Patents

Literature

707results about How to "Reduce evaporation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lens-eye model and method for predicting in-vivo lens performance

InactiveUS6626535B2Easily impartedRate of evaporationSpectales/gogglesPhase-affecting property measurementsModel systemEngineering

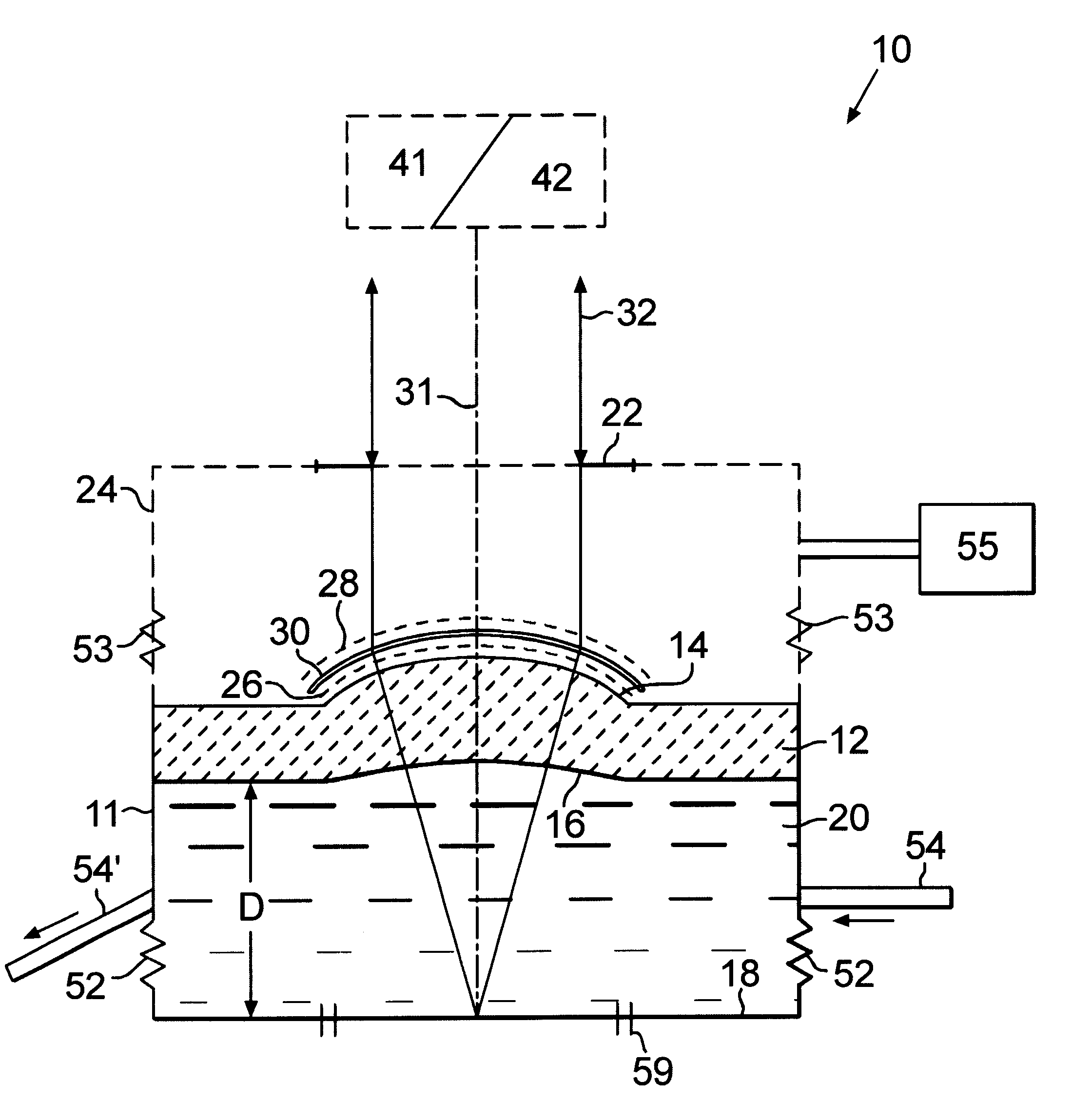

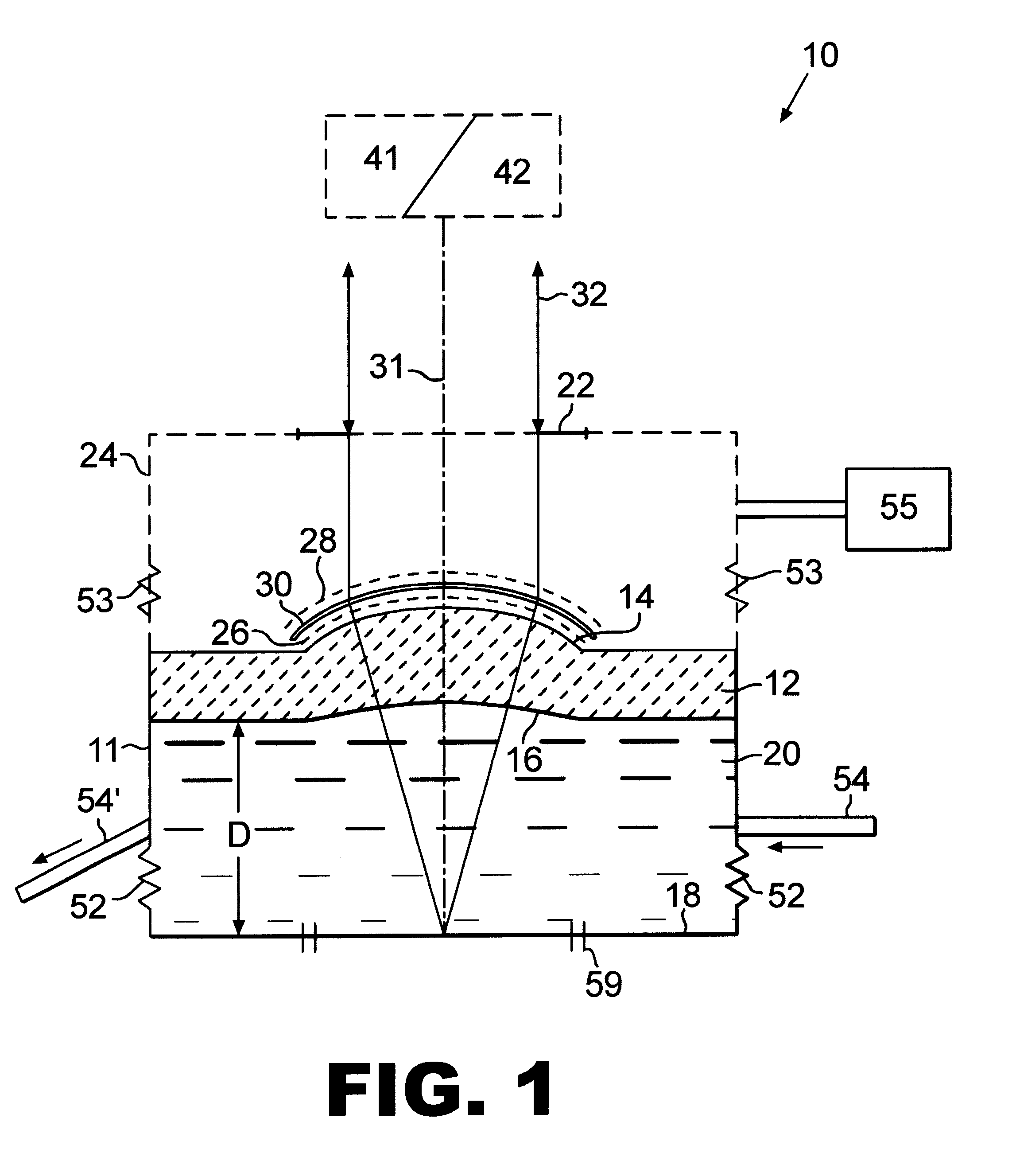

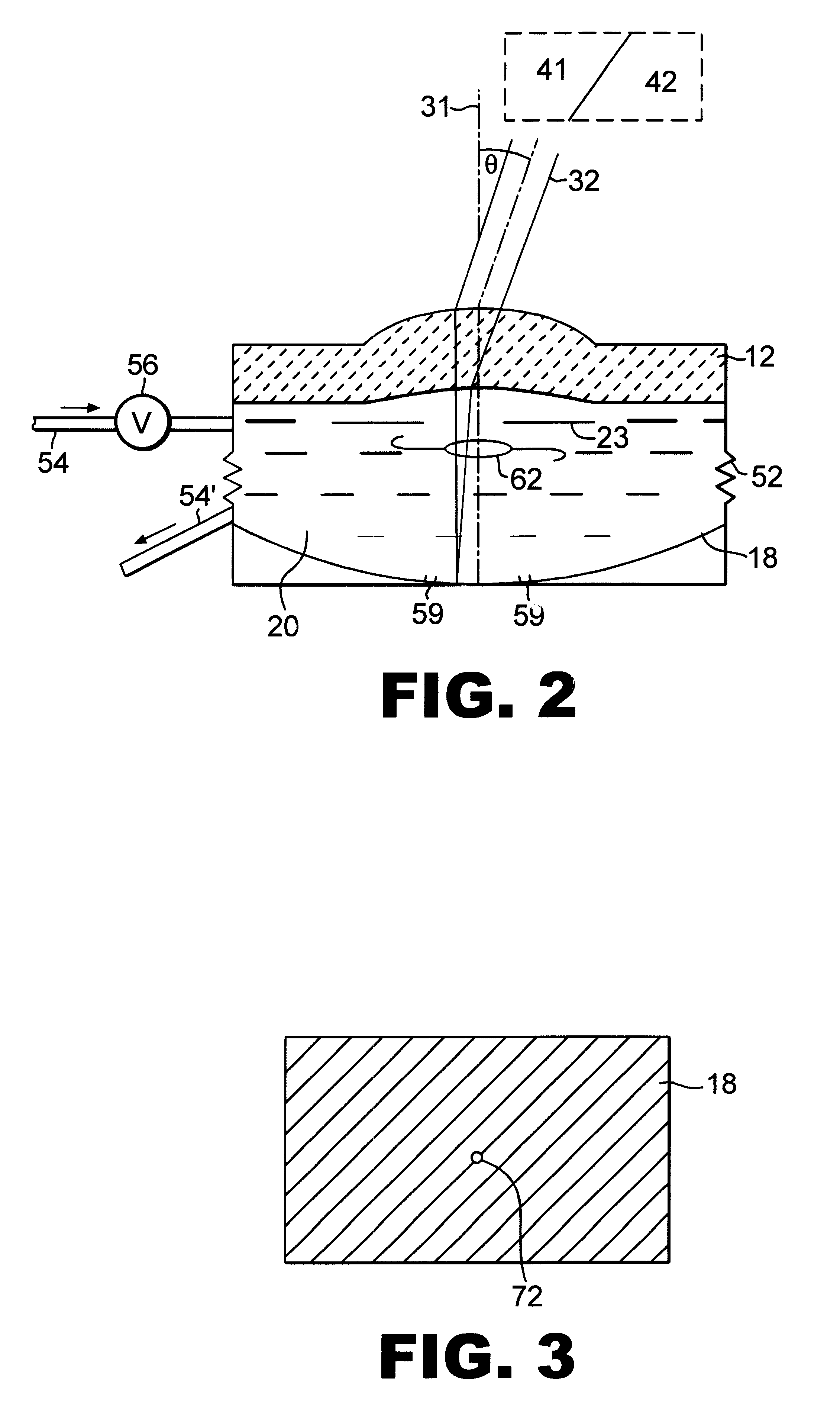

An eye model system for remotely predicting the in-vivo performance of a vision altering optic includes a representative cornea, a dispersion medium, and a retinal surface. The corneal surfaces provide anatomical shape, optical power, and higher order aberration content. The dispersion medium mimics chromatic dispersion in an actual eye. The retinal surface is moveable to provide selected defocus. A humidity and temperature enclosure may be provided. Model eye elements can be tilted or decentered to simulate actual conditions. An associated method for remotely measuring the performance of a vision altering optic to predict its performance in-vivo includes making topography, wavefront, interferometry, PSF, MTF, or other optical and / or physical measurements of the model eye system with and without the optic in combination.

Owner:BAUSCH & LOMB INC

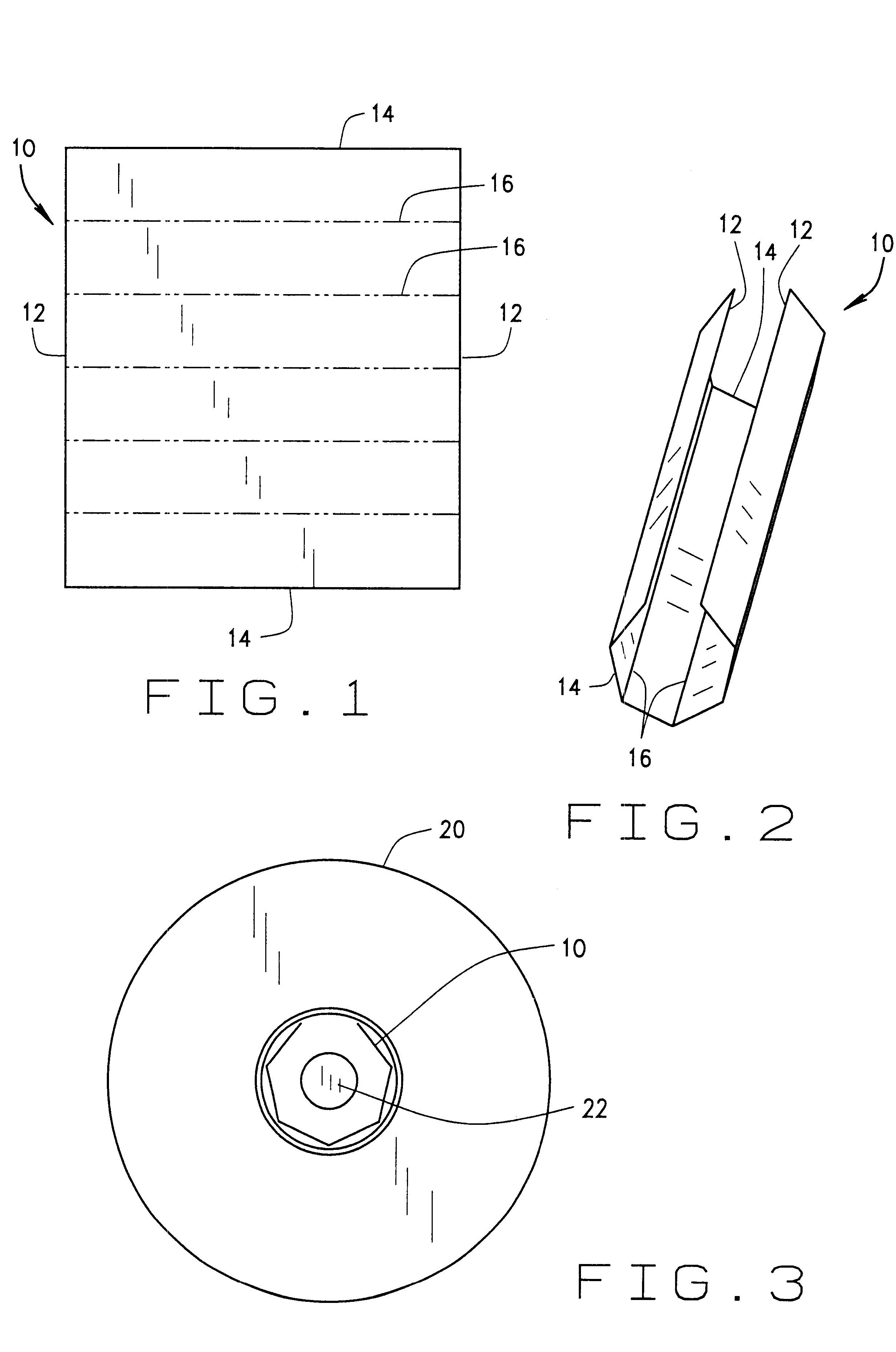

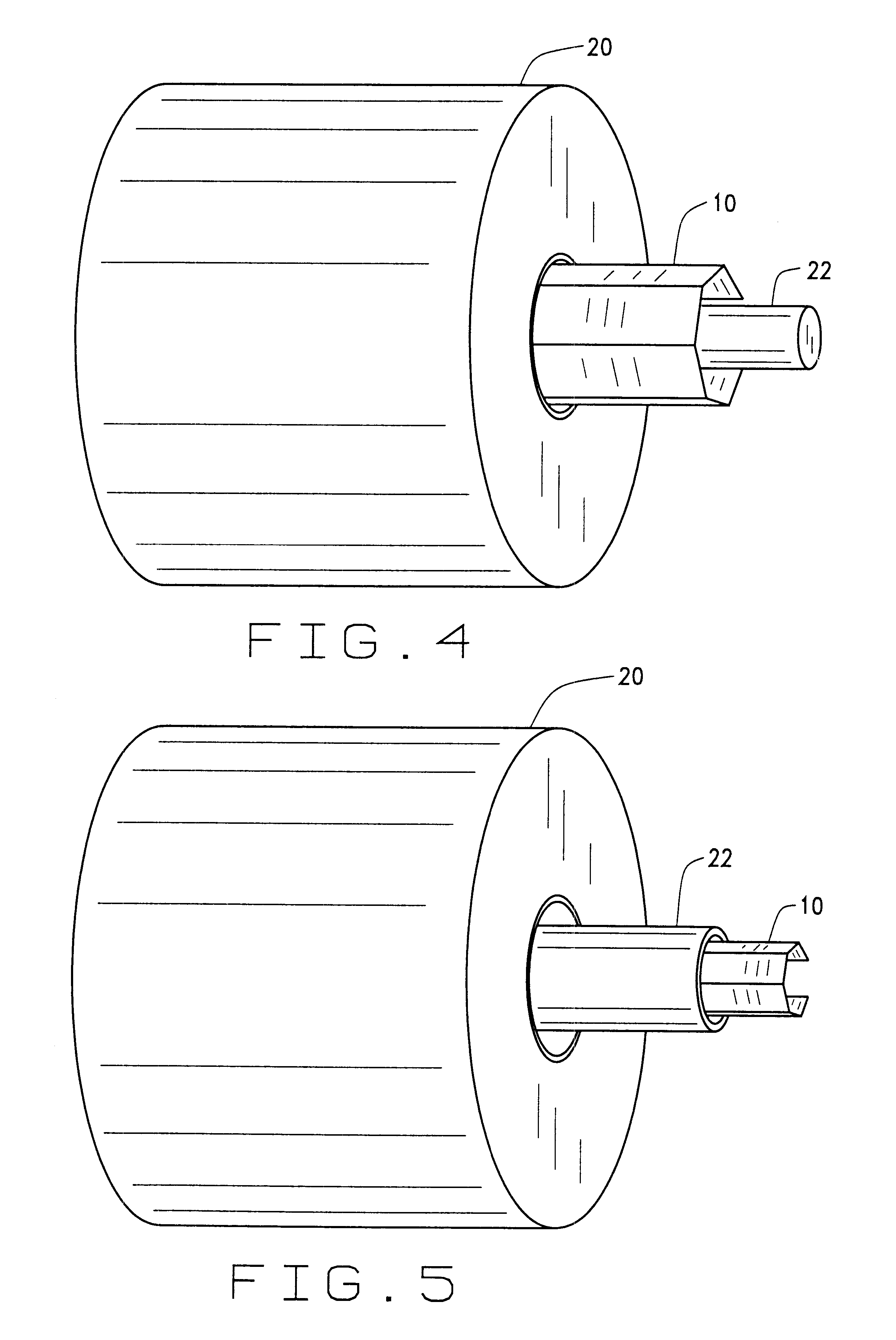

Prescented and custom scented card insert

InactiveUS6575383B2Better friendlinessThicken fragranceSpraying apparatusDe-icing equipmentsPaper towelEngineering

A pre-scented or custom scented card insert designed to fit into any existing toilet paper or paper towel holder. The insert allows consumers to choose a scent additive to freshen their bathroom, kitchens or any other place where these products are used, as well as to scent the toilet paper or paper towel rolls. The insert can be replaced easily to refresh the roll, or additional inserts can be added to create a stronger fragrance impact.

Owner:ORLANDI INC

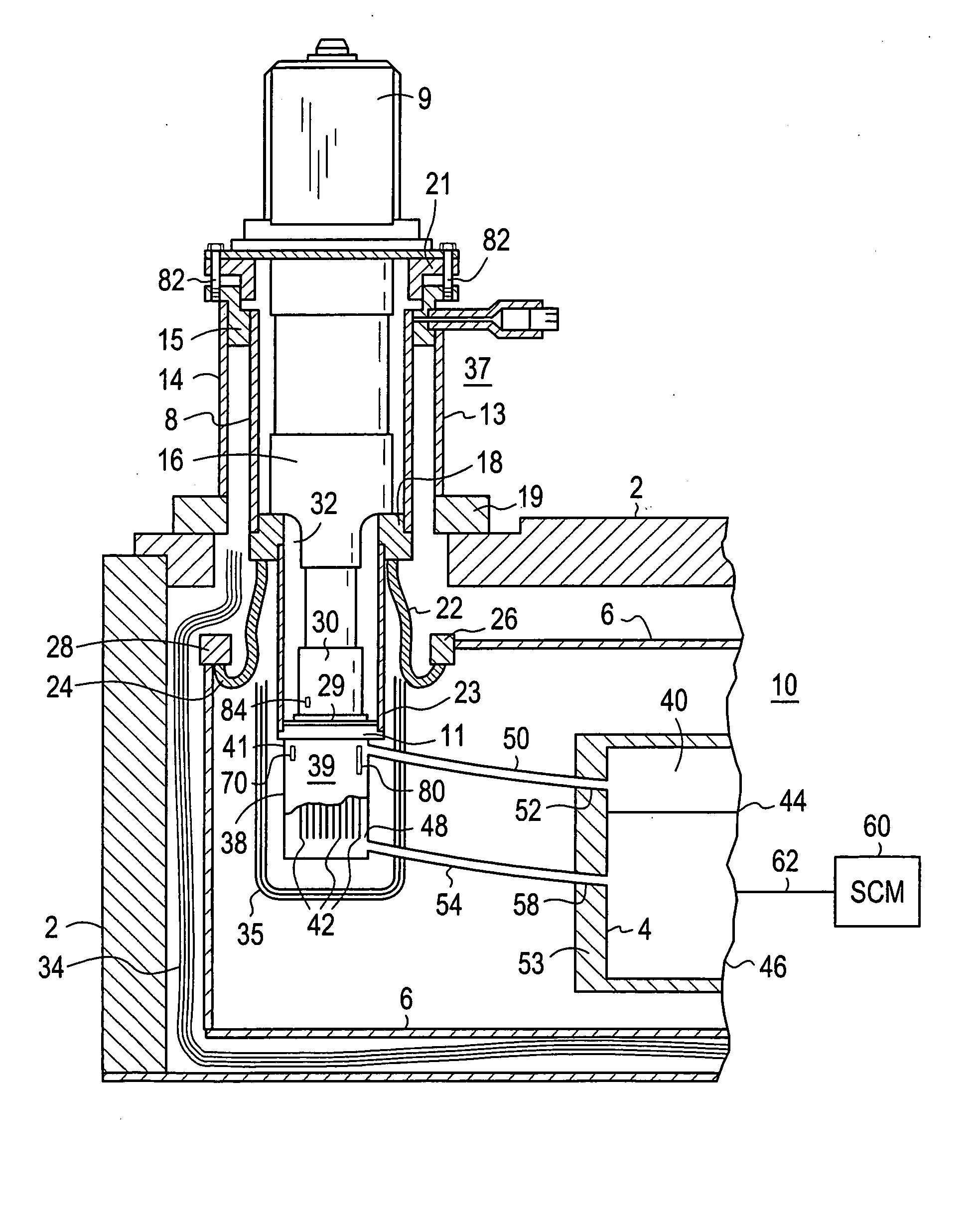

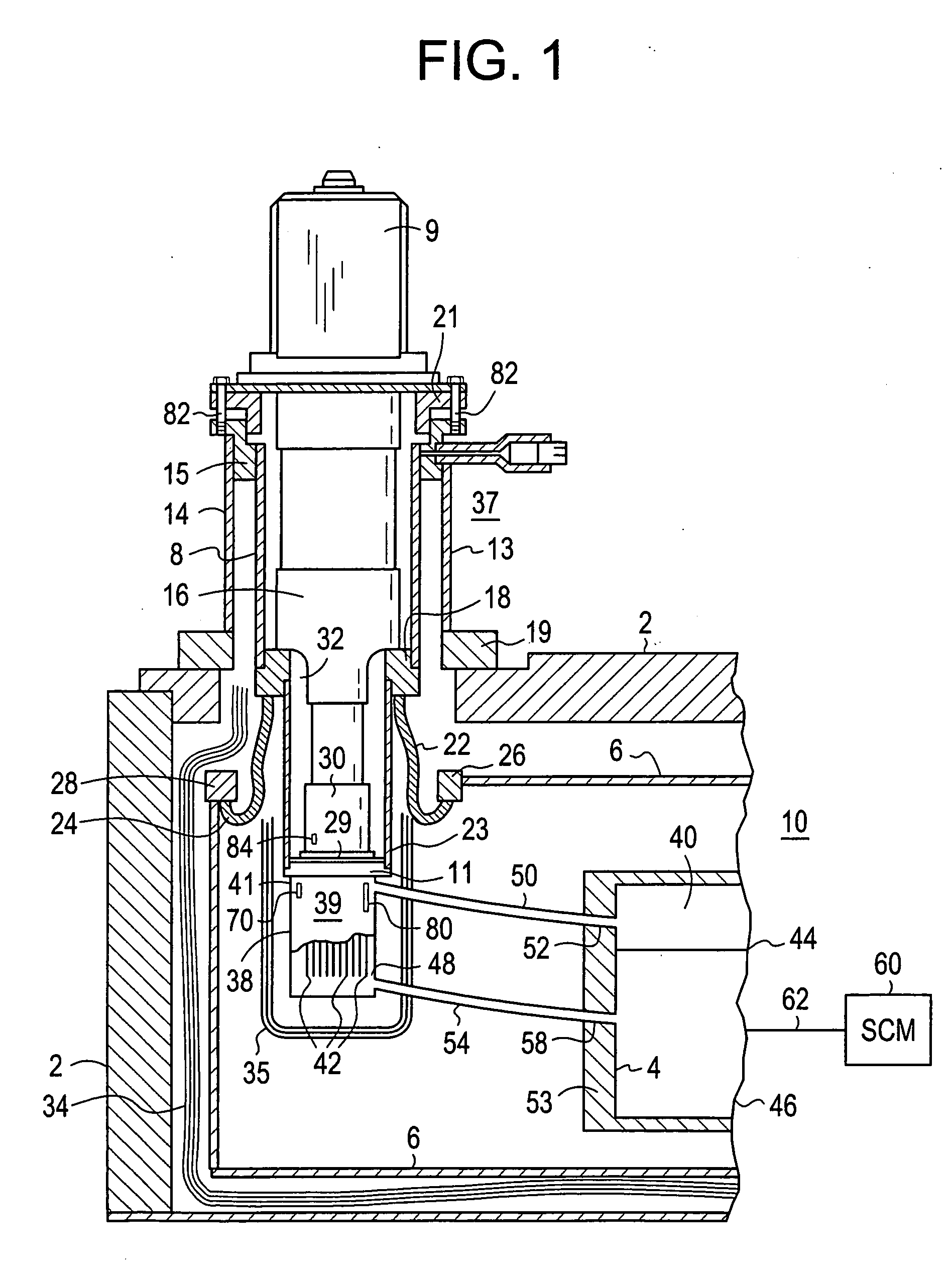

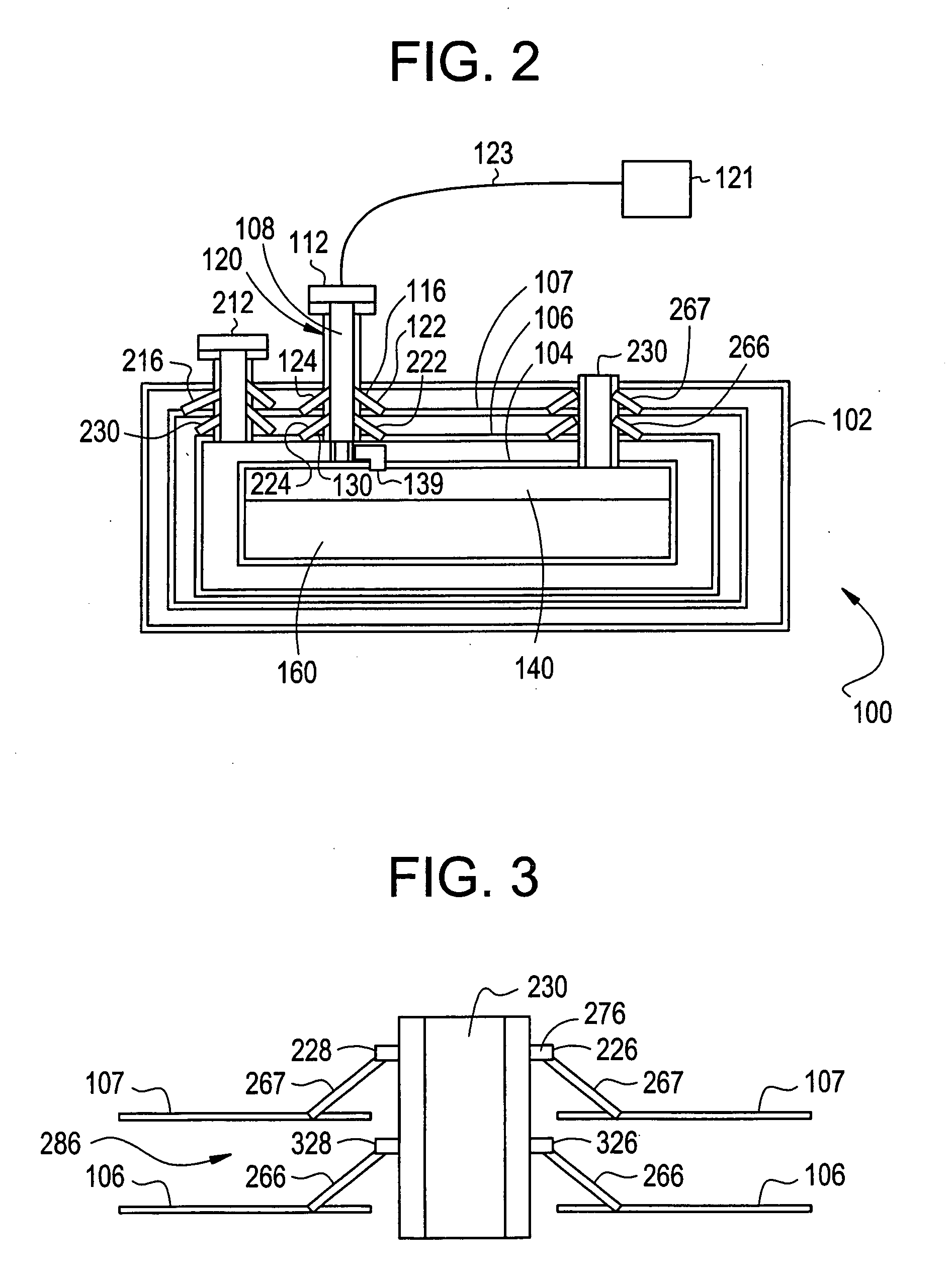

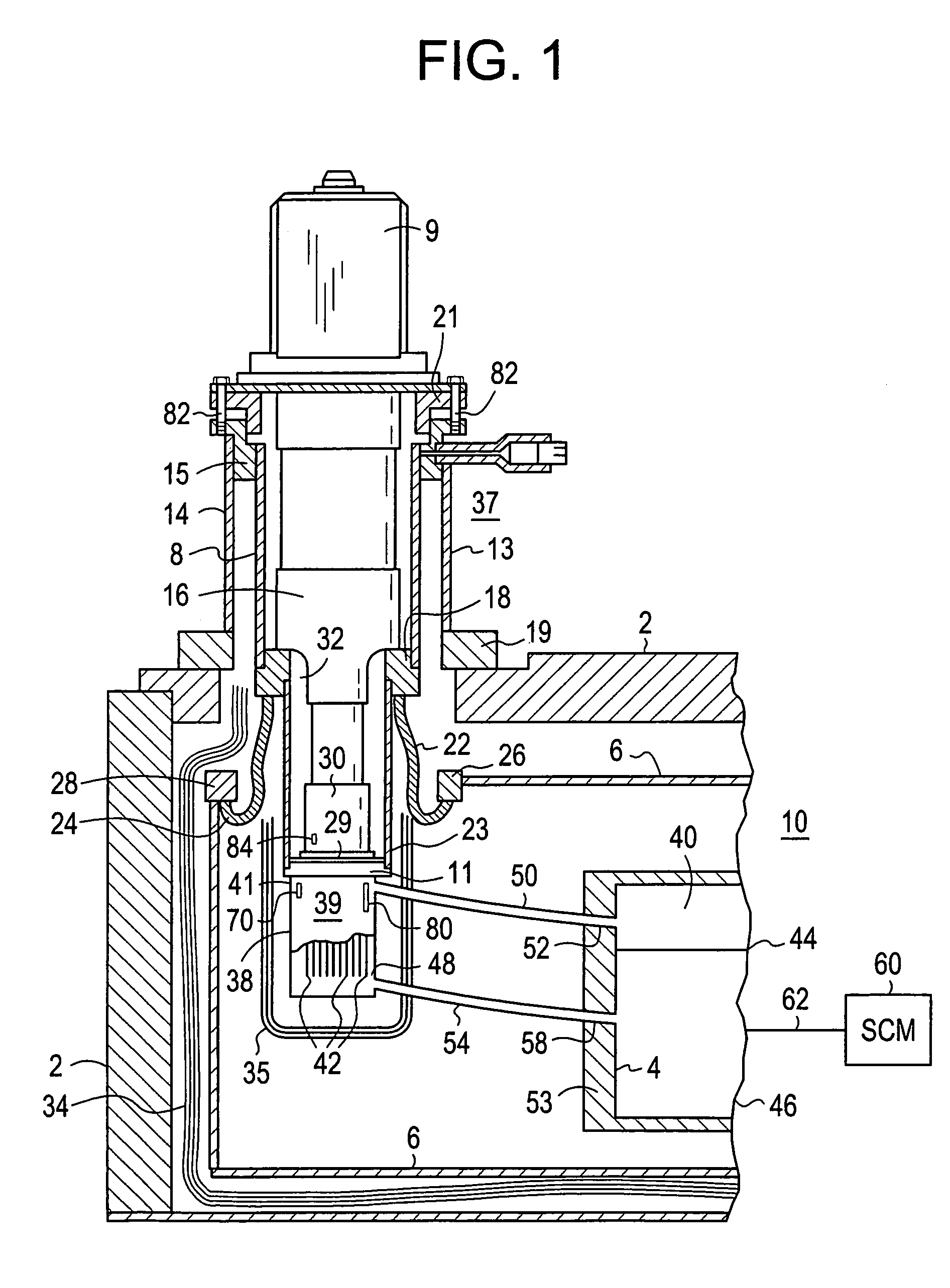

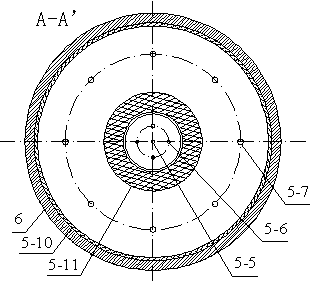

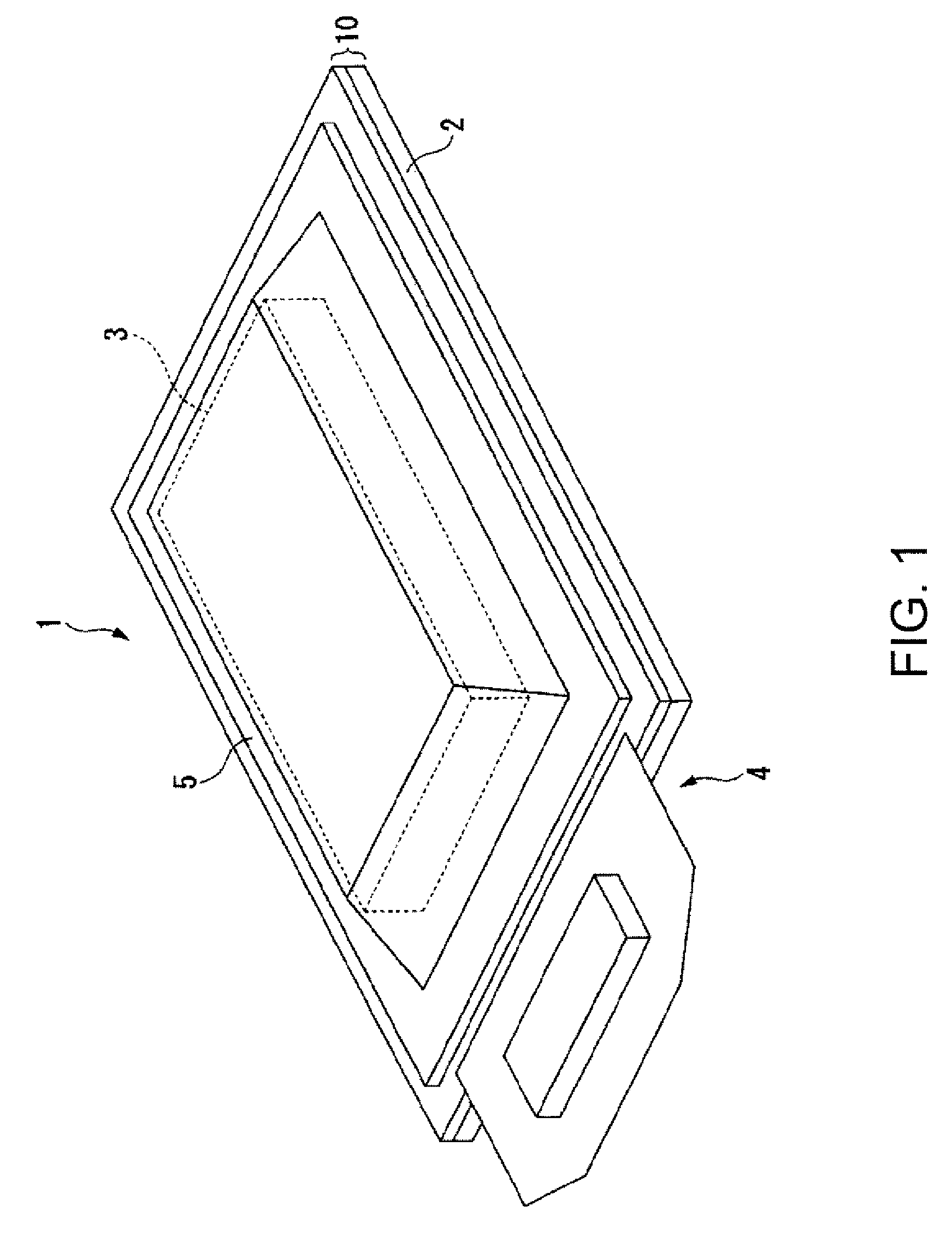

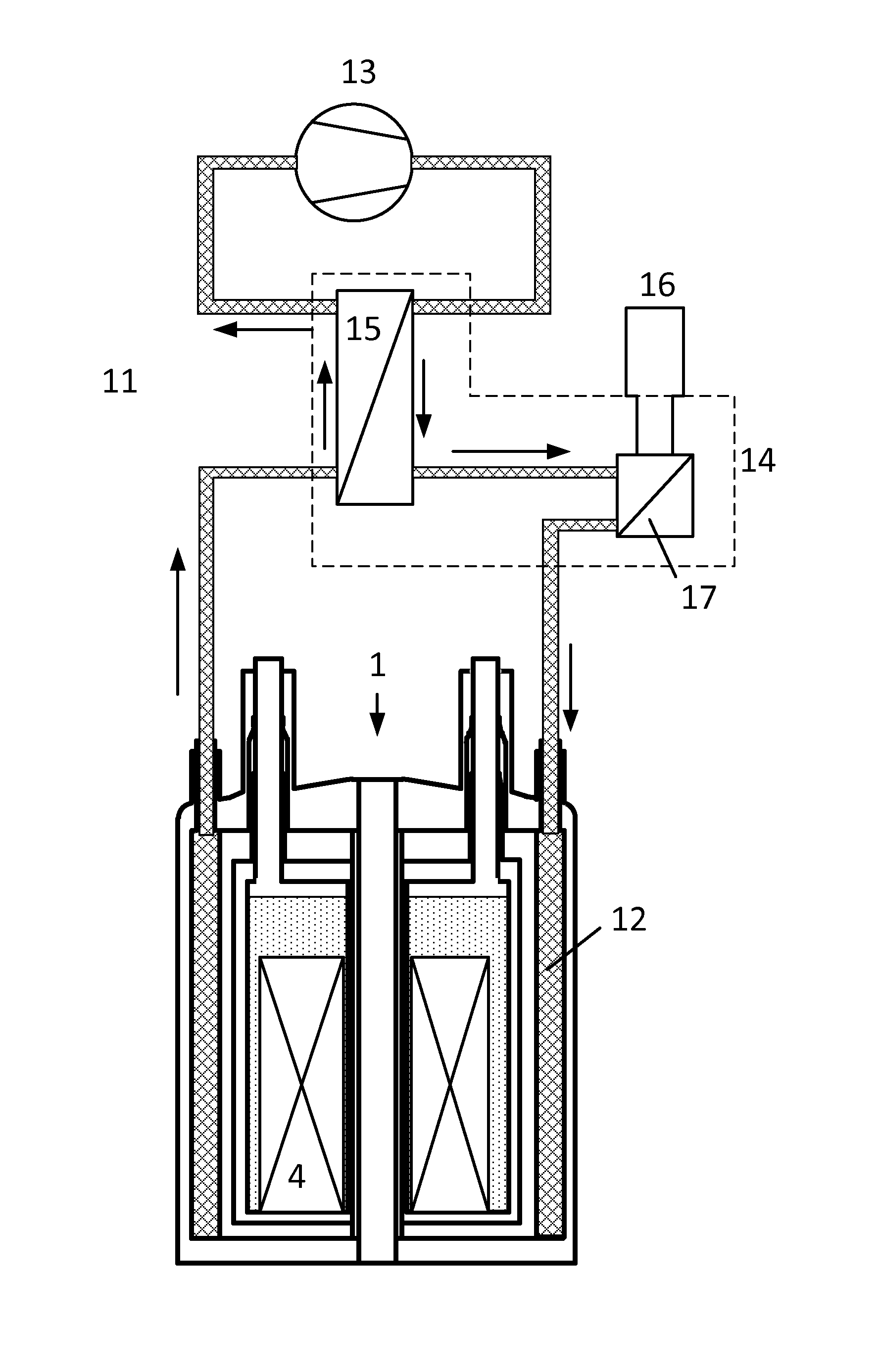

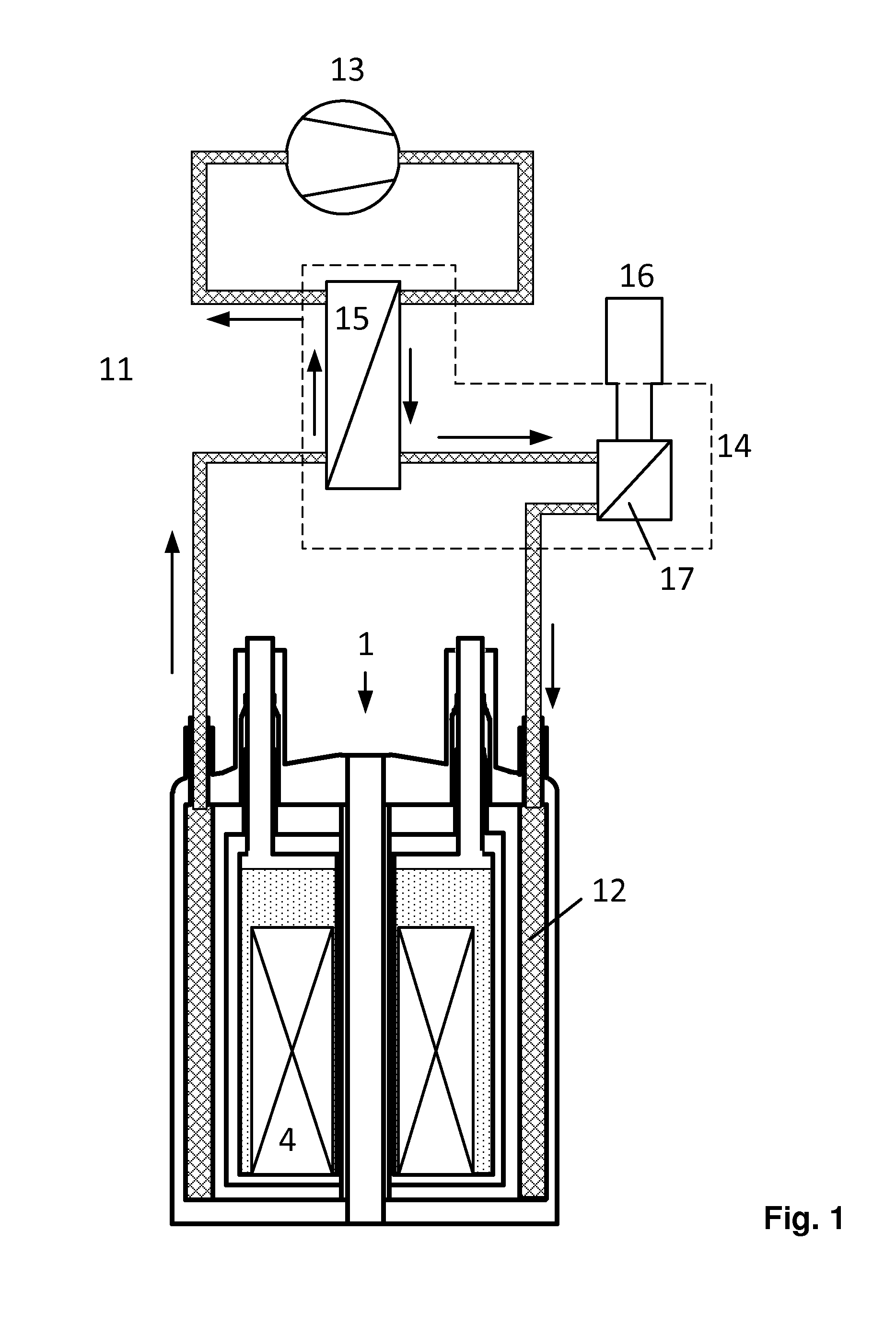

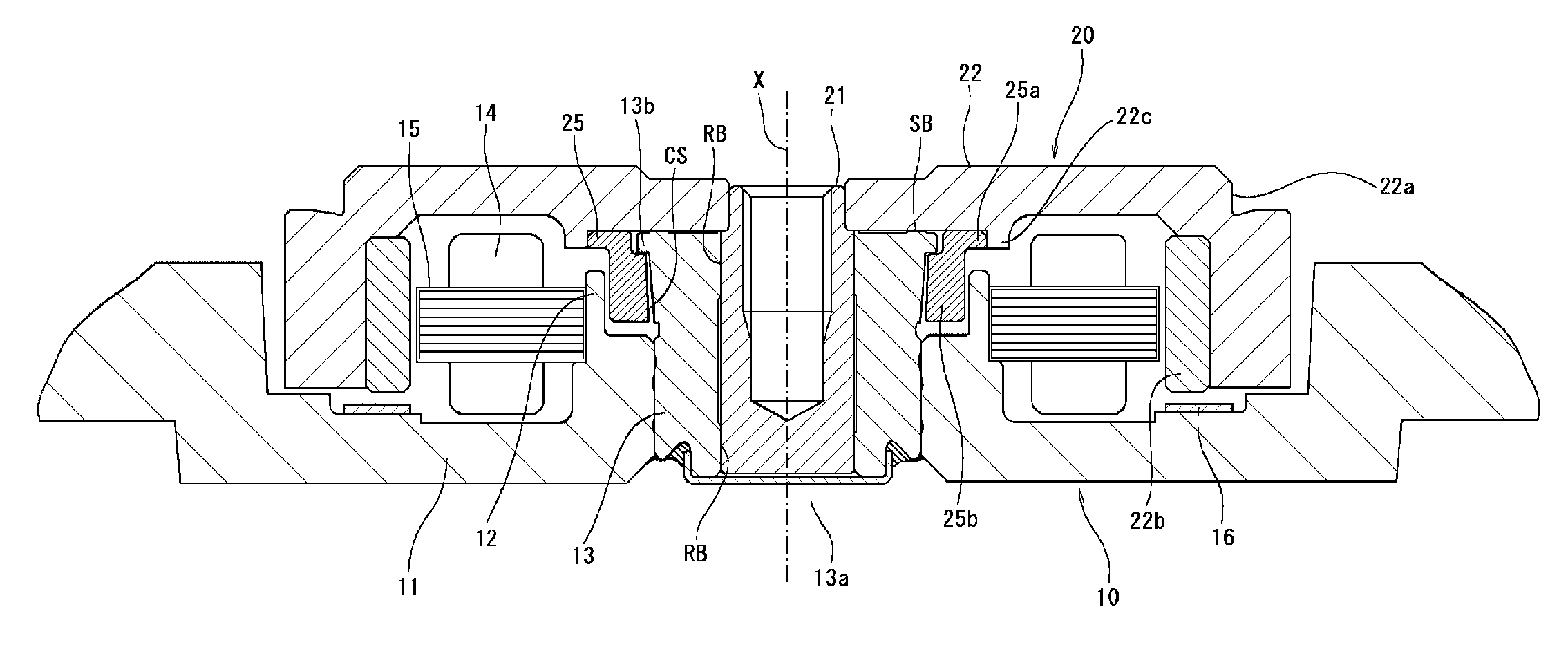

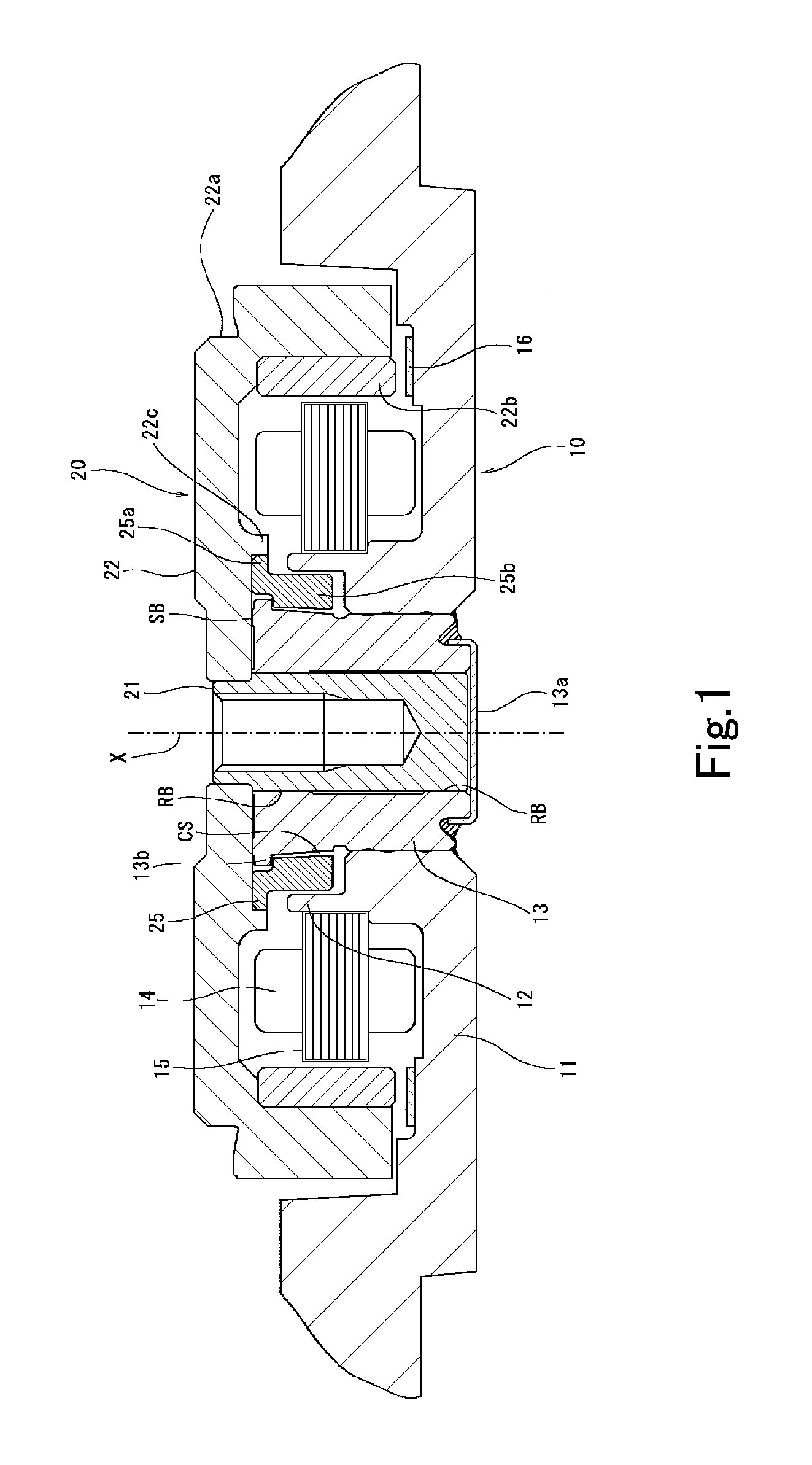

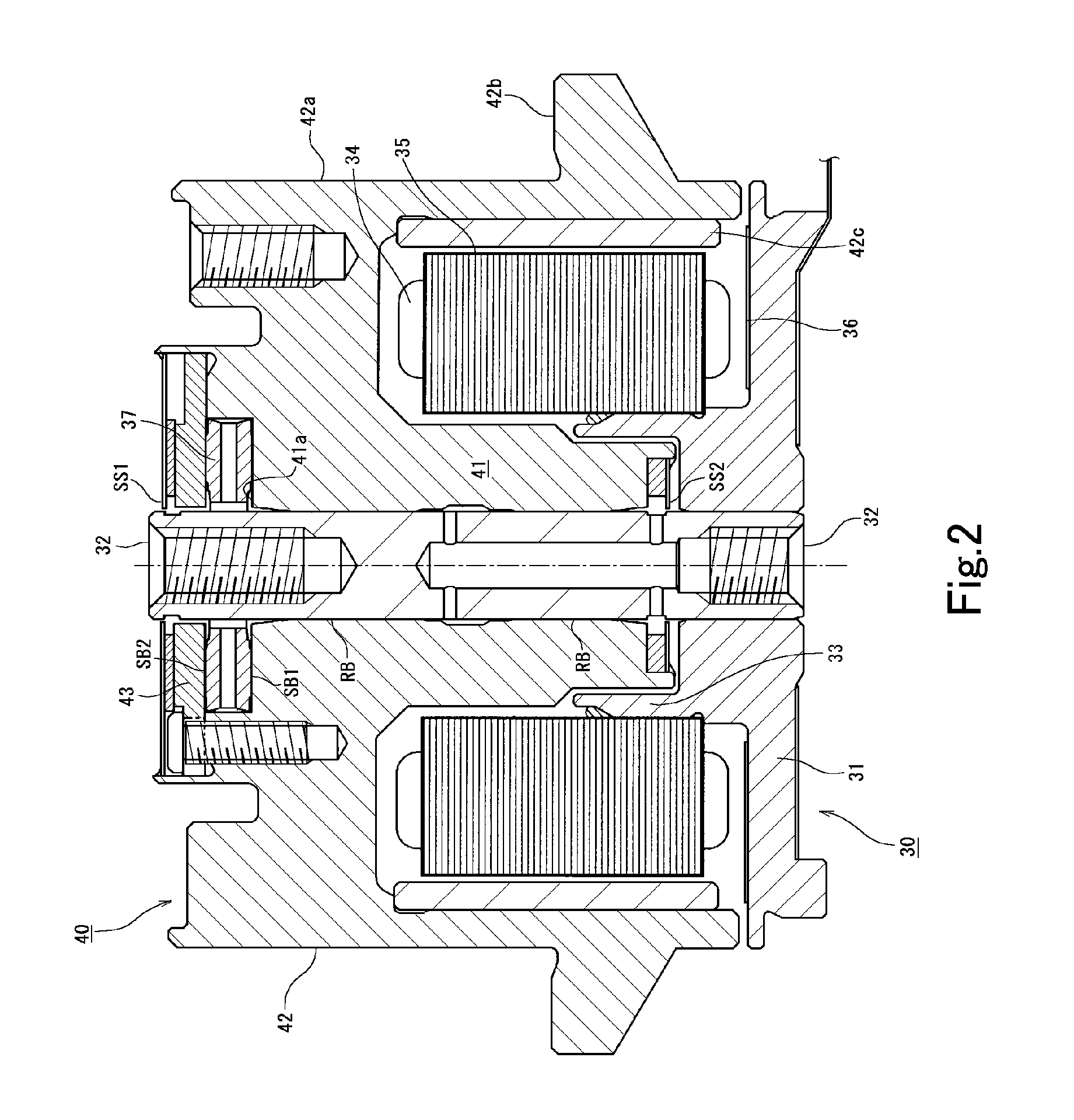

Superconductive magnet including a cryocooler coldhead

ActiveUS20060022779A1Reduce evaporation rateReduce heat loadMagnetic measurementsCompression machinesCryocoolerMechanics

A zero boiloff cryogen cooled recondensing superconducting magnet assembly including superconducting magnet coils suitable for magnetic resonance imaging including a cryogen pressure vessel to contain a liquid cryogen reservoir to provide cryogenic temperatures to the magnet coils for superconducting operation; a vacuum vessel surrounding the pressure vessel and spaced therefrom; a first thermal shield surrounding and spaced from the pressure vessel; a second thermal shield surrounding and spaced from the first thermal shield and intermediate the vacuum vessel and the first shield; a cryocooler thermally connected by a first and a second thermal interface to the first and second thermal shields, respectively; a recondenser positioned in the space between the pressure vessel and the first thermal shield and thermally connected by a thermal interface to the cryocooler to recondense, back to liquid, cryogen gas provided from the pressure vessel; and means for returning the recondensed liquid cryogen the pressure vessel; wherein the second thermal shield surrounding the first thermal shield reduces a radiation heat load from the first thermal shield to the pressure vessel lowering boiloff of cryogen gas under conditions of failure or power off of the cryocooler.

Owner:GENERAL ELECTRIC CO

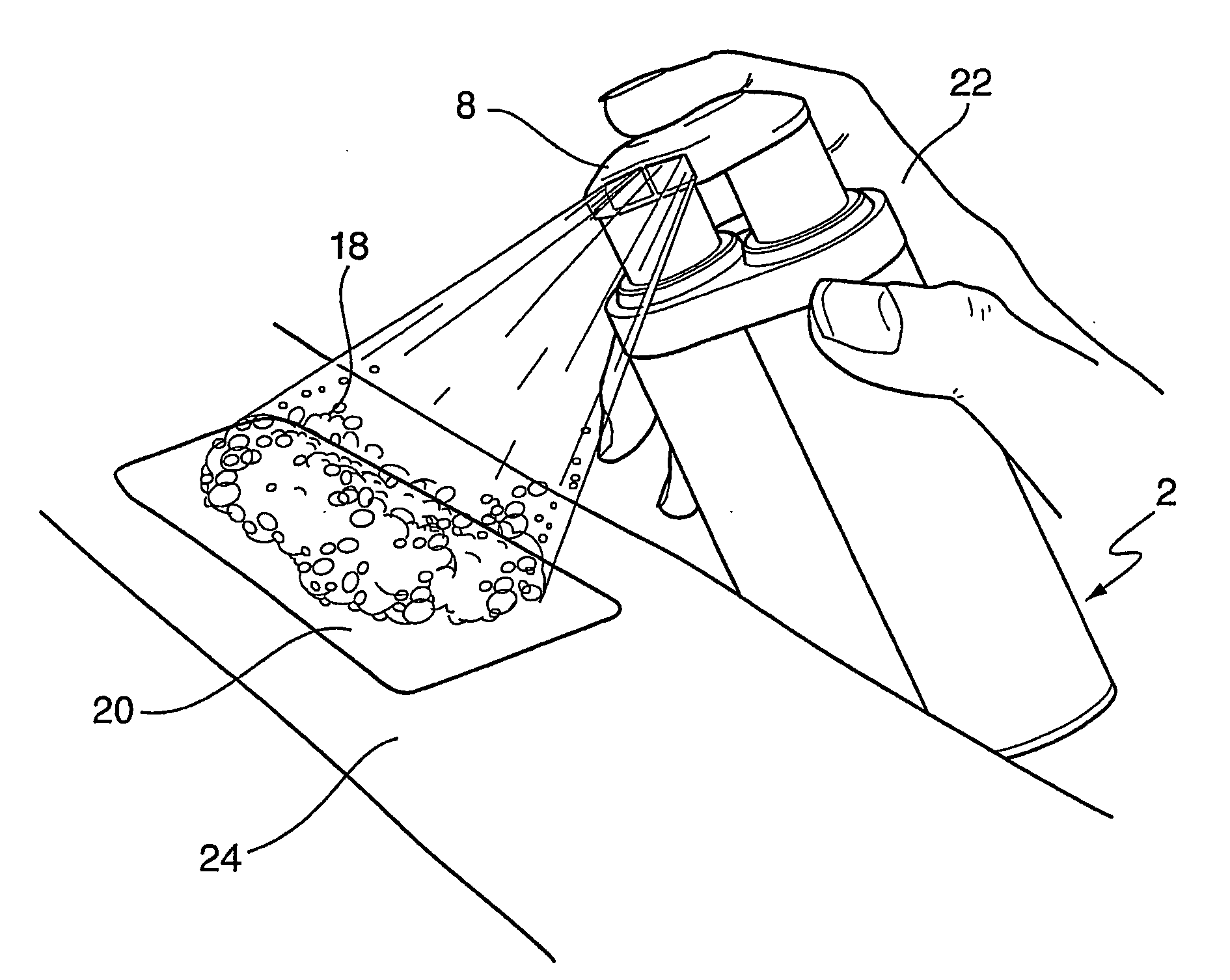

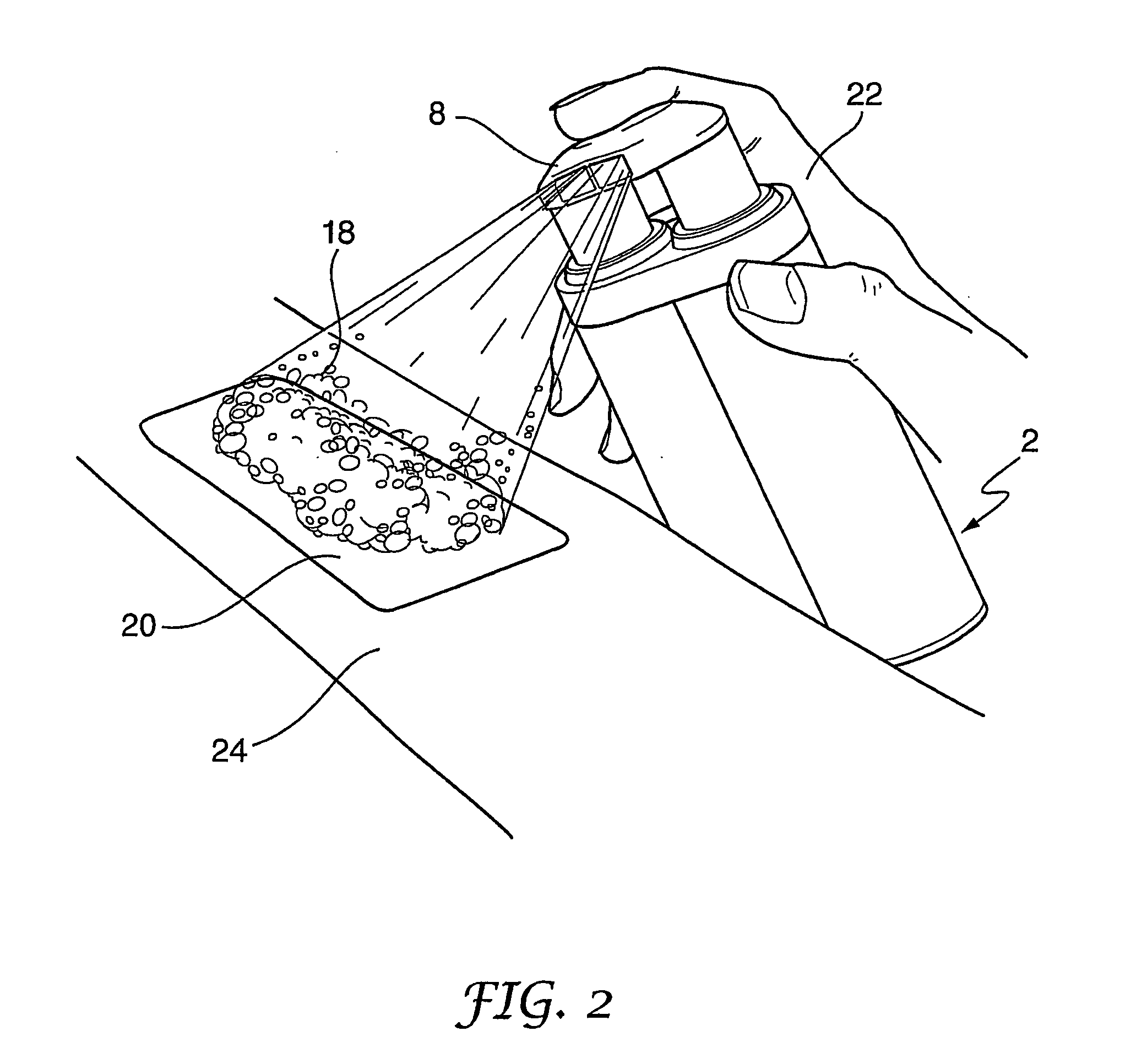

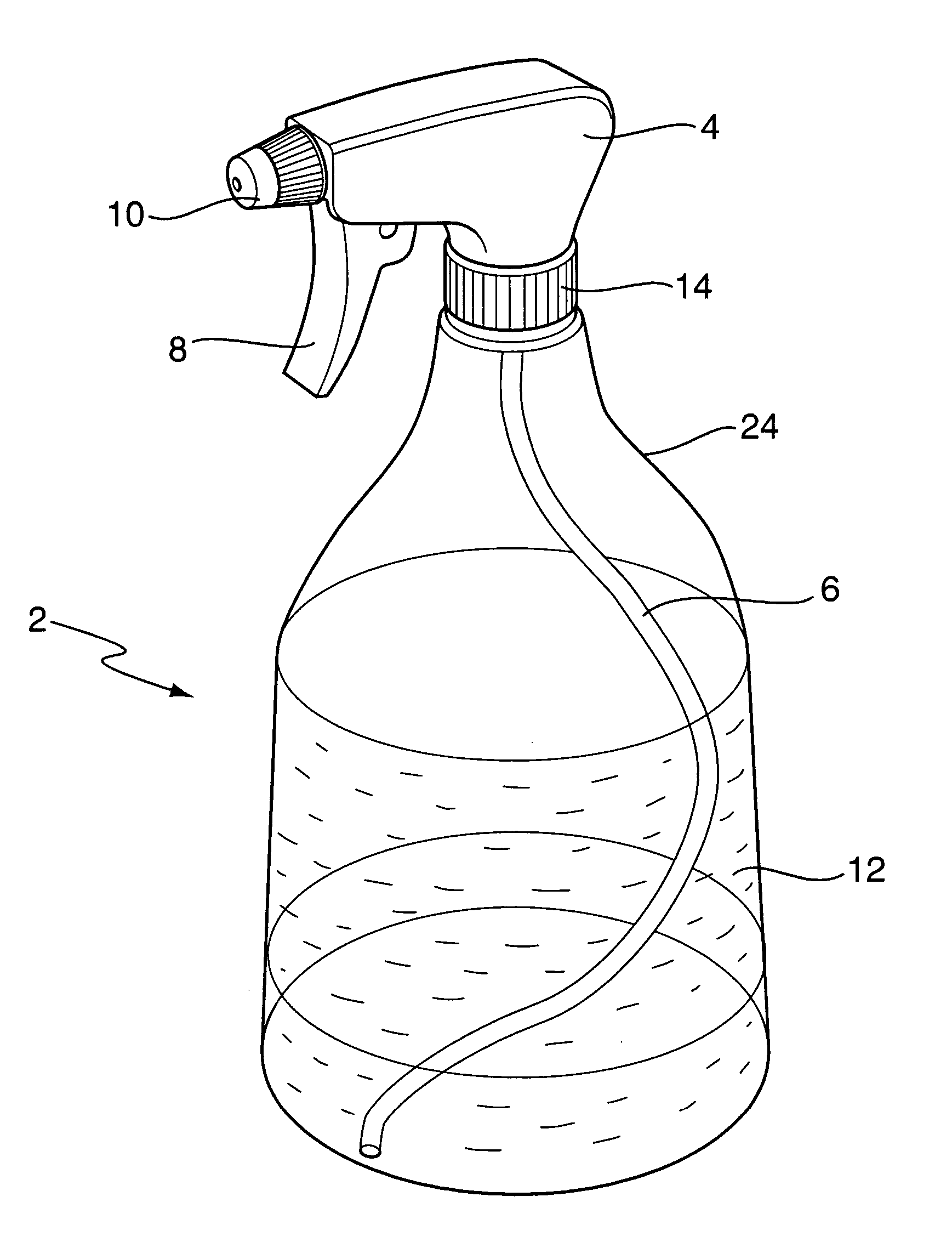

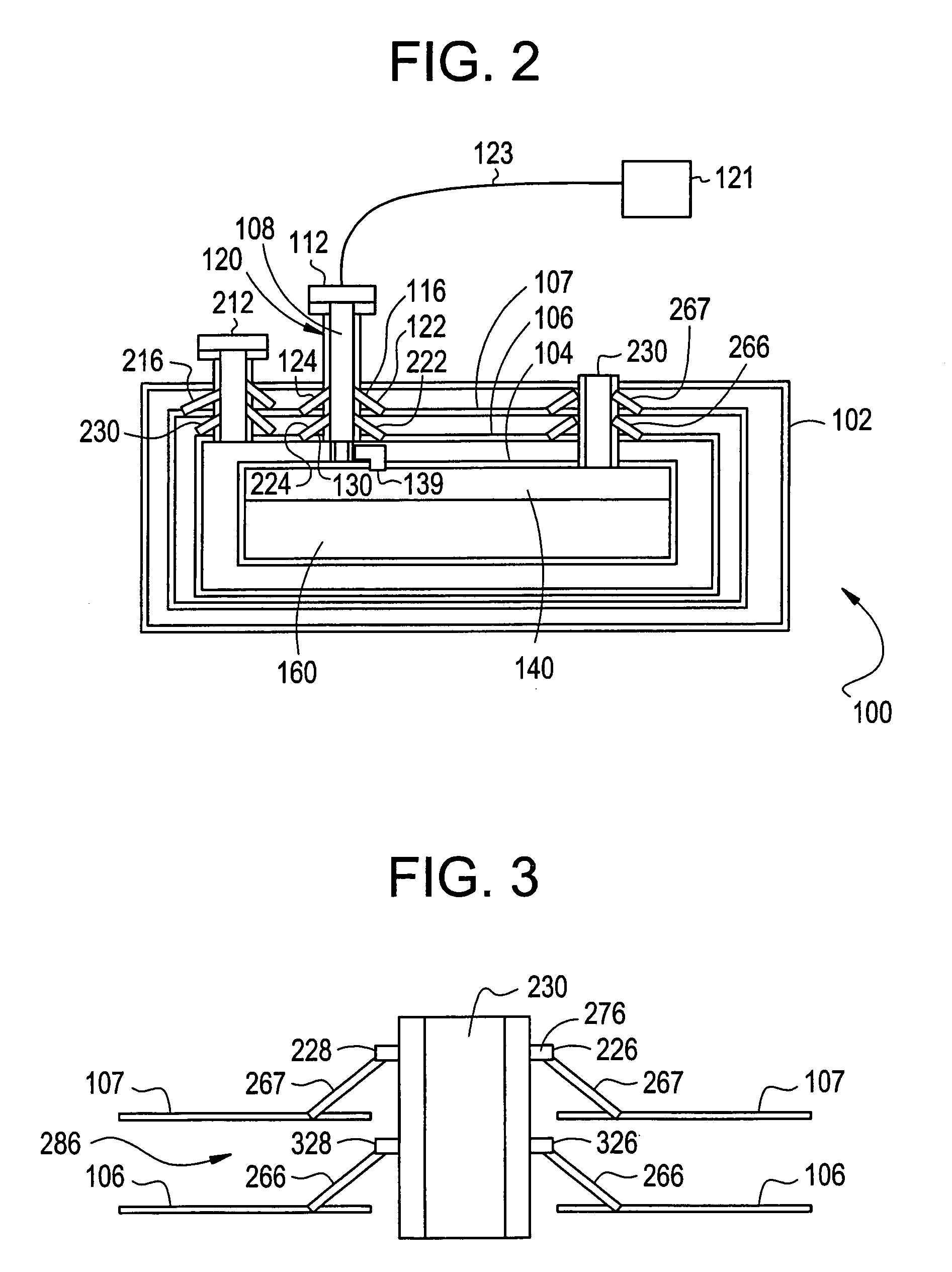

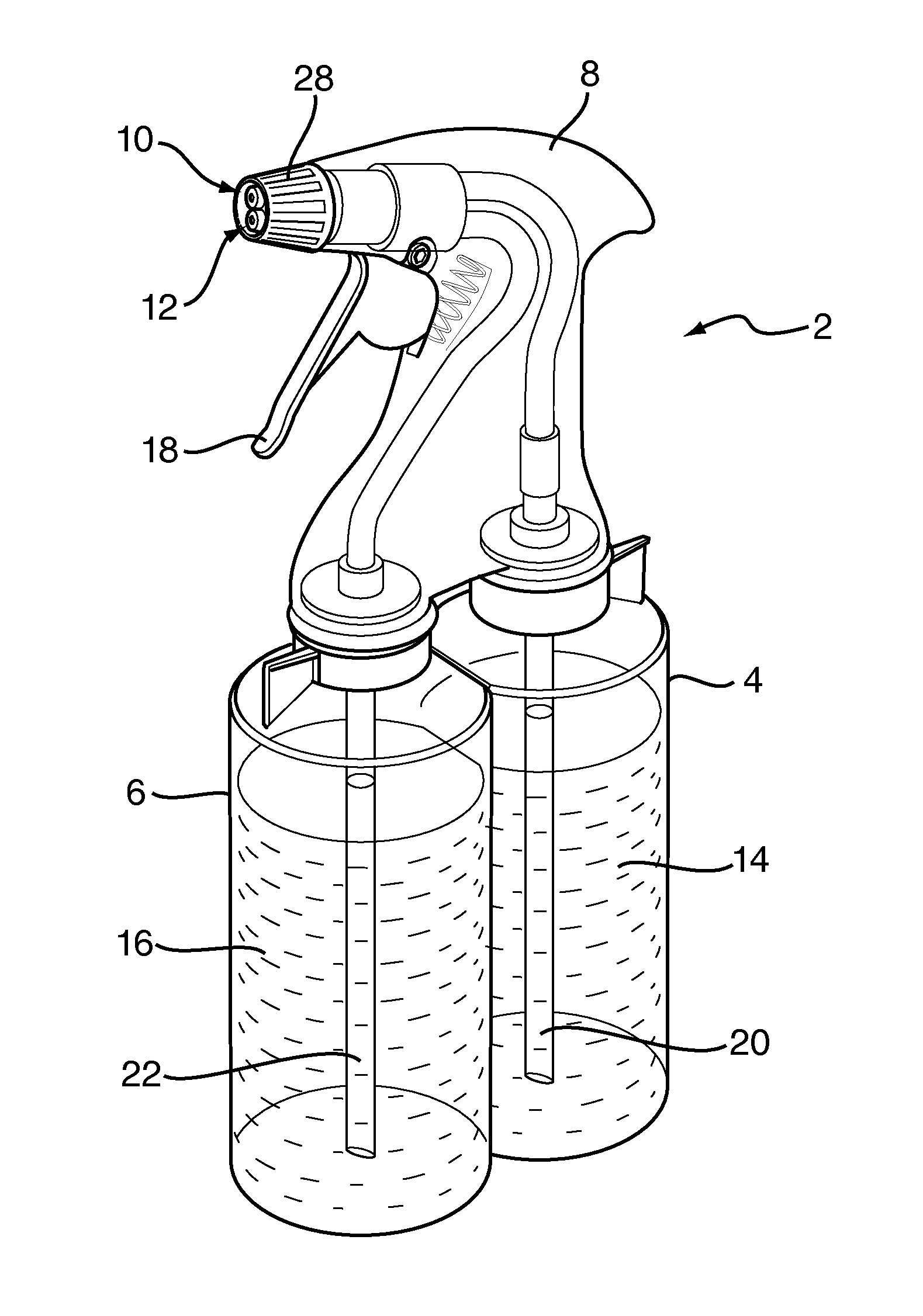

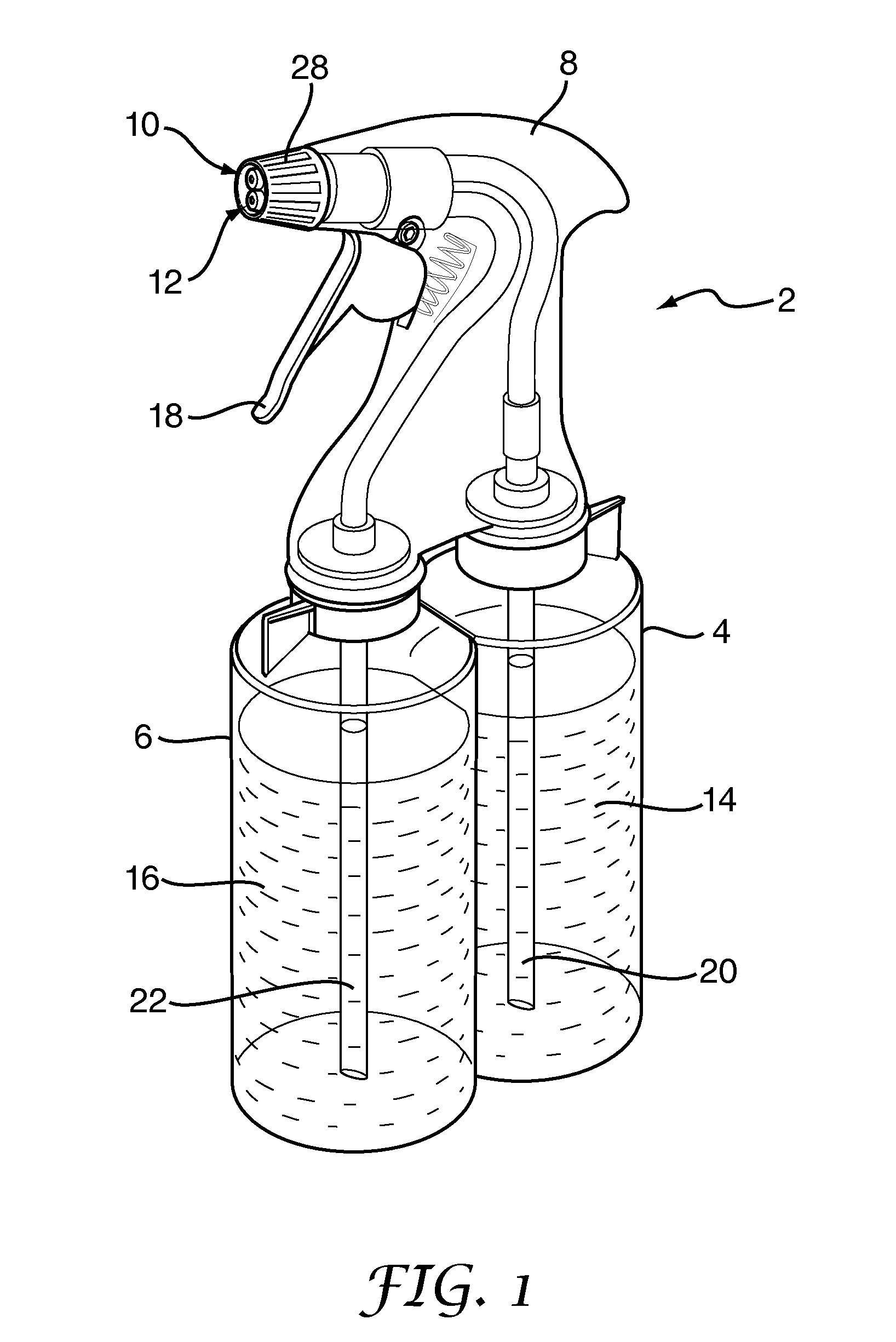

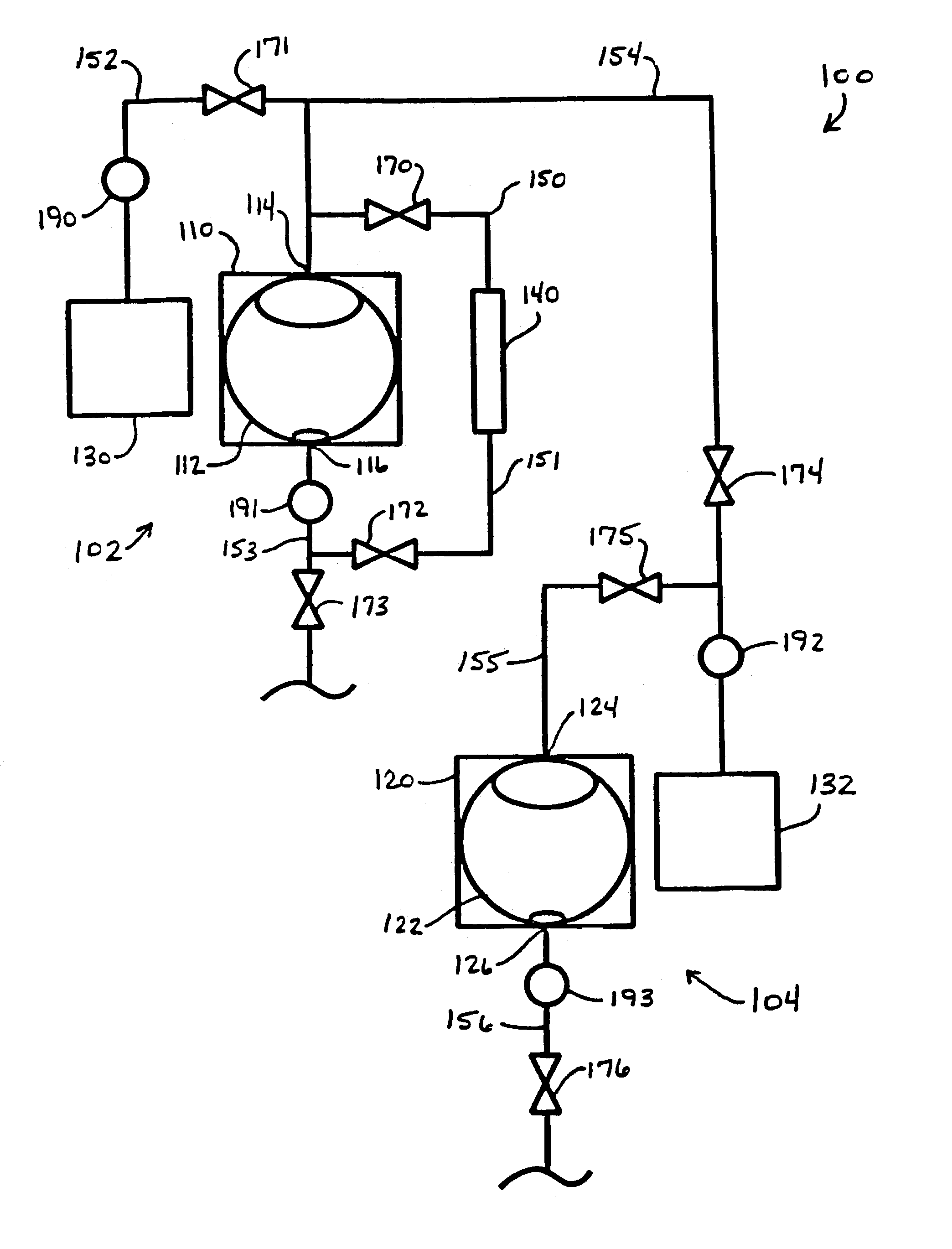

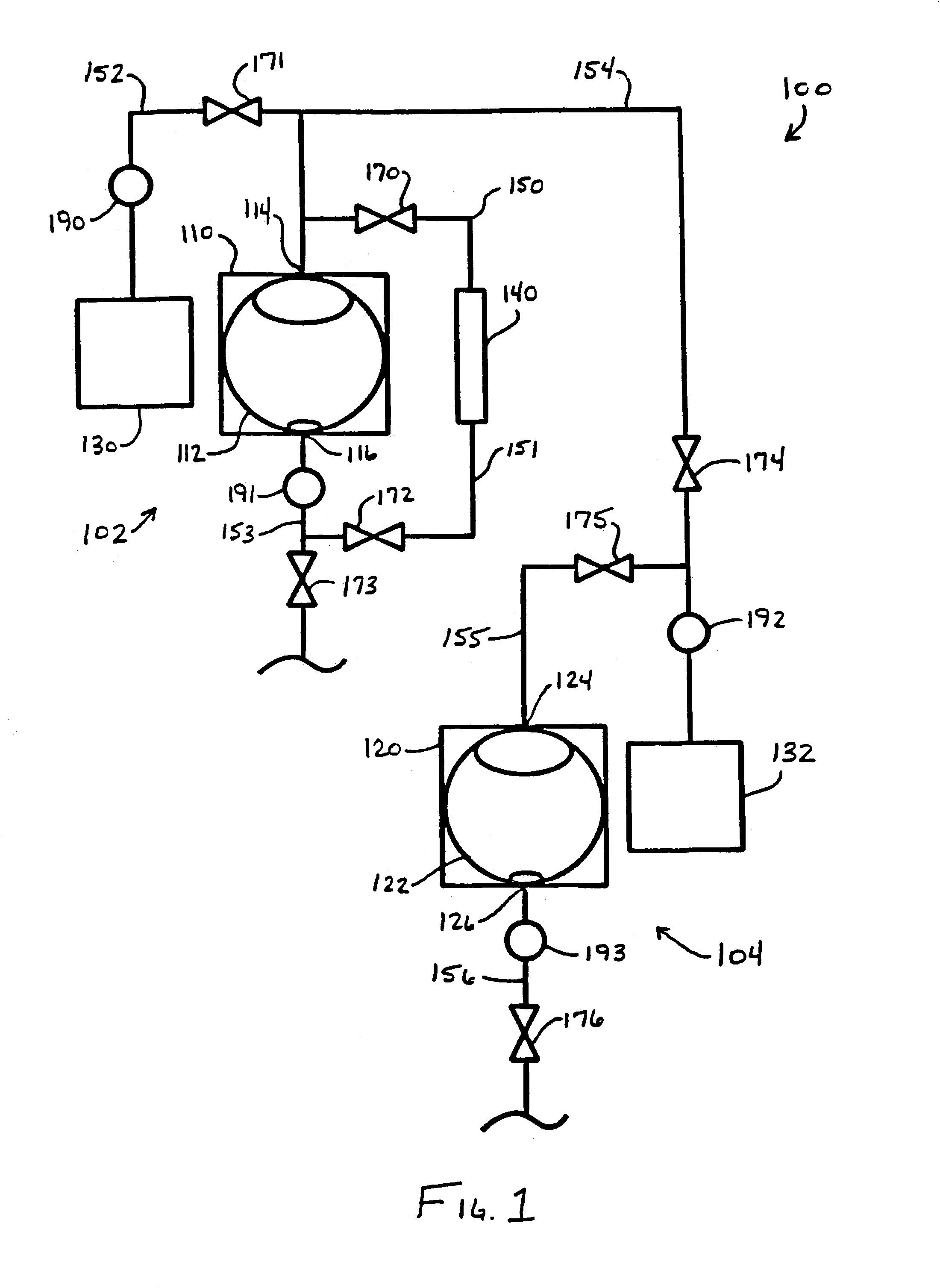

Sterilant system

ActiveUS20100036305A1Stable compoundEnhanced surface contactBiocideDead animal preservationAqueous mediumReagent

A two-part sterilant system comprises: (a) a first part comprising a first reagent in an aqueous medium having a first foam promoter dissolved therein and contained in a first dispenser whereby it may be dispensed as a first foam; and (b) a second part which comprises a second reagent in an aqueous medium having a second foam promoter dissolved therein and contained in a second dispenser whereby it may be dispensed as a second foam; wherein the first reagent and the second reagent will react to provide a sterilising composition when the first foam is mixed with the second foam.

Owner:TRISTEL PCL

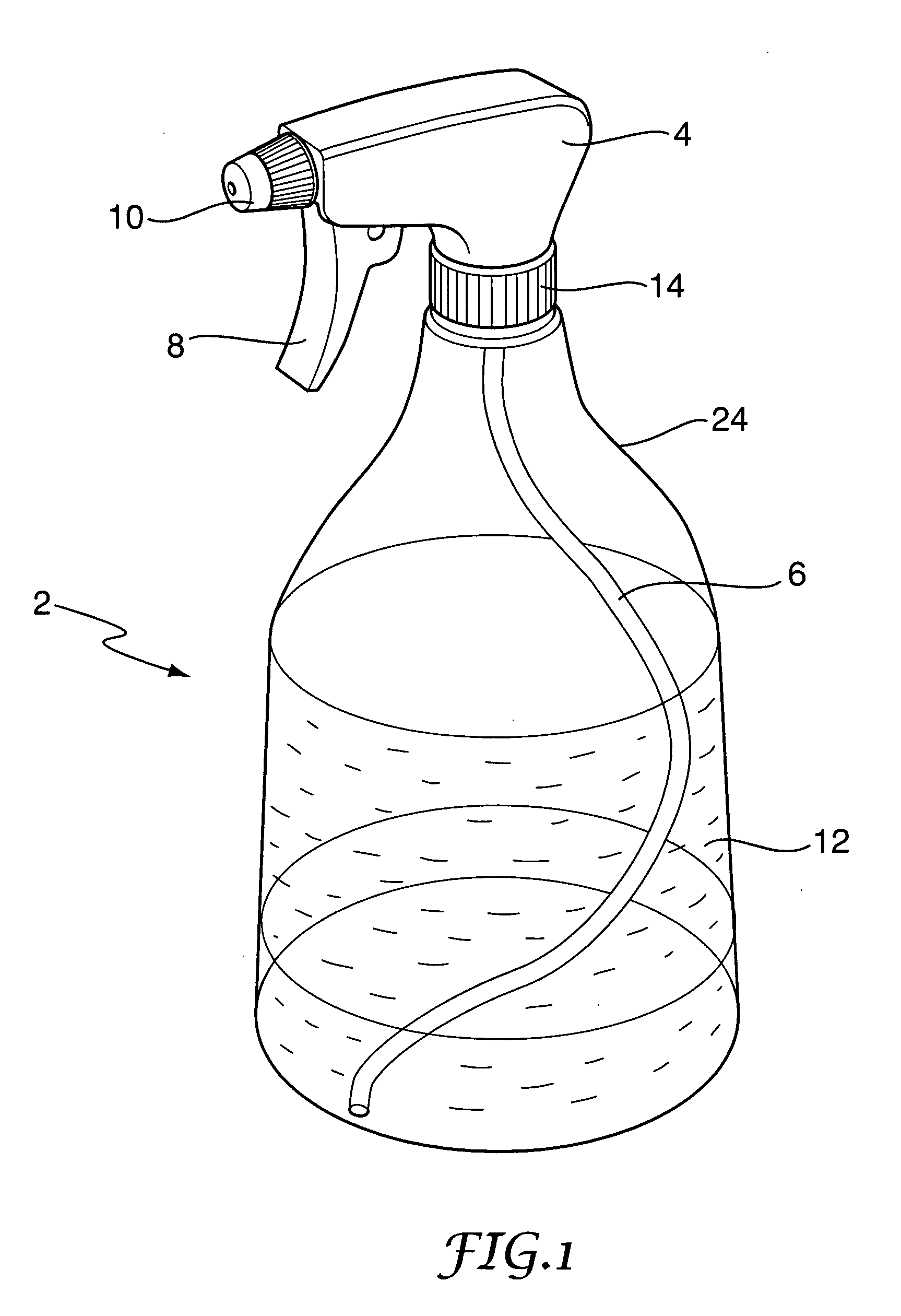

Decontamination system

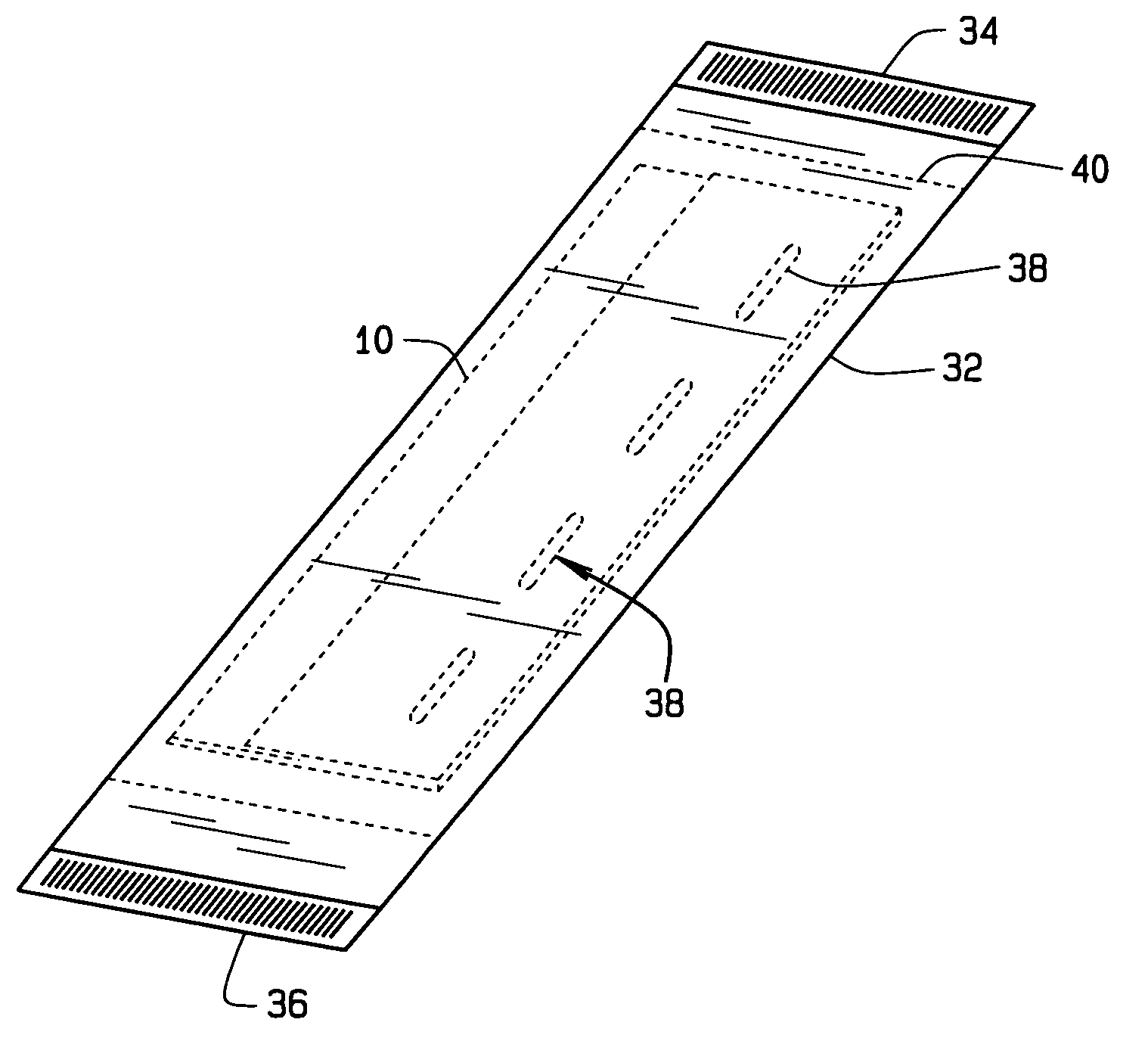

ActiveUS20060051266A1Easy to cleanRemove toxic residueLavatory sanitoryDeodrantsMedical deviceEndoscope

A decontamination system suitable for decontaminating items of medical equipment such as endoscopes, the system comprising: (I) a plurality of pre-clean wipes comprising moist fabric members for wiping an item to be decontaminated; (II) a two-part sterilant system comprising: (a) a first part comprising a first reagent in a carrier medium; and (b) a second part which is miscible with the first part and which comprises a second reagent in a carrier medium; wherein the first reagent and the second reagent will react when mixed to provide a sterilising composition; the first part being contained in a dispenser (2) whereby it may be dispensed as a fluid, and the second part being absorbed or impregnated in a plurality of sterilising wipes (18) each of which comprises a fabric member in a sealed container (20); and (III) a plurality of rinse wipes, each rinse wipe comprising a moist, sterile, fabric member in its own sealed container (40).

Owner:TRISTEL PCL

Superconductive magnet including a cryocooler coldhead

ActiveUS7170377B2Reduce evaporation rateReduce heat loadMagnetic measurementsCompression machinesCryocoolerMechanics

Owner:GENERAL ELECTRIC CO

Carbon/carbon composite material ultrahigh temperature oxidation resistant coating and preparation method thereof

The invention discloses a carbon / carbon composite material ultrahigh temperature oxidation resistant coating. The coating comprises the following components, by volume, 40-60% of ZrB2, 15-25% of SiC, 15-20% of TaB2 and 10-15% of Sc2O3. In addition, the invention also provides a preparation method of the coating. According to the invention, TaB2 and Sc2O3 are added to make the melting point of an external layer oxidation product borosilicate glass be risen, the viscosity of the borosilicate glass be risen, the evaporation rate of the borosilicate glass be reduced, the oxygen dispersion coefficient of the borosilicate glass be reduced, an internal layer oxidation product ZrO2 phase be stable, the melting point of ZrO2 be risen, and the oxygen diffusion coefficient of ZrO2 be reduced, so thecoating can satisfy requirements of the ultrahigh temperature oxidation resistance of a carbon / carbon composite material, the coating can be sintered without applying a pressure through adding TaB2 and Sc2O3, the coating has the advantages of high combination strength, compactness, and good ultrahigh temperature mechanical property, and the preparation process has no damages to matrixes.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

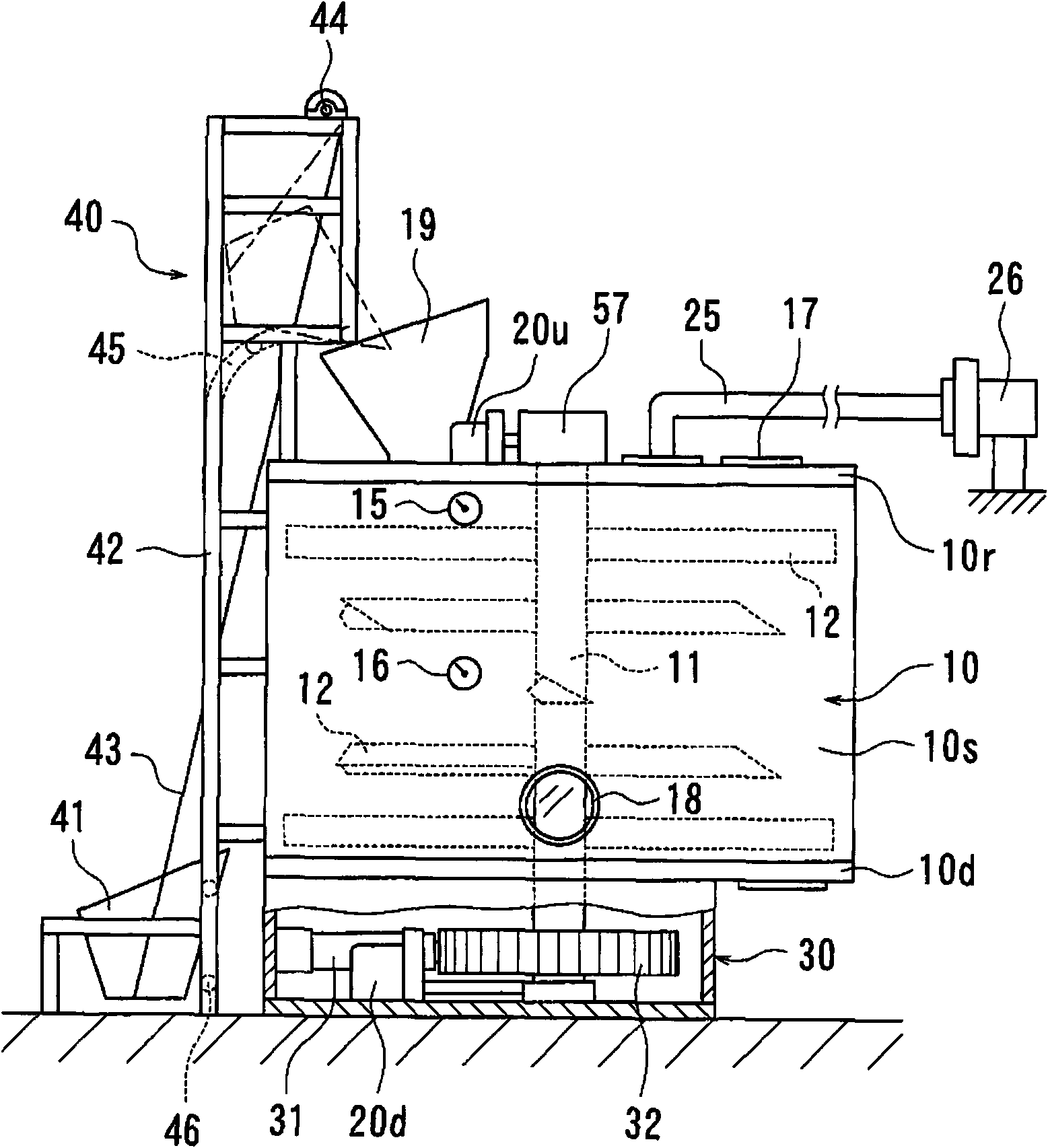

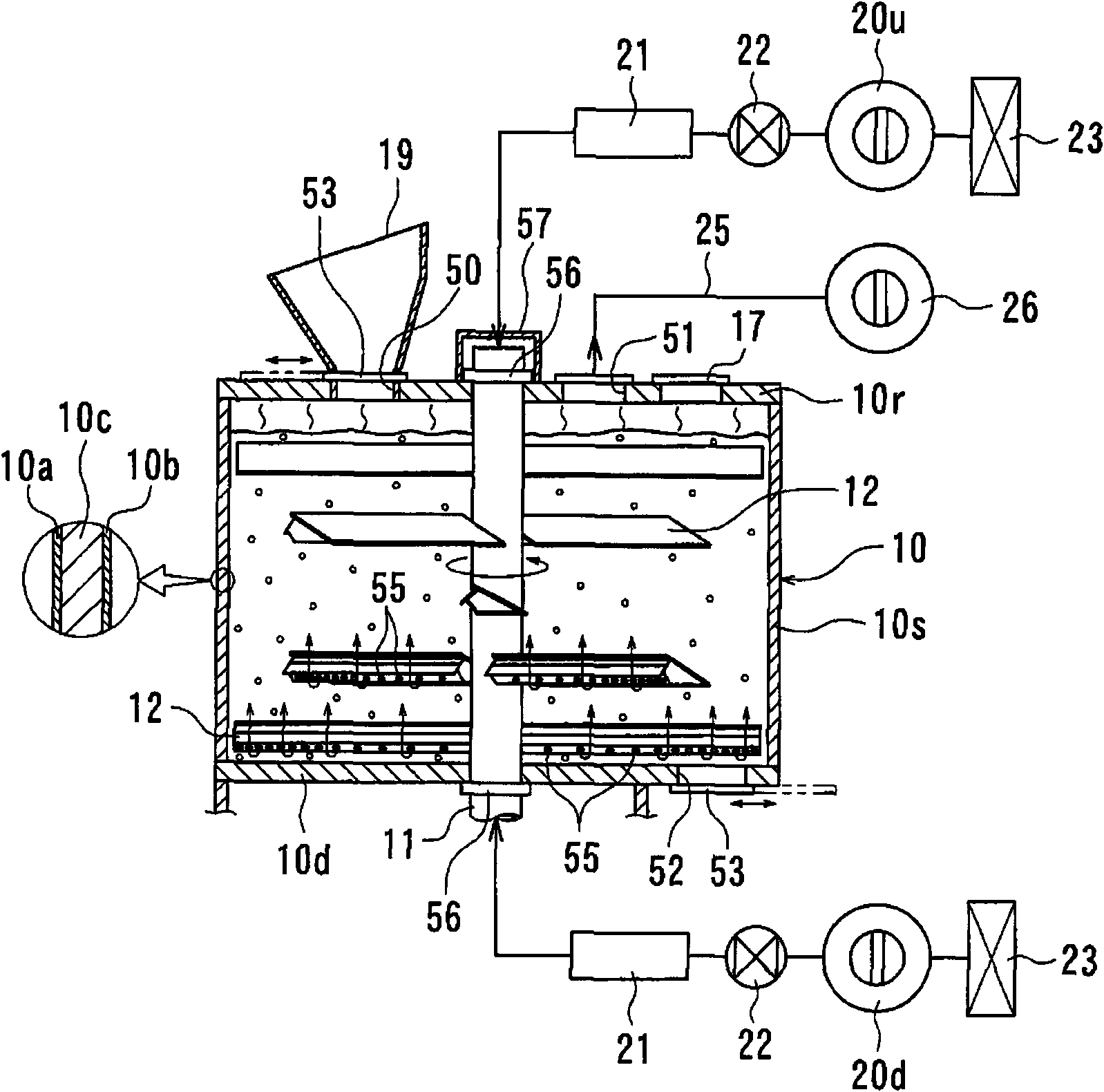

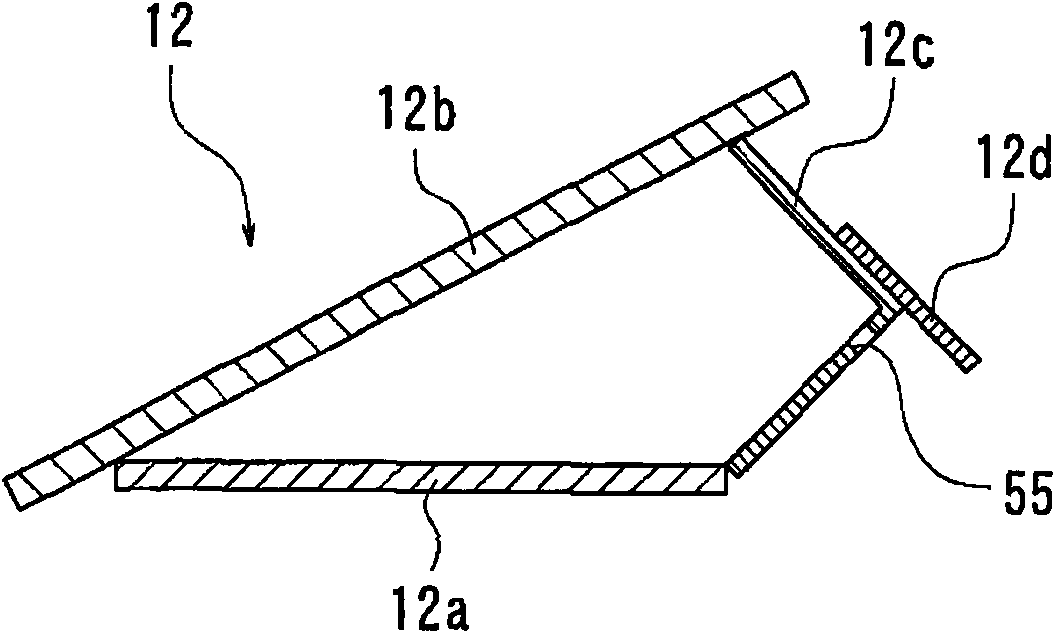

Fermenting and drying treatment device for organic wastes

InactiveCN102030569AAirtightWon't leakBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringMechanical engineering

The invention discloses a fermenting and drying treatment device capable of reliably and effectively fermenting and drying organic wastes with simple structure for avoiding cost increment. The device is provided with an airtight container, a hollow cylindrical rotating shaft rotating freely and vertically arranged in the container, a plurality of stirring blades extending to the horizontal direction from multiple upper and lower positions of the rotating shaft, a driving mechanism for driving the rotating shaft to rotate, an air supply mechanism for supplying air to the container, and an exhaust port for exhausting the air in the container. The plurality of stirring blades comprises stirring blades which have hollow interiors and are provided with through holes communicating the outside from the hollow space, the air supply mechanism is connected at the axial end of the rotating shaft, and the hollow space of the rotating shaft is mutually communicated with the hollow space of the stirring blades. Therefore, the air supplied by using the air supply mechanism is exhausted from the through holes of the stirring blades through the rotating shaft. The organic wastes are put into the container, the air is introduced into the container, the organic wastes are stirred, and the organic wastes are subjected to fermenting treatment and drying treatment based on the action of aerobic microbes.

Owner:CHUBU ECOTEC

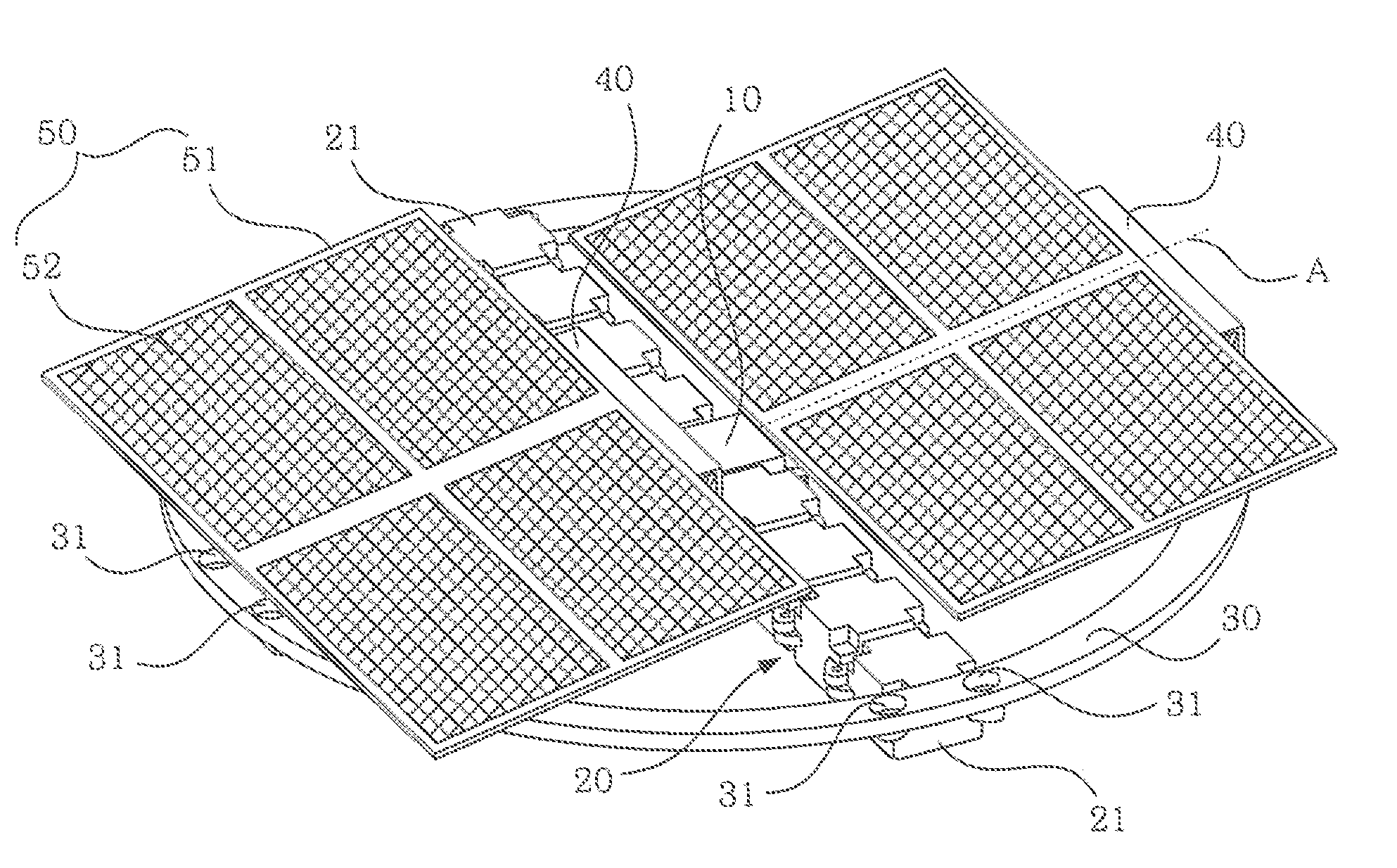

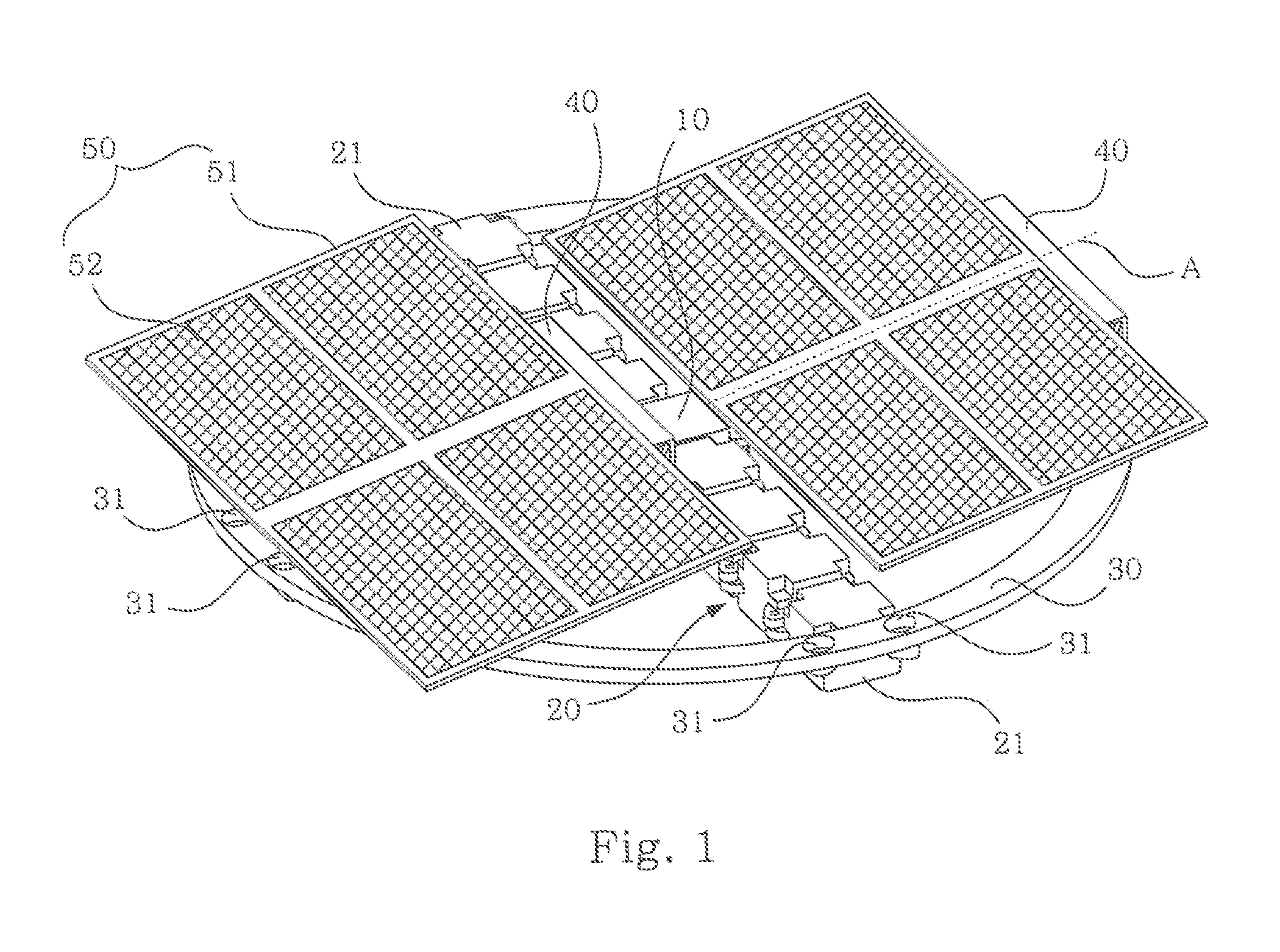

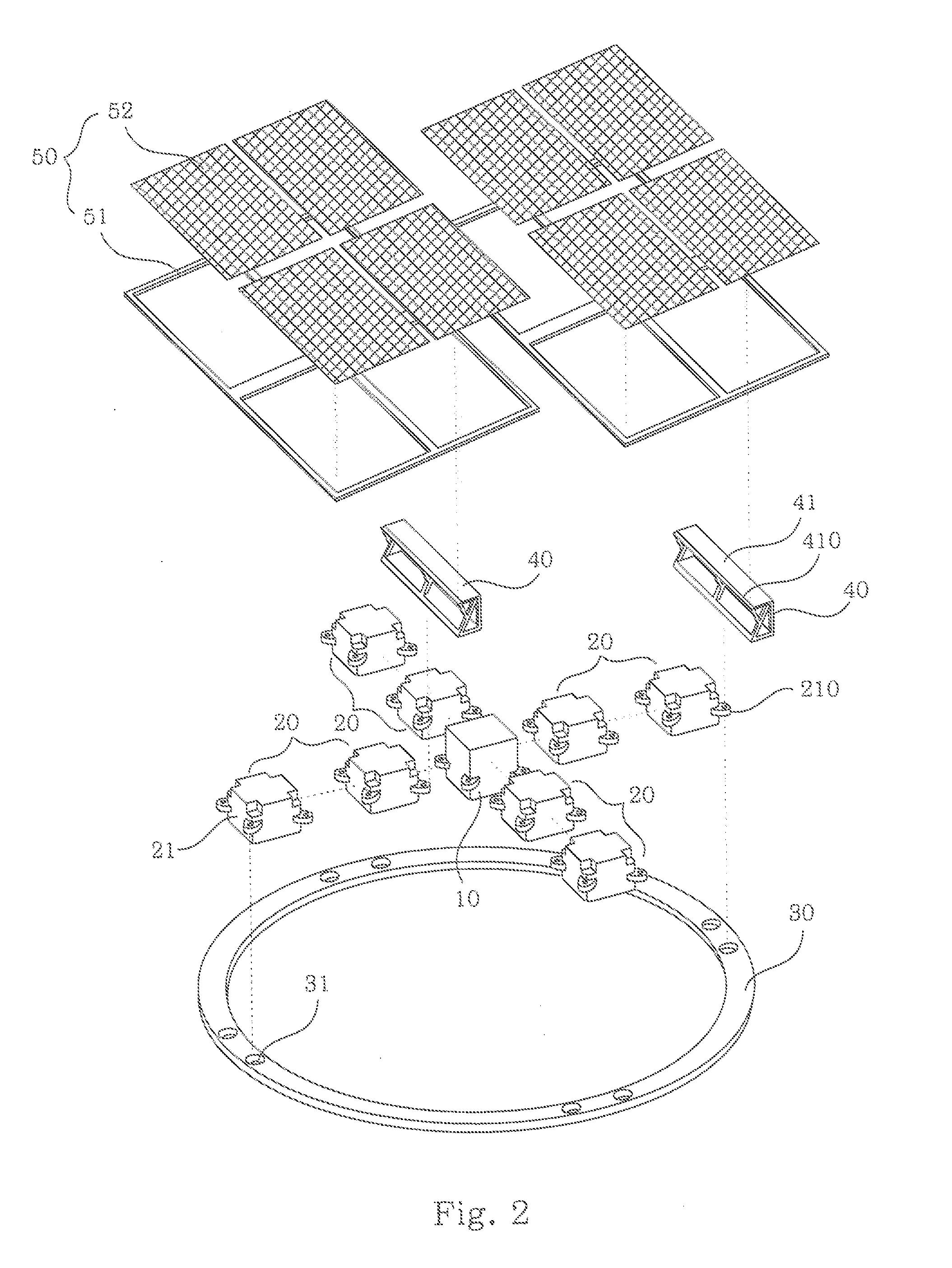

Multi-function floating solar power generating system

InactiveUS20160087573A1Facilitate repair and maintenanceEvaporation rate be reducePhotovoltaic supportsPV power plantsMultiple functionSolar power

The present Invention relates to a multi-function floating solar power generating system, which uses buoys to form buoy sets. A convergence box is used as the center for forming a cross structure, on which solar cell modules installed at an inclination angle of 10 to 15 degrees are carried. According to the present invention, a water-pumping unit below the buoy set is used for pumping the fluid. Then a spray unit is used for spraying the fluid and driving the system to rotate counterclockwise or clockwise, hence achieving the effect of tracking the sun. Alternatively, the fluid can be filtered or used for cleaning the solar cell module.

Owner:INST OF NUCLER ENERGY RES ATOMIC ENERGY COUNCIL EXECUTIVE YUAN R O C

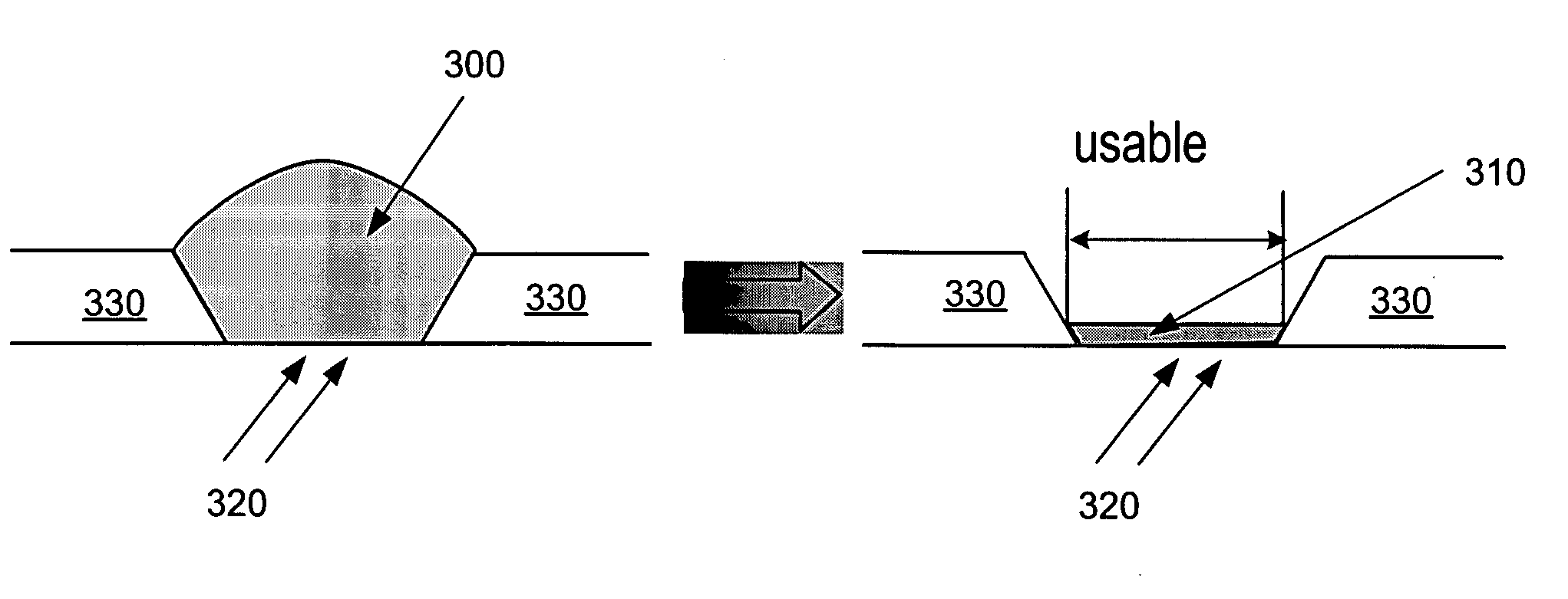

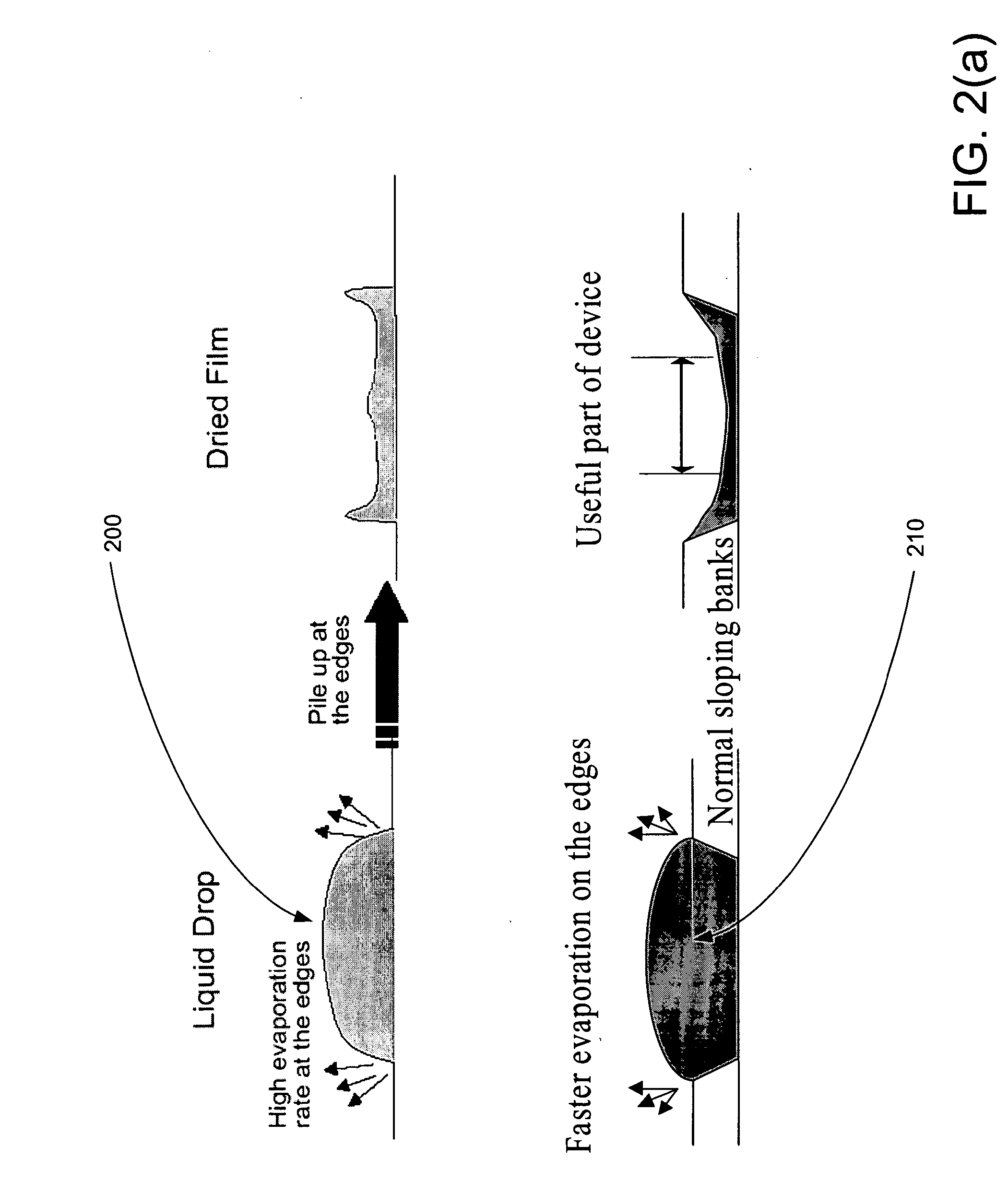

Printing of organic electronic devices

InactiveUS20050153114A1Uniform and flatter profileExtended drying timeDecorative surface effectsSolid-state devicesConductive polymerInorganic chemistry

The composition of a organic (e.g. conducting polymer) solution is reformulated and the device upon which the organic solution is to be deposited is plasma treated to provide a more uniform and flat drying profile for the resulting dried film. This reformulation and treatment induces a more uniform and flatter profile when the reformulated organic solution is allowed to dry into a film on the treated device.

Owner:OSRAM OPTO SEMICONDUCTORS GMBH & CO OHG

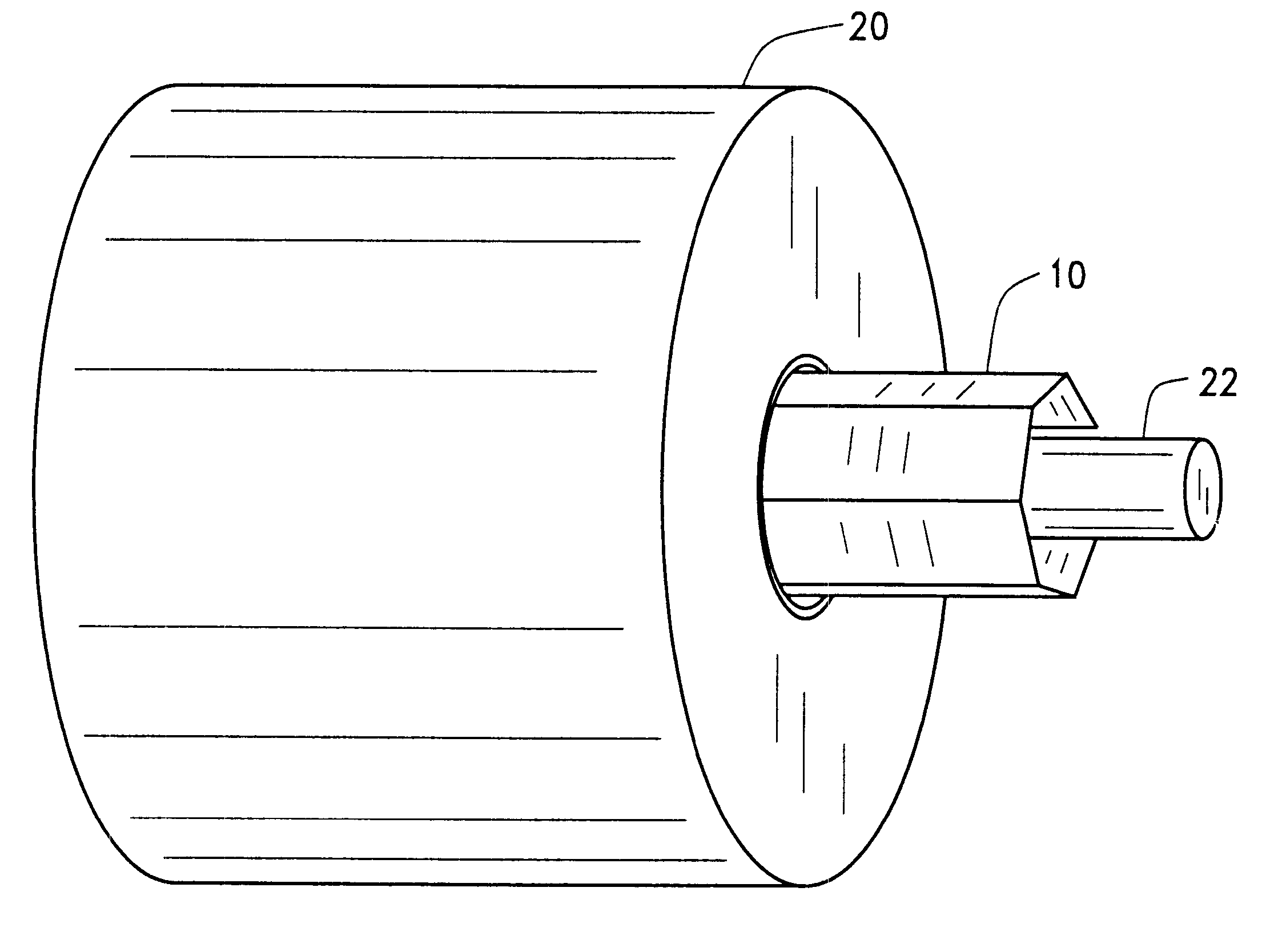

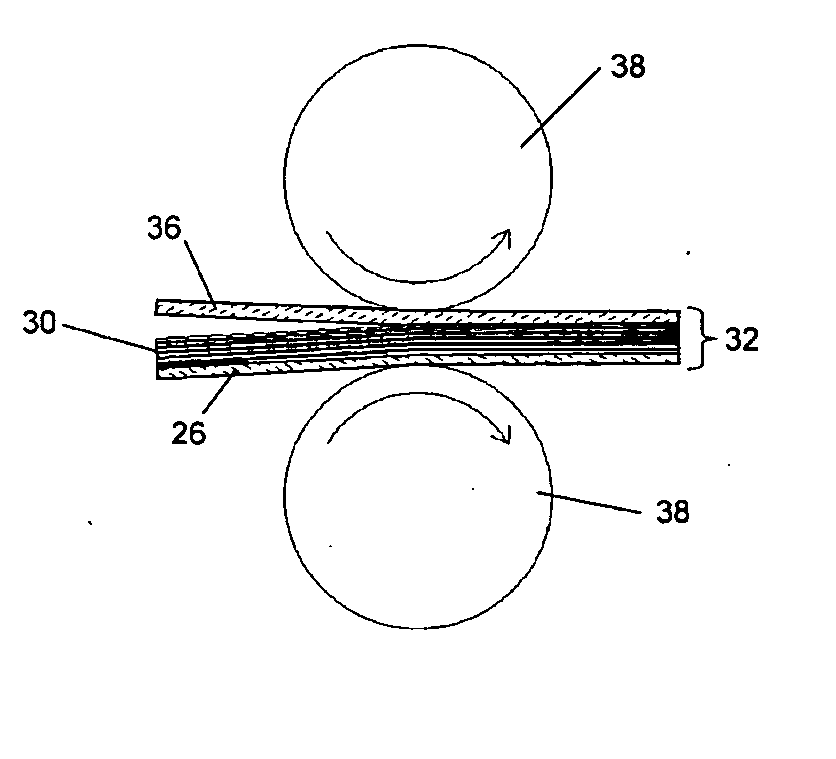

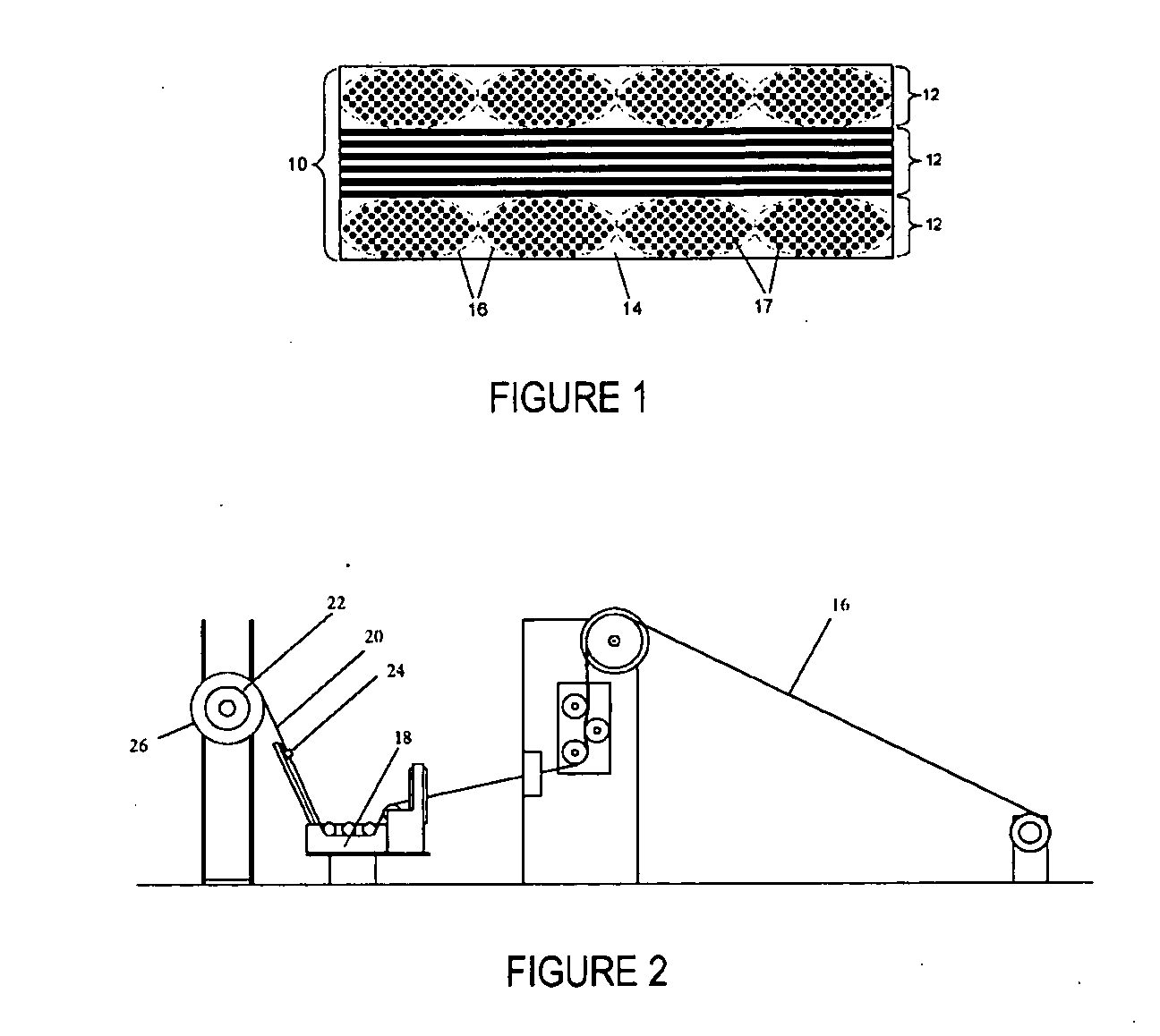

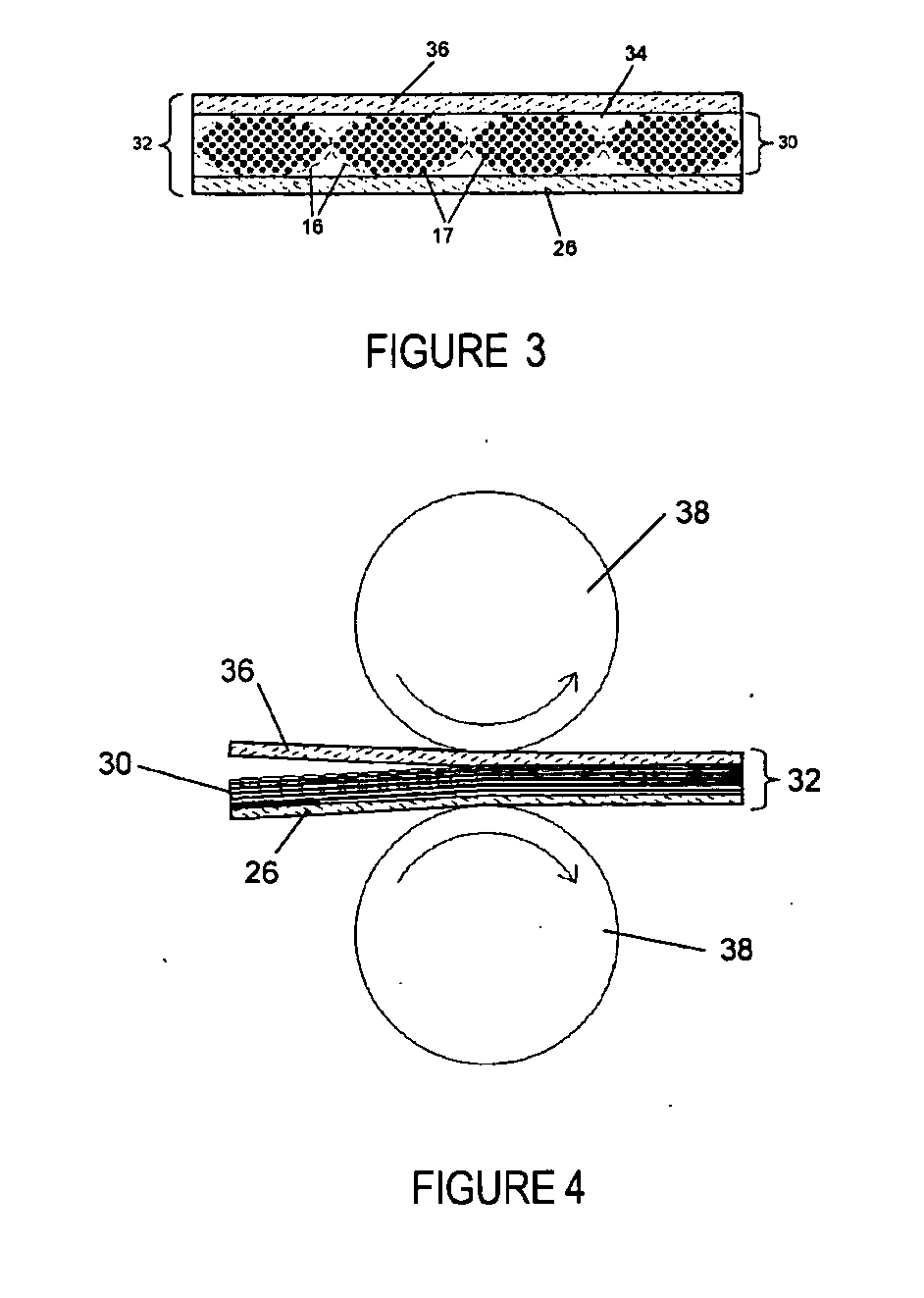

Process of producing ceramic matrix composites

InactiveUS20070096371A1Improved physical and mechanical and microstructural propertyPromoting physical and mechanical propertyCeramic shaping apparatusClaywaresMetallurgySlurry

A process for producing CMC articles, such as turbine components. The process entails applying a release sheet to a drum and then forming on the drum an impregnated tape that overlies the release sheet. The tape comprises a slurry mixture containing a ceramic precursor material and a unidirectionally-oriented filamentary material that may be wound onto the drum dry or already impregnated with the mixture. A second release sheet may be applied to overlie the tape. Alternatively, the filamentary material may be impregnated with the slurry mixture after it has been wound and removed from the drum. The resulting laminate structure may then be passed through an apparatus that flattens the tape and redistributes the slurry mixture within the tape.

Owner:GENERAL ELECTRIC CO

Method for interplanting toadstools with radix ophiopogonis without cover

ActiveCN103907471APromote growthMaintain humidityHorticultureAgricultural engineeringEnvironmental engineering

The invention discloses a method for interplanting toadstools with radix ophiopogonis without a cover, and aims to solve the problems that the resource waste can be caused, the production cost can be improved, the management difficulty and environment pollution can be caused and the like due to the fact that an existing adopted manual planting method for toadstools generally needs a sheltering shed. The method comprises the steps of soil preparation, radix ophiopogonis cultivation, strain surface disinfection of the toadstools and the like. According to the method, the natural shelter of the radix ophiopogonis seedlings can be used, manual high shed shelter can not be needed on fields, the fruiting performance is stable, the yield of the toadstools is high, and the quality is good; furthermore, the yield of fresh sporocarps can achieve 200kg / 666.7m<2>, so that the large-scale cultivation can be carried out, and the requirements of commercial process can be met.

Owner:MIANYANG QINHE AGRI TECH

Zinc-oxide-based nanometer particle ink and preparation method thereof

The invention discloses a zinc-oxide-based nanometer particle ink and a preparation method thereof. The zinc-oxide-based nanometer particle ink comprises the following components, by weight percentage, 0.01-20.0% of zinc-oxide-based nanometer particles and 80.0-99.99% of a solvent. The solvent comprises at least one low-boiling-point alcohols solvent and at least one high-boiling-point alcohols solvent, wherein the amount of low-boiling-point alcohols solvent is 1.0-80.0% of the total amount of the solvent. According to an ink formula in the invention, zinc-oxide-based nanometer particles can be dispersed in the solvent, and the viscosity of the solvent is improved and the volatilization speed of the solvent is lowered by adjusting low-boiling-point alcohols with high-boiling-point alcohols. The ink can meet the index requirements, such as ink viscosity and volatilization speed, of ink-jet printing, and zinc-oxide-based nanometer particles of the ink can be uniformly stably dispersed in the solvent.

Owner:TCL CORPORATION

Agglomerated volcanic ash

InactiveUS20060117655A1Improve skid resistanceImprove water holding capacityGrowth substratesCulture mediaMetallurgySediment

Volcanic ash, which becomes airborne during a volcanic eruption, can be deposited more than a thousand miles from the eruption site. Currently, many volcanic ash deposits are virtually unused. The method and product of the present invention converts this unused volcanic ash material, as well as furnace expanded volcanic ash, or the ash expanded and crushed, into a relatively dust free product with numerous new end applications.

Owner:BODYCOMB FREDERICK M +1

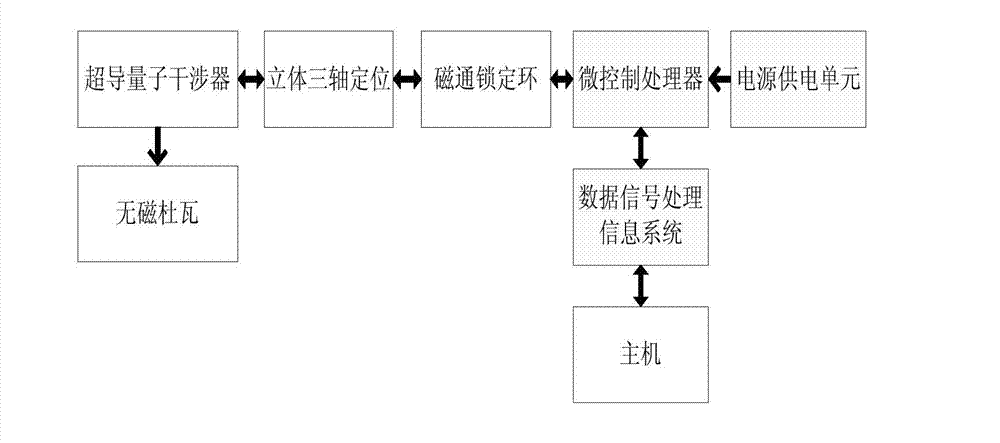

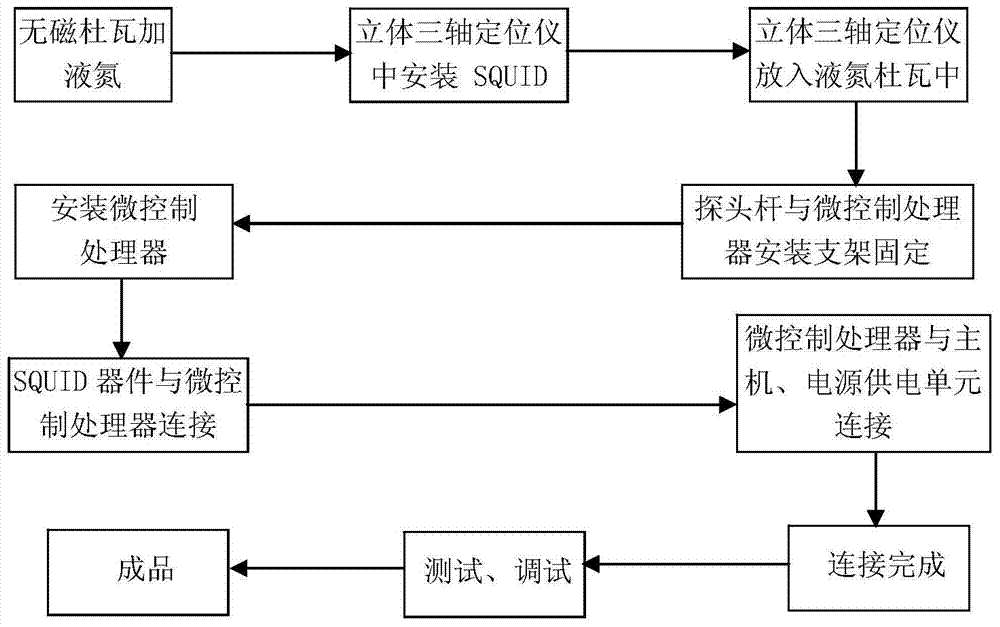

Superconducting weak magnetic signal detection magnetometer

ActiveCN104330754AHigh resolutionHigh precisionMagnetic measurementsElectric/magnetic detectionElectronGeophysical prospecting

The invention discloses a superconducting weak magnetic signal detection magnetometer comprising a superconducting quantum interference device (SQUID), a nonmagnetic dewar, a three-dimensional triaxial locator, a magnetic flux lock loop, a micro-control processor, a power supply unit, a data signal processing system and a host. The low-temperature superconducting quantum interference device substitutes a conventional induction coil to act as a magnetometer probe so that sensitivity and measurement depth and precision of the magnetometer are enhanced. The superconducting weak magnetic signal detection magnetometer is one of the latest international weak magnetic signal detection equipment. Compared with a conventional electronic magnetometer, the superconducting weak magnetic signal detection magnetometer is high in resolution, high in precision, high in intellectualization and high in stability, and can be applied to geophysical prospecting work, medical heart and brain magnetic measurement and engineering nondestructive detection.

Owner:BEIJING MILESTONE SCI & TECH DEV

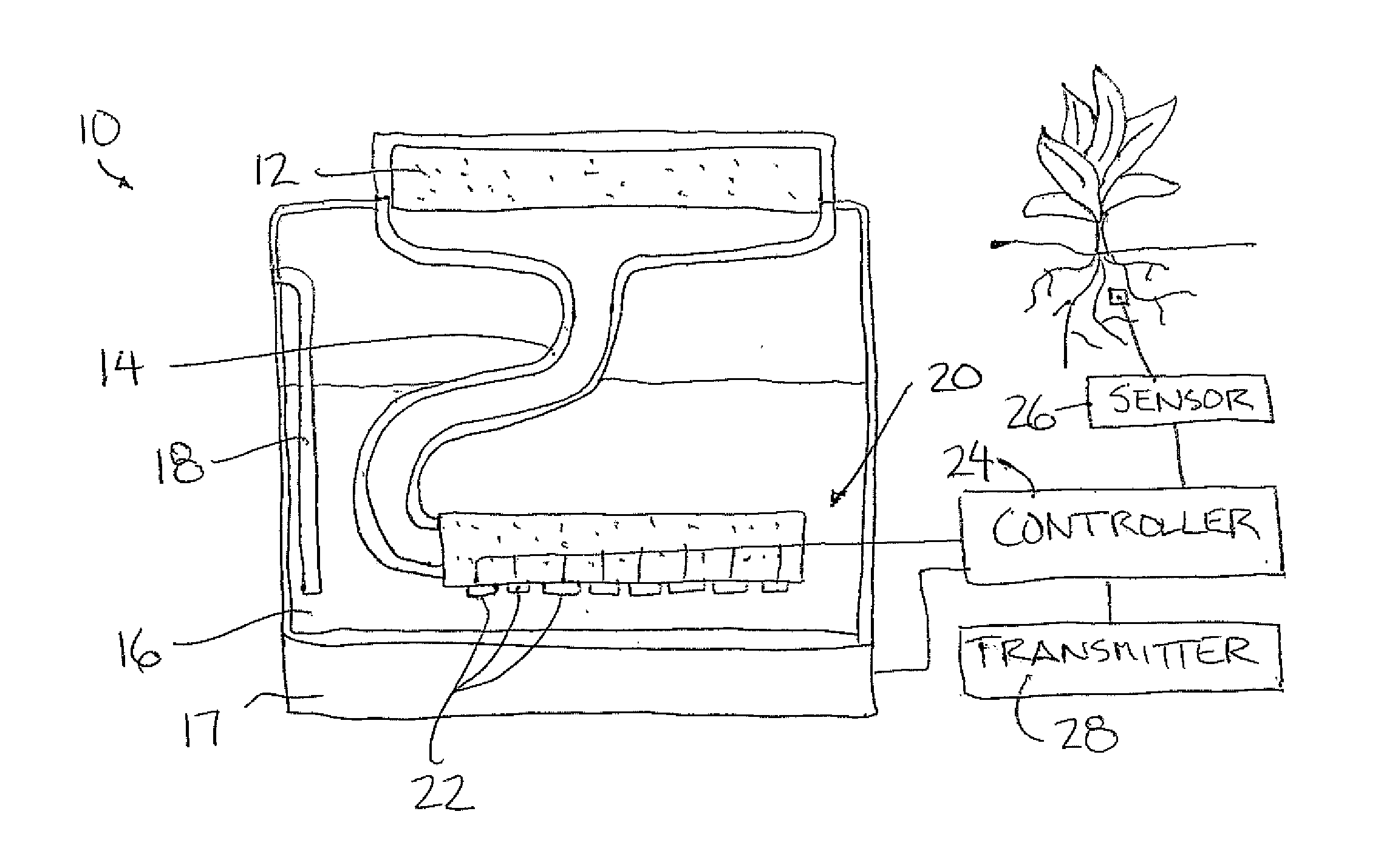

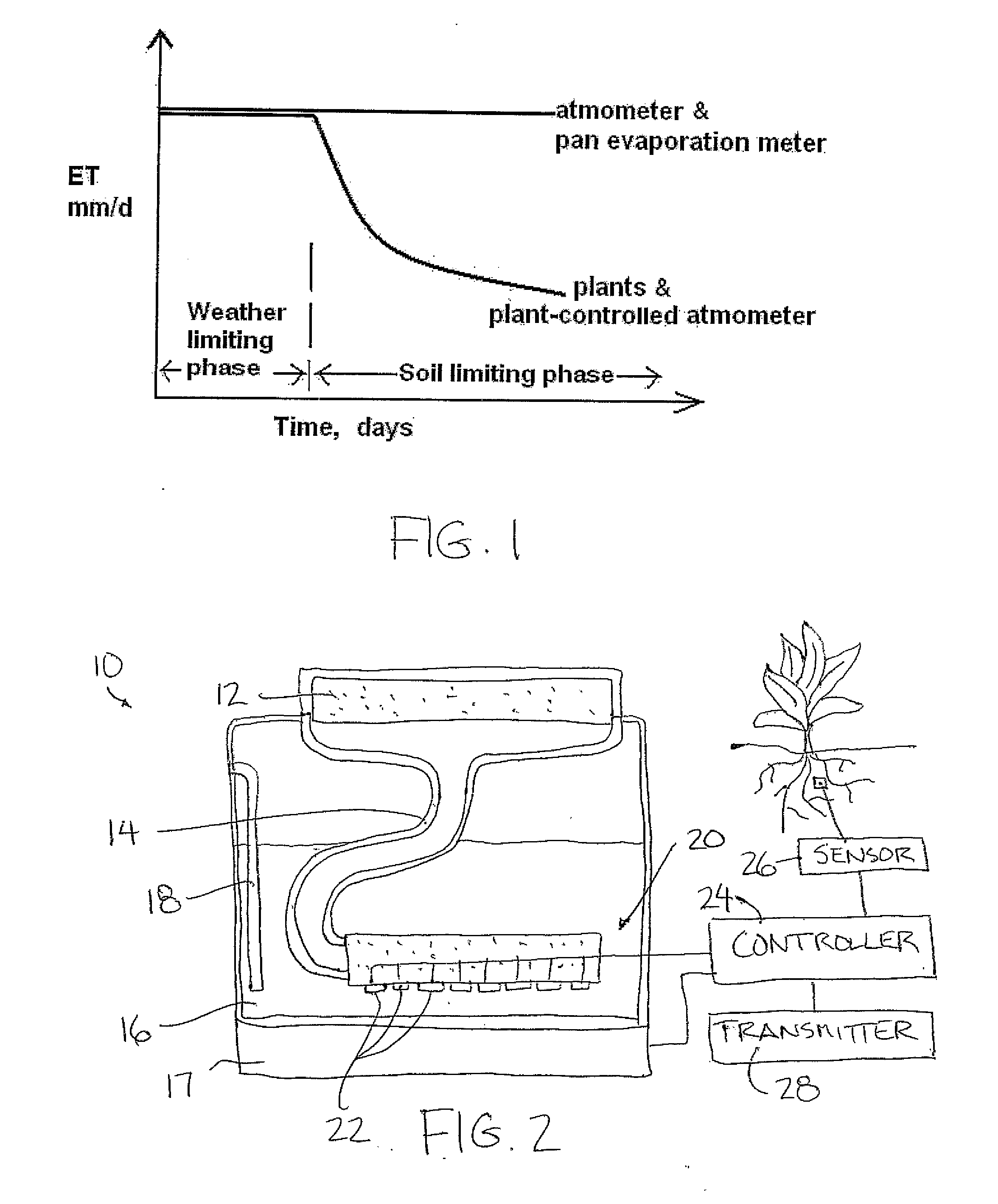

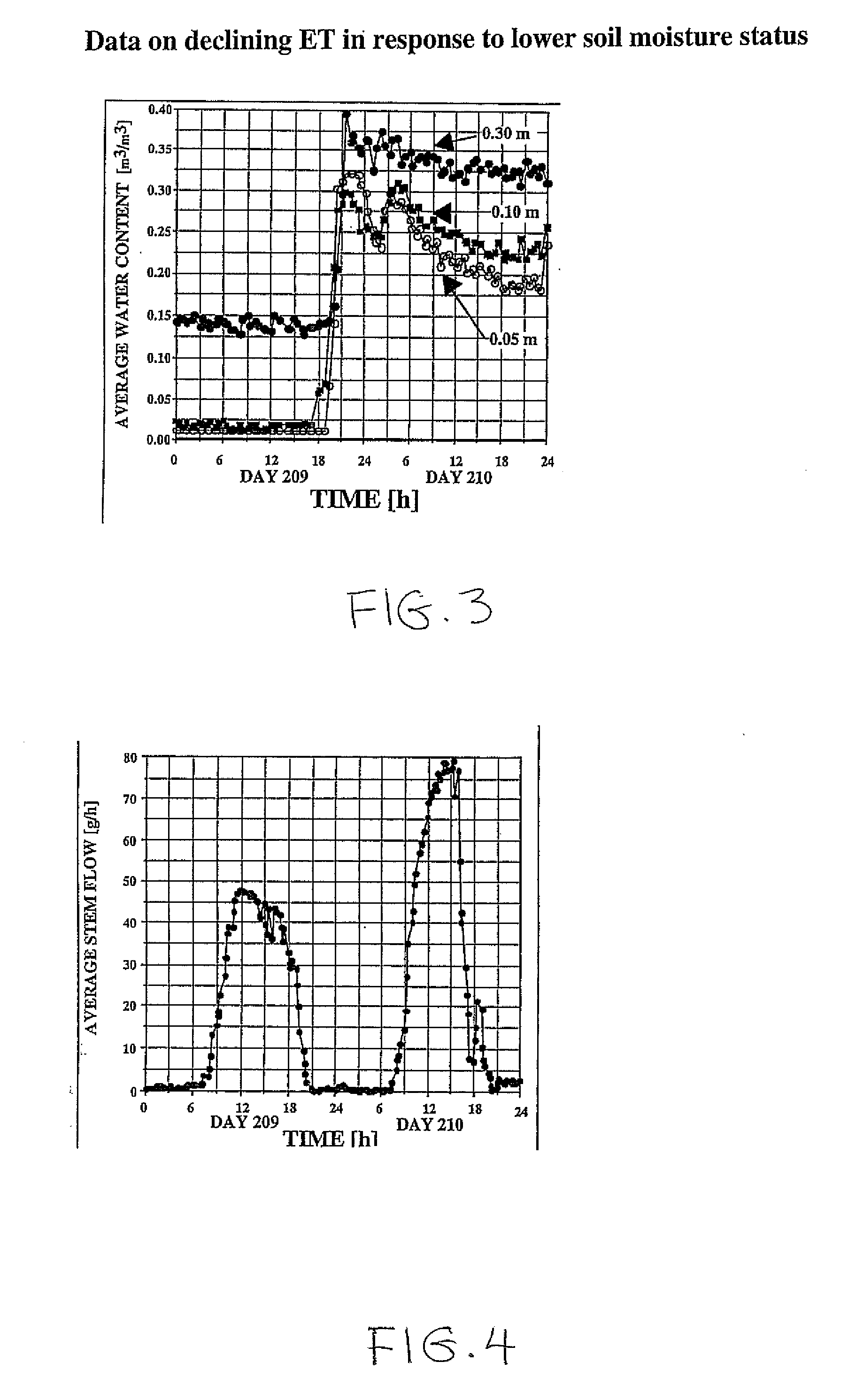

Plant-Controlled Atmometer for Measuring Crop Evapotranspiration

ActiveUS20100212409A1Low rateReduce evaporation rateMaterial moisture contentTesting plants/treesCrop evapotranspirationEngineering

An atmometer device comprises a porous evaporator member, a suction tube communicating water from a reservoir to the porous evaporator member, a sensor measuring a moisture characteristic of soil associated with a crop, a mechanism arranged for controllably varying a rate of evaporation of the water through the porous evaporator member responsive to the moisture characteristic measured by the sensor, and an indicator arranged to indicate water loss in the reservoir. By controlling rate of evaporation of the water through the porous evaporator member responsive to the measured moisture characteristic of the soil, the amount of water loss in the reservoir during the given time period more accurately reflects crop evapotranspiration.

Owner:SRI RANJAN RAMANATHAN

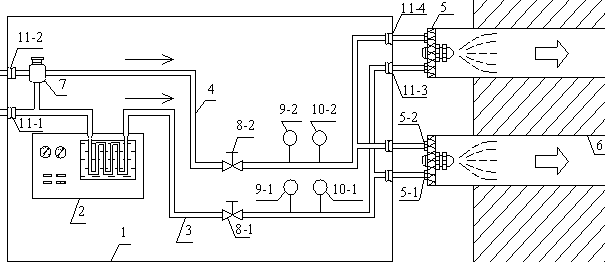

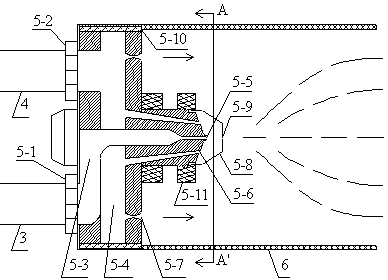

Efficient nitrogen injection and fire extinguishing system for mining

ActiveCN102937033ASmall footprintFlexible moving processDust removalFire preventionNitrogenSpray nozzle

The invention discloses an efficient nitrogen injection and fire extinguishing system for mining. The efficient nitrogen injection and fire extinguishing system comprises a refrigerating machine; an inlet and a liquid inlet of the refrigerating machine are communicated with the lower end of a three-way valve; an outlet of the refrigerating machine is connected with a liquid inlet of an atomizing nozzle through an inhibition liquid pipe; an inlet of the three-way valve is communicated with a gas inlet; an outlet of the three-way valve is communicated with a gas inlet of the atomizing nozzle through a nitrogen injection pipe; a gas pressure adjusting valve, a gas flow meter and a gas pressure meter are connected on the nitrogen pipe; the atomizing nozzle is connected with the back end of the nitrogen injection pipe, and can directly use the conventional nitrogen pipeline and the water transmission pipeline of a mining well. The efficient nitrogen injection and fire extinguishing system has a small occupied space, can be flexibly moved, and is simple in operation. The efficient nitrogen injection and fire extinguishing system can continuously work, and has multiple effects of cooling, inerting, inhibiting and atomizing. The efficient nitrogen injection and fire extinguishing system can be used for efficiently transporting low-temperature atomized nitrogen to a deep part of a fire extinguishing area, so that the technical problems that the nitrogen is easy to diffuse along with wind at a room temperature, the cooling effect is limited, and the fire extinguishing period is long can be solved. The efficient nitrogen injection and fire extinguishing system has wide practical applicability, and is applicable to underground fire extinguishing of a coal mine.

Owner:CHINA UNIV OF MINING & TECH

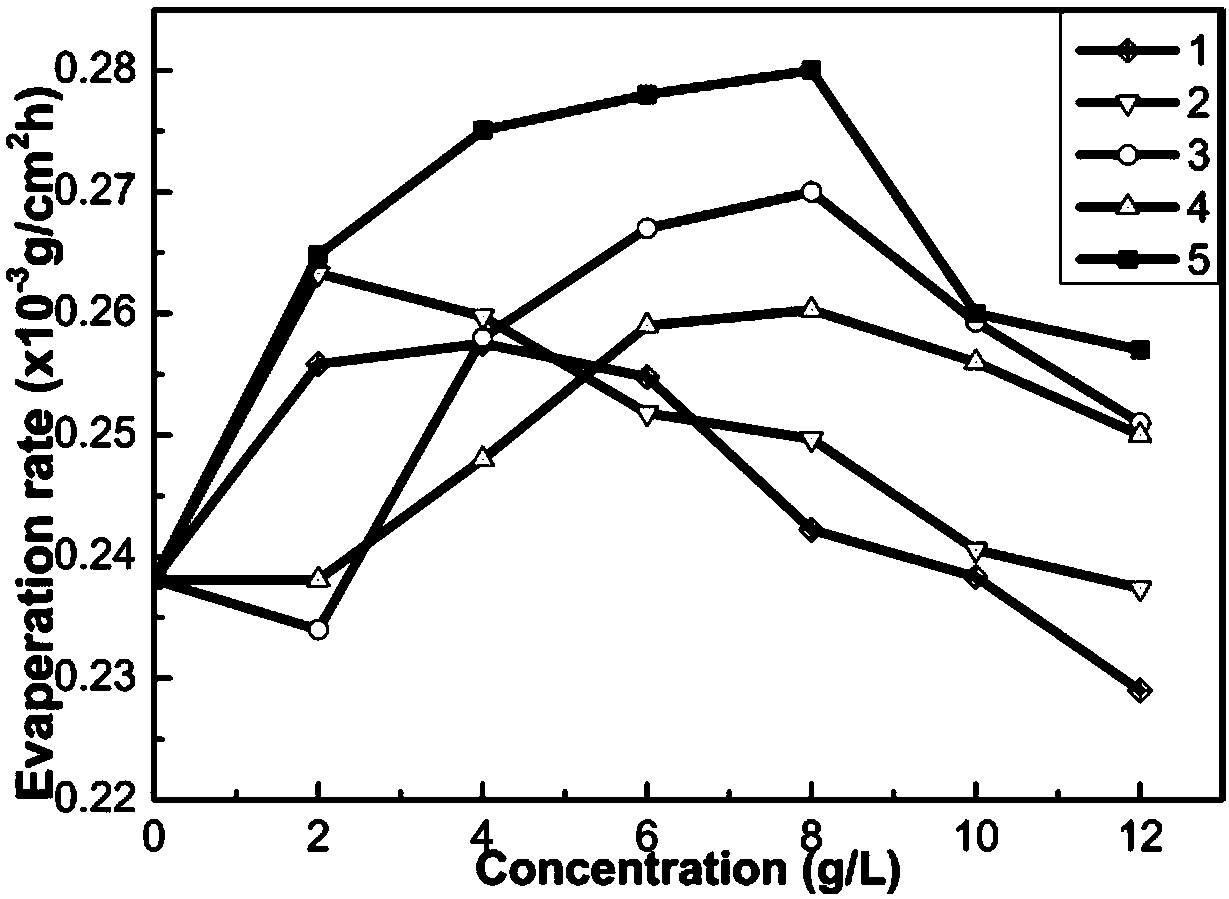

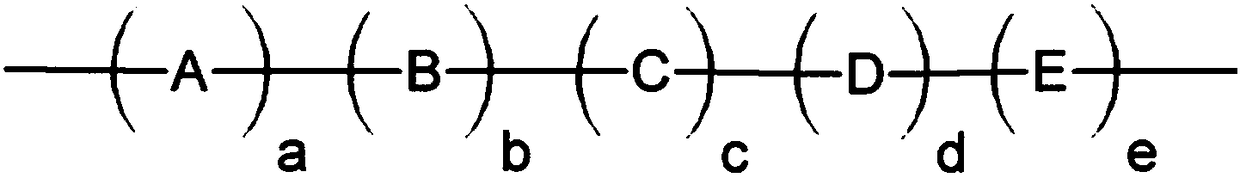

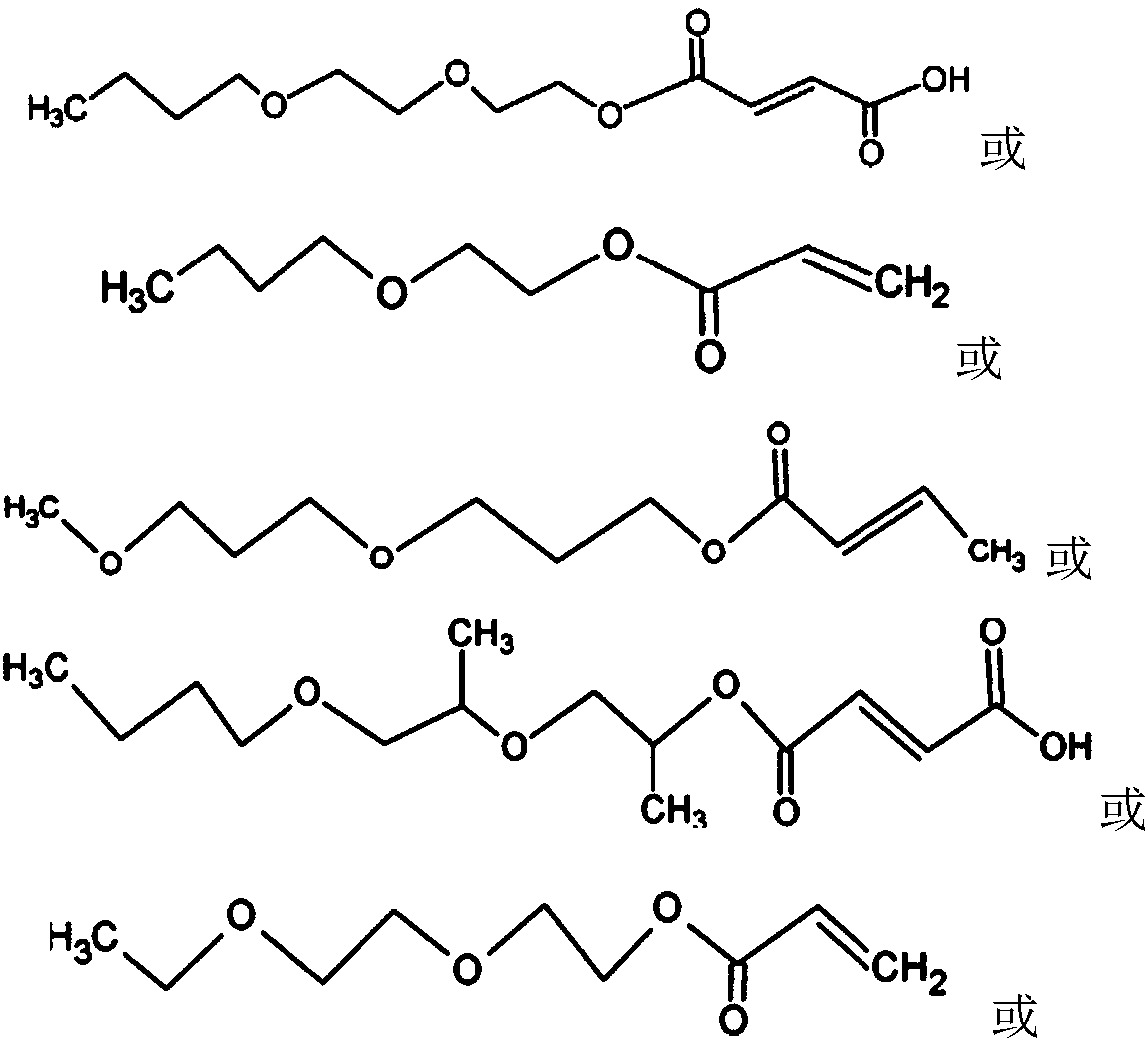

Reduced-type polycarboxylic acid water reducer and preparation method thereof

The invention relates to a reduced-type polycarboxylic acid water reducer and a preparation method thereof. An esterification method is employed for synthesizing a reduced monomer having a low surfacetension, and the reduced polycarboxylic acid water reducer is prepared through polymerization; acid anhydride or unsaturated carboxylic acid and ethers molecules are subjected to an esterification reaction to prepare the reduced monomer under effect of a catalyst, and then the reduced monomer, nonsaturated polyoxyethylene ether, unsaturated carboxylic acid or a mixture of unsaturated carboxylic acid or its acid anhydride, and a molecular weight conditioning agent are subjected to a free radical copolymerization reaction under effect of an initiator. The method has the advantages of easy control, high yield, low cost, environmental protection, and no pollution. During a polymerization process, a reduced group is introduced, so that the water reducer has low surface tension, an anchoring group is introduced, has good cement slurry-cleaning fluidity under common doping, reduces the surface tension force of a cement aperture solution, and reduces evaporation rate of the solution so as toeffectively reduce the mortar contraction. The obtained water reducer presents good water-reducing and reduction characteristic.

Owner:BEIJING UNIV OF TECH

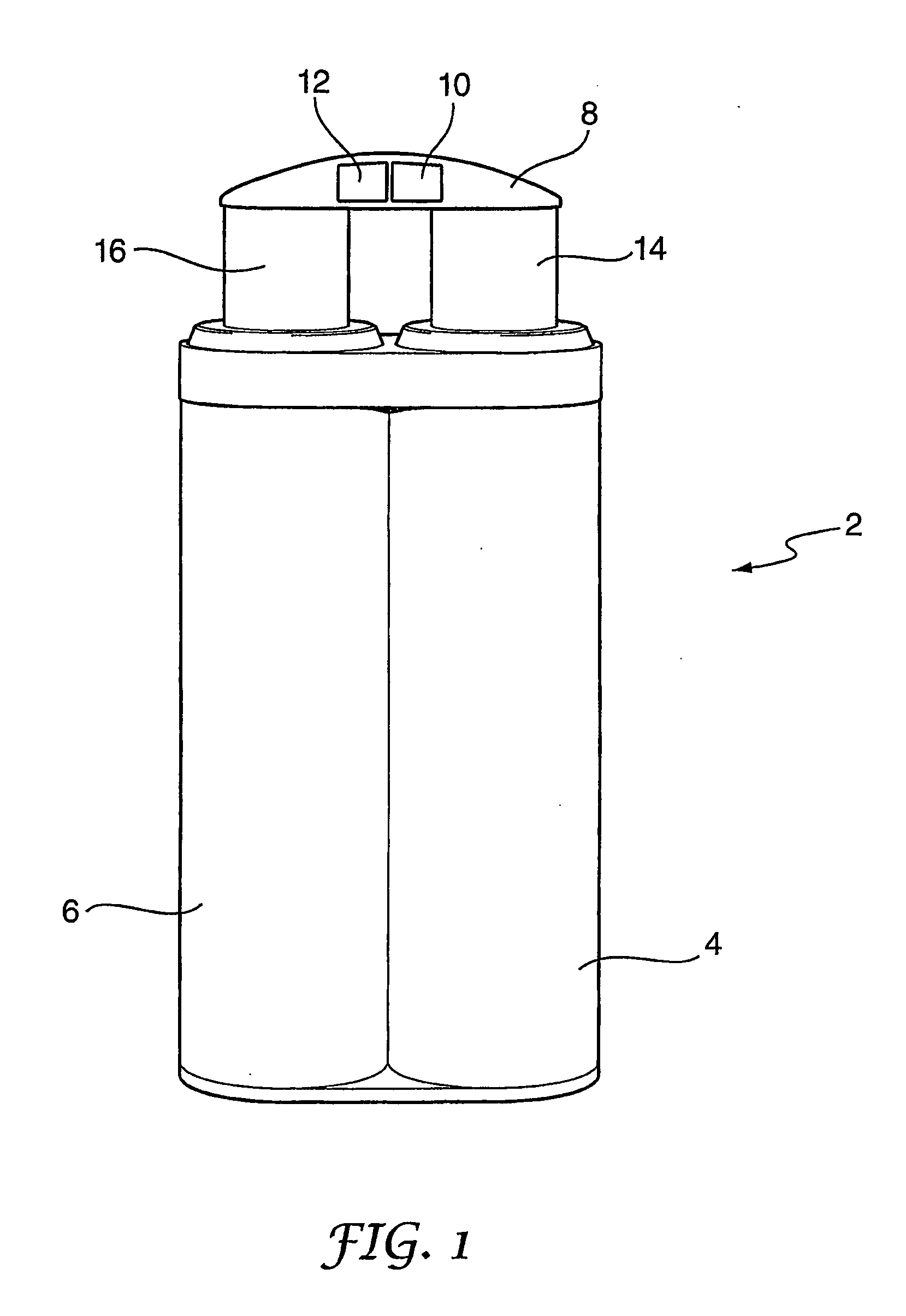

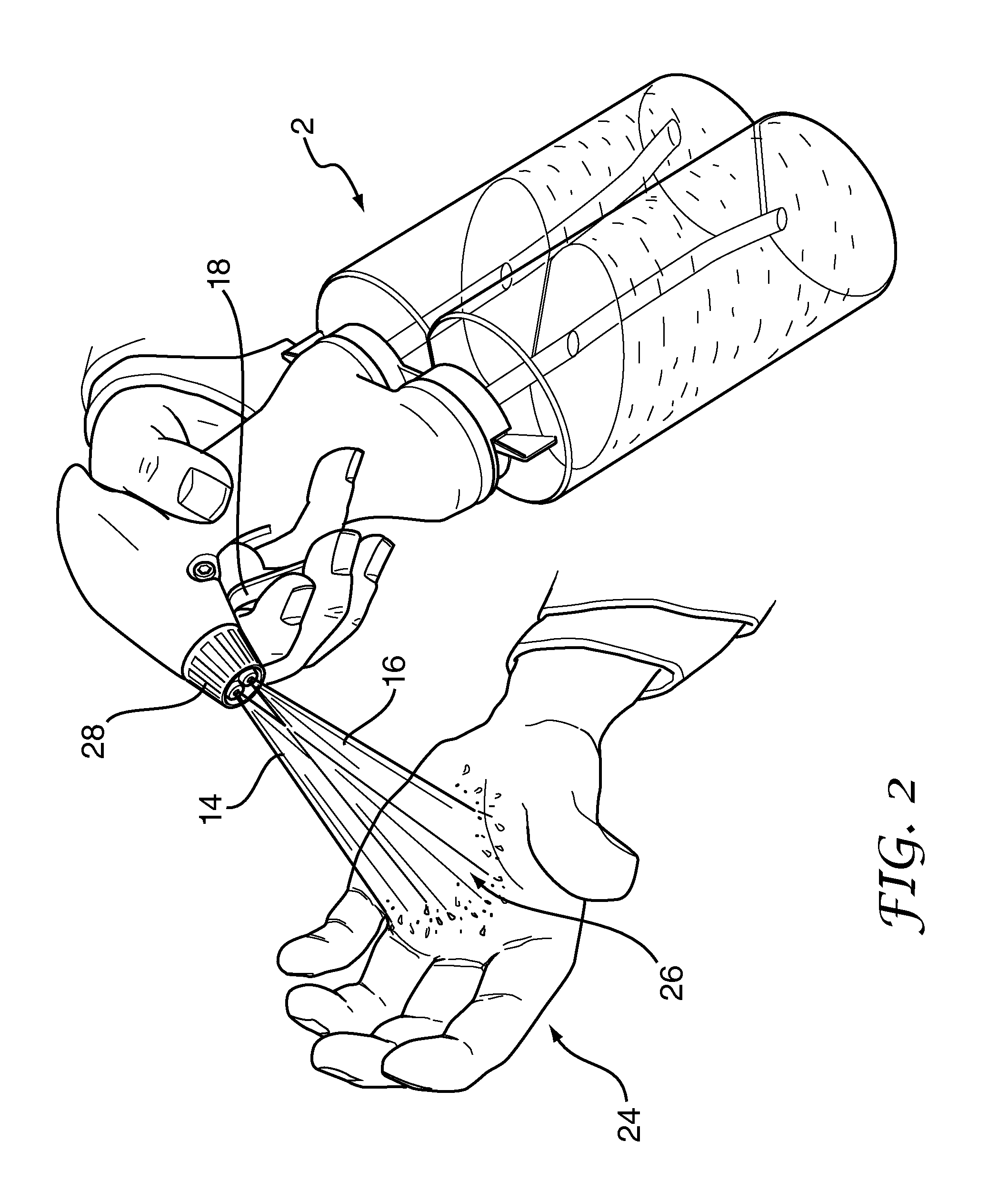

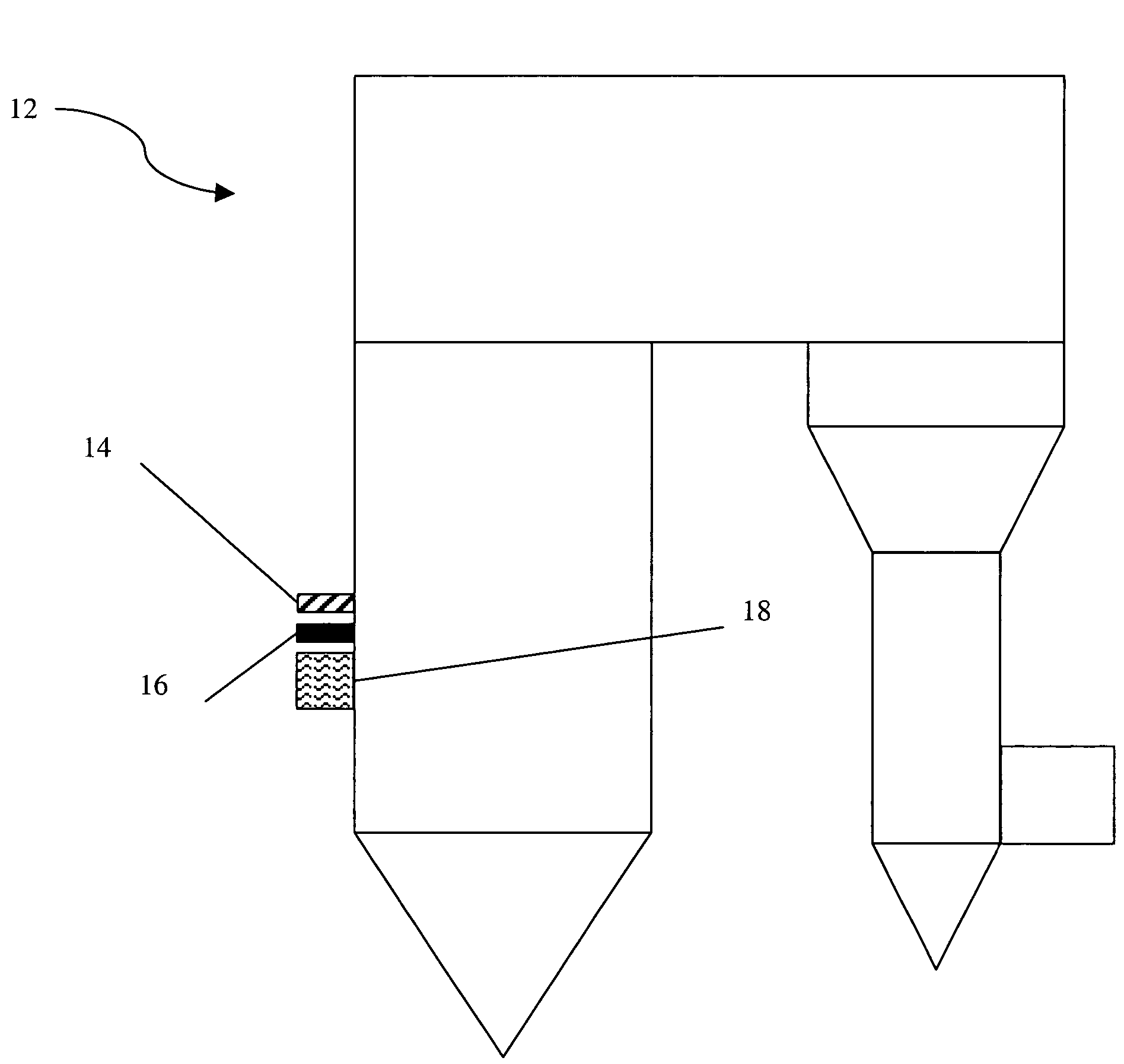

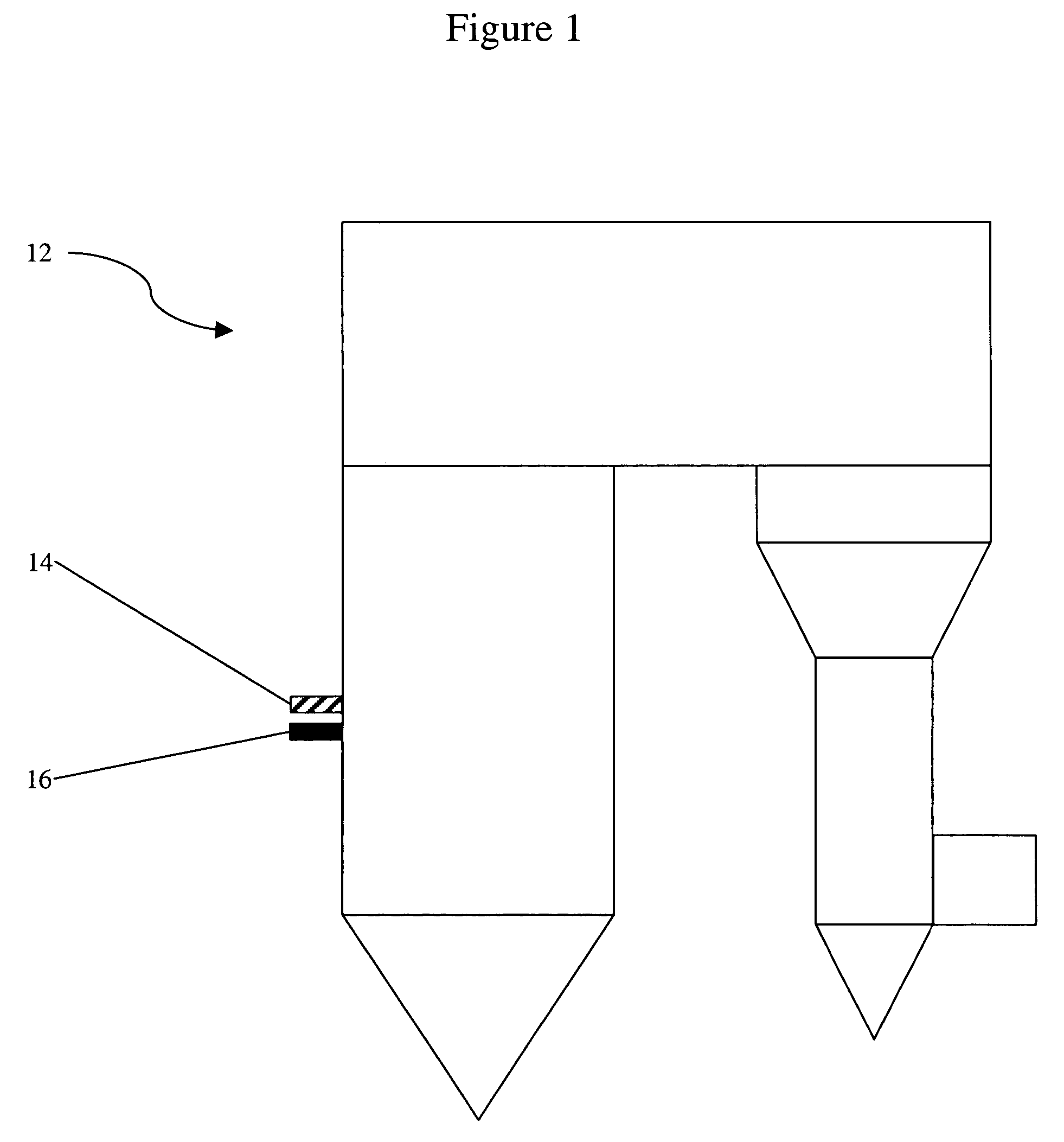

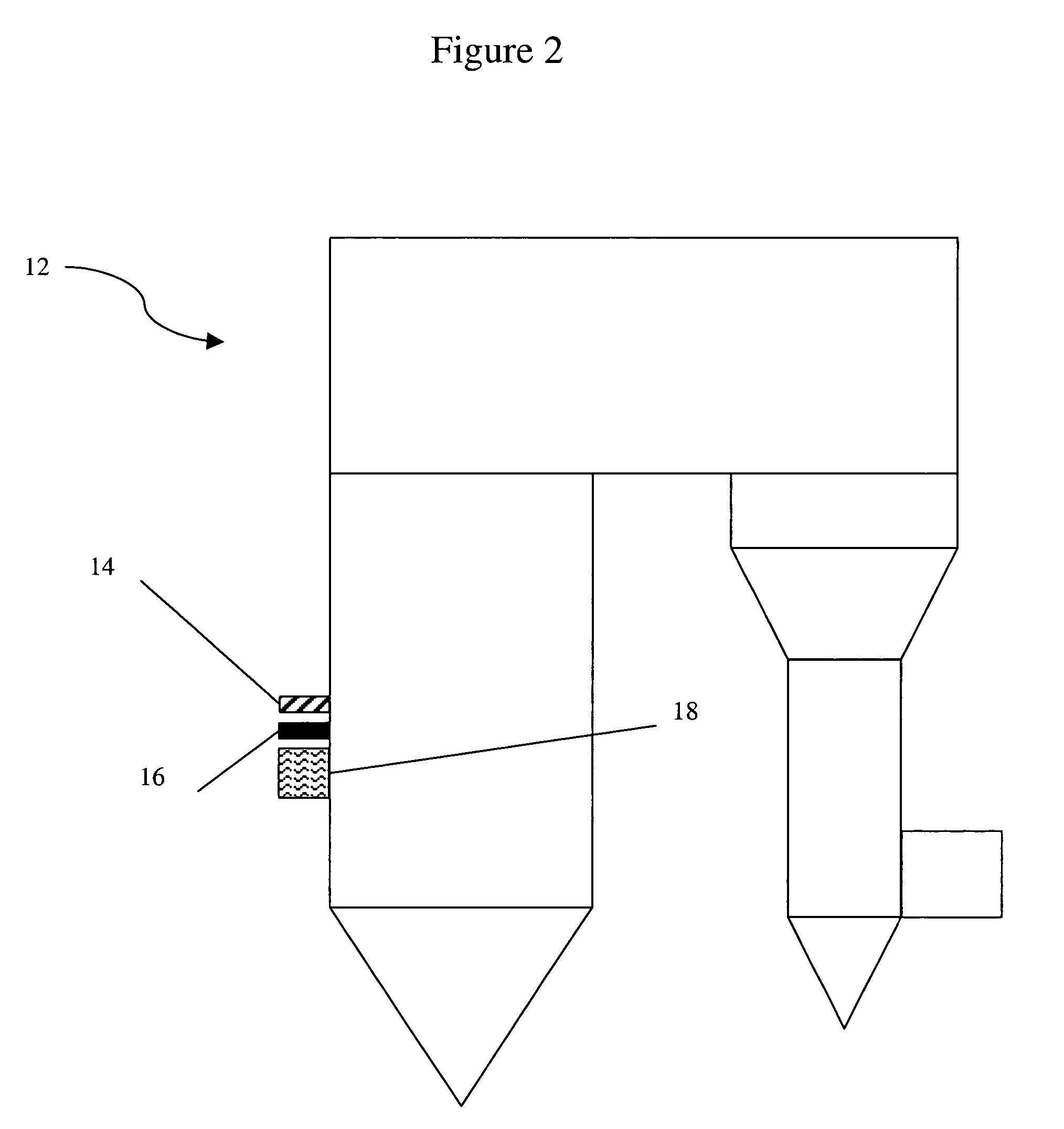

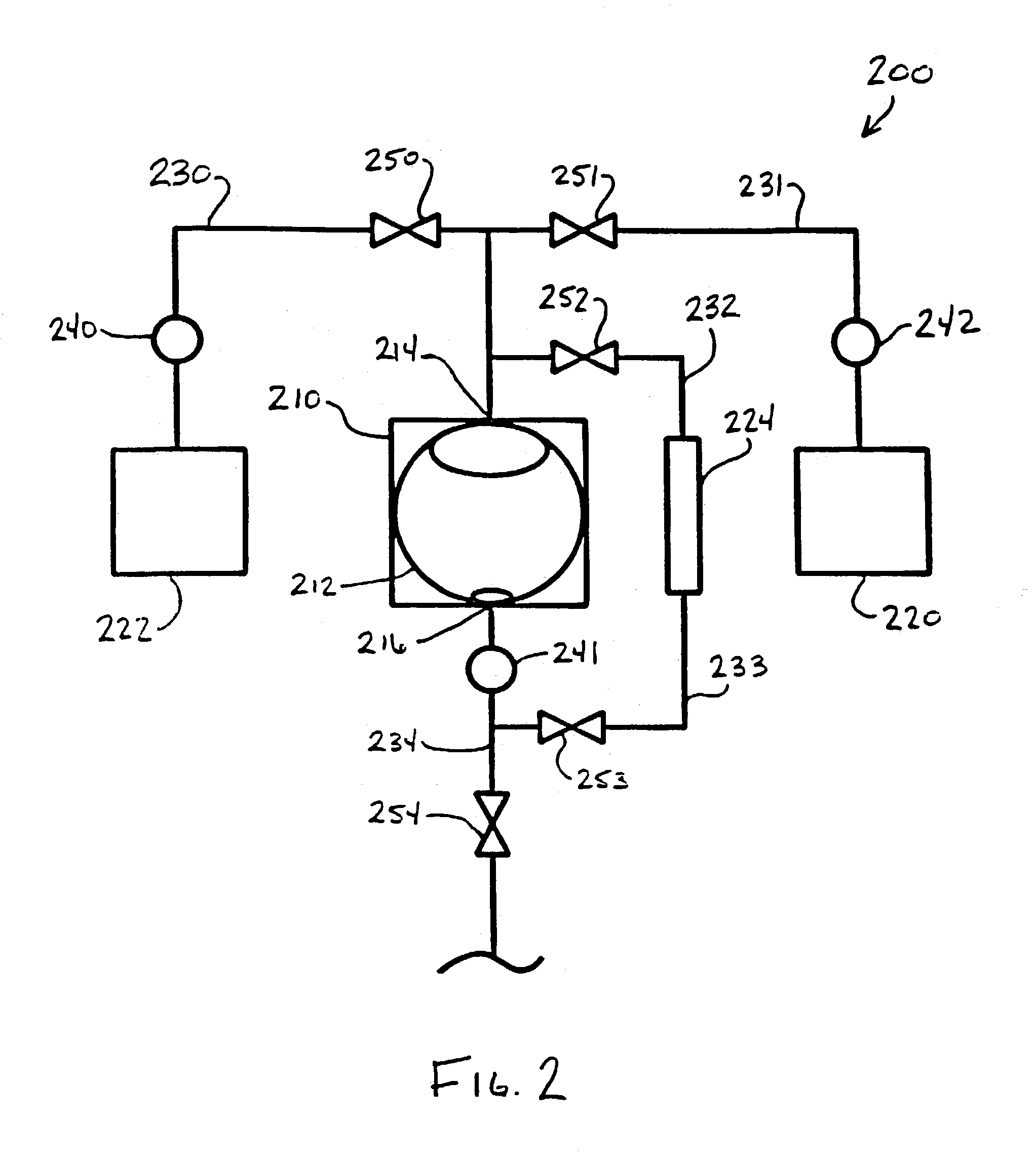

Hand sanitizer

InactiveUS8562907B2Faster drying timeImprove skinBiocideCosmetic preparationsAlcoholChlorine dioxide

A hand sanitizer (2) comprises: (a) a first part (14) comprising a chlorite solution and contained in a first dispenser (4) whereby it will be dispensed as a spray or jet of liquid; and (b) a second part (16) comprising an acid solution and contained in a second dispenser (6) whereby it will be dispensed as a second spray or jet of liquid; wherein the chlorite and the acid will react to provide chlorine dioxide when the first part is mixed with the second part; and wherein a mixture (18) of equal quantities of the first part and the second part contains at least 15% alcohol by weight; and wherein at least a part of the alcohol comprises 3-methoxy-3-methylbutan-1-ol (MMB).

Owner:TRISTEL PCL

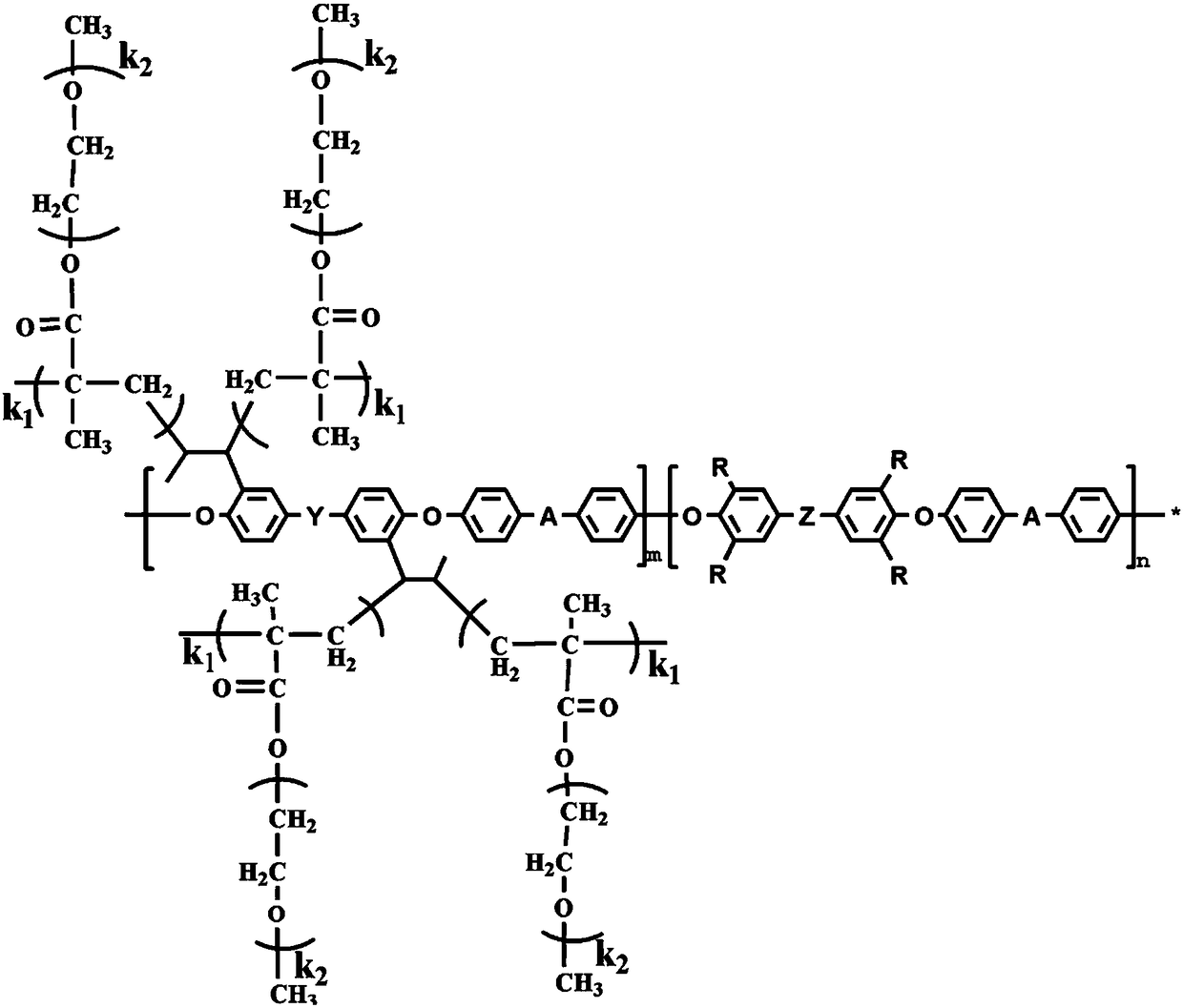

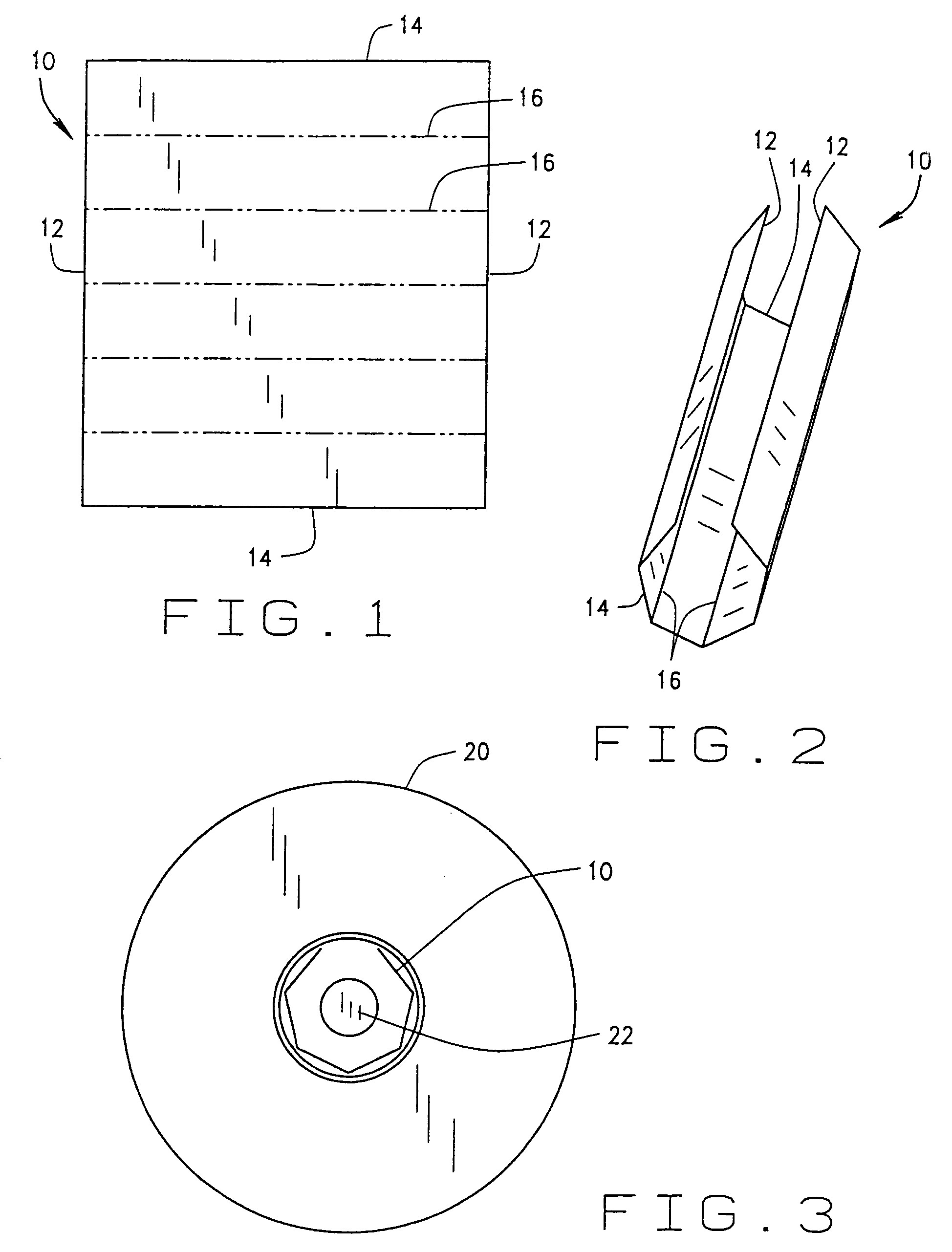

Preparation method of high-safety lithium ion battery diaphragm and preparation of total battery

ActiveCN108400379AImprove mechanical propertiesImprove heat resistanceFinal product manufactureElectro-spinningSide chainLithium metal

The invention discloses a preparation method of a high-safety lithium ion battery diaphragm and a preparation scheme of a total battery. According to the preparation method, a novel polyaryletherketone high polymer material with an active reaction group is prepared, and then the material is prepared into non-woven fabric through an electrospinning technique to be used as a polymer framework, so that the mechanical performance and heat resistance of the diaphragm are improved; through photo initiation or thermal initiation curing, a flexible side chain structure is introduced to the rigid polymer framework, so that electrolyte absorption capability and lithium ion conduction capability of the diaphragm are improved; and a diaphragm curing reaction is performed on a metal lithium sheet or agraphite negative electrode, so that the contact surface between the diaphragm and the metal lithium surface can be enlarged, and formation of lithium dendritic crystal is suppressed and decelerated.The whole battery preparation scheme provided by the invention has the characteristics of no expansion at a temperature of 80 DEG C and high cycle stability (0.5C and 200 cycles), and is expected to be the improved scheme of the high-safety lithium ion battery diaphragm to be applied to a lithium ion secondary battery or a lithium metal secondary battery.

Owner:PEKING UNIV

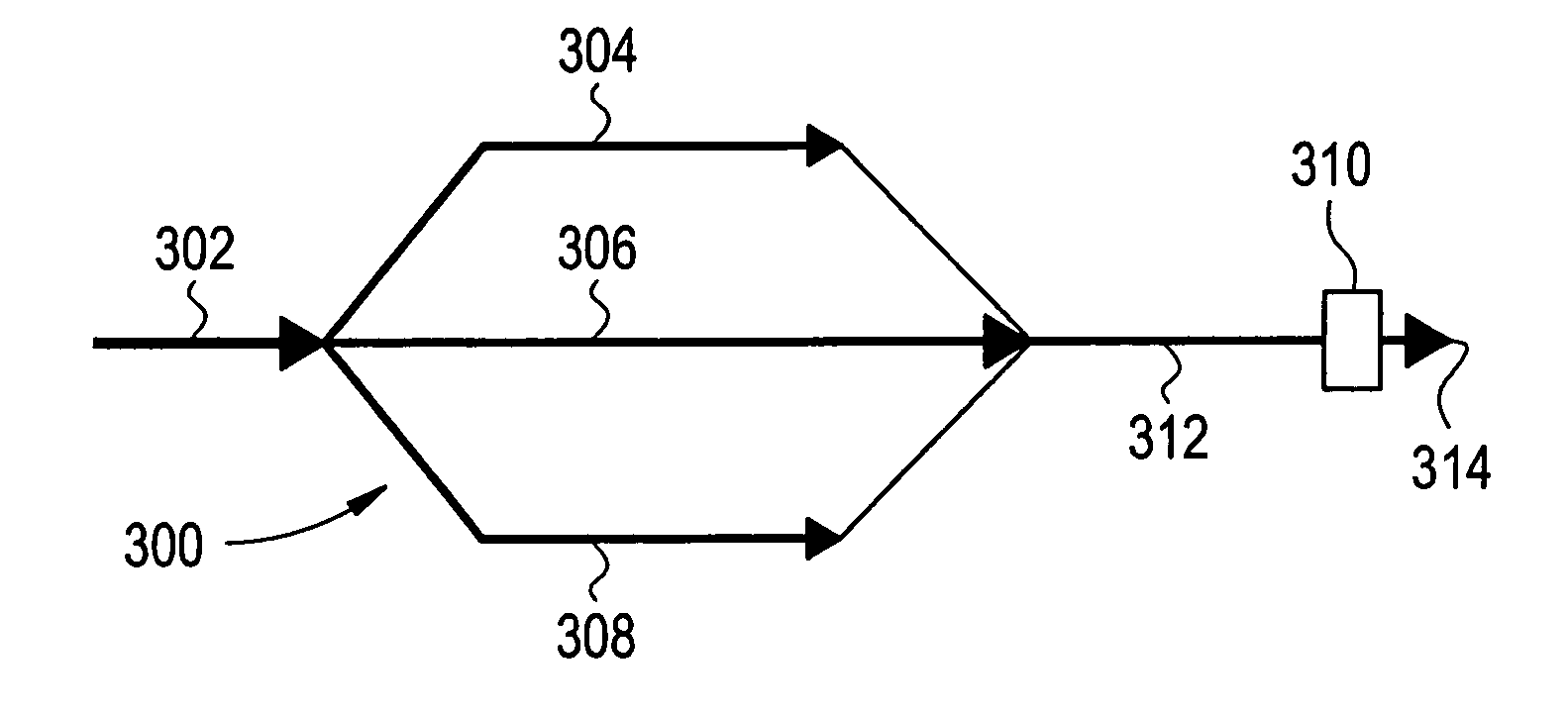

Combustion NOx reduction method

InactiveUS7335014B2Extended half-lifeIncrease vapor pressureCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustionEngineering

A method of extending the droplet half-life of water droplets in a combustion furnace by increasing the relative humidity in the droplets' environment; thereby reducing the evaporation rate of the water from the droplet and increasing the half-life of the droplets in the droplets' environment.

Owner:THE POWER IND GRP

Attractant for juxiaoshi fly

The invention relates to two kinds of Bactrocera dorsalis imago attractant that is made up from 1-20wt% methyleugenol, 4-20wt% sugar, 10-30wt% alcohol, 10-30wt% vinegar, 30-75wt% water. The attractant has good effect to Bactrocera dorsalis and male adult, especially the male adult. The invention is low cost, easy to operate, and has good persistence.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

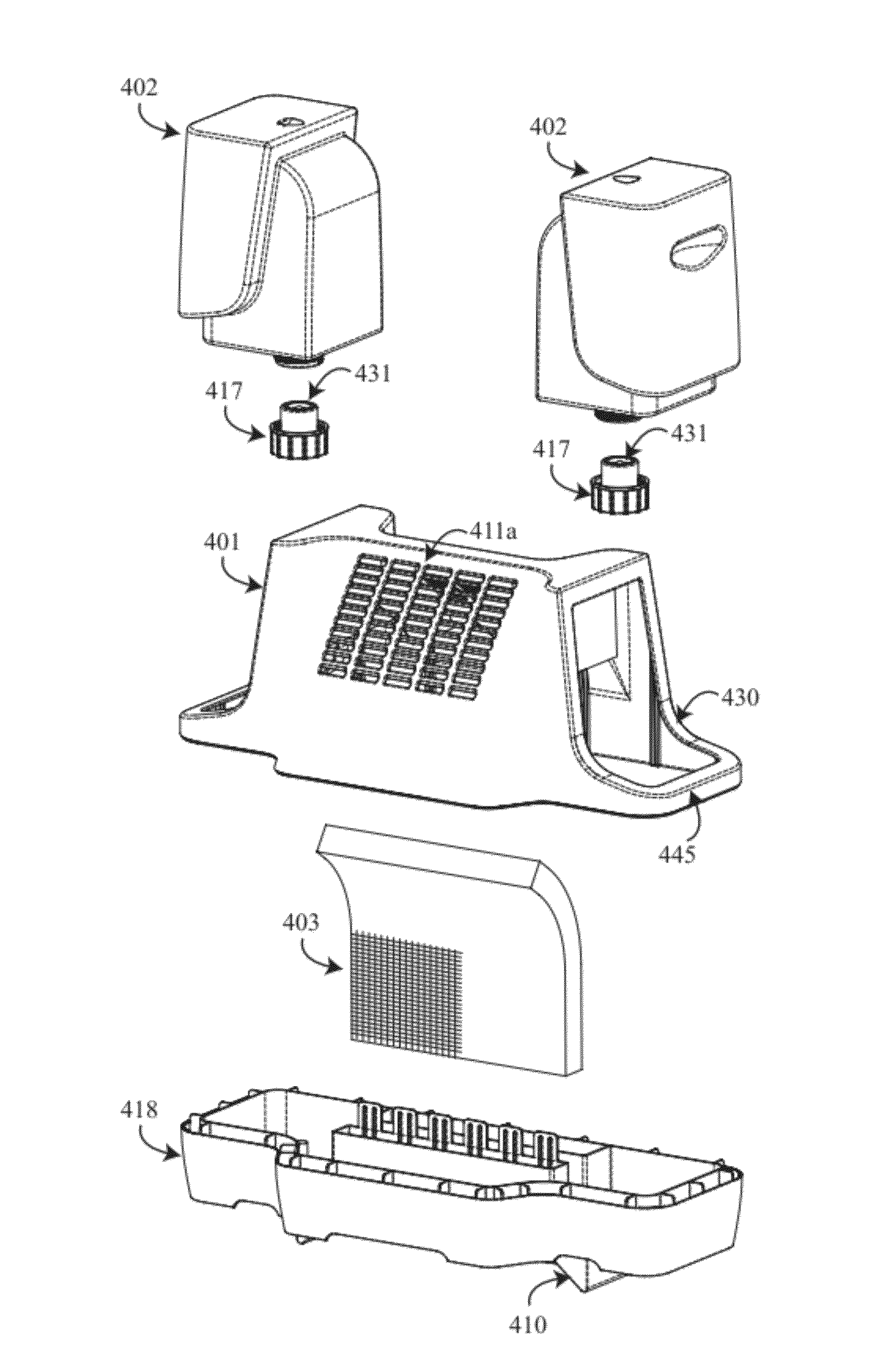

Room vent humidifier

InactiveUS20120267804A1Avoid external damageReduce evaporation rateLighting and heating apparatusMixing methodsFilter elementWaste management

A room humidifying apparatus is provided which operates with minimum cost and without any electrical power. The humidifier is located so as to make use of a stream of air coming from a register. The humidifier has a casing carrying a main water tank, a water pan and an evaporative filter element which are located in the casing. The tank drips water onto the filter element, which has a lower portion located in the water pan to collect any excess water dripping down the filter element and also to moisten it with capillary effect. Heated air from the register becomes humidified on passing through the filter element. The water tank can be filled manually from the top or be detachable and filled through a bottom refill opening. Alternatively, the water tank can be connected to a water source with a valve to regulate the flow of water into the water tank. The water tank may be balanced so as to displace, for example tilt, from a first position when it contains water to a second position when it is empty.

Owner:RODRIGS JERI

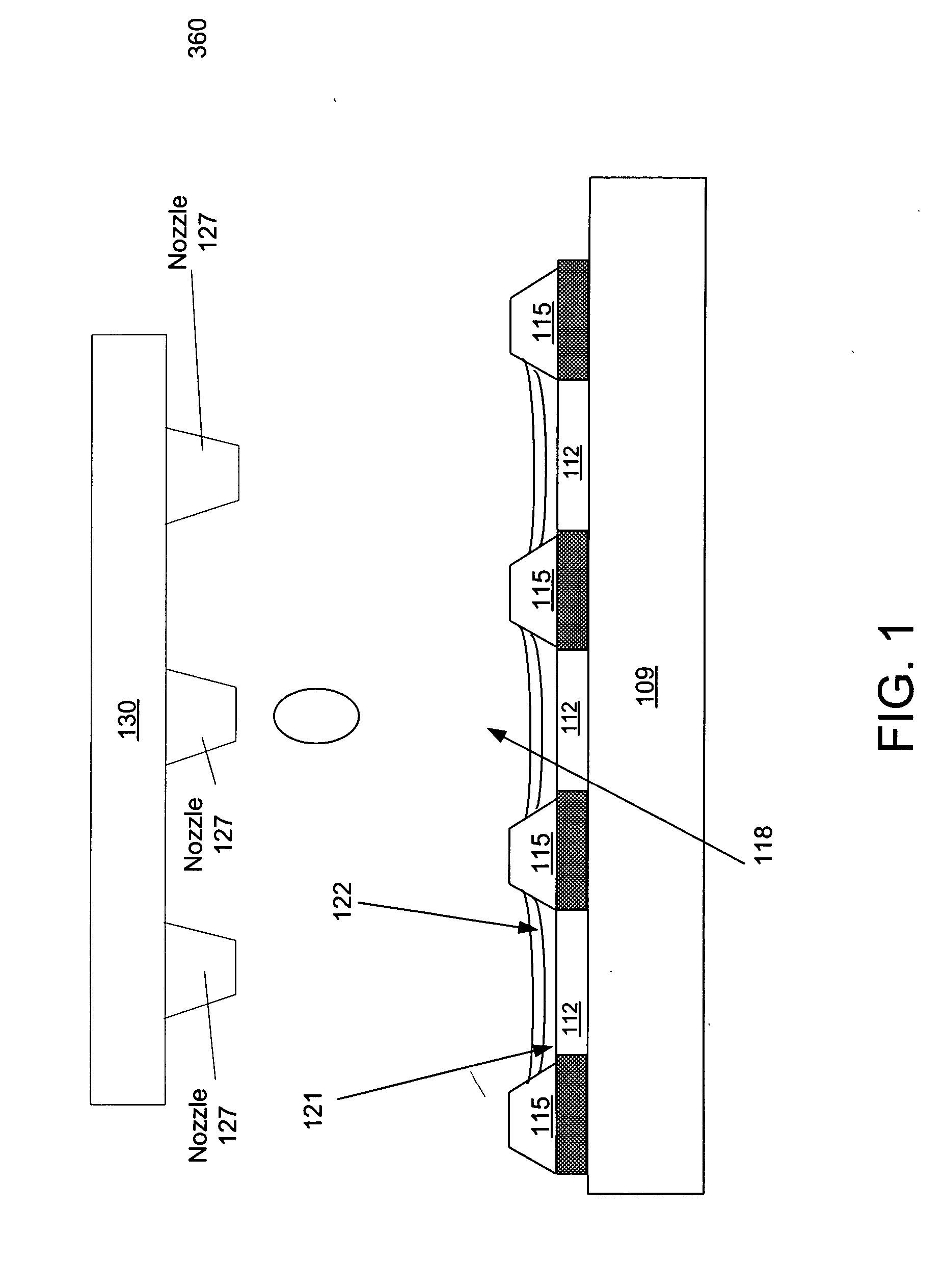

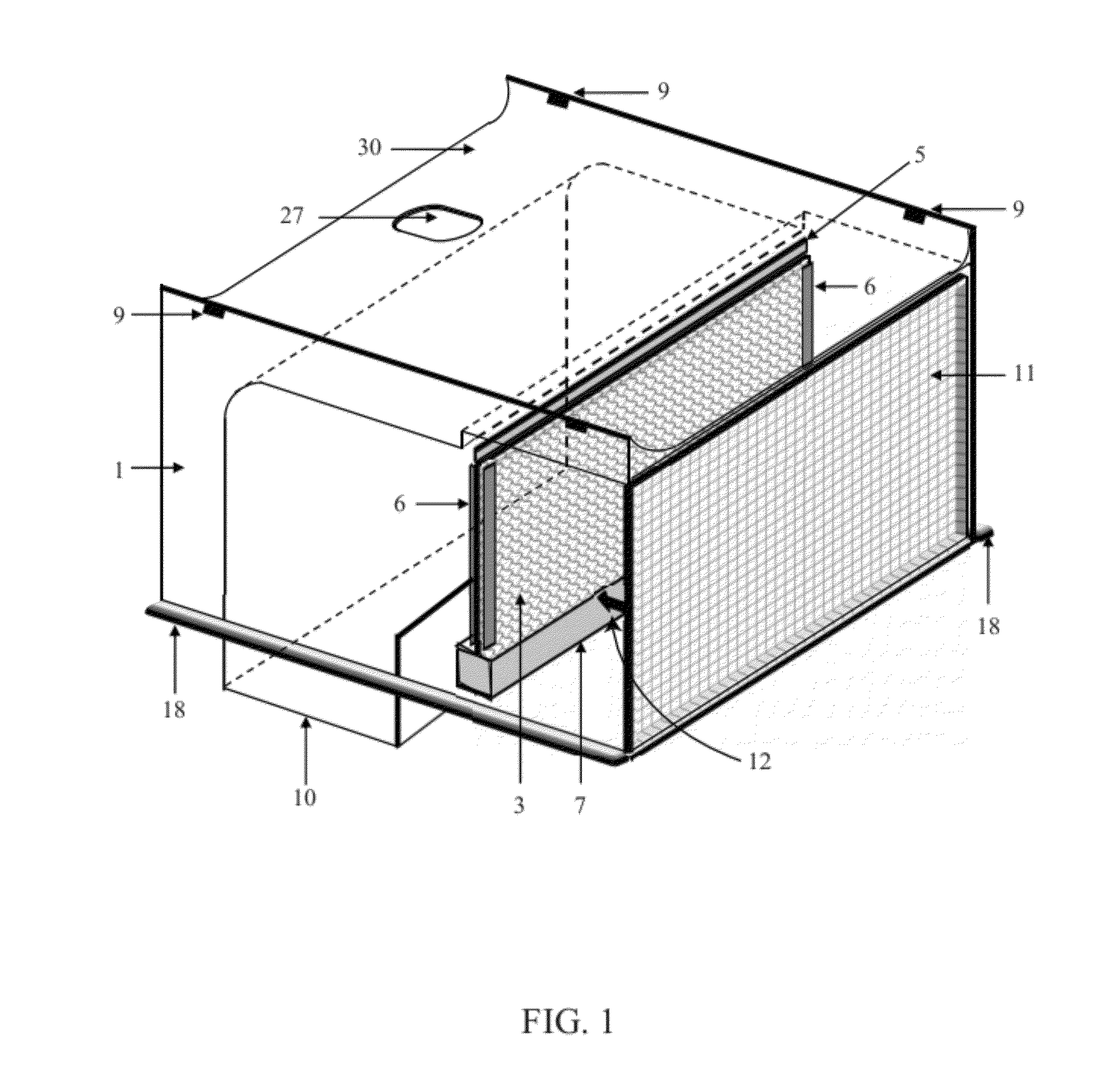

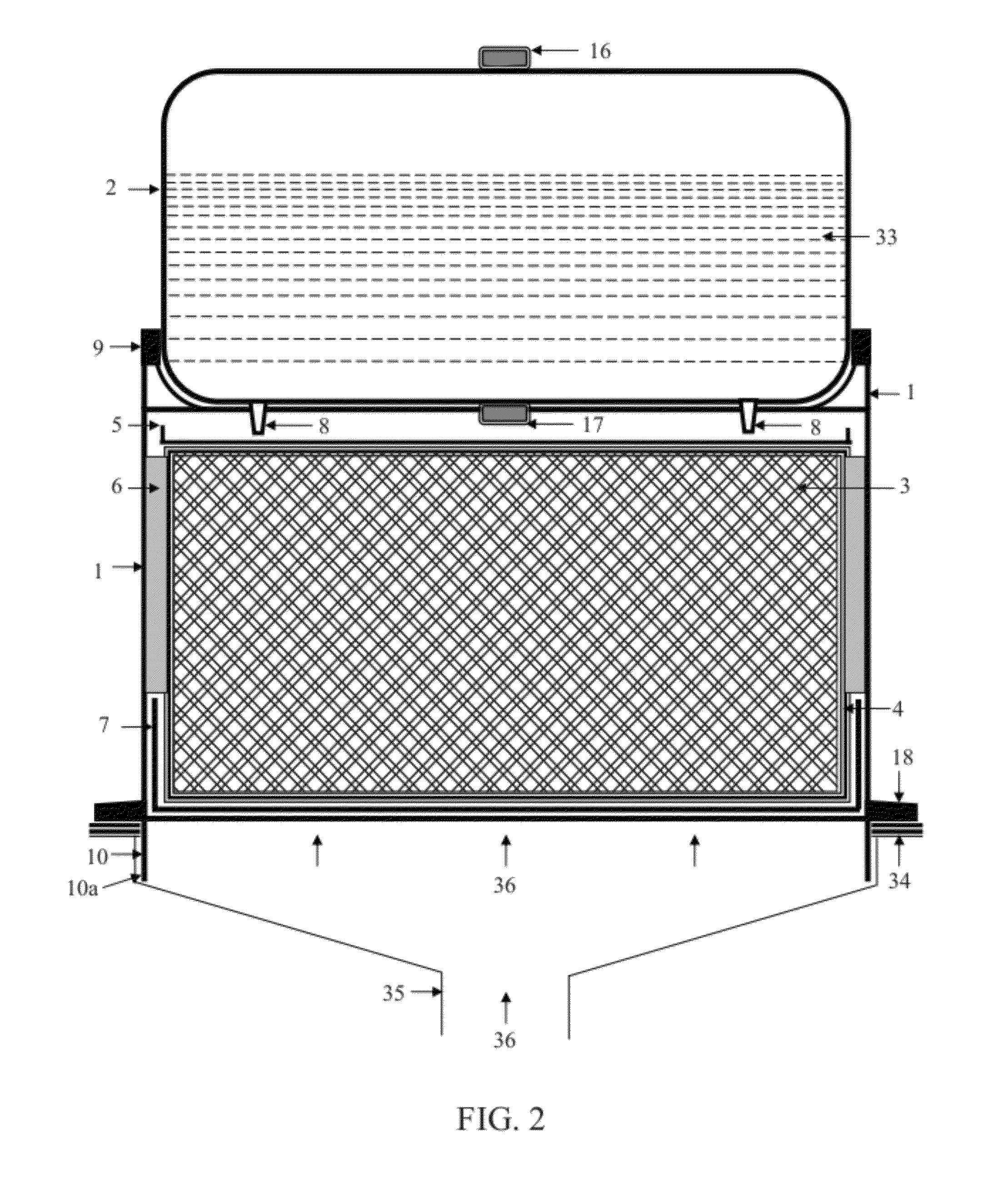

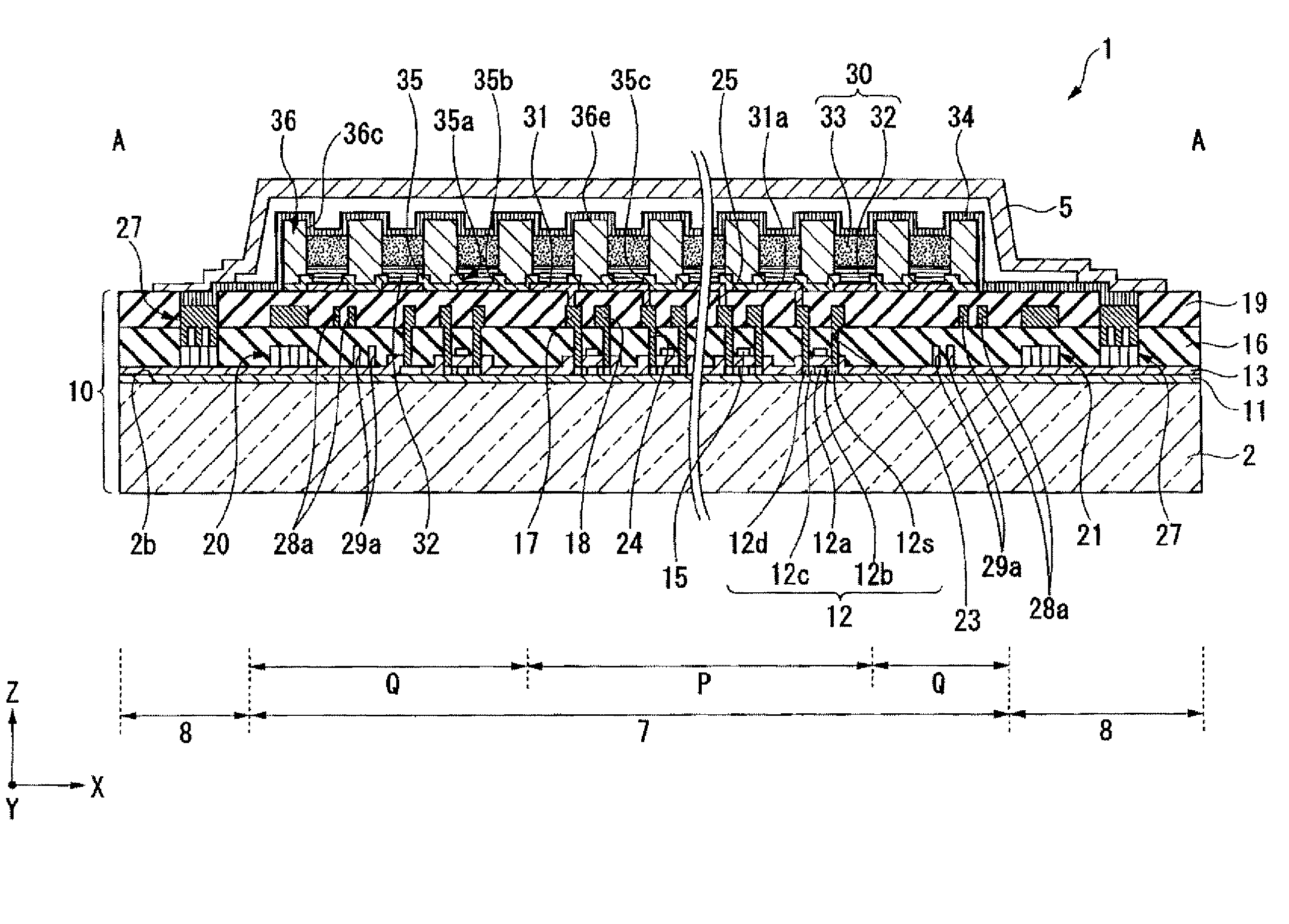

Film forming method, method for manufacturing organic electroluminescent device, organic electroluminescent device, and electronic apparatus

ActiveUS7989025B2Reduce pressureReduce flow rateElectroluminescent light sourcesSolid-state devicesOrganic electroluminescenceSolvent

A film forming method for forming a film including arranging a liquid composition on a substrate and drying the liquid composition, the liquid composition being obtained by dissolving a functional material in a solvent with a plurality of species of liquid mixed therein, is provided. The method includes:a) firstly reducing a pressure surrounding the liquid composition arranged on the substrate at a first depressurizing speed;b) increasing the pressure surrounding the liquid composition to a predetermined pressures after the step a); andc) secondly reducing the pressure surrounding the liquid composition at a second depressurizing speed, after the step b).

Owner:KATEEVA

Prescented and custom scented card insert

InactiveUS7926734B2Better friendlinessThicken fragranceTobacco devicesGaseous substancesPaper towelEvaporation

The present disclosure provides a device sized for insertion into an inner tube of a roll of paper towels or toilet paper comprising a insert card absorb a fragrance and which is bendable, the insert allowing fragrance to emit by evaporation from the insert into the air and an outer packaging for containing the insert card, the packaging being a substantially impervious moisture and odor barrier.

Owner:AIR SQUARED +1

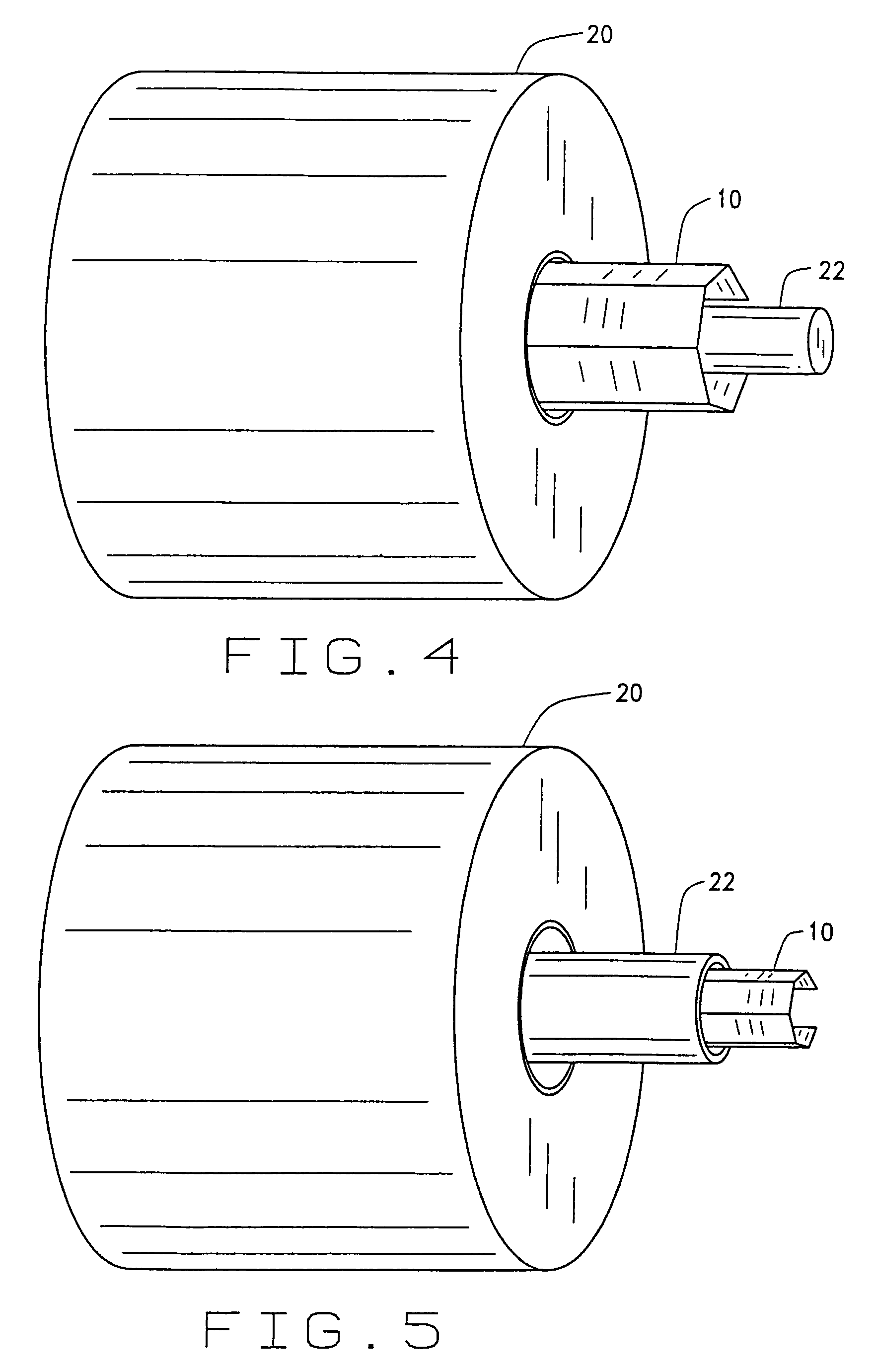

Cleaning system utilizing an organic cleaning solvent and a pressurized fluid solvent

InactiveUS7147670B2Increase vapor pressureLow boiling pointDry-cleaning apparatusDetergent mixture composition preparationSolubilityHalohydrocarbon

A cleaning system that utilizes an organic cleaning solvent and pressurized fluid solvent is disclosed. The system has no conventional evaporative hot air drying cycle. Instead, the system utilizes the solubility of the organic solvent in pressurized fluid solvent as well as the physical properties of pressurized fluid solvent. After an organic solvent cleaning cycle, the solvent is extracted from the textiles at high speed in a rotating drum in the same way conventional solvents are extracted from textiles in conventional evaporative hot air dry cleaning machines. Instead of proceeding to a conventional drying cycle, the extracted textiles are then immersed in pressurized fluid solvent to extract the residual organic solvent from the textiles. This is possible because the organic solvent is soluble in pressurized fluid solvent. After the textiles are immersed in pressurized fluid solvent, pressurized fluid solvent is pumped from the drum. Finally, the drum is de-pressurized to atmospheric pressure to evaporate any remaining pressurized fluid solvent, yielding clean, solvent free textiles. The organic solvent is preferably selected from terpenes, halohydrocarbons, certain glycol ethers, polyols, ethers, esters of glycol ethers, esters of fatty acids and other long chain carboxylic acids, fatty alcohols and other long-chain alcohols, short-chain alcohols, polar aprotic solvents, siloxanes, hydrofluoroethers, dibasic esters, and aliphatic hydrocarbons solvents or similar solvents or mixtures of such solvents and the pressurized fluid solvent is preferably densified carbon dioxide.

Owner:EMINENT TECHNOLOGY

Solar silicon wafer cleaning agent

ActiveCN103484261AStrong detergency and solubilizationGood dispersionInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSolventCleansing Agents

The invention provides a solar silicon wafer cleaning agent including 1 wt%-15 wt% of heterogeneous alcohol polyoxyethylene ether, 1 wt%-15 wt% of propanediol ether, 0.5 wt%-10 wt% of ethylene diamine tetraacetic acid tetrasodium salt, greater than zero and less than or equal to 10 wt% of an anionic surfactant, greater than zero and less than or equal to 20 wt% of a pH regulator, and the balance being water. The anionic surfactant and heterogeneous alcohol polyoxyethylene ether are adopted to compound, so that the cleaning agent has stronger cleaning ability; propanediol ether is selected as a solvent, and the kind of solvent is an organic solvent with low toxicity and no stimulation; meanwhile, ethylene diamine tetraacetic acid tetrasodium salt is also selected as a metal ion complexing agent, and copper, iron and other metal ions on the surface of a silicon wafer can be effectively removed; and finally, the pH regulator is selected to adjust the pH value of the cleaning agent, oil stains on the surface of the silicon wafer are effectively removed, and the cleaning effect is lasting and durable.

Owner:ZHEJIANG SHUNLIAN INTELLIGENT EQUIP CO LTD

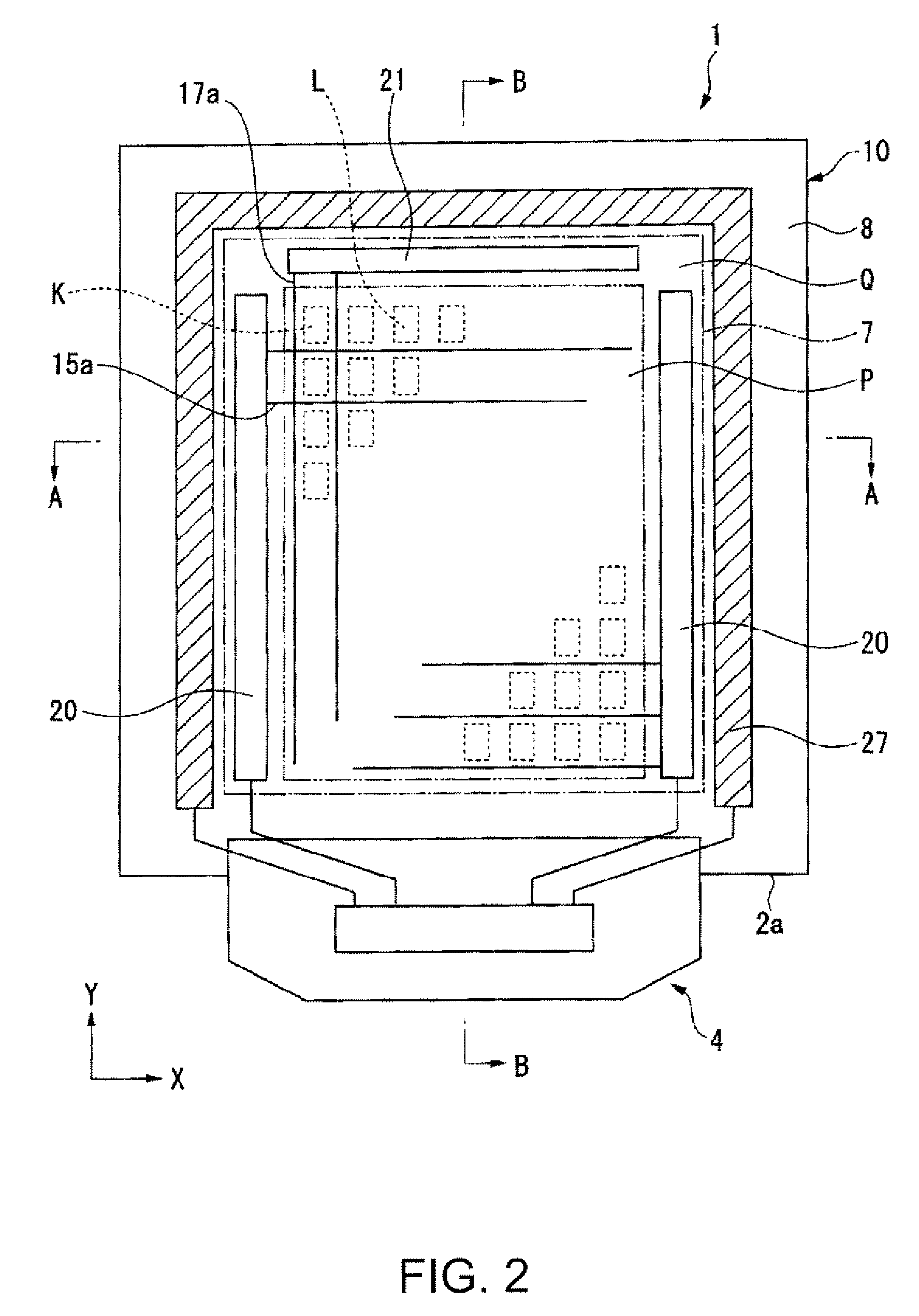

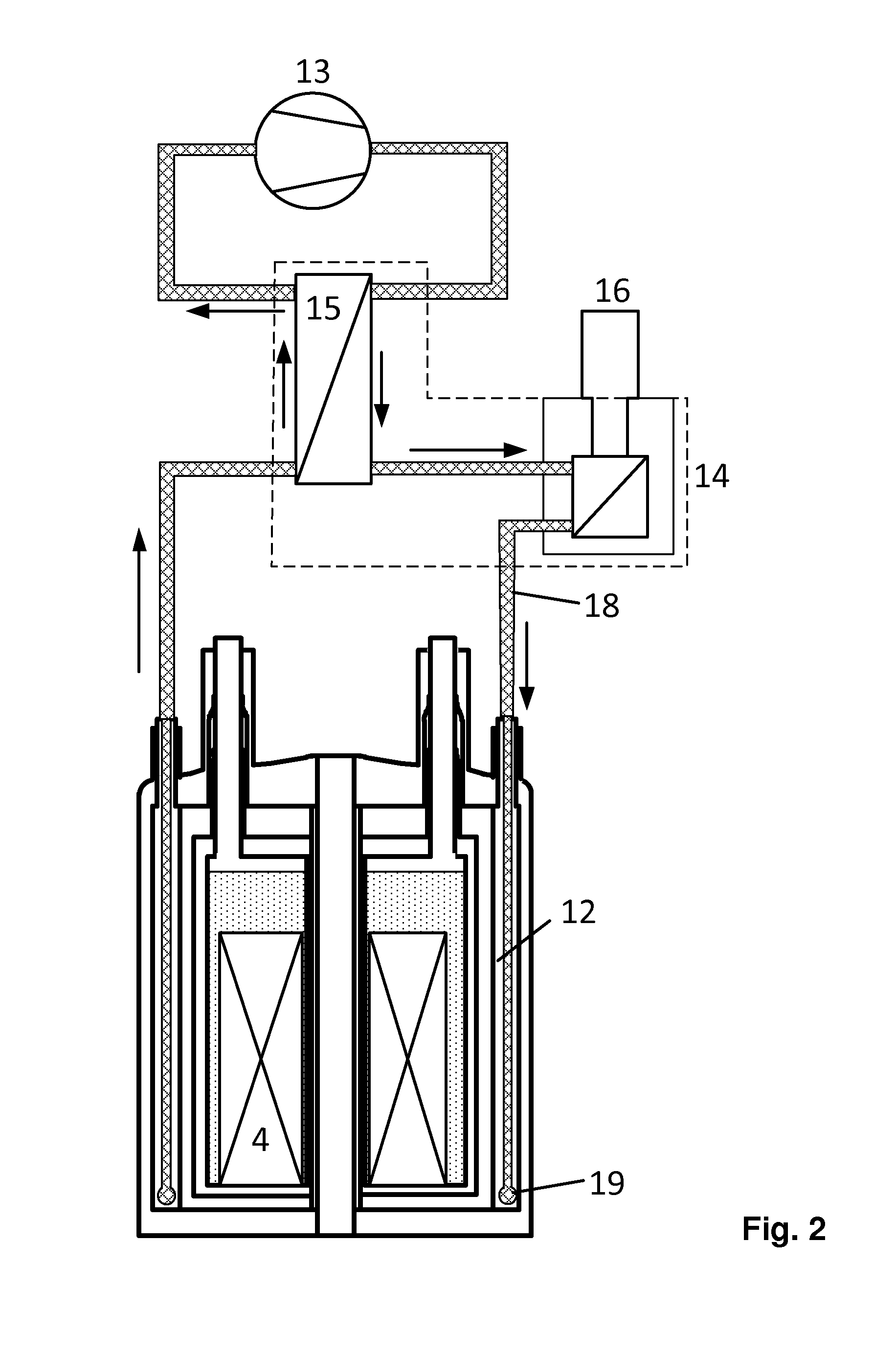

Method for reconfiguring a cryostat configuration for recirculation cooling

ActiveUS20150007586A1Reduce evaporation rateGood thermal contactSuperconductors/hyperconductorsMagnetic measurementsSuperconducting CoilsEngineering

A method for converting a cryostat configuration (1) having a first container (2) with a liquid helium bath (3) and a second container (6) which is filled with liquid nitrogen (7) is characterized in that a cooling medium (12) which is in a gaseous state at a temperature of 60K and a pressure of 1 bar, is introduced into the second container and is cooled by a refrigerator (16) by means of a cooling circuit (11), the coolant lines of which are guided into the second container, to an operating temperature of ≦60K. With this retrofit for existing cryostat configurations that utilize both liquid helium and also liquid nitrogen for cooling a superconducting coil, use of liquid nitrogen can be completely avoided and the evaporation rate of the liquid helium can also be considerably reduced without having to re-liquefy the cryogens used.

Owner:BRUKER SWITZERLAND AG

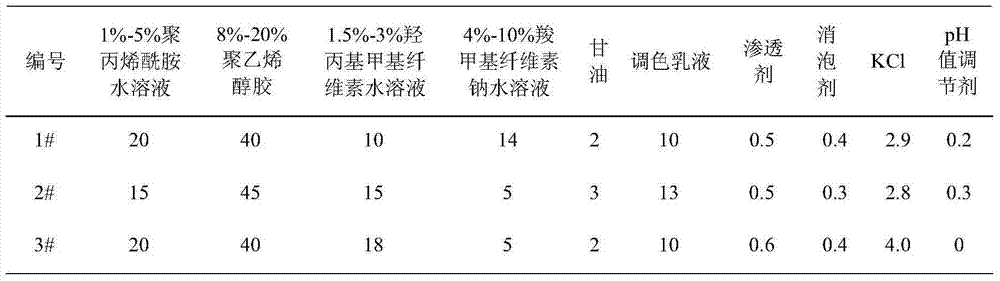

Coal dust inhibitor and preparation method thereof

InactiveCN103756640ALow costReduce evaporation rateOther chemical processesRoad cleaningHydroxypropylmethyl celluloseChemistry

The invention discloses a coal dust inhibitor and a preparation method thereof. The coal dust inhibitor comprises an organic binding agent, a penetrating agent, a humectant, a de-foaming agent and water, wherein the organic binding agent comprises polyacrylamide and polyvinyl alcohol; the humectant comprises hydroxypropyl methyl cellulose, sodium carboxymethylcellulose and glycerol. The preparation method of the coal dust inhibitor comprises the following steps: mixing components in following (1) or (2) and uniformly mixing: (1) the organic binding agent, the penetrating agent, the humectant, the de-foaming agent and water; (2) the organic binding agent, the penetrating agent, the humectant, the de-foaming agent, an pH adjusting value, color modulation emulsion, an auxiliary agent and water. The coal dust inhibitor has a high speed of forming a cured protection layer and has proper mechanical strength and water resistance; the preparation method is simple and has the characteristic that needed production equipment is little. The coal dust inhibitor can be used for dust inhibition of coal transportation, storage, construction sites and the like.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Dynamic-Pressure Bearing Device and Disk Drive

ActiveUS20050088779A1Small viscosityLow evaporation rateCarrier constructional parts dispositionApparatus for flat record carriersIonElectricity

An ionic liquid is utilized as the dynamic-pressure fluid charged inside a bearing space formed in the gap where an axial bushing (axial component) [21] and a bearing sleeve (bearing component) [13] oppose. Designing a dynamic-pressure bearing device is made possible virtually without having to consider such factors as how to control dynamic-pressure-fluid evaporation or how to secure electrical continuity between the axial bushing and the bearing sleeve. Owing to ionic liquids' property of not hydrolyzing, deterioration of the dynamic-pressure fluid from moisture absorption, oxidation, etc. is inhibited, yielding a dynamic-pressure bearing device with a long lifespan.

Owner:NIDEC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com