Patents

Literature

2687 results about "Heat shield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A heat shield is designed to protect an object from overheating by dissipating, reflecting or simply absorbing heat. The term is most often used in reference to exhaust heat management and to systems for dissipation of heat due to friction.

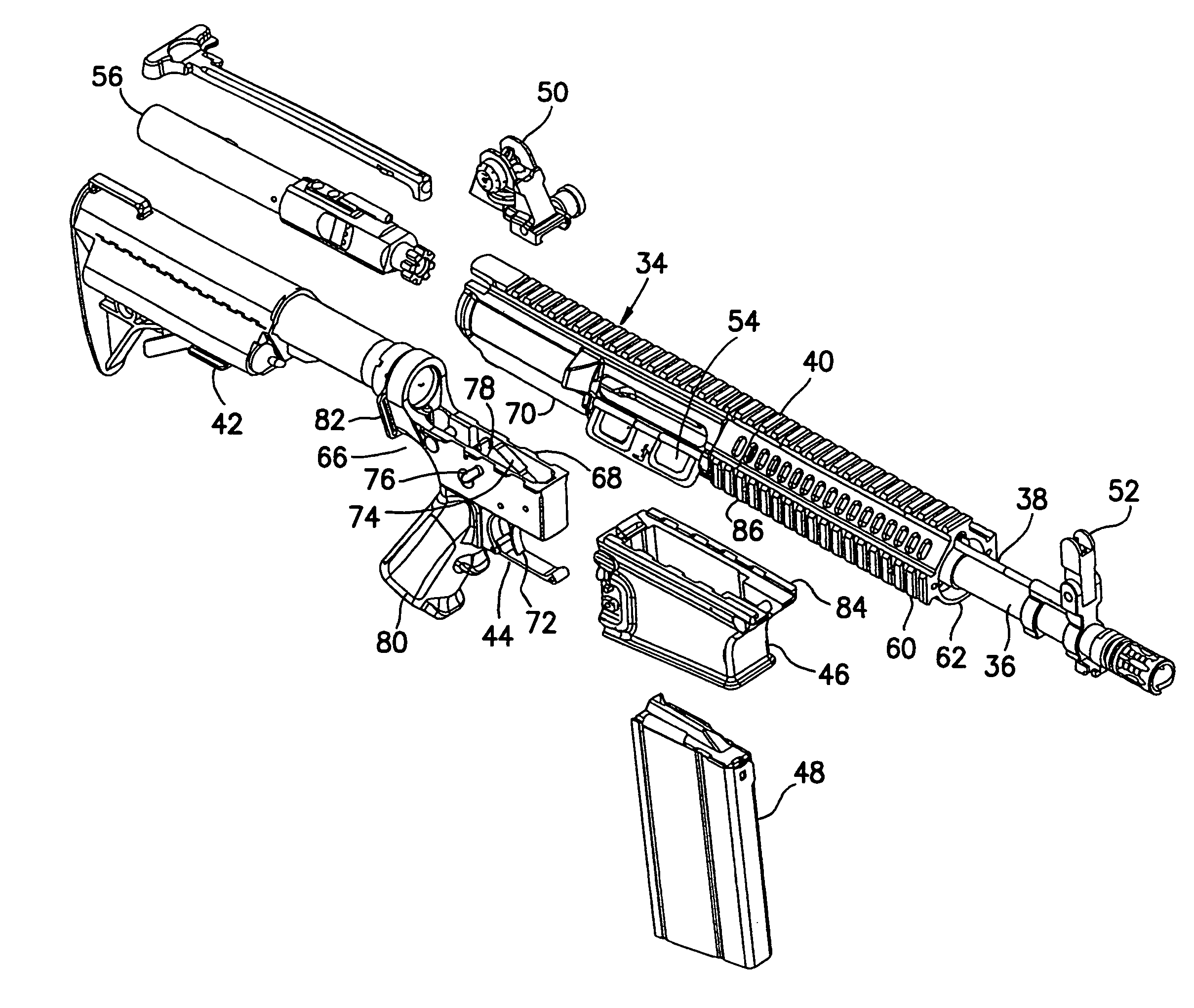

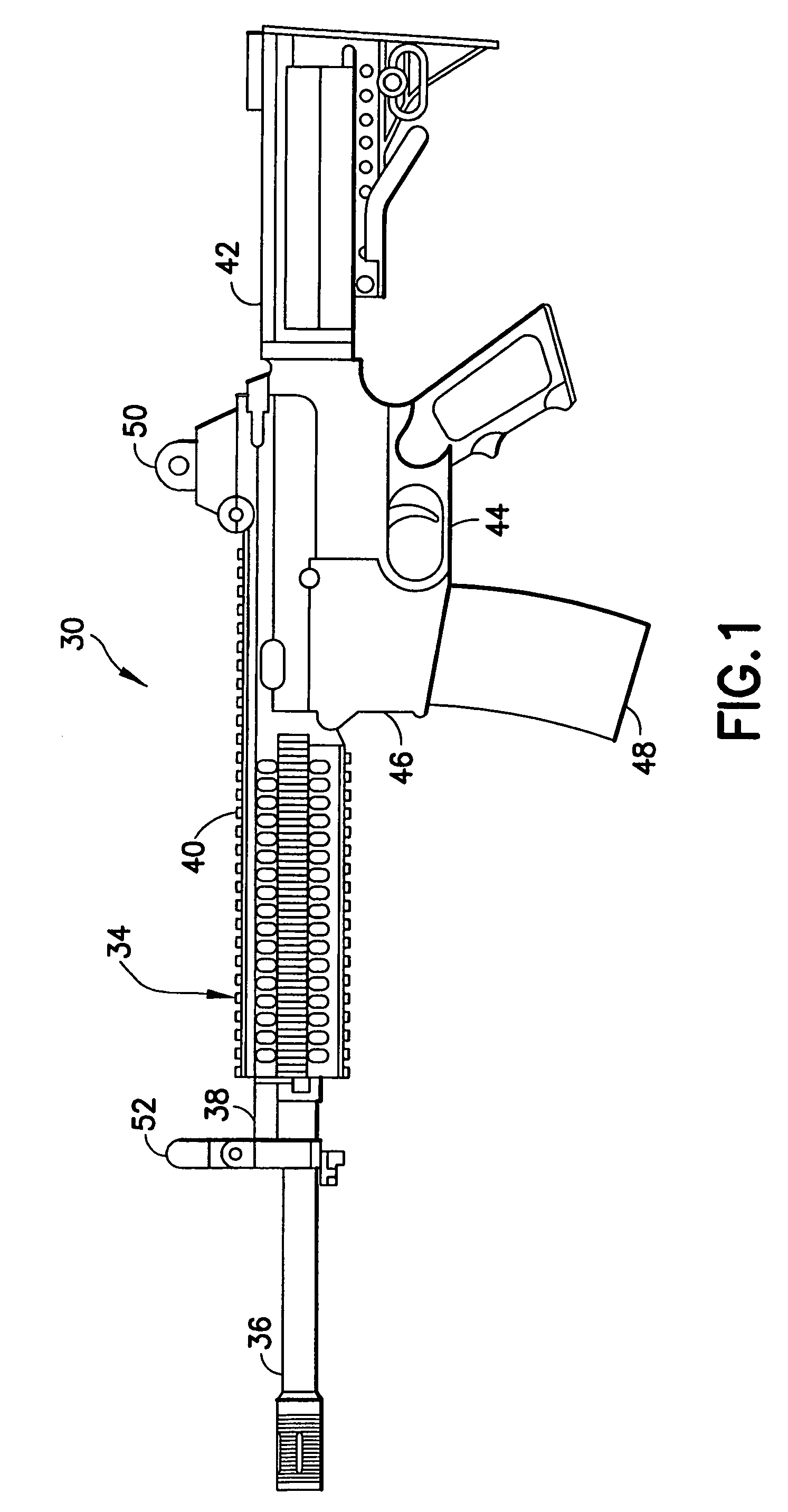

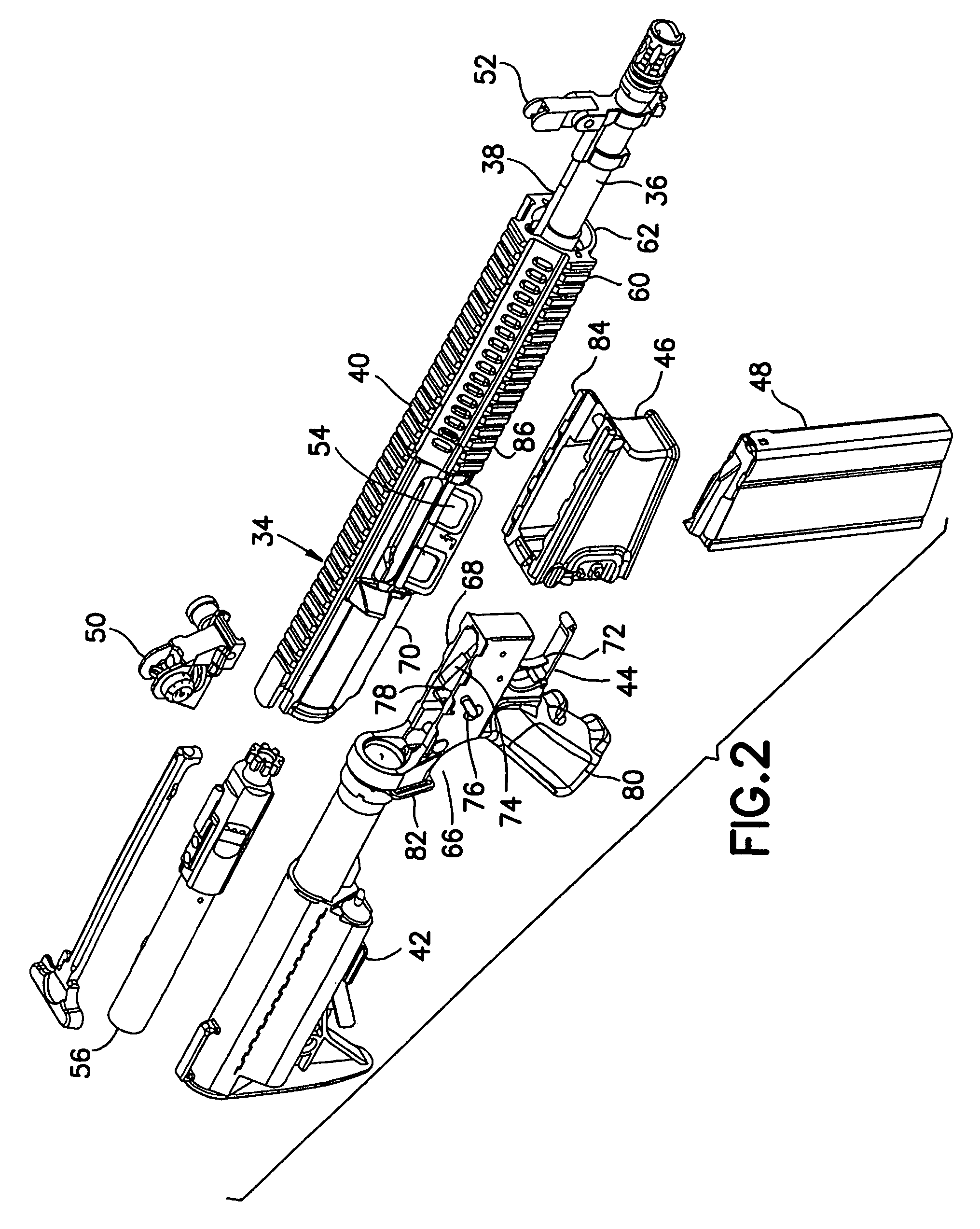

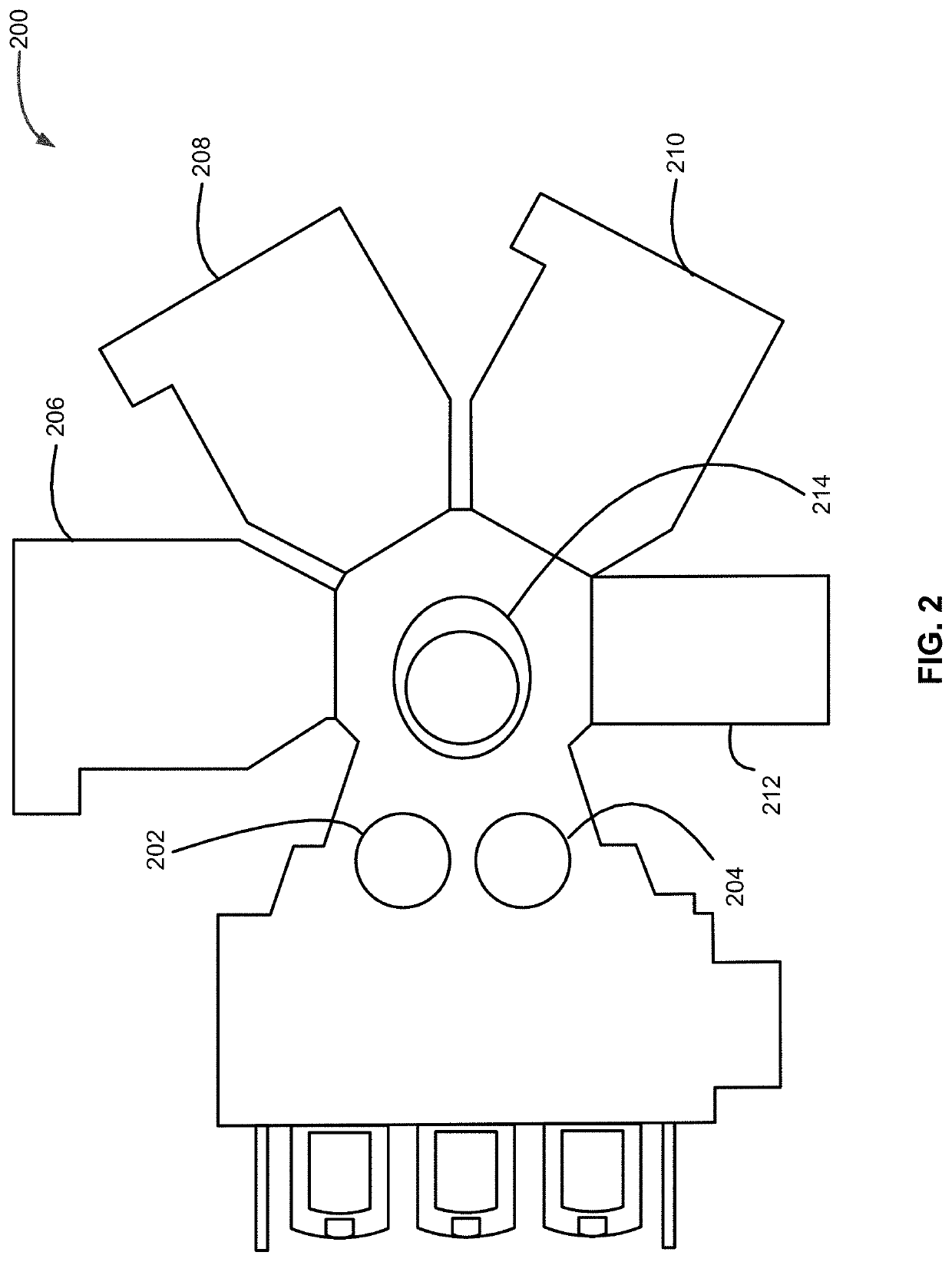

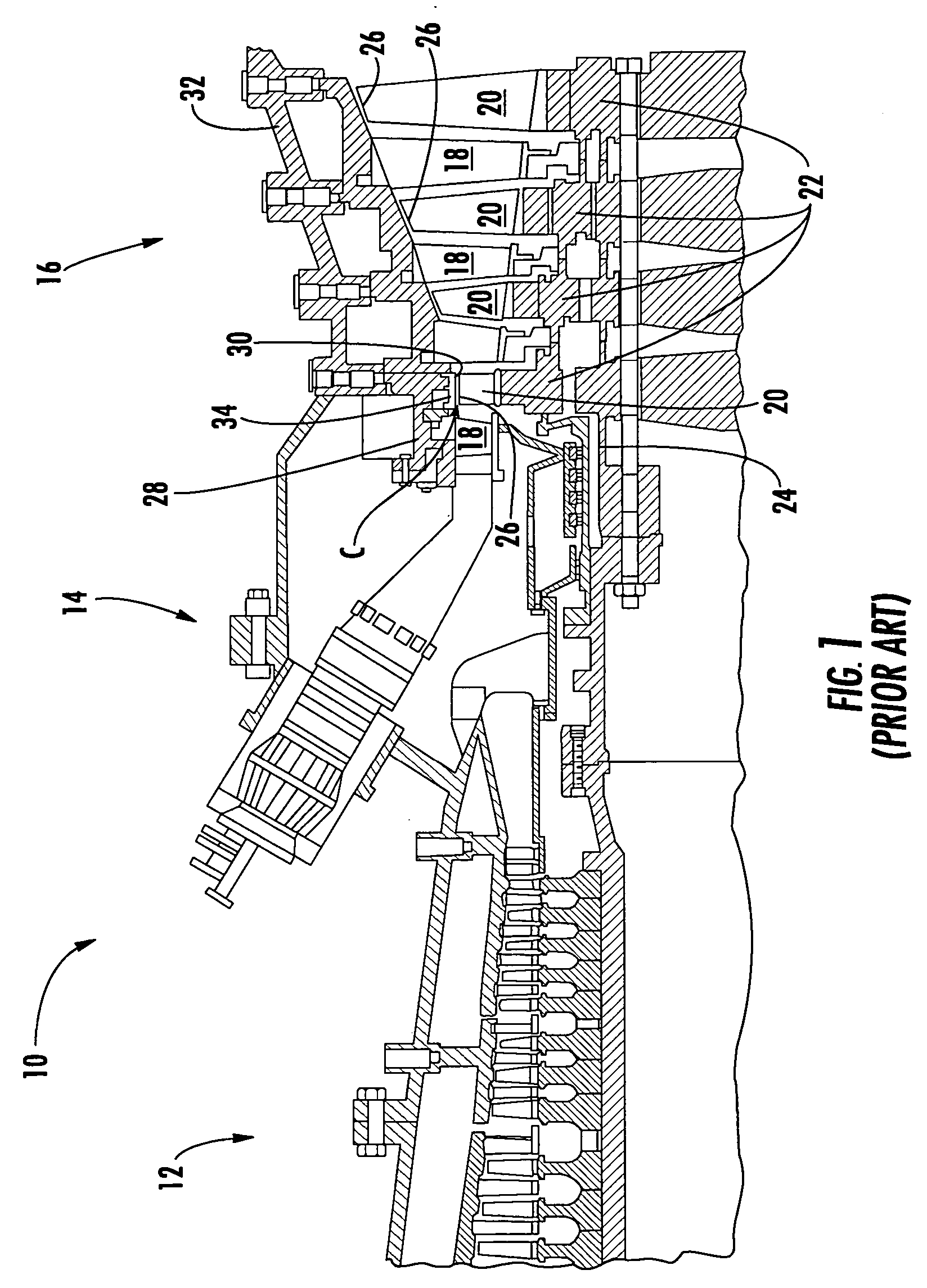

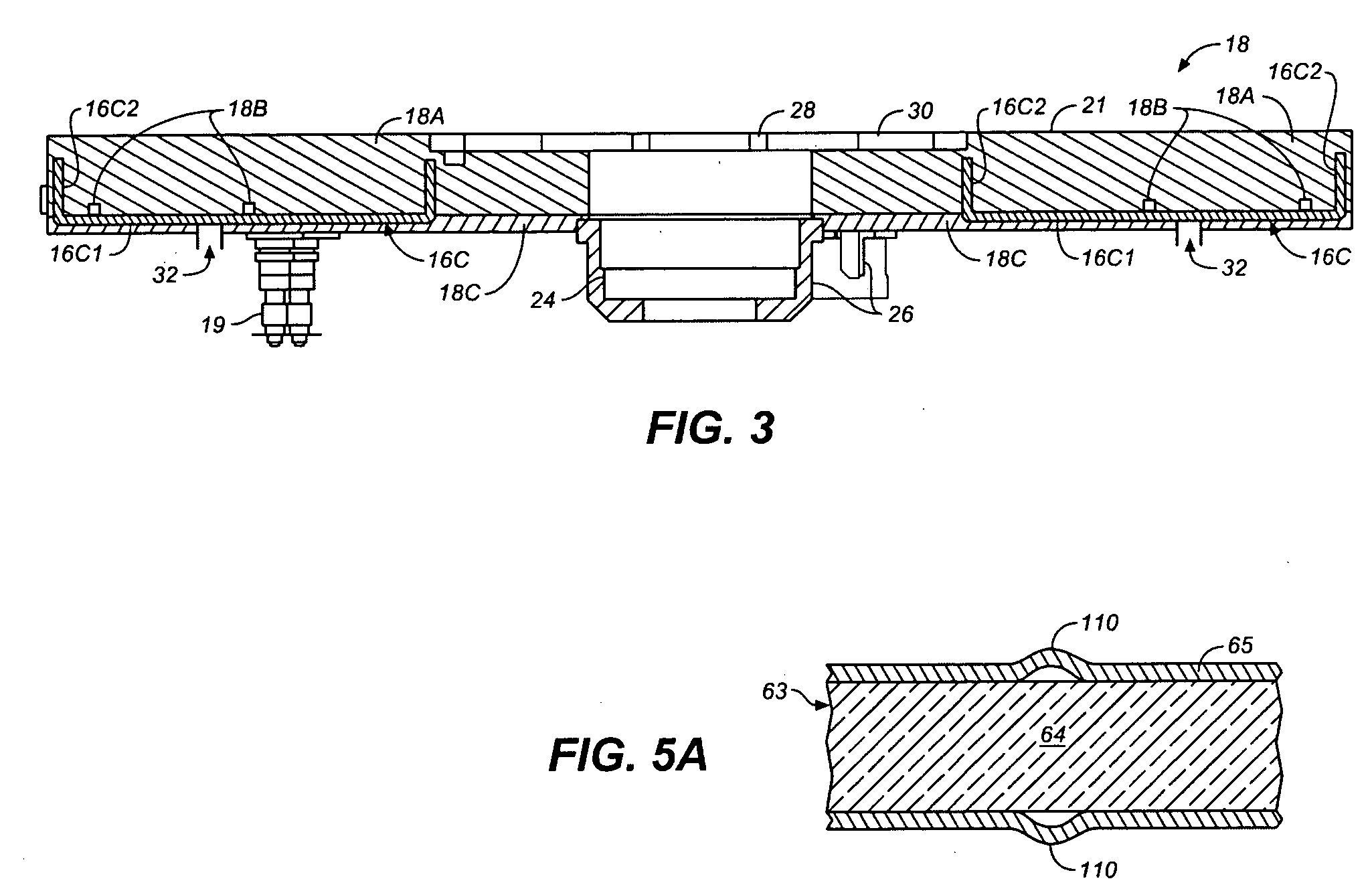

Modular firearm

Owner:COLTS MFG IP HLDG COMPANY

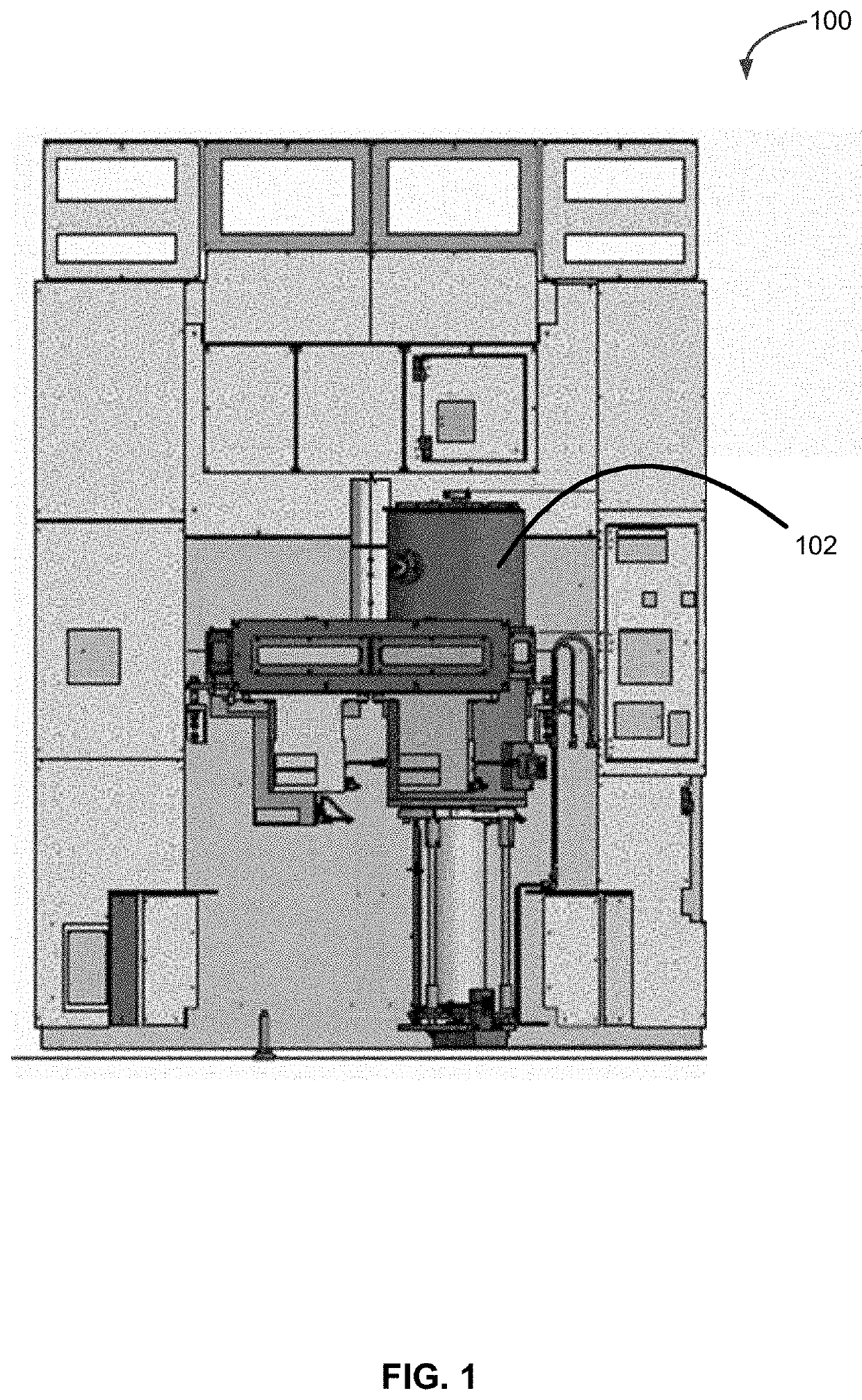

Substrate retaining apparatus, system including the apparatus, and method of using same

PendingUS20200102653A1Reduce pollutionDegradation of surface of substrateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingCooling fluidHeat shield

A substrate retaining apparatus, a load lock assembly comprising the substrate retaining apparatus, and a system including the substrate retaining apparatus are disclosed. The substrate retaining apparatus can include at least one sidewall and one or more heat shields. One or more of the at least one sidewall can include a cooling fluid conduit to facilitate cooling of substrates retained by the substrate retaining apparatus. Additionally or alternatively, one or more of the at least one sidewall can include a gas conduit to provide gas to a surface of a retained substrate.

Owner:ASM IP HLDG BV

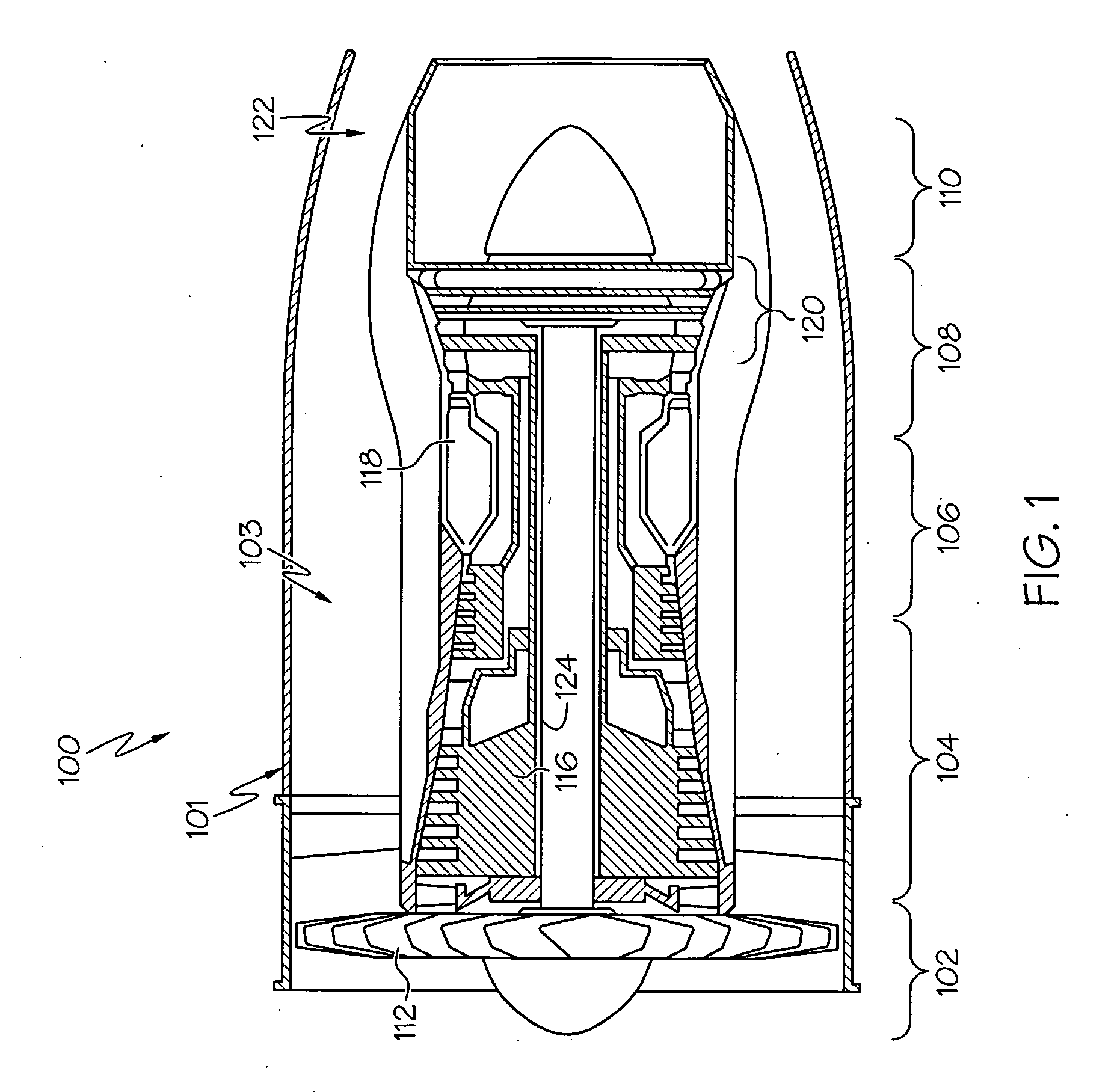

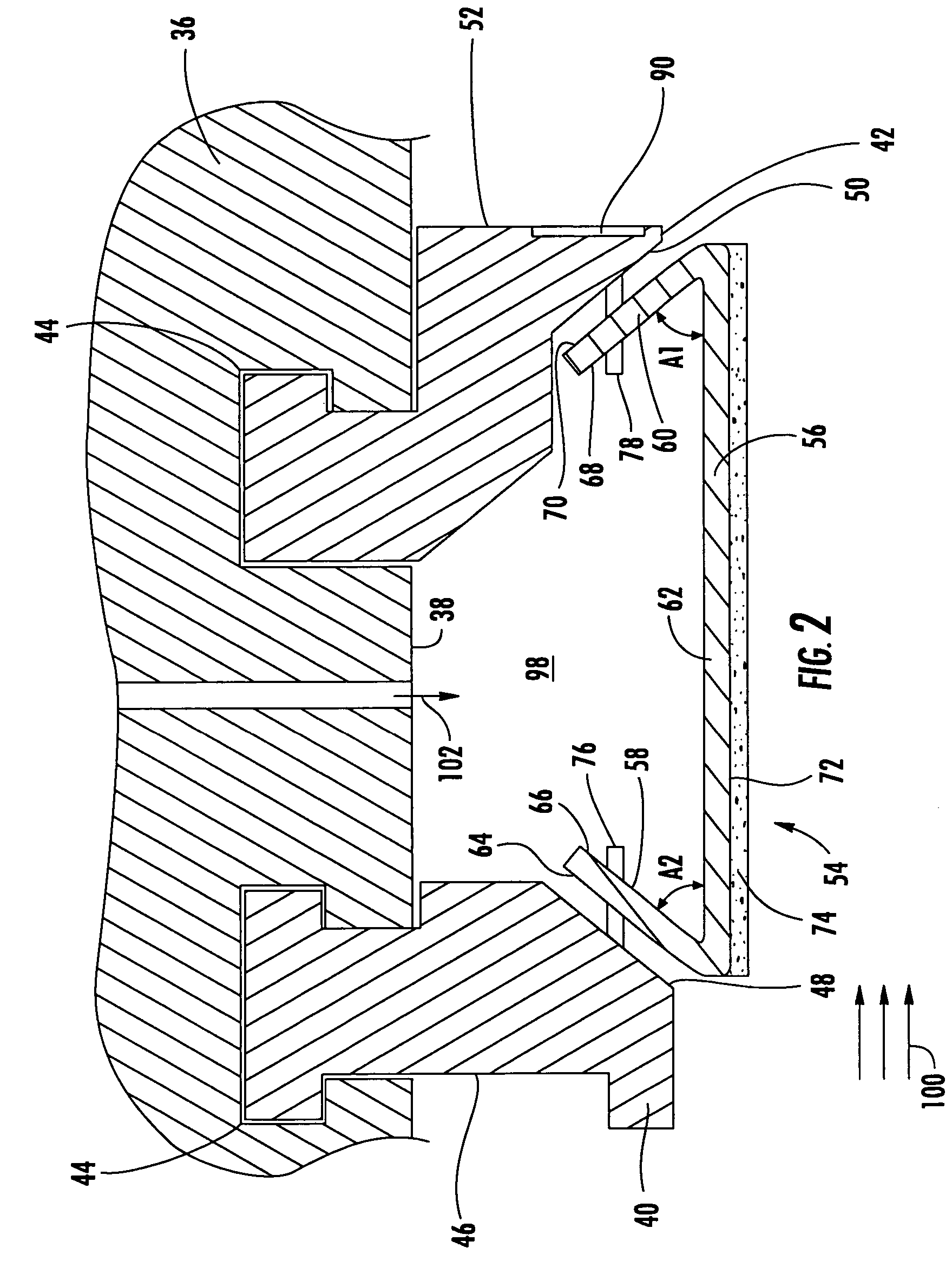

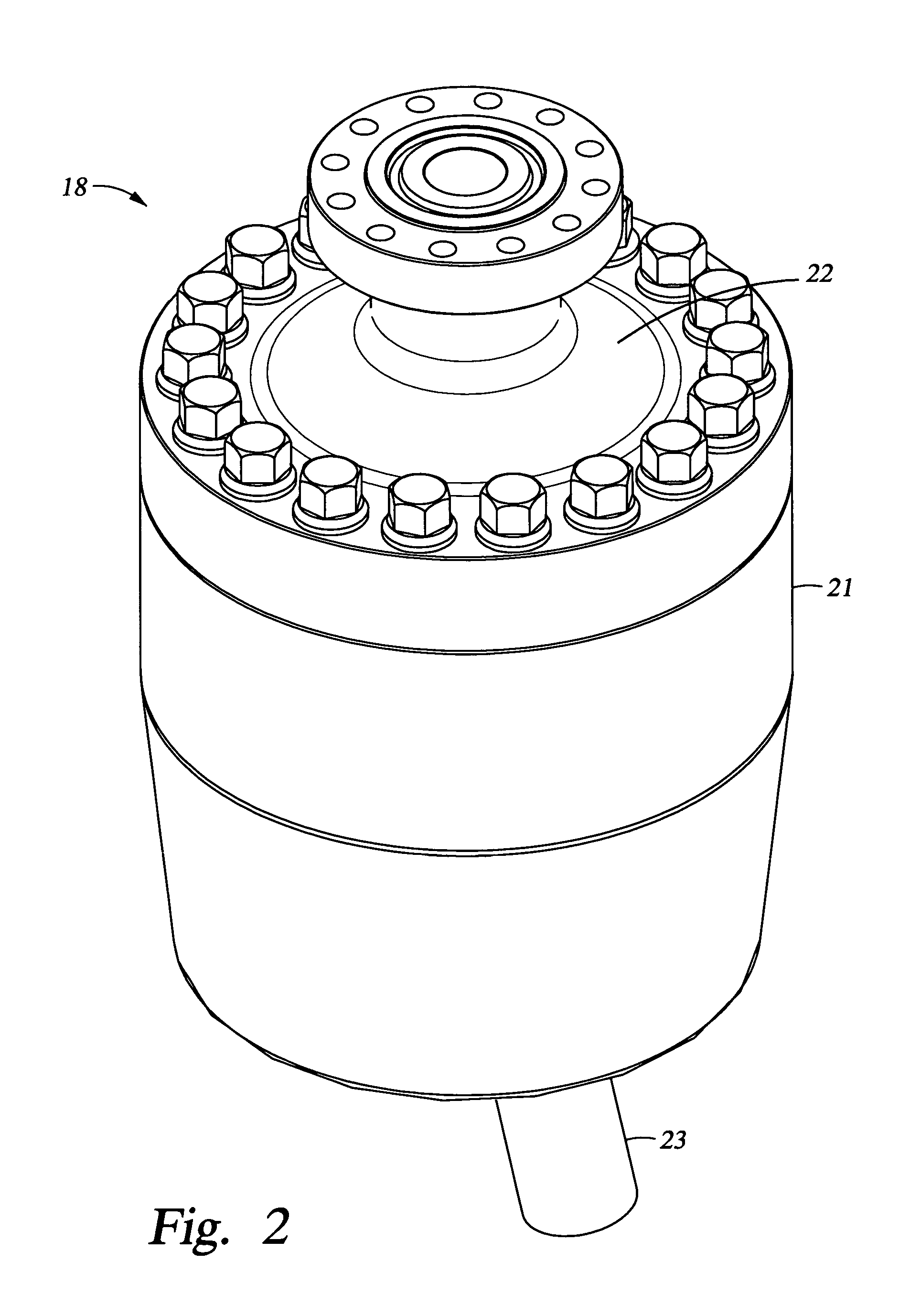

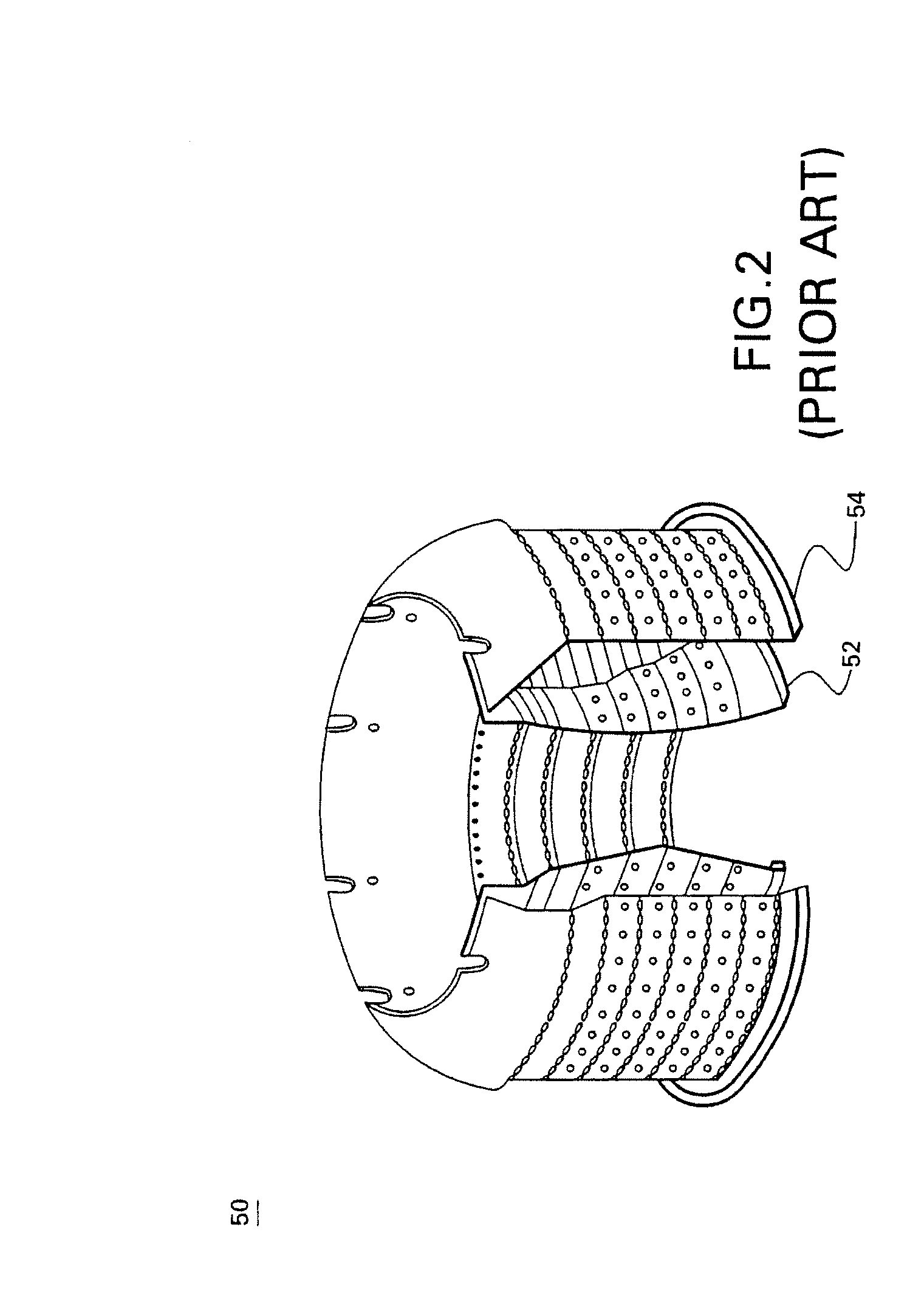

Heat shield panels for use in a combustor for a gas turbine engine

ActiveUS7093439B2Extended service lifeContinuous combustion chamberGas turbine plantsCold sideCombustor

The present invention relates to heat shield panels or liners to be used in combustors for gas turbine engines. The heat shield panels each comprise a hot side and a cold side and at least one isolated cooling chamber on the cold side. Each cooling chamber has a plurality of cooling film holes for allowing a coolant, such as air, to flow from the cold side to the hot side. A combustor having an arrangement of heat shield panels or liners is also described.

Owner:RAYTHEON TECH CORP

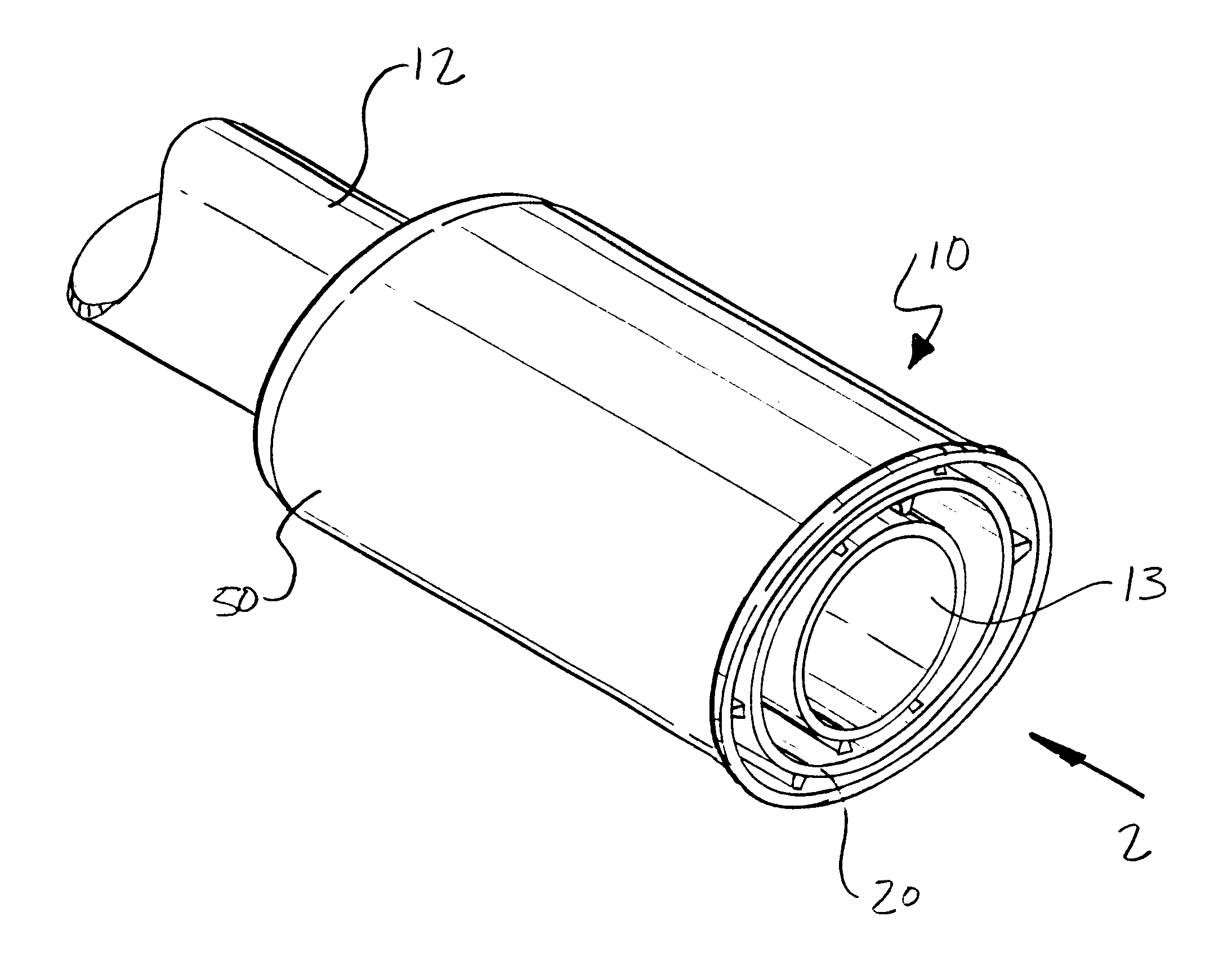

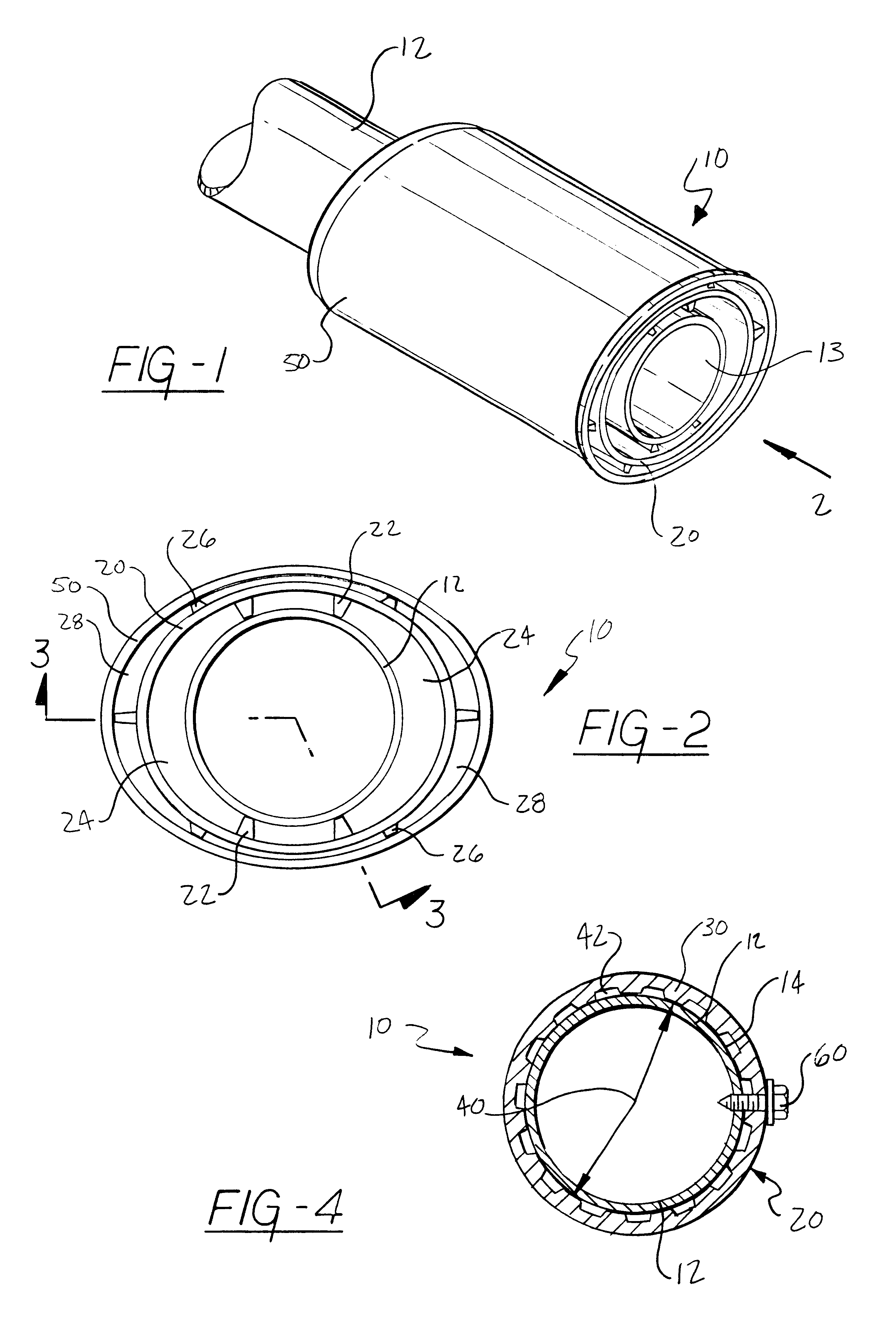

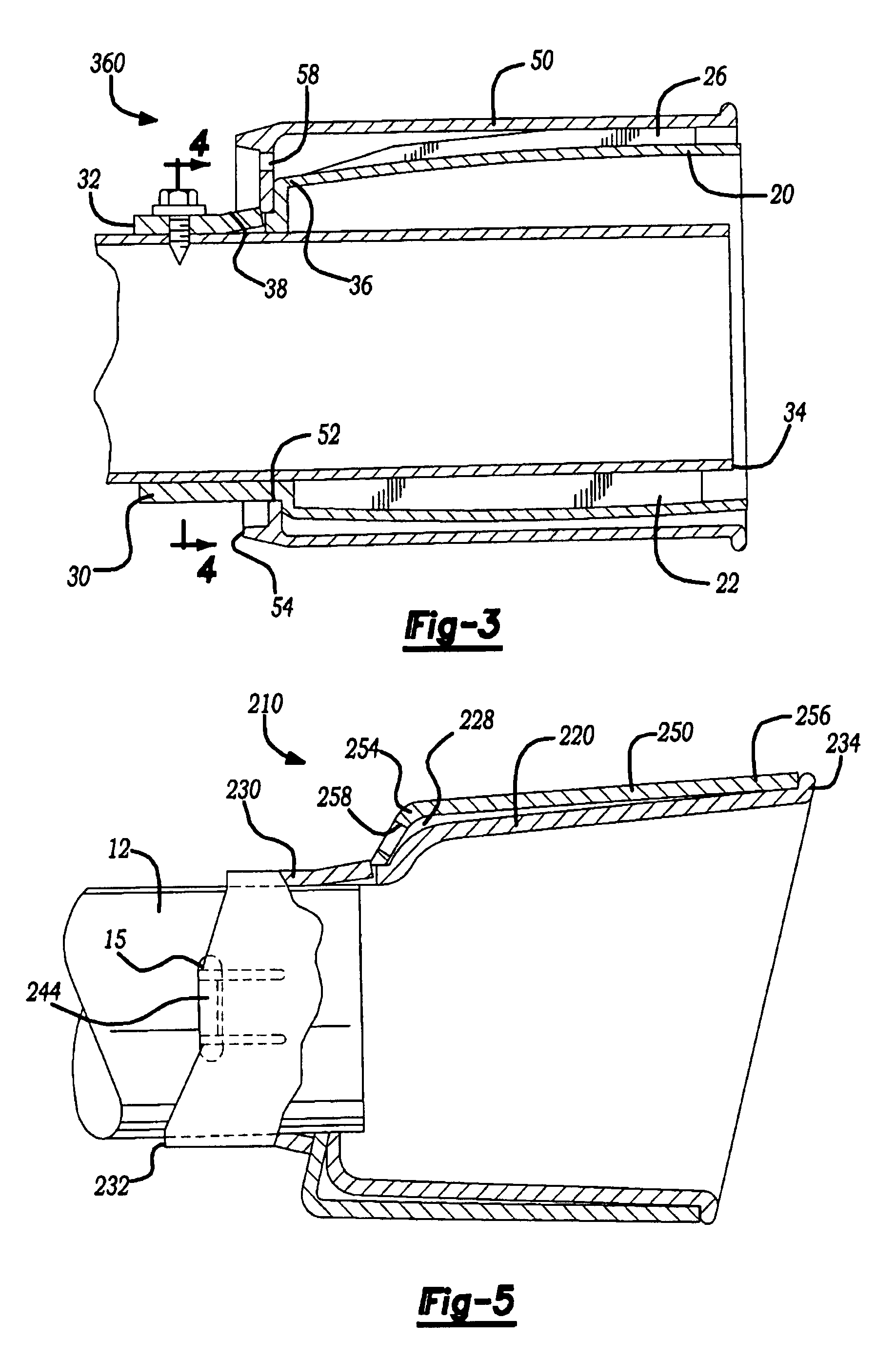

Exhaust tip

InactiveUS7007720B1Severe design restrictionOverall design flexibilityThermal insulationSilencing apparatusEngineeringThermal effect

An exhaust tip for attachment to a tailpipe that includes a thermoset heat shield at least partially surrounding and fastened to the tailpipe, and a thermoplastic decorative cover at least partially surrounding and fastened to the thermoset heat shield. The thermoset heat shield insulates the thermoplastic decorative cover from thermal effects of the tailpipe and spaces the thermoplastic decorative cover a predetermined distance away from the tailpipe.

Owner:LACKS INDUSTRIES INC

Lamp reflector with adjustable curvature

InactiveUS6053624AElongate light sourcesLighting heating/cooling arrangementsLight headPartial reflection

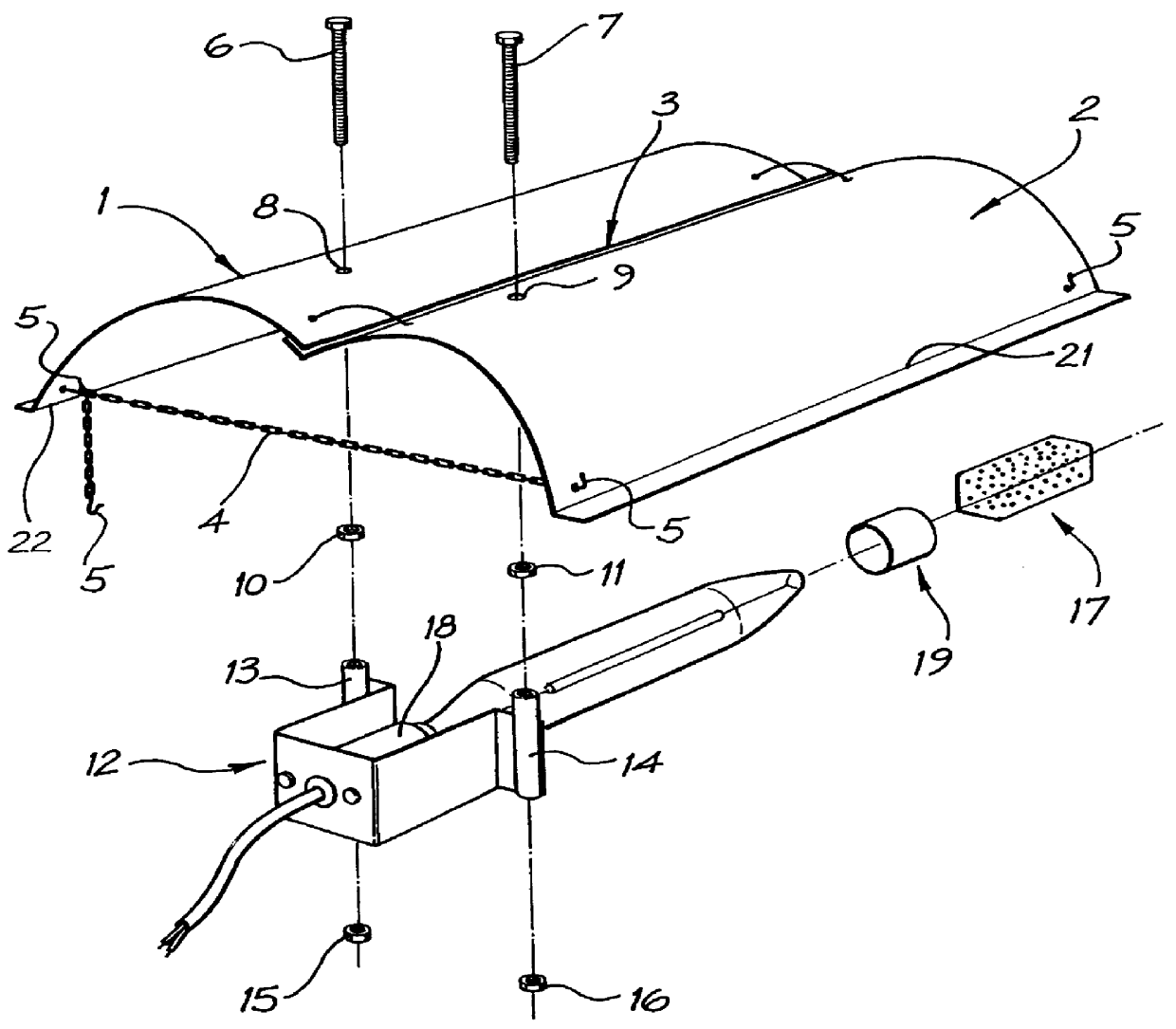

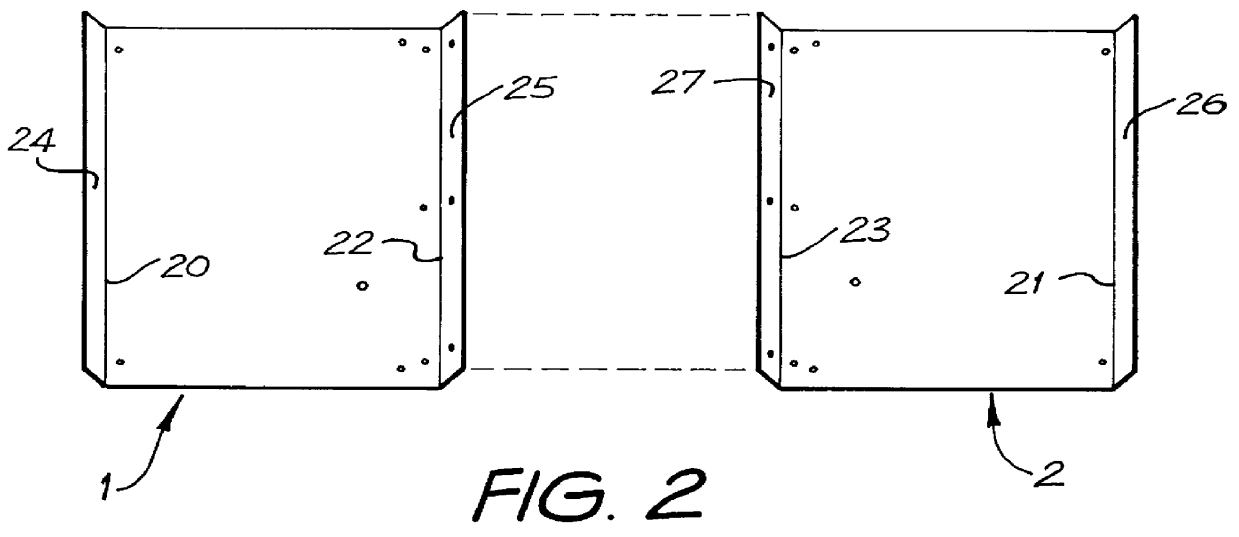

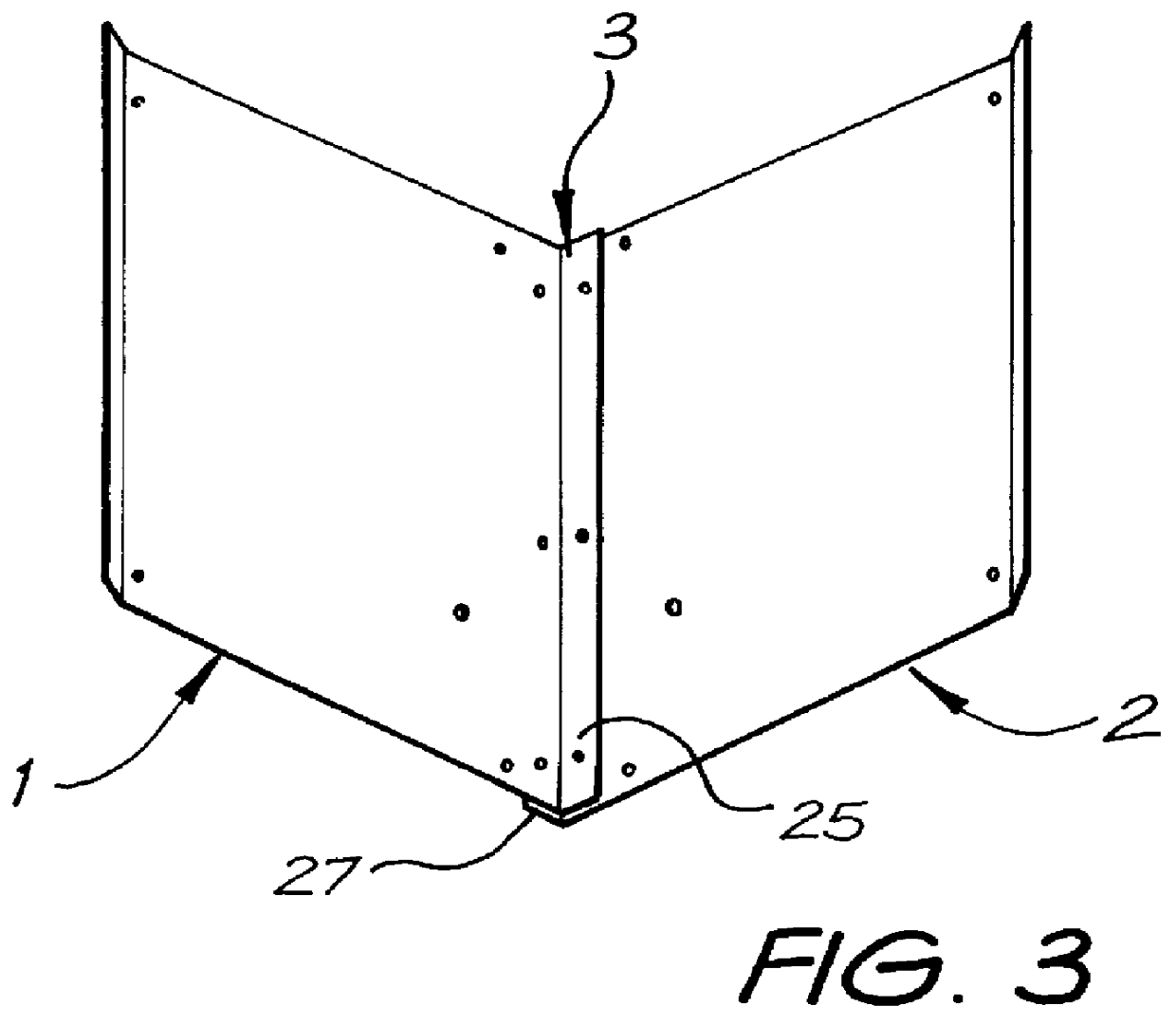

PCT No. PCT / AU95 / 00303 Sec. 371 Date Mar. 10, 1998 Sec. 102(e) Date Mar. 10, 1998 PCT Filed May 24, 1995 PCT Pub. No. WO96 / 37732 PCT Pub. Date Nov. 28, 1996An adjustable reflector device is disclosed. The device consists of an adjustable double parabolic reflective skin (1,2) with an adjustable lamp mount (12), incorporating a V-shaped perforated heat shield (17), attached. The two part reflective skin (1,2) forms a double parabolic shape when flexed back against a reinforced spine (3). This flexible shape is secured by lengthwise adjustable chain retainers (4) attached at both ends of the skin (1,2). The lamp mount (12) slides onto a pair of threaded bolts (6,7) secured to the skin and adjustment is achieved by tightening or loosening the appropriate nuts (15,16). The heat shield (17) slides onto the lamp fitting (18) and is positioned appropriately to deflect incident heat and light. This device can be used to provide variable conditions of artificial illumination.

Owner:CRONK PAUL ANDREW

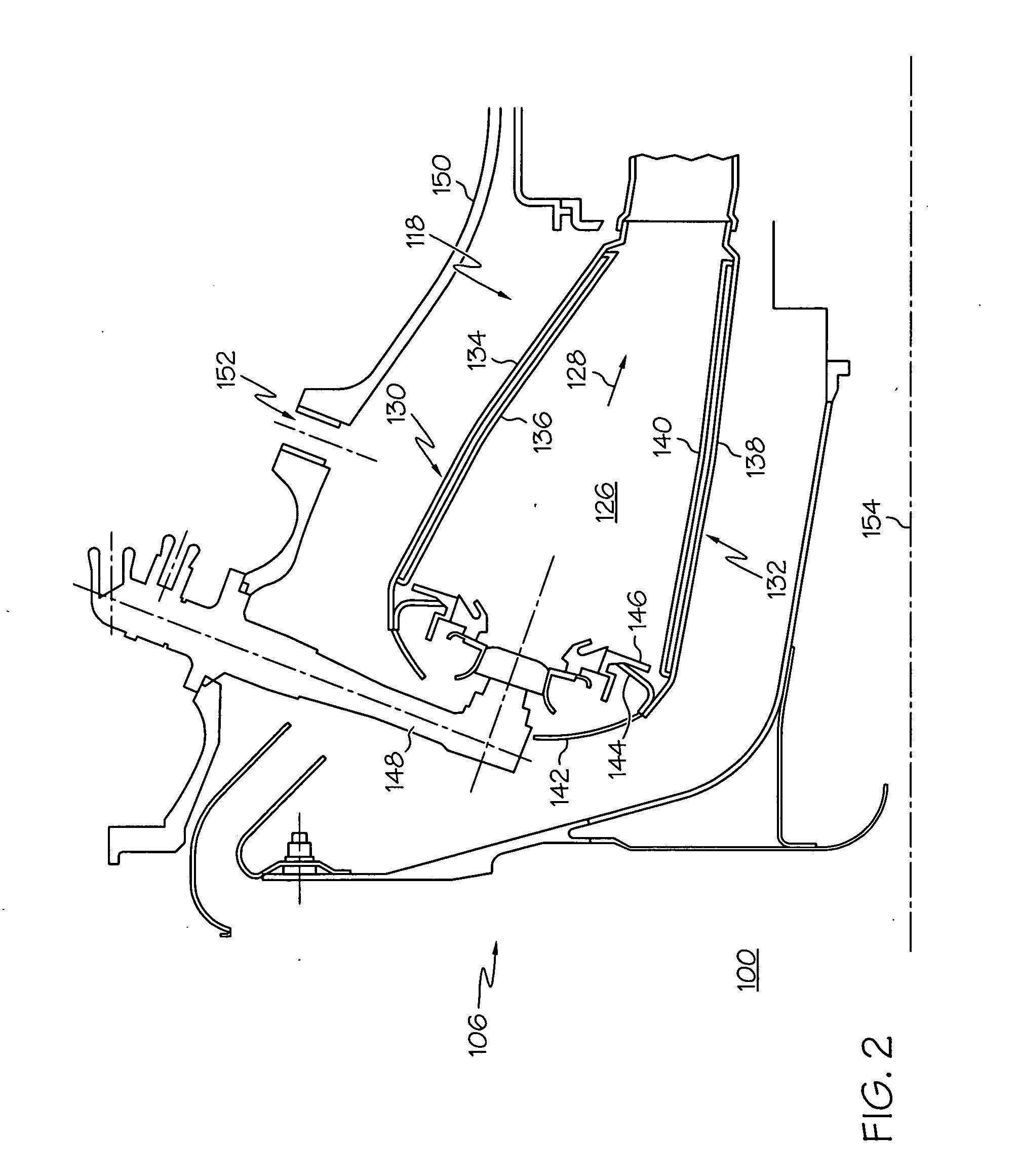

Dual wall structure for use in a combustor of a gas turbine engine

InactiveUS20100095679A1Continuous combustion chamberTurbine/propulsion engine coolingCombustion chamberCombustor

A dual wall structure for a combustor of a gas turbine engine including an inner liner and an outer liner coupled to a combustor dome and defining a combustion chamber there between. Each of the inner liner and the outer liner include an outer wall and an inner wall. Each of the outer walls includes a plurality of impingement holes formed therein for allowing a coolant to flow therethrough. Each of the inner walls is coupled to the outer wall via a plurality of threaded studs and includes a plurality of forward heat shield panels and a plurality of aft heat shield panels. Each of the plurality of forward heat shield panels and aft heat shield panels includes a plurality of side rails, a forward rail, and an aft rail including a plurality of controlled openings, that when coupled to the outer wall defines a single cavity there between. A plurality of cavities being formed by the plurality of forward and aft heat shield panels.

Owner:HONEYWELL INT INC

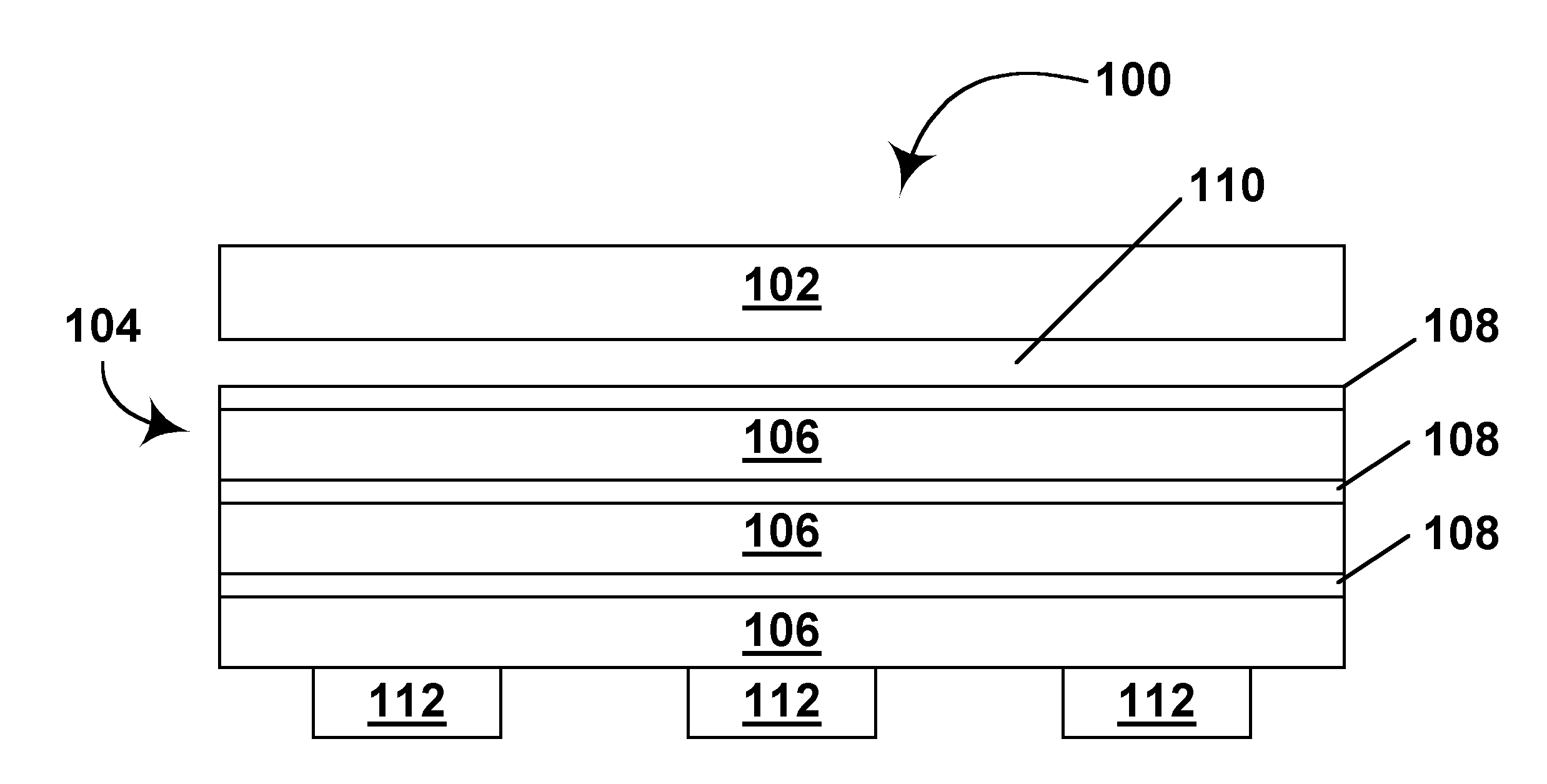

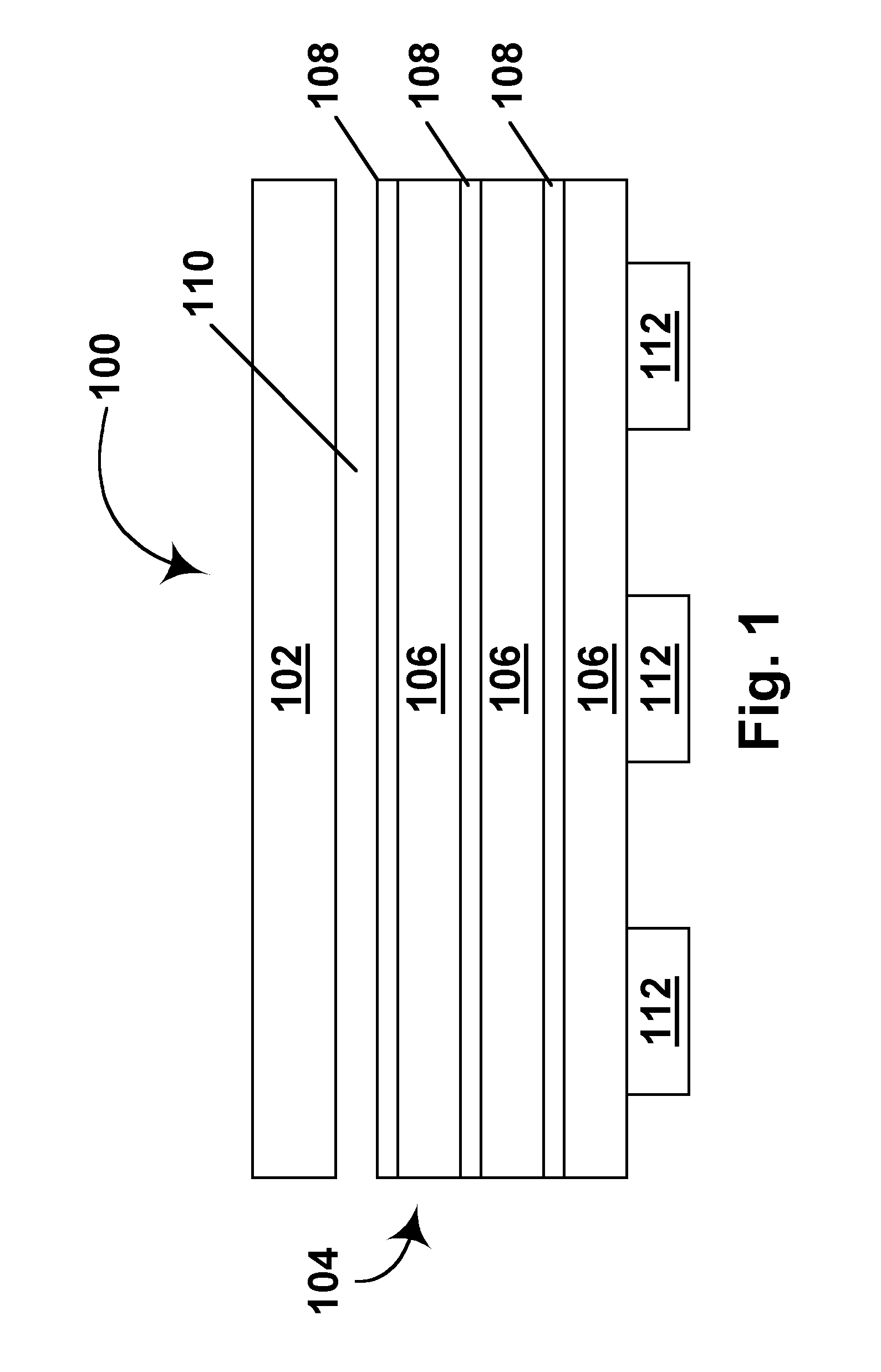

Protection of electro-optic displays against thermal effects

InactiveUS20140078024A1Reduction factorHollow inflatable ballsStatic indicating devicesElectrophoresisHeat conducting

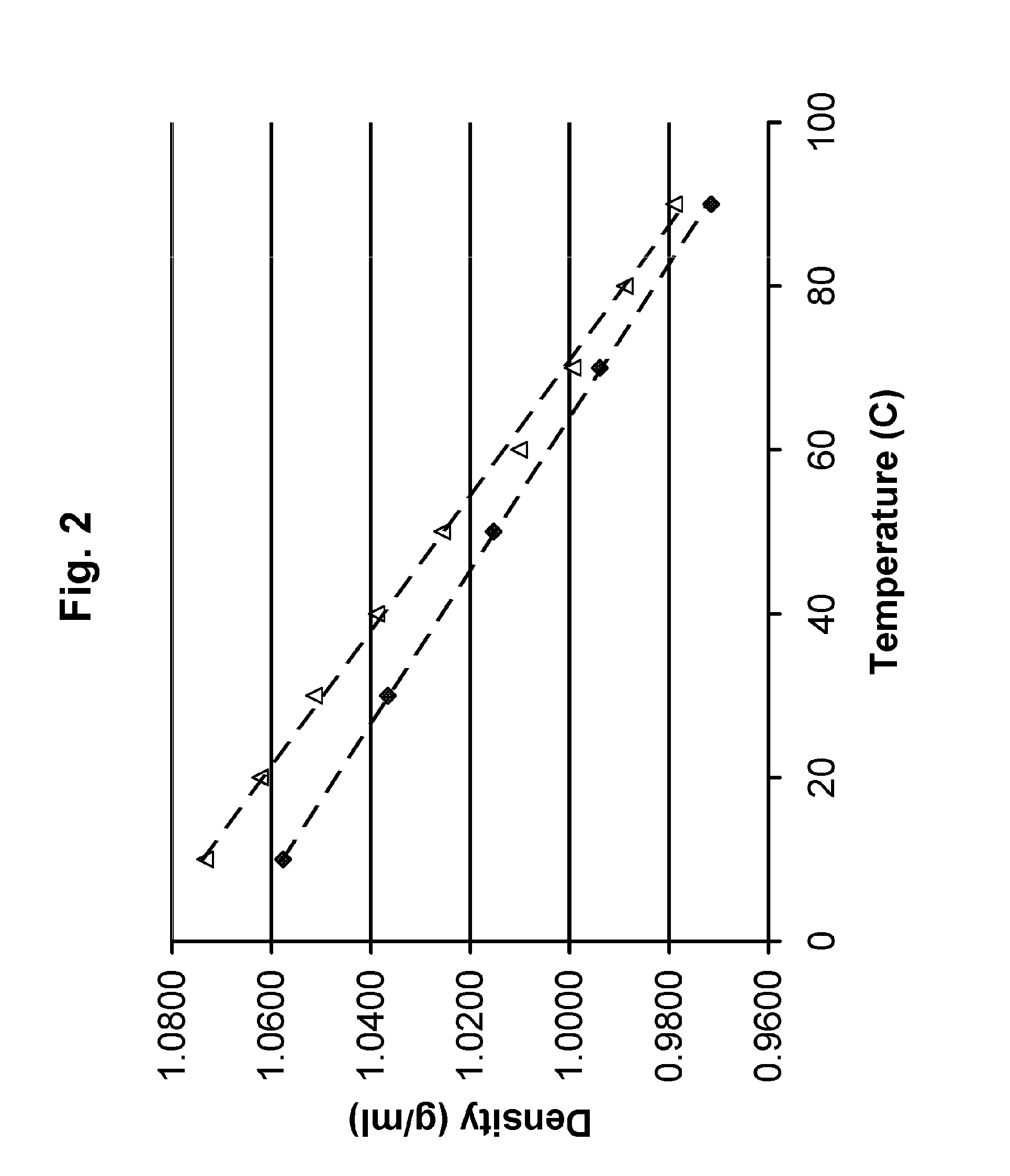

An electro-optic display comprises a layer of reflective electro-optic material capable of changing its optical state on application of an electric field, an electrode, a heat generating component in heat conducting relationship with the electro-optic material, and a heat shield disposed between the heat generating component and the electro-optic material, the heat shield comprising a layer of thermally insulating material and a layer of thermally conducting material, the thermally conducting material being disposed between the thermally insulating material and the electro-optic material. The invention also provides an electrophoretic medium comprising a suspending fluid and a plurality of electrically charged particles suspended in the suspending fluid and capable of moving therethrough upon application of an electrical field to the electrophoretic medium, the suspending fluid containing a compatibilizer to reduce its coefficient of thermal expansion.

Owner:E INK CORPORATION

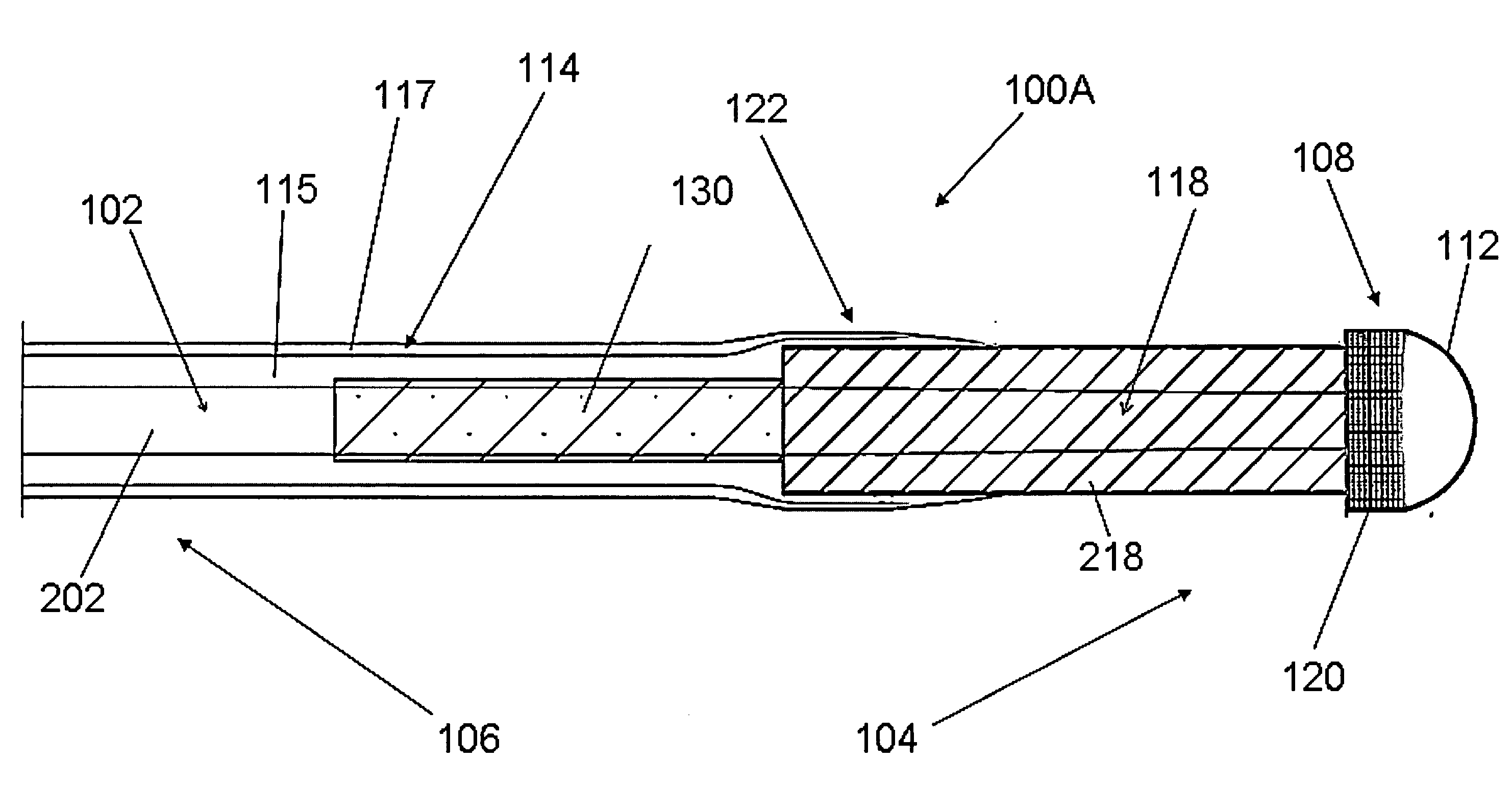

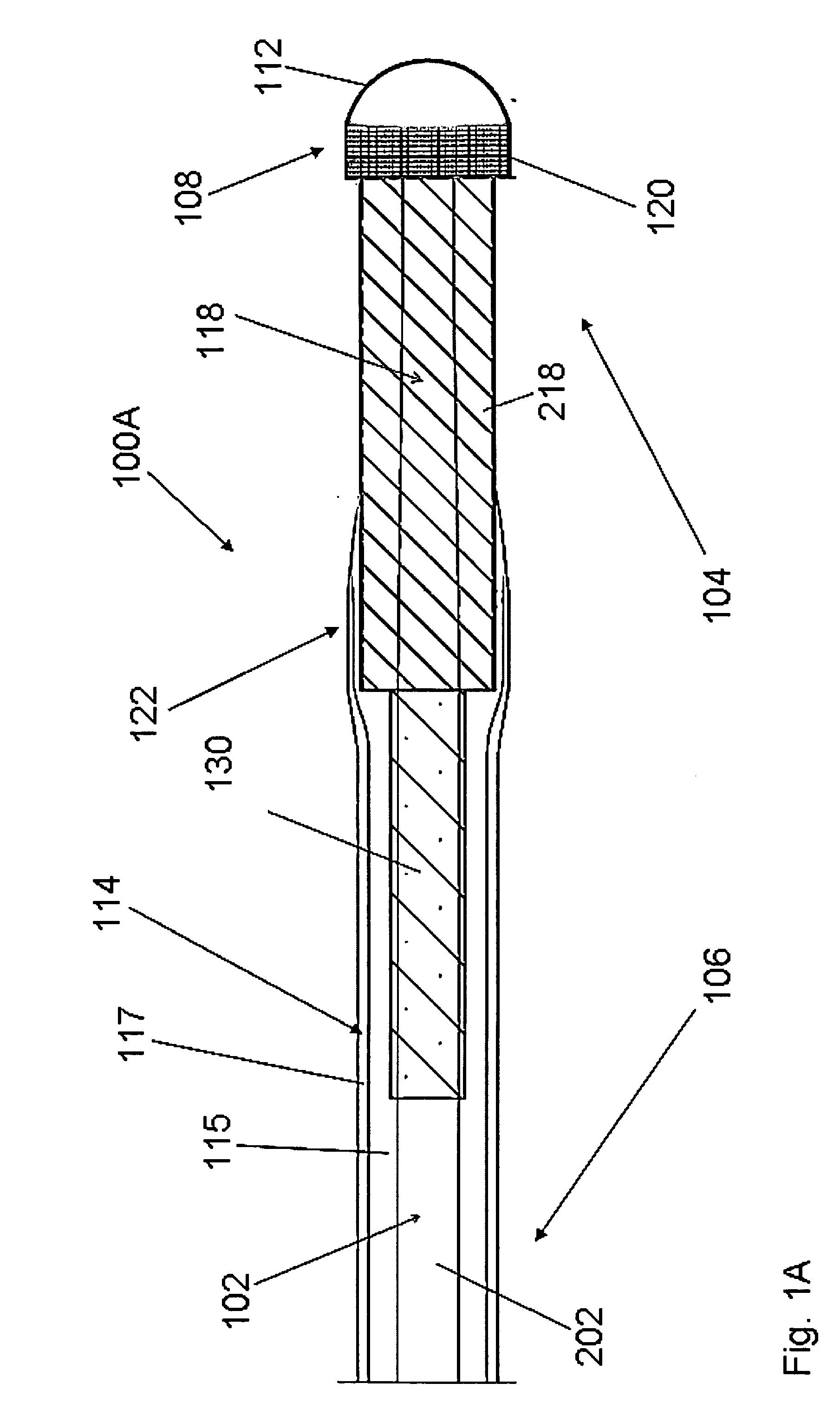

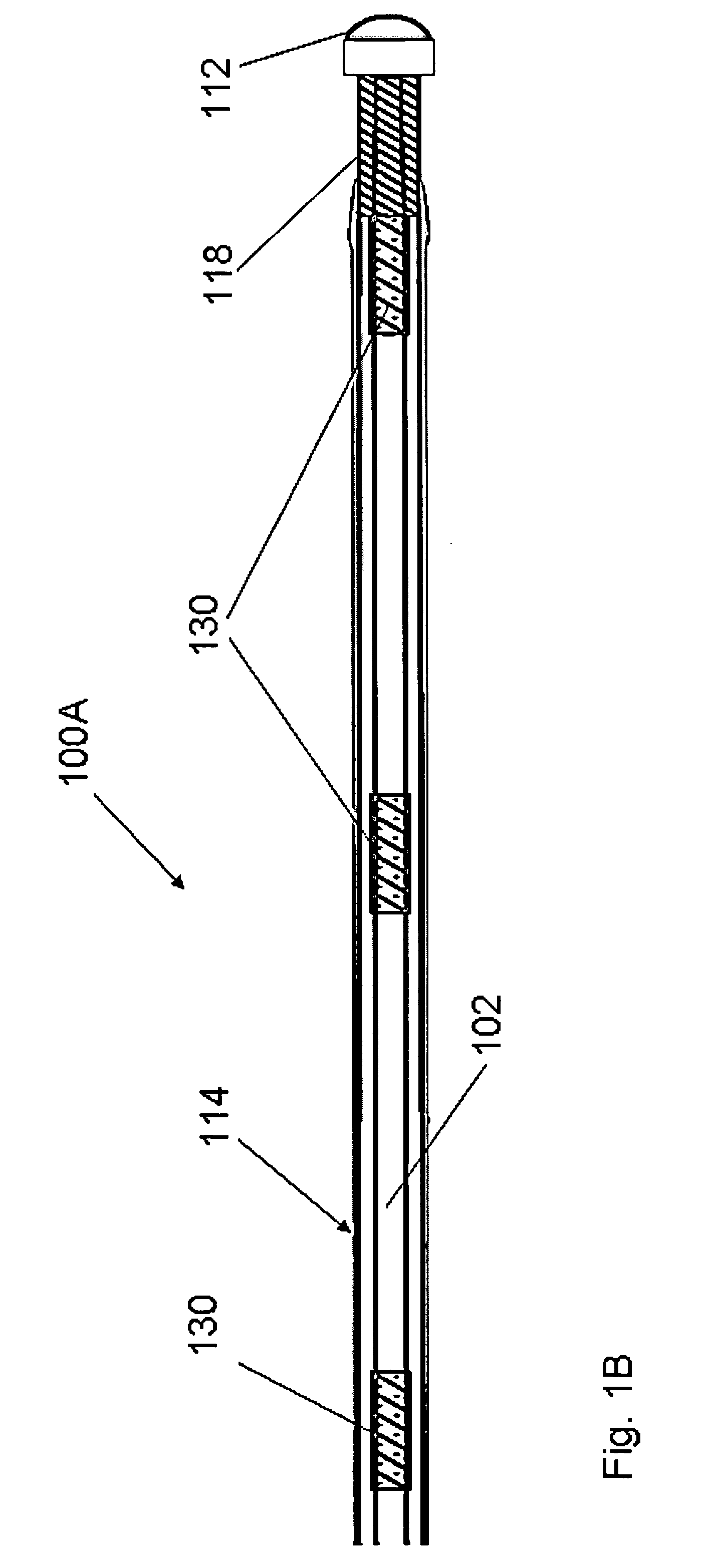

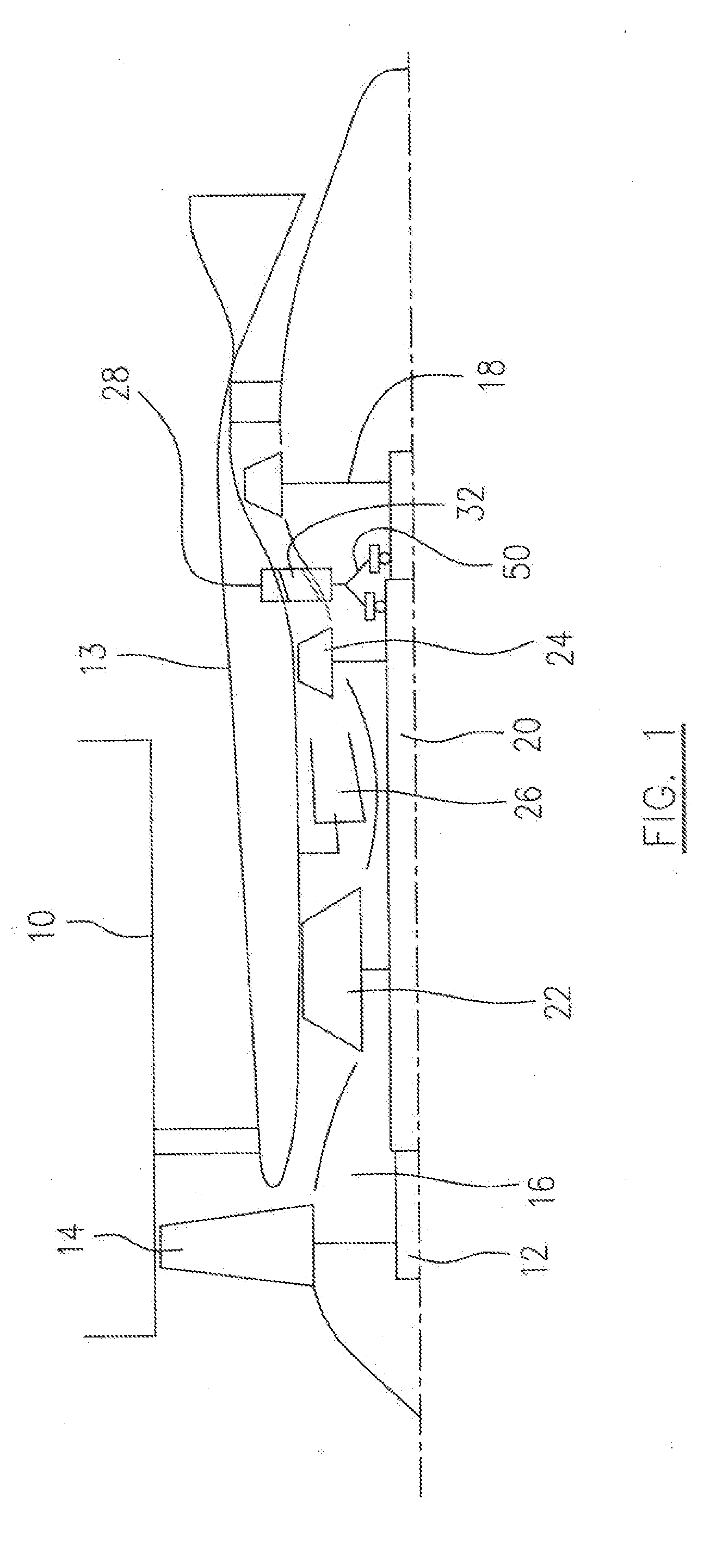

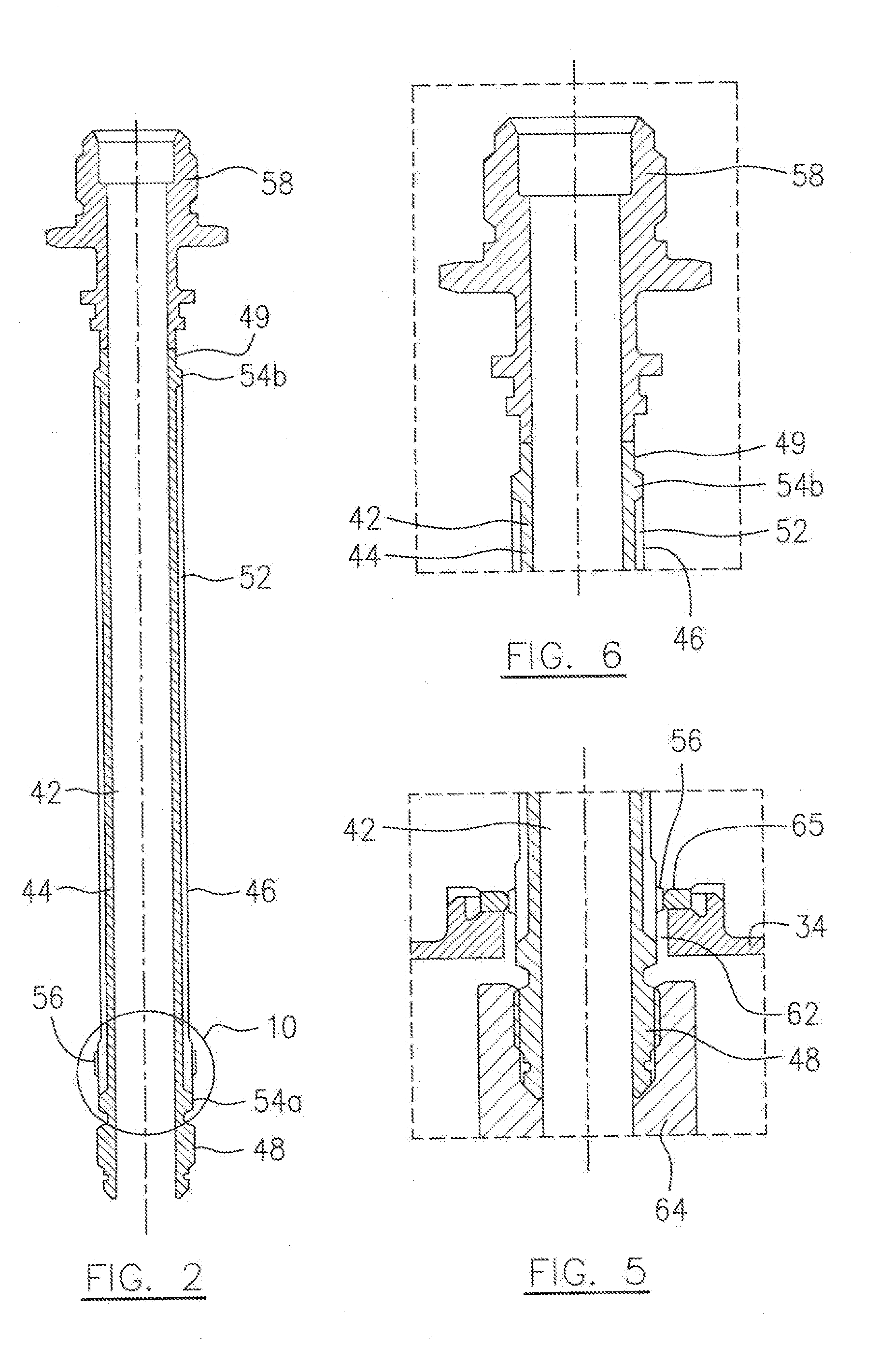

Electrosurgical device for creating a channel through a region of tissue and methods of use thereof

An electrosurgical device and methods are disclosed for creating a channel through a region of tissue. The device comprises an elongate member for receiving the energy from an electrical energy source. An electrical insulation layer surrounds the elongate member along the device proximal region. An electrode tip is coupled to the distal end of the elongate member for delivering the energy, the electrode tip being configured and sized for delivering the energy in a manner such that electrical arcing is generated in the region of tissue in order to create a channel through at least a portion of the region of tissue. An electrically insulative thermal shield is disposed between the electrode tip and the device proximal region for preventing arcing therebetween during the delivery of the energy and for thermally protecting the device proximal region from heat produced by the delivery of the energy through the electrode tip.

Owner:BOSTON SCI MEDICAL DEVICE LTD

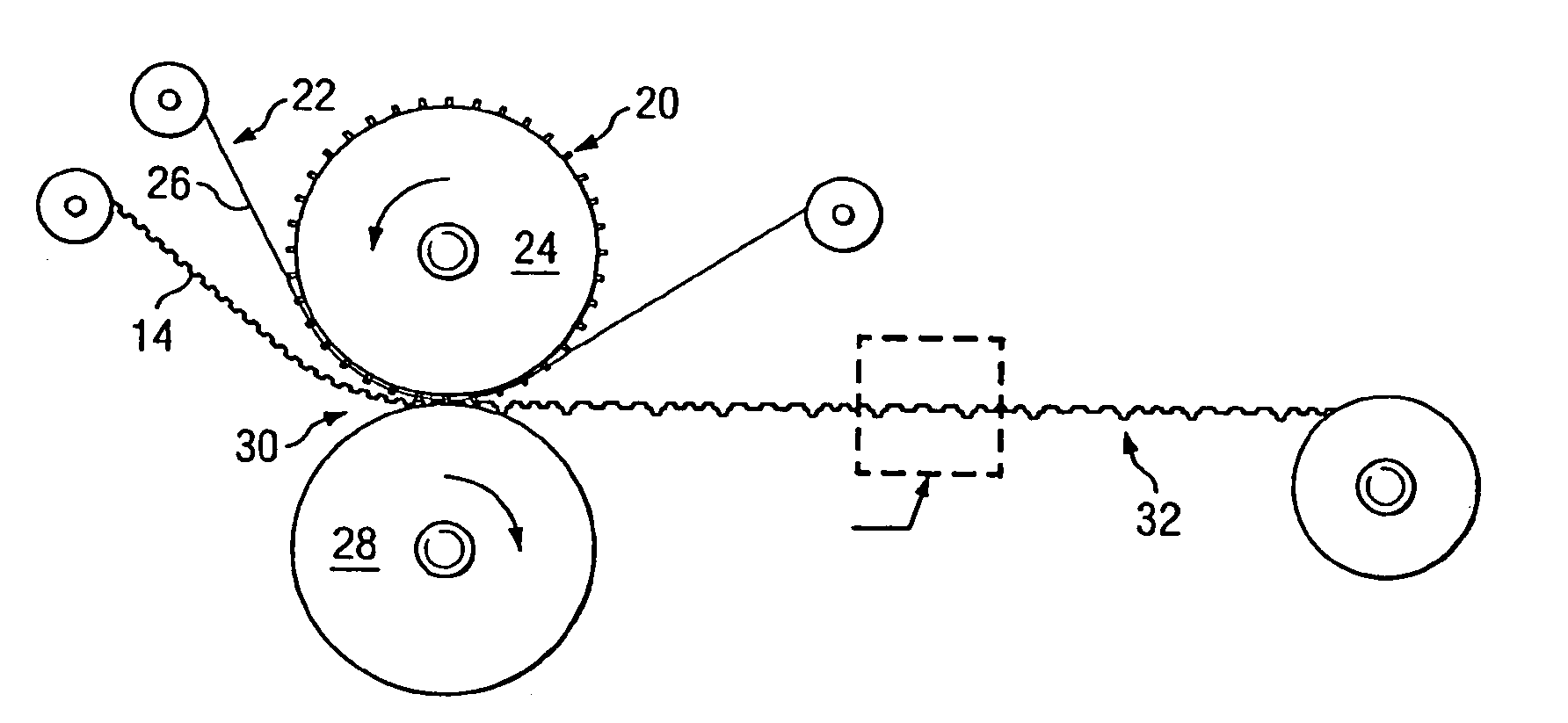

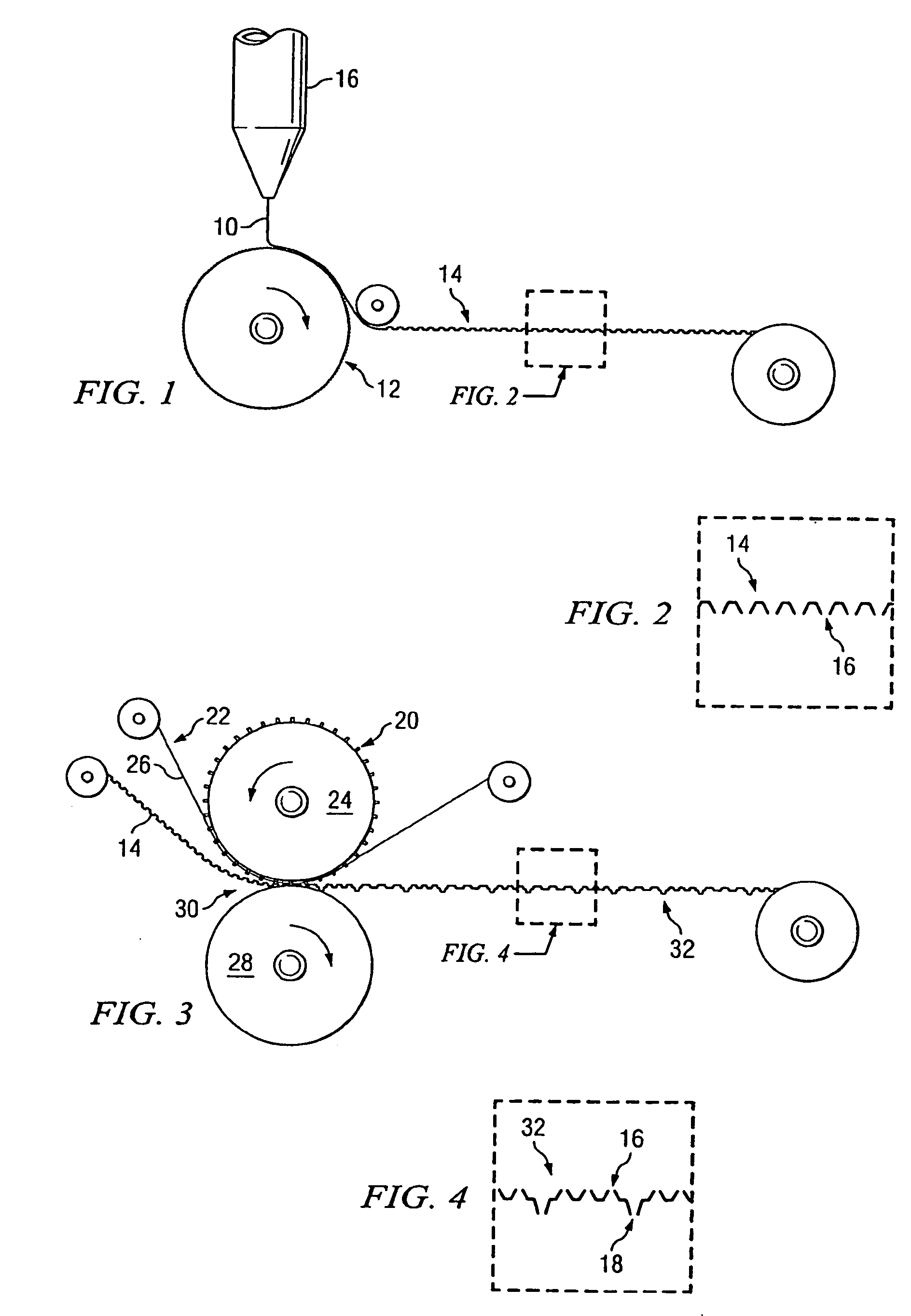

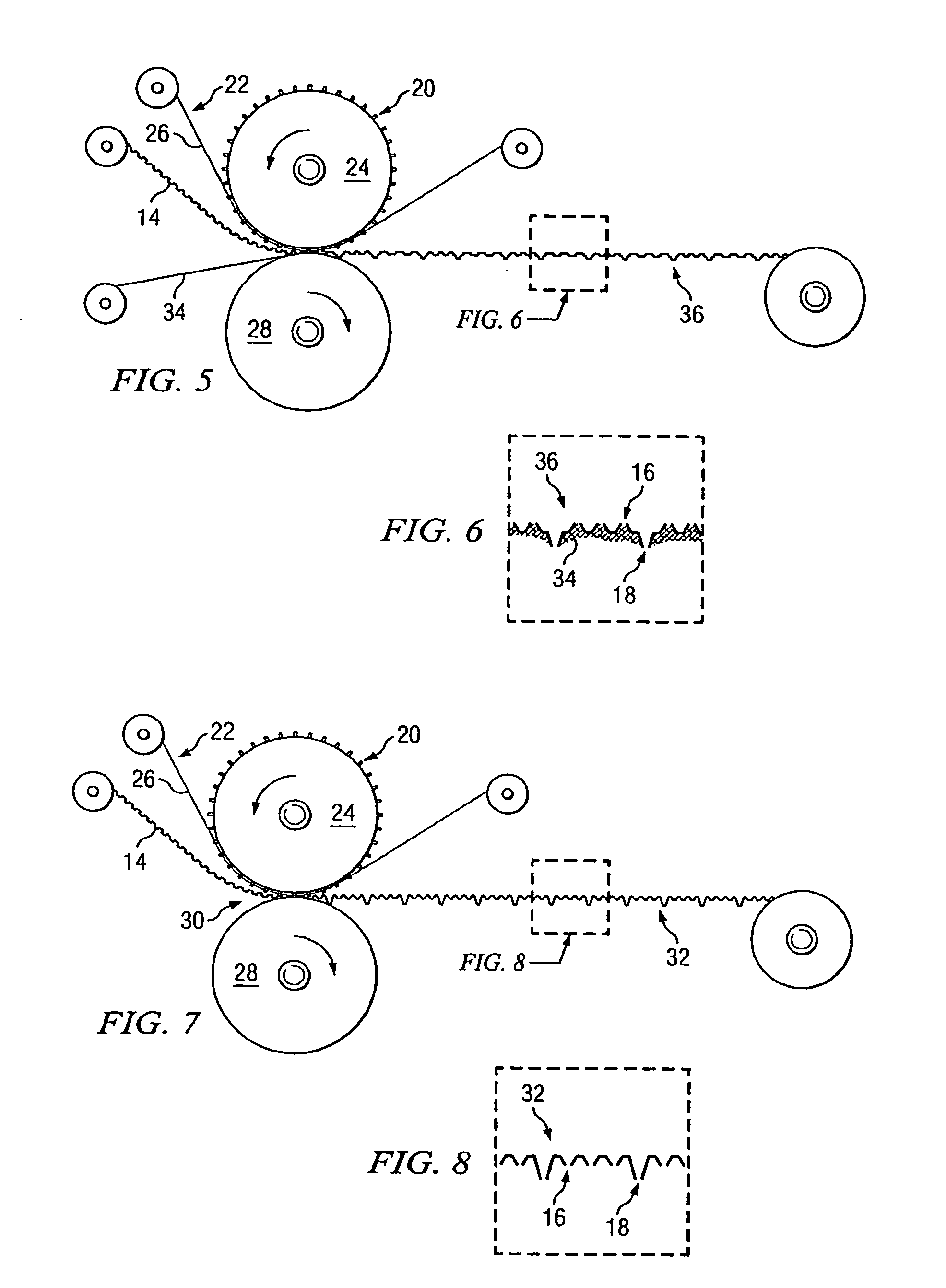

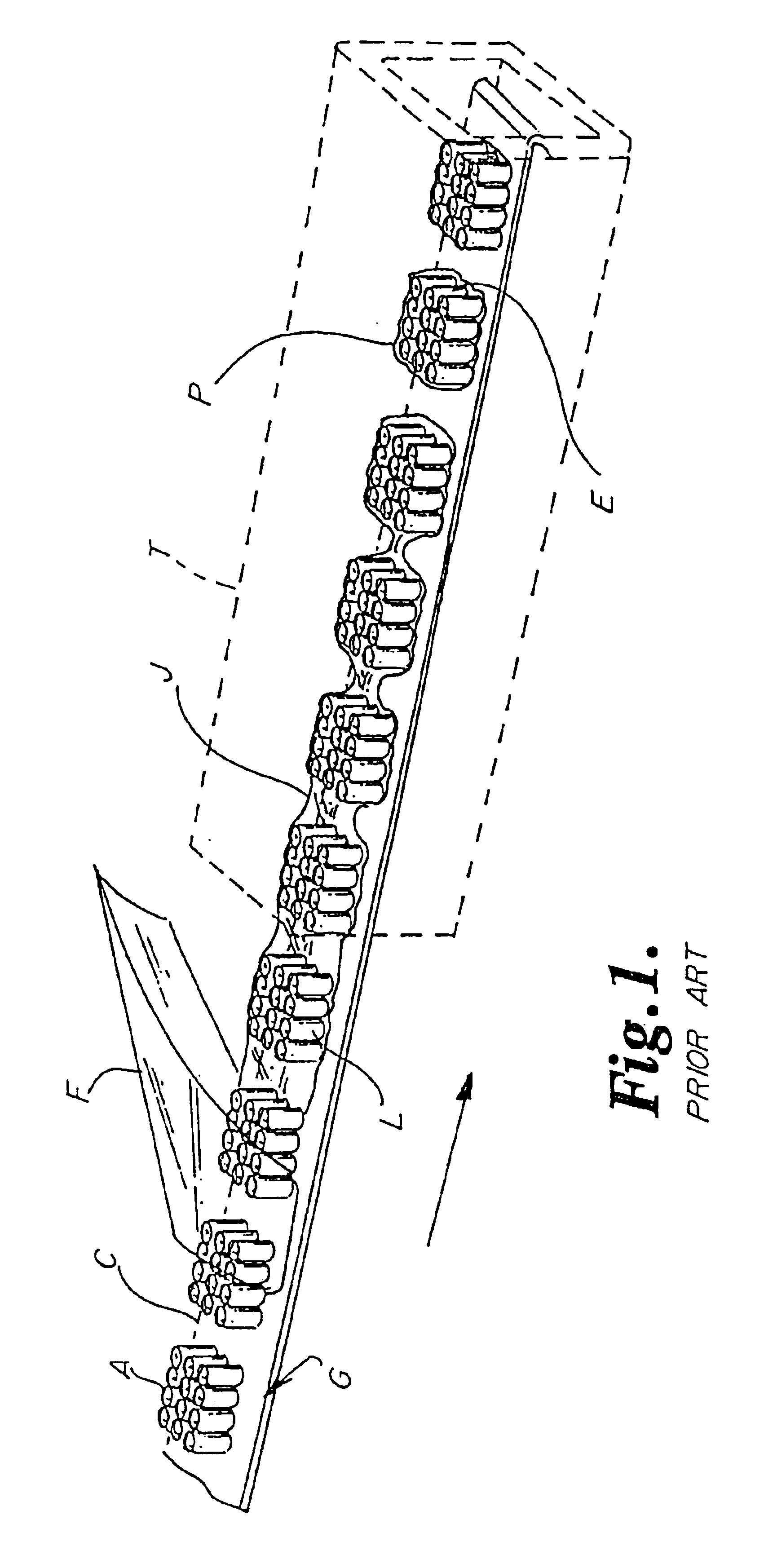

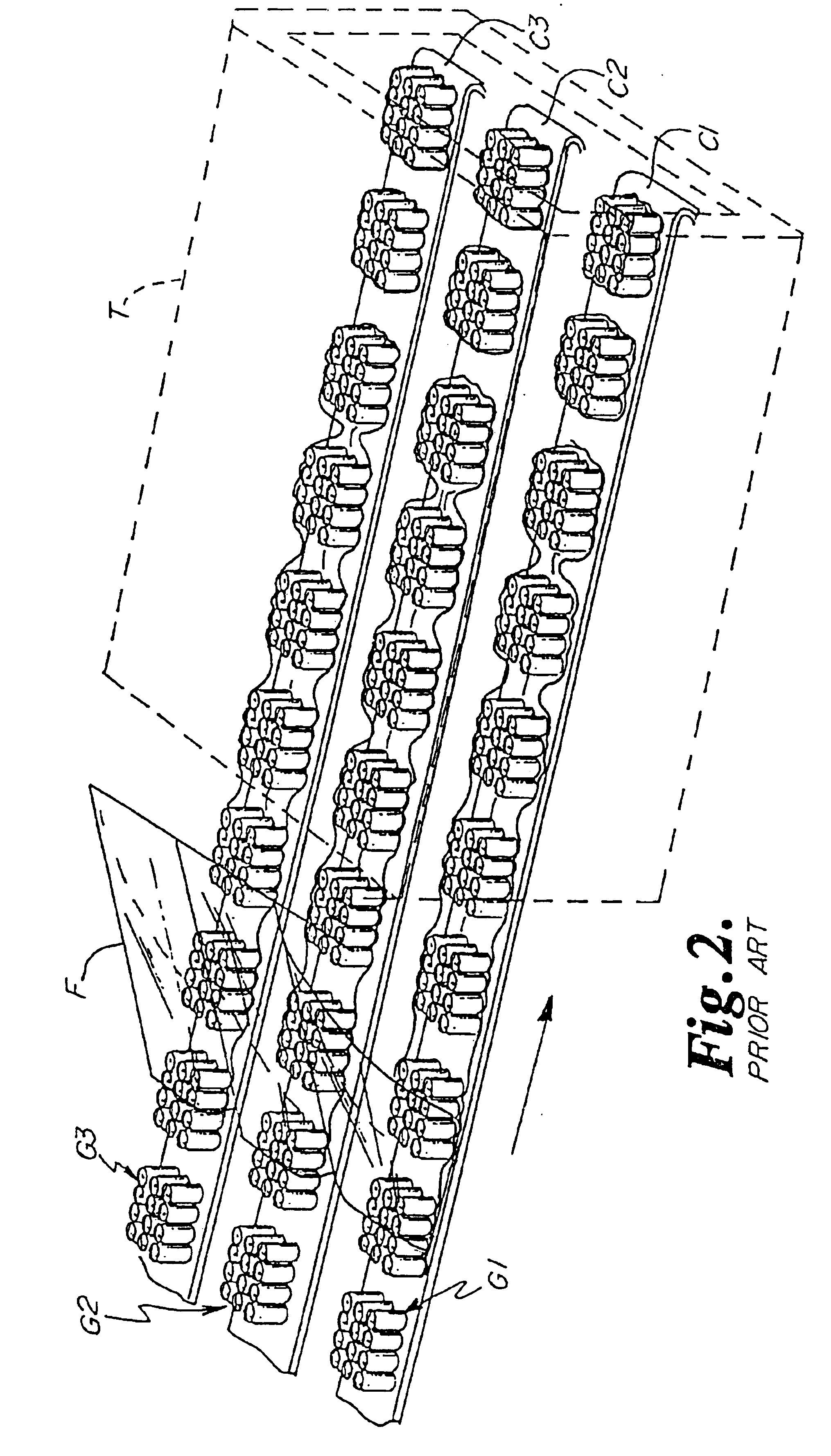

Apertured material for use in absorbent articles

A method of thermo-mechanically forming macrotextures in a microtextured film wherein a heat shield is utilized to thermally insulate the microtexture during the forming process.

Owner:JOSEPH TESSARI

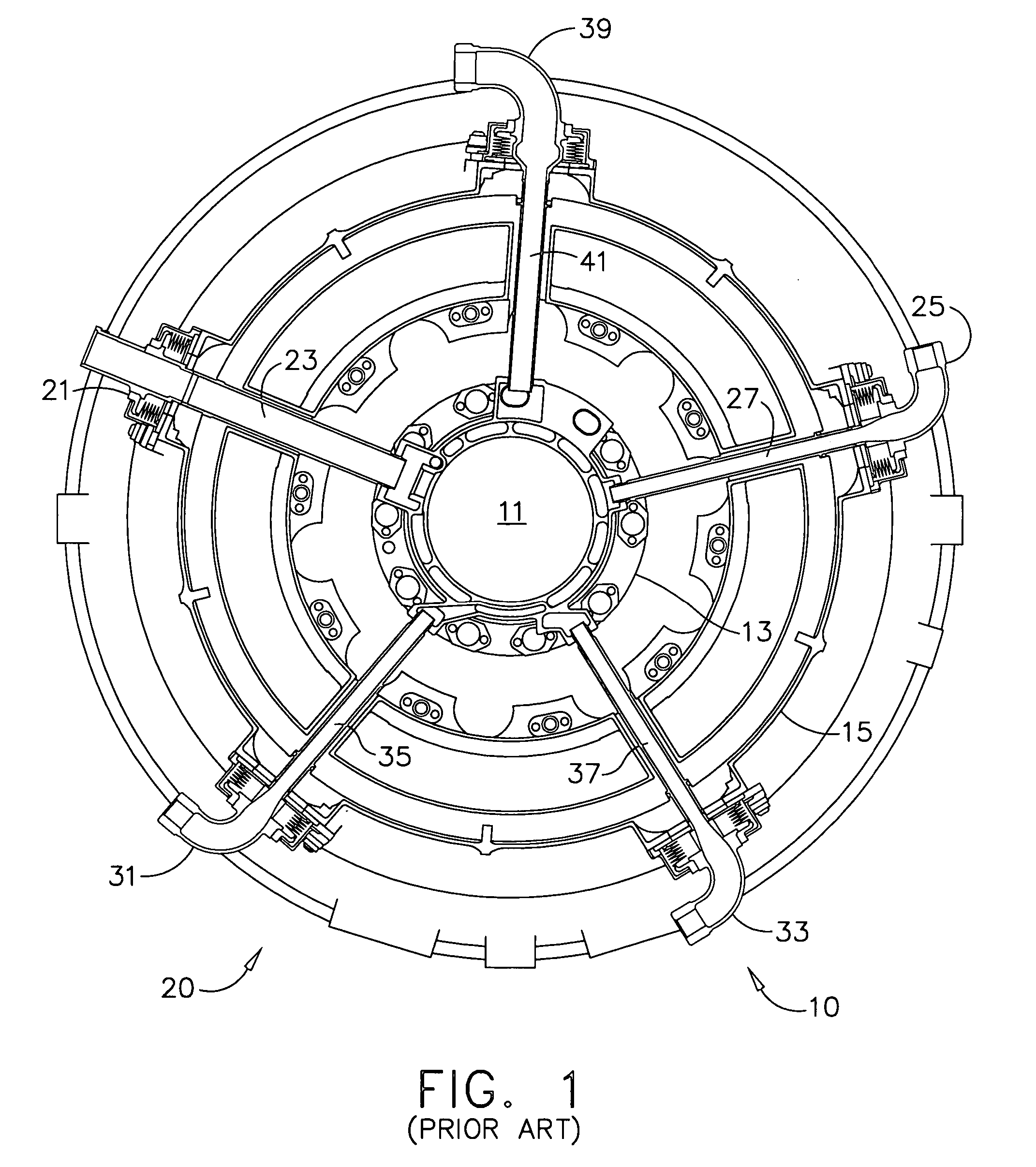

Ring seal system with reduced cooling requirements

Aspects of the invention are directed to systems for reducing the cooling requirements of a ring seal in a turbine engine. In one embodiment, the ring seal can be made of a ceramic material, such as a ceramic matrix composite. The ceramic ring seal can be connected to metal isolation rings by a plurality of pins. The hot gas face of the ring seal can be coated with a thermal insulating material. In another embodiment, the ring seal can be made of metal, but it can be operatively associated with a ceramic heat shield. The metal ring seal can carry the mechanical loads imposed during engine operation, and the heat shield can carry the thermal loads. By minimizing the amount of ring seal cooling, the ring seal systems according to aspects of the invention can result in improved engine performance and emissions.

Owner:SIEMENS ENERGY INC

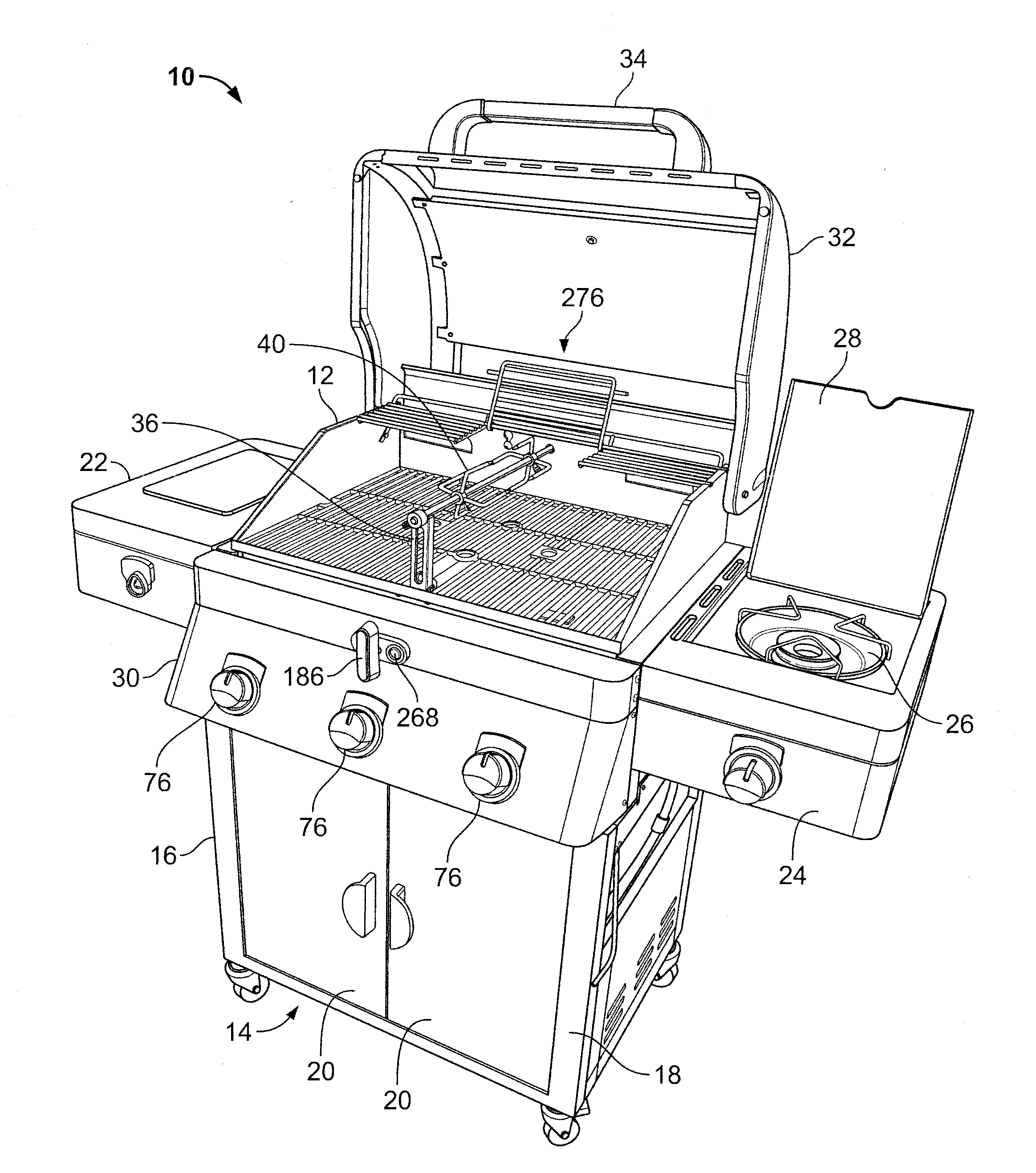

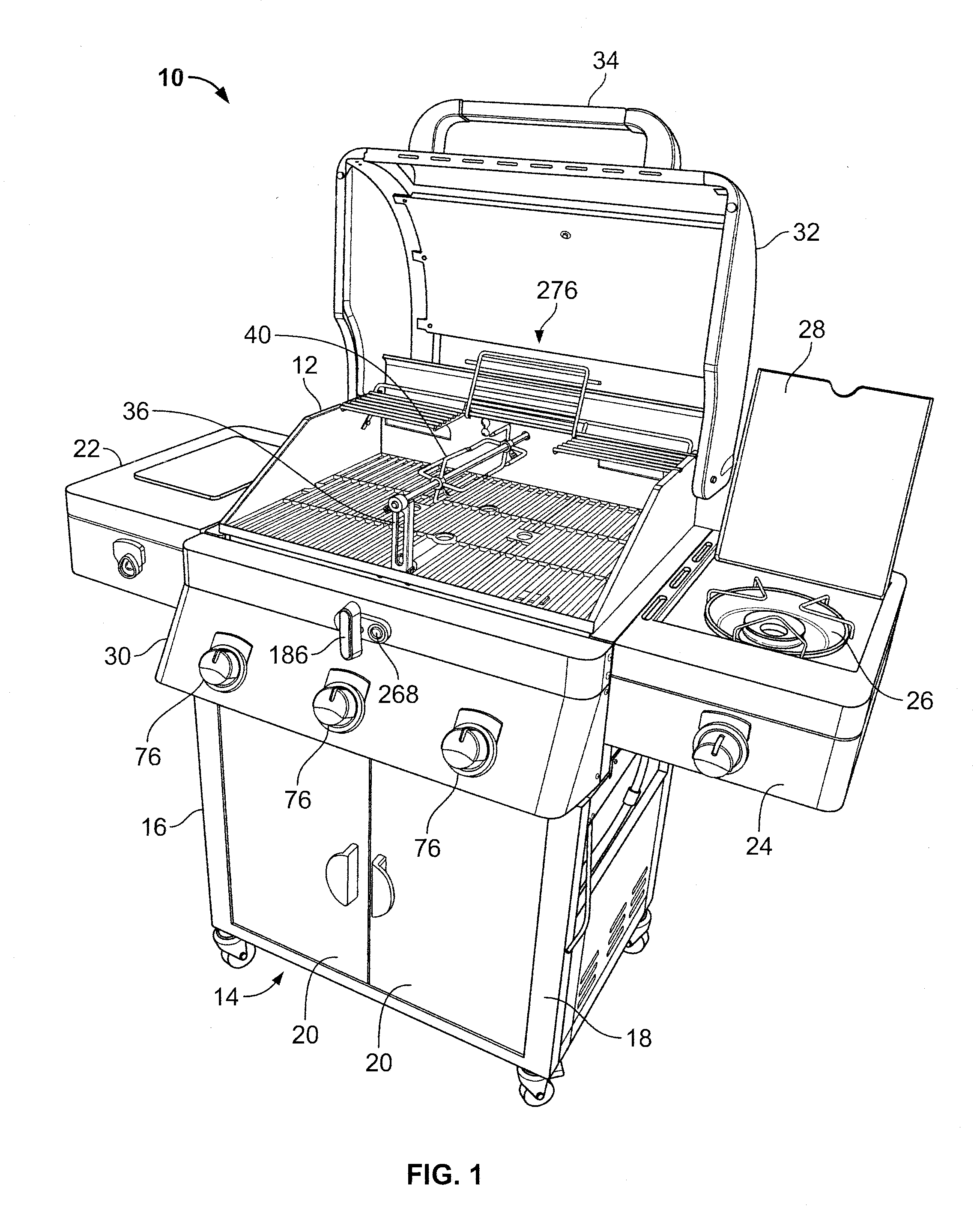

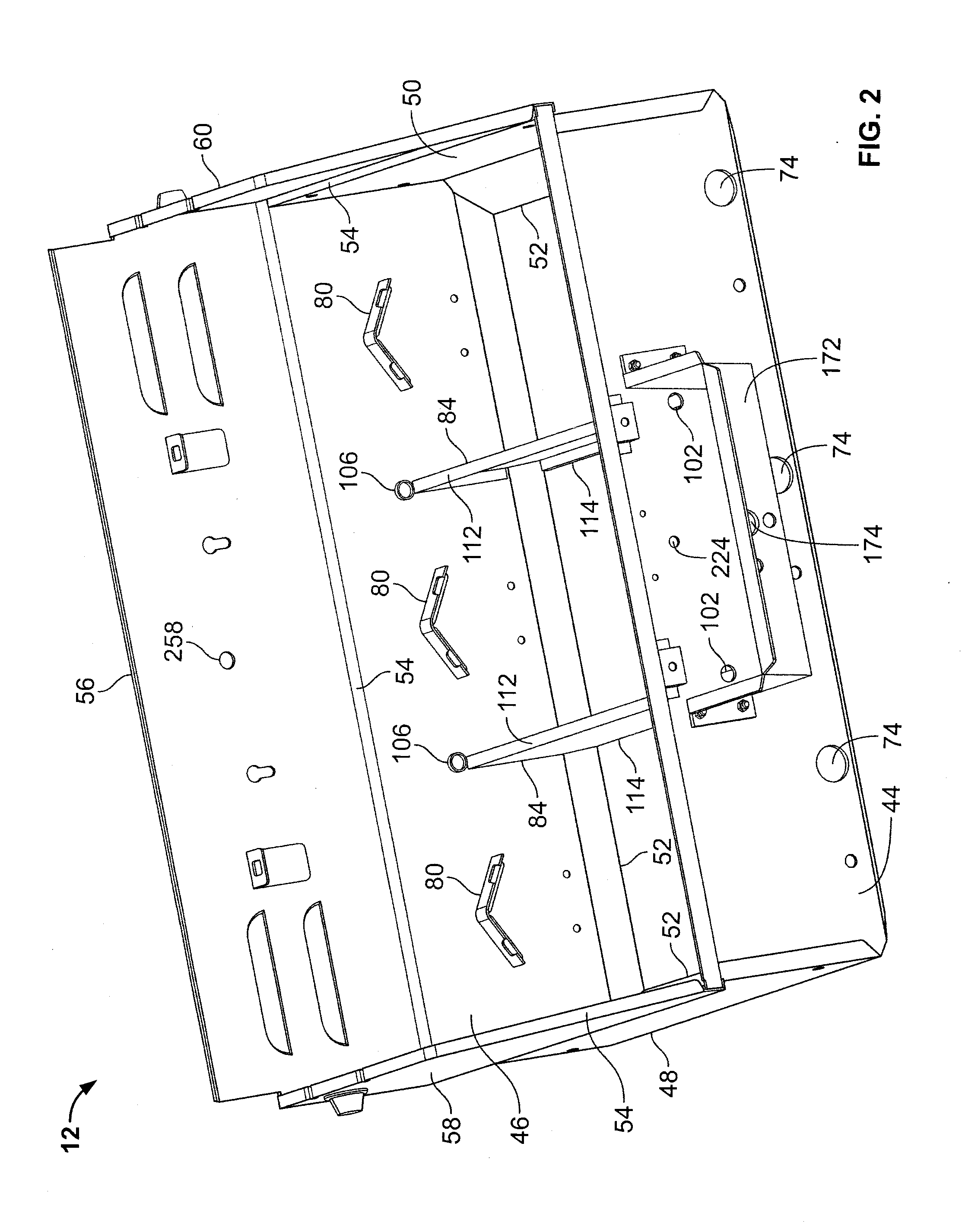

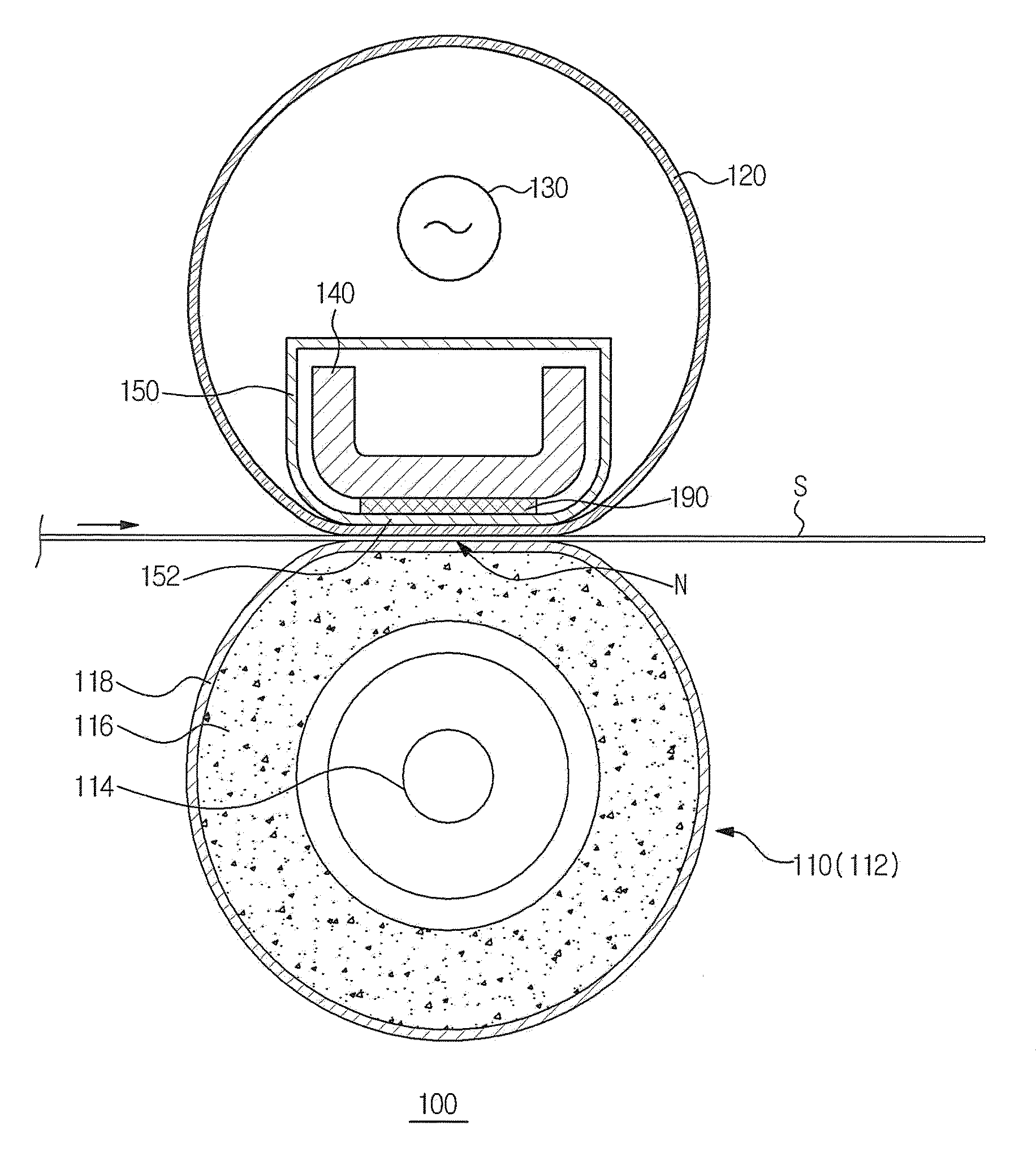

Partitioned grill and rotisserie

The present invention is embodied in a grill having a firebox with a front rotisserie mount assembly and a pair of heat shield assemblies. The front rotisserie mount assembly is to help mount a rotisserie on the grill along a longitudinal axis extending from the front of the grill to the rear of the grill. The front rotisserie mount assembly also acts in conjunction with a pair of heat shield assemblies in the firebox to help concentrate heat generated underneath the rotisserie.

Owner:BRINKMANN AG

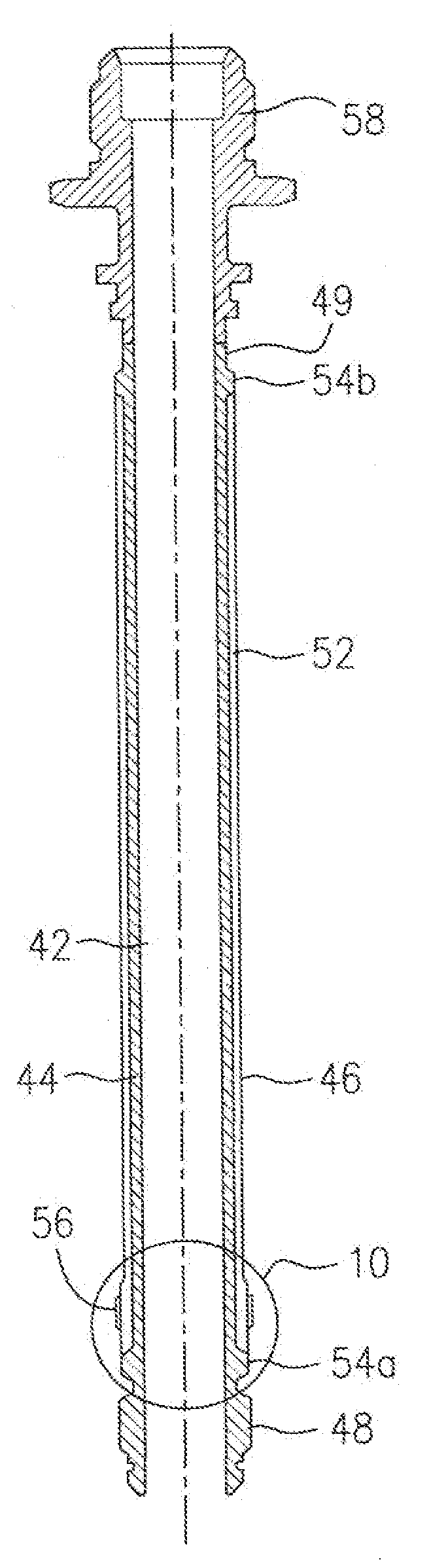

Oil tube with integrated heat shield

A gas turbine engine has an oil tube for delivering oil through a high temperature zone of the engine to an engine component for cooling and lubrication. An insulation tube surrounds the oil tube and extends in a substantial length of the oil tube. The opposed ends of the insulation tube are integrally and sealingly connected to respective end portions of the oil tube to form a dead air annulus between the oil tube and the insulation tube.

Owner:PRATT & WHITNEY CANADA CORP

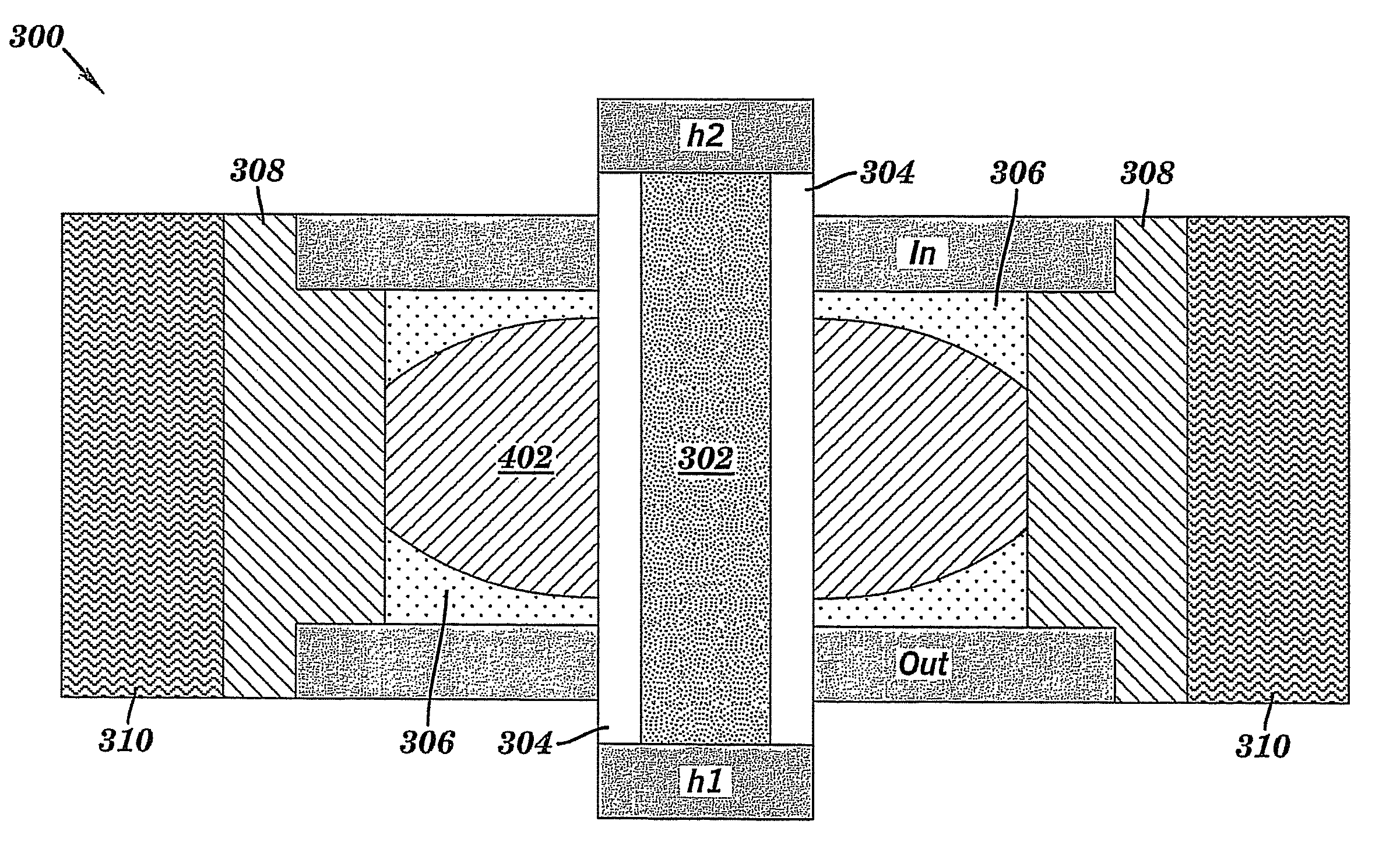

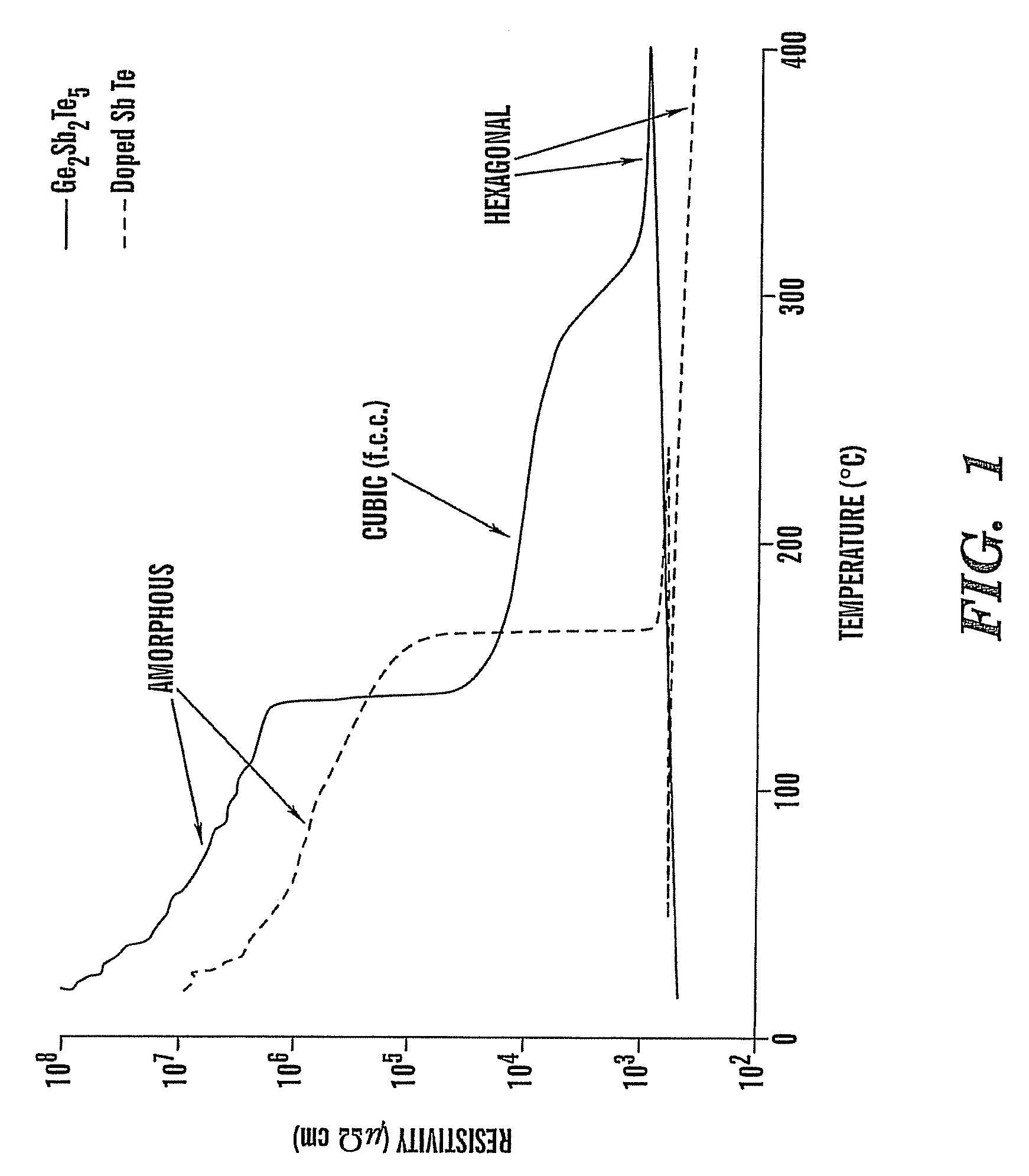

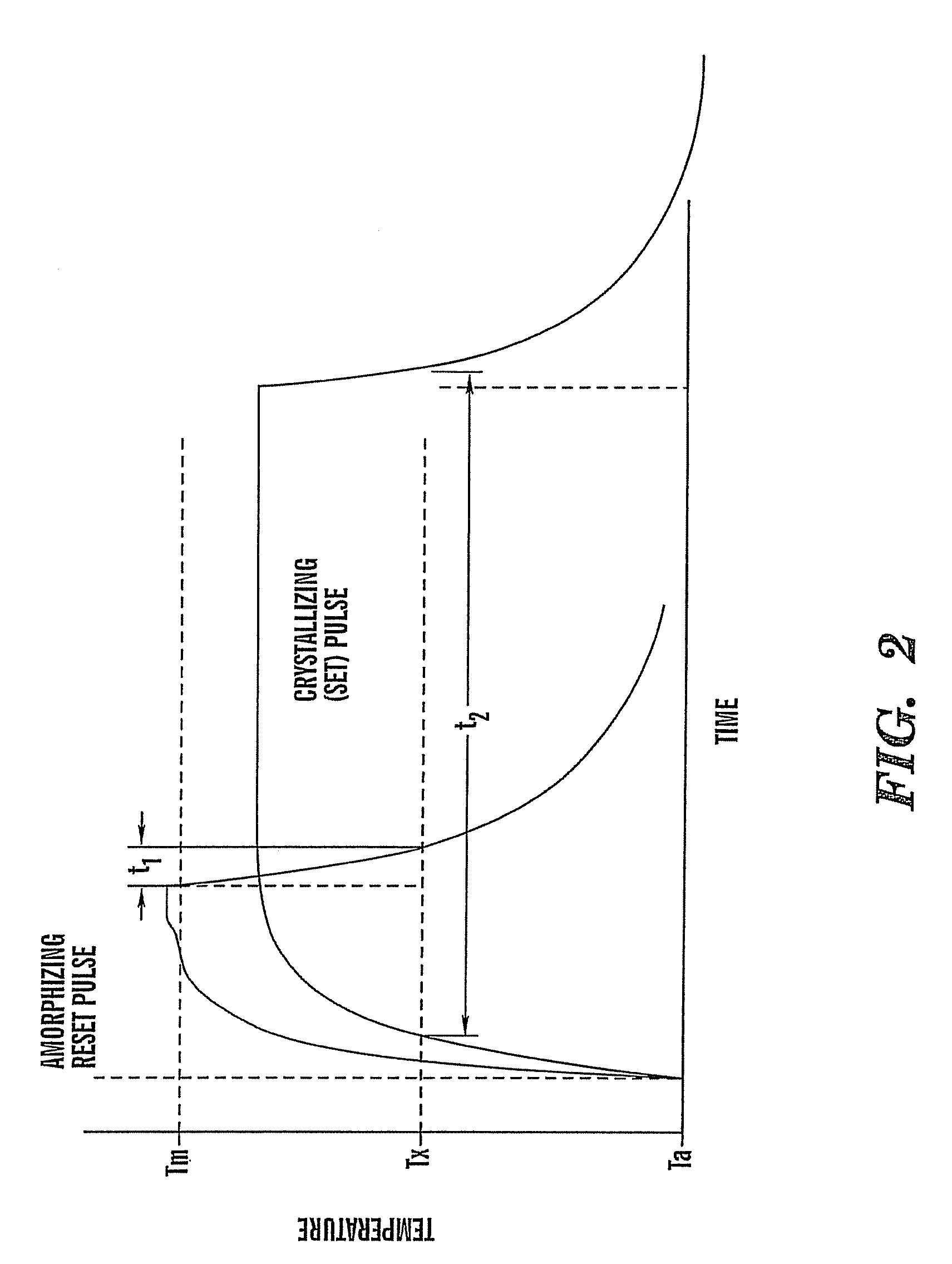

Heat-shielded low power PCM-based reprogrammable EFUSE device

ActiveUS7394089B2Semiconductor/solid-state device detailsSolid-state devicesPhase-change materialHeat shield

An electrically re-programmable fuse (eFUSE) device for use in integrated circuit devices includes an elongated heater element, an electrically insulating liner surrounding an outer surface of the elongated heater element, corresponding to a longitudinal axis thereof, leaving opposing ends of the elongated heater element in electrical contact with first and second heater electrodes. A phase change material (PCM) surrounds a portion of an outer surface of the electrically insulating liner, a thermally and electrically insulating layer surrounds an outer surface of the PCM, with first and second fuse electrodes in electrical contact with opposing ends of the PCM. The PCM is encapsulated within the electrically insulating liner, the thermally and electrically insulating layer, and the first and second fuse electrodes.

Owner:GLOBALFOUNDRIES US INC

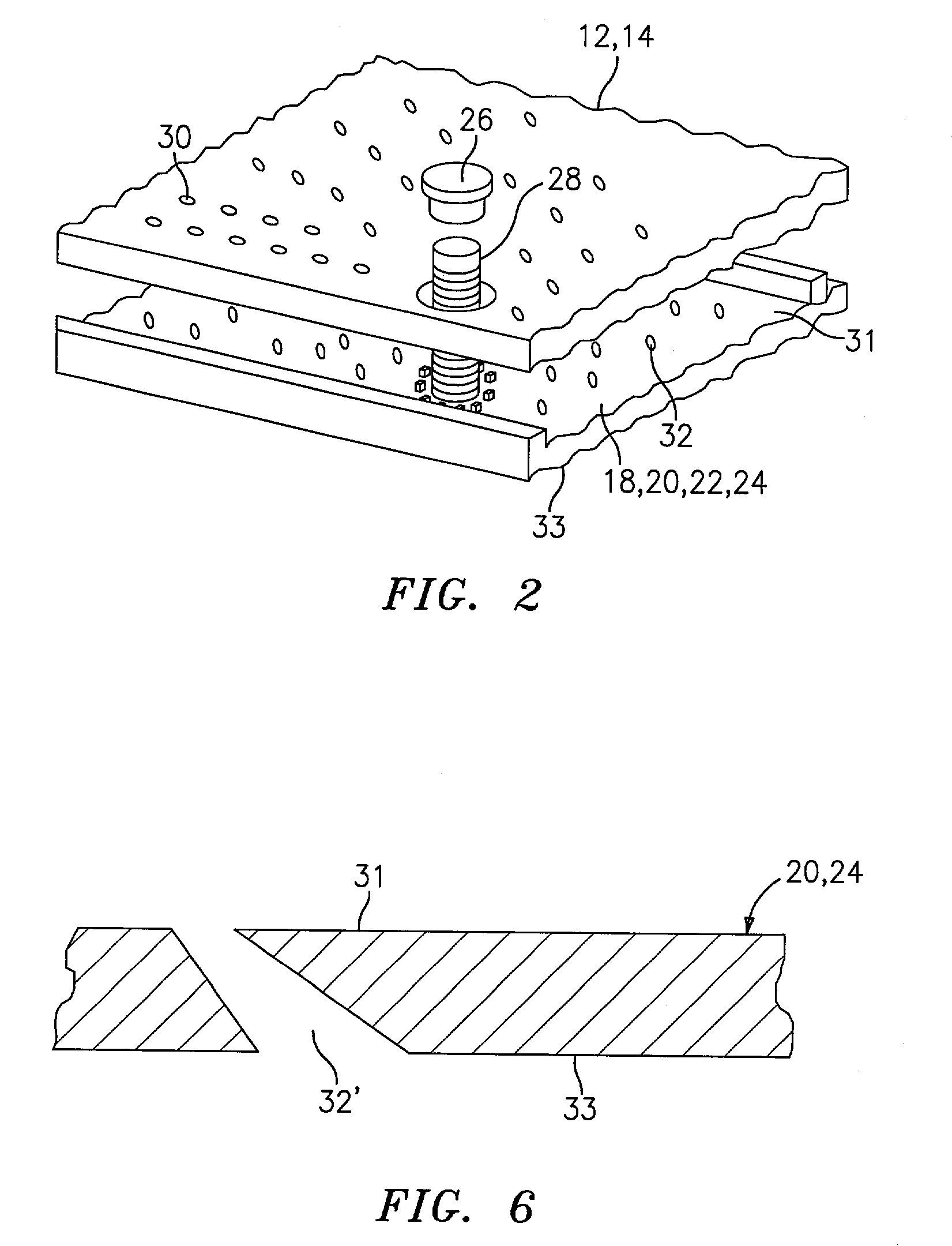

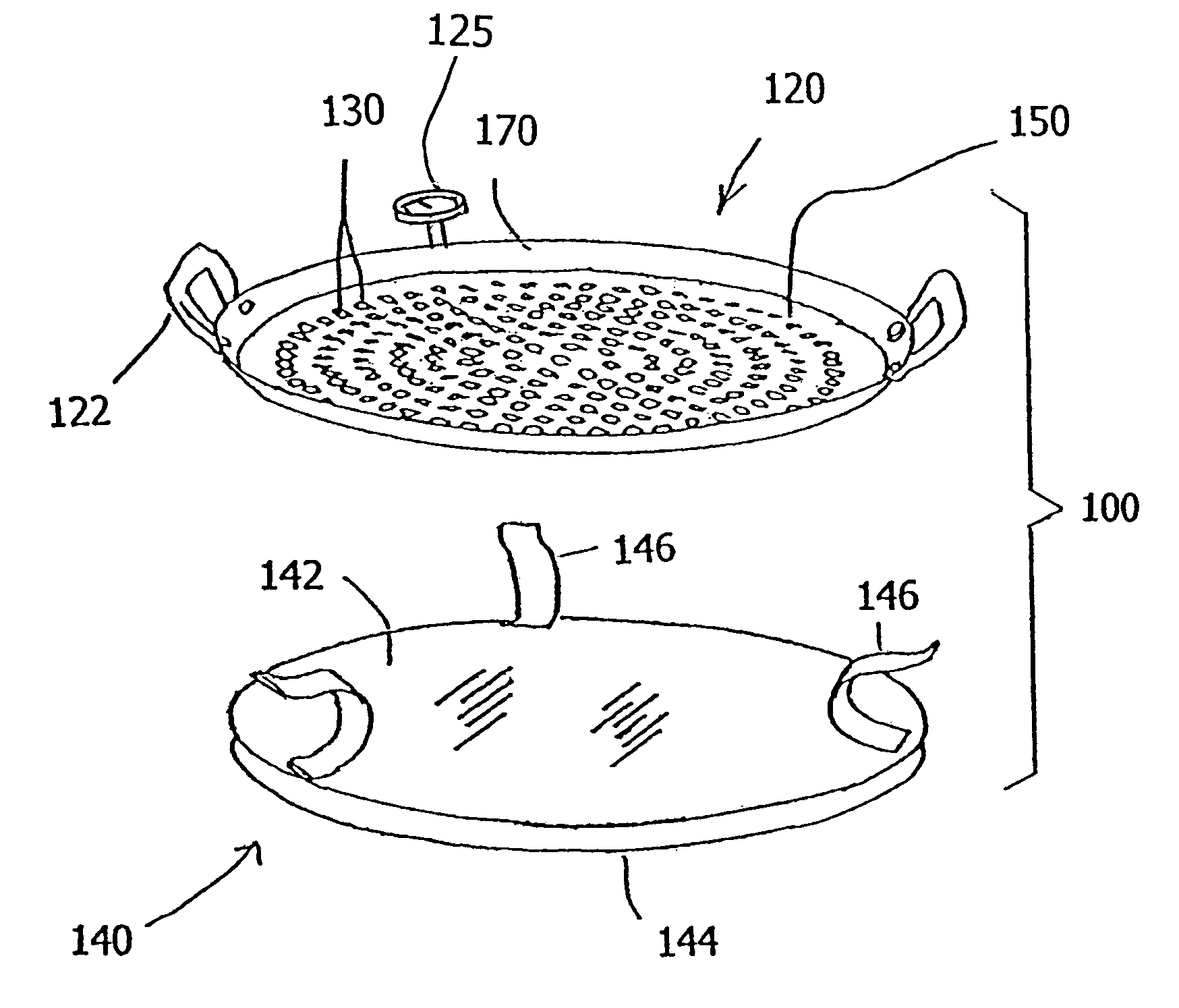

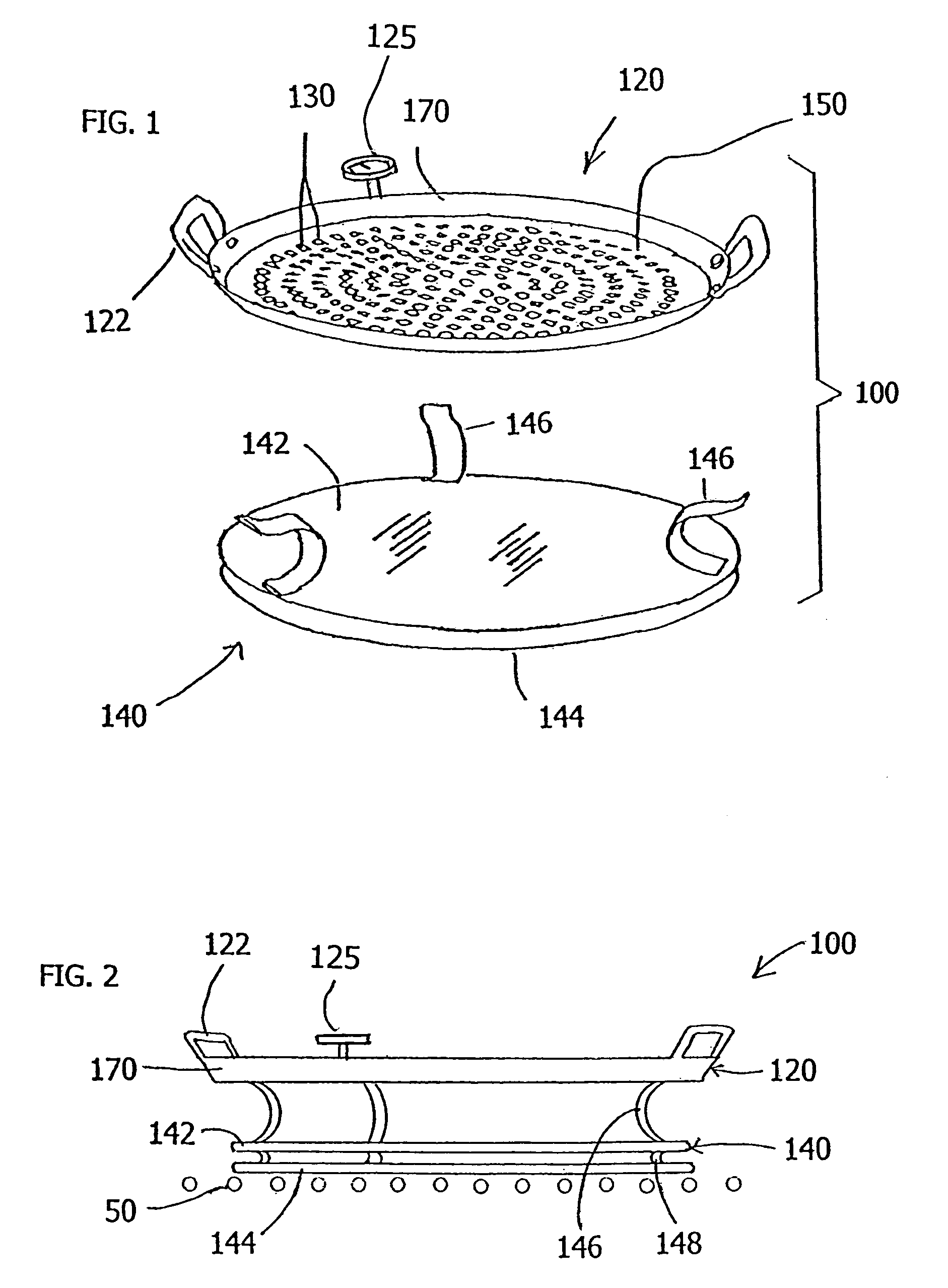

Kit, apparatus and method for use in cooking over an intense heat source

InactiveUS7219663B2Firm supportModerates being transferredDomestic stoves or rangesLiquid heating fuelEngineeringHeat shield

A portable cooking kit, apparatus and method is usable for moderating heat from an intense heat source, such as an outdoor grill or 1. The apparatus includes a food support member, including a perforated panel surrounded by a rim. The food support member rests on top of a heat shield made from a heat-tolerant material. During use, the heat shield is stably suspended over direct, intense heat from a heat source. The food to be cooked is placed on the food support member, and the food support member may then be placed on top of the heat shield. By buffering the direct heat from the heat source, the heat shield allows food placed on the food support member to cook, but protects the underside of the food from becoming scorched. Optionally, a dome-shaped cover may be used to cover both the food support member and the heat shield.

Owner:ISLANDER INNOVATIONS

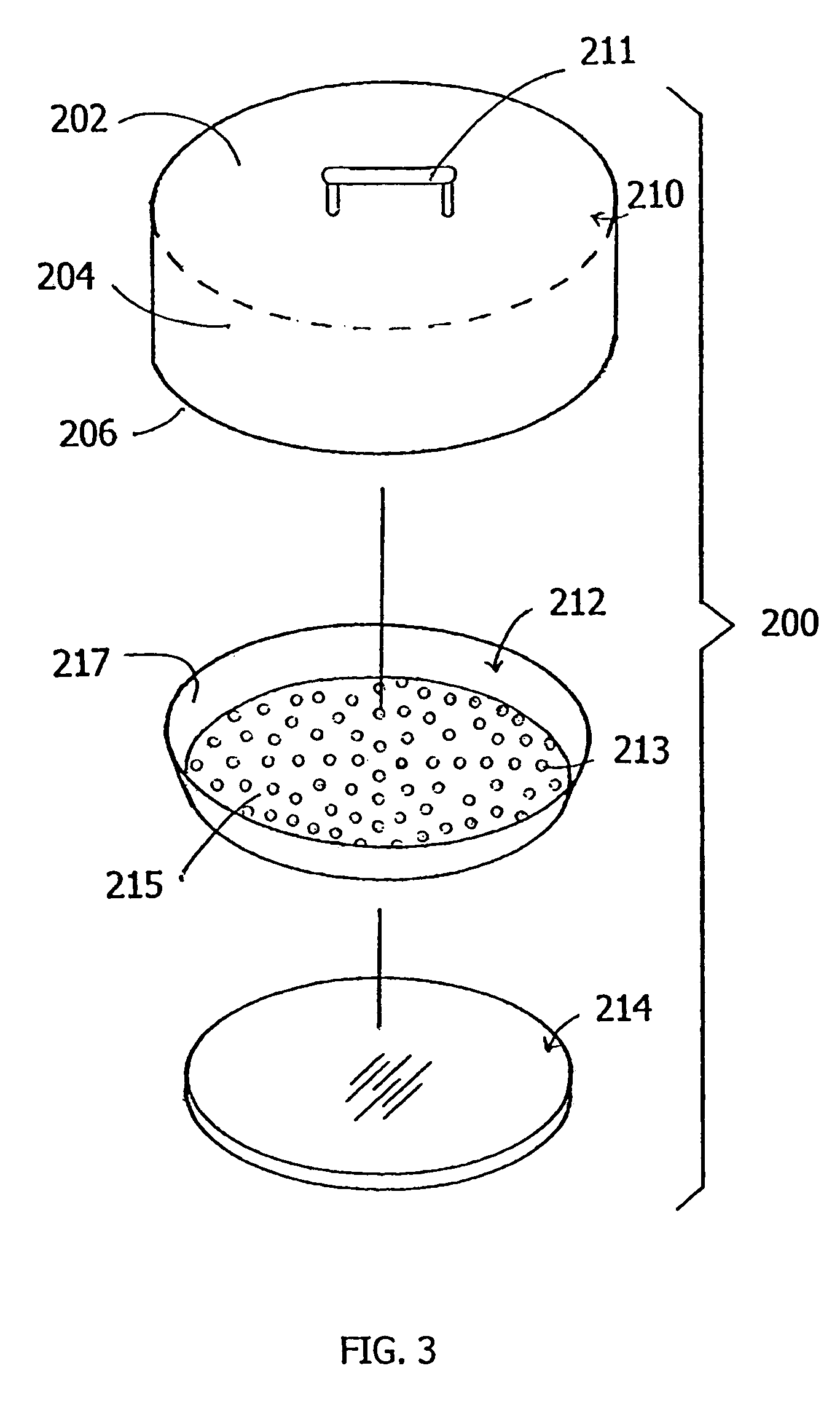

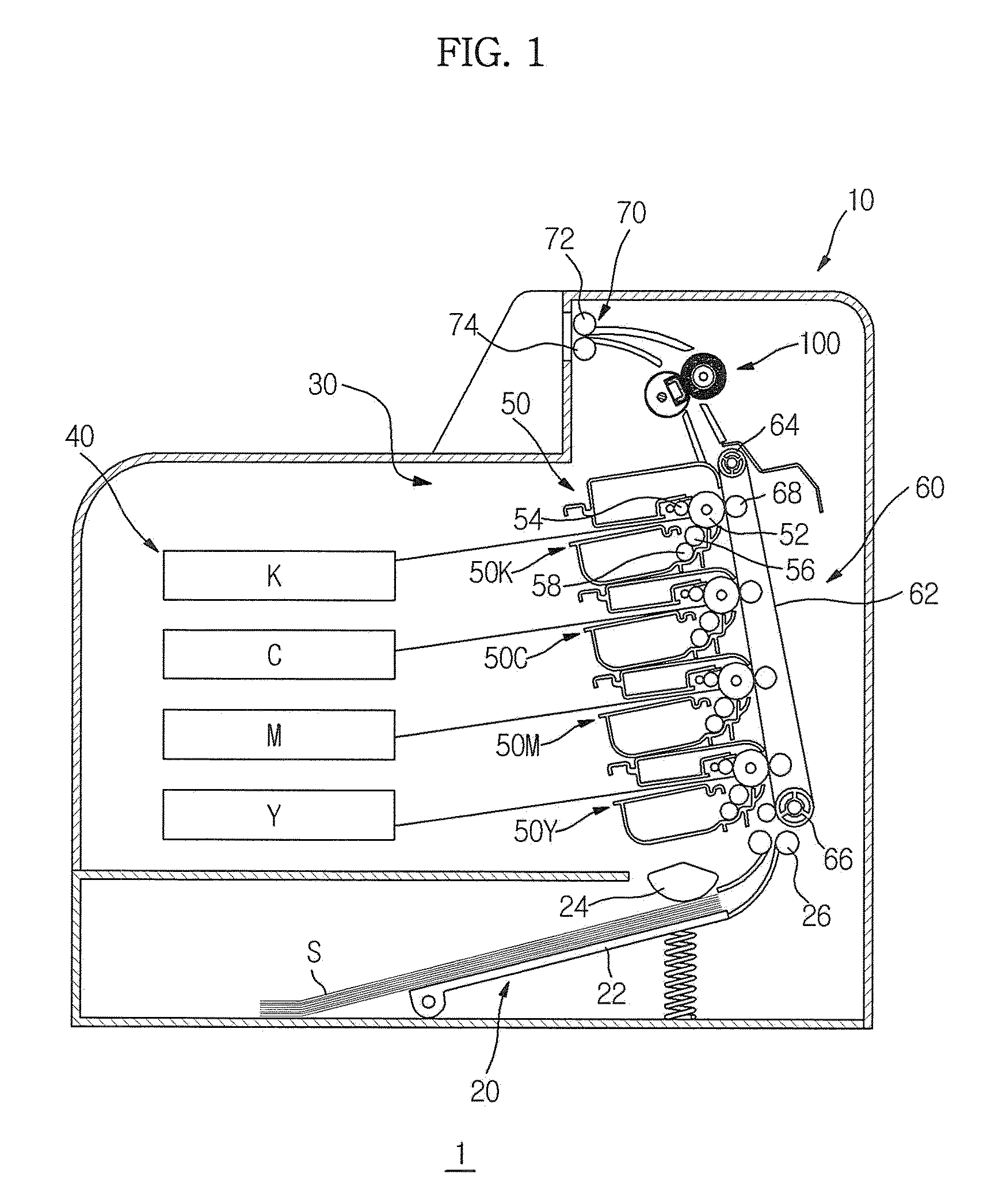

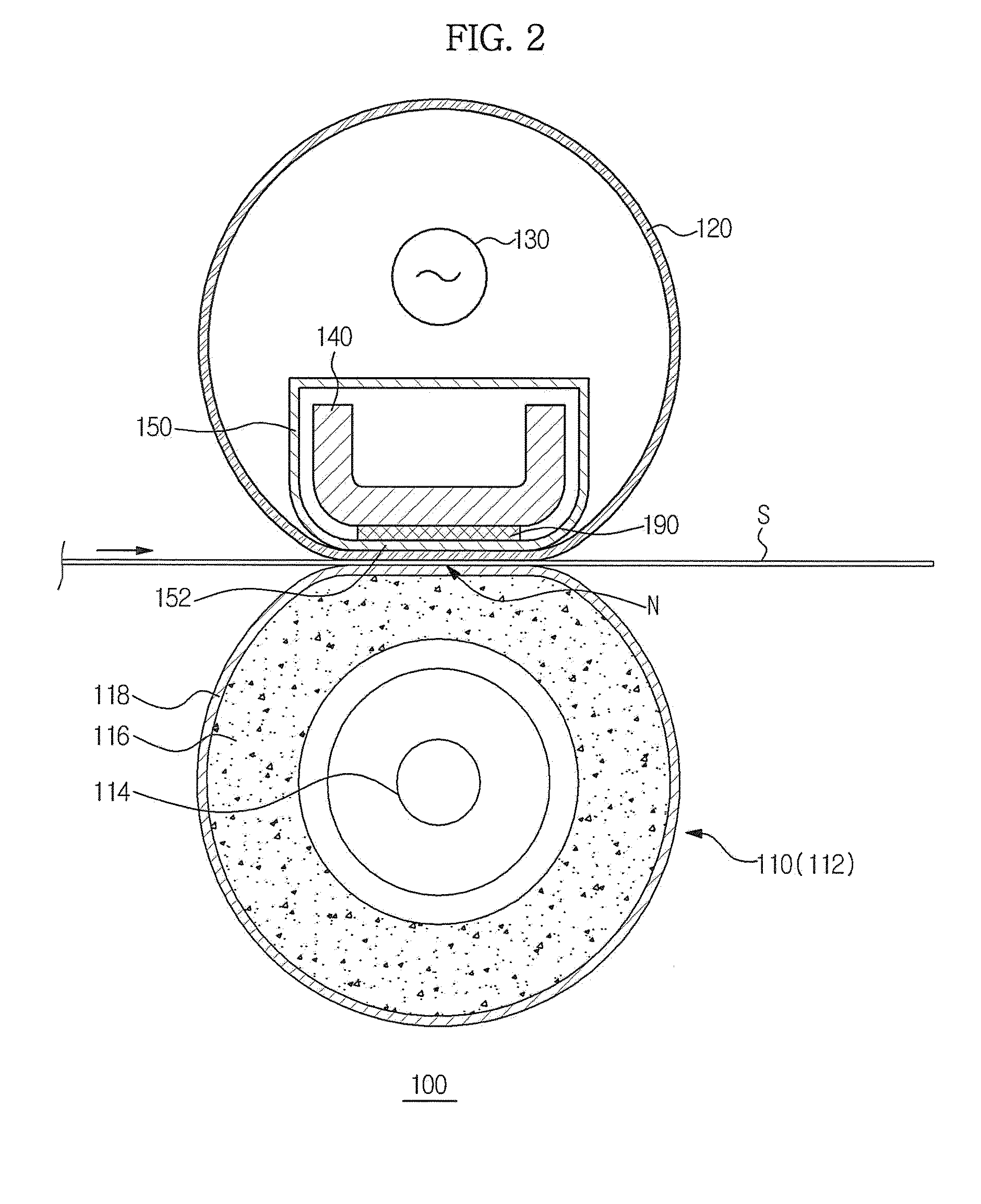

Fusing device and image forming apparatus having the same

Disclosed are a fusing device with improved temperature increase and fusing performance characteristics and an image forming apparatus having the same. The fusing device can include a heater to generate heat, a fusing belt arranged around the heater, a rotating member, a press member and a heat shield unit. The rotating member may be configured to come into contact with an outer periphery of the fusing belt. The press member may be configured to be press a portion of the fusing belt toward the rotating member to define a fusing nip between the fusing belt and the rotating member. The heat shield unit configured to surround the press member to reduce the amount of heat delivered to the press member.

Owner:HEWLETT PACKARD DEV CO LP

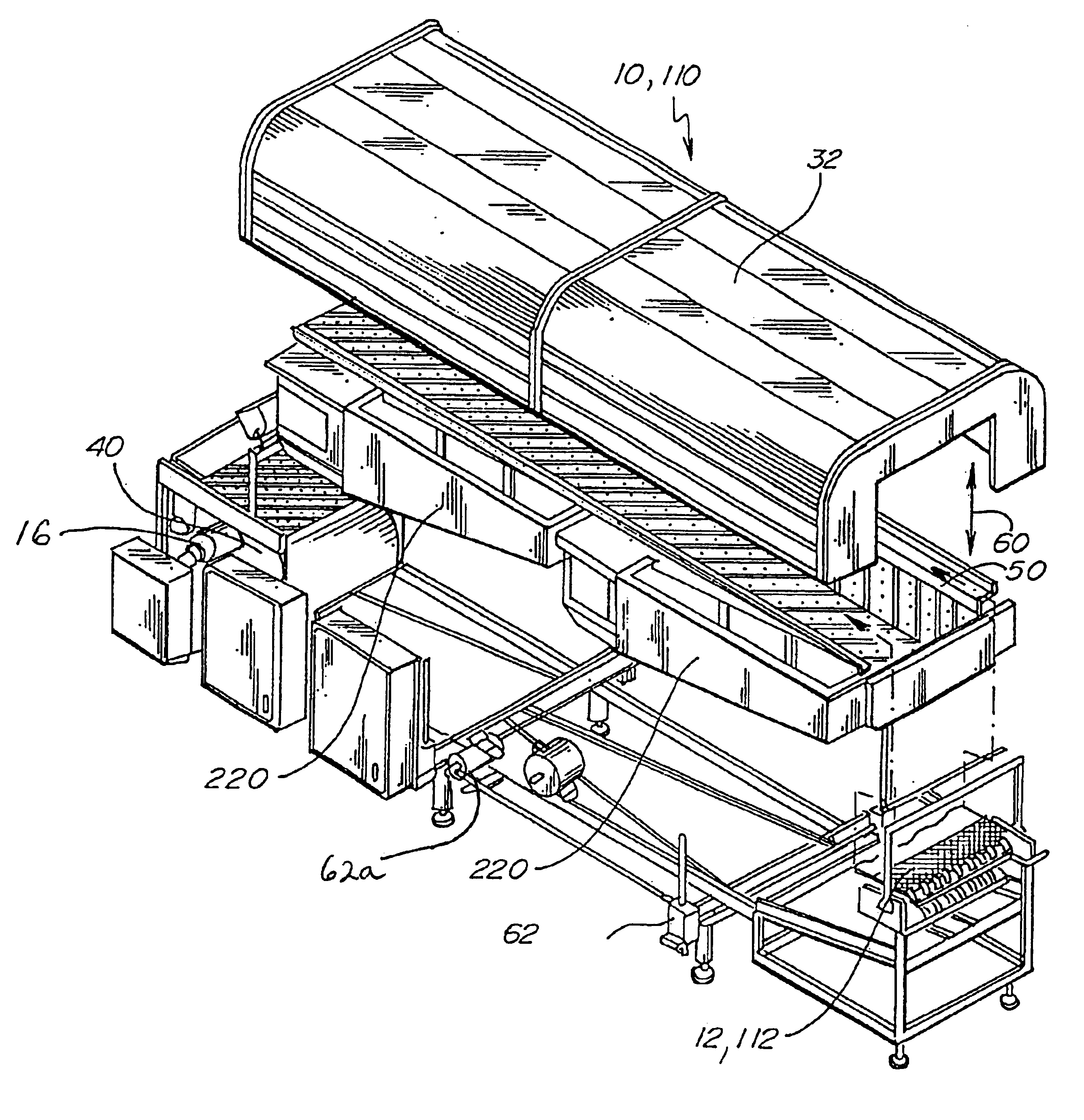

Heat tunnel for film shrinking

InactiveUS7155876B2Minimal distortionMinimum of wrinkles.Wrappers shrinkageFurnace componentsProcess engineeringShrink wrap

Owner:DOUGLAS MACHINE LIABILITY

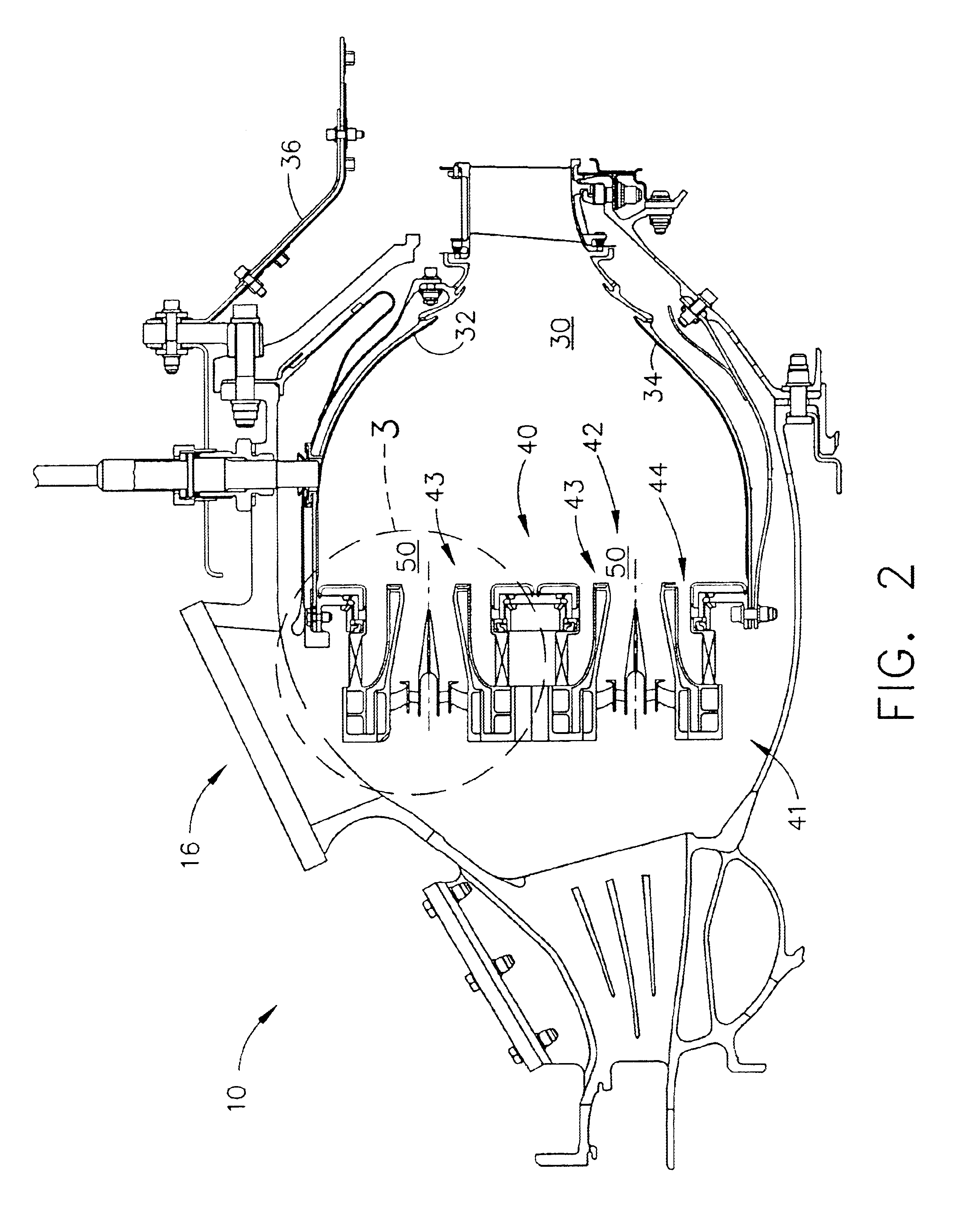

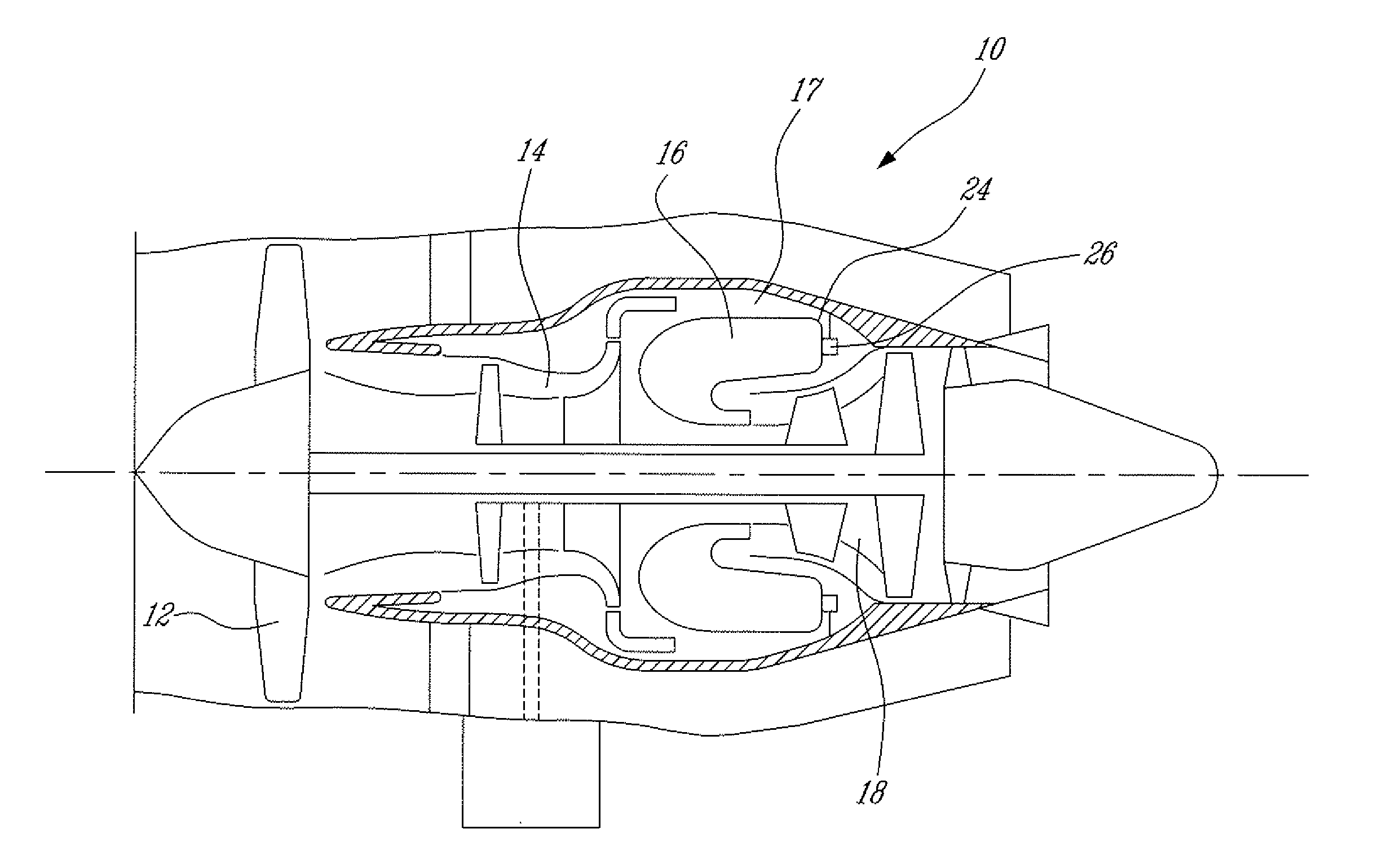

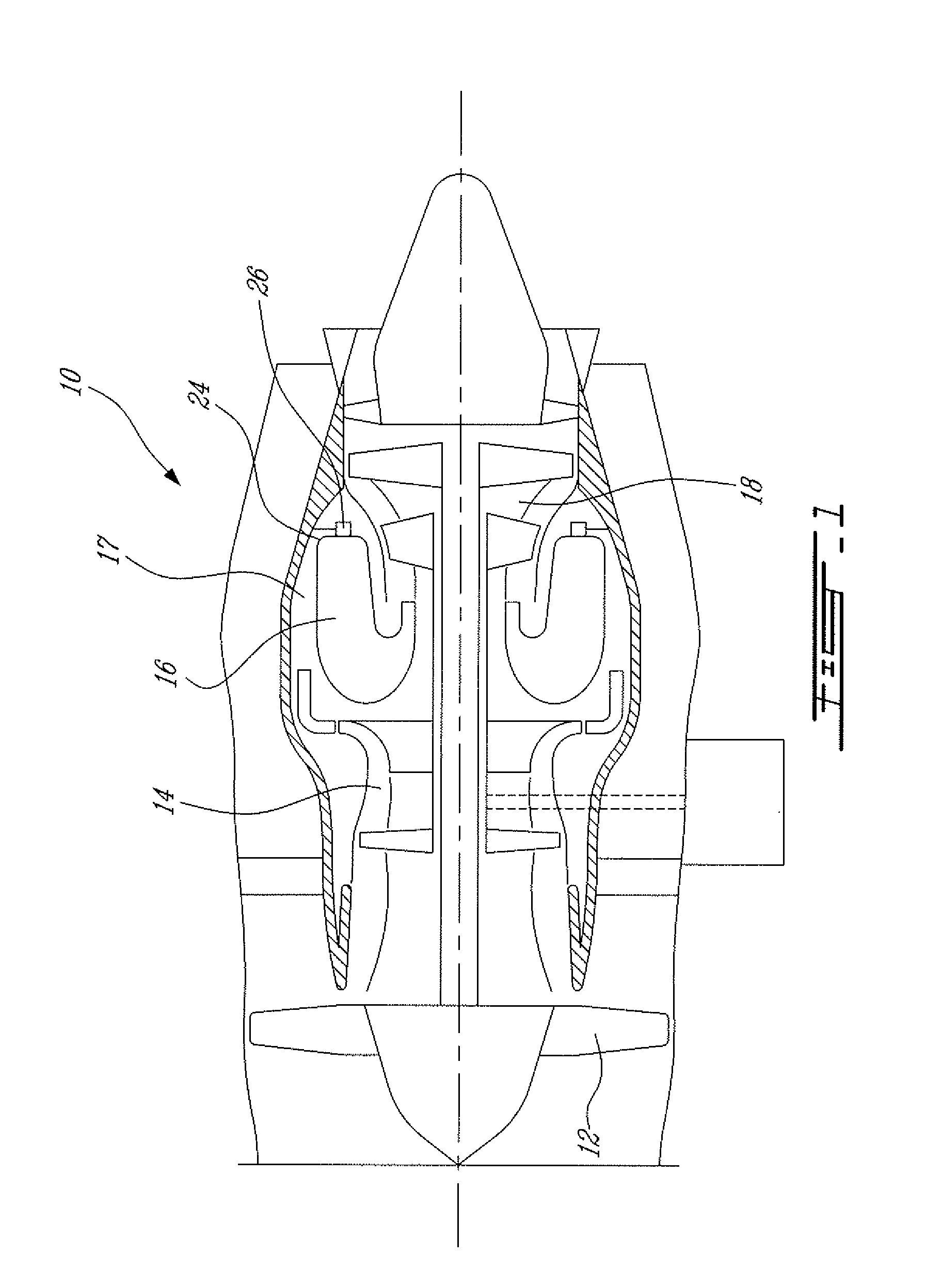

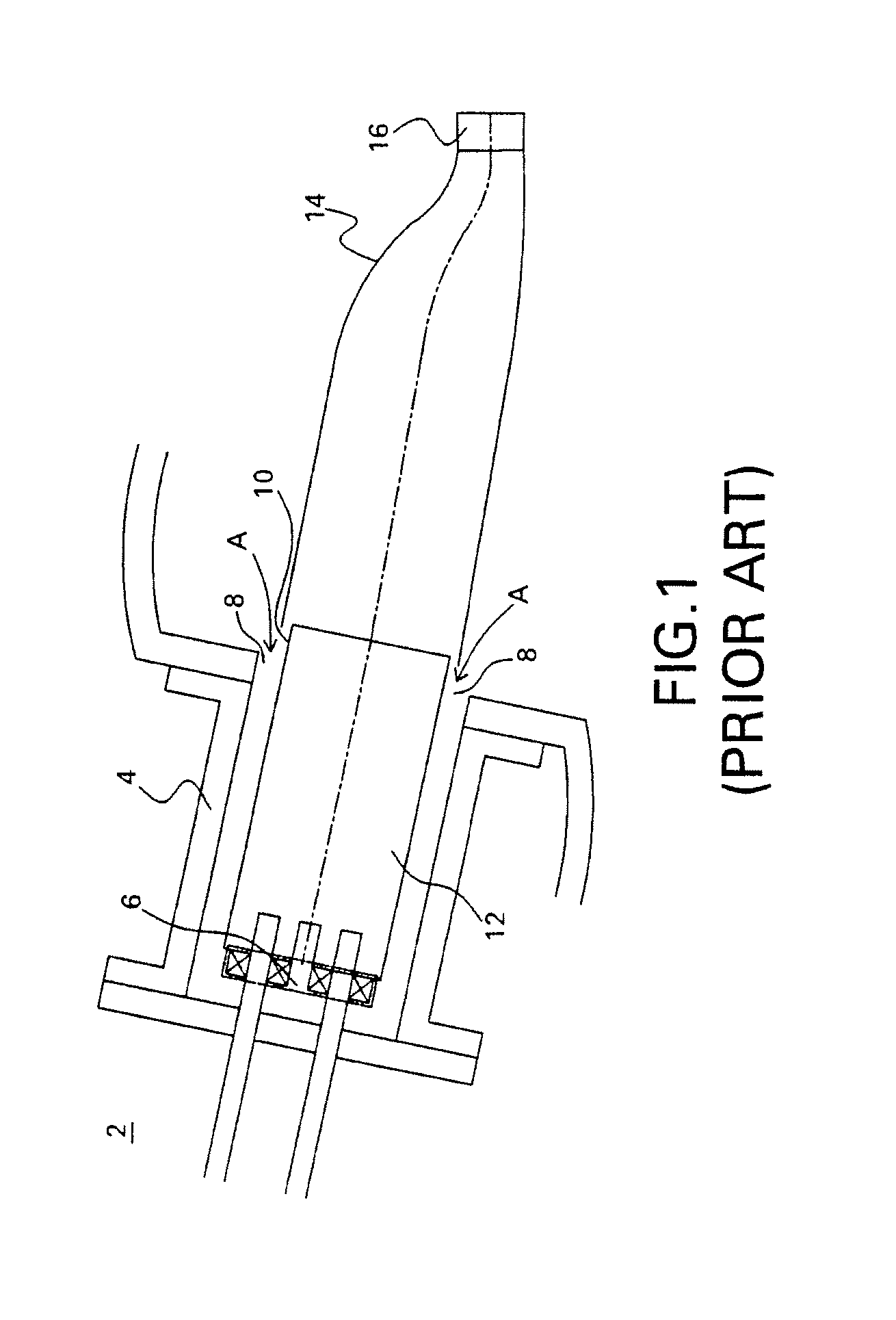

Method and apparatus to decrease gas turbine engine combustor emissions

InactiveUS6871501B2Turbine/propulsion fuel supply systemsContinuous combustion chamberCombustorTurbine

A method enables a gas turbine engine including a combustor to be operated. The combustor includes a mixer assembly including an air swirler, a premixer, a dome plate, and a heat shield. The method comprises discharging fluids from the air swirler into the premixer, and directing cooling fluids through a cooling opening defined in at least one of the swirler and the dome plate towards an upstream side of the heat shield for impingement cooling of the heat shield.

Owner:GENERAL ELECTRIC CO

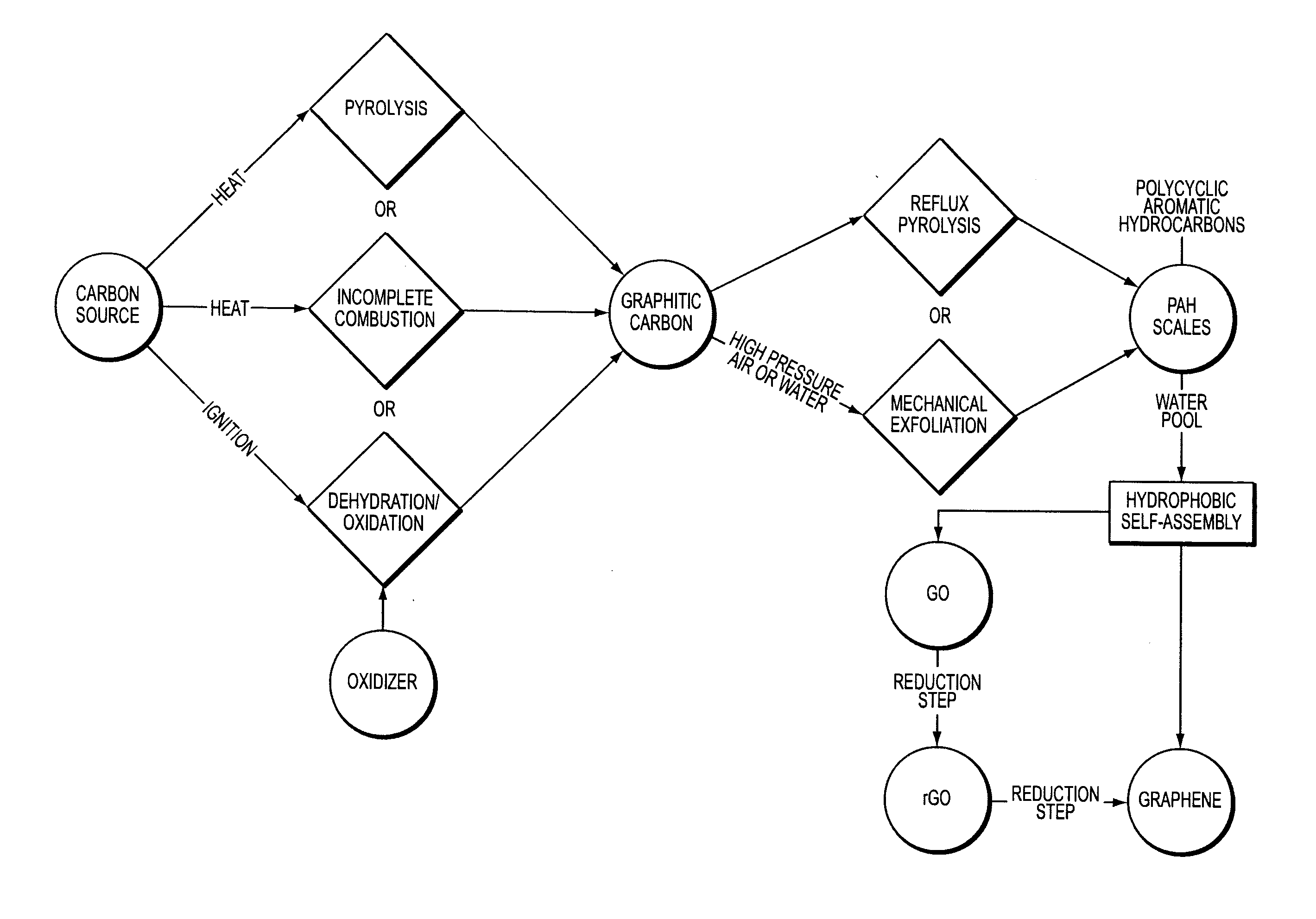

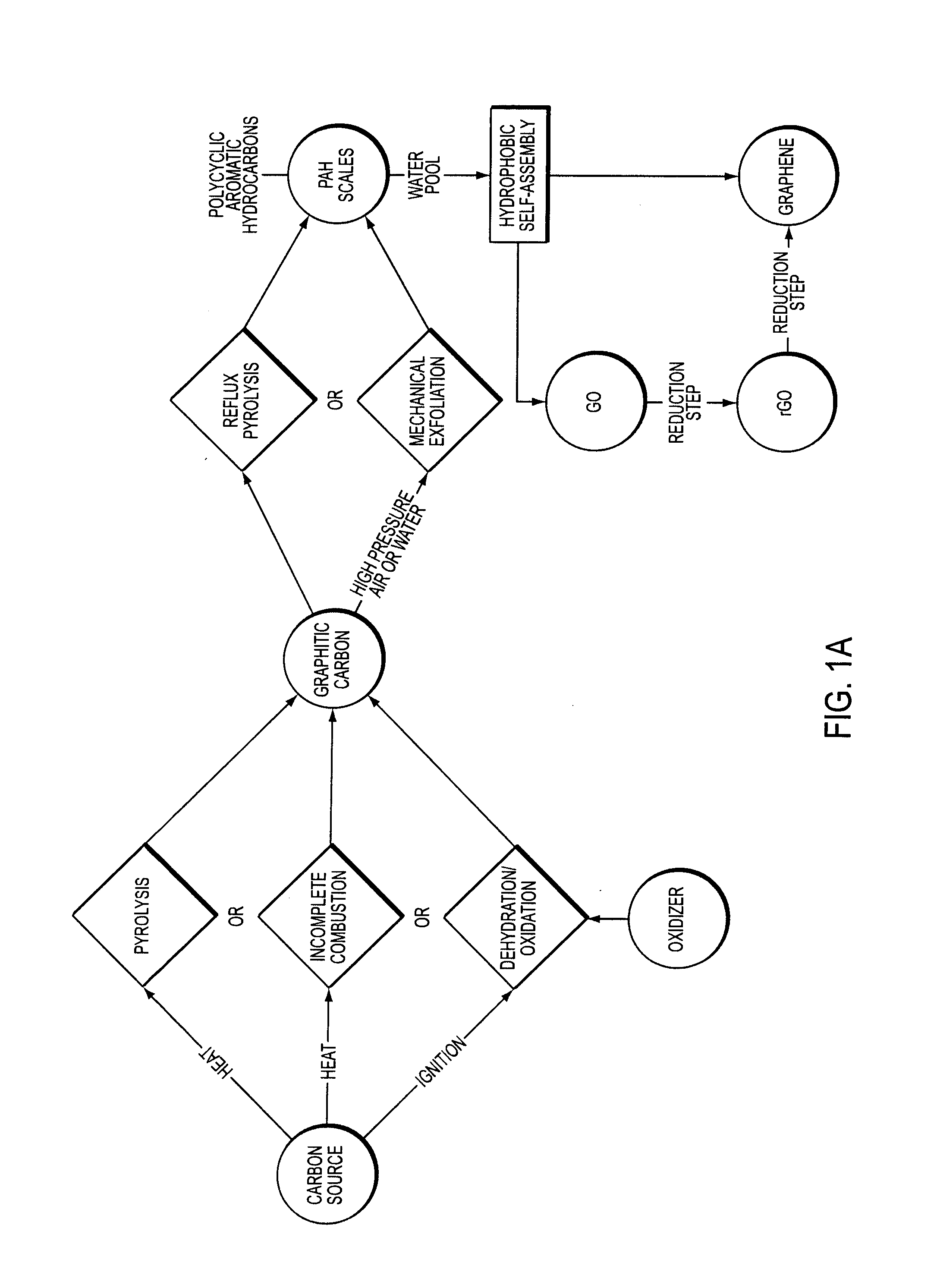

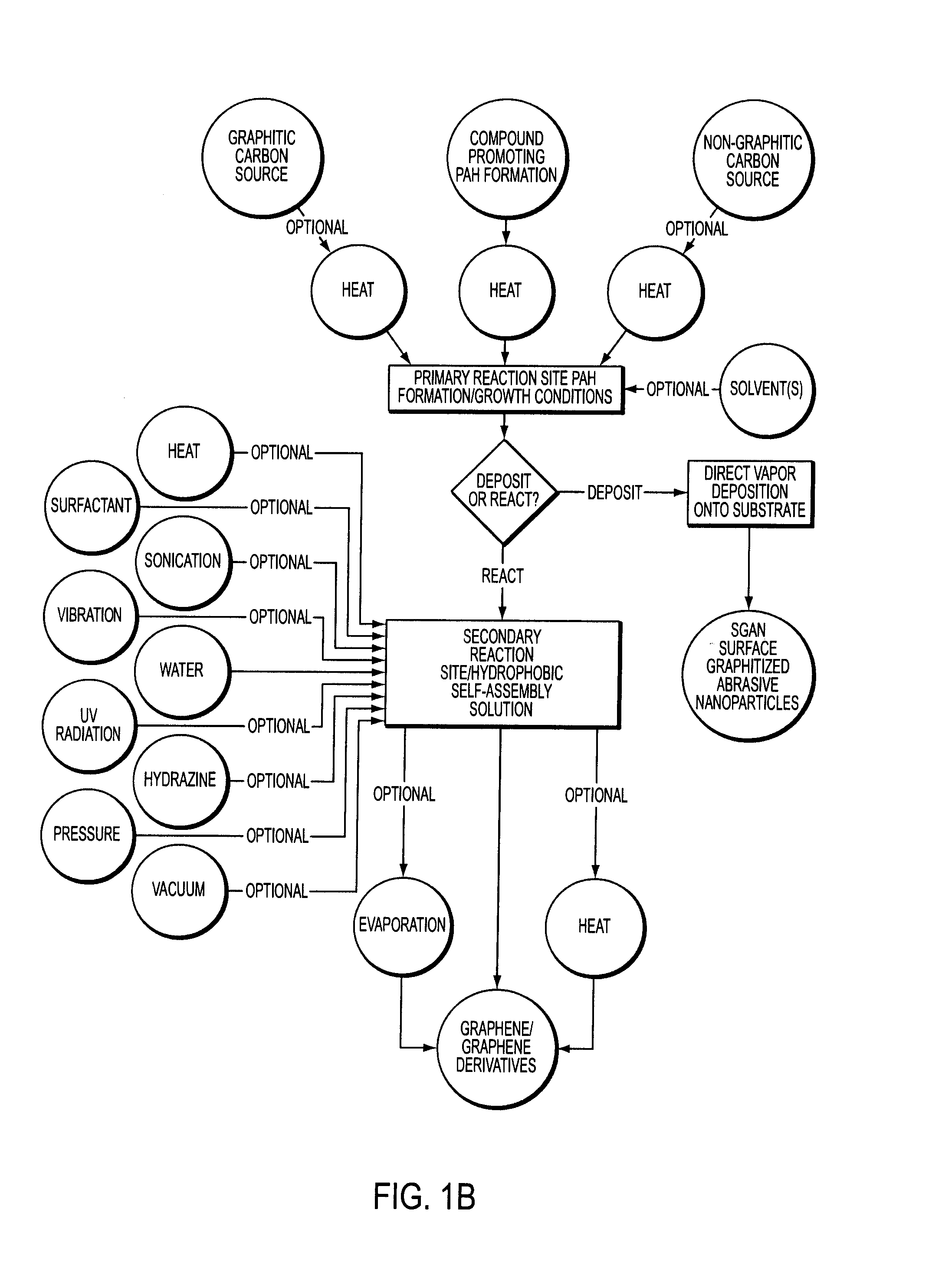

Facile synthesis of graphene, graphene derivatives and abrasive nanoparticles and their various uses, including as tribologically-beneficial lubricant additives

ActiveUS20140134092A1Reduce frictionImprove smoothnessMaterial nanotechnologyCosmetic preparationsNanoparticleGraphene derivatives

Owner:PEERLESS WORLDWIDE

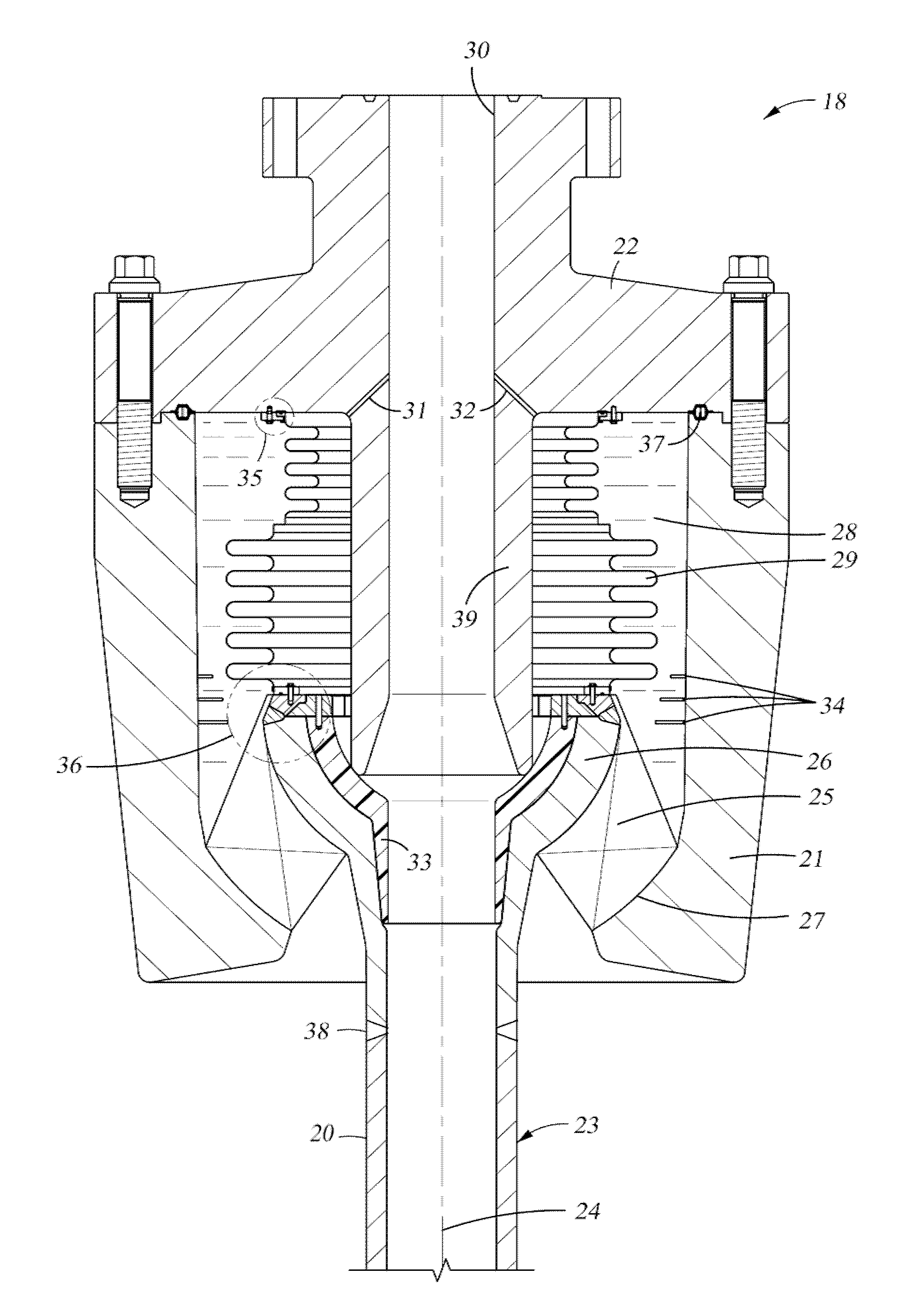

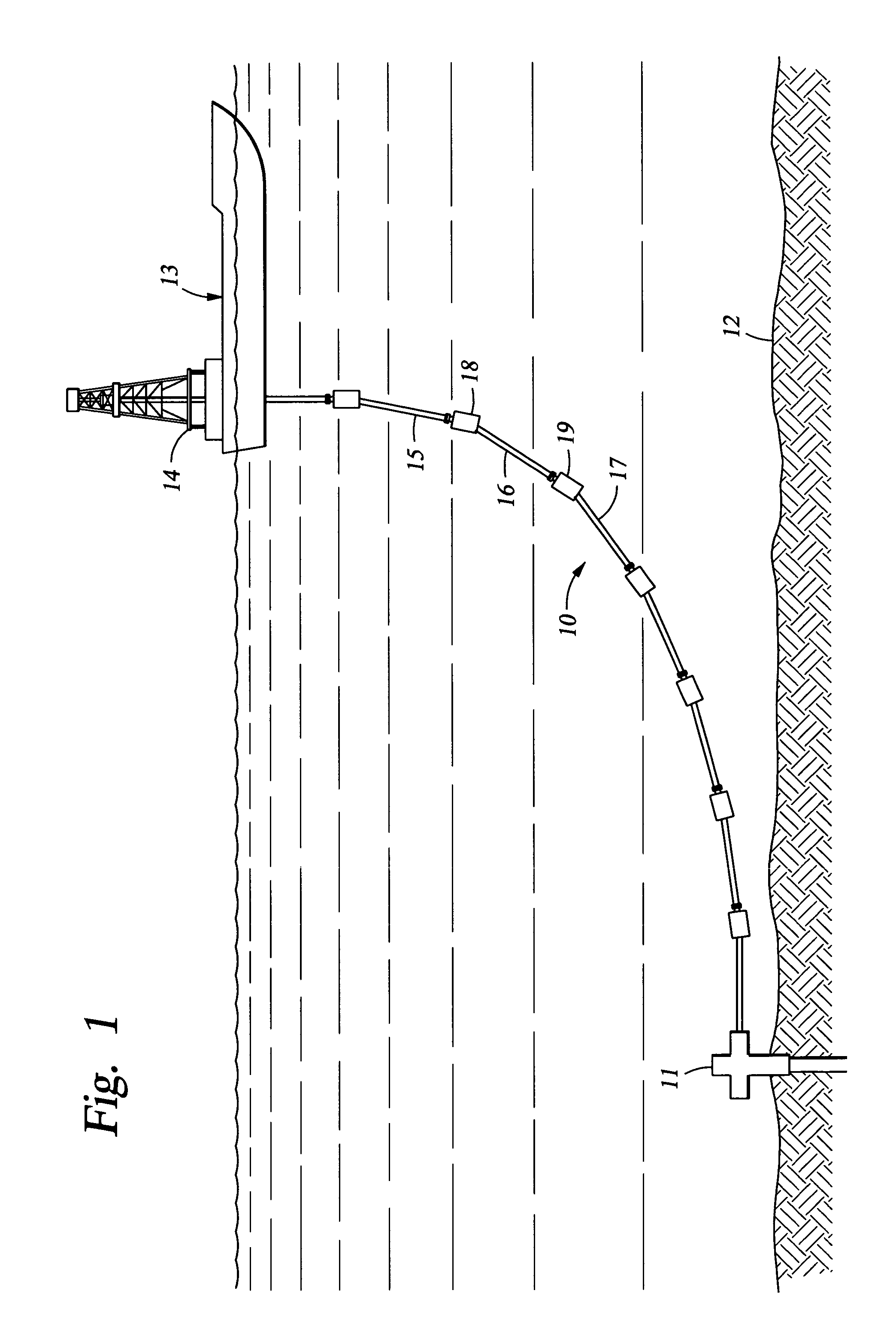

High temperature flexible pipe joint

For continuous high temperature operation over a service life in excess of twenty years, a flexible pipe joint includes various features that tend to reduce the temperature of the load-bearing flex element or reduce strain in the warmer elastomeric layers of the flex element. These features include a heat shield of low heat conductivity material integrated into the inner profile of the pipe extension and interposed between the central bore of the pipe joint and the flex element, low heat conductivity metal alloy components between the hot production fluid and the flex element, high temperature resistant elastomer at least in the warmest inner elastomer layer of the flex element, and a flex element constructed to shift strain from the warmer inner elastomer layers to the colder outer elastomer layers by providing greater shear area, different layer thickness, and / or higher elastic modulus elastomer for the warmer inner elastomer layers.

Owner:WELLS FARGO BANK NAT ASSOC +1

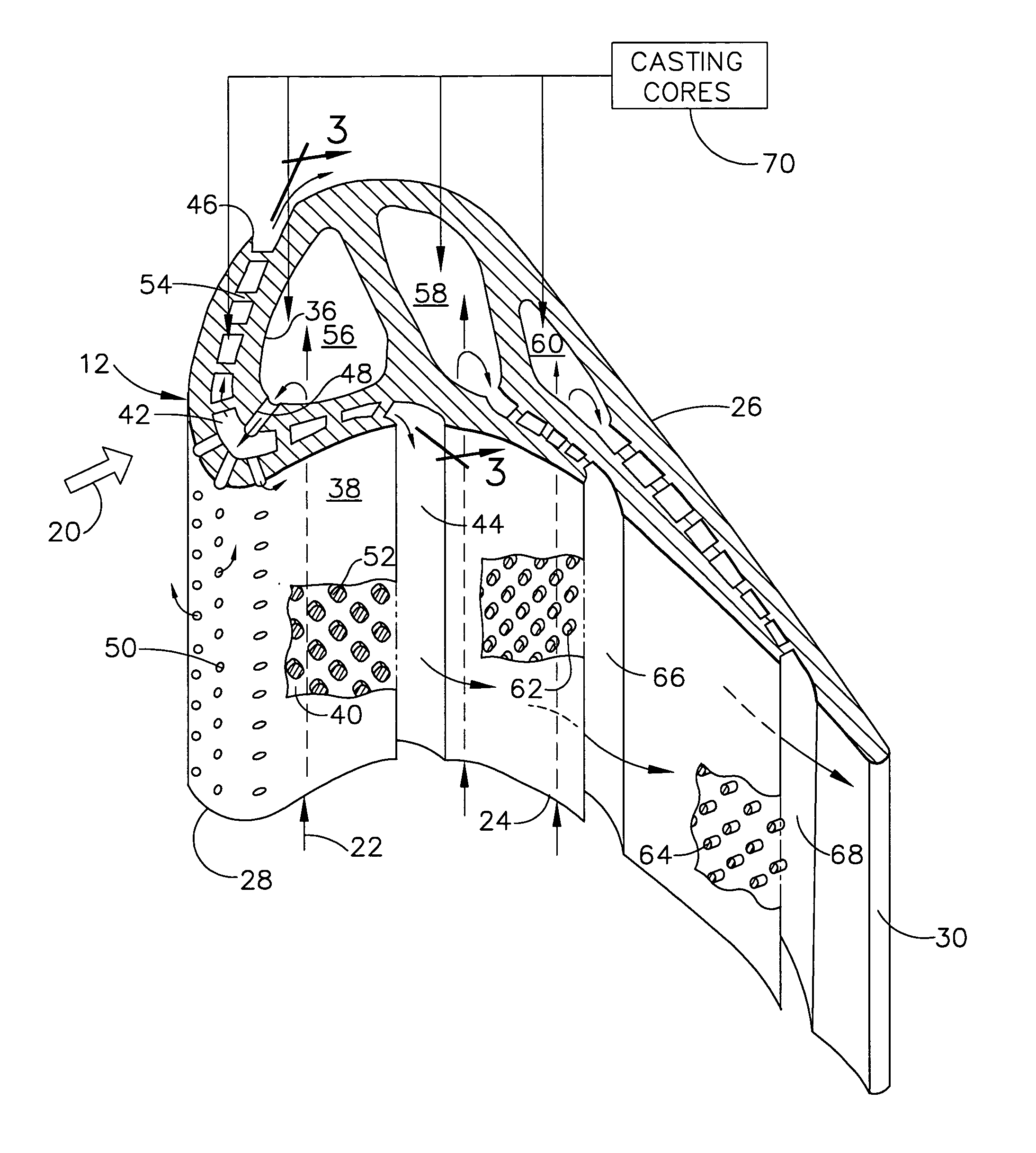

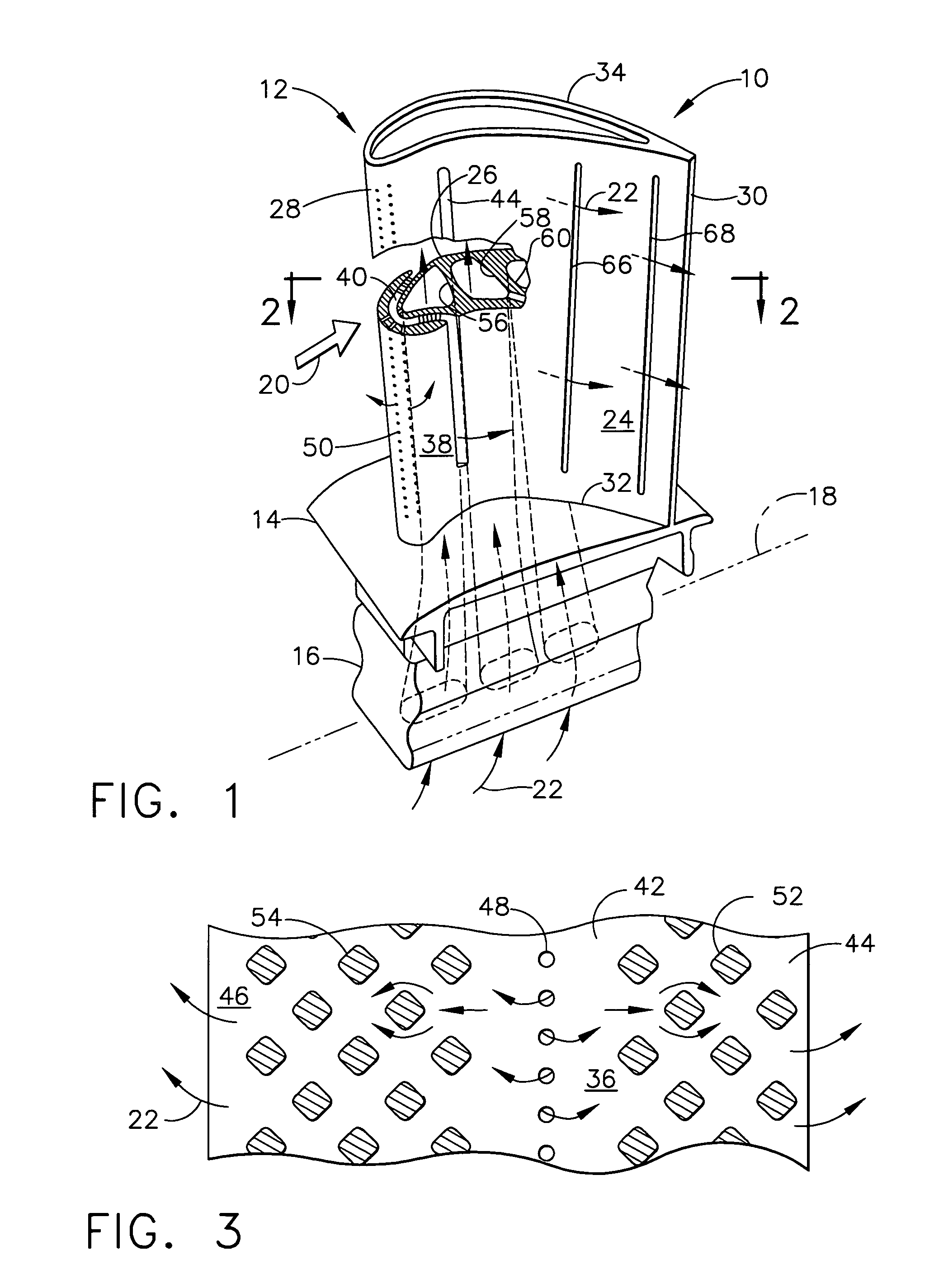

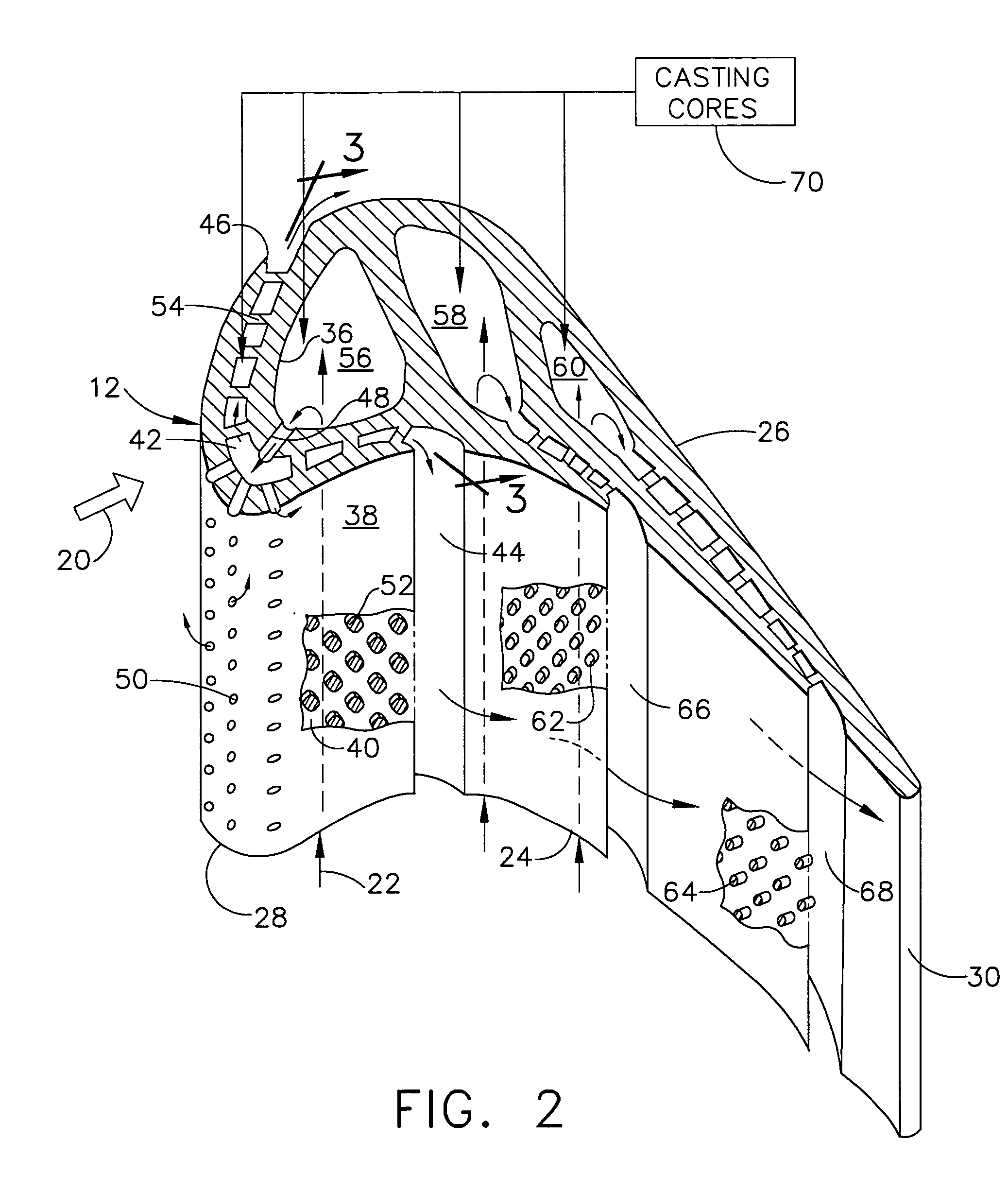

Thermal shield turbine airfoil

Owner:GENERAL ELECTRIC CO

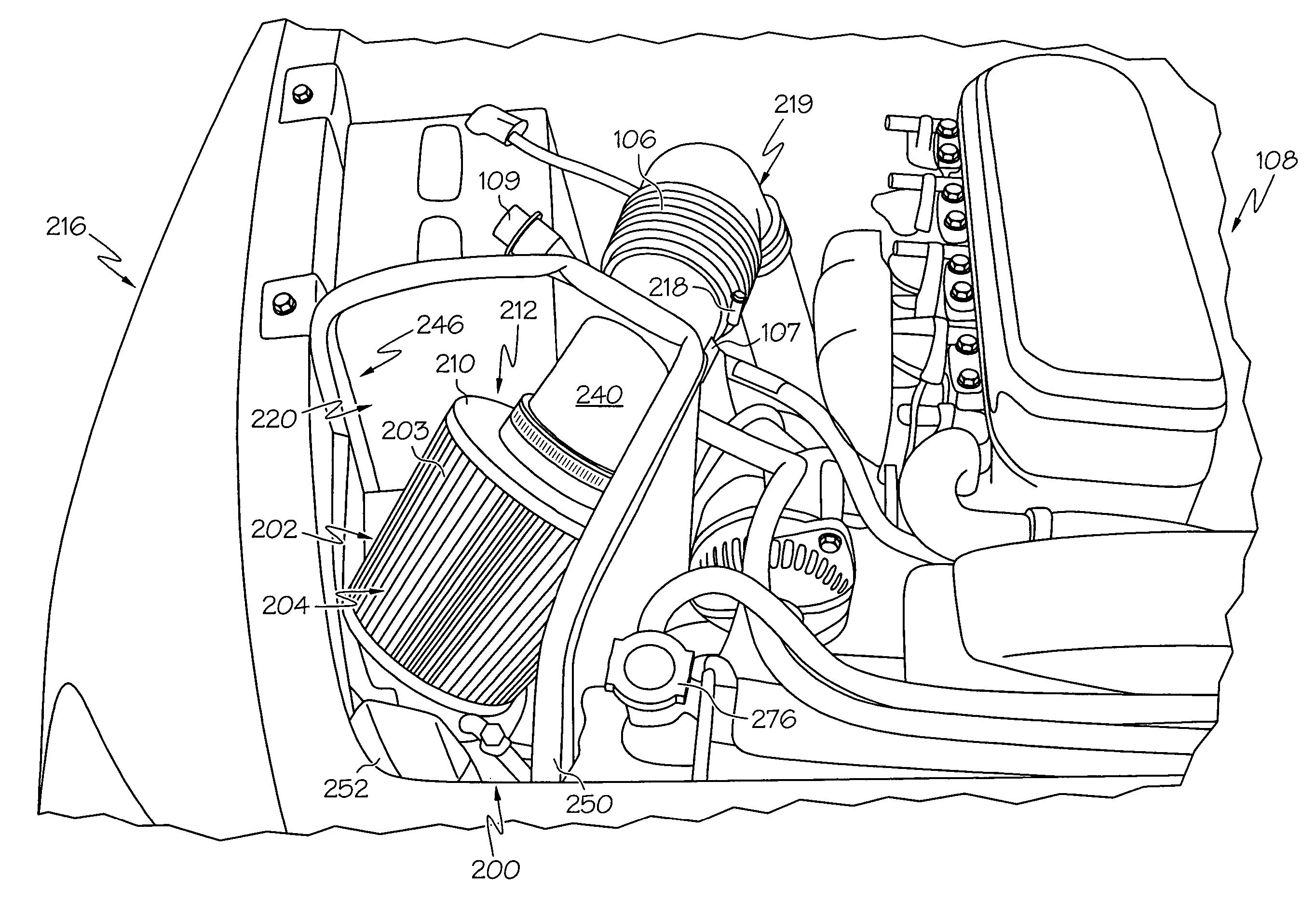

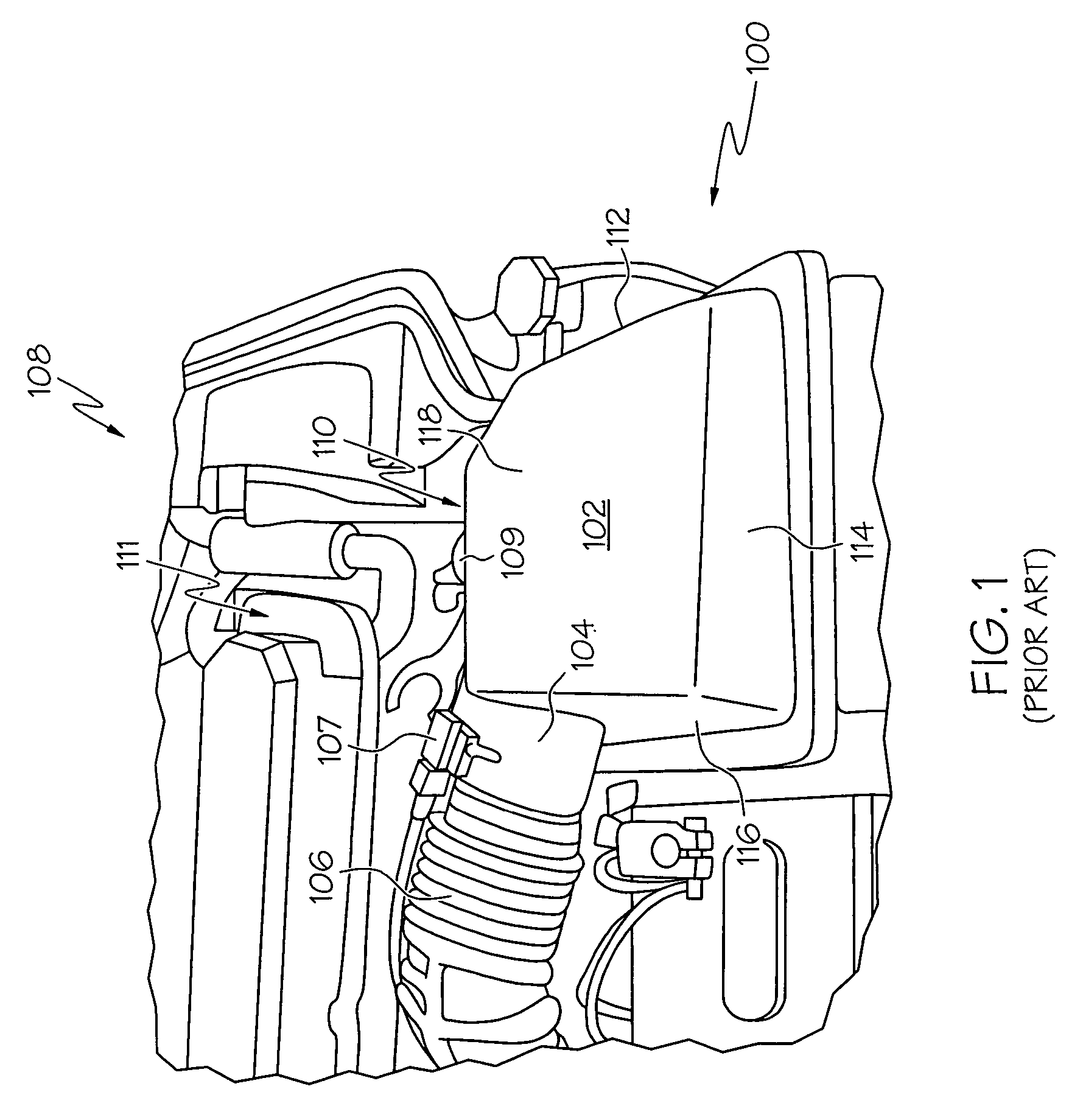

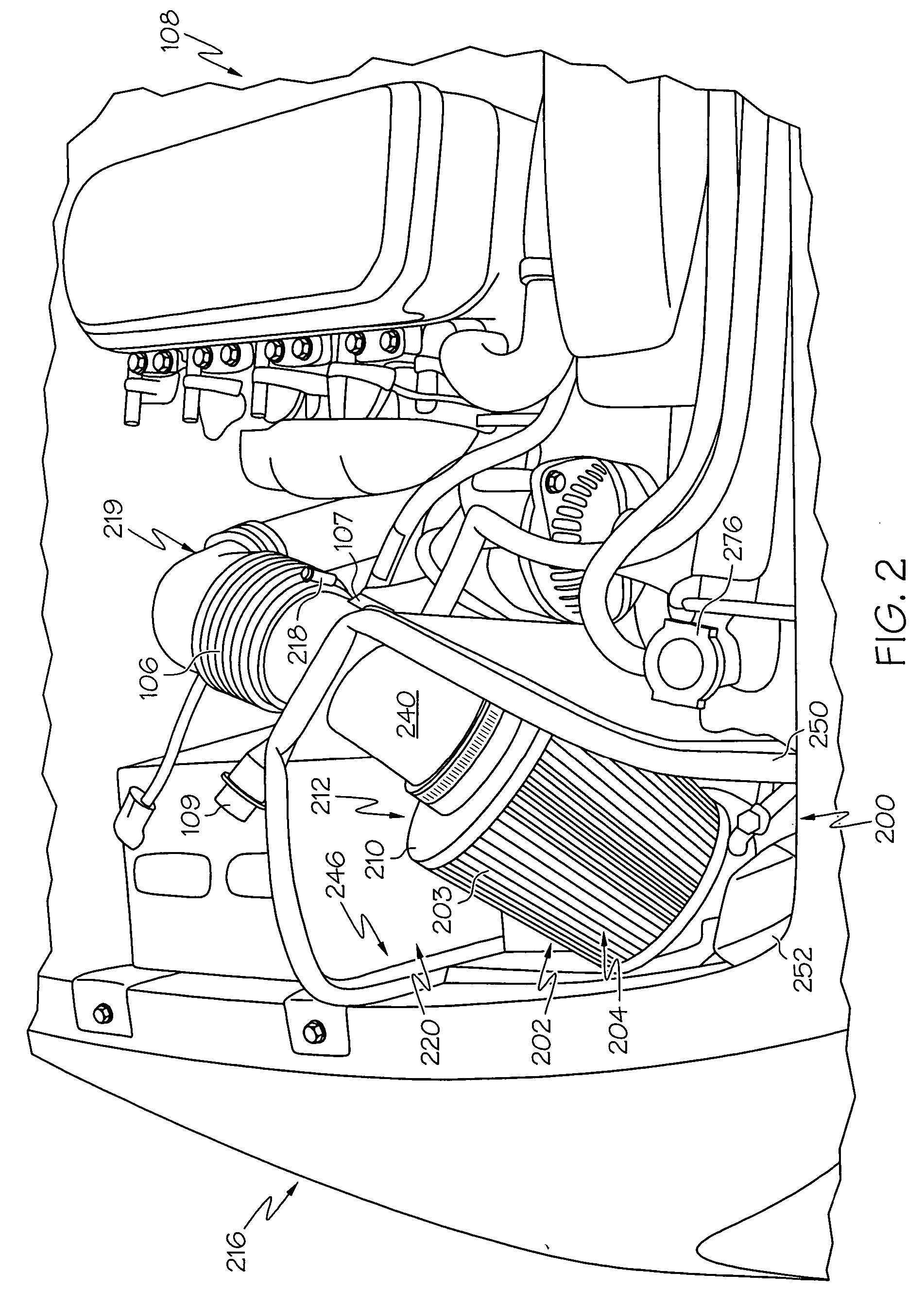

Heat shielded air intake system

InactiveUS20050217625A1Non-fuel substance addition to fuelMachines/enginesThermal isolationAir filtration

An air filter system includes a housing having, for example, a rear panel and a side panel, each having a top edge formed to interface to the hood of a vehicle so that the housing incorporates the vehicle hood to provide thermal isolation of intake air from engine compartment heat. The air filter system connects to a stock air intake tract through an air intake tube. The housing has a diagonal panel that the air intake tube is attached to and passes through. The diagonal panel is disposed at an angle that provides positioning of the air intake tube so that an effluent end of the air intake tube matches the stock location of the stock air intake tract. A washable, reusable air filter supported by the air intake tube filters the intake air and passes it through the air intake tube into the stock air intake tract.

Owner:ADVANCED FLOW ENG

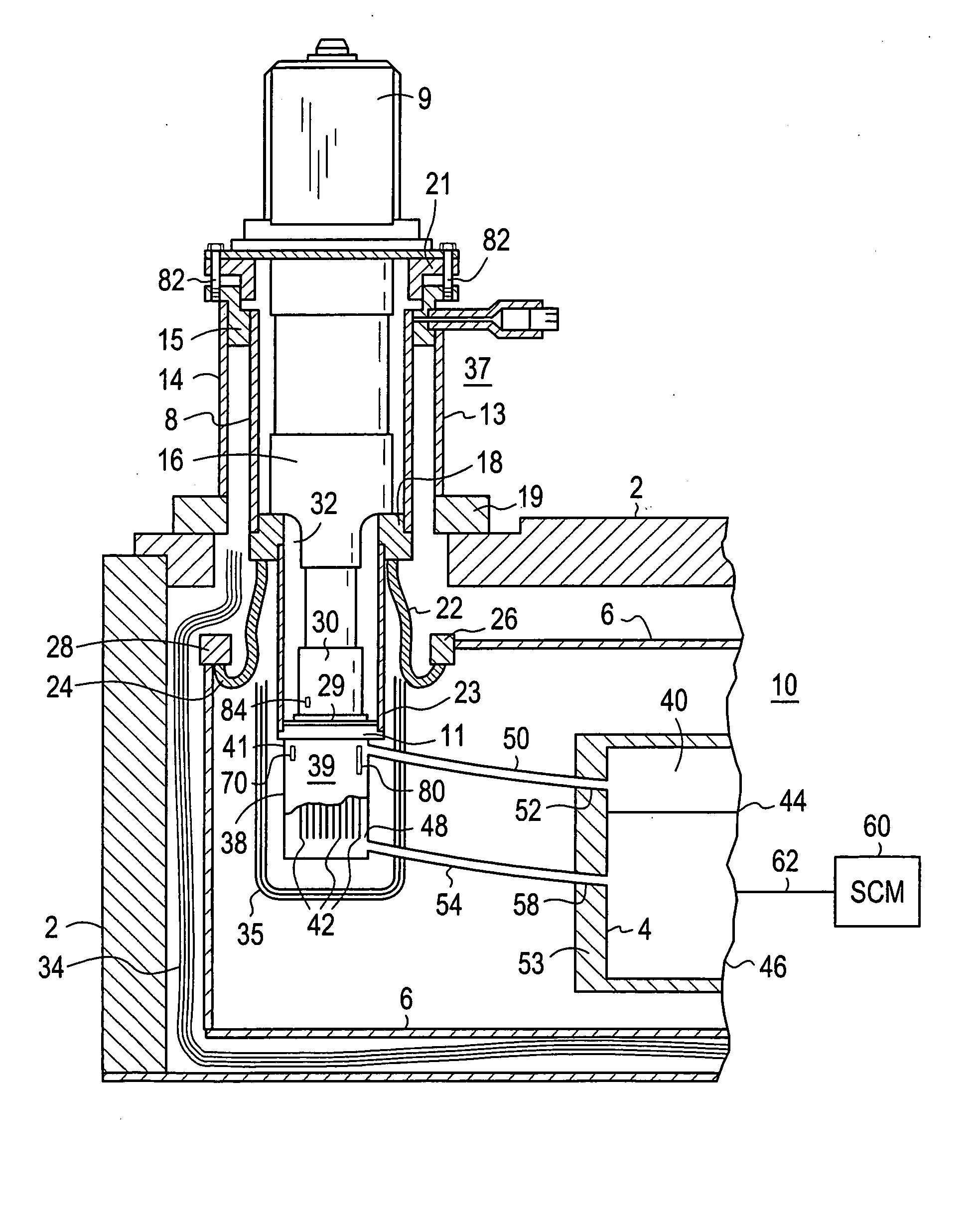

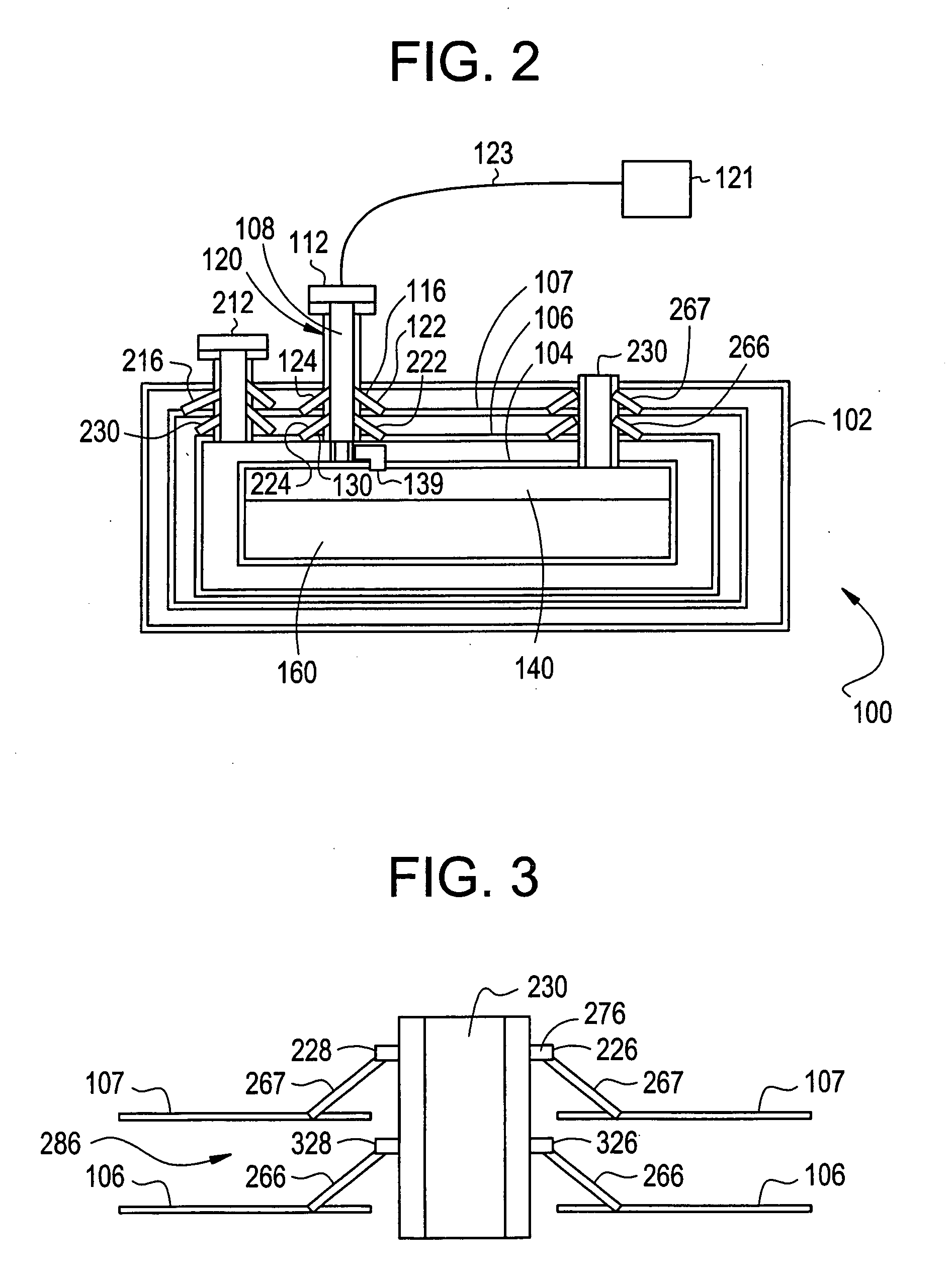

Superconductive magnet including a cryocooler coldhead

ActiveUS20060022779A1Reduce evaporation rateReduce heat loadMagnetic measurementsCompression machinesCryocoolerMechanics

A zero boiloff cryogen cooled recondensing superconducting magnet assembly including superconducting magnet coils suitable for magnetic resonance imaging including a cryogen pressure vessel to contain a liquid cryogen reservoir to provide cryogenic temperatures to the magnet coils for superconducting operation; a vacuum vessel surrounding the pressure vessel and spaced therefrom; a first thermal shield surrounding and spaced from the pressure vessel; a second thermal shield surrounding and spaced from the first thermal shield and intermediate the vacuum vessel and the first shield; a cryocooler thermally connected by a first and a second thermal interface to the first and second thermal shields, respectively; a recondenser positioned in the space between the pressure vessel and the first thermal shield and thermally connected by a thermal interface to the cryocooler to recondense, back to liquid, cryogen gas provided from the pressure vessel; and means for returning the recondensed liquid cryogen the pressure vessel; wherein the second thermal shield surrounding the first thermal shield reduces a radiation heat load from the first thermal shield to the pressure vessel lowering boiloff of cryogen gas under conditions of failure or power off of the cryocooler.

Owner:GENERAL ELECTRIC CO

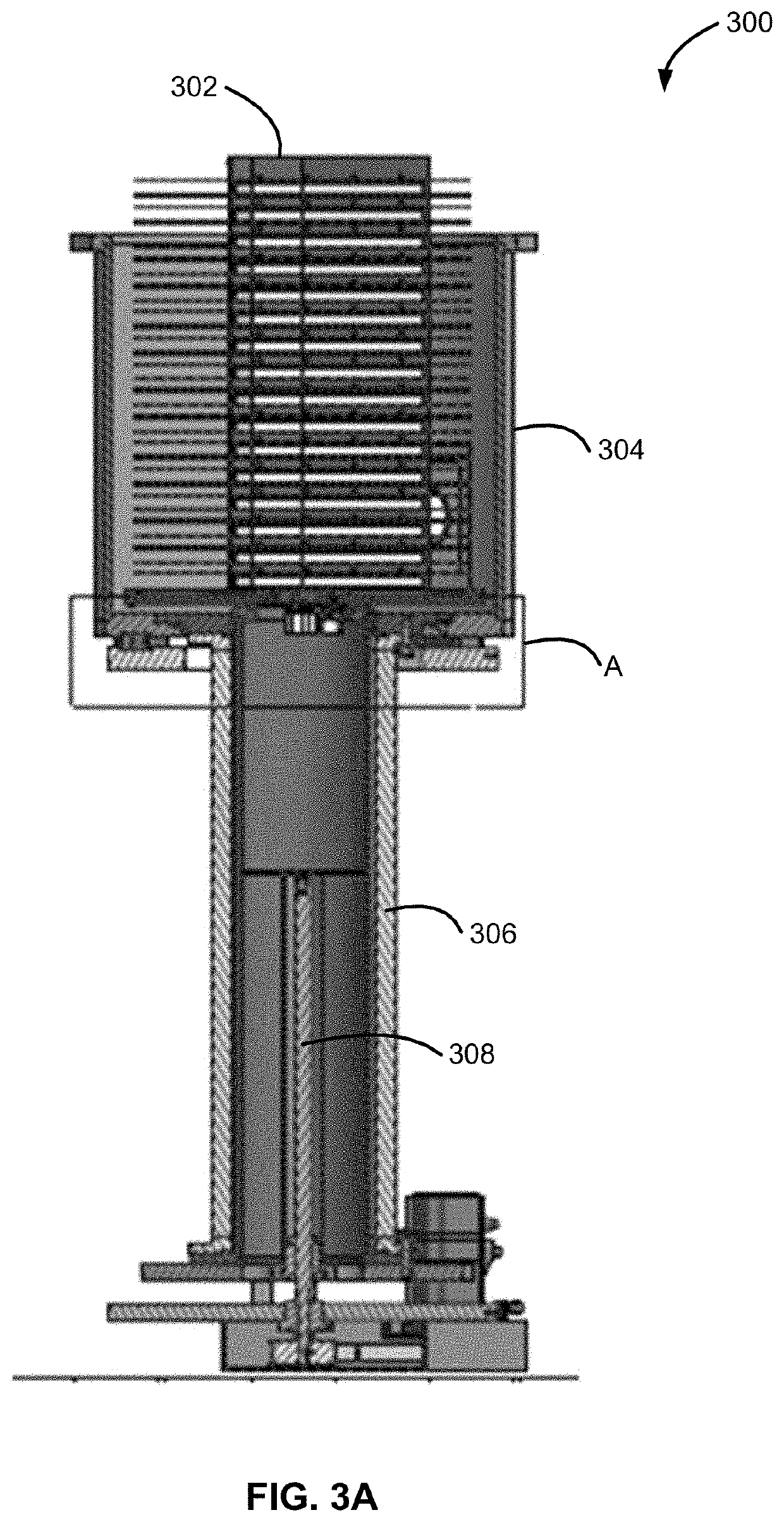

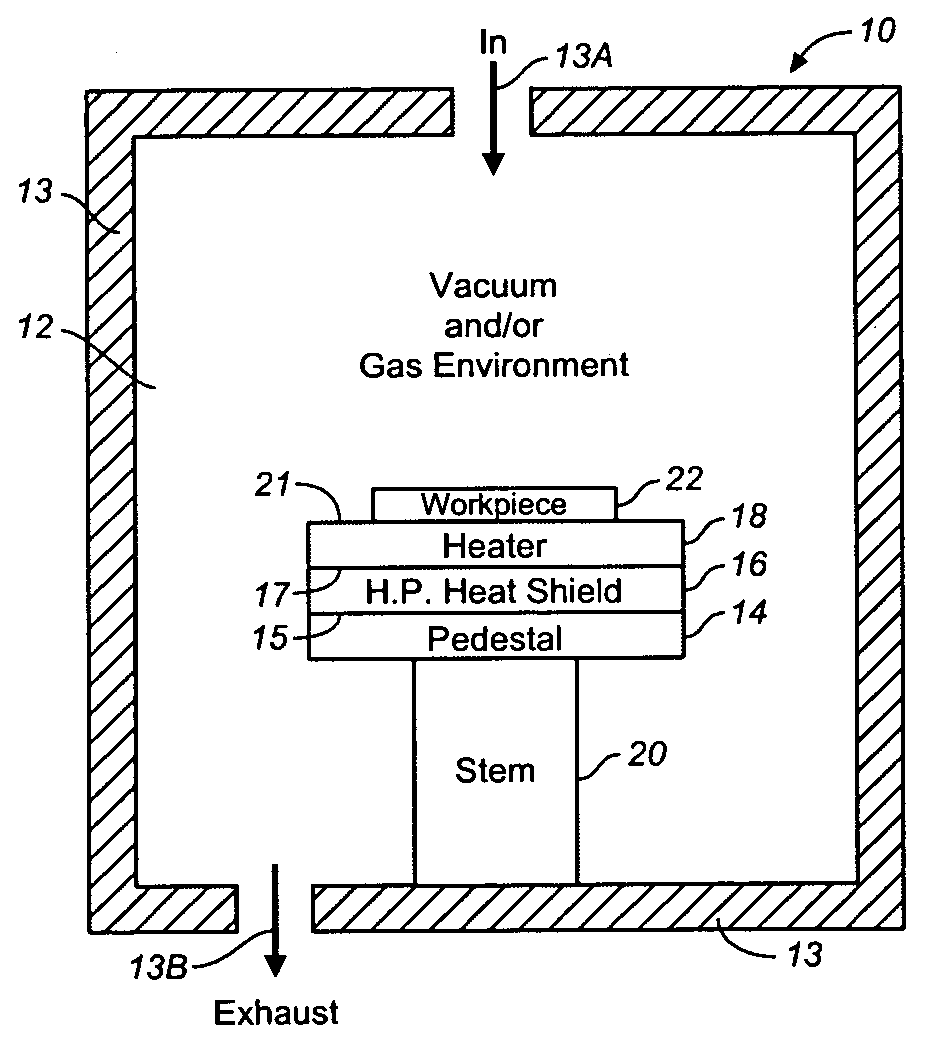

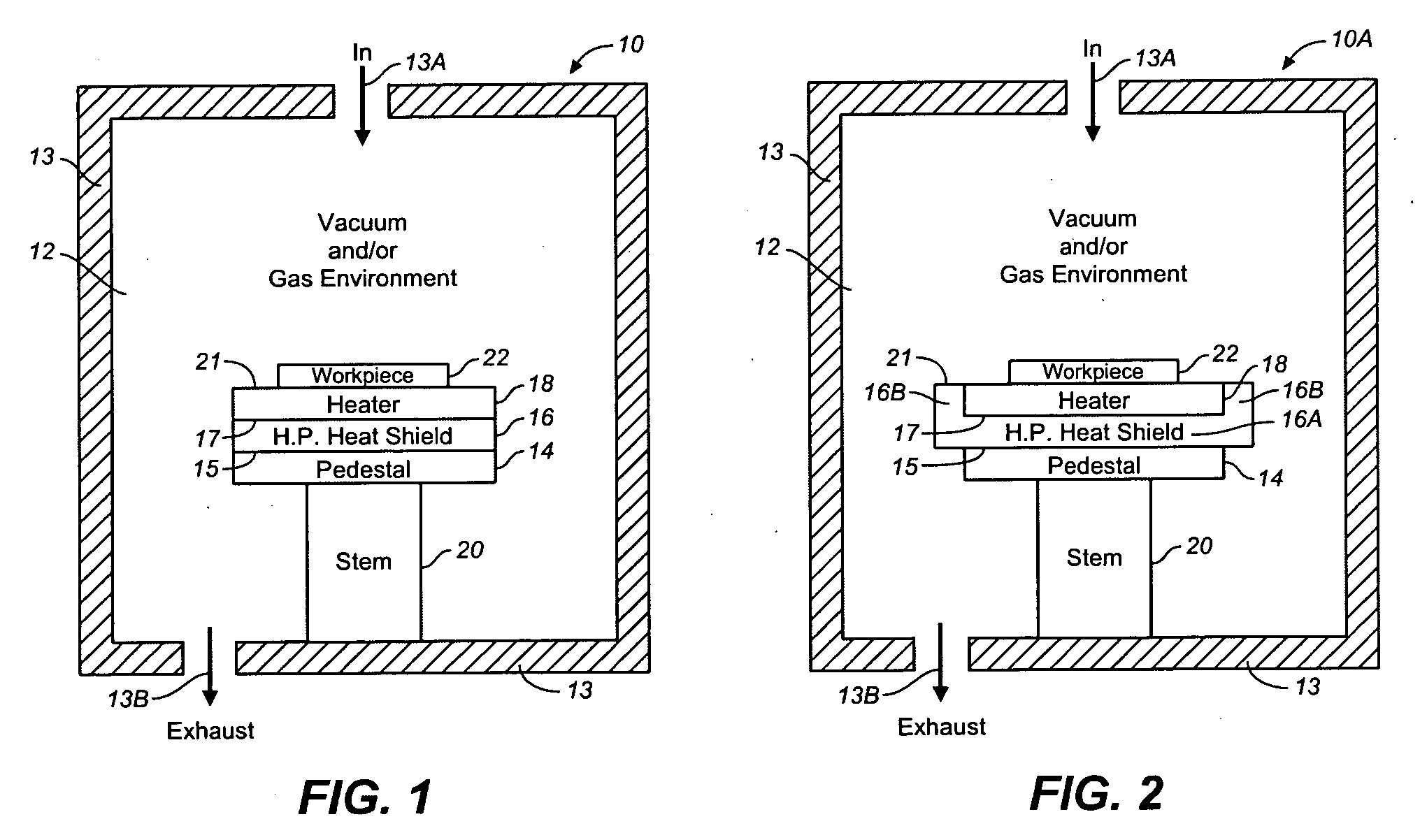

Heat Shield for Heater in Semiconductor Processing Apparatus

ActiveUS20100317197A1Reduce conductivityImprove performanceCellsWave amplification devicesEngineeringOrder of magnitude

A heat shield employed in semiconductor processing apparatus comprises a high performance insulation that has low thermal conductivity, such as, below the thermal conductivity of still air over a wide range of temperatures utilized in operation of the apparatus. As an example, the thermal conductivity of the insulation may be in the range of about 0.004 W / m·h to about 0.4 W / m·h over a temperature range of about 0° C. to about 600° C. or more. The deployment of the high performance heat shield reduces the power consumption necessary for the heater by as much as 20% to reach a desired processing temperature as compared to a case of heater power consumption required to reach the same desired temperature without the shield. Further, the heat shield significantly reduces the amount of undesired depositions from gas-entrained constituents on components in the chamber of the apparatus, particularly below or beyond the heat shield, by as much as 90% since the temperature drop is as much as ten orders of magnitude difference.

Owner:NOVELLUS SYSTEMS

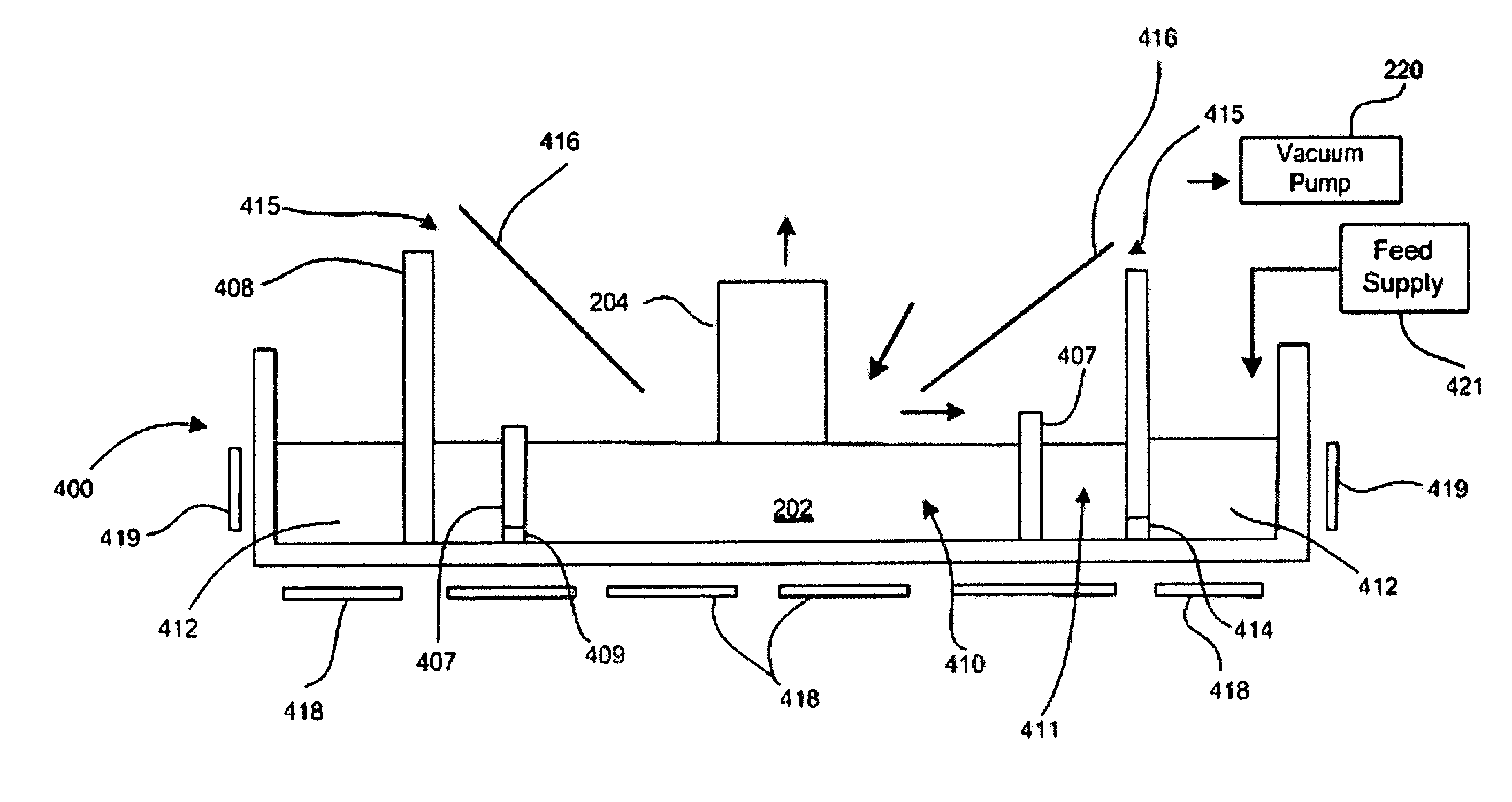

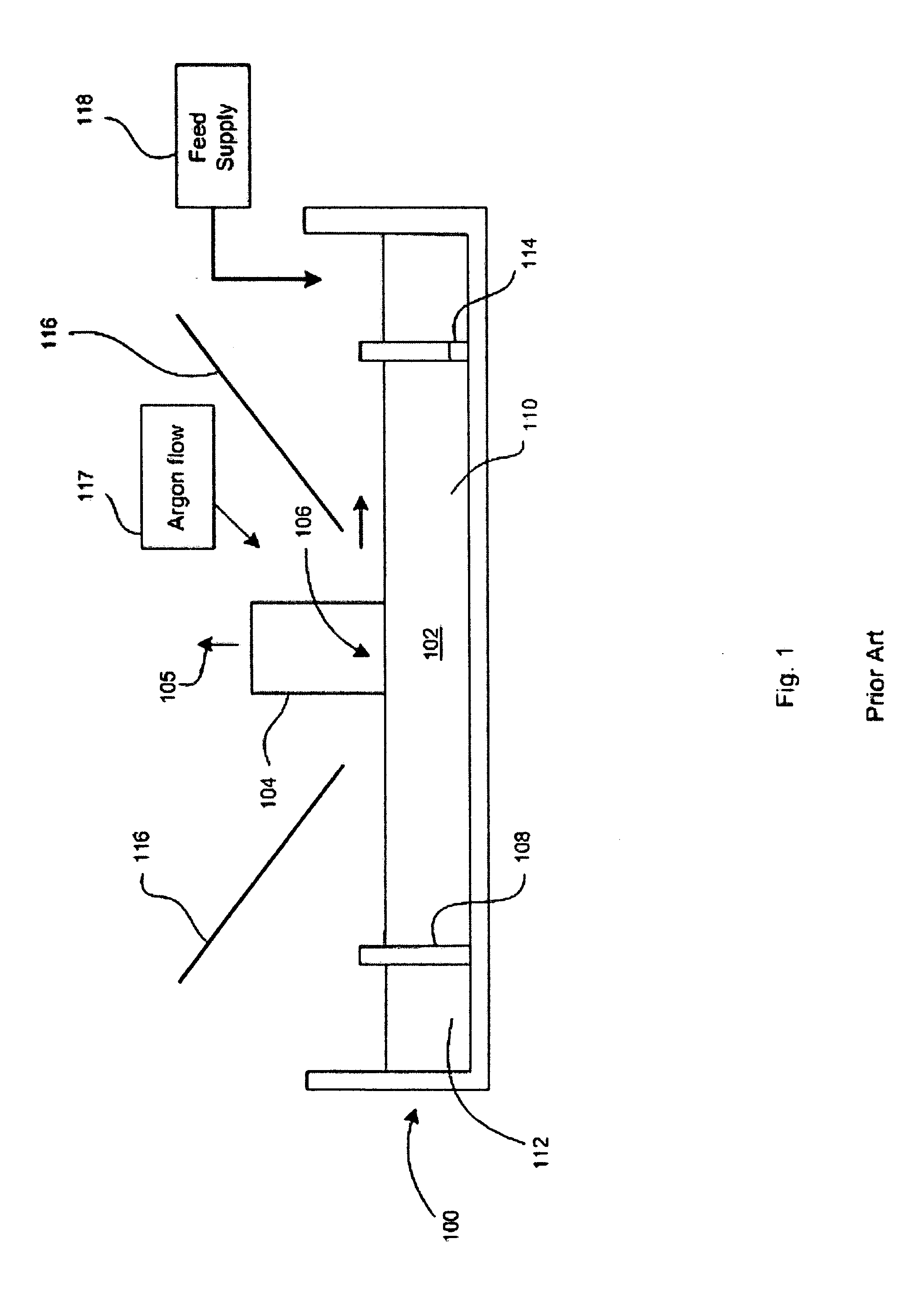

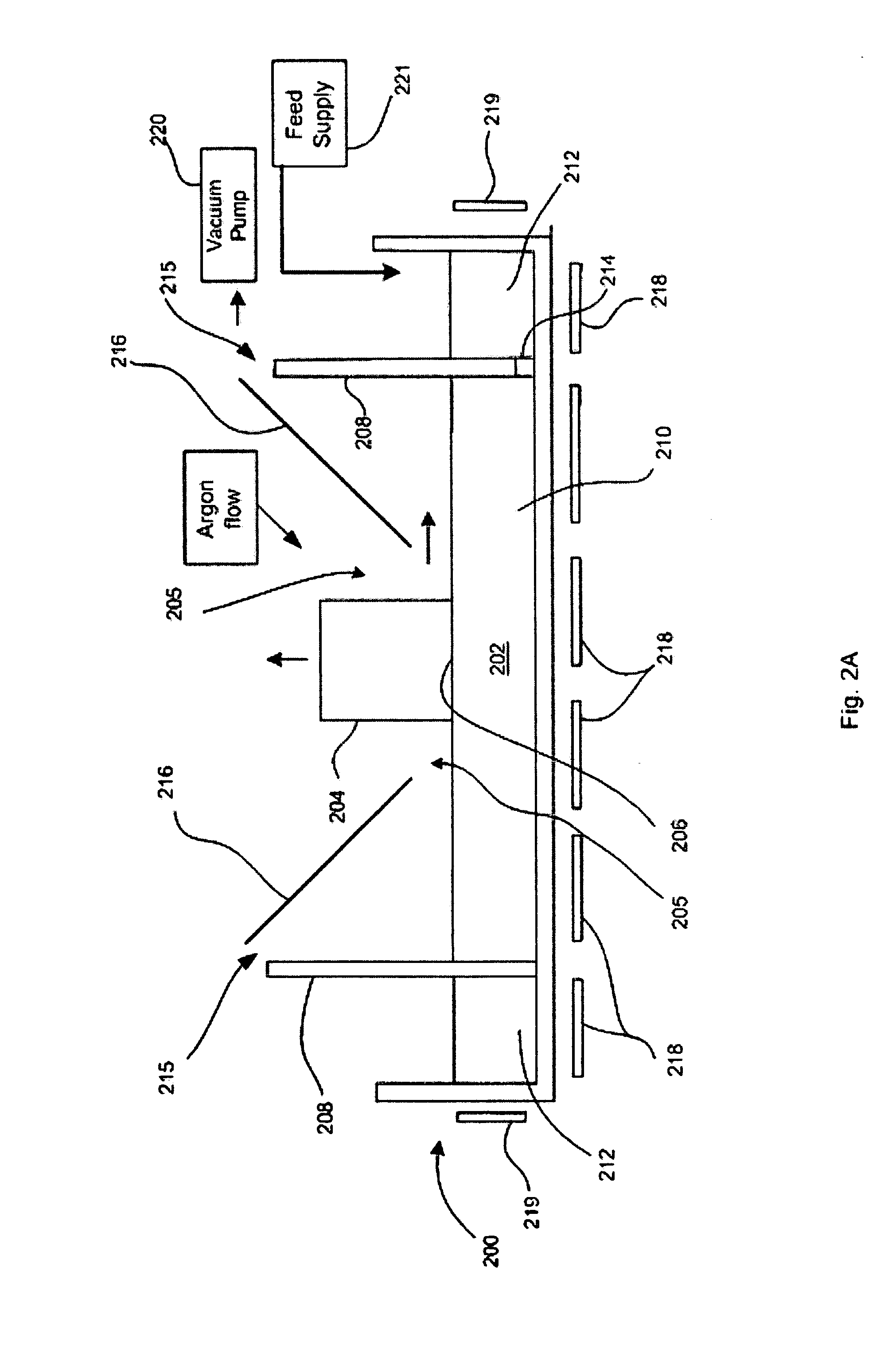

Weir design providing optimal purge gas flow, melt control, and temperature stabilization for improved single crystal growth in a continuous Czochralski process

ActiveUS8262797B1Increase path lengthExtended transit timePolycrystalline material growthBy pulling from meltSingle crystalEngineering

A weir is extended vertically to define an optimal annular gap between the top of the weir and the underside of a super-adjacent heat shield. The annular gap provides a high velocity stream of argon gas to be directed from the growth region to the melt region to substantially eliminate the transport of airborne particles from the melt region to the growth region. The tall weir may be configured as a modular, reusable weir extension supportably engaged with an outer (and / or inner) weir.

Owner:CORNER STAR LTD

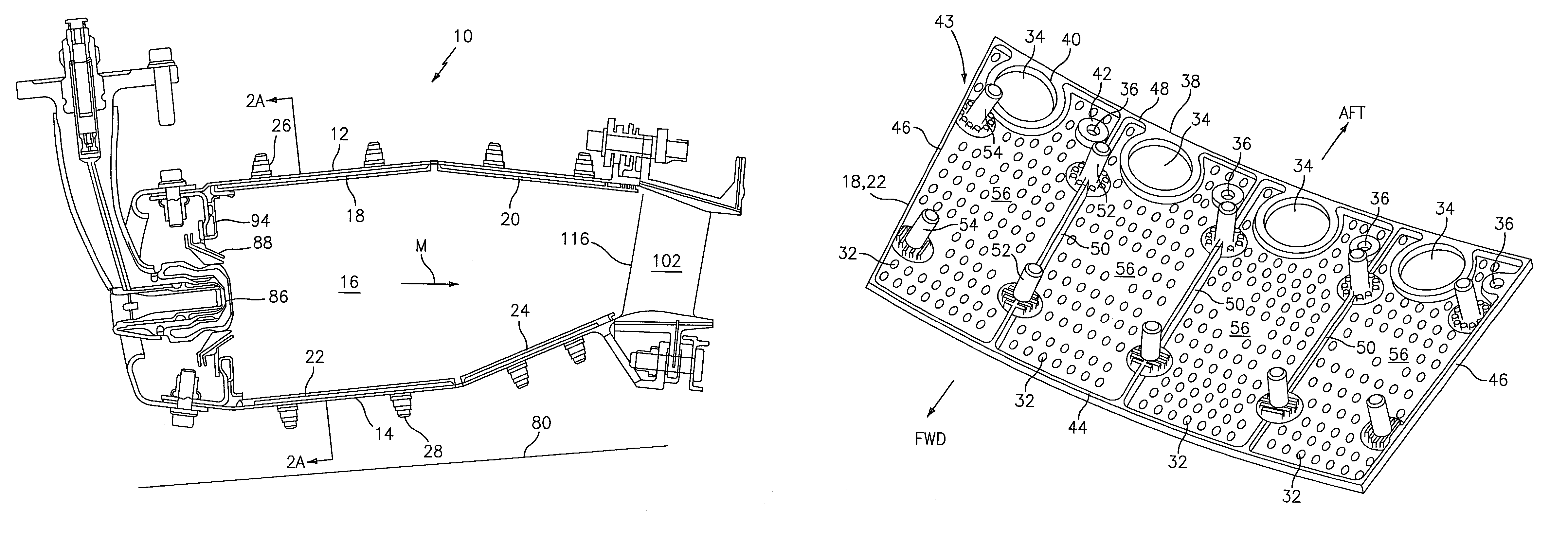

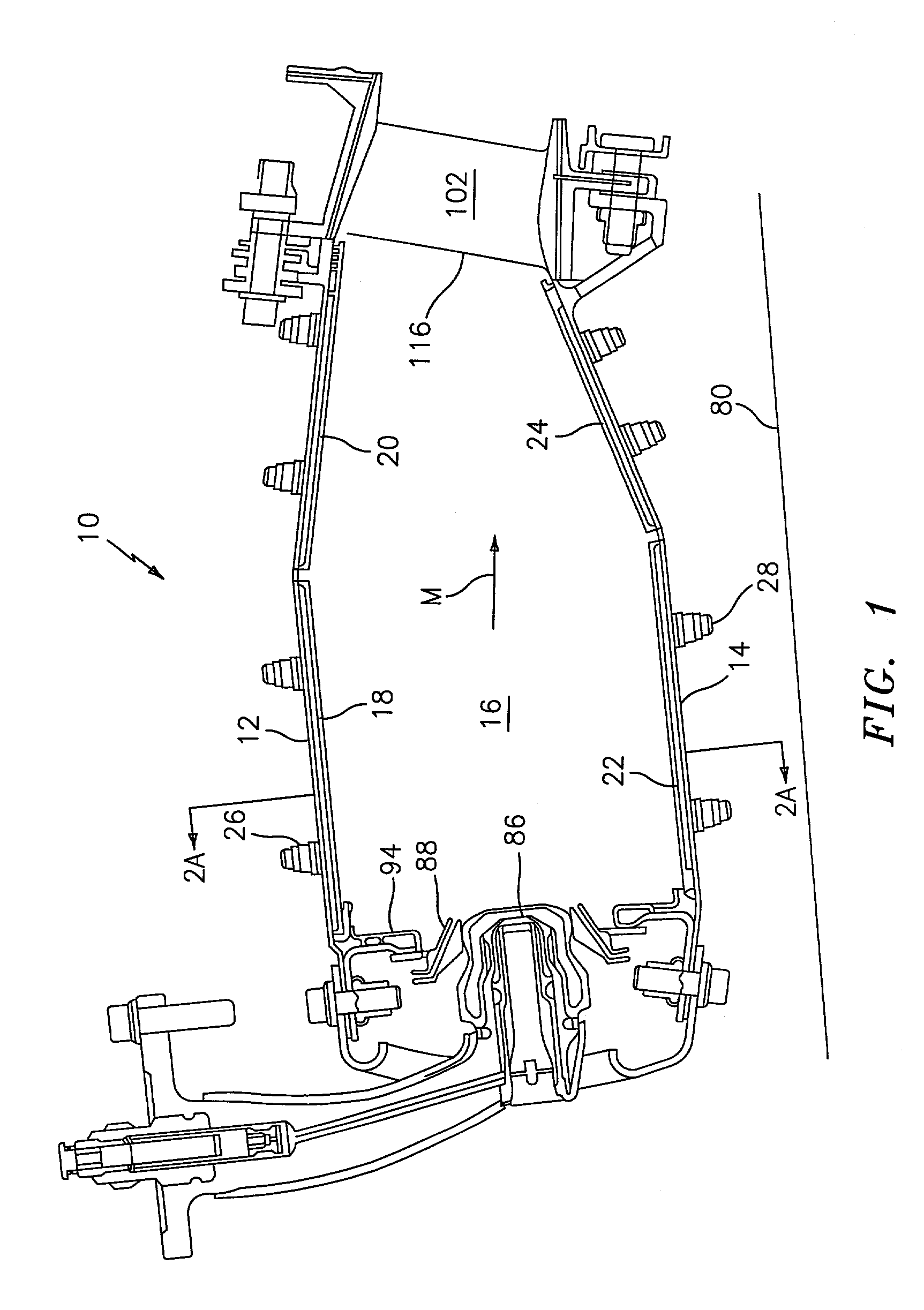

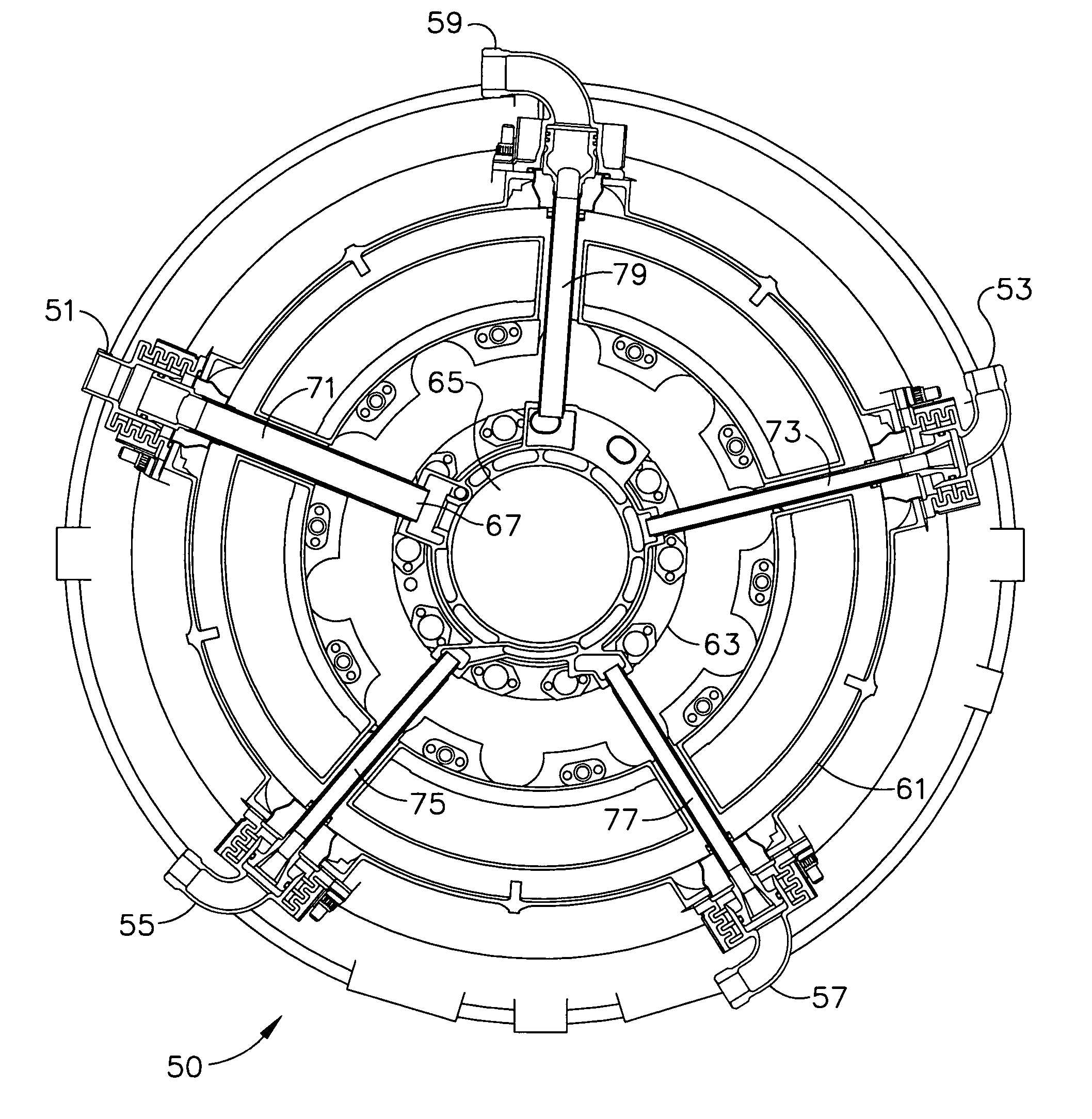

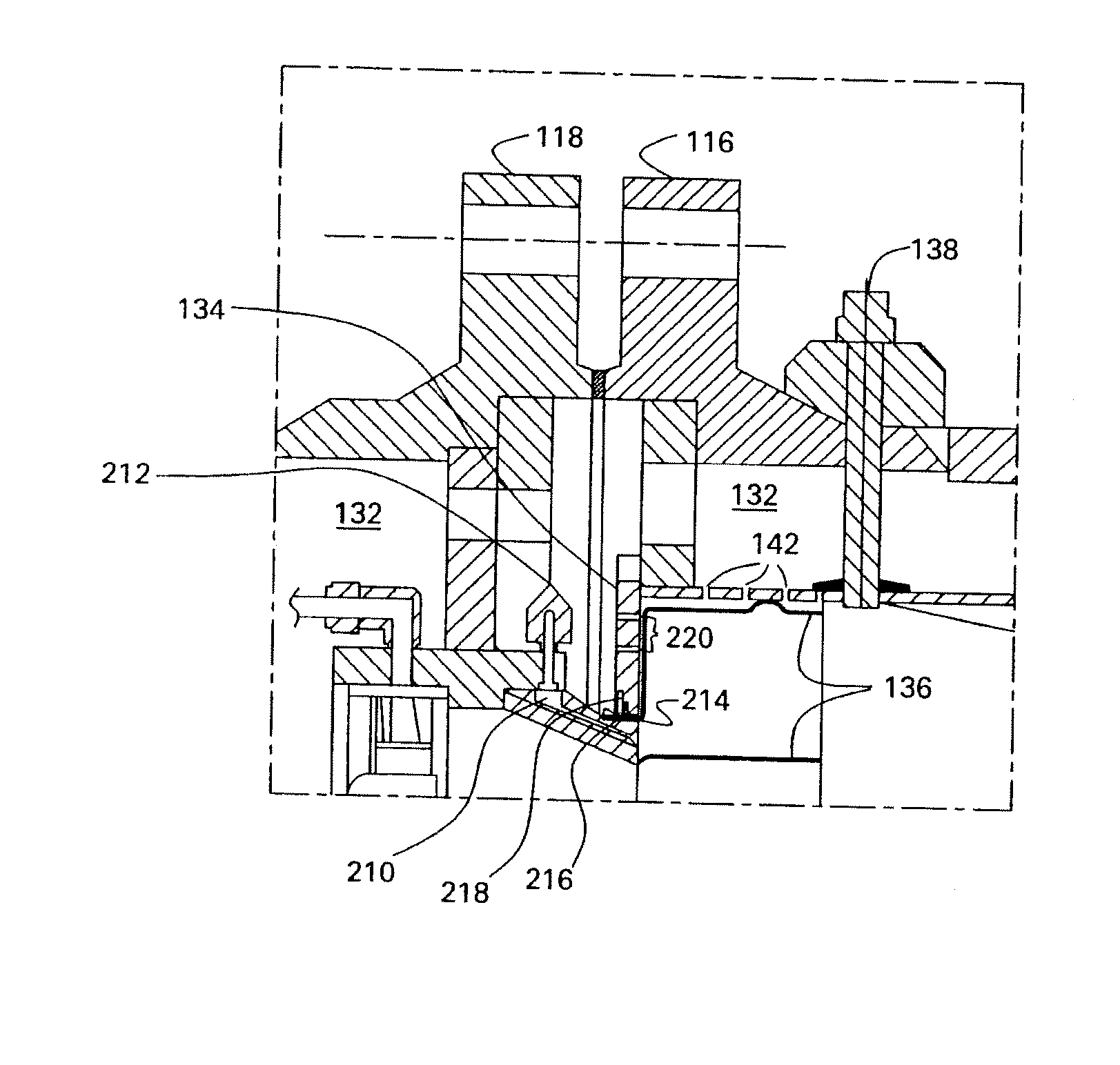

Combustor dome panel heat shield cooling

ActiveUS20080104962A1Interference minimizationReduce distractionsContinuous combustion chamberEngine fuctionsCombustion chamberCombustor

A gas turbine engine combustor having a dome heat shield includes a cooling scheme having a plurality of impingement cooling holes extending through the combustor and a plurality of adjacent ejector holes for directing cooling air past the heat shield lips of the dome heat shields. The impingement and ejector holes are preferably staggered to reduce interaction therebetween.

Owner:PRATT & WHITNEY CANADA CORP

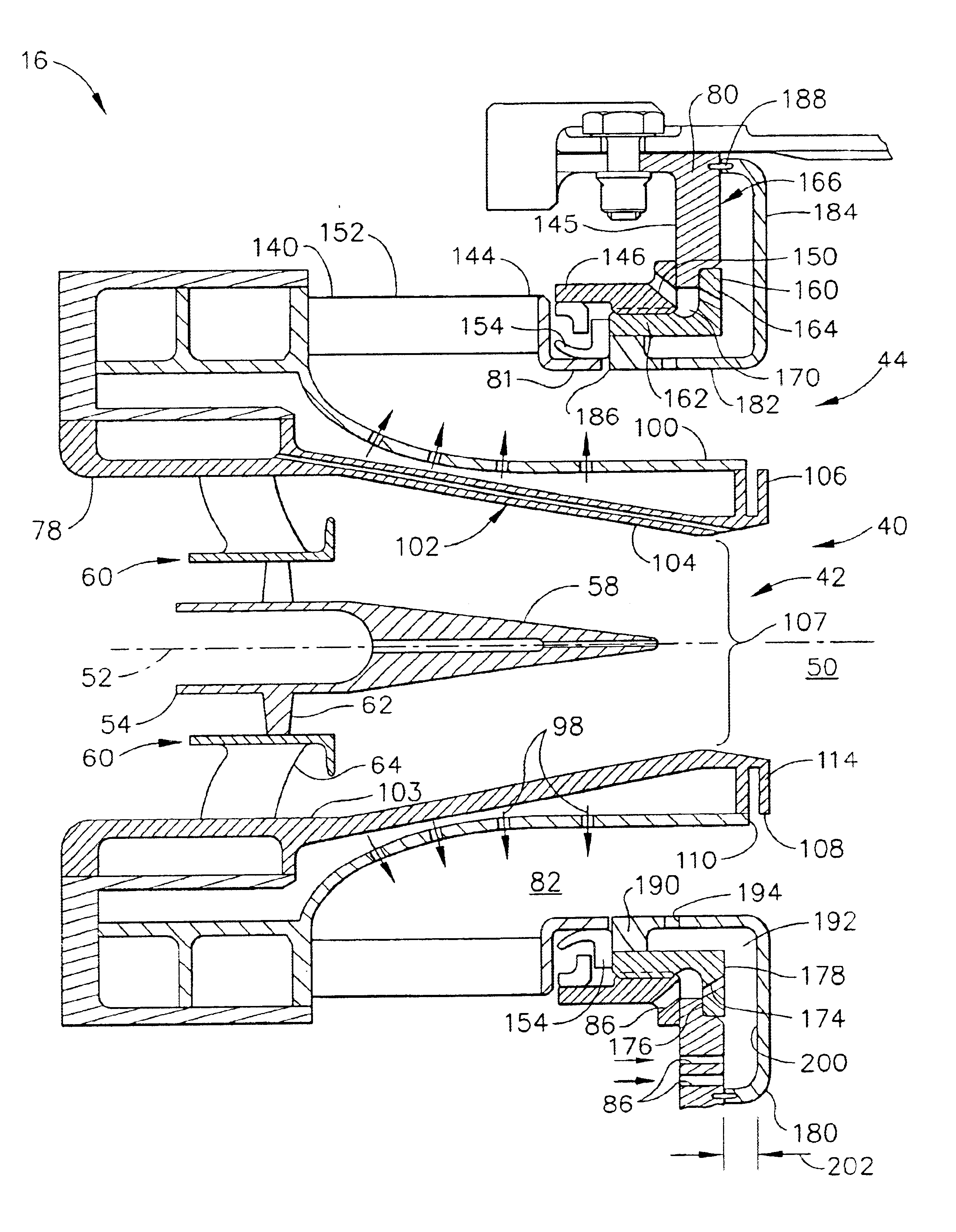

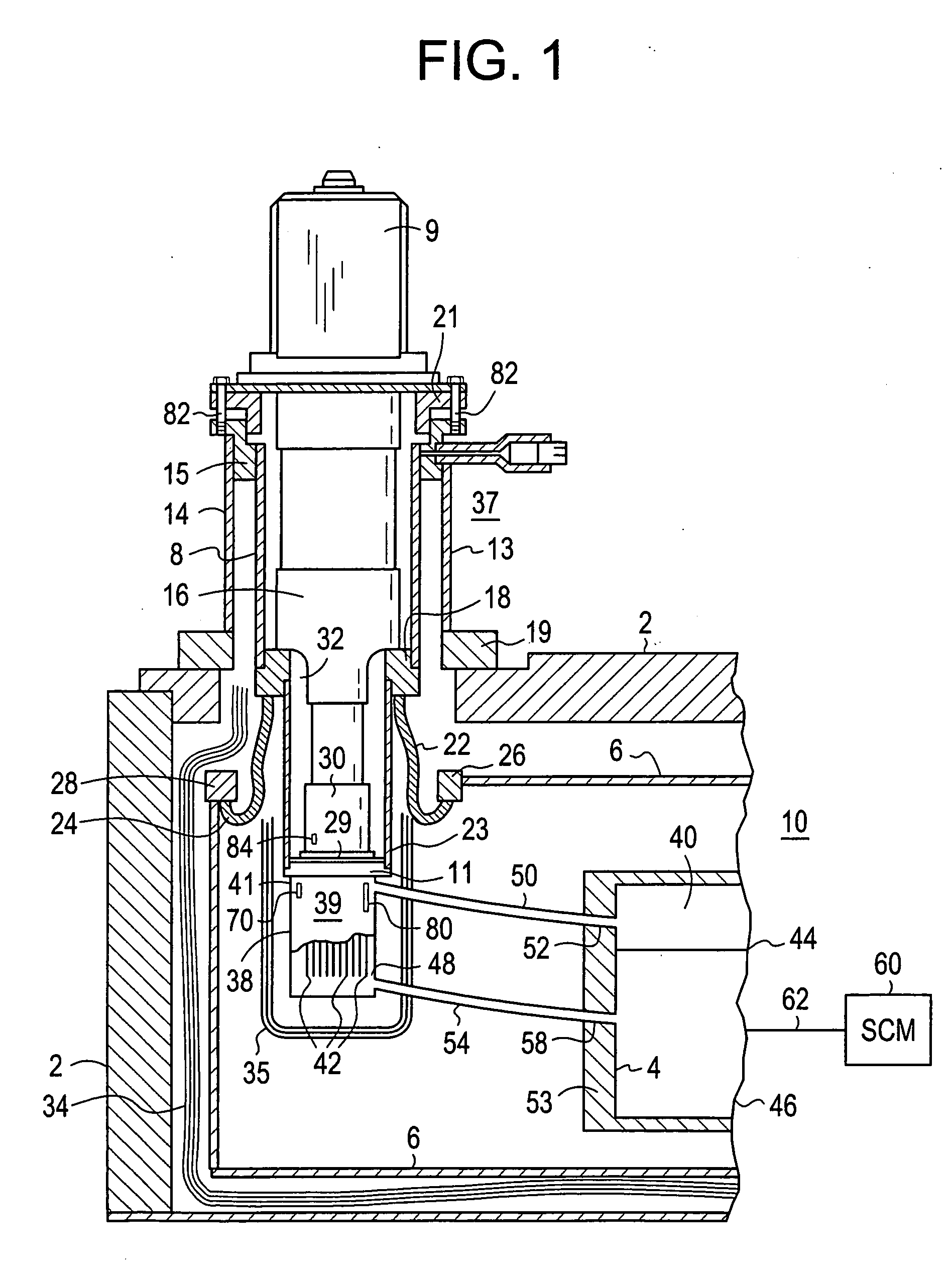

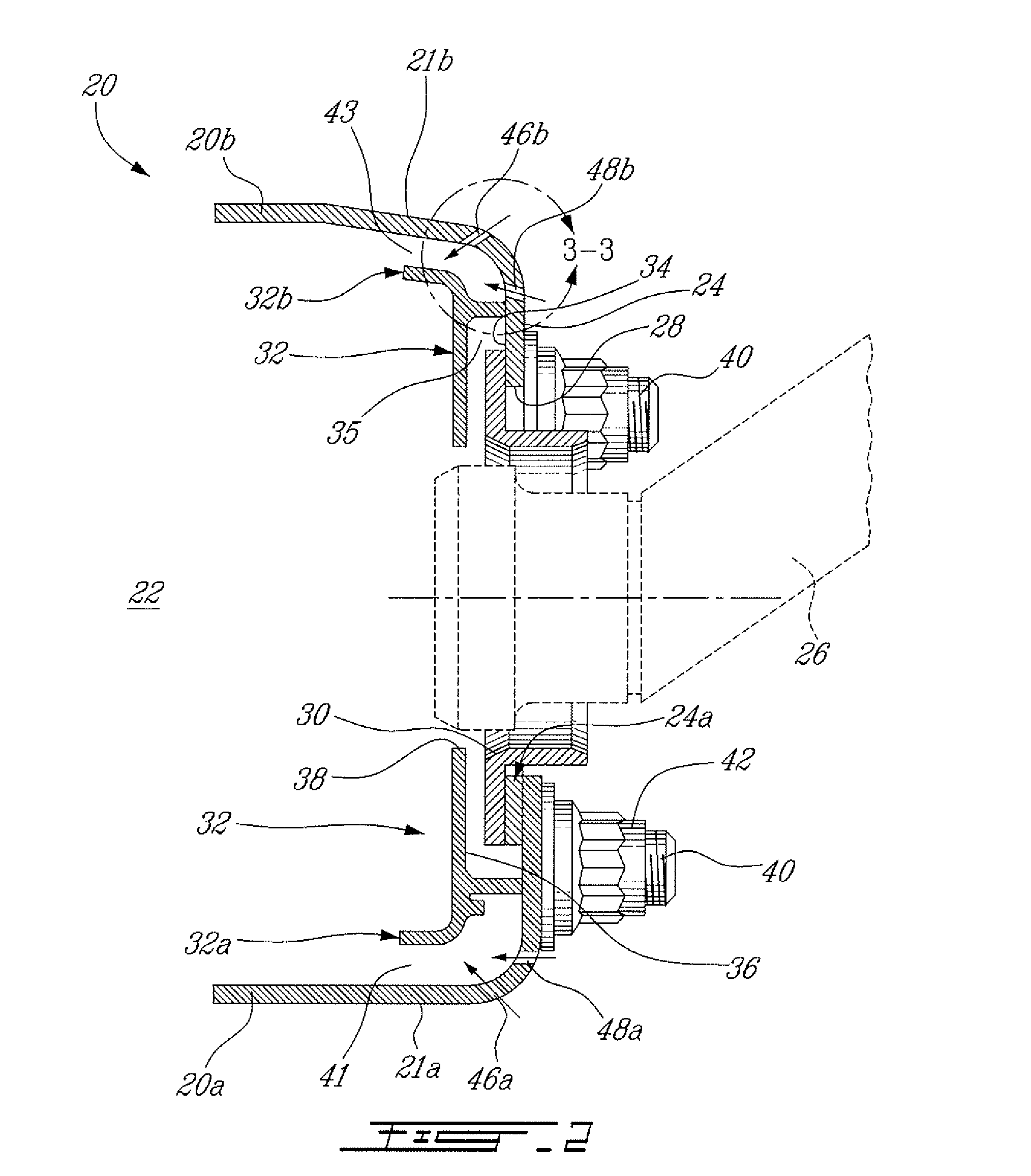

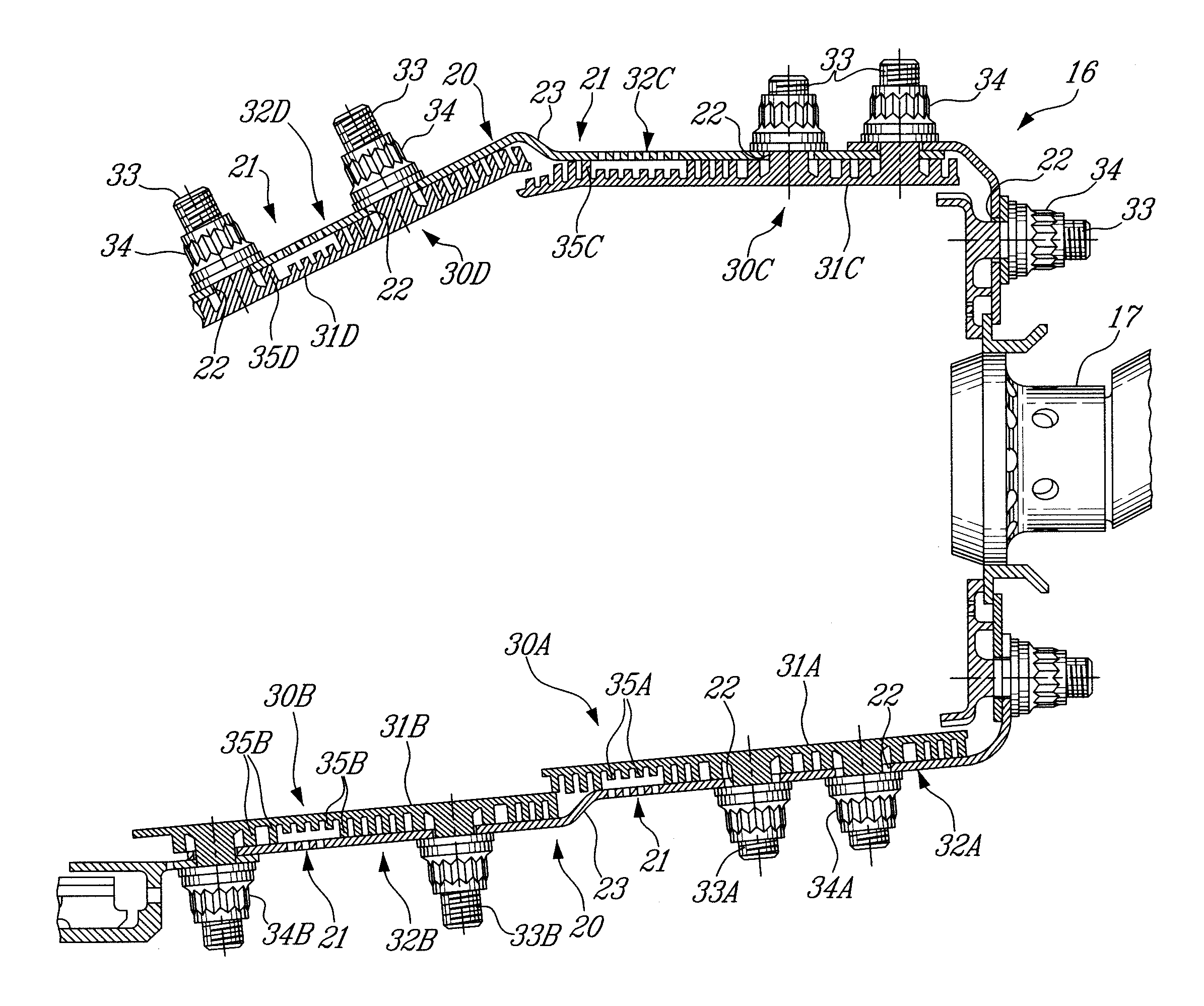

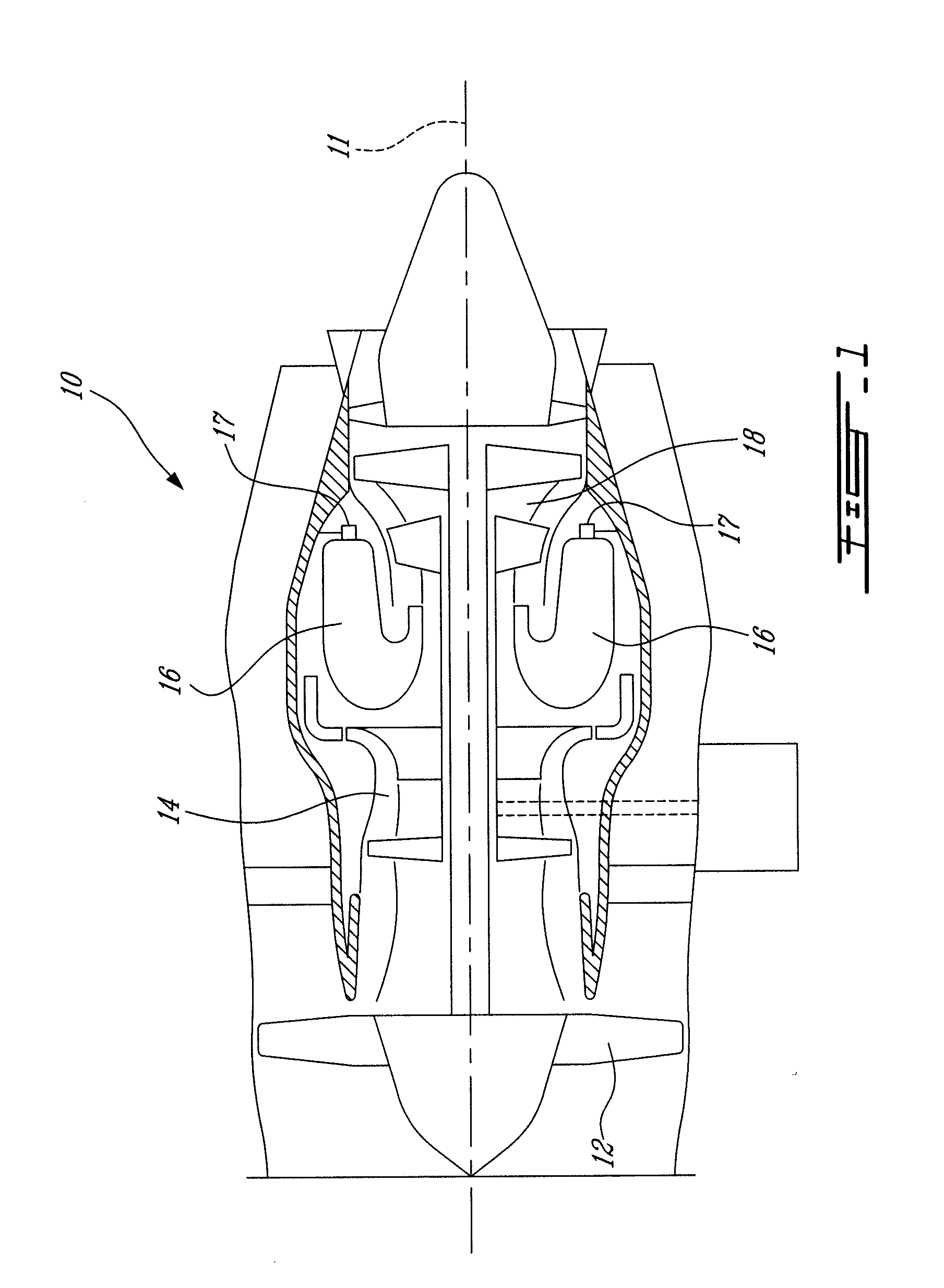

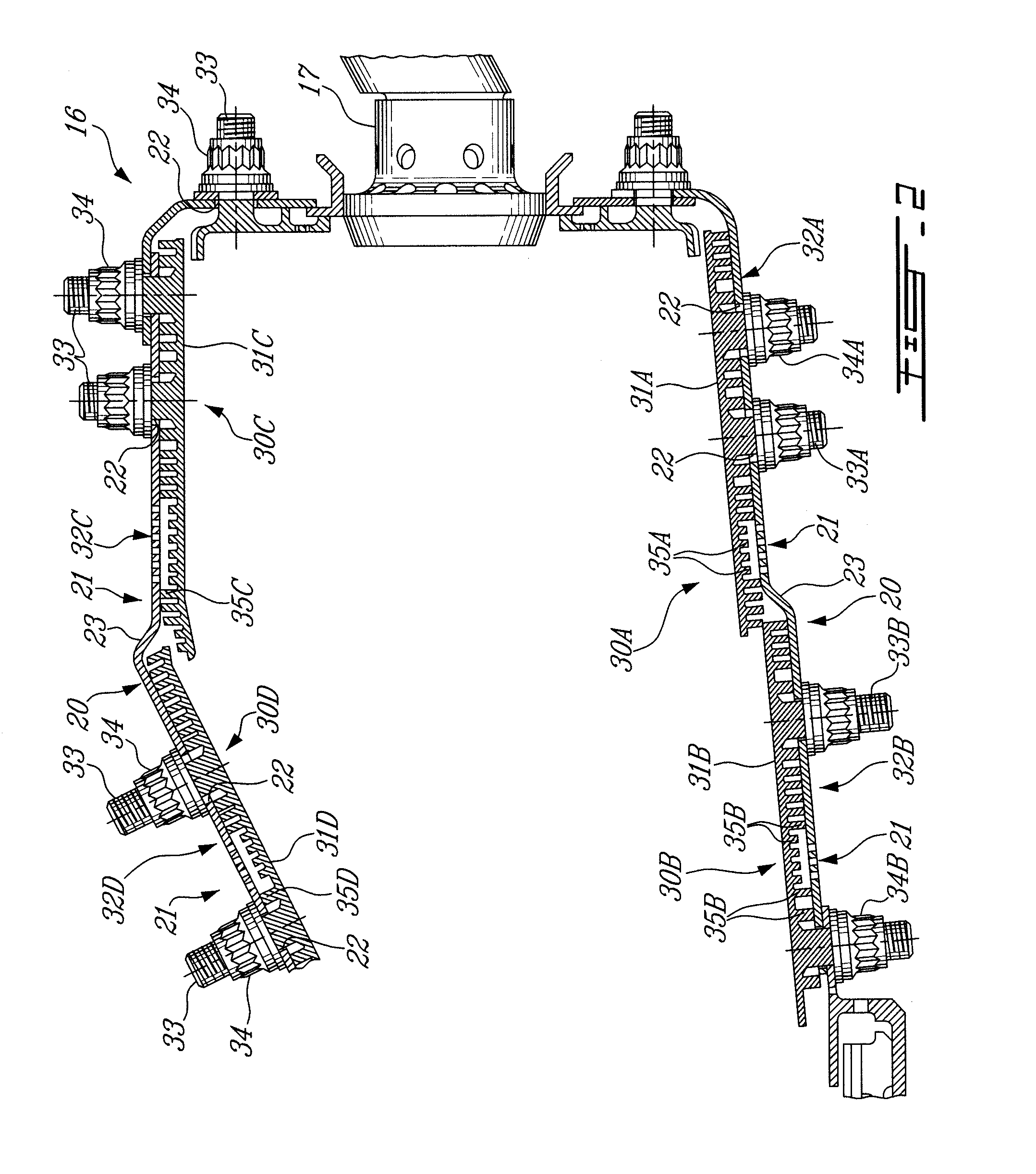

Apparatus and method for bearing lubrication in turbine engines

A lubrication system includes an inlet conduit having an inboard end attached to a bearing support and an outboard end for receiving lubricant. A lubricant inlet assembly is attached to the inlet conduit outboard end and has an inlet cap with a receptacle, an inlet cap body, and a cap base. The inlet receptacle is configured to mate with a lubricant supply line, where the inlet cap body has an outer cap enclosing an inner cap, the outer cap having a convoluted wall. An inlet conduit termination fitting has an outboard fitting section, with an o-ring in a circumferential groove, disposed inside the inlet cap, and an inboard fitting section attached to the inlet conduit outboard end. A cap heat shield encloses the inlet cap and a conduit heat shield is attached to the inlet conduit. The lubricant inlet assembly is mounted to an engine casing with a low-conductivity insulating gasket between the cap base and the engine casing.

Owner:HONEYWELL INT INC

Ceramic hollow fibers made from nanomscale powder particles

The invention relates to a method for producing ceramic hollow fibers from nanoscale particles and to hollow fibers produced in such a manner. The inventive method is characterized in that the ceramic material has a solids content of >25% by volume, preferably >30% by volume and is processed by means of extrusion and spinning. The hollow fiber is sintered according to conventional sintering methods. A hollow fiber produced in this manner is used for metal, polymer and ceramic matrix reinforcements, for artificial organs, for microsystems technology components, for fiber optical waveguides, for ceramic membranes, for solid electrolyte in fuel cells (SOFC), for tissue engineering and for producing extremely light ceramic parts, such as heat shields or brake systems, that are subjected to temperature stresses. The inventive ceramic batch can also be processed by means of silk screening whereby resulting in the production of filigree structures over the ceramic silk screening.

Owner:ITN NANOVATION AG

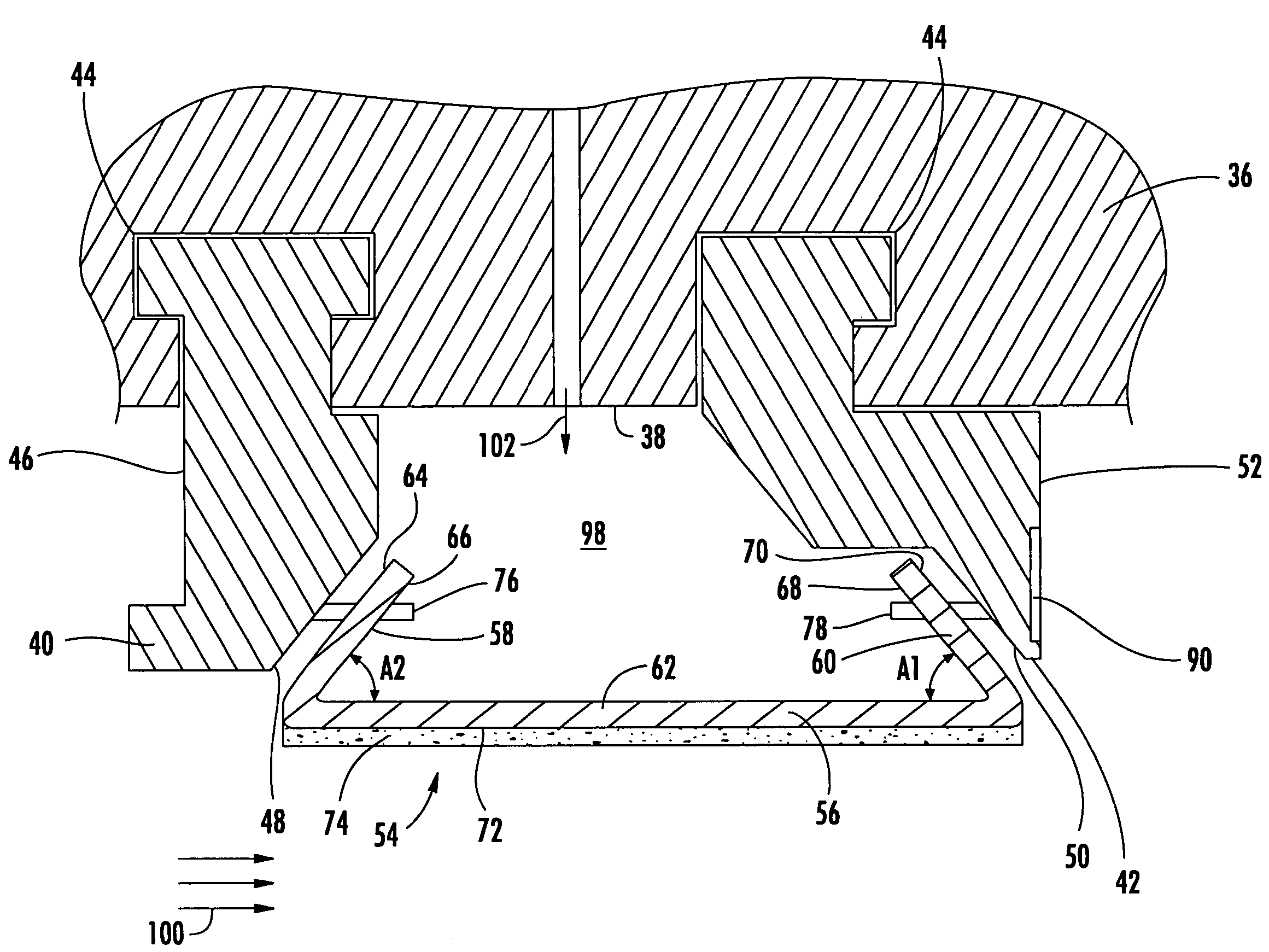

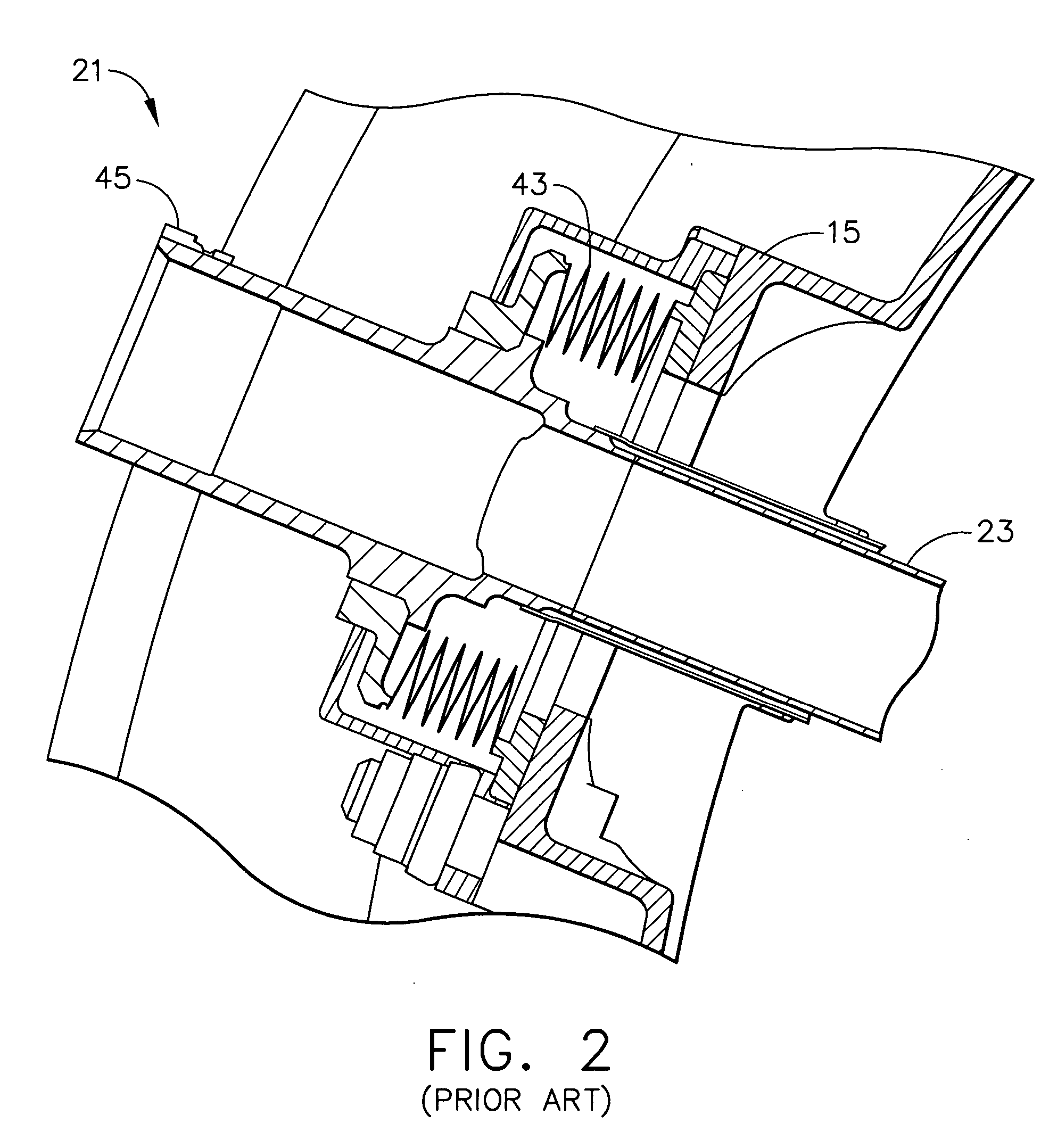

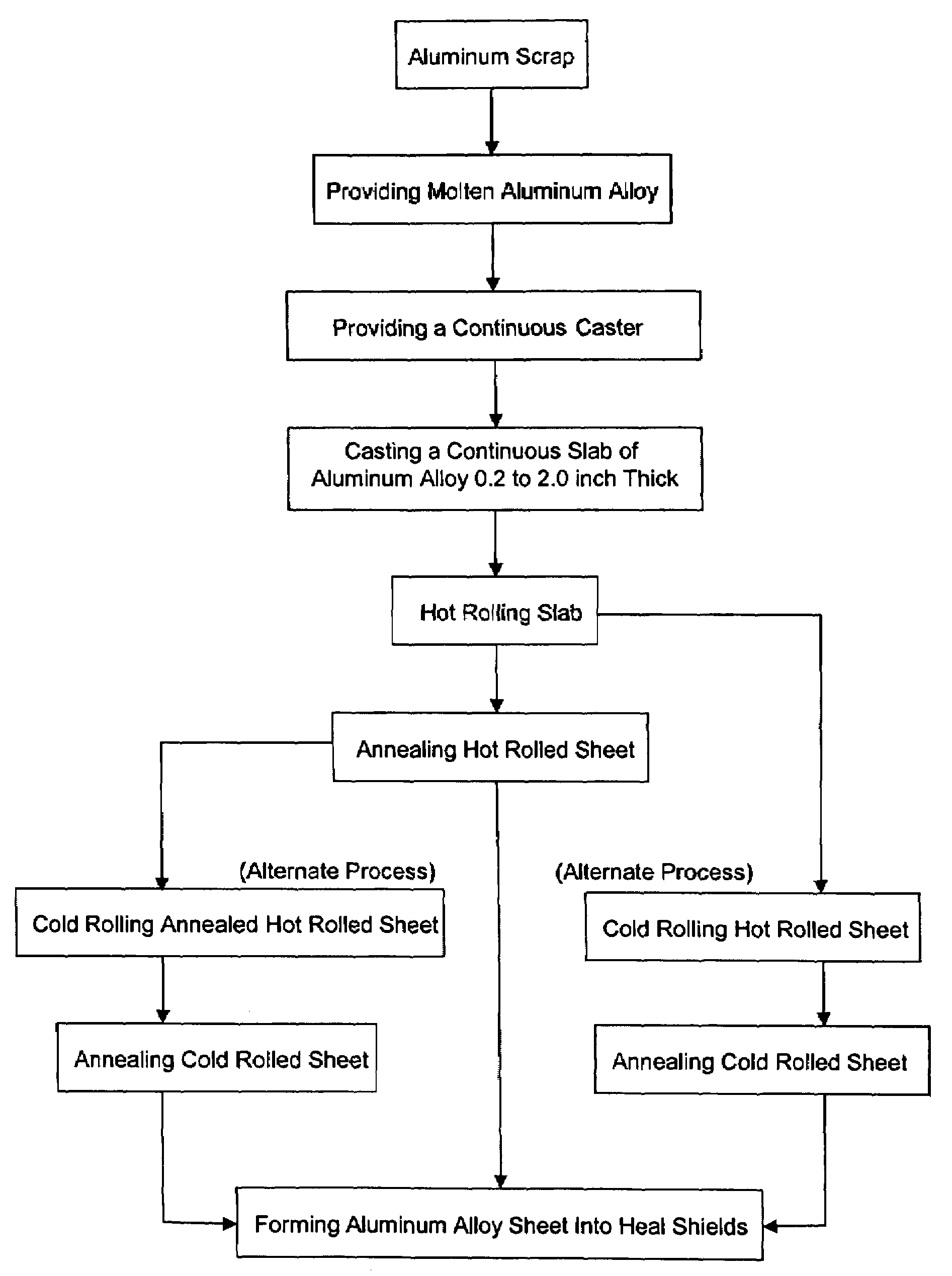

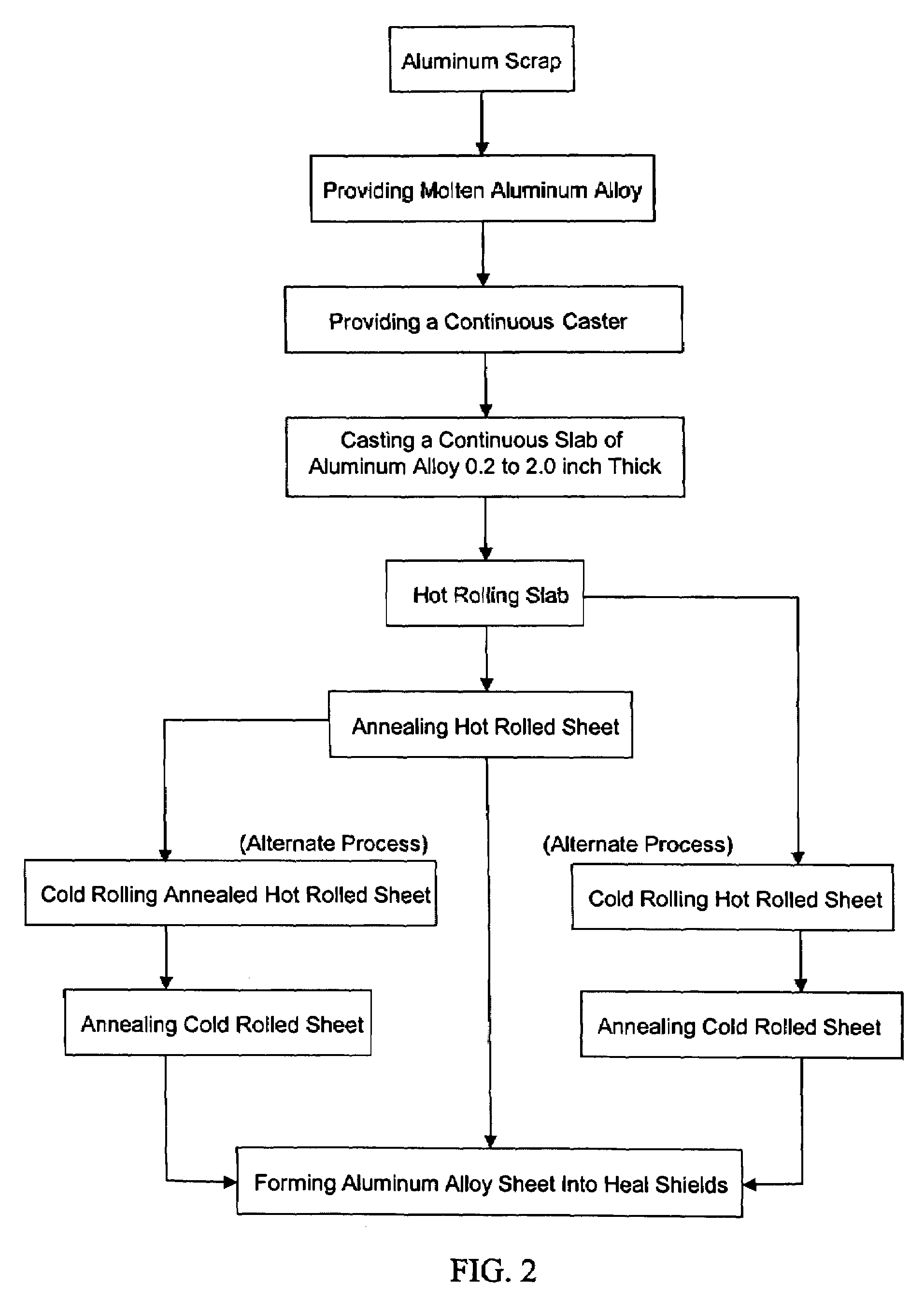

Aluminum automotive heat shields

Disclosed is a method for producing aluminum automotive heat shields or panels such as from scrap derived molten aluminum alloy using a continuous caster to cast the alloy into a slab. The method comprises providing a molten aluminum alloy consisting essentially of 0.1 to 0.7 wt. % Si, 0.2 to 0.9 wt. % Fe, 0.05 to 0.5 wt. % Cu, 0.05 to 1.3 wt. % Mn, 0.2 to 2.8 wt. % Mg, 0.3 wt. % max. Cr, 0.3 wt. % max. Zn, 0.2 wt. % max. Ti, the remainder aluminum, incidental elements and impurities and providing a continuous caster such as a belt caster, block caster or roll caster for continuously casting the molten aluminum alloy. The molten aluminum alloy is cast into a slab which is rolled into a sheet product and then annealed. Thereafter, the sheet product is formed into the automotive heat shield or panel with strength and formability as required by the automotive industry.

Owner:COMMONWELATH IND

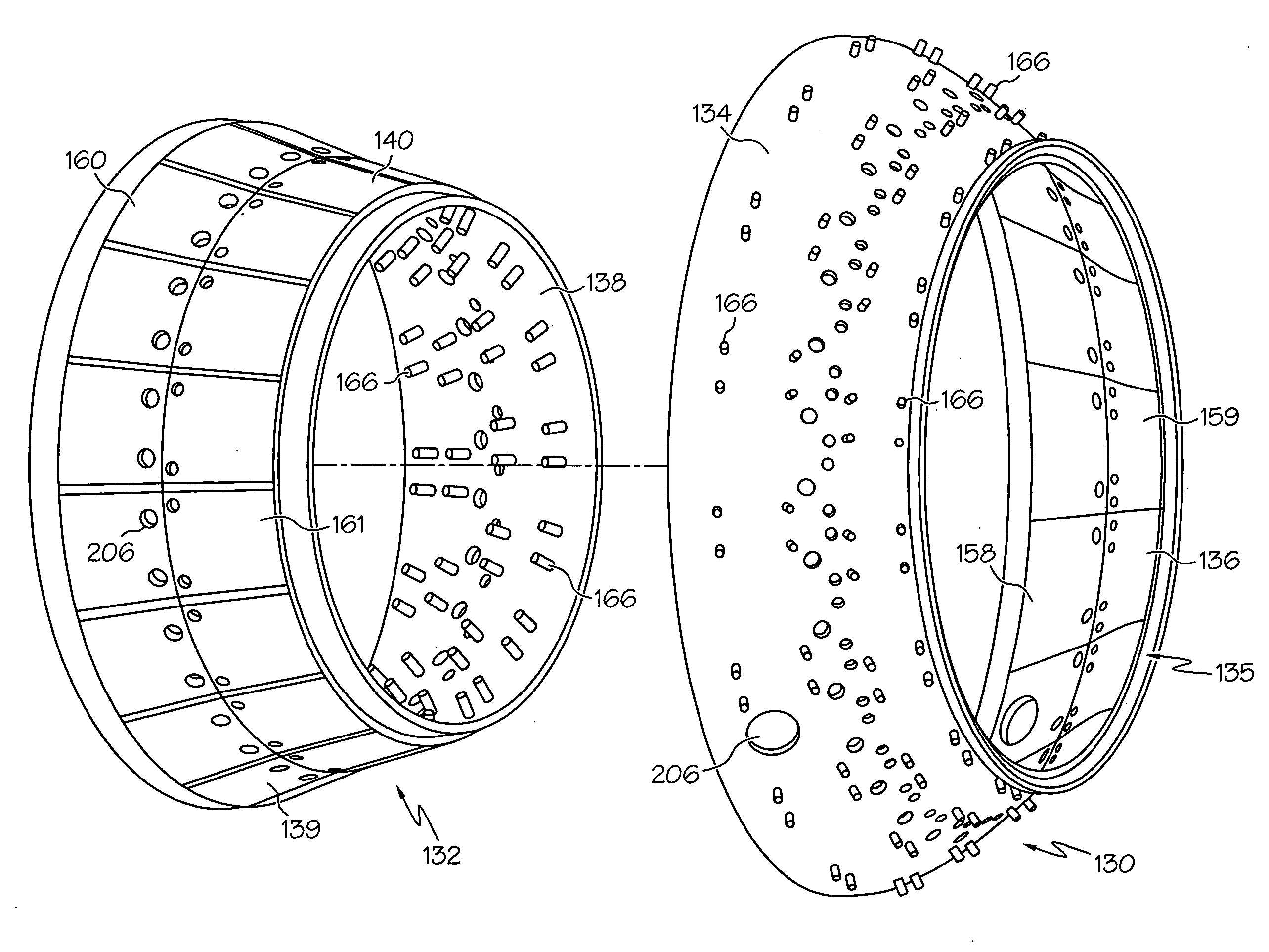

Pin fin arrangement for heat shield of gas turbine engine

ActiveUS20130055722A1Continuous combustion chamberEfficient propulsion technologiesCombustorEngineering

A heat shield unit for a gas turbine engine combustor comprises a panel body secured to a combustor liner. A first surface of the body is oriented toward a combustion zone of a combustor. A second surface is oriented toward the liner. The body is separated into upstream and downstream portions. Pin fins project from the second surface of the body. The pin fins are arranged in arrays of at least two different densities of volume of pin fins per unit volume. One density, lower than the second density, is in the upstream portion and another in the downstream portion of the body. Connectors connect the body to the liner with a line between the upstream and downstream portions of the body aligned with fluid-coolant injection apertures in the liner. A gas turbine engine combustor and a method for cooling a heat shield unit in a combustor liner of a gas turbine engine are also provided.

Owner:PRATT & WHITNEY CANADA CORP

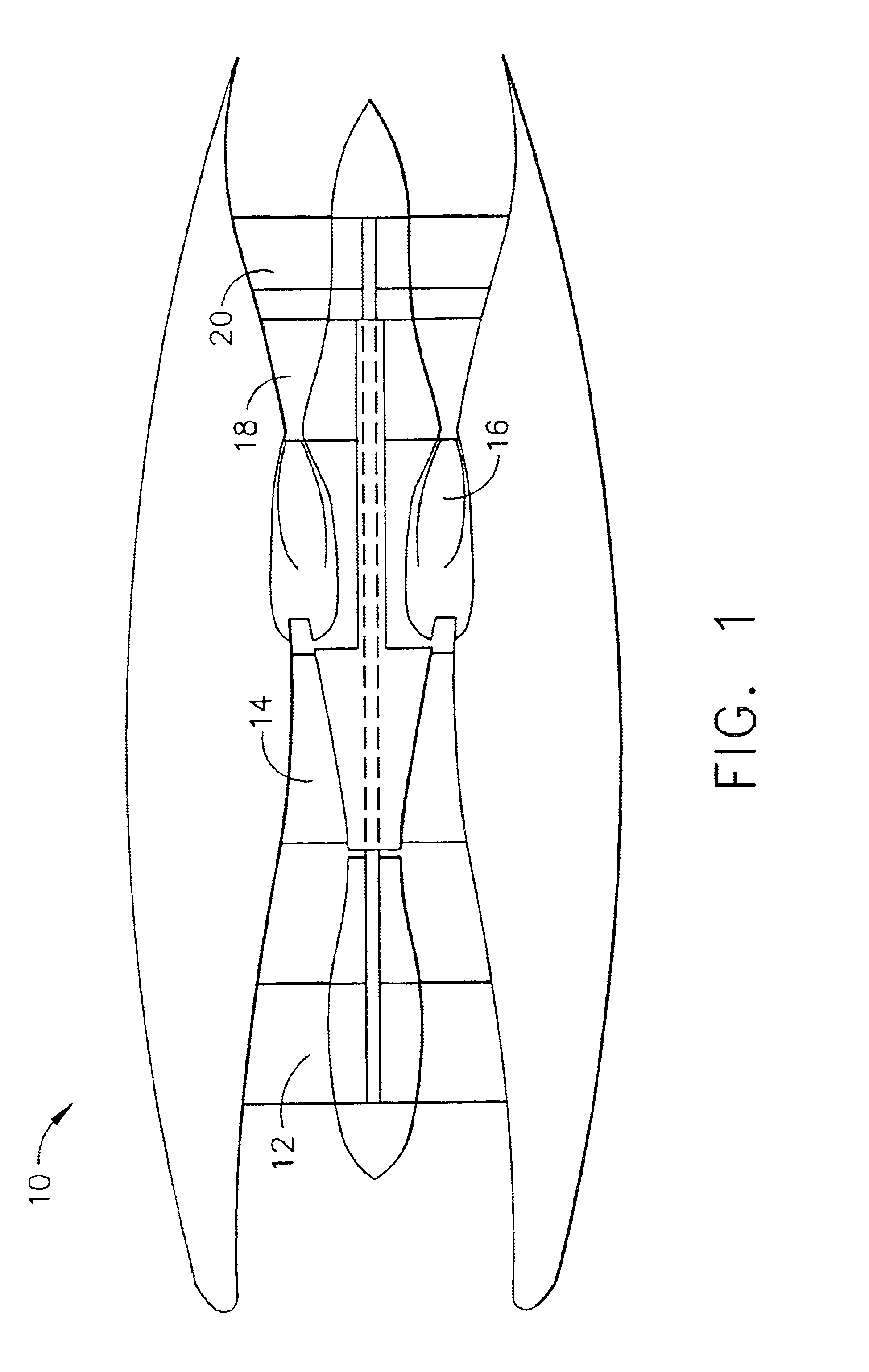

Method and apparatus for reducing gas turbine engine emissions

InactiveUS20080016876A1Emission reductionReduce nitrogen oxide emissionsContinuous combustion chamberEngine manufactureCombustorEngineering

A low emission turbine includes a reverse flow can-type combustor that generally includes a primary and secondary fuel delivery system that can be independently controlled to produce low CO, UHC, and NOx emissions at design set point and at conditions other than design set point. The reverse flow can-type combustor generally includes an annularly arranged array of swirler and mixer assemblies within the combustor, wherein each swirler and mixer in the array includes a primary and secondary fuel delivery system that can be independently controlled. Also disclosed herein is a can-type combustor that includes fluid passageways that perpendicularly impinge the backside of a heat shield. Processes for operating the can-type combustors are also disclosed.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com