Patents

Literature

855 results about "Nitrous oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nitrous oxide, commonly known as laughing gas or nitrous, is a chemical compound, an oxide of nitrogen with the formula N₂O. At room temperature, it is a colourless non-flammable gas, with a slight metallic scent and taste. At elevated temperatures, nitrous oxide is a powerful oxidiser similar to molecular oxygen. It is soluble in water.

Flameless combustor

InactiveUS6019172AEasy to igniteImprove the level ofApparel holdersInsulationCombustorCombustion chamber

A combustor method and apparatus is provided. The method utilizes flameless combustion with one or more of three improvements to enhance ignition of the flameless combustor. A catalytic surface can be provided within a combustion chamber to provide flameless combustion at least in the vicinity of the catalytic surface at a temperature that is much lower than the autoignition temperature of fuel in air without the presence of the catalytic surface. Nitrous oxide or supplemental oxygen may also be used as an oxidant either instead of air or with air to reduce ignition temperatures. Further, electrical energy can be passed through the fuel conduit, raising the temperature of the conduit to a temperature above which the fuel will ignite when combined with the oxidant.

Owner:SHELL OIL CO

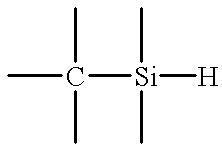

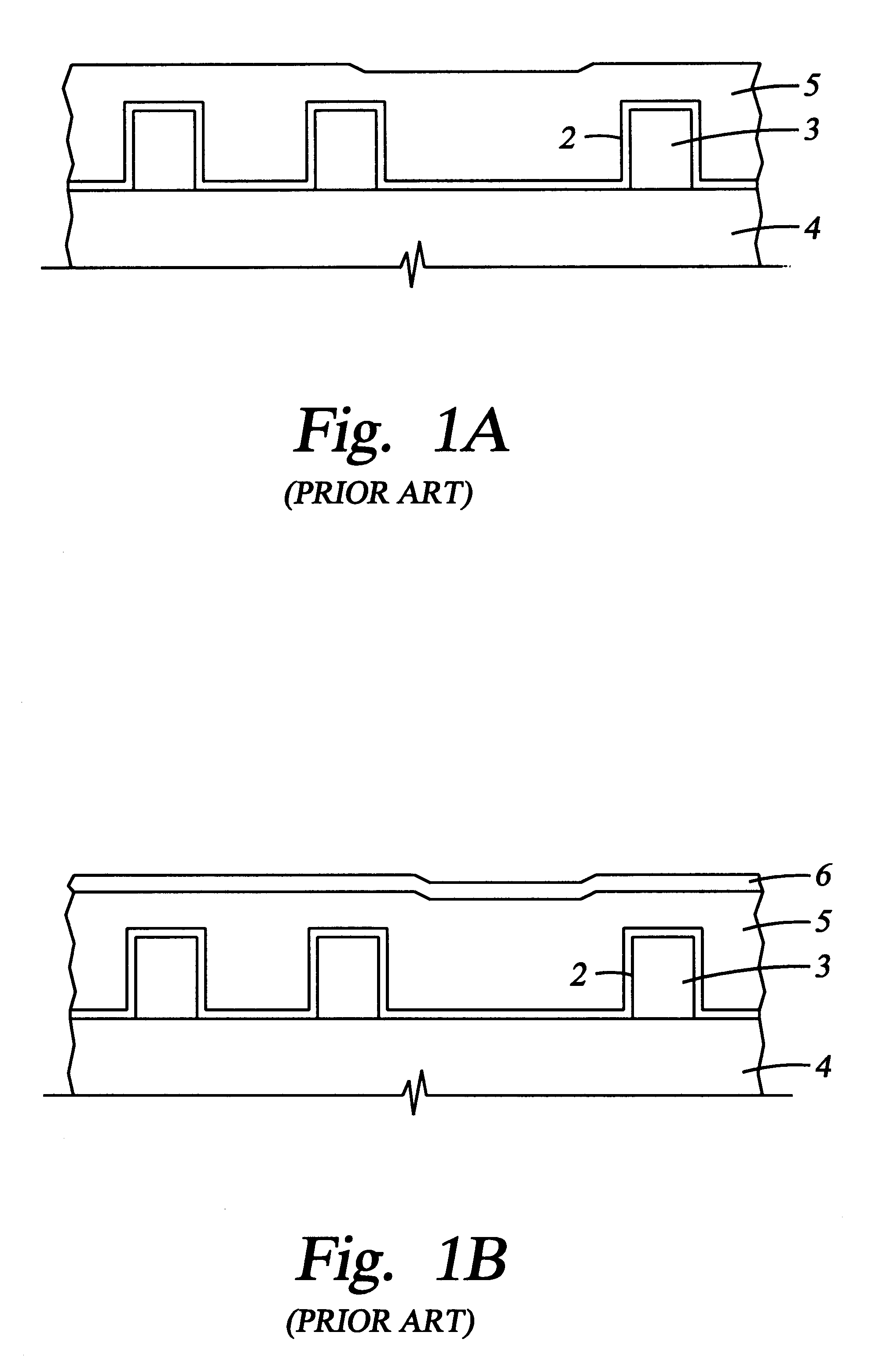

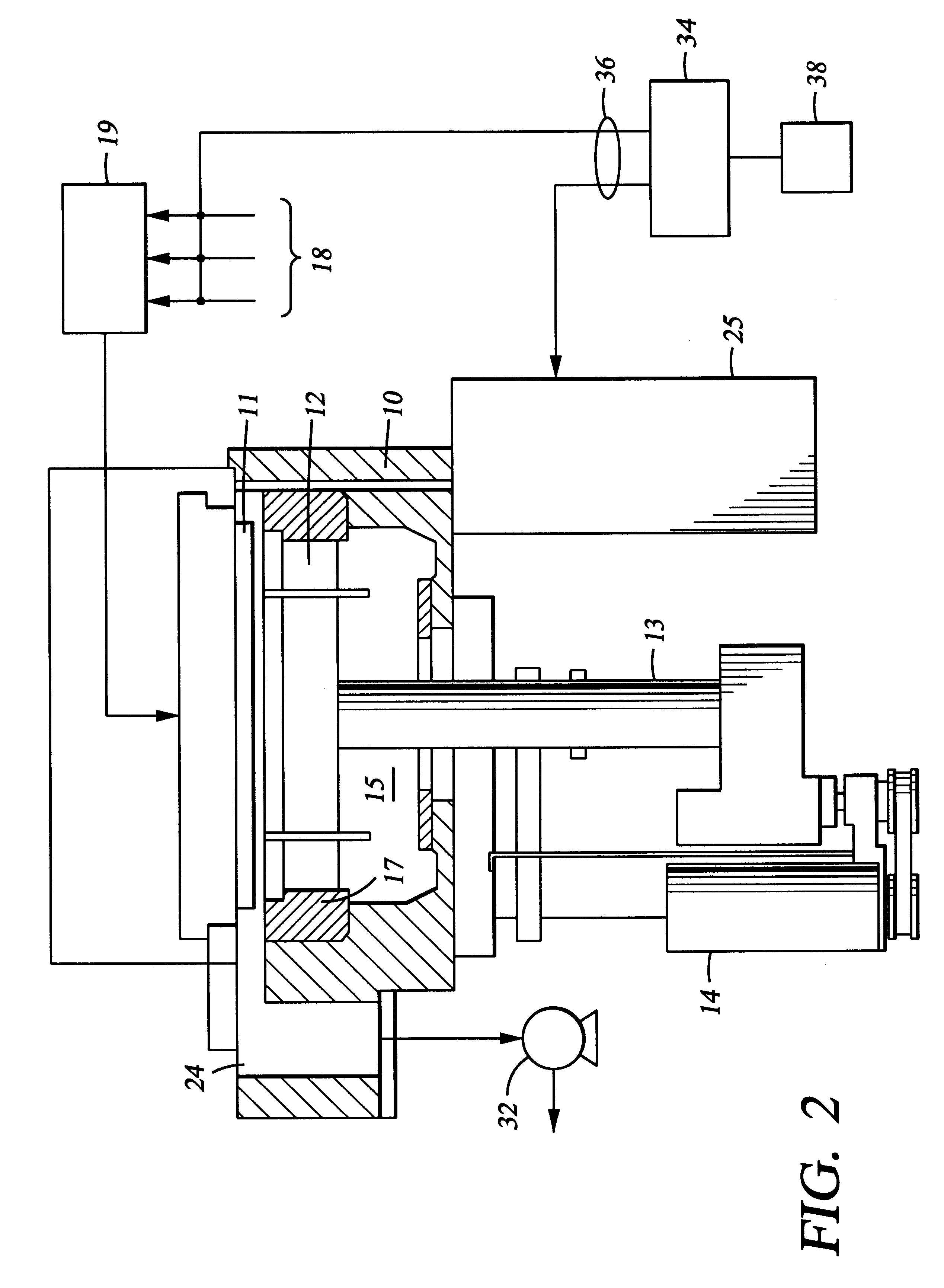

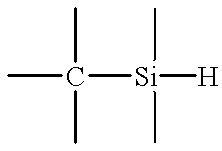

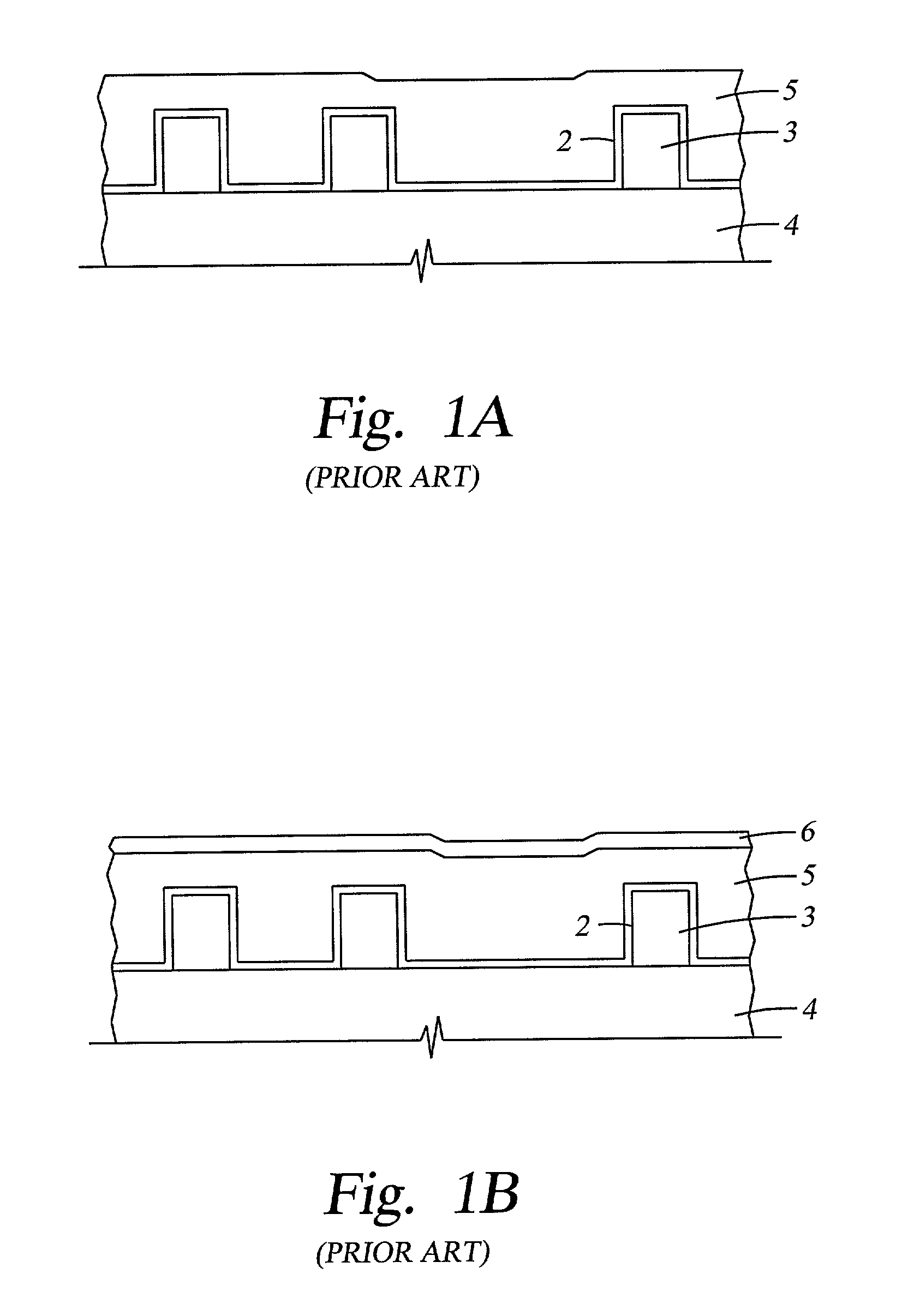

CVD plasma assisted low dielectric constant films

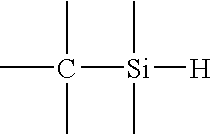

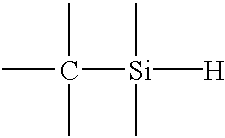

A method and apparatus for depositing a low dielectric constant film by reaction of an organosilane or organosiloxane compound and an oxidizing gas at a low RF power level from 10-250 W. The oxidized organosilane or organosiloxane film has good barrier properties for use as a liner or cap layer adjacent other dielectric layers. The oxidized organosilane or organosiloxane film may also be used as an etch stop or an intermetal dielectric layer for fabricating dual damascene structures. The oxidized organosilane or organosiloxane films also provide excellent adhesion between different dielectric layers. A preferred oxidized organosilane film is produced by reaction of methylsilane, CH3SiH3, or dimethylsilane, (CH3)2SiH2, and nitrous oxide, N2O, at an RF power level from about 10 to 200 W or a pulsed RF power level from about 20 to 250 W during 10-30% of the duty cycle.

Owner:APPLIED MATERIALS INC

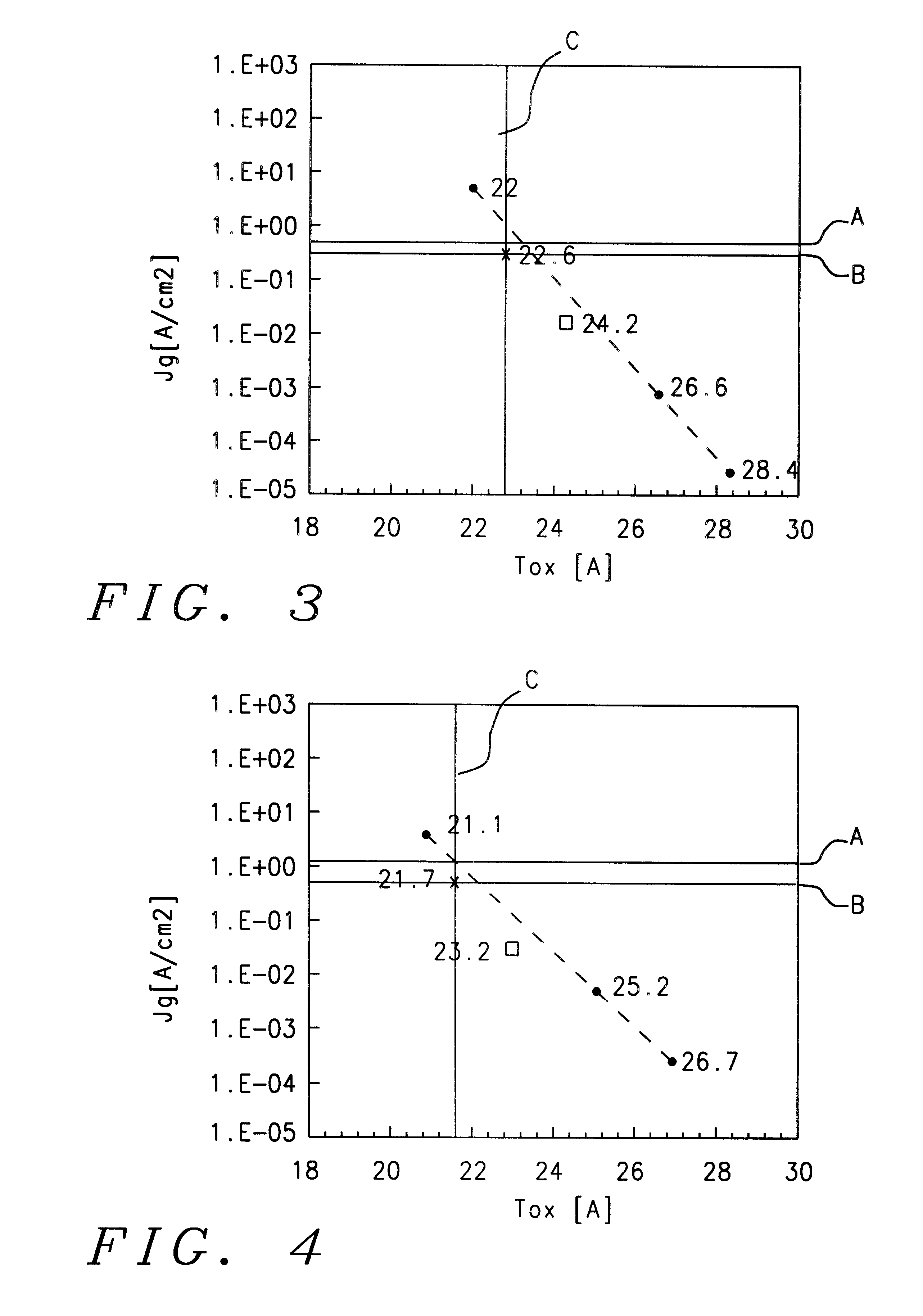

Method of making an ultra thin silicon nitride film

InactiveUS6150286ASemiconductor/solid-state device manufacturingSemiconductor devicesSelf limitingThin oxide

Various methods of fabricating a circuit structure utilizing silicon nitride are provided. In one aspect, a method of fabricating a circuit structure is provided that includes forming a silicon nitride film on a silicon surface, annealing the silicon nitride film in an ammonia ambient and annealing the silicon nitride film in a nitrous oxide ambient to form a thin oxide layer at an interface between the silicon nitride film and the silicon surface. The process of the present invention enables the manufacture of thin silicon nitride films with highly uniform morphology for use as gate dielectrics or other purposes. The thin oxide film is self-limiting in thickness and improves differential mechanical stresses.

Owner:GLOBALFOUNDRIES INC

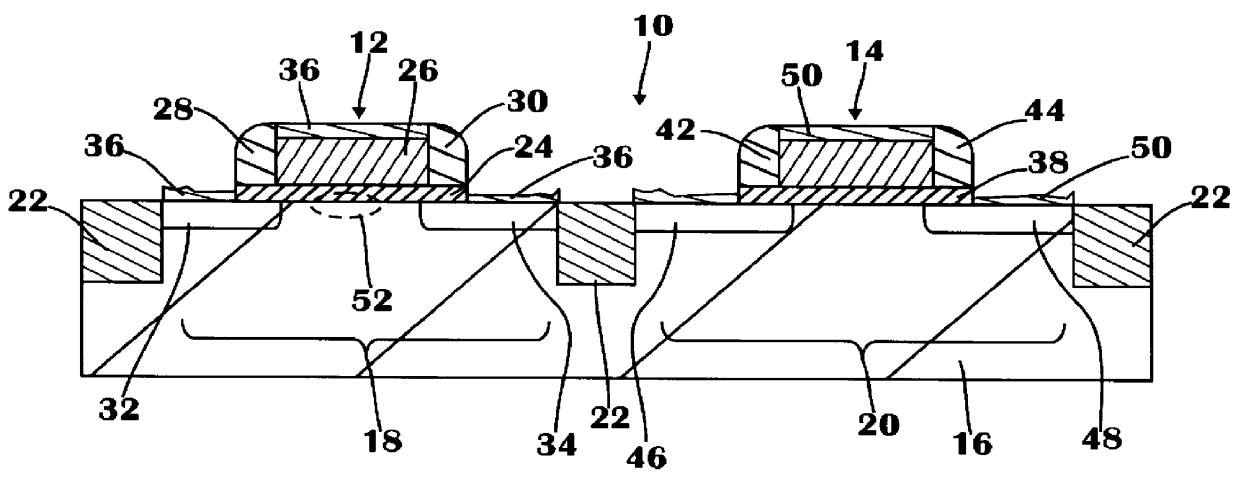

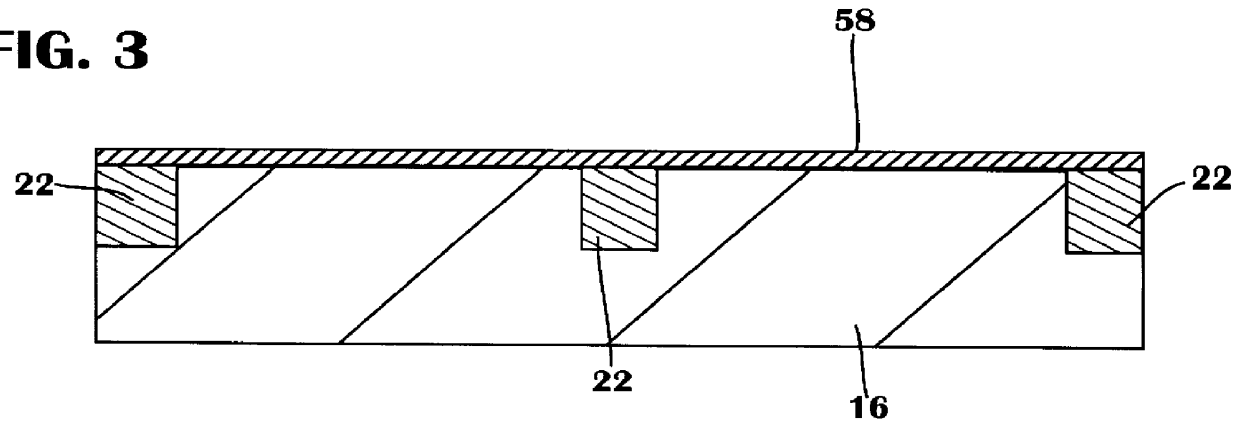

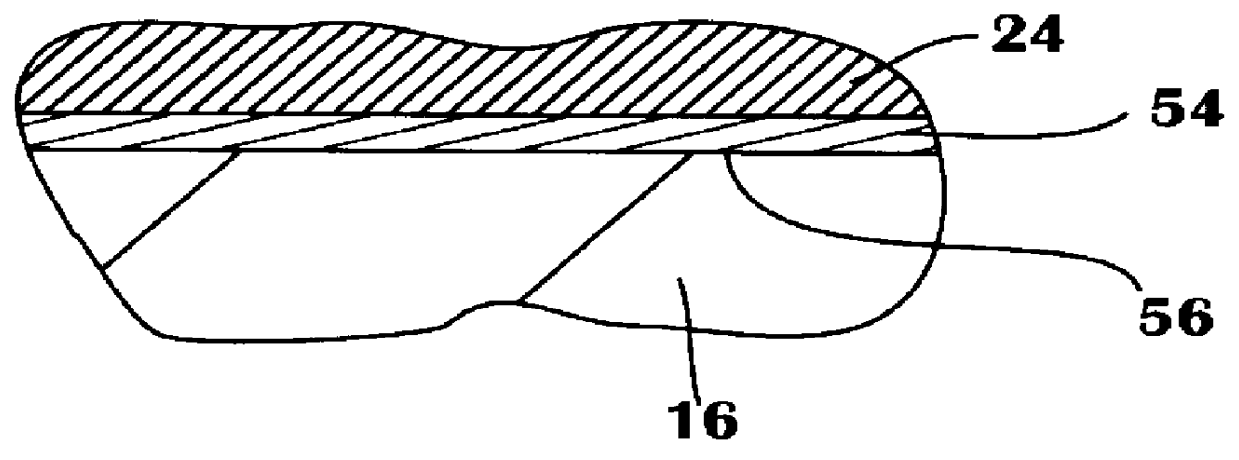

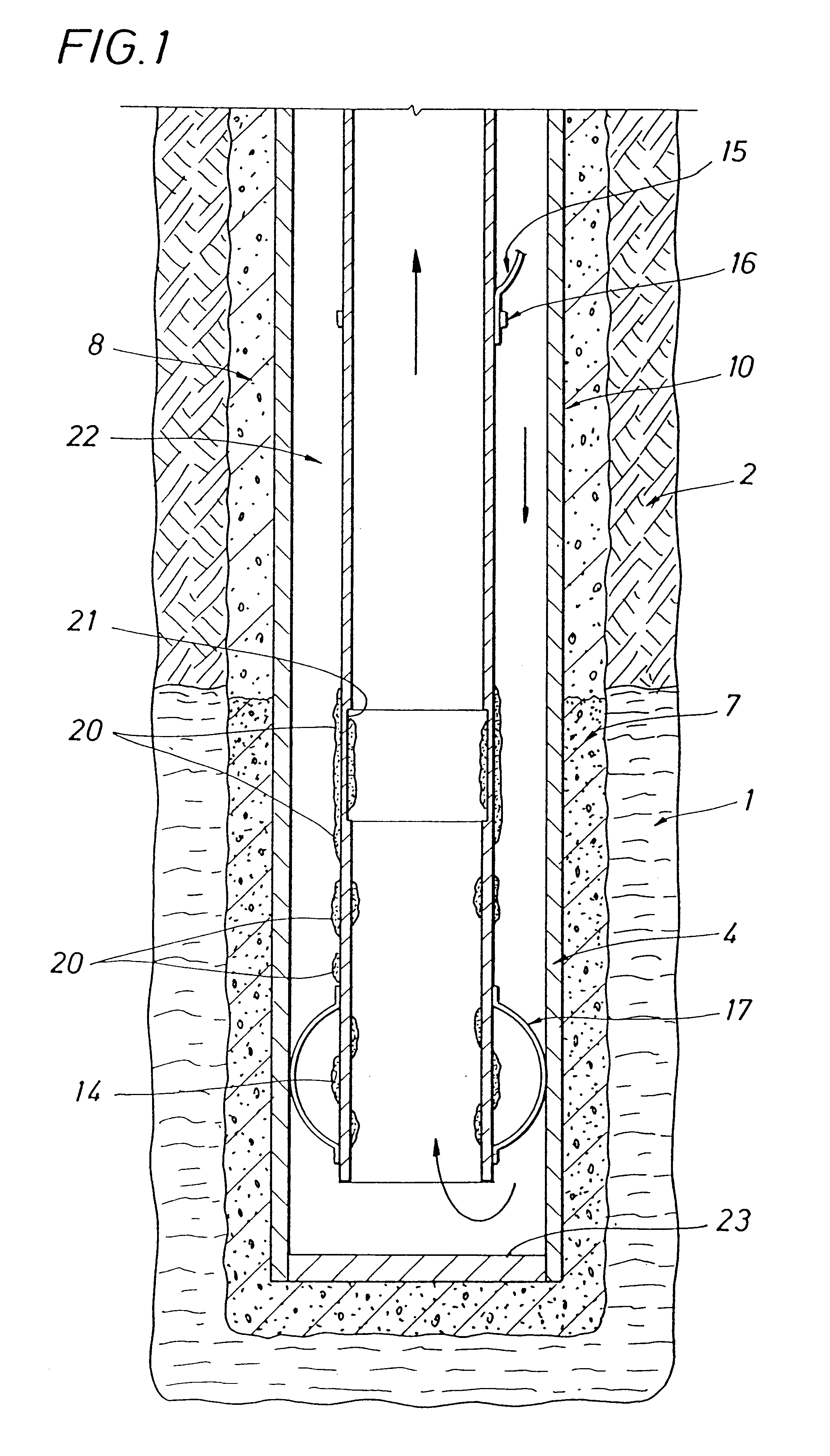

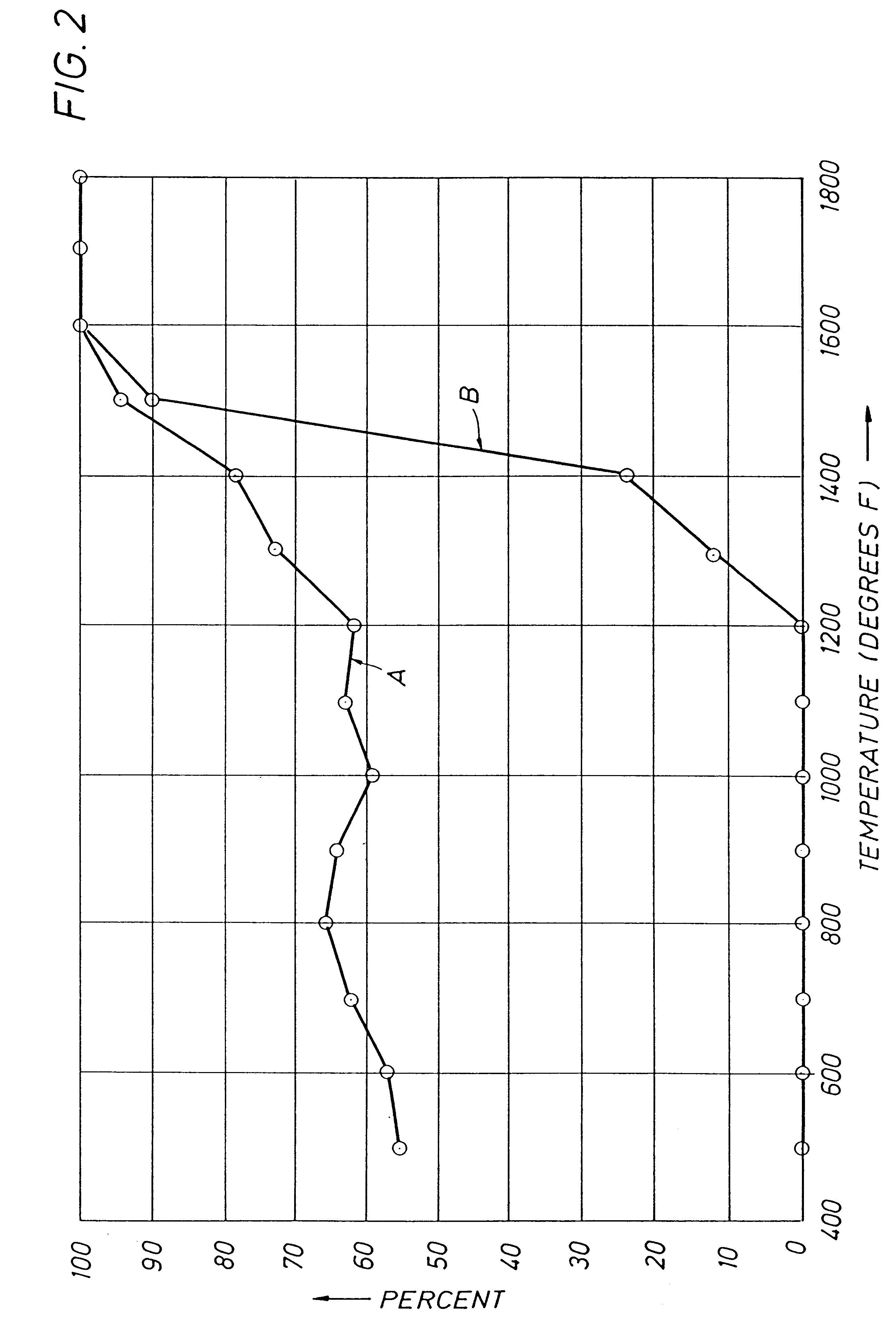

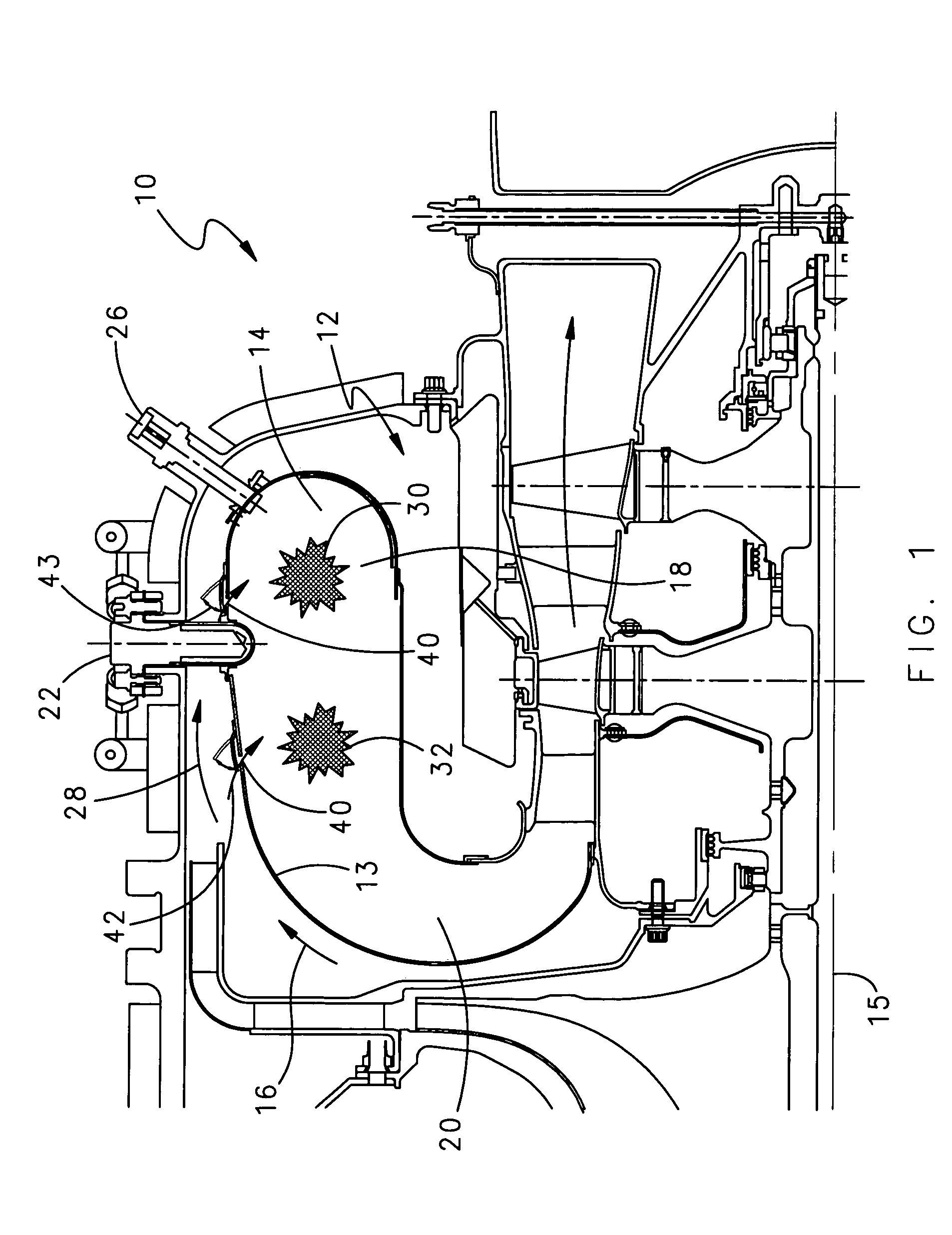

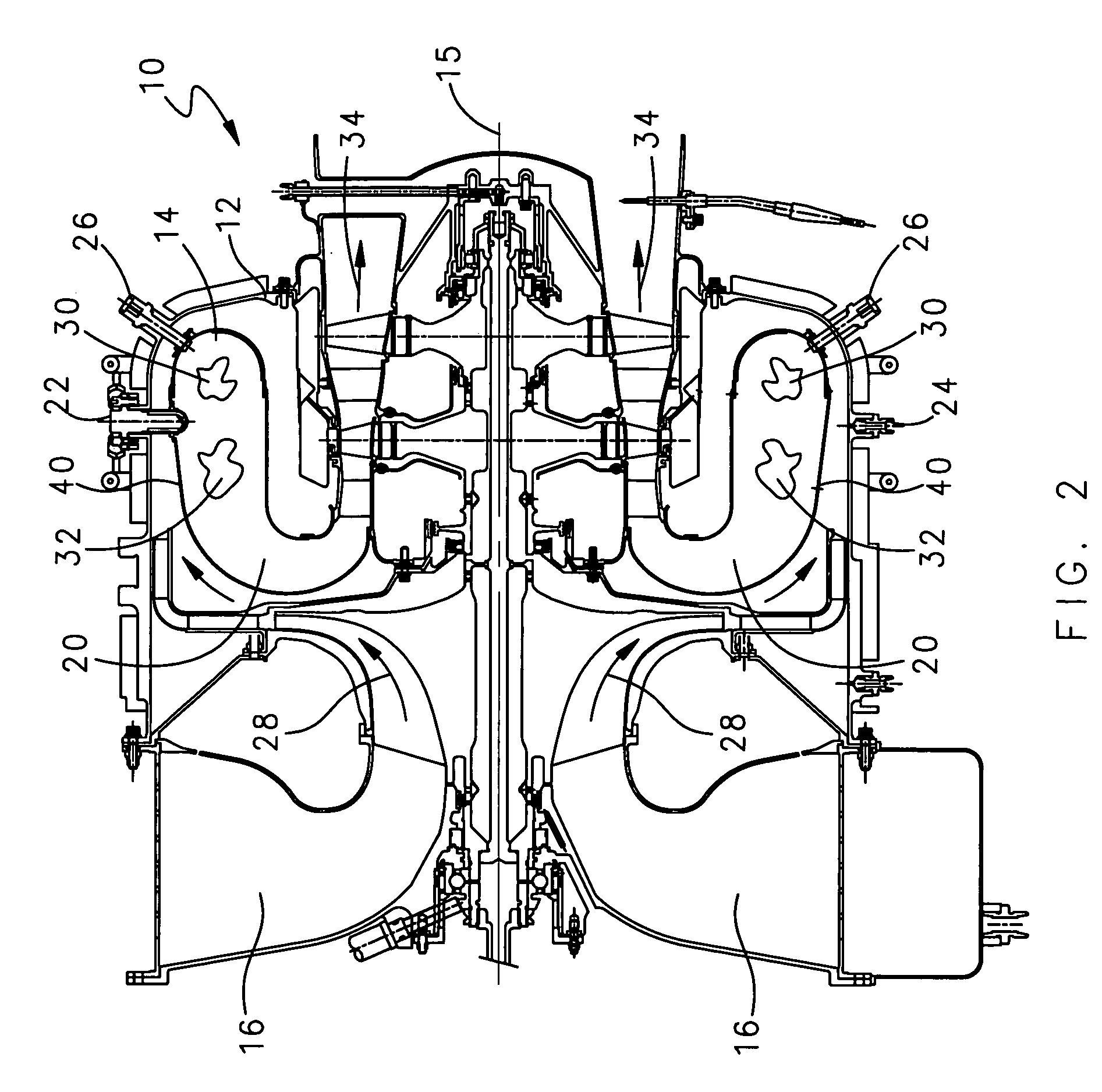

Method for ignition of flameless combustor

InactiveUS6269882B1Easy to igniteImprove the level ofApparel holdersIncandescent ignitionCombustorCombustion chamber

A combustor method and apparatus is provided. The method utilizes flameless combustion with one or more of three improvements to enhance ignition of the flameless combustor. A catalytic surface can be provided within a combustion chamber to provide flameless combustion at least in the vicinity of the catalytic surface at a temperature that is much lower than the autoignition temperature of fuel in air without the presence of the catalytic surface. Nitrous oxide or supplemental oxygen may also be used as an oxidant either instead of air or with air to reduce ignition temperatures. Further, electrical energy can be passed through the fuel conduit, raising the temperature of the conduit to a temperature above which the fuel will ignite when combined with the oxidant.

Owner:SHELL OIL CO

Multi-component removal in flue gas by aqua ammonia

InactiveUS7255842B1Regeneration process is less-costlyIncrease load capacityGas treatmentNitrogen compoundsNitric oxideSlurry

A new method for the removal of environmental compounds from gaseous streams, in particular, flue gas streams. The new method involves first oxidizing some or all of the acid anhydrides contained in the gas stream such as sulfur dioxide (SO2) and nitric oxide (NO) and nitrous oxide (N2O) to sulfur trioxide (SO3) and nitrogen dioxide (NO2). The gas stream is subsequently treated with aqua ammonia or ammonium hydroxide which captures the compounds via chemical absorption through acid-base or neutralization reactions. The products of the reactions can be collected as slurries, dewatered, and dried for use as fertilizers, or once the slurries have been dewatered, used directly as fertilizers. The ammonium hydroxide can be regenerated and recycled for use via thermal decomposition of ammonium bicarbonate, one of the products formed. There are alternative embodiments which entail stoichiometric scrubbing of nitrogen oxides and sulfur oxides with subsequent separate scrubbing of carbon dioxide.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

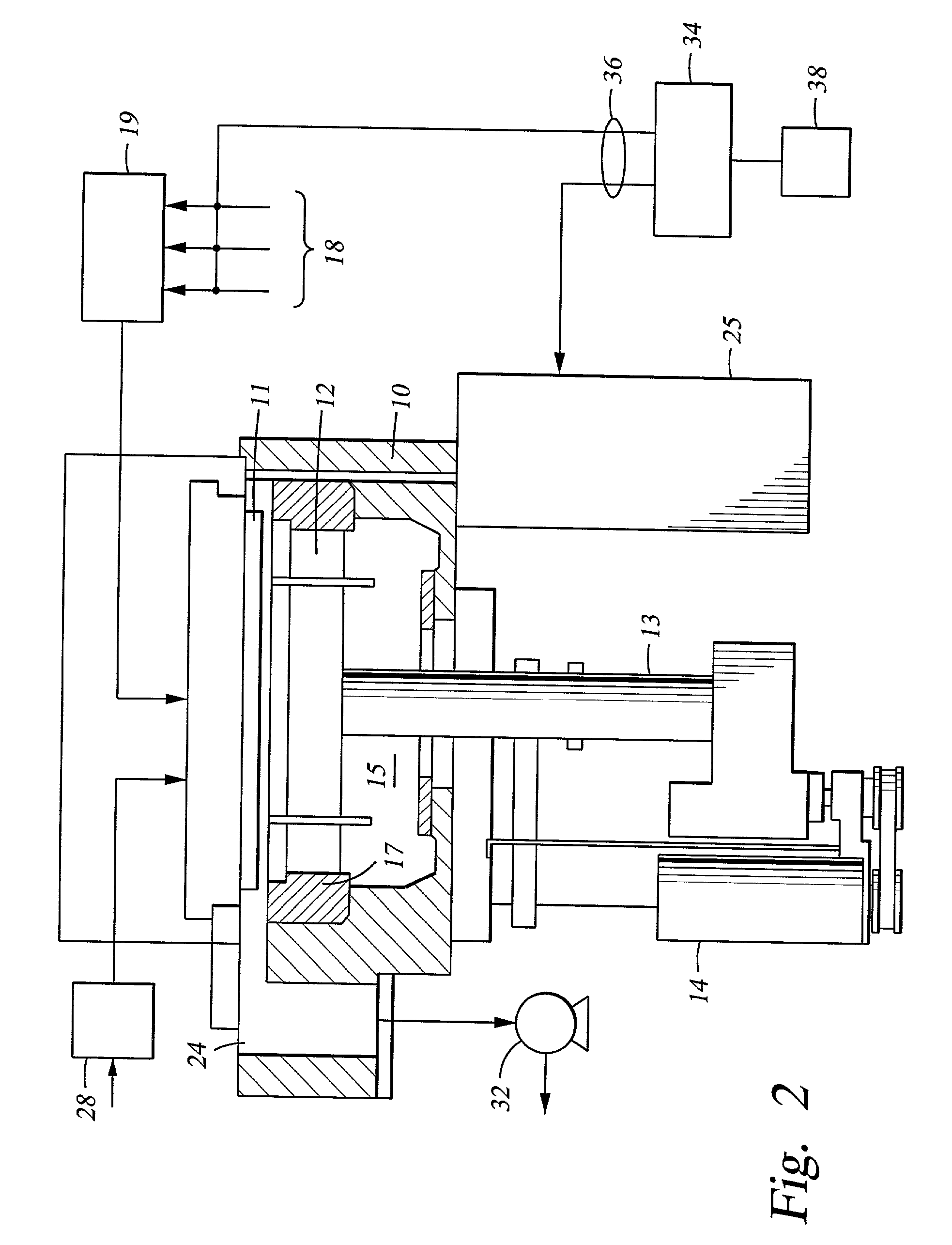

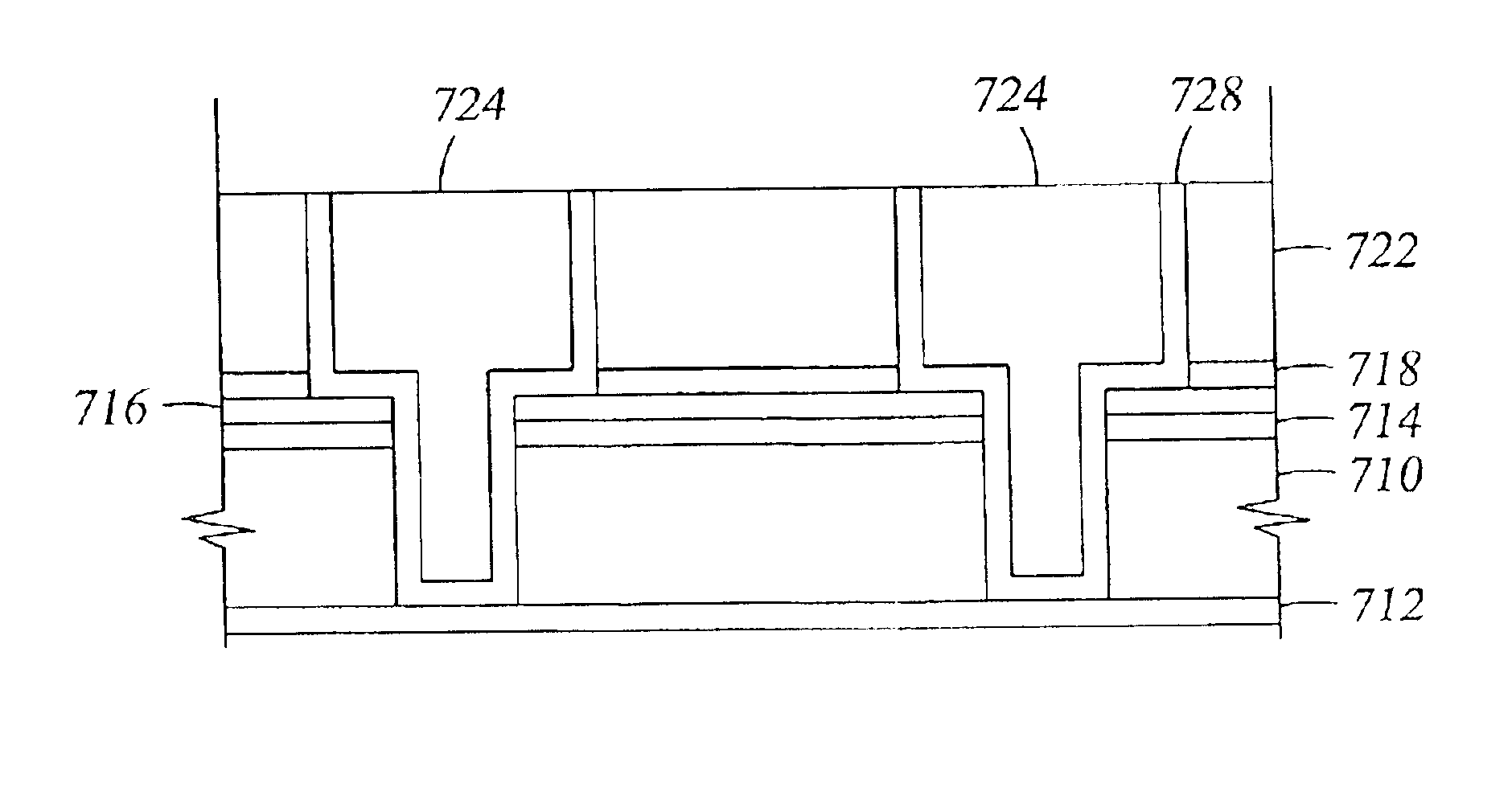

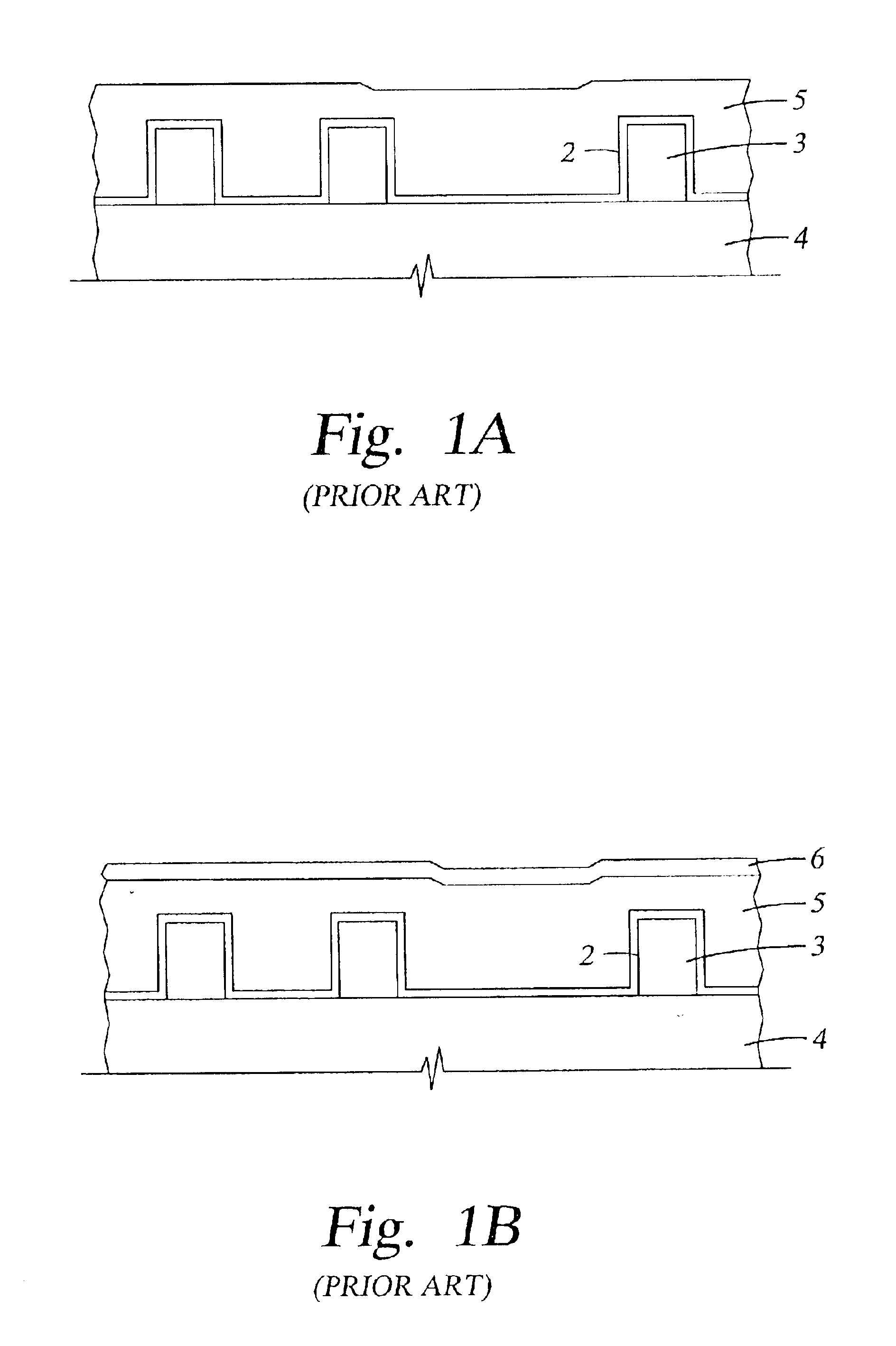

Plasma processes for depositing low dielectric constant films

A method and apparatus for depositing a low dielectric constant film by reaction of an organosilicon compound and an oxidizing gas at a constant RF power level from about 10W to about 200W or a pulsed RF power level from about 20W to about 500W. Dissociation of the oxidizing gas can be increased prior to mixing with the organosilicon compound, preferably within a separate microwave chamber, to assist in controlling the carbon content of the deposited film. The oxidized organosilane or organosiloxane film has good barrier properties for use as a liner or cap layer adjacent other dielectric layers. The oxidized organosilane or organosiloxane film may also be used as an etch stop and an intermetal dielectric layer for fabricating dual damascene structures. The oxidized organosilane or organosiloxane films also provide excellent adhesion between different dielectric layers. A preferred oxidized organosilane film is produced by reaction of methylsilane, CH3SiH3, dimethylsilane, (CH3)2SiH2, or 1,1,3,3-tetramethyl-disiloxane, (CH3)2-SiH-O-SiH-(CH3)2, and nitrous oxide, N2O, at a constant RF power level from about 10W to about 150W, or a pulsed RF power level from about 20W to about 250W during 10% to 30% of the duty cycle.

Owner:APPLIED MATERIALS INC

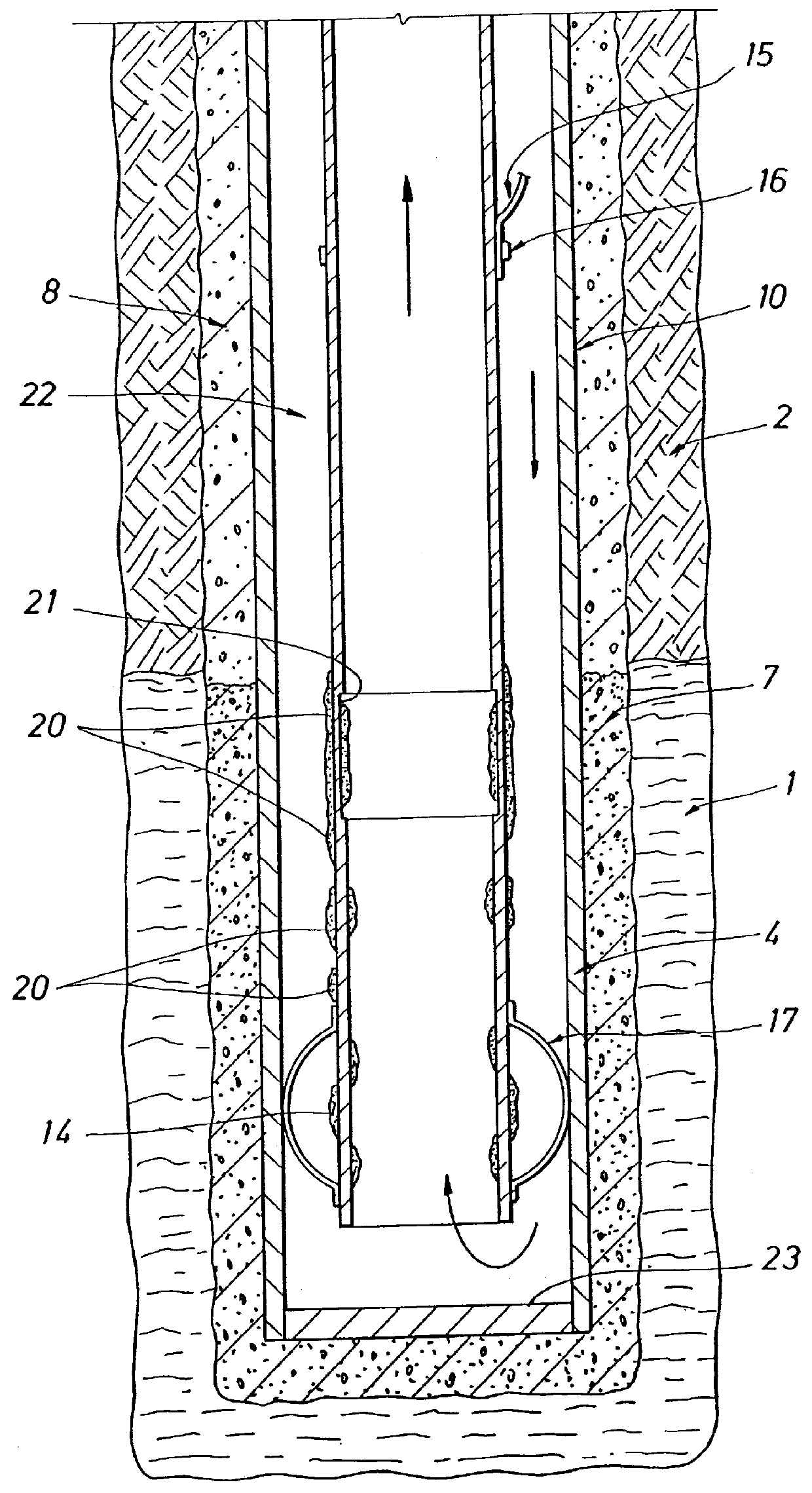

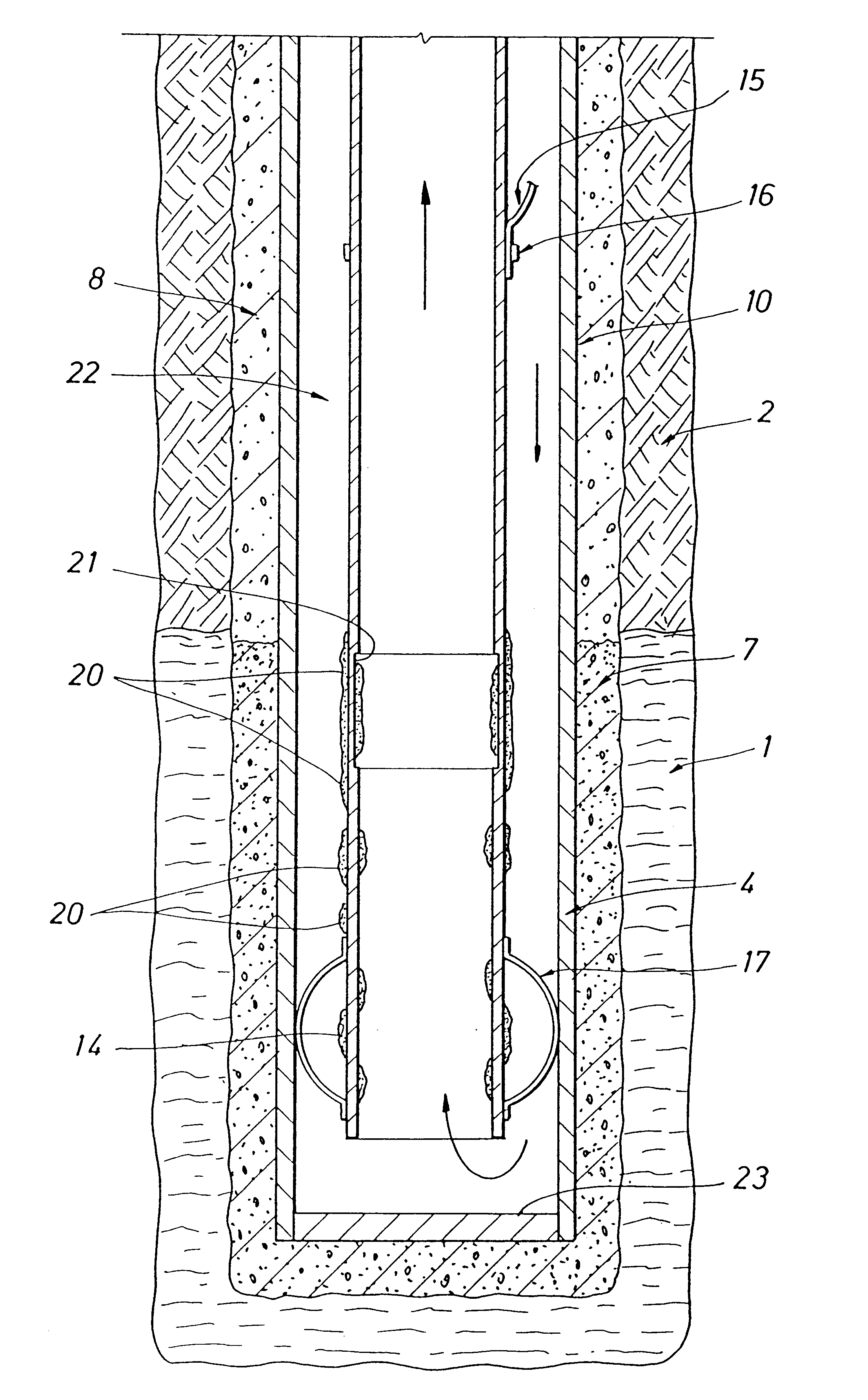

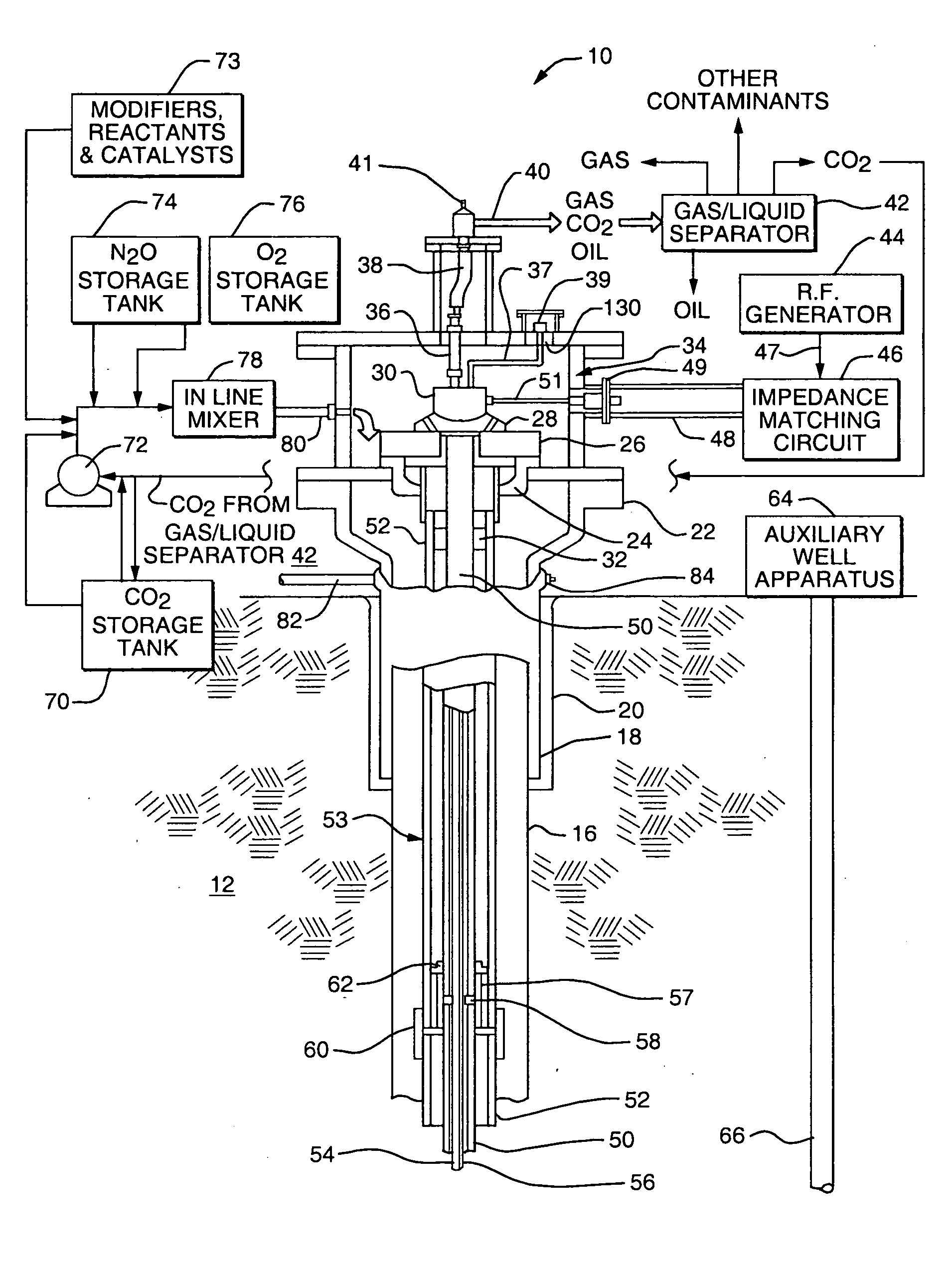

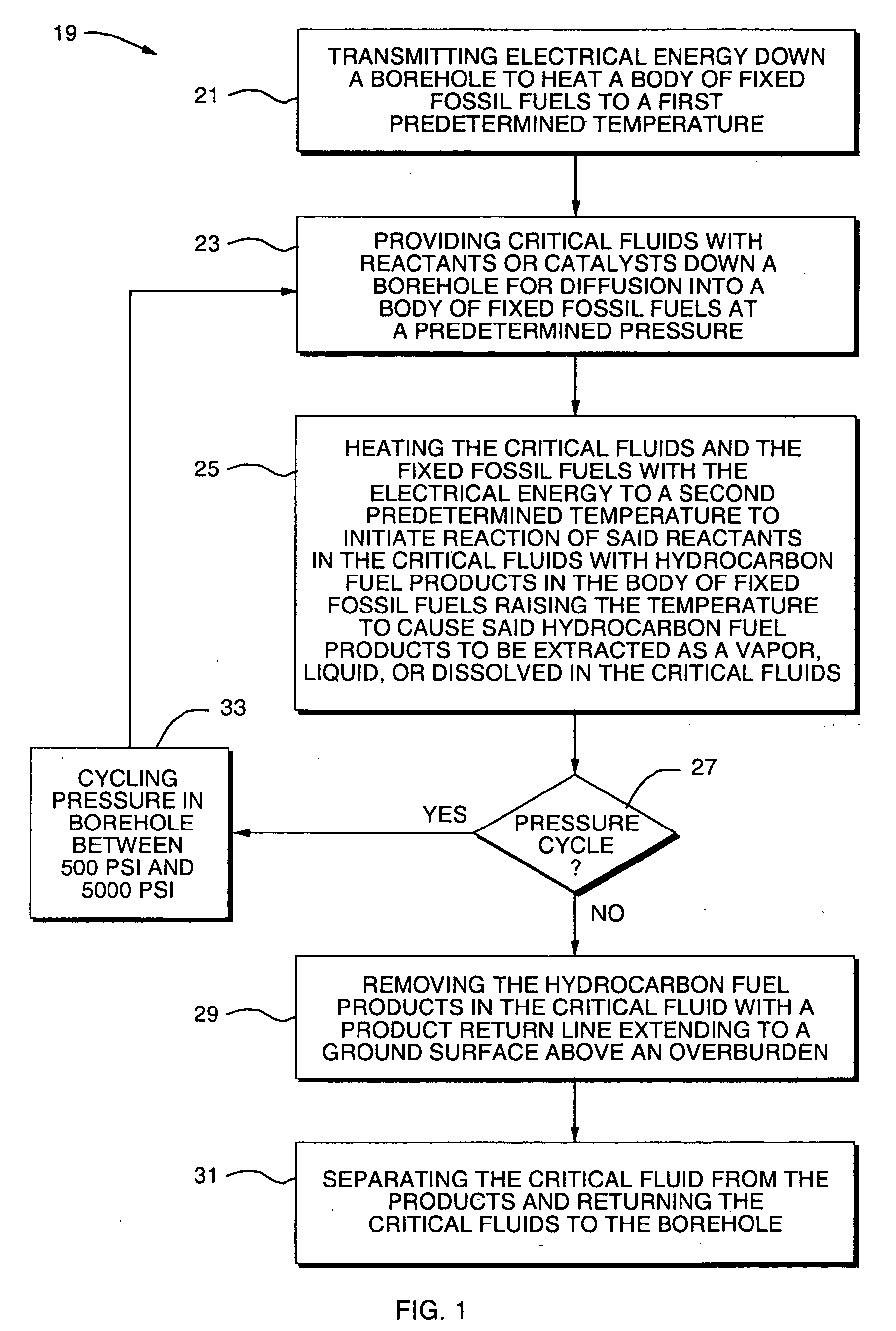

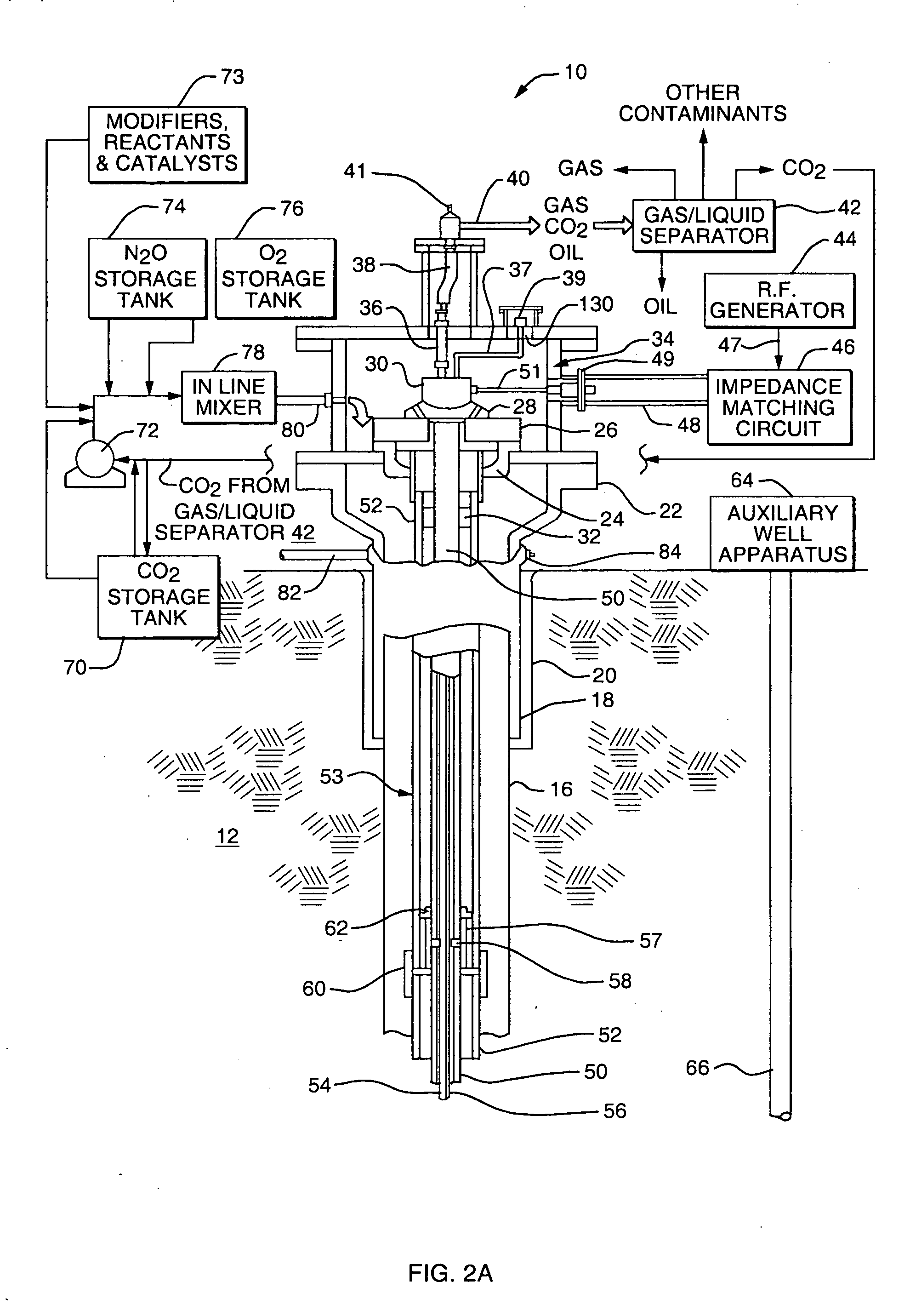

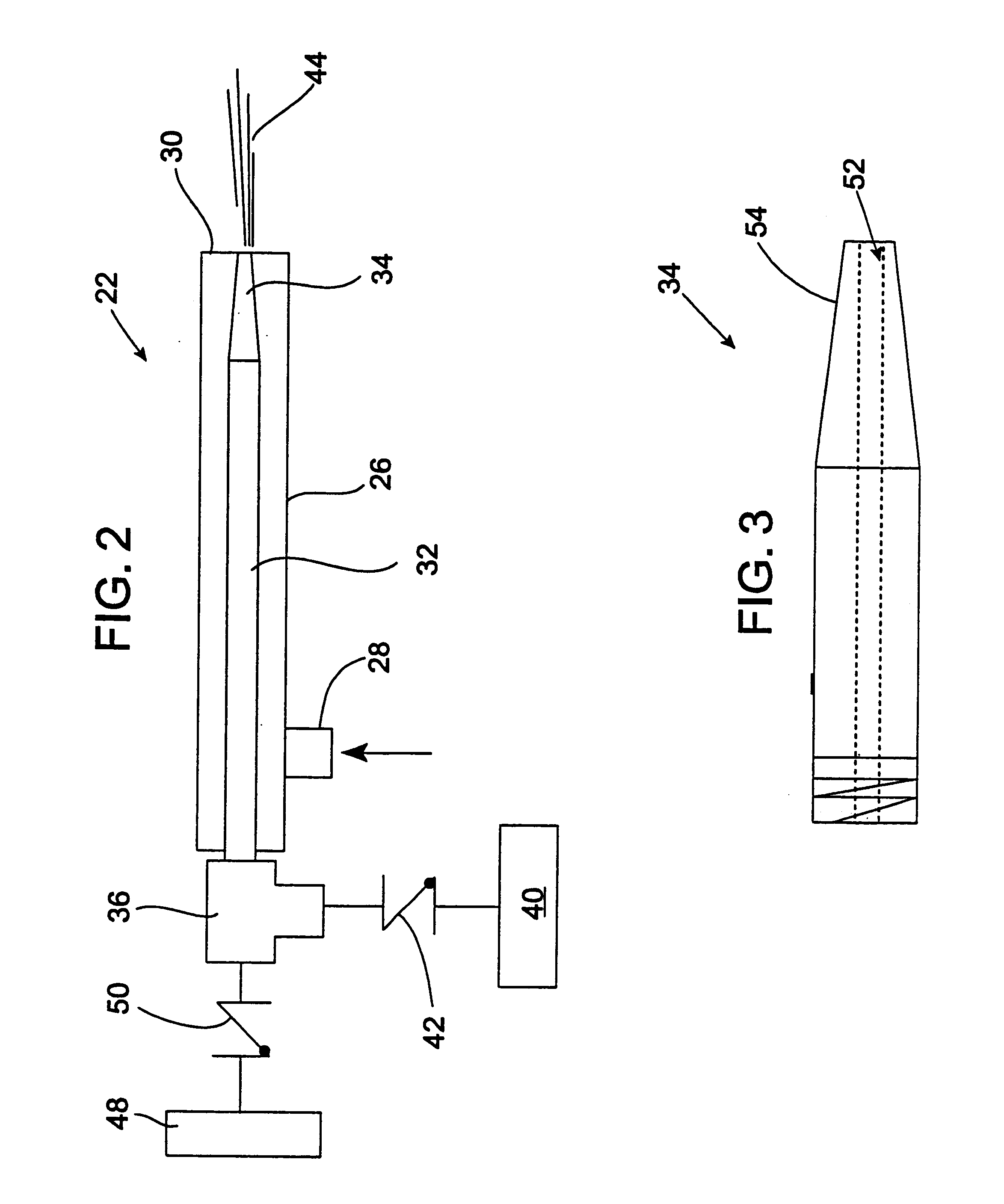

Method for extraction of hydrocarbon fuels or contaminants using electrical energy and critical fluids

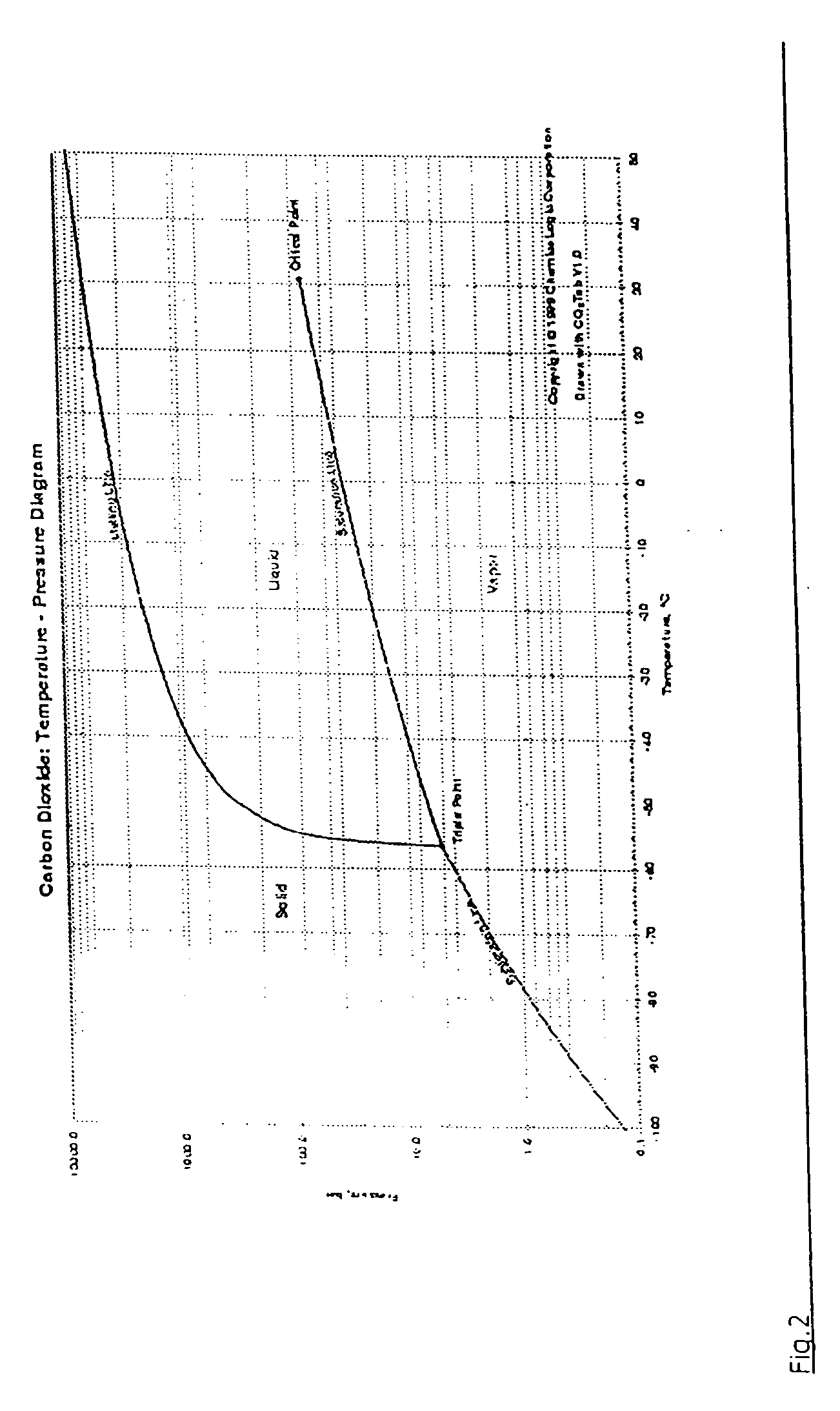

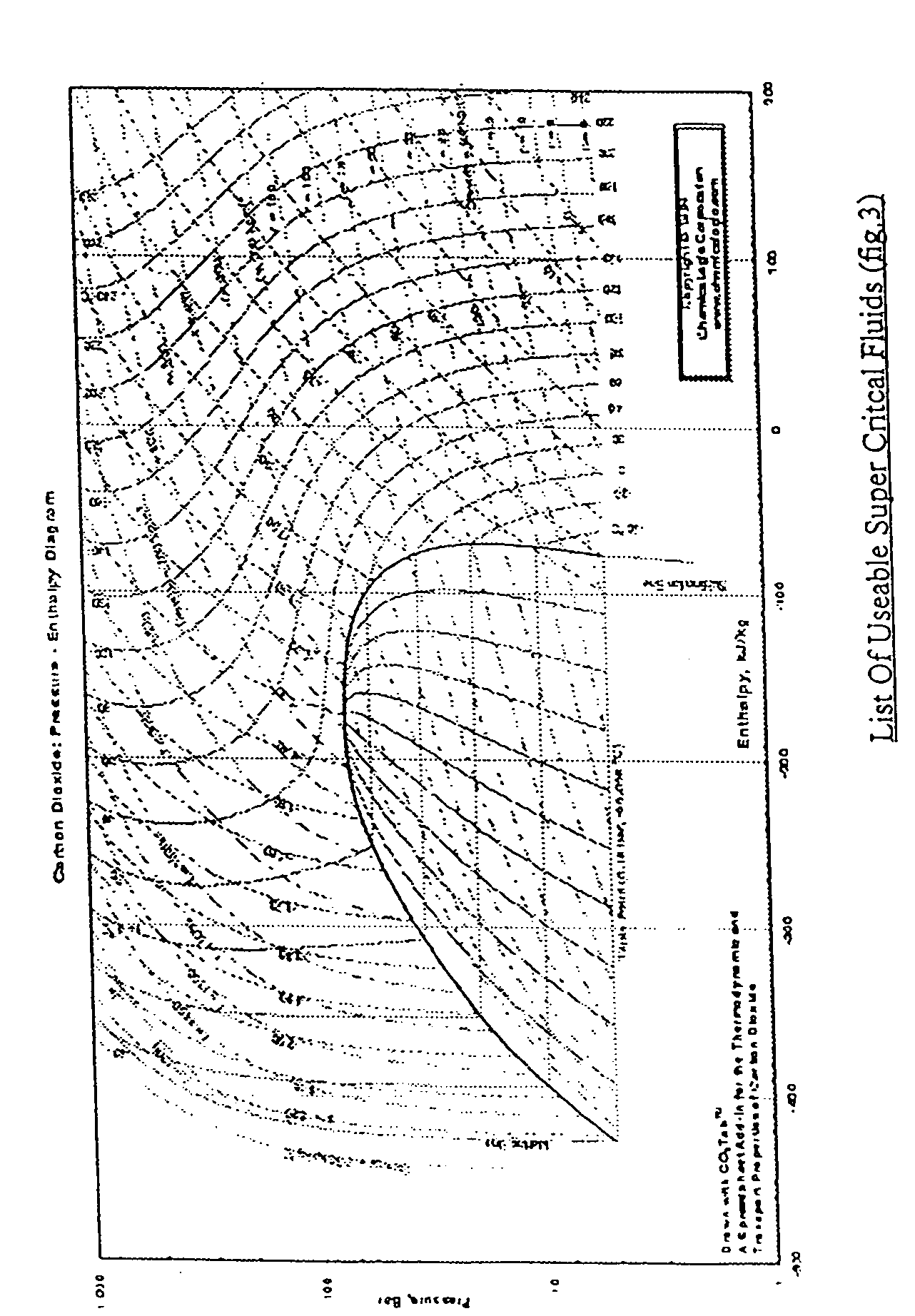

ActiveUS20070137858A1Efficient heatingValid conversionSurveyHollow article cleaningVapor liquidHydrocotyle bowlesioides

The extraction of hydrocarbon fuel products such as kerogen oil and gas from a body of fixed fossil fuels such as oil shale is accomplished by applying a combination of electrical energy and critical fluids with reactants and / or catalysts down a borehole to initiate a reaction of reactants in the critical fluids with kerogen in the oil shale thereby raising the temperatures to cause kerogen oil and gas products to be extracted as a vapor, liquid or dissolved in the critical fluids. The hydrocarbon fuel products of kerogen oil or shale oil and hydrocarbon gas are removed to the ground surface by a product return line. An RF generator provides electromagnetic energy, and the critical fluids include a combination of carbon dioxide (CO2), with reactants of nitrous oxide (N2O) or oxygen (O2).

Owner:SCHLUMBERGER TECH CORP

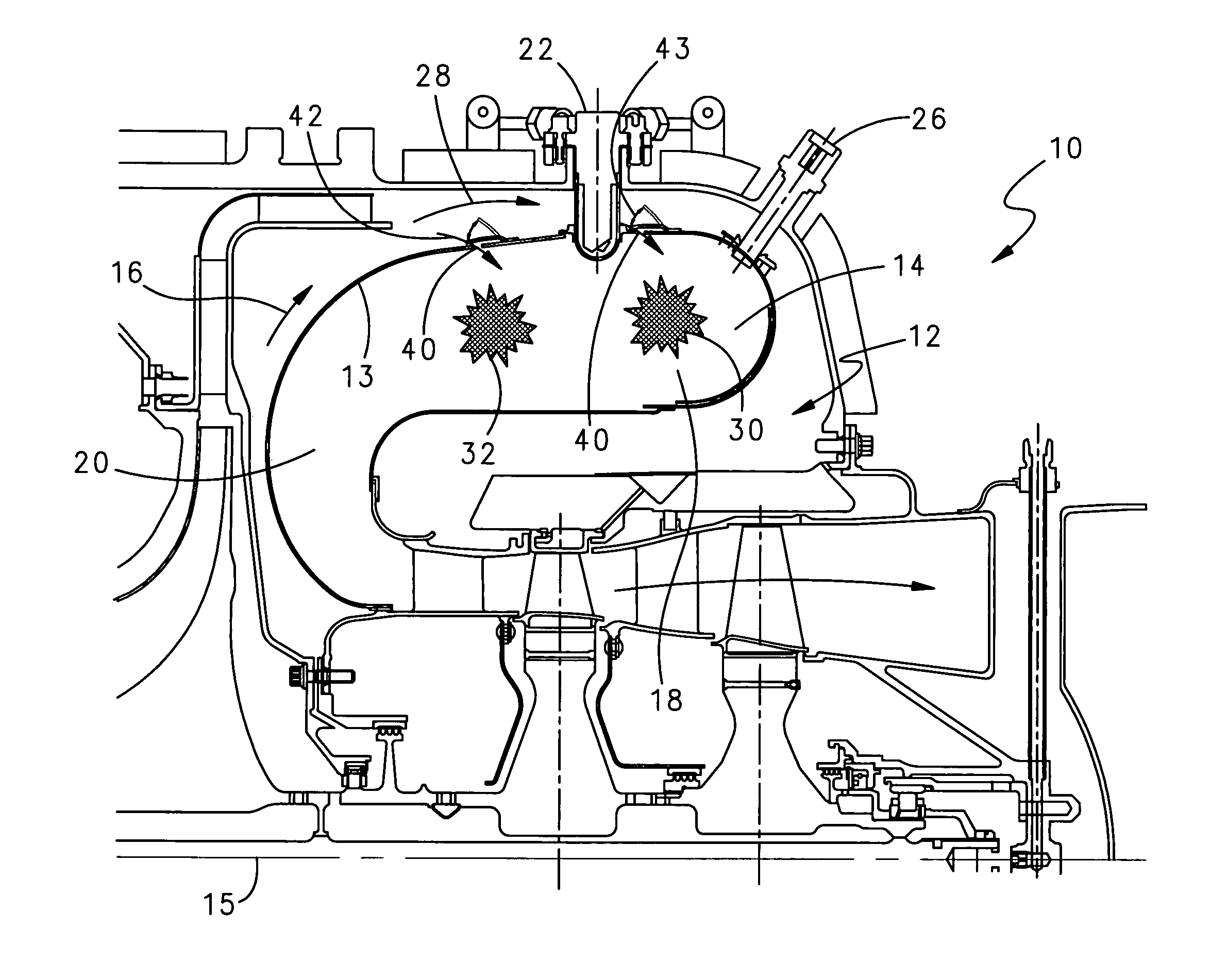

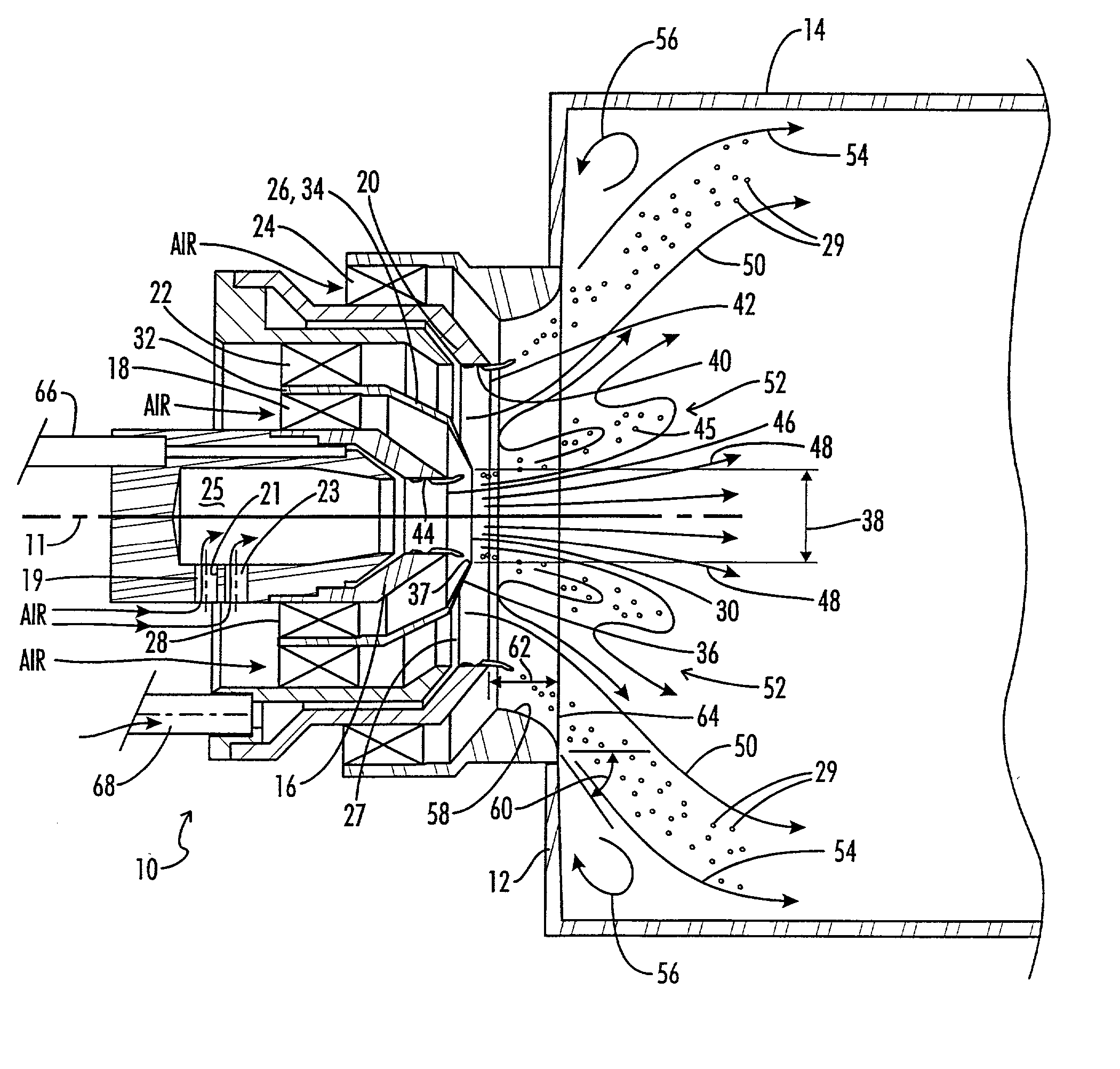

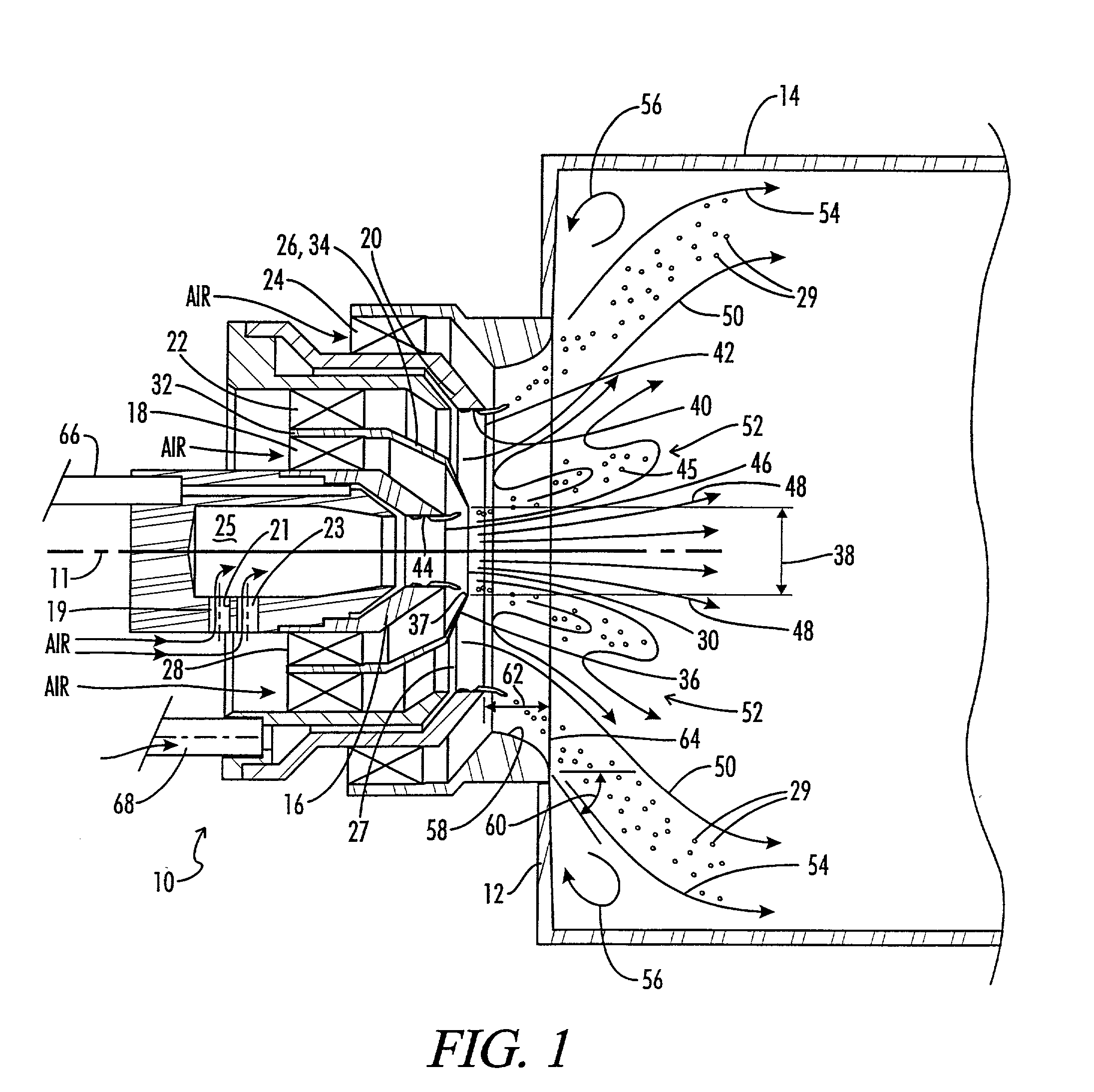

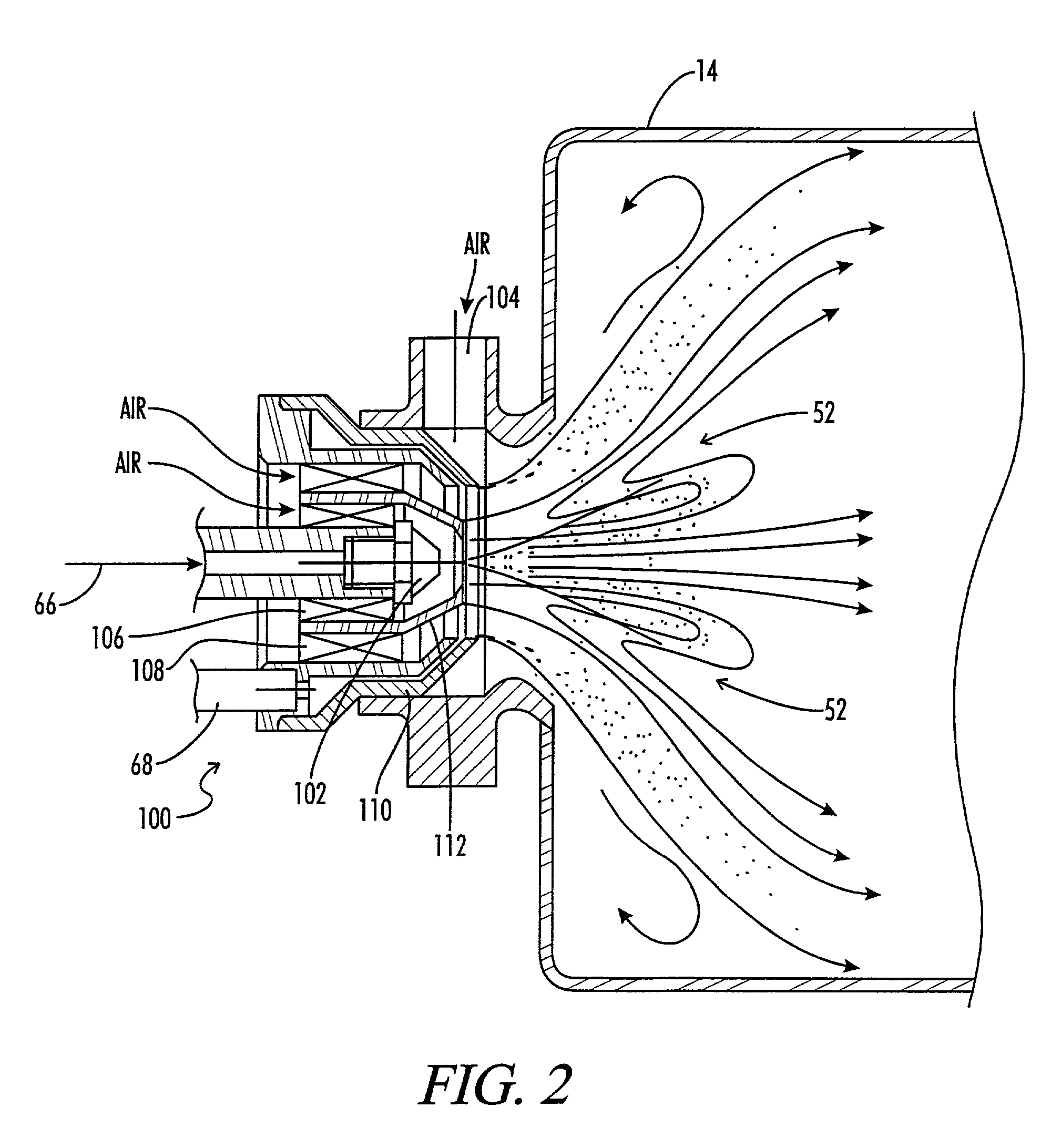

Lean-staged pyrospin combustor

ActiveUS7302801B2High power outputIncrease powerBurnersTurbine/propulsion fuel supply systemsCombustorCombustion chamber

Owner:HAMILTON SUNDSTRAND CORP

Method of retrofitting a furnace to provide oxygen enrichment

An oxygen enrichment system is provided which uses the existing air / fuel burners of a regenerative furnace to distribute additional oxygen to the burners for increased efficiency, and reduced nitrous oxide emissions. The centrally positioned cooling air lances in the burners of a regenerative furnace are modified to deliver oxygen when the burners are firing for oxygen enrichment. During the burmer firing cycle, oxygen is delivered from an oxygen supply through the oxygen lance to provide a central oxygen jet. The fuel is delivered concentrically around the oxygen jet. During the non-firing cycle of the burner, cooling air or other cooling fluid is delivered from the cooling air supply through the oxygen jet for cooling the offside of the furnace.

Owner:AIR LIQUIDE AMERICA INC

Plasma processes for depositing low dielectric constant films

InactiveUS20010005546A1Semiconductor/solid-state device detailsSolid-state devicesDisiloxaneMicrowave

A method and apparatus for depositing a low dielectric constant film by reaction of an organosilicon compound and an oxidizing gas at a constant RF power level from about 10W to about 200W or a pulsed RF power level from about 20W to about 500W. Dissociation of the oxidizing gas can be increased prior to mixing with the organosilicon compound, preferably within a separate microwave chamber, to assist in controlling the carbon content of the deposited film. The oxidized organosilane or organosiloxane film has good barrier properties for use as a liner or cap layer adjacent other dielectric layers. The oxidized organosilane or organosiloxane film may also be used as an etch stop and an intermetal dielectric layer for fabricating dual damascene structures. The oxidized organosilane or organosiloxane films also provide excellent adhesion between different dielectric layers. A preferred oxidized organosilane film is produced by reaction of methylsilane, CH3SiH3, dimethylsilane, (CH3)2SiH2, or 1,1,3,3-tetramethyl-disiloxane, (CH3)2-SiH-O-SiH-(CH3)2, and nitrous oxide, N2O, at a constant RF power level from about 10W to about 150W, or a pulsed RF power level from about 20W to about 250W during 10% to 30% of the duty cycle.

Owner:APPLIED MATERIALS INC

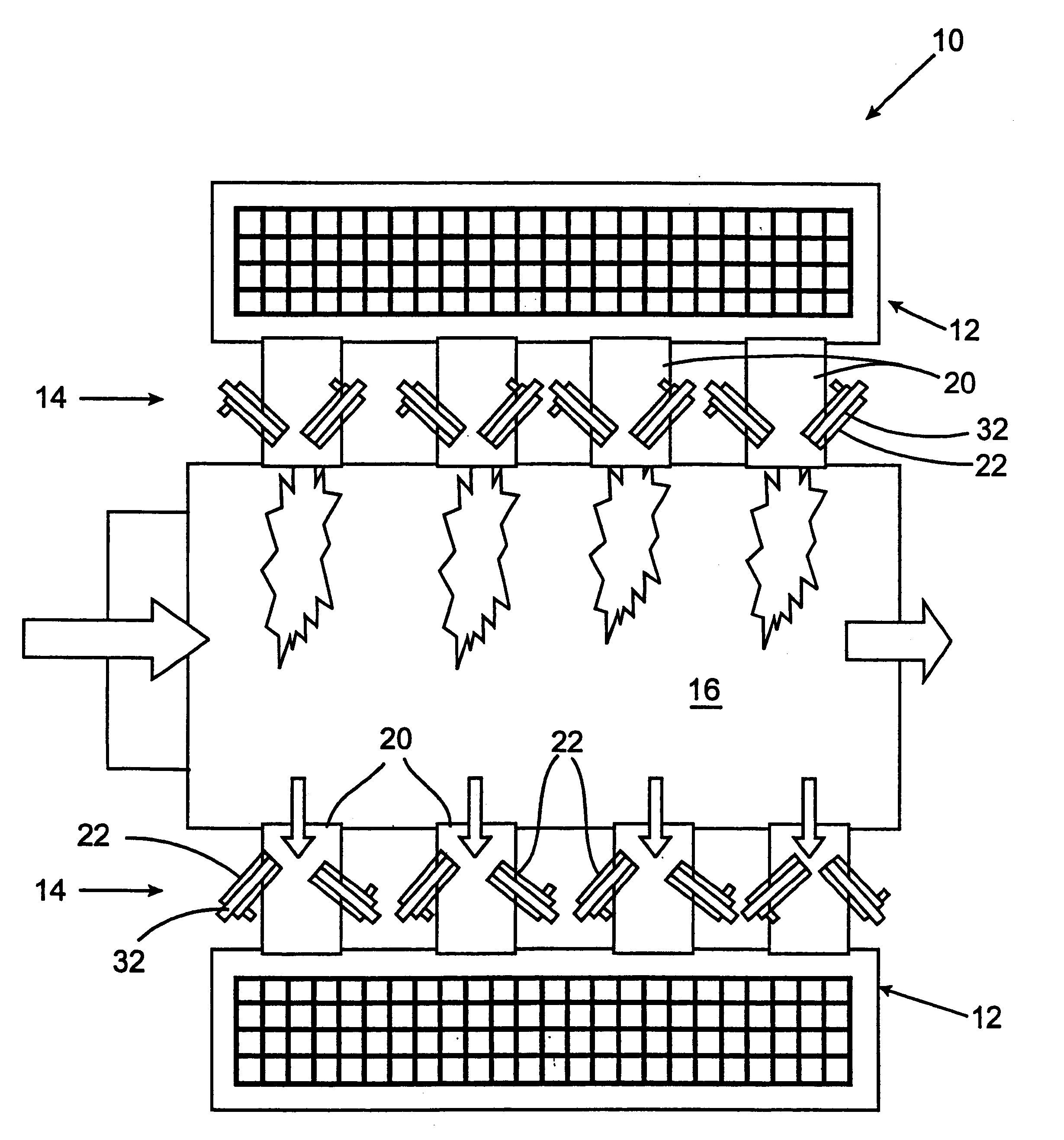

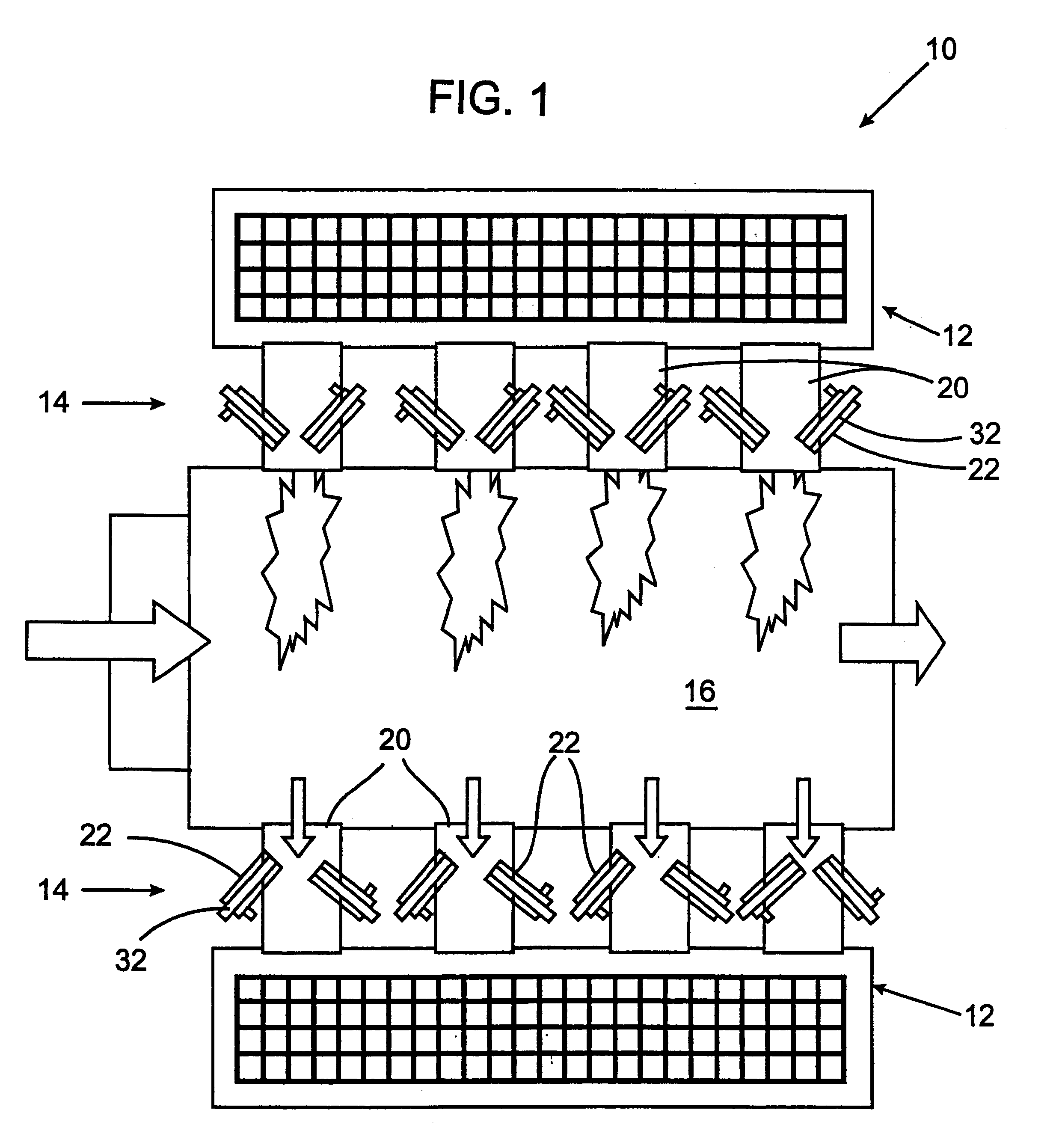

Fuel injector with bifurcated recirculation zone

InactiveUS20020011064A1Low pollutant emissionReduce nitrogen oxide emissionsBurnersTurbine/propulsion fuel supply systemsProcess engineeringNitrous oxide

A gas turbine fuel injection system of the lean direct injector type designed to reduce nitrous oxide (NOx) emissions is provided. The configuration includes a pilot fuel injector for injecting a pilot fuel stream, and a pilot swirler for providing a swirling pilot air stream to atomize and entrain the pilot fuel stream. A main airblast fuel injector is located concentrically about the pilot fuel injector, for injecting a main fuel stream concentrically about the pilot fuel stream. Inner and outer main swirlers provide a swirling main air stream to atomize and entrain the main fuel stream. An air splitter is located between the pilot swirler and the main swirler. The air splitter is so arranged and constructed as to divide the pilot air stream exiting the pilot swirler and the air splitter, from the main air stream exiting the inner main swirler, whereby a bifurcated recirculation zone is created.

Owner:CROCKER DAVID S +2

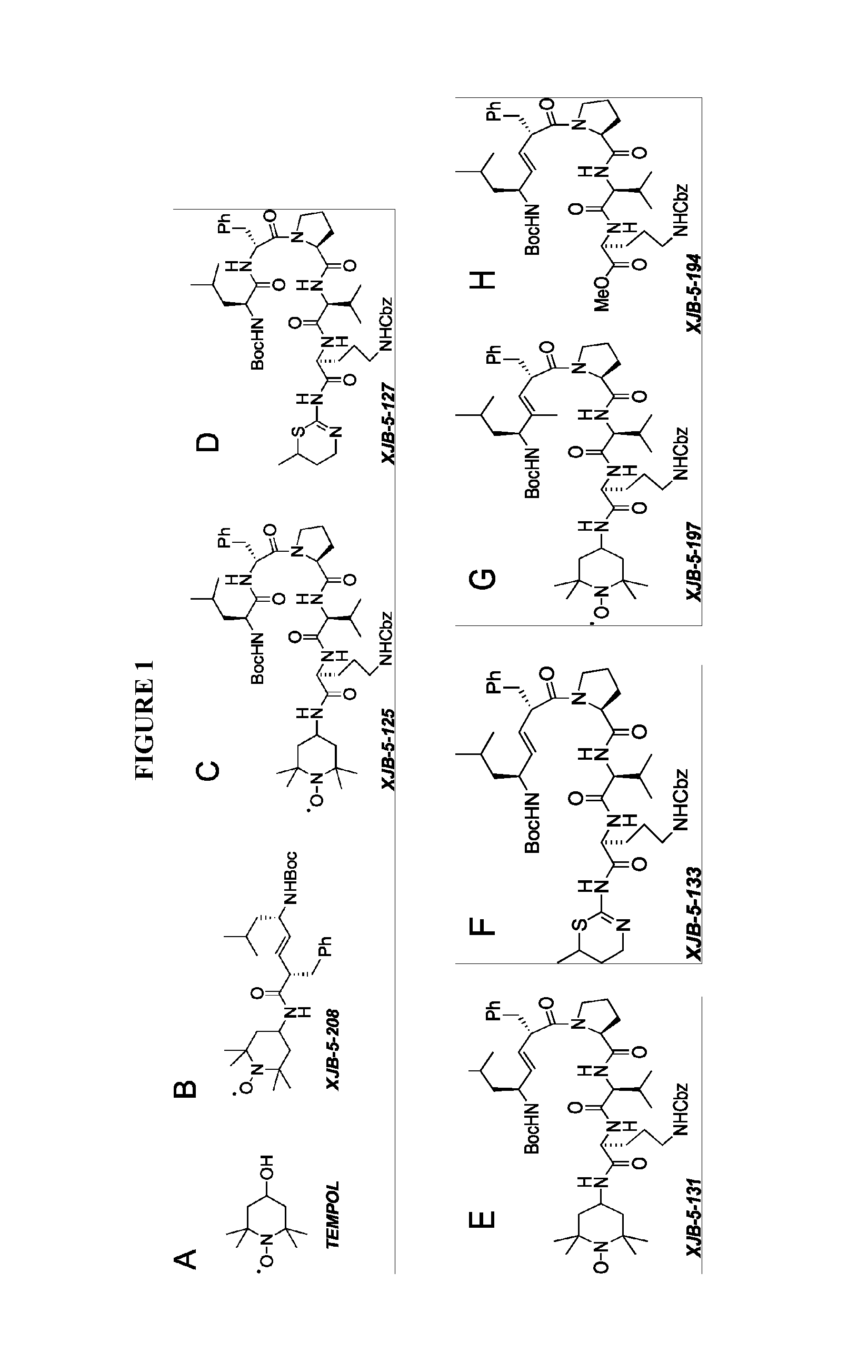

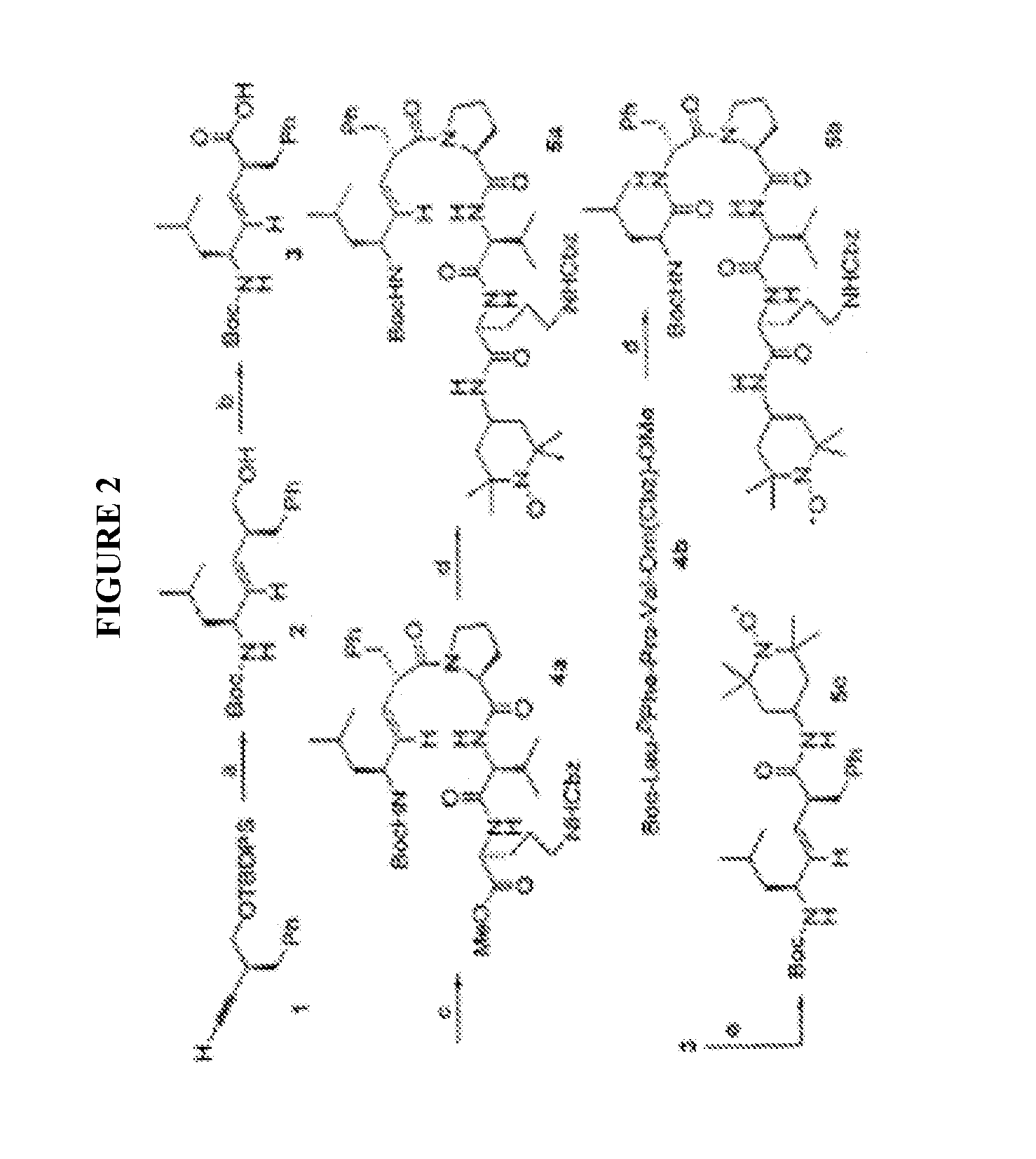

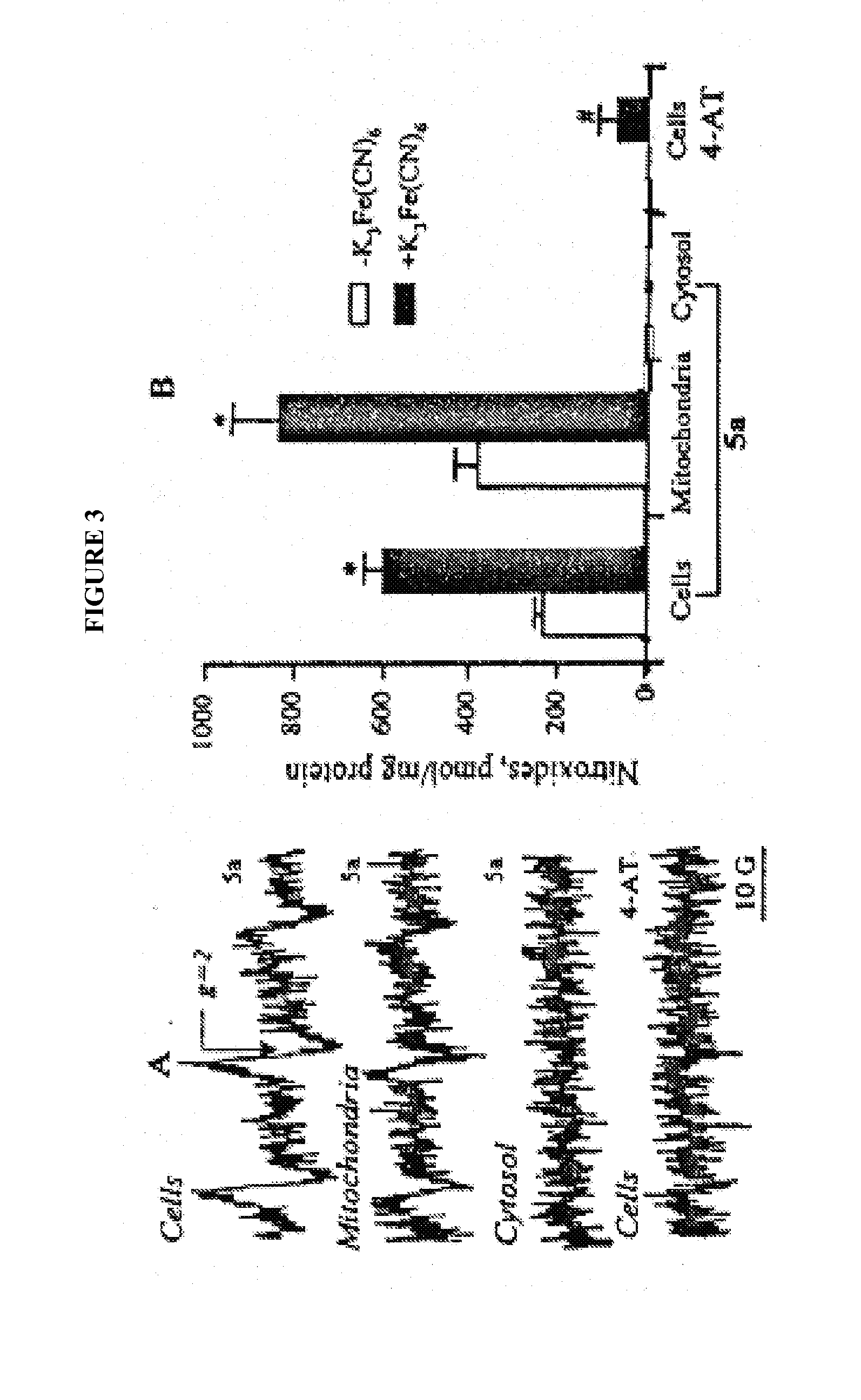

Selective targeting agents for mitcochondria

InactiveUS20070161544A1Efficient deliveryImprove survivalAntibacterial agentsBiocideDiseaseScavenger

The present invention relates to compositions and methods for providing mitochondria-selective targeting agents covalently linked to desired cargo such as radical scavenging agents. Compositions and methods are disclosed for treating an illness that is caused or associated with cellular damage or dysfunction which is caused by excessive mitochondrial production of reaction oxygen species (ROS). Compositions which act as mitochondria-selective targeting agents using specific structural signaling features recognizable by cells as mitochondrial targeting sequences are discussed. A method for delivering these agents effectively into cells and mitochondria where they act as electron scavengers by way of certain targeting sequences is also disclosed. Mitochondria and cell death by way of apoptosis is inhibited as a result of the ROS-scavenging activity, thereby increasing the survival rate of the patient. In a preferred embodiment, the compositions and methods may be administered therapeutically in the field to patients with profound hemorrhagic shock so that survival could be prolonged until it is feasible to obtain surgical control of the bleeding vessels. In further preferred embodiments, the composition for scavenging radicals in a mitochondrial membrane includes a radical scavenging agent and a membrane active compound having a high affinity with said mitochondrial membrane and associated methods. In another embodiment, the cargo transported by mitochondrial-selective targeting agents may include an inhibitor of nitrous oxide system (NOS) enzyme activity.

Owner:UNIVERSITY OF PITTSBURGH

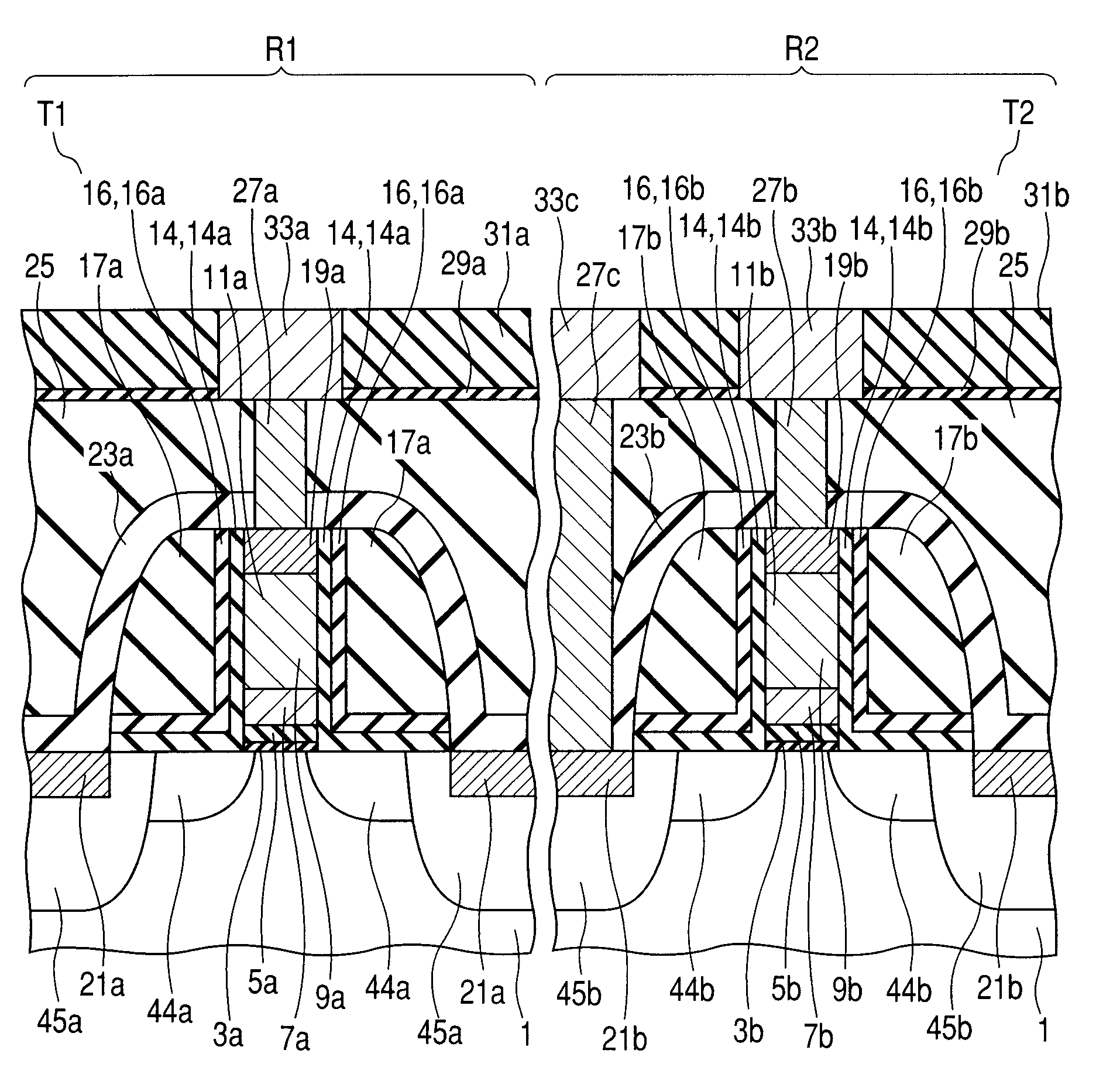

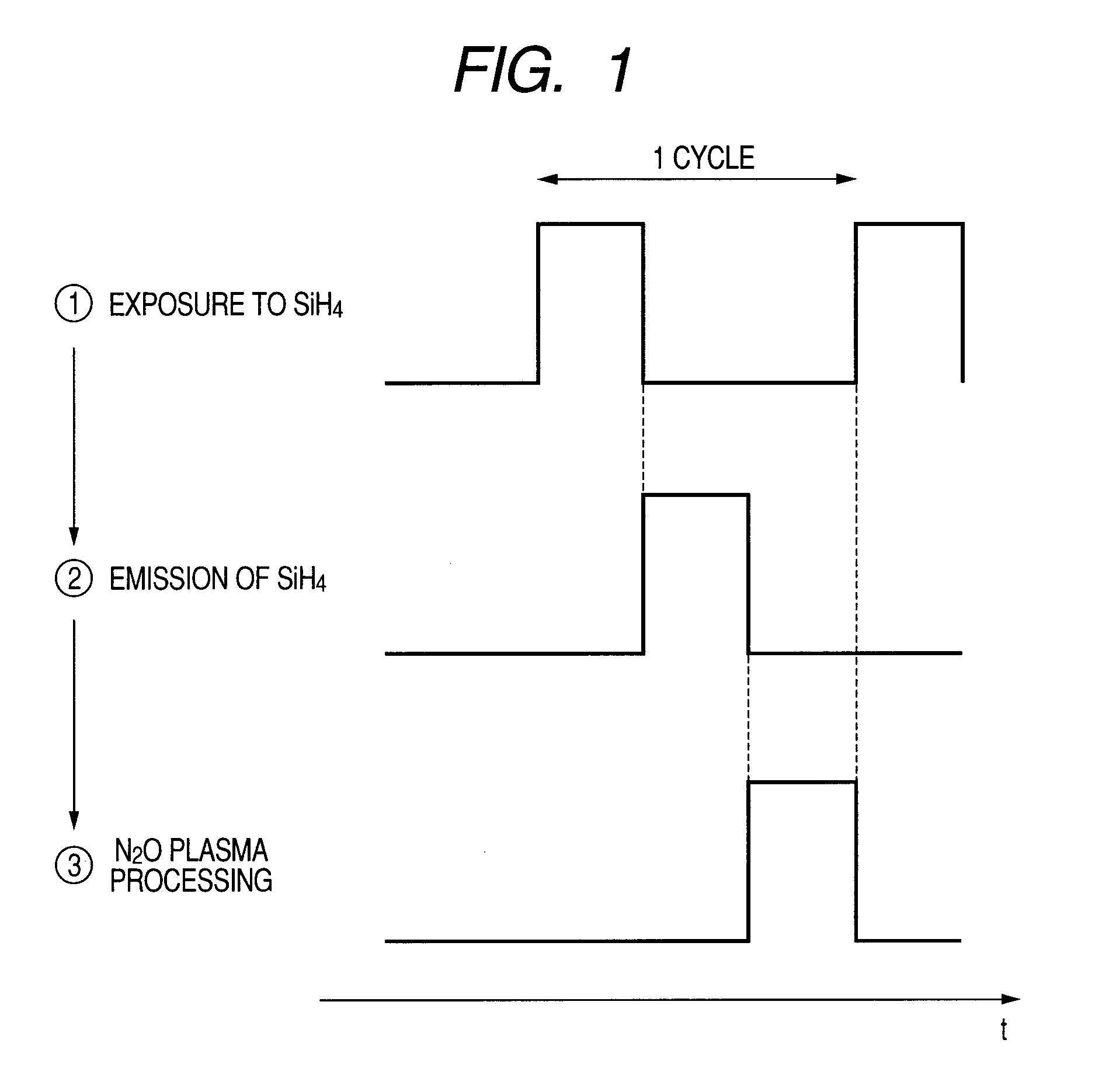

Manufacturing method of semiconductor device

InactiveUS20110003445A1Good and thin silicon oxide filmUniformly formedSolid-state devicesSemiconductor/solid-state device manufacturingSilicon oxideNitrous oxide

A manufacturing method of a semiconductor device is provided which can uniformly form a good and thin silicon oxide film or the like at a relatively low temperature. In step 1, a semiconductor substrate is exposed to monosilane (SiH4). Then, in step 2, the remaining monosilane (SiH4) is emitted. In step 3, the semiconductor substrate is exposed to nitrous oxide plasma. A desired silicon oxide film is formed by repeating one cycle including steps 1 to 3 until a necessary thickness of the film is obtained.

Owner:RENESAS ELECTRONICS CORP

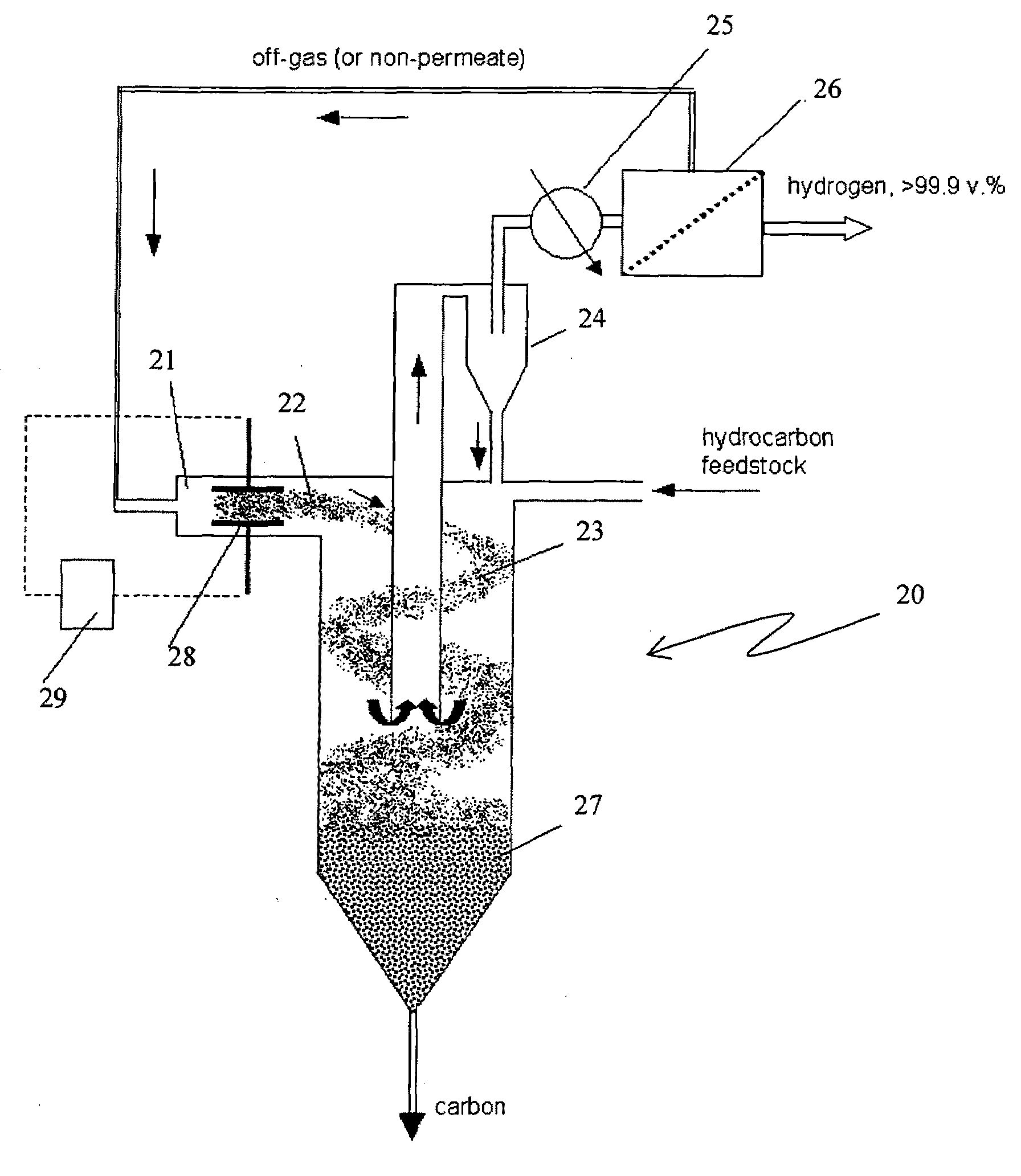

Process and apparatus for hydrogen and carbon production via carbon aerosol-catalyzed dissociation of hydrocarbons

The present invention relates to a novel process for sustainable, continuous production of hydrogen and carbon by catalytic dissociation or decomposition of hydrocarbons at elevated temperatures using in-situ generated carbon particles. Carbon particles are produced by decomposition of carbonaceous materials in response to an energy input. The energy input can be provided by at least one of a non-oxidative and oxidative means. The non-oxidative means of the energy input includes a high temperature source, or different types of plasma, such as, thermal, non-thermal, microwave, corona discharge, glow discharge, dielectric barrier discharge, or radiation sources, such as, electron beam, gamma, ultraviolet (UV). The oxidative means of the energy input includes oxygen, air, ozone, nitrous oxide (NO2) and other oxidizing agents. The method, apparatus and process of the present invention is applicable to any gaseous or liquid hydrocarbon fuel and it produces no or significantly less CO2 emissions compared to conventional processes.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

Computer readable medium for holding a program for performing plasma-assisted CVD of low dielectric constant films formed from organosilane compounds

A method and apparatus for depositing a low dielectric constant film by reaction of an organosilane or organosiloxane compound and an oxidizing gas at a low RF power level from 10-250 W. The oxidized organosilane or organosiloxane film has good barrier properties for use as a liner or cap layer adjacent other dielectric layers. The oxidized organosilane or organosiloxane film may also be used as an etch stop or an intermetal dielectric layer for fabricating dual damascene structures. The oxidized organosilane or organosiloxane films also provide excellent adhesion between different dielectric layers. A preferred oxidized organosilane film is produced by reaction of methylsilane, CH3SiH3, or dimethylsilane, (CH3)2SiH2, and nitrous oxide, N2O, at an RF power level from about 10 to 200 W or a pulsed RF power level from about 20 to 250 W during 10-30% of the duty cycle.

Owner:APPLIED MATERIALS INC

CVD plasma assisted low dielectric constant films

InactiveUS6800571B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDimethylsilaneNitrous oxide

A method and apparatus for depositing a low dielectric constant film by reaction of an organosilane or organosiloxane compound and an oxidizing gas at a low RF power level from 10-250 W. The oxidized organosilane or organosiloxane film has good barrier properties for use as a liner or cap layer adjacent other dielectric layers. The oxidized organosilane or organosiloxane film may also be used as an etch stop or an intermetal dielectric layer for fabricating dual damascene structures. The oxidized organosilane or organosiloxane films also provide excellent adhesion between different dielectric layers. A preferred oxidized organosilane film is produced by reaction of methylsilane, CH3SiH3, or dimethylsilane, (CH3)2SiH2, and nitrous oxide, N2O, at an RF power level from about 10 to 200 W or a pulsed RF power level from about 20 to 250 W during 10-30% of the duty cycle.

Owner:APPLIED MATERIALS INC

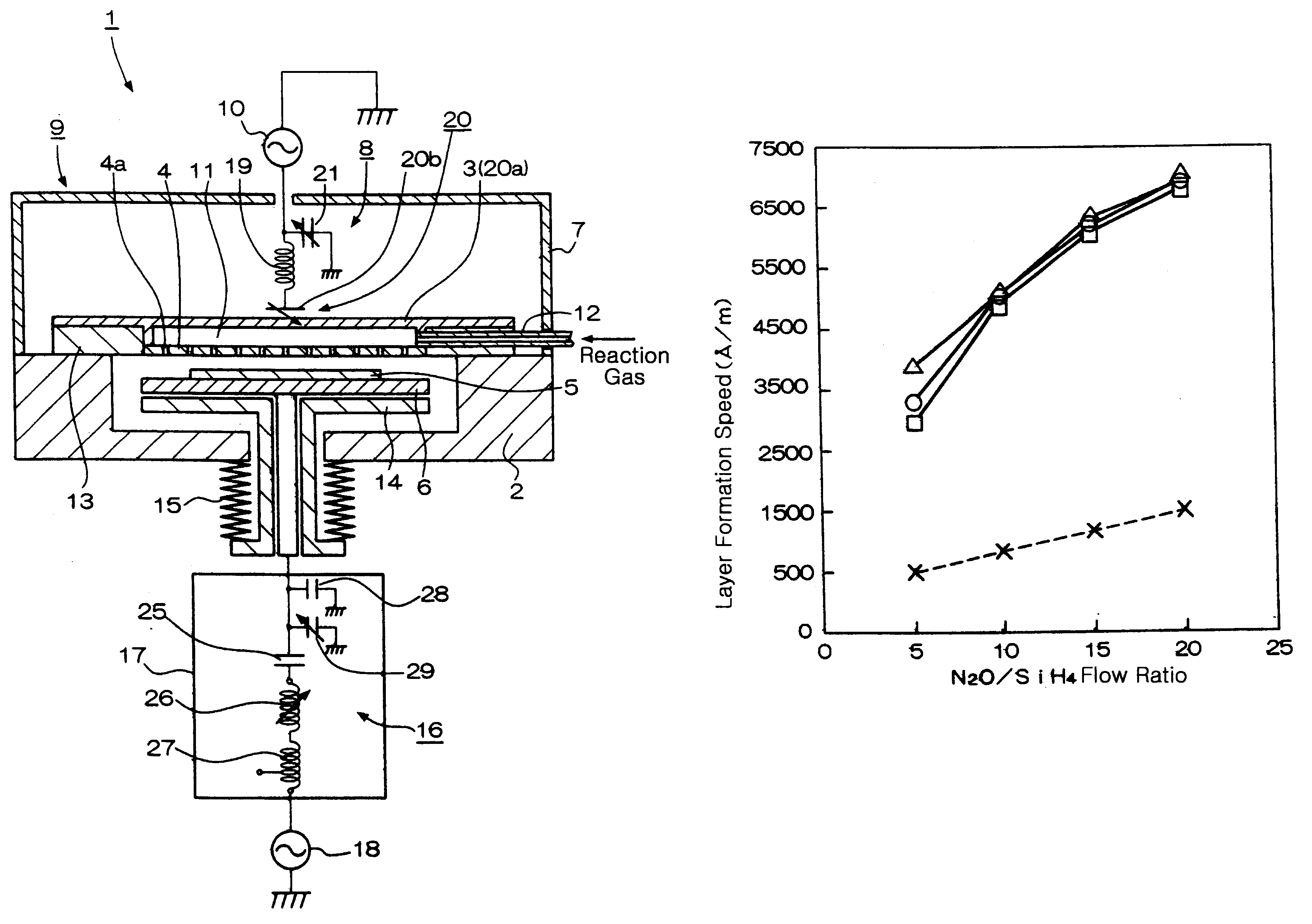

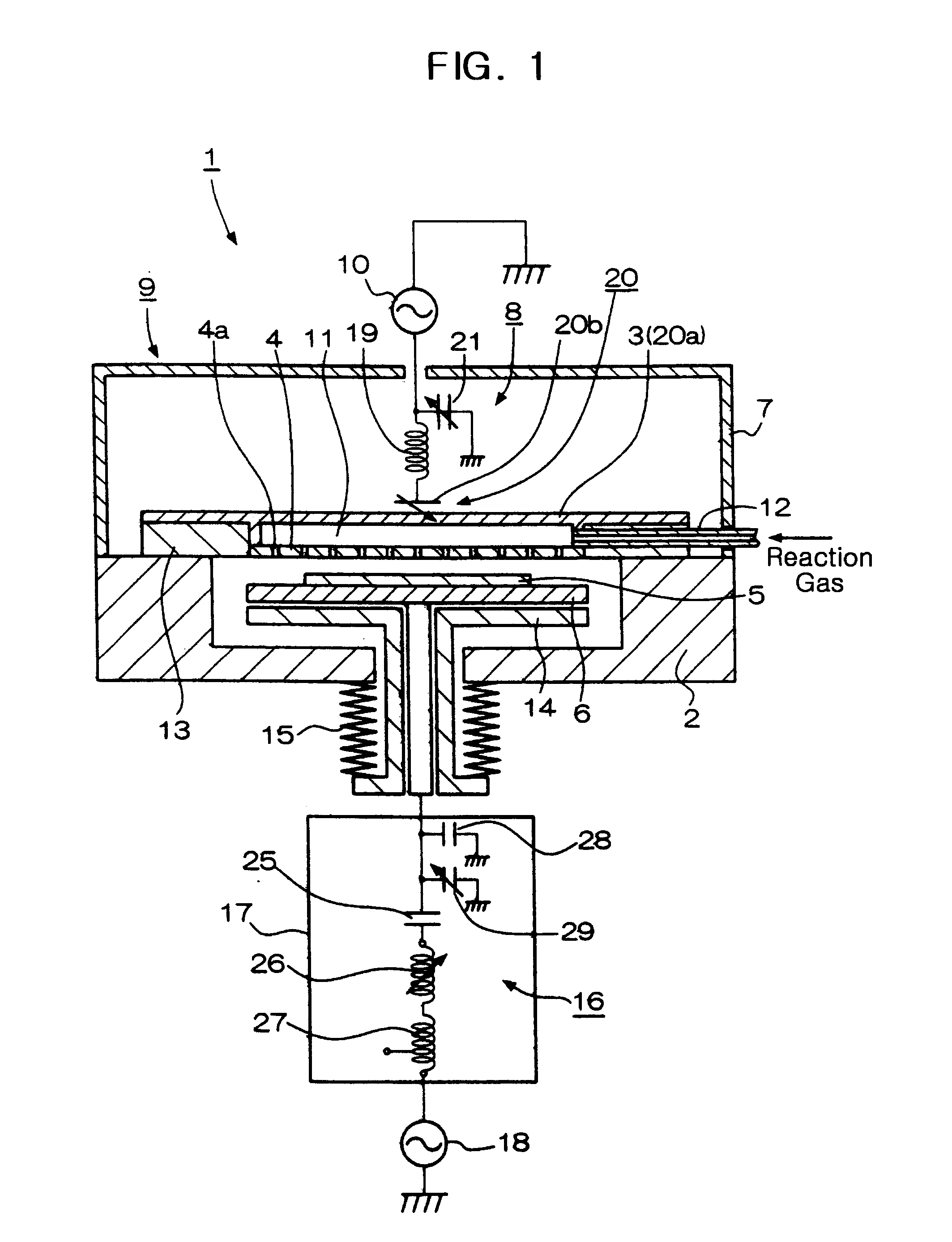

Method of forming silicon oxide layer and method of manufacturing thin film transistor thereby

InactiveUS6337292B1Increase speed of formationStep coverage becomes preferableTransistorElectric discharge tubesSusceptorPresent method

The present method of forming a silicon oxide layer comprises providing two frequency excitation plasma CVD device which comprises a high frequency electrode, a susceptor electrode, and two matching box for impedance matching between the electrodes and a power supply, wherein one side electrode constituting a tuning condenser of a matching box toward the high frequency electrode is the high frequency electrode; placing a substrate on the susceptor electrode; applying high frequency electric power on the high frequency electrode and the susceptor electrode respectively; and forming a silicon oxide layer on the substrate by generating plasma with using a reaction gas of which main reaction gas is a mixing gas of monosilane and nitrous oxide.

Owner:LG DISPLAY CO LTD

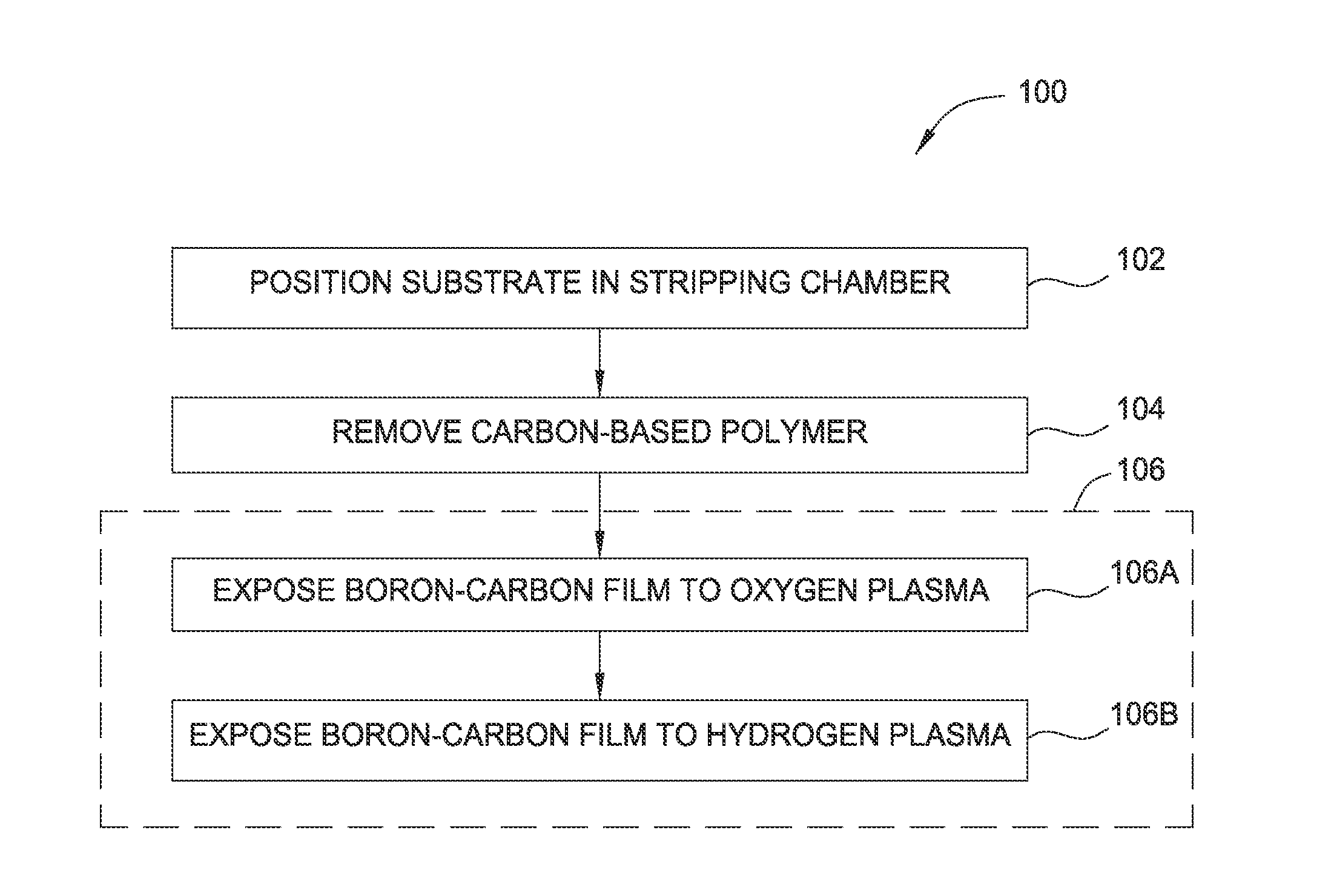

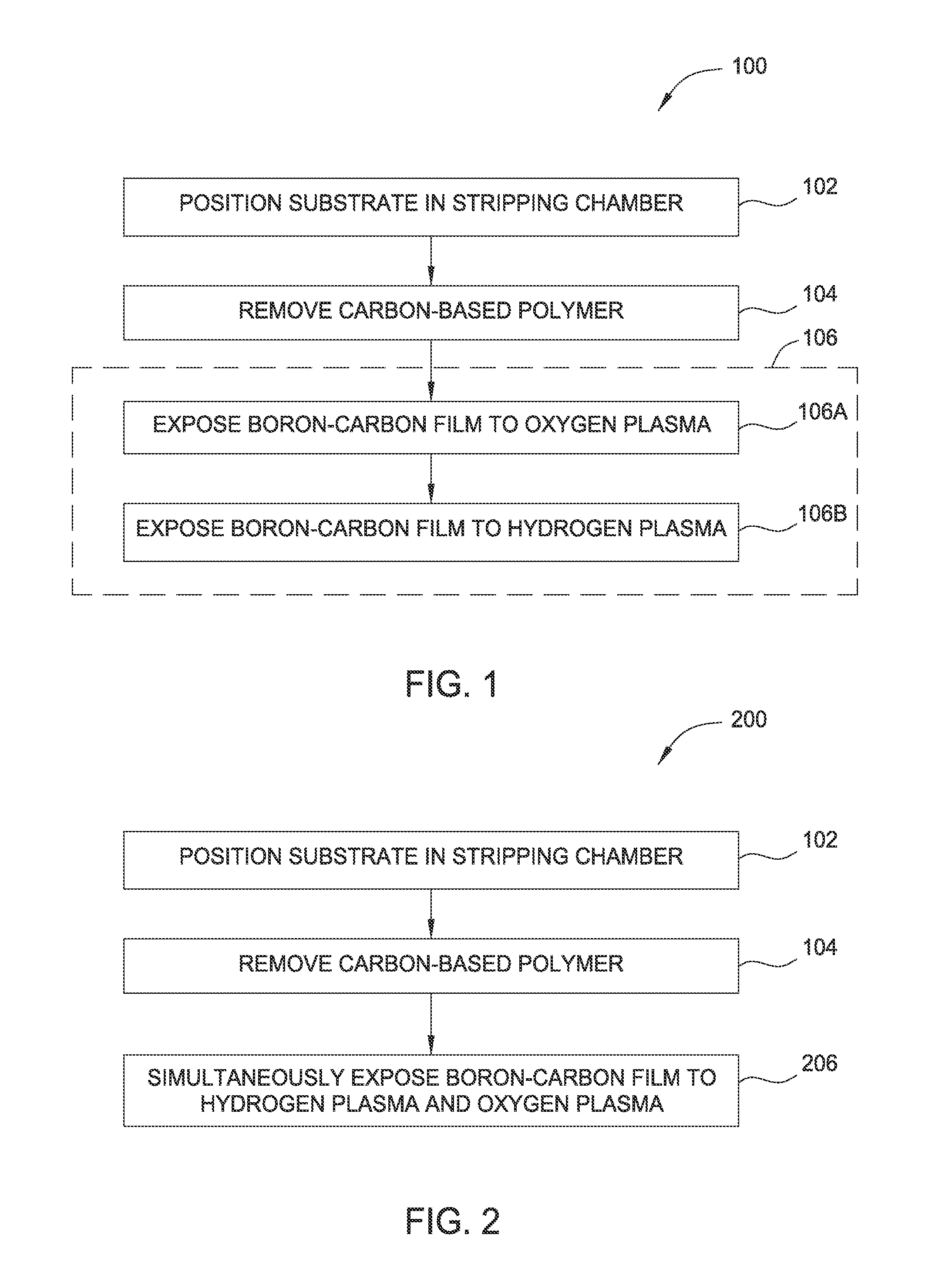

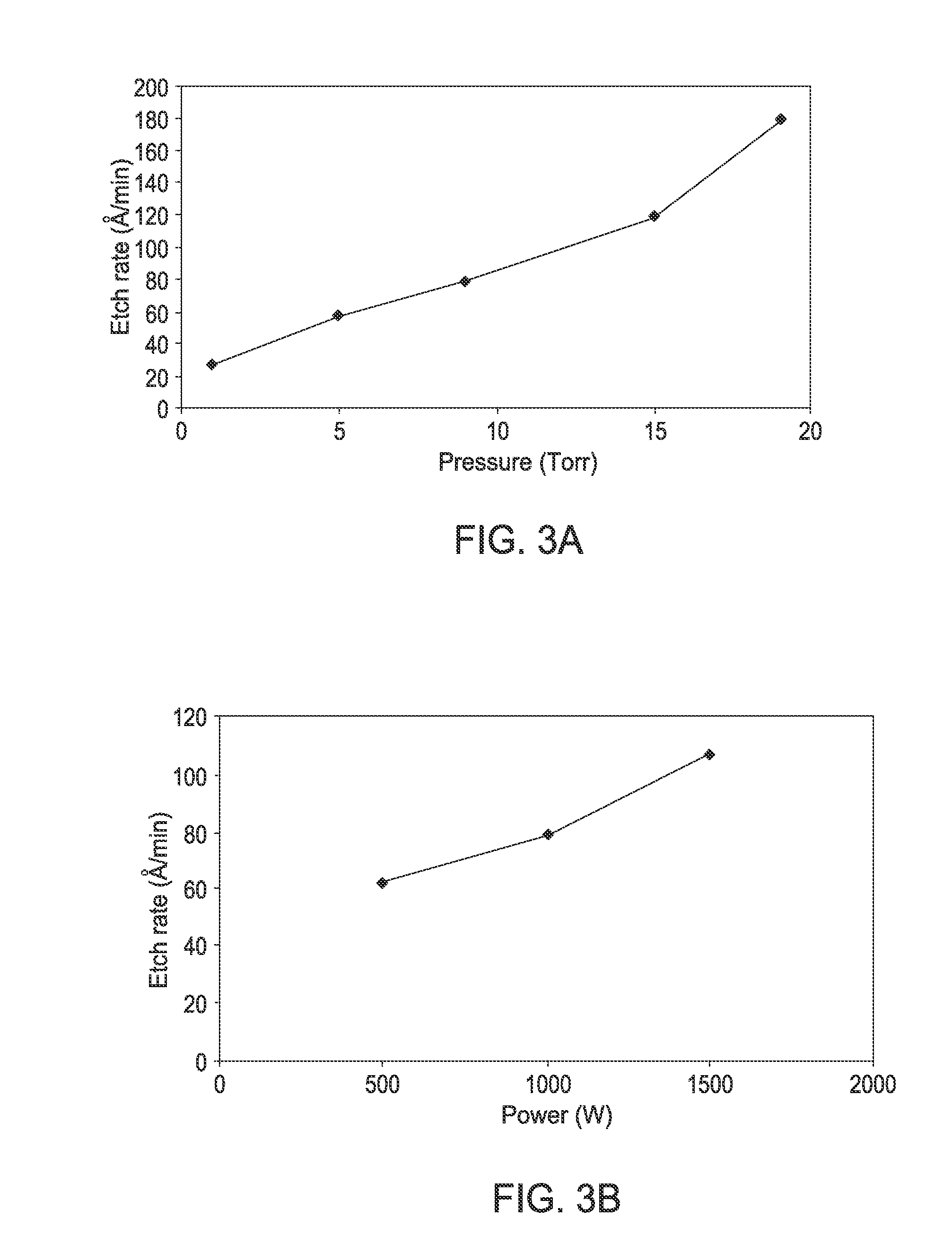

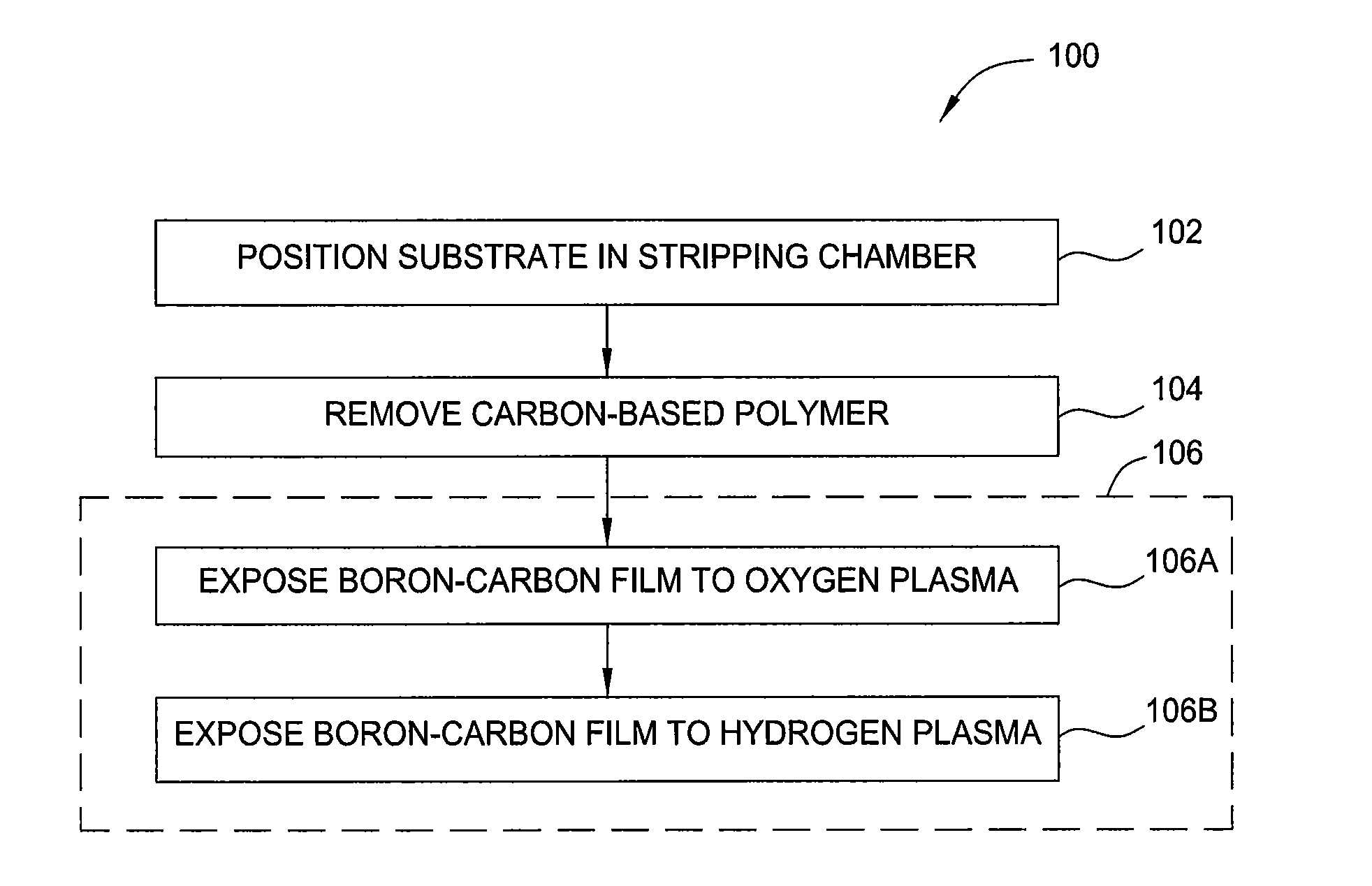

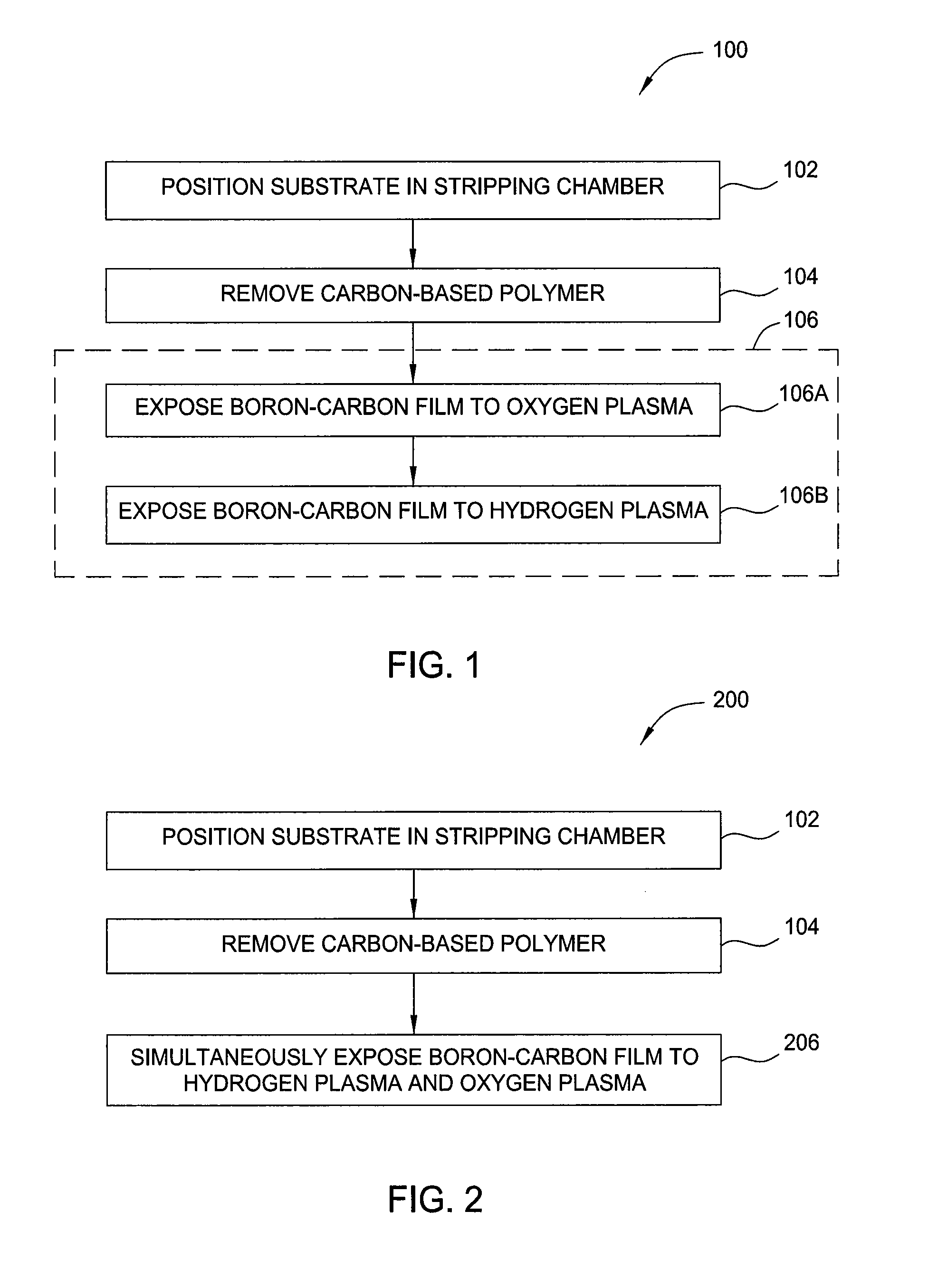

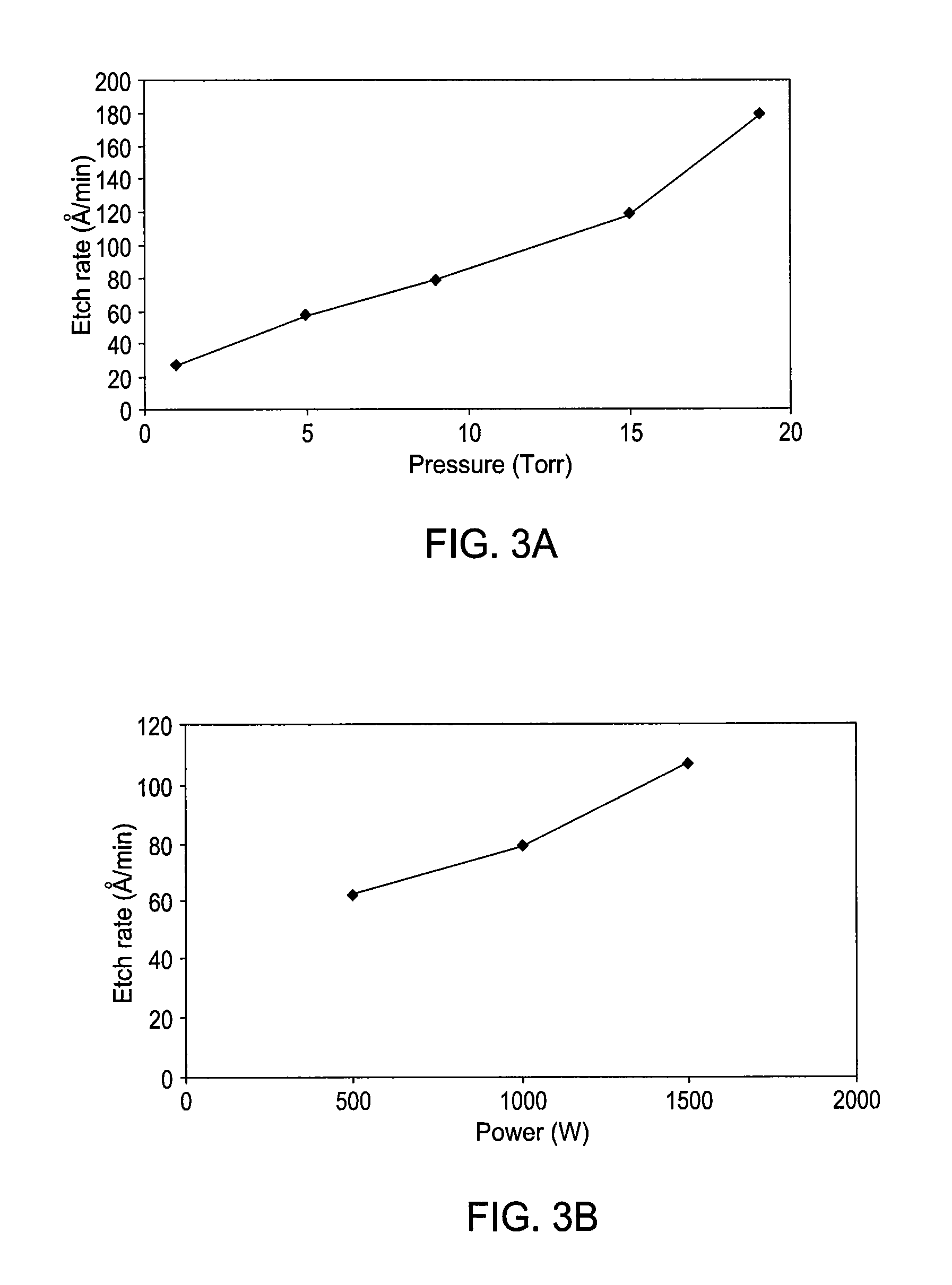

Methods of dry stripping boron-carbon films

ActiveUS20120285492A1Semiconductor/solid-state device manufacturingCleaning using gasesCarbon filmNitrogen plasma

Embodiments of the invention generally relate to methods of dry stripping boron-carbon films. In one embodiment, alternating plasmas of hydrogen and oxygen are used to remove a boron-carbon film. In another embodiment, co-flowed oxygen and hydrogen plasma is used to remove a boron-carbon containing film. A nitrous oxide plasma may be used in addition to or as an alternative to either of the above oxygen plasmas. In another embodiment, a plasma generated from water vapor is used to remove a boron-carbon film. The boron-carbon removal processes may also include an optional polymer removal process prior to removal of the boron-carbon films. The polymer removal process includes exposing the boron-carbon film to NF3 to remove from the surface of the boron-carbon film any carbon-based polymers generated during a substrate etching process.

Owner:APPLIED MATERIALS INC

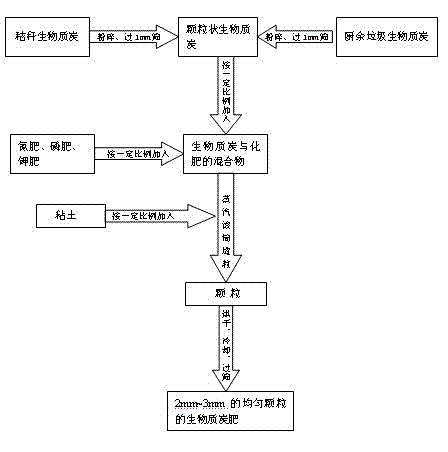

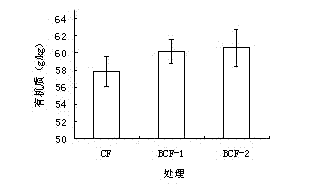

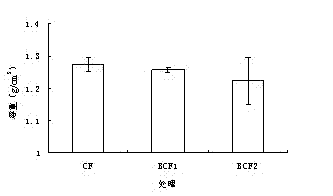

Multi-functional biomass carbon fertilizer produced by using biomass carbon from straws and kitchen waste

The present invention relates to multi-functional biomass carbon fertilizer produced by using biomass carbon from straws and kitchen waste, and belongs to the technical field of organic and inorganic compound fertilizer. The fertilizer mainly comprises the following components, by weight, 15-30% of biomass carbon, 25-35% of nitrogen fertilizer, 15-25% of phosphorus fertilizer, 15-25% of potassium fertilizer and 2-4% of clay, wherein the total nutrient weight percentage of the prepared fertilizer is 35-42%, the organic matter content is 15-20%. The preparation method comprises the following steps: crushing the biomass carbon; screening the crushed biomass carbon by using a 1 mm sieve; uniformly mixing the screened biomass carbon, the nitrogen fertilizer, the phosphorus fertilizer and the potassium fertilizer; then mixing the clay to the resulting mixture; carrying out pelletizing by a steam drum, drying and screening to prepare uniform particles with the particle sizes of 2-3 mm. According to the present invention, the resource utilization of the waste can be effectively realized; the discharge of nitrous oxide of the soil can be significantly reduced; the fixed carbon content in the soil can be improved; the soil bulk density can be regulated; the nitrogen utilization efficiency of the crop can be increased; the yield and the quality of the crop can be substantially improved.

Owner:NANJING AGRICULTURAL UNIVERSITY +1

Cleaning of hydrocarbon-containing materials with critical and supercritical solents

InactiveUS20040065353A1Liquid hydrocarbon mixture productionLiquid solutions solvent extractionAlcoholNitrous oxide

Owner:LOBO LIQUIDS

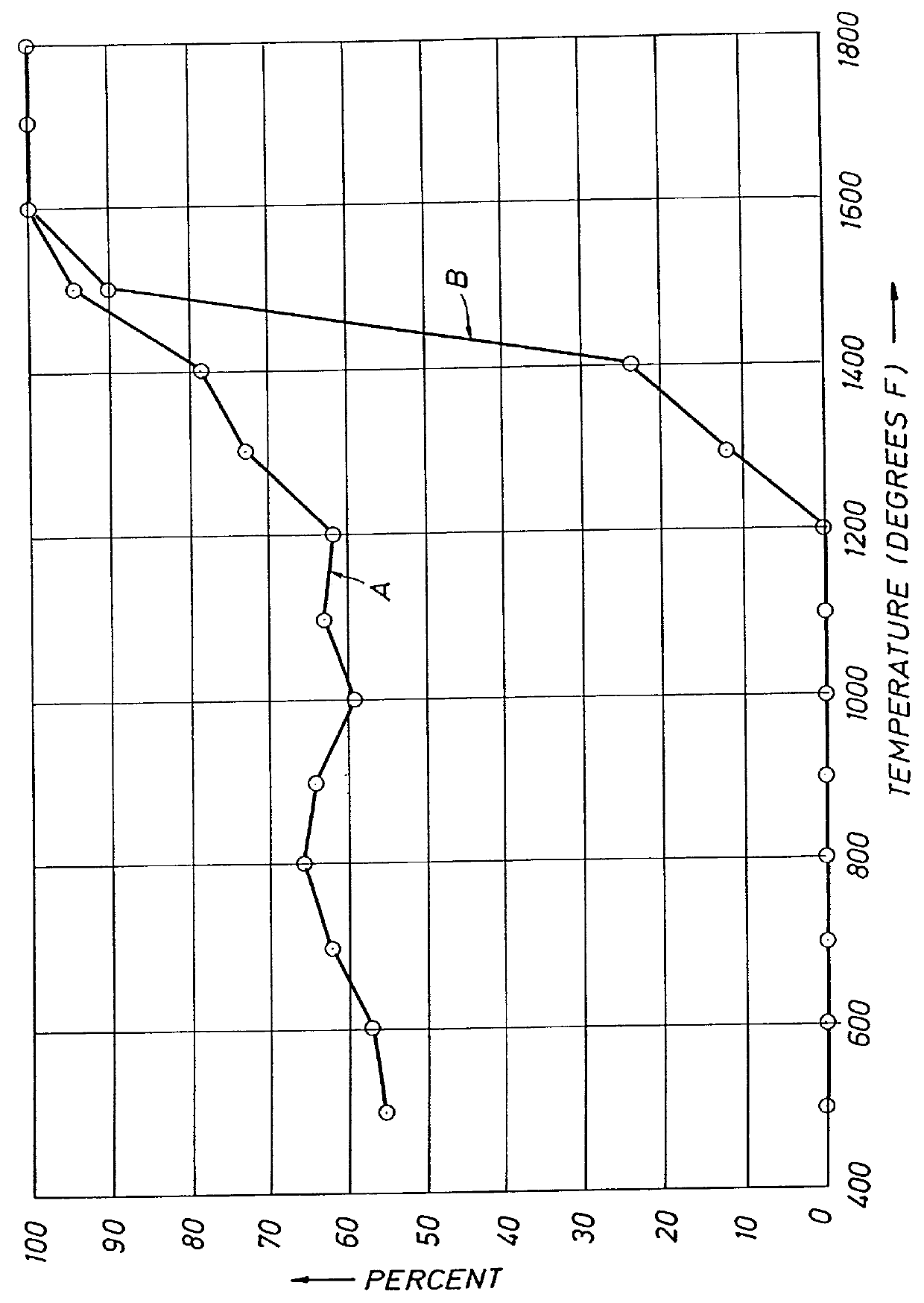

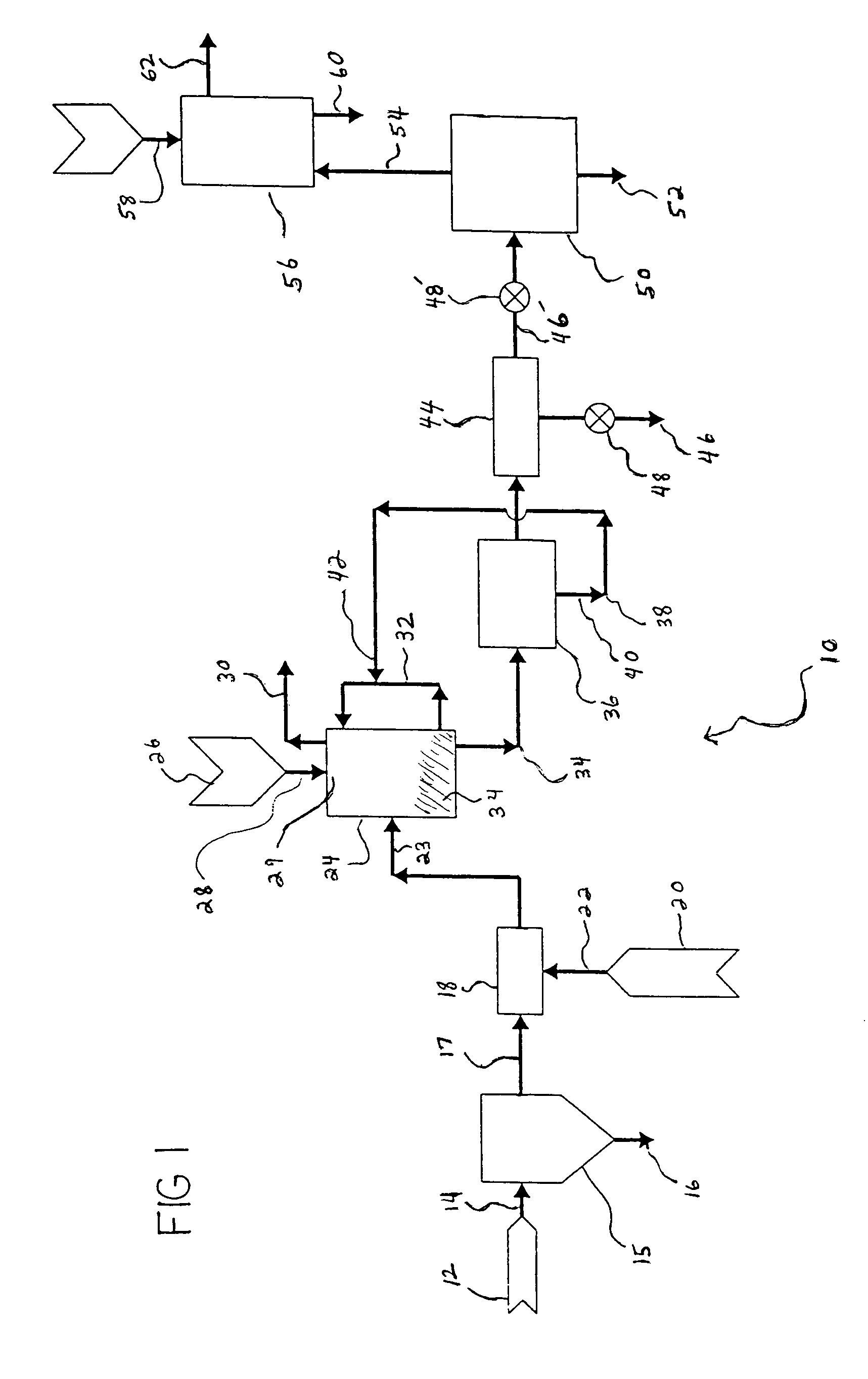

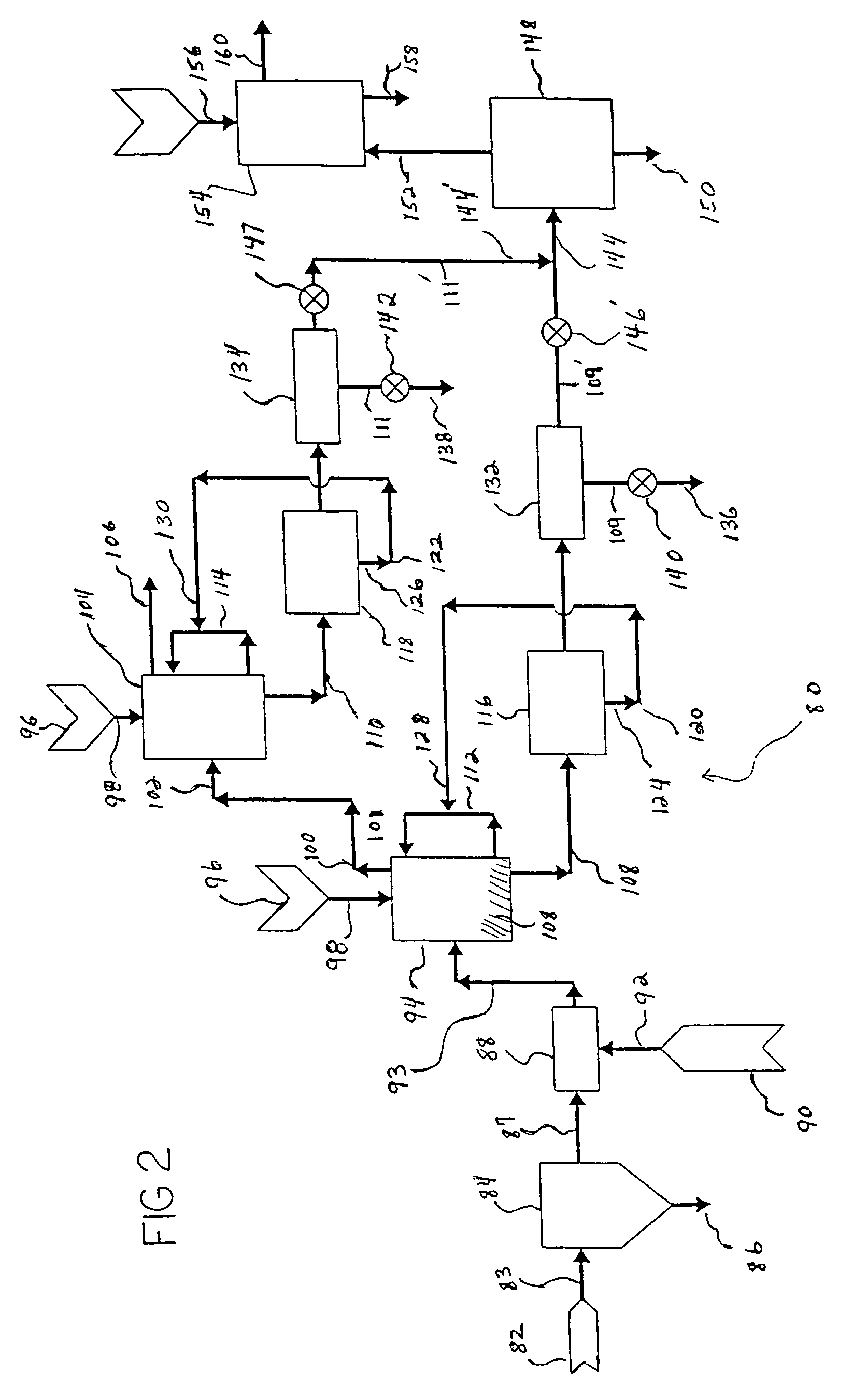

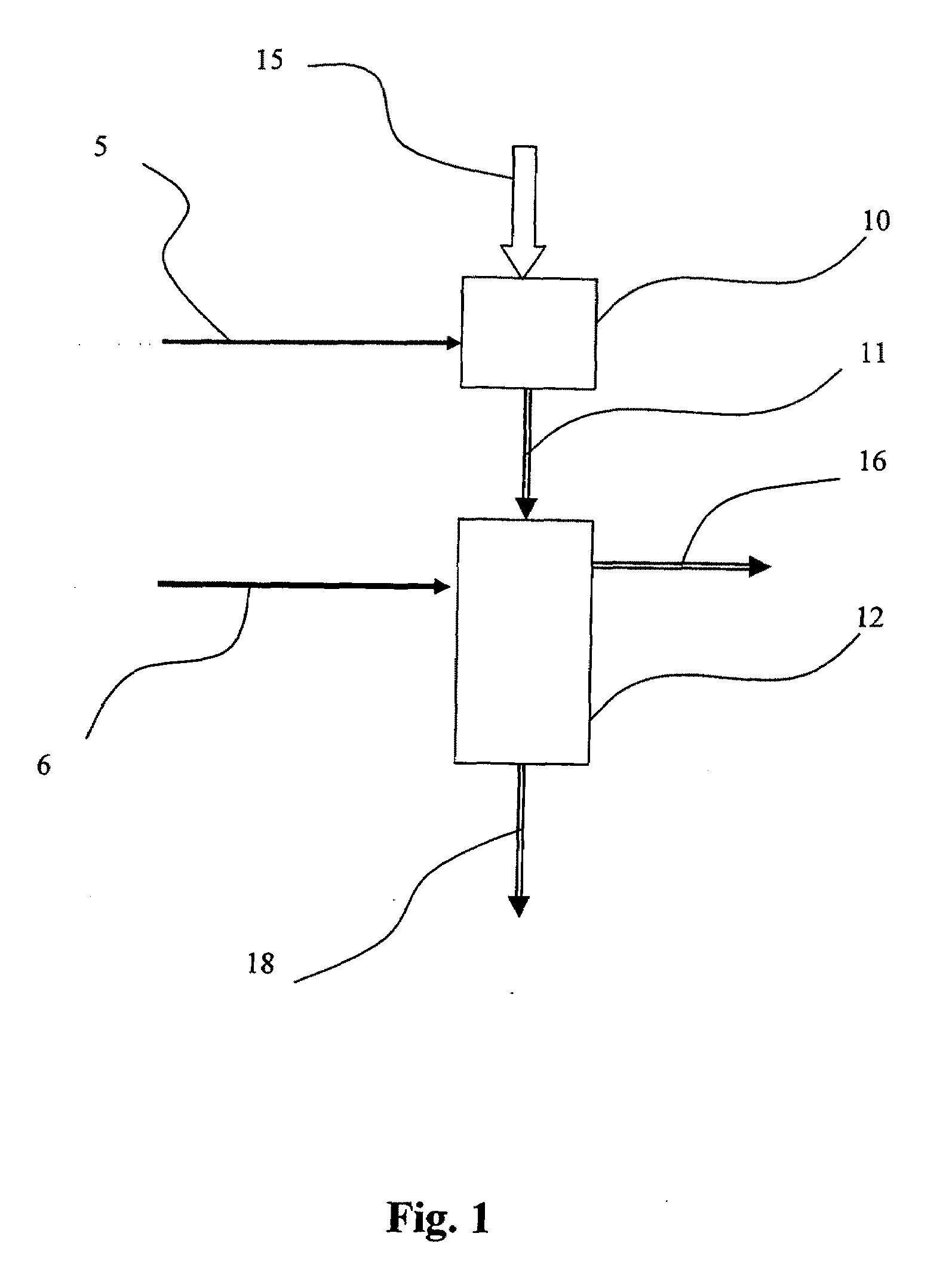

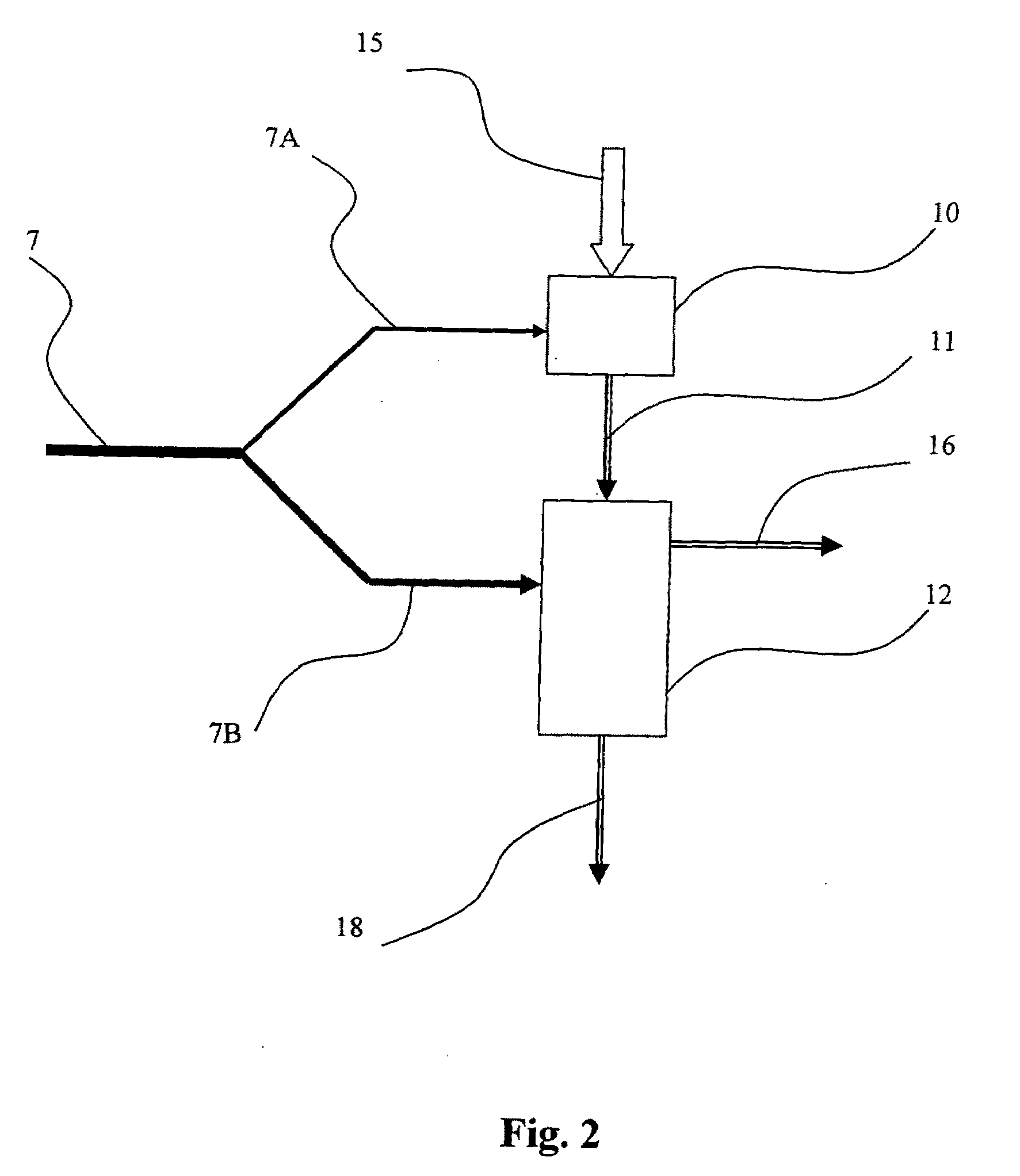

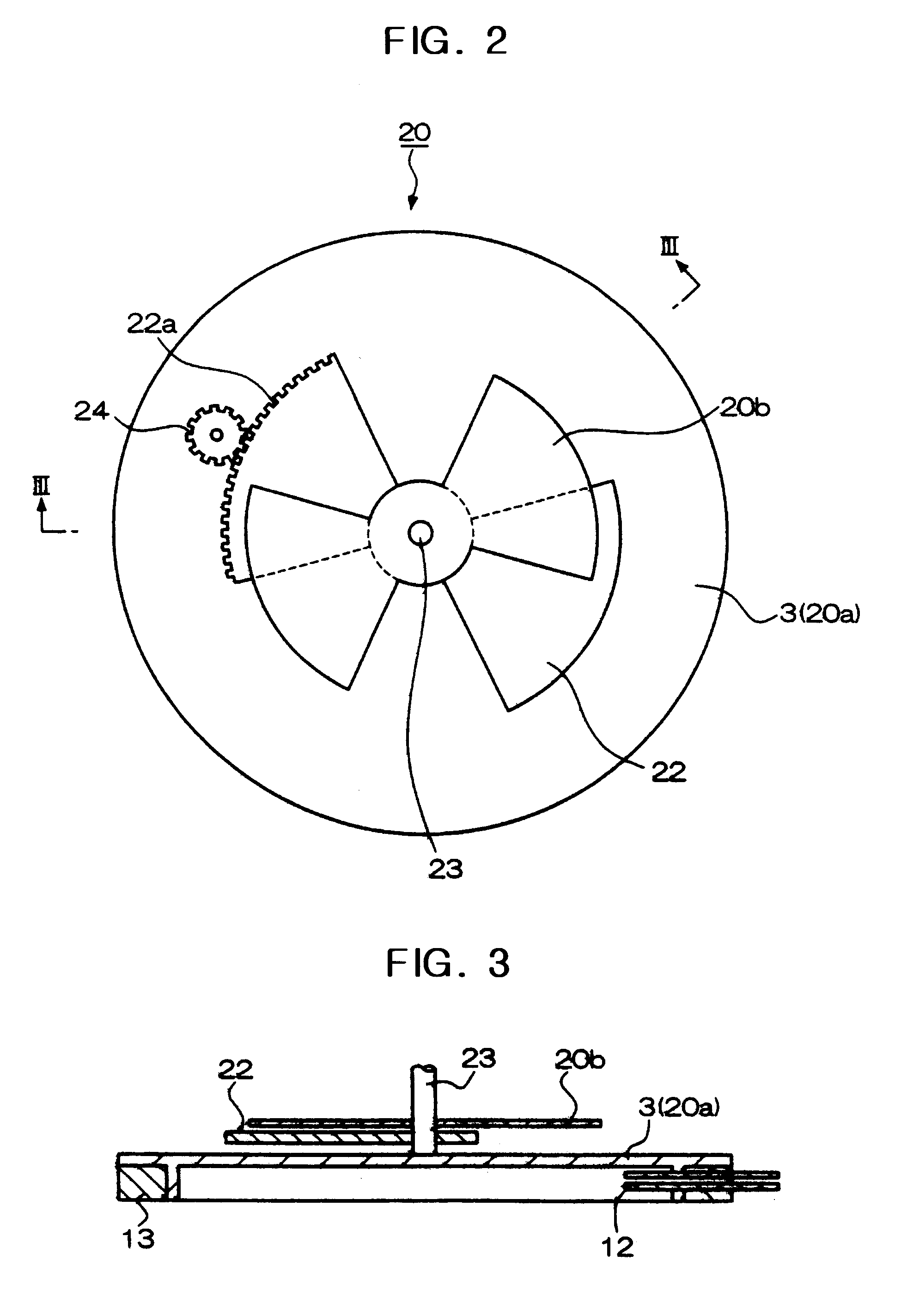

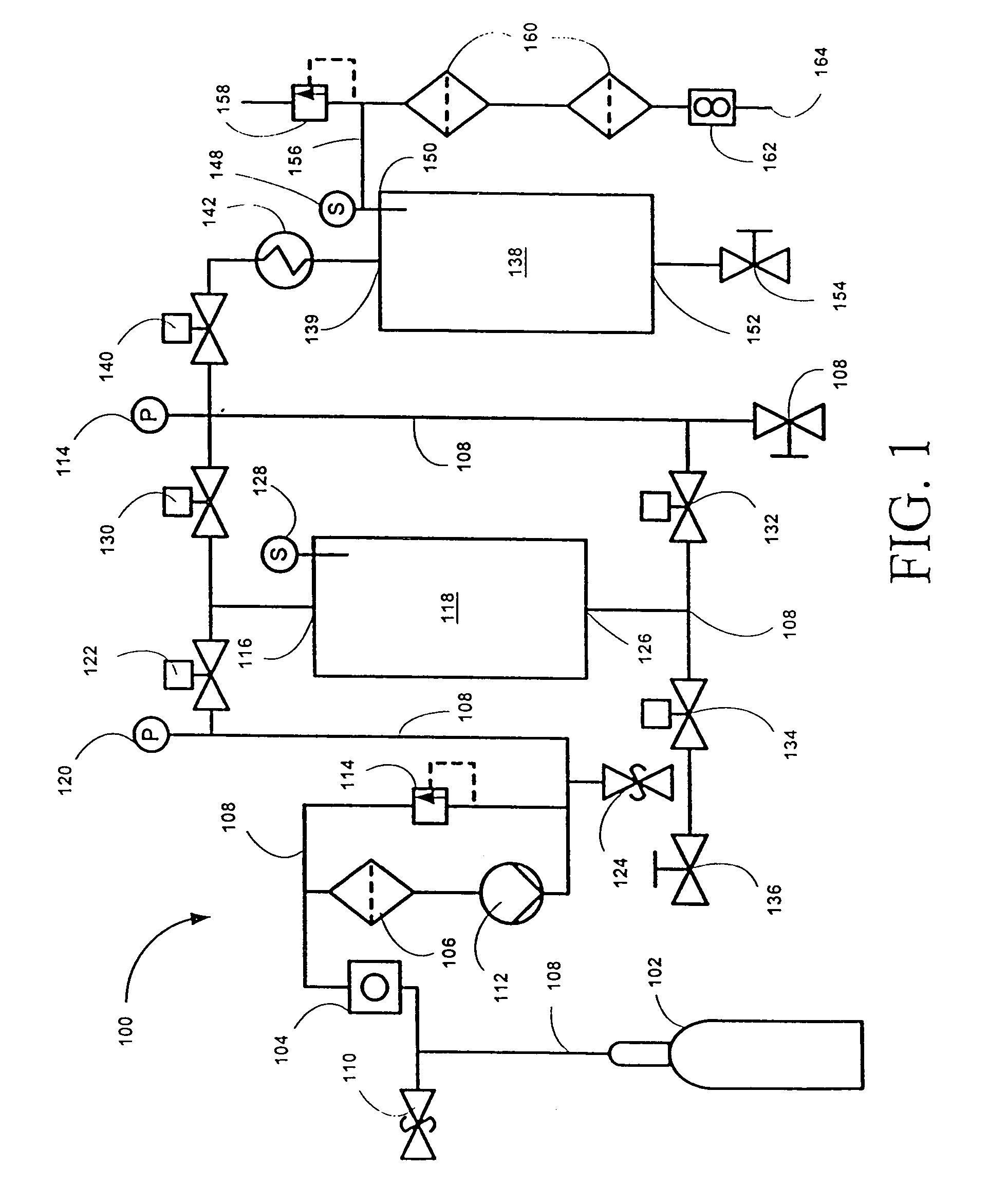

Formation of [2,2]paracyclophane and related compounds and methods for the formation of polymers from cyclophanes

ActiveUS8633289B2Increase in costLimited utilityOrganic compound preparationHydrocarbons from unsaturated hydrocarbon additionReaction intermediateReactive intermediate

An improved process and method for the formation of stable intermediate cyclophanes. Embodiments describe a general method for the production of substituted and unsubstituted cyclophanes. The components include a pyrolysis reaction tube that may be electrically heated into which a flowing stream of nitrous oxide with xylene vapor in an optional inert carrier gas at atmospheric pressure. The exit gas is condensed resulting in the deposition of [2,2′]paracyclophane. Additionally a process and method whereby the reactive intermediates of the reaction described above can be directly deposited and polymerized at atmospheric pressures or thereabout is disclosed.

Owner:CARVER SCI INC

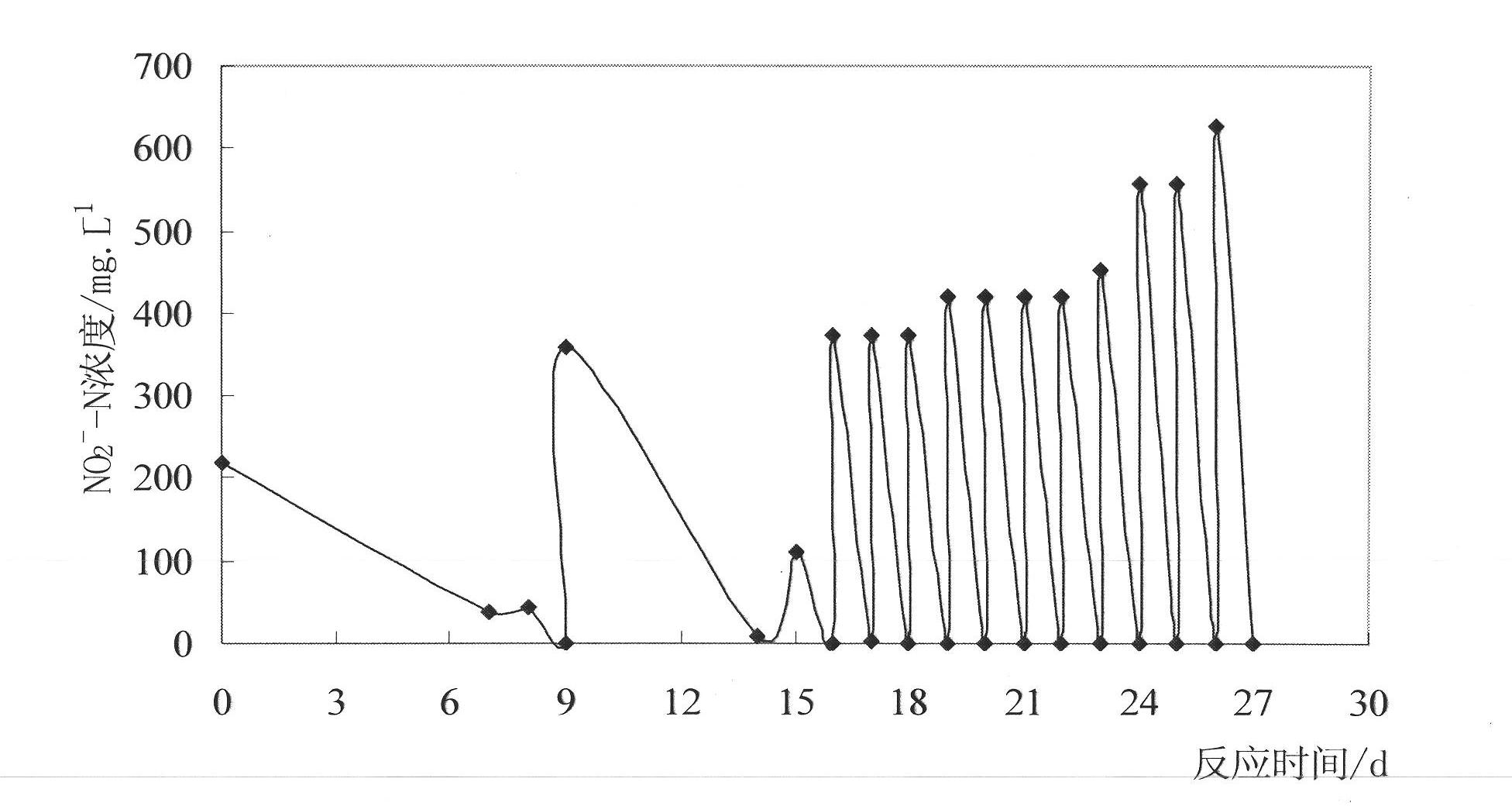

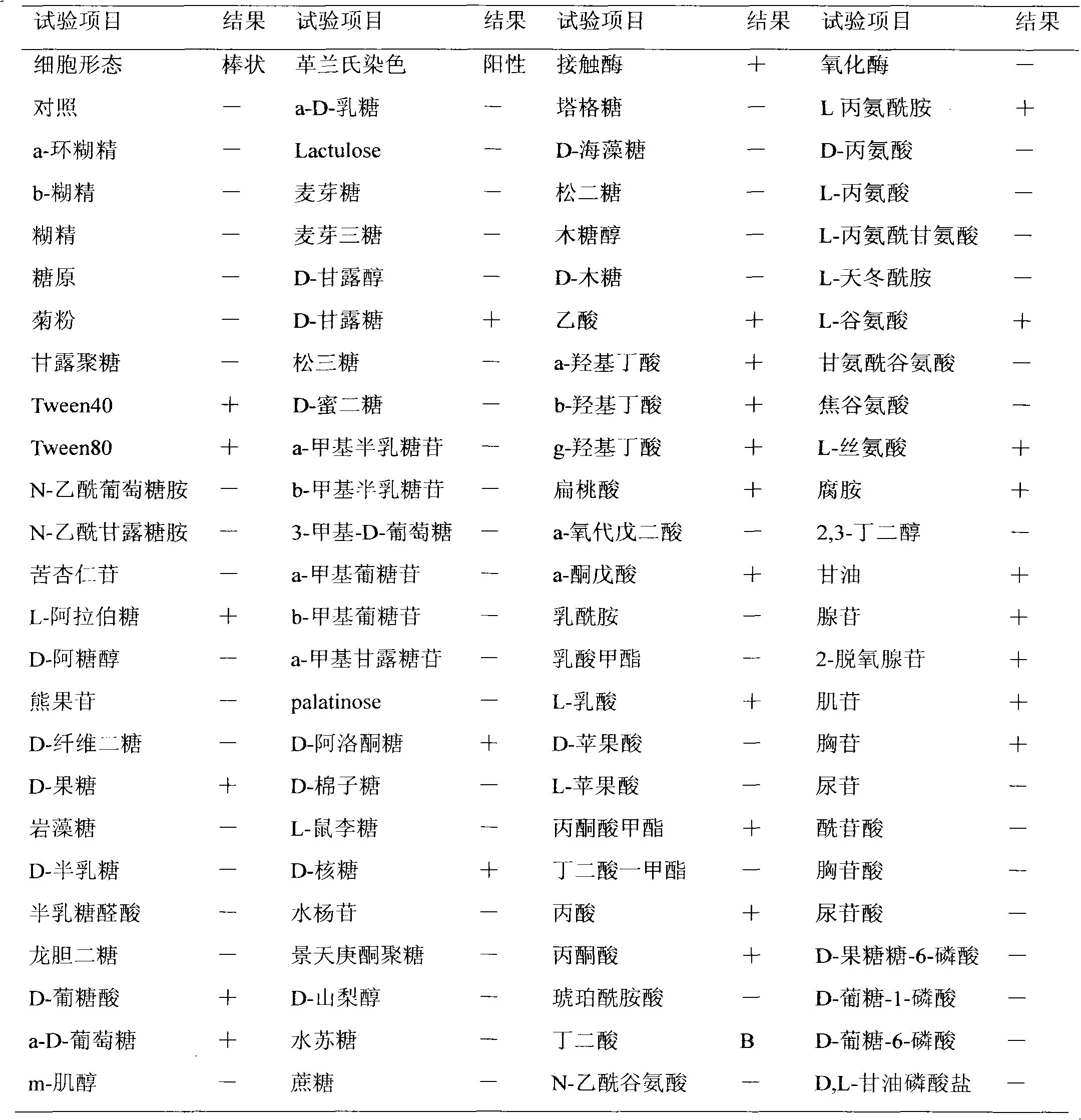

Nitrous acid-type denitrification bacteria strain and application thereof

ActiveCN102465105ACarbon savingSimple processBacteriaTreatment with anaerobic digestion processesHigh concentrationNitrous acid

The invention relates to a bacteria strain for short-cut denitrification and an application thereof. The short-cut denitrification bacteria strain is arthrobacter creatinolyticus FDN-1 and is preserved in Ordinary Microorganism Center of China Committee for Culture Collection of Microorganisms on March 11, 2010, and the preservation number is CGMCC No. 3657. The bacteria strain can directly adopt nitrite nitrogen as a substrate to complete the short-cut denitrification process. When the arthrobacter creatinolyticus FDN-1 is used for processing ammonia-contained waste water, the technique is simple, high denitrification activity can be still obtained under the condition that low-concentration organic carbon source exists, and at the same time the high-concentration organic carbon source can be withstood. When the bacteria strain is in use, the system is rapid to start, and a vast application prospect can be realized in the denitrification treatment process of different types of waste water.

Owner:CHINA PETROLEUM & CHEM CORP +1

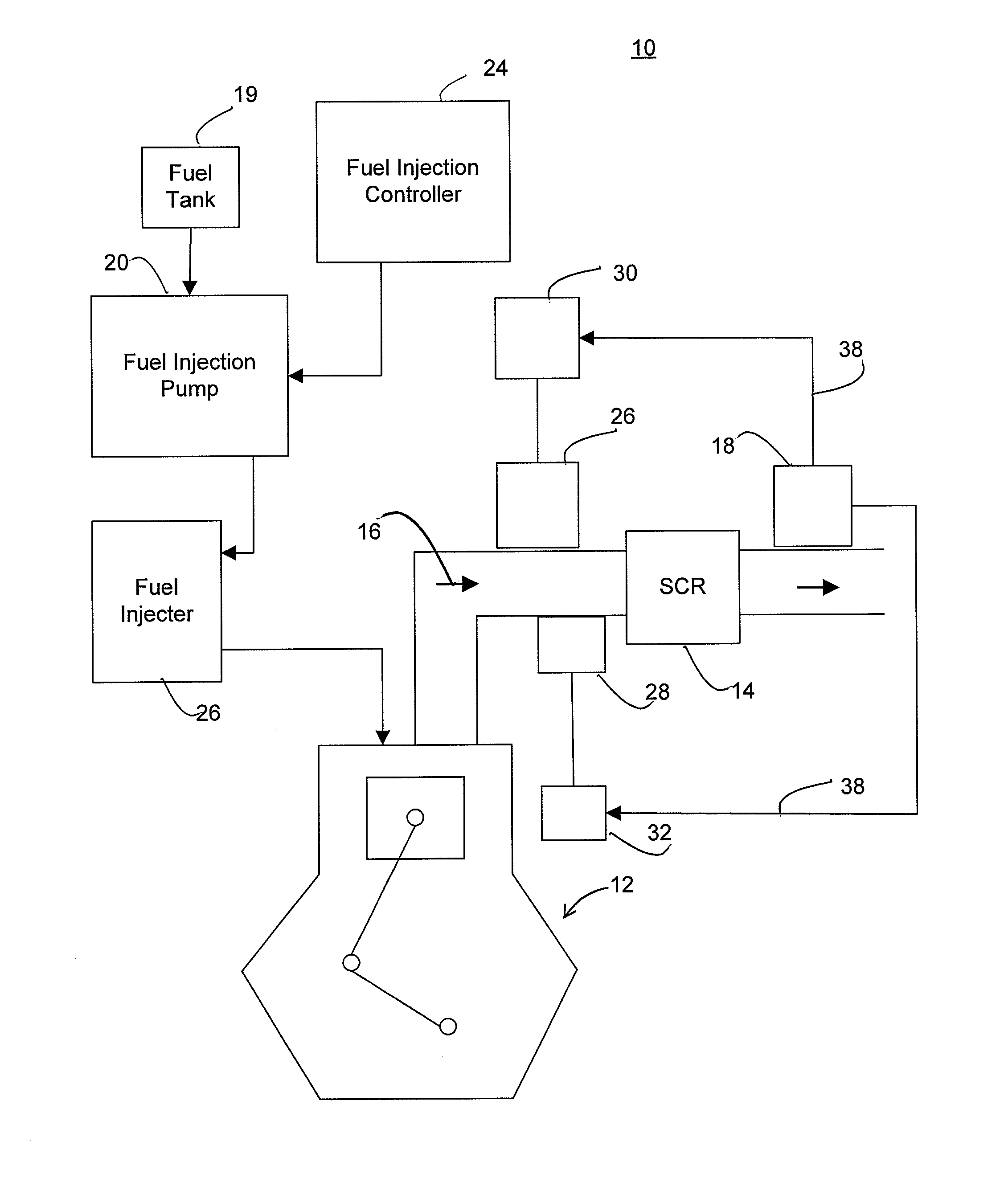

System and Method for Controlling Nitrous Oxide Emissions of an Internal Combustion Engine and Regeneration of an Exhaust Treatment Device

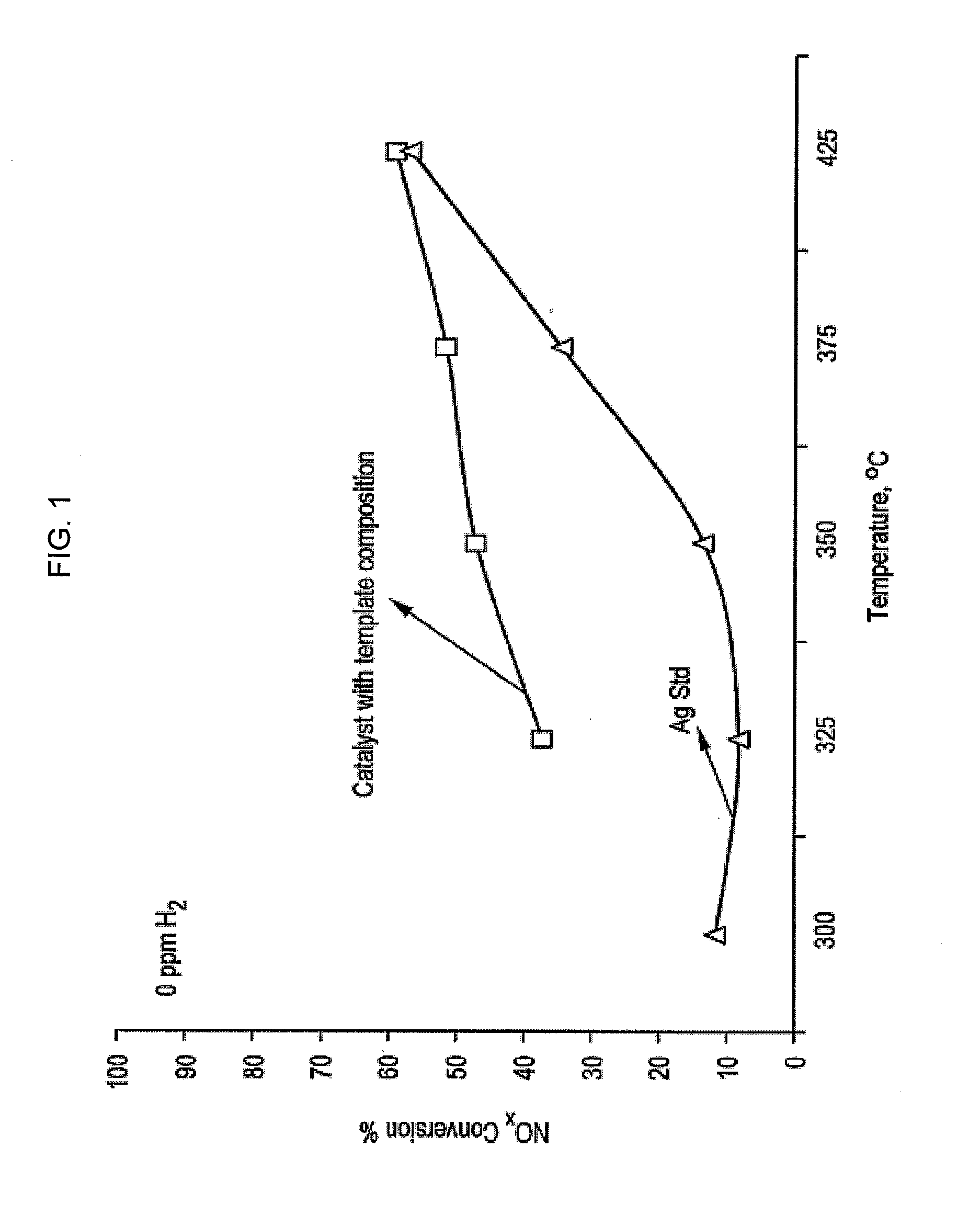

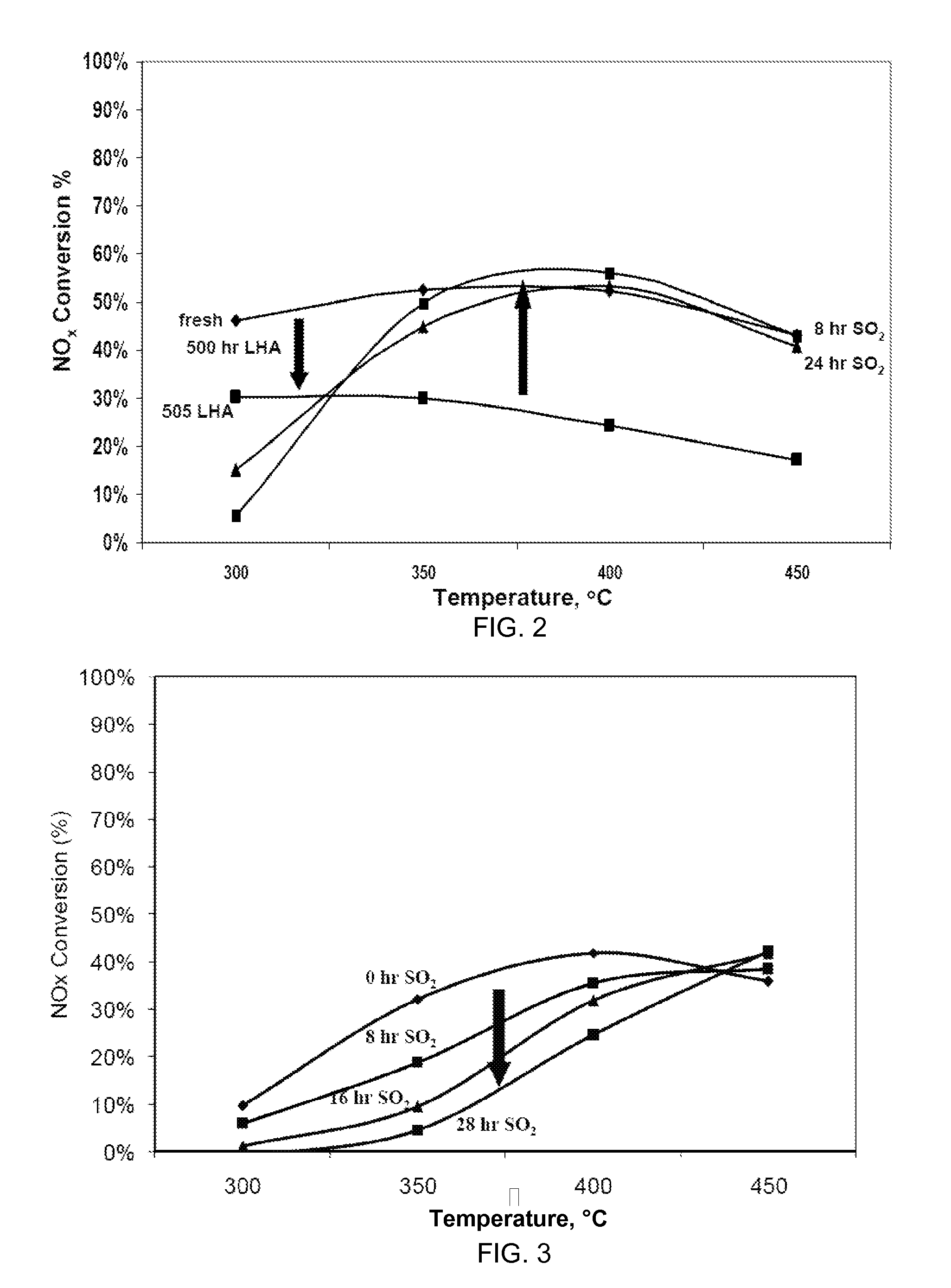

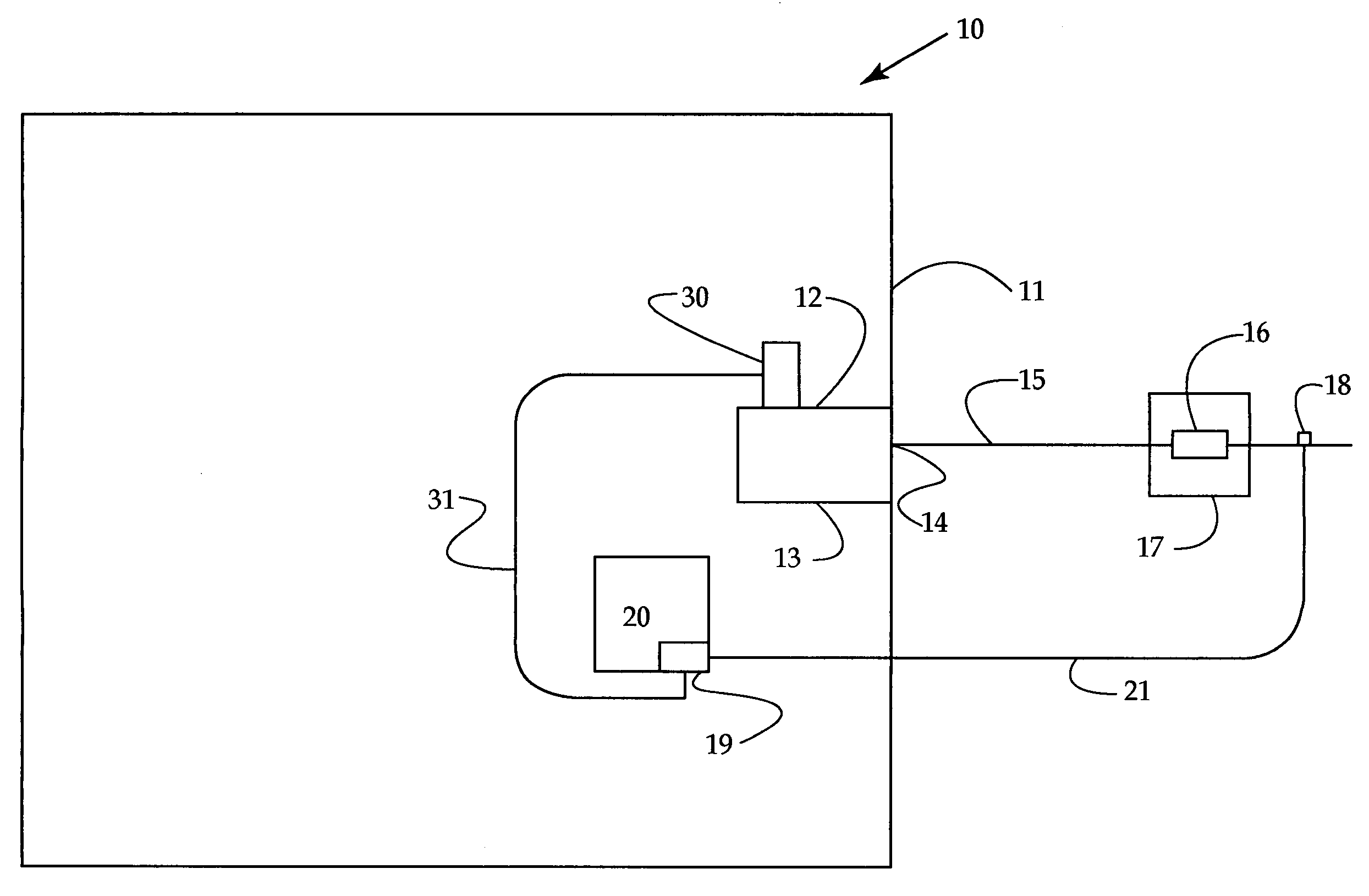

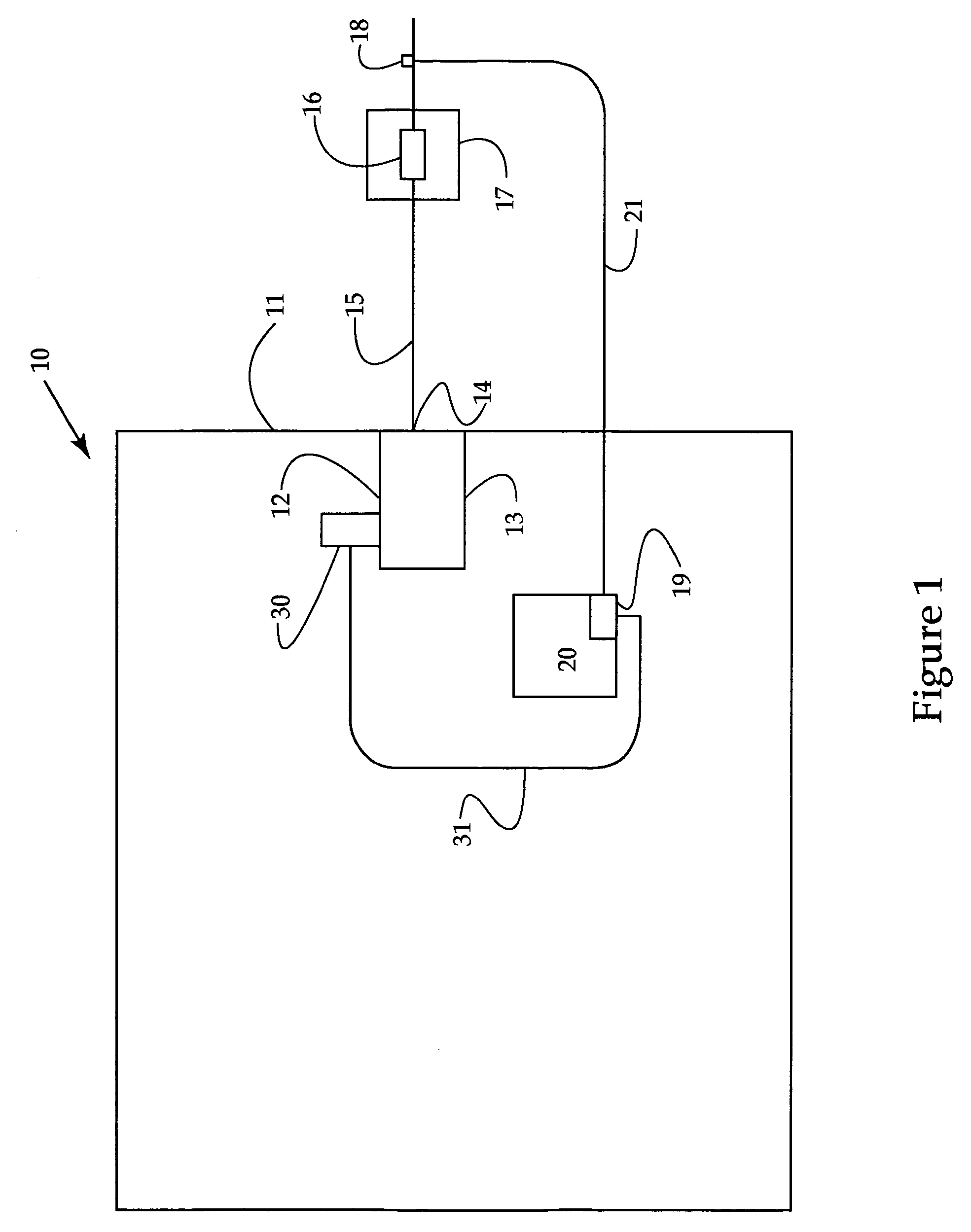

ActiveUS20110209459A1Internal combustion piston enginesExhaust apparatusExhaust fumesCatalytic metal

A catalyst composition is provided that includes a catalytic metal secured to a substrate, and the substrate is mesoporous and has pores that are templated. A catalyst composition includes a catalytic metal secured to a mesoporous substrate. The mesoporous substrate is a reaction product of a reactive solution, a solvent, a modifier, and a templating agent. A method for controlling nitrous oxide emissions including the catalyst composition comprising introducing a regeneration fuel into an exhaust stream upstream relative to the catalyst composition and heating the exhaust stream upstream relative to the catalyst composition. When the regeneration fuel is introduced the air λ of an air / fuel mixture of a lean burn exhaust does not exceed 1.

Owner:GE GLOBAL SOURCING LLC

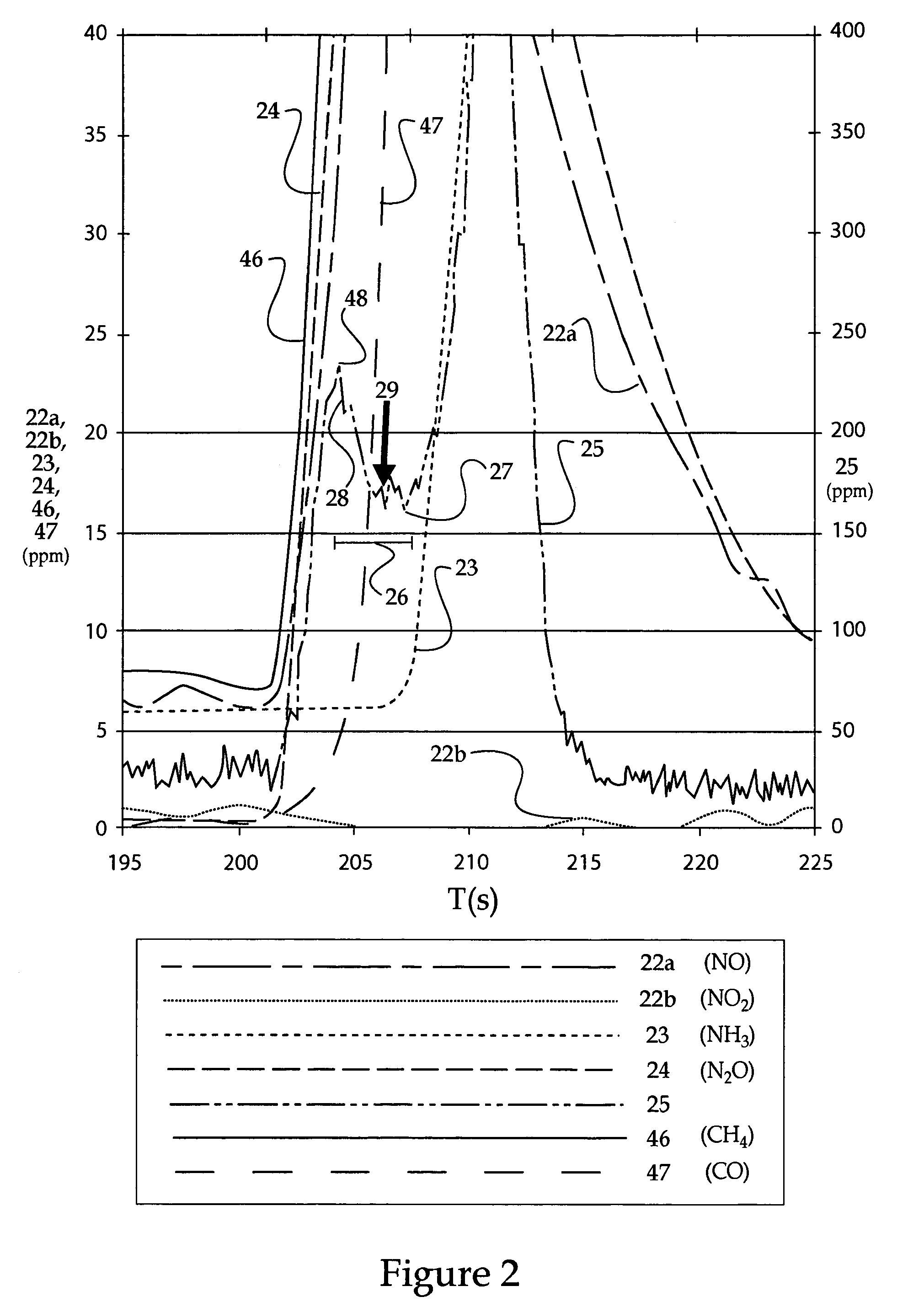

NOx adsorber and method of regenerating same

New technologies, such as NOx adsorber catalytic converters, are being used to meet increasingly stringent regulations on undesirable emissions, including NOx emissions. NOx adsorbers must be periodically regenerated, which requires an increased fuel consumption. The present disclosure includes a method of regenerating a NOx adsorber within a NOx adsorber catalytic converter. At least one sensor positioned downstream from the NOx adsorber senses, in the downstream exhaust, at least one of NOx, nitrous oxide and ammonia concentrations a plurality of times during a regeneration phase. The sensor is in communication with an electronic control module that includes a regeneration monitoring algorithm operable to end the regeneration phase when a time rate of change of the at least one of NOx, nitrous oxide and ammonia concentrations is after an expected plateau region begins.

Owner:CATERPILLAR INC

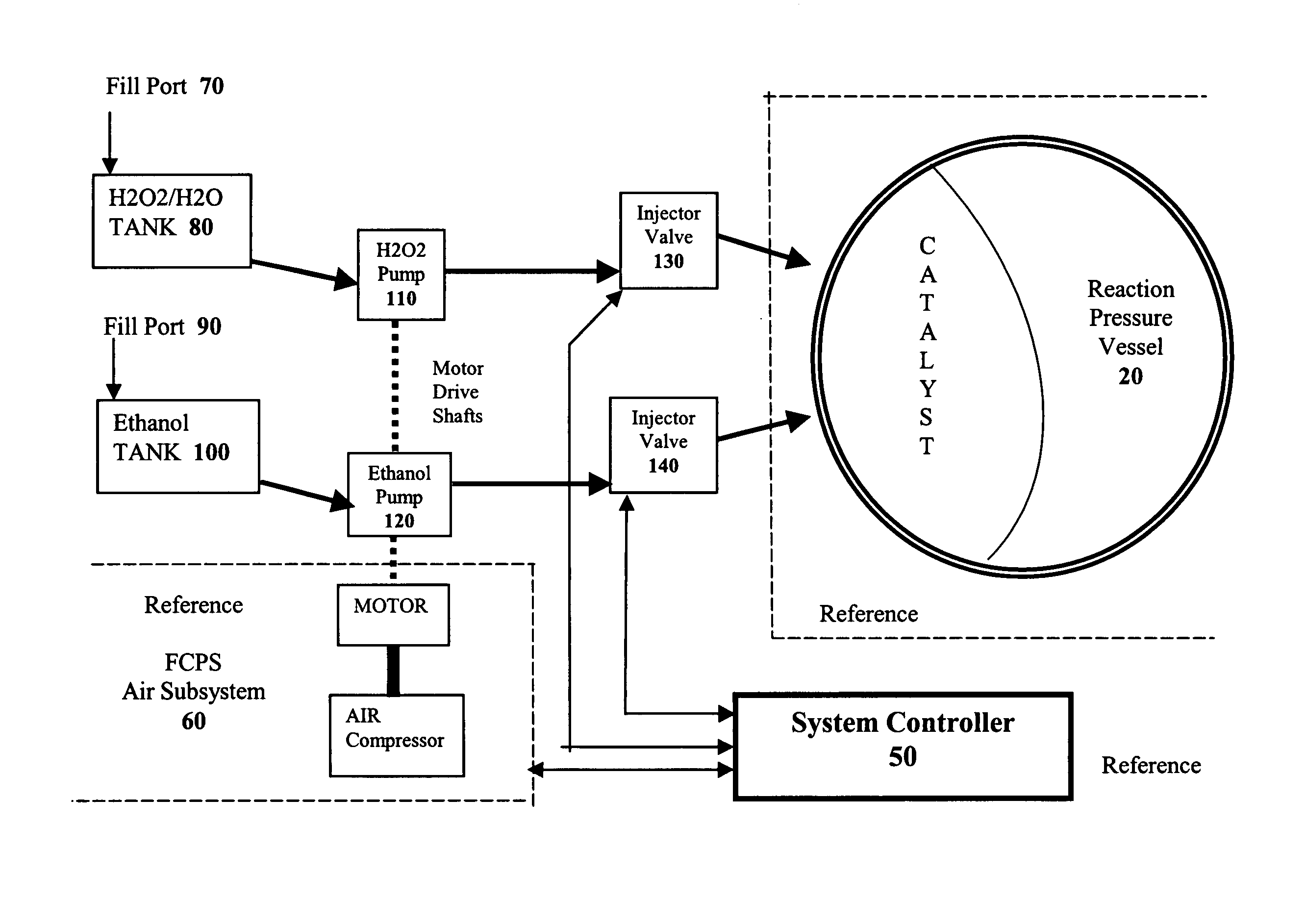

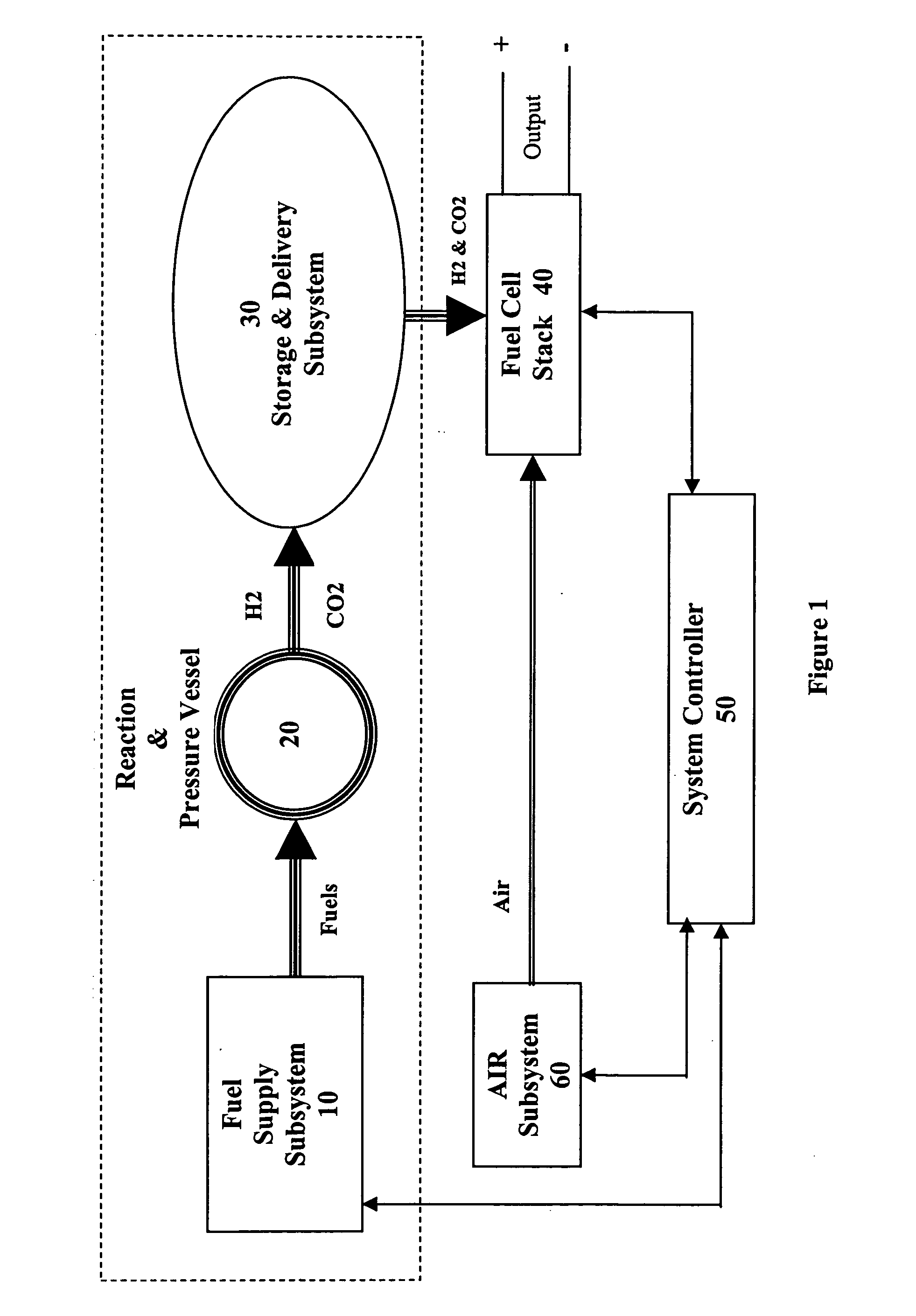

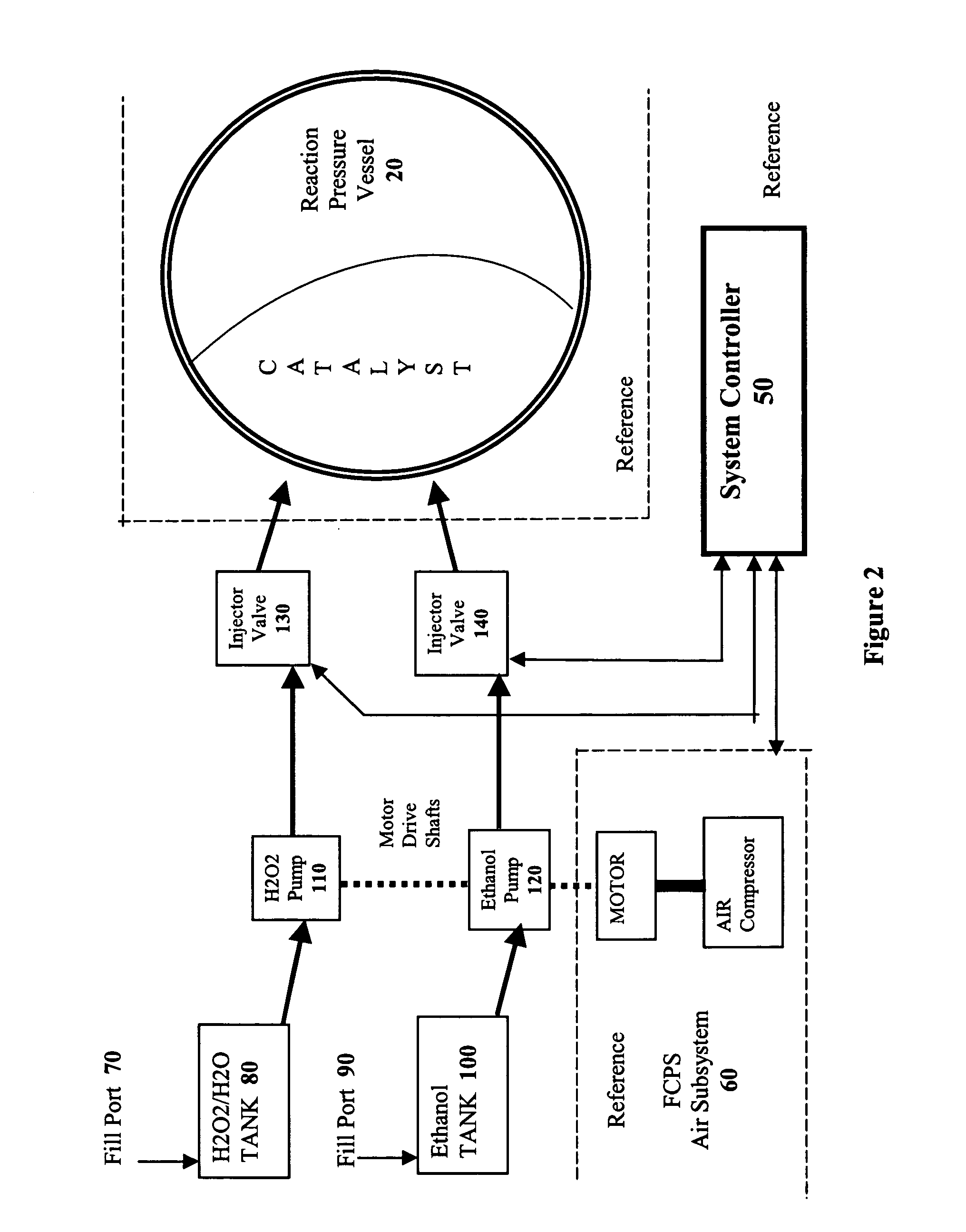

Hypergolic hydrogen generation system for fuel cell power plants

InactiveUS20050031918A1Increased electrical power densityIncrease pressureHydrogen separation using solid contactFuel cell auxillariesHydrocotyle bowlesioidesOxygen

The invention provides a controlled hypergolic approach to using concentrated hydrogen peroxide in combination with certain hydrocarbons such as ethanol, methanol, methane as well as more common fuels such as gasoline, diesel, DME, JP5, JP8 and the like to generate a gas mixture primarily composed of hydrogen and carbon dioxide. Because air is not used as the oxygen source, this novel process does not allow the formation of nitrous oxide (NOx) compounds, thereby avoiding the primary source of nitrogen contamination as well. The process is executed in a constraining system on a micro scale such that the resulting hydrogen supply is self-pressurizing. This enables the incorporation of an “on-demand” hydrogen fuel source for a variable output fuel cell power plant such as those proposed for use in automobiles, marine vessels and stationary power sources. In another embodiment of the present invention hydrogen peroxide is catalytically, or thermally reacted to provide H2O vapor and O2. When this gaseous stream is introduced to the cathode of the fuel cell, the percent concentration of oxygen is increased with no corresponding increase in the parasitic power demand made by an air-moving device. This use of H2O2 as an oxygen source may be continuous, intermittent or limited to specific instances when peak power output demands or high transient loads are placed upon the FCPS.

Owner:CBH2 TECH

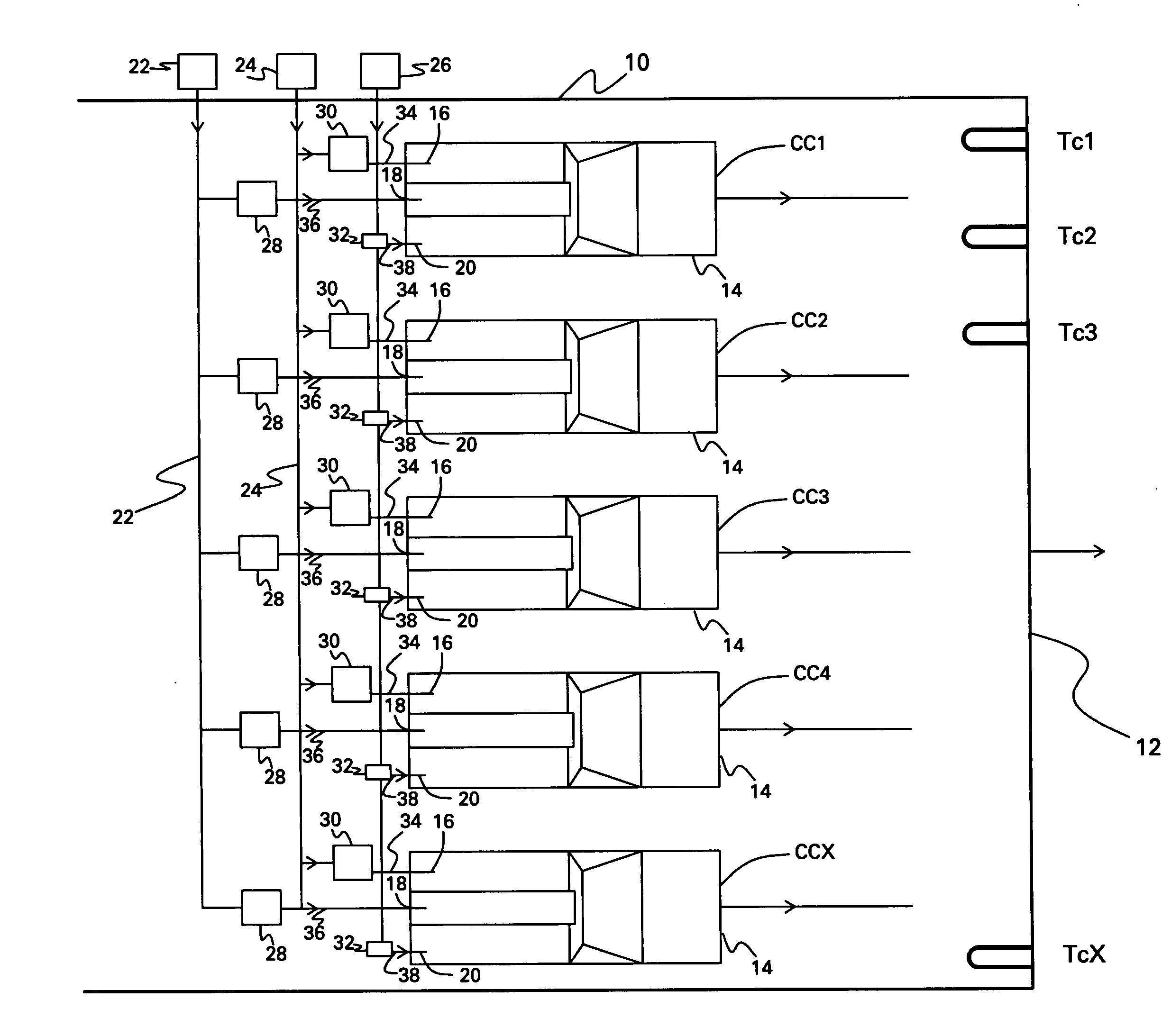

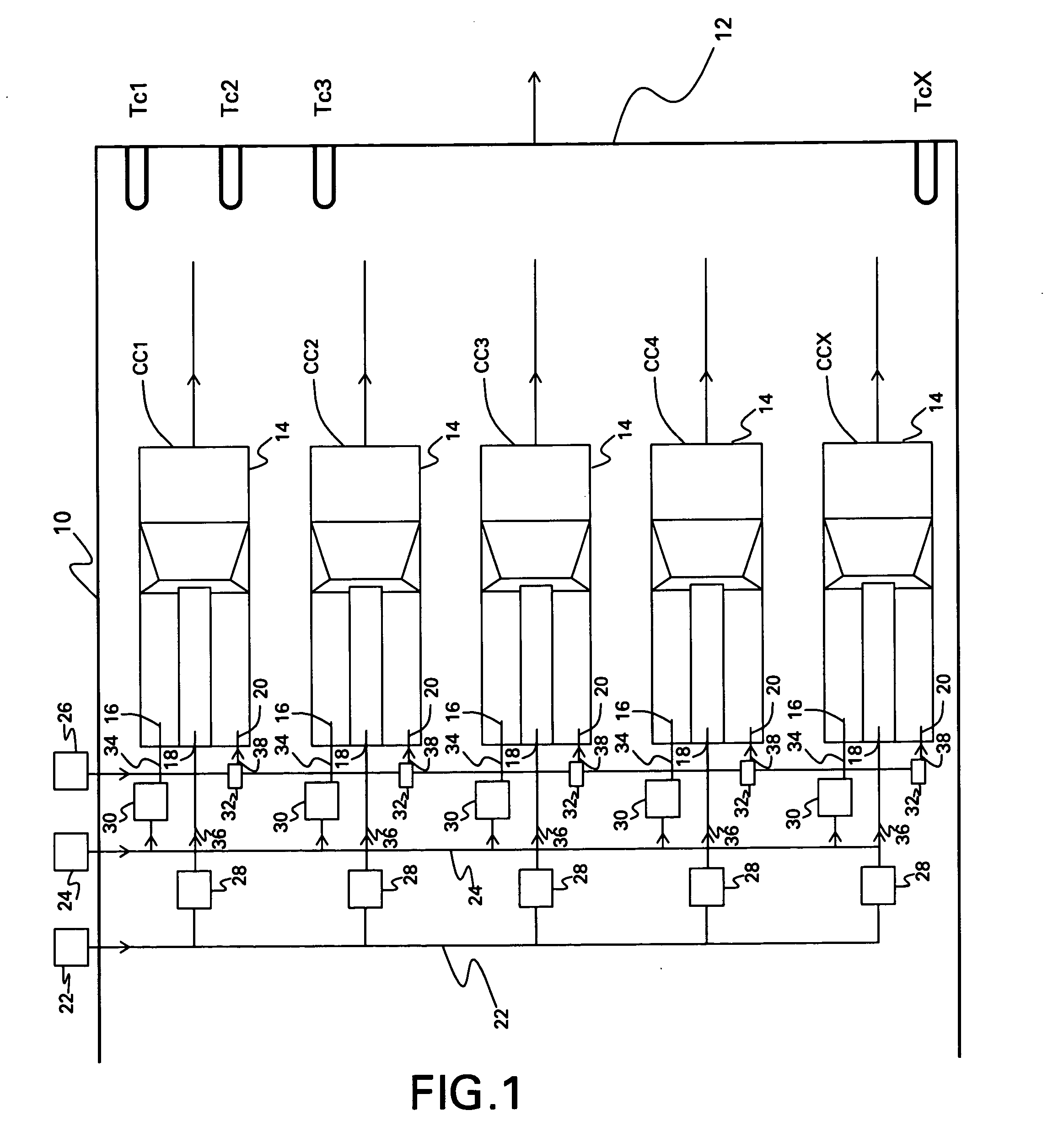

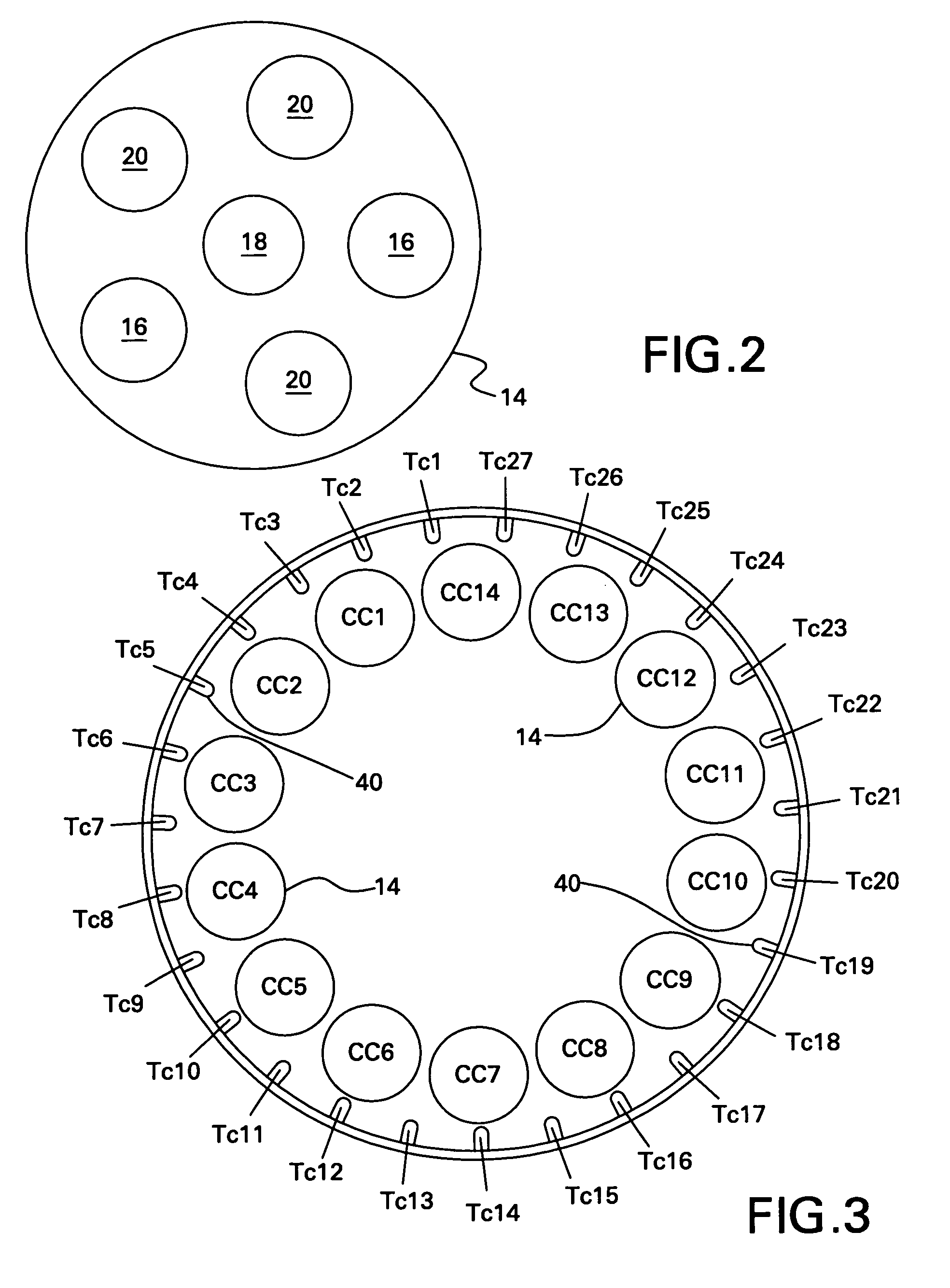

Method and apparatus for actuating fuel trim valves in a gas turbine

ActiveUS20050097895A1Minimized pressure dropOvercomes shortcomingFuel supply regulationContinuous combustion chamberCombustion chamberNitrous oxide

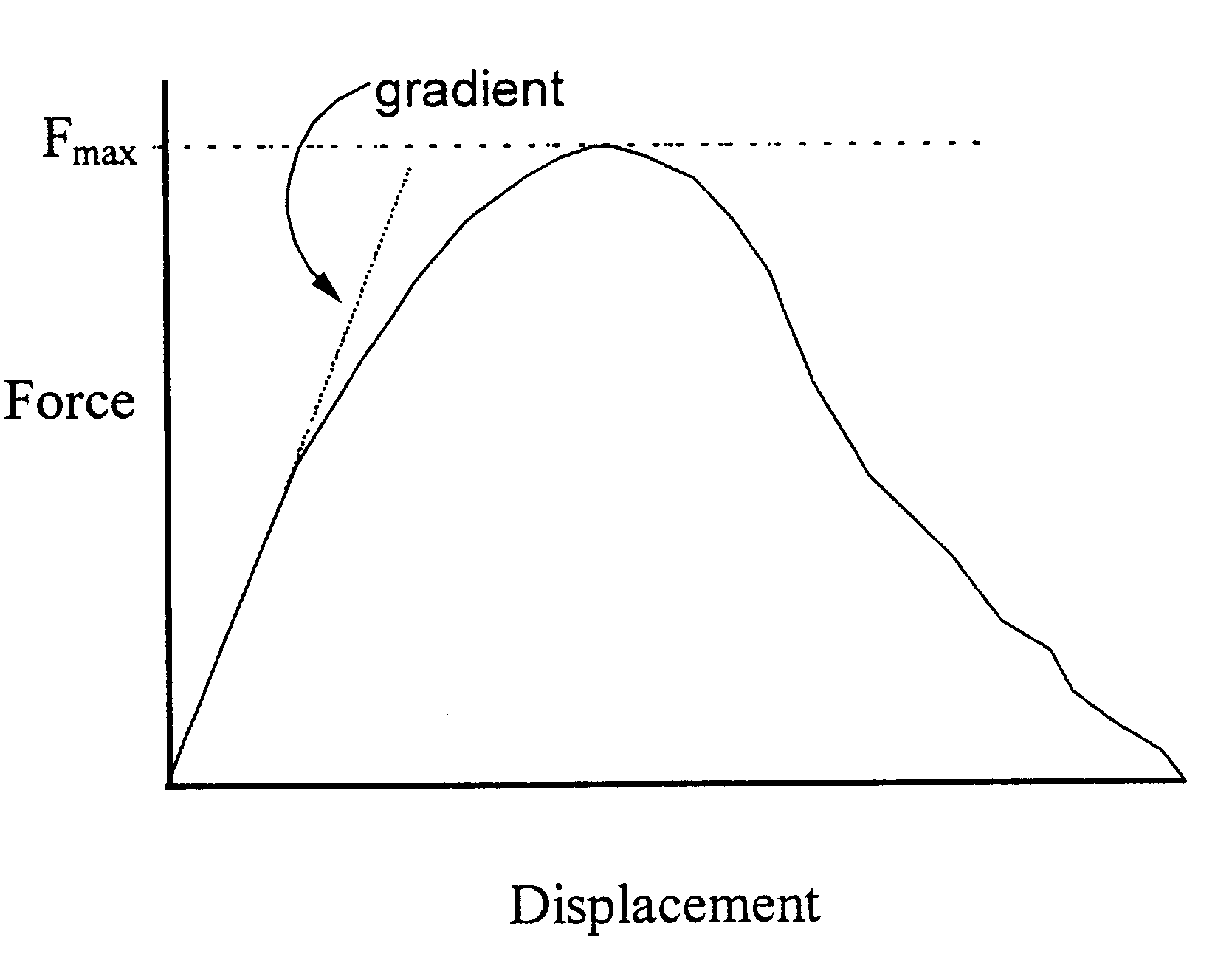

The gas turbines of the present invention have multiple combustion chambers, and within each chamber are multiple fuel nozzles. Each nozzle has its own fuel control valve to control the fuel flowing to the nozzles. To minimize the pressure drop through the fuel control valves, multiple manifolds are employed. Each manifold supplies at least one fuel nozzle in multiple combustion chambers with fuel. The fuel control valves are mounted on the manifolds such that the weight of the fuel control valves and nozzles are carried by the manifolds, not the multiple combustion chambers. A plurality of thermocouples for measuring exhaust gas from said multiple combustion chambers are employed to sense gas exhaust temperature. In carrying out the methods of the present invention for tuning a gas turbine, it is essential to note that the most efficient gas turbine is one which has the least nitrous oxides, the least amount of unburned hydrocarbons, and the least amount of carbon monoxide for a specified energy output. In order to tune the gas turbine to accomplish these objectives, it is desirable that each combustion chamber in the gas turbine be well balanced relative to the remaining combustion chambers. It is an aim of the present invention to tune each of the multiple combustion chambers such that no specific combustion chamber is rich or lean, and all are operating within about 1% of the remaining combustion chambers.

Owner:GENERAL ELECTRIC CO

Ice confection

A water ice comprising an antifreeze protein, a stabilizer and not less than 0.1 wt % of a protein based aerating agent obtainable by a process comprising aerating the ice confection with an aerating gas which contains at least 50% by volume of a water soluble gas such as carbon dioxide, nitrous oxide and mixtures thereof.

Owner:GOOD HUMOR BREYERS ICE CREAM DIV OF CONOPCO

Method for making silicon nitride-oxide ultra-thin gate insulating layers for submicrometer field effect transistors

InactiveUS6323143B1Reduces and prevents boron penetrationSemiconductor/solid-state device manufacturingSemiconductor devicesSilicon oxideField-effect transistor

A method for making an improved ultra-thin silicon nitride-oxide gate insulating layer for field effect transistors (FETs) is achieved. After forming a field oxide to electrically isolate device areas on a silicon substrate, an ultra-thin silicon nitride-oxide insulating layer is formed in two process steps. In the first process step a silicon nitride layer is formed on the device areas on the substrate using a low-pressure rapid thermal process (LP-RTP) and a reactant gas of ammonia (NH3) while insuring that the RTP tool is free of oxygen. Then a second process step is carried out sequentially in the same LP-RTP at an elevated temperature and using an oxygen-rich ambient (dinitrogen oxide N2O) as a reoxidation gas. The non-self-limiting characteristic of the ultra-thin-silicon nitride layer results in the controllable diffusion of the dissociated oxygen (O) and nitrous oxide (NO) through the silicon nitride layer to form a thin good quality silicon oxide layer on and in the substrate surface.

Owner:TAIWAN SEMICON MFG CO LTD

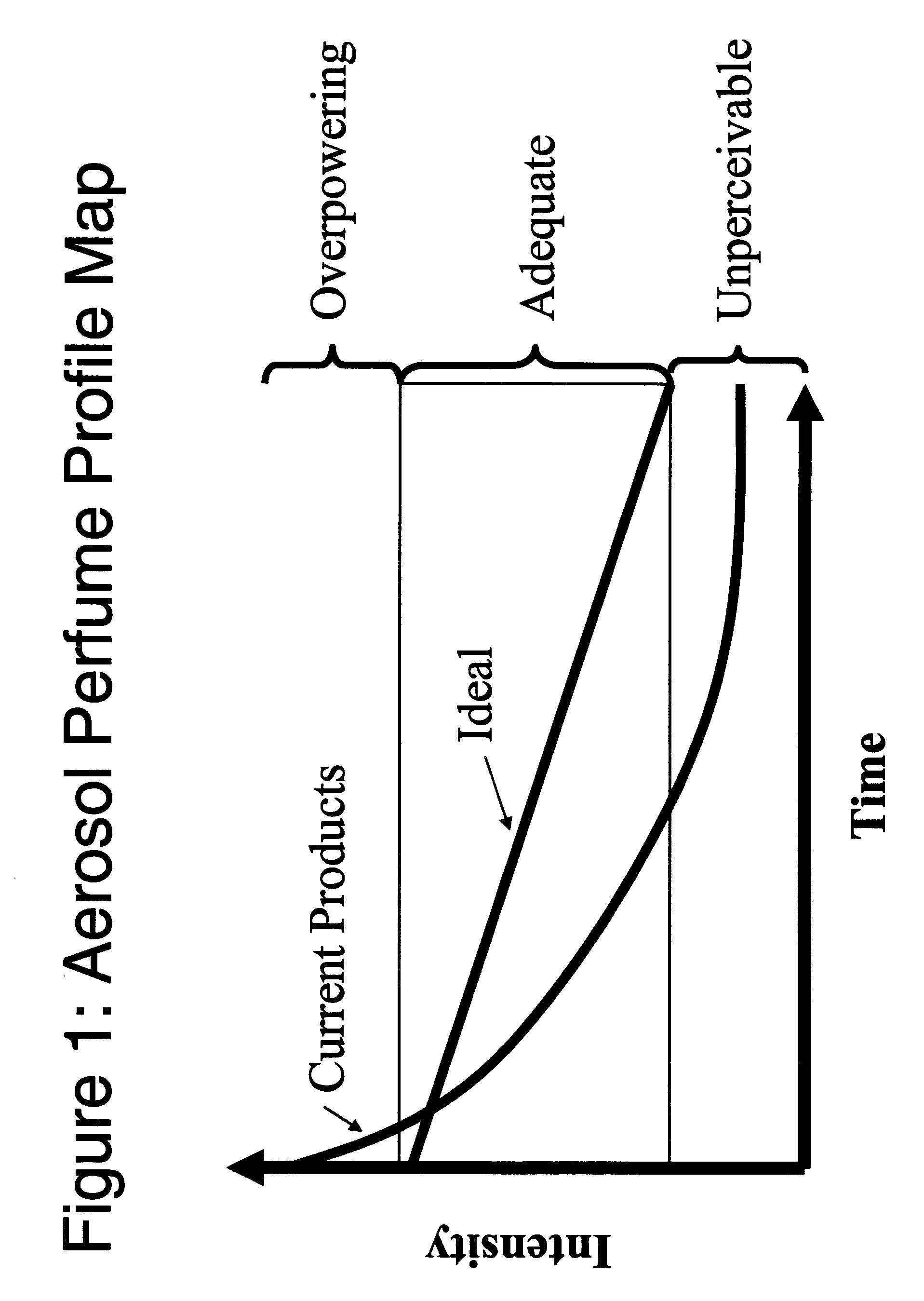

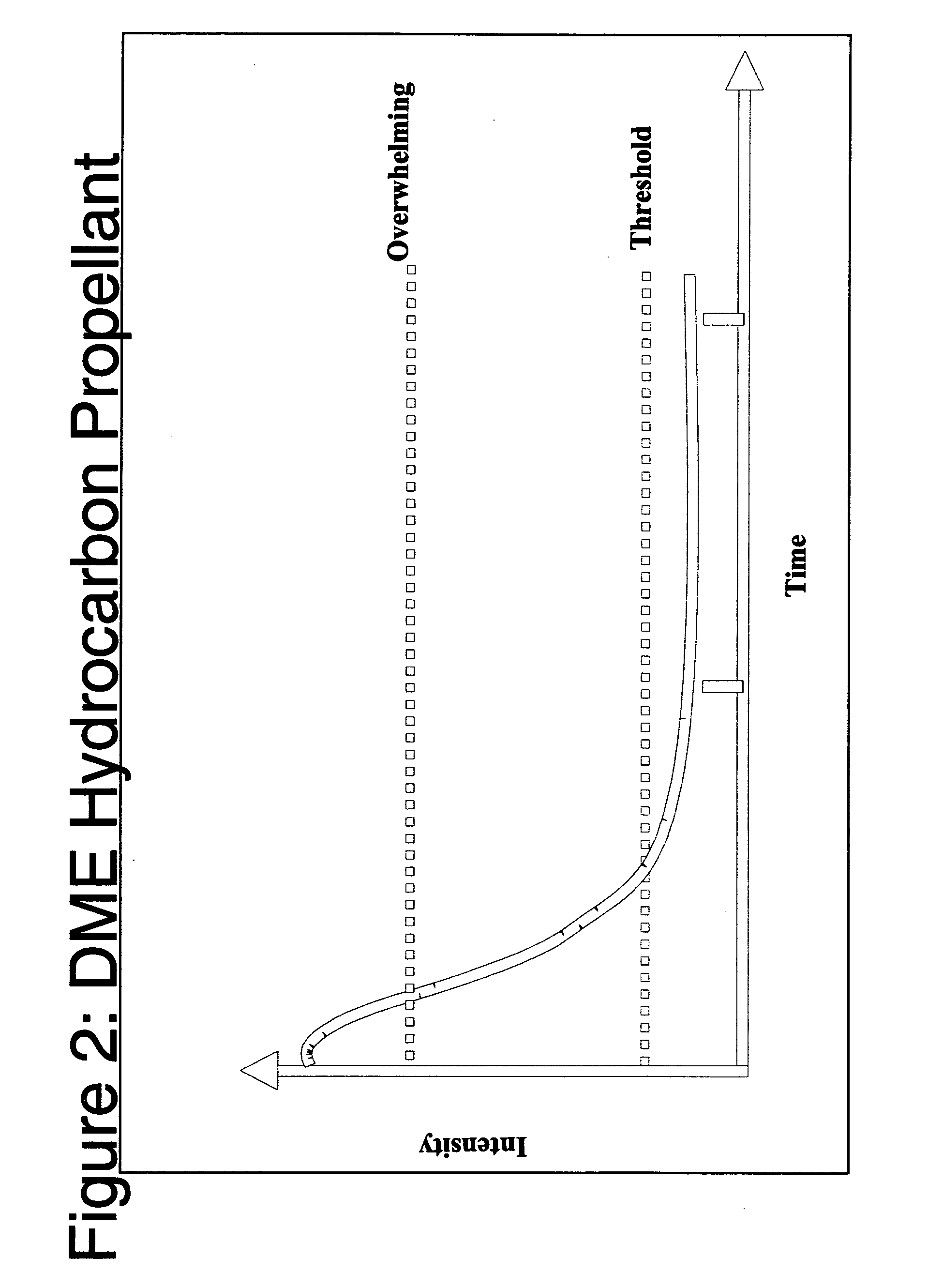

Method of freshening air

ActiveUS20070172382A1Reduce deliveryReduce odorOpening closed containersBottle/container closureEngineeringNitrous oxide

Air freshener products and methods for freshening air are disclosed. In some embodiments, the air freshening product may include a container for storing an air freshening composition that may contain compressed gas such as compressed air, nitrogen, nitrous oxide, inert gases, or carbon dioxide. When the container is completely filled with propellant and air freshening composition, the air freshening composition may be released from the container at a flow rate of from about 0.0001 grams / second to about 1.2 grams / second. The method of freshening air, in certain embodiments, provides improved delivery of an air freshening composition using a non-hydrocarbon propellant. If malodor counteractants are used, the method may also provide a reduction in malodors.

Owner:THE PROCTER & GAMBLE COMPANY

Methods of dry stripping boron-carbon films

Embodiments of the invention generally relate to methods of dry stripping boron-carbon films. In one embodiment, alternating plasmas of hydrogen and oxygen are used to remove a boron-carbon film. In another embodiment, co-flowed oxygen and hydrogen plasma is used to remove a boron-carbon containing film. A nitrous oxide plasma may be used in addition to or as an alternative to either of the above oxygen plasmas. In another embodiment, a plasma generated from water vapor is used to remove a boron-carbon film. The boron-carbon removal processes may also include an optional polymer removal process prior to removal of the boron-carbon films. The polymer removal process includes exposing the boron-carbon film to NF3 to remove from the surface of the boron-carbon film any carbon-based polymers generated during a substrate etching process.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

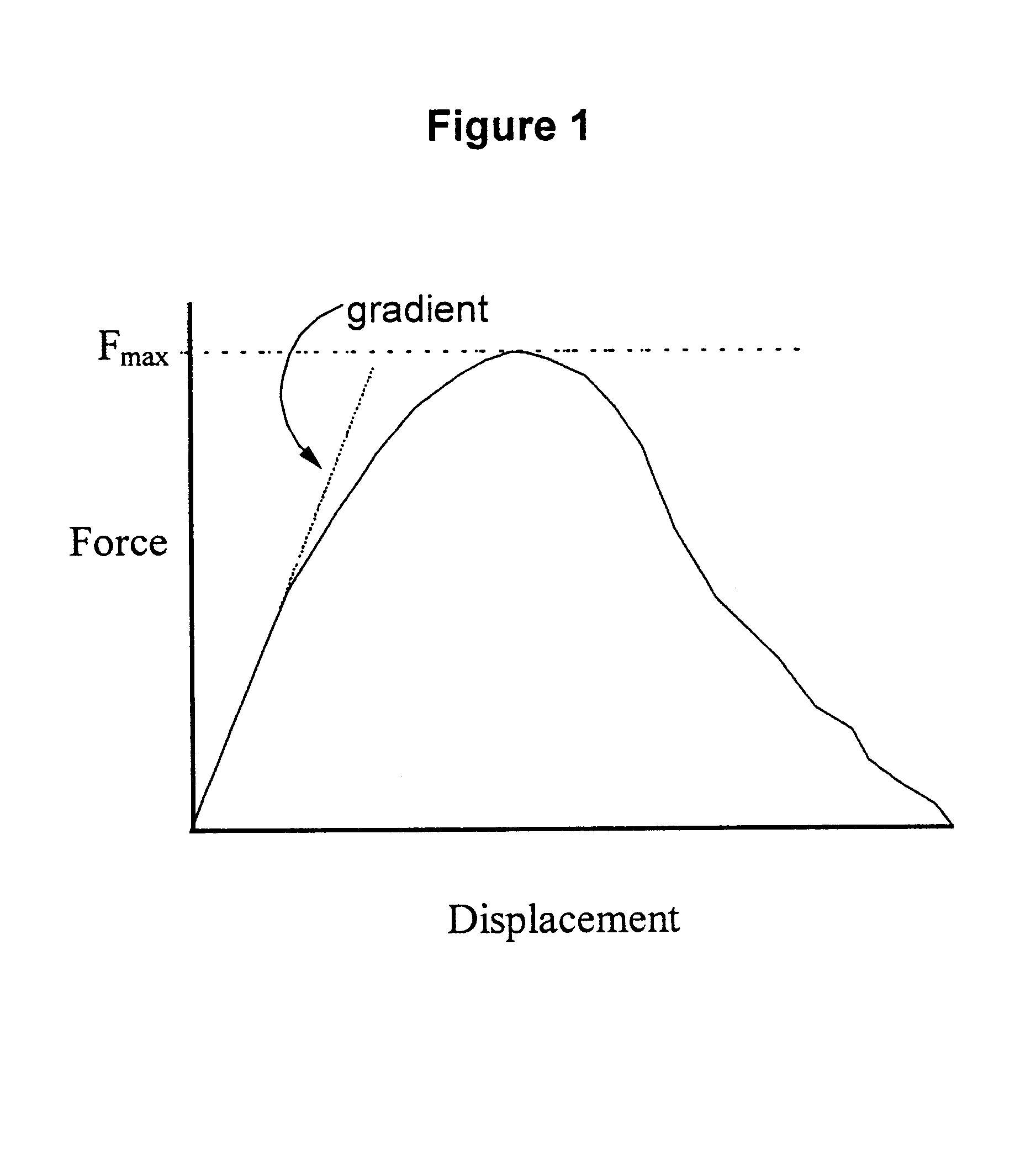

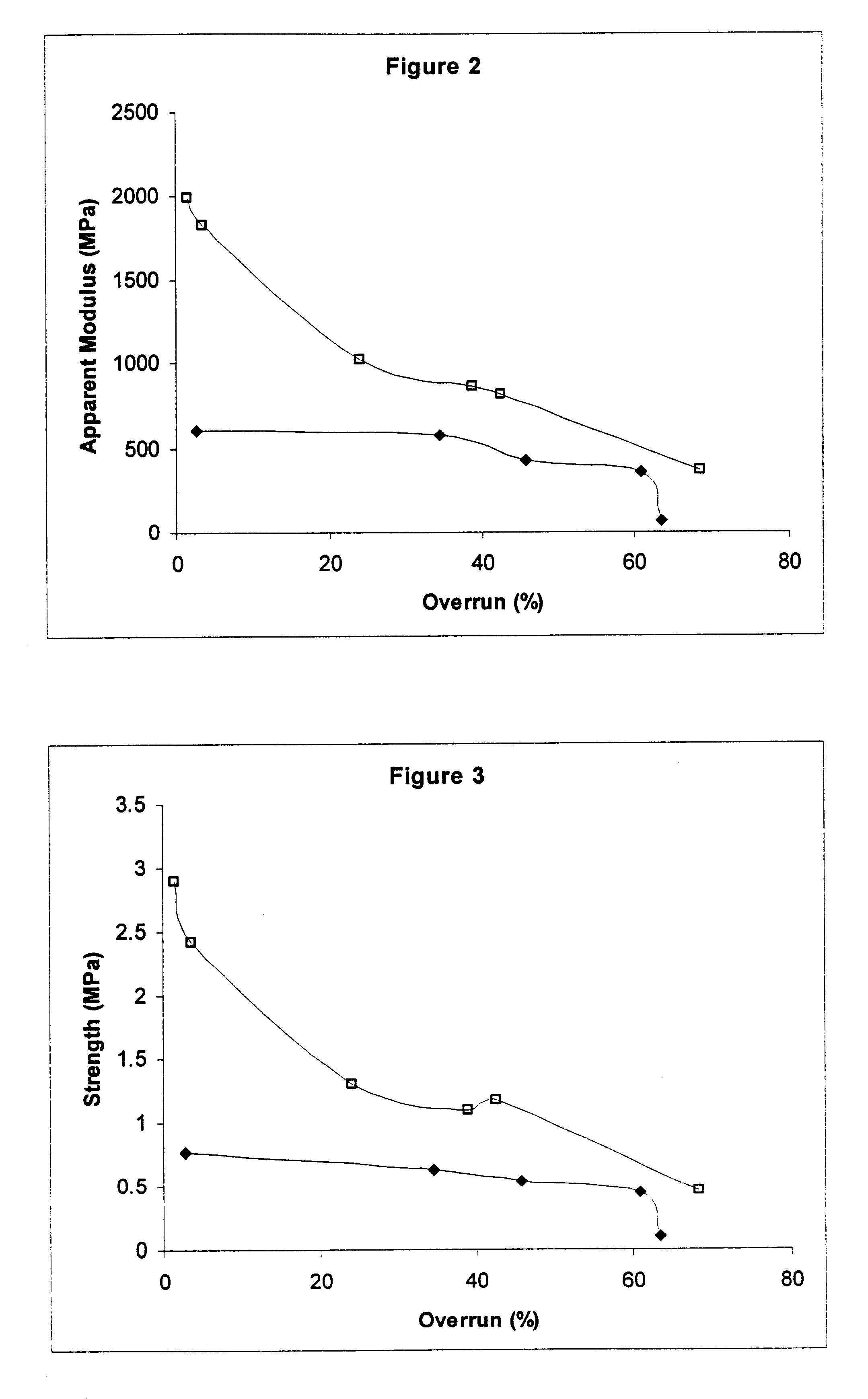

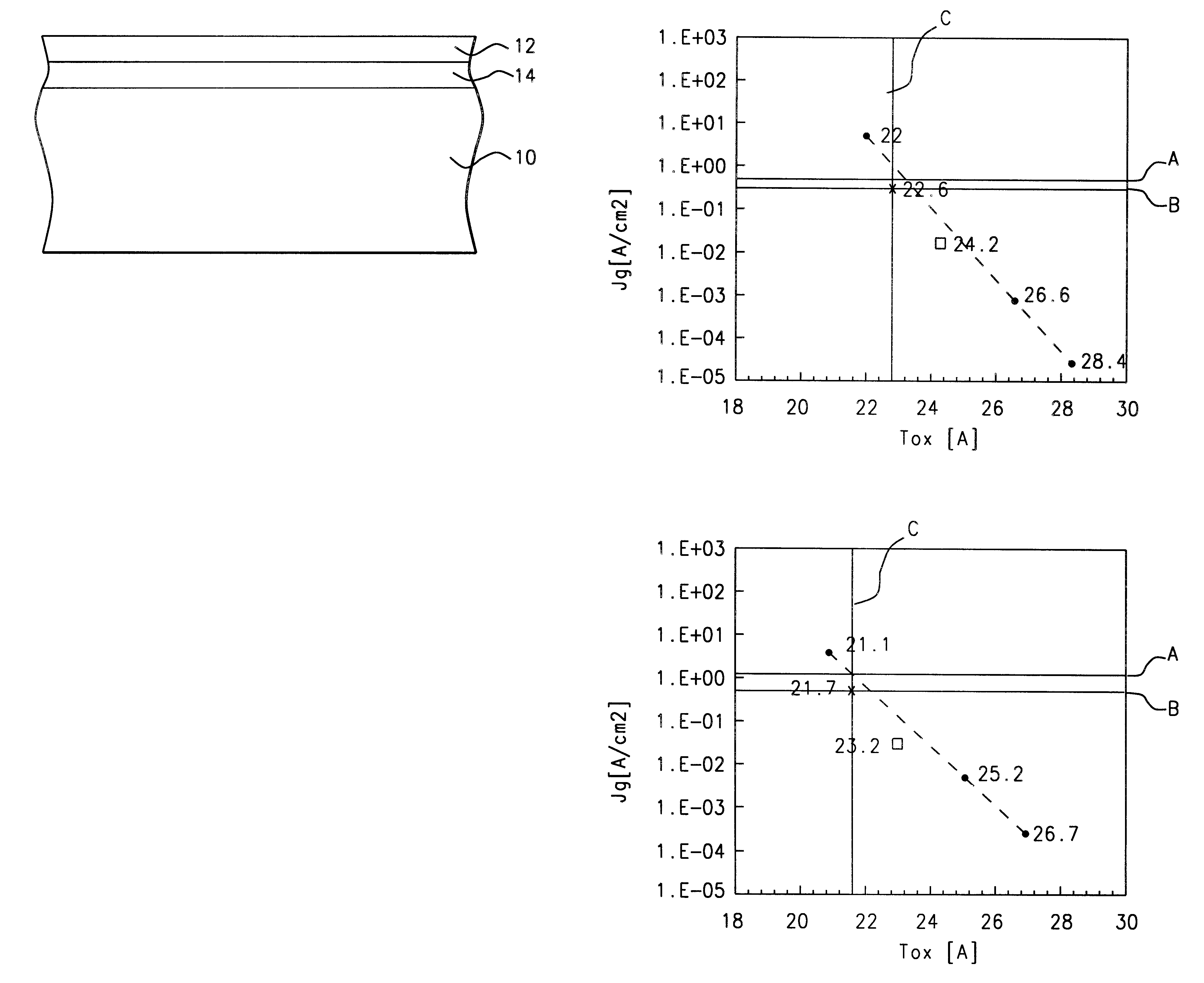

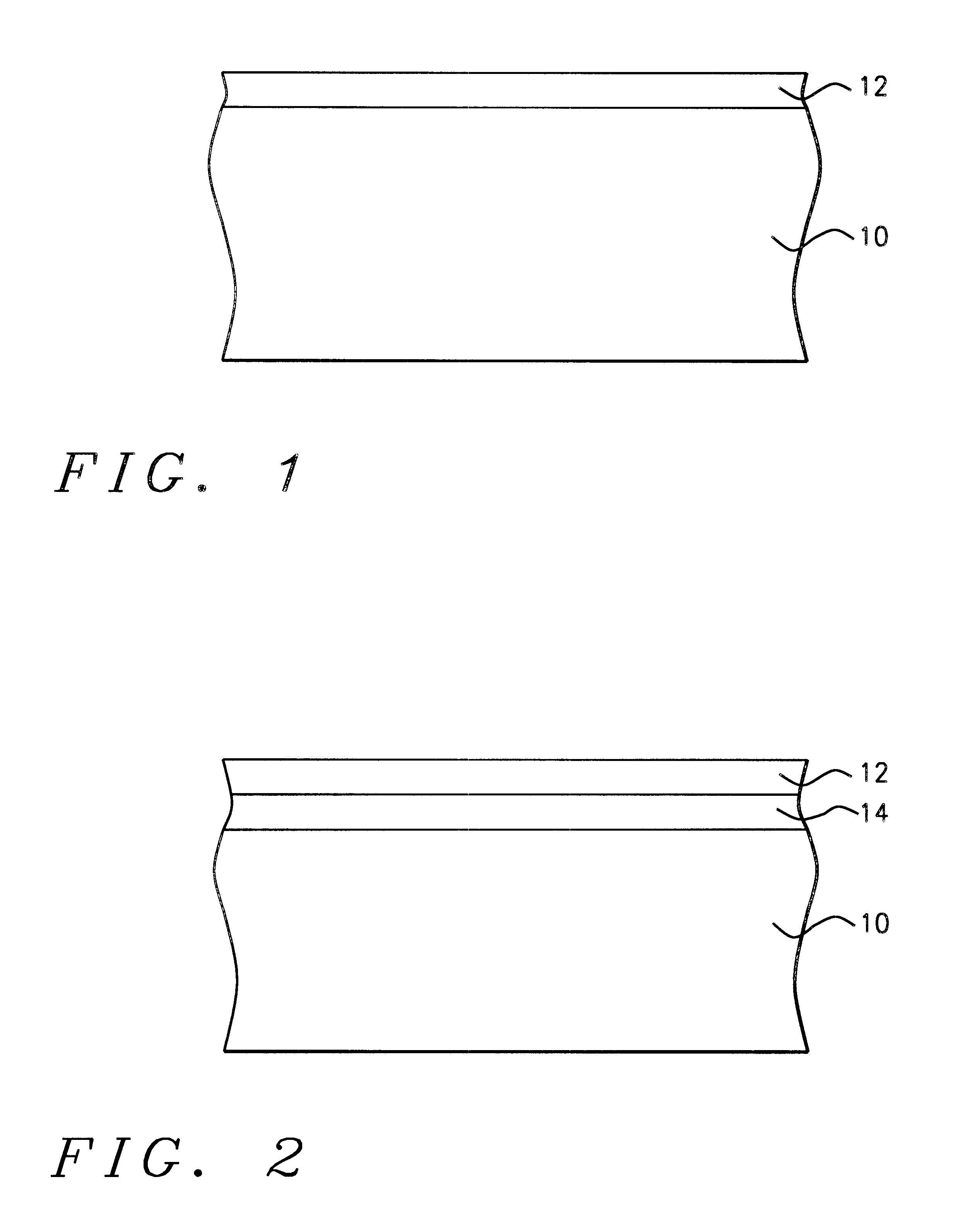

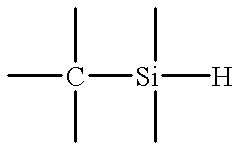

![Formation of [2,2]paracyclophane and related compounds and methods for the formation of polymers from cyclophanes Formation of [2,2]paracyclophane and related compounds and methods for the formation of polymers from cyclophanes](https://images-eureka.patsnap.com/patent_img/4eb334cd-5ed6-4078-97fe-269a42ccd686/US08633289-20140121-D00000.png)

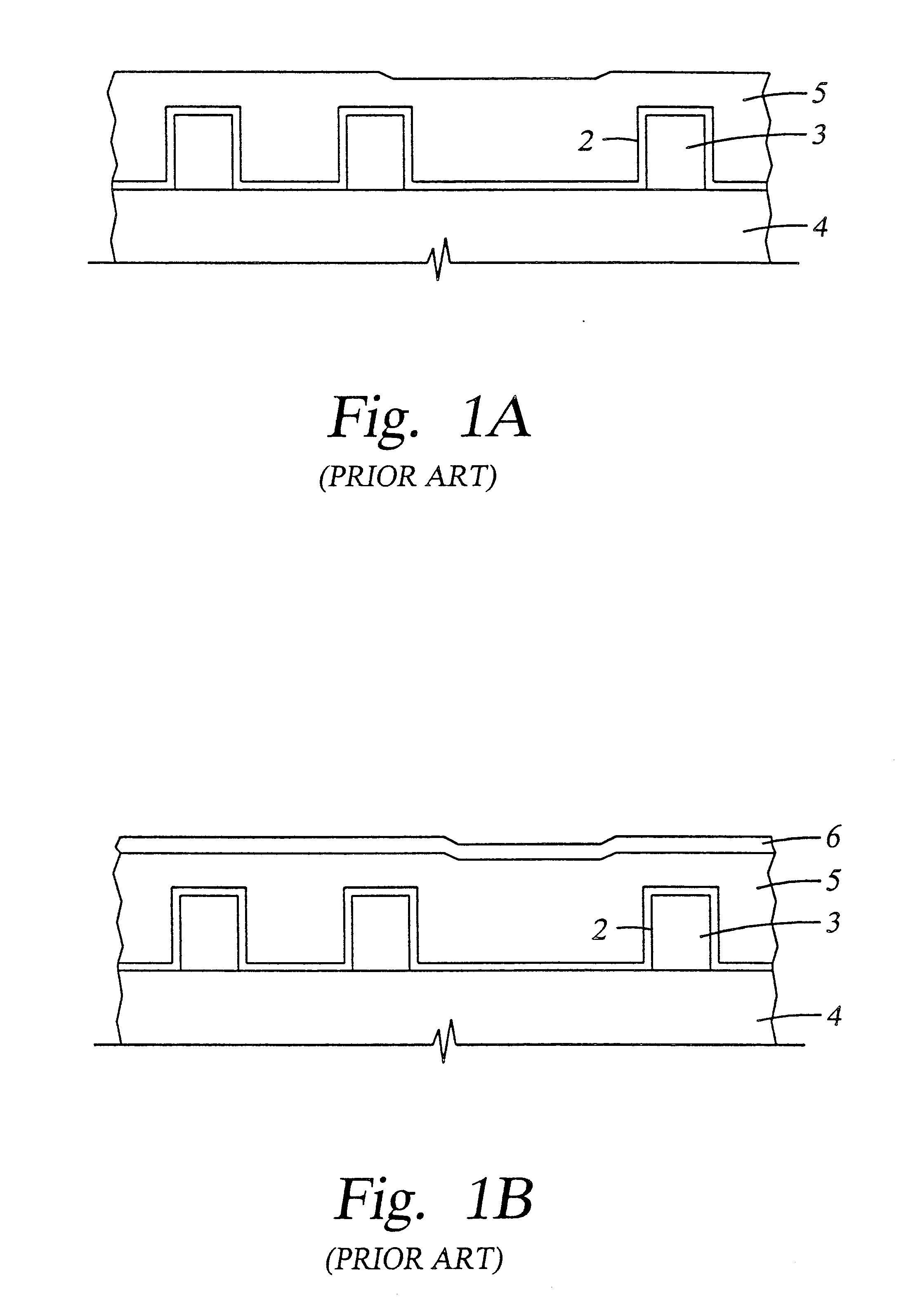

![Formation of [2,2]paracyclophane and related compounds and methods for the formation of polymers from cyclophanes Formation of [2,2]paracyclophane and related compounds and methods for the formation of polymers from cyclophanes](https://images-eureka.patsnap.com/patent_img/4eb334cd-5ed6-4078-97fe-269a42ccd686/US08633289-20140121-D00001.png)

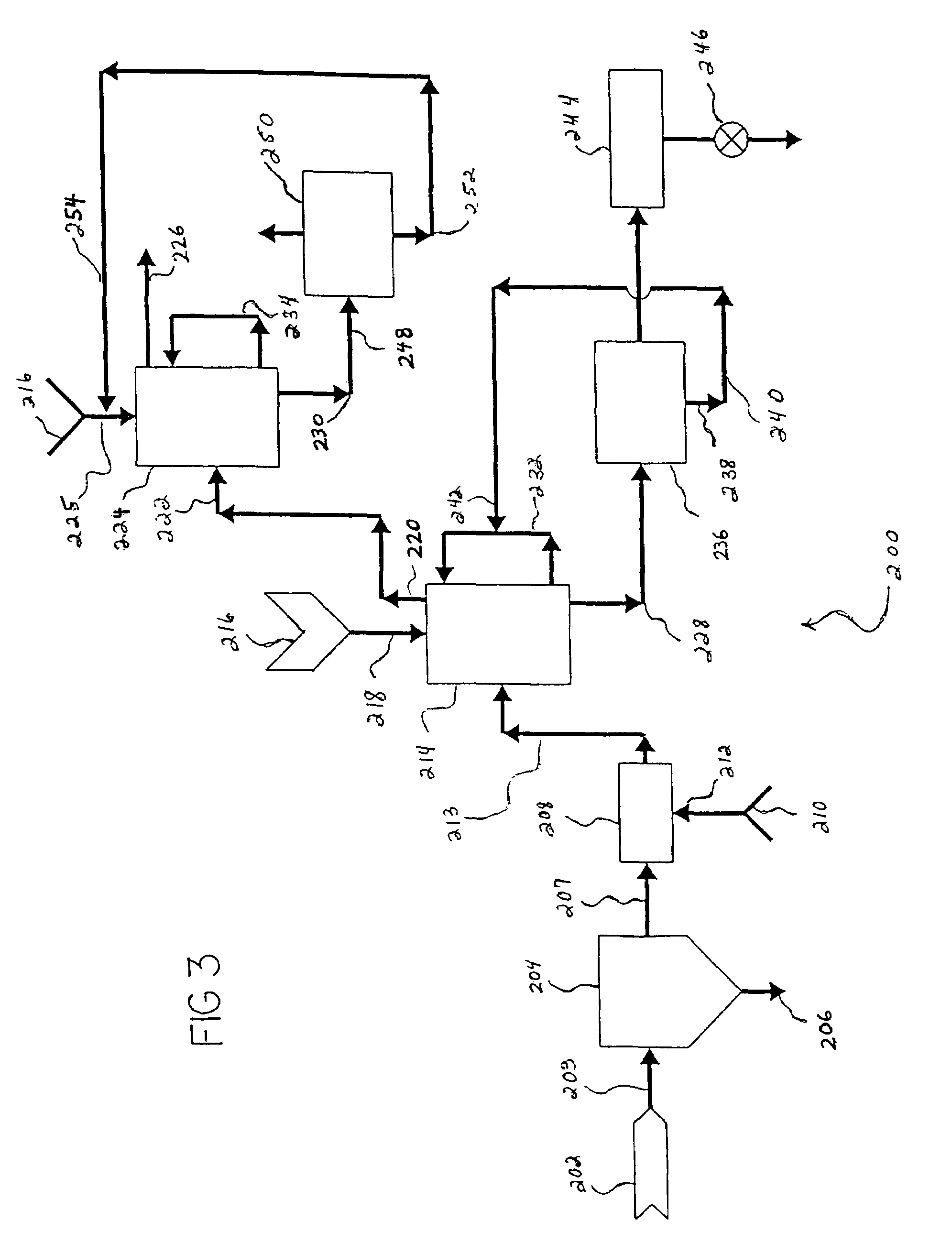

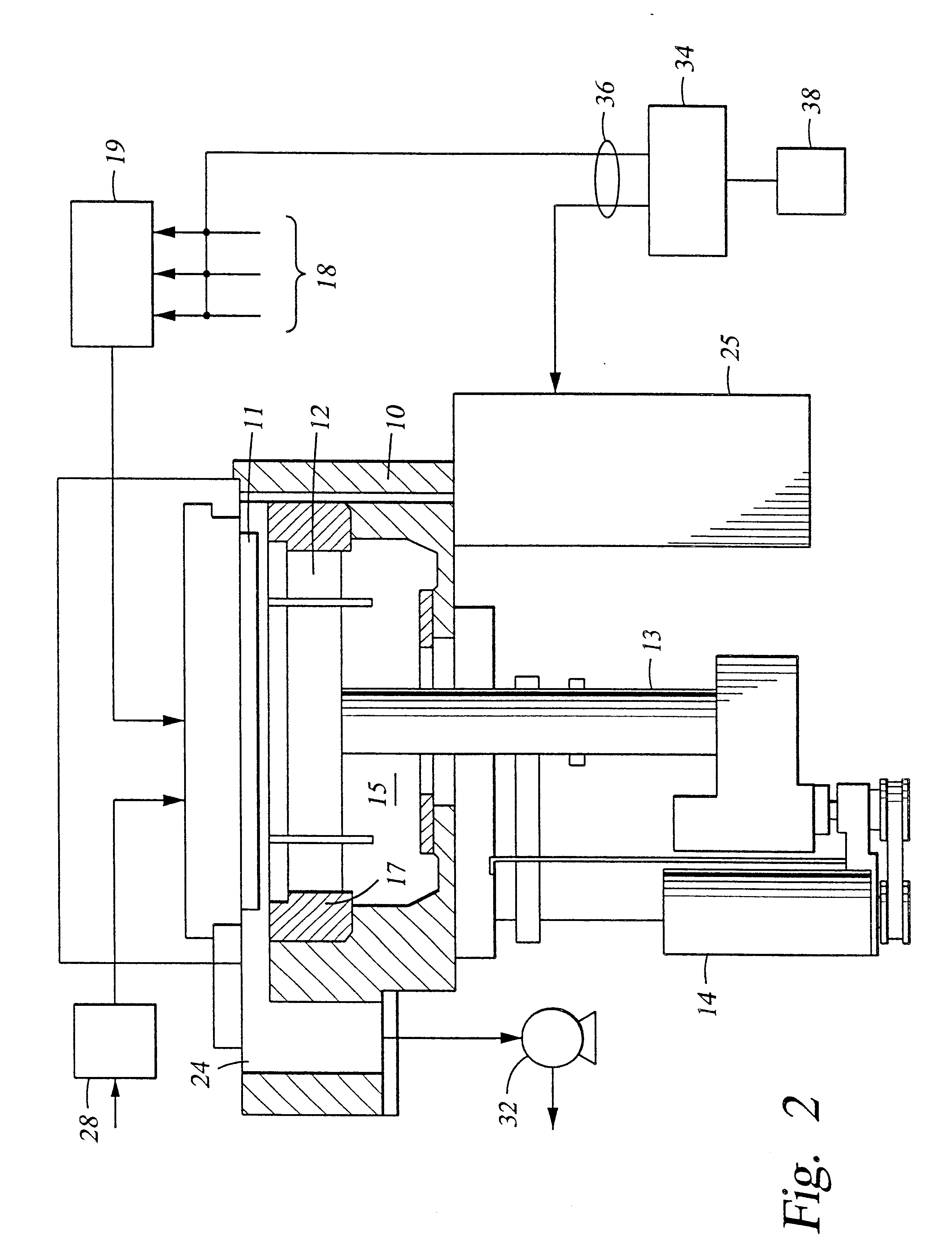

![Formation of [2,2]paracyclophane and related compounds and methods for the formation of polymers from cyclophanes Formation of [2,2]paracyclophane and related compounds and methods for the formation of polymers from cyclophanes](https://images-eureka.patsnap.com/patent_img/4eb334cd-5ed6-4078-97fe-269a42ccd686/US08633289-20140121-D00002.png)