Patents

Literature

1772 results about "Hydrogen fuel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogen fuel is a zero-emission fuel burned with oxygen. It can be used in fuel cells or internal combustion engines . It has begun to be used in commercial fuel cell vehicles such as passenger cars, and has been used in fuel cell buses for many years. It is also used as a fuel for spacecraft propulsion.

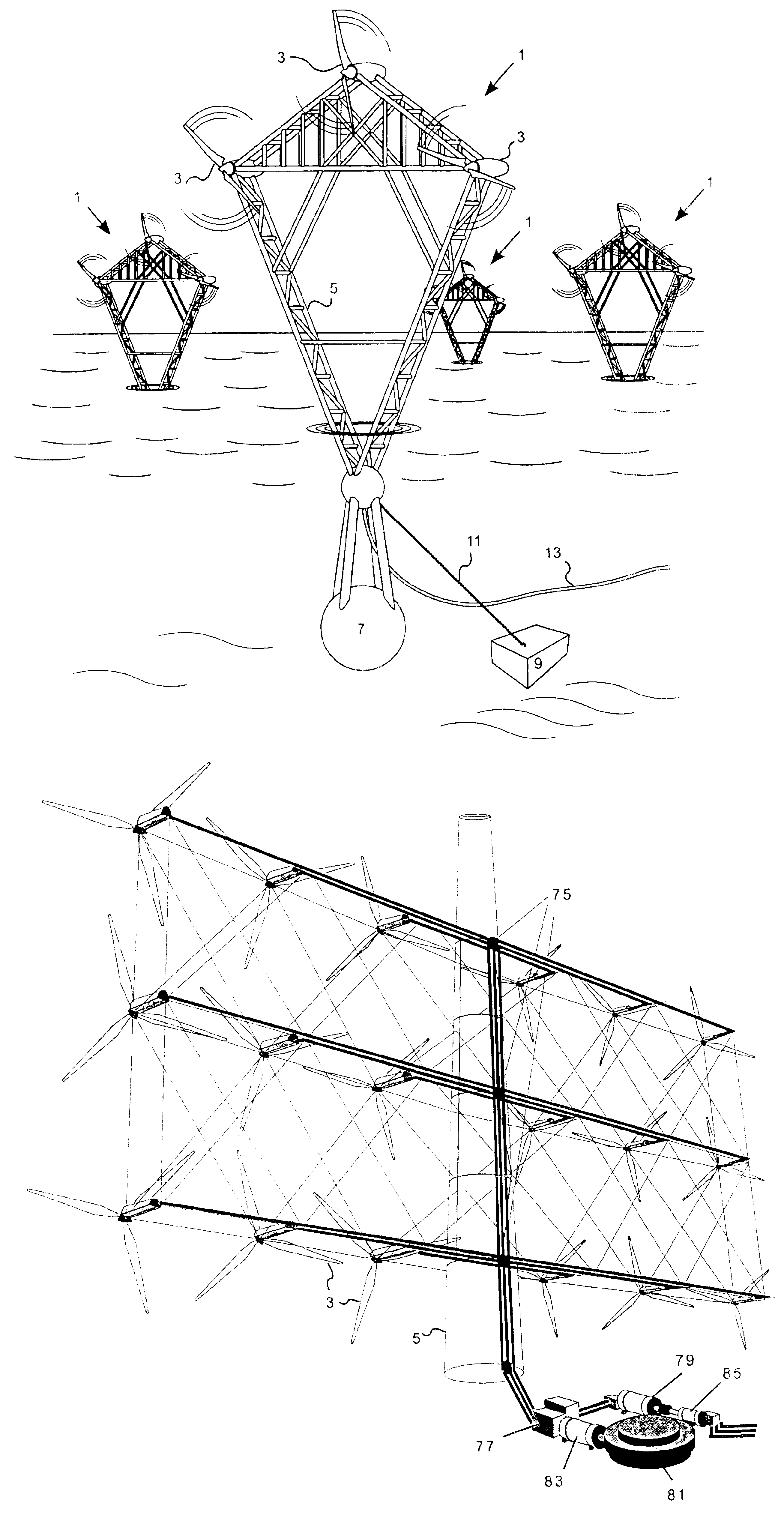

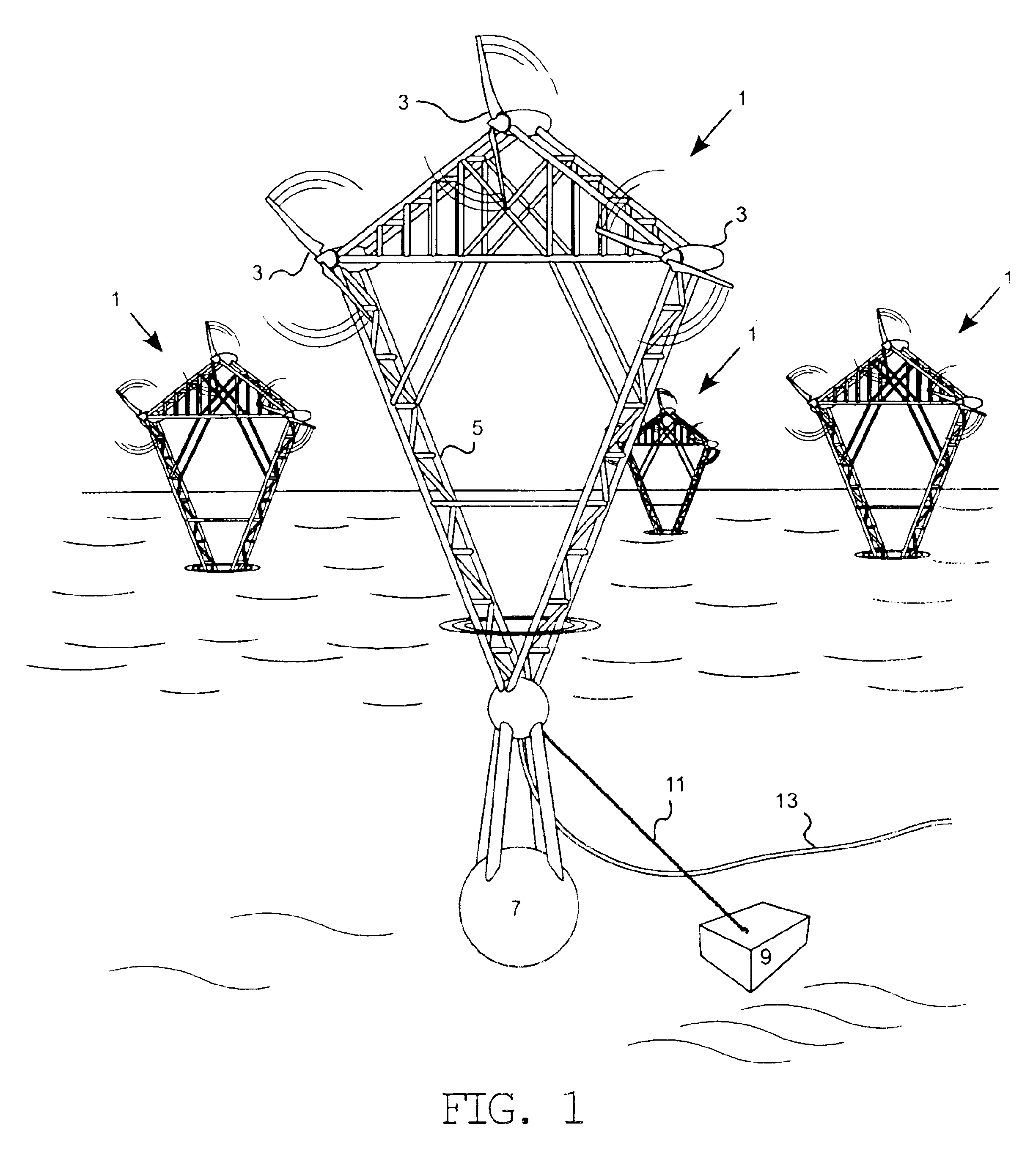

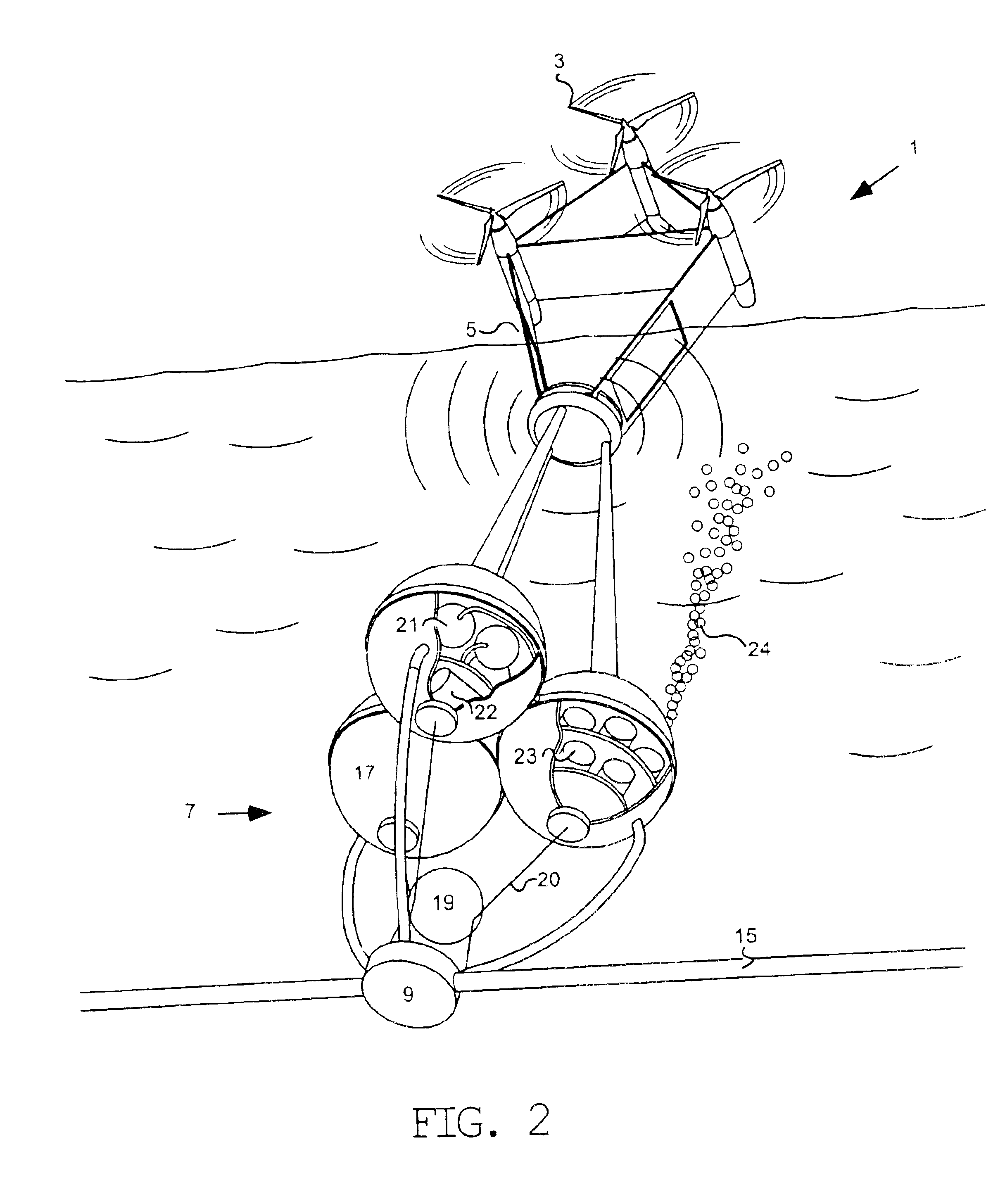

Offshore wind turbine with multiple wind rotors and floating system

ActiveUS7075189B2Reduce weightLean structureGeneral water supply conservationWind motor supports/mountsElectric power transmissionEngineering

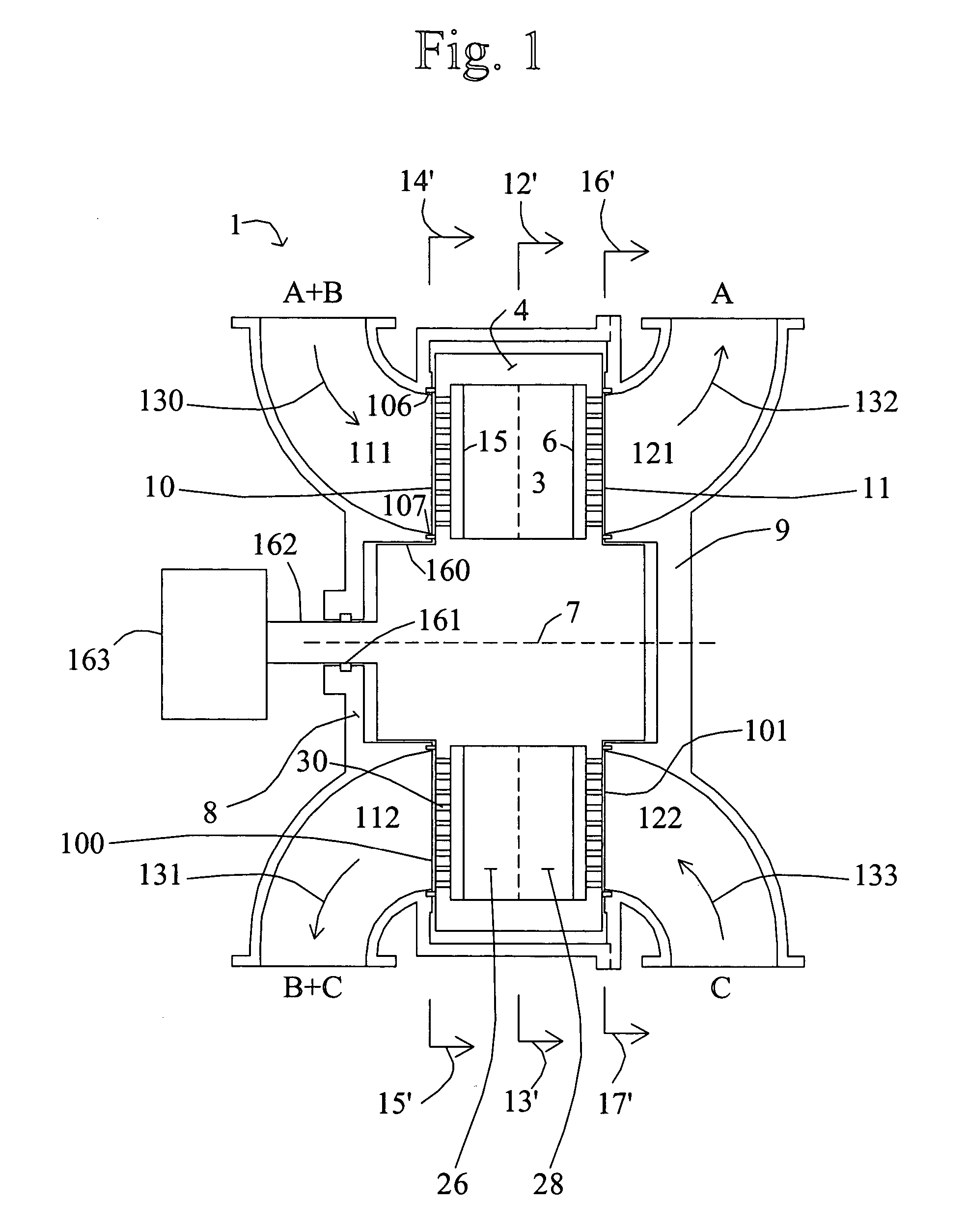

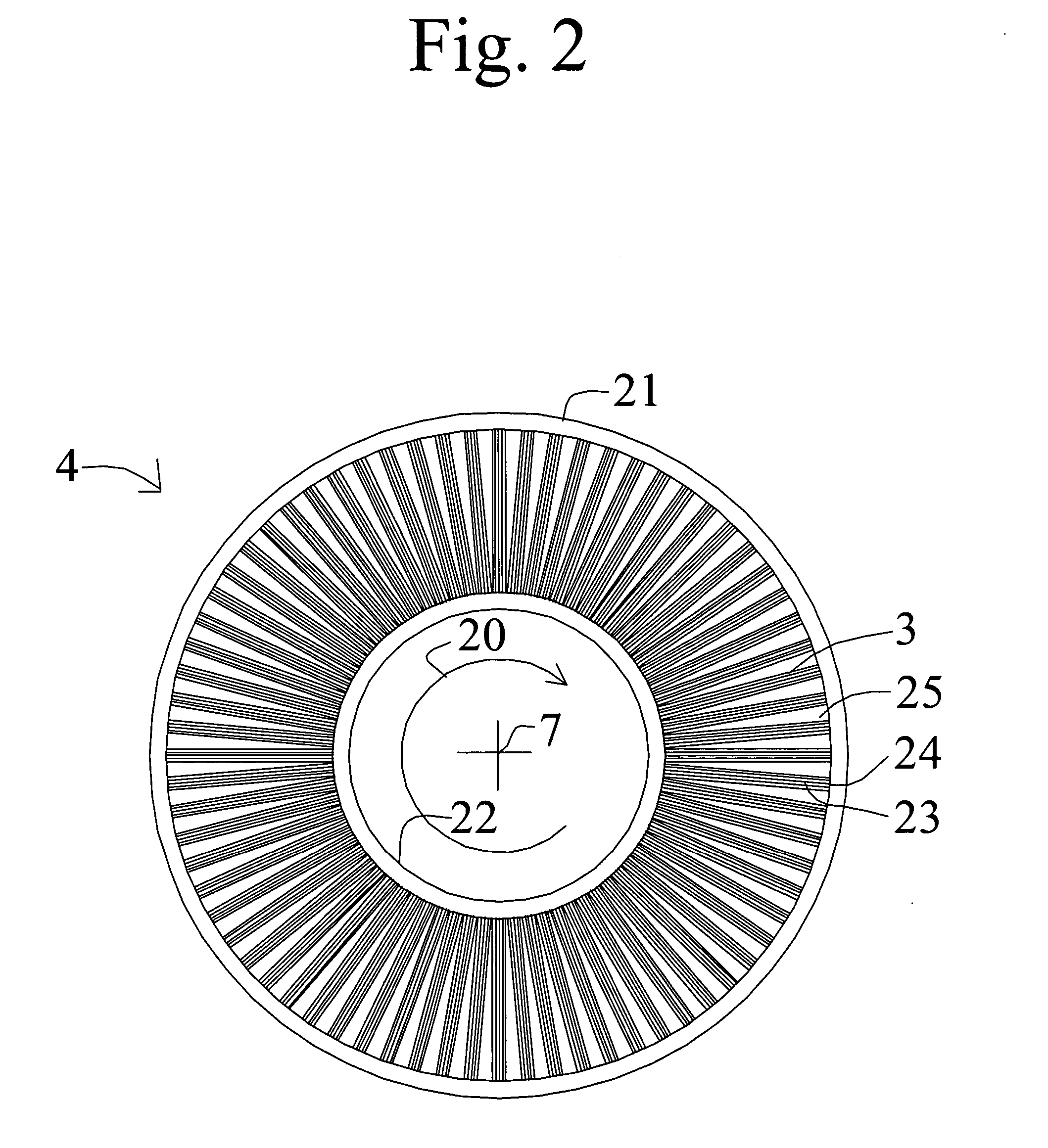

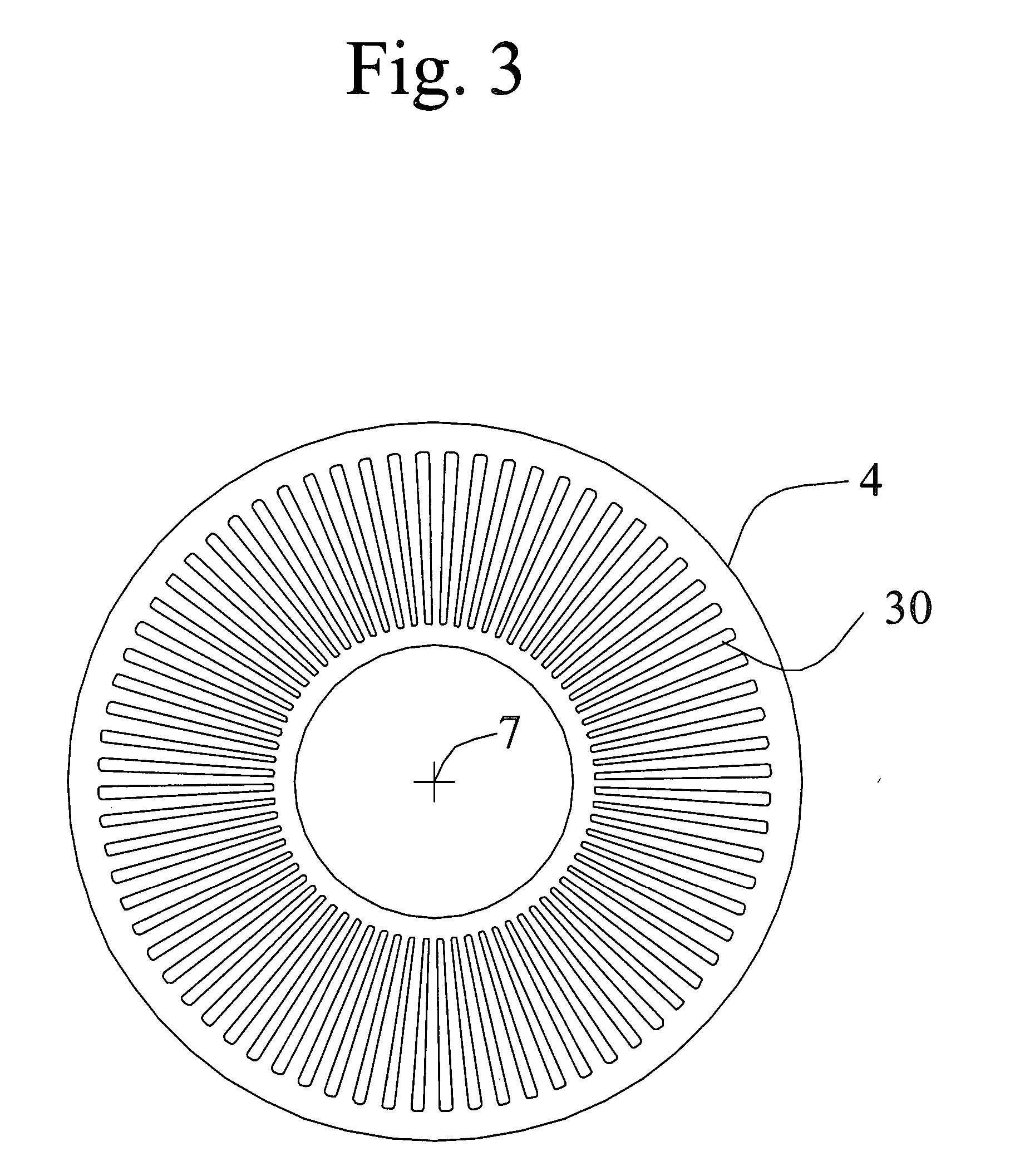

A wind energy conversion system optimized for offshore application. Each wind turbine includes a semi-submersible hull with ballast weight that is moveable to increase the system's stability. Each wind turbine has an array of rotors distributed on a tower to distribute weight and loads and to improve power production performance where windshear is high. As much of the equipment associated with each rotor as possible is located at the base of the tower to lower the metacentric height. The equipment that may be emplaced at the bottom of the tower could include a power electronic converter, a DC to AC converter, or the entire generator with a mechanical linkage transmitting power from each rotor to the base of the tower. Rather than transmitting electrical power back to shore, it is contemplated to create energy intensive hydrogen-based products at the base of the wind turbine. Alternatively, there could be a central factory ship that utilizes the power produced by a plurality of wind turbines to create a hydrogen-based fuel. The hydrogen based fuel is transported to land and sold into existing markets as a value-added “green” product.

Owner:OCEAN WIND ENERGY SYST

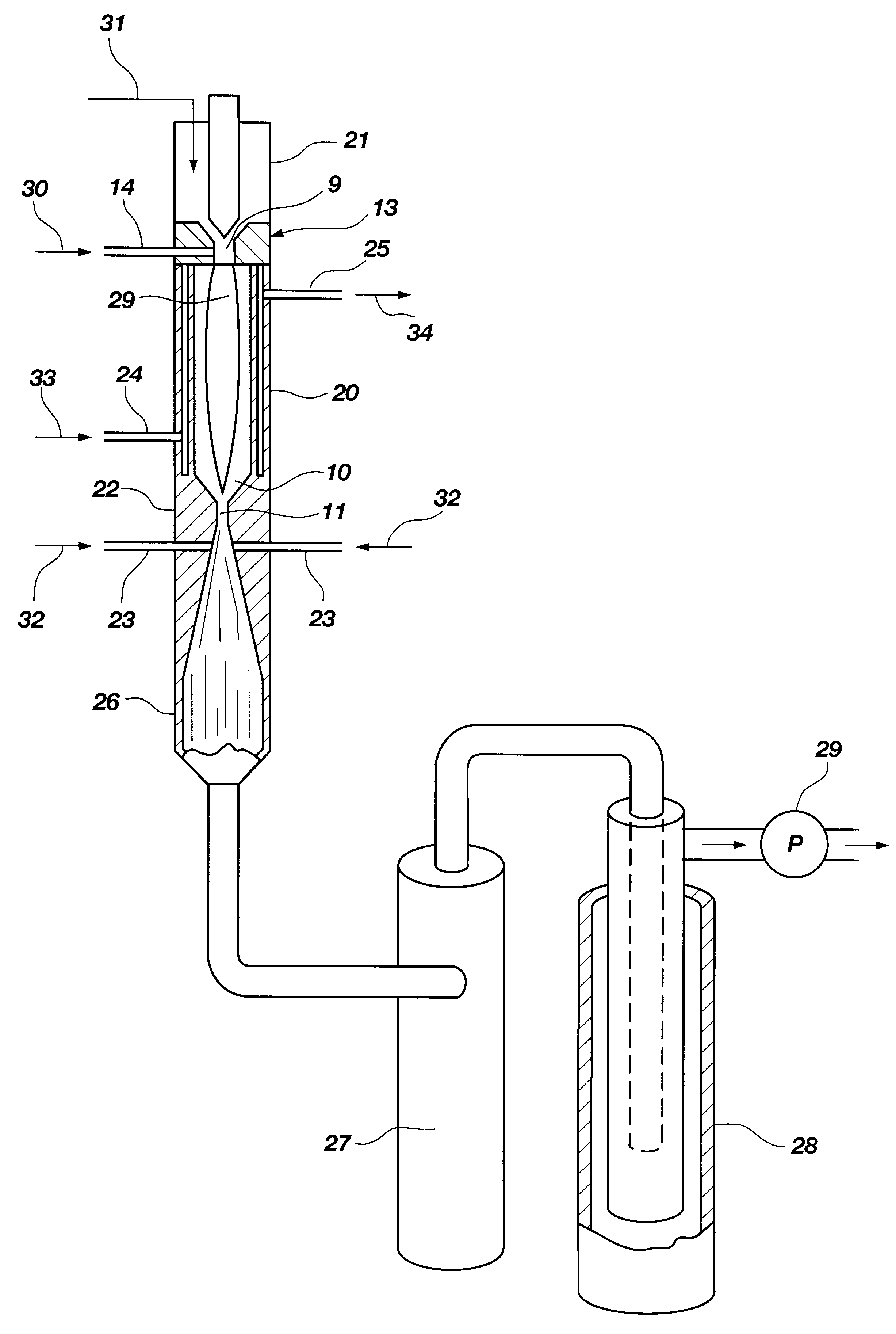

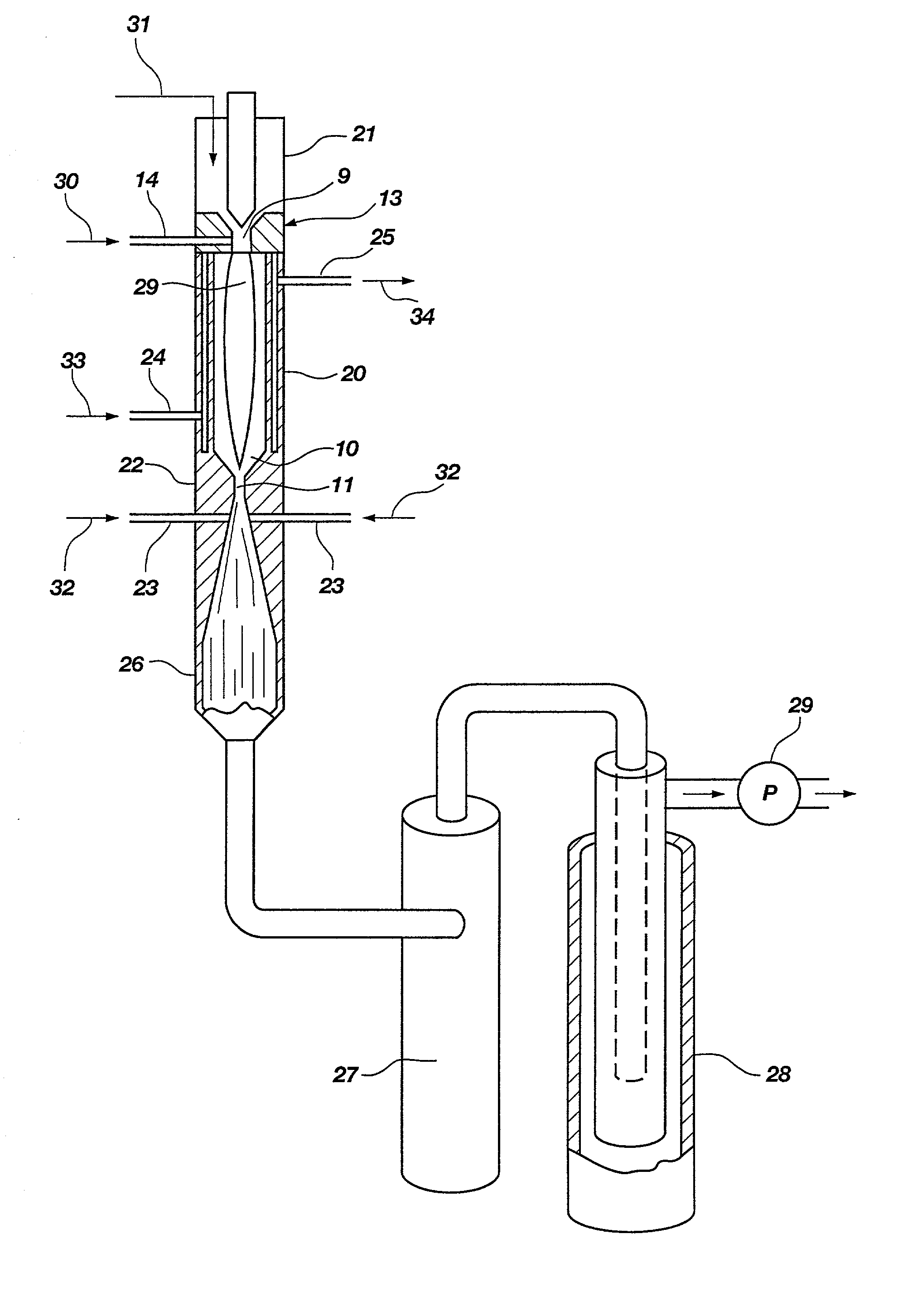

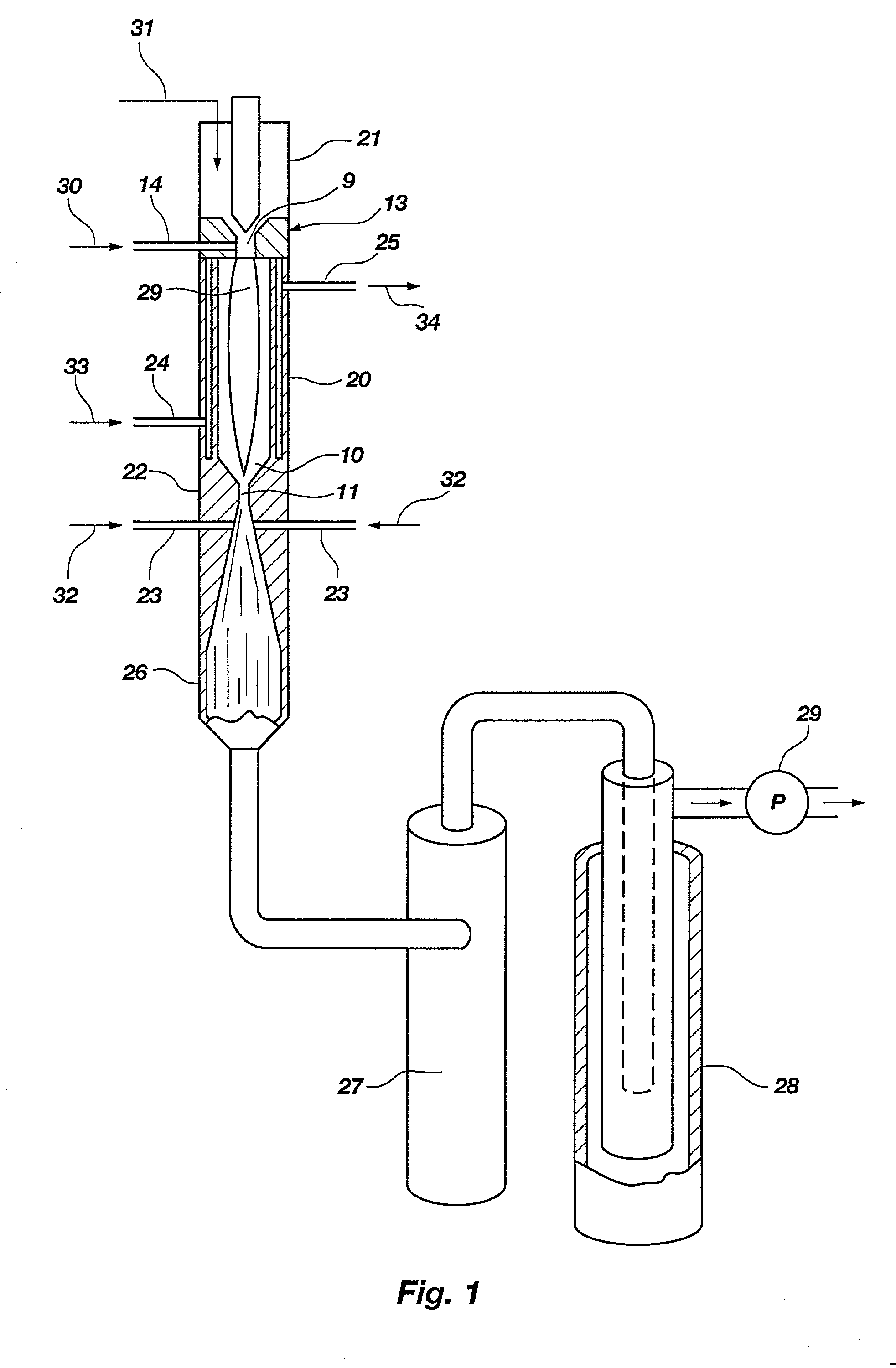

Hydrogen and elemental carbon production from natural gas and other hydrocarbons

InactiveUS6395197B1High quench rateAddressing slow performanceHydrocarbon from carbon oxidesEnergy inputUnsaturated hydrocarbonHydrogen fuel

Diatomic hydrogen and unsaturated hydrocarbons are produced as reactor gases in a fast quench reactor. During the fast quench, the unsaturated hydrocarbons are further decomposed by reheating the reactor gases. More diatomic hydrogen is produced, along with elemental carbon. Other gas may be added at different stages in the process to form a desired end product and prevent back reactions. The product is a substantially clean-burning hydrogen fuel that leaves no greenhouse gas emissions, and elemental carbon that may be used in powder form as a commodity for several processes.

Owner:BATTELLE ENERGY ALLIANCE LLC

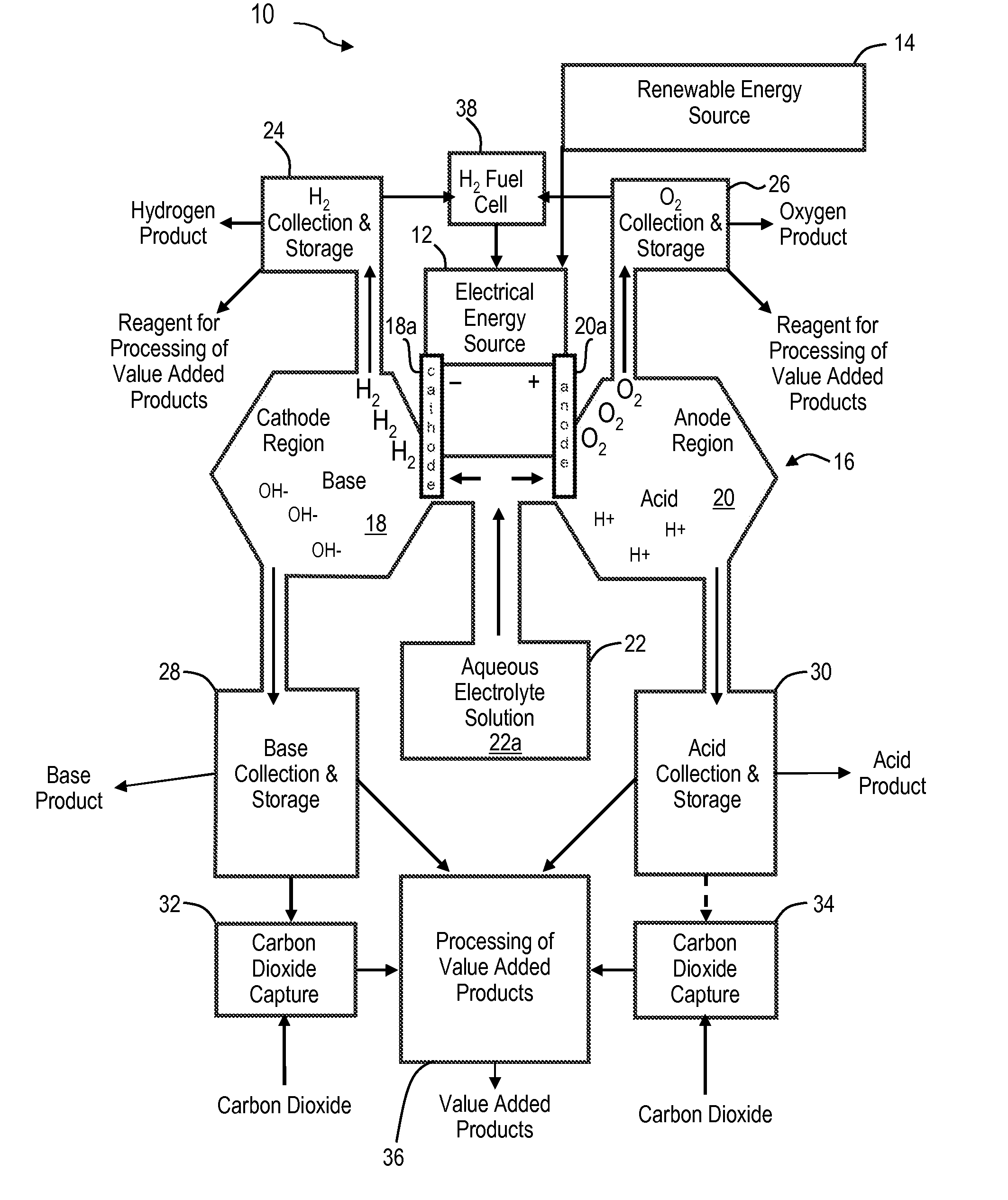

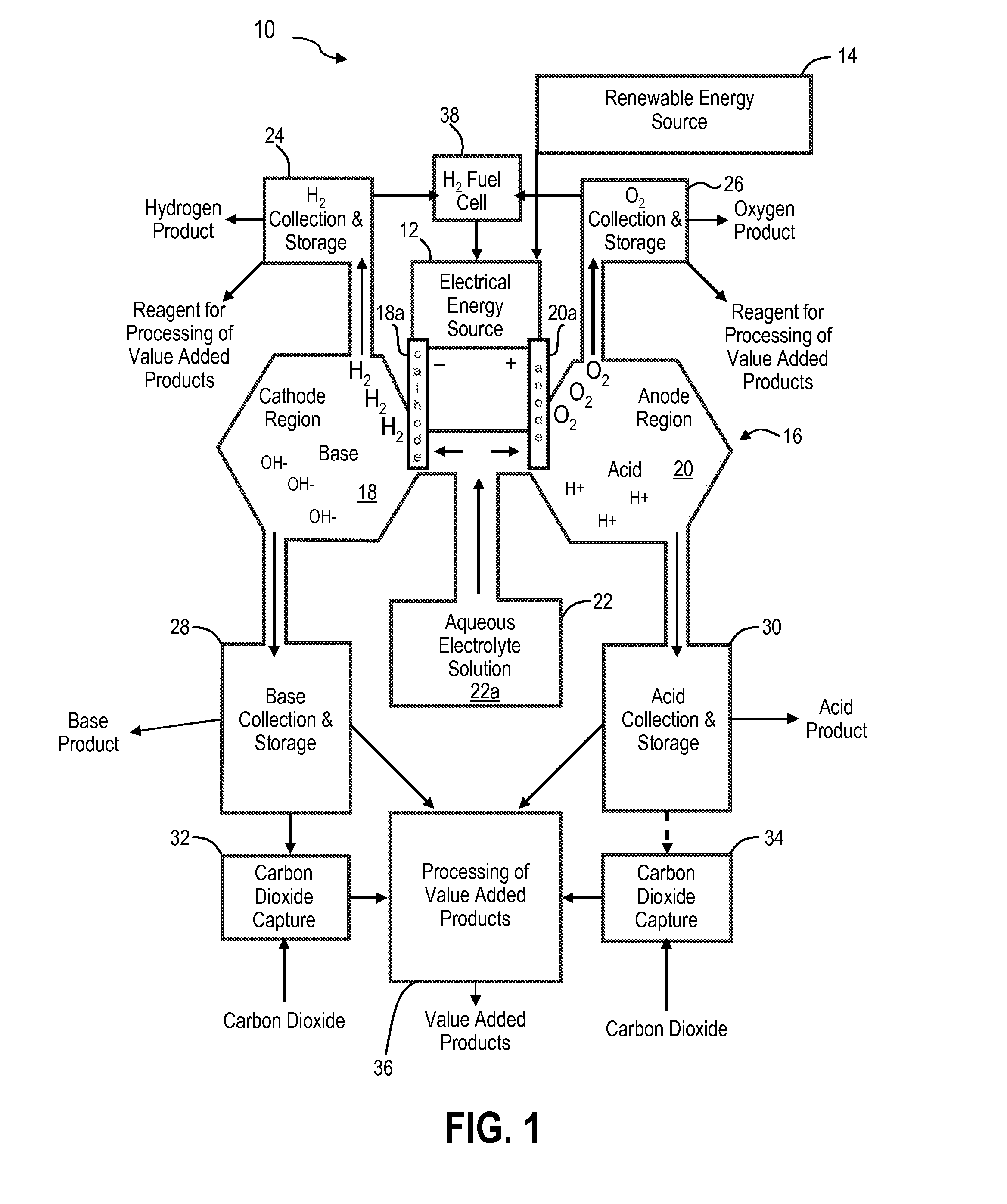

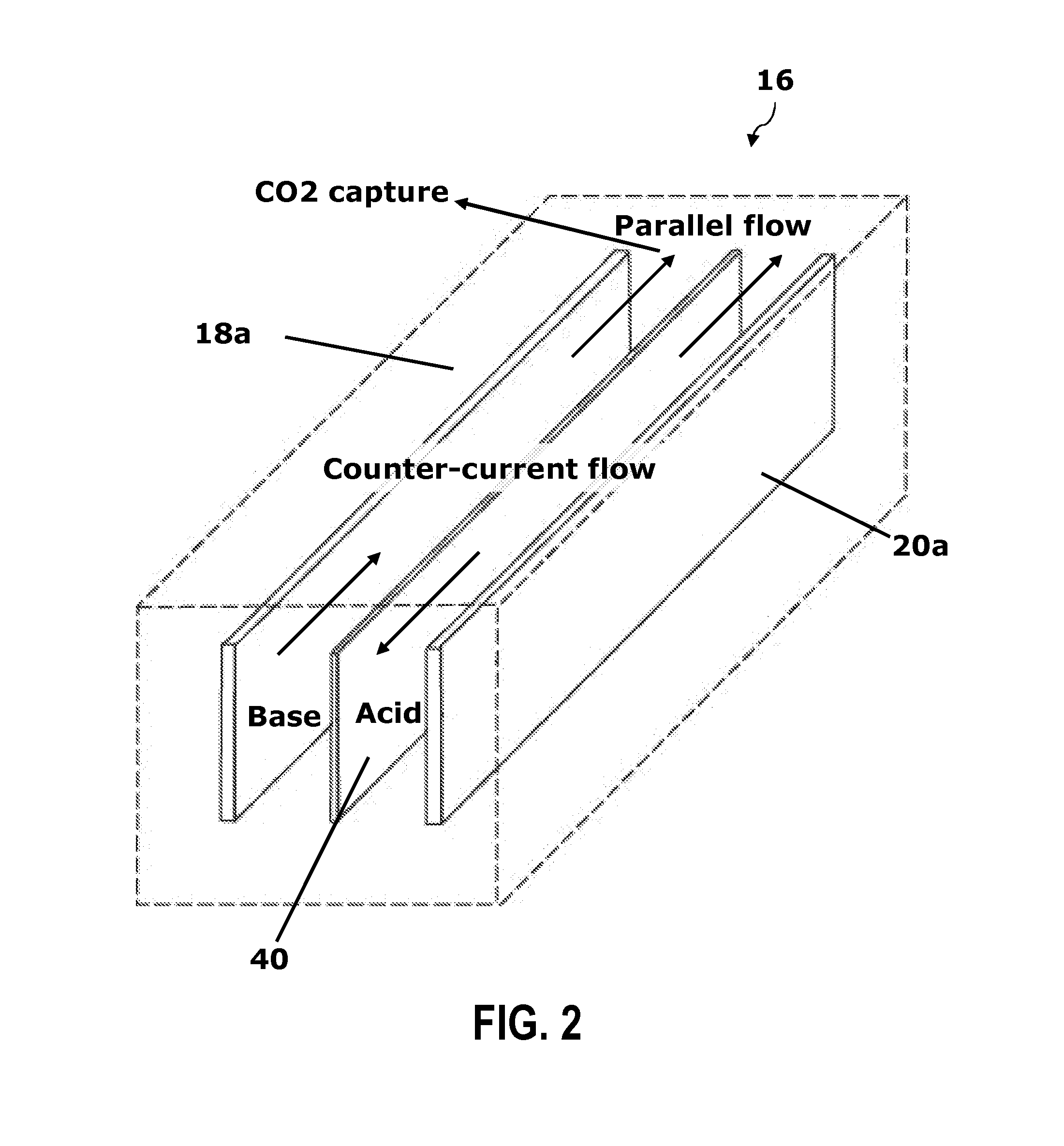

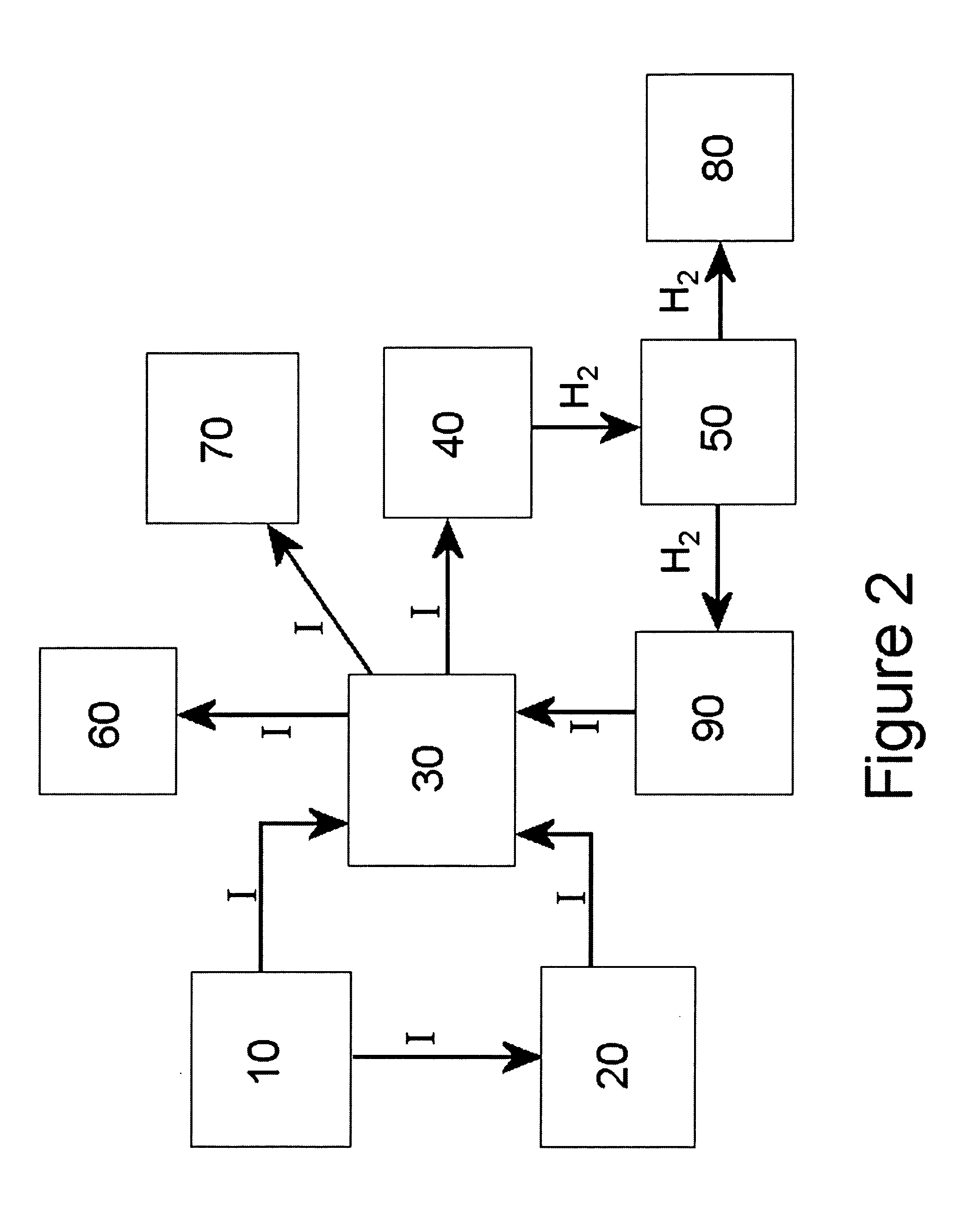

Renewable energy system for hydrogen production and carbon dioxide capture

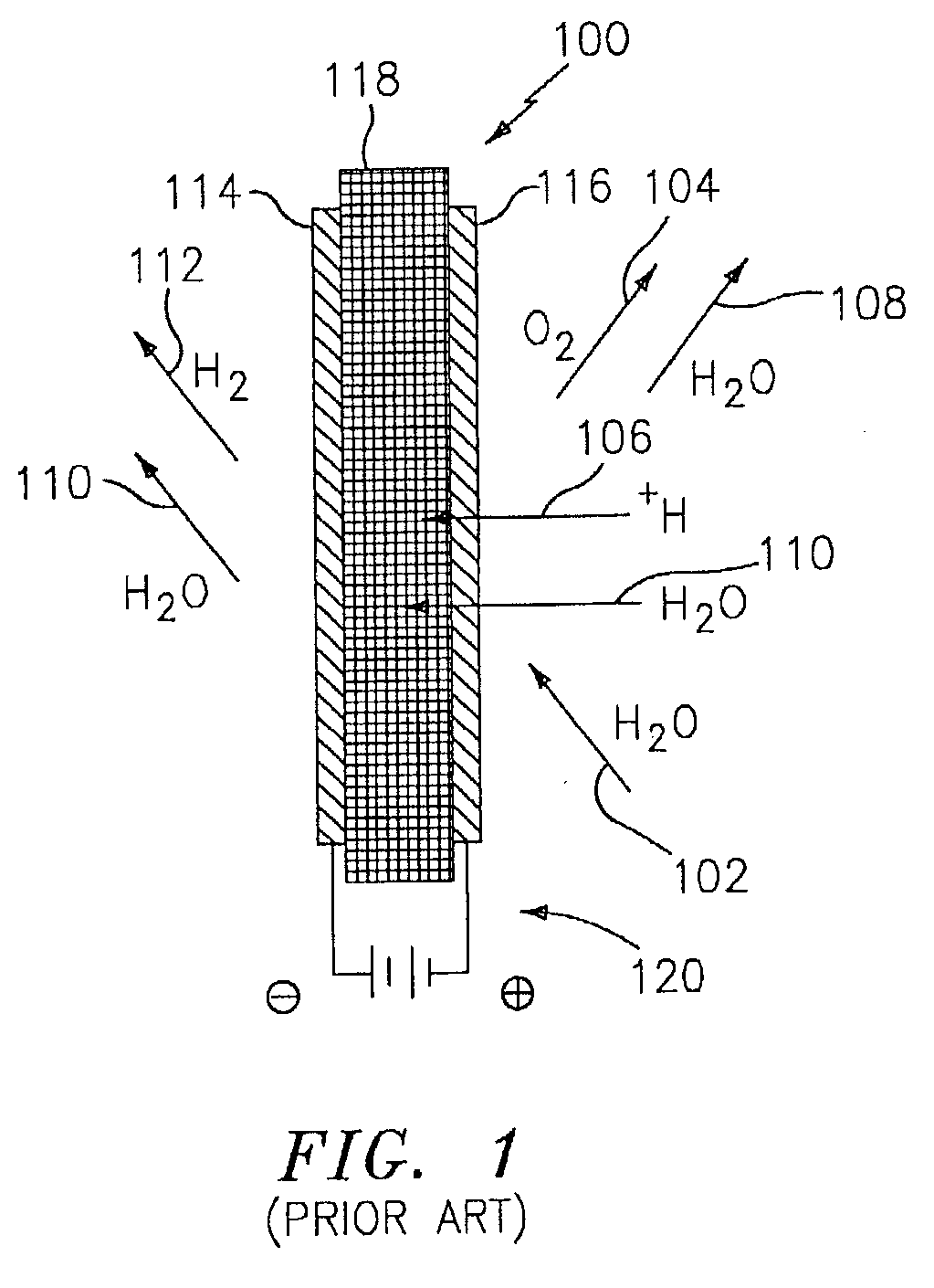

The present invention is an integrated system for the production of hydrogen and the removal of carbon dioxide from the air or gas streams. The integrated system includes an energy source for generating electrical energy and a water source coupled to the energy source. The water source includes ionic electrolytes. The energy source supplies energy to the water source to electrolyze water to produce hydrogen gas, oxygen gas, acid and base. The carbon dioxide reacts with the base. In some embodiments, the energy source is a renewable energy source. The integrated system produces substantially no carbon dioxide and when combined with a renewable energy source, produces clean hydrogen fuel and reduces atmospheric carbon dioxide, resulting in carbon dioxide negative energy and manufacturing strategies.

Owner:SULFURCYCLE INTPROP HLDG CO LLC

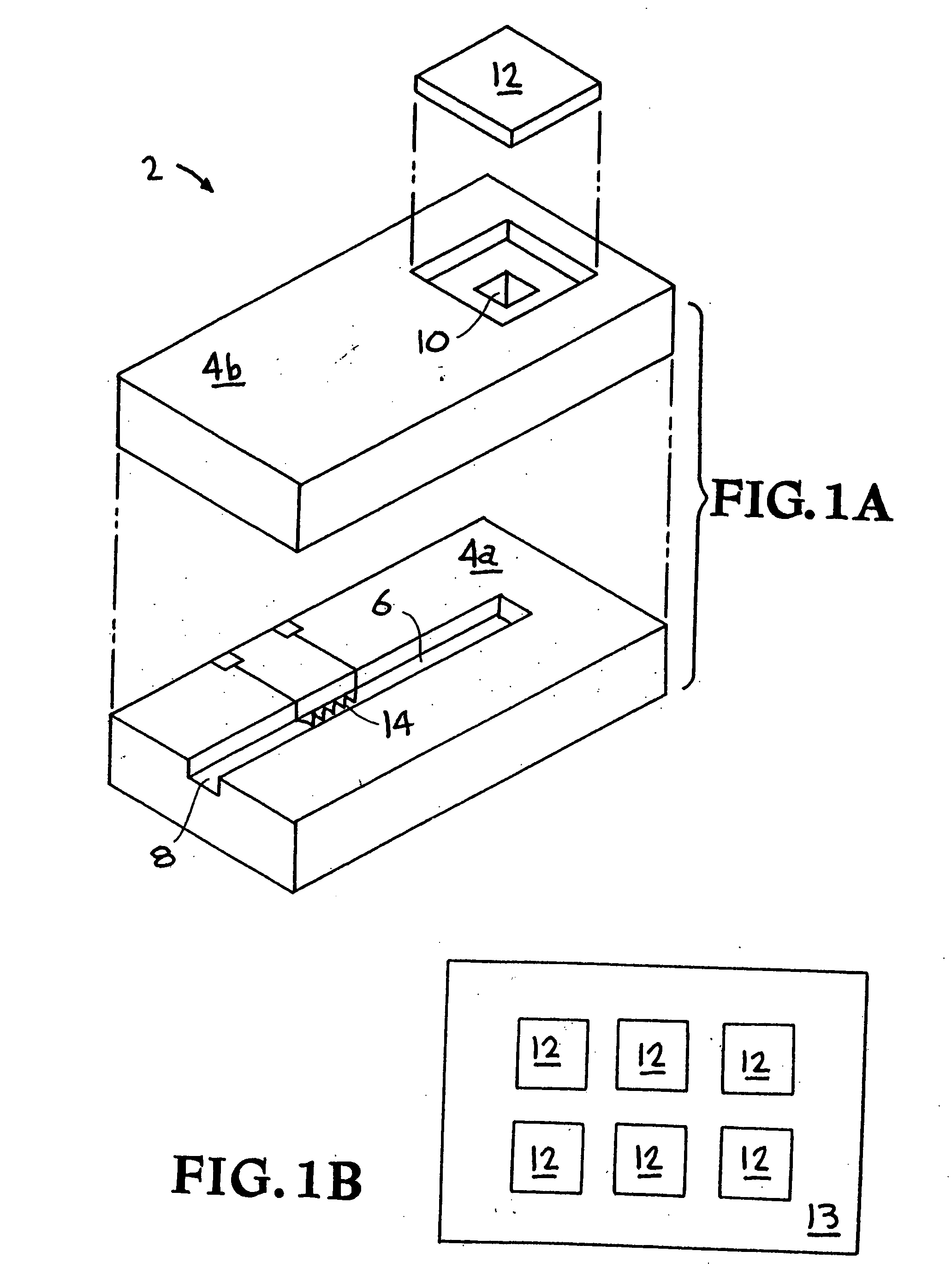

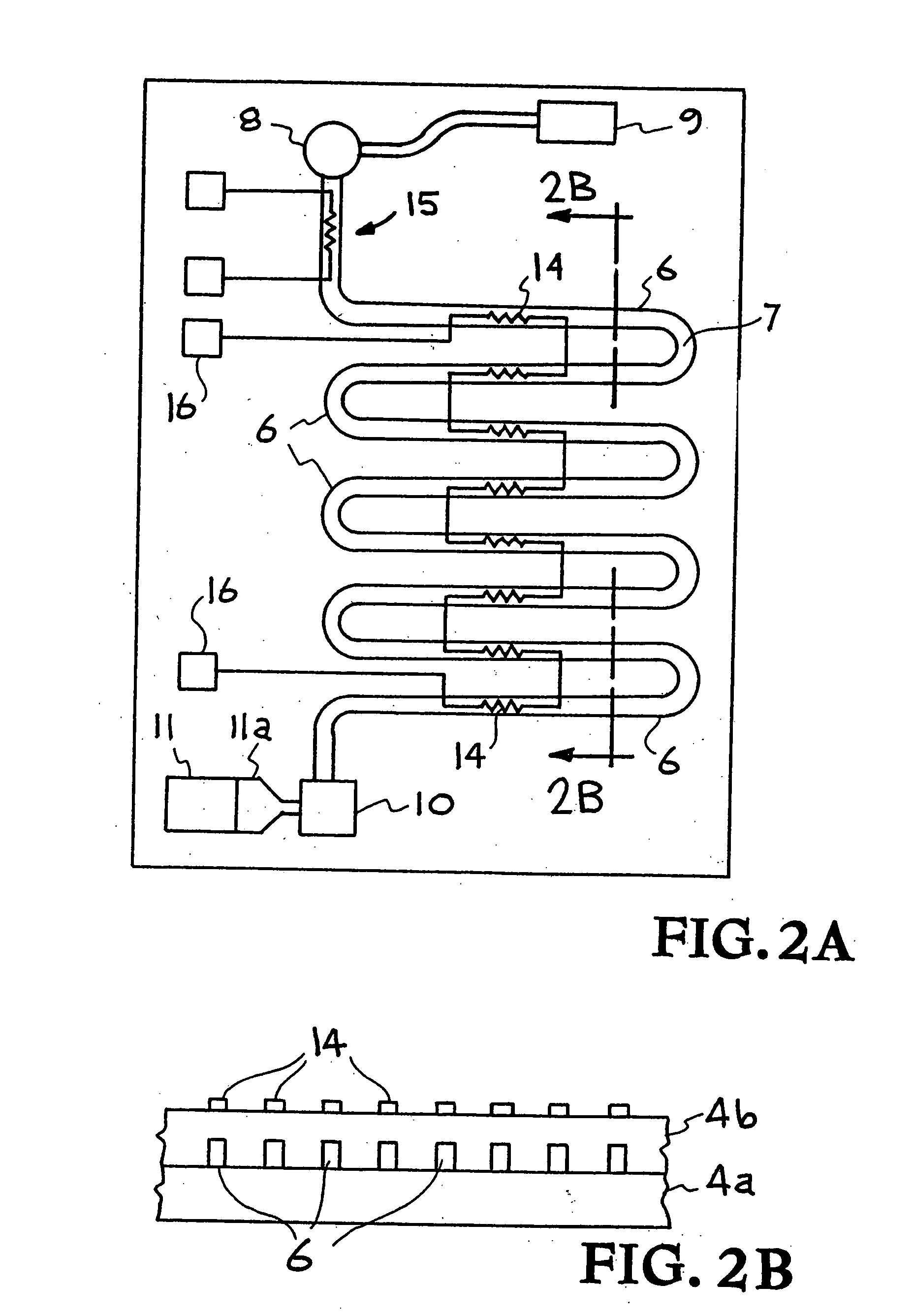

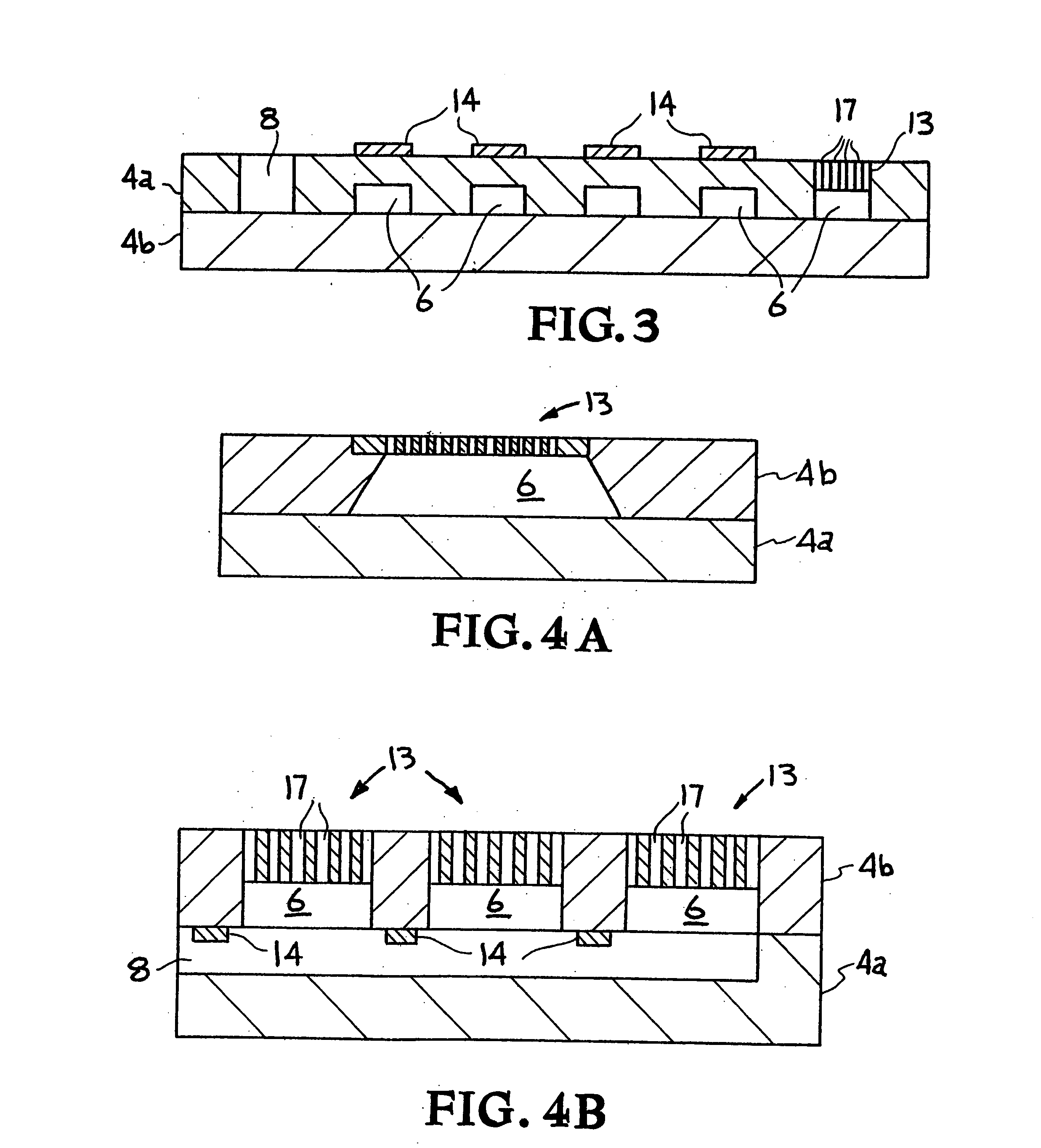

Chemical microreactor and method thereof

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

System for storing and recoving energy and method for use thereof

InactiveUS20040013923A1Decreases hydrogen gas pressureElectricity cogenerationElectrolysis componentsElectricityWorking pressure

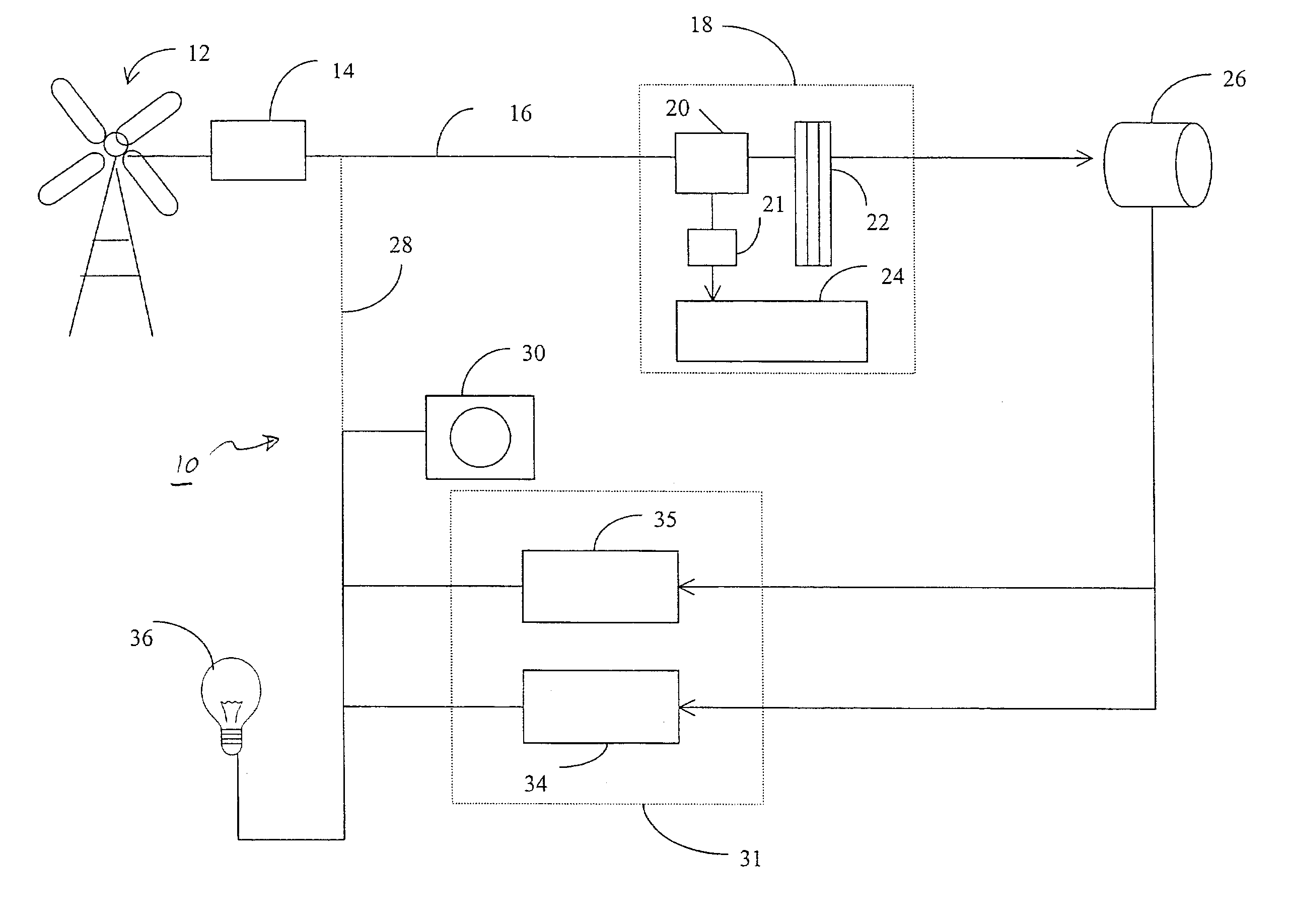

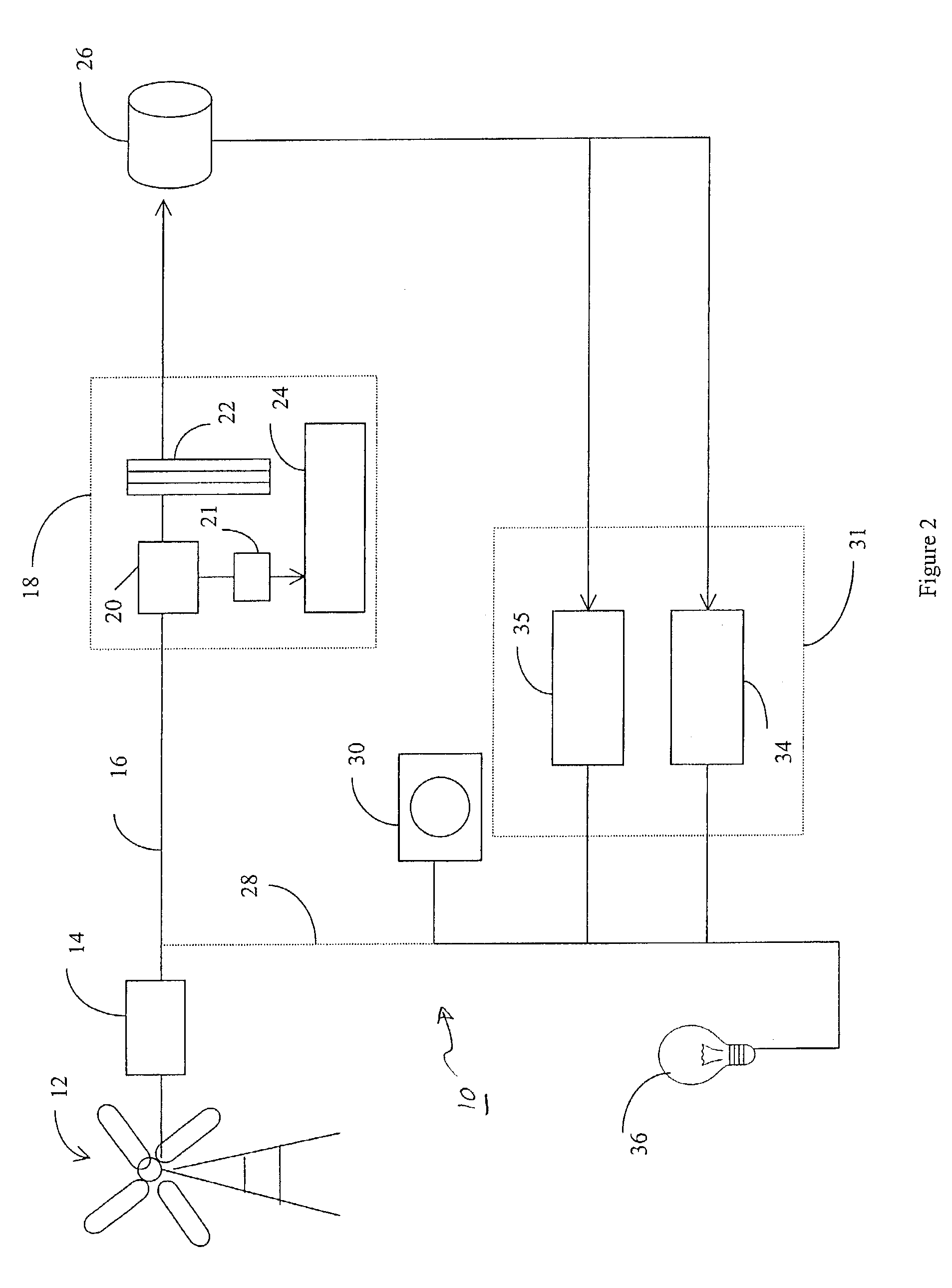

An energy storage and recovery system includes a renewable power source, a hydrogen generation device in electrical communication with the renewable power source, a hydrogen storage device in fluid communication with the hydrogen generation device, a hydrogen fueled electricity generator in fluid communication with the hydrogen storage device, and a pressure regulator interposed between and in fluid communication with the hydrogen fueled electricity generator and the hydrogen storage device. The pressure regulator is set at an operating pressure of the hydrogen fueled electricity generator.

Owner:PROTON ENERGY SYST

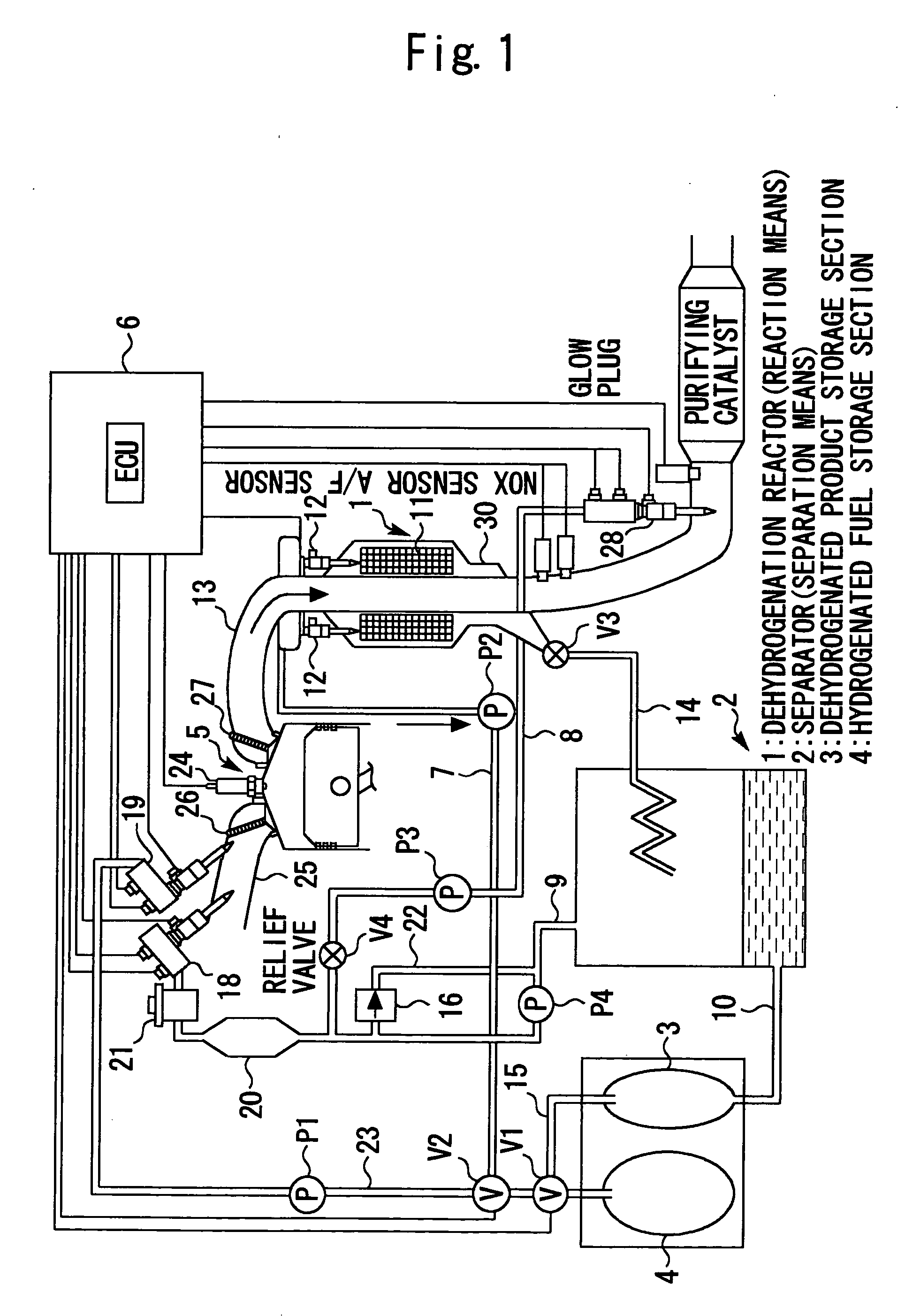

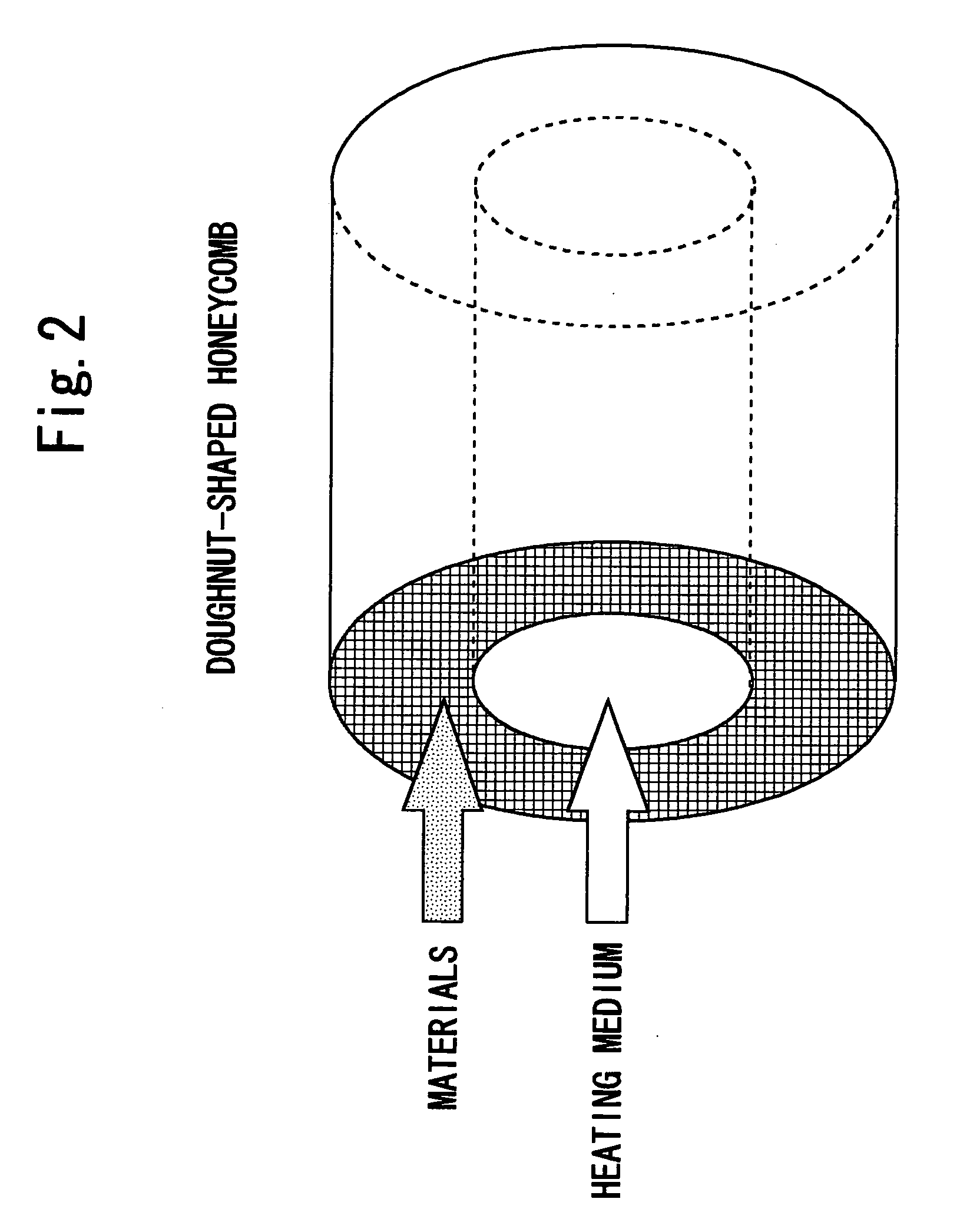

Internal combustion engine utilizing hydrogen

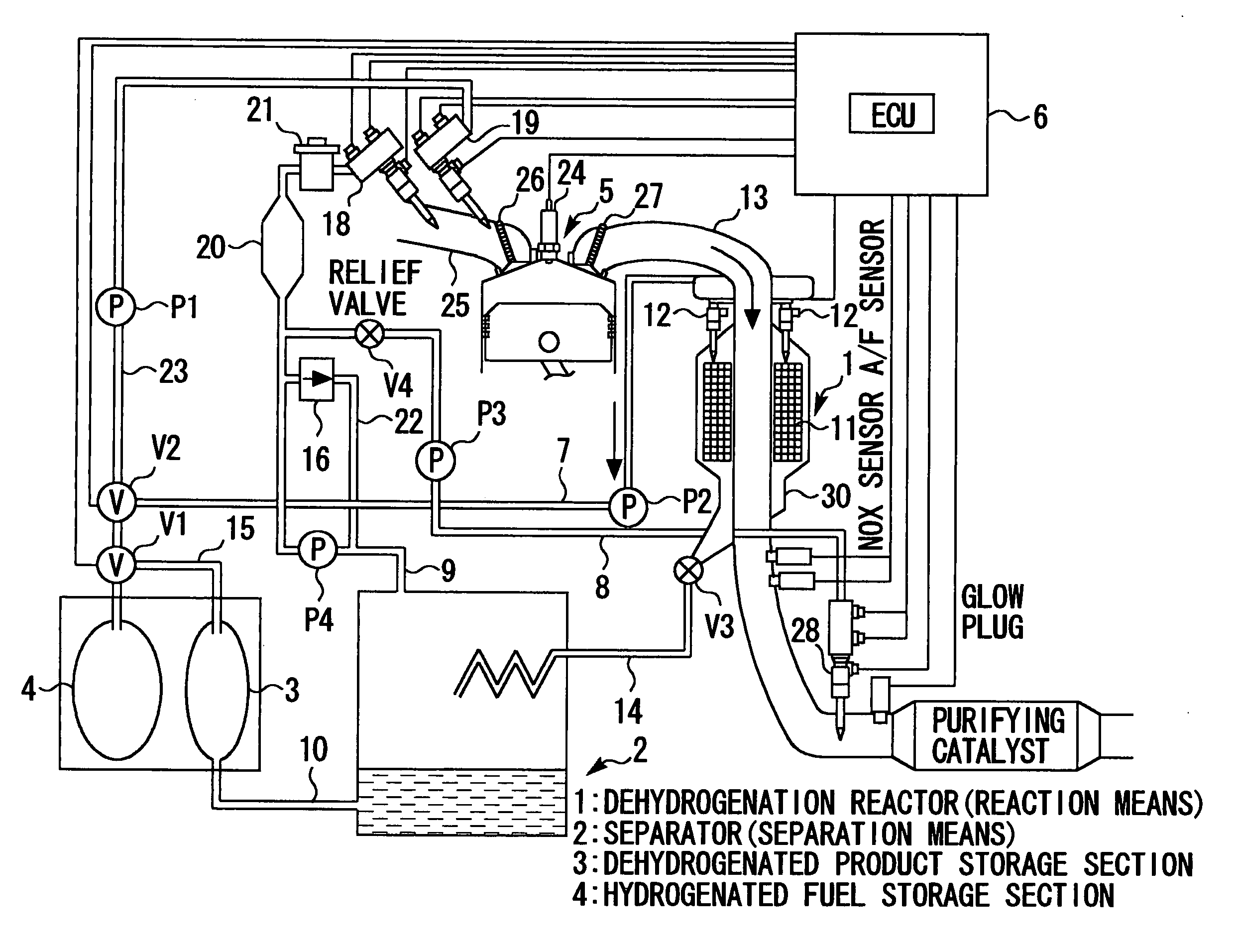

The present invention relates to a system that is capable of freely selecting one or two or more types of fuel and supplying the selected types of fuel to an internal combustion engine. Disclosed is a hydrogen-fueled internal combustion engine that operates upon receipt of one or more types of fuel that are selected from hydrogenated fuel and a dehydrogenated product and hydrogen, which are obtained by dehydrogenating the hydrogenated fuel. The hydrogen-fueled internal combustion engine comprises: a hydrogenated fuel storage section; reaction means for invoking a dehydrogenation reaction; separation means for separating hydrogen-rich gas and dehydrogenated product; and a dehydrogenated product storage section for storing the separated dehydrogenated product.

Owner:TOYOTA JIDOSHA KK

Portable fuel cartridge for fuel cells

InactiveUS20050008908A1Promote hydrogen productionPromote productionFuel cell heat exchangeReactant parameters controlHydrogen fuelElectron

Described herein is a portable storage device that stores a hydrogen fuel source. The storage device includes a bladder that contains the hydrogen fuel source and conforms to the volume of the hydrogen fuel source. A housing provides mechanical protection for the bladder. The storage device also includes a connector that interfaces with a mating connector to permit transfer of the fuel source between the bladder and a device that includes the mating connector. The device may be a portable electronics device such as a laptop computer. Refillable hydrogen fuel source storage devices and systems are also described. The refillable system comprises a hydrogen fuel source refiner that includes the mating connector and provides the hydrogen fuel source to the storage device. Hot swappable fuel storage systems described herein allow a portable hydrogen fuel source storage device to be removed from a fuel processor or electronics device it provides the hydrogen fuel source to, without shutting down the receiving device or without compromising hydrogen fuel source provision to the receiving device for a limited time.

Owner:ULTRACELL LLC

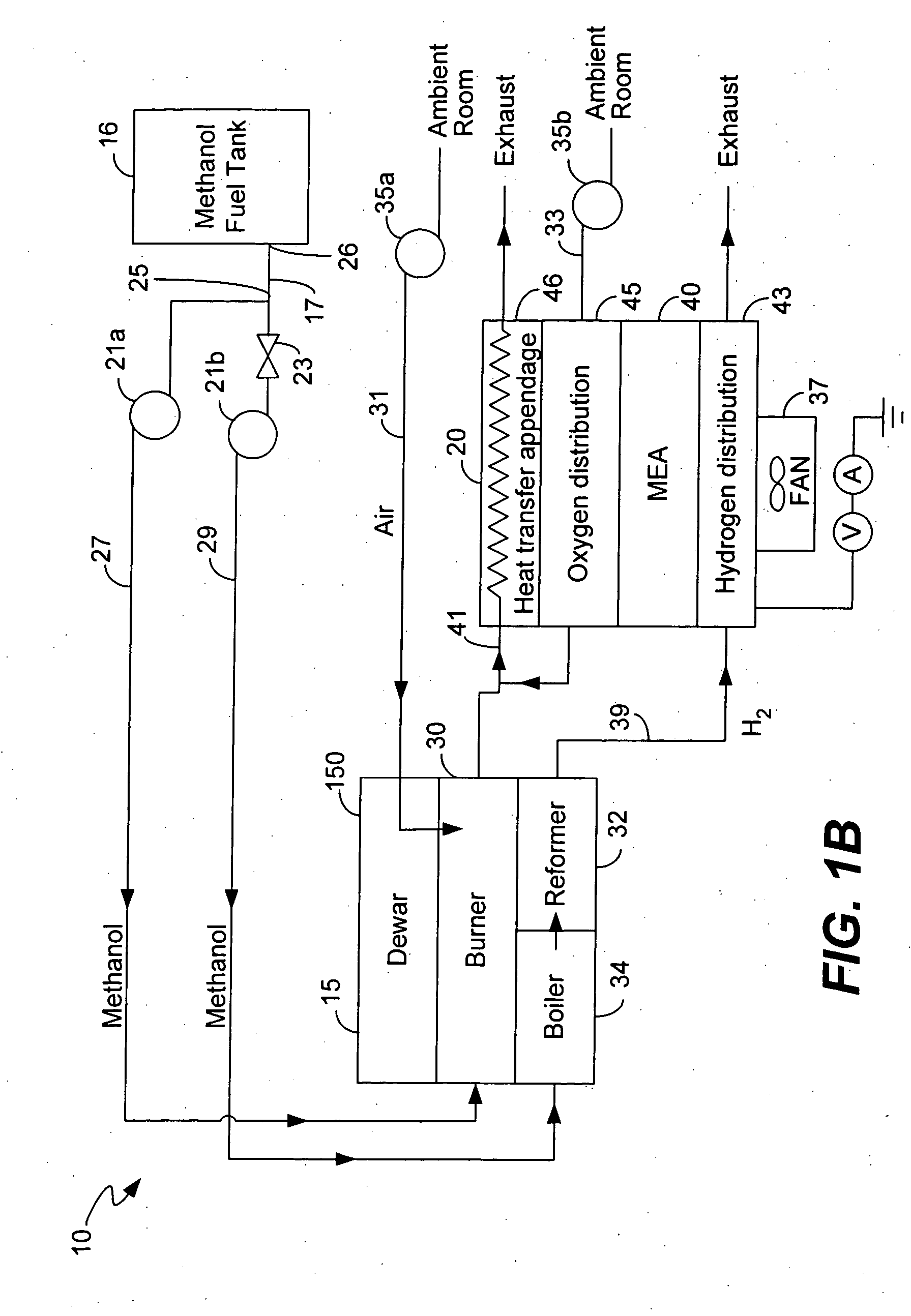

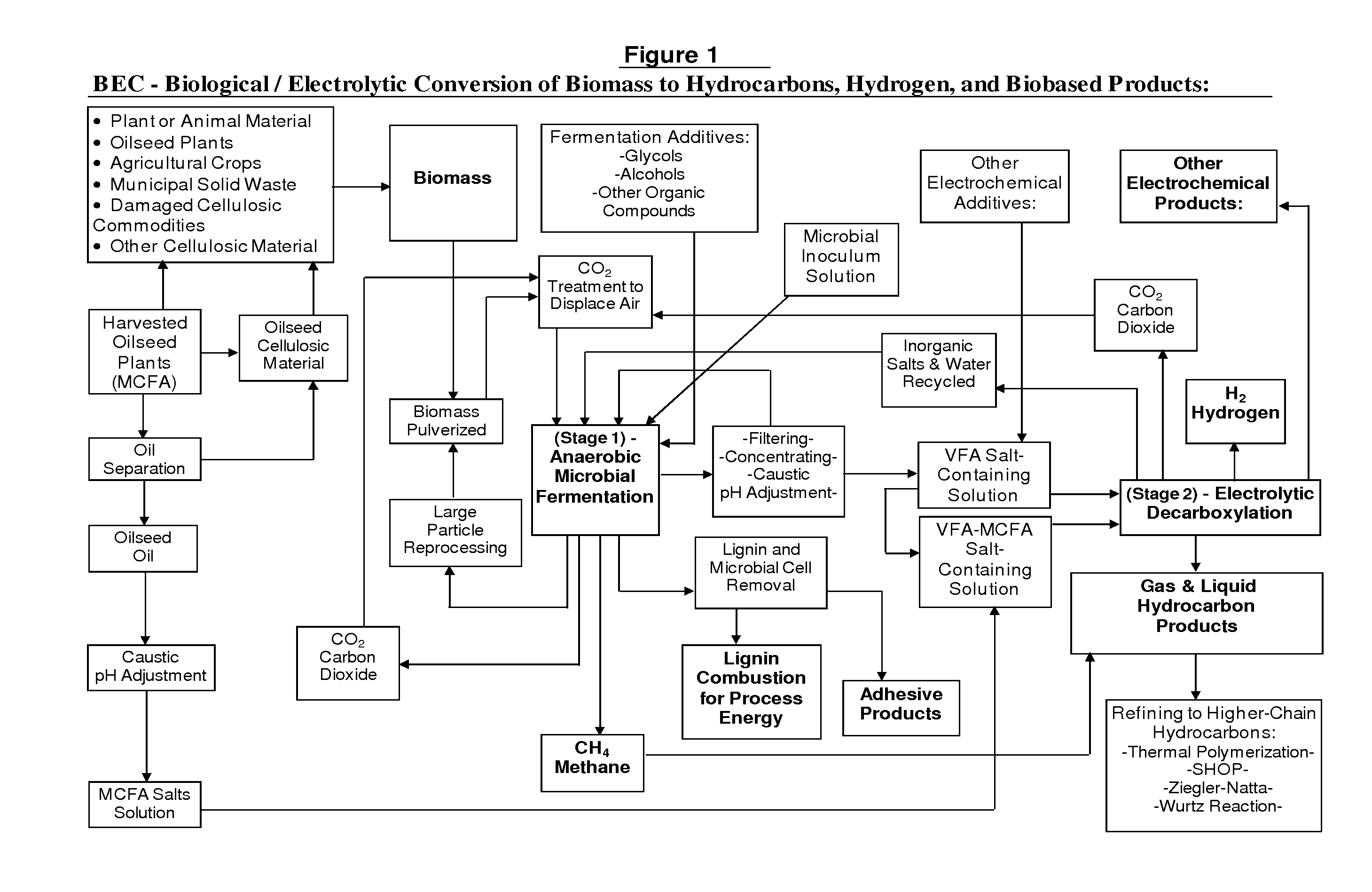

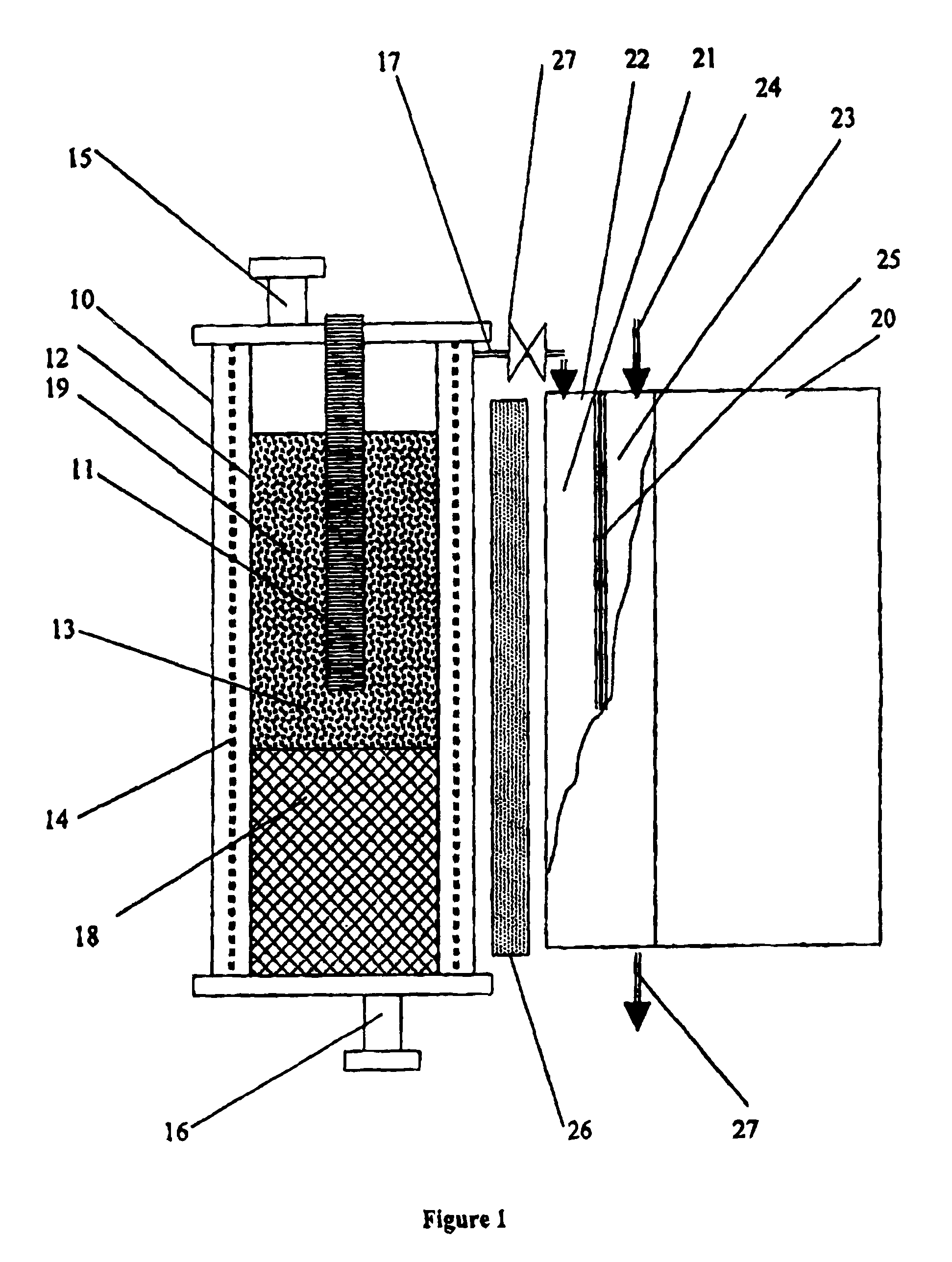

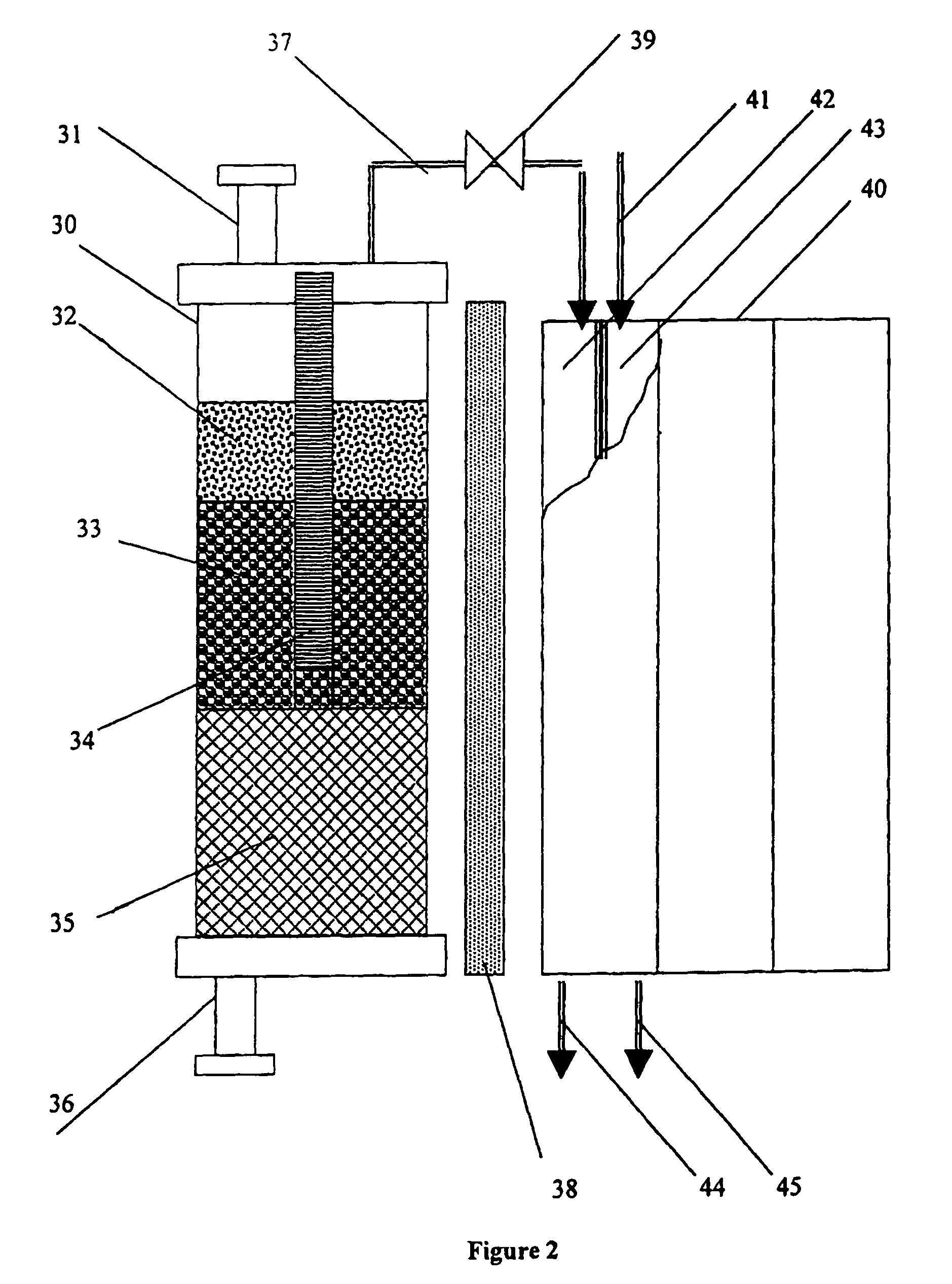

Biological/Electrolytic Conversion of Biomass to Hydrocarbons

ActiveUS20110111475A1Eliminate needInexpensive solutionElectrolysis componentsBacteriaElectrolysisSufficient time

Hydrocarbon and hydrogen fuels and other products may be produced by a process employing a combination of fermentation and electrochemical stages. In the process, a biomass contained within a fermentation medium is fermented with an inoculum comprising a mixed culture of microorganisms derived the rumen contents of a rumen-containing animal. This inoculated medium is incubated under anaerobic conditions and for a sufficient time to produce volatile fatty acids. The resultant volatile fatty acids are then subjected to electrolysis under conditions effective to convert said volatile fatty acids to hydrocarbons and hydrogen simultaneously. The process can convert a wide range of biomass materials to a wide range of volatile fatty acid chain lengths and can convert these into a wide range of biobased fuels and biobased products.

Owner:US SEC AGRI +1

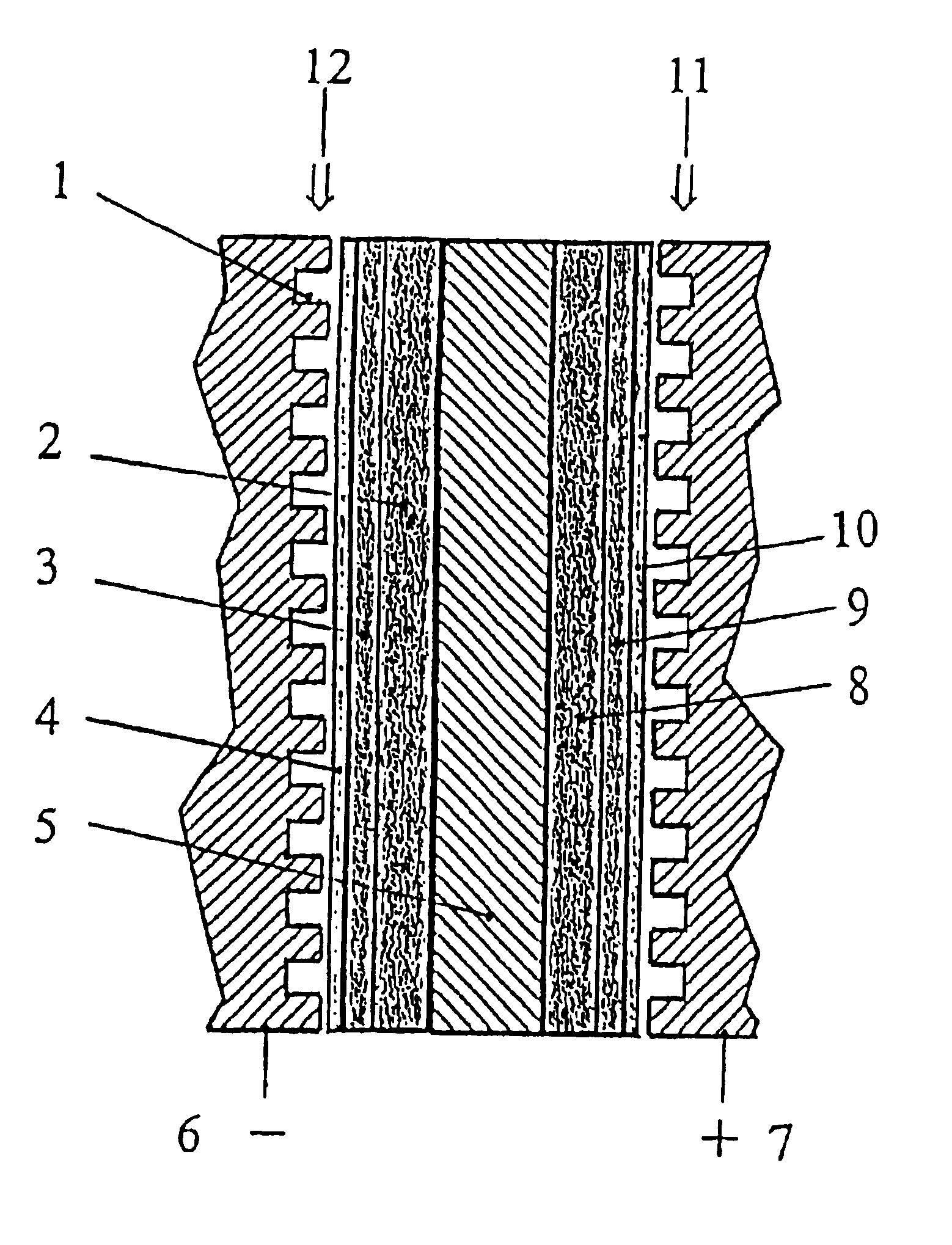

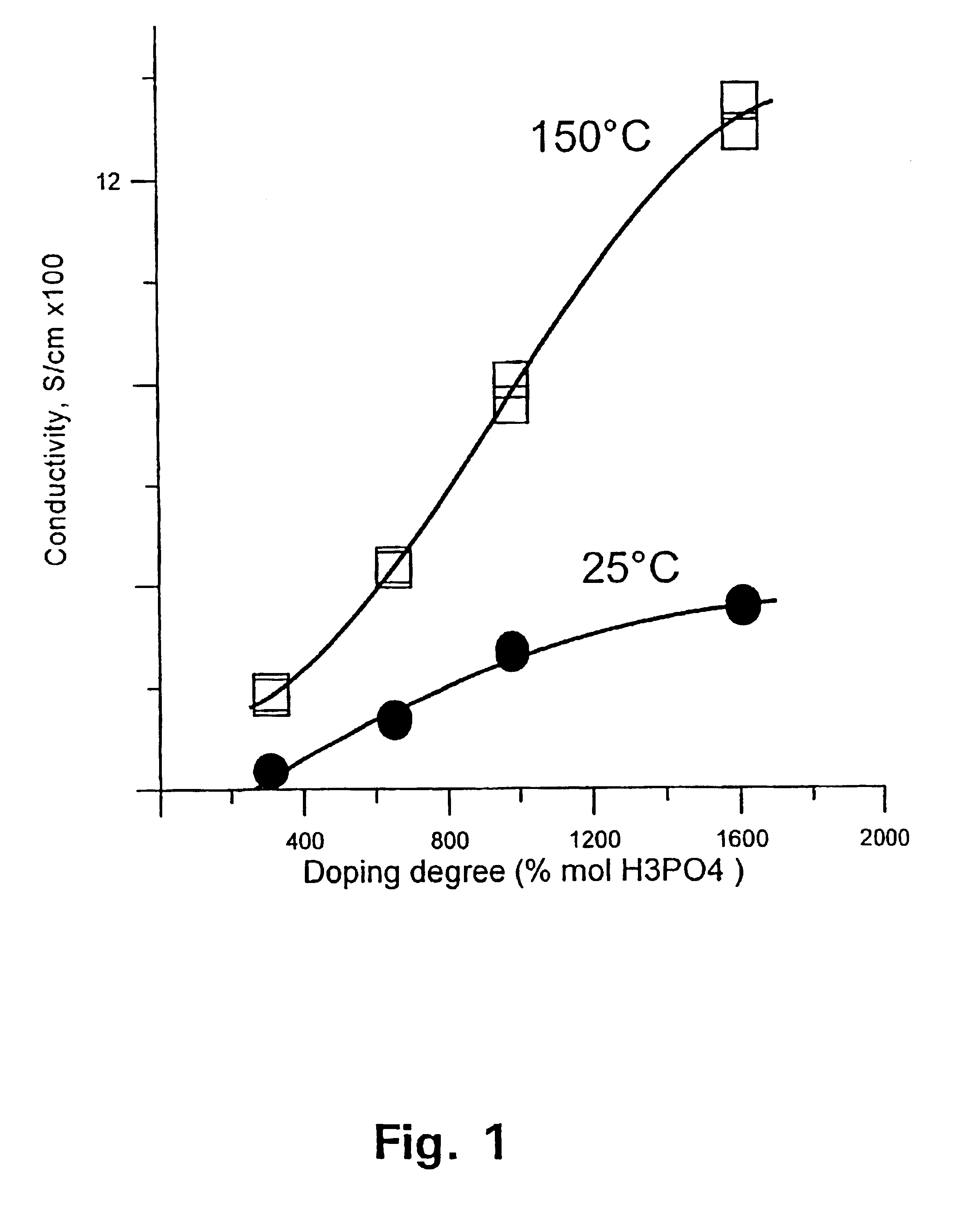

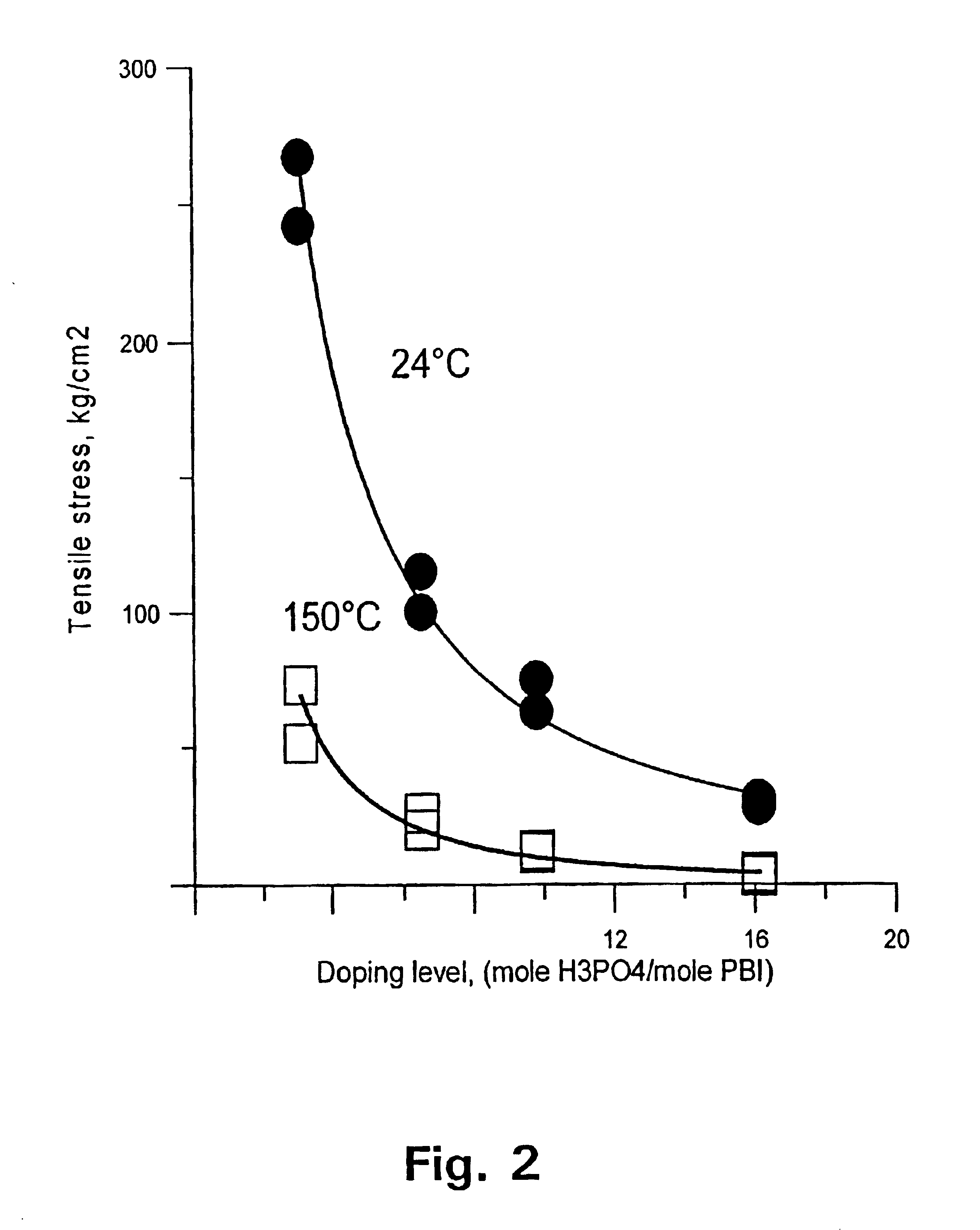

Polymer electrolyte membrane fuel cells

InactiveUS6946211B1Improve performanceImprove toleranceSolid electrolytesPrimary cellsThermoplasticGas diffusion electrode

A method for preparing polybenzimidazole or polybenzimidazole blend membranes and fabricating gas diffusion electrodes and membrane-electrode assemblies is provided for a high temperature polymer electrolyte membrane fuel cell. Blend polymer electrolyte membranes based on PBI and various thermoplastc polymers for high temperature polymer electrolyte fuel cells have also been developed. Miscible blends are used for solution casting of polymer membranes (solid electrolytes). High conductivity and enhanced mechanical strength were obtained for the blend polymer solid electrolytes. With the thermally resistant polymer, e.g., polybenzimidazole or a mixture of polybenzimidazole and other thermoplastics as binder, the carbon-supported noble metal catalyst is tape-cast onto a hydrophobic supporting substrate. When doped with an acid mixture, electrodes are assembled with an acid doped solid electrolyte membrane by hot-press. The fuel cell can operate at temperatures up to at least 200° C. with hydrogen-rich fuel containing high ratios of carbon monoxide such as 3 vol % carbon monoxide or more, compared to the carbon monoxide tolerance of 10-20 ppm level for Nafion®-based polymer electrolyte fuel cells.

Owner:DANISH POWER SYST

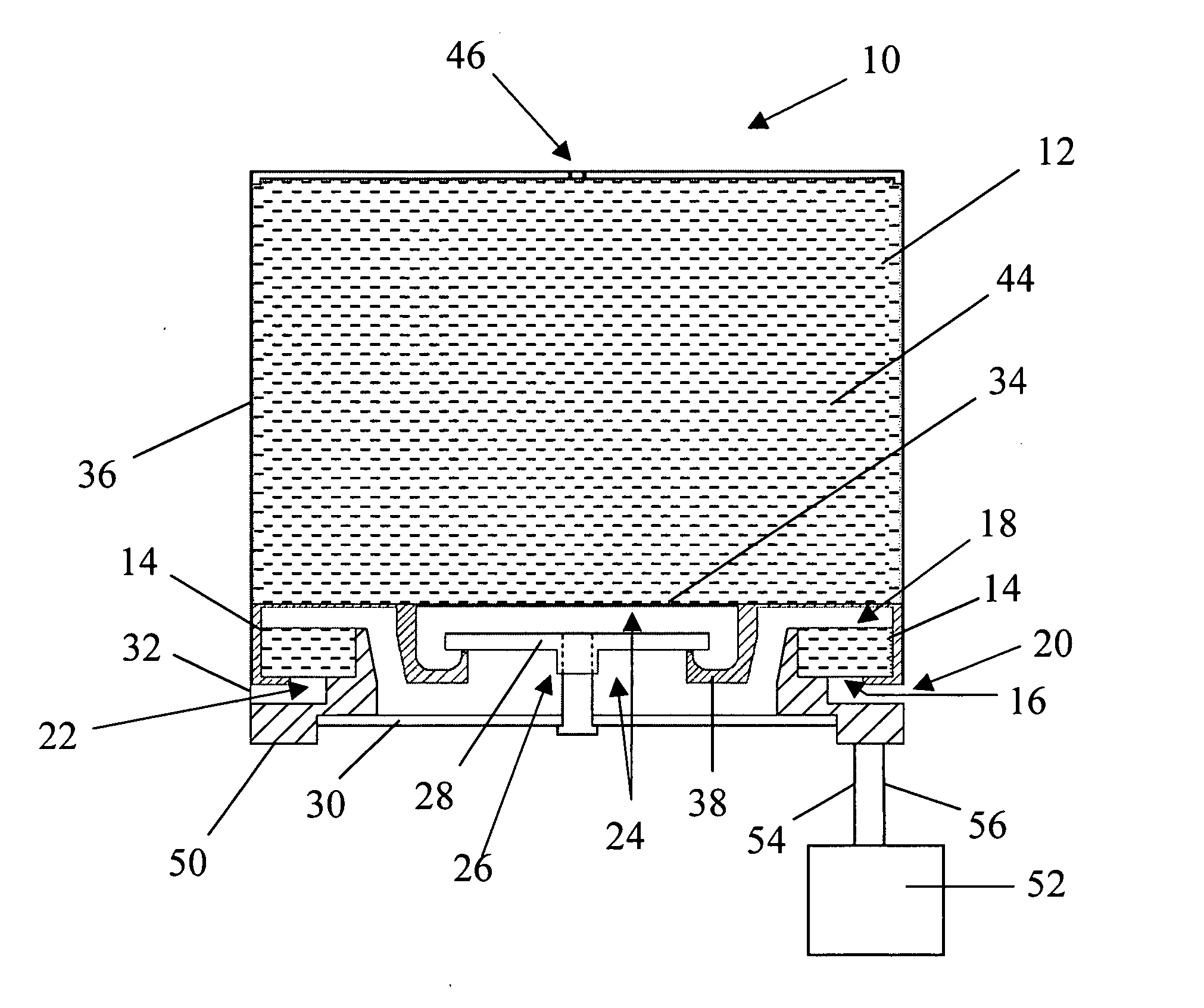

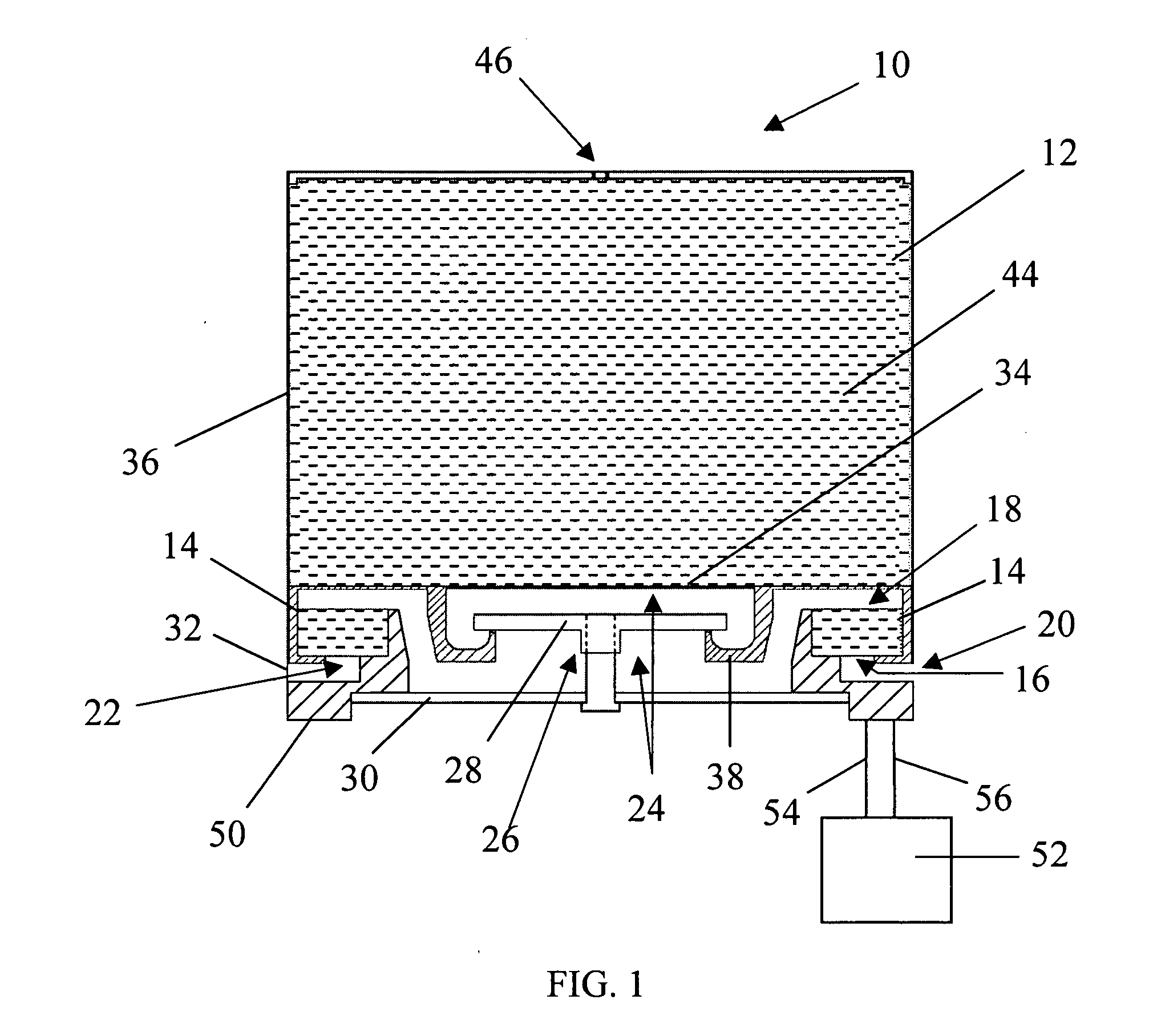

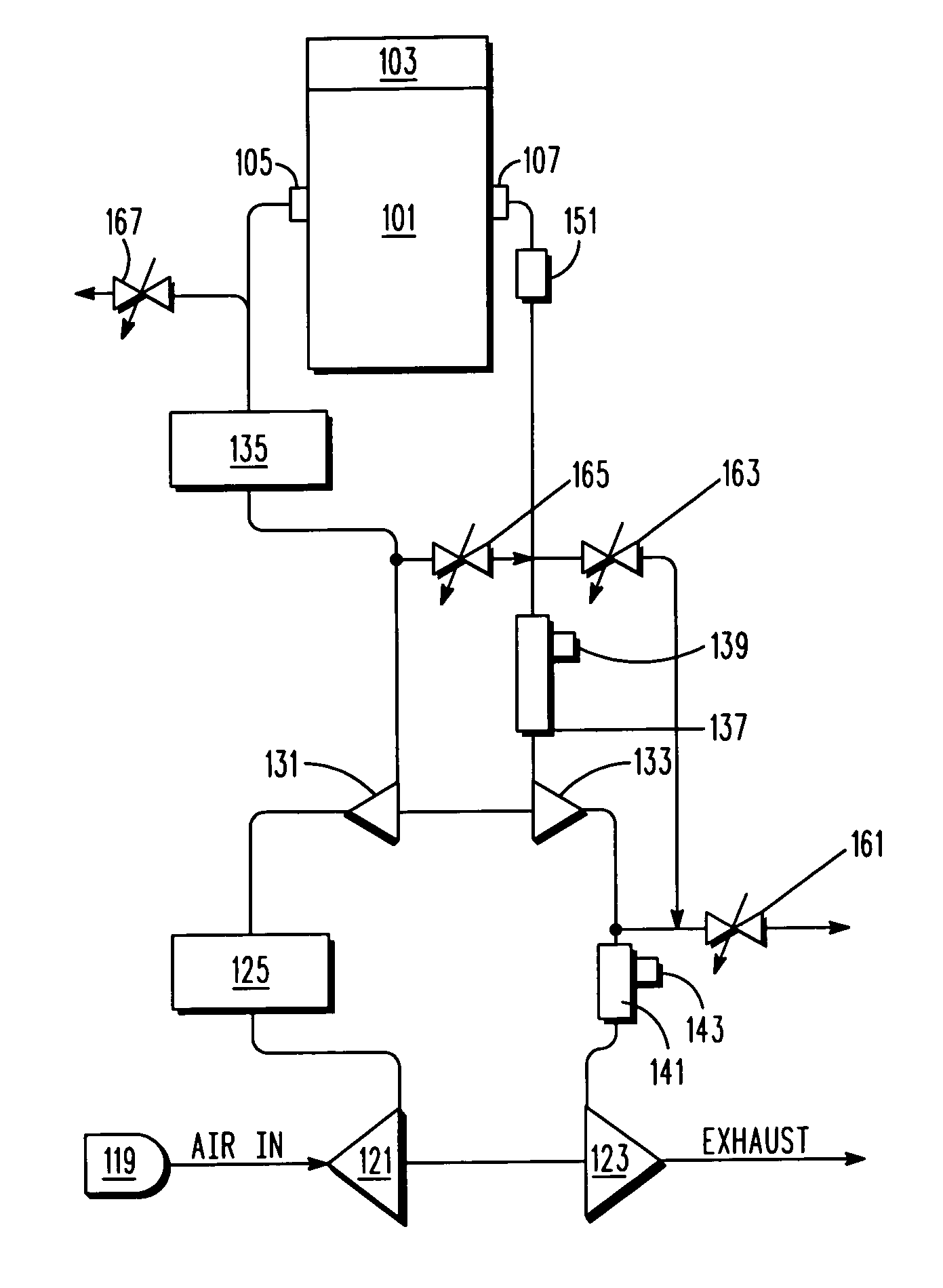

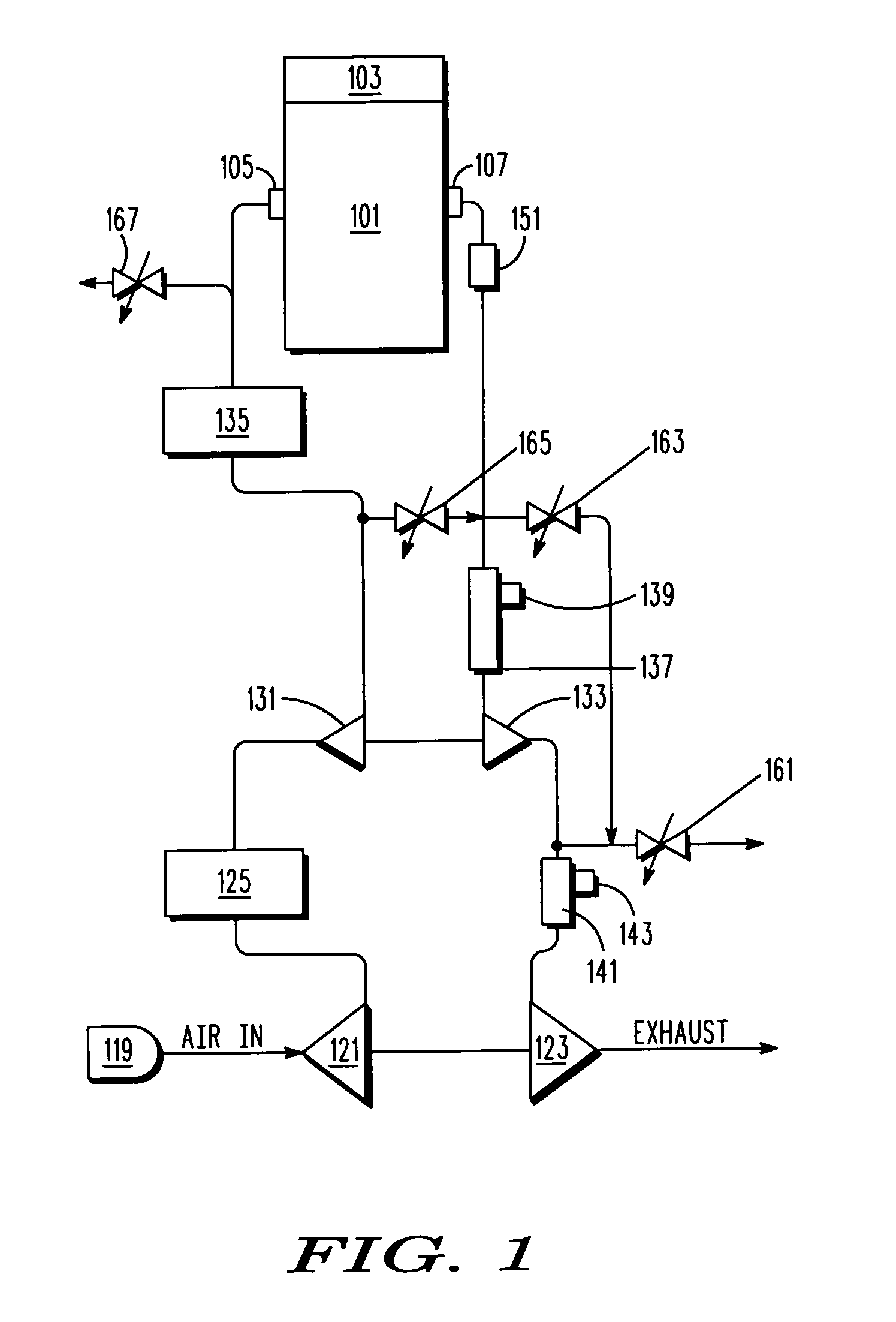

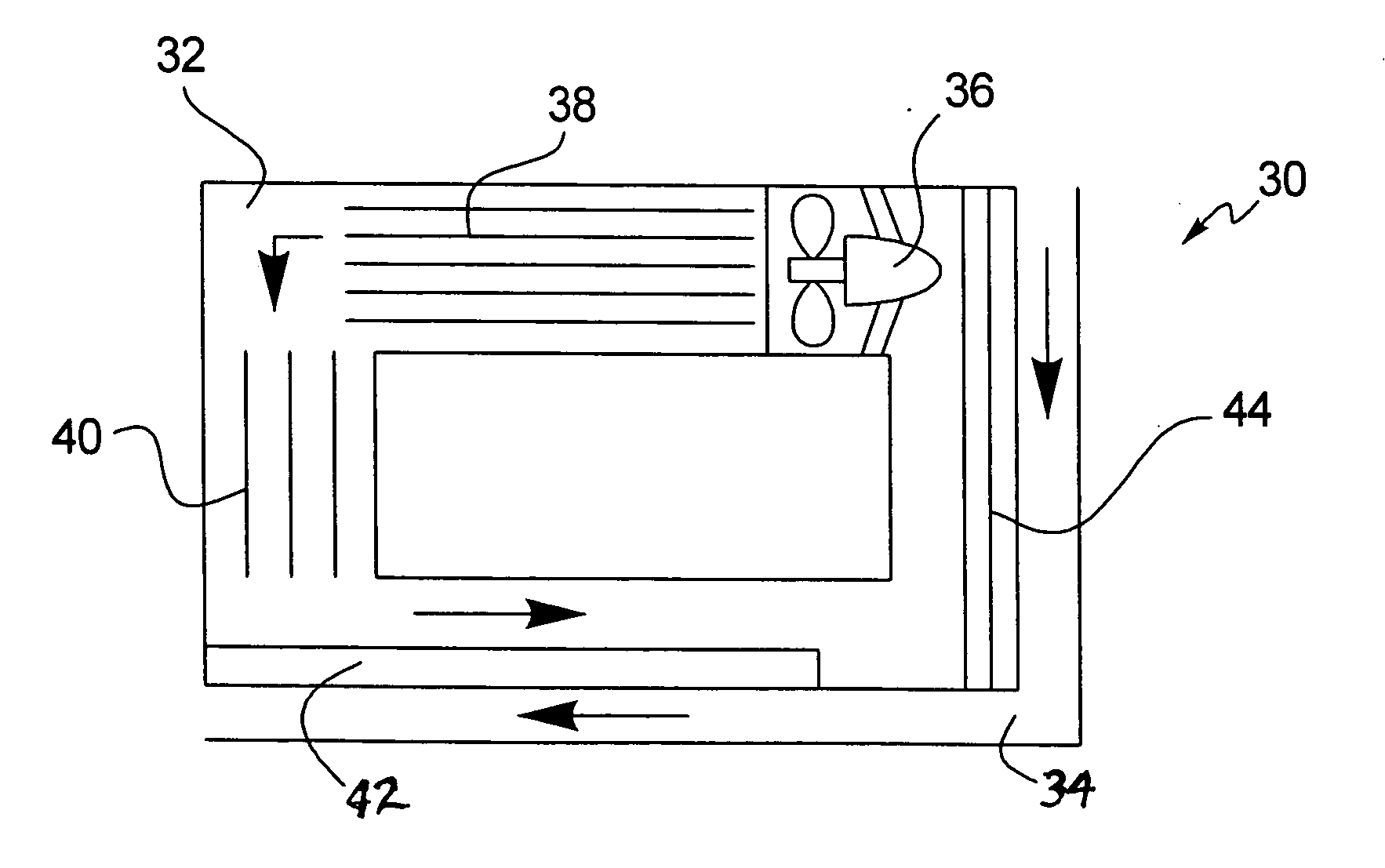

Hydrogen passivation shut down system for a fuel cell power plant

ActiveUS20050031917A1Move quicklyMinimize oxidation corrosionReactant parameters controlFuel cells groupingPower stationEngineering

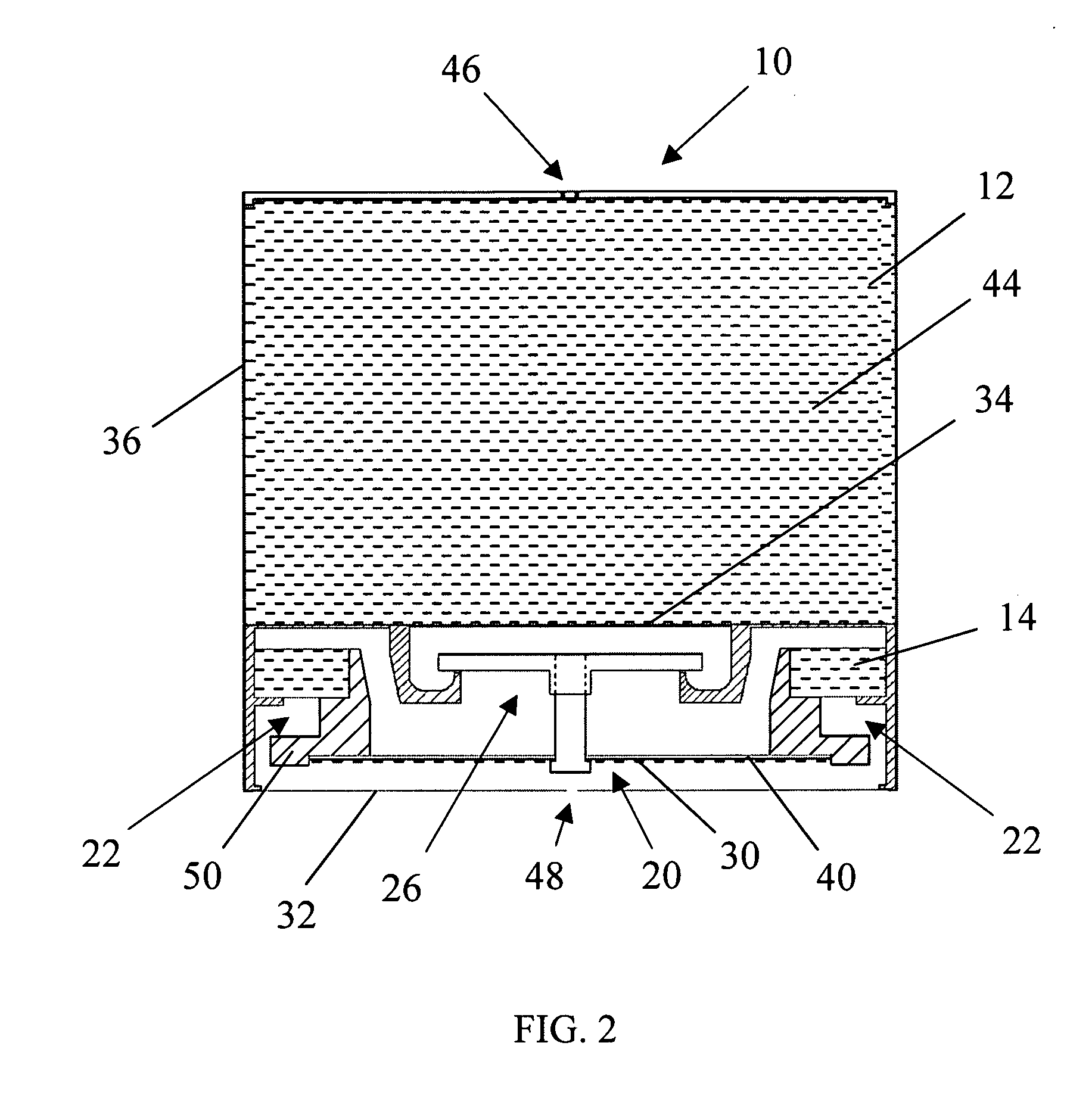

The invention is a hydrogen passivation shut down system for a fuel cell power plant (10). An anode flow path (24) is in fluid communication with an anode catalyst (14) for directing hydrogen fuel to flow adjacent to the anode catalyst (14), and a cathode flow path (38) is in fluid communication with a cathode catalyst (16) for directing an oxidant to flow adjacent to the cathode catalyst (16) of a fuel cell (12). Hydrogen fuel is permitted to transfer between the anode flow path (24) and the cathode flow path (38). A hydrogen reservoir (66) is secured in fluid communication with the anode flow path (24) for receiving and storing hydrogen during fuel cell (12) operation, and for releasing the hydrogen into fuel cell (12) whenever the fuel cell (12) is shut down.

Owner:AUDI AG

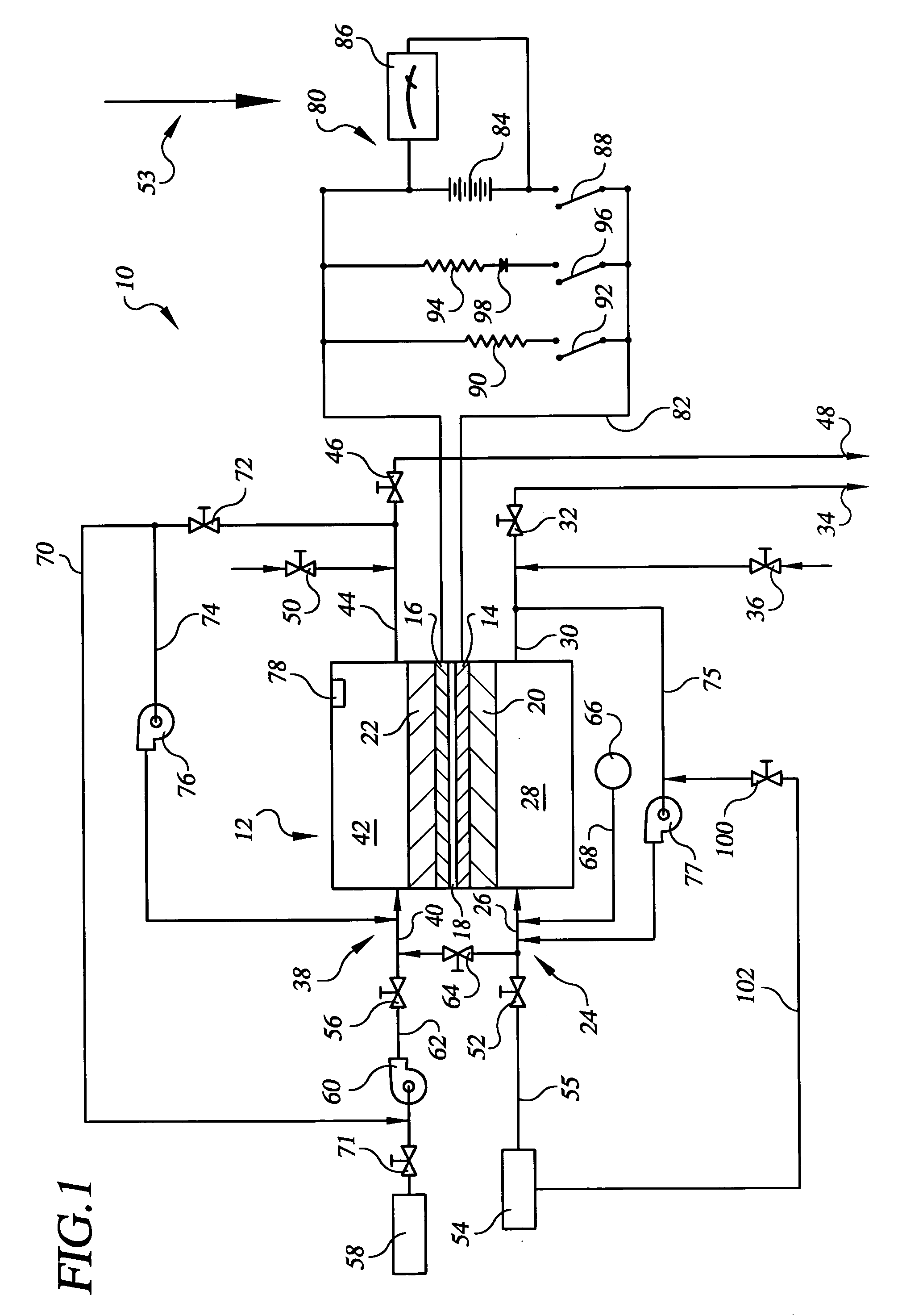

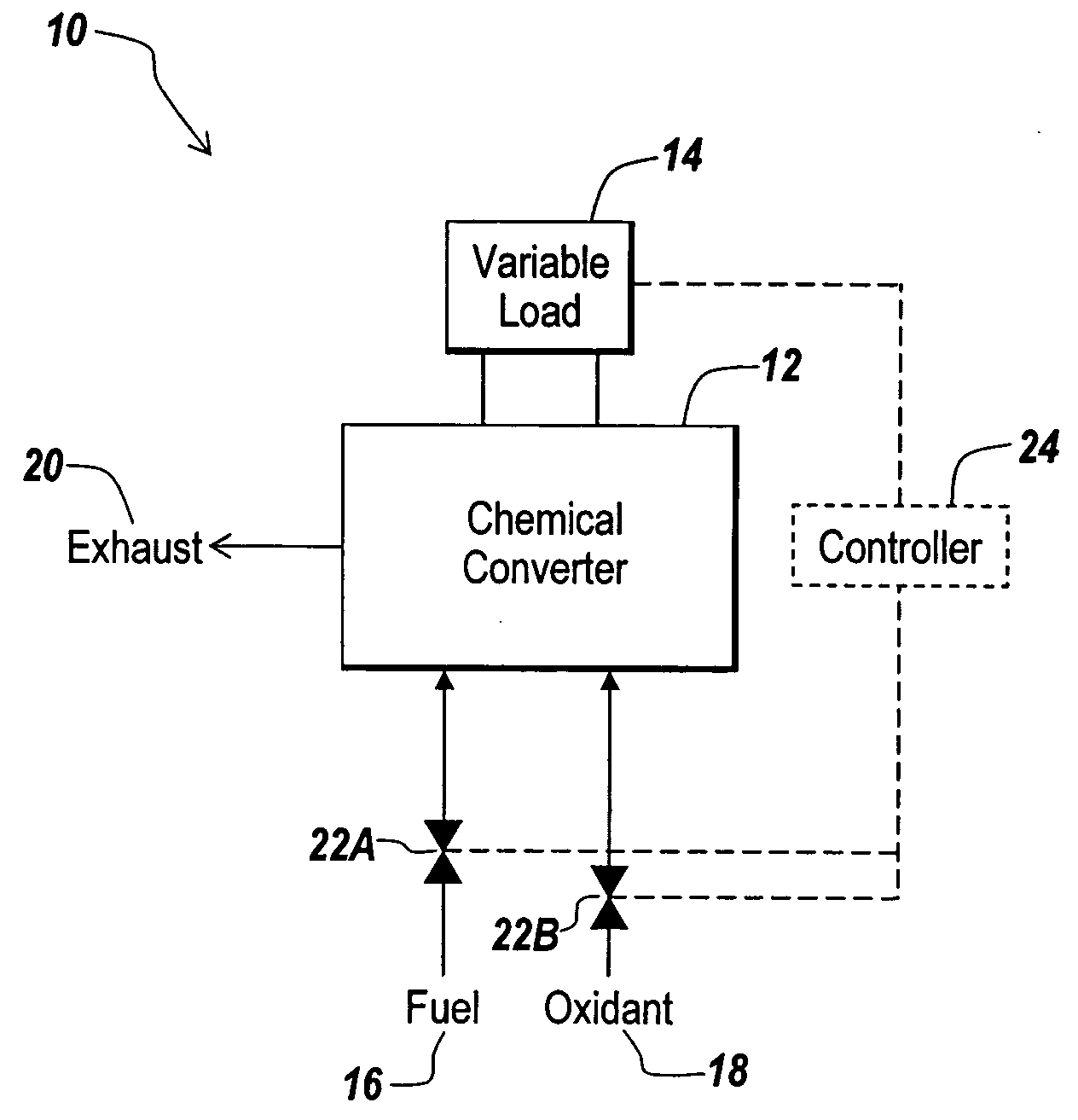

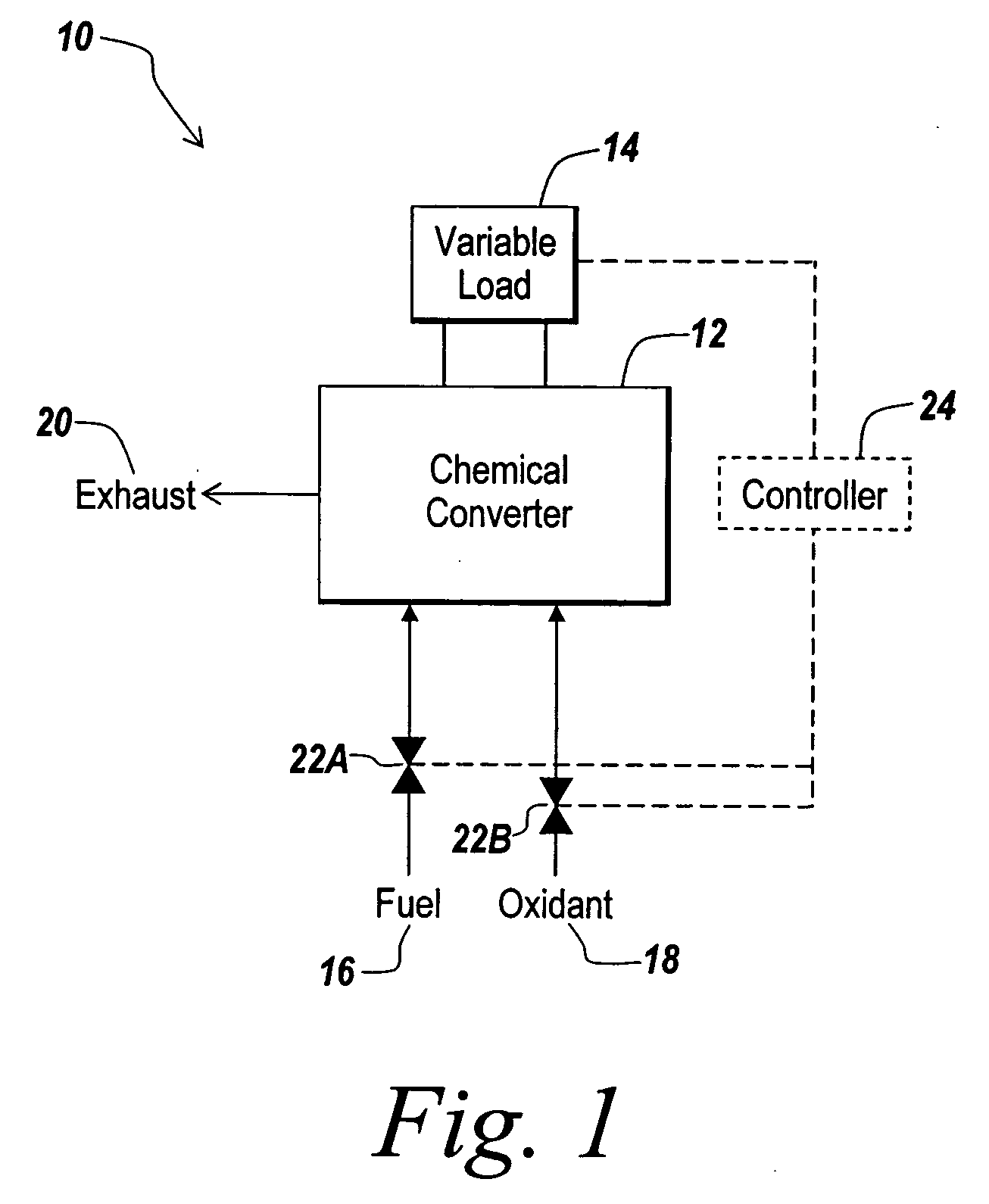

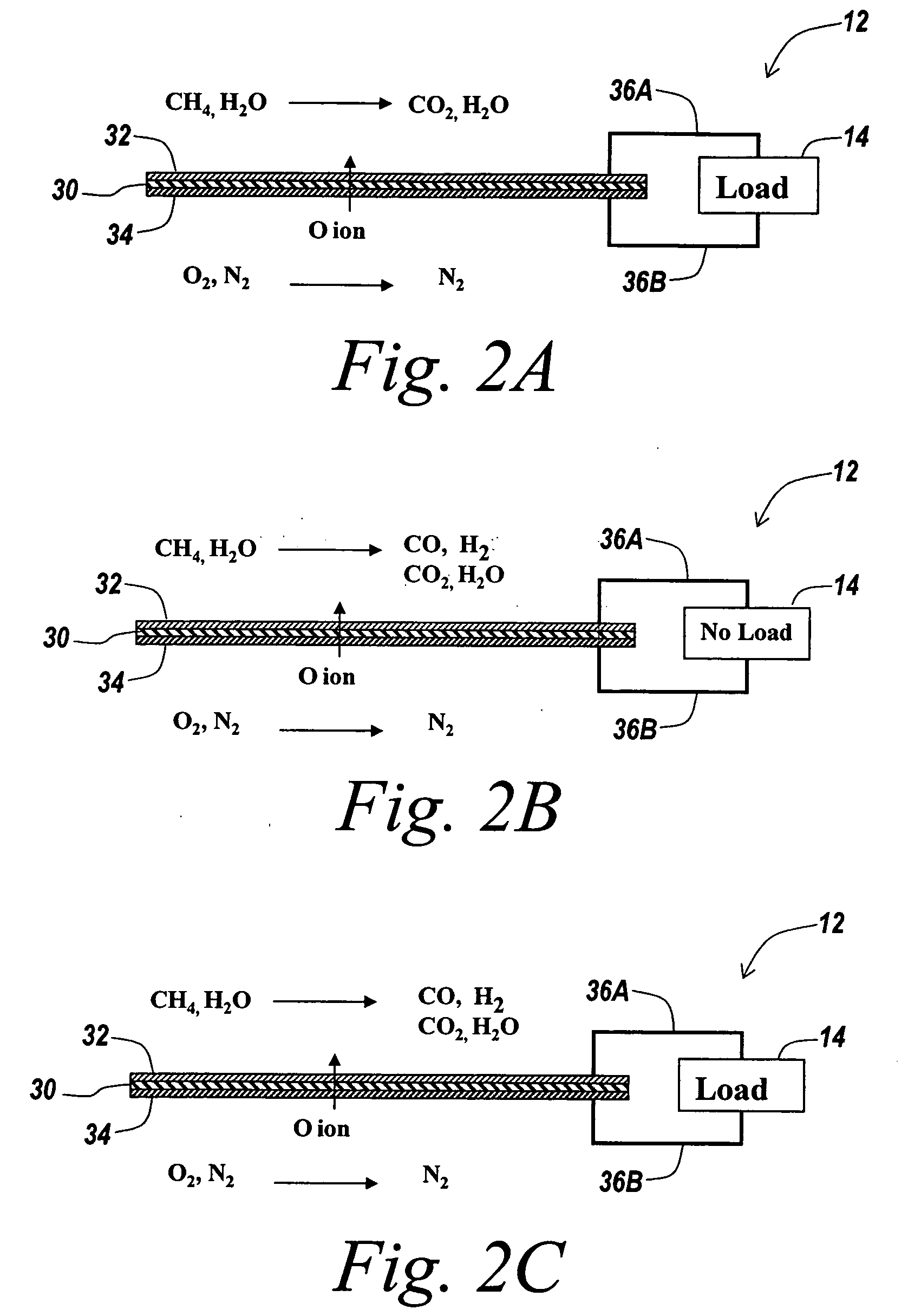

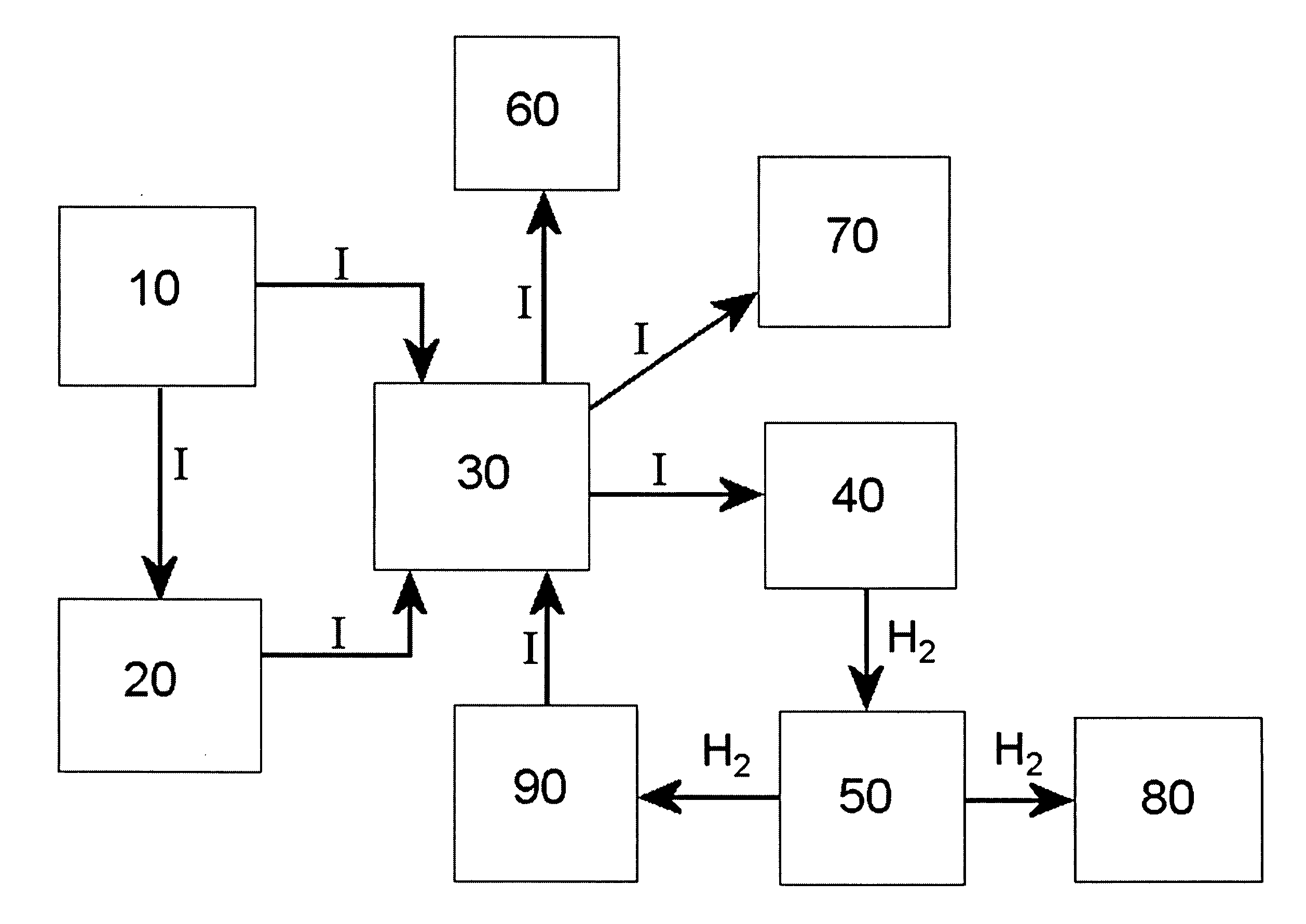

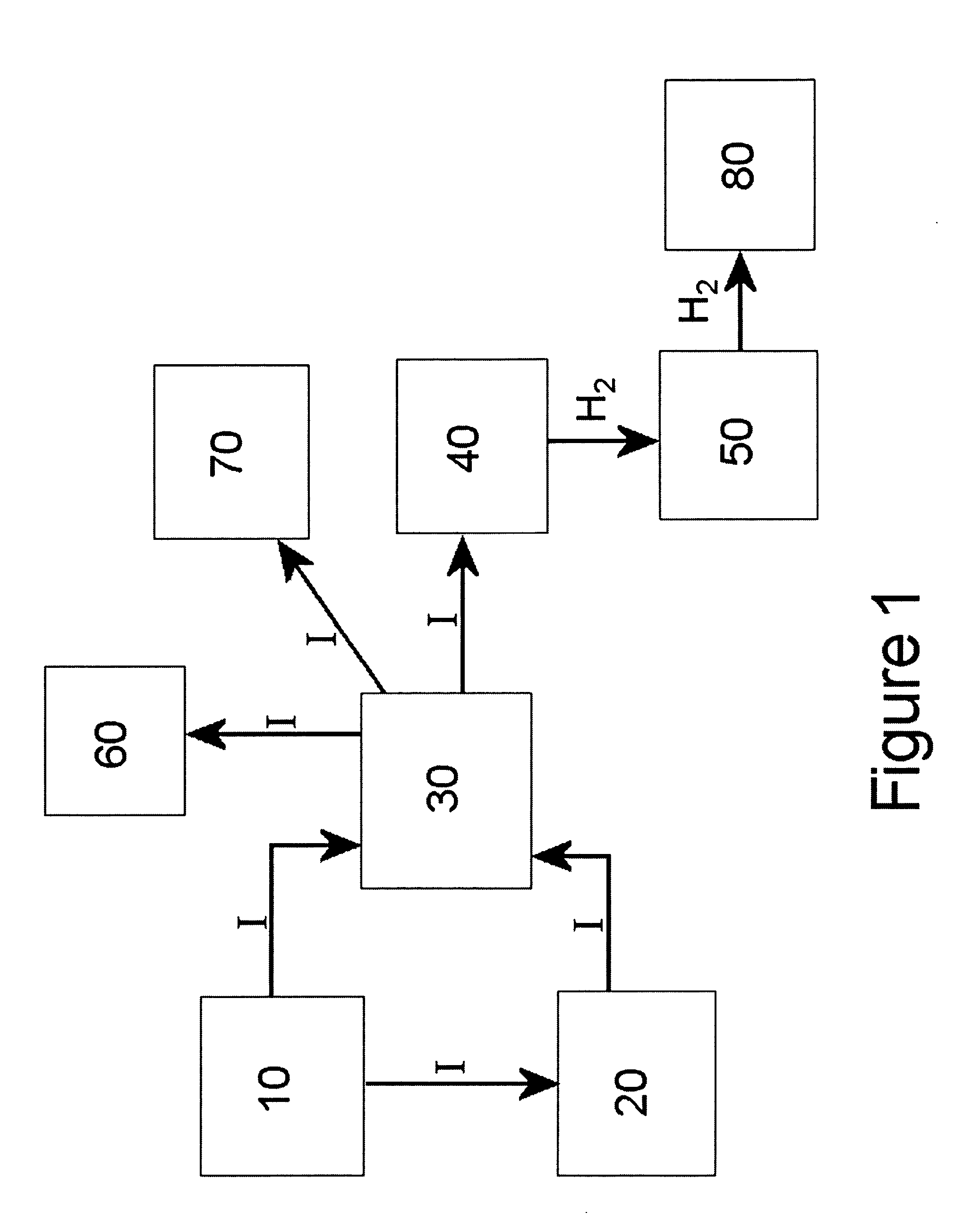

Fuel cell for hydrogen production, electricity generation and co-production

InactiveUS20050112425A1Amount be controlFuel cell combinationsHydrogenElectricityElectrochemical response

A hydrogen-electricity co-production (HECP) system utilizes a fuel cell to produce hydrogen, electricity, or a combination of both hydrogen and electricity. In a first mode, the fuel cell performs an electrochemical reaction by reacting a hydrogen-containing fuel with oxygen to produce electricity, water and heat. In a second mode, the fuel cell utilizes heat released by an electrochemical reaction of the fuel cell to reform a hydrogen-containing fuel to produce hydrogen rich gas. In a third mode, both hydrogen and electricity are co-produced by the fuel cell. The HECP system can control an amount of hydrogen and / or electricity produced and switch between modes by varying an electrical load on the system.

Owner:ZTEK

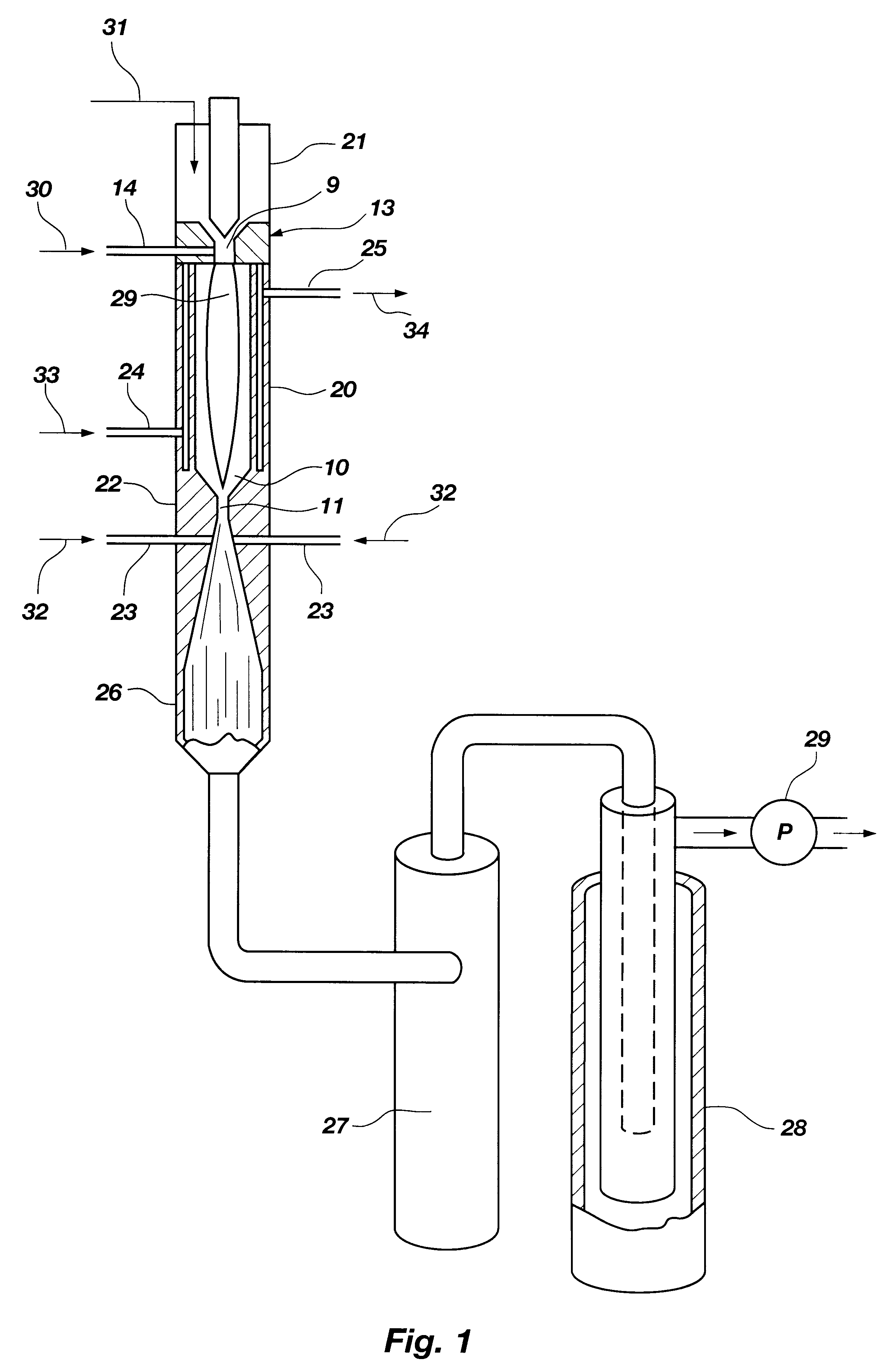

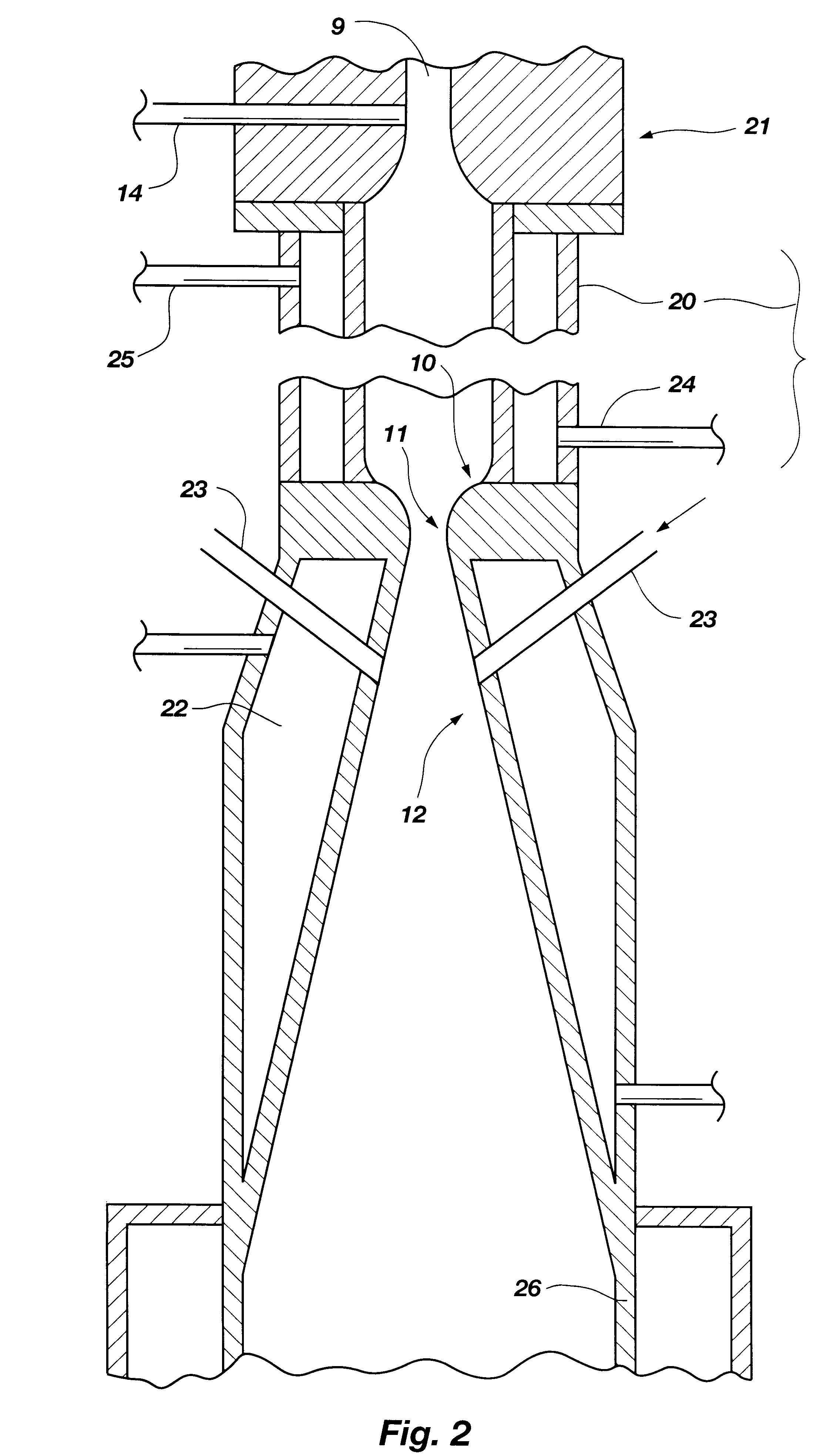

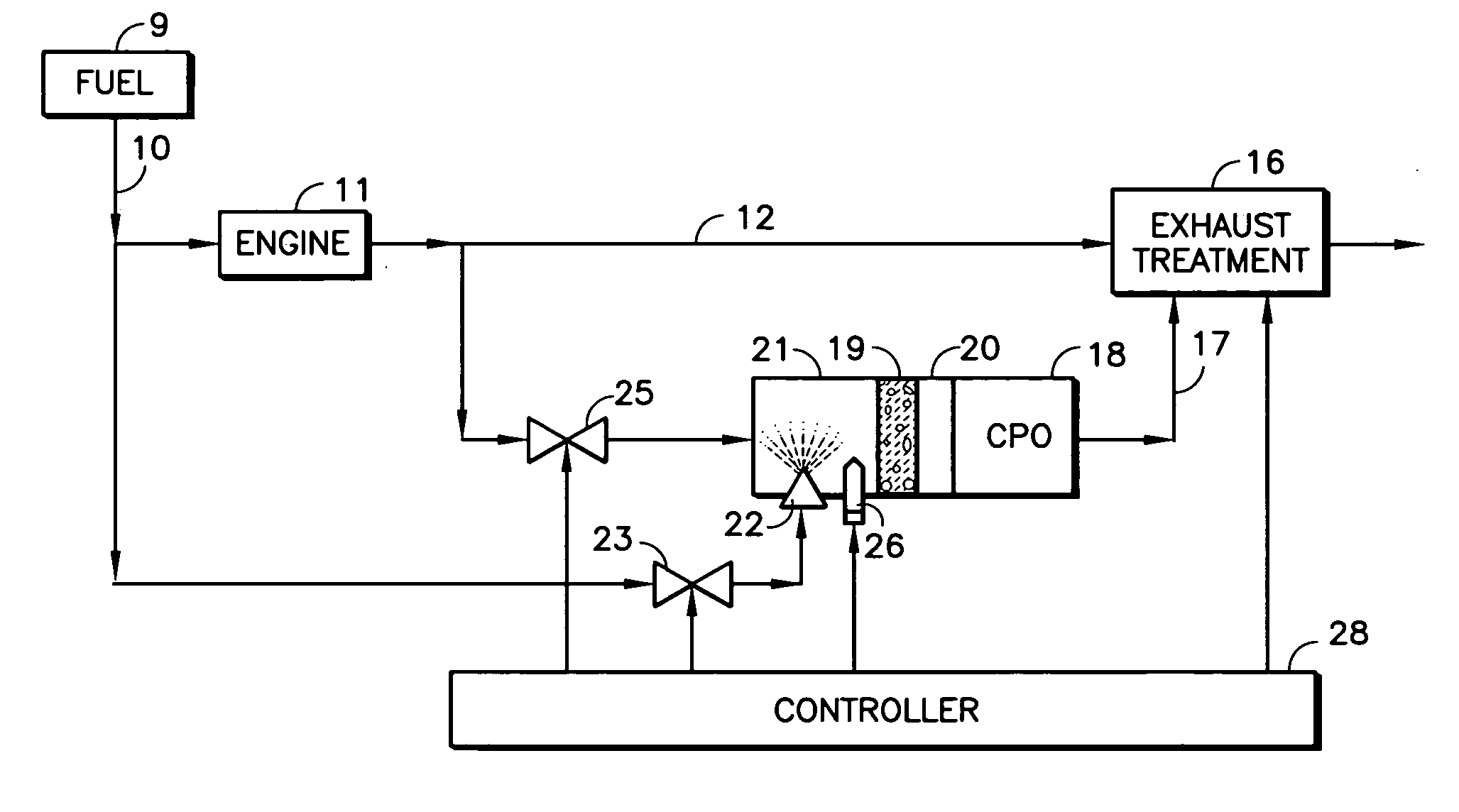

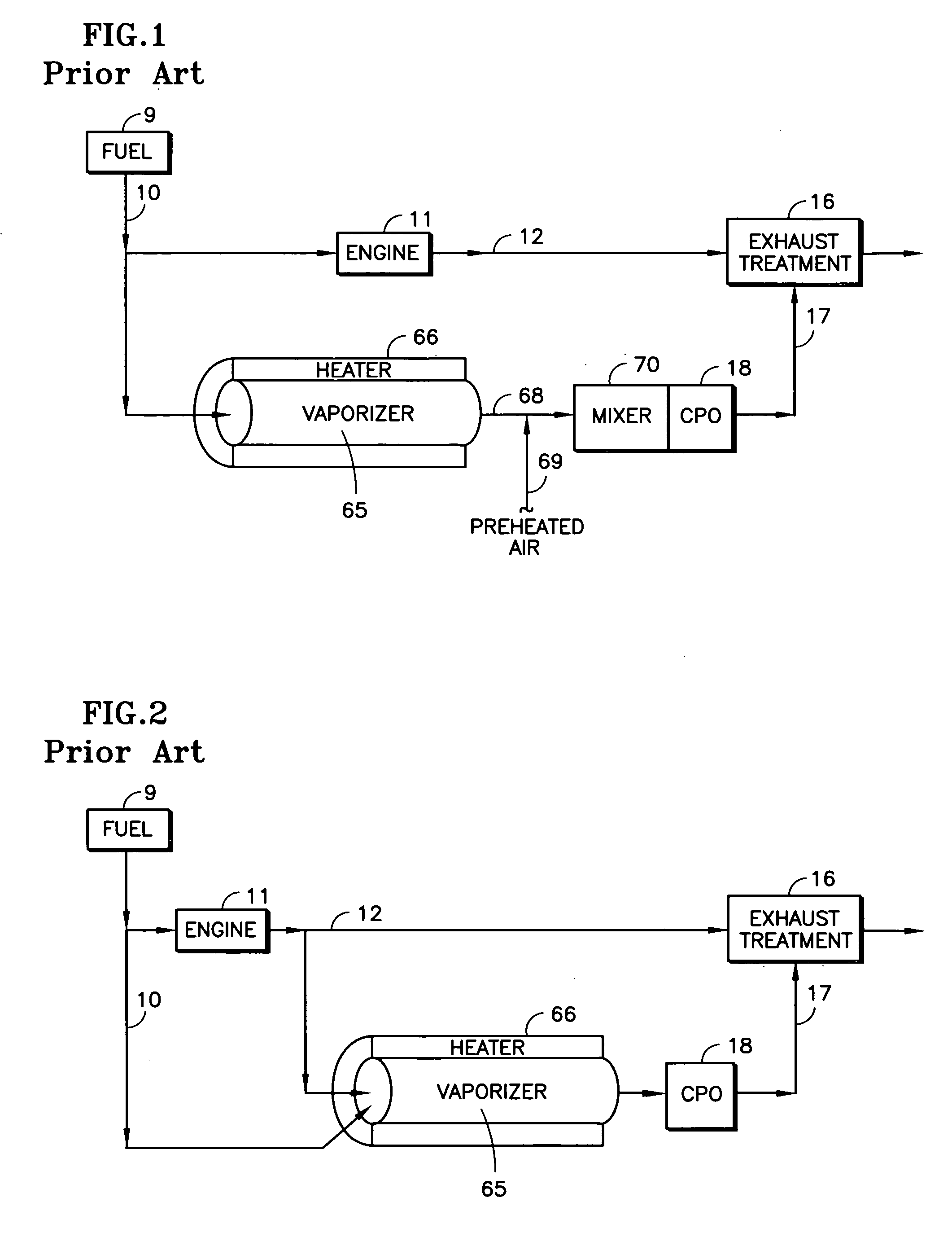

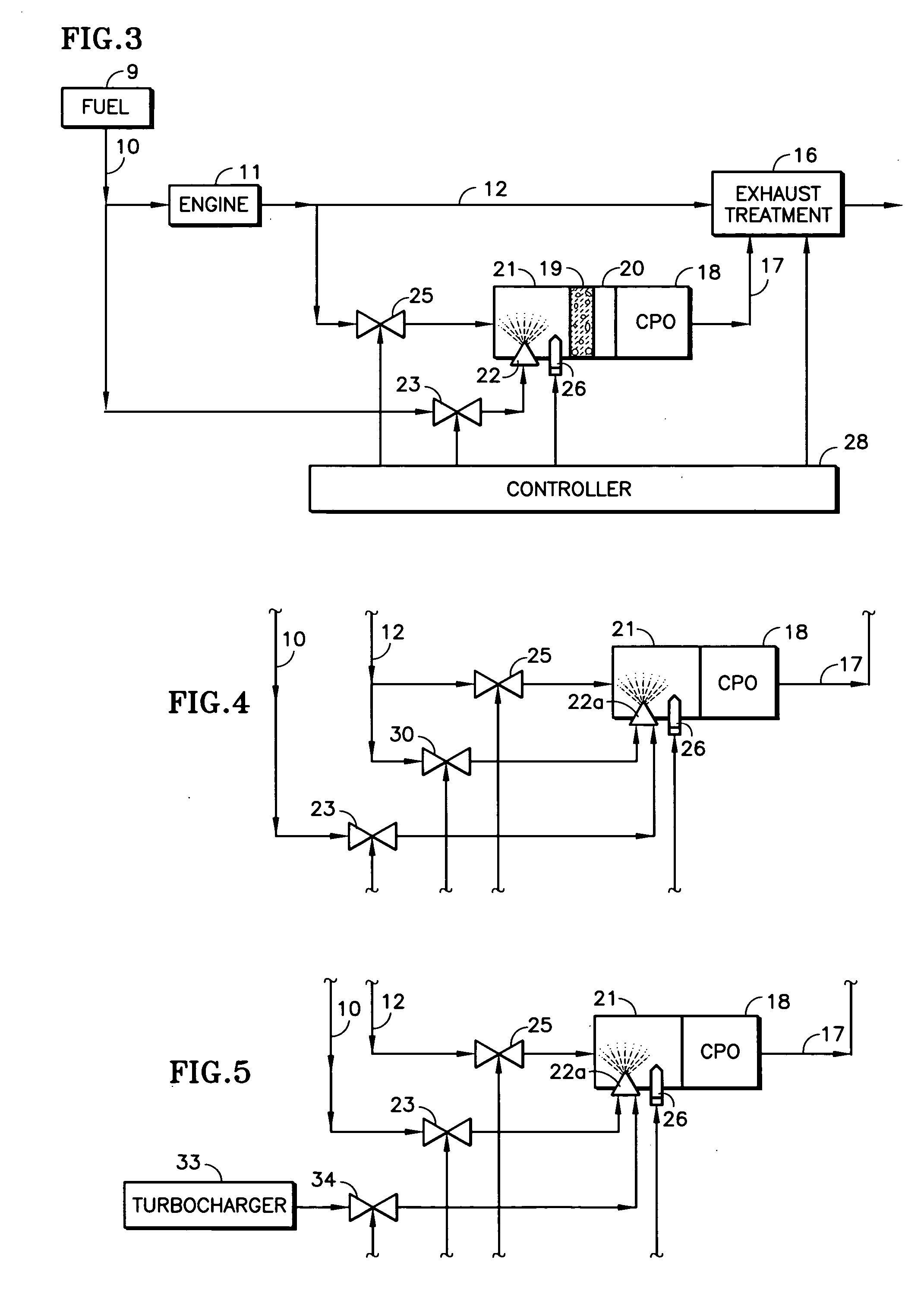

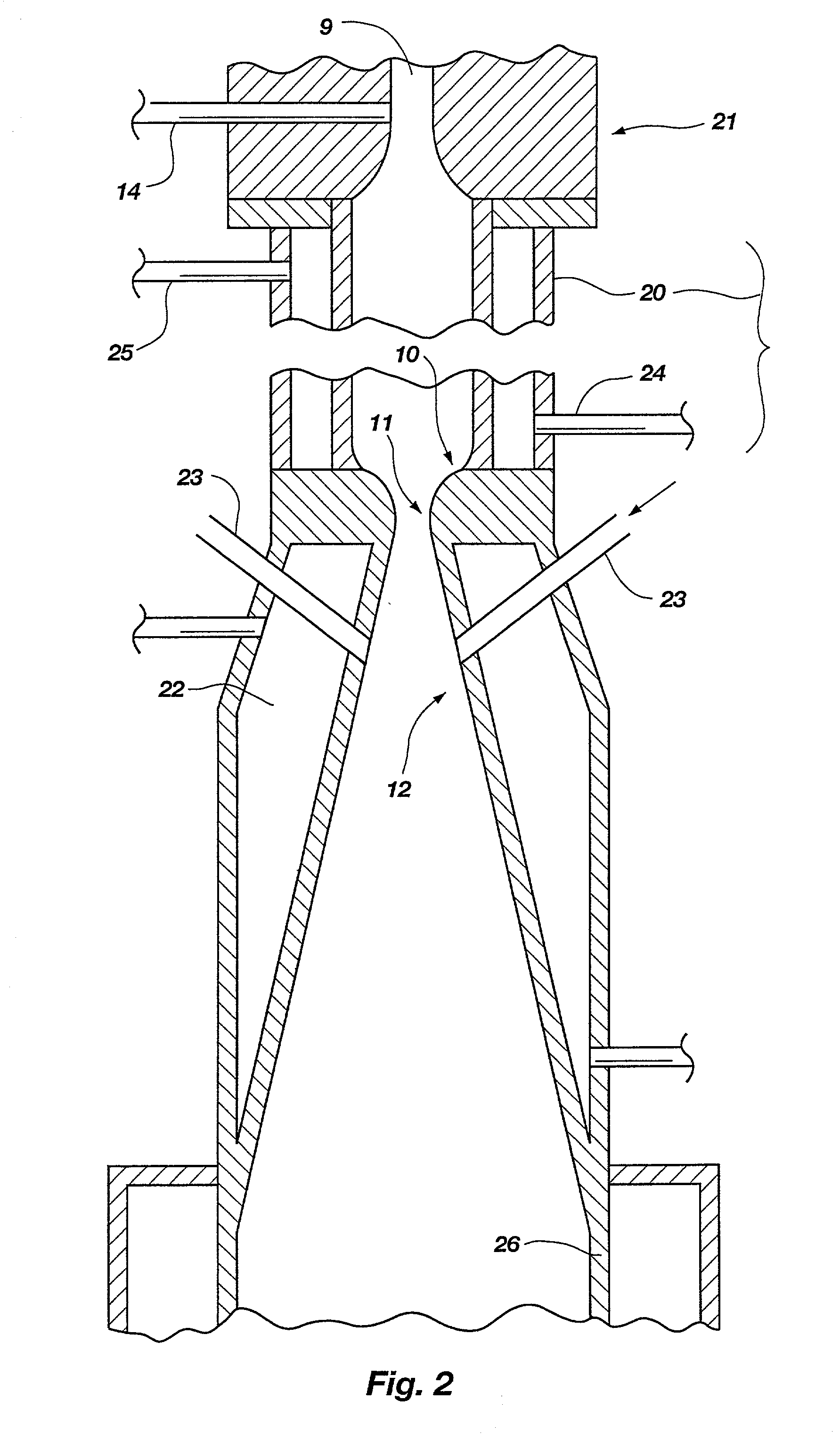

Reforming unvaporized, atomized hydrocarbon fuel

InactiveUS20050274107A1Improved hydrogen generationLow costHydrogenExhaust apparatusKeroseneTurbocharger

A reformer such as a CPO (18) receives a mix of fuel, moisture and oxygen from a mixing region (21) having an igniter (26, 66), which may include an inert ceramic foam (19), the fuel being provided by an atomizing nozzle (22), thereby avoiding the need for a vaporizer before use. The oxygen and moisture may comprise engine exhaust (11, 12). Fuel from a vehicle fuel tank (9), may be gasoline, diesel fuel, kerosene, jet fuel, or JP-8. The atomizing nozzle may be a gas-assist nozzle (22a), receiving the assisting gas from (a) engine exhaust (10), (b) a turbocharger (33), (c) an air pump (50) or (d) a steam generator (57). The oxygen and moisture may comprise moisturized air, which may be achieved by an ejector (41) which ingests water from a tank (43) in response to the flow of air from a pump (50) through a conduit (47). The air may be regeneratively heated (48) with the CPO exhaust. The igniter may be a glow plug (26) or a heater wire (66) coated with catalyst.

Owner:SHELL OIL CO

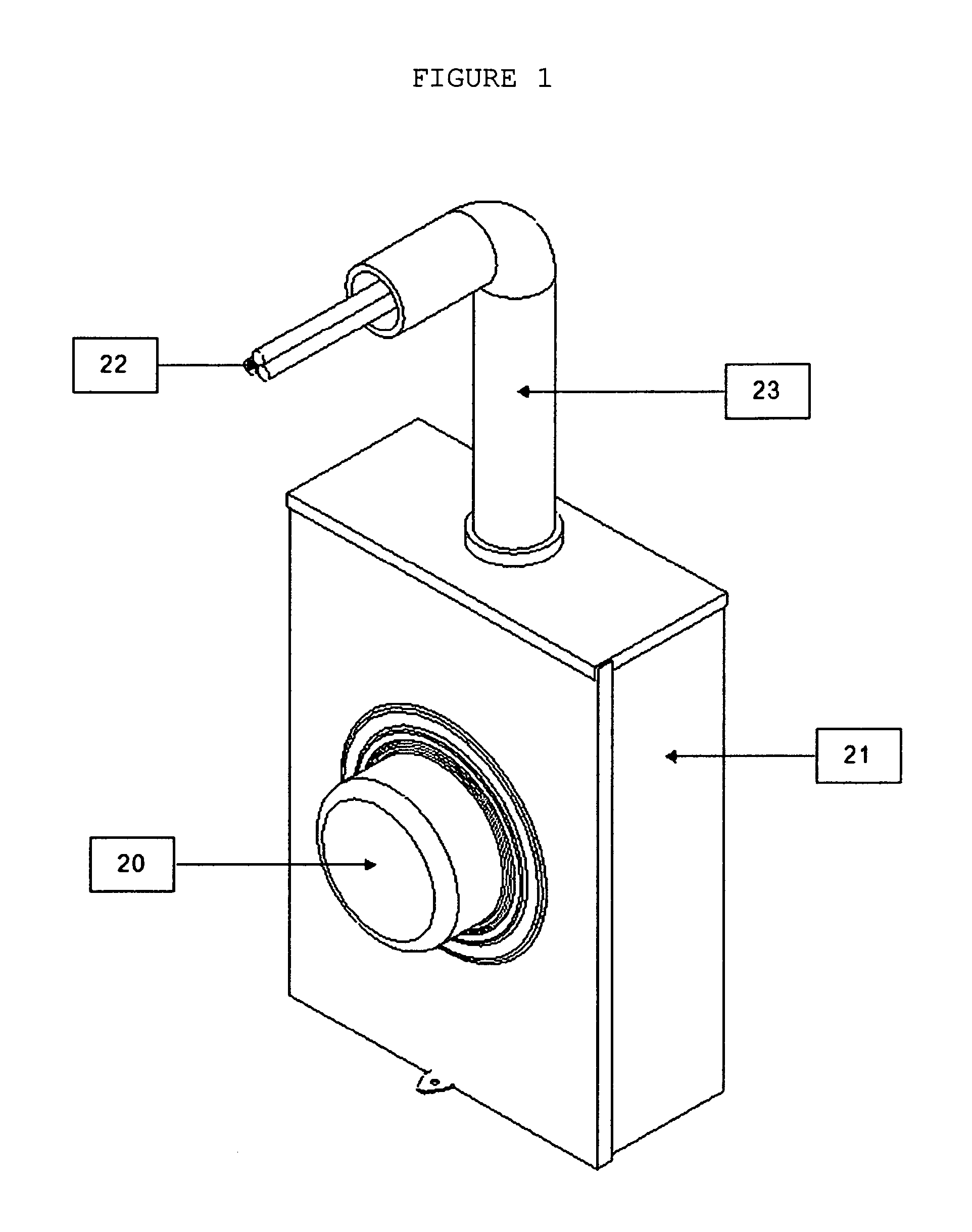

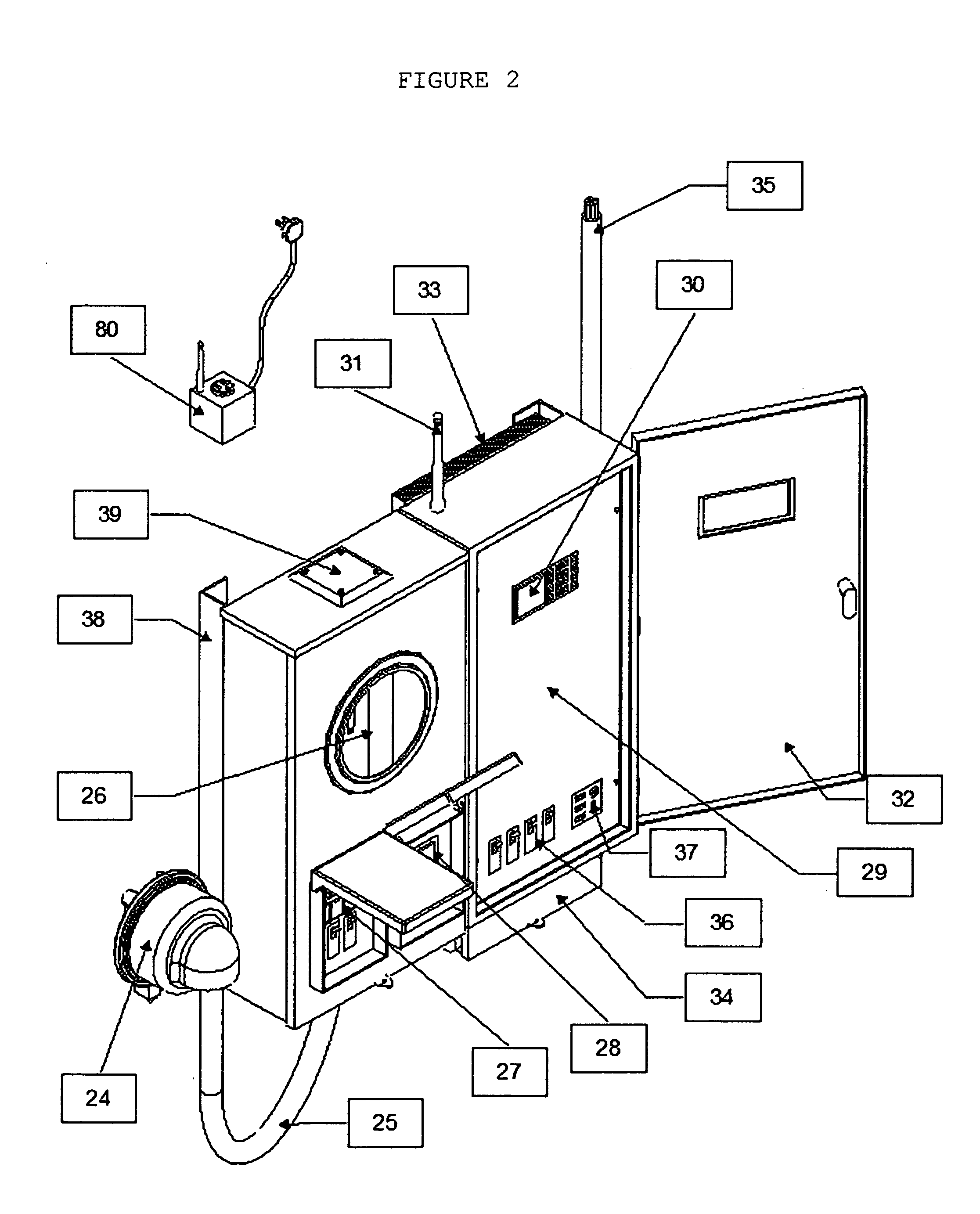

System and method for single plug-in installation of a high voltage intelligent renewable energy grid-tied controller with wireless smart load management

ActiveUS20110004357A1Low costSafety managementLevel controlWind energy generationWireless controlEngineering

This is a system and method for single plug-in installation of a high voltage intelligent renewable energy grid-tied controller with wireless smart load management. The present invention relates to the improvement of integration and management of renewable electric energy in homes and small businesses. The invention offers a lower cost method for safely installing and managing the use of the electric energy either generated or stored onsite by solar collecting panels, wind turbine generators, backup hydrocarbon fueled generators or any other supplemental power sources such as fuel cells and future electric automobiles with smart energy management. Furthermore, the invention utilizes wireless controllers connected to key appliances, motors and systems permitting continuous real time load and energy management of these devices.

Owner:NATUS ENERGY

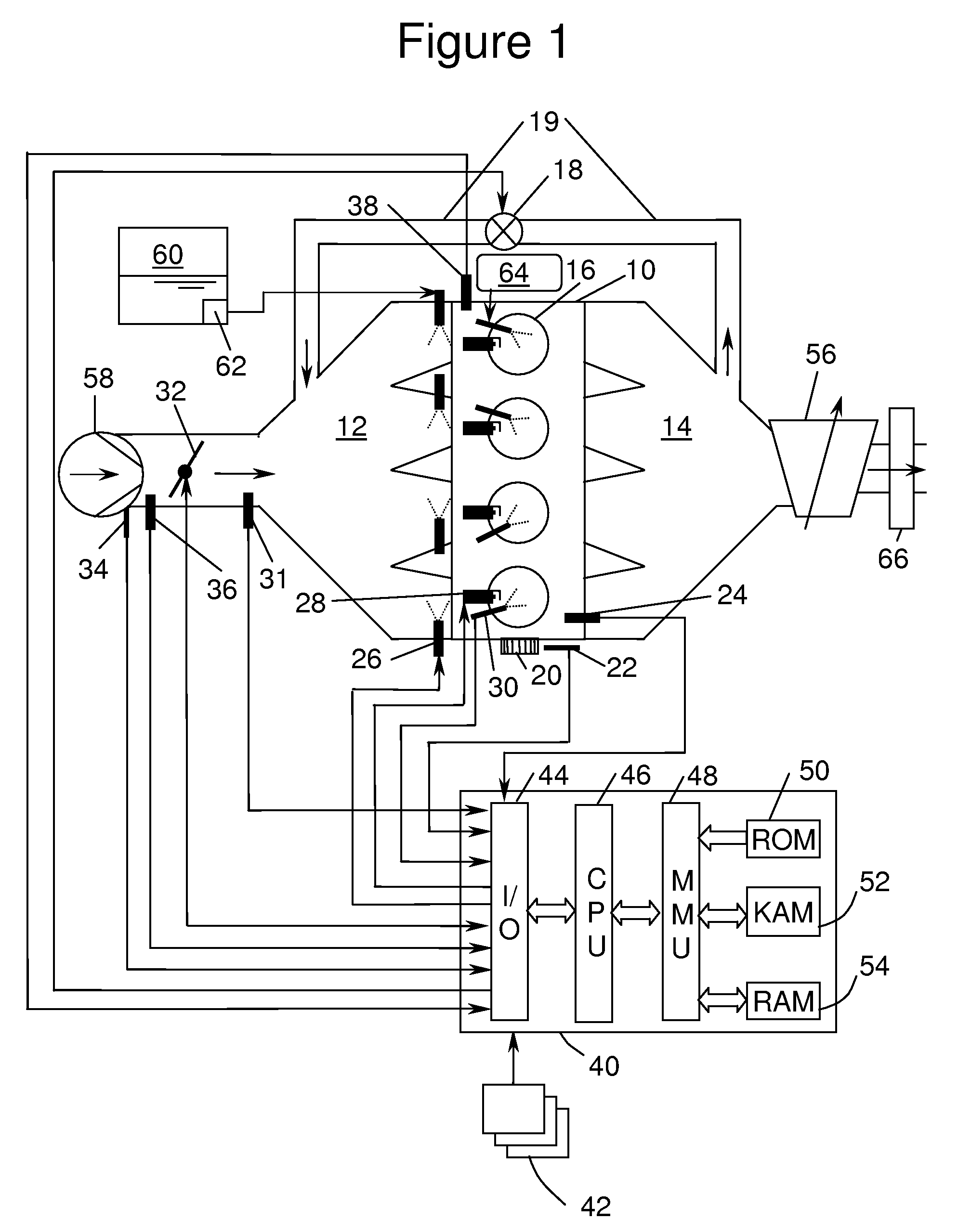

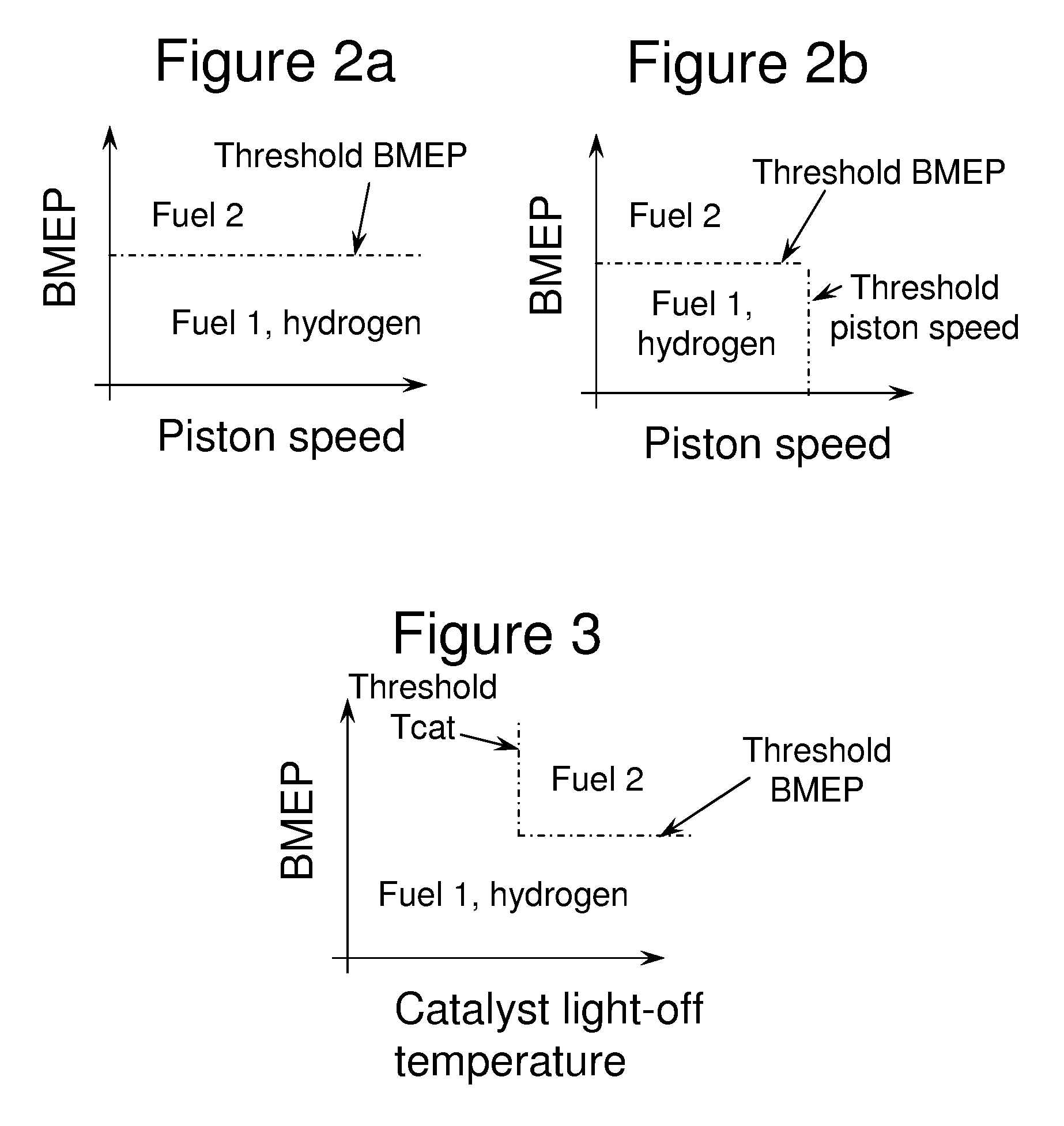

Bi-fuel Engine Using Hydrogen

InactiveUS20090071453A1Internal combustion piston enginesGaseous engine fuelsCombustion chamberEquivalence ratio

A method is disclosed for making a transition from fueling an engine with hydrogen to another fuel. That other fuel may be gasoline, a gasoline and alcohol mixture, or gaseous fuels, as examples. The other fuel has the capability of providing higher BMEP than the hydrogen because of better air utilization and because the other fuel occupies less volume of the combustion chamber. Because a desirable equivalence ratio to burn hydrogen is at 0.5 or less and a desirable equivalence ratio to burn other fuel is at 1.0, when a demand for BMEP that leads to a transition change from hydrogen fuel to the other fuel, the amount of air supplied to the engine is decreased to provide more torque and vice versa. During a transition in which liquid fuel supply is initiated, it may desirable to continue to provide some hydrogen, not leaner than 0.1 hydrogen equivalence ratio.

Owner:FORD GLOBAL TECH LLC

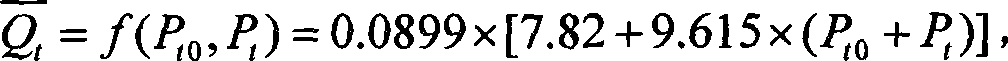

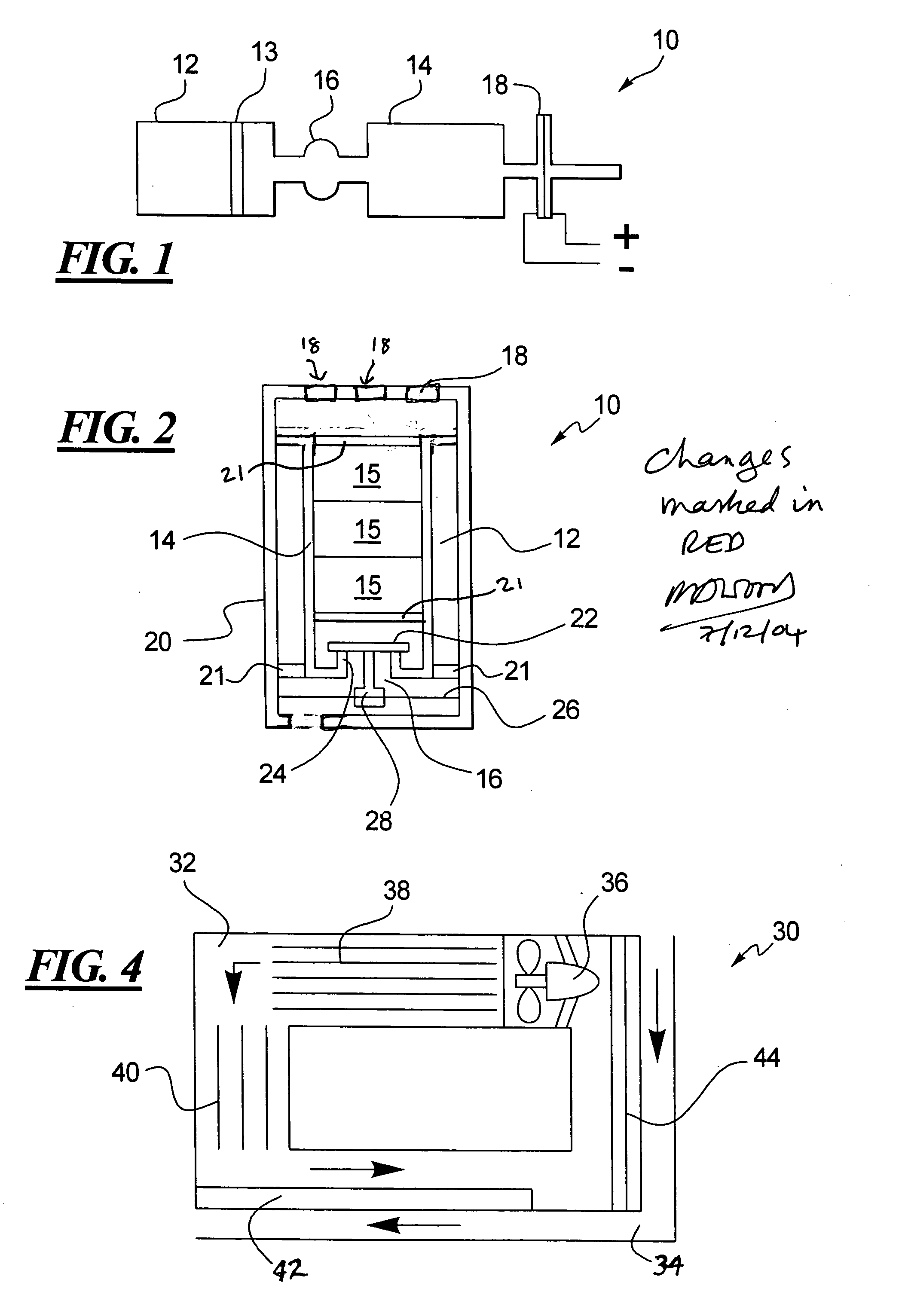

Water reclamation in a micropower generator

A waterless power generator, particularly a waterless electrical power generator and a passively controlled process for producing electricity with a fuel cell using stoichiometric amounts of a solid hydrogen fuel and byproduct water vapor produced by the fuel cell to generate hydrogen gas. A fuel cell reaction of hydrogen and oxygen produces electrical energy as well as by-product water which diffuses back into the power generator as water vapor to react with the hydrogen fuel, producing more hydrogen gas. This generated hydrogen gas is then used as a fuel which allows the fuel cell to generate additional electrical power and additional water. The process runs without any attached water source or water supply other than the water which is produced by the fuel cells themselves.

Owner:HONEYWELL INT INC

Hydrogen recycle for high temperature fuel cells

InactiveUS20040197612A1Improve efficiencyImprove sustainabilityGas treatmentRegenerative fuel cellsOxygenContamination

High temperature fuel cell electrical generation systems are provided that are adapted to enable selective generation of electrical power, and / or hydrogen fuel, and / or useable heat, allowing flexible operation of the generation system. In such embodiments, the high temperature fuel cell may be either a MCFC or a SOFC. The disclosed systems relate to high temperature fuel cells exploiting gas separation devices in which a first gas mixture is to be separated so that a first product of the separation is enriched in a first component, while a second component is mixed with a displacement purge stream to form a second gas mixture, with provision to prevent cross contamination of purge gas components into the first product stream. The process may be applied to hydrogen (component A) enrichment from syngas mixtures such as fuel cell anode exhaust, where dilute carbon dioxide (component B) is to be rejected such as to the atmosphere or for recycle to the fuel cell cathode in the case of molten carbonate fuel cells, by purging with cathode exhaust oxygen-depleted air (as component C).

Owner:QUSIR TECH

Hydrogen and elemental carbon production from natural gas and other hydrocarbons

InactiveUS20020151604A1Addressing slow performanceReduce momentumHydrogenOrganic compound preparationUnsaturated hydrocarbonHydrogen fuel

Owner:BATTELLE ENERGY ALLIANCE LLC

Method for desulfurizing a fuel for use in a fuel cell power plant

A fuel processing system is operable to remove substantially all of the sulfur present in an undiluted hydrocarbon fuel stock supply used to power a fuel cell power plant in a mobile environment, such as an automobile, bus, truck, boat, or the like, or in a stationary environment. The power plant hydrogen fuel source can be gasoline, diesel fuel, naphtha, light hydrocarbon fuels such as butane, propane, natural gas, or other like fuels which contain relatively high levels of organic sulfur compounds such as mercaptans, sulfides, disulfides, and the like. The undiluted hydrocarbon fuel supply is passed through a nickel desulfurizer bed wherein essentially all of the sulfur in the organic sulfur compounds react with the nickel reactant, and are converted to nickel sulfide while the desulfurized organic remnants continue through the remainder of the fuel processing system. The system does not require the addition of steam or a hydrogen source to the fuel stream prior to the desulfurizing step. The system operates at relatively low temperatures and can be used to desulfurize either a liquid or a gaseous fuel stream.

Owner:UNITED TECH CORP

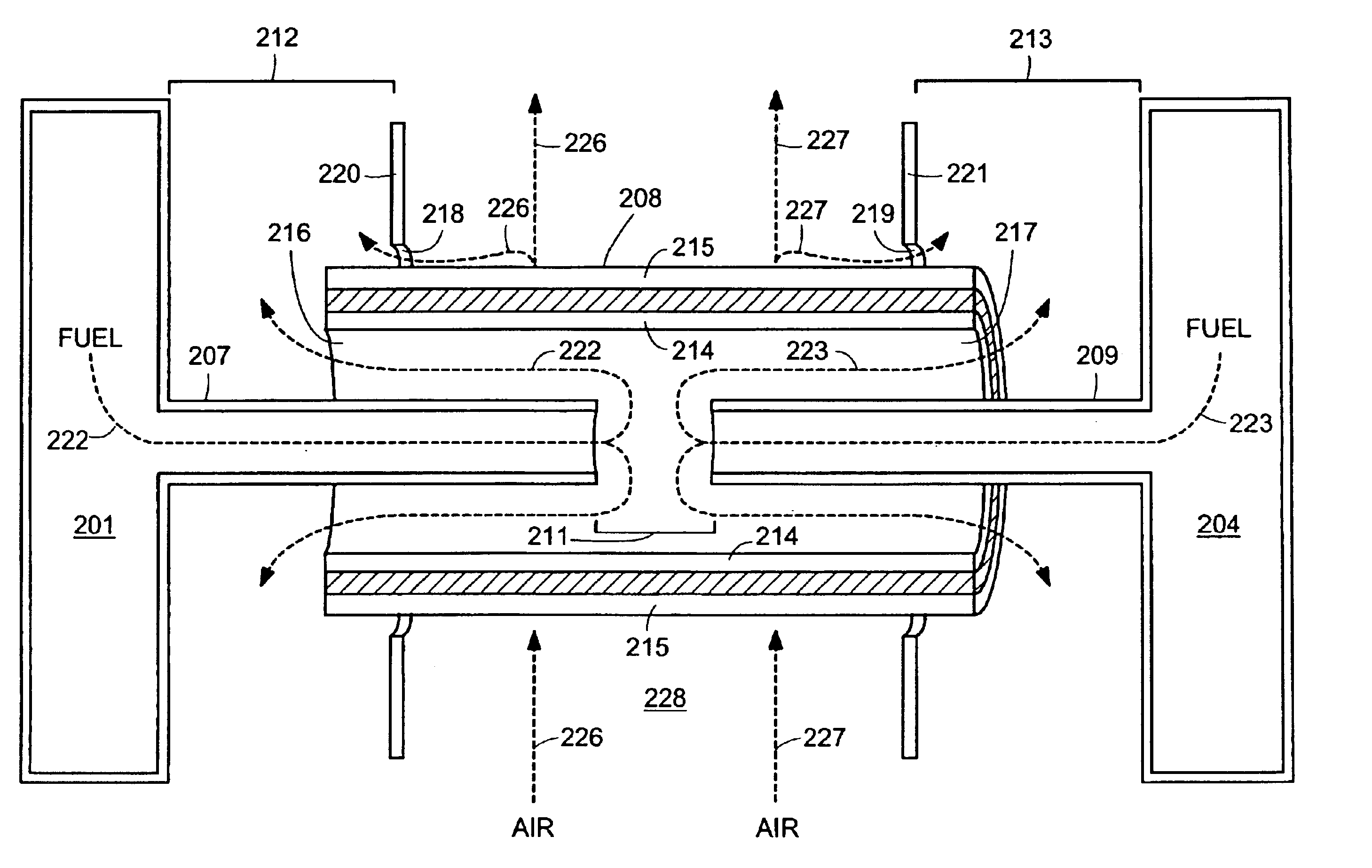

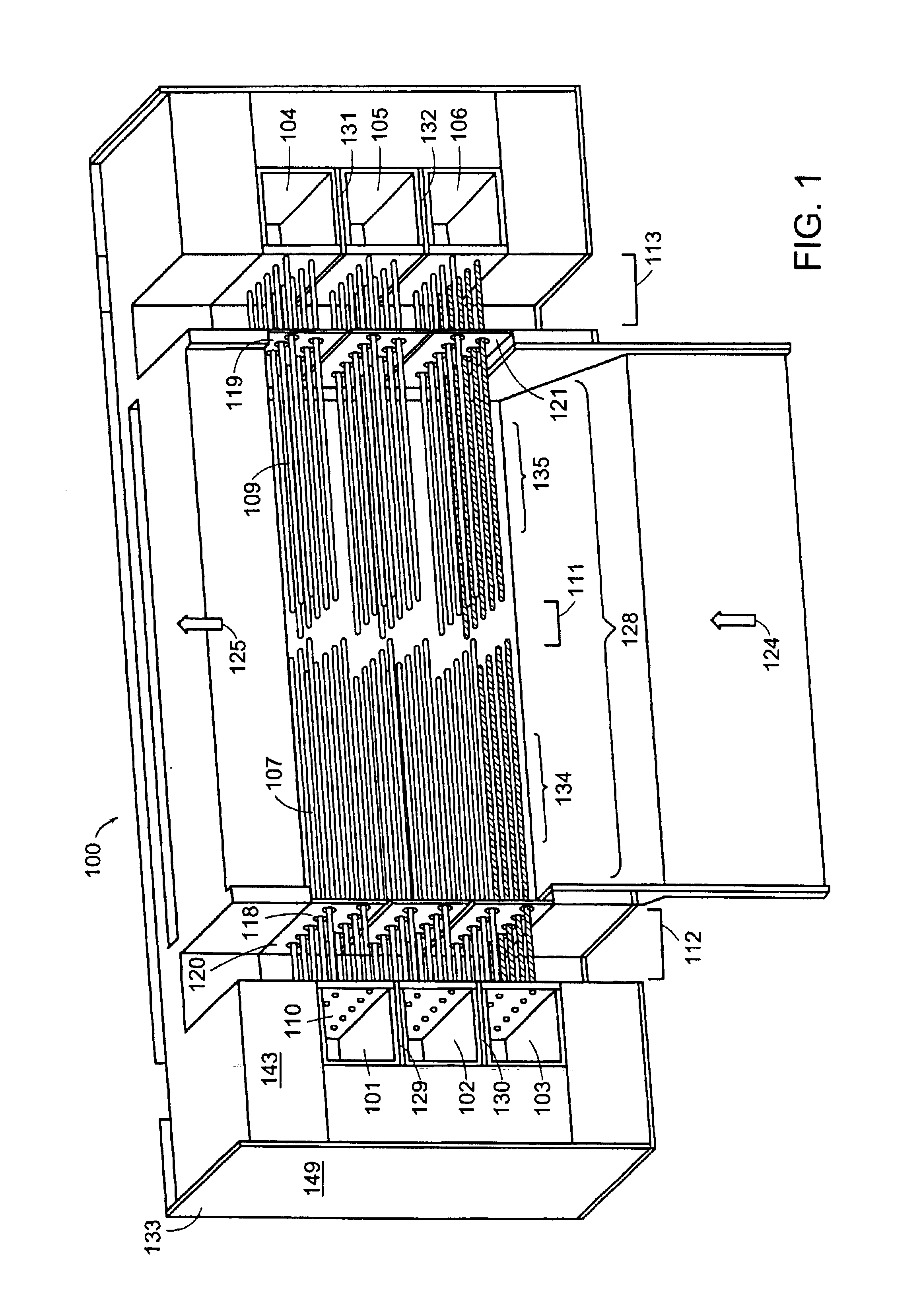

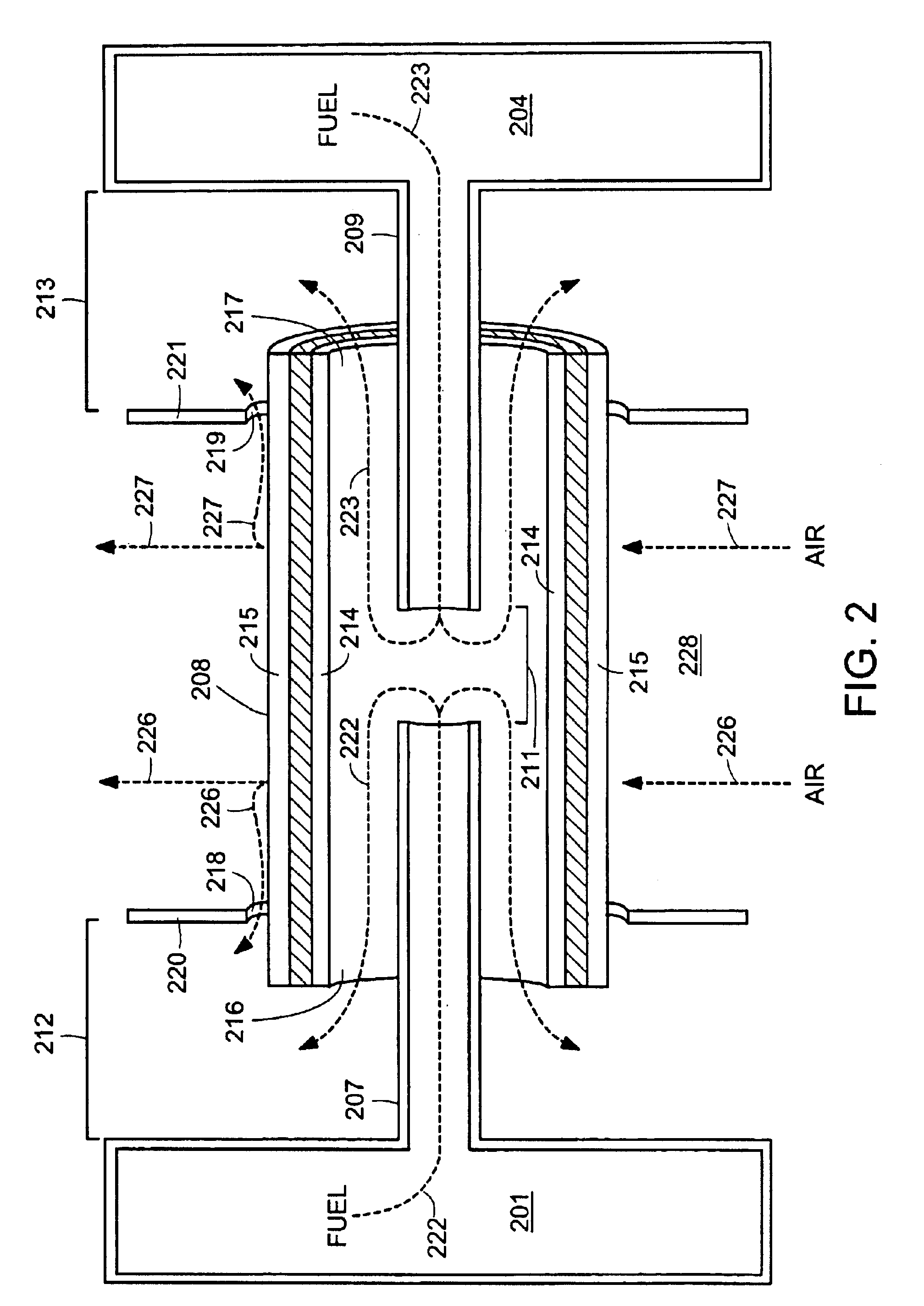

Horizontal fuel cell tube system and methods

In one disclosed embodiment according to the invention, a fuel cell system for generating electrical power comprises: an open-ended tubular solid oxide fuel cell; a first fuel injector tube extending from a first fuel plenum chamber through one open end of the fuel cell; and a second fuel injector tube extending from a second fuel plenum chamber through another open end of the fuel cell; wherein the first and second fuel injector tubes form a gap within the fuel cell from which a hydrogen-containing fuel gas may flow towards the open ends of the fuel cell. Further related systems and method are also disclosed.

Owner:ACUMENTRICS

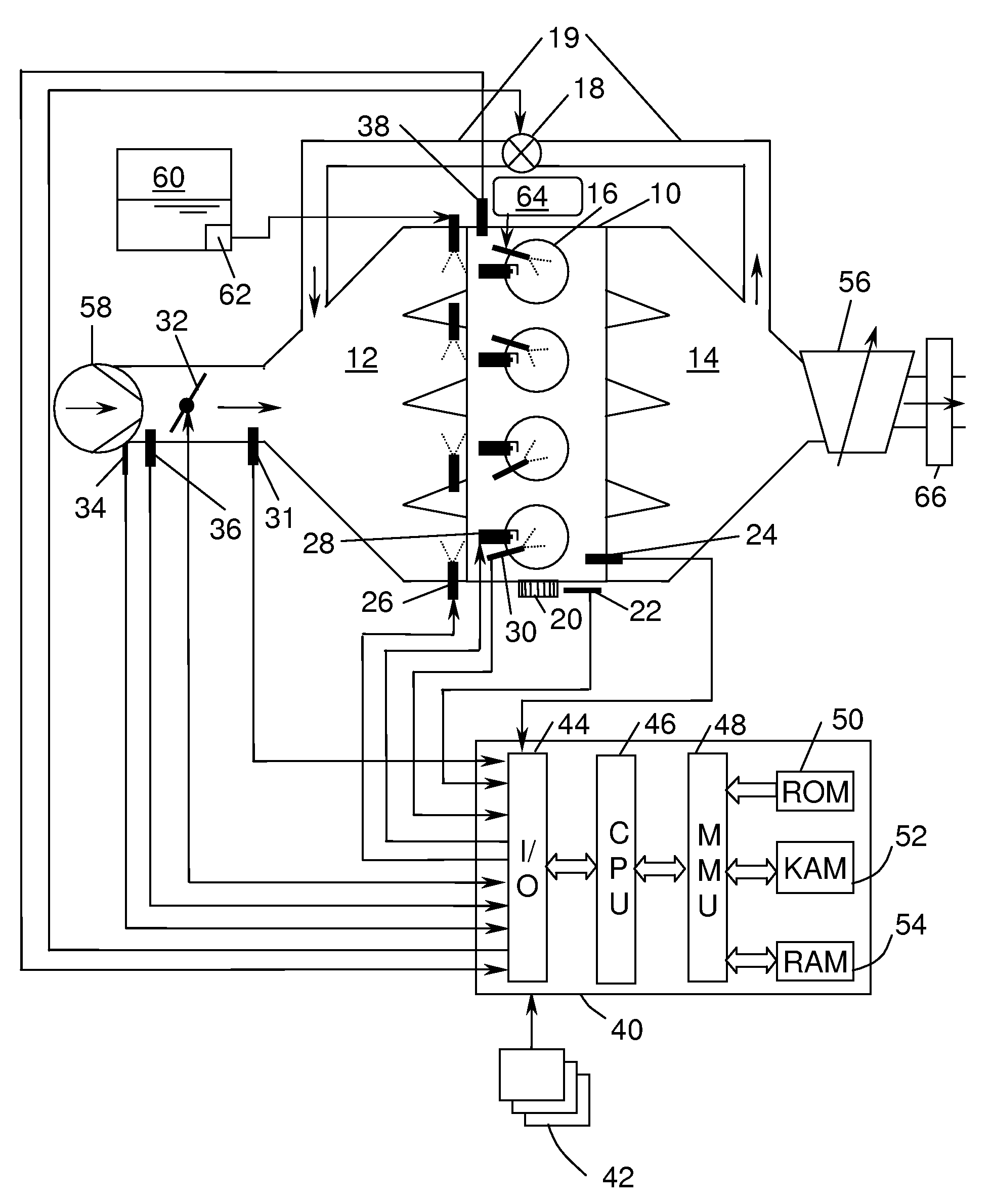

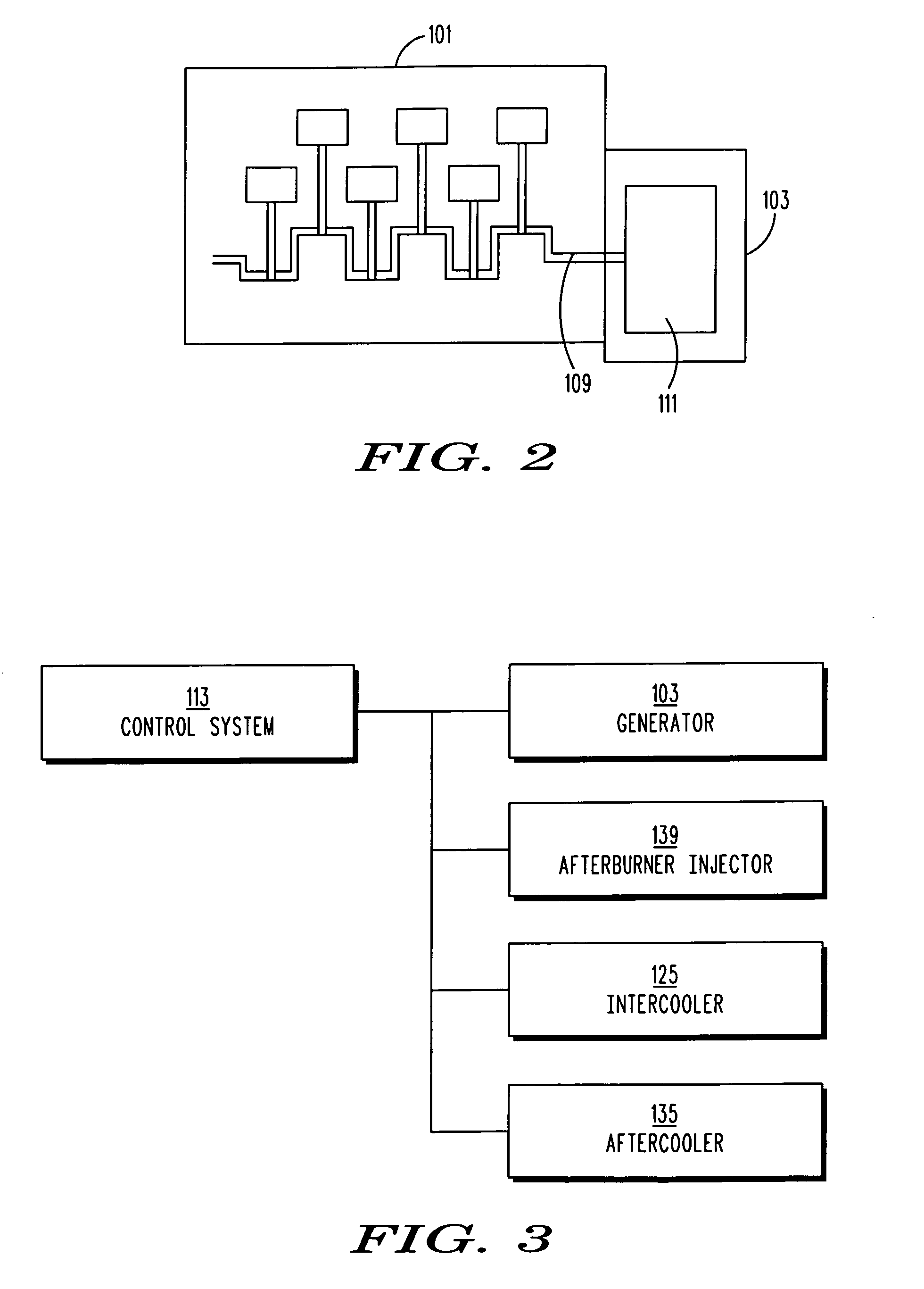

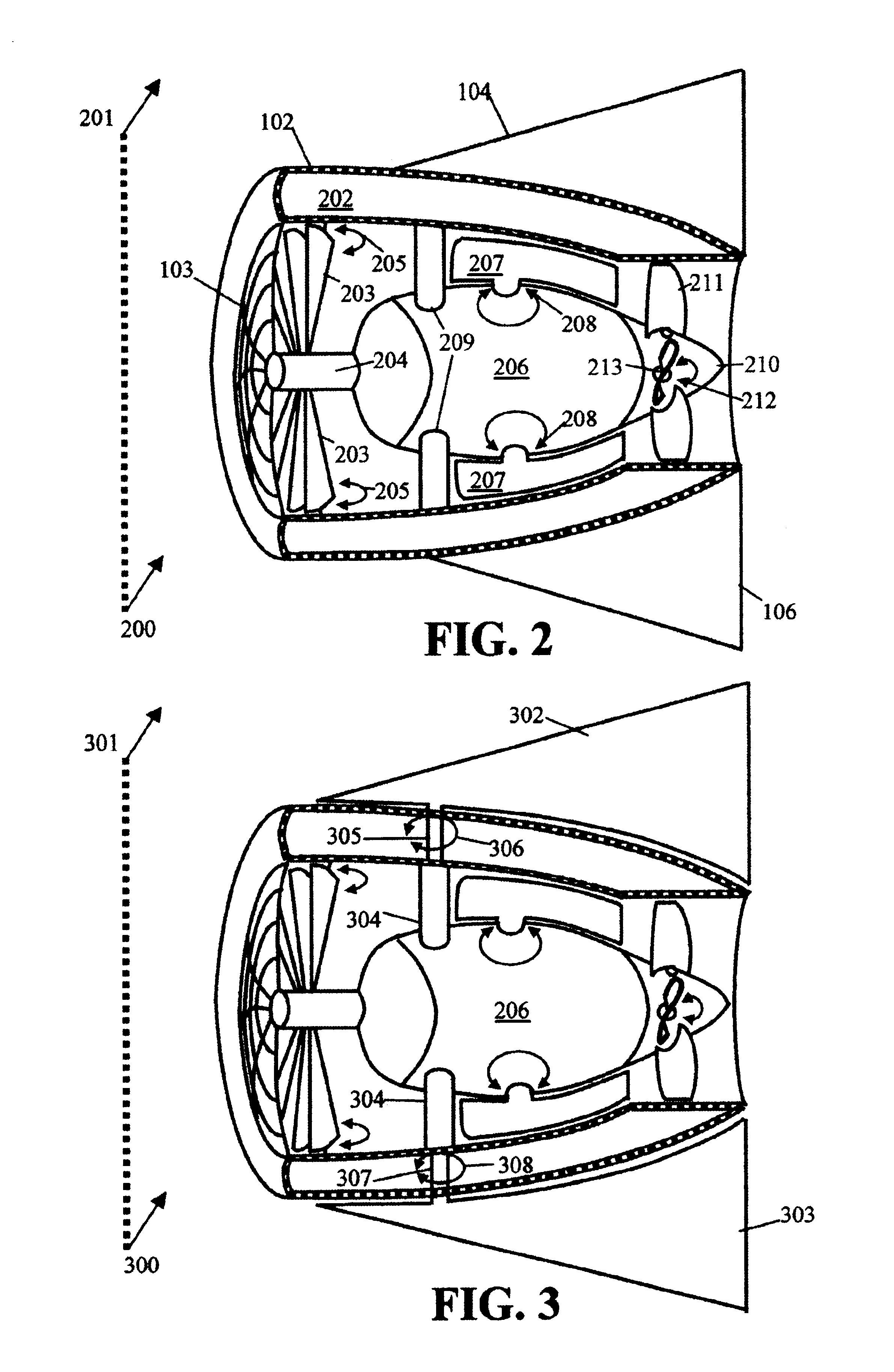

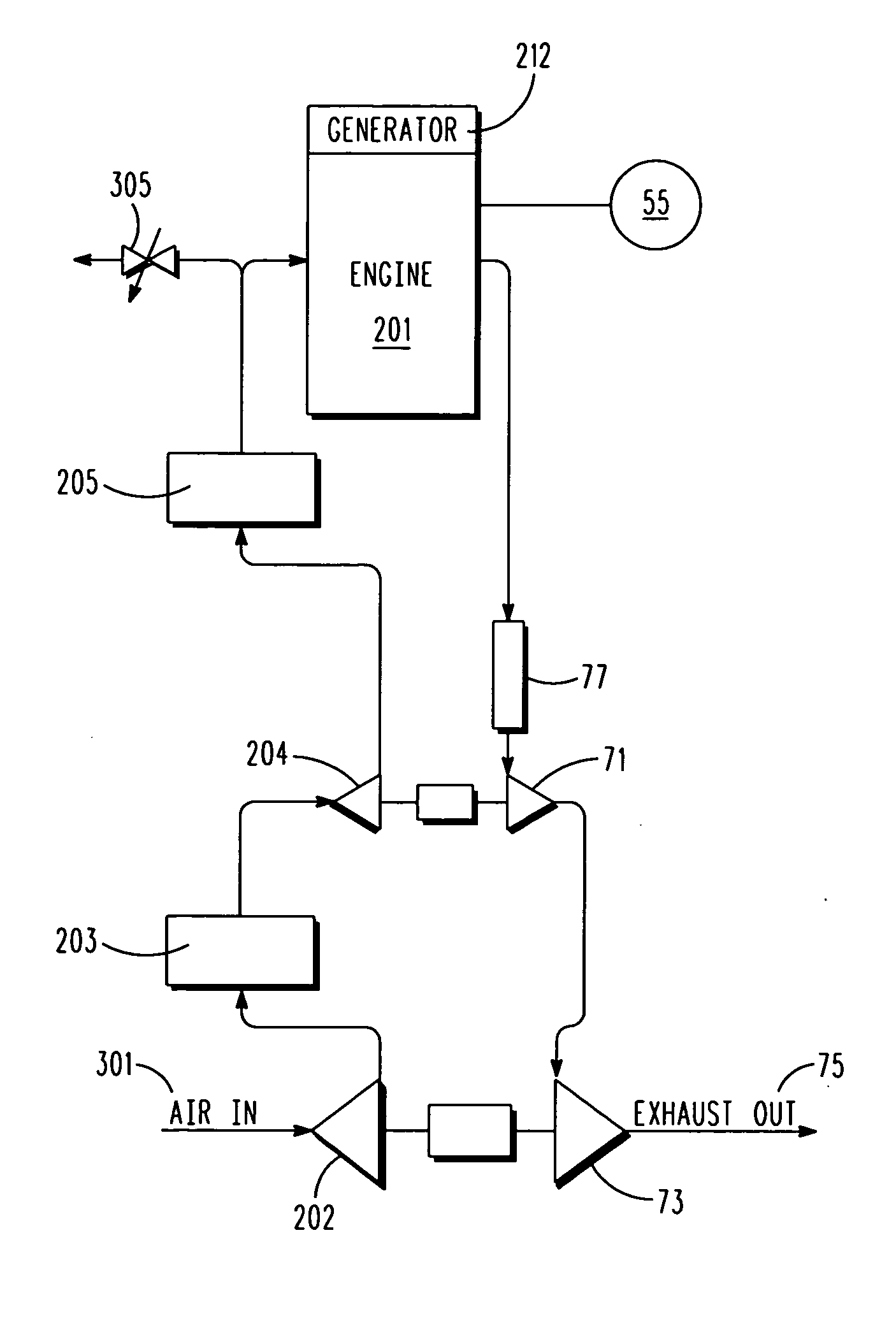

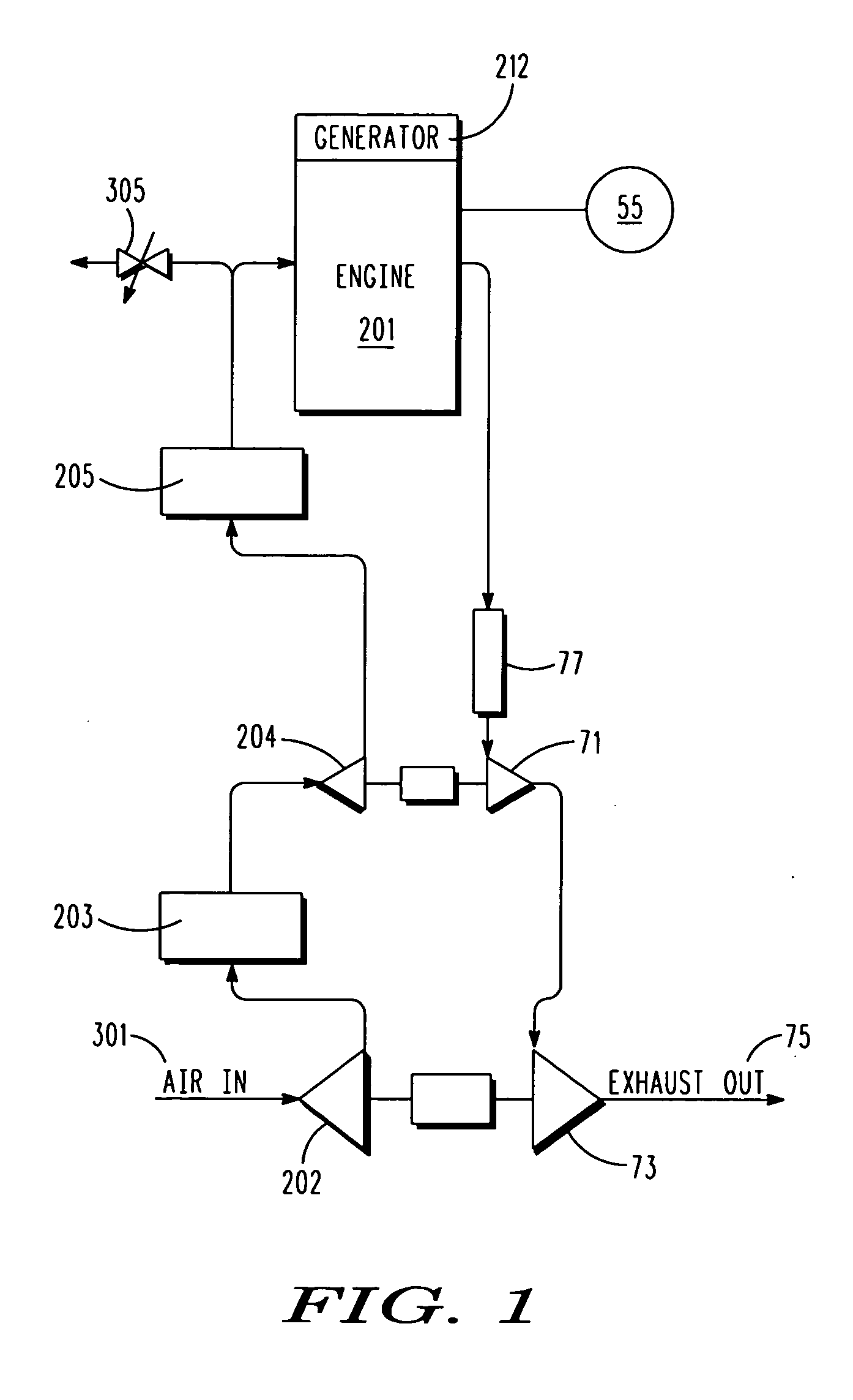

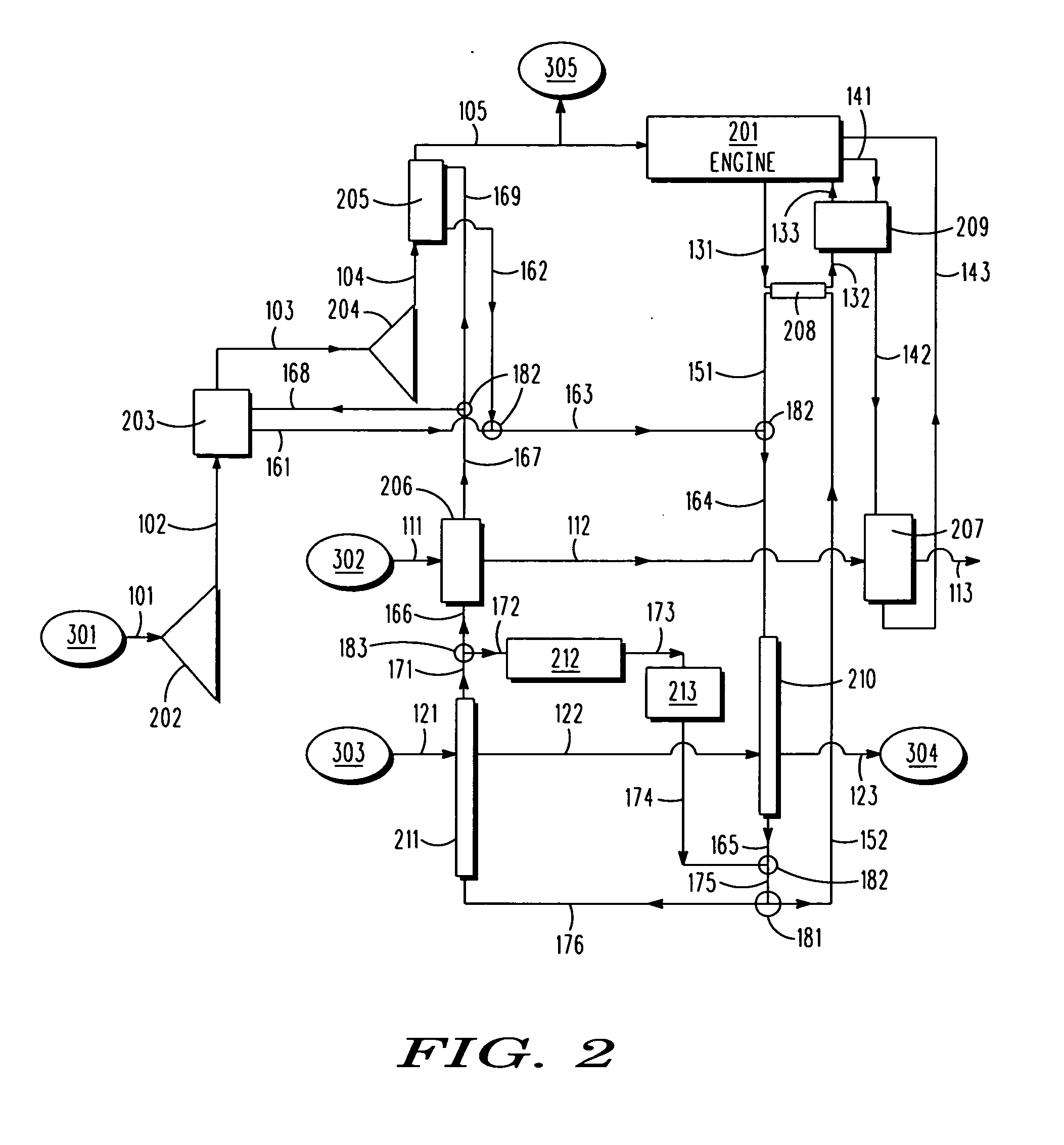

Powerplant and related control system and method

ActiveUS20100100300A1Efficient powerImprove reliabilityInternal combustion piston enginesDigital data processing detailsEquivalence ratioControl system

A hydrogen fueled powerplant including an internal combustion engine that drives a motor-generator, and has a two-stage turbocharger, for an aircraft. A control system controls the operation of the motor-generator to maintain the engine at a speed selected based on controlling the engine equivalence ratio. The control system controls an afterburner, an intercooler and an aftercooler to maximize powerplant efficiency. The afterburner also adds power to the turbochargers during high-altitude restarts. The turbochargers also include motor-generators that extract excess power from the exhaust.

Owner:AEROVIRONMENT INC

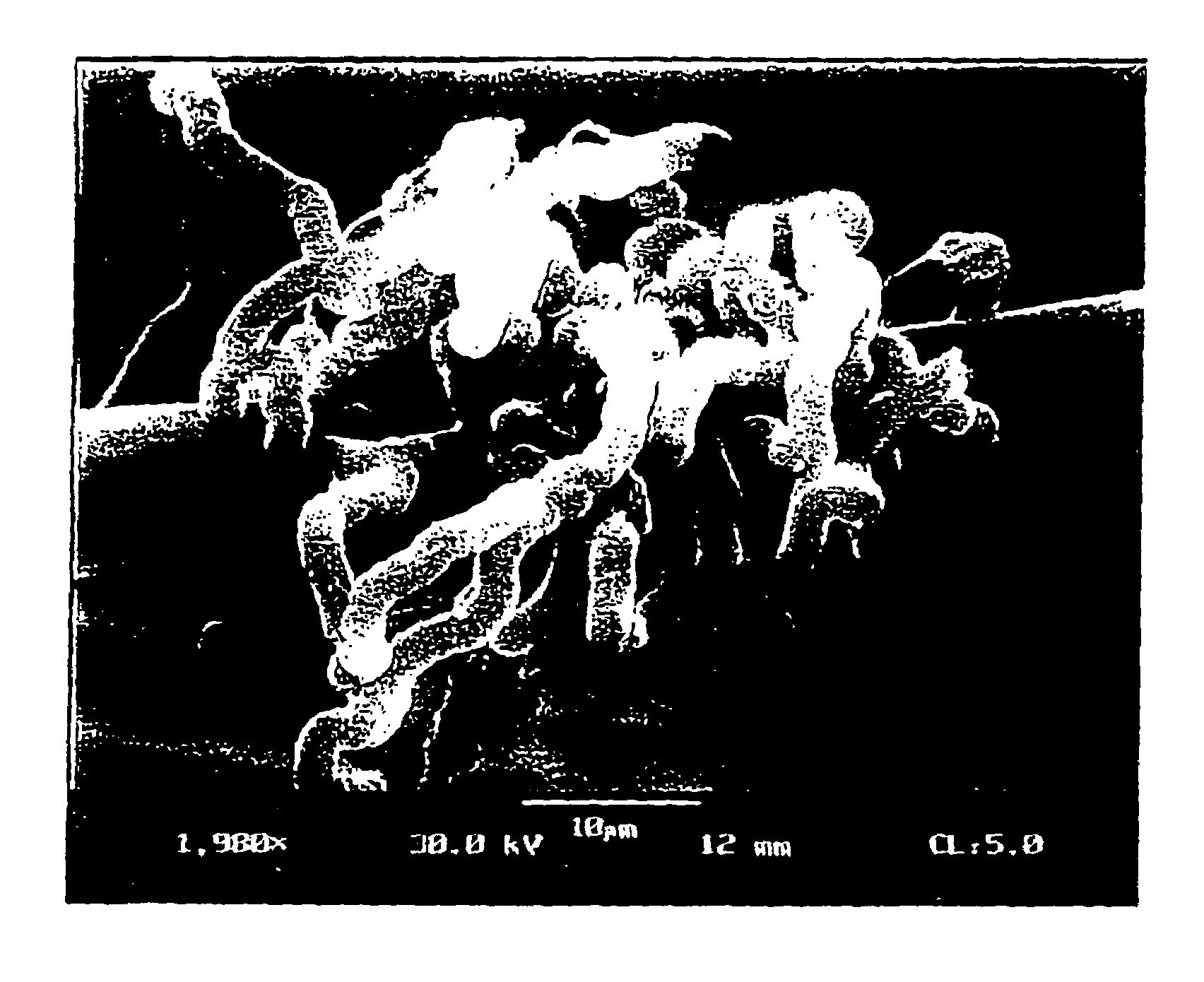

Filamentous carbon particles for cleaning oil spills and method of production

InactiveUS7473466B1Increase specific energy and overall energy efficiencyHydrogen/synthetic gas productionGlass/slag layered productsFiberCarbon nanotube

A compact hydrogen generator is coupled to or integrated with a fuel cell for portable power applications. In the process of producing hydrogen for the generator via thermocatalytic decomposition (cracking, pyrolysis) of hydrocarbon fuels in an oxidant-free environment, novel carbon products are produced with filamentary surfaces, “octopus”-like carbon filaments, single carbon nanotube fibers and the like. Two novel processes are disclosed for the production of carbon filaments and a novel filamentous carbon product useful in the clean-up of oil spills on the surface of water. The apparatus can utilize a variety of hydrocarbon fuels, including natural gas, propane, gasoline, and sulfurous fuels. The hydrogen-rich gas produced is free of carbon oxides or other reactive impurities, so it can be directly fed to any type of a fuel cell. The hydrogen generator can be conveniently integrated with high temperature fuel cells to produce an efficient and self-contained source of electrical power.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

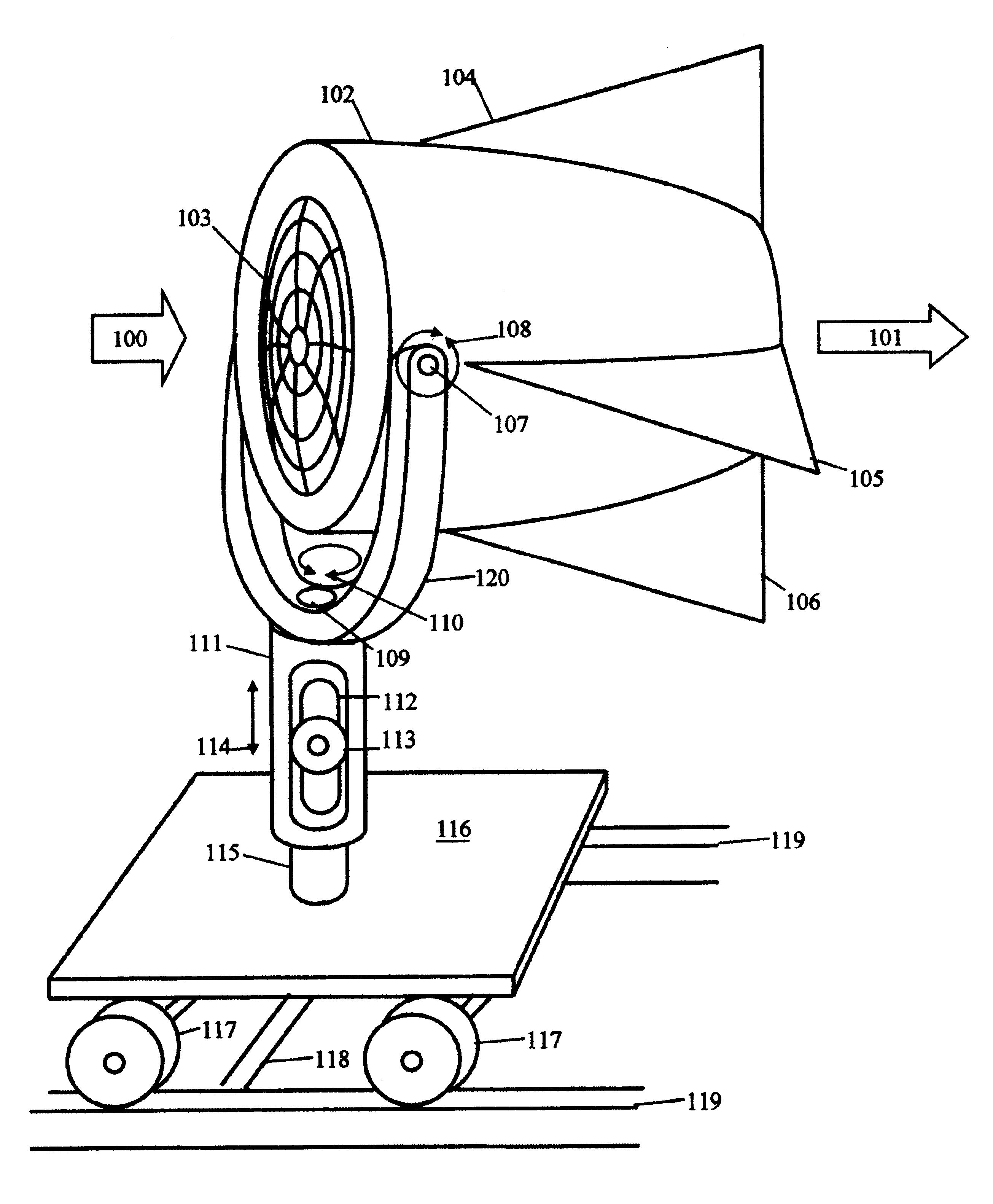

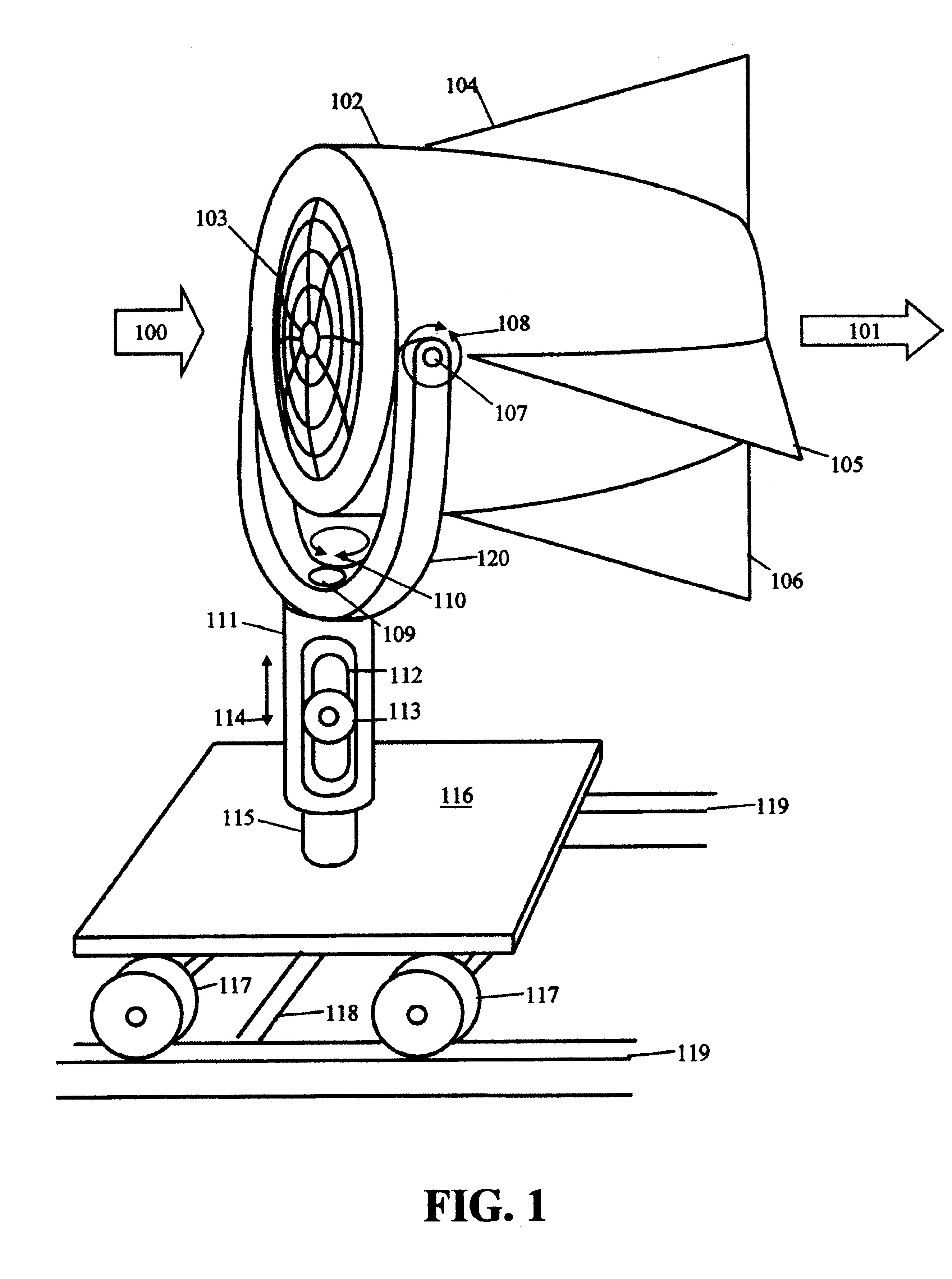

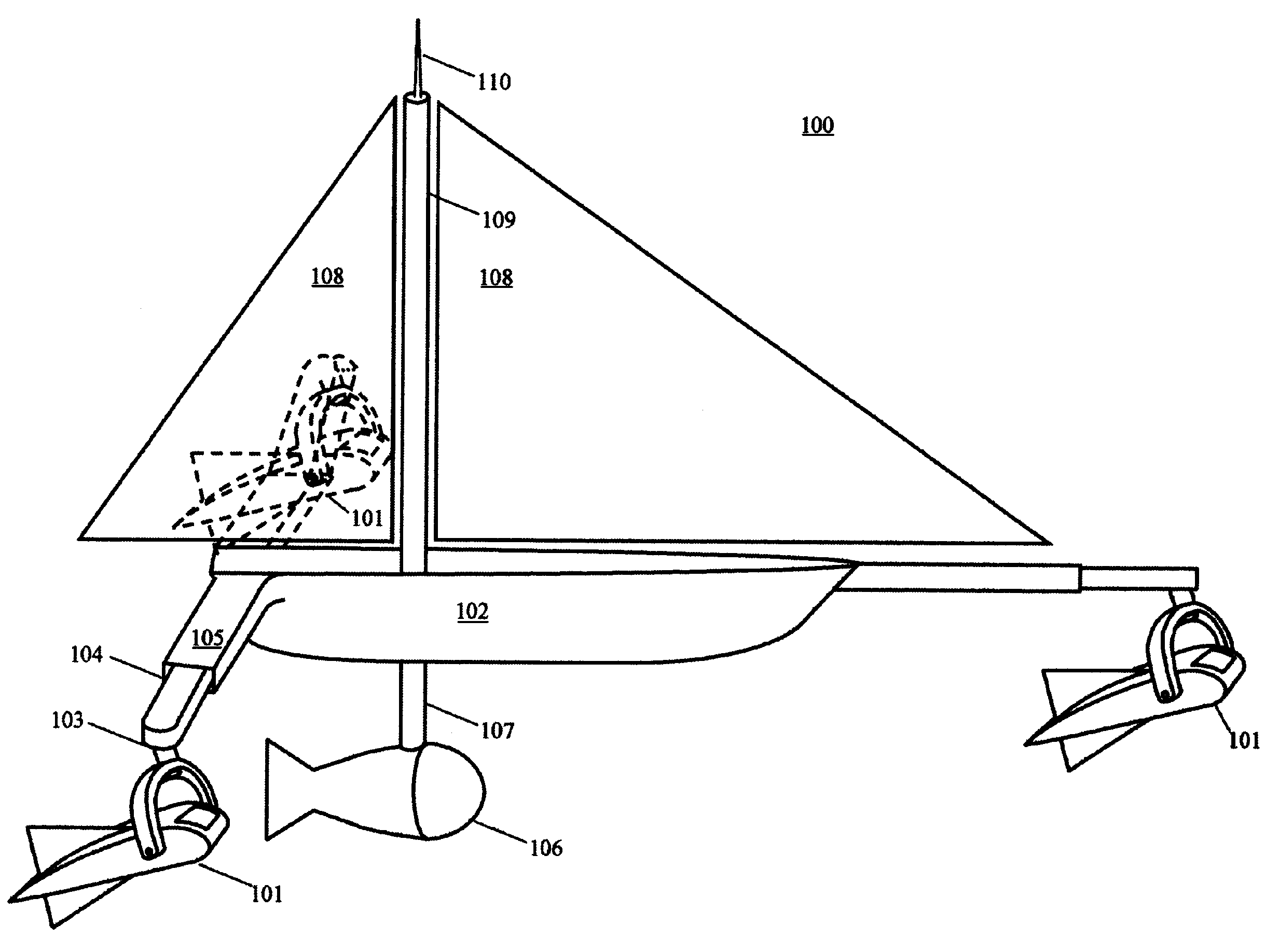

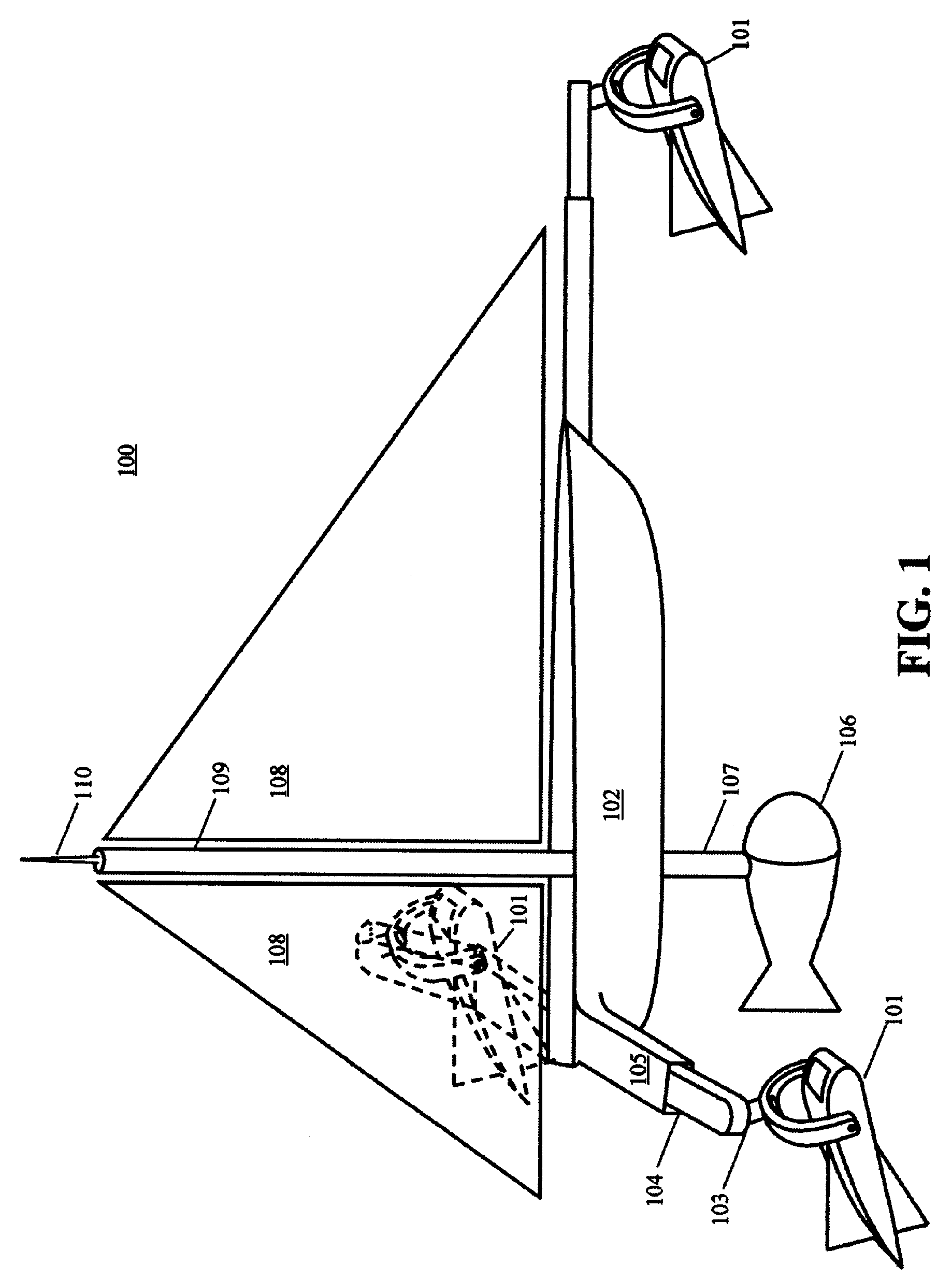

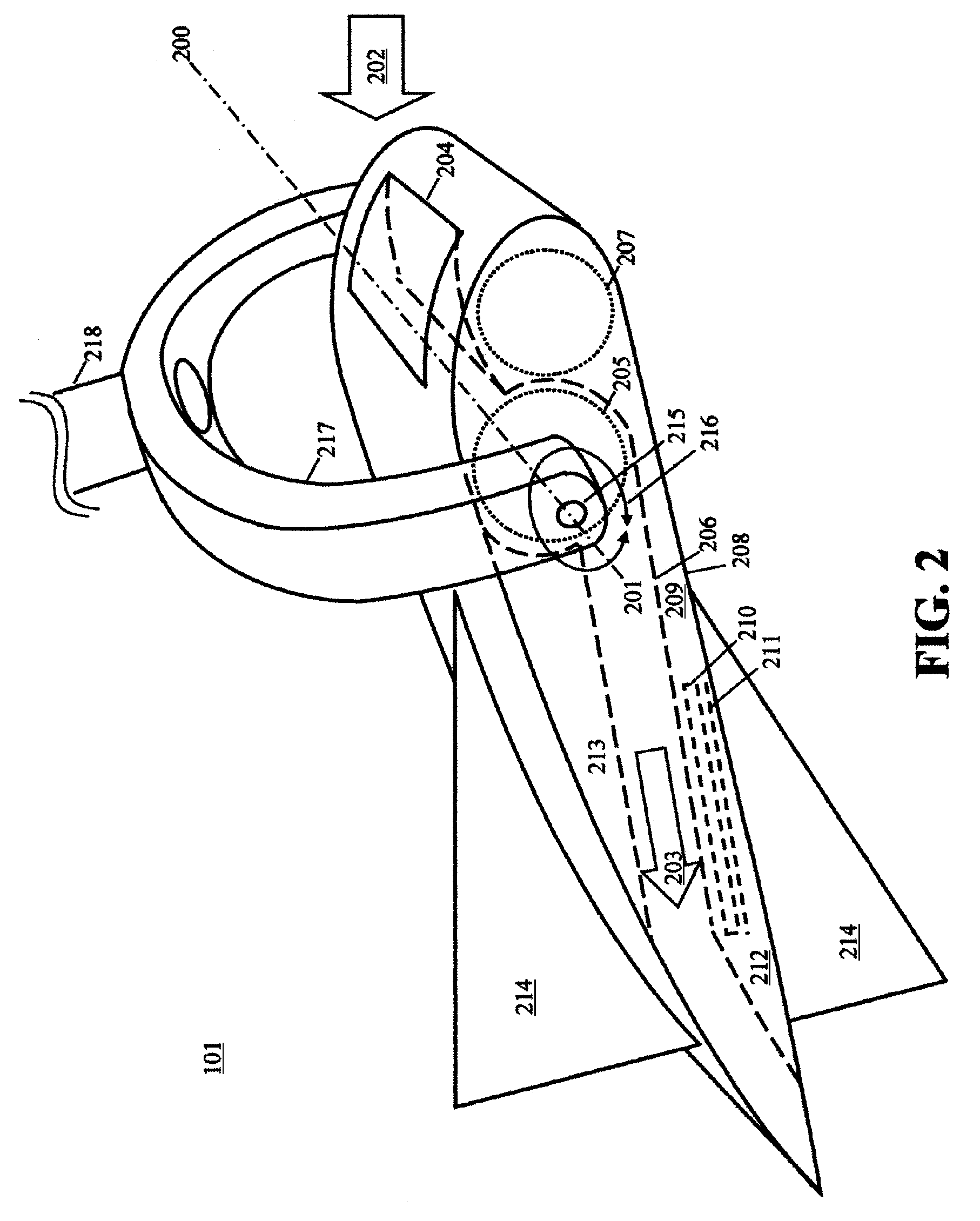

Gimbal-mounted hydroelectric turbine

InactiveUS6956300B2Reduce environmental impactPositive net energyFluid couplingsWind energy with electric storageFluid intakeEngineering

A power plant extracts energy from a free flowing motive fluid by means of a turbine mounted on a gimbal. The shroud element of the fluid intake has external rudders, in conjunction with the gimbal mounting, enabling the enclosed turbine to instantaneously respond to changes in the direction of the free flowing motive fluid thus ensuring the face area of the intake is always physically orthogonal to the direction of the motive fluid streamlines. The shroud element may also be buoyant so as to optimally extract energy from an upper non-turbulent and higher velocity layer of the free flowing motive fluid. To function within an inherently unsteady source of energy, the preferred embodiment of the turbine is coupled to a DC generator which may further be coupled to a voltage and current regulating circuit which either charges a battery, performs electrolysis of water to produce hydrogen fuel, or is further coupled to a DC motor coupled to an AC generator. Alternatively an AC induction generator may be coupled to the turbine. Other mechanical, electrical, electronic, or electromechanical features may optionally be implemented to perform such tasks as adaptively locating the turbine in the maximum velocity flow, adapting internal vane and runner blade pitches for various flow rates and loads, keeping the intake free of obstructions, preventing loss of aquatic life, controlling and communicating the state of charge of the battery, or gauging and controlling the electrolysis process and communicating the fullness of the hydrogen gas output tanks.

Owner:INTEGRATED POWER TECH CORP

Cold fuel cooling of intercooler and aftercooler

ActiveUS20130074812A1Reduce power consumptionNone have achieved superiorInternal combustion piston enginesPower plant arrangements/mountingTurbochargerNuclear engineering

Owner:AEROVIRONMENT INC

Power generation and supply system

A power generation and supply system utilizing one or more solar cells to produce electricity and hydrogen. The power generation and supply system includes an electrolyzer powered by the one or more solar cells for producing hydrogen, a hydrogen distribution system for distributing the hydrogen produced by the electrolyzer, a rechargeable battery for storing electricity produced by the solar cells, and an electricity distribution. The power generation and supply system according may further comprise a hydrogen fueled fuel cell which receives hydrogen produced by the electrolyzer and produces electricity as needed to recharge the rechargeable battery and / or power one or more electrical devices.

Owner:ENERGY CONVERSION DEVICES INC

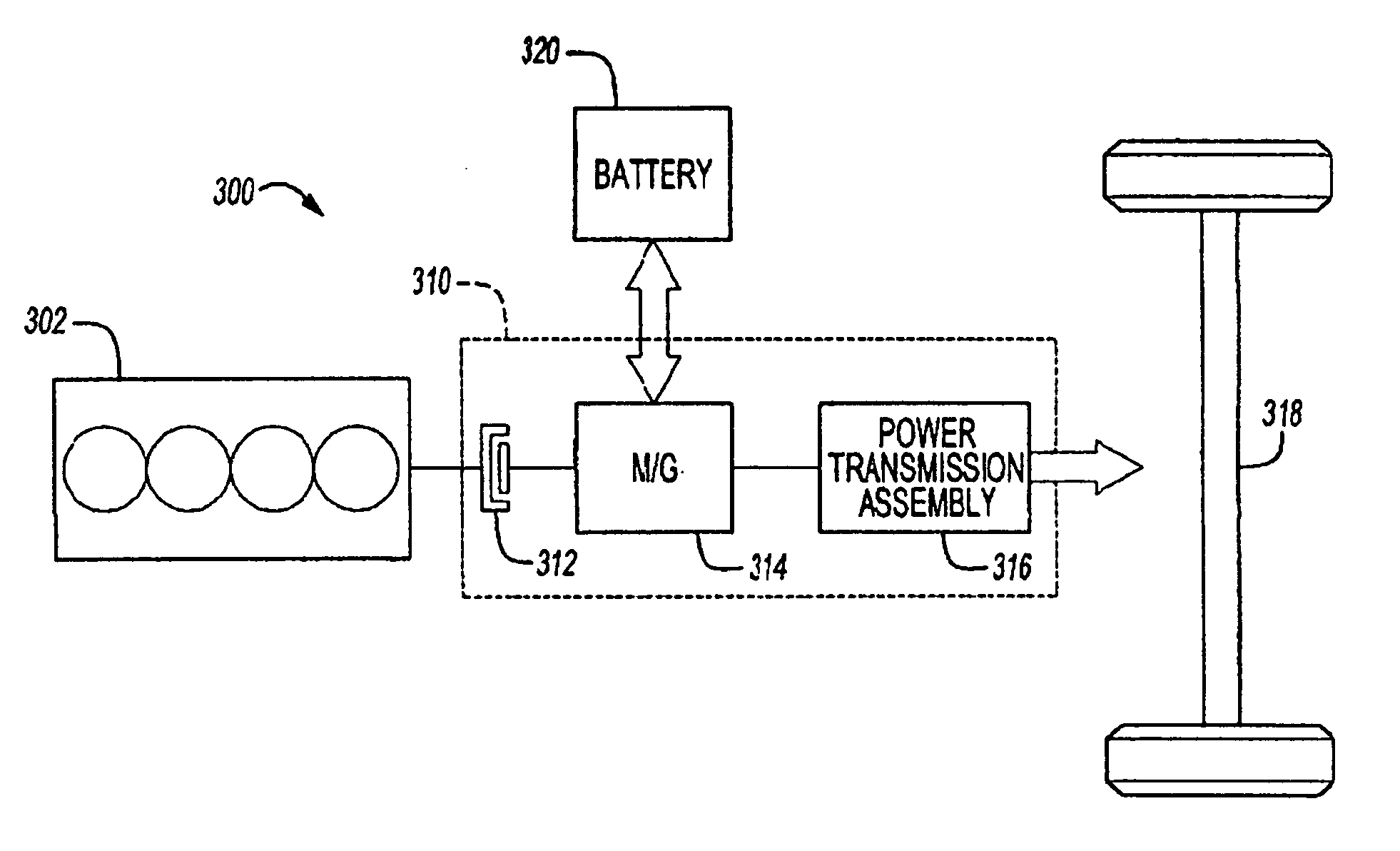

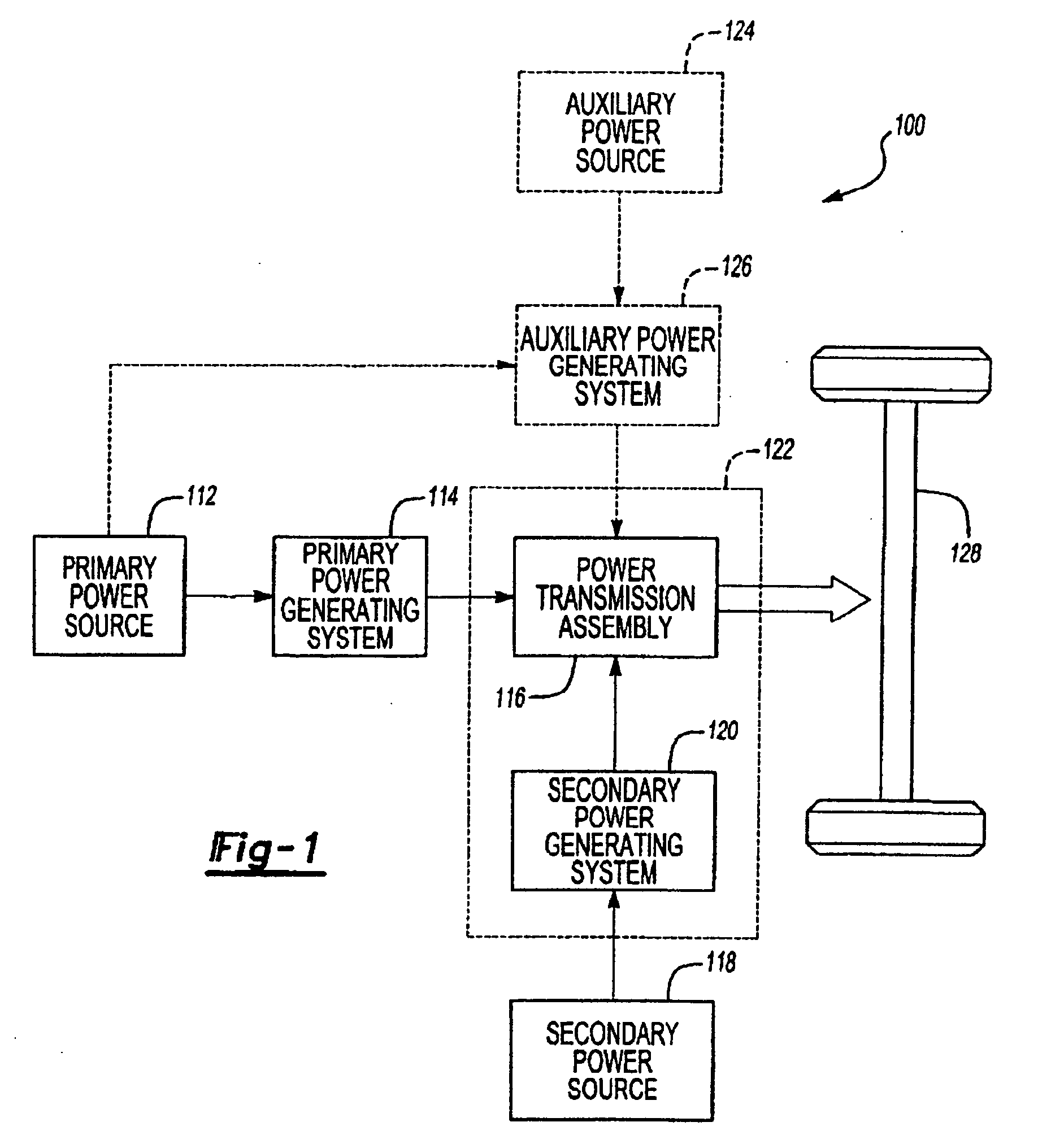

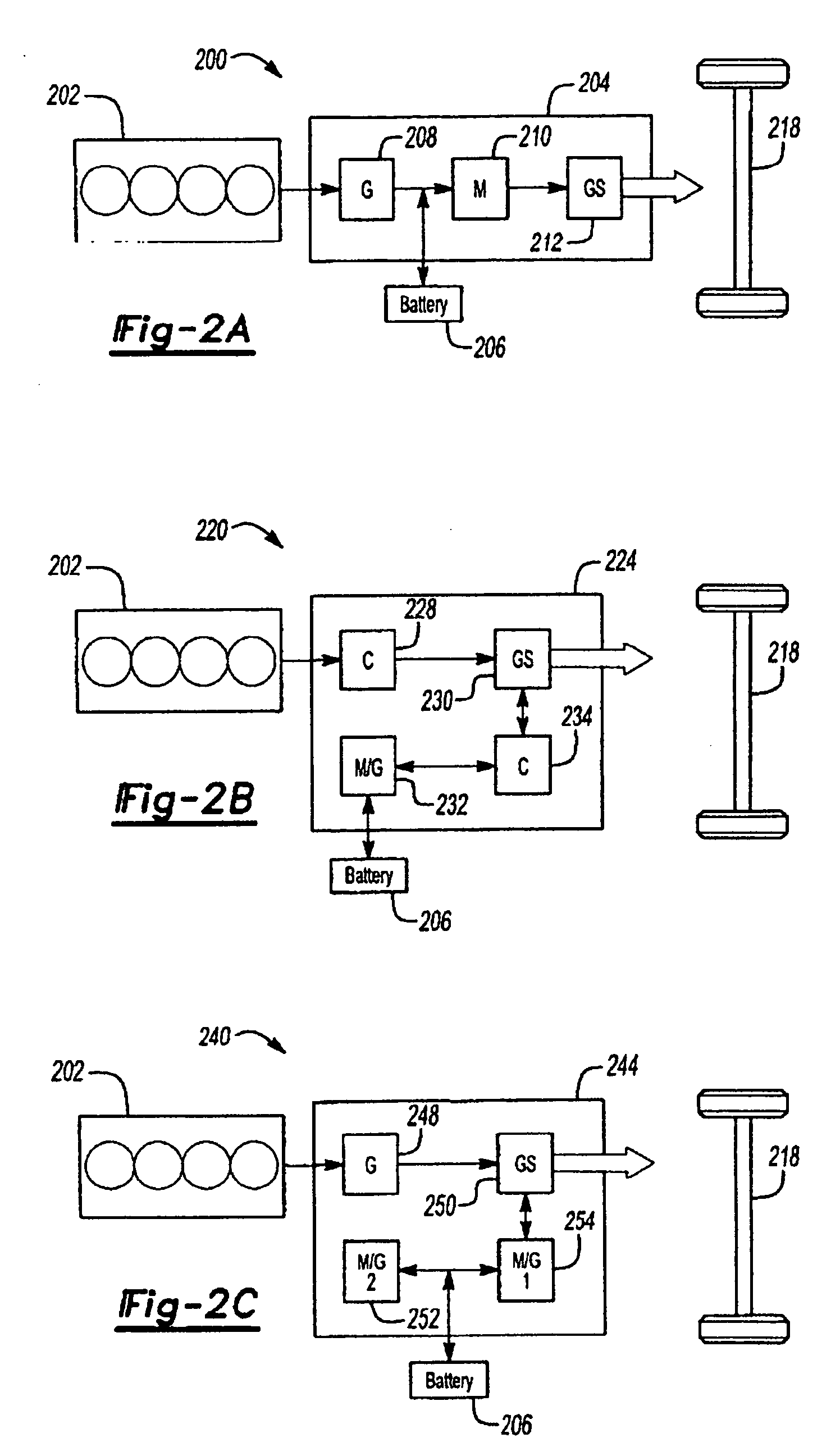

Hydrogen fuelled hybrid powertrain and vehicle

InactiveUS20060174624A1Increase output torqueImprove performanceReciprocating combination enginesElectrical controlDrivetrainEngineering

A hydrogen-powered hybrid powertrain system includes a hydrogen-fuelled internal combustion engine operating at a lean air / fuel mixture, and a supercharger for boosting a primary drive torque produced by the engine primarily over a high operating speed range. An electric motor / generator generates a secondary drive torque for the vehicle, such that the secondary drive torque complements the boosted primary drive torque over at least a low operating speed range of the powertrain. A disconnect clutch disposed between the engine and the motor / generator engages and disengages the engine from the motor / generator, and serves to transfer the boosted primary driver torque through the motor / generator and to a power transmission system. The input at the power transmission is thus a combination of the boosted primary drive torque and the secondary drive torque having an enhanced torque characteristic over at least the low operating speed range.

Owner:FORD GLOBAL TECH LLC

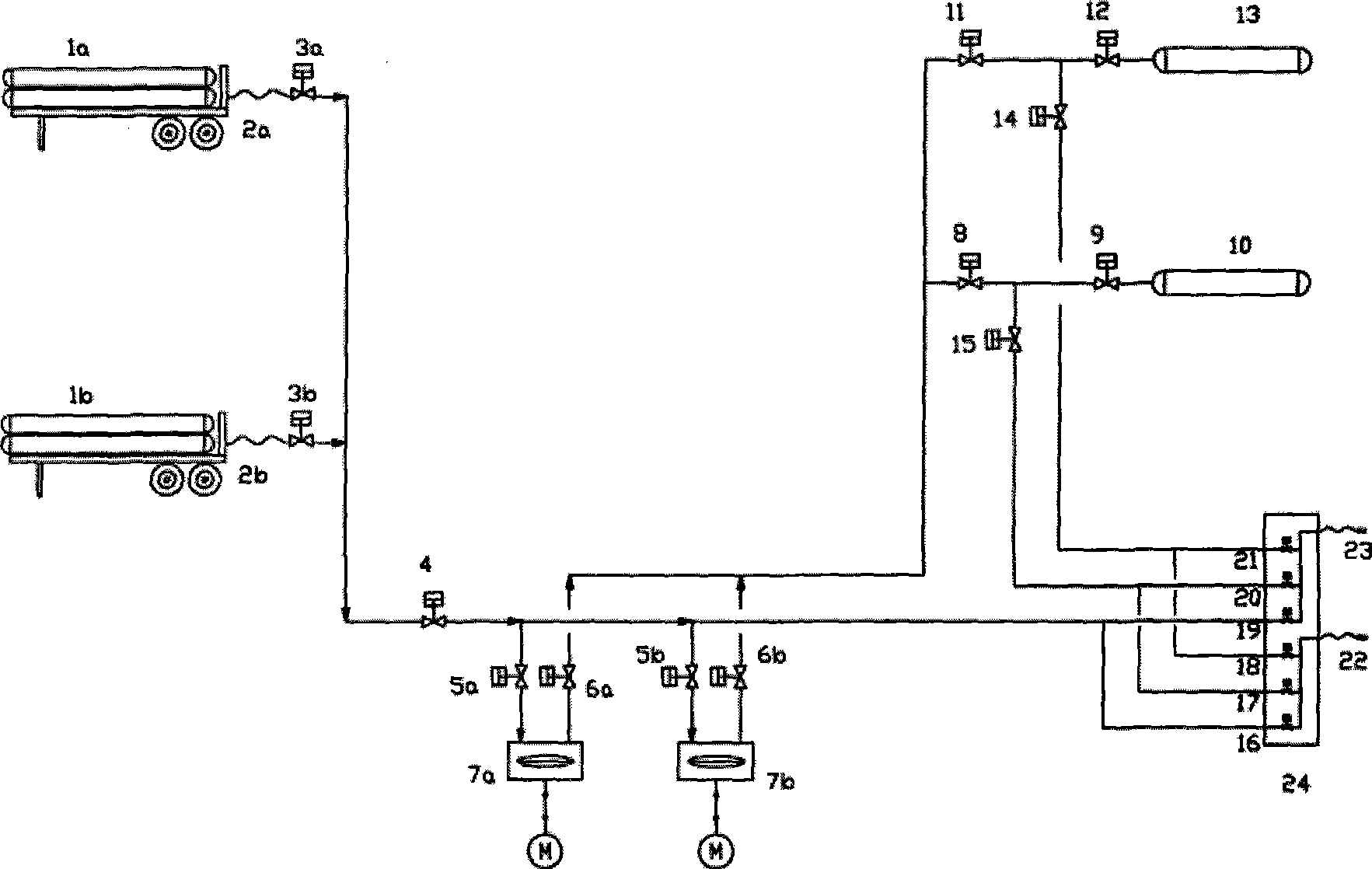

High-pressure hydrogen supply system for exterior hydrogen feeding hydrogenation stations

ActiveCN101418907ASimplified hydrogen supply processLow investment costContainer filling under pressureHigh pressure hydrogenData acquisition

The invention provides a high-pressure hydrogen supply system for an external supplying type hydrogen filling station, which can fill hydrogen fuel for fuel cell powered vehicles. The hydrogen supply system mainly comprises a pipe bundle hydrogen conveying vehicle, a fixed high-pressure hydrogen storage tank group, a parallel multi-compressor pressurizing system, a high-pressure hydrogen filling system, and a data acquiring, processing and safety monitoring system. The high-pressure hydrogen supply system takes the pipe bundle hydrogen conveying vehicle as a part of a hydrogen storage container of the hydrogen filling station and makes the pipe bundle hydrogen conveying vehicle a first stage of the staged hydrogen storage container, adopts the pressurizing system consisting of multiple compressors which are connected in parallel, and introduces the data acquiring, processing and safety monitoring system. The high-pressure hydrogen supply system has the advantages of adjustable hydrogen storage volume, large operation flexibility, cost conservation, convenient maintenance, high service efficiency and so on.

Owner:TONGJI UNIV

Electrical power generator

A power generator has a hydrogen flow path through which moisture is induced to flow to a hydrogen-containing fuel that reacts with the moisture to produce hydrogen. The moisture passes to the hydrogen flow path through a water exchange membrane from a water vapor flow path. A fuel cell between the hydrogen flow path and the water vapor flow path reacts with the hydrogen in the hydrogen flow path to produce electricity, and to also principally produce the moisture in the water vapor flow path.

Owner:HONEYWELL INT INC

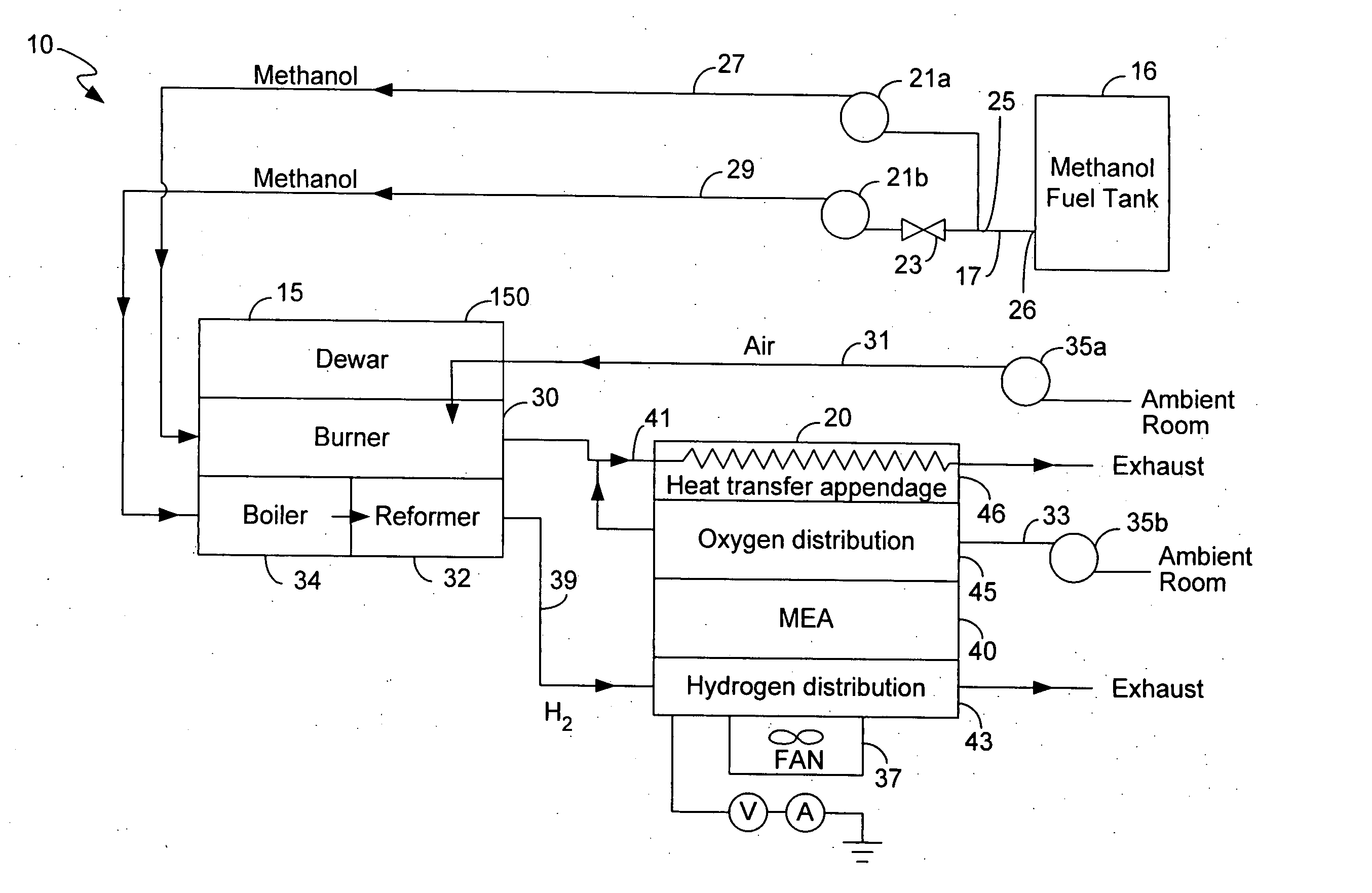

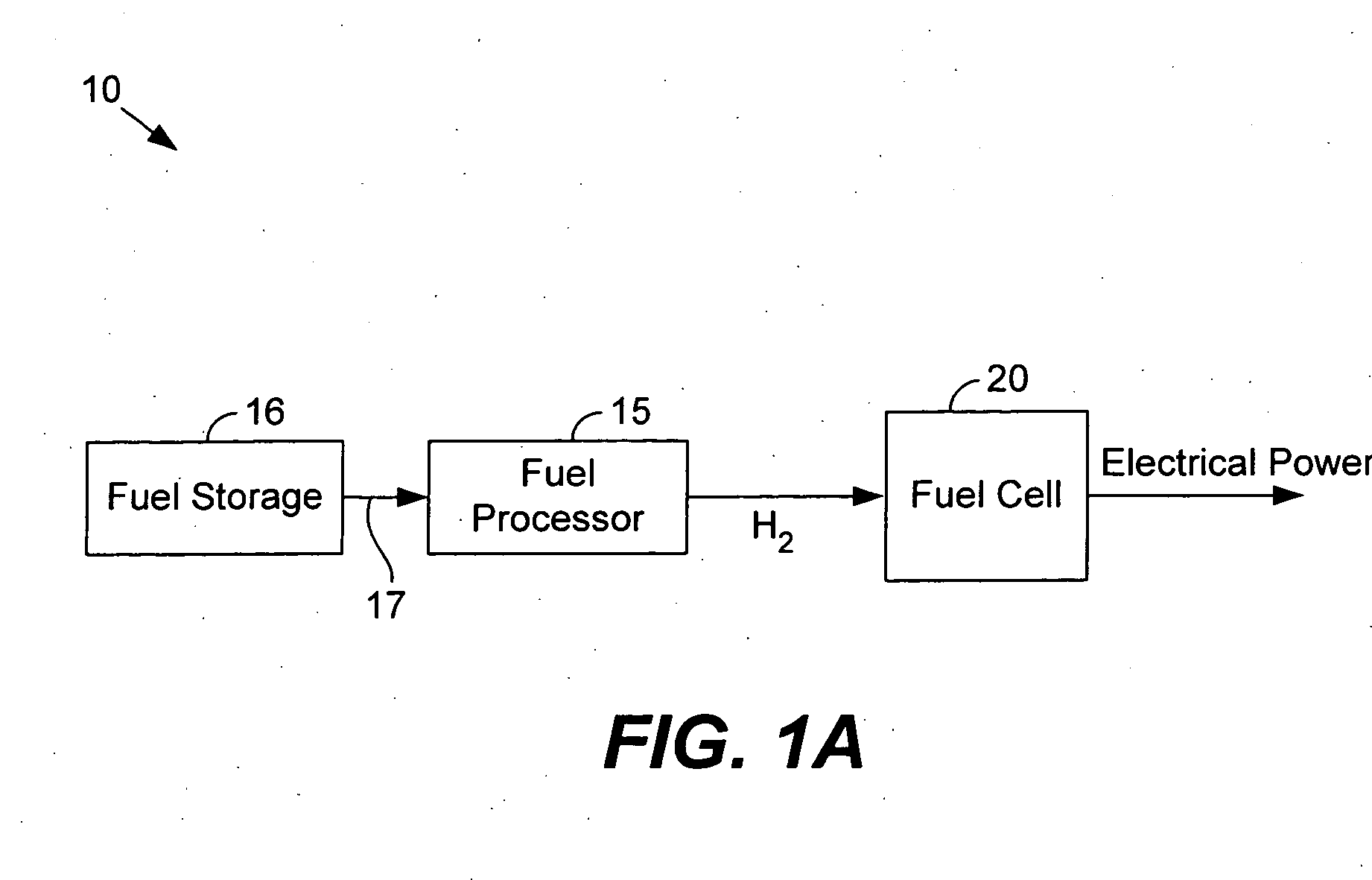

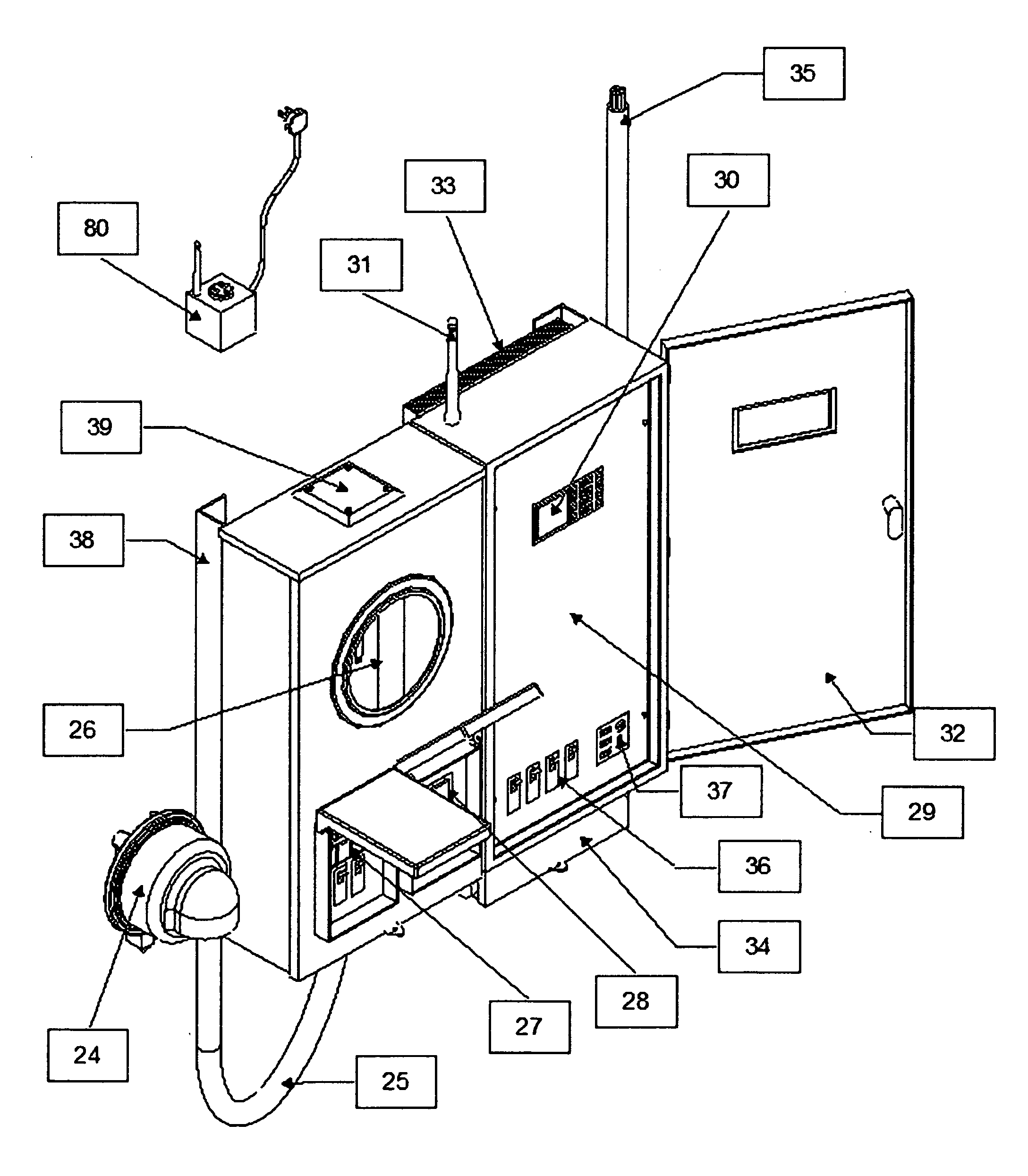

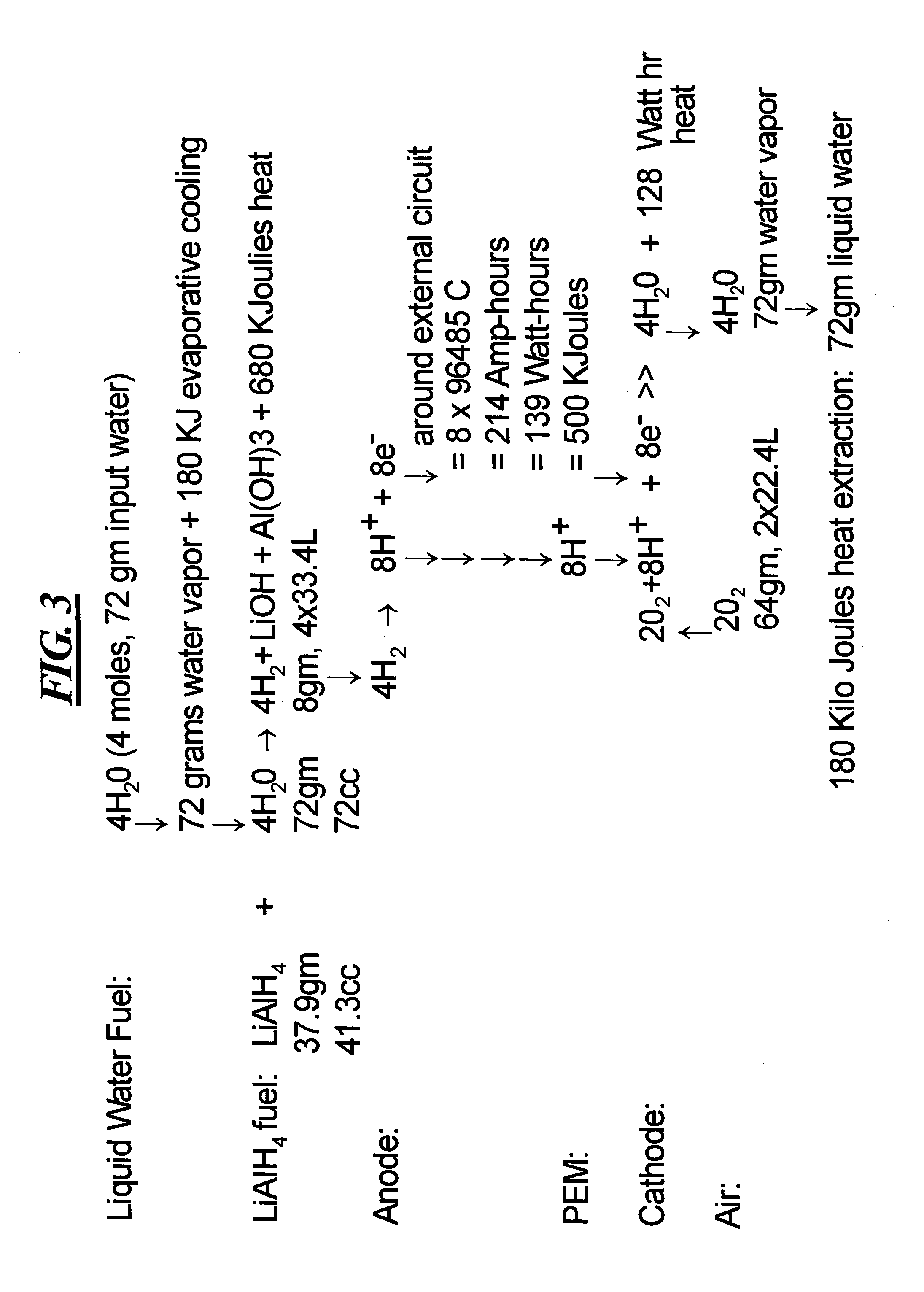

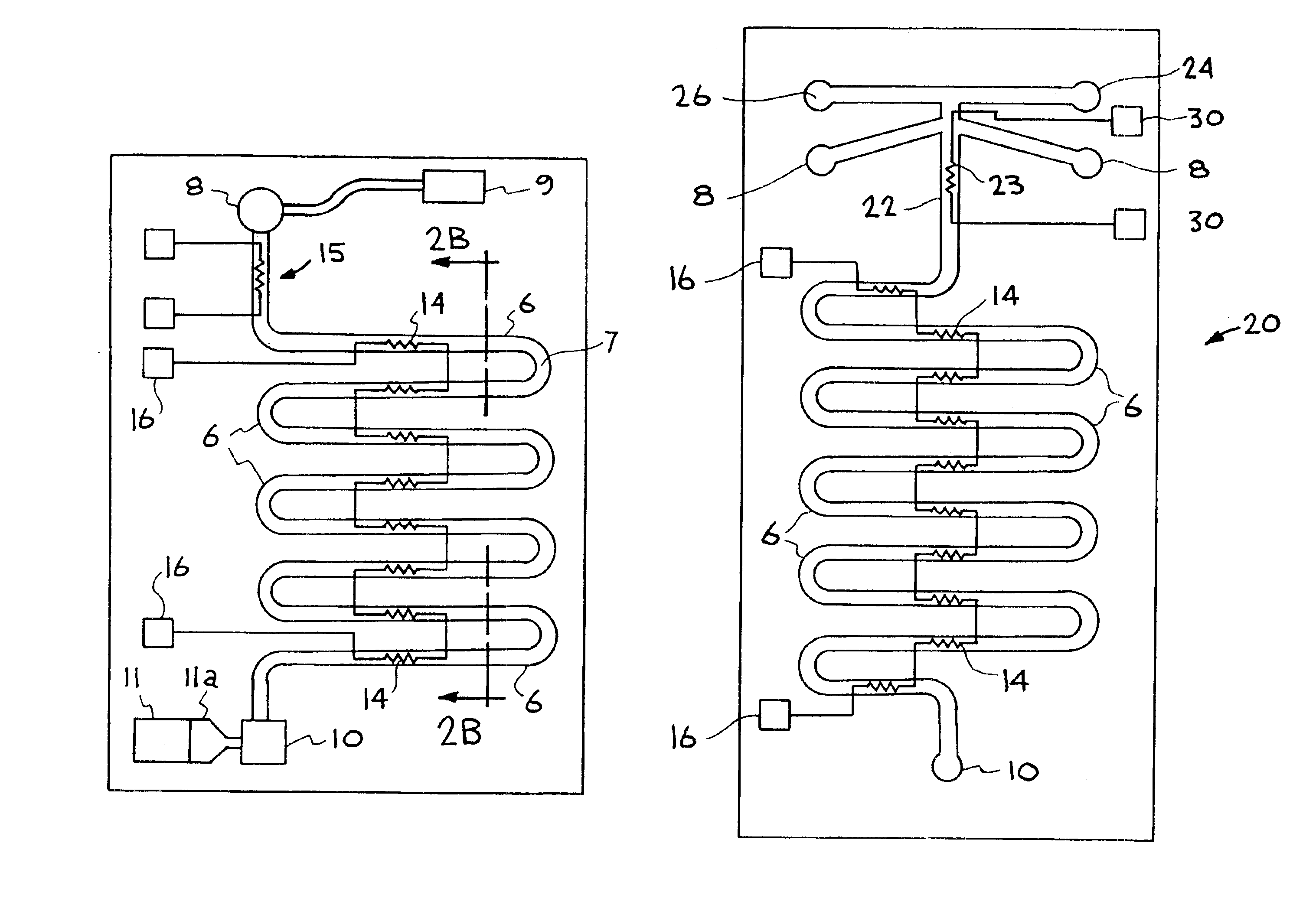

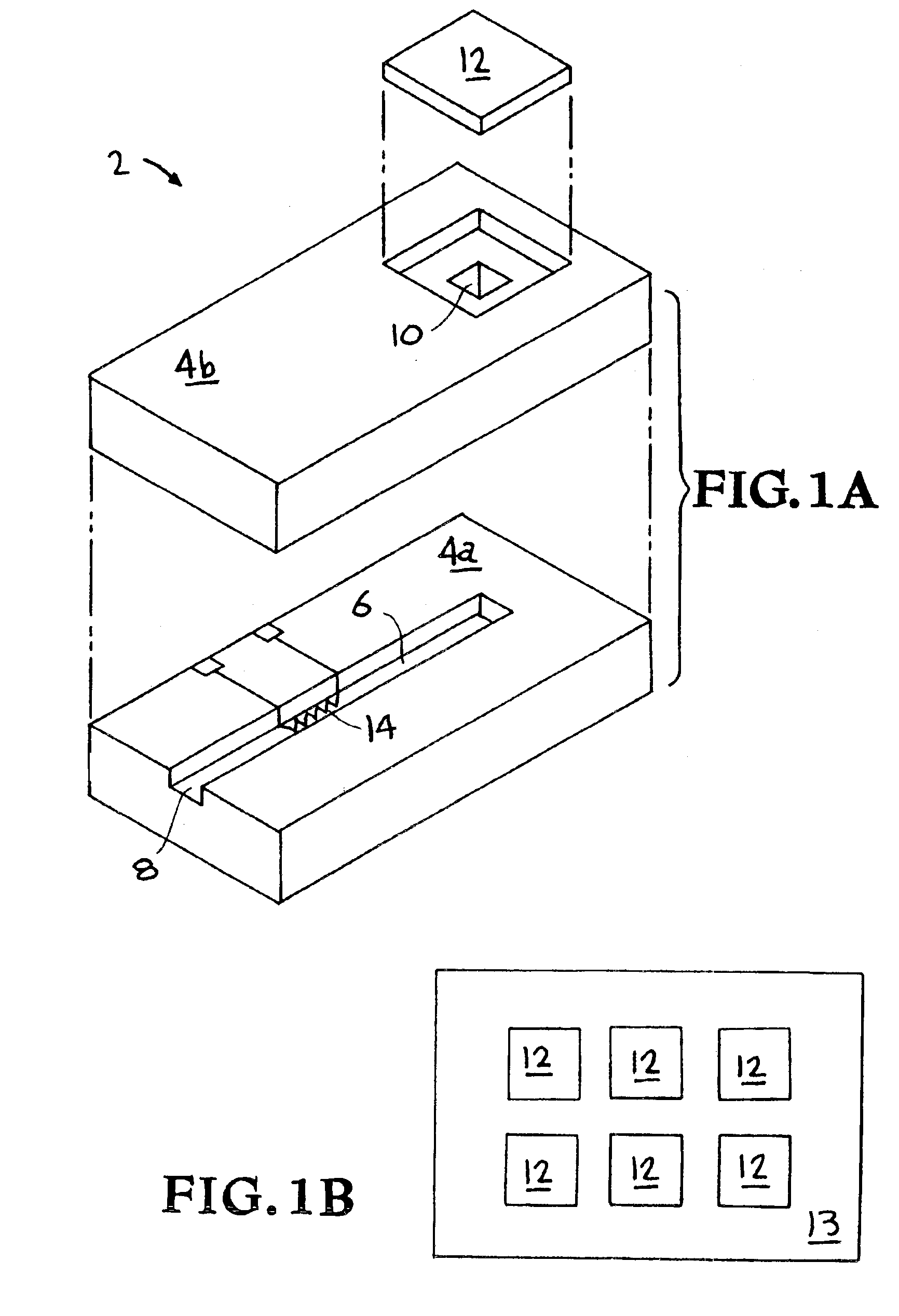

Chemical microreactor and method thereof

InactiveUS6960235B2Physical/chemical process catalystsHydrogen separationMicroreactorSteam reforming

A chemical microreactor suitable for generation of hydrogen fuel from liquid sources such as ammonia, methanol, and butane through steam reforming processes when mixed with an appropriate amount of water contains capillary microchannels with integrated resistive heaters to facilitate the occurrence of catalytic steam reforming reactions. One such microreactor employs a packed catalyst capillary microchannel and at least one porous membrane. Another employs a porous membrane with a large surface area or a porous membrane support structure containing a plurality of porous membranes having a large surface area in the aggregate, i.e., greater than about 1 m2 / cm3. The packed catalyst capillary microchannels, porous membranes and porous membrane support structures may be formed by a variety of methods.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Turbine-integrated hydrofoil

InactiveUS7298056B2Good energyFacilitates maintaining overall stability and guidanceElectrolysis componentsAuxillariesPower overEngineering

Owner:INTEGRATED POWER TECH CORP

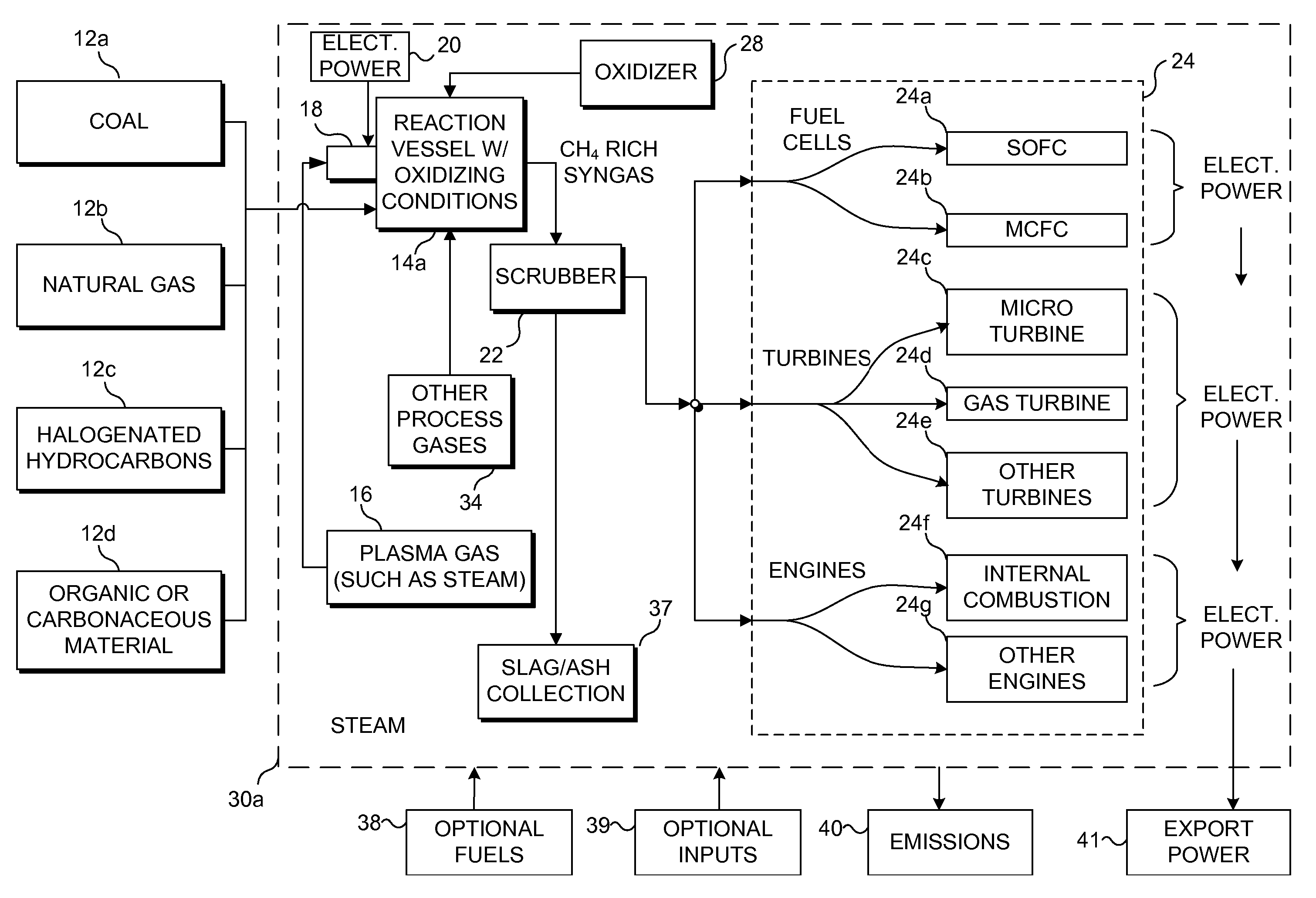

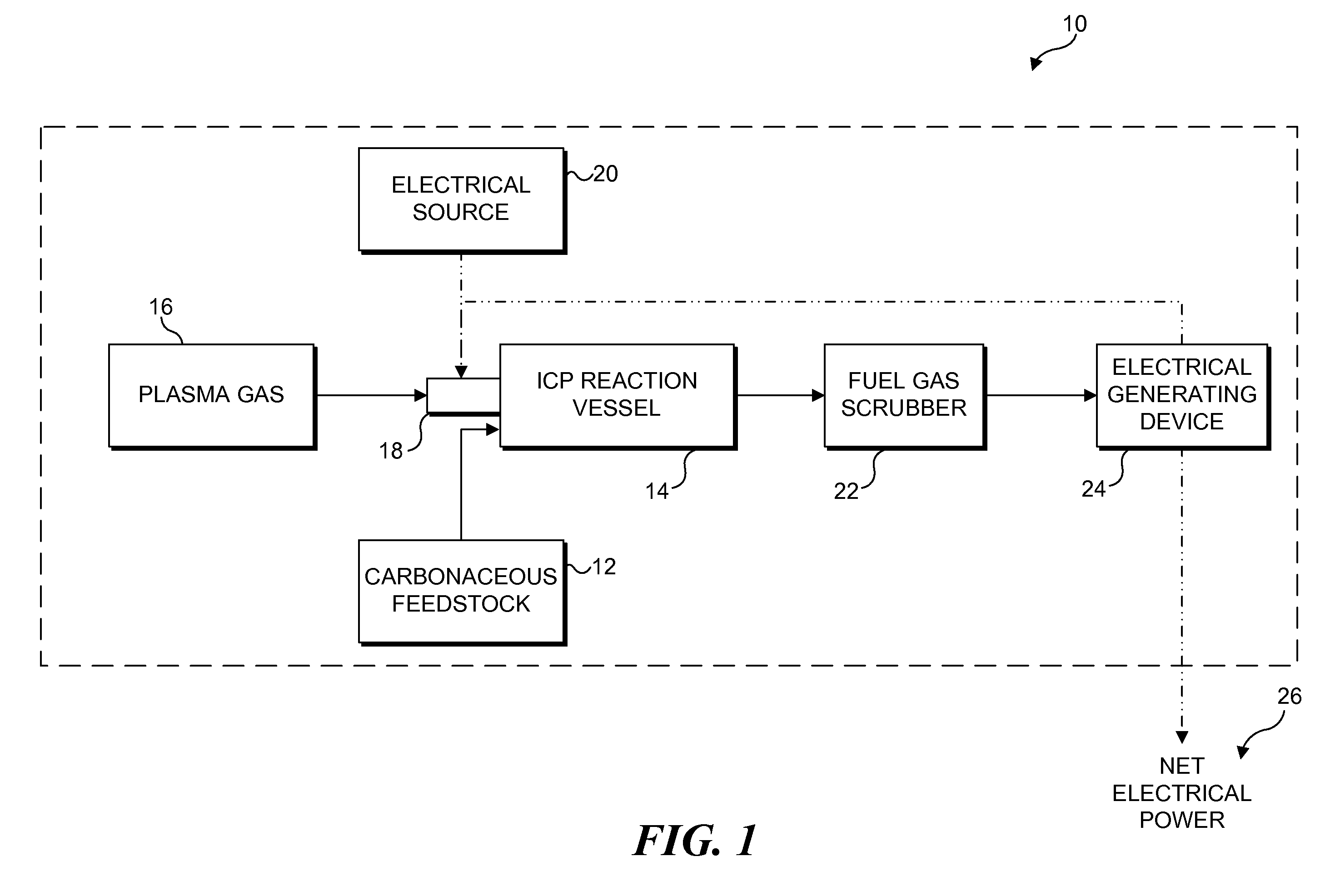

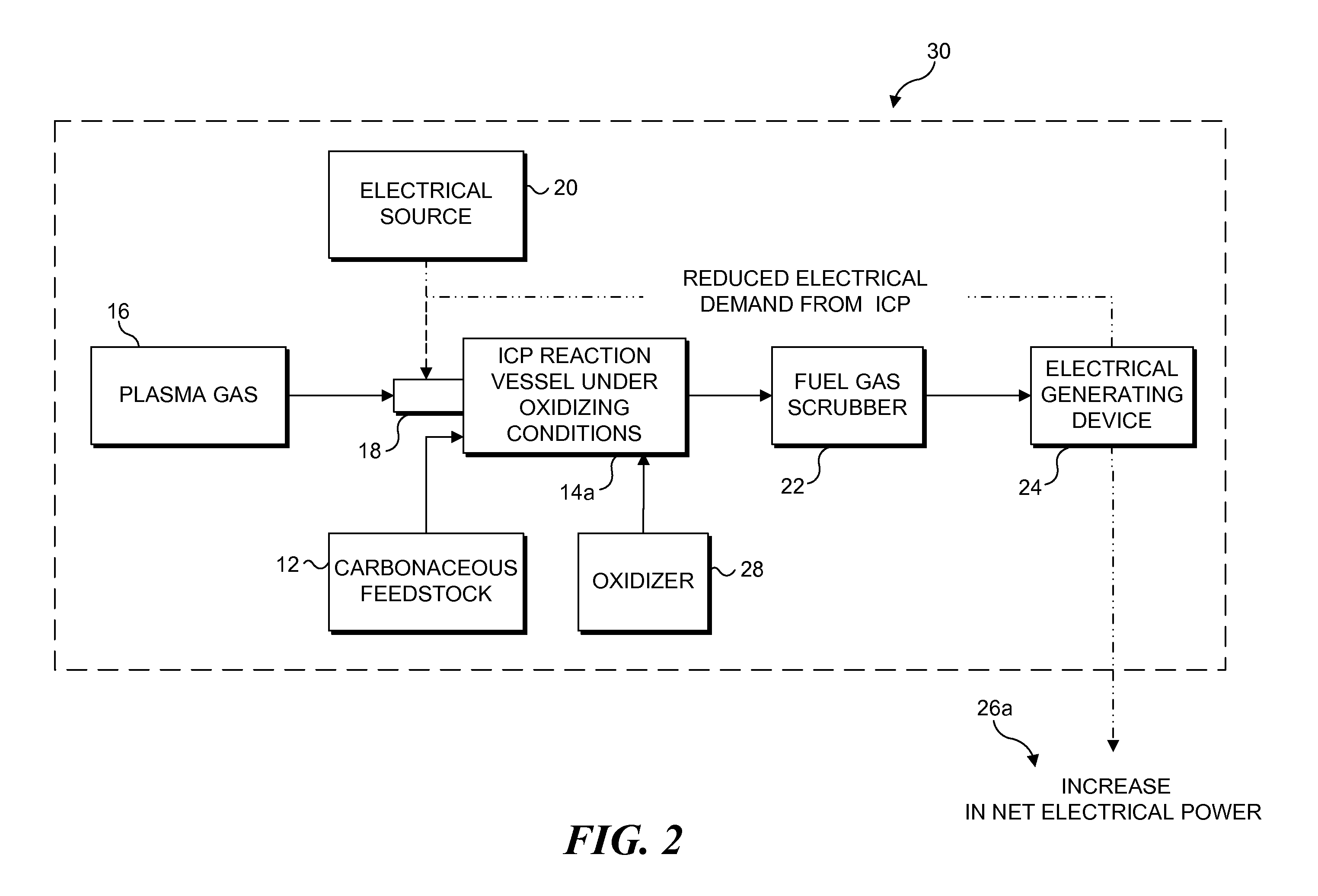

Inductively coupled plasma/partial oxidation reformation of carbonaceous compounds to produce fuel for energy production

InactiveUS20080041829A1Increase the amount of carbonMore electricityElectricity cogenerationFuel cell auxillariesThermal energyPartial oxidation

Owner:SEQUOYAH FINANCE ONE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com