Patents

Literature

19370 results about "Cooling fluid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coolant is a fluid in IC 2 used to make Coolant Cells and to cool a Fluid Reactor. Coolant is made by enriching water or Distilled Water with Lapis Lazuli Dust in the Canning Machine set to Fluid Enrich mode.

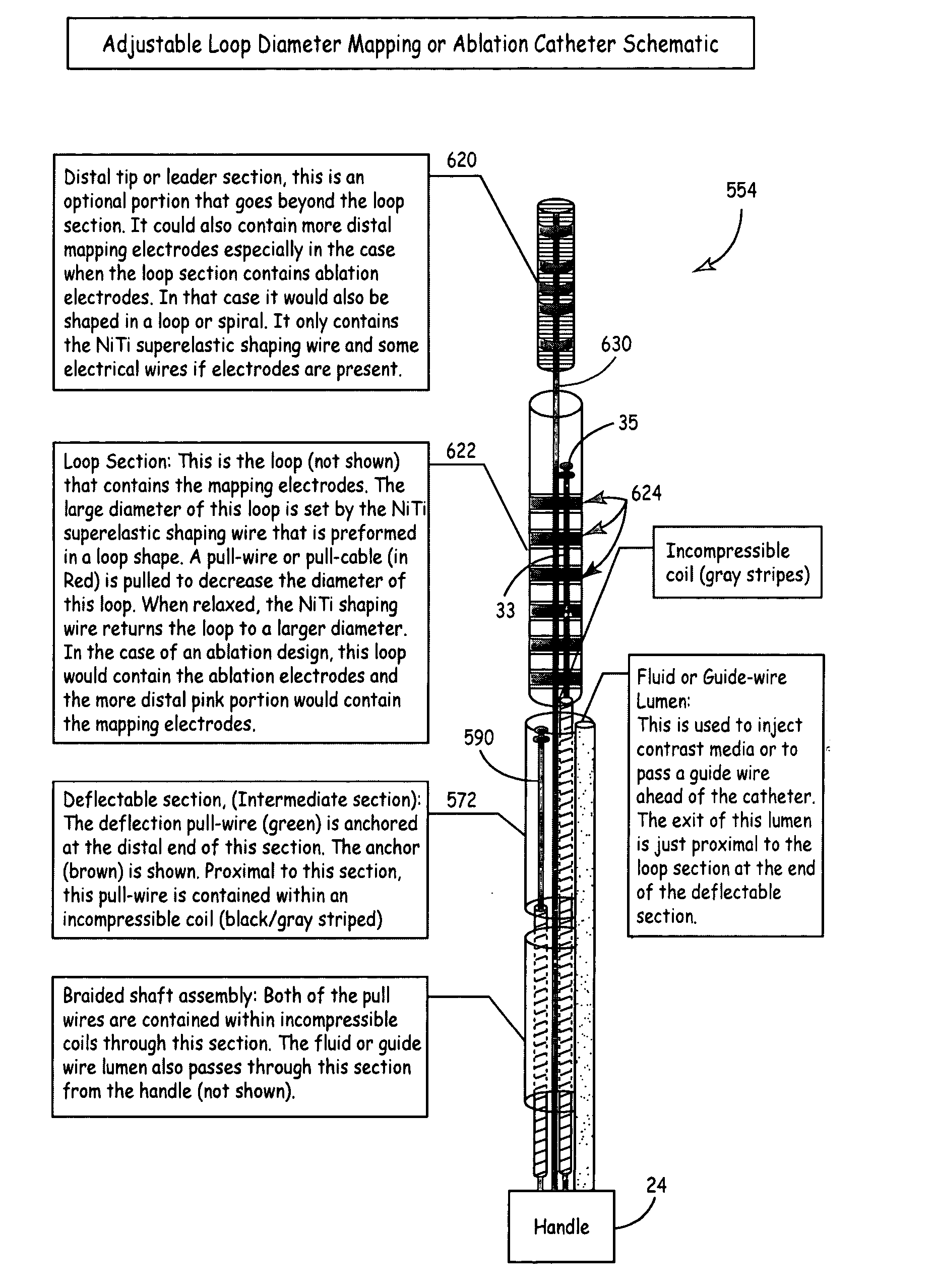

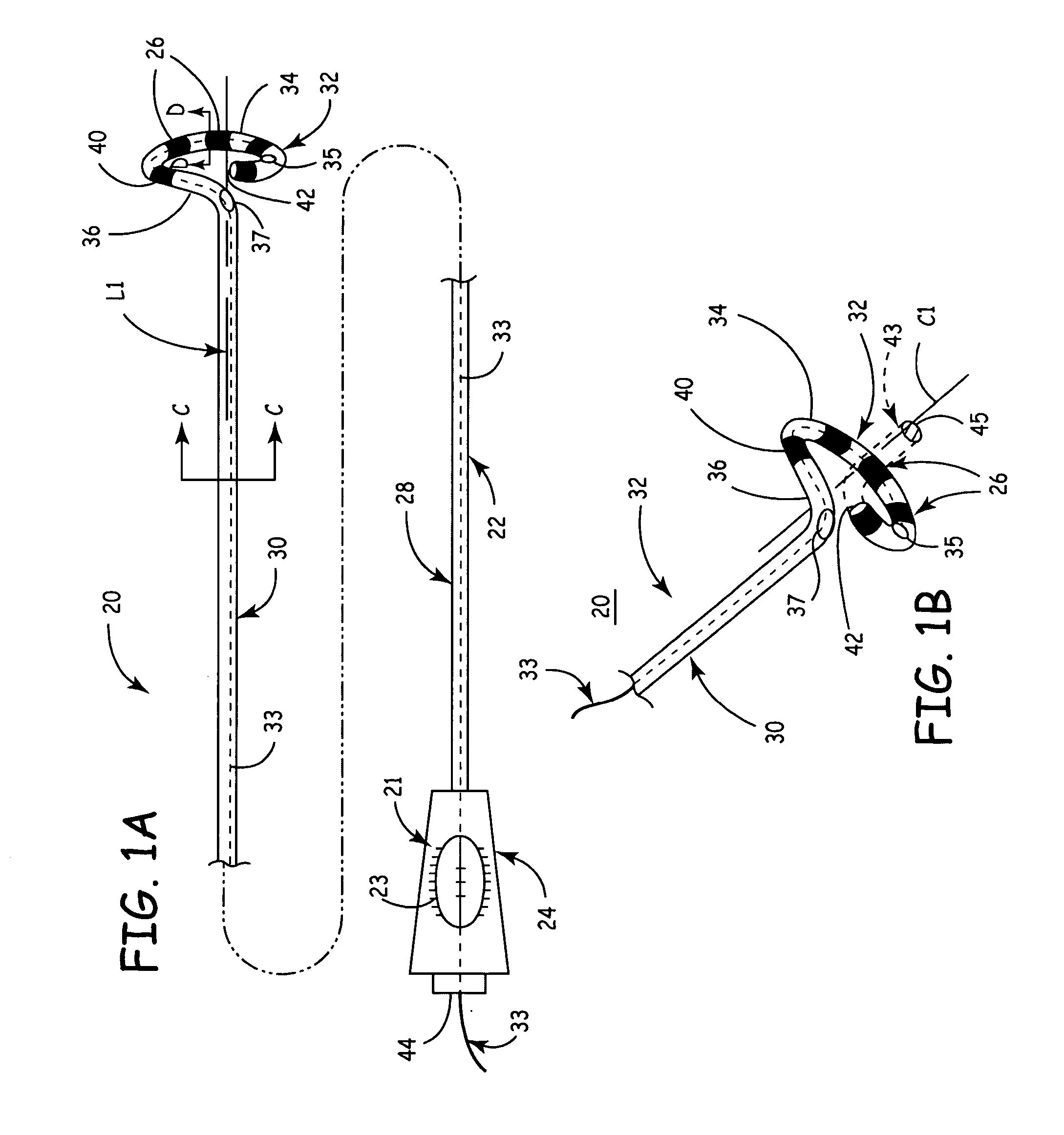

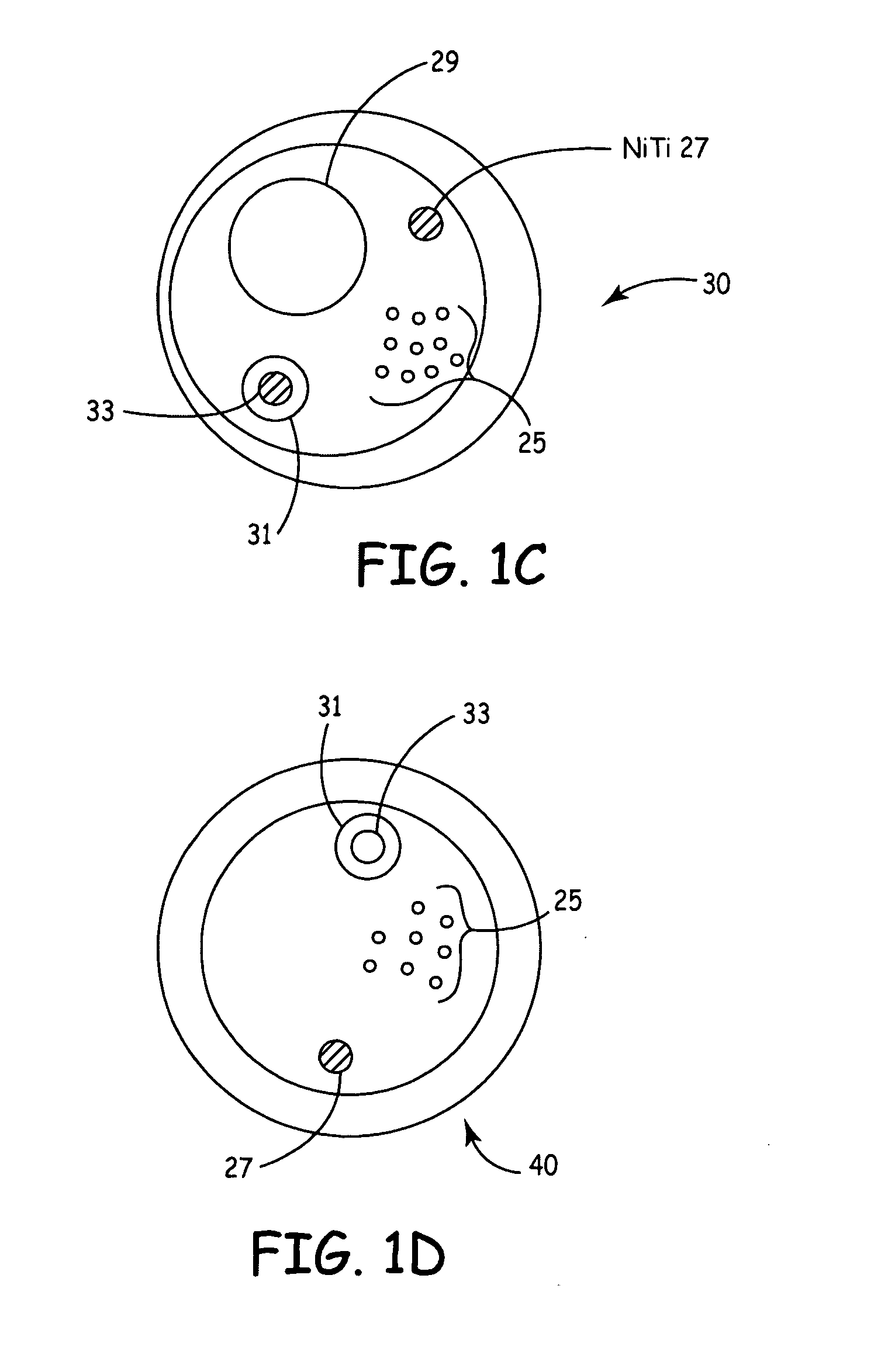

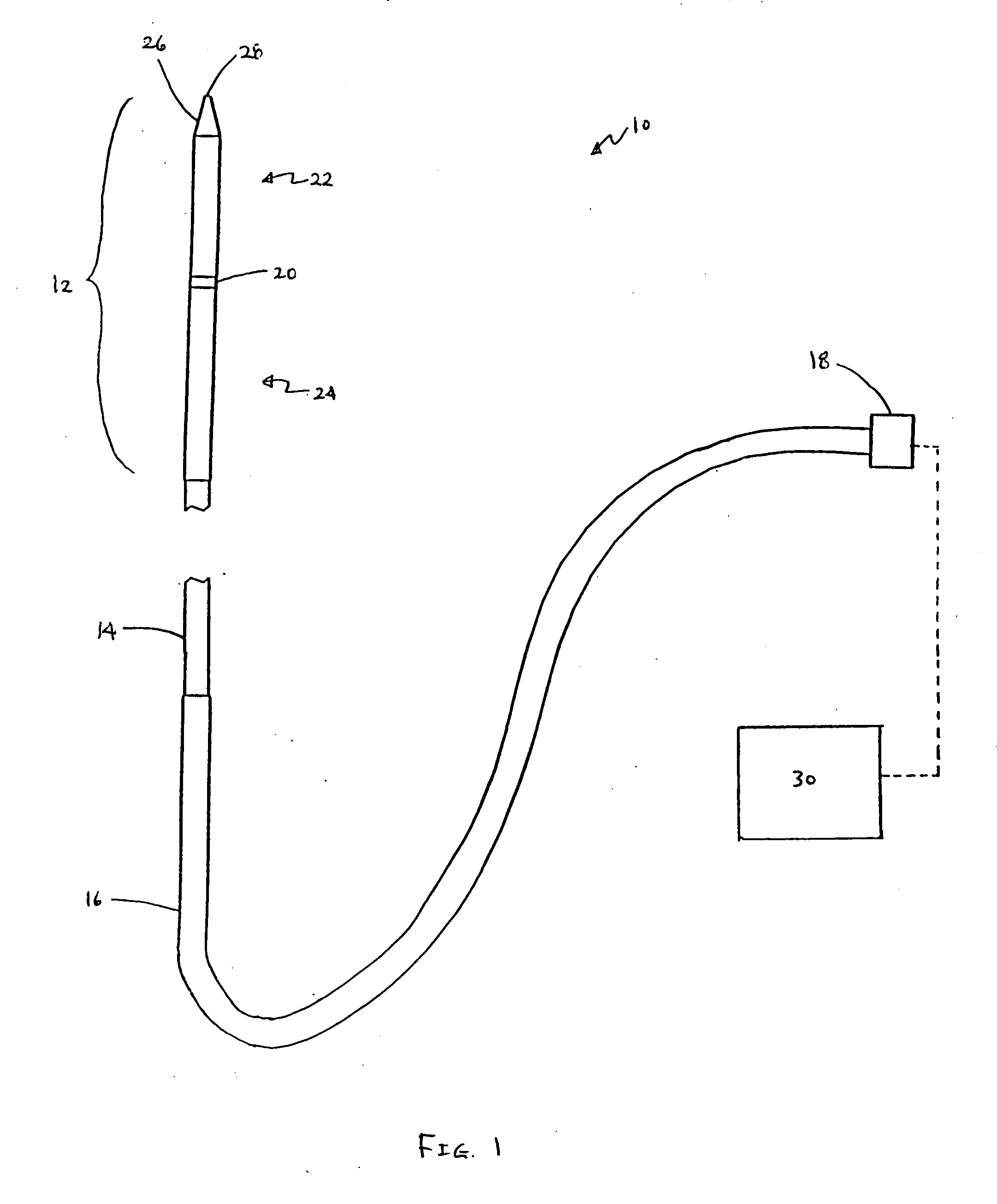

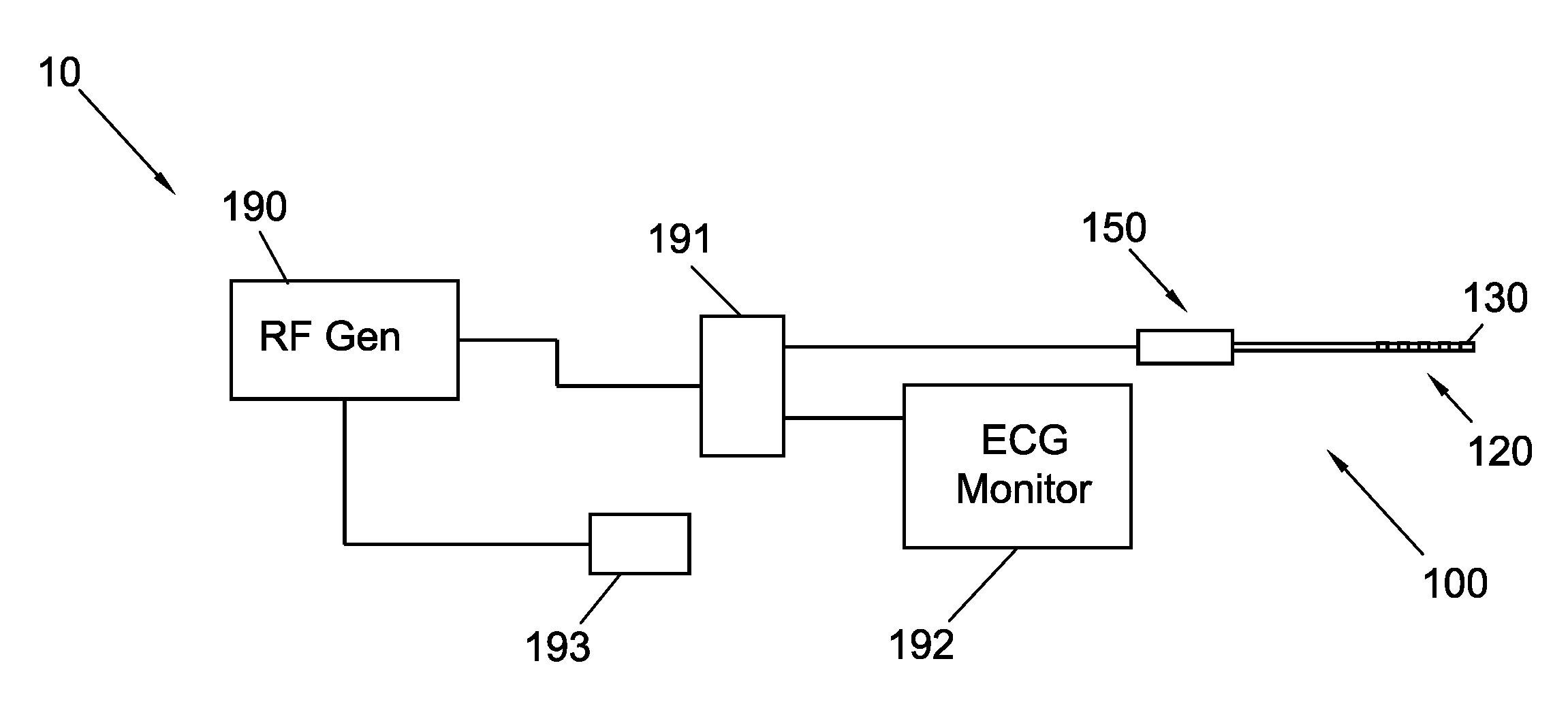

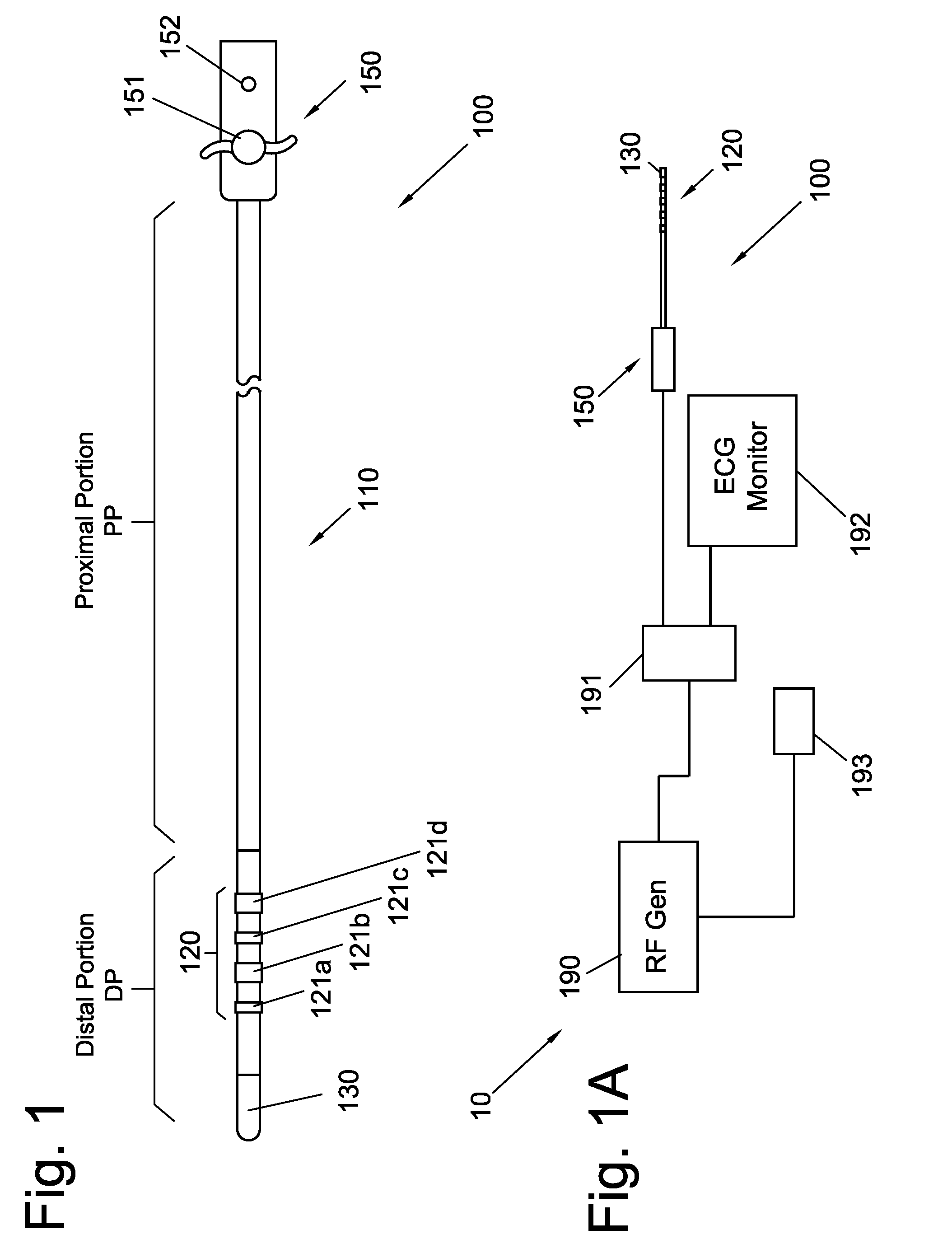

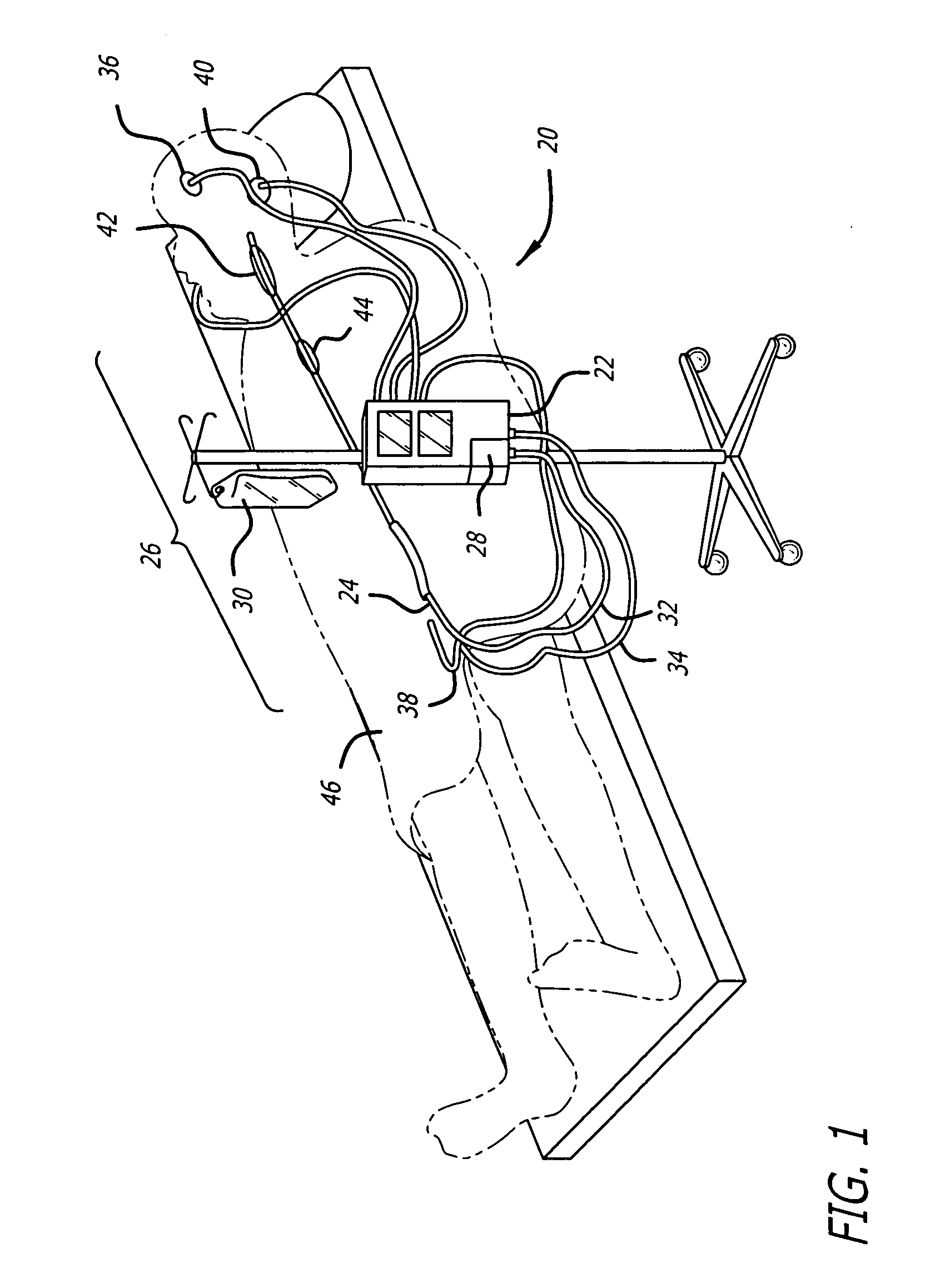

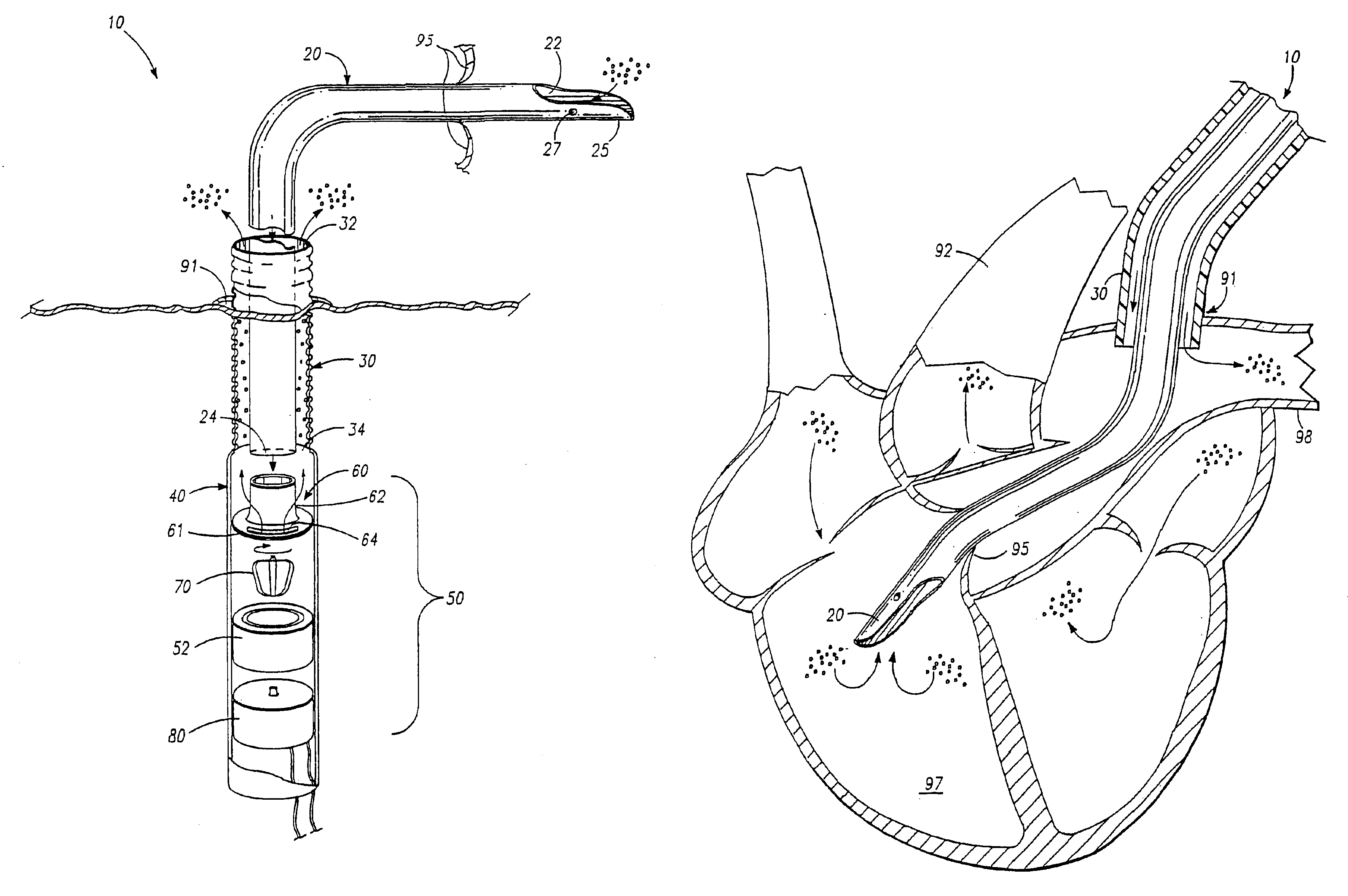

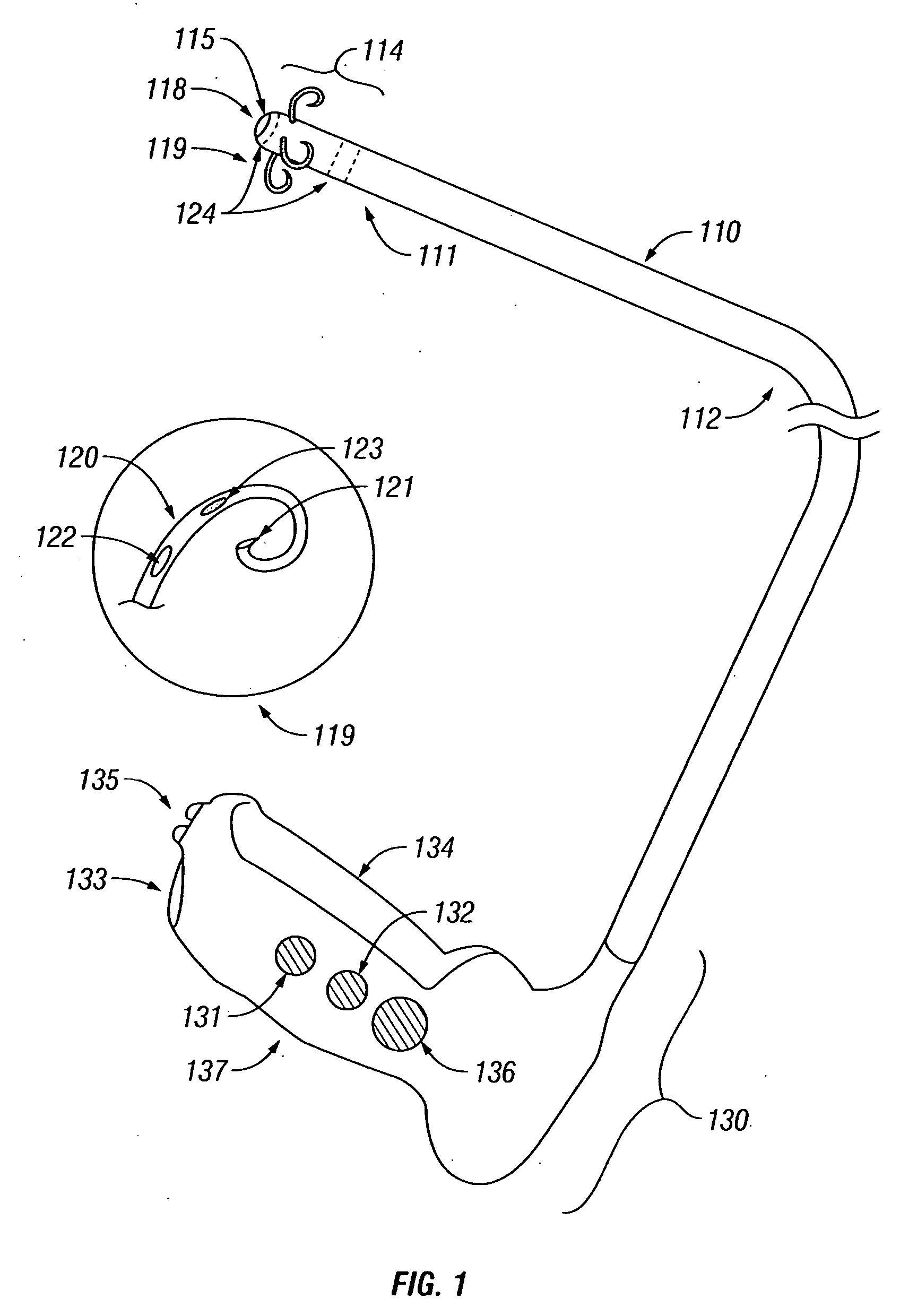

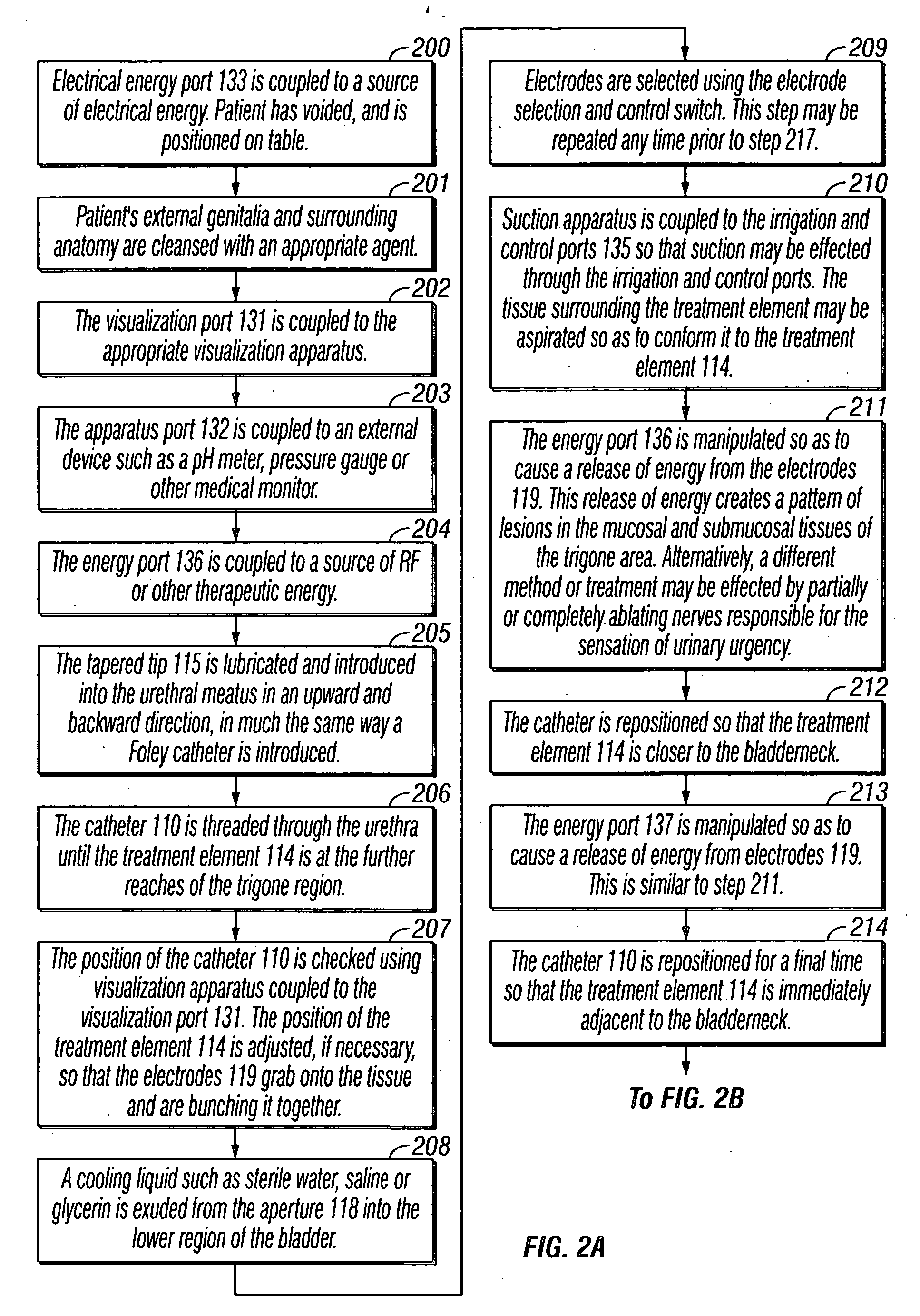

Multi-purpose catheter apparatus and method of use

InactiveUS20050010095A1Easy to adaptEfficiently and accurately deliverElectrocardiographySurgical needlesDistal portionSaline solutions

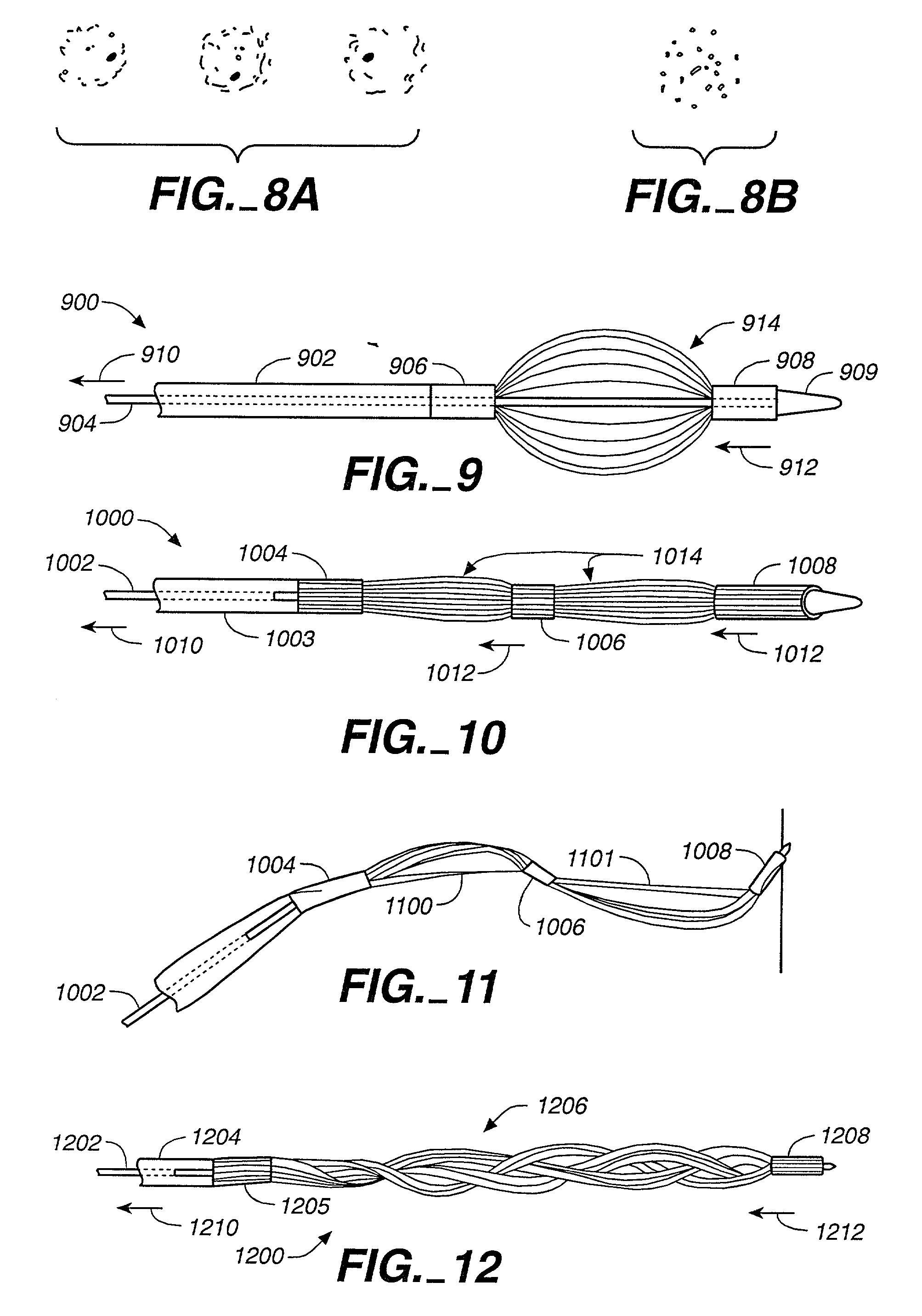

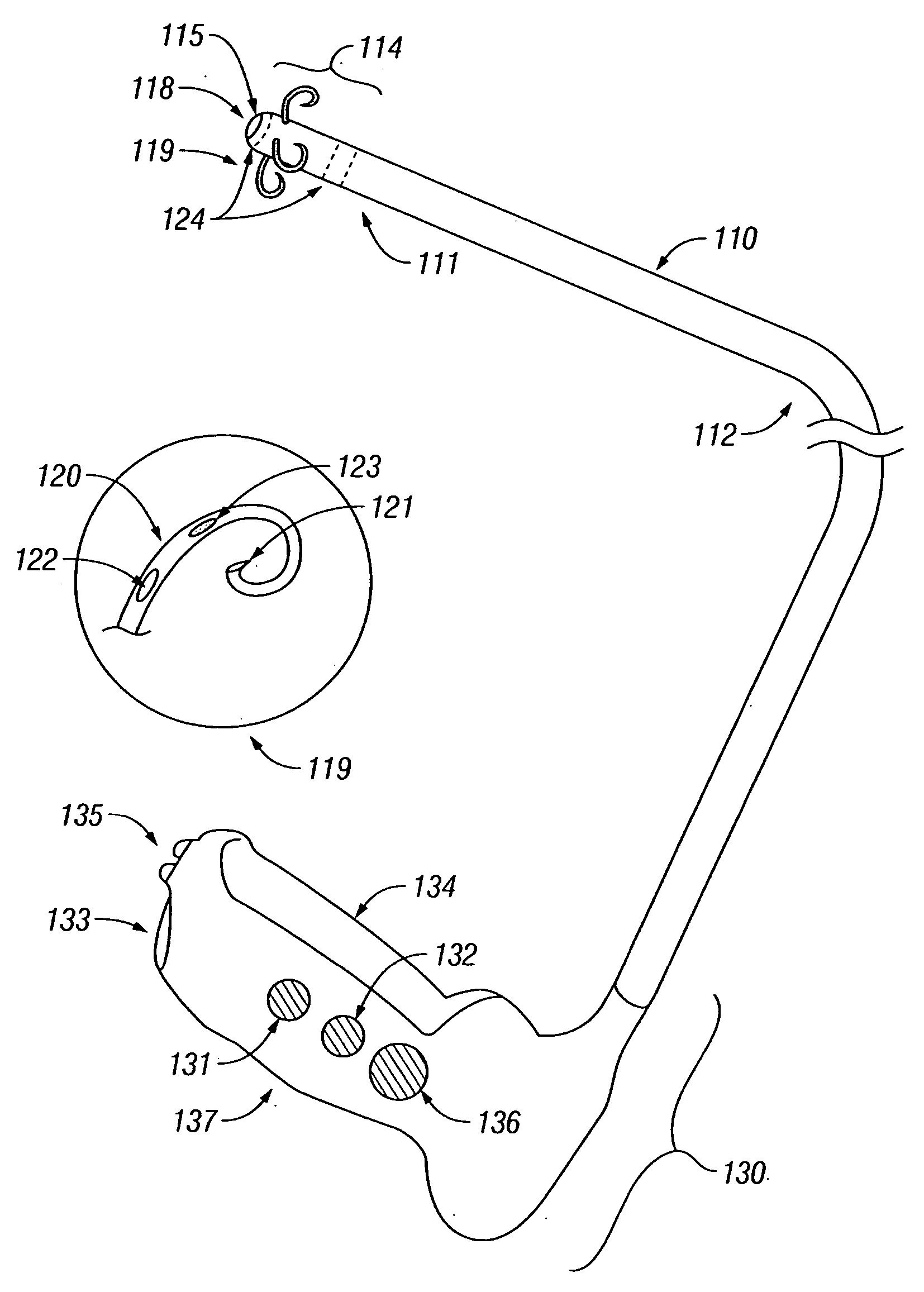

According to the present invention, a catheter having at least one multi-purpose lumen formed through the catheter terminates proximal a relatively complex-shaped distal portion thereof. In one form of this embodiment, the relatively complex-shaped distal portion comprises a looped portion having diagnostic- and / or ablation-type electrodes coupled thereto and an elongated diameter-adjusting member coupled proximal the distal end of the looped portion. The multi-purpose lumen may be used to alternately accommodate a variety of dedicated materials; such as, (i) a guide wire for initial deployment or later repositioning of the catheter, (ii) a volume or flow of a contrast media and the like, (iii) a deployable hollow needle or tube and the like used to biopsy adjacent tissue or dispense a therapeutic agent into a volume of tissue, and (iv) a cooling fluid, such as saline solution and the like dispensed at least during therapeutic tissue ablation procedures.

Owner:MEDTRONIC INC

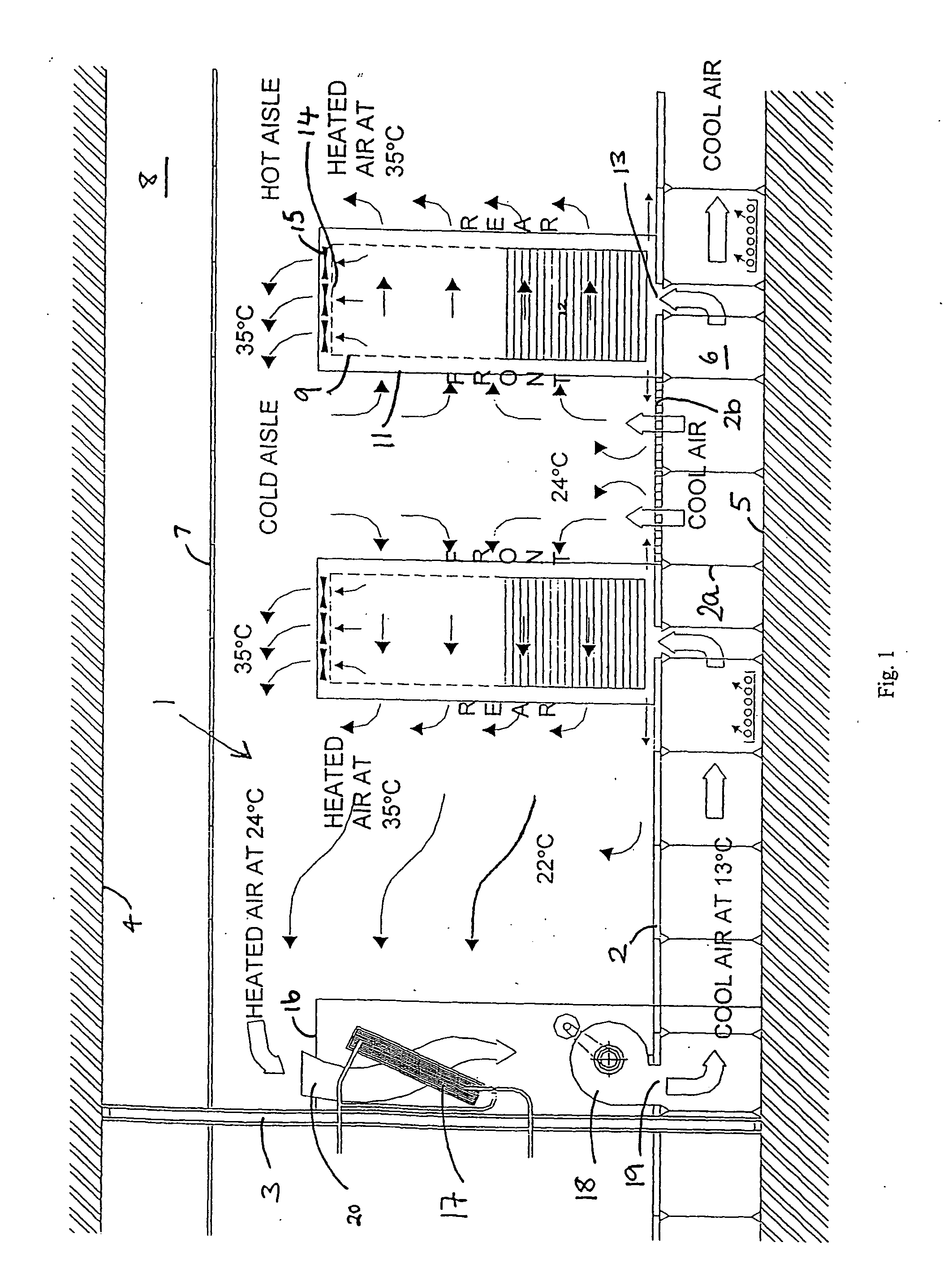

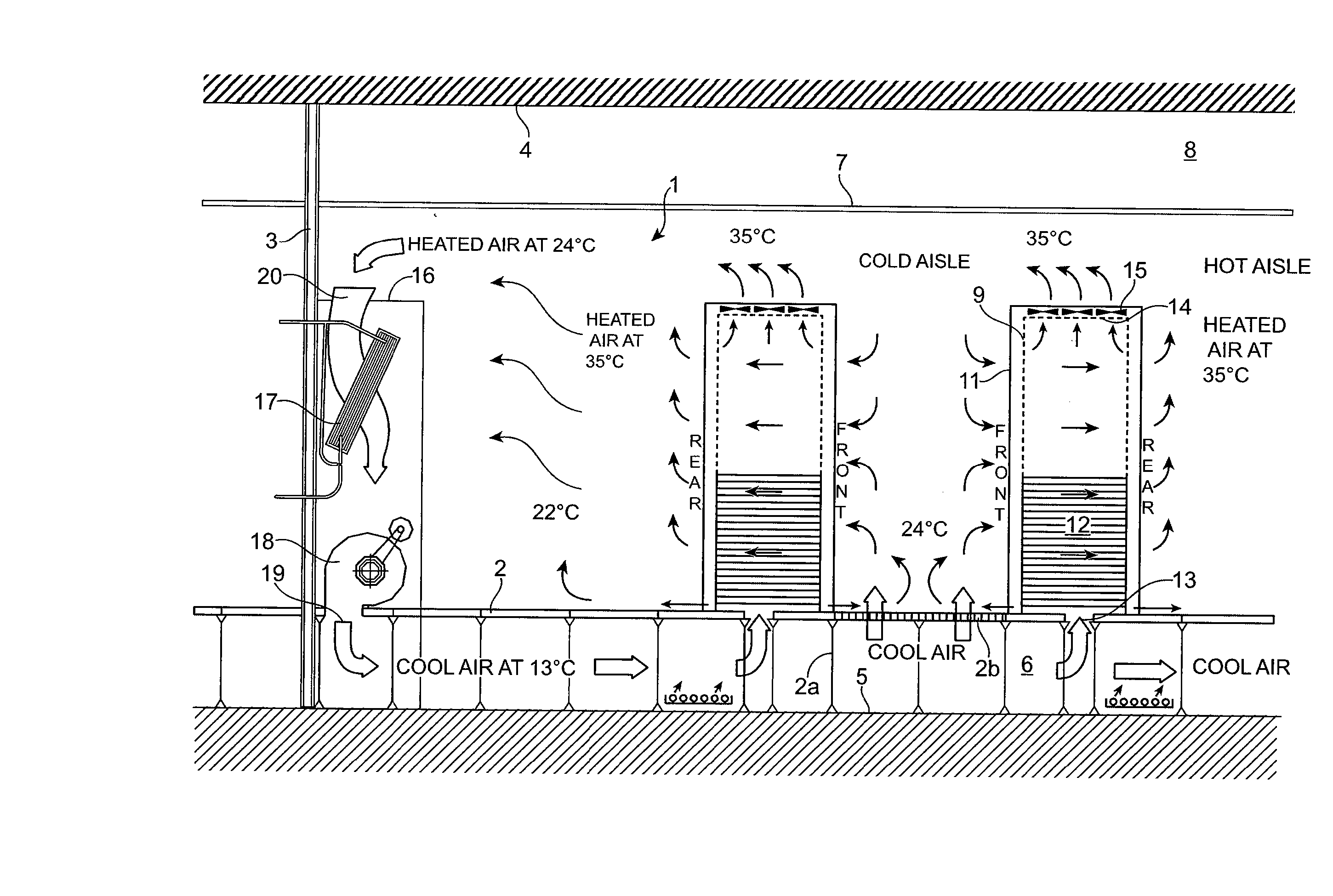

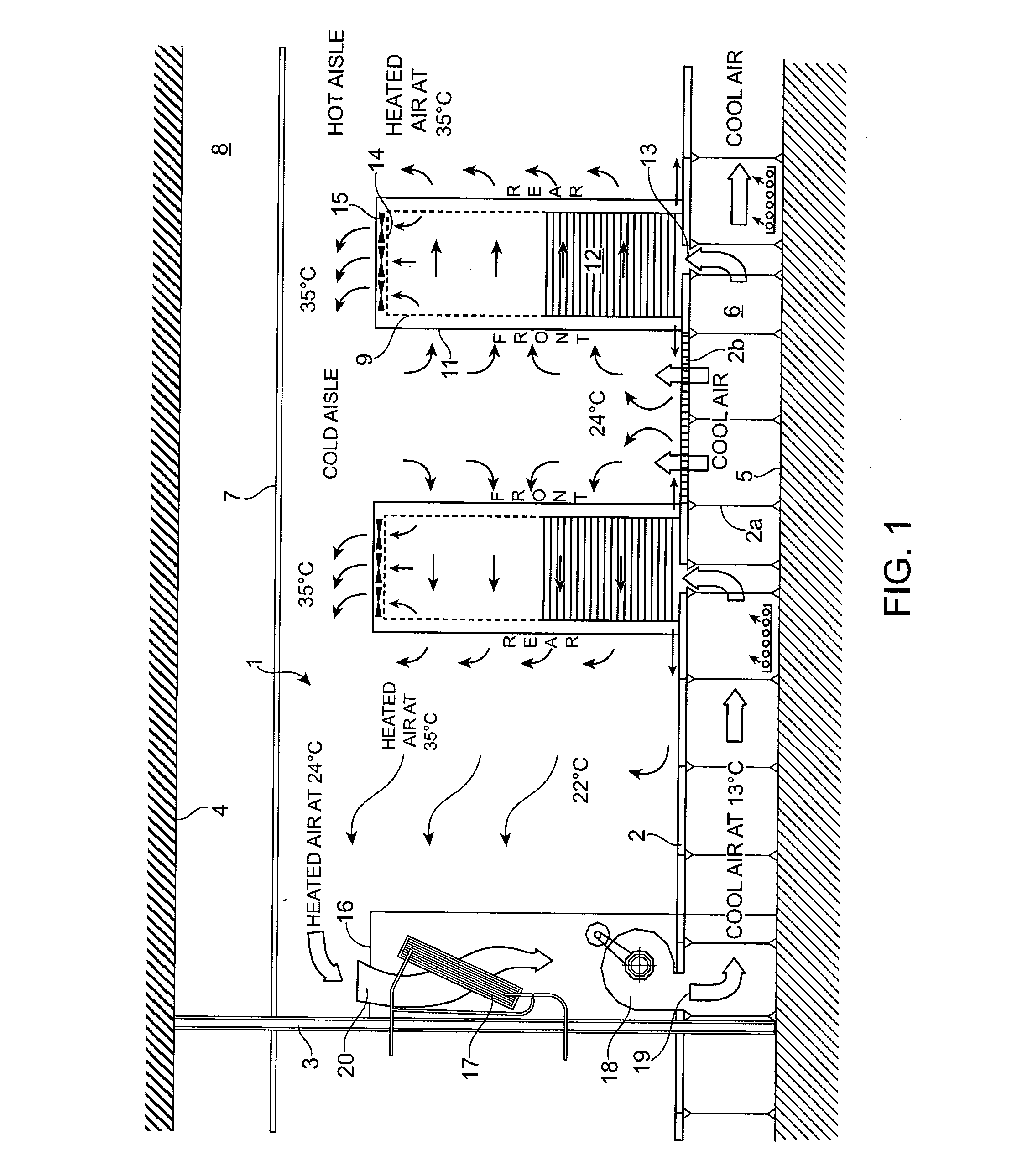

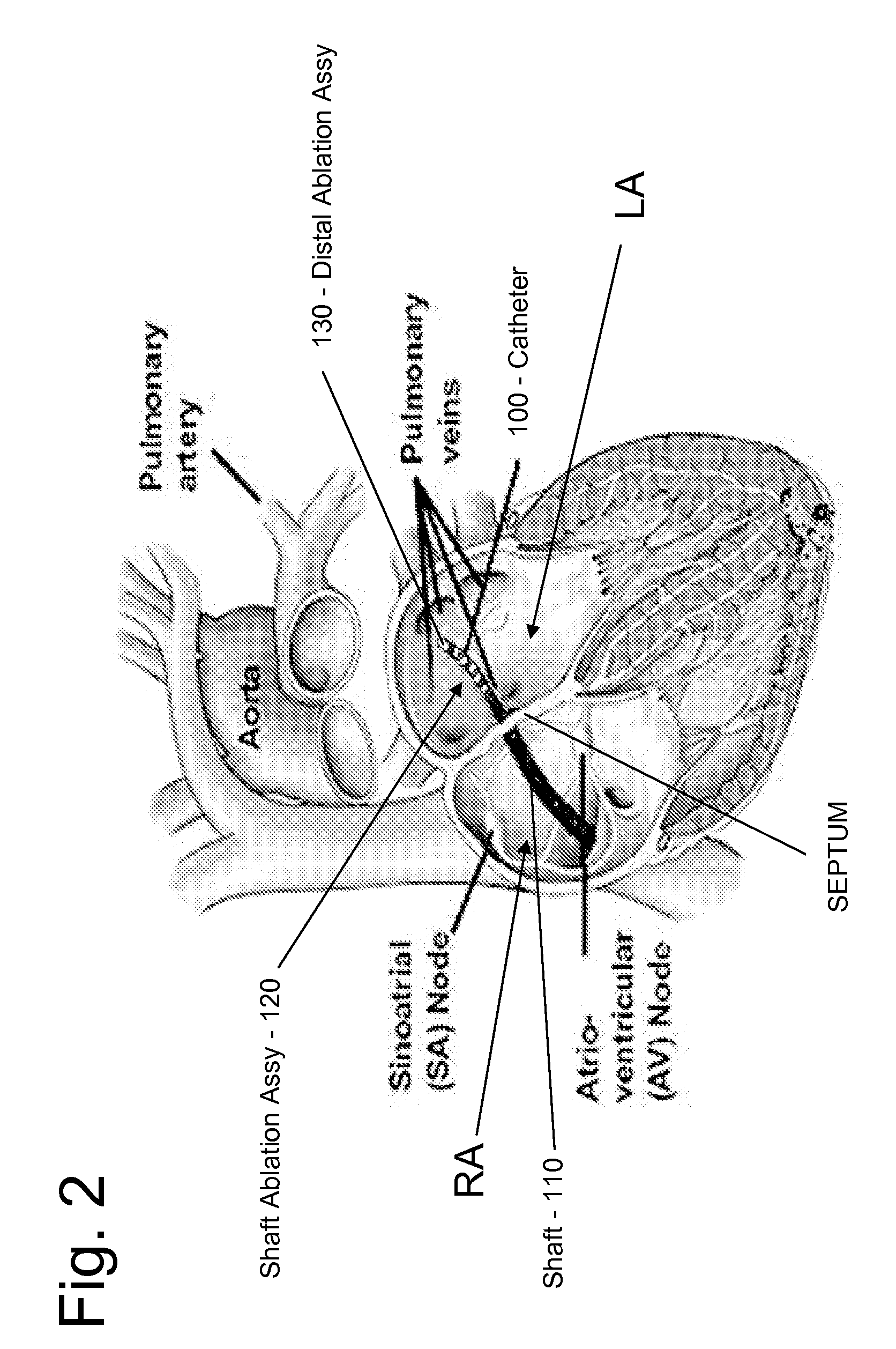

Cooling of a data centre

InactiveUS20050225936A1Improve availabilityHigh fault toleranceLighting and heating apparatusDigital data processing detailsData centerVertical array

Owner:SCHNEIDER ELECTRIC IT CORP

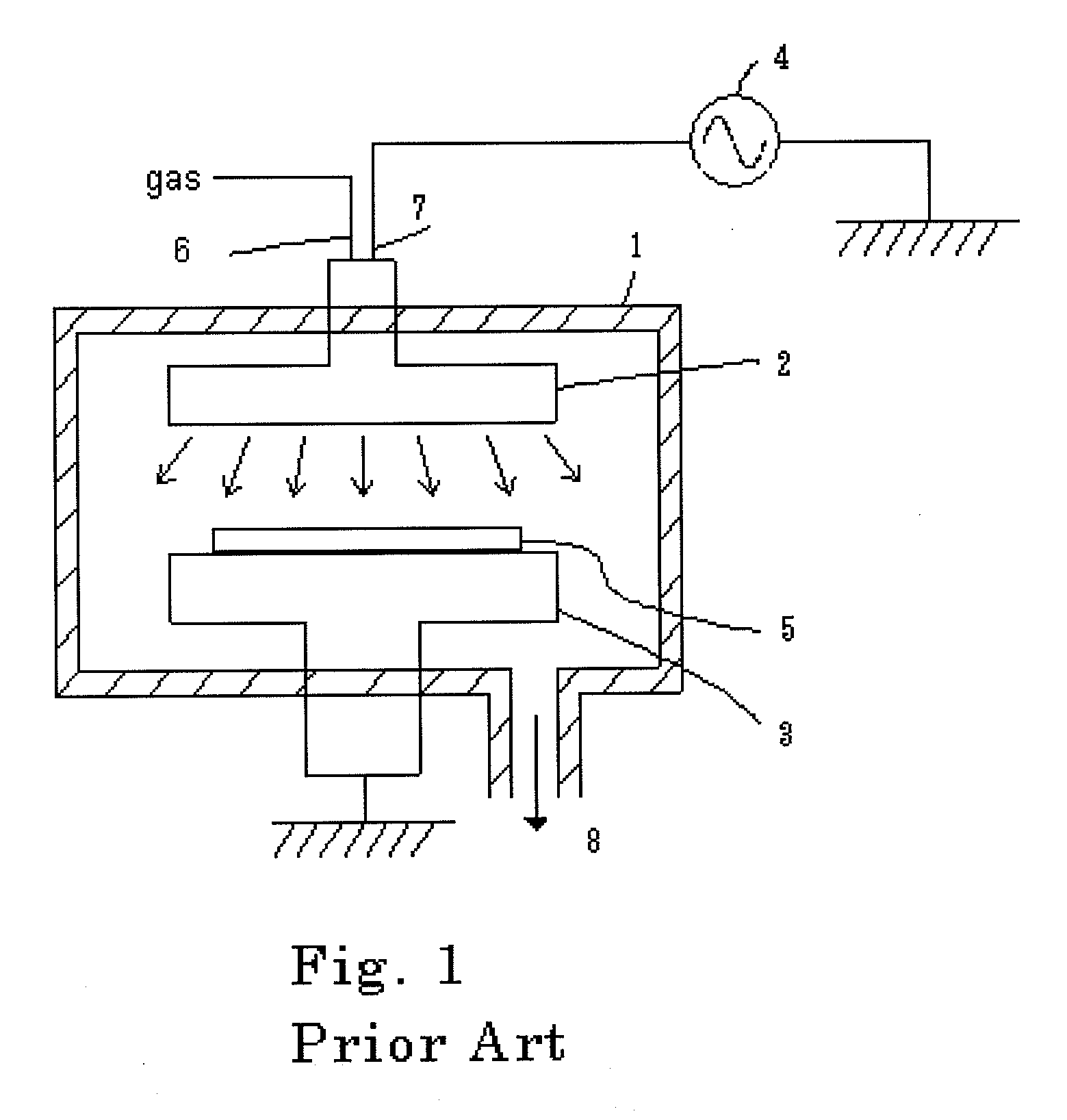

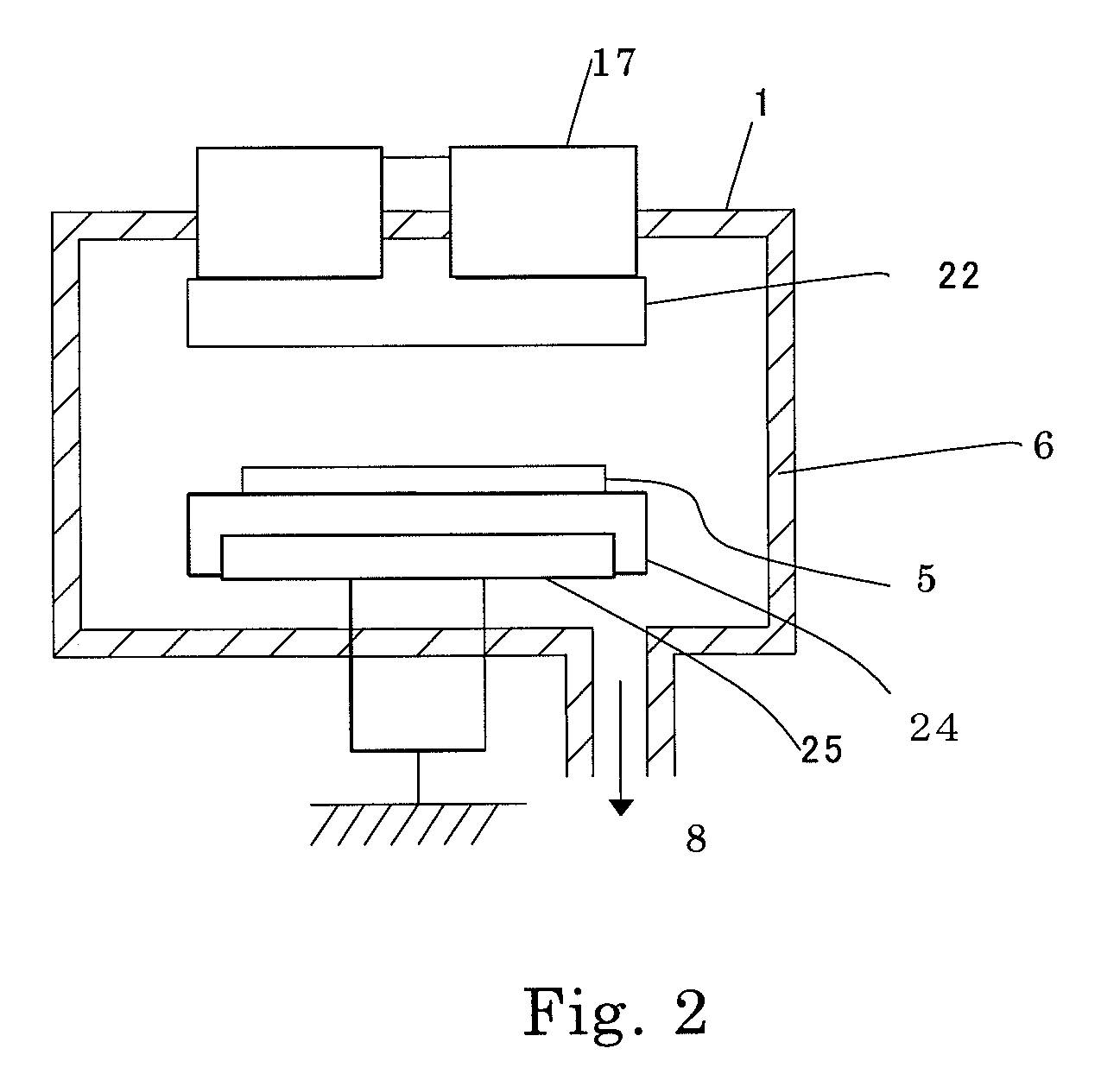

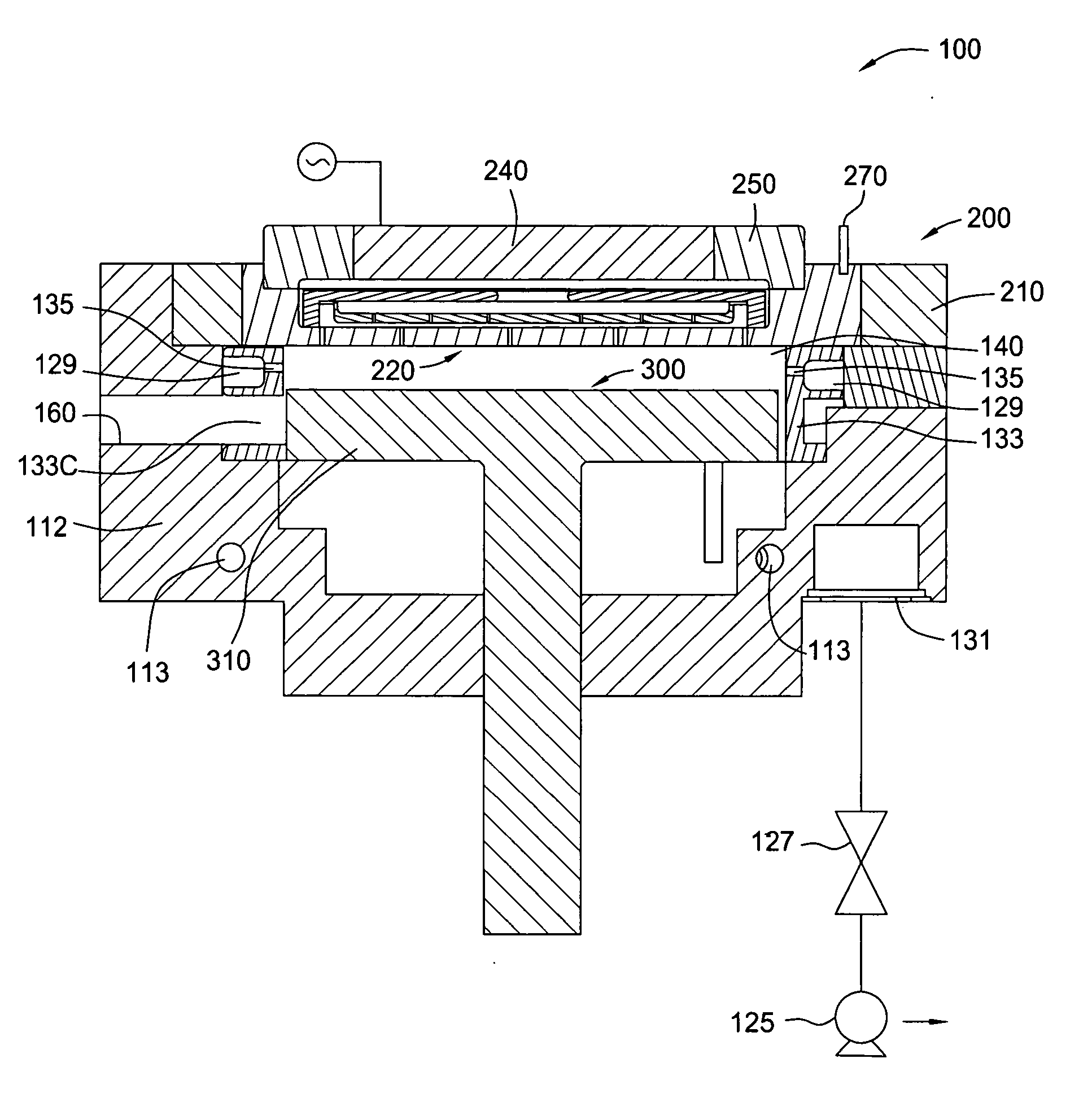

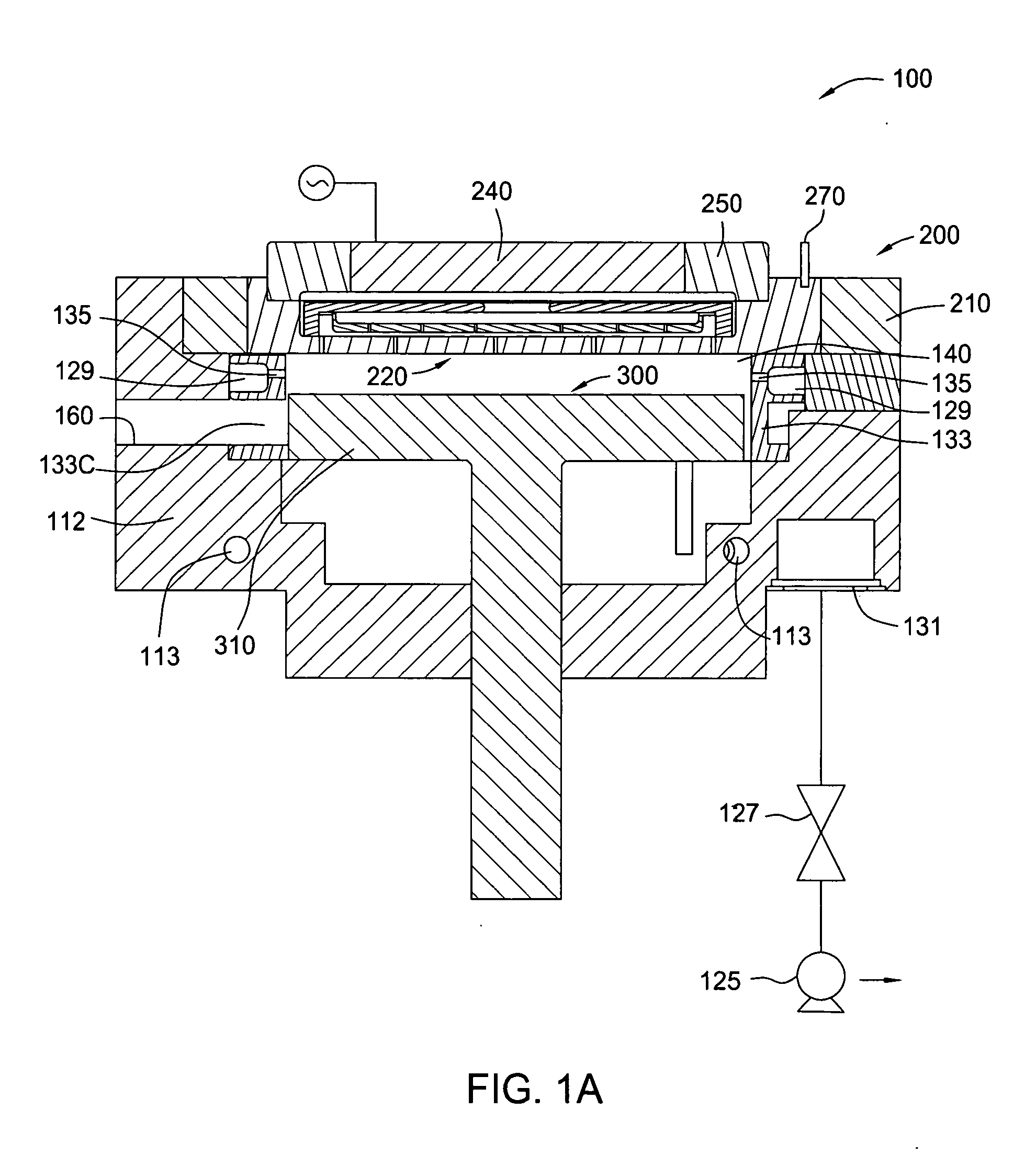

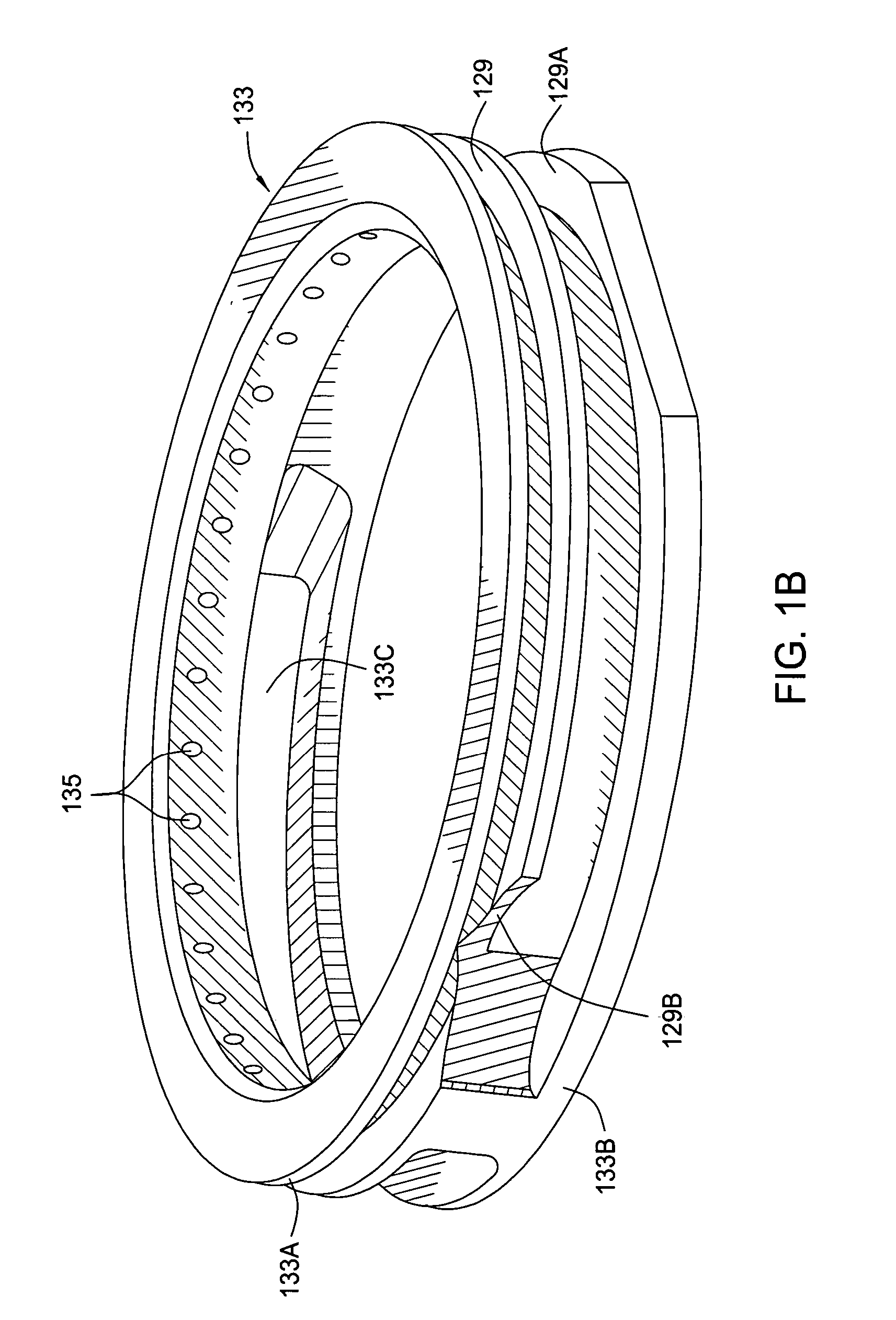

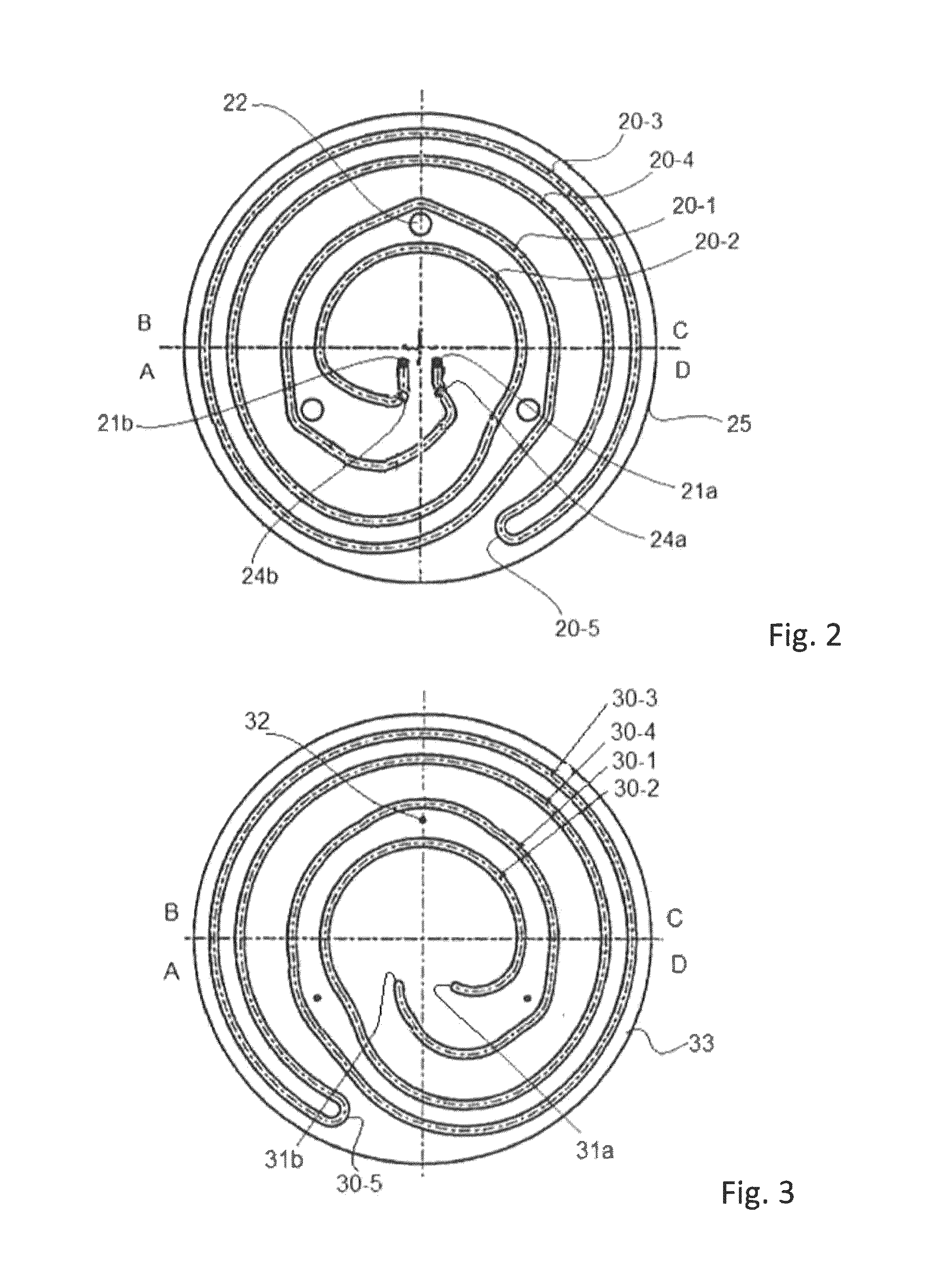

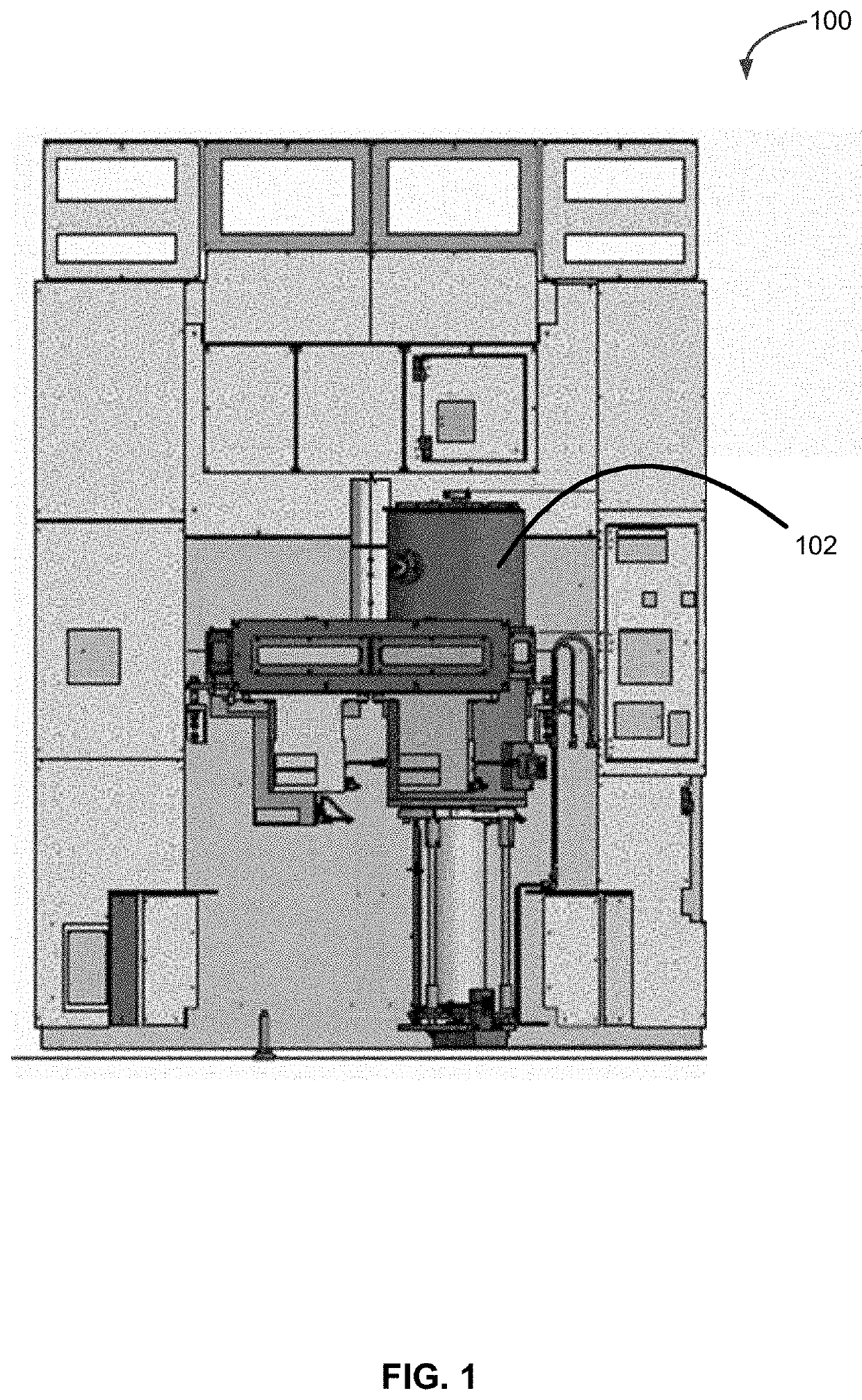

Plasma CVD apparatus having non-metal susceptor

InactiveUS20080299326A1Avoid Metal ContaminationConcerning long-term stabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSusceptorMetallurgy

A plasma CVD apparatus includes: a cooling susceptor for placing a substrate thereon and serving as an electrode; and a shower plate for introducing gas toward the susceptor via multiple throughholes formed therein. The shower plate serves as an electrode and is disposed in parallel to the susceptor. The cooling susceptor is made of a ceramic material provided with a cooling fluid flow path for passing a cooling fluid therethrough.

Owner:ASM JAPAN

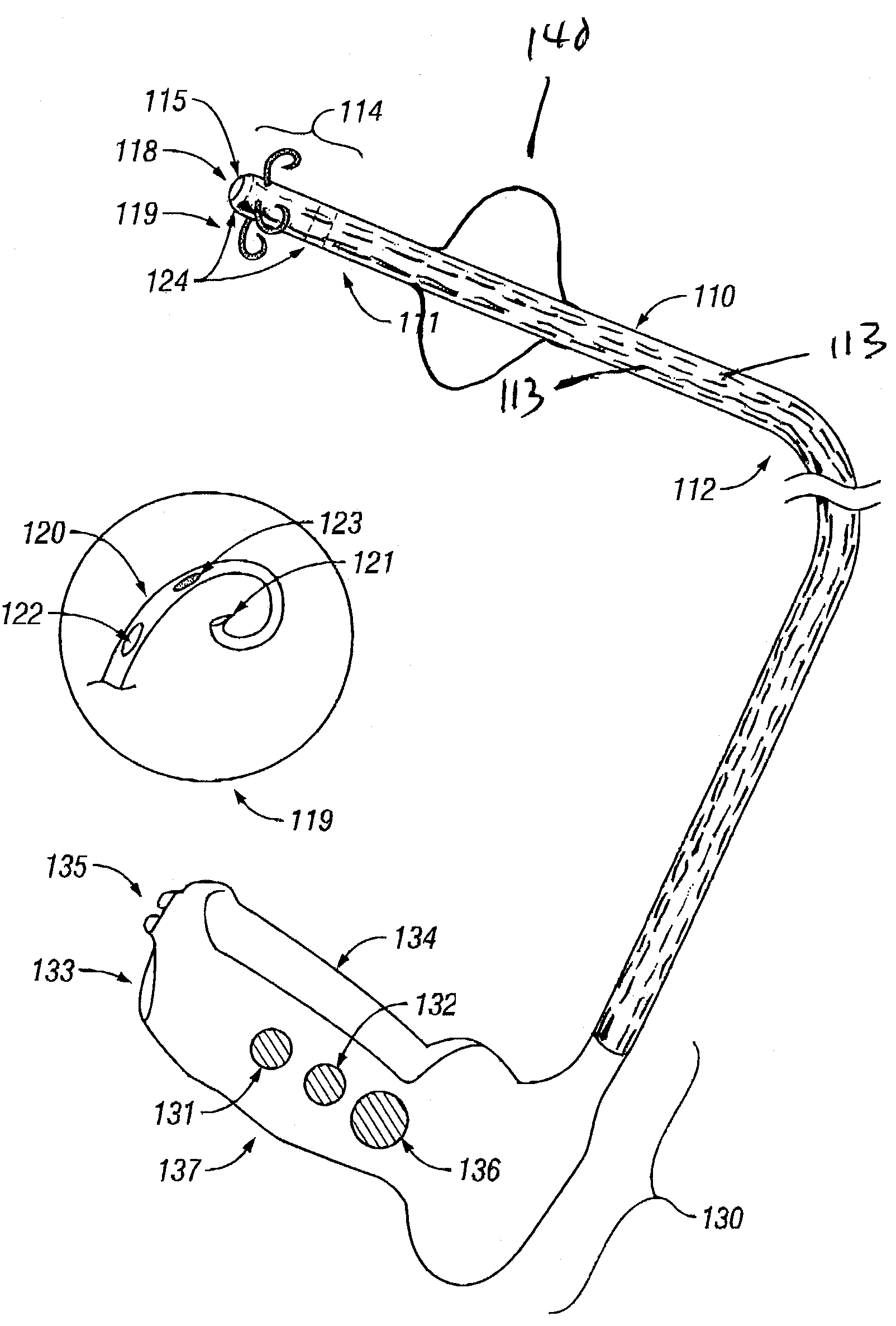

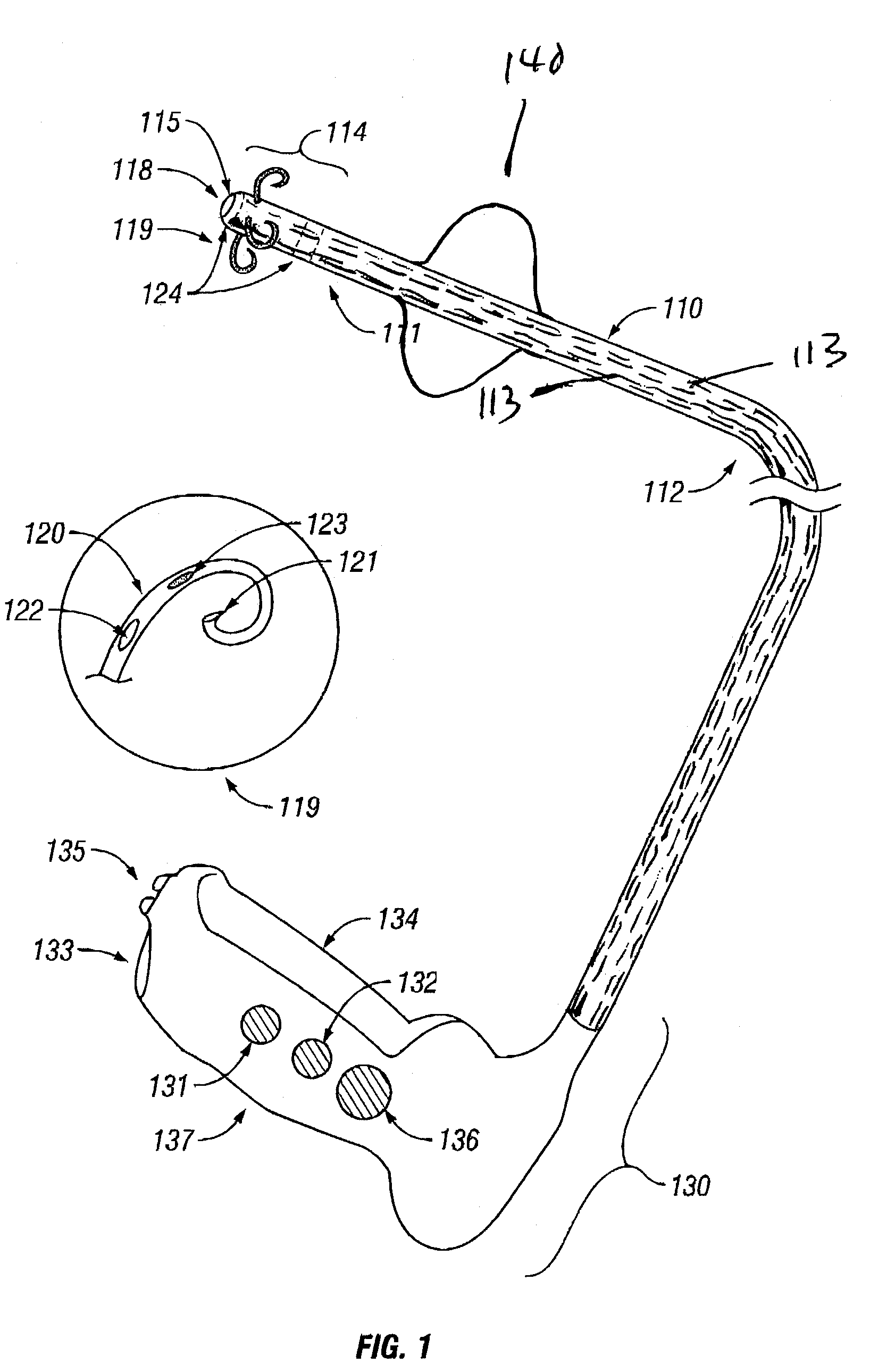

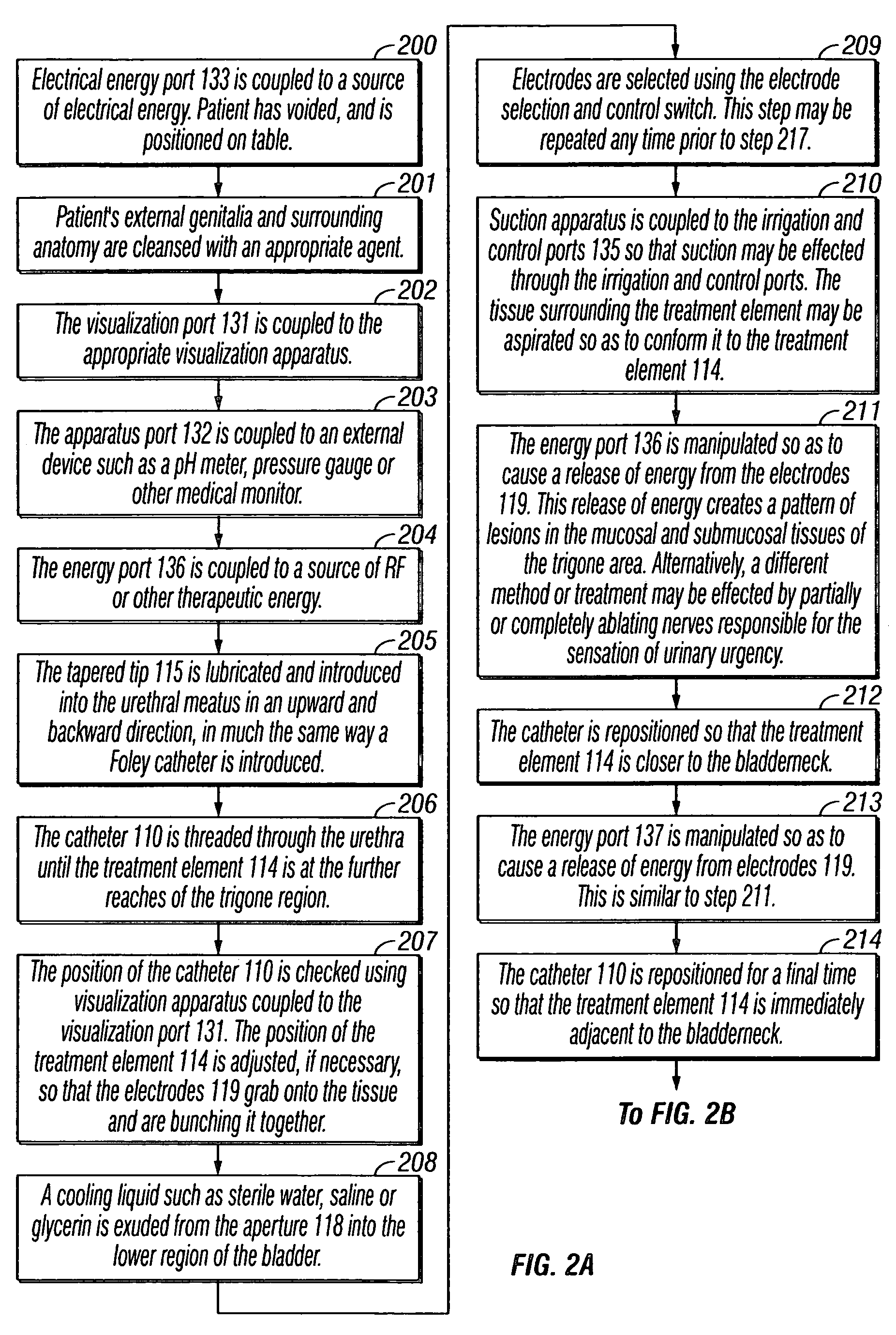

Treatment of urinary incontinence and other disorders by application of energy and drugs

The invention provides a method and system for treating disorders in parts of the body. A particular treatment can include on or more of, or some combination of: ablation, nerve modulation, three-dimensional tissue shaping, drug delivery, mapping stimulating, shrinking and reducing strain on structures by altering the geometry thereof and providing bulk to particularly defined regions. The particular body structures or tissues can include one or more of or some combination of region, including: the bladder, esophagus, vagina, penis, larynx, pharynx, aortic arch, abdominal aorta, thoracic, aorta, large intestine, sinus, auditory canal, uterus, vas deferens, trachea, and all associated sphincters. Types of energy that can be applied include radiofrequency, laser, microwave, infrared waves, ultrasound, or some combination thereof. Types of substances that can be applied include pharmaceutical agents such as analgesics, antibiotics, and anti-inflammatory drugs, bulking agents such as biologically non-reactive particles, cooling fluids, or dessicants such as liquid nitrogen for use in cryo-based treatments.

Owner:VERATHON

In-situ chamber clean process to remove by-product deposits from chemical vapor etch chamber

InactiveUS20060051966A1Electric discharge tubesSemiconductor/solid-state device detailsEngineeringCooling fluid

A method and apparatus for cleaning a processing chamber comprising blocking a flow of cooling fluid to a channel within a support member within a processing chamber, elevating the support member to be within about 0.1 inches of a gas distribution plate, heating the gas distribution plate, and introducing a thermally conductive gas through the gas distribution plate into the processing chamber.

Owner:APPLIED MATERIALS INC

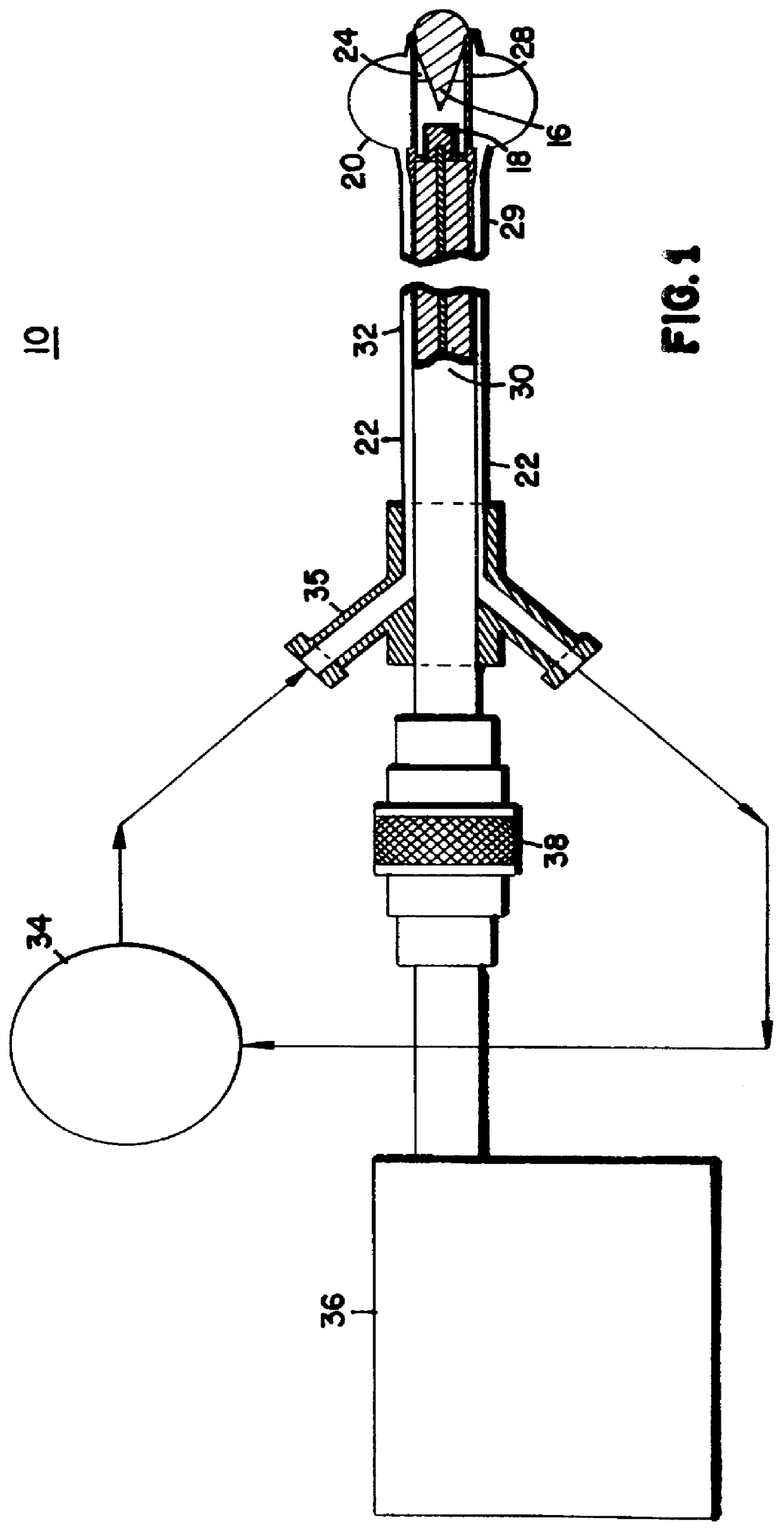

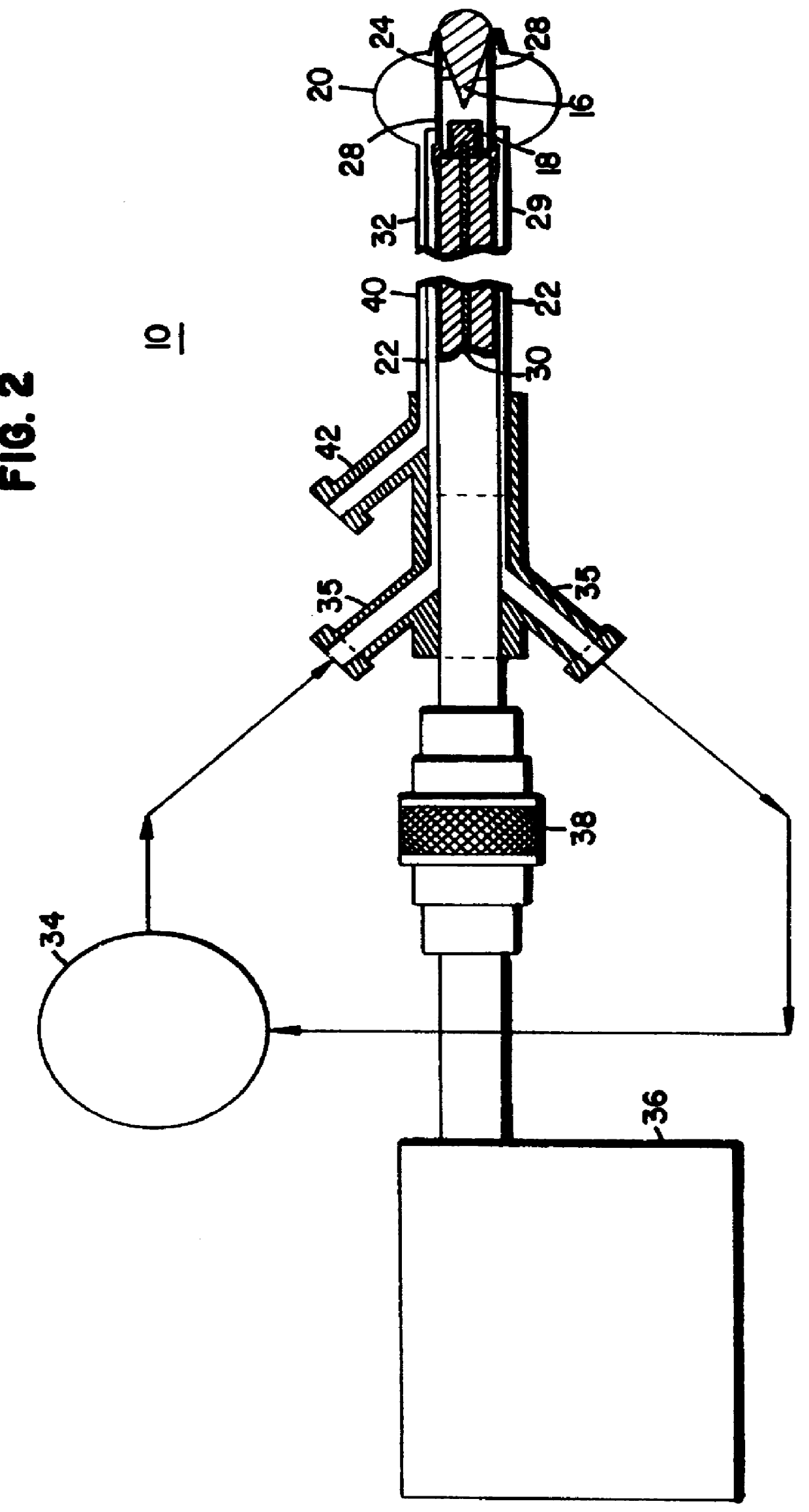

Devices and methods for cooling microwave antennas

InactiveUS20050015081A1Improve cooling effectElectrotherapySurgical instruments for heatingChemical reactionCompound (substance)

Devices and methods for cooling microwave antennas are disclosed herein. The cooling systems can be used with various types of microwave antennas. One variation generally comprises a handle portion with an elongate outer jacket extending from the handle portion. A microwave antenna is positioned within the handle and outer jacket such that cooling fluid pumped into the handle comes into contact directly along a portion of the length, or a majority of the length, or the entire length of the antenna to allow for direct convective cooling. Other variations include cooling sheaths which form defined cooling channels around a portion of the antenna. Yet another variation includes passively-cooled systems which utilize expandable balloons to urge tissue away from the surface of the microwave antenna as well as cooling sheaths which are cooled through endothermic chemical reactions. Furthermore, the microwave antennas themselves can have cooling lumens integrated directly therethrough.

Owner:TYCO HEALTHCARE GRP LP

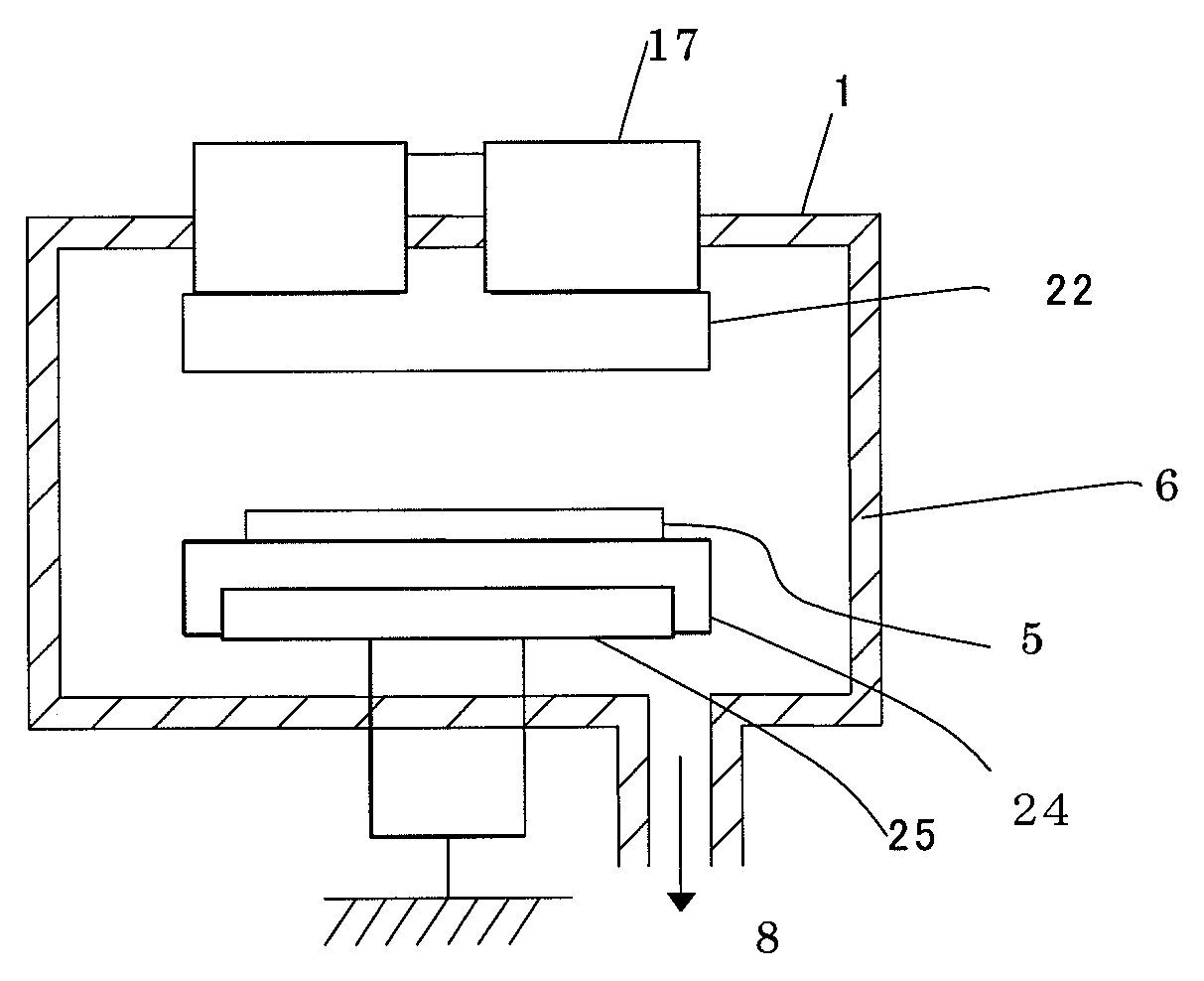

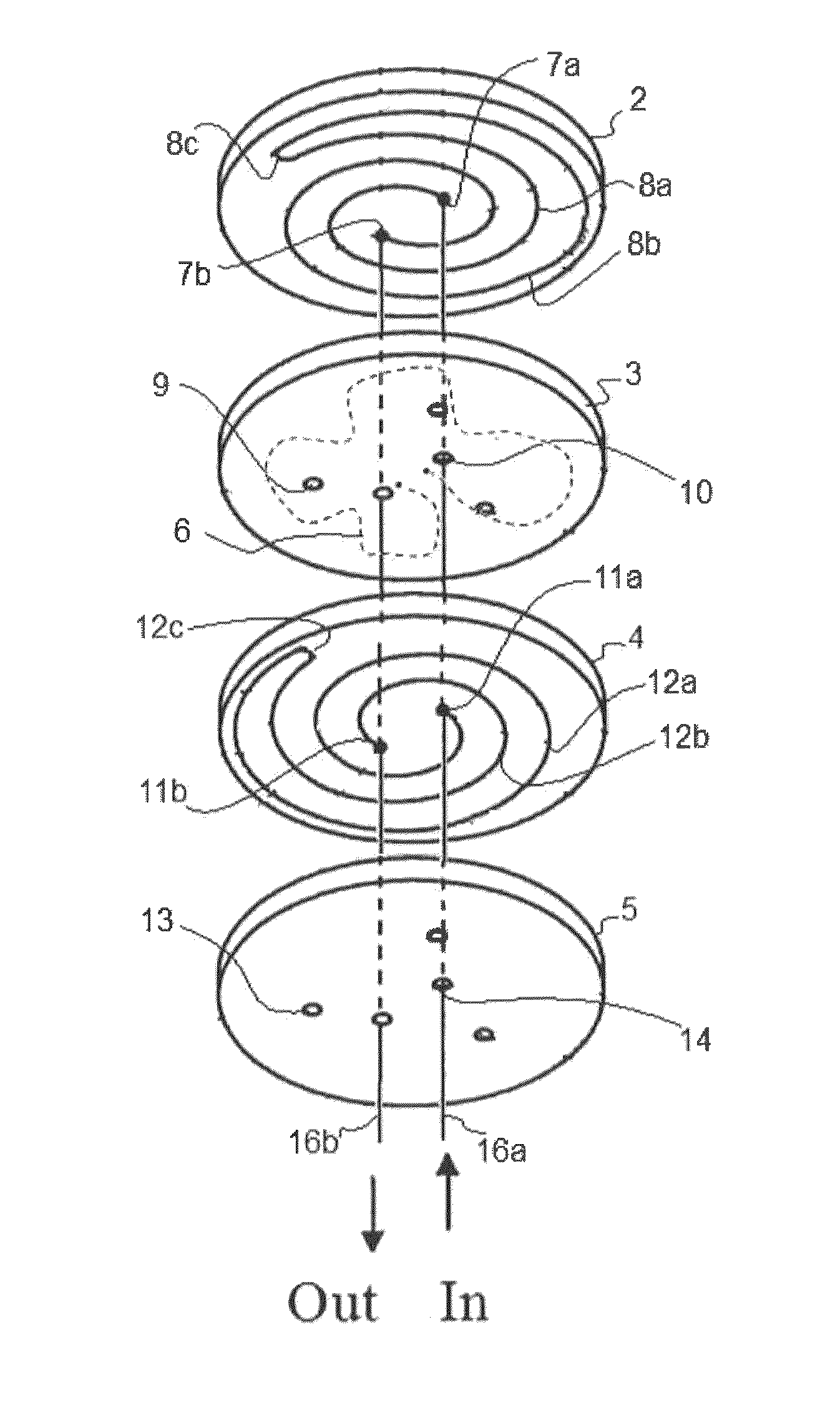

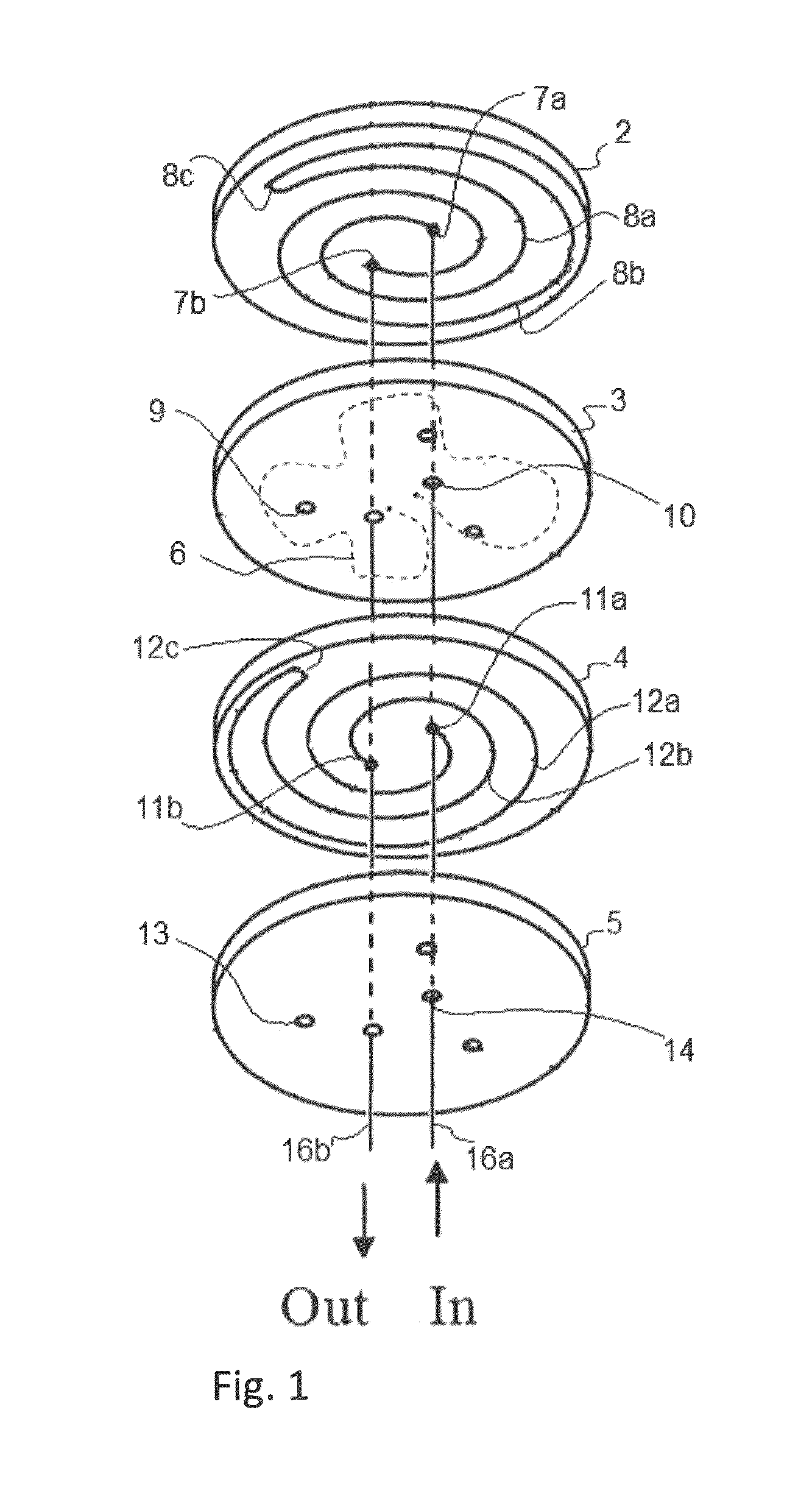

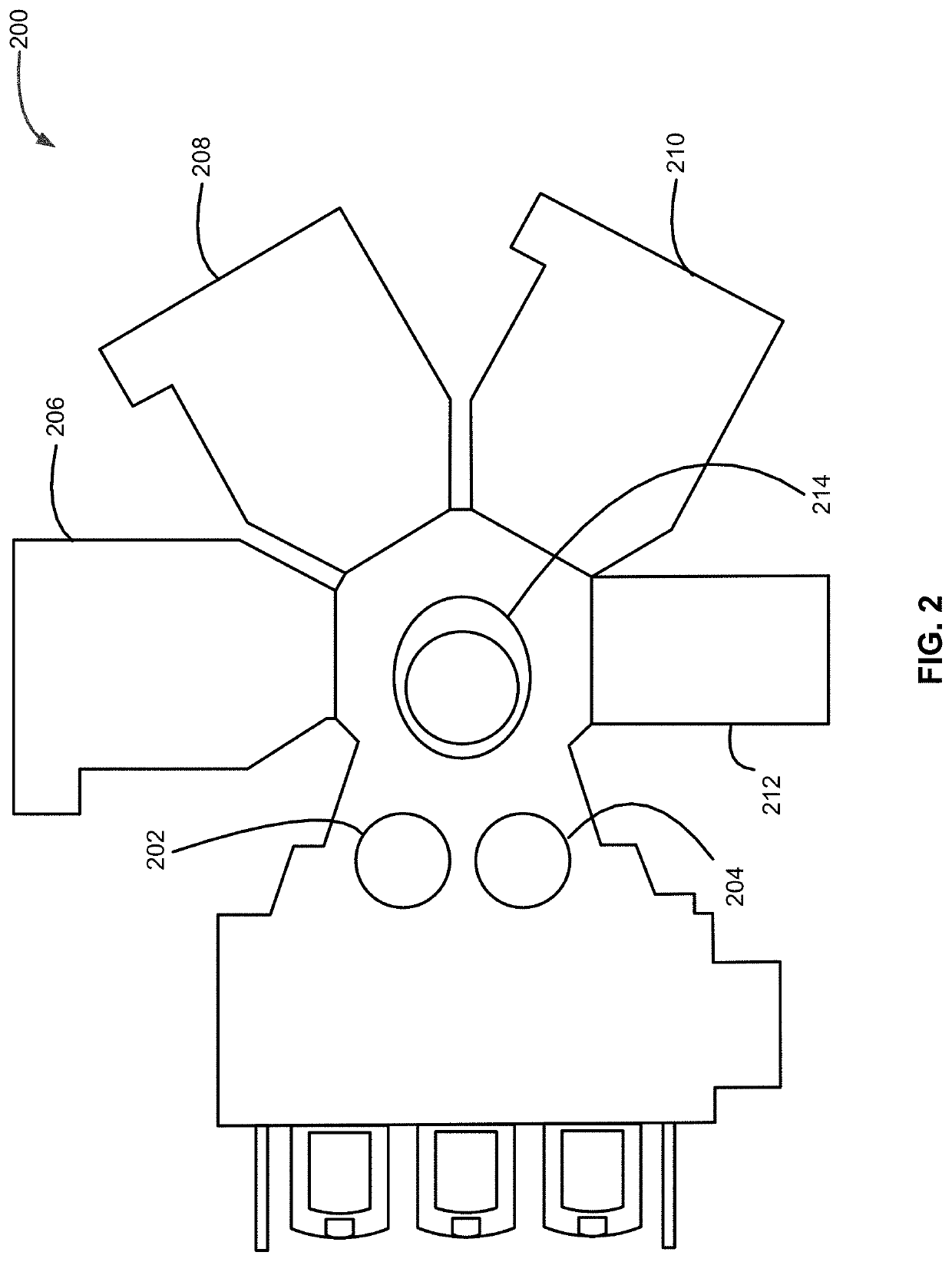

Heating/cooling pedestal for semiconductor-processing apparatus

ActiveUS9353441B2Efficient heatingReduce distortionElectric discharge tubesCharge supportsEngineeringCooling fluid

A pedestal for supporting a substrate includes: a heating plate for heating the substrate; an upper cooling plate for cooling the substrate, installed on the heating plate and provided with an upper fluid path for passing a cooling fluid therethrough; and an lower cooling plate for cooling the substrate, installed under the heating plate and including a lower fluid path for passing a cooling fluid therethrough.

Owner:ASM IP HLDG BV

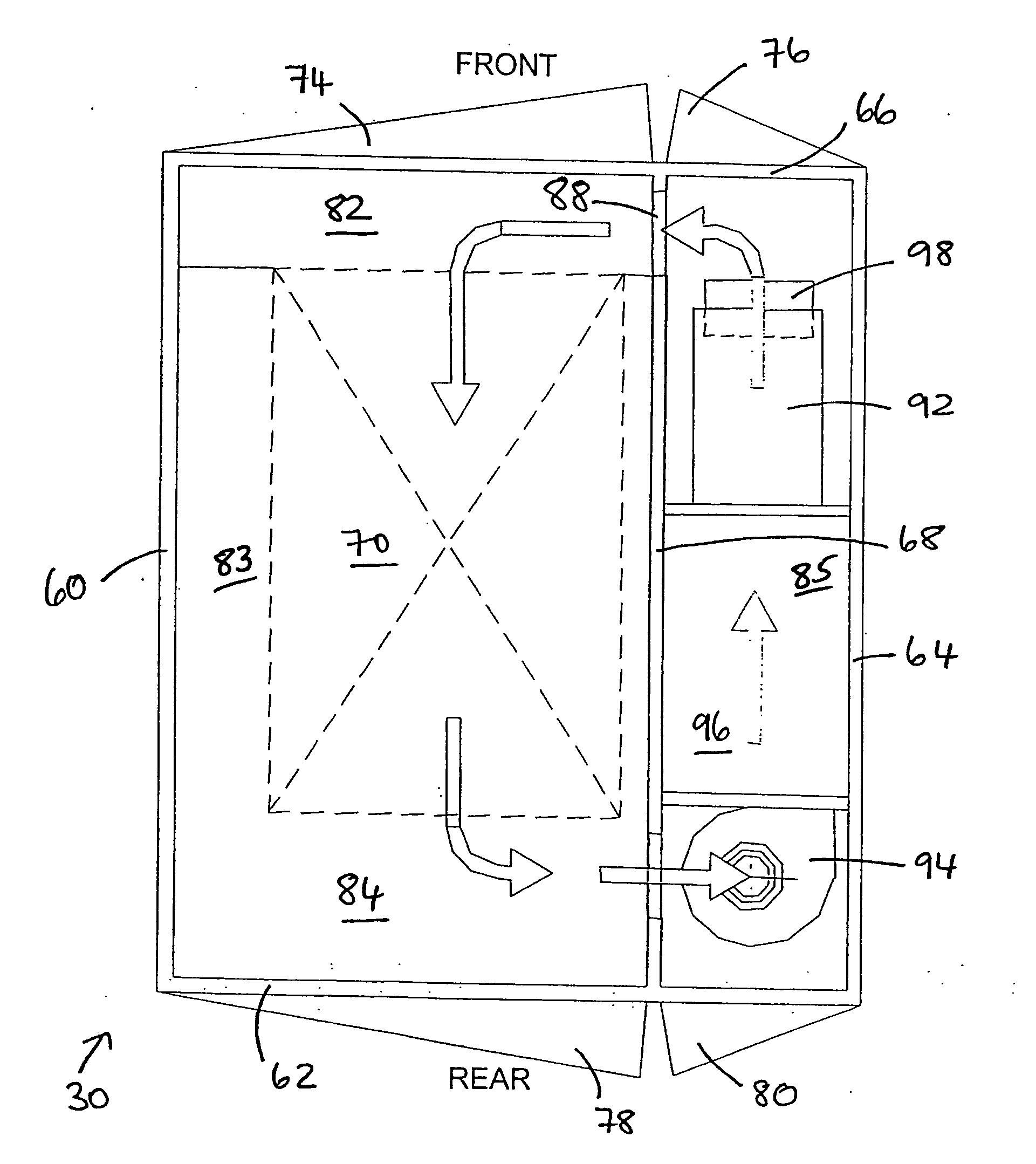

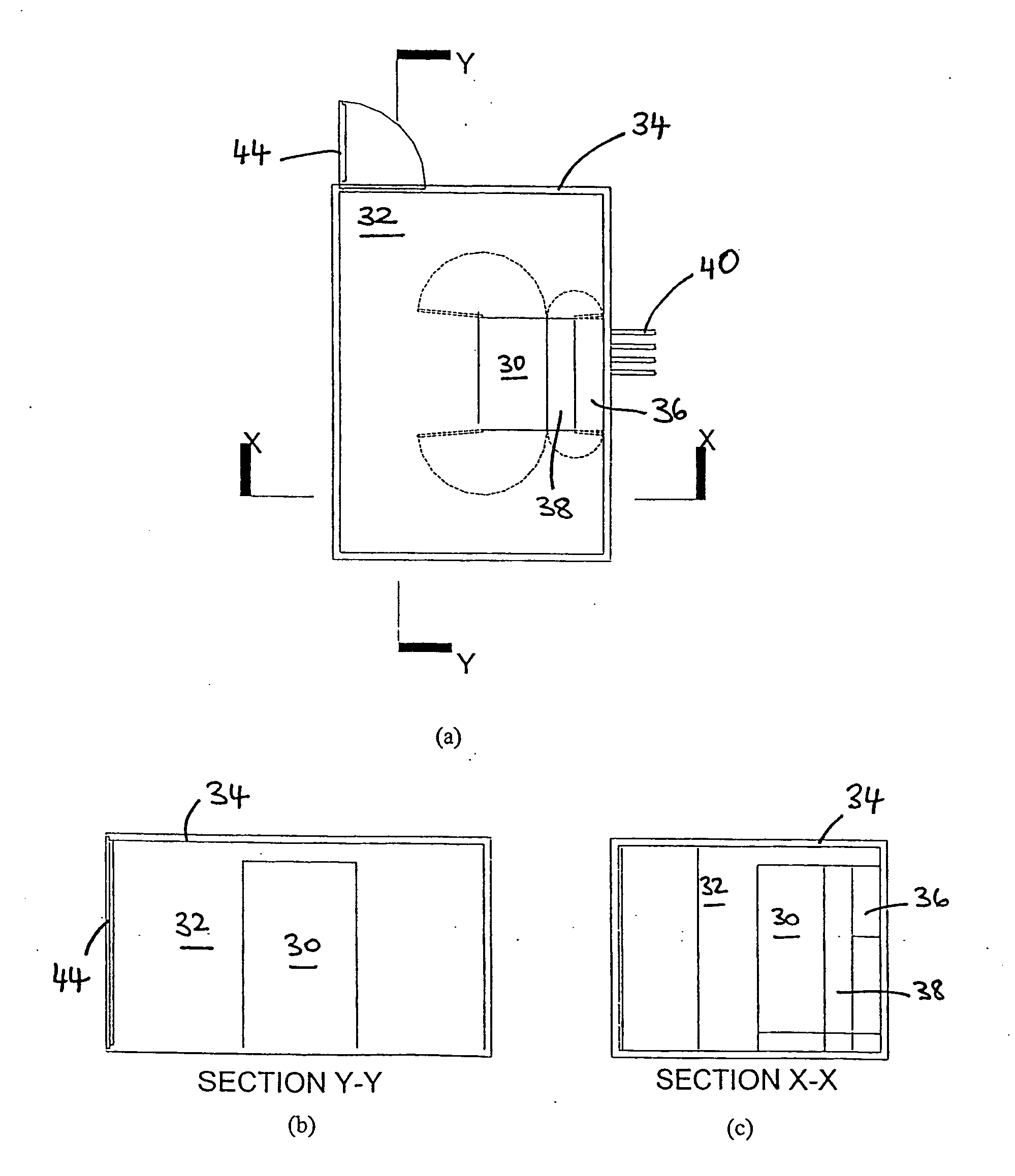

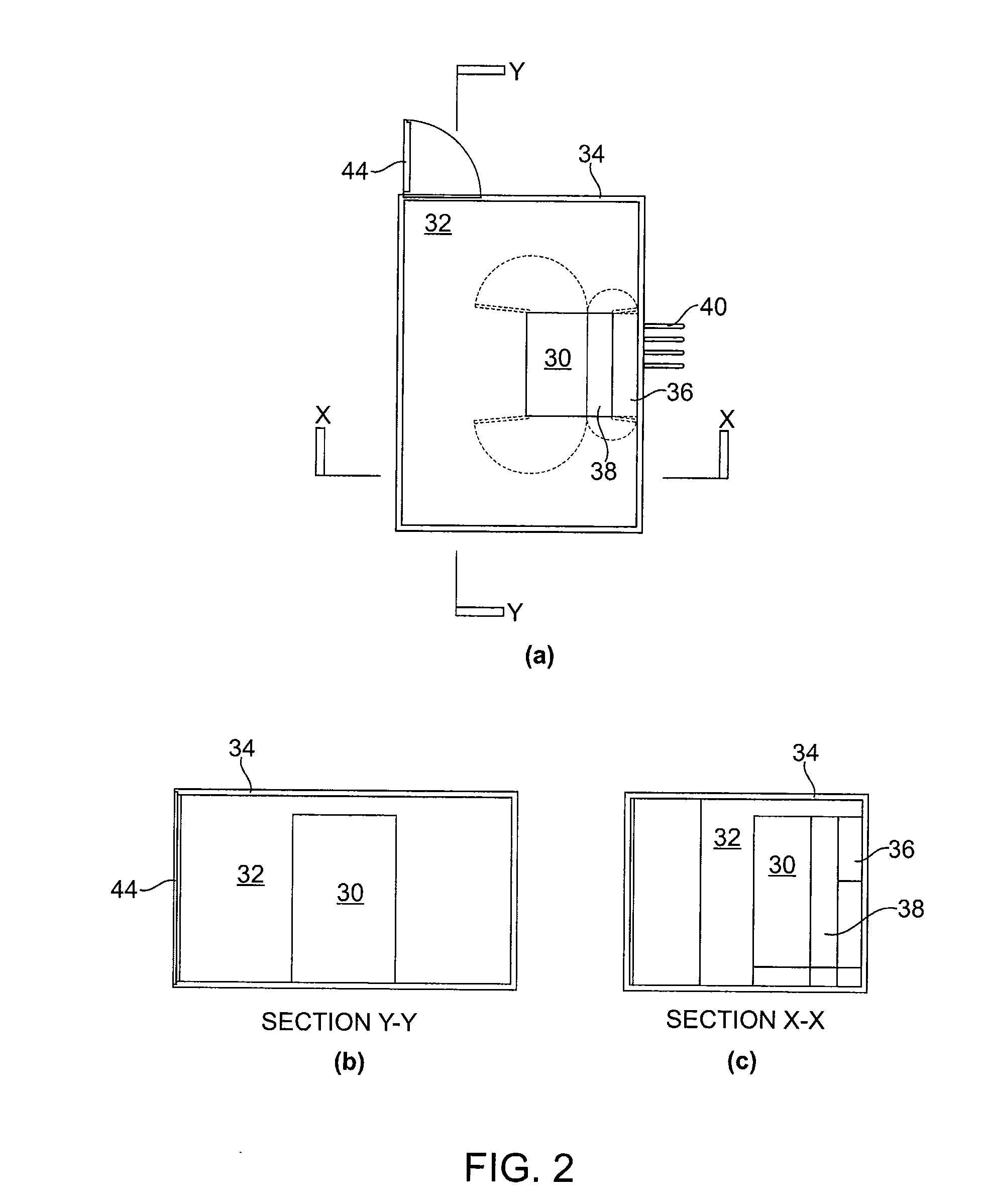

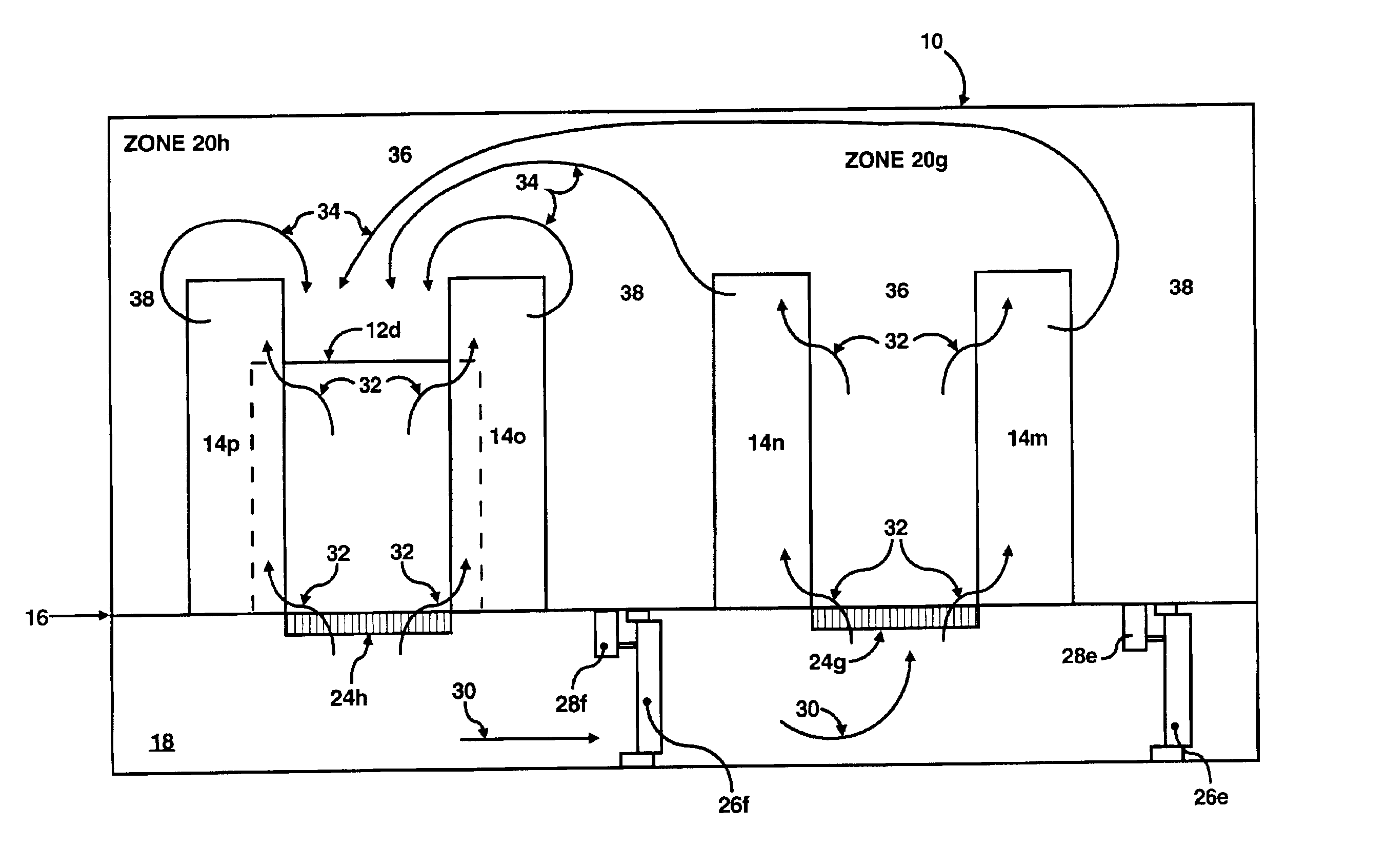

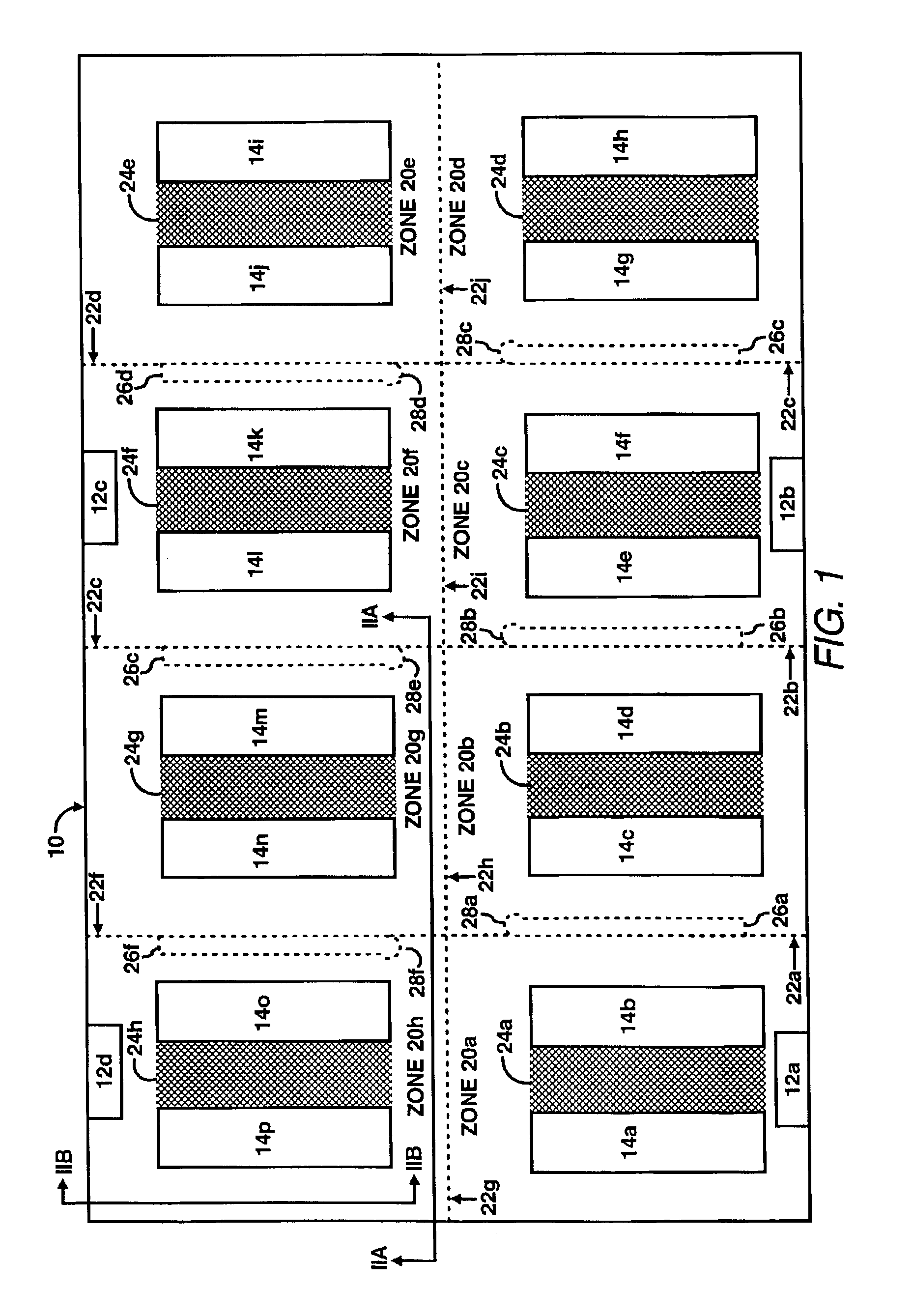

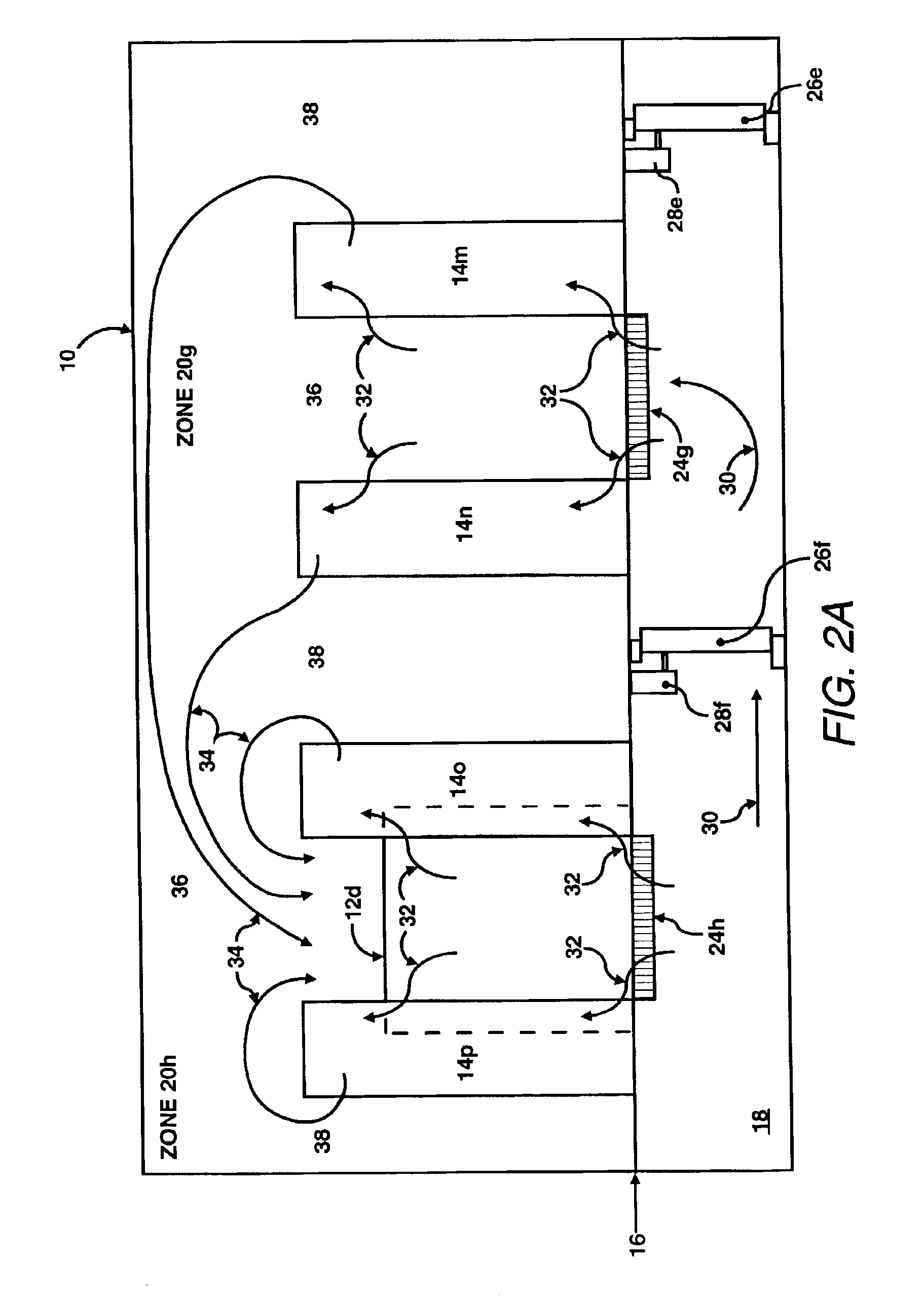

Data Center Cooling

InactiveUS20070213000A1Meet needsDomestic cooling apparatusLighting and heating apparatusData centerEngineering

A system includes a substantially sealed, substantially airtight cabinet sized for housing a vertical array of heat-producing units, the cabinet having an exterior shell and the system including an interior divider wall disposed inside the cabinet, the shell and divider wall providing an equipment chamber adapted to support the array such that the array cooperates with the shell and divider wall in use to define a first plenum, the first plenum having a first inlet defined by the divider wall for receiving a flow of cooling gas and having a first outlet defined by a plurality of openings through the array whereby the first plenum communicates with the openings in use to exhaust substantially all of the flow of cooling fluid through the openings and hence through the array, wherein the divider wall is configured to allow the first inlet to admit the gas to the first plenum in a substantially horizontal direction.

Owner:SCHNEIDER ELECTRIC IT CORP

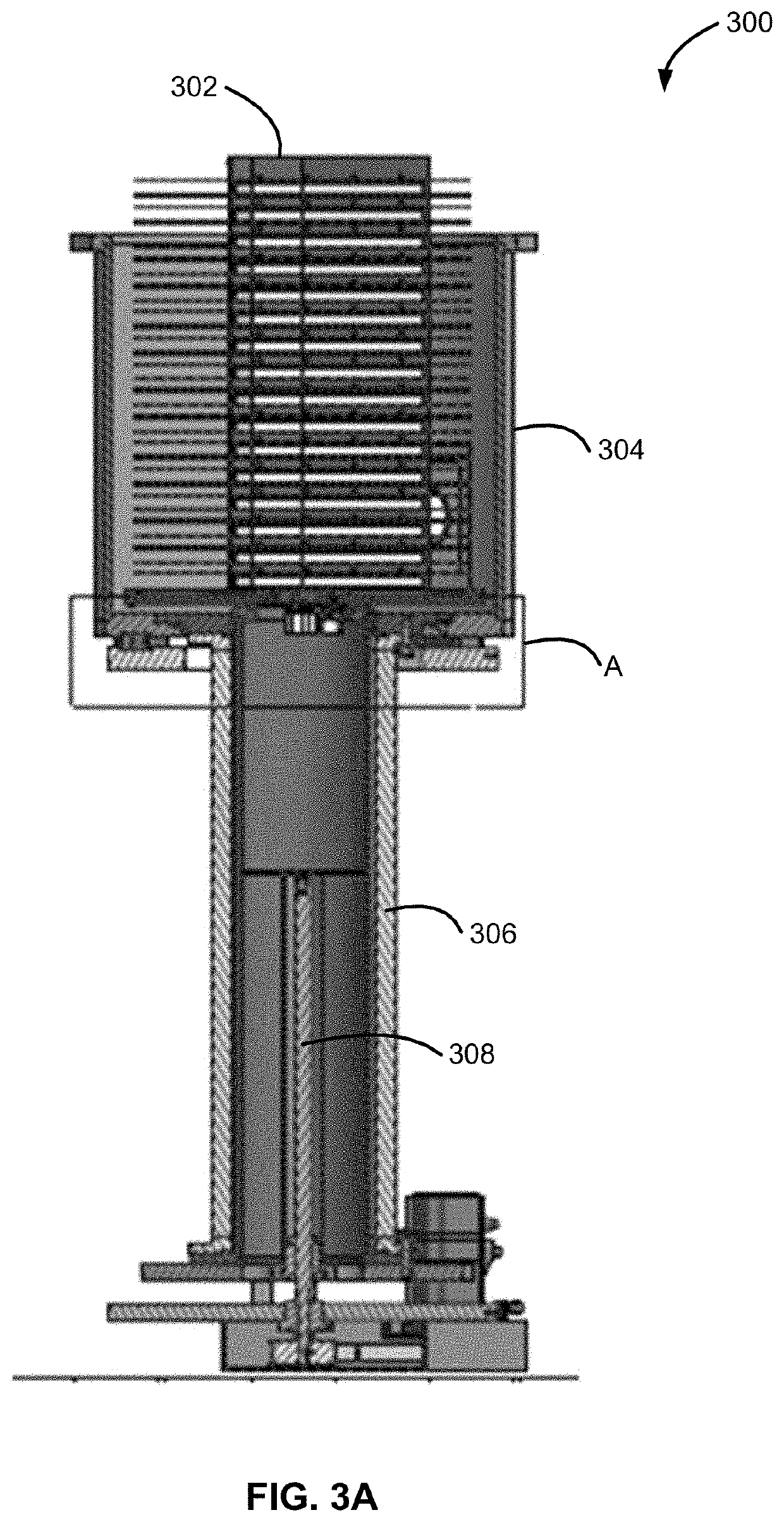

Substrate retaining apparatus, system including the apparatus, and method of using same

PendingUS20200102653A1Reduce pollutionDegradation of surface of substrateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingCooling fluidHeat shield

A substrate retaining apparatus, a load lock assembly comprising the substrate retaining apparatus, and a system including the substrate retaining apparatus are disclosed. The substrate retaining apparatus can include at least one sidewall and one or more heat shields. One or more of the at least one sidewall can include a cooling fluid conduit to facilitate cooling of substrates retained by the substrate retaining apparatus. Additionally or alternatively, one or more of the at least one sidewall can include a gas conduit to provide gas to a surface of a retained substrate.

Owner:ASM IP HLDG BV

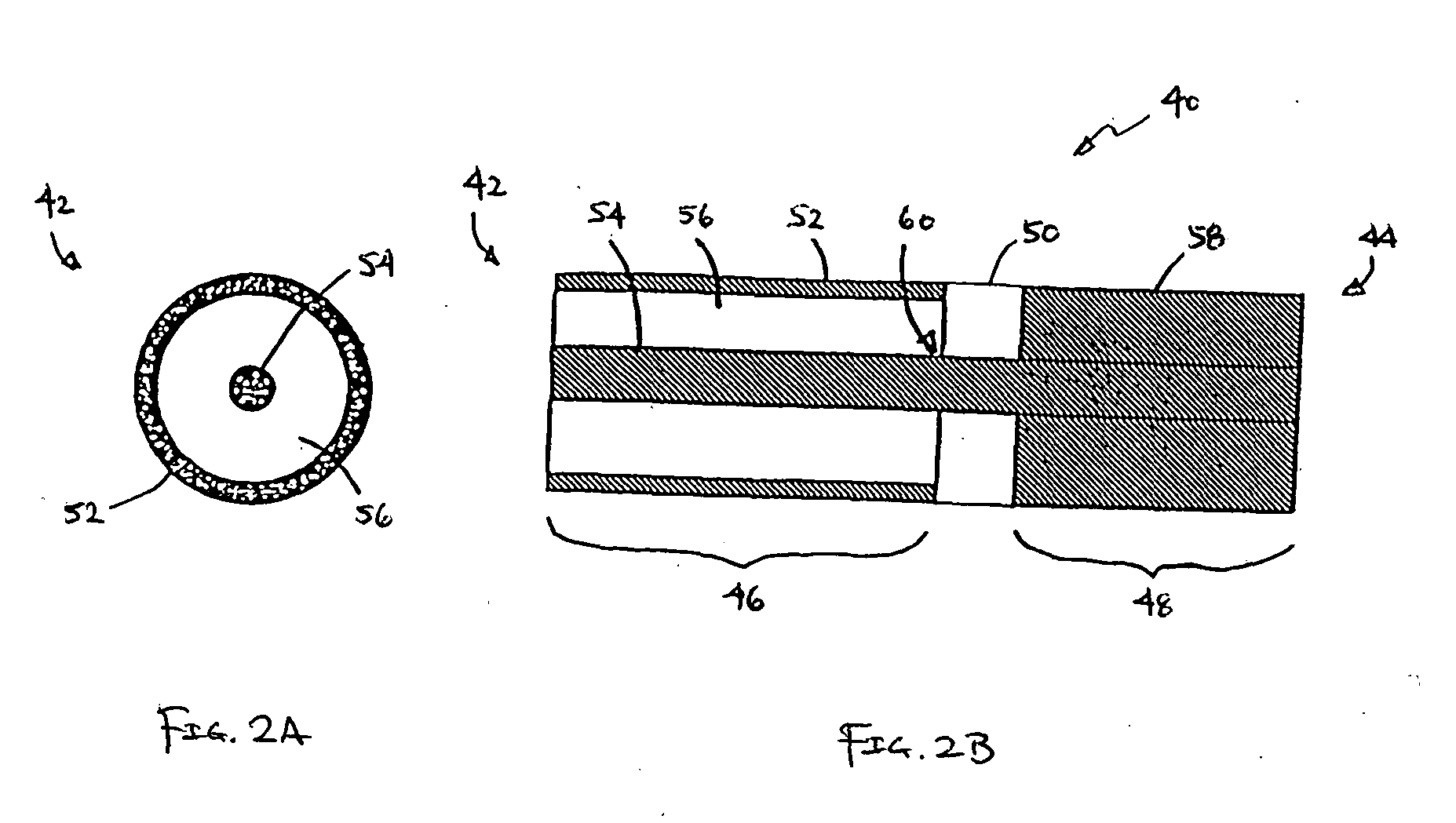

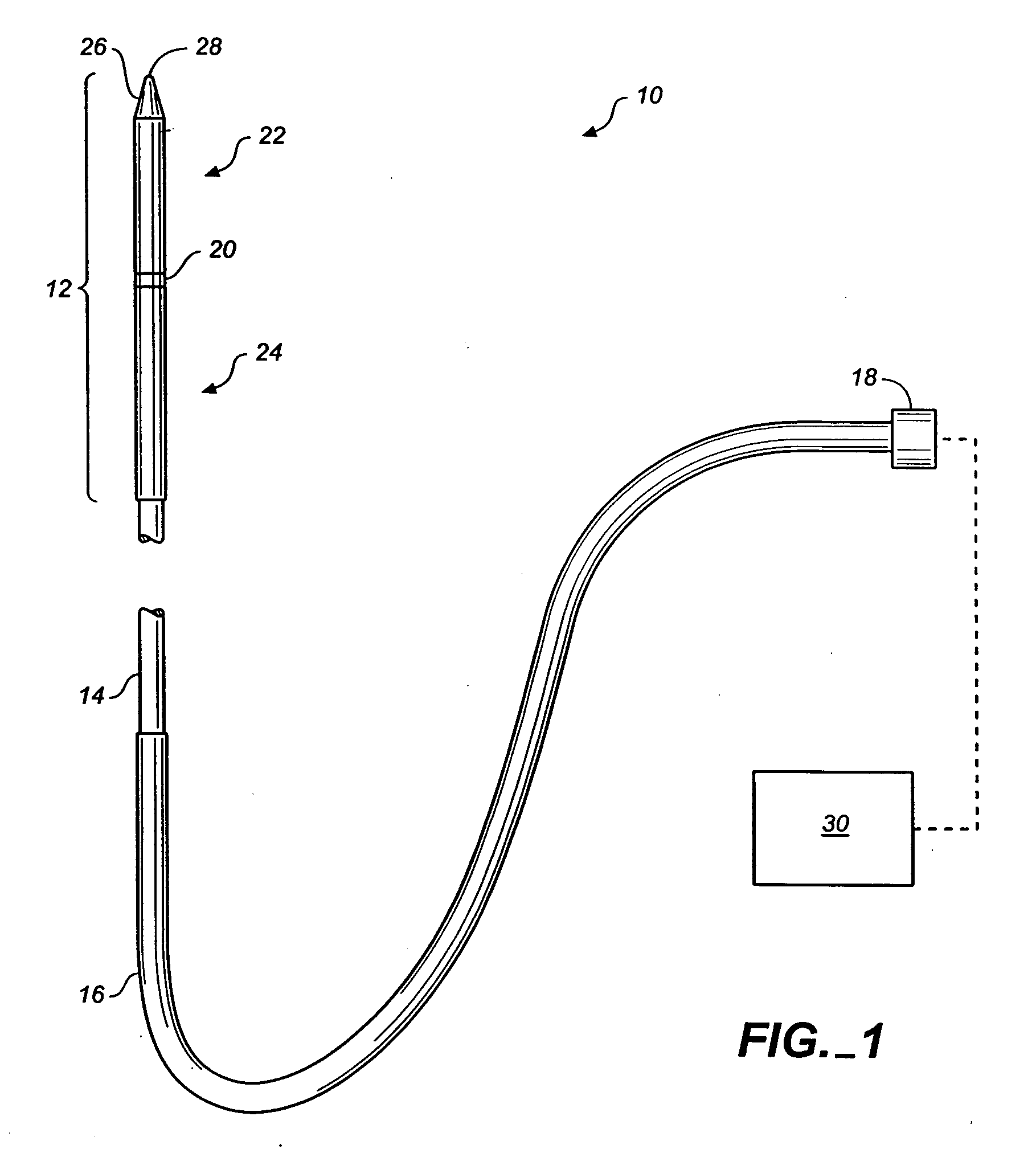

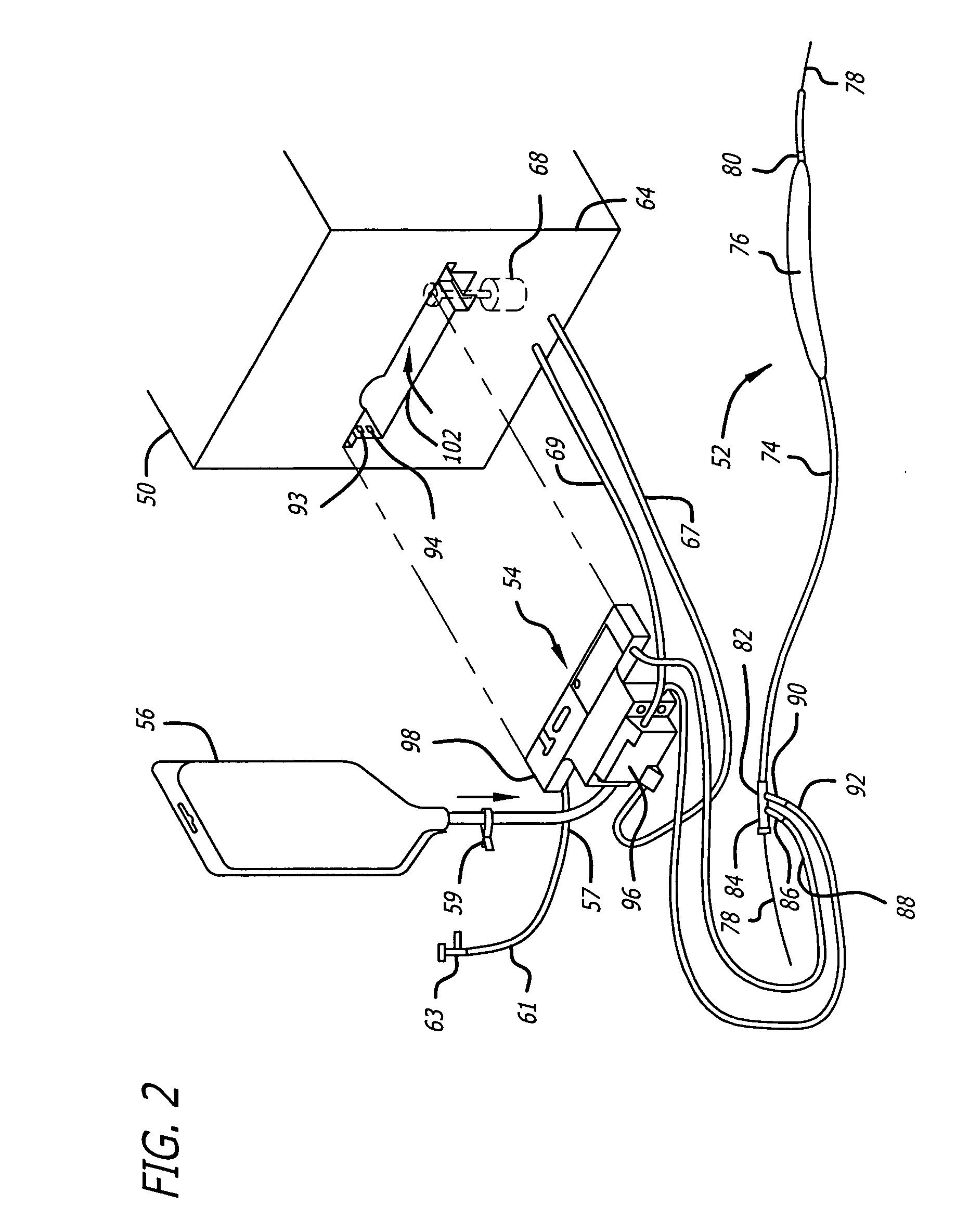

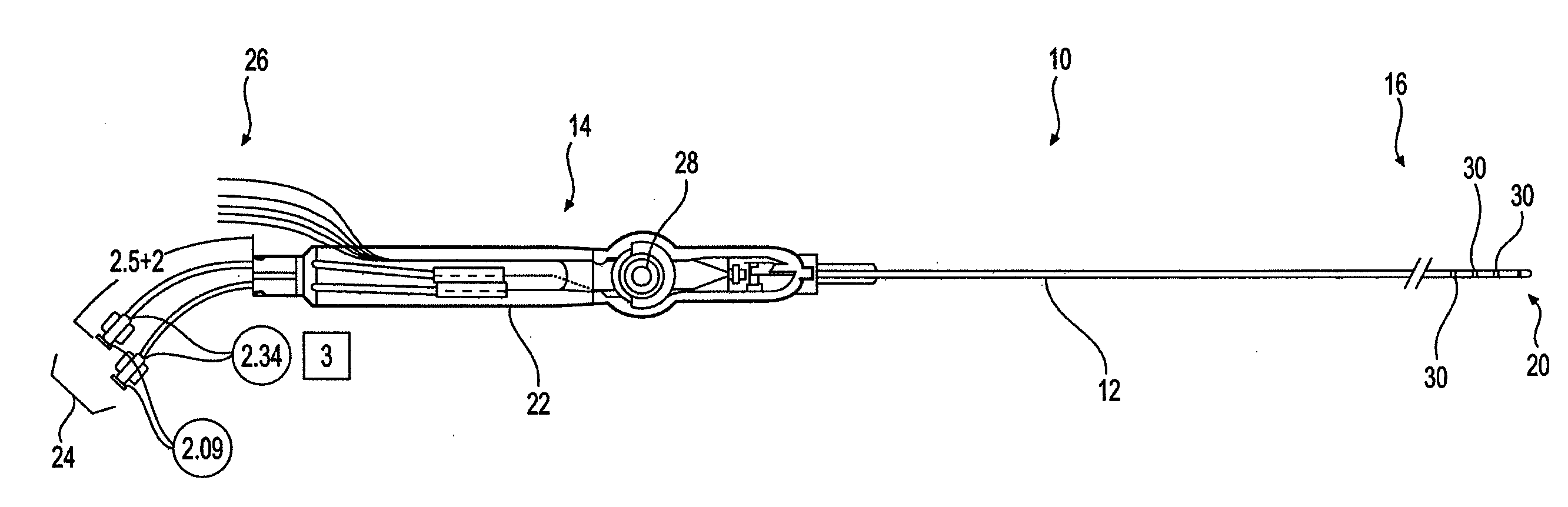

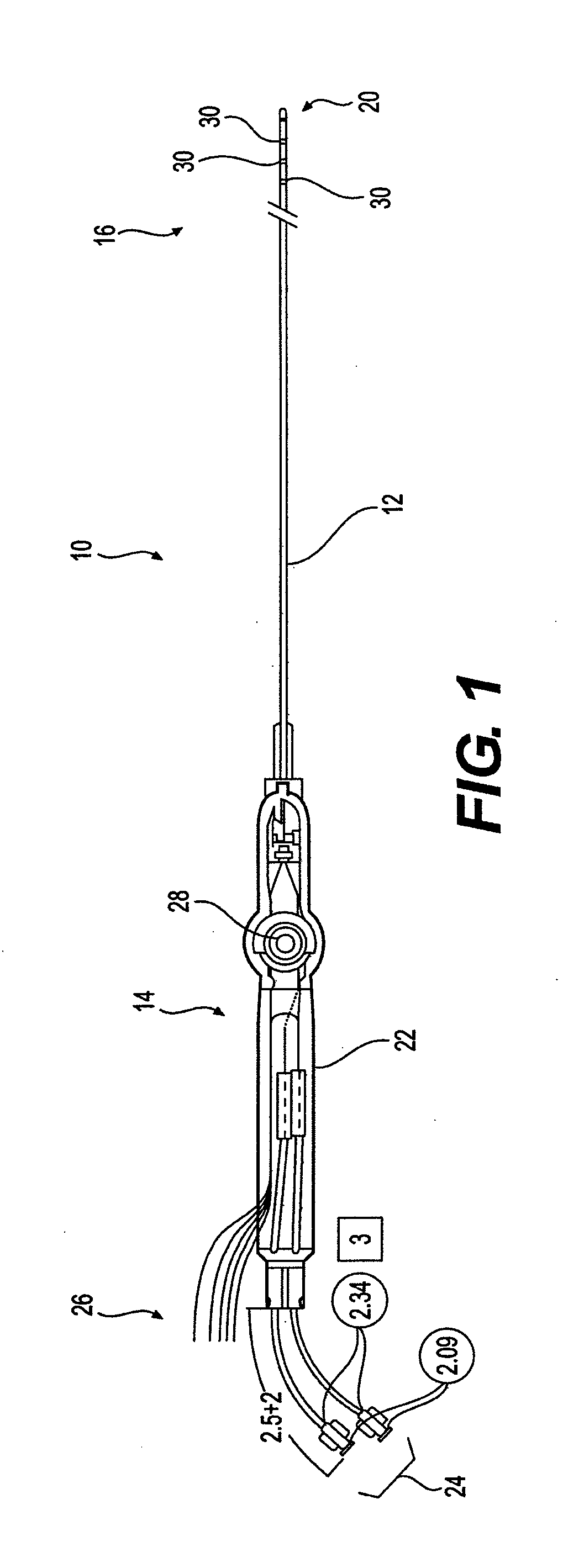

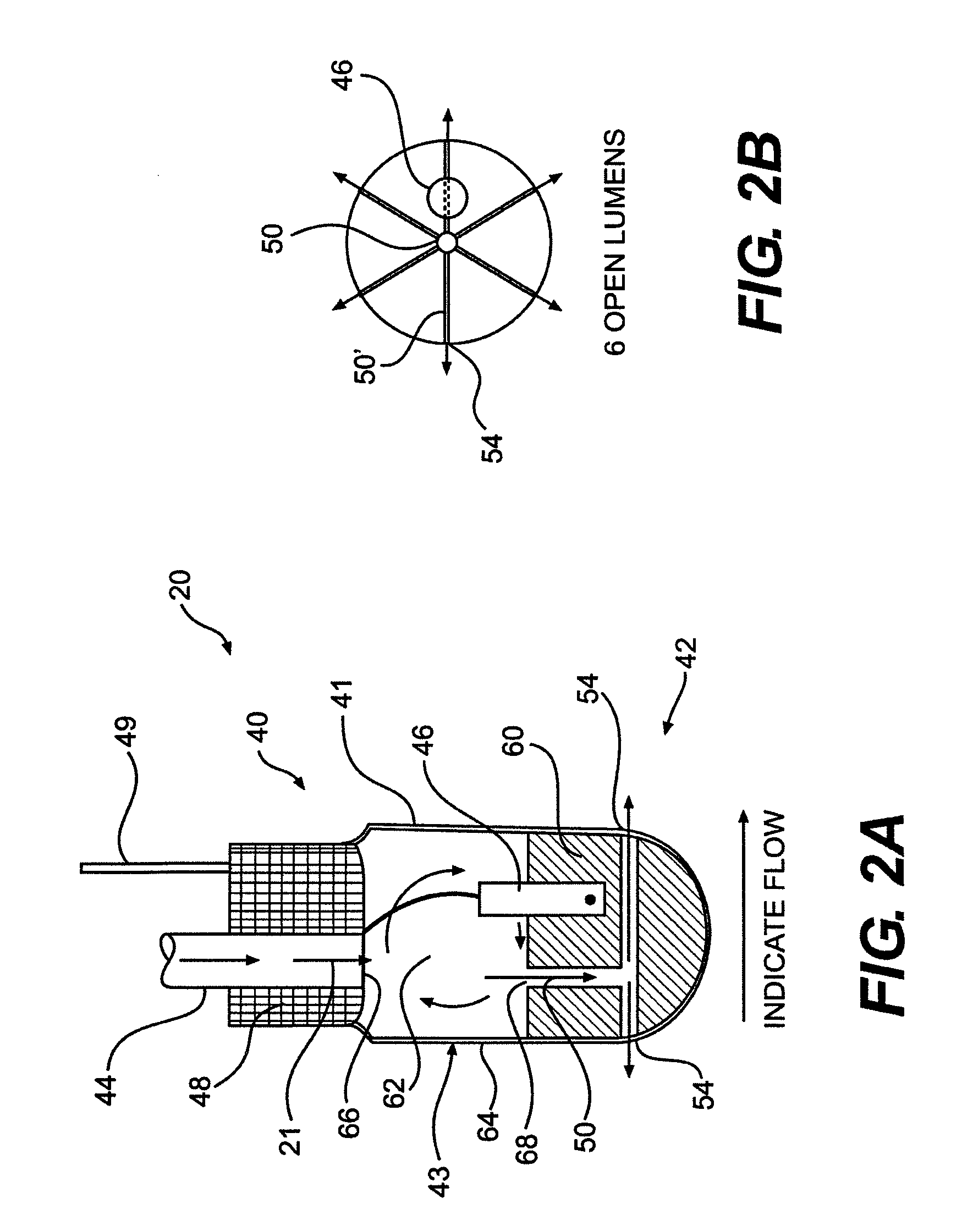

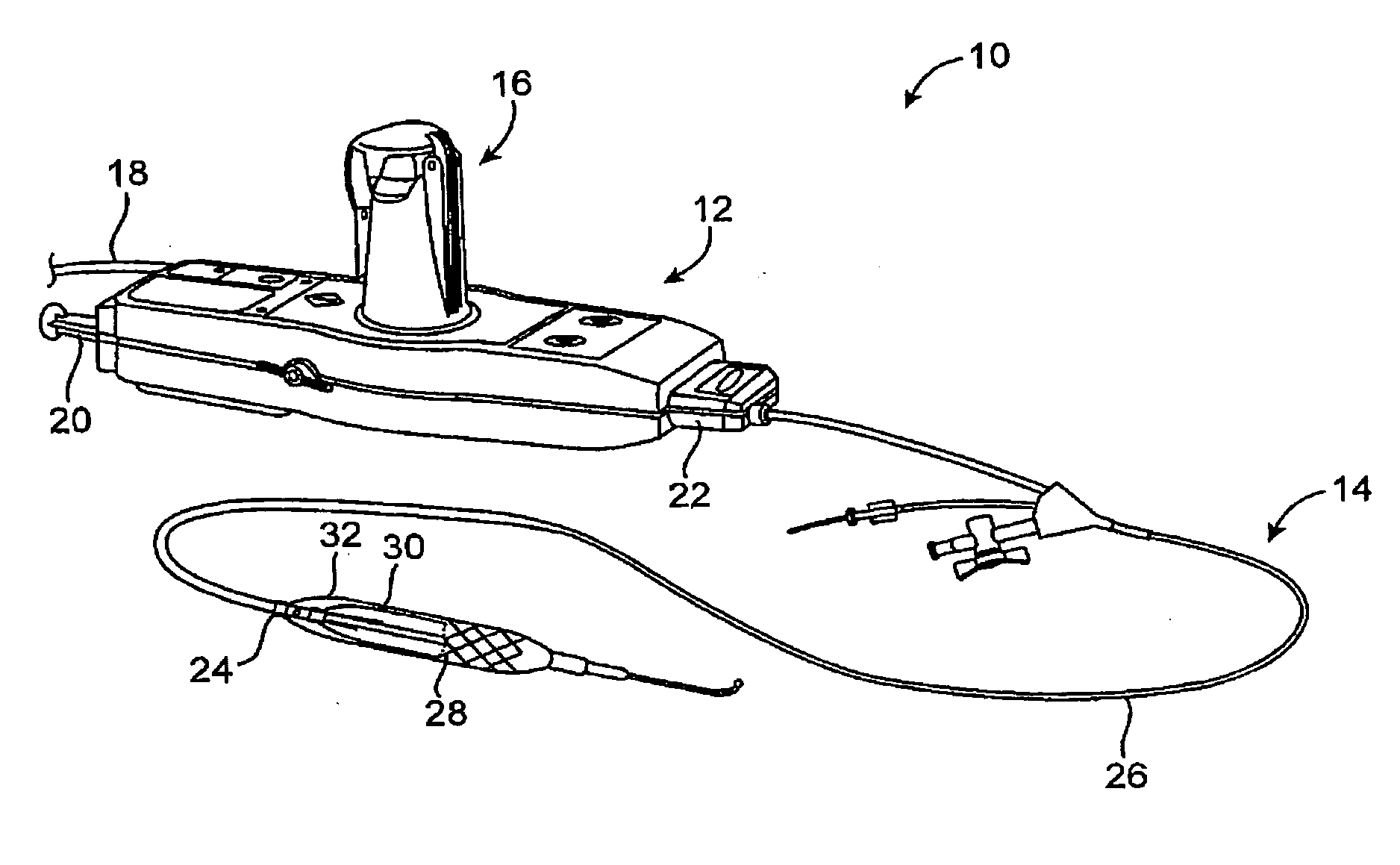

Irrigated Ablation Catheter System and Methods

InactiveUS20100057072A1Increase surface areaGood for healthSurgical instruments for heatingCooling fluidTissue ablation

An ablation catheter for performing tissue ablation, having an elongate shaft with a lumen and a tip ablation electrode at the distal end of the shaft. The tip electrode has a fluid exit port opening through the surface of the tip electrode and at least one channel extending along the surface of the tip electrode to allow fluid passage in the event that the fluid exit port is blocked. The catheter has a connector to a cooling fluid source, and a fluid delivery tube within the shaft lumen to deliver cooling fluid from the connector to the fluid exit port.

Owner:MEDTRONIC ABLATION FRONTIERS

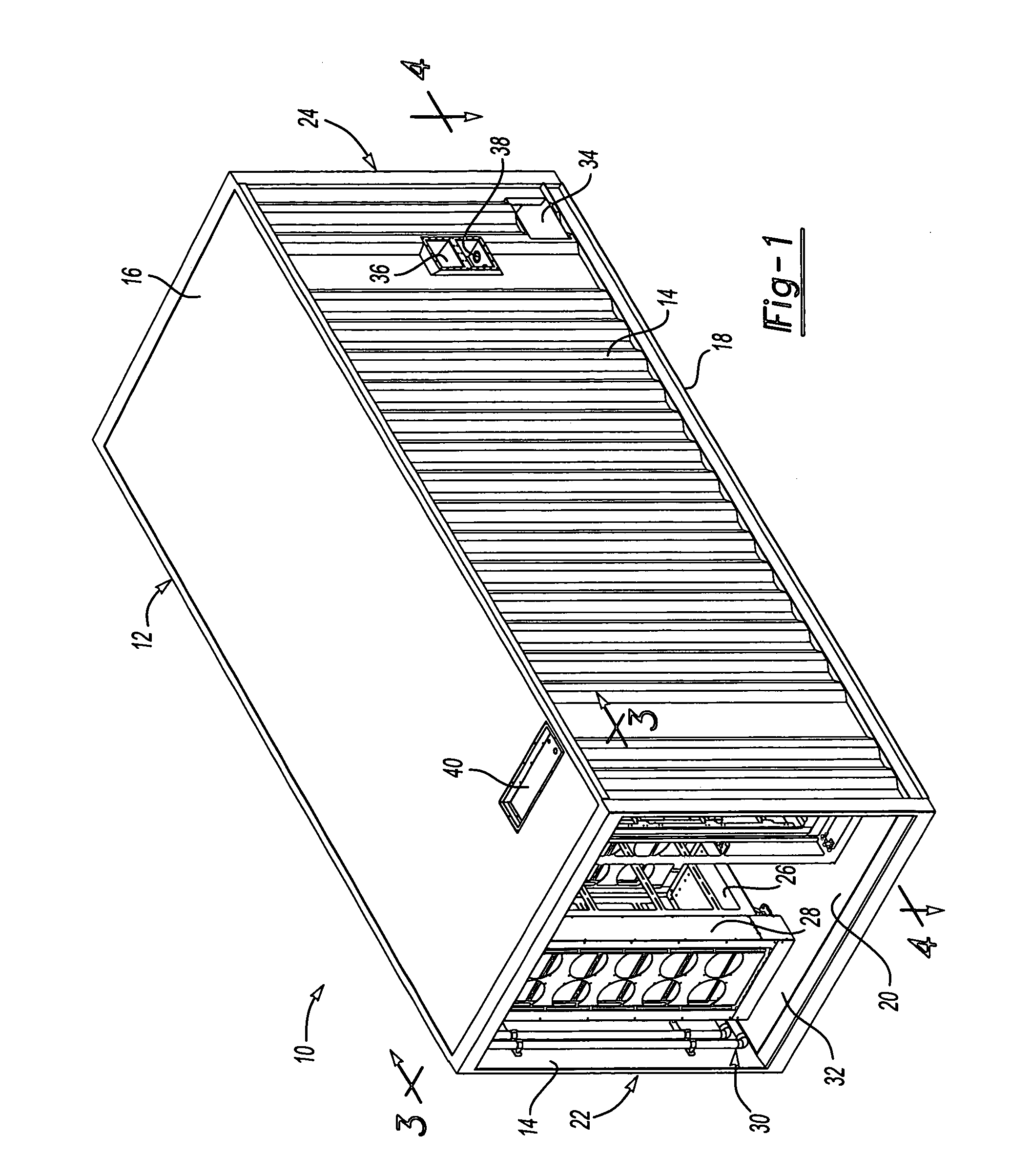

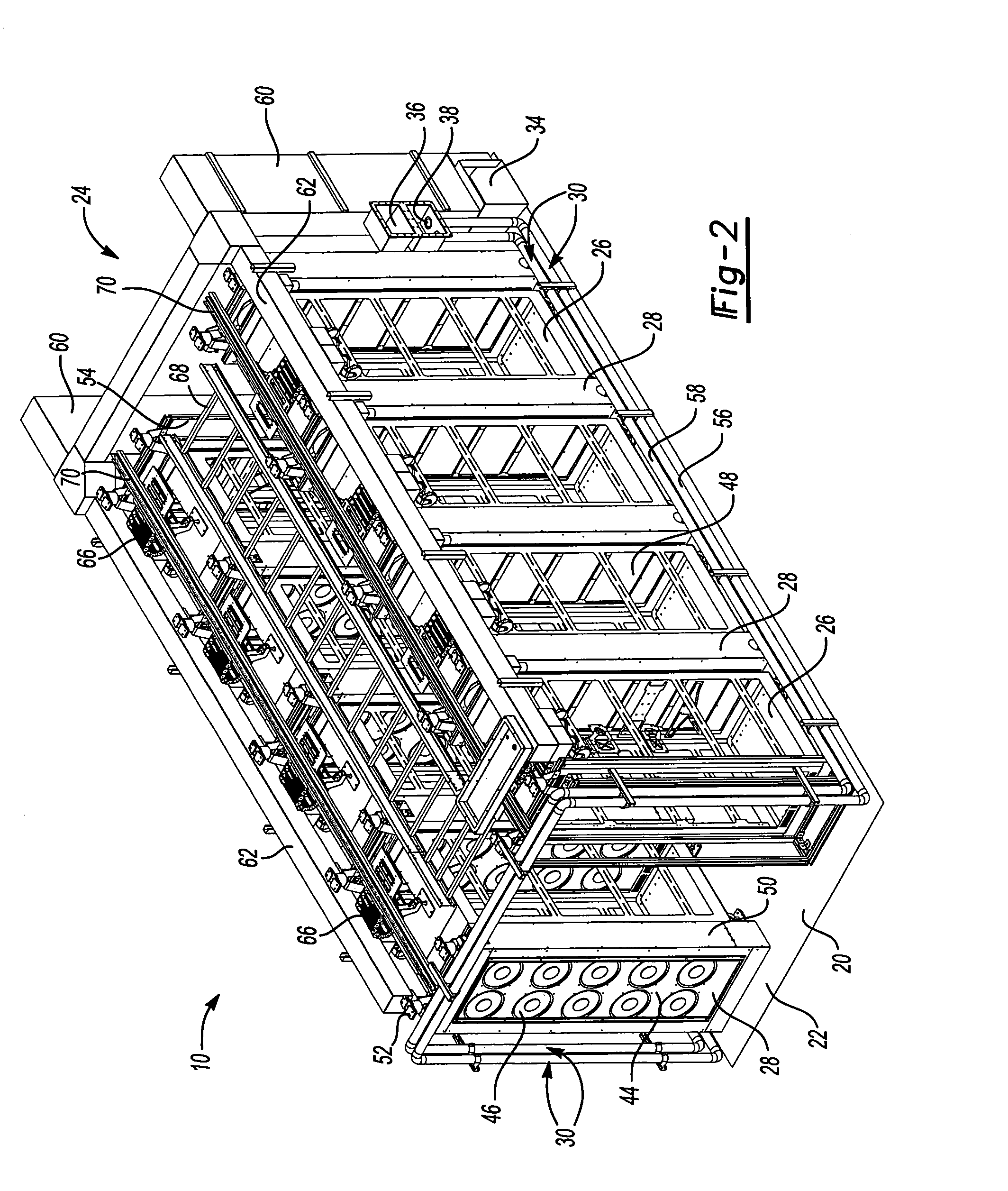

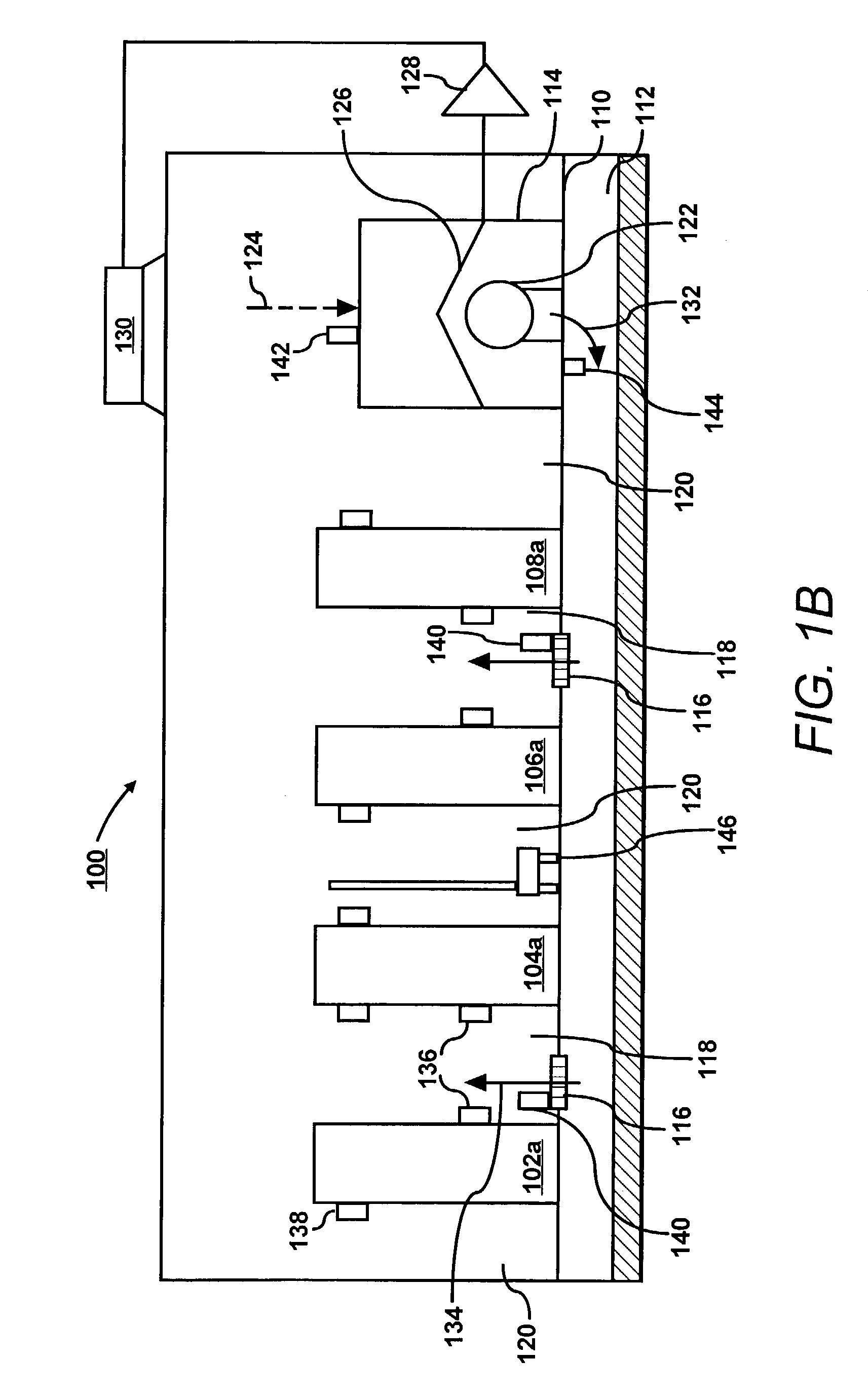

Balanced chilled fluid cooling system for a data center in a shipping container

ActiveUS7511960B2Improve heat transfer performanceServersDigital data processing detailsData centerWater source

A movable data center is disclosed that comprises a movable enclosure having partitions that define a closed-loop air flow path. A plurality of fans and a plurality of data processing modules are disposed in the air flow path. A pipe network is disposed within the enclosure that includes a chilled water supply pipe that receives chilled water from a source of chilled water. A water return pipe is provided that circulates water back to the source of chilled water. A plurality of heat exchange modules is installed in the enclosure in the air flow path. The heat exchange modules receive the chilled water from the chilled water supply pipe. Each of the heat exchange modules has a water circulation tube that connects the chilled water supply pipe to the return water pipe.

Owner:ORACLE INT CORP

Partition for varying the supply of cooling fluid

In a data center, a plurality of racks are cooled by activating a cooling device and opening a controllable partition configured to vary a supply of cooling fluid within a zone of the data center. The zone includes at least one associated rack of the plurality of racks. In addition, the temperature of at least one associated rack is sensed and it is determined whether the sensed temperature is within a predetermined temperature range. Furthermore, the controllable partition is manipulated to vary the supply of the cooling fluid to the zone in response to the sensed temperature being outside the predetermined temperature range.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP +1

Devices and methods for cooling microwave antennas

ActiveUS20050149010A1Improve cooling effectElectrotherapySurgical instruments for heatingChemical reactionCompound (substance)

Devices and methods for cooling microwave antennas are disclosed herein. The cooling systems can be used with various types of microwave antennas. One variation generally comprises a handle portion with an elongate outer jacket extending from the handle portion. A microwave antenna is positioned within the handle and outer jacket such that cooling fluid pumped into the handle comes into contact directly along a portion of the length, or a majority of the length, or the entire length of the antenna to allow for direct convective cooling. Other variations include cooling sheaths which form defined cooling channels around a portion of the antenna. Yet another variation includes passively-cooled systems which utilize expandable balloons to urge tissue away from the surface of the microwave antenna as well as cooling sheaths which are cooled through endothermic chemical reactions. Furthermore, the microwave antennas themselves can have cooling lumens integrated directly therethrough.

Owner:TYCO HEALTHCARE GRP LP

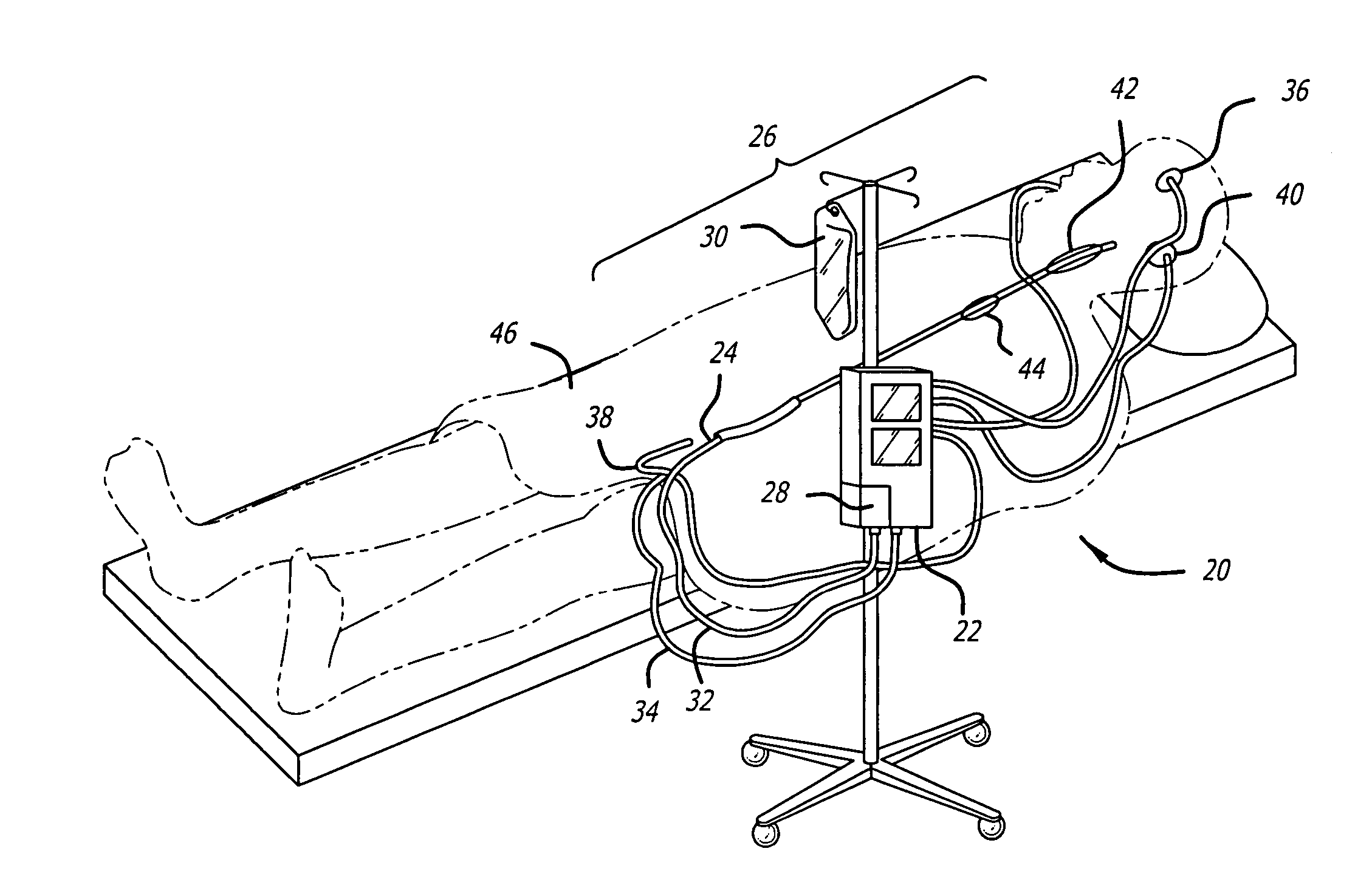

Apparatus and method for providing enhanced heat transfer from a body

ActiveUS20060293734A1Avoid possibilityIncrease volumeMedical devicesIndirect heat exchangersTemperature controlUser input

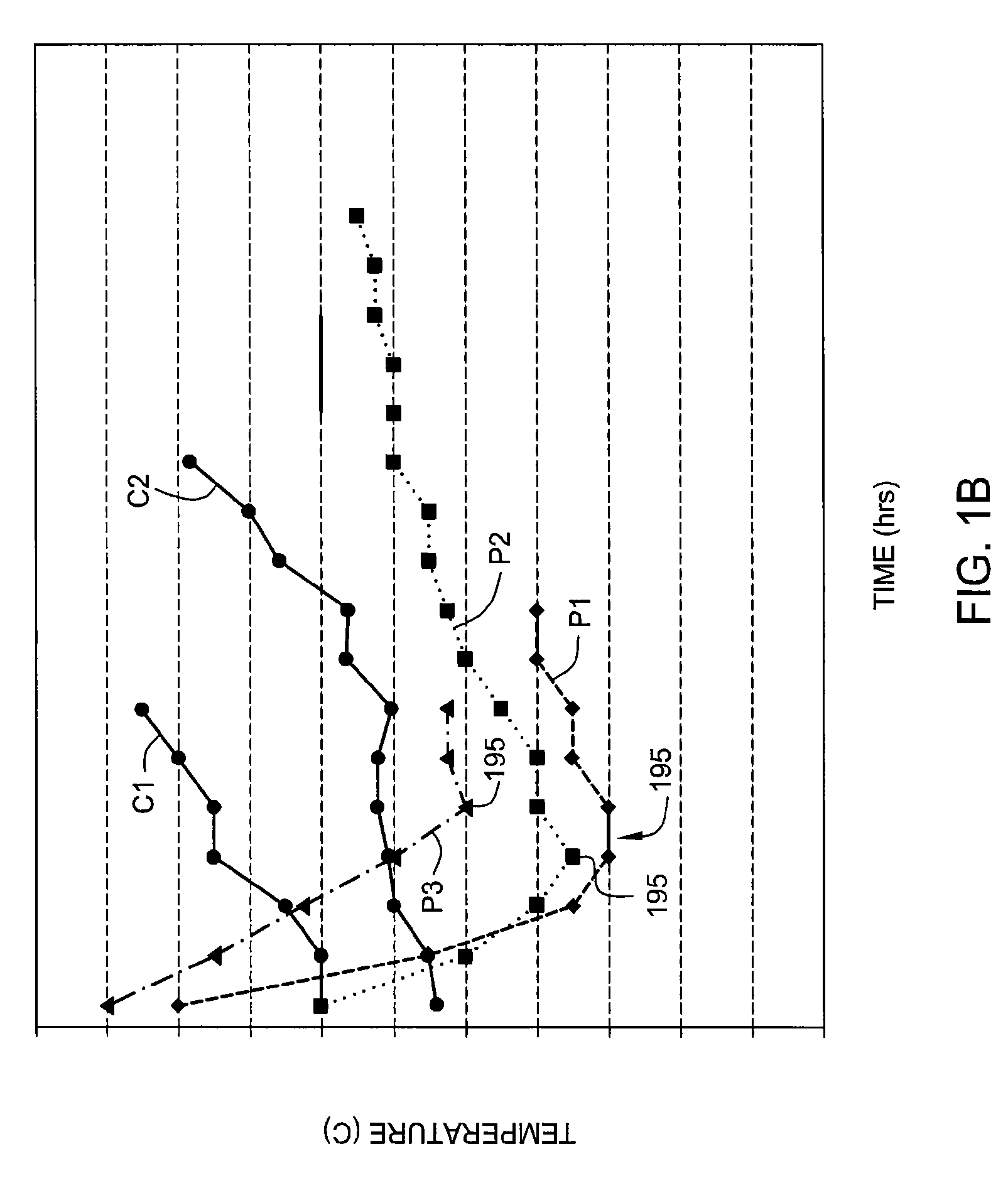

Methods and apparatuses for temperature modification of a patient, or selected regions thereof, including an induced state of hypothermia. The temperature modification is accomplished using an in-dwelling heat exchange catheter within which a fluid heat exchange medium circulates. A heat exchange cassette is attached to the circulatory conduits of the catheter, the heat exchange cassette being sized to engage a cavity within a control unit. The control unit includes a heater / cooler device for providing heated or cooled fluid to a heat exchanger in thermal communication with the fluid heat exchange medium circulating to the heat exchange catheter, a user input device, and a processor connected to receive input from various sensors around the body and the system. A temperature control scheme for ramping the body temperature up or down without overshoot is provided.

Owner:ZOLL CIRCULATION

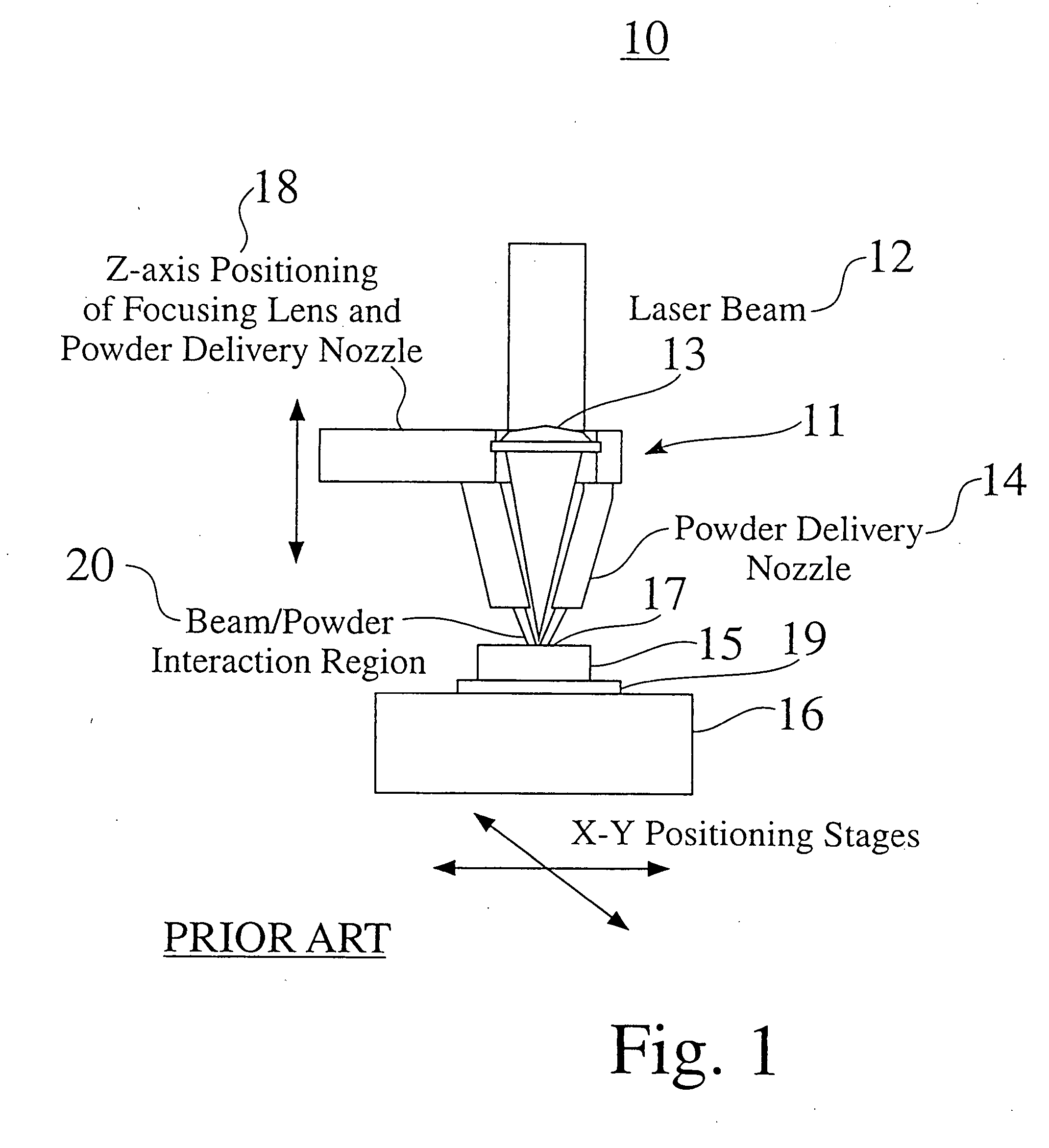

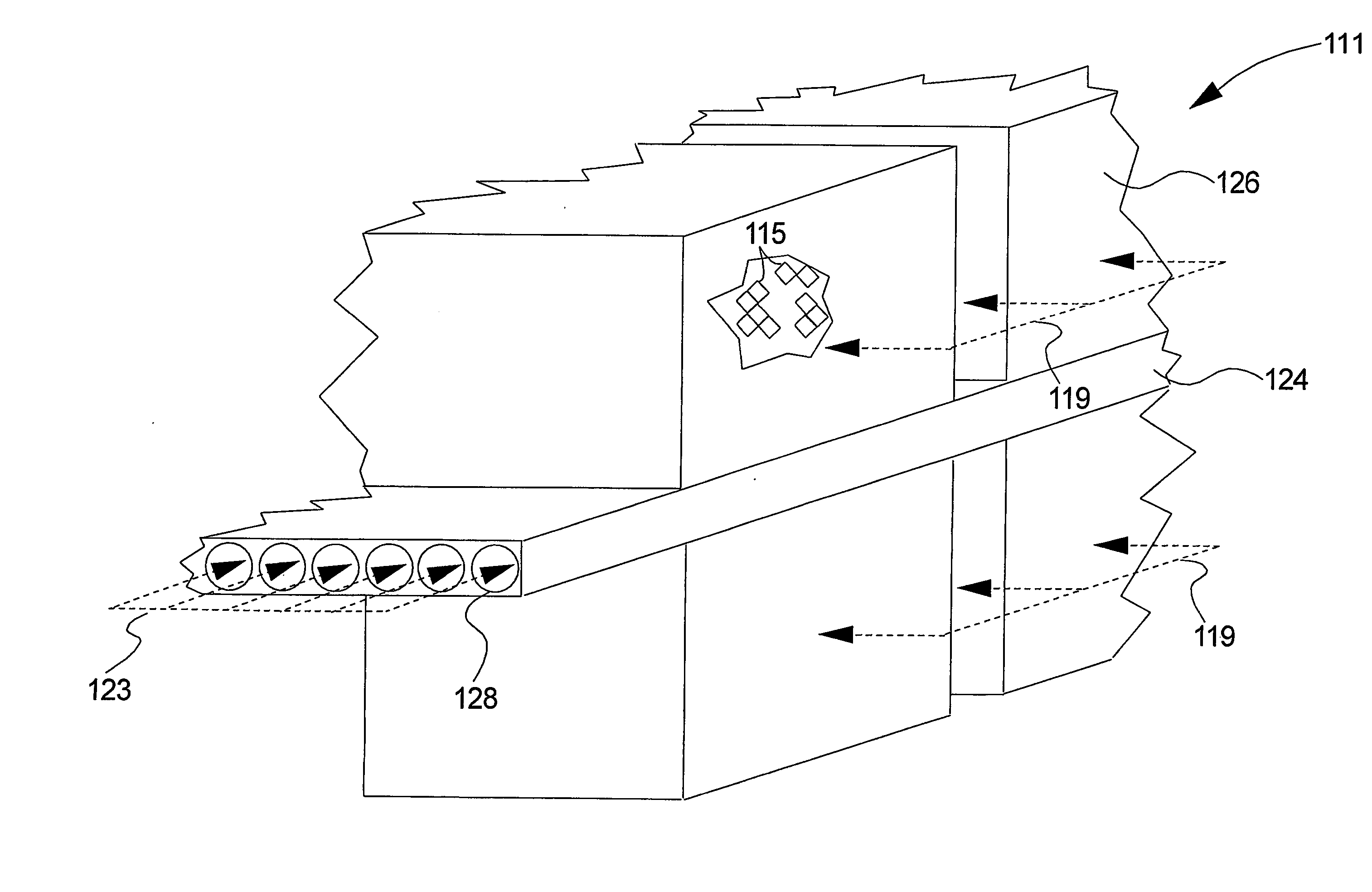

Powder feeder for material deposition systems

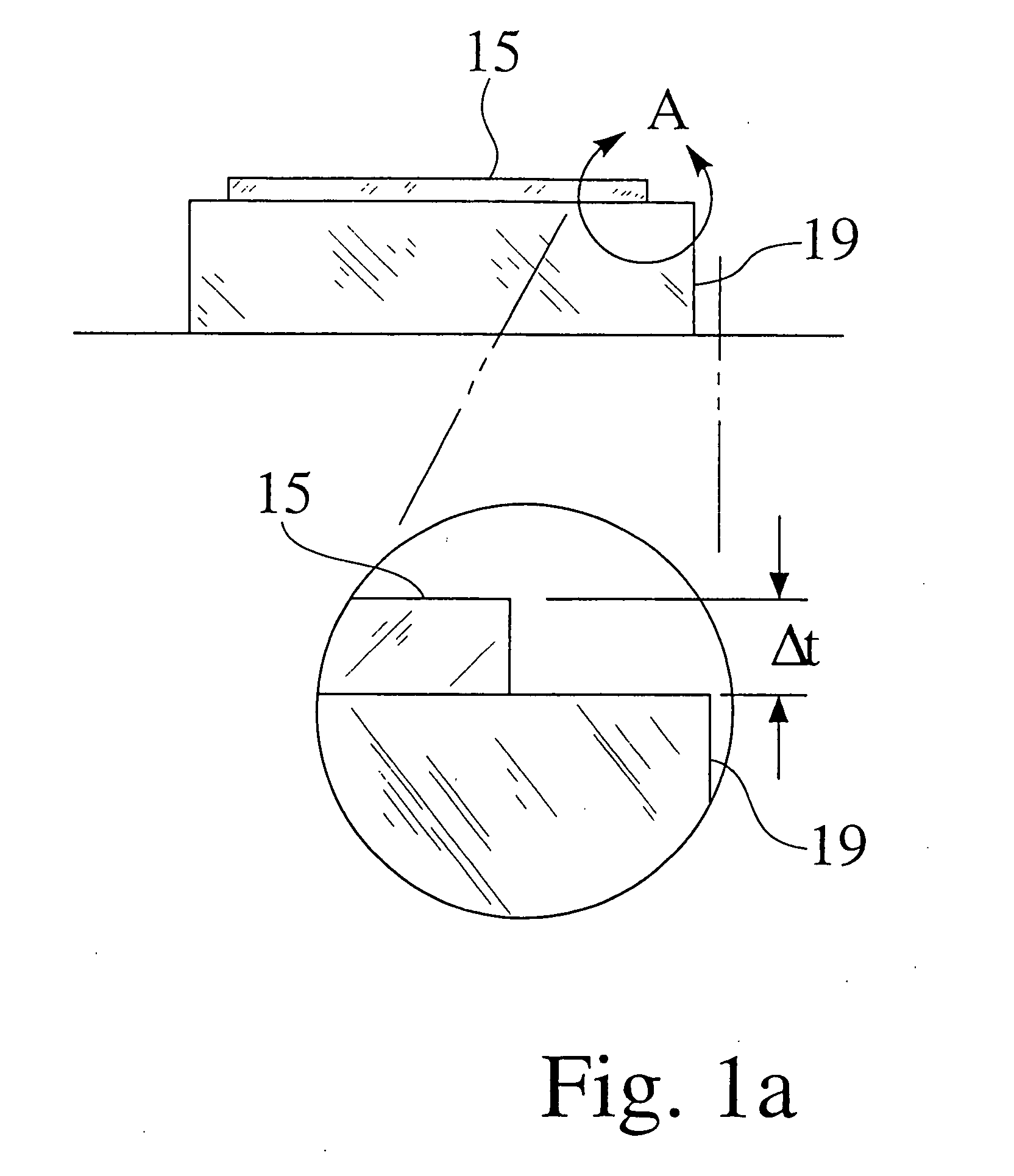

InactiveUS20050133527A1Small sizeEliminate warpingPower operated devices3D object support structuresSolid componentCoolant flow

A method and apparatus for embedding features and controlling material composition in a three-dimensional structure (130) is disclosed. The invention enables the control of material characteristics, within a structure (130) made from a plurality of materials, directly from computer renderings of solid models of the components. The method uses stereolithography and solid model computer file formats to control a multi-axis head (480) in a directed material deposition process (123). Material feedstock (126, 127) is deposited onto a pre-heated substrate (19). Depositions (15) in a layer-by-layer pattern, defined by solid models (141, 146), create a three-dimensional article having complex geometric details. Thermal management of finished solid articles (250-302), not available through conventional processing techniques, is enabled by embedded voids (152) and / or composite materials (126, 127), which include dissimilar metals (210, 216). Finished articles control pressure drop and produce uniform coolant flow and pressure characteristics. High-efficiency heat transfer is engineered within a solid structure by incorporating other solid materials with diverse indexes. Embedding multi-material structures (132, 134) within a normally solid component (141) produces articles with diverse mechanical properties. Laser and powder delivery systems (420, 170) are integrated in a multi-axis deposition head (480) having a focused particle beam (502) to reduce material waste.

Owner:OPTOMEC DESIGN CO

X-ray device having a dilation structure for delivering localized radiation to an interior of a body

Generally, the present invention provides a device for insertion into a body of a subject being treated to deliver localized x-ray radiation, and a method for use of such a device. The device includes an anode and a cathode, disposed within a vacuum housing. The device further includes a balloon coupled to and circumferentially surrounding the vacuum housing, and a fluid loop for circulating a cooling fluid proximate to the vacuum housing. A method for delivering localized x-ray radiation to an interior passage of a body is also described, including the steps of positioning an x-ray device at the passage to be treated and applying a high voltage to the x-ray producing unit to produce localized x-ray radiation.

Owner:MEDTRONIC AVE

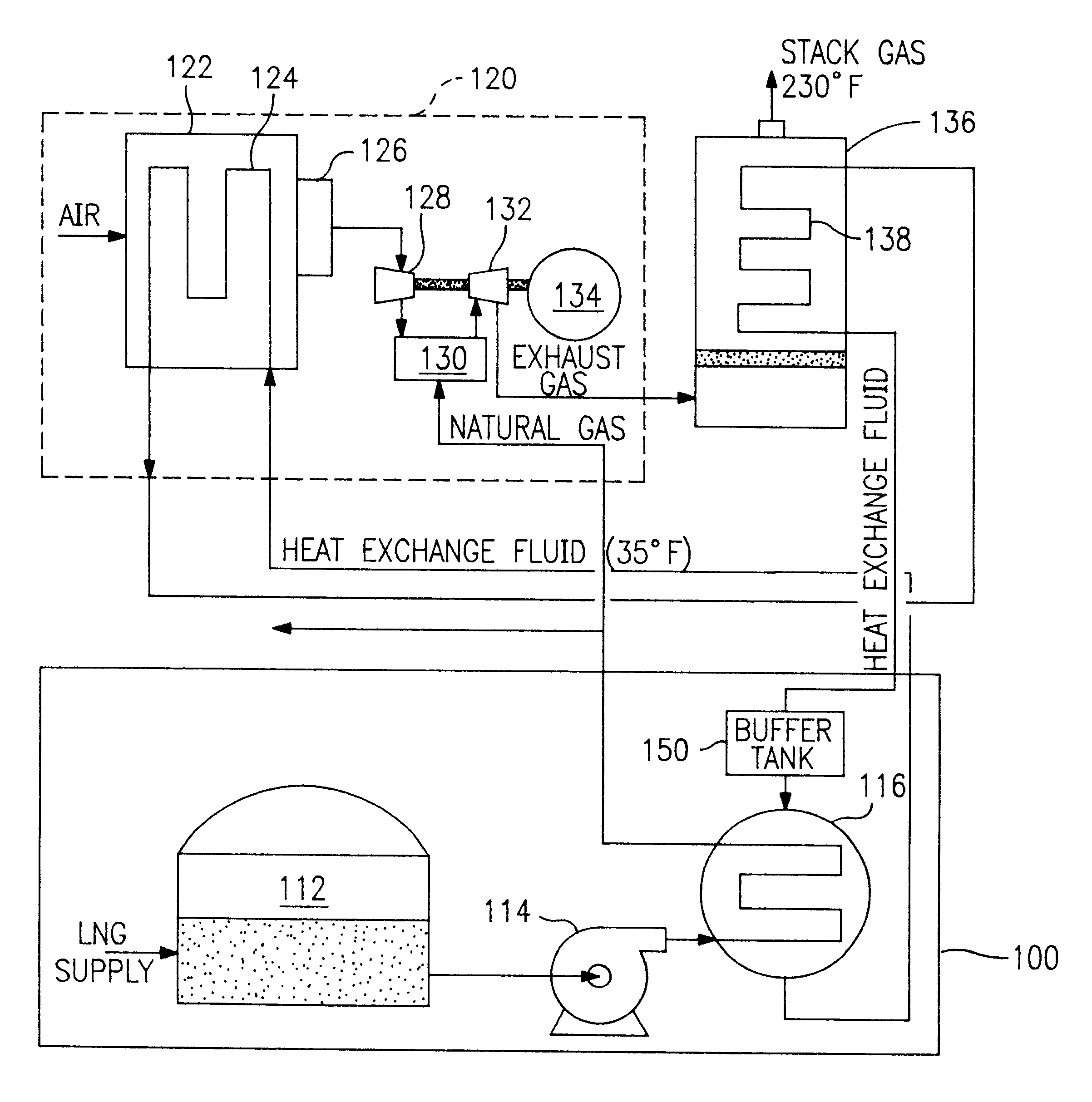

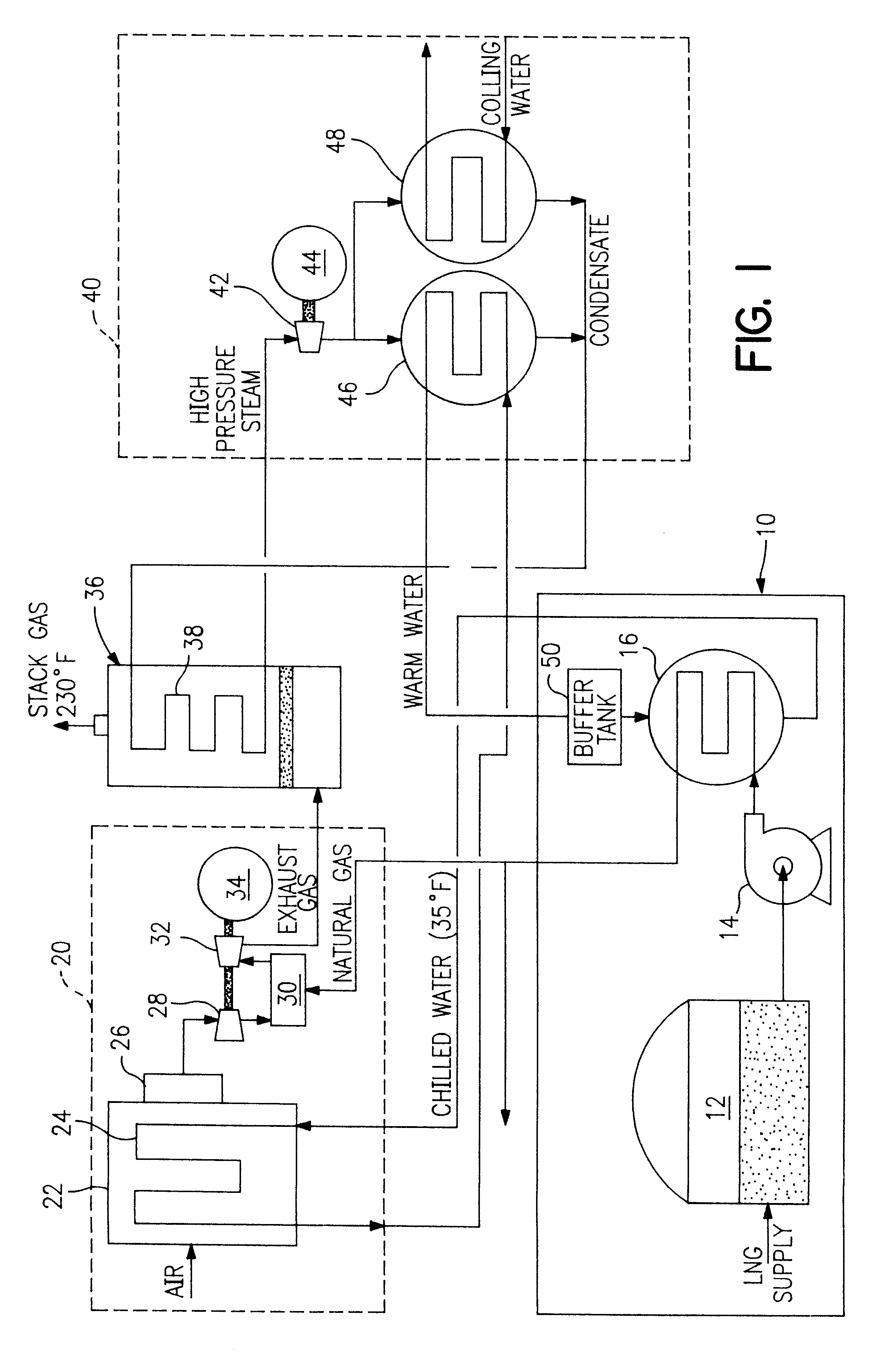

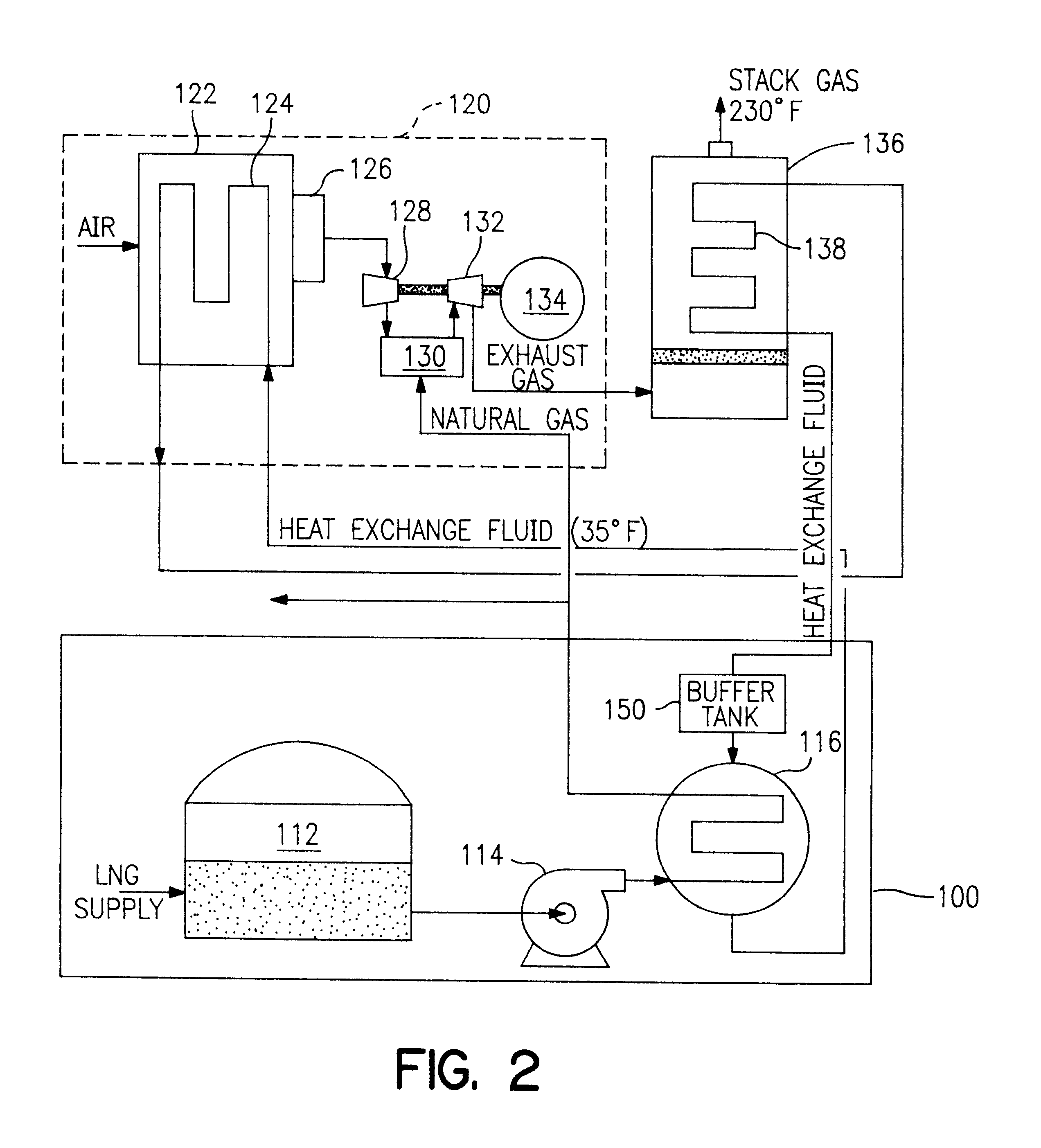

Liquified natural gas (LNG) fueled combined cycle power plant and a (LNG) fueled gas turbine plant

InactiveUS6374591B1Improve efficiencyParts are smallGas handling applicationsGas turbine plantsCombustion chamberPower station

A process and system which improves the capacity and efficiency of a power plant. A LNG supply system fuels the plant. Gasified LNG in a combustor mixes with the air from an air compressor to provide the hot combustion gas for a gas turbine. The expanding LNG is used to chill a heat exchange fluid, e.g. water, which heat exchange fluid cools and densifies the intake air for the air compressor. Subsequently, the heat exchange fluid is used in another heat exchange step and is then re-chilled and recycled to cool and densify the intake air.

Owner:SUEZ LNG NA

Single port cardiac support apparatus

Owner:MAQUET CARDIOVASCULAR LLC

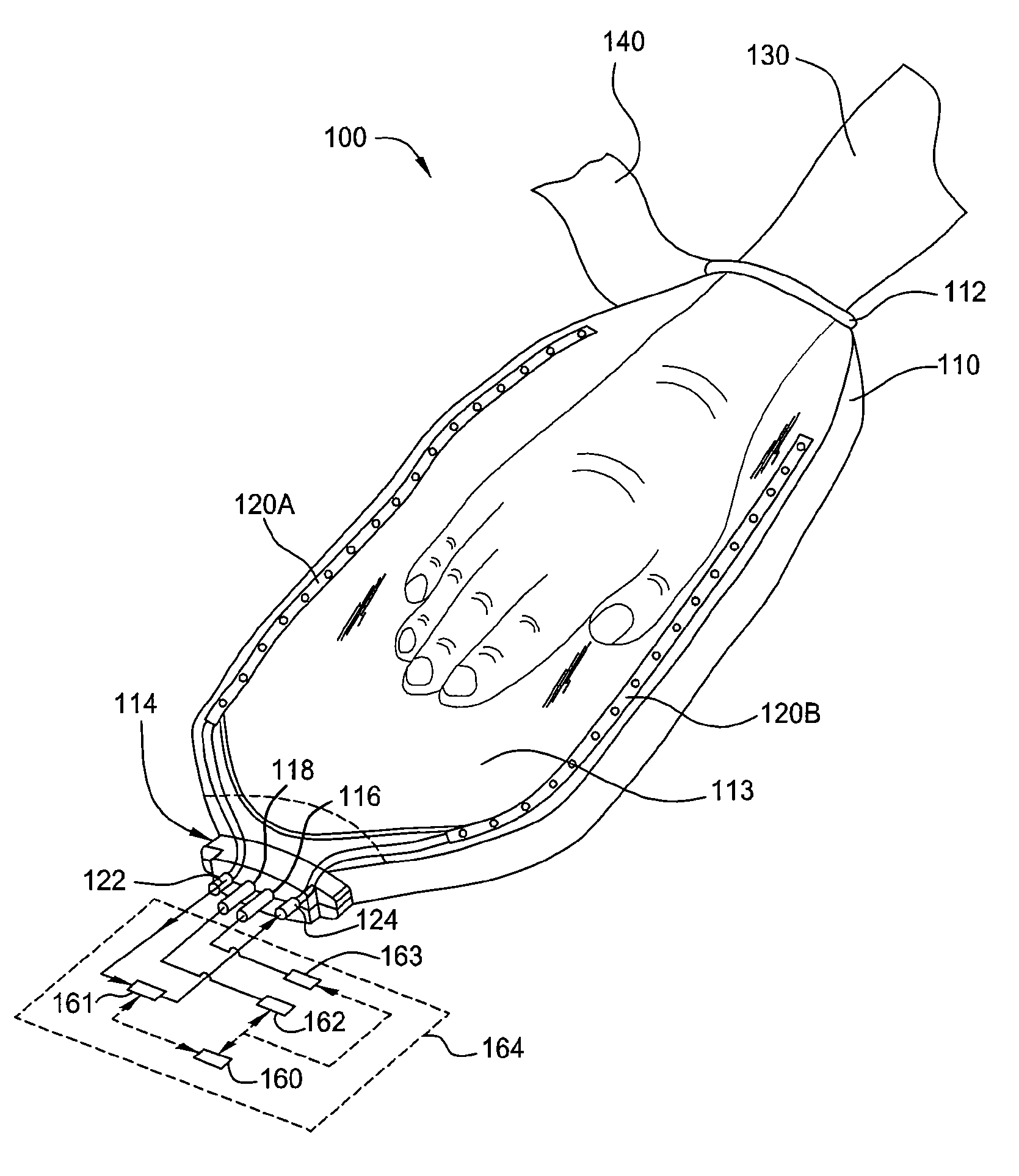

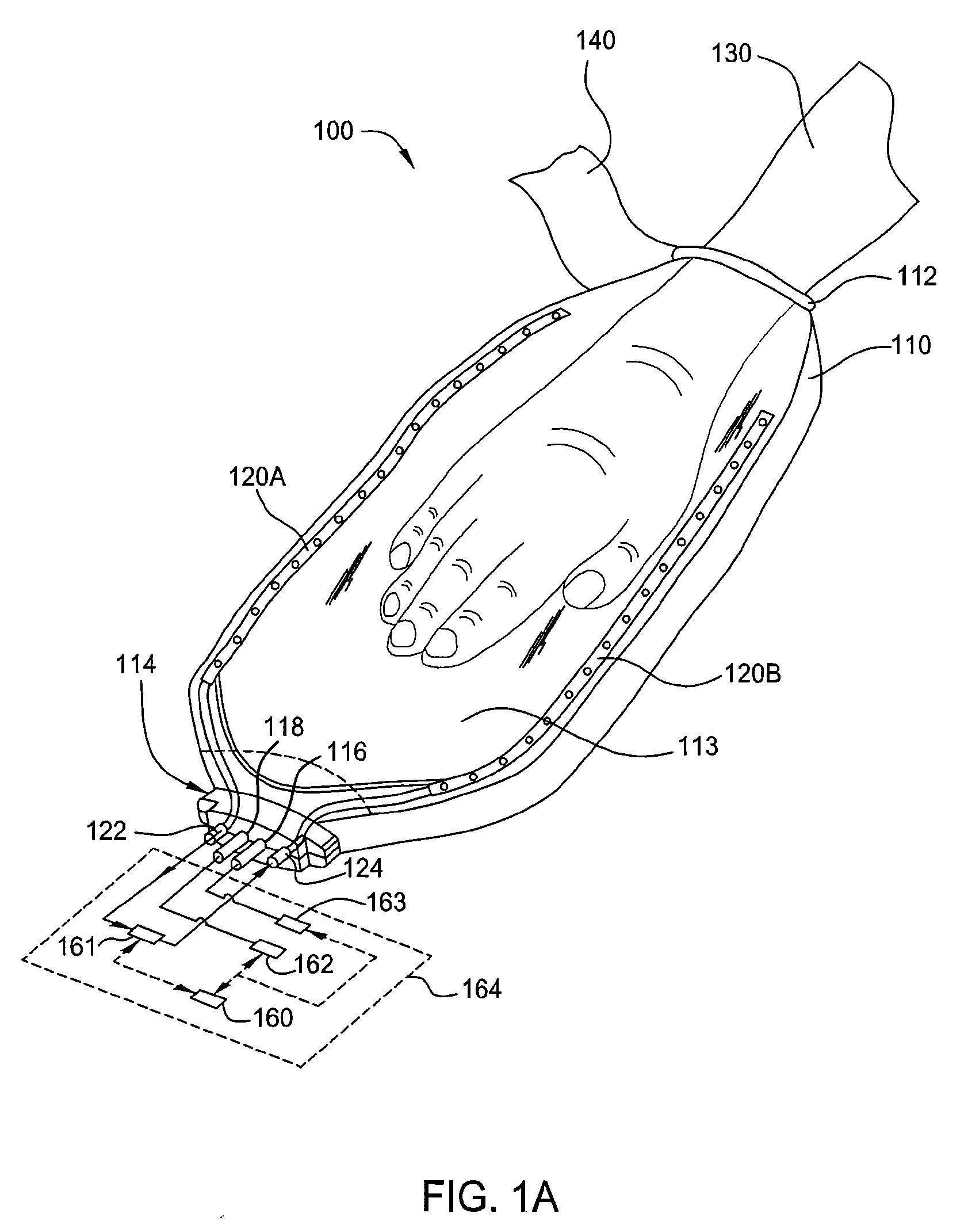

Methods and apparatus for adjusting blood circulation

ActiveUS20080132976A1Good thermal contactIncrease blood flowBlood stagnation preventionElectrotherapyThermal energyEngineering

Embodiments of the invention include a method and a device for increasing blood flow and controlling the temperature of a mammal by applying a desired pressure to extremities of a mammal. The device generally includes one or more collapsible and pliant body elements, capable of expanding from a first volume into an expanded second volume so the device can receive a portion of an extremity of the mammal therein and then be reduced from the expanded second volume into a pressurized third volume to conformably enclose the portion of the extremity. One or more thermal exchange units can be positioned in the one or more collapsible and pliant body elements. Accordingly, the temperature of the extremity of a mammal can be regulated by providing a heated or cooled fluid medium or electric thermal energy to the one or more thermal exchange units. Next, by evacuating the region in which the extremity is enclosed the contact surface area between the extremity of a mammal and the one or more thermal exchange units is increased, due to the external atmospheric pressure acting on the pliant body elements against the skin of the extremity of the mammal. The application of pressure assures that sufficient contact and thermal heat transfer (heating or cooling) is provided to the extremity of the mammal.

Owner:AVACORE TECH

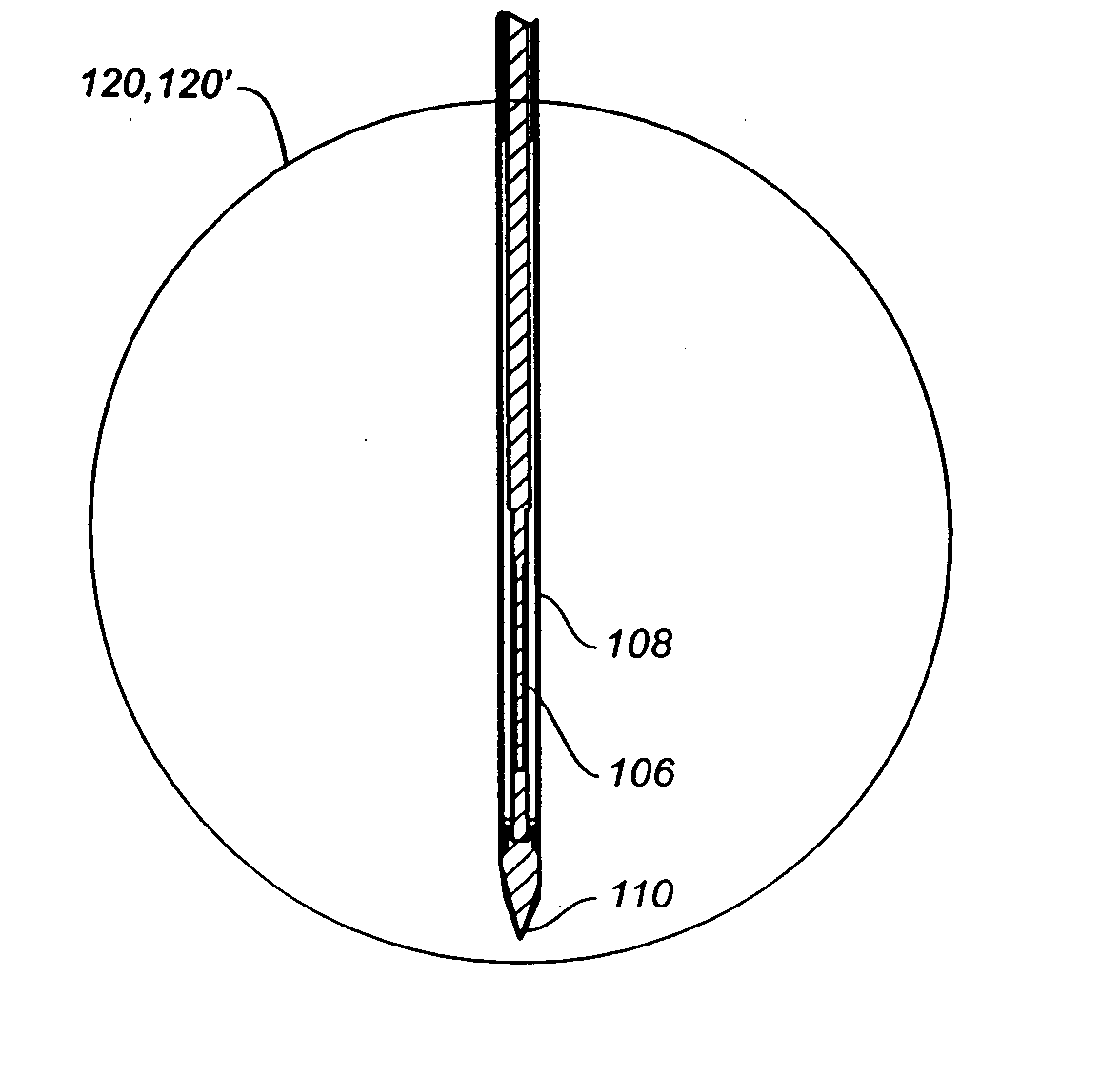

Cooled ablation catheter devices and methods of use

ActiveUS20090093811A1Reduce formationMinimize impactElectrotherapySurgical instruments for heatingDistal portionCooling chamber

Discloses herein are ablative catheters and methods of use. The catheters can include a cooling chamber for circulating cooling fluid within the catheter tip to reduce hot spots within the catheter tip and / or to reduce the formation of coagulum. A proximal cooling chamber can be positioned proximally to a thermal mass for cooling a proximal portion of the catheter. In addition, or alternatively, a distal cooling chamber can be positioned for cooling a distal portion of the catheter tip. The cooling fluid can flow the ablative catheter in an open, closed, or open and closed loop.

Owner:BOSTON SCI SCIMED INC

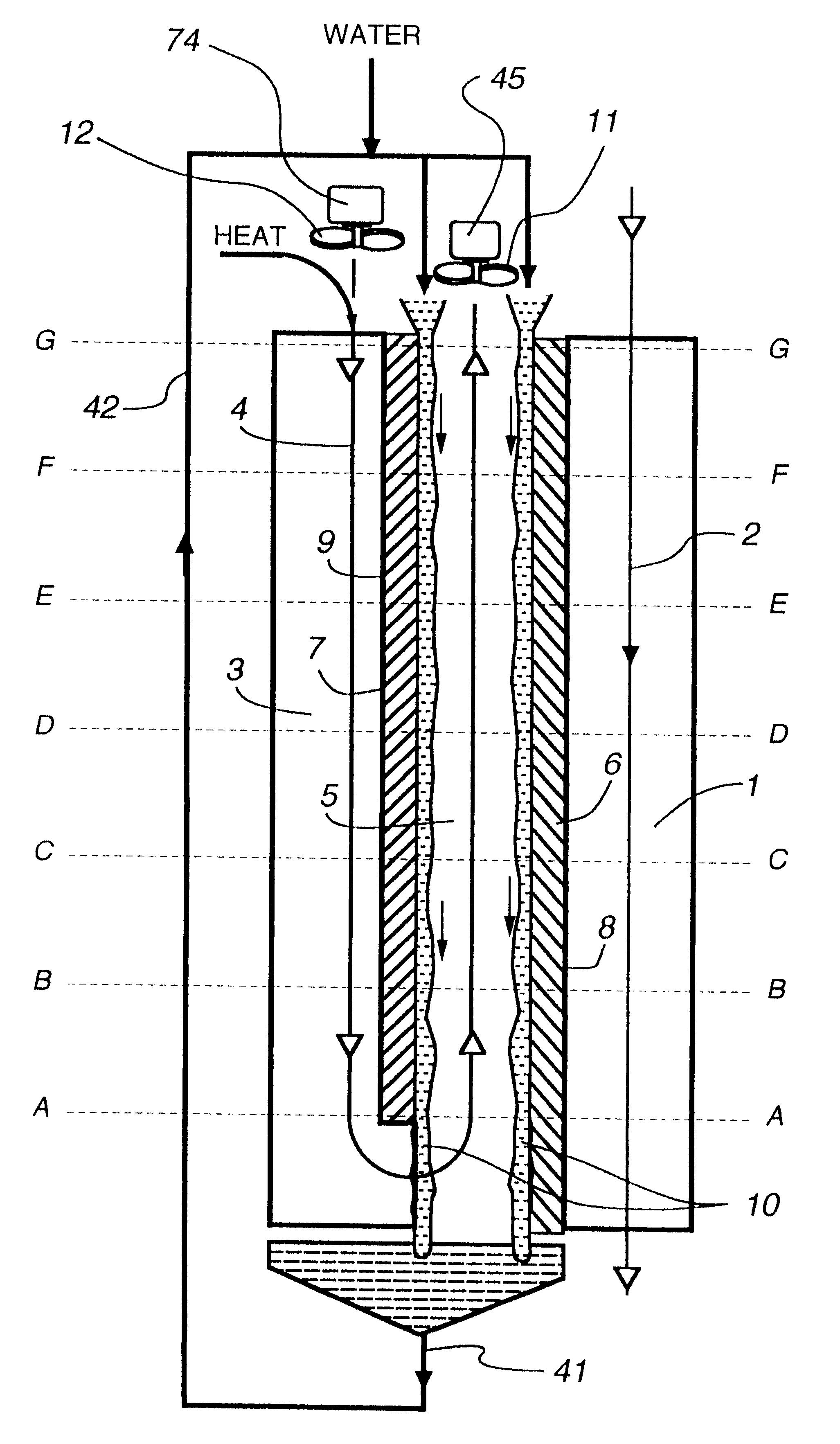

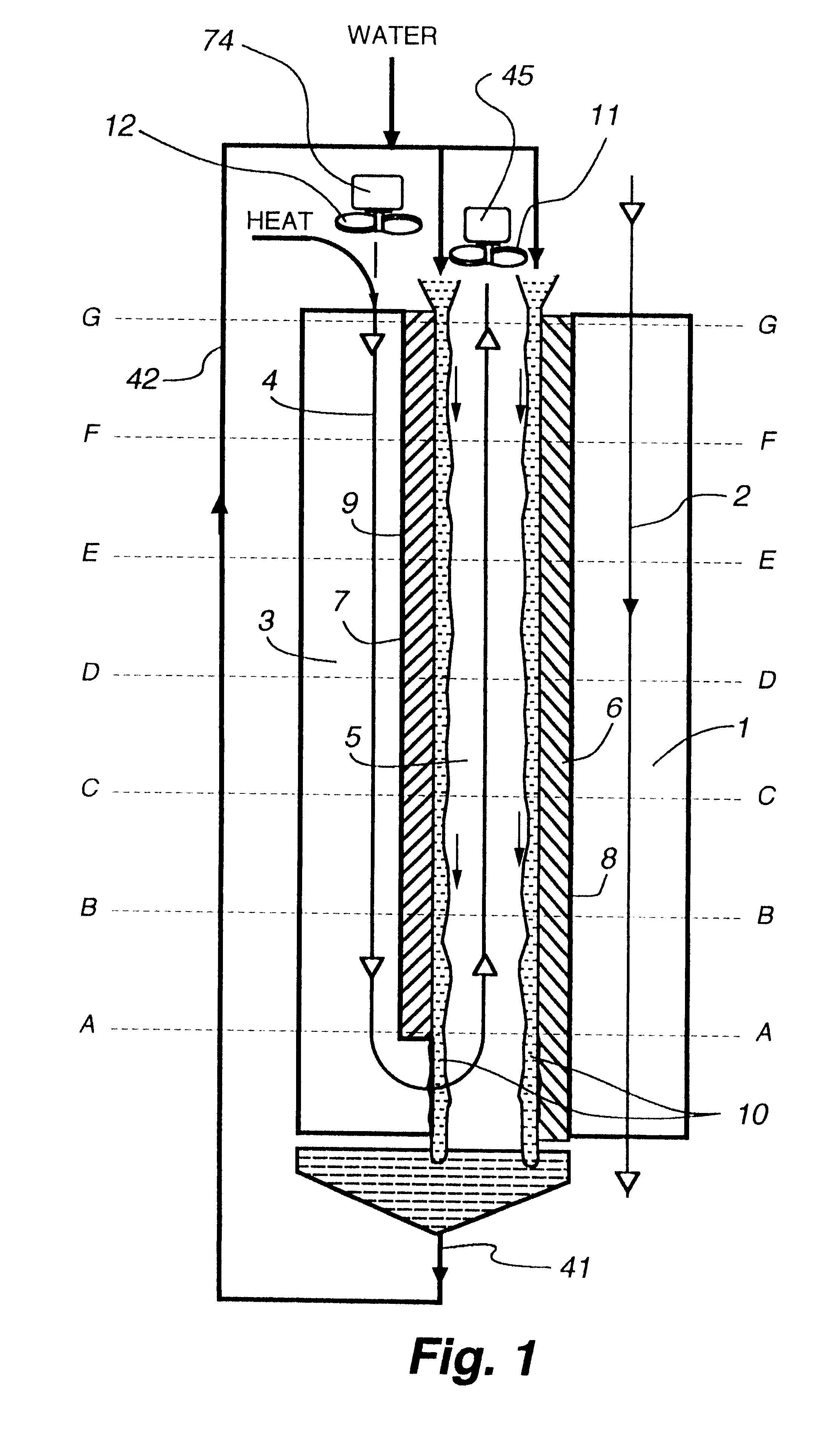

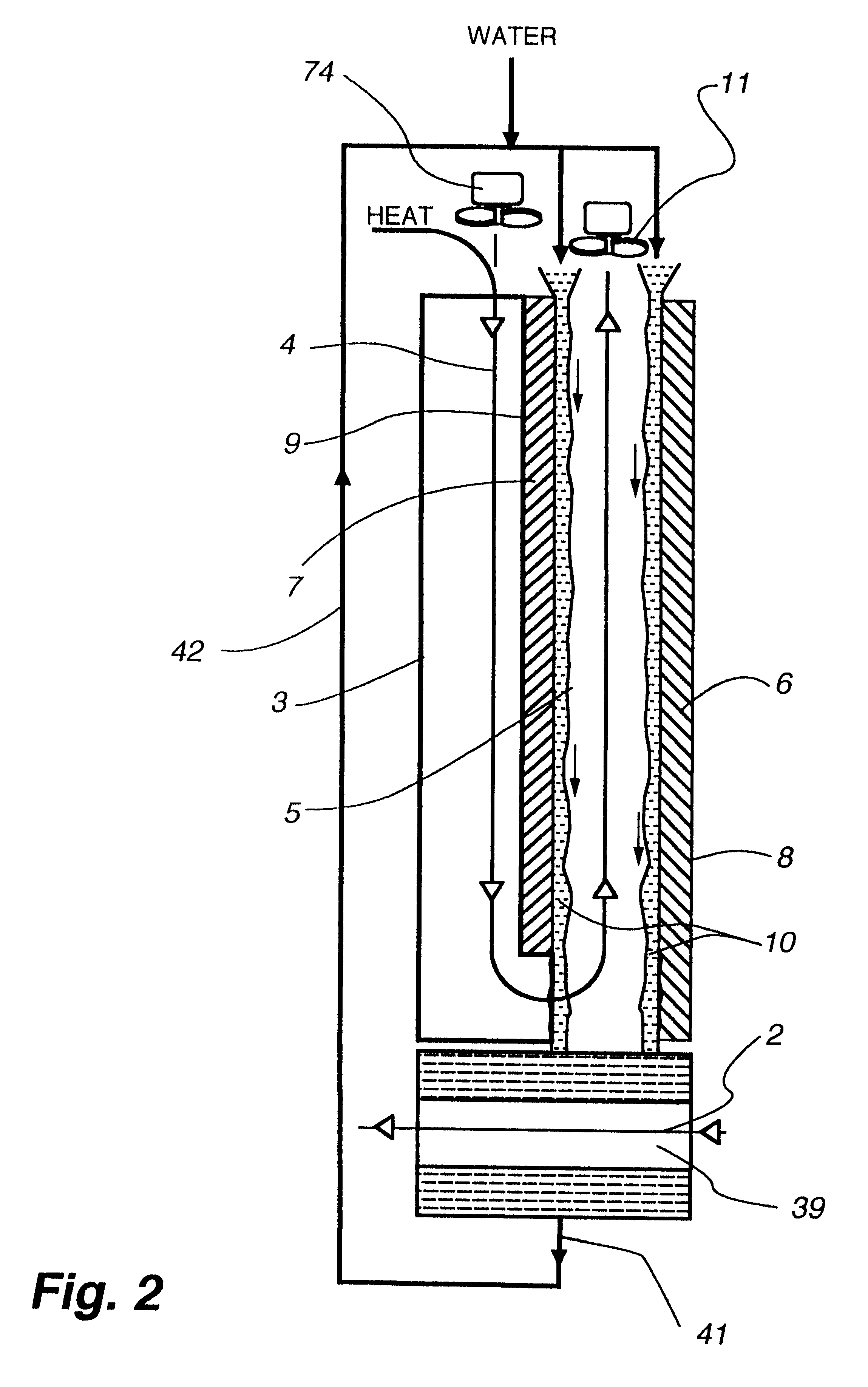

Method and apparatus of indirect-evaporation cooling

InactiveUS6497107B2Less energyHigh energy costFree-cooling systemsStationary conduit assembliesWorking fluidEvaporation

The within invention improves on the indirect evaporative cooling method and apparatus by making use of a working fluid that is pre-cooled with and without desiccants before it is passed through a Wet Channel where evaporative fluid is on the walls to take heat and store it in the working fluid as increased latent heat. The heat transfer across the membrane between the Dry Channel and the Wet Channel may have dry, solid desiccant or liquid desiccant and may have perforations, pores or capillary pathways. The evaporative fluid may be water, fuel, or any substance that has the capacity to take heat as latent heat. The Wet Channel or excess cooled fluid is in heat transfer contact with a Product Channel where Product Fluid is cooled without adding any humidity. An alternative embodiment for heat transfer between adjacent channels is with heat pipes.

Owner:F F SEELEY NOMINEES

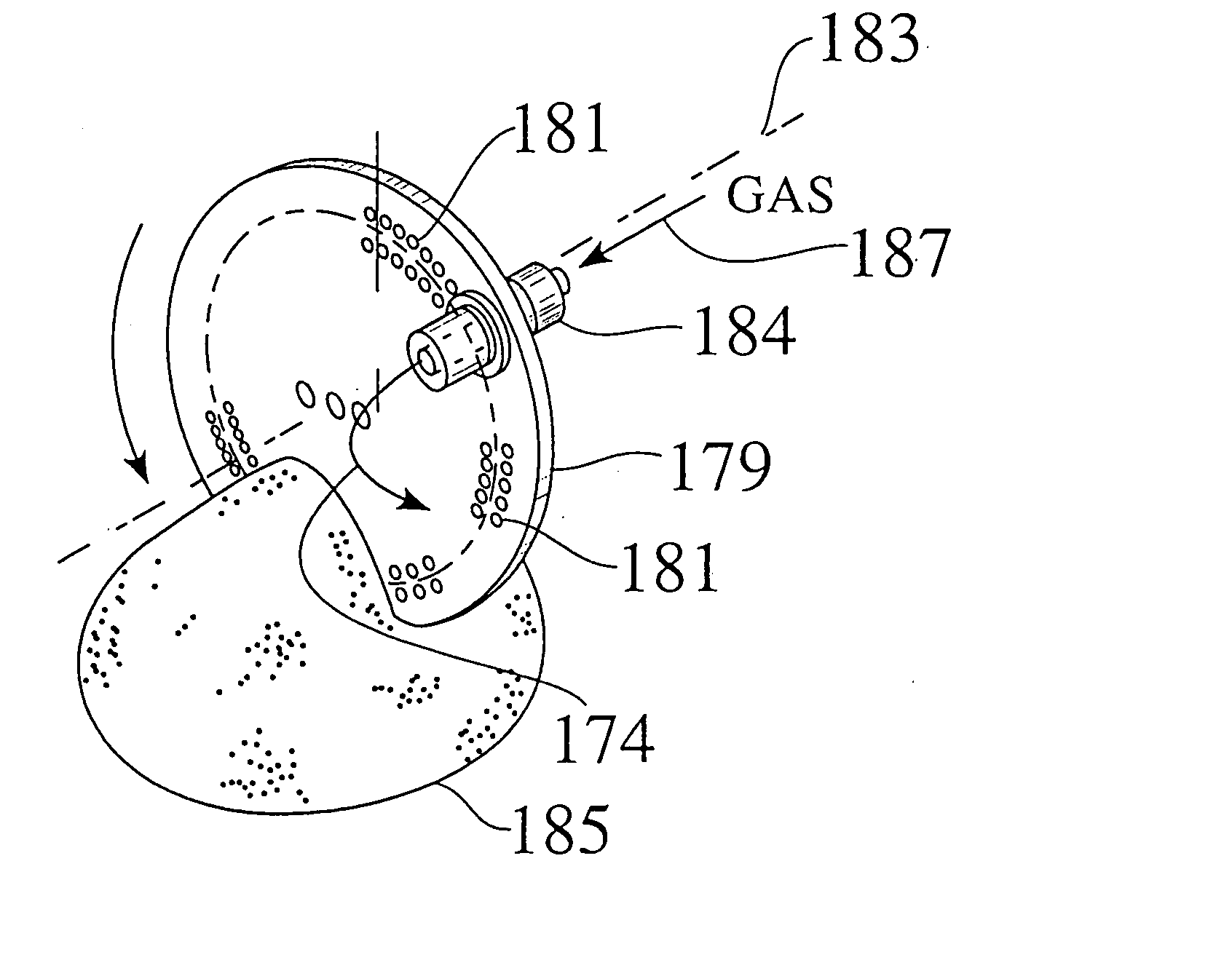

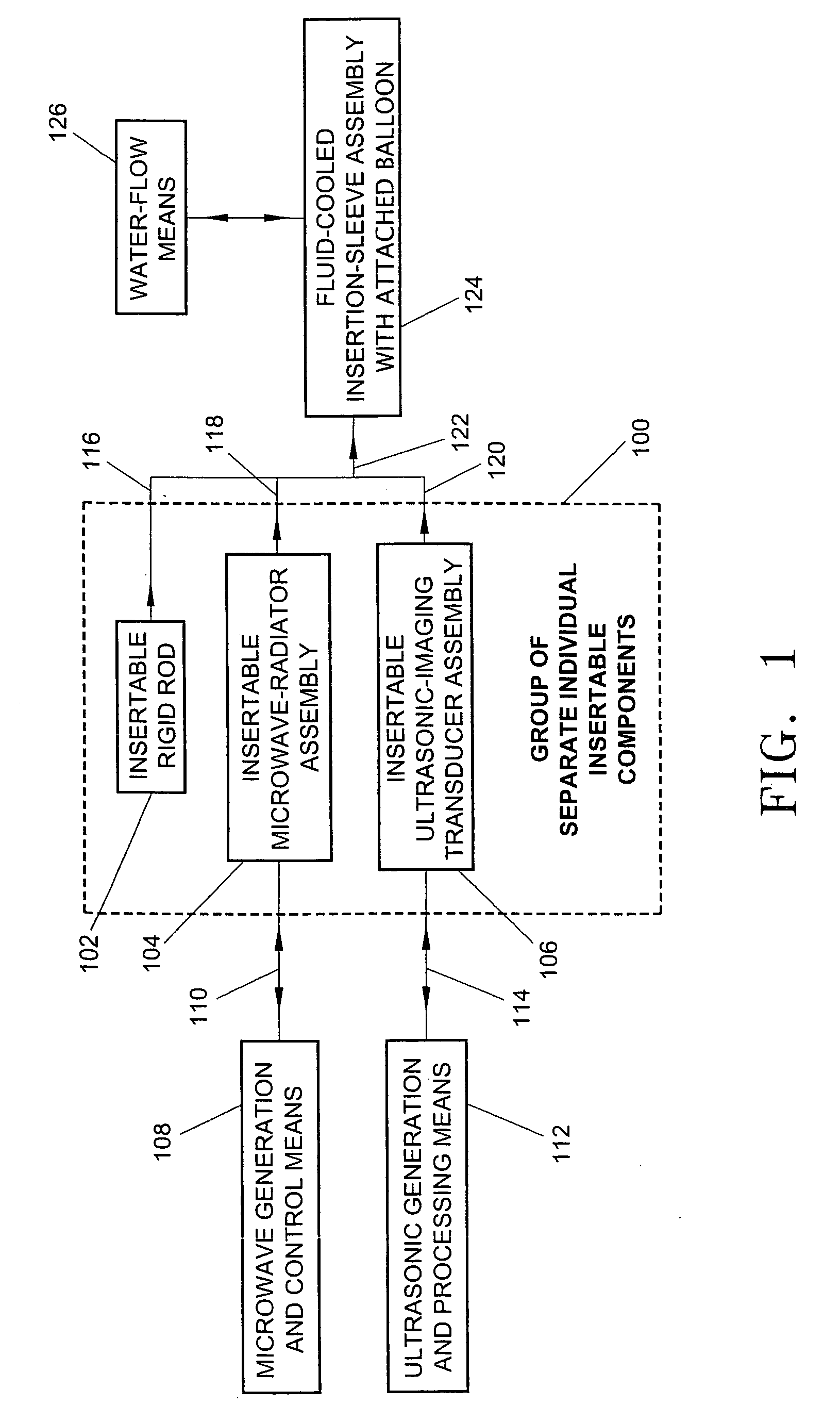

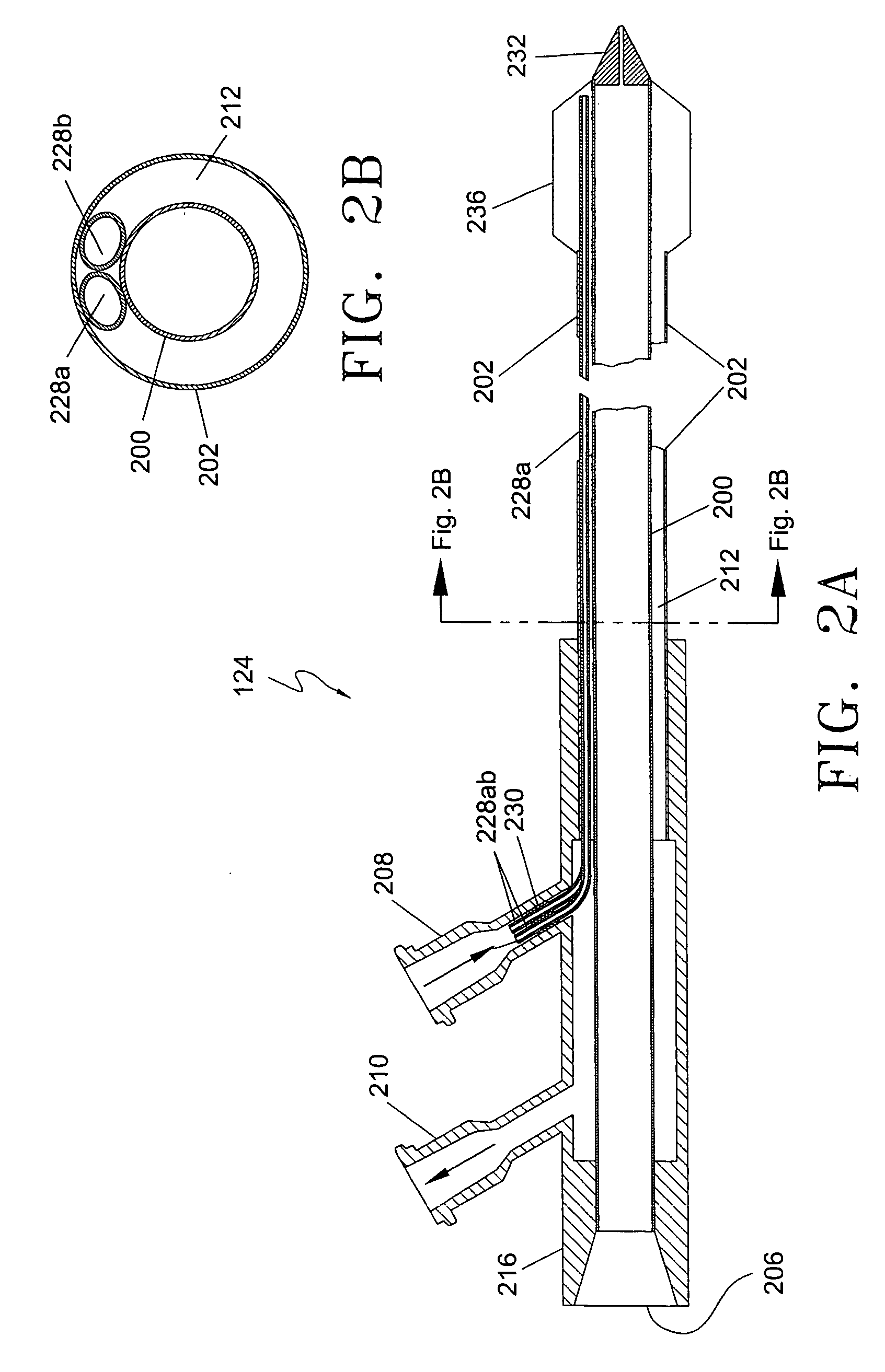

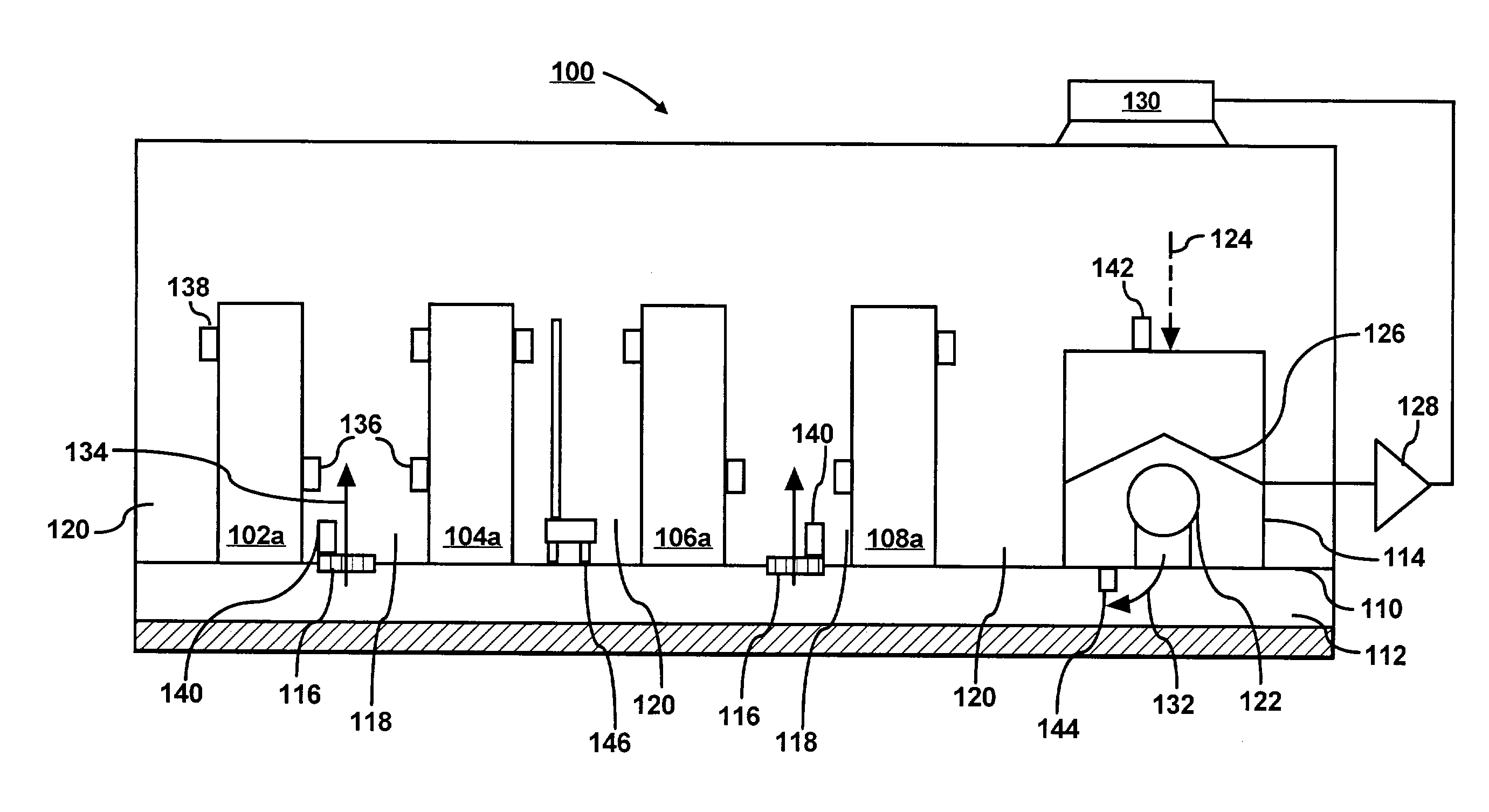

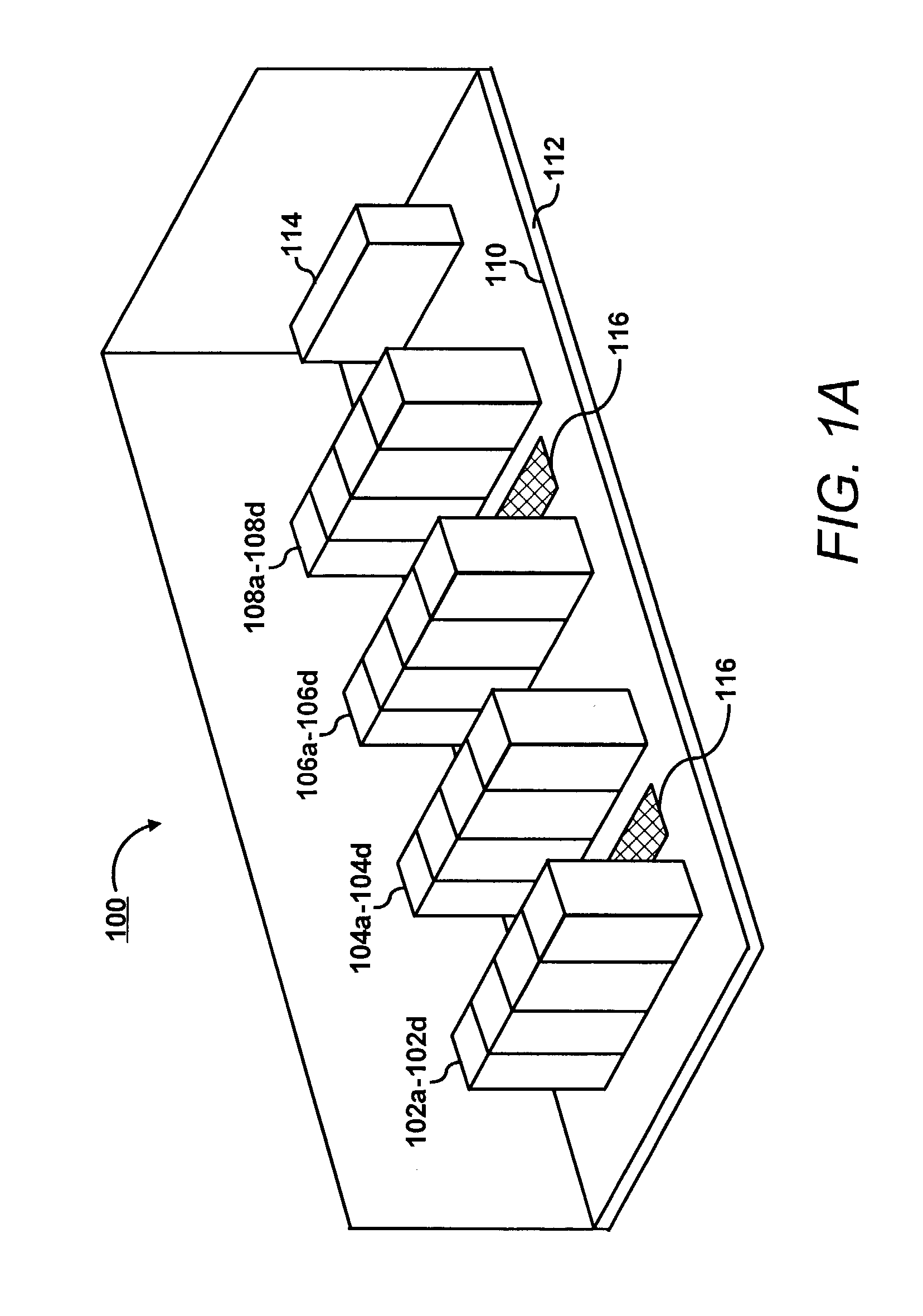

Interstitial microwave system and method for thermal treatment of diseases

A minimally-invasive fluid-cooled insertion sleeve assembly, with an attached balloon and distally-located penetrating tip, into which sleeve any of a group comprising a rigid rod, a microwave-radiator assembly and an ultrasonic-imaging transducer assembly may be inserted, constitutes a probe of the system. The sleeve assembly comprises spaced inner and outer plastic tubes with two fluid channels situated within the coaxial lumen between the inner and outer tubes. The fluid coolant input flows through the fluid channels into the balloon, thereby inflating the balloon, and then exits through that coaxial lumen. An alternative embodiment has no balloon. The method employs the probe for piercing sub-cutaneous tissue and then ablating deep-seated tumor tissue with microwave-radiation generated heat.

Owner:MMTC LTD +1

Air re-circulation index

InactiveUS7051946B2Reducing air re-circulationMechanical apparatusDomestic cooling apparatusData centerEngineering

An index of air re-circulation in a data center having one or more racks is determined to identify the level of heated air re-circulation into cooling fluid delivered to the one or more racks. The one or more racks comprise inlets and outlets and are positioned along a cool aisle and a hot aisle. The index is calculated by dividing the enthalpy rise due to infiltration of heated air into the cool aisle and the total enthalpy rise of the heated air from the outlets of the one or more racks.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

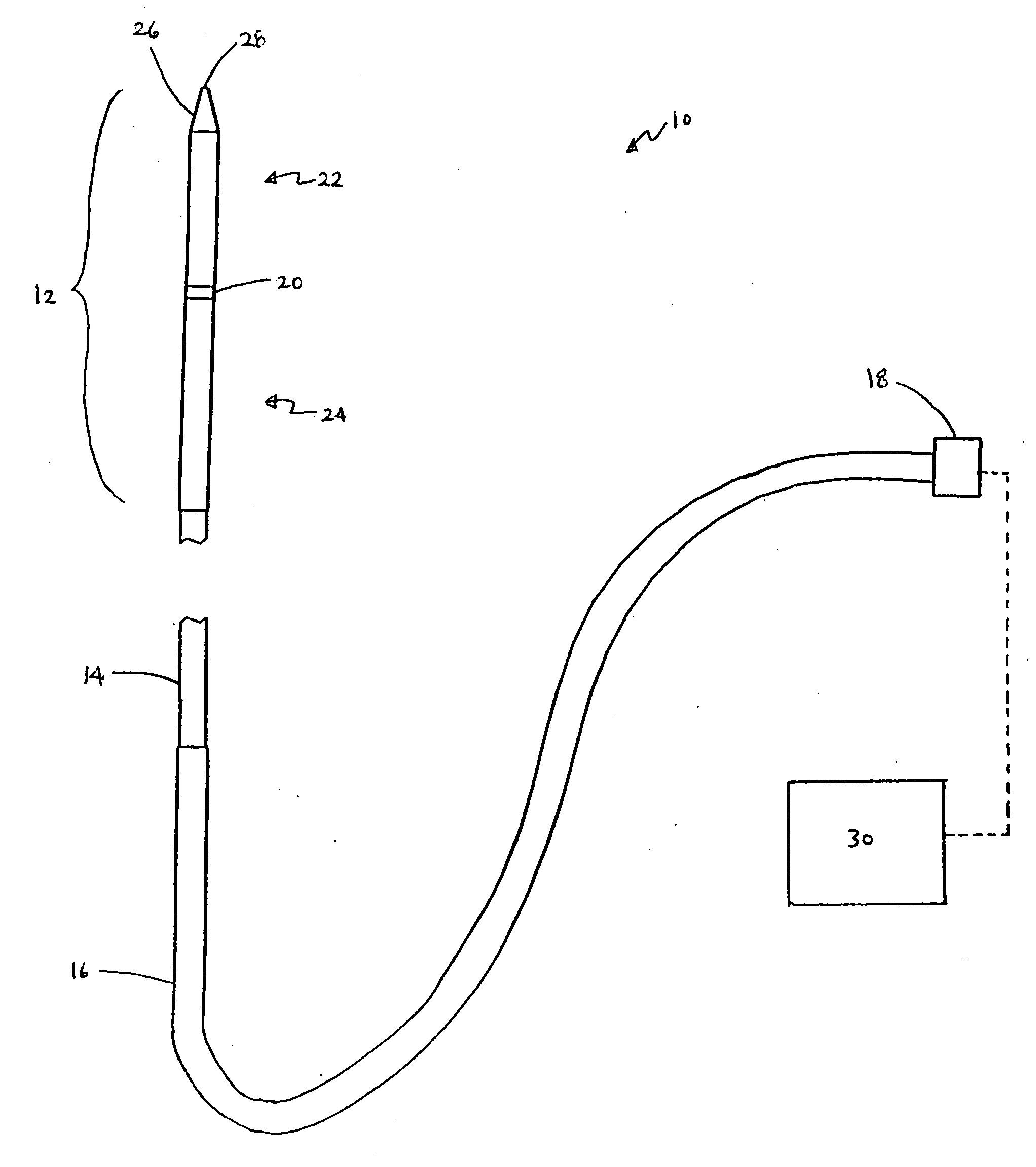

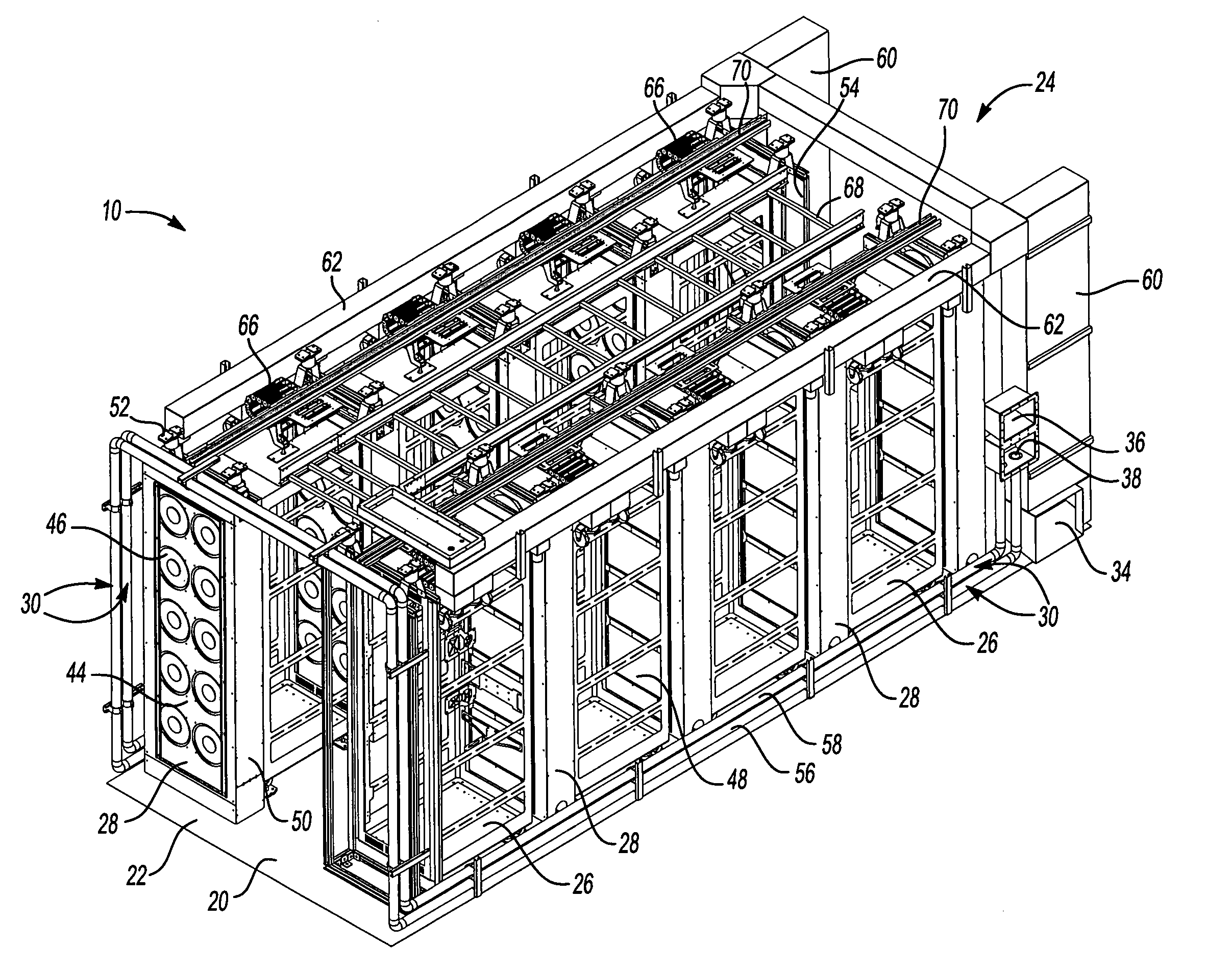

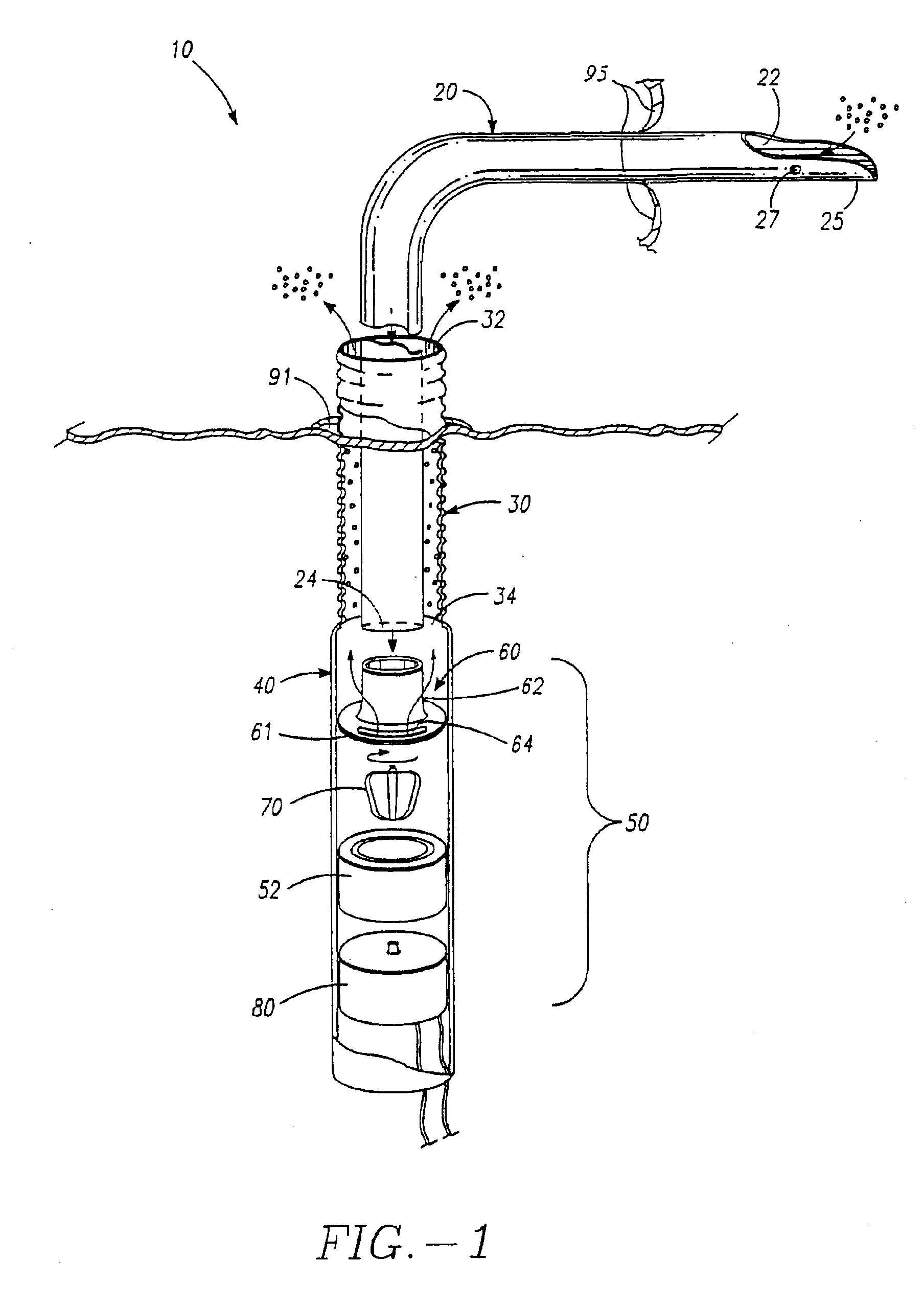

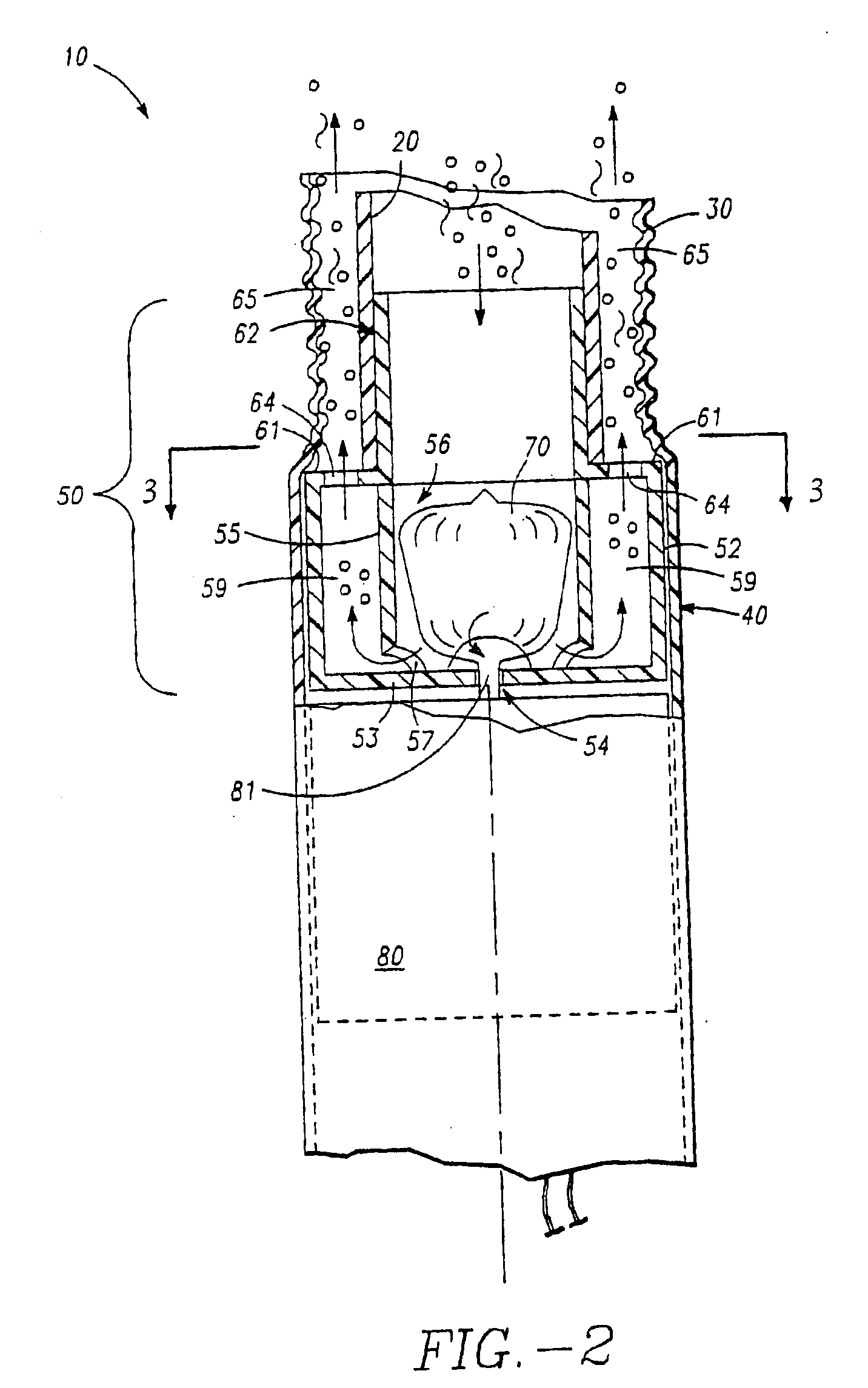

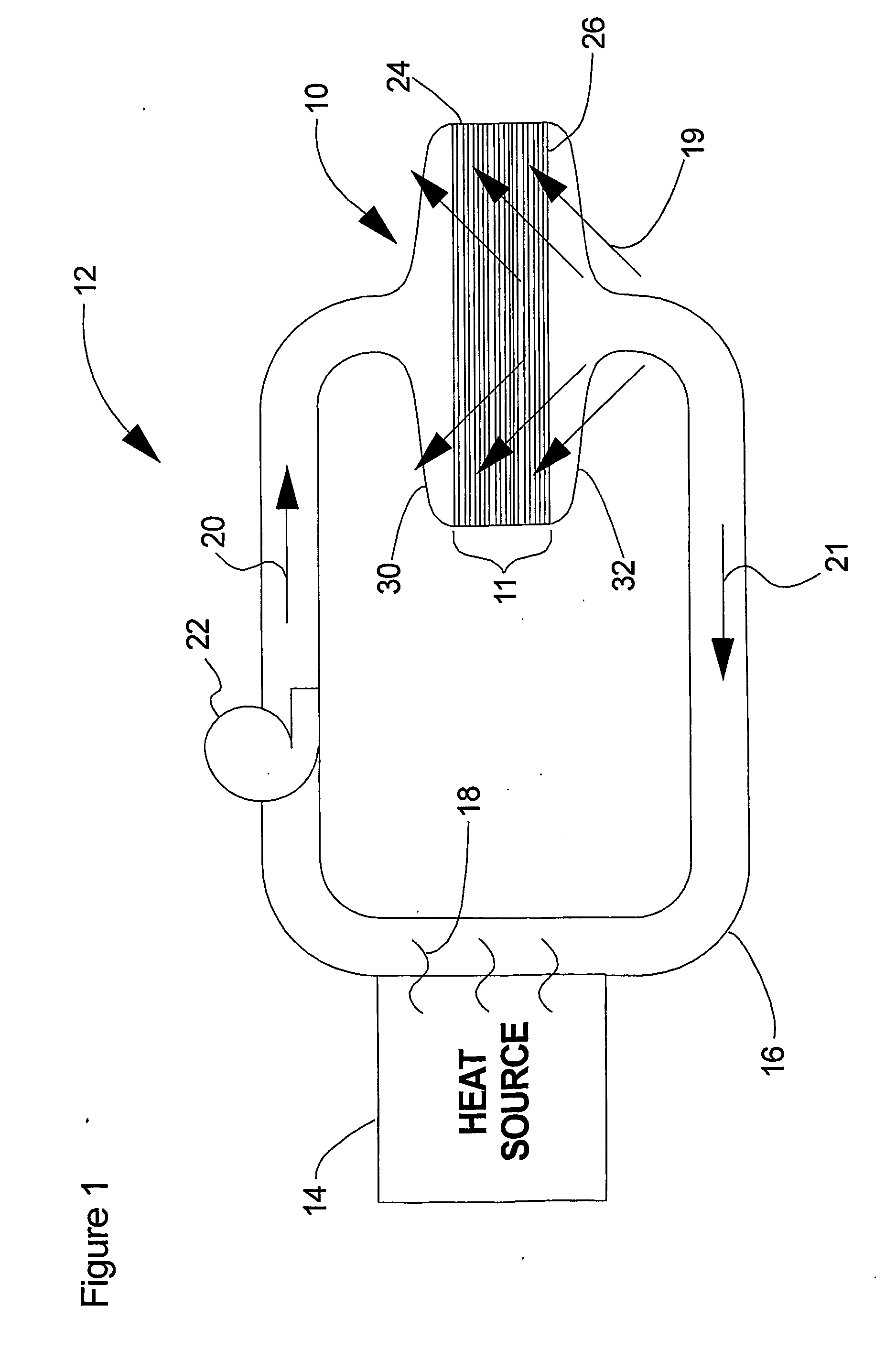

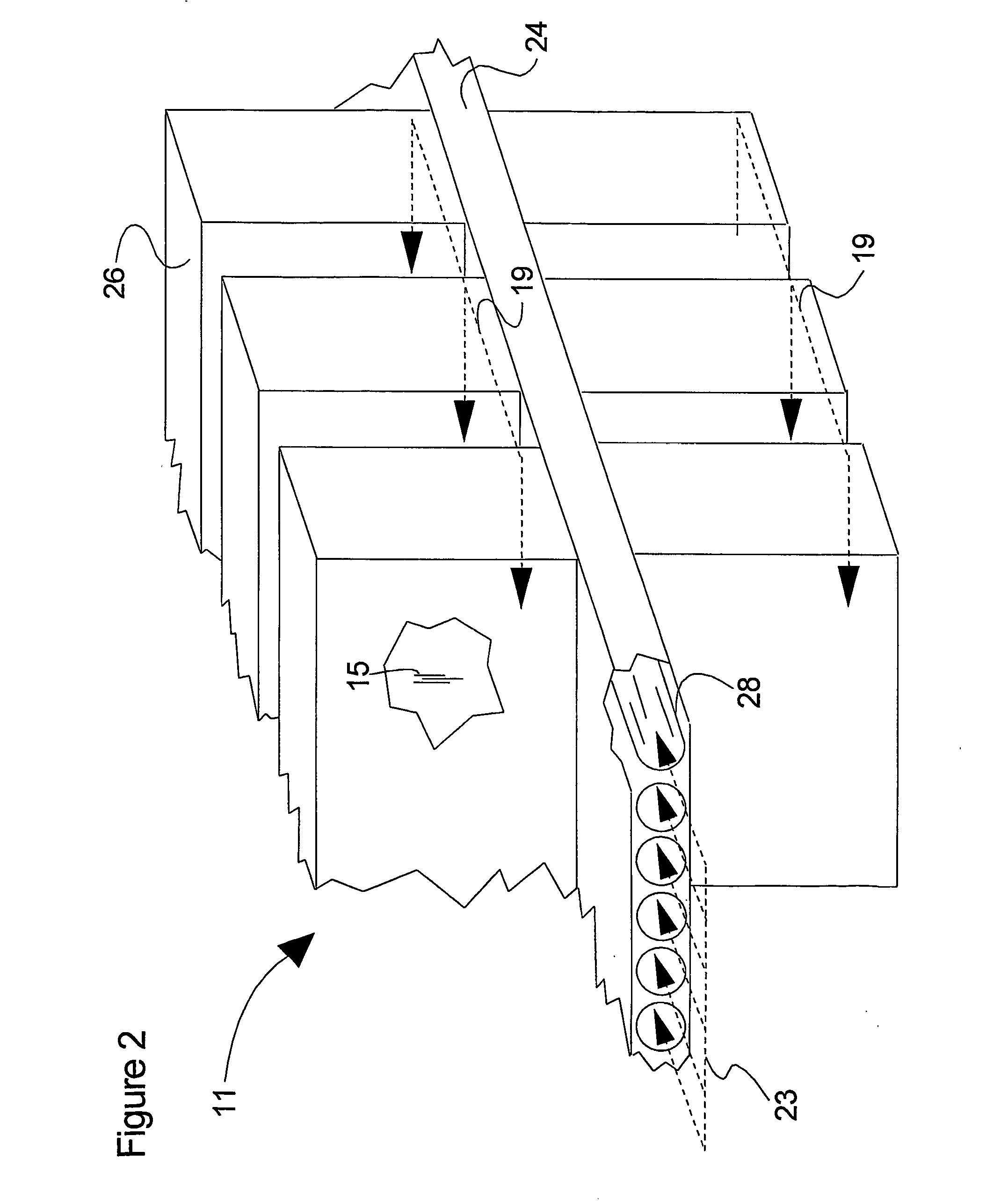

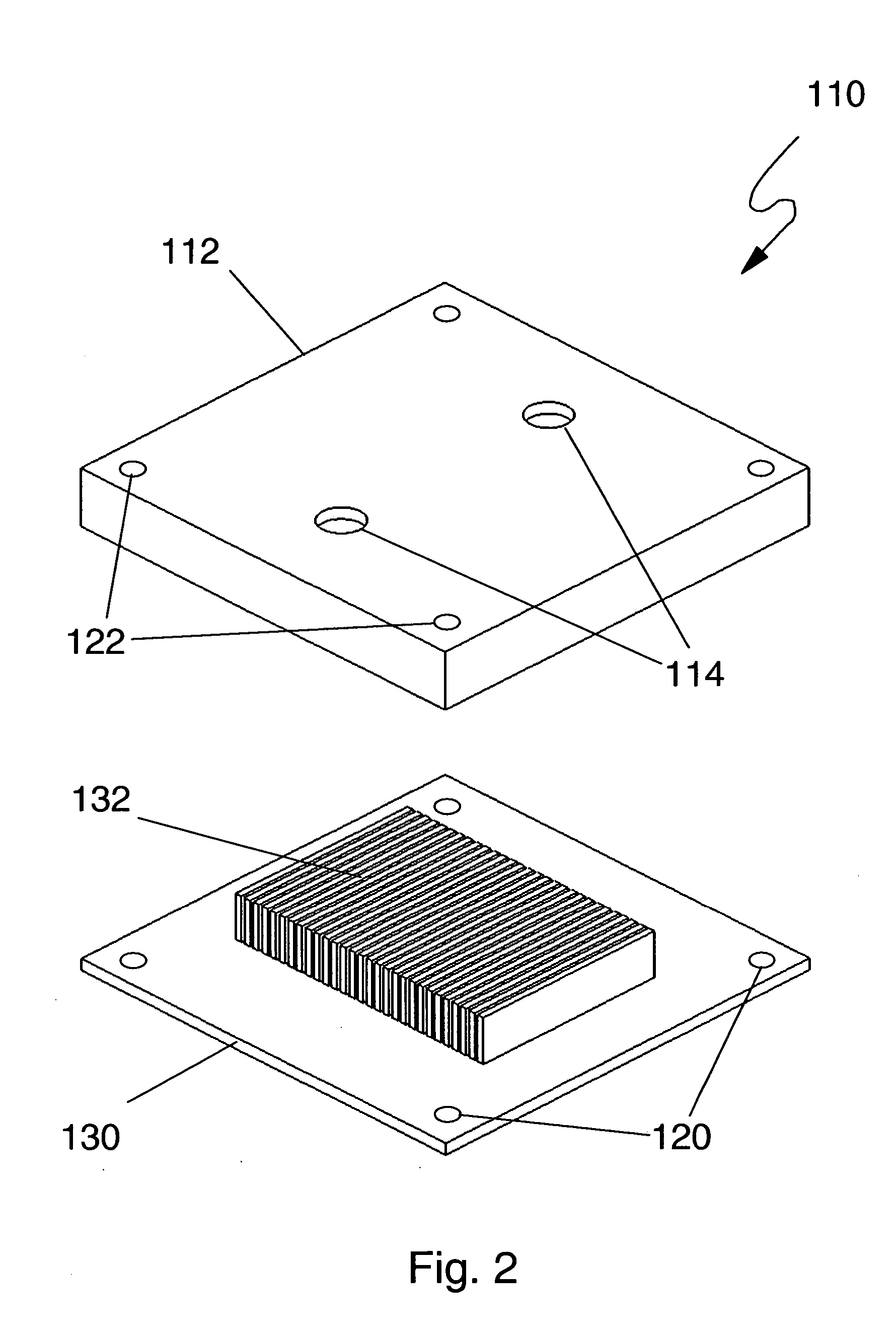

Carbon nanotube heat-exchange systems

InactiveUS20040194944A1Stationary conduit assembliesHeat transfer modificationCarbon nanotubeCooling fluid

A carbon nanotube heat-exchange system (10) and method for producing the same. One embodiment of the carbon nanotube heat-exchange system (10) comprises a microchannel structure (24) having an inlet end (30) and an outlet end (32), the inlet end (30) providing a cooling fluid into the microchannel structure (24) and the outlet end (32) discharging the cooling fluid from the microchannel structure (24). At least one flow path (28) is defined in the microchannel structure (24), fluidically connecting the inlet end (30) to the outlet end (32) of the microchannel structure (24). A carbon nanotube structure (26) is provided in thermal contact with the microchannel structure (24), the carbon nanotube structure (26) receiving heat from the cooling fluid in the microchannel structure (24) and dissipating the heat into an external medium (19).

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

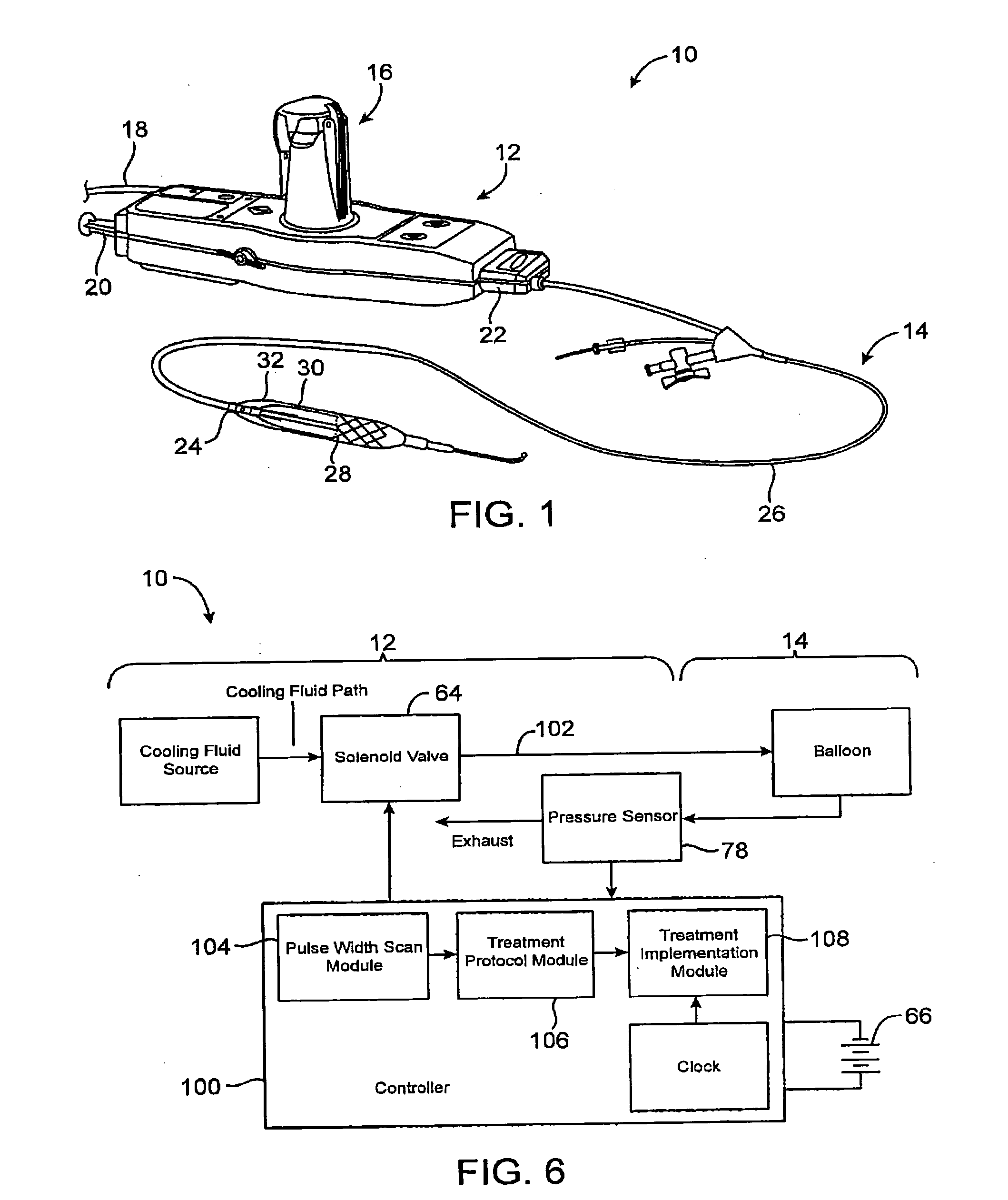

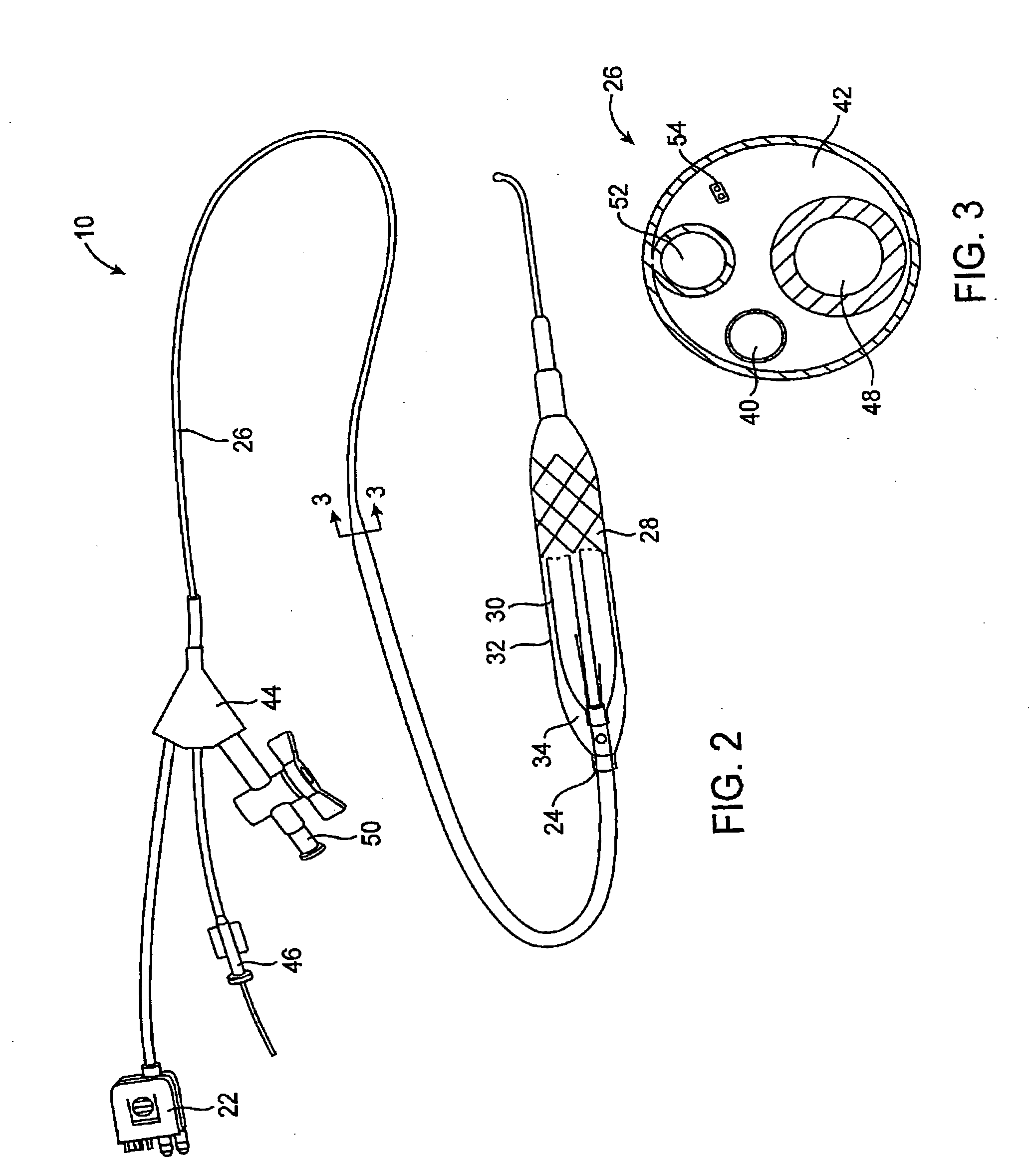

Efficient controlled cryogenic fluid delivery into a balloon catheter and other treatment devices

ActiveUS20060129142A1Avoiding unnecessary releaseEasy to copyOperating means/releasing devices for valvesCatheterSolenoid valveBalloon catheter

Devices, systems, and methods efficiently dilate and / or cool blood vessels and other body tissues. Controlled cooling with balloon catheters and other probes may be effected by a change in phase of a cryogenic fluid, often after measuring a minimum pulse width for actuating an individual solenoid valve along the cooling fluid path, with the measured pulse width allowing gradual inflation of a balloon without excessive venting of cooling fluid.

Owner:BOSTON SCI SCIMED INC

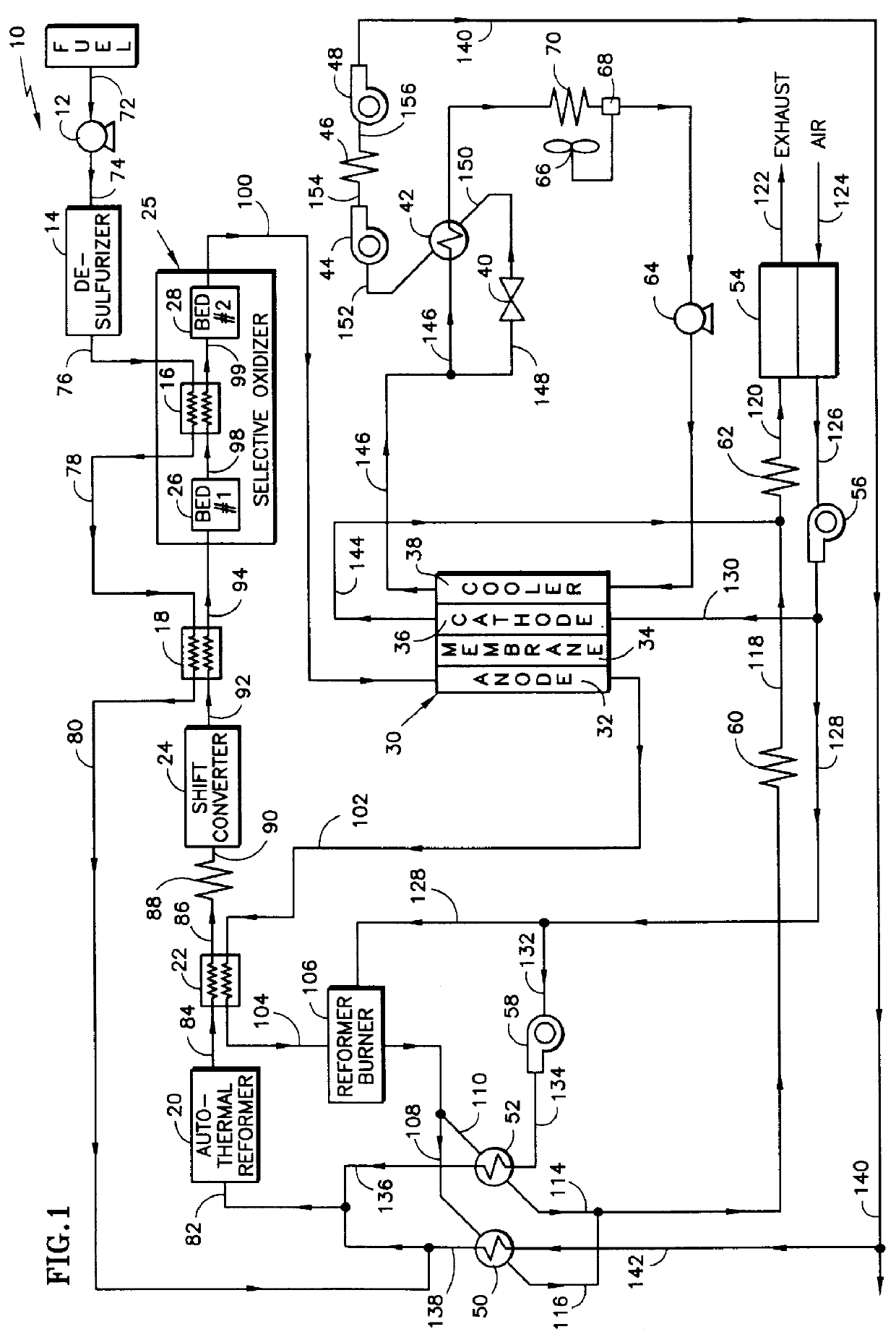

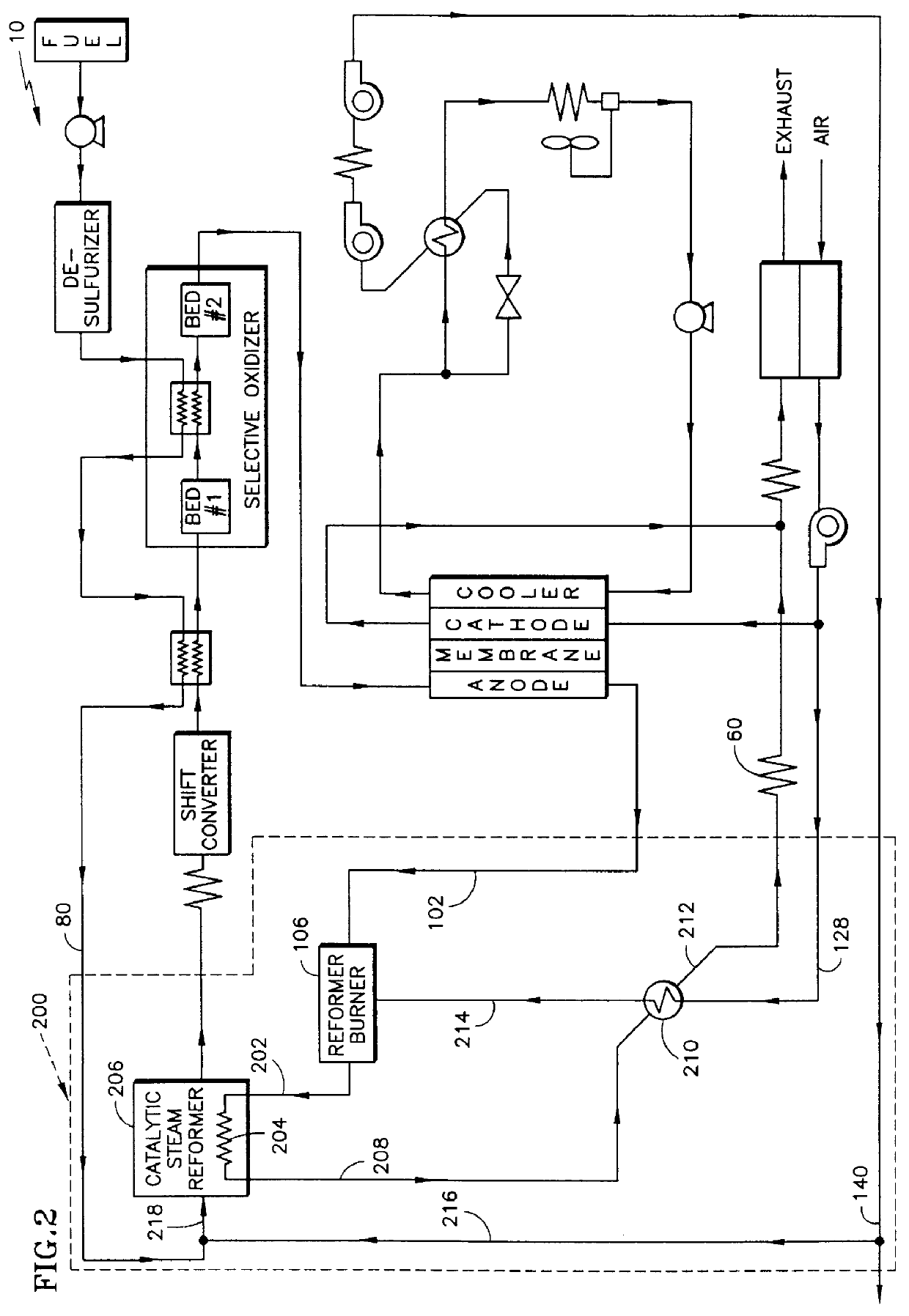

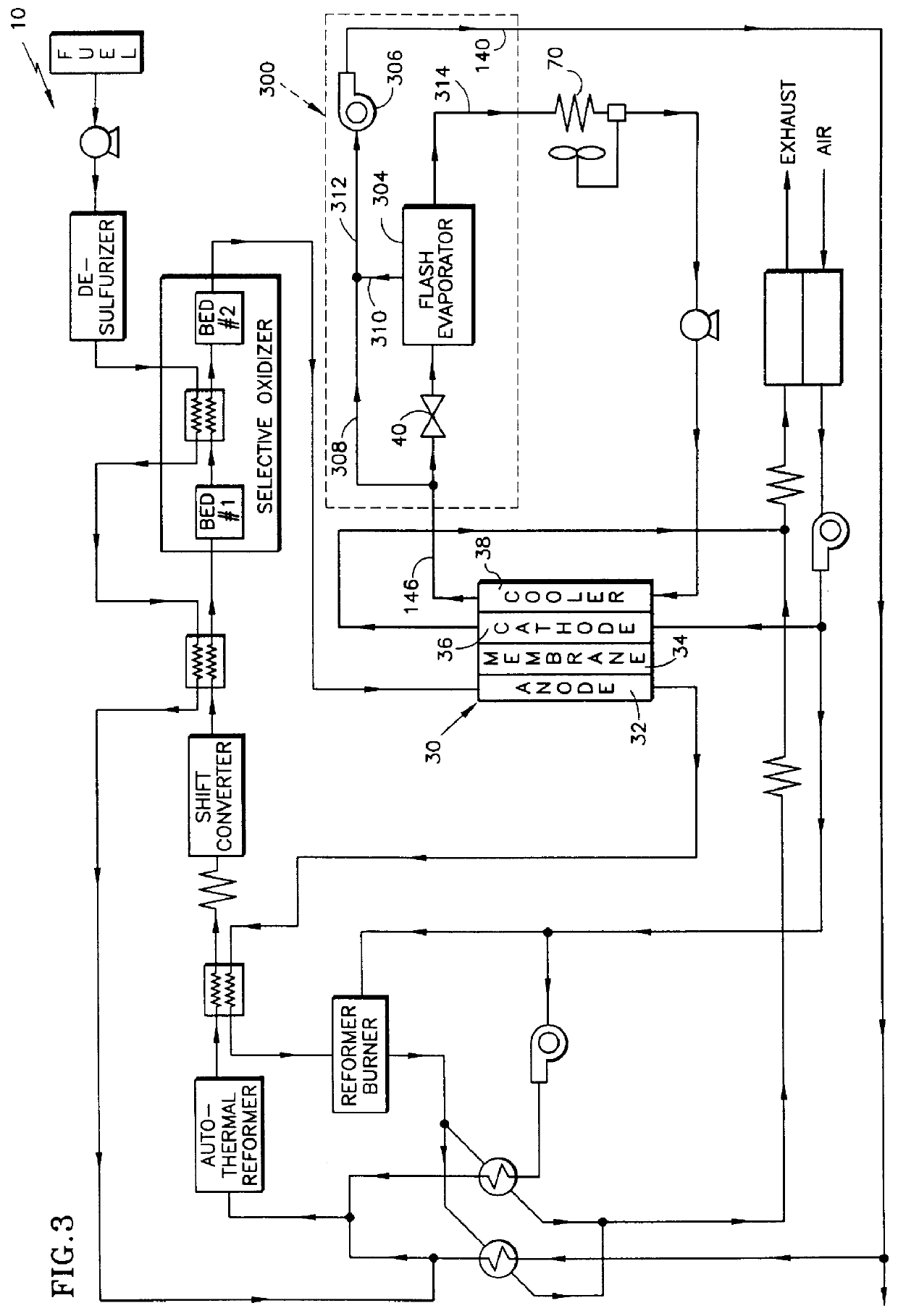

Steam producing hydrocarbon fueled power plant employing a PEM fuel cell

InactiveUS6120923AReduce pressureIncrease steam temperatureHydrogenSolid electrolytesFuel cellsPower station

The present invention relates to a method and apparatus for creating steam from the cooling stream of a proton exchange membrane (PEM) fuel cell. As the cooling stream exits the PEM fuel cell, a portion of the cooling fluid is extracted from the circulating cooling stream, thereby creating a secondary stream of cooling fluid. This secondary stream passes through a restriction, which decreases the pressure of the secondary stream to its saturation pressure, such that when the secondary stream enters a flash evaporator it transforms into steam. Creating steam from the cooling stream of a PEM fuel cell power plant provides the fuel processor with a co-generated source of steam without adding a significant amount of auxiliary equipment to the power plant.

Owner:INT FUEL CELLS

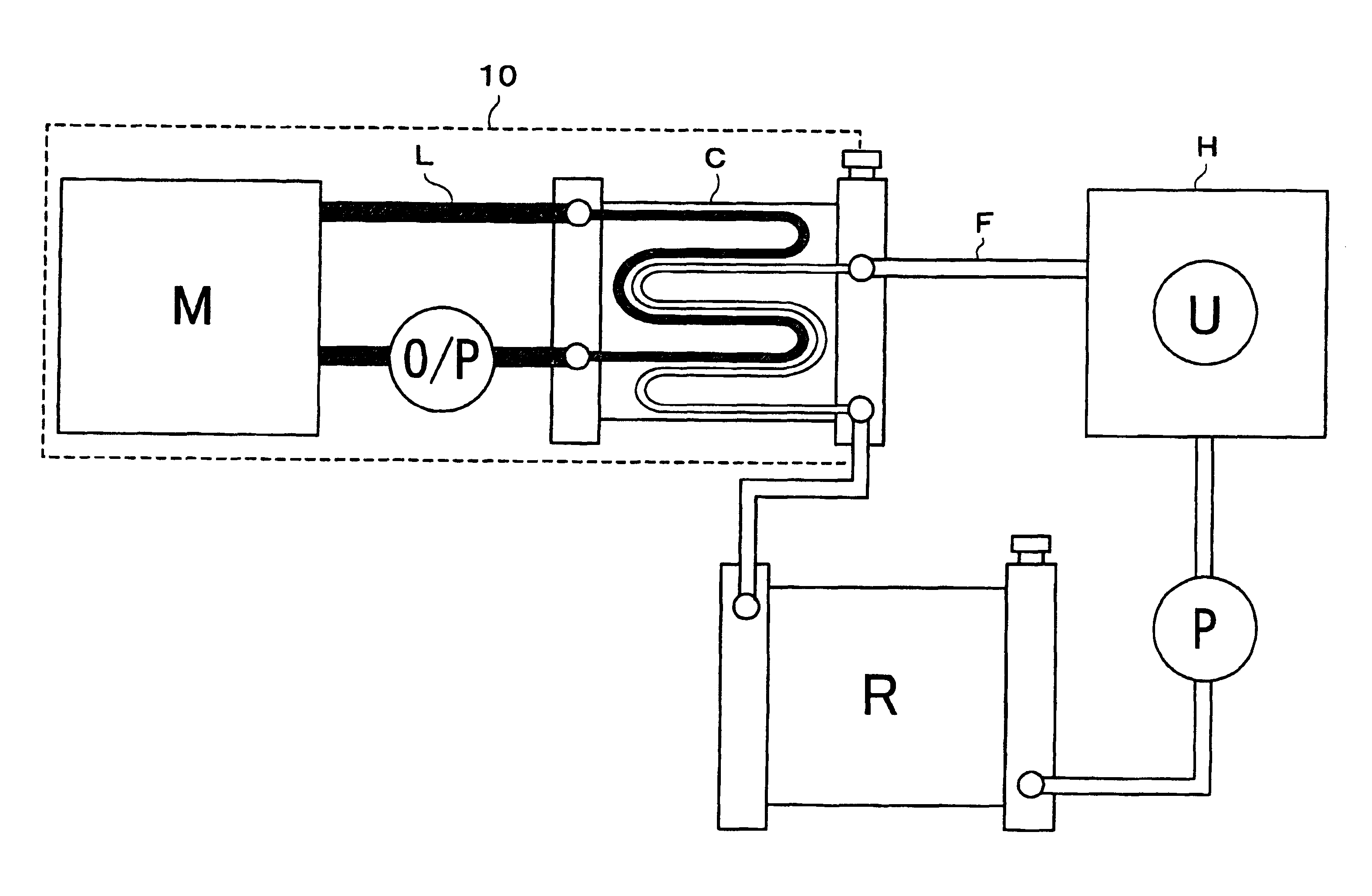

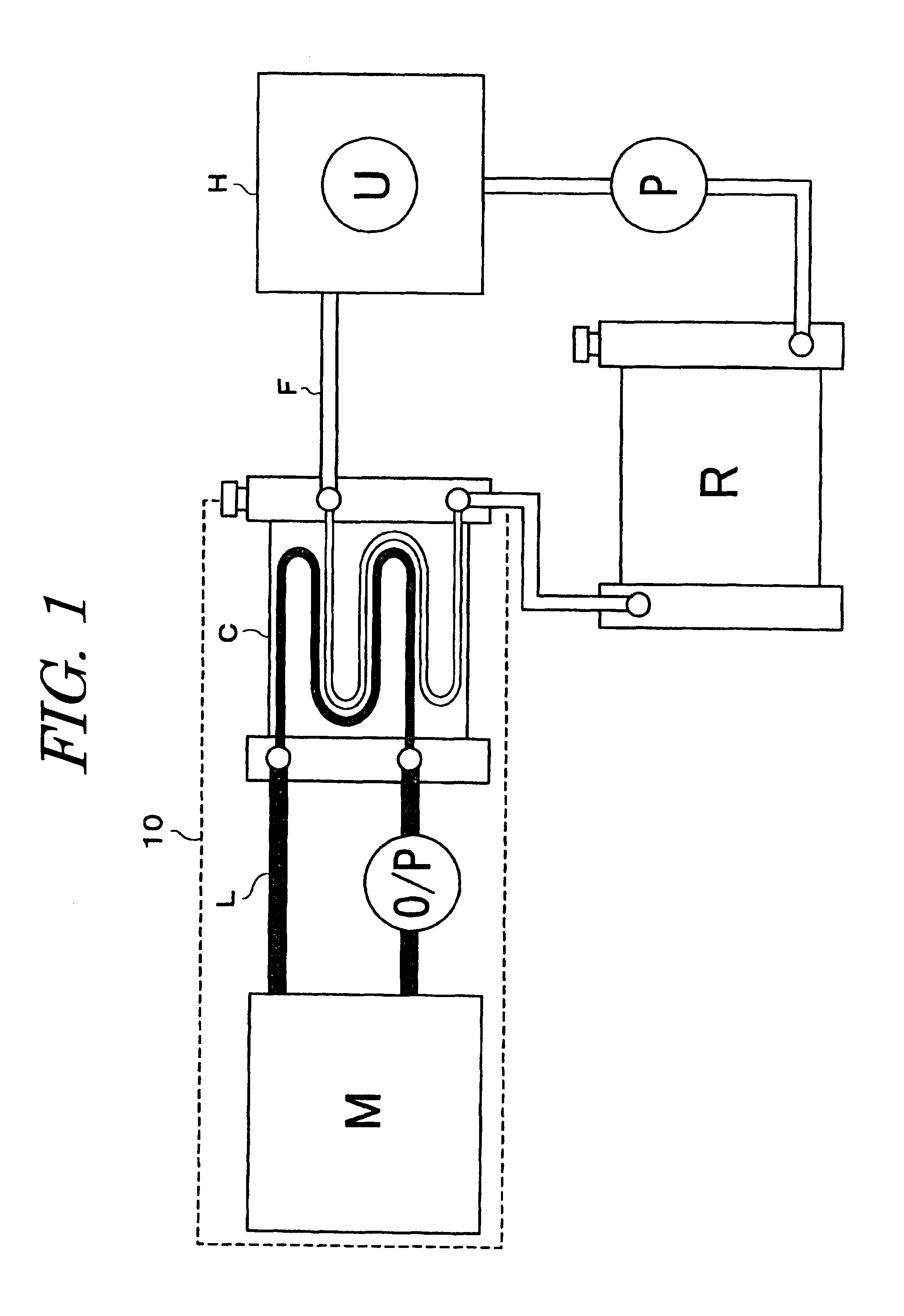

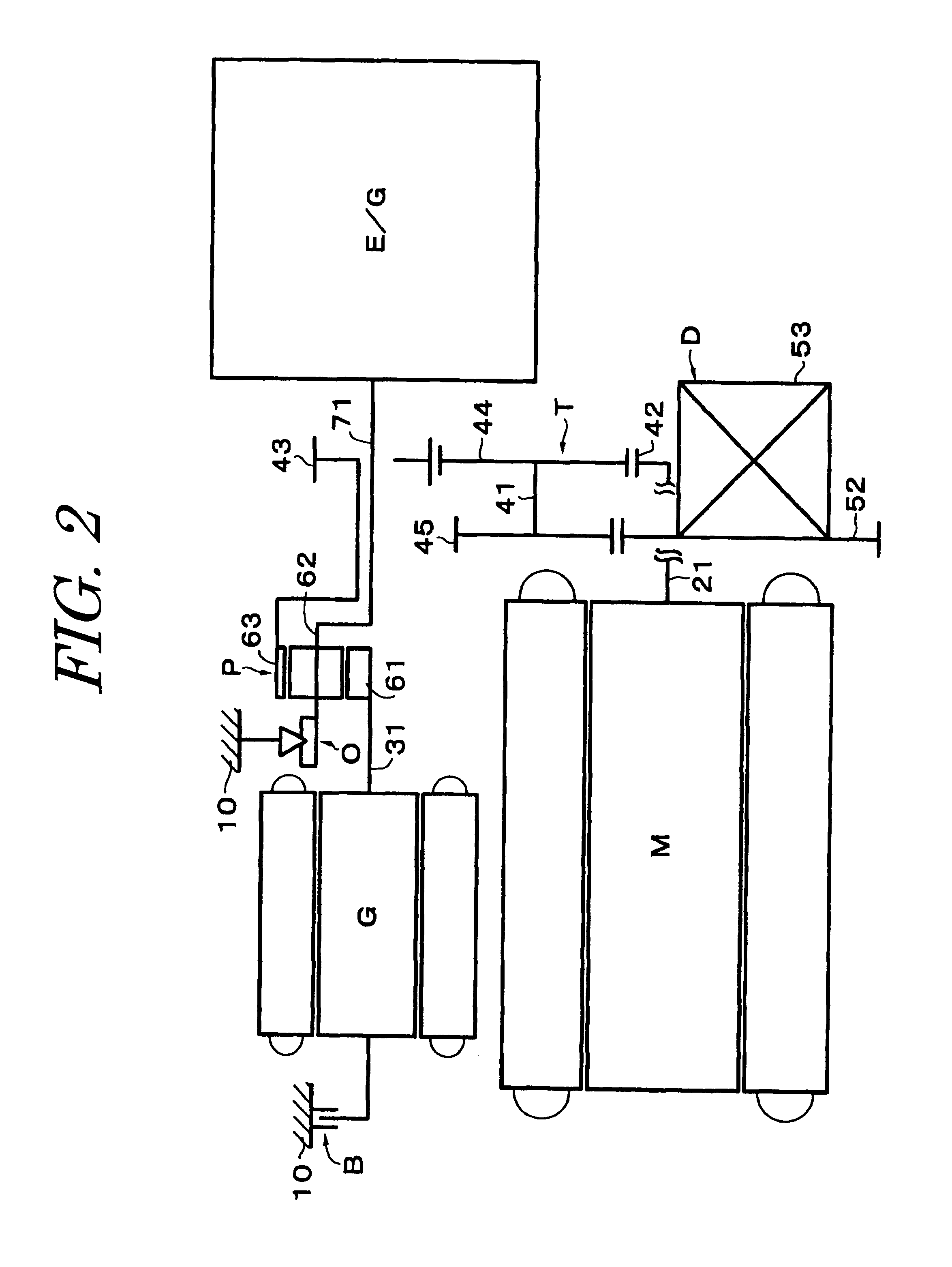

Drive unit with two coolant circuits for electric motor

InactiveUS6323613B1Improve cooling effectHeat exchangerTemperatue controlEmergency protective circuit arrangementsEngineeringCooling fluid

A drive unit includes an electric motor as a power source, and a simplified coolant circuit for cooling the electric motor. The drive unit further includes, in the drive unit case, a circulation passage L for coolant for cooling the motor M. A circulation passage F for a second coolant is provided separate from the circulation passage L for coolant. A heat exchange portion C within the circulation passage L for the first coolant is provided in the drive unit case for heat exchange with the second coolant in the circulation passage F, and the first coolant for cooling the electric motor is cooled by heat transfer to the second coolant in that heat exchange portion C. Accordingly, the coolant circuit in the drive unit case is simplified.

Owner:AISIN AW CO LTD

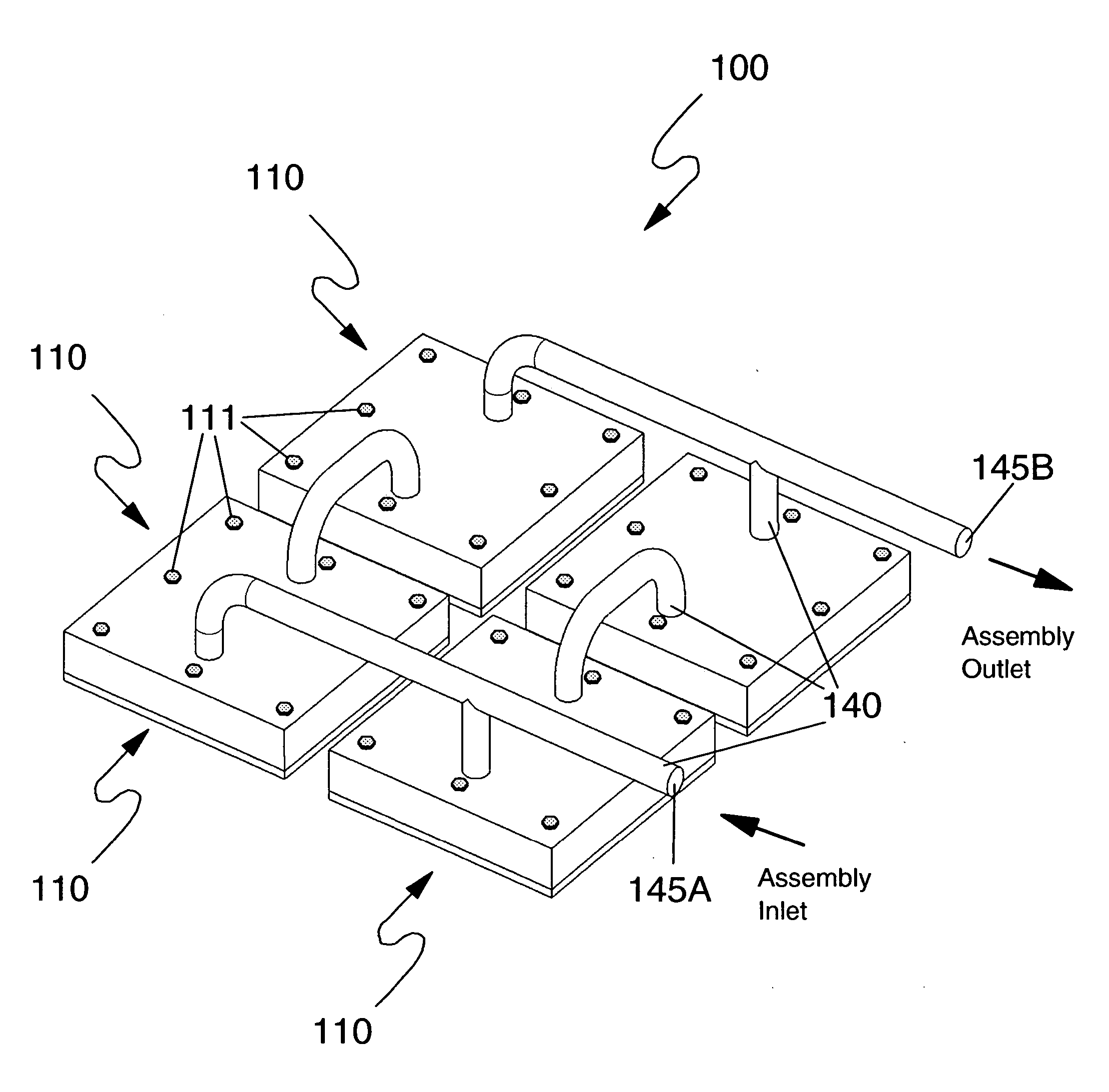

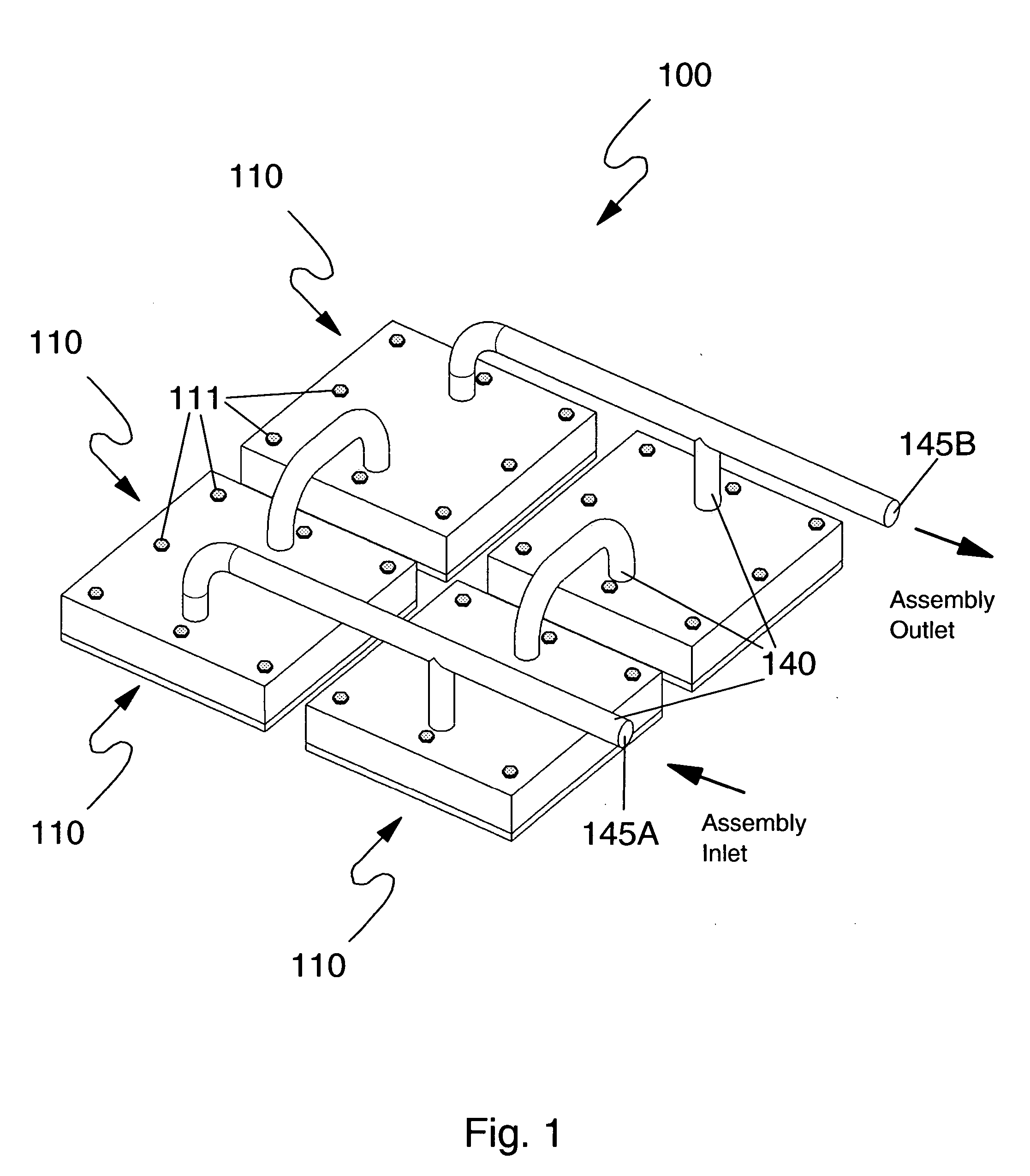

Composite cold plate assembly

InactiveUS20050128705A1Reduce connectionsSolve the lack of flexibilitySemiconductor/solid-state device detailsSolid-state devicesEngineeringCold plate

A cooling fluid distribution assembly for a plurality of electronic modules, using a composite cold plate structure. One cold plate is associated with each electronic module requiring liquid cooling. Each cold plate includes a high thermal conductivity base sealably fastened to a cover, the cover having at least one fluid inlet and at least one fluid outlet. Cover fluid inlets and outlets are connected via a plurality of flexible, nonmetallic conduits, the conduits being bonded to the cover inlets and outlets. Each cold plate cover is formed of a material that is capable of being bonded to the flexible, nonmetallic conduits, covers are therefore formed of a different material than the material comprising the cold plate base. Cold plate structures preferably include internal fluid distribution structures. The resulting cooling fluid distribution assembly provides reliable fluid connections and is sufficiently flexible to adjust for variances in module height etc.

Owner:IBM CORP

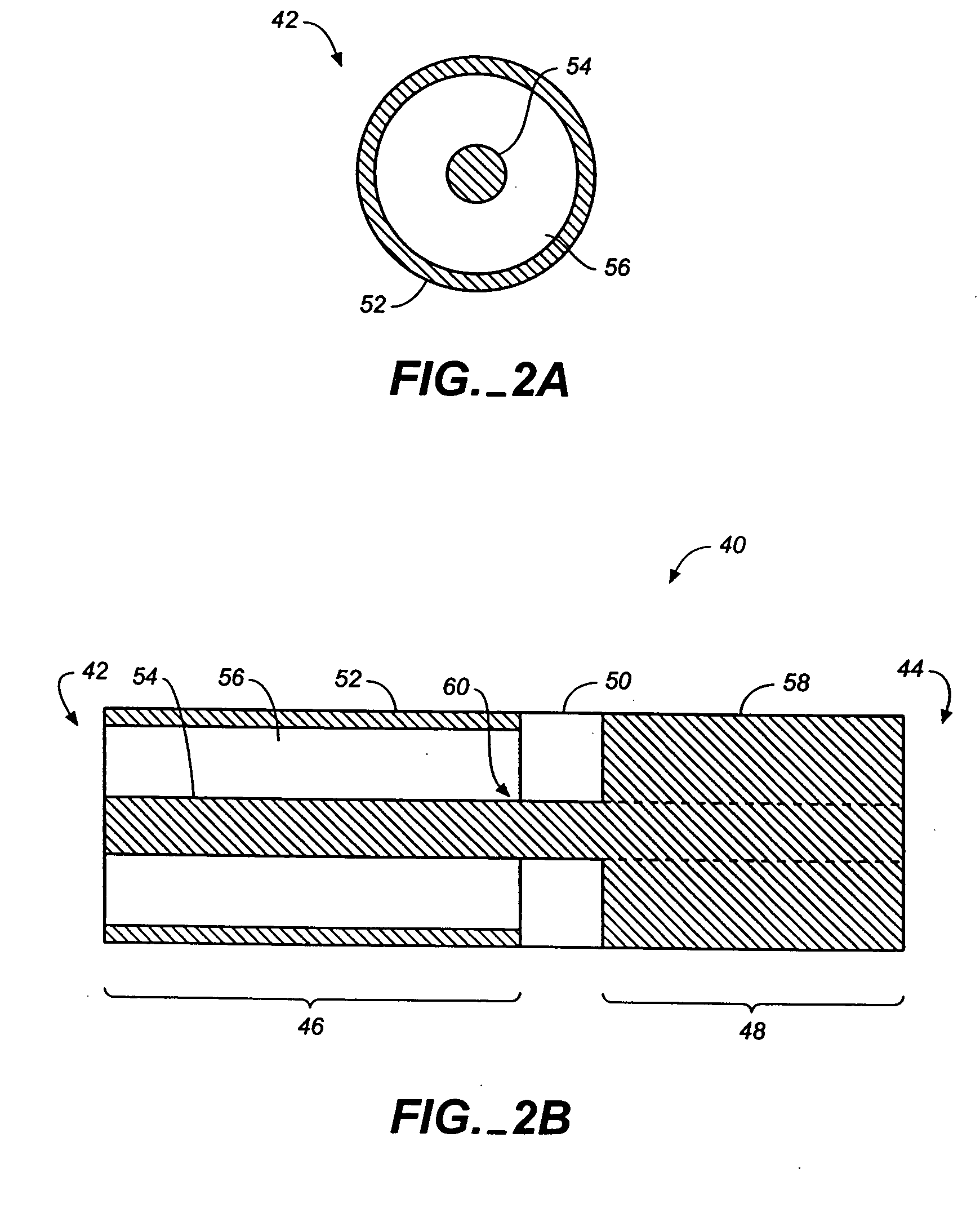

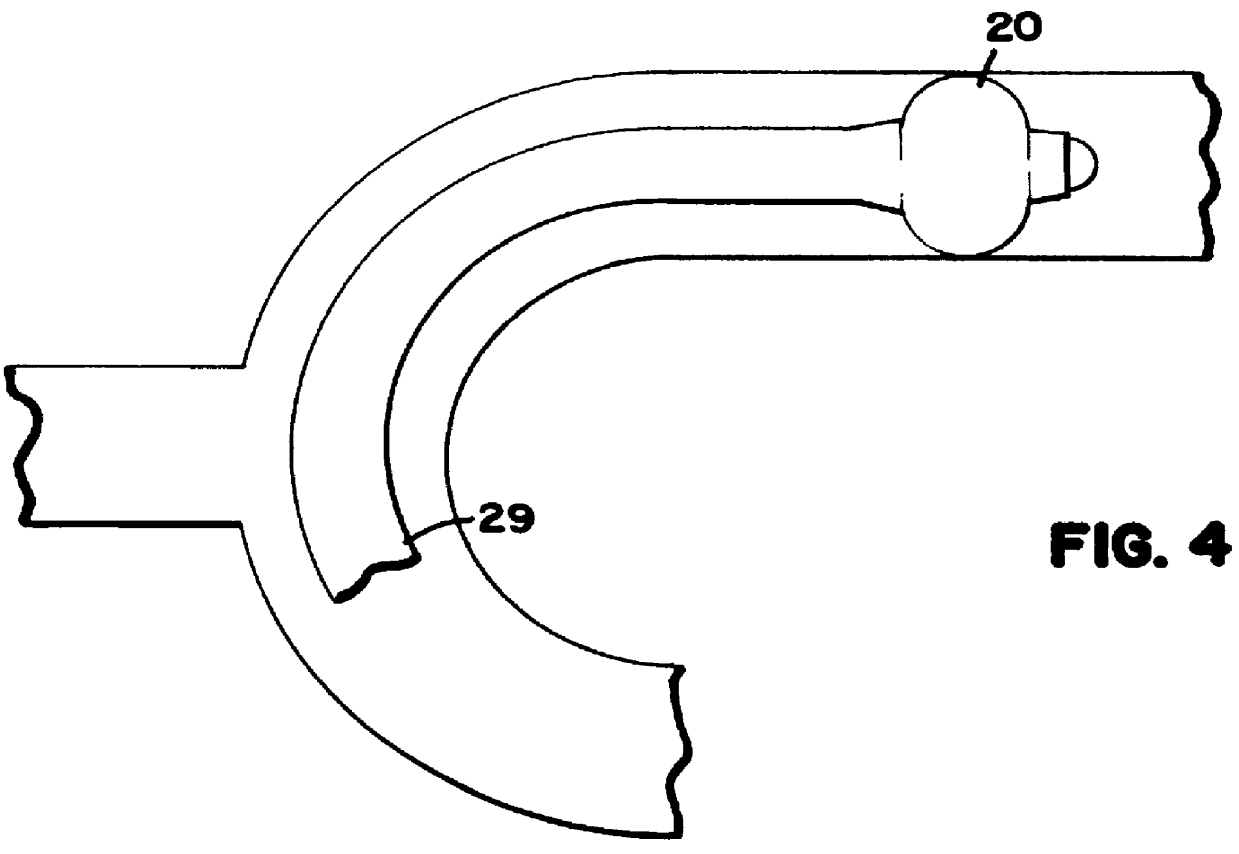

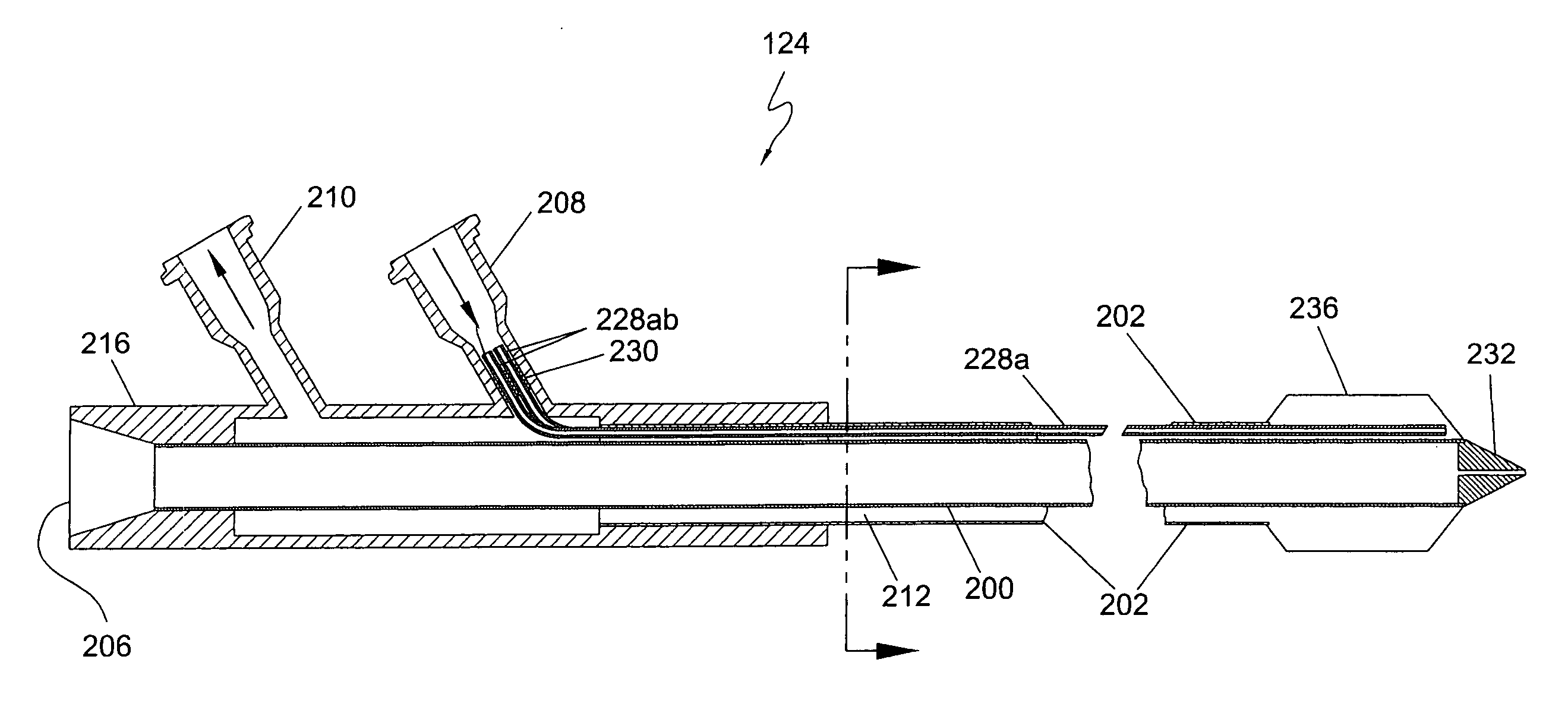

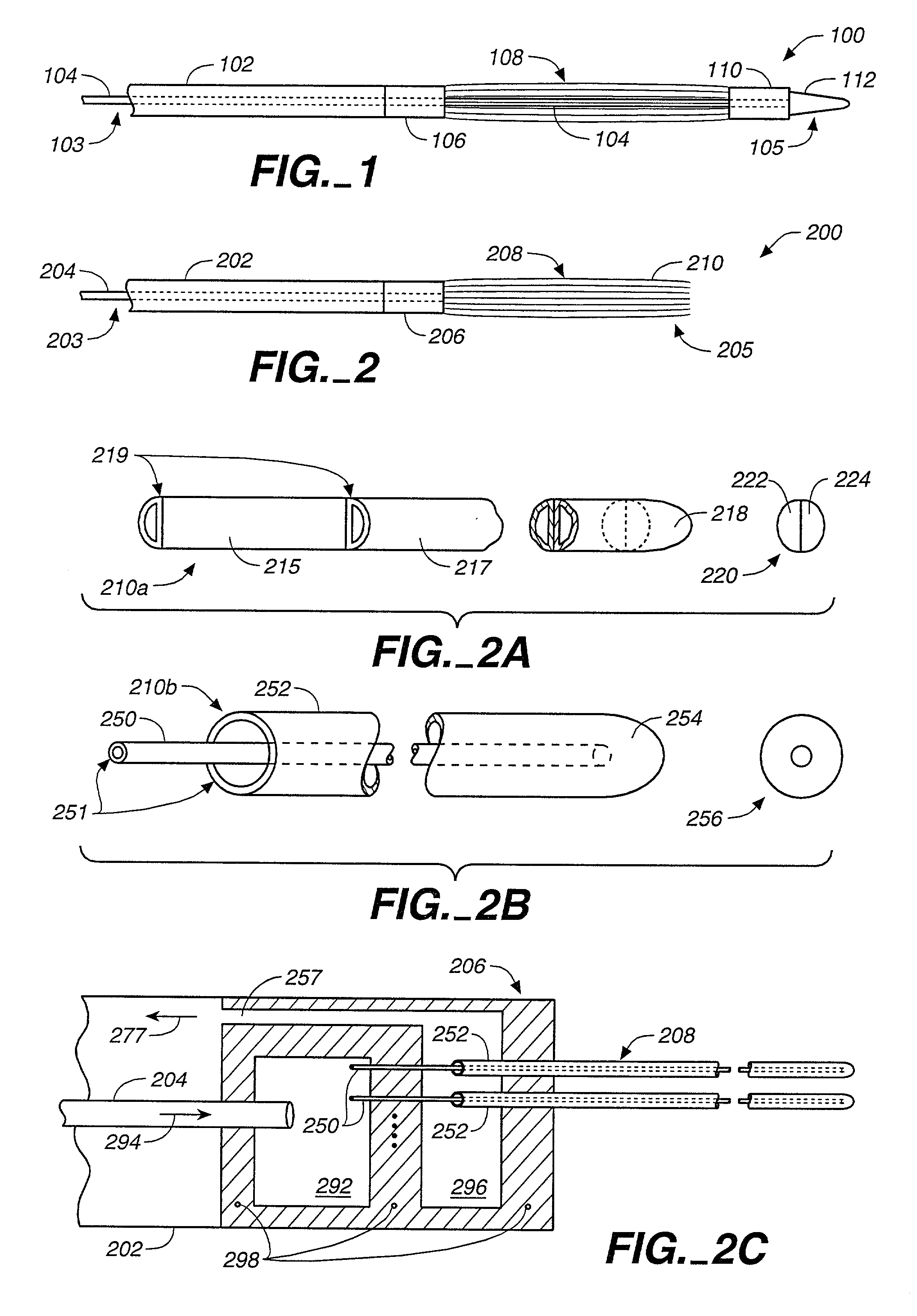

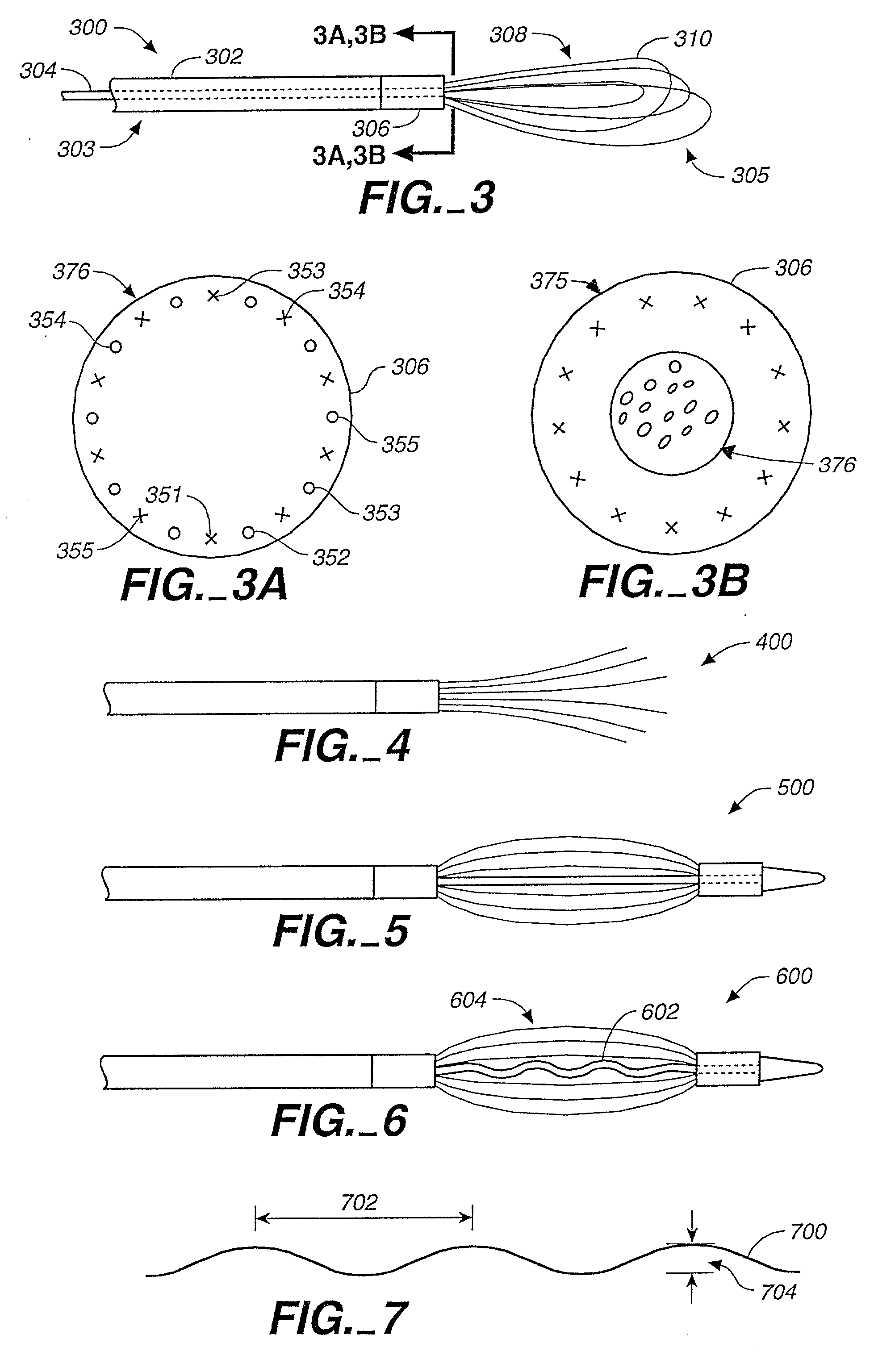

Catheter with multiple heating/cooling fibers employing fiber spreading features

InactiveUS20010031946A1Prevent clottingCool the nearby tissue more efficientlyOther blood circulation devicesElectric heatingFiberBody fluid

A catheter using multiple hollow fibers to carry a heating / cooling fluid employs fiber spreading features to improve heat transfer and help prevent clotting of body fluids within which the catheter is immersed. The catheter includes a length of outer tube surrounding an inner tube. The inner tube conveys fluids in one direction, and the passageway between inner and outer tubes conveys fluids in the opposite direction. The inner and outer tubes have proximal distal ends. The distal end is closed, but the proximal end is open to permit introduction of a heating or cooling fluid into the inner tube, and withdrawal of the fluid from the passageway between the inner and outer tubes. At the tubes' distal end resides a proximal fluid transfer housing coupled to multiple hollow heat exchange fibers. The distal ends of these fibers may be commonly connected to a distal fluid transfer housing and optional reservoir, which cooperatively return fluid to the passageway between inner and outer tubes. In another embodiment, each fiber includes both outflowing and return lumens, enabling the fibers' distal ends to freely move about. In another embodiment, each fiber proceeds outward from the proximal fluid transfer housing, and returns back to form a loop. In each different embodiment, the invention includes one or more actuating structures to spread the fibers. The actuating structure may include, for example, fiber shaping, a retractable spreading member, elastic bias built into the fibers, etc.

Owner:WALKER BLAIR D +4

Treatment of urinary incontinence and other disorders by application of energy and drugs

The invention provides a method and system for treating disorders in parts of the body. A particular treatment can include on or more of, or some combination of: ablation, nerve modulation, three-dimensional tissue shaping, drug delivery, mapping stimulating, shrinking and reducing strain on structures by altering the geometry thereof and providing bulk to particularly defined regions. The particular body structures or tissues can include one or more of or some combination of region, including: the bladder, esophagus, vagina, penis, larynx, pharynx, aortic arch, abdominal aorta, thoracic, aorta, large intestine, sinus, auditory canal, uterus, vas deferens, trachea, and all associated sphincters. Types of energy that can be applied include radiofrequency, laser, microwave, infrared waves, ultrasound, or some combination thereof. Types of substances that can be applied include pharmaceutical agents such as analgesics, antibiotics, and anti-inflammatory drugs, bulking agents such as biologically non-reactive particles, cooling fluids, or dessicants such as liquid nitrogen for use in cryo-based treatments.

Owner:VERATHON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com