Laser processing apparatus

A laser processing and laser technology, which is applied in the direction of fine working devices, metal processing, stone processing equipment, etc., can solve problems such as difficult to connect cracks, difficult to cut wafers, etc., to achieve the effect of realizing production capacity and reducing the number of scans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

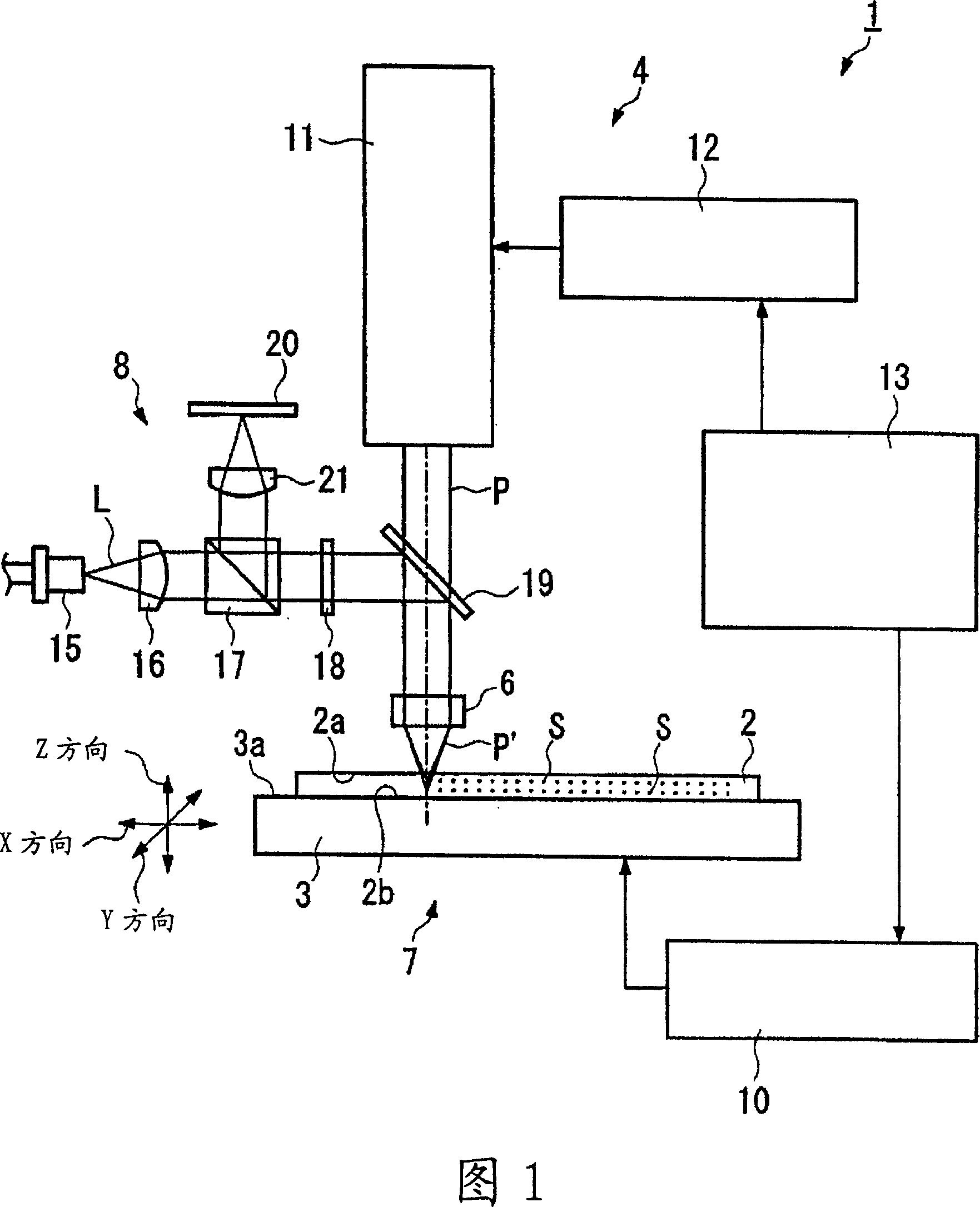

[0127] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

[0128] A first embodiment of the laser processing apparatus of the present invention will be described with reference to FIGS. 1 to 3 . The laser processing apparatus 1 of the present embodiment will be described as an apparatus for finely cutting a circular wafer (object to be processed) 2 having a thickness of, for example, 0.1 mm into sheets by laser processing.

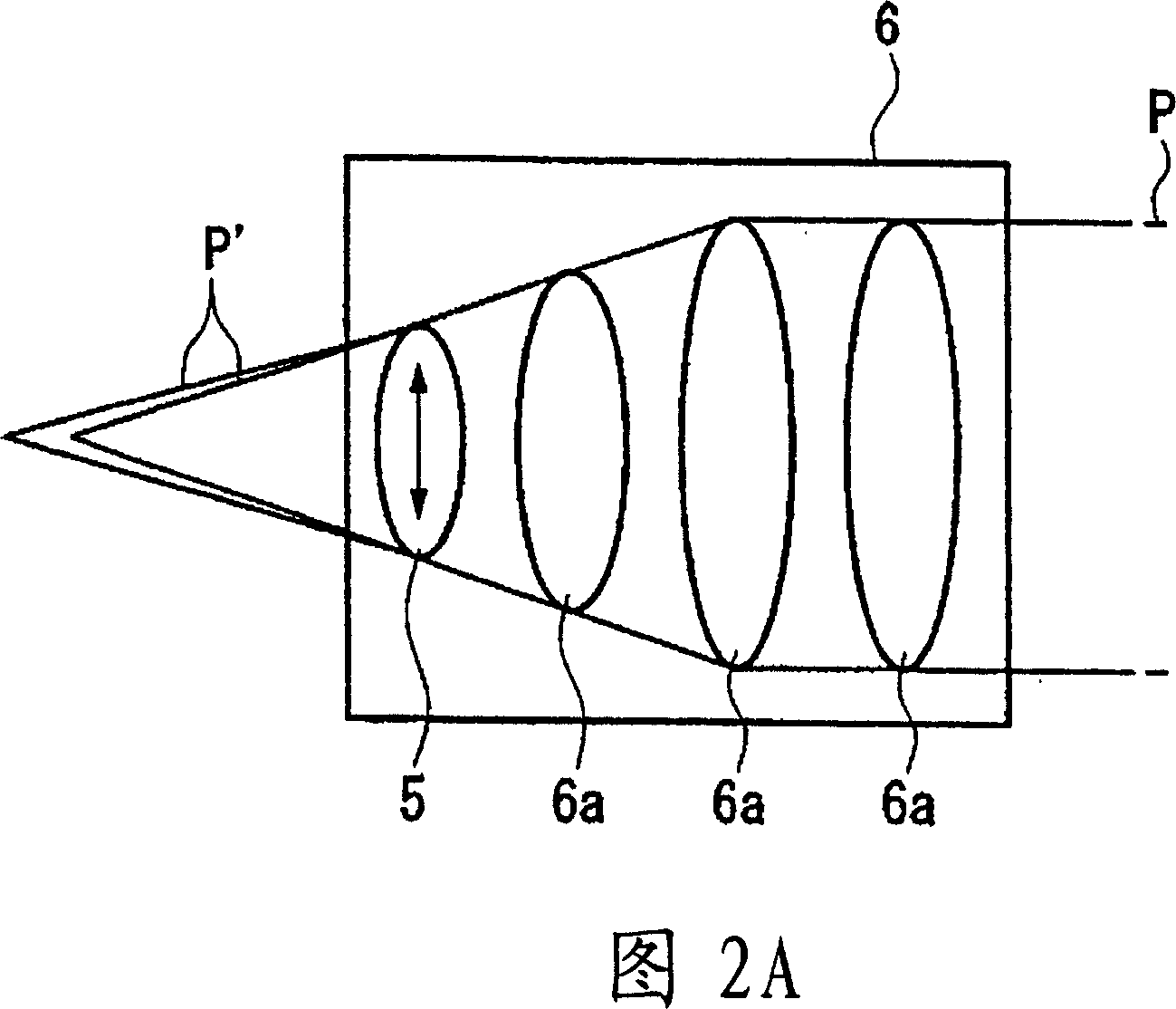

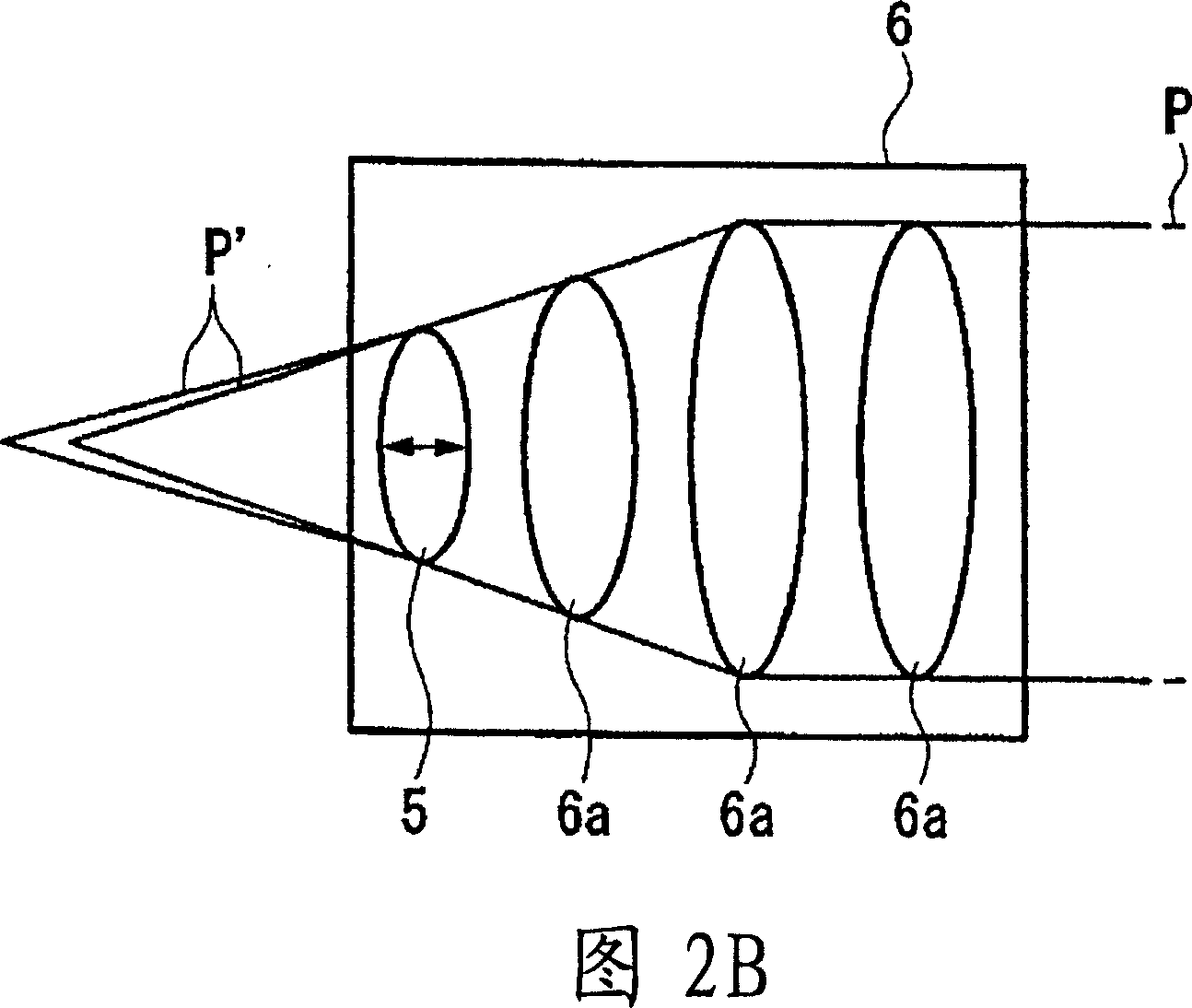

[0129] As shown in FIG. 1, the laser processing apparatus 1 includes: a table 3, which places a wafer 2 on a mounting surface 3a arranged parallel to a horizontal plane; an irradiation unit 4, which emits pulses to the surface 2a of the wafer 2. Laser (laser) P; objective lens (optical system, light-gathering optical system) 6, it has birefringent birefringent material lens (optical axis direction separation element) 5, this birefringent material lens 5 separates pulsed laser light P into multiple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com