Patents

Literature

4189results about "Container filling under pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

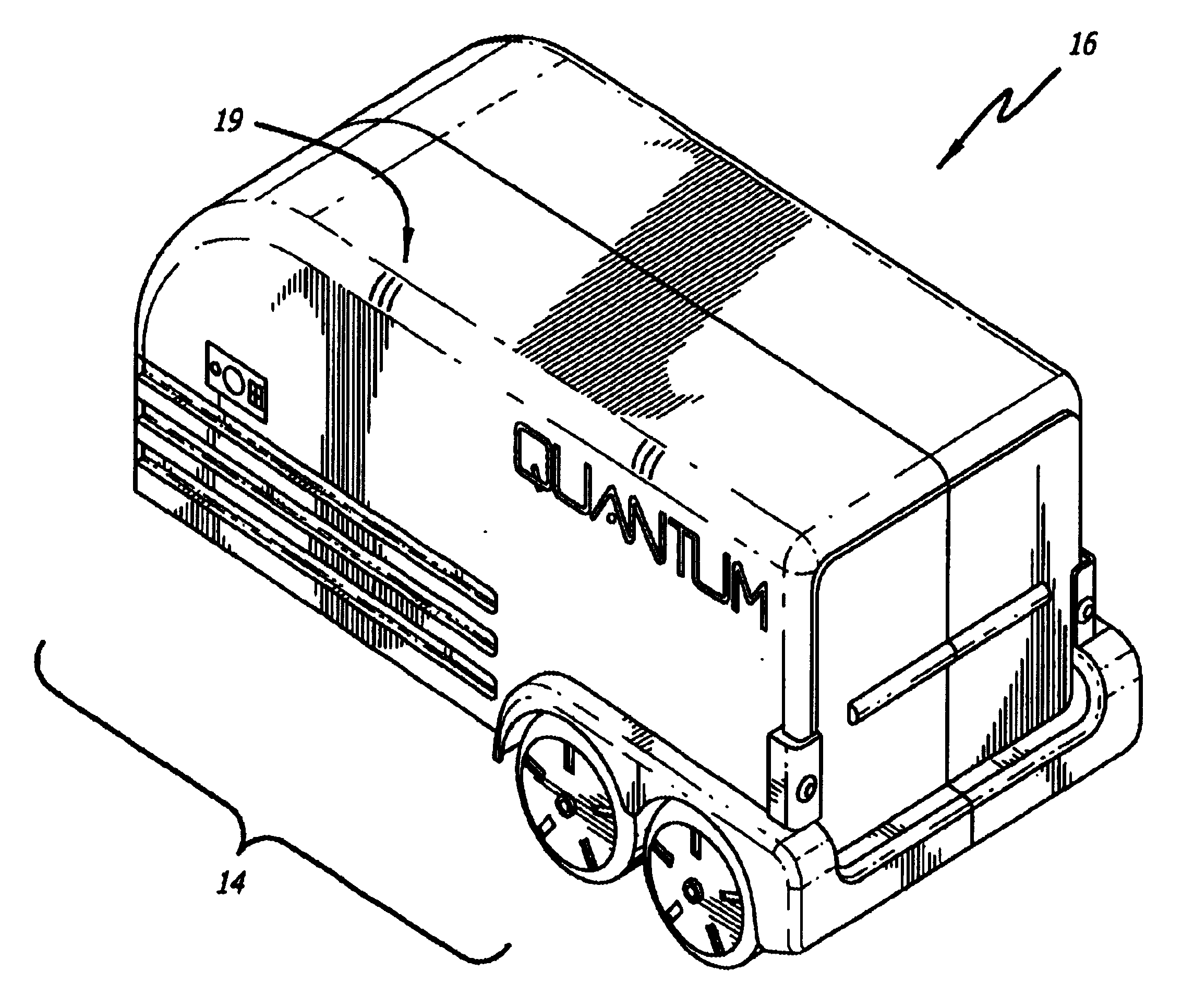

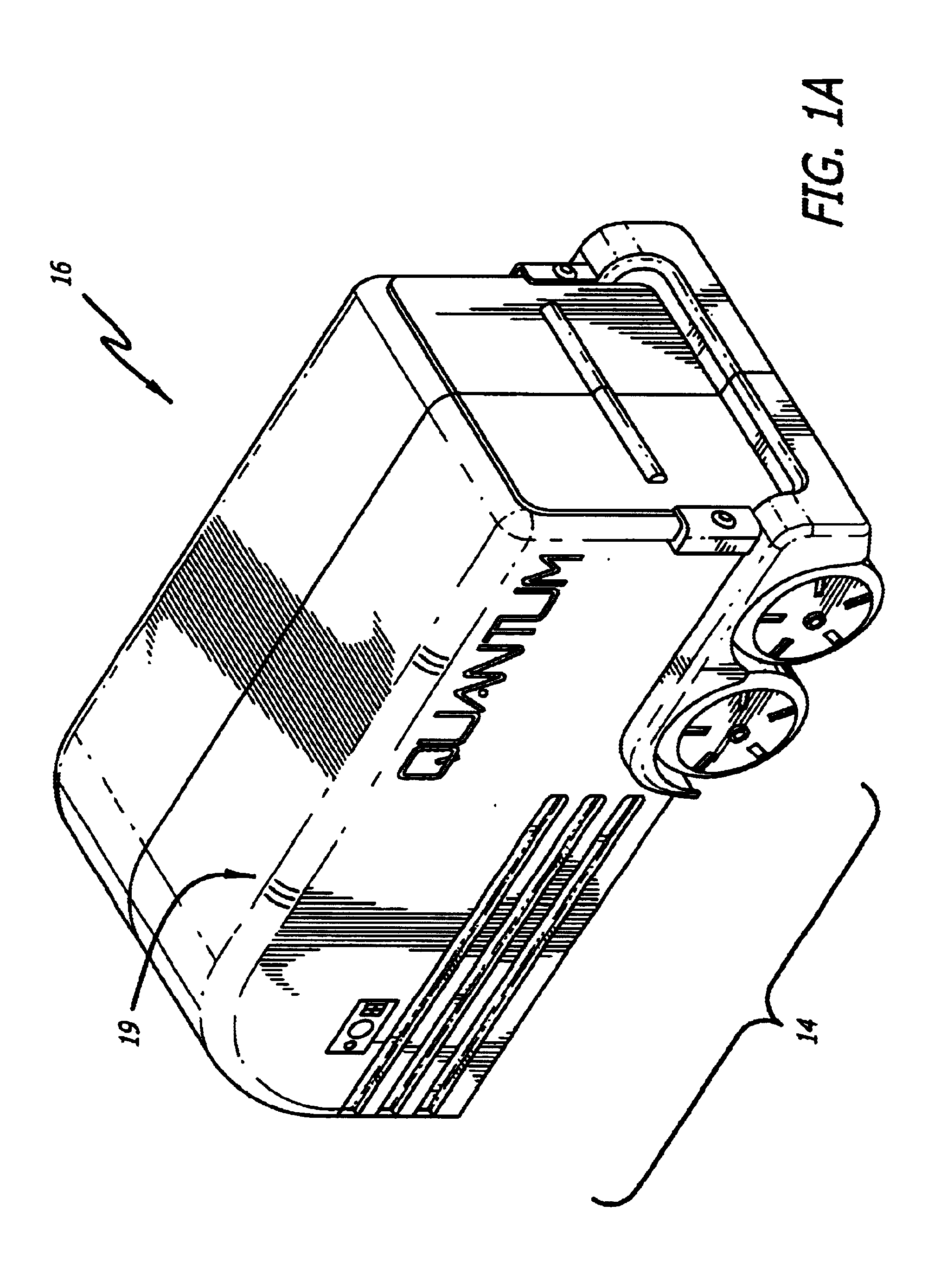

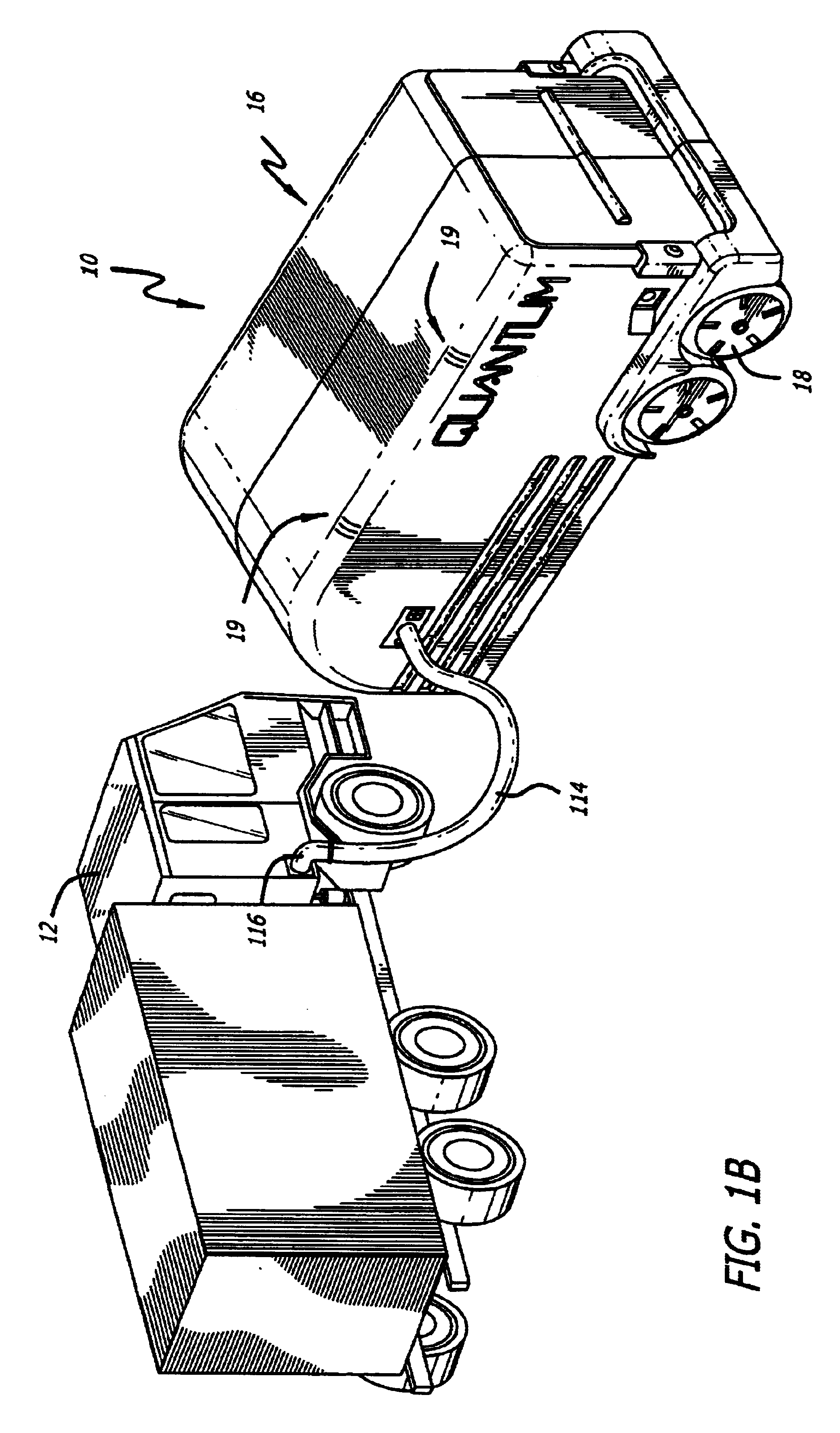

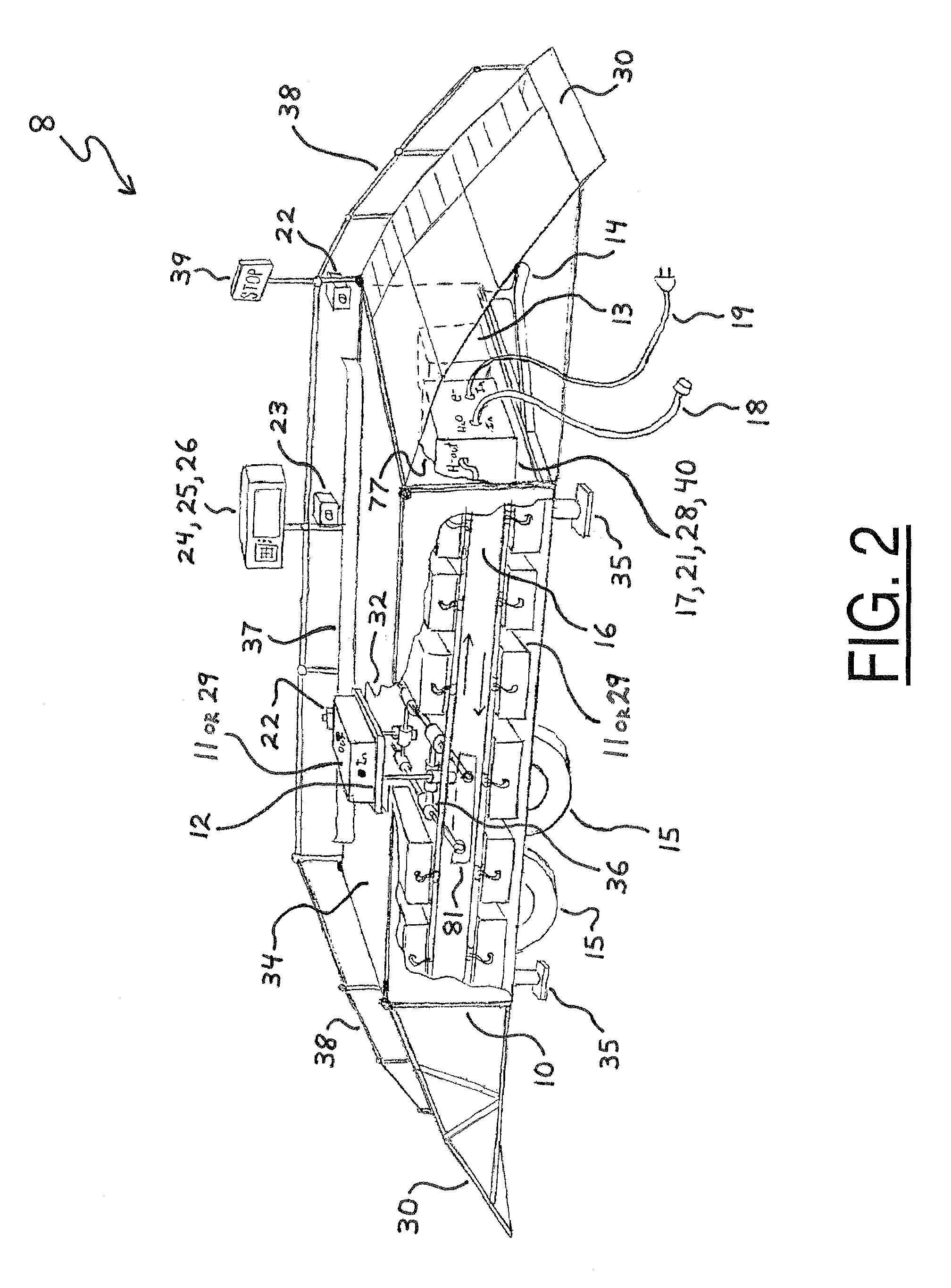

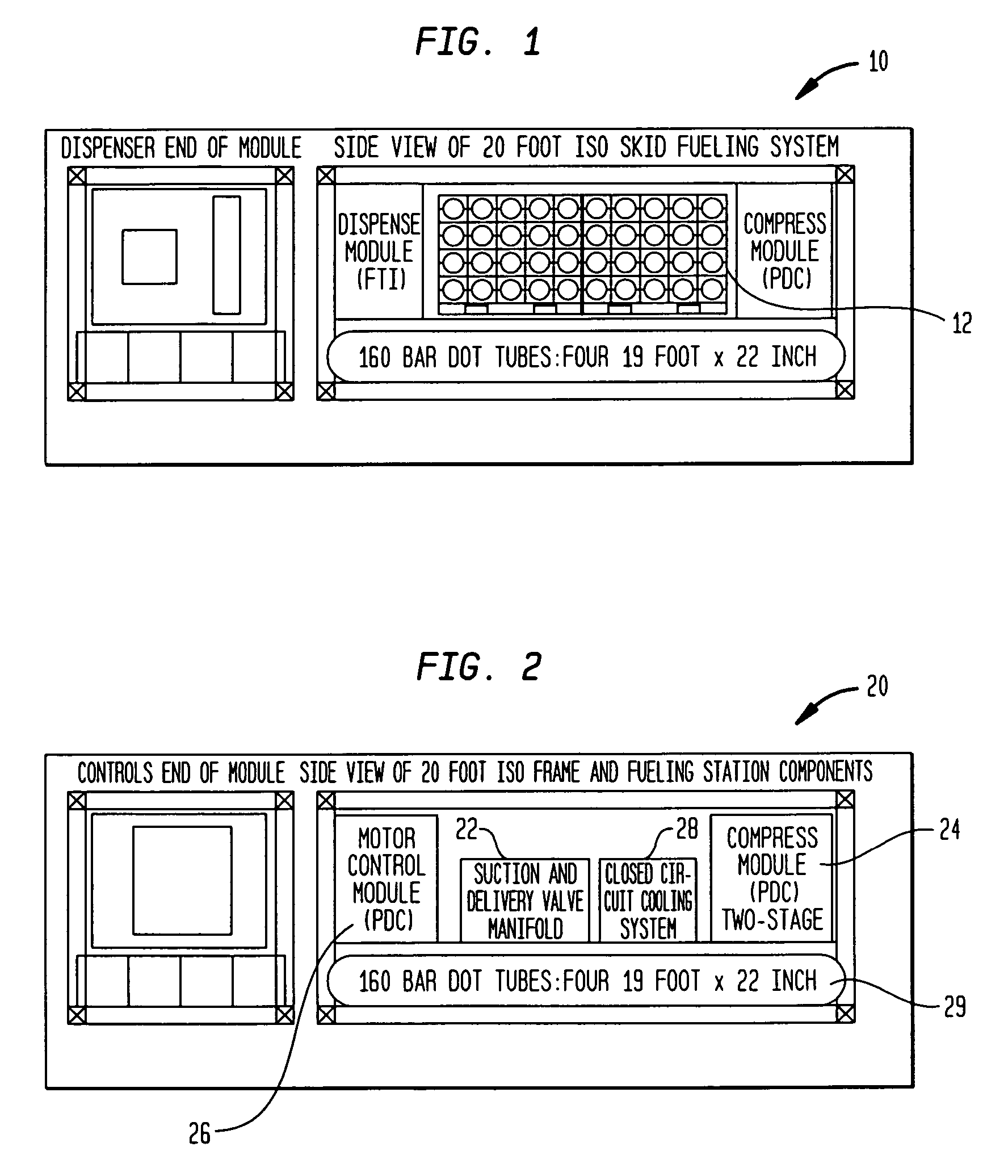

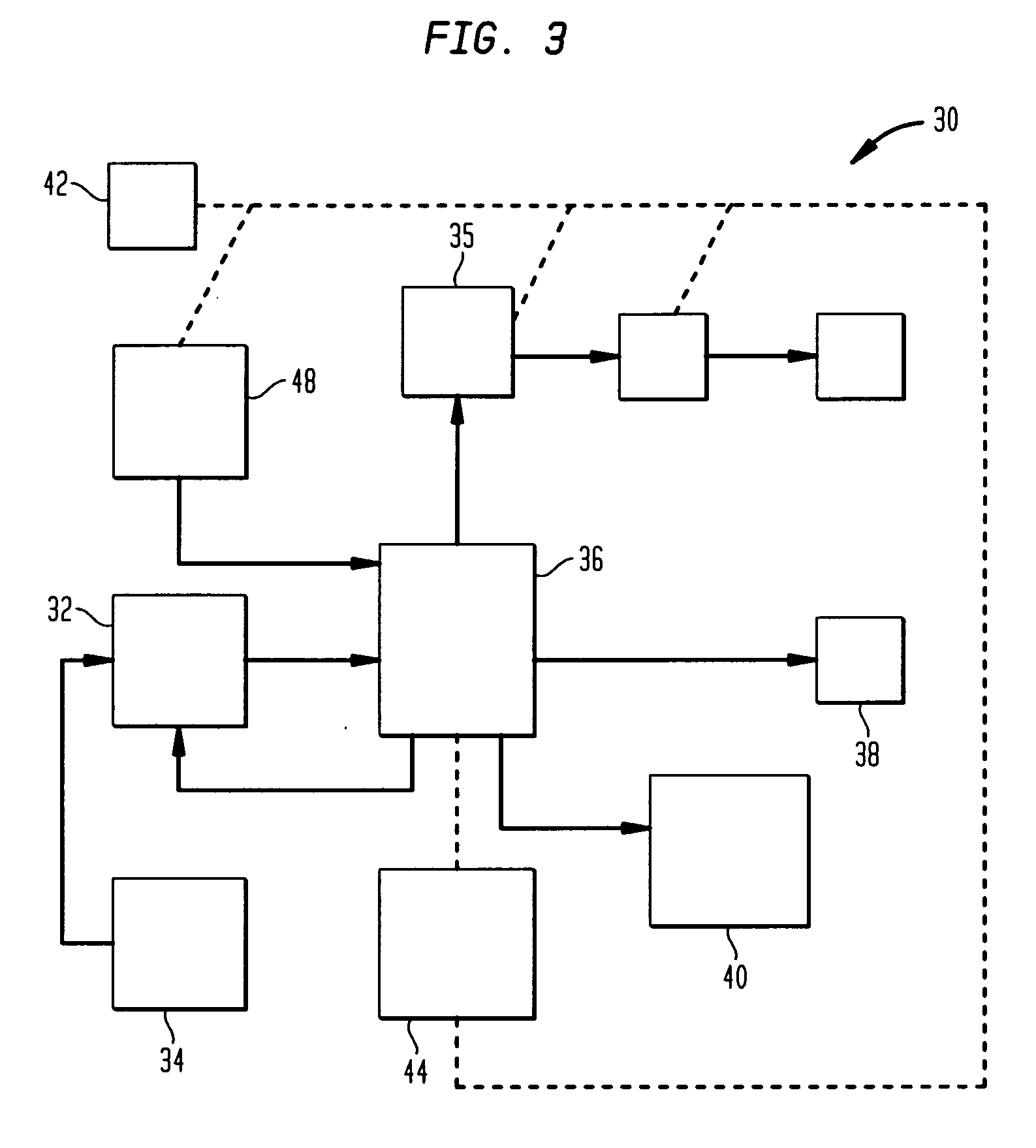

Transportable hydrogen refueling station

InactiveUS6755225B1Easy to monitorReduce riskTank vehiclesGas handling applicationsHigh pressureGaseous hydrogen

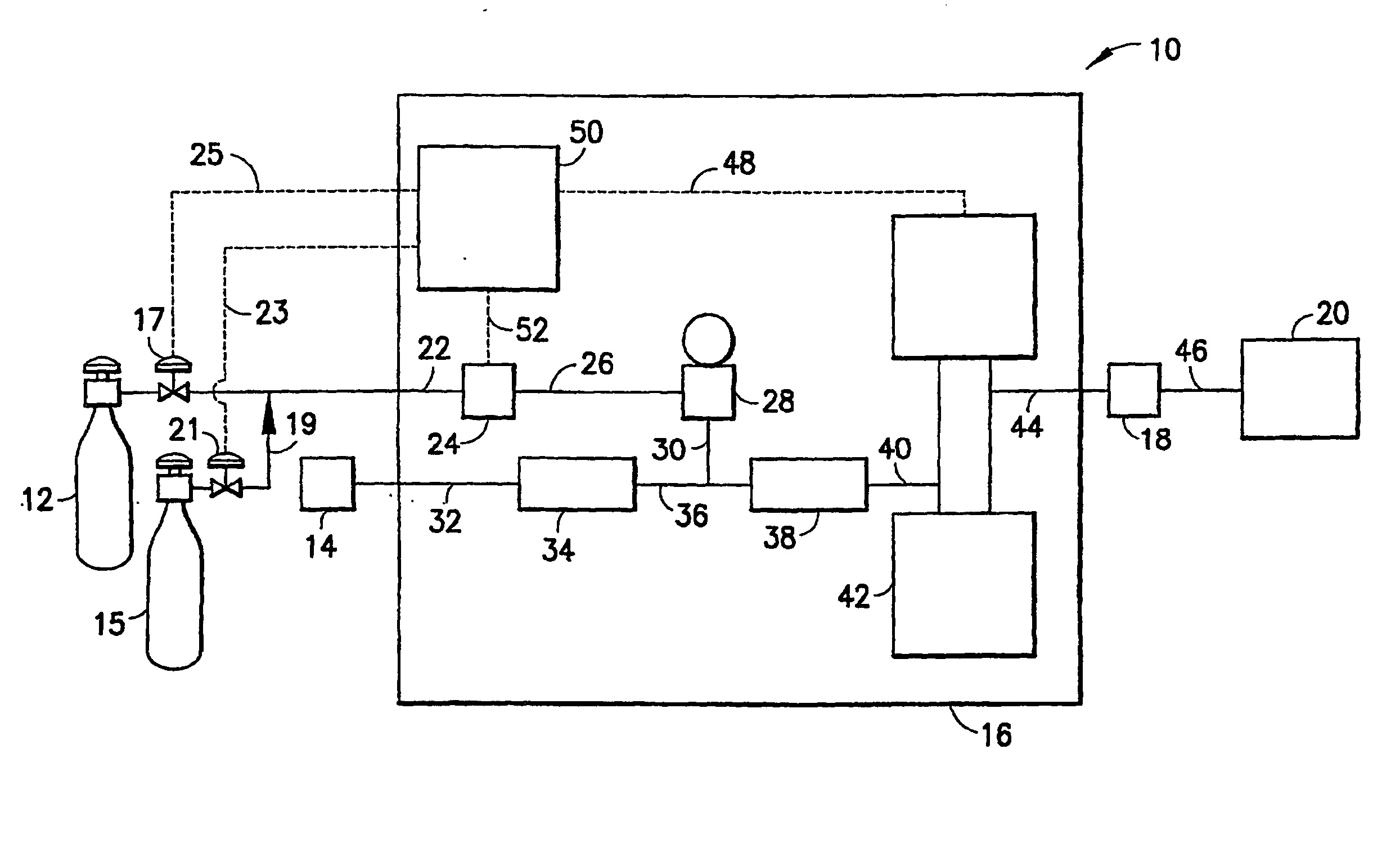

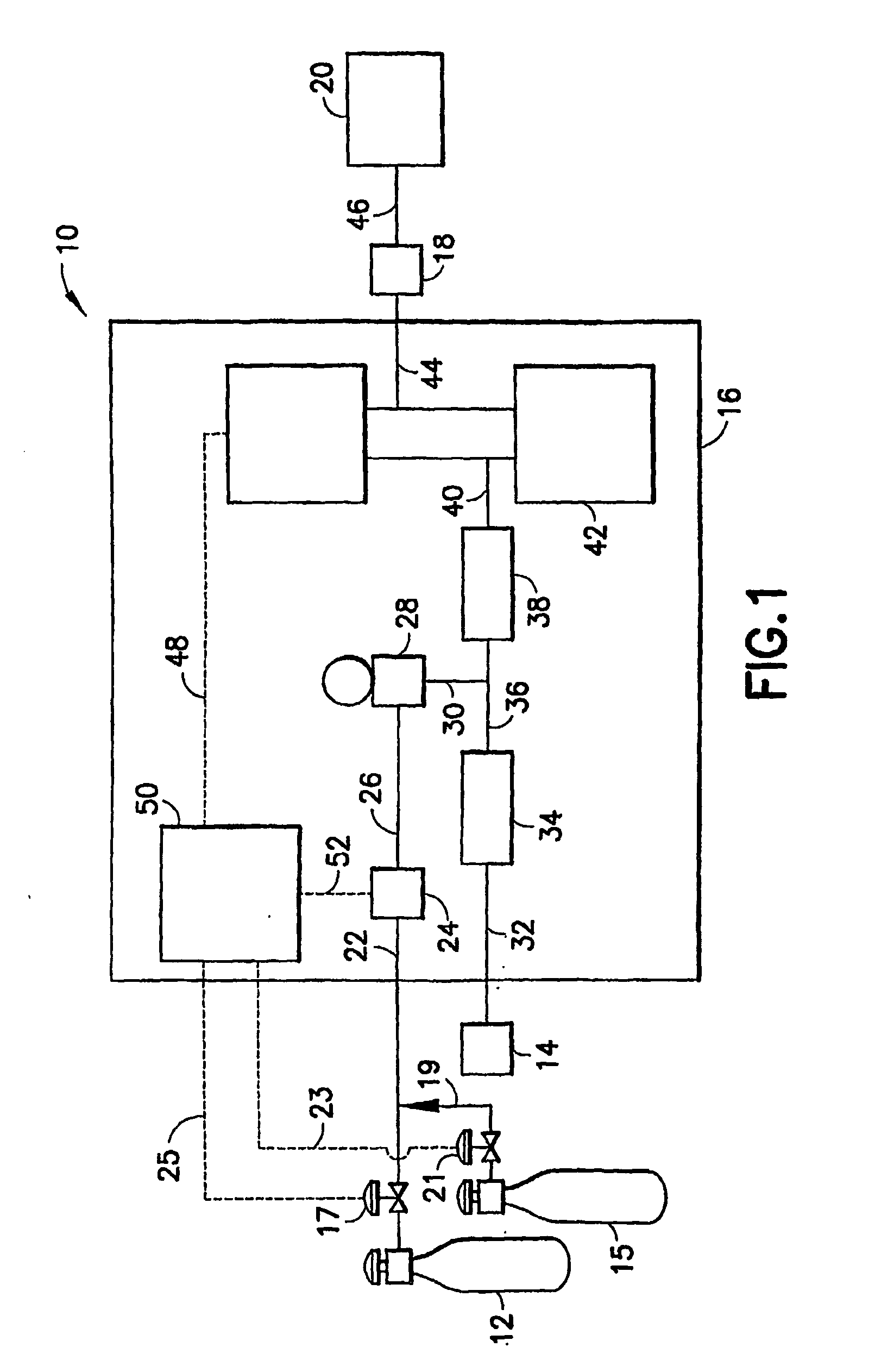

A portable hydrogen refueling stations which can dispense gaseous hydrogen from one or more internal high pressure tanks. The refueling station can be refilled with a lower pressure hydrogen gas feed and then compressed for storage within the refueling station.

Owner:QUANTUM FUEL SYST TECH WORLDWIDE INC

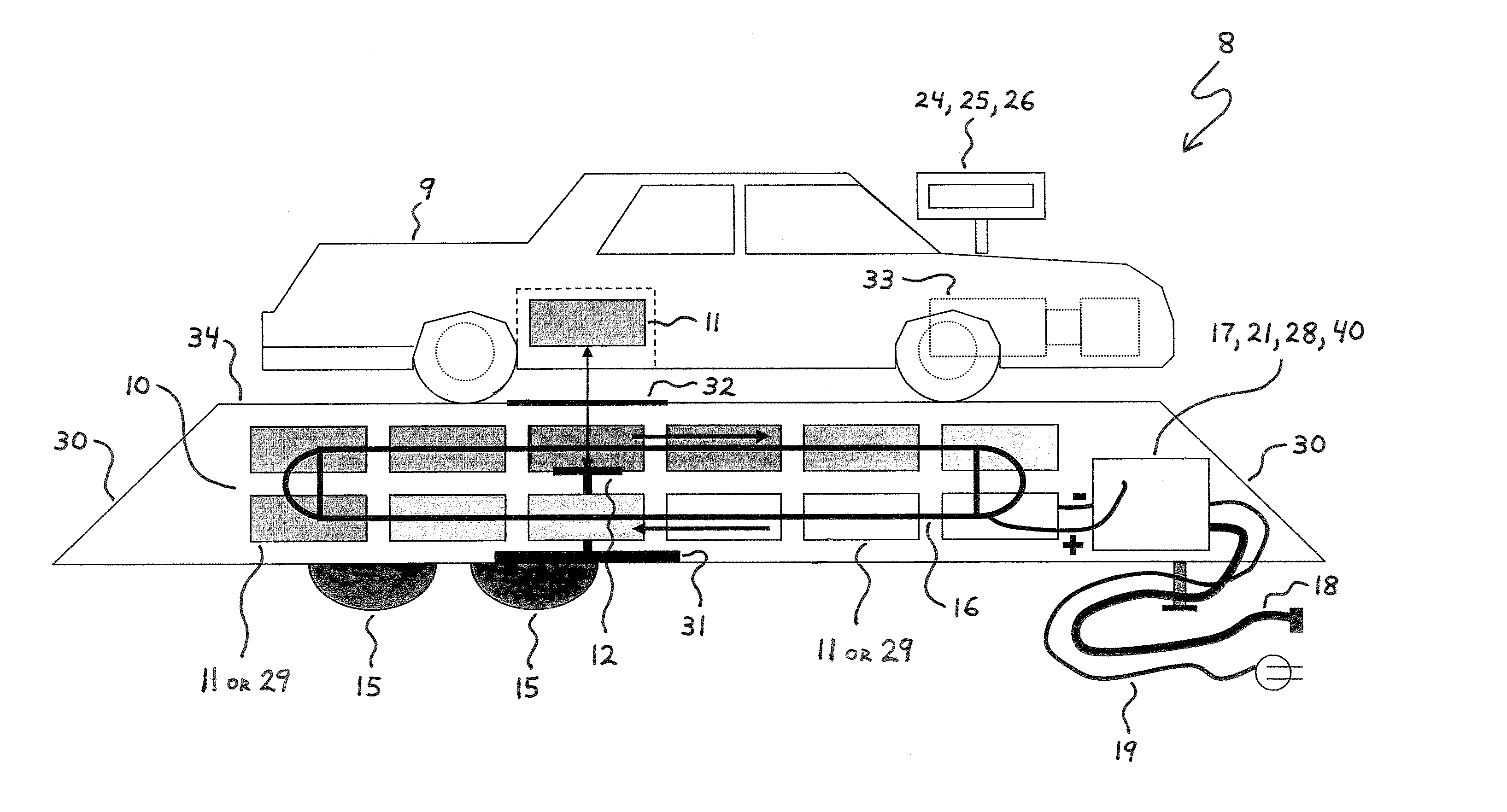

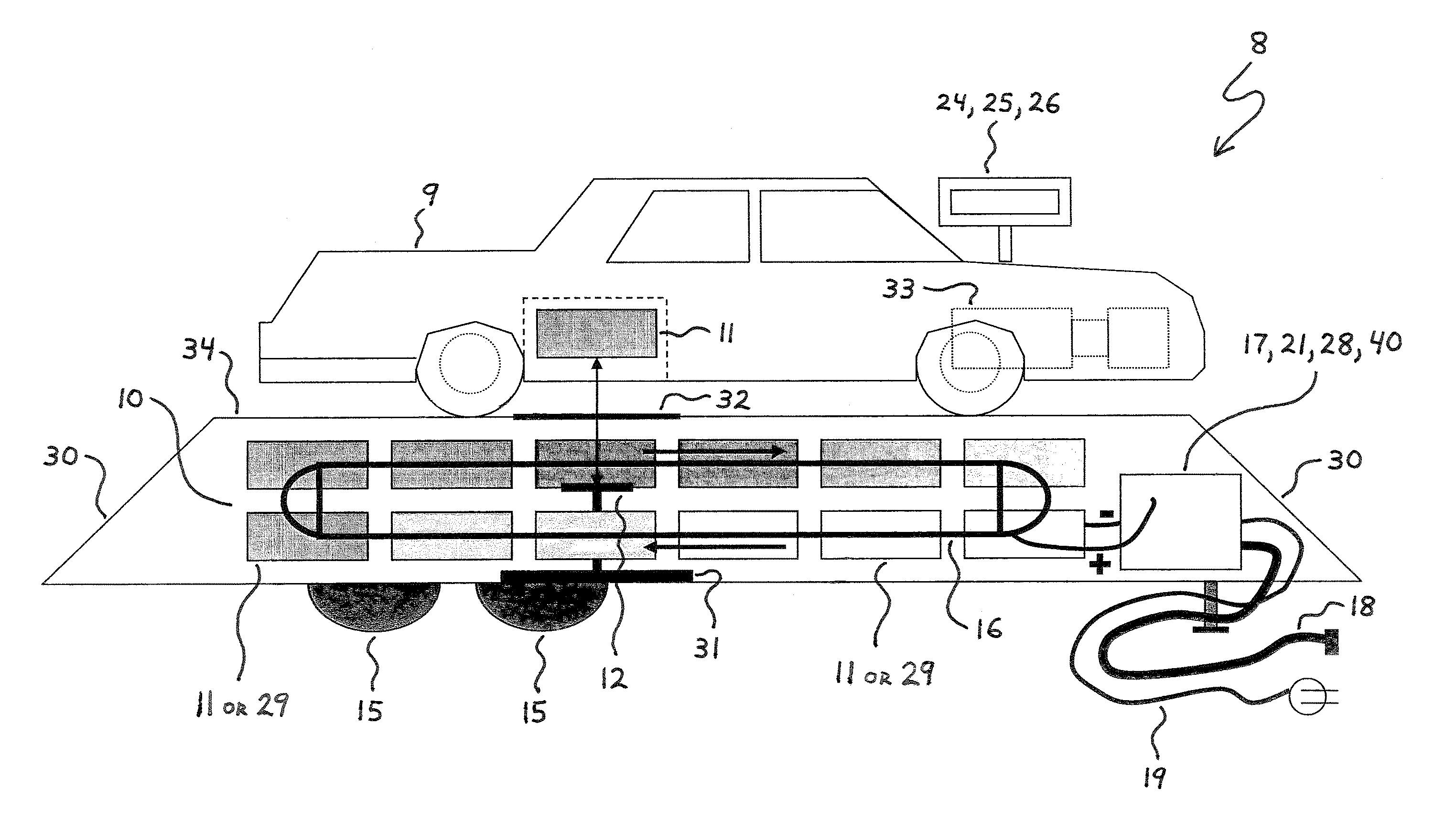

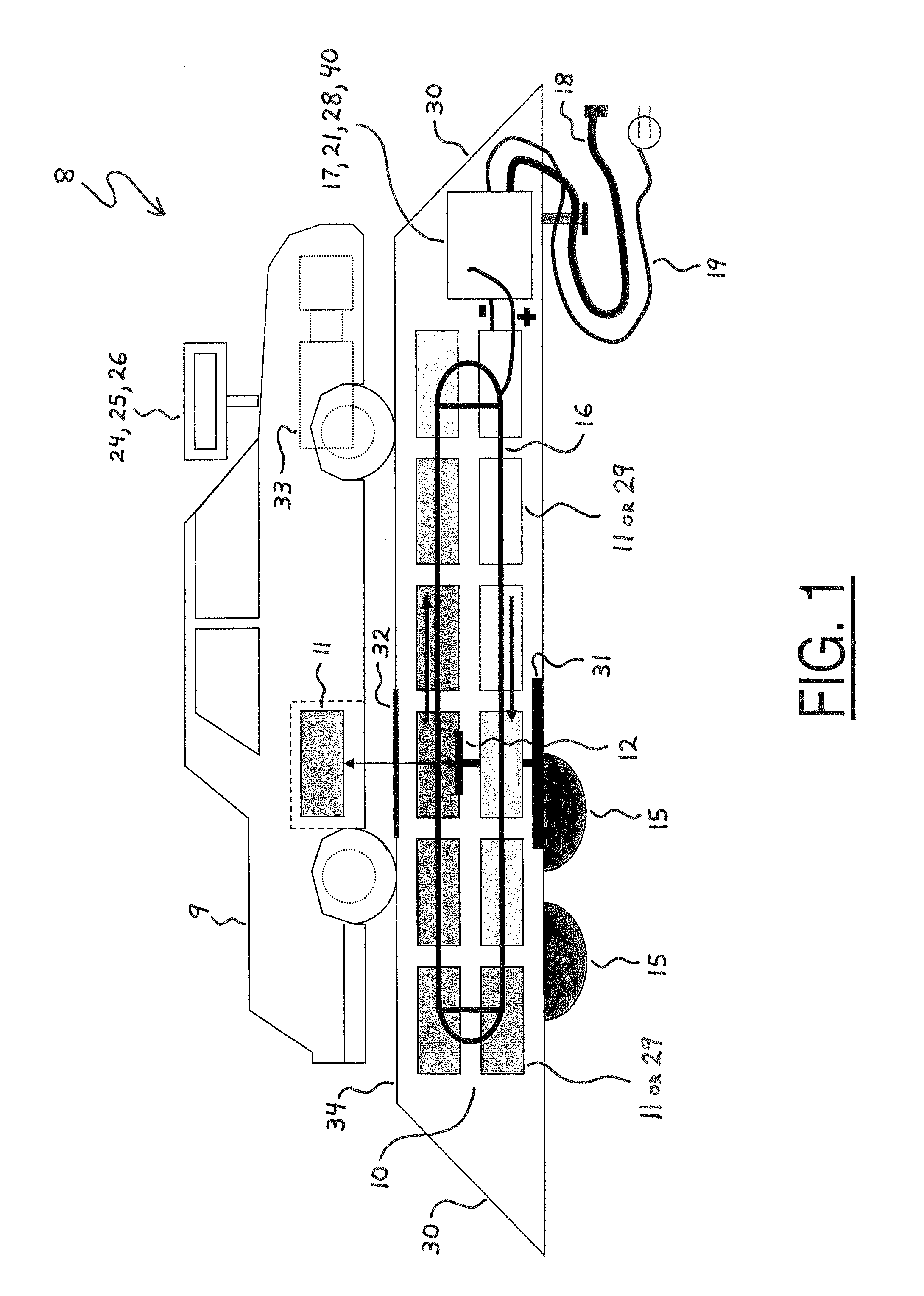

System for replenishing energy sources onboard different types of automotive vehicles

A service station facility for replenishing various motivational energy sources onboard different types of automotive vehicles is disclosed herein. In one embodiment, the service station facility includes a rack, replaceable fuel tanks, a service module, and an electronic computer control system. The replaceable fuel tanks are stocked on the rack and substantially filled with various fluids, such as hydrogen, which are utile as motivational energy sources within fuel-operated automotive vehicles. The service module is mounted on the rack, and the electronic computer control system is connected in electrical communication with the service module. In this configuration, the service module is controllably operable to receive a depleted replaceable fuel tank from a fuel-operated automotive vehicle and also selectively deliver one of the filled replaceable fuel tanks onboard the automotive vehicle. In another embodiment, the service station facility may also stock replaceable batteries for selective delivery onboard battery-operated automotive vehicles.

Owner:CAPIZZO PETER DAVID

System for replenishing energy sources onboard different types of automotive vehicles

Owner:CAPIZZO PETER DAVID

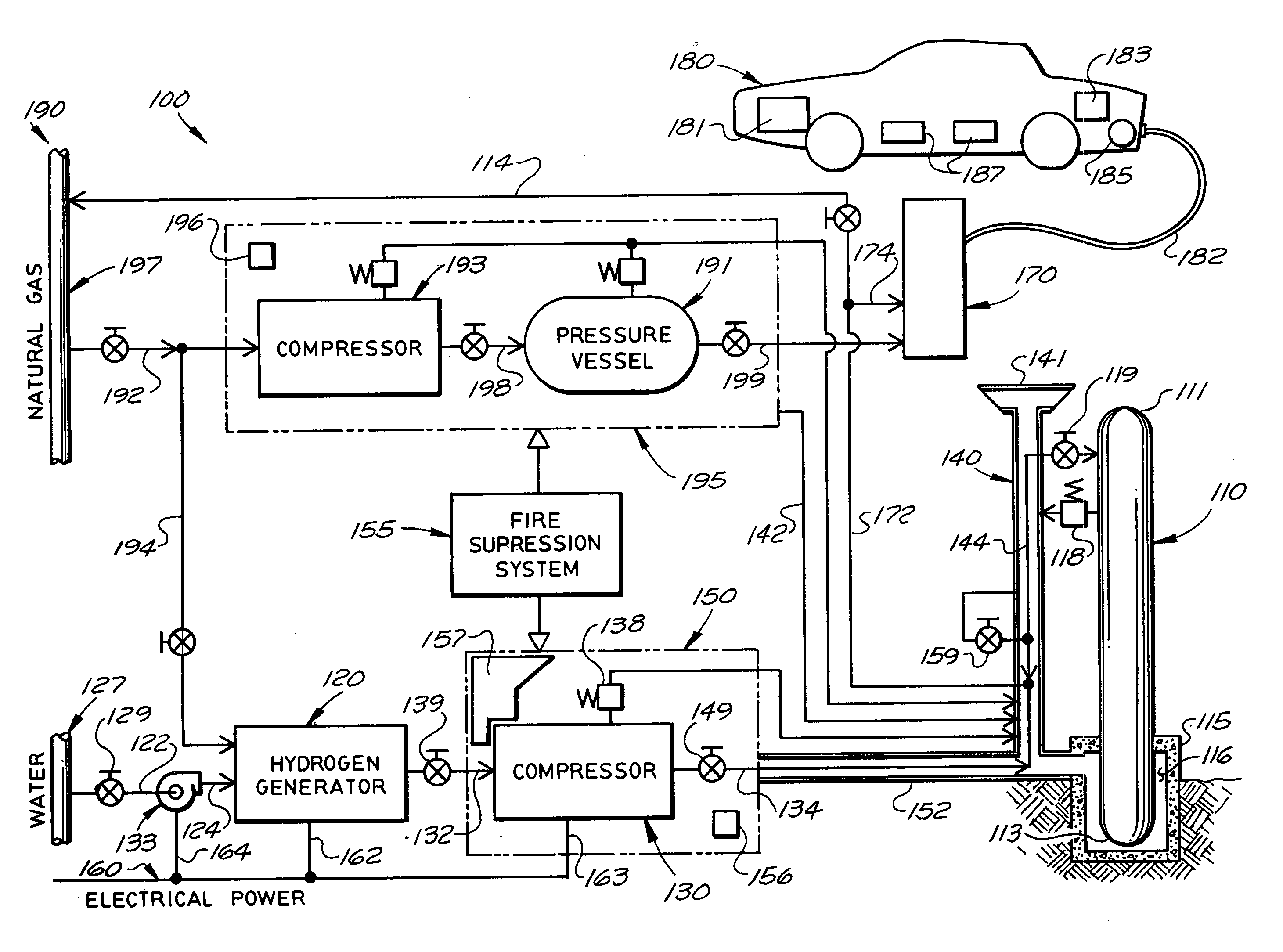

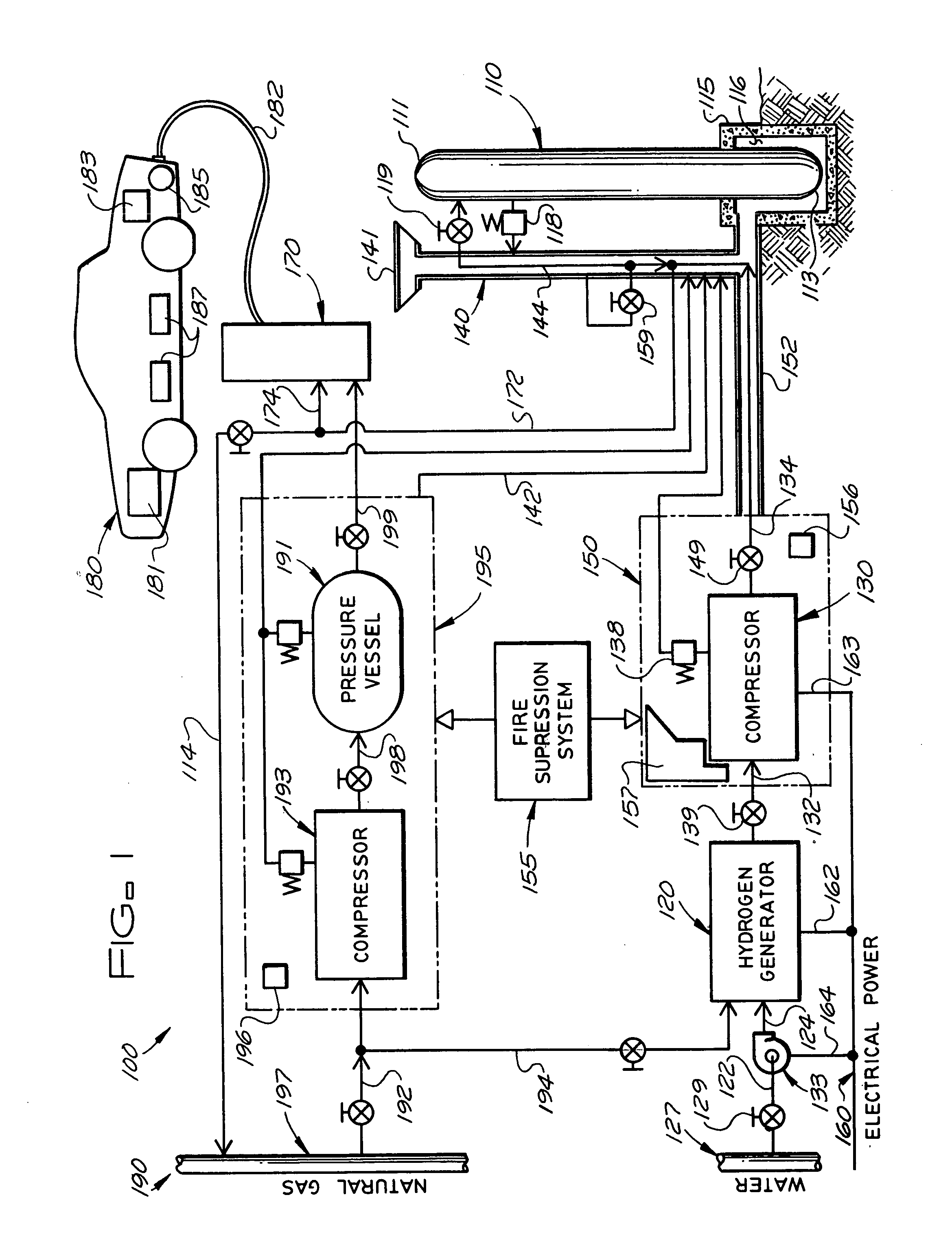

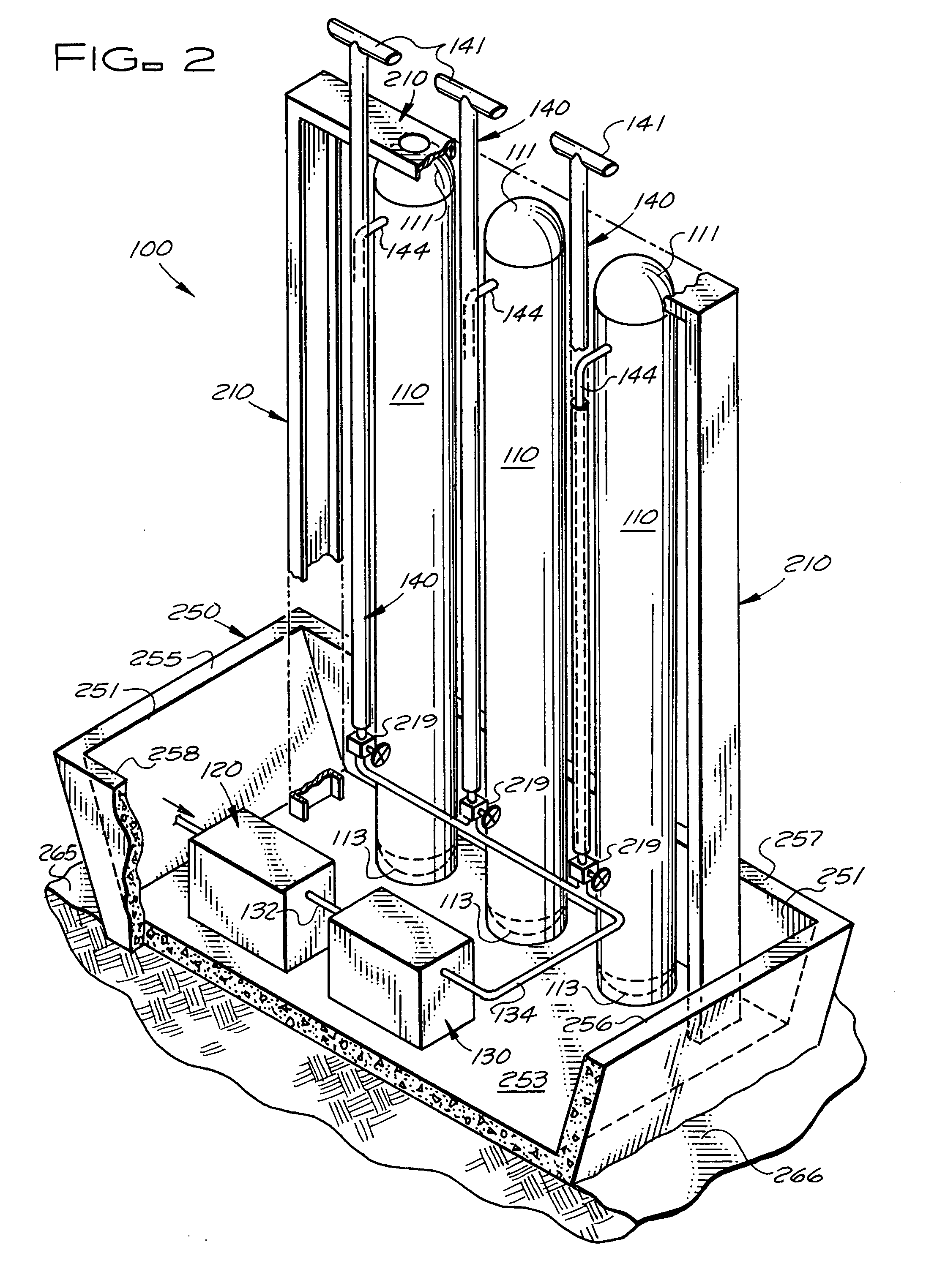

Hydrogen handling or dispensing system

InactiveUS20050000802A1Avoid burnsCheap manufacturingLiquid fillingGas handling applicationsHydrogenHuman life

Systems for handling and / or dispensing hydrogen or a mixture of fuels containing hydrogen gas including refueling stations for hydrogen-powered vehicles. Pure hydrogen or various mixtures ratios of hydrogen and CNG may be dispensed. Hydrogen handling equipment may include a hydrogen generator, a pressurizing apparatus or compressor, pressure vessels, piping, valves, vent pipes, and / or a dispenser. Substantially vertical orientation of pressure vessels may reduce the amount of land required and facilitate installation in urban environments. Pressurization may take place before hydrogen generation to reduce the power required for pressurization. Safety features include enclosures and surrounding walls that lean away from the equipment. Any leaking hydrogen, fires, or explosions may be contained and / or directed upward, protecting human life and property. Systems may be shop assembled and certified.

Owner:ARIZONA PUBLIC SERVICE

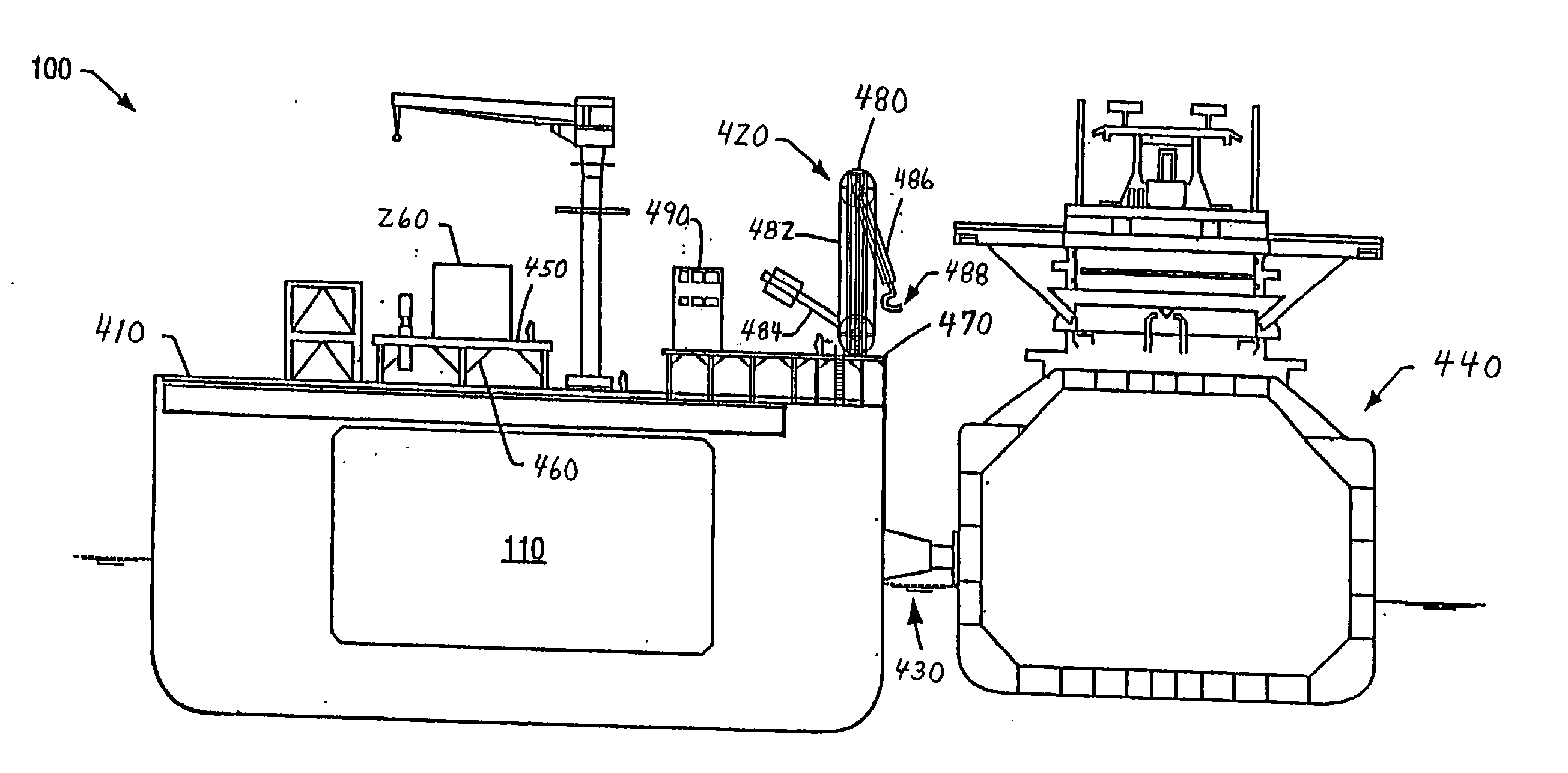

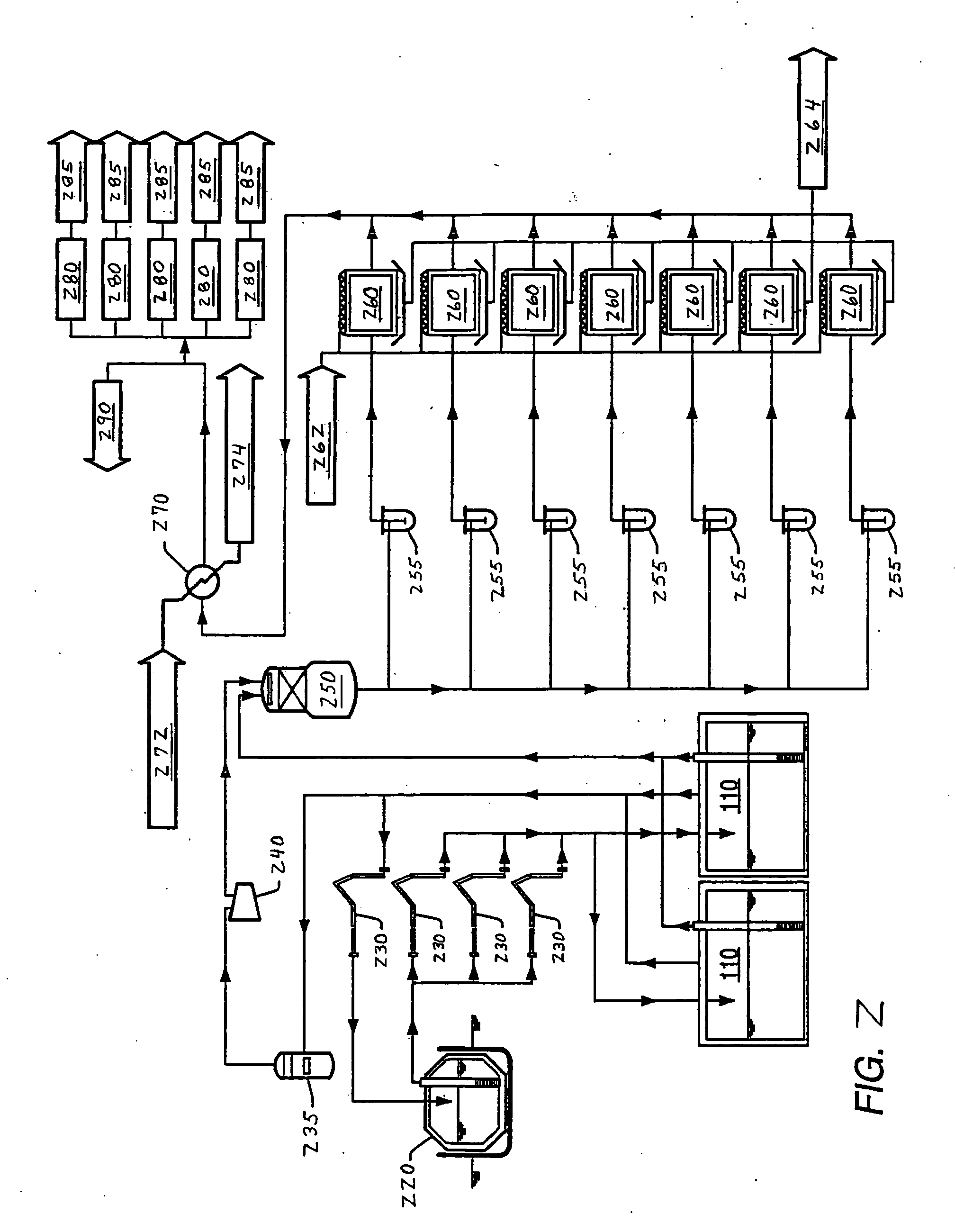

Liquefied natural gas floating storage regasification unit

InactiveUS20060156744A1Reduce the amount requiredProvide protectionGas handling applicationsGas handling/storage effectsMooring systemMarine engineering

An offshore liquefied natural gas floating storage regasification unit that may receive, store, and process liquefied natural gas from carriers. A floating storage regasification unit may include transfer equipment to offload liquefied natural gas from a carrier, a first mooring system to provide for mooring of a floating storage regasification unit at a location in a body of water, a second mooring system to provide for mooring a carrier to the floating storage regasification unit, and combinations thereof. A portion of the floating storage regasification unit may be composed of a double-hull containment structure.

Owner:SHELL OIL CO

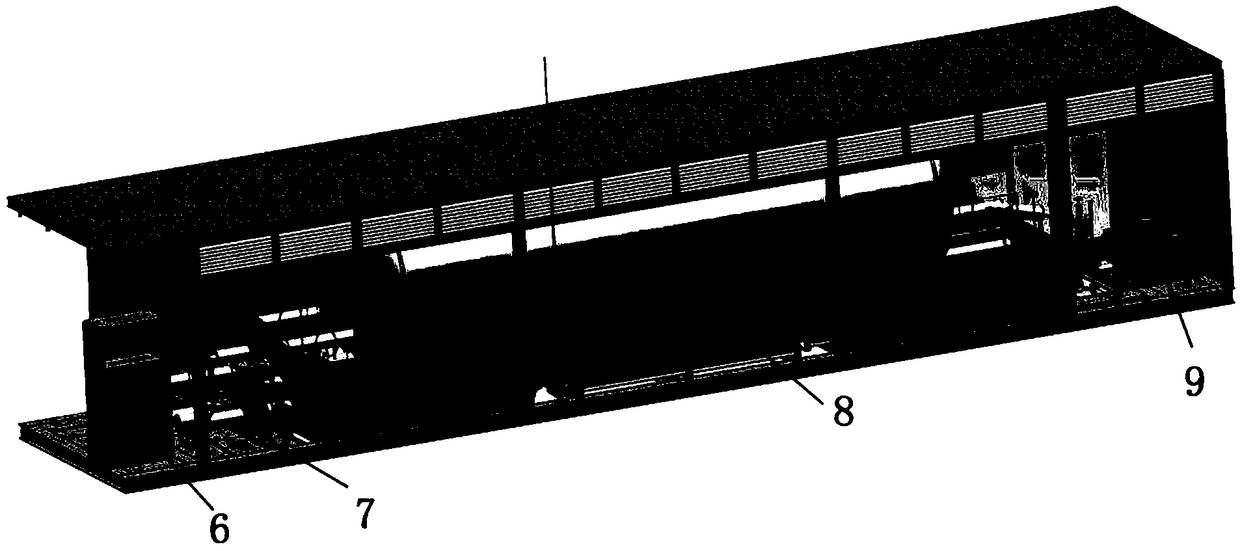

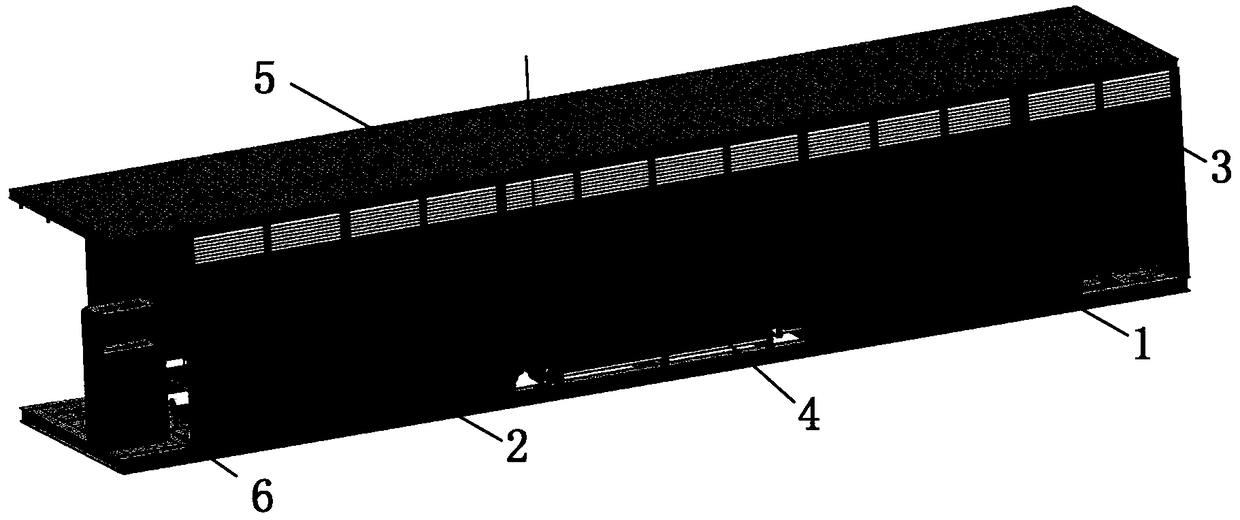

LNG/L-CNG skid-mounted gas station

PendingCN109027662AFunction increaseShort construction periodVessel mounting detailsVessel geometry/arrangement/sizeEngineeringIndustry standard

The invention discloses a LNG / L-CNG skid-mounted gas station. The LNG / L-CNG skid-mounted gas station comprises a first sled base, a second sled base, a LNG pump sled, a low-temperature storage tank, aL-CNG pump sled and a gas filling machine; the L-CNG pump sled is arranged on the first sled base; the low-temperature storage tank, the L-CNG pump sled and the gas filling machine are integrated onthe second sled base in sequence; an unloading table is additionally arranged at the end, near the gas filling machine, of the second sled base; the end, near the low-temperature storage tank, of thesecond sled base is movably connected with the first sled base; the low-temperature storage tank discharges liquid by the head and tail ends; fences are arranged on two sides of the first sled base and the second sled base; the first sled base is connected with the end, near the low-temperature storage tank, of the second sled base; top cover plates are arranged at the tops of the fences; and thehorizontal plane of the top cover plates is higher than the horizontal plane of the top of the low-temperature storage tank. The LNG / L-CNG skid-mounted gas station has the following beneficial effects: through high integration degree, the country and industry standards are met, and the functions of an integrated gas station are expanded; and through the mode of discharging the liquid by the head and tail ends of the low-temperature storage tank, the generation of BOG is greatly reduced, and the liquid outlet speed is accelerated.

Owner:JEREH OIL & GAS ENG

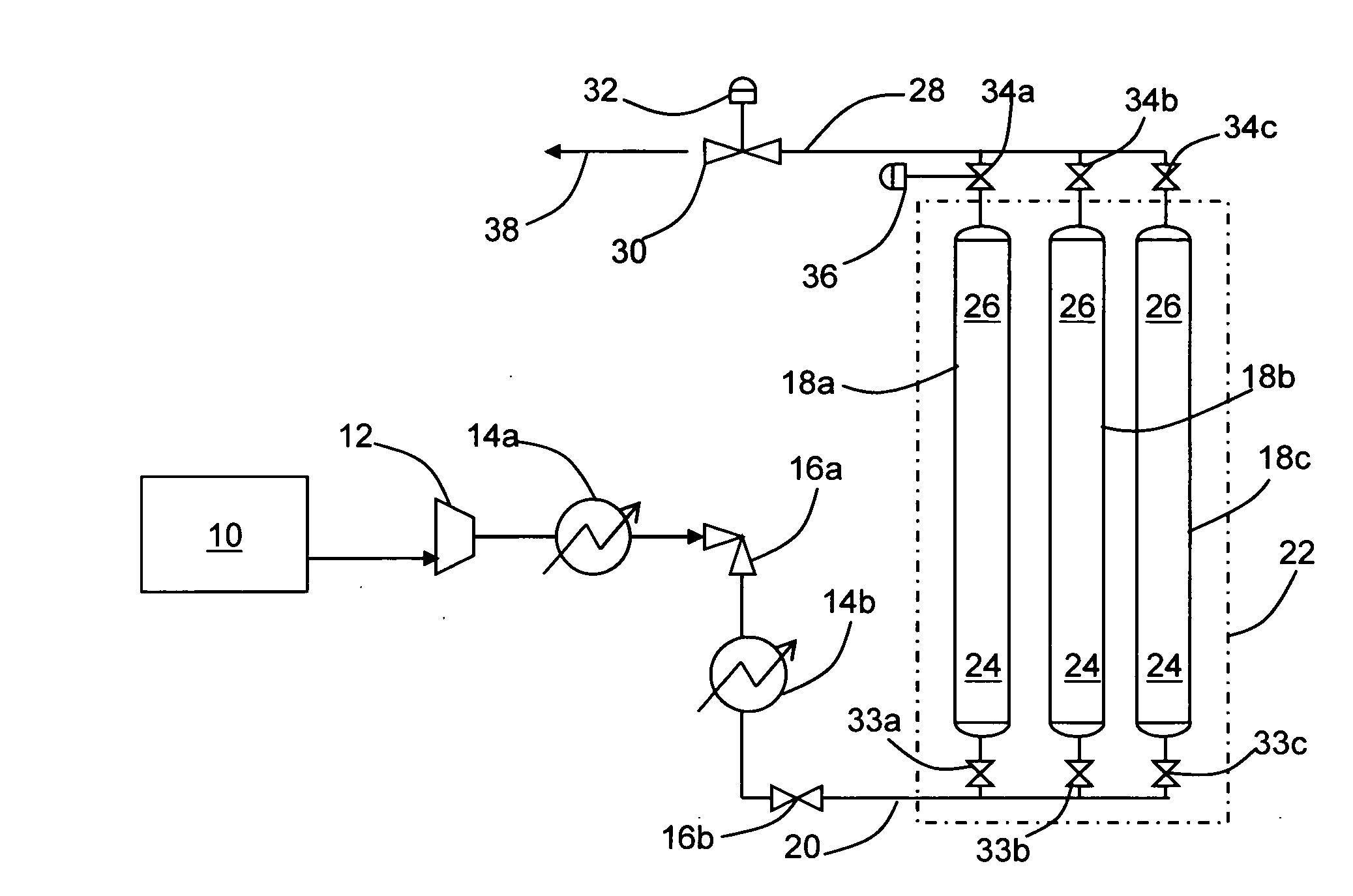

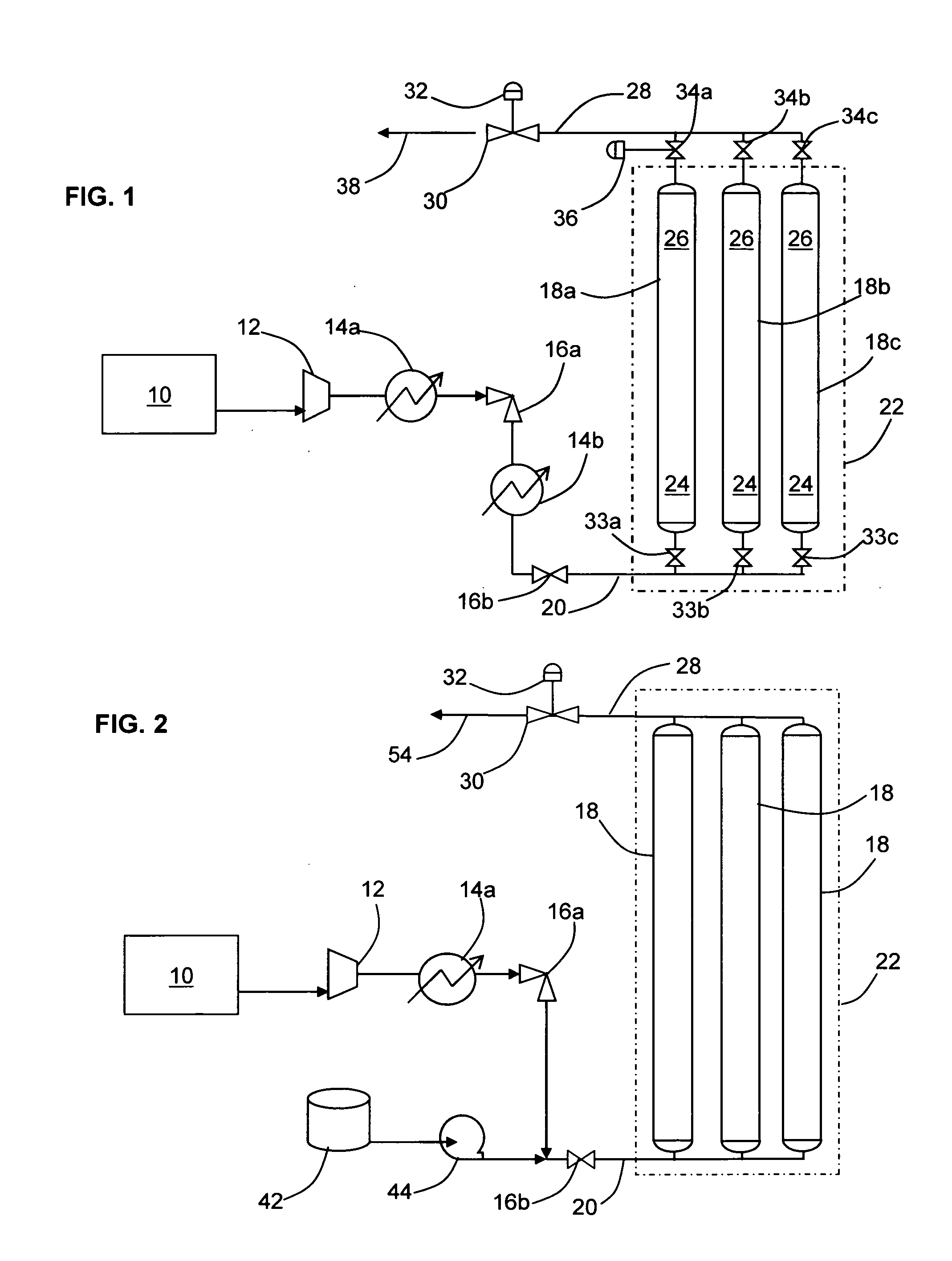

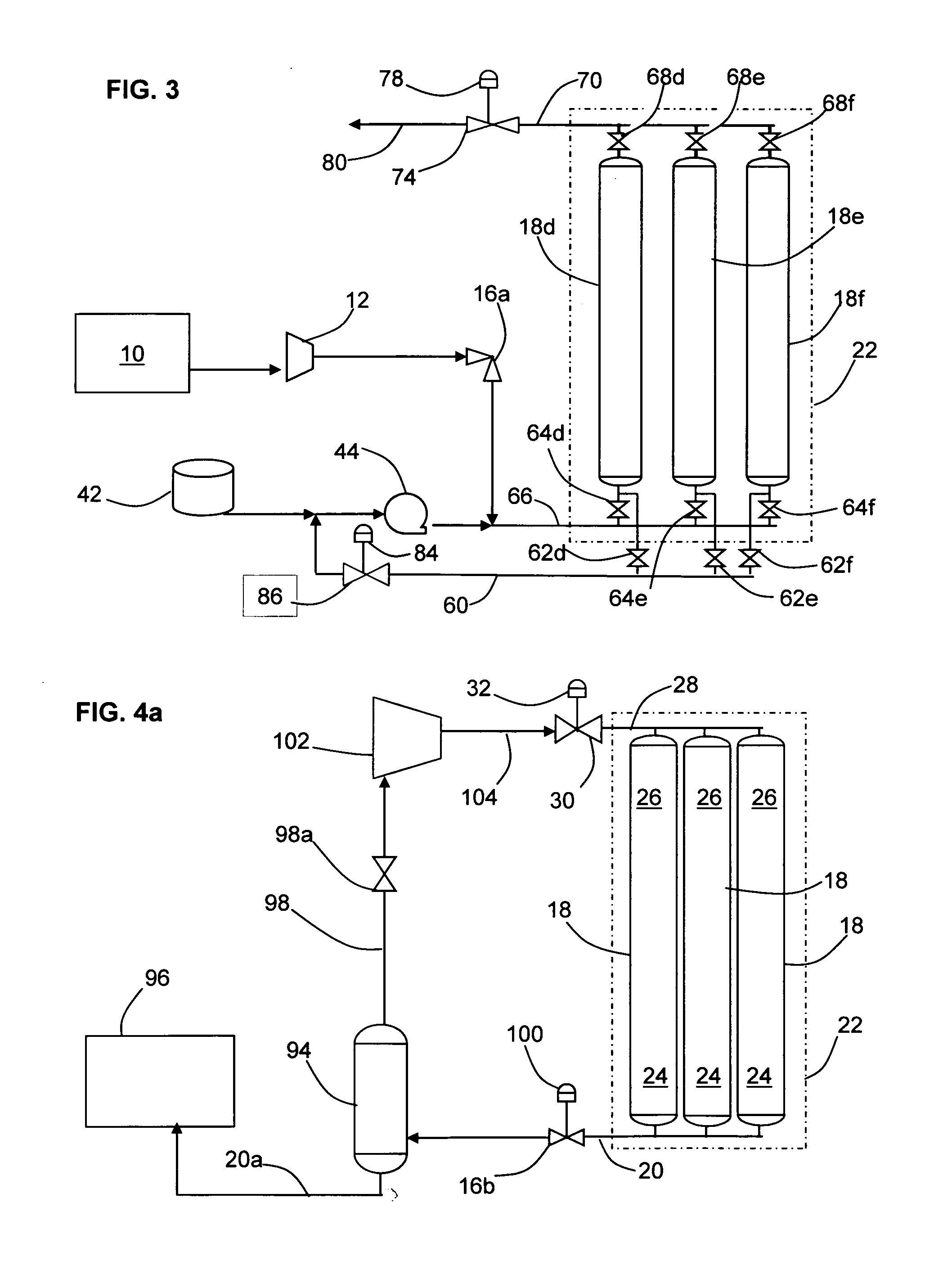

Apparatus and method for flowing compressed fluids into and out of containment

ActiveUS20080209916A1Adjustable temperatureGas handling applicationsGas handling/storage effectsChemical compositionCompressed fluid

Methods for loading a compressed fluid, such as natural gas, into and discharging the compressed fluid out of containment are provided. The compressed fluid is injected into a bottom portion of a container system for storage and / or transport until a target pressure is reached after which gas is withdrawn from an upper portion of the container system at a rate to maintain the target pressure while the compressed fluid is injected in the bottom portion. The compressed fluid is cooled through an expansion valve and by refrigerated chillers or by injecting a cold liquid of the same chemical composition as the compressed fluid, such as liquid natural gas, into the compressed fluid prior to injection into the container system. Withdrawal or discharge from the container system to a receiving facility begins with blow down from the bottom portion of the container system without a displacement fluid and continues until pressure falls below an acceptable differential pressure. The discharge stream is passed through a separator and a light gas from the separator is pressurized and injected into an upper portion of the container system to drive the compressed fluid out the bottom. The light gas is pressurized using either a compressor or a heated tank system, where two vessels operate in parallel, trapping and heating the light gas and then discharging to the container system from one while filling the other and alternating the operation between the two.

Owner:WHITE CHARLES N +1

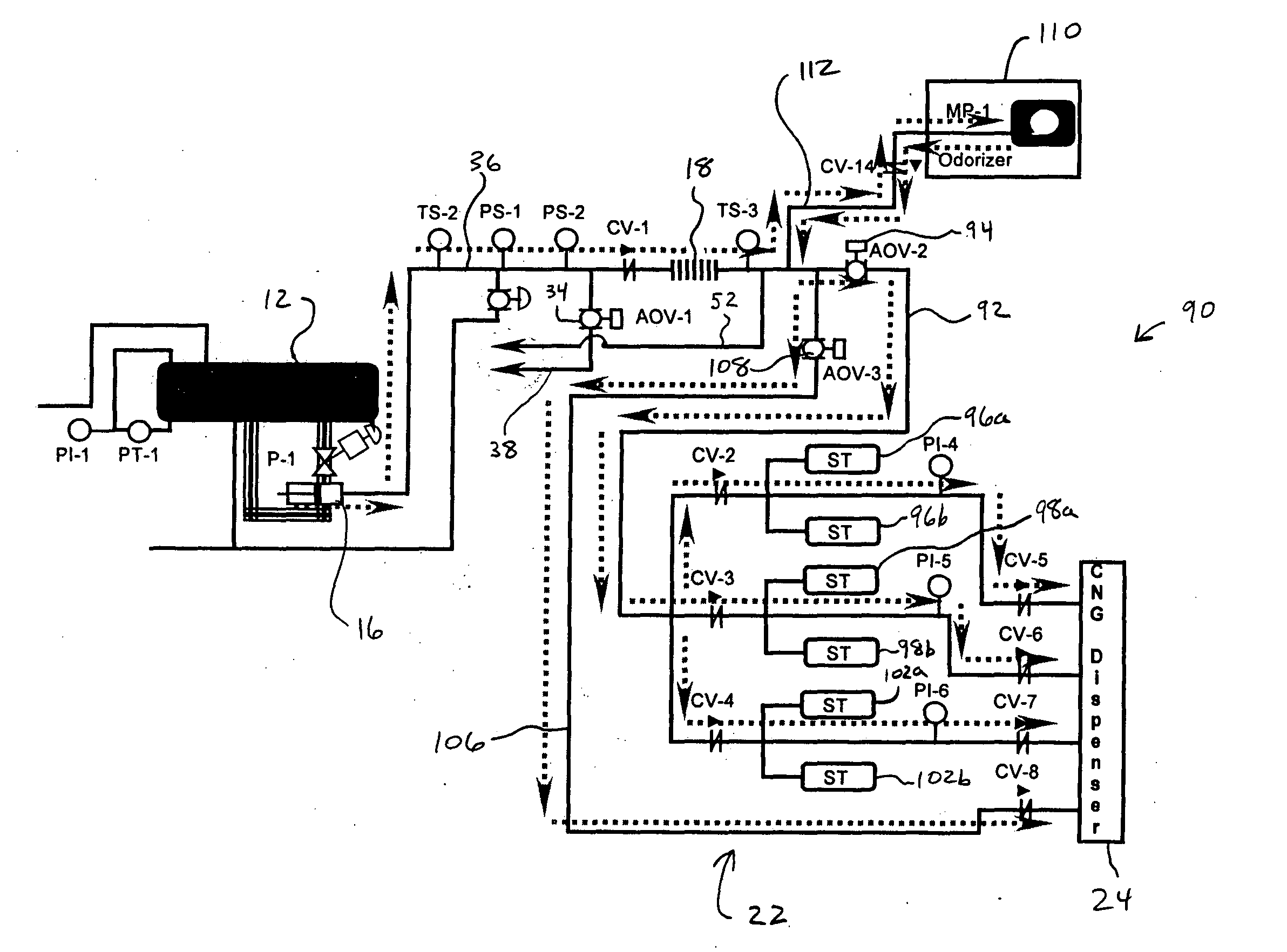

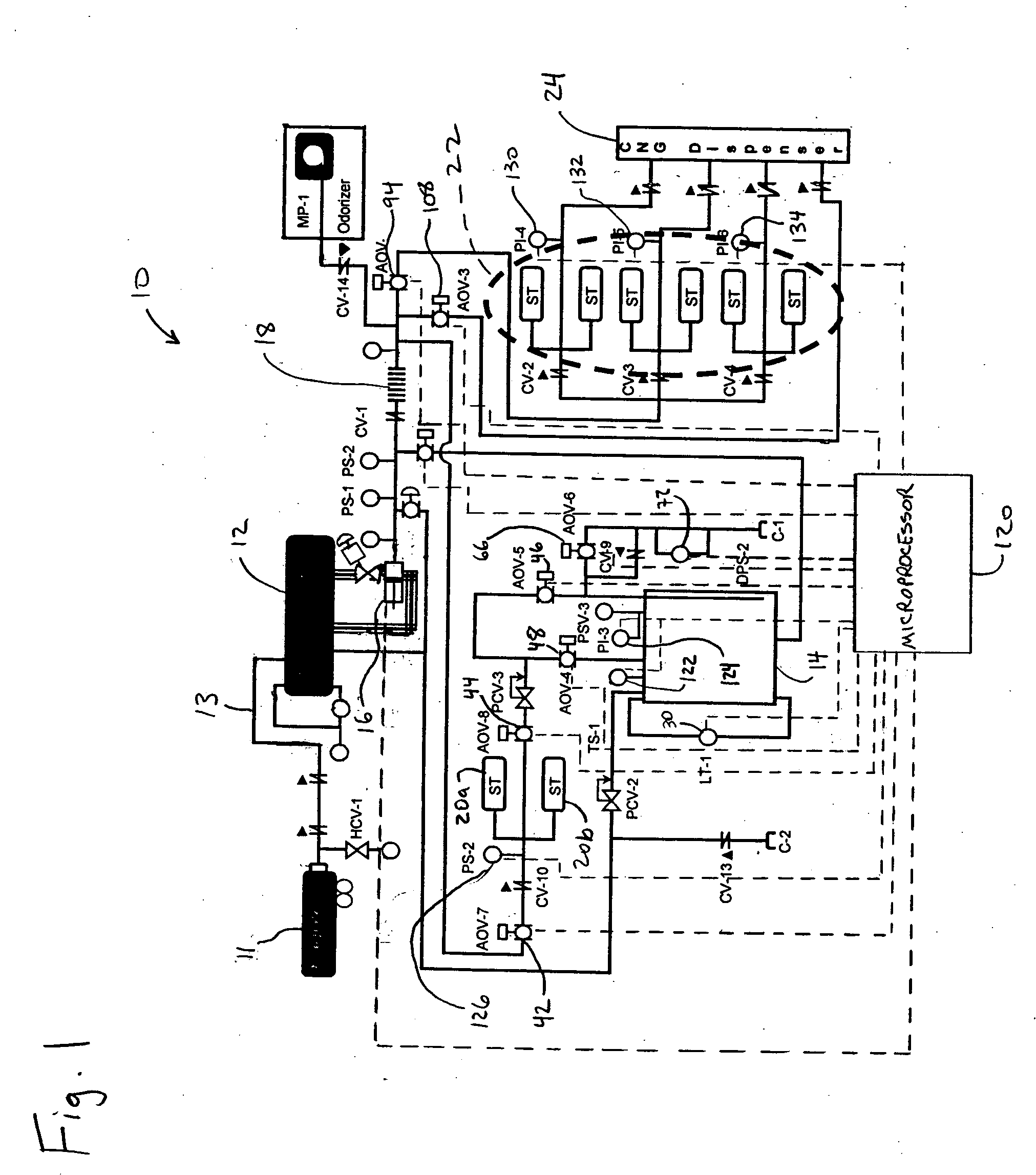

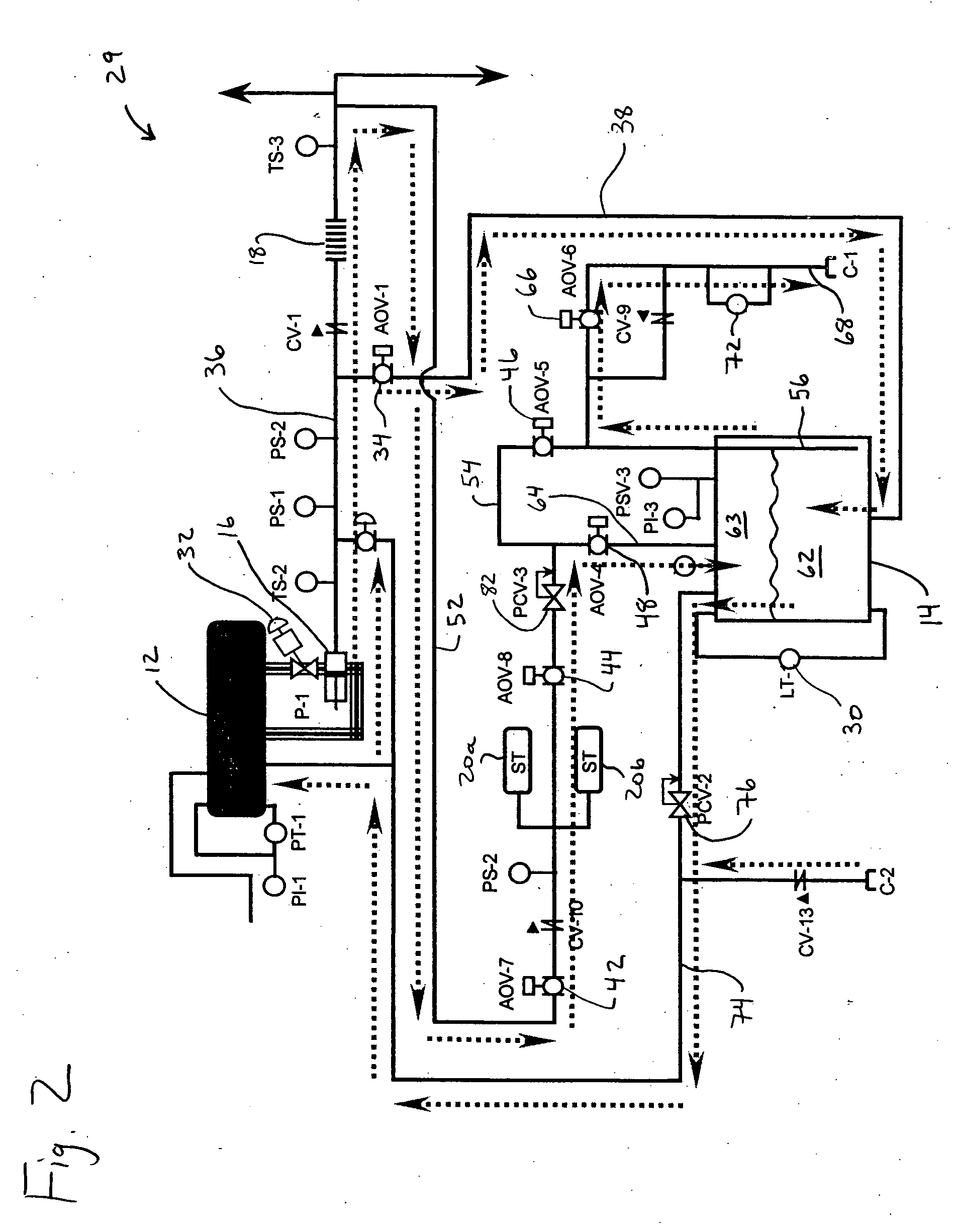

Liquid and compressed natural gas dispensing system

InactiveUS20050016185A1Distribute quicklyEliminate timeGas handling applicationsGas handling/storage effectsCompressed natural gasProcess engineering

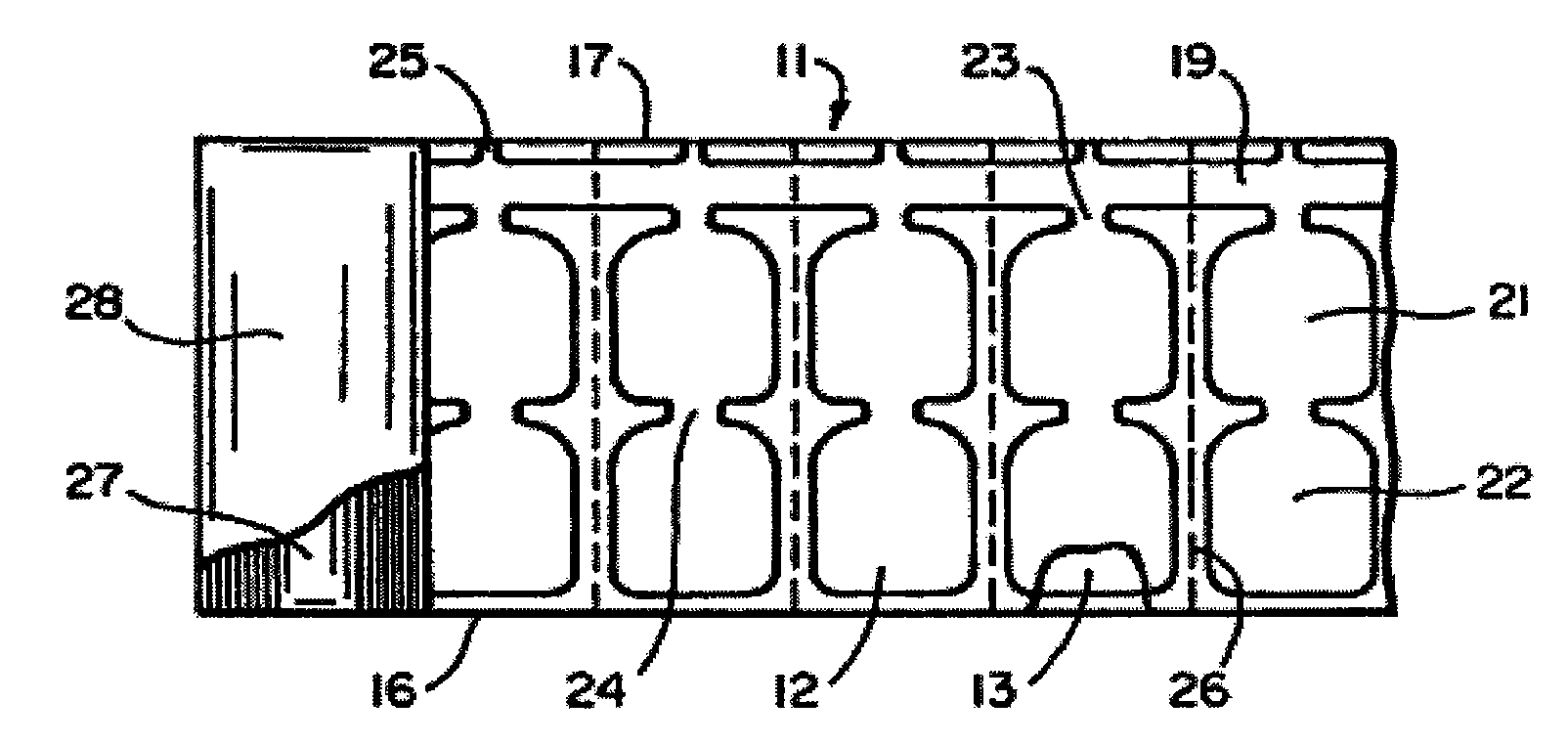

A system dispenses both liquid natural gas (LNG) and compressed natural gas (CNG). A bulk tank contains a supply of LNG which is pumped to a smaller storage tank. After the storage tank is refilled, LNG from the bulk tank is pumped to a vaporizer so that CNG is produced. The CNG may be routed to the LNG in the storage tank to condition it. It is also used to recharge a pressurizing cylinder that is placed in communication with the head space of the storage tank when it is desired to rapidly dispense LNG to a vehicle. A bank of cascaded storage cylinders alternatively may receive CNG from the vaporizer for later dispensing through the system CNG dispenser. The CNG from the vaporizer may also be dispensed directly via the system CNG dispenser.

Owner:CHART INC

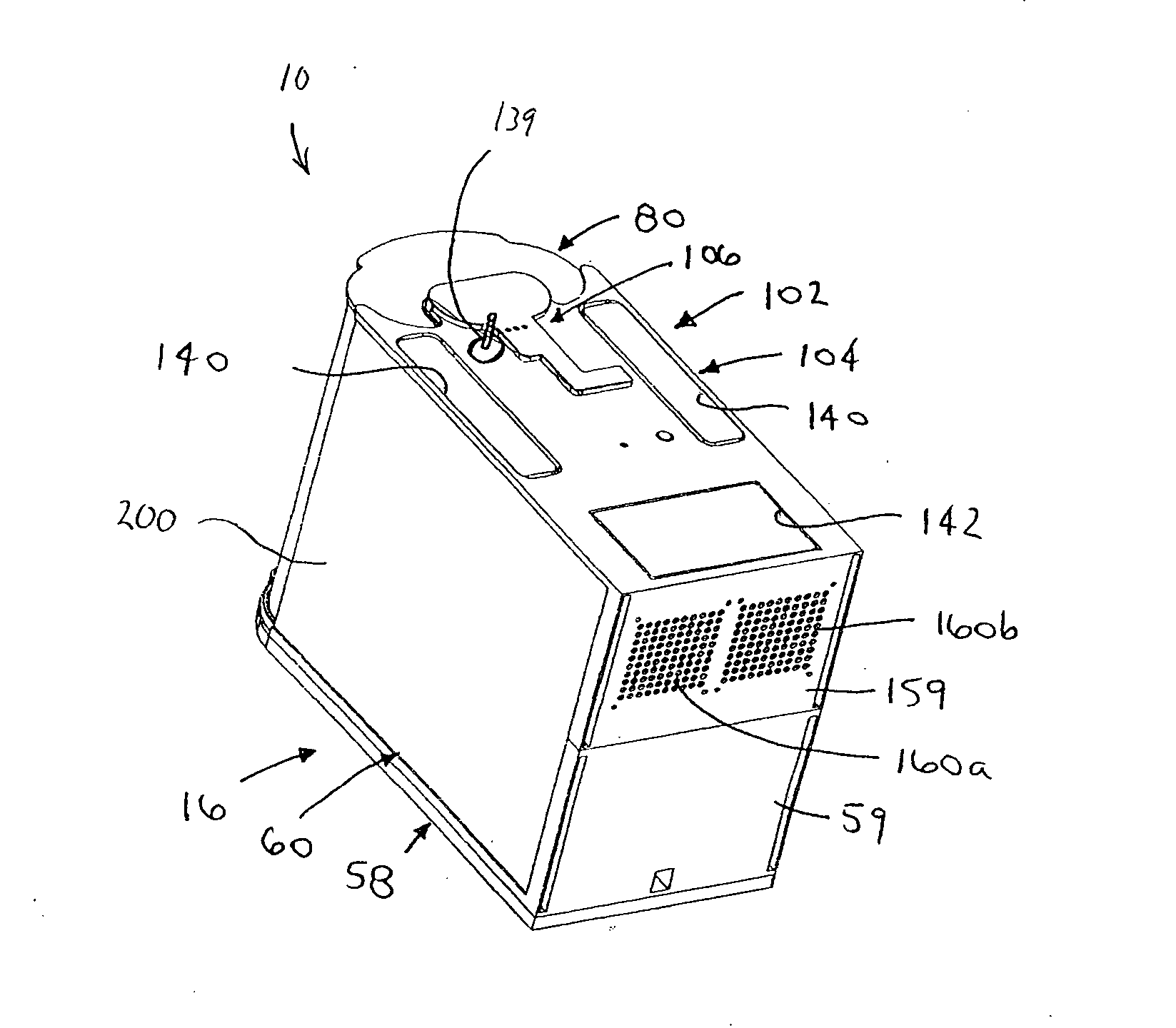

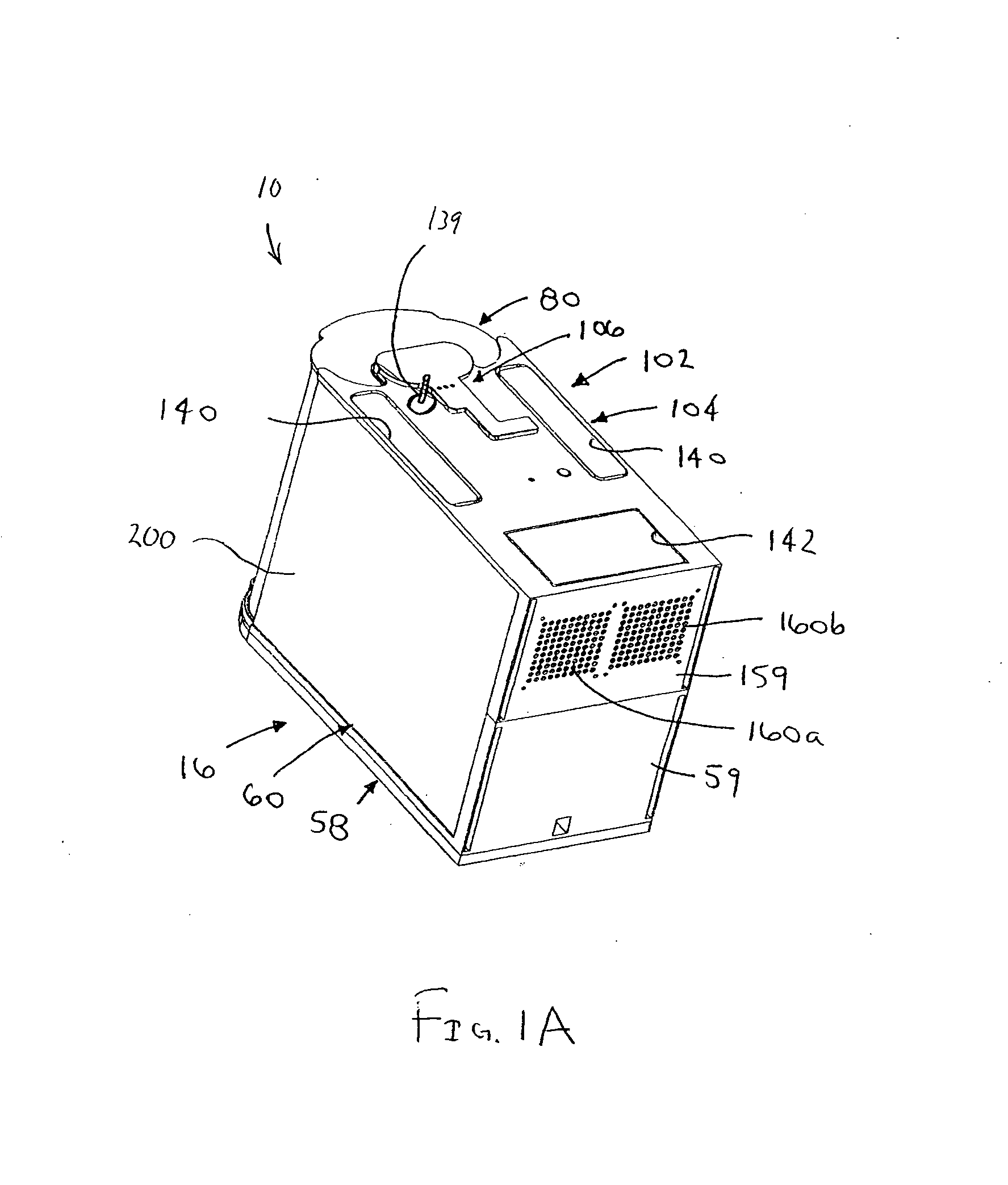

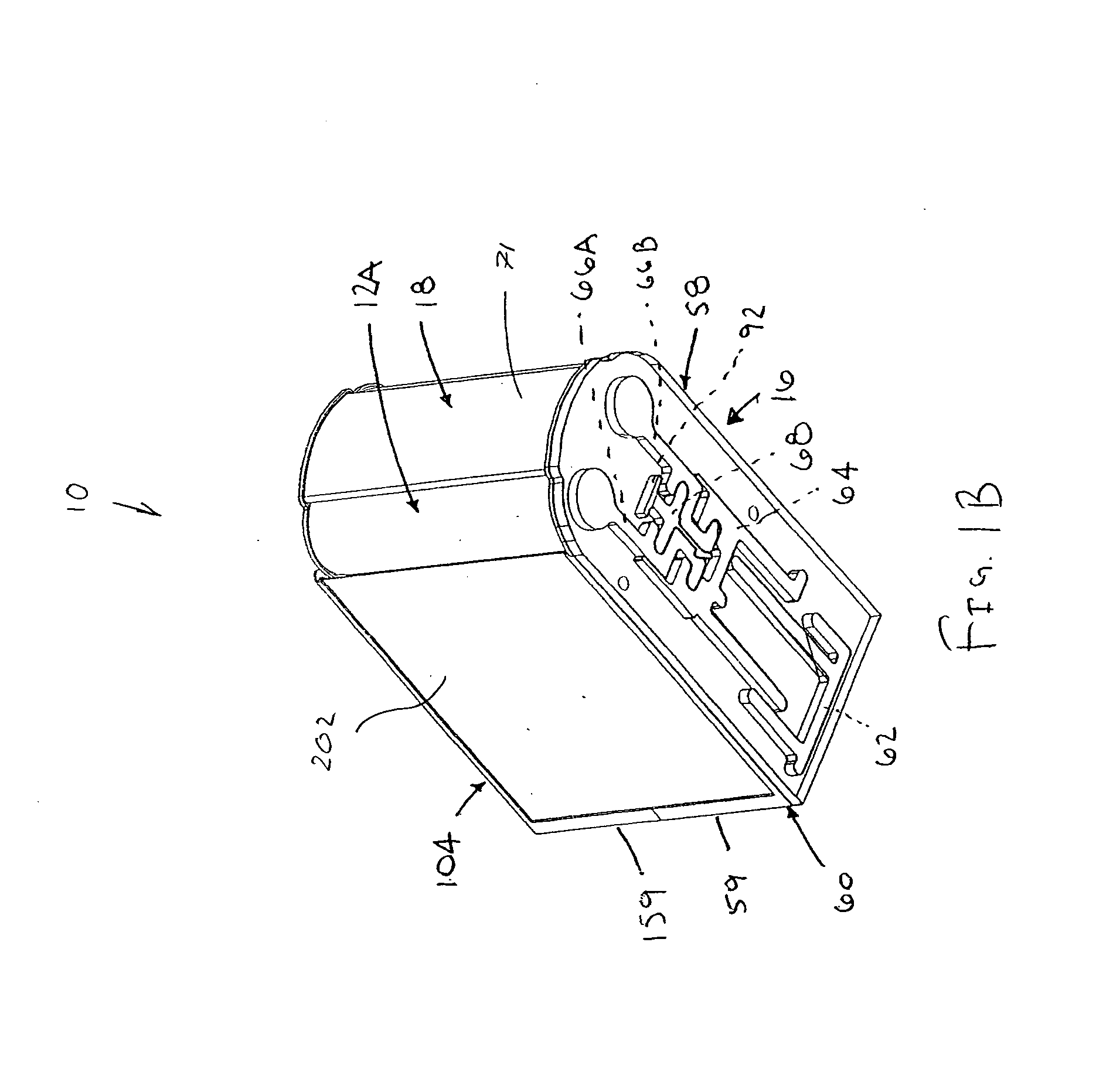

Portable oxygen concentrator

A portable oxygen concentrator includes a pressure swing absorption system defined by a relatively rigid housing adapted to generate a flow of oxygen enriched gas and a battery adapted to provide power to the pressure swing absorption system. The oxygen concentrator has a total weight of less than about 10 lbs, has a maximum flow of 100% O2 equivalent gas of about 0.9 lpm, has a total volume less than about 800 in3, and gas a battery life of at least about 8 hours. The present invention also using a liquefaction or transfill system in combination with such an oxygen concentrator.

Owner:PHILIPS RS NORTH AMERICA LLC

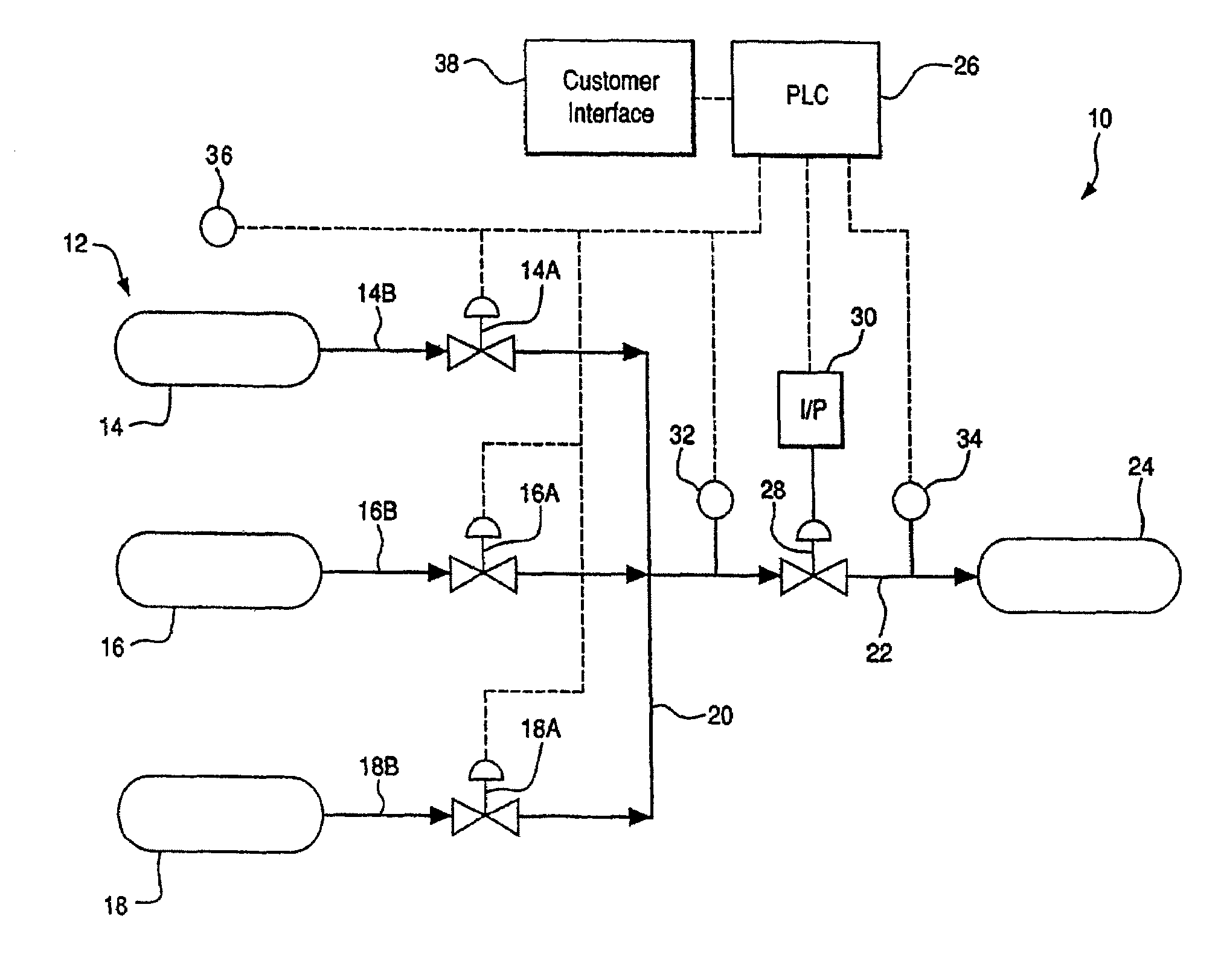

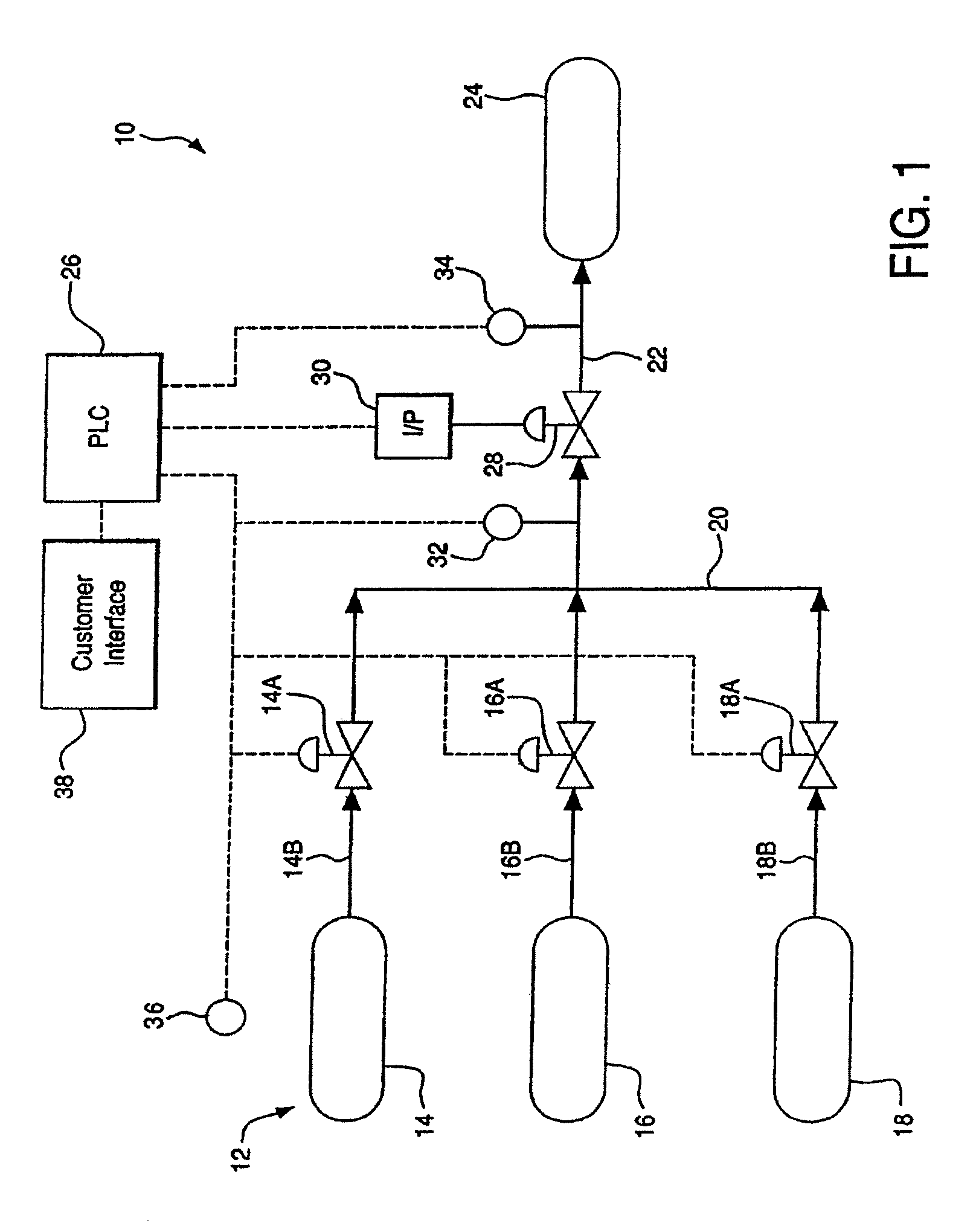

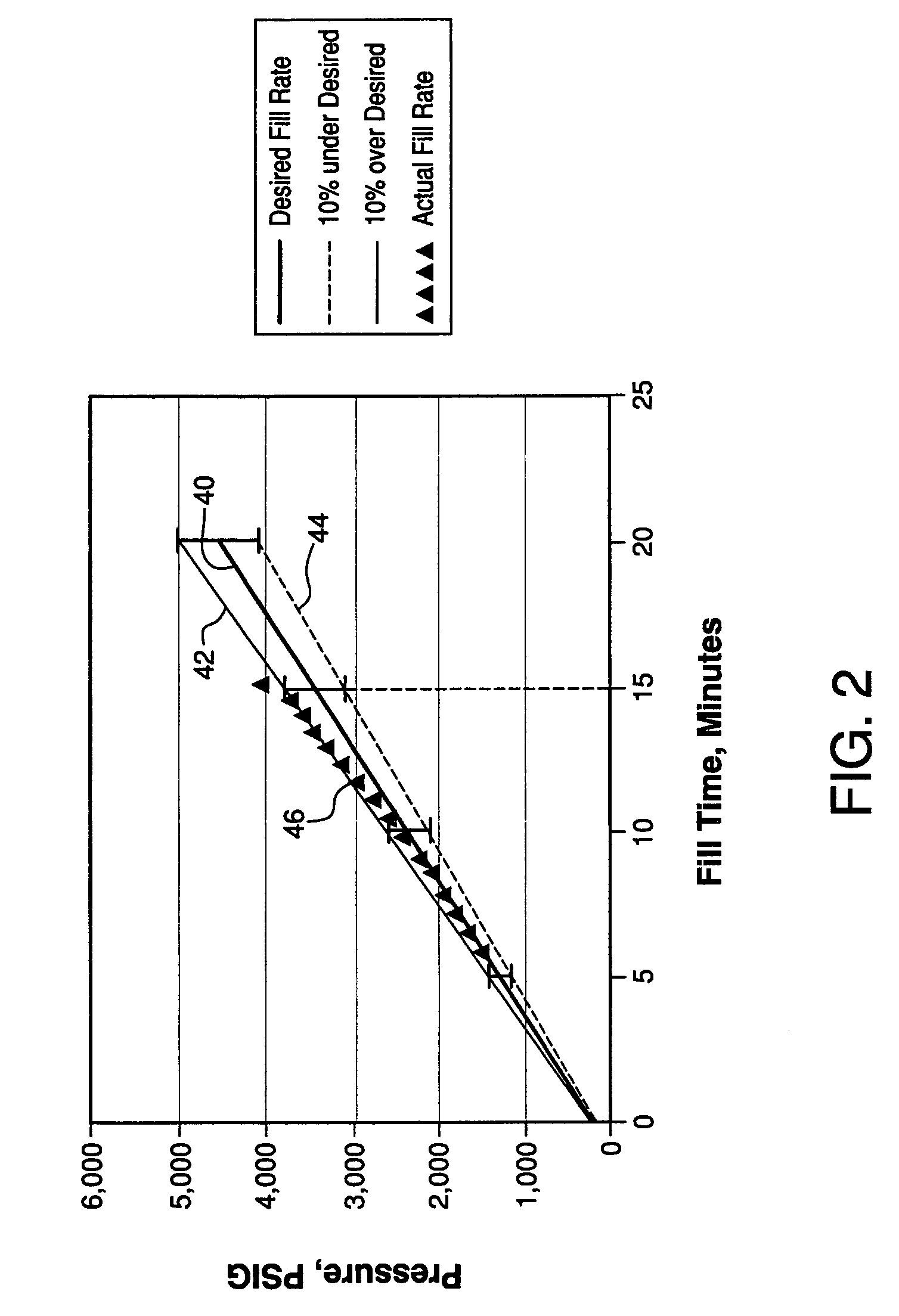

Diagnostic method and apparatus for a pressurized gas supply system

ActiveUS7568507B2Prevent excessive pressure risePreventing a potentially dangerous overheating problemLiquid fillingGas handling applicationsLine tubingEngineering

A diagnostic method for a gas supply system includes: determining a desired ramp rate for filling a vessel from a supply of compressed gas; monitoring the actual pressure of gas entering the vessel; and discontinuing the flow of gas into the vessel when the actual pressure deviates from the intended pressure at the desired ramp rate by an undesired amount. A system for carrying out the method includes a flow controller for controlling operation of the supply system to deliver compressed gas from a source to a vessel through a supply line at a desired ramp rate. The system employs a pressure monitor downstream of a control valve for measuring the pressure of gas directed into the vessel and transmitting pressure-related data to the flow controller, which closes the control valve to discontinue filling of the vessel if the actual pressure exceeds a permissible deviation from the intended pressure.

Owner:AIR PROD & CHEM INC

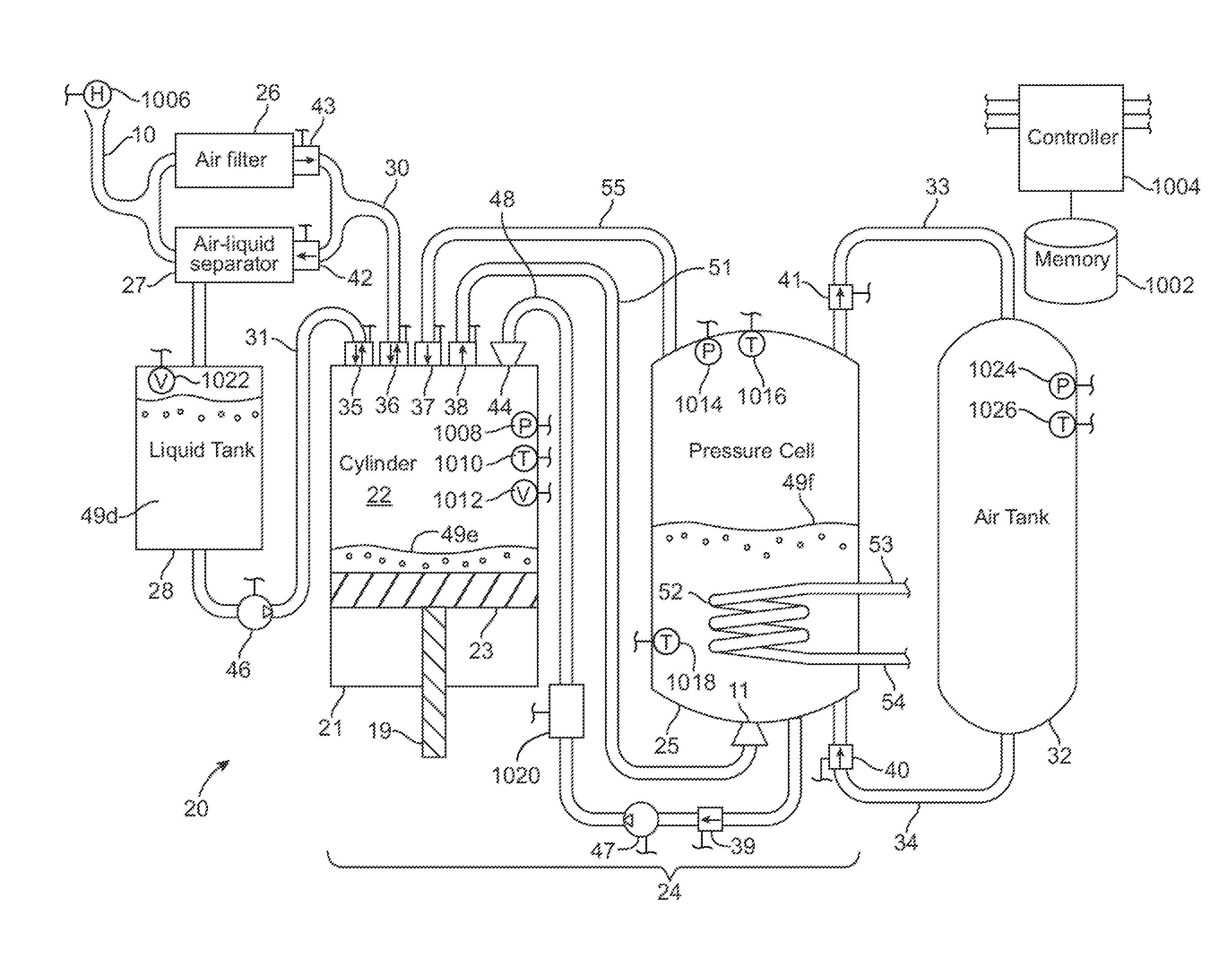

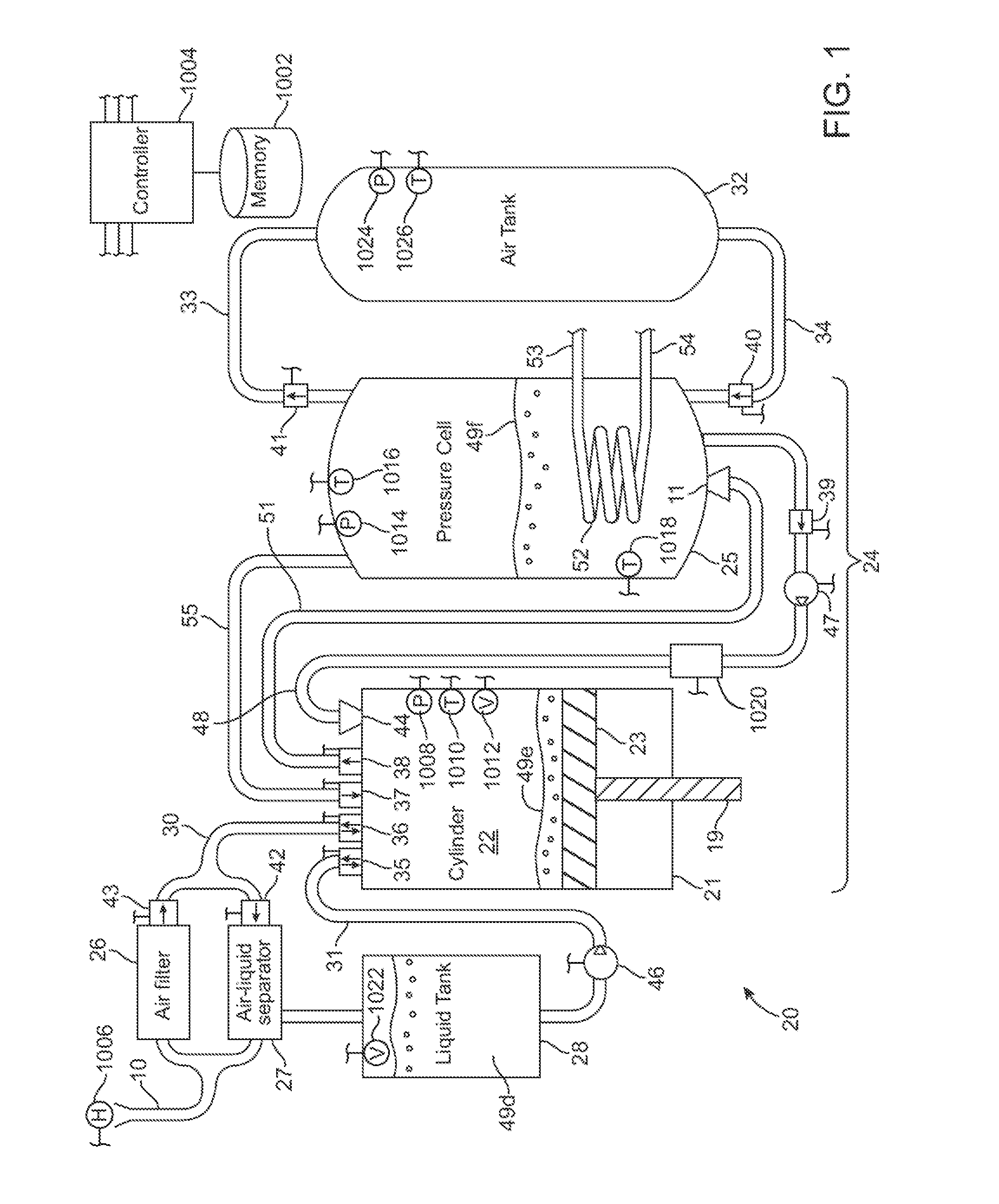

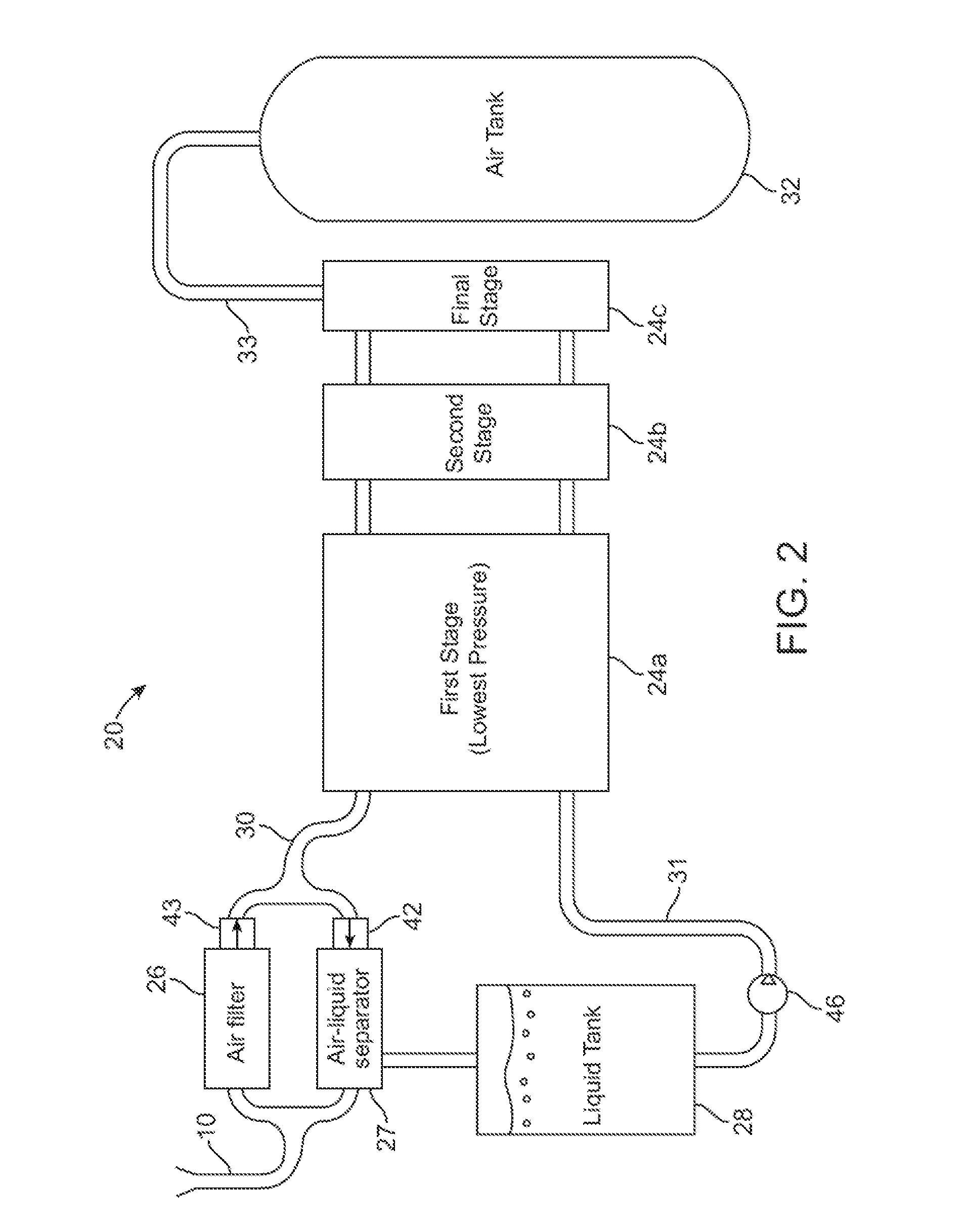

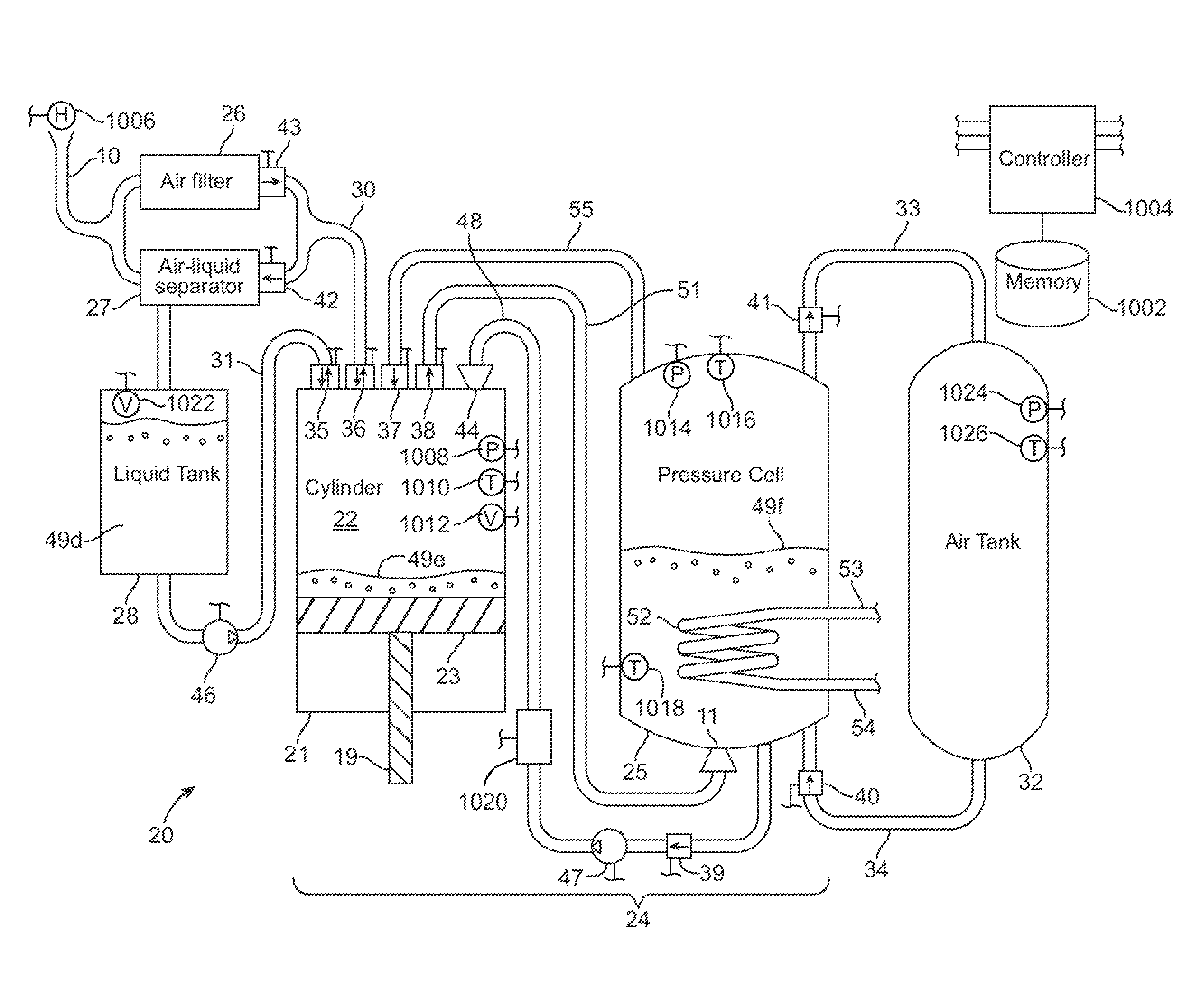

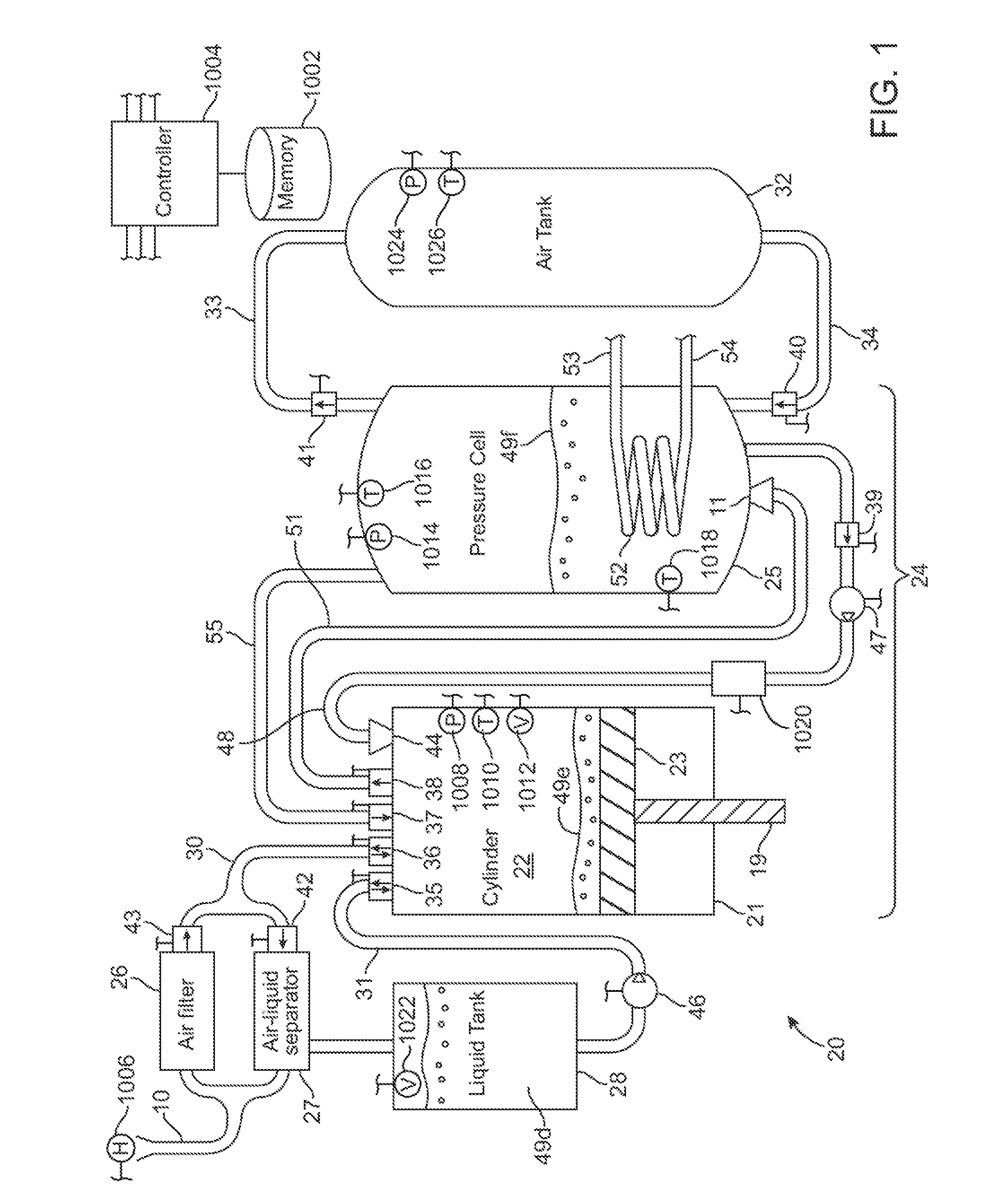

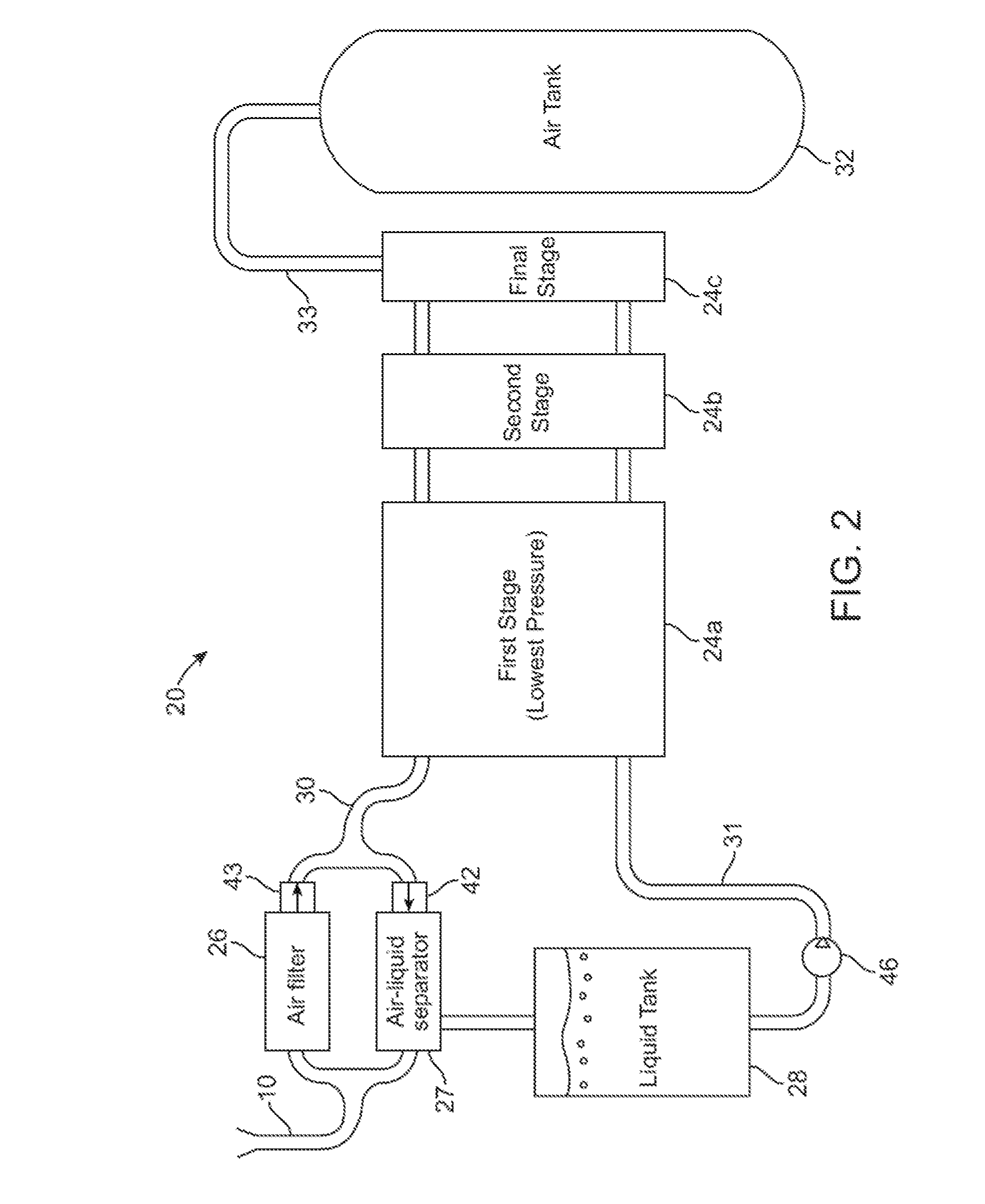

Compressed air energy storage system utilizing two-phase flow to facilitate heat exchange

InactiveUS20100326062A1Facilitate heat exchangeImprove efficiencyElectrical storage systemServomotor componentsThermal energy storageEngineering

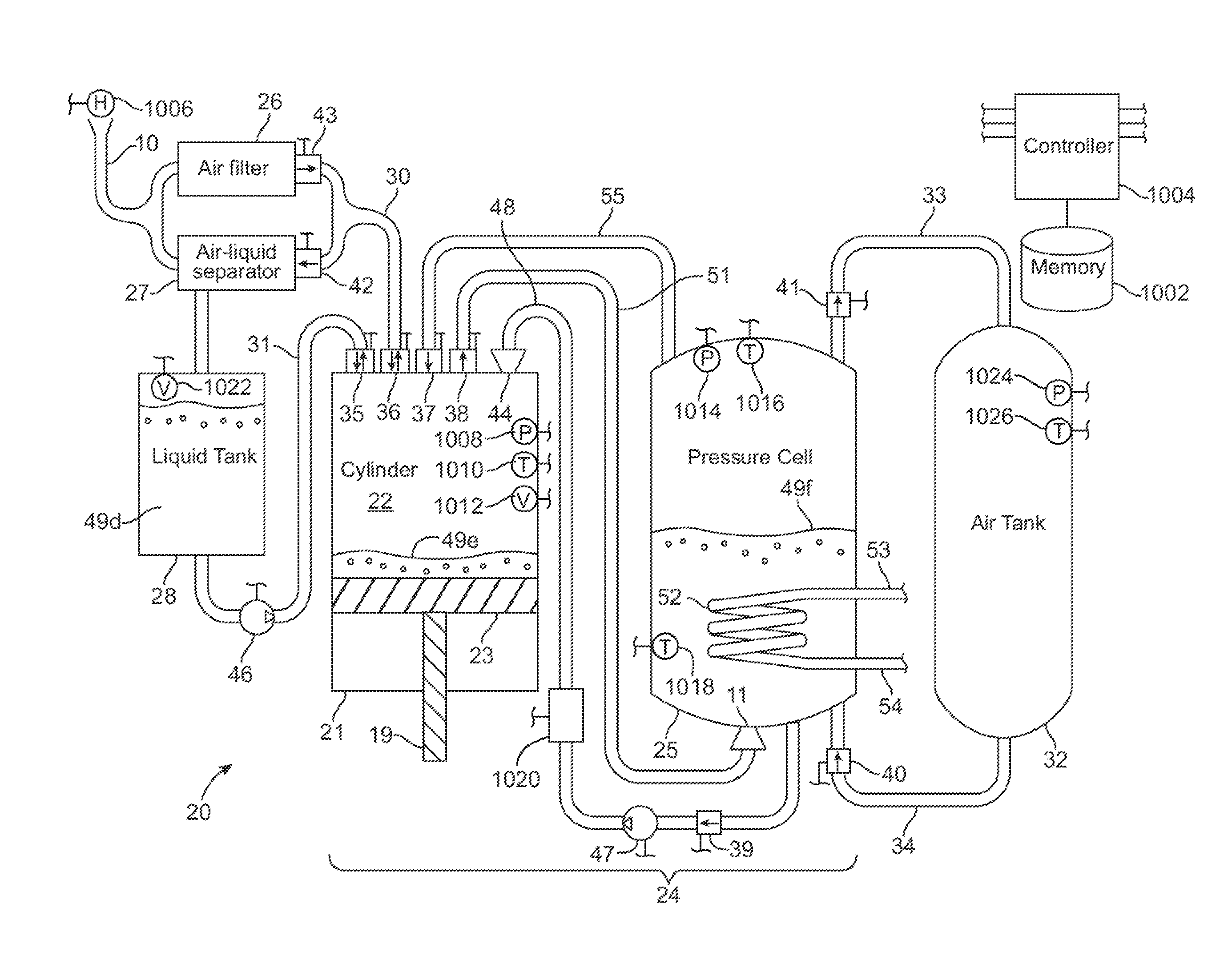

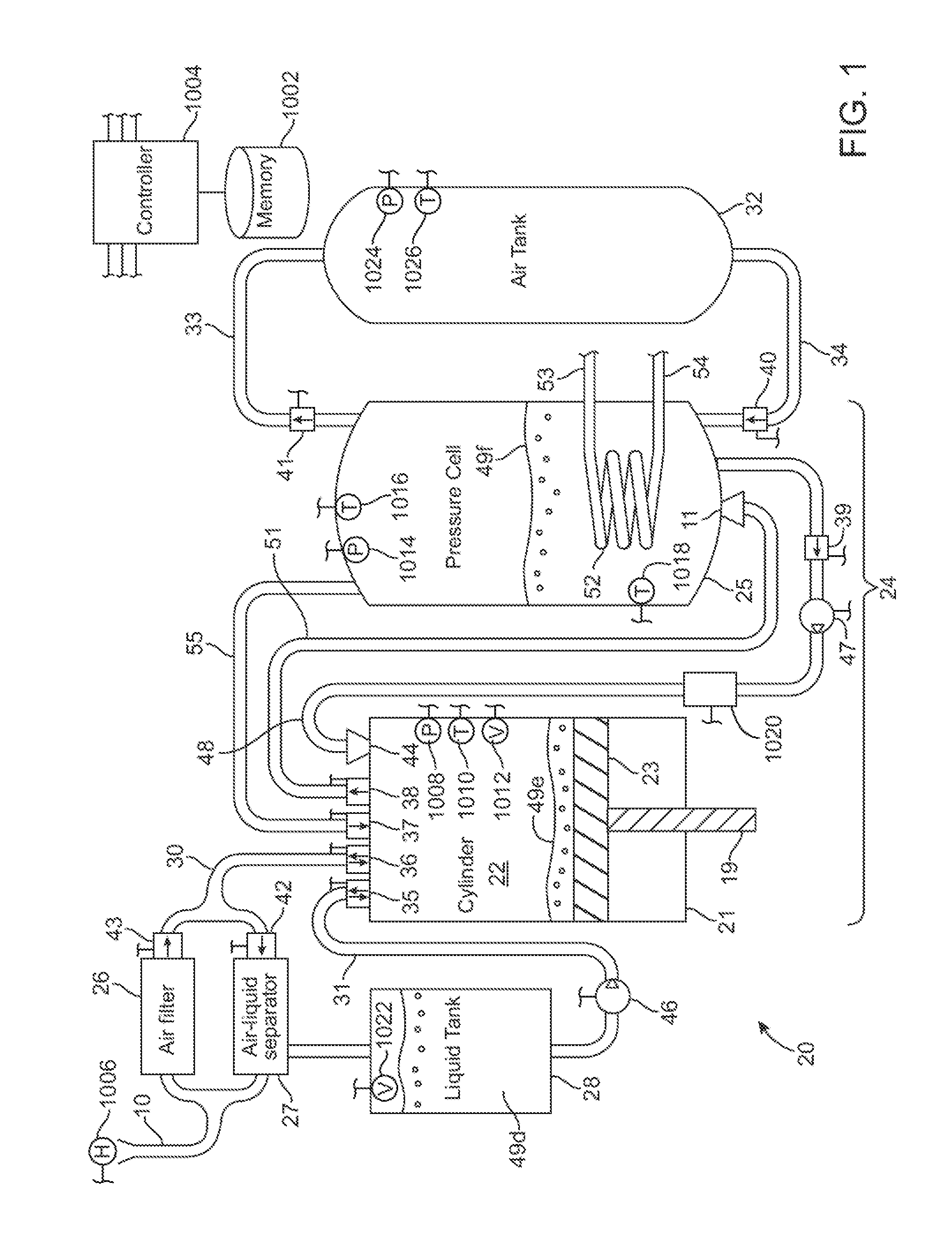

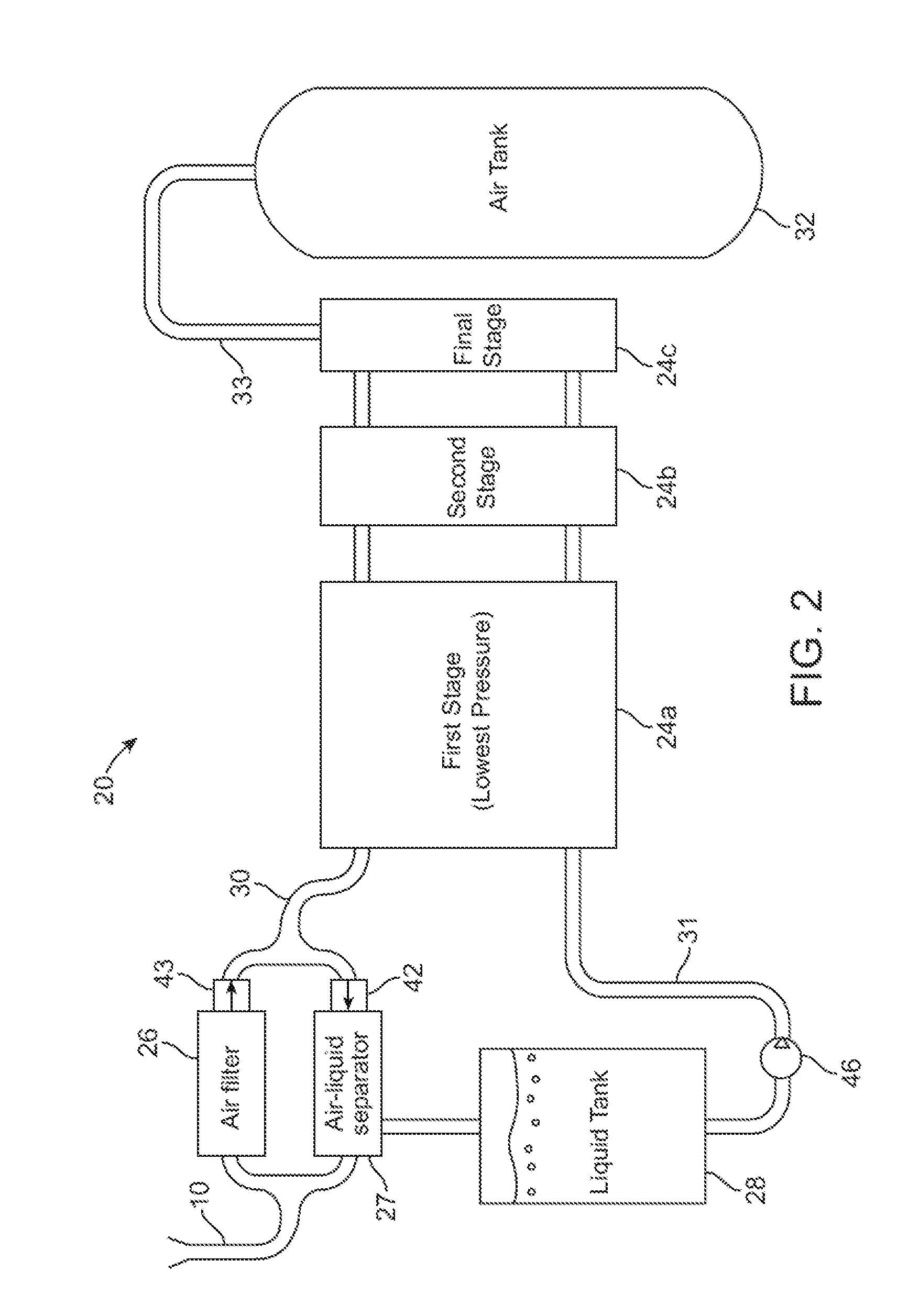

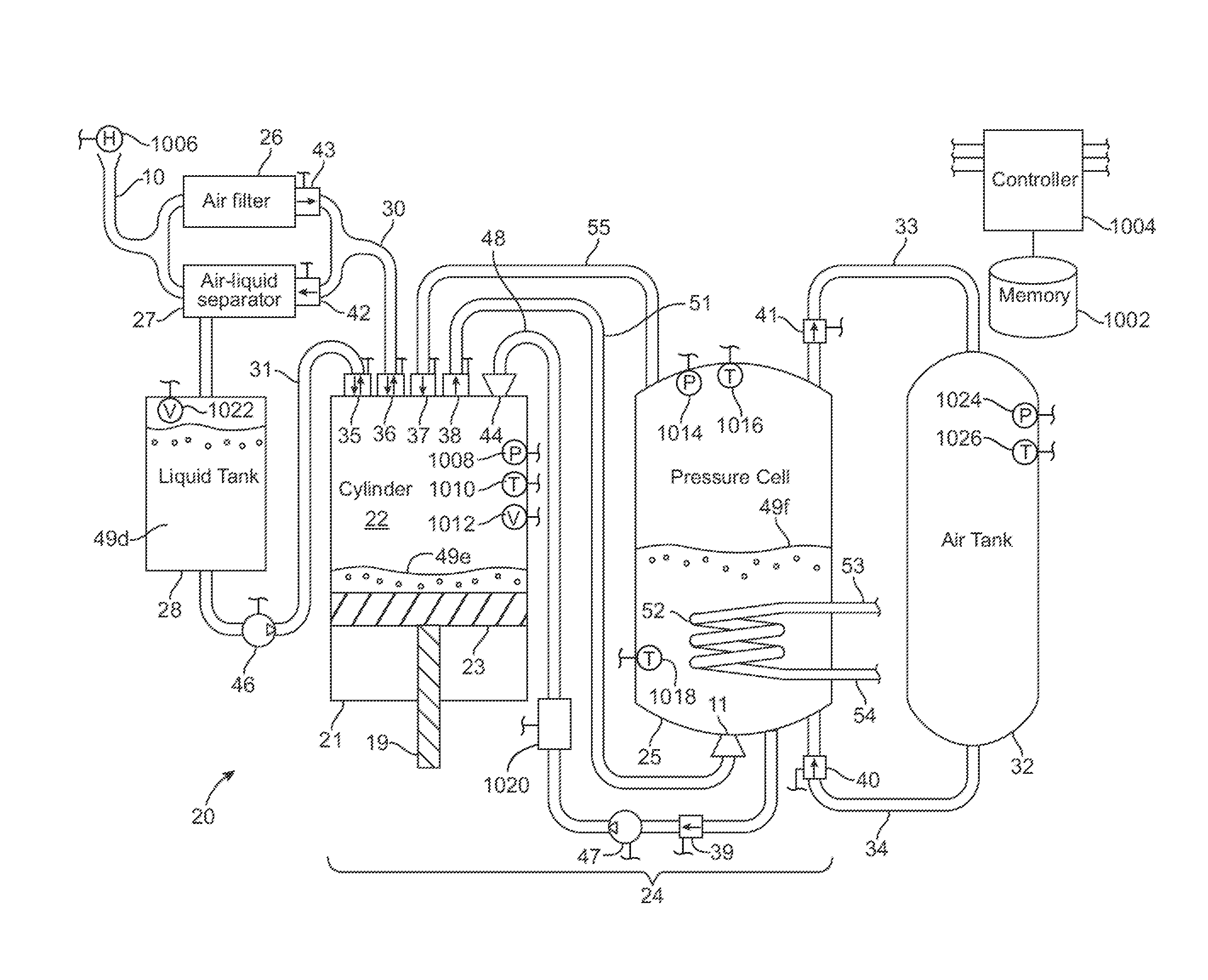

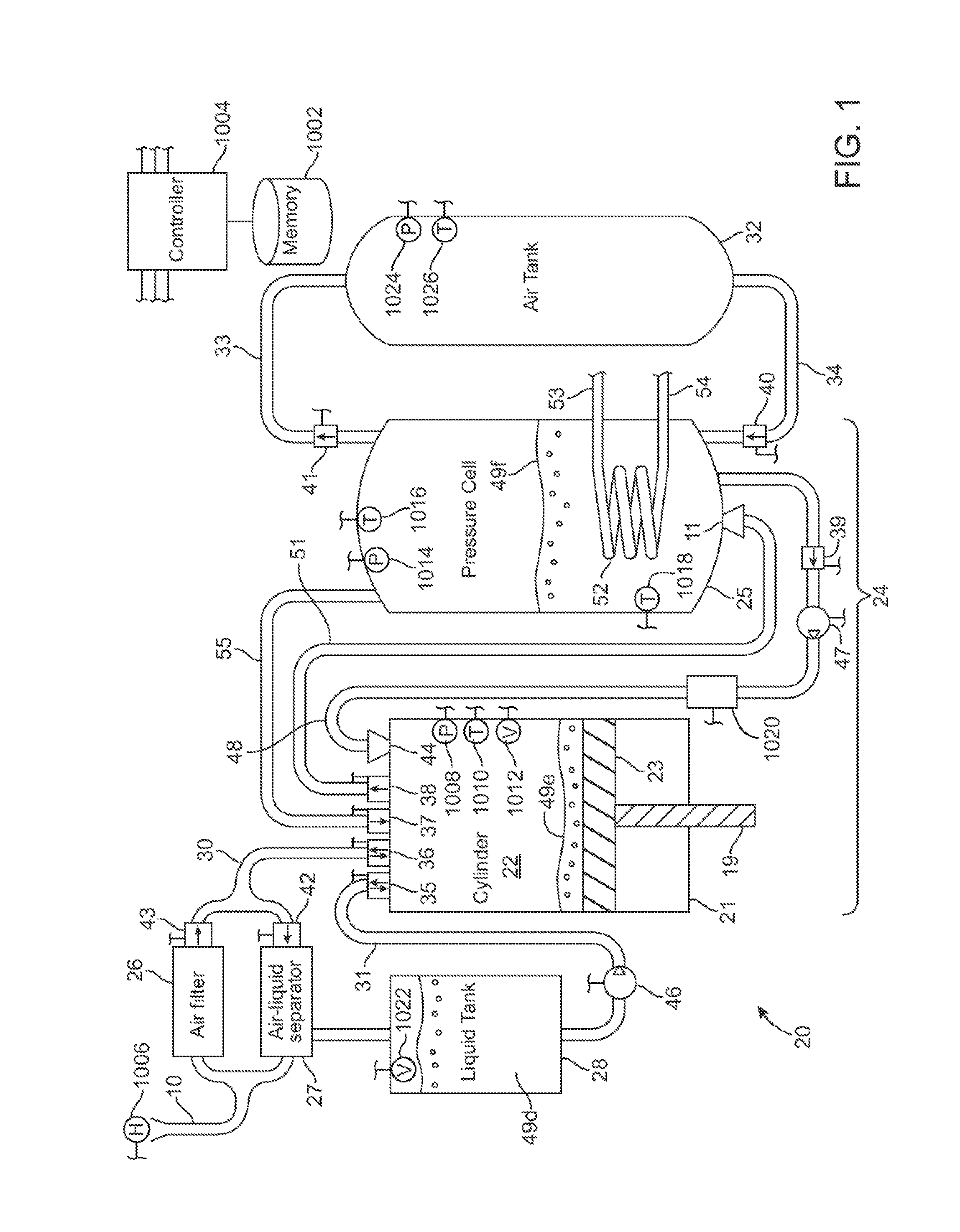

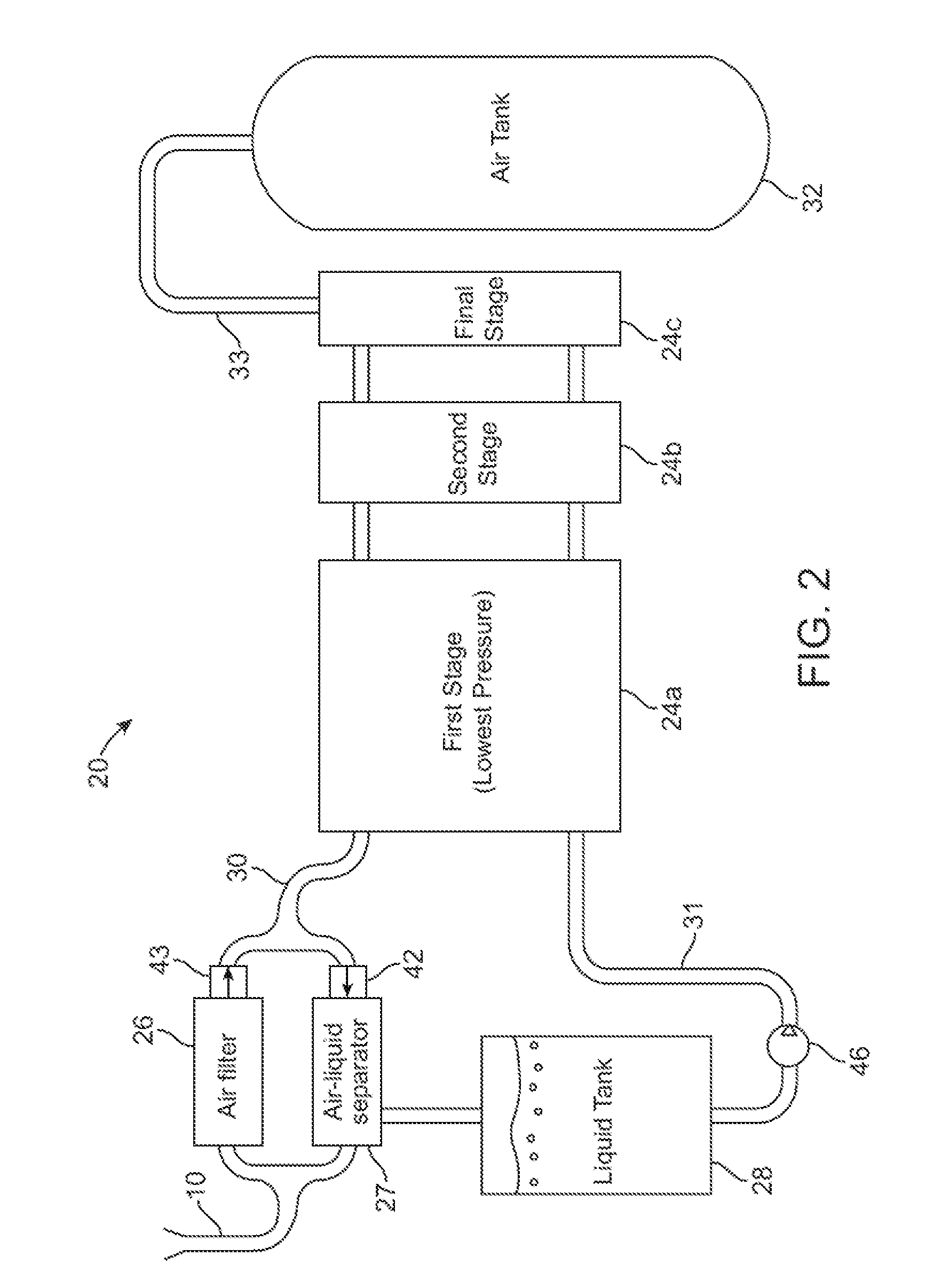

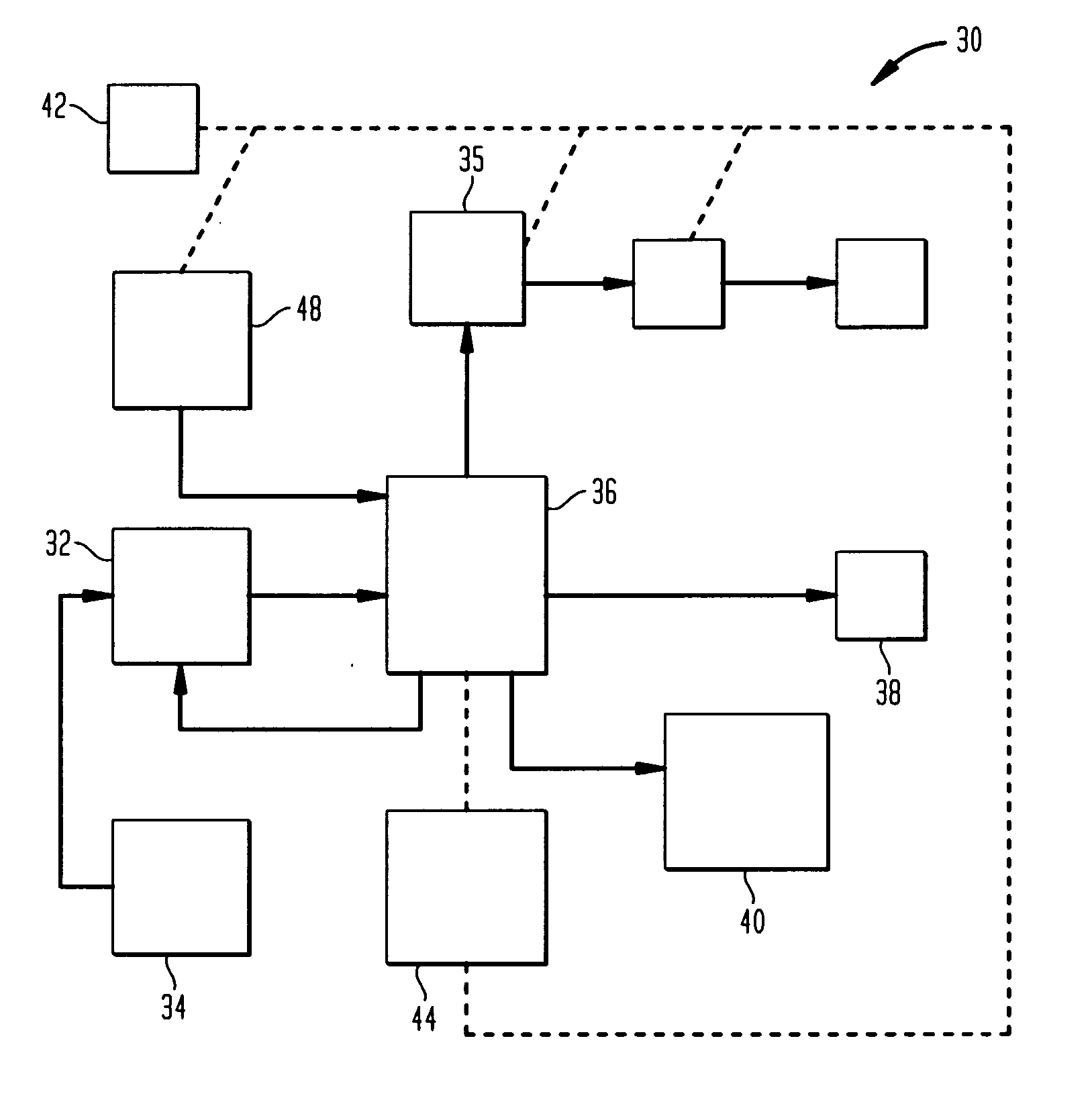

A compressed-air energy storage system according to embodiments of the present invention comprises a reversible mechanism to compress and expand air, one or more compressed air storage tanks, a control system, one or more heat exchangers, and, in certain embodiments of the invention, a motor-generator. The reversible air compressor-expander uses mechanical power to compress air (when it is acting as a compressor) and converts the energy stored in compressed air to mechanical power (when it is acting as an expander). In certain embodiments, the compressor-expander comprises one or more stages, each stage consisting of pressure vessel (the “pressure cell”) partially filled with water or other liquid. In some embodiments, the pressure vessel communicates with one or more cylinder devices to exchange air and liquid with the cylinder chamber(s) thereof. Suitable valving allows air to enter and leave the pressure cell and cylinder device, if present, under electronic control.

Owner:LIGHTSAIL ENERGY

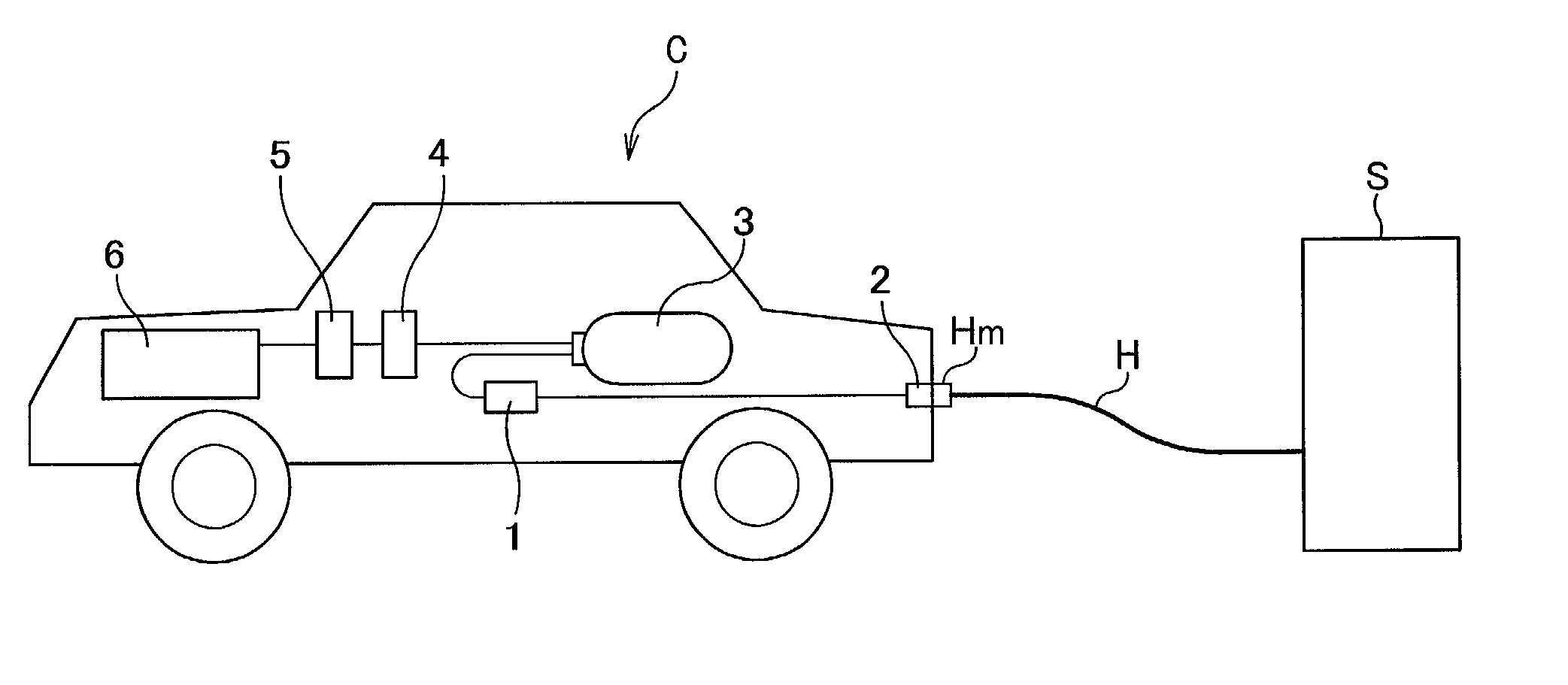

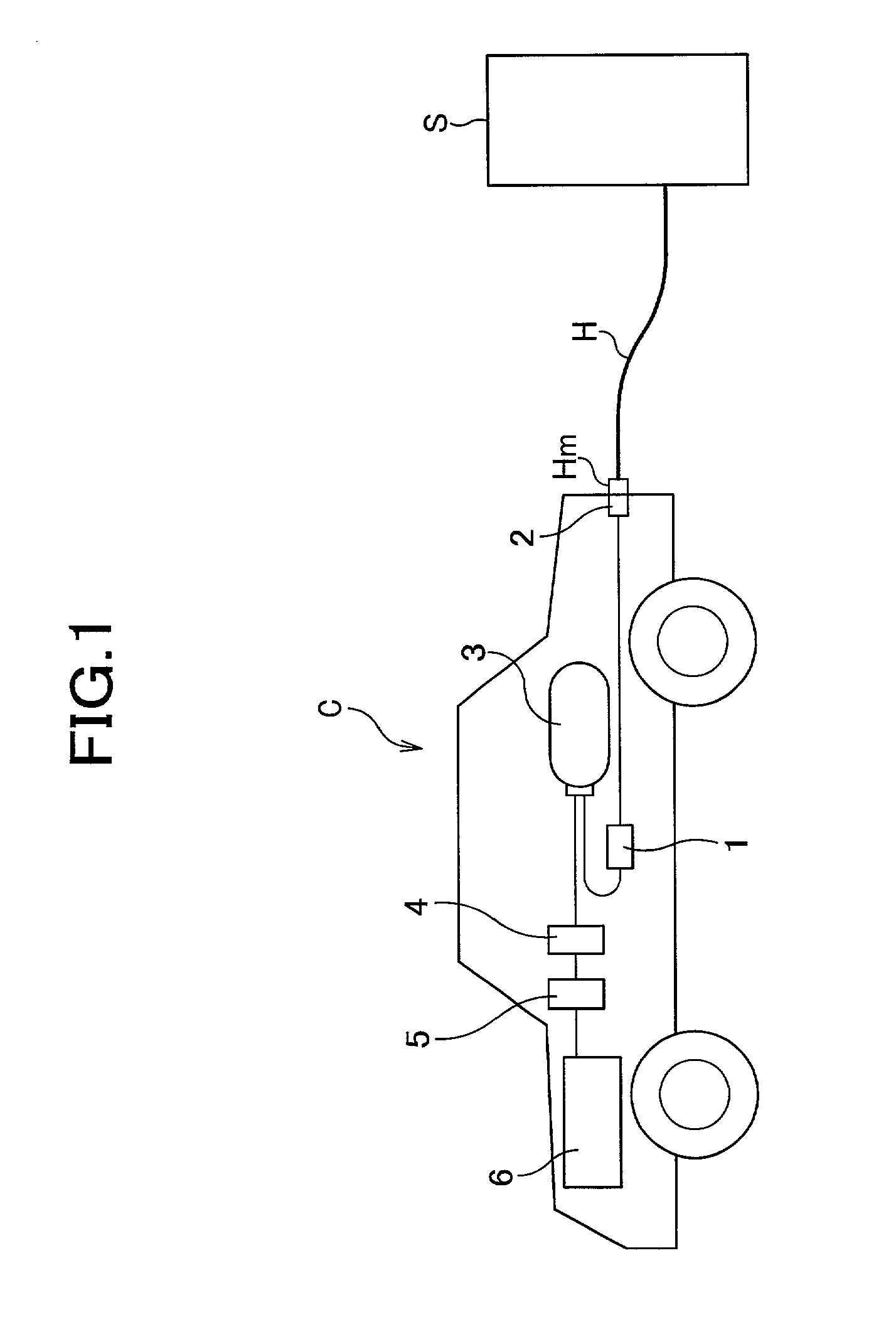

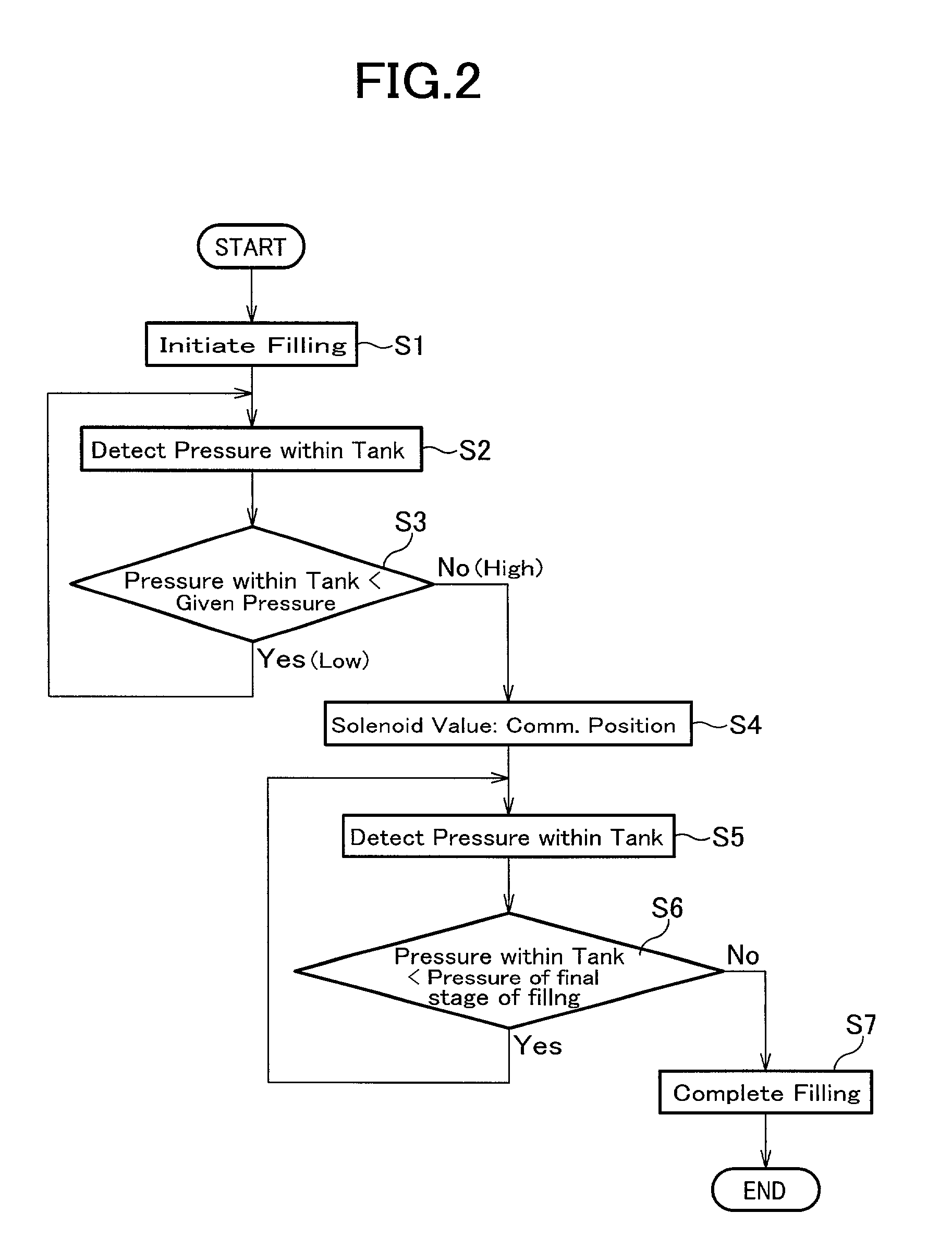

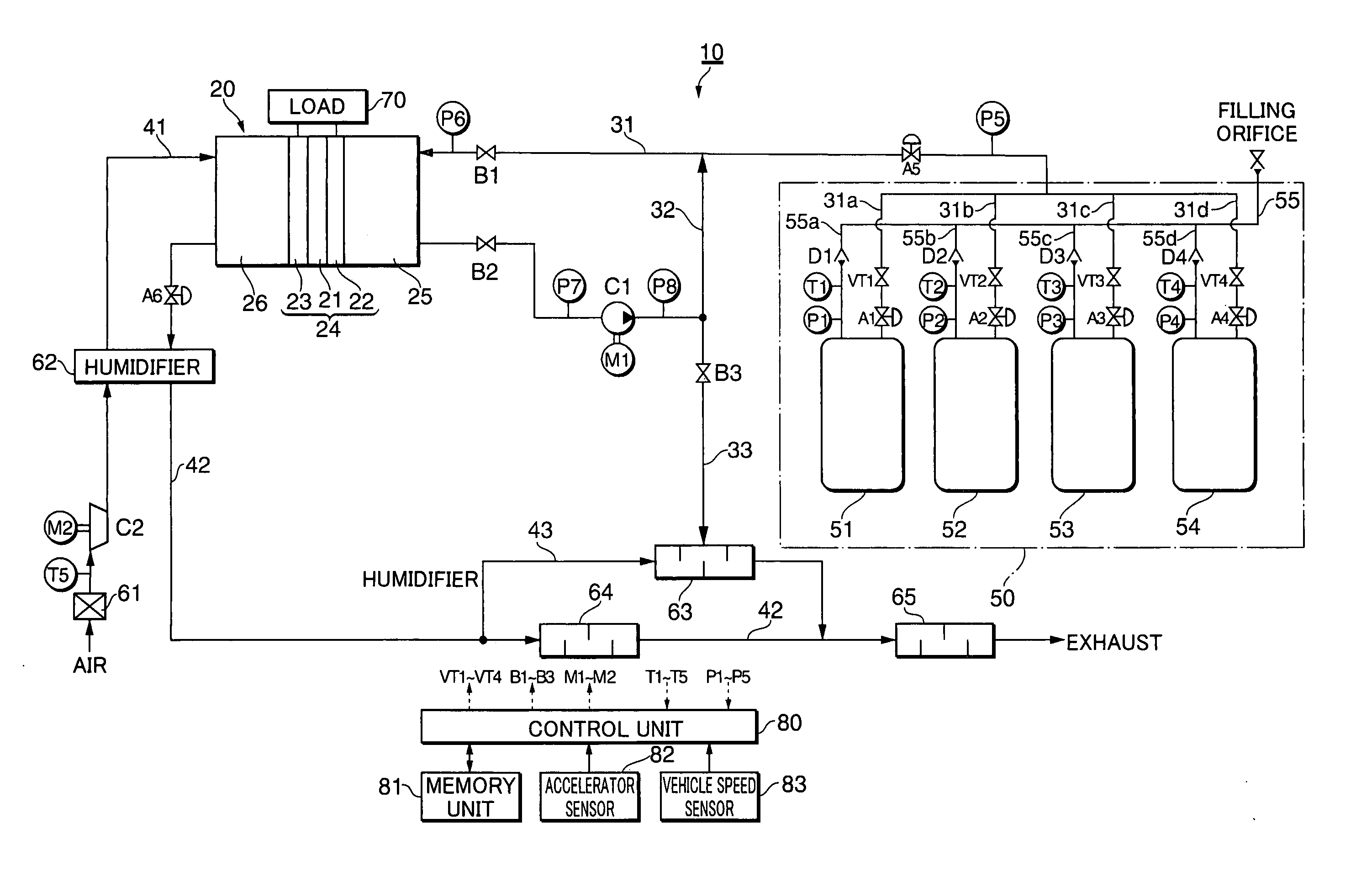

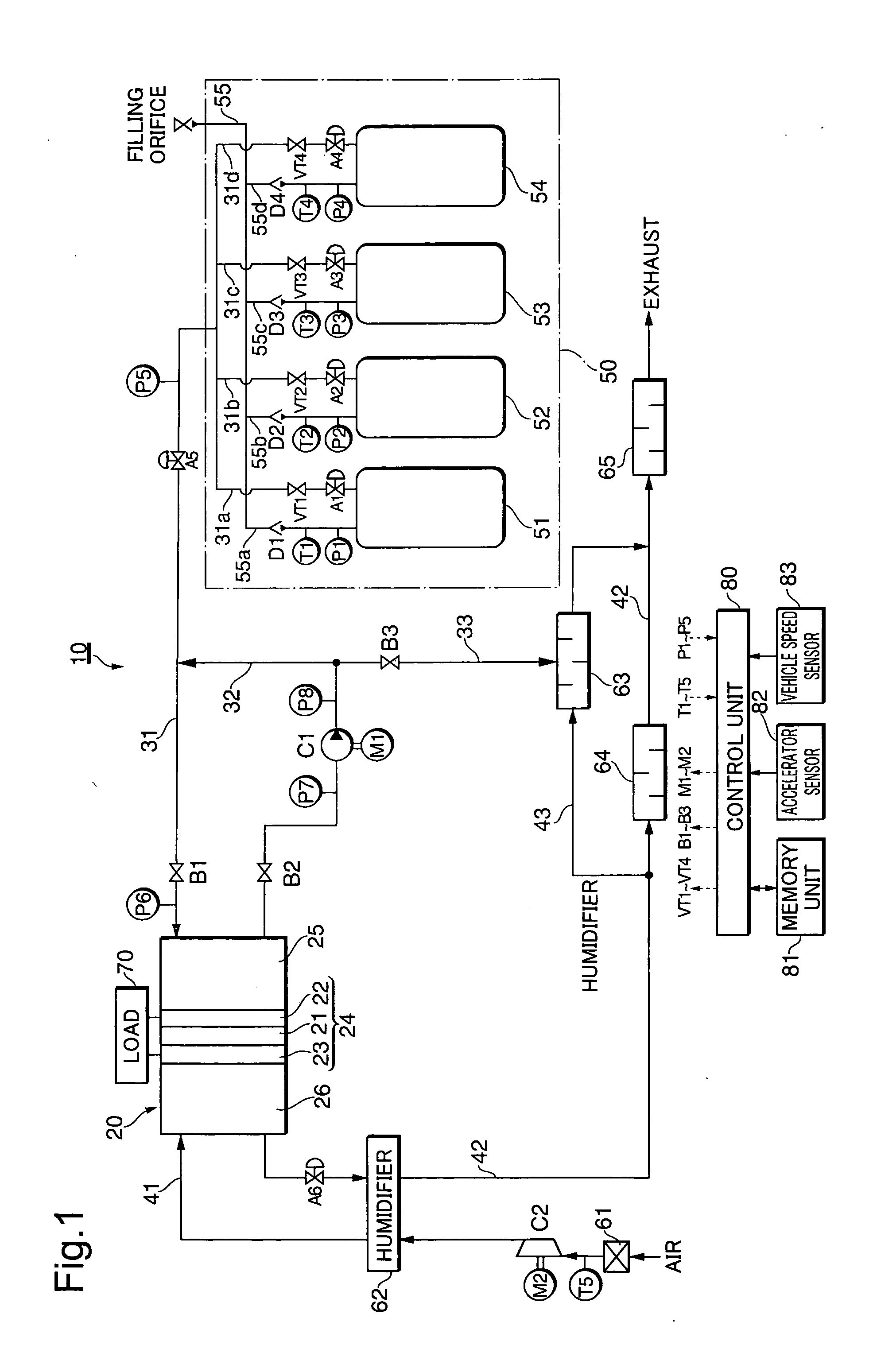

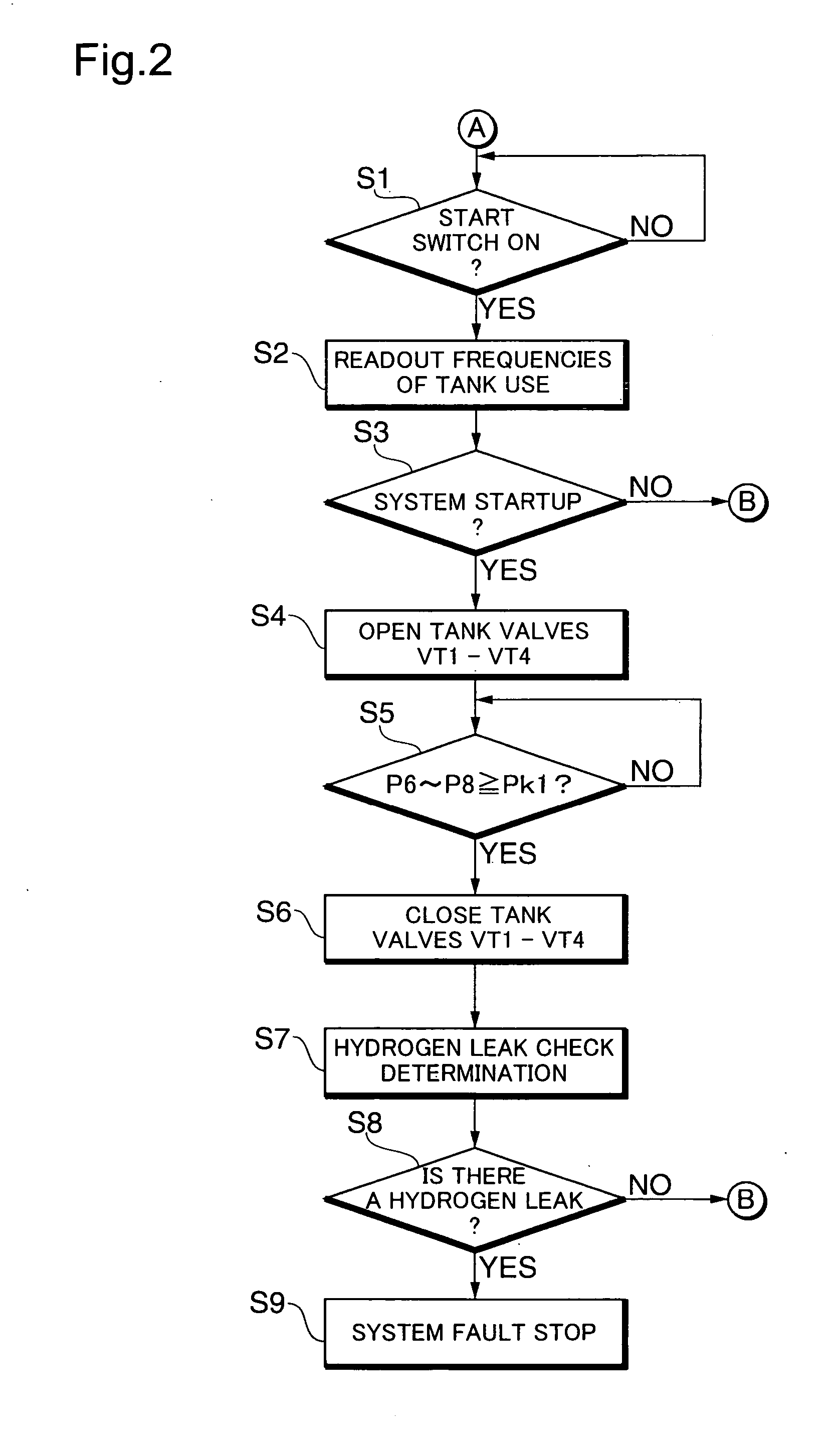

Apparatus and process for rapidly filling with hydrogen

InactiveUS20020014277A1Increase heatIncrease rangeLiquid fillingGas handling applicationsFilling rateDelayed time

An apparatus for rapidly filling a hydrogen tank with a hydrogen gas comprises a hydrogen source; a hydrogen tank; a passage which connects the hydrogen source and said hydrogen tank; and a mechanism for varying the hydrogen-filling rate. The mechanism for varying the hydrogen-filling rate changes the hydrogen-filling rate depending upon the pressure within said hydrogen tank. The apparatus can suppress heat generation at the initial filling stage where the temperature is easily increased. Also, even if it takes longer time for increasing the pressure within the hydrogen tank at the initial filling state, the delayed time can be caught up and, the apparatus and the process of the present invention can totally attain a rapidly filling with hydrogen.

Owner:HONDA MOTOR CO LTD

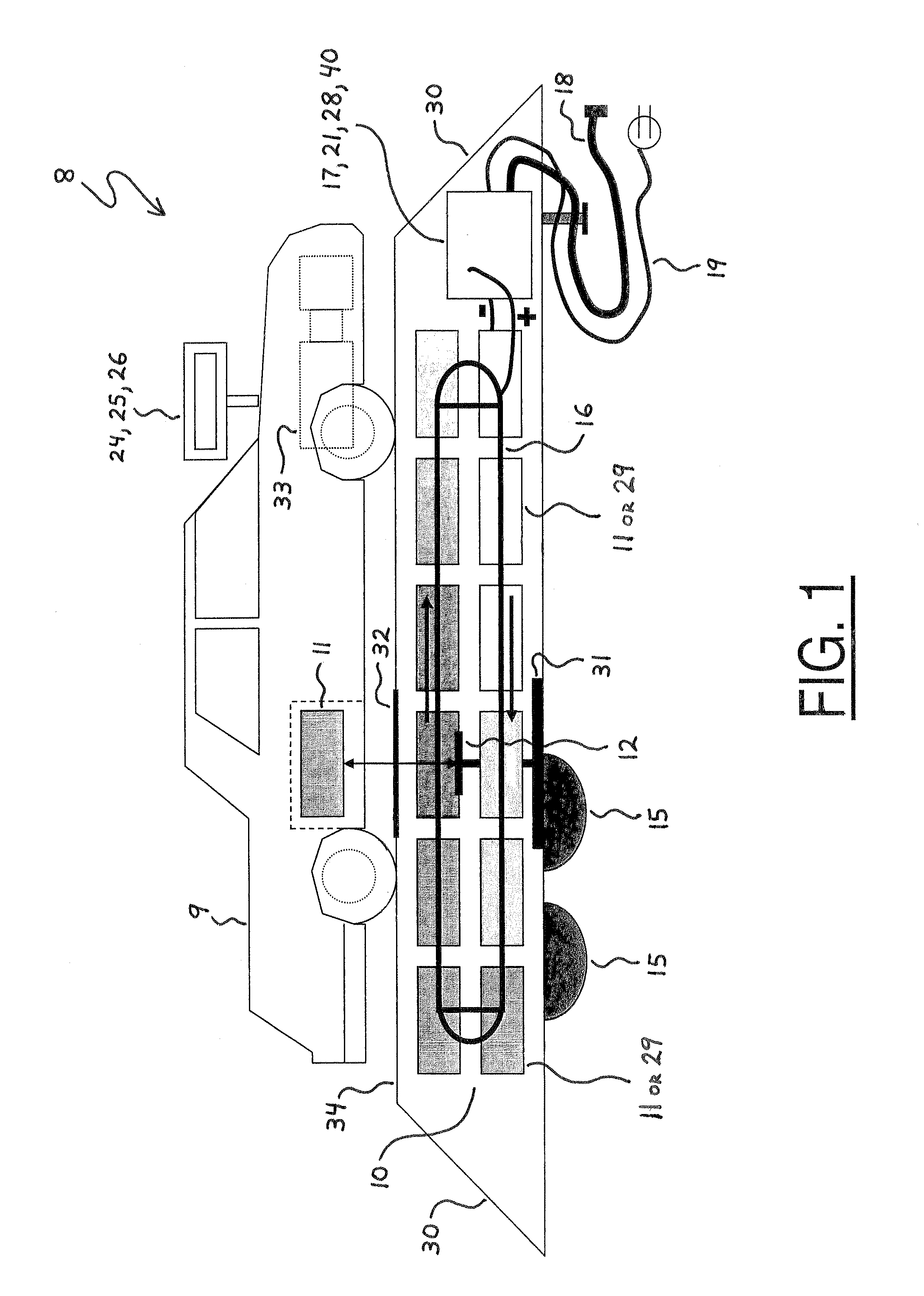

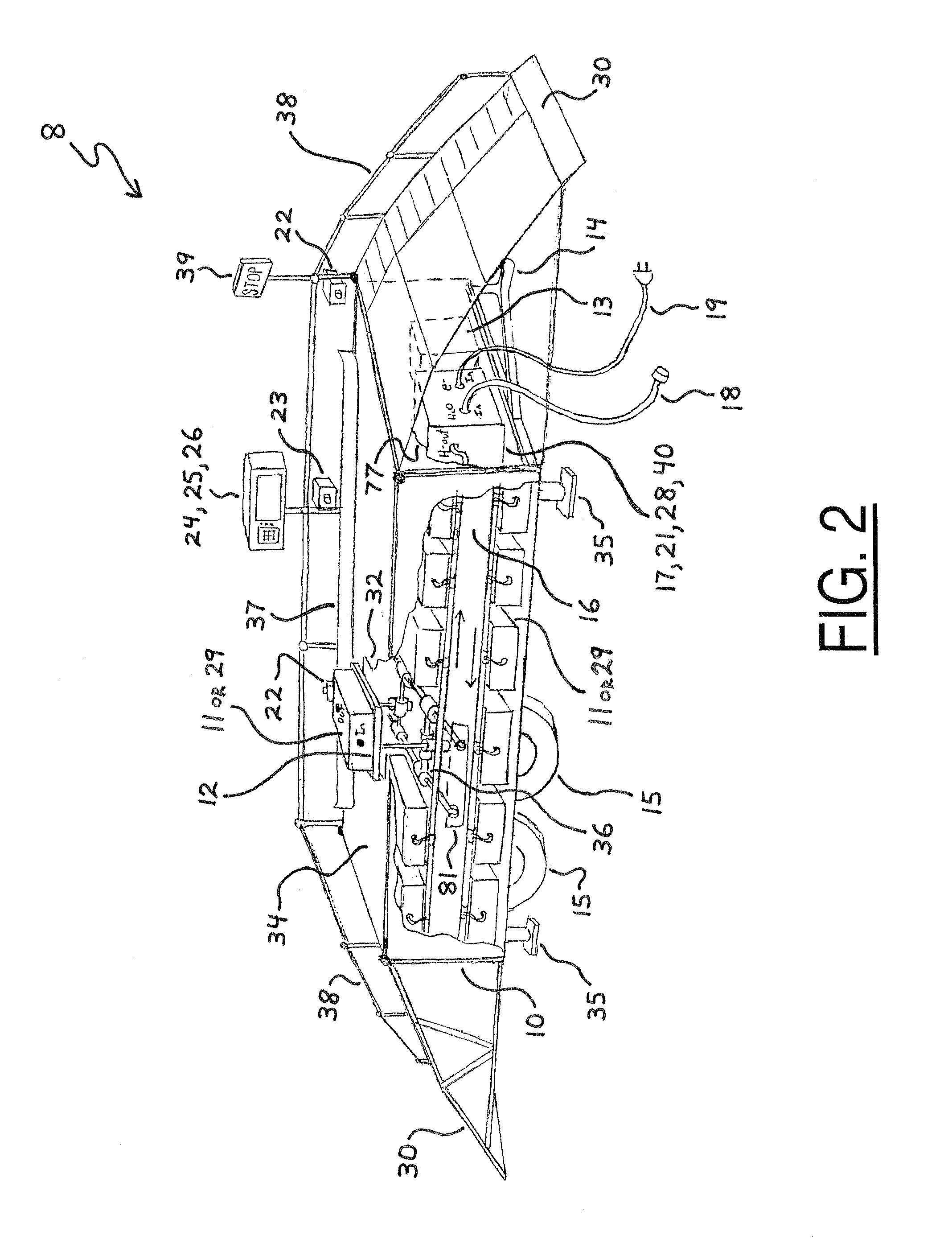

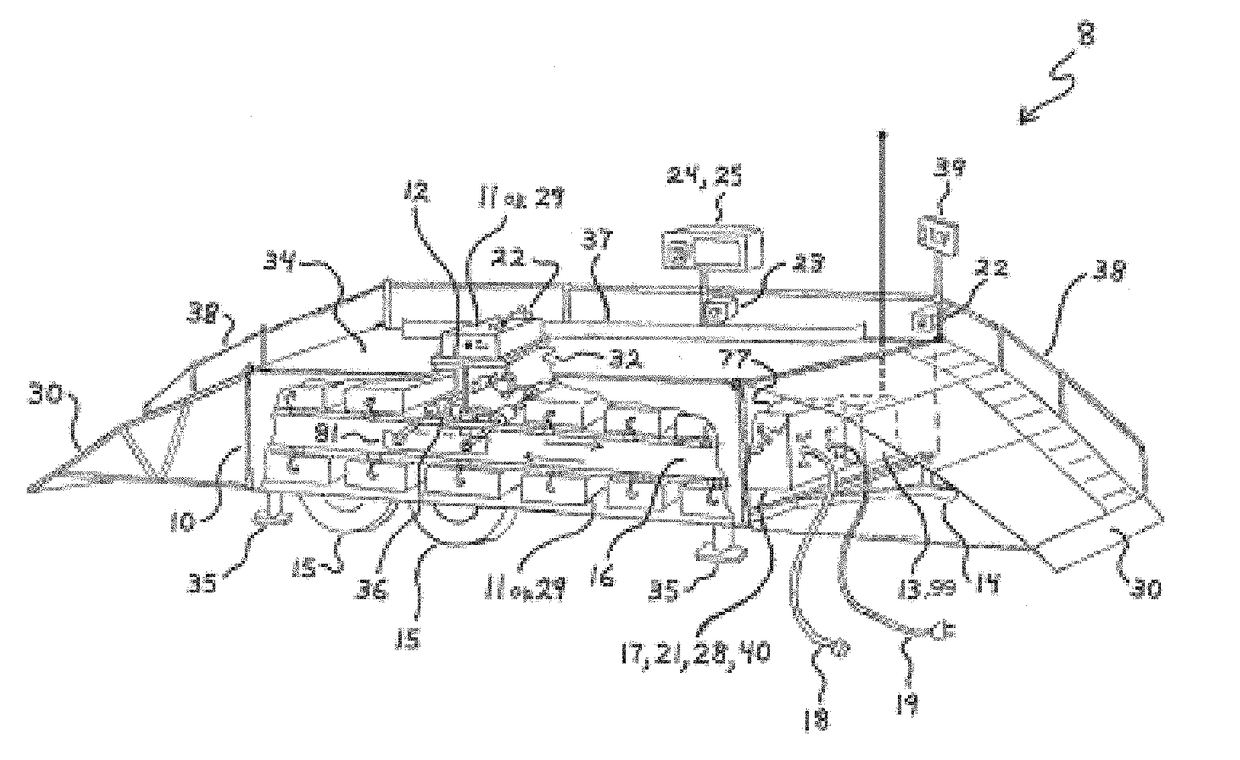

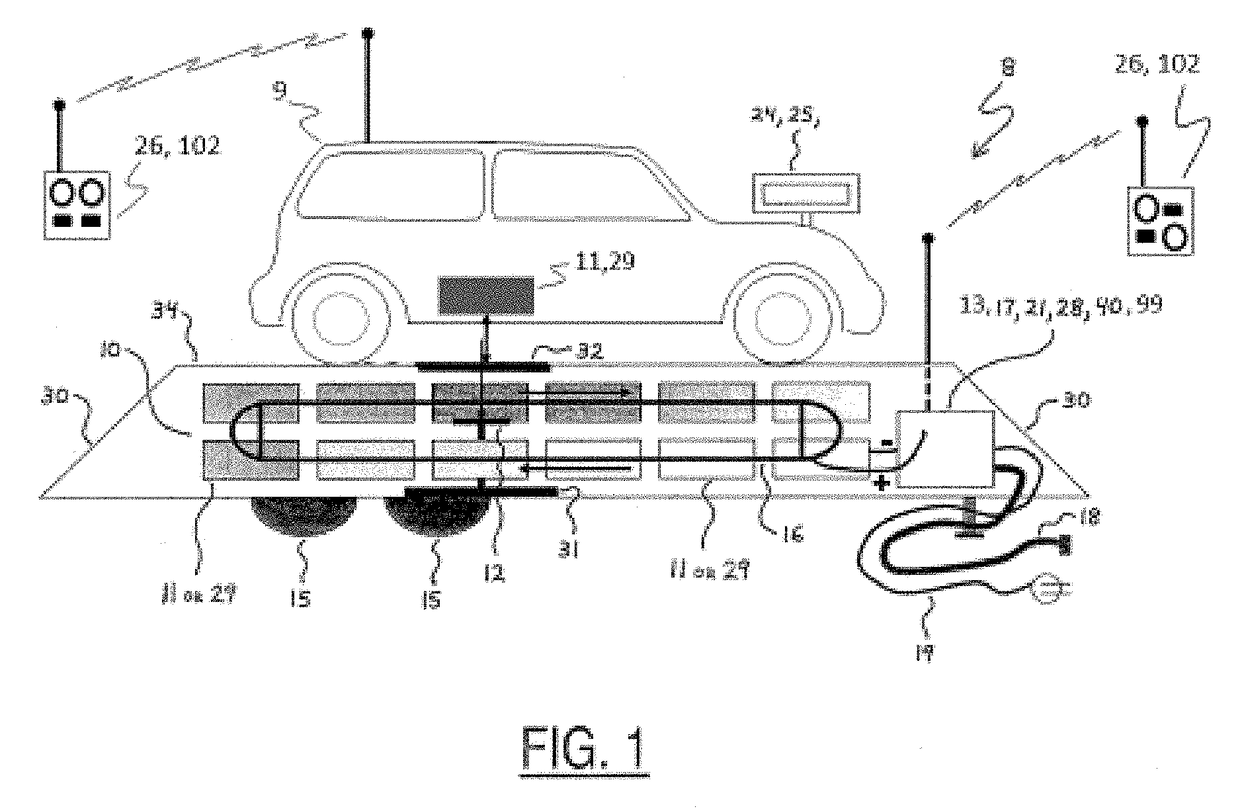

Device for Refueling, Exchanging, and Charging Power Sources on Remote Controlled Vehicles, UAVs, Drones, or Any Type of Robotic Vehicle or Machine with Mobility

ActiveUS20170327091A1Facilitate product distributionIncrease surface areaRemote controlled aircraftElectric/hybrid propulsionElectricityControl system

An Automatic Service Station Facility (ASSF) for replenishing various motivational energy sources onboard different types of AUV, Drones, and Remotely Controlled (RC) or robotic vehicles is disclosed herein. In one embodiment, the automatic service station facility includes a rack, replaceable fuel tanks, a service module, and an electronic computer control system. The replaceable fuel tanks are stocked on the rack and substantially filled with various fluids which are utile as motivational energy sources within fuel-operated vehicles. The service module is mounted on the rack, and the electronic computer control system is connected in electrical communication with the service module. In this configuration, the service module is controllably operable to receive a depleted replaceable fuel tank from a fuel-operated vehicle and also selectively deliver one of the filled replaceable fuel tanks onboard the vehicle. In another embodiment, the service station facility may also stock replaceable batteries for selective delivery onboard battery-operated vehicles. In another embodiment, the ASSF is self-propelled, remotely controlled, and solar powered, being able to move long distances to remote locations which may be hazardous to humans, such as disaster zones or battle fields, where the ASSF can service AUV, Drones, and Remotely Controlled (RC) or robotic vehicles needed for the particular applications. Alternatively, the solar powered ASSF can be made to move continuously and service vehicles continuously for long duration operations like herding cattle for example.

Owner:CAPIZZO PETER D

Gas supply apparatus

InactiveUS20060246177A1Reduce supplyReduce pressureGas handling applicationsSpecial dispensing meansProcess engineeringGas holder

A gas supply apparatus including: a tank unit that includes a tank storing a gas and a discharge mechanism discharging the stored gas to the outside of the tank at a reduced pressure of the stored gas; a temperature detector that detects a temperature of the tank; and a supply regulator that regulates supply of the gas from the tank according to the detected tank temperature.

Owner:TOYOTA JIDOSHA KK

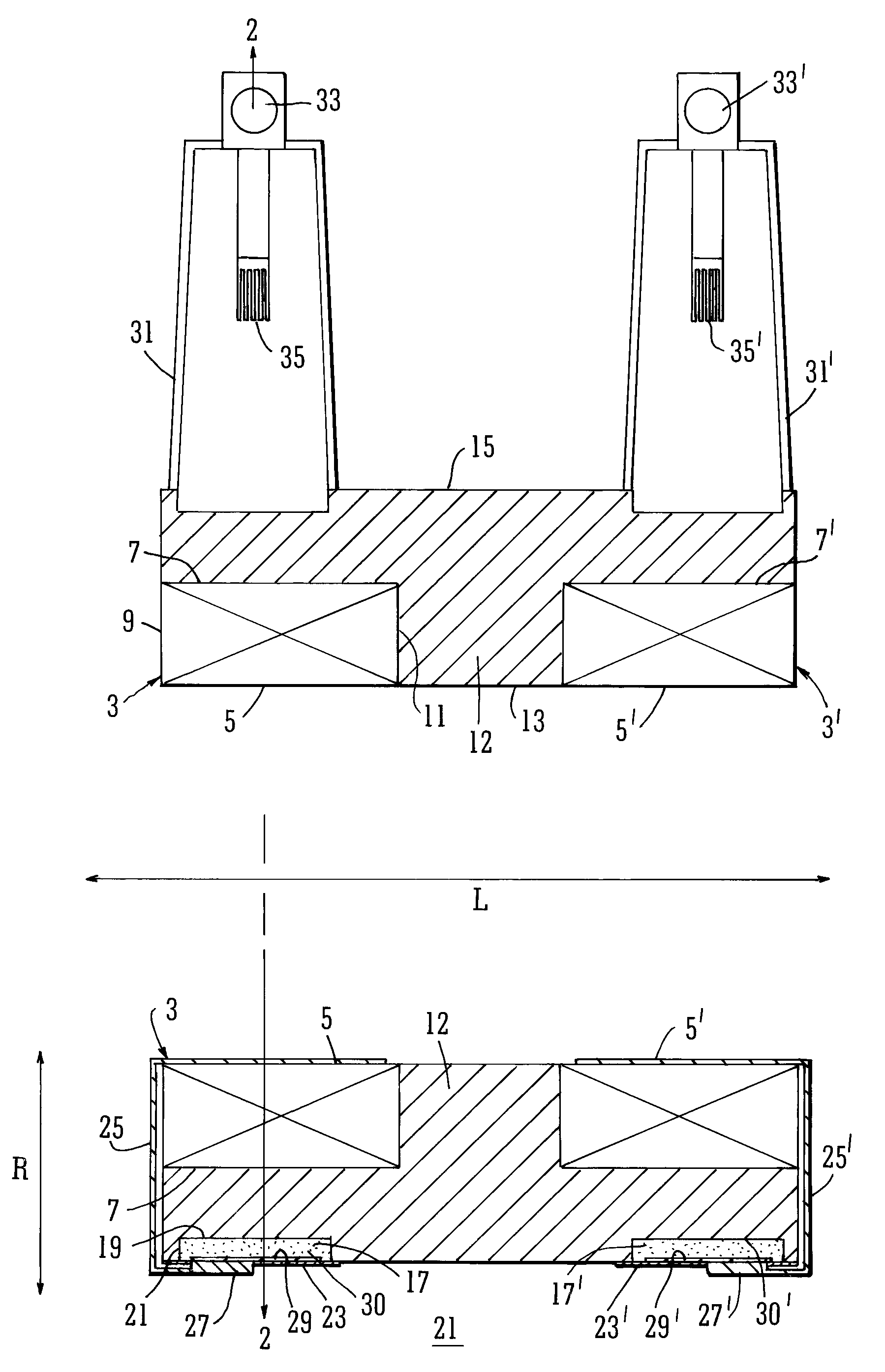

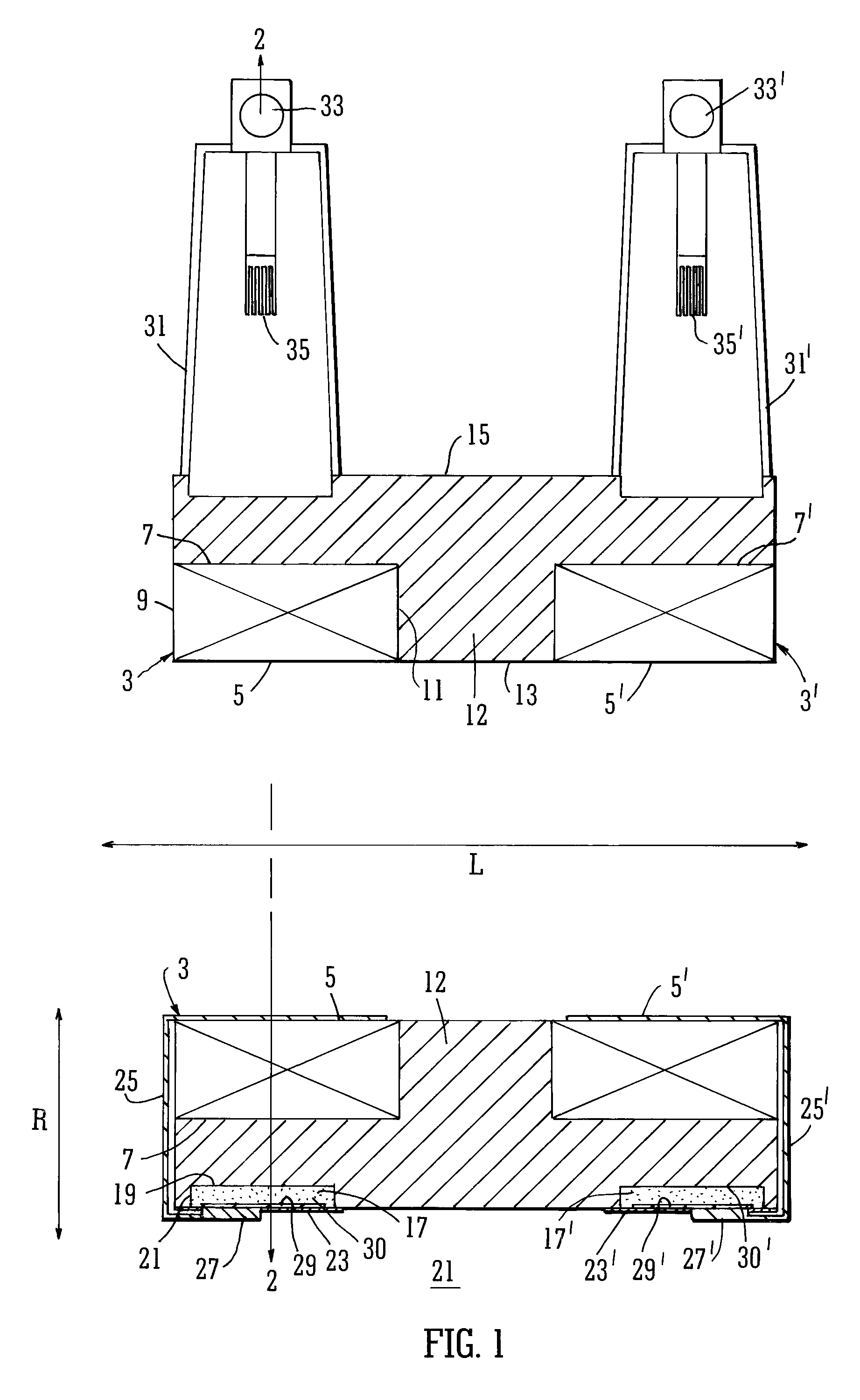

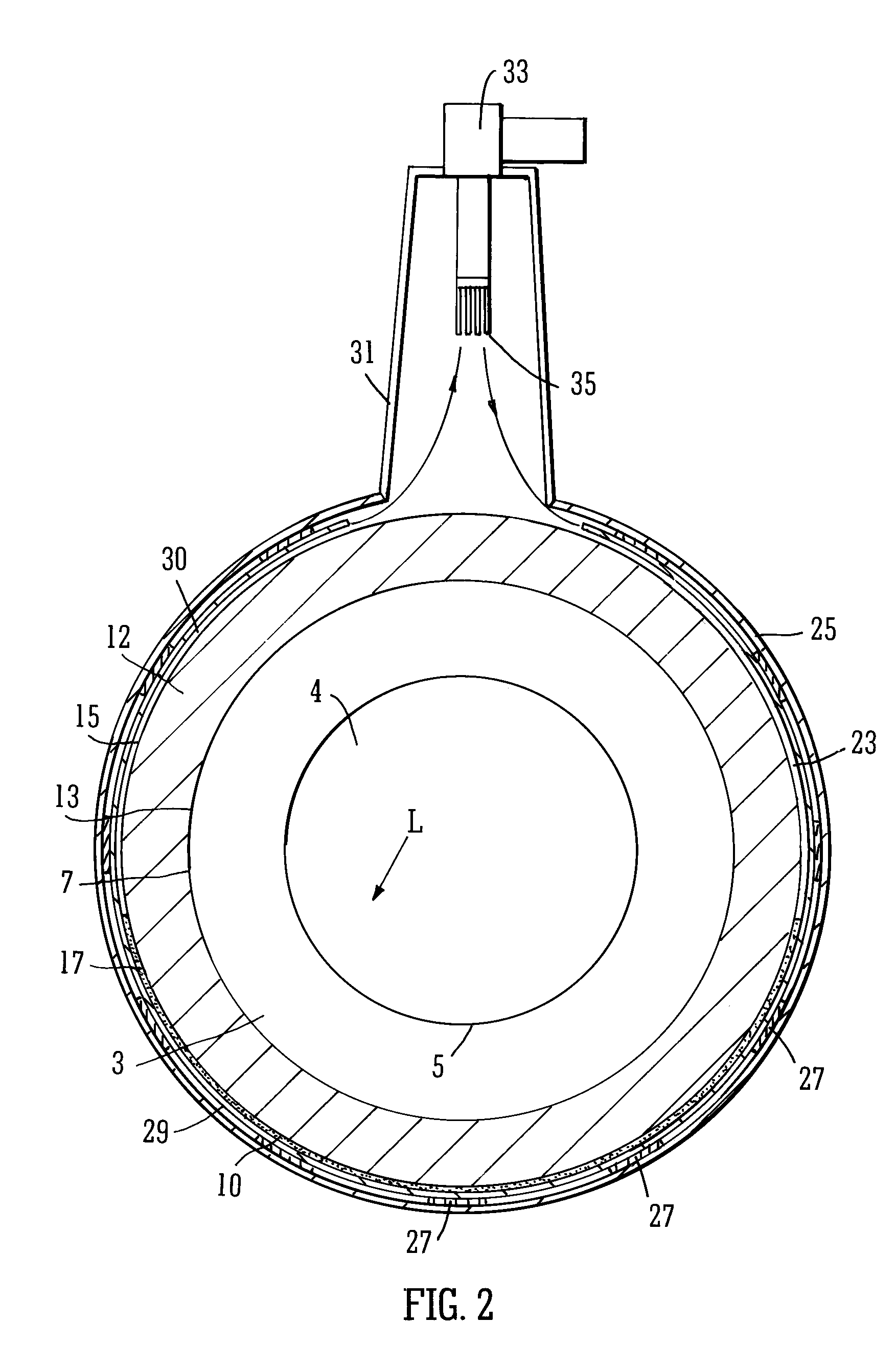

Cooling methods

InactiveUS20090038318A1Improve heat transfer performanceRemove heatTransformers/inductances coolingMagnetic measurementsSuperconducting CoilsEngineering

A superconducting system comprises a superconducting coil (3) mounted in a support (12). The coil is surrounded by a cryogen chamber (17) which is located radially outwardly from the coil (3) on the other side of the support (12). The cryogen chamber is in fluid communication with a cryogen recondensing unit (33) whereby vaporized cryogen may flow from the cryogen chamber (17) to the cryogen recondensing unit (33) to be recondensed in use before returning to the cryogen chamber. Thermally conductive means (25) is arranged to facilitate heat transfer from the superconducting coil (3) to the cryogen chamber (17) to vaporize cryogen contained therein in use and thereby remove heat from the coil. The thermally conductive means (25) is highly thermally conductive at cryogenic temperatures. In use, the highly thermally conductive means (25) facilitates transfer of heat from the coil (3) to the interior of the cryogen chamber (17) to vaporize cryogen located therein. A thermal conduction path is therefore used to transfer heat from the coil to the cryogen in the cryogen chamber. Cryogen vaporized in the cryogen chamber then flows to the cryogen recondensing unit (33) to be recondensed before returning to the chamber, while the vaporized cryogen acts as the heat transfer medium over the longer distance between the cryogen chamber and the recondensing unit.

Owner:TESLA ENG

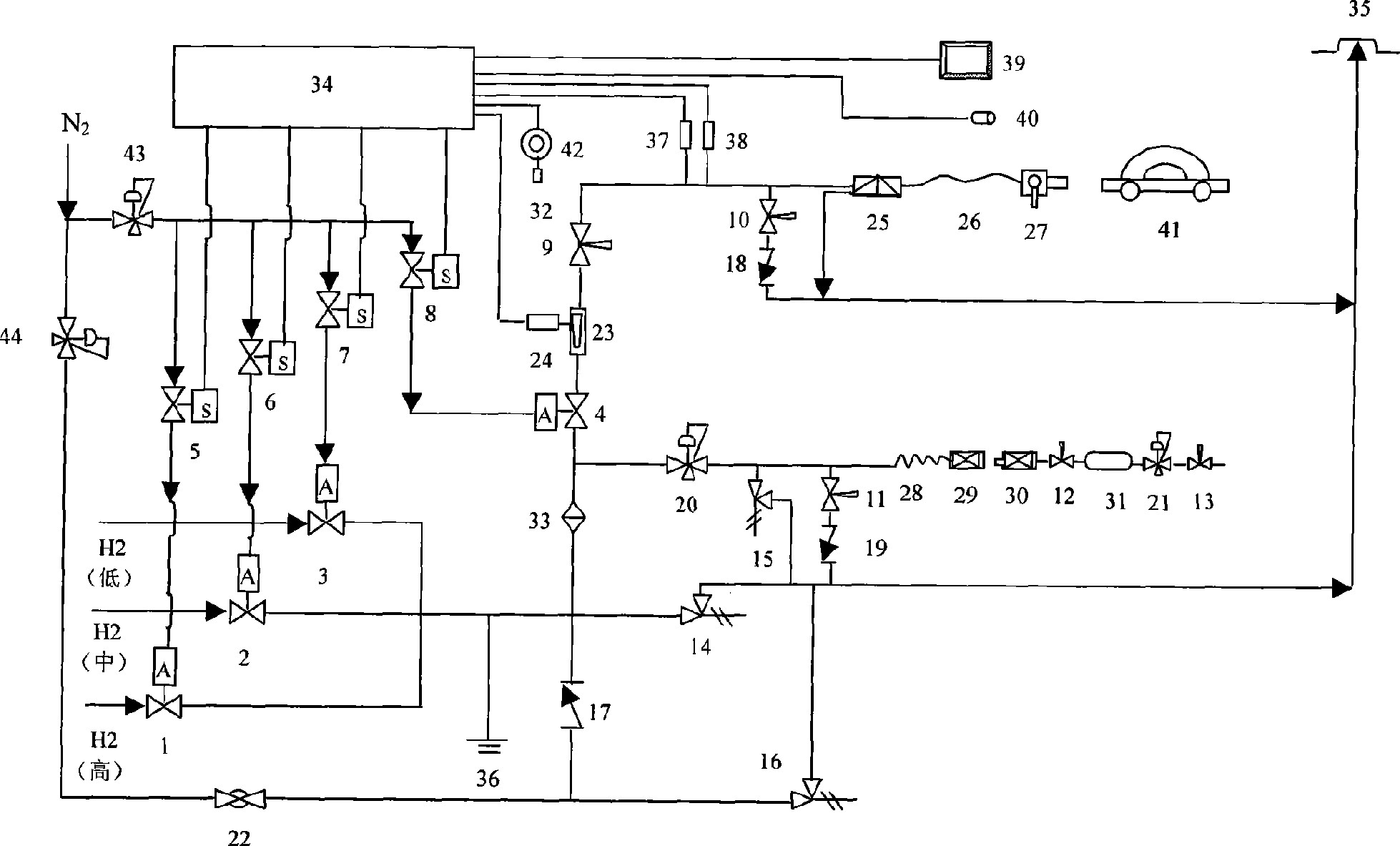

Air entraining system for high-pressure hydrogenation stations

ActiveCN101418908ASimple structureImprove reliabilityContainer filling under pressureFill rateFuel cells

The invention relates to a gas filling system for a high-pressure hydrogen filling station, which comprises a control system, a sampling system, a filling system, an alarm system and a nitrogen purging system, and is the gas filling system which can collect hydrogen sample of the hydrogen filling station and fill high-pressure hydrogen for fuel cell powered vehicles. The gas filling system has the functions of temperature automatic compensation of filling measurement, selectable gas taking procedure in three-stage order, reasonable control of filling rate, alarm of hydrogen leakage and automatic power-down, pulling out prevention and automatic static release in the filling process, overpressure protection of the system, and so on. The sampling points are designed at the tail end of the whole flow of the hydrogen filling station, so that the acquired hydrogen sample can have more representativeness in quality; and through the design of pressure regulation treatment on the high-pressure hydrogen for sampling, the sampling operation is more simple, convenient and quick, and a regular gas sampling steel bottle can also be used together, thereby the sampling cost is low. The gas filling system can improve the gas taking rate of the hydrogen filling station and ensure that the temperature rise of a filled vehicle hydrogen storage tank is strictly controlled within the required temperature range in the quick hydrogen filling process.

Owner:TONGJI UNIV

Compressed air energy storage system utilizing two-phase flow to facilitate heat exchange

InactiveUS20100326069A1Facilitate heat exchangeImprove efficiencyElectrical storage systemServomotor componentsThermal energy storageEngineering

A compressed-air energy storage system according to embodiments of the present invention comprises a reversible mechanism to compress and expand air, one or more compressed air storage tanks, a control system, one or more heat exchangers, and, in certain embodiments of the invention, a motor-generator. The reversible air compressor-expander uses mechanical power to compress air (when it is acting as a compressor) and converts the energy stored in compressed air to mechanical power (when it is acting as an expander). In certain embodiments, the compressor-expander comprises one or more stages, each stage consisting of pressure vessel (the “pressure cell”) partially filled with water or other liquid. In some embodiments, the pressure vessel communicates with one or more cylinder devices to exchange air and liquid with the cylinder chamber(s) thereof. Suitable valving allows air to enter and leave the pressure cell and cylinder device, if present, under electronic control.

Owner:LIGHTSAIL ENERGY

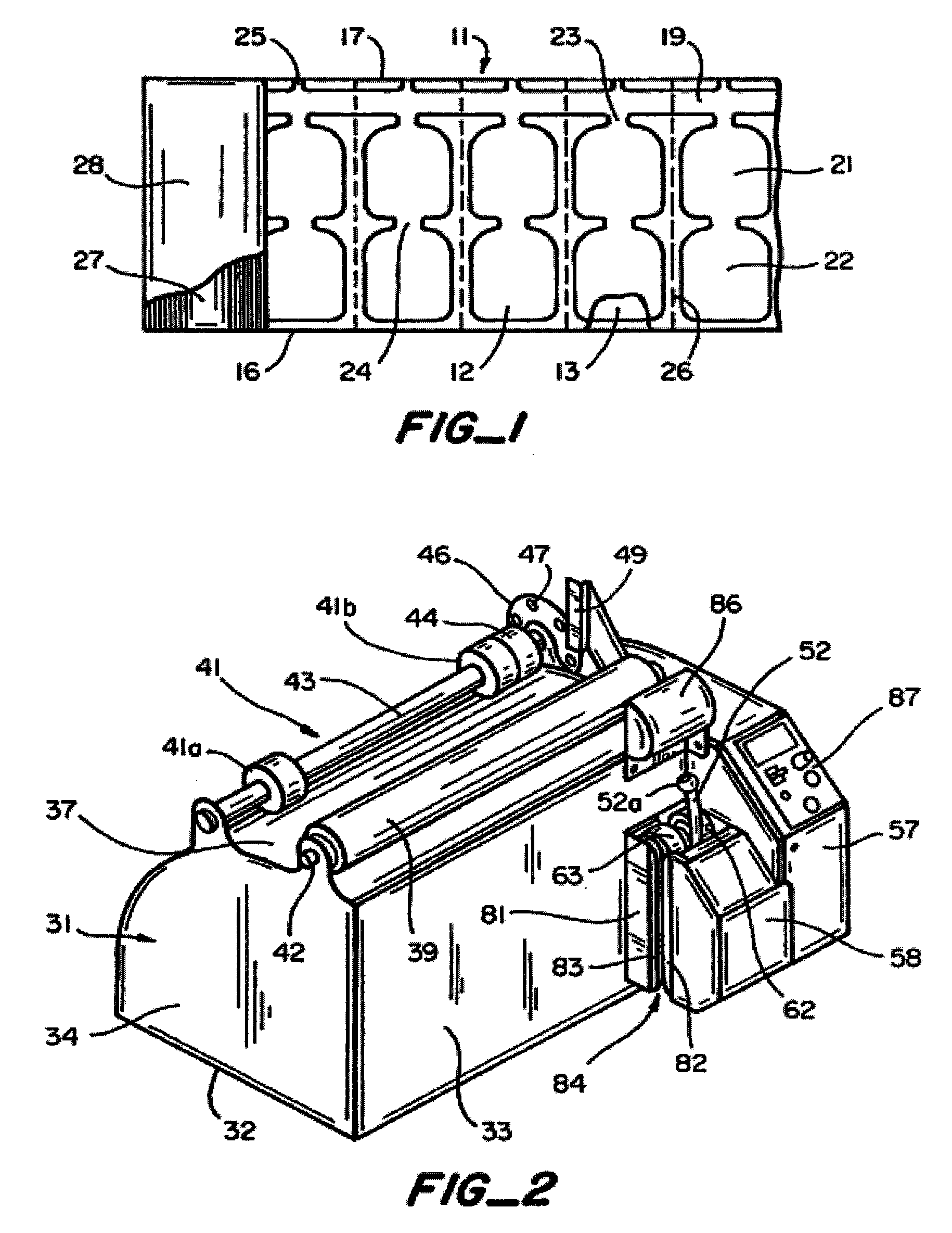

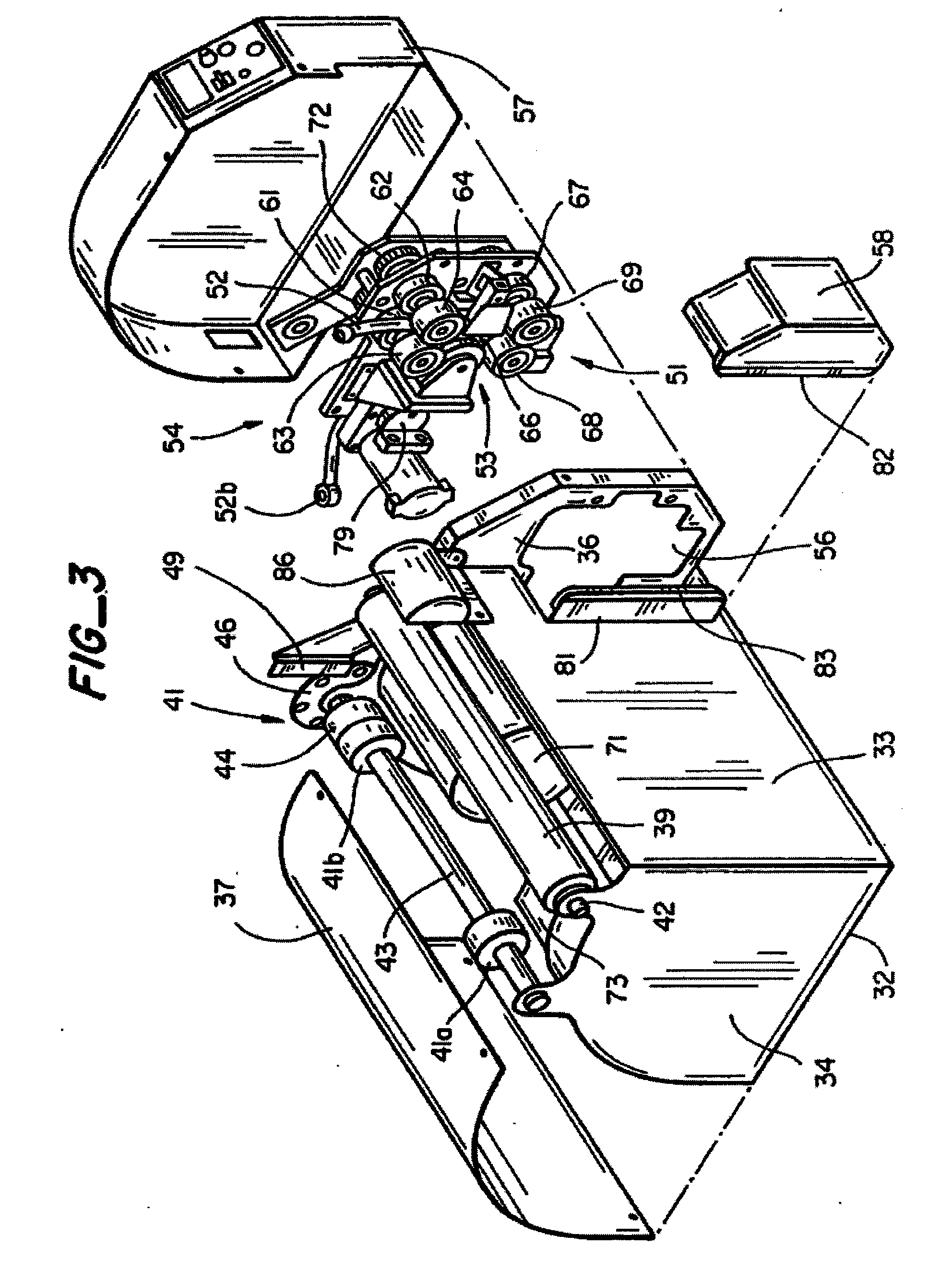

Method And Apparatus For Inflating And Sealing Packing Cushions Employing Film Recognition Controller

An apparatus for inflating and sealing packing cushions utilizes a controller adapted for acquiring information from preconfigured film material and automatically setting one or more operation parameters suitable for inflating and sealing the film. The controller can avoid or limit the need for user input, thus simplifying use of the apparatus.

Owner:PREGIS INNOVATIVE PACKAGING

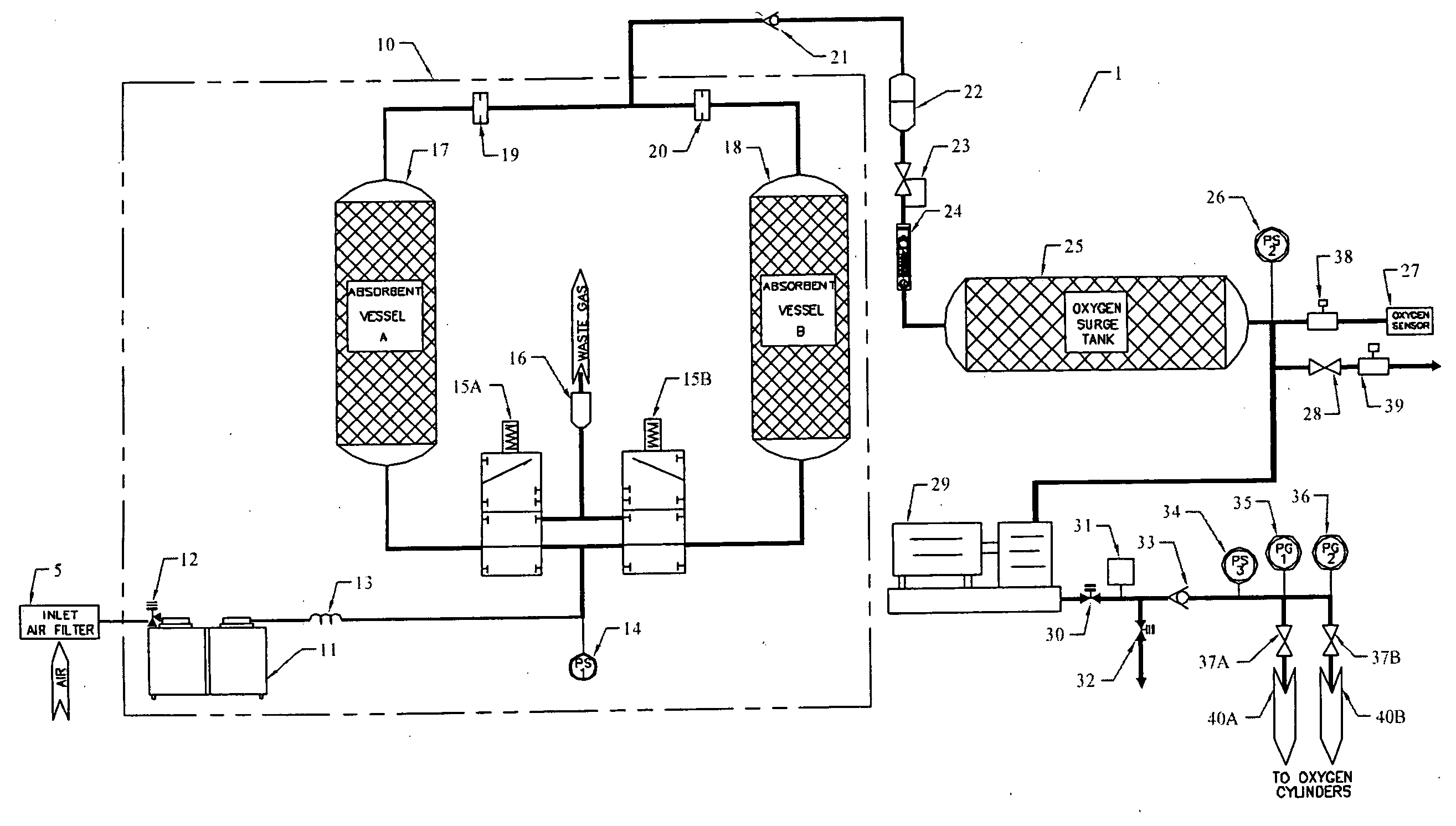

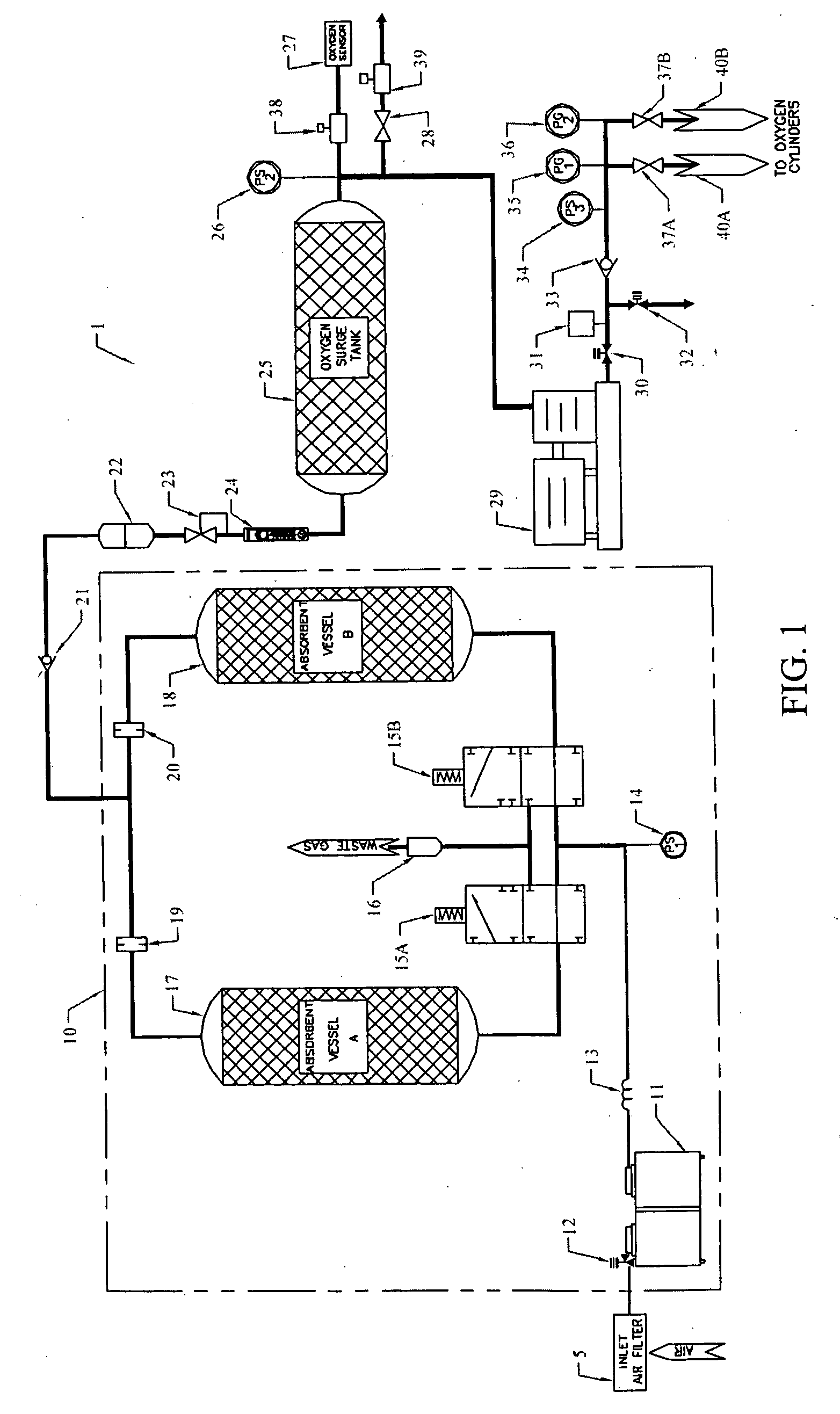

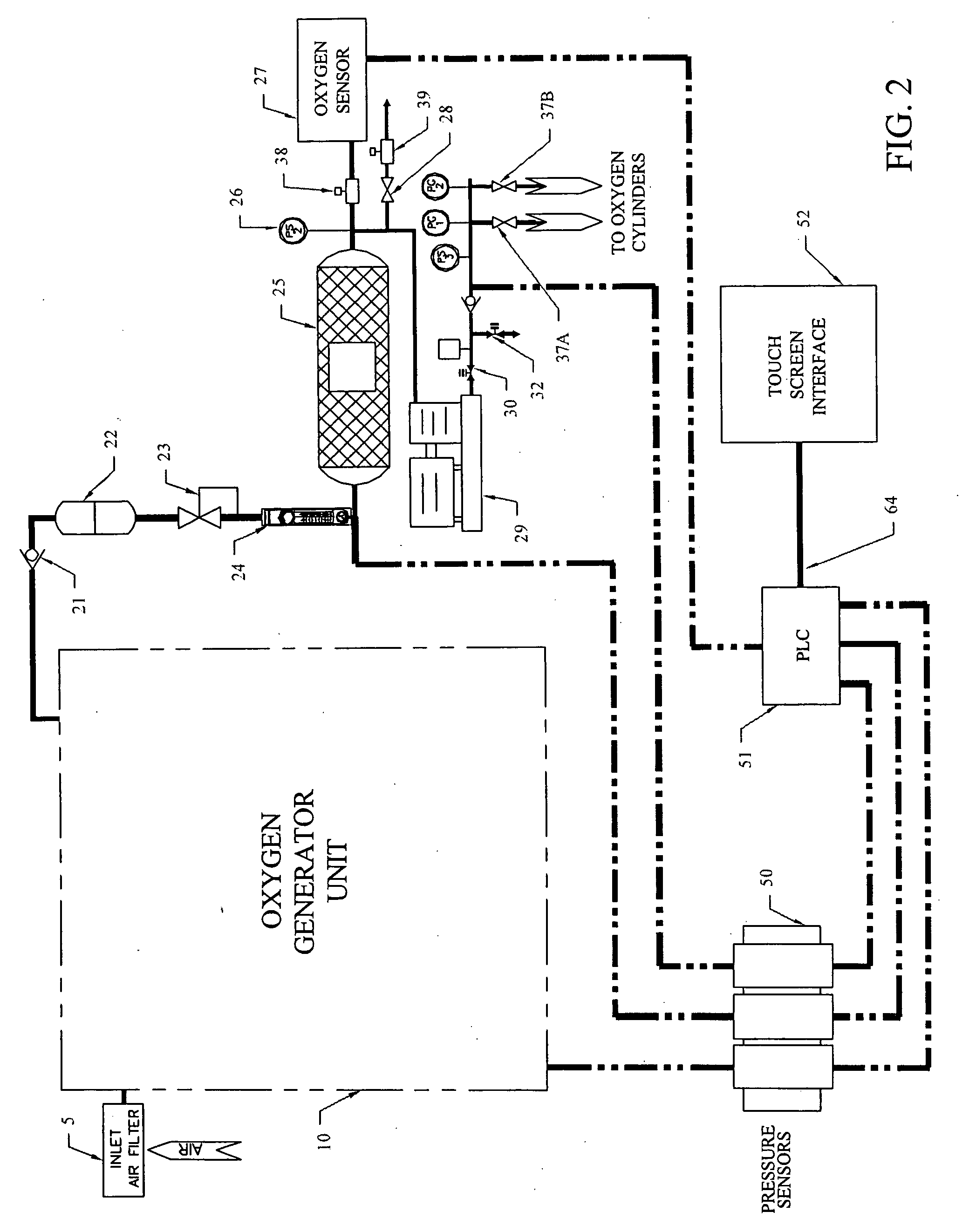

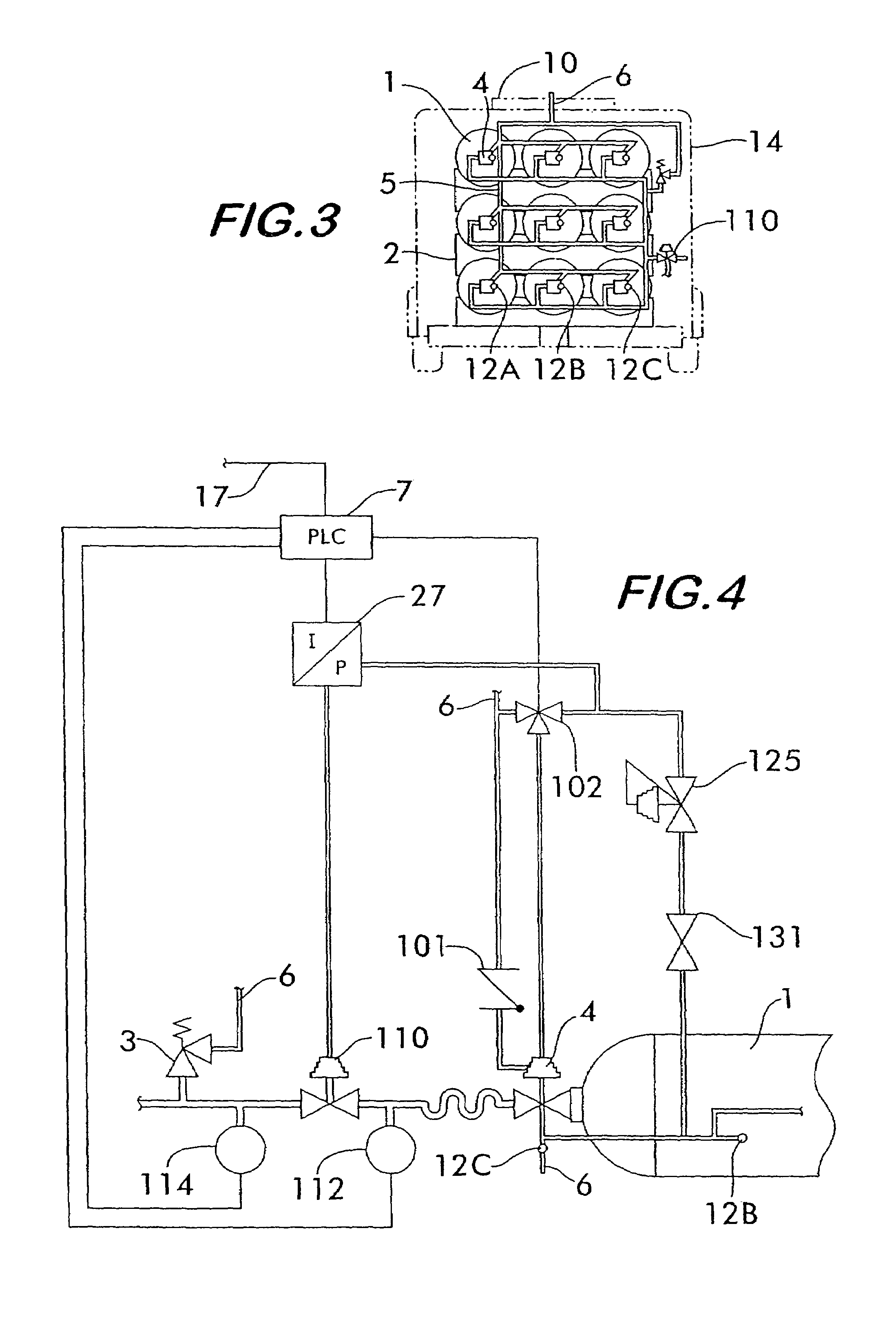

Oxygen filling apparatus

InactiveUS20060260711A1Minimize problemMinimize inefficiencyVessel mounting detailsLiquid fillingGraphicsOxygen sensor

The present invention provides an improved oxygen filling apparatus adapted to provide oxygen to oxygen cylinders for use in connection with EMS services, ambulances, fire departments, hospitals, veterinary clinics and other services and applications. The present invention includes an oxygen generator unit having at least one molecular sieve, a plurality of pressure sensors, an oxygen sensor, and a PLC control unit with a touch sensitive graphical screen interface configured to selectively display current and historical operational parameters. The oxygen filling apparatus may be adapted for wall mounting and may include a data communications port for remote access, monitoring and troubleshooting.

Owner:AUDUBON MACHINERY CORP

Compressed air energy storage system utilizing two-phase flow to facilitate heat exchange

InactiveUS20100326068A1Facilitate heat exchangeImprove efficiencyElectrical storage systemServomotor componentsThermal energy storageEngineering

A compressed-air energy storage system according to embodiments of the present invention comprises a reversible mechanism to compress and expand air, one or more compressed air storage tanks, a control system, one or more heat exchangers, and, in certain embodiments of the invention, a motor-generator. The reversible air compressor-expander uses mechanical power to compress air (when it is acting as a compressor) and converts the energy stored in compressed air to mechanical power (when it is acting as an expander). In certain embodiments, the compressor-expander comprises one or more stages, each stage consisting of pressure vessel (the “pressure cell”) partially filled with water or other liquid. In some embodiments, the pressure vessel communicates with one or more cylinder devices to exchange air and liquid with the cylinder chamber(s) thereof. Suitable valving allows air to enter and leave the pressure cell and cylinder device, if present, under electronic control.

Owner:LIGHTSAIL ENERGY

Compressed air energy storage system utilizing two-phase flow to facilitate heat exchange

InactiveUS20100326064A1Facilitate heat exchangeImprove efficiencyElectrical storage systemServomotor componentsThermal energy storageEngineering

A compressed-air energy storage system according to embodiments of the present invention comprises a reversible mechanism to compress and expand air, one or more compressed air storage tanks, a control system, one or more heat exchangers, and, in certain embodiments of the invention, a motor-generator. The reversible air compressor-expander uses mechanical power to compress air (when it is acting as a compressor) and converts the energy stored in compressed air to mechanical power (when it is acting as an expander). In certain embodiments, the compressor-expander comprises one or more stages, each stage consisting of pressure vessel (the “pressure cell”) partially filled with water or other liquid. In some embodiments, the pressure vessel communicates with one or more cylinder devices to exchange air and liquid with the cylinder chamber(s) thereof. Suitable valving allows air to enter and leave the pressure cell and cylinder device, if present, under electronic control.

Owner:LIGHTSAIL ENERGY

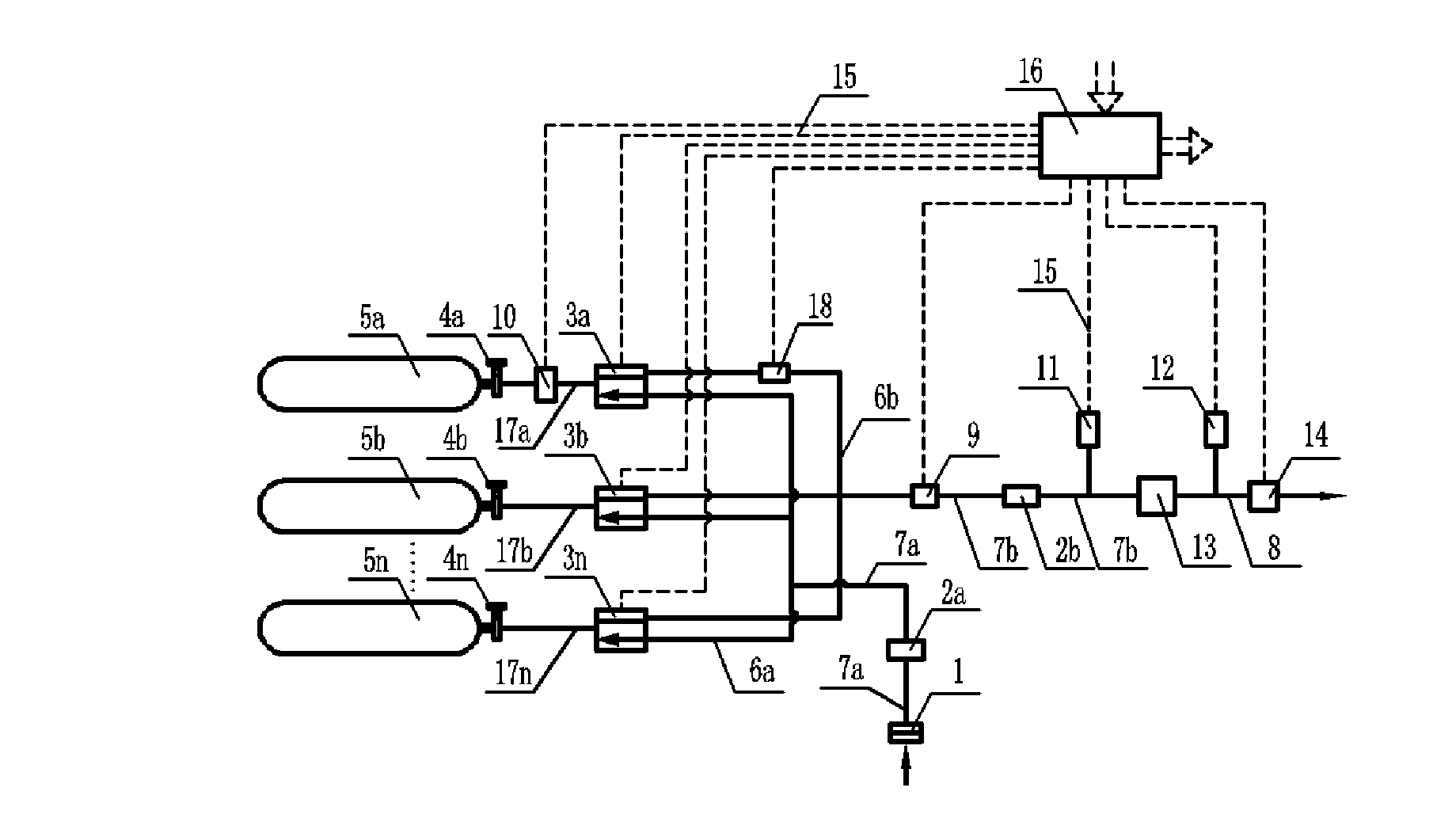

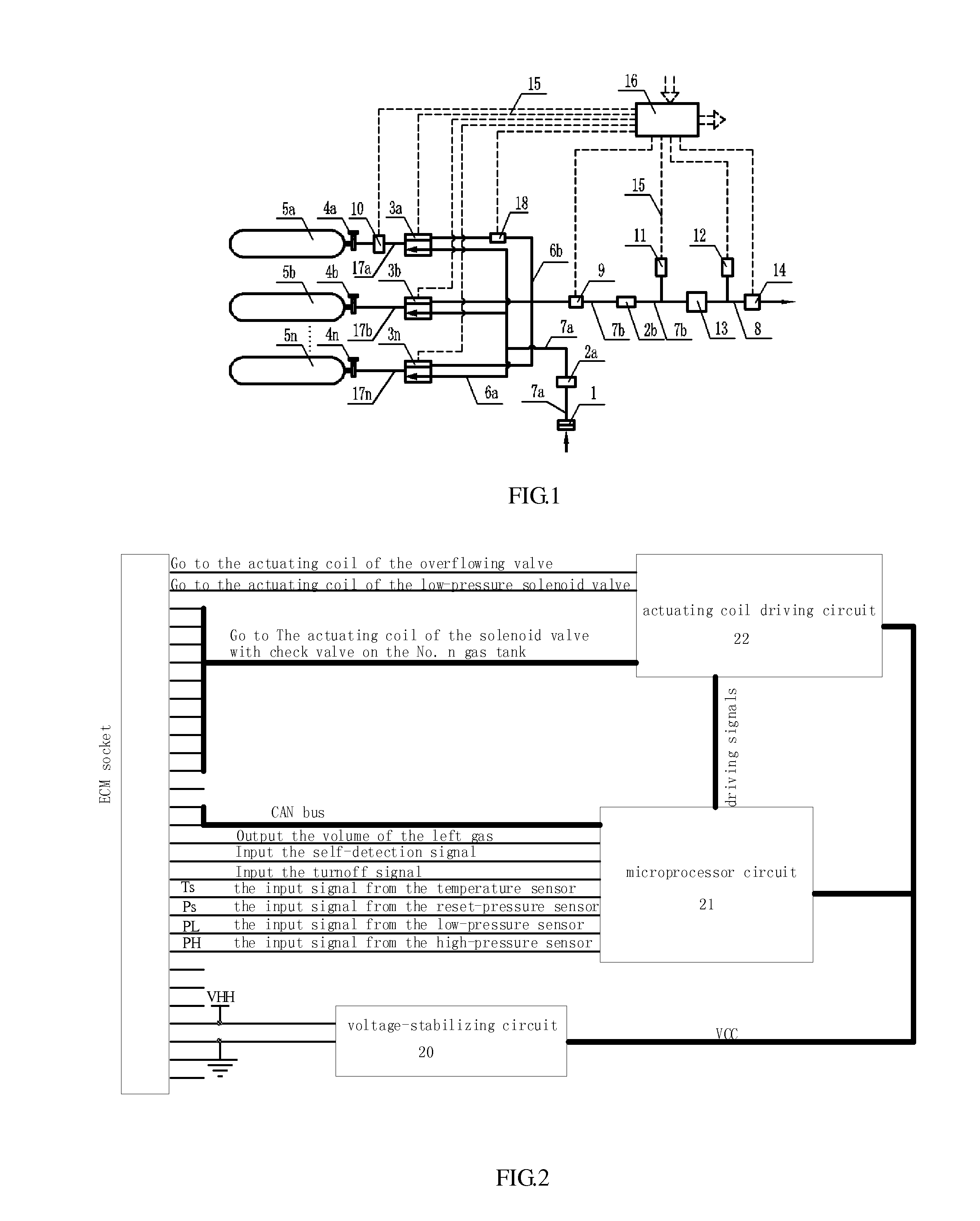

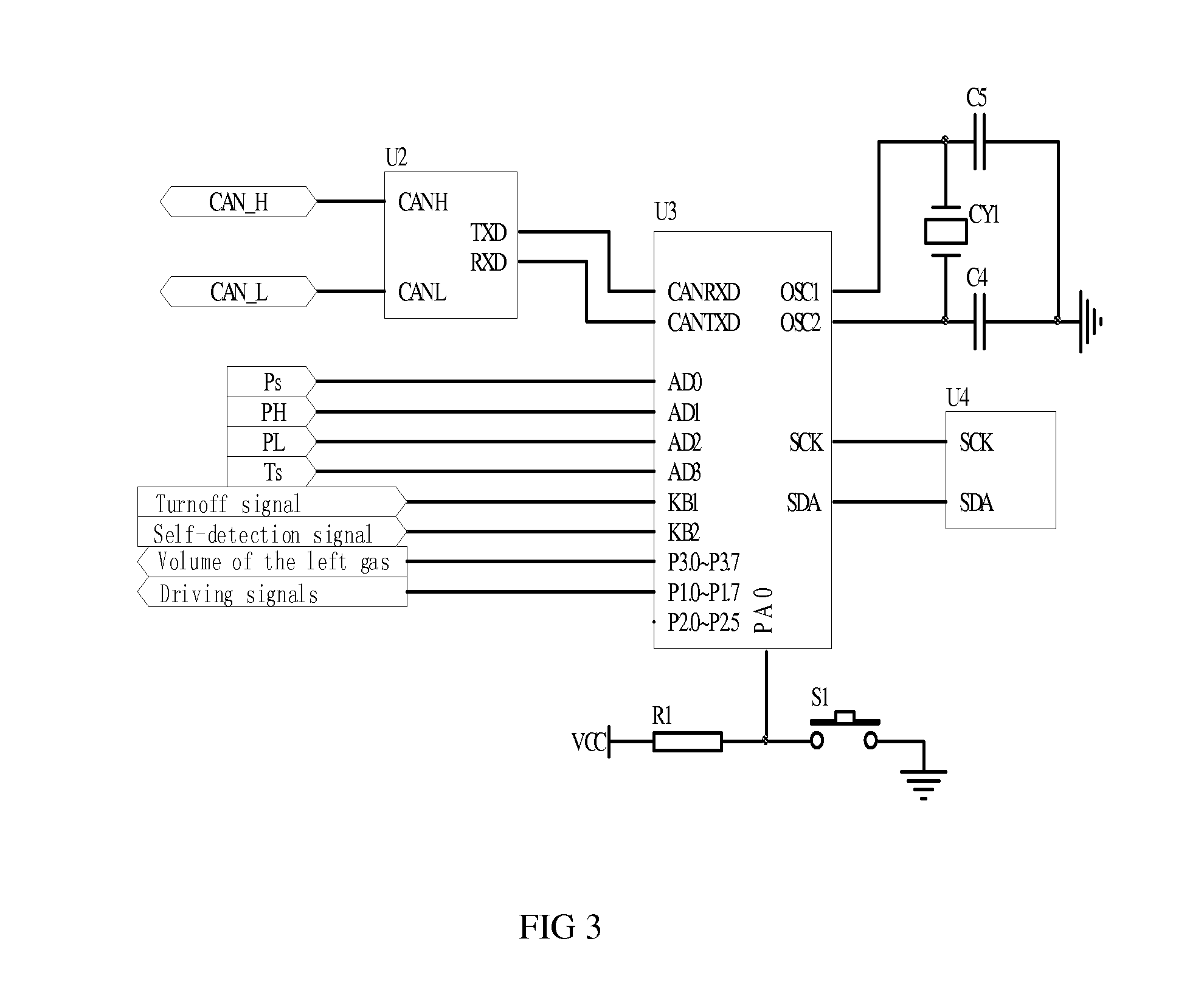

Low consumption and intelligent safe gas-supply system for gas tanks

ActiveUS20100193045A1Simple processImprove reliabilityGas handling applicationsGas handling/storage effectsSolenoid valveHigh pressure hydrogen

A low consumption and intelligent safe gas-supply system for gas tanks comprises: at least two gas tanks and gas tank valves installed on them, charge valves with check valve, at least two gas-filled parallel unit pipes, high-pressure sensor, at least two gas-supply parallel unit pipes, gas-supply main conduit, reset pressure sensor, at least two solenoid valves with check valve, and electronic control module ECM. The invention has the characteristics such as the gas tanks supply gas in sequence, intelligent control, security and reliability for use, low consumption, high display precision for gas volume, decompression transfinite alarm and convenience for installing, use and maintenance etc., and it can be used in the vehicle hydrogen supply system in the fuel cell vehicles or the vehicle compressed natural gas-supply system in the natural gas vehicles, and also the high-pressure hydrogen or natural gas-supply system for gas tanks on the ground.

Owner:BEIJING BOLKEN EQUIP

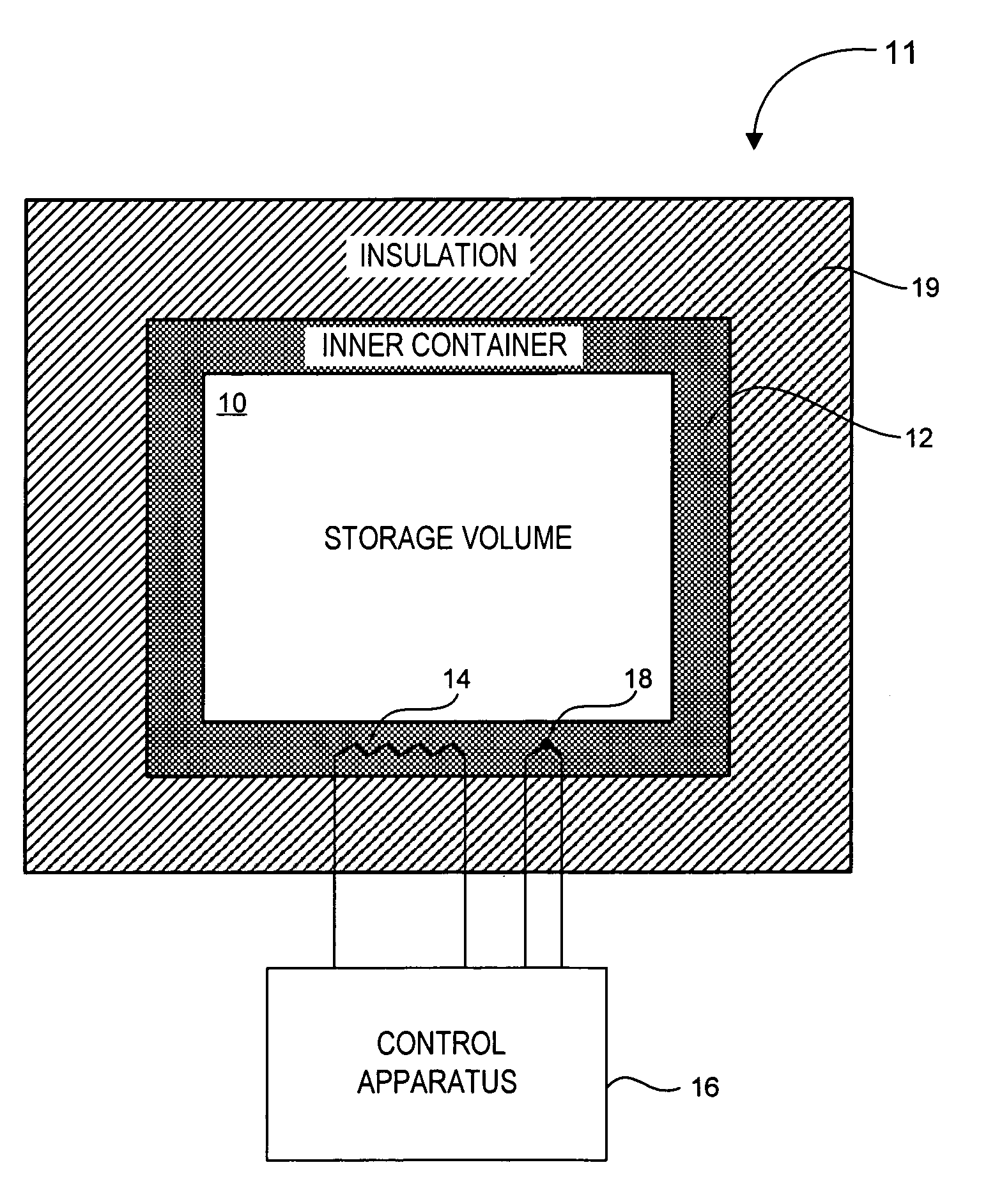

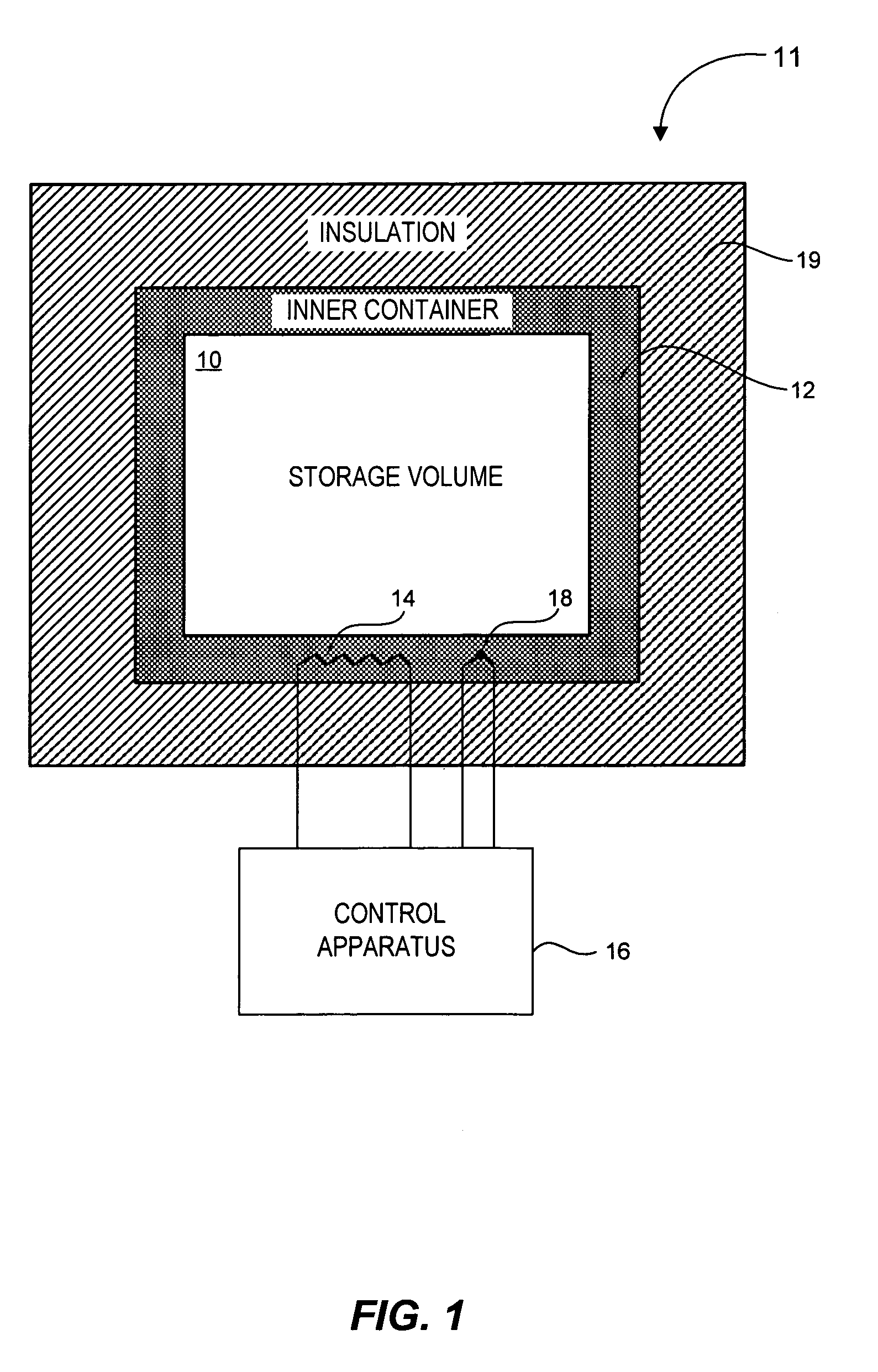

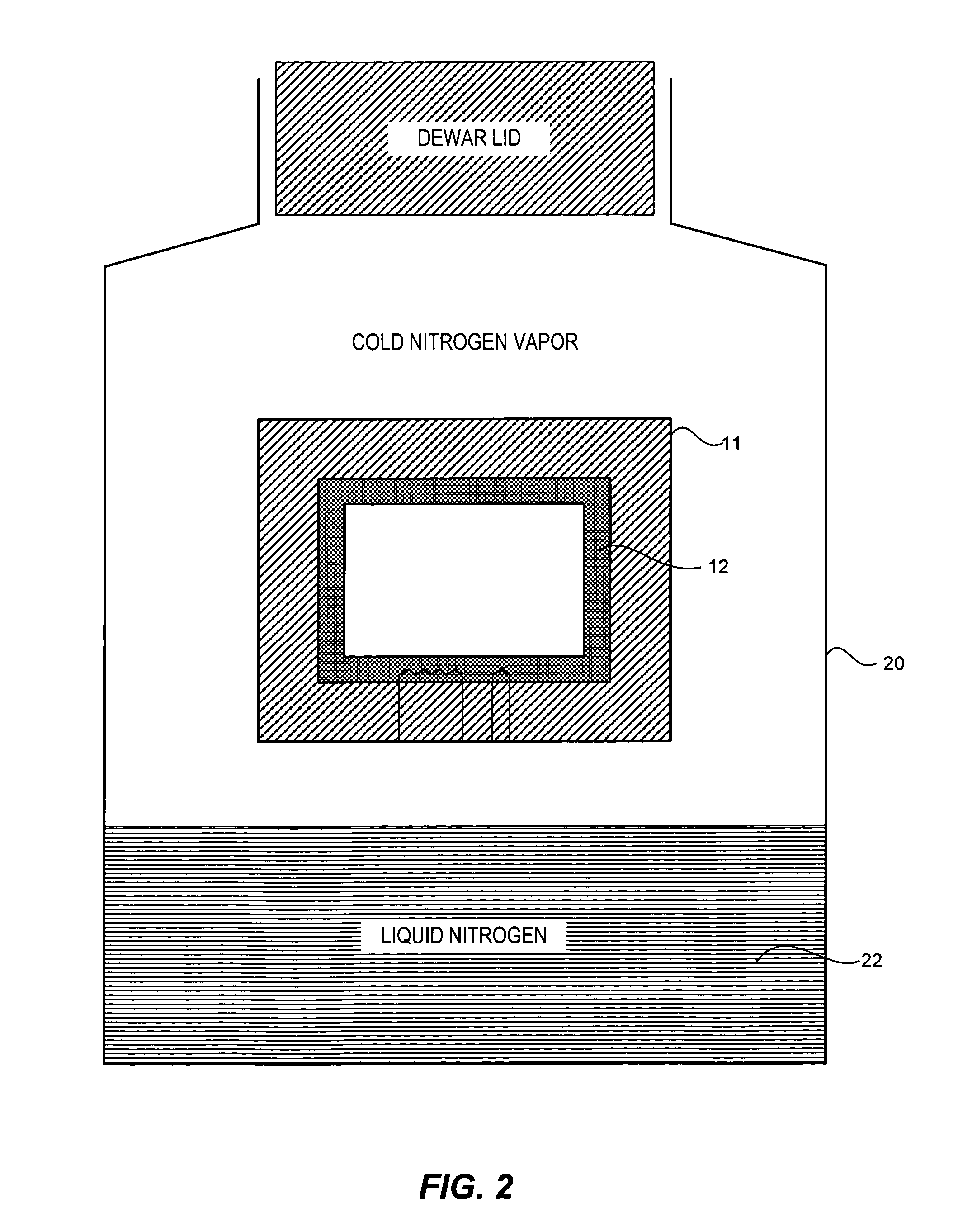

Cryogenic storage system

ActiveUS7278278B2Improve temperature stabilityNon-uniform temperatureVessel mounting detailsDomestic cooling apparatusThermal insulationEngineering

Owner:21ST CENTURY MEDICINE

Apparatus and process for integrated gas blending

InactiveUS20100224264A1Keep the pressureFrozen sweetsSemiconductor/solid-state device manufacturingDiluentEngineering

A system (10) for delivery of dilute fluid, utilizing an active fluid source (12), a diluent fluid source (14), a fluid flow metering device (24) for dispensing of one of the active and diluent fluids, a mixer (28) arranged to mix the active and diluent fluids to form a diluted active fluid mixture, and a monitor (42) arranged to sense concentration of active fluid and / or diluent fluid in the diluted active fluid mixture, and responsively adjust the fluid flow metering device (24) to achieve a predetermined concentration of active fluid in the diluted active fluid mixture. A pressure controller (38) is arranged to control flow of the other of the active and diluent fluids so as to maintain a predetermined pressure of the diluted active fluid mixture dispensed from the system. The fluid dispensed from the system then can be adjustably controlled by a flow rate controller, e.g., a mass flow controller, to provide a desired flow to a fluid-utilizing unit, such as a semiconductor process tool. An end point monitoring assembly is also described, for switching fluid sources (12, 15) to maintain continuity of delivery of the diluted active fluid mixture.

Owner:ENTEGRIS INC

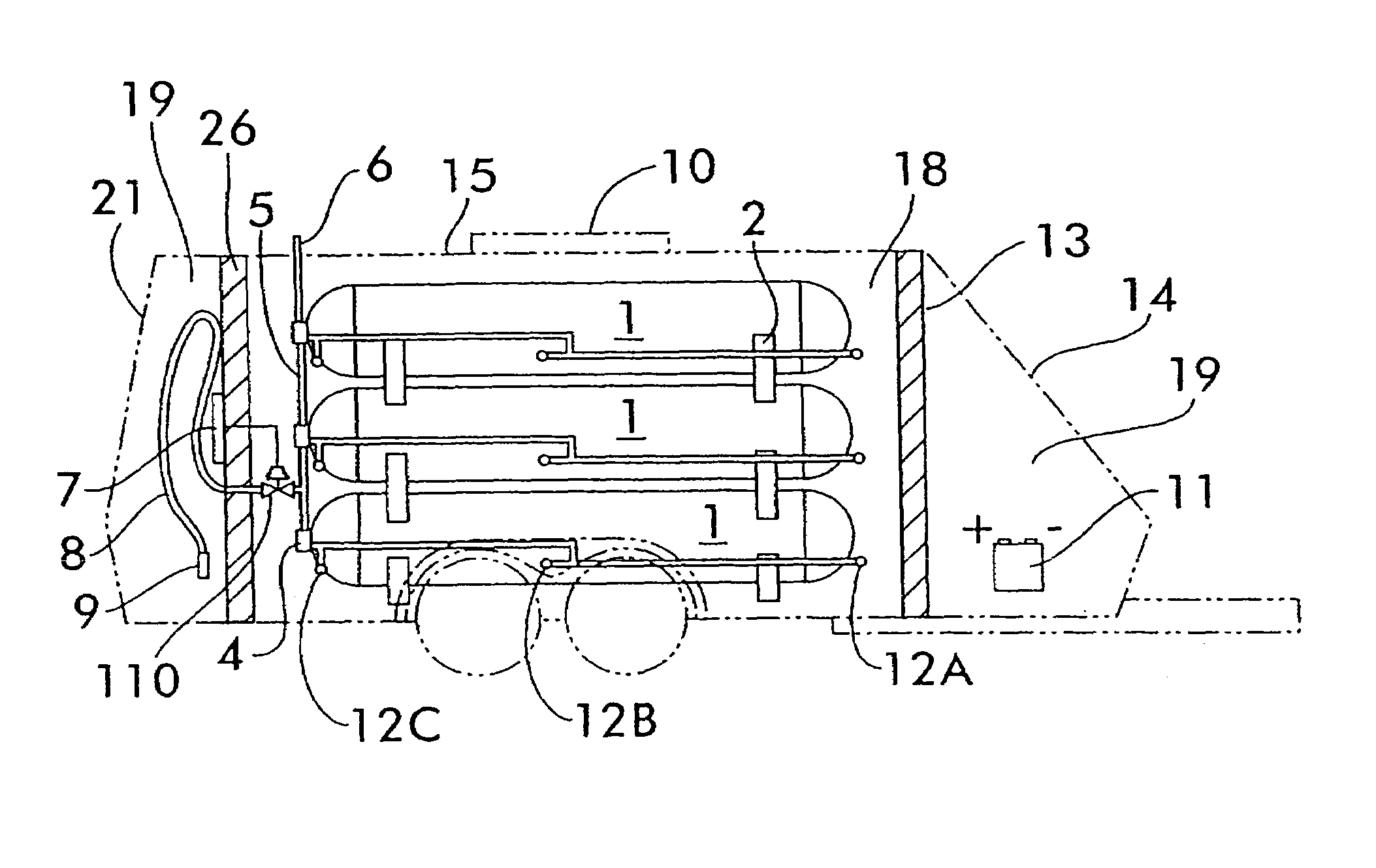

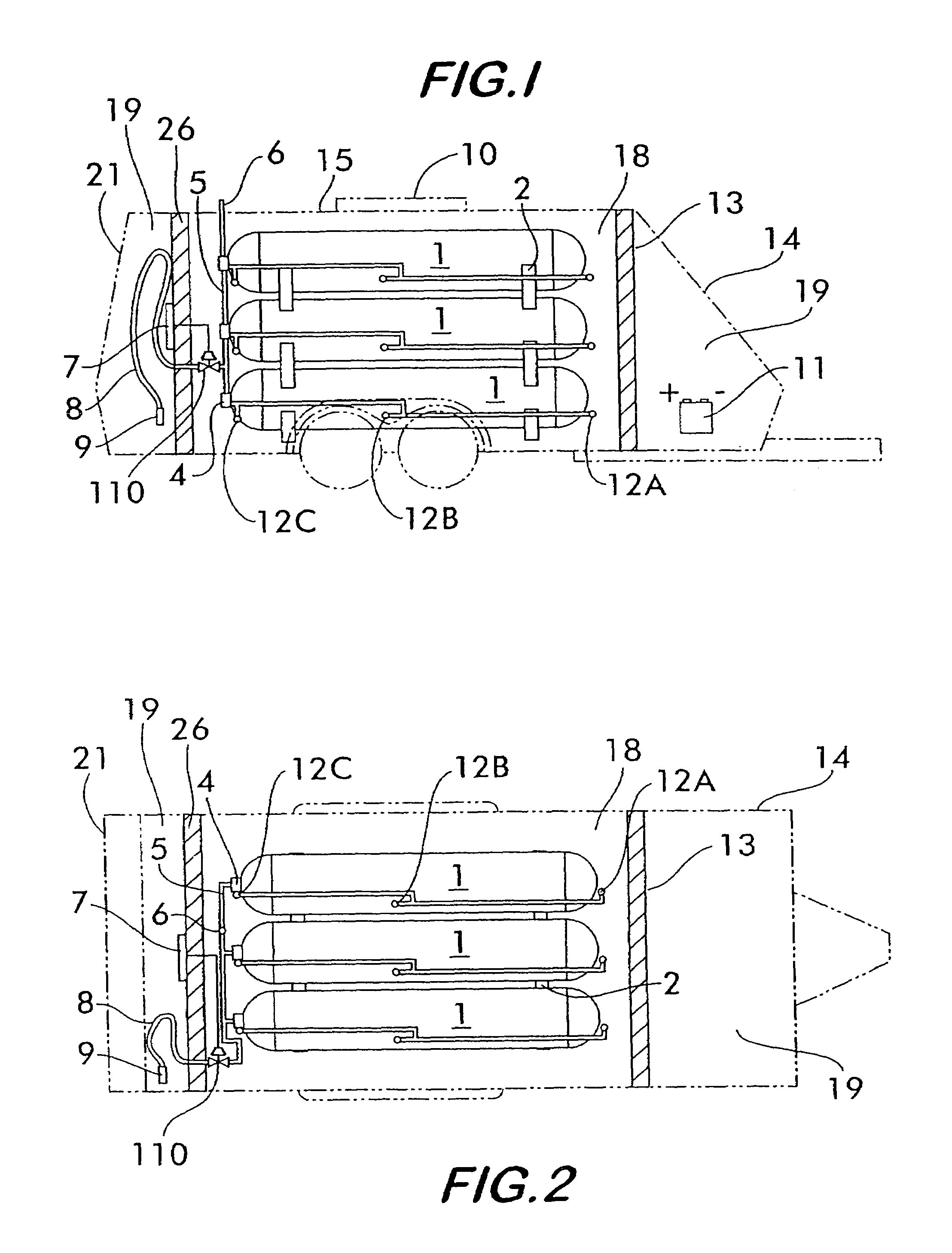

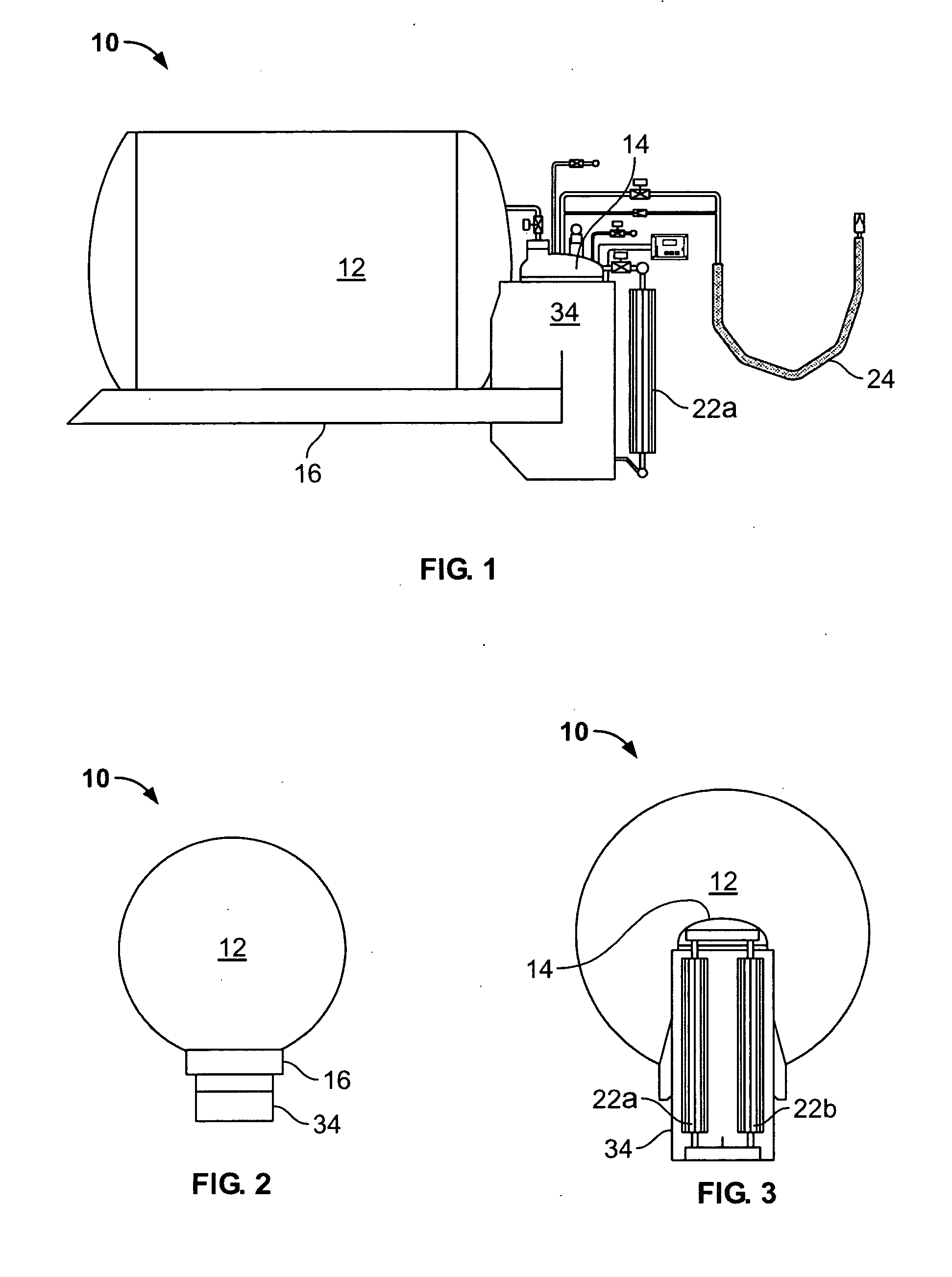

Self-contained mobile fueling station

A mobile self-contained self-powered station having a plurality of vessels delivers a pressurized fluid to a receiving tank (e.g., a fuel tank of a hydrogen-powered vehicle) without using mechanical compression, external electric power, or other external utilities. The station includes first and second vessels, a conduit in fluid communication with the receiving tank and each of the first and second vessels, means for transferring at least a portion of a quantity of the pressurized fluid from the first vessel to the receiving tank, means for measuring continuously a pressure differential between the increasing pressure in the receiving tank and the decreasing pressure in the first vessel, means for discontinuing the transfer from the first vessel when a predetermined limit value is reached, and means for transferring at least a portion of a quantity of the pressurized fluid from the second vessel to the receiving tank.

Owner:AIR PROD & CHEM INC

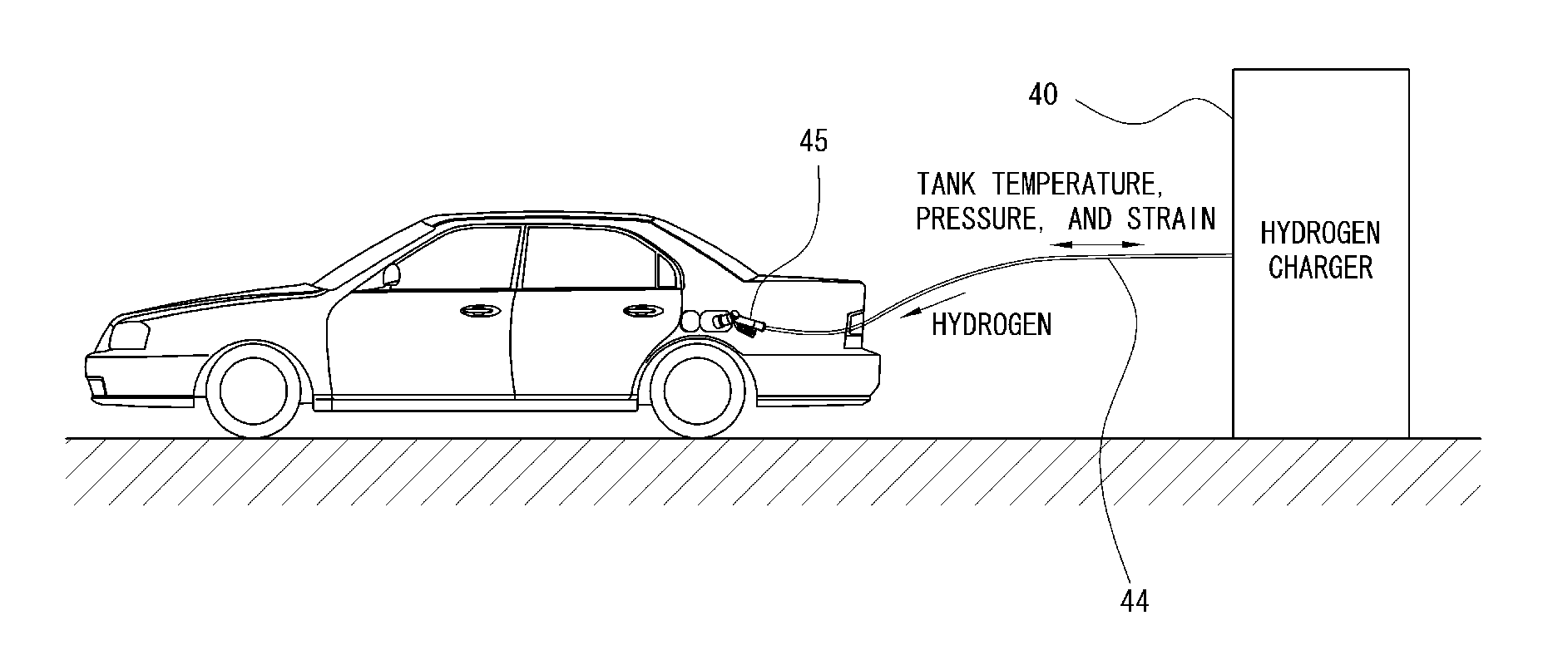

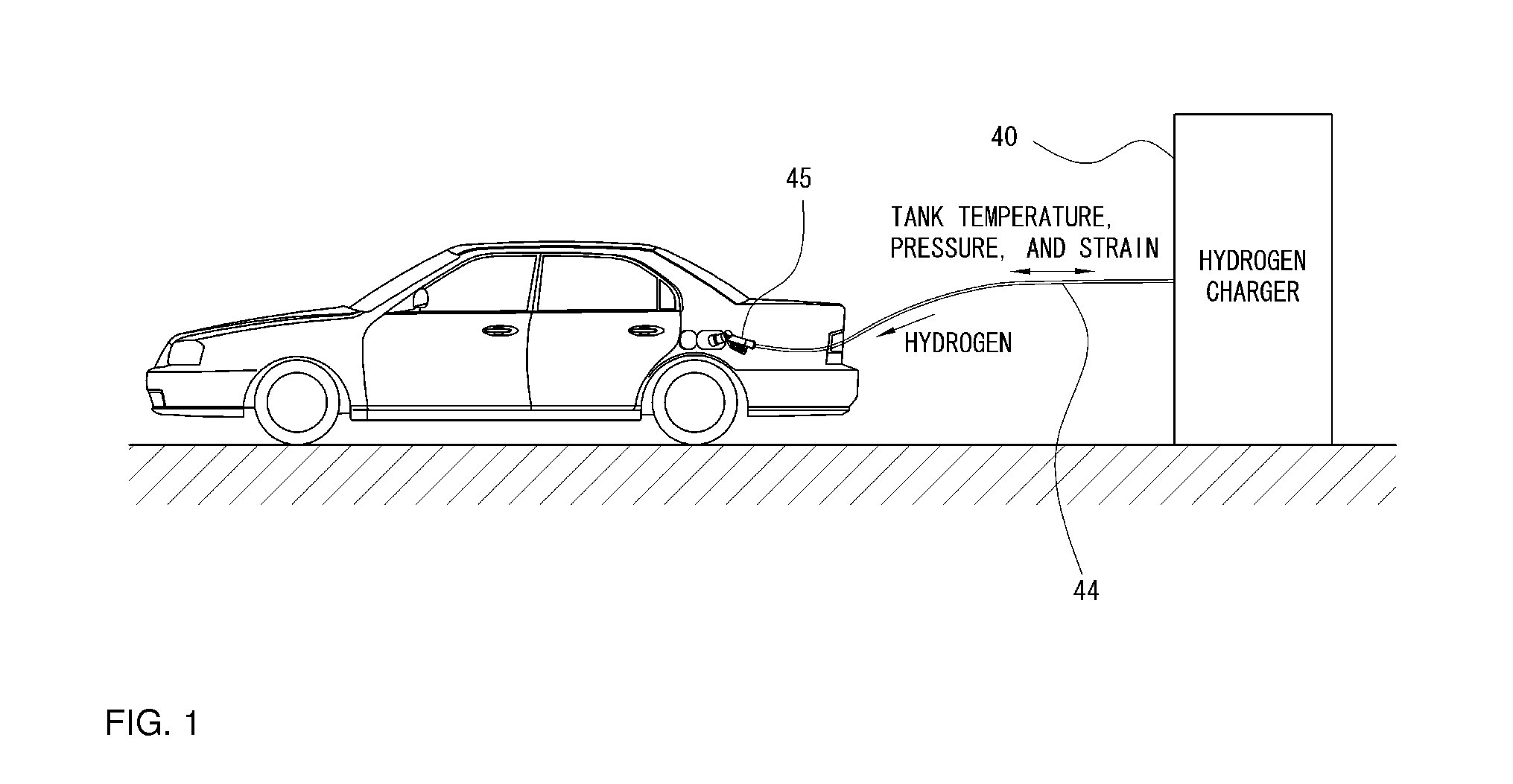

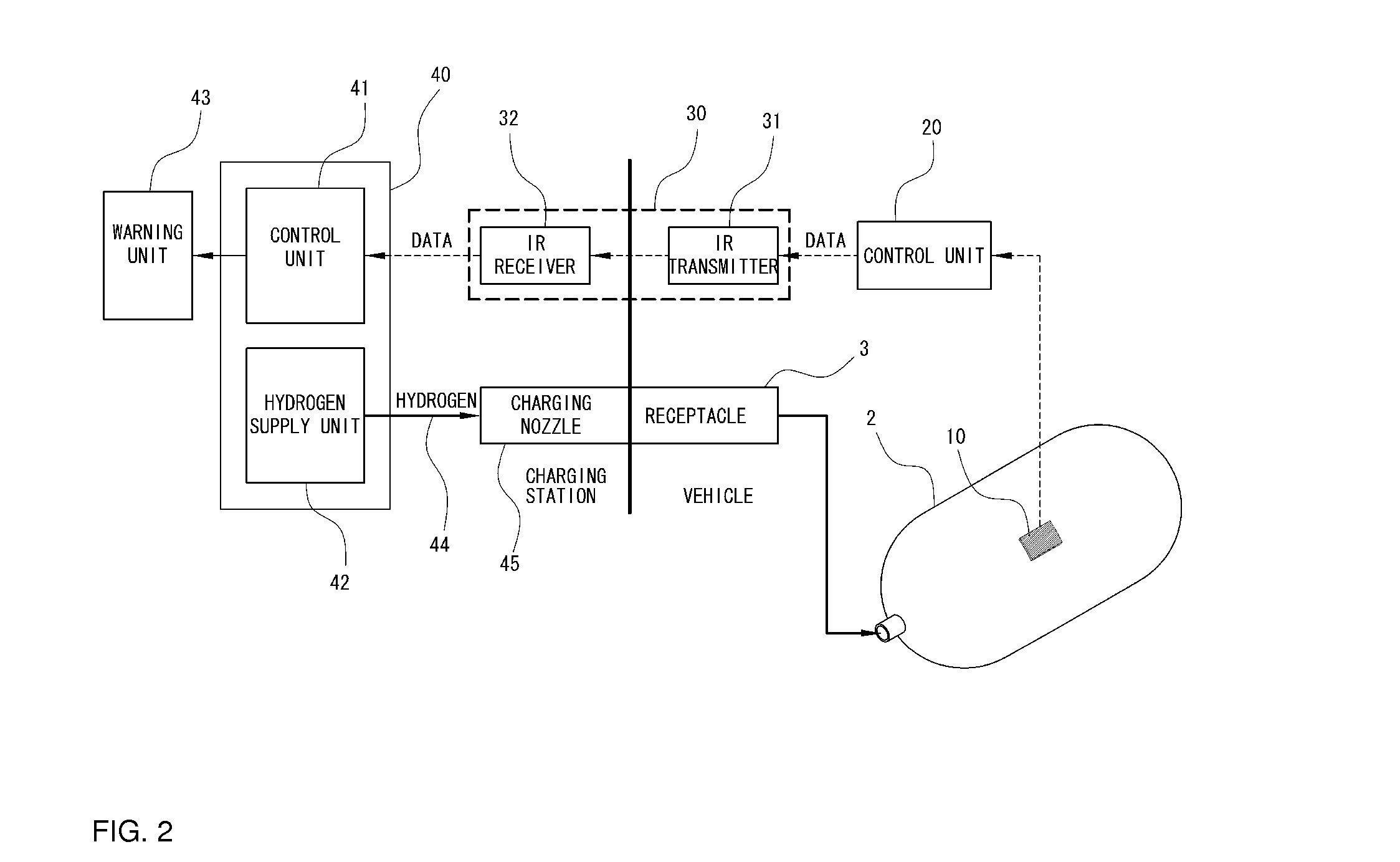

Real-time system for monitoring hydrogen tank expansion and a method for using same

InactiveUS20130139897A1Safely replenishingGas handling applicationsService pipe systemsCommunication unitWireless data

The present disclosure provides a system and method for safely charging hydrogen using real-time hydrogen tank expansion data. The system includes an expansion measurement unit, a vehicle-side control unit, a charging station-side control unit, and a wireless communication unit. The expansion measurement unit is disposed on a hydrogen tank of the vehicle, and measures the degree of expansion of the hydrogen tank and generates a corresponding output signal. The vehicle-side control unit converts the output signal into data wireless output signal. The charging station-side control unit stops hydrogen replenishment by a hydrogen charger when the wireless output signal indicates an unsafe degree of tank expansion based. The wireless communication unit is provided to perform wireless data communication between the vehicle-side control unit and the charging-side control unit.

Owner:HYUNDAI MOTOR CO LTD +1

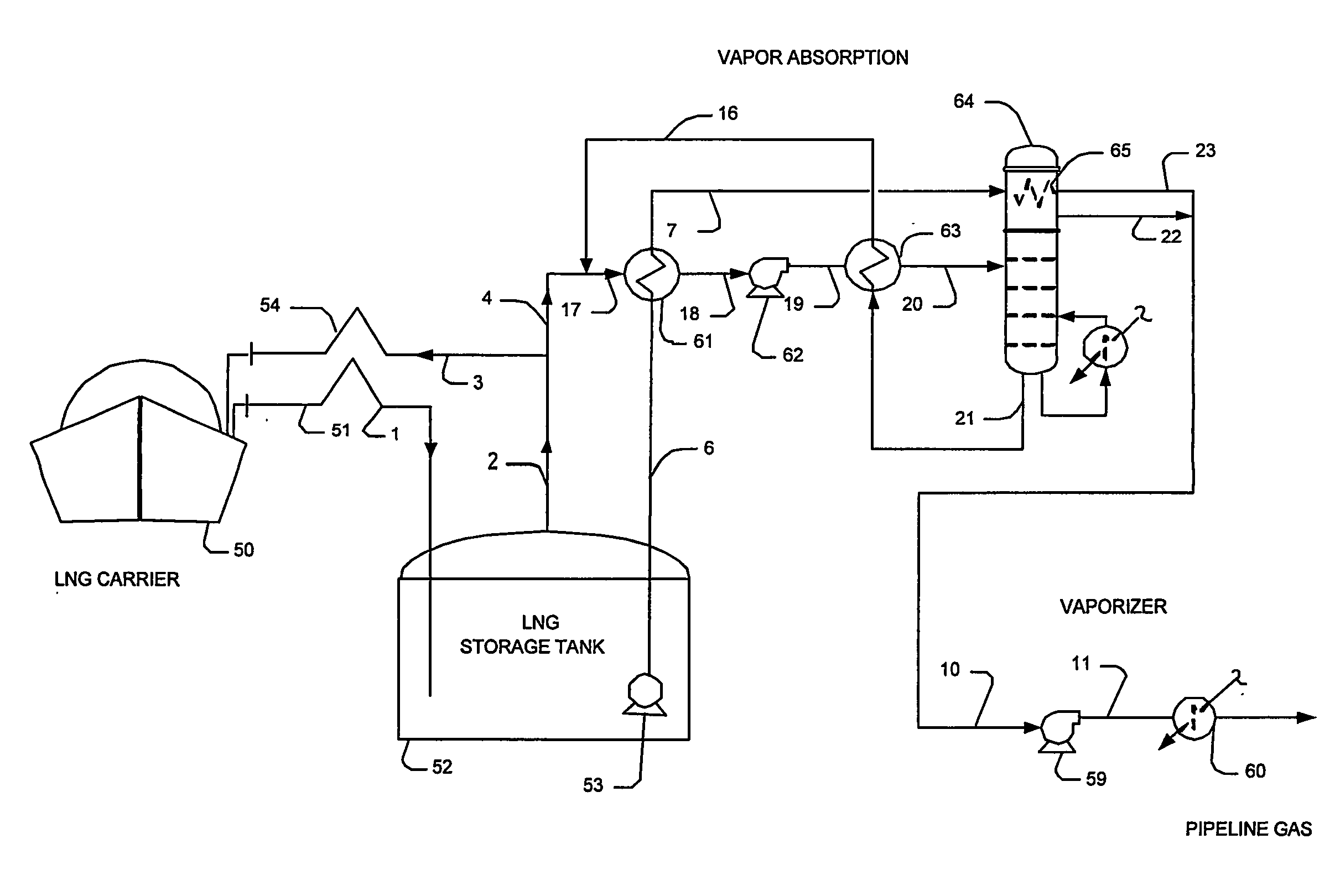

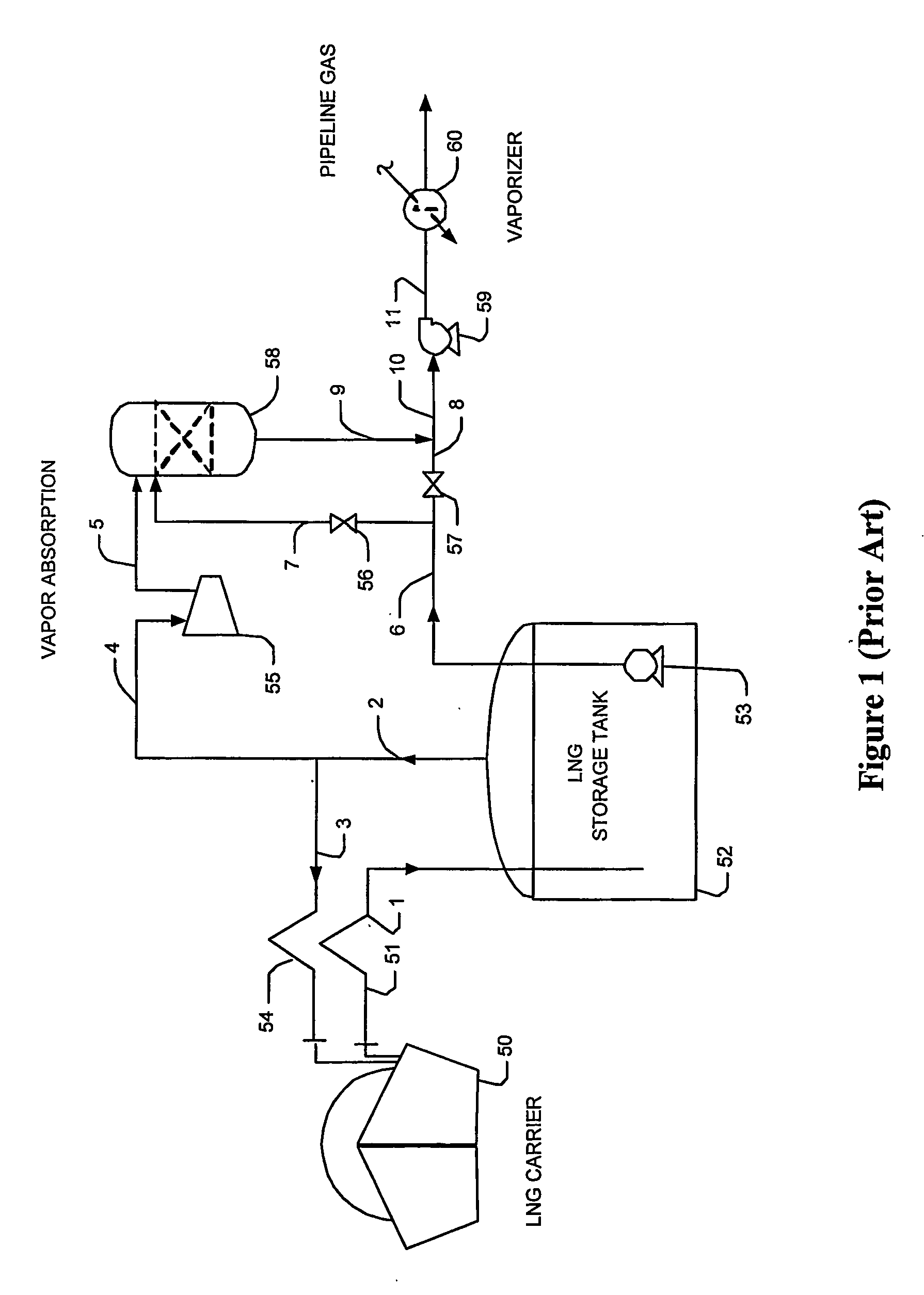

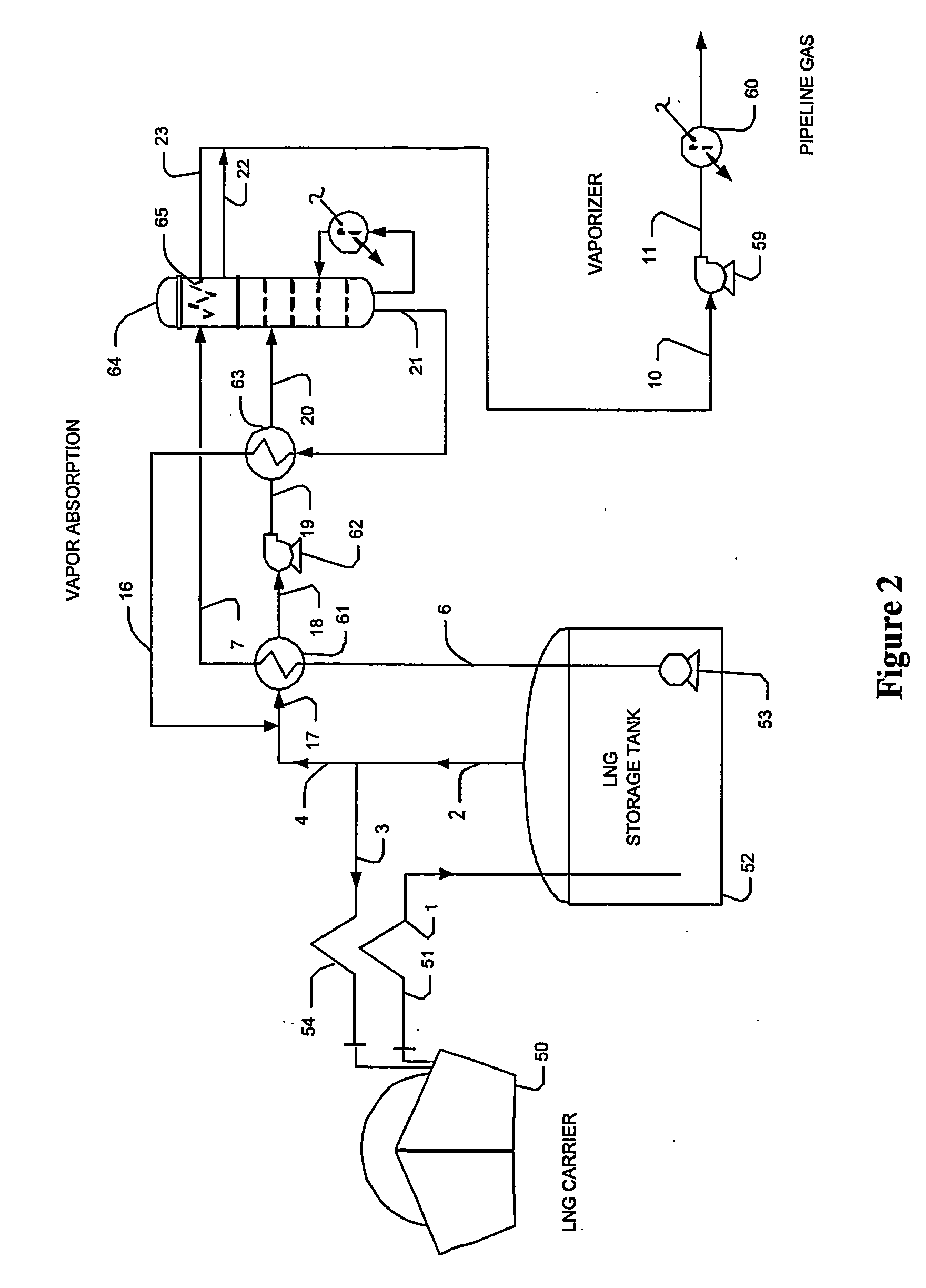

Lng vapor handling configurations and methods

InactiveUS20070125122A1Easy to condenseSolidificationLiquefactionProcess engineeringComponents of crude oil

LNG vapor from an LNG storage vessel is absorbed using C3 and heavier components provided by a fractionator that receives a mixture of LNG vapors and the C3 and heavier components as fractionator feed. In such configurations, refrigeration content of the LNG liquid from the LNG storage vessel is advantageously used to condense the LNG vapor after separation. Where desired, a portion of the LNG liquid may also be used as fractionator feed to produce LPG as a bottom product.

Owner:FLUOR TECH CORP

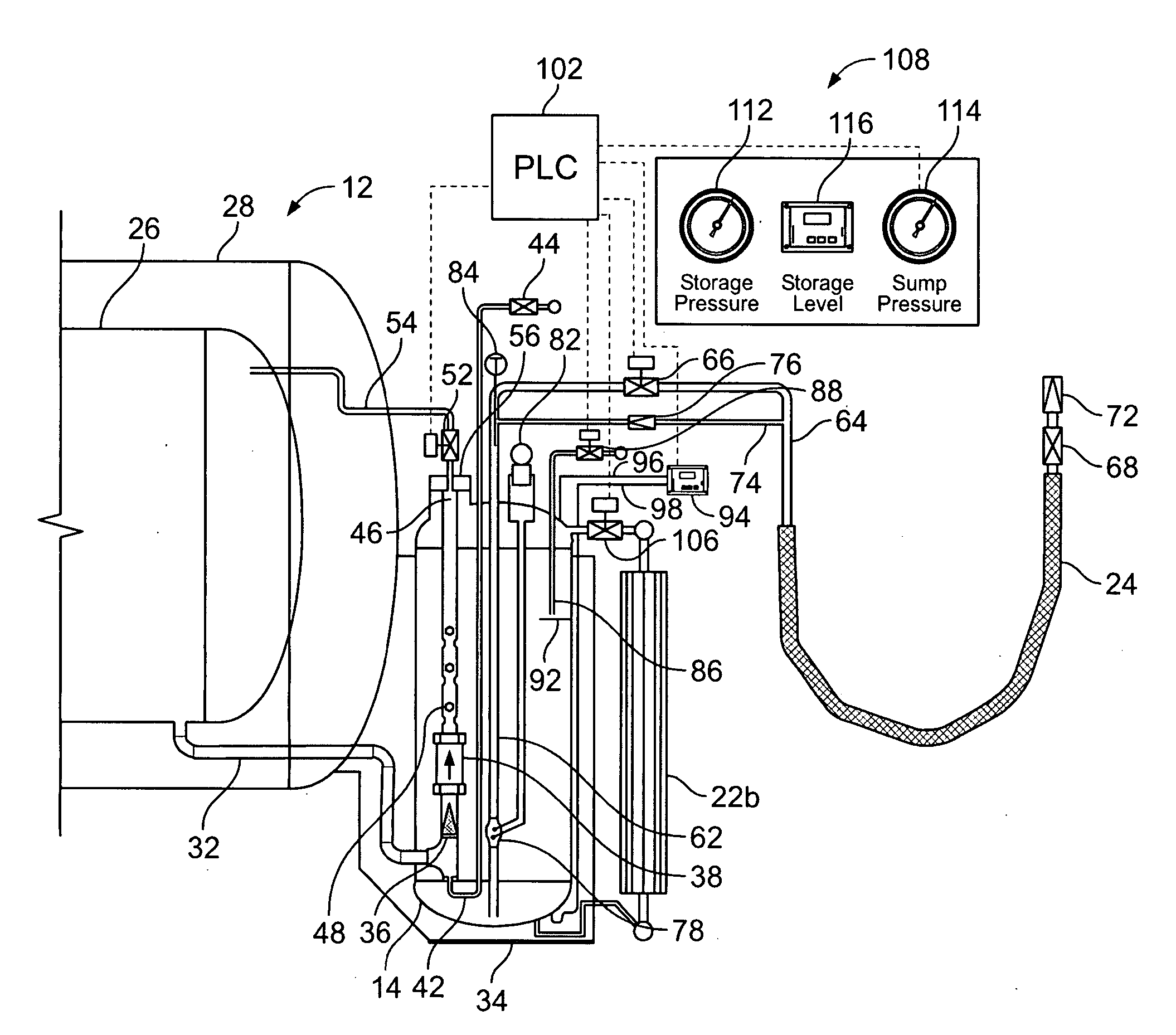

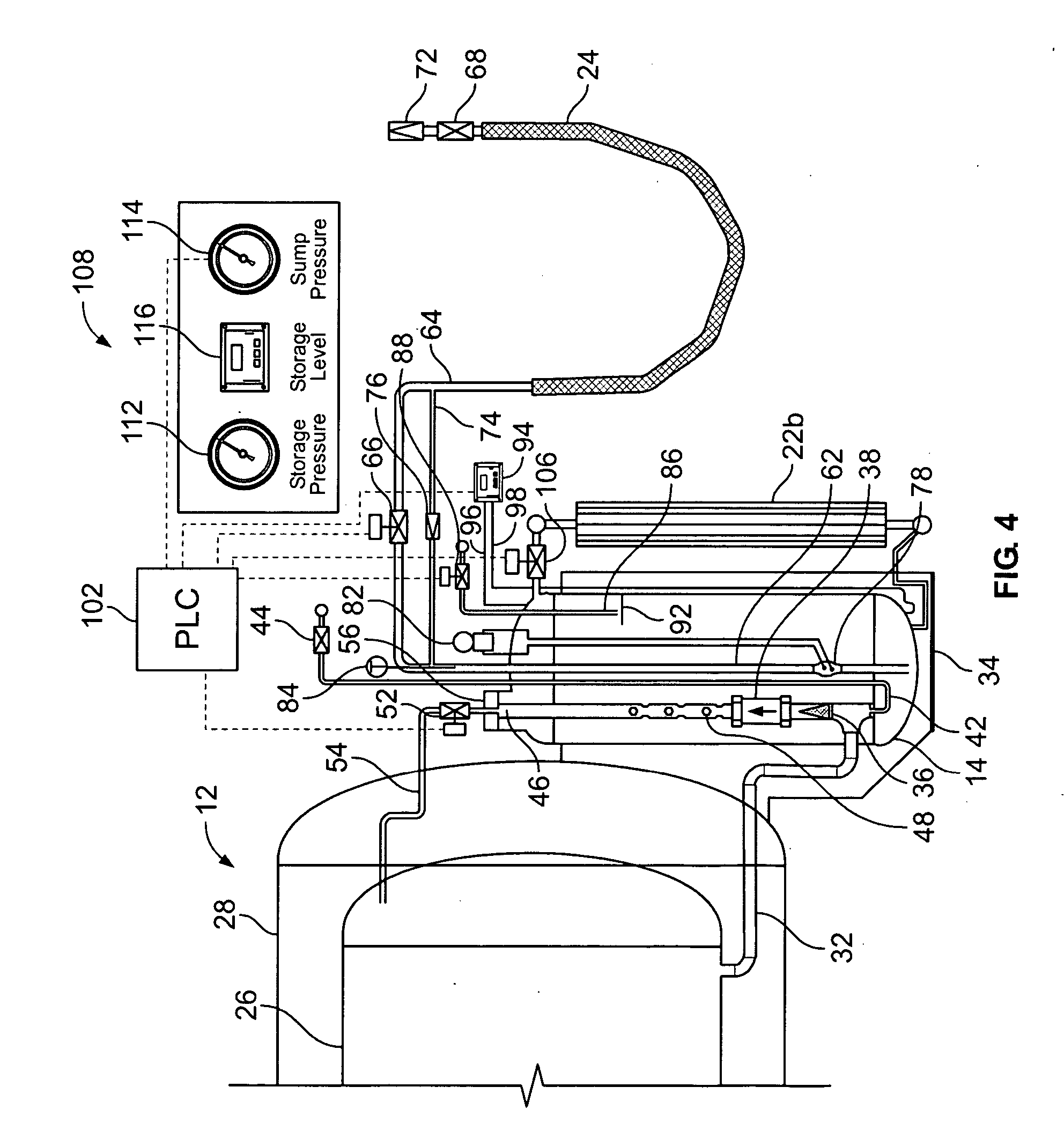

Cryogenic fluid dispensing system

InactiveUS20060218941A1Vessel mounting detailsVessel geometry/arrangement/sizeProcess engineeringHigh pressure

A mobile system for dispensing cryogenic liquid to a use point includes a low pressure bulk tank containing a supply of cryogenic liquid and a high pressure sump in communication with the bulk tank so as to receive cryogenic liquid therefrom. A heat exchanger is in communication with the sump and selectively receives and vaporizes a portion of cryogenic liquid from the sump. The resulting vapor is directed to the sump so as to increase the pressure therein. A pressure builder is in circuit between the sump and the bulk tank. The pressurized cryogenic liquid may be dispensed from the sump via a dispensing hose or directed to the pressure builder so as to pressurize the bulk tank. If the latter is selected, pressurized cryogenic liquid is dispensed from the bulk tank via a second dispensing hose. Operation of the system valves is automated by a controller.

Owner:CHART INDS

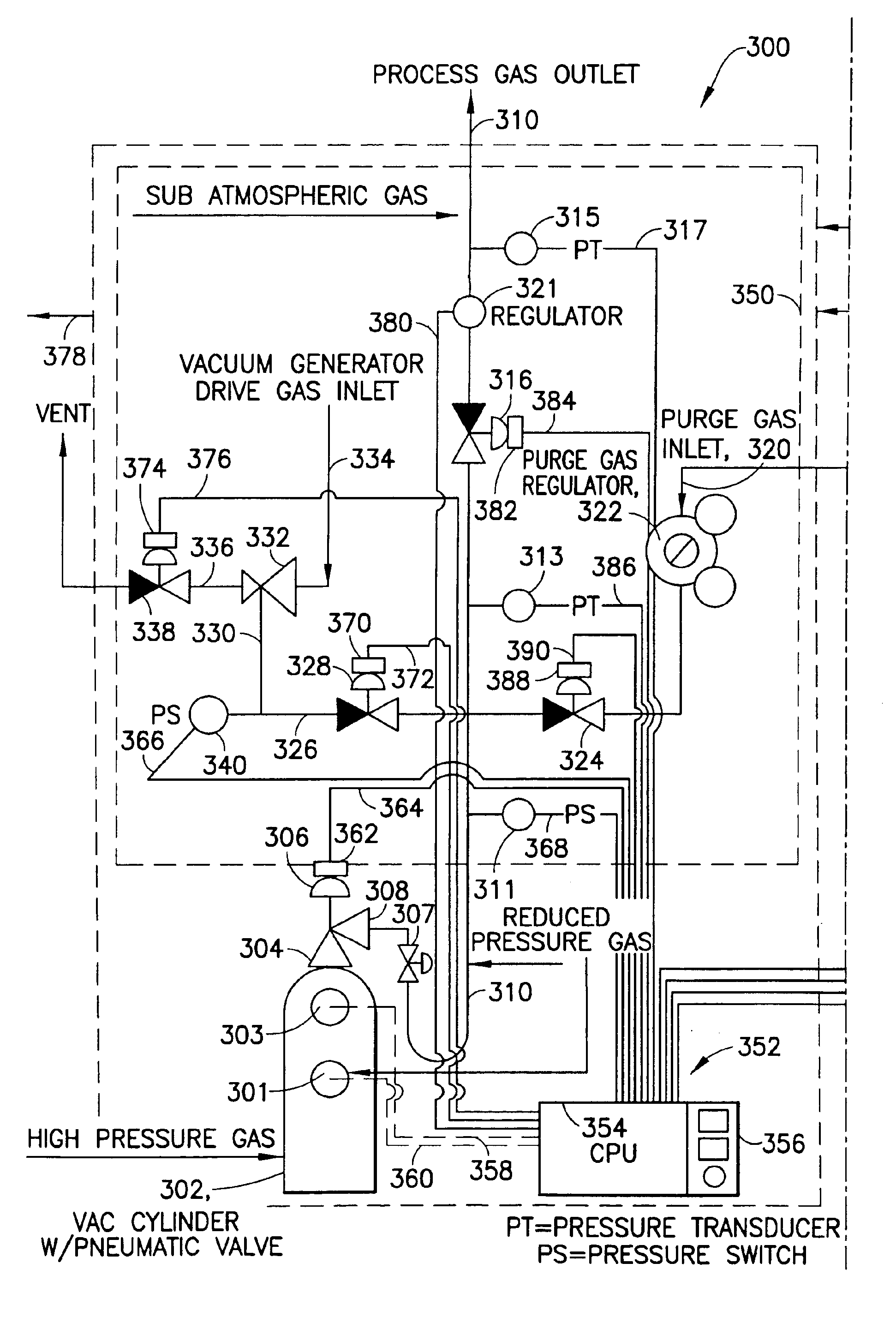

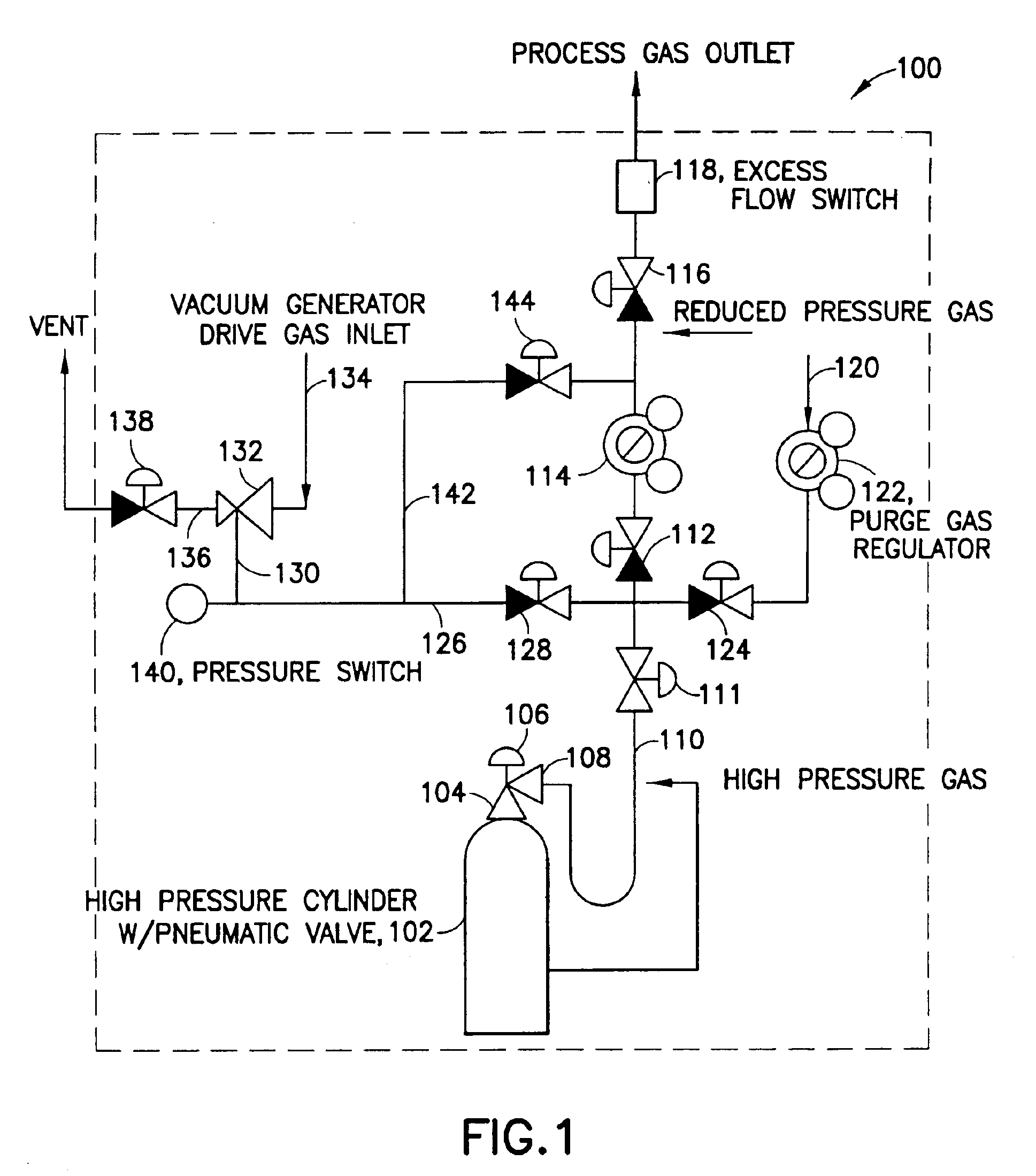

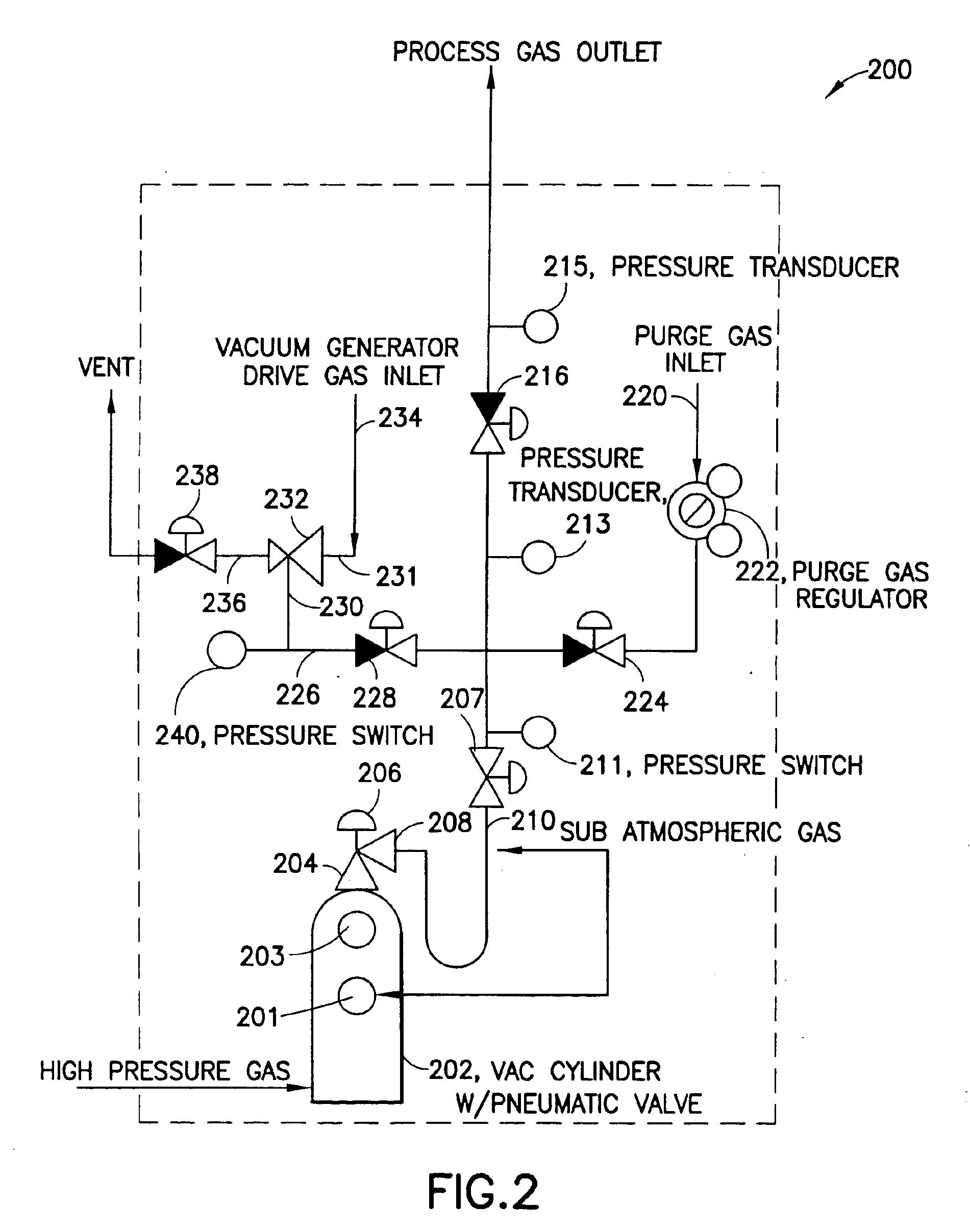

Pressure-based gas delivery system and method for reducing risks associated with storage and delivery of high pressure gases

InactiveUS6857447B2Extended service lifeInflated body pressure measurementFluid pressure measurement by electric/magnetic elementsProduct gasEngineering

Apparatus and method for dispensing a gas using a gas source coupled in selective flow relationship with a gas manifold. The gas manifold includes flow circuitry for discharging gas to a gas-using zone, and the gas source includes a pressure-regulated gas source vessel containing the gas at superatmospheric pressure. The pressure-regulated gas source vessel can be arranged with a pressure regulator at or within the vessel and a flow control valve coupled in flow relationship to the vessel, so that gas dispensed from the vessel flows through the regulator prior to flow through the flow control valve, and into the gas manifold. The apparatus and method permit an enhancement of the safety of storage and dispensing of toxic or otherwise hazardous gases used in semiconductor processes.

Owner:ENTEGRIS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com