Indexable cutting inserts and methods for producing the same

a technology of indexable cutting inserts and cutting inserts, which is applied in the direction of cutting inserts, shaping cutters, manufacturing tools, etc., can solve the problems of difficult and expensive machining of “trumpet” style holes in superhard materials, difficult to achieve the effect of machining, and difficult to accurately cu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]Exemplary arrangements and techniques according to the present invention will now be described by reference to the drawing figures.

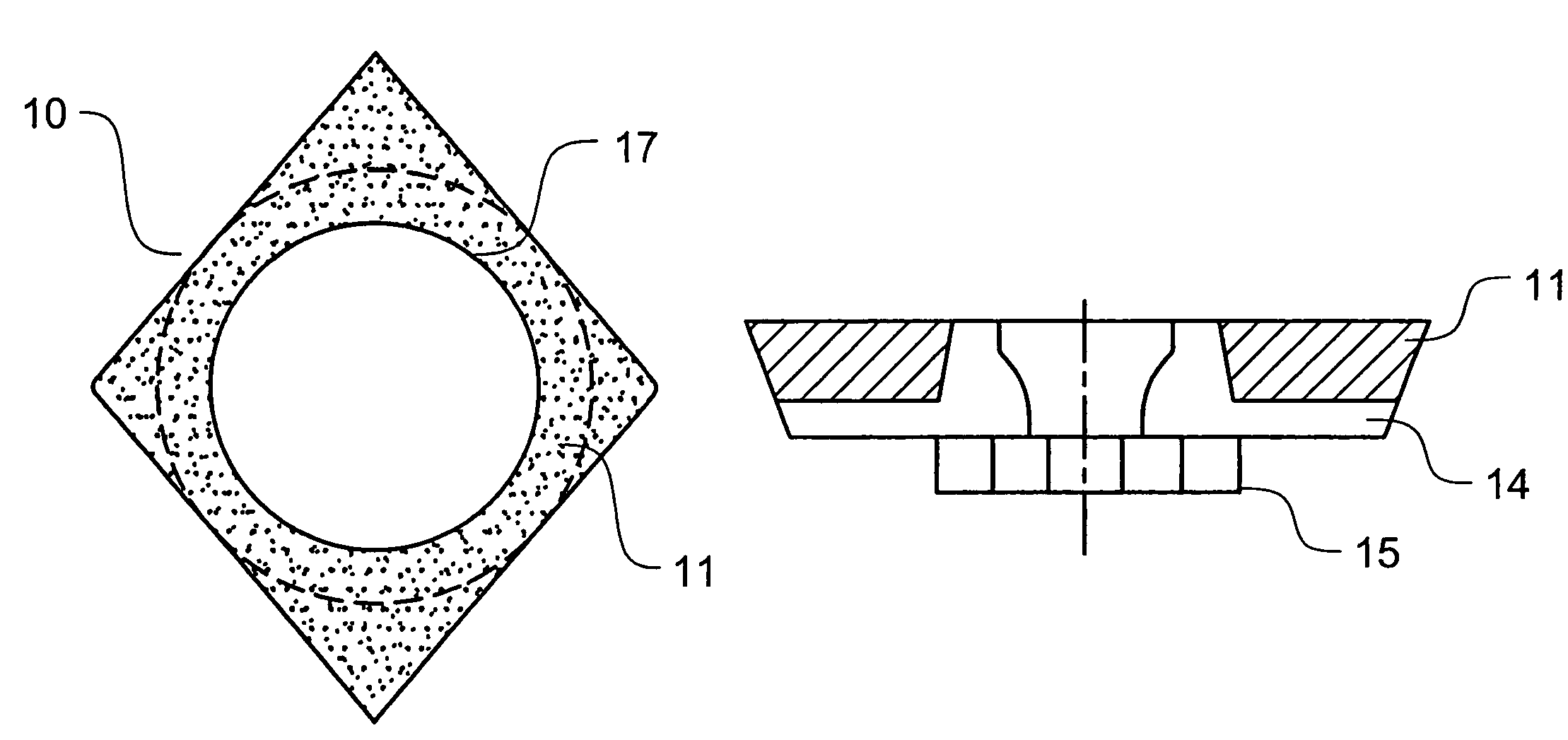

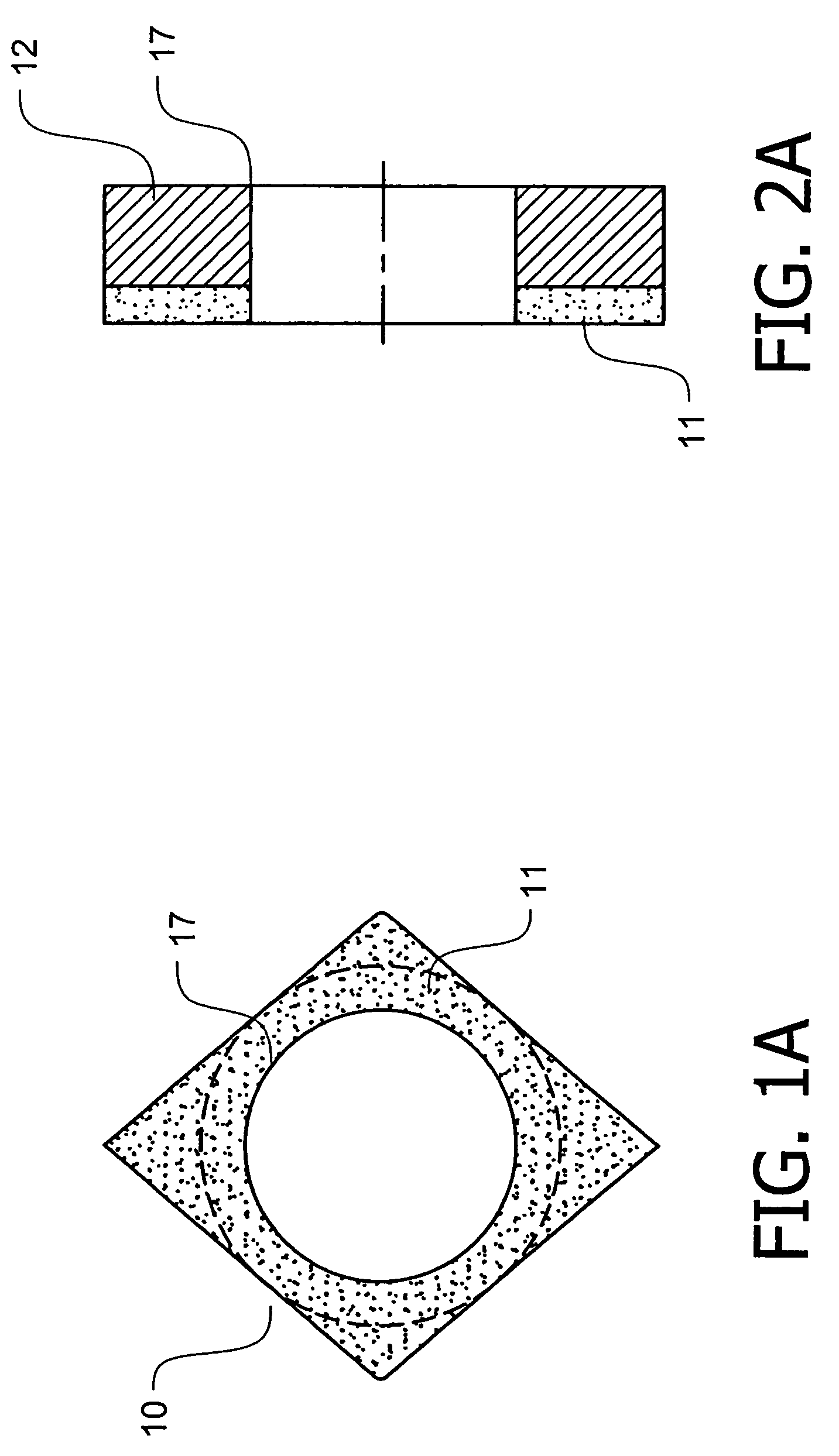

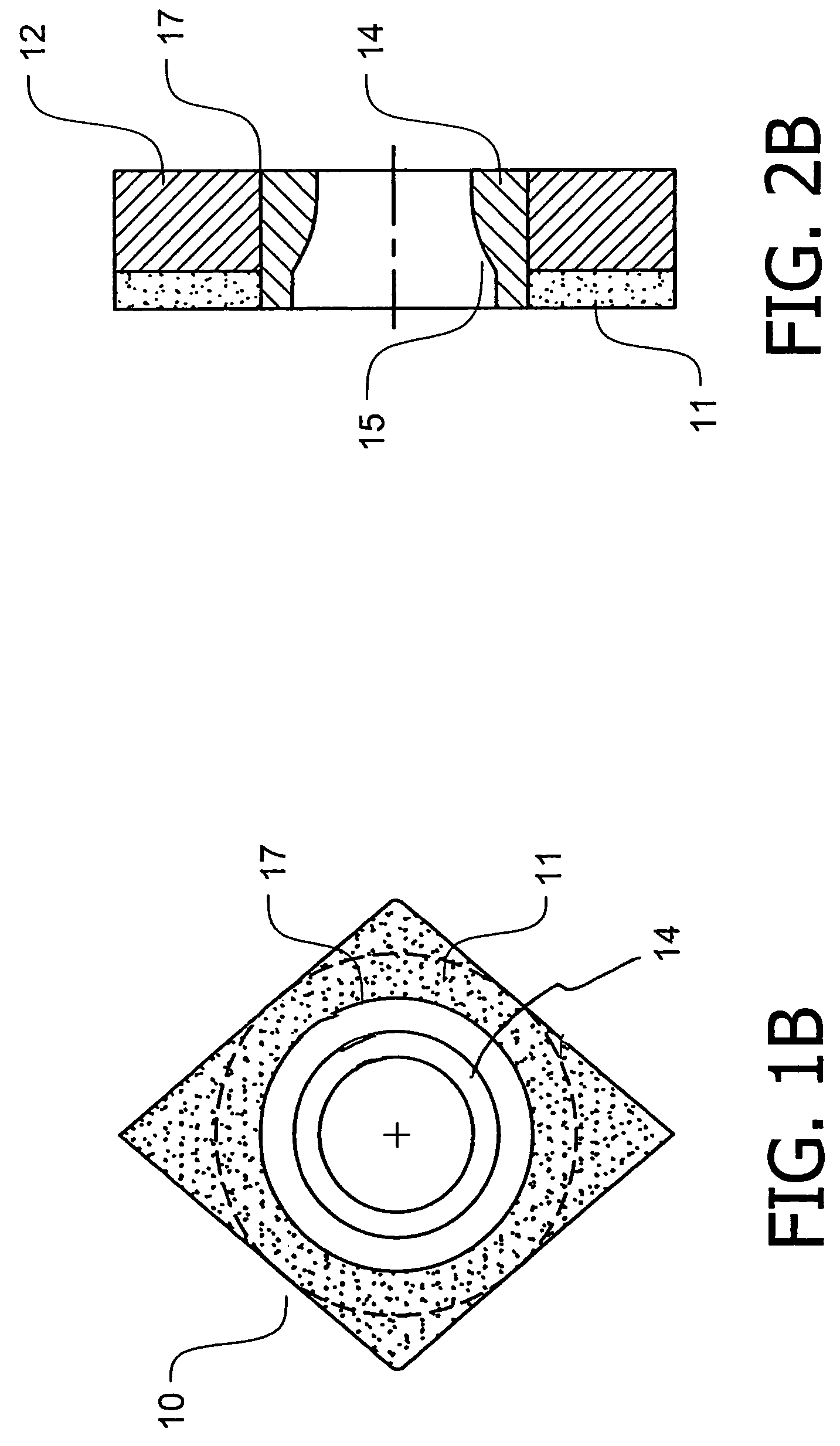

[0025]According to the present invention, a blank is formed from a superhard cutting material. The blank can also be formed from at least one hard material and at least one superhard cutting material. An illustrative embodiment of such a latter blank is shown in FIGS. 1A, 1B, 2A and 2B. As shown therein, the blank 10 comprises a top layer or portion 11 of a superhard material and a bottom layer or portion 12 of a hard material. While the blank 10 is illustrated as having a polygonal-like shape, other geometries are clearly possible, such as circular.

[0026]Generally, the superhard cutting material and the hard material are sintered together using conventional high-pressure and high-temperature techniques to form a solid body in disc form. Such techniques are conventional and are disclosed, for example, in U.S. Pat. No. 5,676,496. When made only of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| cross-section | aaaaa | aaaaa |

| sintering | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com