Multilevel particle cutter

A particle and cutter technology, applied to instruments, scientific instruments, sampling, etc., can solve the problems of easy maintenance, high process requirements, complex structure, etc., and achieve good cutting effect, good adsorption effect, and easy cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

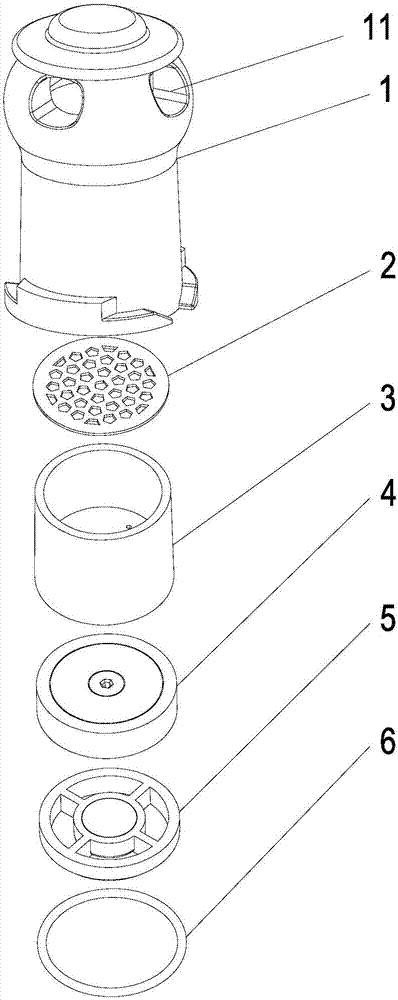

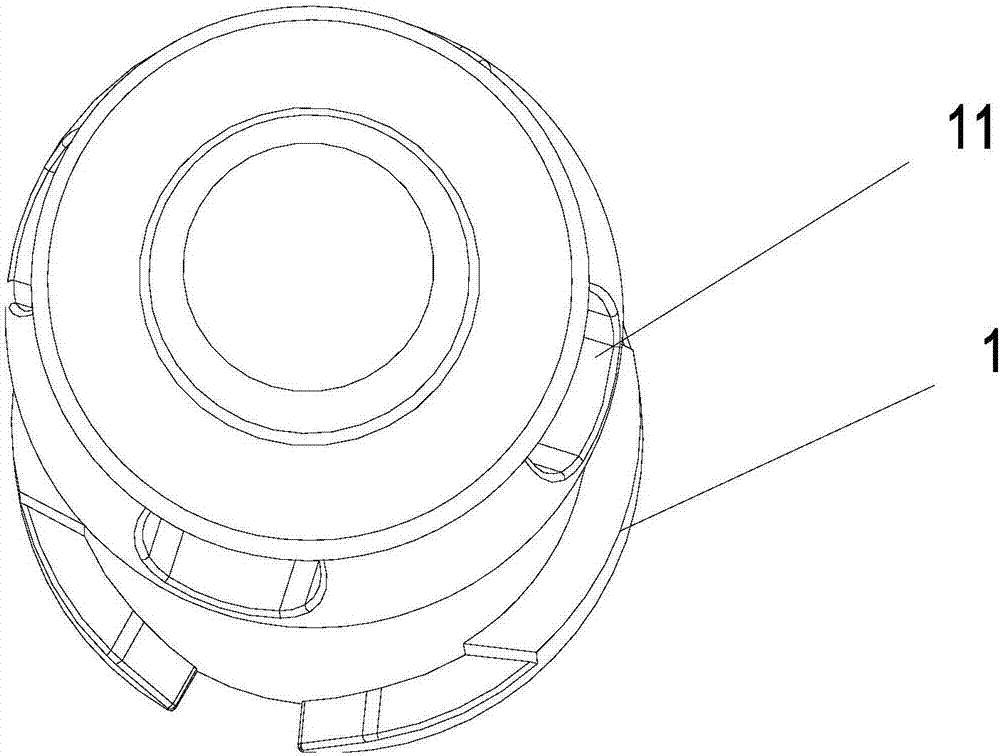

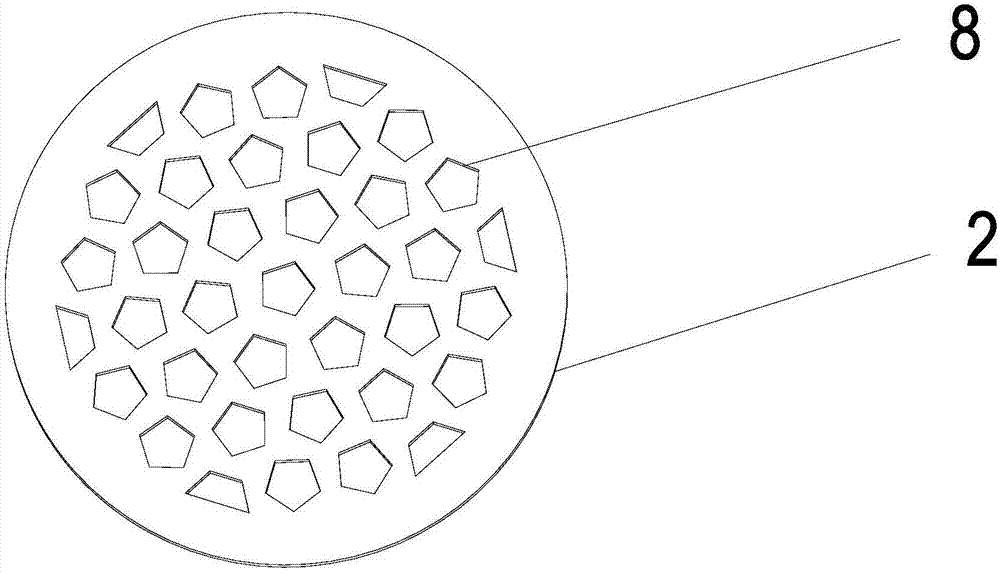

[0027] like Figure 1-7 As shown, the multi-stage particle cutter includes an air intake hood 1, the top of the air intake hood 1 is provided with an air intake hole 11, and the air intake hood 1 is sequentially provided with a filter screen 2, a nozzle 3, and a filter screen connected to each other from top to bottom. A cutting box 4, a second cutting box 5 and a sealing ring 6, the second cutting box 5 is sealed and connected with the inner wall of the air intake cover 1, the filter screen 2 is provided with several first filter holes 8, the nozzle 3 and the filter screen 2 There is an impact chamber 12 formed between them, the nozzle 3 is located at the bottom of the impact chamber 12 to be provided with a second filter hole 9, the upper surface of the first cutting box 4 is provided with a first adsorption layer 10 corresponding to the second filter hole 9 up and down, the first On the opposite side of the first adsorption layer 10, the cutting box 4 is provided with a pri...

Embodiment 2

[0030] PM2.5: The difference from Example 1 is that when the particles enter the nozzle, a certain weight will be generated due to the inertia of the air flow. When the diameter of the particles is ≥0.4 mm, they will stay in the nozzle and will not enter the cutter. In the next part, particles with a diameter of 4 microns, When it hits the first cutting box 4, it will be absorbed by the silicone oil on the surface of the first cutting box 4, and particles with a diameter of ≤4 microns enter the second cutting box 5 through the hexagonal hole in the middle of the first cutting box 4. Inertia will produce a certain weight. When the particle diameter > 2.5 microns, it hits the second cutting box 5 and will be absorbed by the silicone oil on the surface of the second cutting box 5. Particles with a diameter of ≤ 2.5 microns pass through the middle of the second cutting box 5 Four fan-shaped holes enter the inside of the instrument for detection.

Embodiment 3

[0032]PM10: The difference from Example 1 is that when the particles enter the nozzle from the surroundings, a certain weight will be generated due to the inertia of the airflow. When the diameter of the particles is ≥ 1 mm, they will stay in the nozzle and will not enter the lower part of the cutter. Particles with a diameter of less than 1 mm enter the first cutting box 4 through the four hexagonal second filter holes 9 in the middle of the nozzle 3, and a certain weight will be generated due to the inertia of the air flow. When the diameter of the particles is greater than 12 microns, When it hits the first cutting box 4, it will be absorbed by the silicone oil on the surface of the first cutting box 4, and particles with a diameter of ≤12 microns enter the second cutting box 5 through the hexagonal hole in the middle of the first cutting box 4, due to the airflow Inertia will produce a certain weight. When the diameter of the particle is larger than 10 microns, it hits the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com