High-pressure hydrogen supply system for exterior hydrogen feeding hydrogenation stations

A technology of hydrogen refueling station and external hydrogen supply, which is applied in the fields of equipment loaded into pressure vessels, container filling methods, gas/liquid distribution and storage, etc. The purchase cost of the compressor in the hydrogen refueling station, the increase in the operation and maintenance cost of the compressor, etc., can achieve the effect of large operation flexibility and operation stability, saving investment cost, and simplifying the hydrogen supply process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The contents, advantages and objects of the present invention will be set forth in the following description of the embodiments.

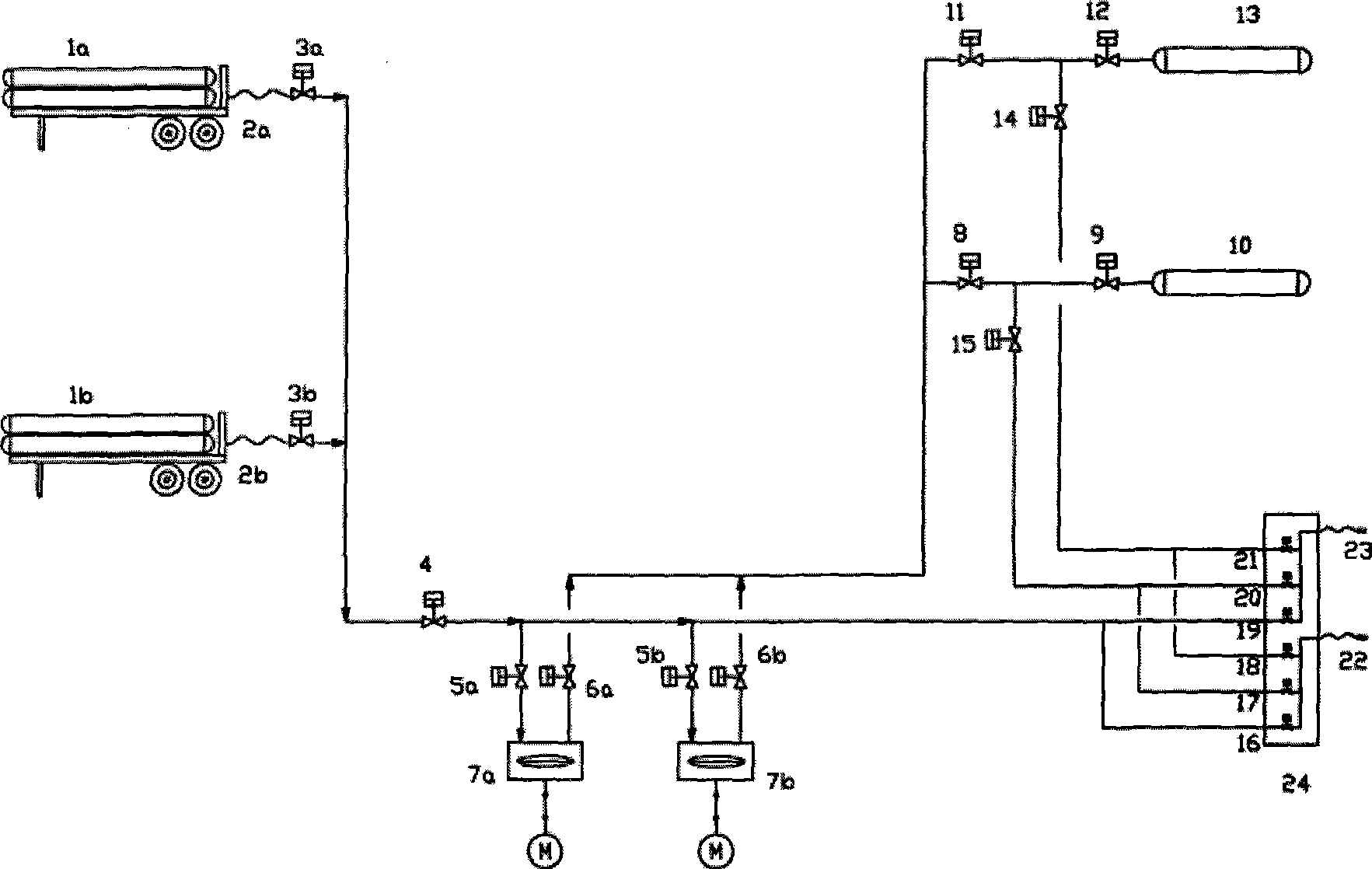

[0040] According to the present invention, the hydrogen supply system is composed of subsystems such as hydrogen supply, compression, storage, filling, data collection, processing and safety monitoring.

[0041] According to the present invention, the hydrogen supply system of this embodiment consists of 2 tube bundle hydrogen transport vehicles 1a and 1b and 2 gas unloading columns. Two tube-bundle hydrogen transport vehicles send the gaseous hydrogen purified and compressed to 20MPa (maximum) from the hydrogen production plant to the hydrogen refueling station. When one tube-bundled hydrogen transport vehicle supplies hydrogen to the hydrogen refueling station, the other one can return to the hydrogen source for rotation. When the gas consumption of the hydrogen refueling station is large, two tube-bundle hydrogen transportation vehicles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com