Patents

Literature

8874results about "Pressure vessels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

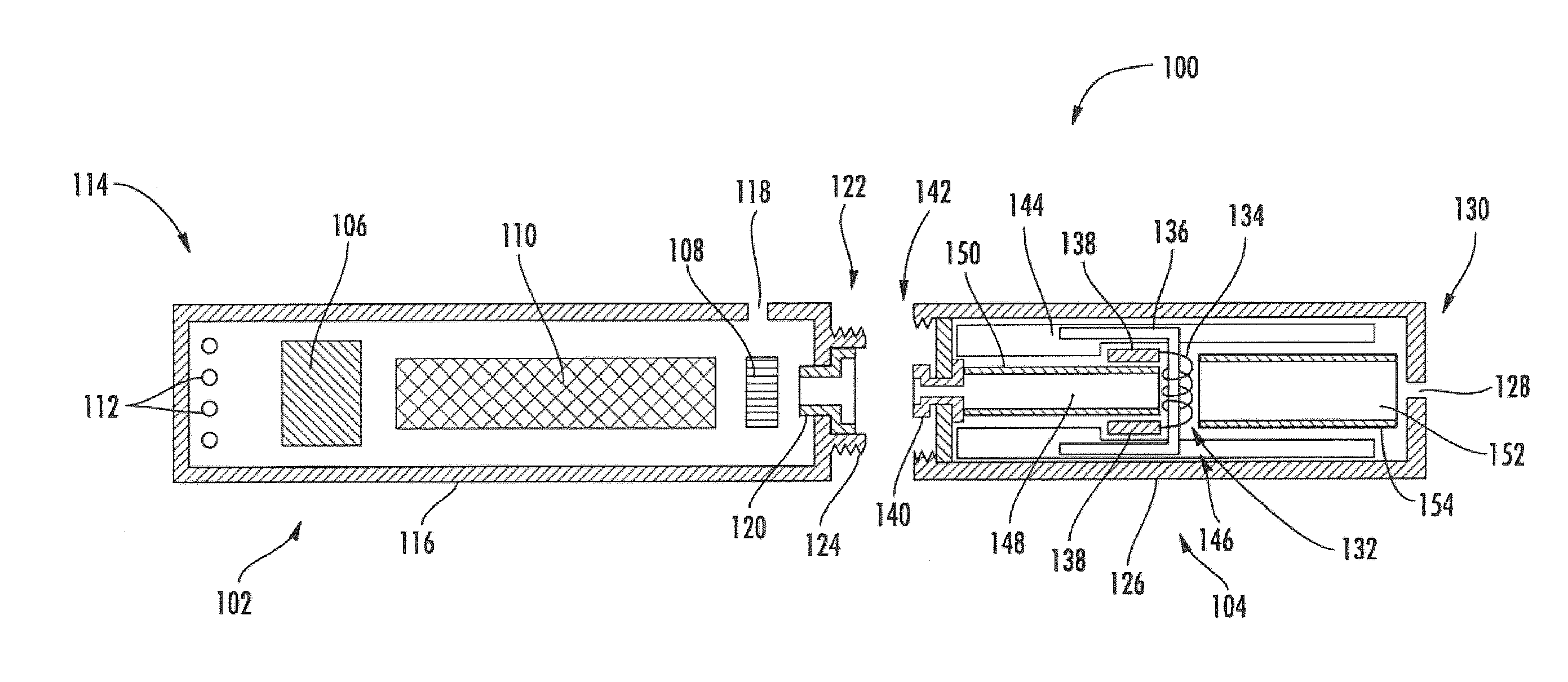

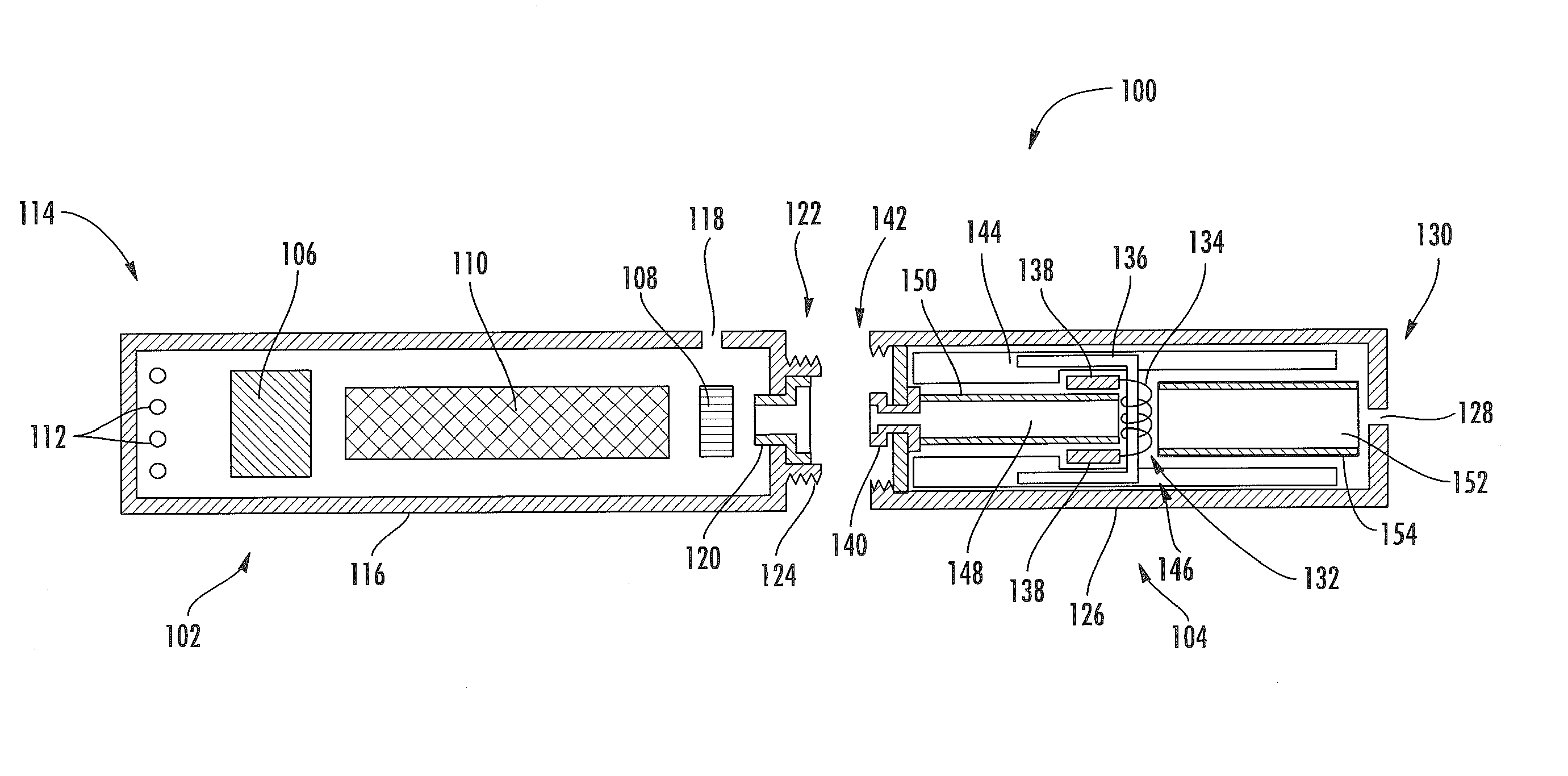

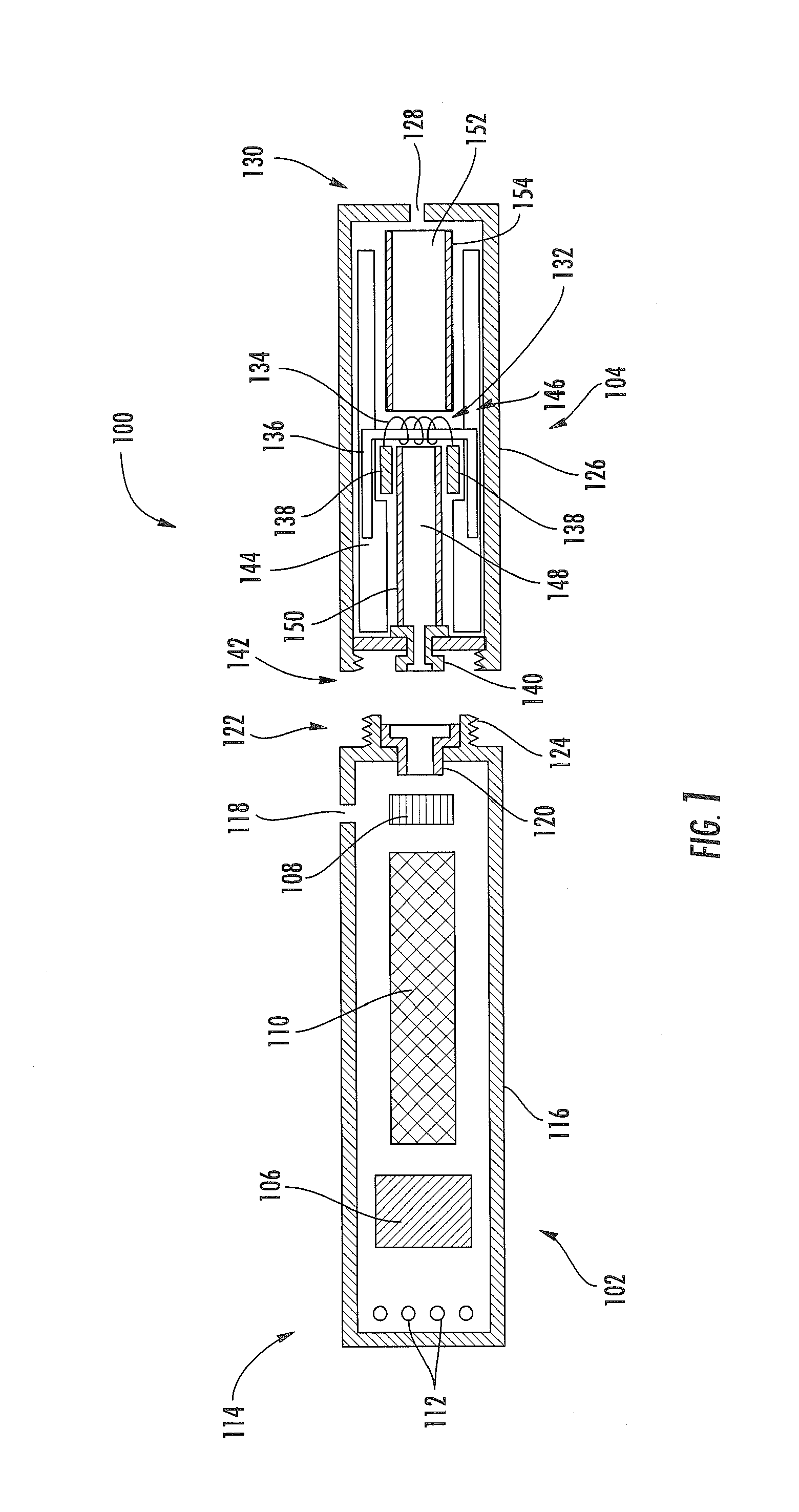

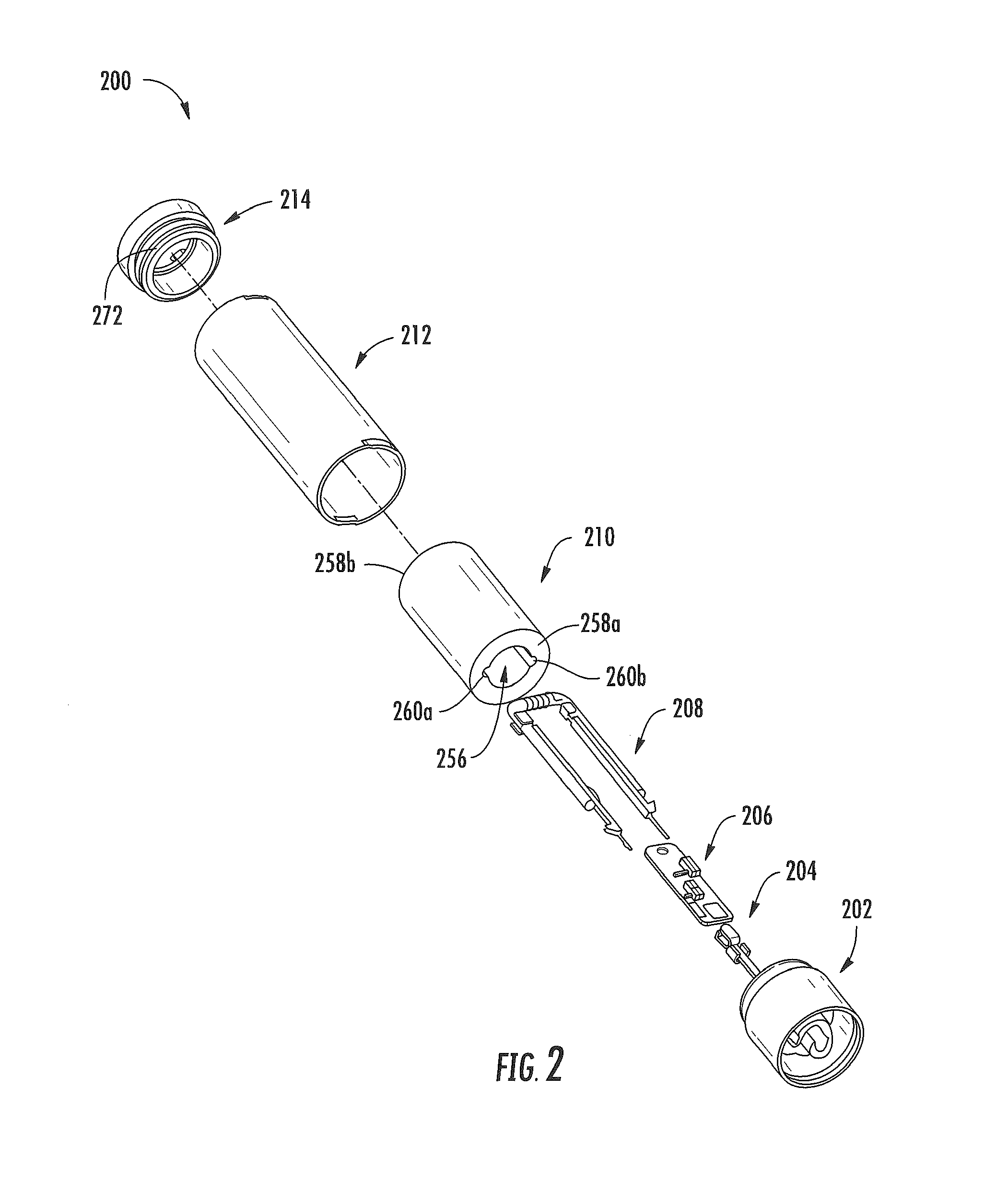

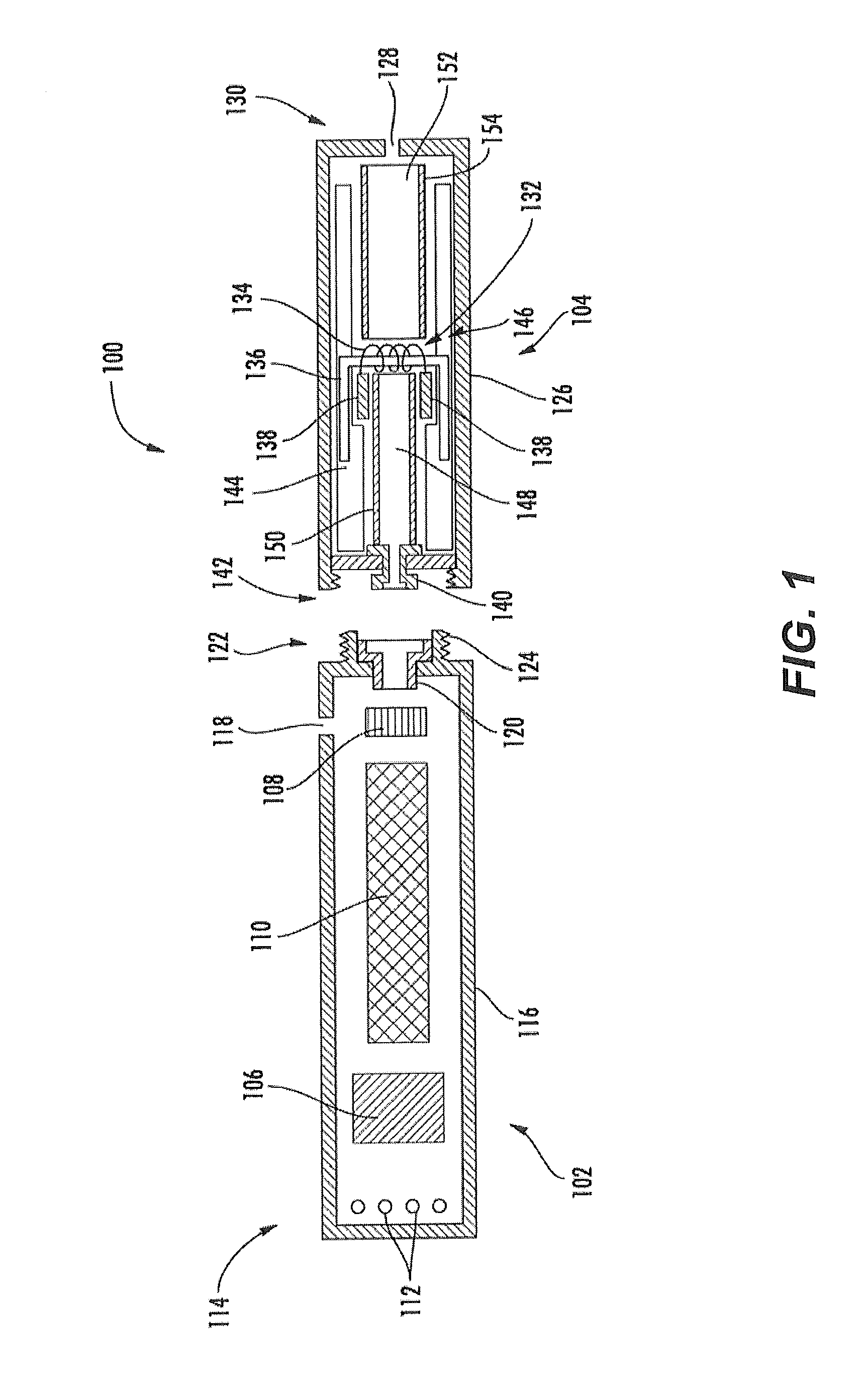

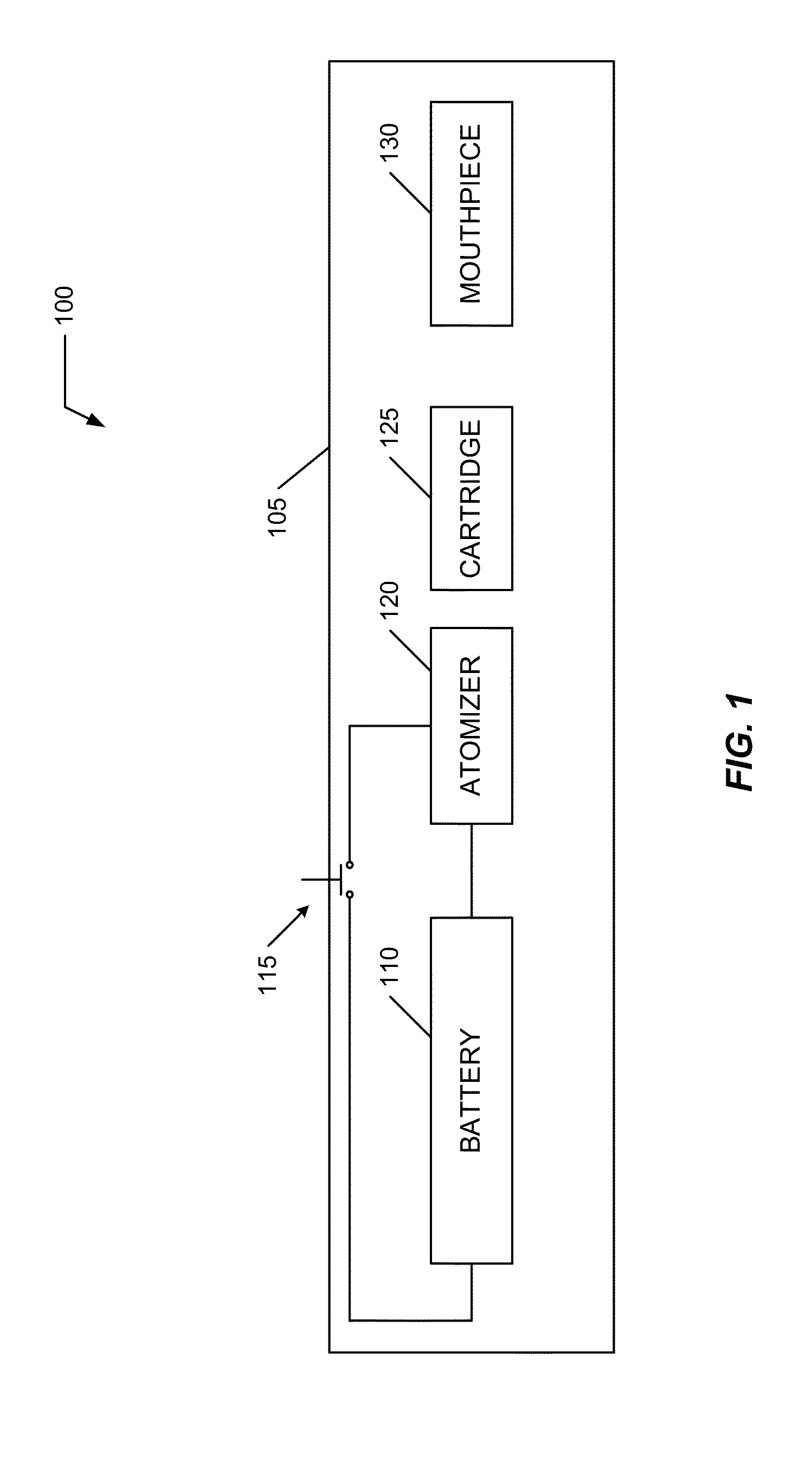

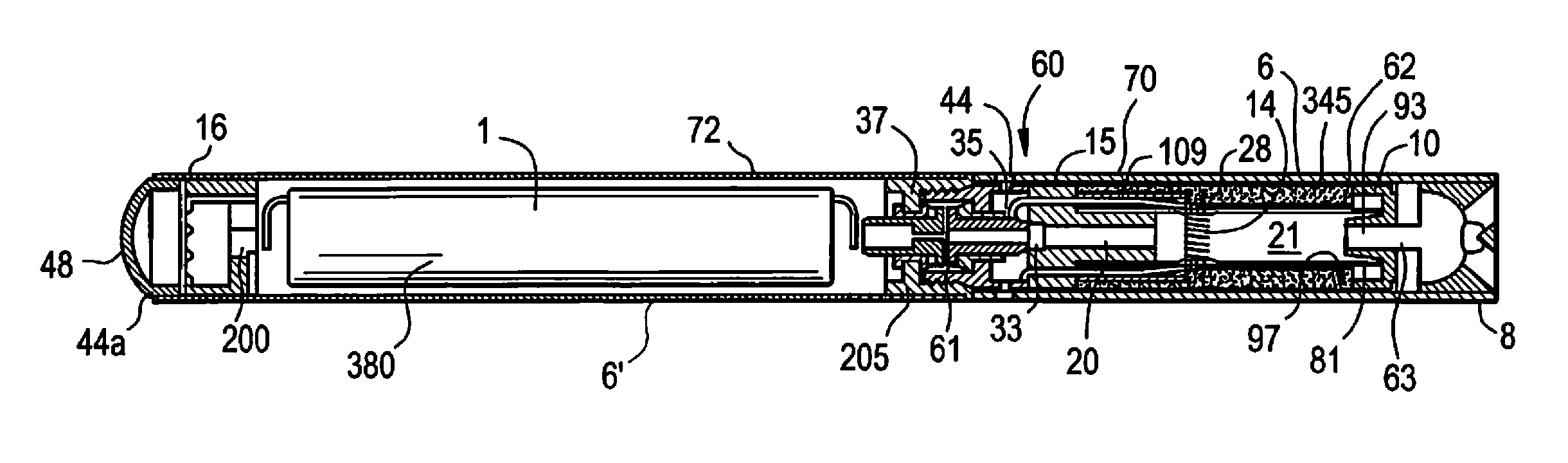

Atomizer for an aerosol delivery device formed from a continuously extending wire and related input, cartridge, and method

ActiveUS20140270730A1Steam generation heating methodsOhmic-resistance electrodesDevice formAerosol delivery

The present disclosure relates to atomizers for an aerosol delivery device such as a smoking article. The atomizer may include a liquid transport element and a wire continuously extending along a longitudinal length thereof. The wire may define end portions, contact portions, and a heating portion. The wire may be continuously wound about the liquid transport element such that each of the portions of the wire defines coils. A related input, cartridge, and method of forming atomizers also provided.

Owner:RAI STRATEGIC HLDG INC

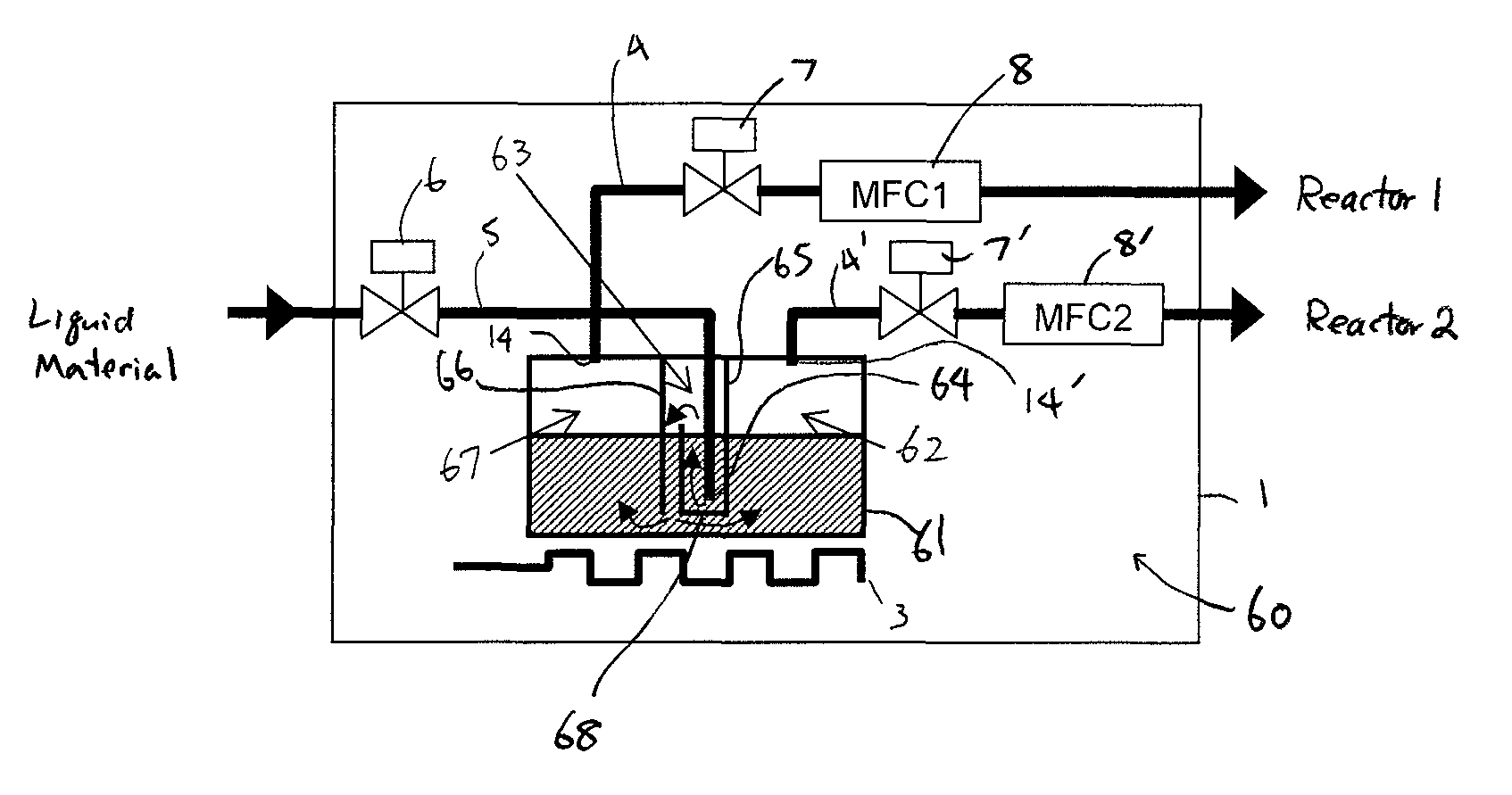

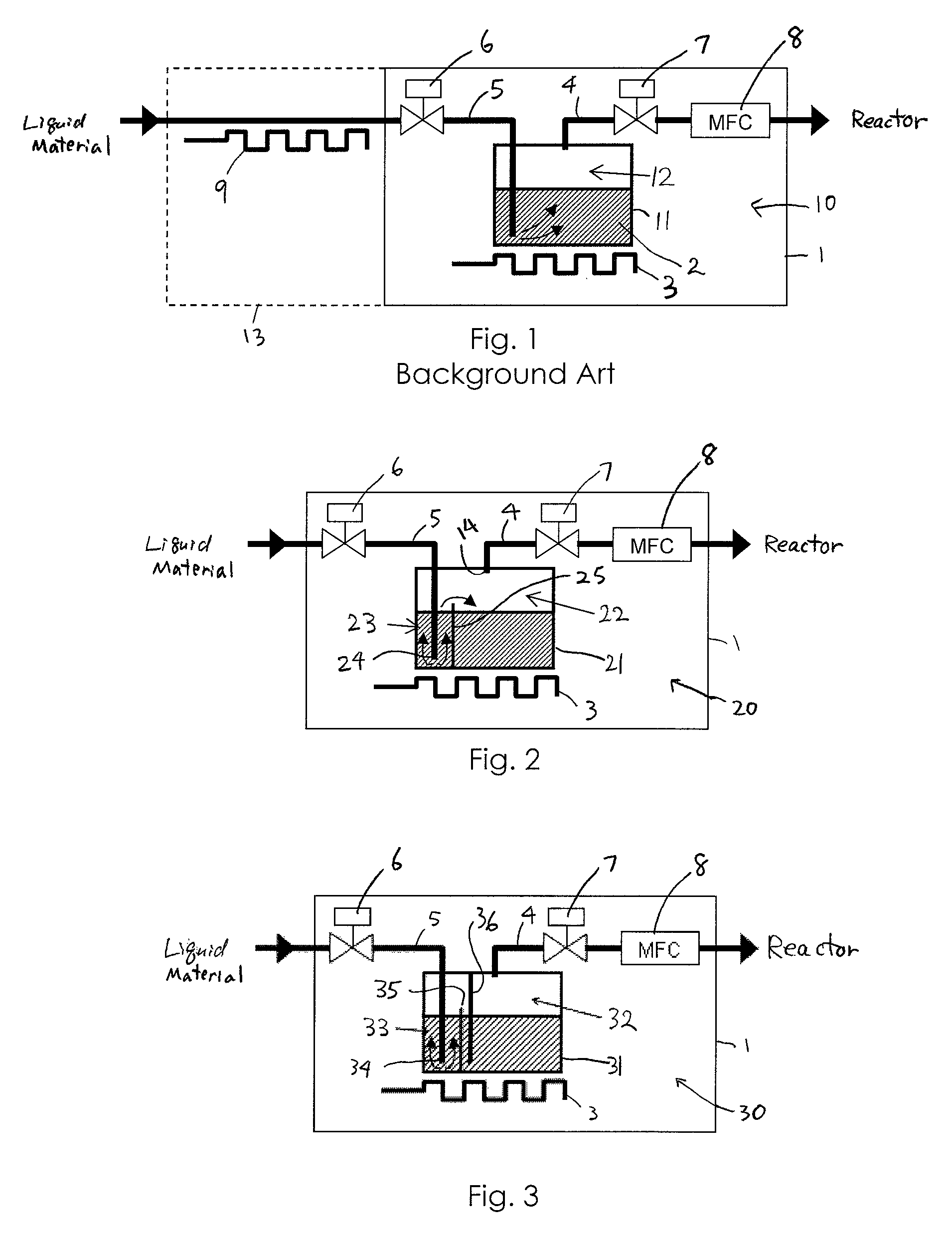

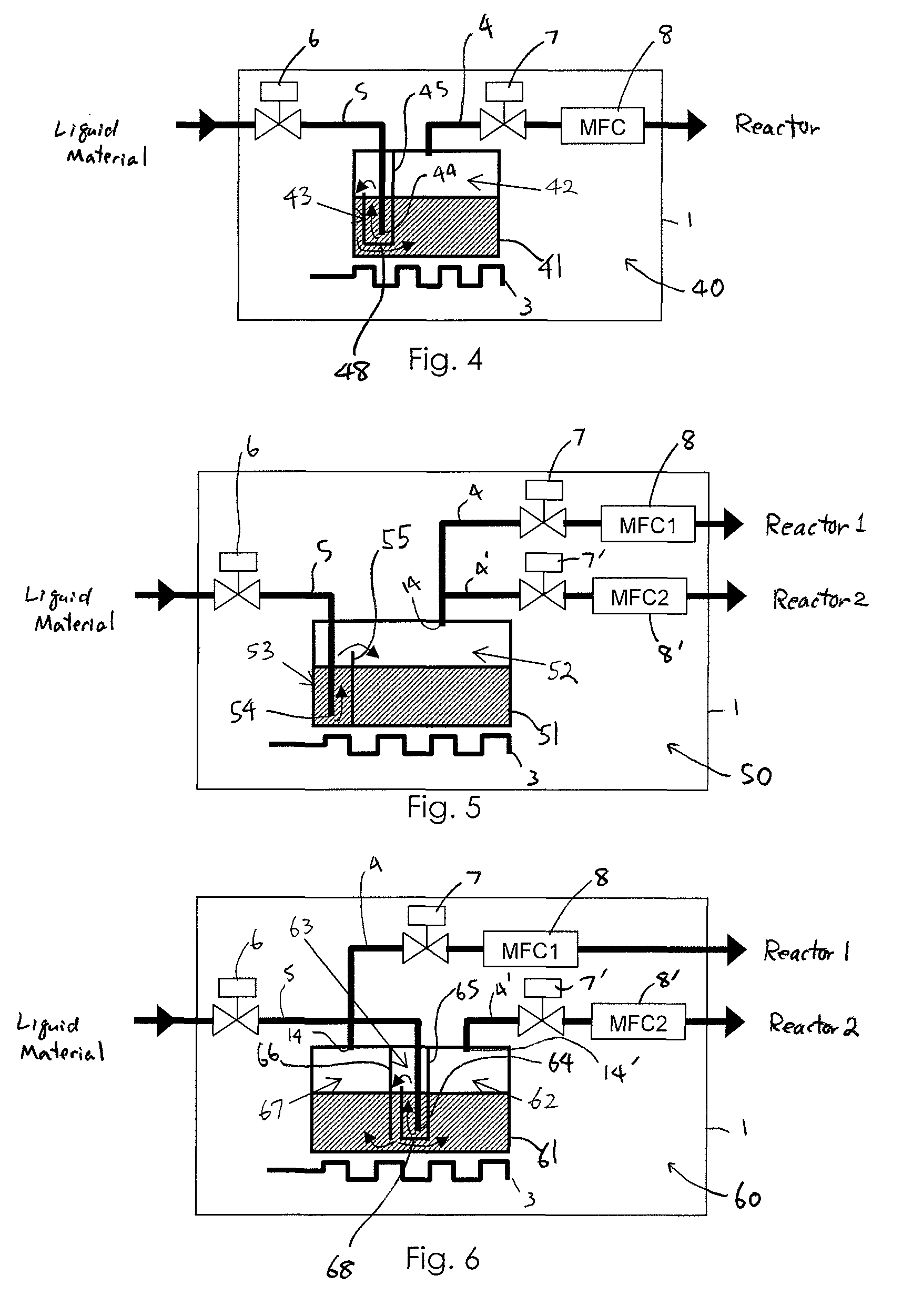

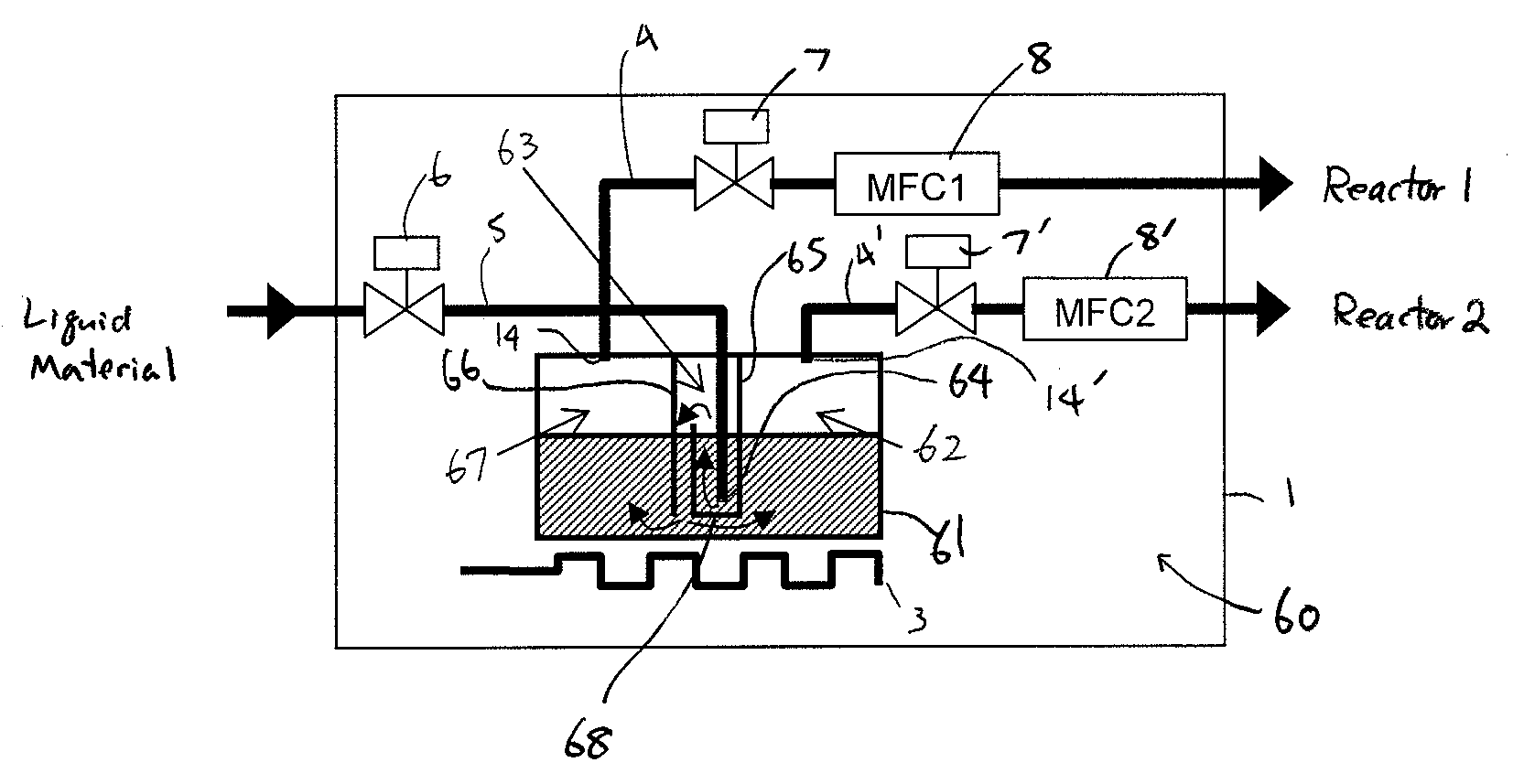

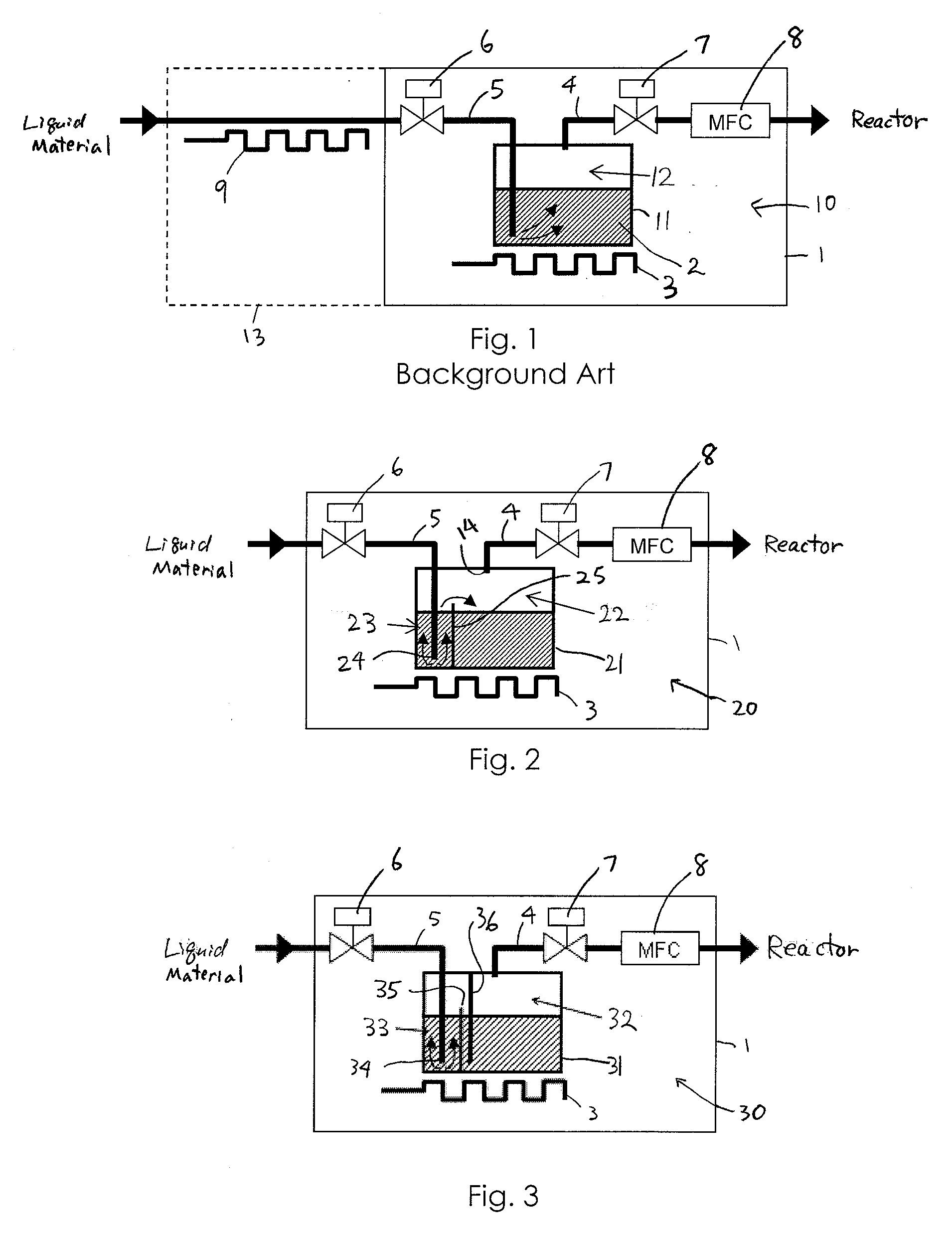

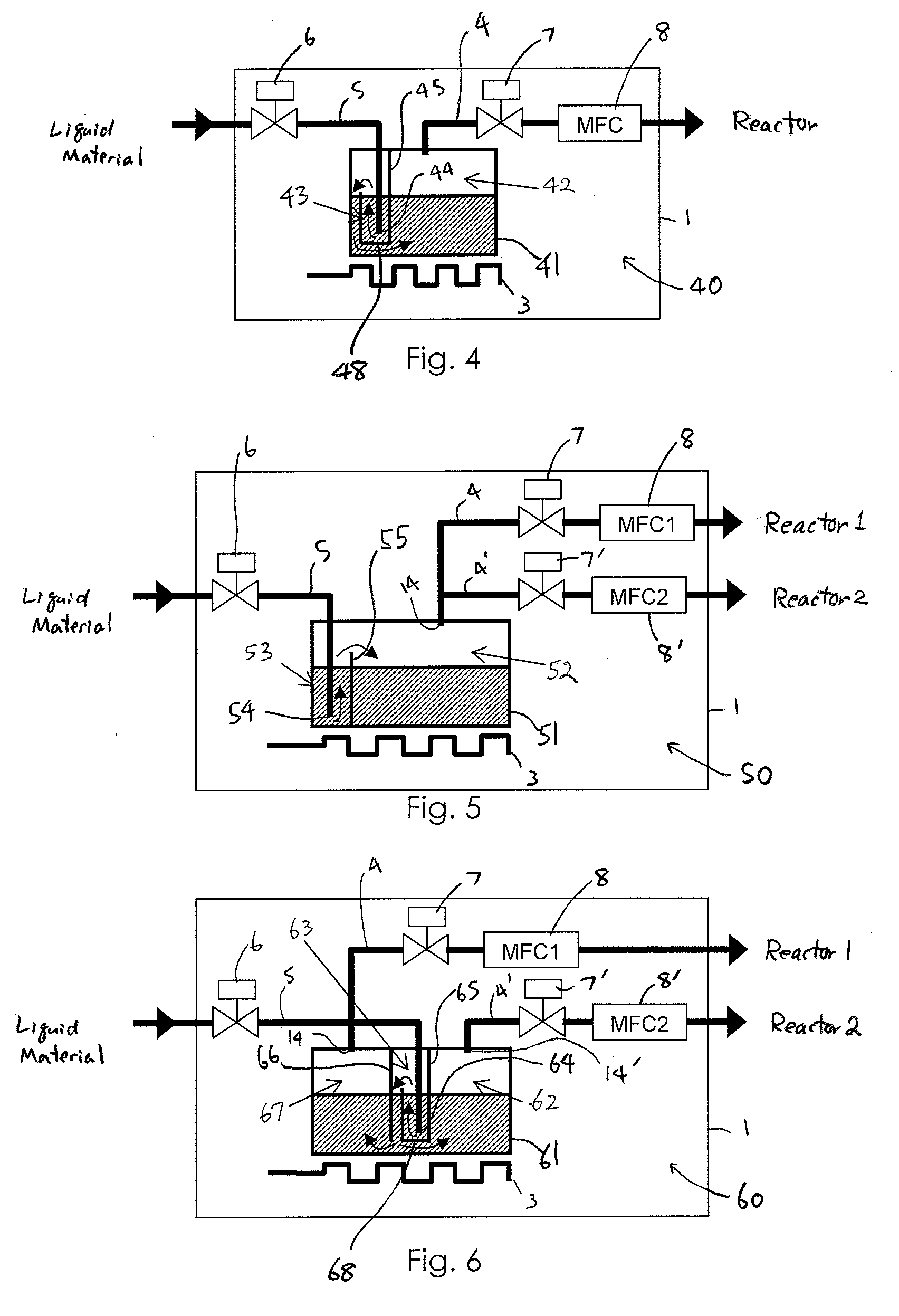

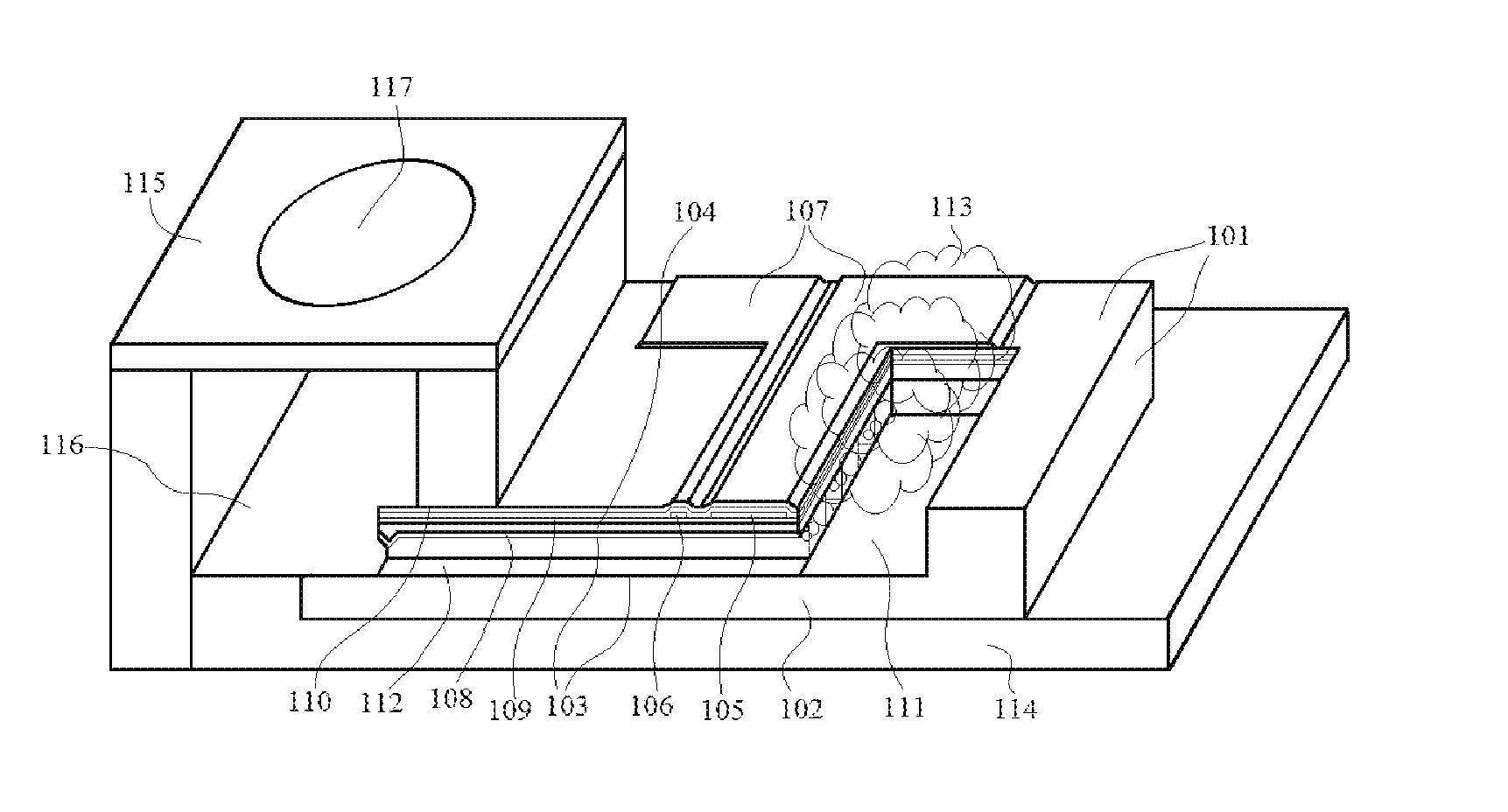

Liquid material vaporization apparatus for semiconductor processing apparatus

ActiveUS7833353B2Reduce the temperatureInhibition is effectiveSteam generation heating methodsSpray nozzlesVaporizationEngineering

A liquid material vaporization apparatus for a semiconductor processing apparatus includes: a vaporization tank; an inner partition wall disposed in the tank for dividing the interior of the tank into a charging compartment and a vaporization compartment which are liquid-communicatable with each other over an upper edge of the inner partition wall. A liquid material charged in the charging compartment overflows over the upper edge of the inner partition wall toward the vaporization compartment to store and vaporize the liquid material in the vaporization compartment.

Owner:ASM JAPAN

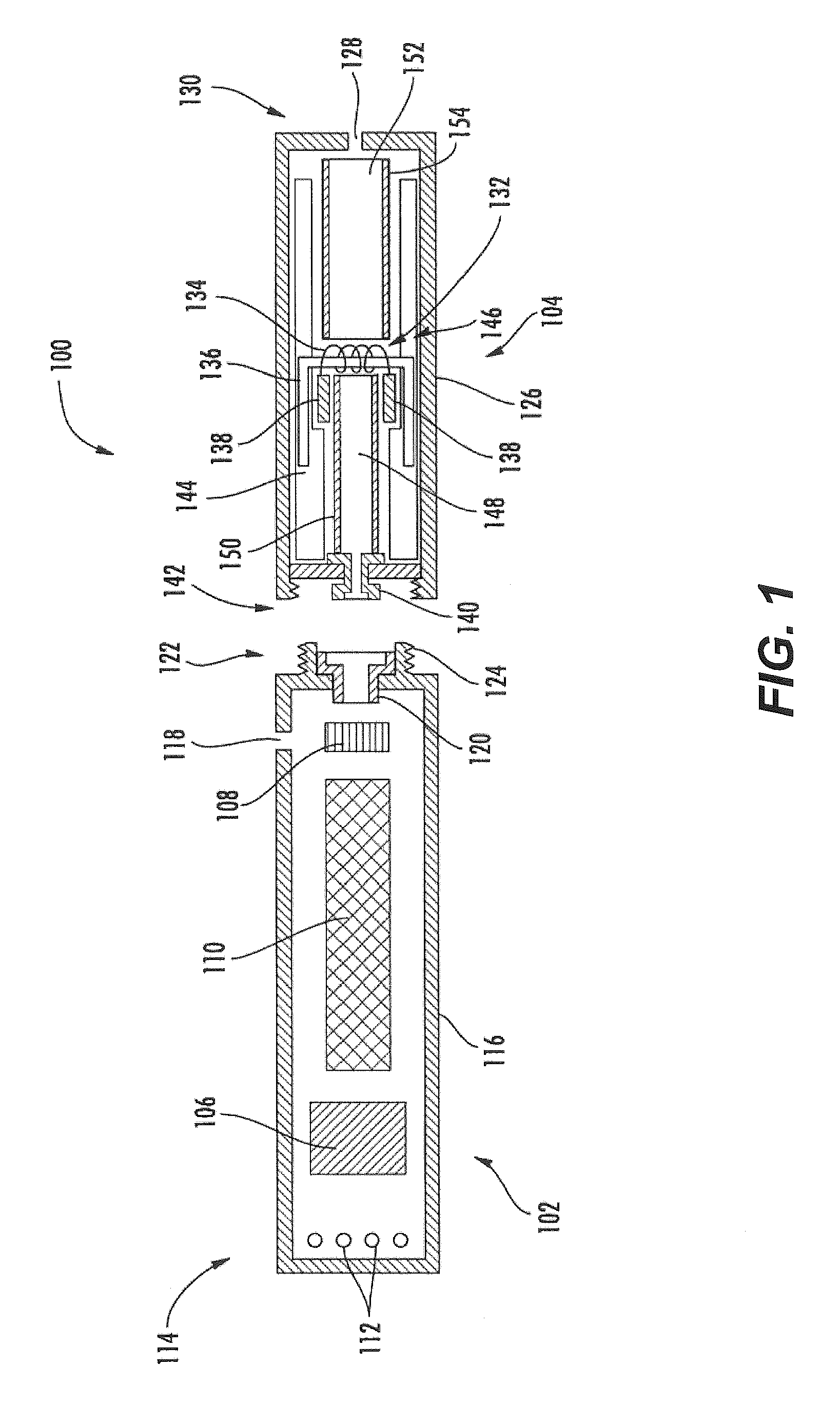

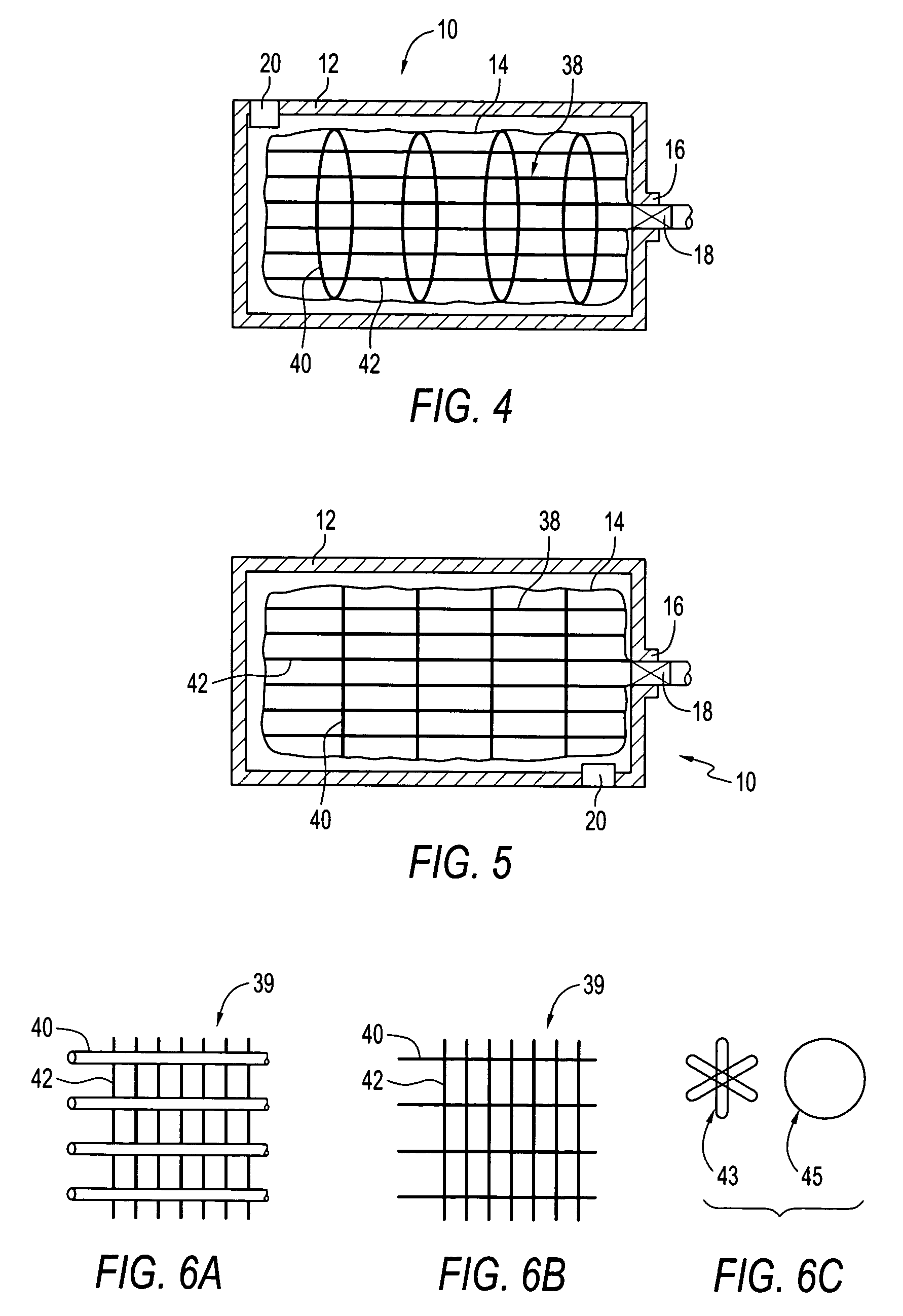

Heating elements formed from a sheet of a material and inputs and methods for the production of atomizers

The present disclosure relates to an input for production of atomizers and atomizers formed from a sheet of a material, and which may be employed in an aerosol delivery device such as a smoking article. The input may include a carrier and heating elements coupled thereto. The heating elements may include first and second ends and interconnected alternating loops disposed therebetween. The heating elements may be oriented parallel to a longitudinal axis of the carrier, or perpendicular thereto. The heating elements may be coupled to a liquid transport element by bending the interconnected loops at least partially around the liquid transport element. The ends of the heating element may be coupled to heater terminals. A related method for forming atomizers is also provided.

Owner:RAI STRATEGIC HLDG INC

Liquid material vaporization apparatus for semiconductor processing apparatus

ActiveUS20080173240A1Reduce the temperatureLow thermal conductivitySteam generation heating methodsSpray nozzlesVaporizationEngineering

A liquid material vaporization apparatus for a semiconductor processing apparatus includes: a vaporization tank; an inner partition wall disposed in the tank for dividing the interior of the tank into a charging compartment and a vaporization compartment which are liquid-communicatable with each other over an upper edge of the inner partition wall. A liquid material charged in the charging compartment overflows over the upper edge of the inner partition wall toward the vaporization compartment to store and vaporize the liquid material in the vaporization compartment.

Owner:ASM JAPAN

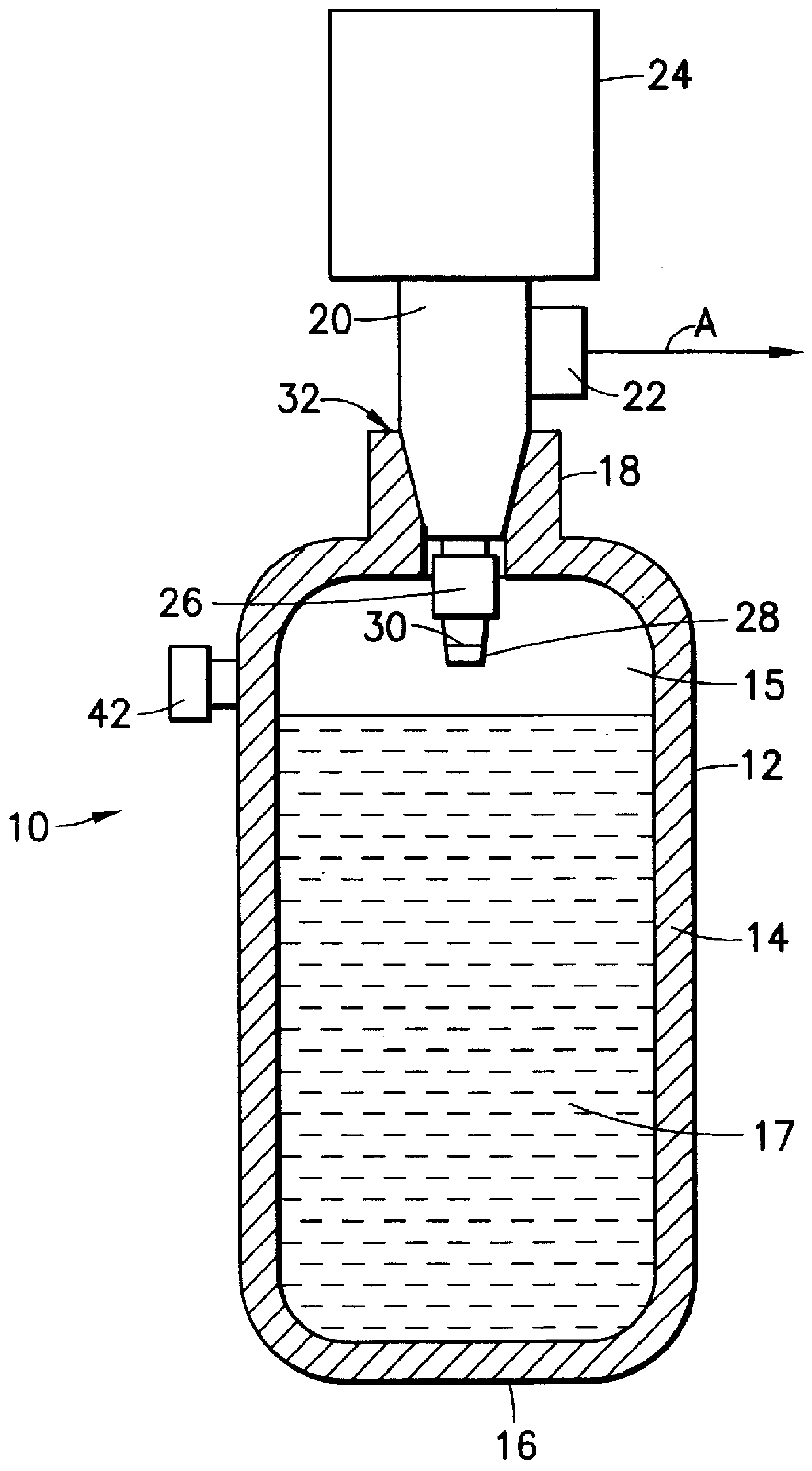

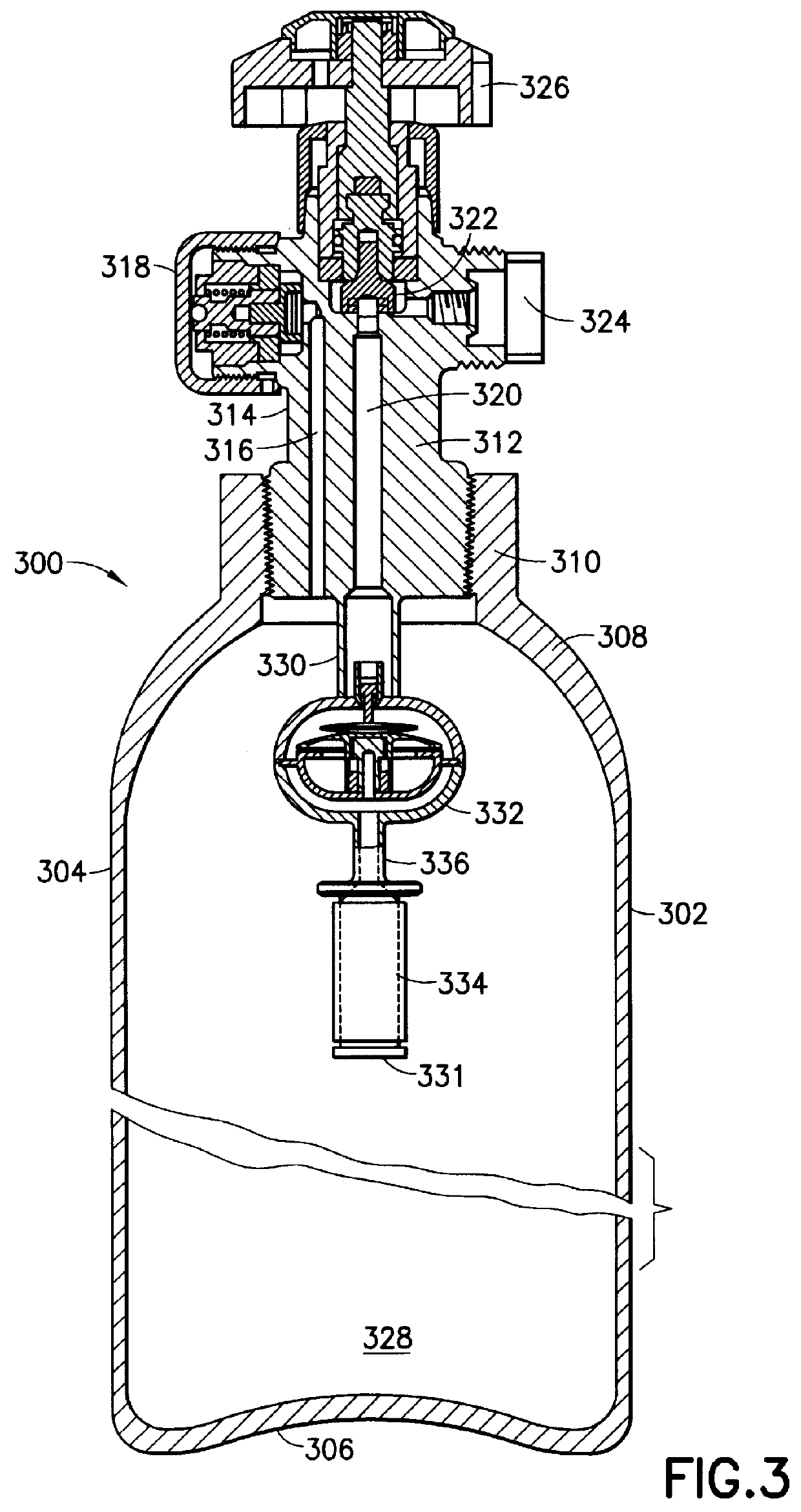

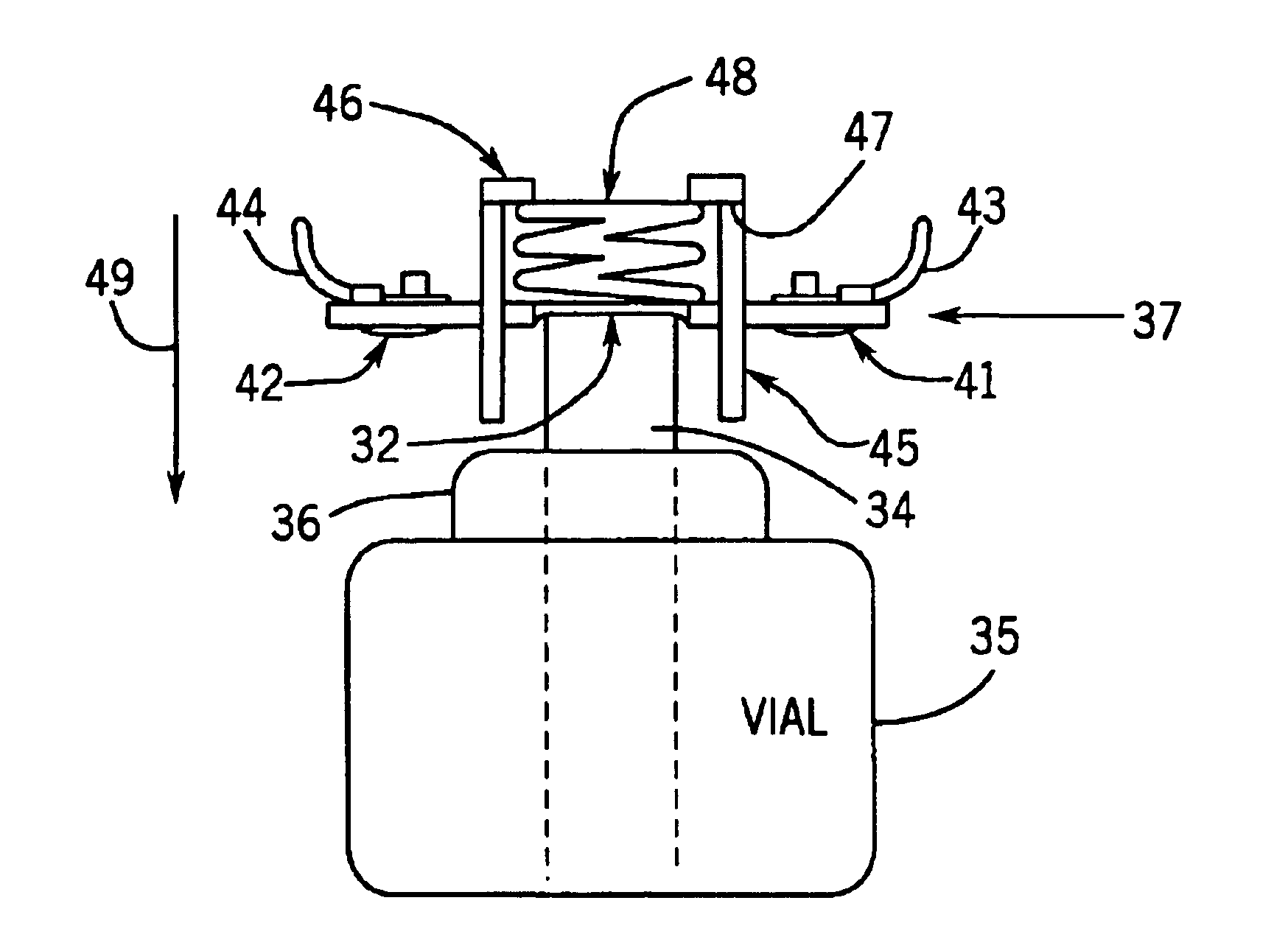

Fluid storage and dispensing system

InactiveUS6089027ACostPerformanceContainer filling methodsVacuum evaporation coatingSingle stageSorbent

A fluid storage and dispensing system comprising a vessel for holding a fluid at a desired pressure. The vessel has a pressure regulator, e.g., a single-stage or multi-stage regulator, associated with a port of the vessel, and set at a predetermined pressure. A dispensing assembly, e.g., including a flow control means such as a valve, is arranged in gas / vapor flow communication with the regulator, whereby the opening of the valve effects dispensing of gas / vapor from the vessel. The fluid in the vessel may be constituted by a liquid that is confined in the vessel at a pressure in excess of its liquefaction pressure at prevailing temperature conditions, e.g., ambient (room) temperature. In another aspect, the vessel contains a solid-phase sorbent material having sorbable gas adsorbed thereon, at a pressure in excess of 50 psig. The vessel may have a >1 inch NGT threaded neck opening, to accommodate the installation of an interior regulator.

Owner:ENTEGRIS INC

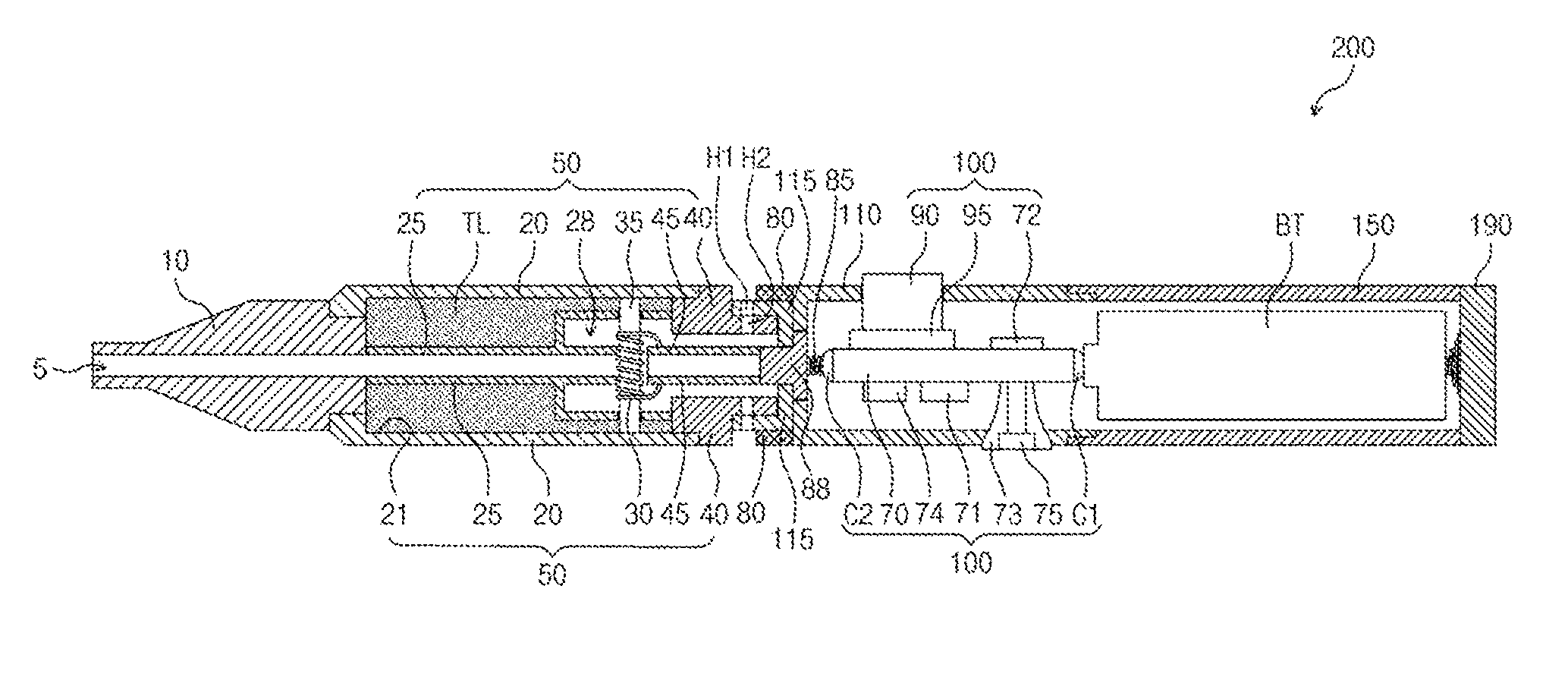

Atomizer for an aerosol delivery device and related input, aerosol production assembly, cartridge, and method

The present disclosure relates to atomizers for an aerosol delivery device such as a smoking article. The atomizer may include a liquid transport element and a wire extending along at least a portion of a longitudinal length thereof. The wire may define contact portions configured to engage heater terminals and a heating portion configured to produce heat. The heating portion may include a variable coil spacing. In other atomizers, the wire may extend at least partially through the liquid transport element proximate the contact portions. Related inputs, cartridges, aerosol production assemblies, and methods of forming atomizers are also provided.

Owner:RAI STRATEGIC HLDG INC

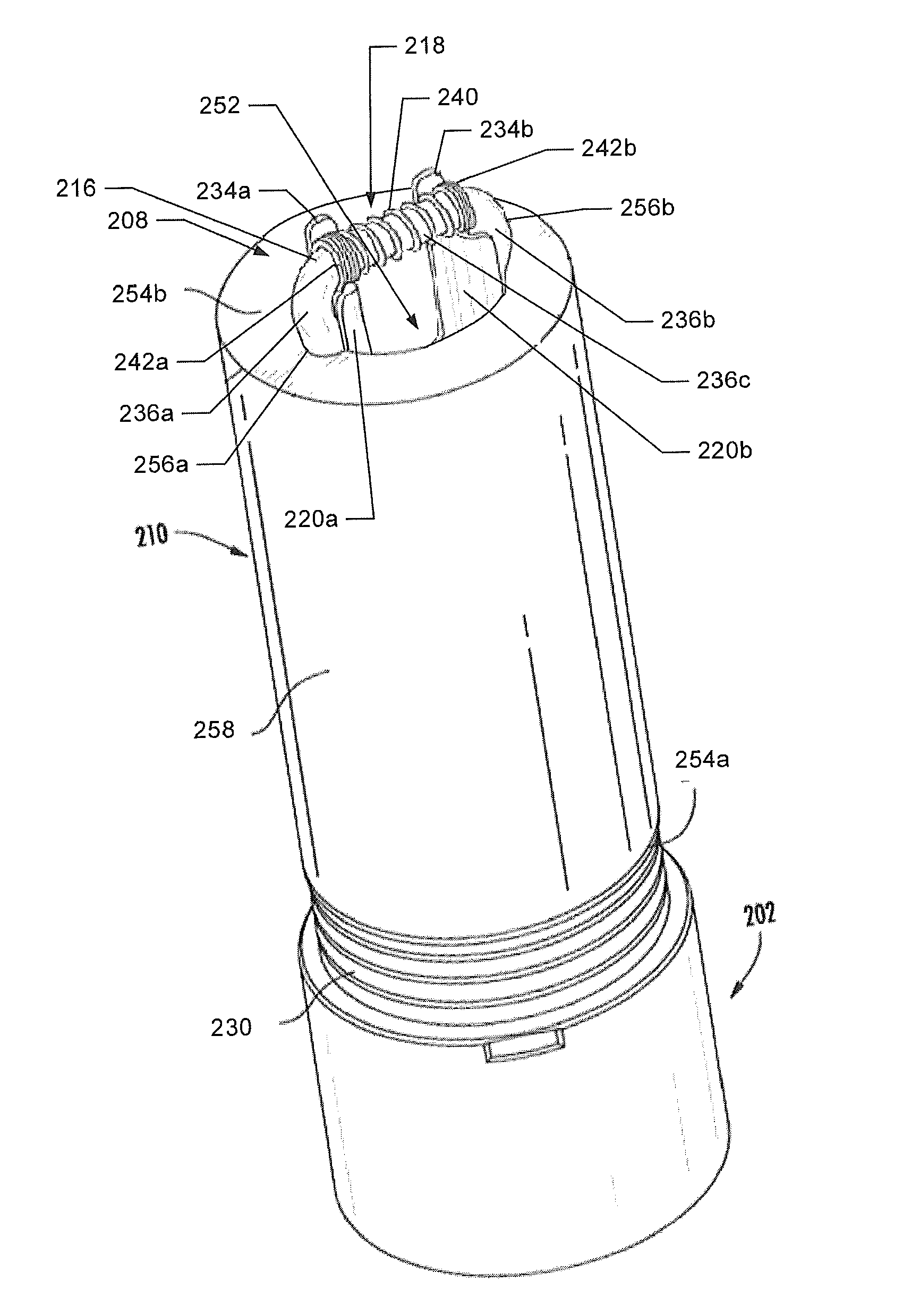

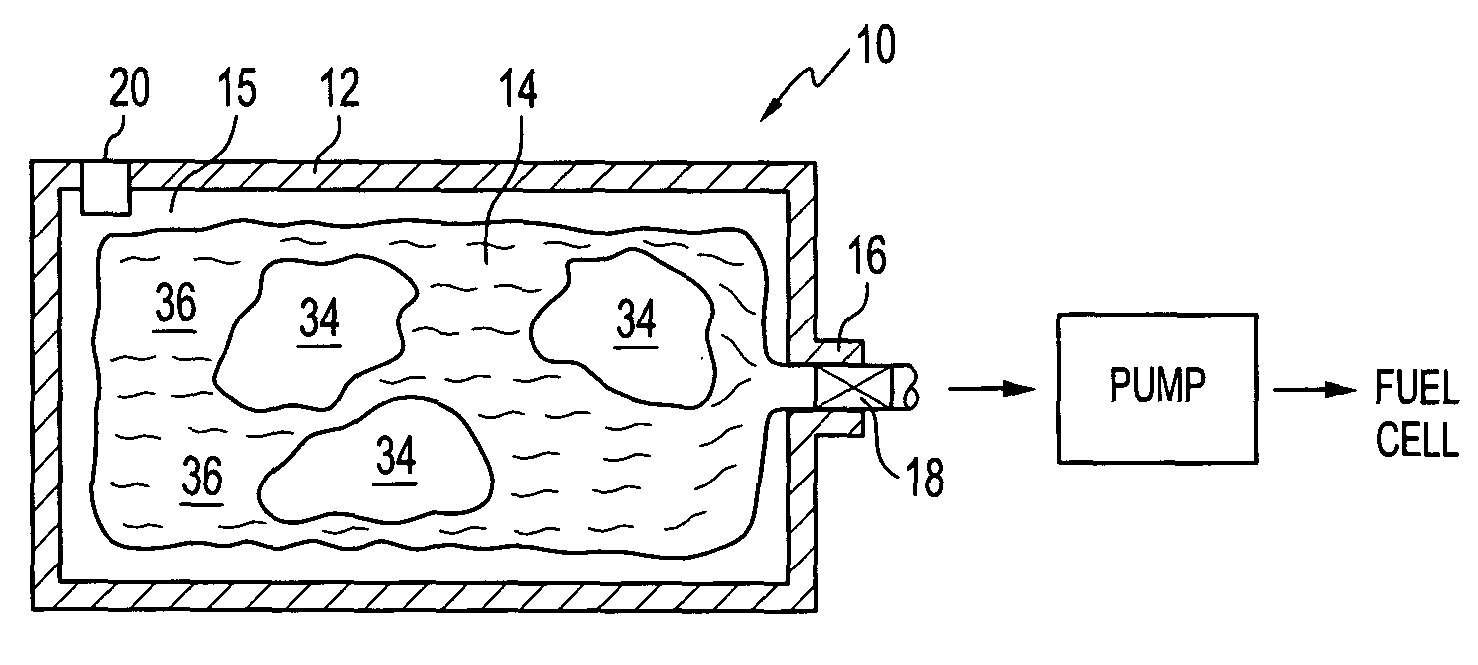

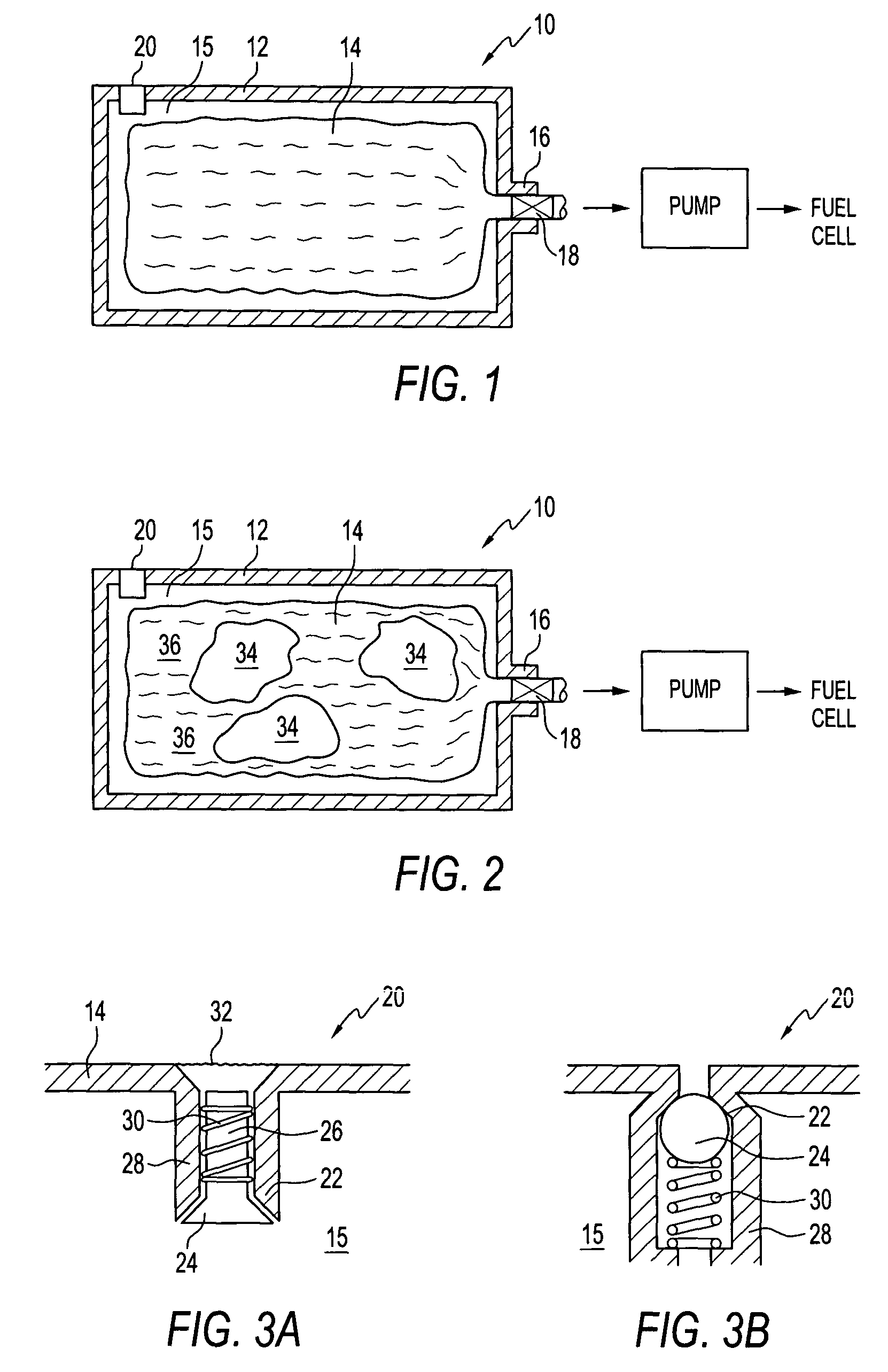

Fuel cartridge with flexible liner

A cartridge connectable to a fuel cell is disclosed. The cartridge comprises an outer casing and an inner flexible liner containing fuel for the fuel cell. The inner flexible liner may have an insert disposed inside the inner liner to facilitate the transport of fuel from the cartridge to the fuel cell. The insert minimizes the fuel that is trapped within the cartridge. The inner flexible liner can be used without the outer casing. The outer casing can be substantially rigid or flexible. The cartridge is also adaptable to receive byproducts from the fuel cell. The cartridge can also be pressurized to push fuel to the fuel cell. Unidirectional relief valves are also disclosed to prevent internal pressure in the cartridge from becoming too high or too low.

Owner:INTELLIGENT ENERGY LTD

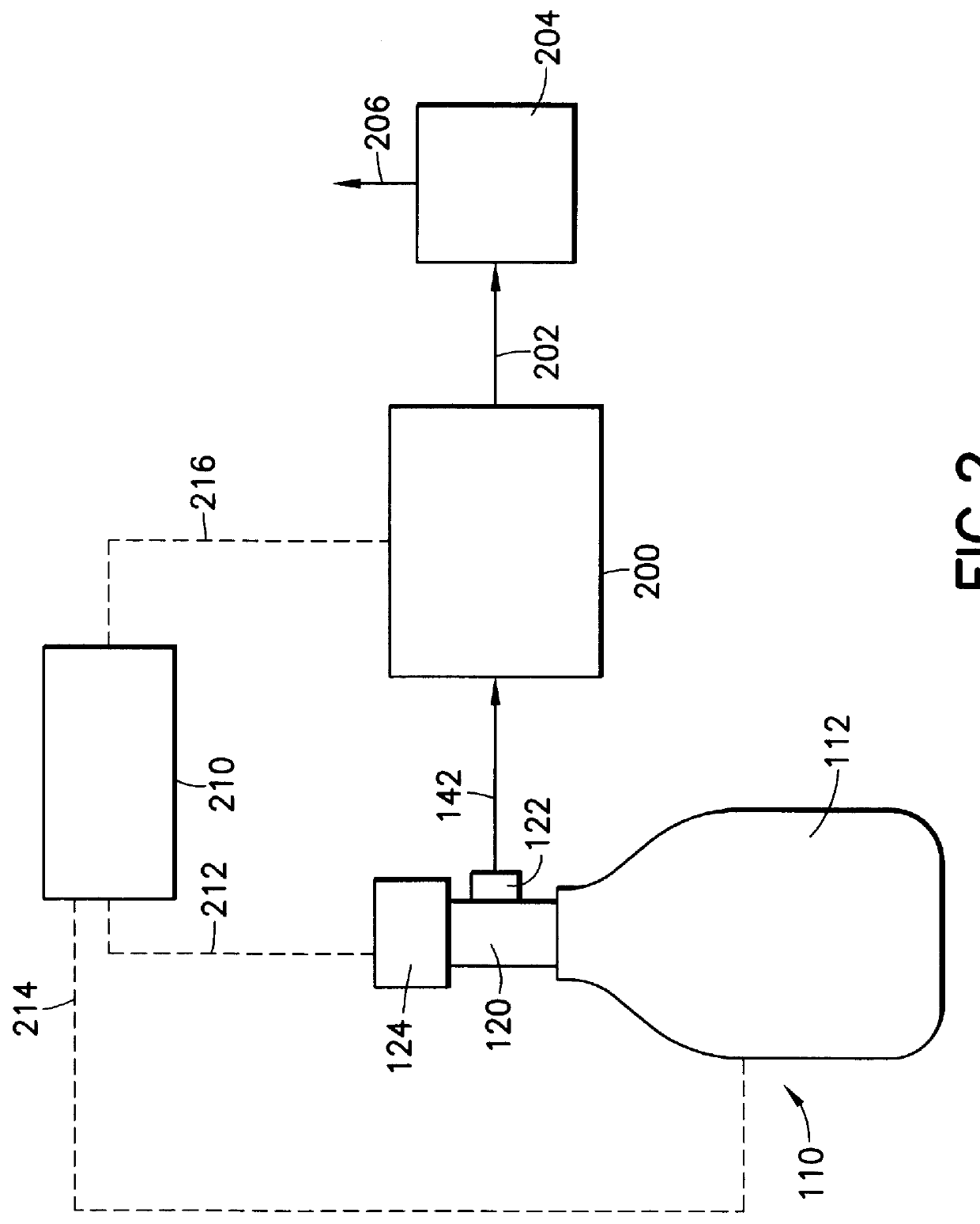

Fluid storage and dispensing system

InactiveUS6101816AMinimize the possibilityUse minimizedContainer filling methodsVacuum evaporation coatingLiquid stateProduct gas

A fluid storage and dispensing system comprising a vessel for holding a fluid at a desired pressure. The vessel has a pressure regulator associated with a port of the vessel, and set at a predetermined pressure. A dispensing assembly, e.g, including a flow control means such as a valve, is arranged in gas / vapor flow communication with the regulator, whereby the opening of the valve effects dispensing of gas / vapor from the vessel. The fluid in the vessel may be constituted by a liquid which is confined in the vessel at a pressure in excess of its liquefaction pressure at prevailing temperature conditions, e.g., ambient (room) temperature. A phase separator such as a gas / vapor-permeable liquid-impermeable membrane, may be associated with the regulator, as a barrier to flow of liquid into the regulator, when the contained fluid in the vessel is in a liquid state.

Owner:ENTEGRIS INC

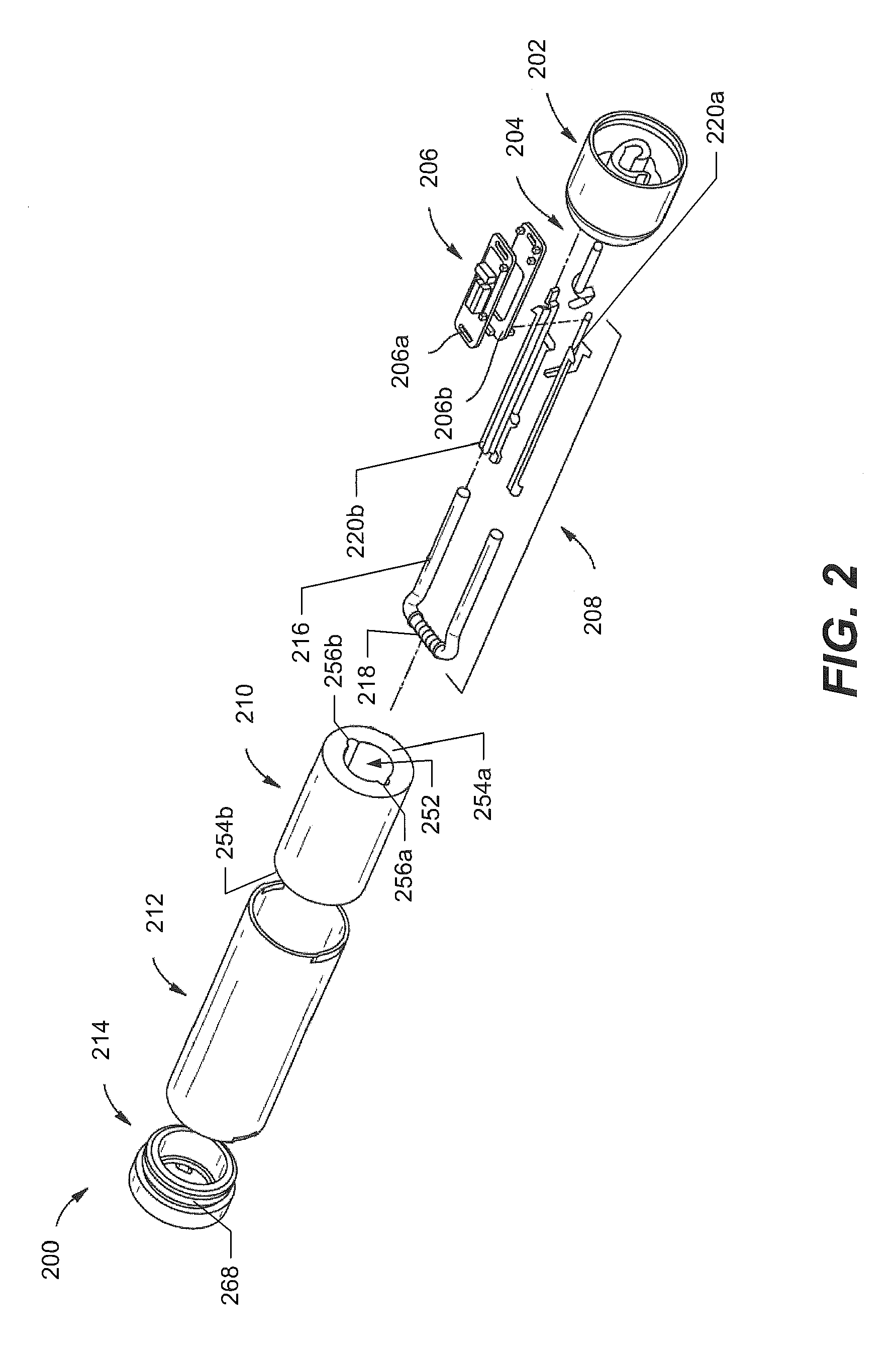

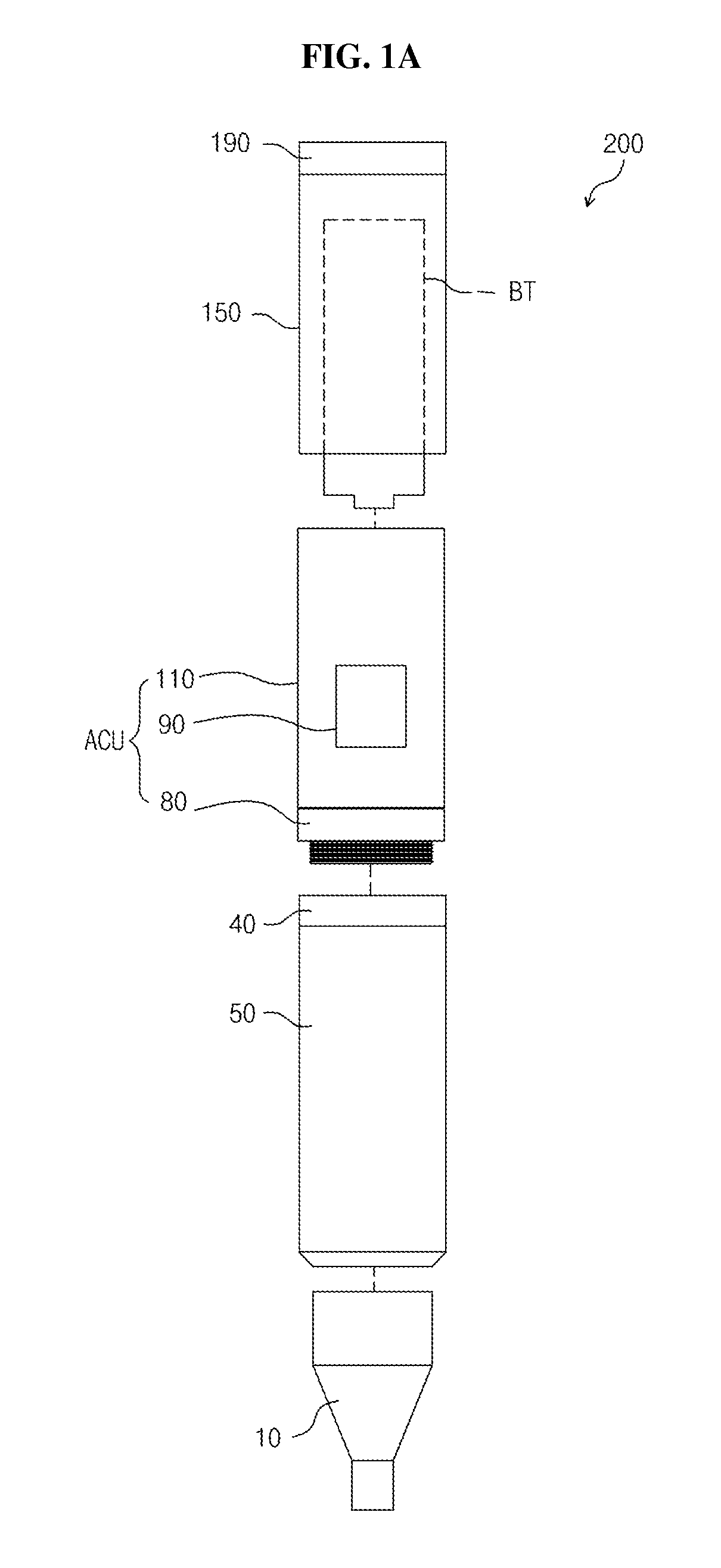

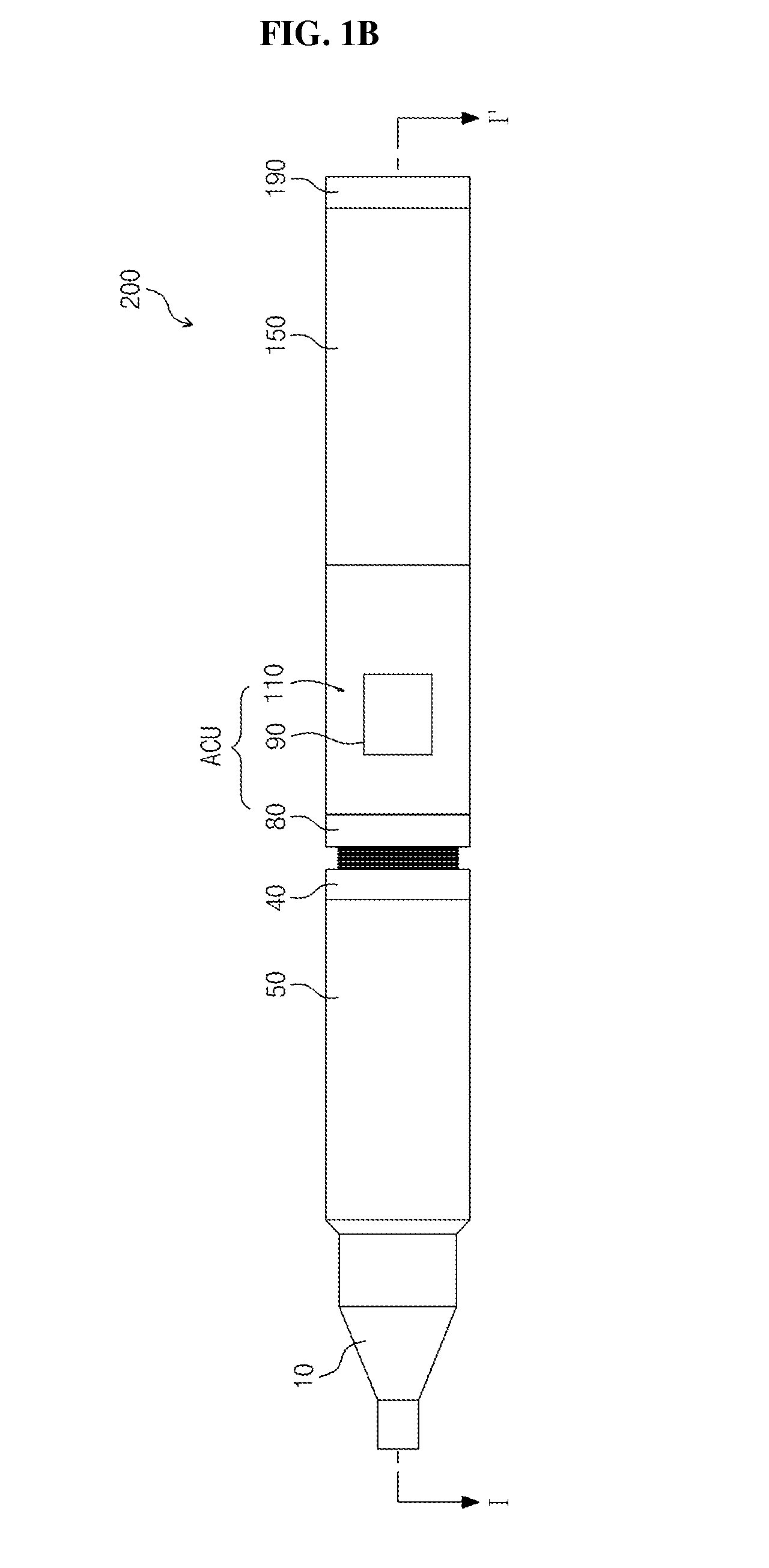

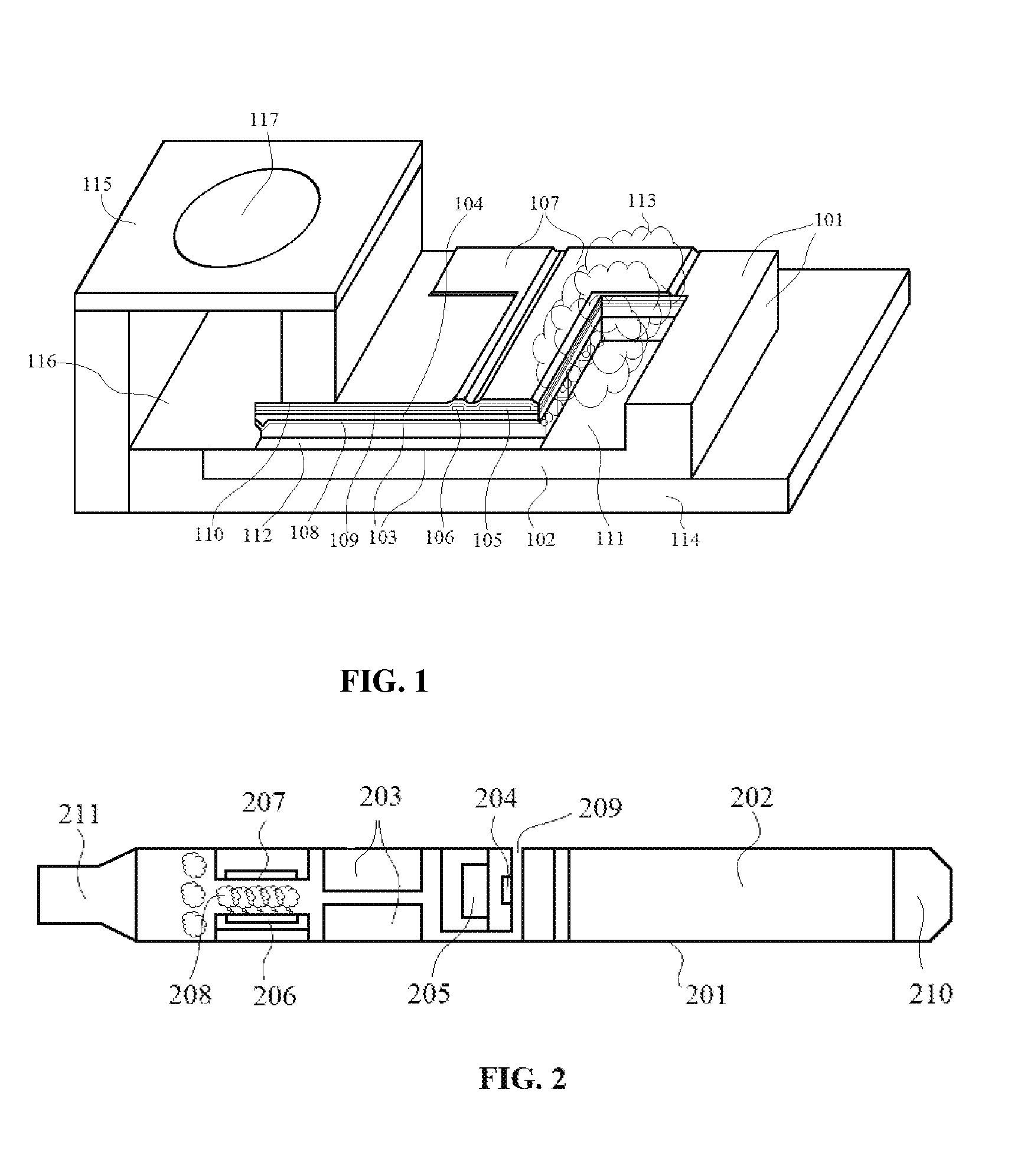

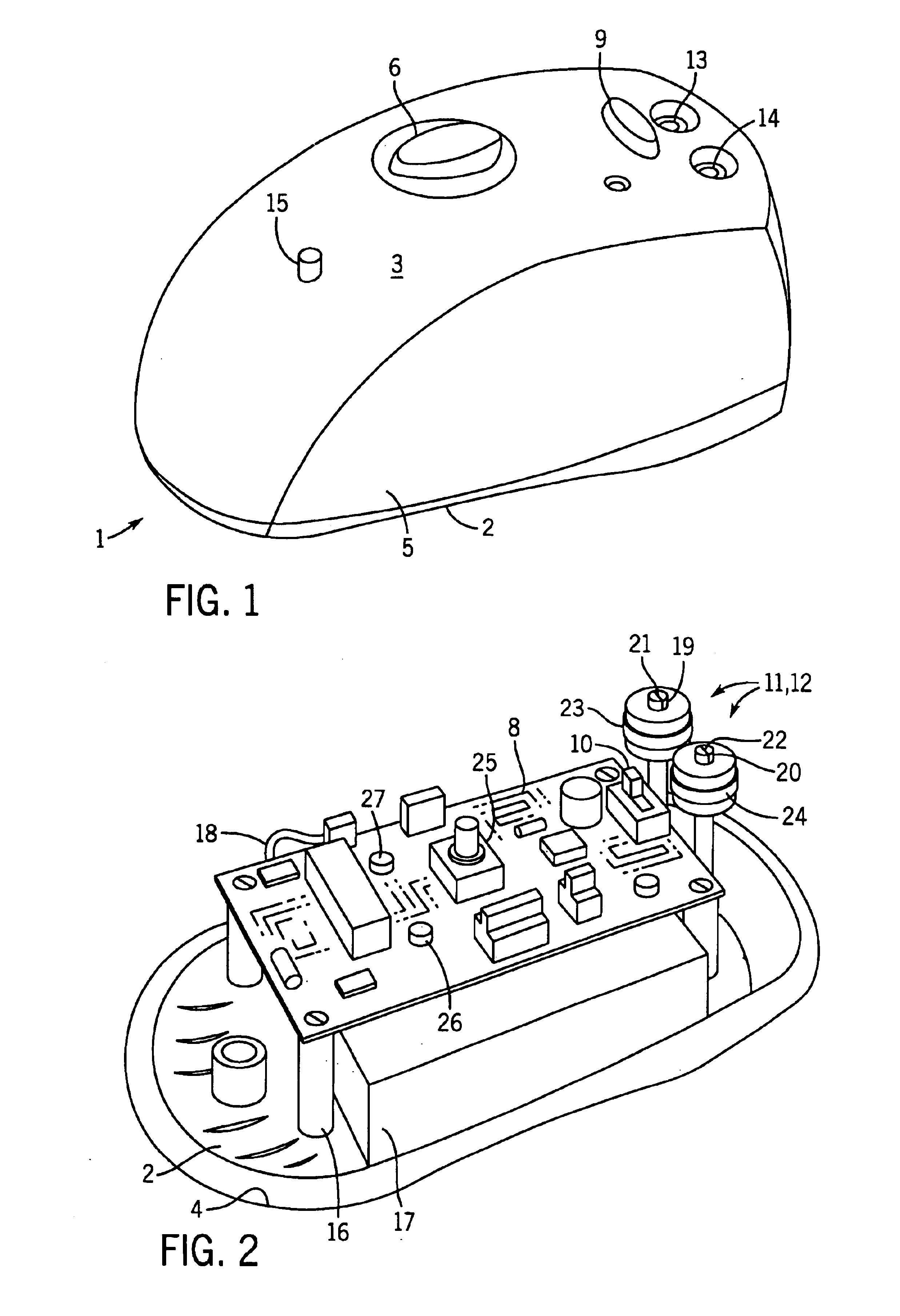

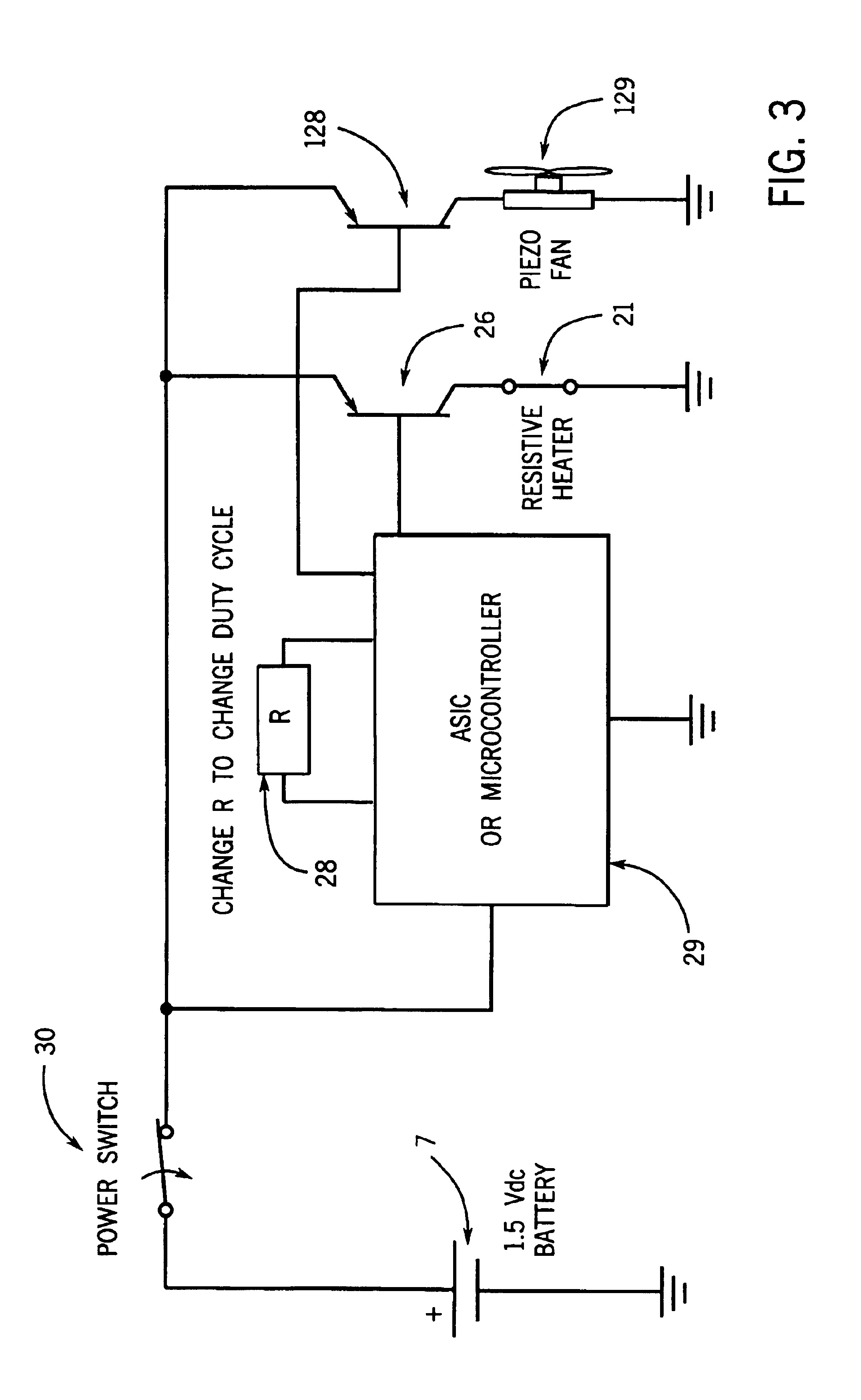

Atomization control unit and a portable atomizing apparatus having the same

InactiveUS20140334804A1Constant power supplyReduce smokeSteam generation heating methodsMedical devicesElectricitySource material

A portable atomizing apparatus according to the present invention includes a battery case, an atomizing device, a body case, a control unit, and a suction adjustment. The battery case receives a battery, and the atomizing device includes a heating member electrically connected to the battery for generating heat to atomize a source material. The body case is connected between the battery case and the atomizing device. Besides, the control unit is mounted inside the body case, electrically connected to the battery and to the heating member, so that the control unit receives an electrical power from the battery to control the output signal delivered to the heating member. Also, the suction adjustment opens or closes an air inlet of the atomizing apparatus so as to adjust the amount of air entering the atomizing apparatus.

Owner:ENBRIGHT

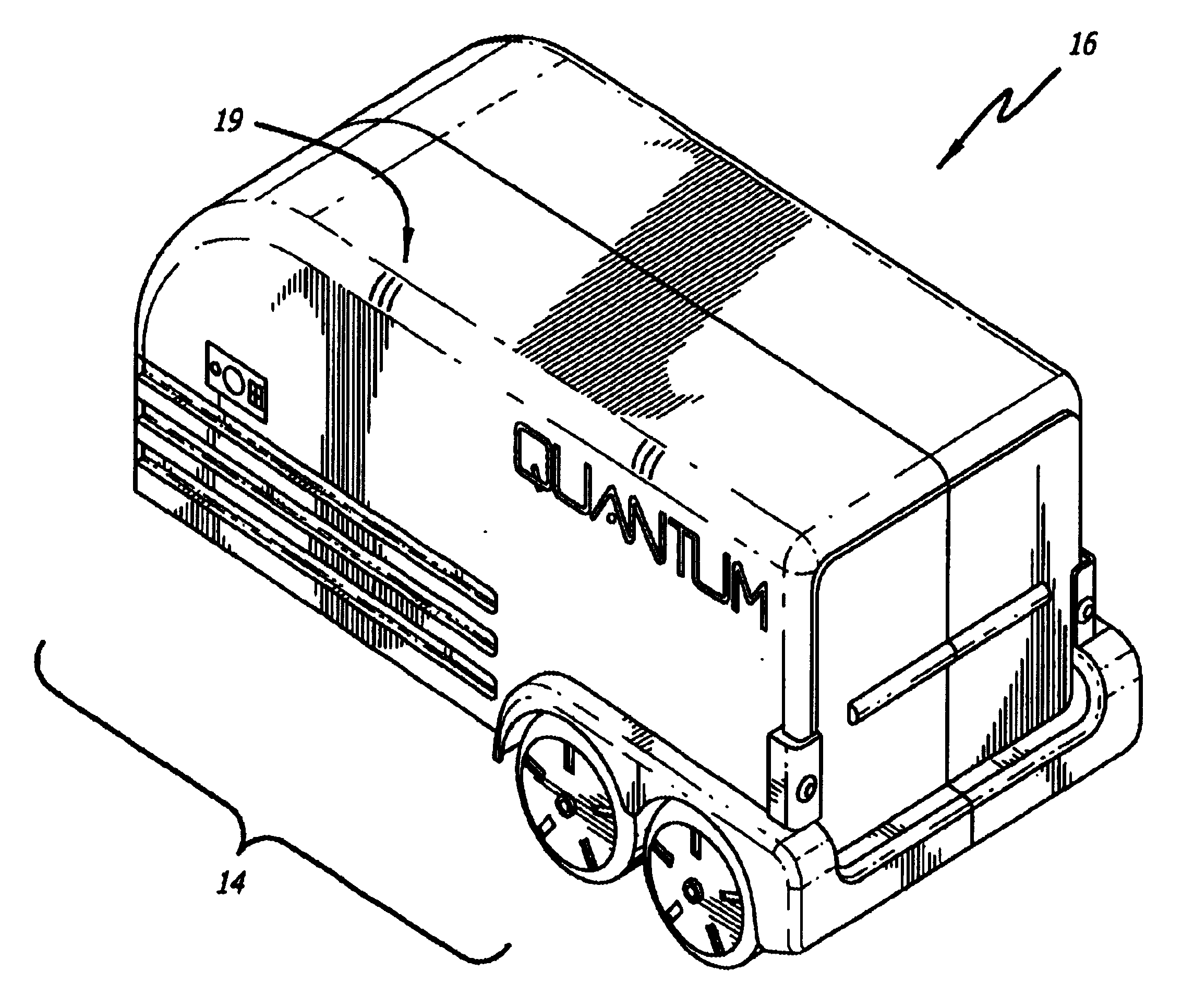

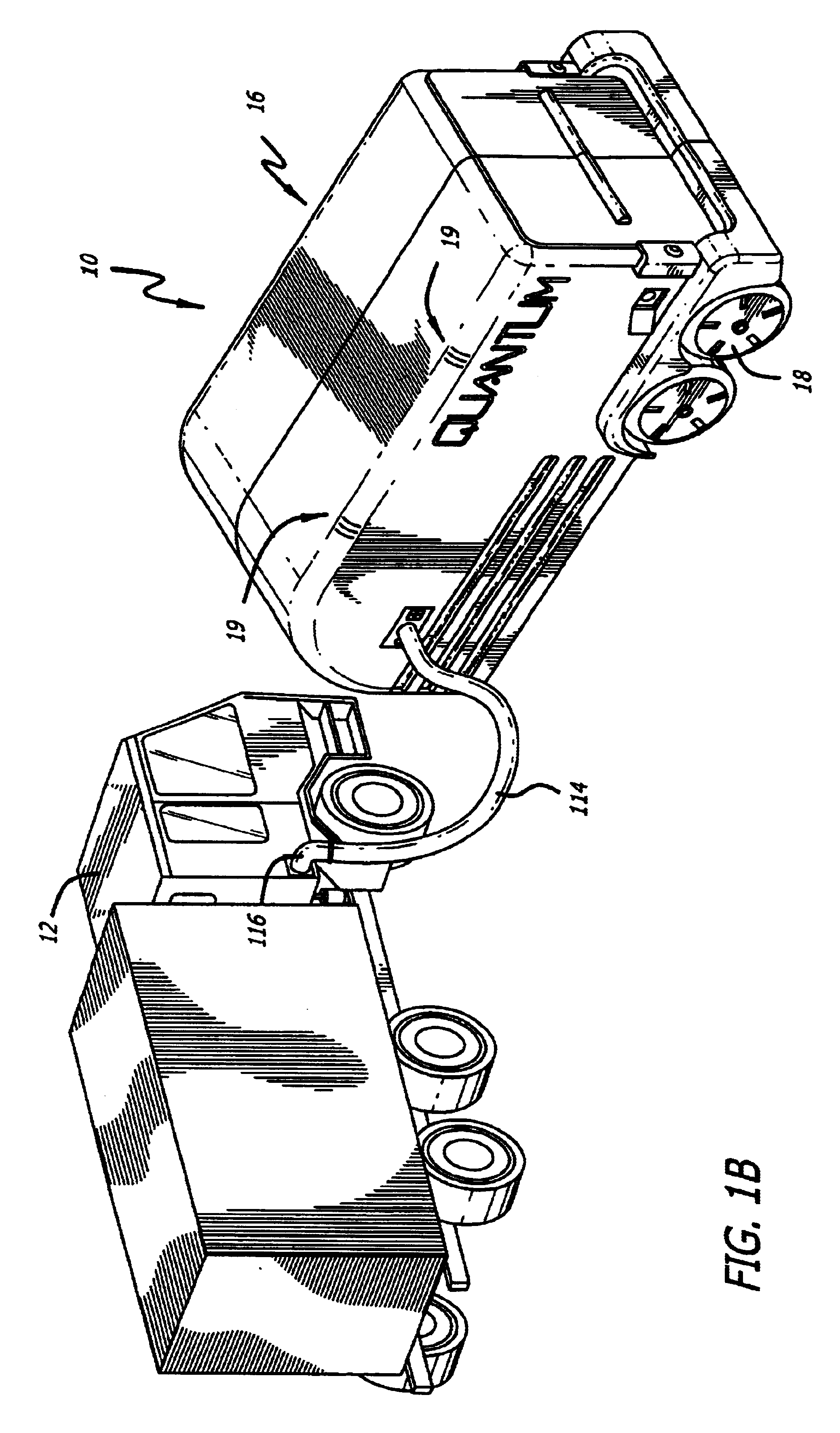

Transportable hydrogen refueling station

InactiveUS6755225B1Easy to monitorReduce riskTank vehiclesGas handling applicationsHigh pressureGaseous hydrogen

A portable hydrogen refueling stations which can dispense gaseous hydrogen from one or more internal high pressure tanks. The refueling station can be refilled with a lower pressure hydrogen gas feed and then compressed for storage within the refueling station.

Owner:QUANTUM FUEL SYST TECH WORLDWIDE INC

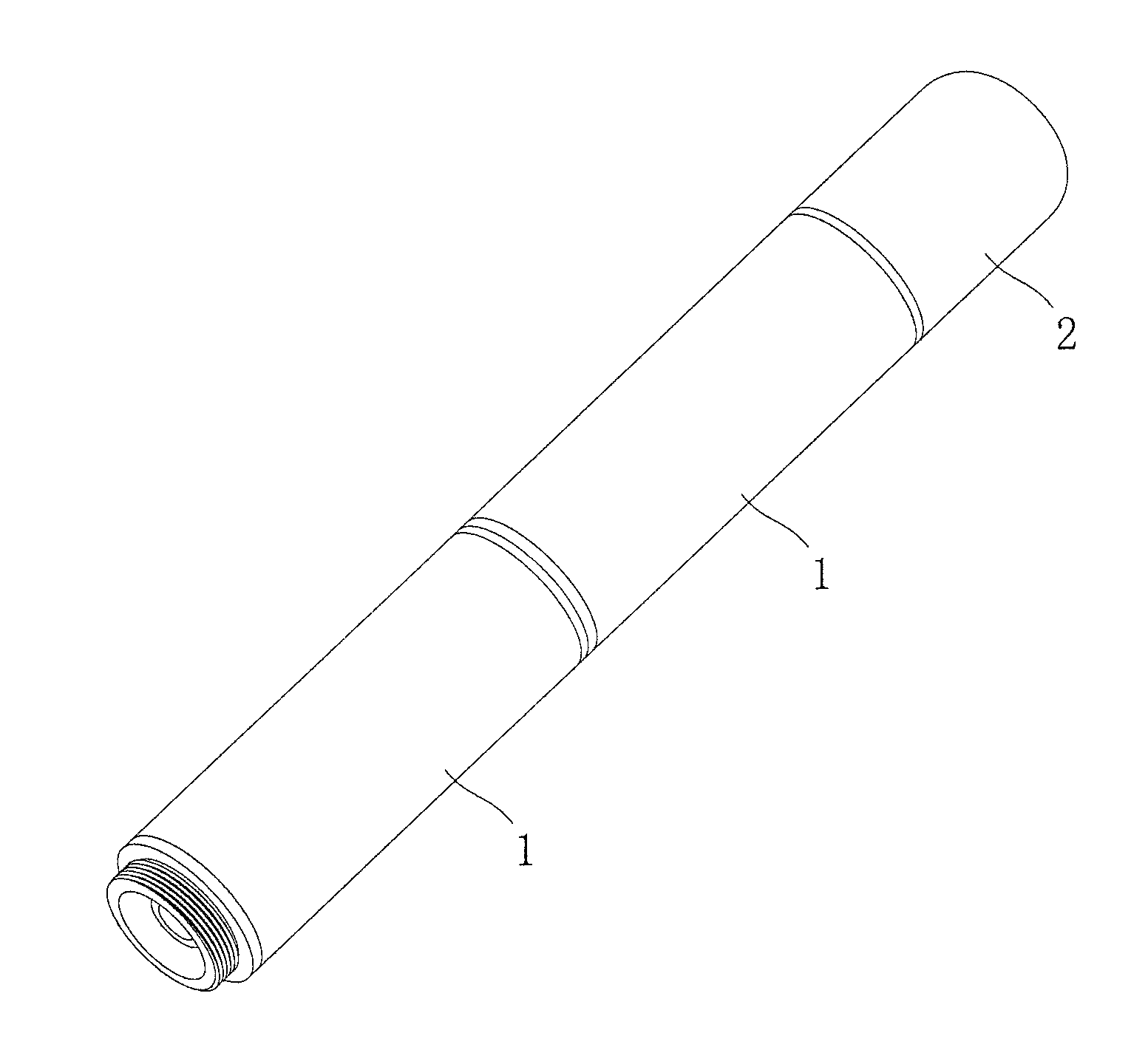

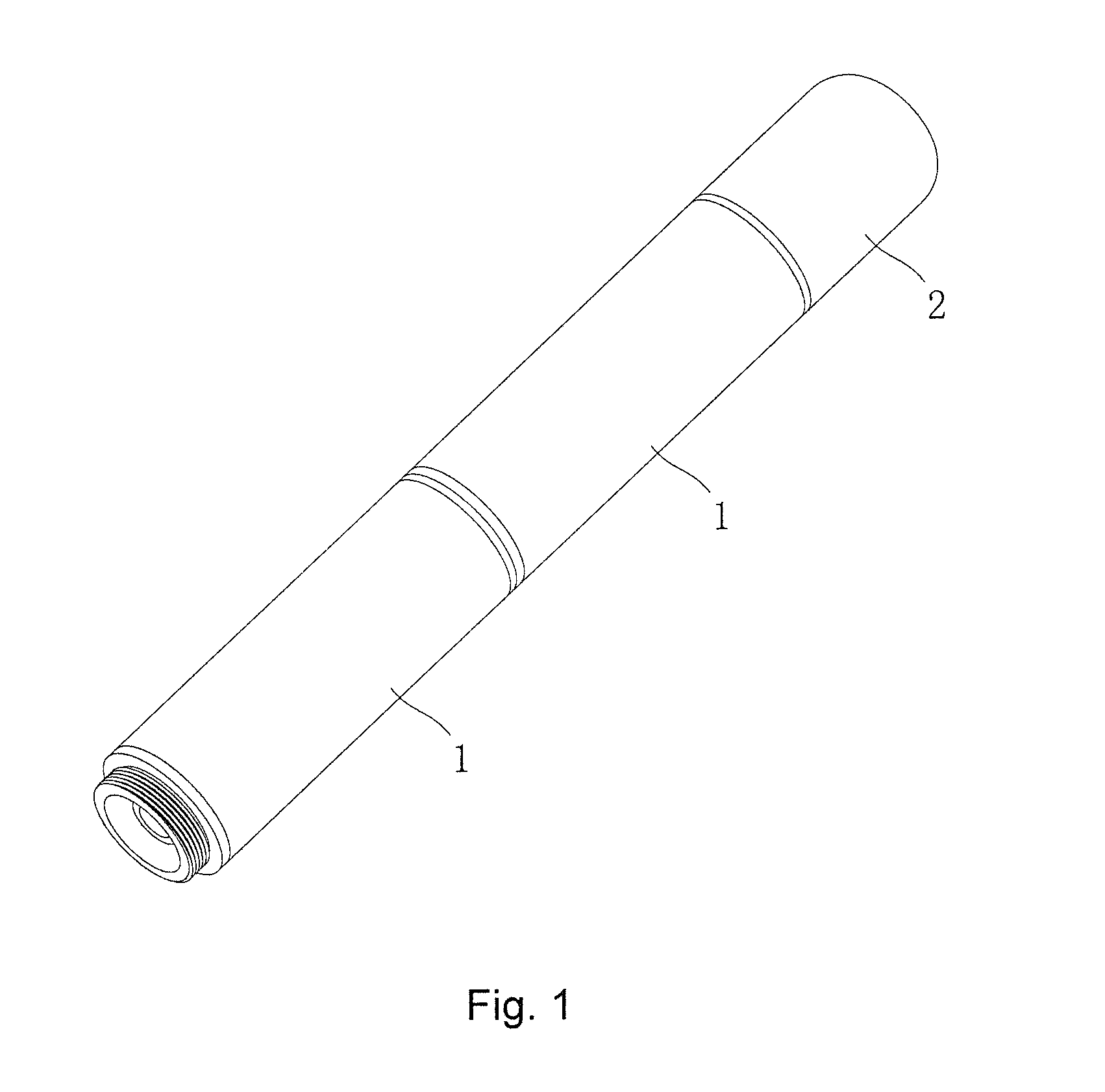

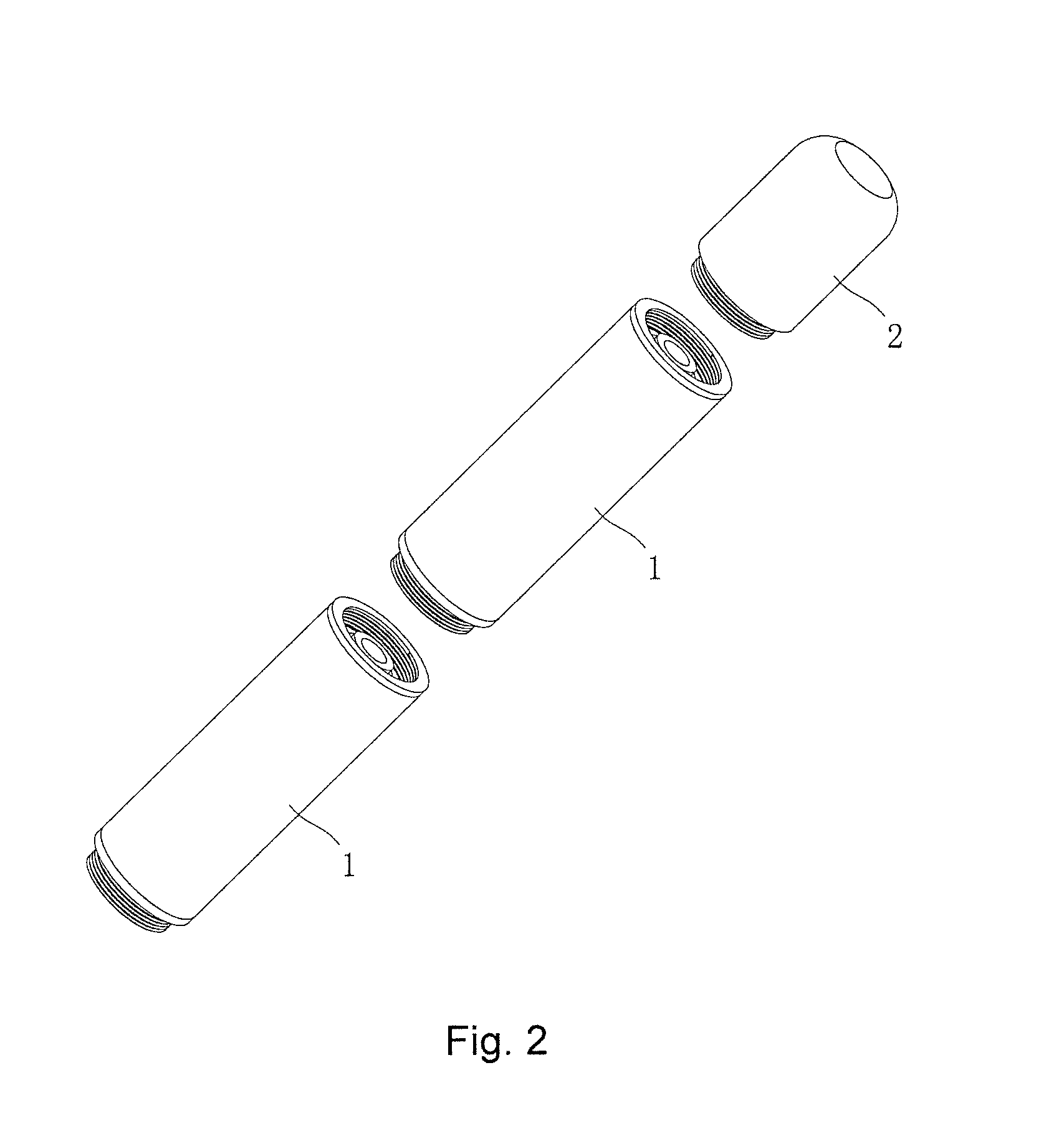

Electronic cigarette atomizer and electronic cigarette using the same

InactiveUS20150196059A1Generate large amount of smokeIncrease the amount of smokeTobacco pipesTobacco devicesElectricityEngineering

The present application discloses an electronic cigarette atomizer and an electronic cigarette using the electronic cigarette atomizer. The electronic cigarette atomizer comprises a plurality of atomizing assemblies, and each atomizing assembly includes at least one heating wire and defines a smoke channel configured to discharge smoke. The atomizing assemblies are all coaxial and thereby form a string, and the smoke channels of every two adjacent atomizing assemblies communicate with each other. The heating wires of all the atomizing assemblies are electrically connected successively, and the heating wire of each atomizing assembly is entirely or partially received in the smoke channel of the atomizing assembly. Pluralities of detachable connecting structure are mounted between every two adjacent atomizing assemblies to detachably connect every two adjacent atomizing assemblies with each other.

Owner:HUIZHOU KIMREE TECH

Method of passivating a gas vessel or component of a gas transfer system using a silicon overlay coating

A method of passivating the interior surface of a gas storage vessel to protect the surface against corrosion. The interior surface of the vessel is first dehydrated and then evacuated. A silicon hydride gas is introduced into the vessel. The vessel and silicon hydride gas contained therein are heated and pressurized to decompose the gase. A layer of silicon is deposited on the interior surface of the vessel. The duration of the silicon depositing step is controlled to prevent the formation of silicon dust in the vessel. The vessel is then purged with an inert gas to remove the silicon hydride gas. The vessel is cycled through the silicon depositing step until the entire interior surface of the vessel is covered with a layer of silicon. The vessel is then evacuated and cooled to room temperature.

Owner:SILCOTEK CORP

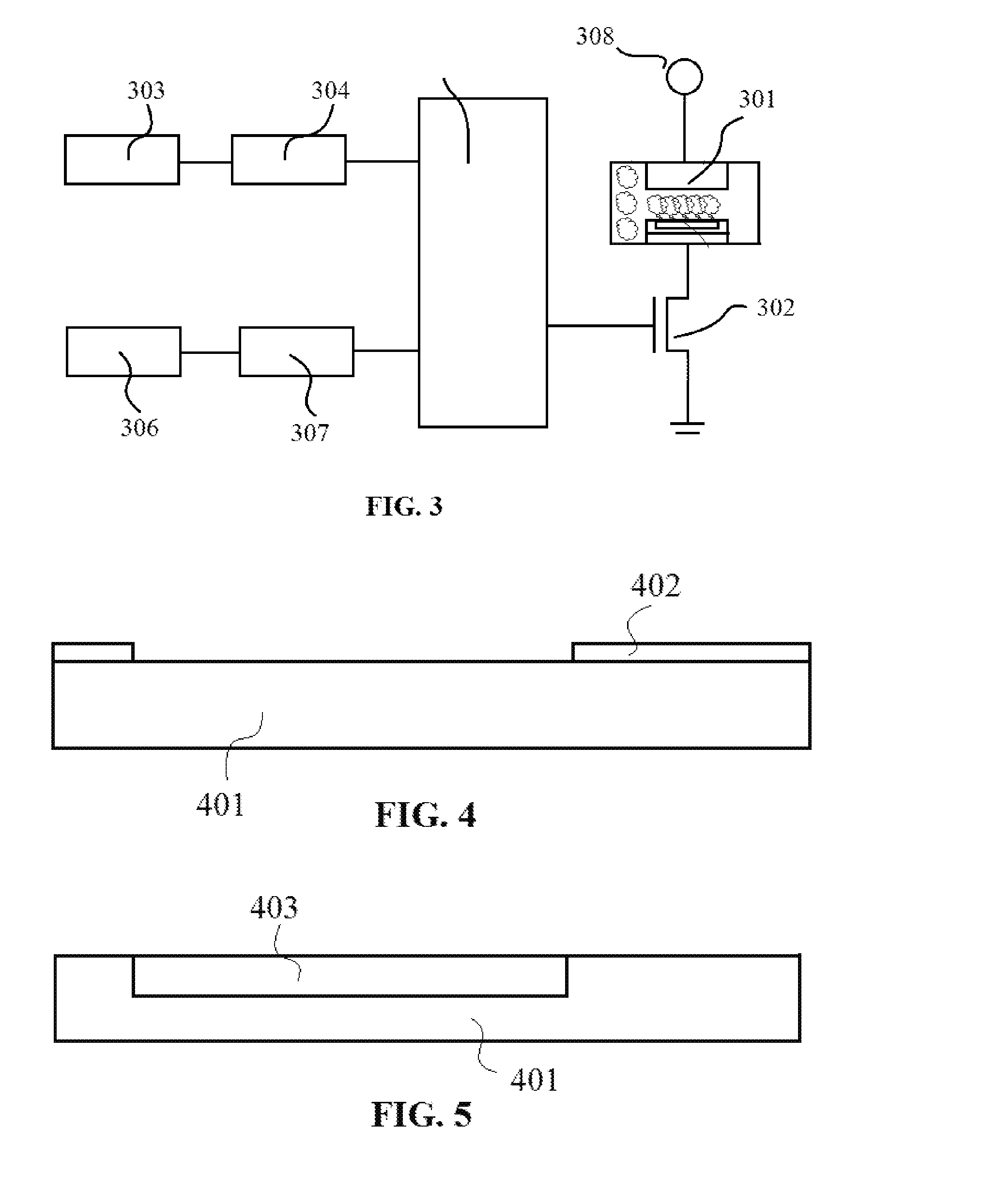

MEMS Vaporizer

ActiveUS20160007653A1Low costImprove reliabilityExhaust apparatusSemiconductor/solid-state device manufacturingEngineeringElectronic cigarette

A MEMS vaporizer is described which can be used for electronic cigarettes. The vaporizer mainly composes: a silicon substrate, a micro-channel array, a membrane suspending over the micro-channel array and supported by the silicon substrate, a resistance heater and a resistance temperature sensor are disposed on the membrane. Since the vaporizer is a silicon-based integrated actuator which provides advantages including small size, compact structure, lower power consumption, lower cost, increased reliability, higher precision, and more environmental friendliness.

Owner:POSIFA TECH LTD

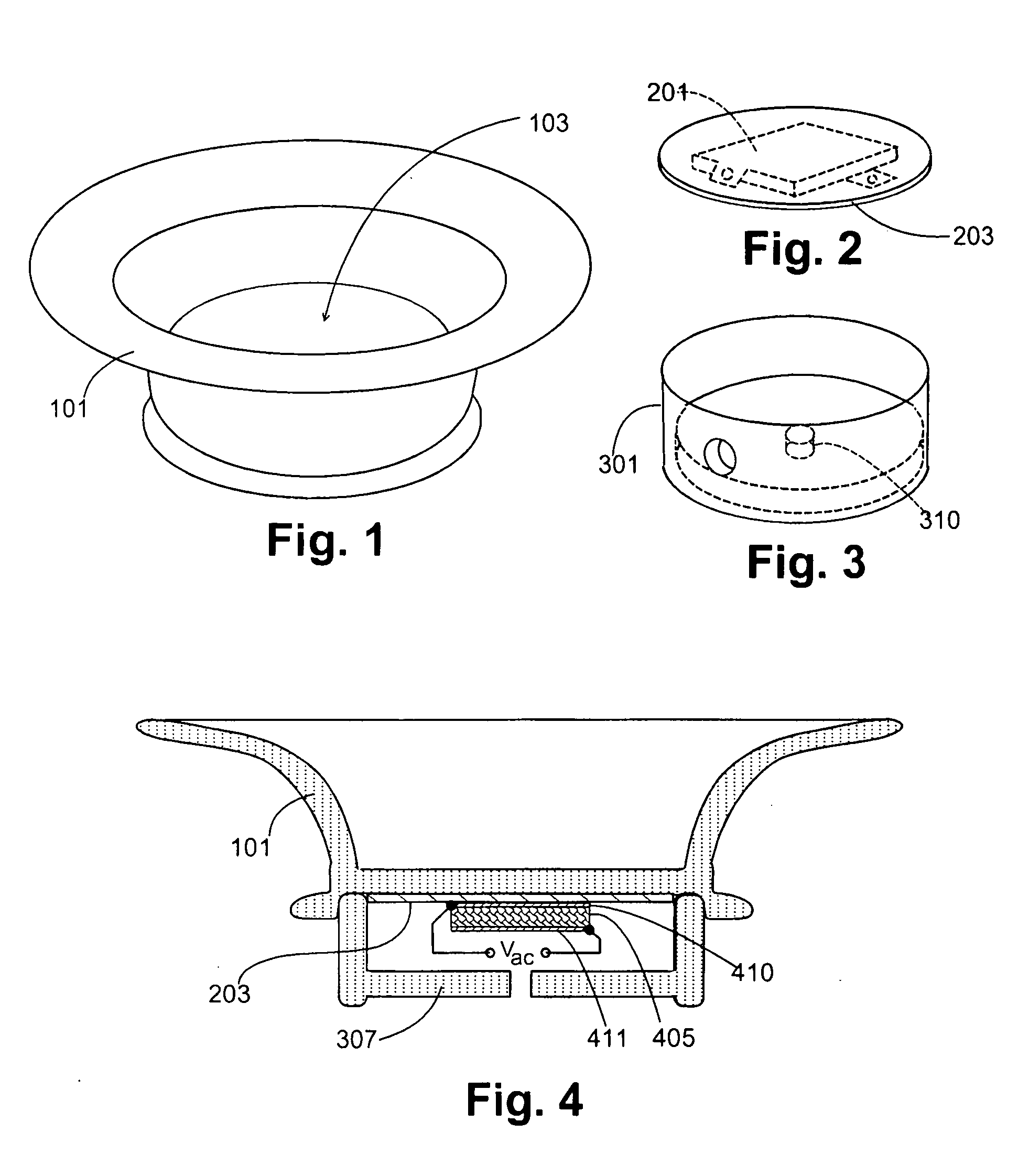

Localized surface volatilization

InactiveUS6909840B2Improved vaporizationIncrease vapor pressureDomestic stoves or rangesLiquid heating fuelElectrical resistance and conductanceProduct gas

The present invention relates to an apparatus and method for rapid flash-like volatilization of high and low vapor pressure components from liquid or solid emanators which is in contact with a point or localized heat source. Vaporization is promoted by a geometrically small electrically resistive heating element with variable activation for pulsed or cyclic heating of an emanating surface containing the volatile components. The apparatus is primarily directed towards the treatment of residential air for fragrancing, odor elimination, treatment of insects or pests, air sanitization, air and surface antibacterial or antimicrobial treatment, or other ambient air or surface modification by way of gas or vapor distribution.

Owner:SC JOHNSON & SON INC

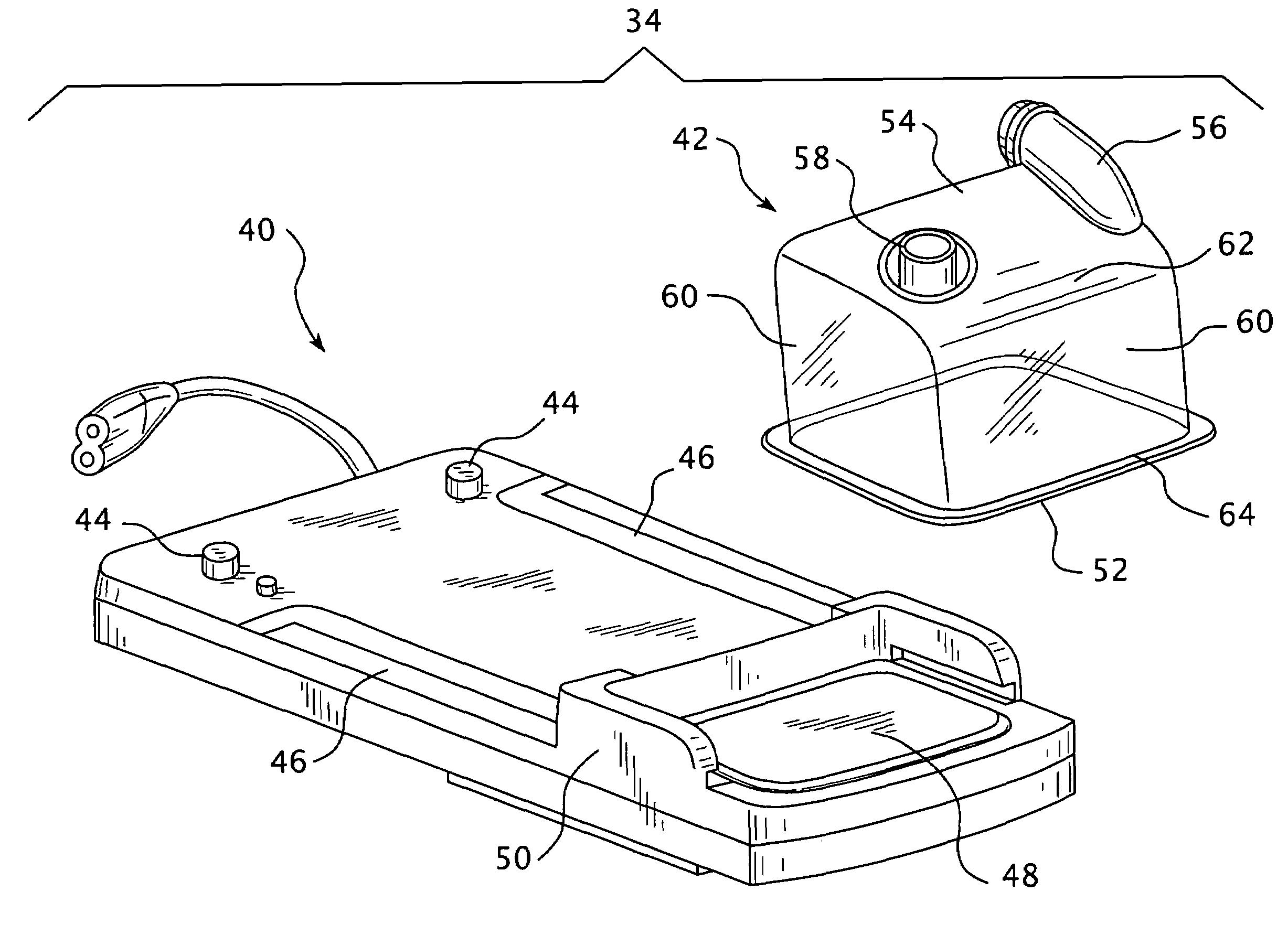

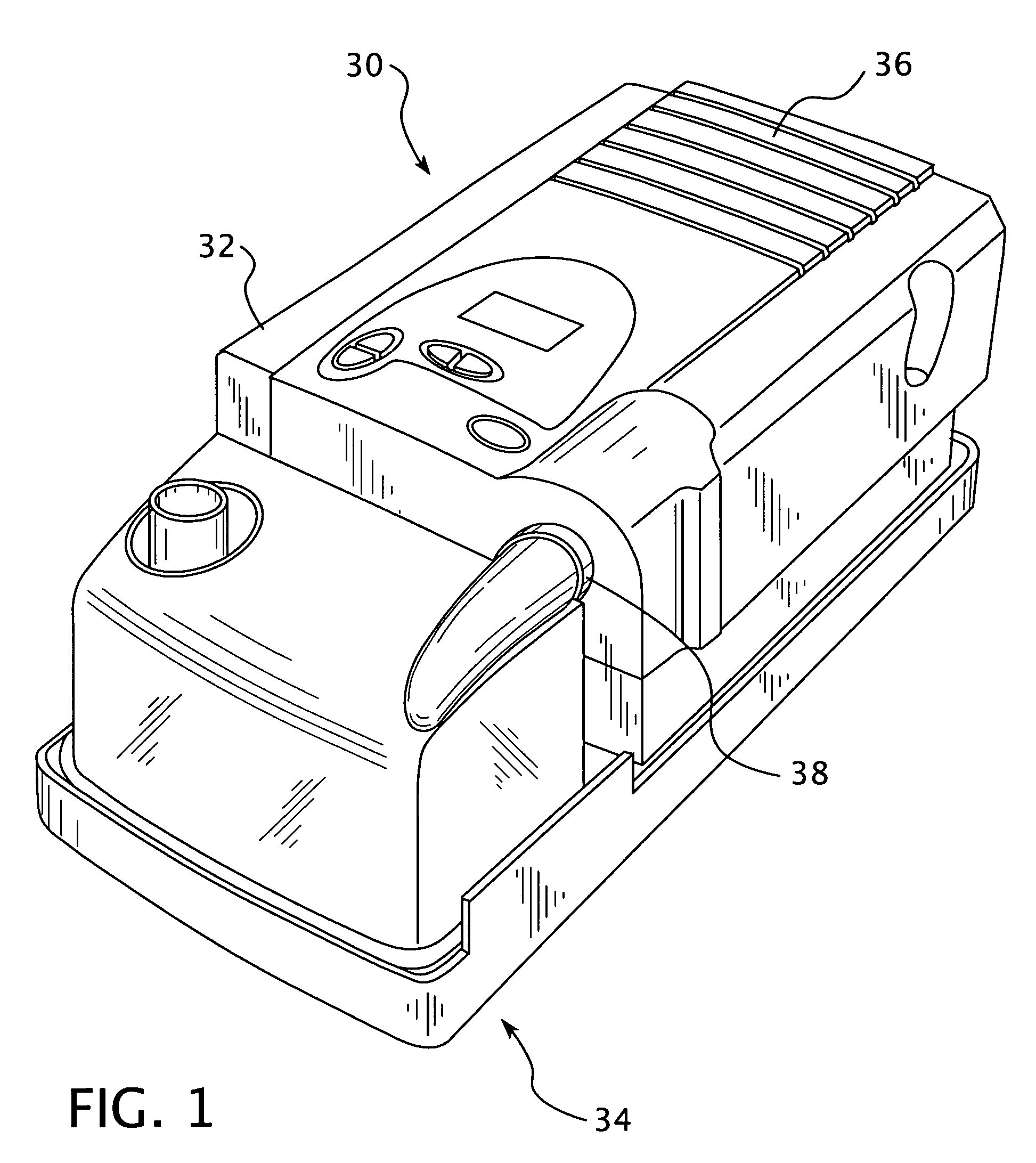

Molded water chamber base plate for use in a humidifier and ventilator assembly

A molded base plate for use in a humidifier and ventilation assembly is disclosed. The base plate is connected to a cover which forms the water chamber of the humidifier. A thermally conductive material is used in the molding process of the base plate so that heat applied to the base plate is conducted into the water.

Owner:RIC INVESTMENTS LLC

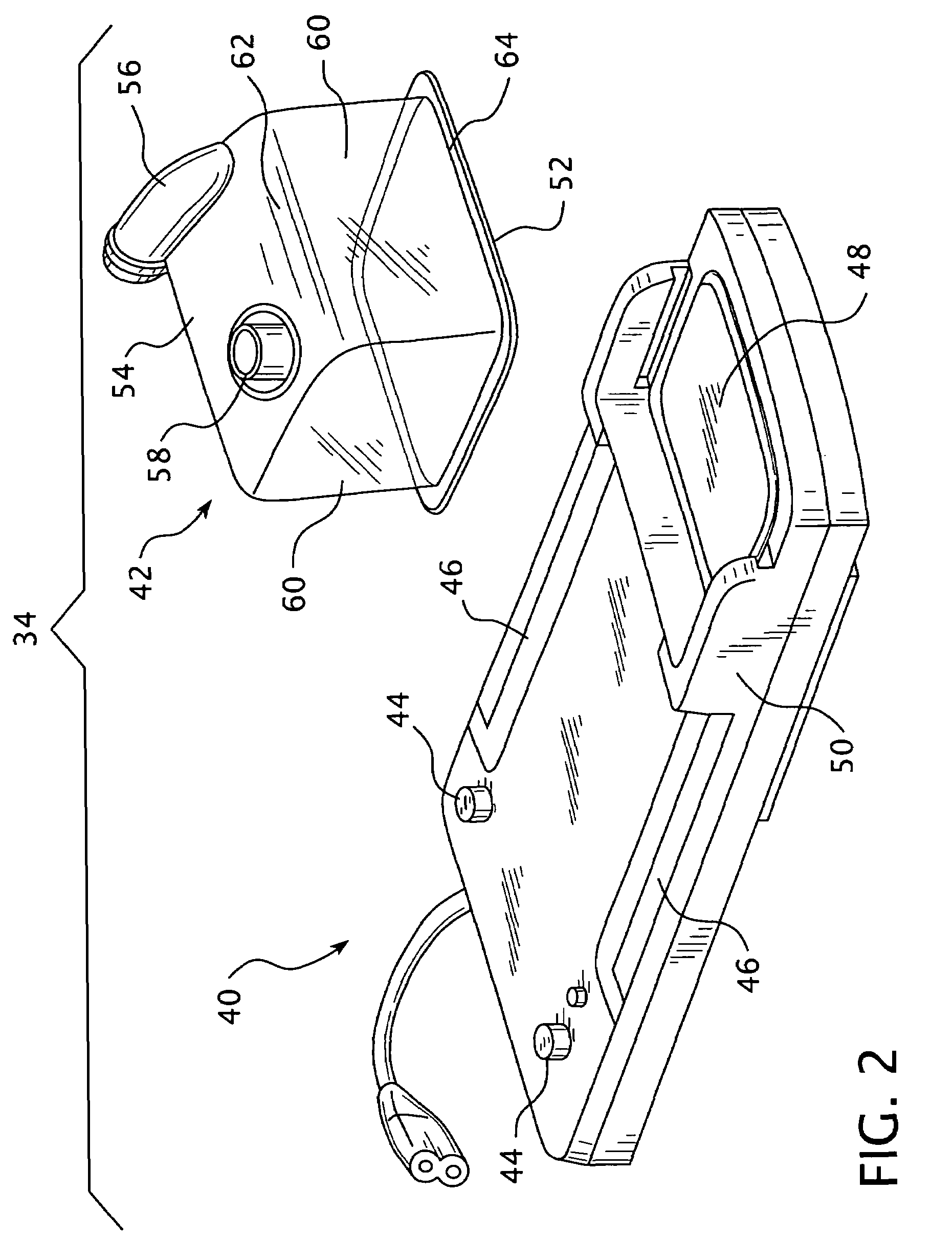

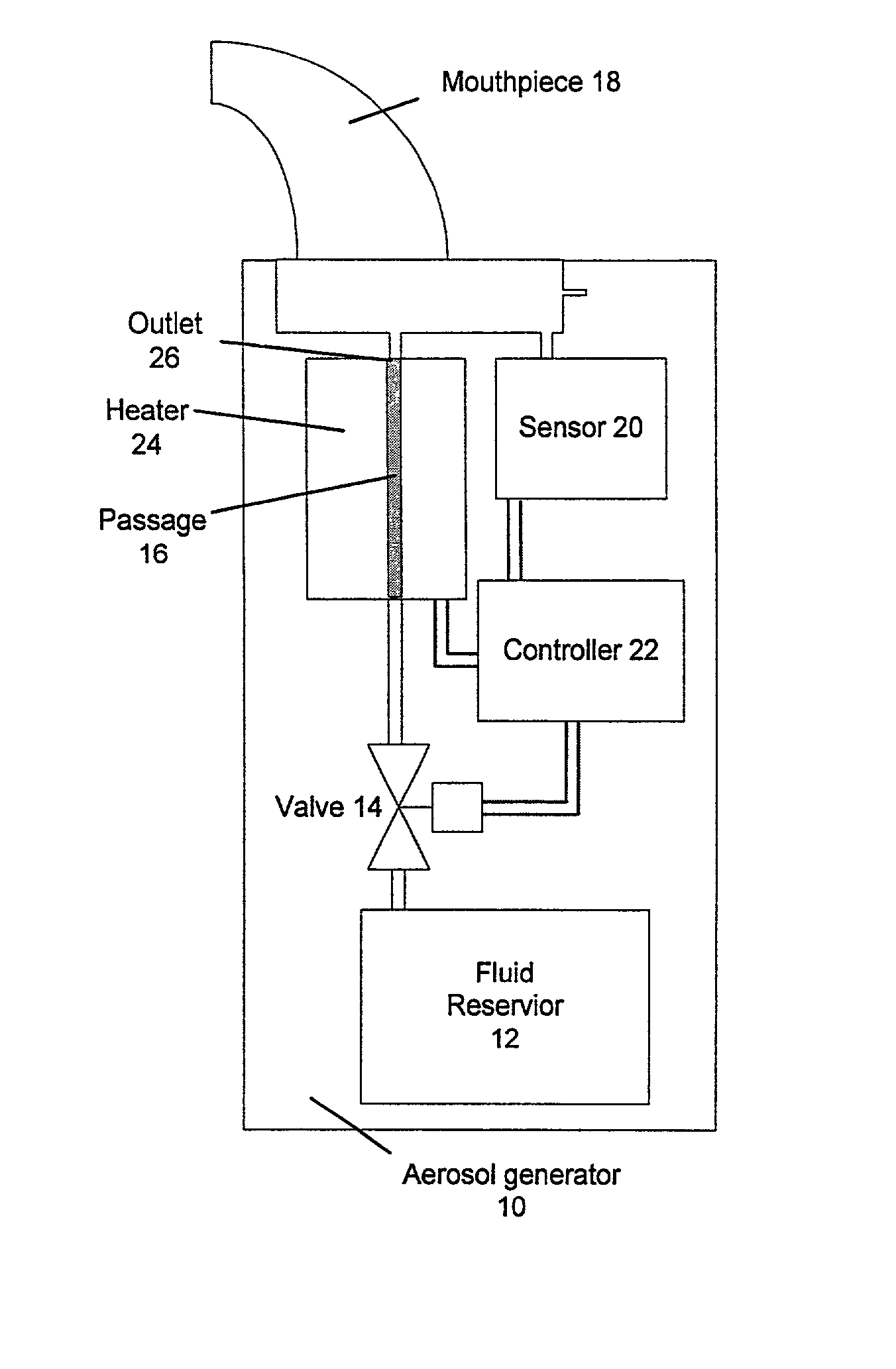

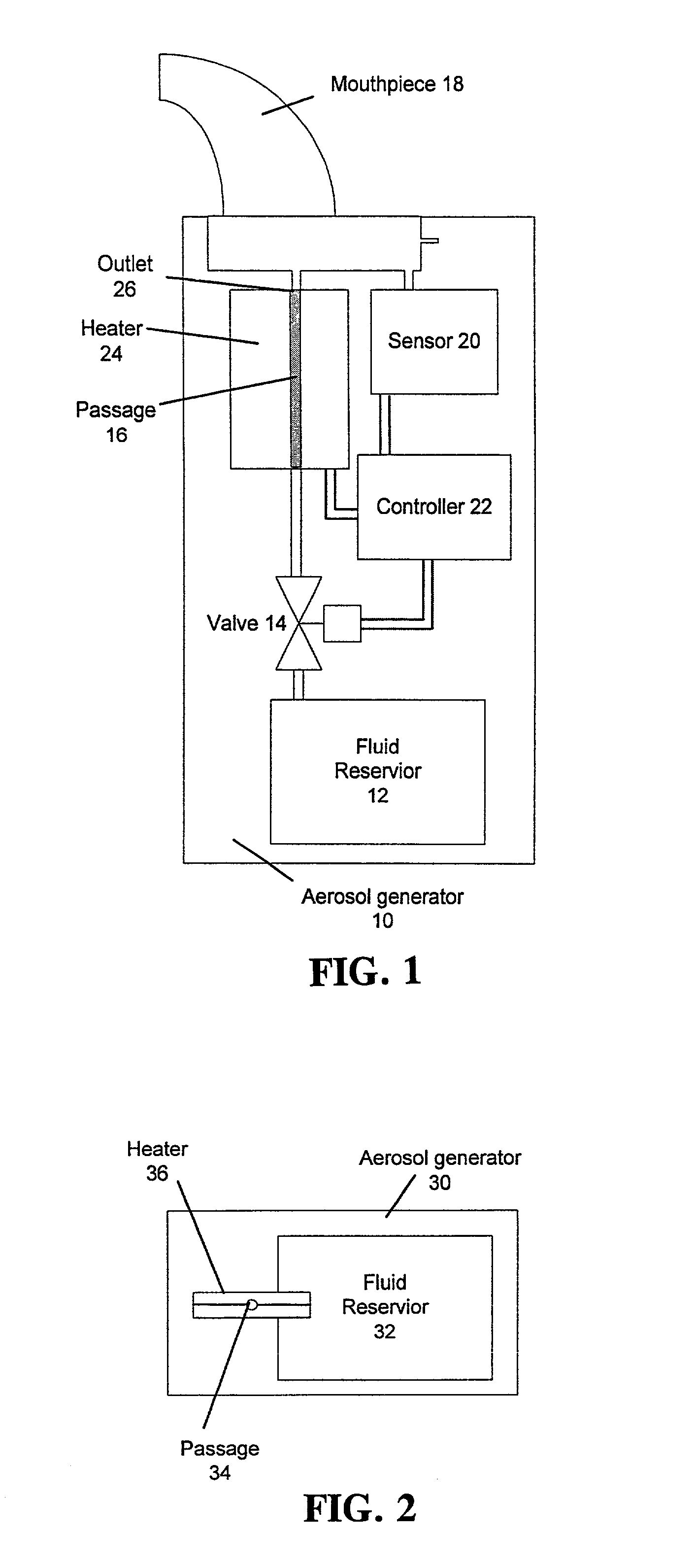

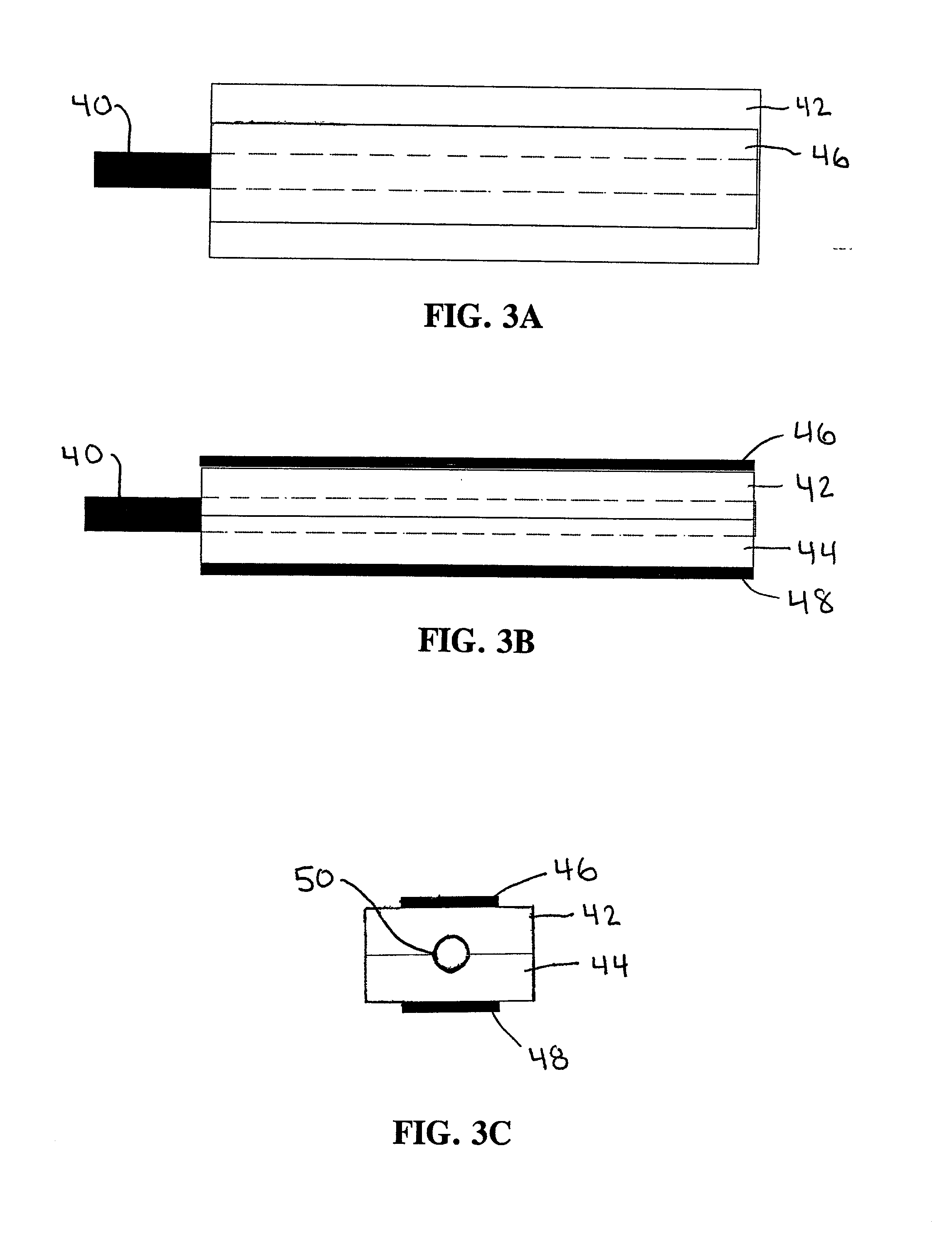

Aerosol generator having heater arranged to vaporize fluid in fluid passage between bonded layers of laminate

InactiveUS20030108342A1Internal combustion piston enginesWater-tube boilersCapillary TubingEngineering

An aerosol generator includes a fluid supply which supplies fluid to a fluid passage and a heater which heats the fluid into a gaseous state, the fluid passage being located between opposed layers of a laminate. The fluid passage can be a capillary sized passage formed by locating a mandrel between opposed layers of the laminate, bonding the layers together and removing the mandrel such that the space previously occupied by the mandrel forms the fluid passage. The opposed layers of the laminate can be copper sheets and ceramic layers can be provided on the outside of the copper layers. The aerosol generator can be used to generate aerosols containing medicated materials.

Owner:PHILIP MORRIS USA INC

System and process for transporting LNG by non-self-propelled marine LNG carrier

Marine LNG carrier and method of operating the marine LNG carrier. The LNG carrier carries LNG in at least one tank. Gas composed of evaporated LNG within the at least one tank is removed. The gas is fed to at least one gas consuming prime mover of the LNG carrier. Power is provided with the at least one gas consuming prime mover. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:ARGENT MARINE MANAGEMENT

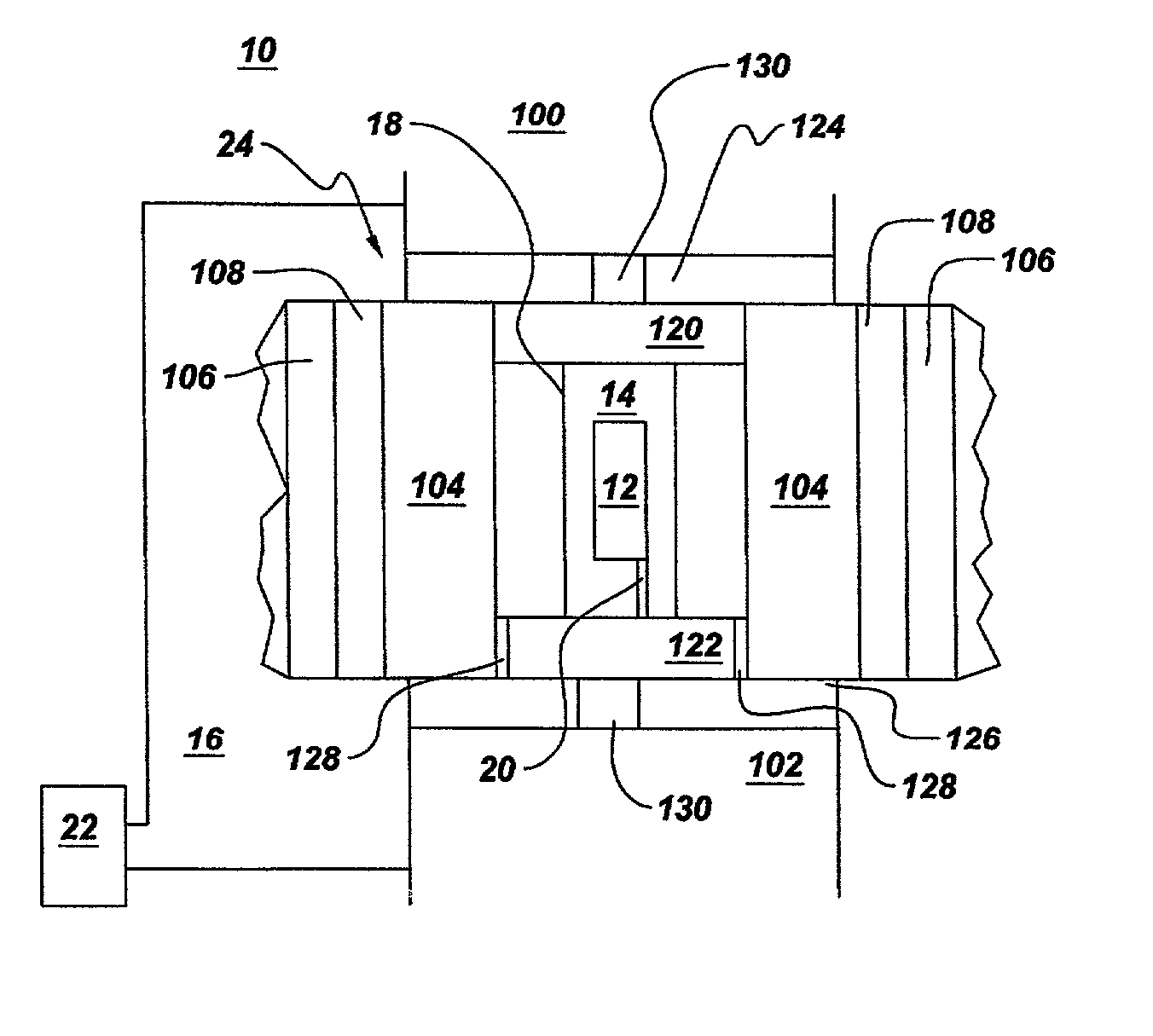

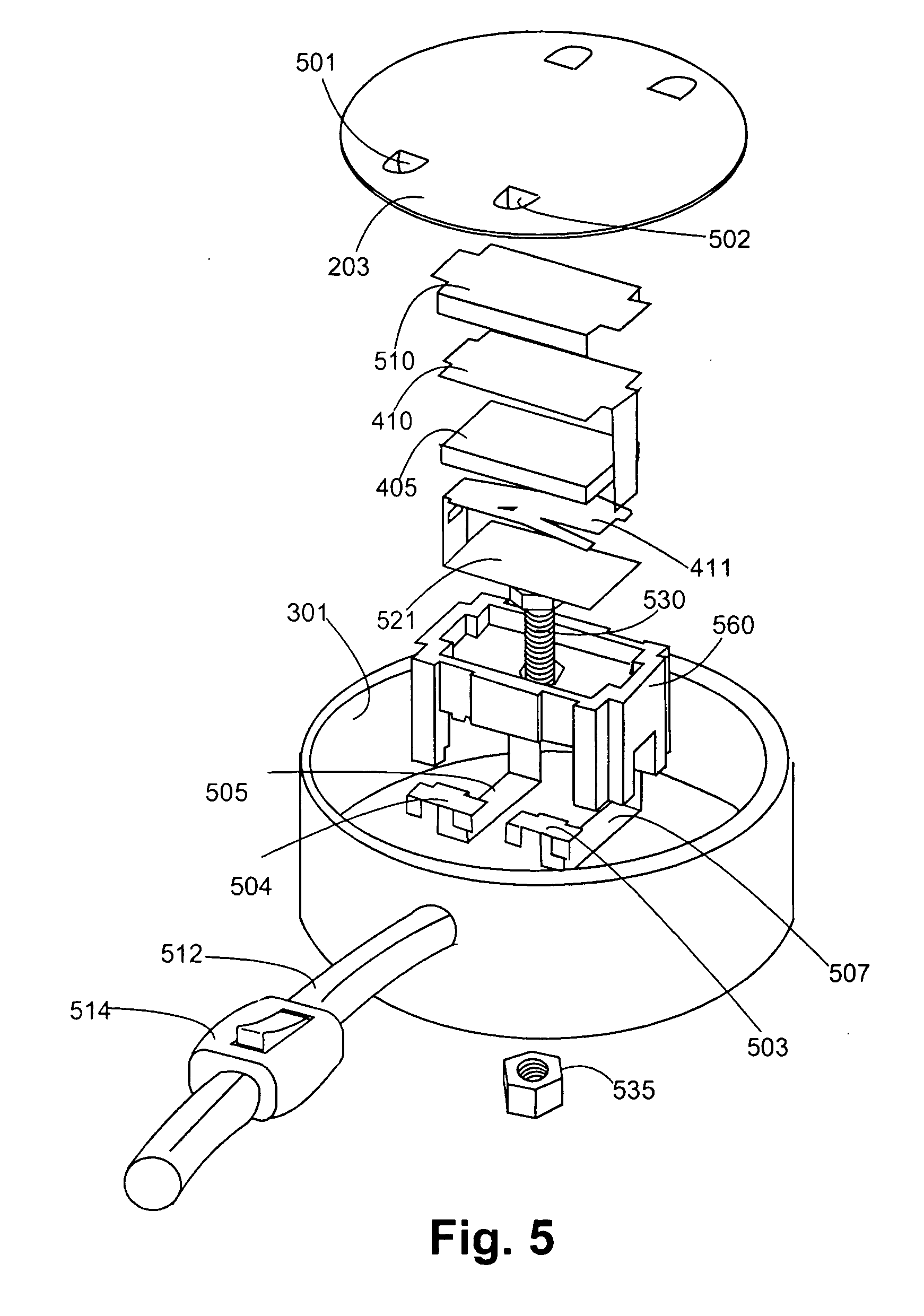

Pressure vessel

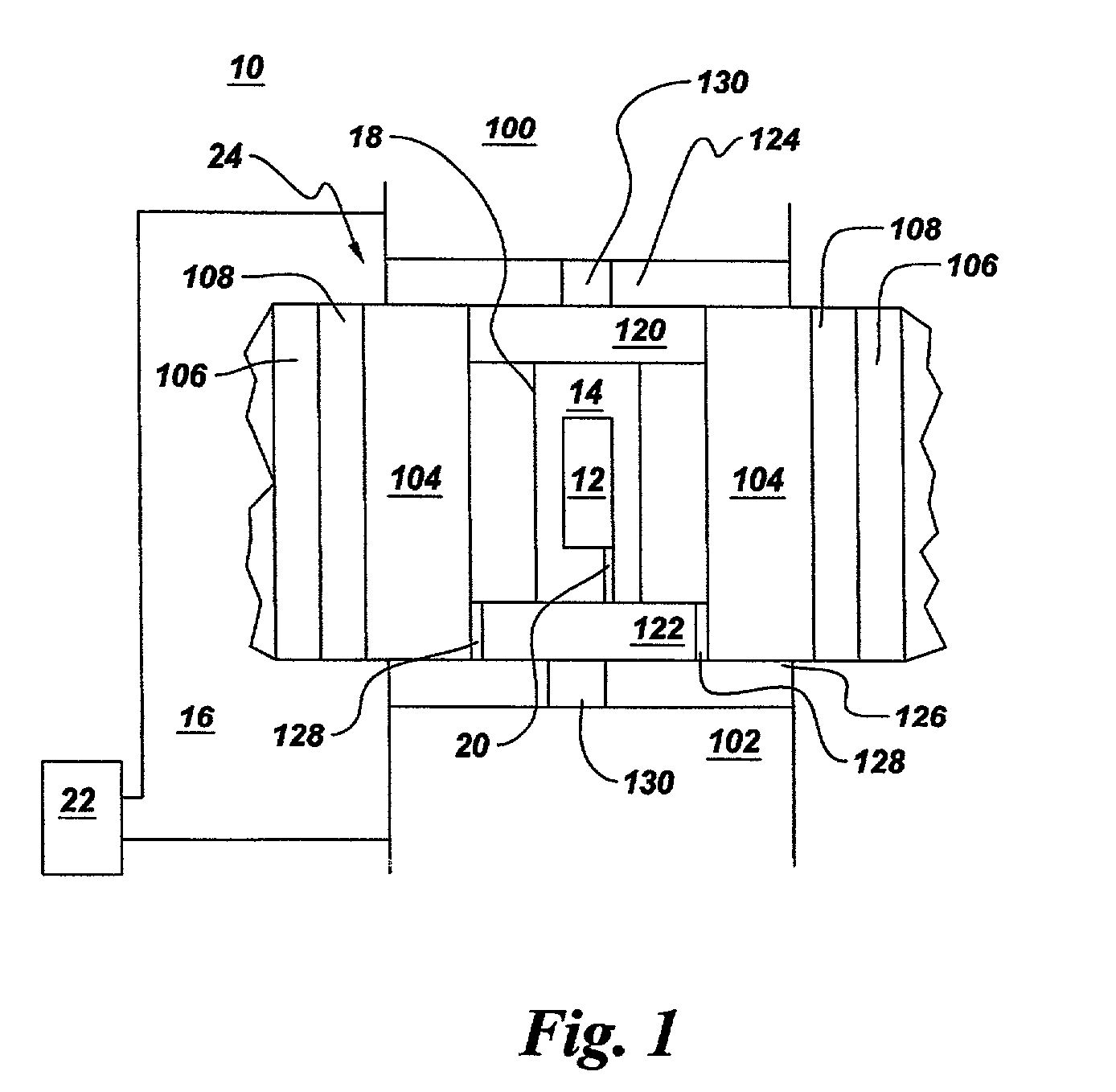

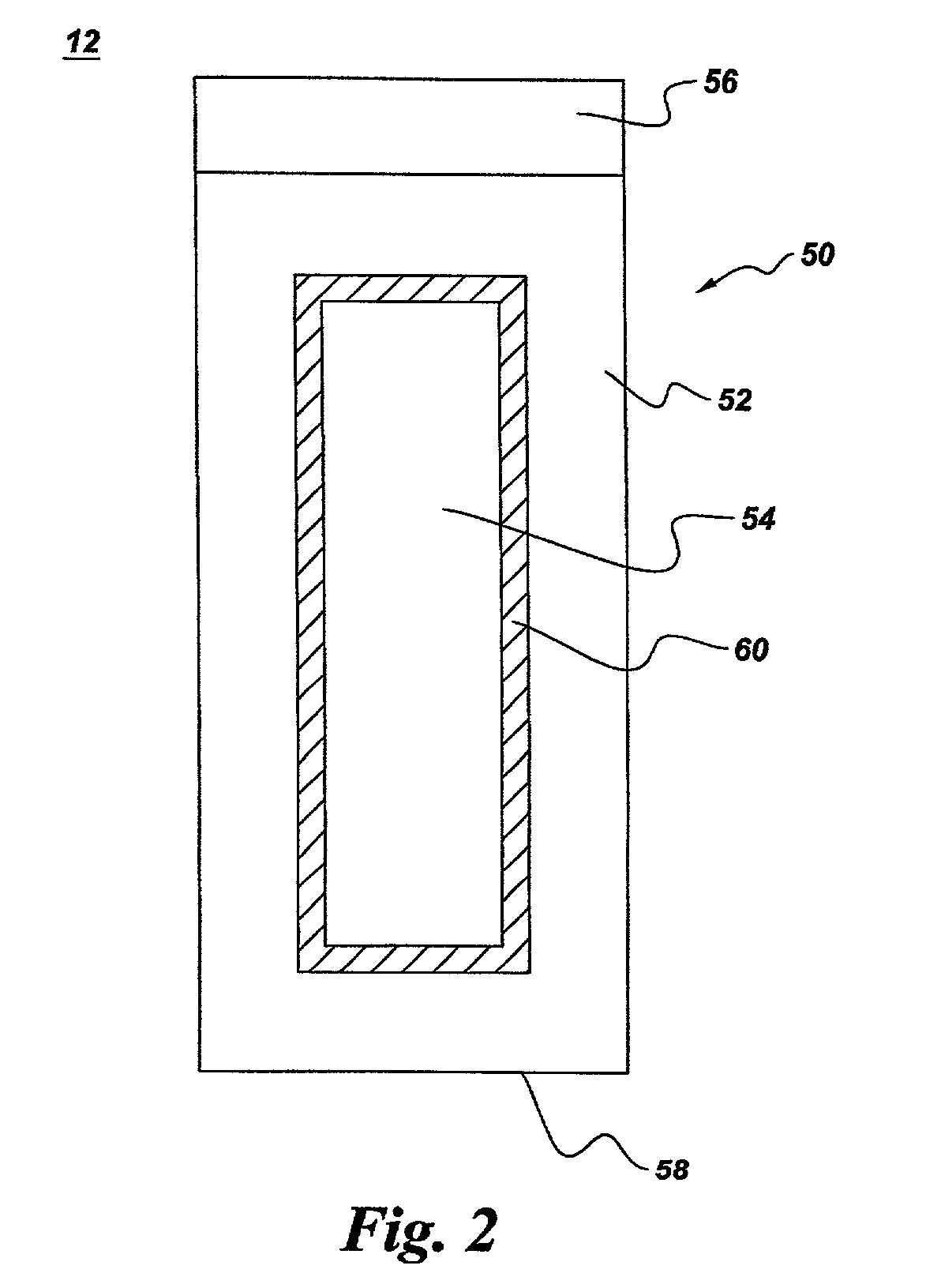

InactiveUS20030140845A1Prevent escapeAvoid creatingFrom gel statePolycrystalline material growthTemperature controlPressure transmission

A pressure vessel for processing at least one material in a supercritical fluid. The pressure vessel includes a self-pressurizing capsule for containing at least one material and the supercritical fluid in a substantially air-free environment, a pressure transmission medium surrounding the capsule for maintaining an outer pressure on the capsule, at least one heating element insertable in the pressure transmission medium such that the heating element surrounds the capsule, a temperature measurement means for measuring a temperature of the capsule, a temperature controller for controlling the temperature and providing power to the heating element, a restraint to contain and hold in place the capsule, the pressure transmission medium, and the heating element, and at least one seal between the restraint and the pressure transmission medium for preventing escape of the pressure transmission medium. Methods of using the pressure vessel, processing a material at high temperature and high pressure in the presence of a supercritical fluid within the capsule are also described.

Owner:SORAA

Liquefied natural gas floating storage regasification unit

InactiveUS20060156744A1Reduce the amount requiredProvide protectionGas handling applicationsGas handling/storage effectsMooring systemMarine engineering

An offshore liquefied natural gas floating storage regasification unit that may receive, store, and process liquefied natural gas from carriers. A floating storage regasification unit may include transfer equipment to offload liquefied natural gas from a carrier, a first mooring system to provide for mooring of a floating storage regasification unit at a location in a body of water, a second mooring system to provide for mooring a carrier to the floating storage regasification unit, and combinations thereof. A portion of the floating storage regasification unit may be composed of a double-hull containment structure.

Owner:SHELL OIL CO

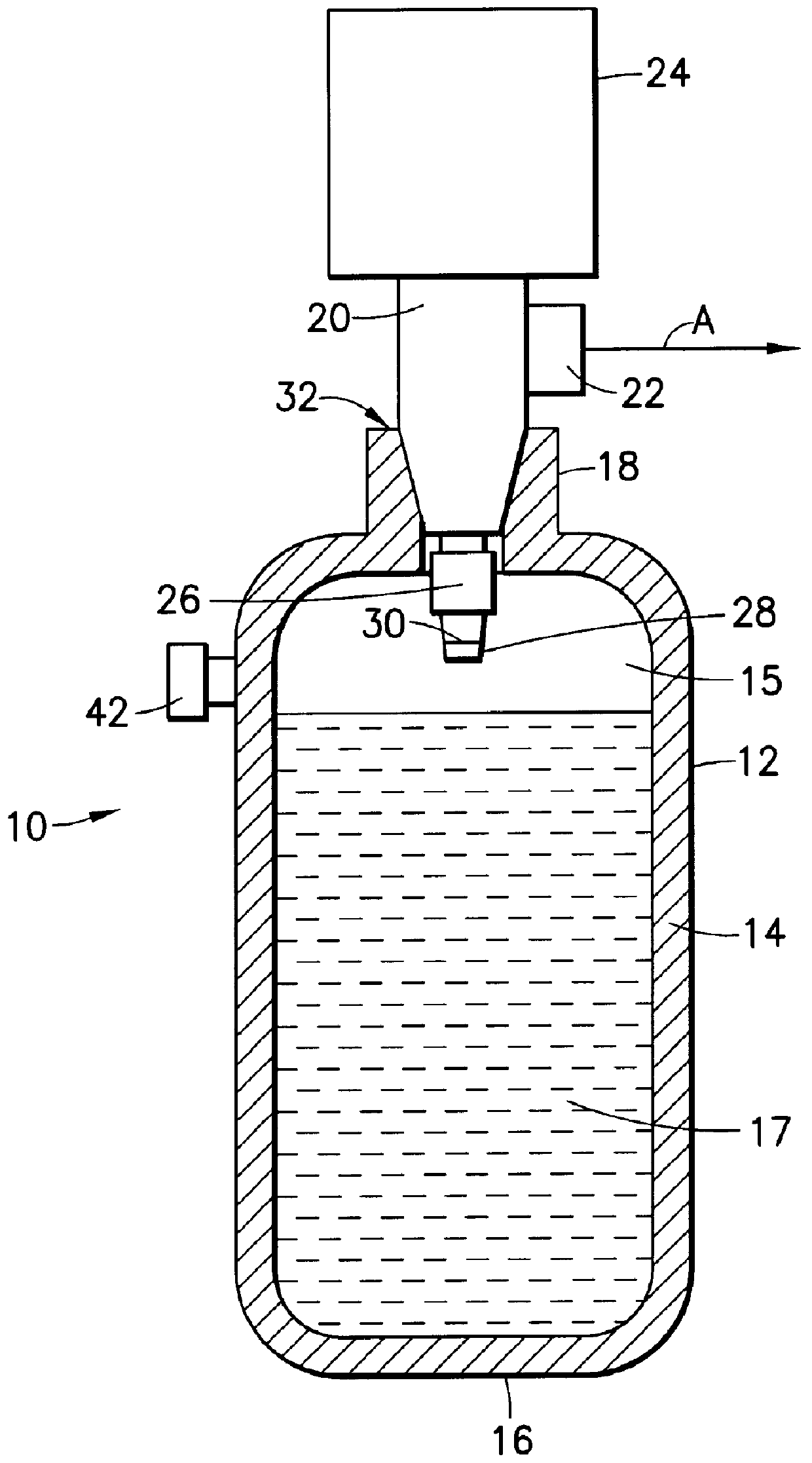

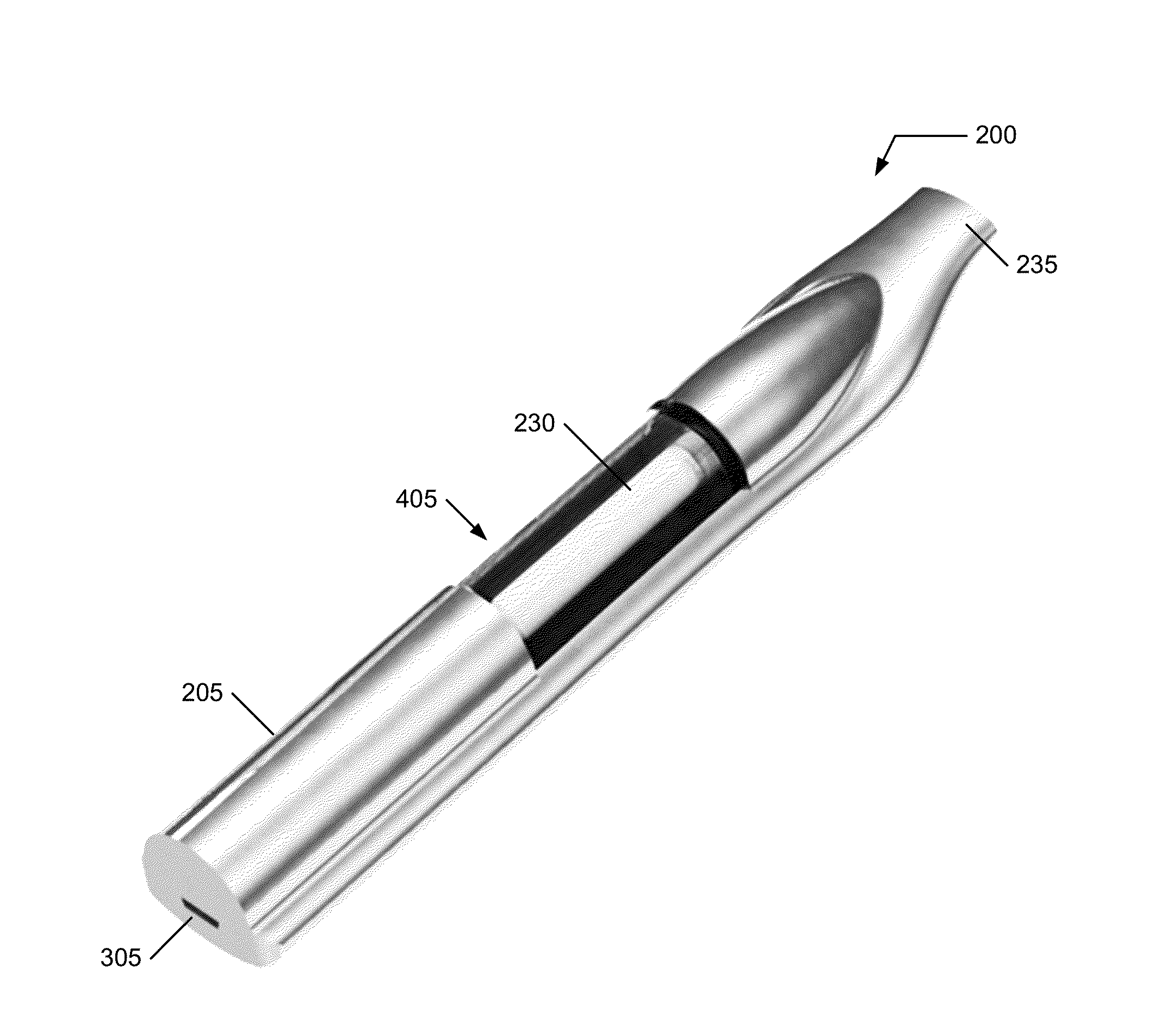

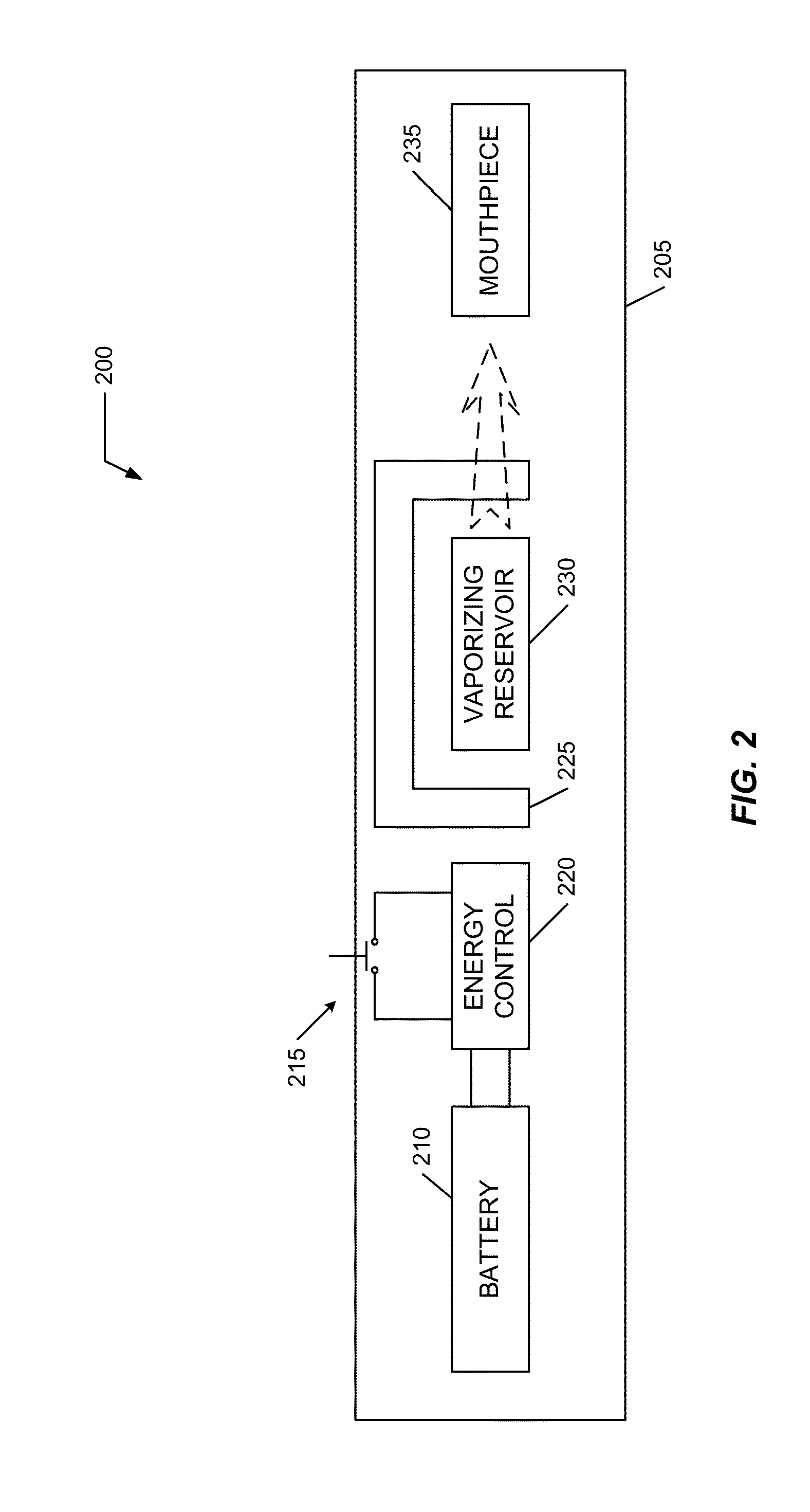

Vaporizing reservoir

InactiveUS20160150828A1Less-prone to leakingEasy to change out flavorSpace heating and ventilationTobacco devicesElectricityEngineering

A vaporizing reservoir including a containment vessel having a first shaft port exposed to ambient and one or more sidewalls defining a body portion having an interior cavity and a vaporizing portion communicated to the interior cavity; an inductive coil disposed within the vaporizing portion, the inductive coil electrically disconnected outside of the containment vessel and configured for inductive heating; and an air shaft communicated to the vaporizing portion and extending to the first shaft port. Fluid or solid material may be present in the interior cavity for vaporization. For fluid material, a wick may be included with the inductive coil to facilitate communication of the material to the inductive coil. An exterior inductive coil heats the inductive coil within the vaporizing portion and vaporizes the material communicated to the interior inductive coil. Vapor from the heated interior inductive coil is extracted through the air shaft.

Owner:GOLDSTEIN GABRIEL MARC

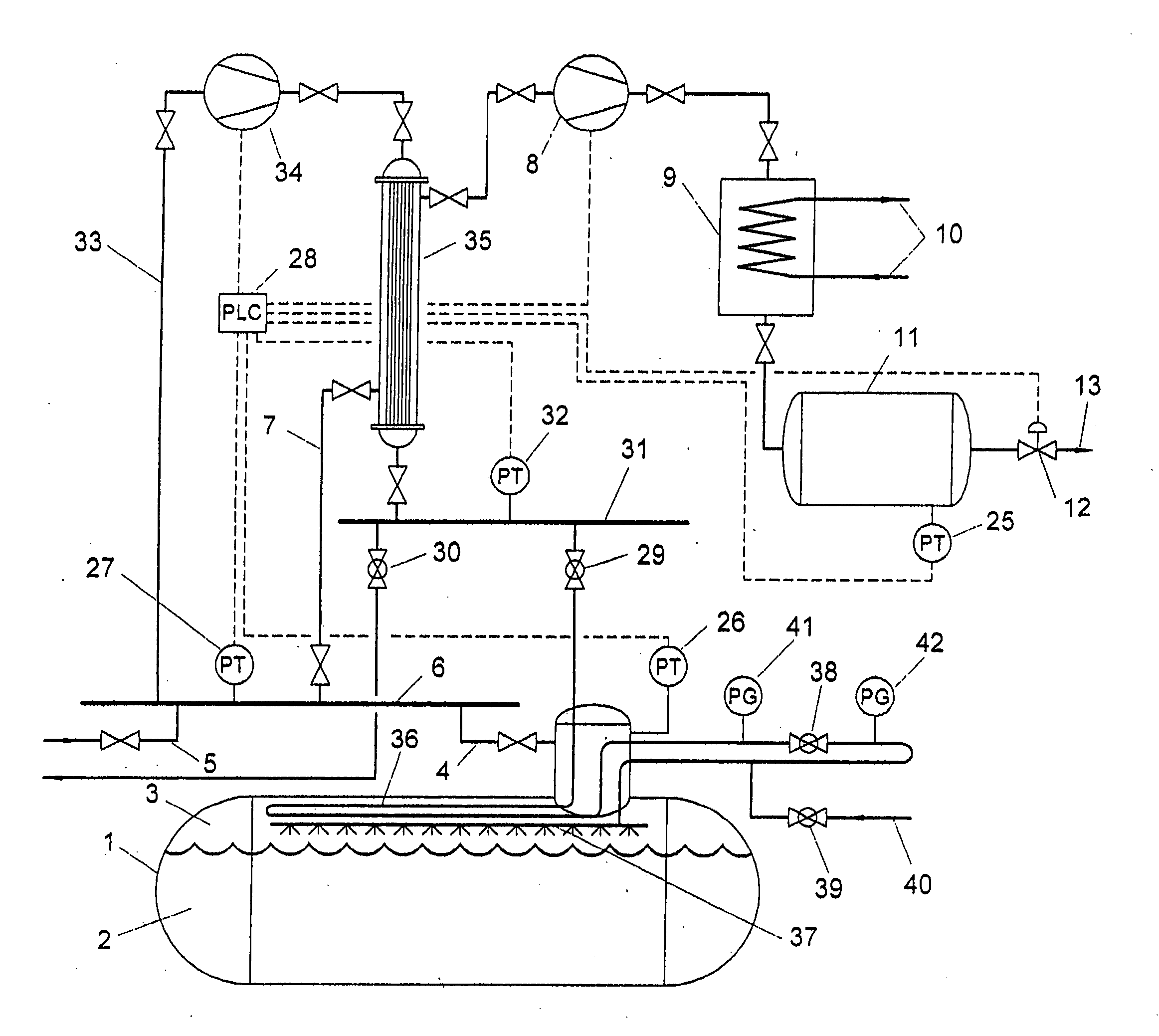

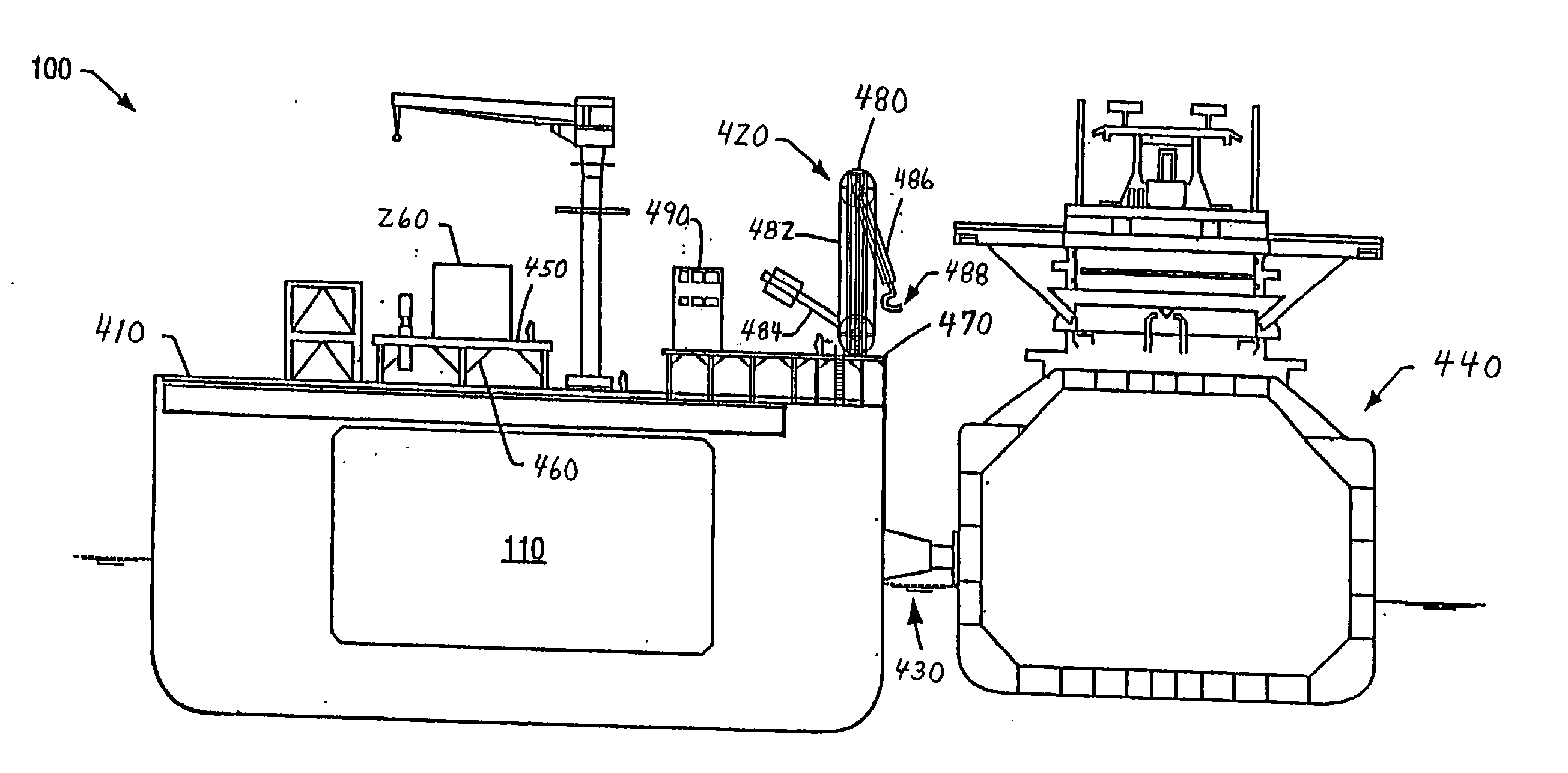

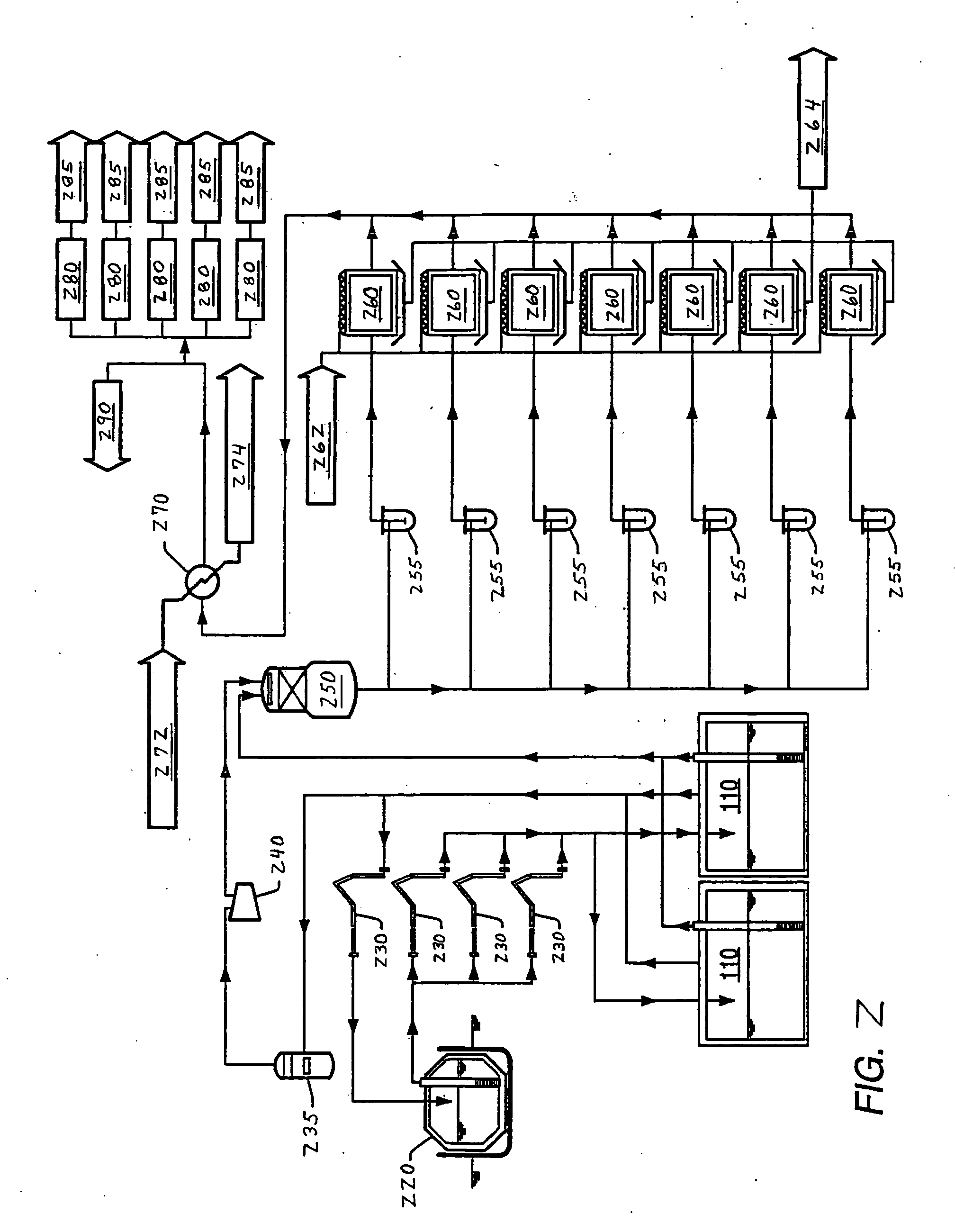

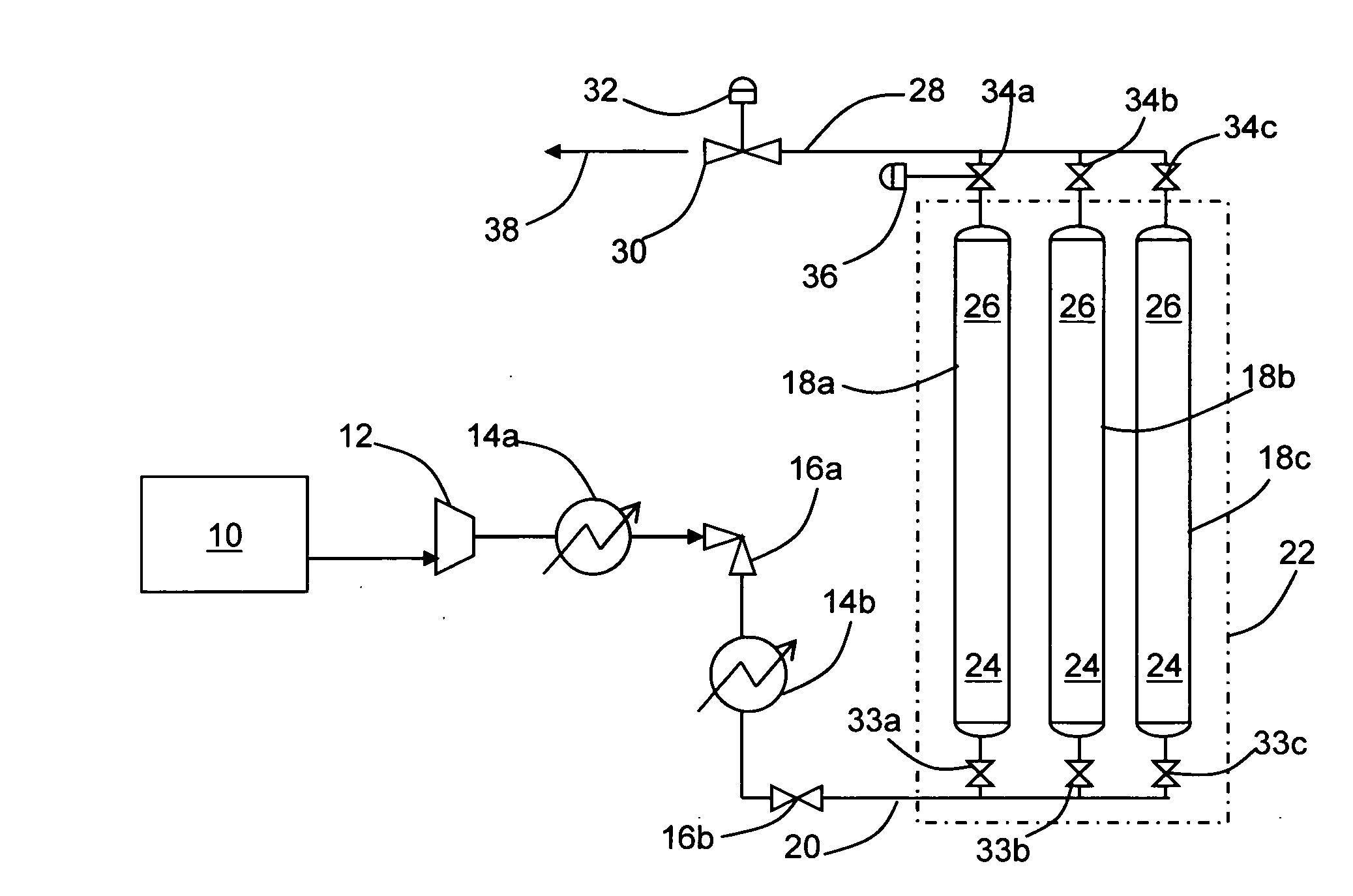

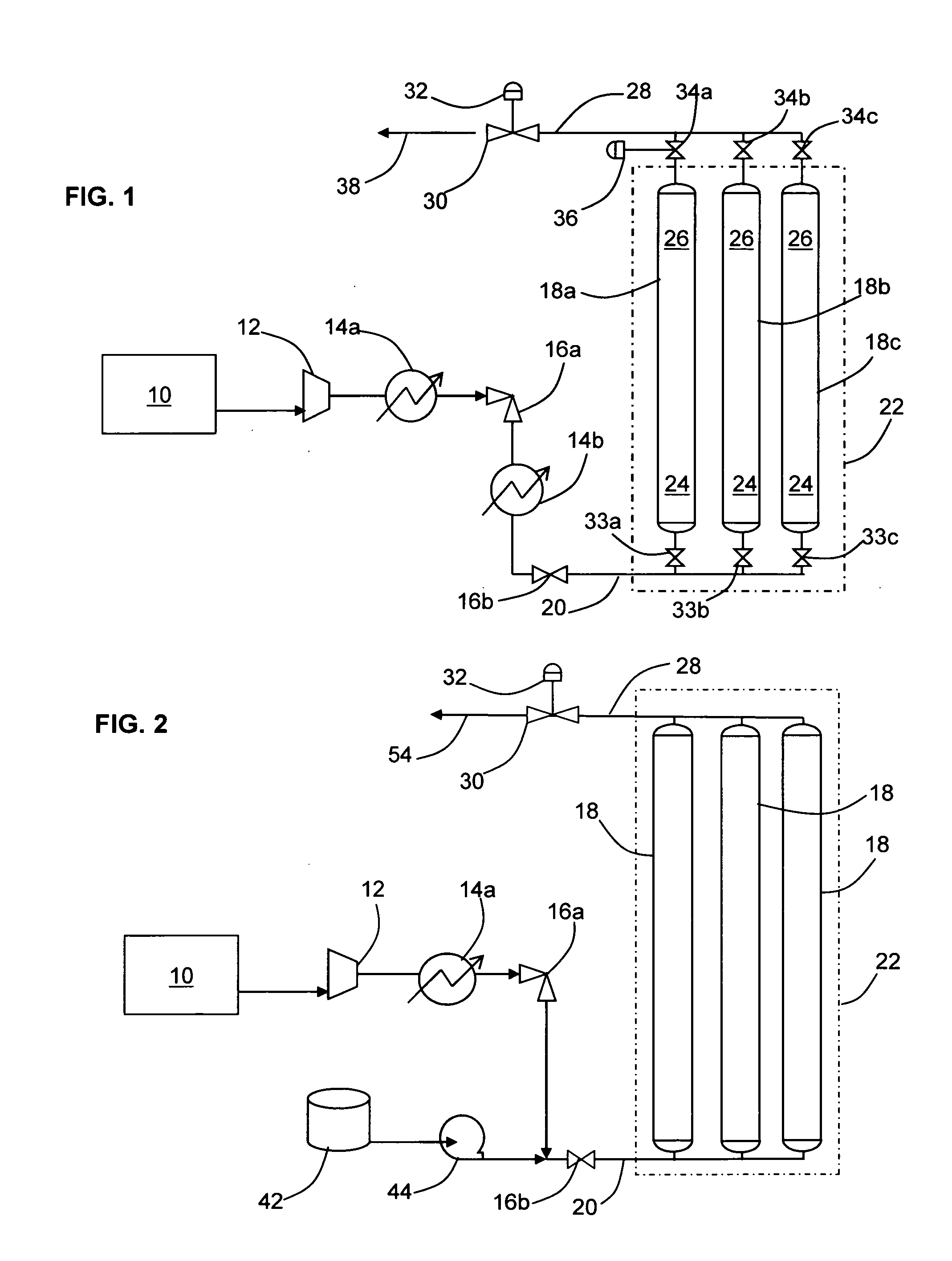

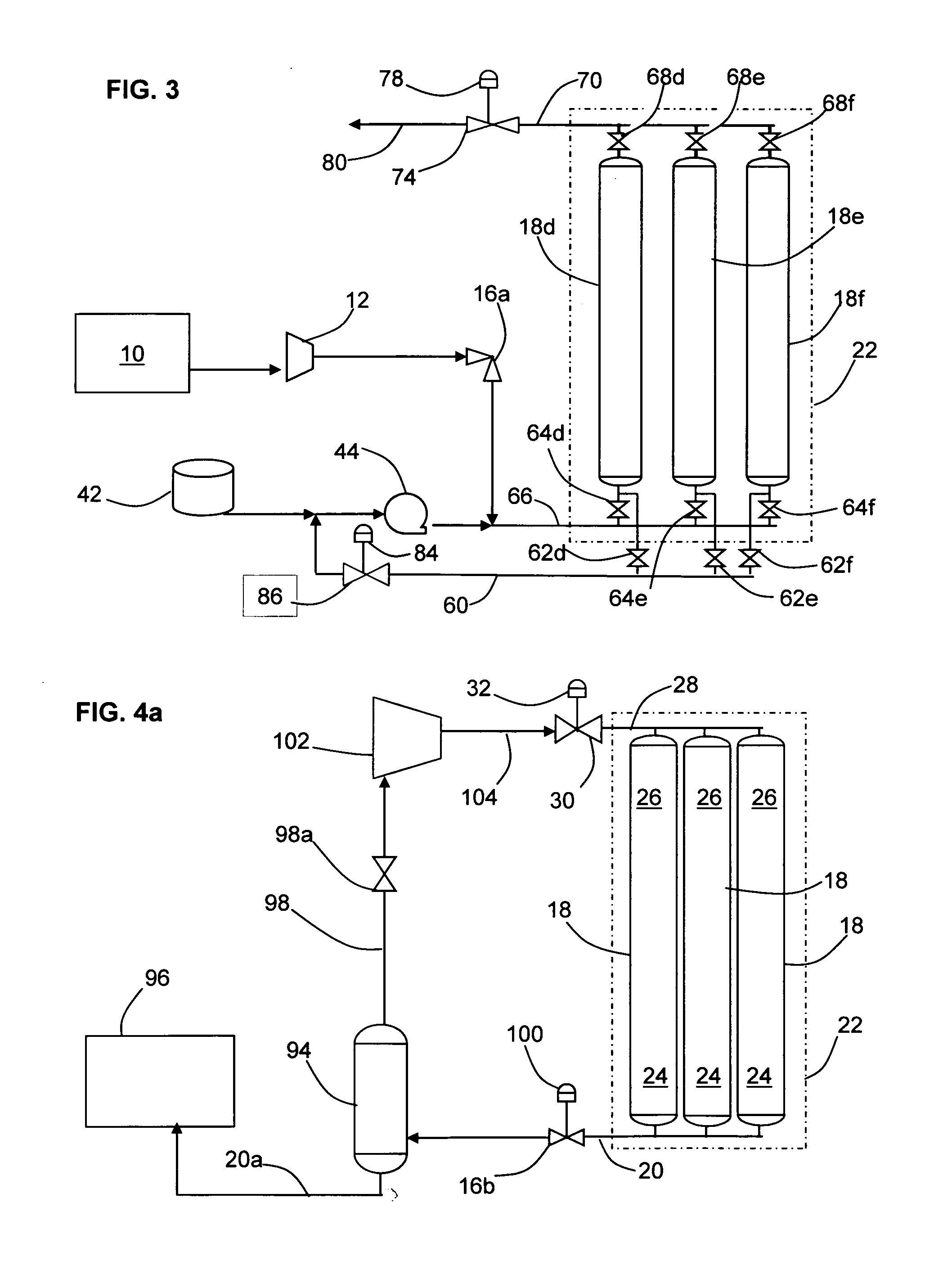

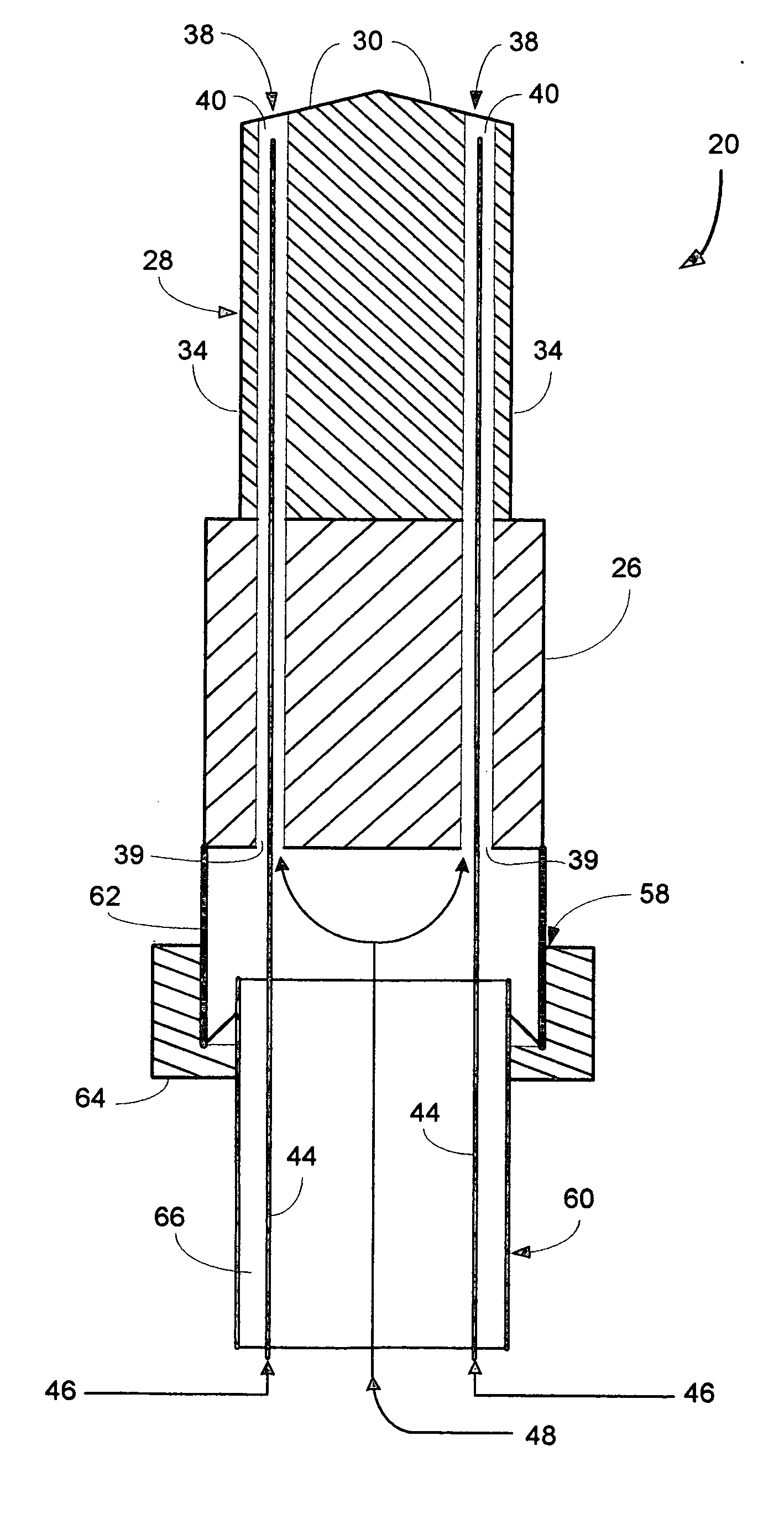

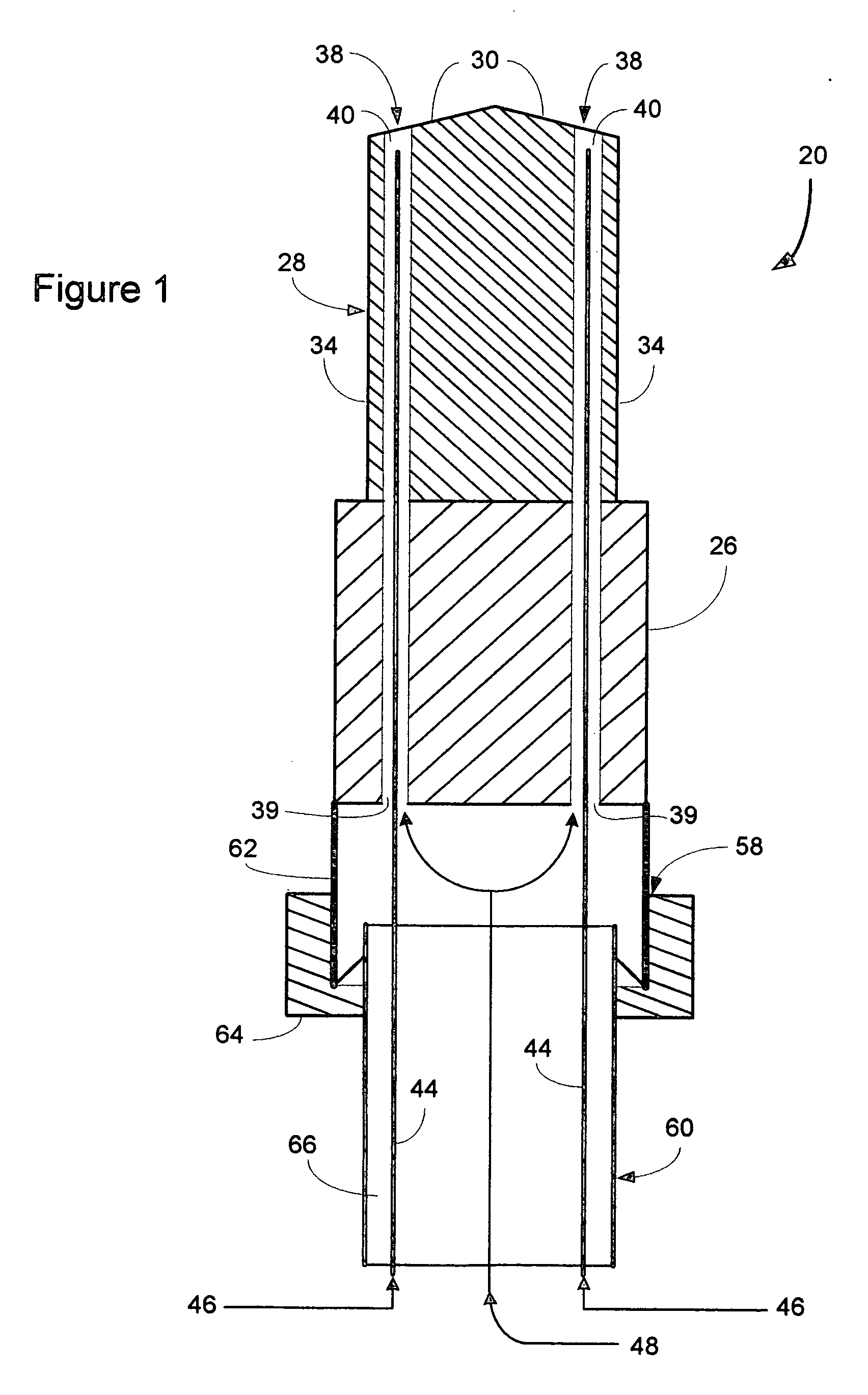

Apparatus and method for flowing compressed fluids into and out of containment

ActiveUS20080209916A1Adjustable temperatureGas handling applicationsGas handling/storage effectsChemical compositionCompressed fluid

Methods for loading a compressed fluid, such as natural gas, into and discharging the compressed fluid out of containment are provided. The compressed fluid is injected into a bottom portion of a container system for storage and / or transport until a target pressure is reached after which gas is withdrawn from an upper portion of the container system at a rate to maintain the target pressure while the compressed fluid is injected in the bottom portion. The compressed fluid is cooled through an expansion valve and by refrigerated chillers or by injecting a cold liquid of the same chemical composition as the compressed fluid, such as liquid natural gas, into the compressed fluid prior to injection into the container system. Withdrawal or discharge from the container system to a receiving facility begins with blow down from the bottom portion of the container system without a displacement fluid and continues until pressure falls below an acceptable differential pressure. The discharge stream is passed through a separator and a light gas from the separator is pressurized and injected into an upper portion of the container system to drive the compressed fluid out the bottom. The light gas is pressurized using either a compressor or a heated tank system, where two vessels operate in parallel, trapping and heating the light gas and then discharging to the container system from one while filling the other and alternating the operation between the two.

Owner:WHITE CHARLES N +1

Device for applying cryogenic composition and method of using same

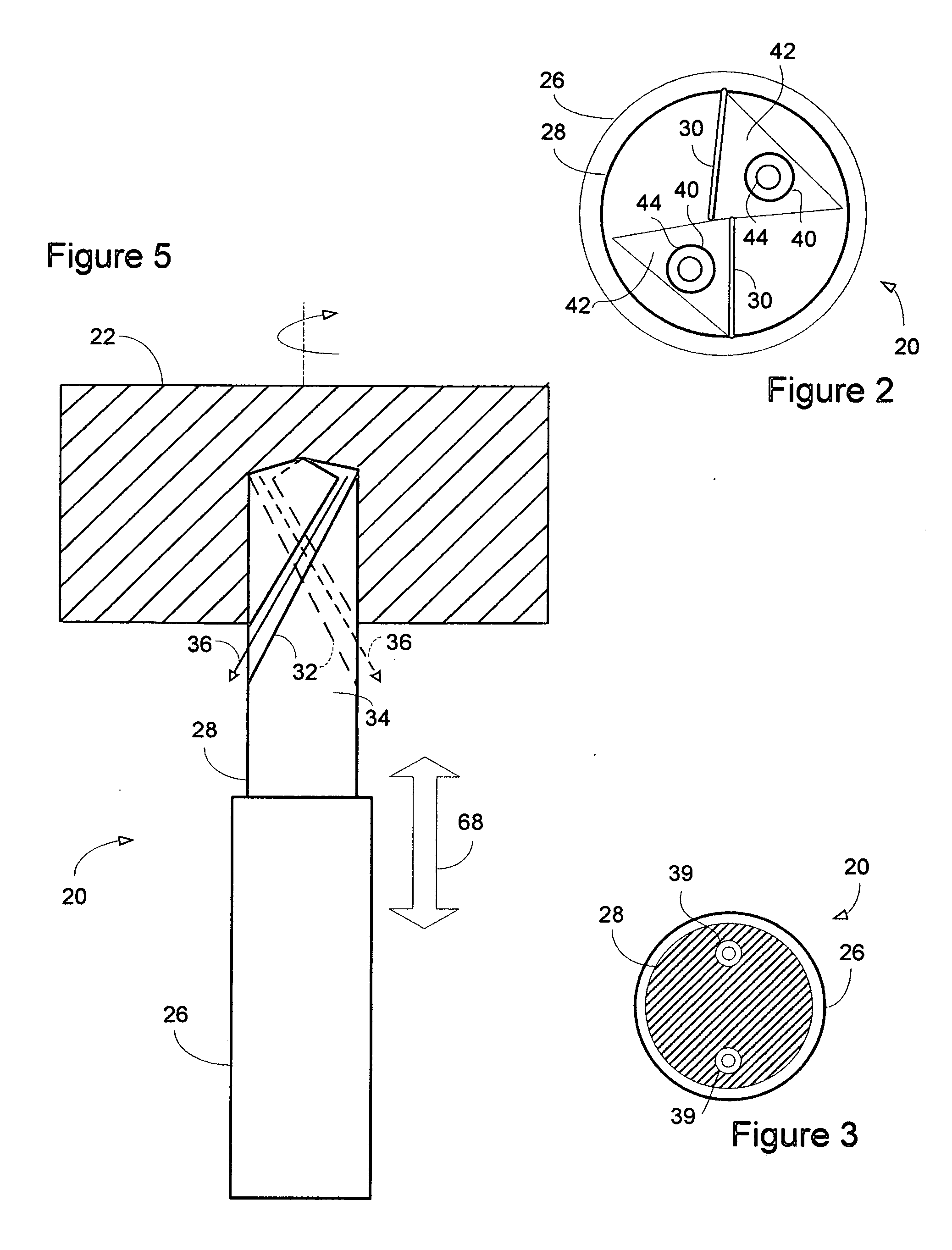

A device of the present invention for applying a cryogenic composition includes a machining tool or tool holder having a channel positioned therethrough and a capillary tube positioned within the channel. A dense cryogenic fluid is passed through the capillary tube while a diluent or propellant fluid is passed through the channel. The diluent or propellant fluid flows within the channel and about the capillary tube. Upon exiting the capillary tube, the dense fluid admixes with the diluent or propellant fluid to form a cryogenic composite fluid or spray. The cryogenic composite fluid or spray is selectively directed onto a substrate for cooling or lubrication purposes, or onto the machining tool for cooling purposes.

Owner:COOL CLEAN TECH

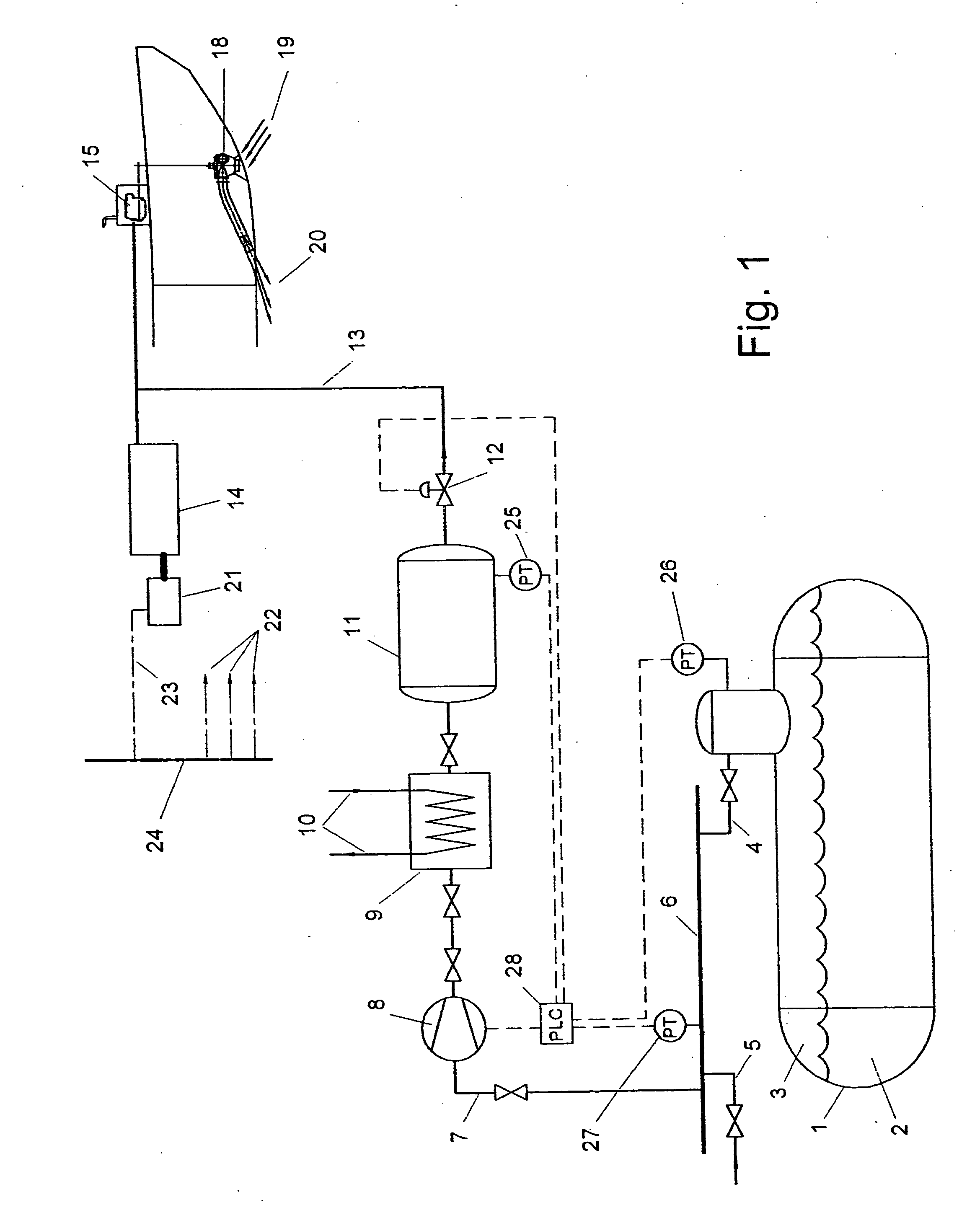

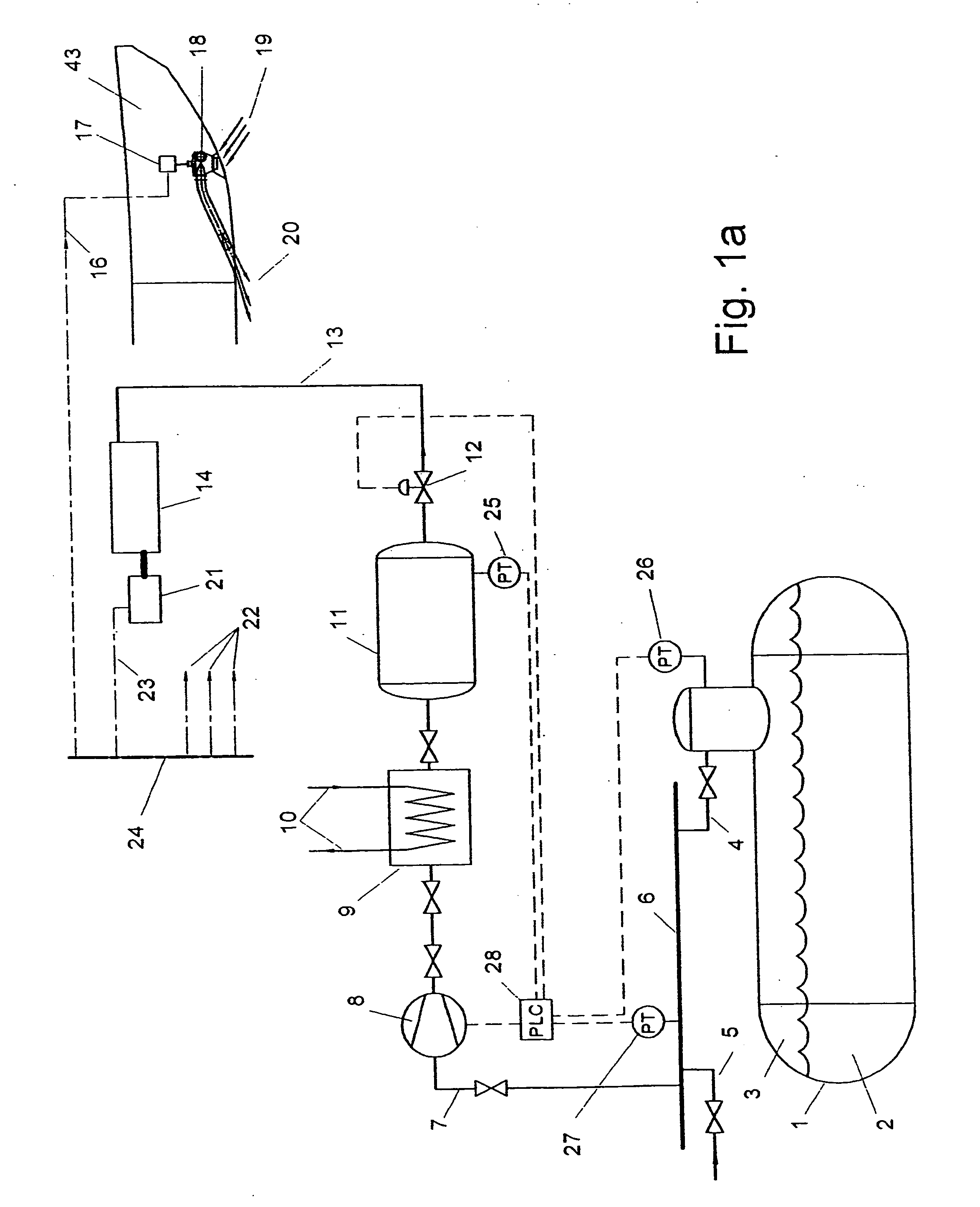

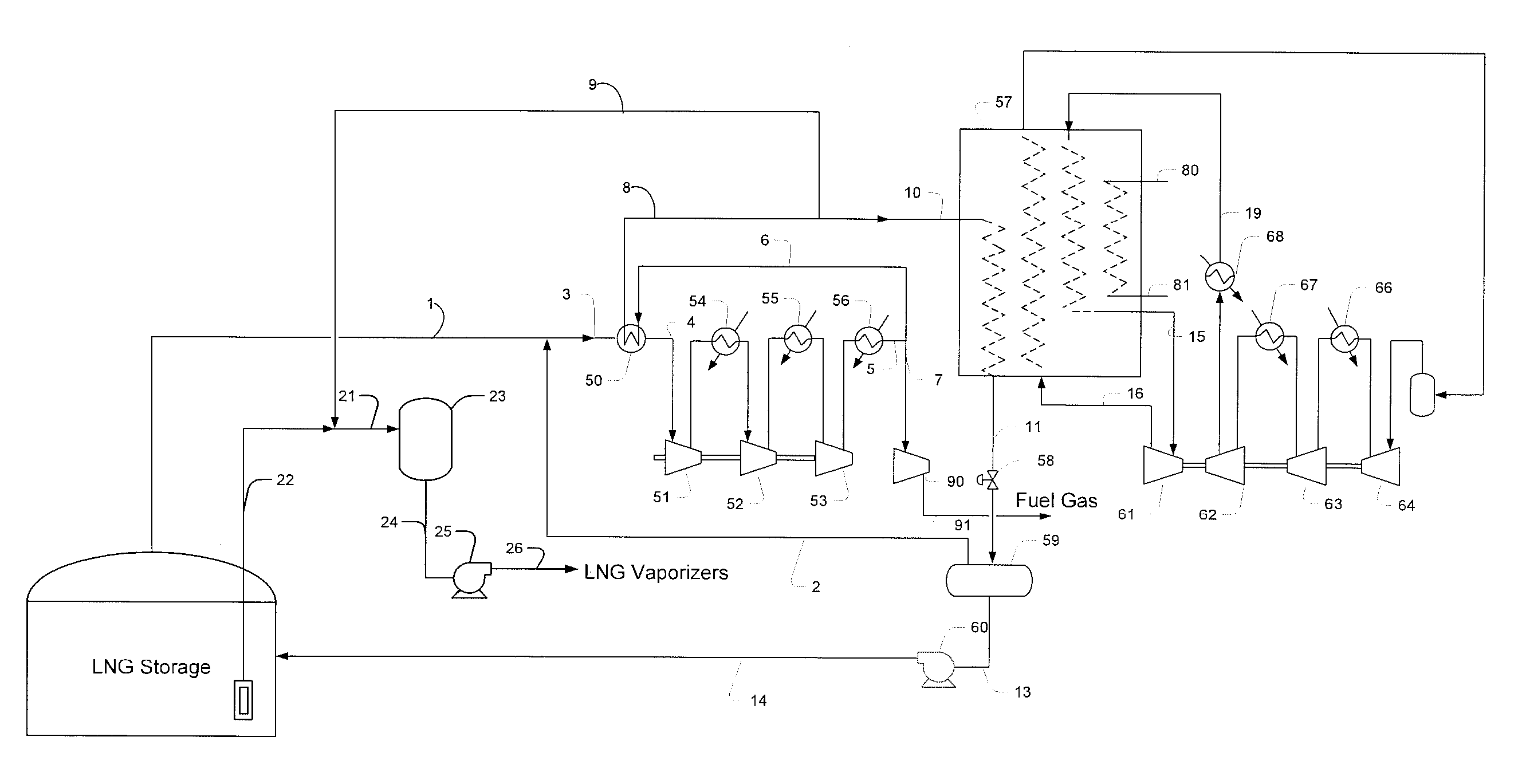

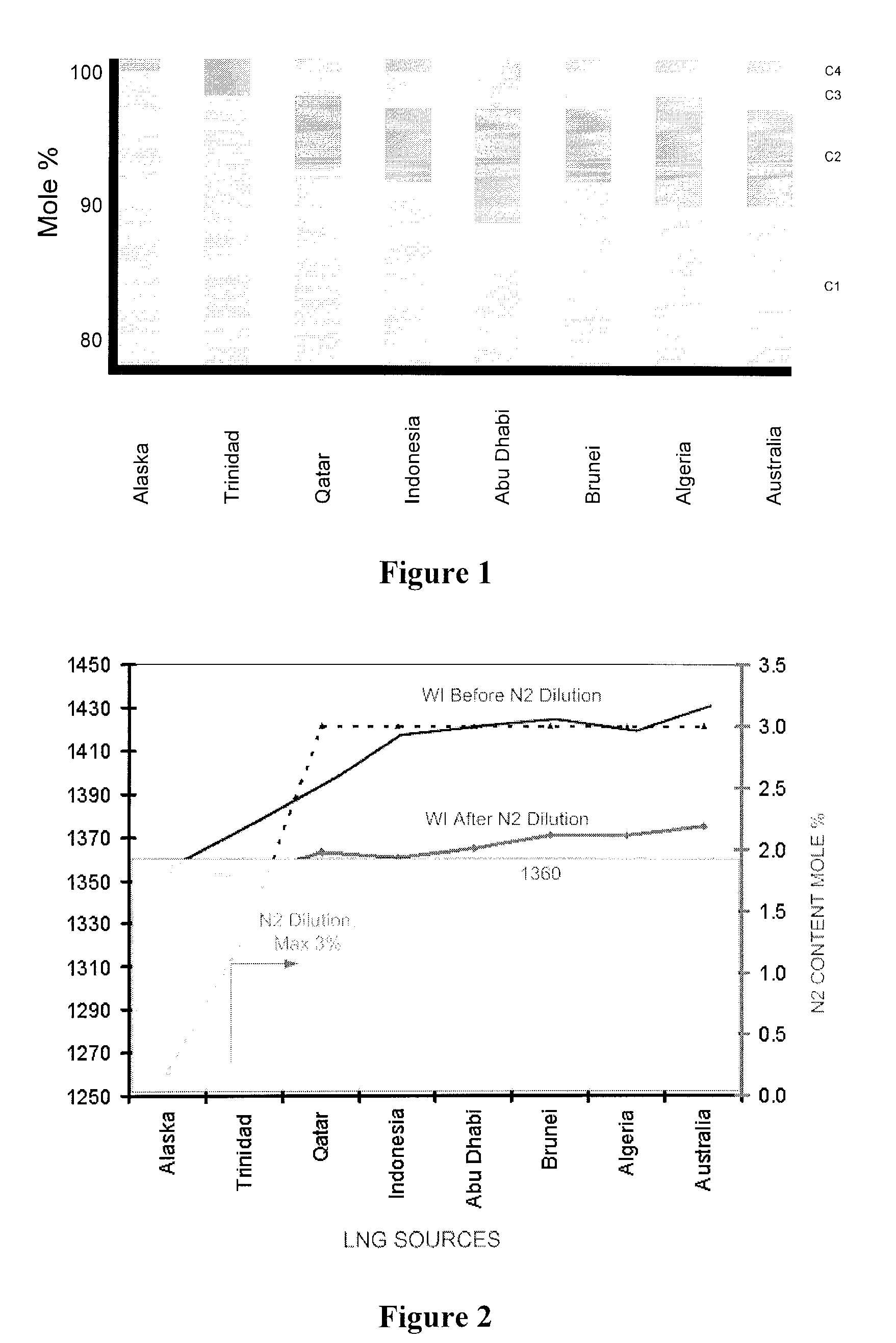

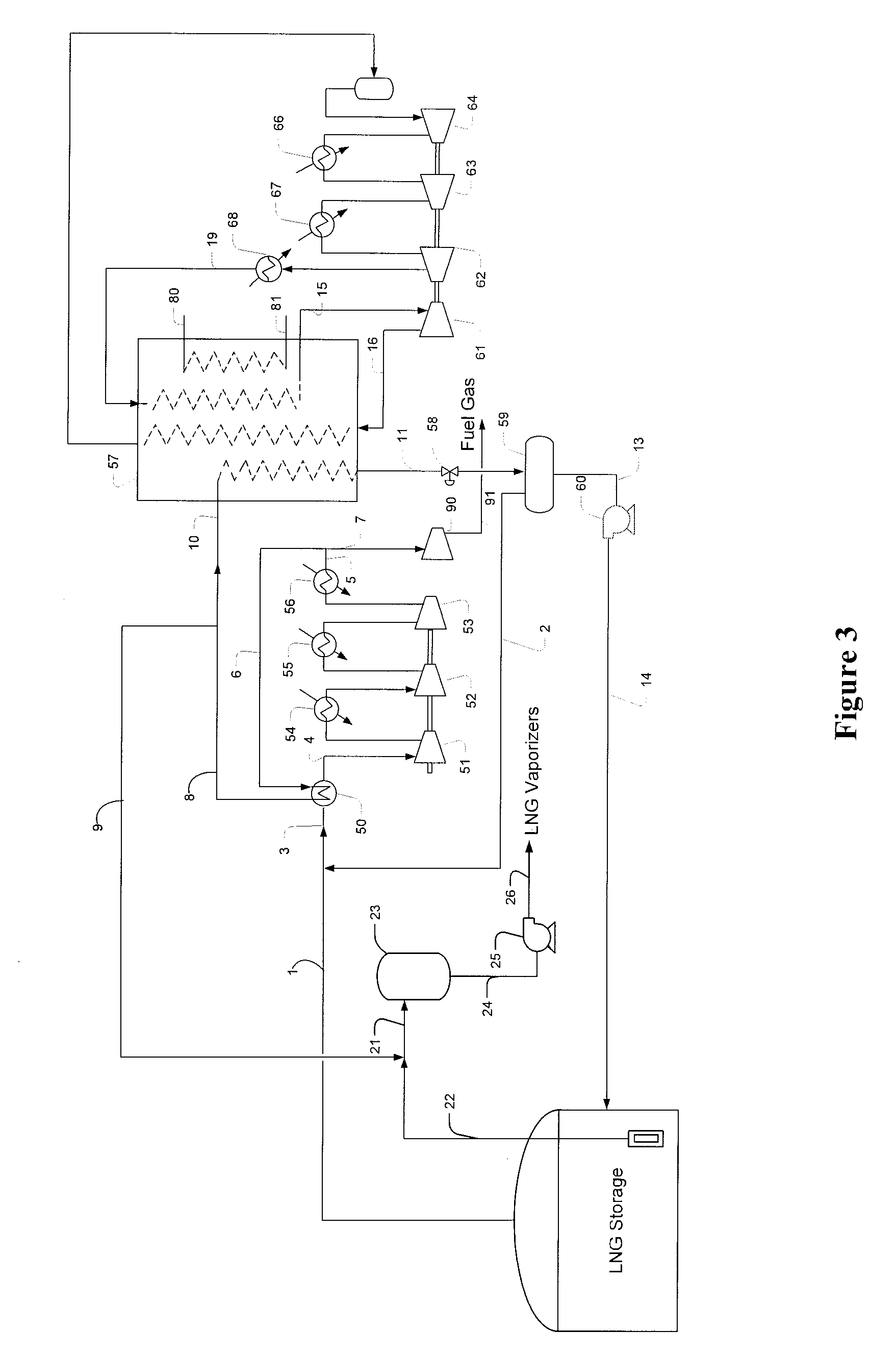

Methods and Configurations of Boil-off Gas Handling in LNG Regasification Terminals

InactiveUS20110056238A1Stable storage tank pressure controlStable controlSolidificationLiquefactionProcess engineeringWobbe index

A LNG storage and regasification plant includes a reliquefaction unit in which boil-off vapors from the storage tanks are re liquefied and recycled back to the LNG storage tanks for tank pressure and Wobbe index control. Preferably, LNG cold is used for reliquefaction and operational flexibility is achieved by feeding a portion of the pressurized boil-off gas to a fuel gas header and / or to be recondensed by the sendout LNG.

Owner:FLUOR TECH CORP

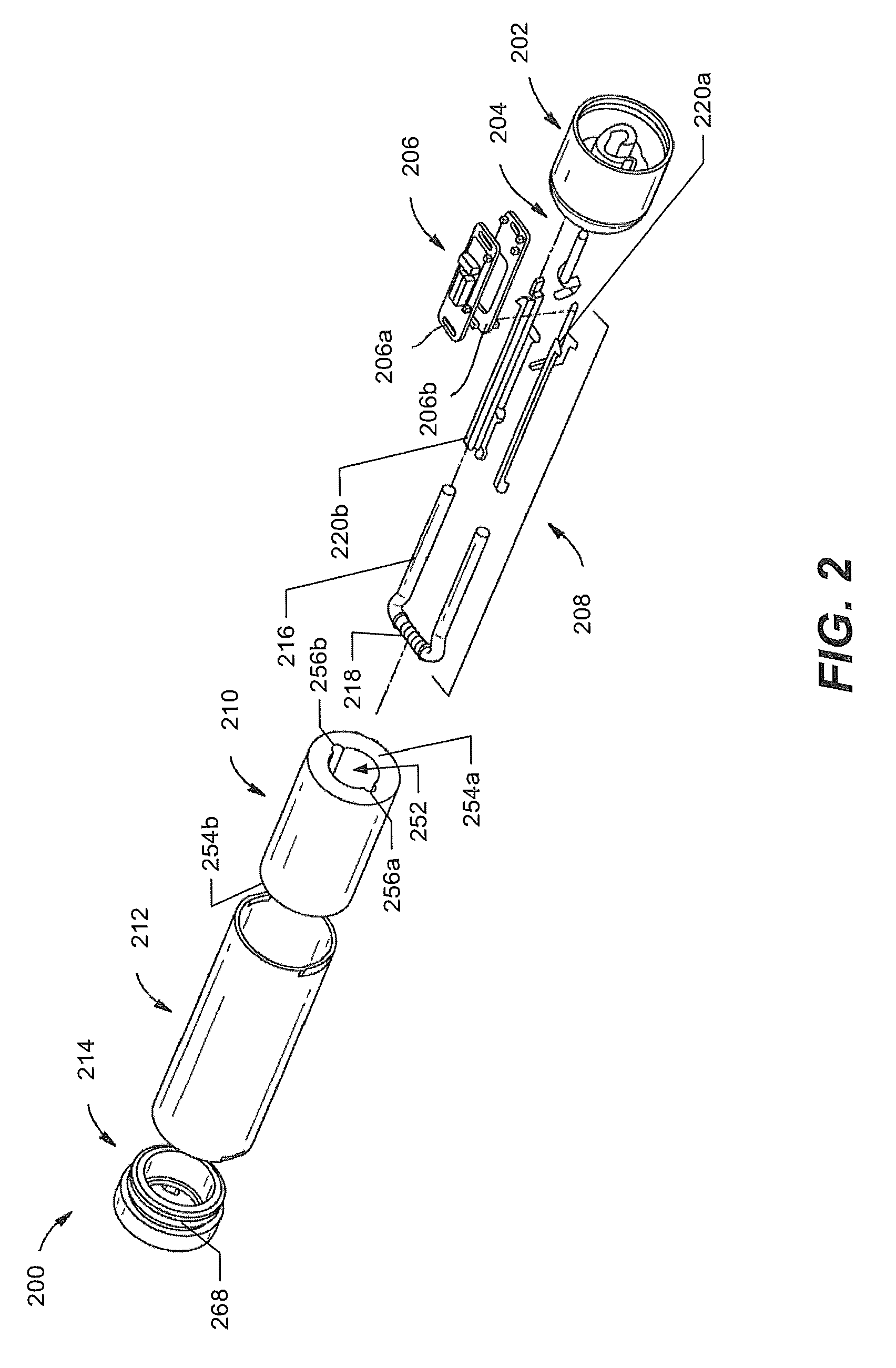

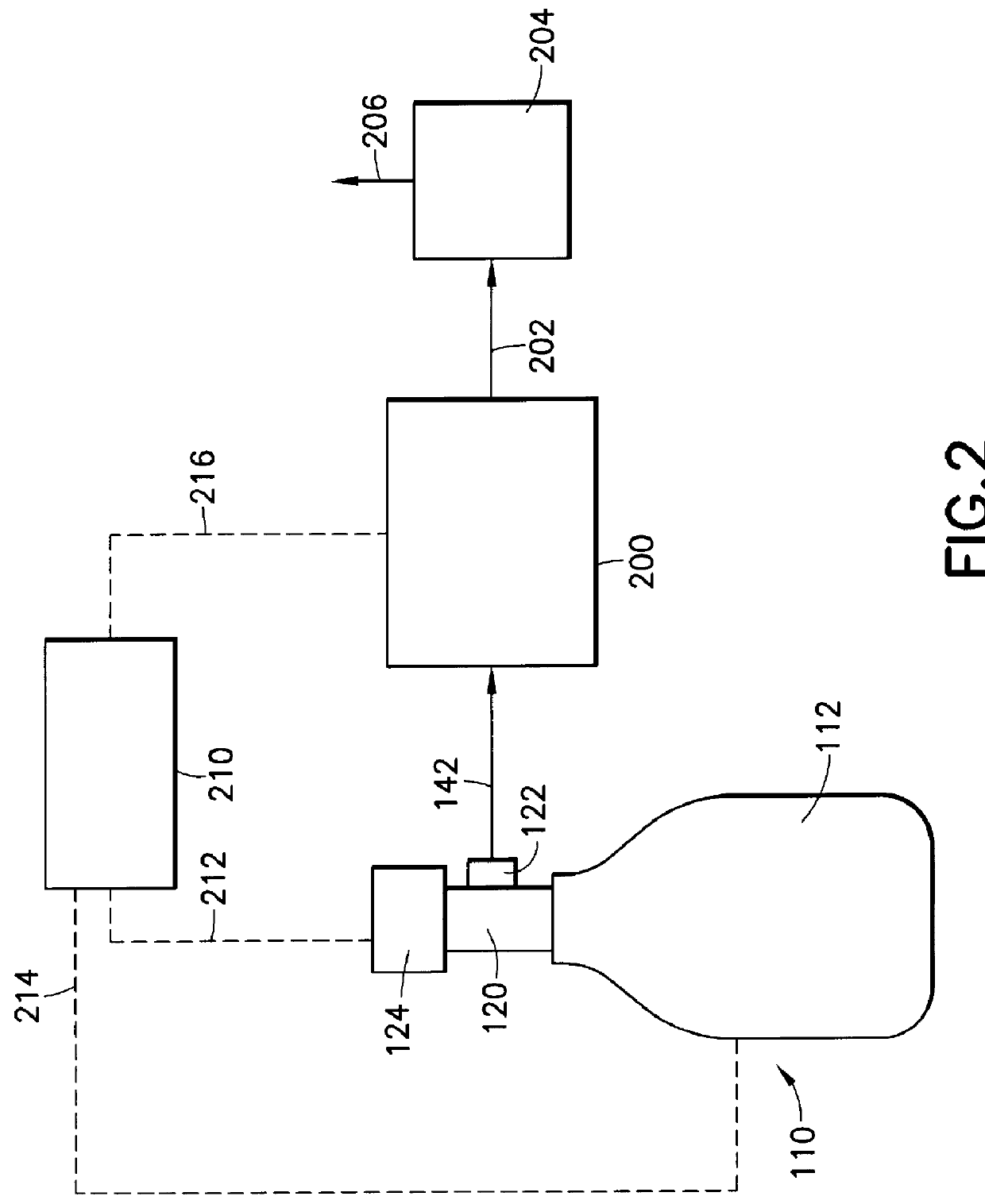

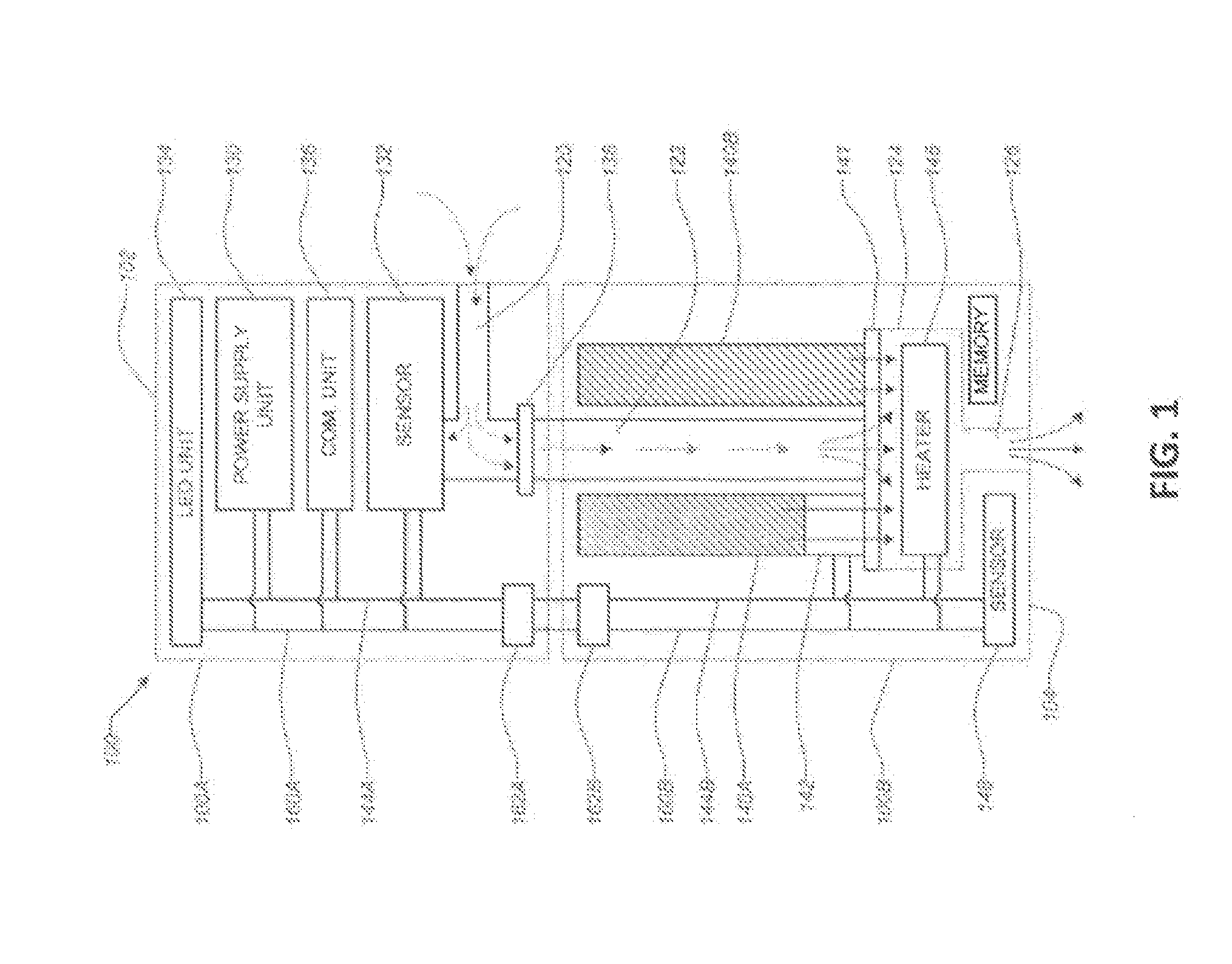

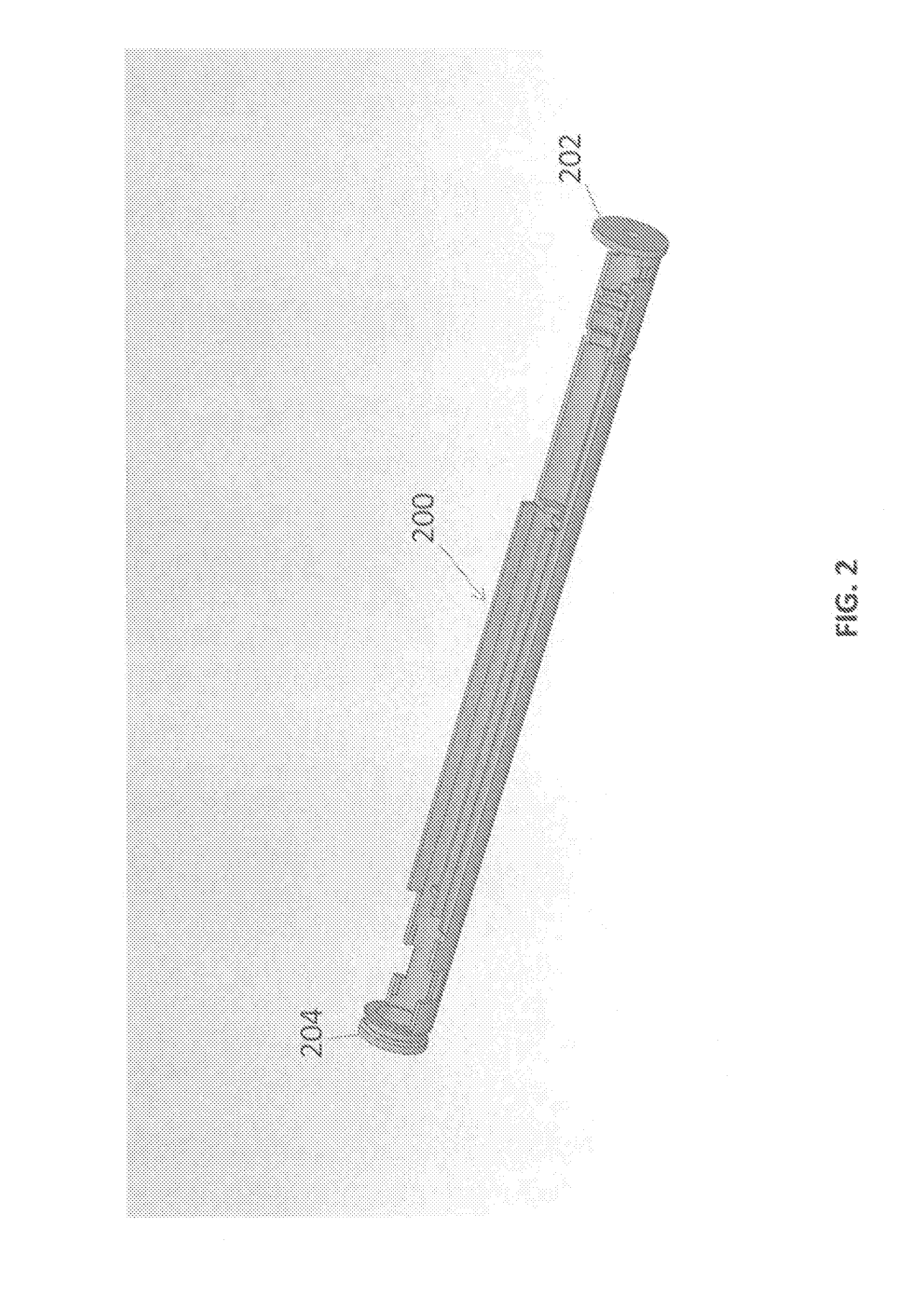

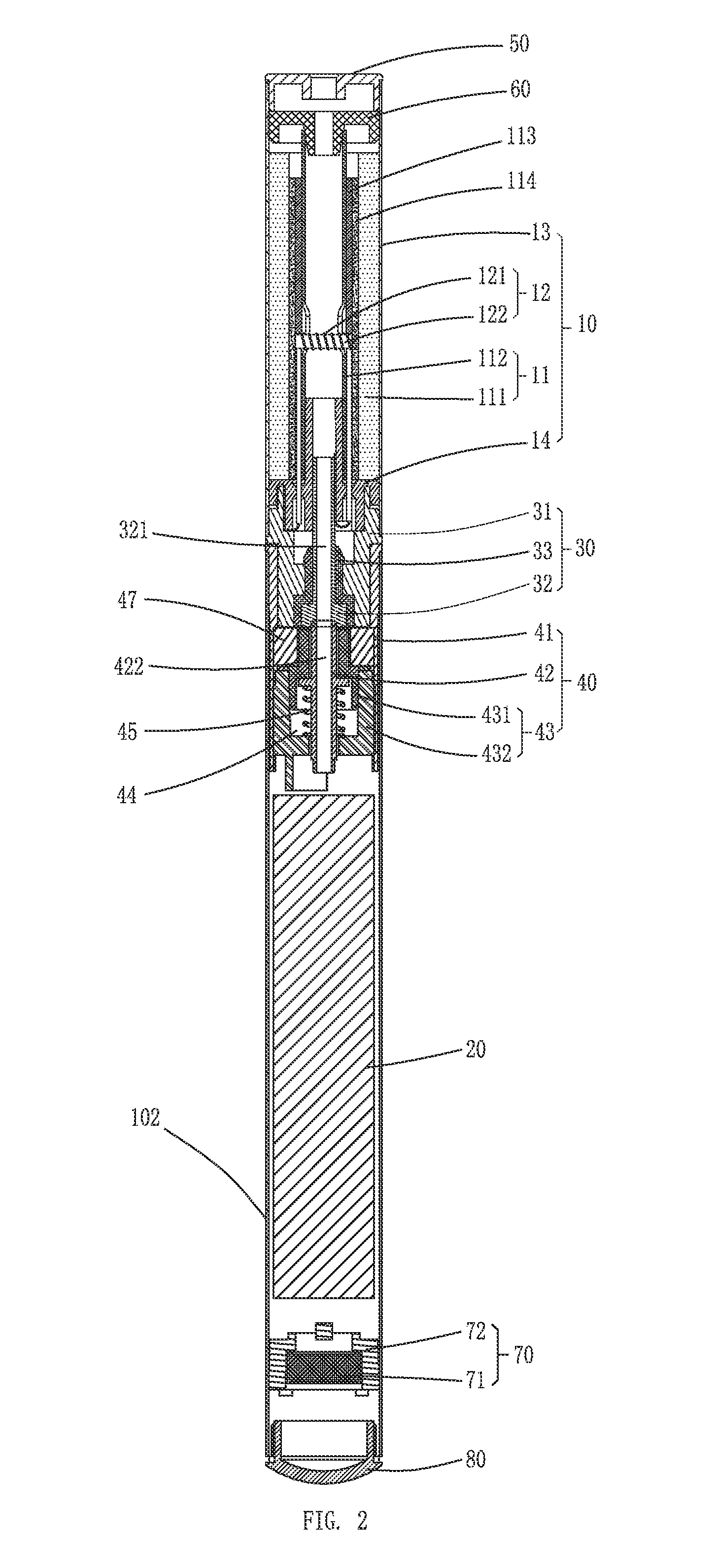

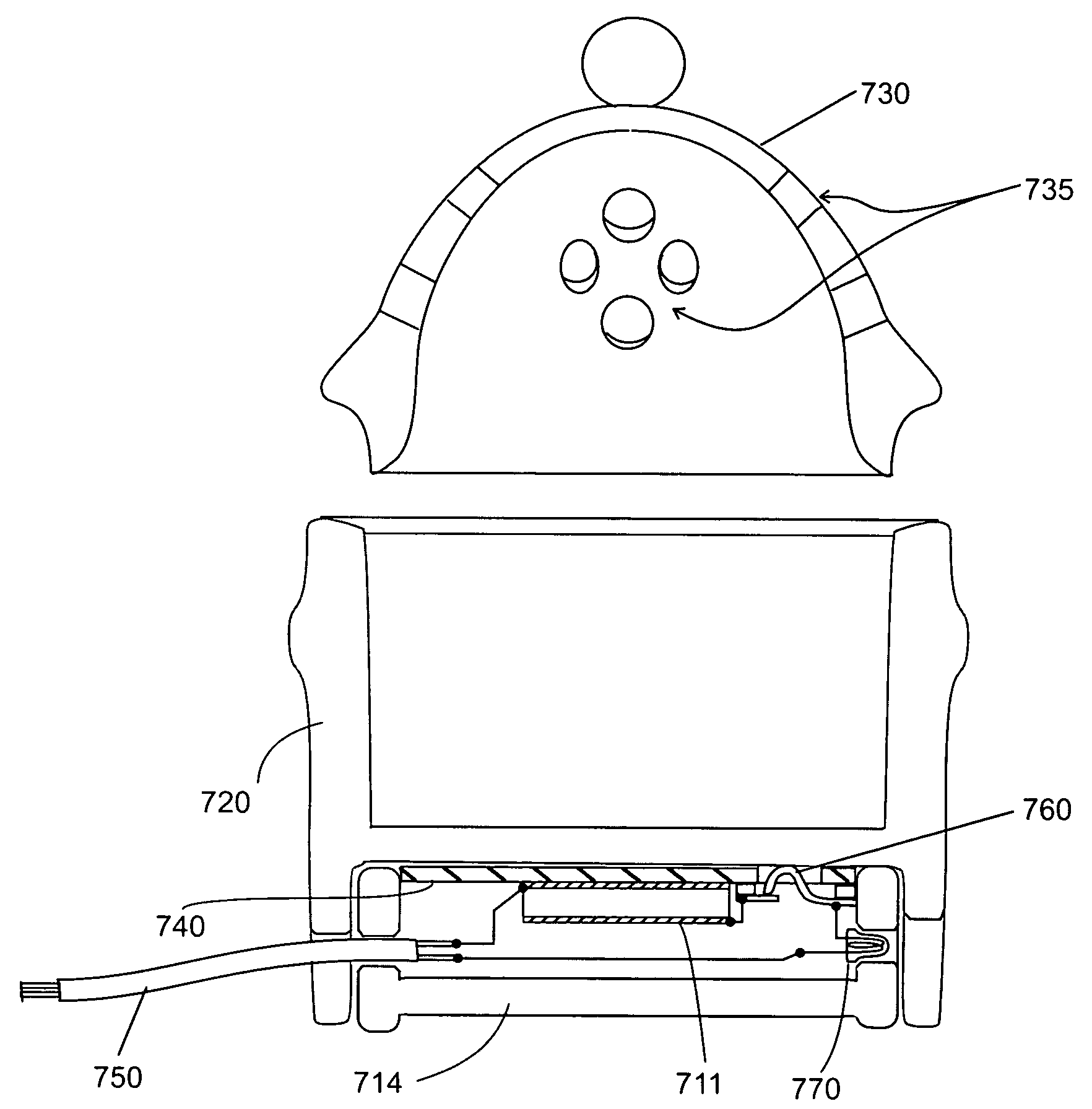

Electronic smoking device configured for automated assembly

According to one non-limiting example of the disclosure, a system, a method, a device and a computer program are provided for the automated manufacture of electronic cigarettes. The apparatus comprises an electronic smoking device for delivering a vaporized liquid comprising a frame (200), an air flow path (122), an air inlet, a container (140) for storing a smoking liquid, and a circuit. At least a part of the circuit comprising traces printed on the frame (1306). The method comprises a frame, that can include slots configured for mating with and containing various components of the electronic smoking device. The computer readable medium comprises sections or segments of code that, when executed on a computer, cause the processes described herein to be carried, such as, for example, the process of assembling the electronic smoking device.

Owner:FONTEM HLDG 1

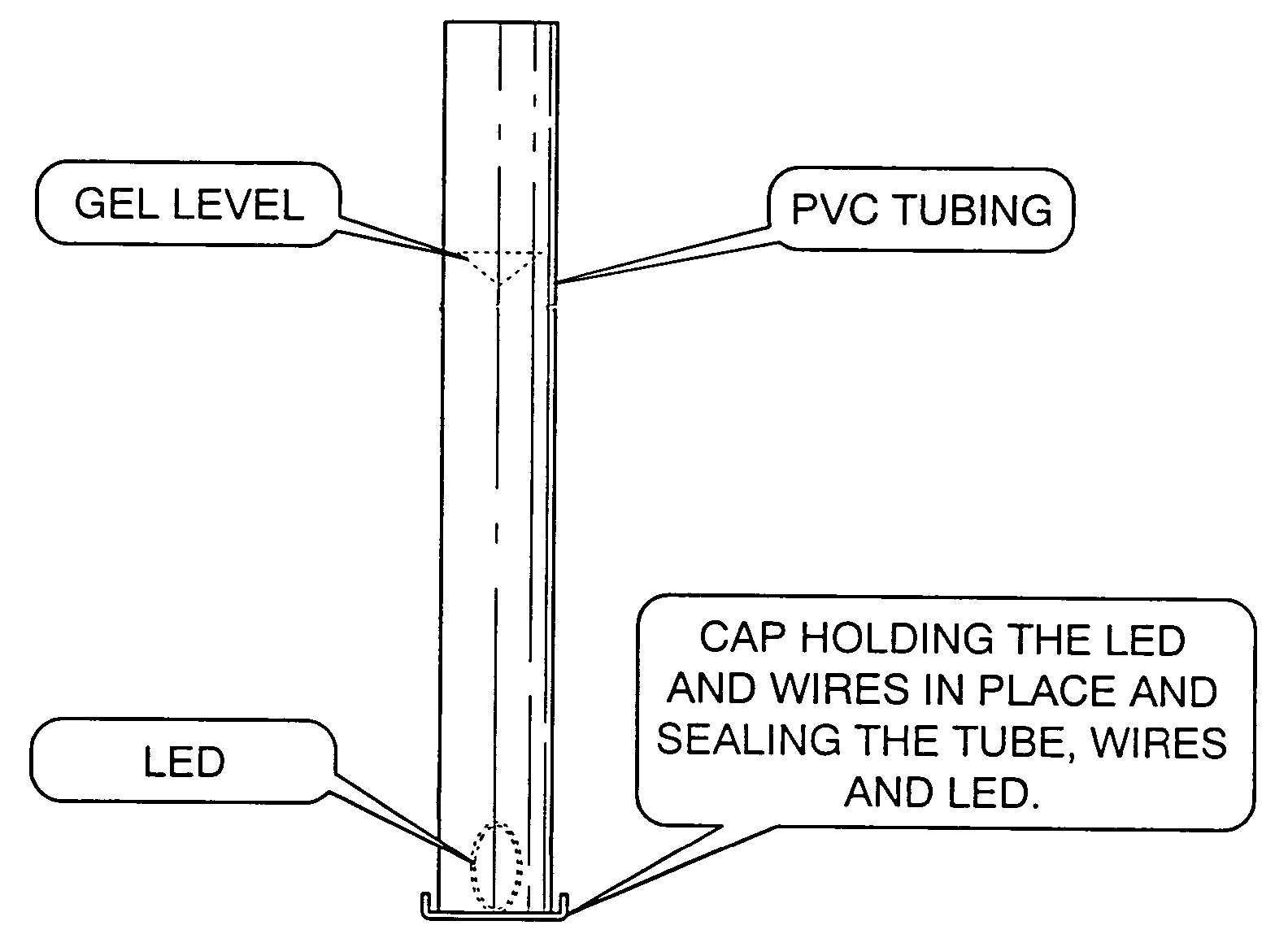

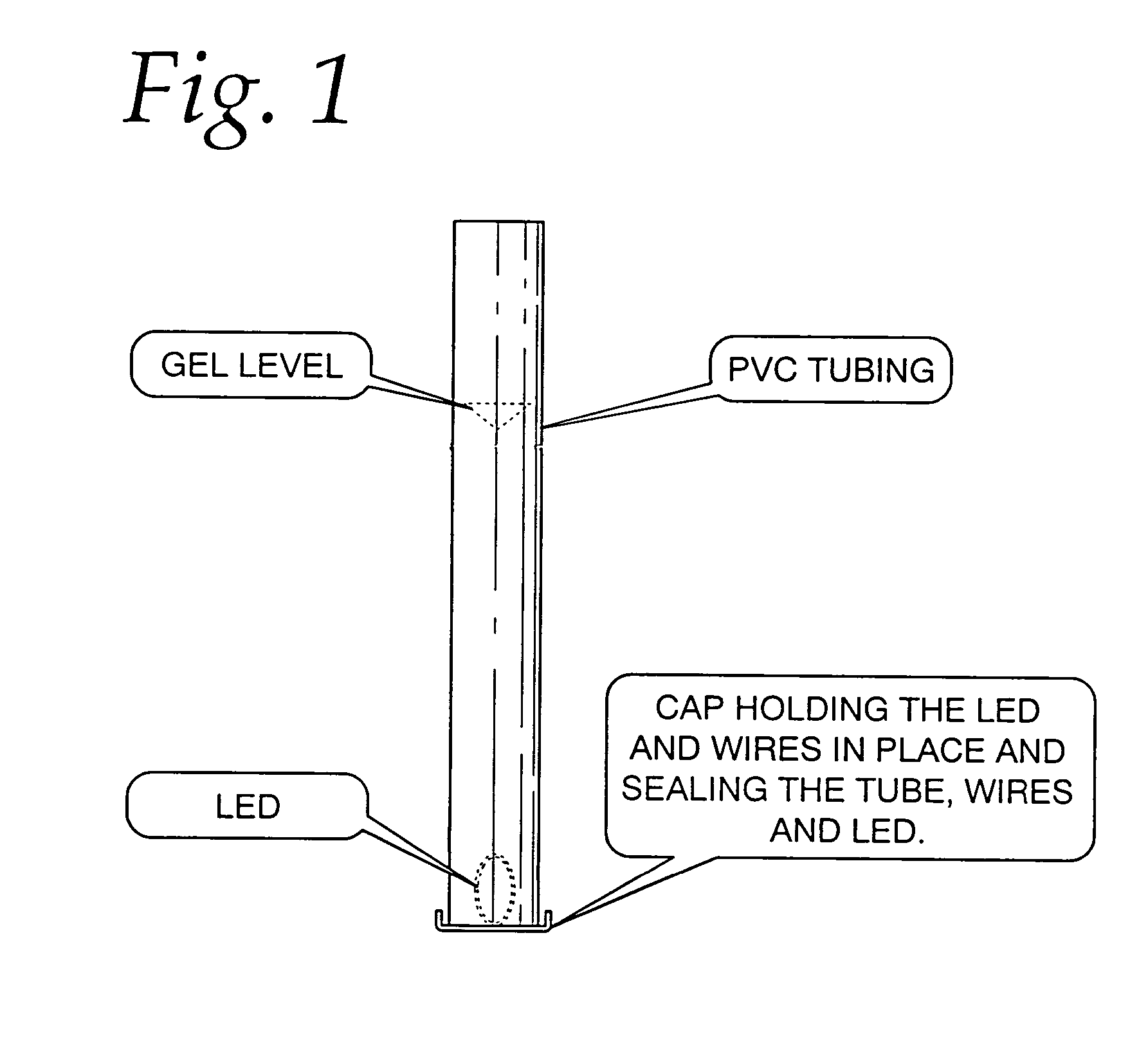

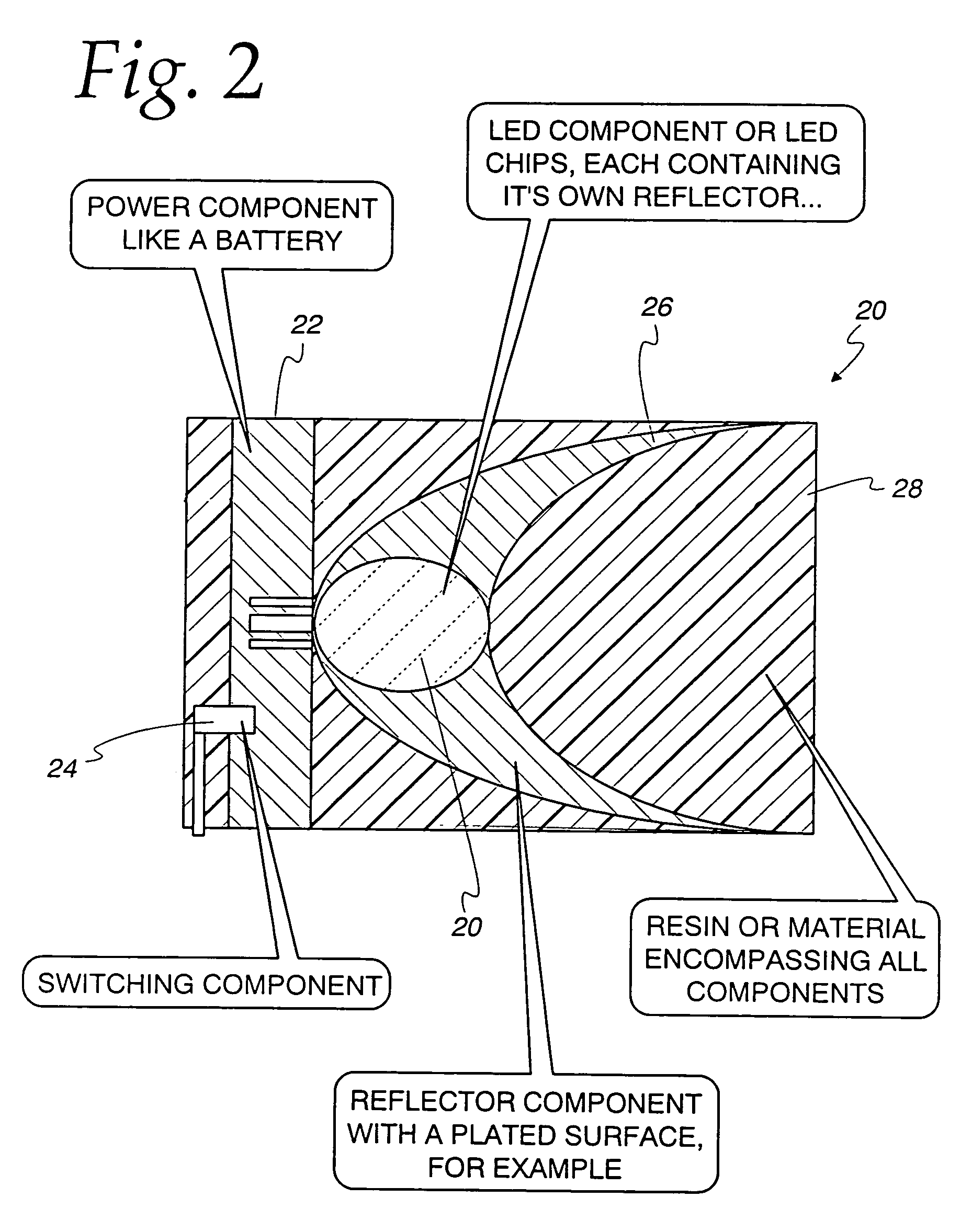

Light emitting medium and illumination system

Owner:ZARIAN JAMES ROUBEN +1

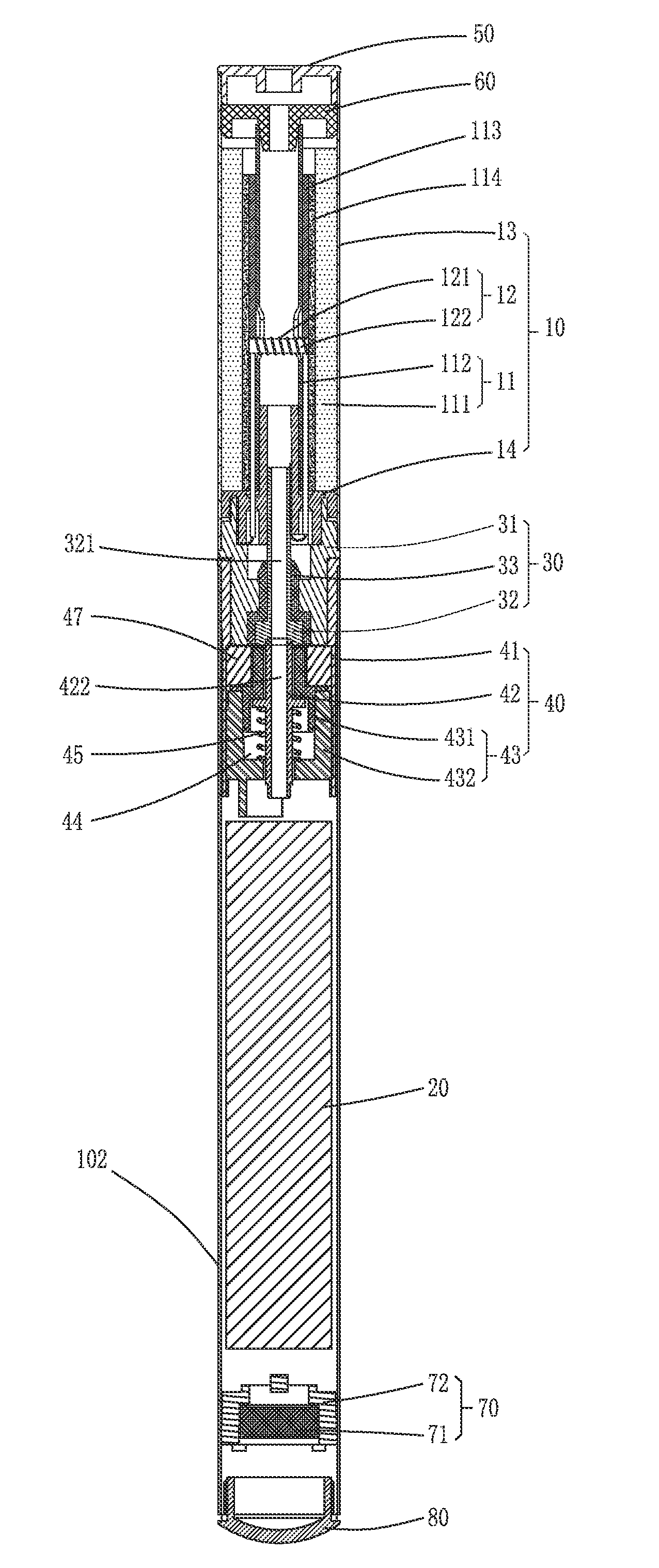

Electronic Cigarette Device, Electronic Cigarette, and Atomizing Device Used in the Same

InactiveUS20140332019A1Improve connection stabilityRespiratorsSteam generation heating methodsEngineeringElectronic cigarette

An atomizing device comprises an atomizing seat, and an atomizer having a heating wire and disposed at one side of the atomizing seat. A first electrode assembly is disposed at another side of the atomizing seat away from the atomizer. The first electrode assembly includes a first seat body and a first electrode post, two of which two of which are insulated from each other and respectively connected with two ends of the heating wire to form the positive and negative electrode. The first seat body resists the atomizing seat and clamps a first end of the heating wire therebetween, and the first electrode post resists the atomizing seat and clamps a second end of the heating wire therebetween. The heating wire is secured by the squeezing of the atomizing seat and the first electrode assembly, the atomizing sleeve, which has a stable structure and low cost.

Owner:HUIZHOU KIMREE TECH

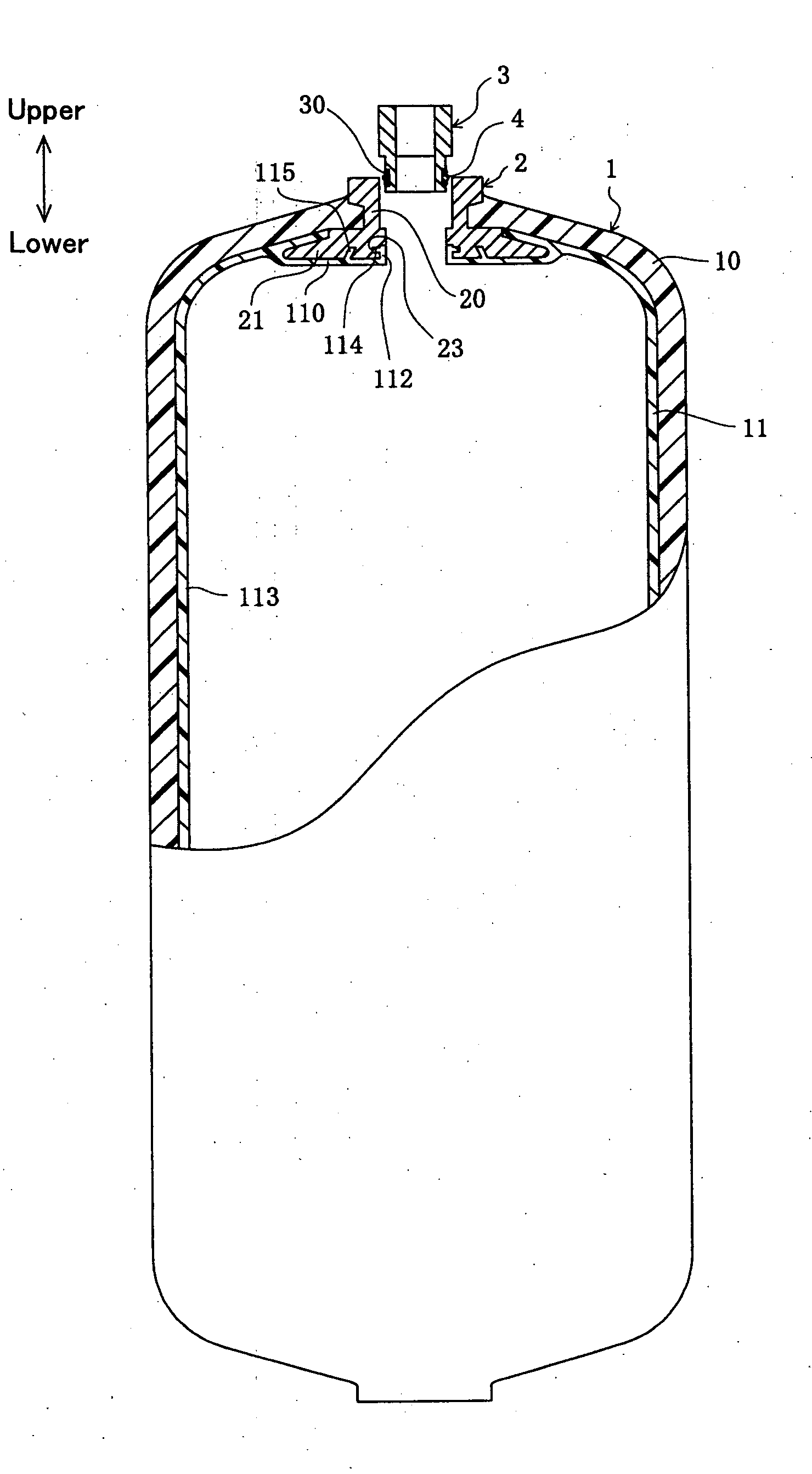

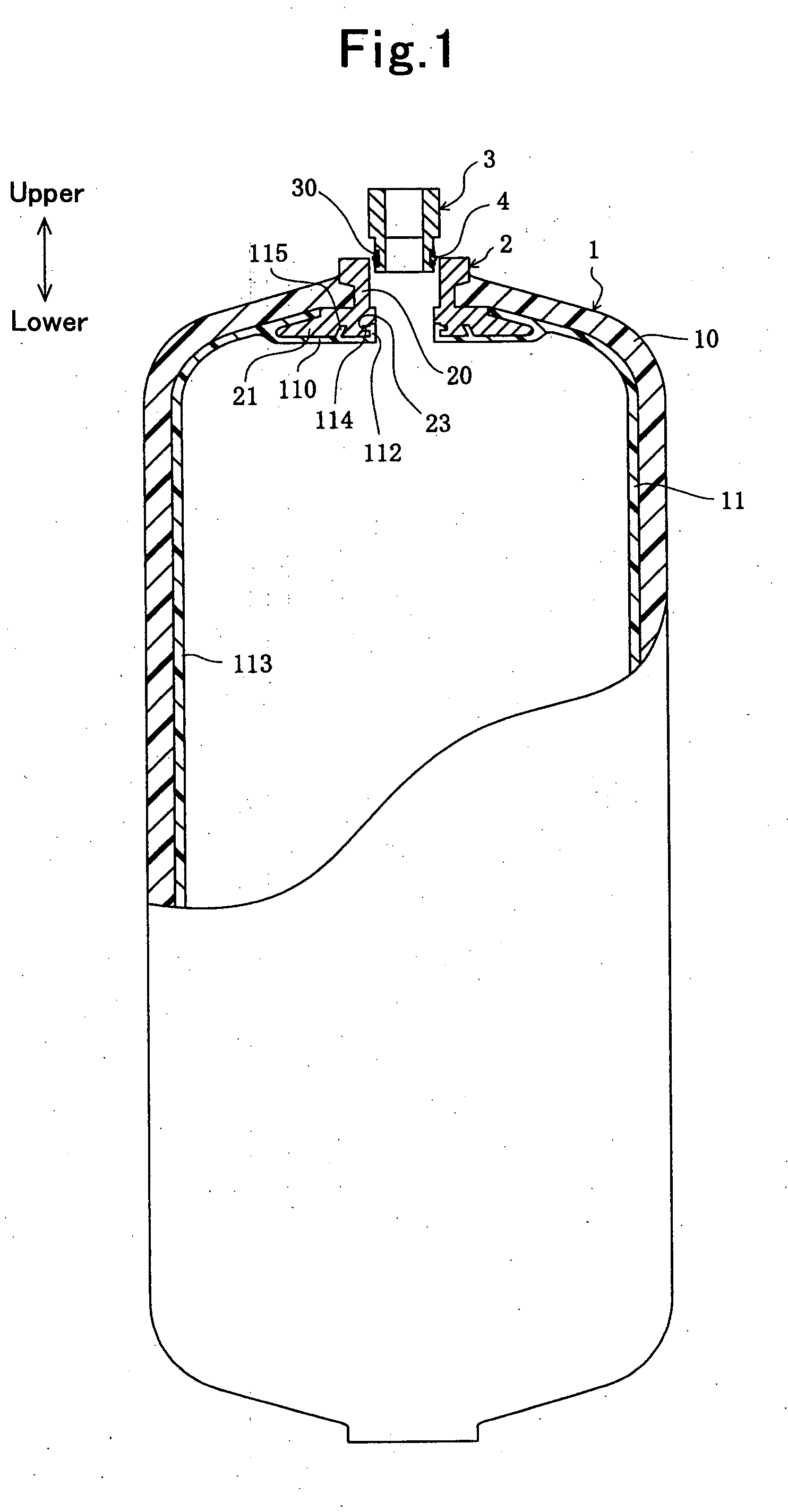

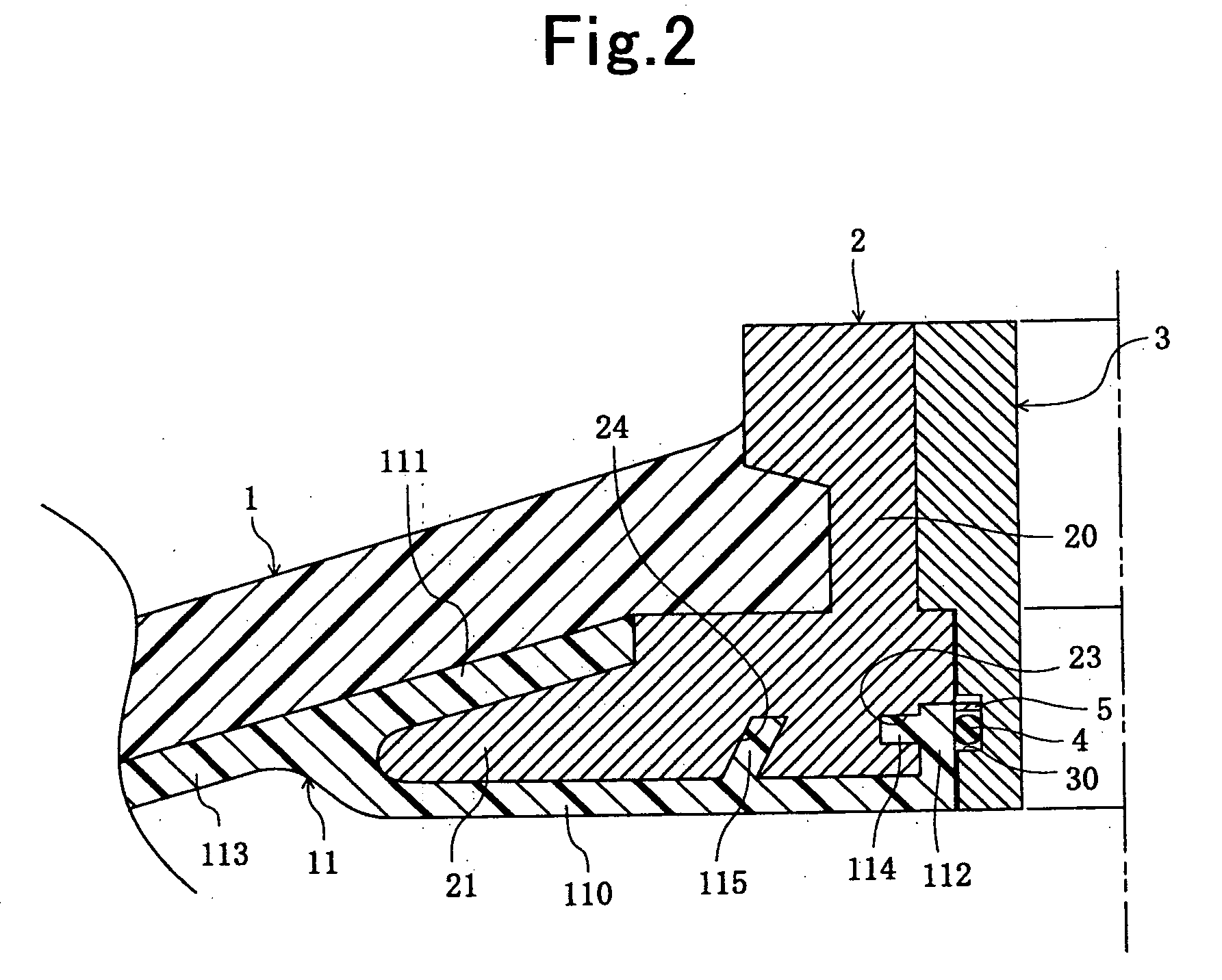

Pressure vessel

A pressure vessel capable of securely sealing a mouth ring with a liner portion, and being manufactured at low costs. A boss seal part 112 is provided in a liner portion 11 of the pressure vessel, and an inner peripheral surface of a boss part 20 of a mouth ring 2 is covered with the boss seal part 112. A boss-side collar part 114 is provided in the boss seal part 112 so as to project outwardly, and a sealing member 4 composed of a resilient body is disposed in a space between an inner peripheral surface of the boss seal part 112 and an outer peripheral surface of the valve 3.

Owner:TOYODA GOSEI CO LTD +1

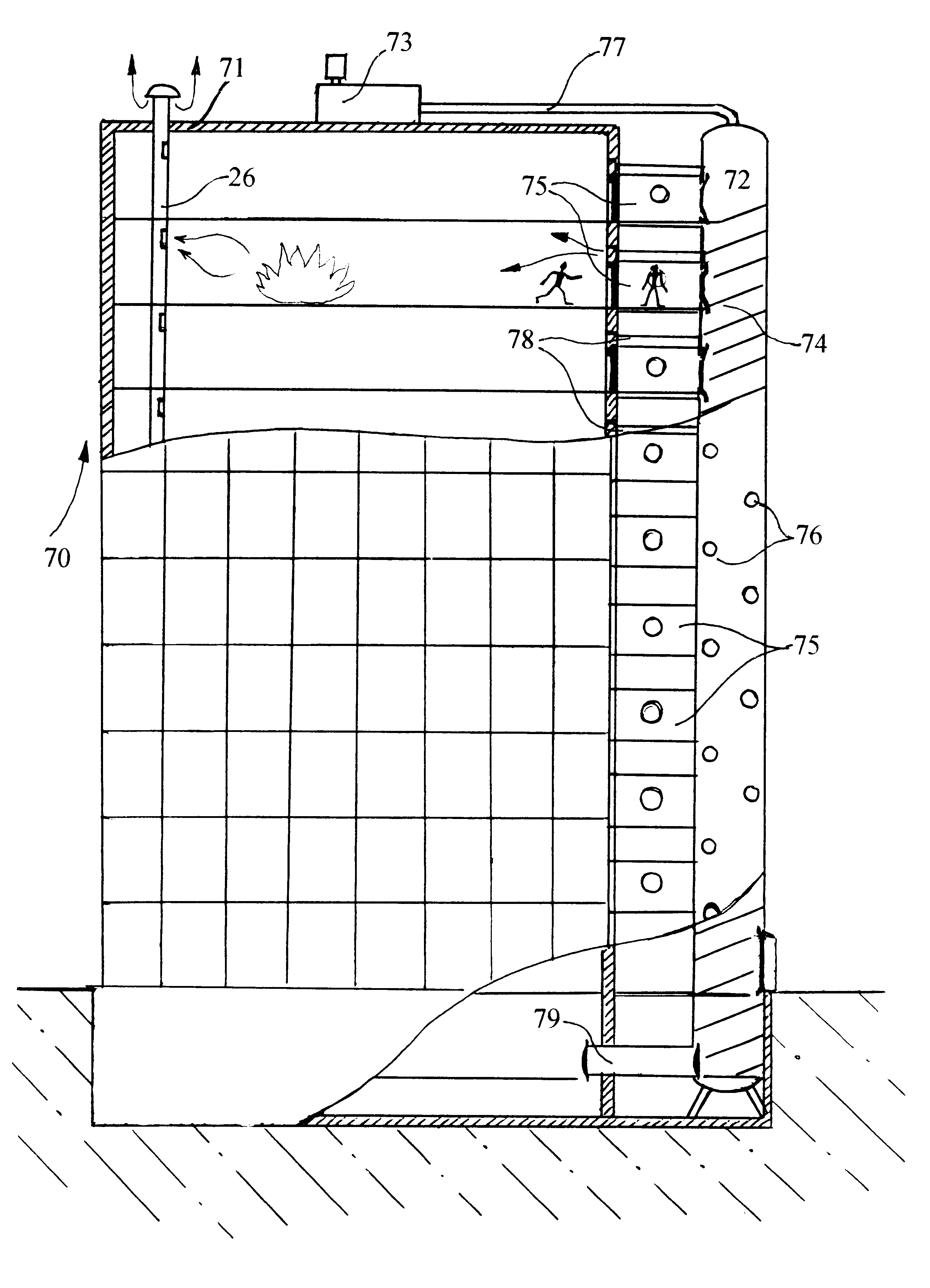

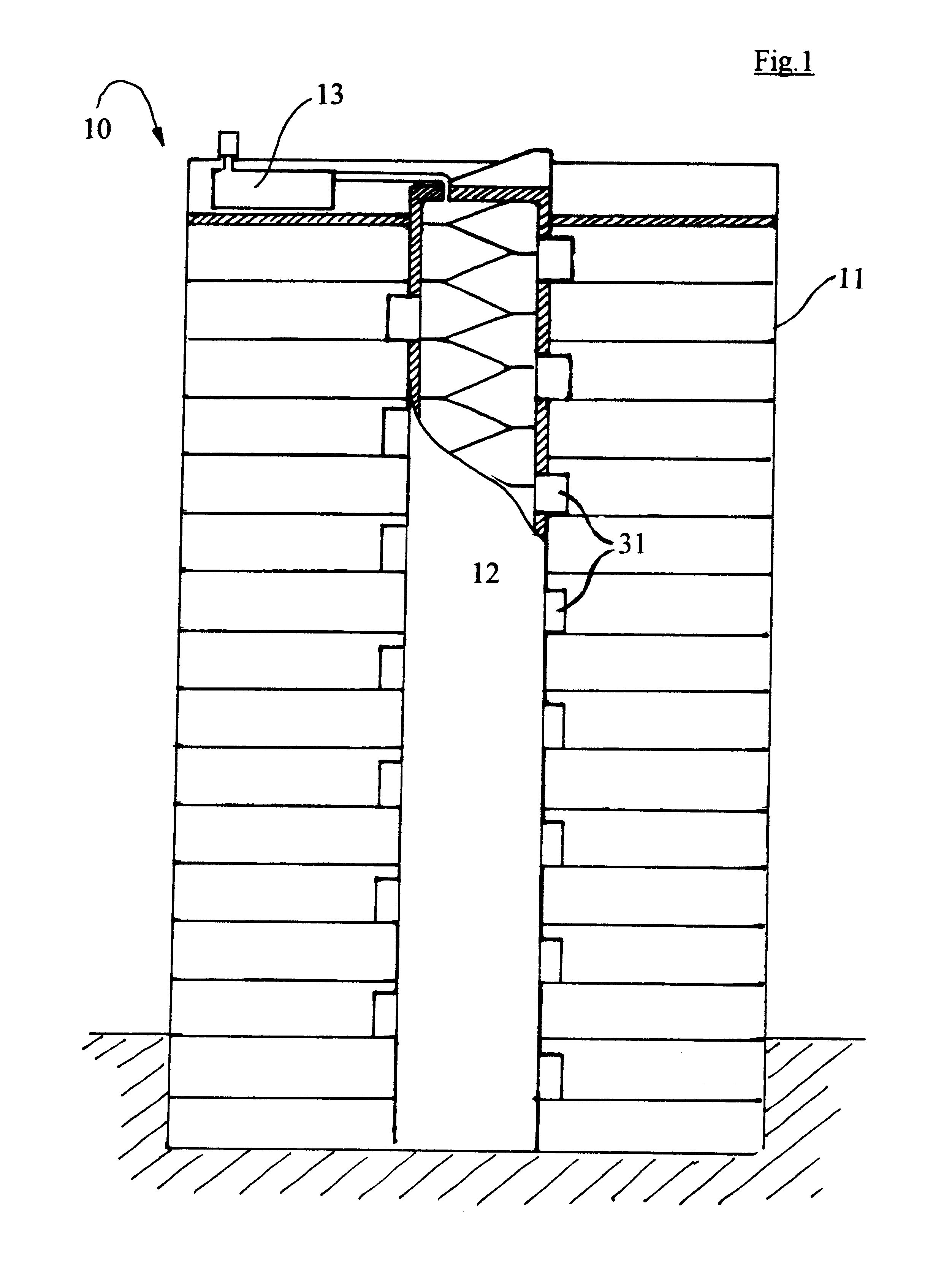

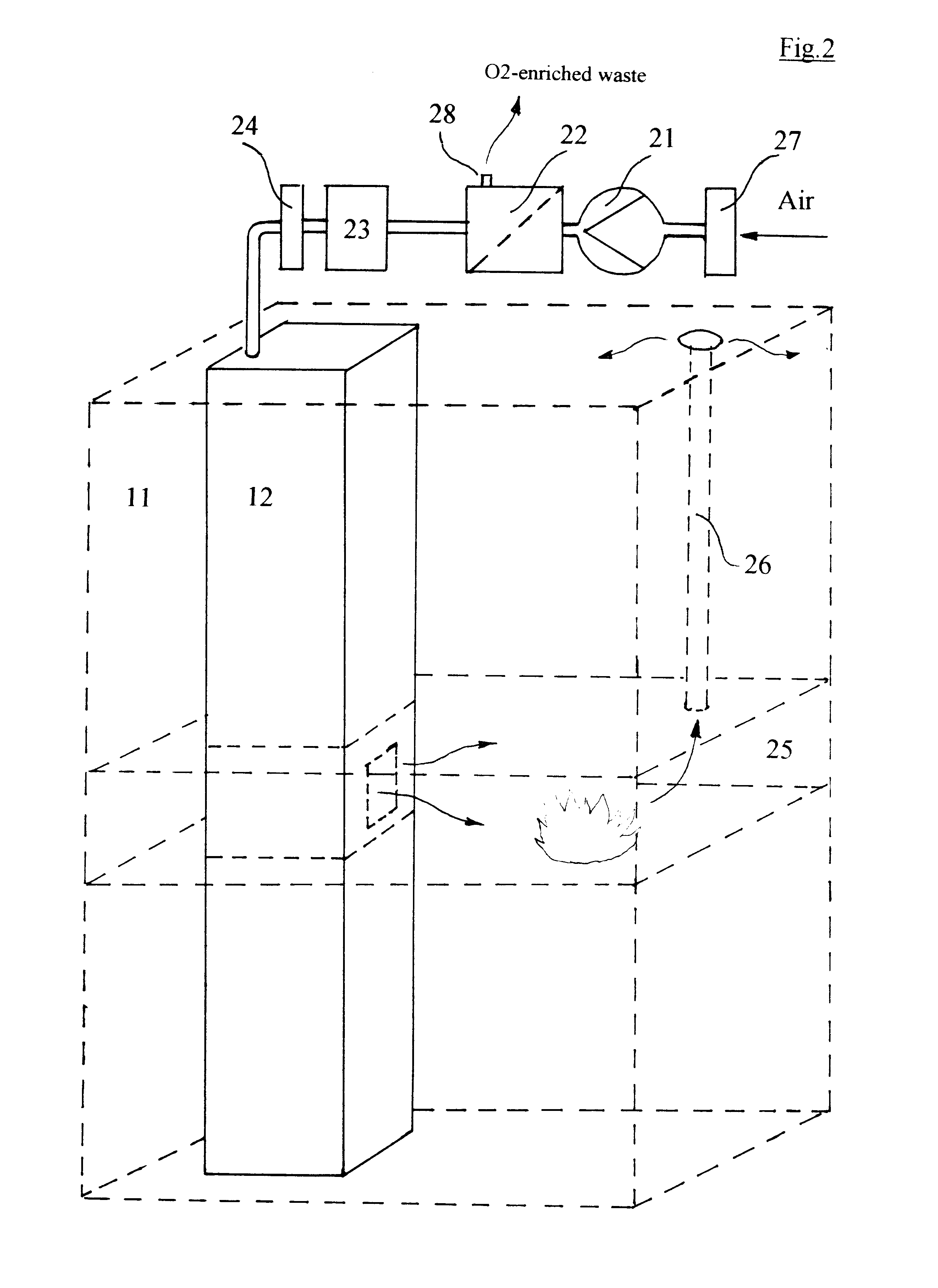

Hyperbaric hypoxic fire escape and suppression systems for multilevel buildings, transportation tunnels and other human-occupied environments

Hyperbaric Hypoxic Fire Escape and Suppression System is provided for multilevel buildings, transportation tunnels and other human-occupied environments. The system produces and maintains a hypoxic hyperbaric environment in a separate part of a building (staircase shaft) or a tunnel (service tunnel) in order to provide an entirely secure escape area in case of a fire emergency and instantly extinguish an ongoing fire in a building or a tunnel by releasing a breathable hyperbaric hypoxic fire-extinguishing composition into location affected by fire. Additionally, the system provides continuing adequate protection against biological and chemical warfare and contaminants by filtering ambient air before processing it by the system and by establishing breathable fire-suppressive atmosphere at a positive atmospheric pressure inside a building or tunnel.

Owner:FIREPASS CORP

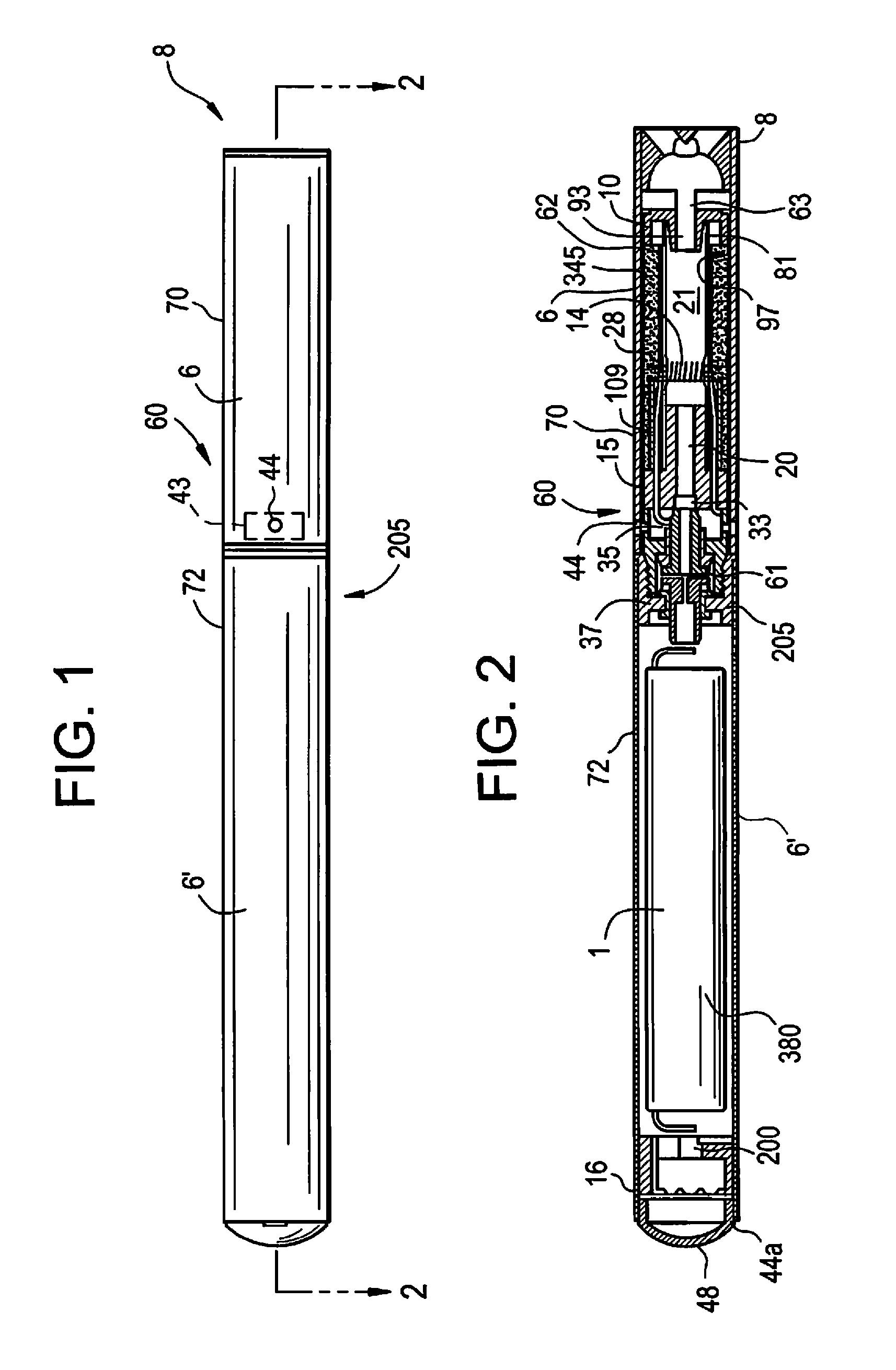

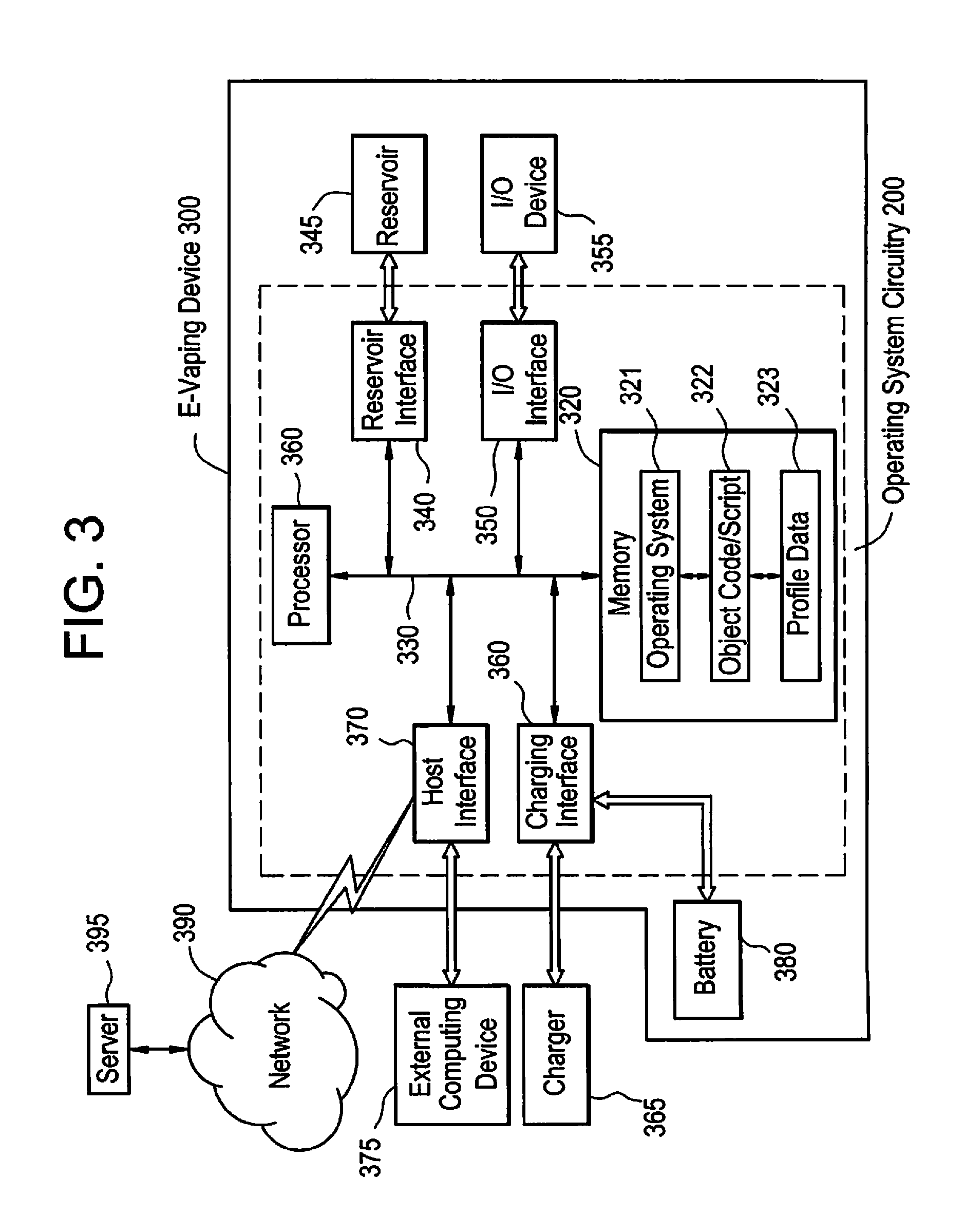

Method and device for executing an e-vaping device operating system, e-vaping programming language, and e-vaping application programming interface

ActiveUS20160143361A1Steam generation heating methodsTobacco devicesApplication programming interfaceObject code

An electronic vaping device includes a housing extending in a longitudinal direction, the housing including a mouth-end and a connection-end, a reservoir containing a pre-vapor formulation, the reservoir in the housing, a heating element in the housing, the heating element in fluid communication with the reservoir, the heating element configured to generate a vapor, and a rechargeable battery configured to power at least the heating element and any other potential power consuming element(s) such as electronic circuits. The electronic vaping device also includes a first memory having stored thereon computer readable instructions relating to an electronic vaping operating system (OS), and at least one processor configured to execute the OS computer readable instructions to execute the operating system, the operating system including a real-time kernel configured to operate the electronic vaping device, and execute object code related to electronic vaping device functionality.

Owner:AKRIA CLIENT SERVICES LLC

Electrically-operated temperature-regulated scented wax warmer

InactiveUS20050016985A1Efficiently transfer heatImprove thermal conductivityRespiratorsHand ironContact padEngineering

An electrically operated scented wax holder that forms a receptacle for receiving unmelted blocks of wax which are heated to the melting point and thereafter maintained at a safe temperature by a temperature-regulated electrical heating element. The wax receptacle is removable mounted on a base section that houses a positive temperature coefficient (PTC) thermistor which has a transition temperature substantially higher than the melting point of the wax to insure that the wax is rapidly melted, but substantially below the temperature that would constitute a danger to a human who might touch the exterior surface of the warmer, or constitute a fire hazard. The heating element is preferably placed in thermal contact with a contact pad having high thermal conductivity that is in turn placed closely adjacent to the wax receptacle, thereby efficiently transferring heat from the electrically operated temperature regulated heating element to the wax in the receptacle. A switch is positioned to de-energize the heating element whenever the wax receptacle is removed from the base section, and a visible pilot light is illuminated whenever the heating element is energized.

Owner:HAAS RODNEY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com