Brazing-hot pressing diamond tool and manufacturing method thereof

A diamond tool, hot-pressing sintering technology, applied in the direction of manufacturing tools, metal processing equipment, wheels with flexible working parts, etc., can solve the problems of affecting cutting efficiency, insufficient holding force of diamond abrasive grains, and low service life. , to achieve the effect of improving cutting life and cutting speed, excellent cutting effect, and strong chemical metallurgical combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

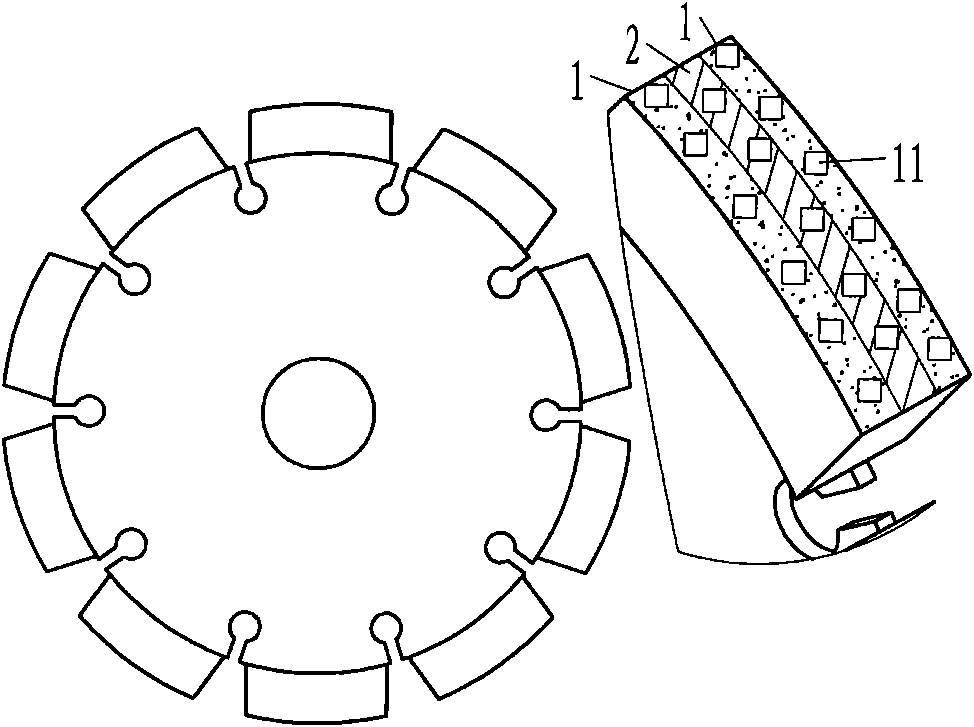

[0028] Such as figure 1 As shown, there are three layers of diamond in the cutter head structure, which are composed of two different alloy powders. The diamond abrasive grains 11 can be distributed in the brazing alloy layer 1 and the pre-alloyed carcass powder 2 in an orderly manner according to the designer's requirements. Brazing The alloy layer is on the outside of the cutter head. The cutter head structure of this embodiment is put into a vacuum furnace after pre-pressing for hot-pressing sintering. Interactions such as dissolution, diffusion, and compounding occur on the metal matrix interface, thereby forming a strong chemical metallurgical bond between the matrix material on the outer layer of the cutter head and the diamond, while the pre-alloyed matrix layer inside the cutter head firmly wraps the diamond. Inlaid in the metal matrix, the diamond tool of this structure forms a sandwich structure during the cutting process, maintaining an excellent edge-out effect. T...

Embodiment 2

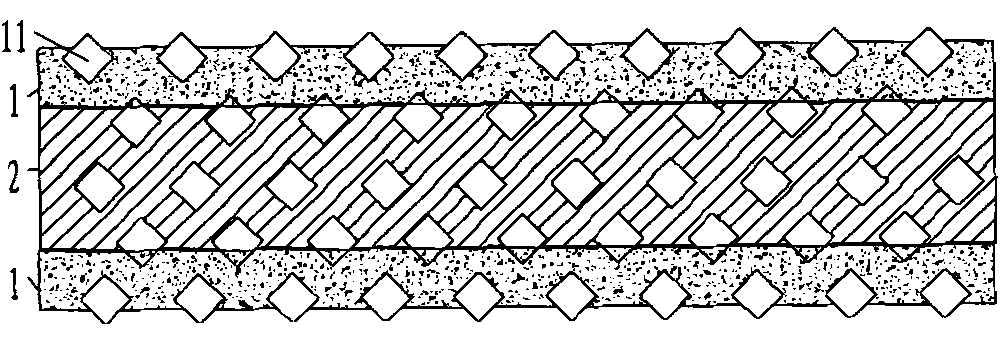

[0030] Such as figure 2 As shown, the present embodiment is a five-layer diamond, a cutter head structure composed of two alloy powders, diamond abrasive grains 11 are evenly and orderly distributed in the brazing alloy powder and pre-alloyed matrix powder according to the designer's requirements, namely Single-layer diamond brazing alloy layers and multi-layer diamond pre-alloyed carcass layers are arranged alternately. Brazing alloy 1 is on both sides of the cutter head, and pre-alloyed carcass 2 is inside the cutter head. The pre-alloyed carcass layer consists of three layers Small flakes are superimposed, and the resulting cutter head is cold-pressed and then put into a vacuum furnace for hot-press sintering.

Embodiment 3

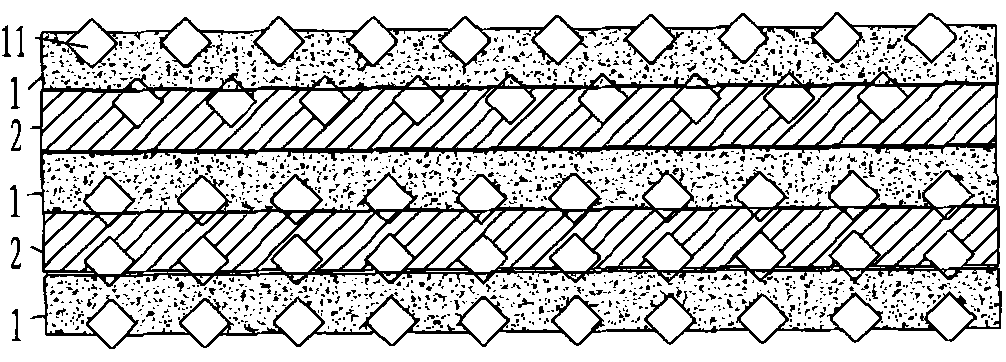

[0032] Such as image 3 As shown, the invention consists of five layers of diamond and a cutter head structure composed of two alloy powders. In this structure, the single-layer diamond brazing alloy layer and the single-layer diamond pre-alloyed carcass layer are alternately arranged, and the outer layer is brazed The alloy layer 1, the second layer is a pre-alloyed carcass alloy layer 2, and the third layer is a brazing alloy layer 1, and the resulting cutter head is cold-pressed and put into a vacuum furnace for hot-press sintering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com