Patents

Literature

191273 results about "Inorganic chemistry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inorganic chemistry deals with the synthesis and behavior of inorganic and organometallic compounds. This field covers all chemical compounds except the myriad organic compounds (carbon-based compounds, usually containing C-H bonds), which are the subjects of organic chemistry. The distinction between the two disciplines is far from absolute, as there is much overlap in the subdiscipline of organometallic chemistry. It has applications in every aspect of the chemical industry, including catalysis, materials science, pigments, surfactants, coatings, medications, fuels, and agriculture.

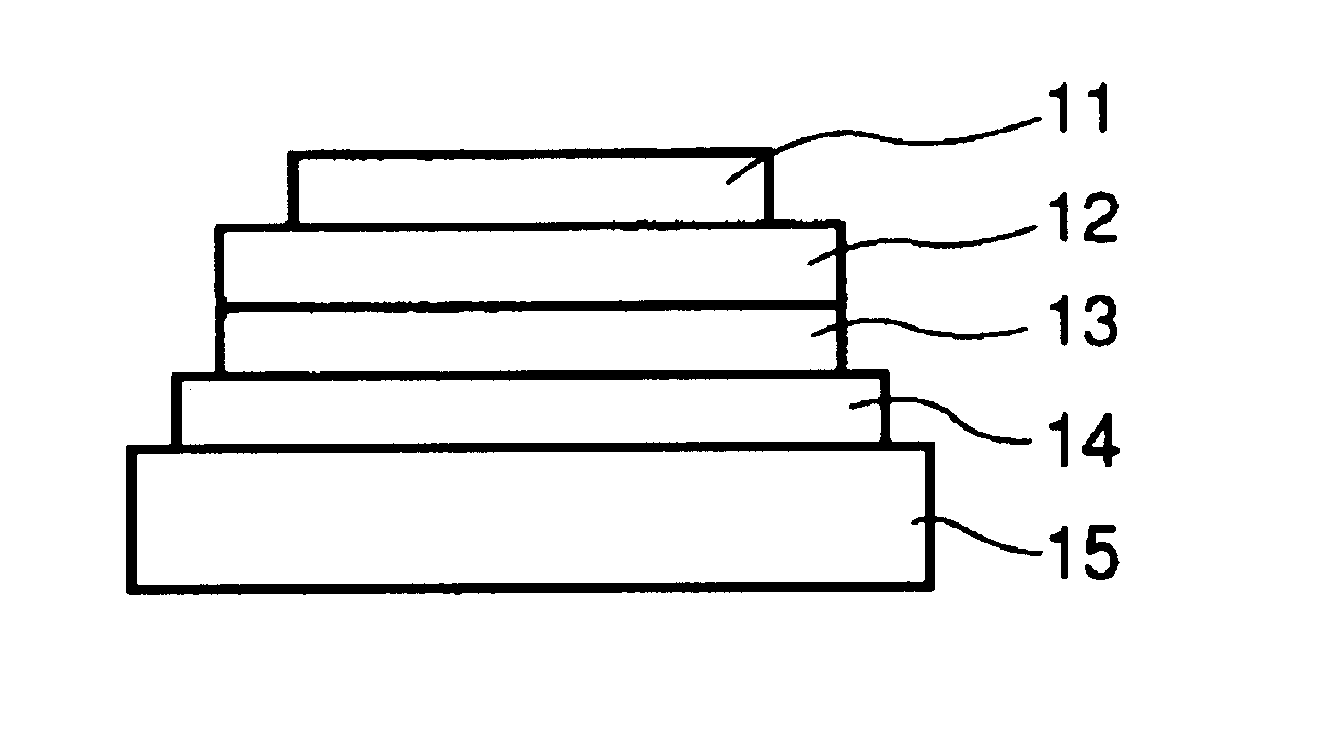

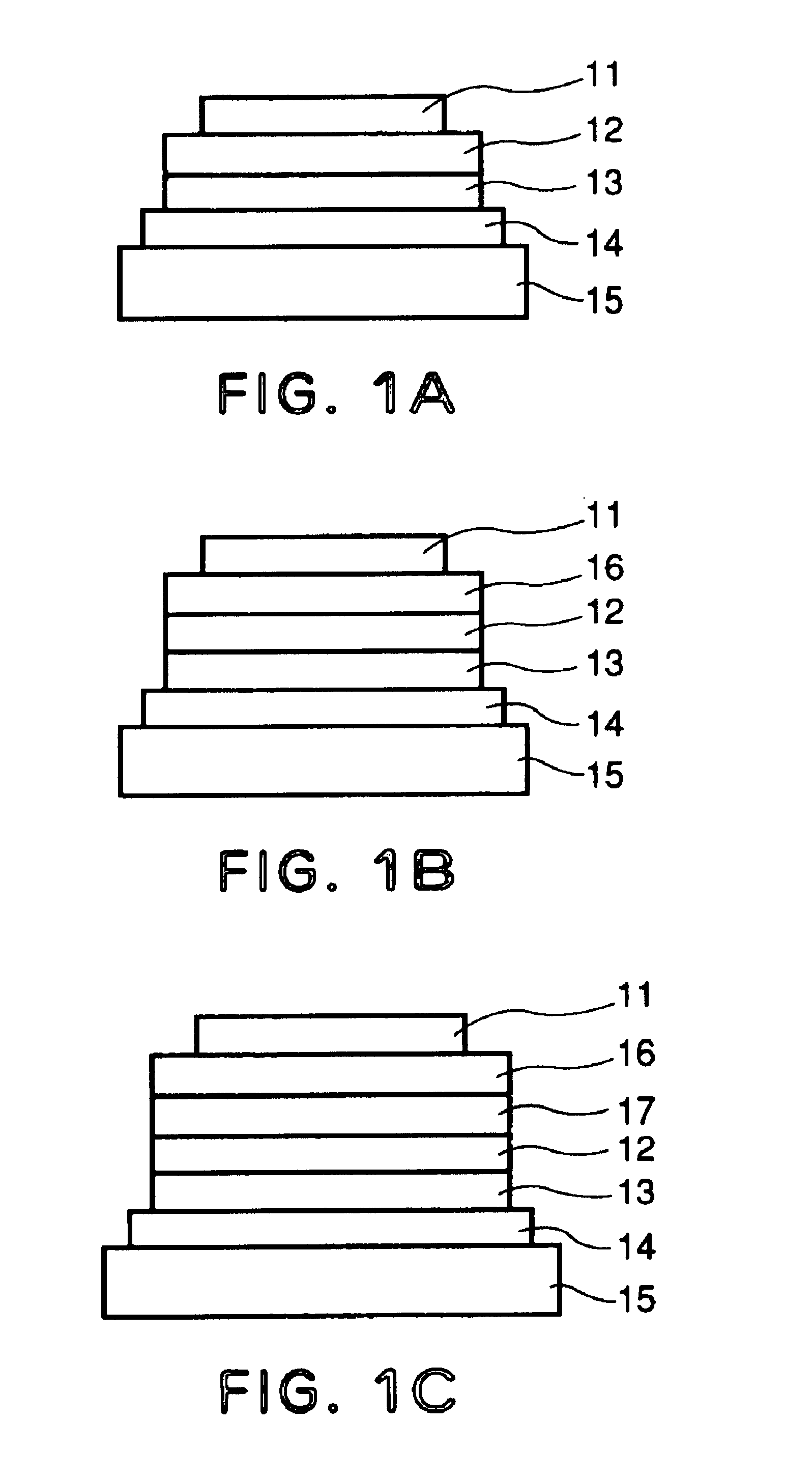

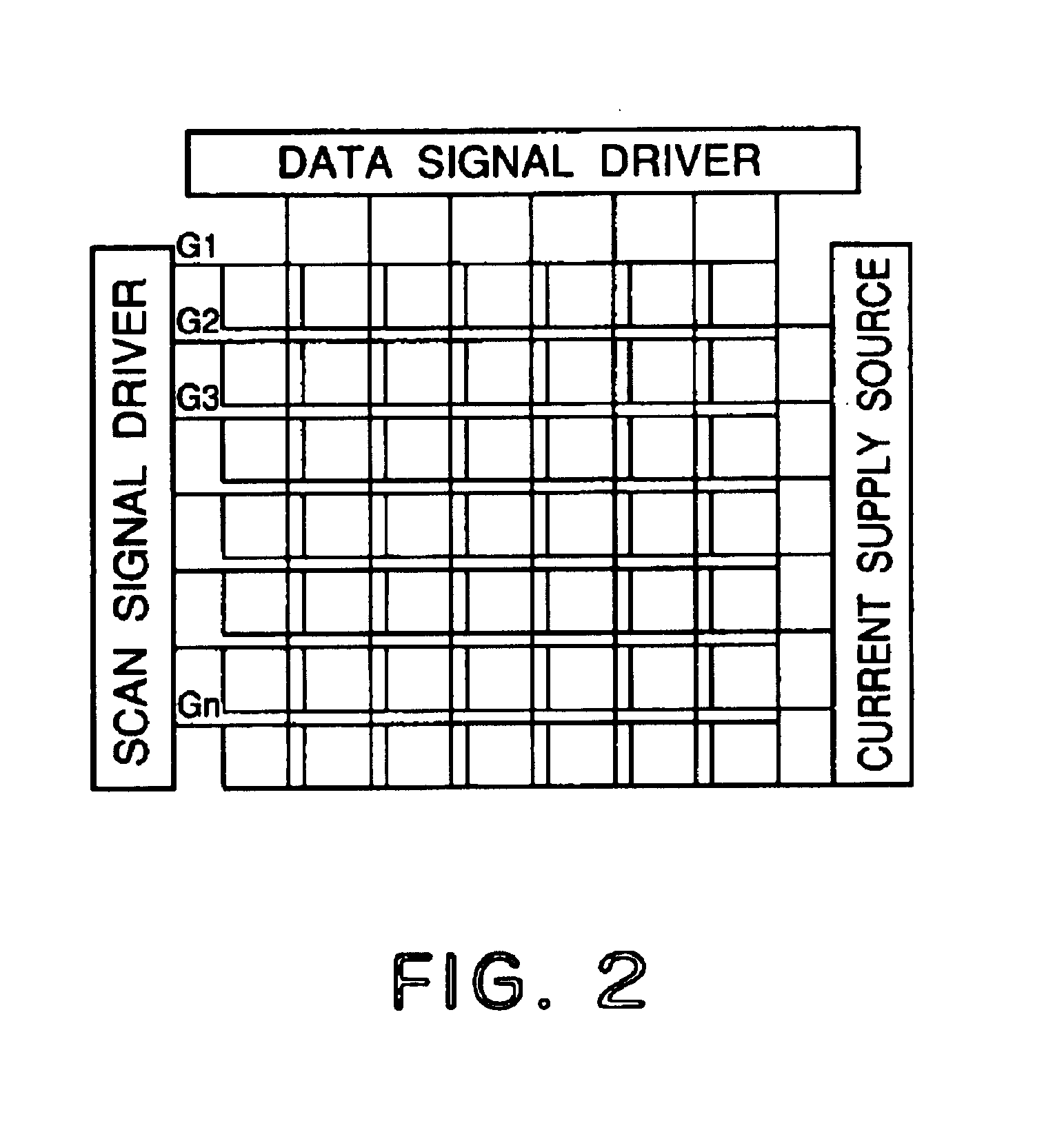

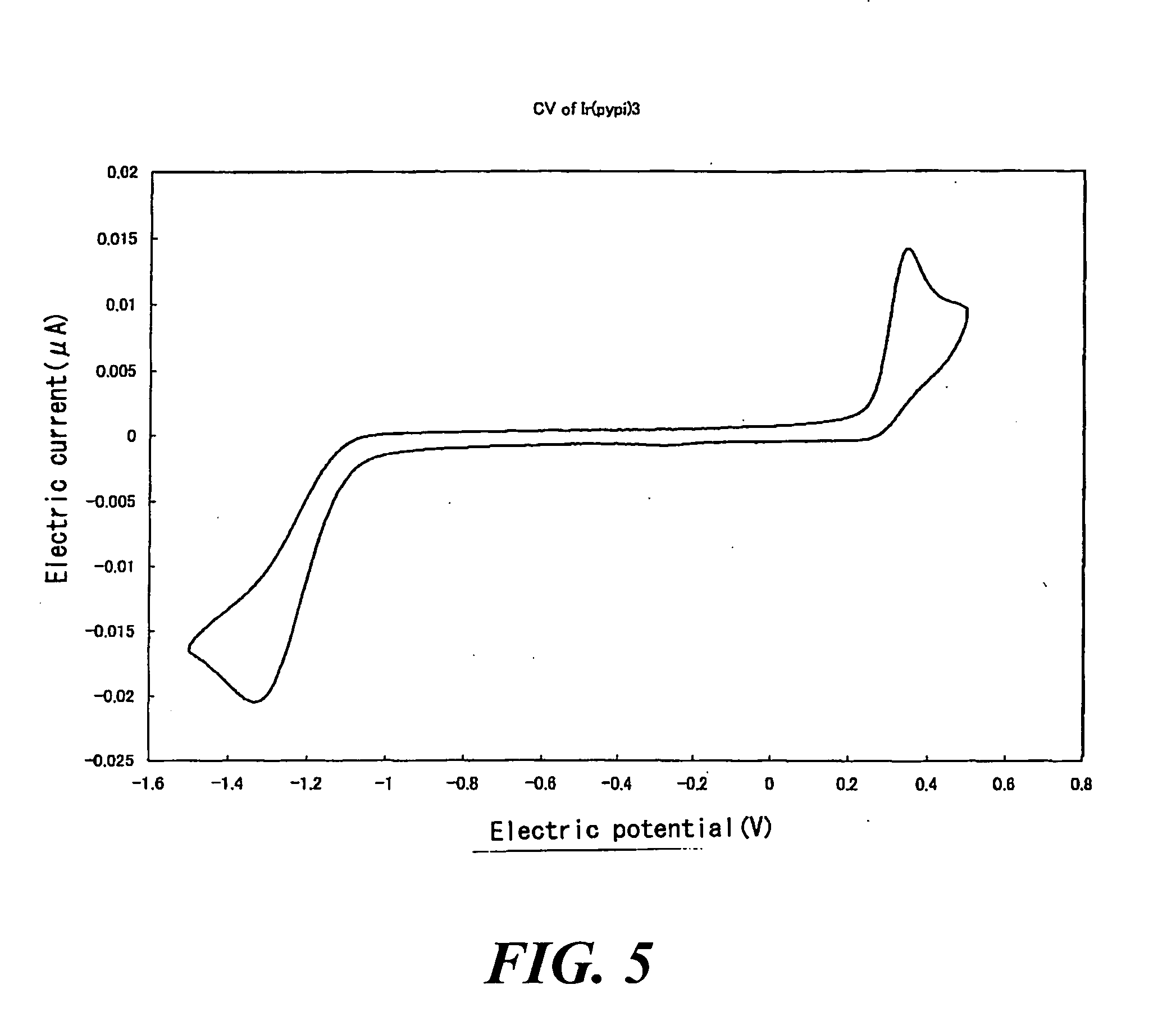

Metal coordination compound, luminescence device and display apparatus

InactiveUS6921915B2High luminous efficiencyIncrease brightnessIndium organic compoundsDischarge tube luminescnet screensLuminescenceHigh luminance

Owner:SAMSUNG ELECTRONICS CO LTD

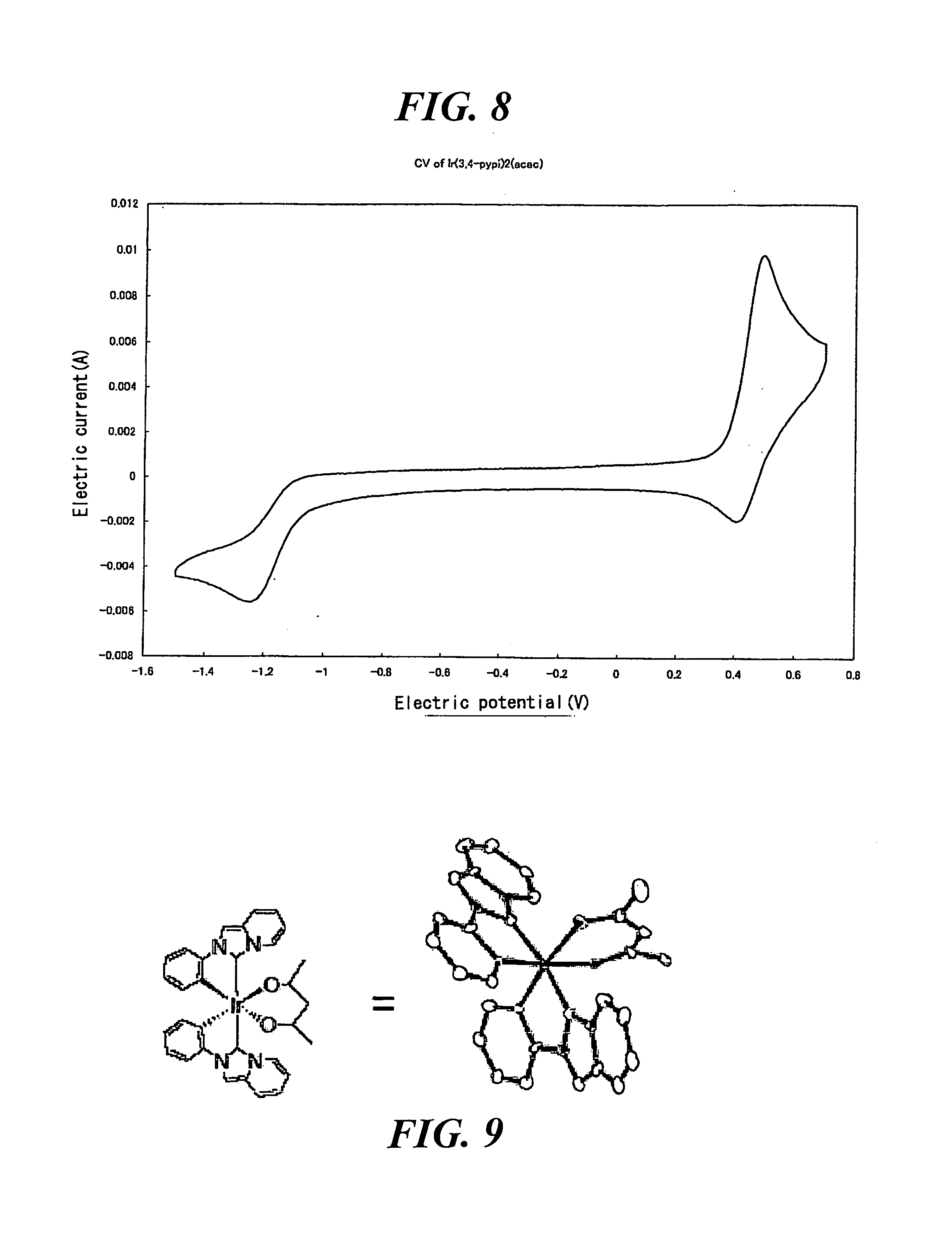

Organometallic complex and organic light-emitting element using same

InactiveUS20090039776A1Improve efficiencyIncreased durabilityGroup 5/15 element organic compoundsSolid-state devicesSimple Organic CompoundsOrganic compound

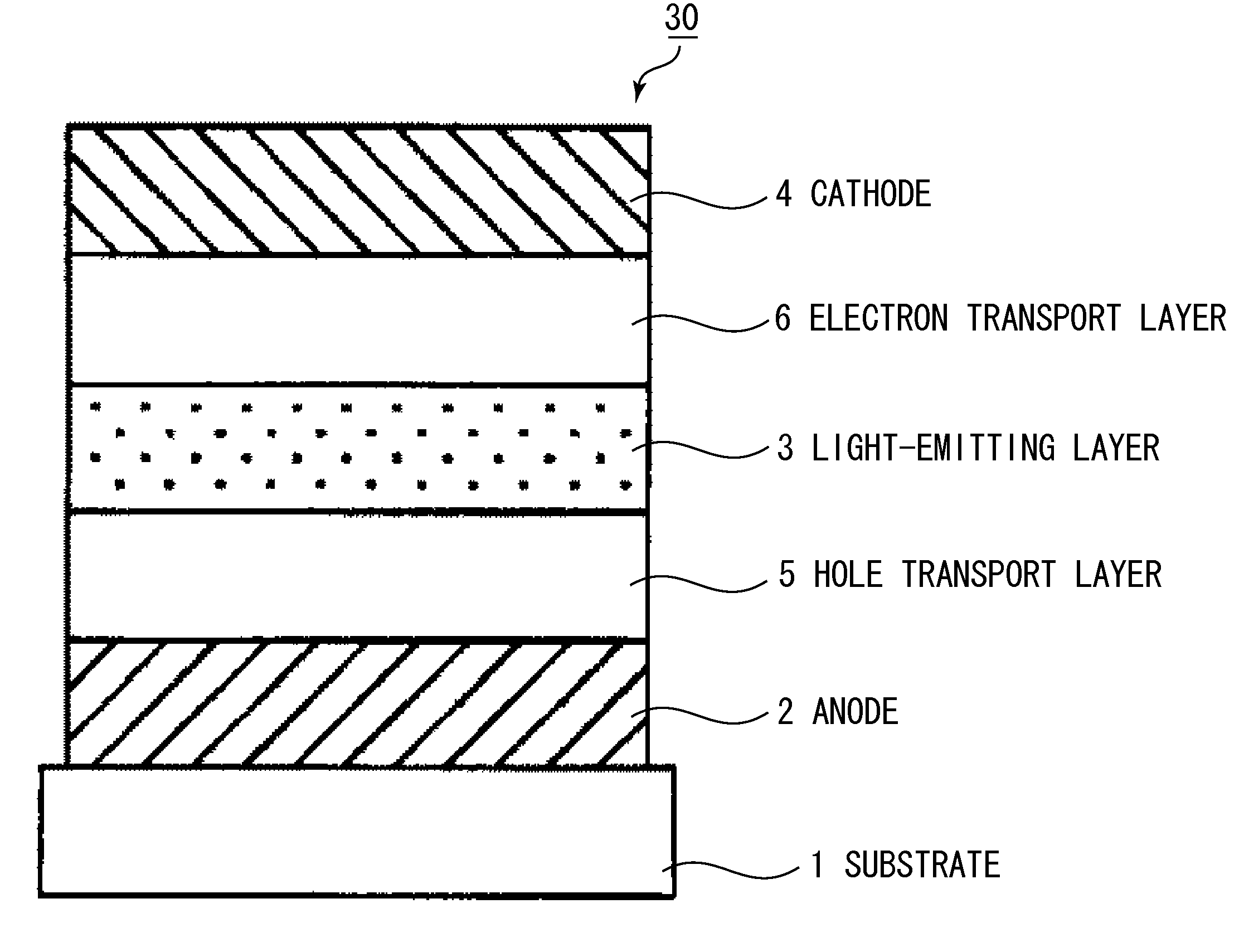

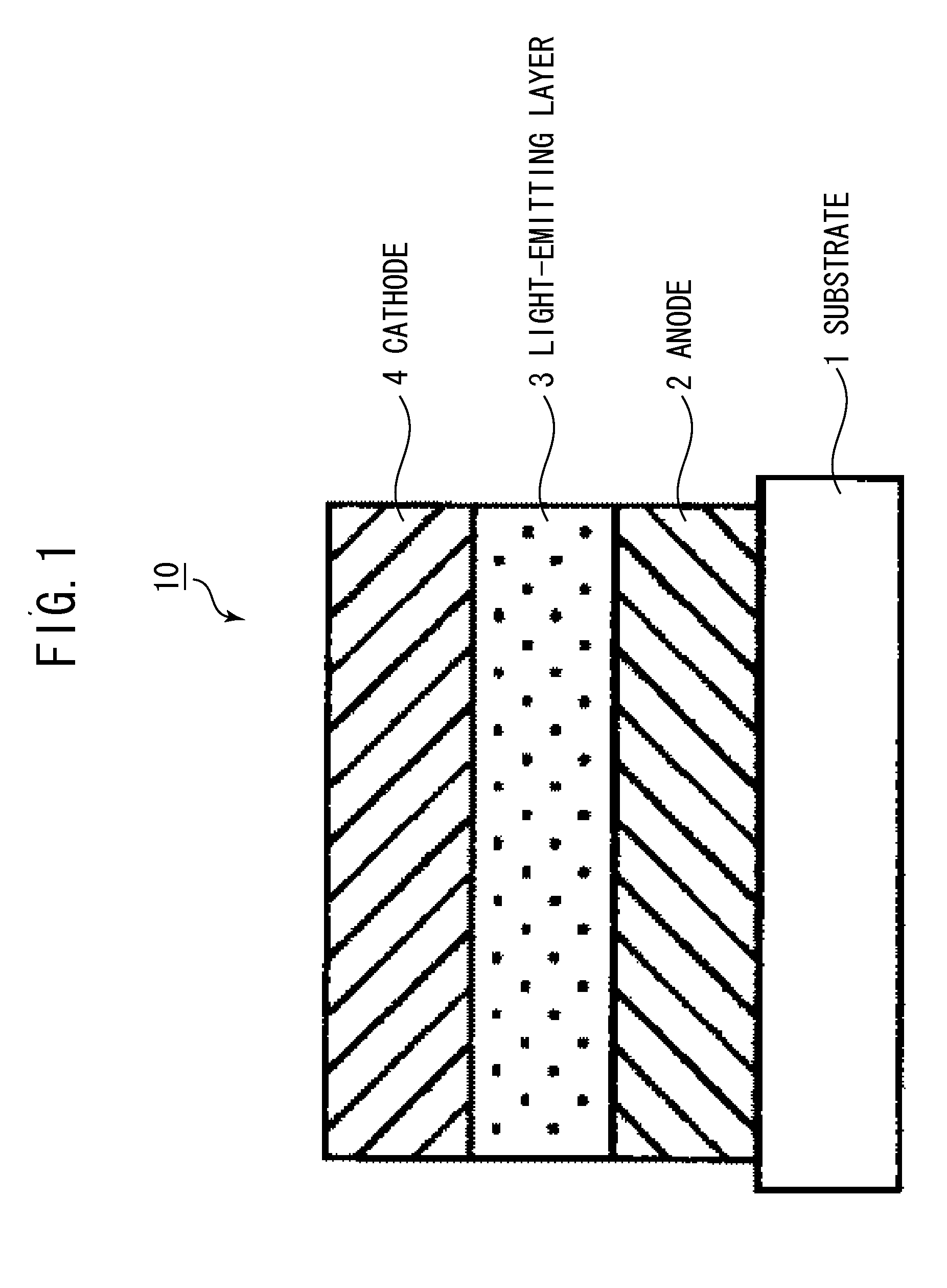

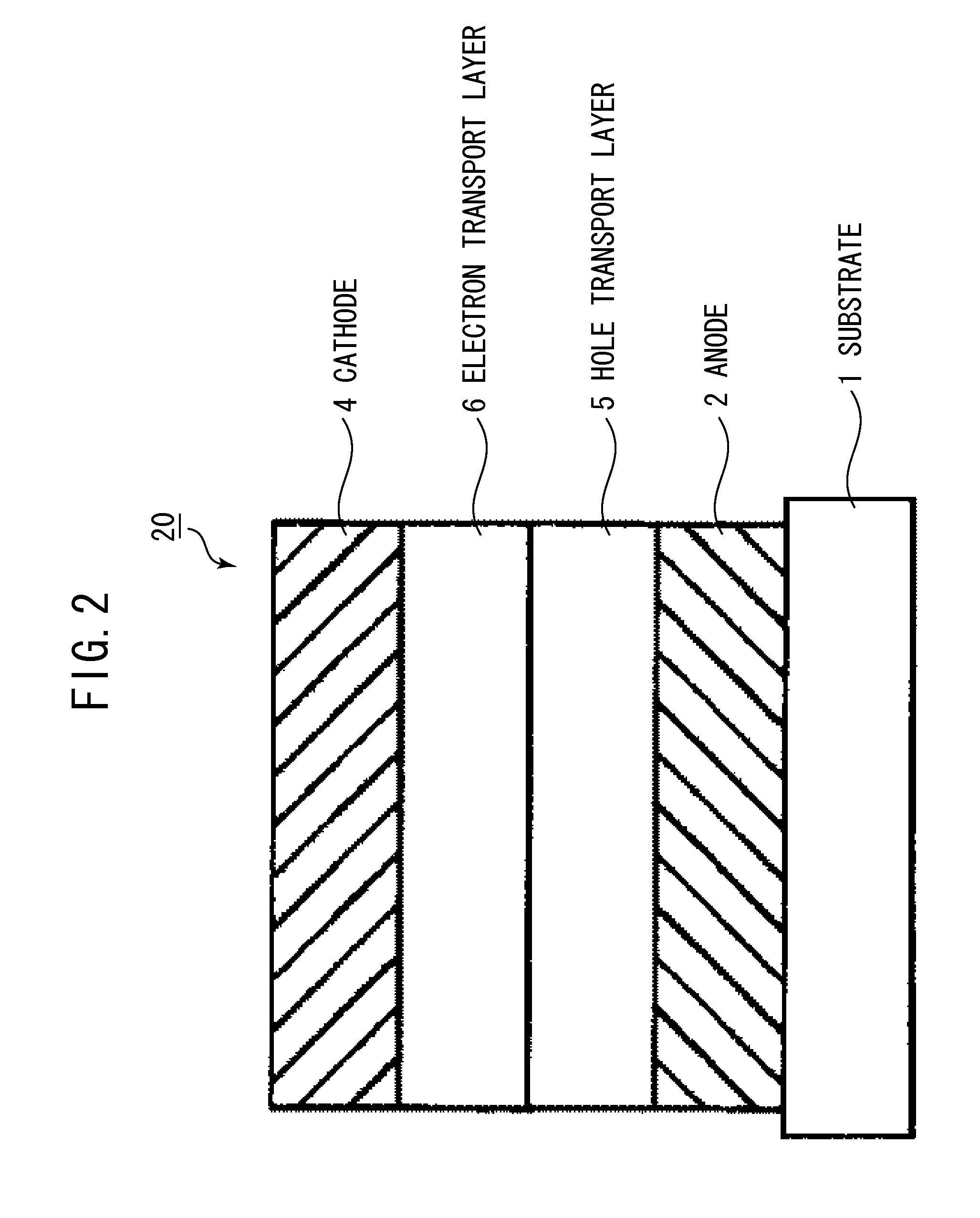

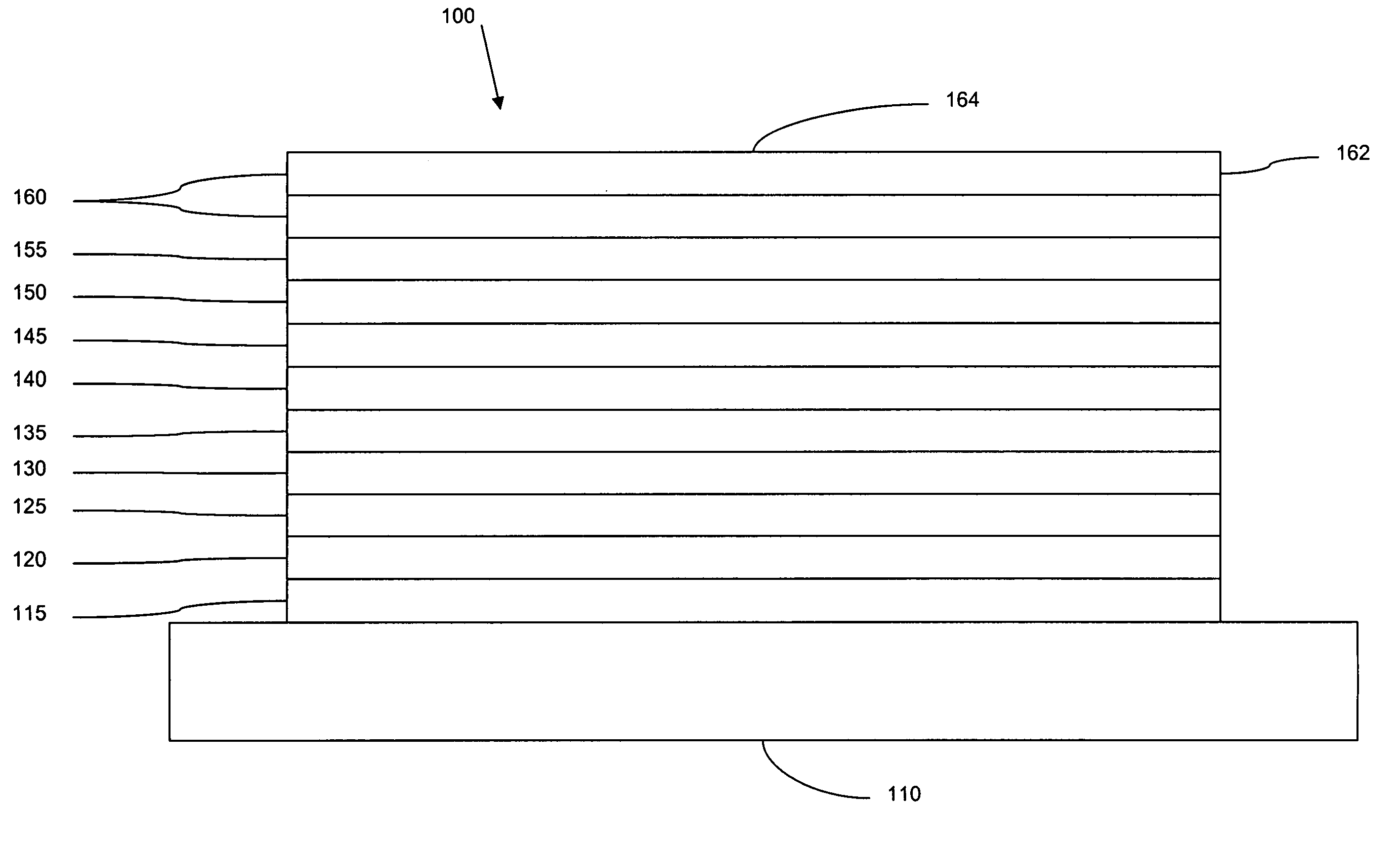

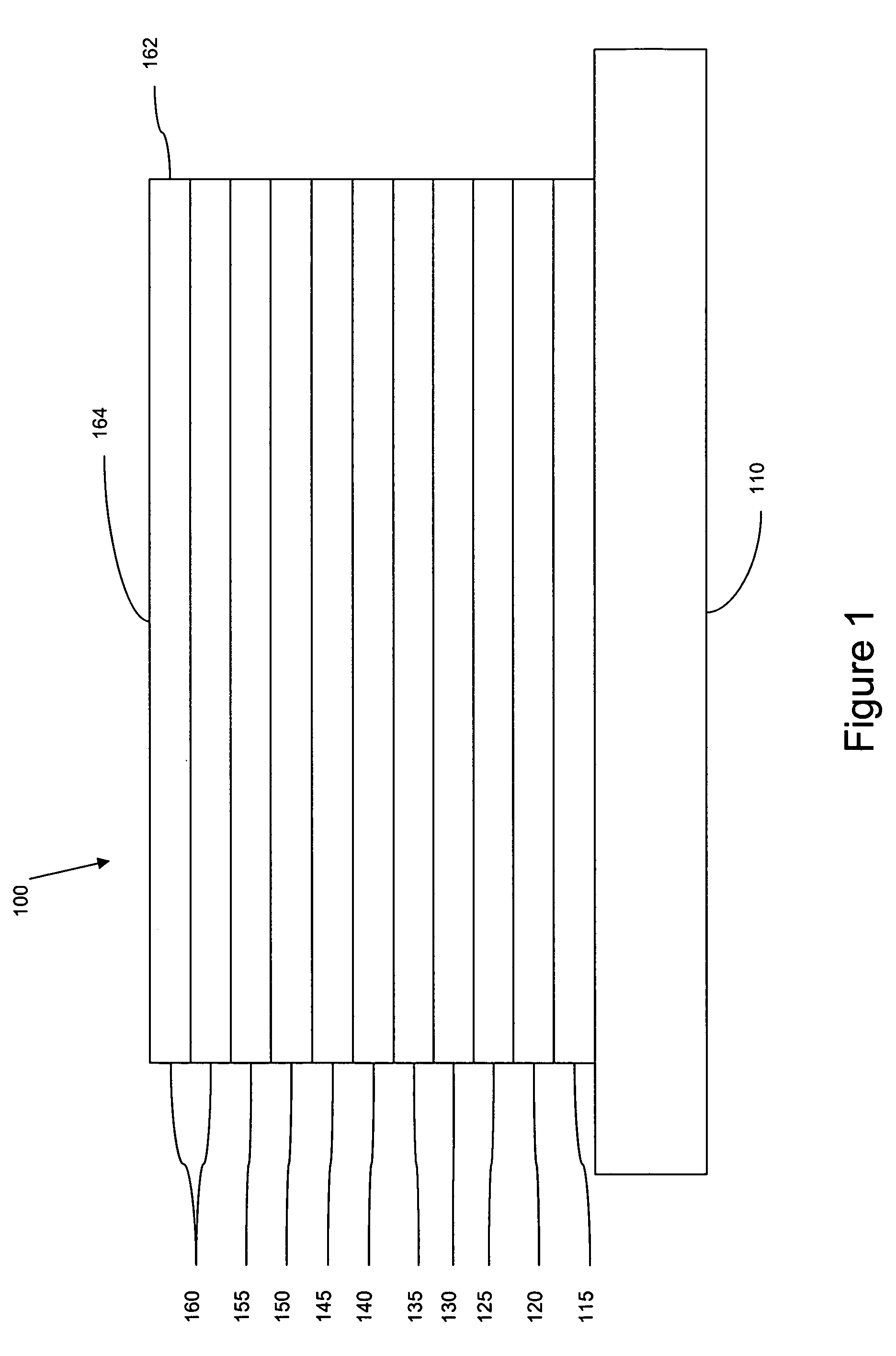

An organometallic complex and an organic light-emitting element containing the complex which has a very high efficiency, a high luminance, and durability. The organic light-emitting element has an anode, a cathode, and a layer including an organic compound sandwiched between the anode and cathode. The layer containing the organic compound includes at least one organometallic complex represented by General Formula [I] below.

Owner:CANON KK

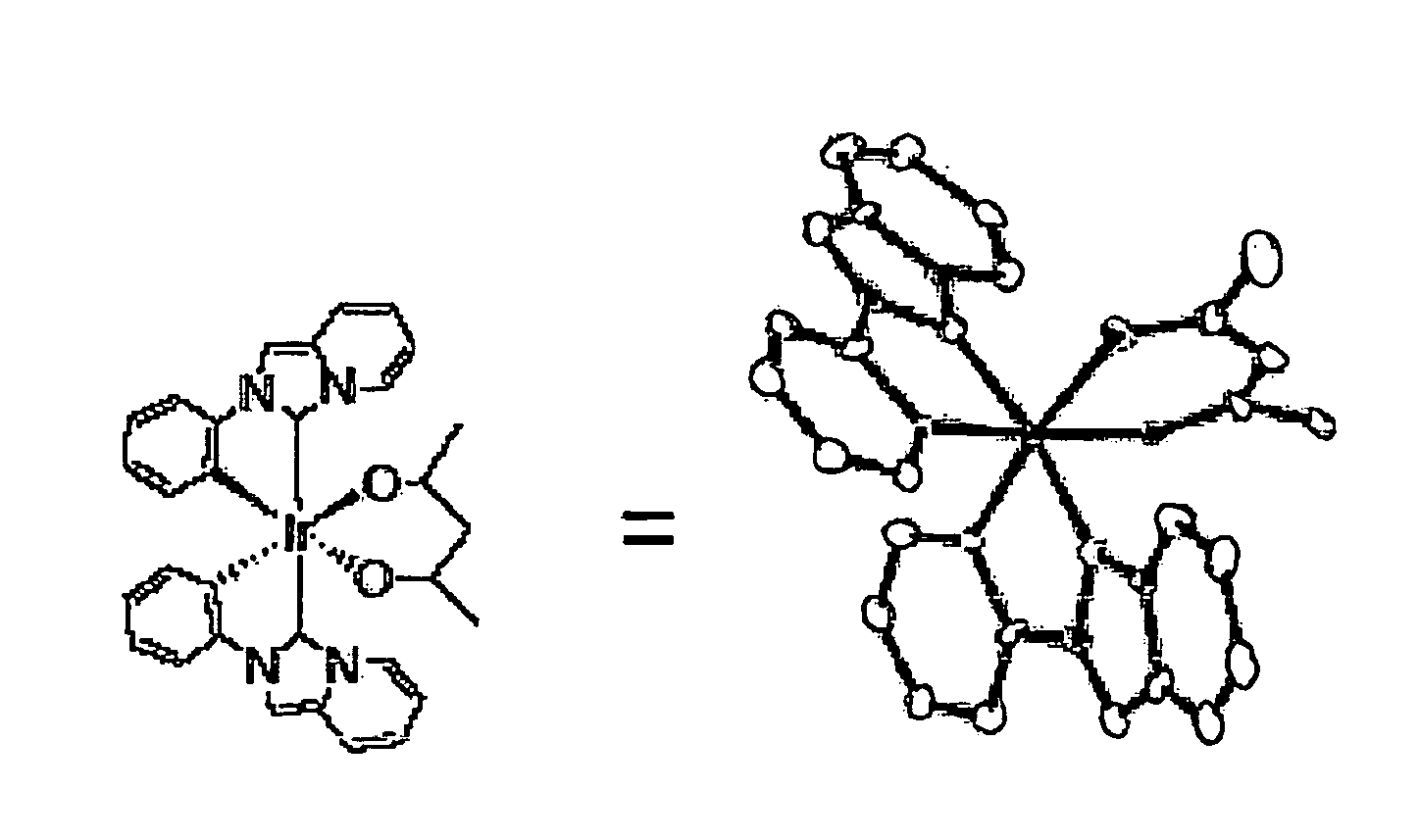

Cyclometallated iridium carbene complexes for use as hosts

ActiveUS7154114B2Electrolysis componentsElectroluminescent light sourcesDopantOrganic light emitting device

An organic light emitting device is provided. The device has an anode, a cathode and an organic layer disposed between the anode and the cathode. The organic layer comprises a host and a dopant, and the host comprises a compound having at least one carbene atom coordinated to iridium, and the compound has the structure:

Owner:UNIVERSAL DISPLAY +1

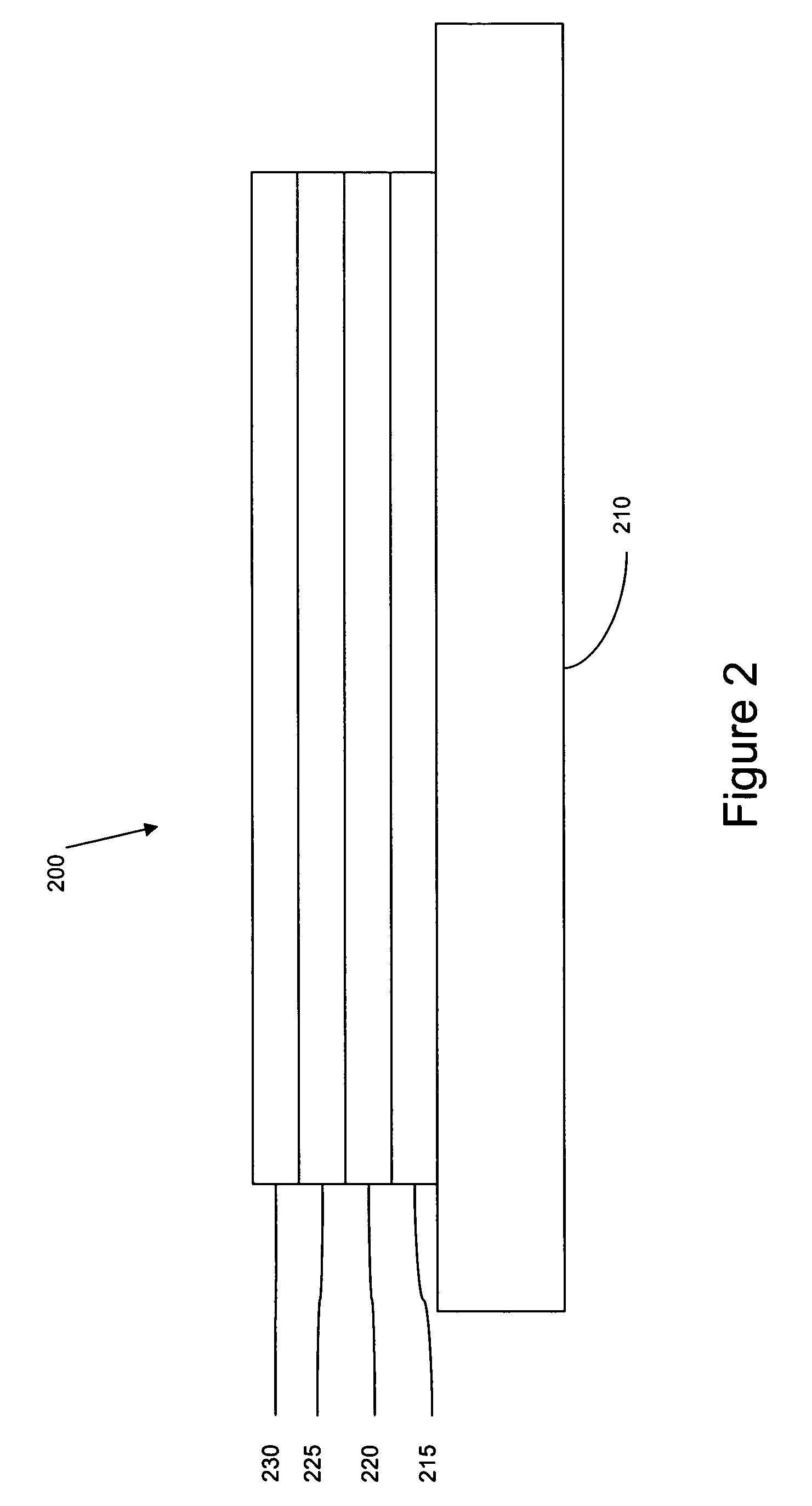

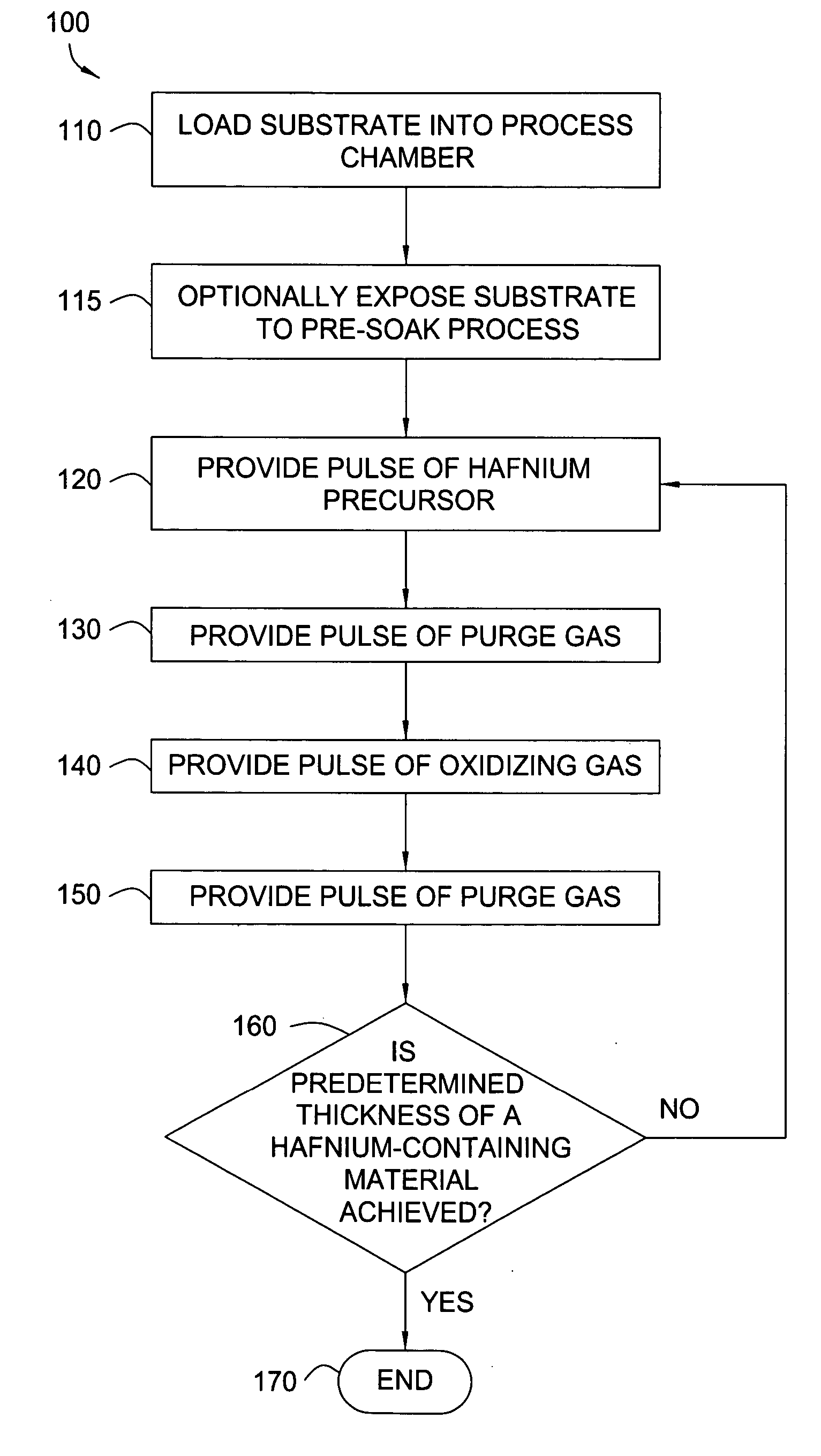

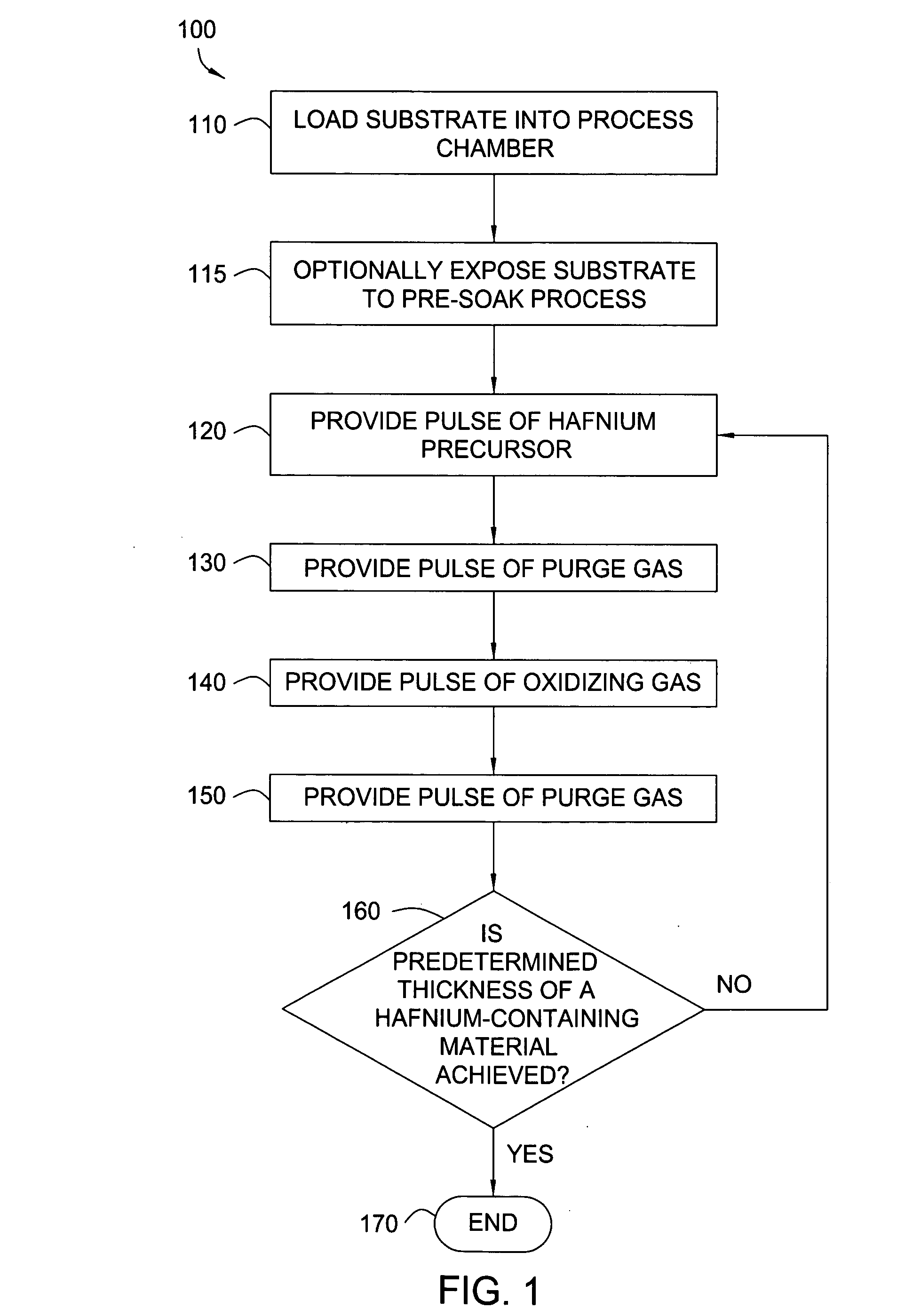

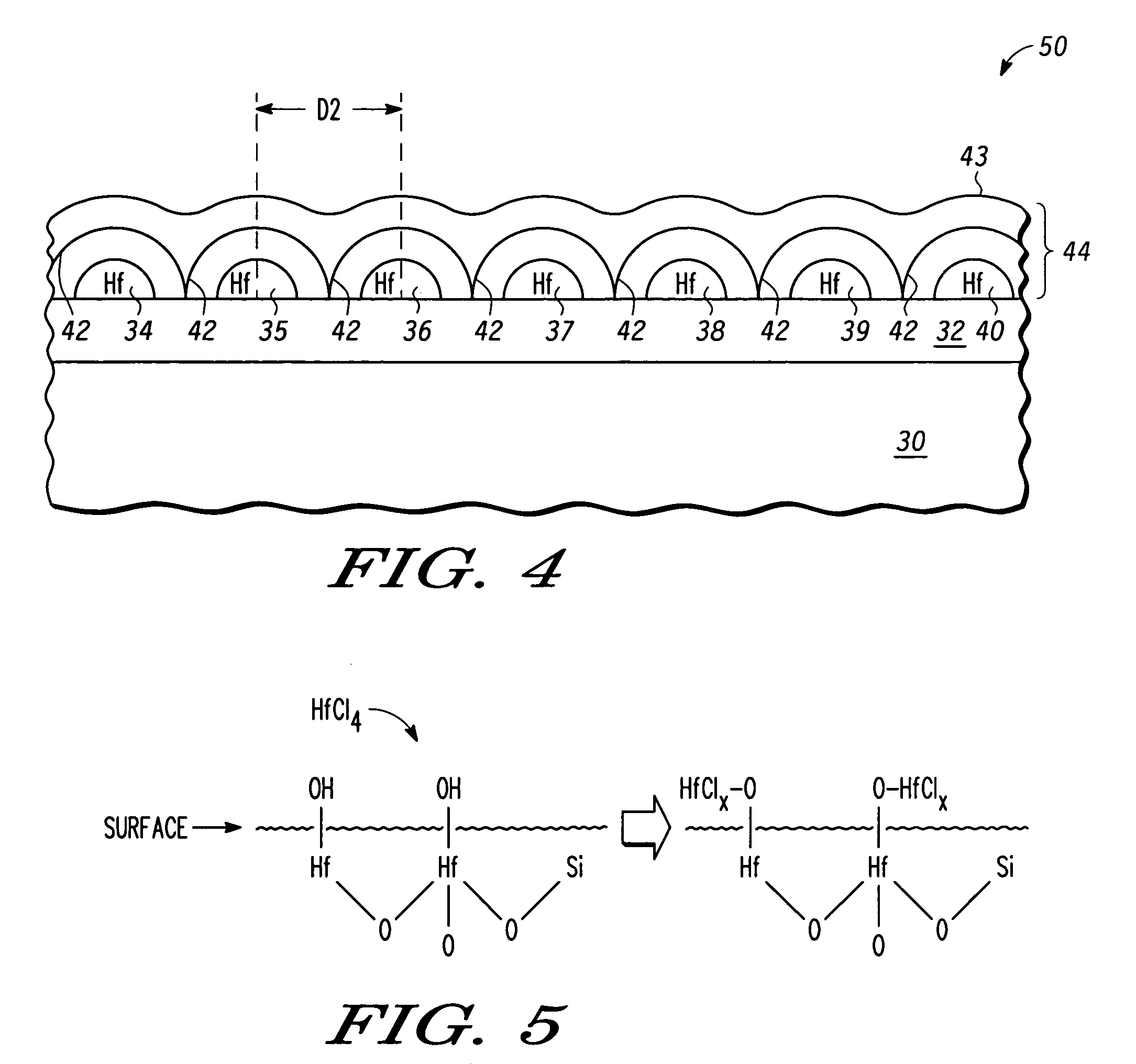

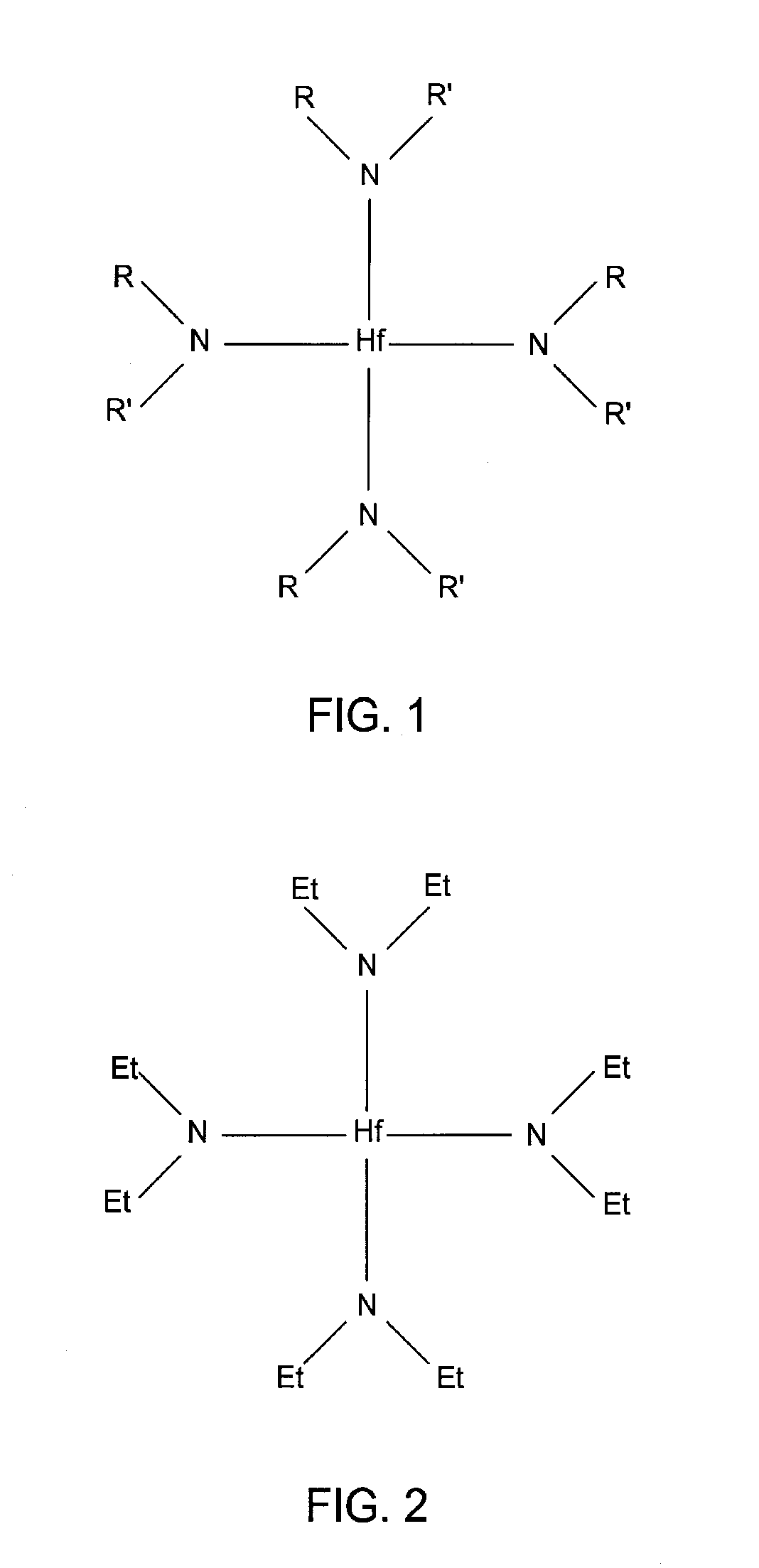

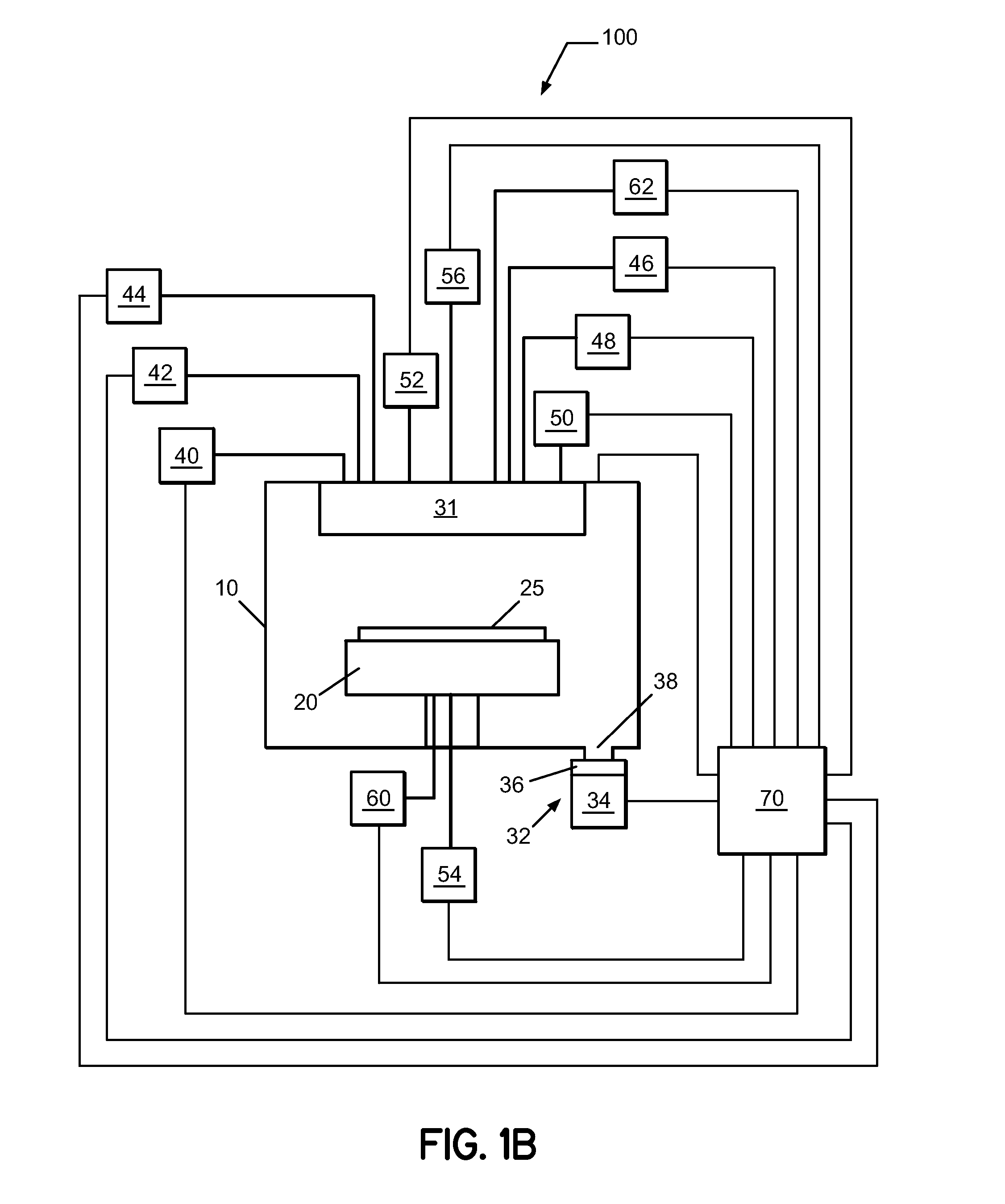

Apparatuses and methods for atomic layer deposition of hafnium-containing high-k dielectric materials

InactiveUS20050271813A1Steam generation heating methodsDecorative surface effectsGas phaseWater vapor

Embodiments of the invention provide methods for depositing dielectric materials on substrates during vapor deposition processes, such as atomic layer deposition (ALD). In one example, a method includes sequentially exposing a substrate to a hafnium precursor and an oxidizing gas to deposit a hafnium oxide material thereon. In another example, a hafnium silicate material is deposited by sequentially exposing a substrate to the oxidizing gas and a process gas containing a hafnium precursor and a silicon precursor. The oxidizing gas usually contains water vapor formed by flowing a hydrogen source gas and an oxygen source gas through a water vapor generator. In another example, a method includes sequentially exposing a substrate to the oxidizing gas and at least one precursor to deposit hafnium oxide, zirconium oxide, lanthanum oxide, tantalum oxide, titanium oxide, aluminum oxide, silicon oxide, aluminates thereof, silicates thereof, derivatives thereof or combinations thereof.

Owner:APPLIED MATERIALS INC

Low Temperature Deposition of Silicon-Containing Films

ActiveUS20100304047A1Low deposition temperatureSemiconductor/solid-state device manufacturingSpecial surfacesLow temperature depositionDeposition temperature

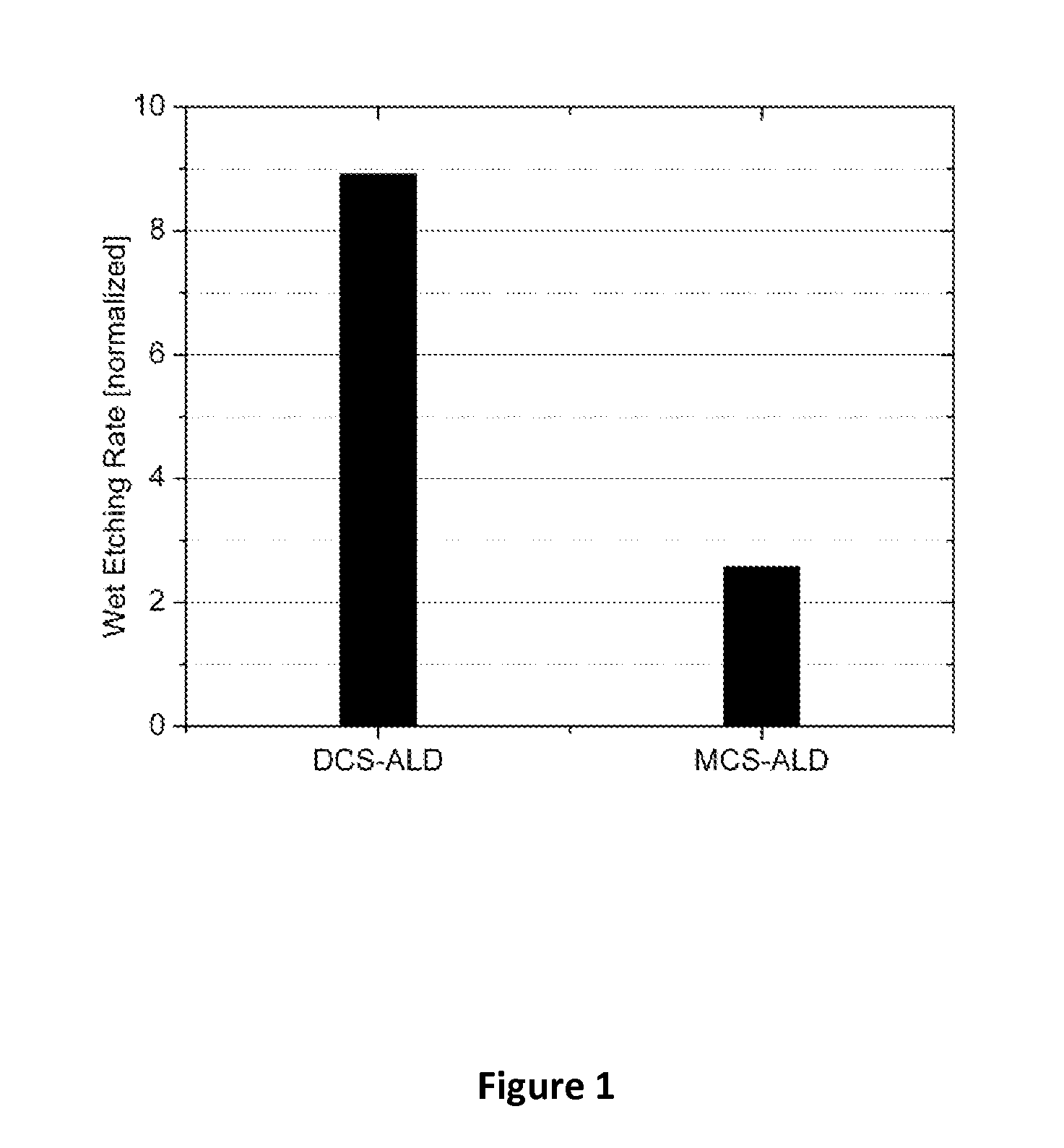

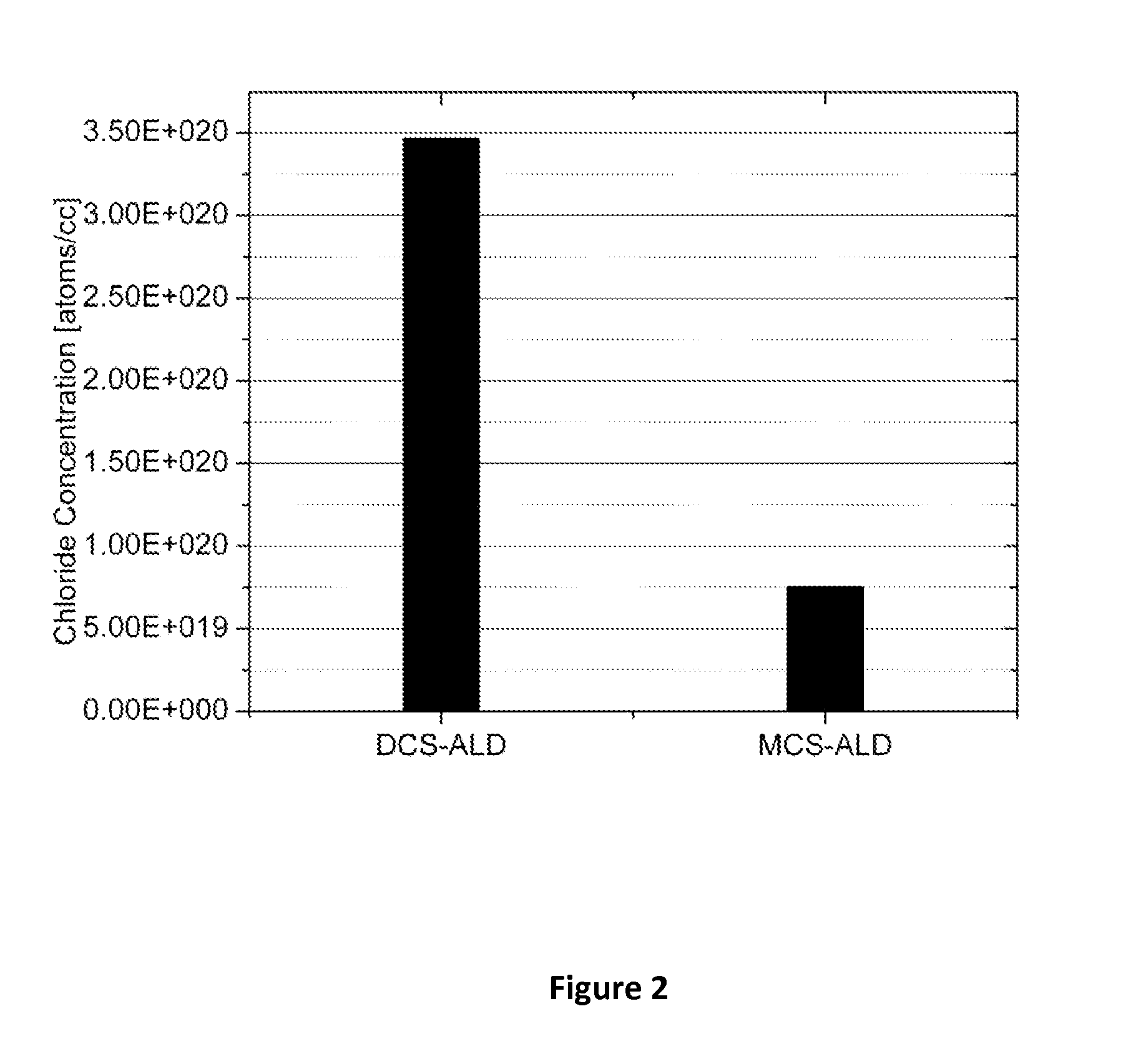

This invention discloses the method of forming silicon nitride, silicon oxynitride, silicon oxide, carbon-doped silicon nitride, carbon-doped silicon oxide and carbon-doped oxynitride films at low deposition temperatures. The silicon containing precursors used for the deposition are monochlorosilane (MCS) and monochloroalkylsilanes. The method is preferably carried out by using plasma enhanced atomic layer deposition, plasma enhanced chemical vapor deposition, and plasma enhanced cyclic chemical vapor deposition.

Owner:TOKYO ELECTRON LTD +1

Doping of dielectric layers

InactiveUS20130217243A1Increase etch tolerancePrevent shrinkageSemiconductor/solid-state device manufacturingDeposition temperaturePhysical chemistry

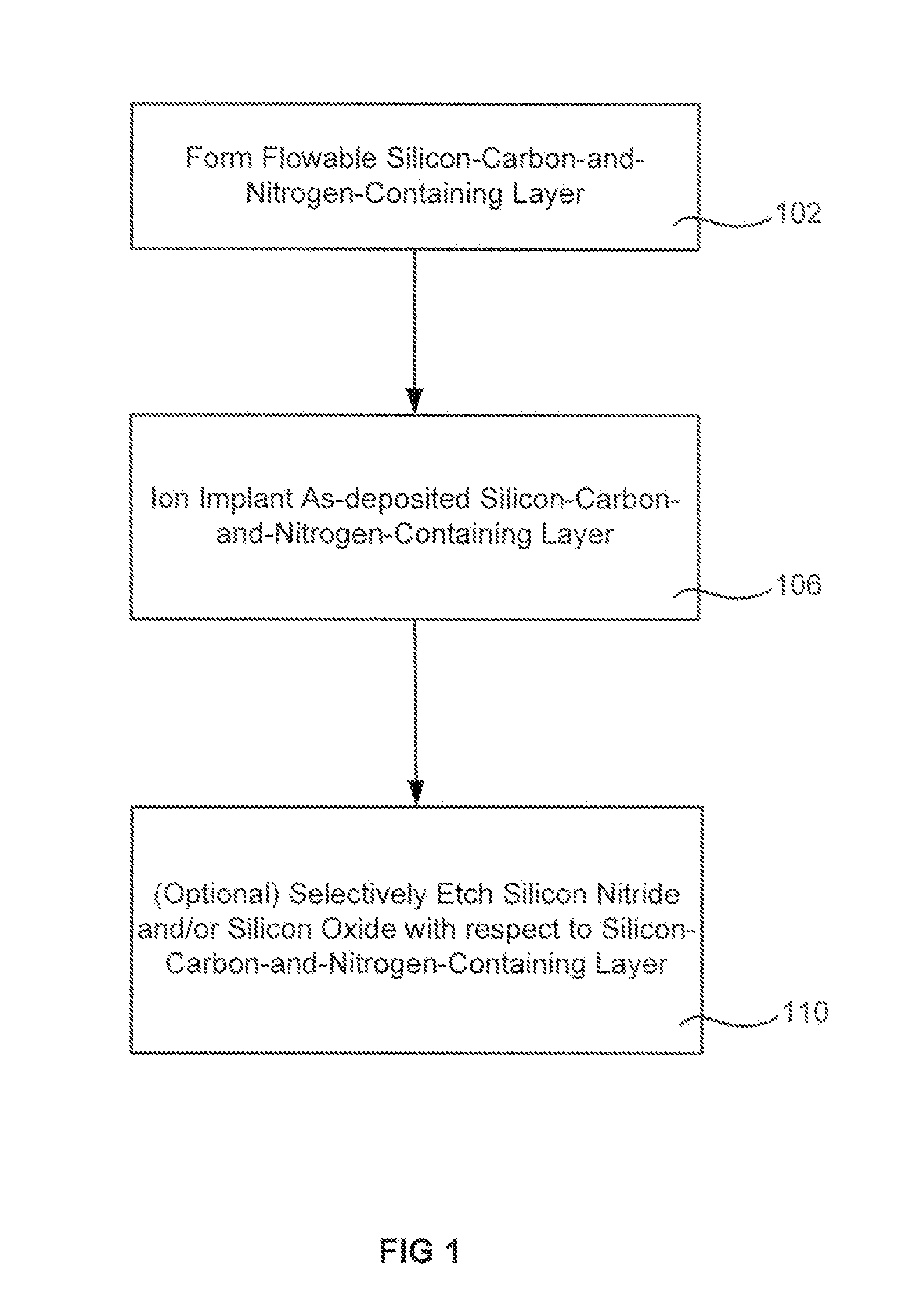

Methods are described for forming and treating a flowable silicon-carbon-and-nitrogen-containing layer on a semiconductor substrate. The silicon and carbon constituents may come from a silicon-and-carbon-containing precursor while the nitrogen may come from a nitrogen-containing precursor that has been activated to speed the reaction of the nitrogen with the silicon-and-carbon-containing precursor at lower deposition temperatures. The initially-flowable silicon-carbon-and-nitrogen-containing layer is ion implanted to increase etch tolerance, prevent shrinkage, adjust film tension and / or adjust electrical characteristics. Ion implantation may also remove components which enabled the flowability, but are no longer needed after deposition. Some treatments using ion implantation have been found to decrease the evolution of properties of the film upon exposure to atmosphere.

Owner:APPLIED MATERIALS INC

Atomic layer deposition method of depositing an oxide on a substrate

The invention includes atomic layer deposition methods of depositing an oxide on a substrate. In one implementation, a substrate is positioned within a deposition chamber. A first species is chemisorbed onto the substrate to form a first species monolayer within the deposition chamber from a gaseous precursor. The chemisorbed first species is contacted with remote plasma oxygen derived at least in part from at least one of O2 and O3 and with remote plasma nitrogen effective to react with the first species to form a monolayer comprising an oxide of a component of the first species monolayer. The chemisorbing and the contacting with remote plasma oxygen and with remote plasma nitrogen are successively repeated effective to form porous oxide on the substrate. Other aspects and implementations are contemplated.

Owner:MICRON TECH INC

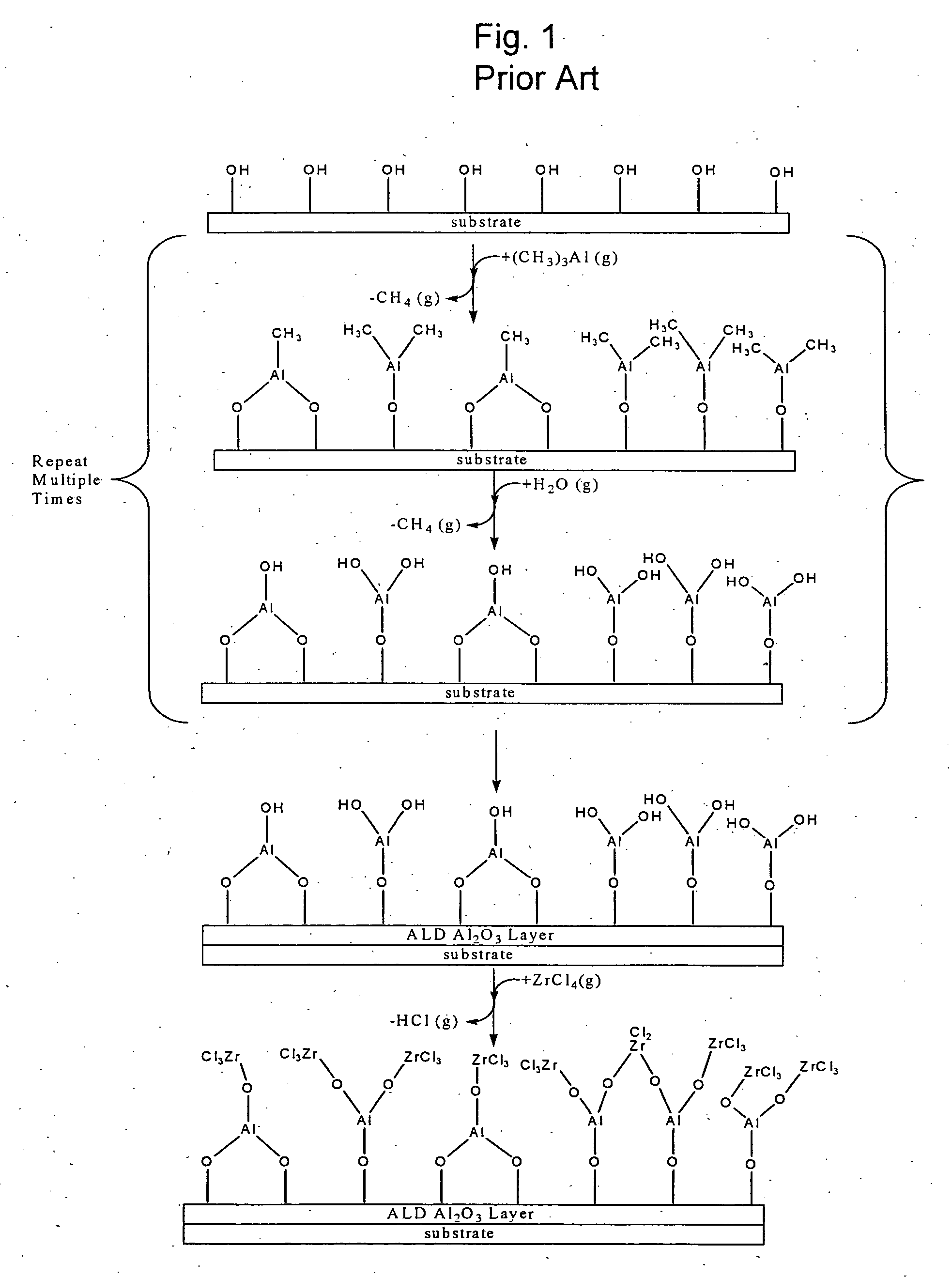

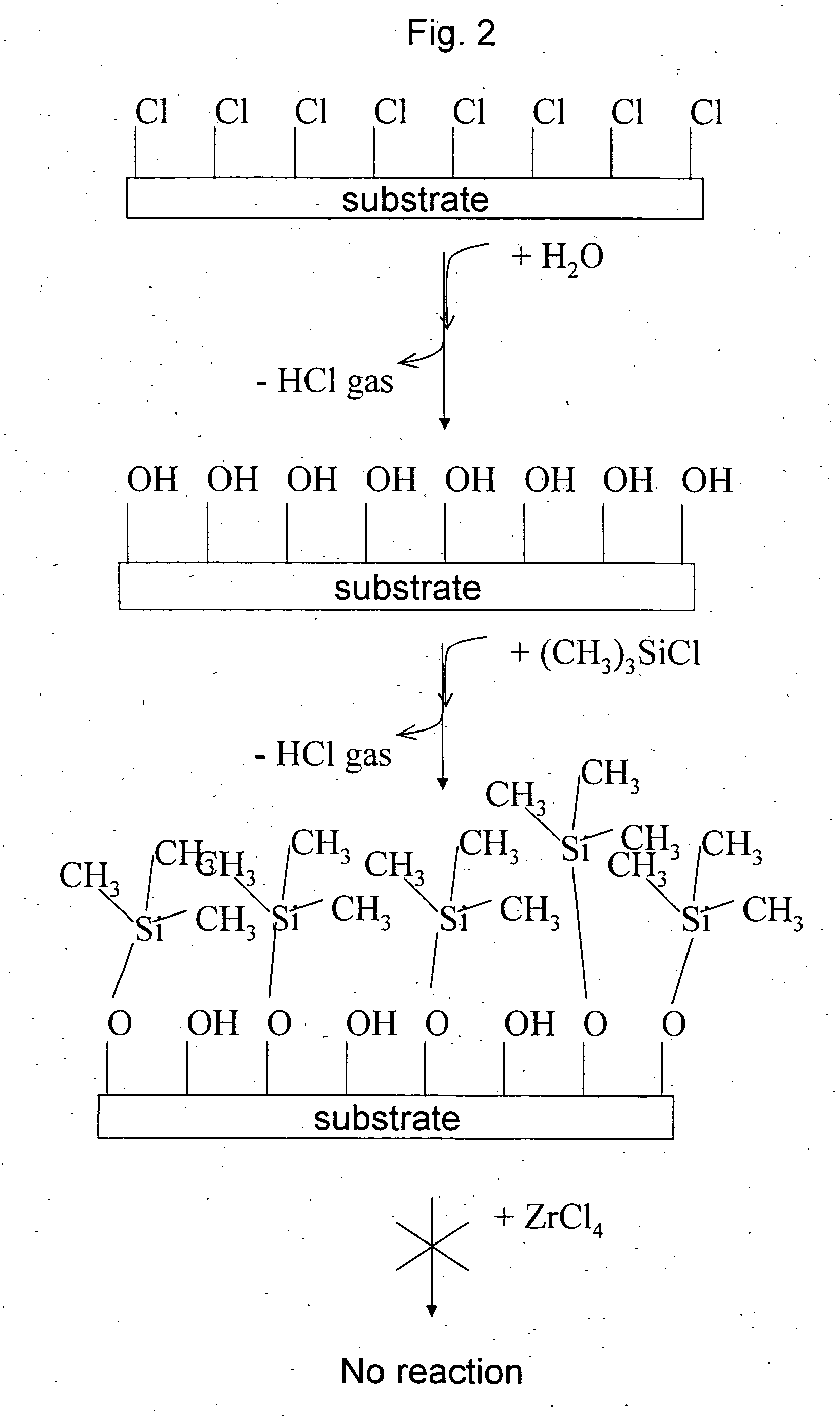

Passivating ALD reactor chamber internal surfaces to prevent residue buildup

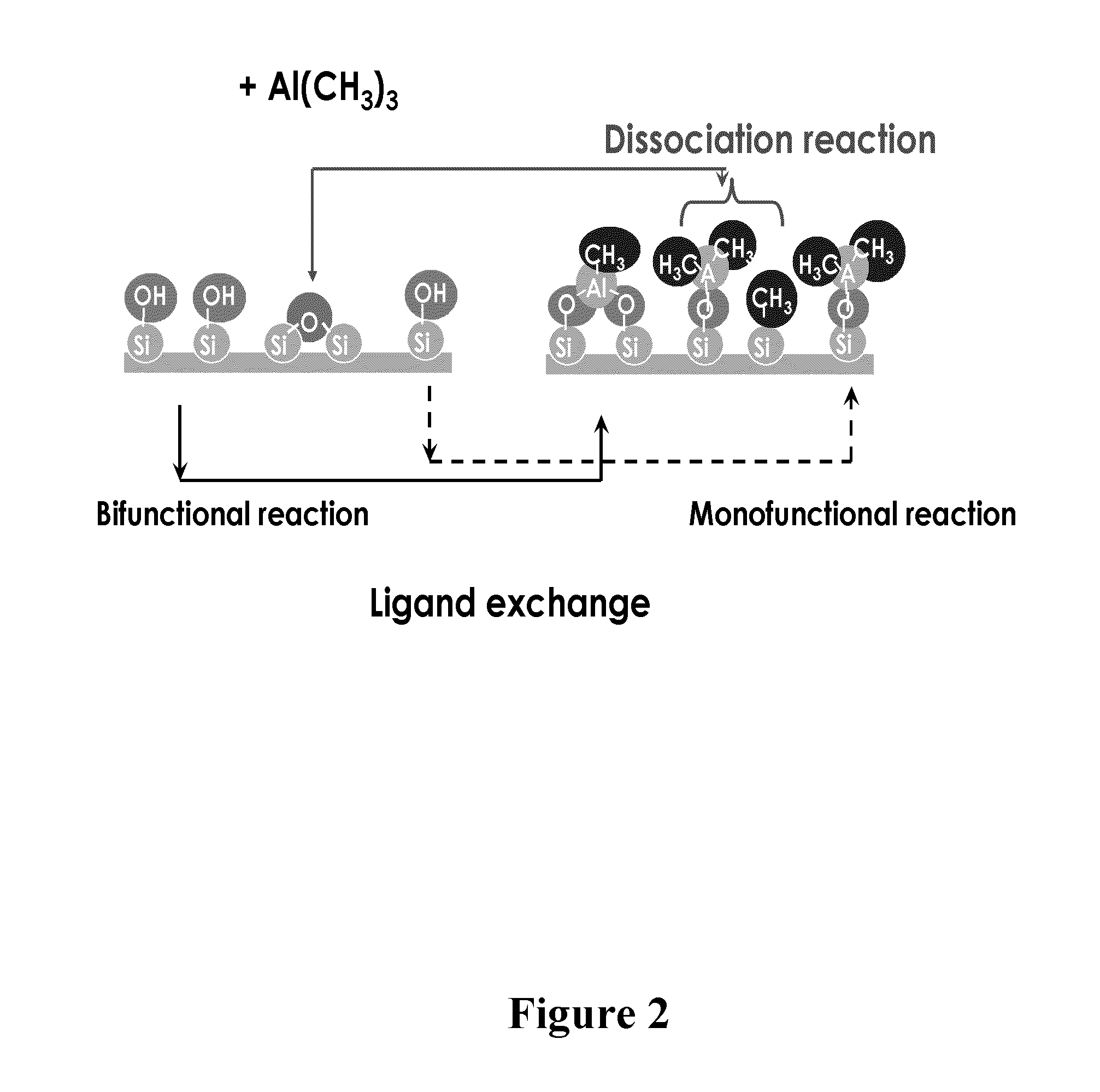

InactiveUS20060040054A1Minimizing undesired chemisorptionReduce accumulationChemical vapor deposition coatingImproved methodDeposition process

This invention is directed to an improved method for preventing deposition residue buildup on the internal surfaces of an ALD reactor chamber. In an ALD deposition process, the surfaces of a substrate are treated with an initiating precursor generating a labile atom reactive with a deposition precursor. Excess initiating precursor is removed from the reactor and the substrate surface then is exposed to a deposition precursor reactive with the labile atom under conditions for generating a fugitive reaction product containing the labile atom and leaving a deposition product. The process is repeated generating alternate layers of initiation and deposition precursor reaction products. The improvement in the ALD process resides in passivating the internal surfaces of the reactor by removing labile atoms reactable with either the initiating or deposition precursors prior to effecting ALD deposition.

Owner:VERSUM MATERIALS US LLC

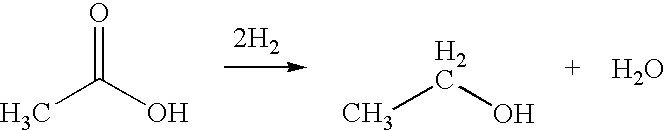

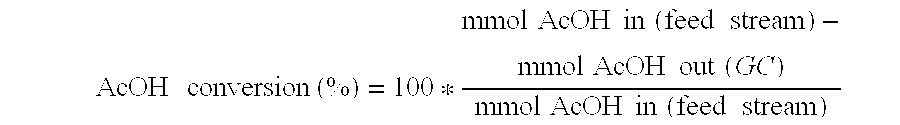

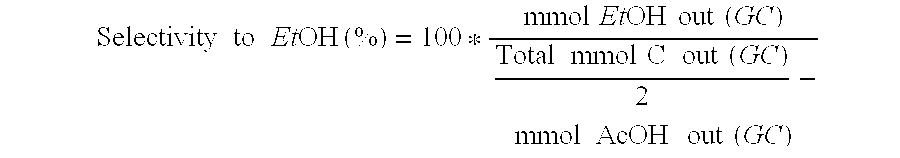

Direct and selective production of ethanol from acetic acid utilizing a platinum/tin catalyst

InactiveUS7863489B2High selectivityHigh yieldOrganic compound preparationOxygen compounds preparation by reductionCalcium silicateAcetic acid

A process for the selective production of ethanol by vapor phase reaction of acetic acid over a hydrogenating catalyst composition to form ethanol is disclosed and claimed. In an embodiment of this invention reaction of acetic acid and hydrogen over a platinum and tin supported on silica, graphite, calcium silicate or silica-alumina selectively produces ethanol in a vapor phase at a temperature of about 250° C.

Owner:CELANESE INT CORP

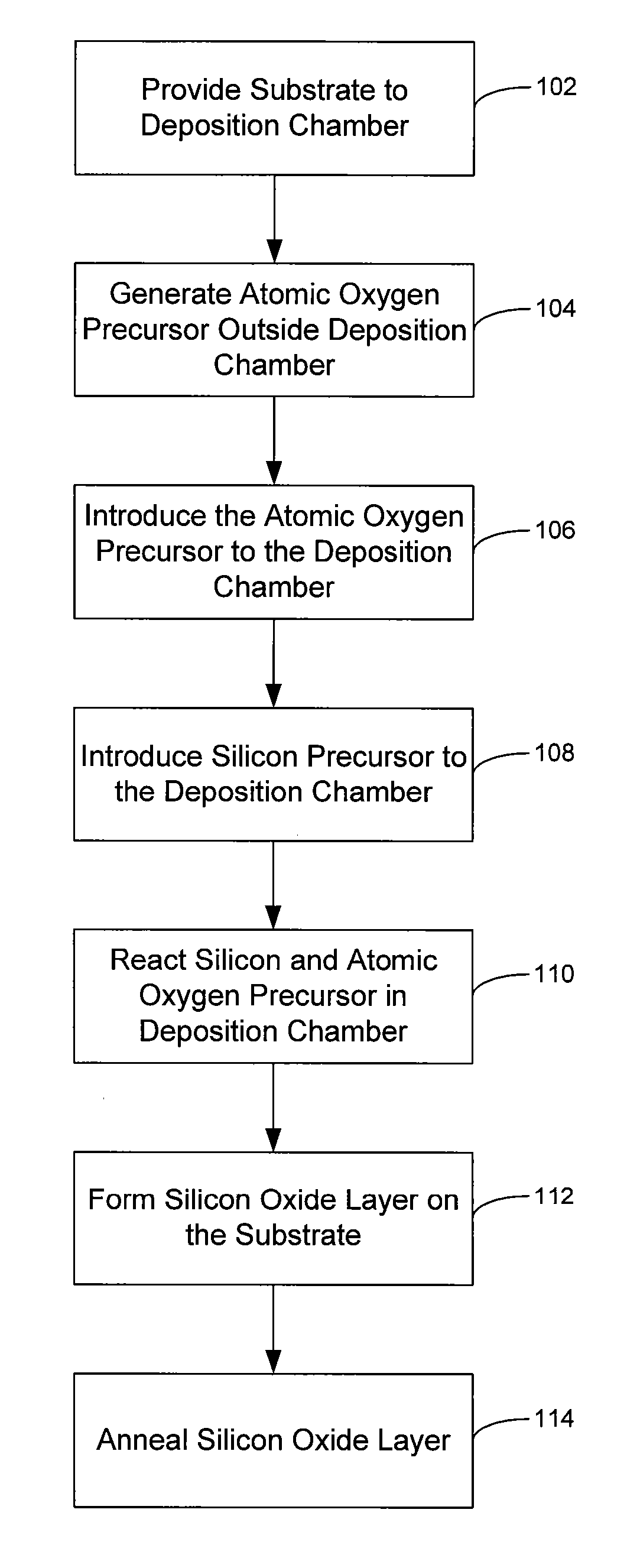

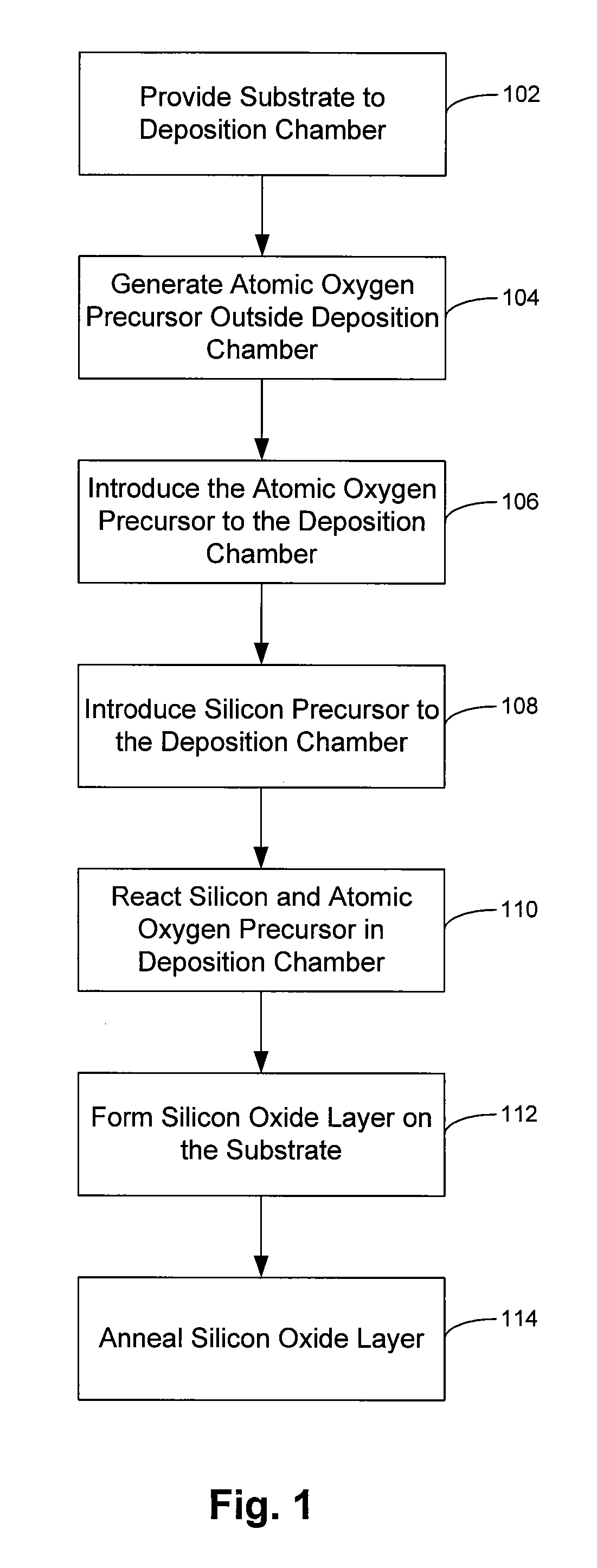

Chemical vapor deposition of high quality flow-like silicon dioxide using a silicon containing precursor and atomic oxygen

ActiveUS20070281496A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseSilicon oxide

Methods of depositing a silicon oxide layer on a substrate are described. The methods may include the steps of providing a substrate to a deposition chamber, generating an atomic oxygen precursor outside the deposition chamber, and introducing the atomic oxygen precursor into the chamber. The methods may also include introducing a silicon precursor to the deposition chamber, where the silicon precursor and the atomic oxygen precursor are first mixed in the chamber. The silicon precursor and the atomic oxygen precursor react to form the silicon oxide layer on the substrate, and the deposited silicon oxide layer may be annealed. Systems to deposit a silicon oxide layer on a substrate are also described.

Owner:APPLIED MATERIALS INC

Modified oxygen reduced valve metal oxides

InactiveUS6639787B2Maintain good propertiesWear minimizationOxide/hydroxide preparationLiquid electrolytic capacitorsFluidized bedPhysical chemistry

Owner:GLOBAL ADVANCED METALS USA

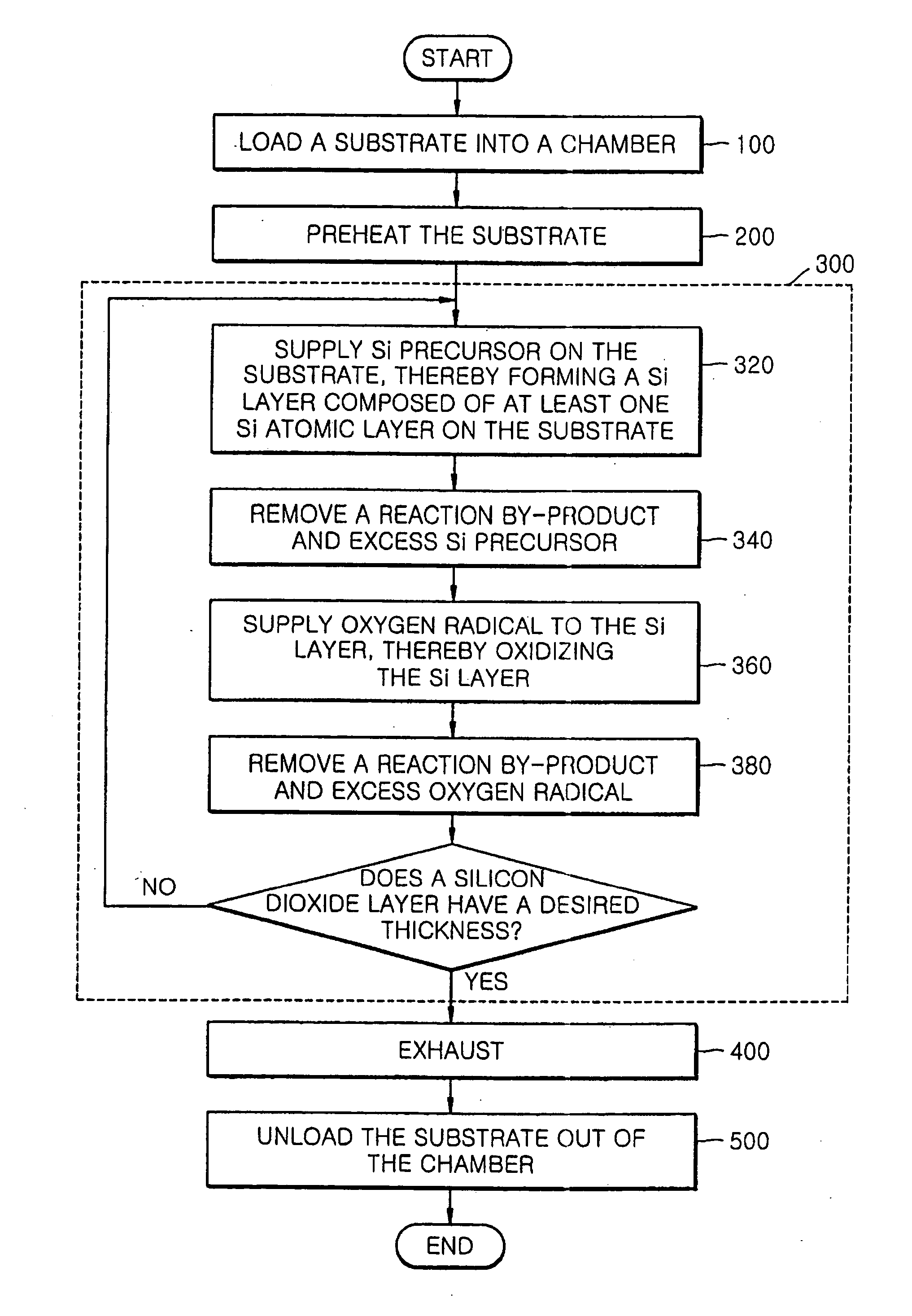

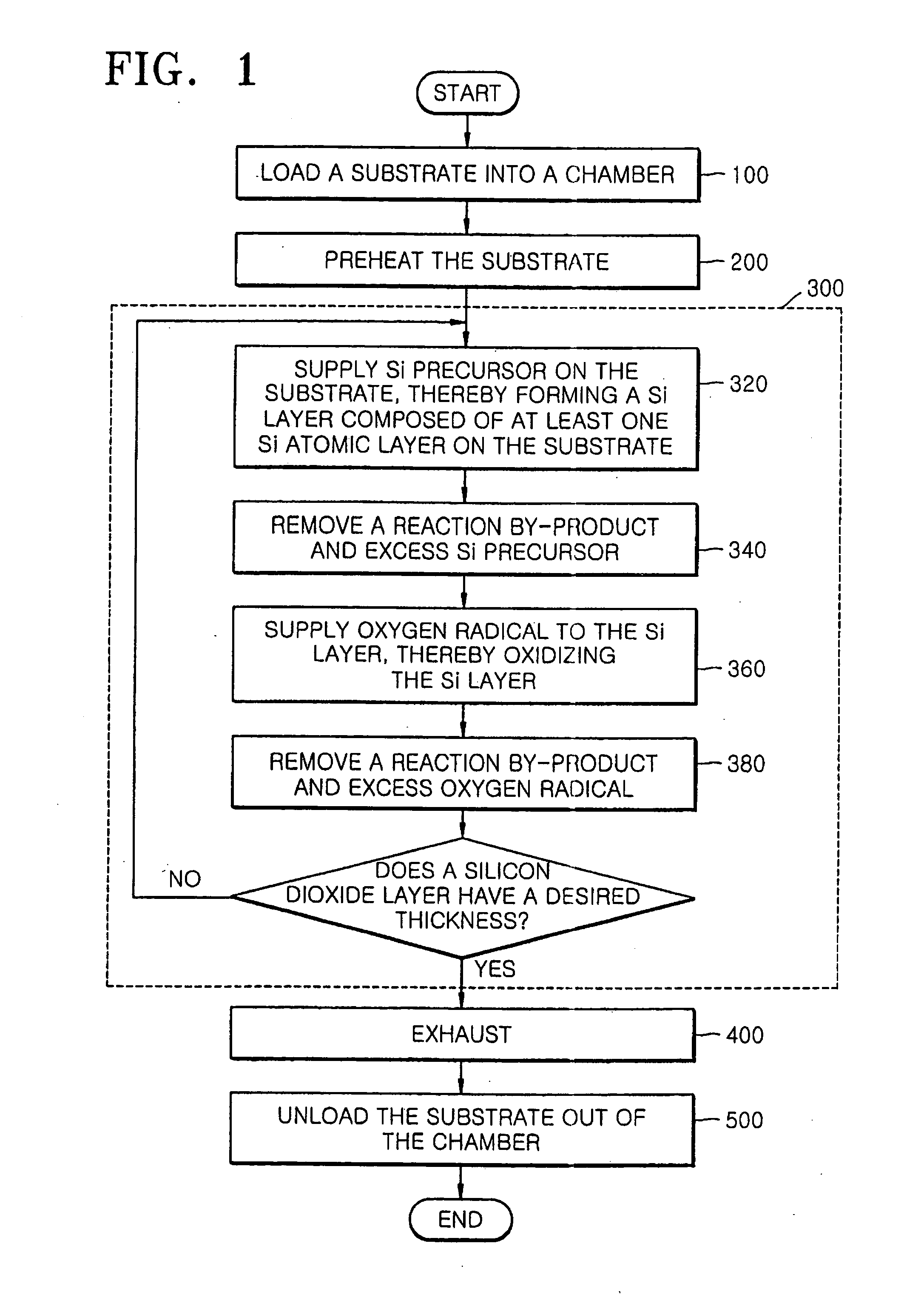

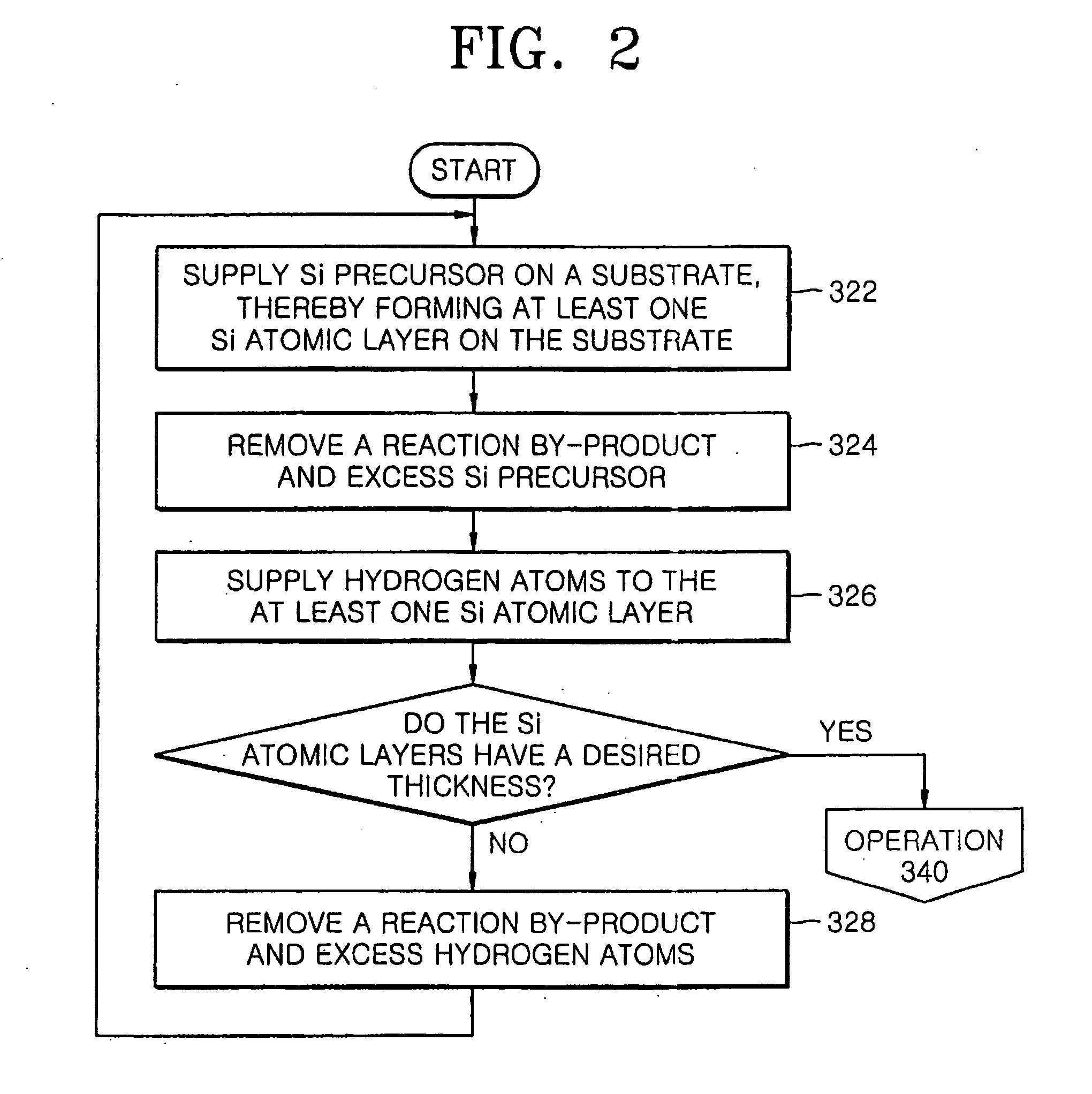

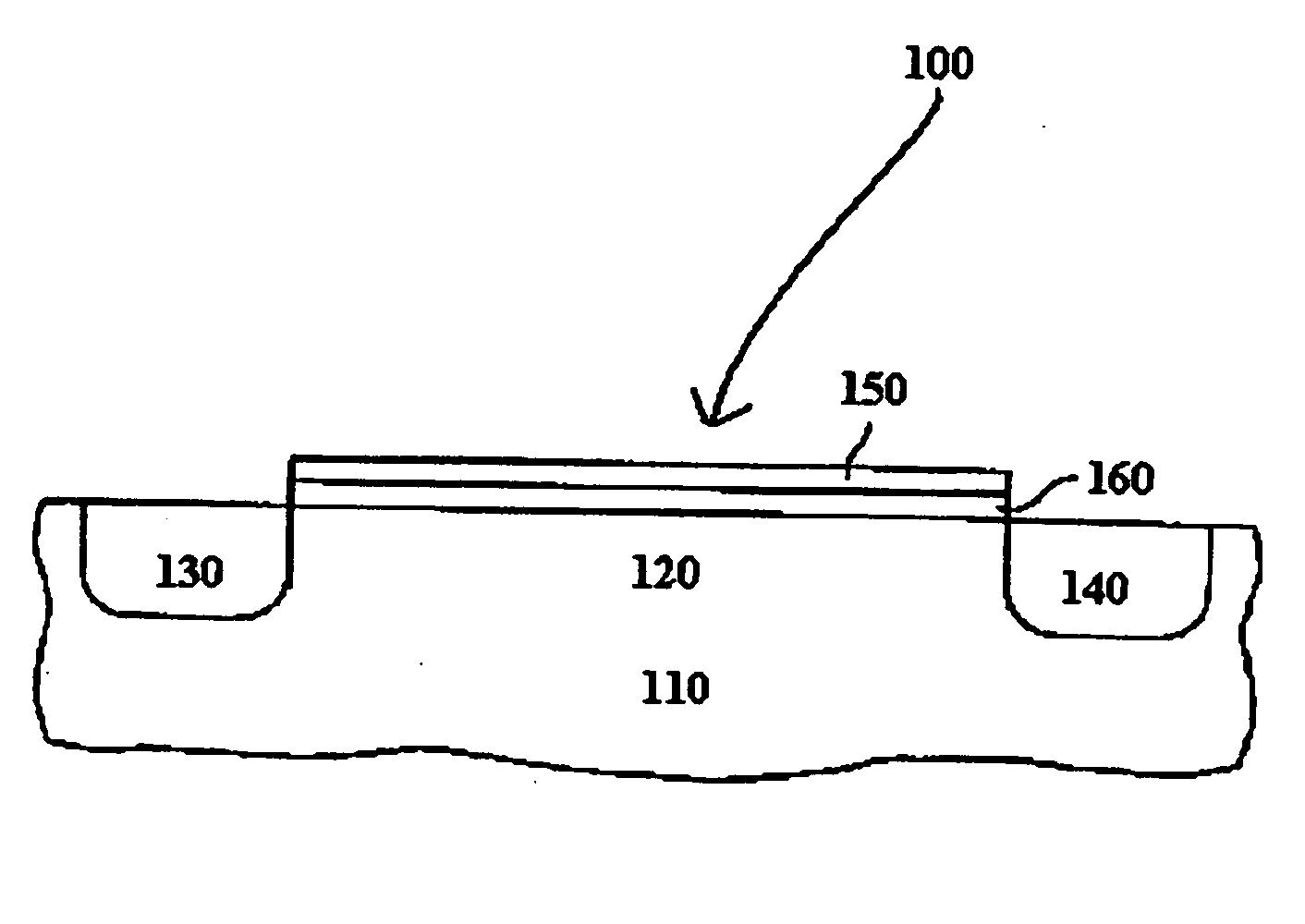

Methods of forming silicon dioxide layers using atomic layer deposition

InactiveUS20070111545A1Good step coverageReduce trap densitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingOptoelectronicsOxygen

Provided herein are methods of forming a silicon dioxide layer on a substrate using an atomic layer deposition (ALD) method that include supplying a Si precursor to the substrate and forming on the substrate a Si layer including at least one Si atomic layer; and (b) supplying an oxygen radical to the Si layer to replace at least one Si—Si bond within the Si layer with a Si—O bond, thereby oxidizing the Si layer, to form a silicon dioxide layer on the substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

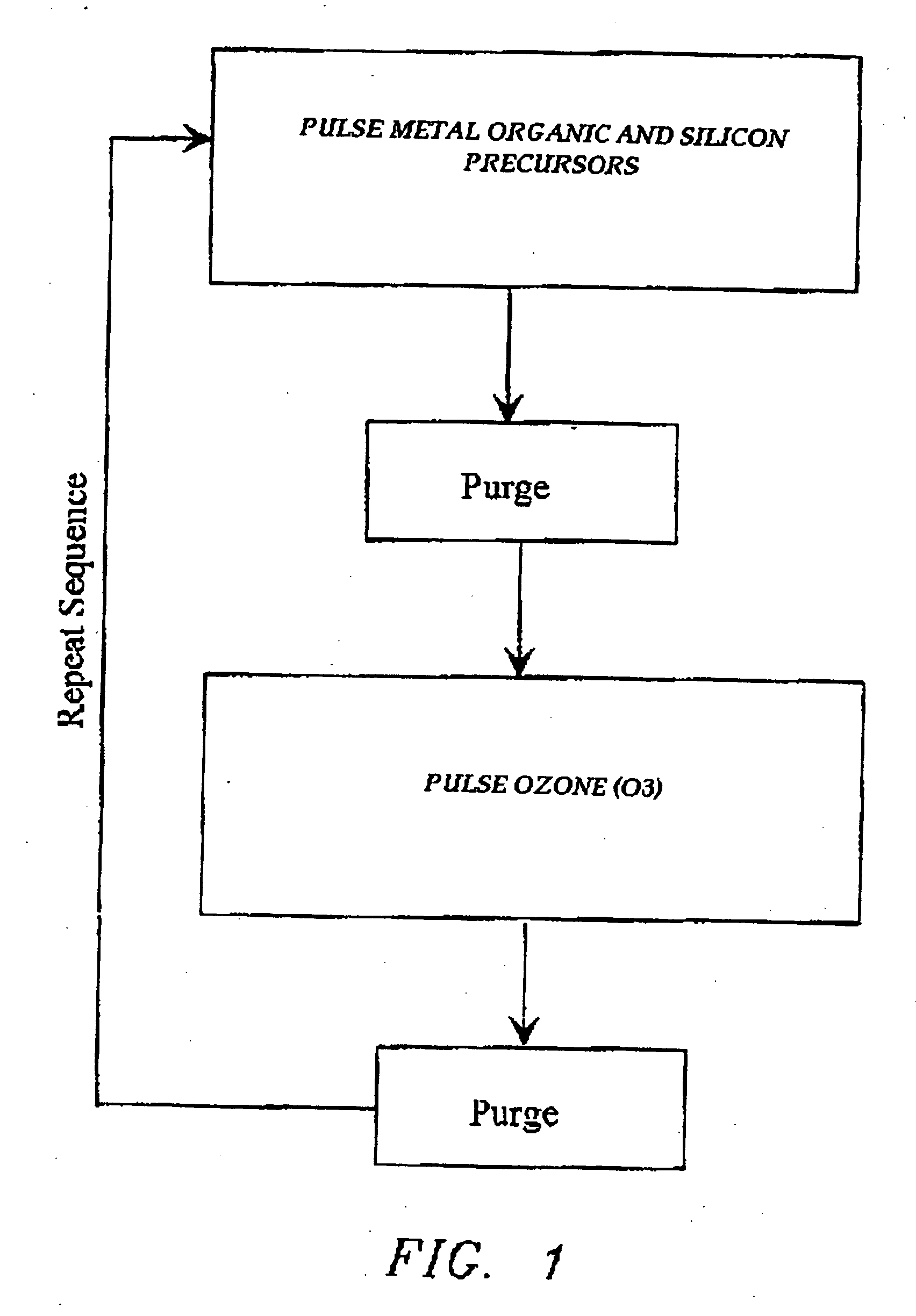

Atomic layer deposition of high k metal silicates

InactiveUS20060228888A1Reduce carbon pollutionReduce stepsSolid-state devicesSemiconductor/solid-state device manufacturingHafniumAtomic layer deposition

The present invention relates to the atomic layer deposition (“ALD”) of high k dielectric layers of metal silicates, including hafnium silicate. More particularly, the present invention relates to the ALD formation of metal silicates using metal organic precursors, silicon organic precursors and ozone. Preferably, the metal organic precursor is a metal alkyl amide and the silicon organic precursor is a silicon alkyl amide.

Owner:AVIZA TECHNOLOGY INC +1

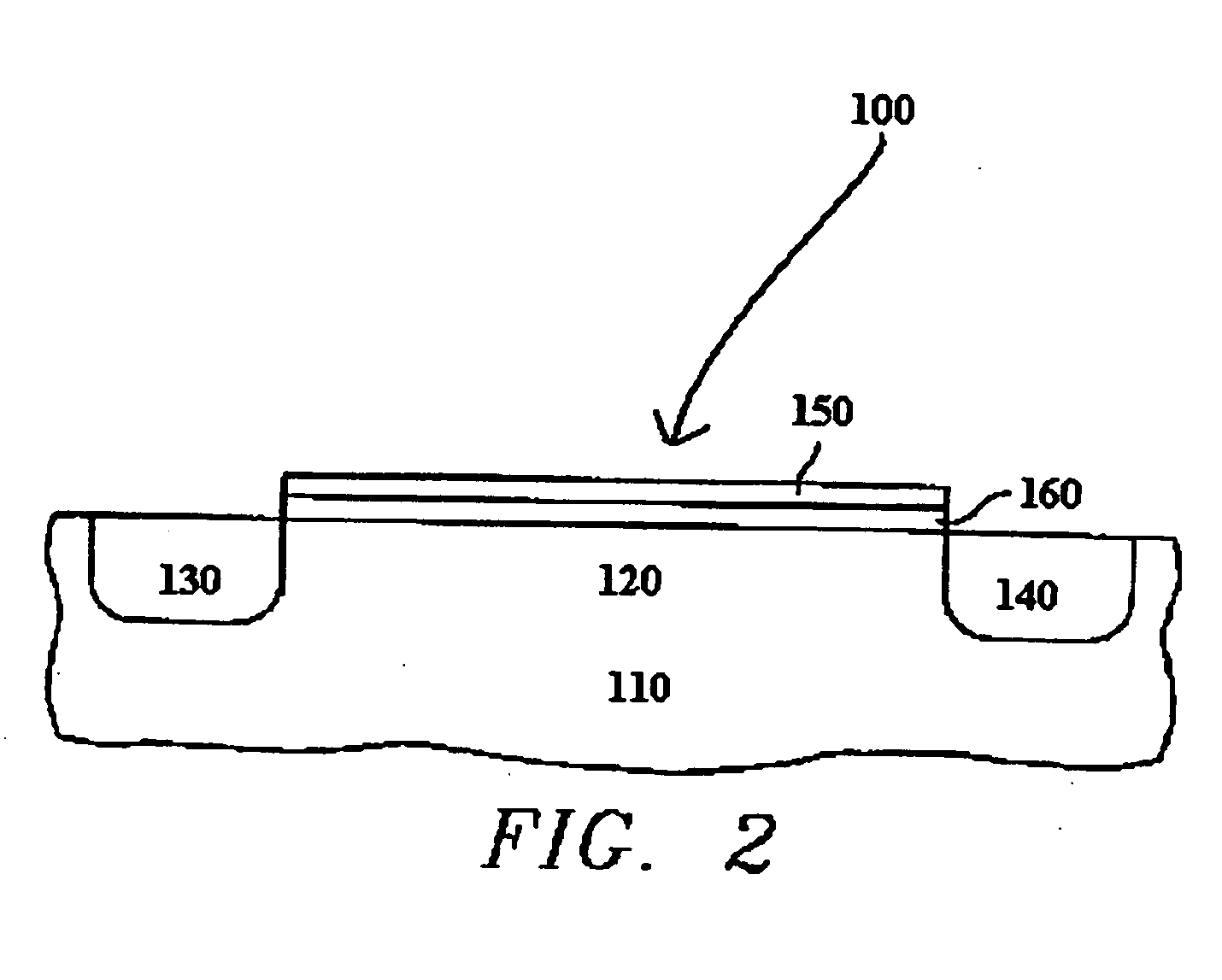

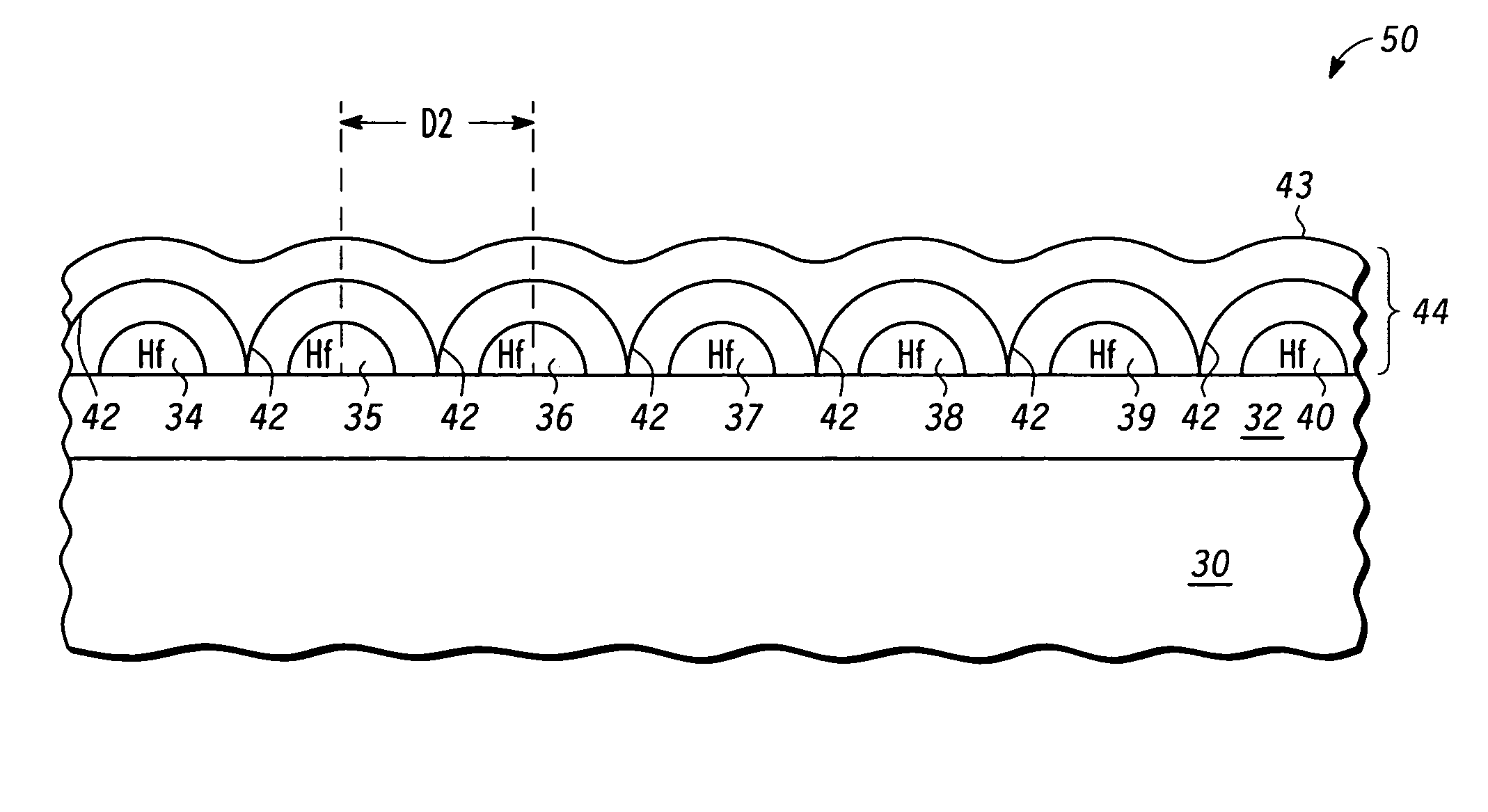

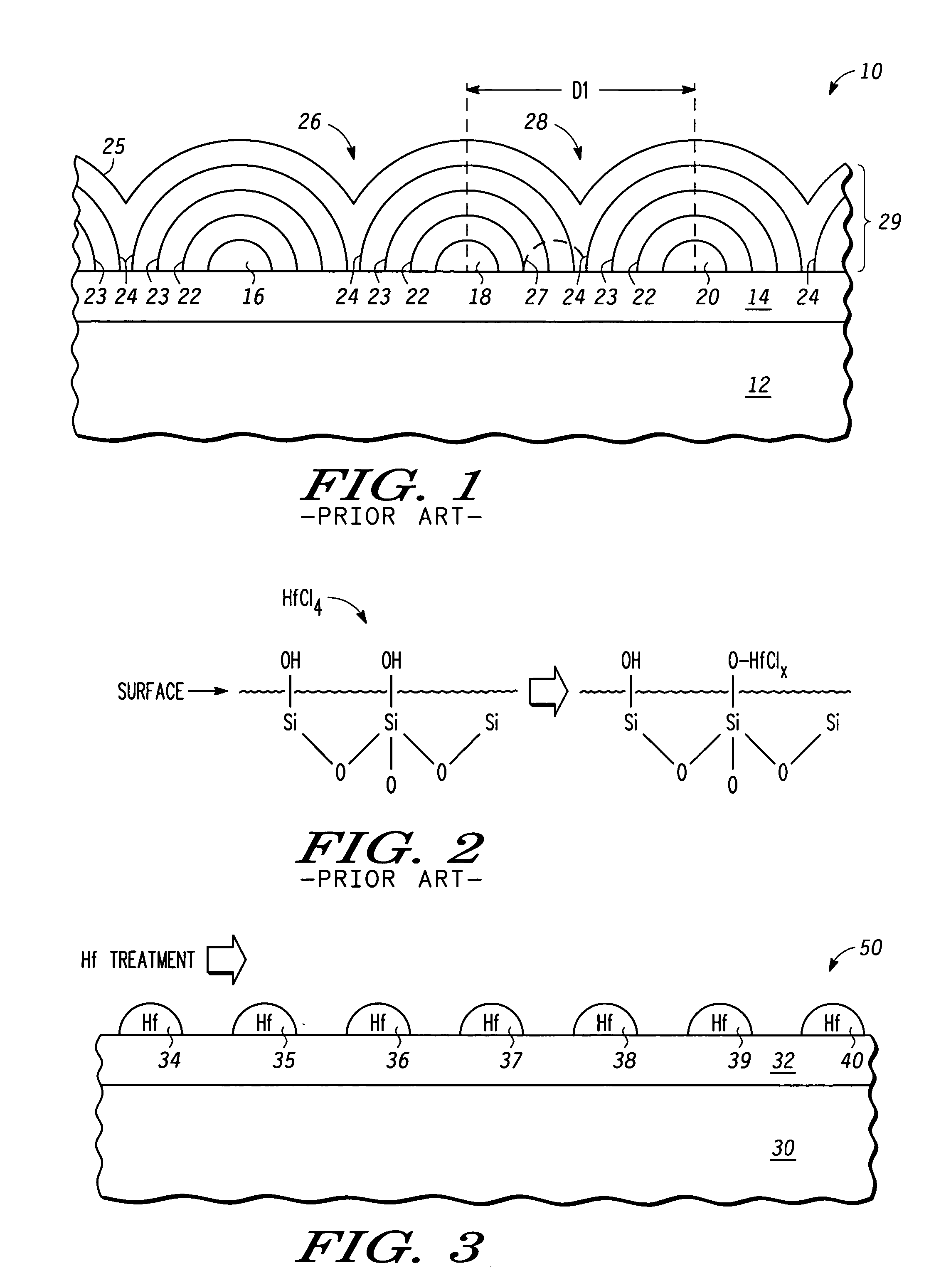

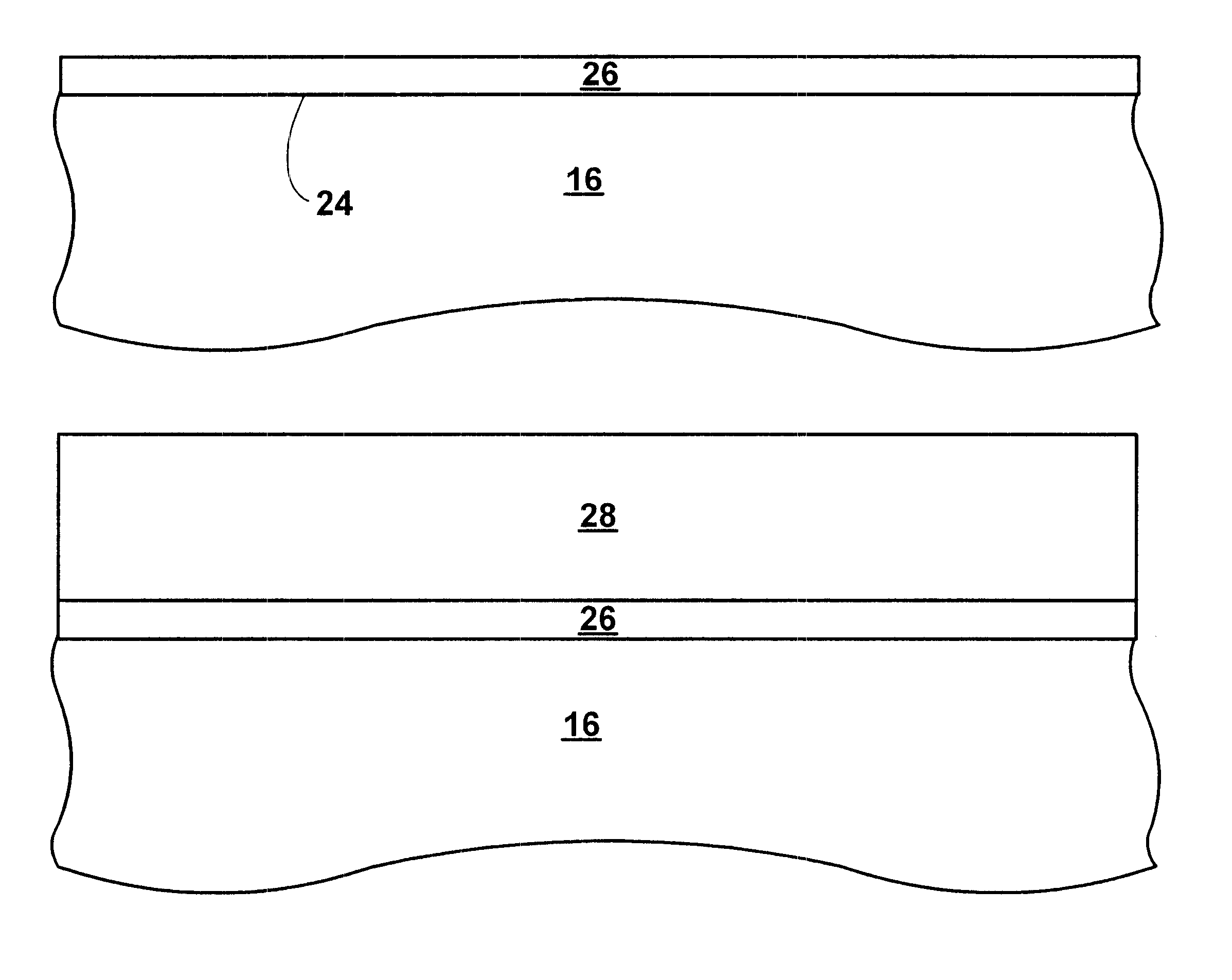

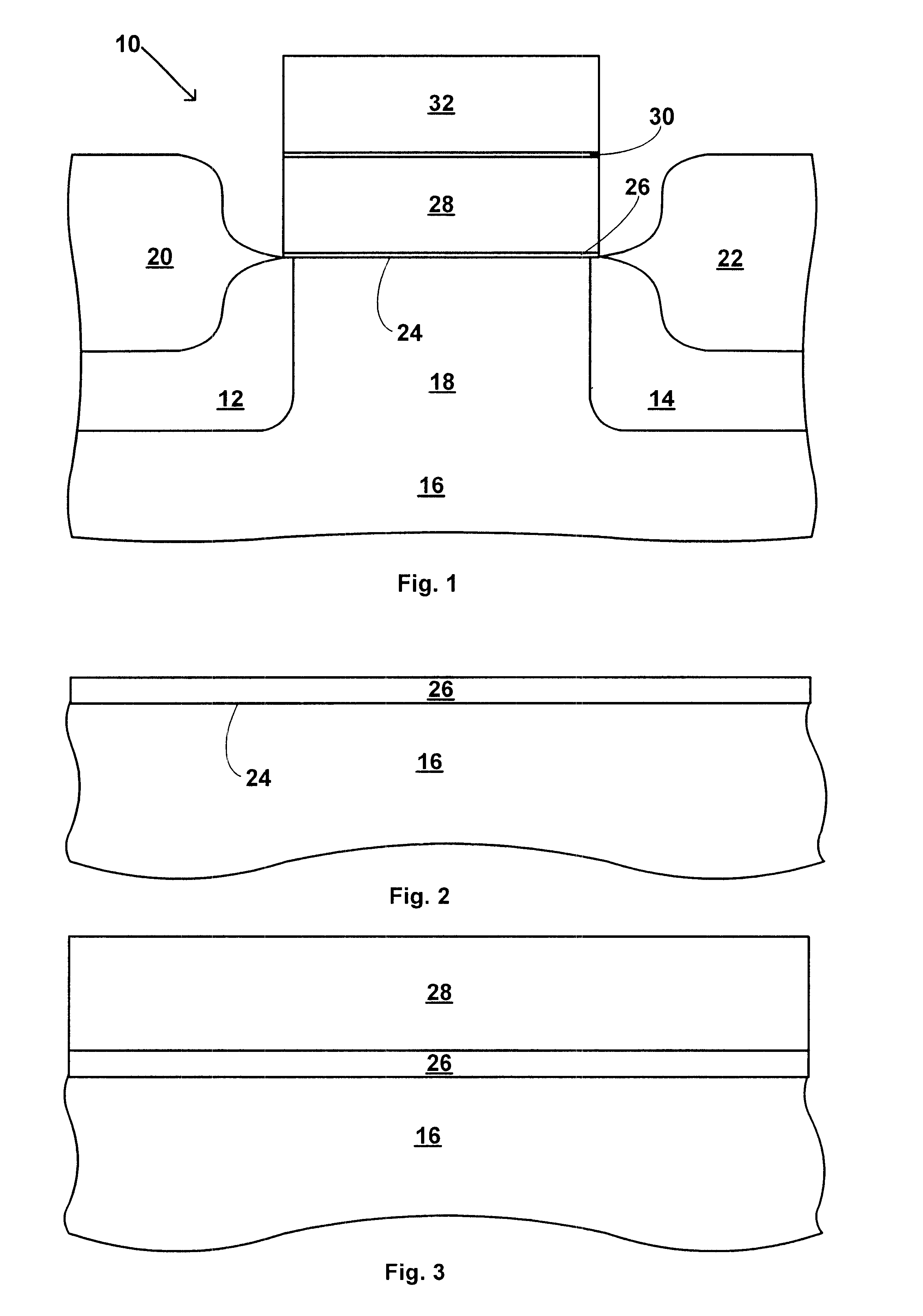

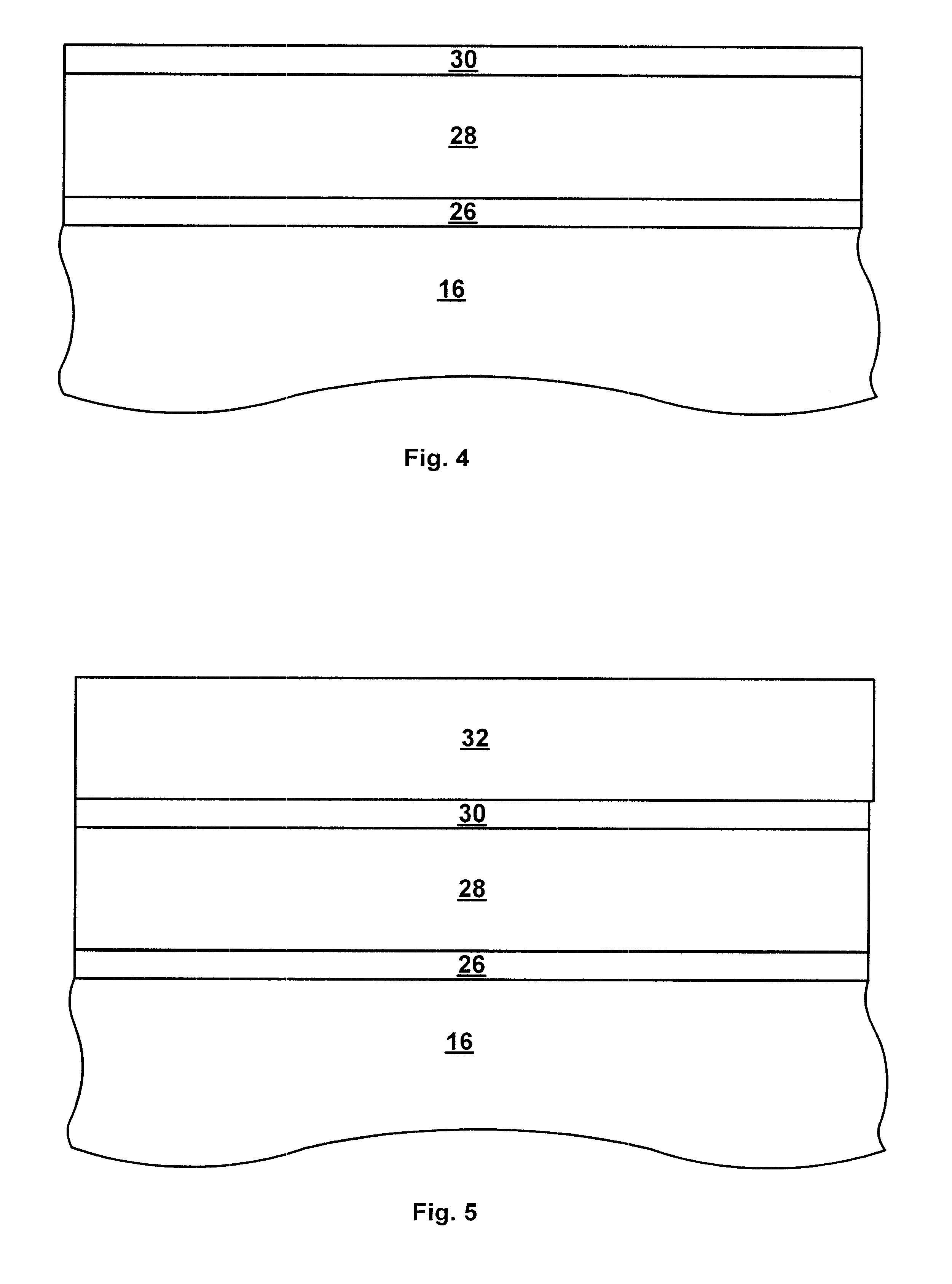

Method for treating a semiconductor surface to form a metal-containing layer

ActiveUS7132360B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingMaterial growthPhysical chemistry

A method for treating a semiconductor surface to form a metal-containing layer includes providing a semiconductor substrate having an exposed surface. The exposed surface of the semiconductor substrate is treated by forming one or more metals overlying the semiconductor substrate but not completely covering the exposed surface of the semiconductor substrate. The one or more metals enhance nucleation for subsequent material growth. A metal-containing layer is formed on the exposed surface of the semiconductor substrate that has been treated. The treatment of the exposed surface of the semiconductor substrate assists the metal-containing layer to coalesce. In one embodiment, treatment of the exposed surface to enhance nucleation may be performed by spin-coating, atomic layer deposition (ALD), physical layer deposition (PVD), electroplating, or electroless plating. The one or more metals used to treat the exposed surface may include any rare earth or transition metal, such as, for example, hafnium, lanthanum, etc.

Owner:NXP USA INC +1

Formation of well-controlled thin SiO, SiN, SiN, SiON layer for multilayer high-K dielectric applications

A process for fabricating a semiconductor device having a high-K dielectric layer over a silicon substrate, including steps of growing on the silicon substrate an interfacial layer of a silicon-containing dielectric material; and depositing on the interfacial layer a layer comprising at least one high-K dielectric material, in which the interfacial layer is grown by laser excitation of the silicon substrate in the presence of oxygen, nitrous oxide, nitric oxide, ammonia or a mixture of two or more thereof. In one embodiment, the silicon-containing material is silicon dioxide, silicon nitride, silicon oxynitride or a mixture thereof.

Owner:ADVANCED MICRO DEVICES INC

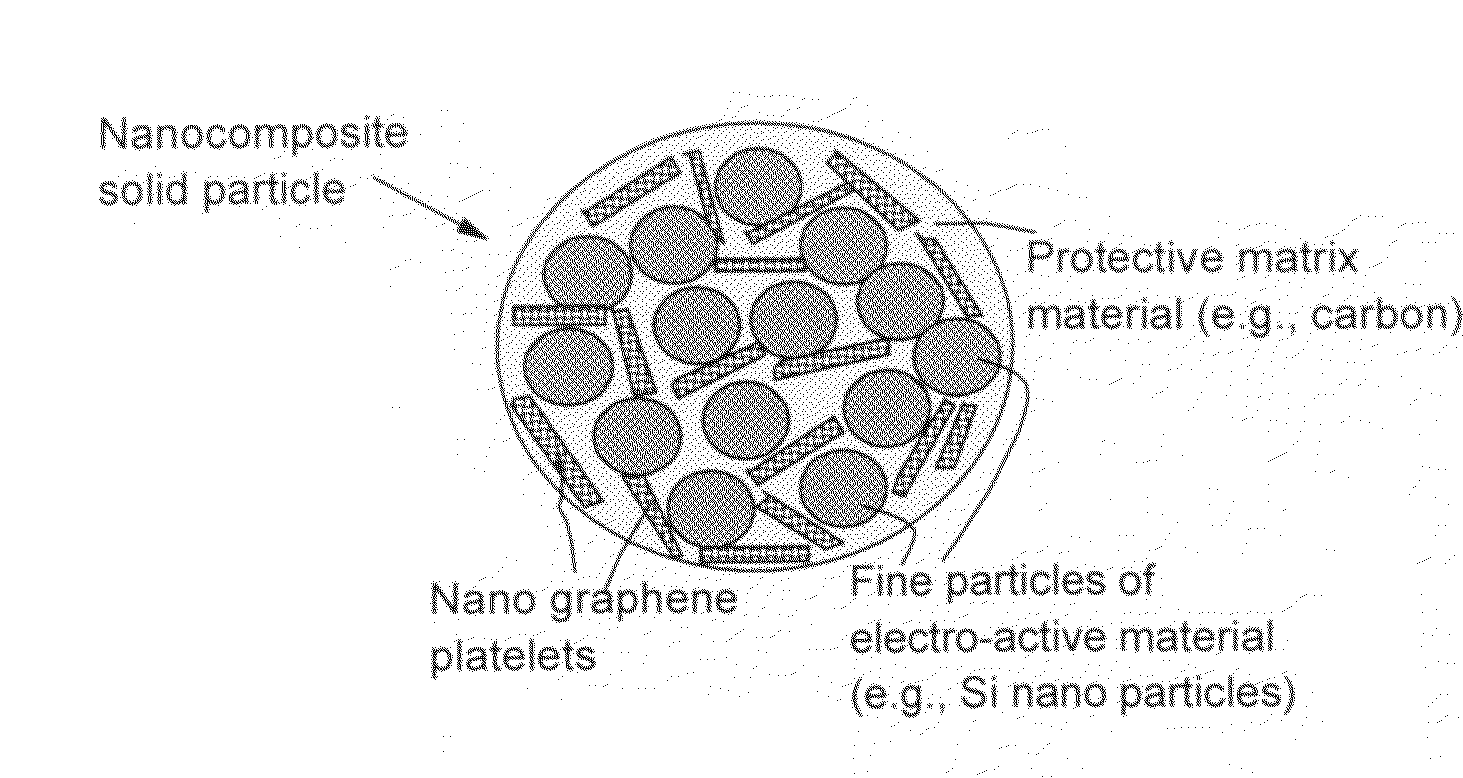

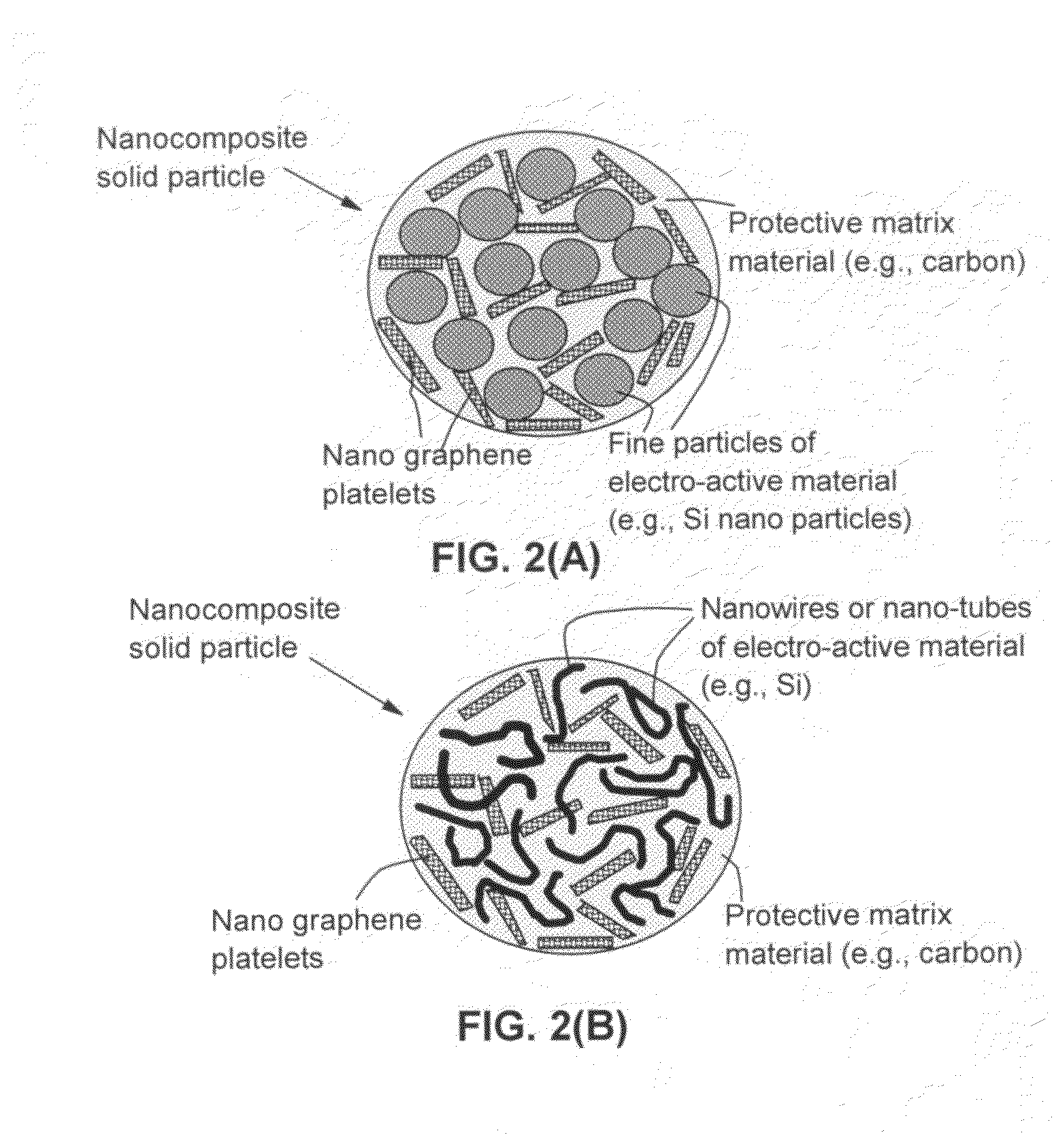

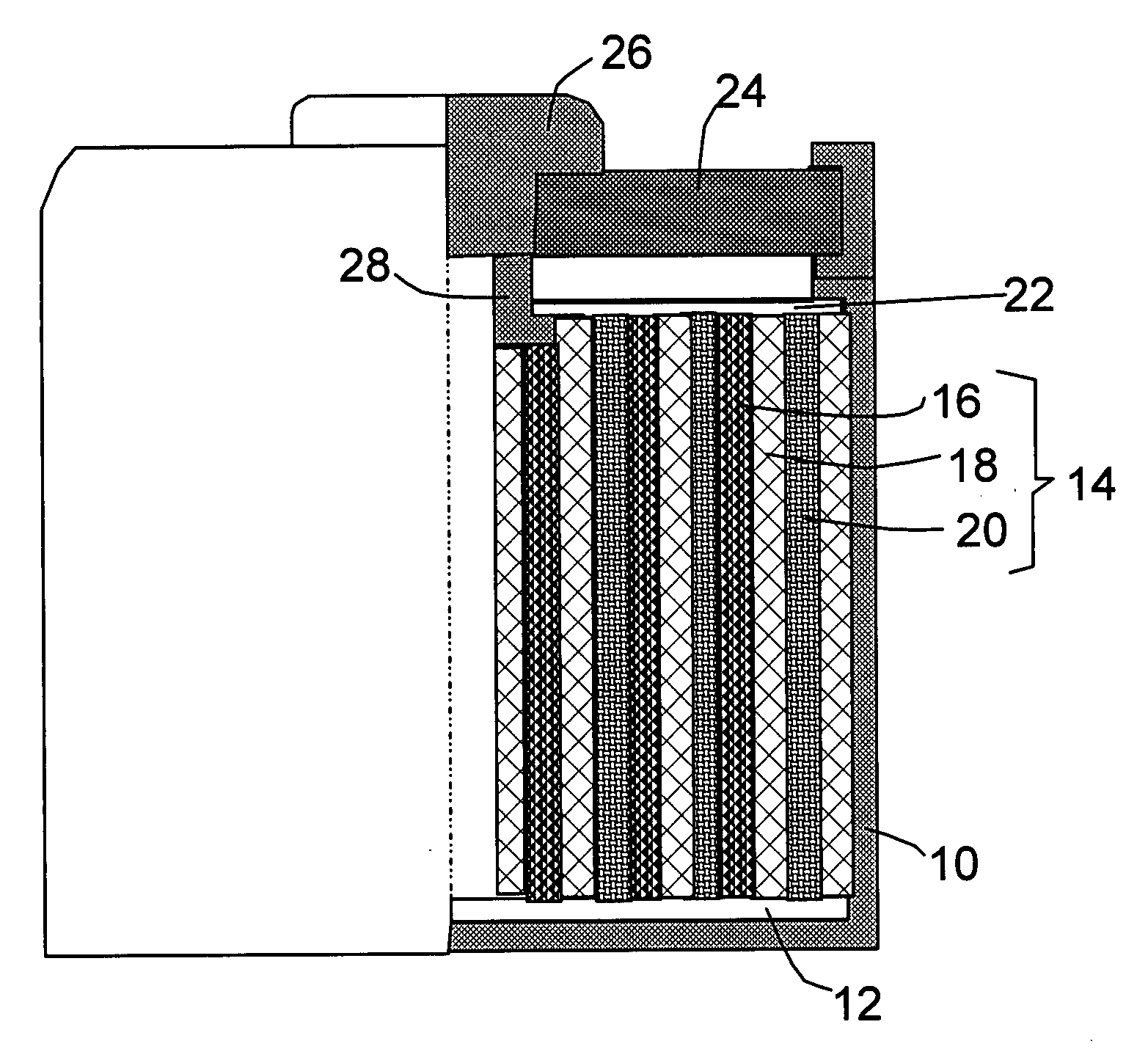

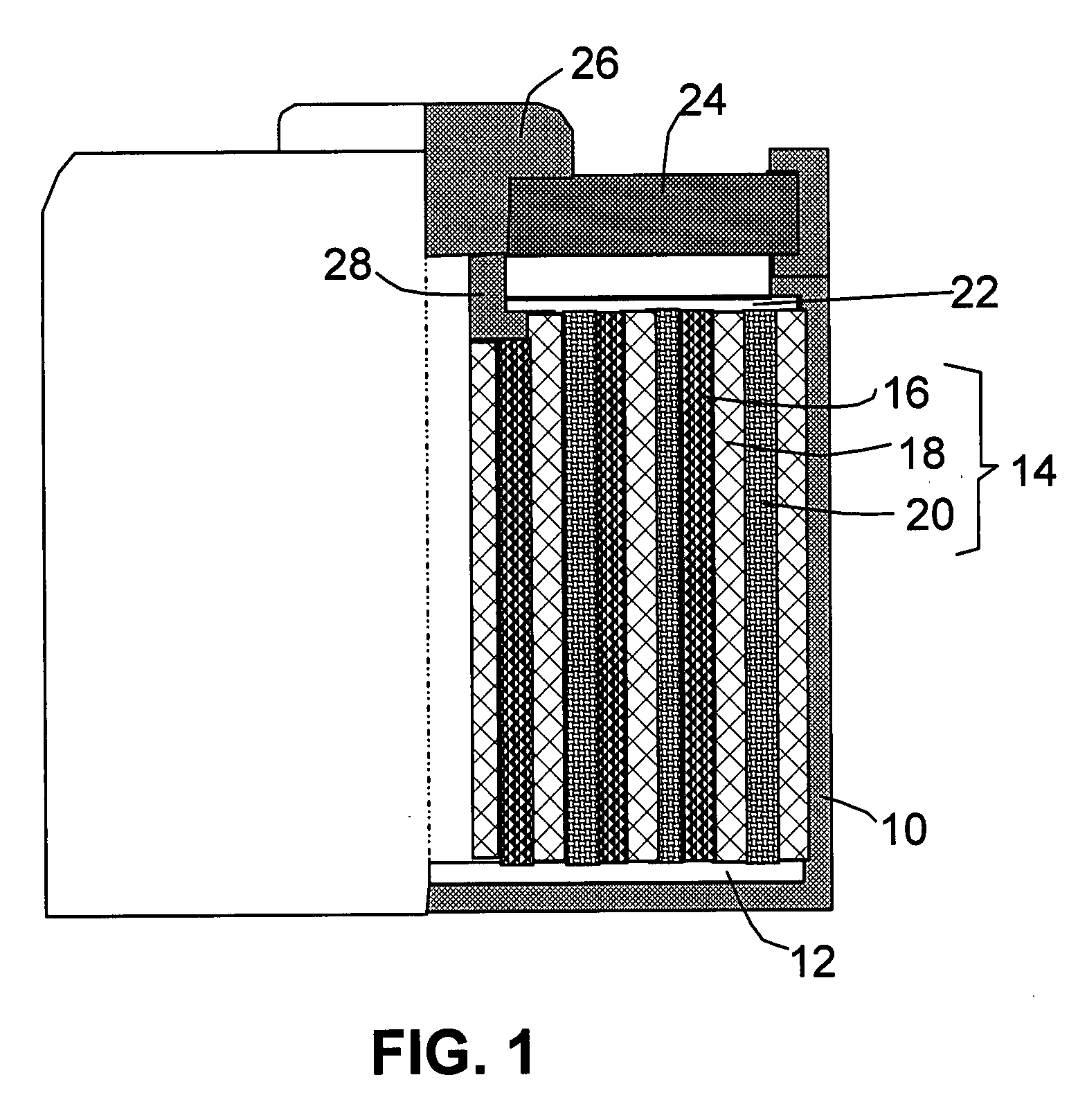

Nano graphene reinforced nanocomposite particles for lithium battery electrodes

ActiveUS20100143798A1Increase stiffnessHigh strengthActive material electrodesSecondary cellsLithium metalNanocomposite

A solid nanocomposite particle composition for lithium metal or lithium ion battery electrode applications. The composition comprises: (A) an electrode active material in a form of fine particles, rods, wires, fibers, or tubes with a dimension smaller than 1 μm; (B) nano graphene platelets (NGPs); and (C) a protective matrix material reinforced by the NGPs; wherein the graphene platelets and the electrode active material are dispersed in the matrix material and the NGPs occupy a weight fraction wg of 1% to 90% of the total nanocomposite weight, the electrode active material occupies a weight fraction wa of 1% to 90% of the total nanocomposite weight, and the matrix material occupies a weight fraction wm of at least 2% of the total nanocomposite weight with wg+wa+wm=1. For a lithium ion battery anode application, the matrix material is preferably amorphous carbon, polymeric carbon, or meso-phase carbon. Such a solid nanocomposite composition provides a high anode capacity and good cycling stability. For a cathode application, the resulting lithium metal or lithium ion battery exhibits an exceptionally high cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD

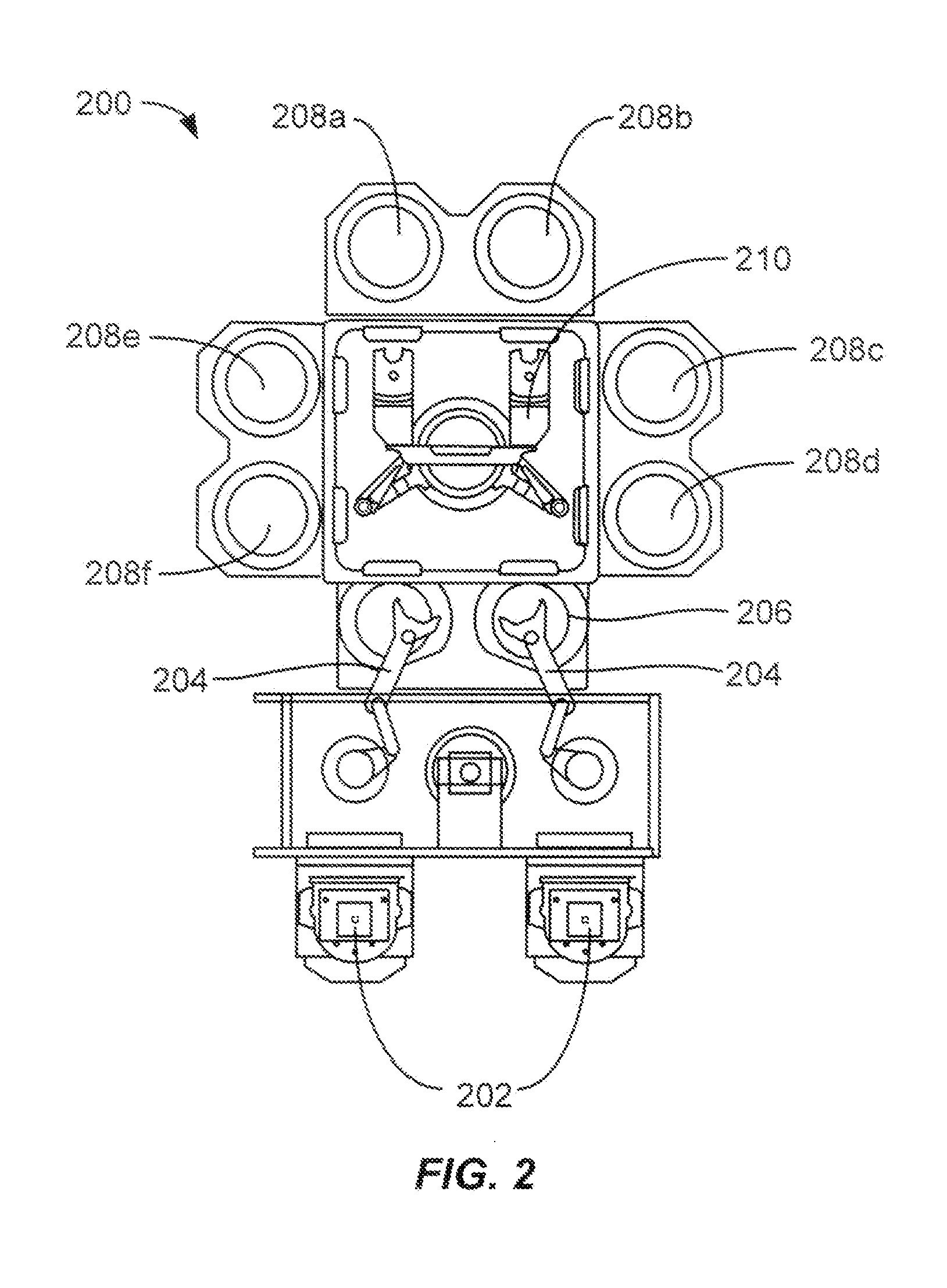

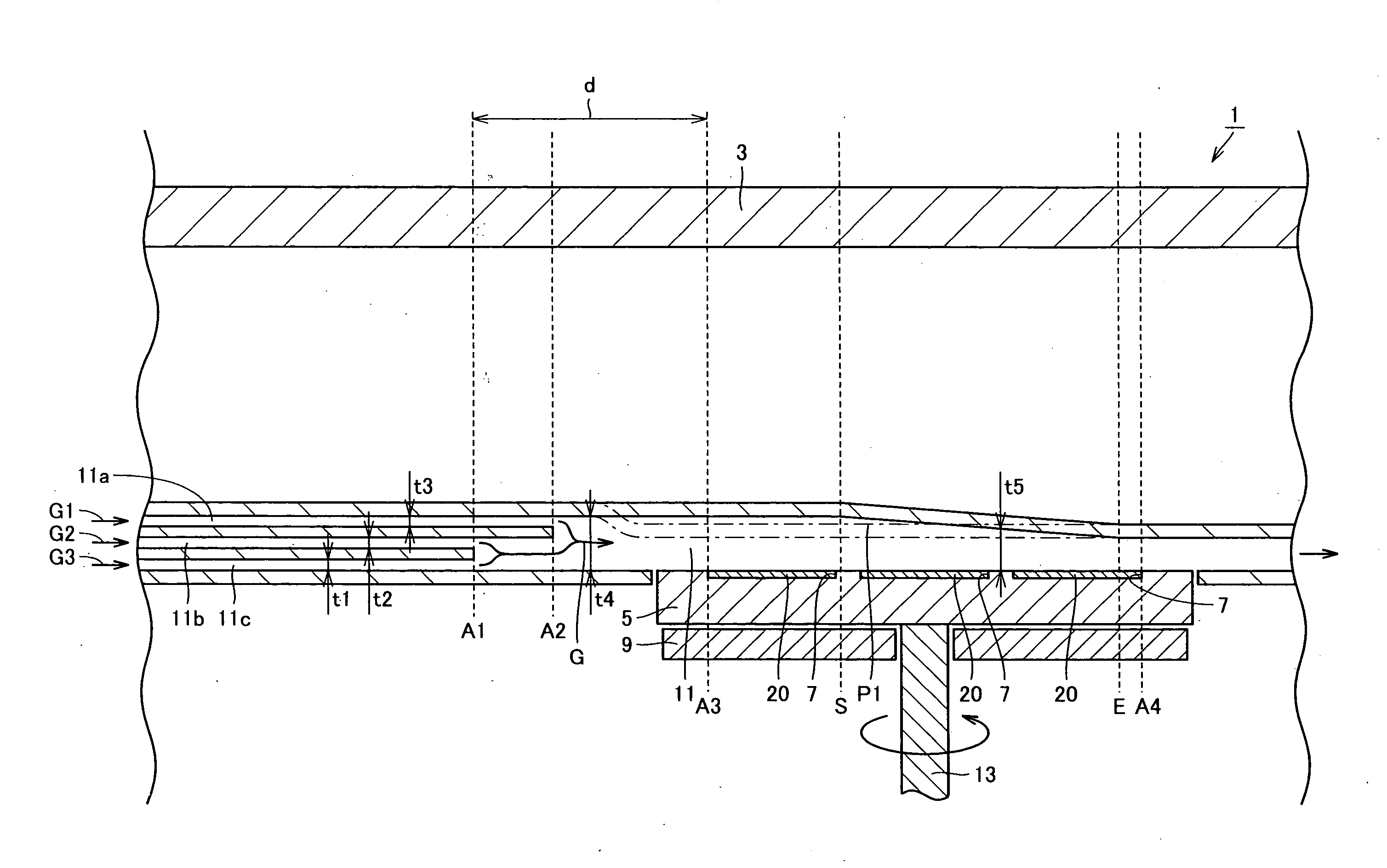

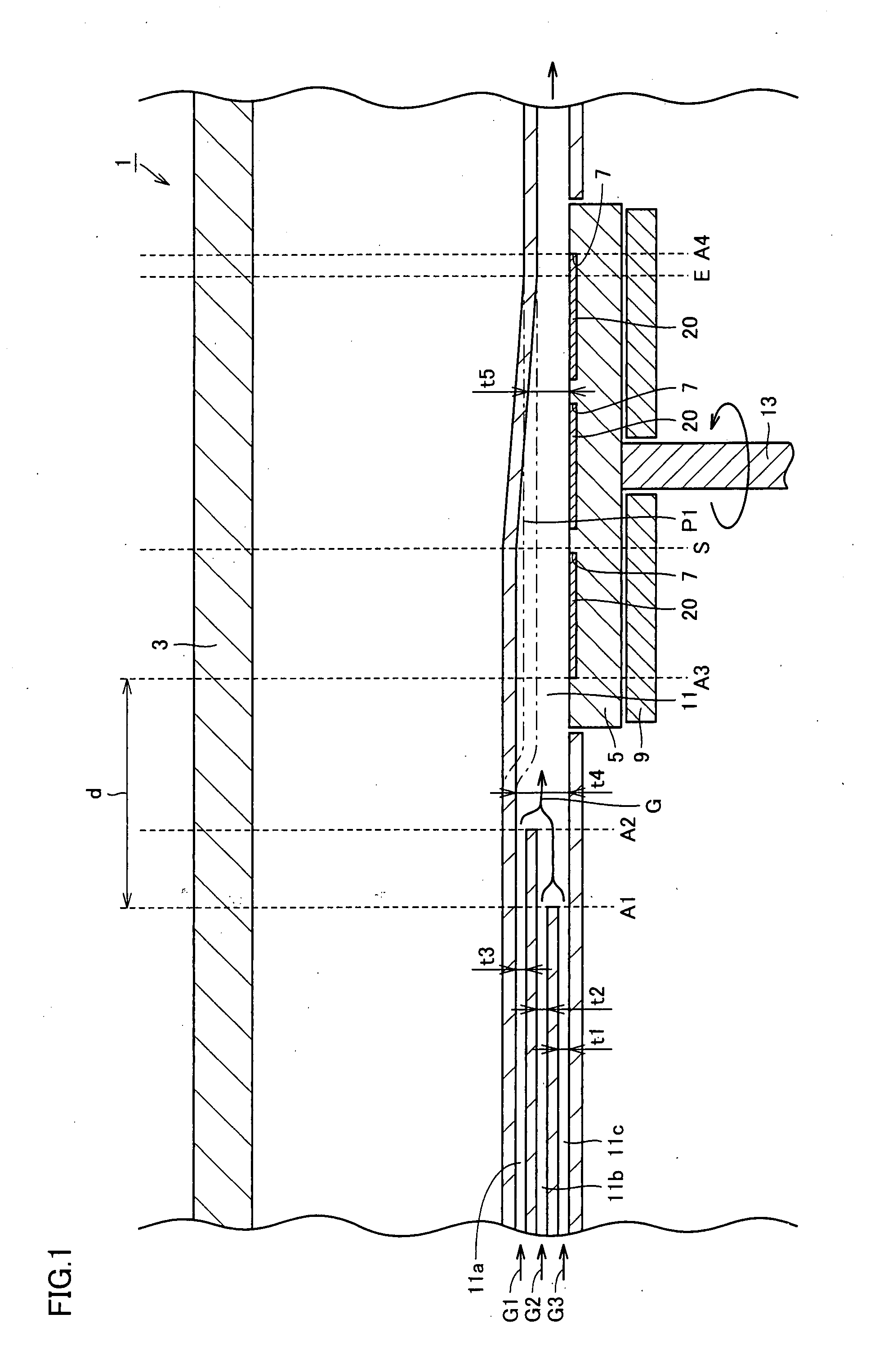

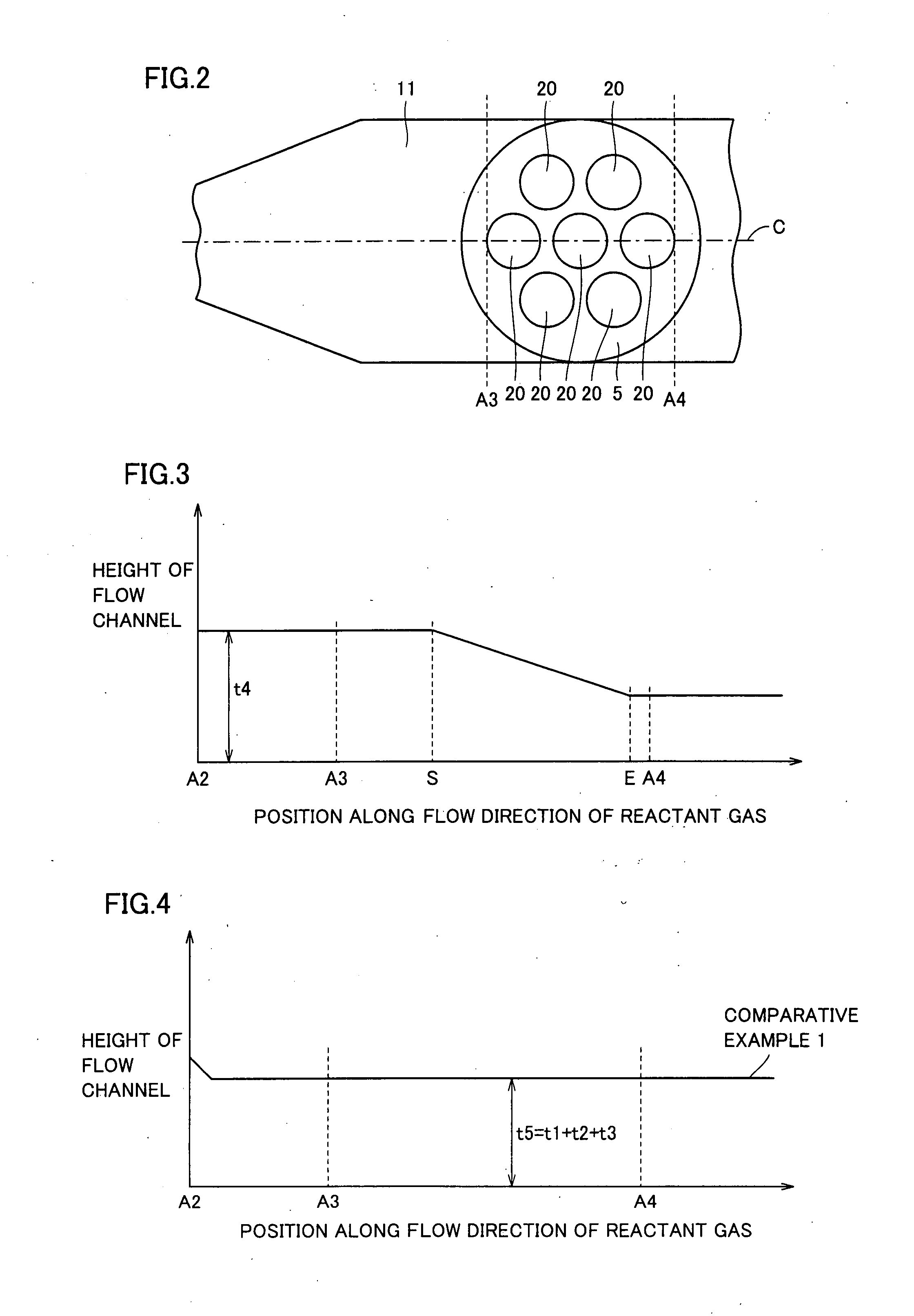

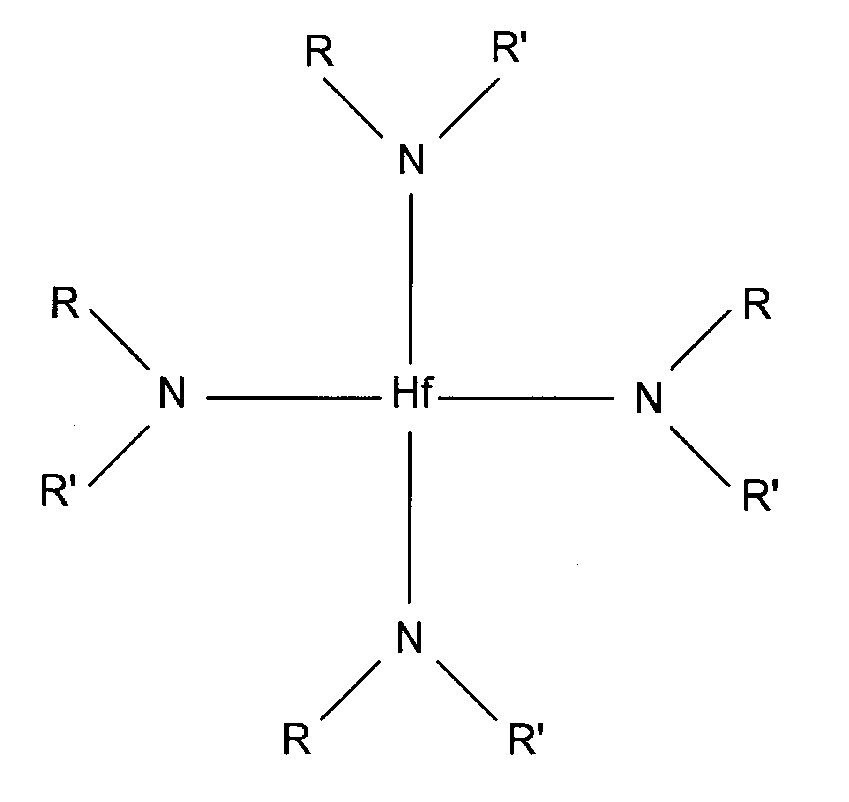

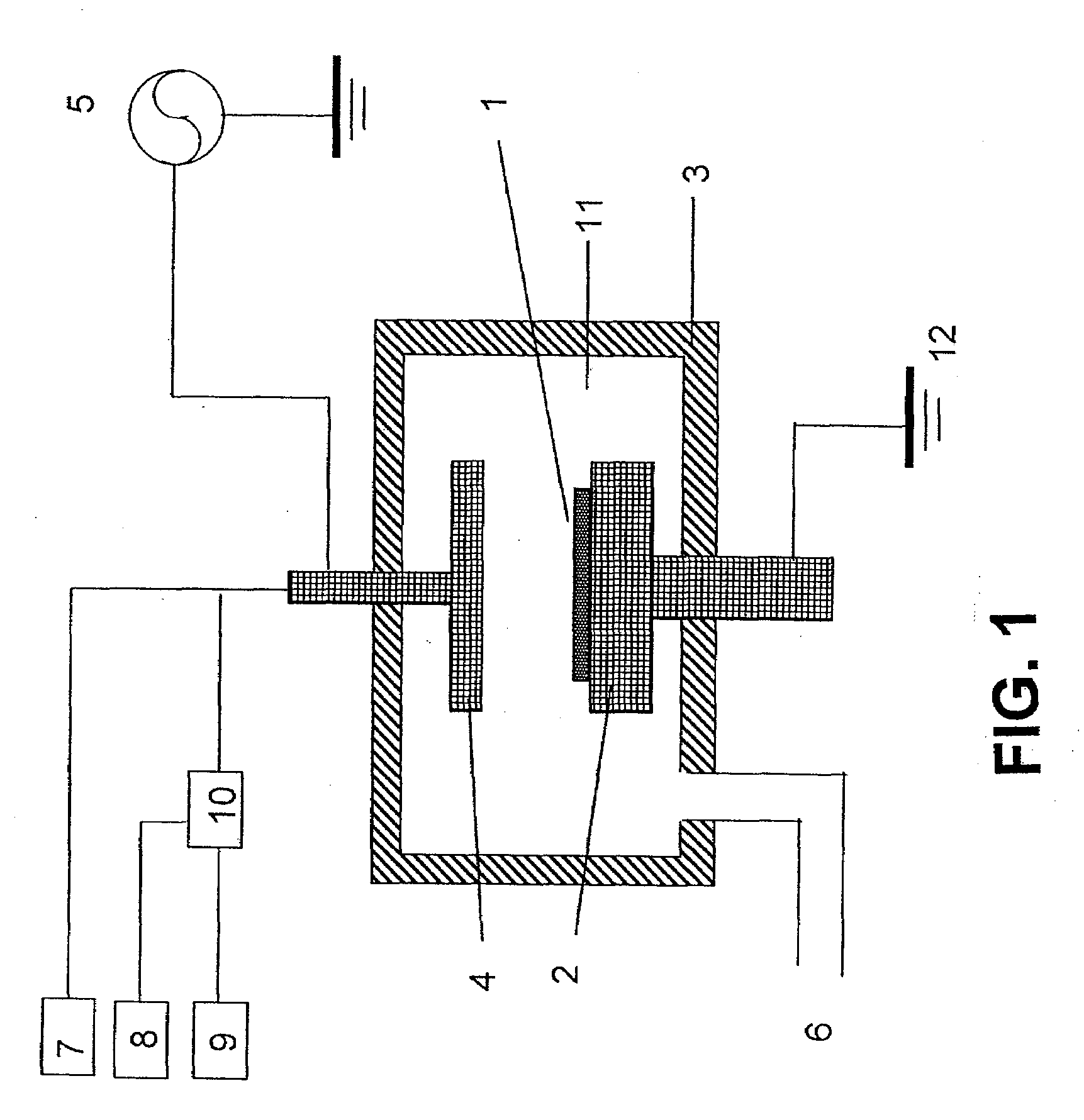

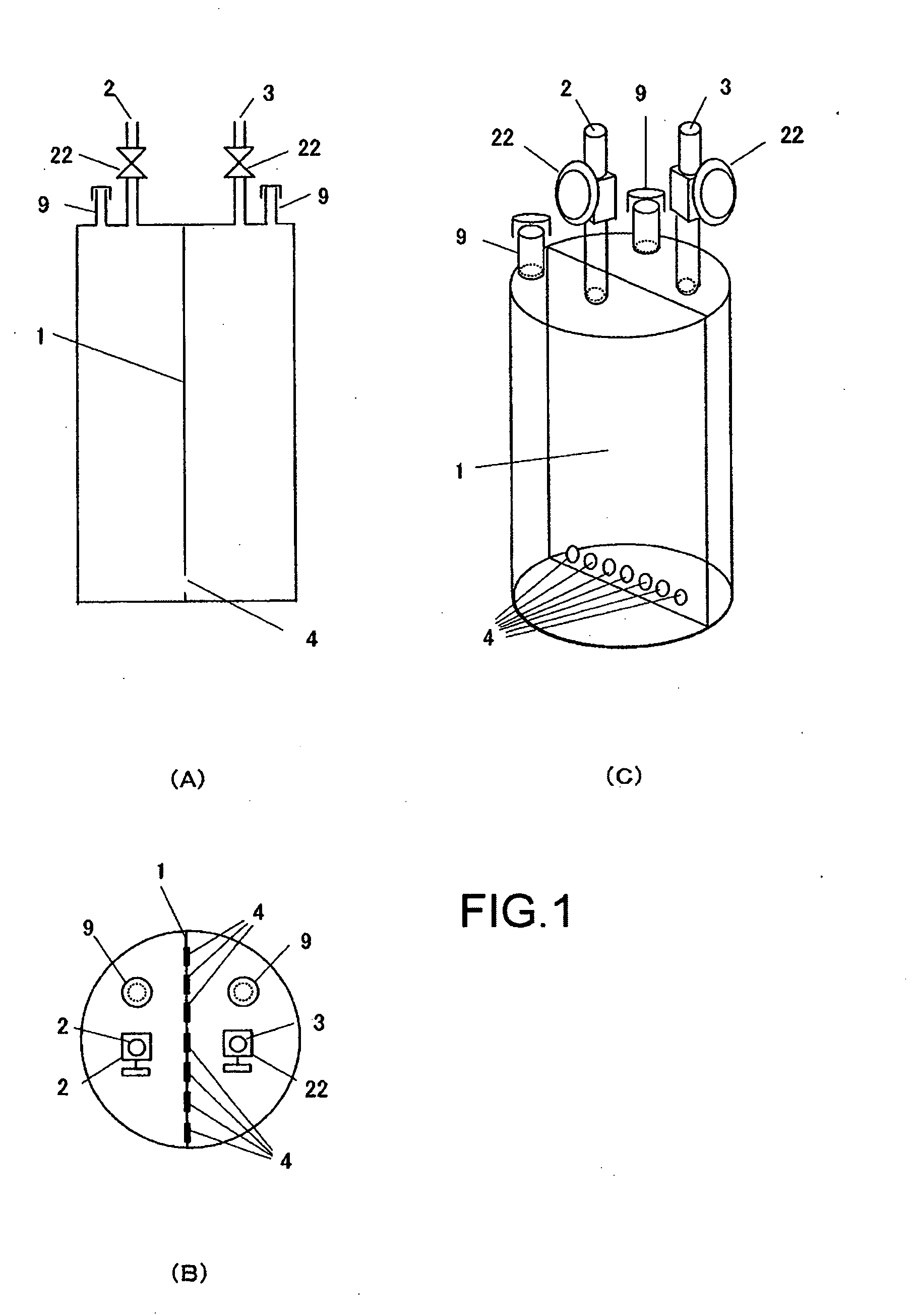

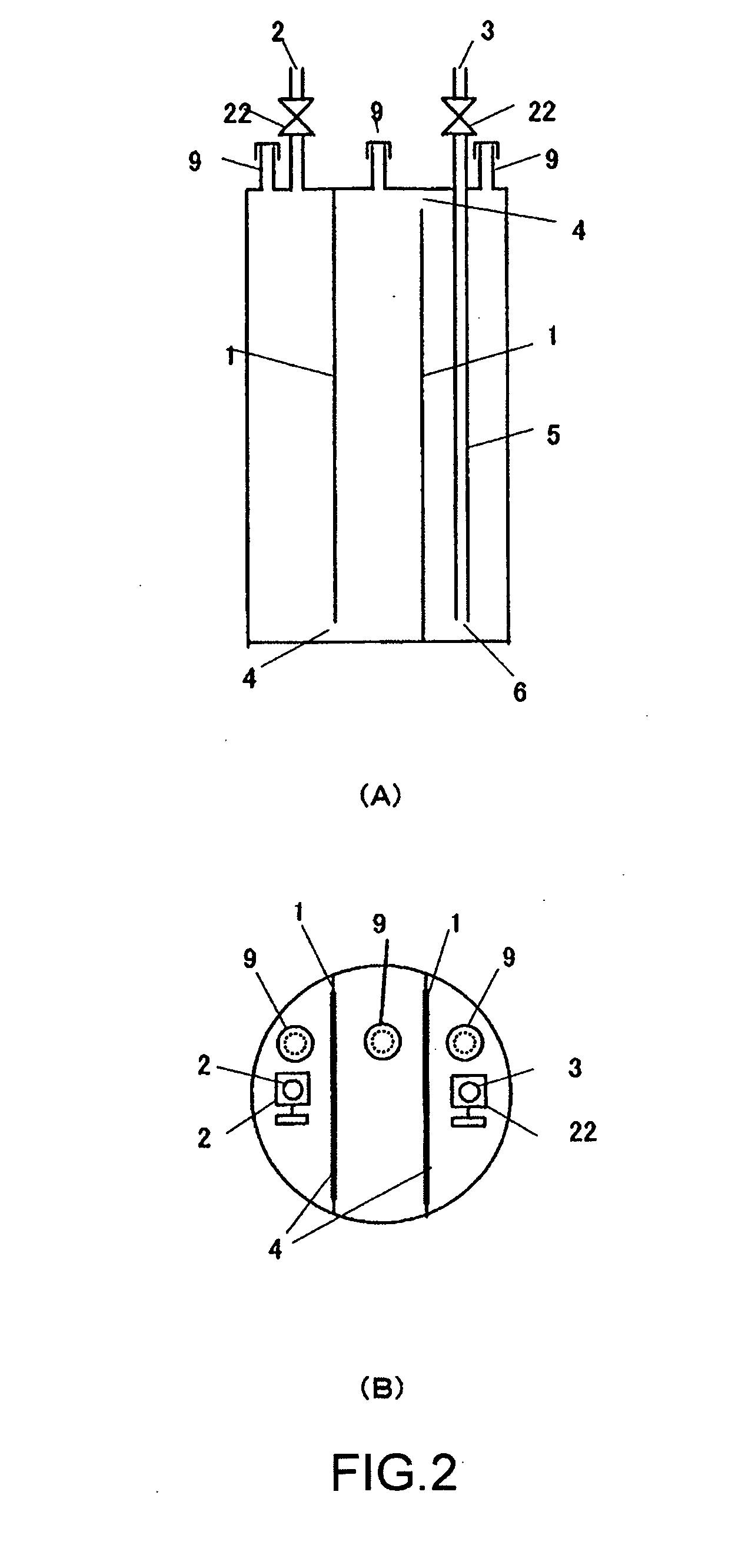

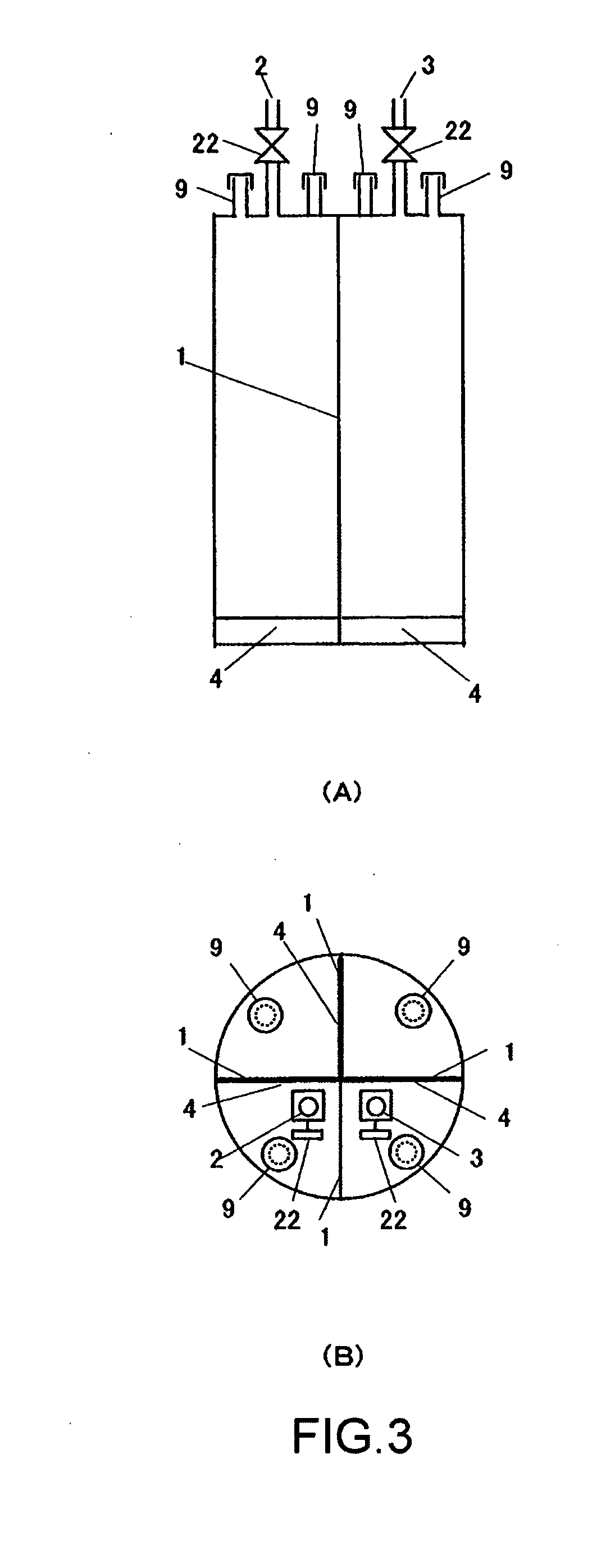

Metal organic chemical vapor deposition equipment

InactiveUS20080006208A1Uniform film thicknessImprove formation efficiencyAfter-treatment apparatusFrom chemically reactive gasesSusceptorProduct gas

Metal organic chemical vapor deposition equipment is metal organic chemical vapor deposition equipment for forming a film on a substrate by using a reactant gas, and includes a susceptor heating the substrate and having a holding surface for holding the substrate, and a flow channel for introducing the reactant gas to the substrate. The susceptor is rotatable with the holding surface kept facing an inner portion of the flow channel, and a height of the flow channel along a flow direction of the reactant gas is kept constant from a position to a position, and is monotonically decreased from the position to the downstream side. It is thereby possible to improve film formation efficiency while allowing the formed film to have a uniform thickness.

Owner:SUMITOMO ELECTRIC IND LTD

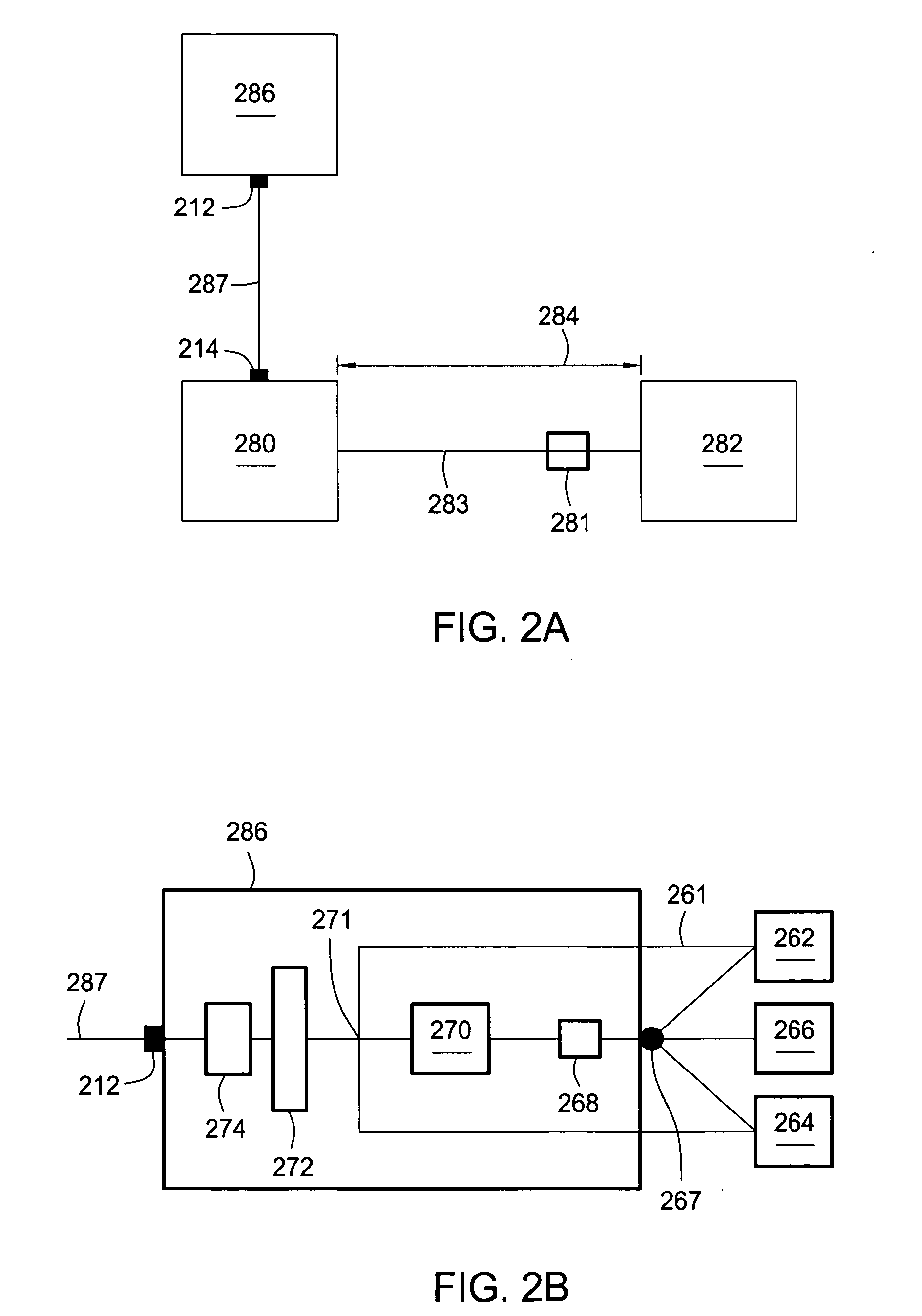

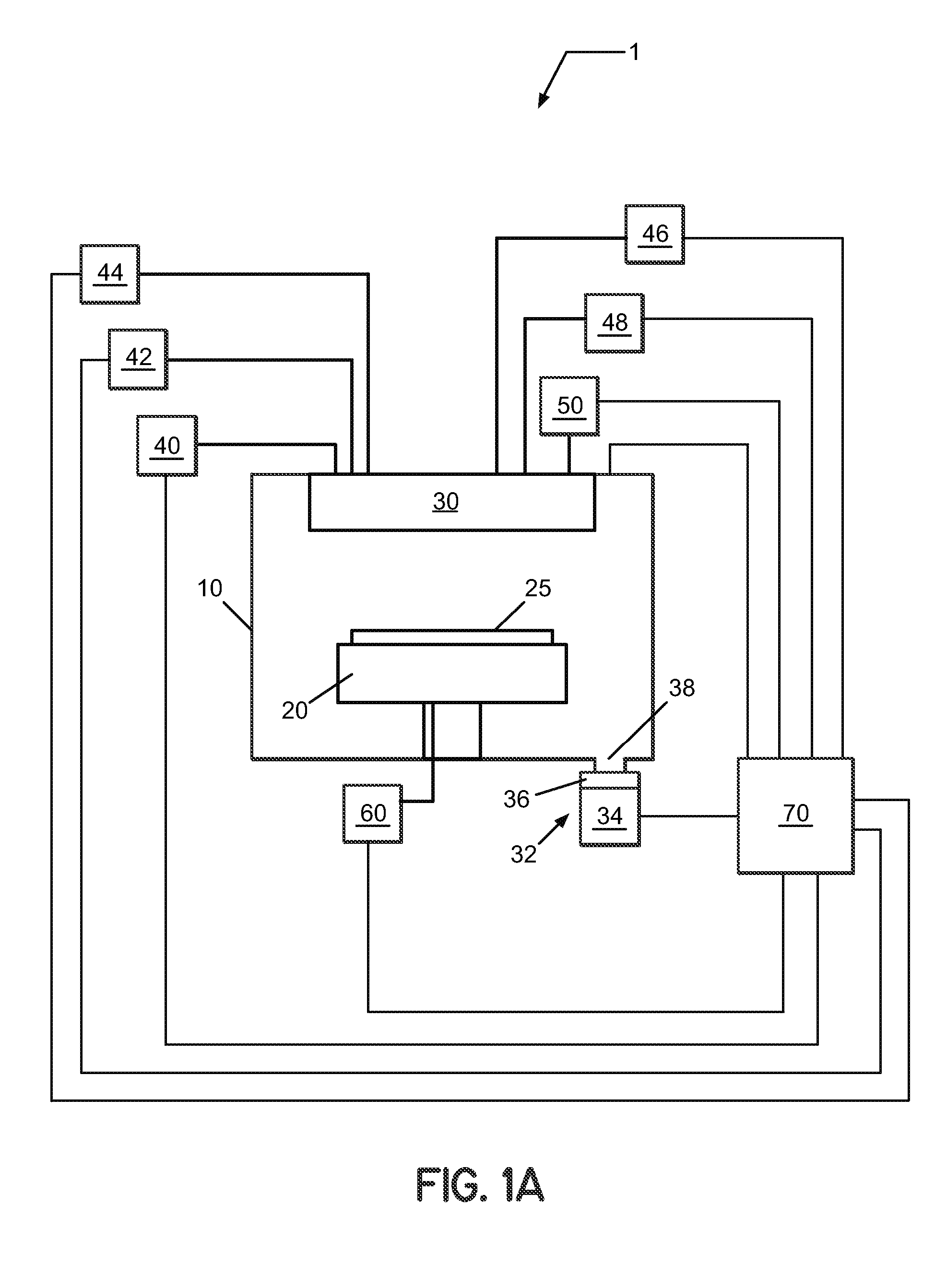

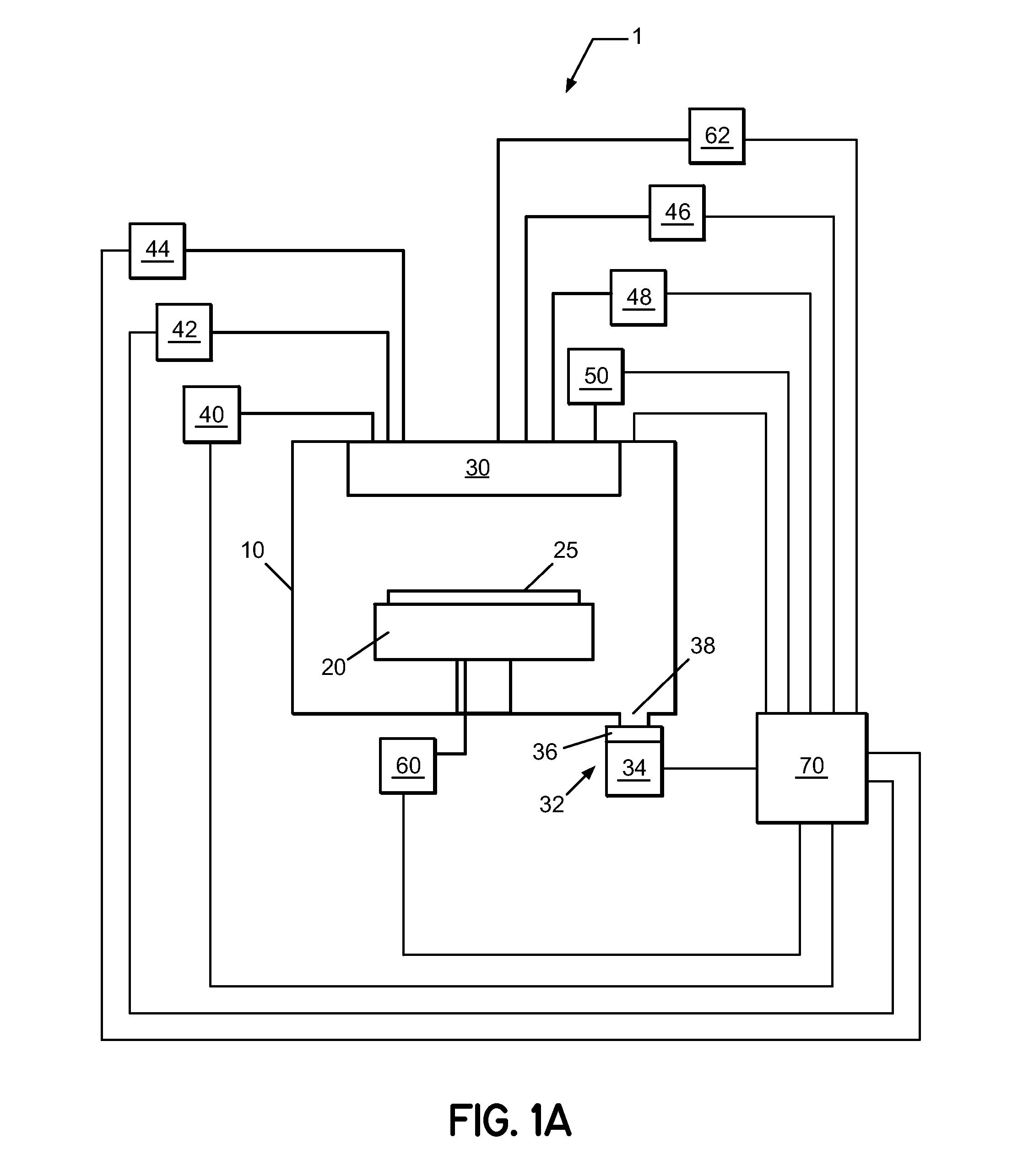

Ald metal oxide deposition process using direct oxidation

InactiveUS20070059948A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogenHafnium

Embodiments of the invention provide methods for forming hafnium materials, such as oxides and nitrides, by sequentially exposing a substrate to hafnium precursors and active oxygen or nitrogen species (e.g., ozone, oxygen radicals, or nitrogen radicals). The deposited hafnium materials have significantly improved uniformity when deposited by these atomic layer deposition (ALD) processes. In one embodiment, an ALD chamber contains an expanding channel having a bottom surface that is sized and shaped to substantially cover a substrate positioned on a substrate pedestal. During an ALD process for forming hafnium materials, process gases form a vortex flow pattern while passing through the expanding channel and sweep across the substrate surface. The substrate is sequentially exposed to chemical precursors that are pulsed into the process chamber having the vortex flow.

Owner:APPLIED MATERIALS INC

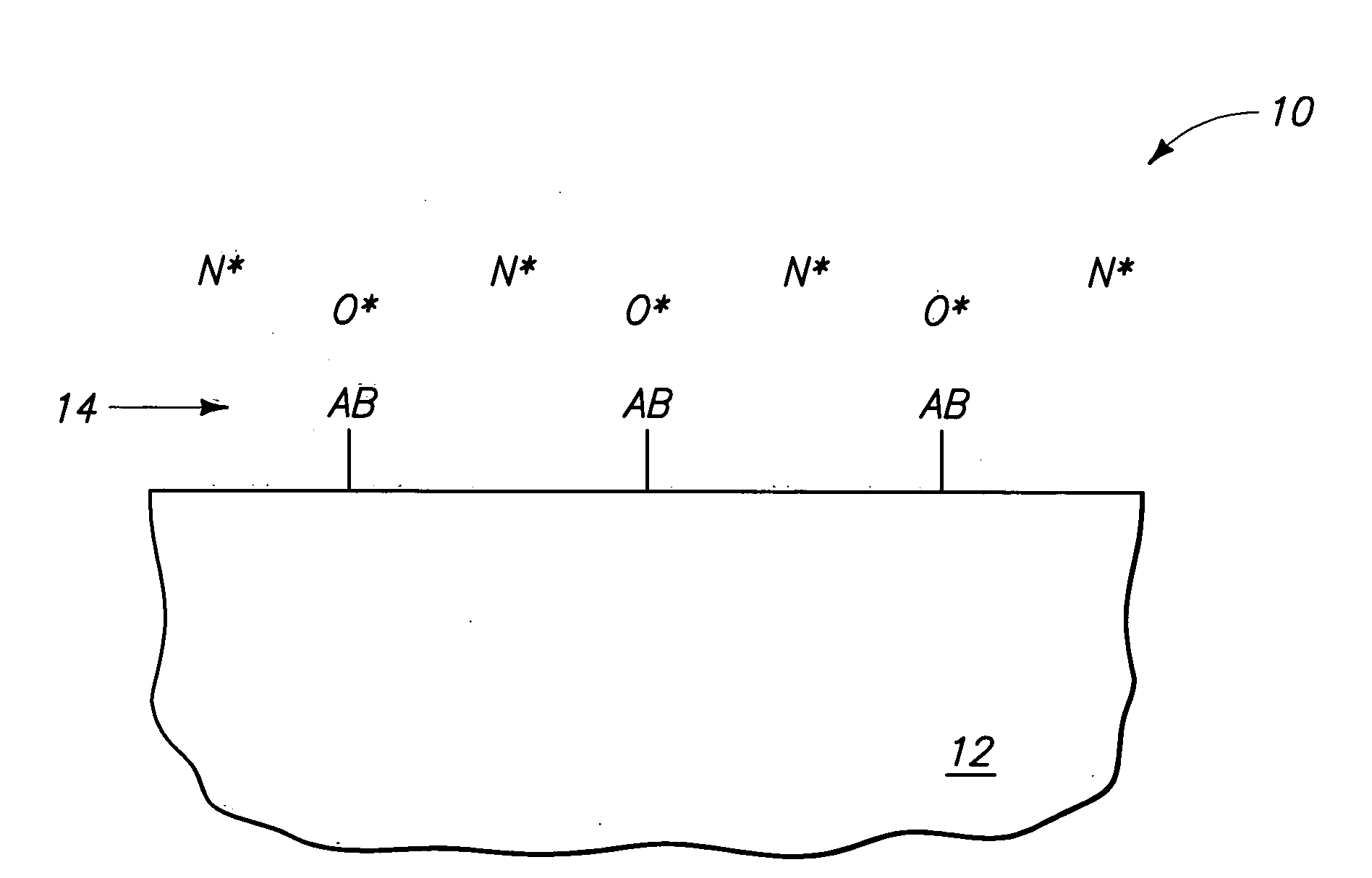

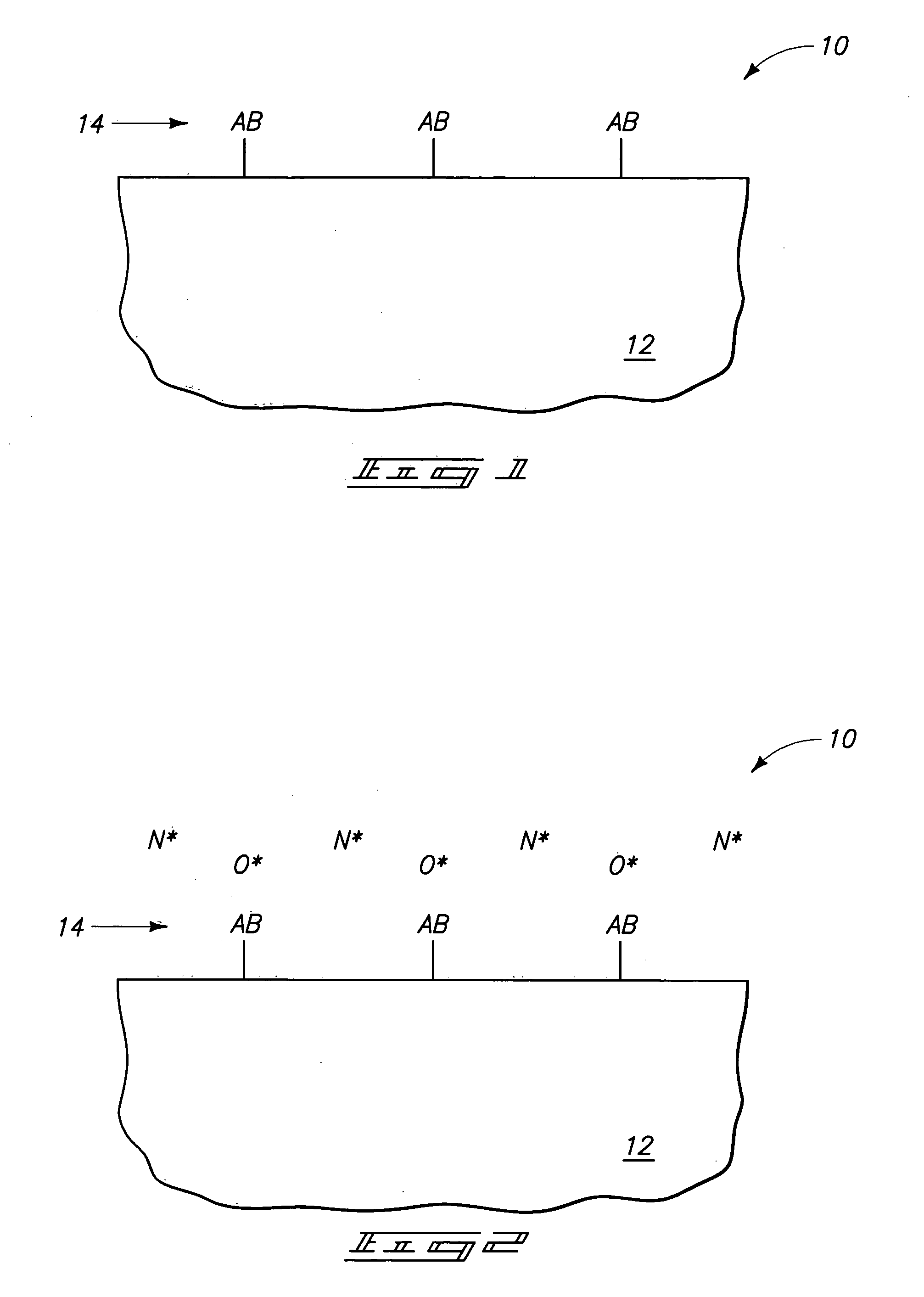

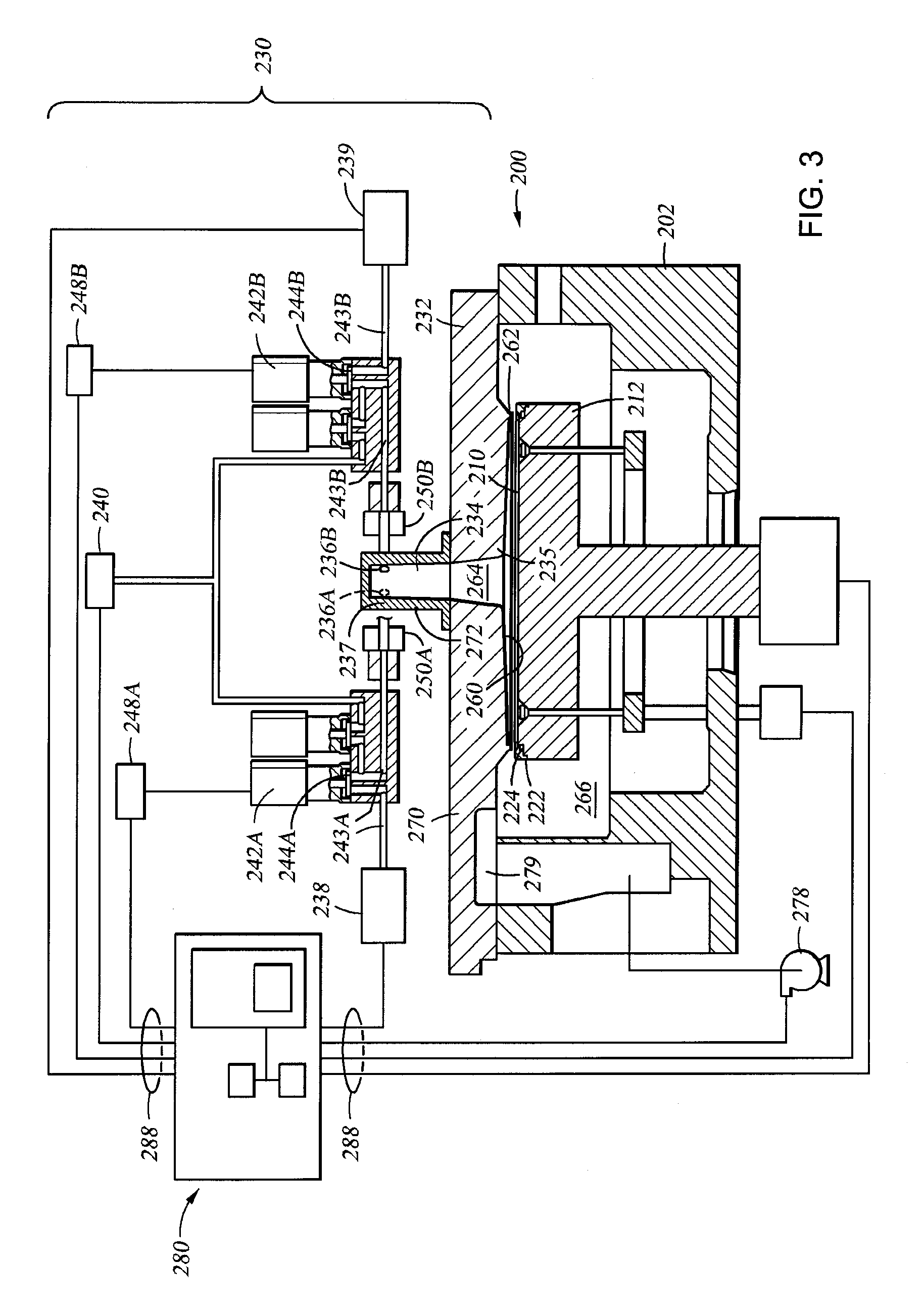

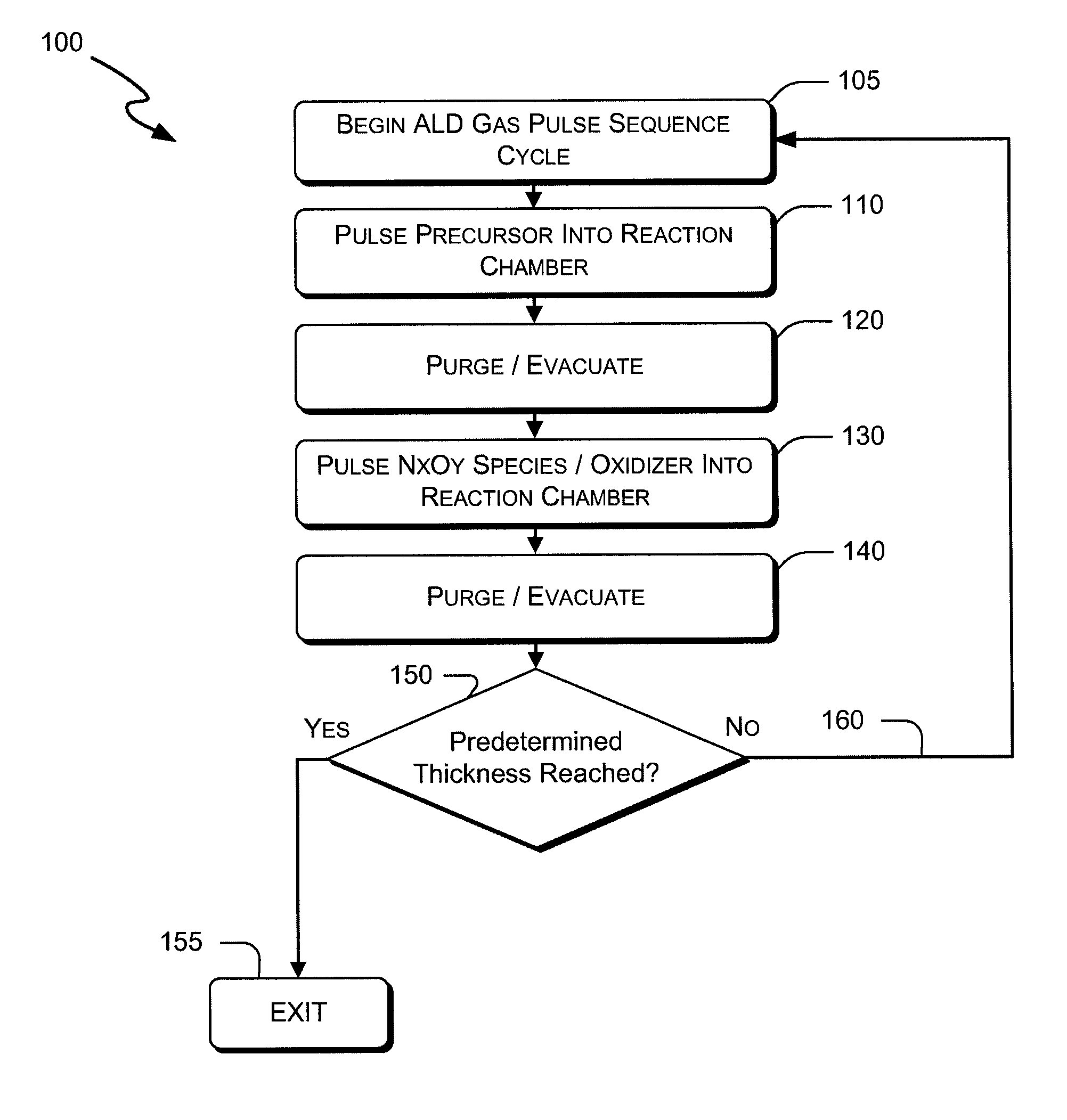

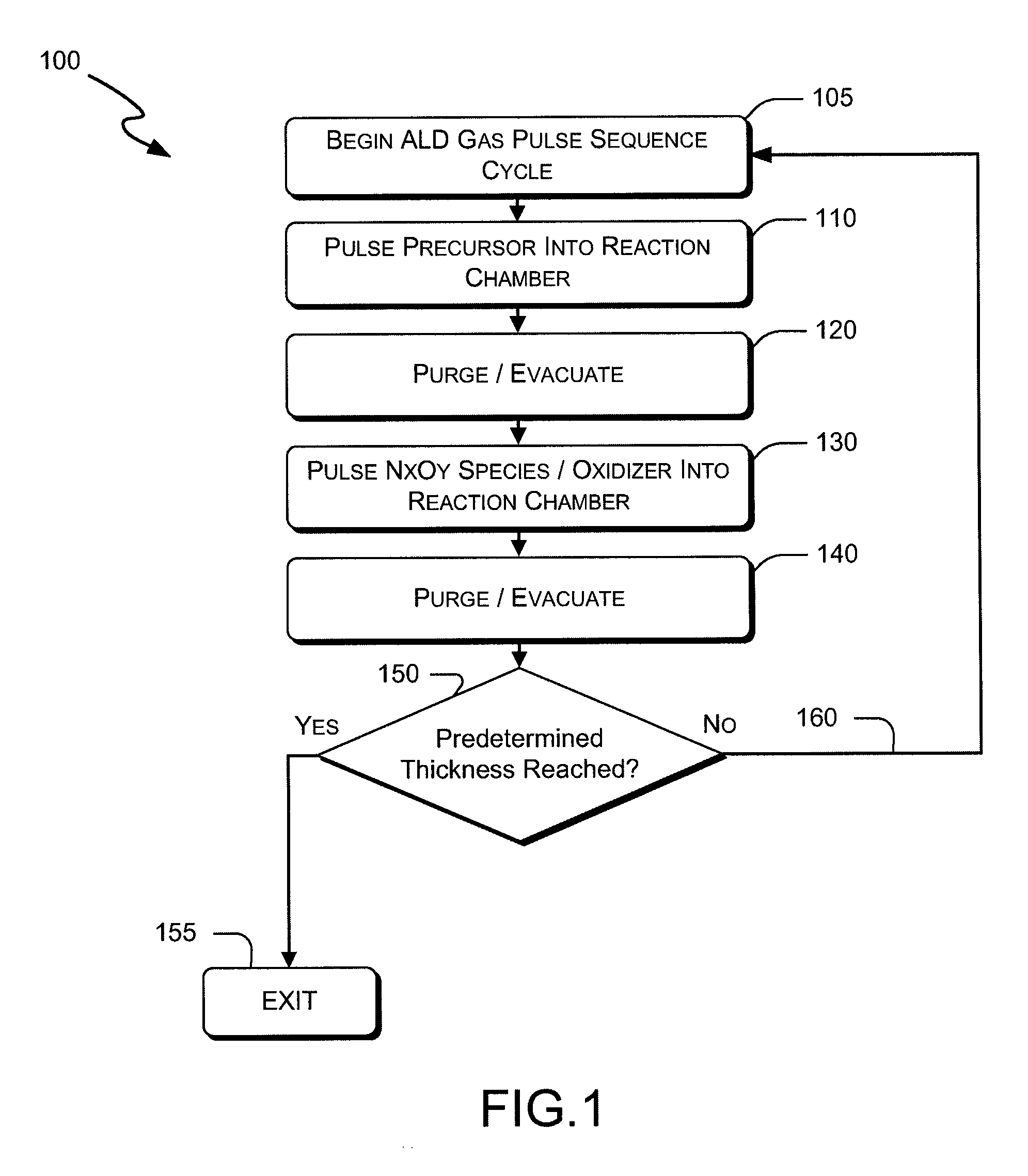

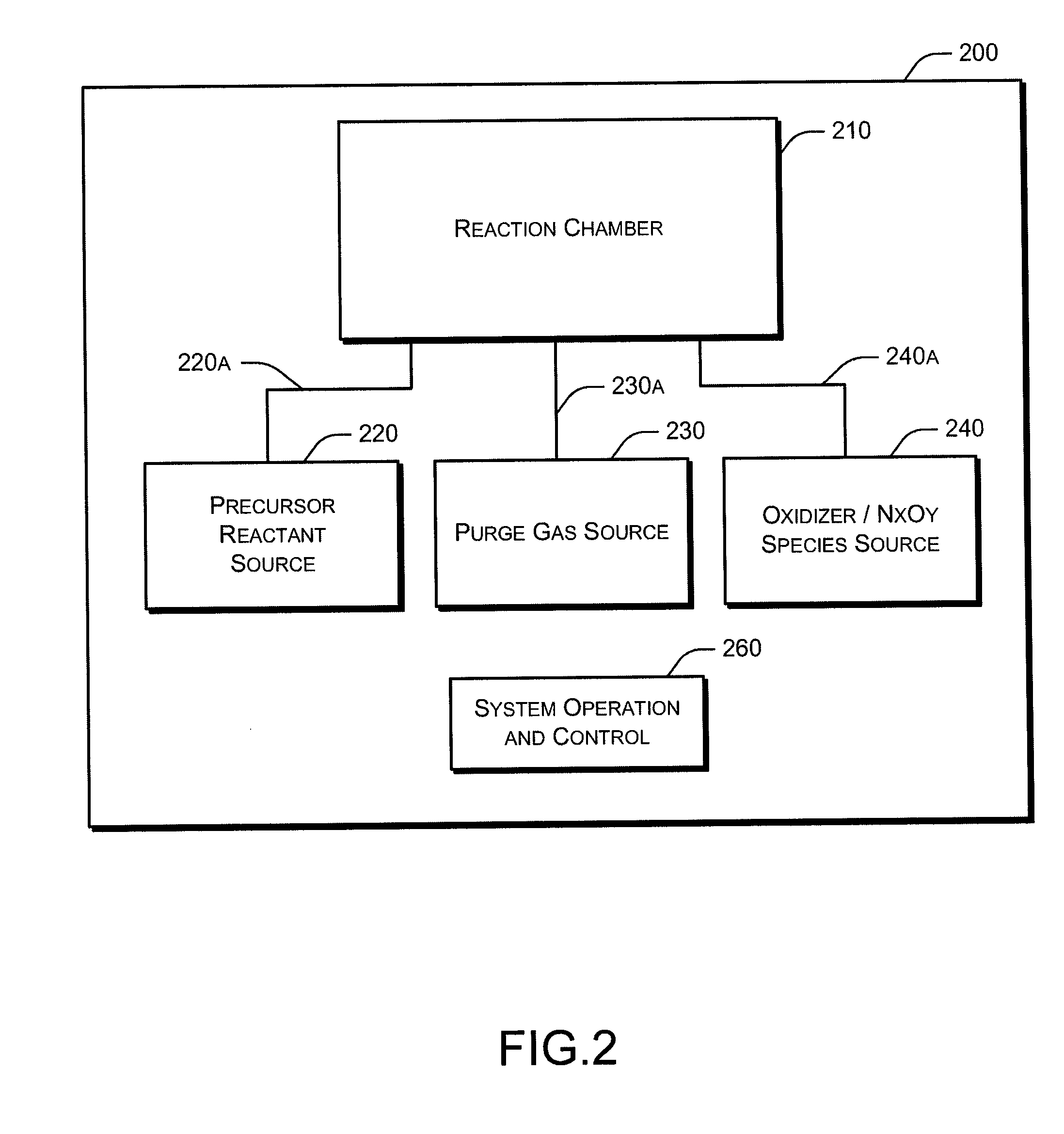

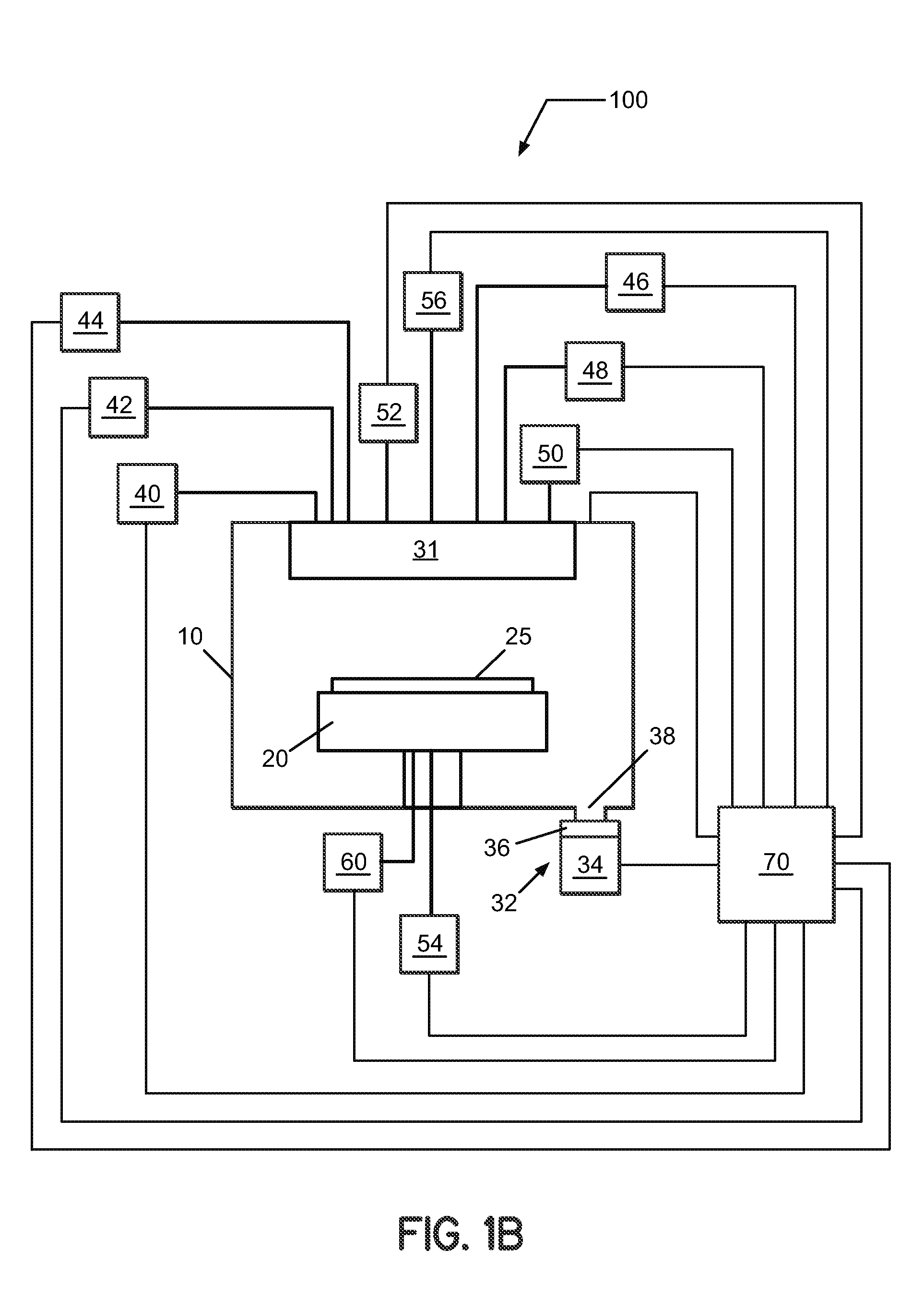

Systems and methods for thin-film deposition of metal oxides using excited nitrogen-oxygen species

ActiveUS8877655B2Enhance growth rate and uniformityUniform growthLiquid surface applicatorsSemiconductor/solid-state device manufacturingNitrogenOptoelectronics

The present invention relates to a process and system for depositing a thin film onto a substrate. One aspect of the invention is depositing a thin film metal oxide layer using atomic layer deposition (ALD).

Owner:ASM IP HLDG BV

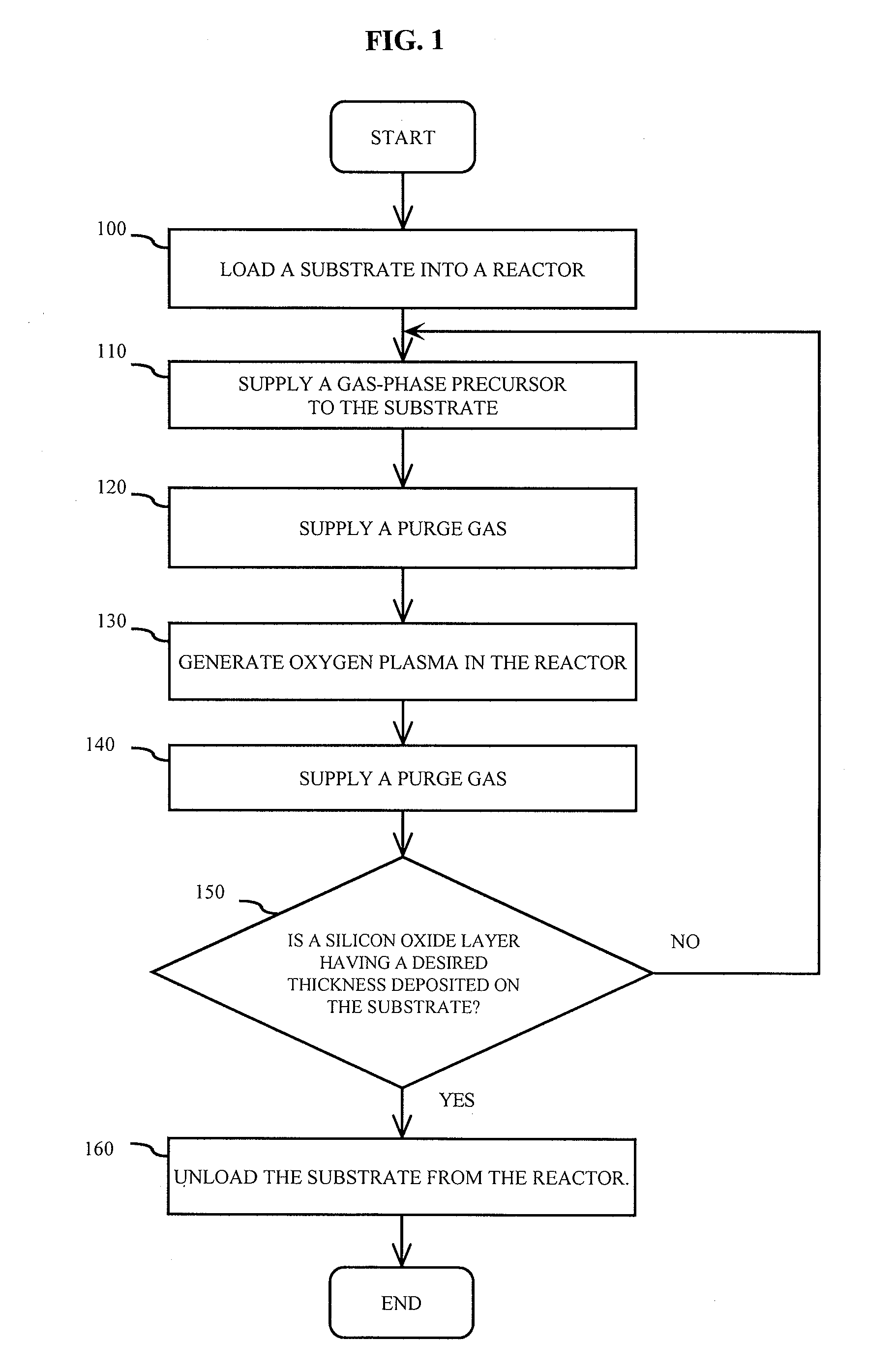

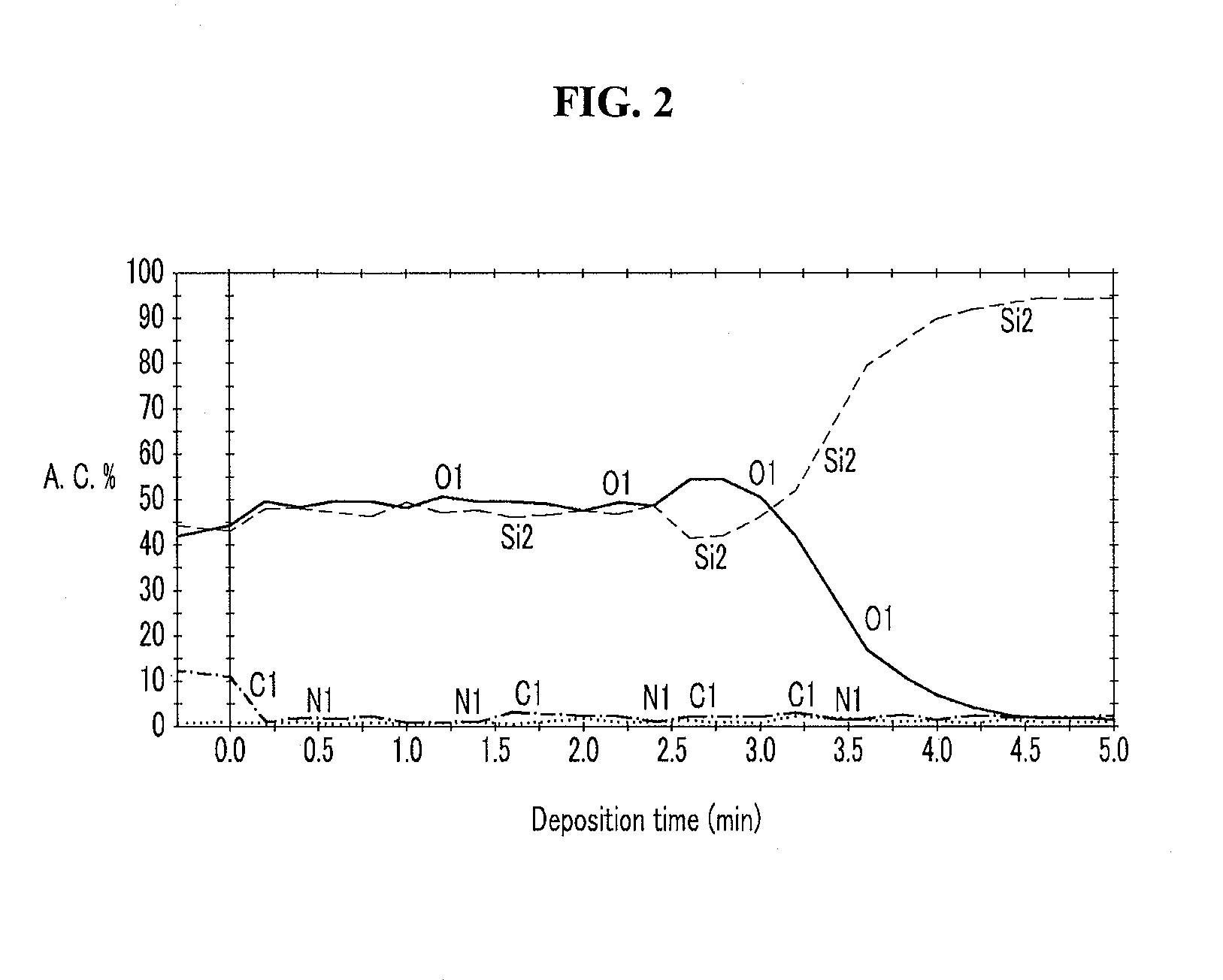

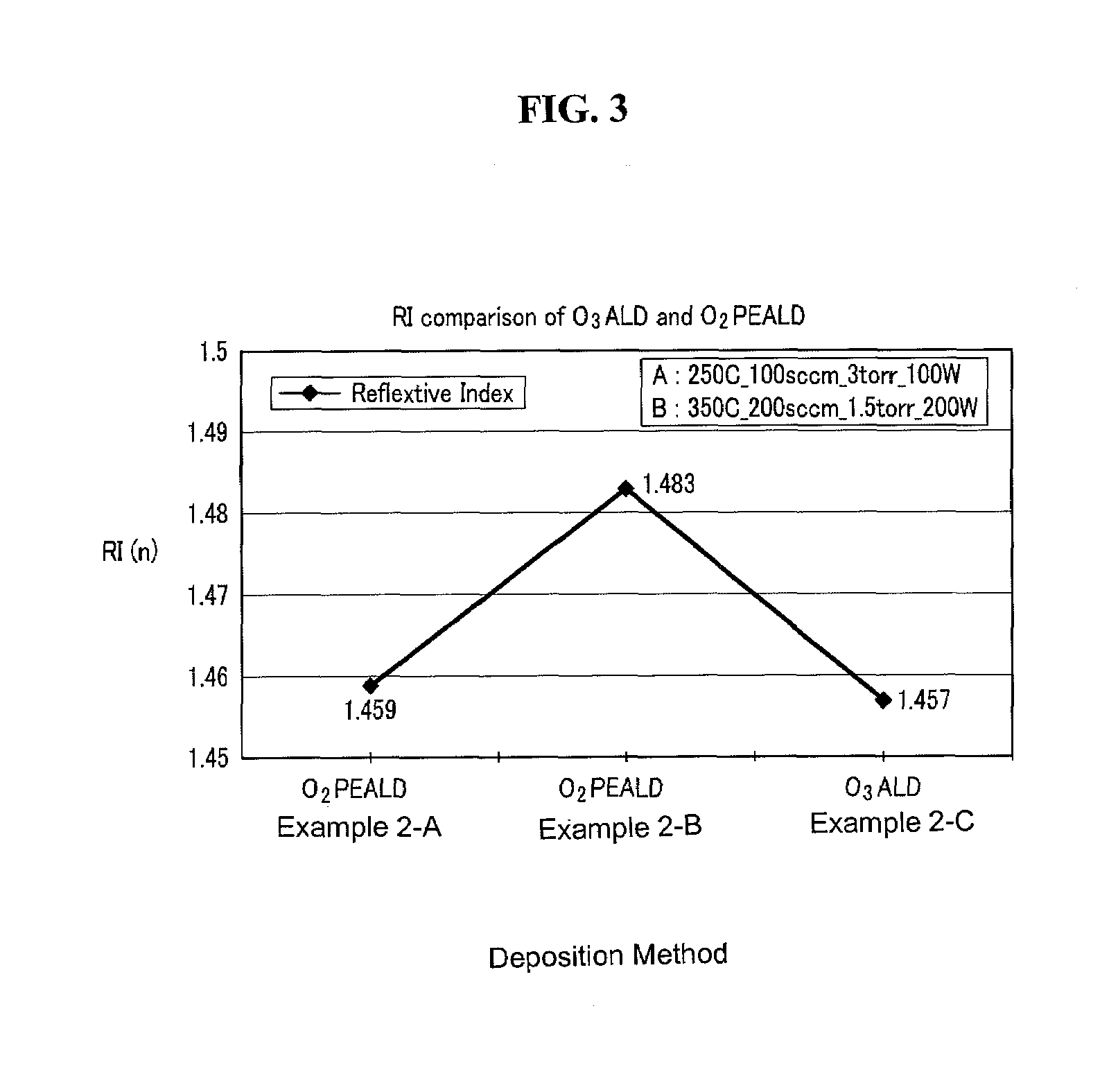

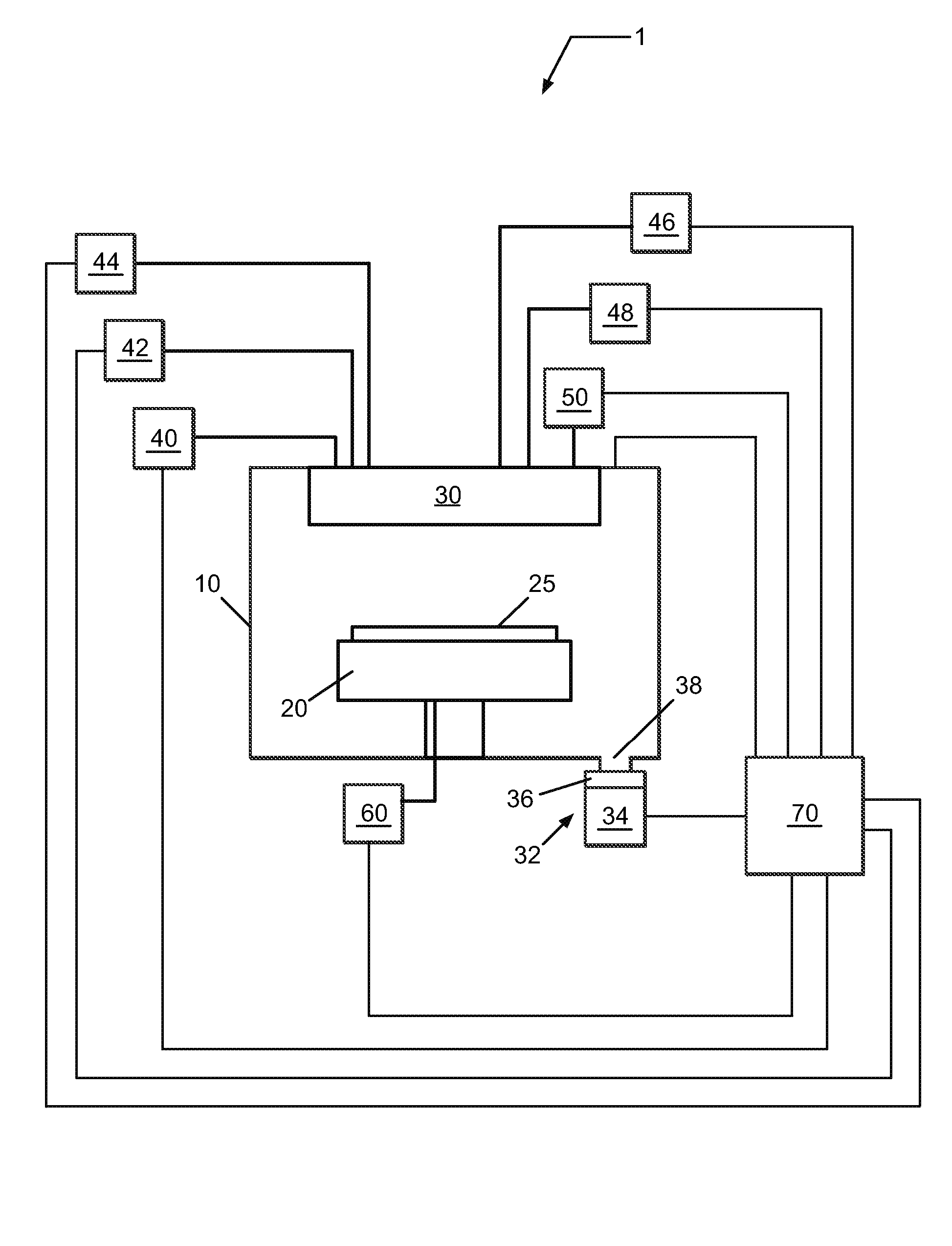

Method of depositing silicon oxide films

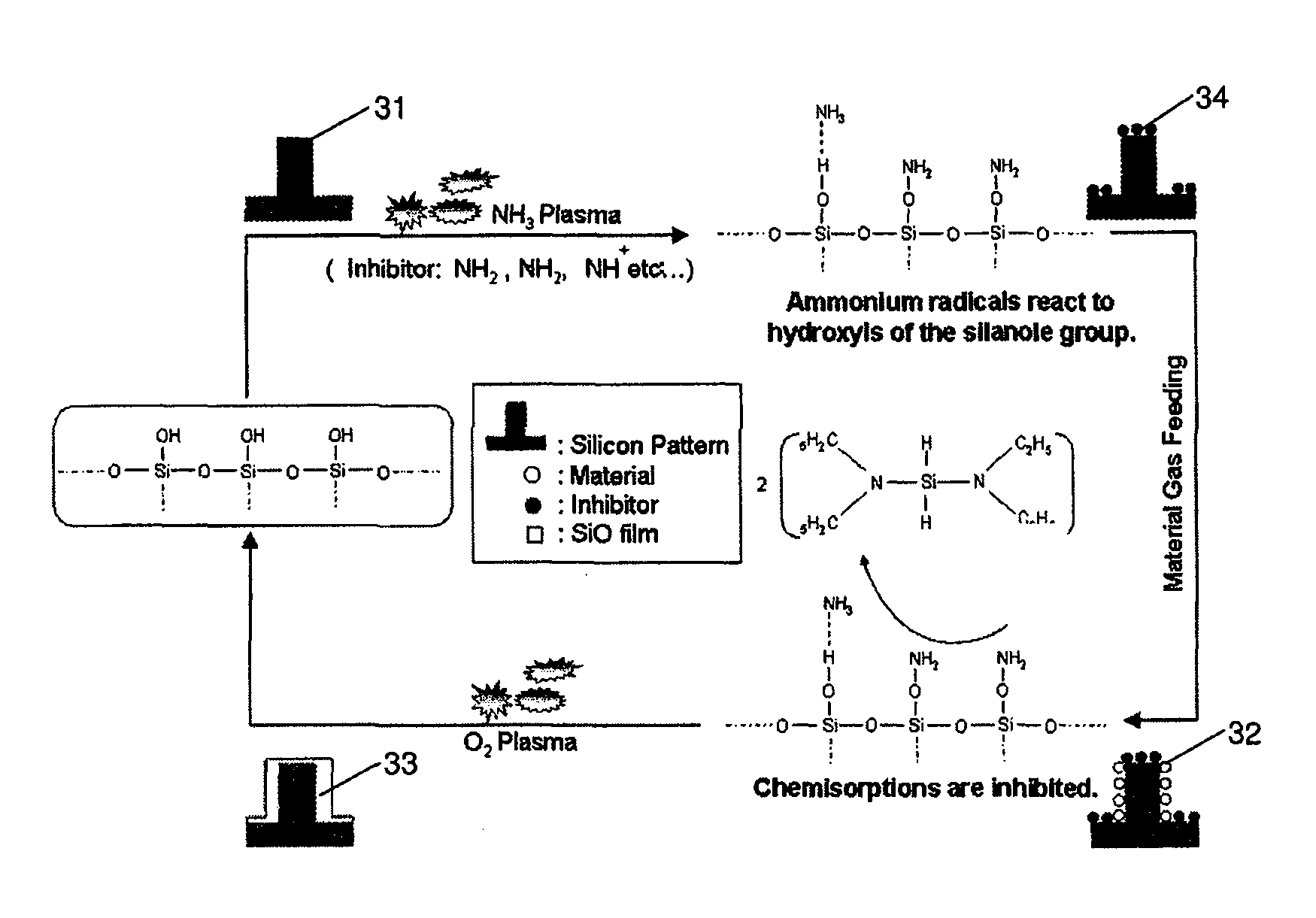

InactiveUS20090041952A1Semiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingOxygen plasmaGas phase

Methods of depositing a silicon oxide film are disclosed. One embodiment is a plasma enhanced atomic layer deposition (PEALD) process that includes supplying a vapor phase silicon precursor, such as a diaminosilane compound, to a substrate, and supplying oxygen plasma to the substrate. Another embodiment is a pulsed hybrid method between atomic layer deposition (ALD) and chemical vapor deposition (CVD). In the other embodiment, a vapor phase silicon precursor, such as a diaminosilane compound, is supplied to a substrate while ozone gas is continuously or discontinuously supplied to the substrate.

Owner:ASM KOREA LTD

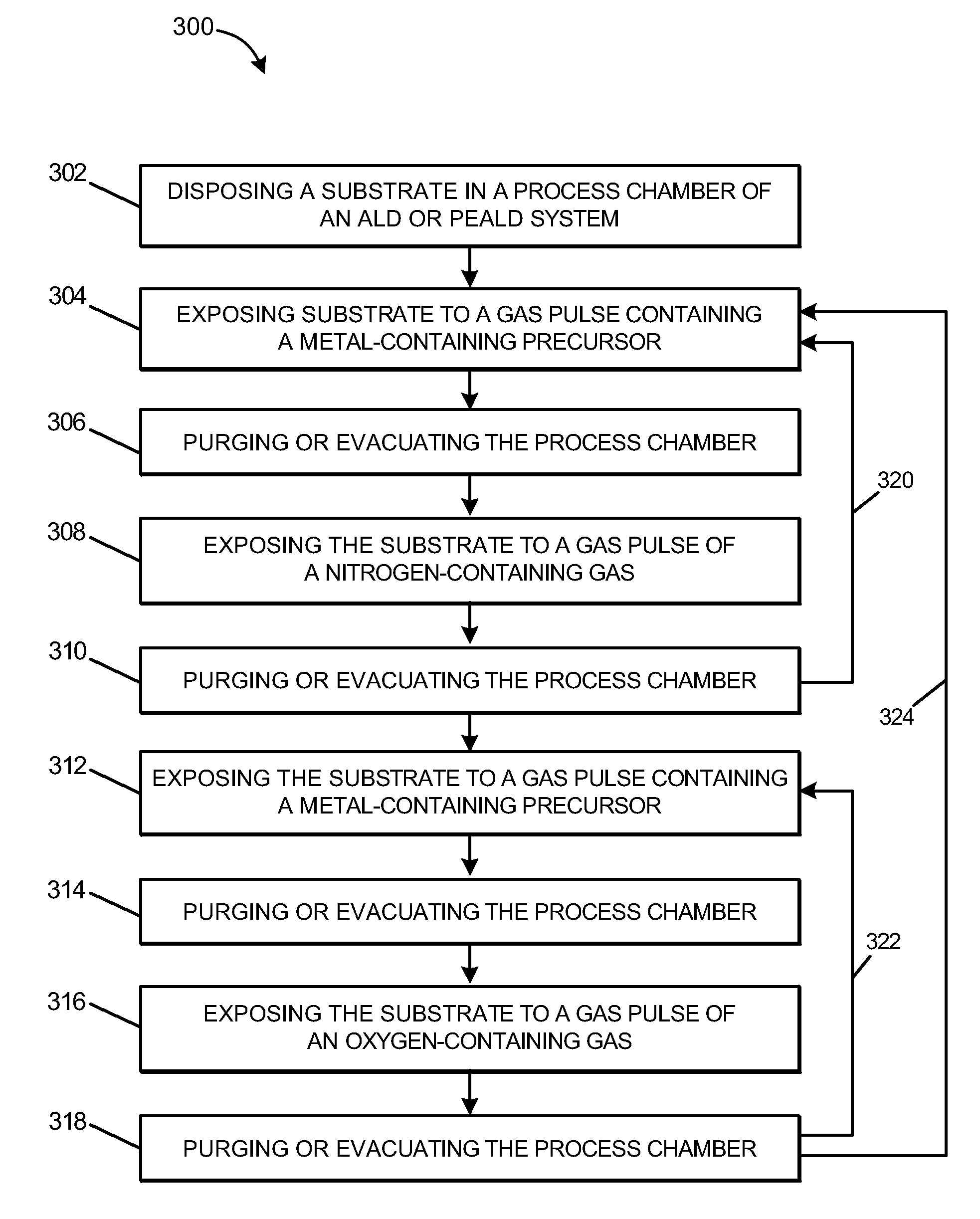

Method of forming mixed rare earth oxide and aluminate films by atomic layer deposition

InactiveUS20070237697A1Rare earth metal compoundsChemical vapor deposition coatingAluminiumAluminate

A method is provided for depositing a gate dielectric that includes at least two rare earth metal elements in the form of an oxide or an aluminate. The method includes disposing a substrate in a process chamber and exposing the substrate to a gas pulse containing a first rare earth precursor and to a gas pulse containing a second rare earth precursor. The substrate may also optionally be exposed to a gas pulse containing an aluminum precursor. Sequentially after each precursor gas pulse, the substrate is exposed to a gas pulse of an oxygen-containing gas. In alternative embodiments, the first and second rare earth precursors may be pulsed together, and either or both may be pulsed together with the aluminum precursor. The first and second rare earth precursors comprise a different rare earth metal element. The sequential exposing steps may be repeated to deposit a mixed rare earth oxide or aluminate layer with a desired thickness. Purge or evacuation steps may also be performed after each gas pulse.

Owner:TOKYO ELECTRON LTD

Nitrogen profile engineering in nitrided high dielectric constant films

InactiveUS20080081113A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingRare-earth elementNitrogen

A method of forming a nitrided high-k film by disposing a substrate in a process chamber and forming the nitrided high-k film on the substrate by a) depositing a nitrogen-containing film, and b) depositing an oxygen-containing film, wherein steps a) and b) are performed in any order, any number of times, so as to oxidize at least a portion of the thickness of the nitrogen-containing film. The oxygen-containing film and the nitrogen-containing film contain the same one or more metal elements selected from alkaline earth elements, rare earth elements, and Group IVB elements of the Periodic Table, and optionally aluminum, silicon, or aluminum and silicon. According to one embodiment, the method includes forming a nitrided hafnium based high-k film. The nitrided high-k film can be formed by atomic layer deposition (ALD) or plasma-enhanced ALD (PEALD).

Owner:TOKYO ELECTRON LTD

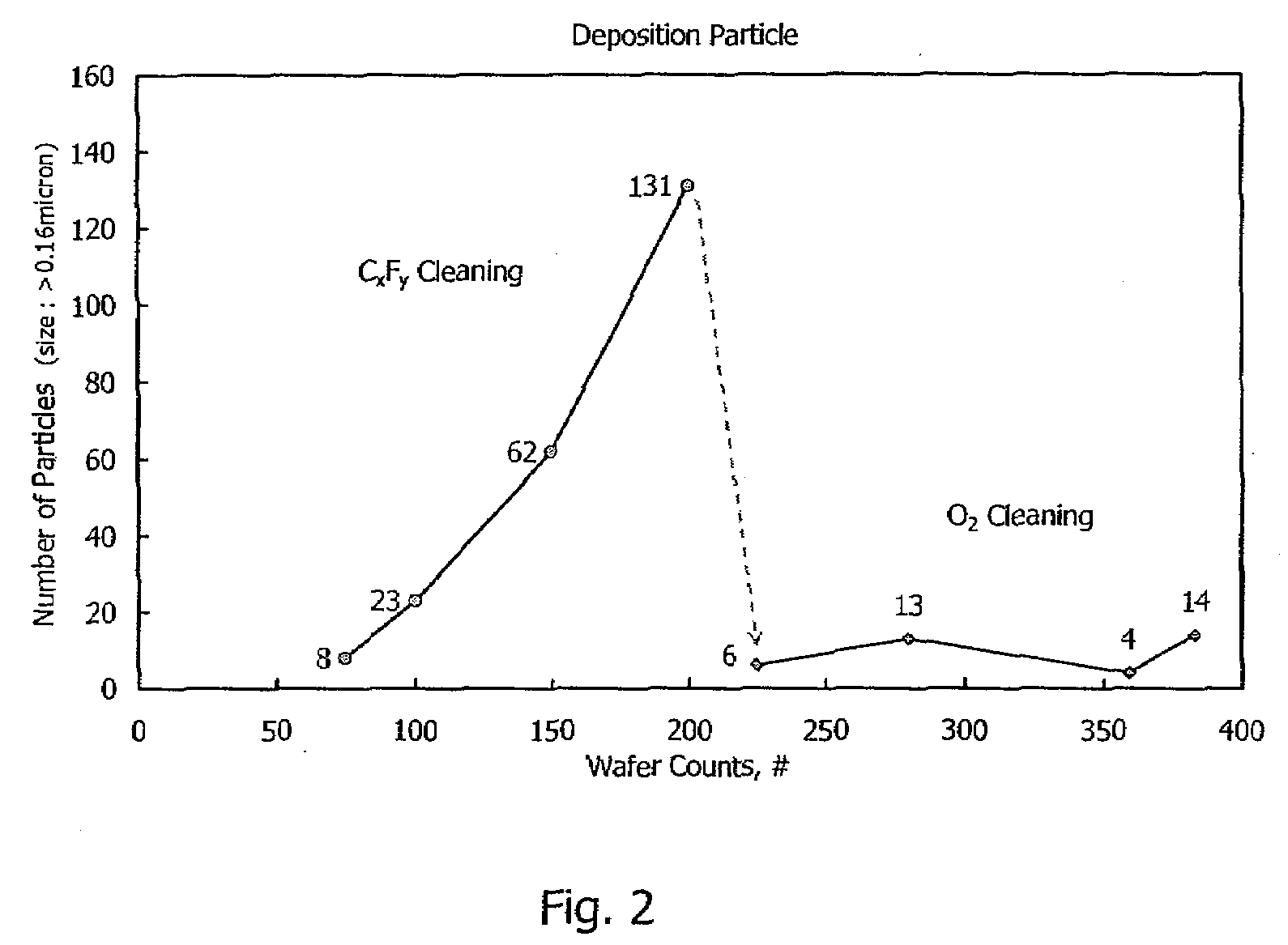

Method of self-cleaning of carbon-based film

InactiveUS20070248767A1Hollow article cleaningVacuum evaporation coatingNitrogen oxidePlasma reactor

A method of self-cleaning a plasma reactor upon depositing a carbon-based film on a substrate a pre-selected number of times, includes: (i) exciting oxygen gas and / or nitrogen oxide gas to generate a plasma; and (ii) exposing to the plasma a carbon-based film accumulated on an upper electrode provided in the reactor and a carbon-based film accumulated on an inner wall of the reactor.

Owner:ASM JAPAN

Transition metal complex compound

InactiveUS20080233410A1Solve low luminous efficiencyHigh luminous efficiencyIndium organic compoundsThin material handlingOrganic electroluminescenceMonolayer

The present invention provides a transition metal complex compound of a specific structure having a metal carbene bond, a production process for the same and an organic EL device in which an organic thin film layer comprising a single layer or plural layers having at least a luminescent layer is interposed between an anode and a cathode, wherein at least one layer in the above organic thin film layers contains the transition metal complex compound having a metal carbene bond described above. Provided are a novel transition metal complex compound having a metal carbene bond which has an electroluminescent characteristic and which can provide an organic electroluminescent device having a high luminous efficiency and a production process for a transition metal complex compound.

Owner:IDEMITSU KOSAN CO LTD +1

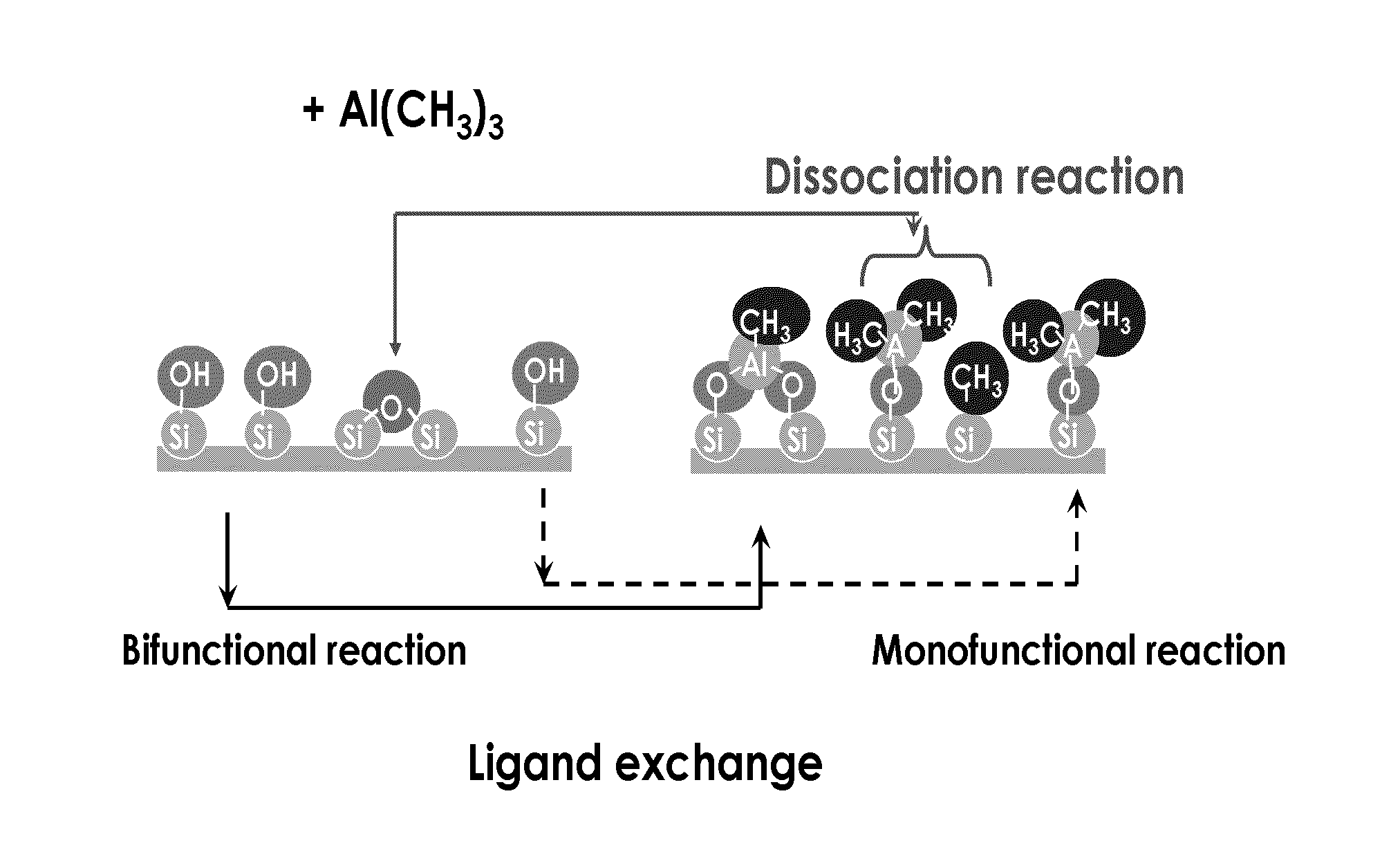

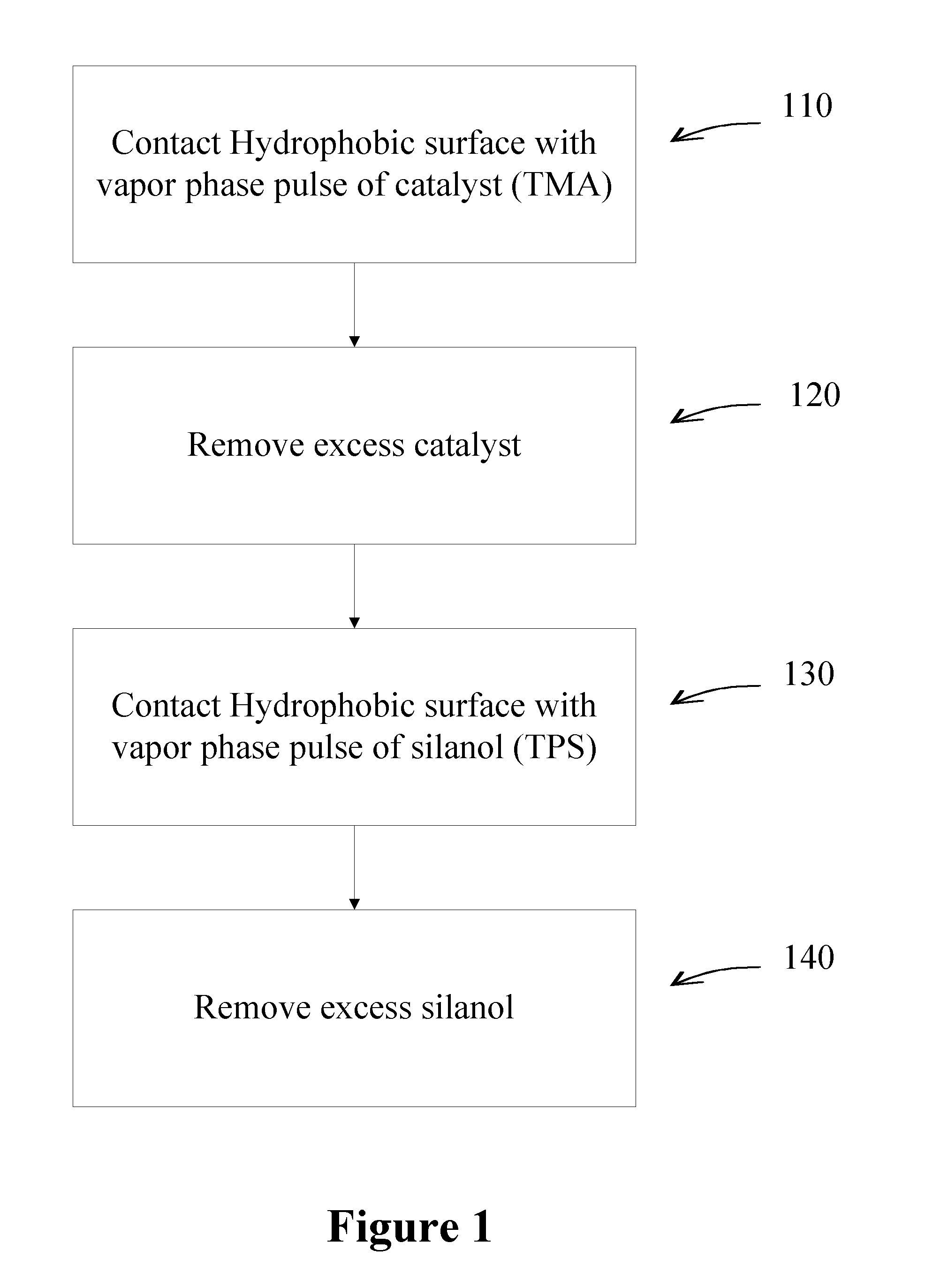

Deposition of silicon dioxide on hydrophobic surfaces

InactiveUS20120263876A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilanolSilicon dioxide

Methods for forming silicon dioxide thin films on hydrophobic surfaces are provided. For example, in some embodiments, silicon dioxide films are deposited on porous, low-k materials. The silicon dioxide films can be deposited using a catalyst and a silanol. In some embodiments, an undersaturated dose of one or more of the reactants can be used in forming a pore-sealing layer over a porous material.

Owner:ASM IP HLDG BV

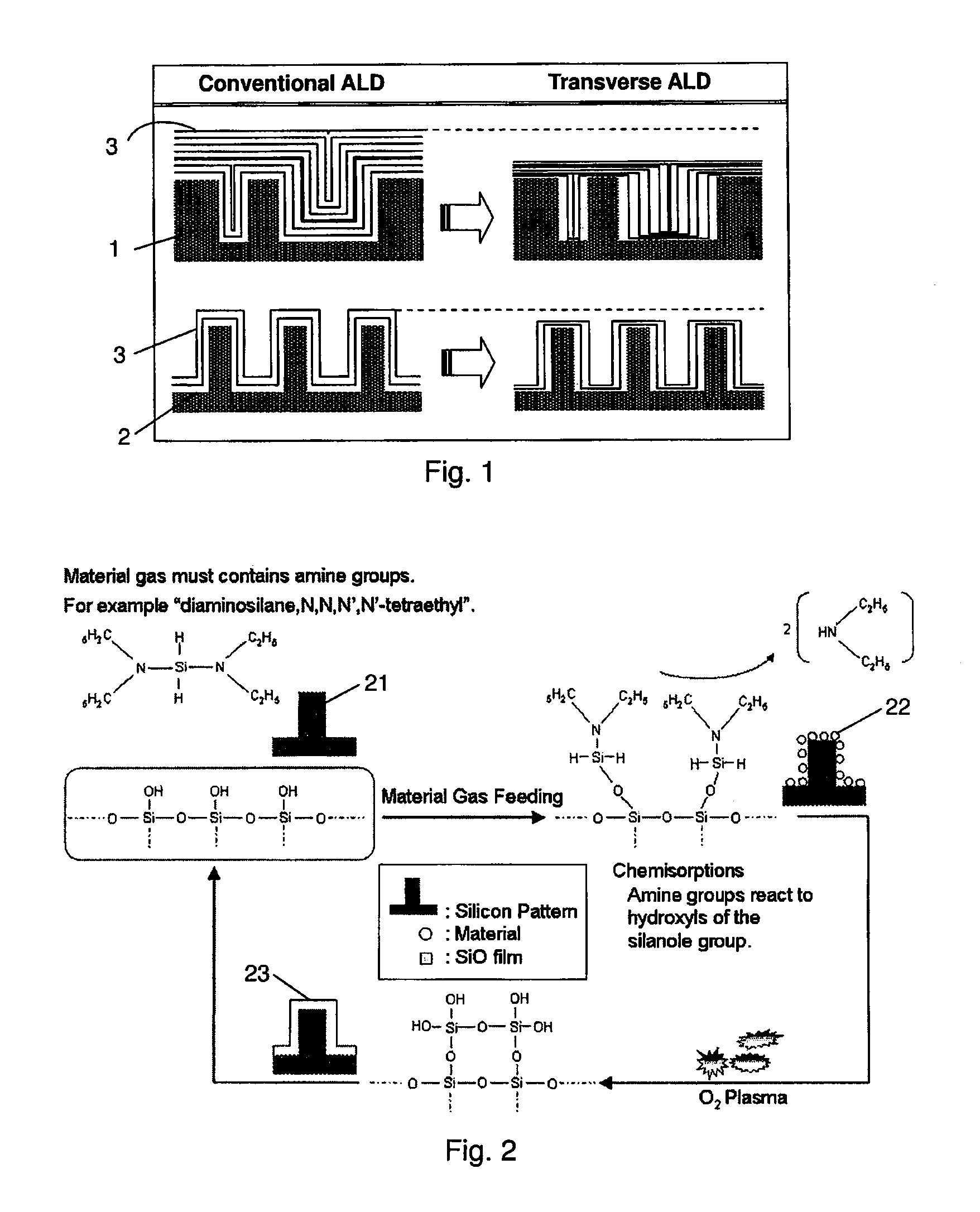

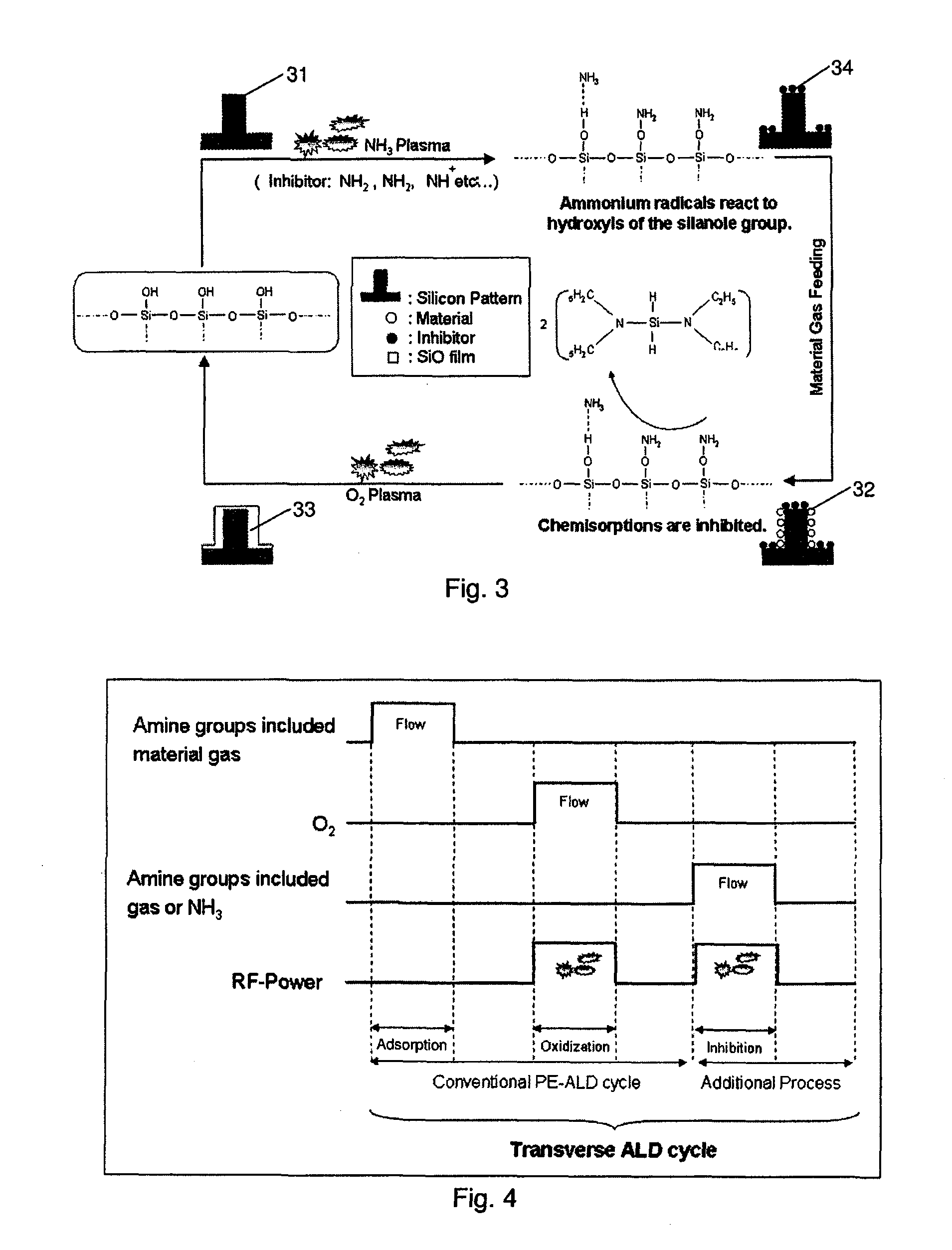

Atomic layer deposition for controlling vertical film growth

ActiveUS8592005B2Improve directionVacuum evaporation coatingSputtering coatingPhysical chemistryThin membrane

Owner:ASM JAPAN

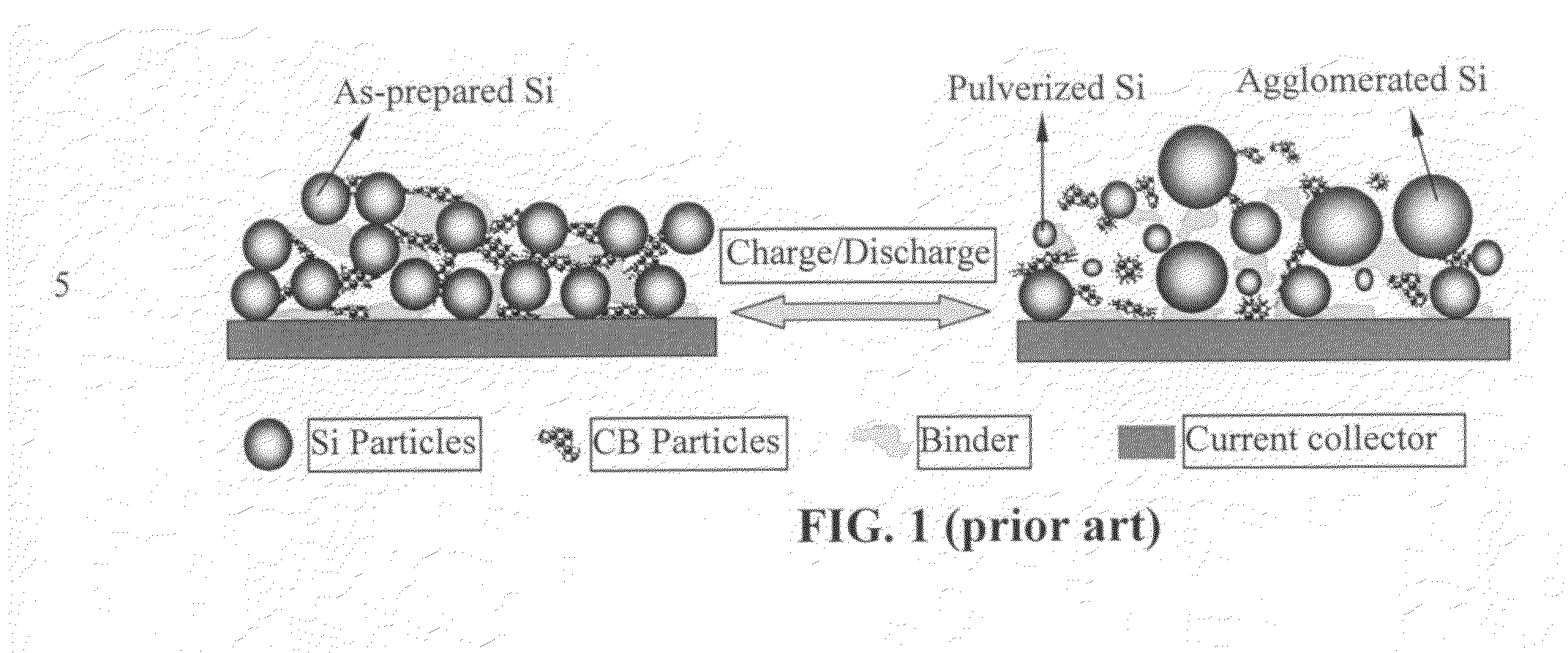

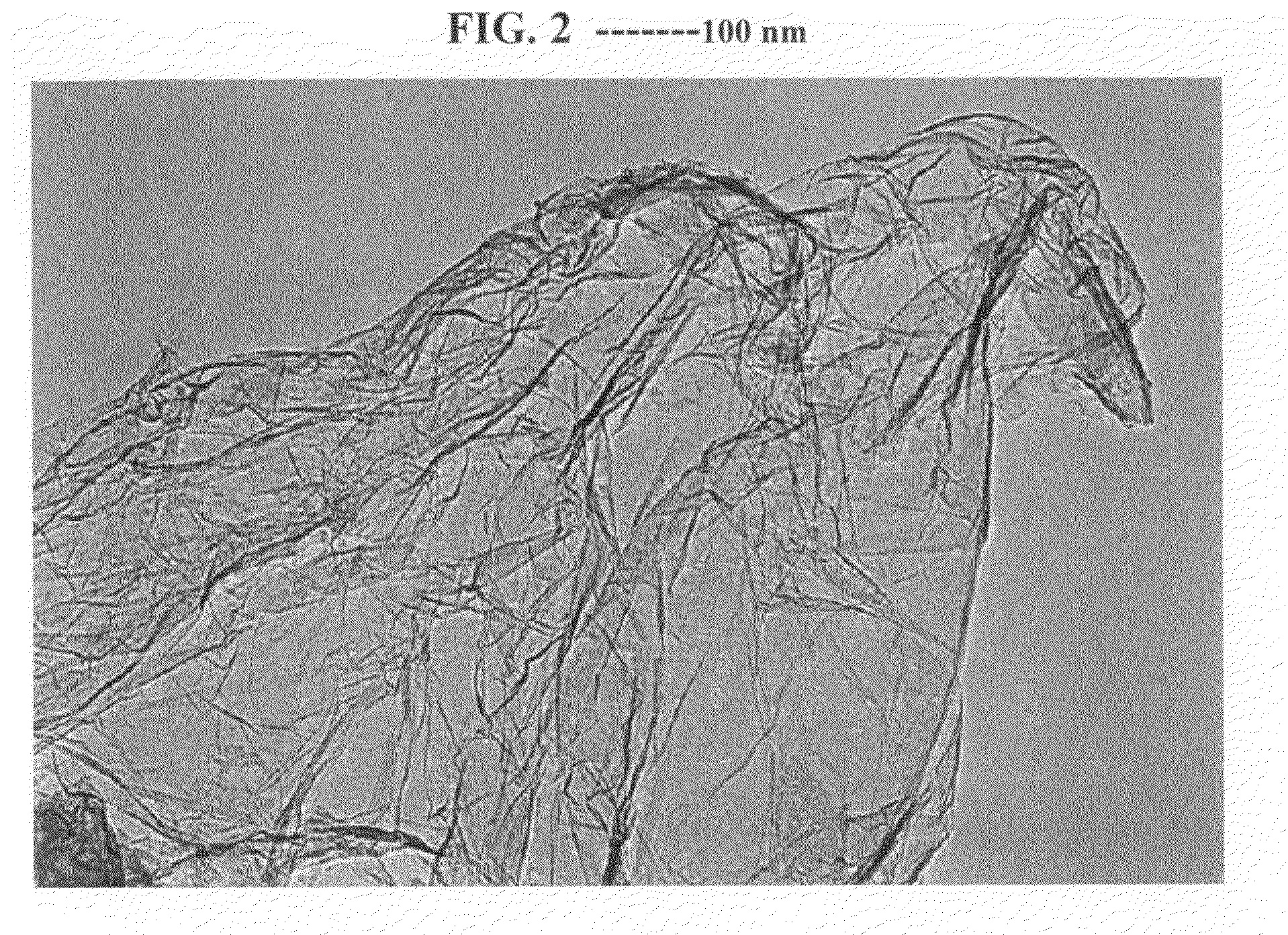

Nano graphene platelet-based composite anode compositions for lithium ion batteries

ActiveUS20090117467A1Improve conductivityLower internal resistanceElectrolytic capacitorsSecondary cellsGraphene flakeGraphite

The present invention provides a nano-scaled graphene platelet-based composite material composition for use as an electrode, particularly as an anode of a lithium ion battery. The composition comprises: (a) micron- or nanometer-scaled particles or coating which are capable of absorbing and desorbing lithium ions; and (b) a plurality of nano-scaled graphene platelets (NGPs), wherein a platelet comprises a graphene sheet or a stack of graphene sheets having a platelet thickness less than 100 nm; wherein at least one of the particles or coating is physically attached or chemically bonded to at least one of the graphene platelets and the amount of platelets is in the range of 2% to 90% by weight and the amount of particles or coating in the range of 98% to 10% by weight. Also provided is a lithium secondary battery comprising such a negative electrode (anode). The battery exhibits an exceptional specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for packing solid organometallic compound and packed container

InactiveUS20070175397A1Ensure supply stabilityStable supplyChemical vapor deposition coatingThin material handlingCompound (substance)Vapor phase

A method for packing a solid organometallic compound into a container for packing the compound is provided, wherein the solid organometallic compound can be stably supplied to a vapor phase epitaxial growth apparatus such as an MOCVD apparatus at a constant concentration for a long period of time. In the method for packing a solid organometallic compound into a container for packing, the compound is composed of grains having a grain size of 8 mm or less and the grains of the compound essentially comprise grains having a grain size of 2.5 to 6 mm.

Owner:TOSOH FINECHEM CORP

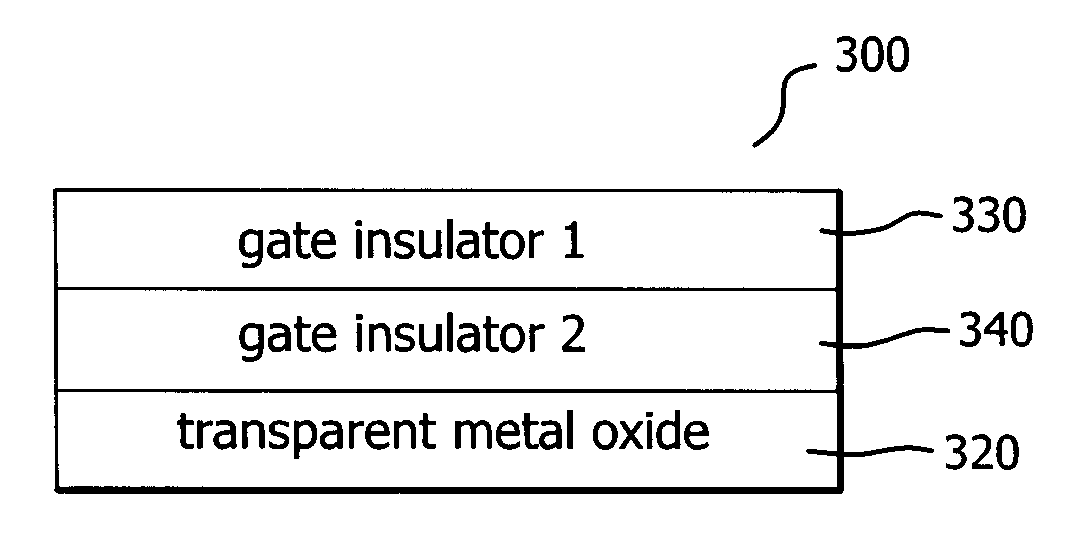

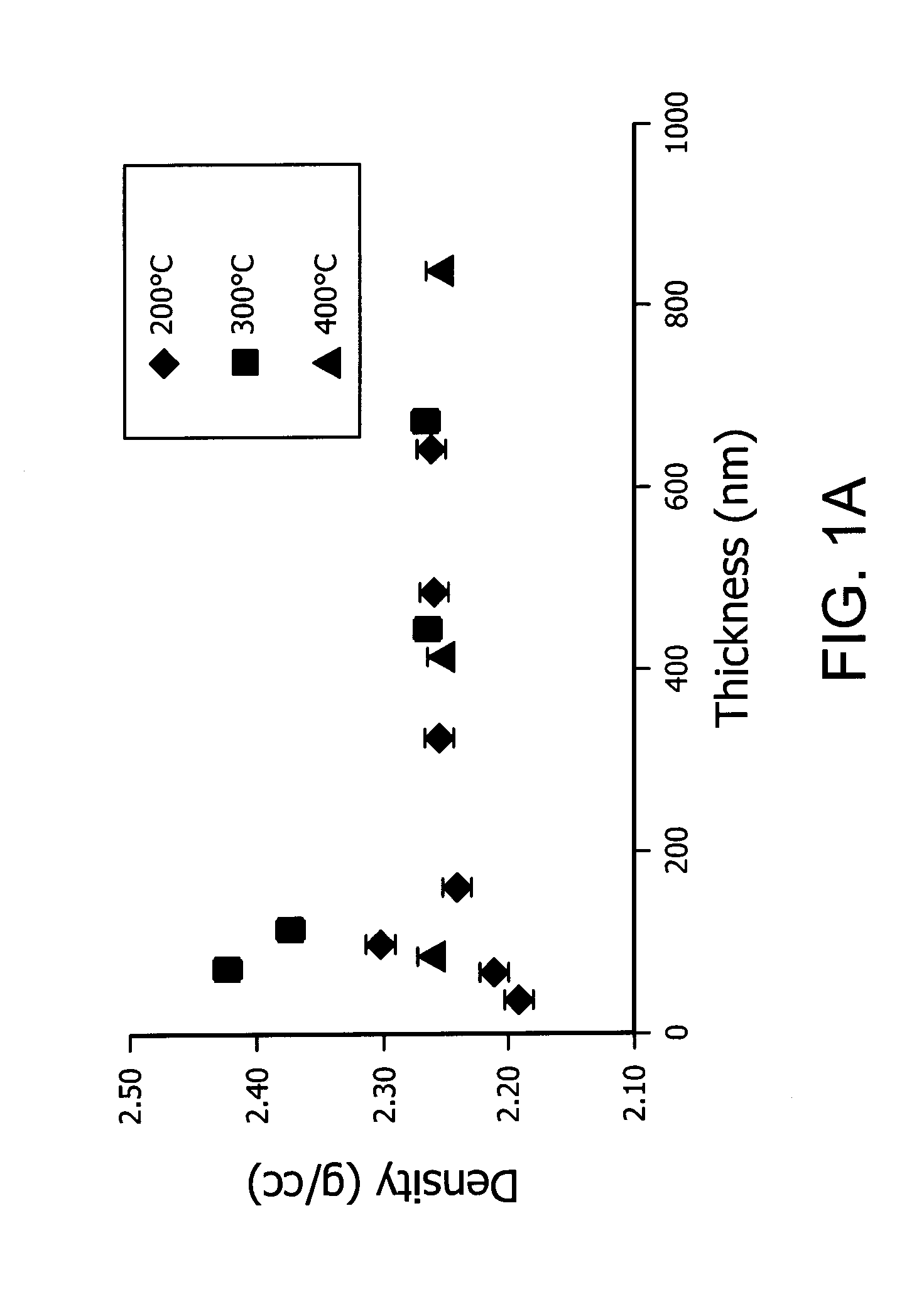

Compositions and methods for making silicon containing films

ActiveUS20150014823A1Semiconductor/solid-state device detailsSolid-state devicesTriethylsilaneDeposition process

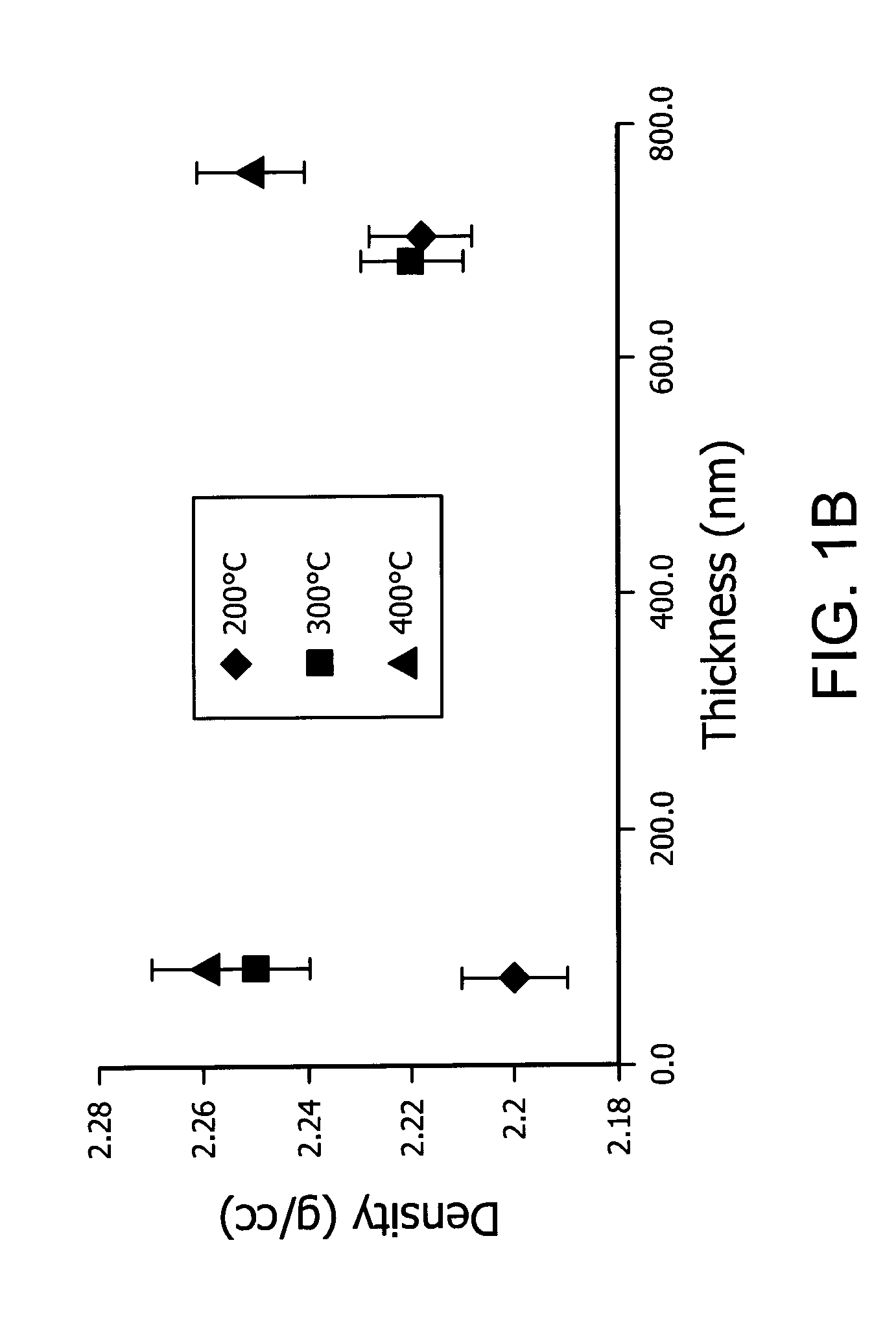

Described herein are low temperature processed high quality silicon containing films. Also disclosed are methods of forming silicon containing films at low temperatures. In one aspect, there are provided silicon-containing film having a thickness of about 2 nm to about 200 nm and a density of about 2.2 g / cm3 or greater wherein the silicon-containing thin film is deposited by a deposition process selected from a group consisting of chemical vapor deposition (CVD), plasma enhanced chemical vapor deposition (PECVD), cyclic chemical vapor deposition (CCVD), plasma enhanced cyclic chemical vapor deposition (PECCVD, atomic layer deposition (ALD), and plasma enhanced atomic layer deposition (PEALD), and the vapor deposition is conducted at one or more temperatures ranging from about 25° C. to about 400° C. using an alkylsilane precursor selected from the group consisting of diethylsilane, triethylsilane, and combinations thereof.

Owner:VERSUM MATERIALS US LLC

Method for Growing a Monocrystalline Tin-Containing Semiconductor Material

InactiveUS20140020619A1Efficiently provideEfficient methodPolycrystalline material growthAdditive manufacturing apparatusSemiconductor materialsPhysical chemistry

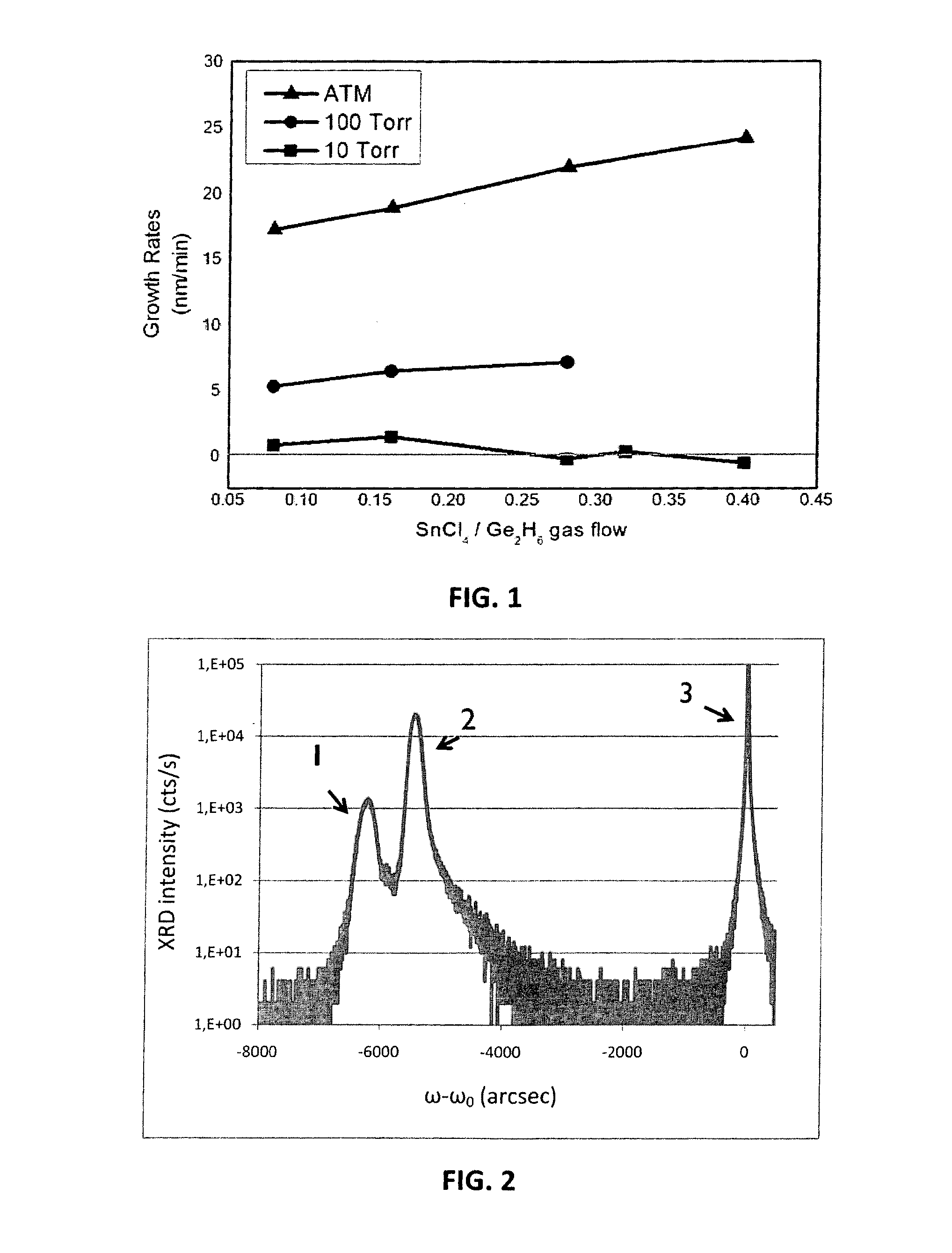

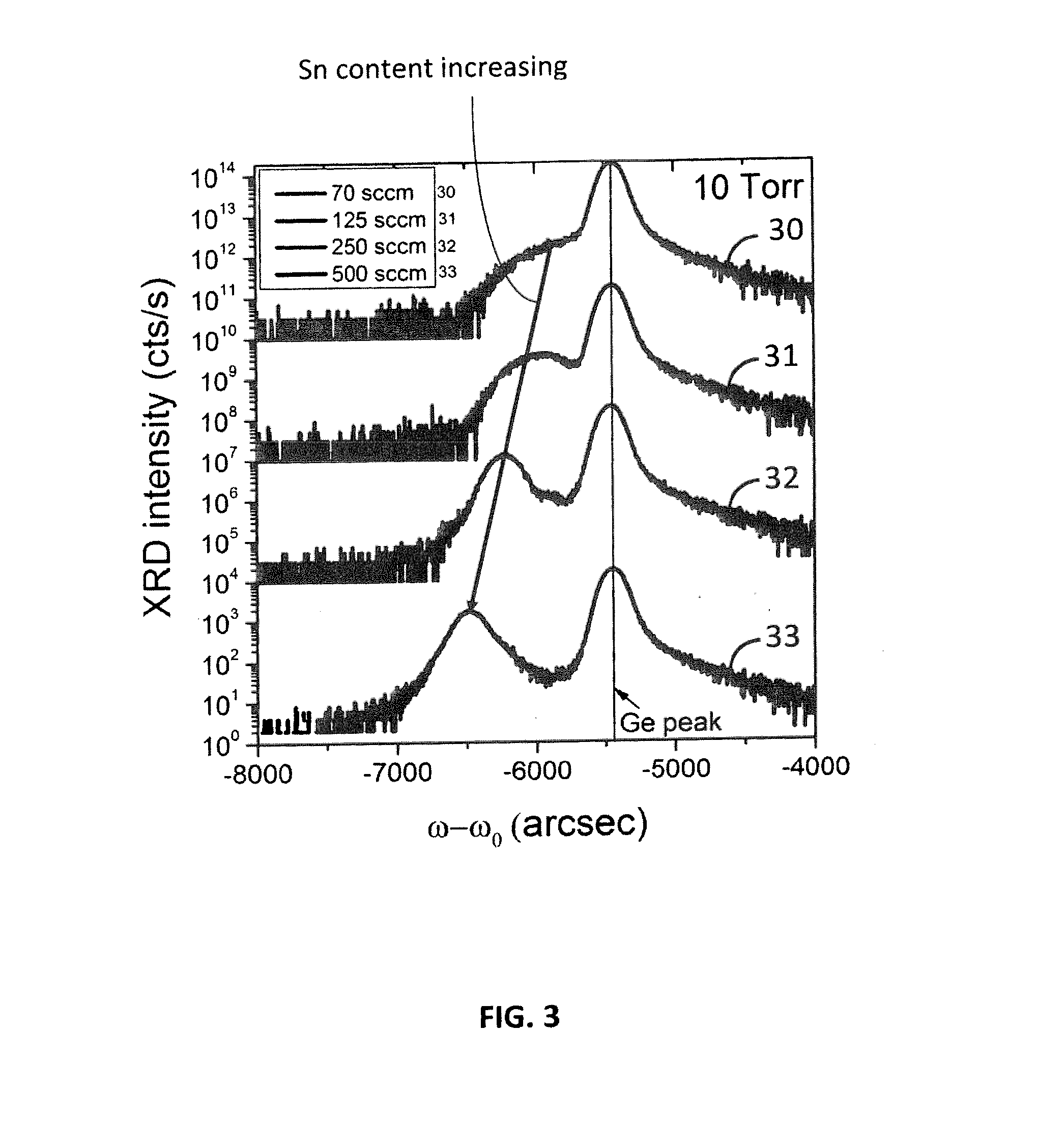

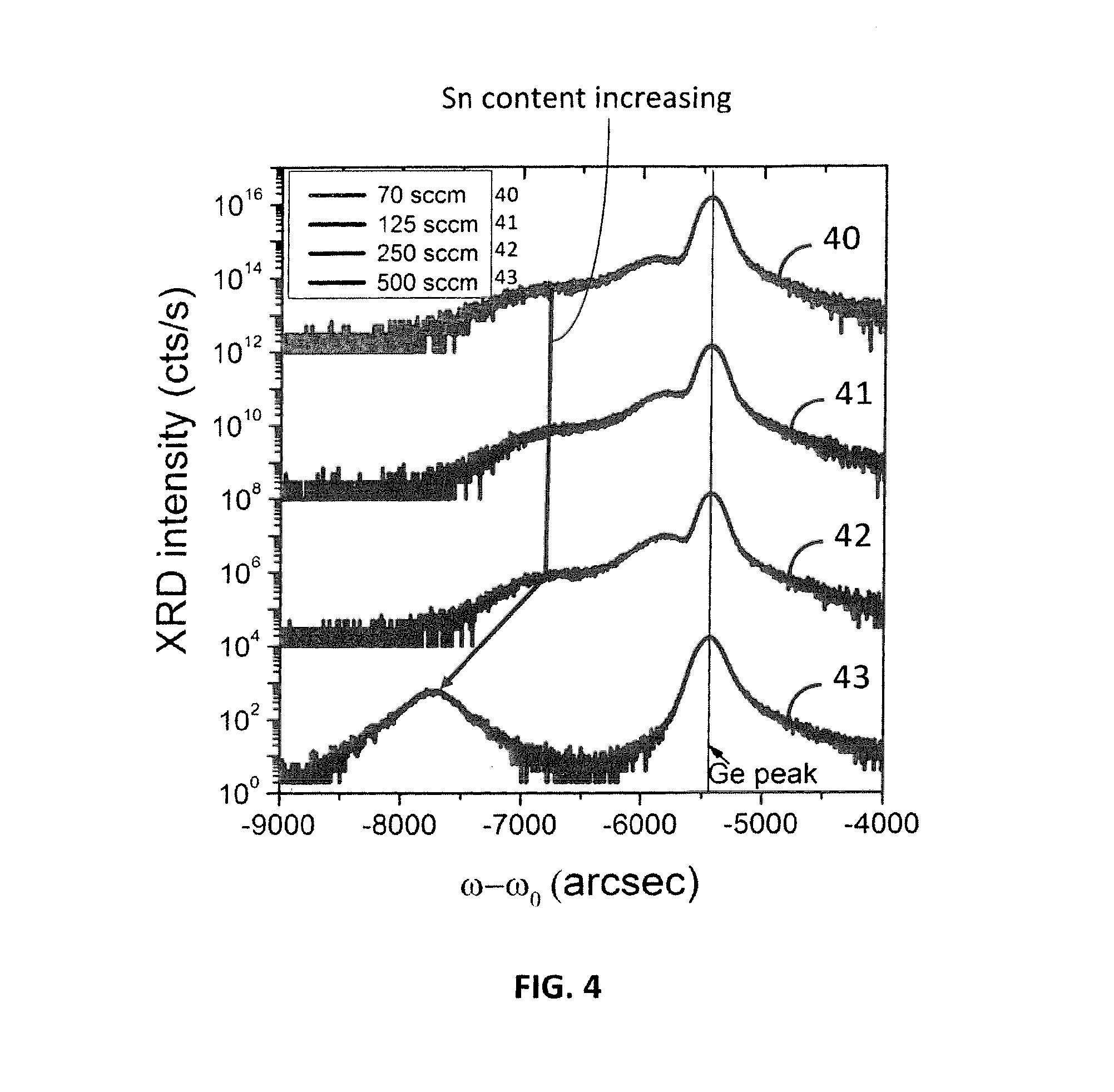

Disclosed are methods for growing Sn-containing semiconductor materials. In some embodiments, an example method includes providing a substrate in a chemical vapor deposition (CVD) reactor, and providing a semiconductor material precursor, a Sn precursor, and a carrier gas in the CVD reactor. The method further includes epitaxially growing a Sn-containing semiconductor material on the substrate, where the Sn precursor comprises tin tetrachloride (SnCl4). The semiconductor material precursor may be, for example, digermane, trigermane, higher-order germanium precursors, or a combination thereof. Alternatively, the semiconductor material precursor may be a silicon precursor.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW) +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com