Patents

Literature

83results about How to "Reduce cutting efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

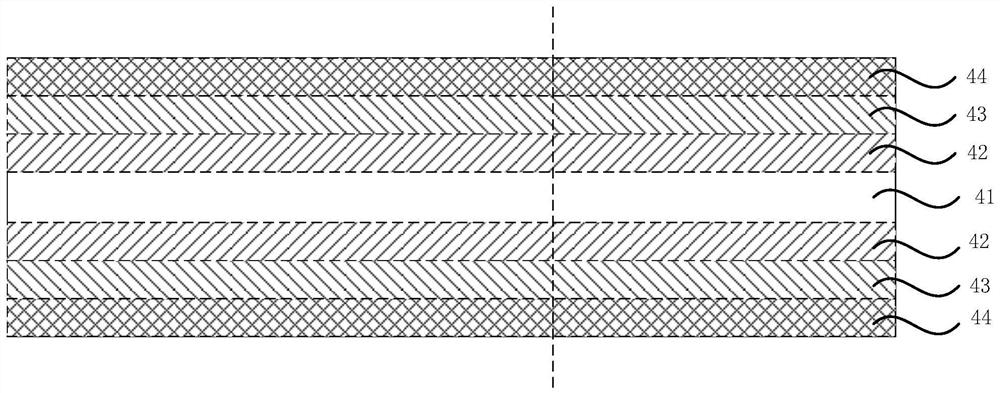

Cutting elements and bits incorporating the same

Cutting elements and bits incorporating such cutting elements are provided. The cutting elements have a substrate, a first ultra hard material layer formed over the substrate, and a second ultra hard material layer formed over the first ultra hard material layer. The second ultra hard material layer has a thickness in the range of 0.05 mm to 2 mm.

Owner:SMITH INT INC

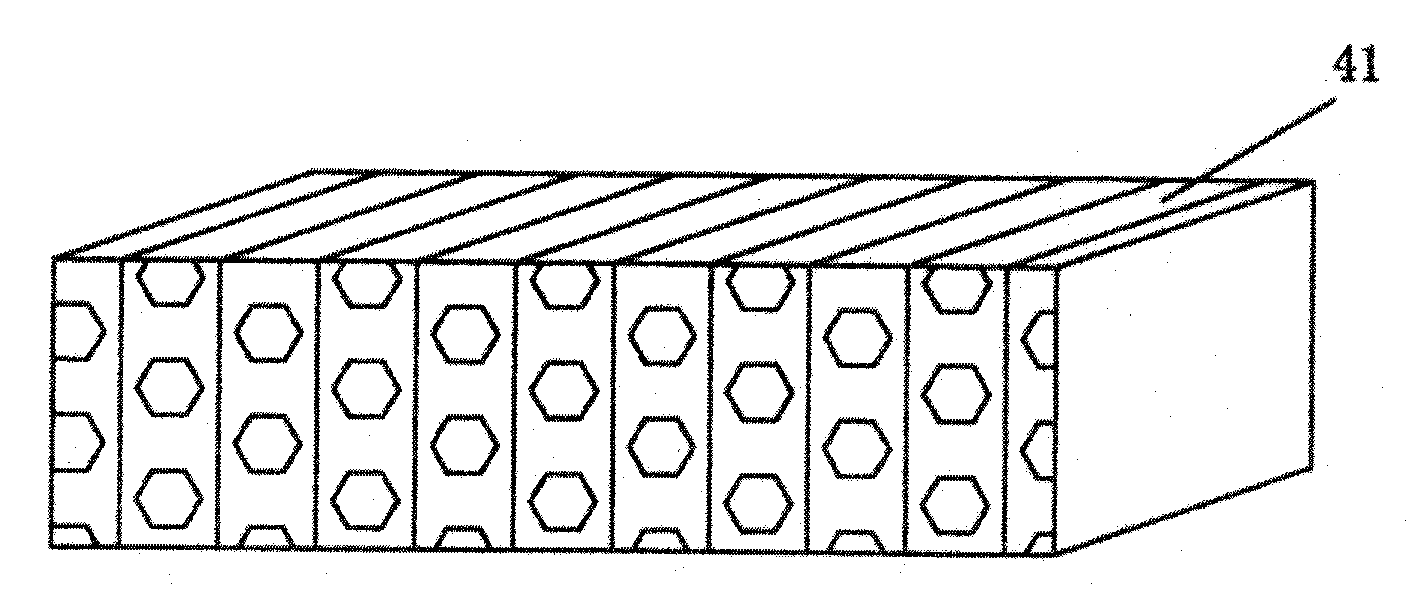

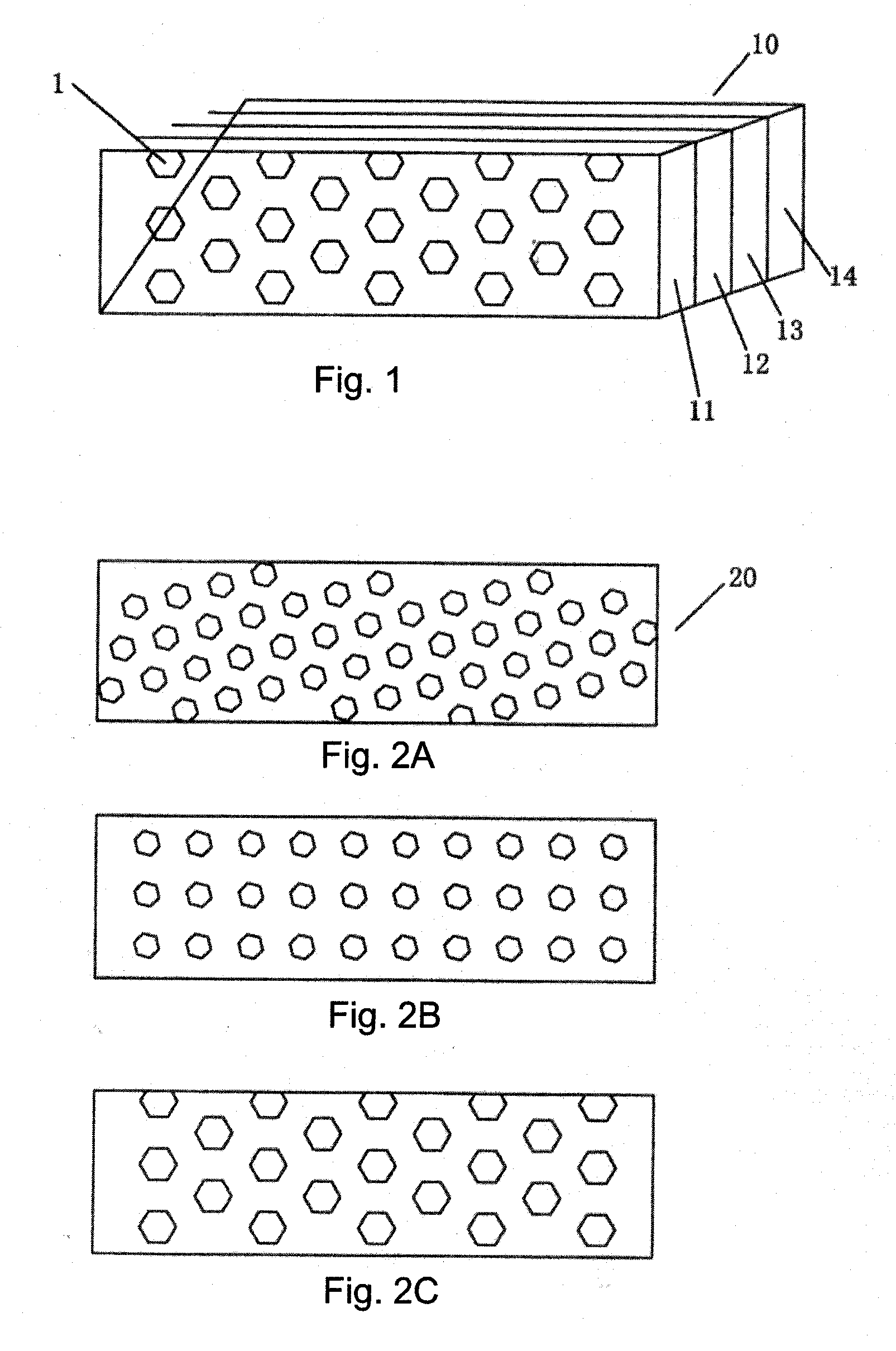

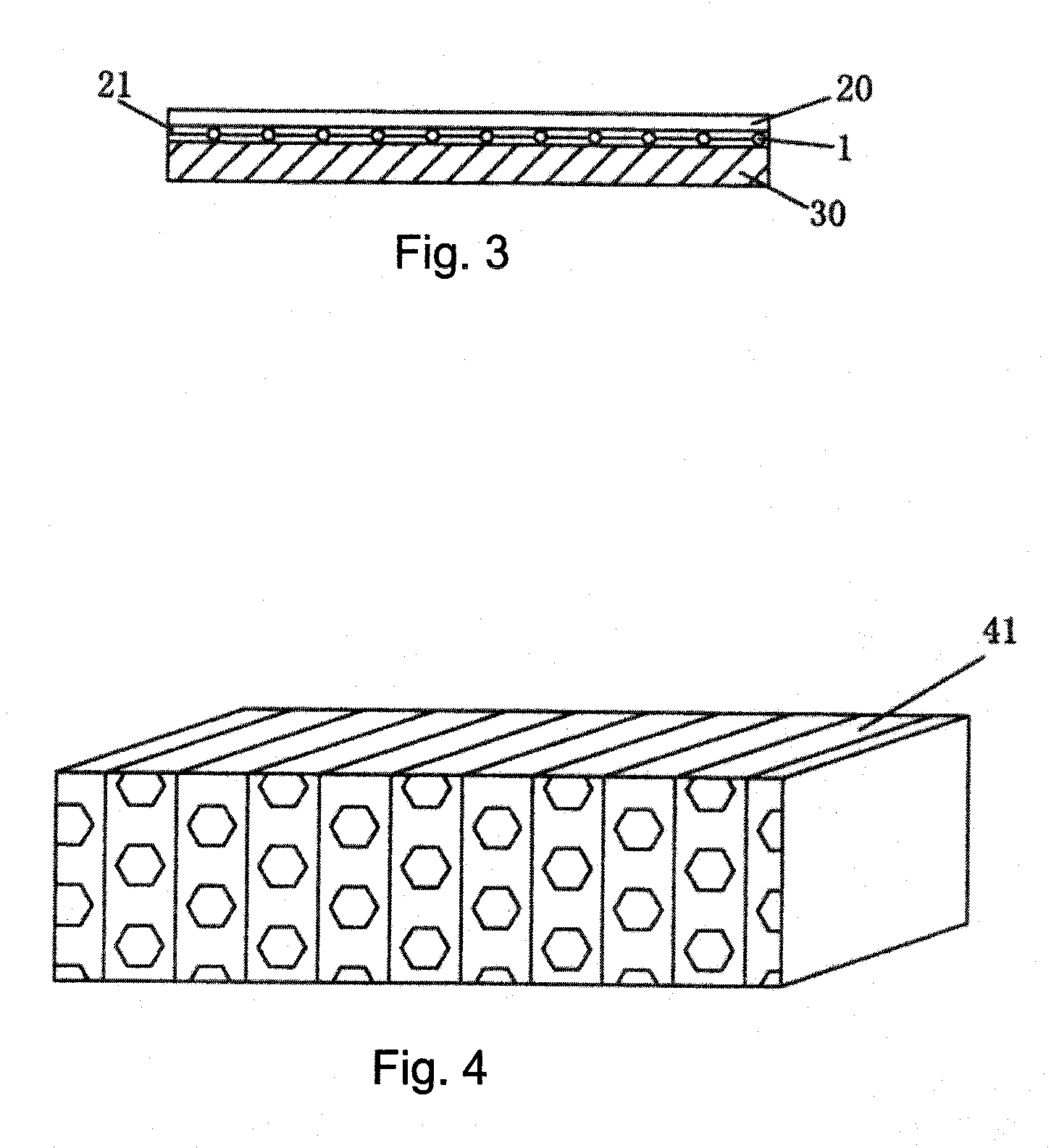

Grinding Tools that Contain Uniform Distribution of Abrasive Grits and Method of Manufacture Thereof

InactiveUS20090094902A1Evenly distributedIncrease concentrationPigmenting treatmentOther chemical processesTemplate designWear particle

The present invention relates to a method of uniformly distributing abrasive grits on grinding tools. It can be applied in the cutting, grinding segments of diamond tools, which are typically used in cutting and drilling various hard and fragile materials, such as granite, marble, concrete, asphalt, etc. The present invention provides a template, the template designed based on the arranging requirement of abrasive particles such as diamond grits. The template can adsorb only a single layer of abrasive particles and is then placed onto a sheet, where the diamond grits are pressed into the sheet, with the diamond grits distributed uniformly on the sheet.

Owner:HOU JIAXIANG

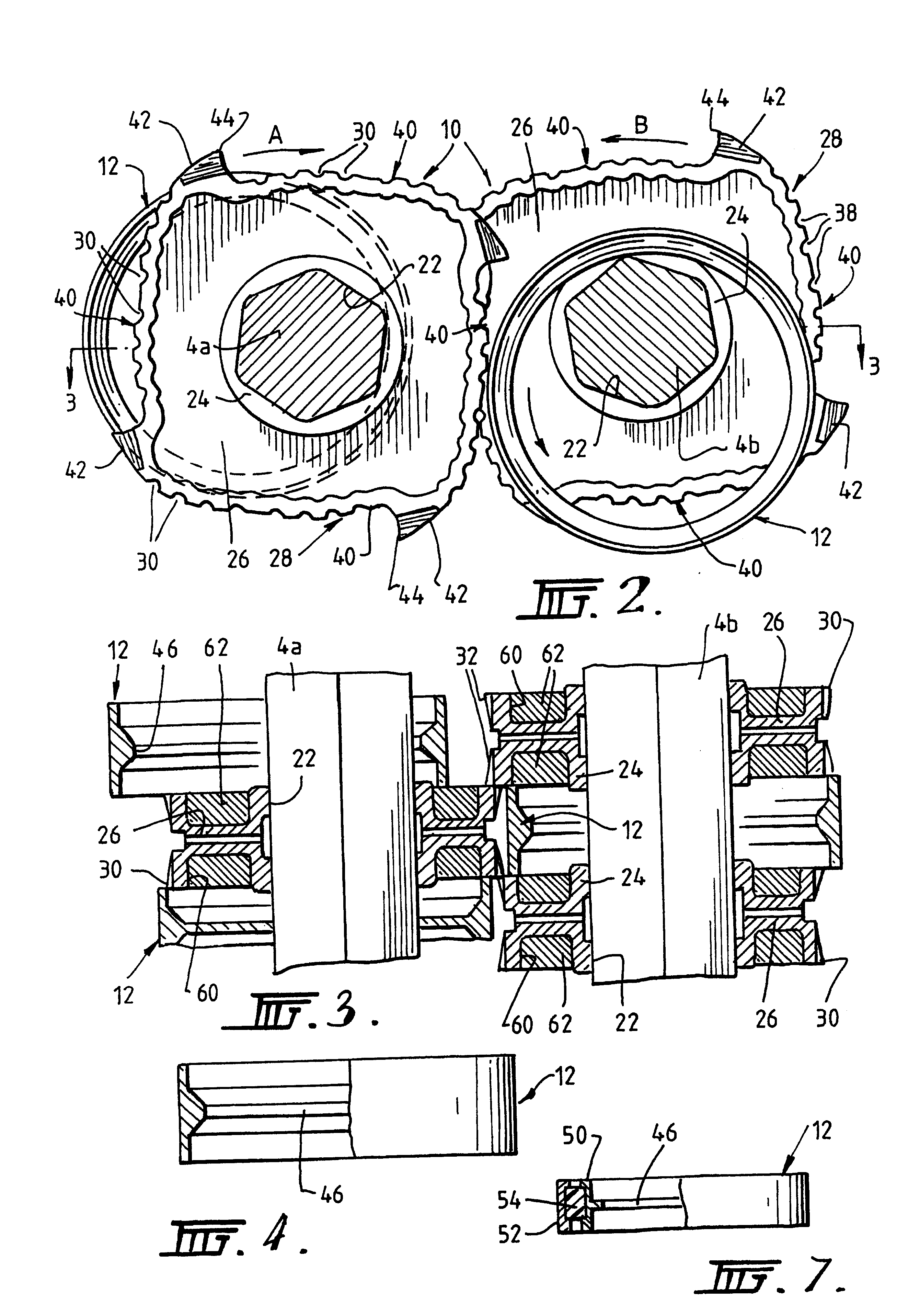

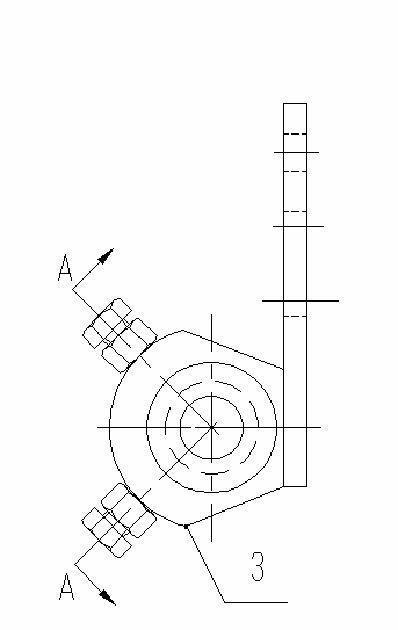

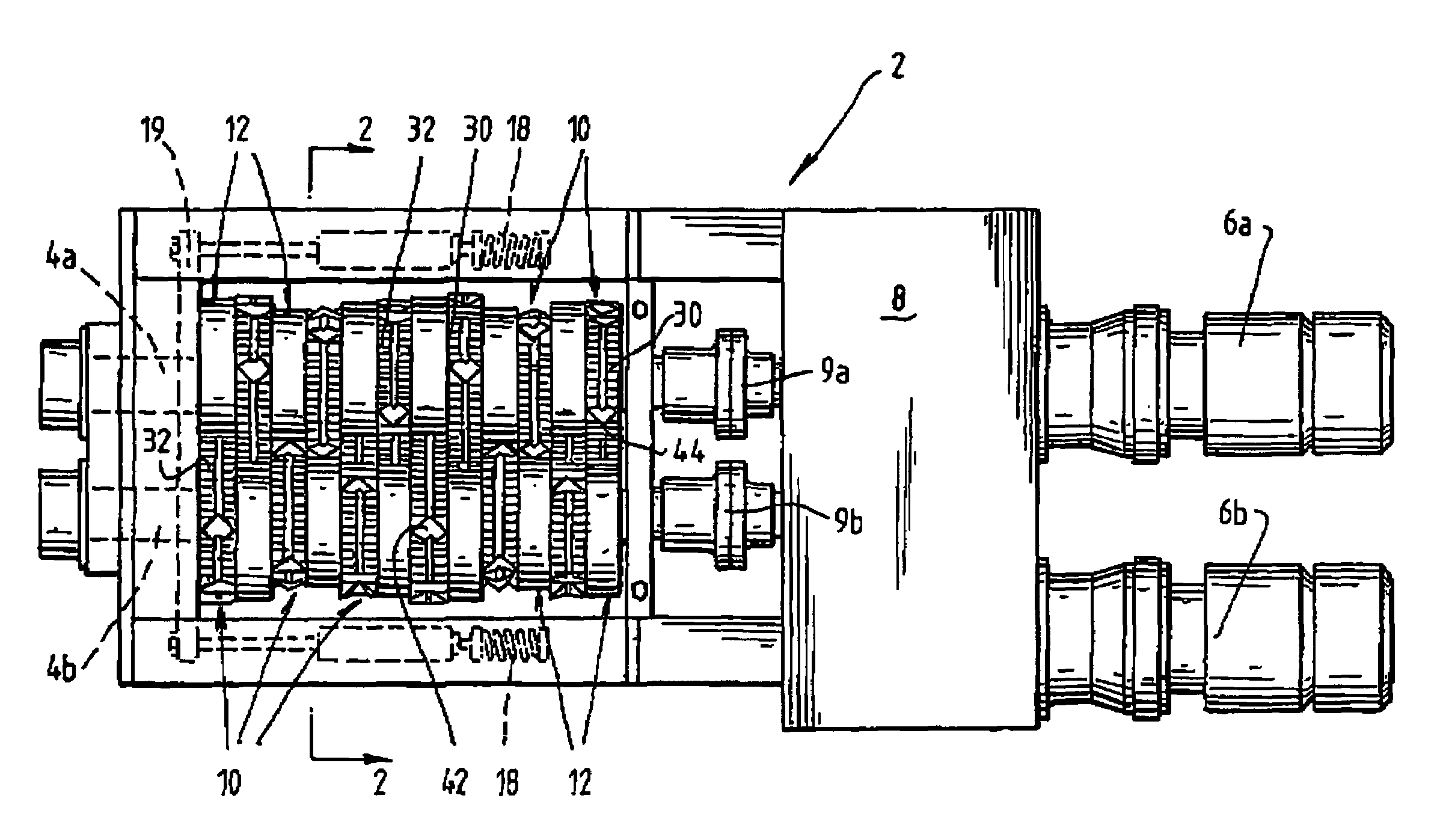

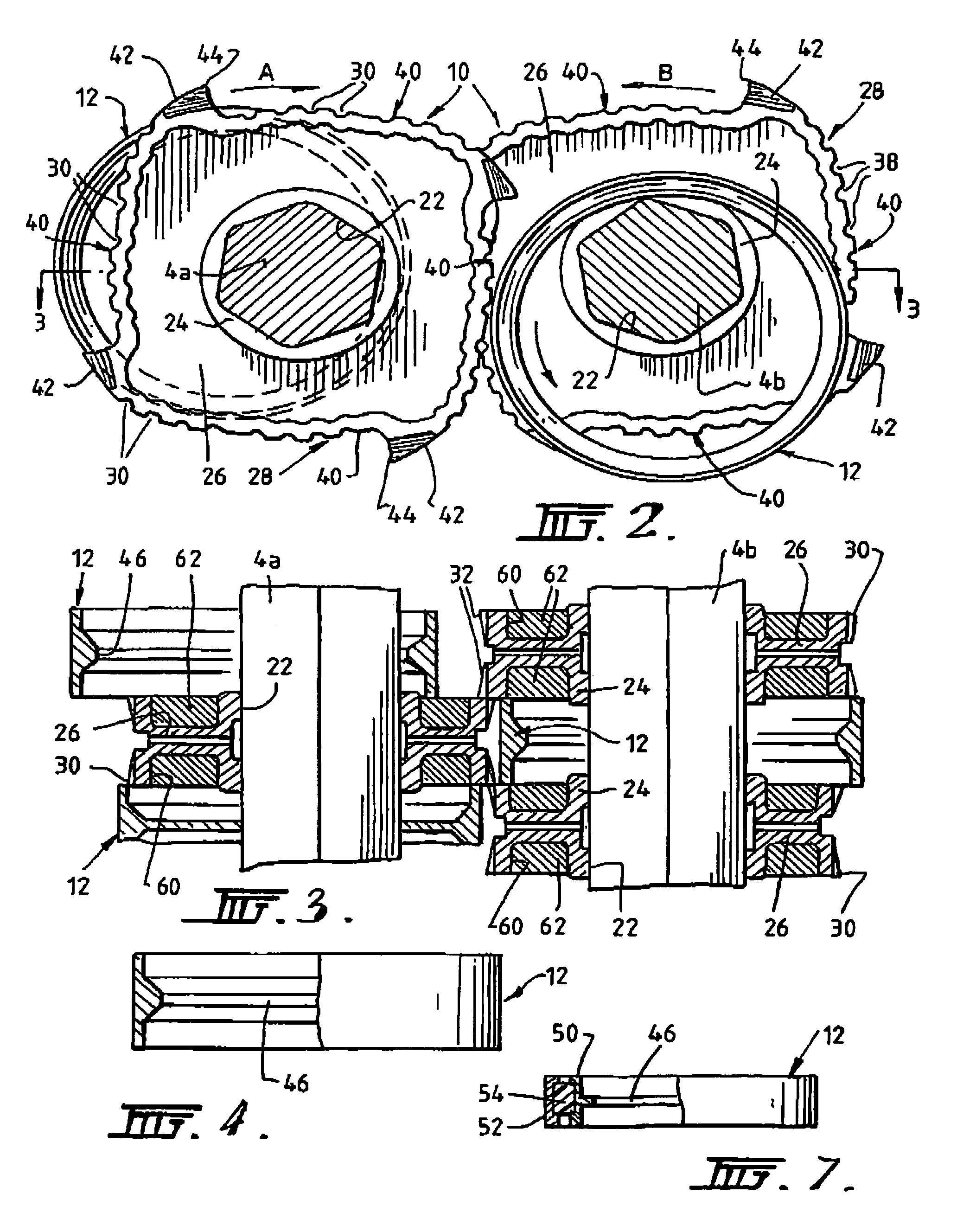

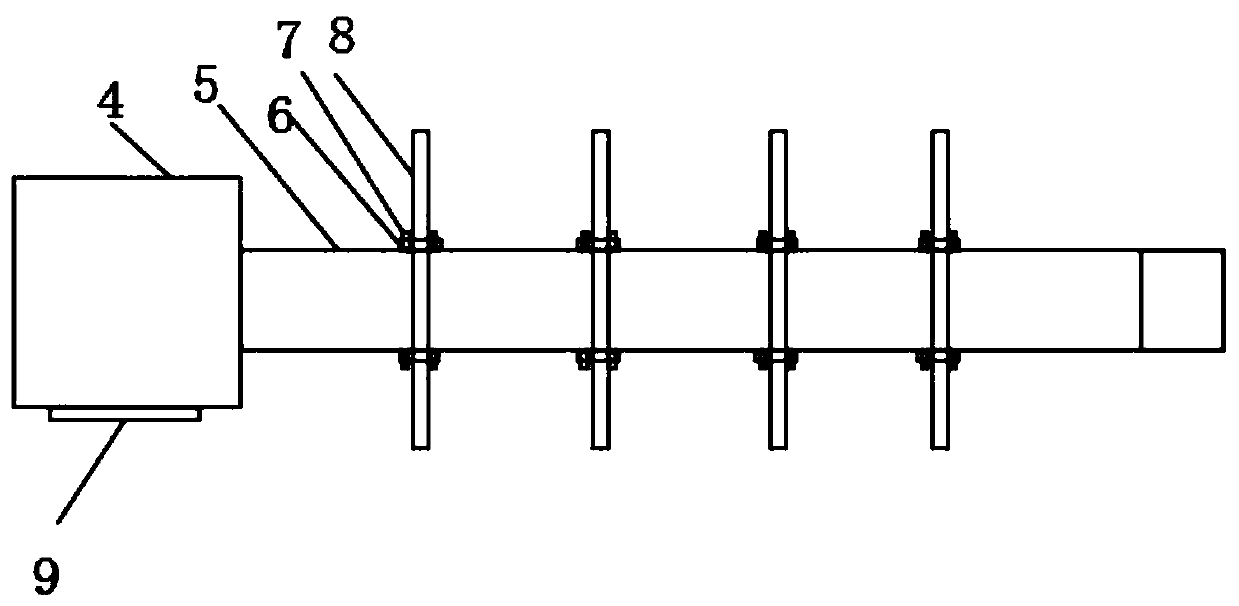

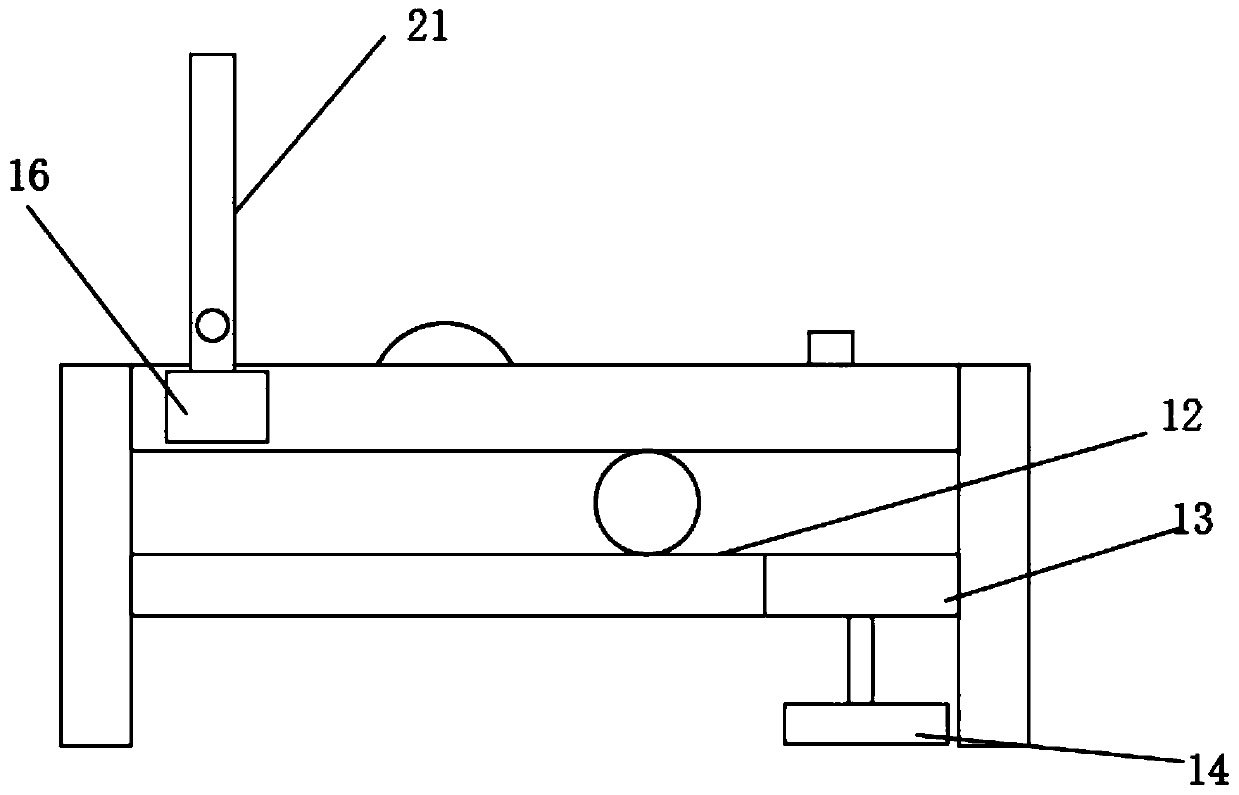

Self cleaning shredding device having movable cleaning rings

InactiveUS20050040263A1Prevent bulk materialEffective anti-wrapping arrangementSolid waste disposalCocoaEngineeringLinear motion

A self cleaning cutting assembly is provided, having an array of counter rotating cutters in which a plurality of cutters rotating in a first direction are mounted on a first shaft and a plurality of second cutters are mounted on a second shaft for rotating in an opposite direction. The array of cutters is provided with a plurality of clearing or cleaning rings located alternately with the cutters on each shaft. The cutting array is kept clear of debris or partially cut material by movement of the clearing or cutting rings against adjacent cutters. Movement of the clearing or cleaning rings is a combination of rotary motion and linear motion, in which the linear motion is imparted by the cutter located opposite the cleaning ring striking the cleaning rings so as to push the cleaning ring beyond the position of the widest part of the cutter to completely dislodge material from the cutter.

Owner:TERRANCE JAMES PARKE

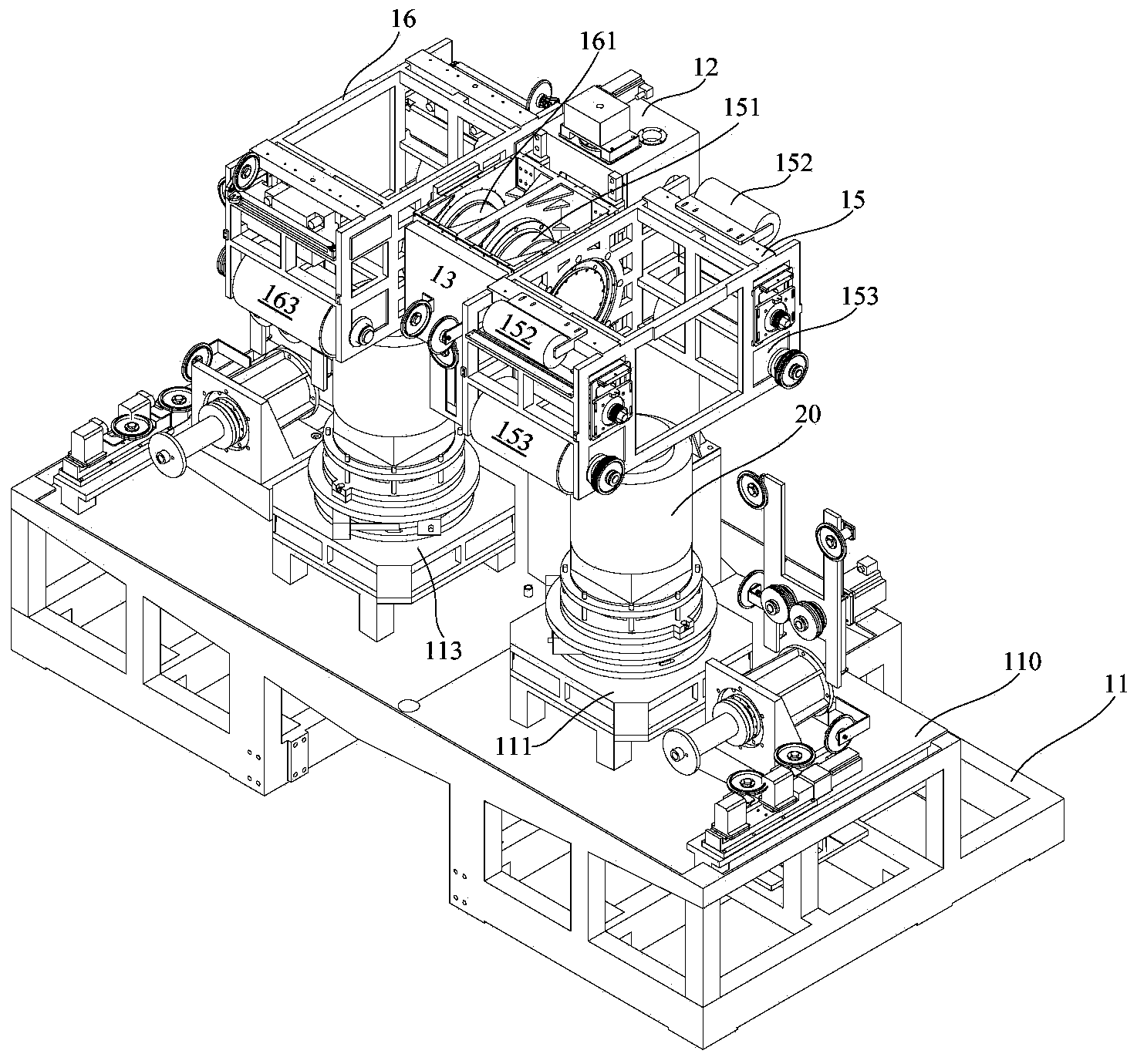

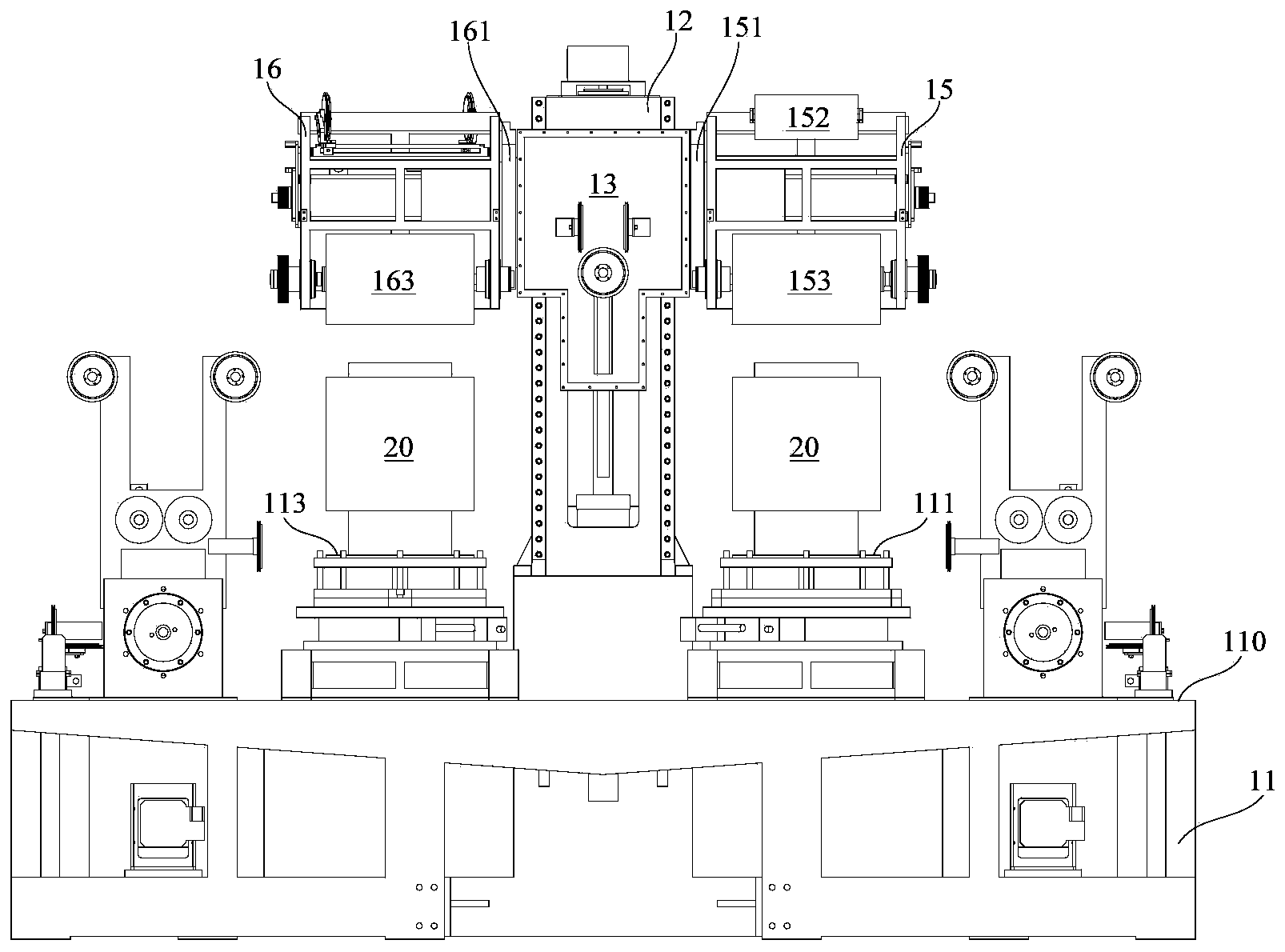

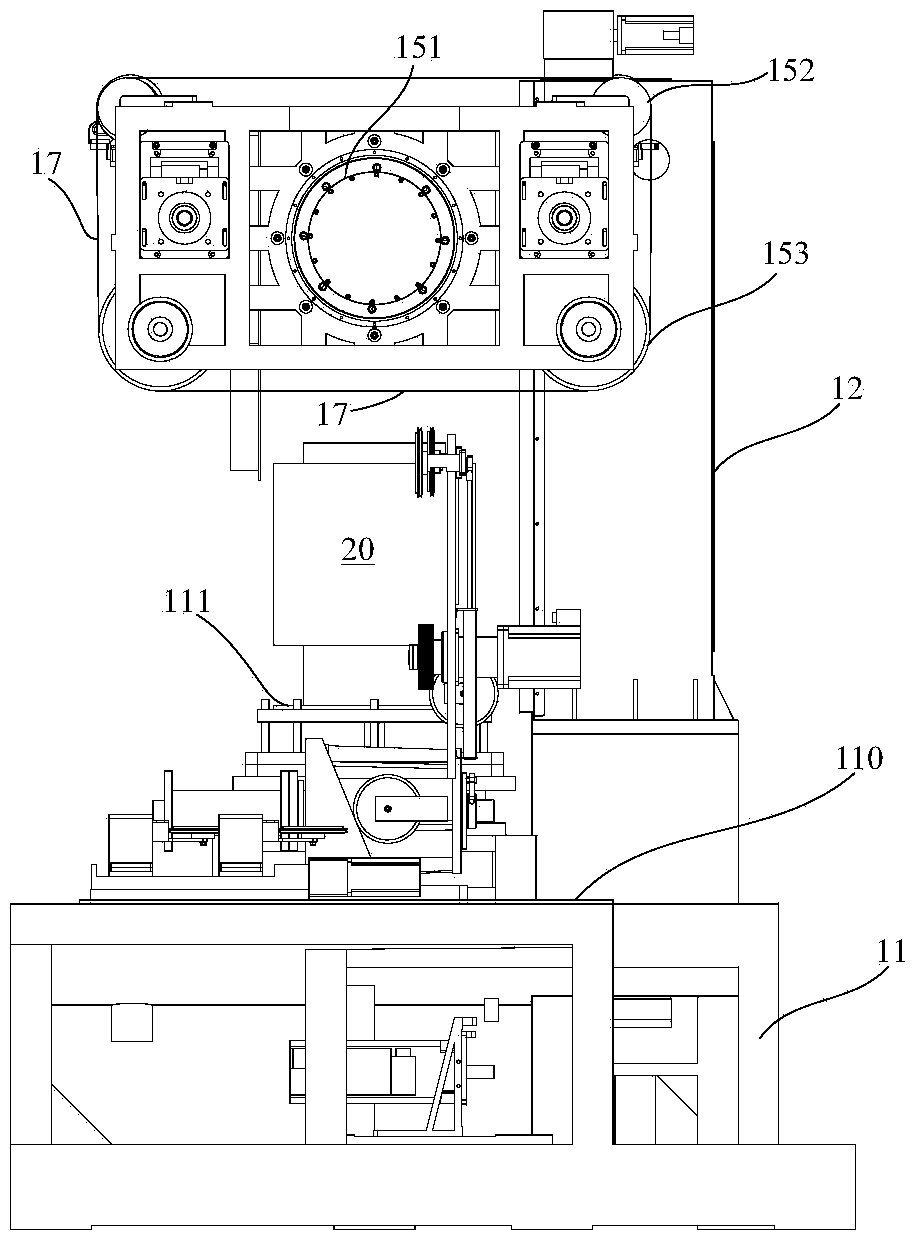

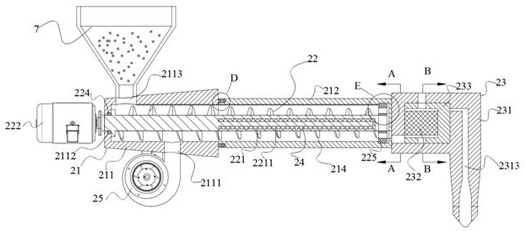

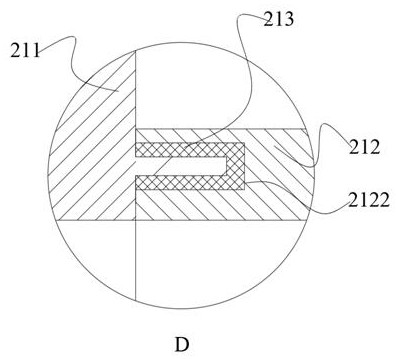

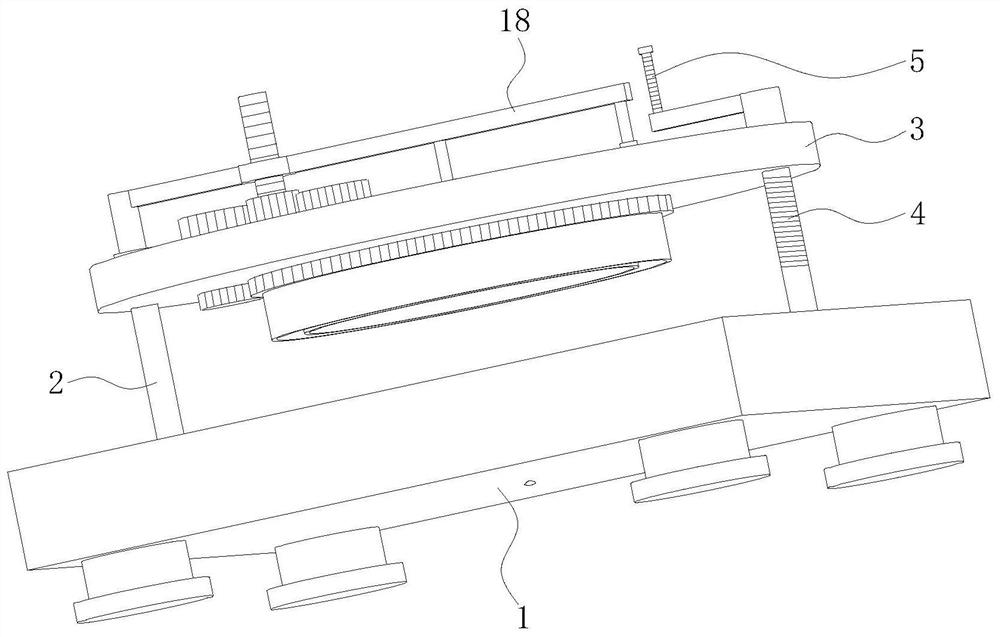

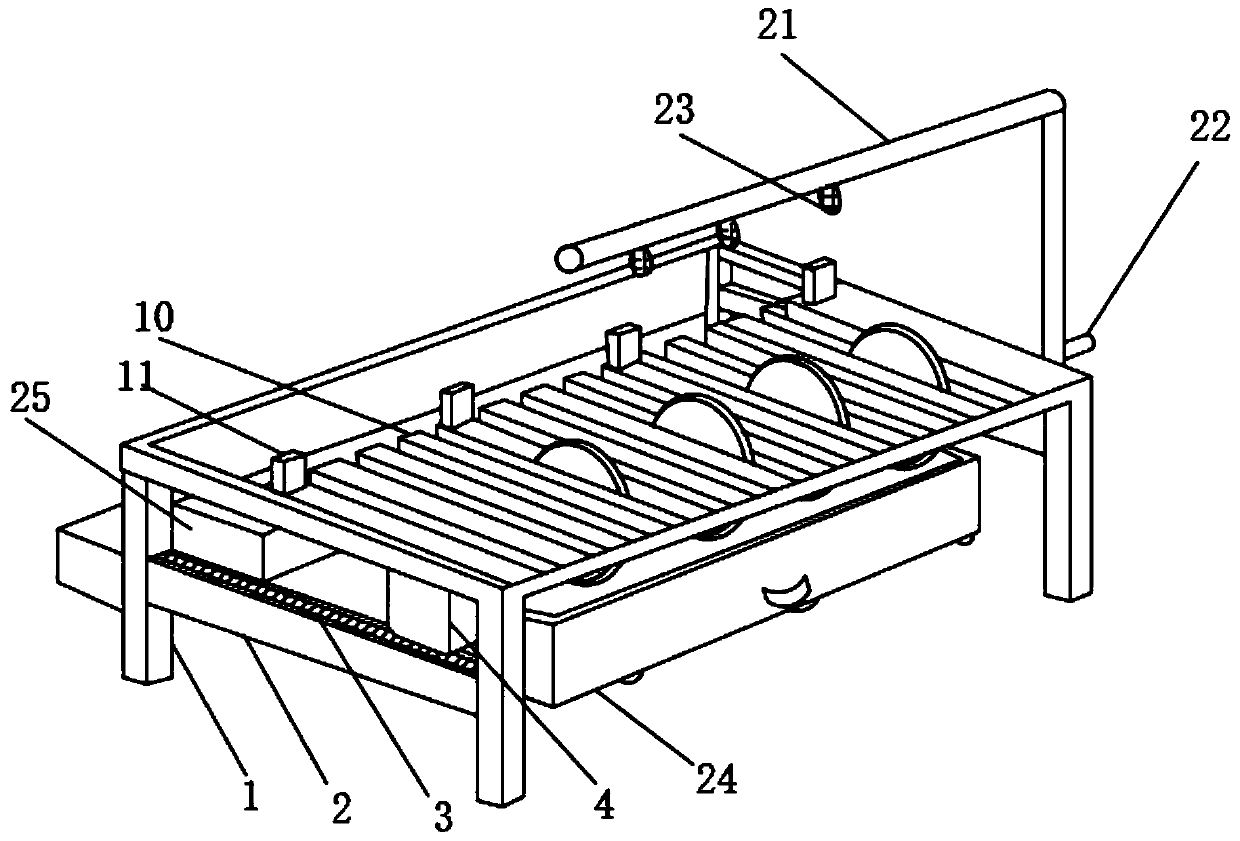

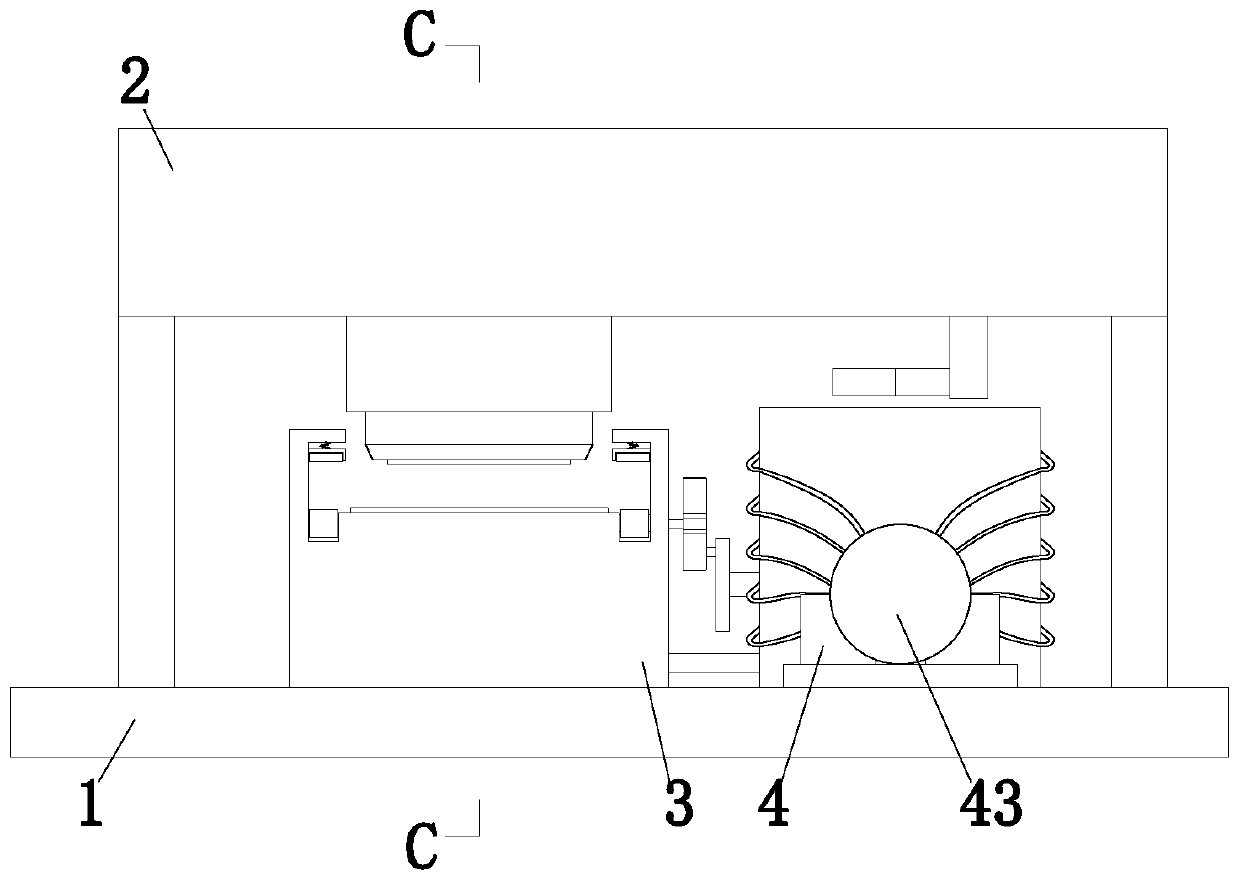

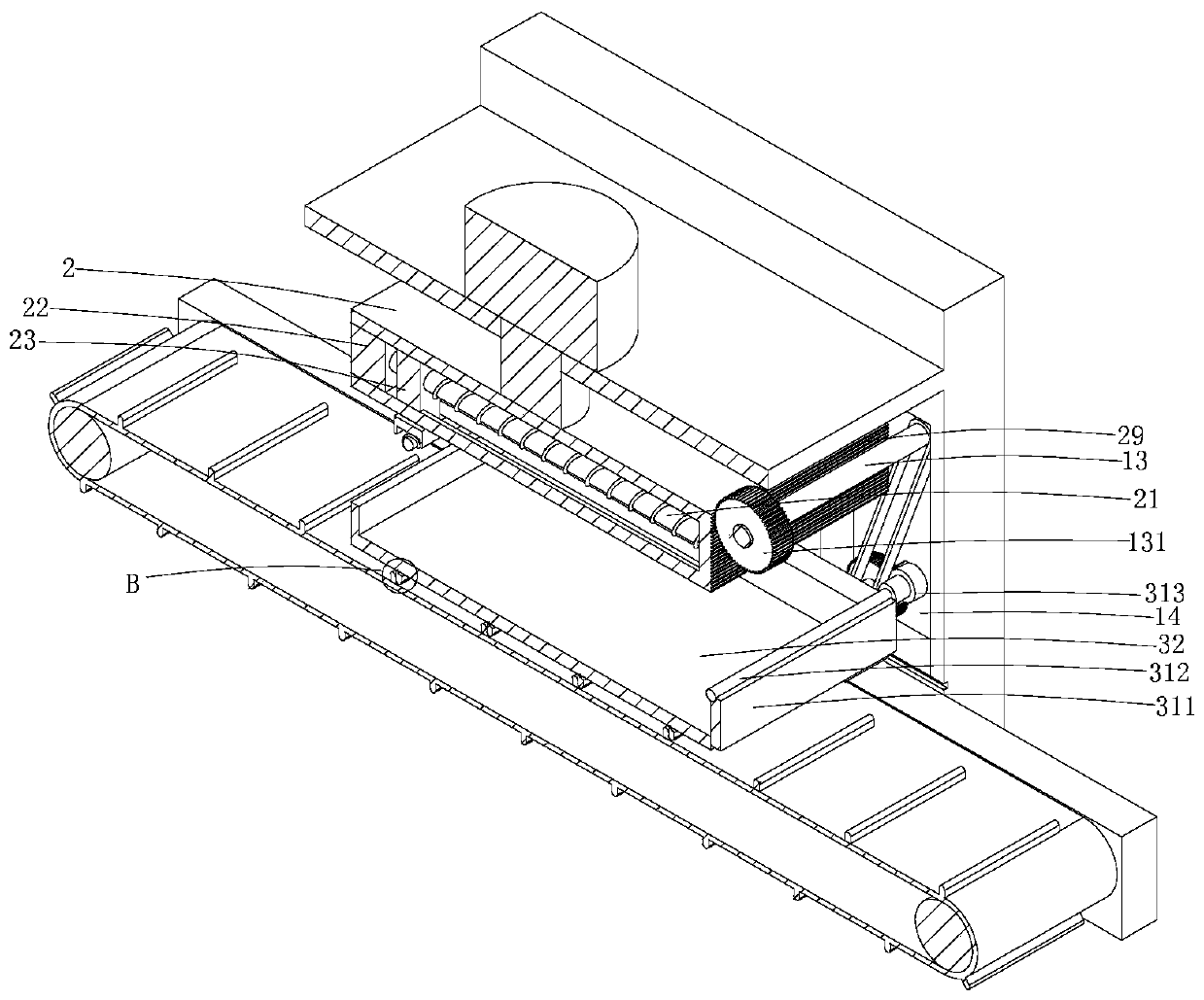

Diamond wire squaring machine

ActiveCN103921360AResolve resistanceSolve cutting difficultiesFine working devicesCouplingEngineering

The invention provides a diamond wire squaring machine which comprises a rack. The rack is provided with a rack platform, two workbenches, a supporting stand column, a turning-connection support and two wire stands, wherein the two workbenches and the supporting stand column are arranged on the rack platform, the turning-connection support is arranged on the supporting stand column in a lifting mode, and the two wire stands are connected to the two sides of the turning-connection support in a coupling and rotating mode. Each wire stand is provided with a cutting roller, a server motor and a diamond wire which is wound on the cutting roller. Any wire stand rotates relative to the turning-connection support in a coupling mode to drive the diamond wire to alternatively and obliquely cut machined parts on the workbenches relative to the horizontal line, the entire cutting process is smooth, control is easy, the cutting time is greatly shortened, and the cutting precision and the cutting efficiency are improved.

Owner:海宁市日进科技有限公司

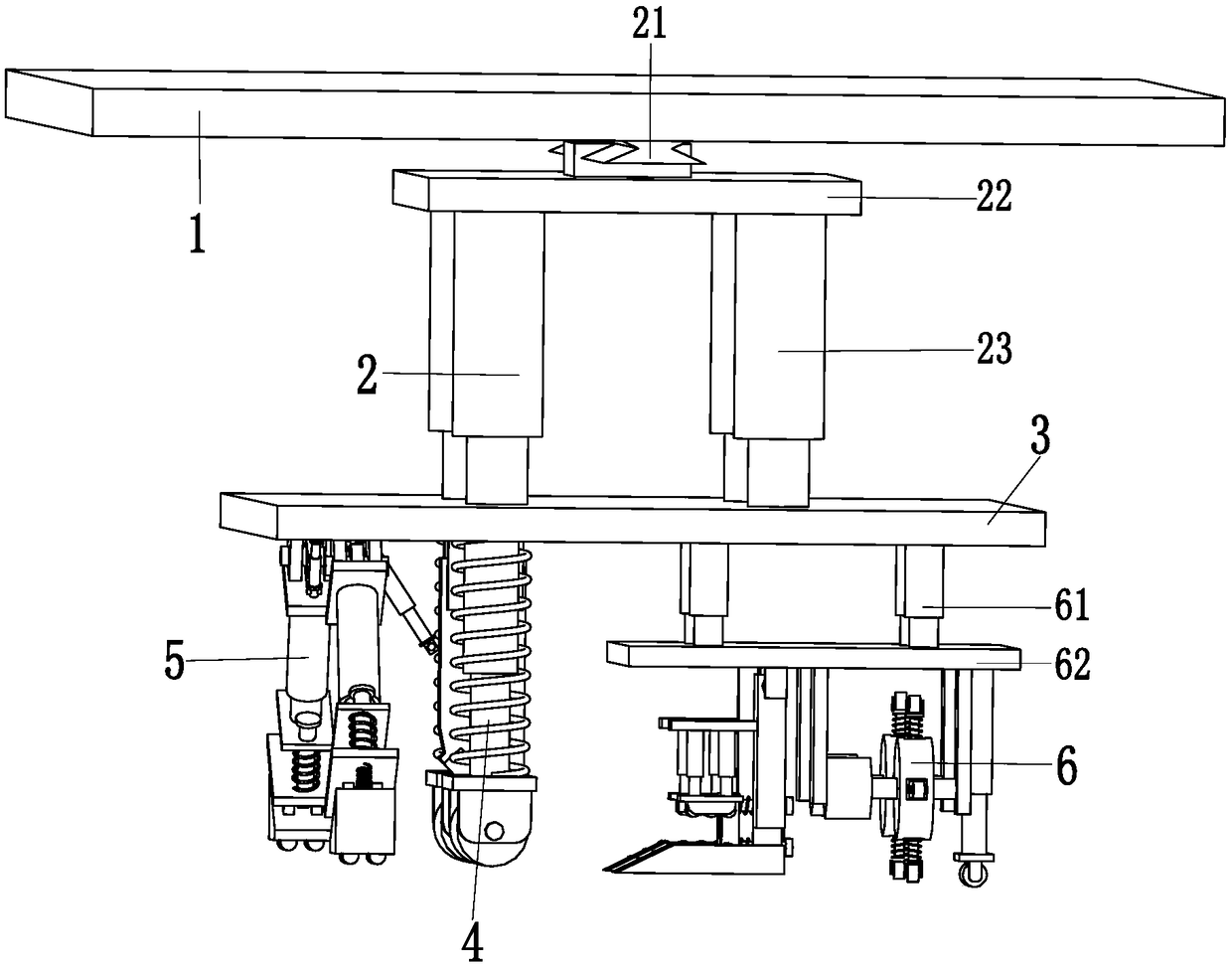

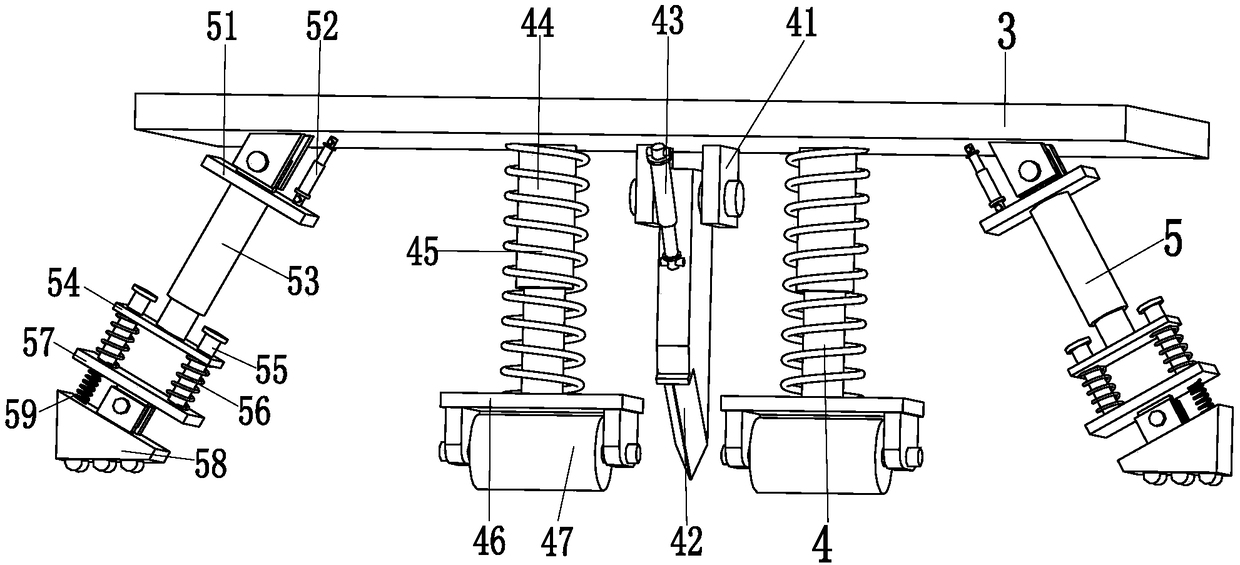

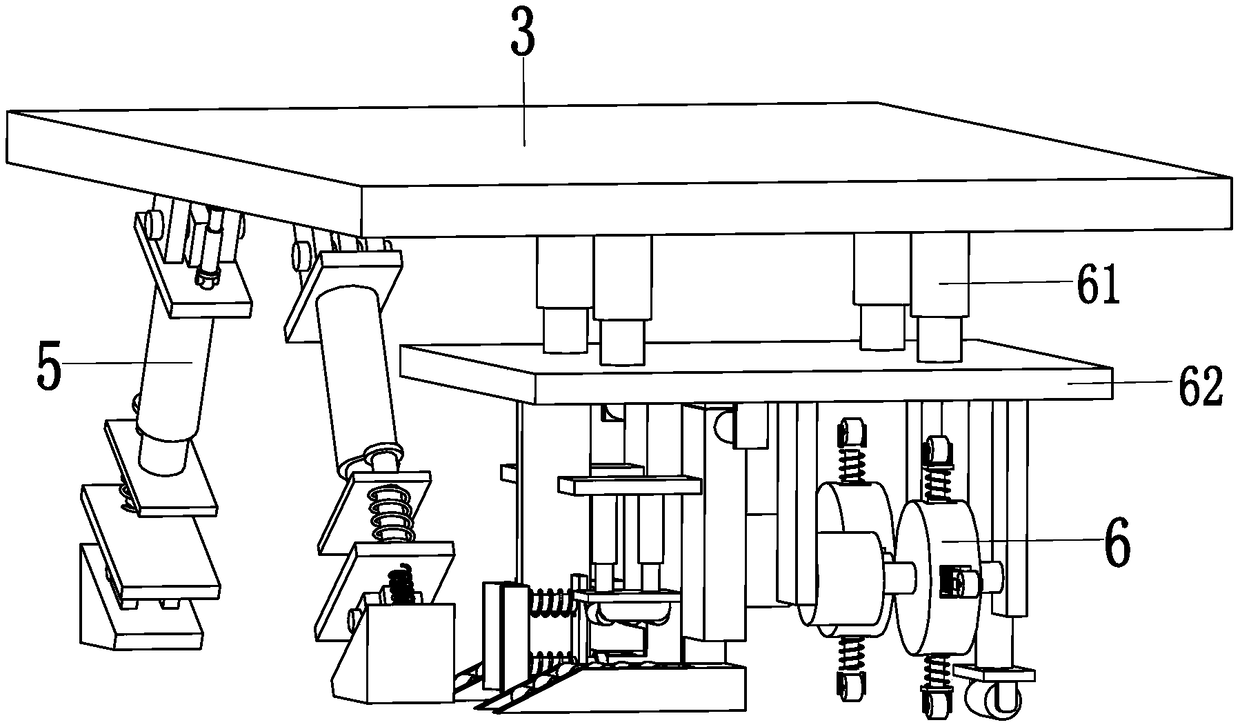

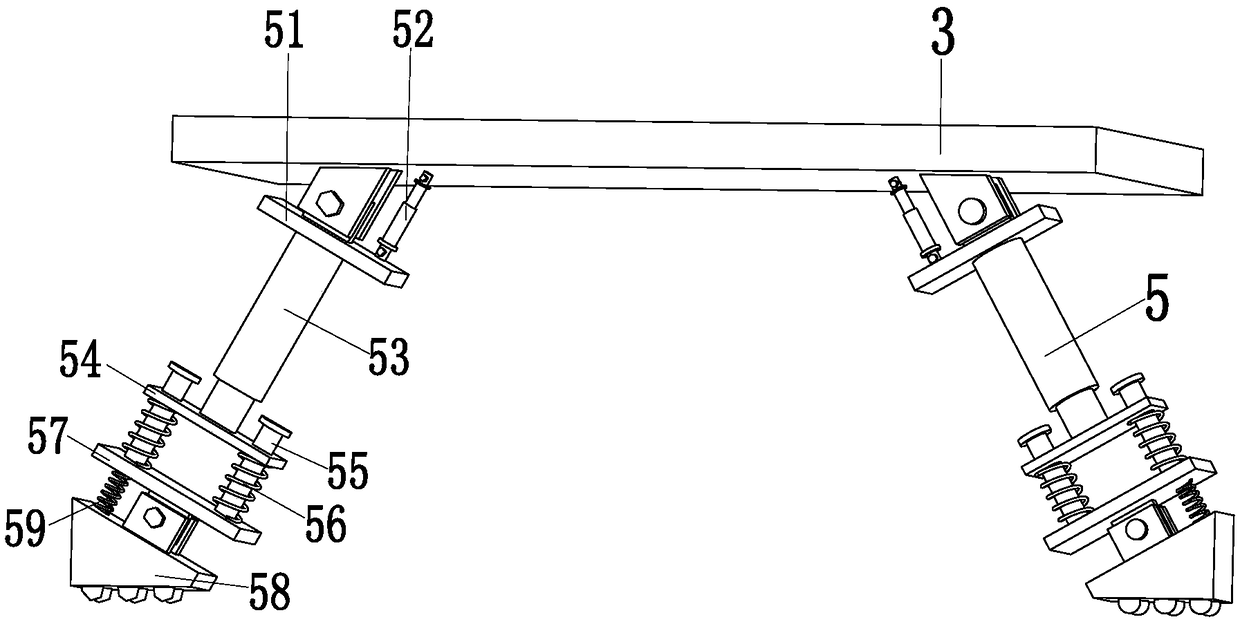

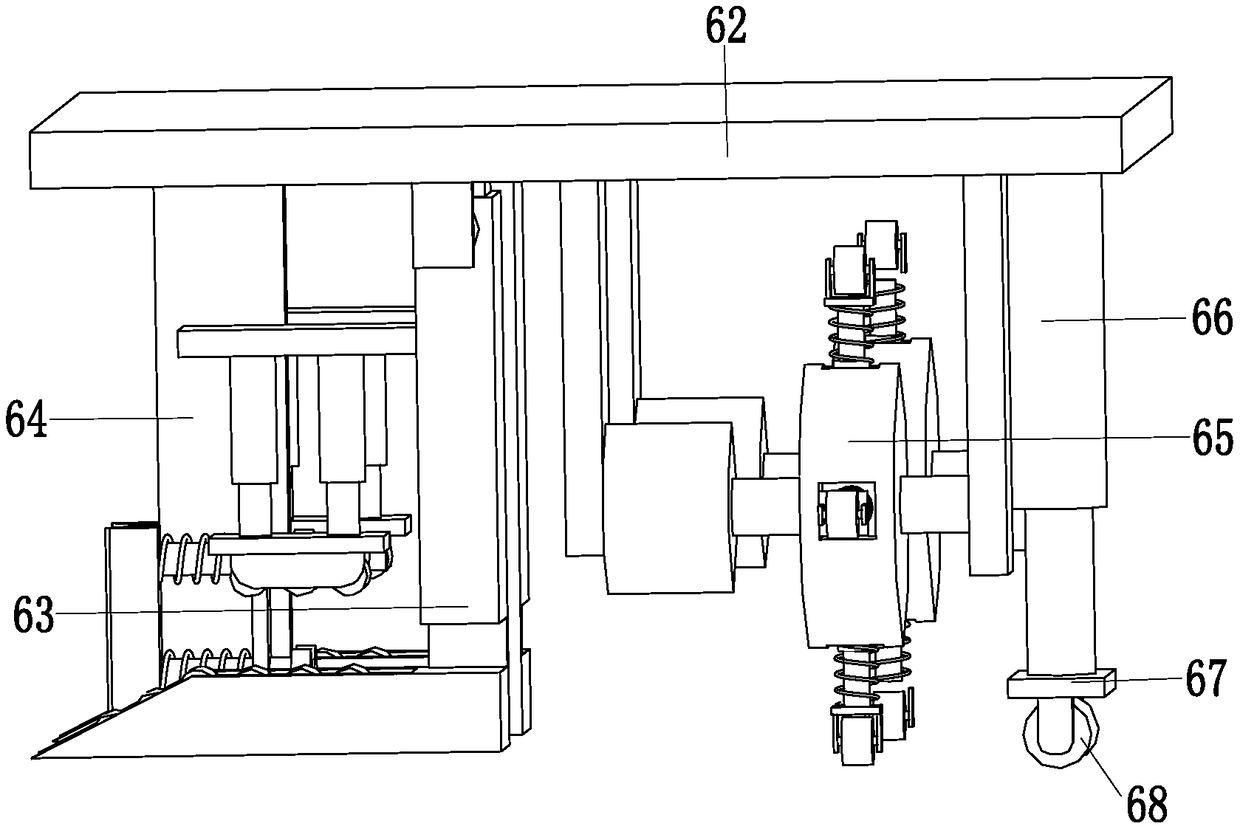

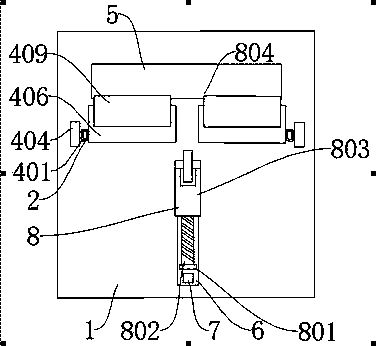

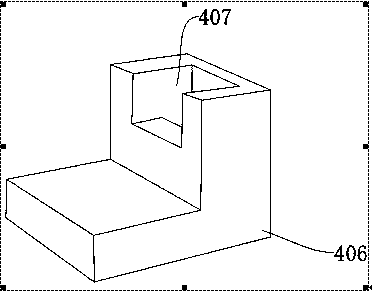

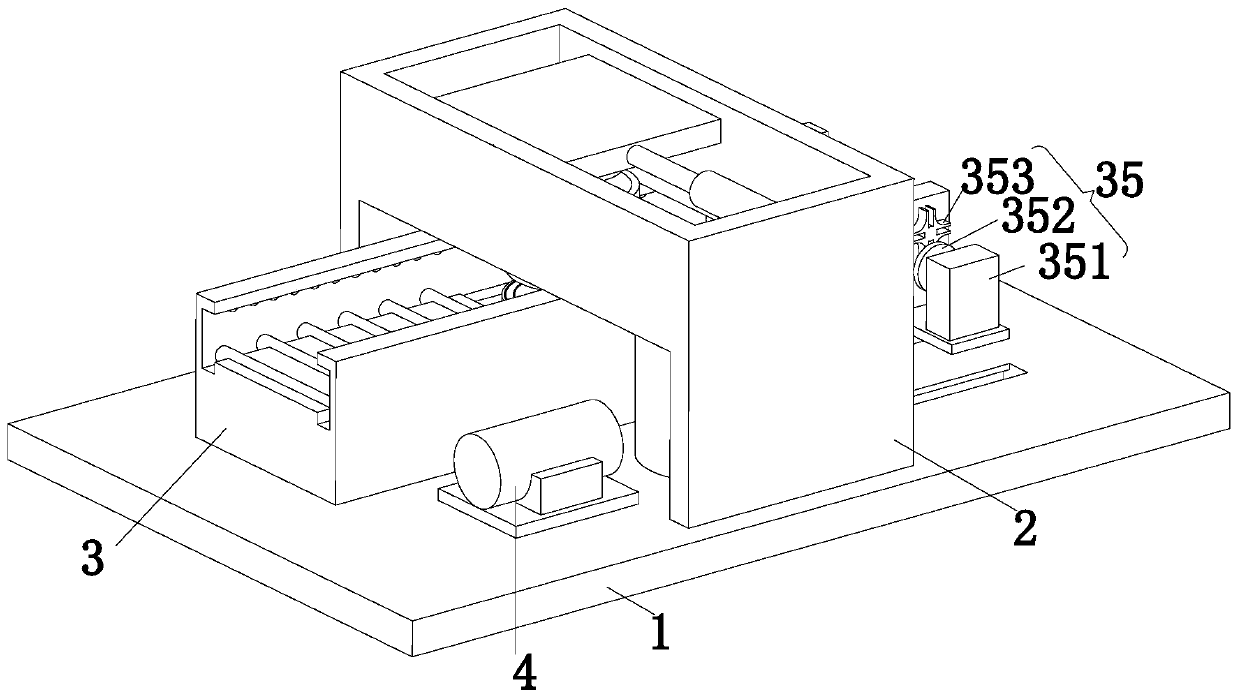

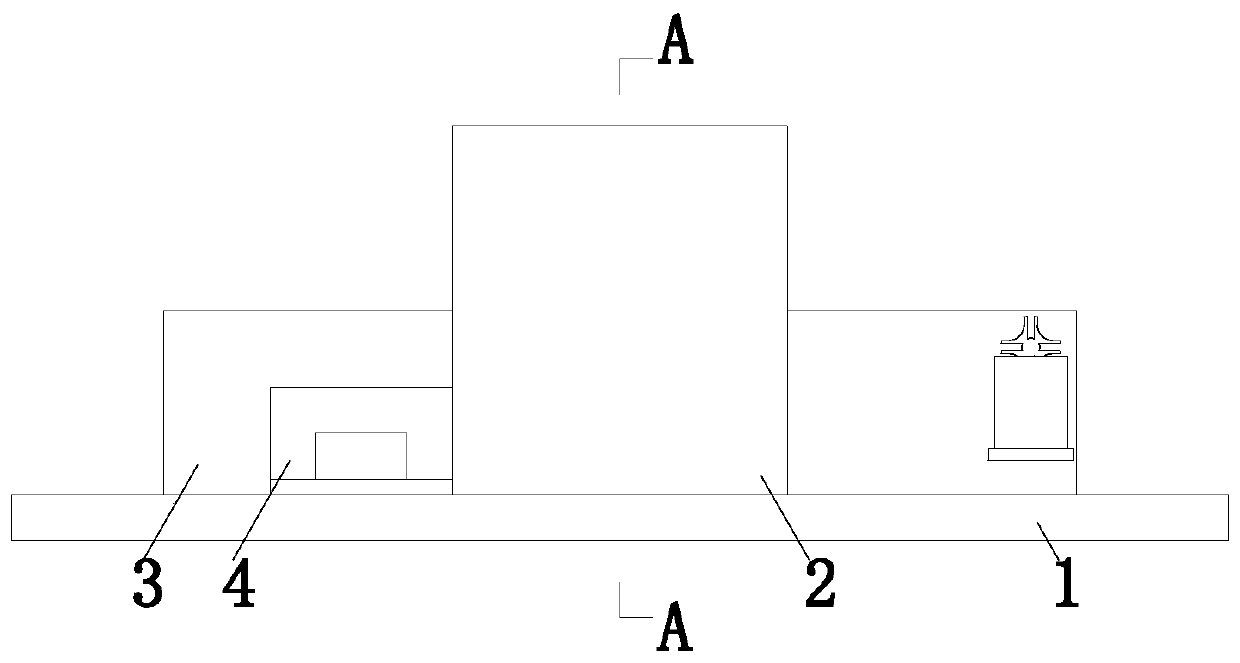

Automatic cast aluminum plate cutting machine

ActiveCN108972000ARealize automatic multi-angle cuttingReduce labor intensityOther manufacturing equipments/toolsMetal working apparatusEngineering

The invention relates to an automatic cast aluminum plate cutting machine, which comprises a supporting top plate, a regulation mechanism, a regulation top plate, cutting devices, stretching mechanisms and a correction device. The regulation mechanism is mounted at the bottom of the supporting top plate, the regulation top plate is mounted at the lower end of the regulation mechanism, the stretching mechanisms are mounted at front and rear ends of the left side of the regulation top plate respectively, the cutting devices are positioned on the right sides of the stretching mechanisms and mounted at the bottom of the regulation top plate, and the correction device is mounted at the right bottom of the regulation top plate. The automatic cast aluminum plate cutting machine has the advantagethat problems of high labor intensity, low cutting efficiency, failure in stretching of the aluminum plates in cutting, requirement of manual holding of two sides of the aluminum plates in cutting, failure in automatic cutting angle adjustment, requirement of manual checking of aluminum plate cutting conditions, failure in automatic correction and rolling of cut aluminum plates and the like duringcutting of existing cast aluminum plates can be solved.

Owner:重庆新西亚铝业(集团)股份有限公司

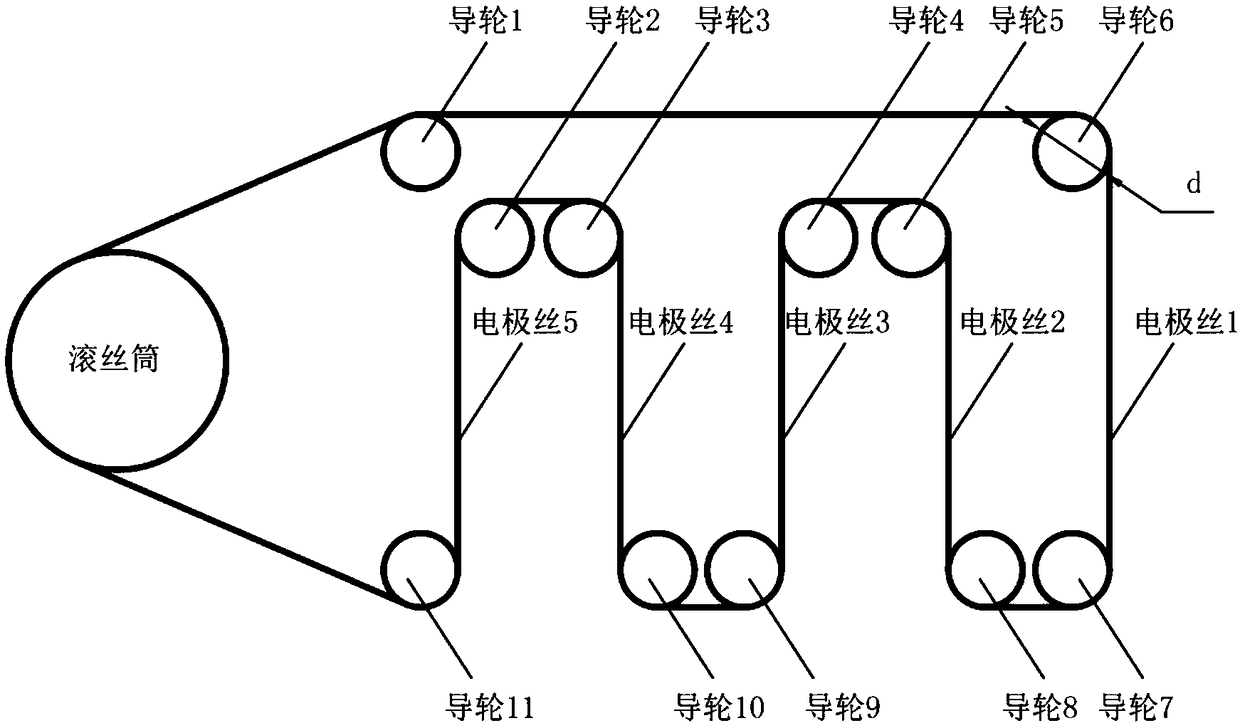

On-line preparation method of line electrode of minuteness group lines

ActiveCN103521864AEasy to installEasy to disassembleElectrical-based machining electrodesElectrolytic agentWire cutting

The invention discloses an on-line preparation method of a line electrode of minuteness group lines, and belongs to the field of precise minuteness electrochemical machining. The on-line preparation method of the line electrode of minuteness group lines is characterized in that the following steps are included: (1) a micron-order tungsten filament is mounted on a clamp of the line electrode of the minuteness group lines, a cathode tool is mounted in an electrolytic cell, and the cathode tool is provide with a cathode hole corresponding to a wire electrode, and is of a sandwich butt joint structure formed by a metal layer and insulating layers on the two sides of the metal layer; (2) an alkaline electrolyte is added into the electrolytic cell to immerse the cathode tool completely; (3) a tool cathode and the line electrode are connected to the positive electrode and the negative electrode of a direct current power source respectively to achieve the enlargement of the diameter of the cathode hole of the metal layer in the tool cathode to form an inward concave structure; (4) the line electrode of the minuteness group lines and the tool cathode are connected to the positive electrode and the negative electrode of the direct current power source respectively, and the line electrode is made to carry out straight reciprocating motion; (5) the electrolyte is replaced by an acid electrolyte, the tool cathode is replaced by workpieces, the line electrode of the minuteness group lines and the workpieces are made to be connected with the positive electrode and the negative electrode of an ultrahigh-frequency narrow-pulse power source to achieve minuteness electrolytic wire-electrode cutting machining.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

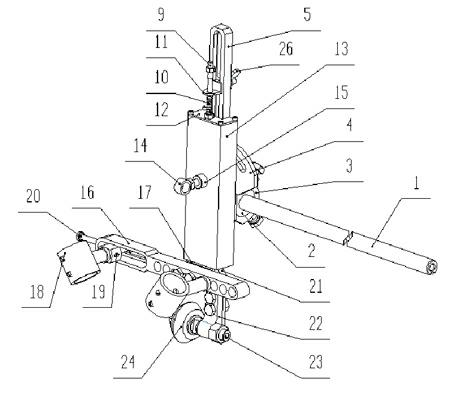

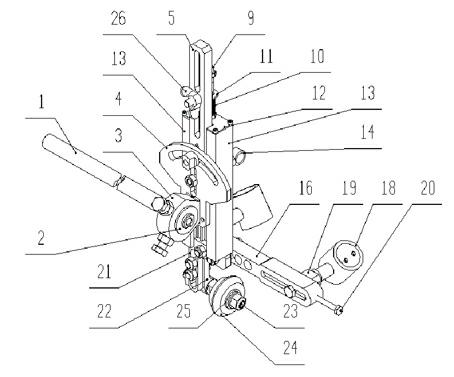

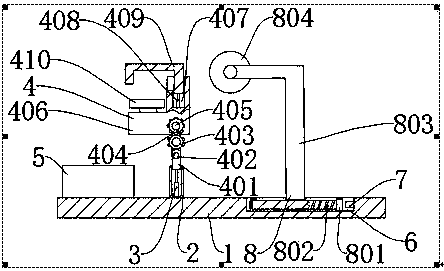

Spring pressure-assisted cutting fixing device with double cutting torches and application method of spring pressure-assisted cutting fixing device

ActiveCN102581534AStrong structural rigiditySmall frictional resistanceWelding/cutting auxillary devicesAuxillary welding devicesSheet steelMechanical engineering

The invention discloses a spring pressure-assisted cutting fixing device with double cutting torches and an application method of the spring pressure-assisted cutting fixing device, which are quite suitable for cutting grooves of petals of spherical tanks and can simultaneously carry out one-step groove forming cutting for two groove surfaces. The fixing device comprises a transverse adjusting rod, a cutting torch fixing sleeve and a supporting guide wheel, the transverse adjusting rod is connected with an arc seam cutting adjusting mechanism, the cutting torch fixing sleeve is mounted on a cutting torch positioning mechanism, the supporting guide wheel is mounted in a supporting guide wheel mounting mechanism, the arc seam cutting adjusting mechanism is fixed onto a spring pressure assisting mechanism by a bolt, and the cutting torch positioning mechanism and the supporting guide wheel mounting mechanism are mounted on the lower portion of the spring pressure assisting mechanism. The application method includes cutting an upper groove angle beta 1 by the aid of a positioning cutting torch; and cutting a lower groove angle beta 2 by the aid of an adjustable cutting torch in the movable cutting torch fixing sleeve, leading the positioning cutting torch and the adjustable cutting torch to realize cutting simultaneously, and forming an X-shaped cutting line on a spherical shell plate. Owing to spring pressure assistance, the supporting guide wheel always contacts with the steel spherical shell plate along with change of the shape of a cutting plate.

Owner:中石化胜利油建工程有限公司

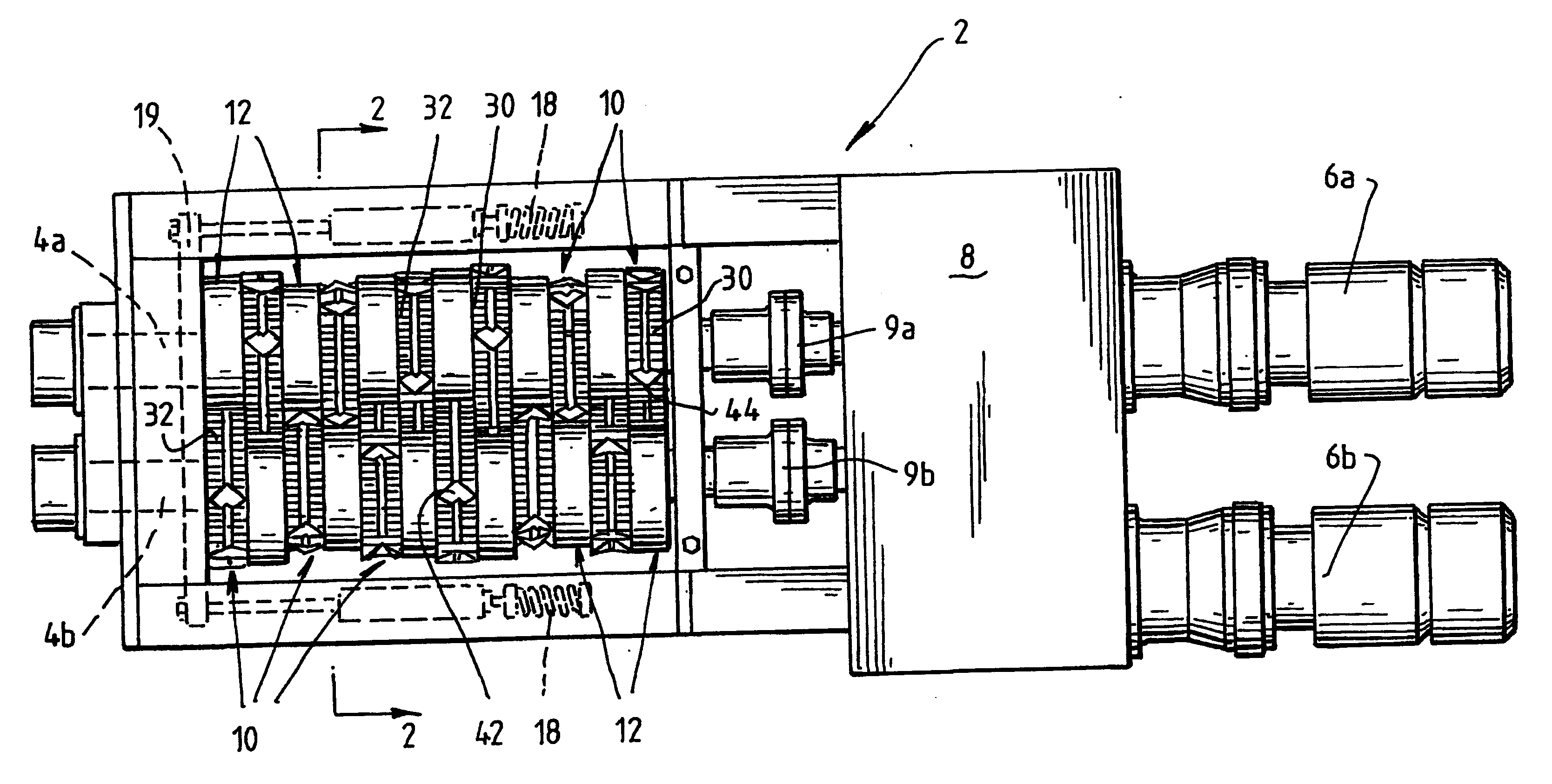

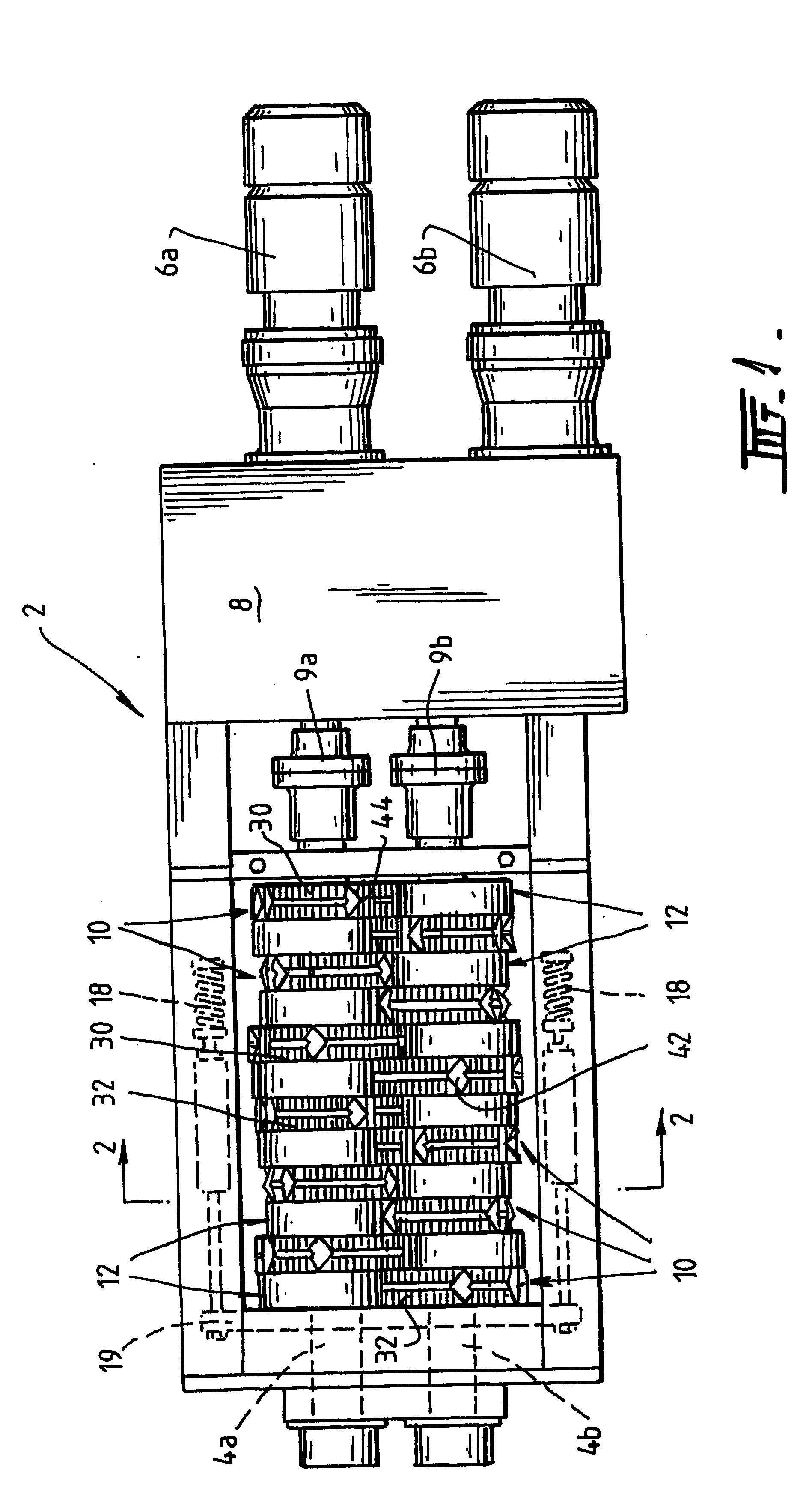

Self cleaning shredding device having movable cleaning rings

InactiveUS7311279B2Effective anti-wrapping arrangementReducing and preventing amount of materialSolid waste disposalCocoaLinear motionCounter rotating

A self cleaning cutting assembly is provided, having an array of counter rotating cutters in which a plurality of cutters rotating in a first direction are mounted on a first shaft and a plurality of second cutters are mounted on a second shaft for rotating in an opposite direction. The array of cutters is provided with a plurality of clearing or cleaning rings located alternately with the cutters on each shaft. The cutting array is kept clear of debris or partially cut material by movement of the clearing or cutting rings against adjacent cutters. Movement of the clearing or cleaning rings is a combination of rotary motion and linear motion, in which the linear motion is imparted by the cutter located opposite the cleaning ring striking the cleaning rings so as to push the cleaning ring beyond the position of the widest part of the cutter to completely dislodge material from the cutter.

Owner:TERRANCE JAMES PARKE

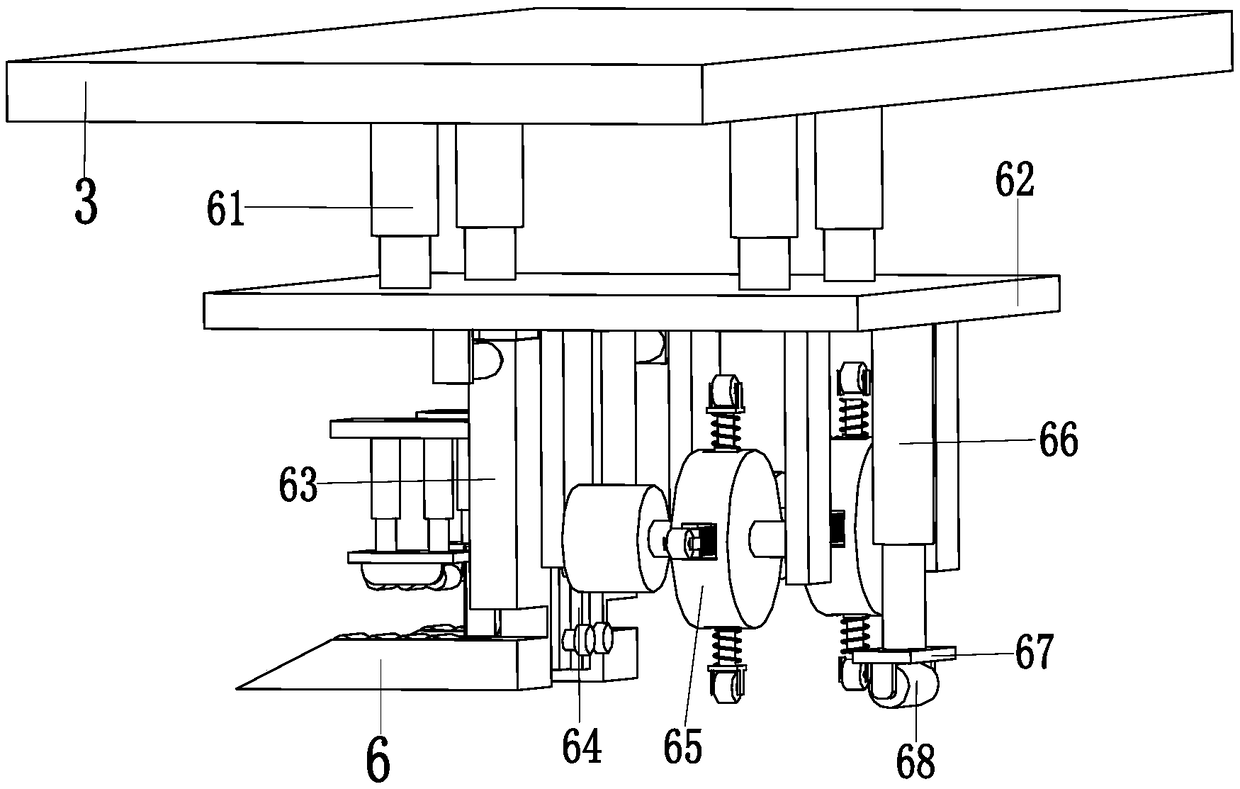

Automatic cutting and rolling system for aluminum plate and processing technology of the system

ActiveCN108890303AThe phenomenon of not cutting in place will not appearReduce labor intensityOther manufacturing equipments/toolsMetal working apparatusAgricultural engineering

The invention relates to an aluminum plate automatic cutting and rolling system and a processing technology of the system, comprising an adjusting top plate, a stretching mechanism and a correcting device. The left front and rear ends of the adjusting top plate are distributed with a stretching mechanism, the stretching mechanism is installed on the bottom of the adjusting top plate, and the correcting device is installed on the bottom of the right end of the adjusting top plate. The straightening device comprises a straightening push rod, a straightening connecting plate, a lifting mechanism,a cutting mechanism, a straightening mechanism, a rolling push rod, a rolling connecting frame and a rolling wheel. The present invention can solve the problems of high labor intensity and low cutting efficiency when the existing cast aluminum plate is cut, and the aluminum plate can not be stretched when the aluminum plate is cut, and the phenomenon that the aluminum plate is not cut in place easily in cutting, and the incision of the aluminum plate is uneven, and the aluminum plate after being cut can not be automatically corrected and rolled, and the like.

Owner:广州金纪金属制造有限公司

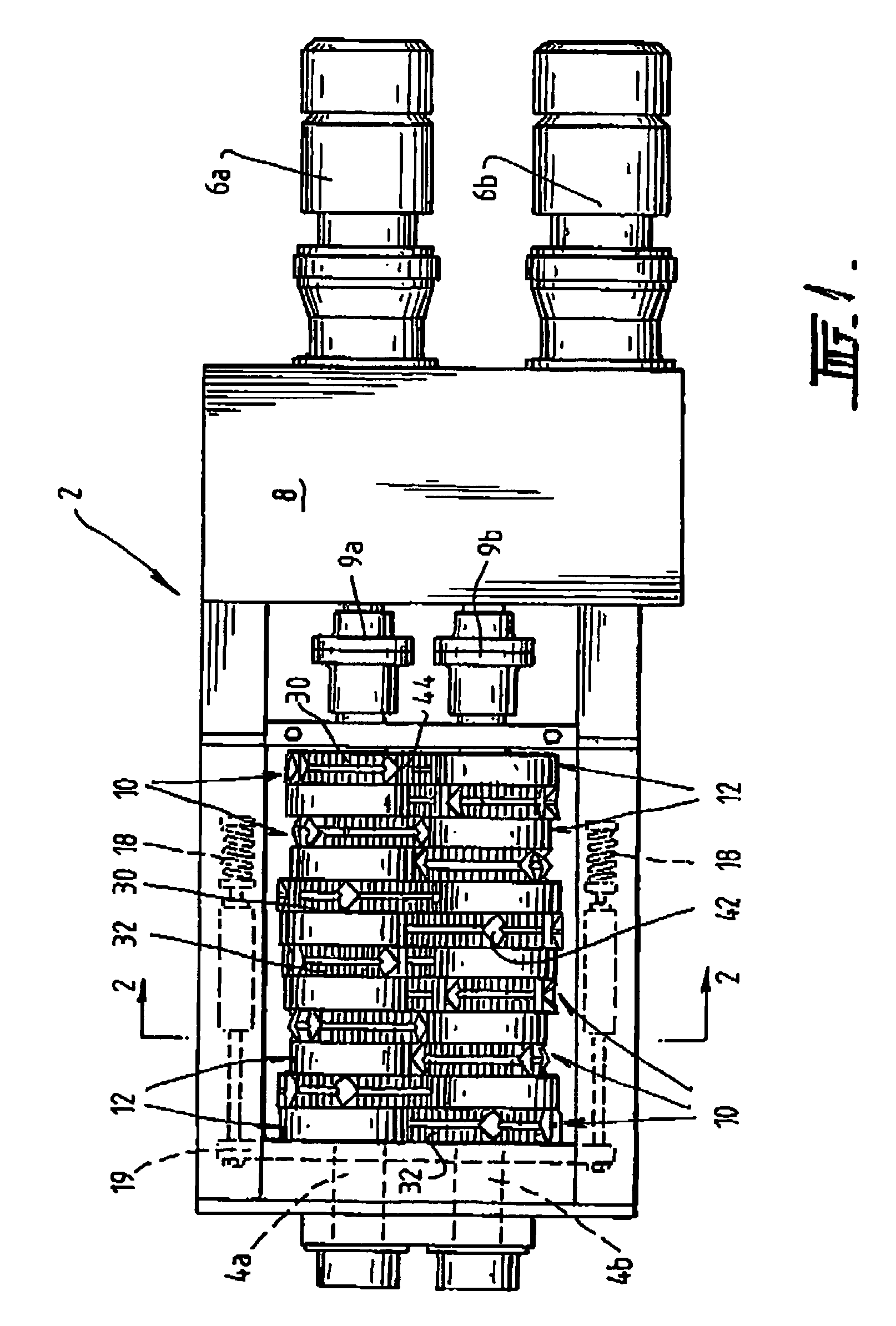

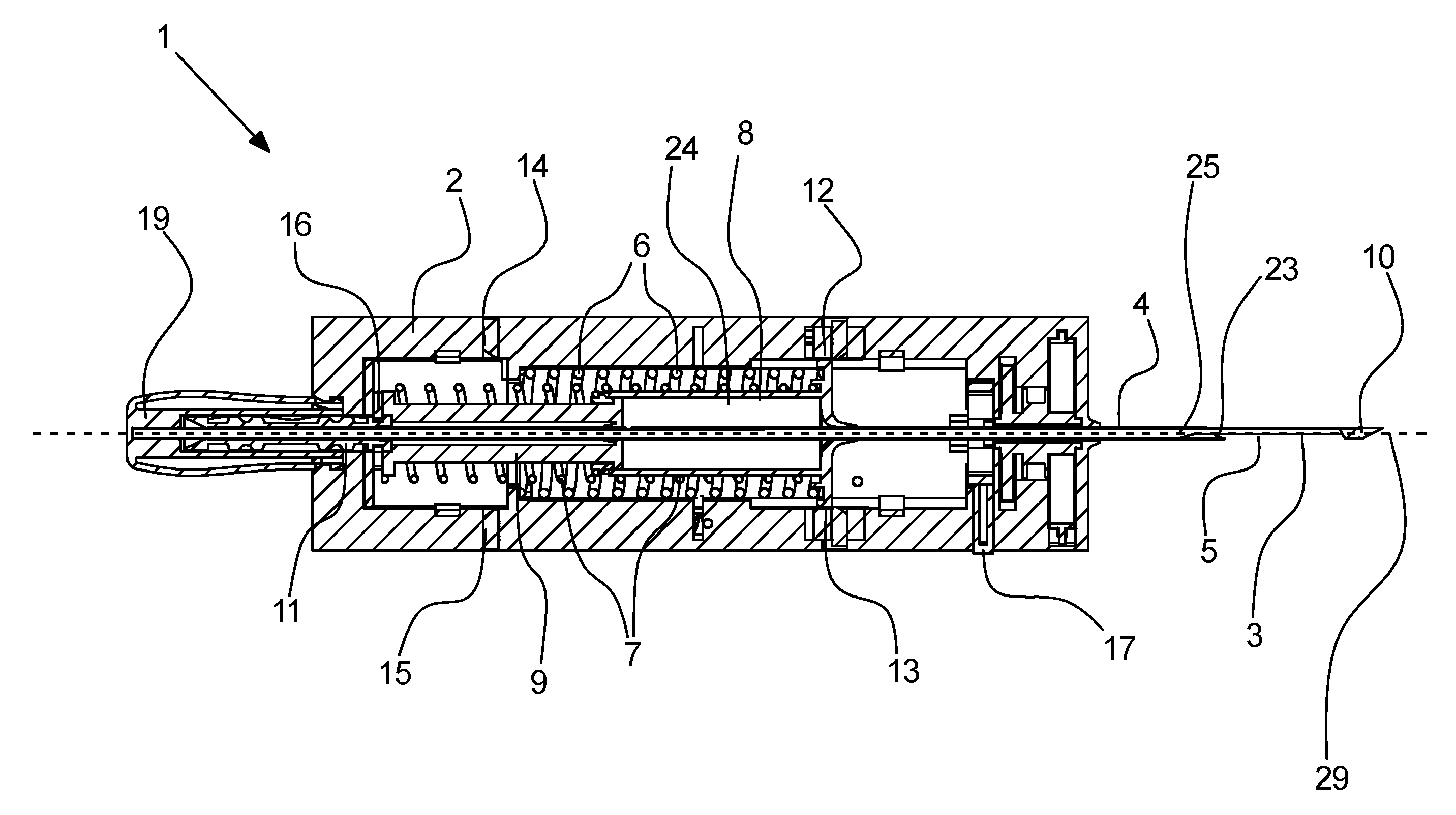

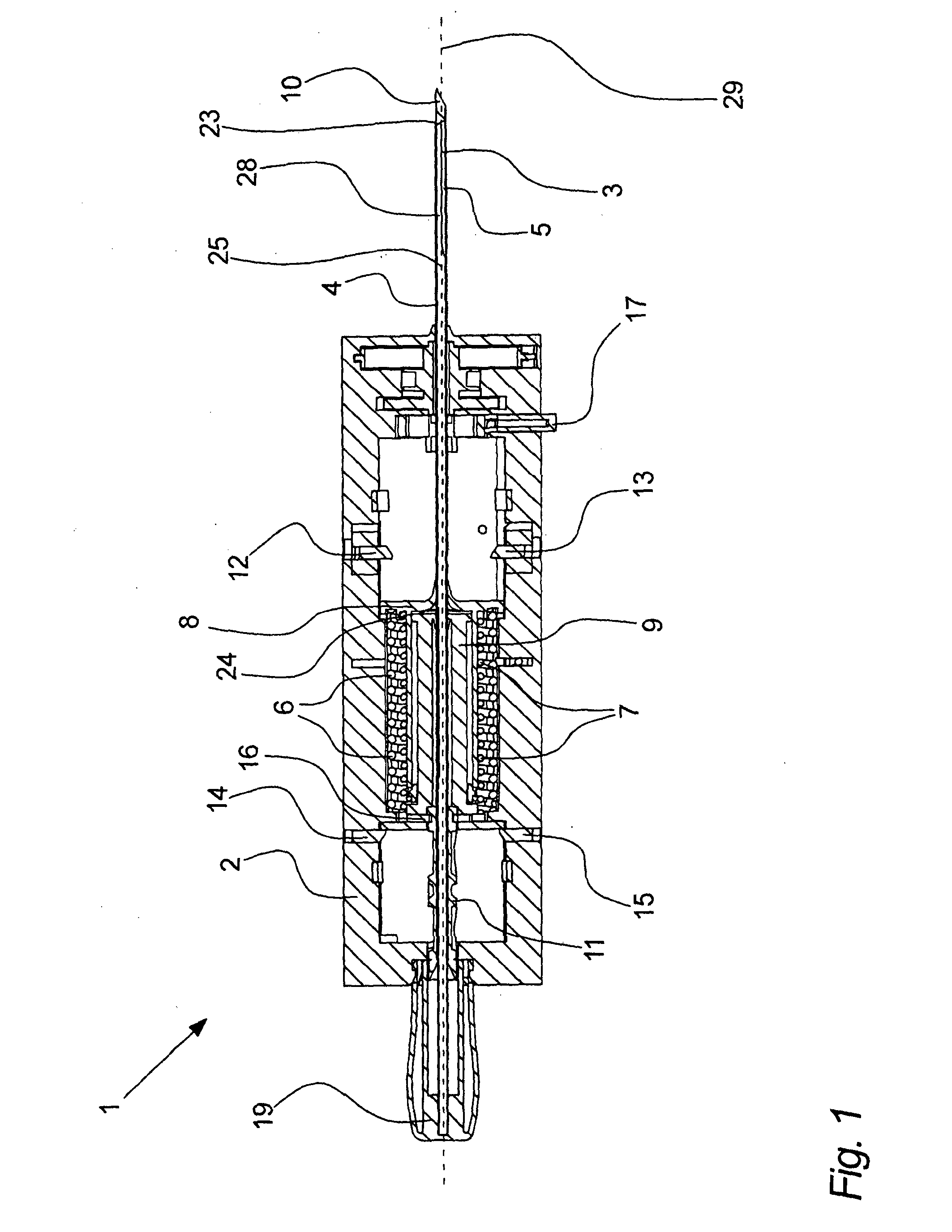

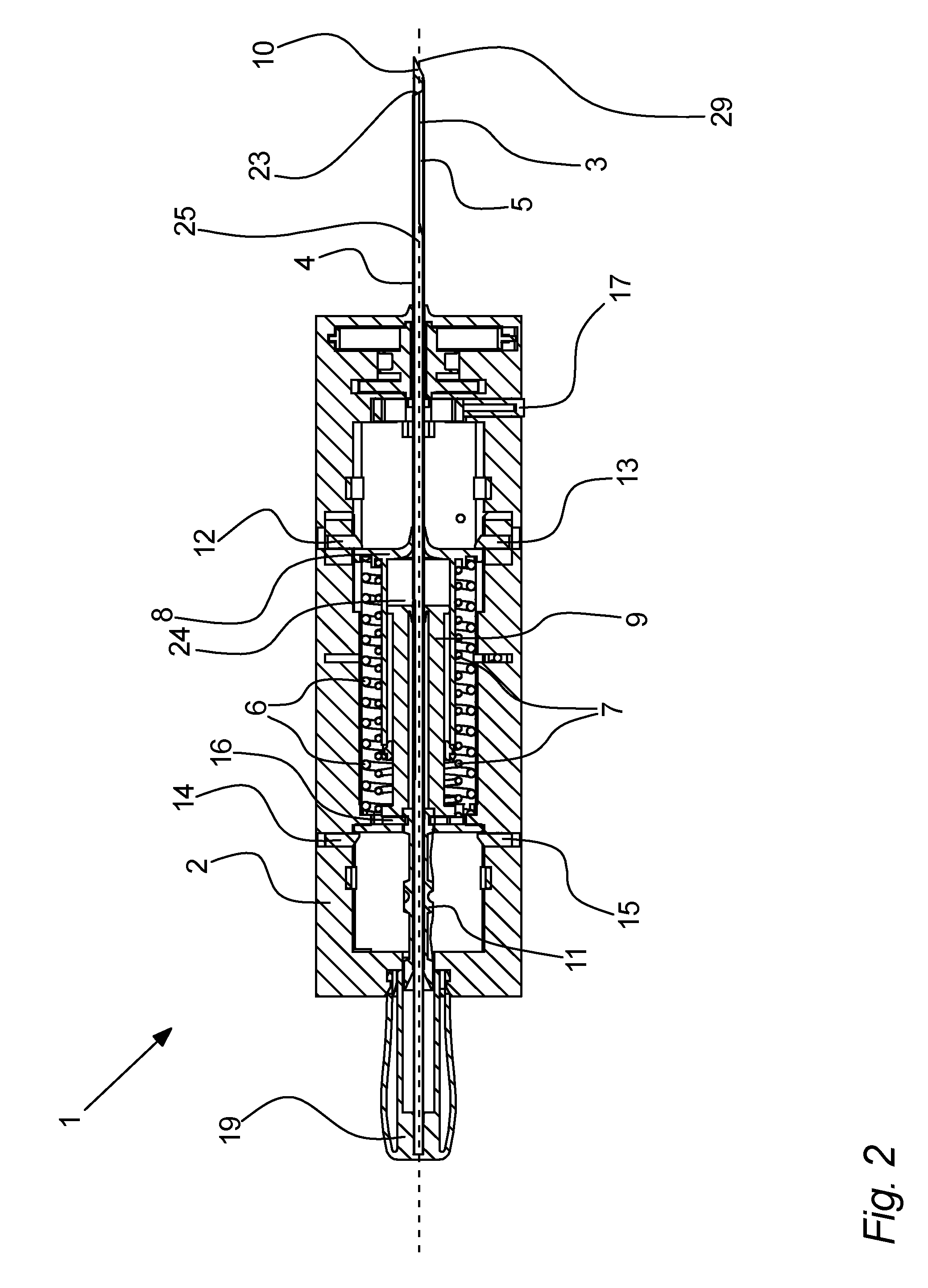

Handheld tissue sample extraction device

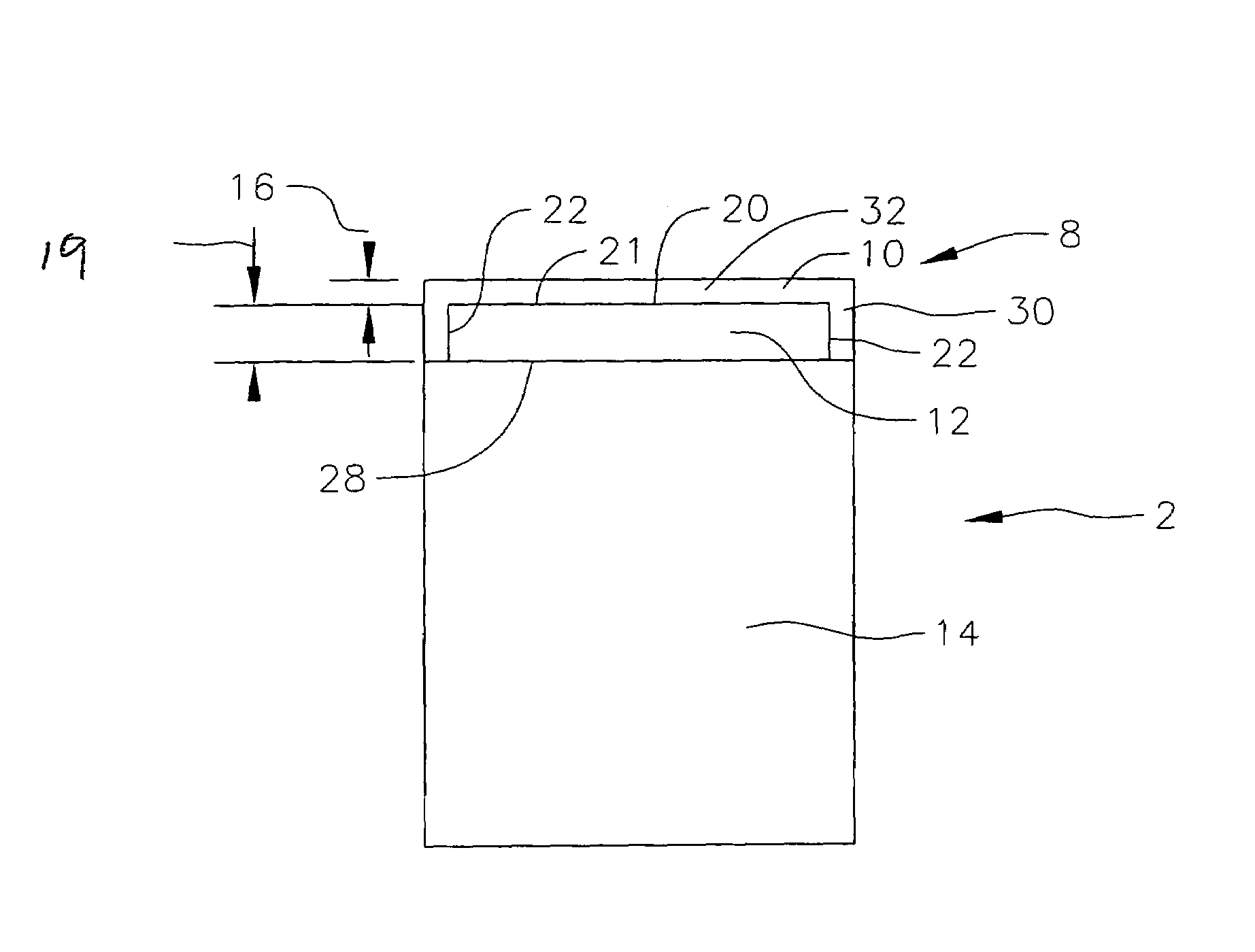

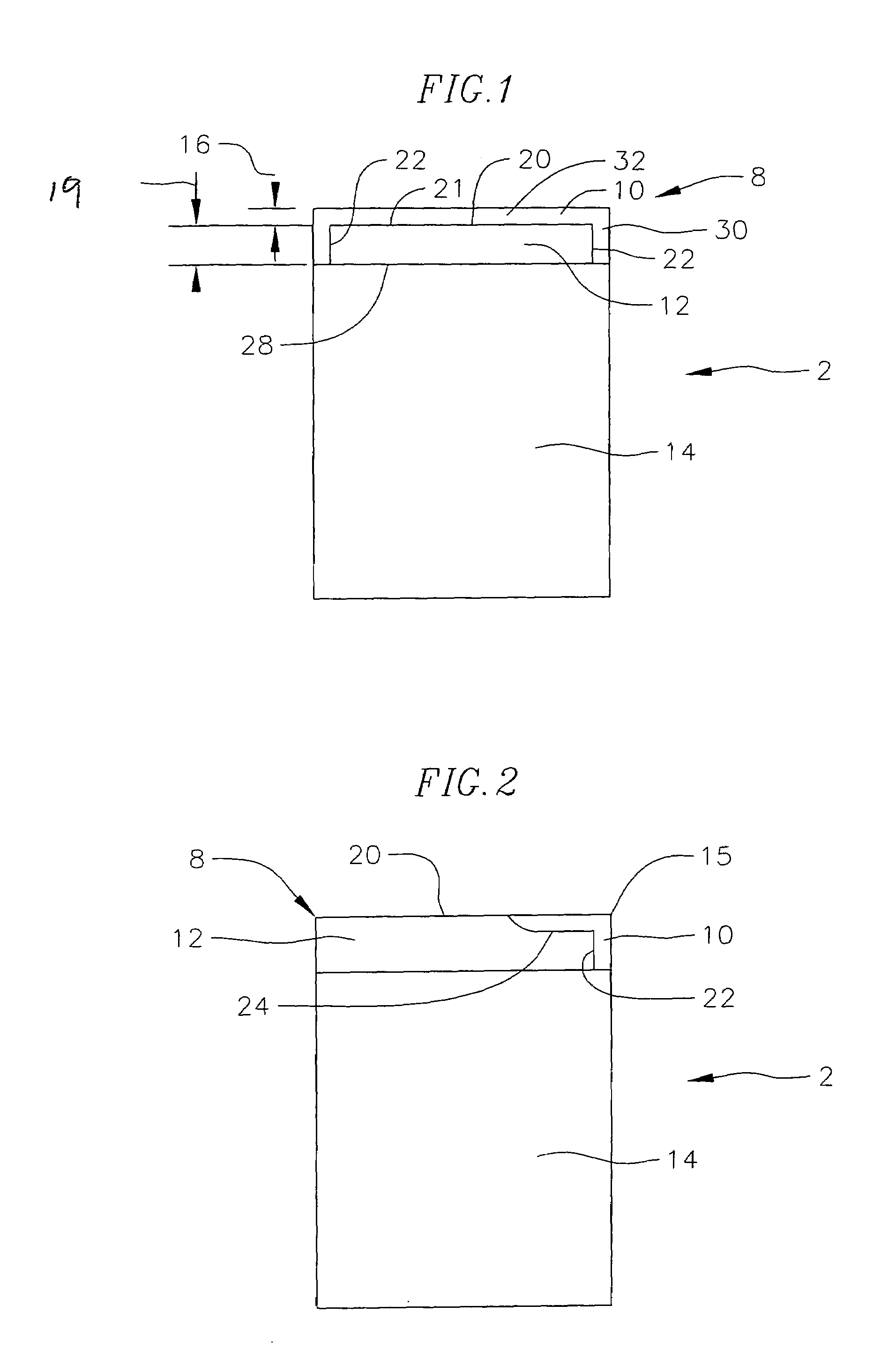

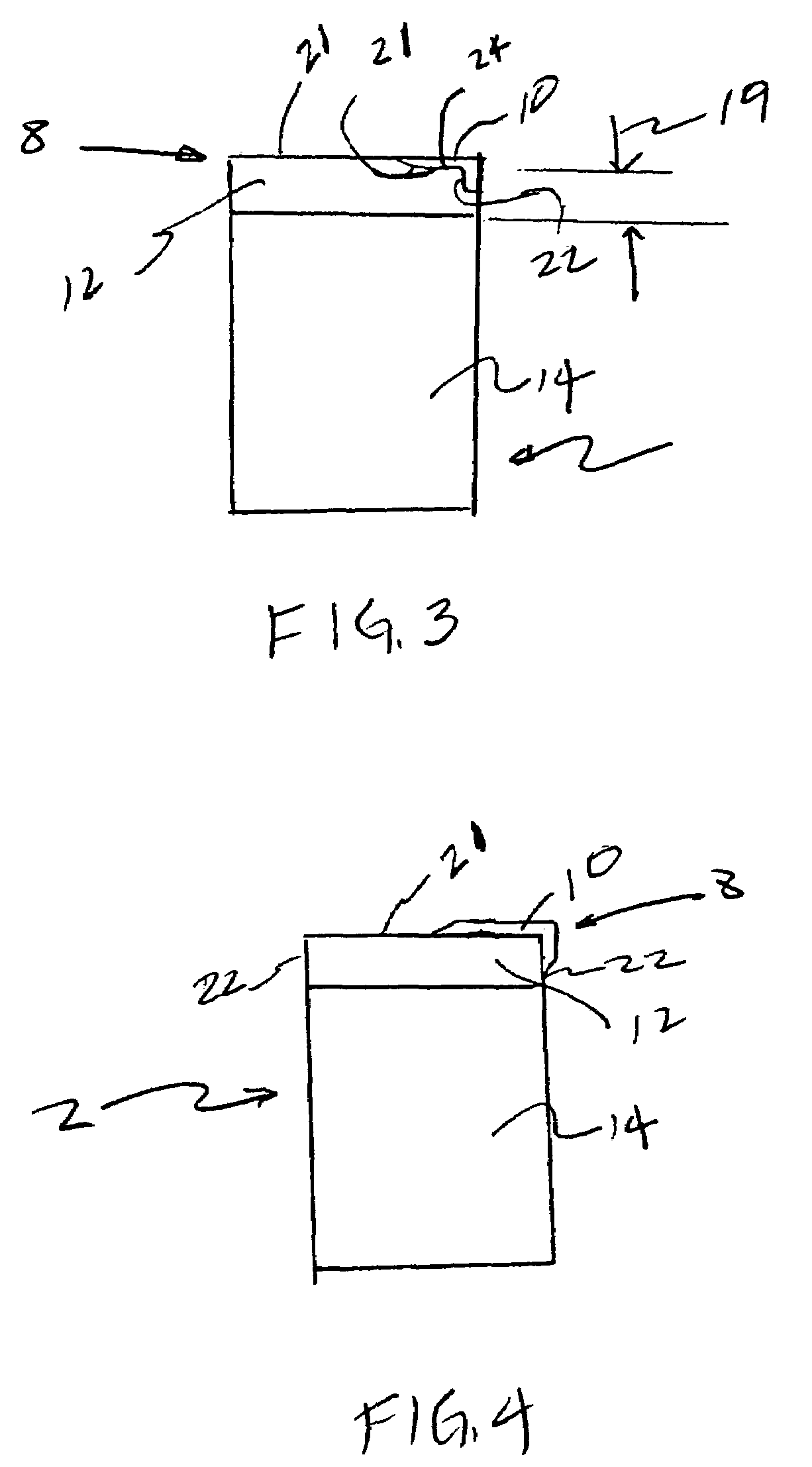

ActiveUS20150057571A1Reduce cutting efficiencyImprove cutting efficiencySurgical needlesVaccination/ovulation diagnosticsTissue sampleHand held

A handheld device (1) for extraction of tissue samples (27) is disclosed, comprising a needle arrangement (25) and control arrangement (2), said needle arrangement (25) comprising a cutting needle (4) and a sample extraction needle (3), said needle arrangement (25) having a first end (28) for inserting into tissue (30),—said cutting needle (4) comprising a cutting edge (23) for cutting said tissue sample (27) from said tissue (30),—said sample extraction needle (3) comprising a side opening (5) for receiving said tissue (30), said control arrangement (2) comprising a vacuum chamber (24) in fluid communication with said sample extraction needle (3), the vacuum chamber (24) comprising a first member (8) and a second member (9), said first and second members (8, 9) being adapted to move relative to each other, wherein said first member is mechanically connected to said cutting needle (4), and wherein said handheld device (1) is configured so that—a movement between said first member and said second member to increase the volume of said vacuum chamber (24) and thereby reduce the pressure in said sample extraction needle induces—a movement between said cutting needle (4) and said sample extraction needle (3) to expose said side opening (5) of said sample extraction needle (3).

Owner:TEESUVAC APS

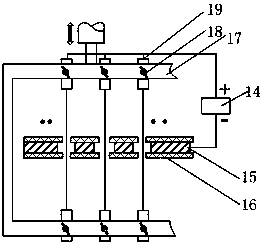

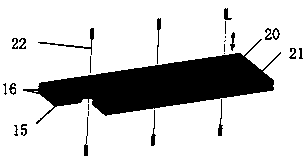

TPU color-changing film production device and production method

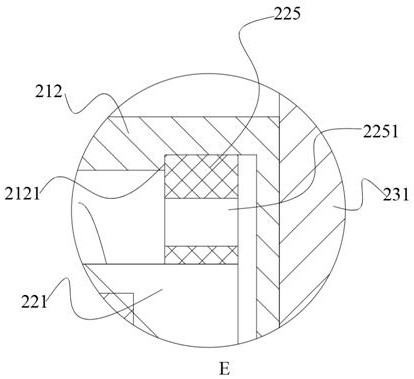

The invention discloses a TPU color-changing film production device and a production method. The TPU color-changing film production device comprises a fixing device; the fixing device is sequentially provided with forming devices, a cooling device, a gluing device and an attaching device; the forming devices are fixedly connected with the fixing device, and the two forming devices are arranged in the vertical direction; the cooling device is fixedly connected with the fixing device; the gluing device is connected with the fixing device; the attaching device is connected with the fixing device; the fixing device comprises a frame and a workbench; one side of the frame is fixedly connected with one side of the workbench; and each forming device is located on the upper side of the workbench and comprises a shell, a transmission assembly and a die head assembly, wherein the shell is connected with the transmission assembly, and one side of the shell is connected with the die head assembly. The production method mainly comprises the following steps: raw material crushing, melting and extruding; base film cooling and extrusion forming; gluing and drying; hot melting and double layer base film lamination; and cooling and rolling.

Owner:南通纳科达聚氨酯科技有限公司

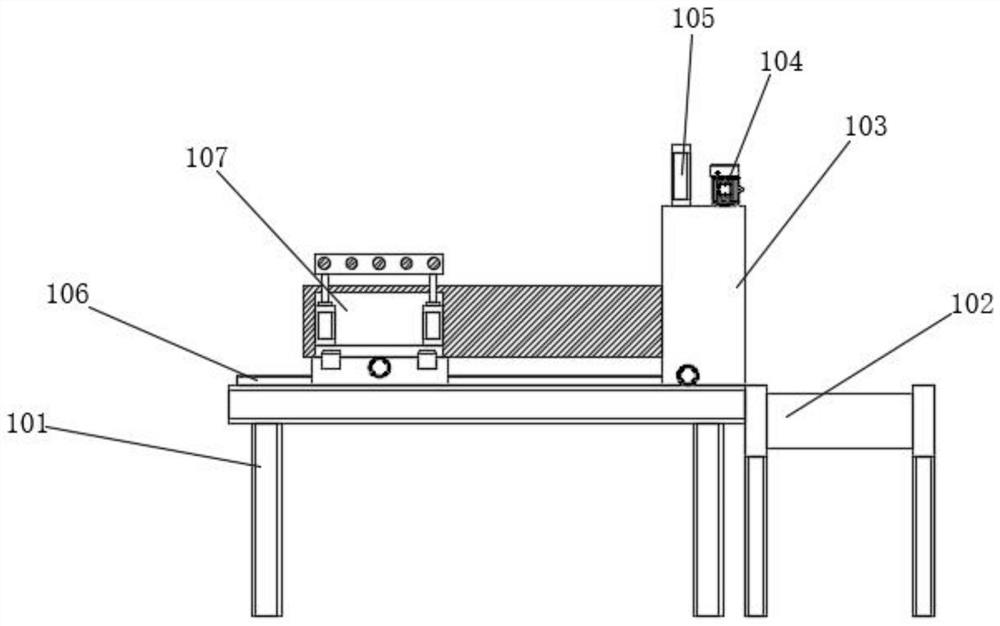

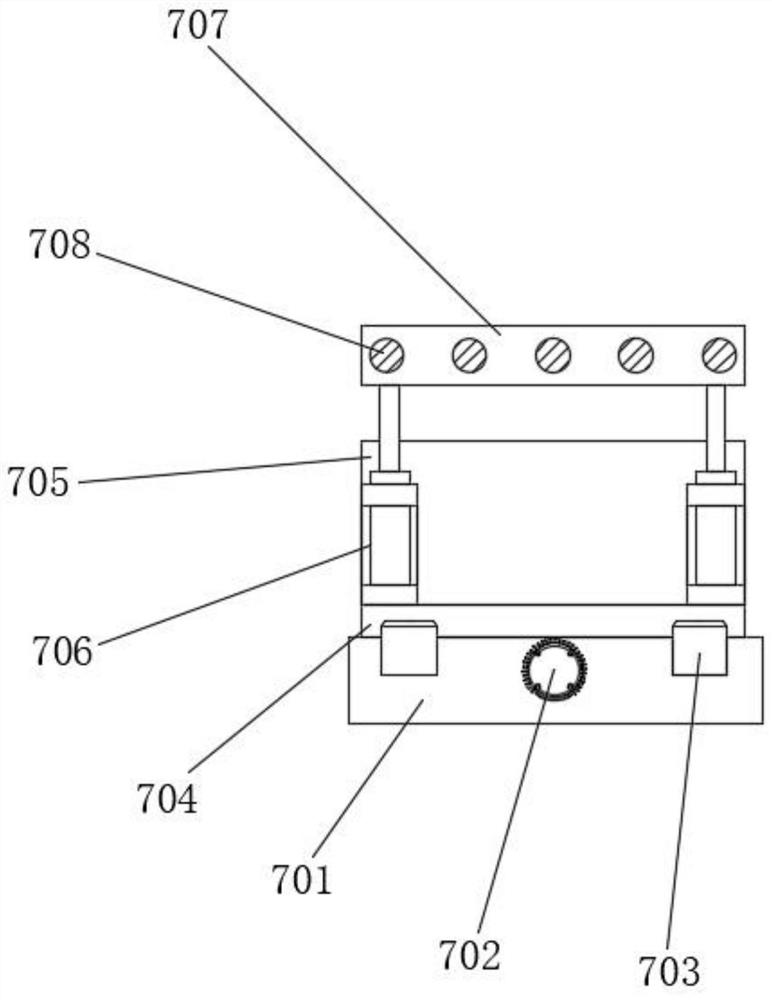

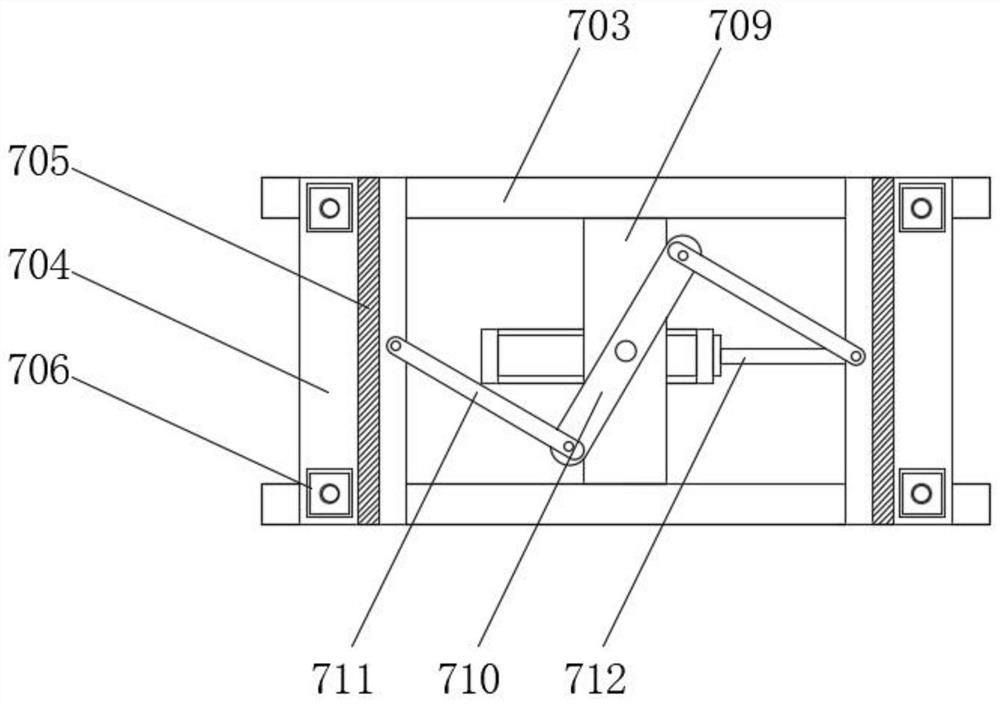

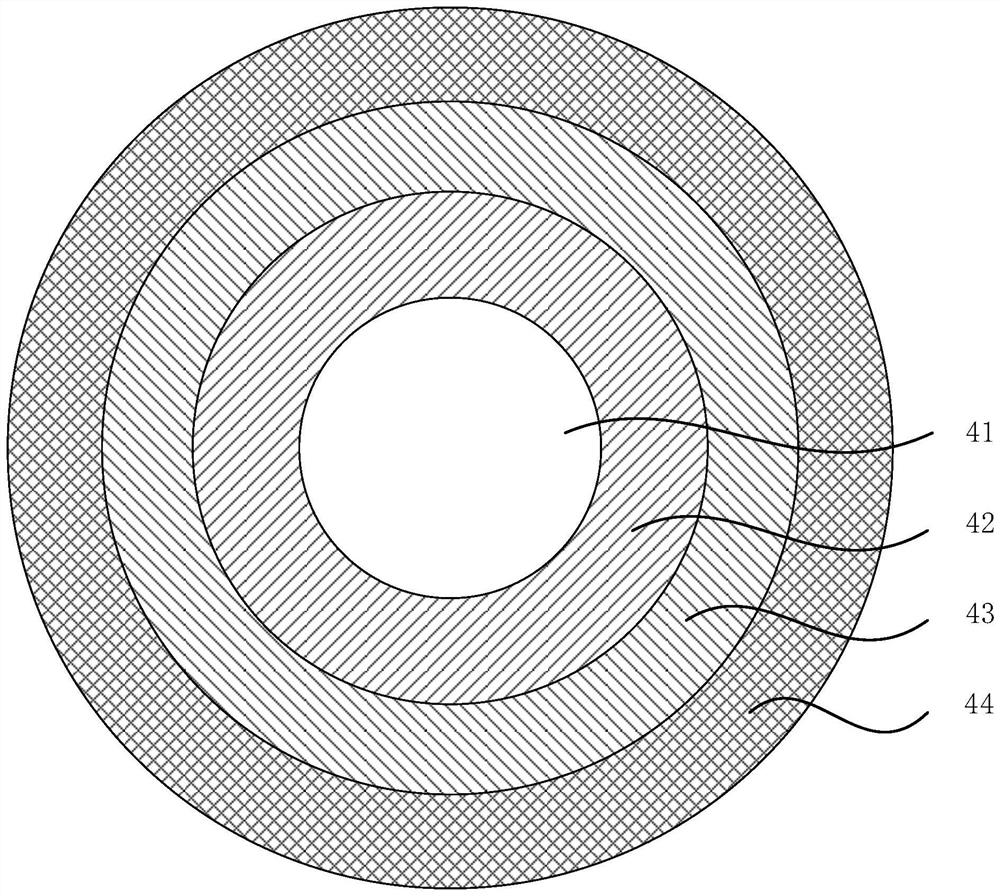

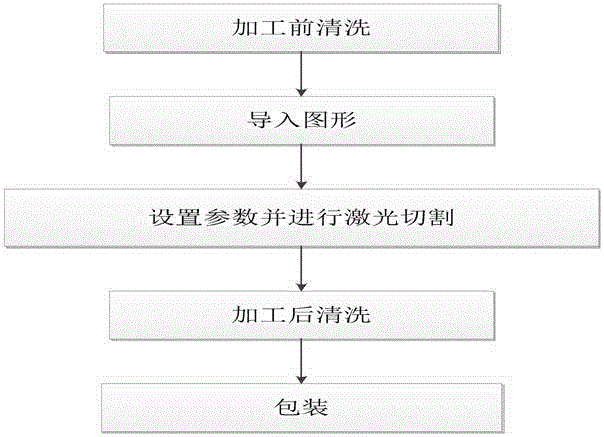

Production process of semiconductor-grade quartz ring

ActiveCN113370405AHigh dimensional accuracyHigh surface cleanlinessFlexible article cleaningWorking accessoriesMetallurgySurface cleaning

The invention discloses a production process of a semiconductor-grade quartz ring, and relates to the field of semiconductor high-purity quartz machined rings. A quartz material used in the production process is a high-purity quartz base material, and the semiconductor-grade quartz ring is finally obtained through ingot cutting, water jet cutting, plane grinding, MC machining, degreasing cleaning, chemical cleaning and packaging. The production process has the advantages of being simple in process route, high in size precision of quartz machined products, high in cleanliness of surface cleaning, capable of achieving batch manufacturing, and capable of meeting the requirements of current semiconductor industries. According to the production process, ingot cutting equipment is used for performing ingot cutting on a quartz ingot. The ingot cutting equipment clamps the quartz ingot through a position-limiting base and a clamping mechanism, thereby achieving high clamping stability, avoiding the situation that cutting is not smooth enough due to shaking of the quartz ingot in the cutting process, ensuring ingot cutting accuracy, and further reducing the material loss of the quartz ingot. The automation degree is high, and the use is convenient.

Owner:江苏富乐德石英科技有限公司

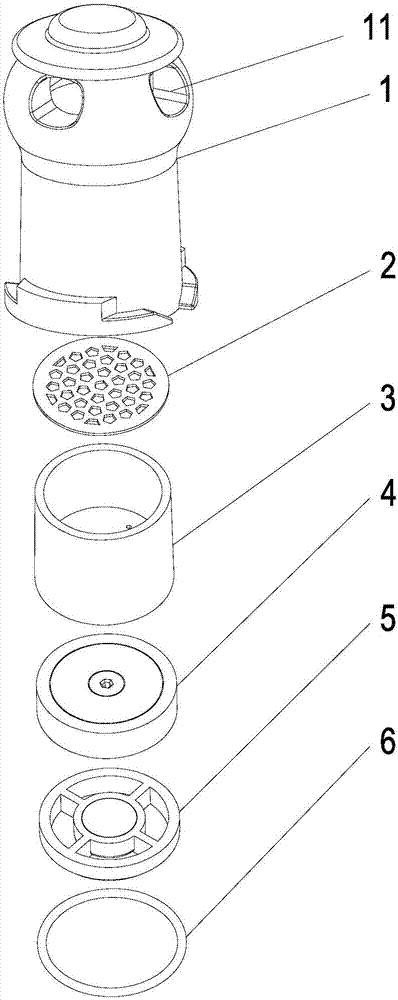

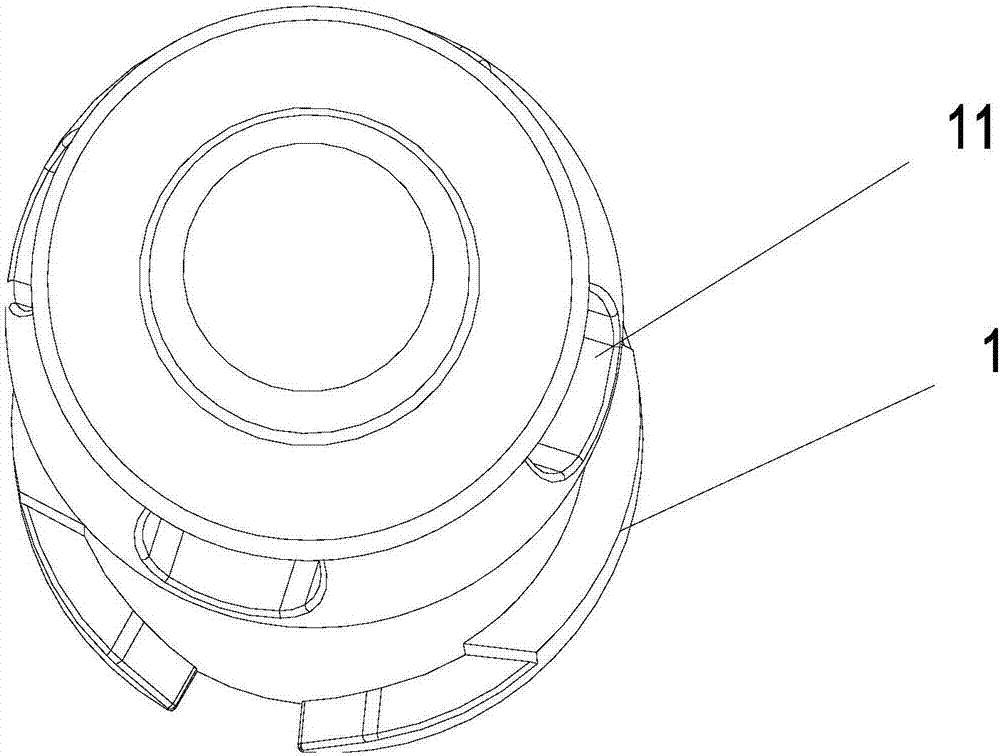

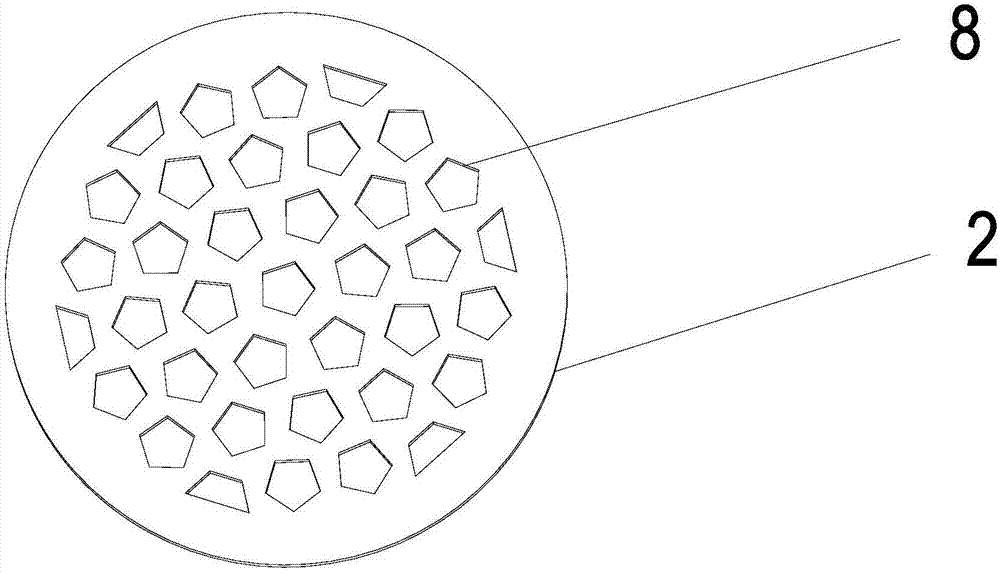

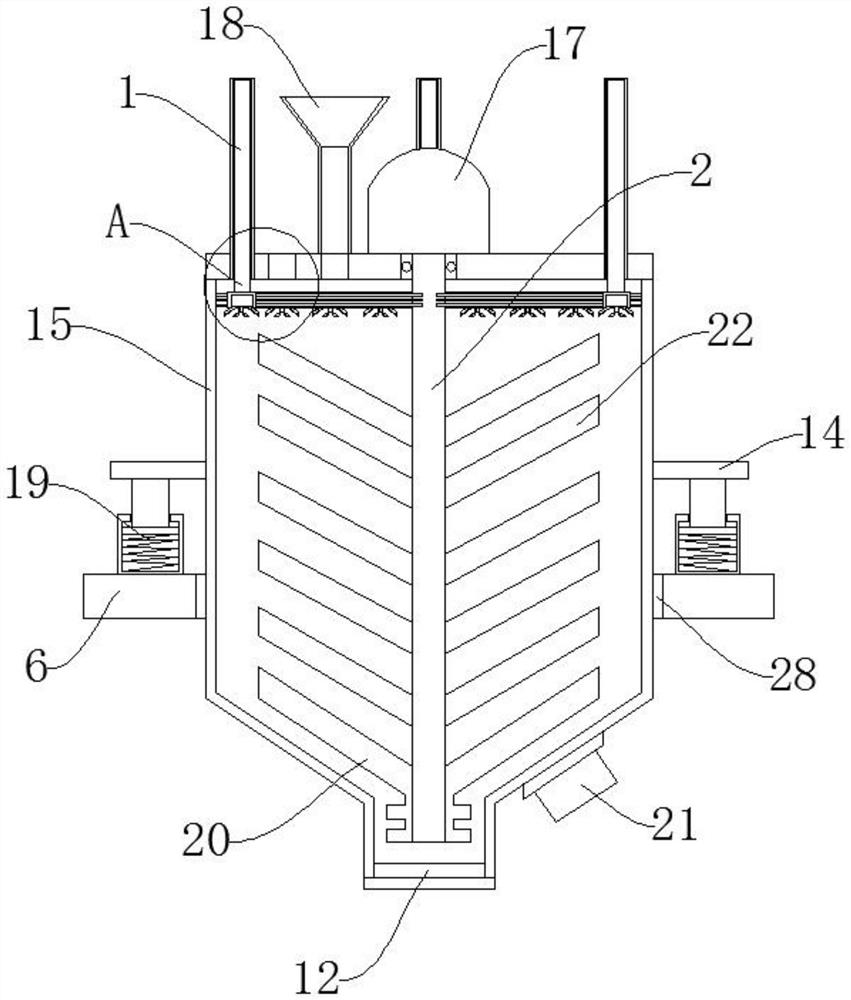

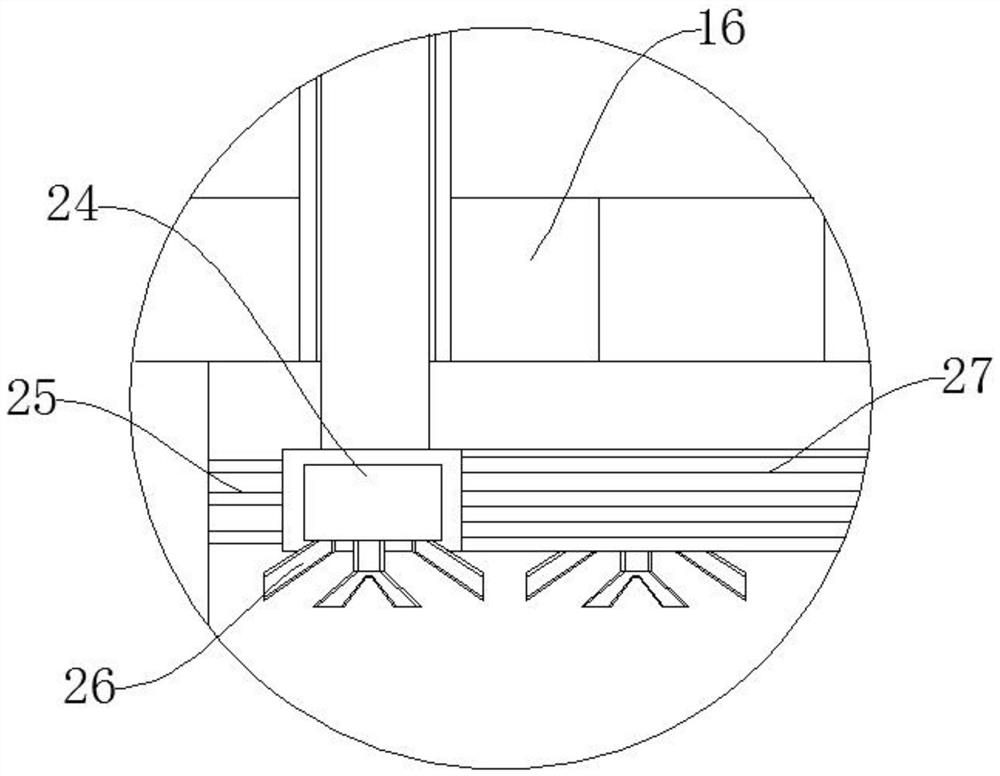

Multilevel particle cutter

PendingCN107036859AImprove cutting effectAvoid collisionWithdrawing sample devicesPreparing sample for investigationParticulatesEngineering

The invention mainly discloses a multilevel particle cutter. The cutter comprises an air intake hood, as well as a filtering screen, a nozzle, cutting boxes and a sealing ring which are in the air intake hood; the cutting boxes and an inner wall of the air intake hood are connected in tight connection; the filtering screen and the nozzle are provided with filtering apertures; an upper surface of a first cutting box is provided with a first adsorption layer which is up and down corresponding to filtering apertures on the top, primary filtering apertures are arranged on one side of the first cutting box opposite to the first adsorption layer; the upper surface of a second cutting box is provided with a second adsorption layer which is up and down corresponding to primary filtering apertures, and secondary filtering apertures are arranged on one side of the second cutting box opposite to the second adsorption layer. The structure has good cutting effects, the adsorption layer and the filtering apertures on the upper cutting box are respectively corresponding to the filtering apertures and the adsorption layer on the lower cutting box, in order to avoid adsorption of large particles in the filtering apertures which causes obstruction of filtering apertures in the effect of inertia; the adsorption layers absorb large particles, in order to facilitate cleaning of particles, and at the same time avoid impact of large particles and other particles after adsorption which causes reduction of cutting efficiency.

Owner:HANGZHOU KEMAI ENVIRONMENTAL SCI & TECH CO LTD

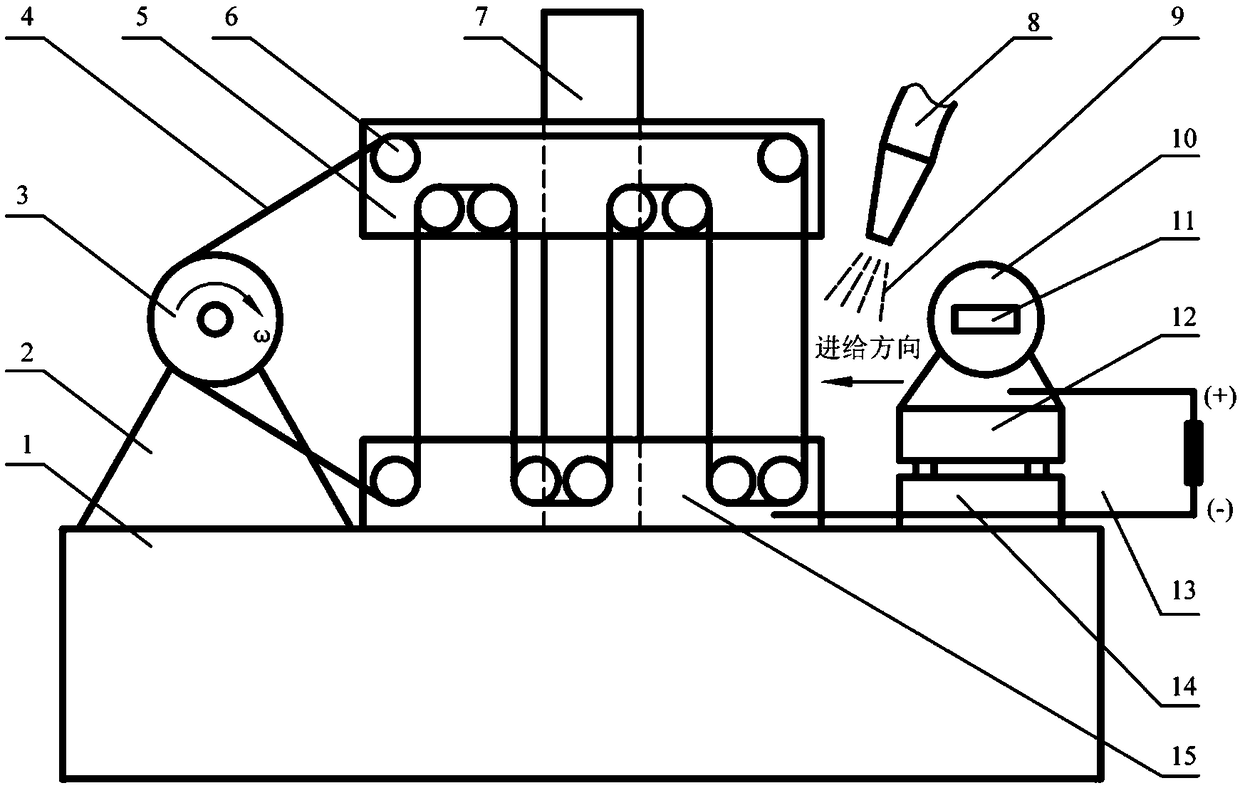

Cutting device for conductor materials and working method thereof

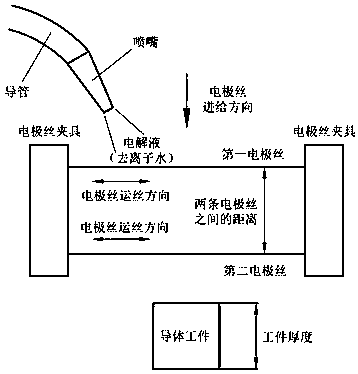

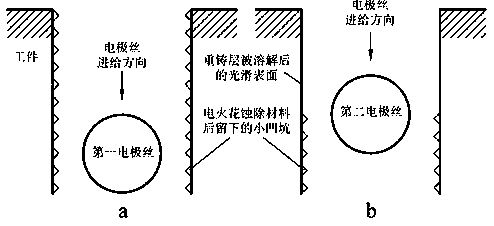

ActiveCN109396581AImprove surface qualityNo reduction in cutting efficiencyElectrical-based machining electrodesConductive materialsBiomedical engineering

The invention relates to the technical field of workpiece cutting, in particular to a cutting device for conductor materials. The cutting device aims to solve the problem that the surface quality of aworkpiece cut by an existing electrical sparkle cutting technique is not high. A multi-wire wire electrode device for cutting workpieces is provided. Deionized water with low resistivity is used as electrolyte, and multi-wire wire electrode is used as a cutter to cut the workpieces at the same position. According to the multi-wire wire electrode cutting device, electrolytic machining and the electrical sparkle cutting technique are combined, pits and recasting layers on the surfaces of the workpieces after the workpieces are cut by electrical sparkles can be removed, and the surface quality of the workpieces cut by the electrical sparkles is improved. The multi-wire wire electrode cutting device is suitable for cutting all conductive materials and has a wide application range.

Owner:XIAN TECH UNIV

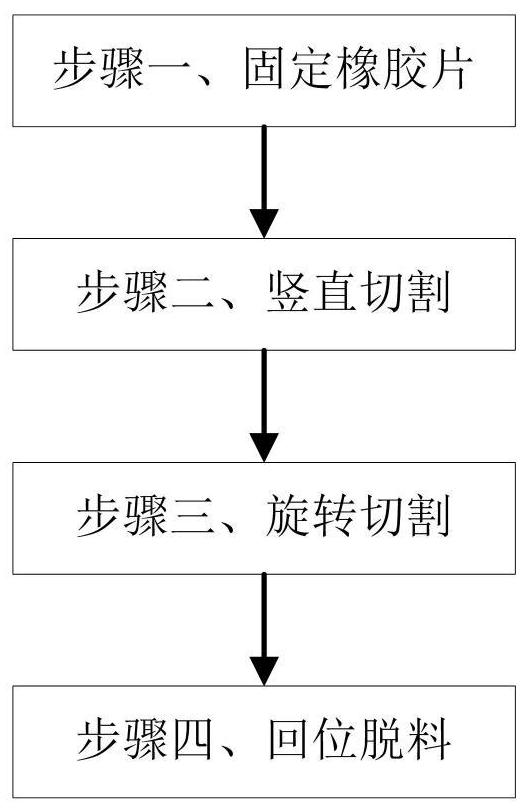

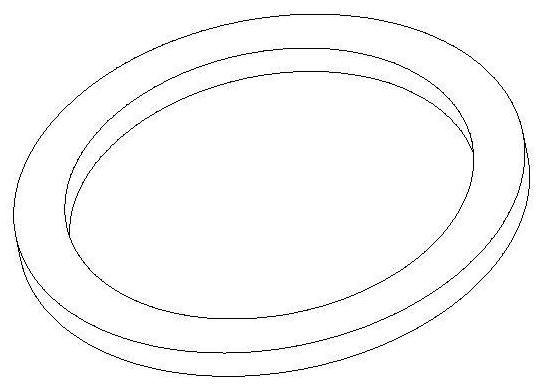

Rubber sealing ring press-cutting forming processing method

The invention belongs to the technical field of rubber sealing elements, and particularly relates to a rubber sealing ring press-cutting forming processing method which is completed by adopting a rubber sealing ring press-cutting forming processing machine in a matched mode. The method comprises the following steps that 1, a rubber sheet is fixed, specifically, the rubber sheet is horizontally placed on the upper surface of a base; 2, vertical cutting is conducted, specifically, a first annular blade and a second annular blade are driven to cut the rubber sheet in the vertical direction; 3, rotary cutting is conducted, specifically, a first annular blade and a second annular blade are driven to rotate in opposite directions, and therefore the rubber sheet is rotationally cut; and 4, returning and stripping are conducted, specifically, the first annular blade and the second annular blade are driven to vertically move upwards. The rubber sealing ring and a rubber wafer automatically fall off under the action of air pressure. The smooth cutting surface is ensured, rotation of the rubber sheet is avoided, and the cutting efficiency is improved; and the rubber sealing ring does not need to be manually taken out by an operator, the efficiency is improved, and injury to the operator is avoided.

Owner:东莞市华霖硅橡胶制品有限公司

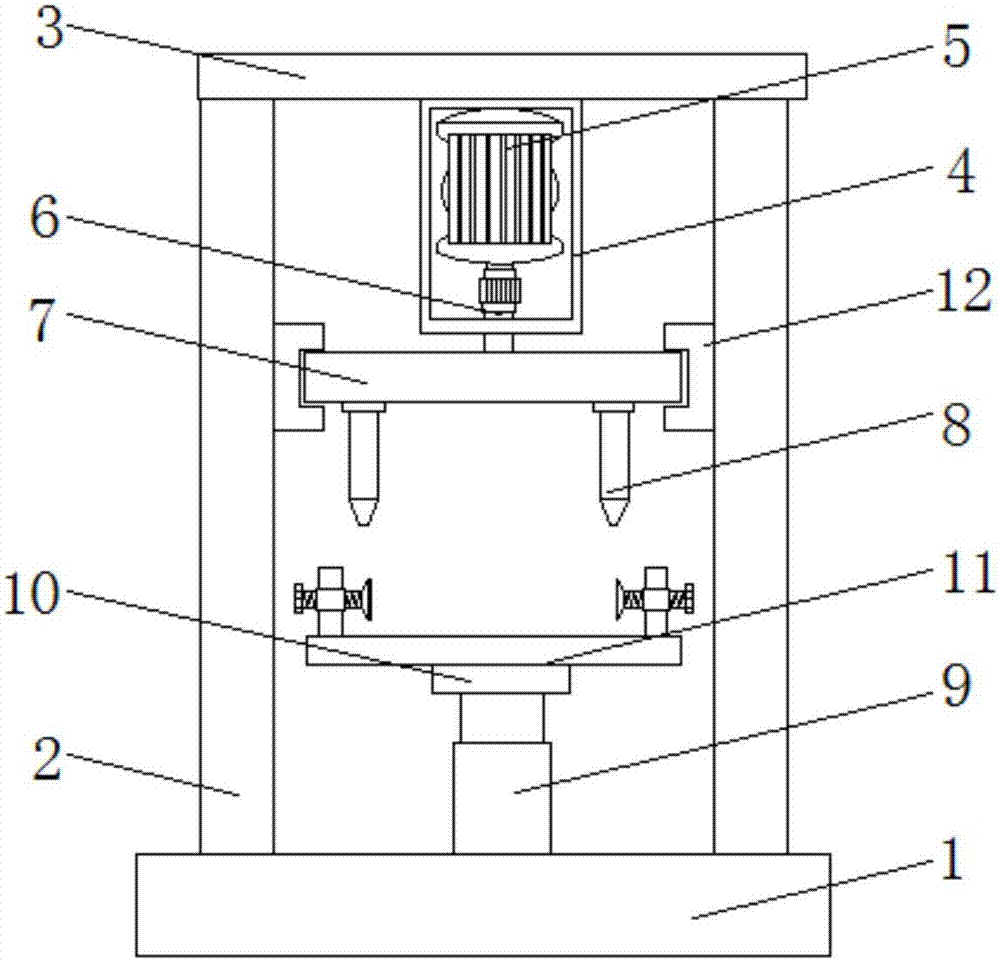

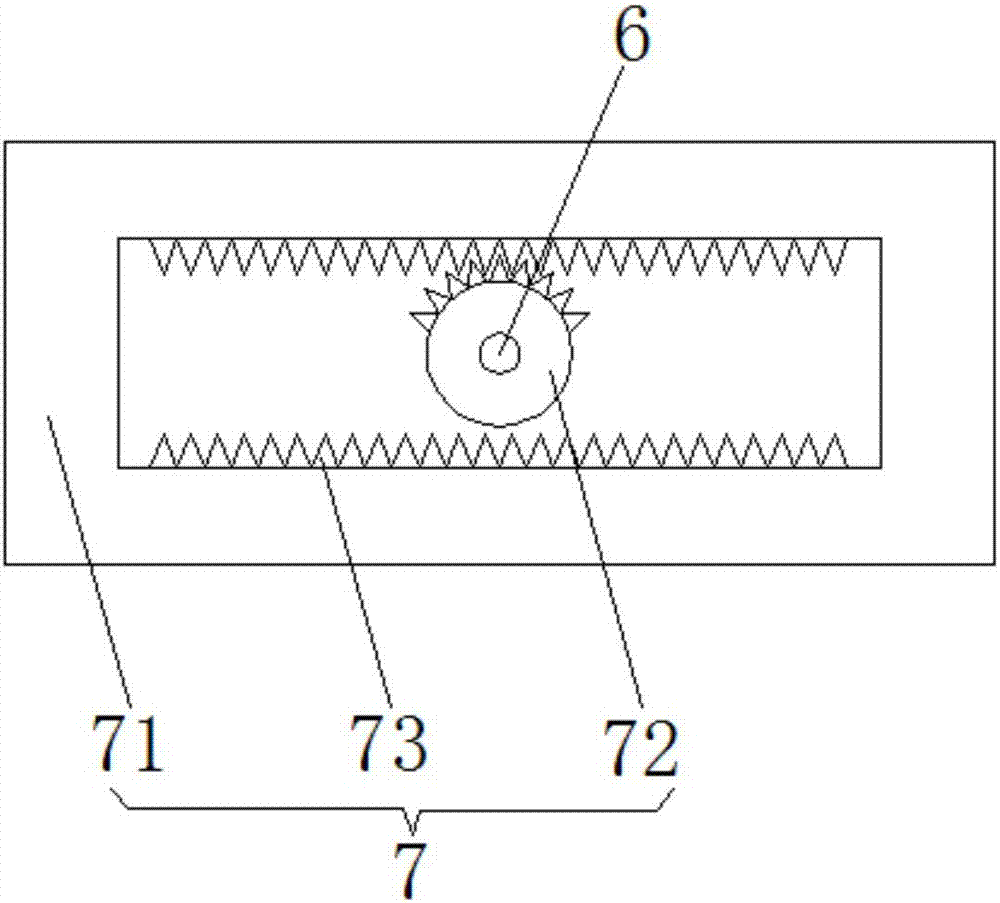

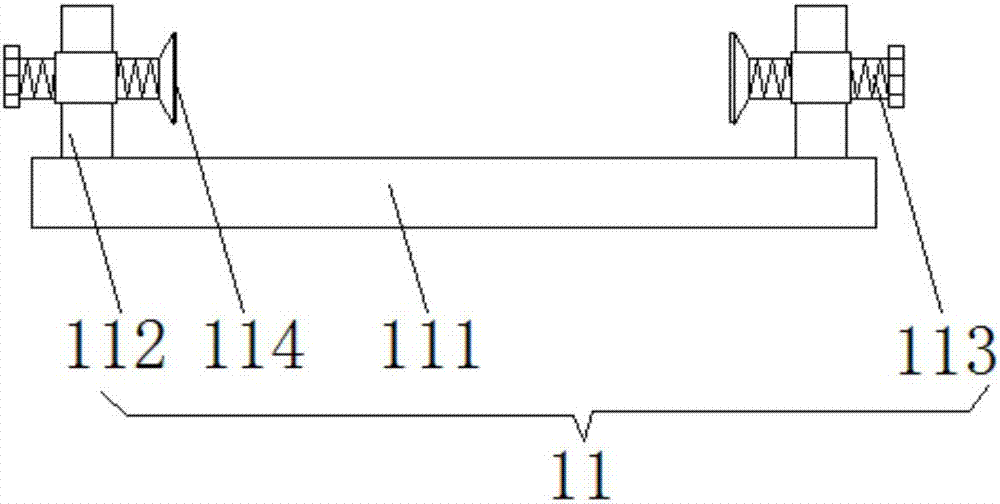

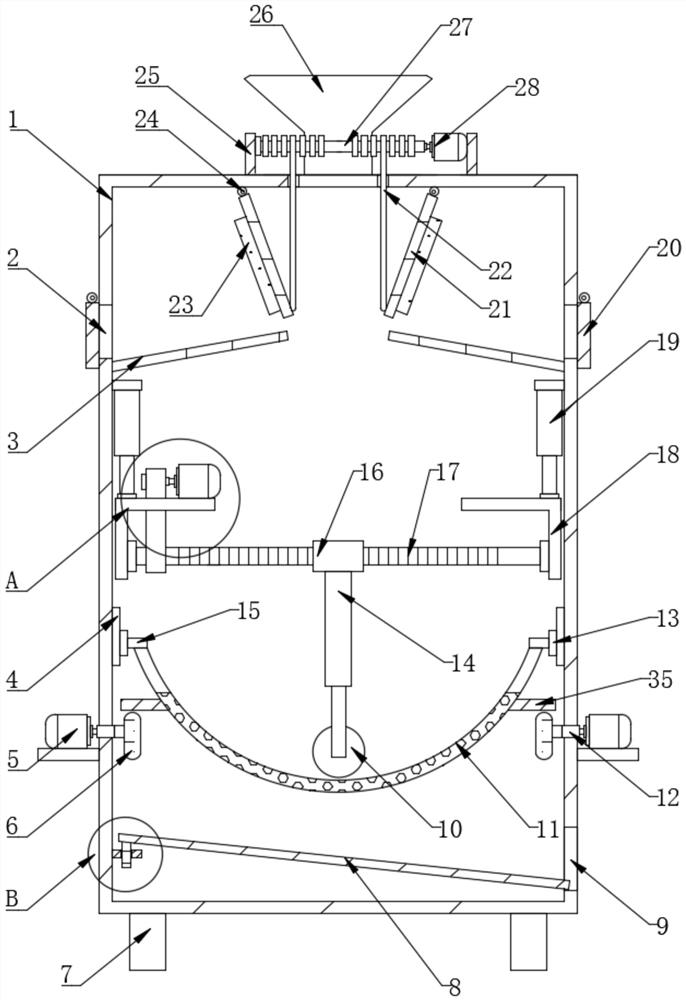

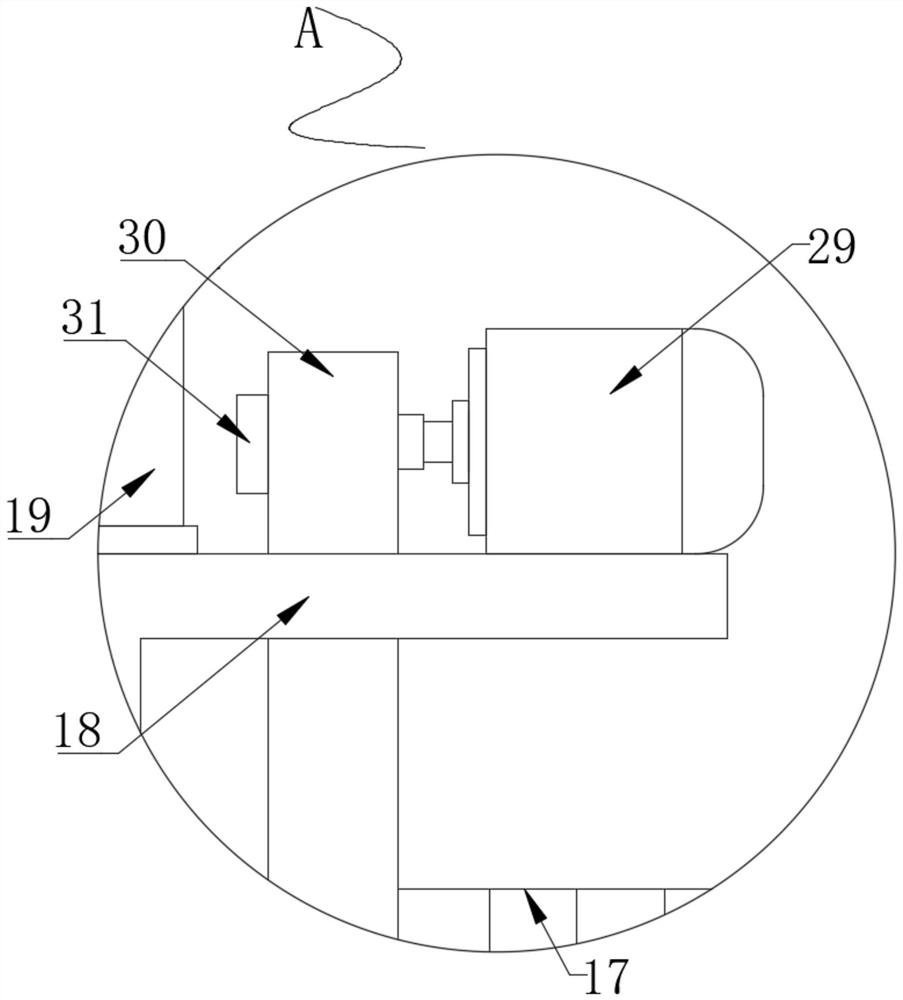

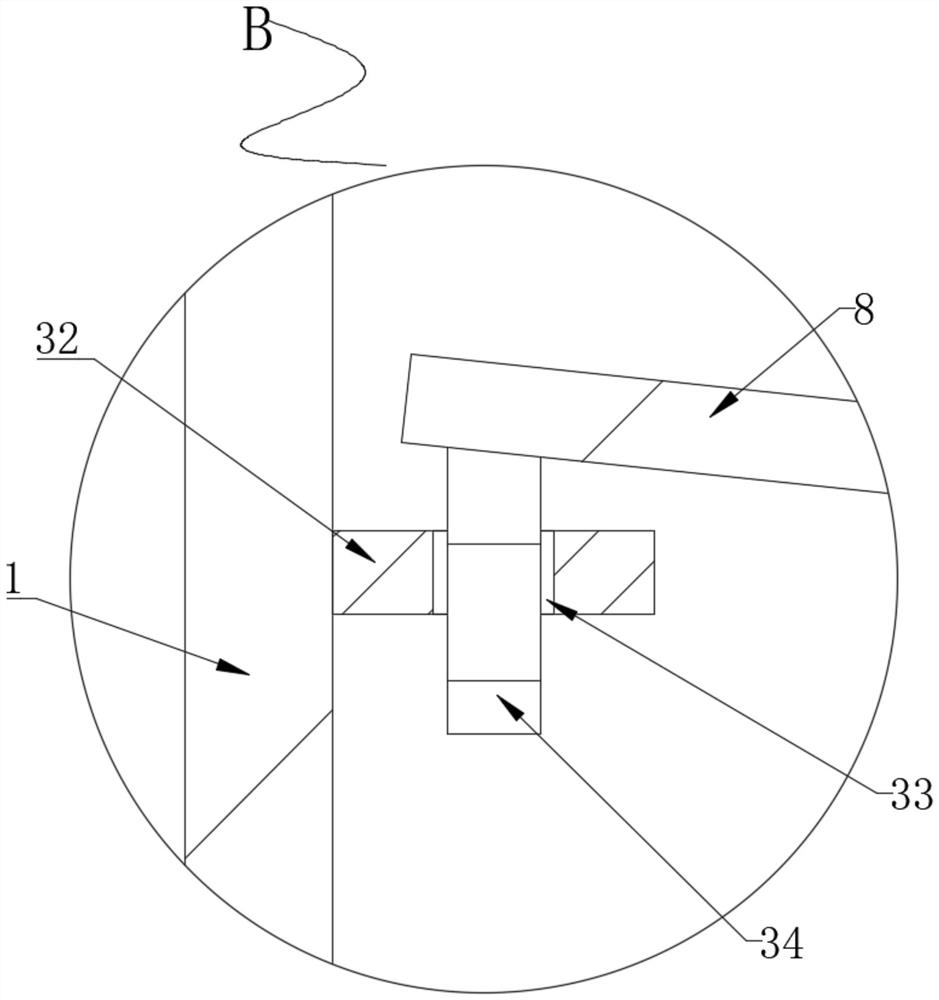

Multidirectional cutting device for part machining

InactiveCN107263127AEasy to cutReduce cutting efficiencyFeeding apparatusLarge fixed membersCouplingEngineering

The invention discloses a multi-directional cutting device for parts processing, which includes a base, a support plate is fixedly connected to both sides of the top of the base, and a top plate is fixedly connected to the top of the support plate, and the bottom of the top plate is located on both sides. A motor box is fixedly connected between the two support plates, the inside of the motor box is fixedly connected with a motor, and the output shaft of the motor is fixedly connected with a connecting rod through a coupling, and the bottom end of the connecting rod runs through the motor box and extends to bottom of the motor box. The invention relates to the technical field of parts processing. The multi-directional cutting device for parts processing solves the situation that the existing cutting equipment only has a single direction for cutting processing, and can better perform multi-directional cutting, avoiding the It leads to the reduction of cutting efficiency, shortens the cutting time, ensures a good cutting effect of parts, and meets the development requirements of mechanical parts processing.

Owner:CHENZHOU JINTONG INFORMATION TECH CO LTD

Small building material grinding device for constructional engineering

InactiveCN112317055AReduce cutting efficiencyAvoid cloggingGrain treatmentsHydraulic cylinderConstruction engineering

The invention discloses a small building material grinding device for constructional engineering. The small building material grinding device comprises a grinding box body, wherein supporting legs areconnected to the four corners of the bottom end of the grinding box body, a discharging hopper is arranged at the top end of the grinding box body, and a grinding disc is arranged on the inner side of the grinding box body. According to the small building material grinding device, through a third motor, a conveying belt, a third rotating rod, a supporting base, a hydraulic cylinder, a sliding block, a connecting plate, a sliding rail, a first motor, impact plates, a first rotating rod and eccentric blocks, when screen holes of the grinding disc are blocked by building materials or more building materials remain on the surface of the grinding disc after grinding is completed, the grinding disc can vibrate up and down in the grinding box body by a small amplitude in the mode that the two eccentric blocks continuously impact the two impact plates, so that the building materials on the surface of the grinding disc are vibrated out and are separated from the grinding disc through the screen holes, and as a result, the situation that the building materials block the screen holes in the grinding disc, and consequently the discharging efficiency of the grinding disc is reduced and the waste of the building materials is caused is avoided.

Owner:杜维

Clamp device facilitating bamboo cutting

InactiveCN108858402AHigh precisionEasy to operateCane mechanical workingMetal working apparatusEngineeringMechanical engineering

The invention discloses a clamp device facilitating bamboo cutting. The clamp device comprises a base, an installing base is arranged on the base, a first air cylinder is arranged in the installing base, a clamping device is connected to the first air cylinder and comprises a fixed rod, a first motor, a driving gear, a driven gear, a rotating shaft, a fixed base, a first groove, a second air cylinder, a sliding base and a conveying belt, the first air cylinder is fixedly arranged below the fixed rod, a second motor is arranged on the fixed rod and is in drive connection with the driving gear,and therefore bamboos can be more stable in the cutting process, the cutting accuracy is improved, the needed cutting size does not need to be manually adjusted, safety is better achieved, operation is better facilitated, meanwhile, the cutting efficiency is accelerated, manual collection is not needed, the cutting internal time is shortened, the overall cutting efficiency is improved, meanwhile,manpower resources are saved, the bamboo cutting cost is reduced, and the clamp device is simple in operation, high in practicability and convenient to use and popularize.

Owner:安庆市金丝制刷有限公司

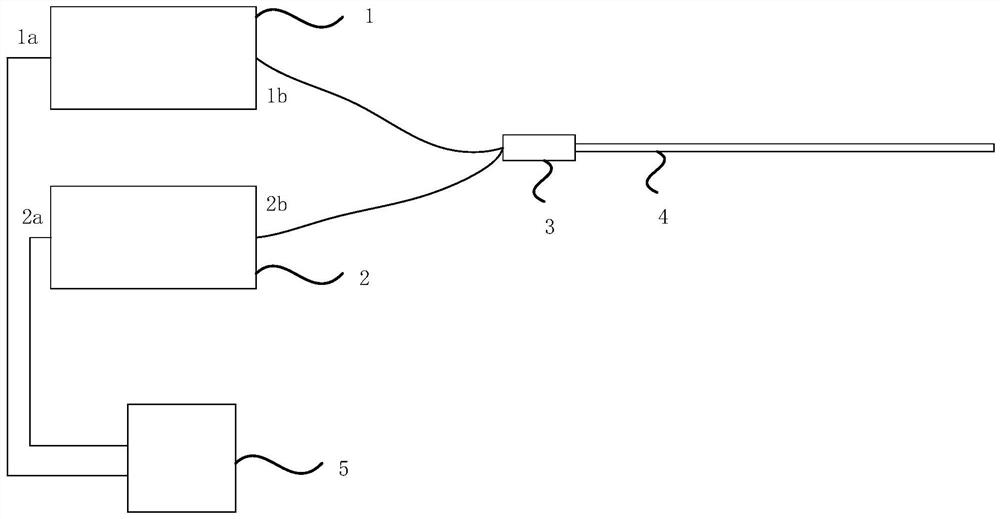

Fusion wave laser output device and laser therapy apparatus

PendingCN113964640AGood hemostatic abilityReduce cutting efficiencySurgical instrument detailsLaser arrangementsErbium lasersBlood loss

The embodiment of the invention discloses a fusion wave laser output device and a laser therapy apparatus. The fused wave laser output device comprises a first laser, the first laser comprises a first controlled end and a continuous laser output end, and the first laser is used for outputting continuous laser through the continuous laser output end according to a first control signal received by the first controlled end; a second laser comprises a second controlled end and a pulse laser output end, and the second laser is used for outputting pulse laser through the pulse laser output end according to a second control signal received by the second controlled end; a controller is used for simultaneously sending the first control signal and the second control signal; an output fiber; and a beam combiner is used for coupling the continuous laser and the pulse laser into the output optical fiber. According to the embodiment, the operation efficiency can be improved, the visual field condition in the operation is improved, the postoperative recovery speed of a patient is increased, and the blood loss amount in the operation is reduced.

Owner:上海瑞柯恩激光技术有限公司

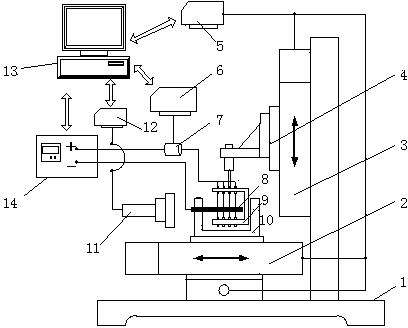

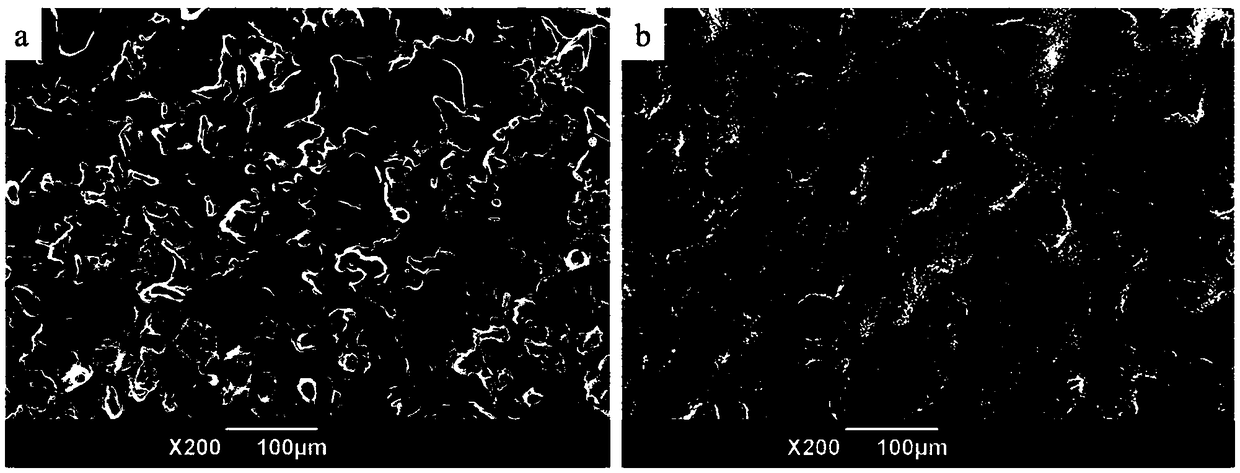

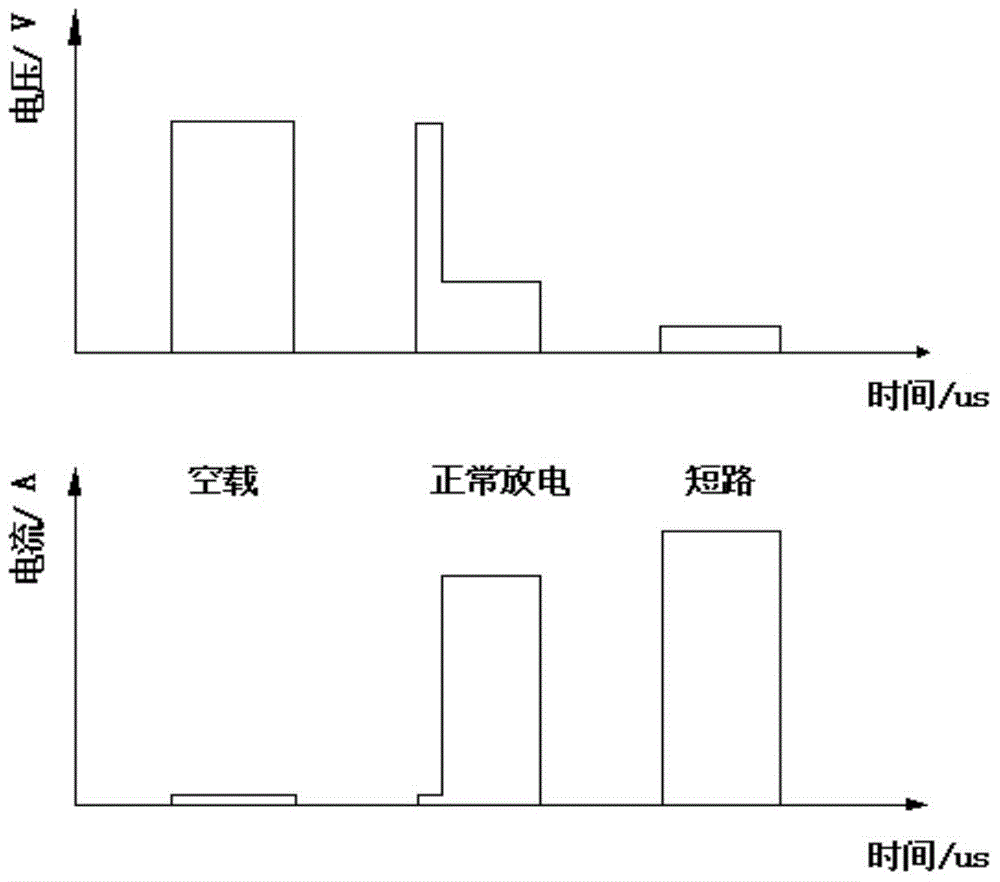

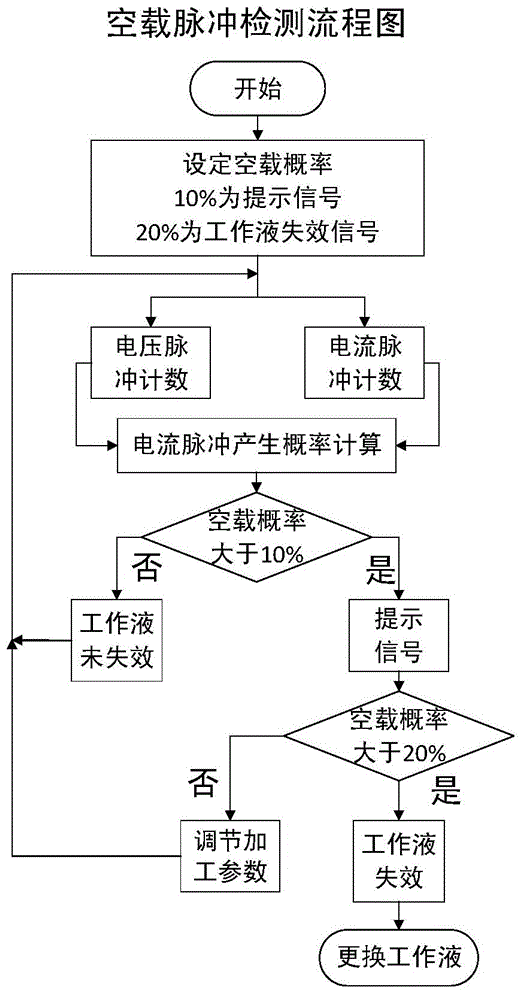

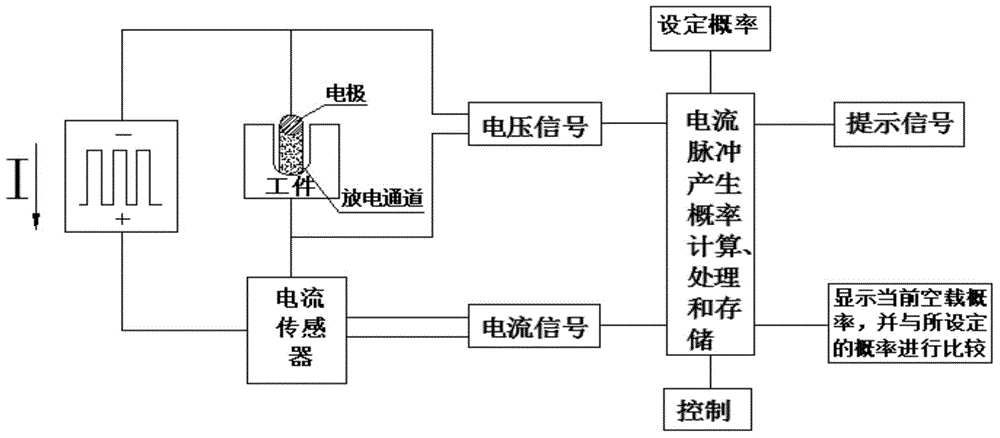

High-speed reciprocation wire cut electrical discharge machining working solution service life online fast determining method

The invention relates to a high-speed reciprocation wire cut electrical discharge machining working solution service life online fast determining method. The method is characterized by including: firstly, using a sampling circuit to regularly sample no-load current pulse count or (short circuit+discharge) current pulse count in one sampling cycle; secondly, calculating the proportion of the no-load current pulse count or (short circuit+discharge) current pulse count accounting for the pulse in the sampling cycle; thirdly, processing according to the obtained proportion: if no-load current pulse proportion is not larger than 10% or the (short circuit+discharge) current pulse proportion is not smaller than 70%, determining that working solution operates normally; if the no-load current pulse proportion ranges from 10% to 20% or the (short circuit+discharge) current pulse proportion ranges from 60% to 70%, determining that cutting can be performed normally by adjusting cutting parameters; if the no-load current pulse proportion is larger than 20% or the (short circuit+discharge) current pulse proportion is smaller than 60%, determining that the working solution fails and needs to be replaced. The method is simple, practical, good in instantaneity and high in accuracy.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for cutting conductor material

InactiveCN108080756AImprove surface qualityEasy to operateElectrical-based auxillary apparatusEngineeringElectrolyte

The invention relates to the technical field of workpiece cutting, in particular to a method for cutting a conductor material. The purpose of the invention is to solve the problem that the surface quality of a cut workpiece is not high in the existing electric spark cutting technology. In order to achieve the purpose, the invention provides the method for cutting the workpiece; and low-resistivitydeionized water is used as an electrolyte, and two electrode wires are used for cutting the workpiece at the same position. According to the method, an anode dissolving principle is introduced into the electric spark cutting technology, so that re-cast layers on the surface of the workpiece subjected to electric spark cutting can be removed, and the surface quality is improved. The method is suitable for cutting all conductive materials, and is wide in application range.

Owner:XIAN TECHNOLOGICAL UNIV

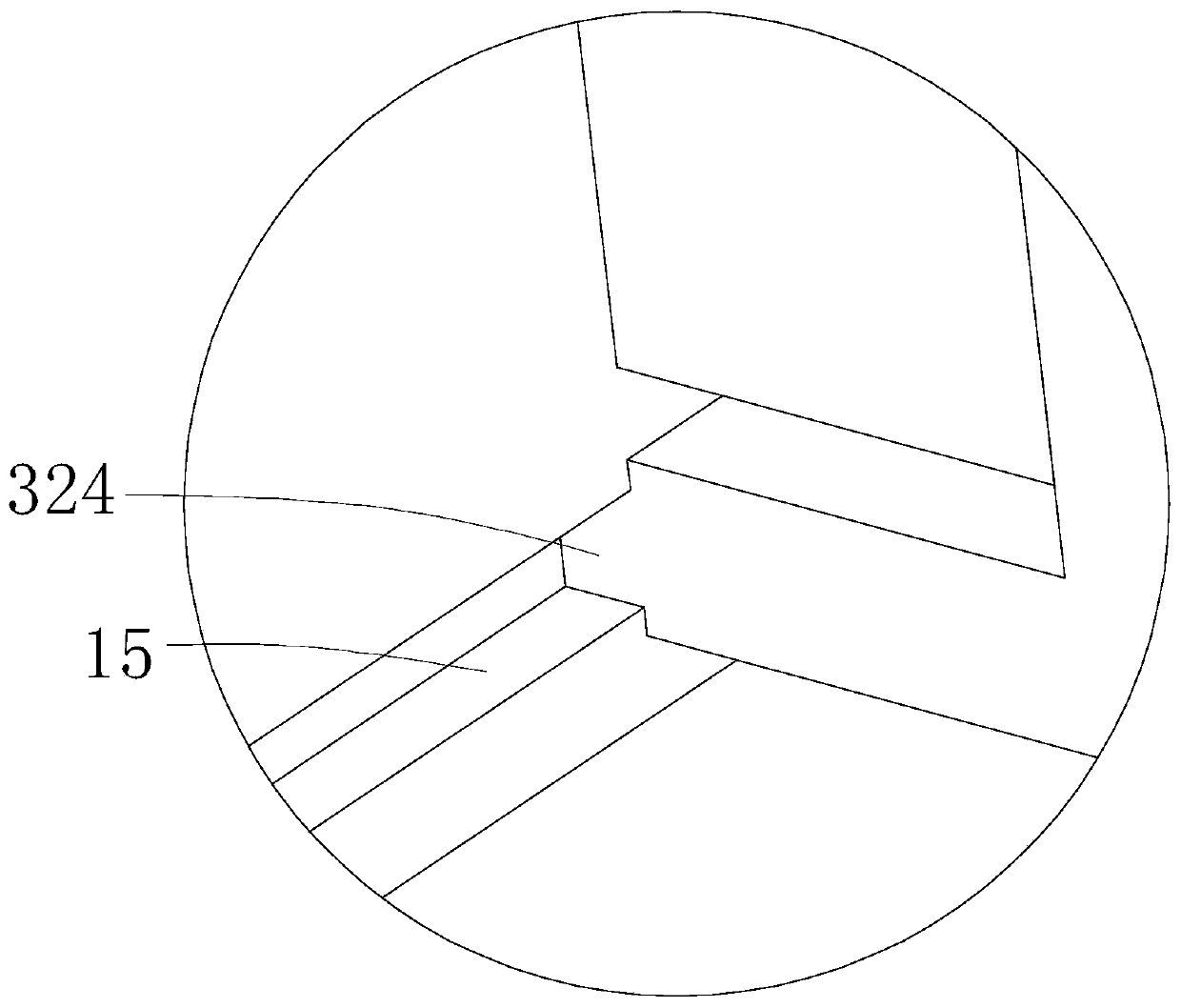

Cutting treatment device for aluminum plate finish machining

ActiveCN111299682AAchieve multi-segment cutting effectEasy to operateTube shearing machinesMaintainance and safety accessoriesDrive shaftElectric machinery

The invention discloses a cutting treatment device for aluminum plate finish machining. A supporting frame is included, and a first cross beam is fixedly installed on one side of the supporting frame;the surface of the first cross beam is provided with a part groove in which a hydraulic push rod is arranged; a motor is installed on the surface of the hydraulic push rod in an engaging manner, anda driving shaft is rotationally connected to the motor; a cutting mechanism is fixedly installed on the surface of the driving shaft; the cutting mechanism comprises cutting blades, positioning piecesand fastening bolts; each cutting blade is in a shape of a circle, and the position of the circle center of each cutting blade is provided with a through hole; the driving shaft penetrates through the through holes of the cutting blades, and the cutting blades are fixedly installed on the driving shaft through the fastening bolts in the positioning pieces; and a workbench is fixedly connected tothe upper end of the supporting frame. The cutting treatment device for aluminum plate finish machining solves the problems that a cutting device can only cut one position at a time, the cutting efficiency is low, it is needed that a user manually pushes a plate to move during cutting, the labor force is increased, and position adjusting and number adjusting cannot be performed according to the specific using requirement.

Owner:河南鑫瑞佳新材料有限公司

Packaging material polyethylene foamed plastic circular cutting machine

ActiveCN110883808AIncrease manpower and material resourcesReduce power efficiencyMetal working apparatusMaterial resourcesPolyethylene

The invention relates to a packaging material polyethylene foamed plastic circular cutting machine, which comprises a bottom plate, a circular cutting device, a conveying device and a collecting device, wherein the circular cutting device is installed at the upper end of the bottom plate; the conveying device is arranged below the circular cutting device; and the conveying device is installed on the bottom plate. The problems that when the existing equipment performs circular cutting on the polyethylene foamed plastic, the foamed plastic cannot be pressed in the case of circular cutting, the phenomenon of deformation or irregular shape after circular cutting is easy to occur, material waste is thus caused, manpower and material resources are increased, the foamed plastic cannot be subjected to edge pressing treatment, the foamed plastic is prone to falling off, wrinkling and the like during circular cutting, the cutting success rate and the cutting efficiency are thus reduced, meanwhile, when the circular-cut foamed plastic is collected, the foamed plastic gets stuck easily, scraps remaining on the foamed plastic cannot be removed, and therefore the collecting efficiency is reducedare solved.

Owner:JIANGXI MINGHUI ENVIRONMENTAL PROTECTION TECH CO LTD

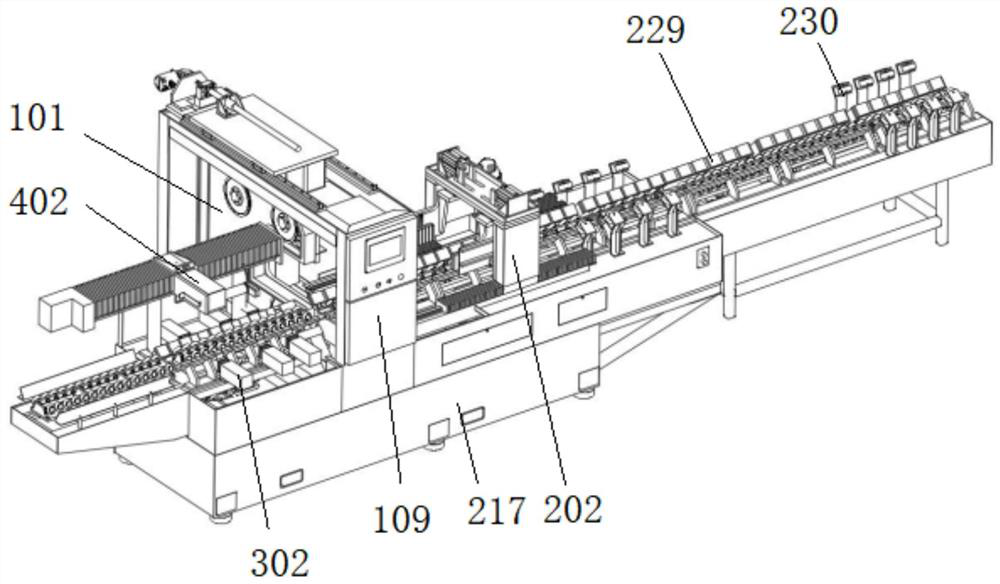

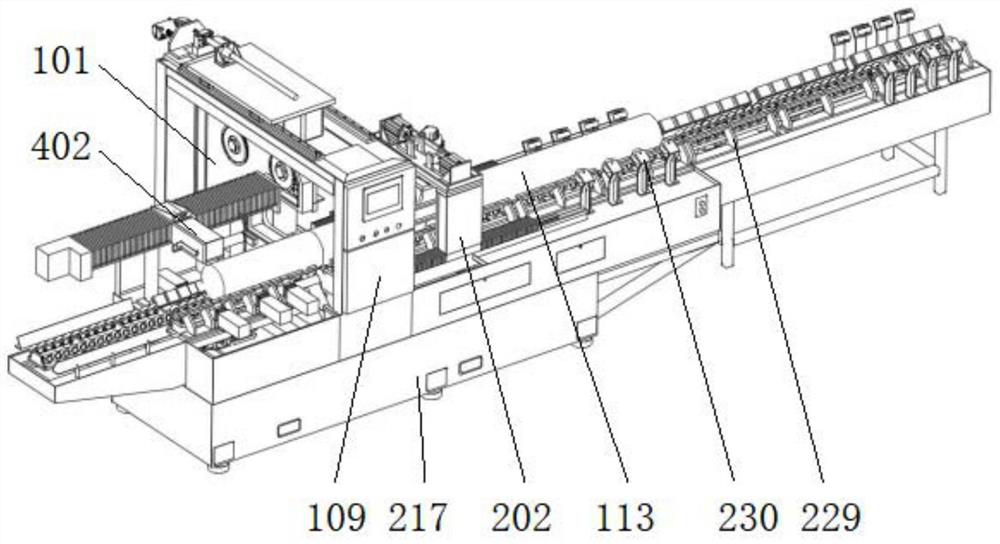

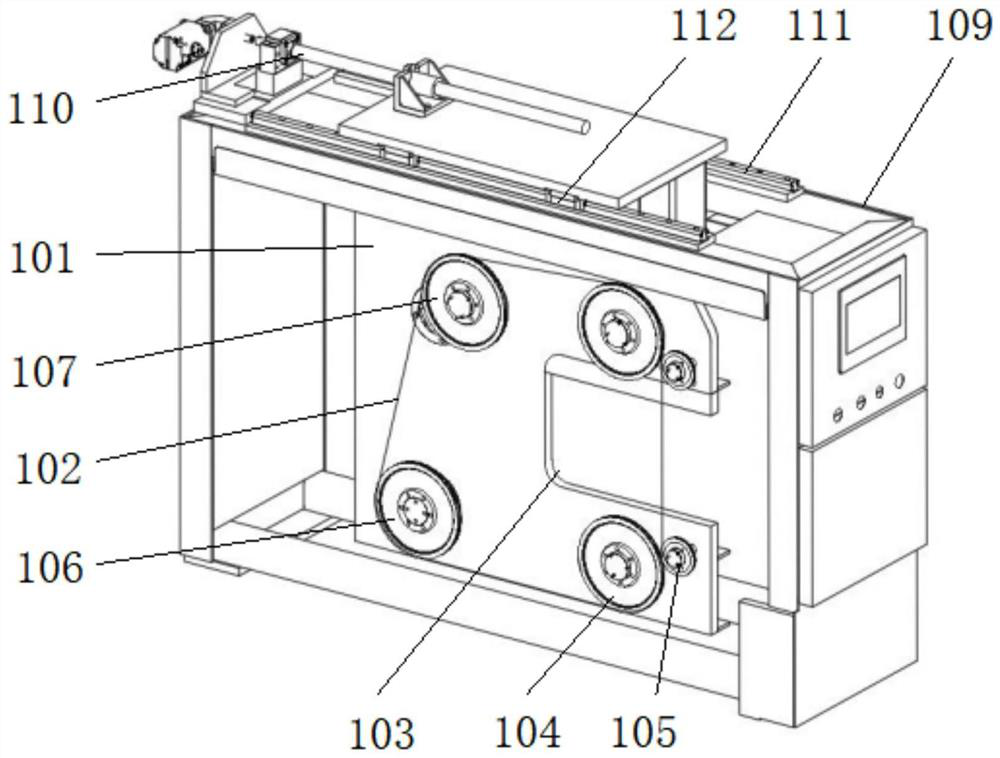

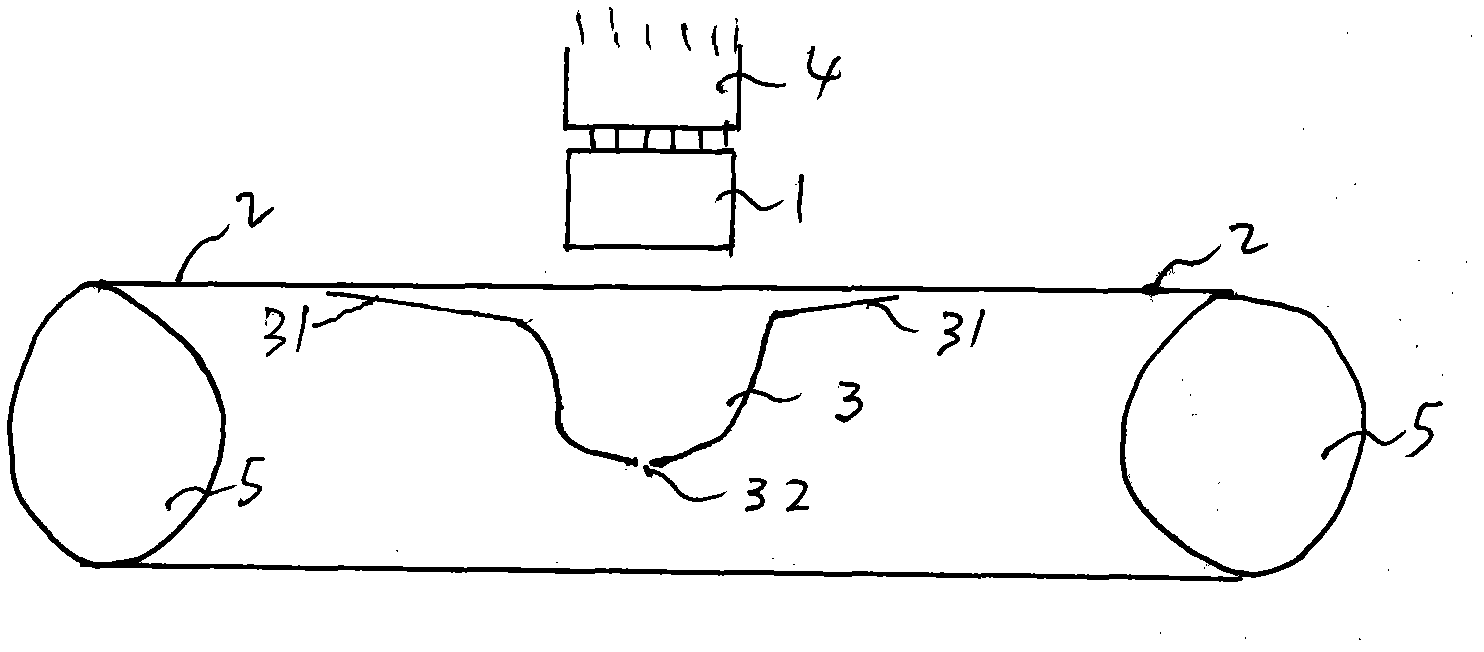

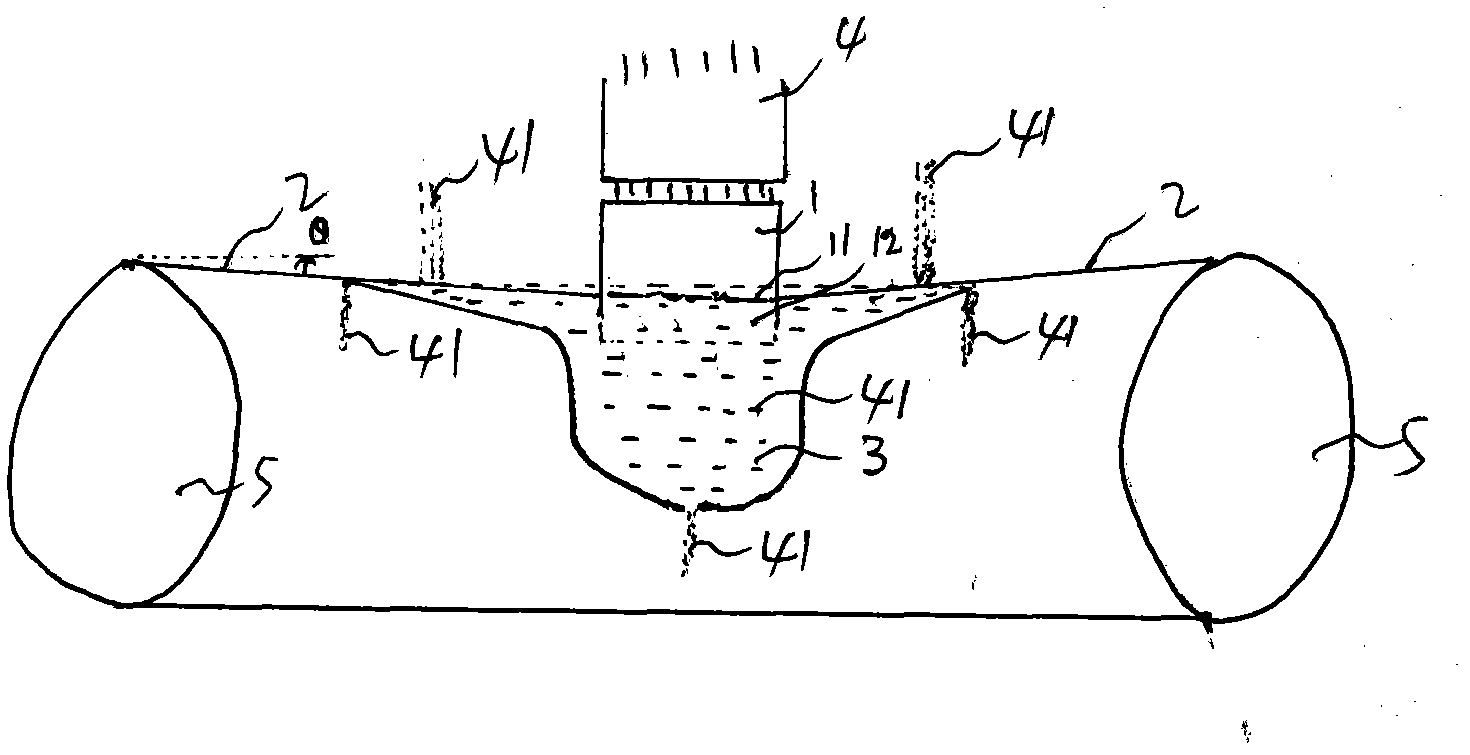

Reciprocating cutting machine through diamond wire

PendingCN112078042AStable cutting lengthImprove cutting strengthWorking accessoriesFine working devicesEngineeringSupport point

The invention discloses a reciprocating cutting machine through a diamond wire. The reciprocating cutting machine comprises a base frame, the diamond wire which is arranged on the base frame and usedfor cutting a silicon rod and a limiting assembly which is used for achieving reciprocating cutting of the diamond wire, and the diamond wire is wound in the limiting assembly to form a reciprocatingcutting position. According to the reciprocating cutting machine through the diamond wire, the limiting assembly is arranged to limit the diamond wire to always have a short stress supporting point atthe reciprocating cutting position, so that the cutting length of the diamond wire at the reciprocating cutting position is kept stable as much as possible, the size of a wire bow in the cutting process is controlled, the cutting strength of the diamond wire at the reciprocating cutting position is improved, reduction of the cutting efficiency due to overlarge wire bow caused by reversing cuttingis avoided, reciprocating cutting is carried out on the silicon rod at the reciprocating cutting position, the tool retracting process in multi-section cutting of the silicon rod is omitted, the cutting speed is increased, and the production efficiency is improved.

Owner:QINGDAO GAOCE TECH CO LTD

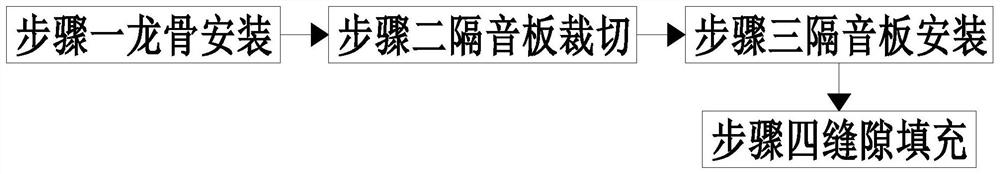

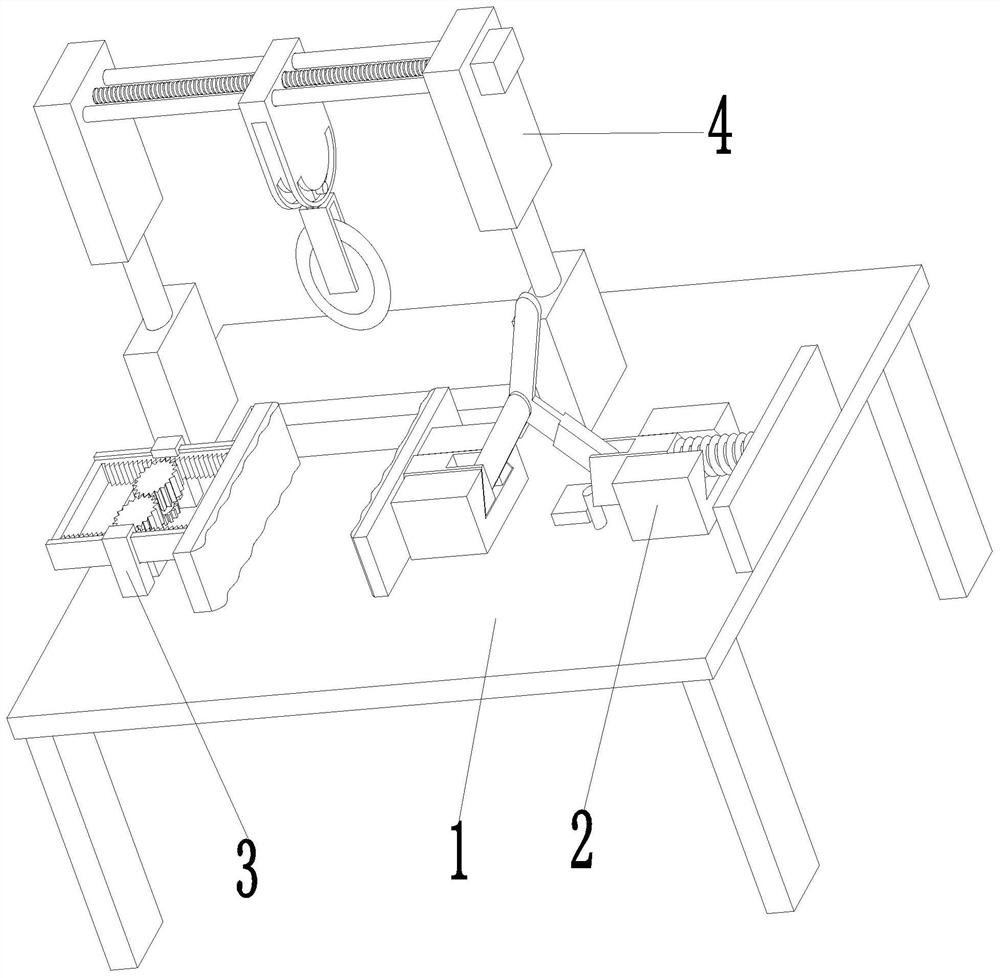

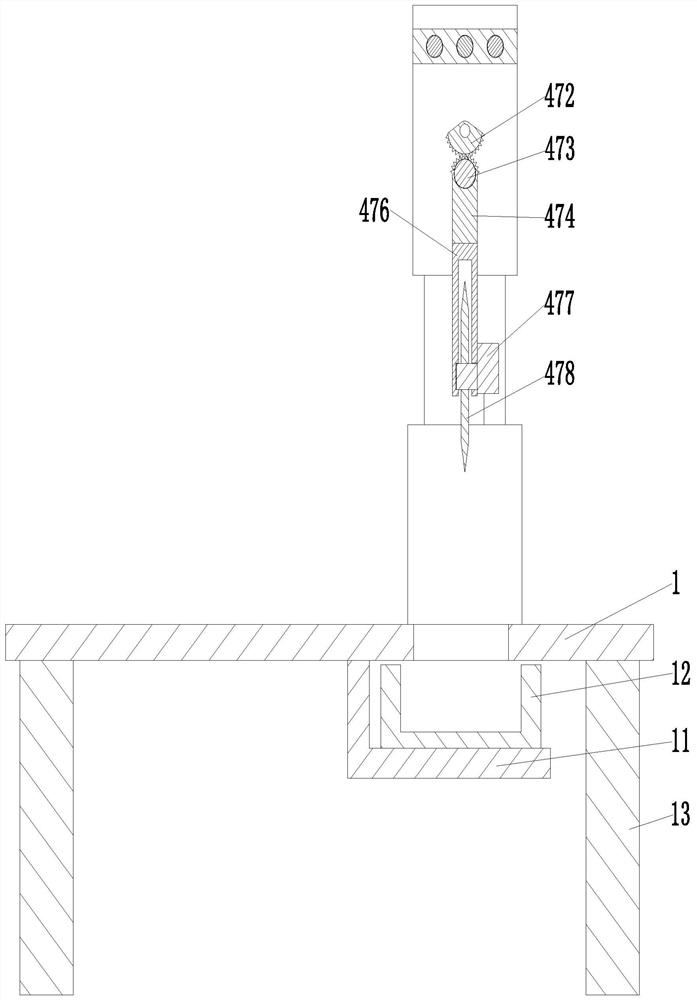

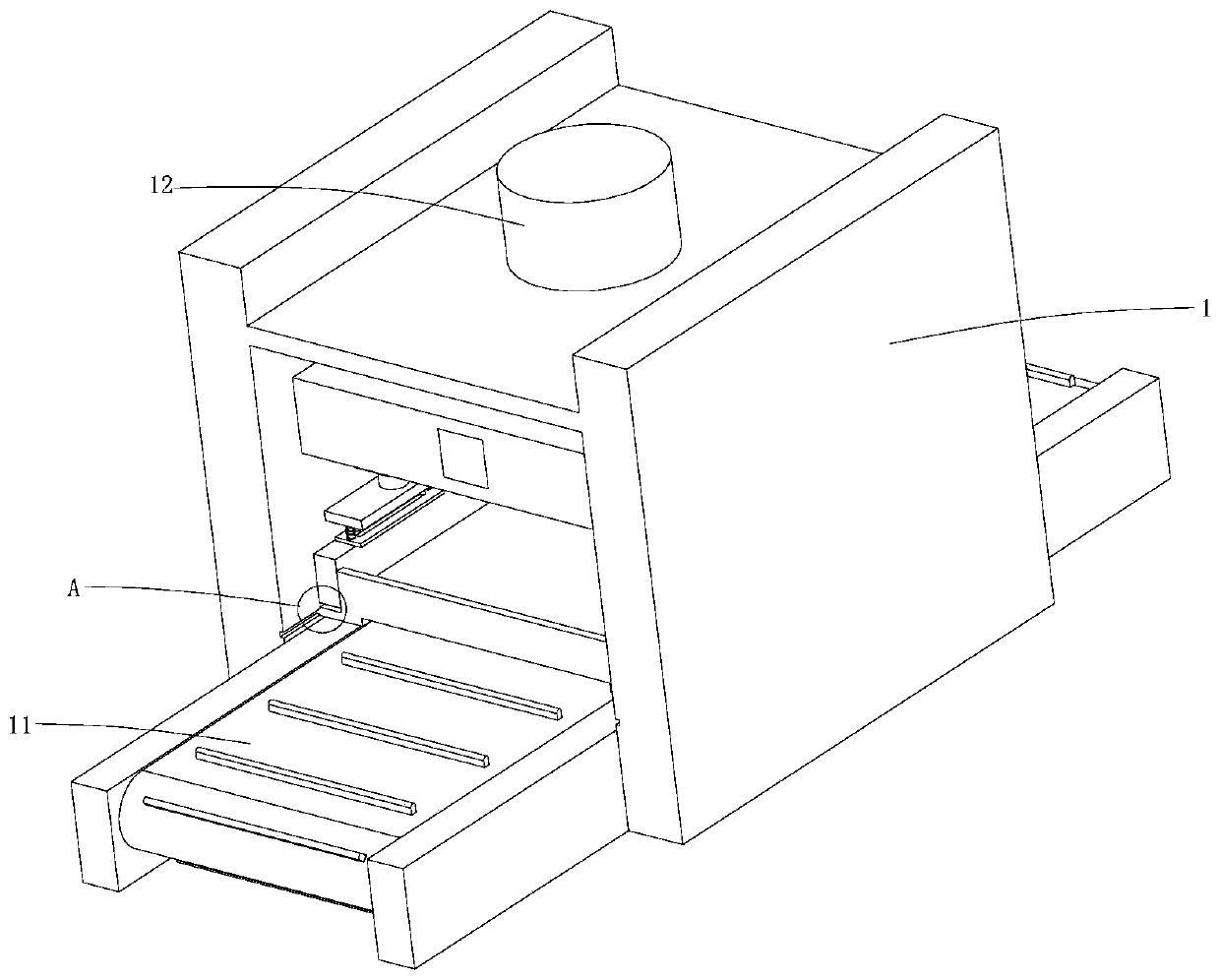

A cutting device for building sound insulation panels

InactiveCN111997213BReduce installation efficiencyImprove crop qualitySound proofingClassical mechanicsEngineering

The present invention relates to a cutting device for building sound insulation panels. The method for installing the sound insulation panels using the cutting equipment for building sound insulation panels mainly includes the following steps: keel installation, sound insulation panel cutting, and sound insulation panel installation As well as various processes such as gap filling, the sound insulation panel cutting equipment used includes a bottom plate, a positioning device, a pressing device and a cutting device. The present invention can solve the following problems existing in the existing sound insulation panel cutting, a. Traditional When cutting the sound insulation board, it is necessary to manually hold the cutting tool to cut the sound insulation board. The safety hazard of manual cutting of the sound insulation board is relatively large, and the labor intensity of manual cutting is high, and the cutting efficiency is low, which reduces the quality of the sound insulation board. For the efficiency of installation, the manually cut sound insulation panels often have burrs, which affects the use of the sound insulation panels.

Owner:安徽中南天开建设集团有限公司

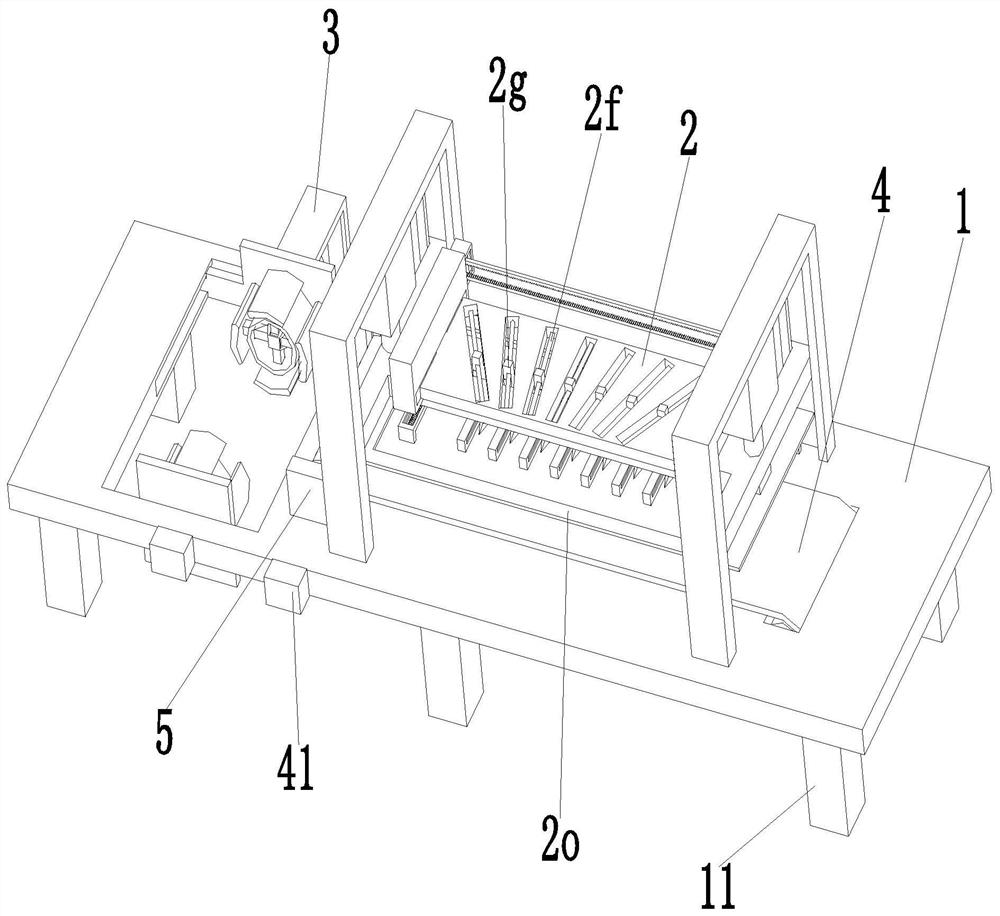

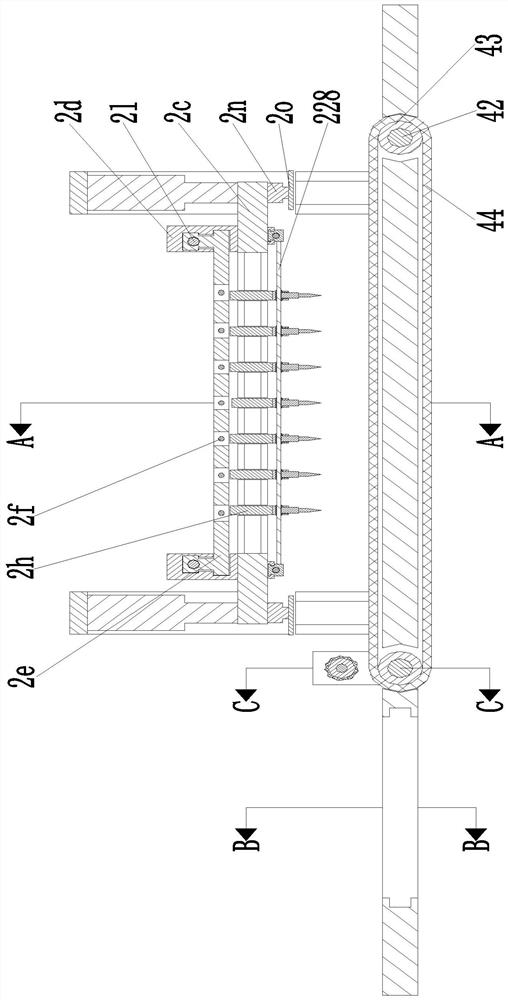

Anti-abrasion corrugated box processing equipment

ActiveCN110539522BReliable compressionPrevent movementBox making operationsPaper-makingEngineeringStructural engineering

The invention discloses anti-wear corrugated paper box machining equipment. The equipment comprises a fixing frame, a vertically movable supporting plate and a conveying part used for conveying a machined corrugated paper board; a first driving part used for driving the supporting plate to vertically move is arranged on the fixing frame; and a machining device used for carrying out joint-cutting machining on the corrugated paper board is arranged at the bottom of the supporting plate, a limiting frame used for stabilizing a corrugated paper box is fixedly arranged below the supporting plate, and a movable feeding bottom plate is arranged on the conveying part. Through the arrangement of the above structures, the effective joint-cutting on the corrugated paper box through the machining equipment is realized, and the corrugated paper box can be supported and limited by the limiting frame and the feeding bottom plate so that the corrugated paper box can keep stable and tidy when being pressed, the offset of the corrugated paper box is avoided, the machining effect is improved, and the machining quality is guaranteed.

Owner:浦江丰收包装有限公司

Improved multi-line cutting device

InactiveCN103128866AImprove cooling effectImproved dispersion and carry awayFine working devicesEngineeringFront edge

The invention relates to a multi-line cutting device used for multi-line cutting or slicing of solid material. An existing solid material multi-line cutting device is low in cutting efficiency, relatively poor in cutting evenness and high in cost. Based on an improved cutting method, the improved multi-line cutting device is provided, the cutting mode that the solid material to be cut is pressed on a cutting line net from the top to the bottom can be adopted, the cut part and a cutting front edge of the solid material are maintained submerged in cutting liquid, and the effects that in a cutting process, the cutting liquid is even and uniform and has good cutting ability are ensured, cutting efficiency and cutting evenness can be greatly improved, and cutting cost is observably reduced.

Owner:赵钧永

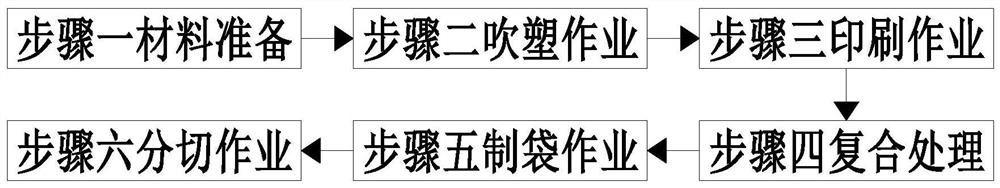

Manufacturing method of environment-friendly paper-plastic packaging bag

InactiveCN112172237AReduce cutting efficiencyImprove cutting efficiencyBox making operationsPaper-makingBlow moldingMaterials preparation

The invention relates to a manufacturing method of an environment-friendly paper-plastic packaging bag. The manufacturing method of the environment-friendly paper-plastic packaging bag mainly comprises the following steps of material preparation, blow molding operation, printing operation, composite treatment, bag manufacturing operation, slitting operation and other multiple processes. Paper-plastic bag slitting equipment used comprises a bottom plate, a slitting device, a roll feeding device, a conveying device and an abutting device. The manufacturing method of the environment-friendly paper-plastic packaging bag provided by the invention can solve the following problems existing in existing paper-plastic packaging bag slitting: a, when a traditional paper-plastic packaging bag is slit,a cutter is generally used for cutting the traditional paper-plastic packaging bag manually, cutting deviation often occurs when the paper-plastic packaging bag is cut manually, the production quality of the paper-plastic packaging bag is influenced, raw materials are wasted, workers are prone to fatigue in the cutting process, and the phenomenon that the workers are prone to being scratched occurs; and b, when existing paper-plastic packaging bag slitting equipment is used for slitting paper-plastic packaging bags, only single packaging bag can be cut out, and the slitting efficiency of thepaper-plastic packaging bags is reduced; and the slitting efficiency and the slitting quality of the paper-plastic packaging bags can be improved.

Owner:宛群

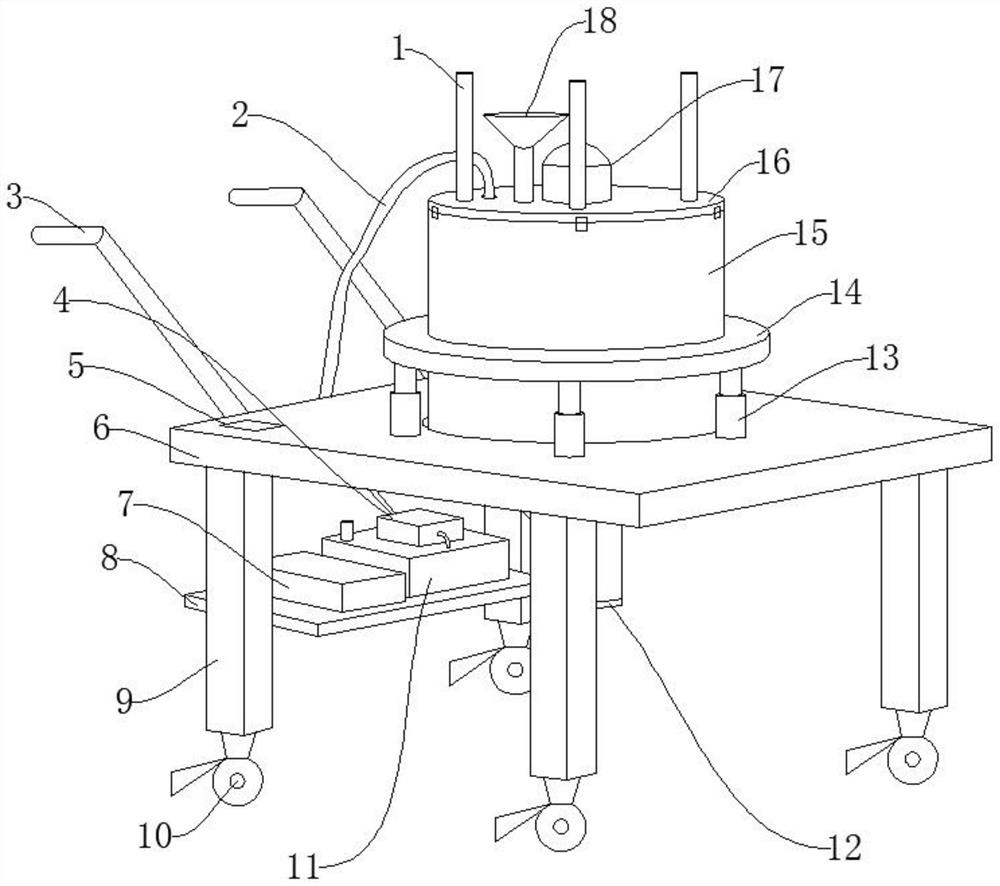

Agricultural forage grass seed dressing device and using method thereof

InactiveCN112715092AImprove cleaning efficiencyRealize automatic cleaningHollow article cleaningSeed coating/dressingAgricultural scienceAgricultural engineering

The invention discloses an agricultural forage grass seed dressing device and a using method thereof. The agricultural forage grass seed dressing device comprises a support table, a stirring tank, a water spraying ring and a vibration motor, wherein the stirring tank penetrates through the middle of the upper end of the support table. The device has the beneficial effects that through the design of the water spraying ring, spray heads, a long brush strip, a short brush strip, electric push rods, a water pipe, a water pump and a water tank, the interior of the device can be conveniently cleaned on the premise that the device is not disassembled after seed dressing is completed, the cleaning efficiency of the interior of the device is greatly improved, and next-time use of the device is facilitated; and through the design of telescopic rods, springs, sliding holes and a vibration motor, forage grass seeds can fall off under the action of vibration after seed dressing is completed, blockage of a discharging opening of the device is effectively avoided, the discharging efficiency is improved, besides, the forage grass seeds adhering to the inner wall of the device can be shaken off in the discharging process, and therefore, adhesion waste of the seeds is avoided.

Owner:LANZHOU INST OF ANIMAL SCI & VETERINARY PHARMA OF CAAS

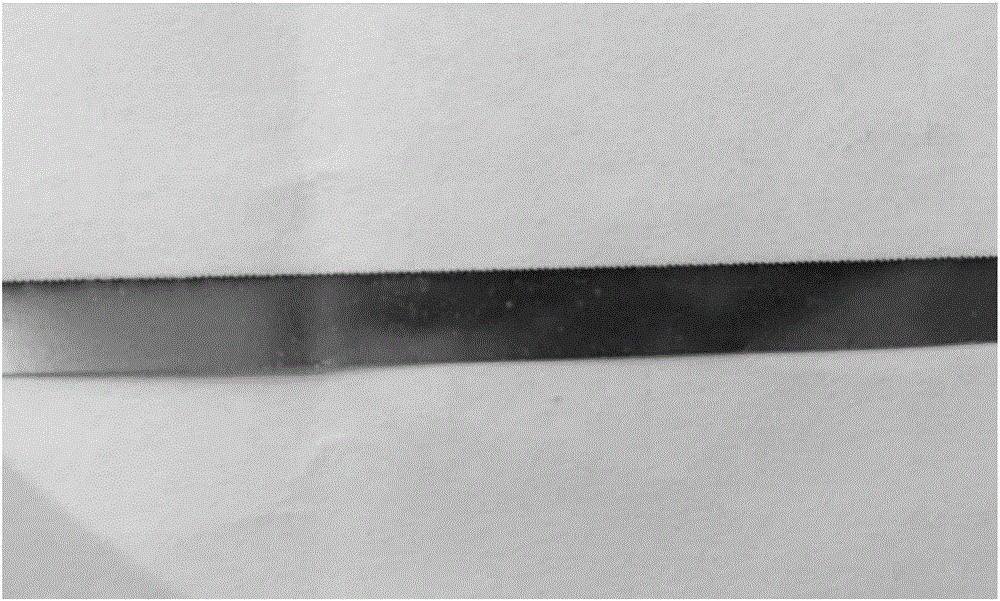

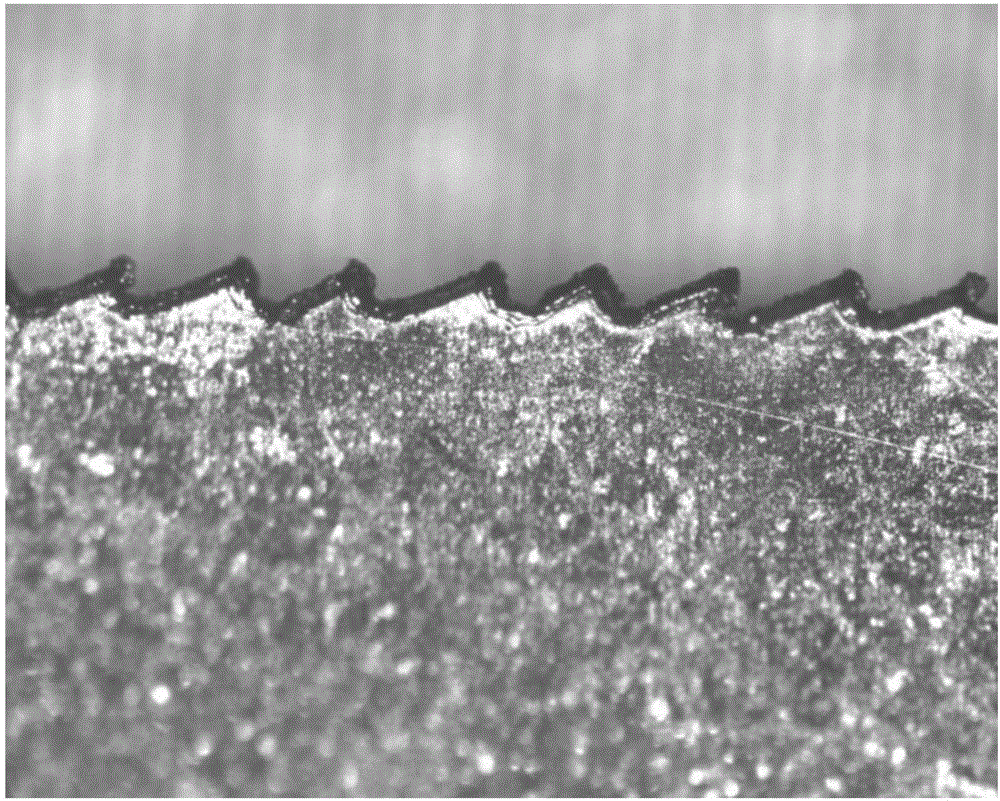

Cutting saw for proximal surface sheet of fixed partial denture and processing method of cutting saw

The invention discloses a cutting saw for a proximal surface sheet of fixed partial denture and a processing method of the cutting saw. The cutting saw is of a toothed structure; the width of teeth is 10mu m, the apex angle of the teeth is 30 to 60 degrees, the total length of the saw is 50 to 150mm, the width of the saw is 2 to 10mm, and thickness of the saw is 30 to 100mu m; during processing, a cleaned stainless steel sheet is putted on a laser cutting machine by adopting a laser cutting method, and parameters of the laser cutting machine are adjusted for micro processing; during use, the current of a laser power supply is 10 to 20A, and the scribing speed is 1 to 3mm / s; finally, edges are deburred and cleaned again. The cutting saw disclosed by the invention can be used for quickly removing a residual bonding agent of the proximal surface of the teeth and polishing the surface; compared with other cutting saws for the proximal surface, the process disclosed by the invention has the advantages of high microprocessing precision, excellent processing speed, higher rate of finished product and good removing effect on the proximal surface; the product can be repeatedly used, the working efficiency can be improved, and the use cost is reduced.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com