Patents

Literature

3356results about How to "Improve cutting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

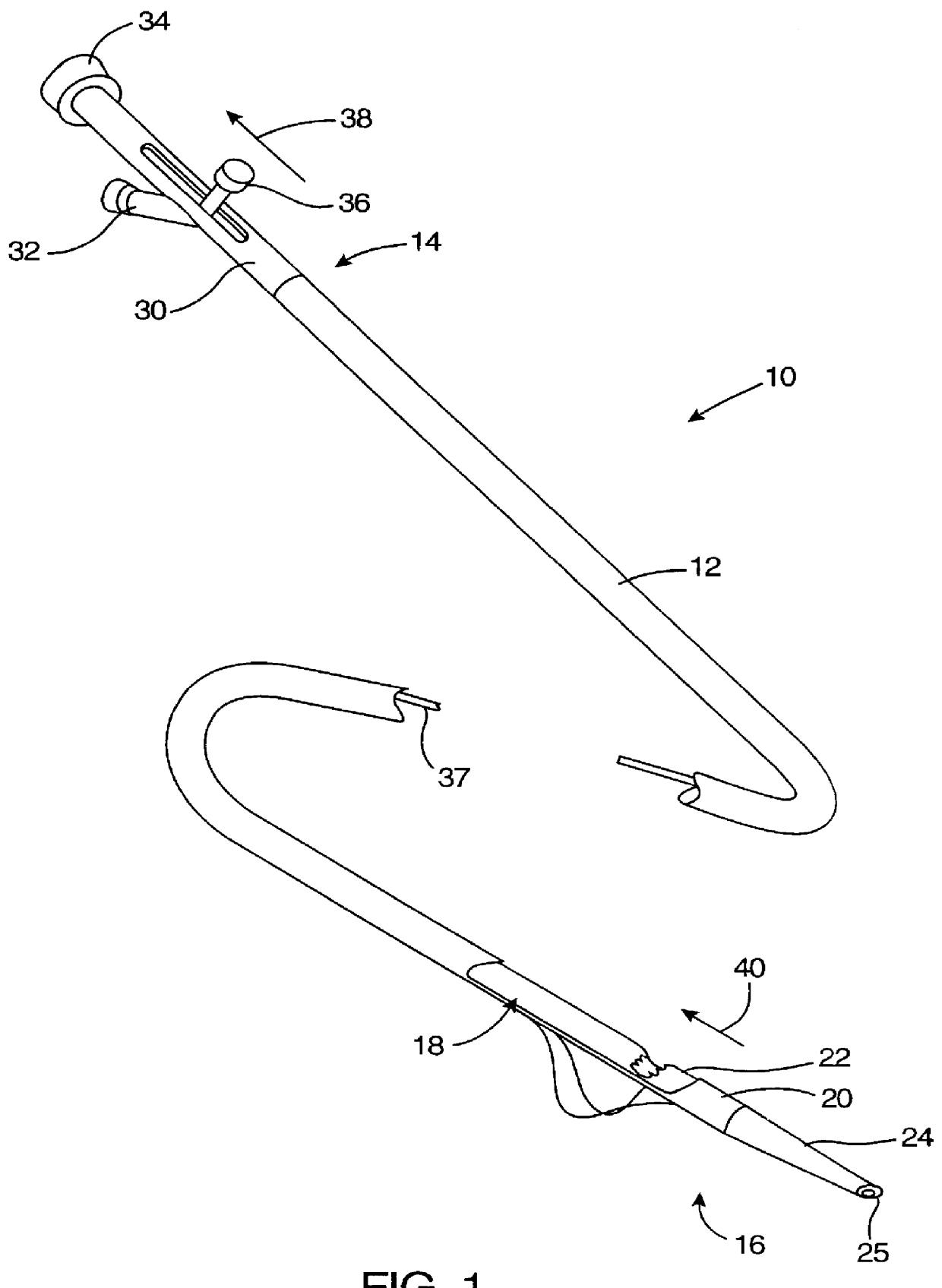

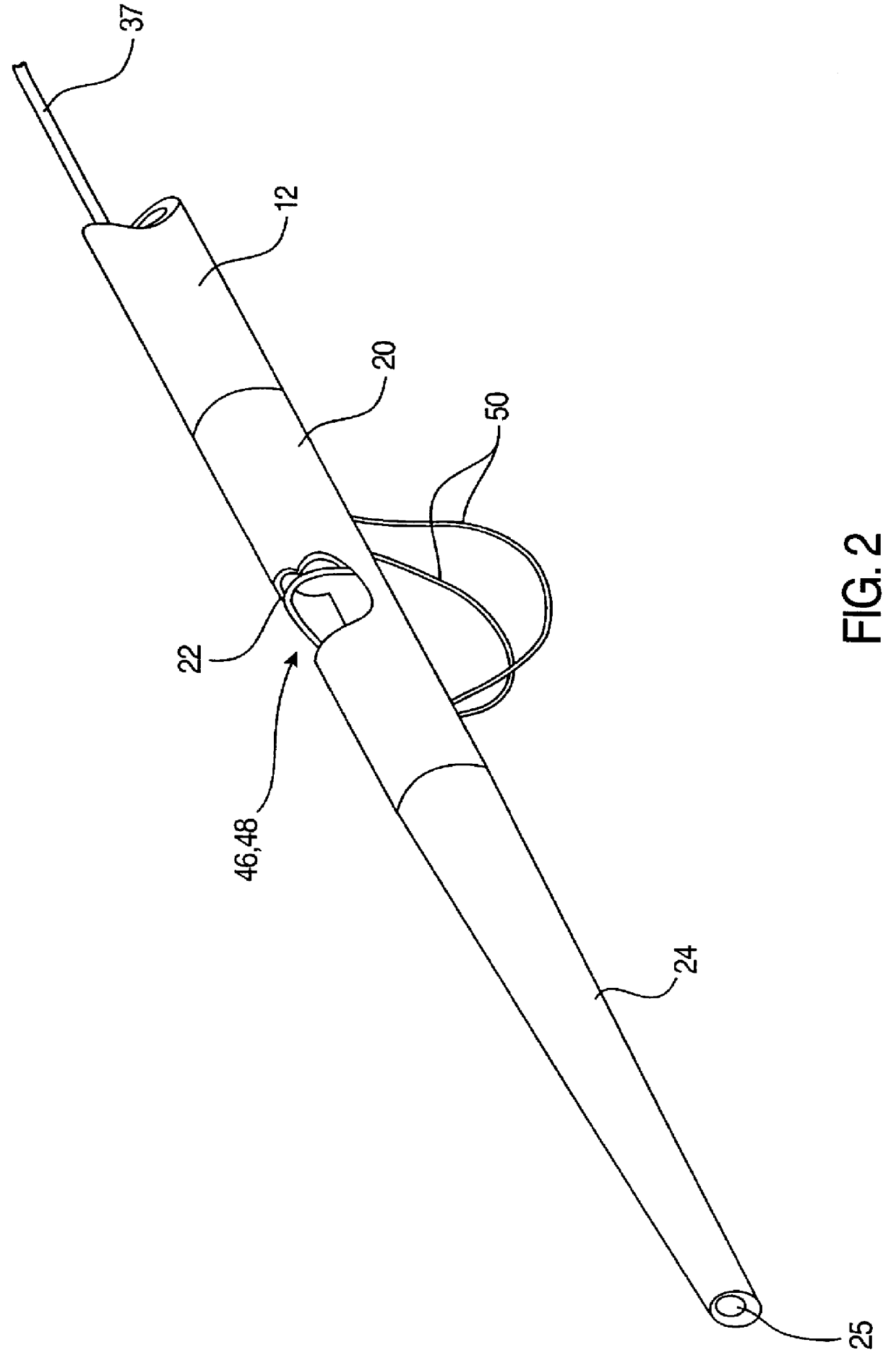

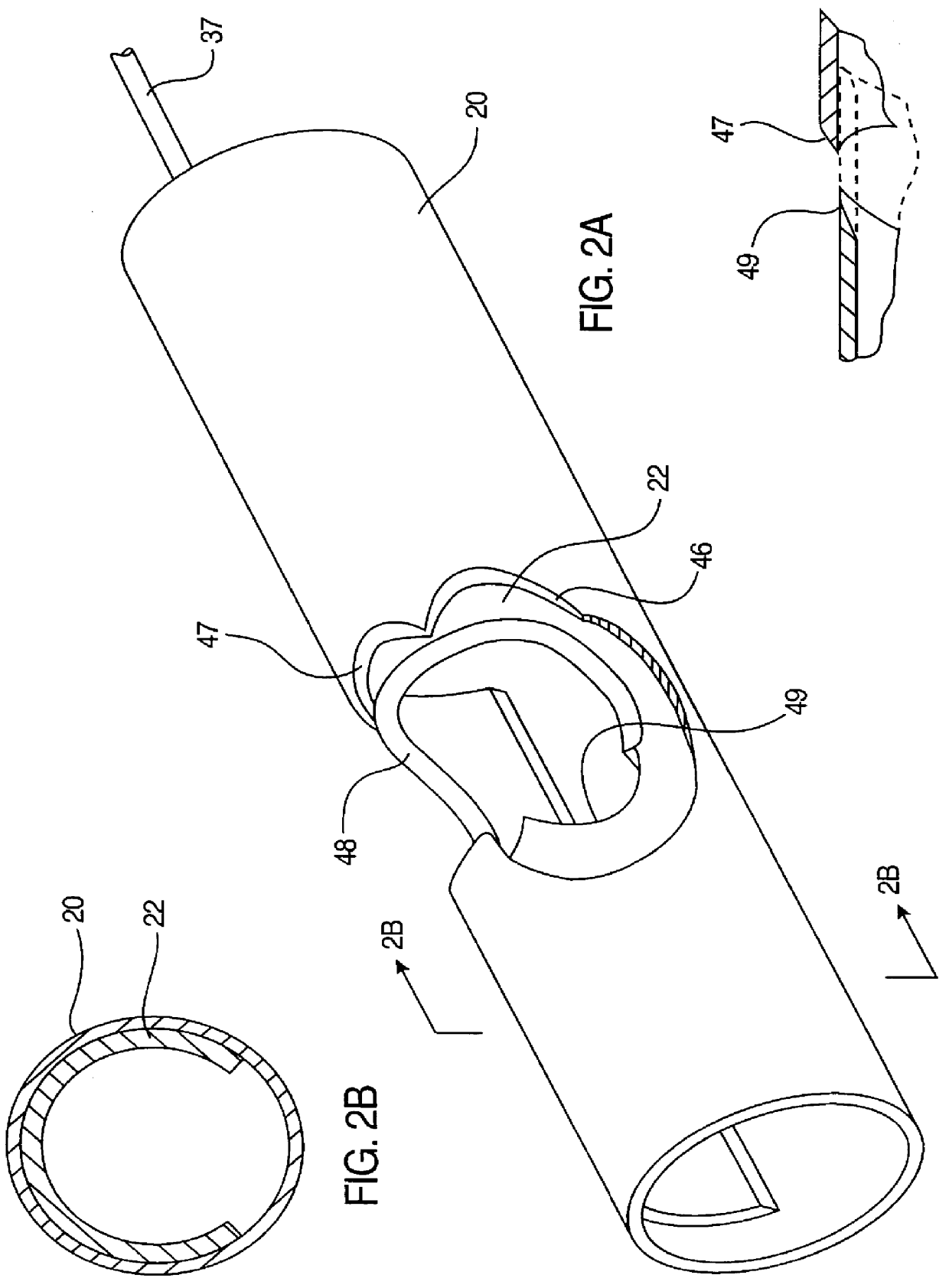

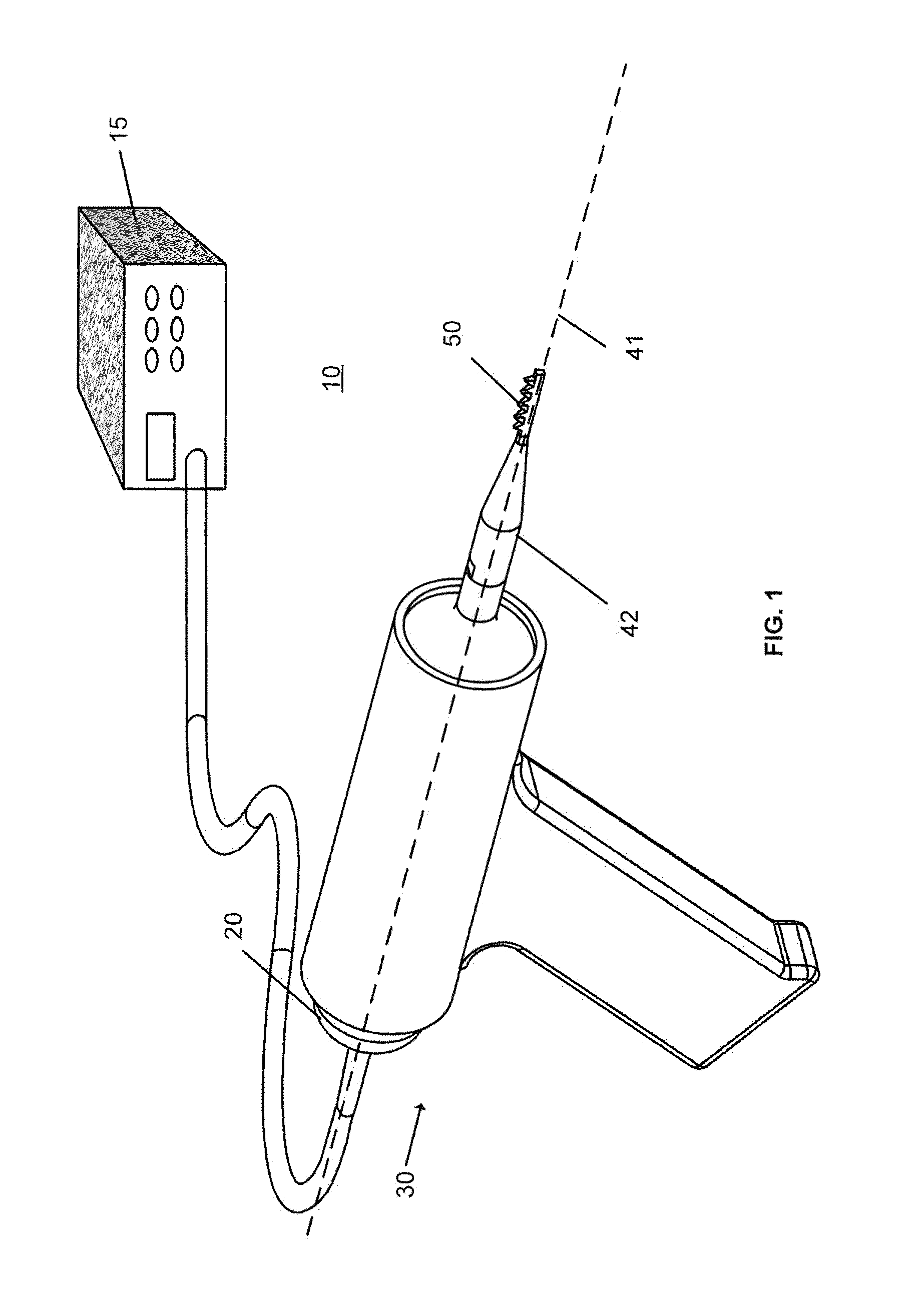

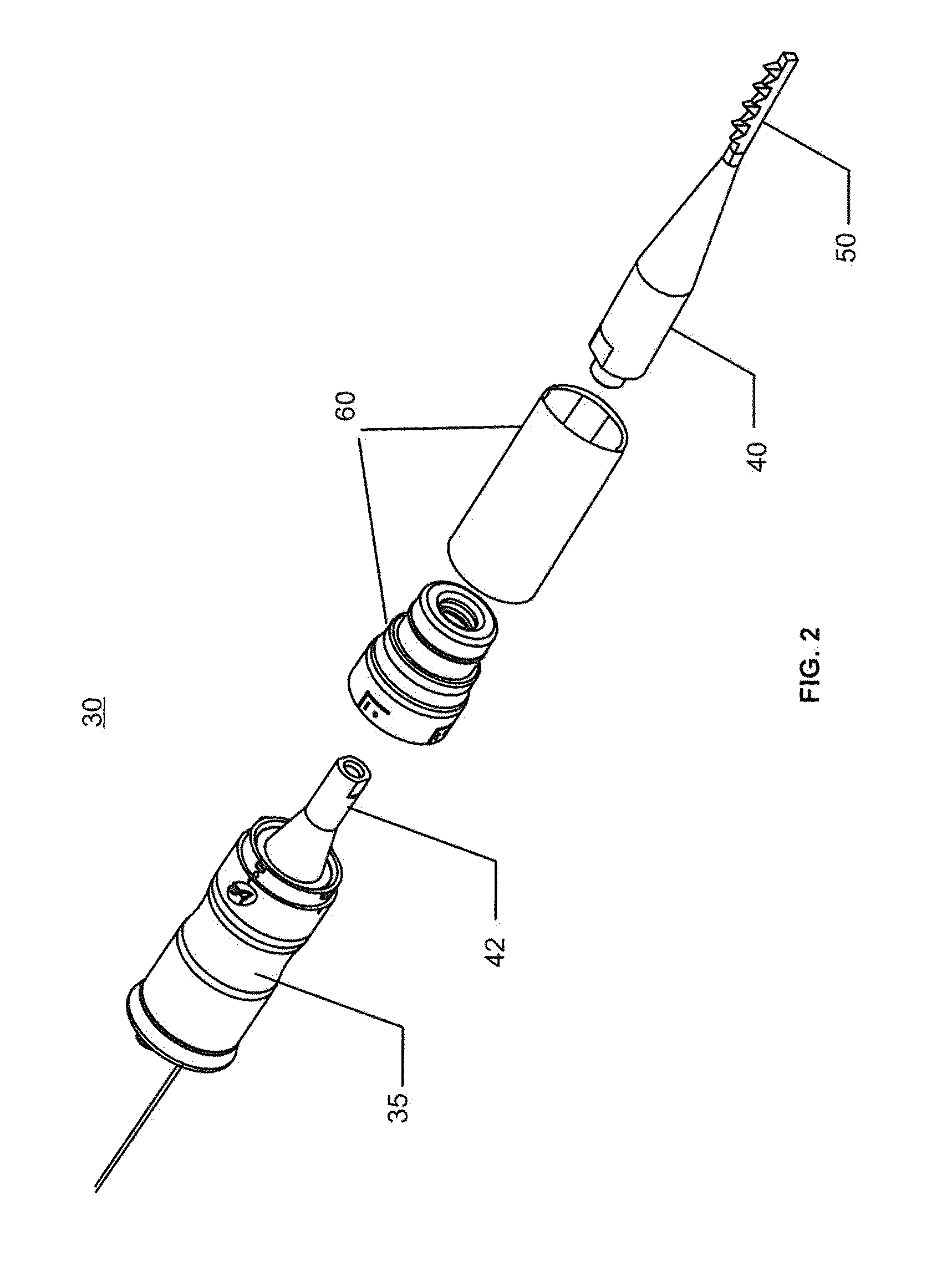

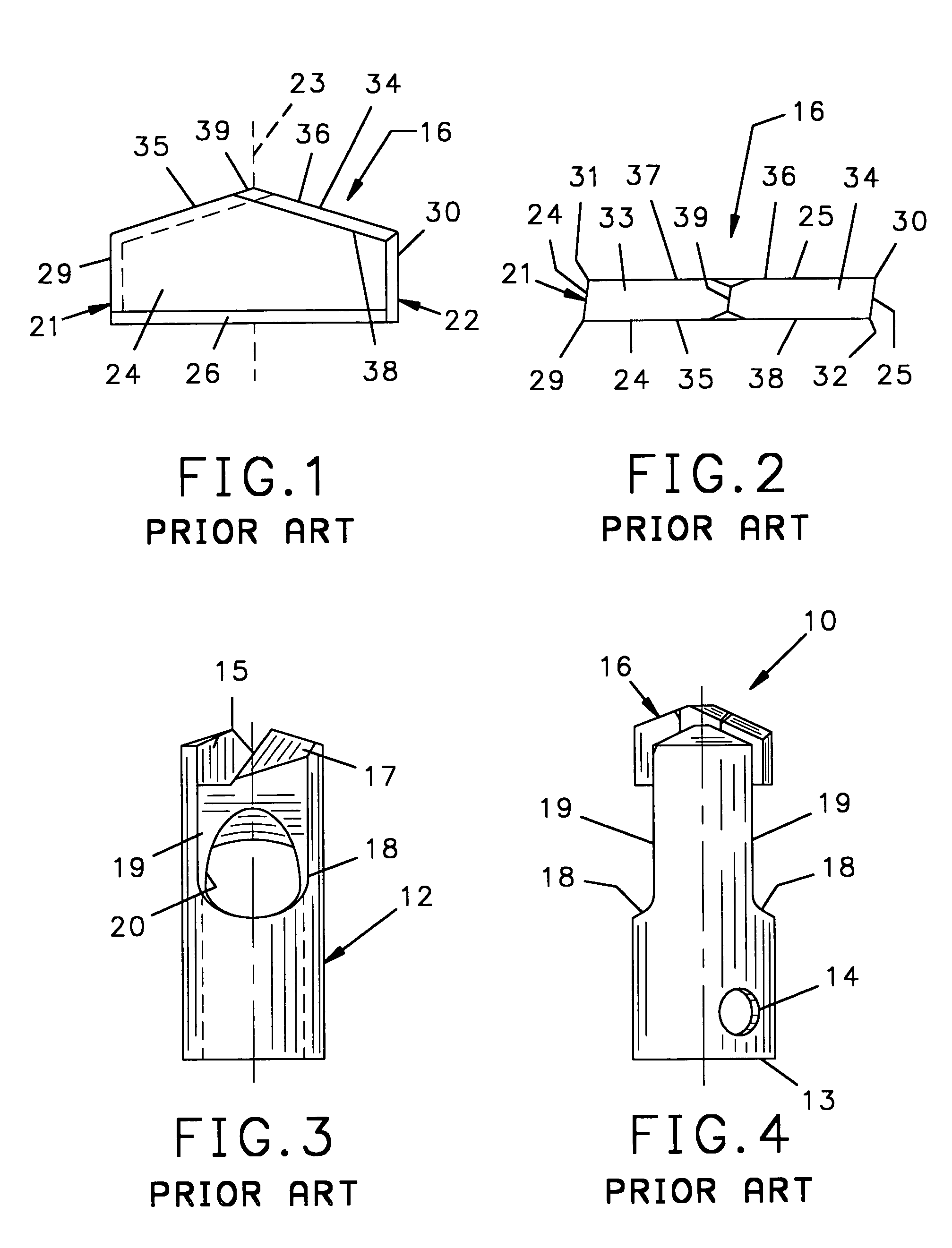

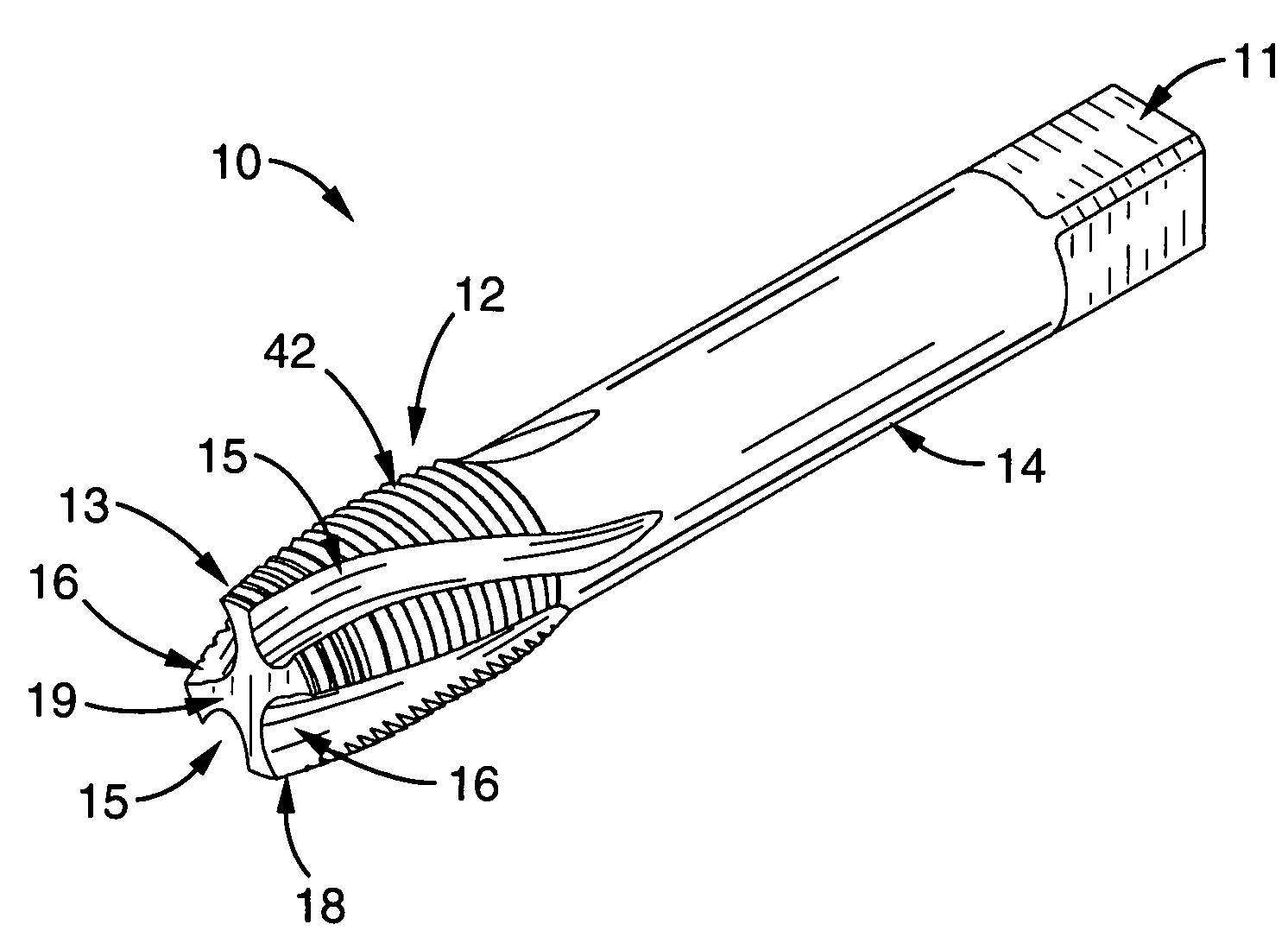

Apparatus and method for removing occluding material from body lumens

InactiveUS6027514AImprove cutting effectImproved penetration ability have notCannulasVaccination/ovulation diagnosticsAtherectomyEngineering

An atherectomy catheter includes a catheter body having a blade assembly at its distal end. The blade assembly includes first blade and a second blade, where each blade has an opposed cutting edge. At least one of the cutting edges will have a penetrating point formed thereon. Preferably, both edges will have at least one aligned cutting point, more preferably at least two or more aligned cutting points. When the blades are actuated to shear tissue therebetween, the cutting points act to penetrate and capture the material to be sheared.

Owner:FOX HOLLOW TECH

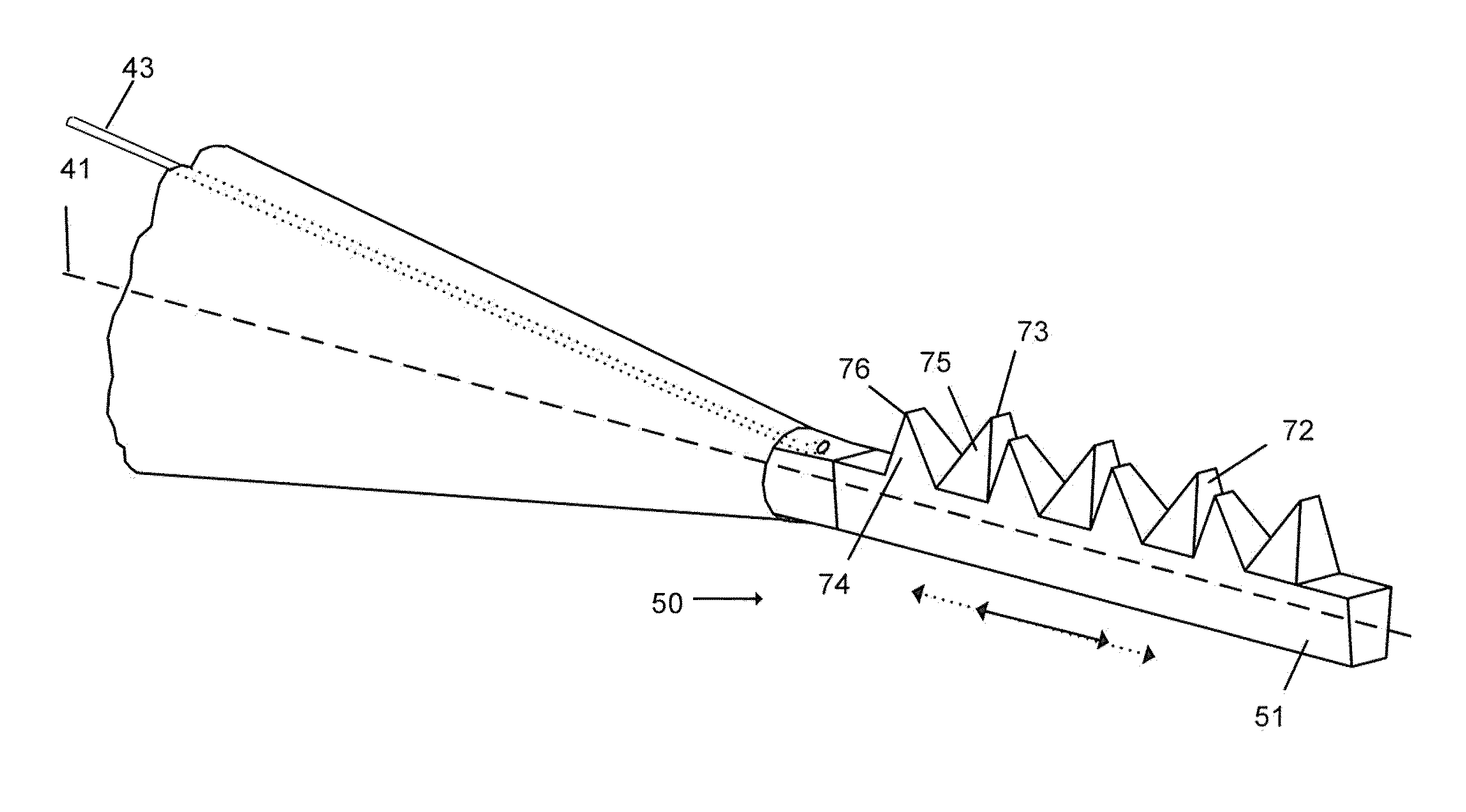

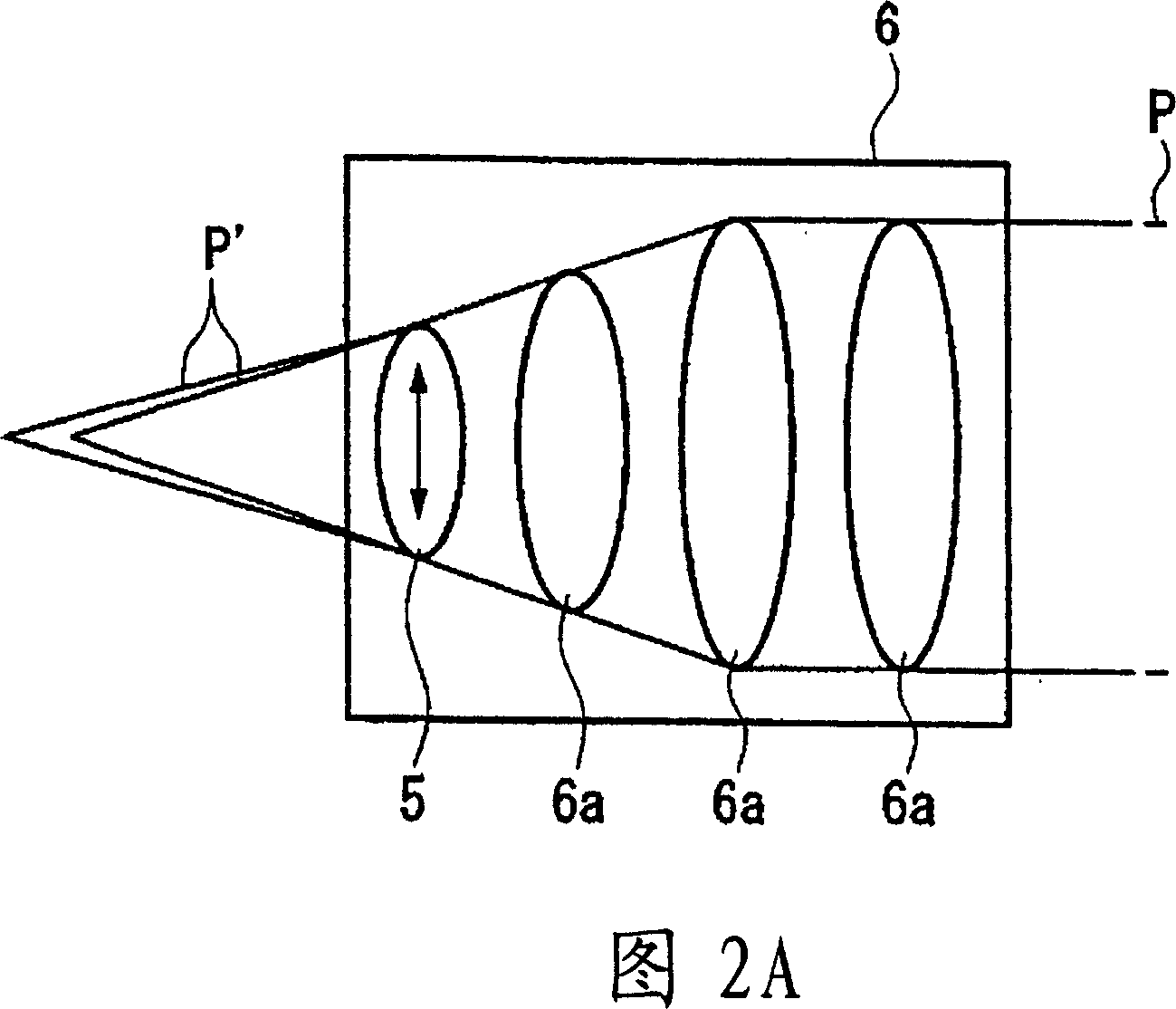

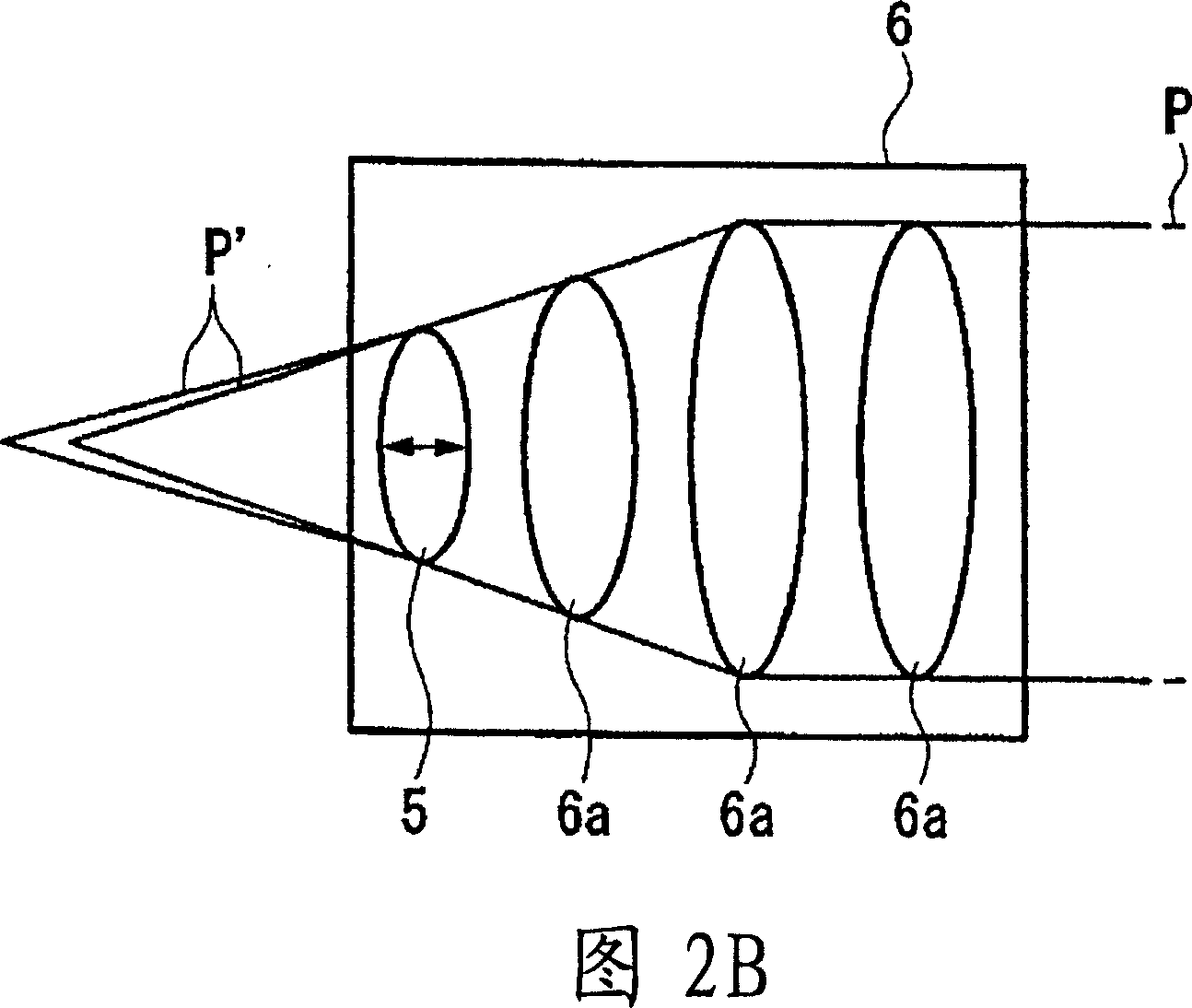

Ultrasound surgical saw

This invention discloses methods and devices using ultrasound energy for resecting bone tissue during surgical procedures. The disclosure describes the use of ultrasound surgical saw consisting of an ultrasound generator, ultrasound transducer and ultrasound horn including a cutting blade to resect bone tissue without excessive temperature rise during typical surgical procedures. The cutting blade provides a self-clearing design that includes at least two teeth disposed to prevent accumulation of bone chips within the proximity of the teeth. The design of the cutting blade allows the mechanical motion of the blade and the emission of the ultrasound energy to remove accumulated bone chips and prevent excessive temperature rise.

Owner:BABAEV ELIAZ

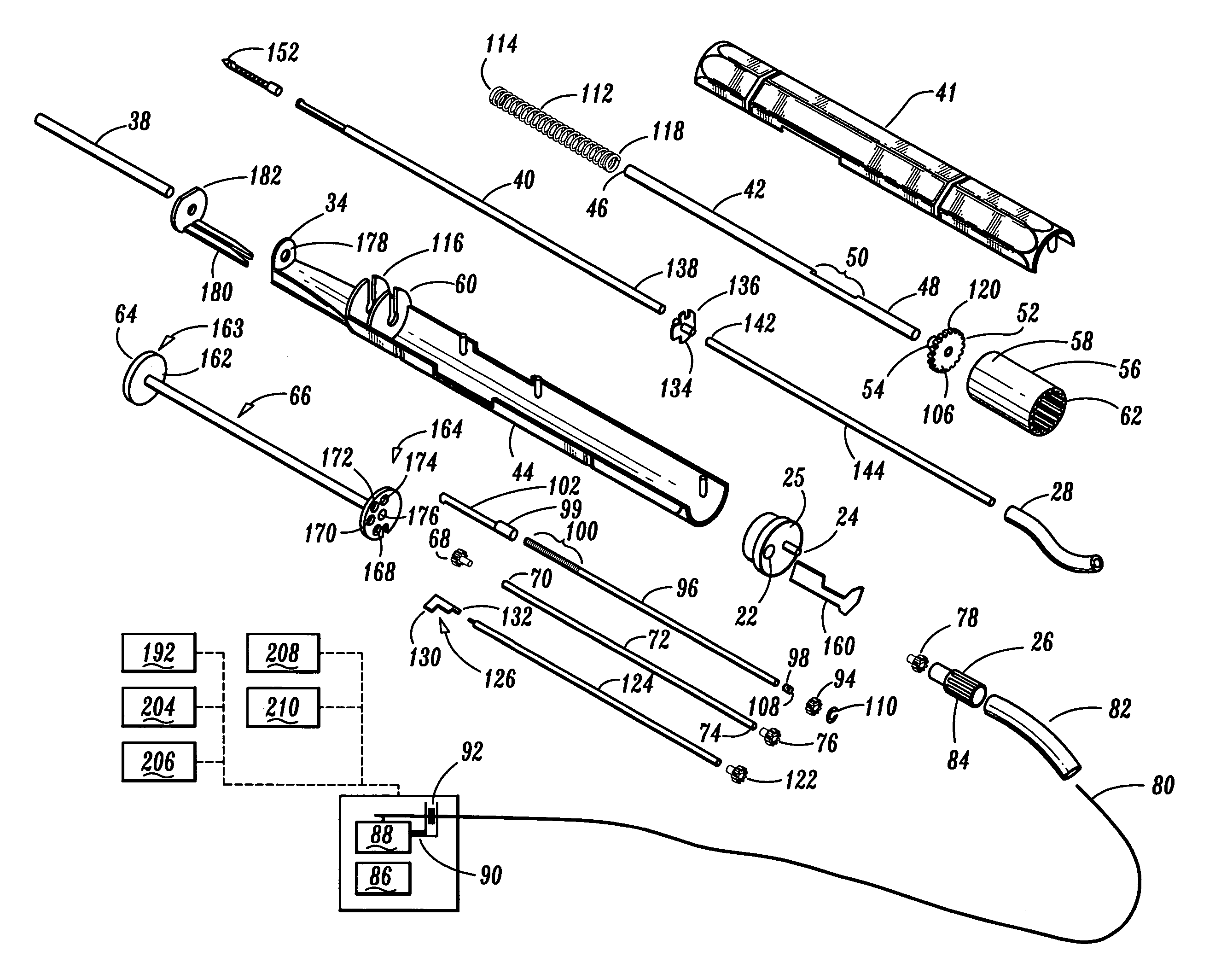

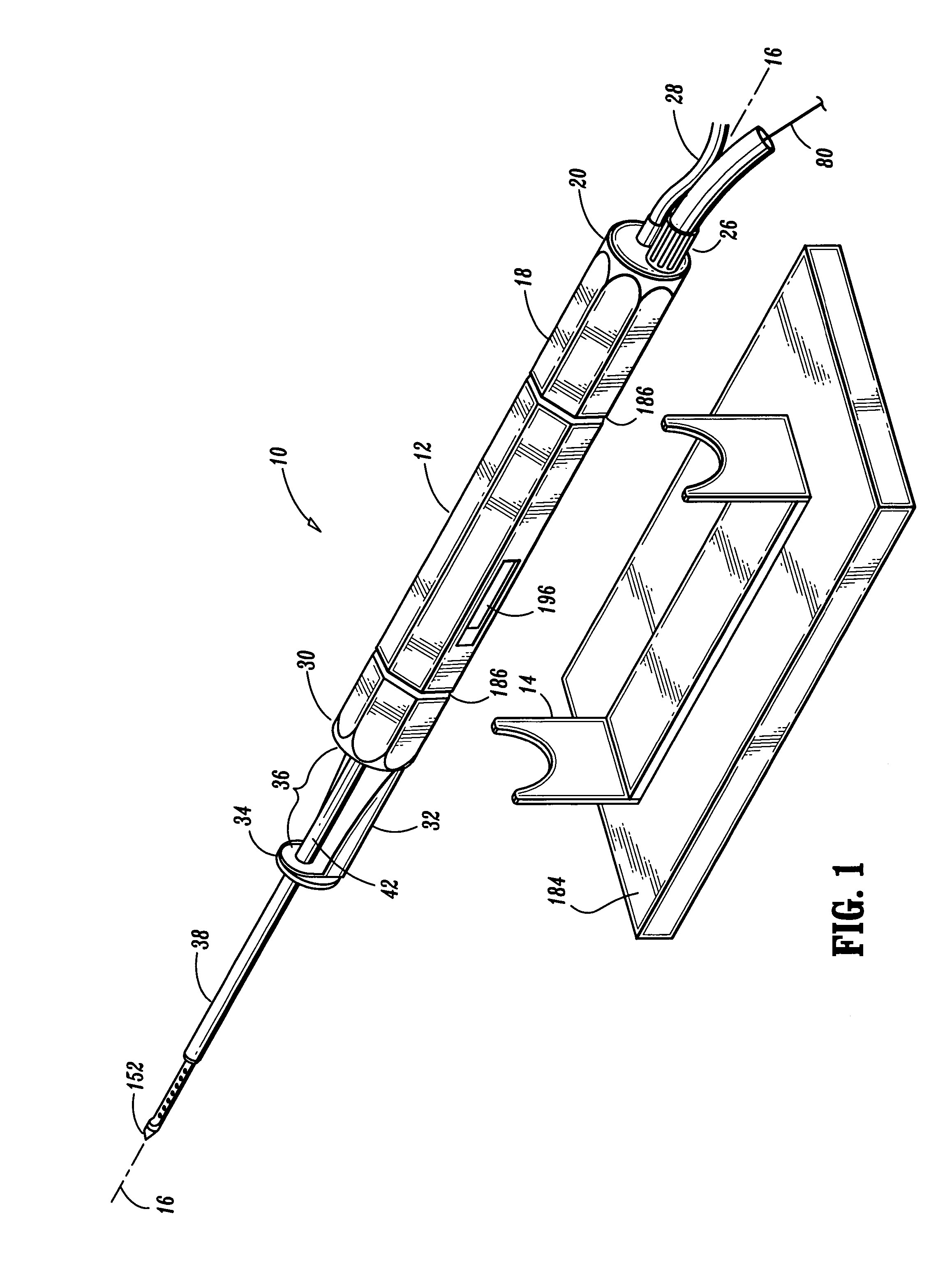

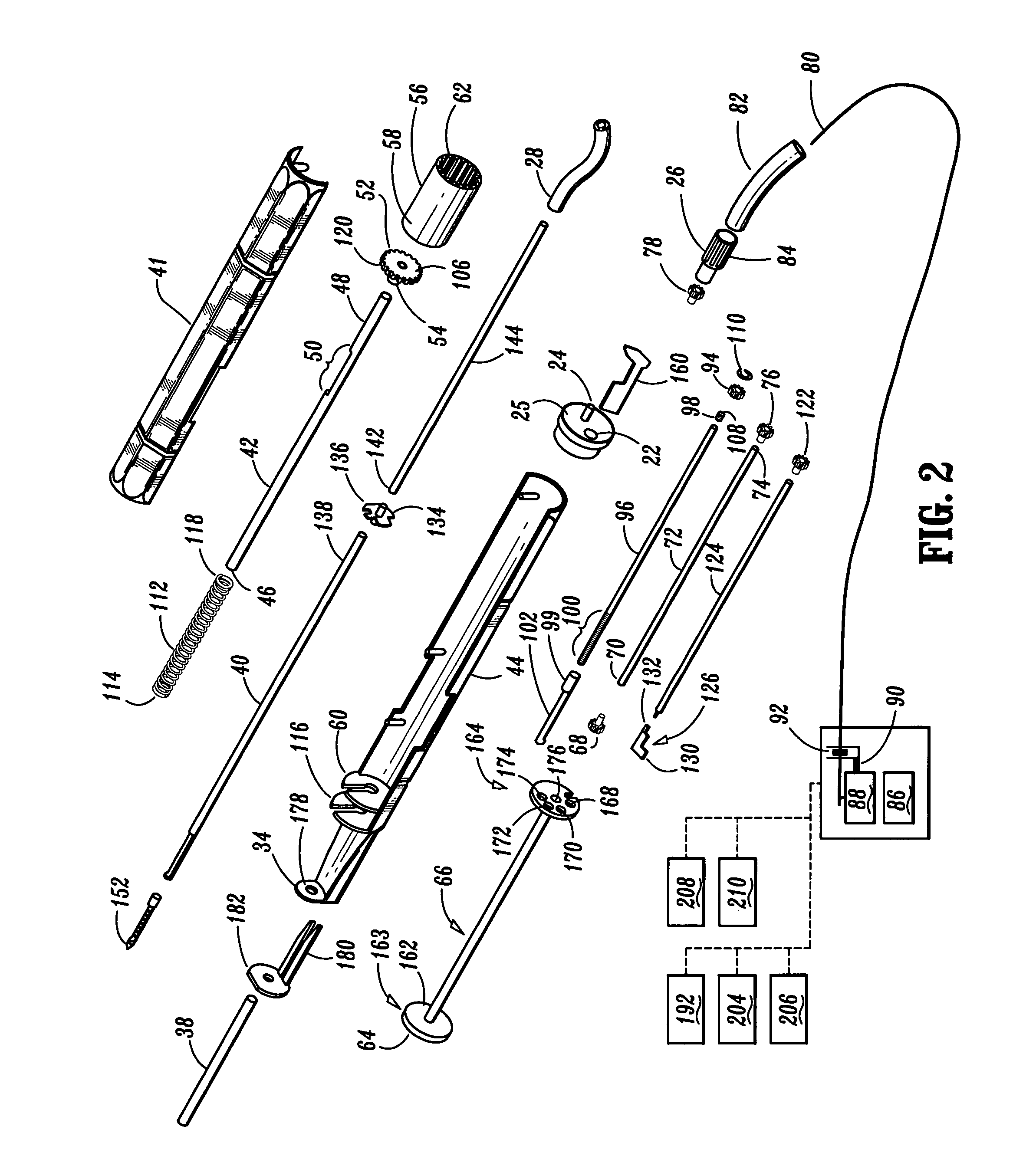

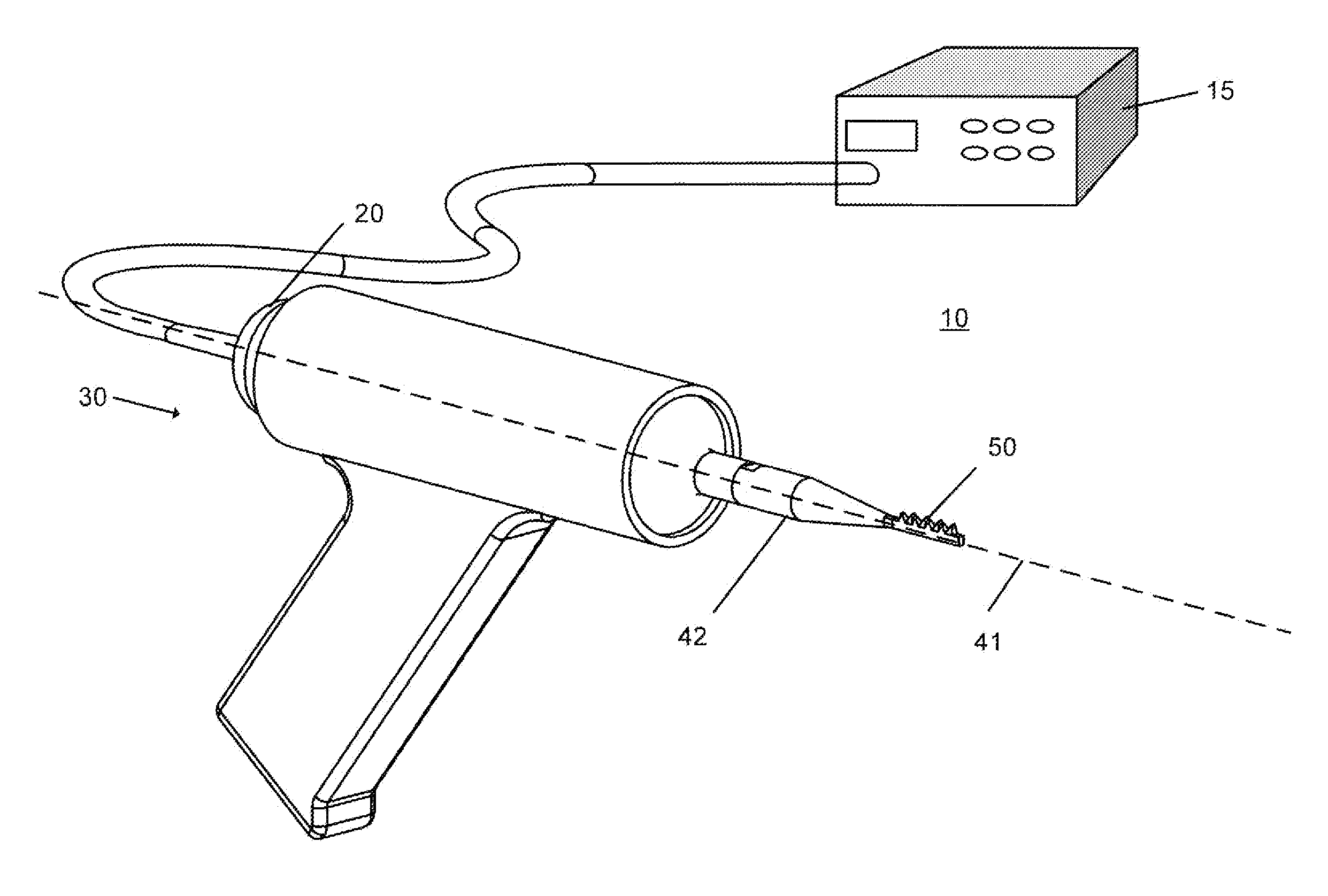

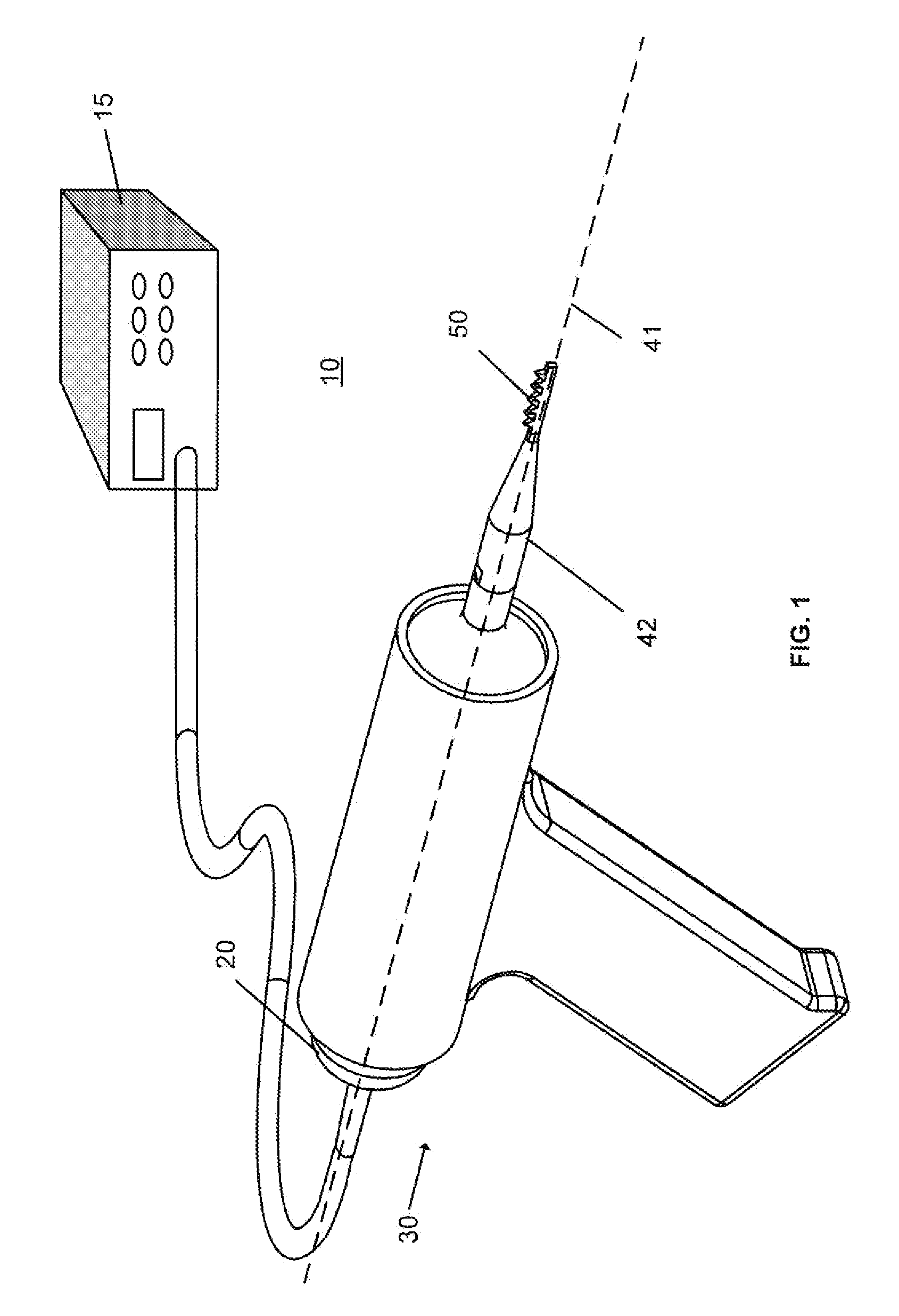

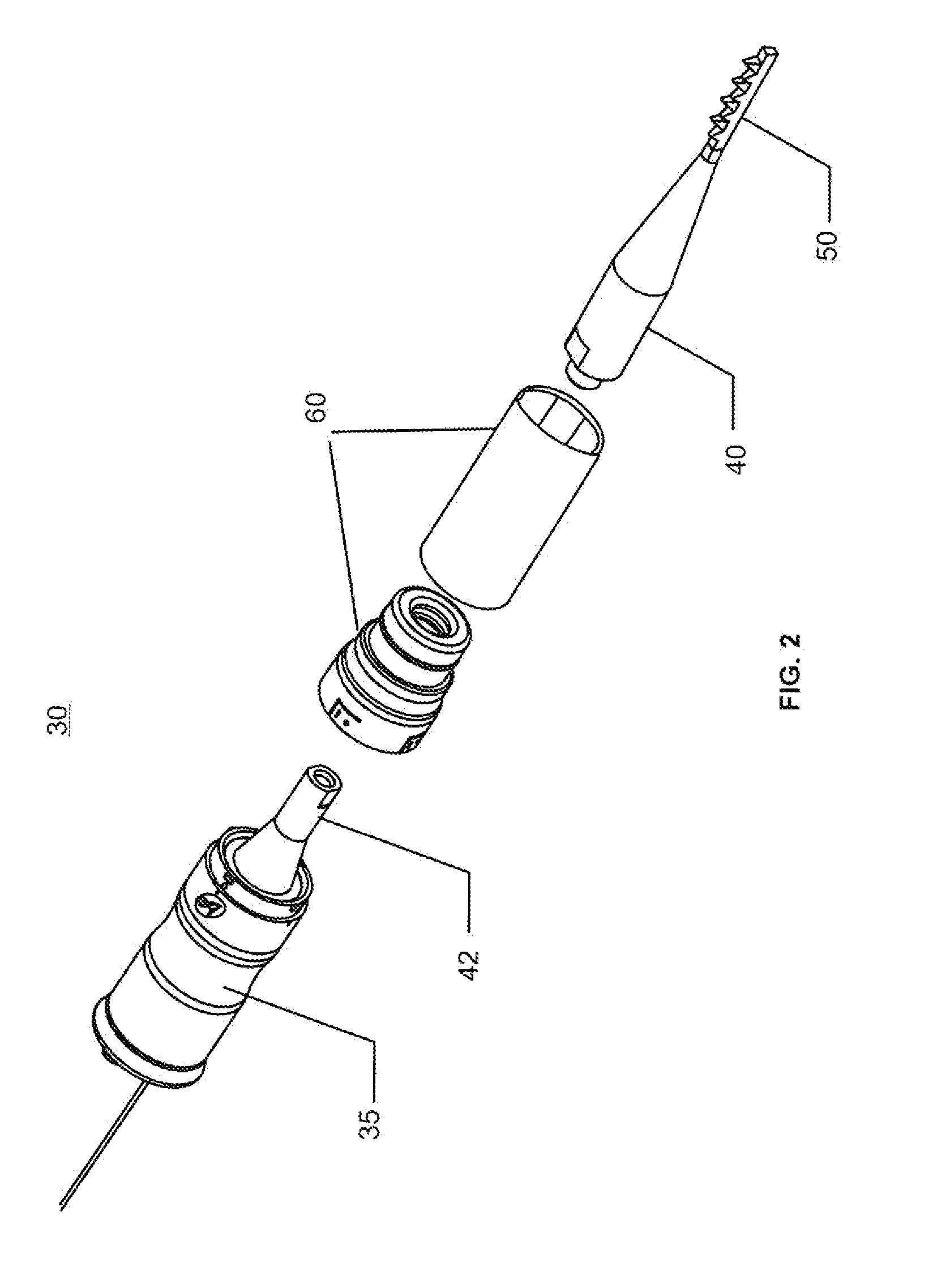

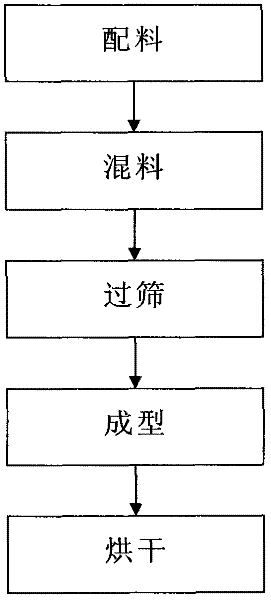

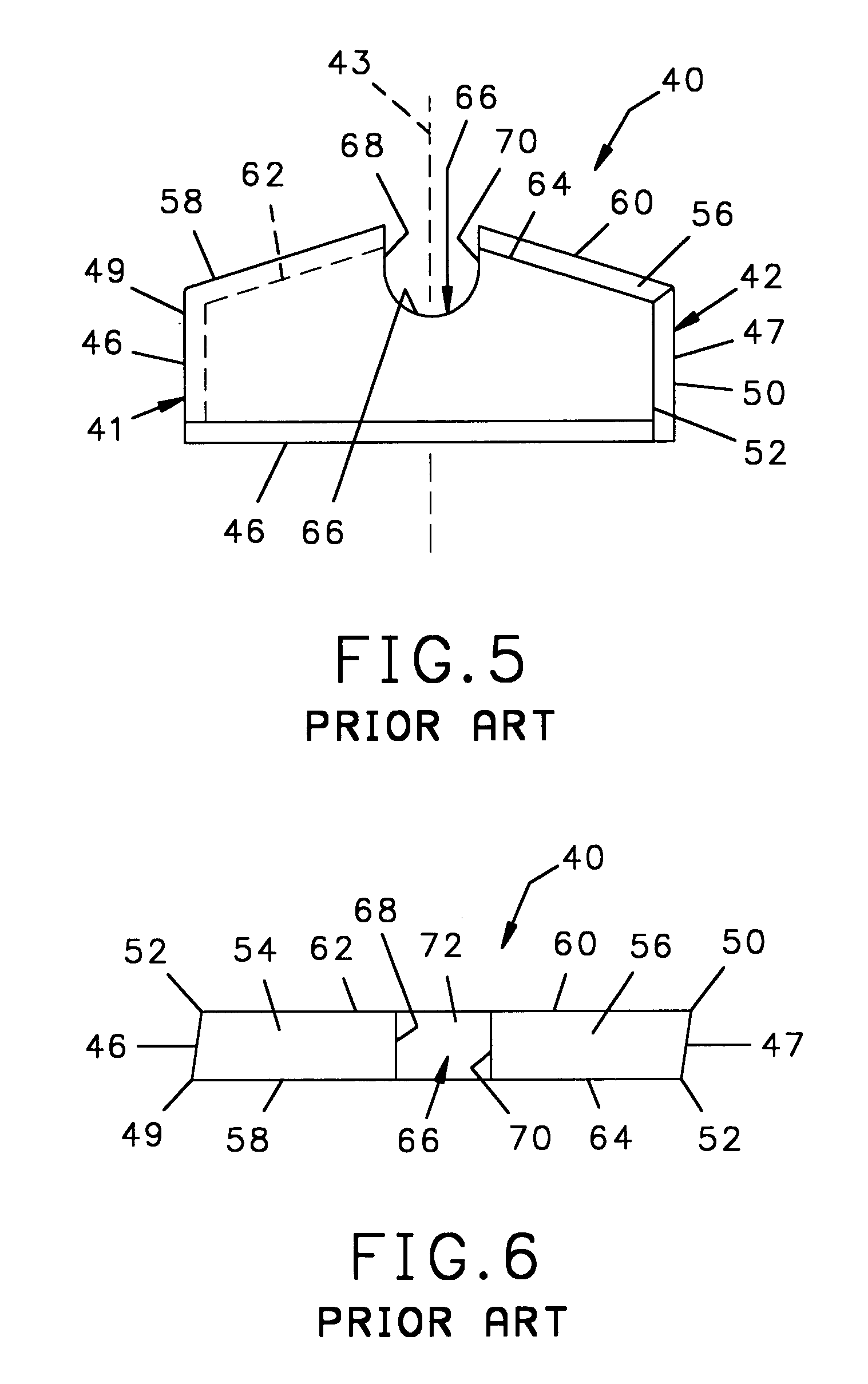

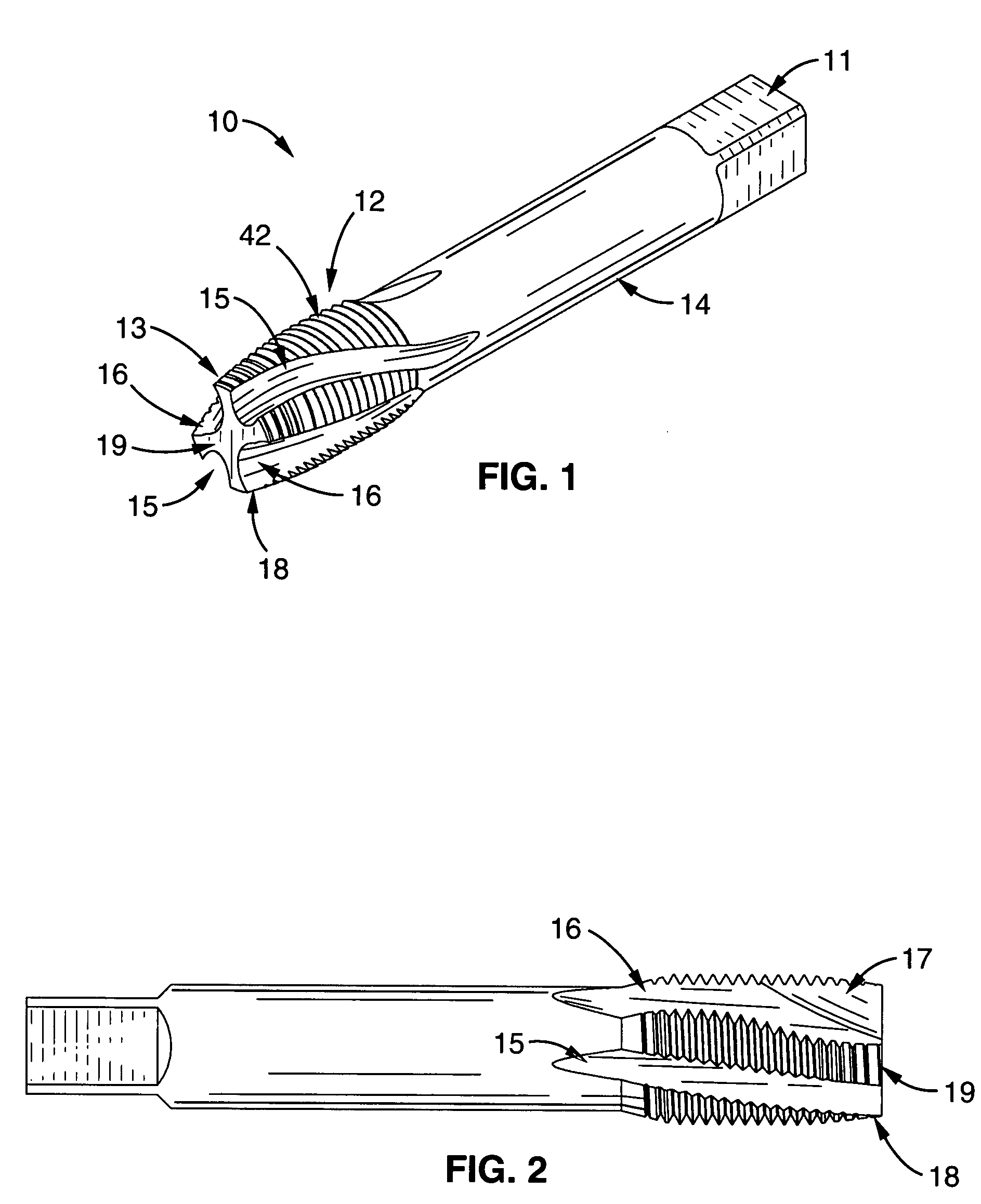

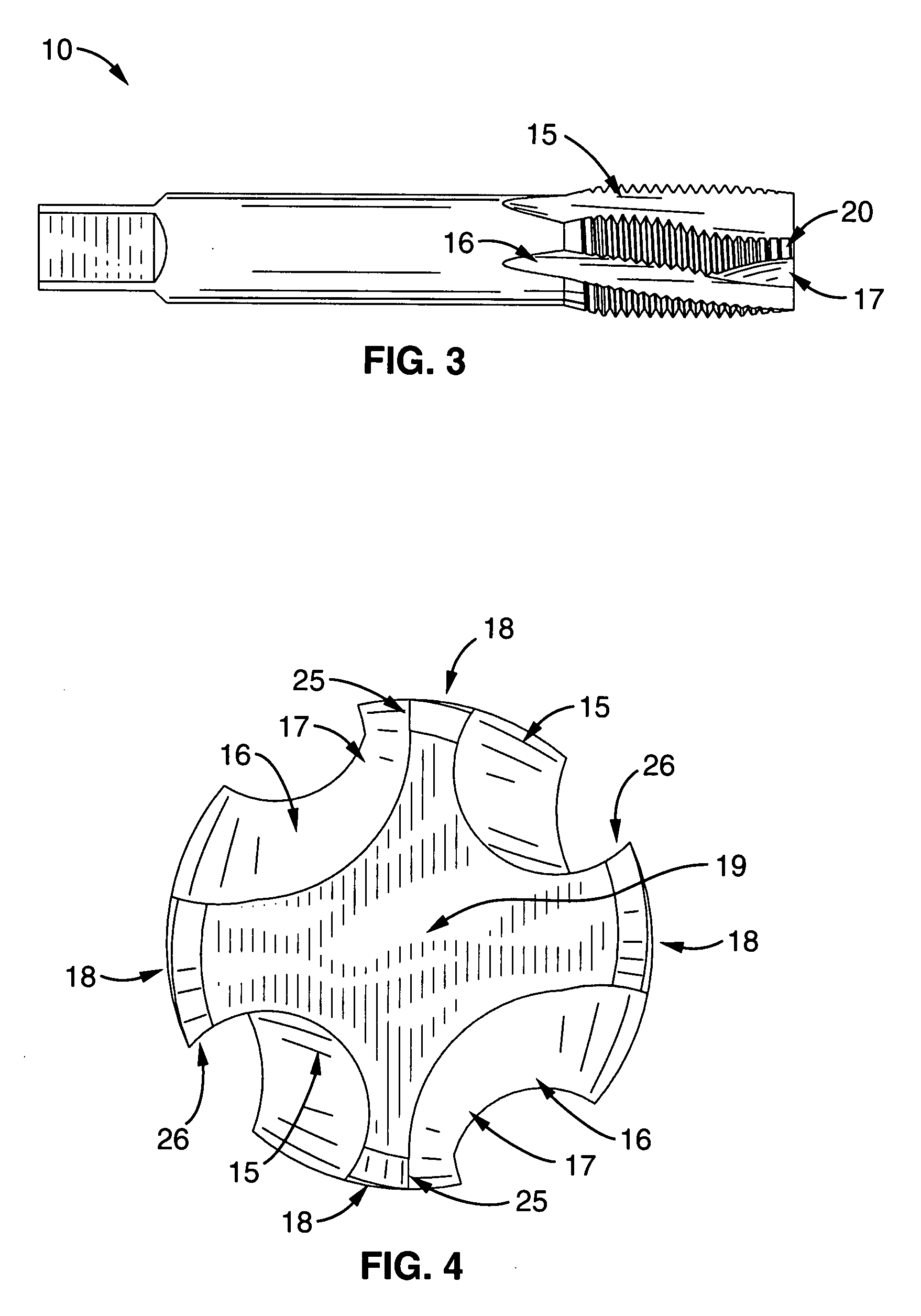

Tissue sampling and removal apparatus and method

InactiveUS7513877B2Improve cutting effectAbility to retrieve multiple samplesSurgical needlesVaccination/ovulation diagnosticsVacuum pressureTissue sample

A tissue sampling device (10) for retrieving one or more tissue samples from a patient is either handheld or mounted to a moveable carriage (184) and advanced so that the needle tip (152) is introduced into the patient. The needle tip (152) is advanced until the tissue receiving basket (154) reaches the tissue sample target zone (190). Vacuum pressure is supplied to the basket (154) via a vacuum tube (144) so that tissue to be sampled is drawn into the basket (154). The cutter (42) is rotated and advanced linearly to cut a tissue sample (212) which is then retrieved by retracting the needle (40).

Owner:TYCO HEALTHCARE GRP LP

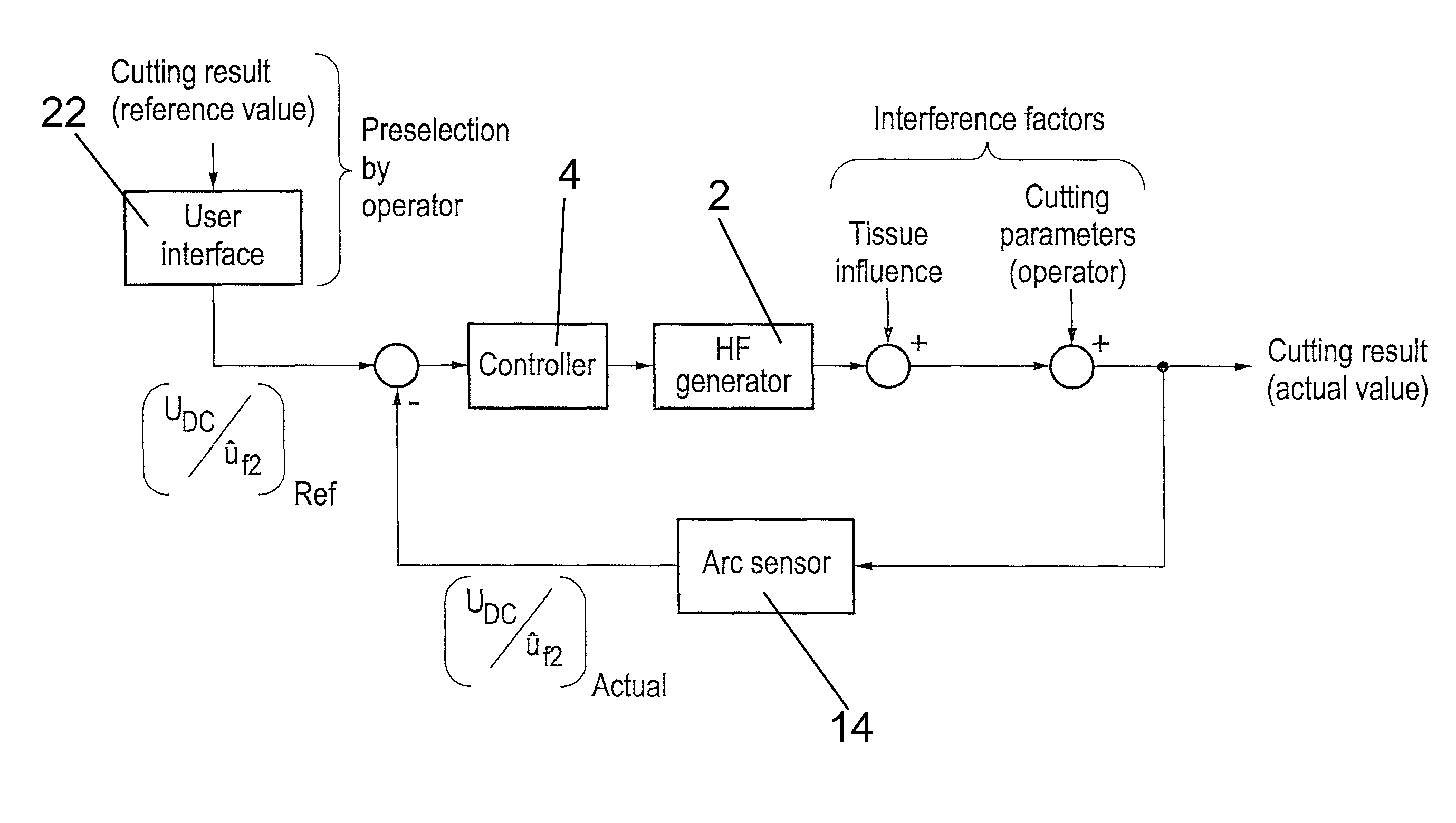

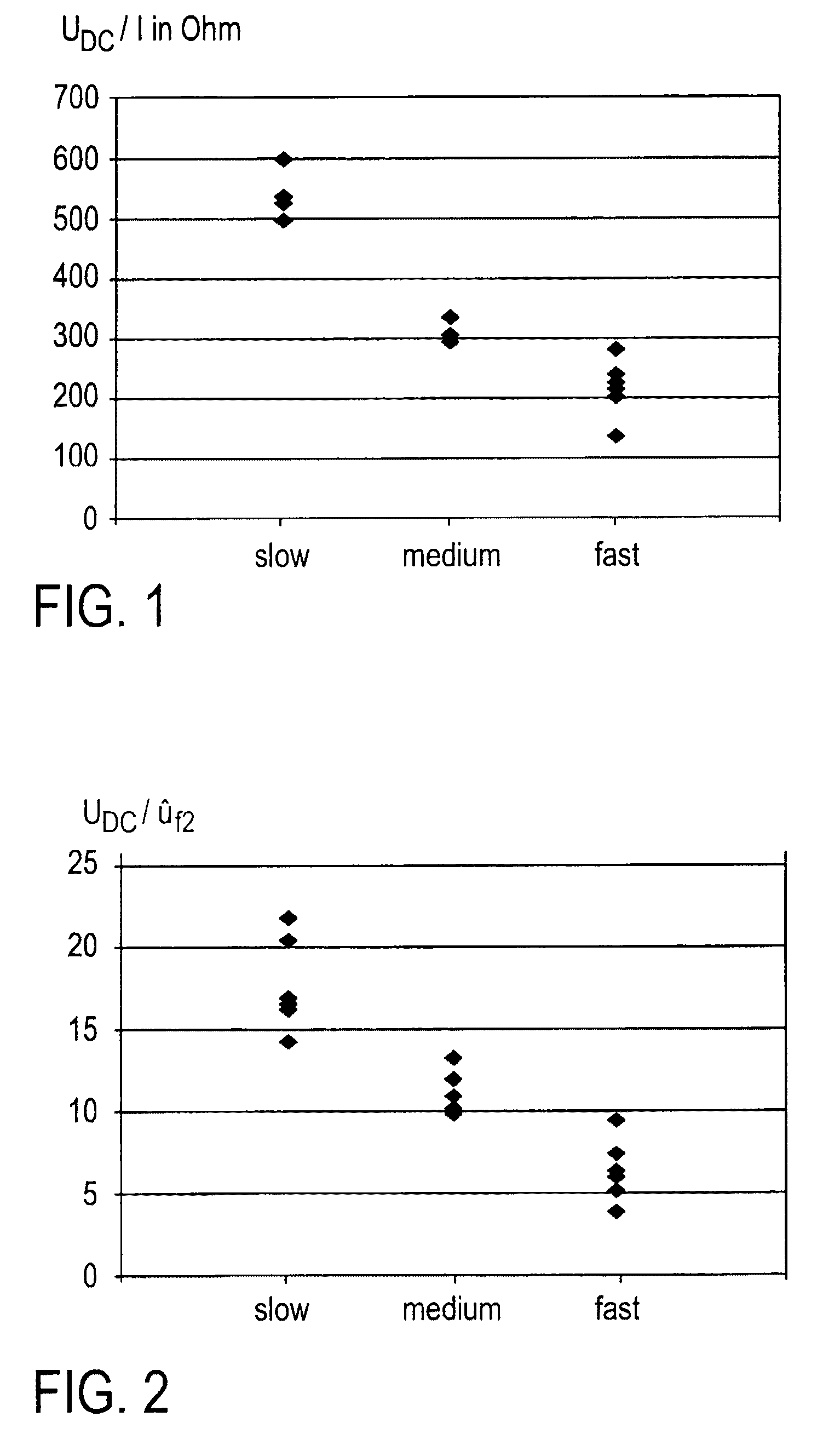

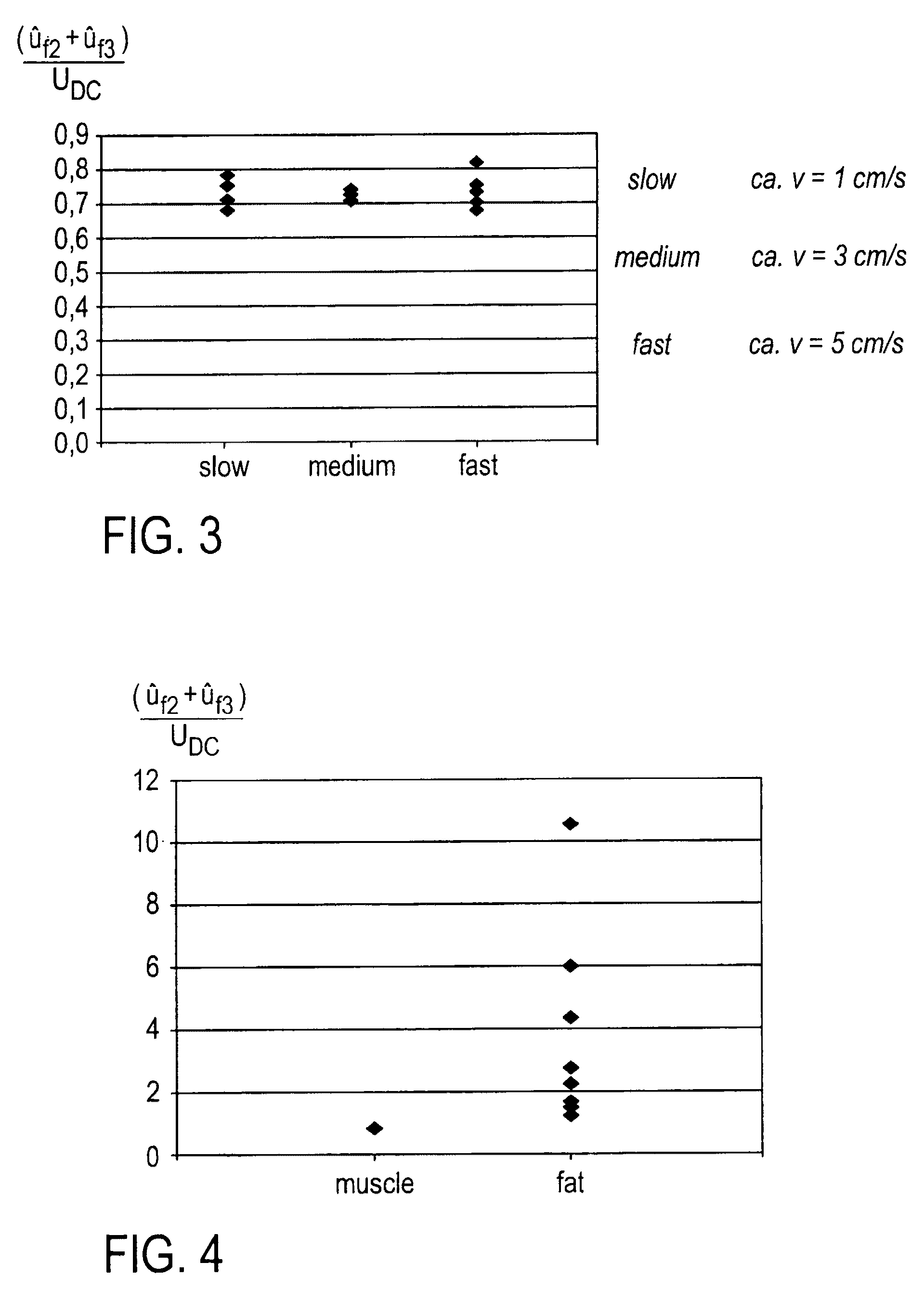

High frequency surgery apparatus and method of operating same

ActiveUS9186199B2Uniform cutting qualityHigh-frequency surgerySurgical instruments for heatingHarmonicFundamental frequency

The invention concerns a high frequency surgery apparatus for cutting and / or coagulating biological tissue and methods of operating same. The high frequency surgery apparatus includes at least one high frequency generator which in operation forms a high frequency circuit with the tissue to be treated, with the production of an arc, and at least one measuring and calculating device which is connected for signal transmission to the high frequency circuit and which is adapted in operation to ascertain both a DC voltage in the high frequency circuit and also the amplitudes of at least one even and at least one odd harmonic of a fundamental frequency of the high frequency generator and to form a first tissue parameter representative of the kind of tissue to be treated from the relationship of the sum of the amplitudes of the even and the odd harmonics to the DC voltage and to output a tissue signal dependent on the first tissue parameter for subsequent processing.

Owner:OLYMPUS WINTER & IBE

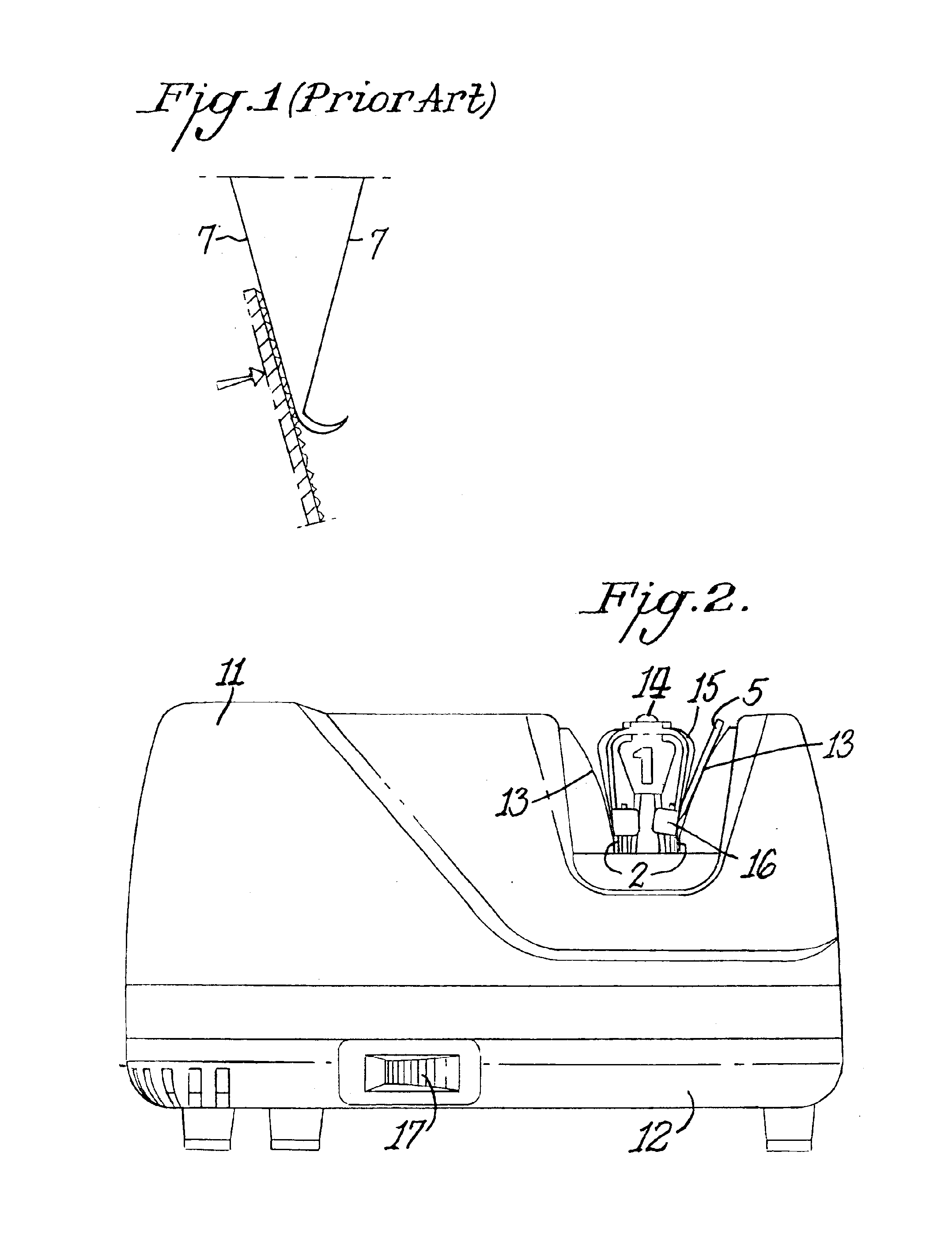

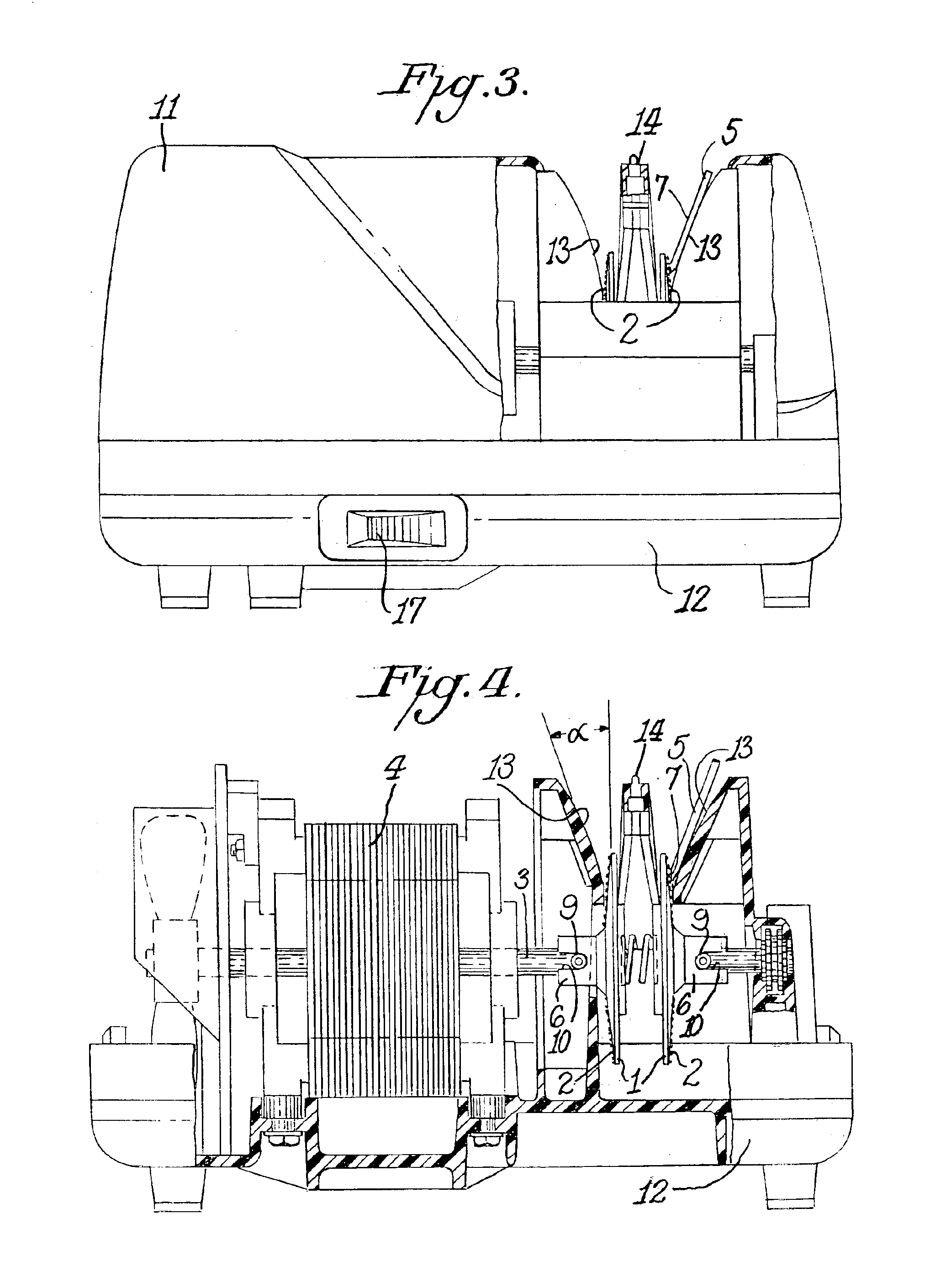

Sharpening device

ActiveUS6875093B2Highly effectiveReduce spring forceEdge grinding machinesPortable grinding machinesMotor driveUltra fine

A sharpener includes a motor driven shaft with at least one slidably mounted sharpening assembly consisting of a supporting hub structure mounted by its central bore hole on the shaft. The hub structure supports a symmetrically shaped rotating surface containing an ultra fine abrasive material. The rotating surface is pressed with a force of less than 0.2 lb. by a spring action to make sustained rotating abrading contact with a facet of a knife positioned by a knife guide to align the facet into contact with the surface containing the abrasive materials.

Owner:EDGECRAFT

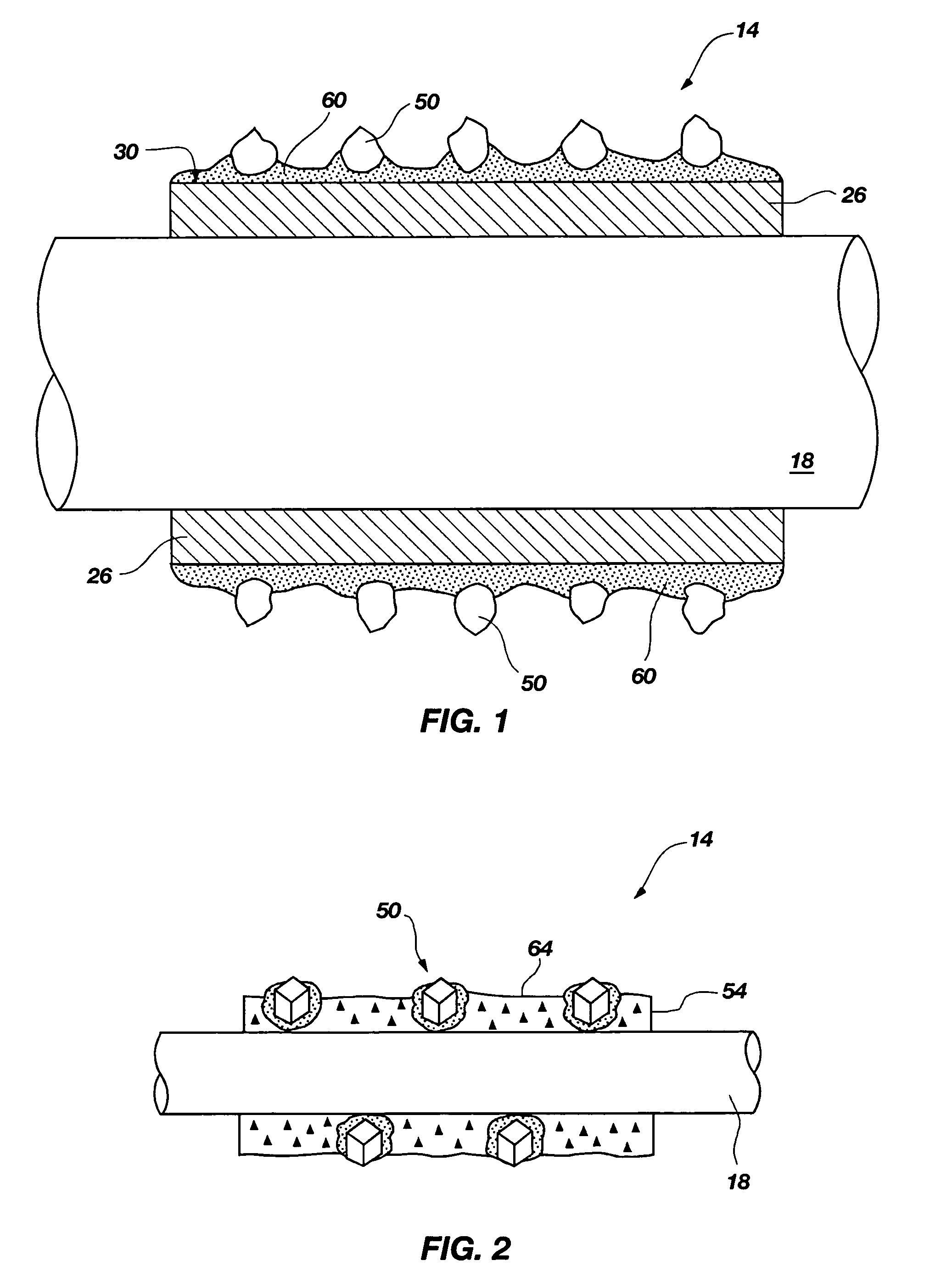

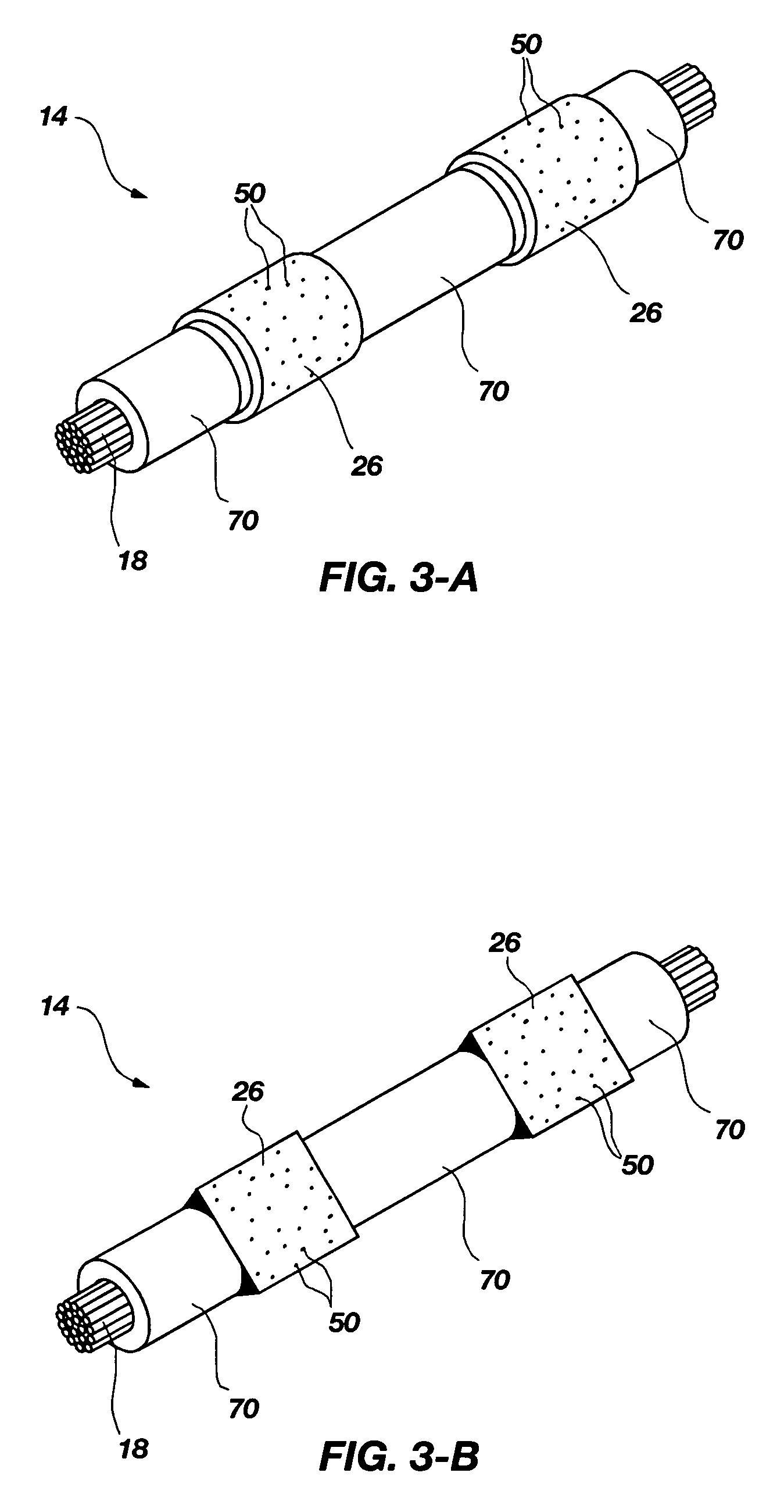

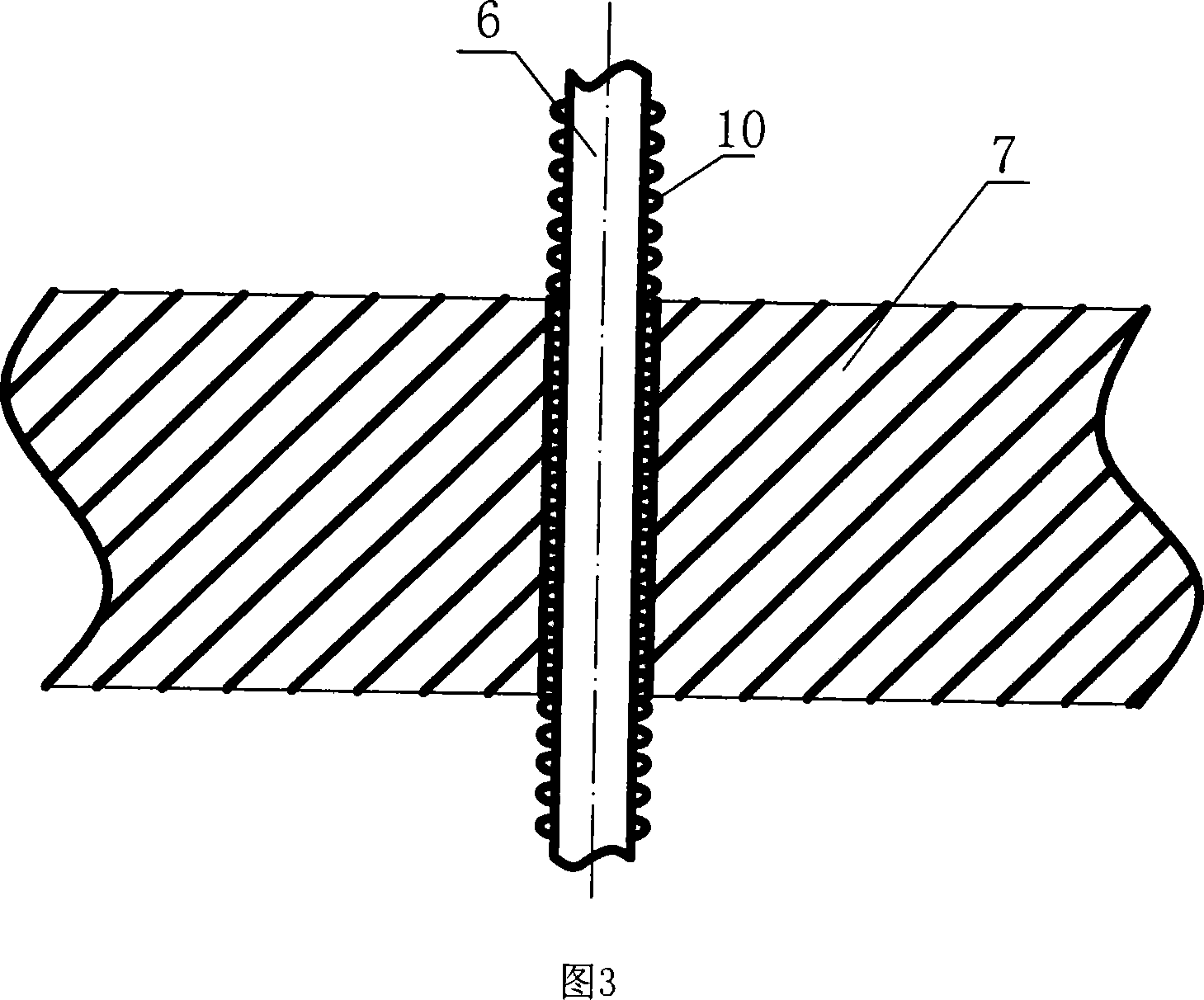

Reciprocating wire saw for cutting hard materials

InactiveUS7089925B1Low costIncrease valueBelt grinding machinesMetal sawing toolsEngineeringWire saw

The present invention features a reciprocating wire saw particularly adapted or configured for cutting hard materials. In one aspect, the reciprocating wire saw comprises (a) a flexible wire; (b) a plurality of cutting segments fittable onto the flexible wire, wherein each of the cutting segments comprises an outer surface; and a (c) plurality of superabrasive particles braze bonded onto the outer surface of the cutting segments to form a cutting wire. In another aspect, the reciprocating wire saw comprises a plurality of superabrasive particles braze bonded directly to the wire itself to form a cutting wire. The cutting wire is unique in that it comprises a pre-determined superabrasive particle concentration and is configured to cut various materials, such as granite, in a reciprocating manner.

Owner:KINIK

Ultrasound surgical saw

This invention discloses methods and devices using ultrasound energy for resecting bone tissue during surgical procedures. The disclosure describes the use of ultrasound surgical saw consisting of an ultrasound generator, ultrasound transducer and ultrasound horn including a cutting blade to resect bone tissue without excessive temperature rise during typical surgical procedures. The cutting blade provides a self-clearing design that includes at least two teeth disposed to prevent accumulation of bone chips within the proximity of the teeth. The design of the cutting blade allows the mechanical motion of the blade and the emission of the ultrasound energy to remove accumulated bone chips and prevent excessive temperature rise.

Owner:BABAEV ELIAZ

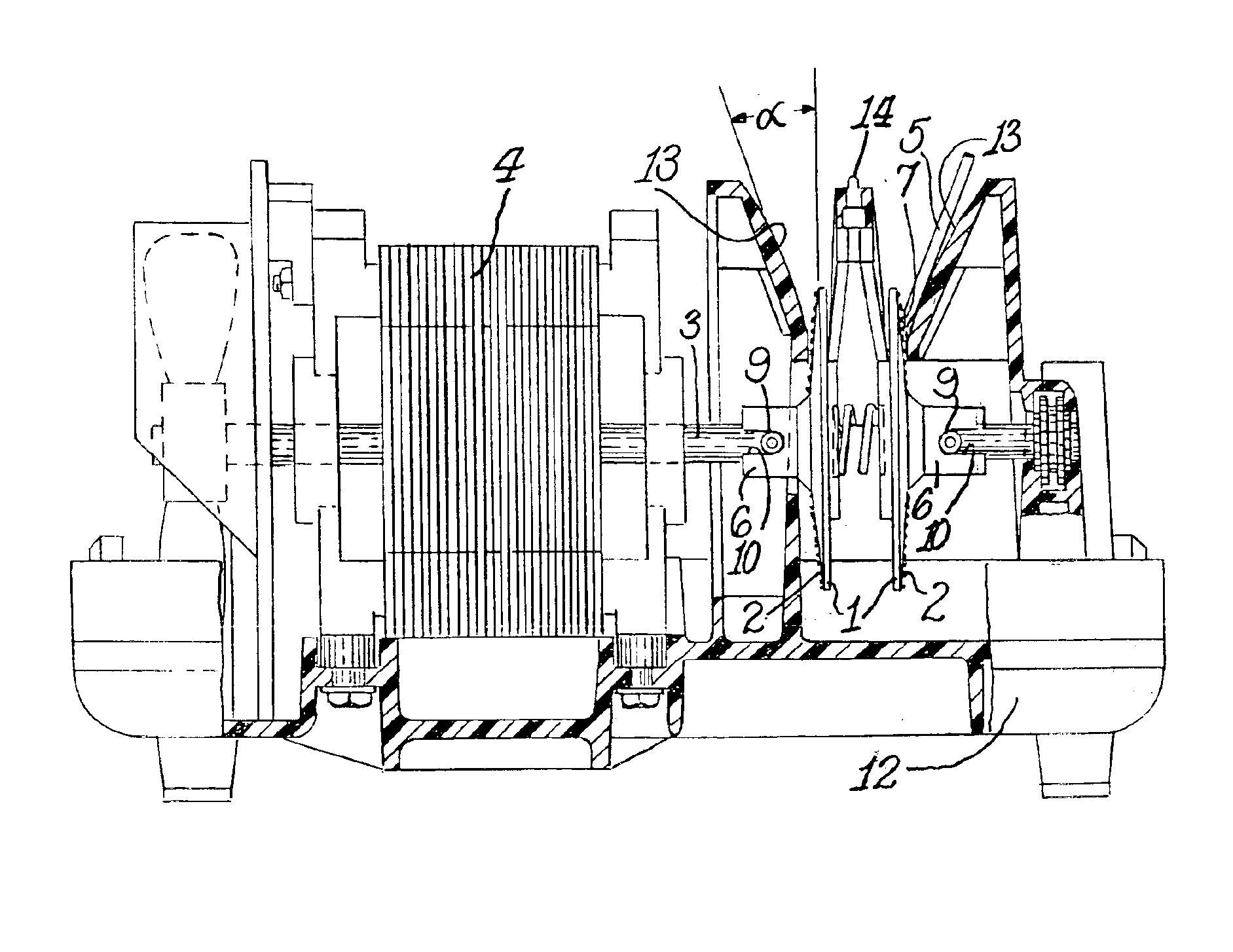

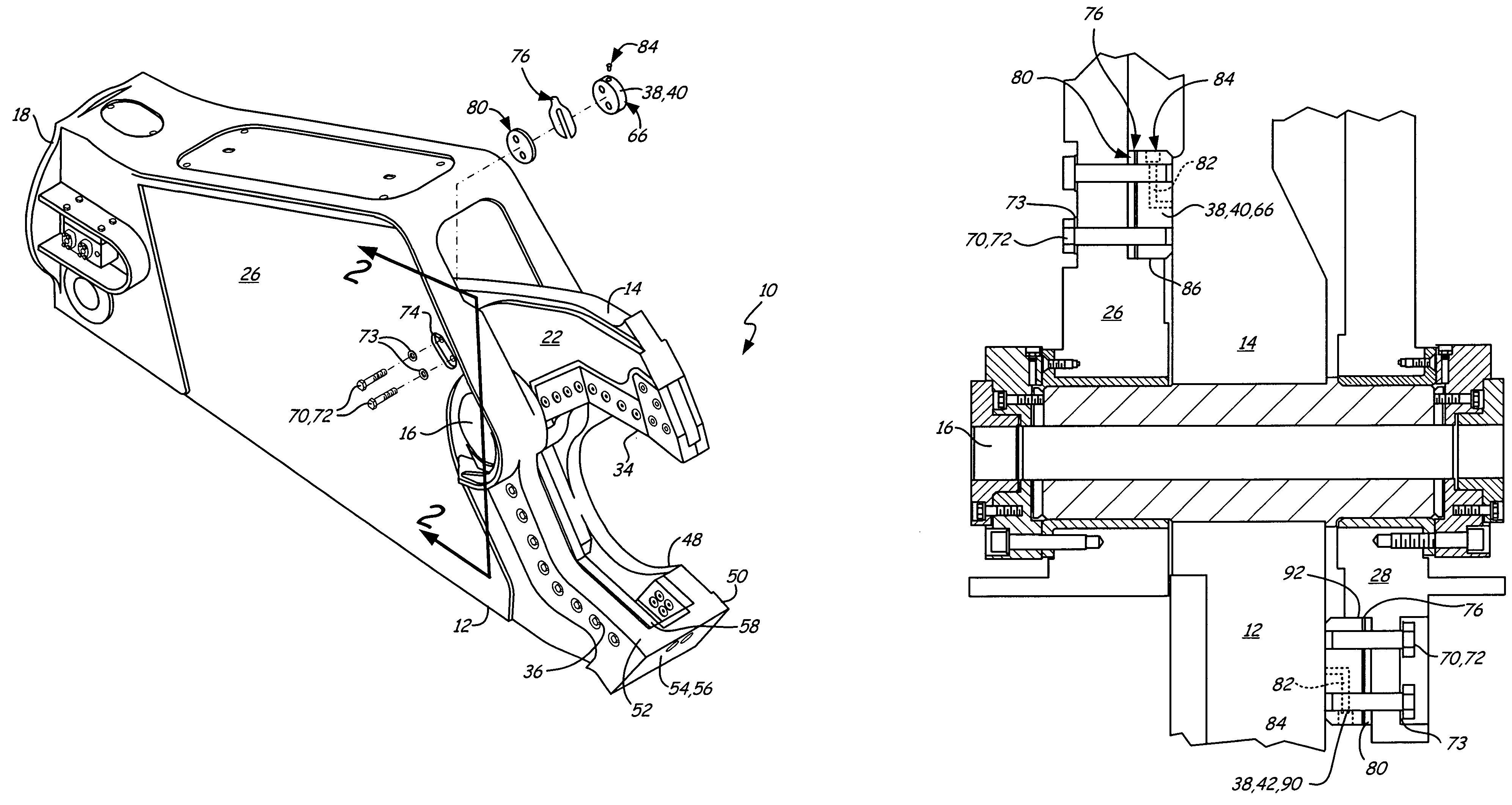

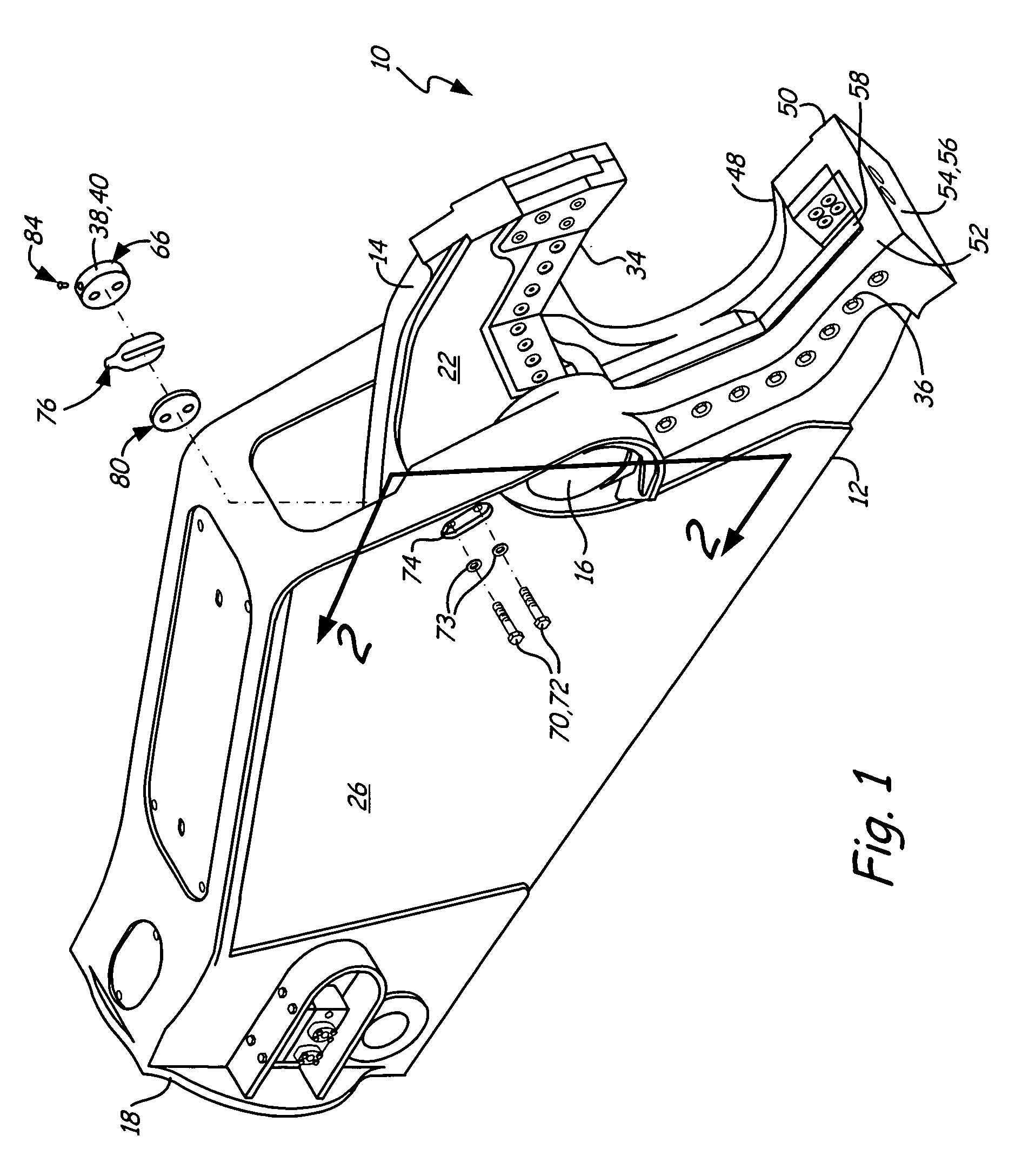

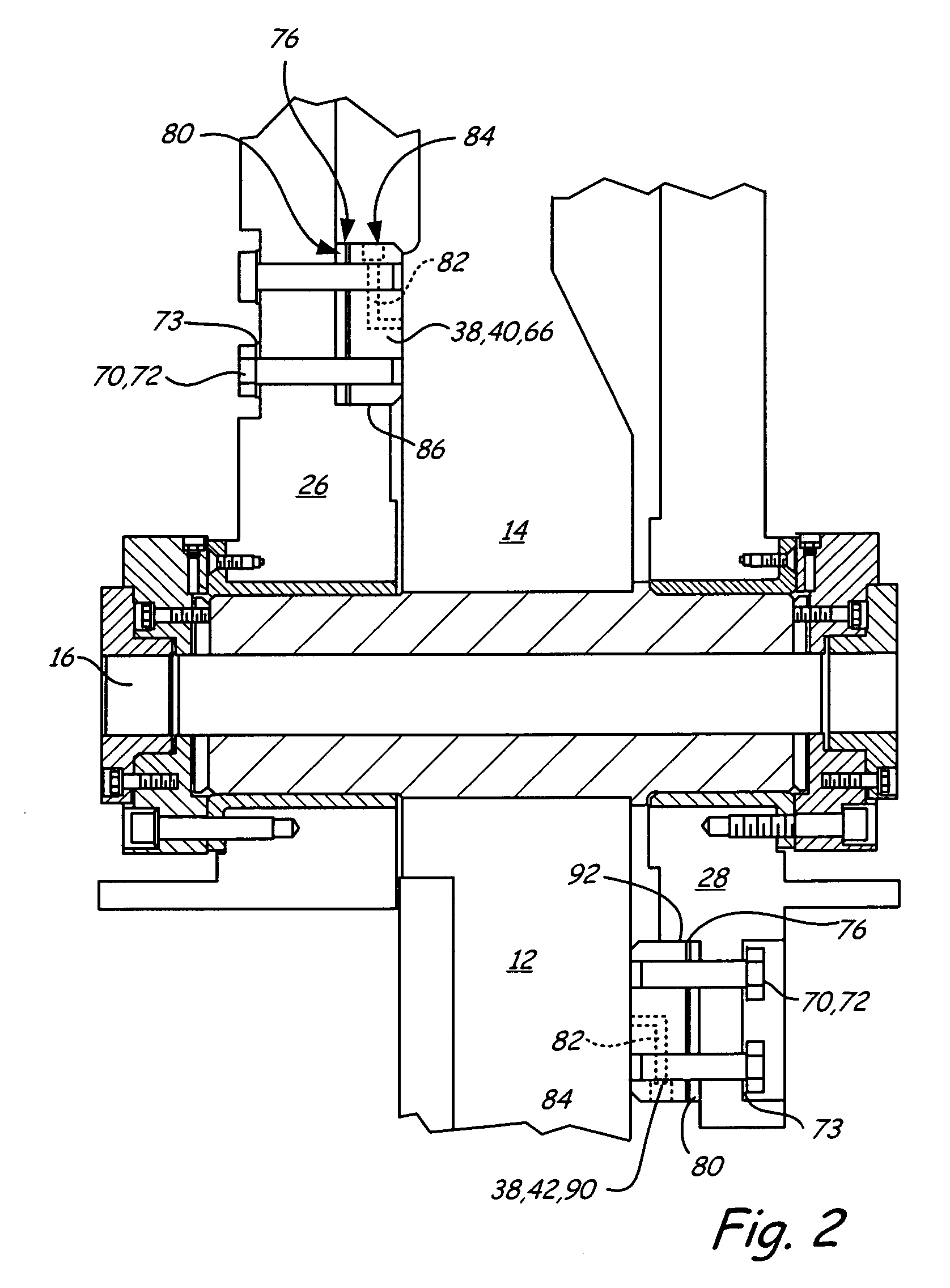

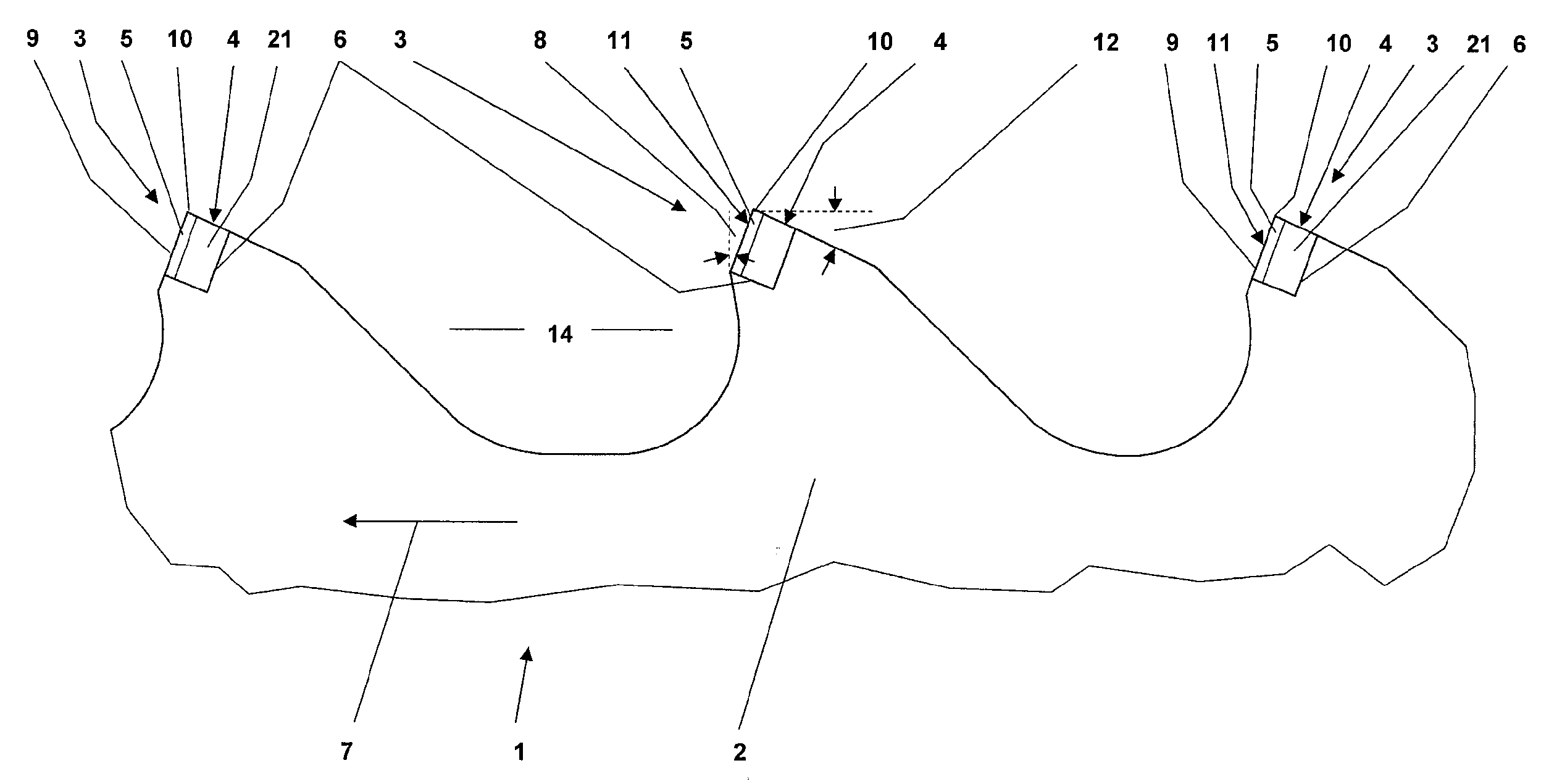

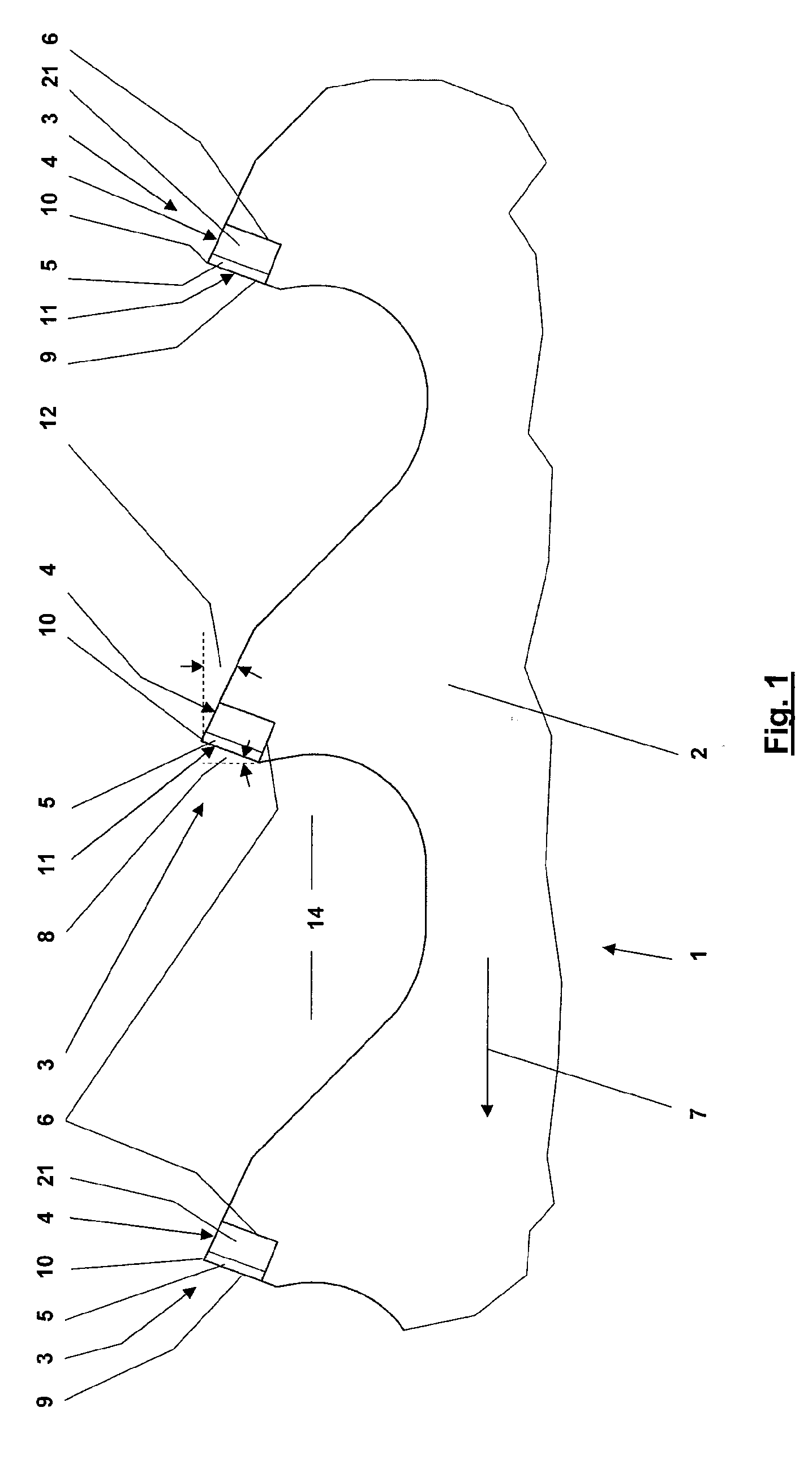

Heavy-duty demolition apparatus with blade stabilizing puck

ActiveUS7216575B2Improve cutting effectReduce lateral stressMechanical machines/dredgersBuilding repairsEngineeringHeavy duty

A blade stabilizer device for a heavy-duty material handling demolition tool for shearing and crushing scrap material which includes a lower jaw connected to the boom structure of a hydraulic system of an excavator has an upper jaw pivotally connected to and closable upon the lower jaw at a pivot point. The blade stabilizing device consists of a wear guide pad supported by the lower jaw adjacent the pivot point slidably engaging the movable upper jaw to keep the upper jaw in close engagement with the lower jaw. The wear guide pad is mounted behind the pivot point. A second wear guide pad may be mounted in front of the pivot point on the opposite side of the upper jaw to cross-brace the upper jaw.

Owner:GENESIS ATTACHMENTS

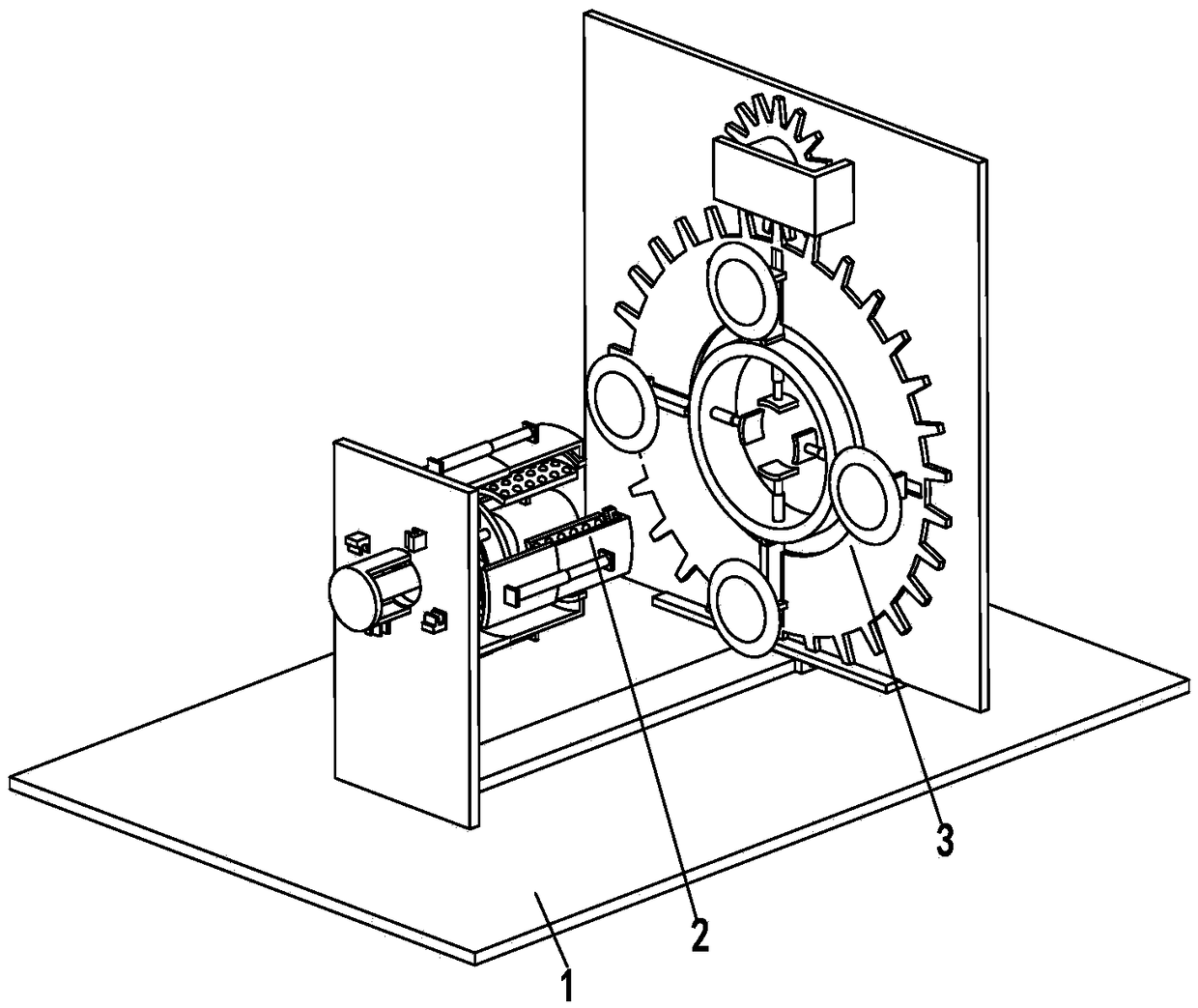

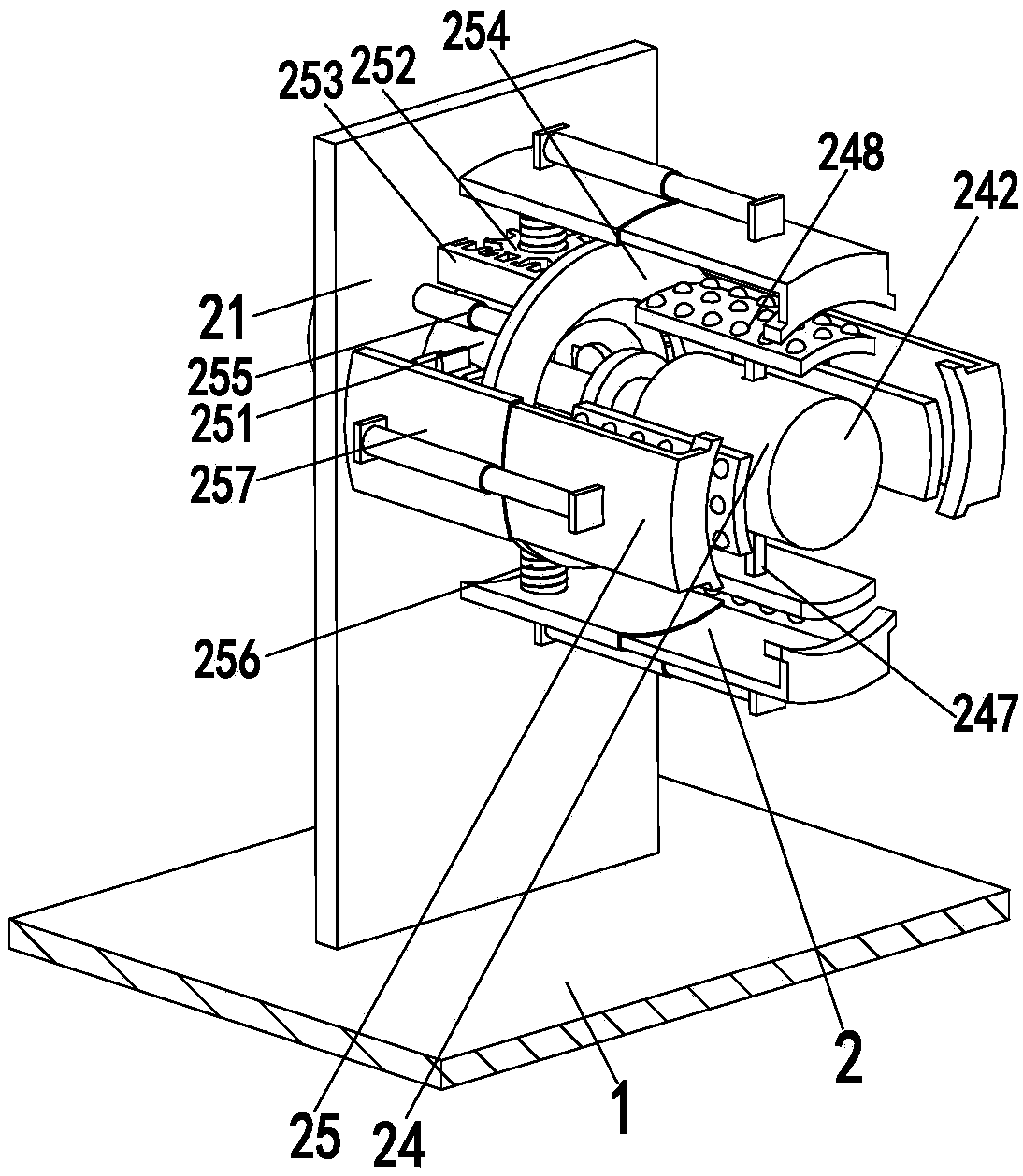

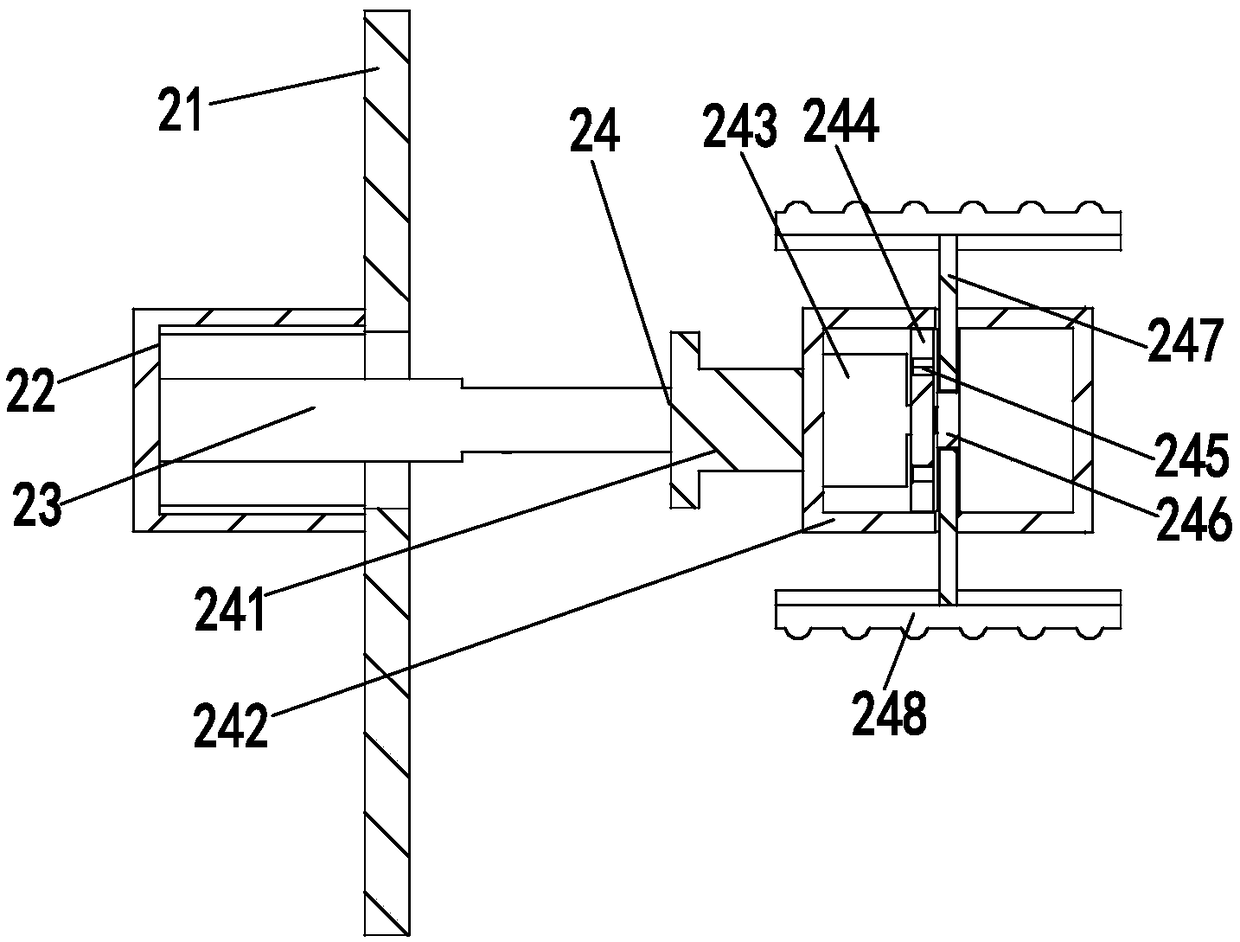

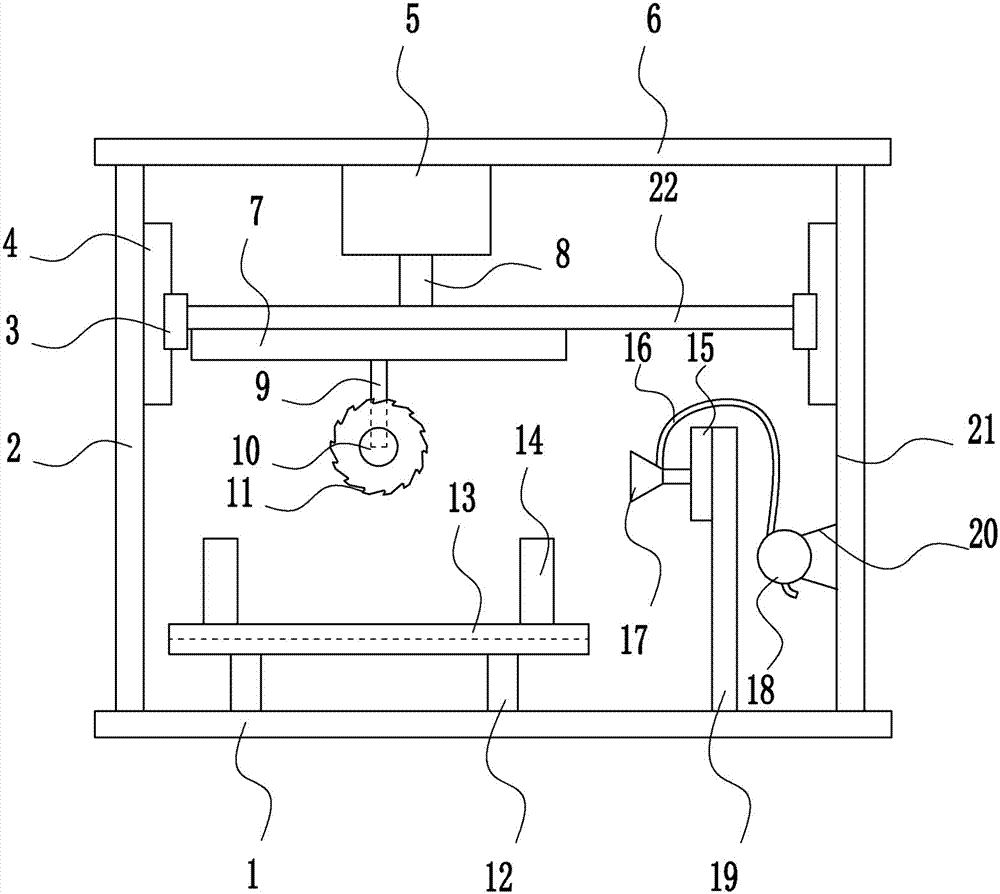

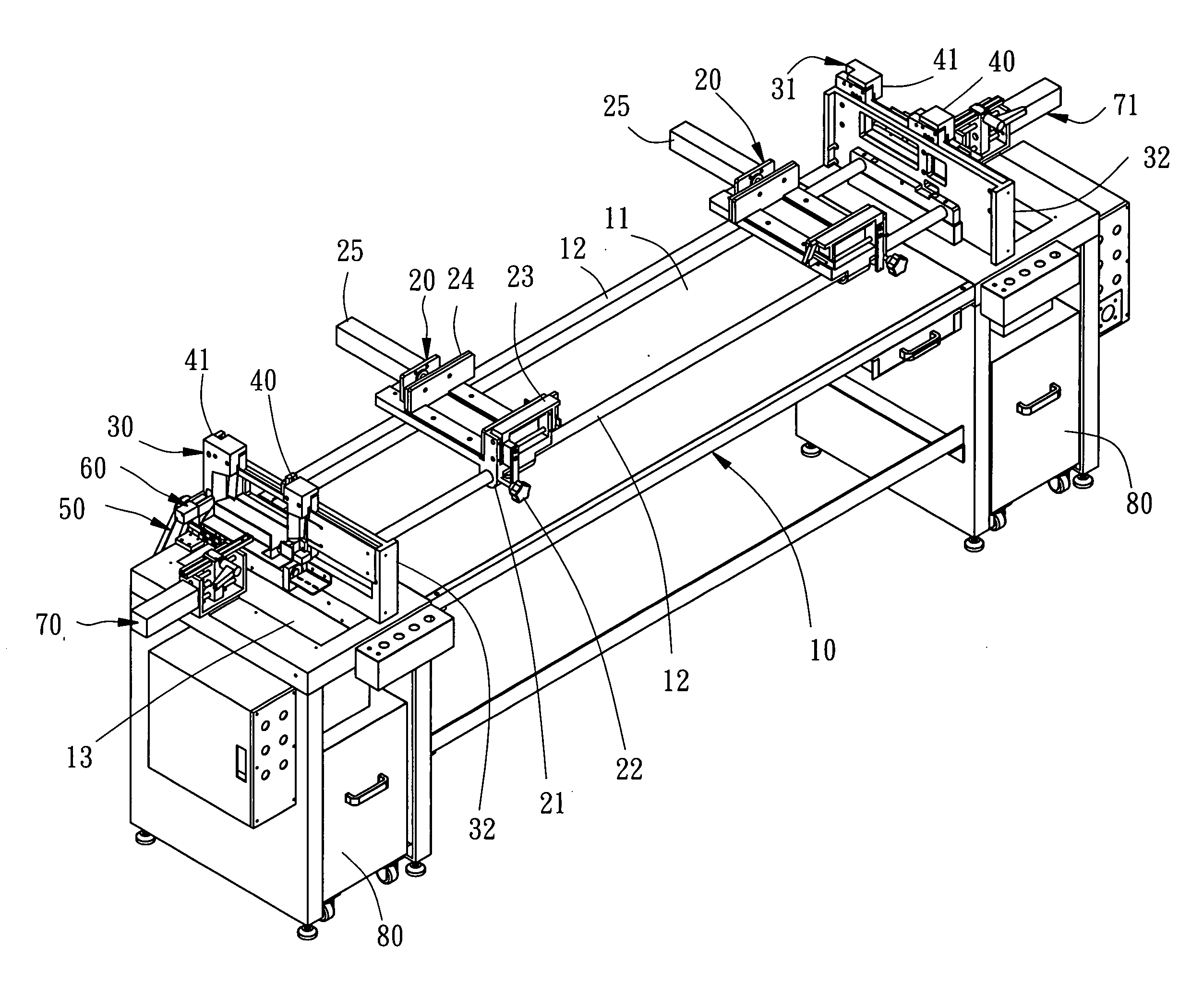

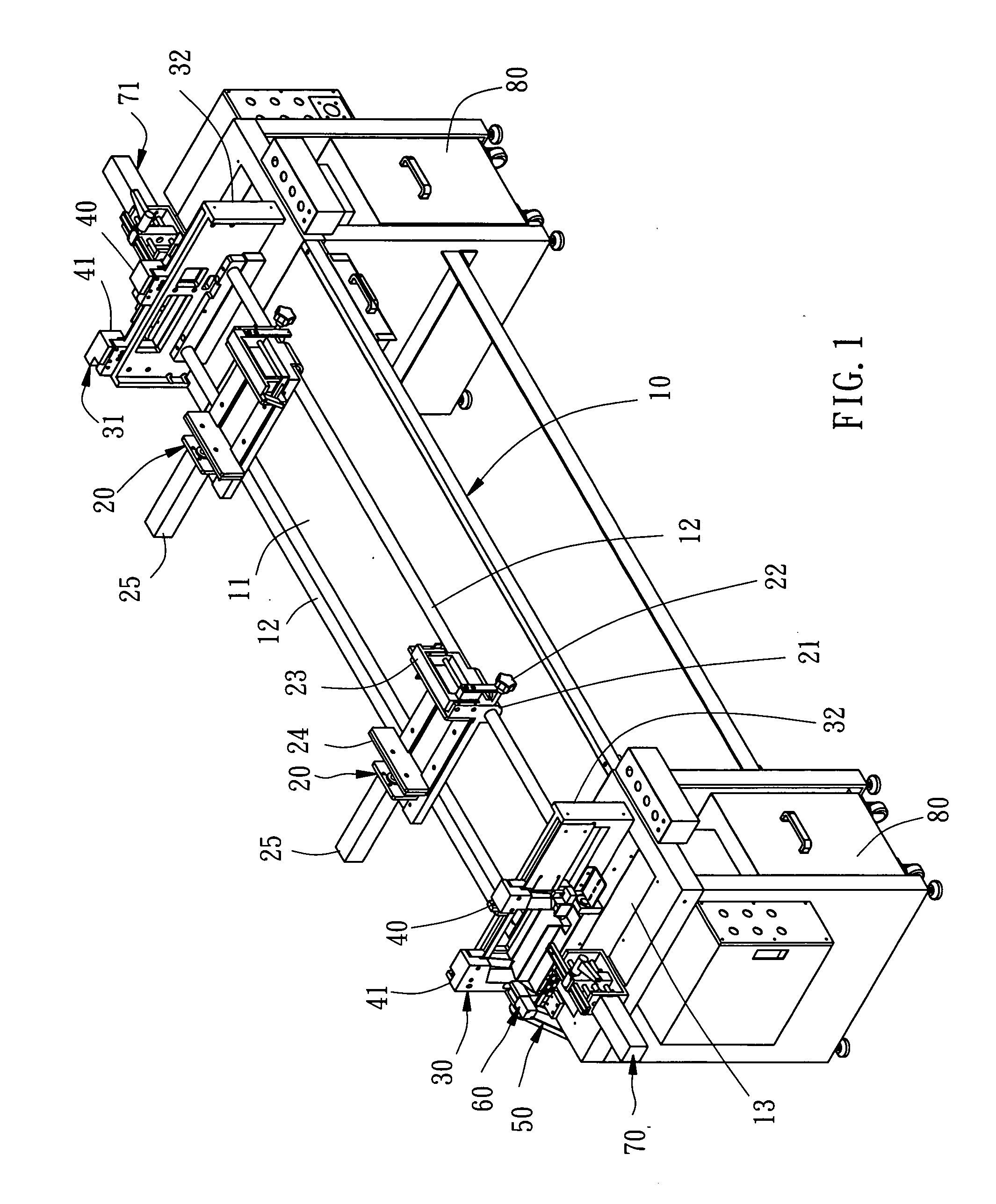

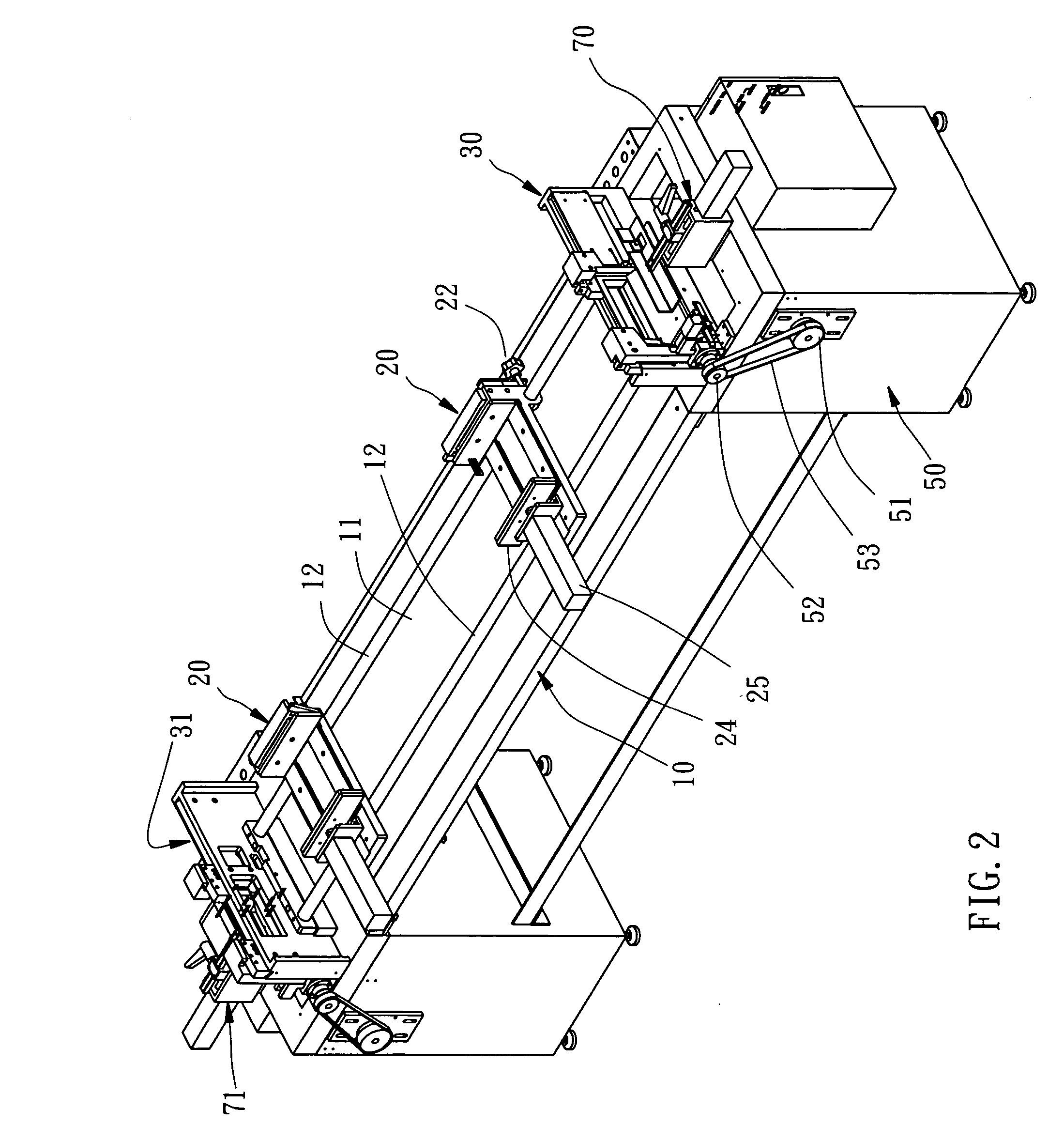

Automatic rubber hose cutting equipment and automatic rubber hose cutting technology

ActiveCN109227674ARealize automatic cuttingNot easy to scratchMetal working apparatusGear wheelFixed frame

The invention relates to automatic rubber hose cutting equipment and an automatic rubber hose cutting technology. The automatic rubber hose cutting equipment comprises a bottom plate, a supporting device and a cutting device, and the supporting device and the cutting device are sequentially installed on the bottom plate from left to right; the supporting device comprises a fixing plate, a fixed frame, a movable air cylinder, an inner wall supporting mechanism and an outer wall supporting mechanism; the cutting device comprises a linear guide rail, an electric sliding block, a working plate, aworking gear, a driving gear, a driving motor, a rotating ring, a rotating gear, a rotating motor, a supporting air cylinder, a supporting plate, a rotating rod, a sliding frame, a mounting frame, a cutting motor and a cutting blade. The invention further provides a using method of the automatic rubber hose cutting equipment. The equipment and the technology can solve the problems that in an existing rubber hose cutting process, the labor cost is high, the working efficiency is low, the cutting surface is not smooth, safety hidden hazards exist and the surface of a rubber hose is easily scratched, and the function of automatically cutting the rubber hose can be achieved.

Owner:中金液压胶管股份有限公司

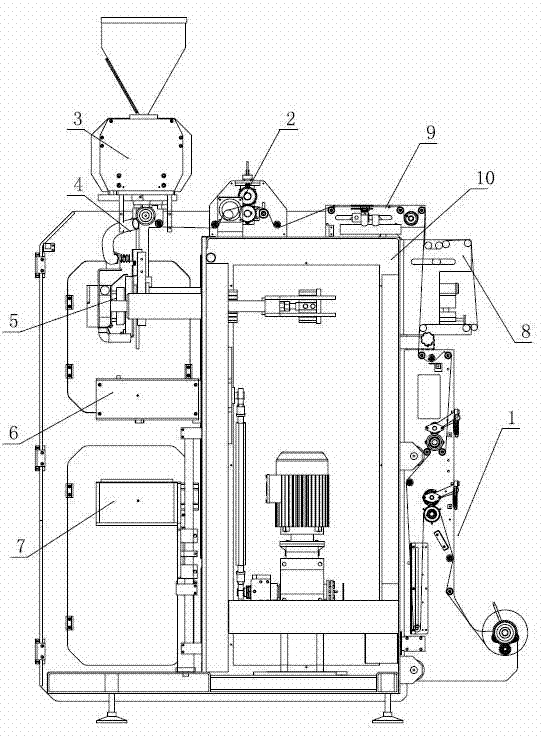

Multicolumn strip packing machine

ActiveCN102730214AIncrease productivitySimple structureWrapping material feeding apparatusWrapper twisting/gatheringReciprocating motionEngineering

The invention relates to a multicolumn strip packing machine, in particular to a multicolumn strip packing machine capable of carrying out continuous bag-making and packing through automatic operation, comprising a frame, and a film feeding mechanism, a slitting cutter mechanism, a feeding mechanism, a bag molding mechanism, a longitudinal sealing mechanism, a transverse sealing mechanism and a cut-off mechanism arranged on the frame respectively, wherein the transverse sealing mechanism comprises a transverse sealing device which comprises a transverse sealing floating device, two transverse sealing holders, and transverse sealing seats arranged on the two transverse sealing holders respectively; a plurality of transverse sealing guide shafts are together sleeved to transverse beam sliders on the same side; at least one transverse sealing seat is connected to a transverse sealing cylinder for driving the transverse sealing seat to do reciprocating motion; and the axial direction of the transverse sealing guide shaft is consistent with the motion direction of the transverse sealing seat. The transverse sealing mechanism of the multicolumn strip packing machine is capable of providing a buffering force for an object to be packed so that the impact on the object to be packed can be reduced and the object to be packed can be protected against damage; and a plurality of combined components are arranged in a multi-row parallel manner, so that the production of a plurality of packing bags can be completed at the same time; as a result, the production efficiency is greatly improved.

Owner:SHANGHAI SOONTRUE MACHINERY EQUIP

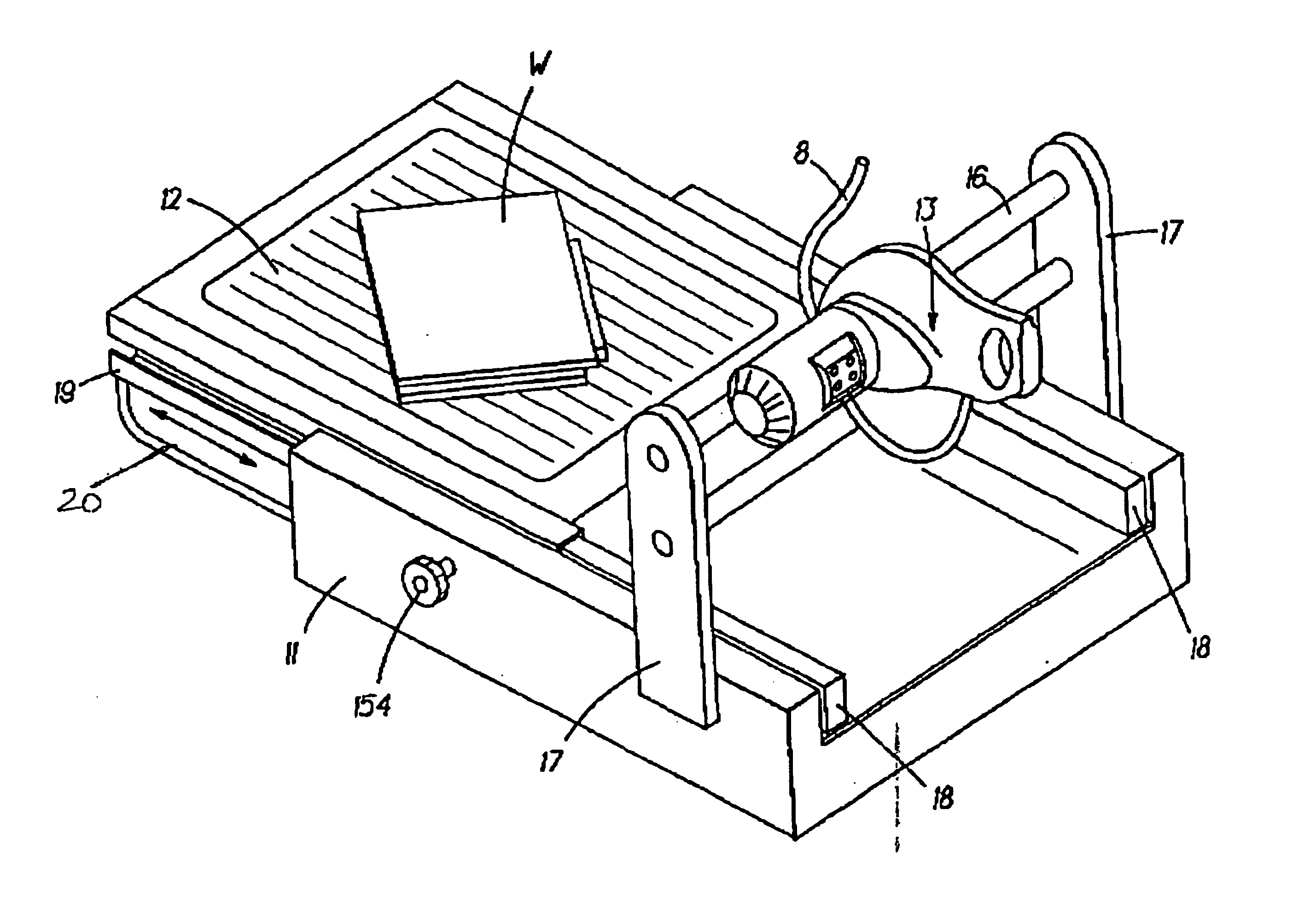

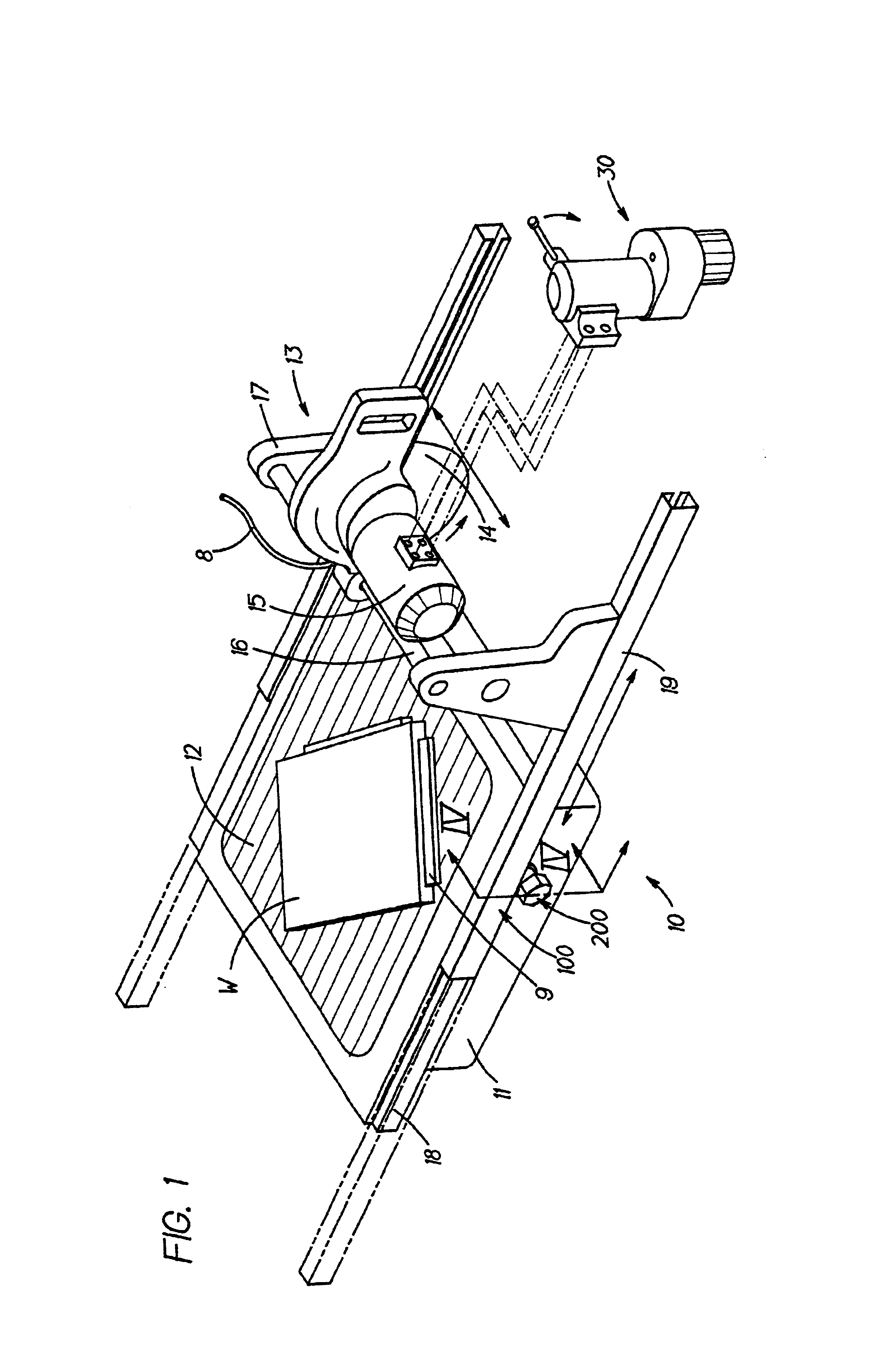

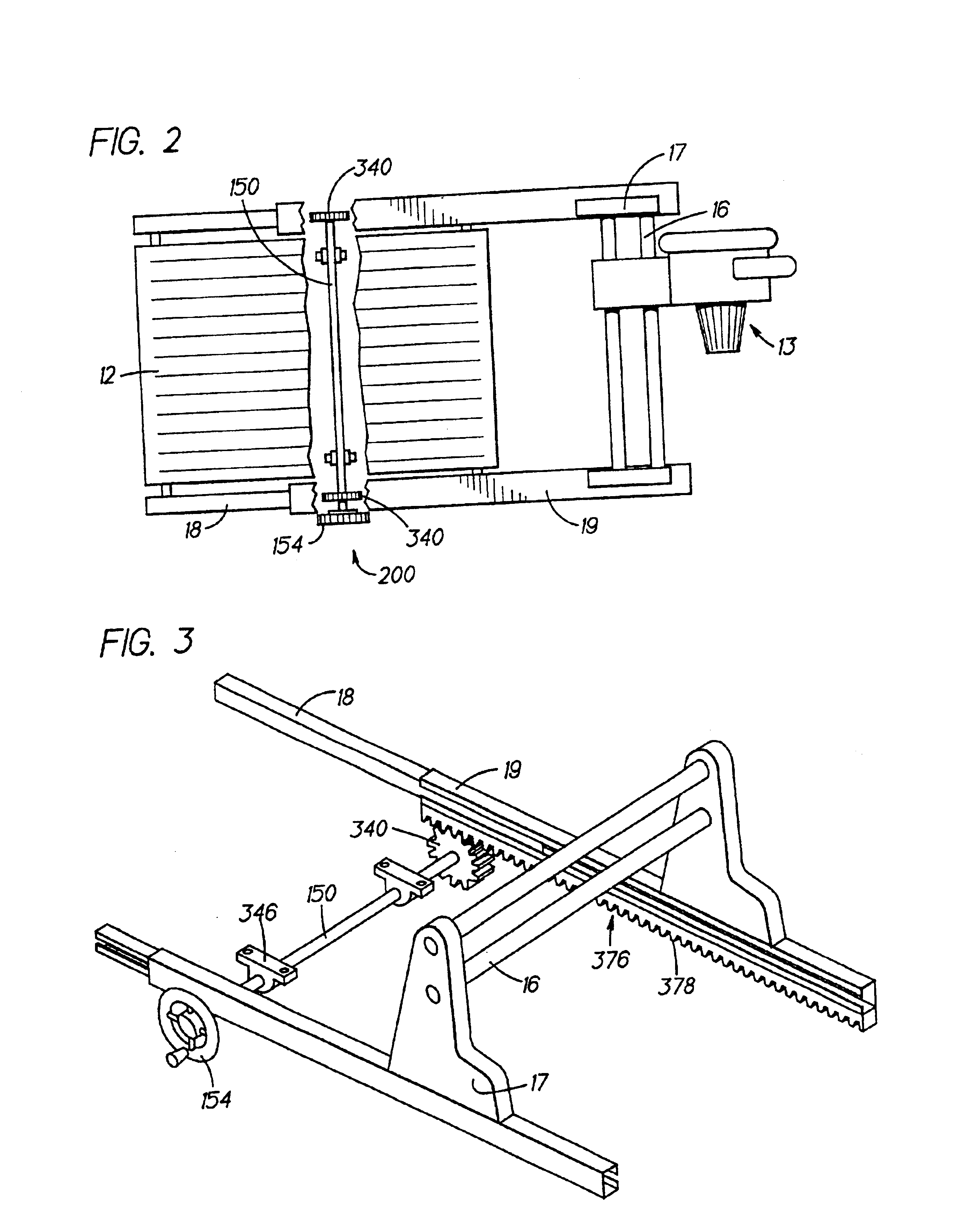

Tile saw

InactiveUS6845768B2Improve cutting effectSacrificing portabilityMetal sawing devicesGrinding drivesGear wheelPinion

A saw includes a base having a first length extending generally along a first direction, a table disposed on the base, a saw unit disposed on the base, wherein one of the table and the saw unit is movable relative to the base along the first direction over a range which exceeds the first length. The saw may also include a first stationary rail connected to the base and extending generally along the first direction and a first movable rail engaging the first stationary rail and extending generally parallel to the first stationary rail, the first movable rail being connected to the one of the table and saw unit. Preferably, the first movable rail is slidingly received over the first stationary rail. The saw may also include a first rack disposed on the first movable rail, and a first pinion disposed on the base, wherein the first pinion meshes with the first rack so that the first movable rail moves along the first direction upon rotation of the first pinion. Preferably, the saw further includes a second stationary rail connected tot the base and extending generally along the first direction and substantially parallel to the second stationary rail, and a second movable rail engaging the second stationary rail and extending generally parallel to the first movable and second stationary rails, the second movable rail being connected to the one of the table and saw unit.

Owner:BLACK & DECKER INC

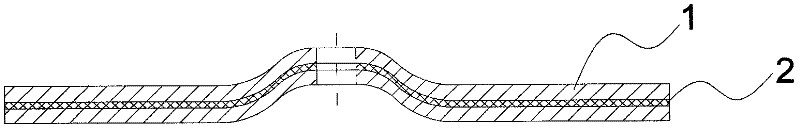

Resin abrasive cutting wheel and manufacturing method thereof

ActiveCN102343558AHigh strengthImprove cutting effectBonded abrasive wheelsGrinding devicesCarbideGrinding wheel

The invention provides a resin abrasive cutting wheel and a manufacturing method thereof, belonging to the field of grinding tools. The resin abrasive cutting wheel solves the problem that the traditional brown corundum resin grinding wheel has low cost but bad cutting performance. The resin abrasive cutting wheel comprises a grinding body and a reinforcing sheet which is arranged inside the grinding body to reinforce the rotation strength of the grinding body, wherein the grinding body comprises the following raw materials in proportions by weight: 62-70% of brown corundum, 4-10% of black silicon carbide, 18-20% of phenolic resin and the balance of packing. The invention also provides a manufacturing method of the resin abrasive cutting wheel. According to the manufacturing method, the cutting performance of the abrasive cutting wheel is increased by increasing a special proportion of black silicon carbide under the condition that the cost is not increased.

Owner:NINGBO DAHUA GRINDING WHEEL

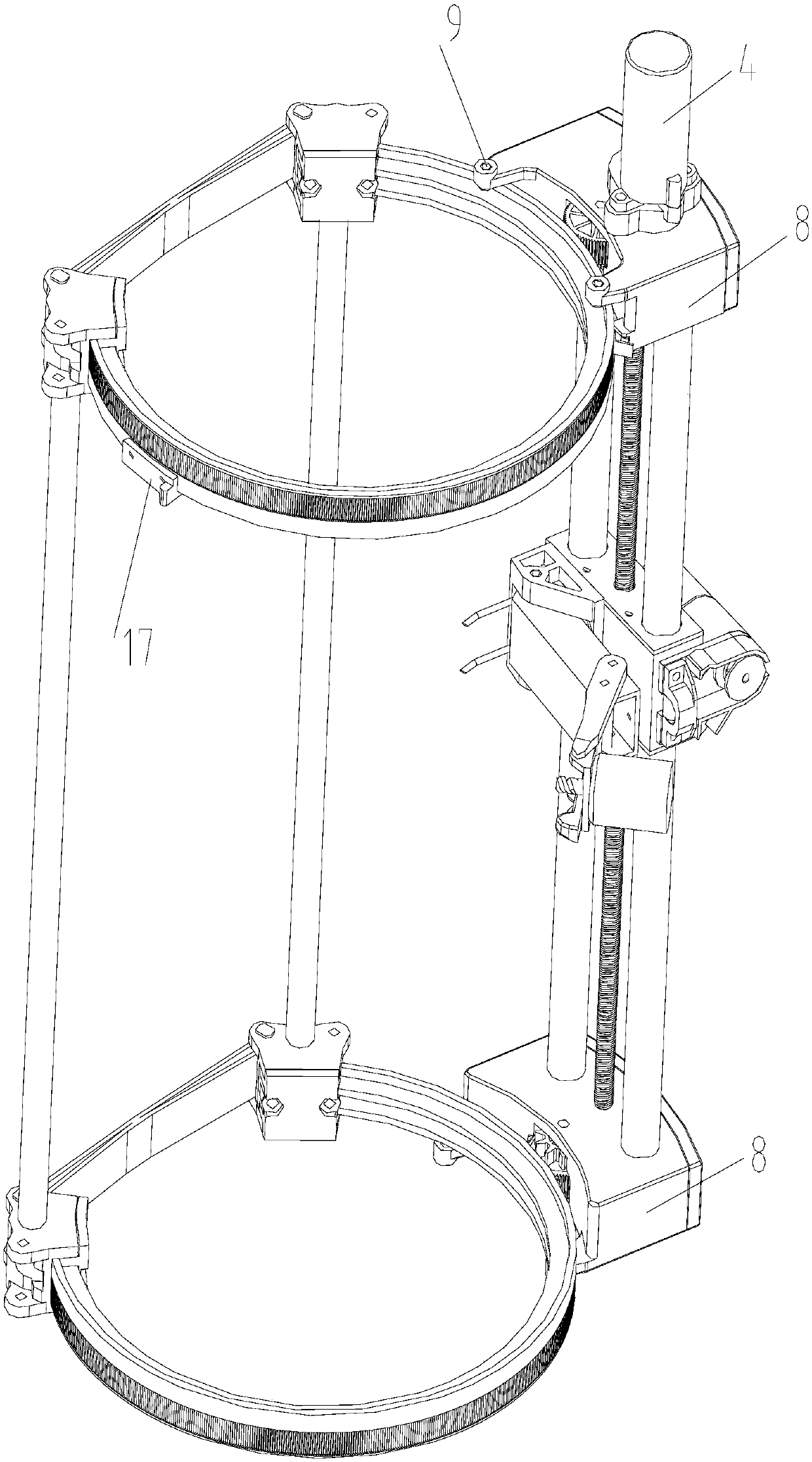

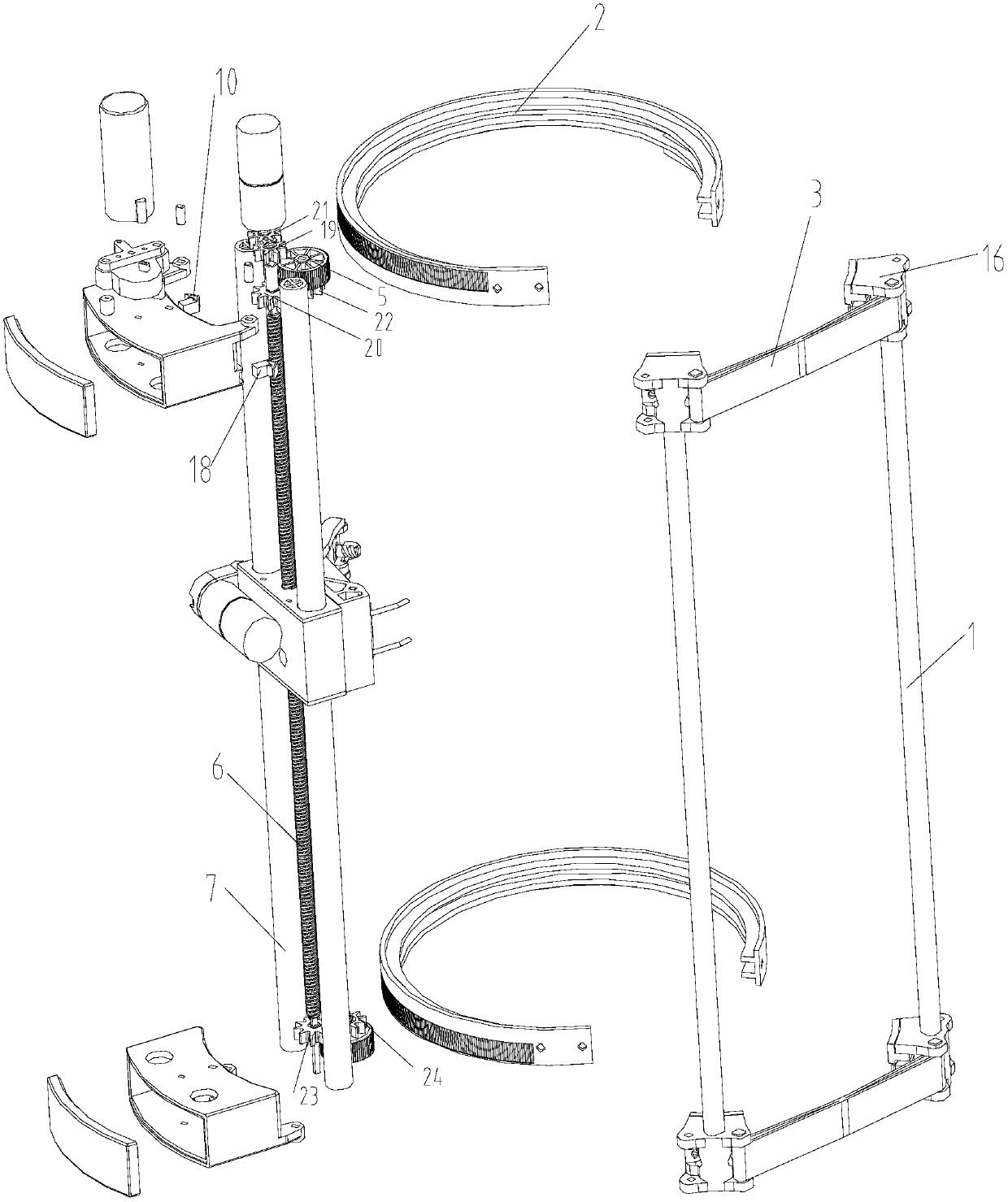

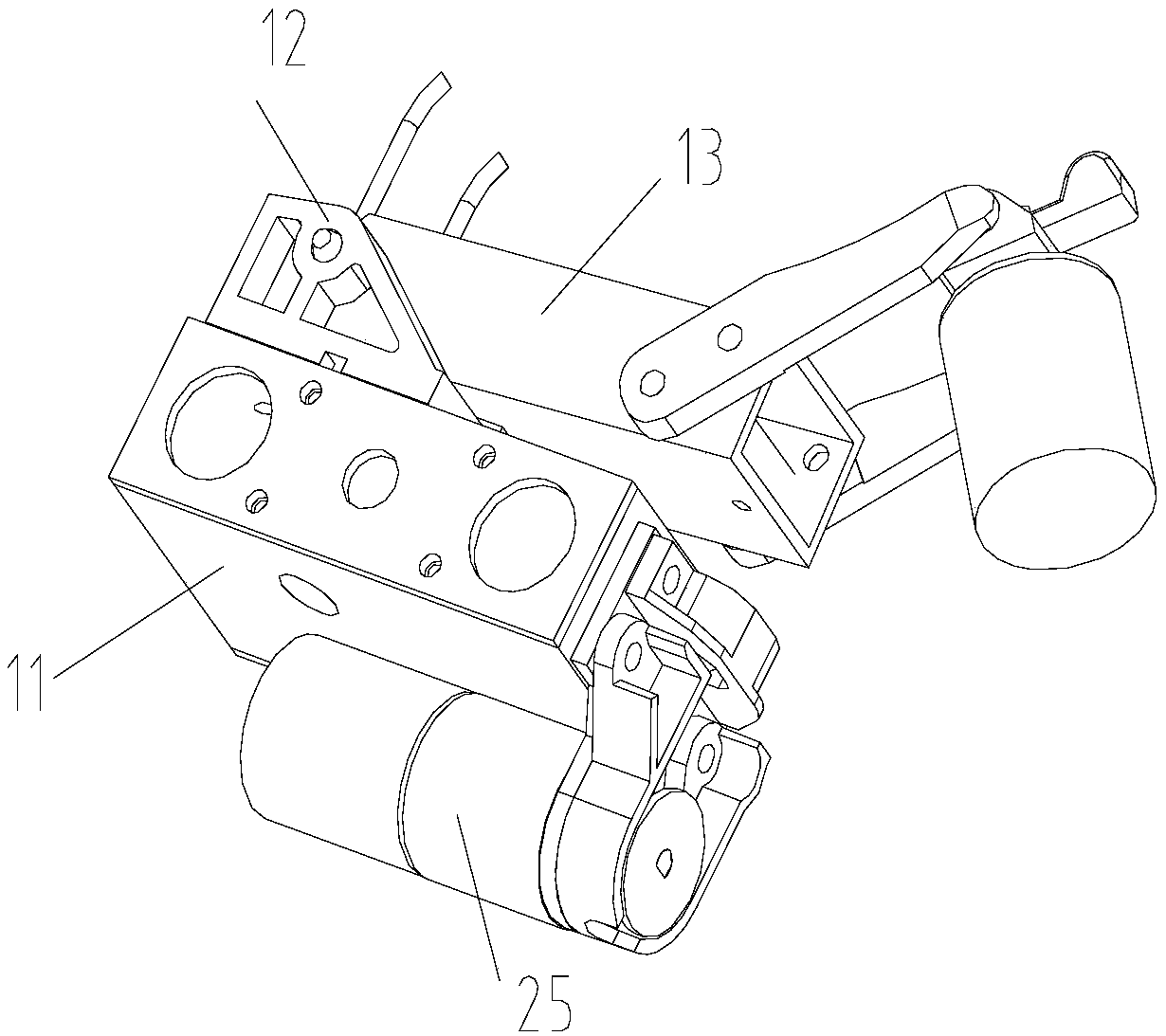

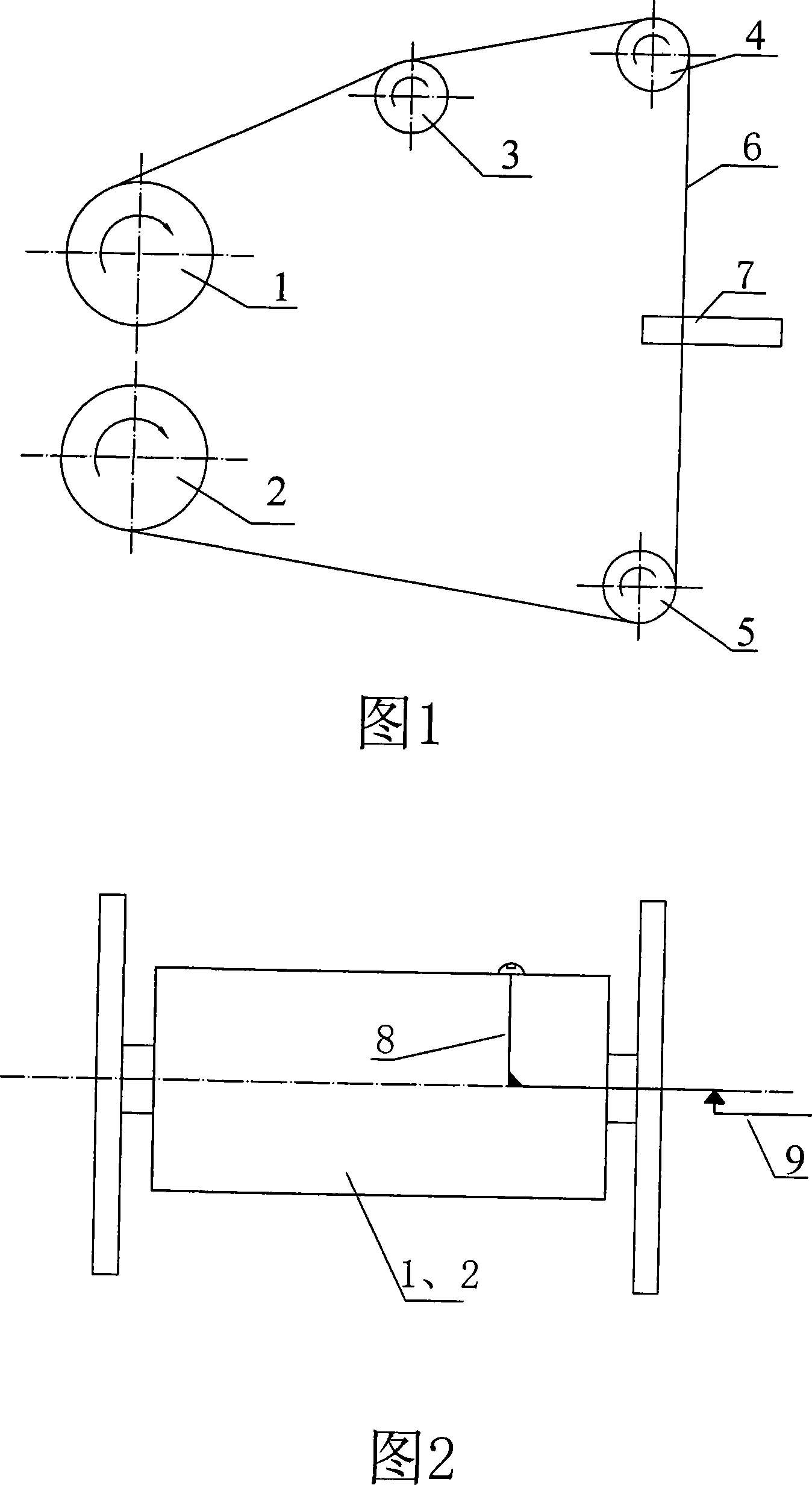

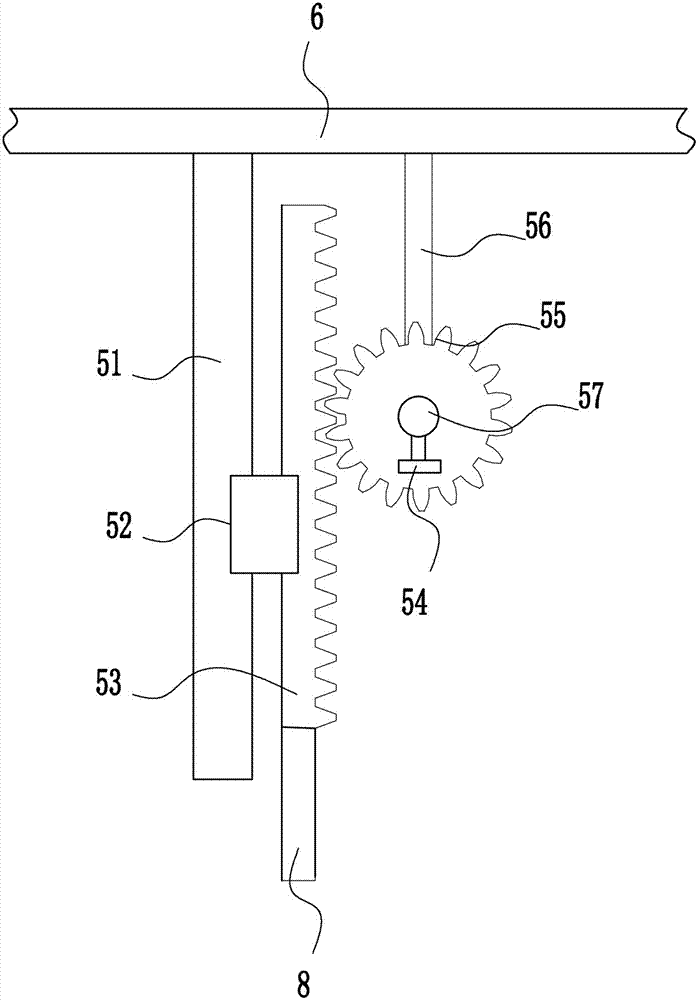

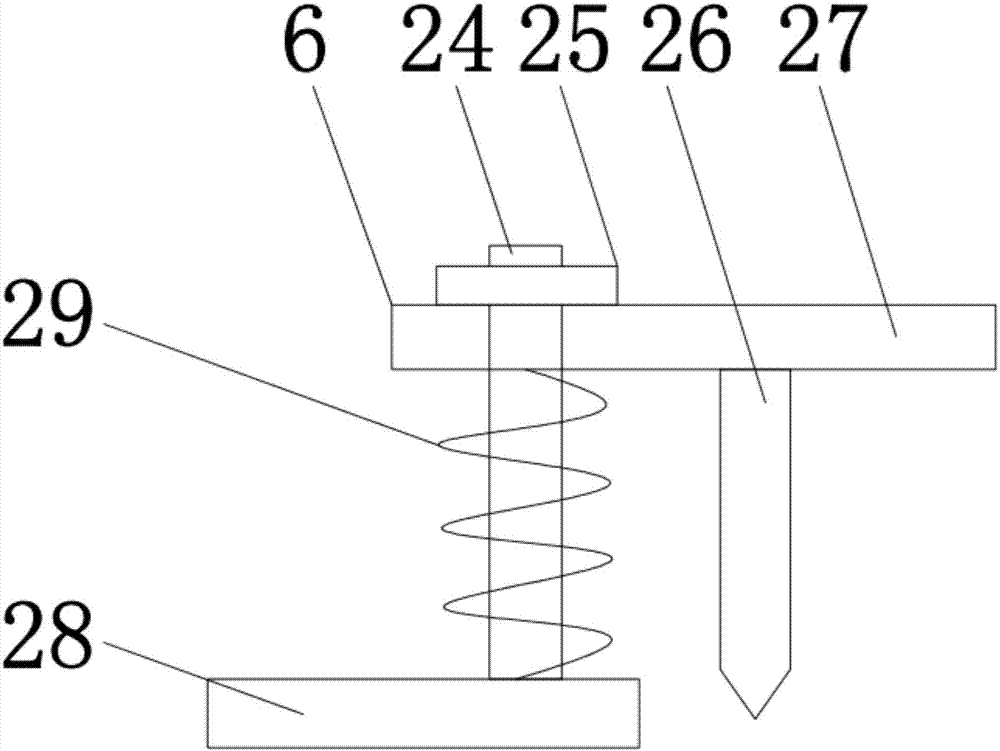

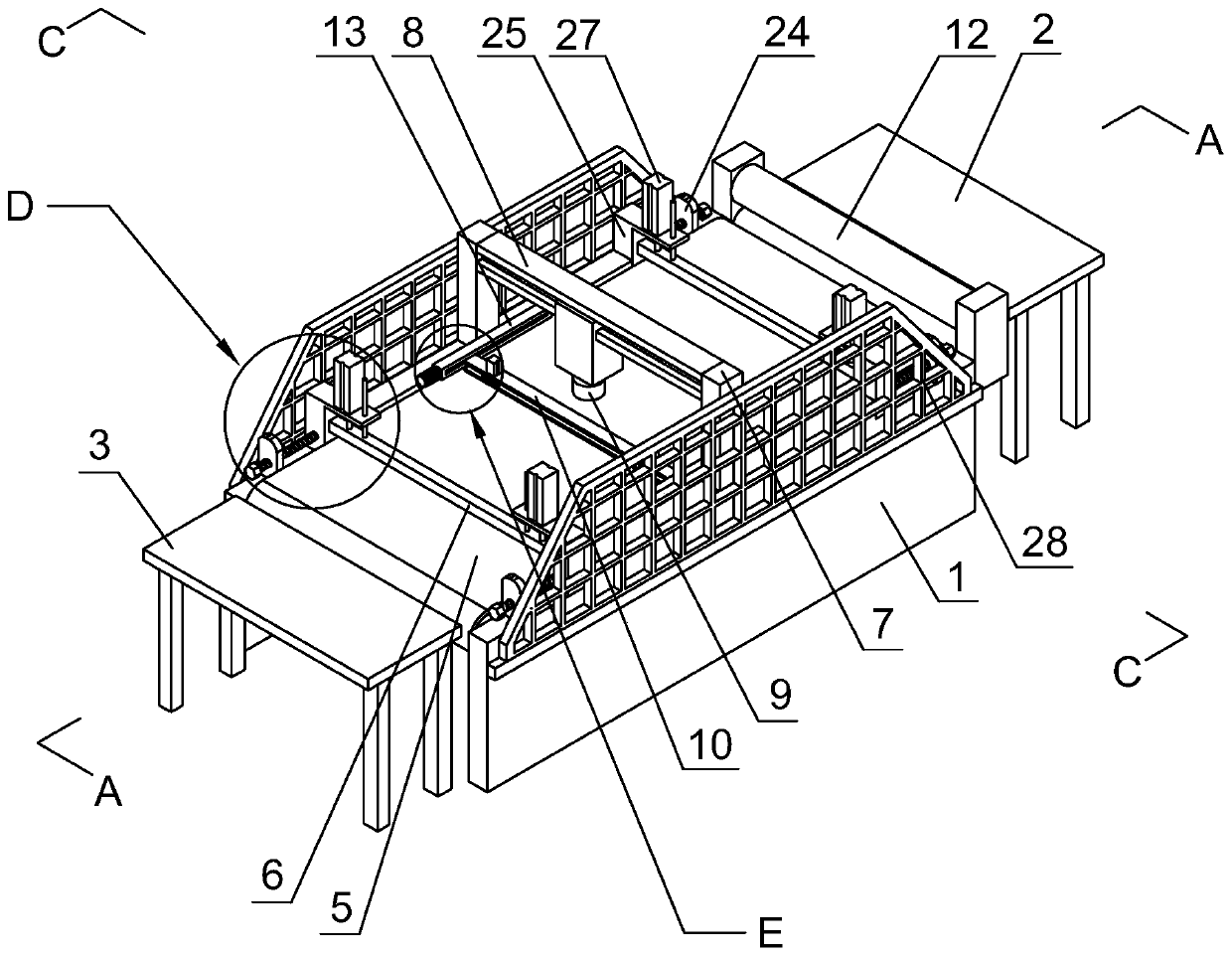

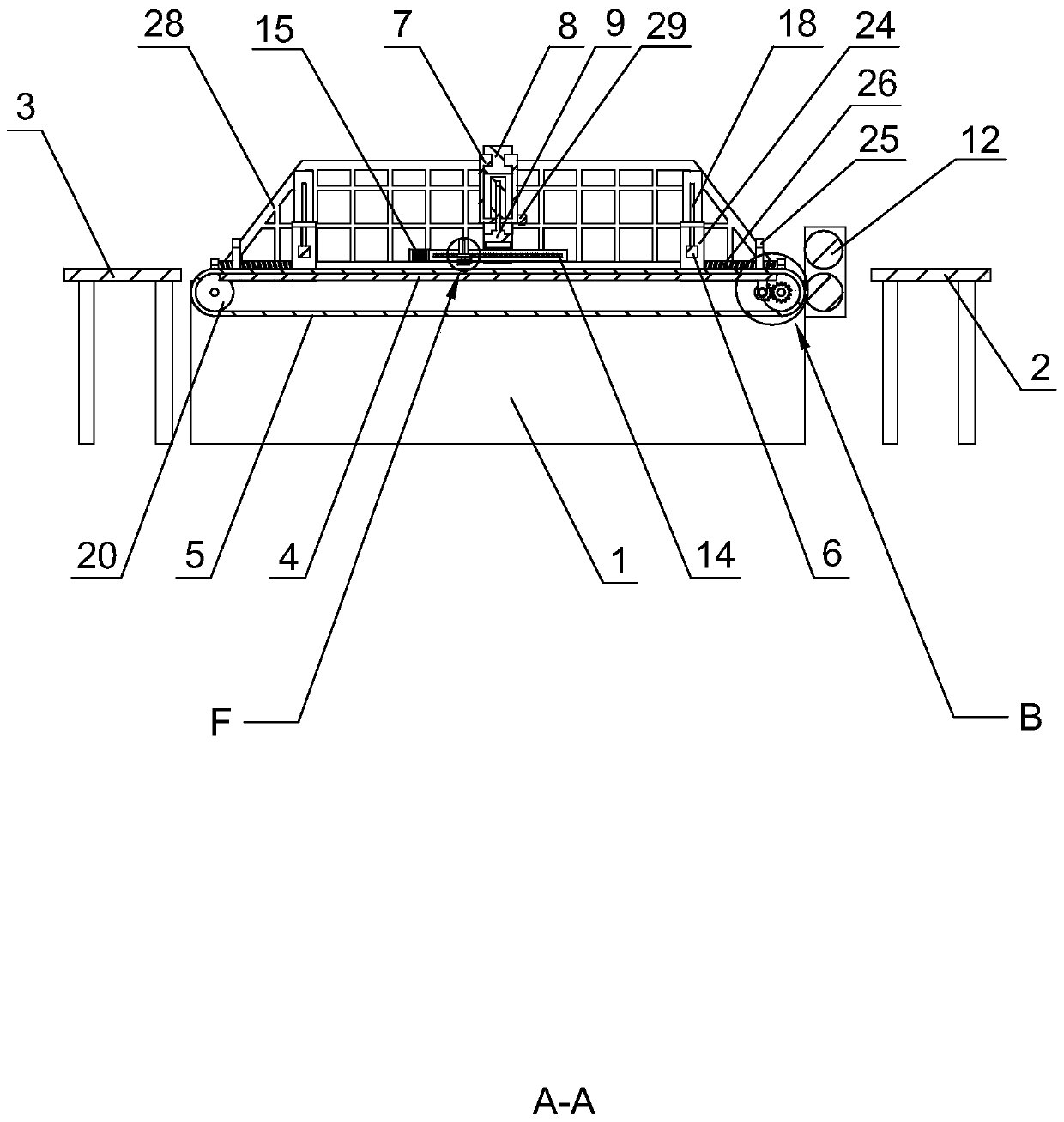

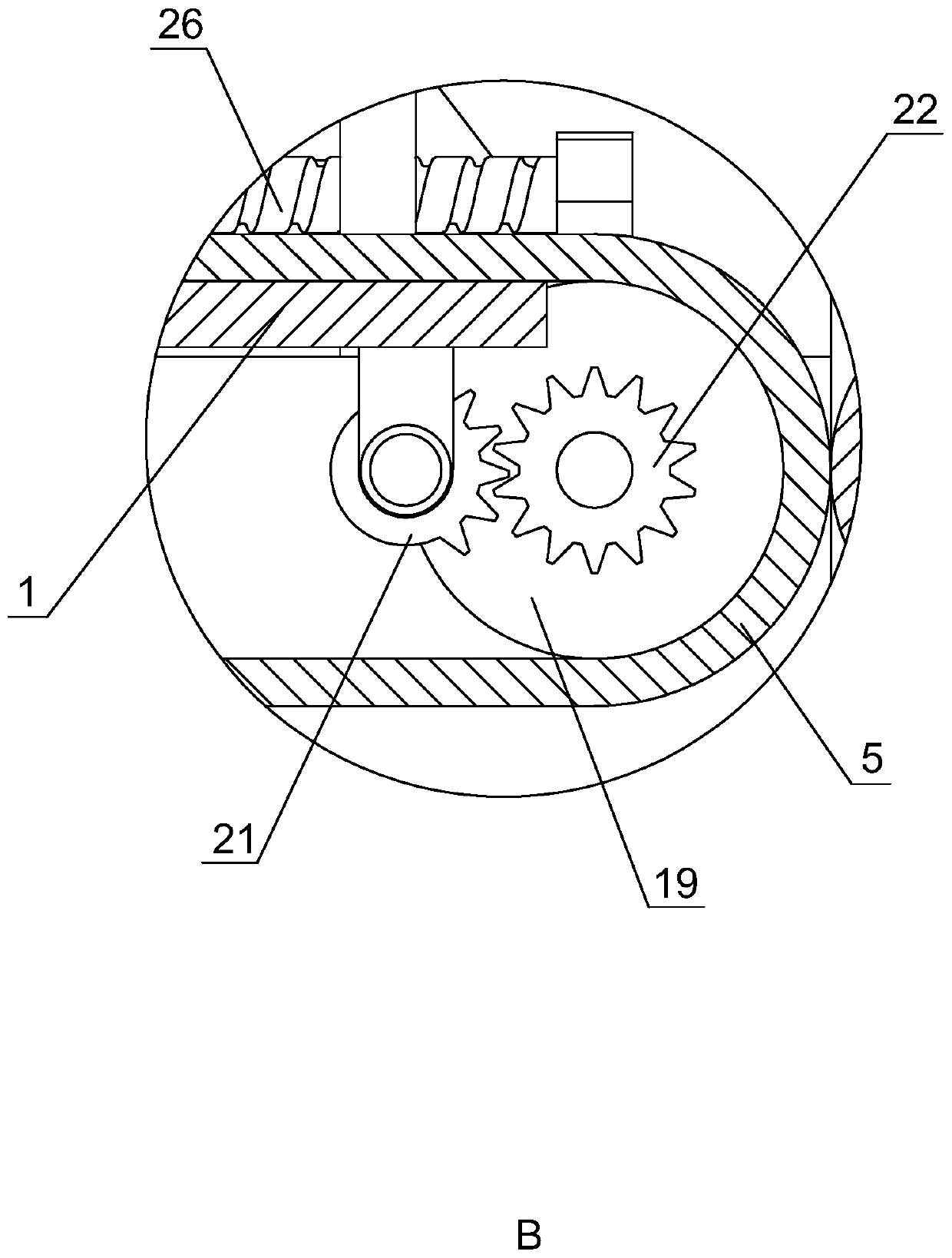

Rubber tapping machine and rubber tapping method

PendingCN107711410ARealize unmanned automatic tappingSolve labor intensityForestryEngineeringUltimate tensile strength

The invention discloses a rubber tapping machine and a rubber tapping method. The rubber tapping machine comprises support rods, a knife rest assembly and a rubber tapping knife assembly. A side of one of the support rods is connected with a side of the other support rod by flexible guide rails, the other side of each support rod is connected with the other side of the other support rod by tightening belts, and the flexible guide rails are opposite to the tightening belts on the sides opposite to the flexible guide rails; the knife rest assembly is provided with a motor, two track wheels capable of rolling along the outer sides of the flexible guide rails are mounted at the upper end and the lower end of the knife rest assembly, a lead screw and more than one fixing rod are further mountedin the knife rest assembly along the vertical directions, and the track wheels and the lead screw can be driven by the motor in the knife rest assembly to rotate. The rubber tapping machine and the rubber tapping method have the advantages that labor can be replaced by automatic machinery, accordingly, rubber can be automatically tapped from rubber trees in an unmanned manner, and the problems ofhigh labor intensity of manual rubber tapping and insufficient fineness of manual rubber tapping can be solved to the greatest extent.

Owner:NINGBO CIHEVEA TECH CO LTD

Monocrystalline silicon high-efficient composite cutting method and cutting system thereof

InactiveCN101138869AImprove cutting effectSave the texture processFine working devicesMetalElectric spark

An efficiently composite cutting method of monocrystalline silicon is characterized in that a monocrystalline silicon rod for cutting is installed and nipped at an electric spark linear cutting machine; metallic thread which is concreted with diamond grinding material is used as cutting wire to make the electric spark linear cutting; the advantages that the processing speed of the electric spark linear cutting is high and the cutting effect of the diamond grinding material at the metallic thread of the concreted grinding material is good are completely exerted; the purpose to realize the quickly and efficiently cutting towards the monocrystalline silicon rod is achieved; at the same time the surface of the cut monocrystalline silicon naturally forms a fleece-faced texture which has the effect of anti-reflection. The present invention has a series of advantages of simple method, high efficiency of processing, good quality etc.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Brazing-hot pressing diamond tool and manufacturing method thereof

The invention relates to a grinding tool, in particular to a brazing-hot pressing diamond tool. The diamond tool consists of a steel matrix and a diamond tool bit, wherein the diamond tool bit consists of a plurality of alloy layers which are vertical to a working surface of the tool bit; the alloy layers are prepared from two alloy matrixes with different formulas by a vacuum hot pressing method; a prearranged diamond abrasive particle layer is arranged inside each alloy matrix layer; outer layers on two sides of the tool bit are brazing alloy matrix layers (1); a single-layer prearranged diamond abrasive particle layer is arranged inside each brazing alloy matrix layer (1); an intermediate layer of the tool bit is a pre-alloying matrix layer (2); and a single-layer or multi-layer prearranged diamond abrasive particle layer is arranged inside the pre-alloying matrix layer (2). The brazing-hot pressing diamond tool solves the problem that a multi-layer brazing tool is covered by a thick solder layer so as to cause low exposure effect and also solves the problem that a sintered diamond tool is insufficient in diamond holding force so as to make the diamond fall off too early. Therefore, the service life of the diamond tool is greatly prolonged and the processing efficiency thereof is greatly improved.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

Silane cross-linked polyethylene insulating material and production method thereof

InactiveCN102532664AEvenly dispersedIncrease the degree of cross-linkingPlastic/resin/waxes insulatorsSilanesAntioxidant

The invention provides a silane cross-linked polyethylene insulating material composition, which comprises a material A and a material B, wherein the material A is composed of the following components in parts by weight: 100 parts of polyethylene, 0.01-1 parts of initiator, 0.2-5 parts of silane cross-linking agent, and 0.1-0.5 parts of antioxidant; the material B is composed of the following components in parts by weight: 100 parts of polyethylene, 0.5-5 parts of catalyst, 0.01-5 parts of processing aid, and 0.1-0.5 parts of antioxidant; and the material A is mixed and extruded by a reciprocating single-screw extruder.

Owner:ORIGIANL DOW ADVANCED COMPOUNDS SHANGHAI

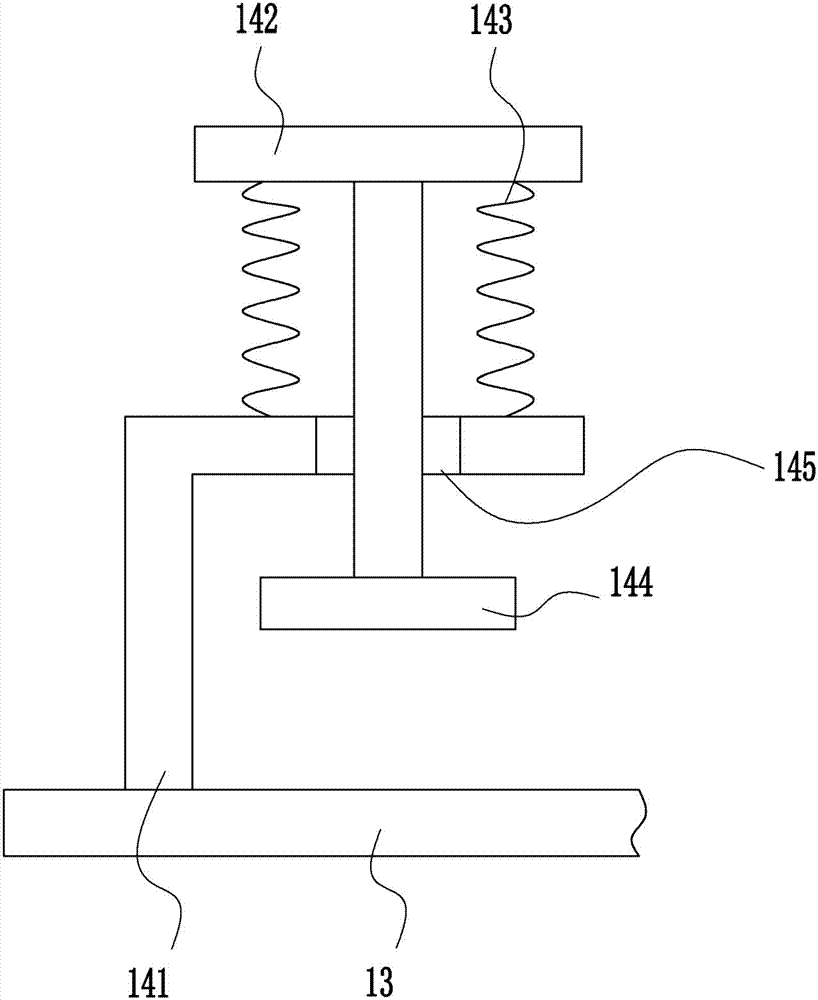

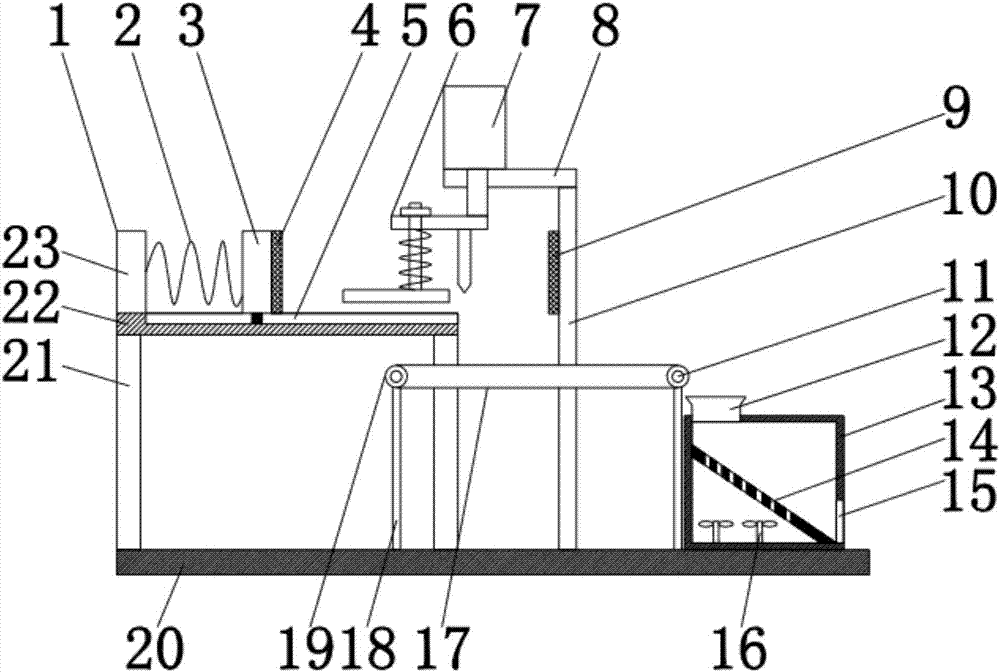

Steel plate clad cutting device for circuit board production

ActiveCN106985185AEasy accessImprove cutting effectMetal working apparatusCircuit precursor manufactureSheet steelEngineering

The invention relates to a steel plate clad cutting device, in particular to a steel plate clad cutting device for circuit board production. The steel plate clad cutting device for the circuit board production aims to achieve the technical effects of being light, handy, high in cutting precision and good in cutting effect. The steel plate clad cutting device for the circuit board production comprises a base plate, a left frame, a first sliding block, a first sliding rail, a lifting device, a top plate, a moving device, a lifting rod, an installation rod, a second motor, a blade, a first support and the like. The left frame is welded to the left side of the top of the base plate. A right frame is welded to the right side of the top of the base plate. The top plate is welded to the top ends of the left frame and the right frame. The lifting device is arranged in the middle of the bottom of the top plate. According to the steel plate clad cutting device for the circuit board production, a worker manually shakes a rocker bar, the lifting device is controlled to move up and down, the height of the blade is controlled to be more appropriate, the cutting effect is better, and the blade is driven to move leftwards and rightwards through the moving device.

Owner:秦皇岛市东旭达黏胶制品有限公司

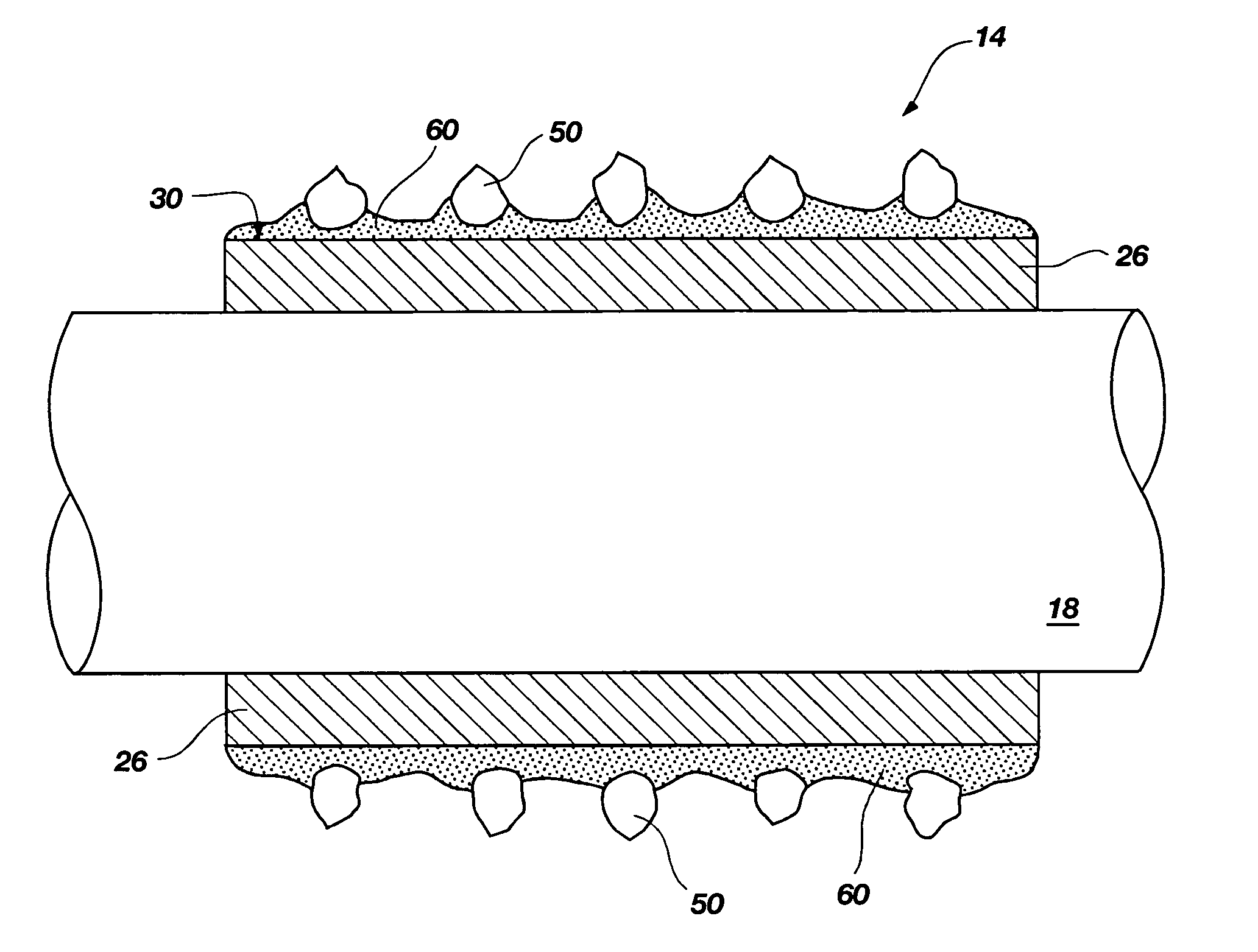

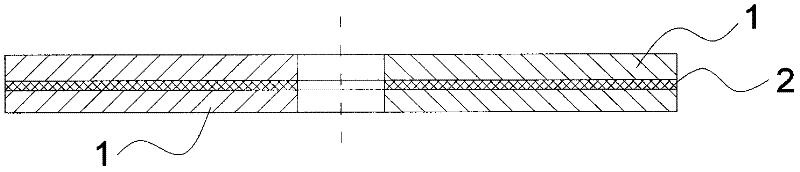

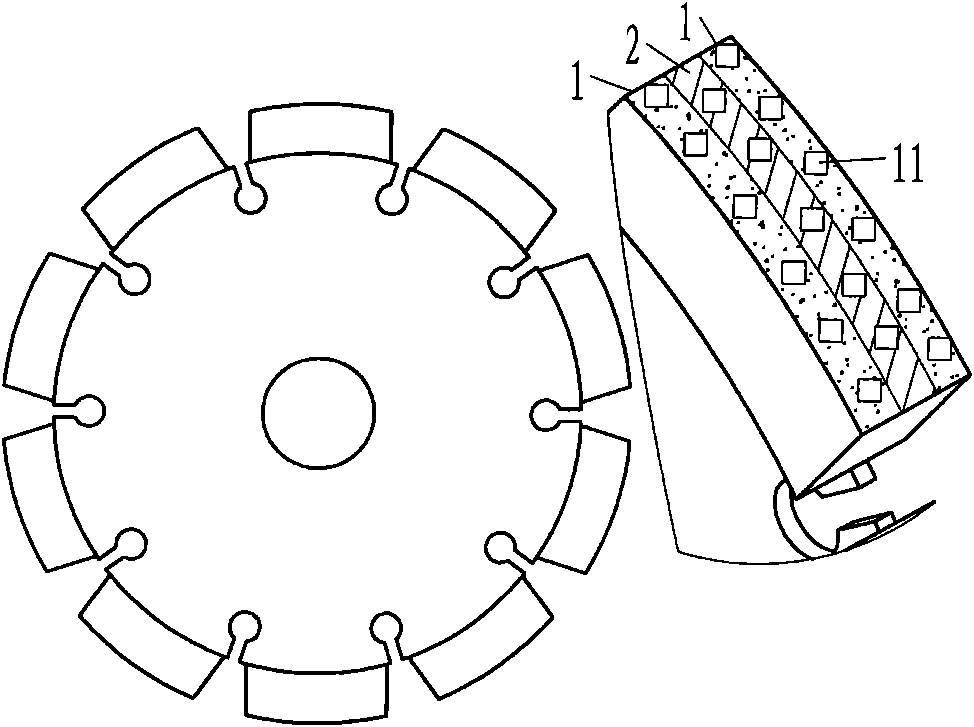

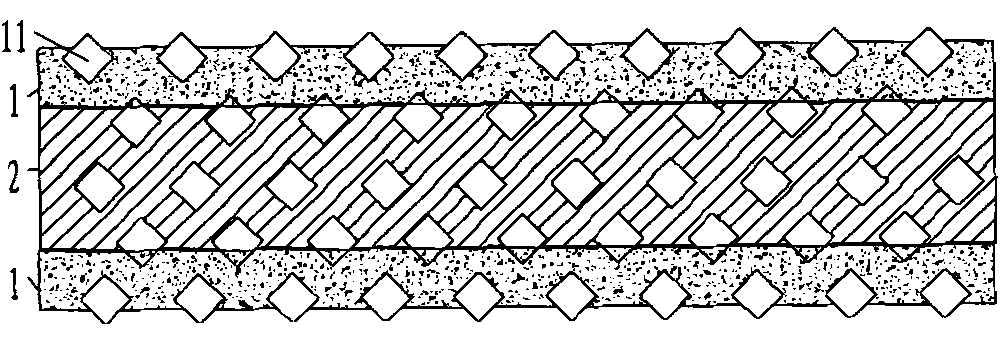

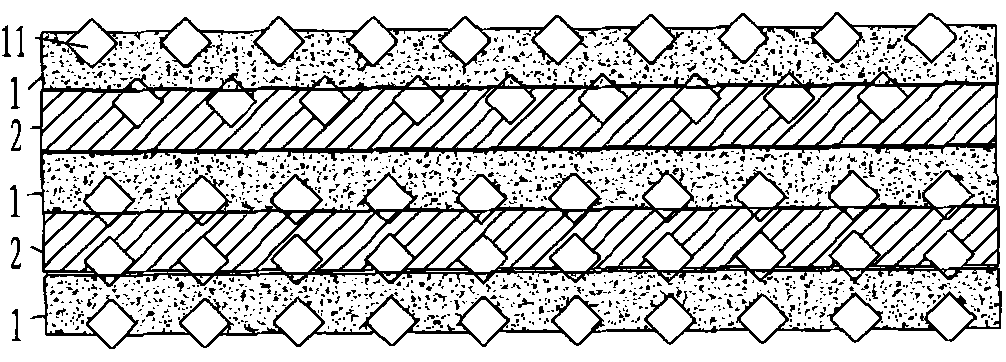

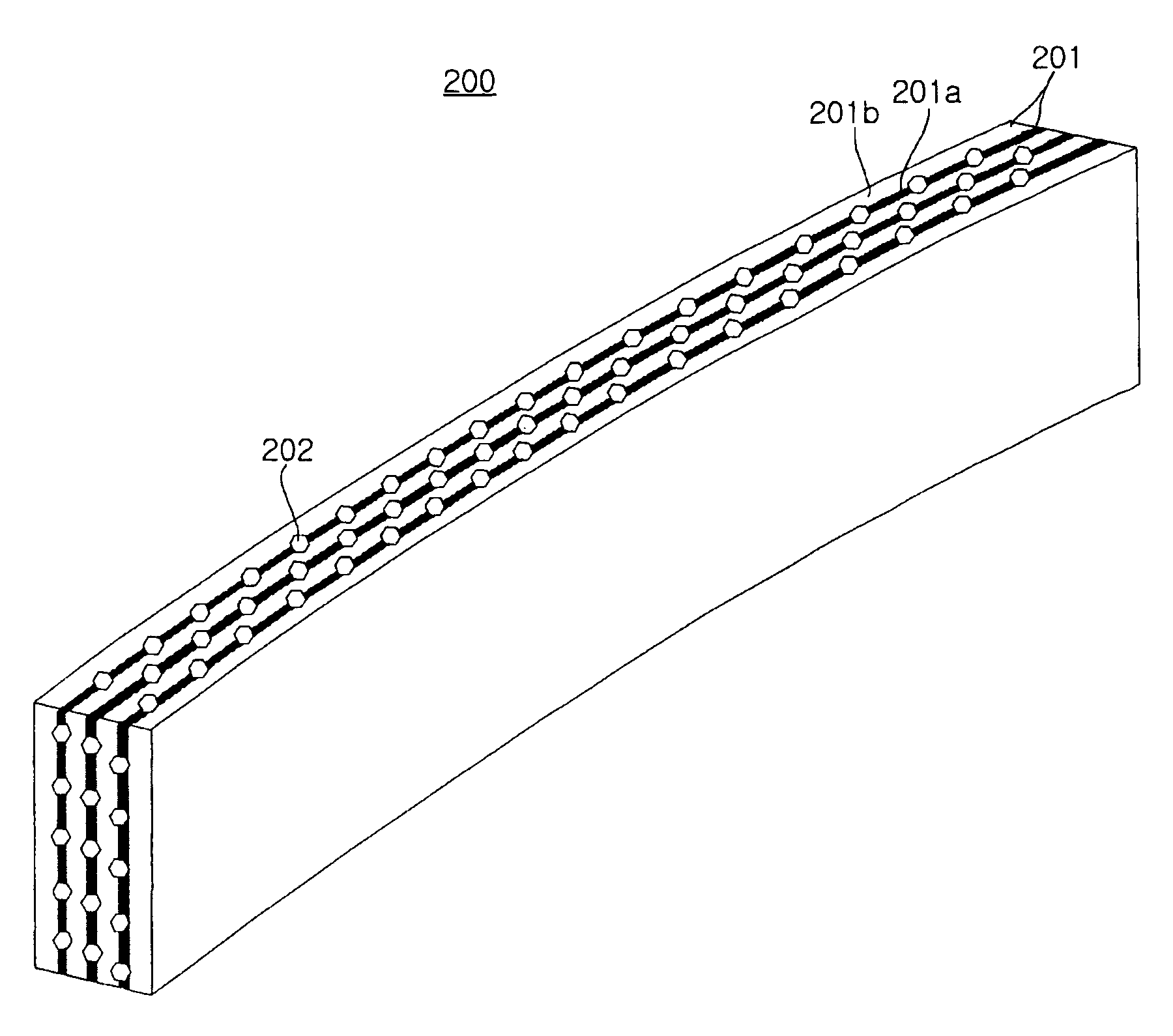

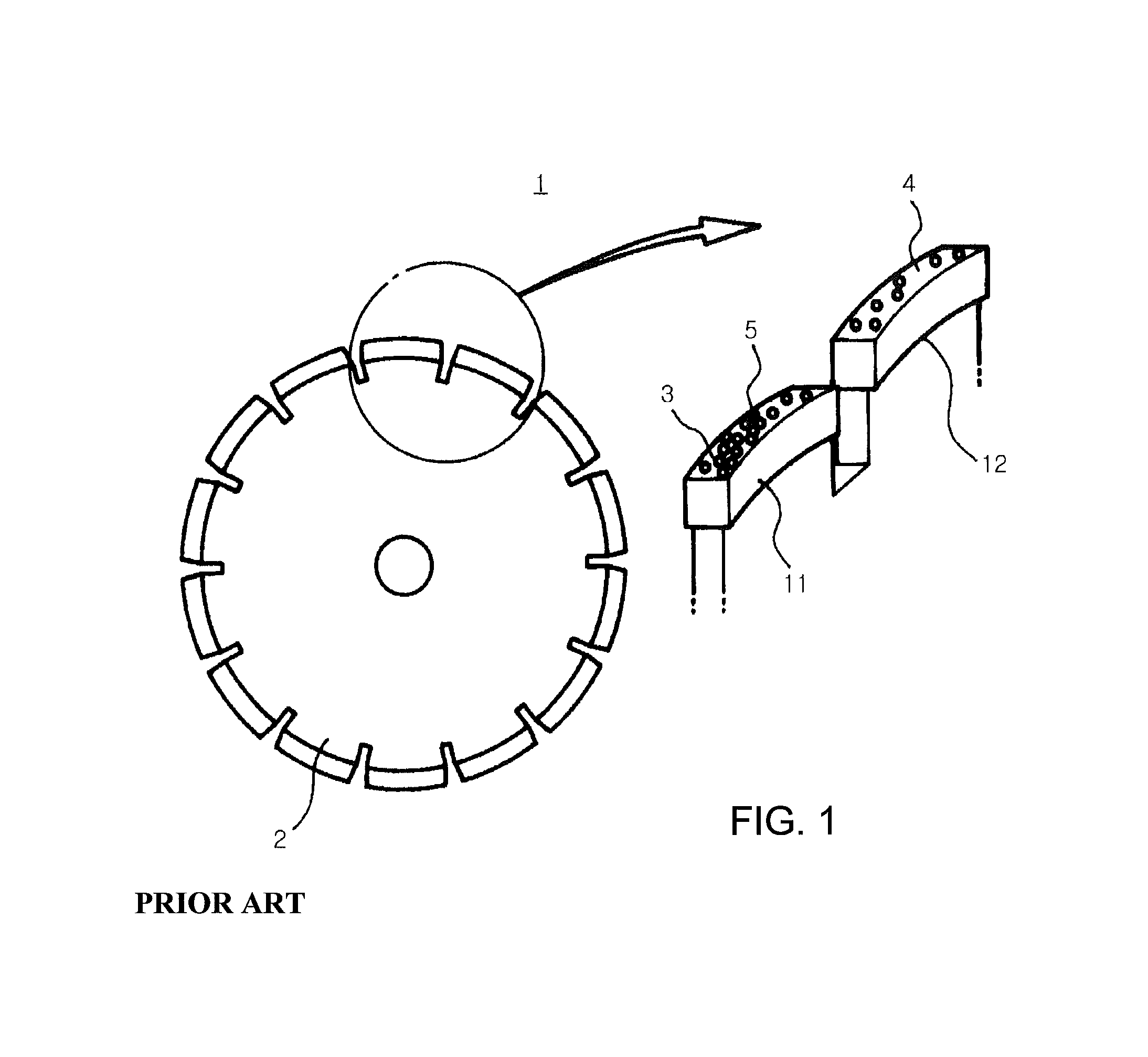

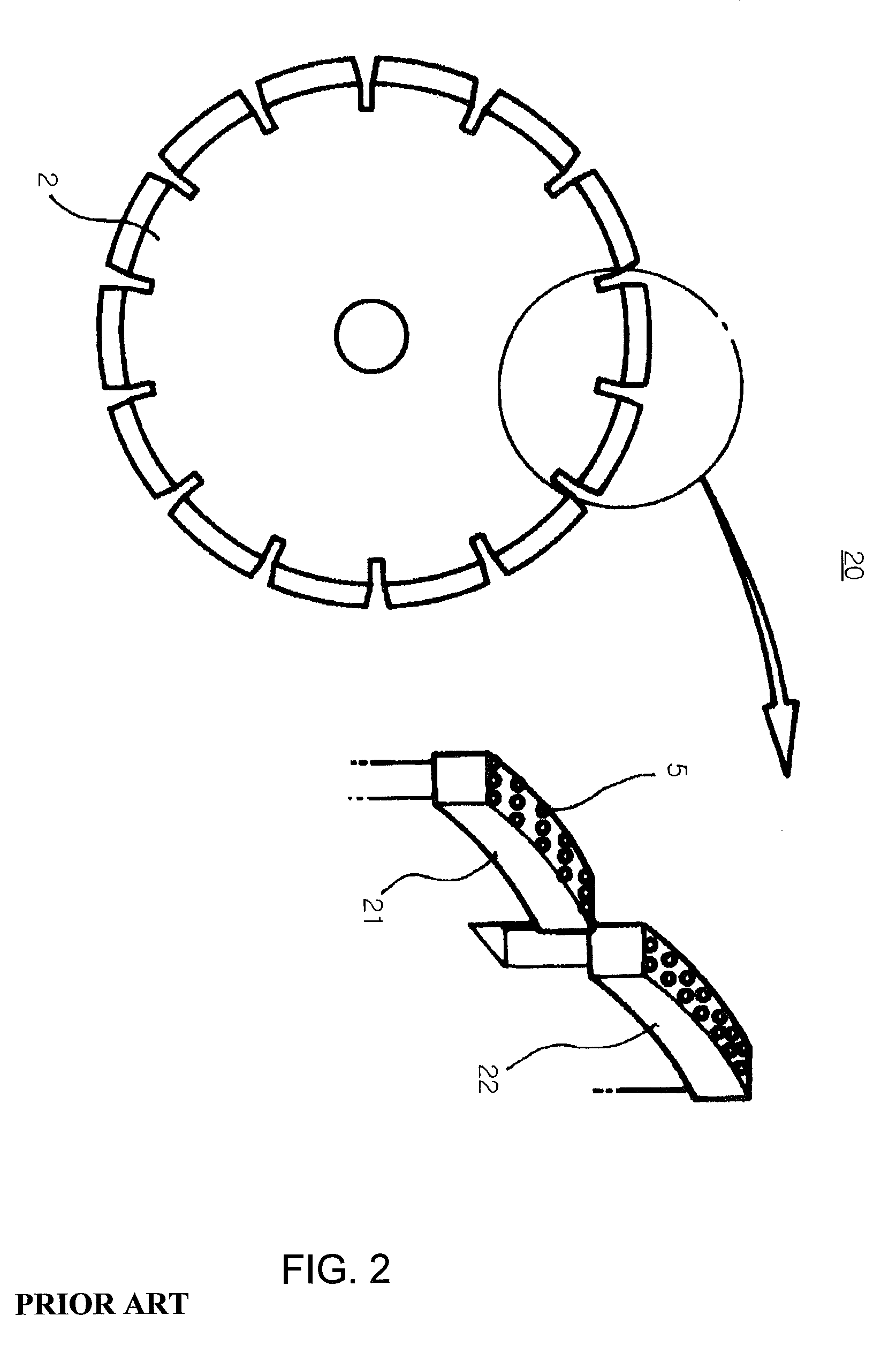

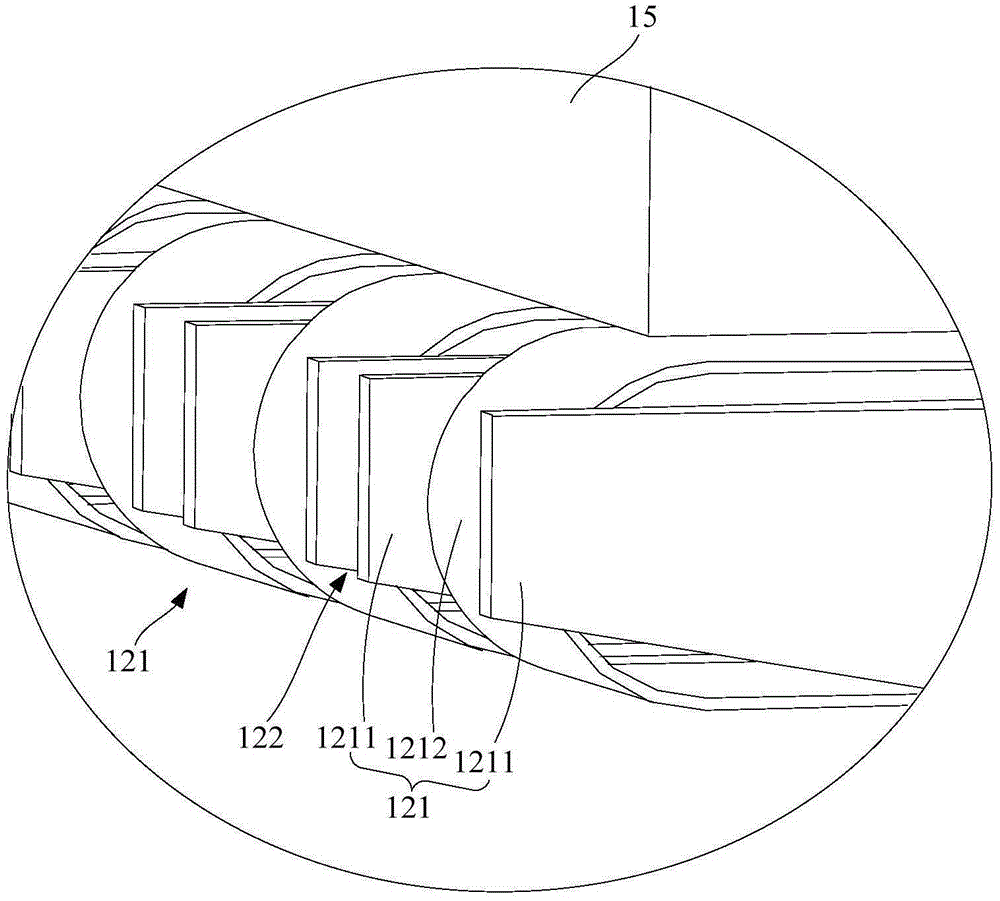

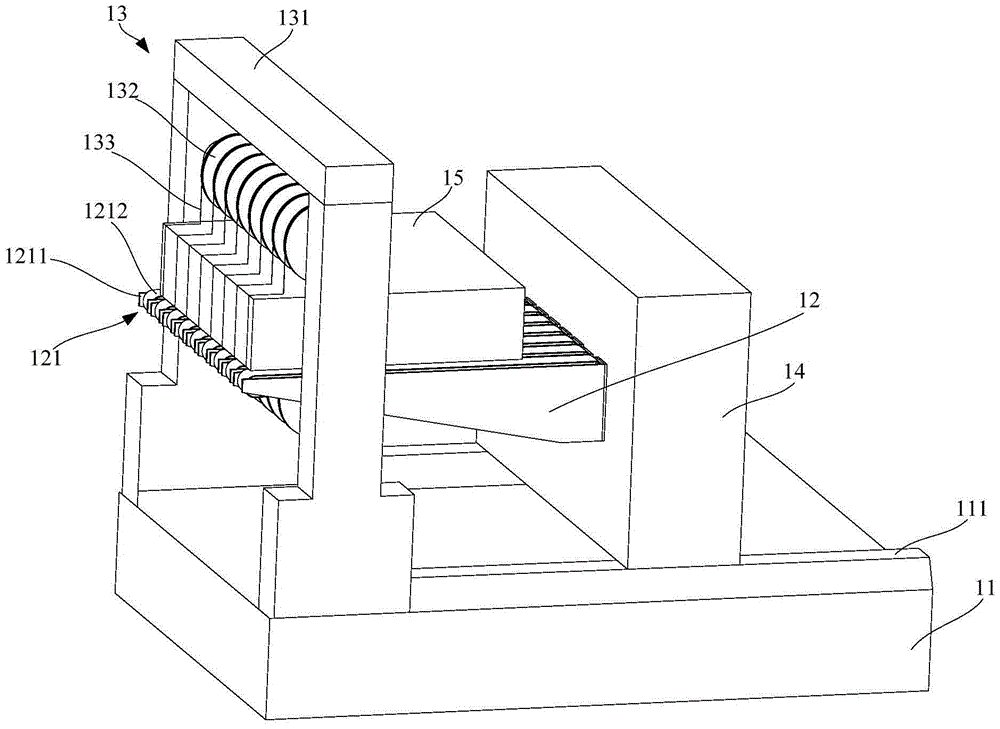

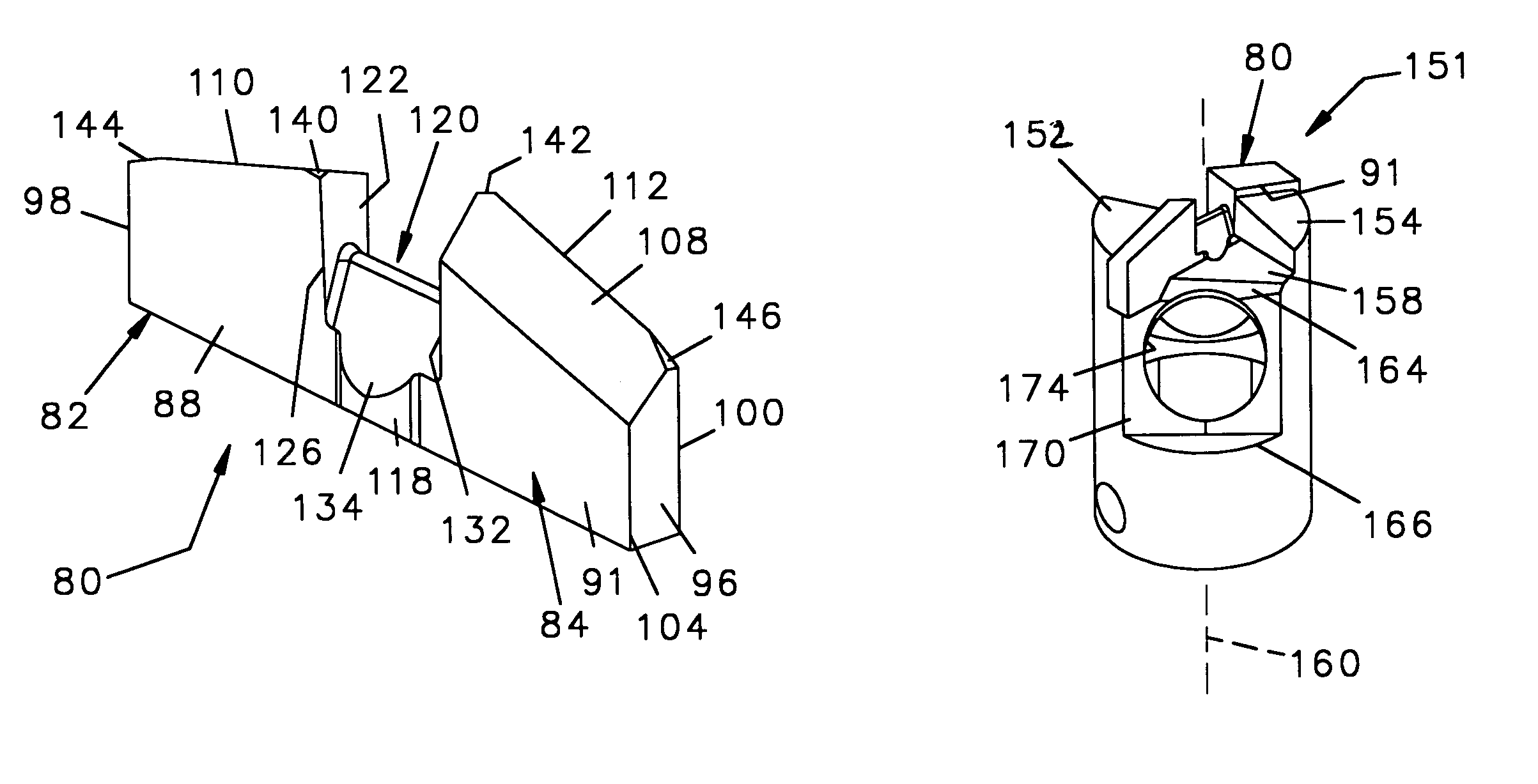

Cutting segment, method of manufacturing cutting segment, and cutting tool

InactiveUS7134430B2Improve cutting effectSimple manufacturing processRevolution surface grinding machinesMetal sawing toolsManufacturing cost reductionBrick

A cutting segment for a cutting tool used for cutting or drilling a brittle workpiece, such as stone, brick, concrete and asphalt, a method of manufacturing the segment and a cutting tool provided with the segment are disclosed. The segment comprises a plurality of plate-shaped metal matrix layers laminated perpendicular to a cutting surface of the segment while being parallel to a cutting direction of the segment, the plate-shaped metal matrix layers being integrally combined with each other and made of a ferrous or non-ferrous material; and diamond particle layers arranged between the plate-shaped metal matrix layers such that diamond particles can be provided in an array on the cutting surface. The segment has an excellent cutting capability, and can be made by a simplified manufacturing process, thereby remarkably reducing manufacturing costs.

Owner:NIWA DAIYAMONDO INDS

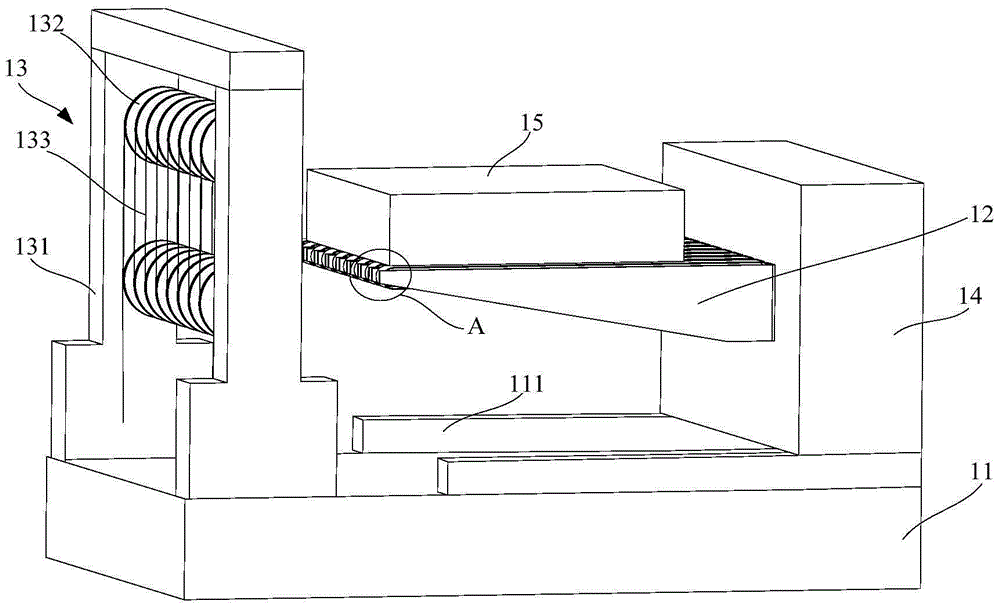

Multi-wire cutting device applied to block forming of silicon ingot

ActiveCN105216128AReduce labor costsIncrease productivityFine working devicesMicrocontrollerAutomatic control

The invention provides a multi-wire cutting device applied to block forming of a silicon ingot. The multi-wire cutting device comprises a base, a bearing table arranged on the base for bearing the silicon ingot to be cut and a cutting mechanism. The bearing table is provided with a plurality of bearing assemblies which are arranged in parallel, and a cutting clearance is reserved between every two adjacent bearing assemblies. Each bearing assembly comprises a pair of bearing supports, a traction roller, a traction belt arranged on the traction roller in a sleeving manner, and a first drive motor. The cutting mechanism comprises a cutting support arranged on the base, at least one pair of cutting rollers erected on the cutting support, cutting wires and a second drive motor. The cutting wires are correspondingly wound on at least one pair of cutting rollers to form a cutting net. The cutting wires on the cutting rollers are used for cutting the silicon ingot to be cut on the bearing table under the drive of the second drive motor, and the cutting wires are located in the cutting clearances when cutting the silicon ingot. According to the multi-wire cutting device, a workpiece can be cut into blocks, the workpiece to be cut is controlled by a microcontroller to rotate, automatic control is achieved in the whole process, and the cutting effect is good.

Owner:海宁市日进科技有限公司

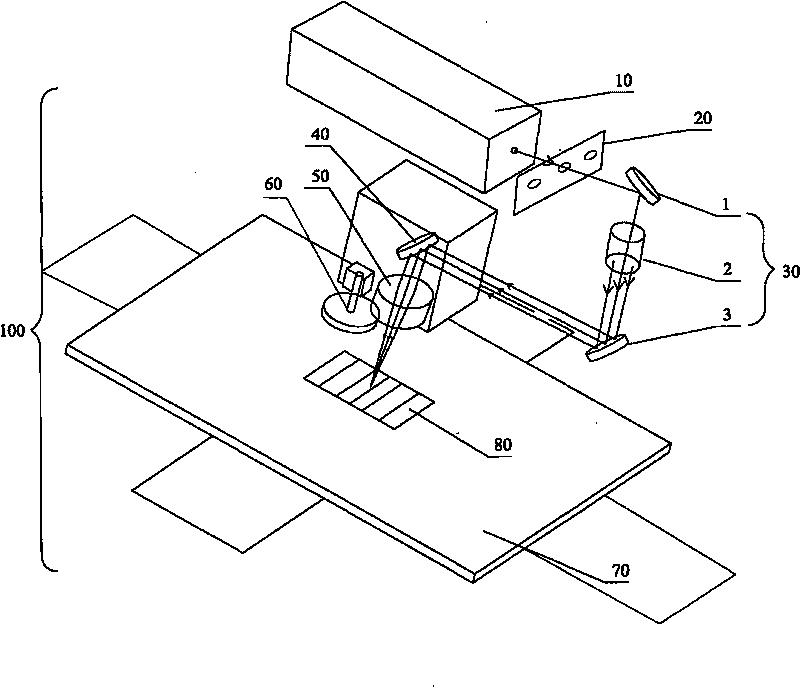

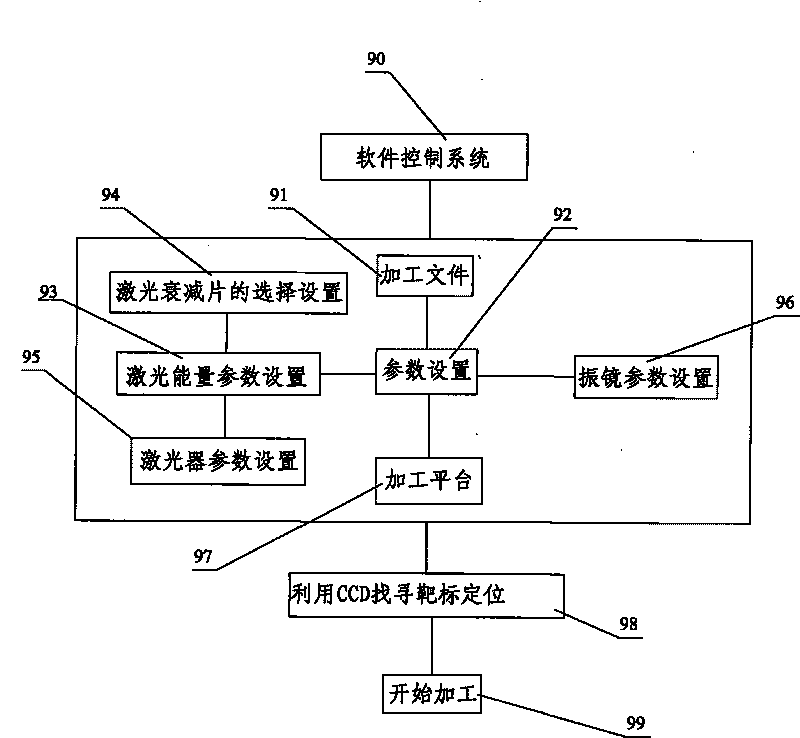

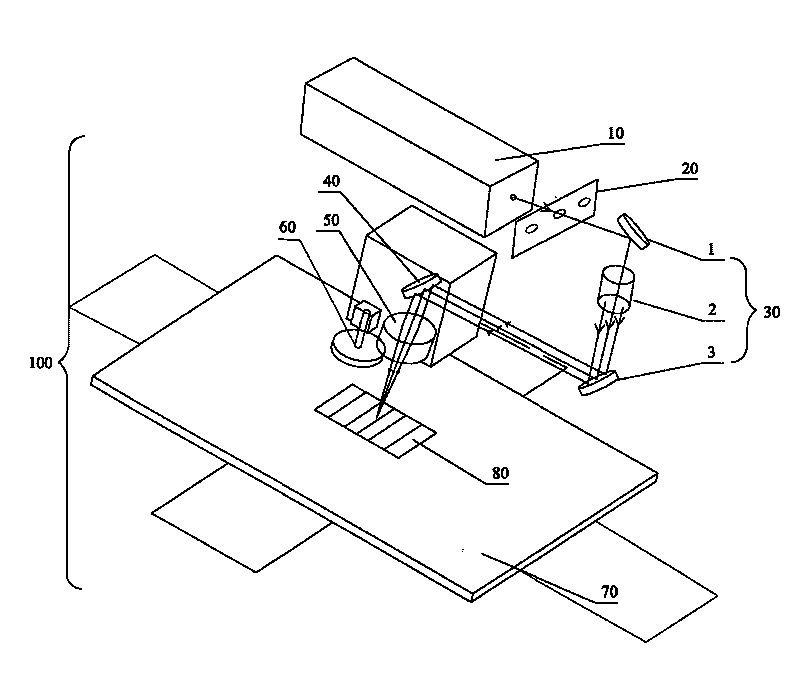

Laser cutting machine

The invention relates to a laser cutting machine. The laser cutting machine comprises a laser, a laser energy control system, an optical conduction system, a galvanometer scanning system and a laser focusing system, wherein the wavelength of laser emitted by the laser is between 490 and 580 nm; light beams emitted by the laser firstly pass through the energy control system, are reflected to the galvanometer scanning system through the optical conduction system and then are reflected to the laser focusing system to be focused into small light spots; and then the galvanometer scanning system utilizes the small light spots to cut a part to be cut. Compared with the prior art, the laser cutting machine utilizes the small light spots to cut the part to be cut, which can achieve the effects of high accuracy and high quality on the cutting of hard board materials.

Owner:HANS CNC SCI & TECH

Mine ceiling drill bit and blade

InactiveUS7100714B1Prevent deterioration of cutting surfaceMinimal resistanceDrill bitsWood turning toolsDrill bitDrill hole

A drill bit consists of a bit body having a forward end and a slot in the forward end to hold a hardened cutting blade. The bit body has a table near the center of the blade to reduce the speed at which the drill bores into hard material. The blade has a central slot extending into the forward end thereof such that the slot defines inner side walls and a bridge extending between the inner side walls. The bridge has sloping sides the define a central cutting edge so as to cut particles of hard material accumulating in the slot. The inner side walls intersect the leading faces of the blade and form cutting edges which further cut particles loosened at the center of the cut. Also, relief flats relieve the concentration of forces at the ends of the primary cutting edges of the blade.

Owner:THE SOLLAMI COMPANY

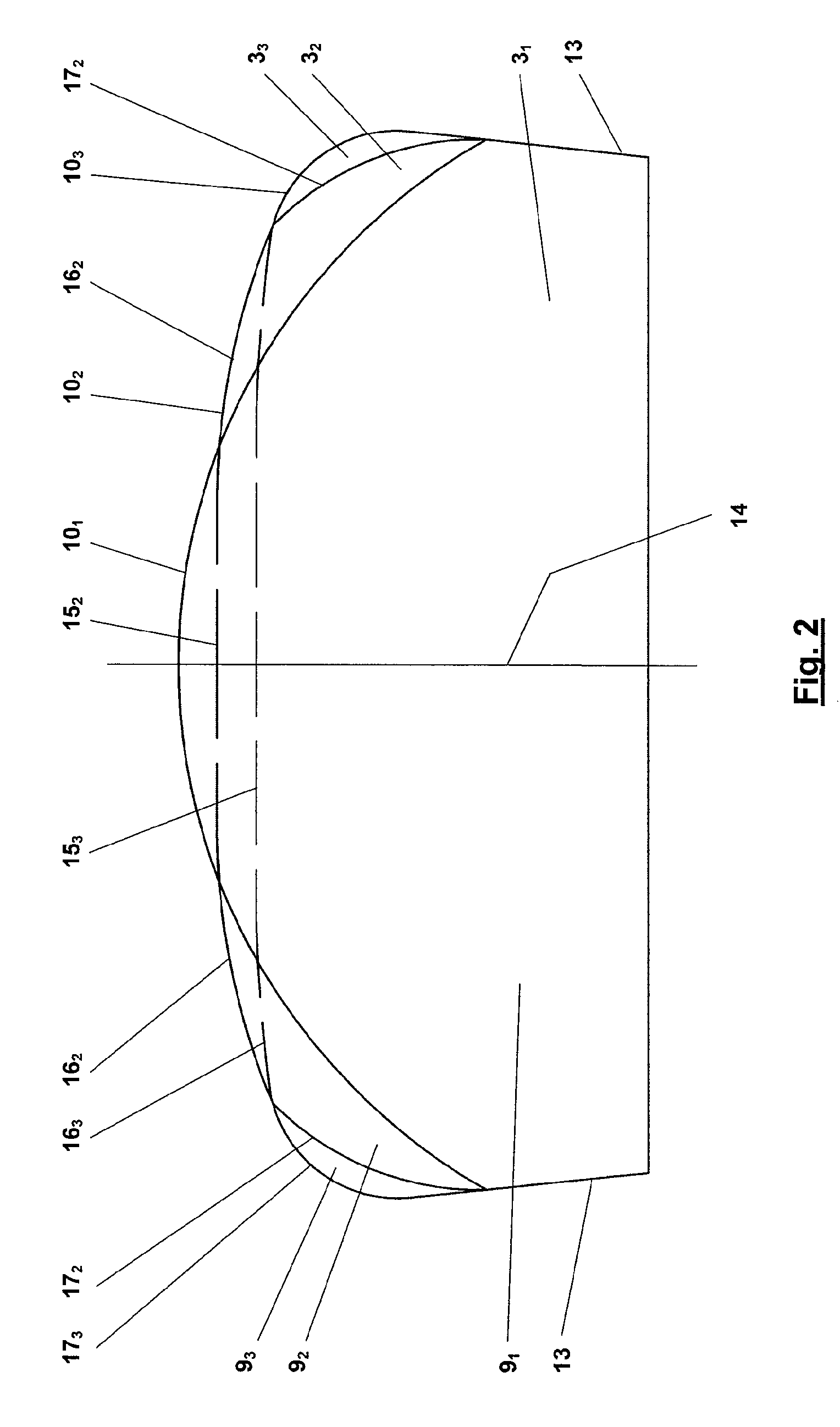

Stone Saw Blade

InactiveUS20090126712A1Avoid wear and tearHigh hardnessMetal sawing toolsStone-like material working toolsHard metalHardness

A stone saw blade (1) includes an elongated base body (2) and a plurality of teeth (3). The teeth (3) are designed and arranged to be unset and to include geometrically defined cutting portions (11). The teeth (3) include a form body (4) being connected to the base body (2). The form body (4) includes a carrier (21) being made of hard metal and a layer (5) forming the cutting portion (11). The layer (5) has a hardness of at least 5,000 HK.

Owner:WIKUS SAGENFAB WILHELM H KULLMANN

Laser-welding diamond disc and preparation method thereof

ActiveCN101456216AGood self-sharpeningGood edge cutting effectStone-like material working toolsLow speedCobalt

The invention relates to a laser welding diamond round saw blade and a preparation method thereof, which belong to the technical field of powder metallurgy material. The saw blade is used for solving the problem that the laser welding diamond round saw blade has lower speed and easy edge feed when used for cutting hard stones. The material of a cutting head is prepared from the following powder raw materials by weight percentage: 36 to 46 percent of copper, 28 to 38 percent of iron, 10 to 20 percent of cobalt, 3 to 10 percent of nickel, 3 to 9 percent of tin, 1 to 2.5 percent of silicon-chromium alloy, 1 to 1.6 percent of liquid paraffin wax and 1.0 to 2.2 percent of diamond, wherein the silicon-chromium alloy contains 40 percent of silicon, 30 percent of chromium and the balance being iron and small quantities of impurities according to mass proportion. The method adopts a mixed base material of the copper, the iron and the cobalt to improve the service life and the sintering performance of the saw blade and the added silicon-chromium alloy powder is dispersively distributed in a fetal body, thereby effectively improving the sintering performance of the fetal body so as to make the fetal body accelerate an alloying process. At the same time, the self-sharpening performance of the fetal body is improved, the holding force of the fetal body to the diamond is enhanced and the service life and the cutting performance of the saw blade are improved, thereby making the wear performance of the fetal body and the wear performance of the diamond be matched.

Owner:BOSUN TOOLS CO LTD

Cutting device for root-shaped Chinese herbal medicine

PendingCN107160449AImprove cutting effectAffect fixed effectsDrying gas arrangementsMetal working apparatusMedicinal herbsAdditive ingredient

The invention discloses a cutting device for root-shaped traditional Chinese medicine, which comprises a push plate, a second rubber pad, a first rubber pad, a conveying device and a fan. The friction force between one end prevents one end of the medicinal material from sliding on the push plate, which affects the fixing effect of the medicinal material. At the same time, it protects the medicinal material and improves the practicability of the equipment. The second rubber pad further improves the The effect of fixing the medicinal materials is to save manpower by setting the conveying device to transport the cut medicinal materials to the top of the receiving funnel. After the medicinal materials fall into the receiving funnel, they further enter the air-drying box, and the fan is used to fan the air and pass through the inclined plate A number of through holes opened on the slant plate are used to preliminarily air-dry the medicinal materials on the inclined plate, thereby facilitating the subsequent processing and preservation of the medicinal materials, and improving the practicability of the equipment.

Owner:湖南丹尼尔智能科技有限公司

Automatic cutting machine for non-woven fabric

InactiveCN109825998AImprove detection accuracyImprove cutting accuracySevering textilesMetal working apparatusWoven fabricEngineering

The invention discloses an automatic cutting machine for a non-woven fabric, and relates to the technical field of mask fabric cutting devices. The problems that non-woven fabrics are loose, and the cutting positions of the non-woven fabrics are likely to shift, so that non-woven fabrics are wasted are solved. The machine comprises a machine body, a feeding table and a discharging table; a workbench is fixedly arranged inside the machine body, and a conveyor belt is intermittently and rotationally arranged on the workbench; two pressing plates are arranged inside the machine body in a liftingmode; the two sides of the workbench are each fixedly provided with a supporting base, the two supporting bases are jointly fixedly connected with a tool rest, and a cutter is slidably arranged on thetool rest; a transverse beam is slidably arranged between the two supporting bases, a stroking plate is arranged at one side of the beam in a lifting mode; two flattening rollers are rotationally arranged at one side of the machine body. The loose non-woven fabrics are compressed through the flattening rollers, the non-woven fabrics are stroked and compressed by sliding the stroking plate, the non-woven fabric is more flat, the cutting effect of the non-woven fabric is better, the phenomenon that non-woven fabrics are not cut through is avoided, and the mask fabric yield is increased.

Owner:上海即索实业有限公司

Method of manufacturing A1-Mg-Si series alloy plate excellent in thermal conductivity and intensity

InactiveUS20020174923A1Improve thermal conductivityImprove cutting effectThermal conductivityAluminium

An Al-Mg-Si series alloy ingot consisting essentially of Si:0.2-0.8 wt %, Mg:0.3-0.9 wt %, Fe:0.35 wt % or less, Cu:0.20 wt % or less and the balance of aluminum and inevitable impurities is prepared. The alloy ingot is homogenized, then subjected to rough hot rolling and finish hot rolling, and finally to cold rolling. One of the rough hot rolling is controlled such that material temperature immediately before one of the rough hot rolling is from 350 to 440° C., cooling rate between one of the rough hot rolling and rough hot rolling subsequent thereto is 50° C. / min or more, material temperature immediately after one of the rough hot rolling is from 250 to 340° C. and plate thickness immediately after one of the rough hot rolling is 10 mm or less. The cold rolling is controlled such that rolling reduction is 30% or more.

Owner:SHOWA DENKO KK

Double helix thread cutting tap

ActiveUS20080075550A1Poor surface finishReduce cutting pressureThread cutting toolsWood turning toolsFluteLeft handed

Owner:LOCK N STITCH INC

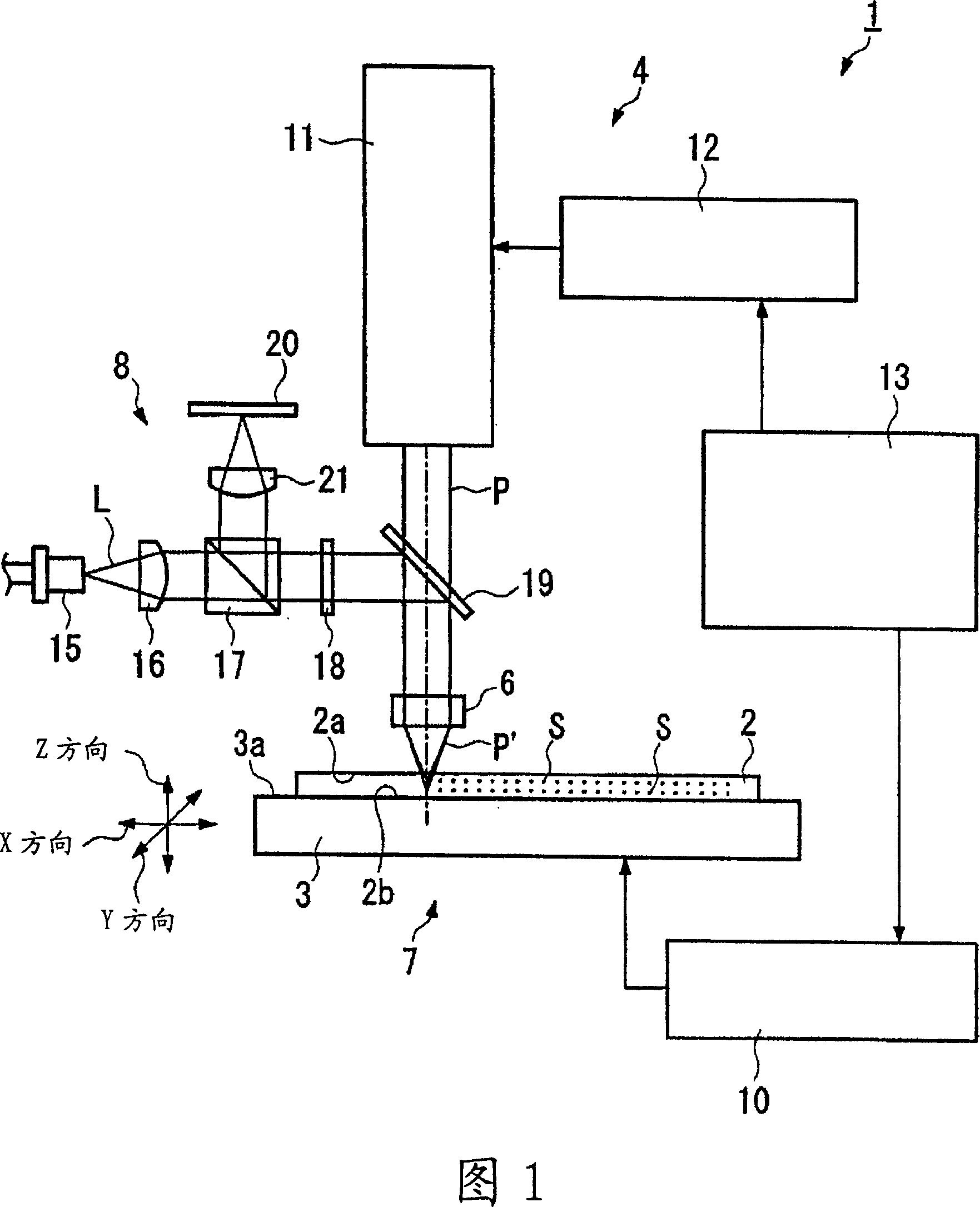

Laser processing apparatus

InactiveCN1925945ADoes not change repetition rateHigh speed machiningFine working devicesWelding/soldering/cutting articlesLaser processingLight beam

A laser machining apparatus, provided with a stage on which a workpiece is placed, an emission device for emitting laser light toward a surface of the workpiece, an optical system for splitting the laser light into a plurality of beams, and for focusing the beams as a plurality of spots on the surface of or within the workpiece, and a movement device for moving the plurality of spots in a horizontal direction relative to the workpiece.

Owner:OLYMPUS CORP

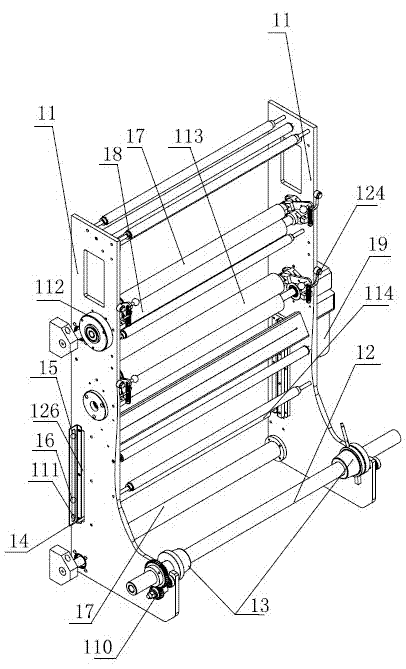

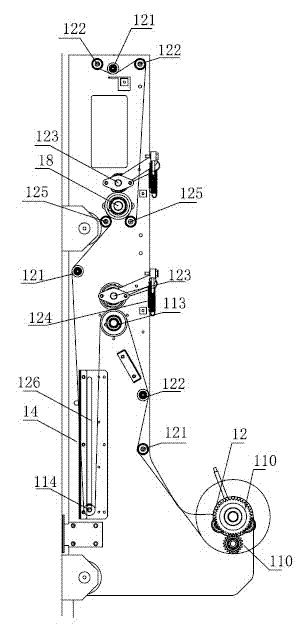

Machine for cutting parts of a window blind

InactiveUS20050150344A1Improve cutting effectEasy to cutDoor/window protective devicesStock shearing machinesLouverClutch

A machine for cutting parts of a window blind includes a machine base and two cutting units mounted respectively on the machine base. Each cutting unit includes two locating holes for insertion of the parts of the window blind, two cutters movable relative to the locating holes, a clutch for connecting and disconnecting the cutters, and a driving mechanism. The driving mechanism drives the cutters to move synchronously to cut off the parts of the window blind that extend out of the locating holes when the cutters are connected by the clutch. The driving mechanism drives only one of the cutters to move to cut off the parts of the window blind that extend out of one of the locating holes when the cutters are disconnected.

Owner:NIEN MADE ENTERPRISE CO LTD

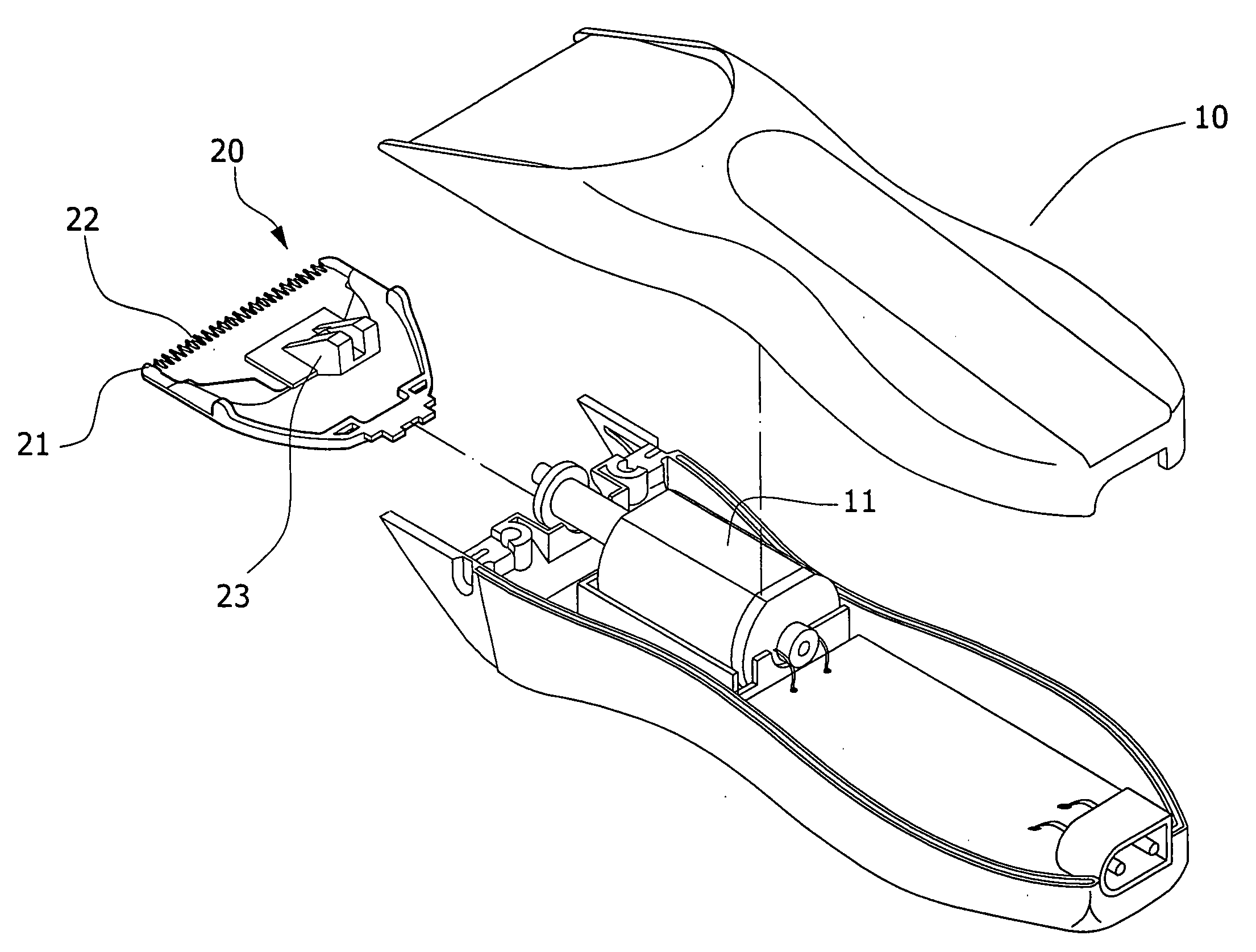

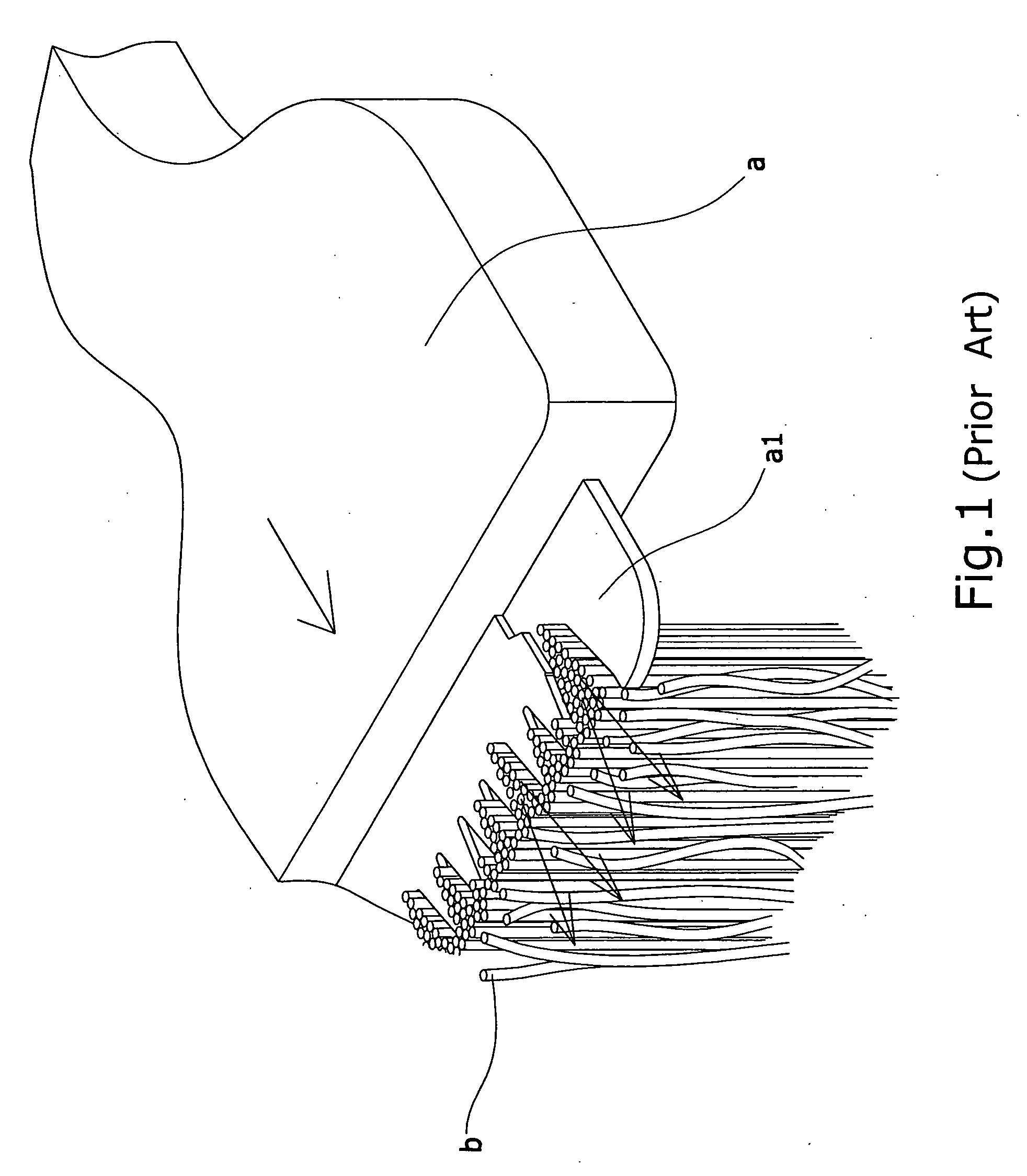

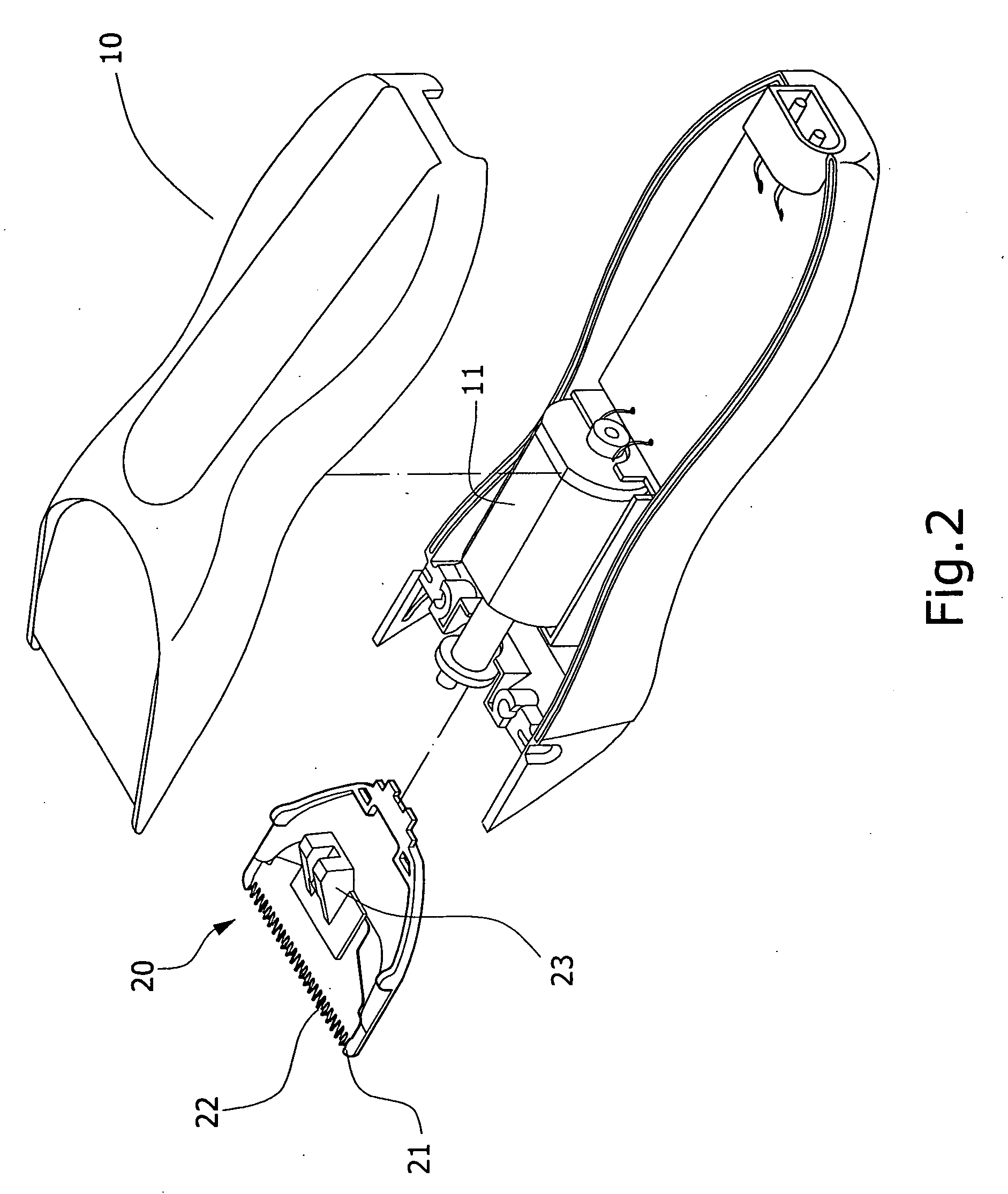

Electric hair clipper structure

InactiveUS20070214654A1Good shearing effectImprove blade structureMetal working apparatusElectric machineryEngineering

The present invention provides a shearing tool set formed on a front end of a housing. The shearing tool set comprises a stationary blade and a vibratory base having a moving blade, wherein the stationary blade is positioned at a suitable location on an exterior of the vibratory base such that the moving blade forms a superimposed structure on the stationary blade. The vibratory base is driven by motor inside the housing such that the moving blade and the stationary blade form cross-over displacements, and continuous gaps are provided on a suitable location on an internal surface of each saw-tooth on the respective cutting edges of the stationary blade and the moving blade. When the gaps on the stationary blade converge relative to the gaps on the moving blade, a temporary space is formed for holding hair, thereby preventing the hair from sliding during shearing and affecting the shearing effects.

Owner:CHEN CHENG HSIANG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com