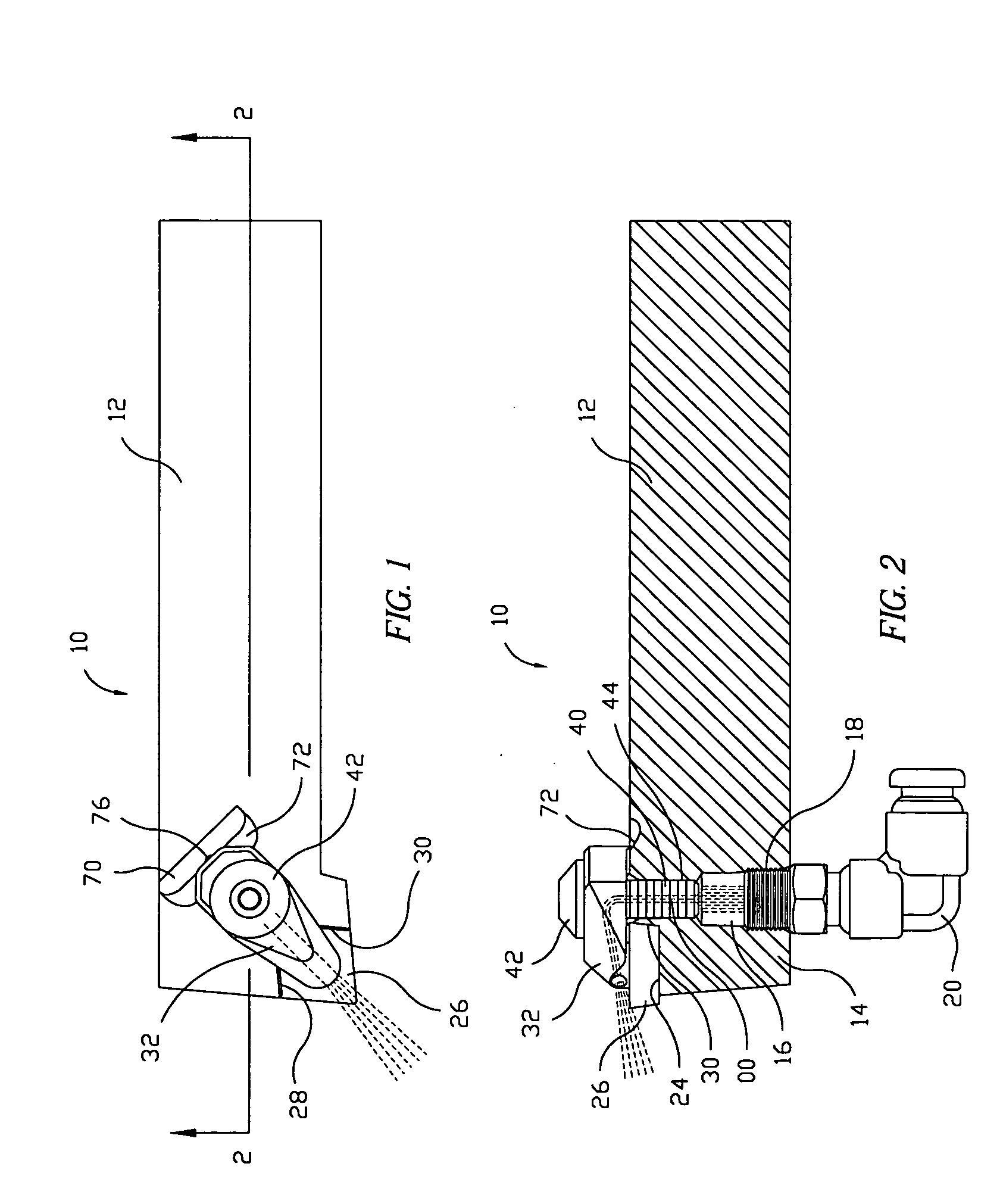

Machine tool holder having internal coolant supply and cutter retaining and coolant distribution cutter insert retaining clamp assembly

InactiveUS20070283794A1Minimizes heat induced wear and deteriorationExtended service lifeLathesCutting insertsCooling fluidMachine tool

A boring bar has a shank having a cutter support head at one end. A flow passage extends to the cutter support head and intersects a transverse flow passage that is defined in part by a clamp screw passage of the head. A metal cutting insert is clamped to the cutter support head by a clamp that is secured by a clamp screw being threaded into the clamp screw passage. The clamp screw defines an internal or external passage that communicates with the internal coolant fluid passage and completes a coolant distribution circuit. The clamp defines an internal coolant fluid passage having a discharge opening located and oriented to direct a jet of coolant fluid onto the metal cutting insert immediately at the site of cutting engagement within the rotating workpiece. The cutter support head also has a passage and chip removal jet nozzle that orients a jet of coolant fluid adjacent the cutter insert for remove metal chips during machining.

Owner:GIANNETTI ENRICO R

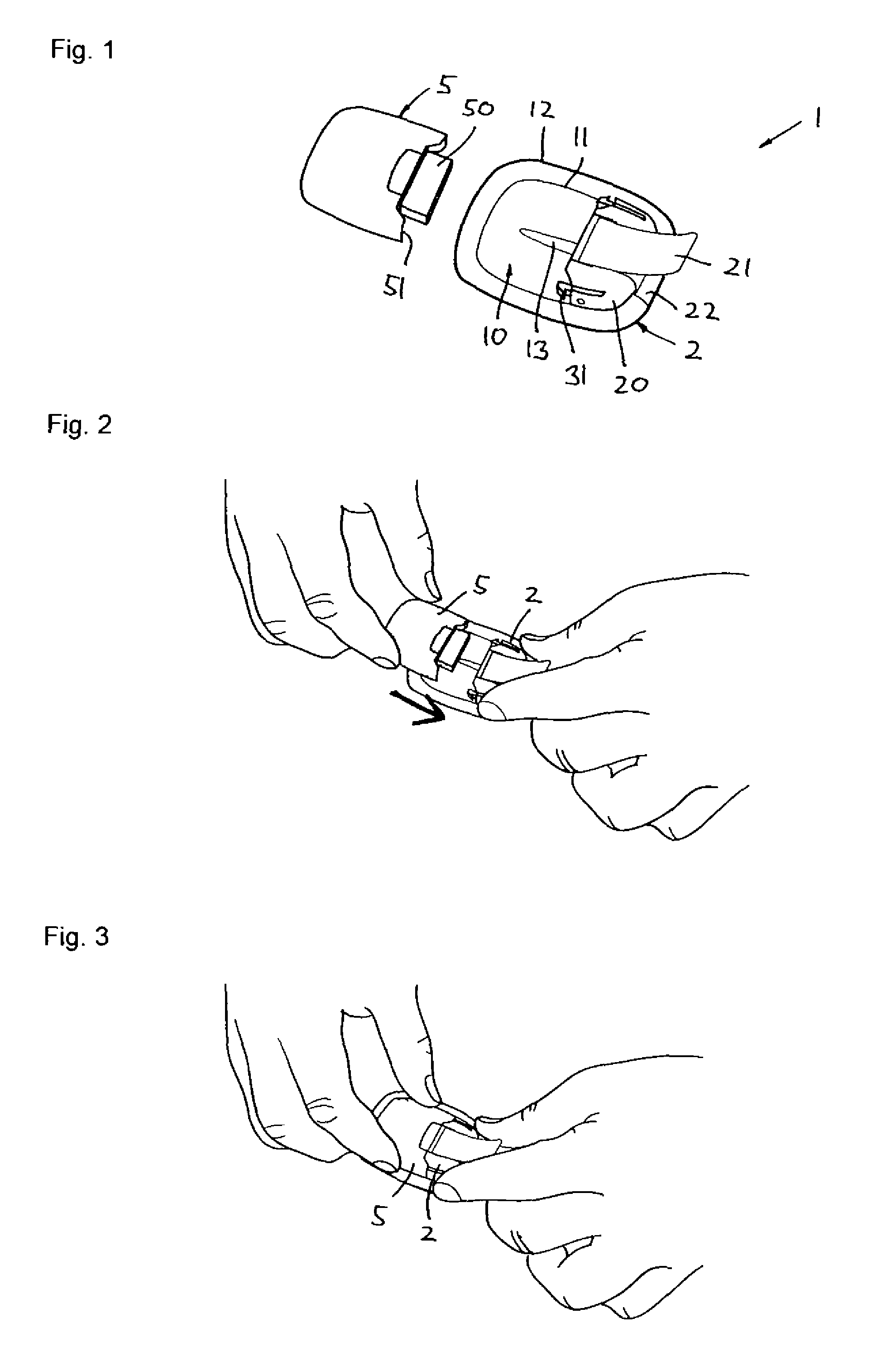

Ventilated Skin Mountable Device

InactiveUS20090048563A1Easy to operateEasy to usePressure infusionInfusion needlesSkin surfaceEngineering

A medical device is provided comprising a transcutaneous device unit and a process unit. The transcutaneous device unit is adapted to be mounted to a skin surface of a subject and comprises a first housing, a transcutaneous device, and may comprise a flexible patch portion with an upper surface and a lower mounting surface adapted for application to the skin of a subject. The process unit comprises a second housing with a lower surface and a process assembly. The first and second housings are adapted to be secured to each other in such a way that the lower surface of the second housing is allowed to move freely relative to at least a portion of the underlying skin surface or patch. In this way a relatively flexible patch portion can adapt to the skin surface to which it is mounted both statically and dynamically without being restricted in its movements by the normally much stiffer process unit.

Owner:NOVO NORDISK AS

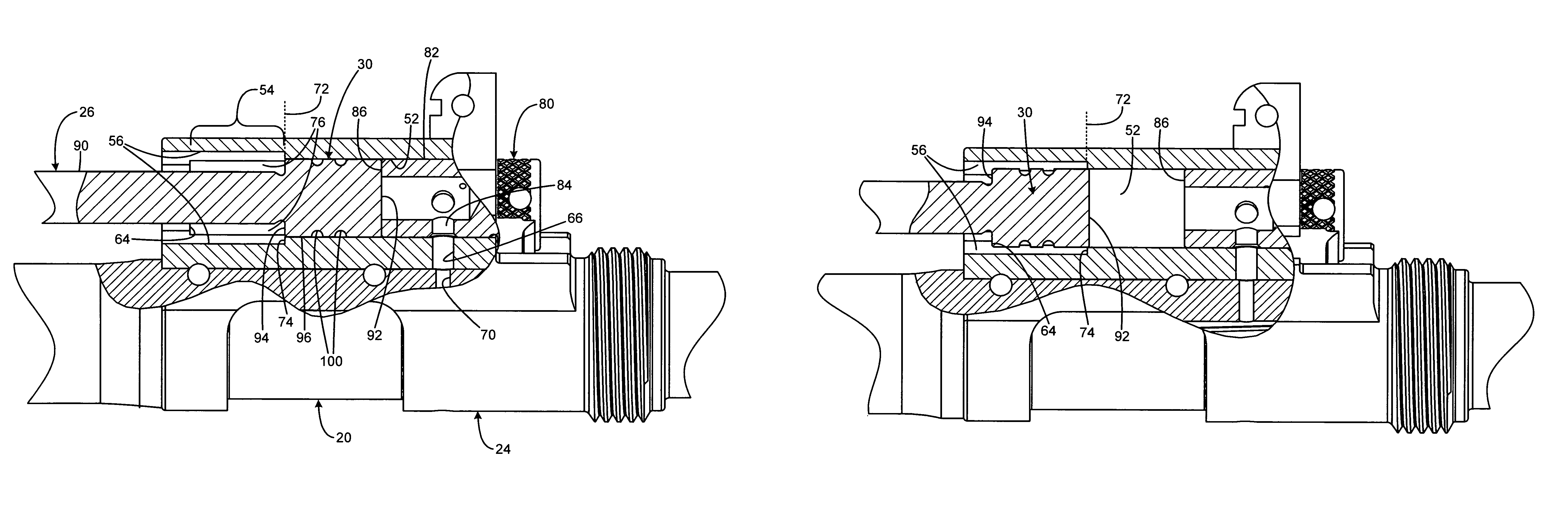

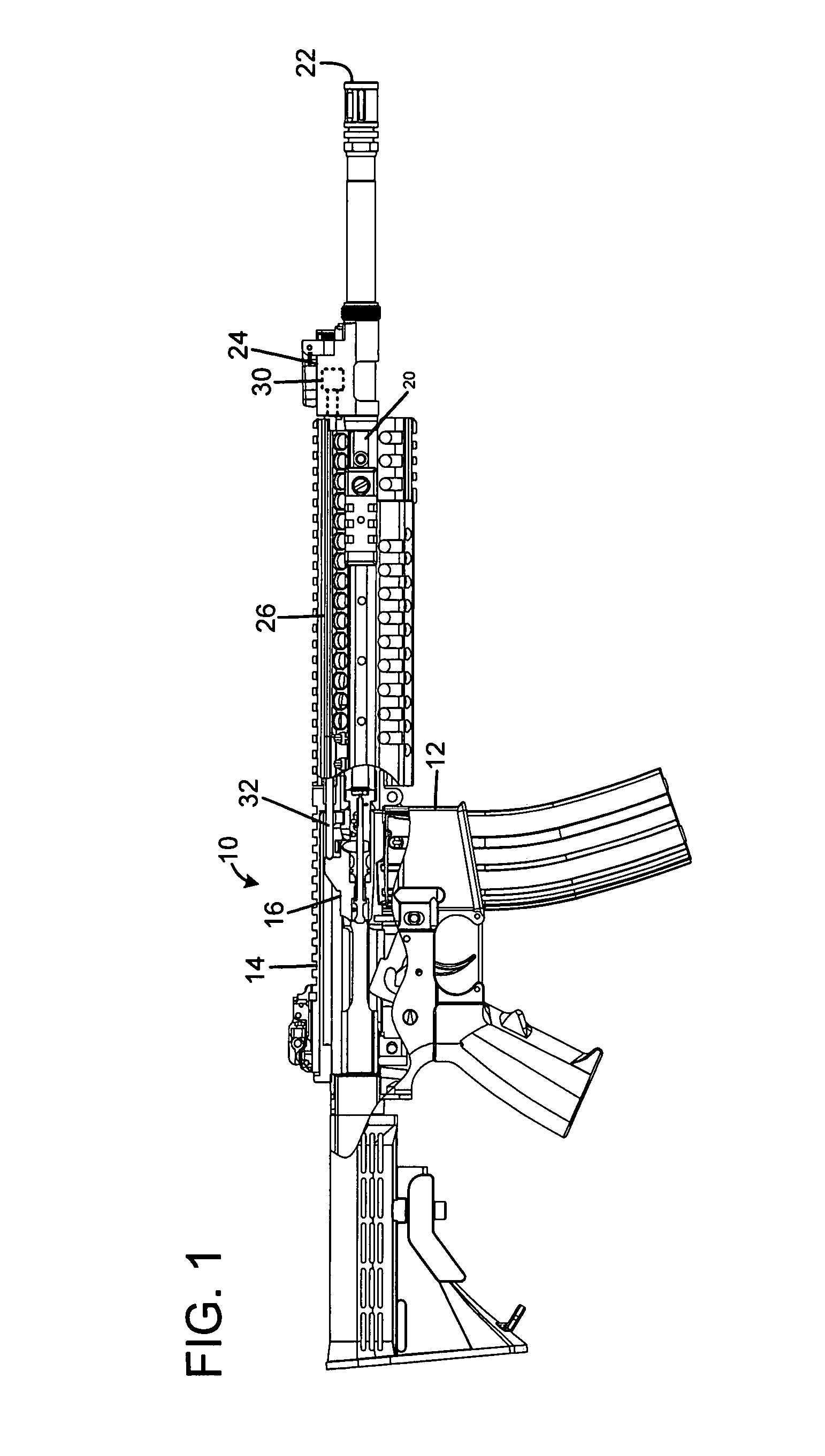

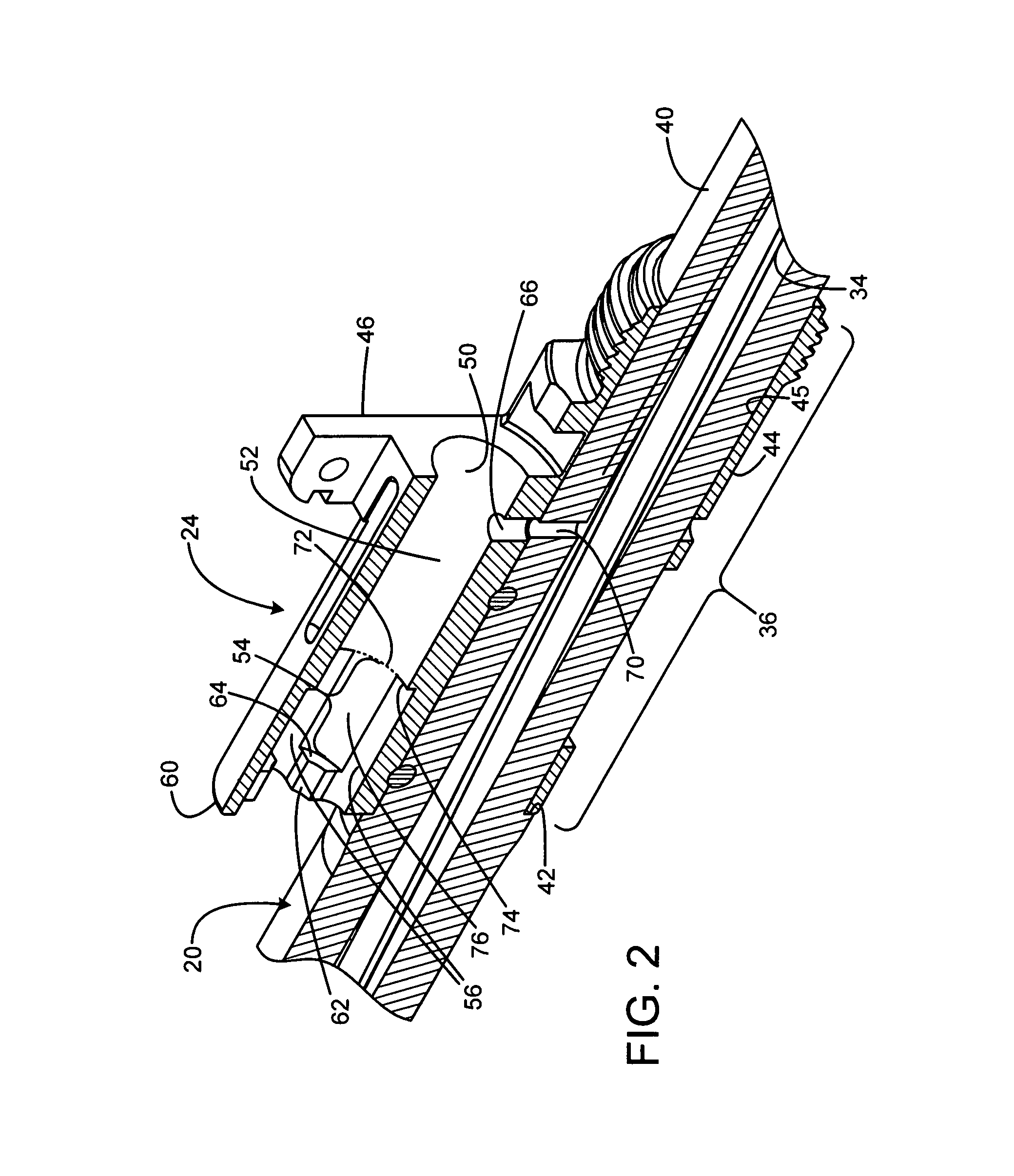

Auto-loading firearm with gas piston facility

ActiveUS7832326B1Prevent accumulationOvercome limitationWeapon cleaningWeapon testingPistonReciprocating motion

A firearm has a body with a bolt assembly reciprocating within the body. A barrel having a bore extends from the body. A gas block with an elongated chamber is connected to the barrel, and a gas passage connects the barrel bore to the gas block chamber. An operating rod has a forward end portion closely received in the gas block chamber and a rear end positioned to operably engage the bolt assembly. The gas block chamber has a forward portion closely receiving the forward end portion of the rod, and the gas block chamber has a rear portion with a profile larger than the forward portion. The forward portion of the rod may be a cylinder, and the rear portion of the gas block chamber may be fluted to provide clearance for flushing out contaminants. The rod may rotate freely to prevent accumulation of contaminants.

Owner:BARRETT FIREARMS MFG INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com