Patents

Literature

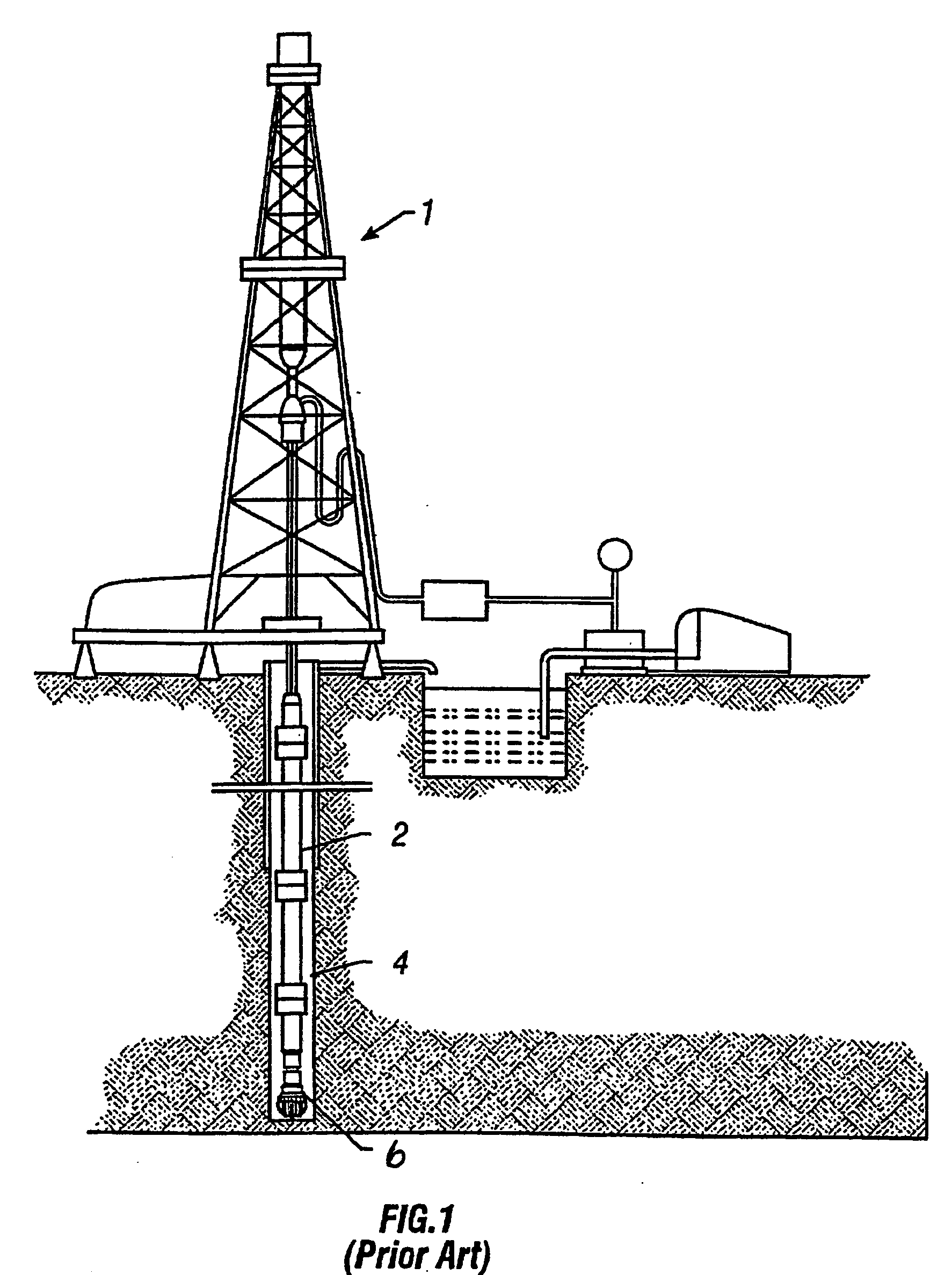

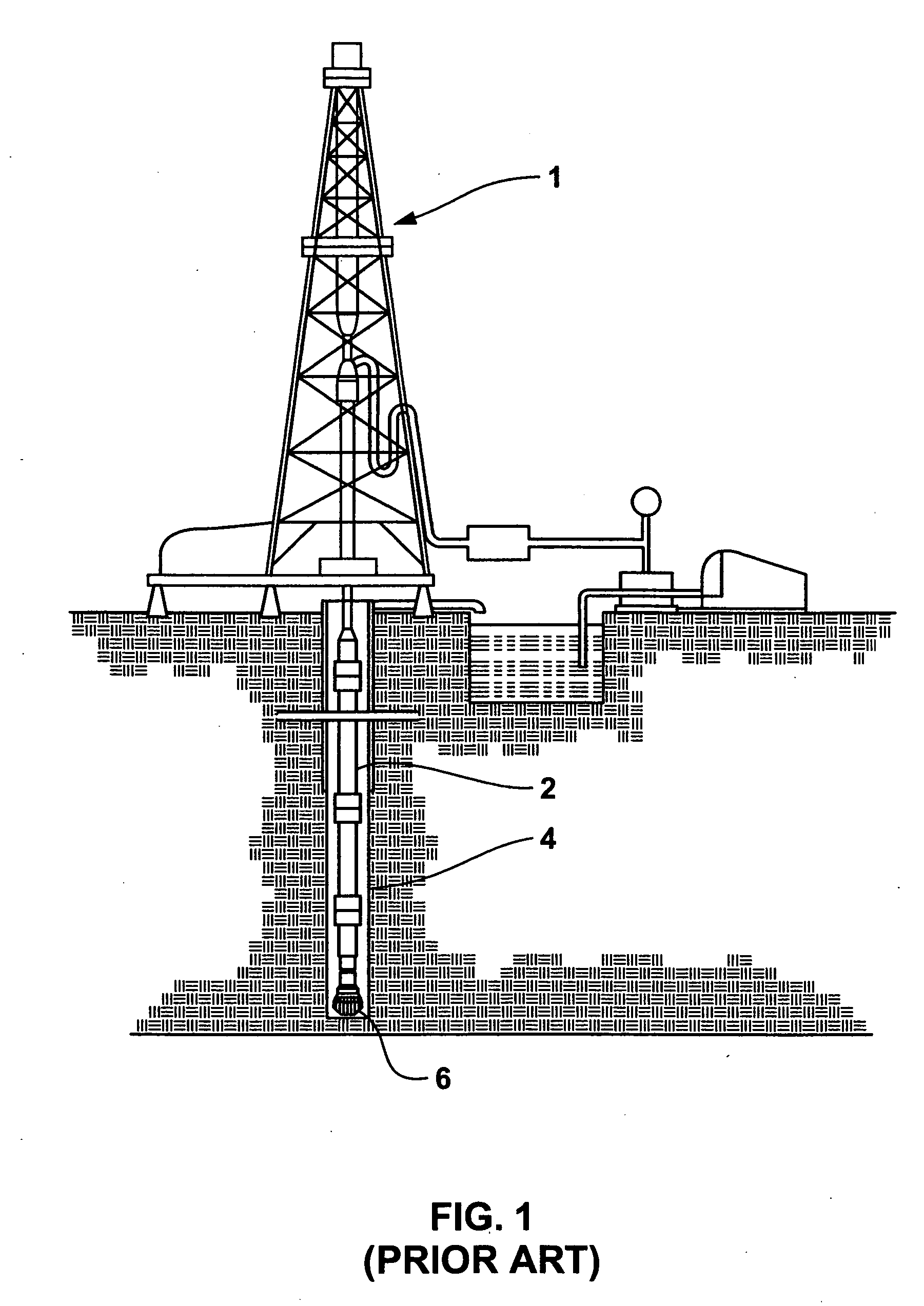

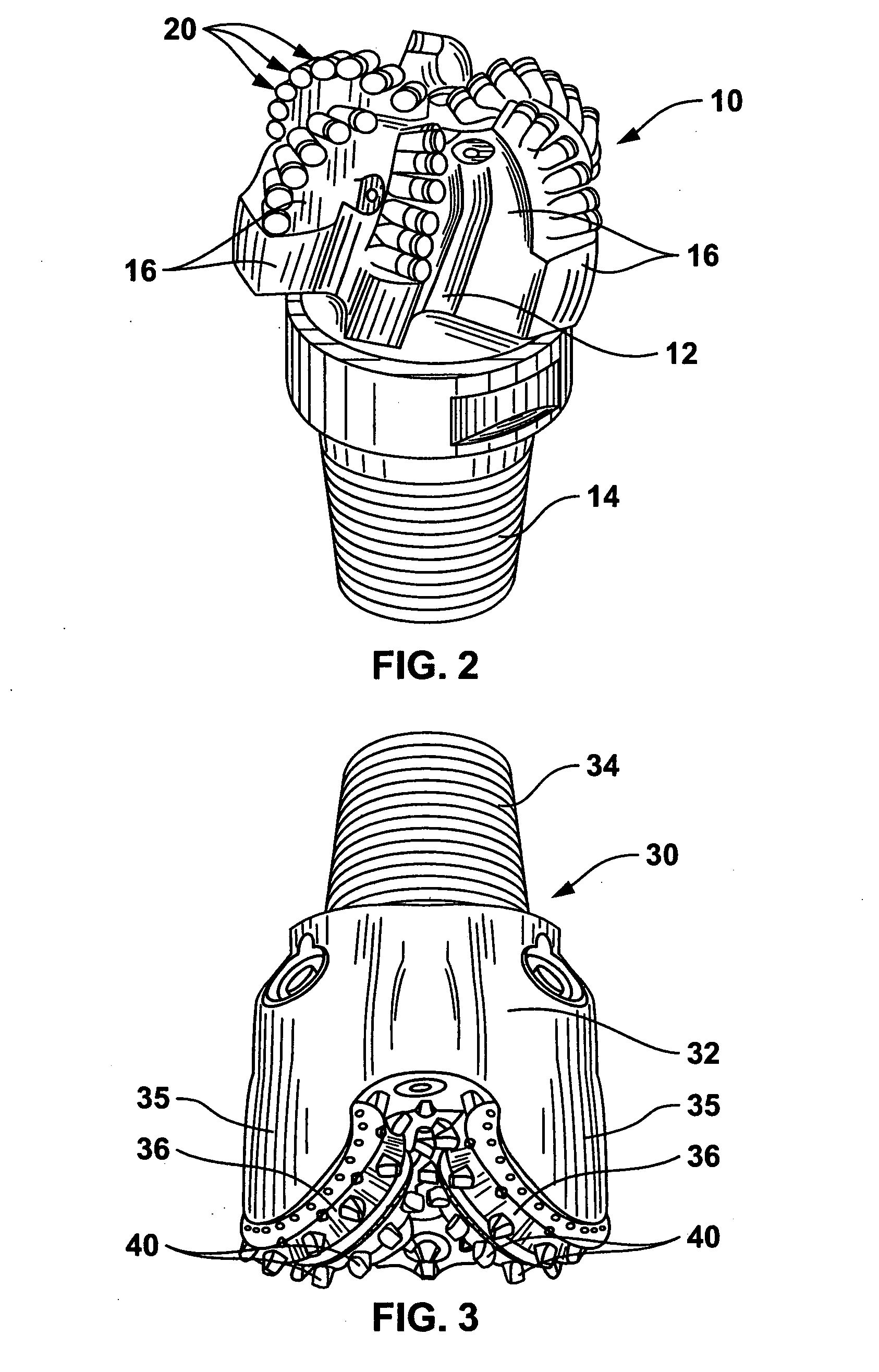

1930results about "Drilling tools" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

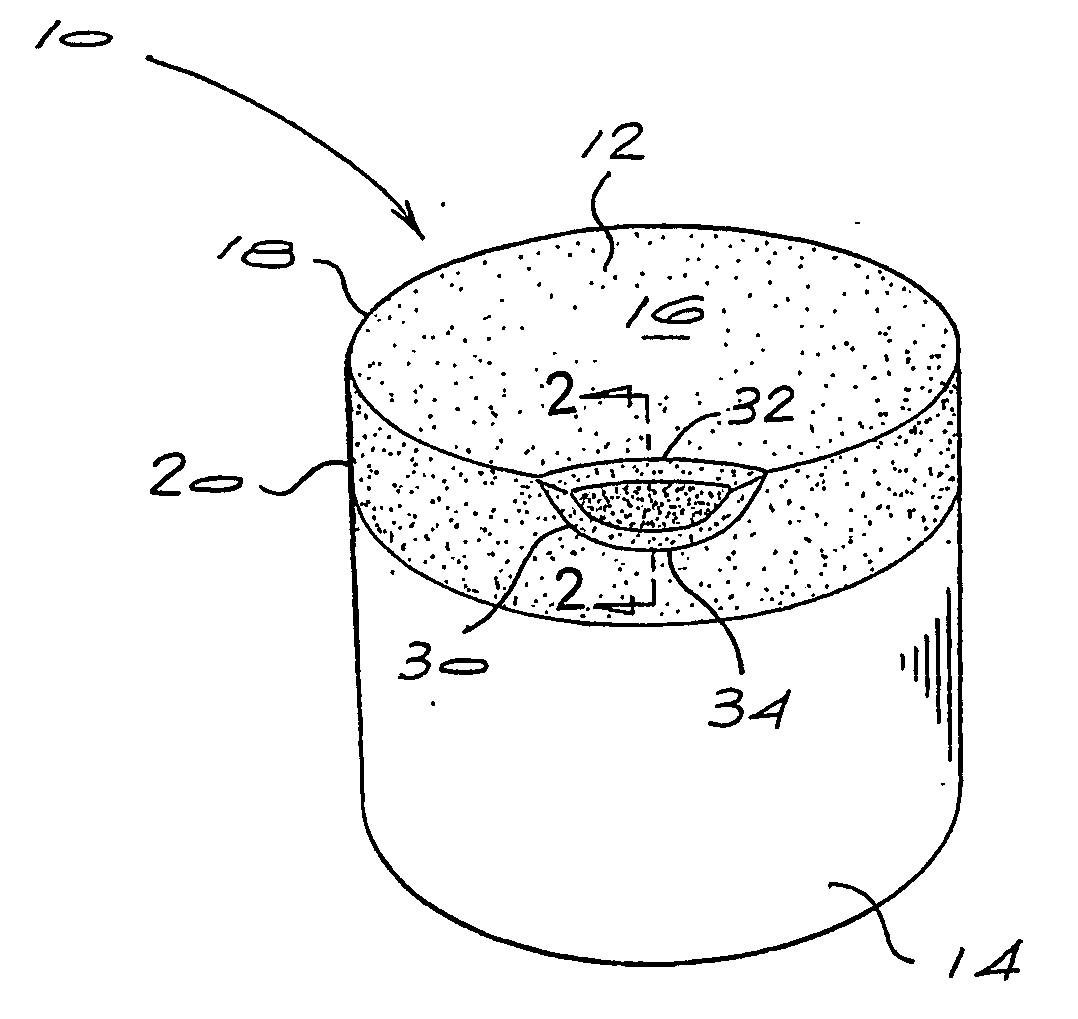

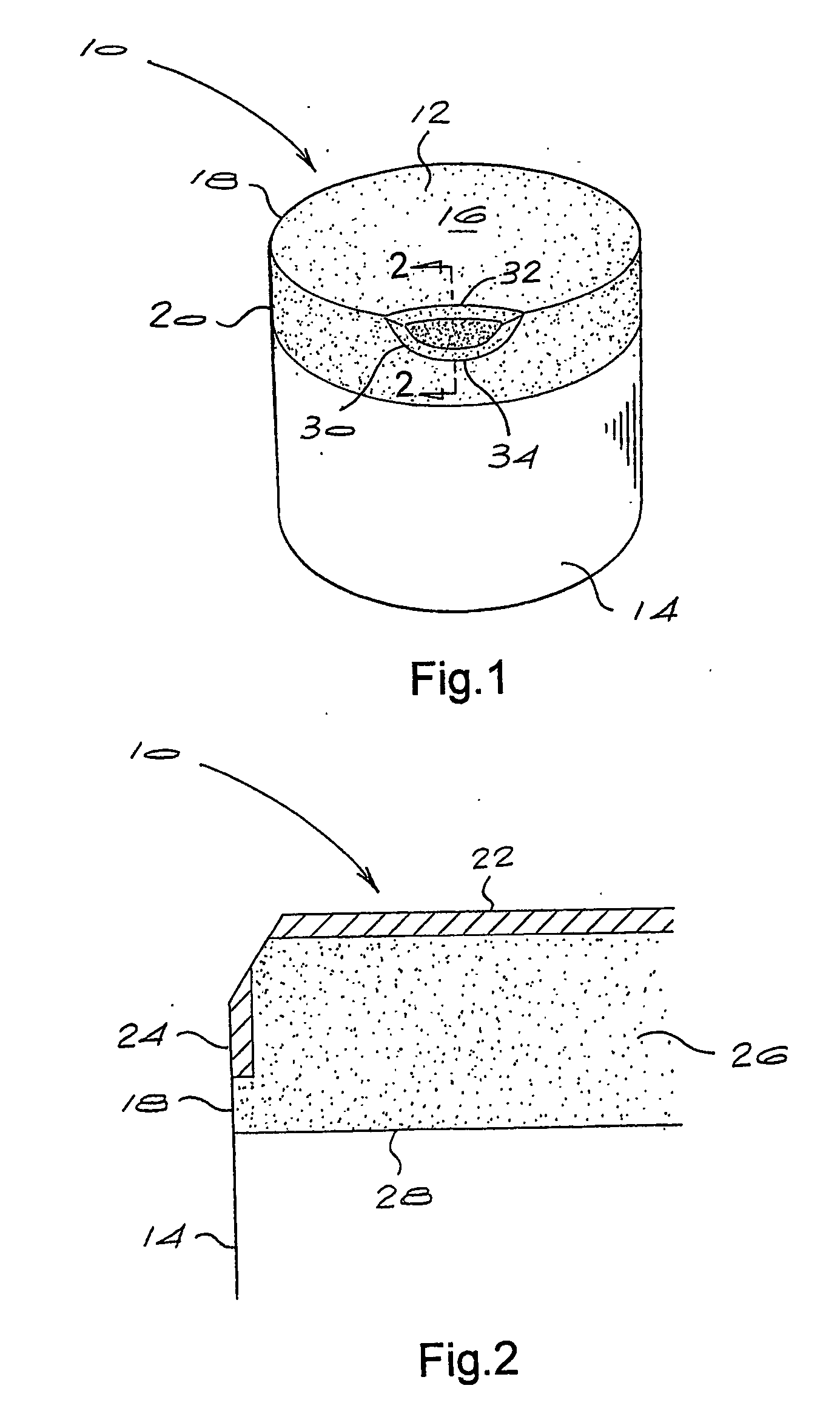

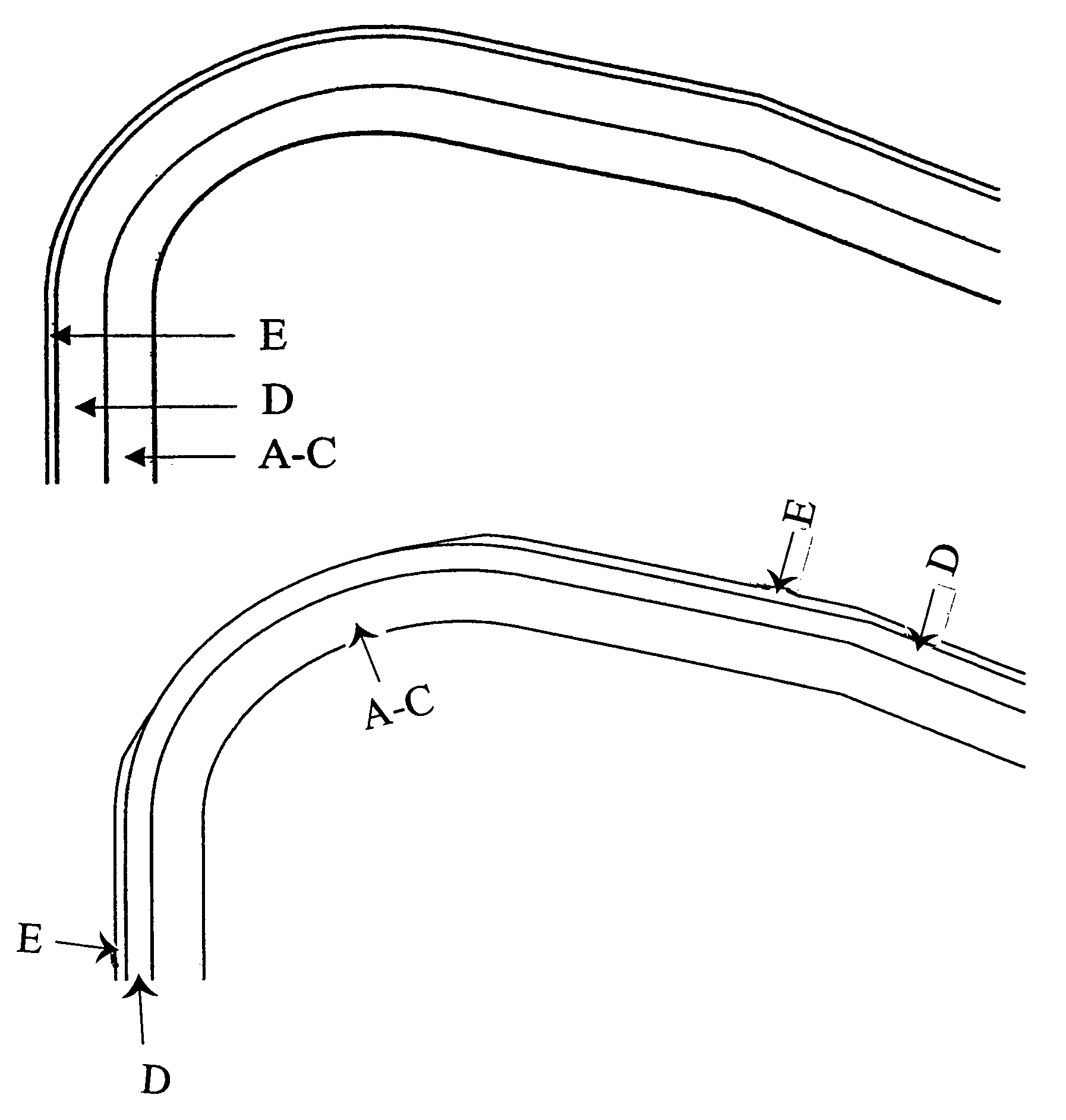

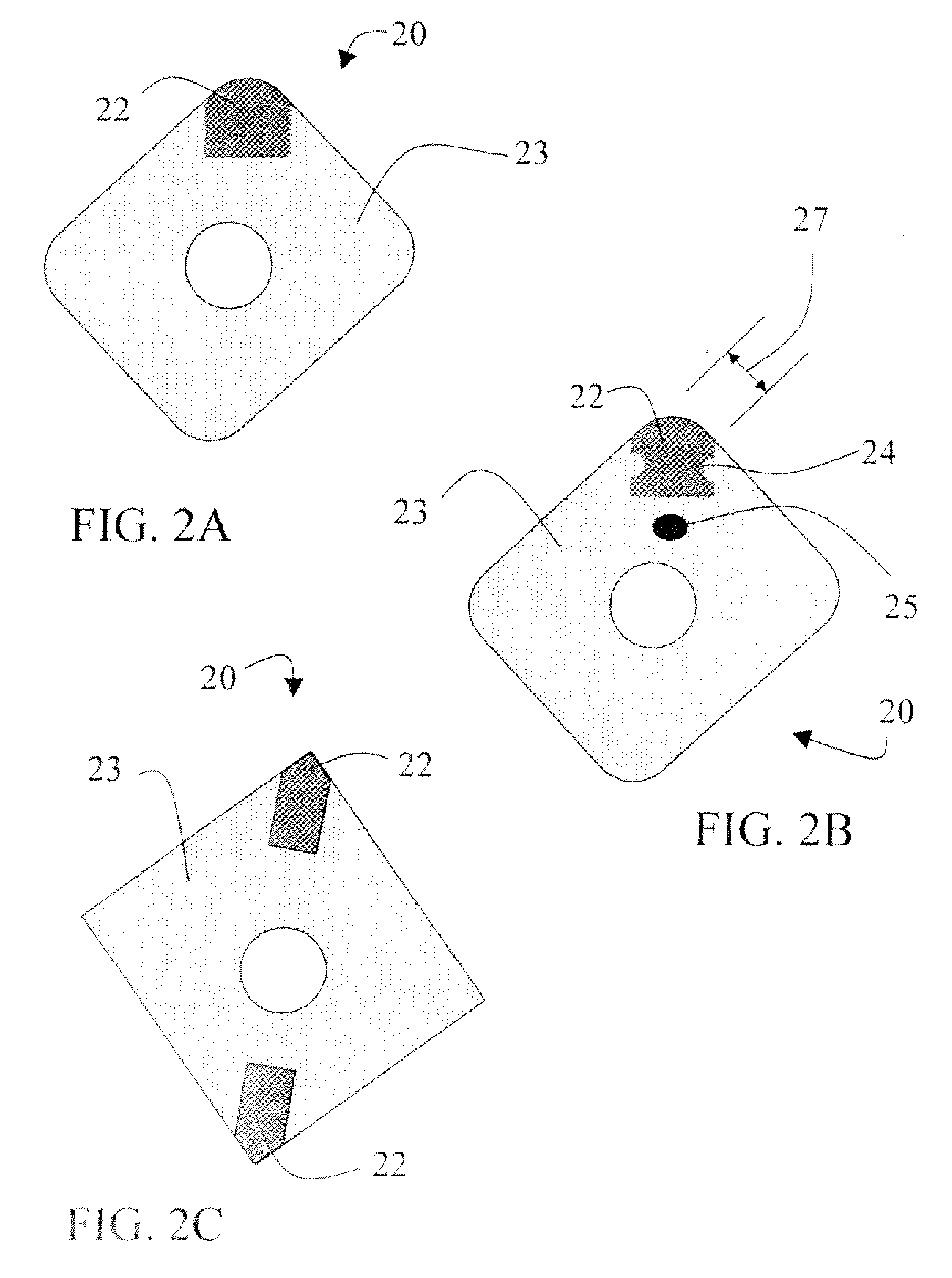

Doubled-sided and multi-layered PCD and PCBN abrasive articles

InactiveUS20050050801A1Improve propertiesIncreasing the thicknessPigmenting treatmentTool workpiece connectionHigh pressureMaterials science

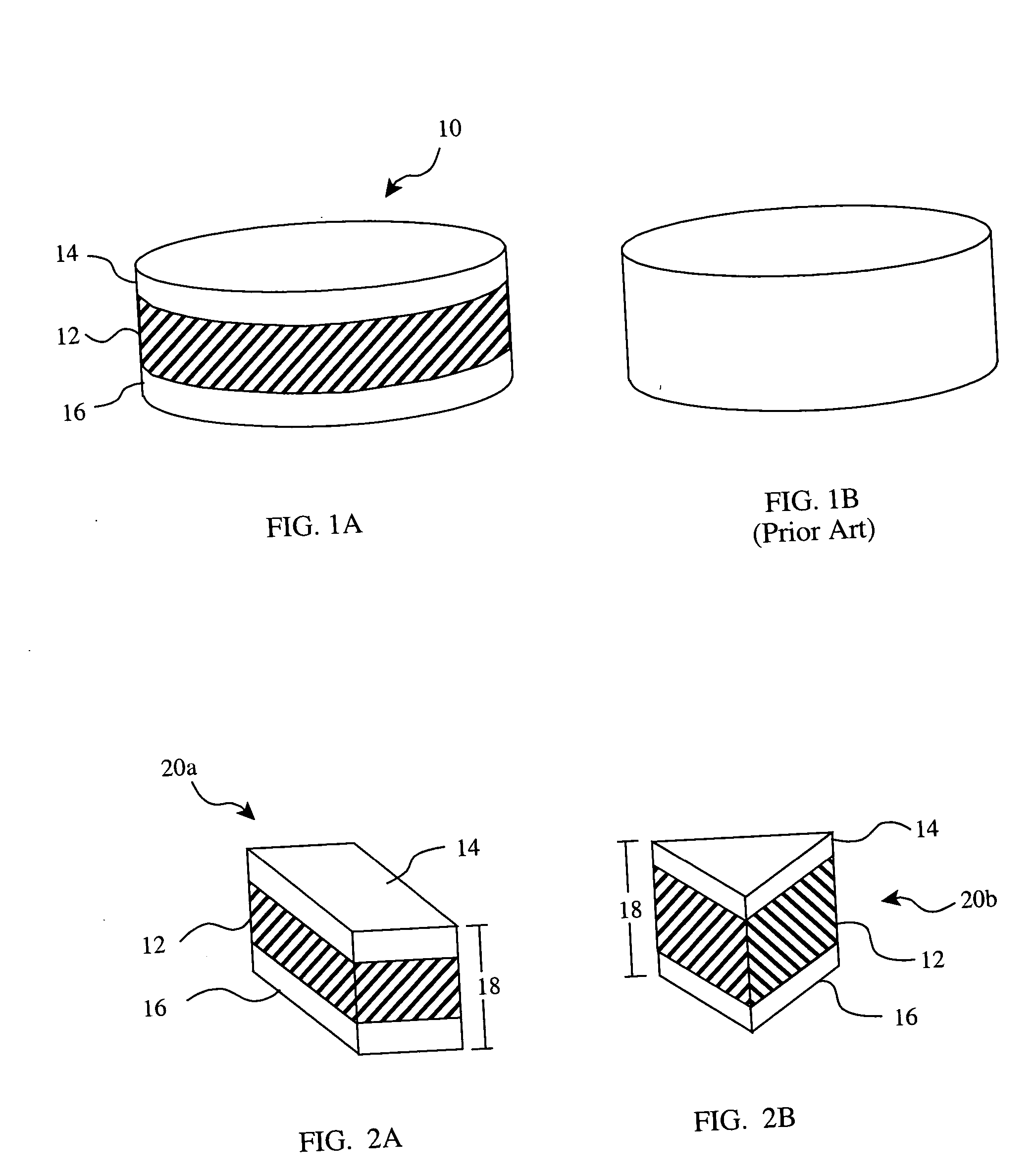

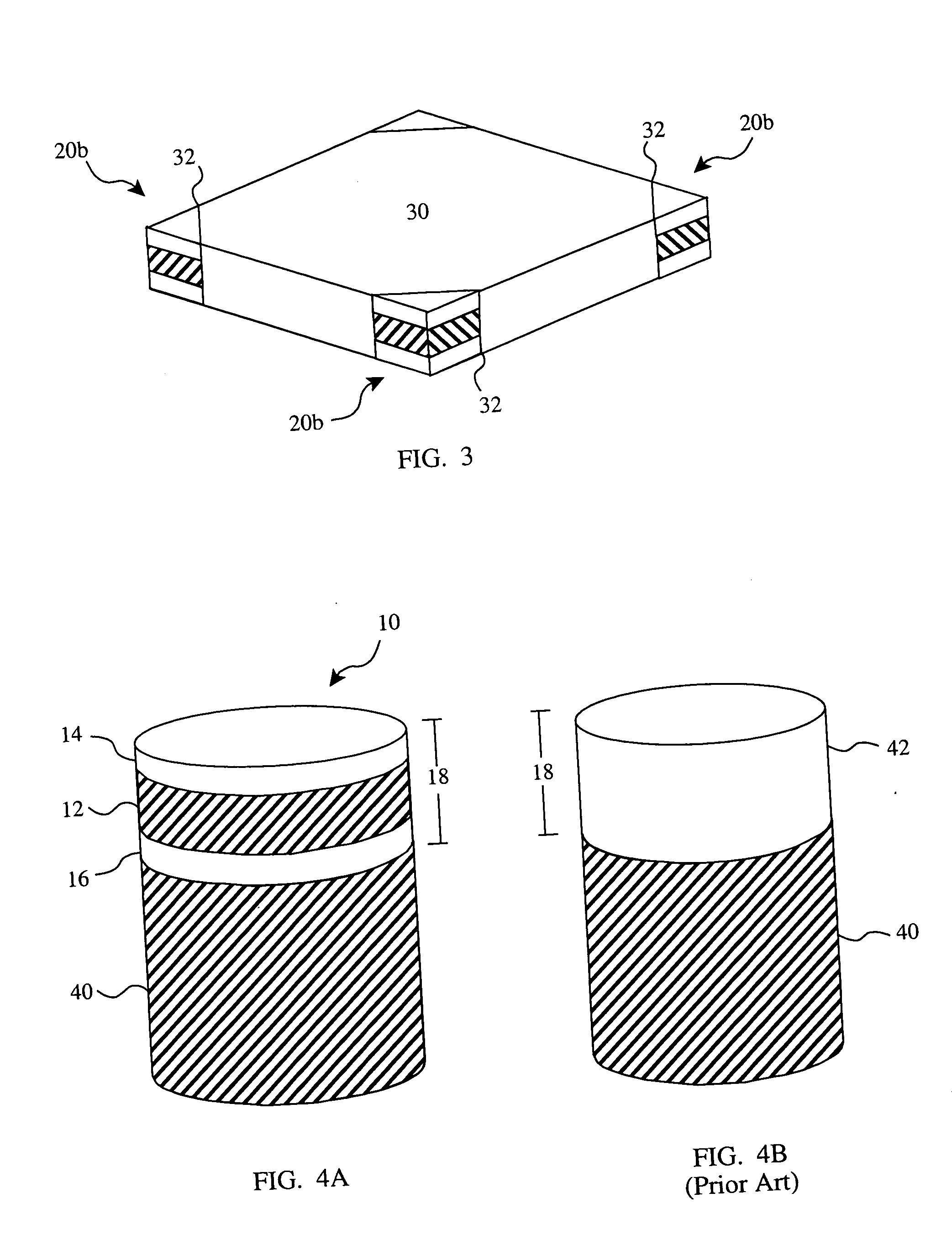

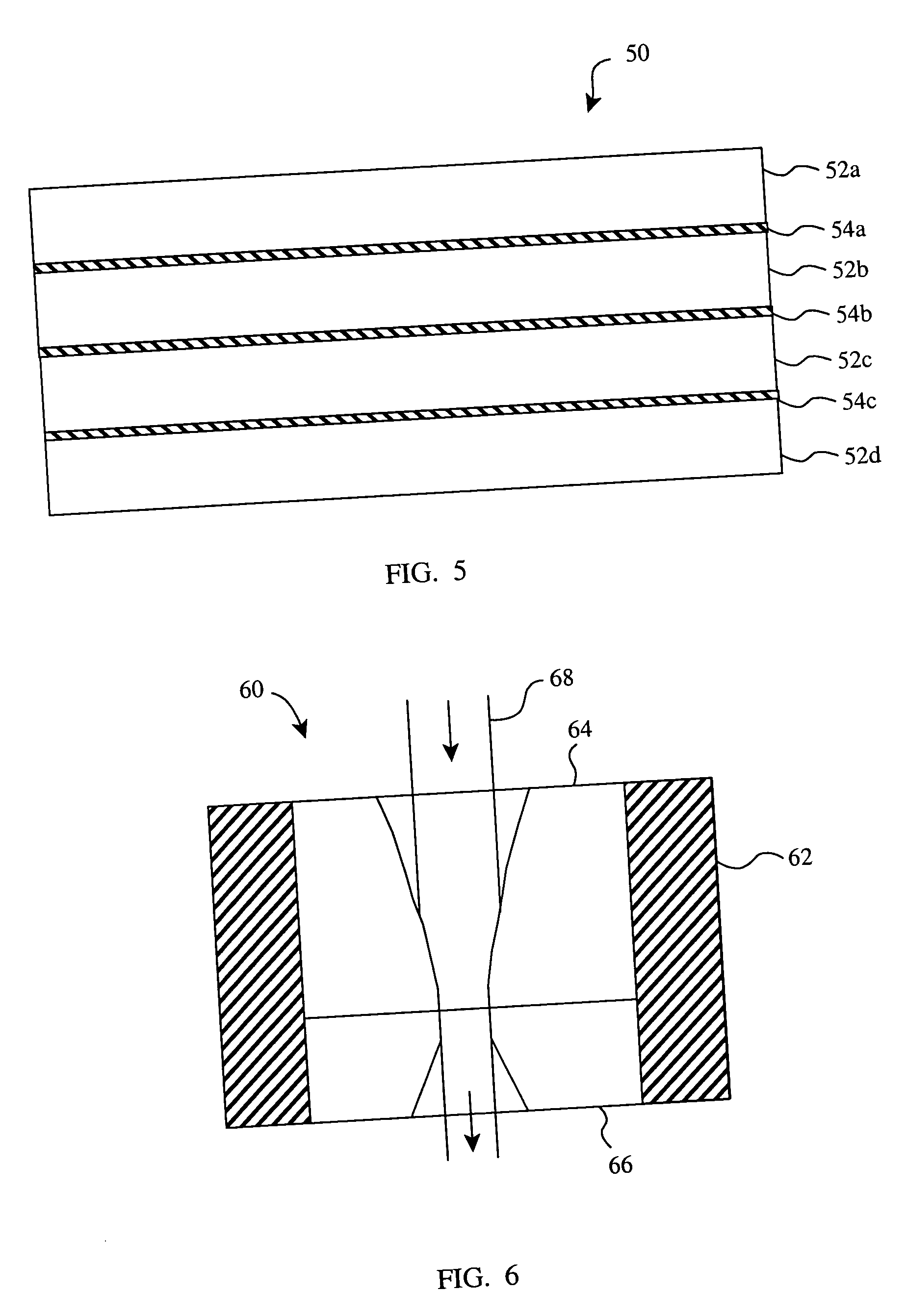

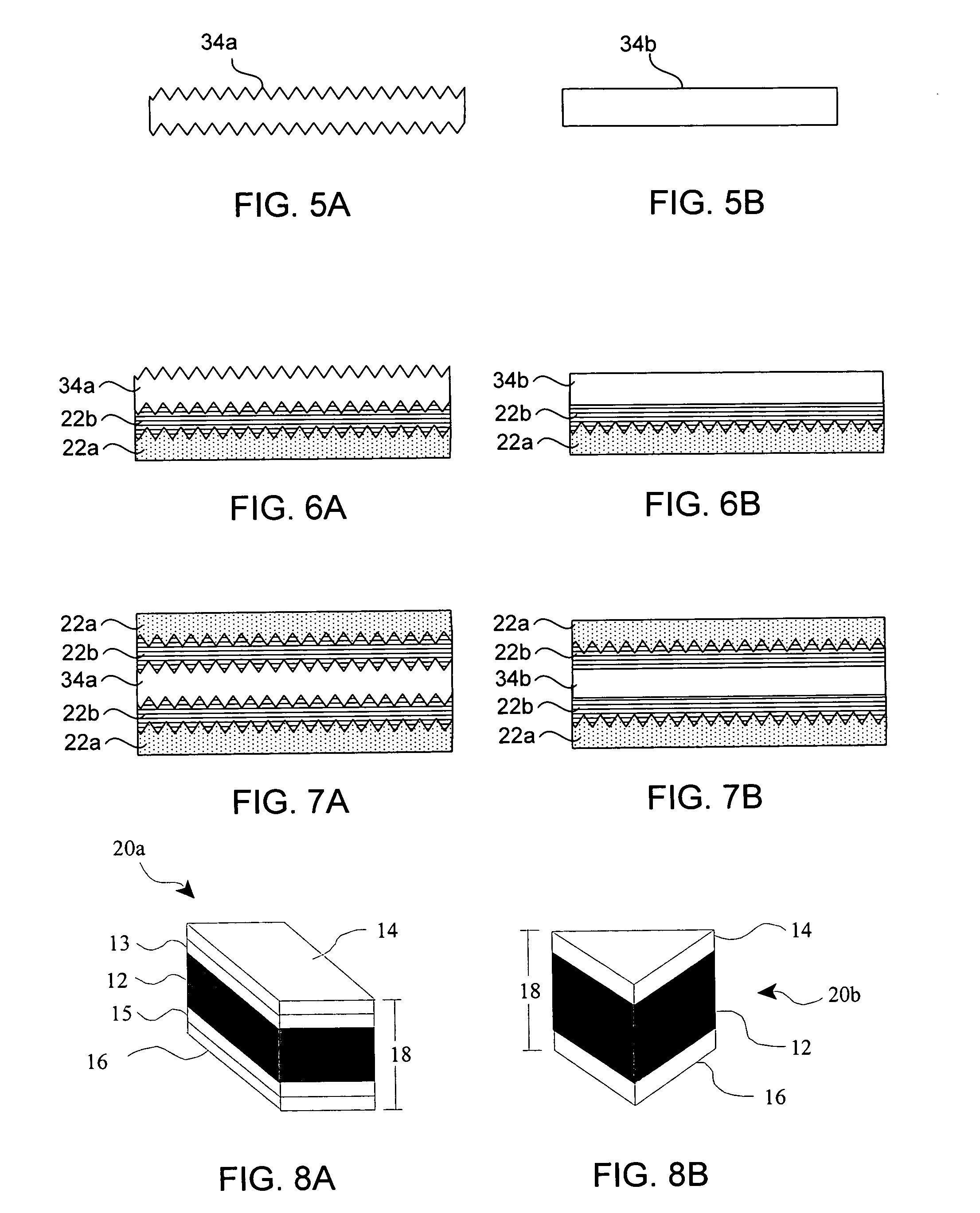

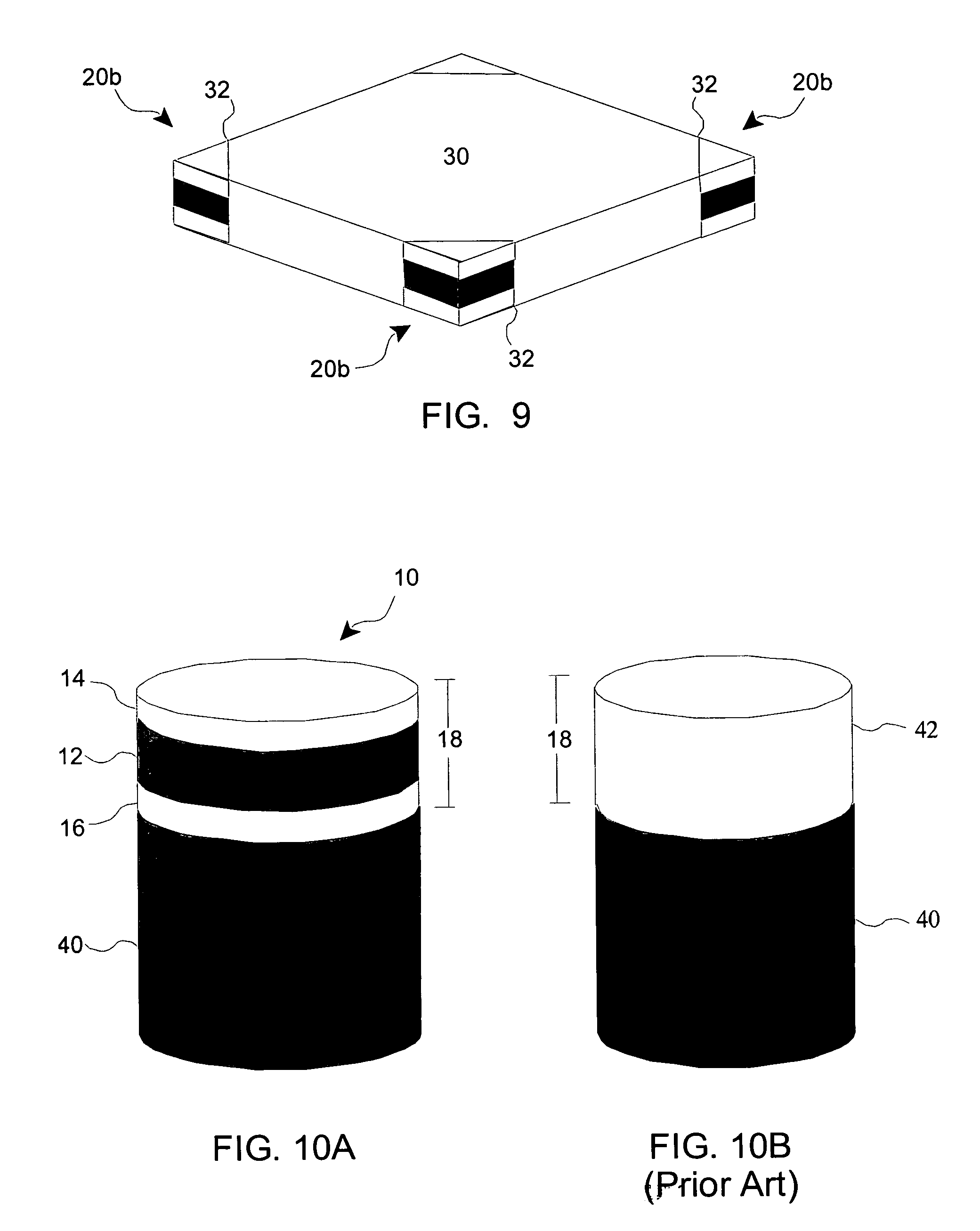

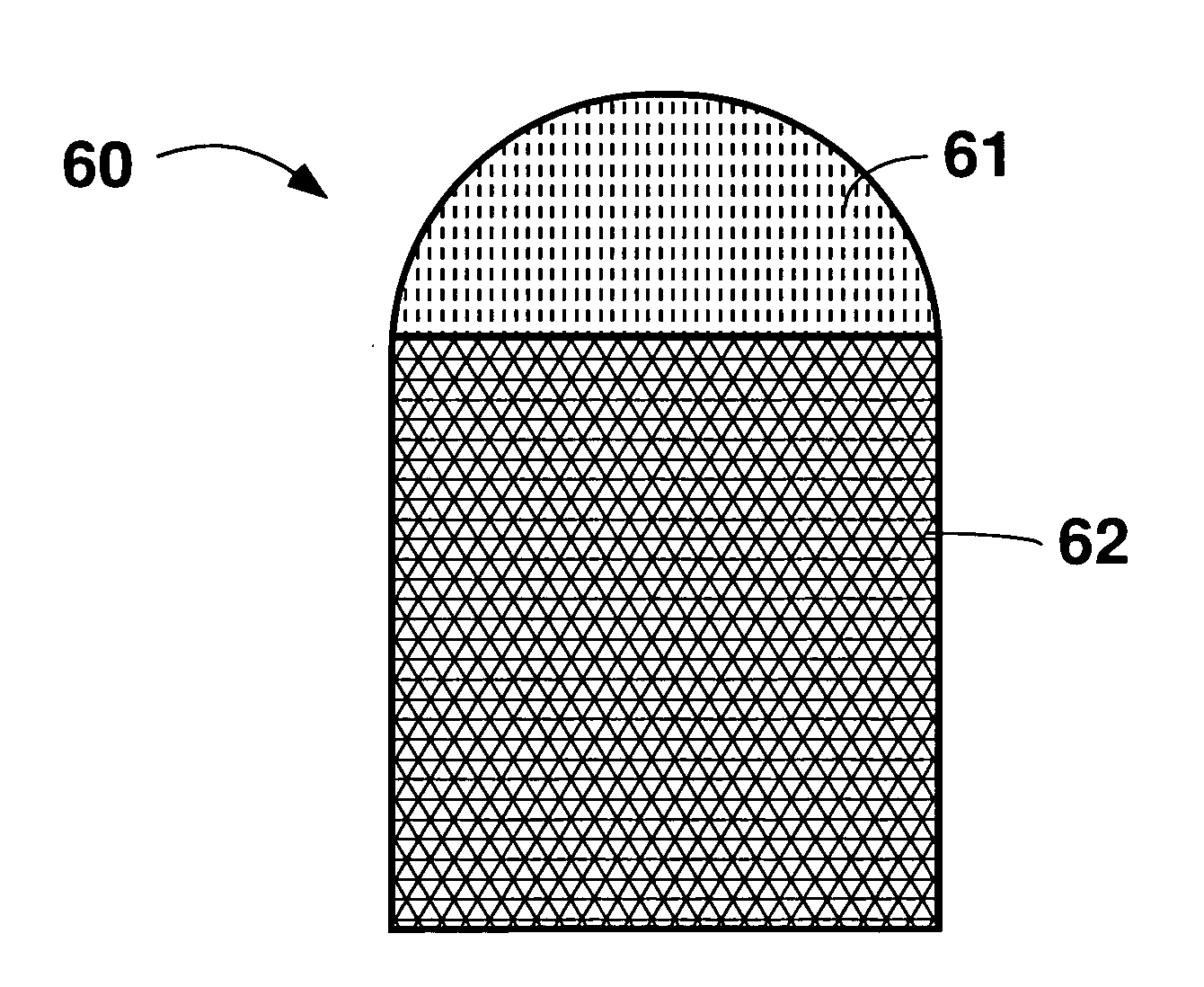

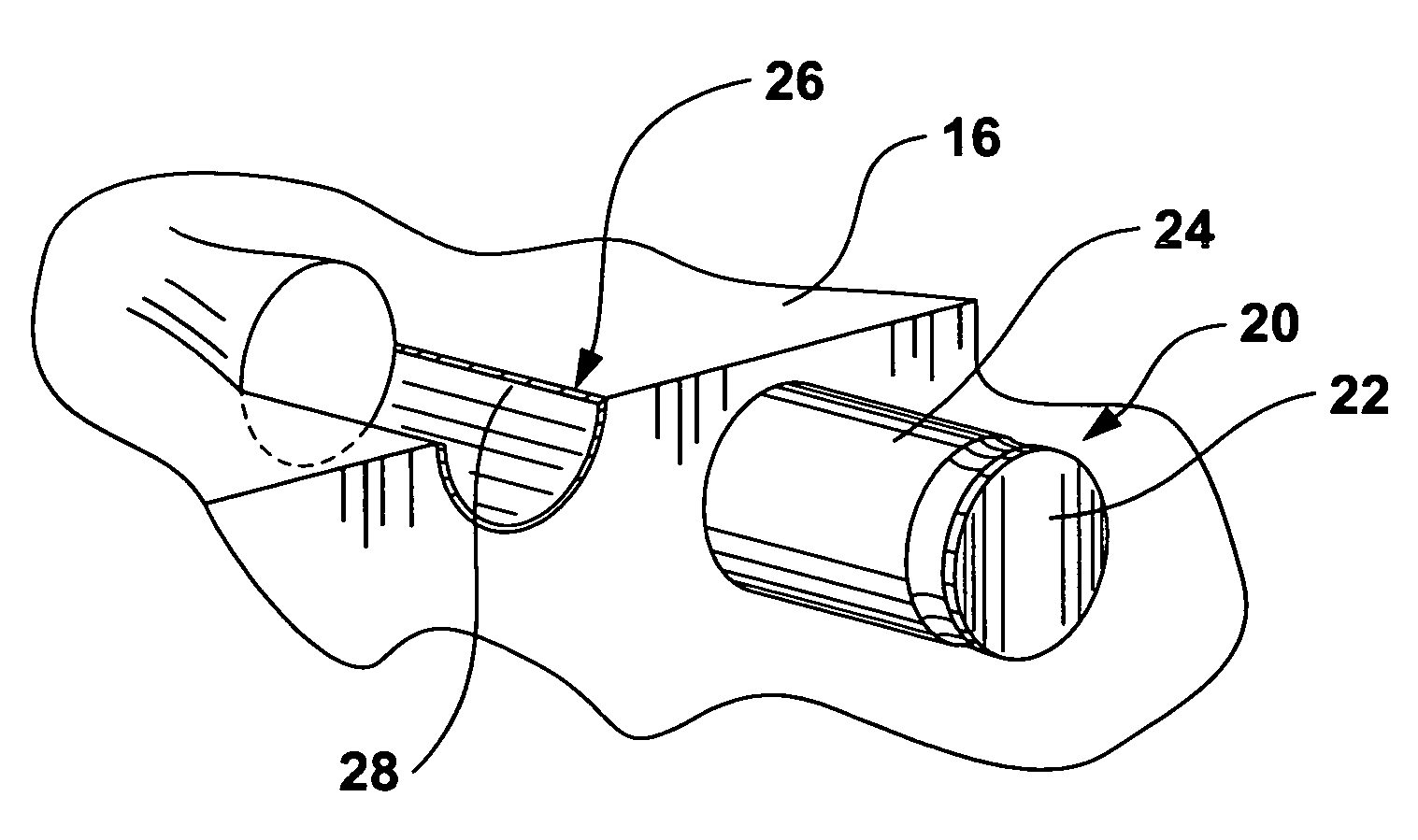

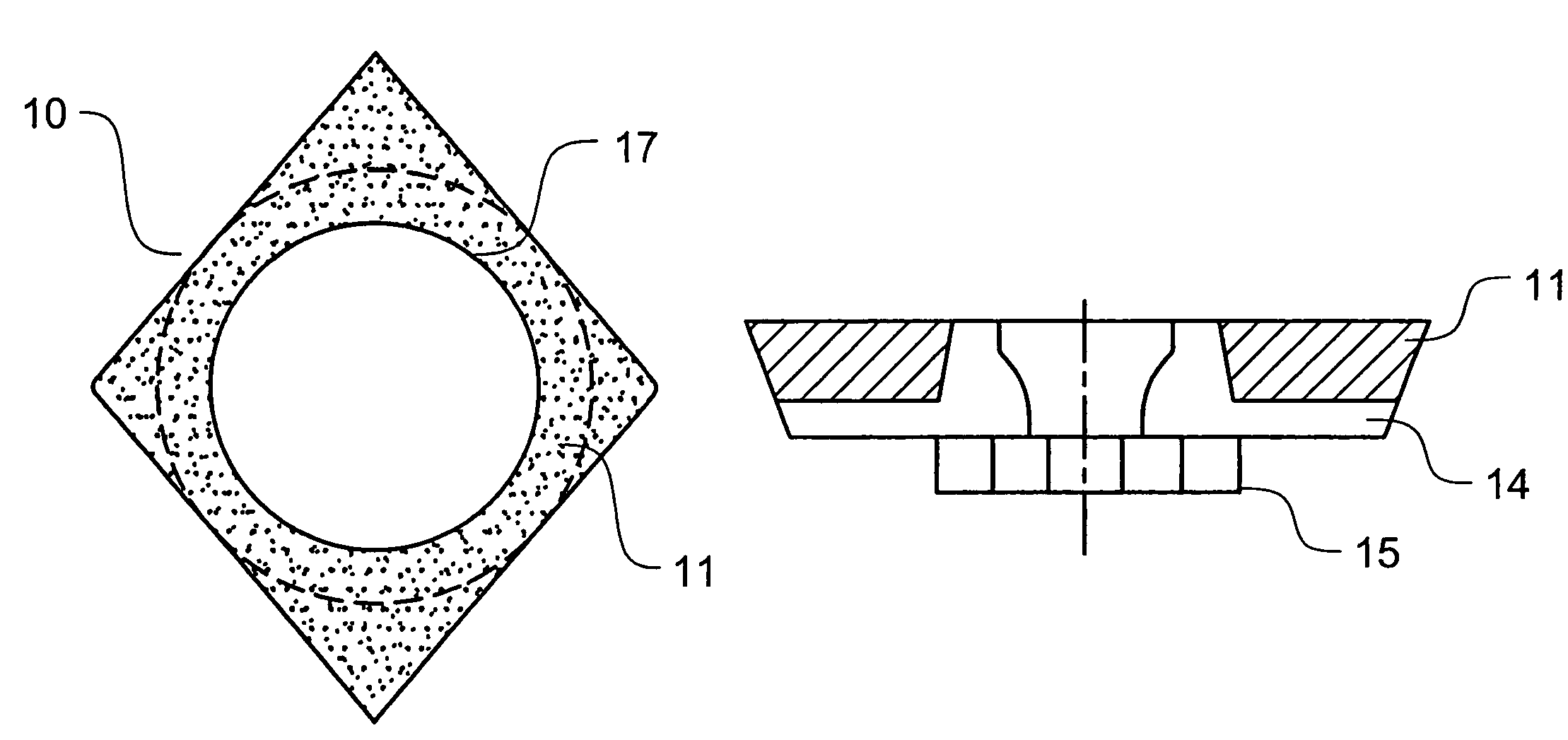

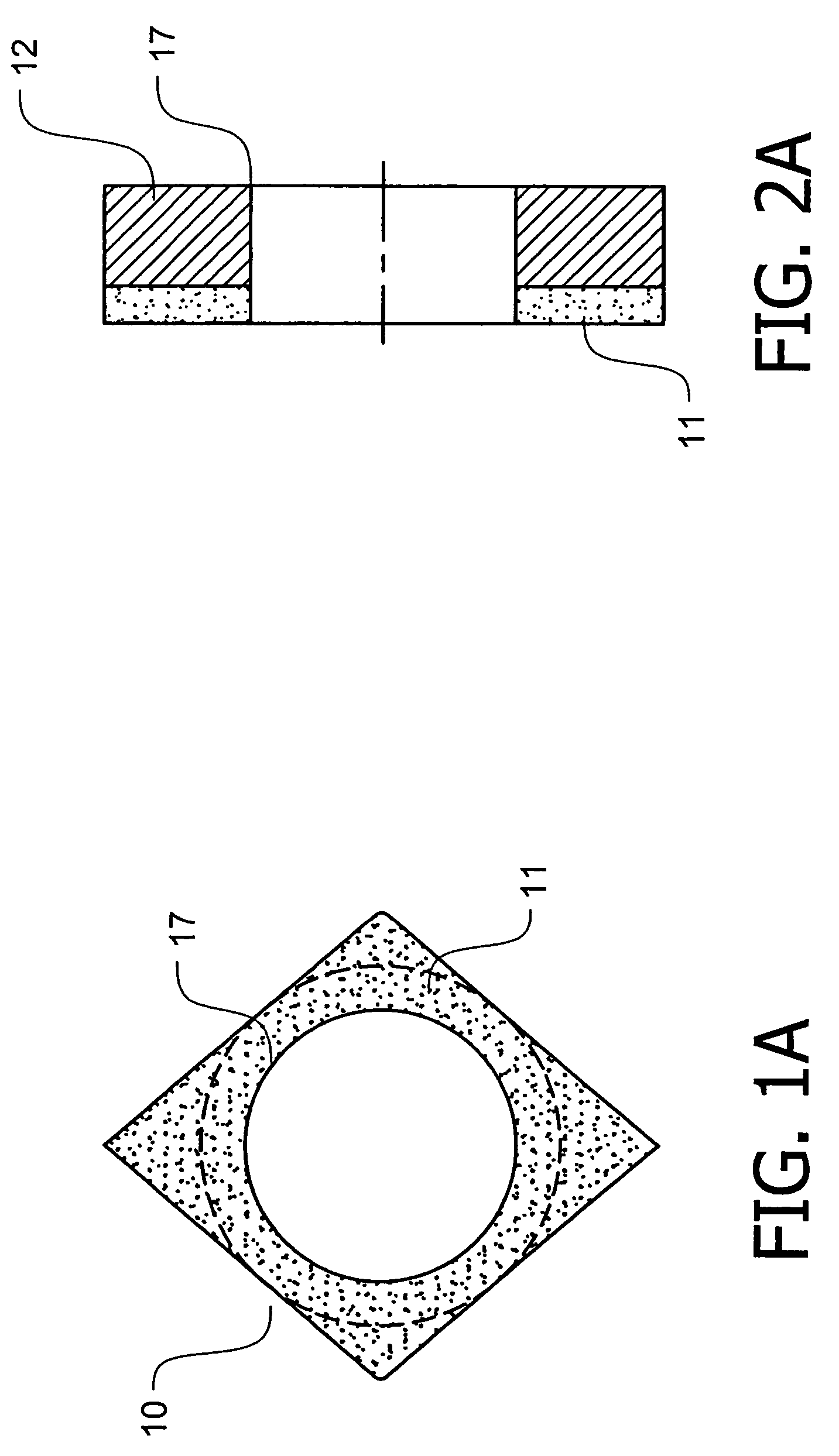

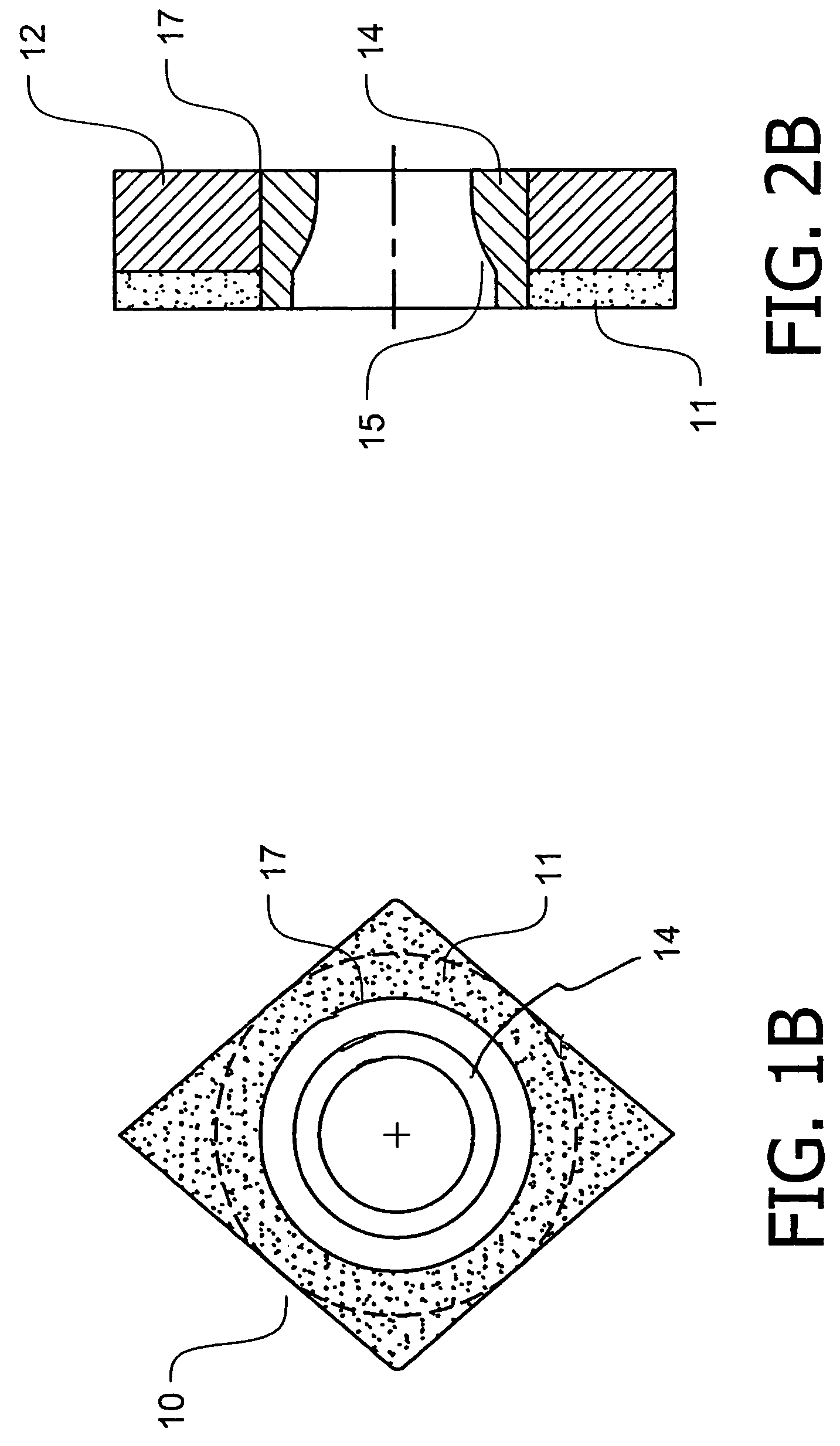

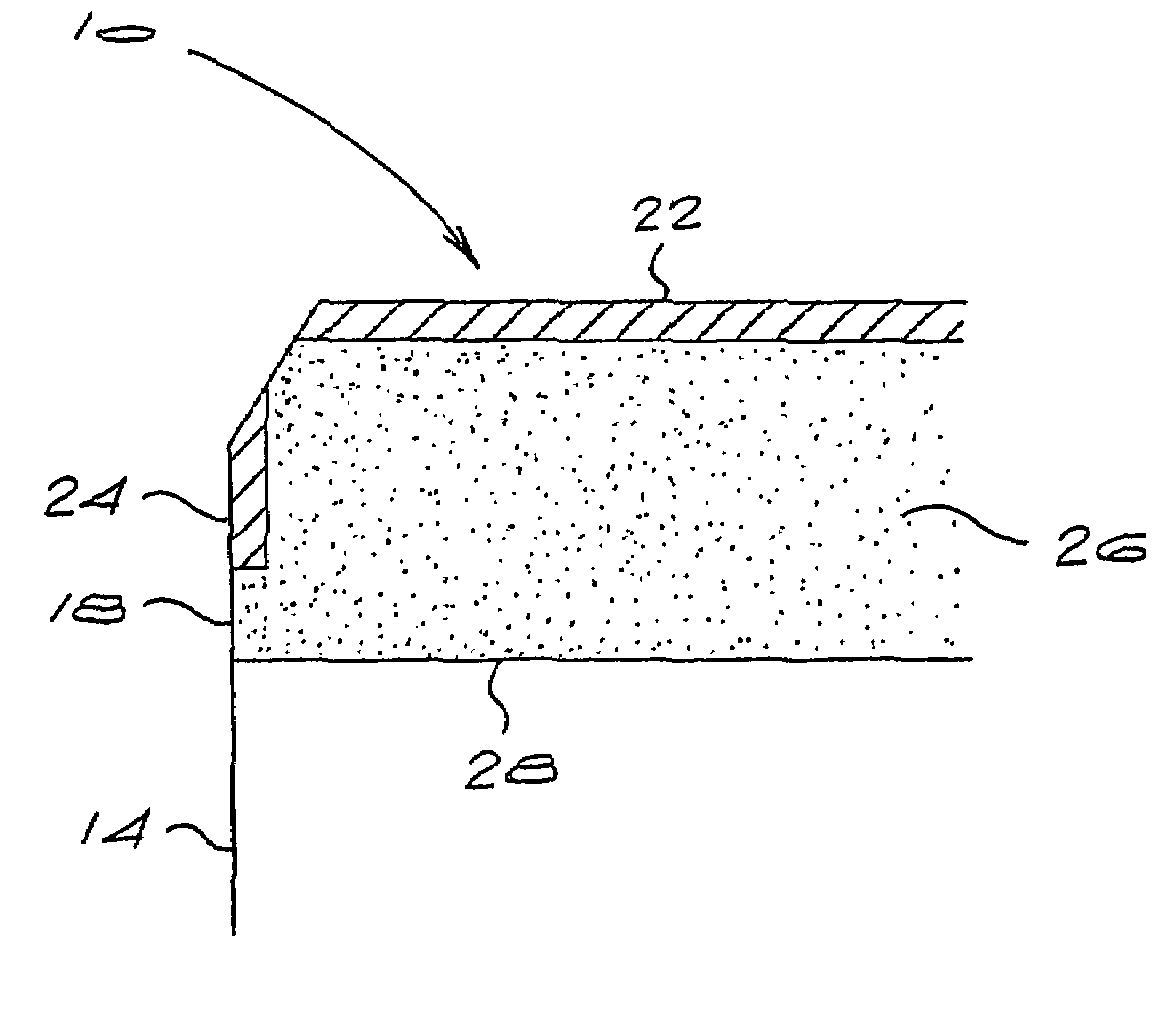

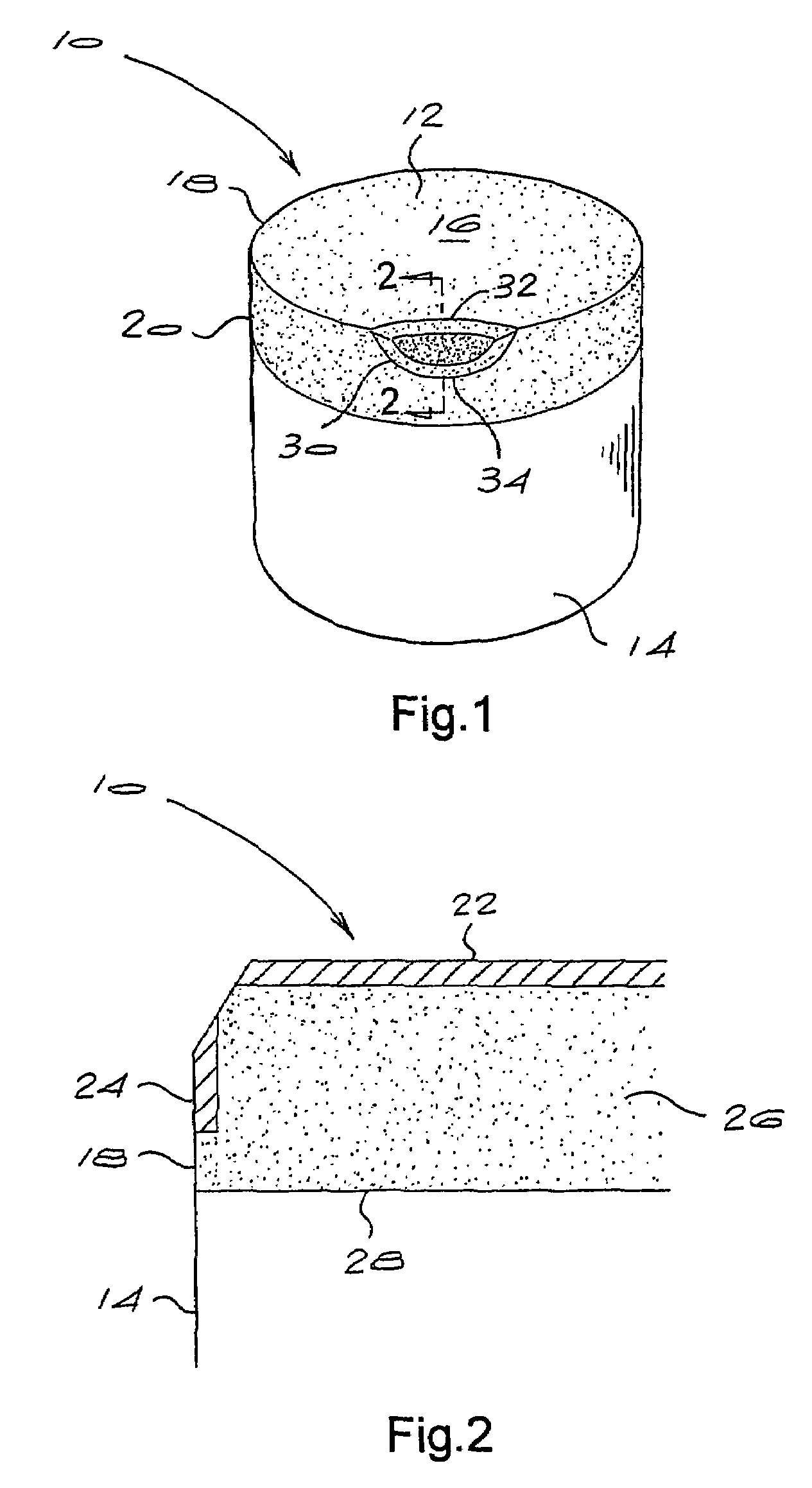

A doubled-sided PCD or PCBN compact as well as a new multi-layered PCD and PCBN can be produced using high pressure high temperature processes allowing for increased effective thickness of abrasive tools. A polycrystalline compact can include a substrate having a first surface and a second surface which are non-contiguous. Additionally, a first polycrystalline layer can be attached to the first surface of the substrate and a second polycrystalline layer attached to the second surface of the substrate. The first and second polycrystalline layers can include superabrasive particles bonded together by sintering or chemical bonding with an additional metal. Such double-sided PCD and PCBN compacts as well as a new multiple layered PCD and PCBN allow for increased effective thickness of a tool without suffering from non-homogenous results typical of standard PCD and PCBN compacts, regardless of superabrasive particle size. Each polycrystalline layer can include superabrasive particles of varying particle sizes such that the final tool is tailored for specific abrading characteristics. Such doubled-sided and / or multiple layered PCD and PCBN compacts can be incorporated into a wide variety of abrasive tools for use in cutting, milling, grinding, polishing, drilling and other similar abrasive applications.

Owner:CHO HYUN SAM +2

Doubled-sided and multi-layered PCBN and PCD abrasive articles

InactiveUS20050210755A1Improve propertiesIncreasing the thicknessPigmenting treatmentTool workpiece connectionWear particleHigh pressure

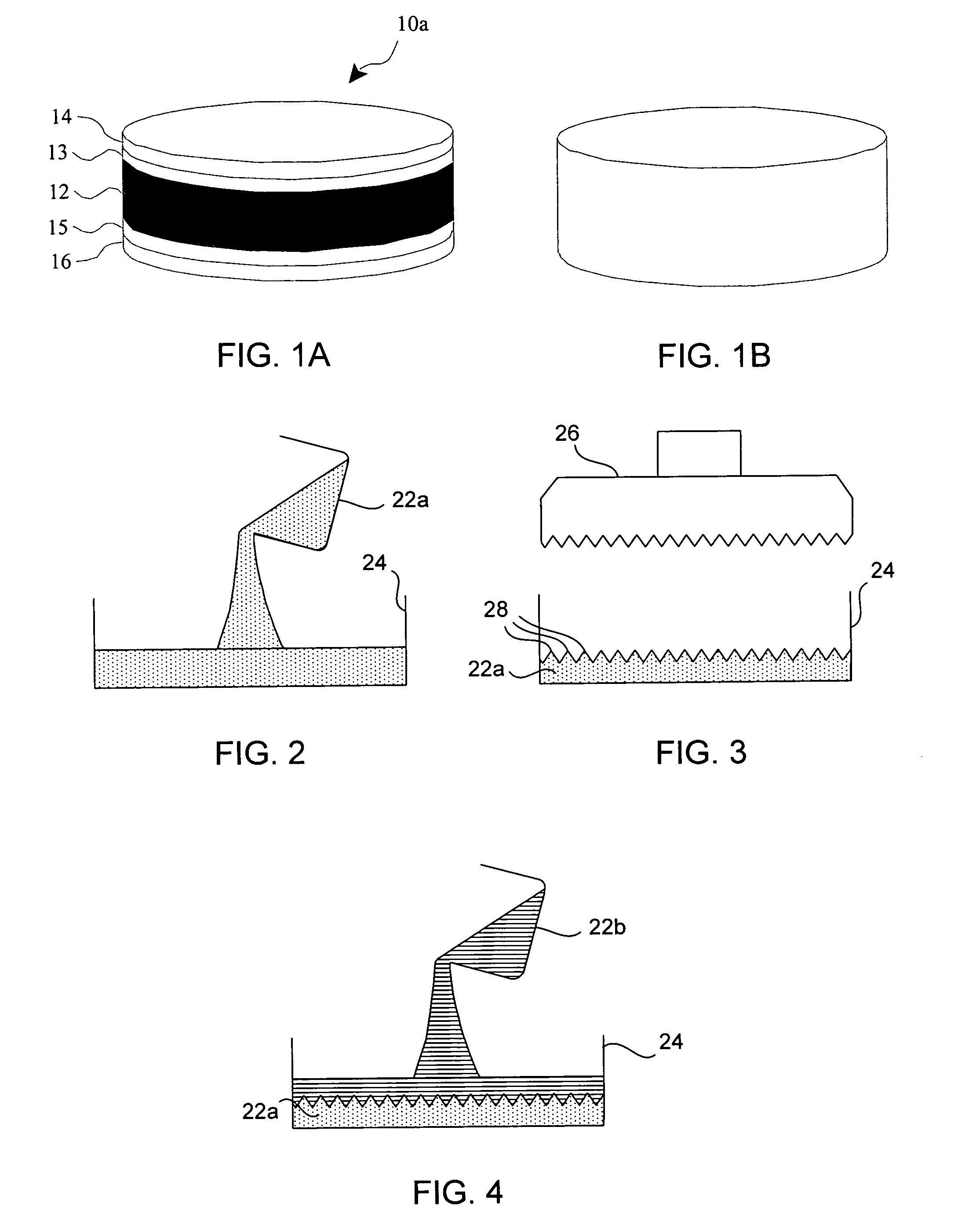

A doubled-sided PCBN and / or PCD compact can be produced using high pressure high temperature processes allowing for increased effective thickness of abrasive tools, decreased delamination, and increased useful service life. A polycrystalline compact can include a substrate having a first surface and a second surface which are non-contiguous. Additionally, a first polycrystalline layer can be attached to the first surface of the substrate and a second polycrystalline layer attached to the second surface of the substrate. The first and second polycrystalline layers can be attached to the substrate via an intermediate layer containing superabrasive particles. Such double-sided PCBN and PCD compacts allow for increased effective thickness of a tool without suffering from non-homogenous results typical of standard PCD and PCBN compacts, regardless of superabrasive particle size. Each polycrystalline layer can include superabrasive particles of varying particle sizes such that the final tool is tailored for specific abrading characteristics. Such doubled-sided PCBN and PCD compacts can be incorporated into a wide variety of abrasive tools for use in cutting, milling, grinding, polishing, drilling and other similar abrasive applications.

Owner:ADICO ASIA POLYDIAMOND

Device for applying cryogenic composition and method of using same

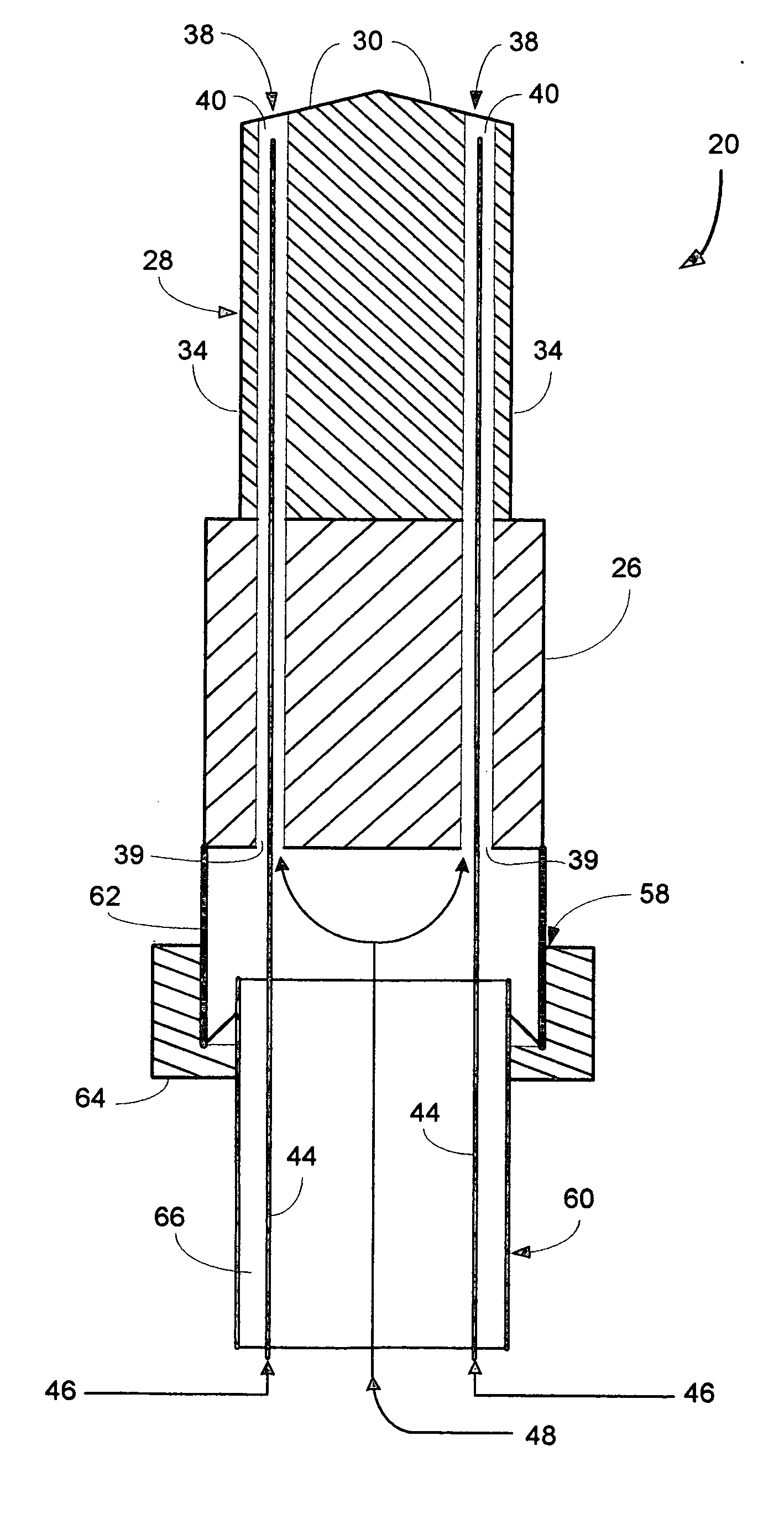

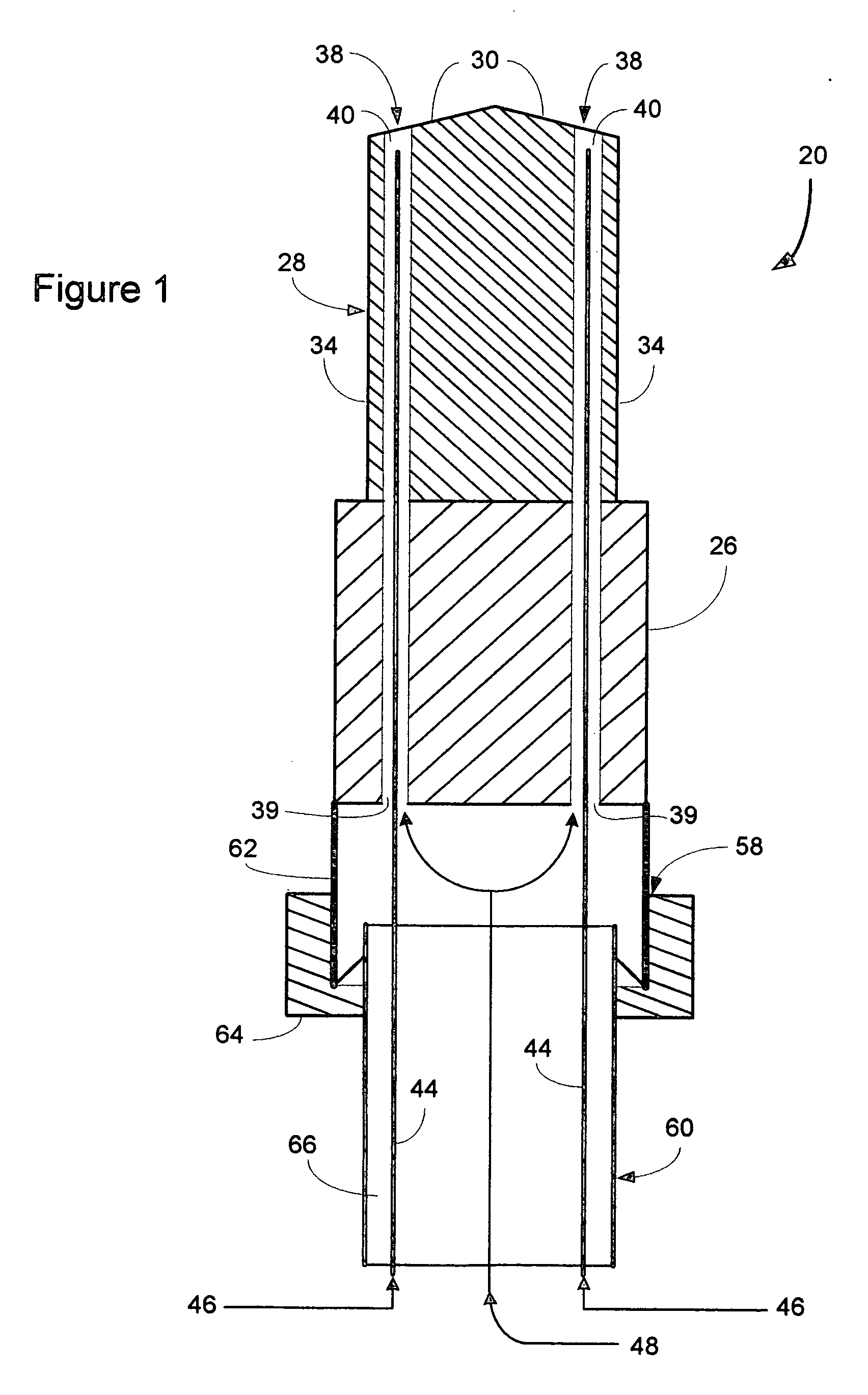

A device of the present invention for applying a cryogenic composition includes a machining tool or tool holder having a channel positioned therethrough and a capillary tube positioned within the channel. A dense cryogenic fluid is passed through the capillary tube while a diluent or propellant fluid is passed through the channel. The diluent or propellant fluid flows within the channel and about the capillary tube. Upon exiting the capillary tube, the dense fluid admixes with the diluent or propellant fluid to form a cryogenic composite fluid or spray. The cryogenic composite fluid or spray is selectively directed onto a substrate for cooling or lubrication purposes, or onto the machining tool for cooling purposes.

Owner:COOL CLEAN TECH

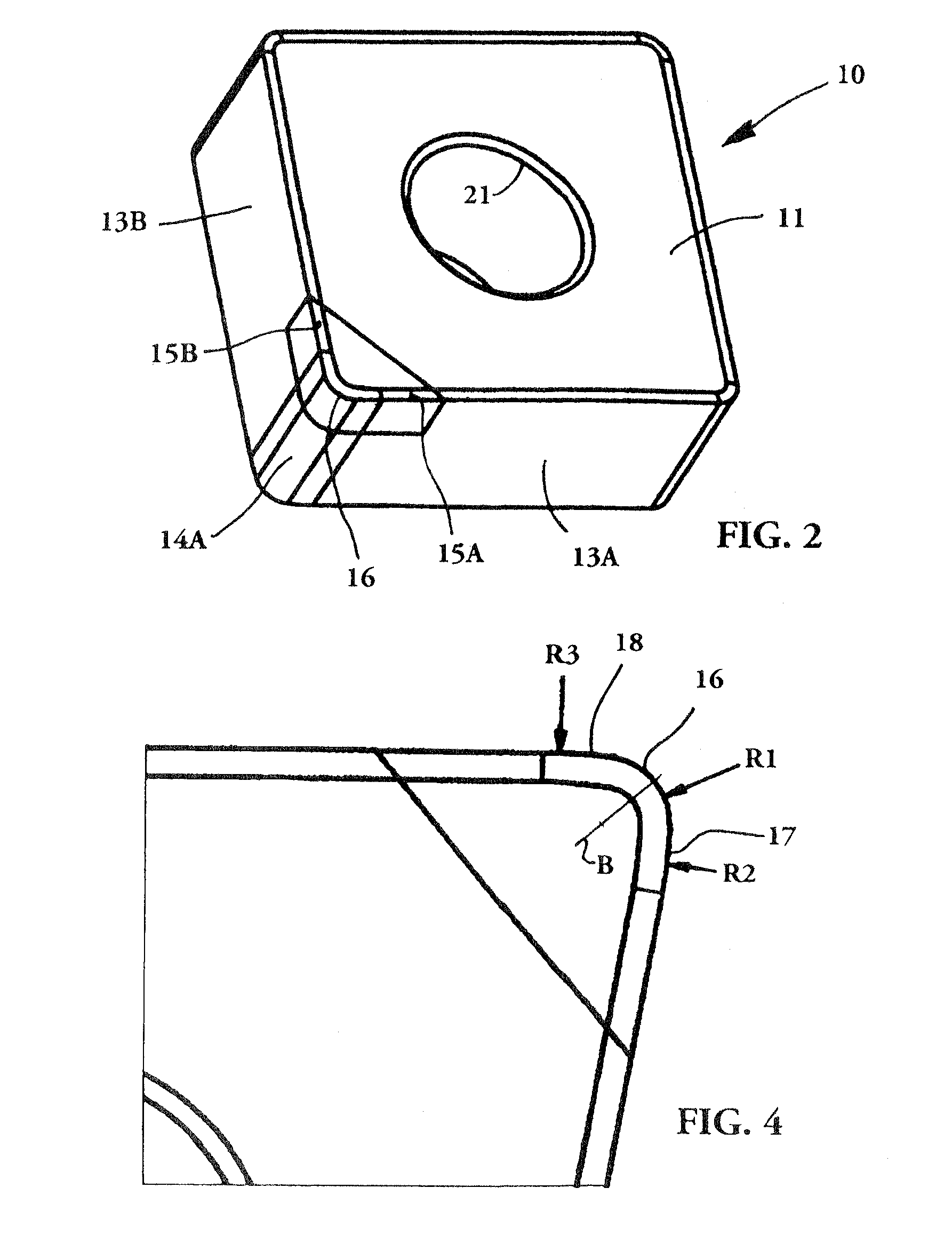

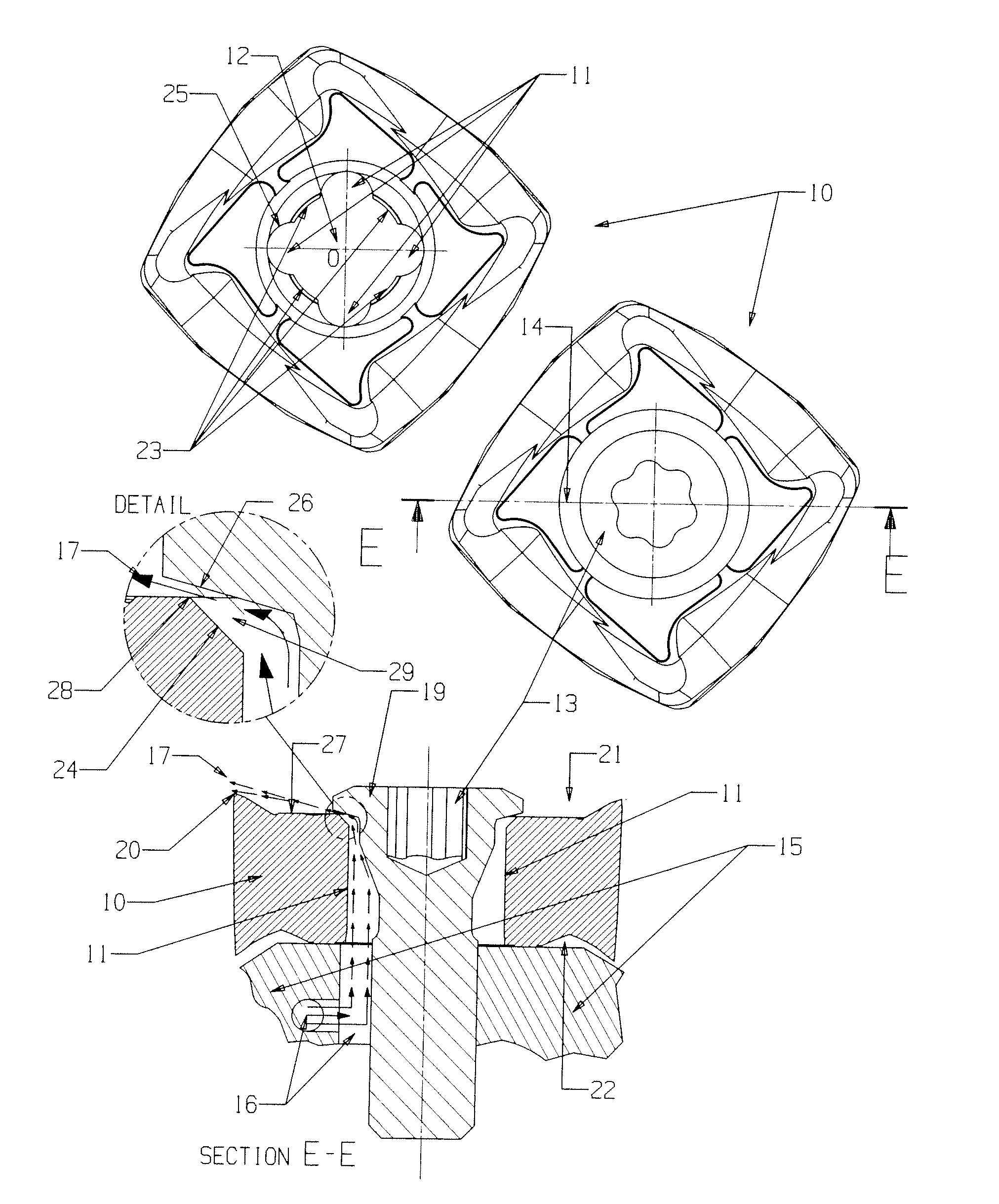

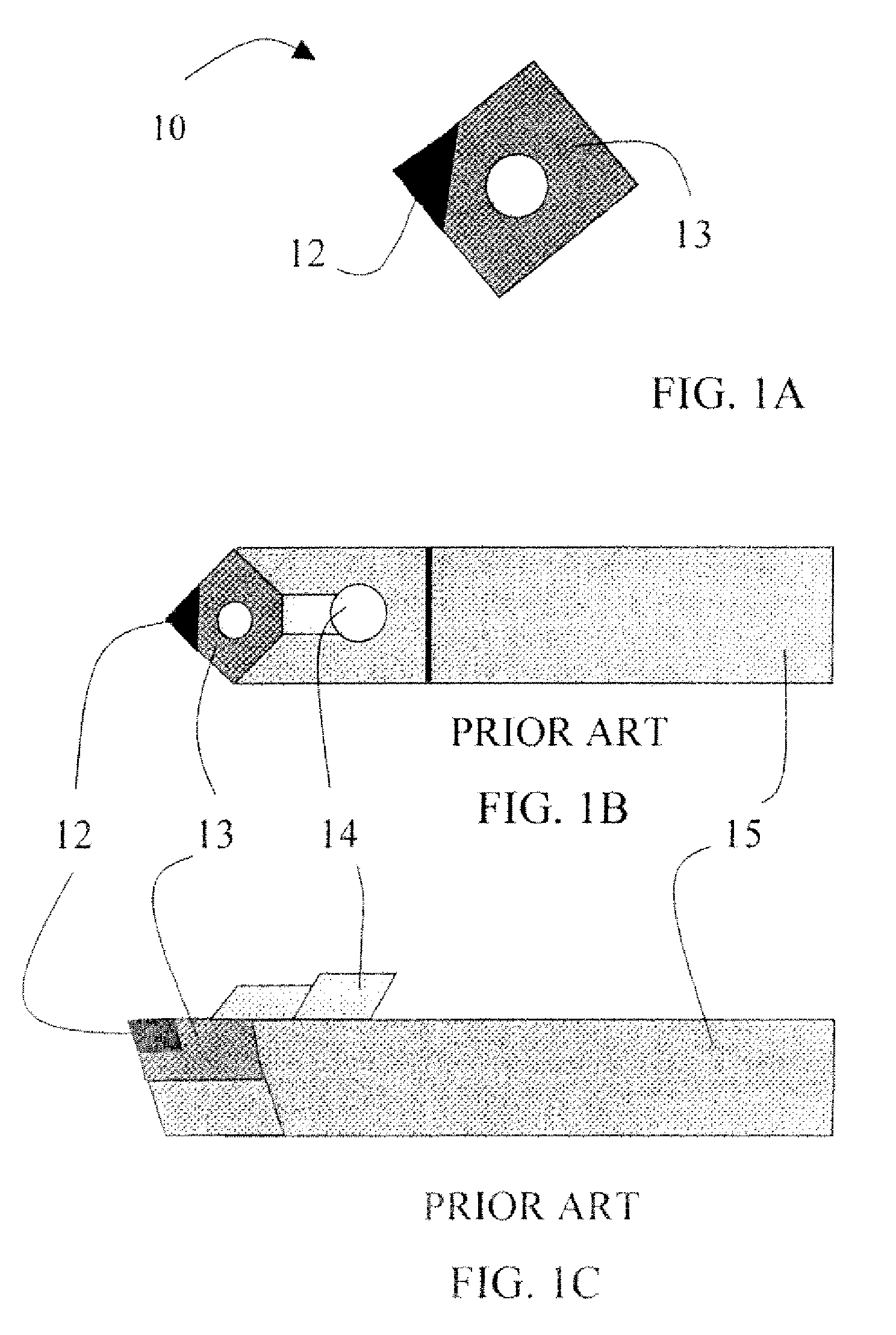

Cutting tool insert

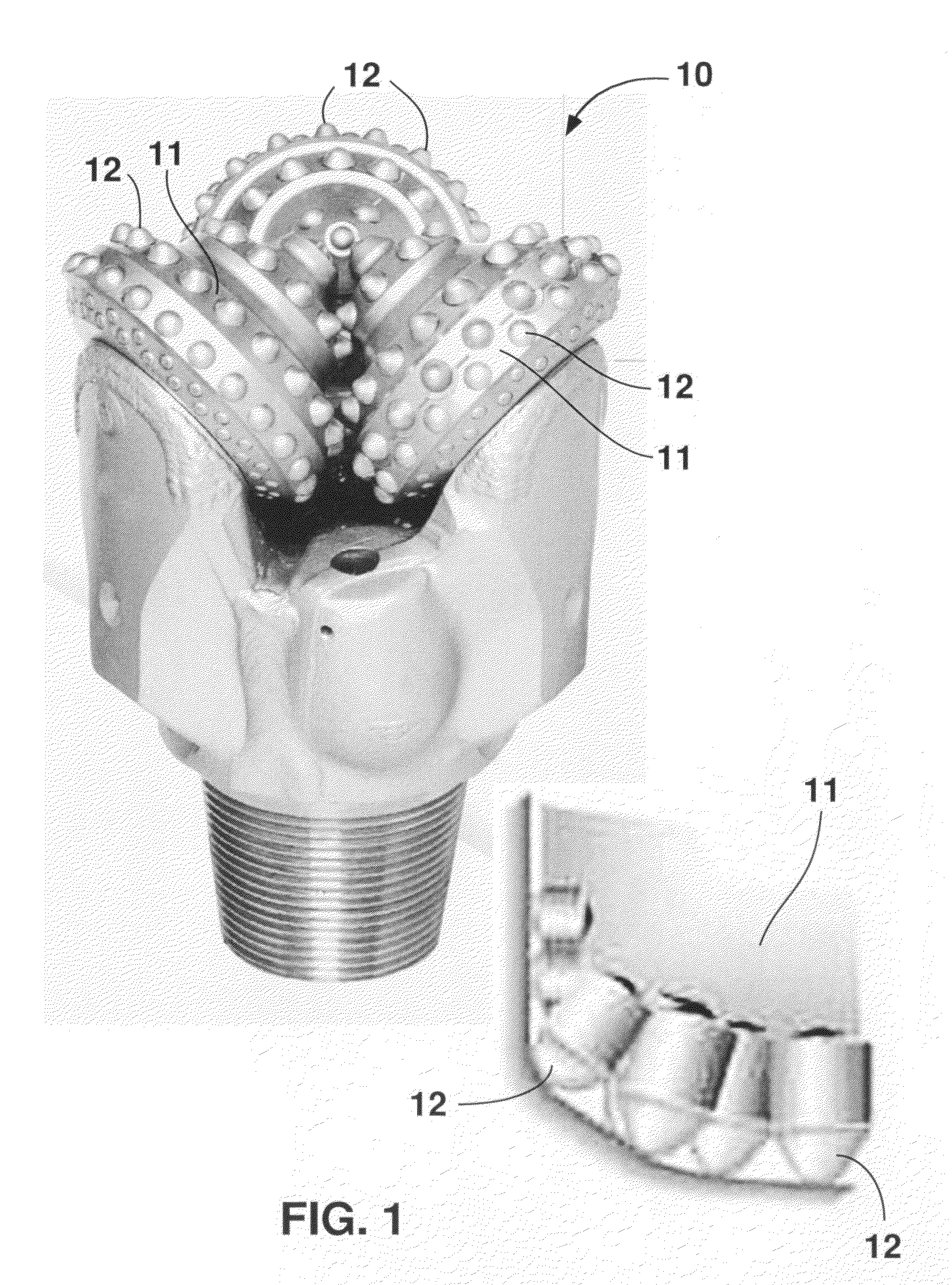

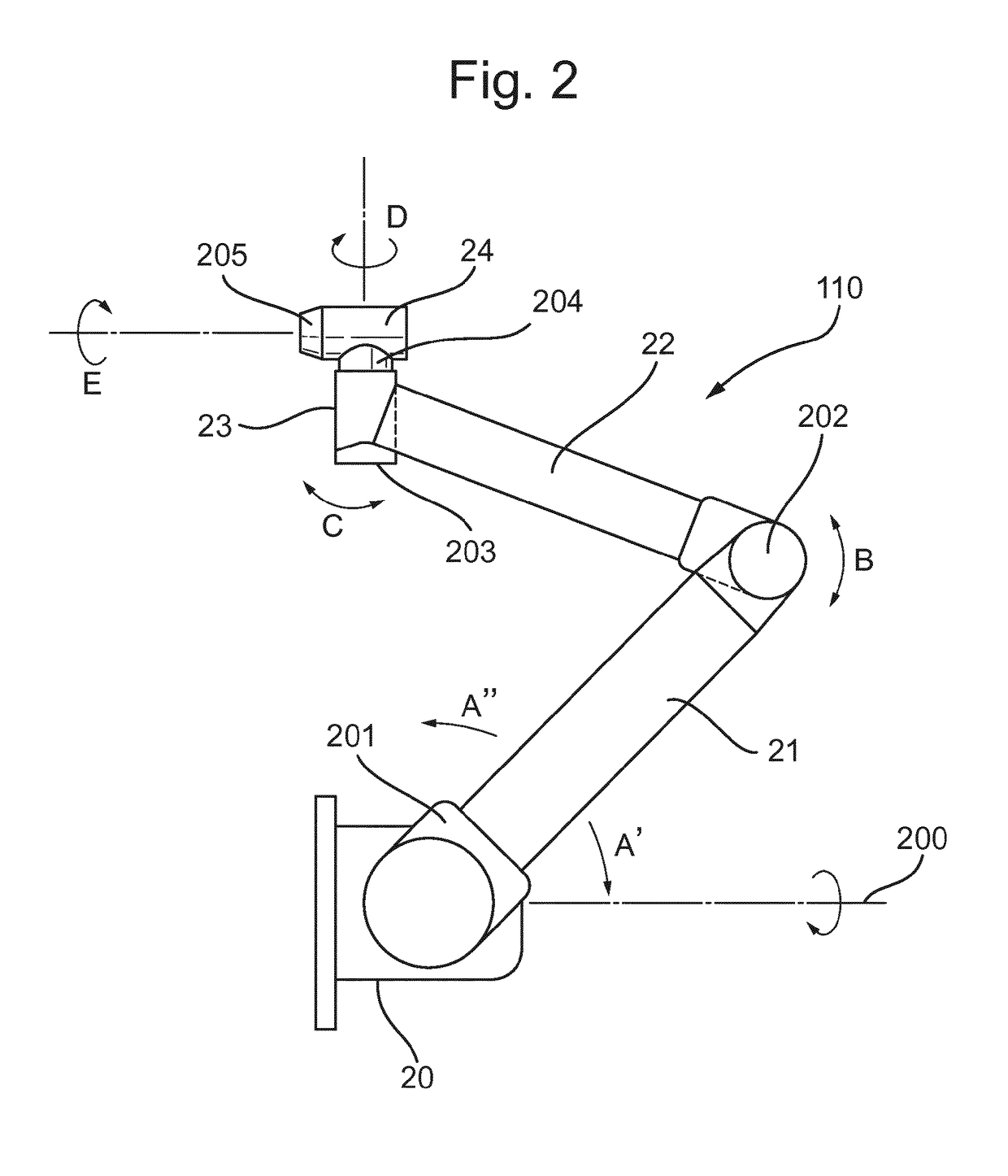

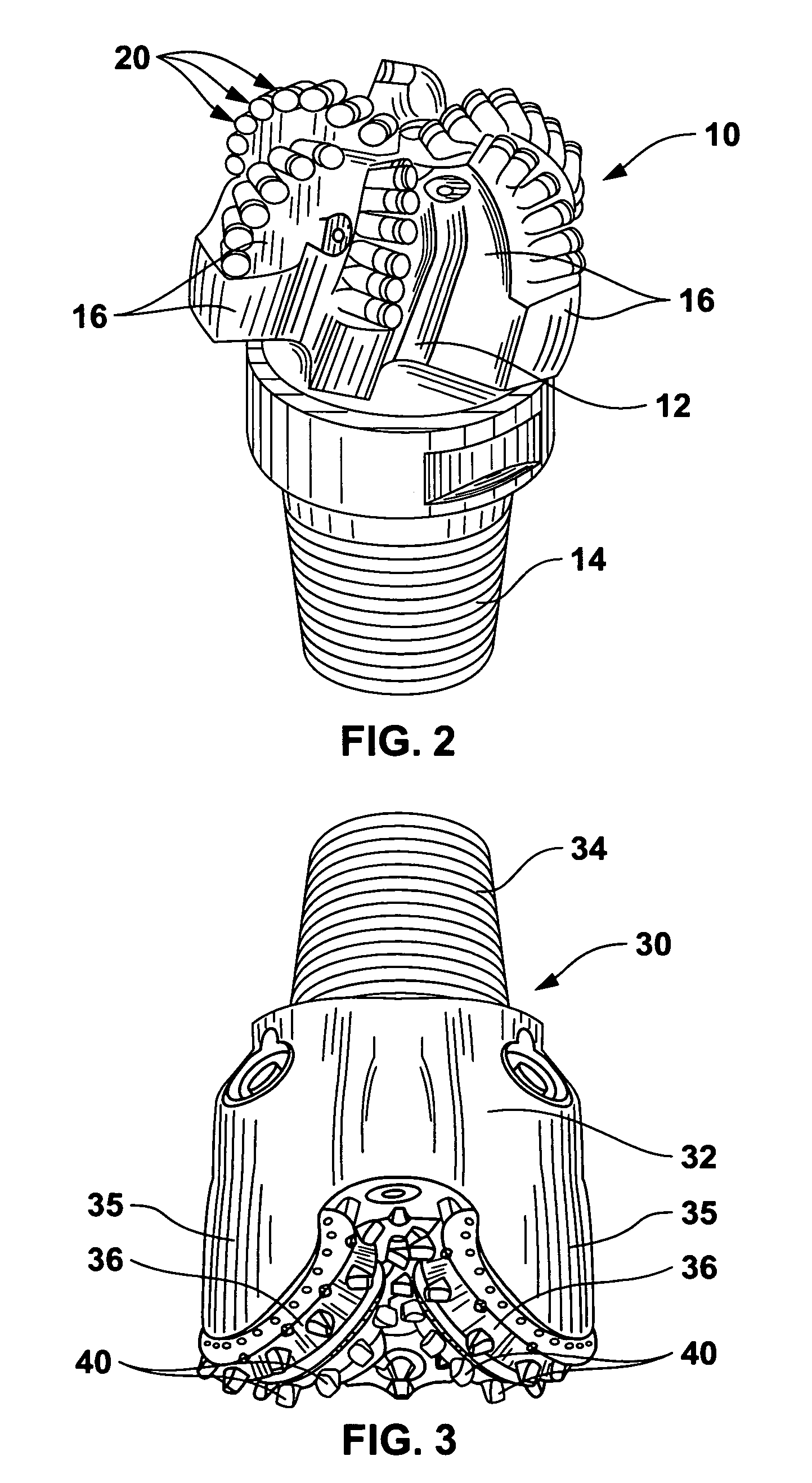

ActiveUS20070039762A1Reducing and preferably eliminating and spalling and chipping typeImproved wear behaviorDrill bitsWorkpiecesLeading edgeMetallurgy

A polycrystalline diamond abrasive cutting element consists generally of a layer of high grade polycrystalline diamond bonded to a cemented carbide substrate. The polycrystalline diamond layer has a working surface and an outer peripheral surface and is characterized by having an annular region or a portion thereof adjacent the peripheral surface that is lean in catalysing material. A region adjacent the working surface is also lean in catalysing material such that in use, as a wear scar develops, both the leading edge and the trailing edge thereof are located in a region lean in catalysing material.

Owner:BAKER HUGHES INC

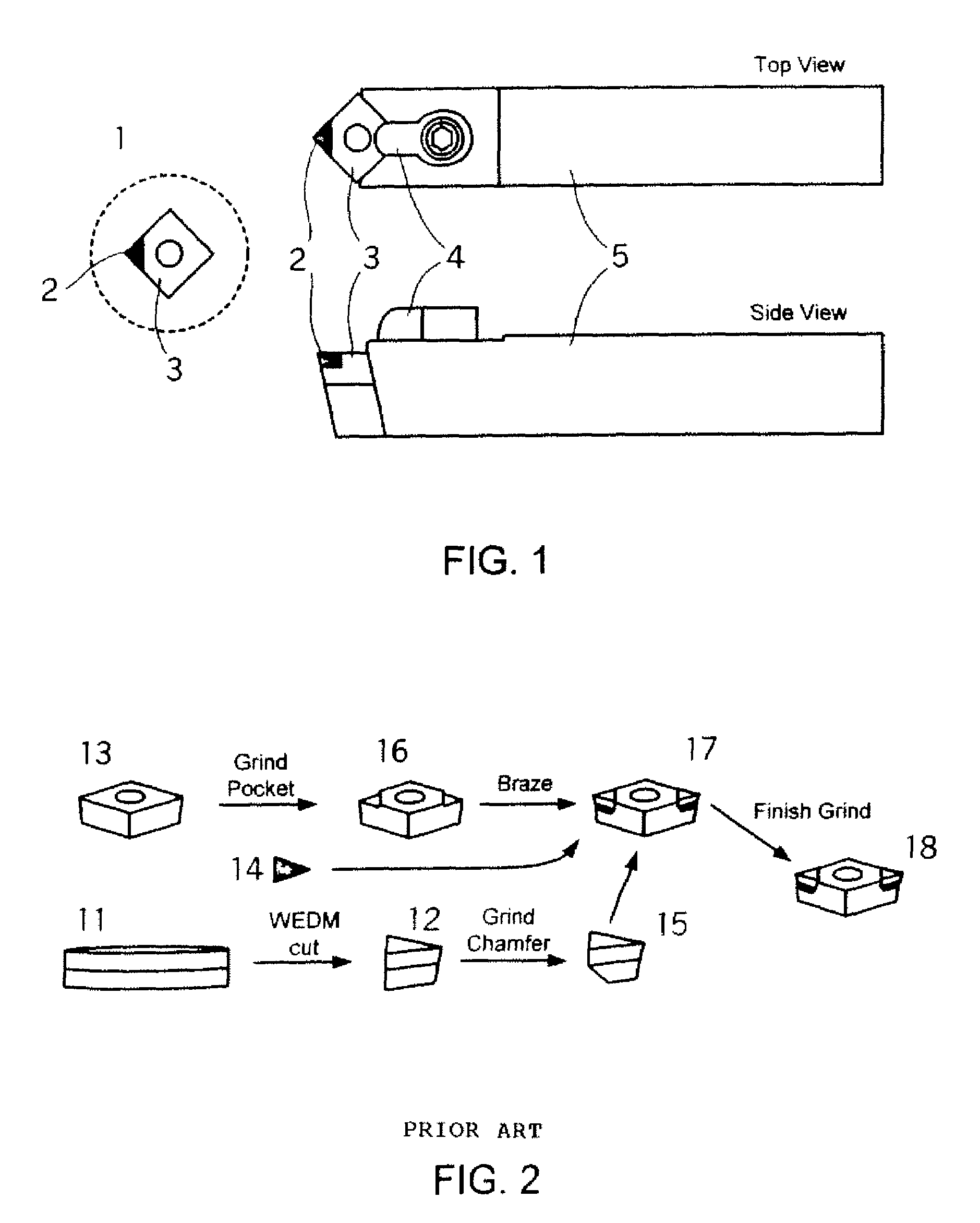

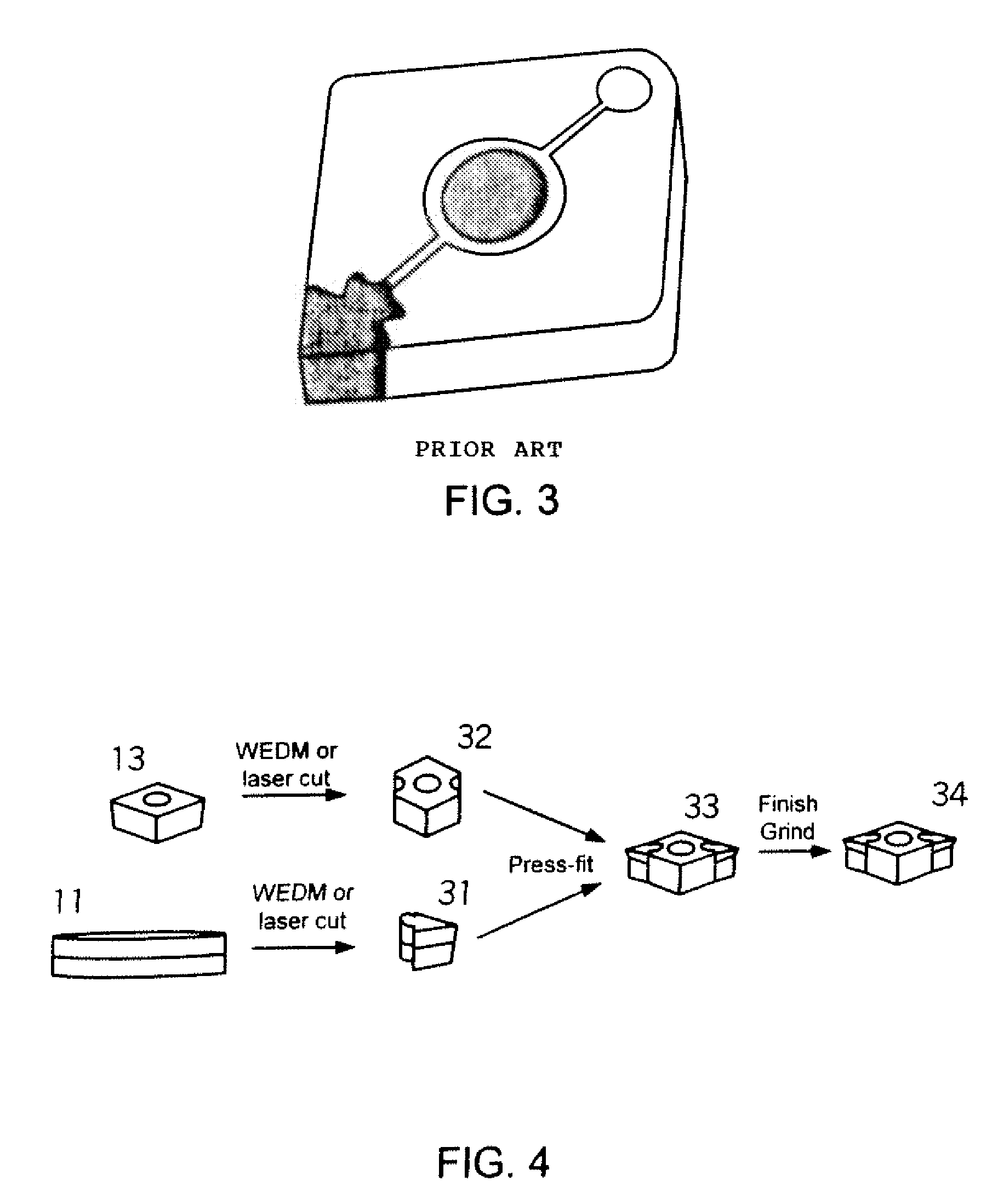

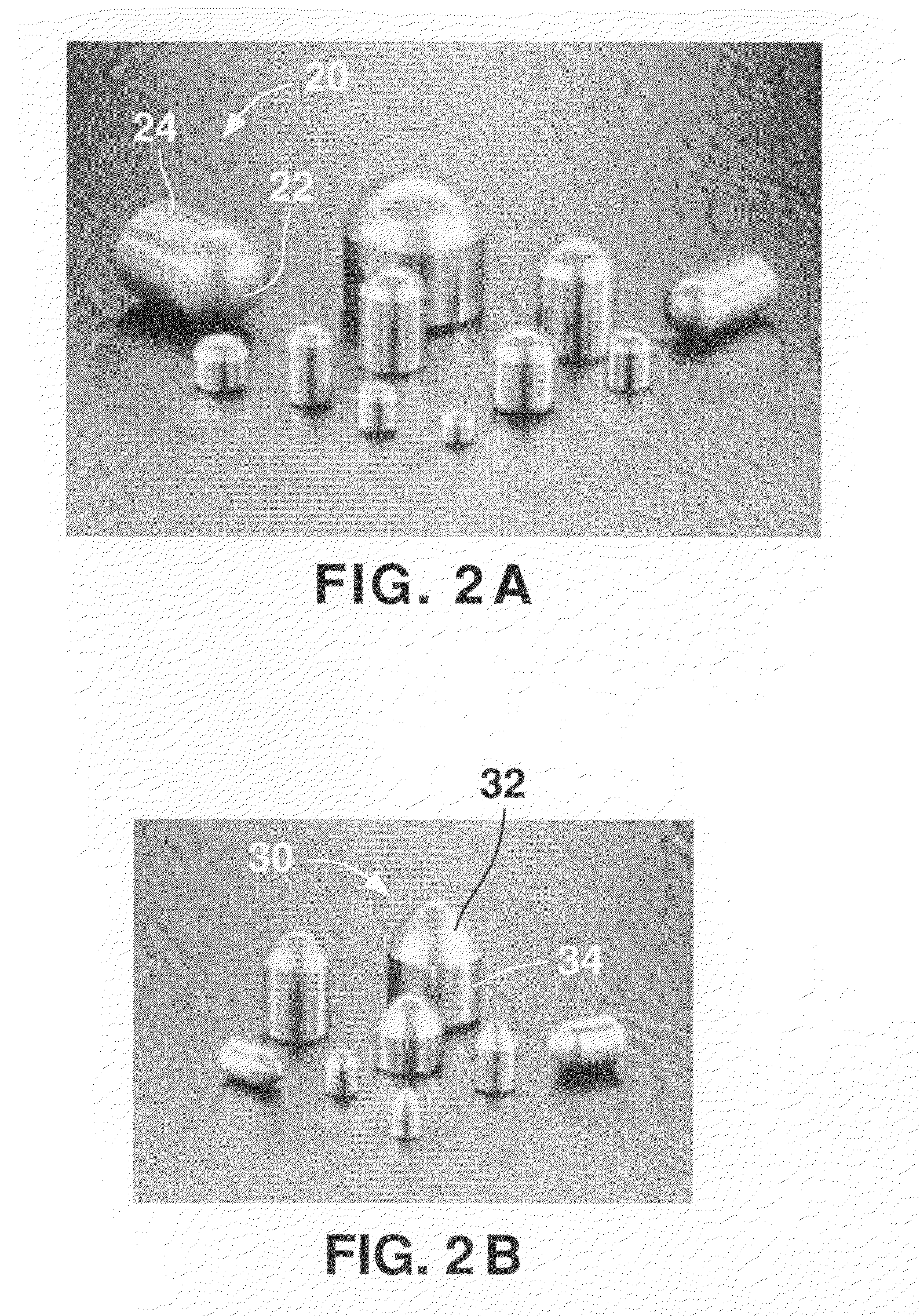

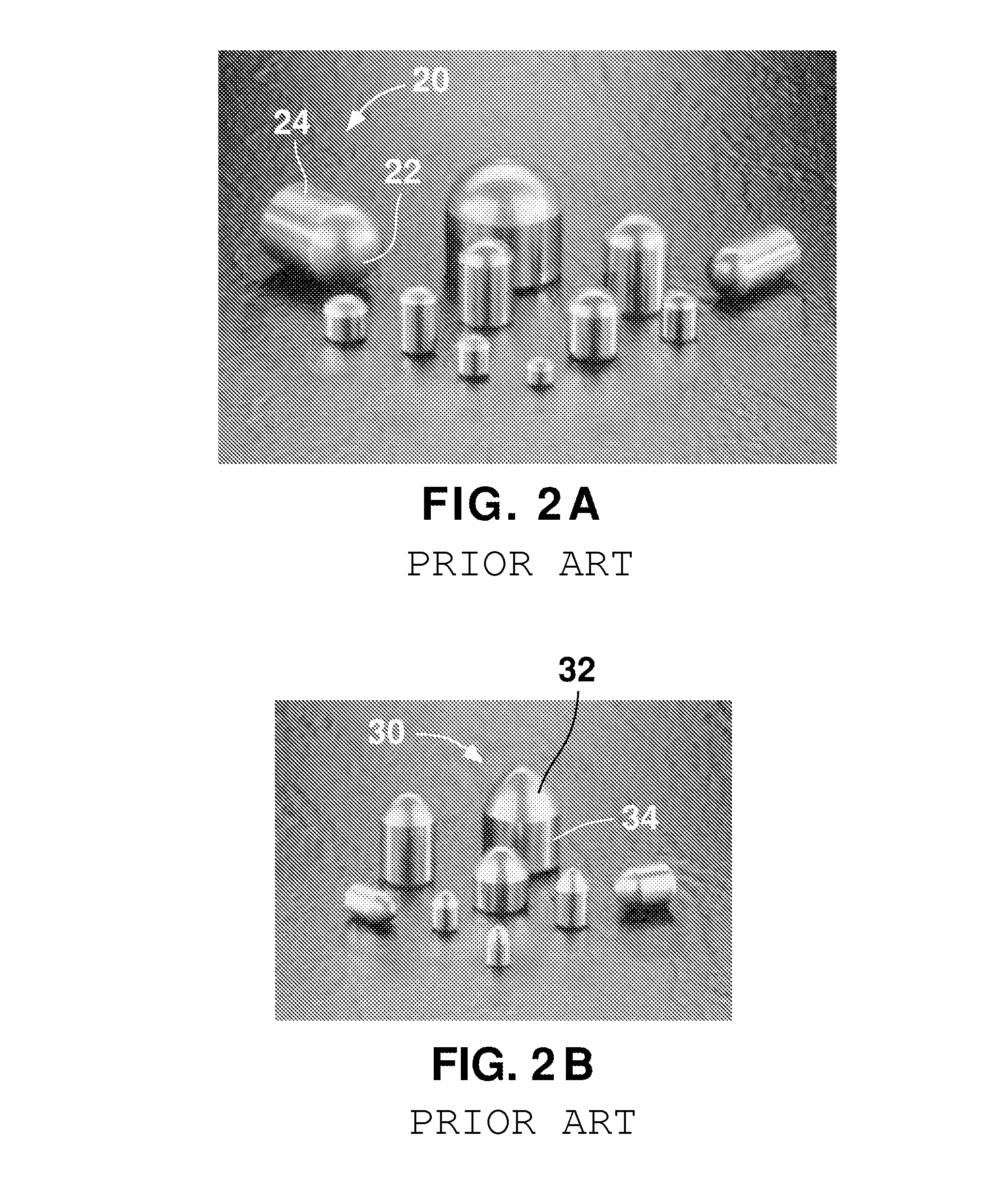

Cutting tool inserts and methods to manufacture

The present invention relates to cutting tool inserts. A cutting tool insert includes an abrasive tip of a hard material, an abrasive or superabrasive material. A cutting tool insert is bonded to an insert body by mechanical force. The mechanical forces are generated through deformation of mating geometric features on the abrasive tip and insert body.

Owner:DIAMOND INNOVATIONS INC

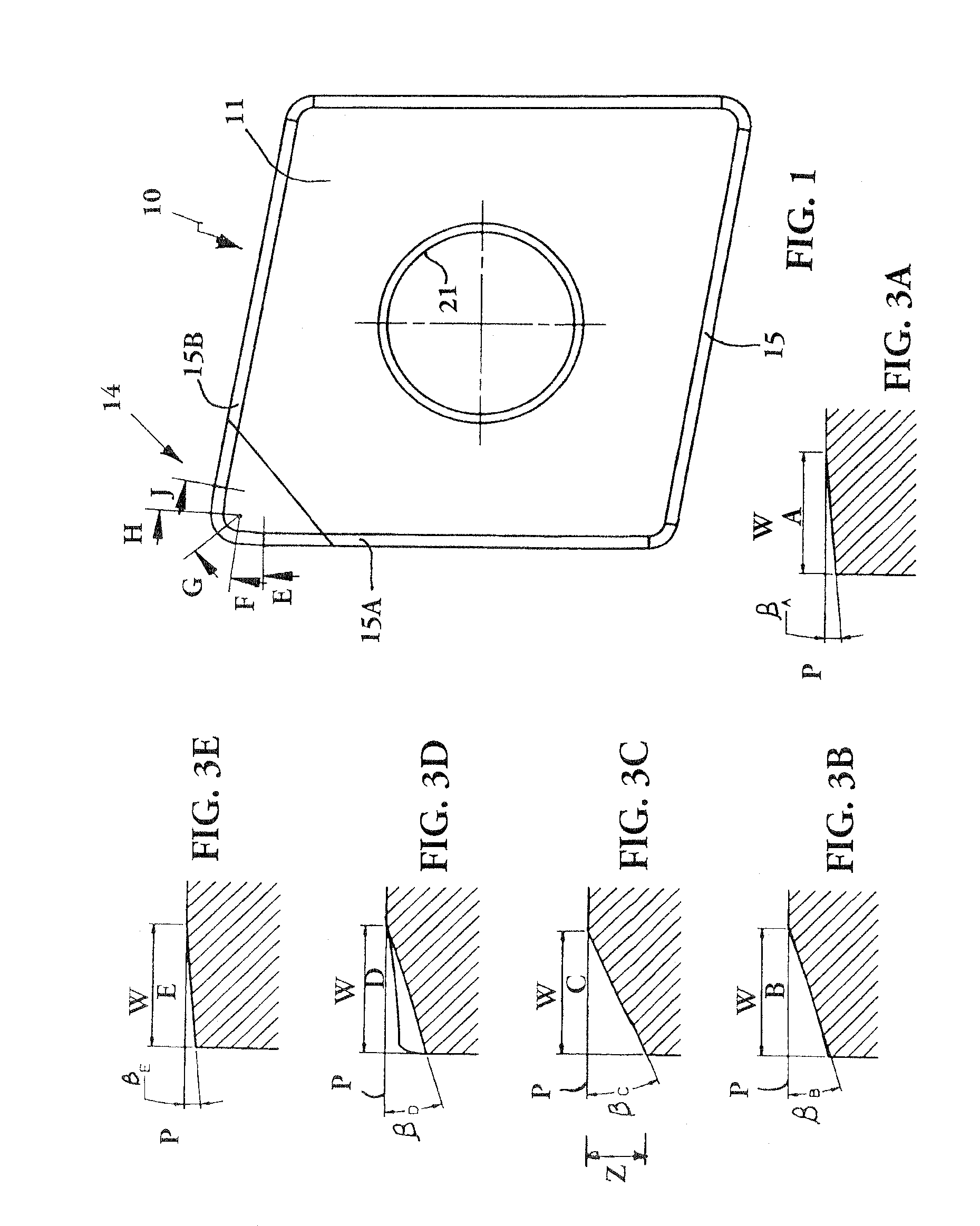

A cutting insert

ActiveUS20060228179A1Improve finenessLittle changeCutting insertsWorkpiecesEngineeringMechanical engineering

The present invention relates to a metal cutting insert that is primarily intended for turning operations. The cutting insert comprises an upper surface, a lower surface substantially parallel with said upper surface, and at least three side surfaces extending between said upper and lower surfaces. A transition between two adjacent side surfaces forms a rounded nose radius surface at a cutting insert corner. The cutting insert includes a peripheral land bridging the upper and side surfaces at least at the corner portion at a chamfer angle. An intersection of the land and the nose radius surface forms a nose cutting edge. The nose cutting edge is defined by at least one radius. The cutting corner includes at least one curved wiper edge. The chamfer angle in a cross-section at the nose cutting edge is larger than the chamfer angle in a cross-section a distance away from the nose cutting edge.

Owner:SECO TOOLS AB

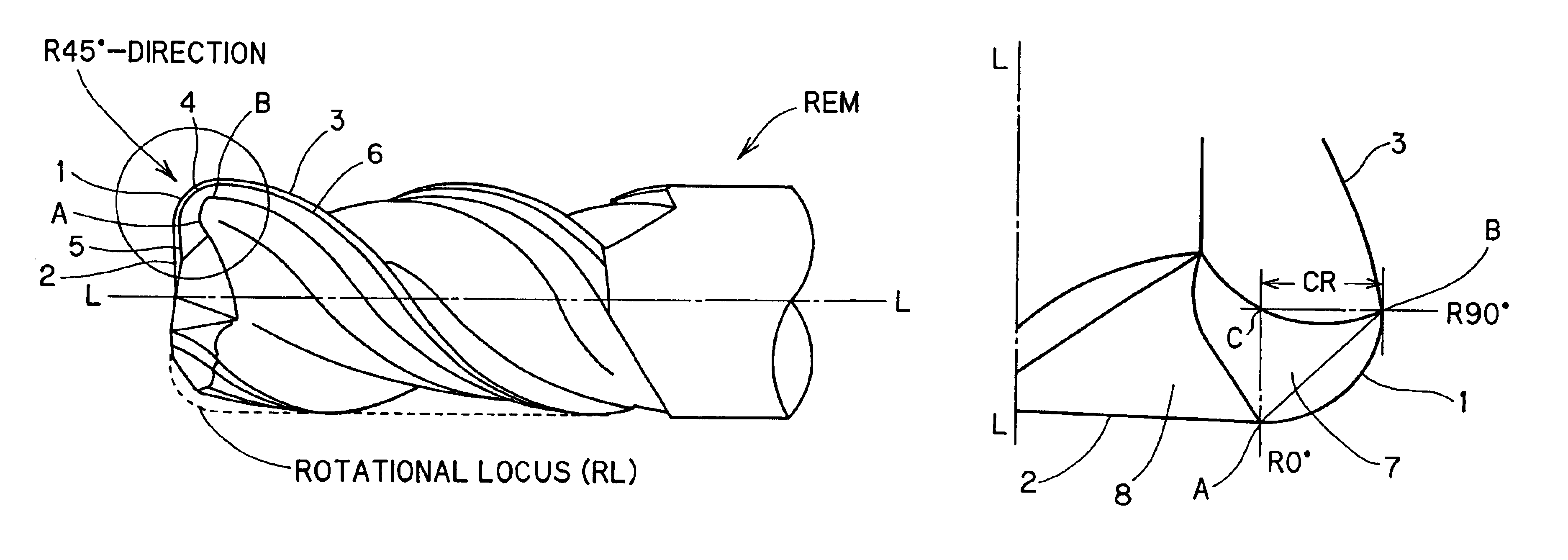

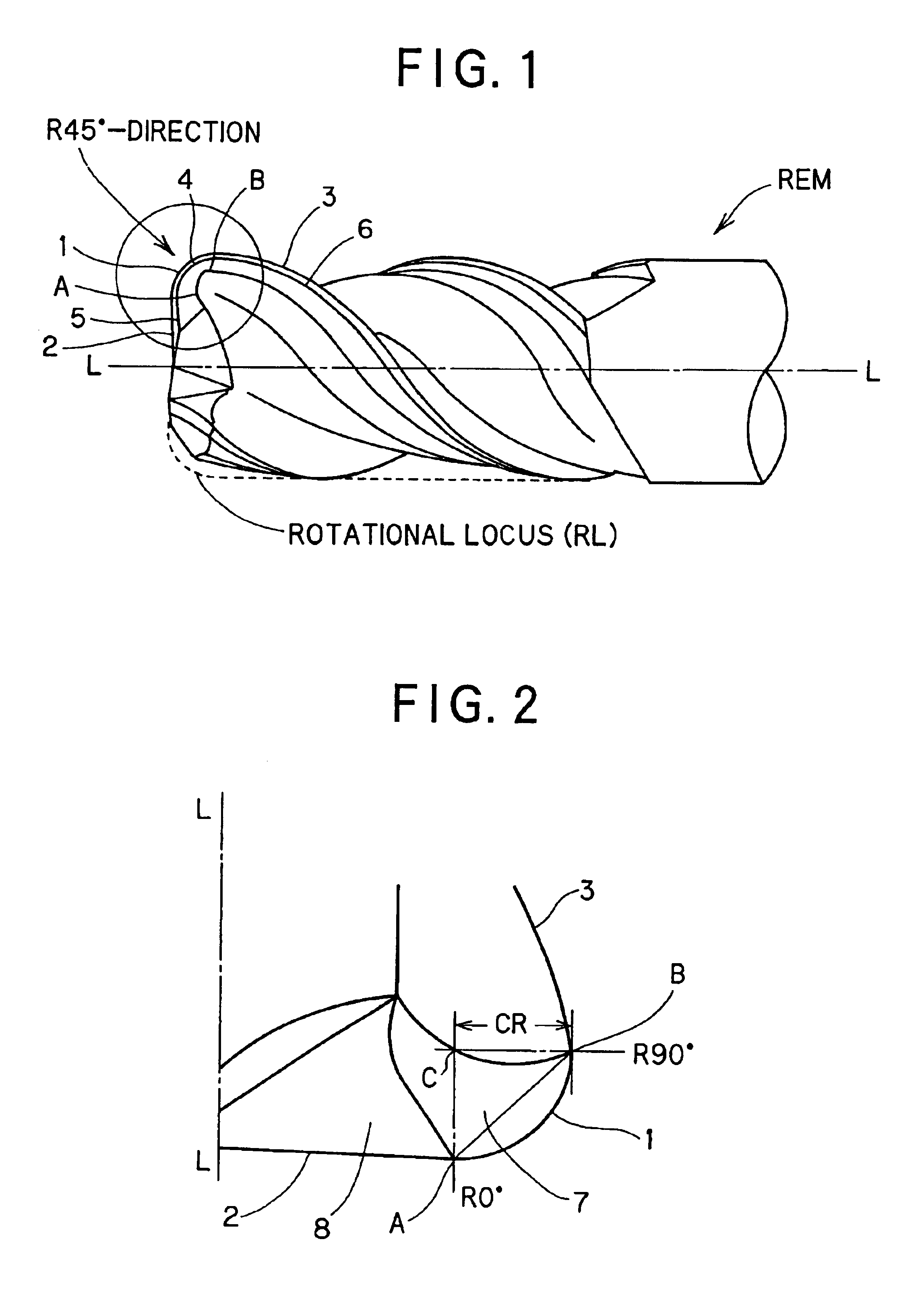

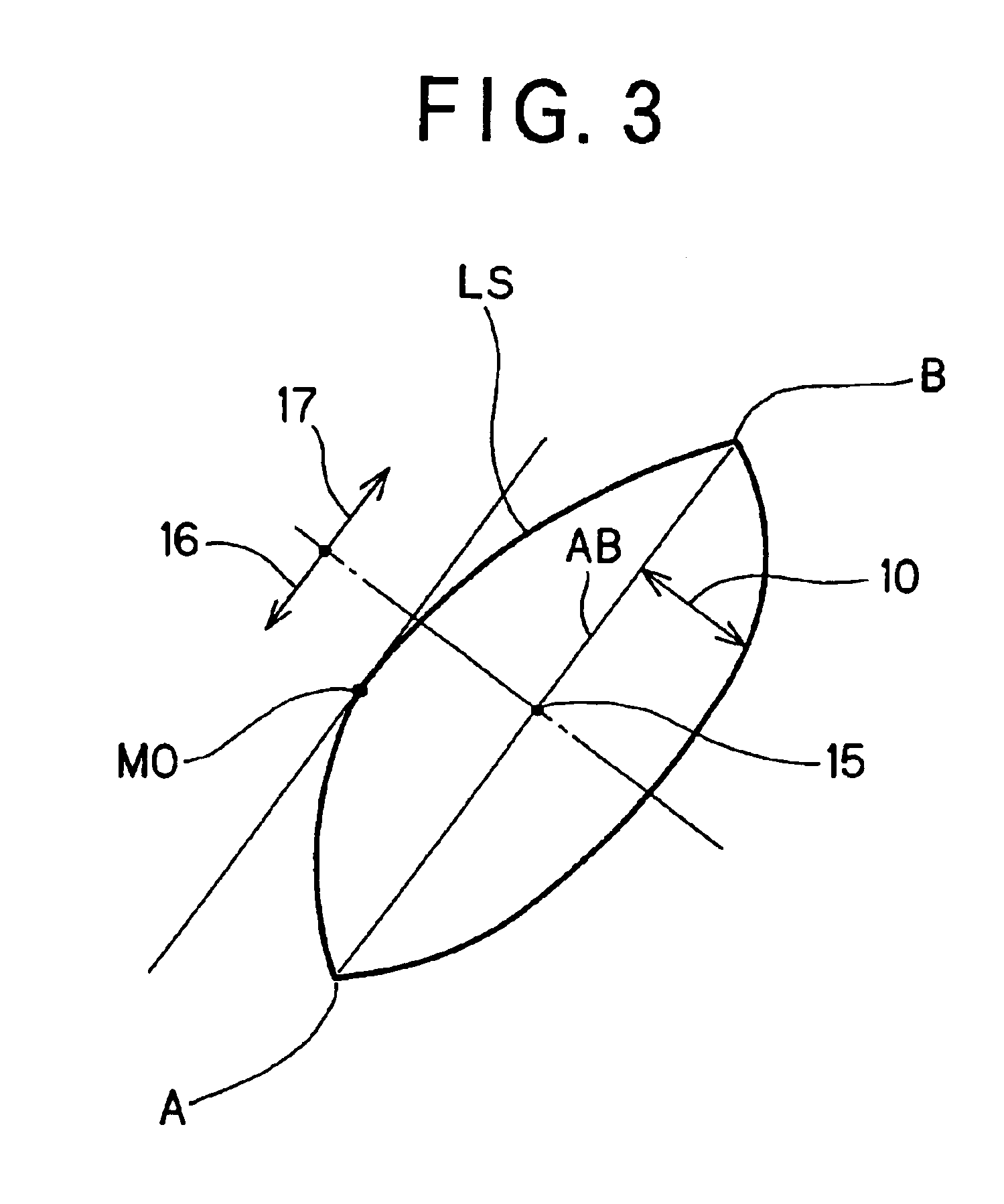

Radius end mill having radius edge enhanced in resistance to chipping and fracture

InactiveUS6846135B2Suppress chipping and fractureHigh-feed cuttingMilling cuttersWorkpiecesEngineeringCurve line

In a radius end mill having a bottom edge formed on the end face thereof, a radius edge designed in a substantially quarter arc shape and formed at a corner portion thereof, and an outer peripheral edge formed spirally on the side surface thereof, the bottom edge and the radius edge being continuously connected to each other at a connecting point A while the radius edge is continuously connected to each other at a connecting point B, when a view taken along a plane that passes through the connecting points A and B and crosses a rake face of the radius edge is represented by an R cross-sectional view, the rake face of the radius edge is designed to have a convex curved line extending from the connecting point A to the connecting point B in the R cross-sectional view.

Owner:HITACHI TOOL ENG LTD

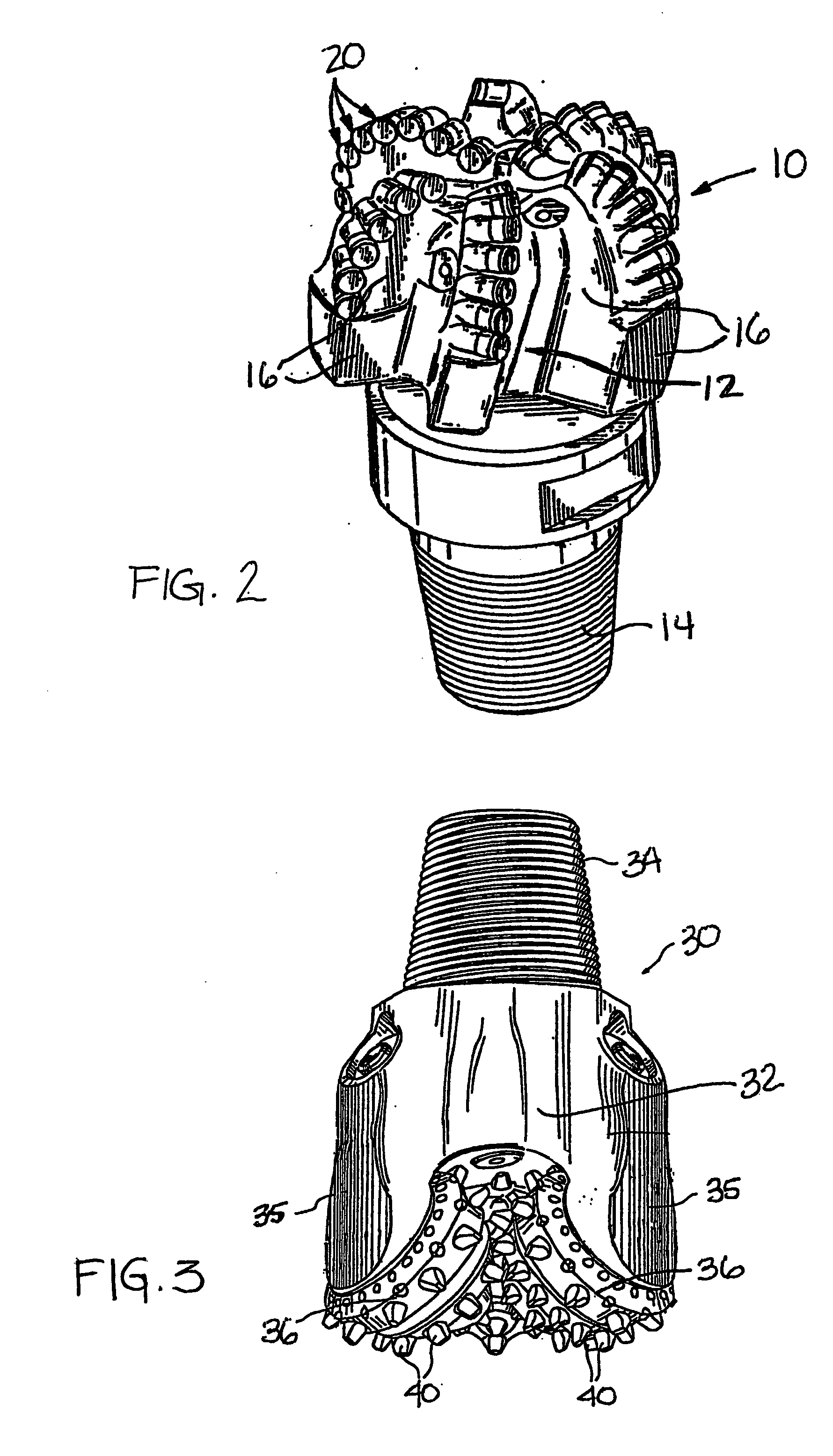

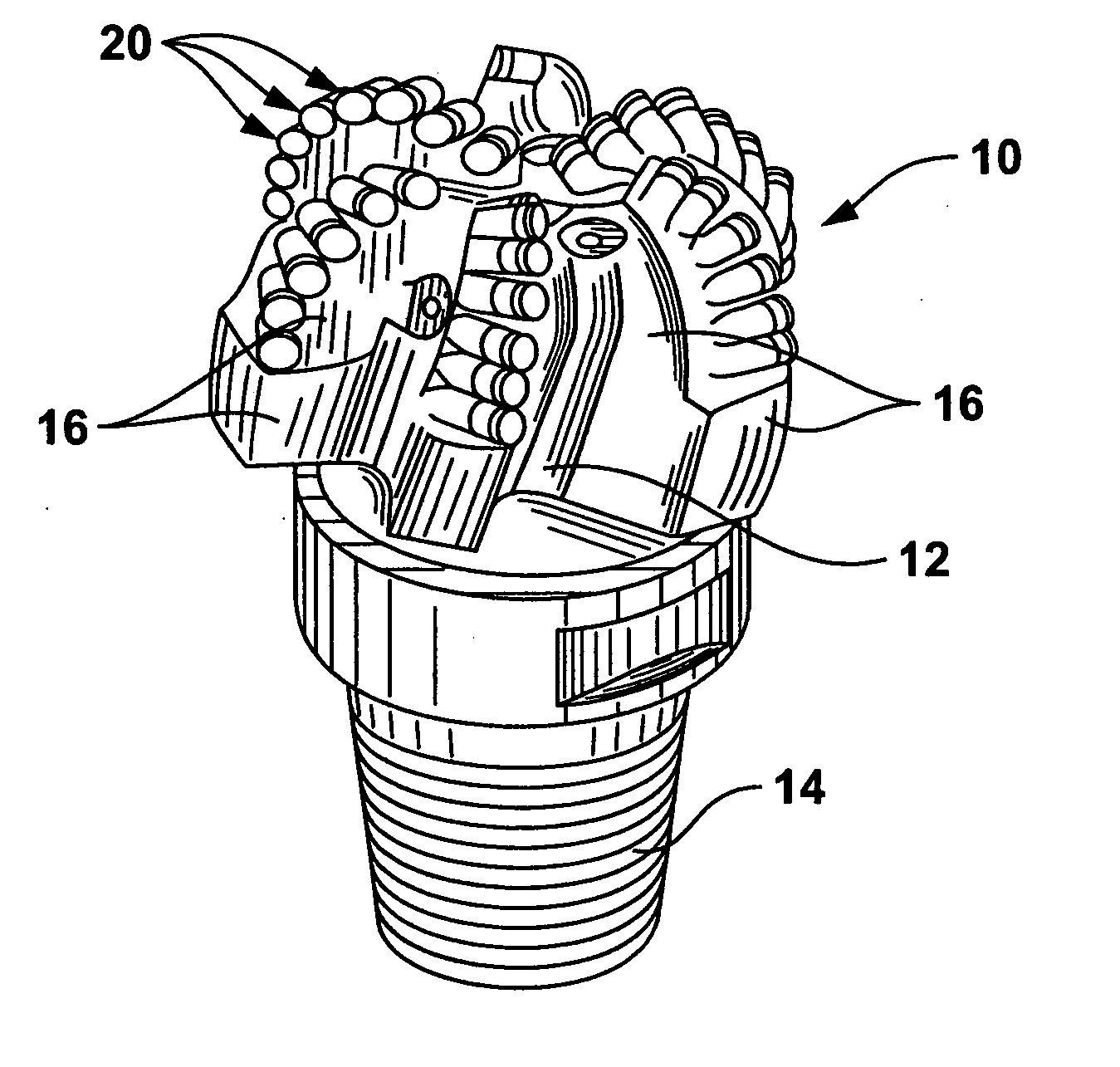

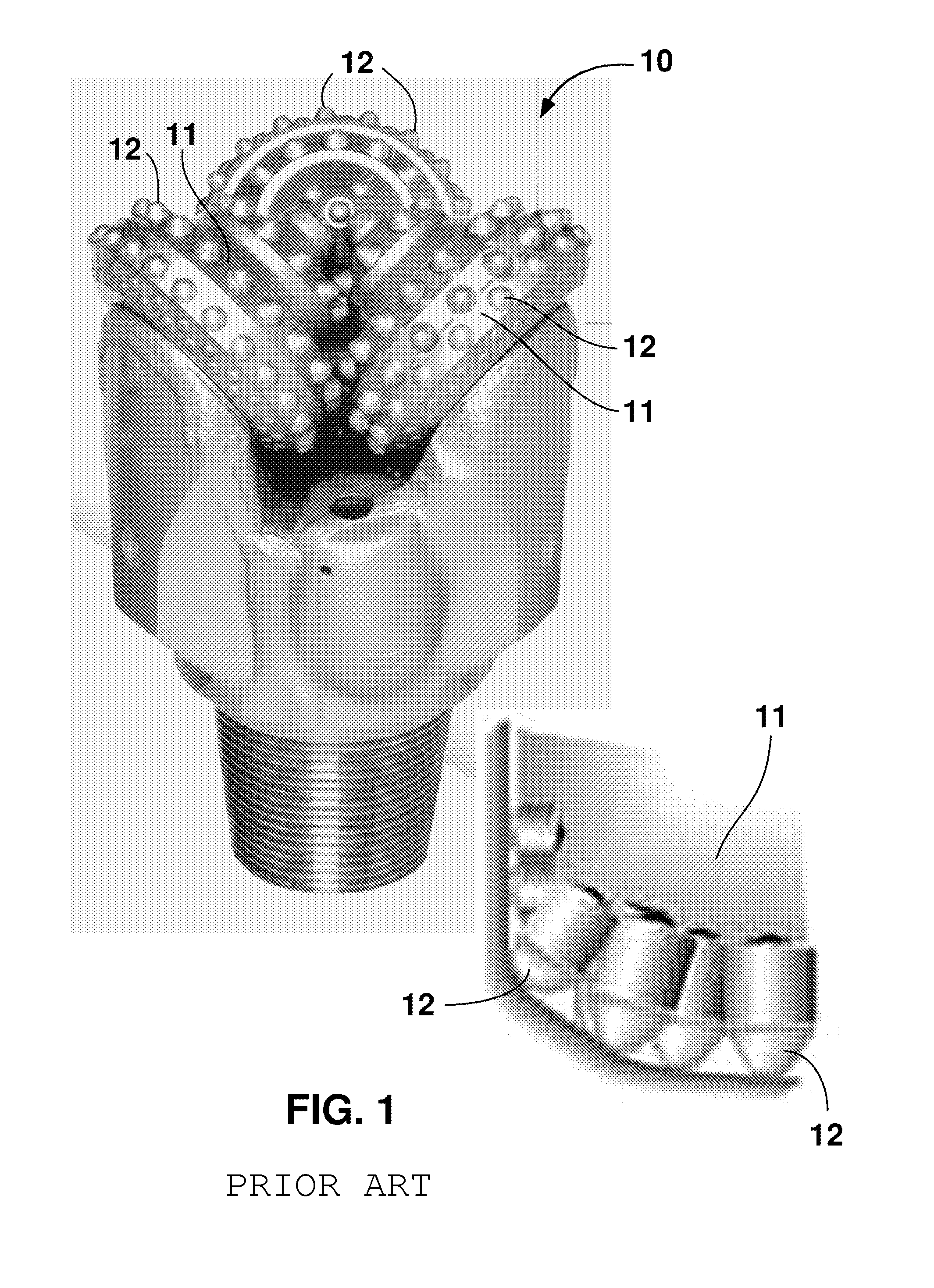

Braze alloy for drilling applications

A down hole cutting tool includes a cutting element support structure. The cutting element support structure has at least one cavity formed therein. A cutting element is disposed in the cavity. Braze alloy is also disposed in the cavity between the cutting element and the cutting element support structure. The braze alloy comprises between about 0.5% and about 10% by weight of at least one selected from the group of gallium (Ga), indium (In), thallium (Tl). Methods for building a down hole tool using the braze alloy are also disclosed.

Owner:SMITH INT INC +1

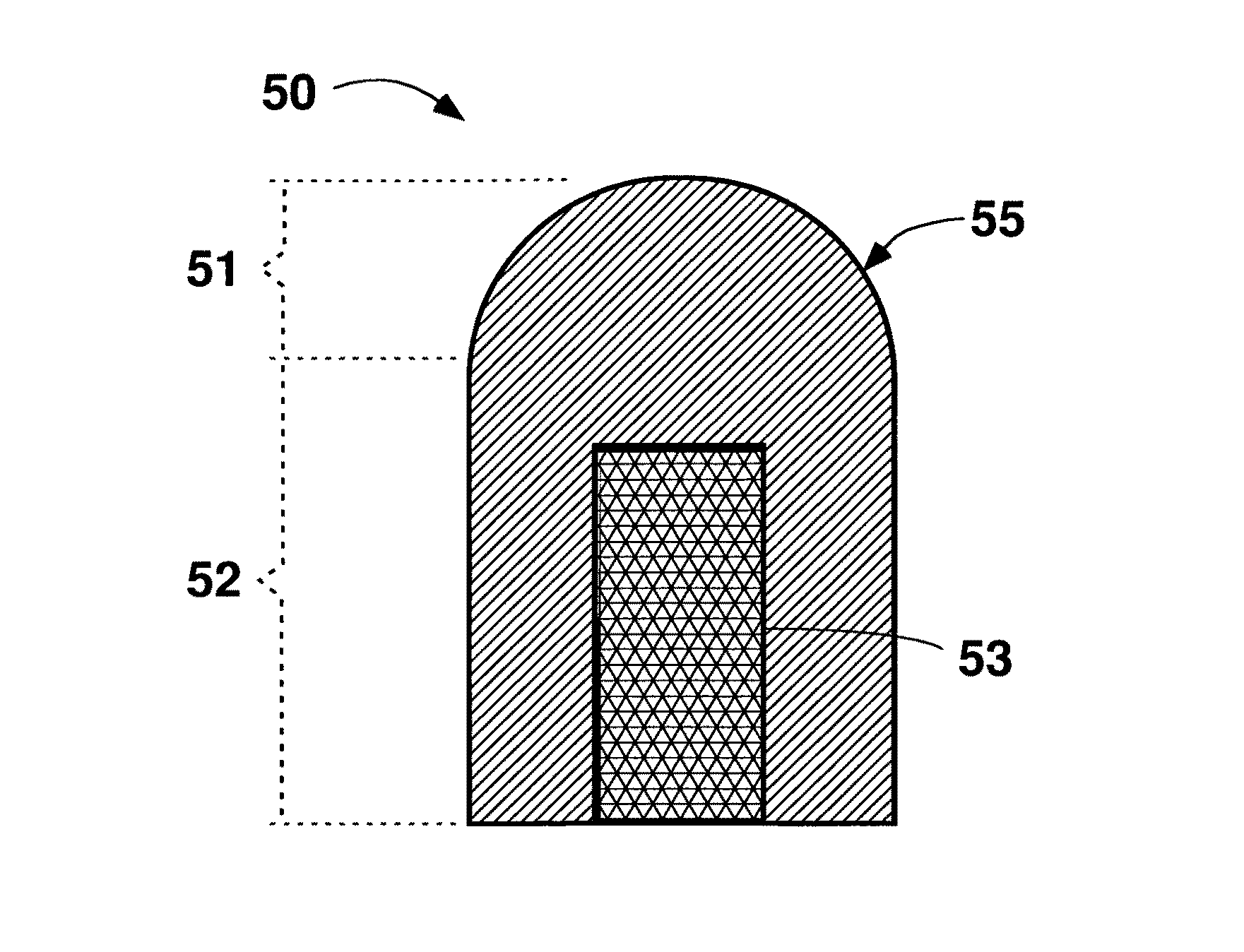

Articles Having Improved Resistance to Thermal Cracking

An article includes a working portion including cemented carbide, and a heat sink portion in thermal communication with the working portion. The heat sink portion includes a heat sink material having a thermal conductivity greater than a thermal conductivity of the cemented carbide. Also disclosed are methods of making an article including a working portion comprising cemented carbide, and a heat sink portion in thermal communication with the working portion and including a heat sink material having a thermal conductivity that is greater than a thermal conductivity of the cemented carbide. The heat sink portion conducts heat from the working portion.

Owner:KENNAMETAL INC

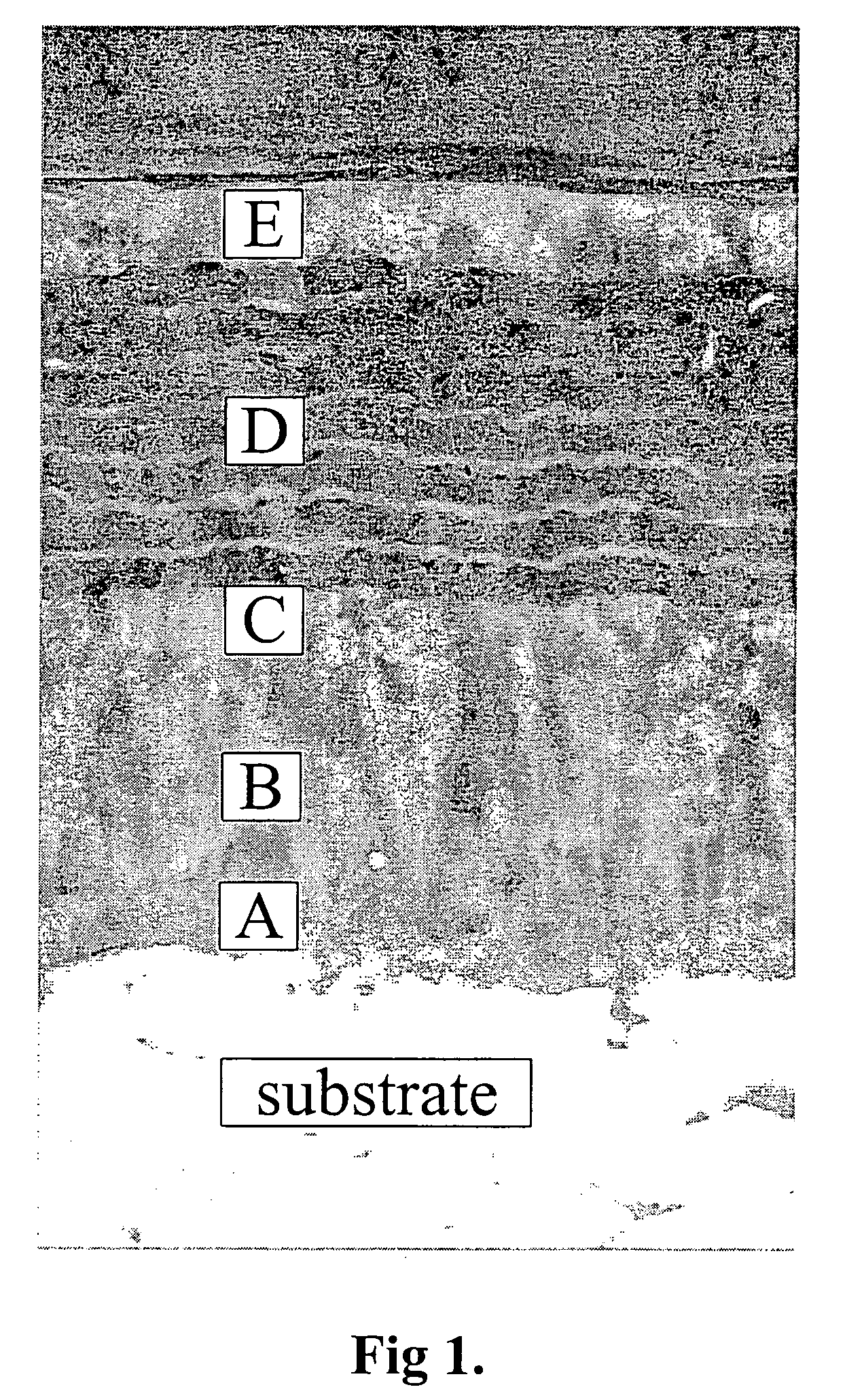

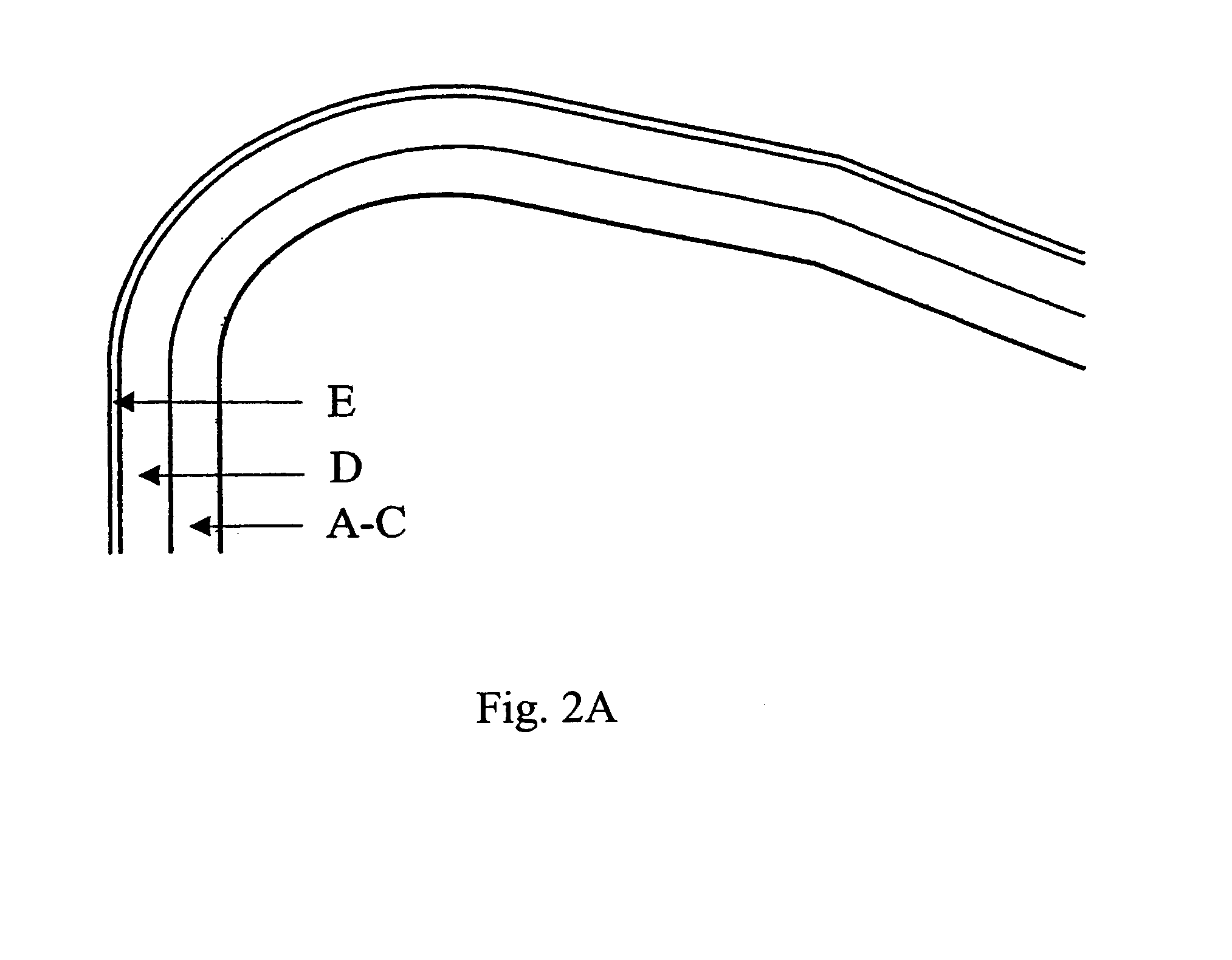

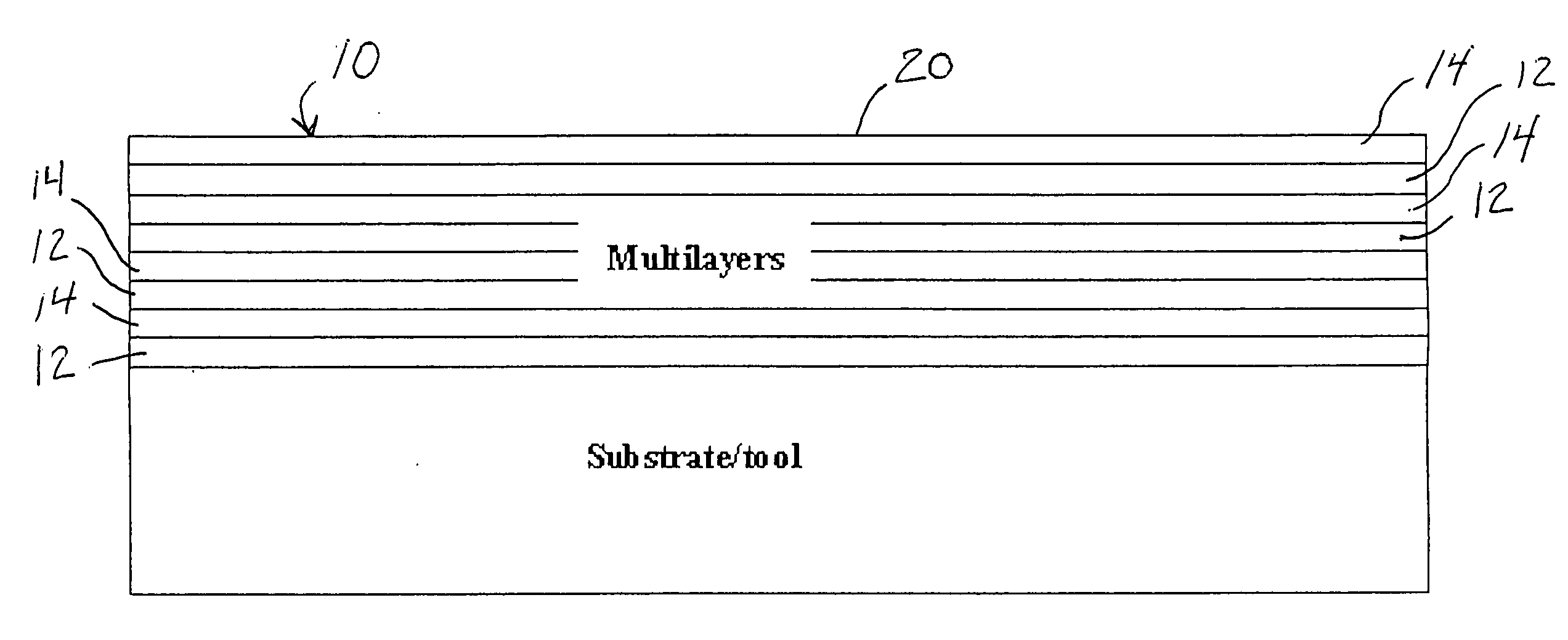

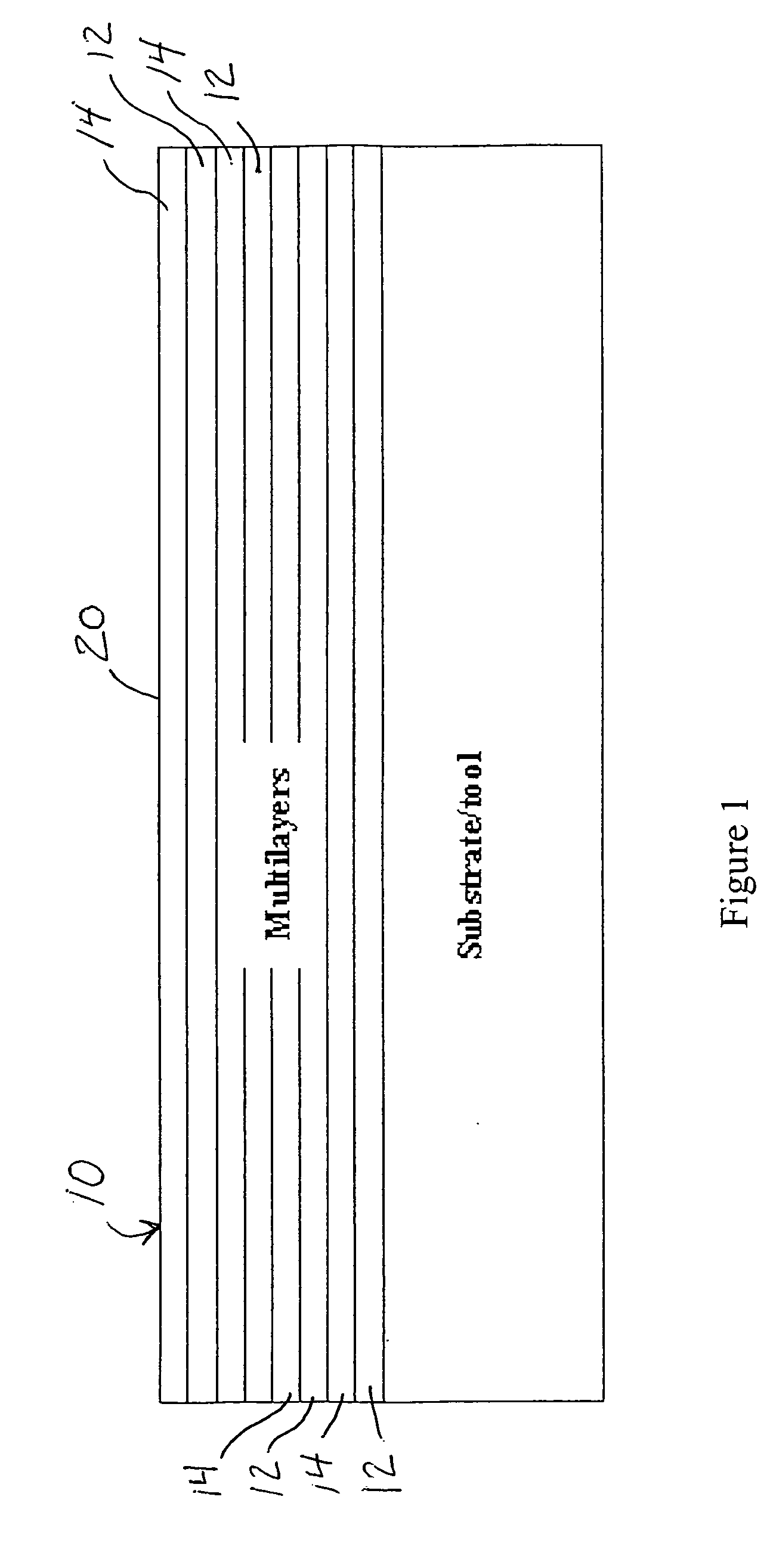

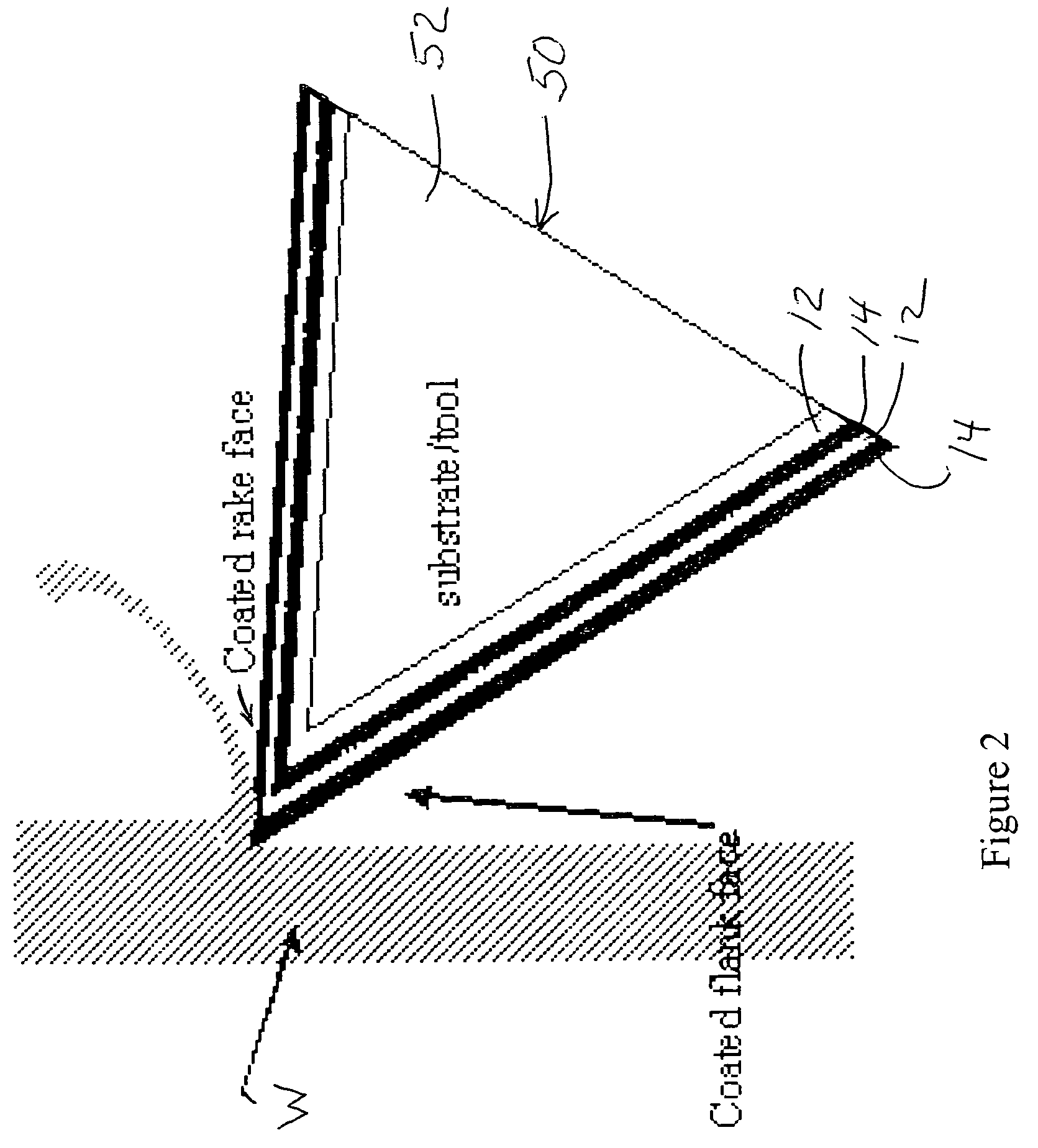

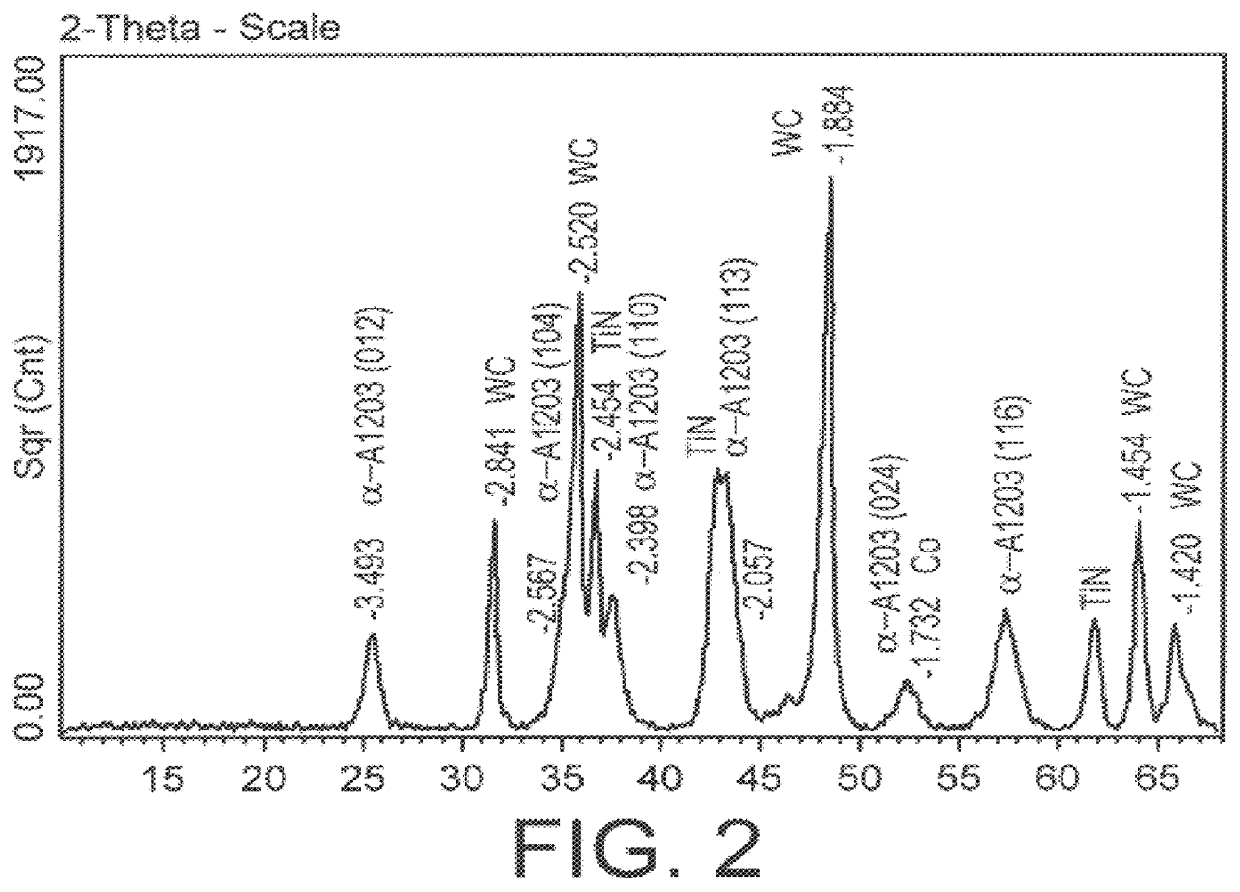

Coated cemented carbide insert

ActiveUS7153562B2Eliminate deficienciesImprove performancePigmenting treatmentCutting insertsAlloyCemented carbide

The present invention relates to a cutting tool insert particularly for turning of steel comprising a cemented carbide body, a coating with a post treatment witha first, innermost layer system of one or several layers of TiCxNyOz with x+y+z≦1 with a total thickness of 0.7–4.5 μma second multilayer system consisting of a totally 5–31 alternating Al2O3 and TiCxNyOz (x+y+z≦1), preferably κ-Al2O3 and TiN, the Al2O3-layers having an individual layer thickness of <0.5 μm and the TiCxNyOz-layers 0.01–0.2 μm with a total thickness of the multilayer of 1.0–4.0 μm. The multilayer is exposed along the edge line and into the rake and flank face, at least 0.02 mm, from the edge line on the rake face, preferably the contact length of the chip at most 0.9 mm, and 0.02–0.20 mm on the flank face.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

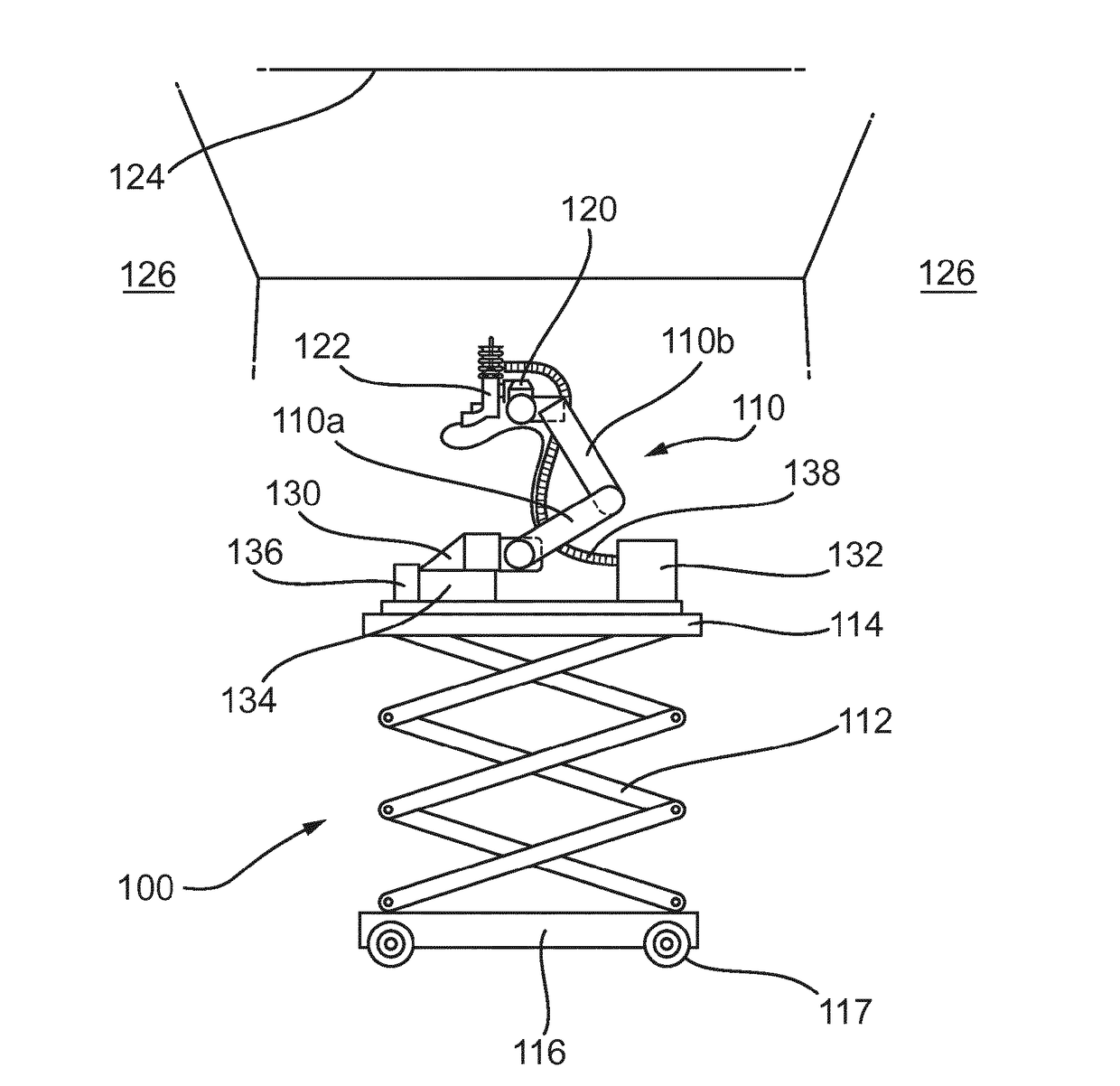

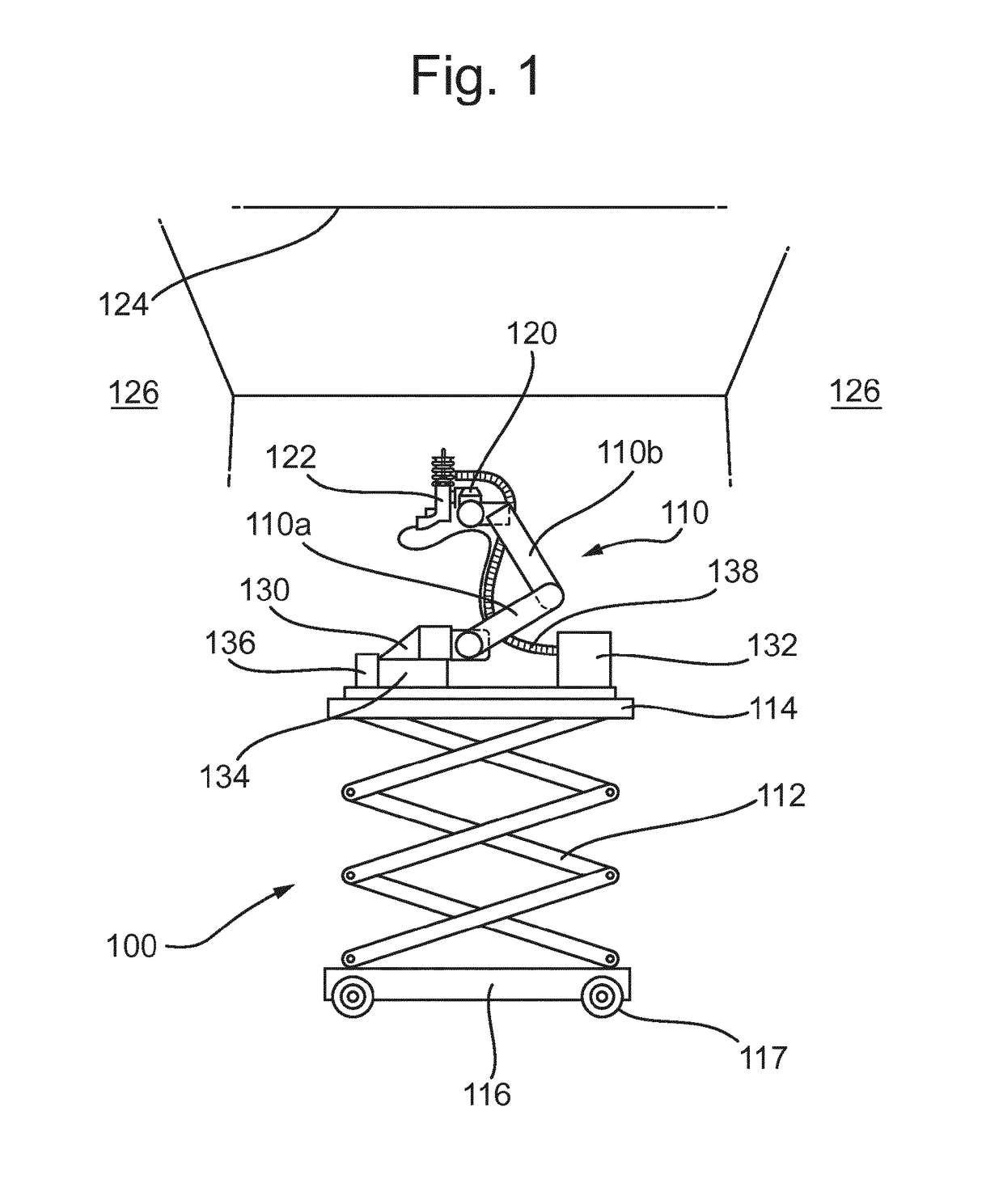

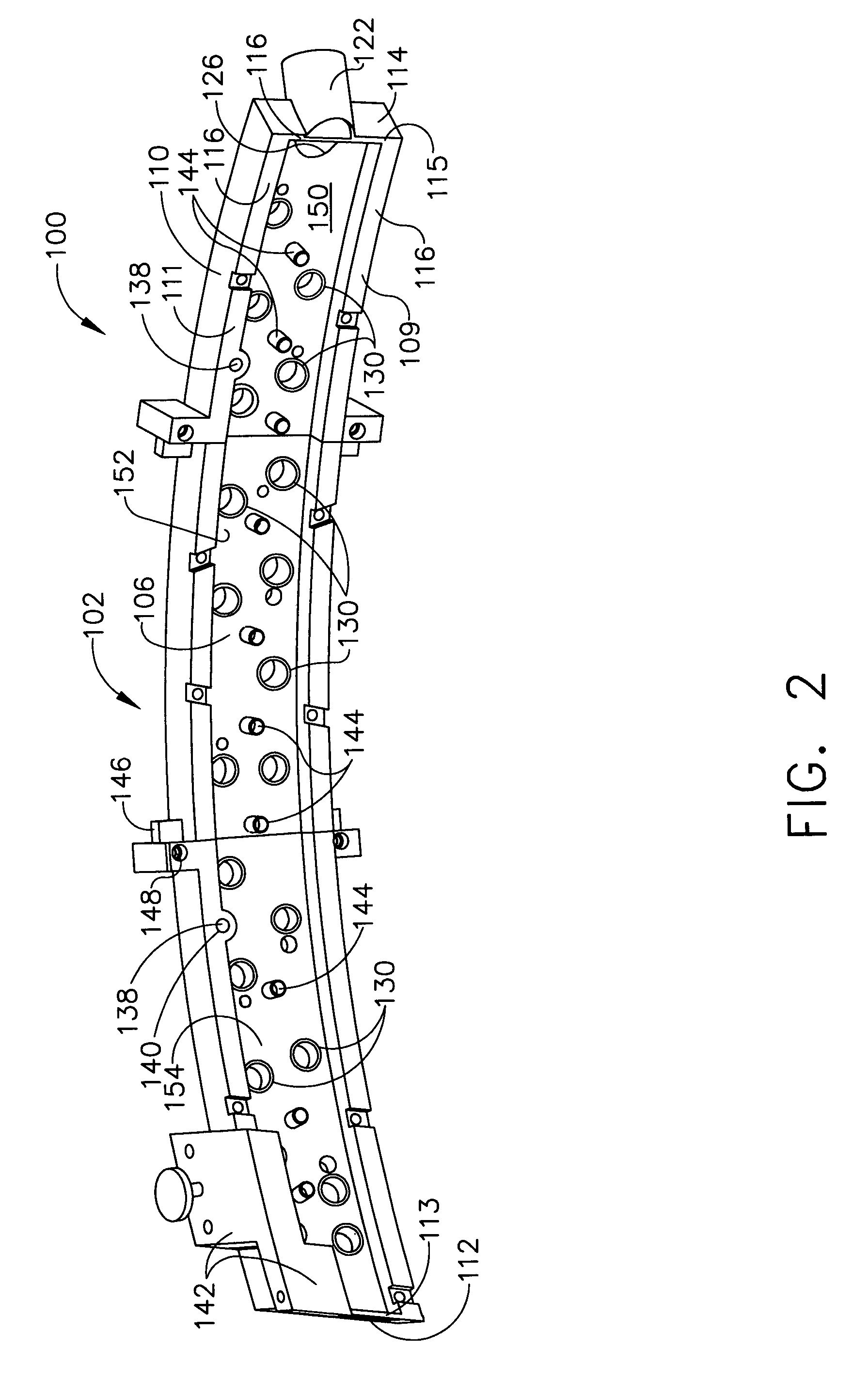

Mobile robotic drilling apparatus and method for drilling ceilings and walls

PendingUS20180326507A1Precise drillingDelay in reachingProgramme-controlled manipulatorWorkpiecesThree-dimensional spaceRobotic arm

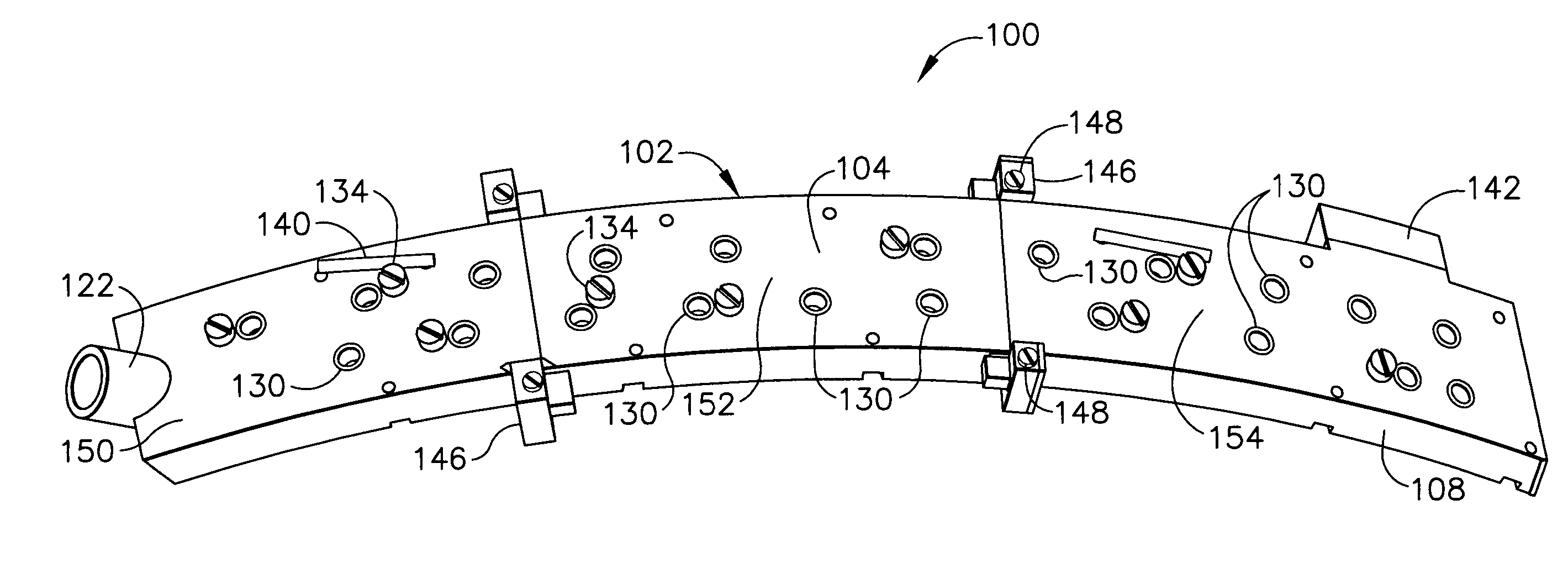

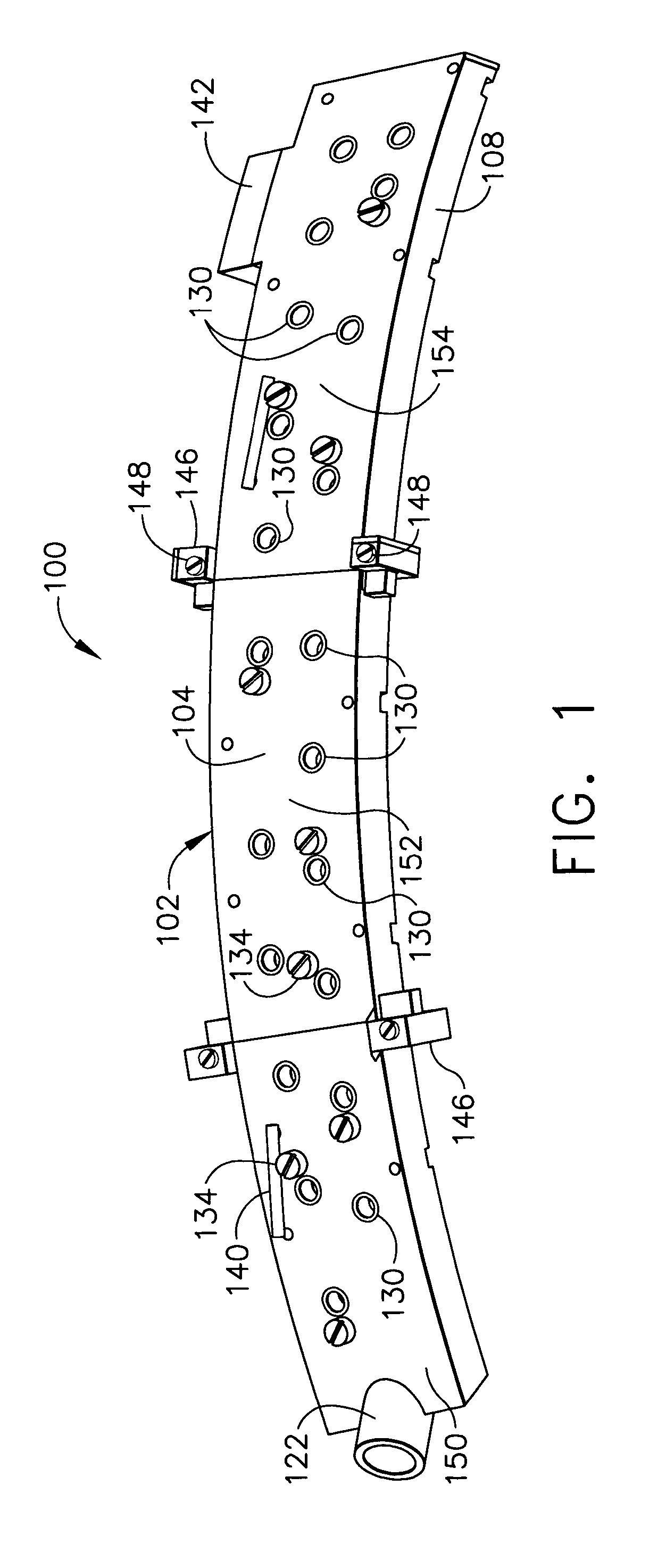

A robotic drilling apparatus is described which has been adapted for drilling holes in ceilings and walls on a construction site. The apparatus (100) comprises a robotic arm (110) mounted to a substructure (112), the substructure comprising a lifting mechanism arranged to lift the robotic arm to a working position, wherein the robotic arm has a base end (110a) and a movable end (110b), the base end being mounted to an upper surface (114) of the lifting mechanism and the movable end being capable of movement with respect to the base end in a three dimensional space, wherein the robotic drilling apparatus further comprises a mount (120) provided on the movable end for holding a drilling device (122) and a control unit (134) for controlling the operation of the robotic arm. The lifting mechanism preferably comprises a scissor-jack lifting platform. The robotic arm (110) and any support structure (134) for the robotic arm weighs less than 43 kg, and preferably individually weigh less than 23 kg.

Owner:HILTI CORPOARATION

Braze alloy

A braze alloy is described which includes indium and / or thallium as alloying elements. For example, between about 0.5% and about 10% by weight of indium (In) and / or thallium (Tl) can be added to a braze alloy to reduce the braze temperature without substantially effecting braze strength. Braze alloys that are alloyed to including indium (In) and / or thallium (Tl) can be use in brazing cutting elements to drilling tools. These alloying elements may also be added to braze alloys used for other applications to reduce braze temperature.

Owner:KEMBAIYAN KUMAR T

Drill template with integral vacuum attach

A drill template includes a vacuum housing with a skirt having a CAD-formed contact surface formed to an exact fit with a mold line surface of a structure. The drill template includes at least one drill guide bushing extending through the vacuum housing from a top surface to an interior surface of the vacuum housing; a vacuum port integral to the vacuum housing; and at least one index hole for positioning and aligning the vacuum housing on the structure. Index holes extend from the top surface through to the CAD-formed contact surface of the vacuum housing. A CAD-formed edge of part locator is formed according to a CAD solid model of the aircraft fuselage and fits to a precise location of the structure for precisely positioning the template on the structure. A vacuum port provides vacuum to the interior of the vacuum housing for removing drilling debris and dust.

Owner:THE BOEING CO

Braze alloy and method of use for drilling applications

A down hole cutting tool includes a cutting element support structure. The cutting element support structure has at least one cavity formed therein. A cutting element is disposed in the cavity. Braze alloy is also disposed in the cavity between the cutting element and the cutting element support structure. The braze alloy comprises between about 0.5% and about 10% by weight of at least one selected from the group of gallium (Ga), indium (In), thallium (Tl). Methods for building a down hole tool using the braze alloy are also disclosed.

Owner:SMITH INT INC +1

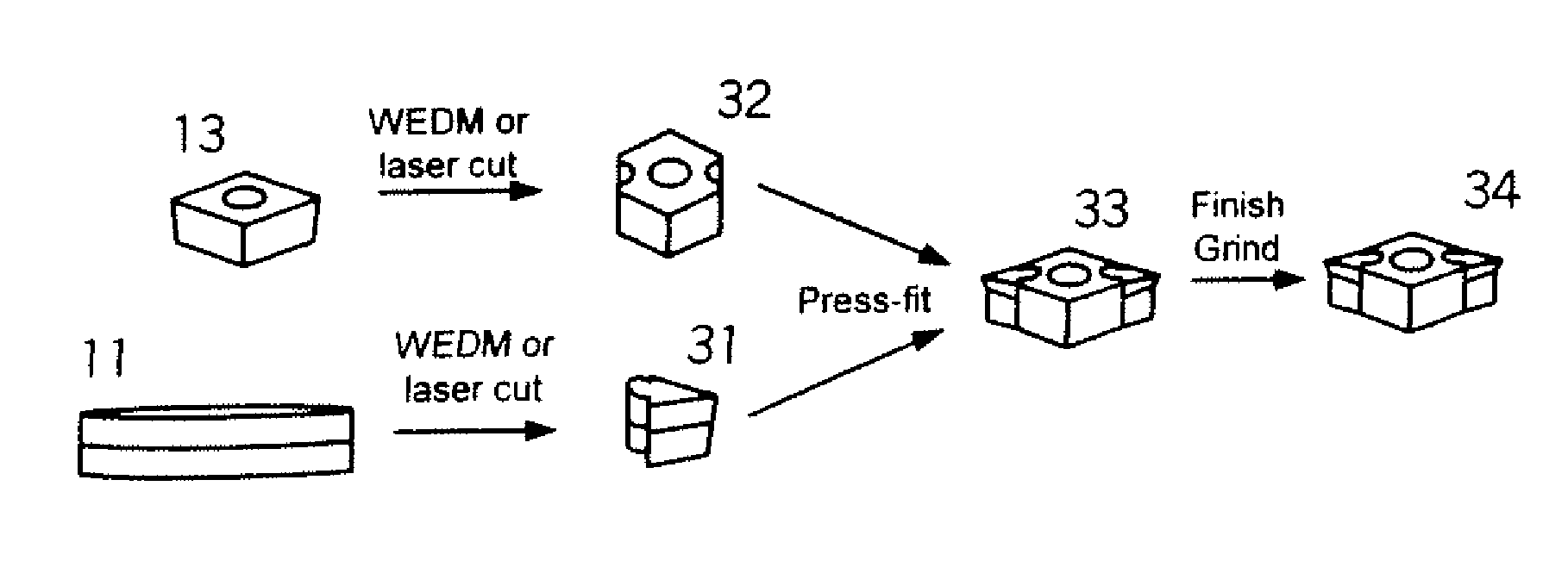

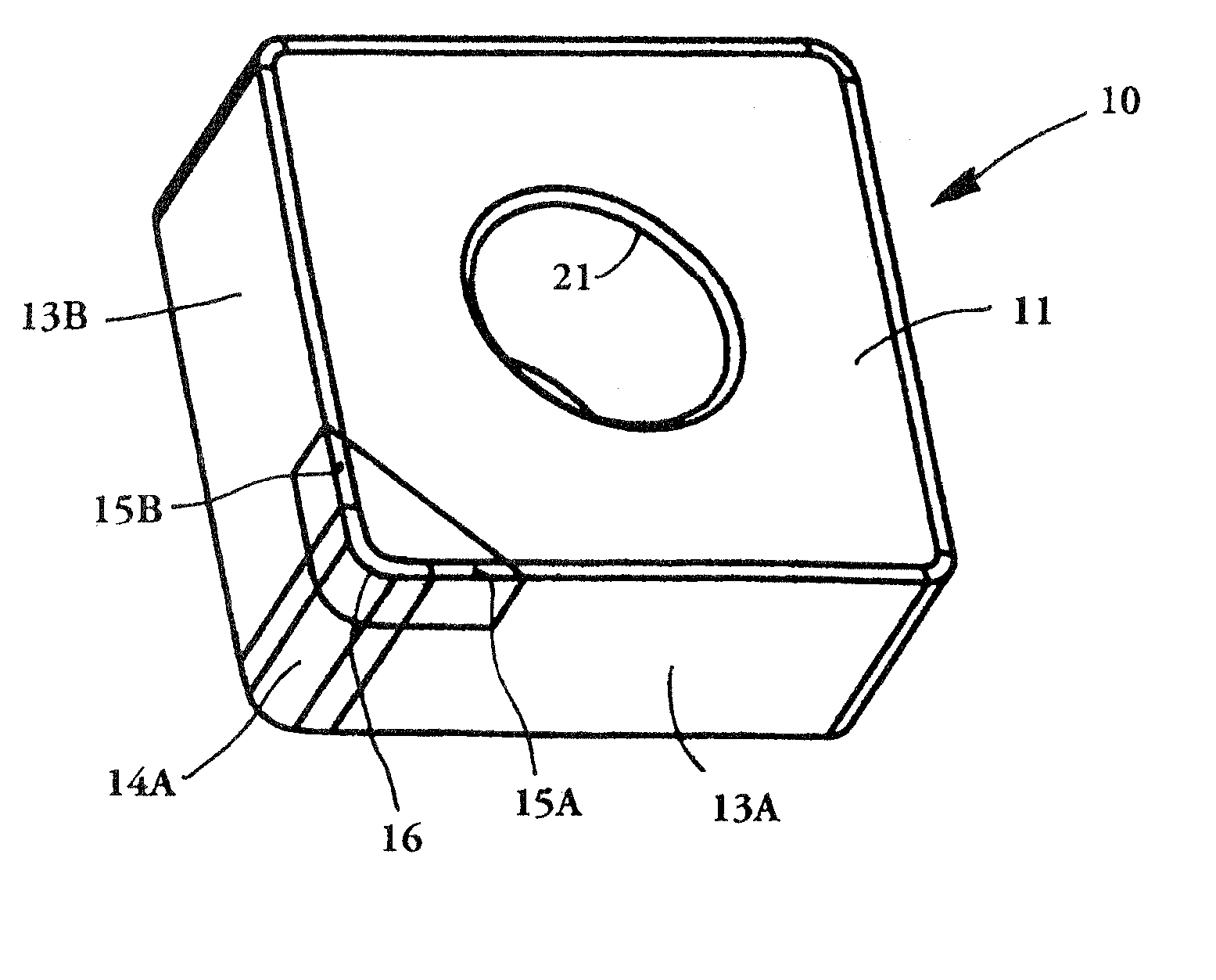

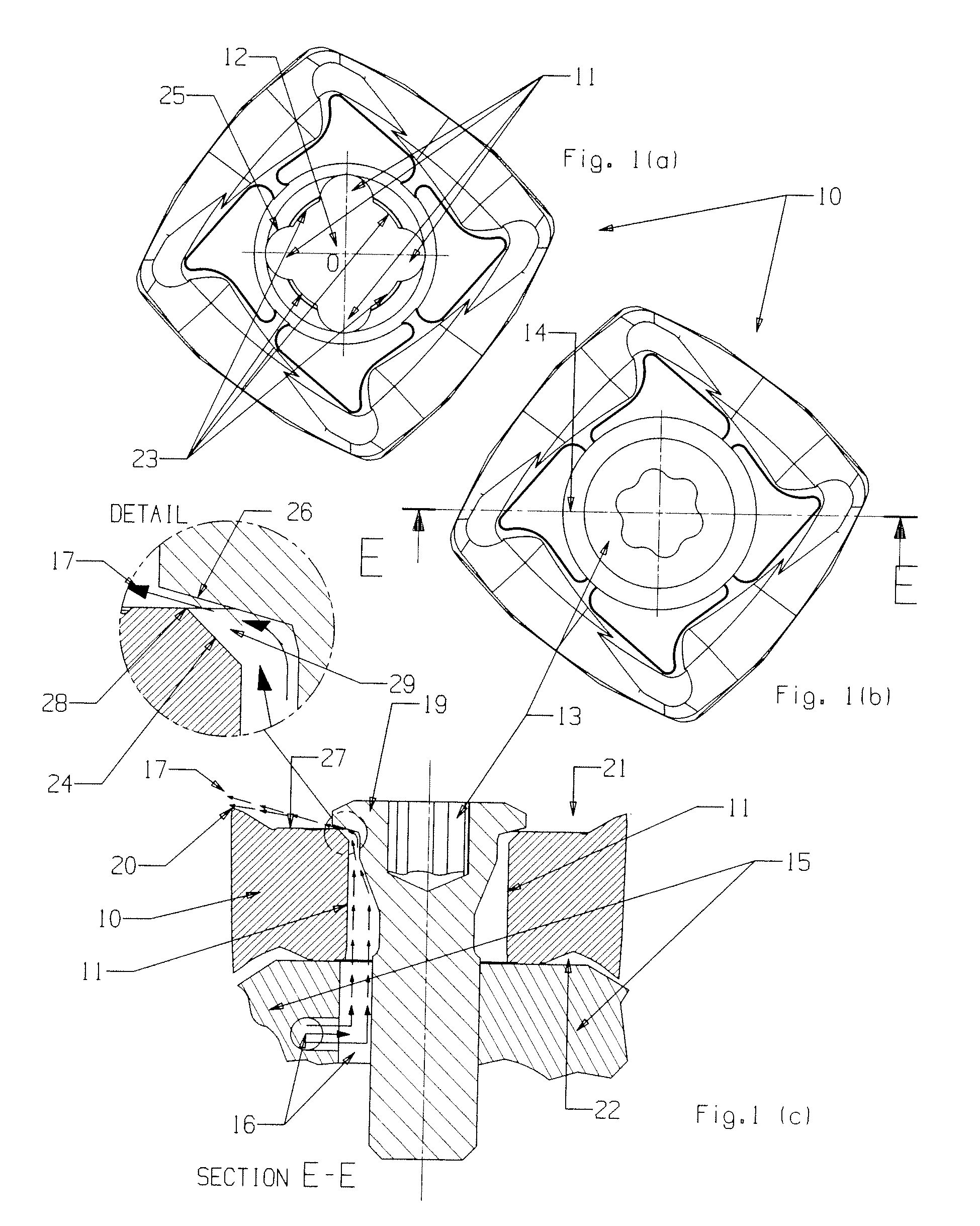

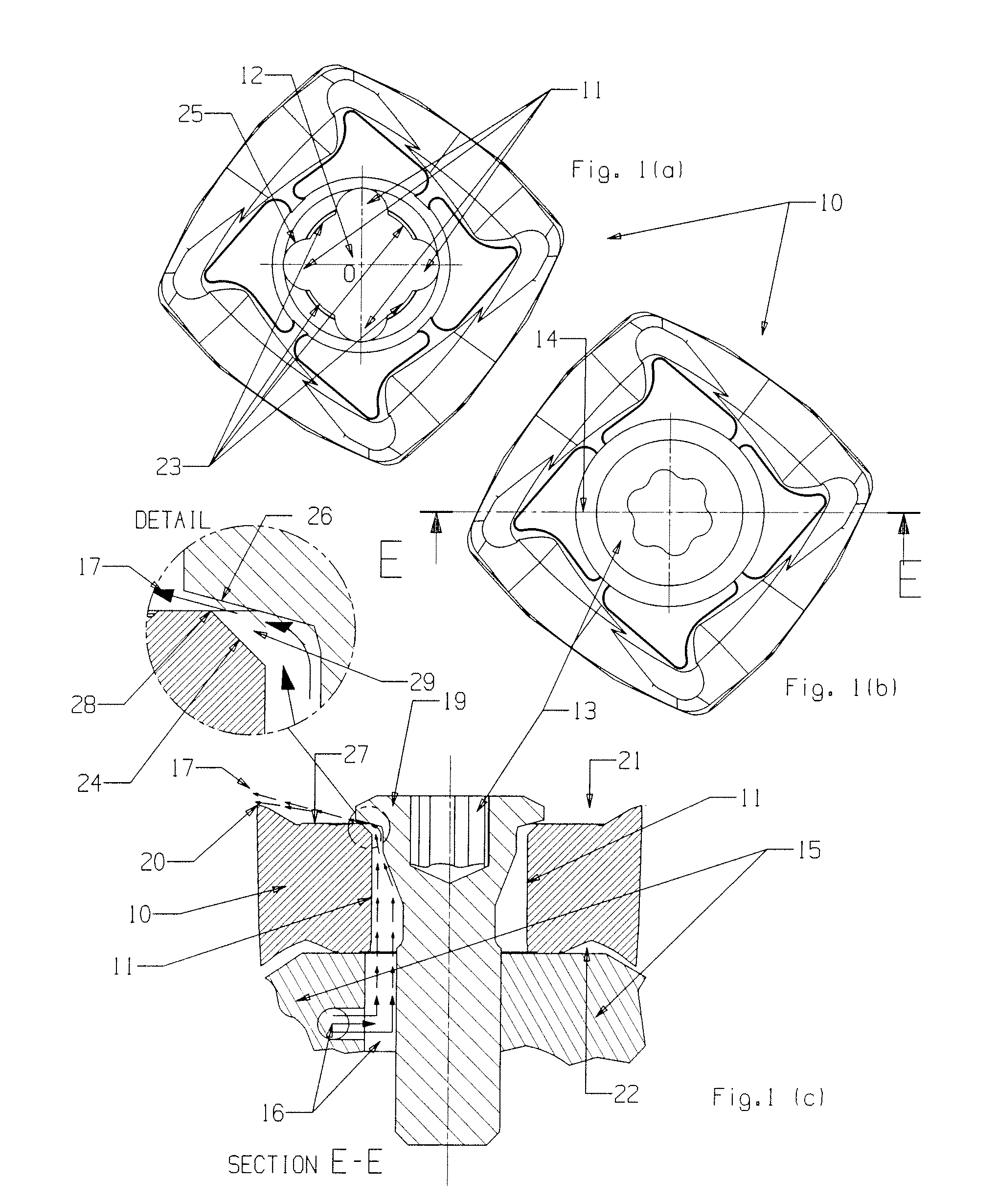

Indexable cutting inserts and methods for producing the same

A cutting insert has a body formed of a superhard material or a superhard material and a cemented carbide, and has a hole through said body and a preformed hole inlay in said hole to allow securing of the insert to a holder. The method of making same is also disclosed.

Owner:SANDVIK INTPROP AB

Cutting tool insert and drill bit so equipped

ActiveUS7730977B2Reducing and preferably eliminating and spalling and chipping typeImproved wear behaviorDrill bitsWorkpiecesLeading edgeMetallurgy

Owner:BAKER HUGHES INC

Articles having improved resistance to thermal cracking

An article includes a working portion including cemented carbide, and a heat sink portion in thermal communication with the working portion. The heat sink portion includes a heat sink material having a thermal conductivity greater than a thermal conductivity of the cemented carbide. Also disclosed are methods of making an article including a working portion comprising cemented carbide, and a heat sink portion in thermal communication with the working portion and including a heat sink material having a thermal conductivity that is greater than a thermal conductivity of the cemented carbide. The heat sink portion conducts heat from the working portion.

Owner:KENNAMETAL INC

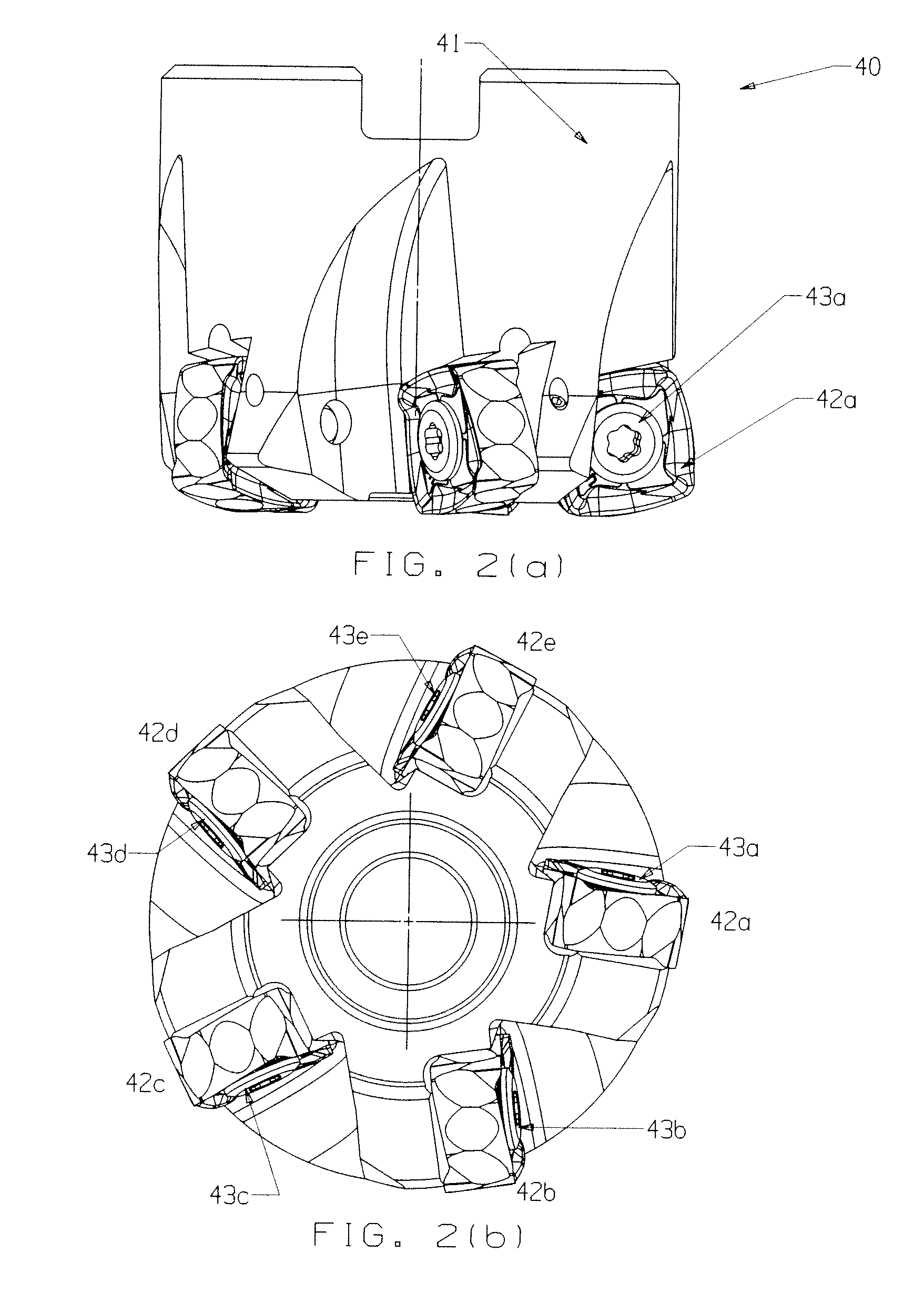

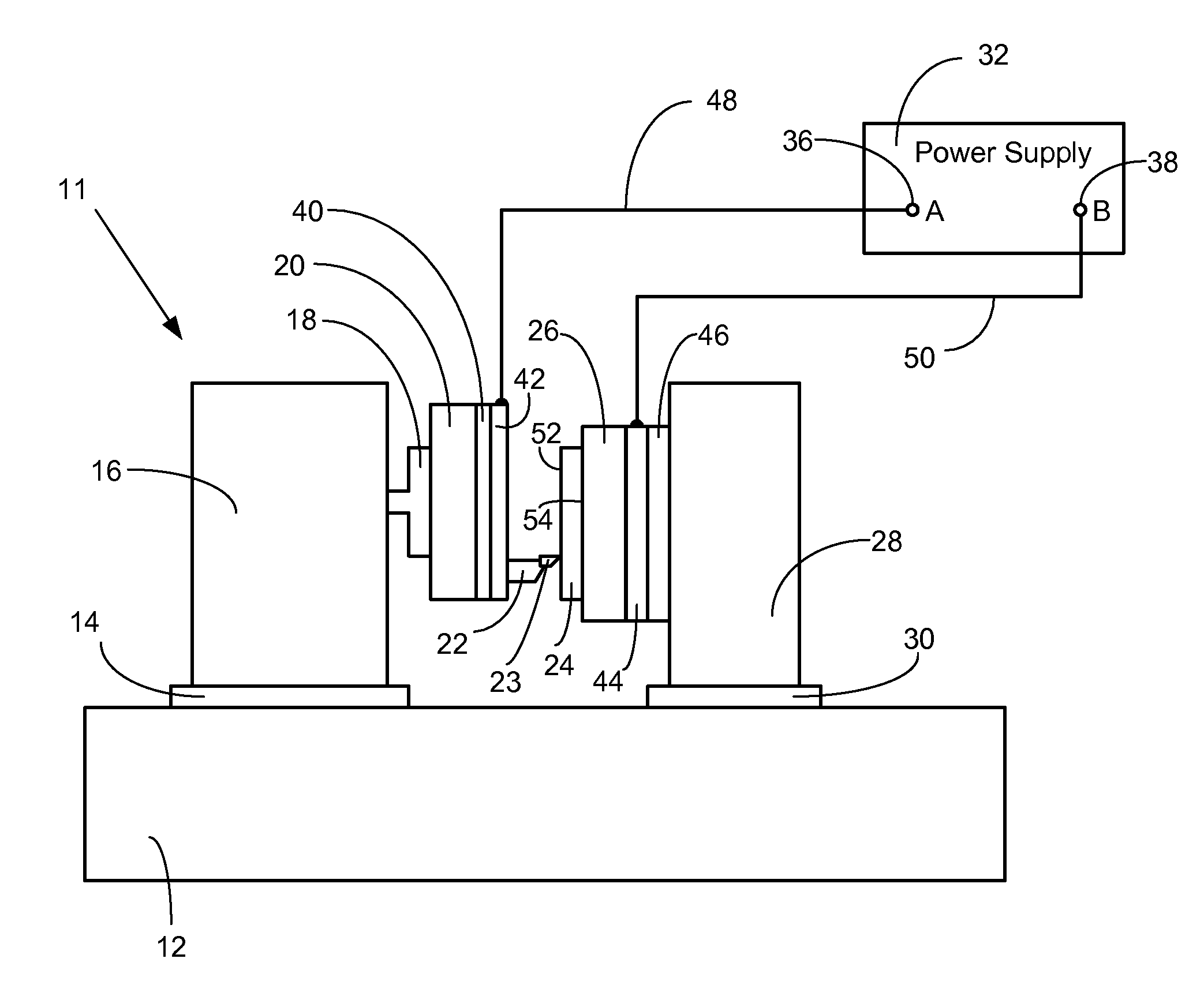

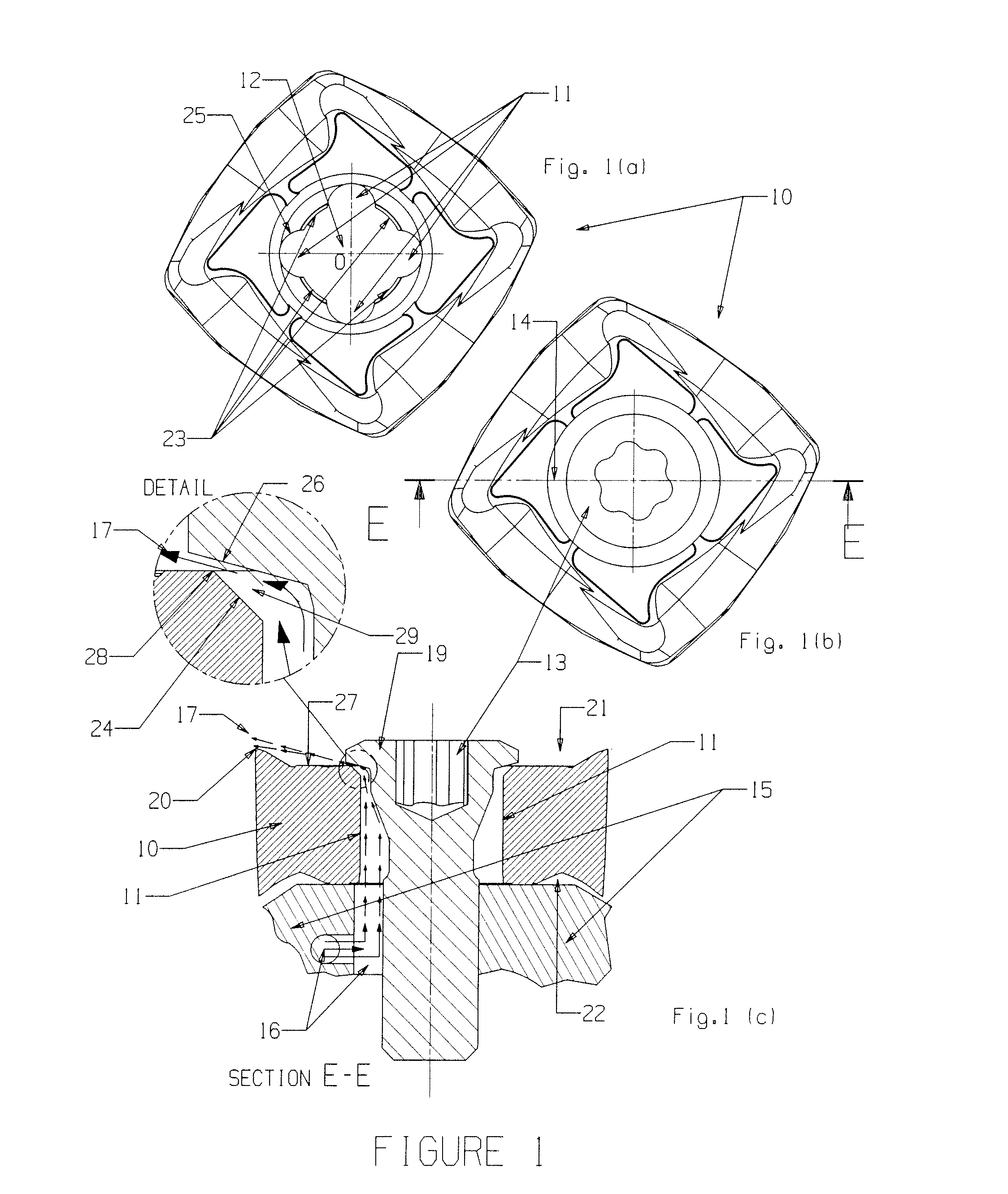

Cutting tools and cutting inserts including internal cooling

A cutting tool comprises a cutting insert, a tool holder, and a fastener. The cutting insert comprises a cutting edge and a fastener bore adapted to accept a fastener for fastening together the cutting tool and tool holder. A coolant flow recess in the fastener bore is adapted to direct coolant though the coolant flow recess and toward a head portion of the fastener. The tool holder comprises an insert pocket adapted to removably fasten the cutting insert and fastener to the tool holder, and a coolant bore adapted to direct the coolant from the tool holder to the coolant flow recess of the fastener bore. The head portion of the fastener and the coolant flow recess of the fastener bore define a gap that directs the coolant to the cutting edge of the cutting insert.

Owner:SECO TOOLS AB

Method for extending diamond tool life in diamond machining of materials that chemically react with diamond

InactiveUS7198043B1Improve tool lifeAvoid chemical reactionsMilling cuttersArc welding apparatusChemical reactionMachining

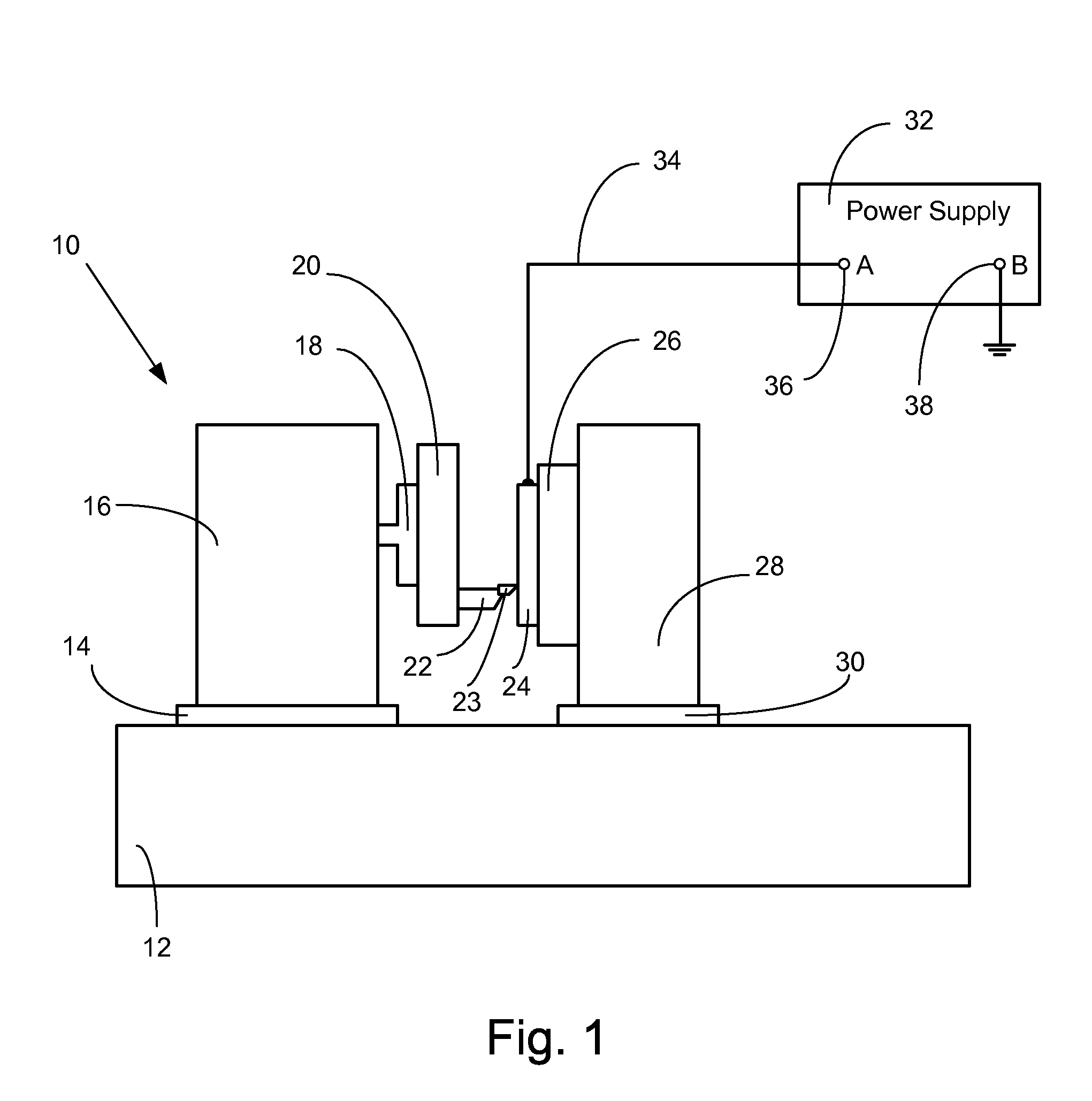

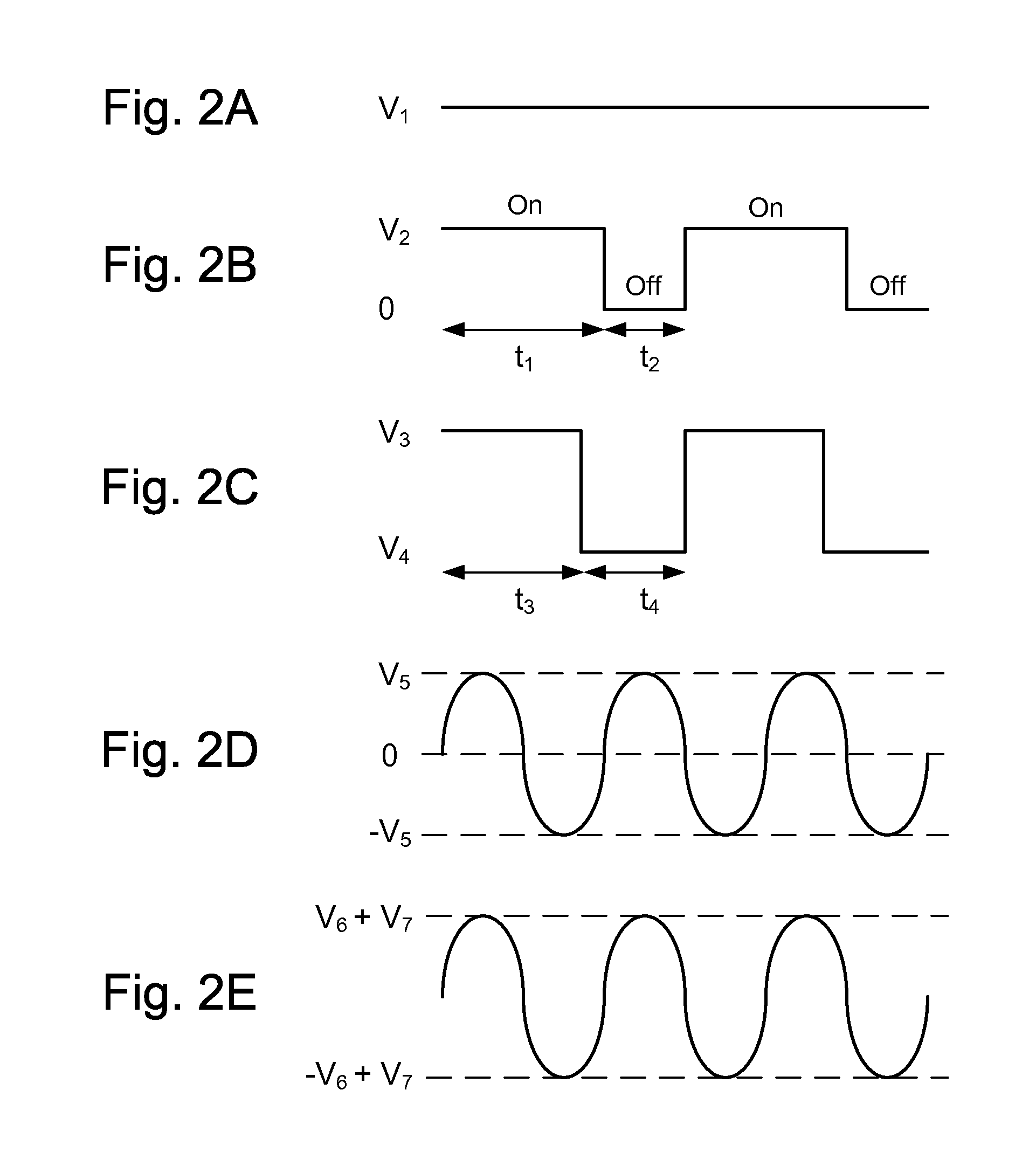

The present invention provides a method for extending diamond tool life in diamond machining of materials that chemically react with the diamond tool in which the surface electric potential of the workpiece is adjusted or tuned to be adequate to inhibit the chemical reaction between the diamond tool and the workpiece during the diamond machining operation. As the chemical reaction is inhibited, the chemical wear rate of the diamond tool is reduced and diamond tool life is extended. The surface electric potential of the workpiece can be adjusted by electrically charging the workpiece. In one embodiment, conduction charging is used to adjust the surface electric potential of the workpiece to inhibit the chemical reaction between the diamond tool and the workpiece. In another embodiment, induction charging is used to adjust the surface electric potential of the workpiece to inhibit the chemical reaction between the diamond tool and the workpiece.

Owner:ZHANG GANG

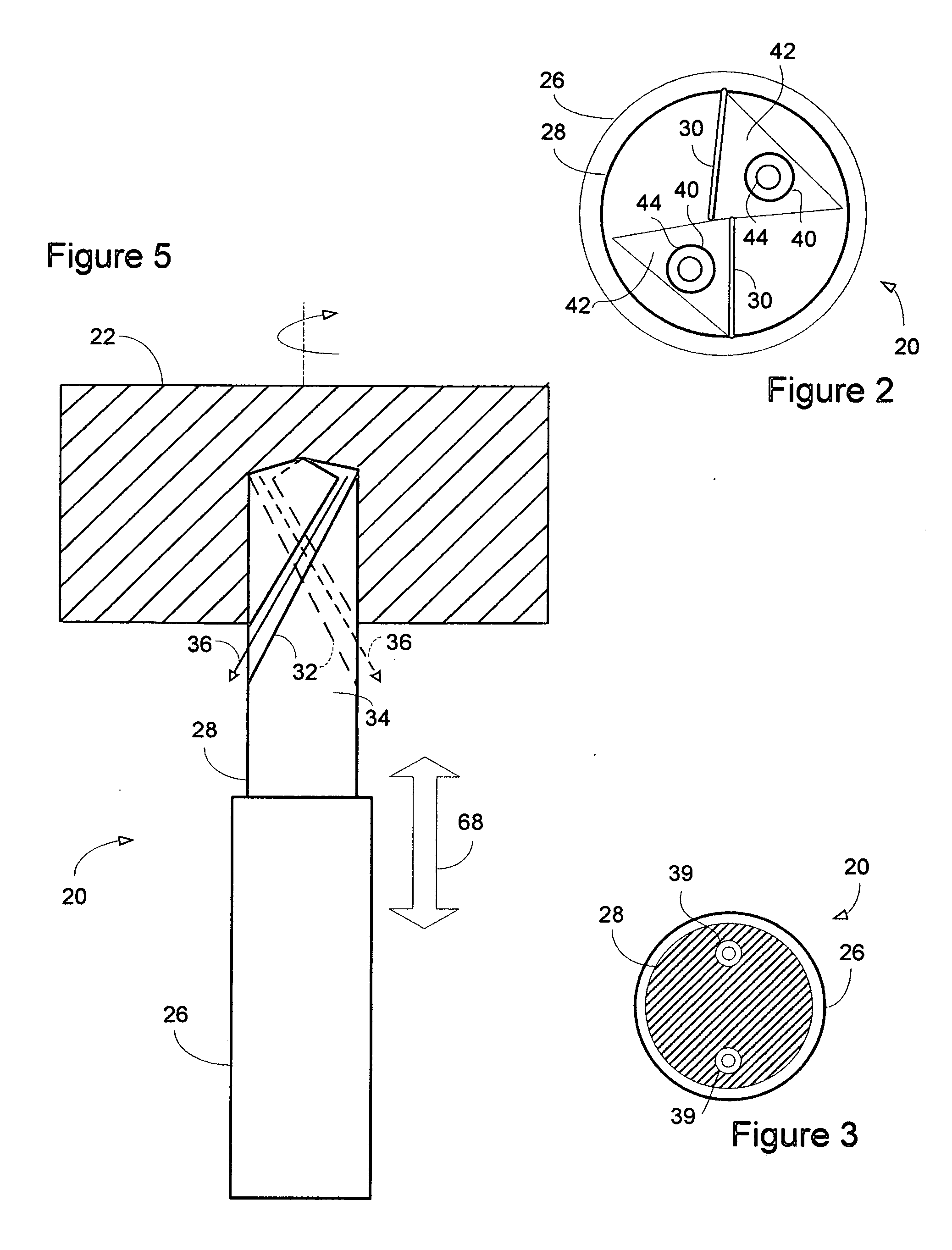

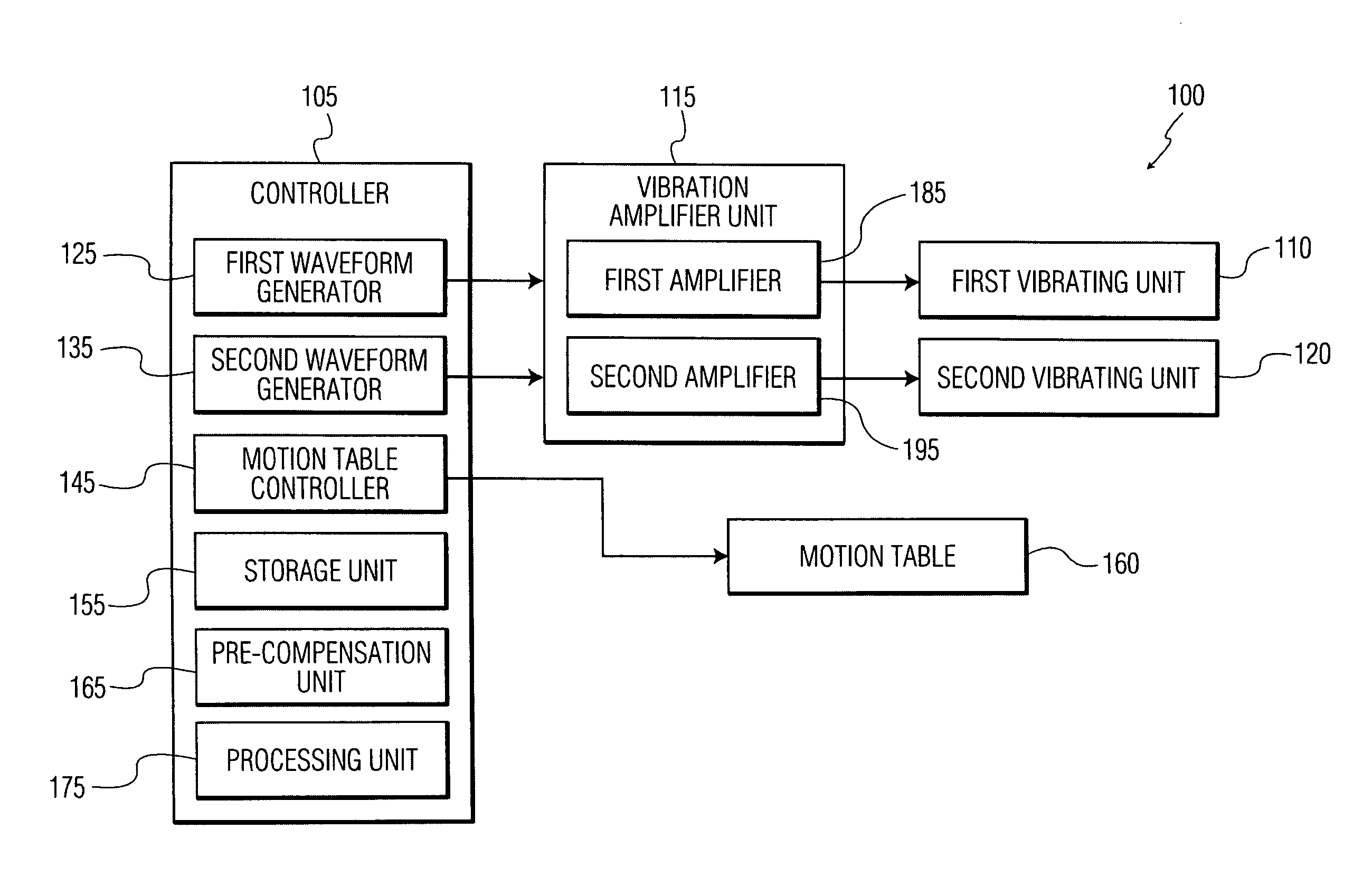

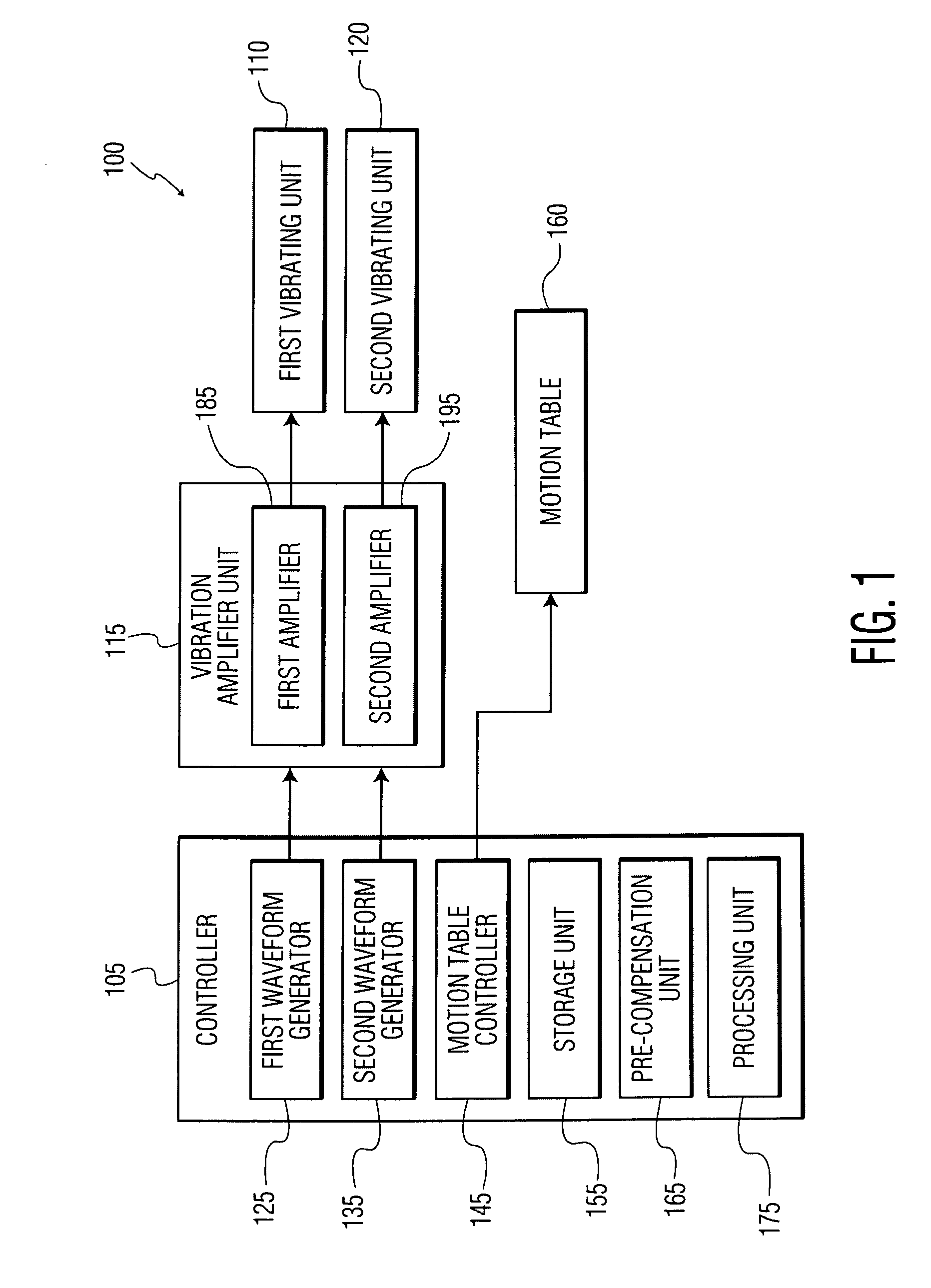

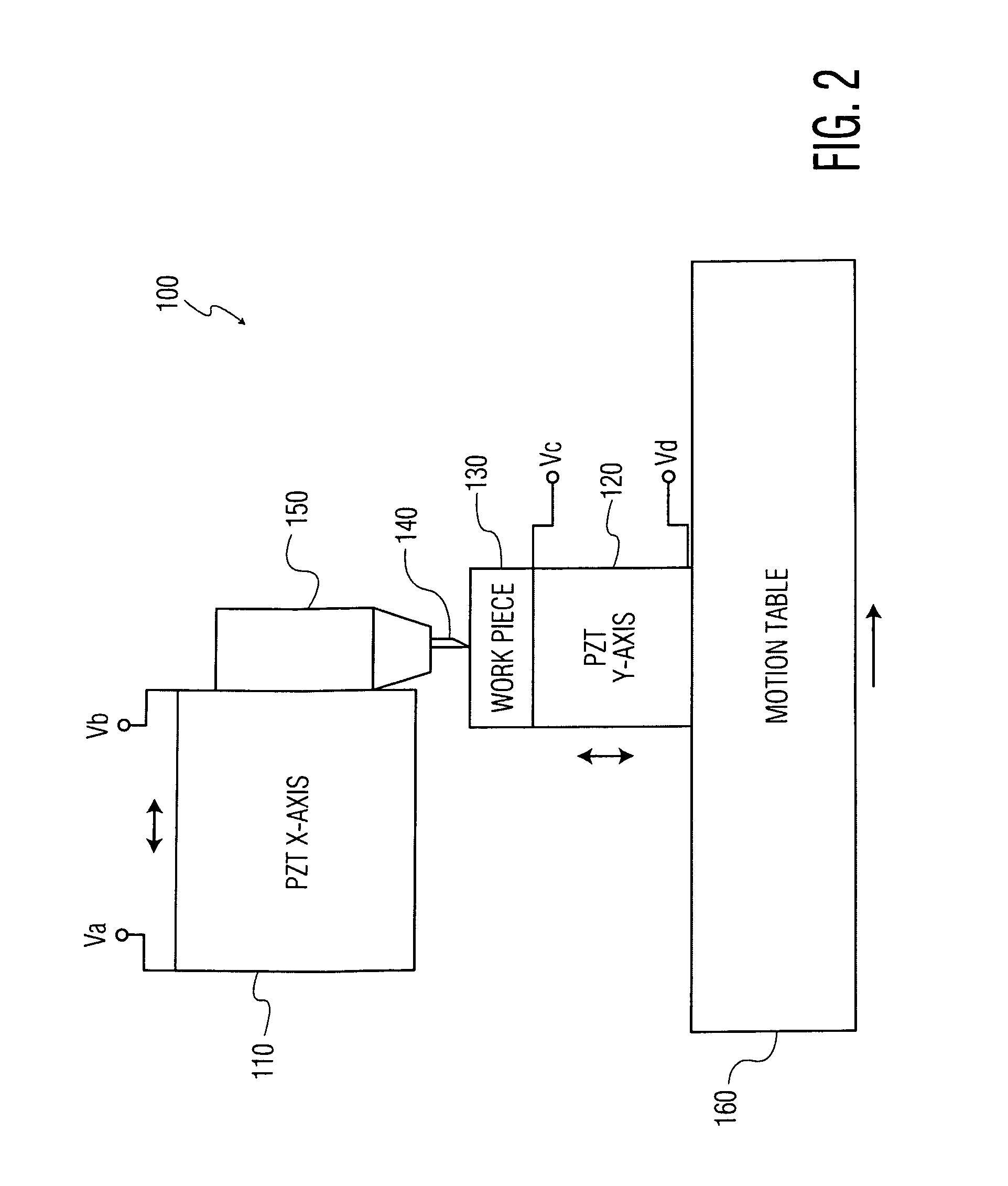

Method and apparatus for vibration machining with two independent axes

InactiveUS20070052326A1Piezoelectric/electrostriction/magnetostriction machinesWorkpiecesEngineeringMechanical engineering

A vibration machining apparatus and method of use. The vibration machining apparatus includes a cutting tool and a motion stage coupled to one of the cutting tool or the workpiece to move the cutting tool relative to the workpiece. A tangent to a machine path and a normal to the surface of the workpiece define a vibration plane. The vibration machining apparatus further includes a first vibrating unit coupled to one of the cutting tool or the workpiece to vibrate it along a first vibrational direction, substantially in the vibration plane, and a second vibrating unit coupled with one of the cutting tool or the workpiece to vibrate the one of the cutting tool or the workpiece coupled to the second vibrating unit along a second vibrational direction, different from the first direction and substantially in the vibration plane.

Owner:PANASONIC CORP

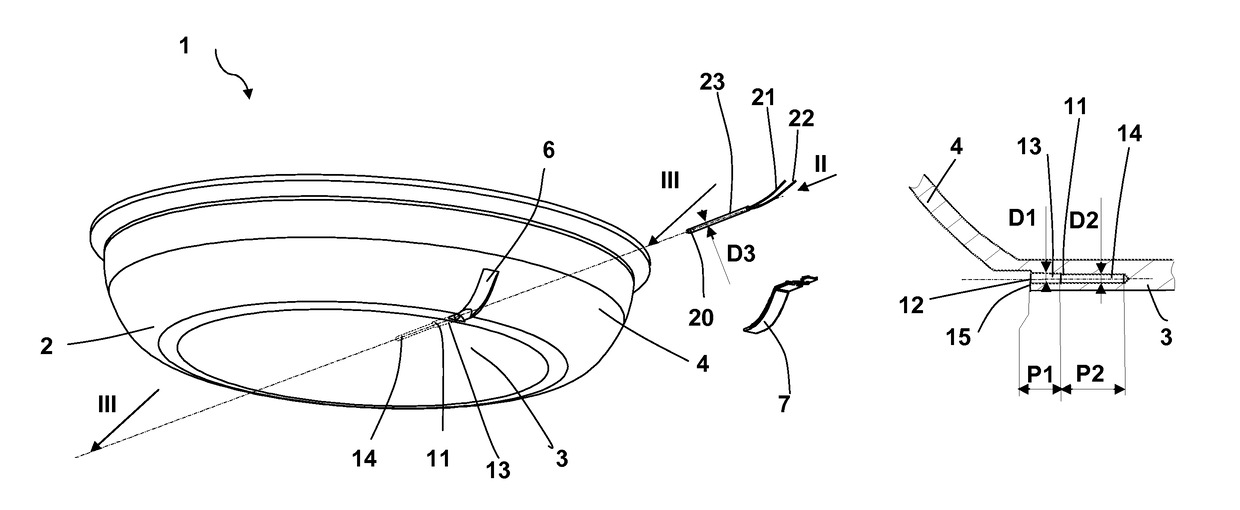

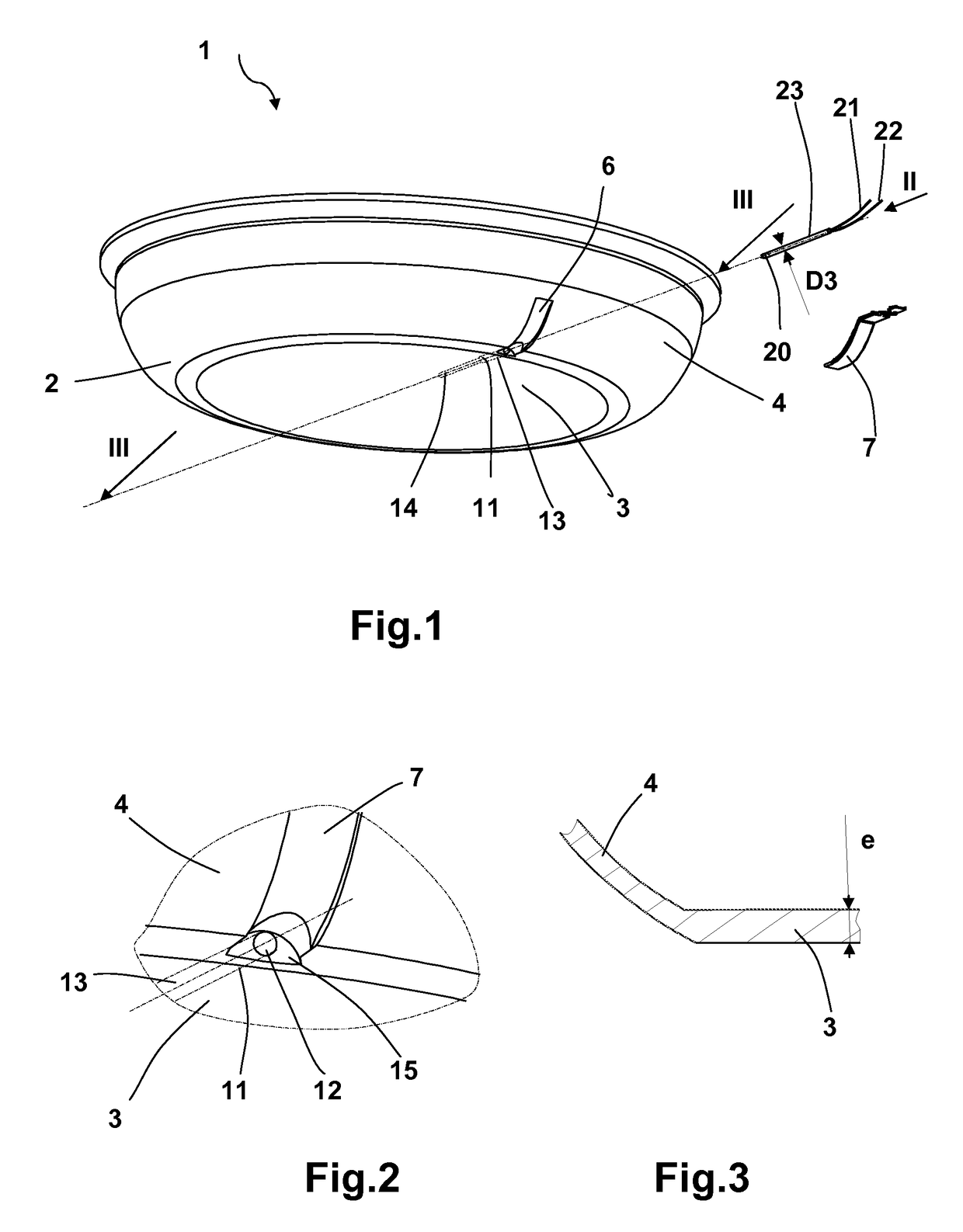

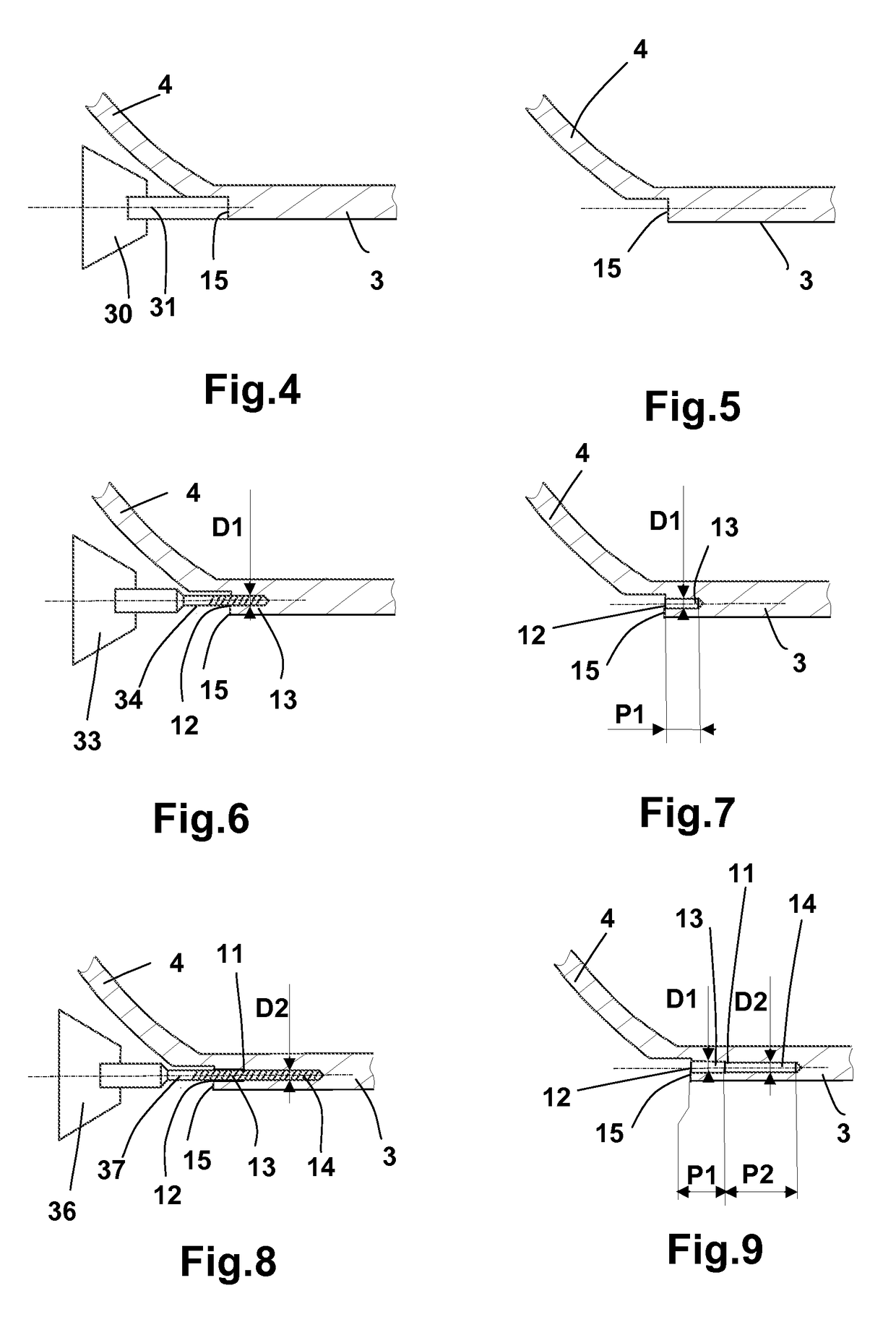

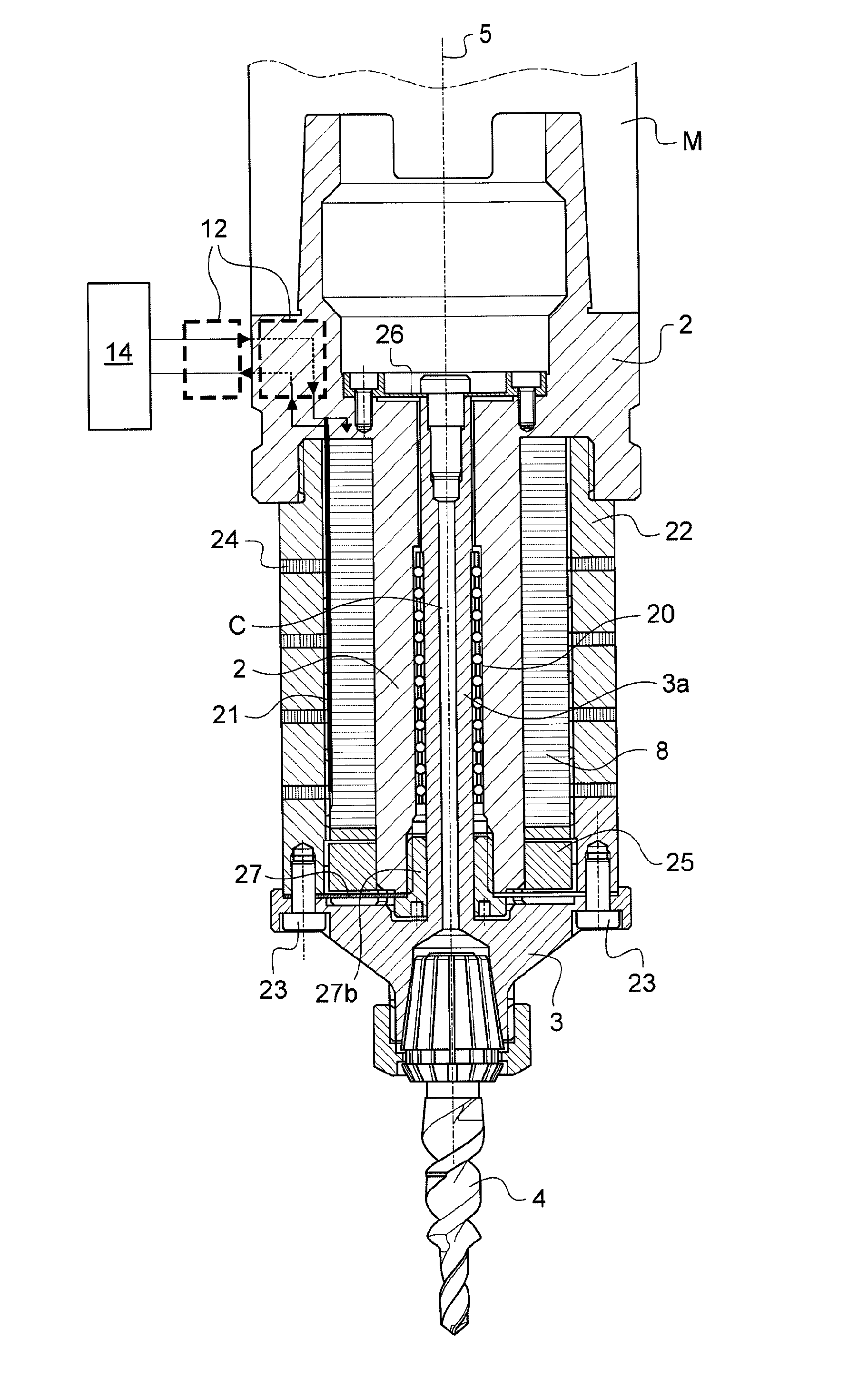

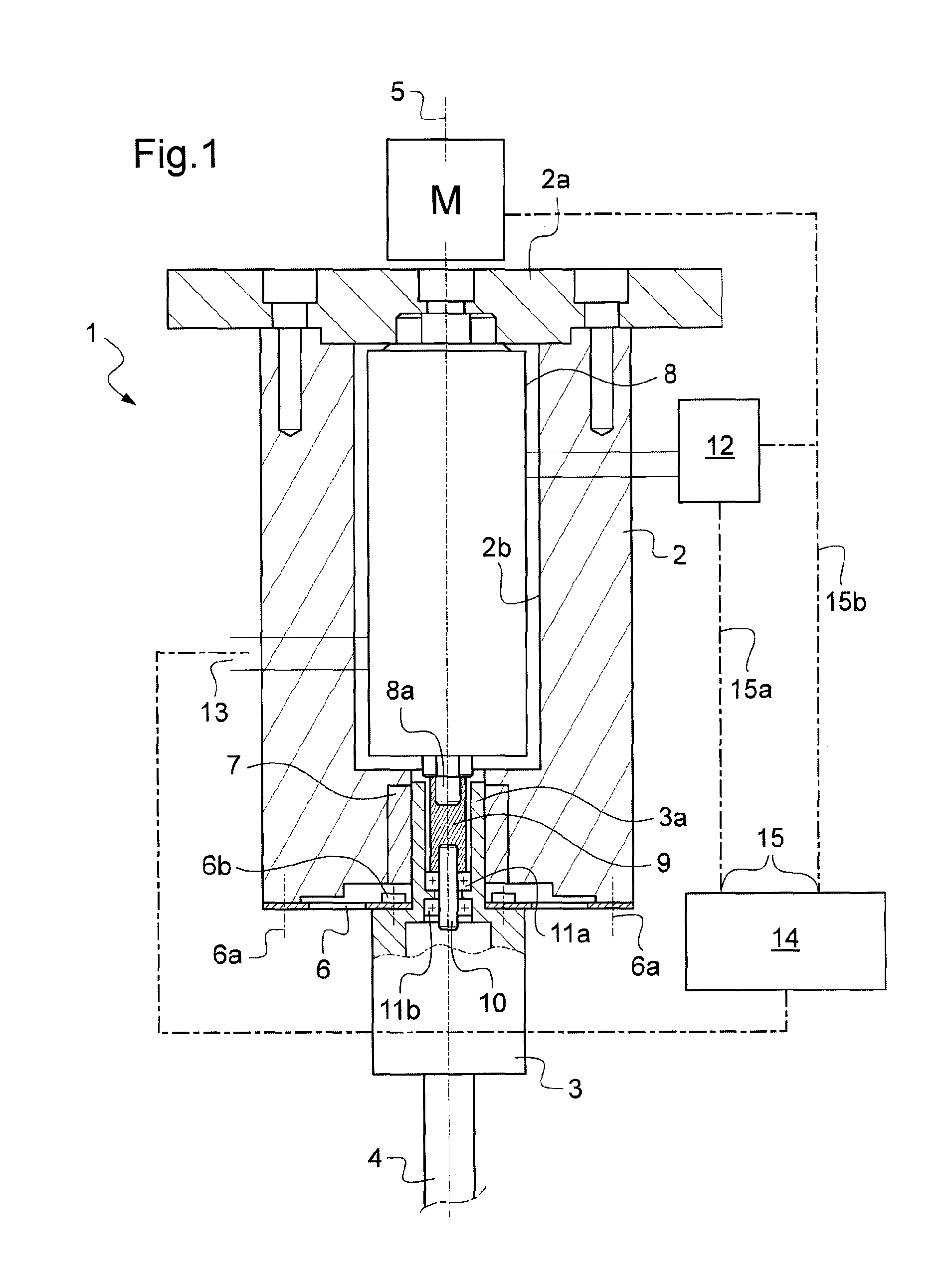

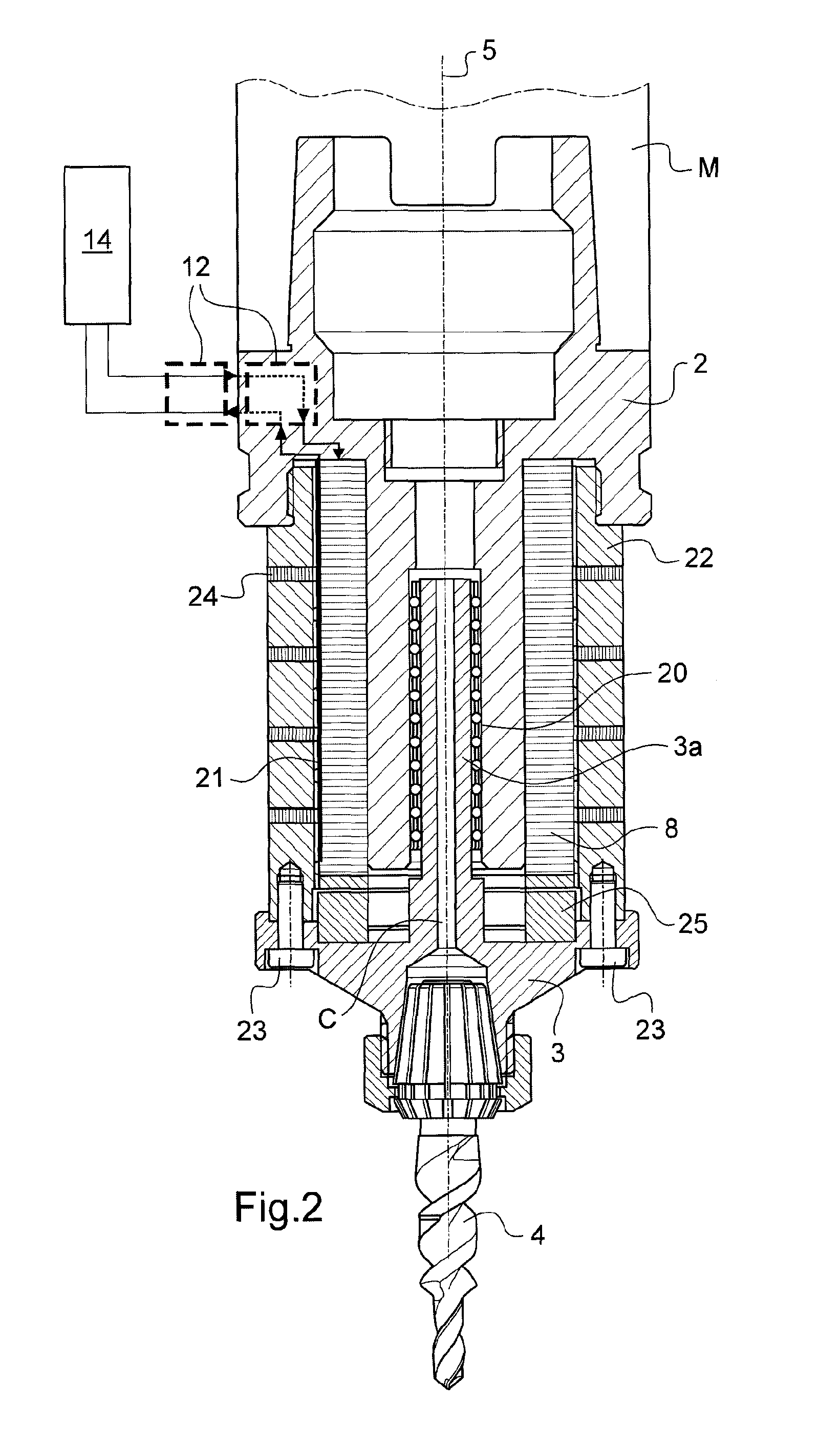

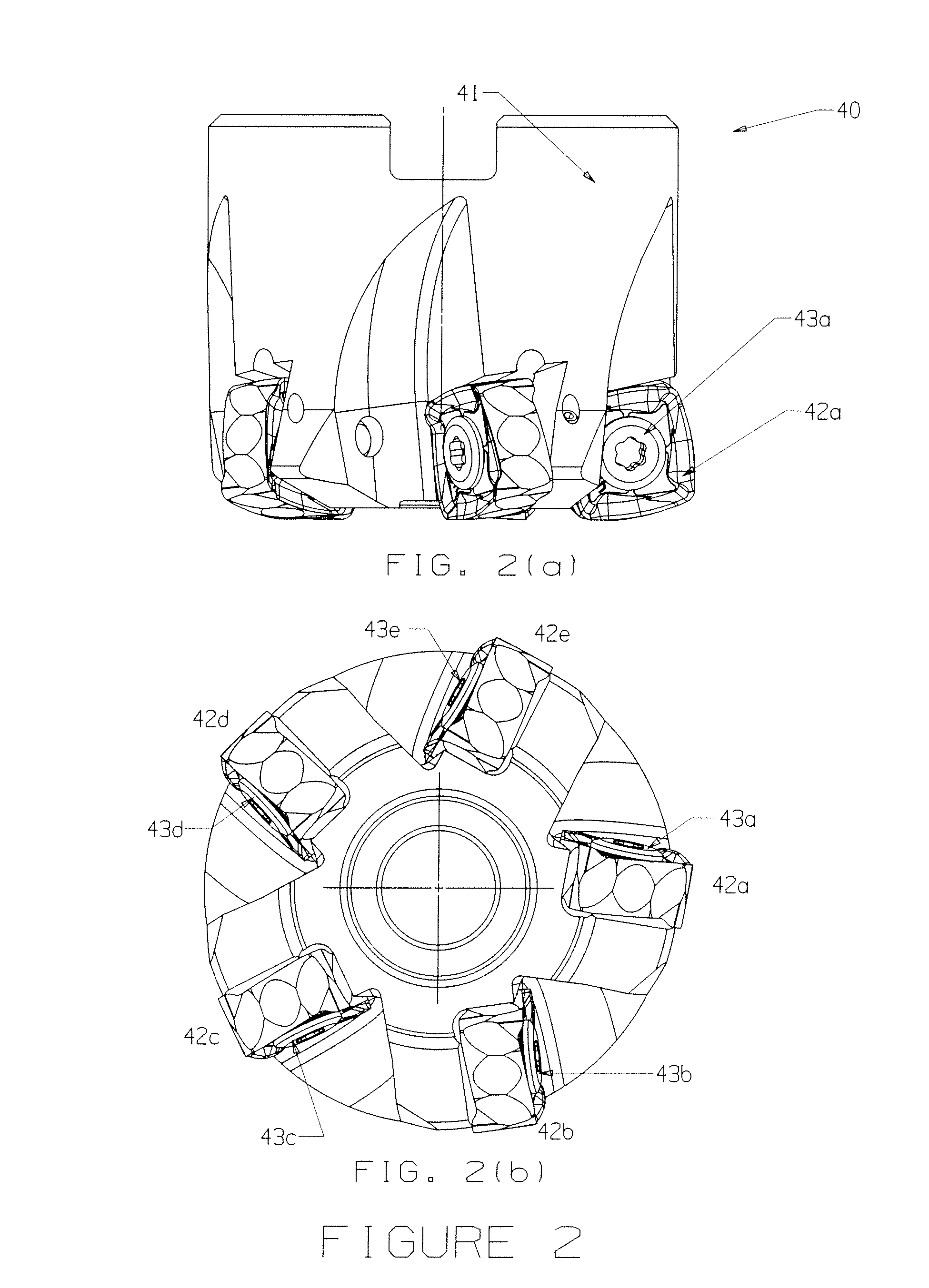

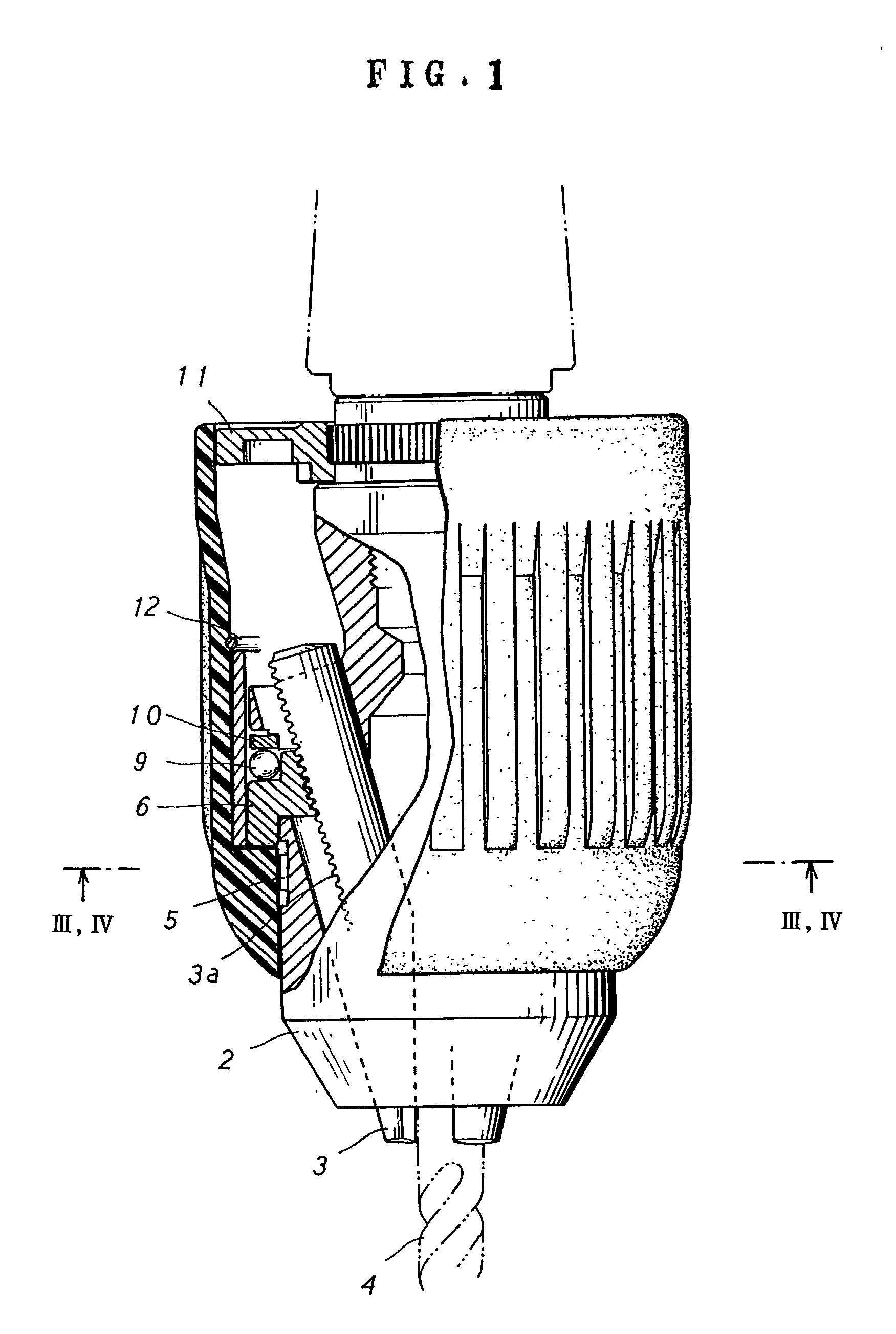

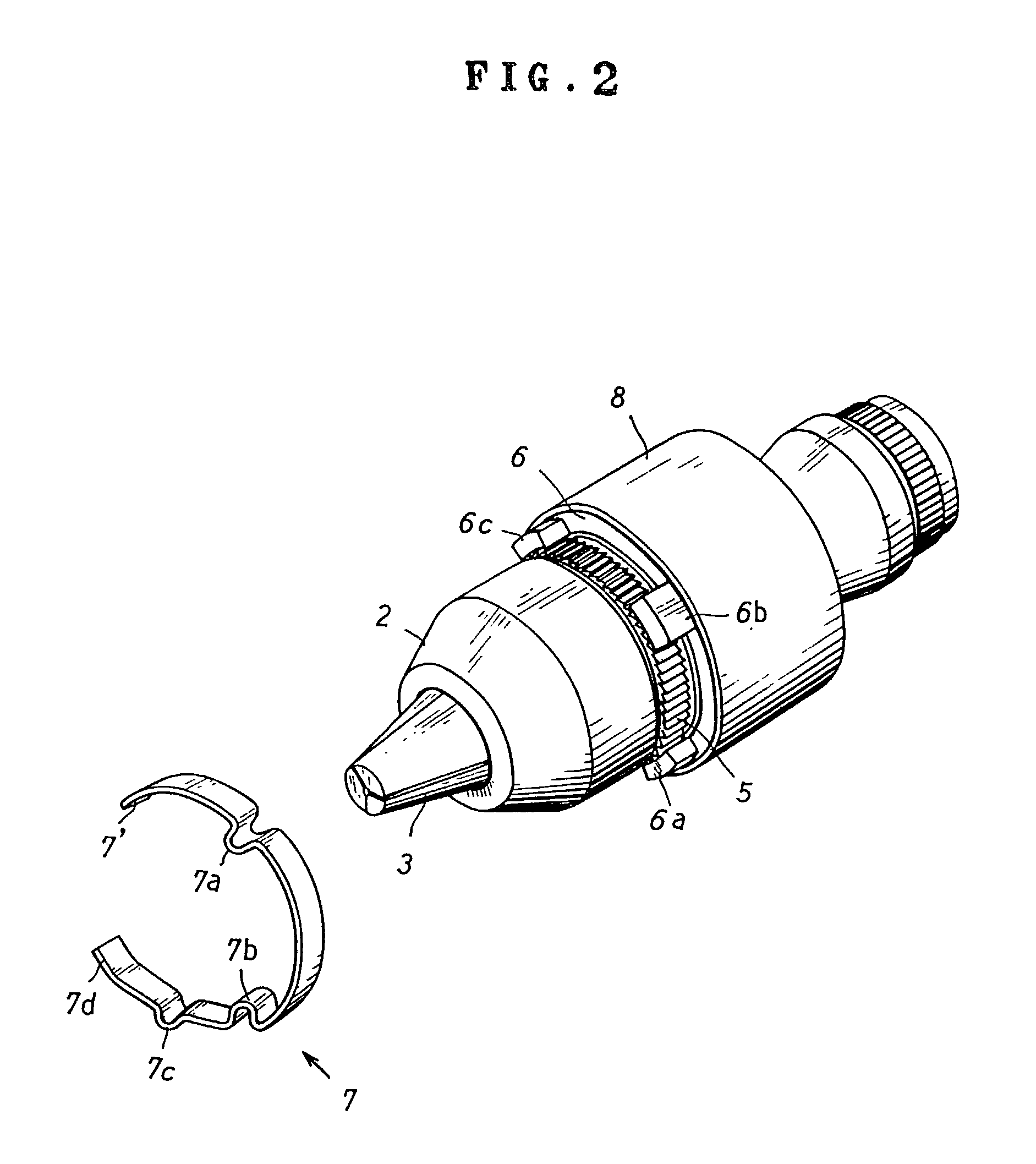

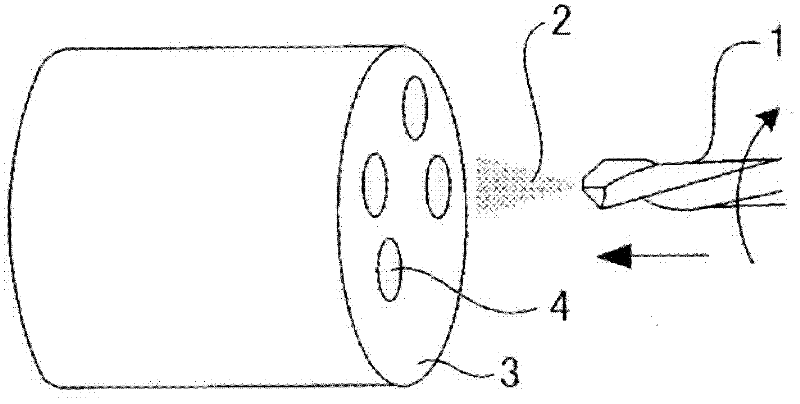

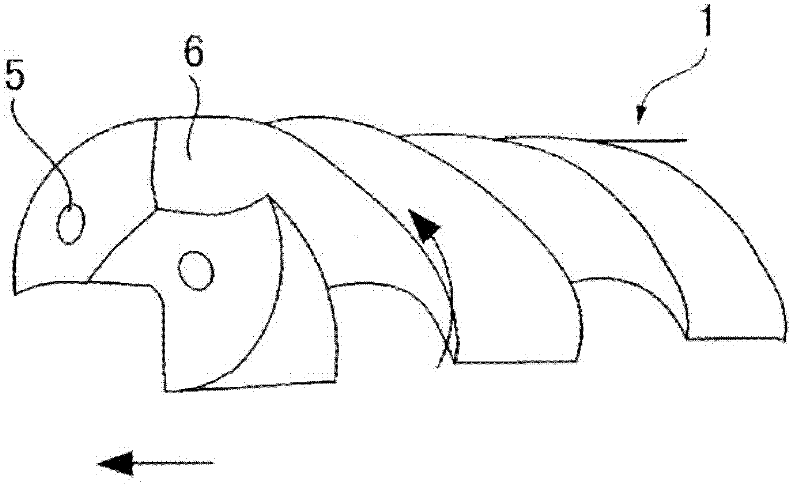

Drilling head with axial vibrations

ActiveUS20120107062A1Relieve shimAdjustable preloadWorkpiecesTurning toolsCouplingReciprocating motion

A drilling head (1) with an axial oscillation generator, includes a mounting (2) for coupling the head to a motor for rotating the mounting about an axis, the mounting (2) having a longitudinal axis (5) coinciding with the axis of rotation of the motor, a tool holder (3), an elastically deformable element (6) for retaining the tool holder (3) in the mounting (2) and an element (7) for guiding the tool holder (3) in the mounting (2) along the longitudinal axis (5) of the mounting, wherein the mounting of the drilling head includes a controlled generator (8) of reciprocating movements in the direction of the aforementioned axis (5) positioned between the mounting (2) and the tool holder, the tool holder and the generator being connected by a longitudinal coupling member (9) suitable for damping the impacts withstood by the tool holder while enabling the transmission of the reciprocating movements.

Owner:ARTS +1

Cutting tool including an internal coolant system and fastener for a cutting tool including an internal coolant system

A cutting insert fastener adapted to secure a cutting insert to a cutting tool holder. The fastener comprises a fastener head portion comprising at least one feature adapted to direct a coolant fluid to an insert cutting edge of a cutting insert when the cutting insert is secured to a cutting tool holder by the cutting insert fastener. Cutting tools comprising internal coolant systems and fastened with a cutting insert fastener comprising a fastener head portion with at least one feature adapted to direct a coolant fluid to an insert cutting edge are also disclosed.

Owner:KENNAMETAL INC

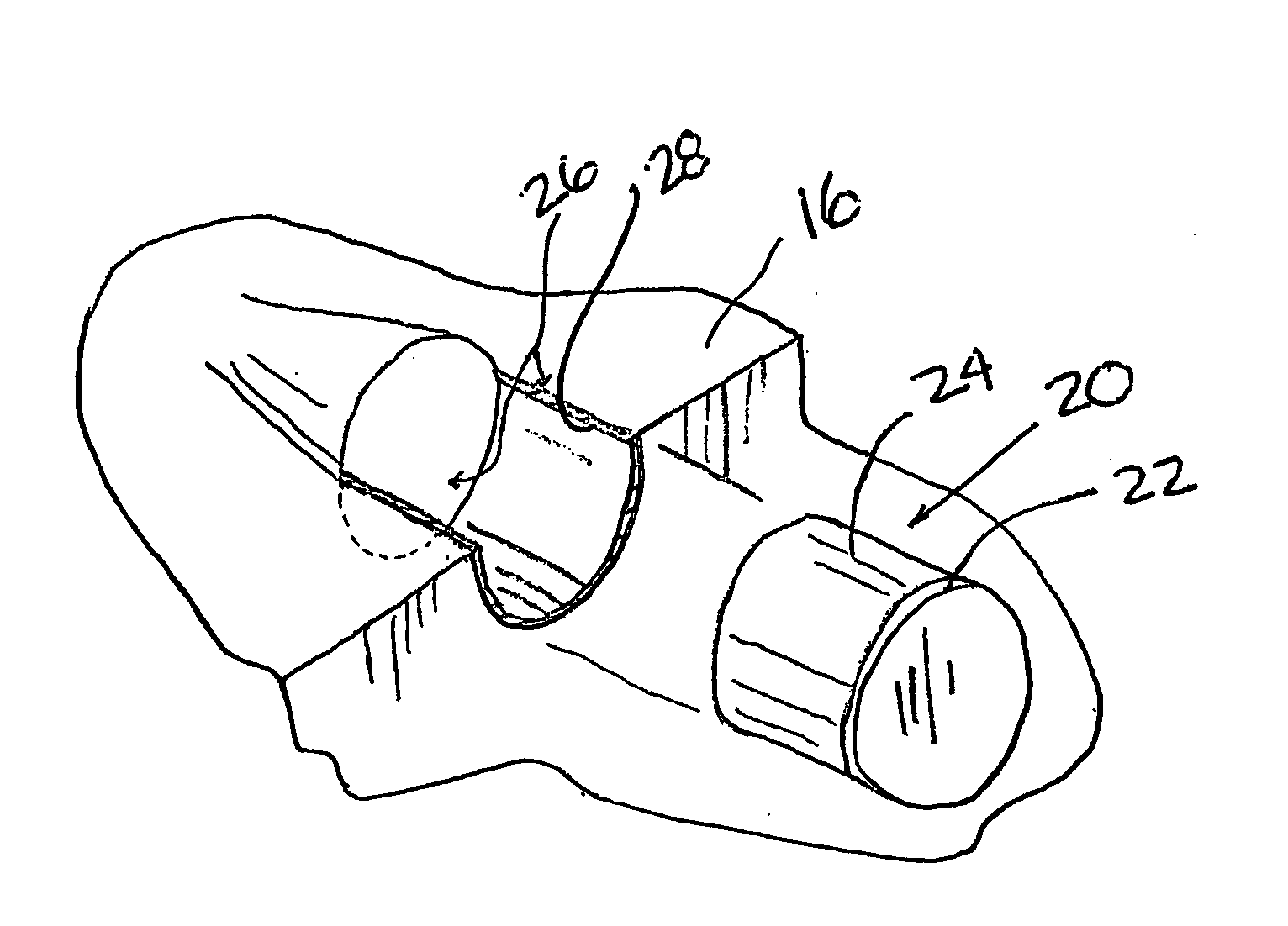

Chuck device

InactiveUS20030141676A1Reduce coefficient of frictionEasy to moveSleeve/socket jointsAnodisationFrictional coefficientEngineering

To provide a chuck device for preventing the loosening of the fastening condition, a plurality of claws inserted into a hole provided at an end of a body are opened, closed and slid by the rotation of a rotary sleeve and a tool is clamped by means of the claws. A coating that is hard and has a low frictional coefficient as much as possible is applied to an inner surface of the hole.

Owner:YUKIWA SEIKO

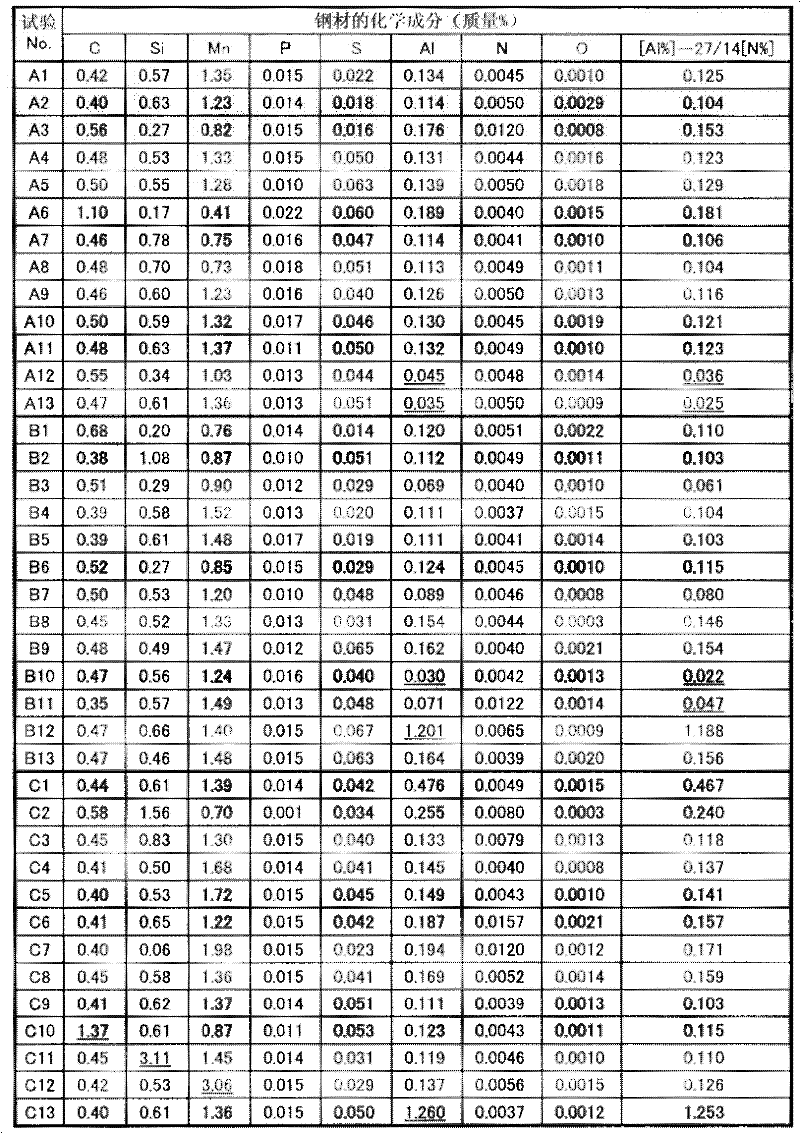

Cutting method for steel for use in machine structure

InactiveCN102470502AImprove overall lifespanMilling cuttersWorkpiecesMechanical engineeringGas mixing

Owner:NIPPON STEEL CORP

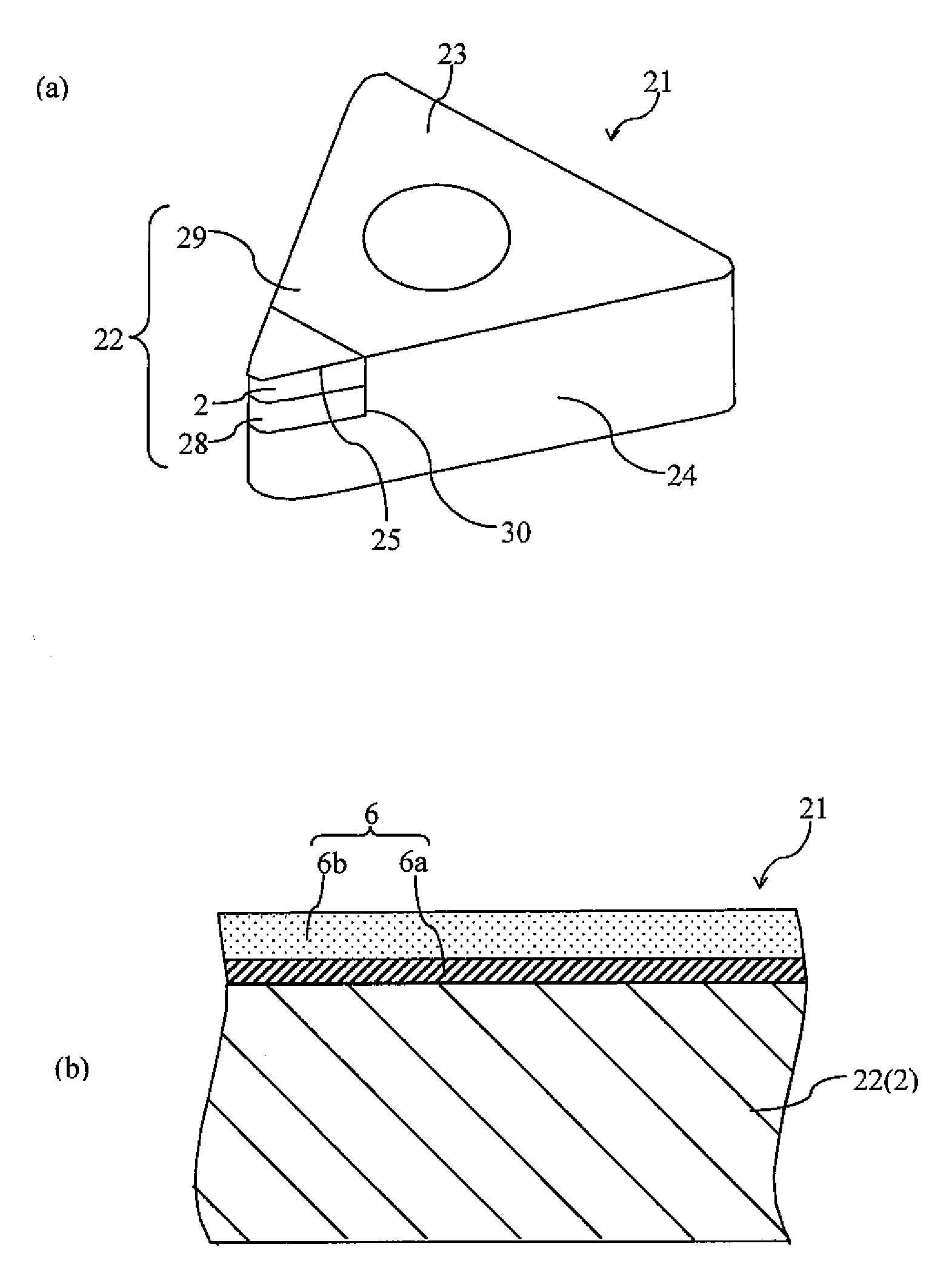

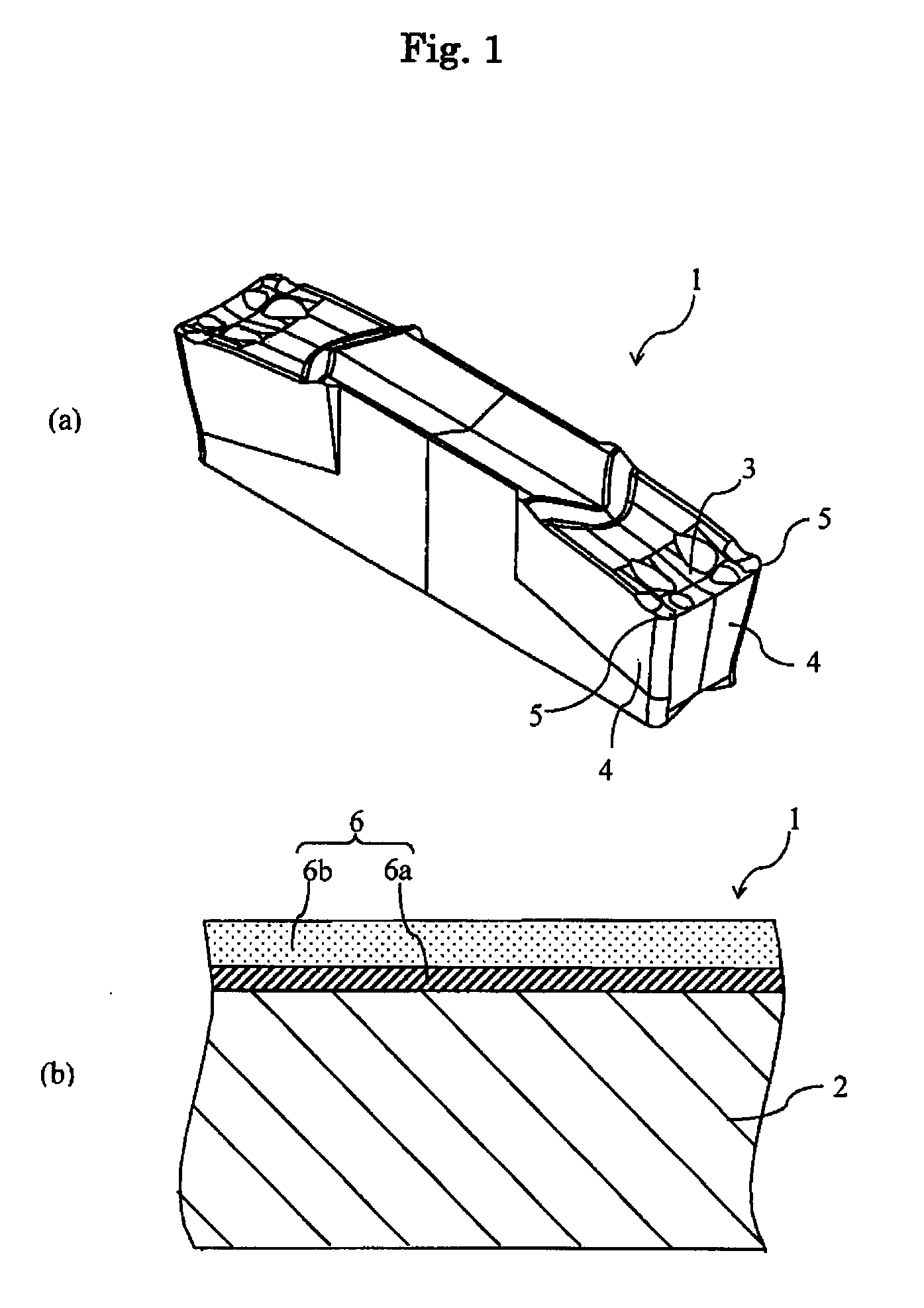

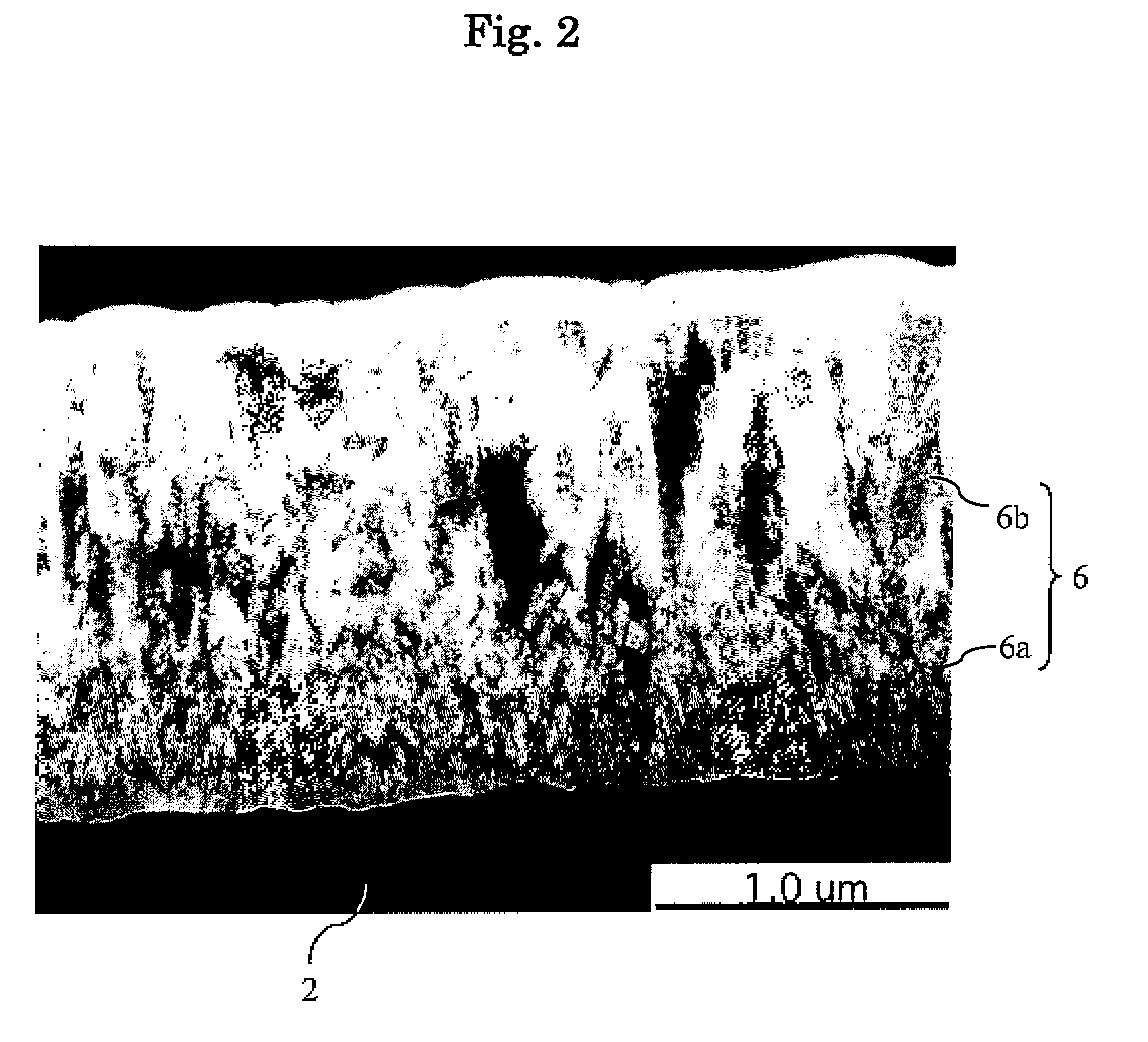

Surface Coated Tool

InactiveUS20090130434A1Improve fracture resistanceImprove wear resistanceLayered productsVacuum evaporation coatingCoated surfaceRare-earth element

A surface coated tool including a substrate, and stacked layers composed of two coating layers represented by the following general formula (1) on the substrate is provided. A first coating layer to be coated on the surface of the substrate, which has a thickness of 0.1 to 1 μm, is composed of a granular crystal having a mean crystal diameter of 0.01 to 0.1 μm. A second coating layer to be coated on the surface of the first coating layer, which has a thickness of 0.5 to 5 μm, is composed of columnar crystal grown in a direction perpendicular to the substrate, and the columnar crystal has a mean crystal width of 0.05 to 0.3 μm in a direction parallel to the substrate while a mean crystal width thereof is larger than the mean crystal diameter of the first coating layer.[Formula 3]M1-aAla(CbN1-b) (1)wherein, M represents at least one metal element selected from the group consisting of the elements of Groups 4, 5 and 6 of the periodic table, Si and rare earth elements, “a” satisfies the relation of 0.25≦a≦0.75, and “b” satisfies the relation of 0≦b≦1.

Owner:KYOCERA CORP

Reduced-friction coatings

InactiveUS20090074522A1Reduce major source of industrial wasteSave energyWorkpiecesMixingUltimate tensile strengthNitride

A coating is provided having a first metal or non-metal nitride layer and a second metal or non-metal nitride layer wherein the first and second nitride layers are sufficiently resistant to interdiffusion to maintain respective individual layer structure and strength at an elevated operating temperature when a coating contact surface is in sliding contact with another material and wherein one of the first layer or second layer includes a component that is oxidizable at the contact surface to form a friction-reducing lubricous oxide material at the contact surface.

Owner:NORTHWESTERN UNIV

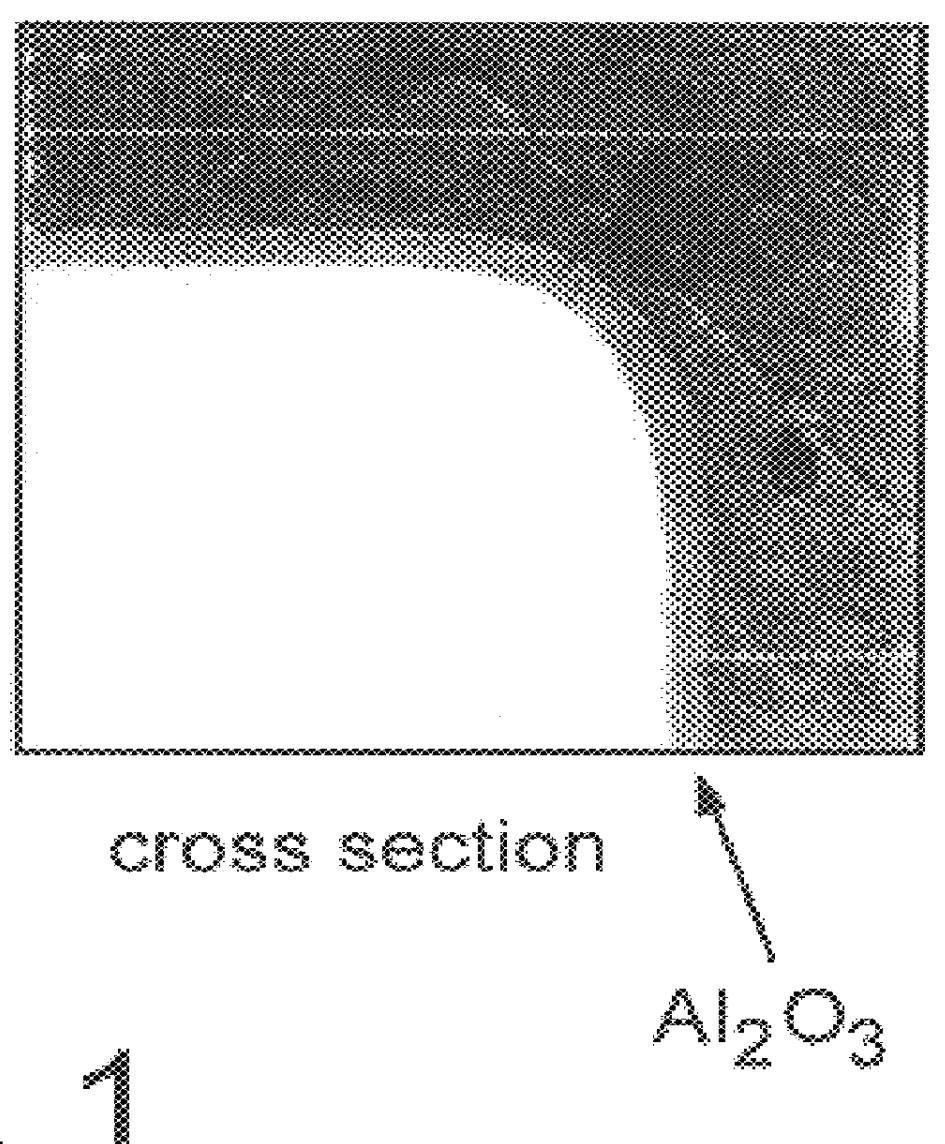

Method for depositing fine-grained alumina coatings on cutting tools

A method for depositing refractory alumina (A2O3) thin layers on cutting tools made of cemented carbide, cermet, ceramics or high speed steel is disclosed. The present method is a Plasma Activated Chemical Vapor Deposition (PACVD) process in which the plasma is produced by applying a bipolar pulsed DC voltage across two electrodes to which the tool substrates to be coated are fixtured and electrically connected. In contrast to prior art methods, built-up electrical charge on non-conducting surfaces is suppressed and hence, no arcing occurs on said surfaces. This will permit stable, long-term processing, With the present method, high-quality coatings of either single phase gamma-Al2O3 or of a mixture of gamma- and alpha-Al2O3 phases can be deposited on cutting tools at deposition temperatures as low as 500 DEG C. When coated cemented carbide tools according to the invention are used in the machining of steel or cast iron, several important improvements to prior art produced Al2O3-coated tools have been observed.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

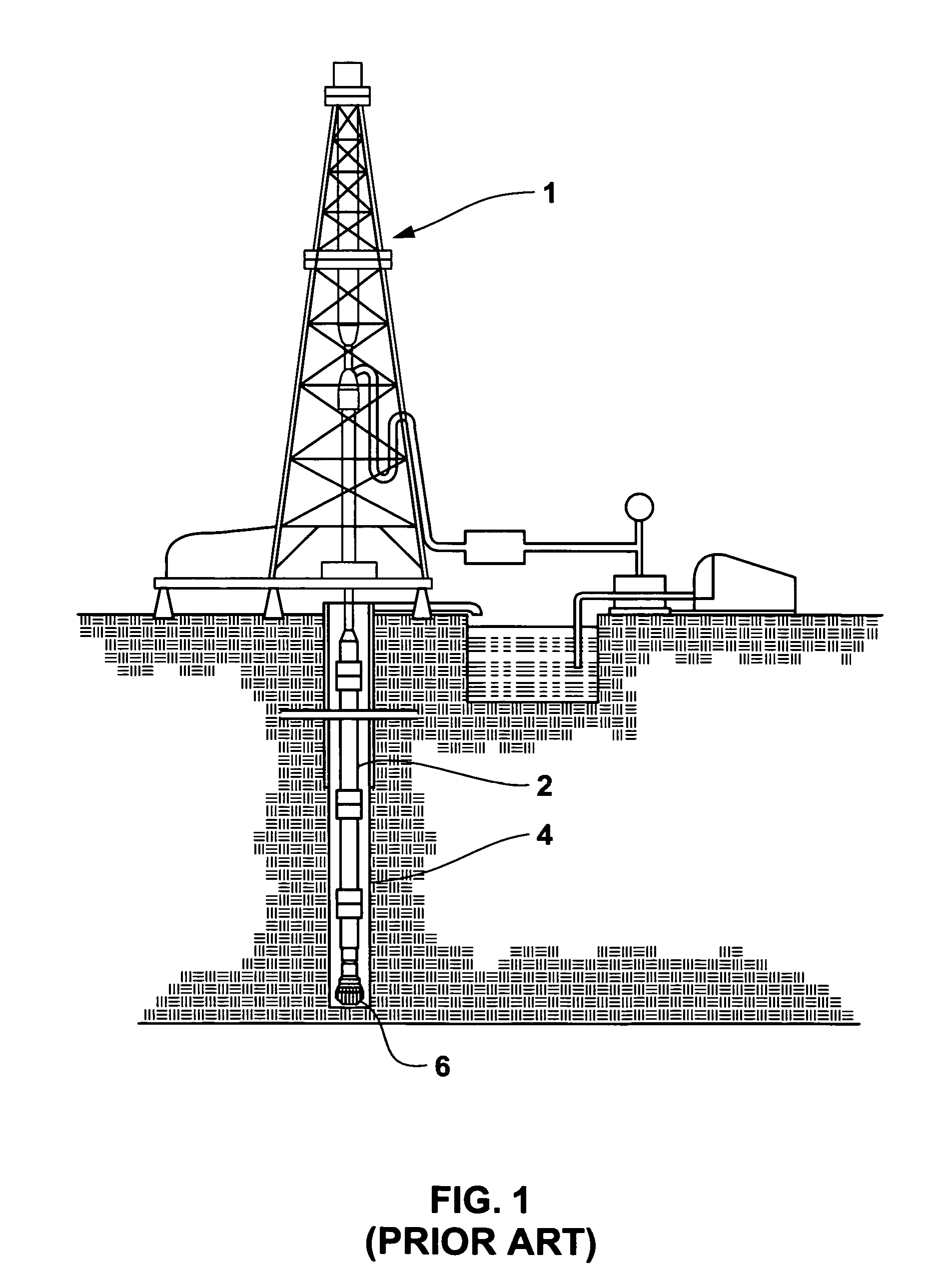

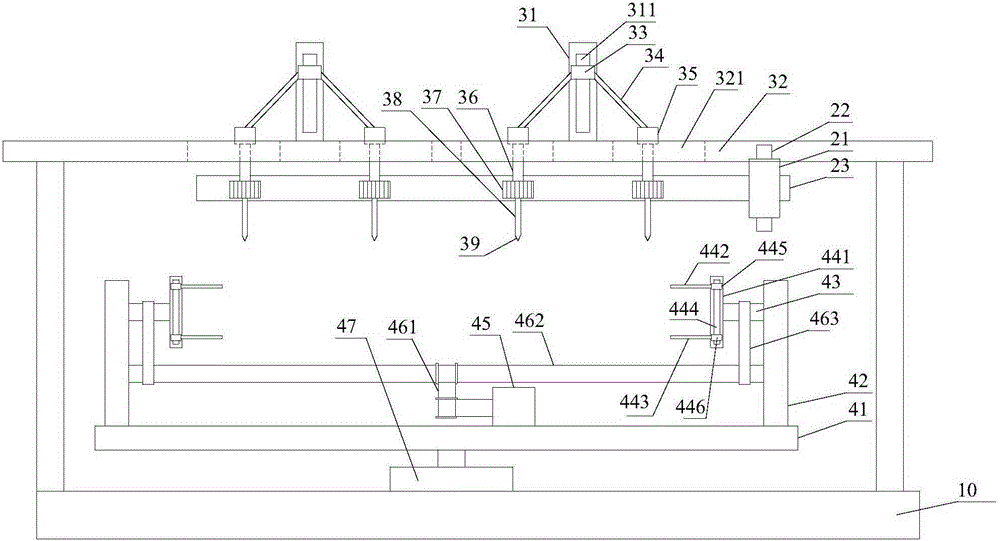

Steel tube drilling device provided with multiple drill heads

The invention provides a steel tube drilling device provided with multiple drill heads. The device comprises a workbench, a driving mechanism, a drilling mechanism and a clamping mechanism, wherein the driving mechanism comprises a first gear, a rack and a drive shaft; the drilling mechanism comprises multiple drilling apparatuses, and each drilling apparatus comprises a stand column mounted on the workbench, a cross bar mounted on the stand column, a connecting plate mounted on the stand column and at least two drilling units; each drilling unit comprises a slider, a first connecting rod, a second gear and a drill rod; the connecting plates are hinged with the sliders through second connecting rods with equal lengths; the clamping mechanism comprises a mounting plate, a first drive device and clamping devices symmetrically arranged at two ends of the mounting plate; each clamping device comprises a bracket, a first rotating shaft and a clamping unit, the first rotating shaft is horizontally and rotationally mounted on the bracket, and the clamping unit is mounted on the first rotating shaft; the first drive device is in transmission connection with the first rotating shafts through transmission mechanisms. The device can drill multiple holes in the same steel tube, and the product quality is high.

Owner:芜湖精钻机电技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com