Patents

Literature

4787 results about "Brazing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Brazing is a metal-joining process in which two or more metal items are joined together by melting and flowing a filler metal into the joint, the filler metal having a lower melting point than the adjoining metal.

Chamber material made of Al alloy and heater block

InactiveUS20010019777A1Not be restrictElectric discharge tubesSemiconductor/solid-state device manufacturingHigh-temperature corrosionContamination

A chamber material made of Al alloy excellent in thermal cracking resistance and chemical and / or physical corrosion resistance and capable of reducing contamination excellently and further having excellent and wide applicable brazing property in a high temperature corrosive circumstance, in which the substrate aluminum material for the chamber material made of Al alloy having an anodized film comprises 0.1 to 2.0% Si, 0.1 to 3.5% Mg, 0.02 to 4.0% Cu on the mass % basis and the balance of Al and impurity element with Cr in the impurity elements being less than 0.04%. Preferably, Fe is 0.1% or less and Mn is 0.04% or less in the impurity element and, further, the total sum of impurity elements other than Cr and Mn being restricted to 0.1$ or less. This invention can be utilized suitably to various materials used in high temperature corrosive circumstance, particularly, in high temperature corrosive gas or plasma atmosphere.

Owner:KOBE STEEL LTD

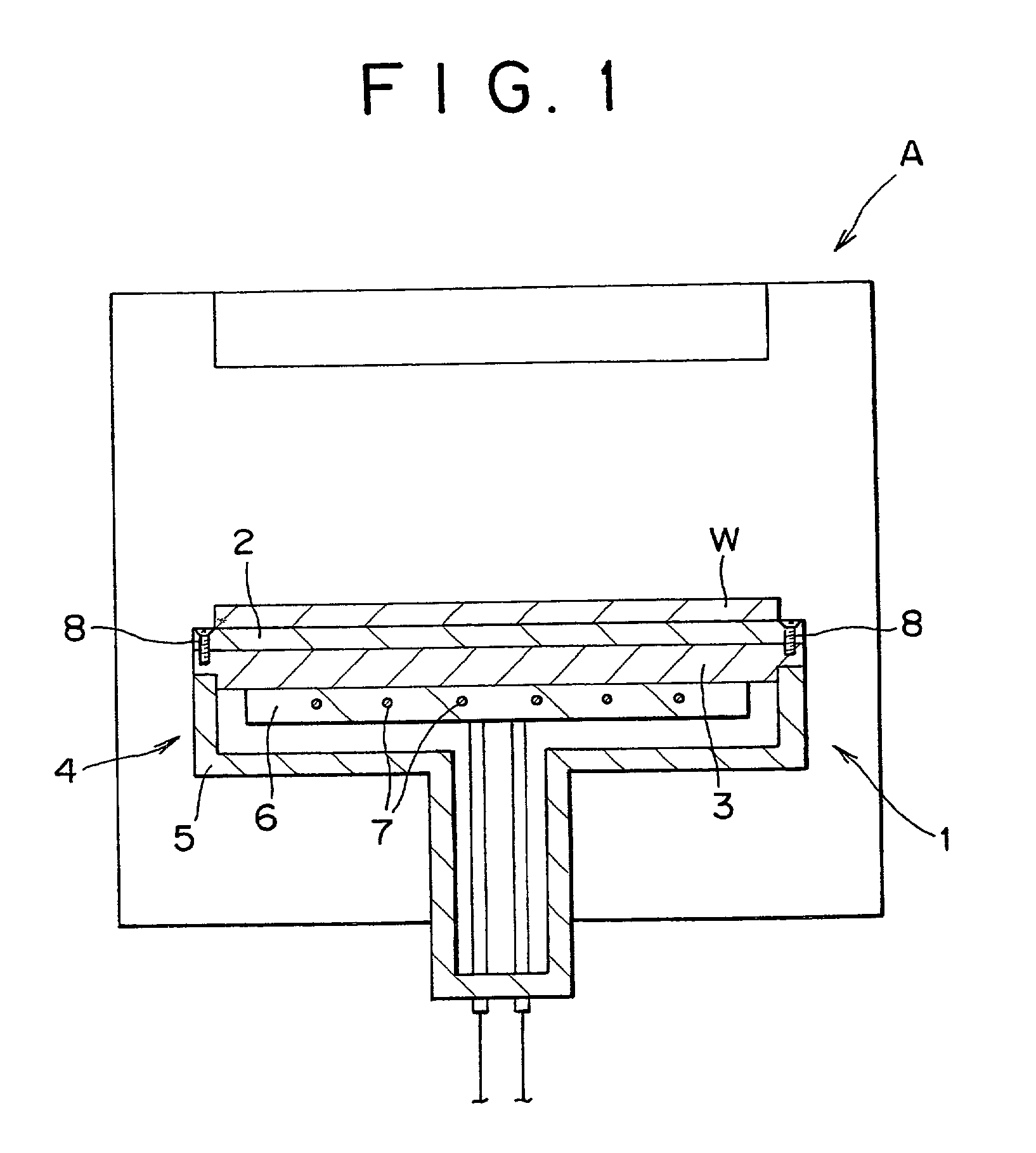

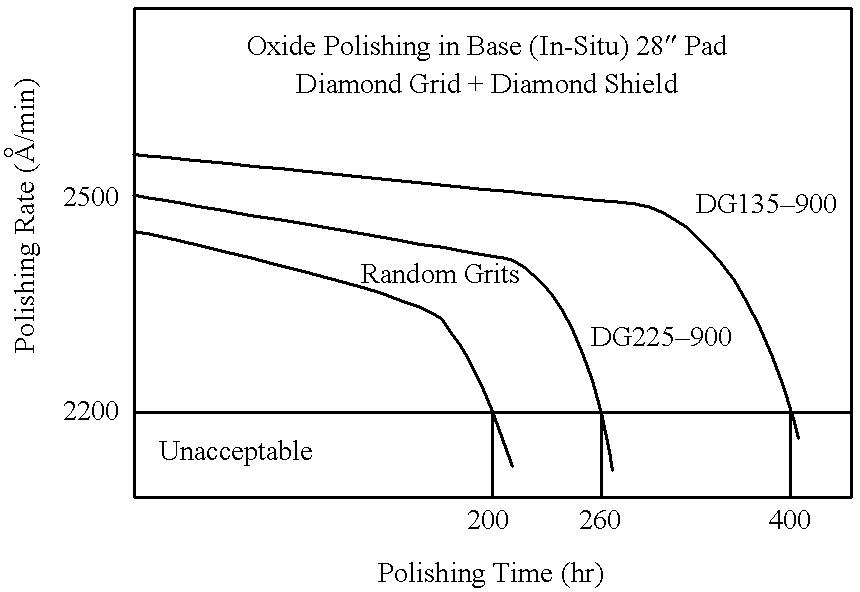

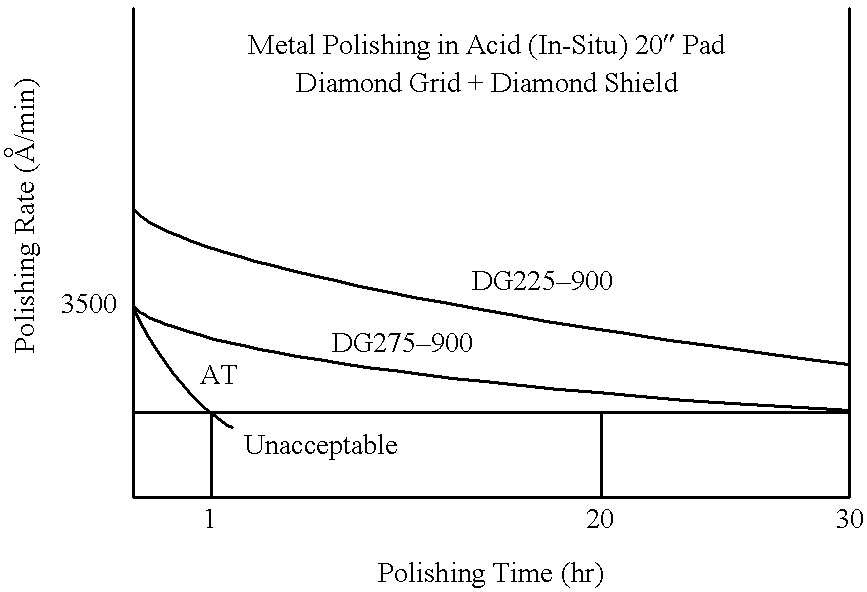

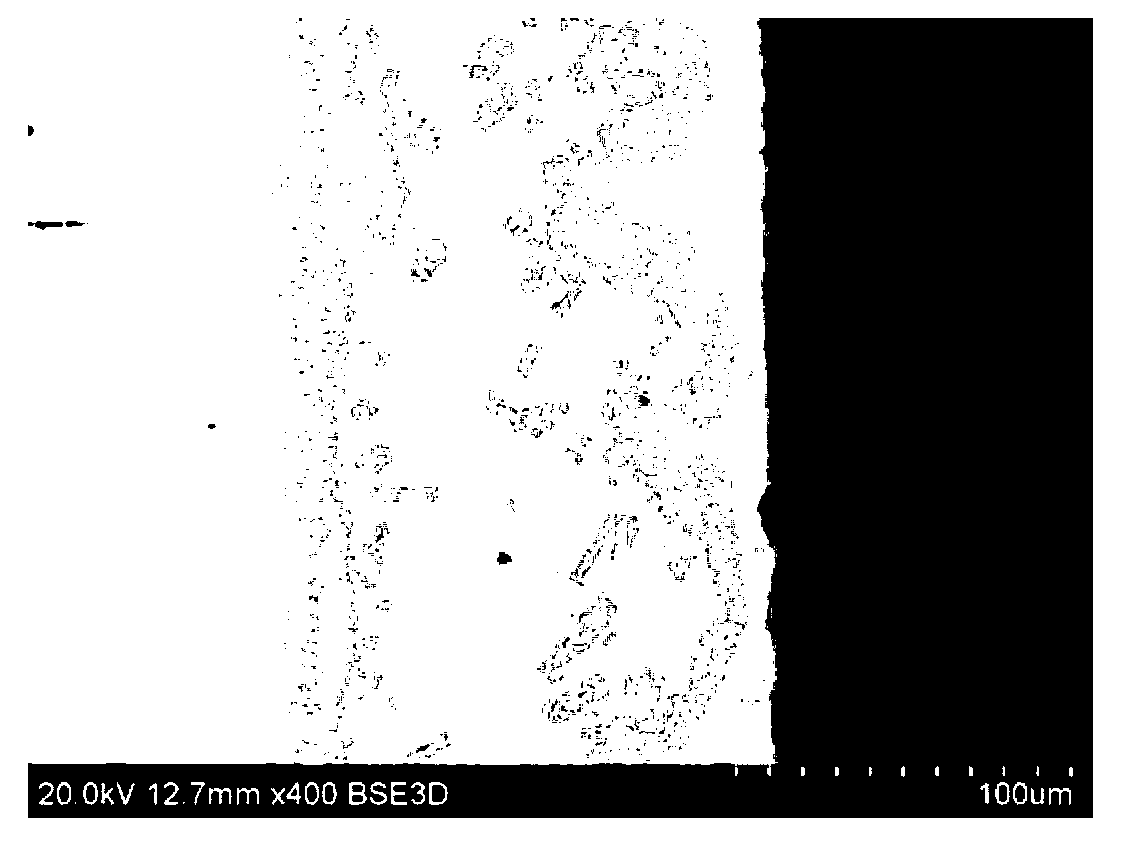

Diamond grid CMP pad dresser

InactiveUS6368198B1Improve polishing efficiencyExtended service lifePolishing machinesRevolution surface grinding machinesSuperhard materialDiamond-like carbon

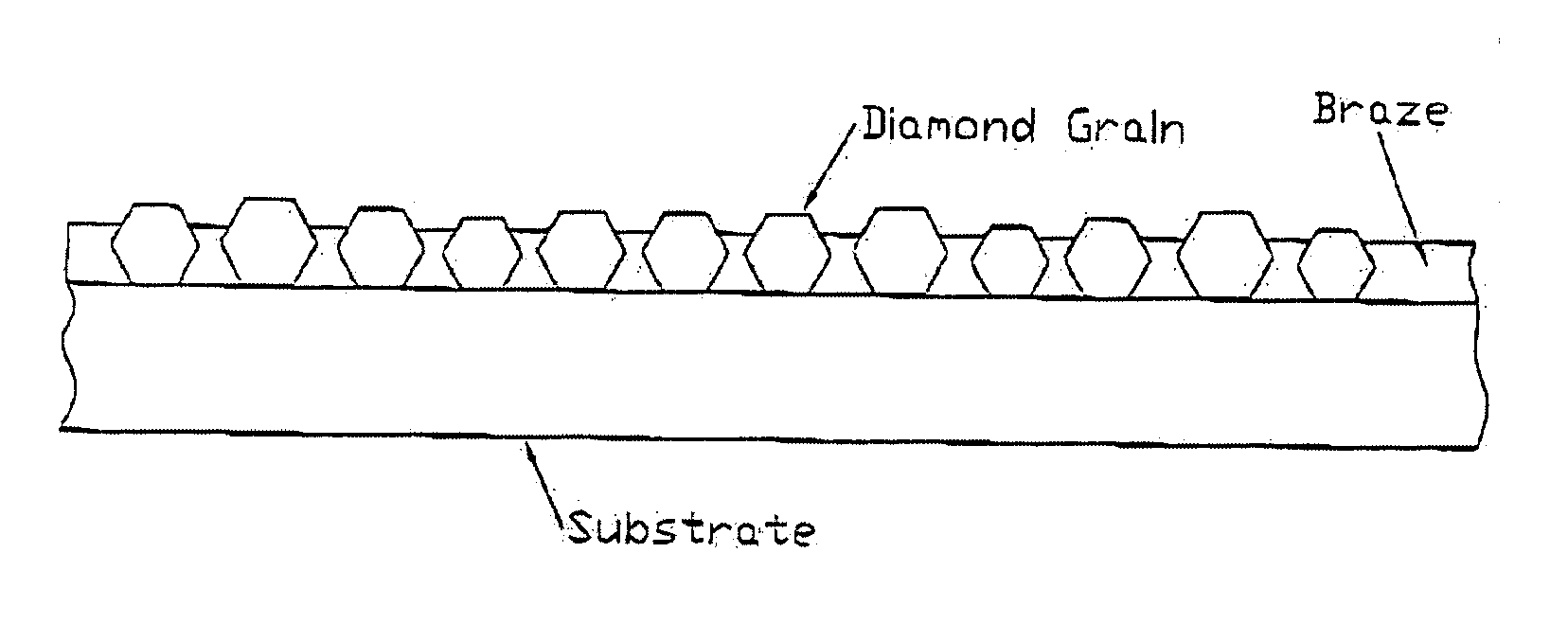

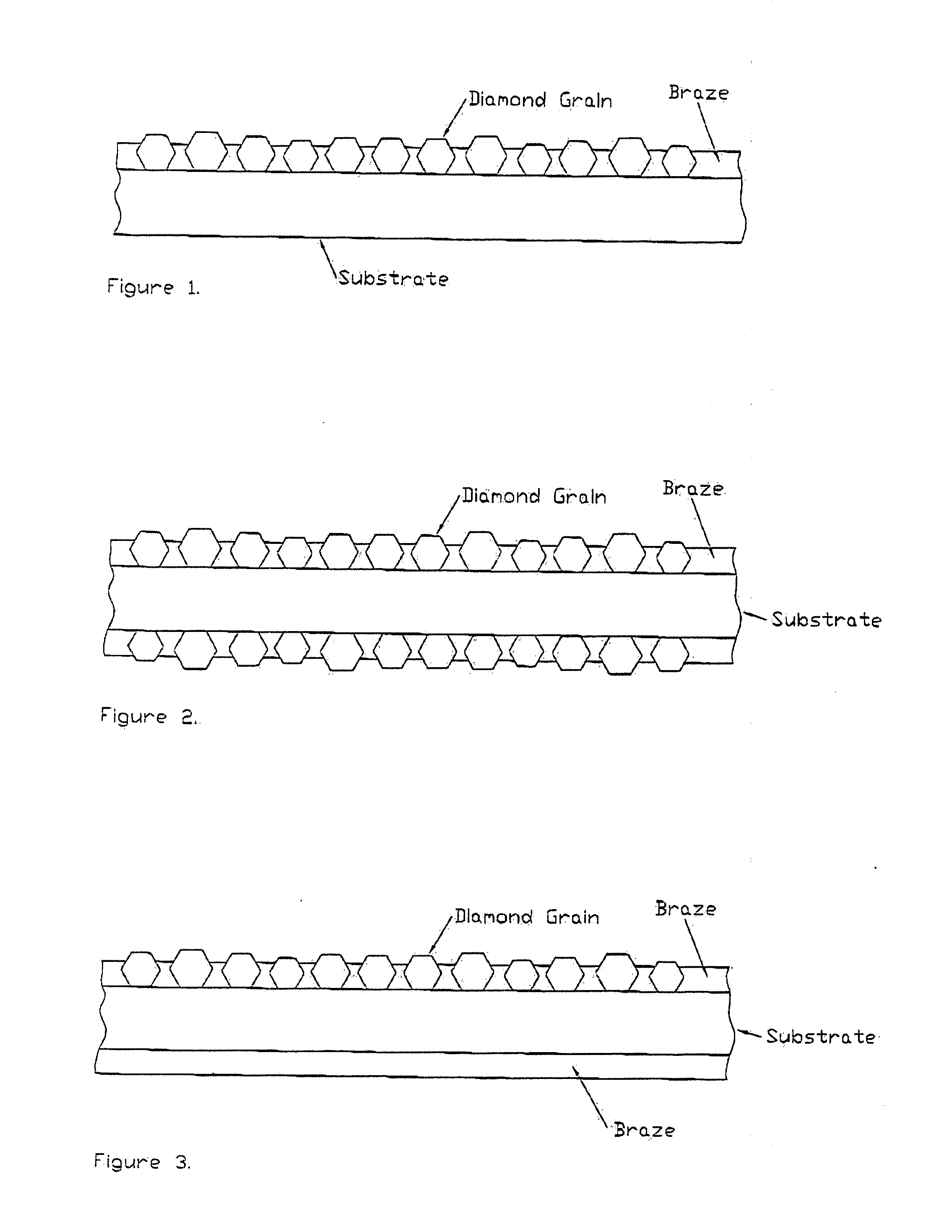

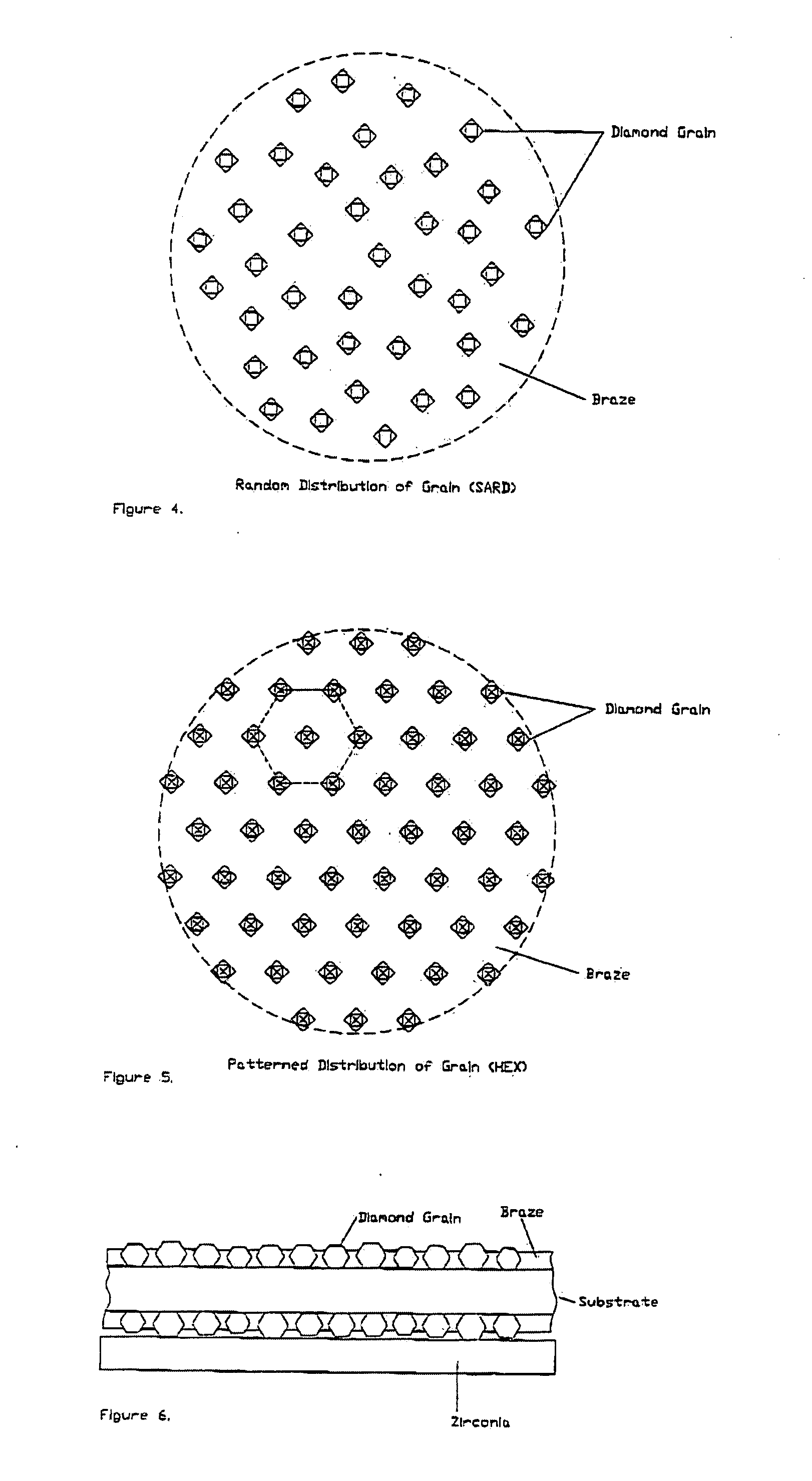

The present invention discloses a CMP pad dresser which has a plurality of uniformly spaced abrasive particles protruding therefrom. The abrasive particles are super hard materials, and are typically diamond, polycrystalline diamond (PCD), cubic boron nitride (cBN), or polycrystalline cubic boron nitride(PcBN). The abrasive particles are brazed to a substrate which may be then coated with an additional anti-corrosive layer. The anti-corrosive layer is usually a diamond or diamond-like carbon which is coated over the surface of the disk to prevent erosion of the brazing alloy by the chemical slurry used in conjunction with the CMP pad. This immunity to chemical attack allows the CMP pad dresser to dress the pad while it is polishing a workpiece. In addition to even spacing on the substrate, the abrasive particles extend for a uniform distance away from the substrate, allowing for even grooming or dressing of a CMP pad both in vertical and horizontal directions. A method of producing such a CMP pad dresser is also disclosed.

Owner:KINIK

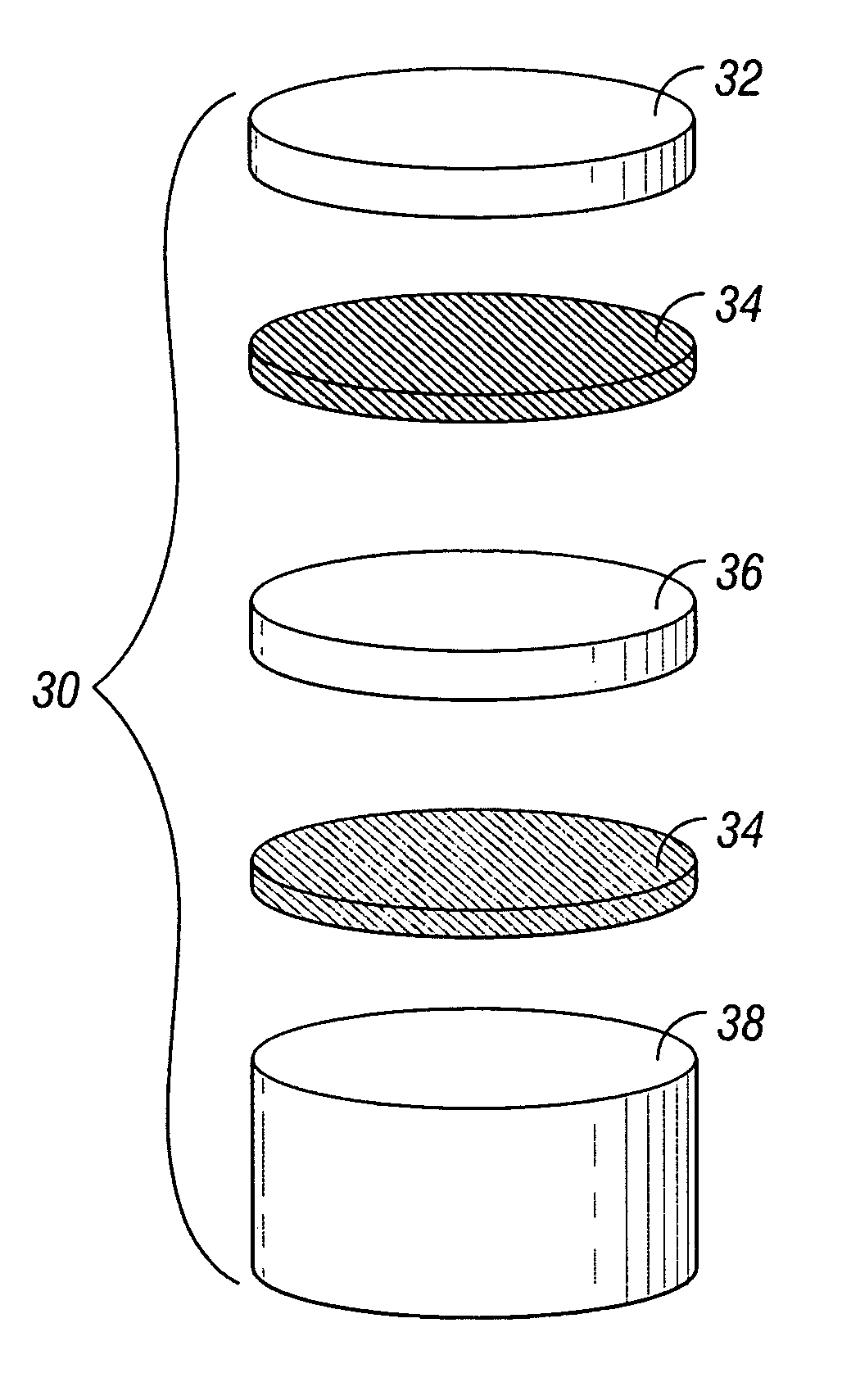

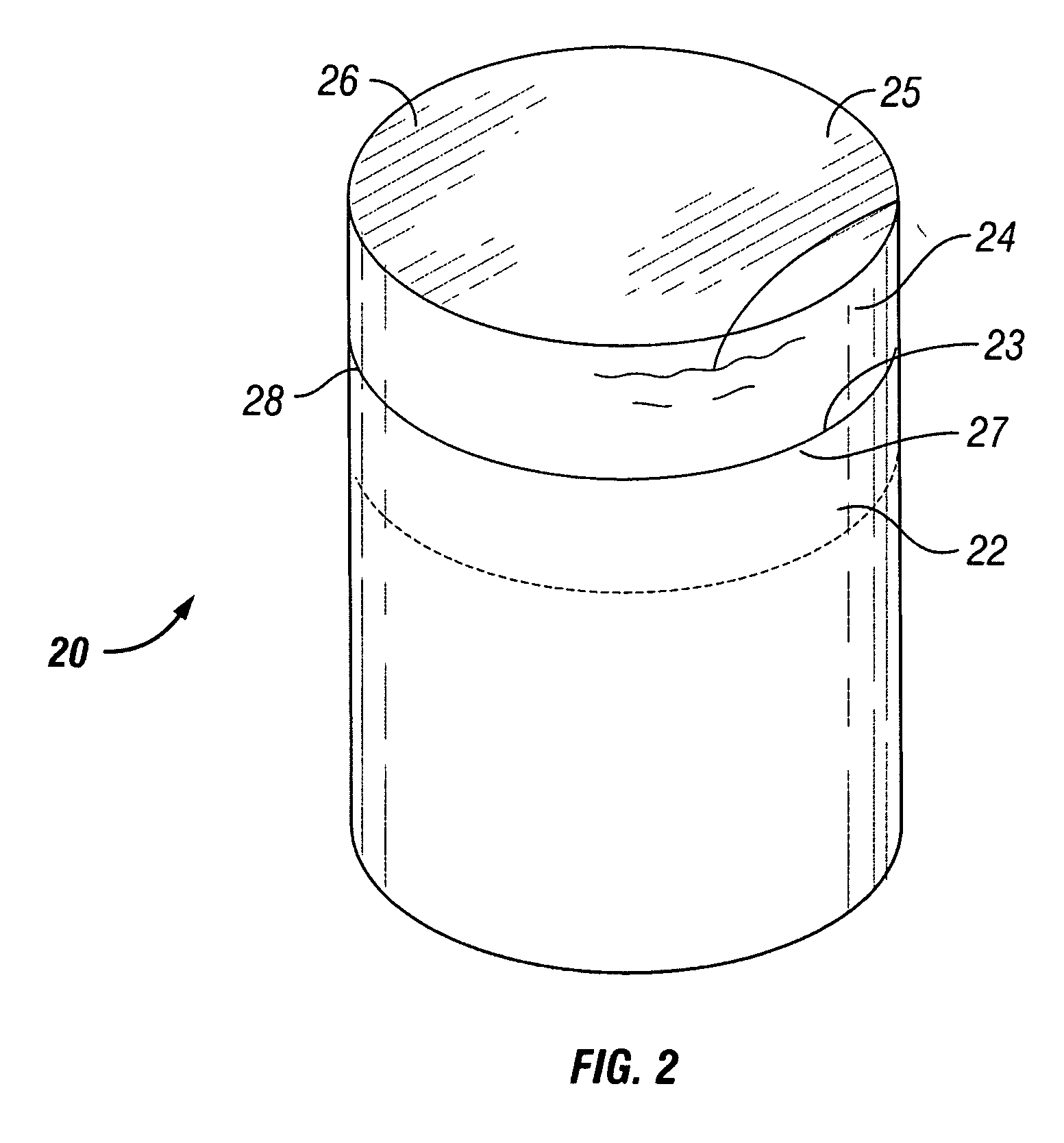

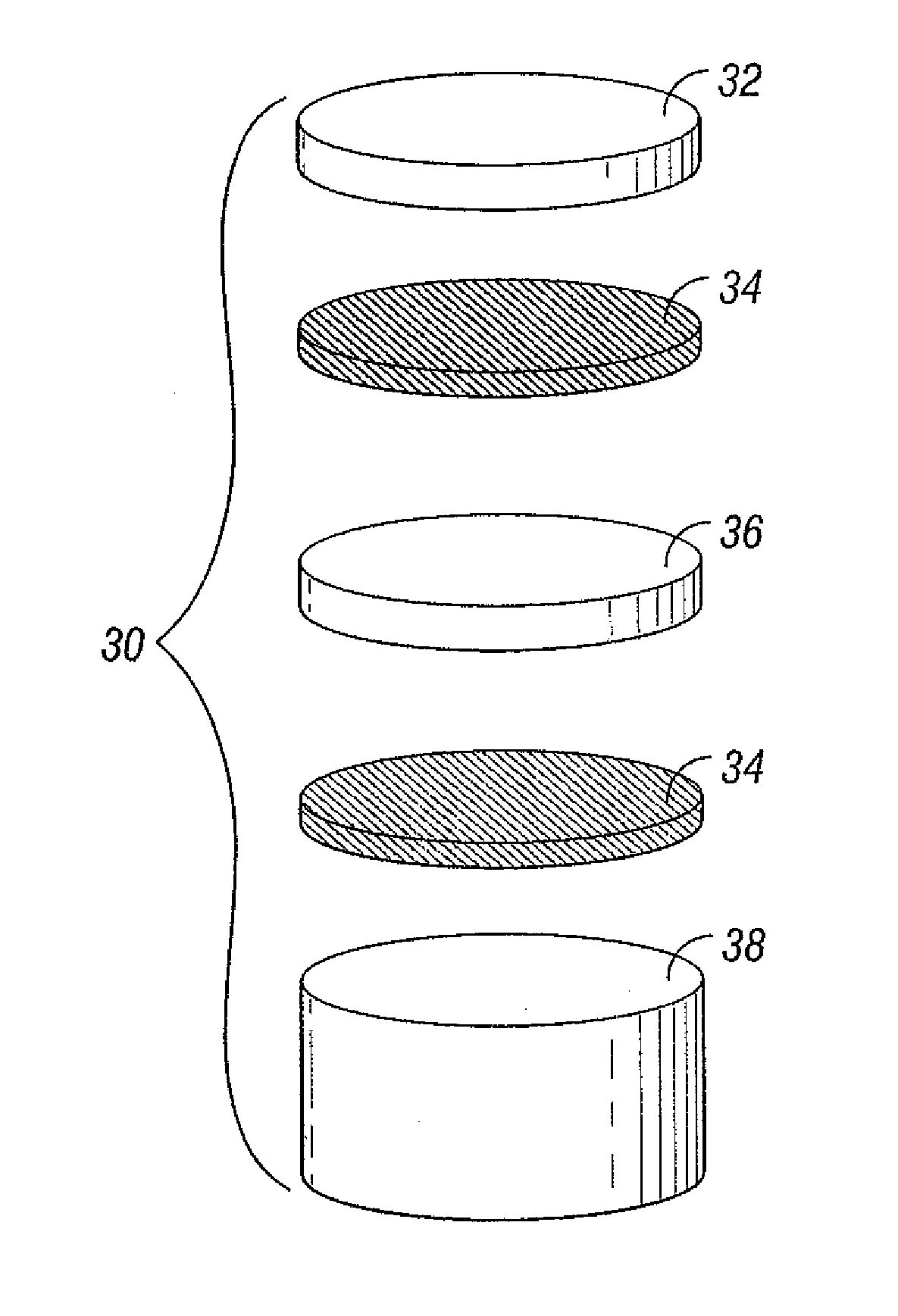

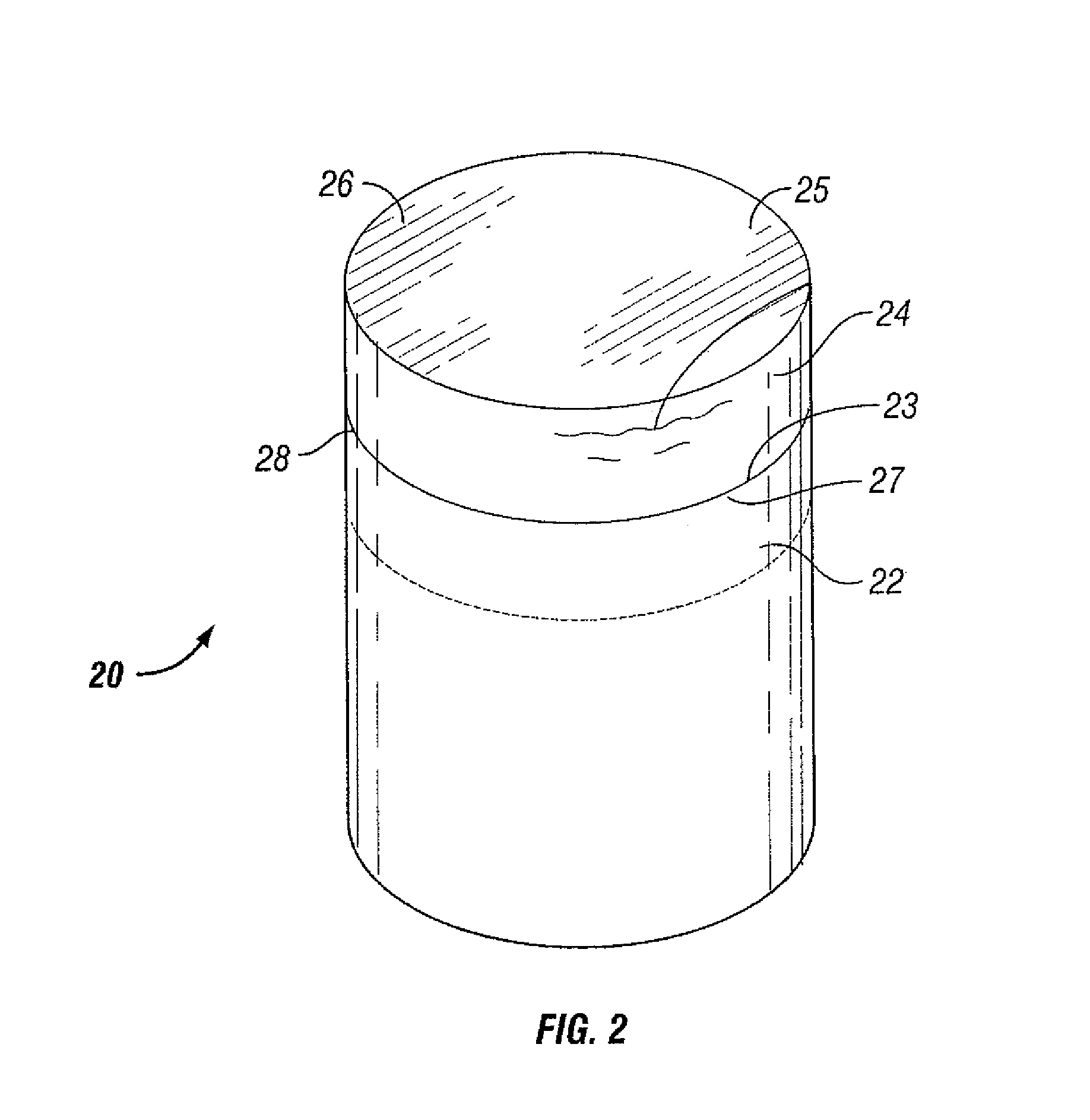

Thermally stable diamond brazing

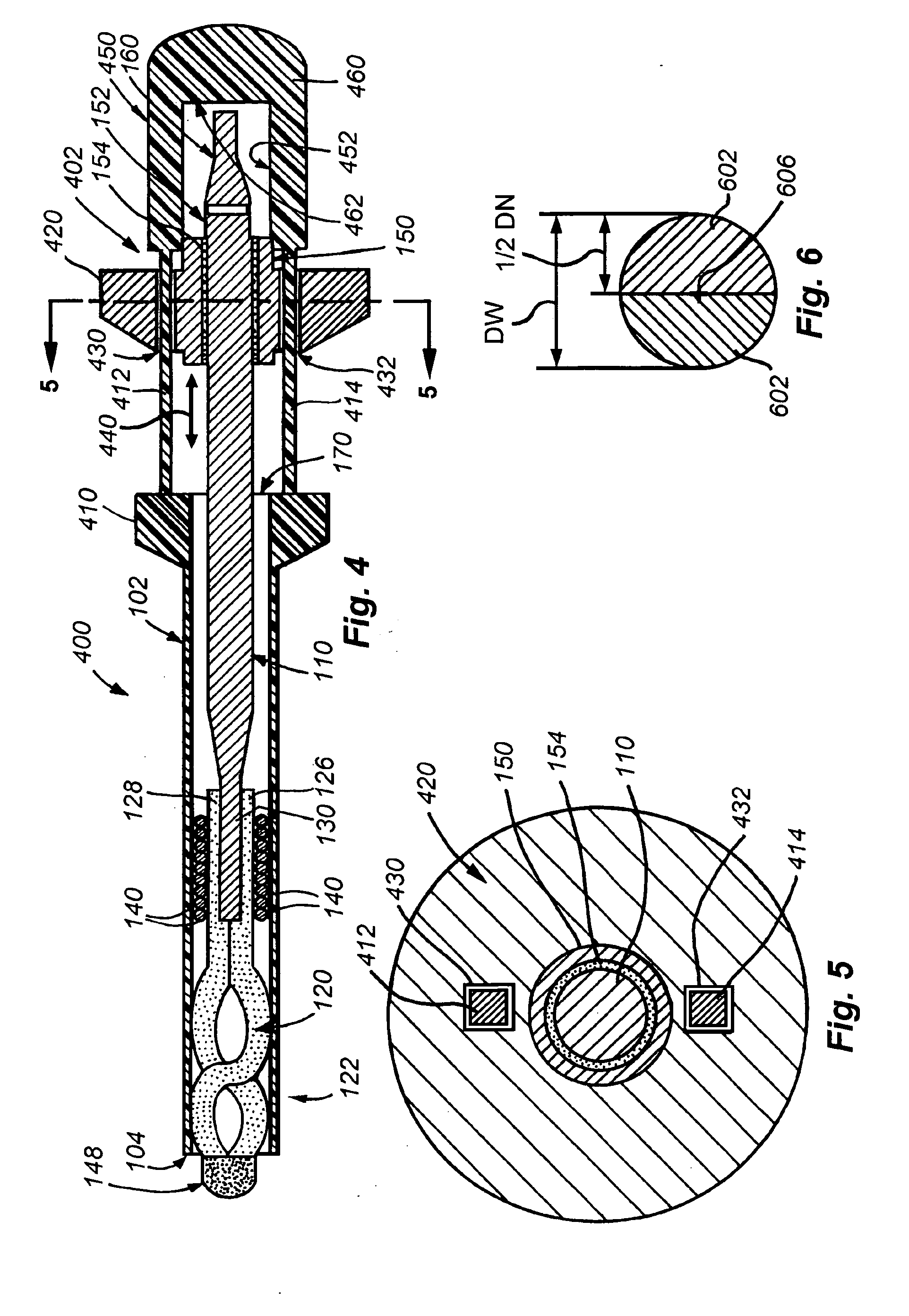

A cutting element and a method for forming a cutting element is described and shown. The cutting element includes a substrate, a TSP diamond layer, a metal interlayer between the substrate and the diamond layer, and a braze joint securing the diamond layer to the substrate. The thickness of the metal interlayer is determined according to a formula. The formula takes into account the thickness and modulus of elasticity of the metal interlayer and the thickness of the TSP diamond. This prevents the use of a too thin or too thick metal interlayer. A metal interlayer that is too thin is not capable of absorbing enough energy to prevent the TSP diamond from fracturing. A metal interlayer that is too thick may allow the TSP diamond to fracture by reason of bending stress. A coating may be provided between the TSP diamond layer and the metal interlayer. This coating serves as a thermal barrier and to control residual thermal stress.

Owner:RADTKE ROBERT P

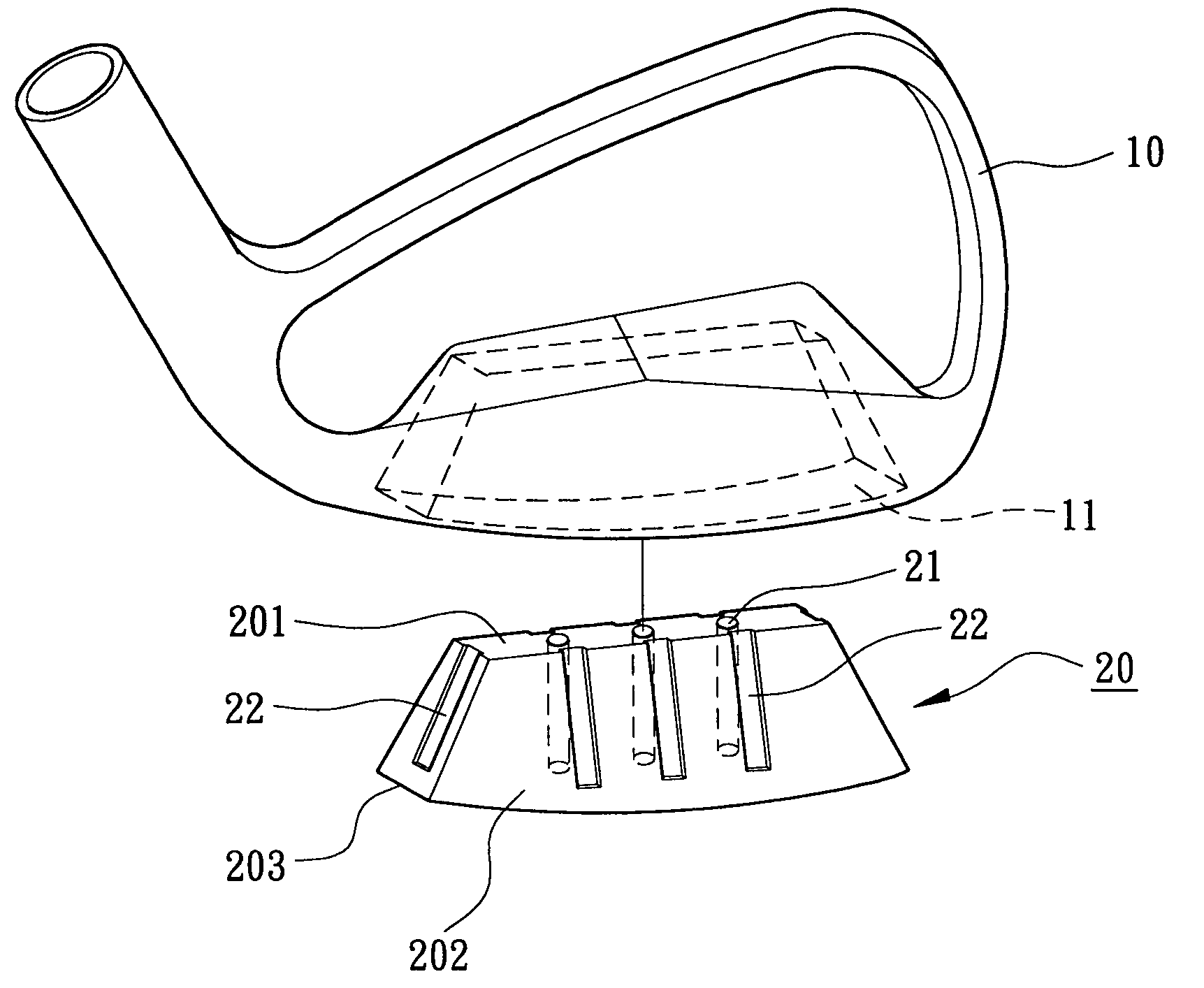

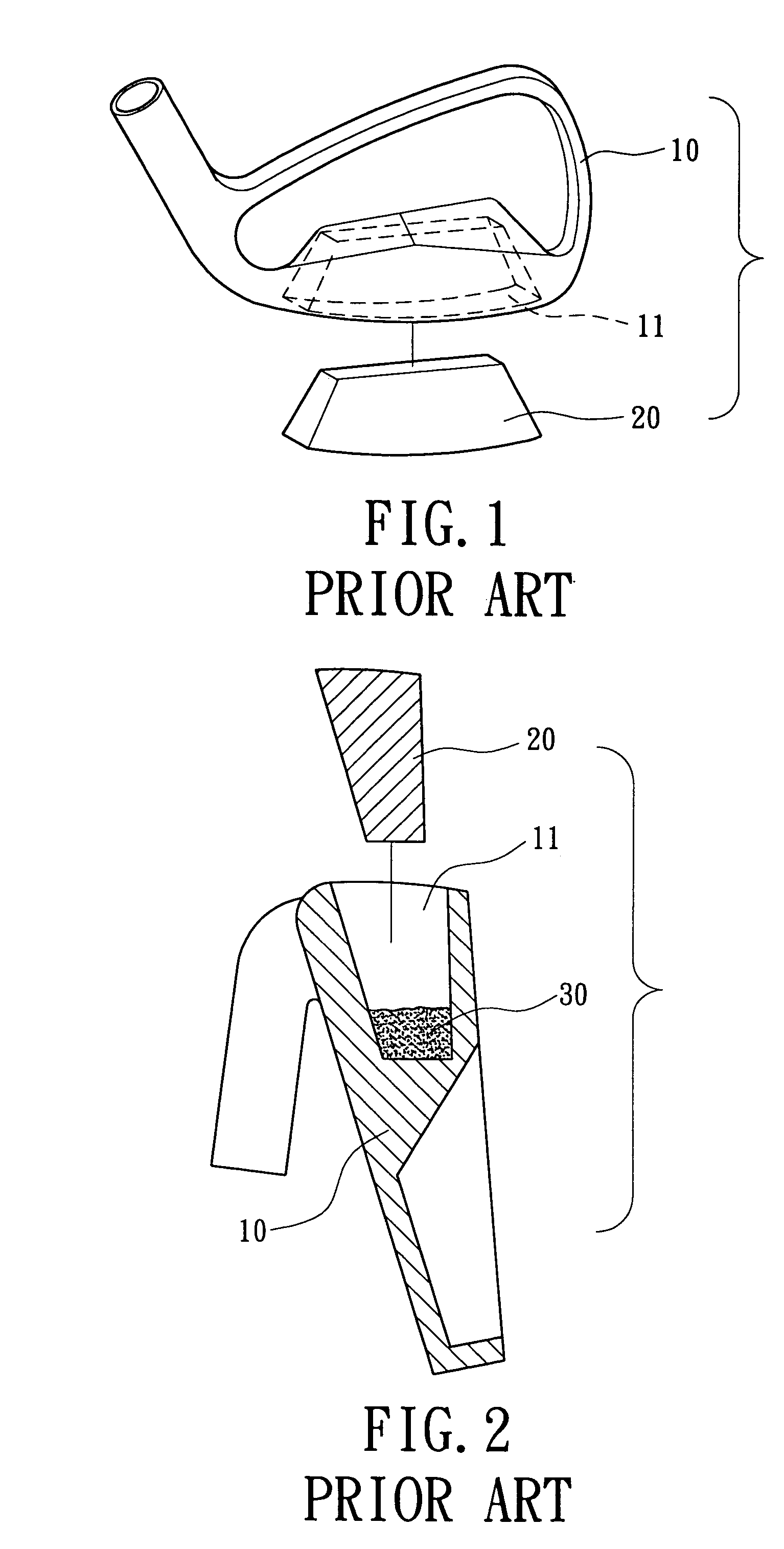

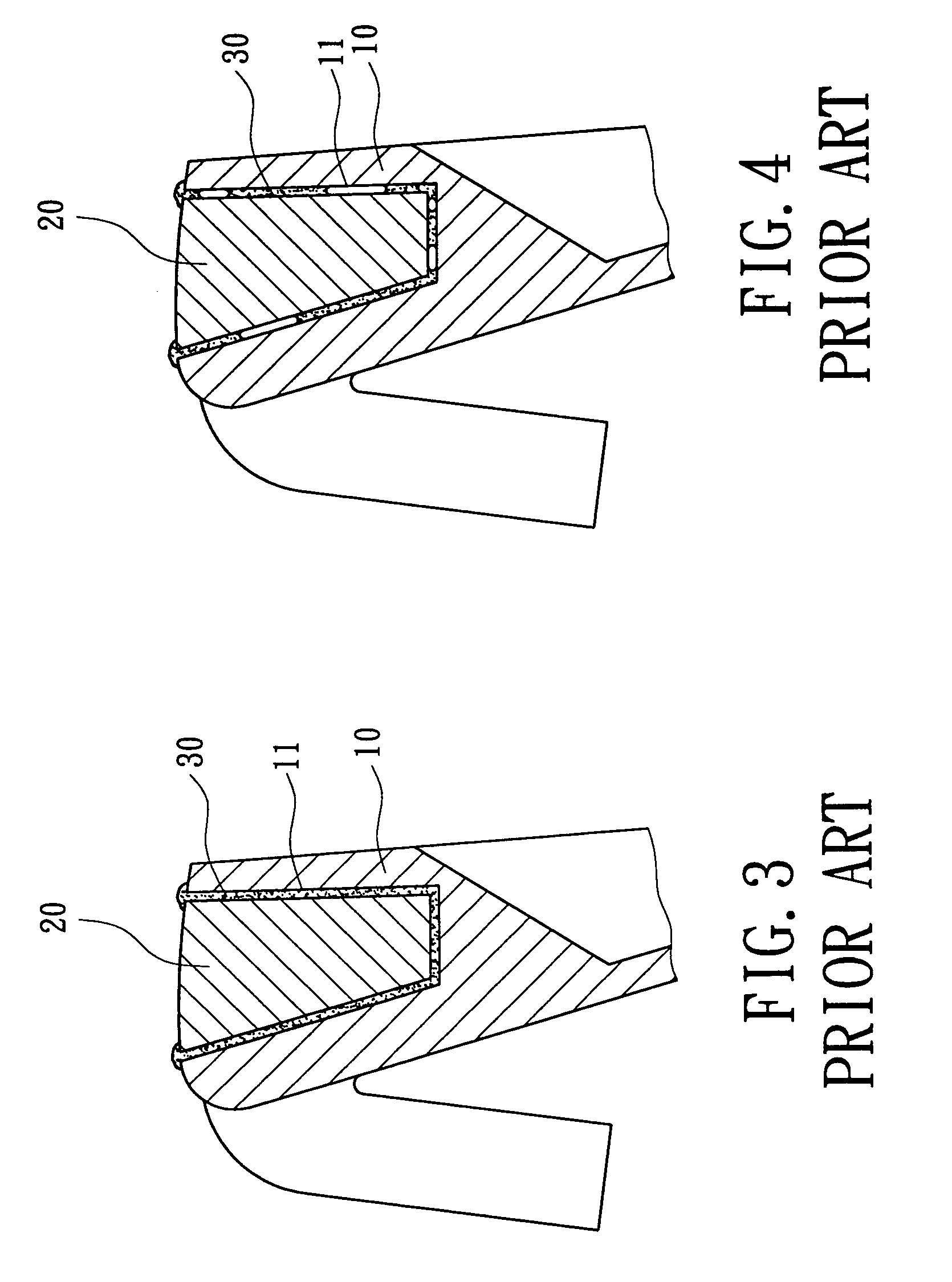

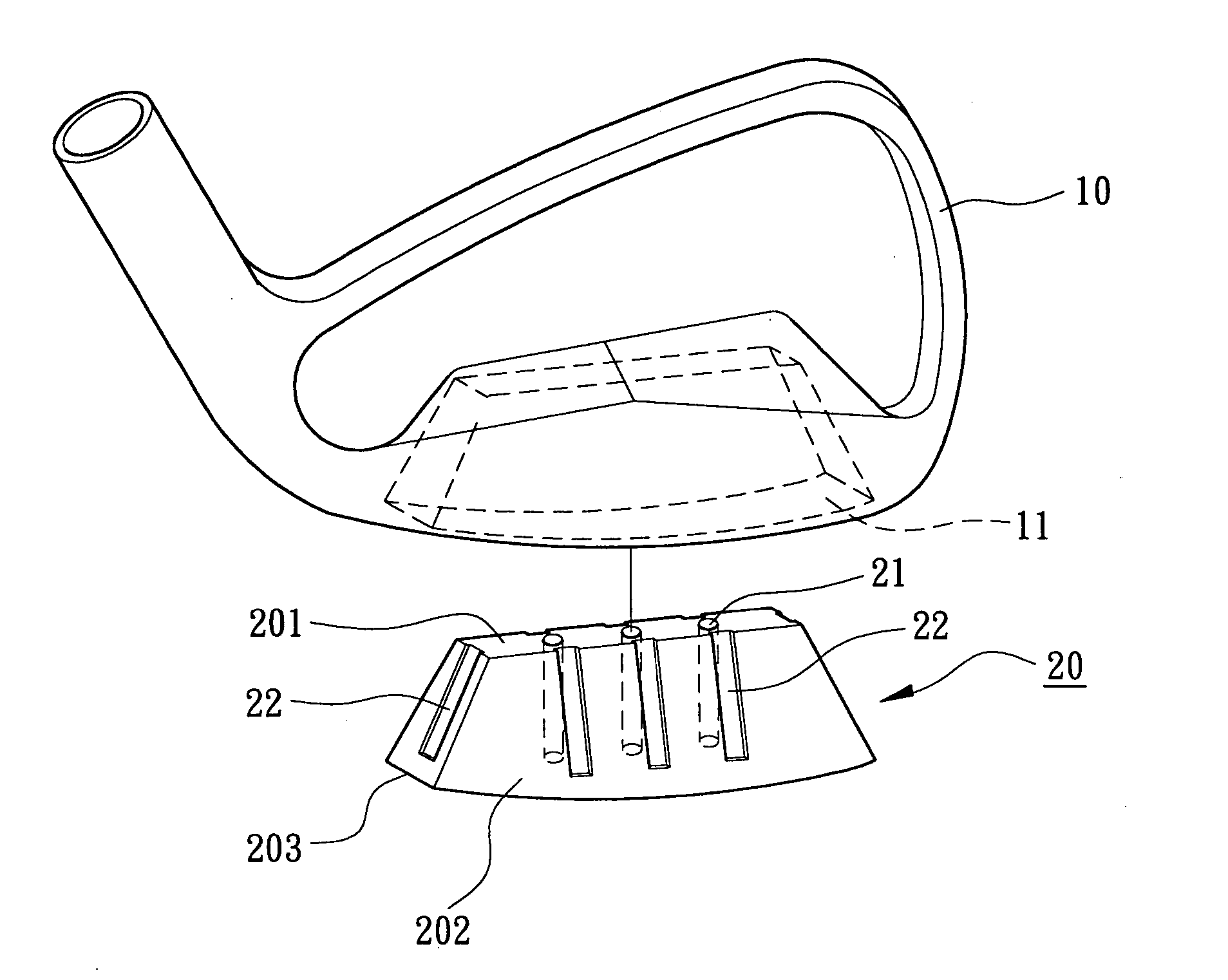

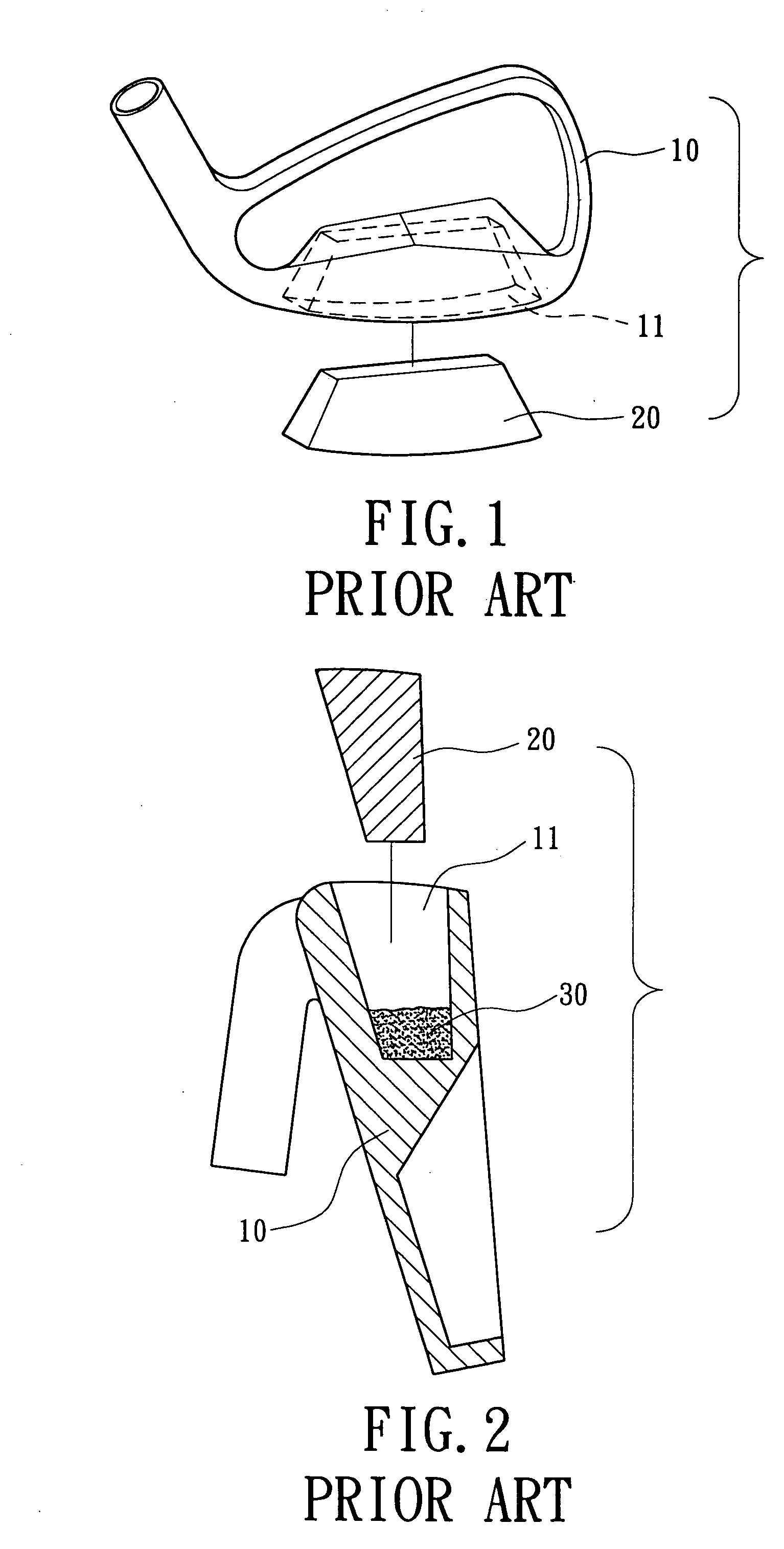

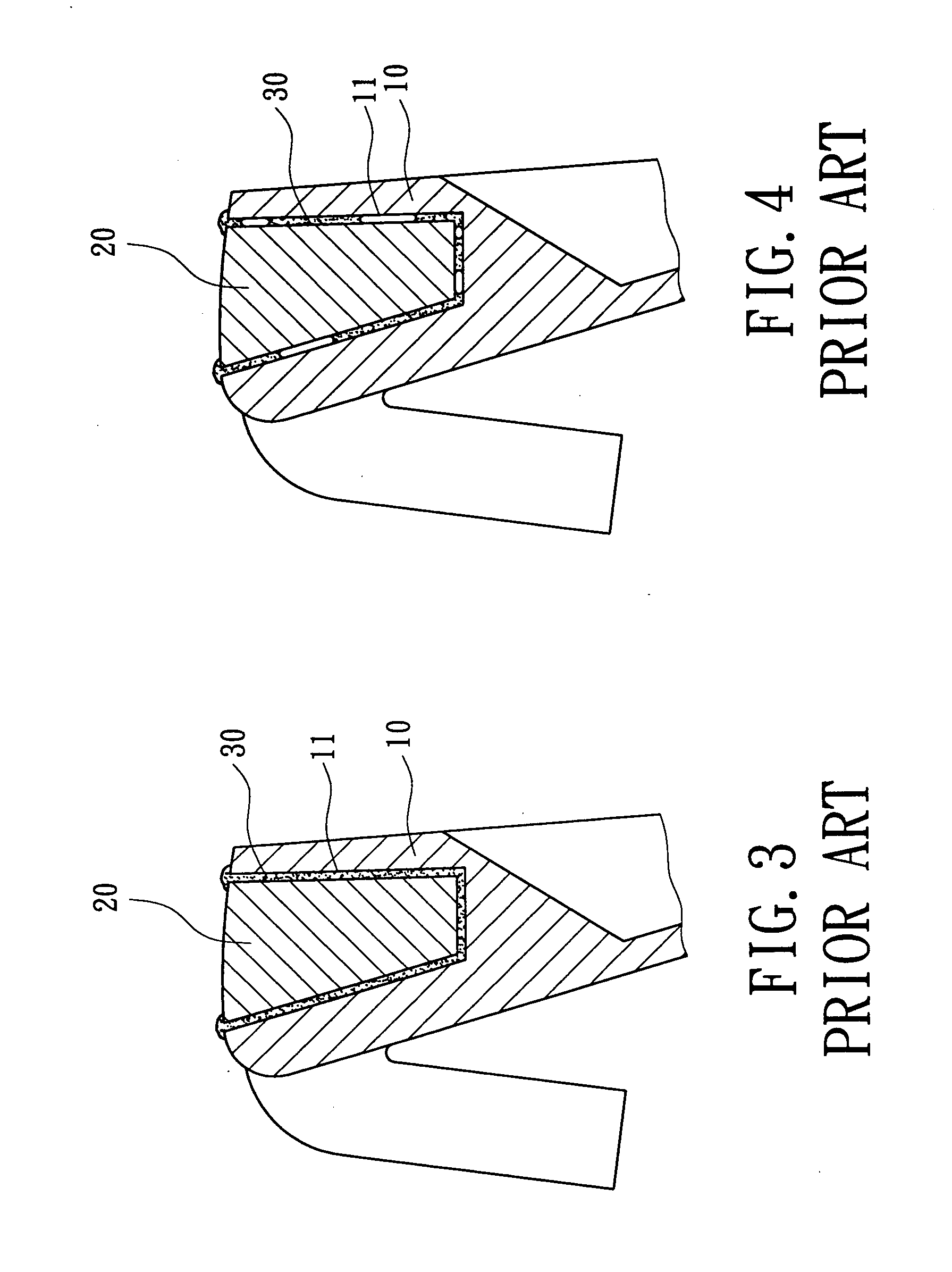

Weight member for a golf club head

InactiveUS7086964B2Improve reliabilityRaise the ratioSoldering apparatusGolf clubsFilling materialsEngineering

A golf club head includes a golf club head body and a weight member mounted in a recession of the golf club head body. The weight member includes at least one compartment for receiving a filling material. The weight member is mounted in the recession of the golf club head body before a brazing process for bonding the weight member with the golf club head body. During the brazing process, the filling material is melted and fills a gap between the weight member and walls delimiting the recession of the golf club head body to thereby increasing bonding strength between the weight member and the walls delimiting the recession of the golf club head body.

Owner:FUSHENG IND CO LTD

Diamond grid CMP pad dresser

InactiveUS6884155B2Easy to monitorUniform sizePolishing machinesRevolution surface grinding machinesSuperhard materialDiamond-like carbon

The present invention discloses a CMP pad dresser which has a plurality of uniformly spaced abrasive particles protruding therefrom. The abrasive particles are super hard materials, and are typically diamond, polycrystalline diamond (PCD), cubic boron nitride (cBN), or polycrystalline cubic boron nitride(PcBN). The abrasive particles are brazed to a substrate which may be then coated with an additional anti-corrosive layer. The anti-corrosive layer is usually a diamond or diamond-like carbon which is coated over the surface of the disk to prevent erosion of the brazing alloy by the chemical slurry used in conjunction with the CMP pad. This immunity to chemical attack allows the CMP pad dresser to dress the pad while it is polishing a workpiece. In addition to even spacing on the substrate, the abrasive particles extend for a uniform distance away from the substrate, allowing for even grooming or dressing of a CMP pad both in vertical and horizontal directions. A method of producing such a CMP pad dresser is also disclosed.

Owner:KINIK

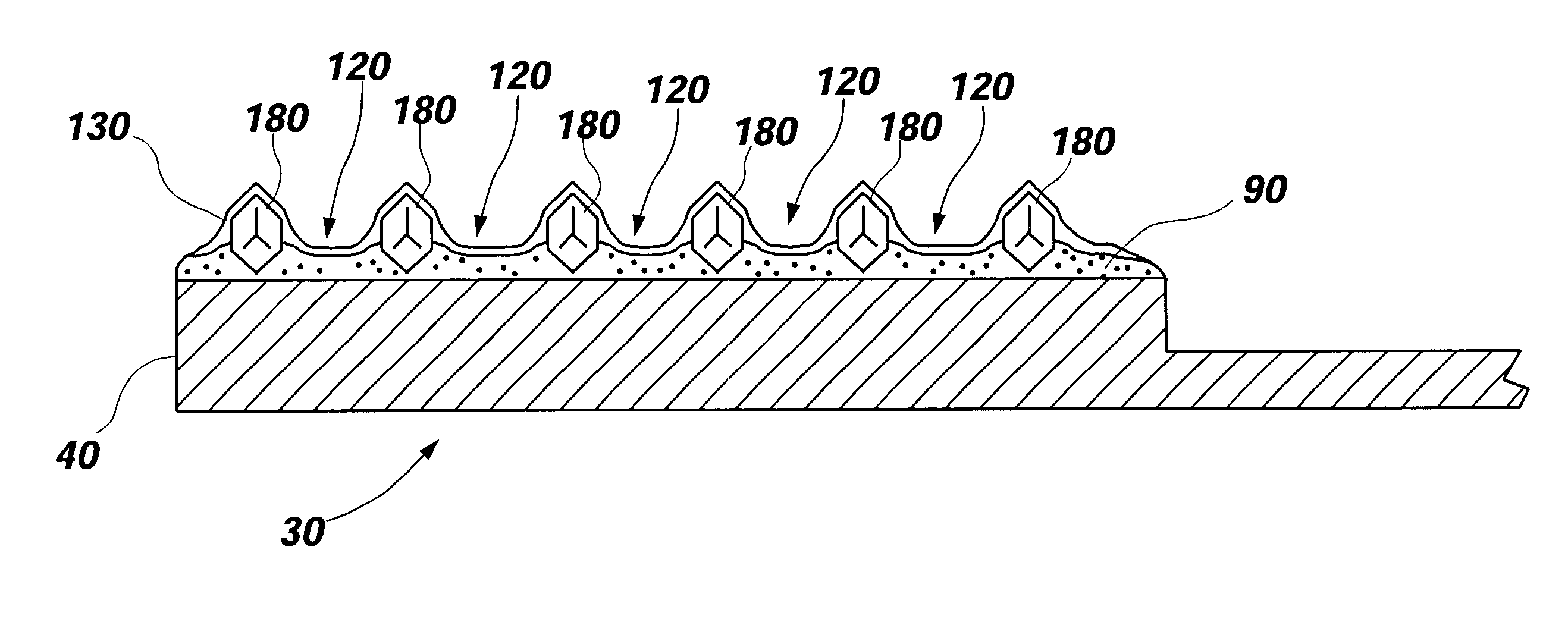

Conditioning tools and techniques for chemical mechanical planarization

InactiveUS20080271384A1Reduce the overall heightPigmenting treatmentOther chemical processesCopperMetal

Tools for conditioning chemical mechanical planarization (CMP) pads comprise a substrate with abrasive particles coupled to at least one surface. The tools can have various particle and bond configurations. For instance, abrasive particles may be bonded (e.g., brazed or other metal bond technique) to one side, or to front and back sides. Alternatively, abrasive particles are bonded to a front side, and filler particles coupled to a back side. The abrasive particles can form a pattern (e.g., hexagonal) and have particle sizes that are sufficiently small to penetrate pores of a CMP pad during conditioning, leading to fewer defects on wafers polished with the conditioned CMP pad. Grain bonding can be accomplished using brazing films, although other metal bonds may be used as well. Also, balanced bond material (e.g., braze on both sides) allows for low out-of-flatness value.

Owner:SAINT GOBAIN ABRASIFS INC +1

Weight member for a golf club head

InactiveUS20050049075A1Improve reliabilityRaise the ratioSoldering apparatusGolf clubsFilling materialsEngineering

A golf club head includes a golf club head body and a weight member mounted in a recession of the golf club head body. The weight member includes at least one compartment for receiving a filling material. The weight member is mounted in the recession of the golf club head body before a brazing process for bonding the weight member with the golf club head body. During the brazing process, the filling material is melted and fills a gap between the weight member and walls delimiting the recession of the golf club head body to thereby increasing bonding strength between the weight member and the walls delimiting the recession of the golf club head body.

Owner:FUSHENG IND CO LTD

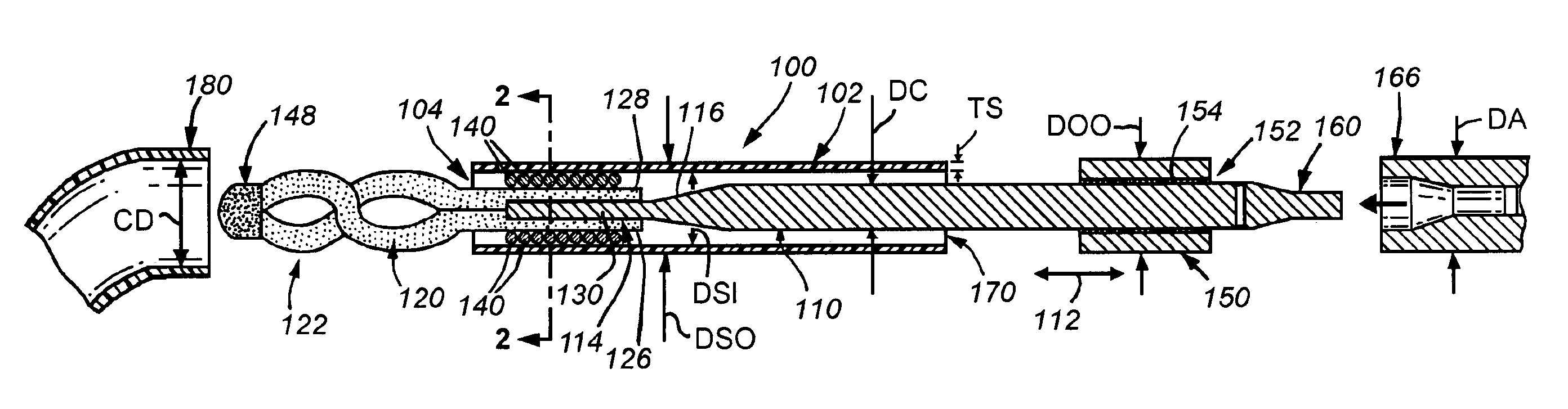

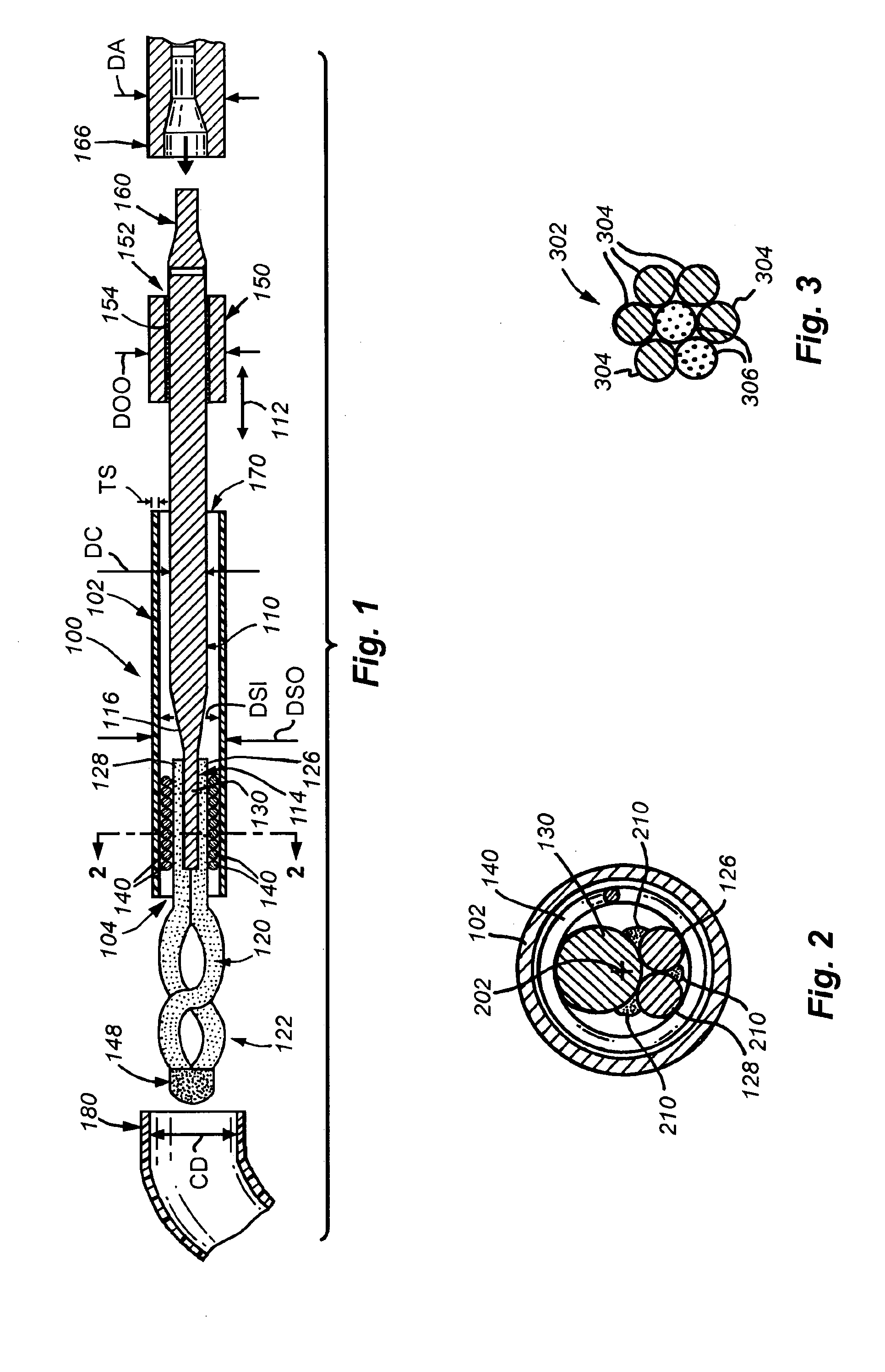

Small-diameter snare

InactiveUS20050234474A1Maximize supportReduced cross sectionDiagnostic markersExcision instrumentsDistal portionEngineering

This invention provides a small diameter snare device consisting of a hollow, elongate, thin-walled polymer outer sheath. A single central core wire extends through the entire length of the sheath. The outer diameter of the core wire is sized close to the inner diameter of the sheath while allowing for axial sliding, in order to maximize the support to the body portion of the snare device. The distal end of the core wire has a tapered section of reduced diameter or cross section to provide a “guidewire-like” flexibility to the distal portion of the device. A second wire of about fifty percent of the inner diameter of the sheath is shaped to form a snare loop and the two ends are attached to the distal most portion of the central core wire via welding, soldering, or brazing. After assembly of the core and sheath, a second short, hollow tube is fitted over the proximal end of the central core and attached thereto to provide an actuating handle to slideably move the central core within the sheath, thus exposing and retracting the snare loop from the open distal end of the sheath. The loop is typically circular or oval shaped and can also be multiplanar (for example, a twisted, figure eight shape) so as to increase the ability to ensnare and capture objects. The loop attachment to the core wire is facilitated and strengthened by a wrapped coupling coil formed typically of 0.001-inch platinum wire applied to secure the loop prior to soldering (brazing or other metal-flowing joining techniques), and through which solder flows to permanently secure the loop to the core wire.

Owner:VASCULAR SOLUTIONS

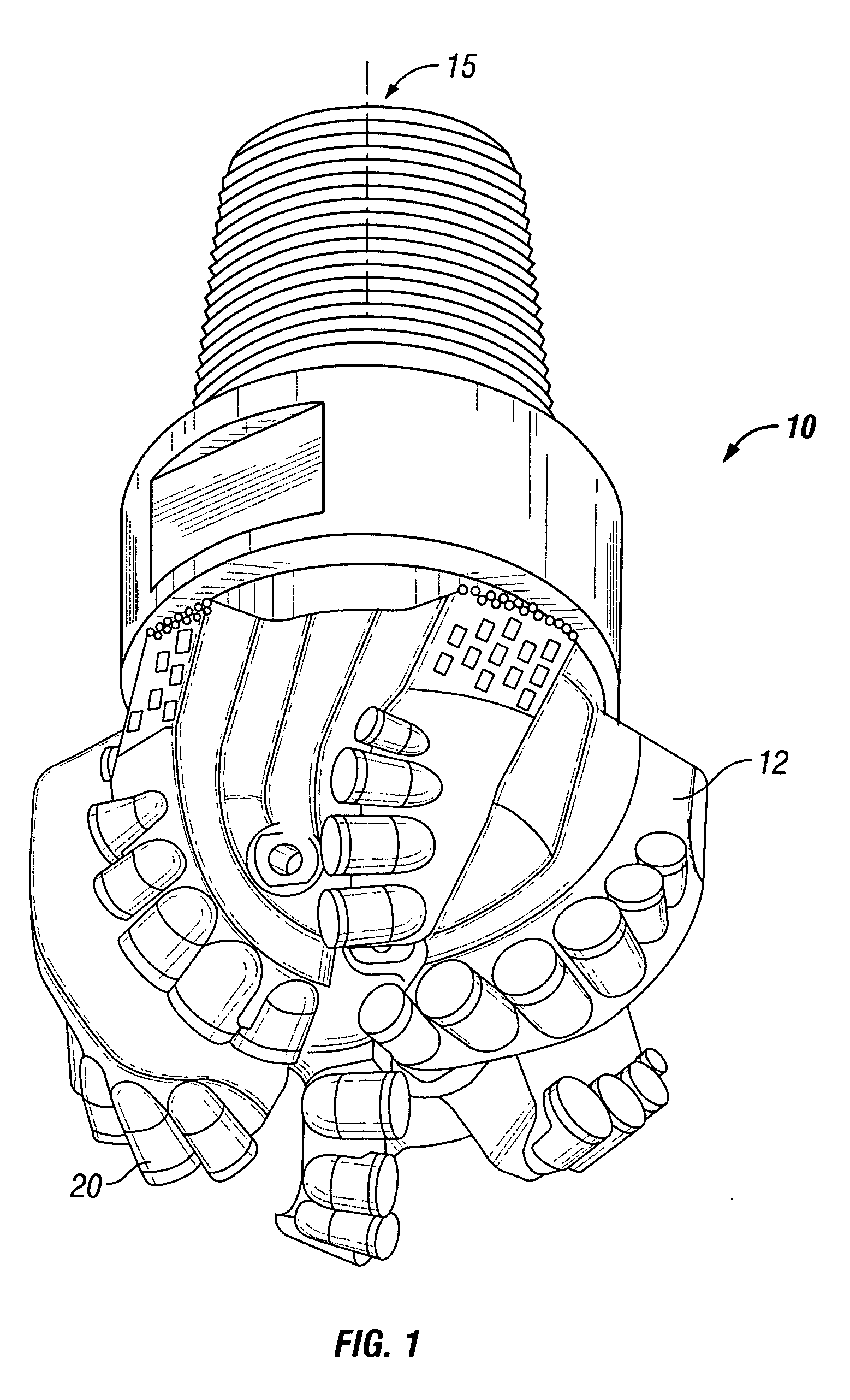

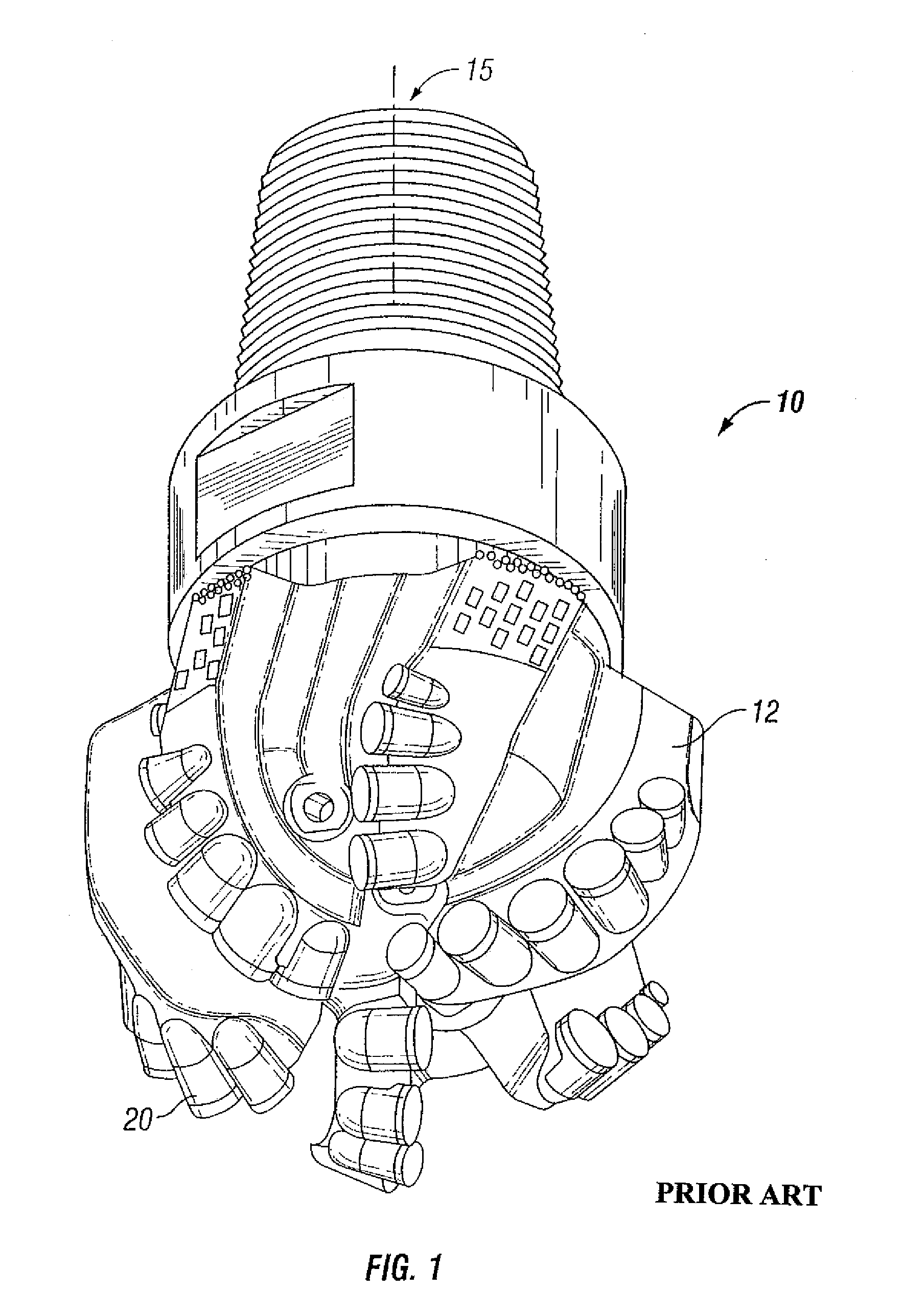

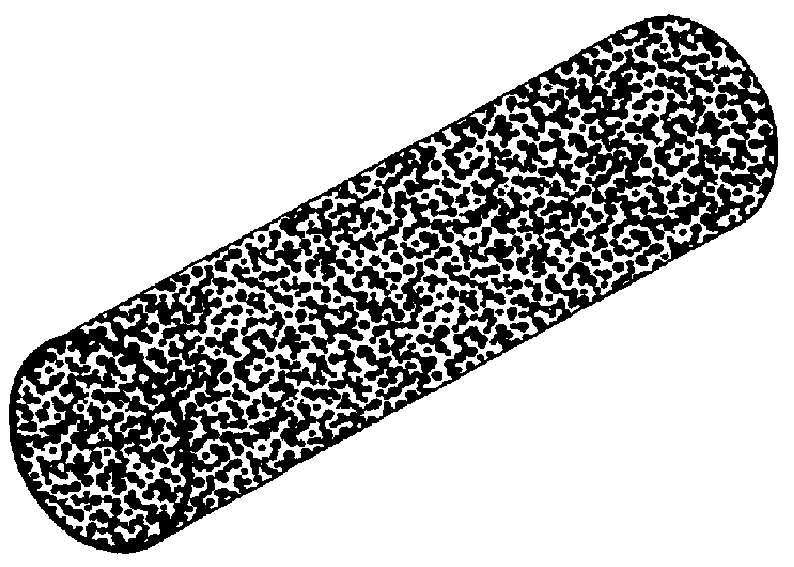

Composite materials including nickel-based matrix materials and hard particles, tools including such materials, and methods of using such materials

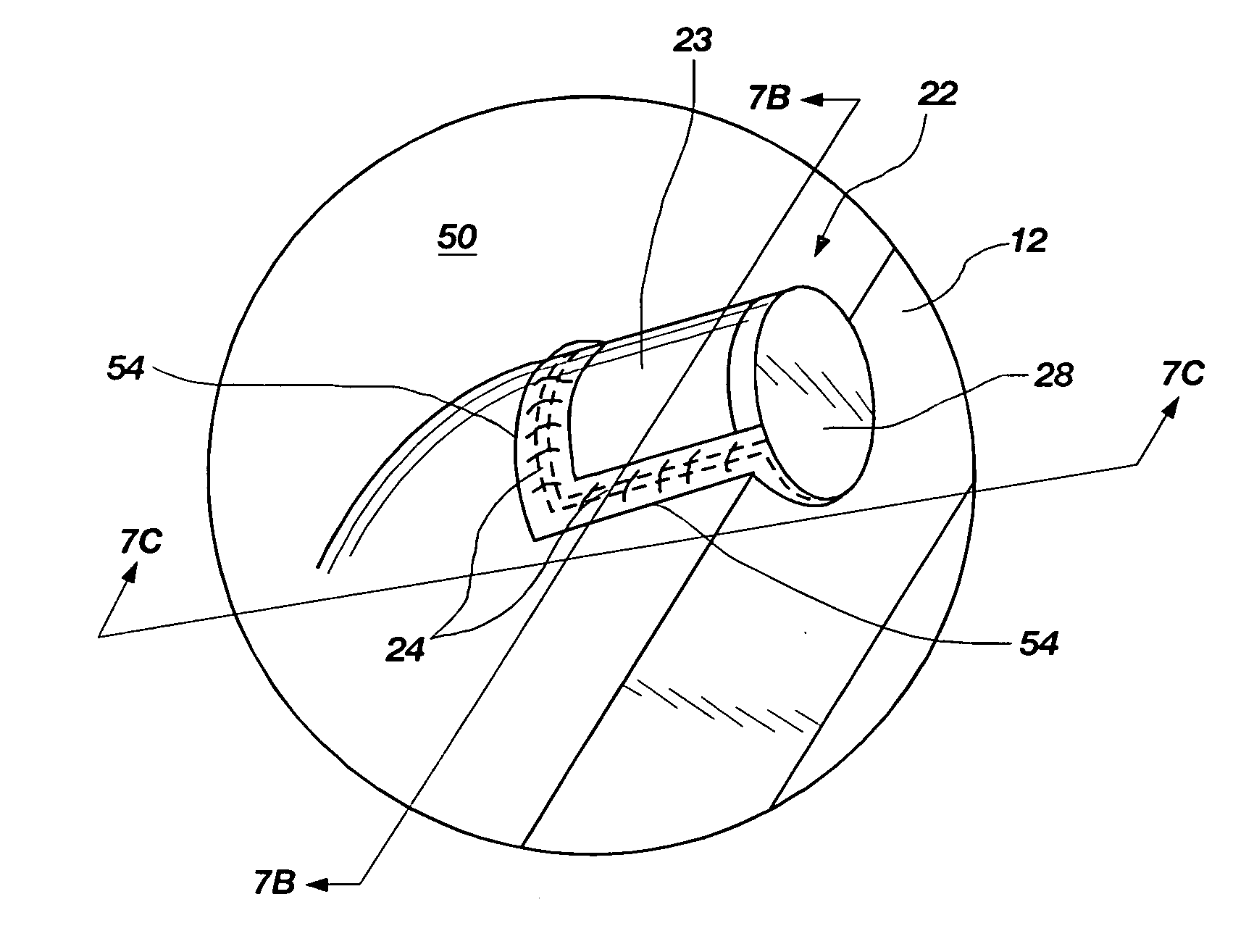

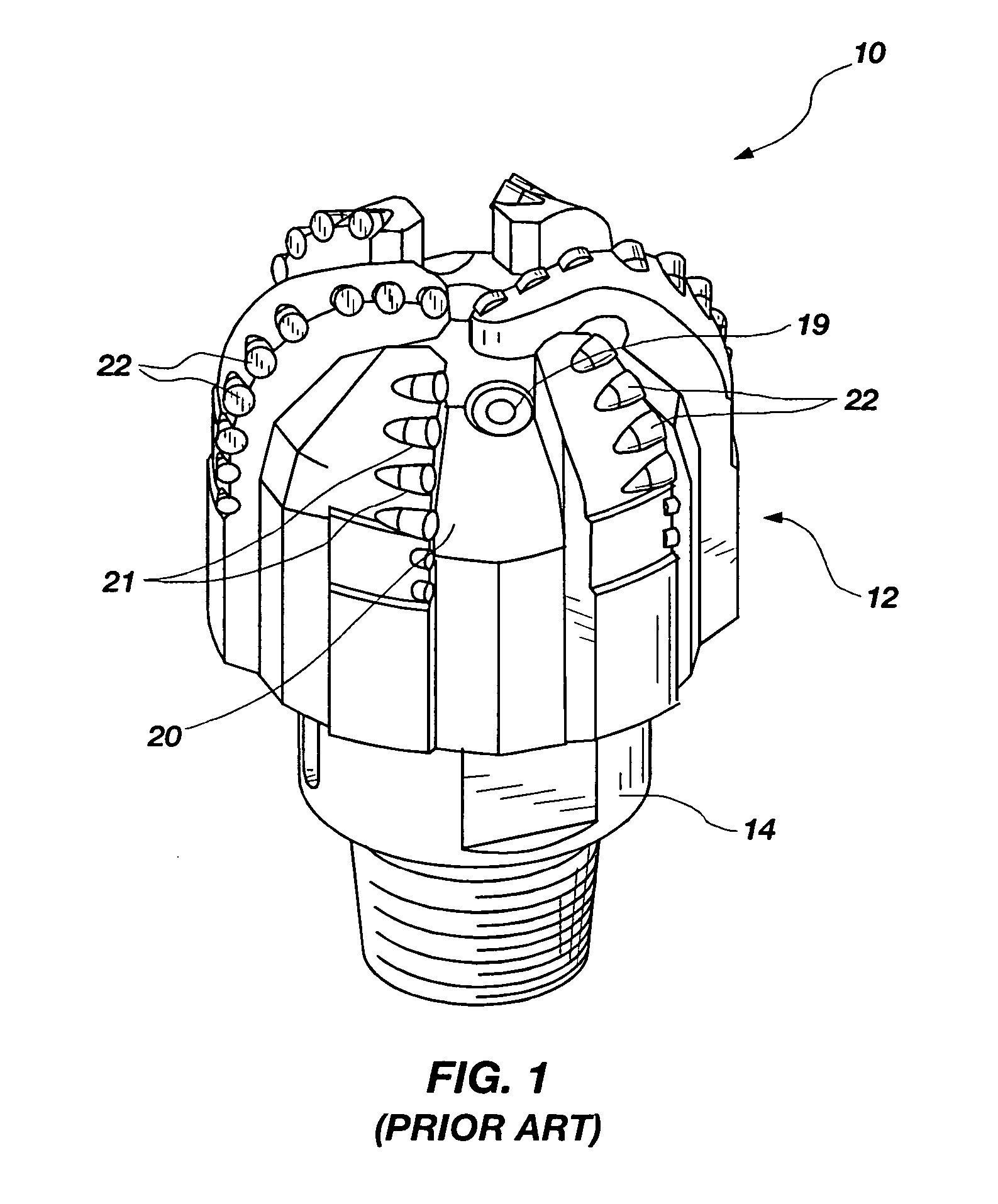

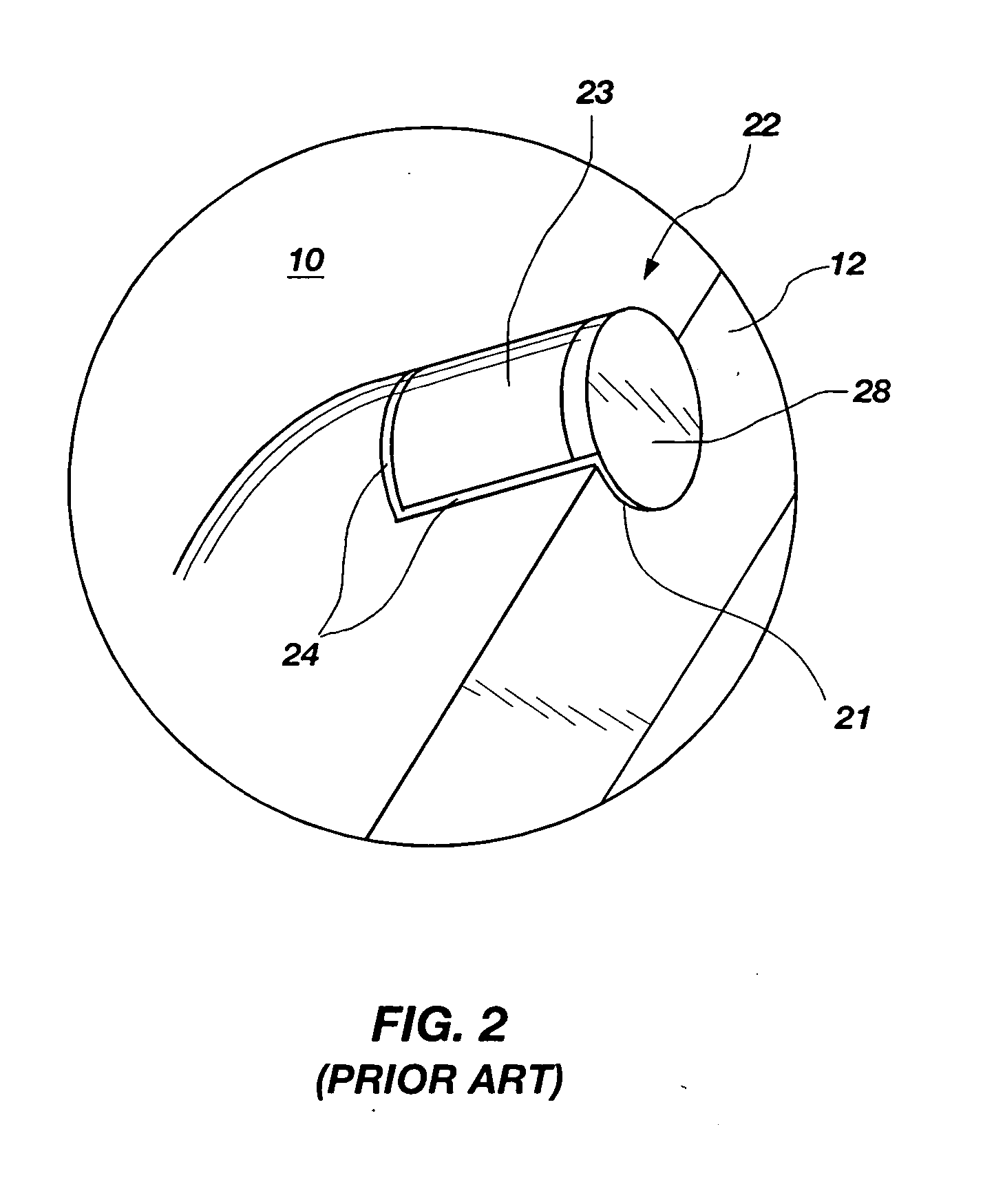

An abrasive wear-resistant material includes a matrix and sintered and cast tungsten carbide granules. A device for use in drilling subterranean formations includes a first structure secured to a second structure with a bonding material. An abrasive wear-resistant material covers the bonding material. The first structure may include a drill bit body and the second structure may include a cutting element. A method for applying an abrasive wear-resistant material to a drill bit includes providing a bit, mixing sintered and cast tungsten carbide granules in a matrix material to provide a pre-application material, heating the pre-application material to melt the matrix material, applying the pre-application material to the bit, and solidifying the material. A method for securing a cutting element to a bit body includes providing an abrasive wear-resistant material to a surface of a drill bit that covers a brazing alloy disposed between the cutting element and the bit body.

Owner:BAKER HUGHES INC

High strength aluminium alloy brazing sheet, brazed assembly and method for producing same

ActiveUS20050079376A1Good brazing propertyGood formability characteristicFurnace typesWelding/cutting media/materialsSiluminManganese

The present invention a high strength aluminium alloy brazing sheet, comprising an Al—Zn core layer and at least one clad layer, the core layer including the following composition (in weight percent): Zn1.2 to 5.5Mg0.8 to 3.0Mn0.1 to 1.0Cu<0.2Si <0.35Fe<0.5optionally one or more of: Zr<0.3Cr<0.3V<0.3Ti<0.2Hf<0.3Sc<0.5,the balance aluminium and incidental elements and impurities. The clad layer includes an Al—Si based filler alloy and is applied on at least one side of the core layer. The invention relates furthermore to a brazed assembly including such brazing sheet, to the use of such brazing sheet and to method for producing an aluminium alloy brazing sheet.

Owner:ALERIS ALUMINUM KOBLENZ GMBH

Flexible composite middle layer brazing alloy and method of utilizing brazing ceramic and metal

InactiveCN102699558AEnables direct brazingIncreased shear strengthWelding/cutting media/materialsSoldering mediaHeating furnaceUltimate tensile strength

The invention discloses flexible composite middle layer brazing alloy and a method of utilizing brazing ceramic and metal, and relates to the composite brazing alloy and the method of utilizing the brazing ceramic and metal. The flexible composite middle layer brazing alloy and the method aim at solving the problems that the conventional method is high in cost and the forming of brittle compound of a joint can not be restrained. The flexible composite middle layer brazing alloy is prepared from upper layer brazing alloy, a flexible middle layer and lower layer brazing alloy. The brazing method comprises the steps of: cleaning greasy dirt and impurity on a pre-welding surface; processing the upper-layer brazing alloy, the flexible middle layer and the lower-layer brazing alloy into small sheets; and ultrasonically cleaning and airing ceramic to be welded, metal to be welded, the upper layer brazing alloy, the flexible middle layer and the lower layer brazing alloy by acetone, assembling a workpiece to be welded, and putting the workpiece to be welded into a vacuum heating furnace to braze. According to the method disclosed by the invention, the operation is simple; the residual stress of the joint is released by adding the flexible middle layer; and the forming of the brittle compound of the joint is restrained, and the shearing strength of the joint is improved by 30-109%. The method disclosed by the invention is used for brazing the ceramic and the metal.

Owner:HARBIN INST OF TECH

Package for a semiconductor light emitting device

InactiveUS20050045901A1Effective coolingEasy to mountSemiconductor/solid-state device detailsSolid-state devicesAs DirectedCopper

A semiconductor light emitting device package includes a substrate with a core and a copper layer overlying the core. The light emitting device is connected to the substrate directly or indirectly through a wiring substrate. The core of the substrate may be, for example, ceramic, Al2O3, AlN, alumina, silicon nitride, or a printed circuit board. The copper layer may be bonded to the core by a process such as direct bonding of copper or active metal brazing.

Owner:LUMILEDS

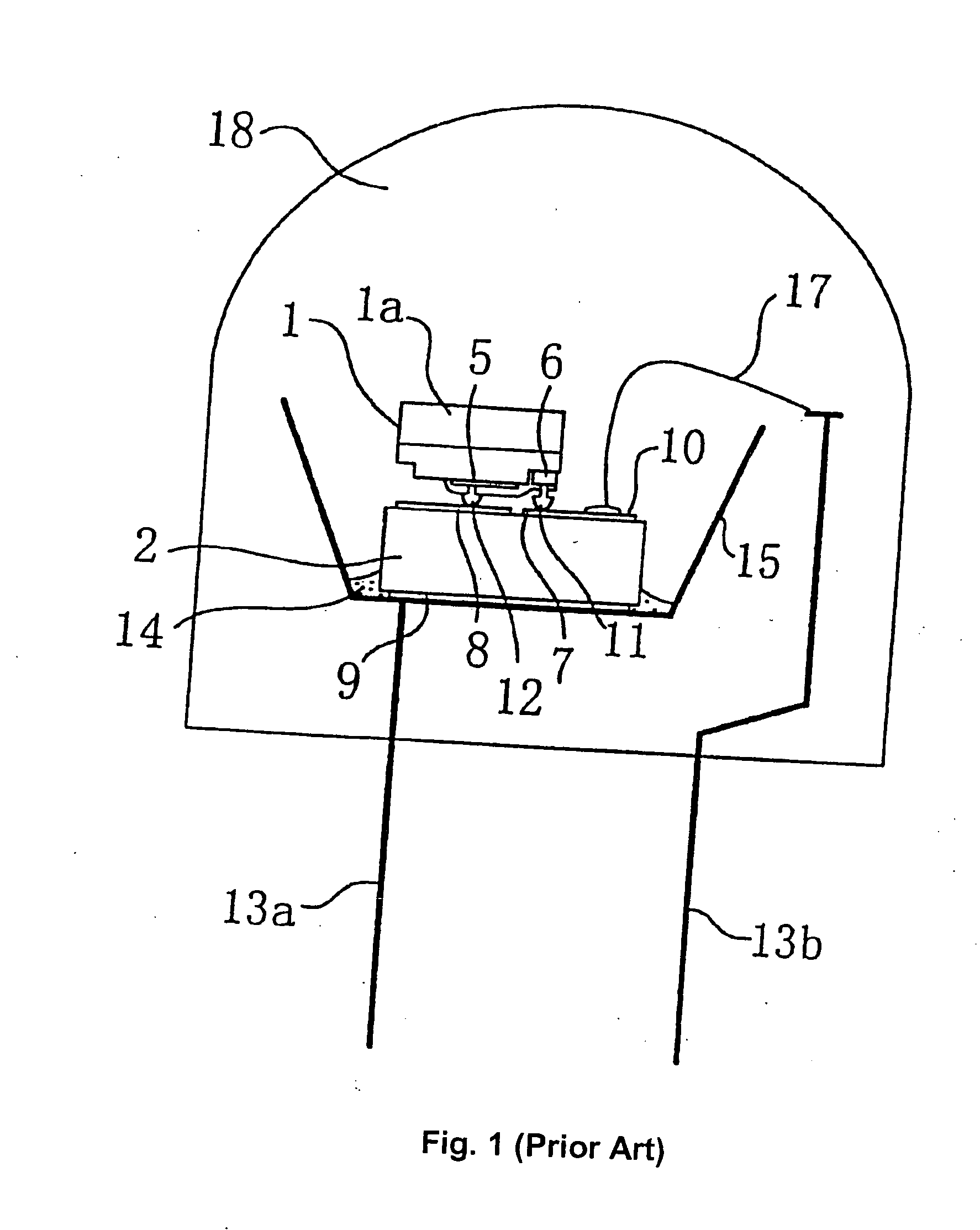

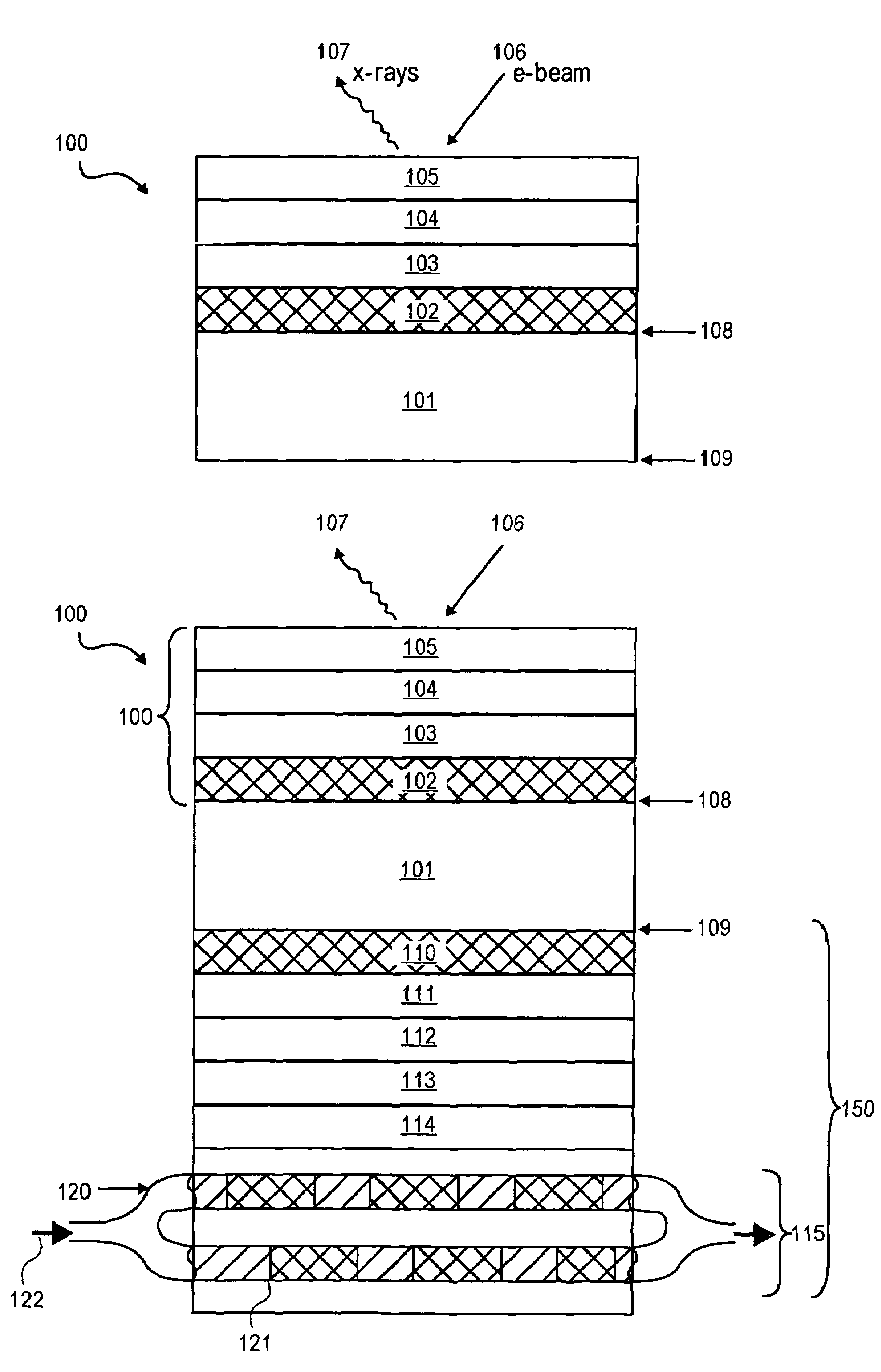

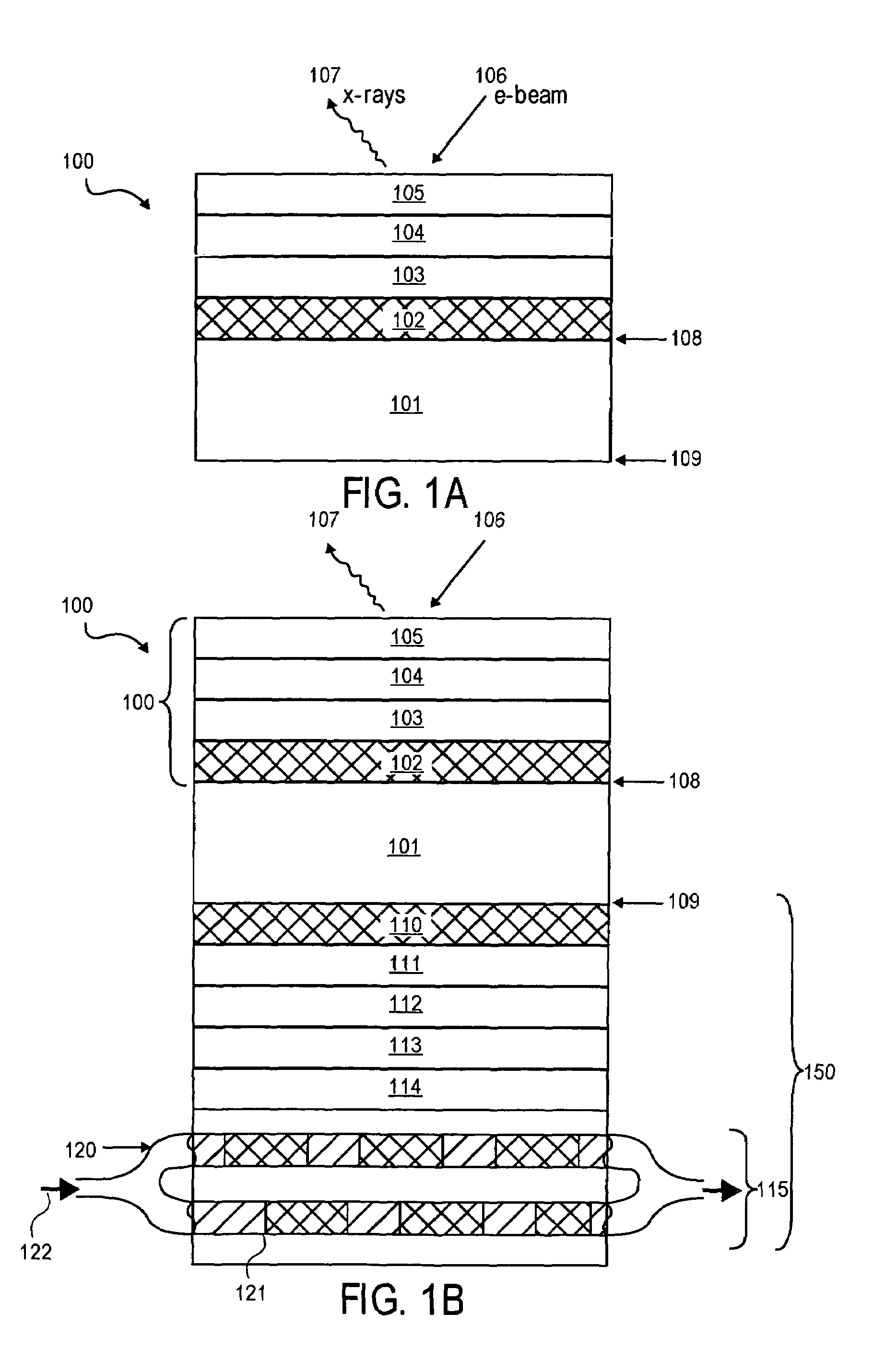

Diamond anode

ActiveUS7359487B1Avoid damageImprove cooling effectX-ray tube laminated targetsX-ray tube anode coolingOptoelectronicsMaterials science

According to one aspect of the invention a robust anode structure and methods of making and using said structure to produce ionizing radiation are disclosed. An ionizing radiation producing layer is bonded to the target side of a highly conductive diamond substrate, by a metal carbide layer. The metal carbide layers improves the strength and durability of the bond, thus improving heat removal from the anode surface and reducing the risk of delaminating the ionizing radiation producing layer, thus reducing degradation and extending the anode's life. A smoothing dopant is alloyed into the radiation producing layer to facilitate keeping the layer surface smooth, thus improving the quality of the x-ray beam emitted from the anode. In an embodiment, the heat sink comprises a metal carbide skeleton cemented diamond material. In another embodiment, the heat sink is bonded to the diamond substrate structure in a high temperature reactive brazing process.

Owner:NOVA MEASURING INSTRUMENTS INC

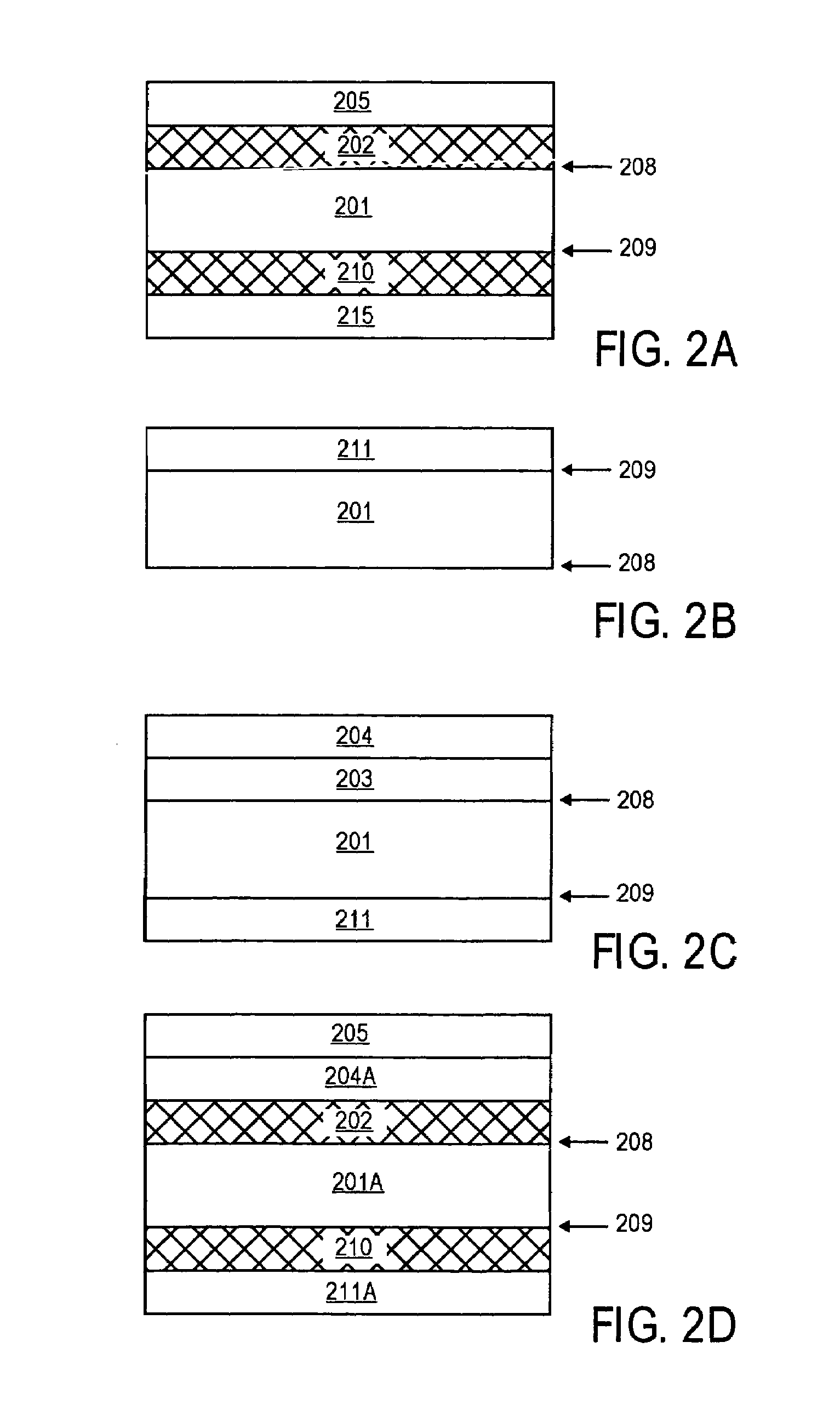

Ultra-longlife, high formability brazing sheet

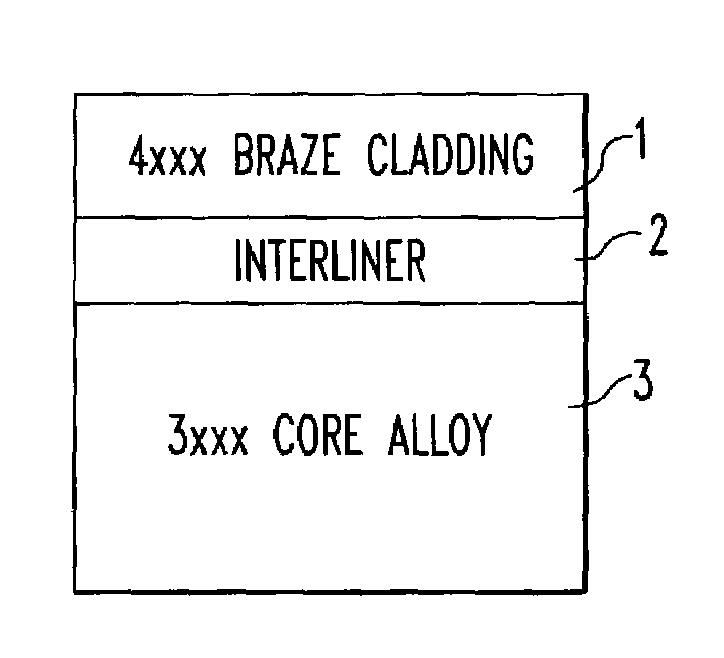

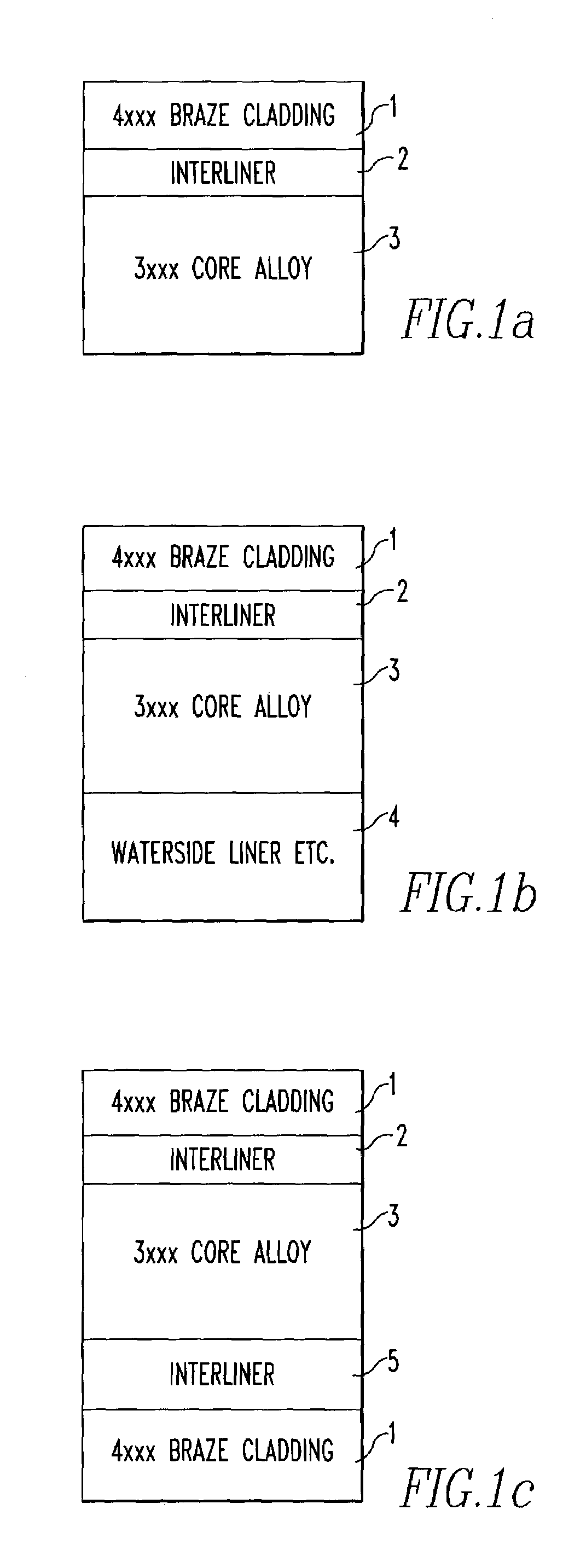

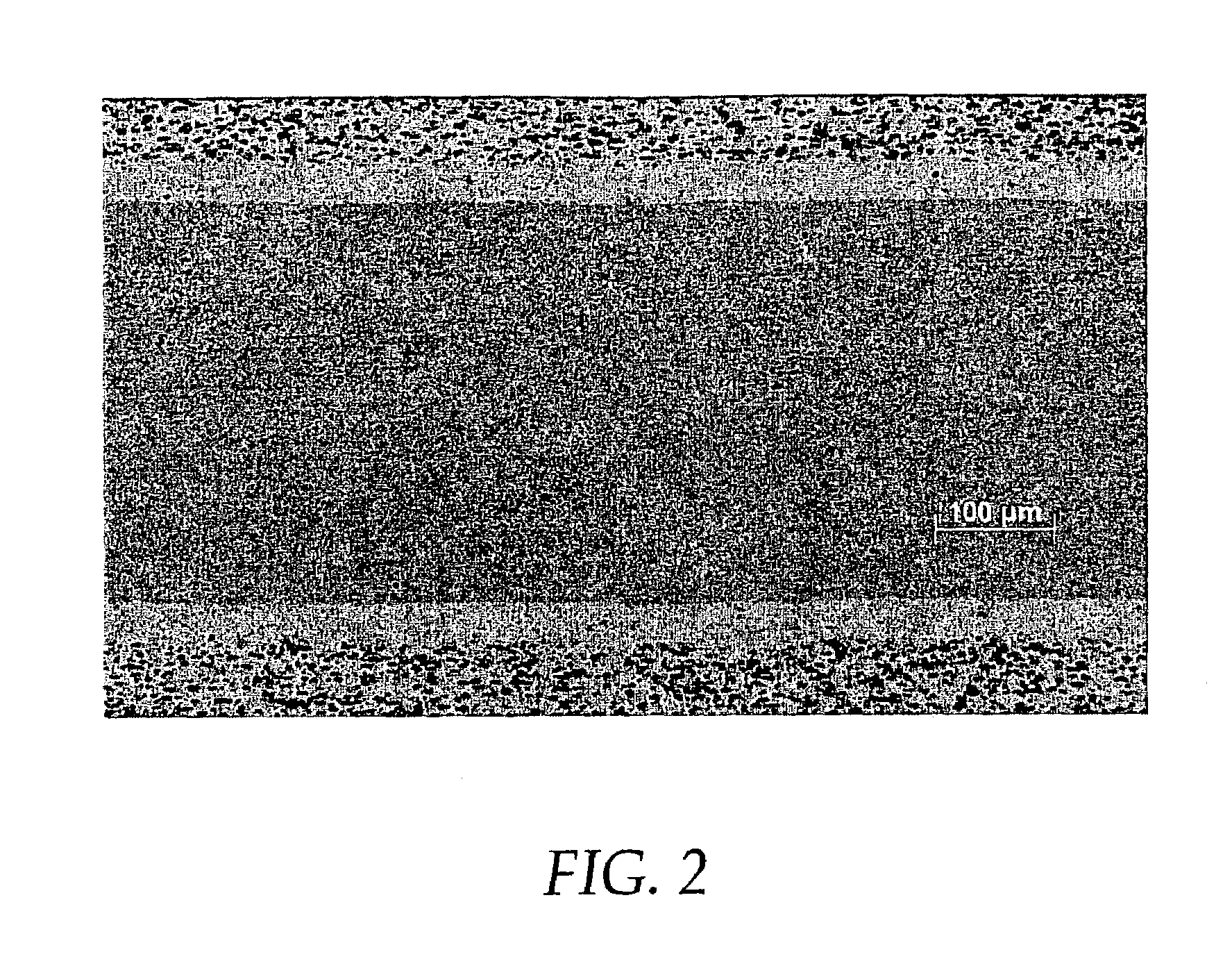

InactiveUS7255932B1Improve corrosion resistanceWelding/cutting media/materialsHeat exchange apparatusOptoelectronicsMultiple layer

The present invention relates to multiple layer aluminum brazing sheet having a core, a braze cladding, and an interliner therebetween that, when fabricated in the fully annealed condition (O-temper), forms a continuous and dense dispersoid band in the core in addition to having an additional sacrificial layer for exceptional post brazed corrosion resistance. This present invention also relates to the process used to fabricate these alloys.

Owner:ARCONIC TECH LLC

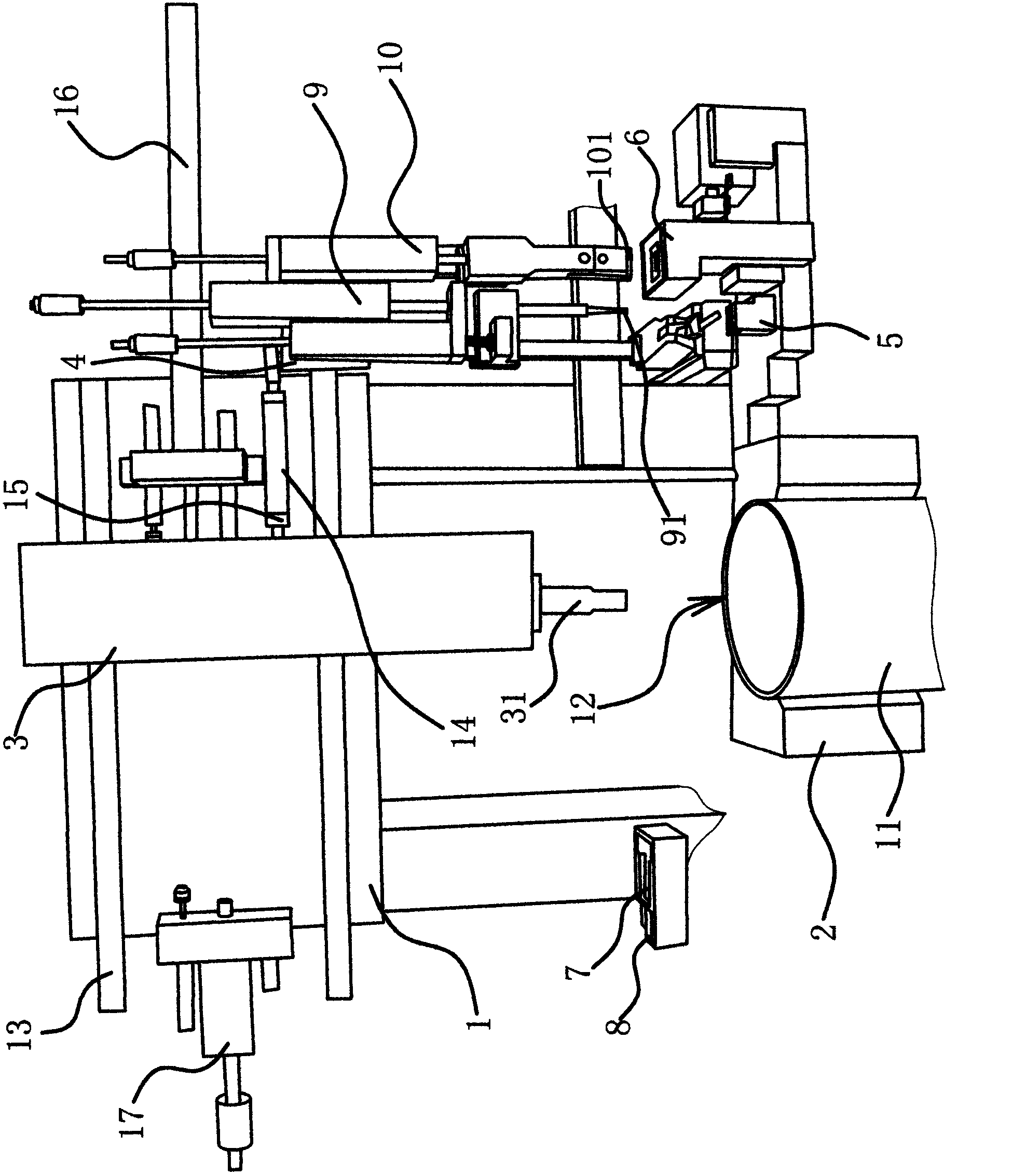

Diamond tool welding machine

ActiveCN103223538AReasonable arrangementSimple structureMetal working apparatusEngineeringMechanical engineering

The invention provides a diamond tool welding machine, and belongs to the technical field of operation. The welding machine solves the problem that the conventional brazing is low in automaticity. The welding machine comprises a machine frame and a positioning tooling fixed on the machine frame, wherein a tool bit clamping device is arranged above the positioning tooling, the tool bit clamping device is connected with the machine frame through linear guide components, and a driving part is arranged between the tool bit clamping device and the machine frame; a welding rod and a dipple glue station I are arranged on the motion trajectory of the tool bit clamping device corresponding to one side of the positioning tooling in sequence, and a dipple glue station two and a tool bit positioning base are arranged on the motion trajectory of the tool bit clamping device corresponding to the other side of the positioning tooling in sequence; a translational base is also arranged on the linear guide components, and a soldering lug sucking device corresponding to the welding rod and a dipple glue device corresponding to the dipple glue station I are arranged on the translational base; and the translational base is in rigid connection with the tool bit clamping device. The welding machine provided by the invention has the advantages that the welding machine is reasonable in arrangement, has a simple structure, and is convenient to operate and low in manufacturing cost.

Owner:项大清

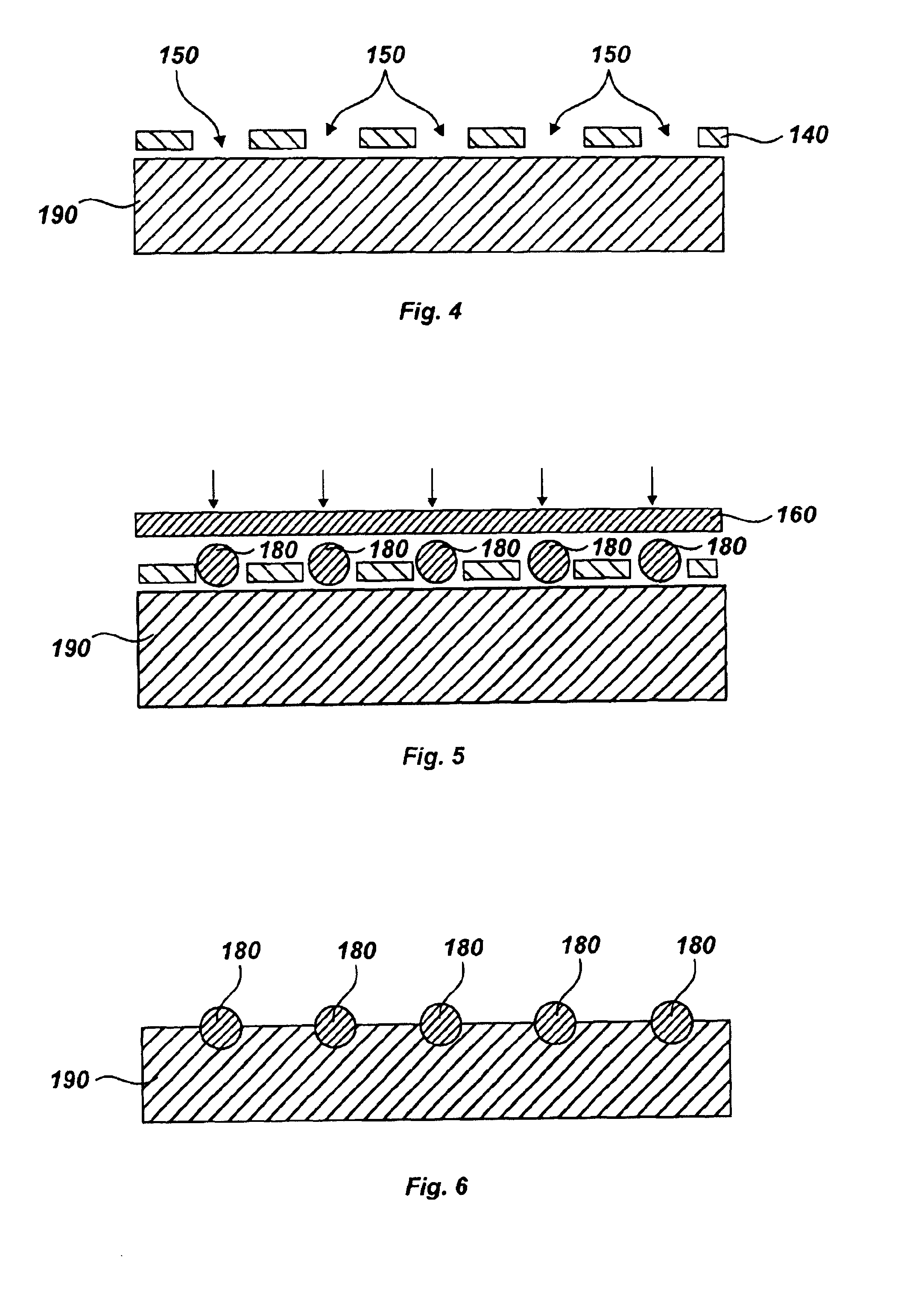

Bead pack brazing with energetics

InactiveUS7644854B1Reduce energy consumptionPrevent movementFluid removalWelding/cutting media/materialsEnergeticsUnit structure

A method of making porous shapes from unit structures such as beads involves coating the beads with two or more layers of material deposited such that it forms an energetic material. These bi-layer energetic materials are formed from a variety of materials including, but not limited to: Ti & B, Zr & B, Hf & B, Ti & C, Zr & C, Hf & C, Ti & Si, Zr & Si, Nb & Si, Ni & Al, Zr & Al, or Pd & Al, all of which can be deposited from vapor. Pressure is applied to prevent the components from moving and the solid-state reaction between the alternating layers produces exothermic heat. Heat from the reaction alone or in conjunction of an applied brazing compound joins the beads forming a porous shape that is desired. The reaction in the materials may be activated with a small pulse of local energy that can be applied using optical, electrical, or thermal sources. Common examples include an electrical pulse, spark, hot filament, a laser beam, etc. The method reduces energy consumption and the need for specialized equipment. The reactive materials and optional brazing material are preferably applied in a fluidized CVD furnace.

Owner:BAKER HUGHES INC

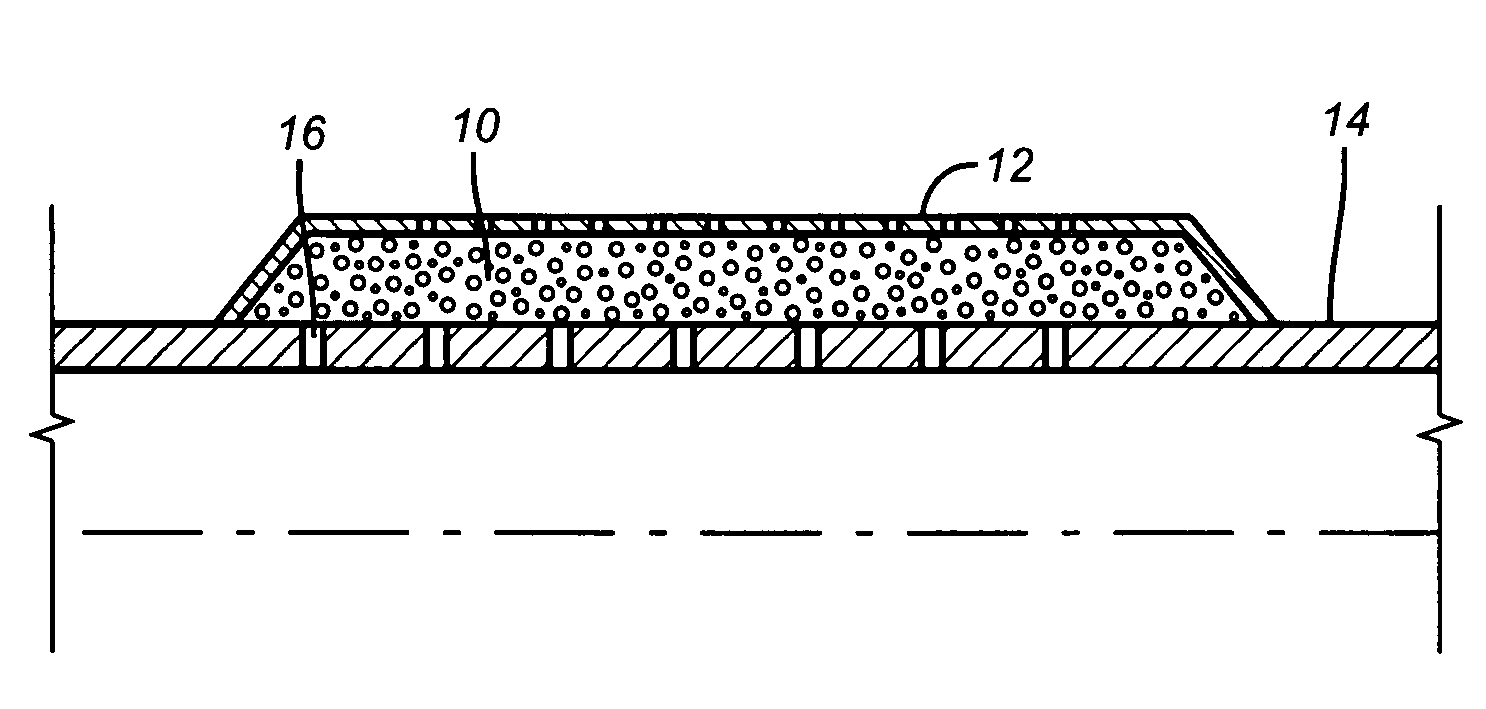

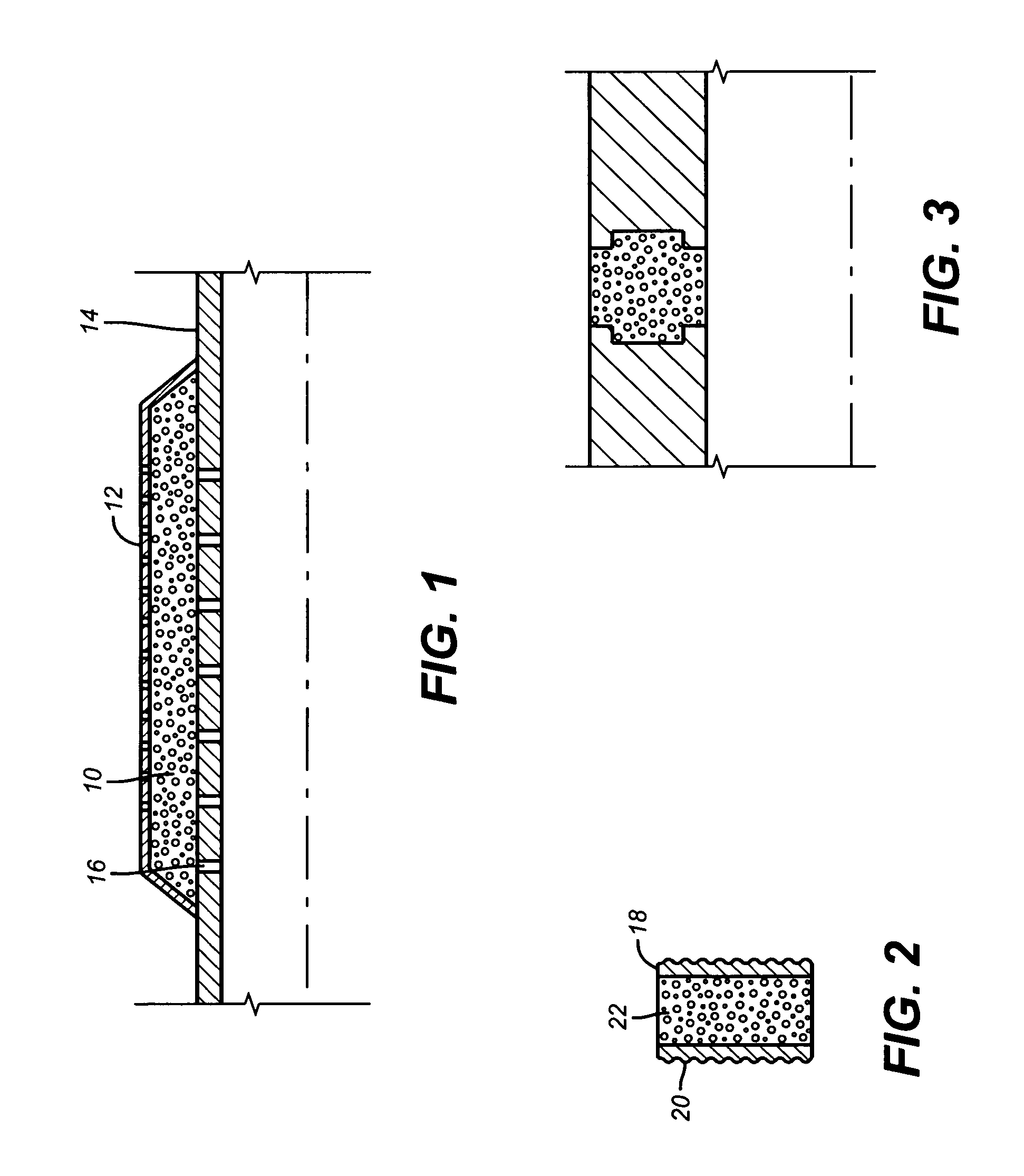

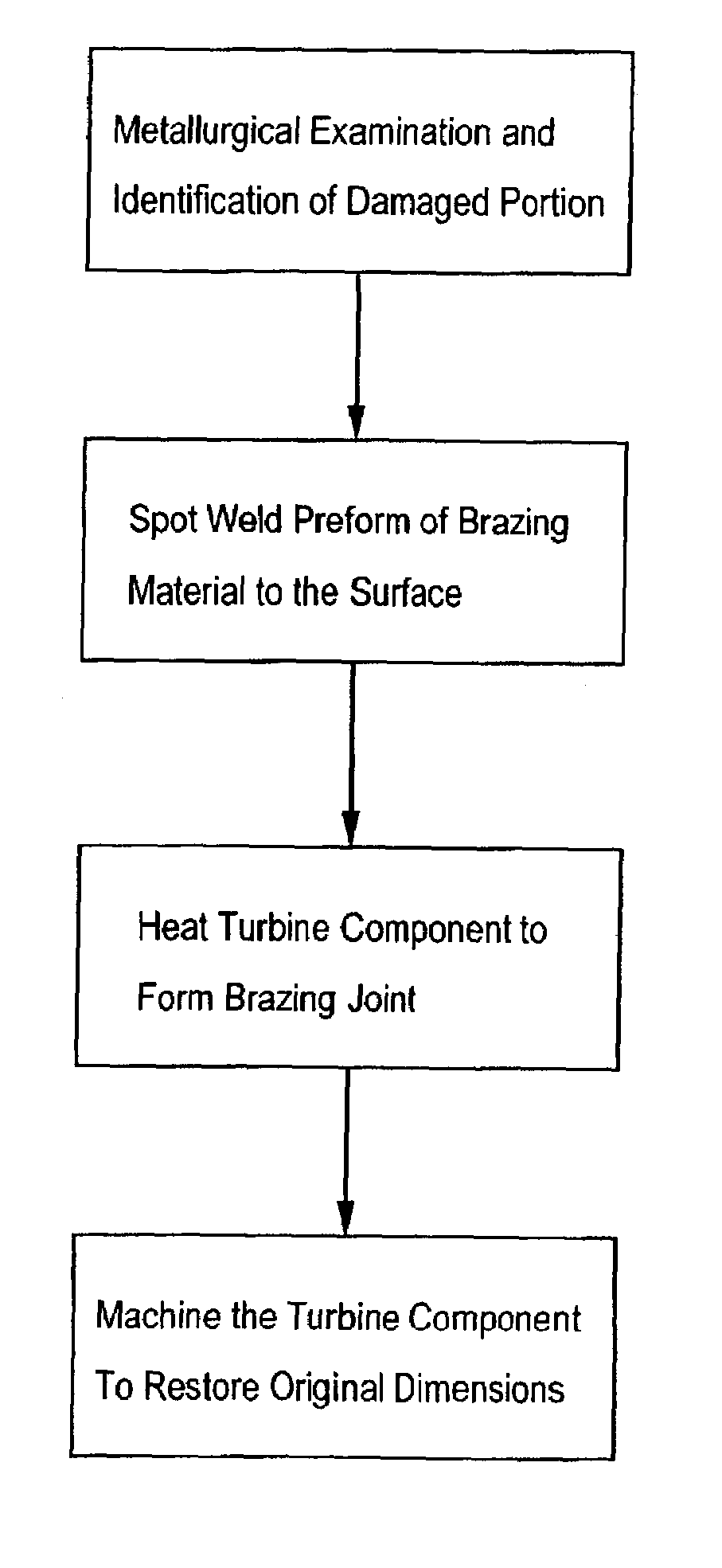

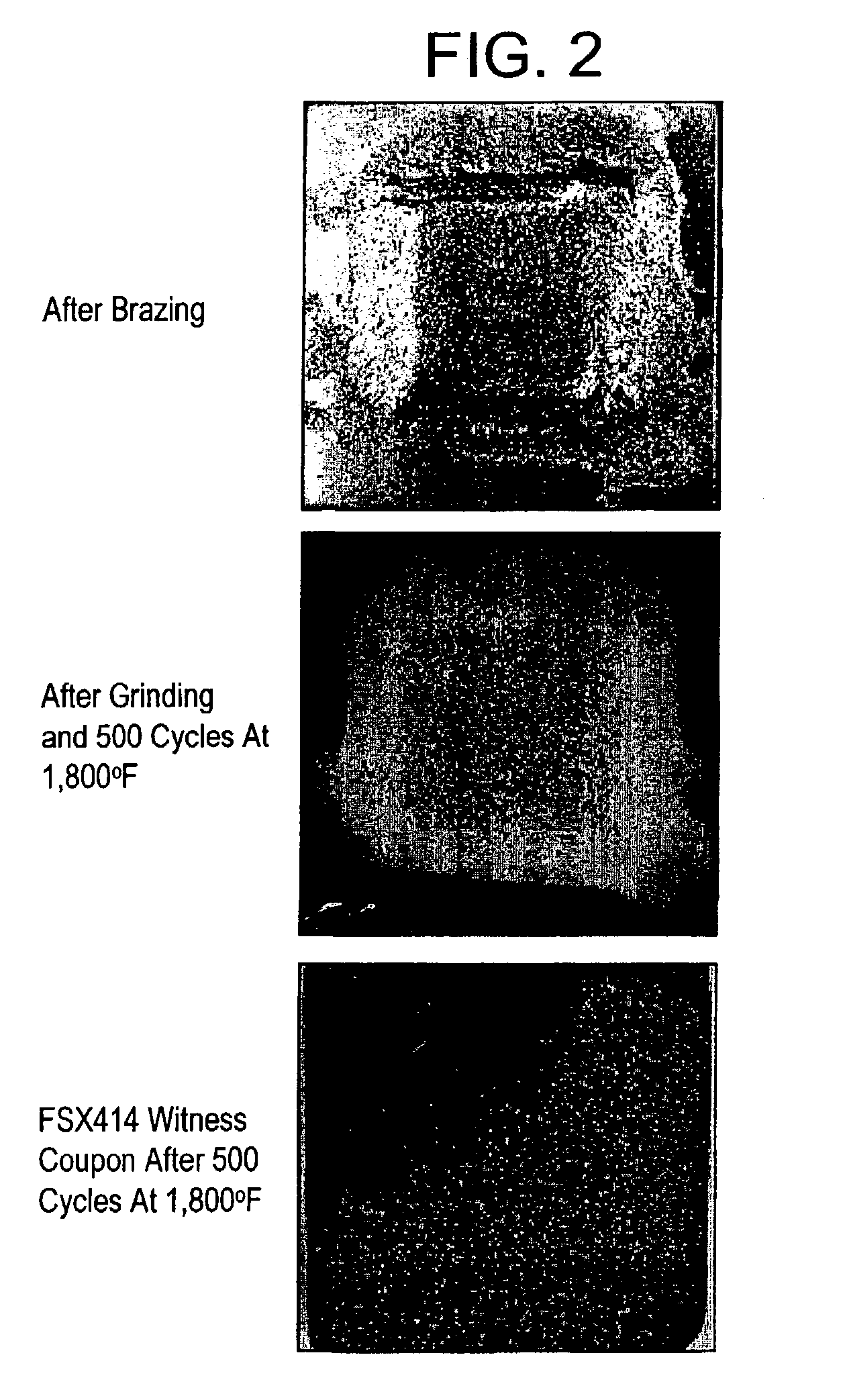

Process for repairing turbine components

A process for repairing a turbine component comprises overlaying a preform of a brazing material onto a surface of the turbine component, wherein the surface comprises a damaged portion; securing the preform of a brazing material to the surface; and heating the turbine component to a temperature effective to form a brazed joint between the brazing material and the turbine component. Also disclosed is a repaired turbine component repaired by the process.

Owner:GENERAL ELECTRIC CO

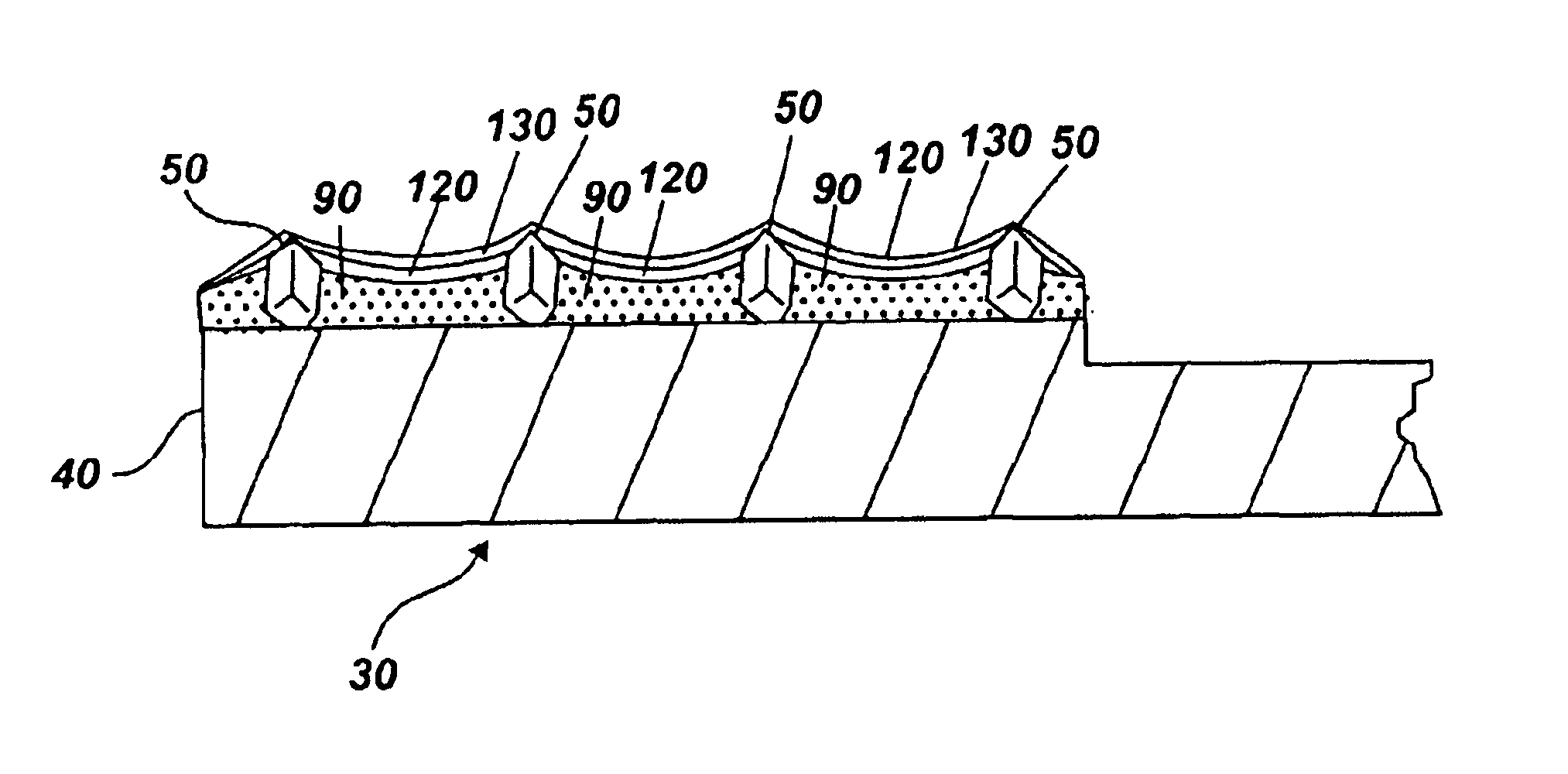

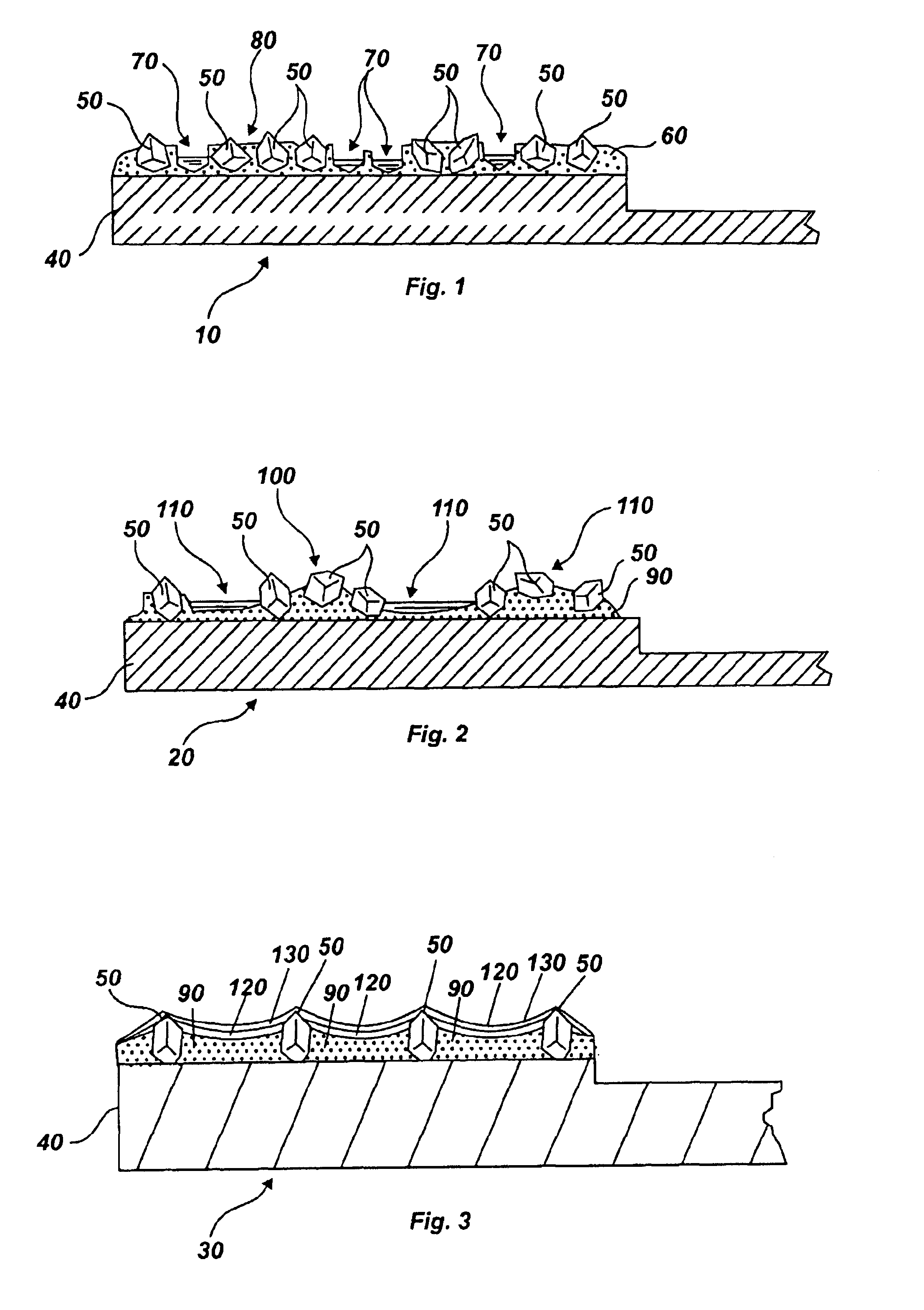

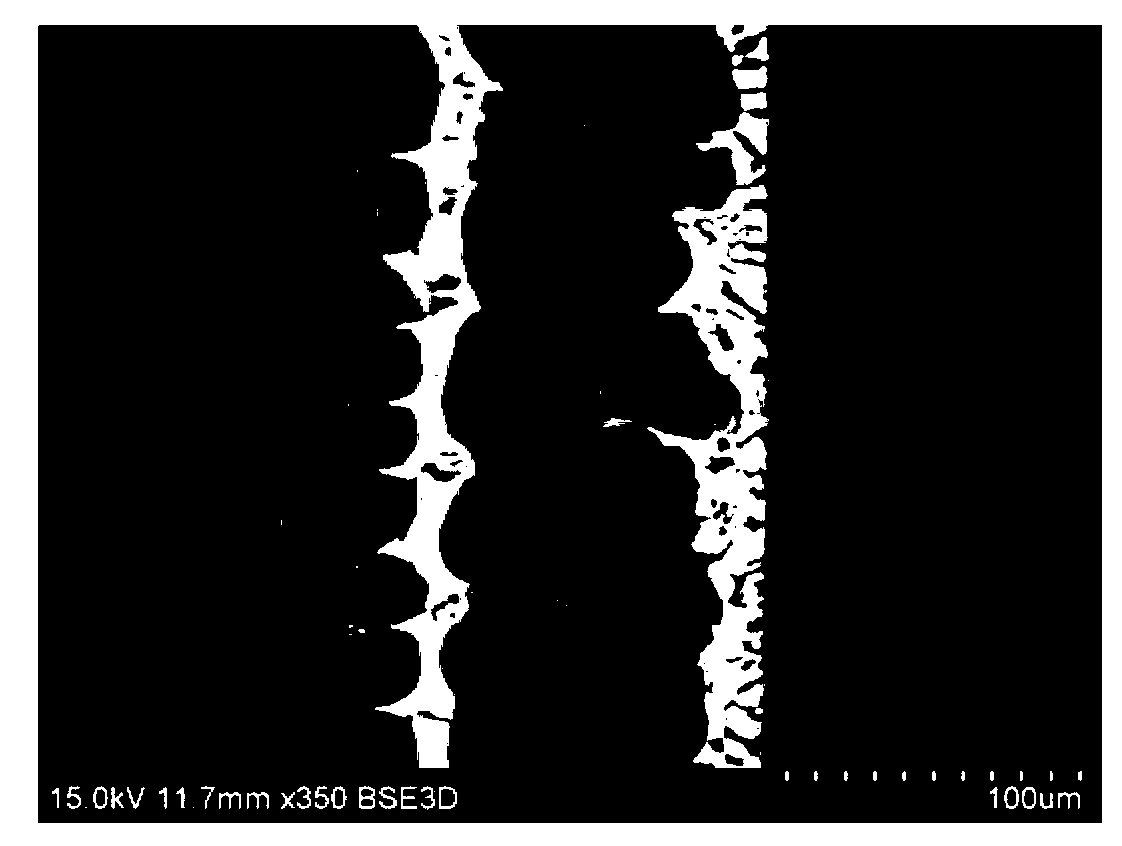

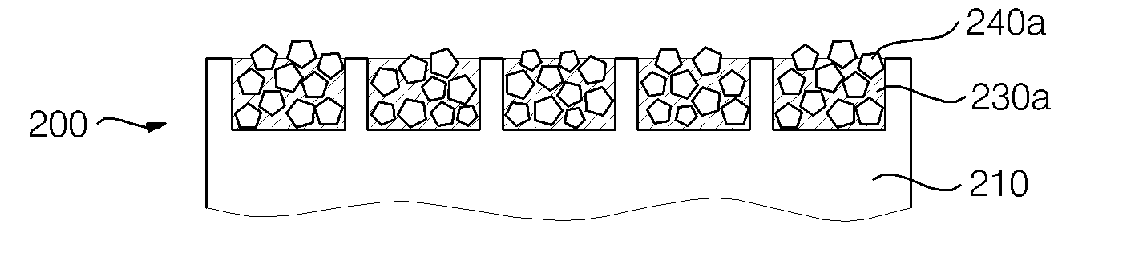

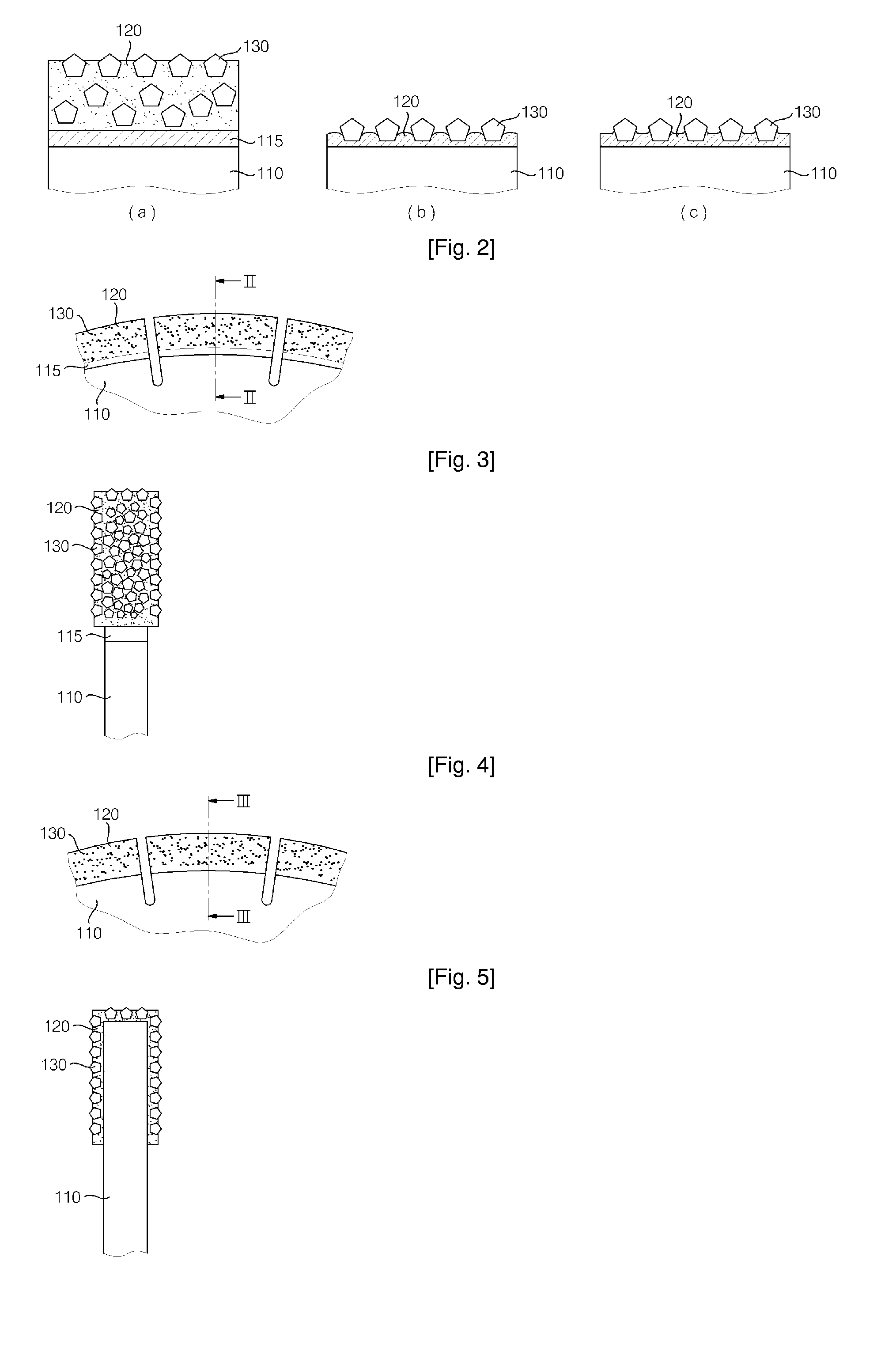

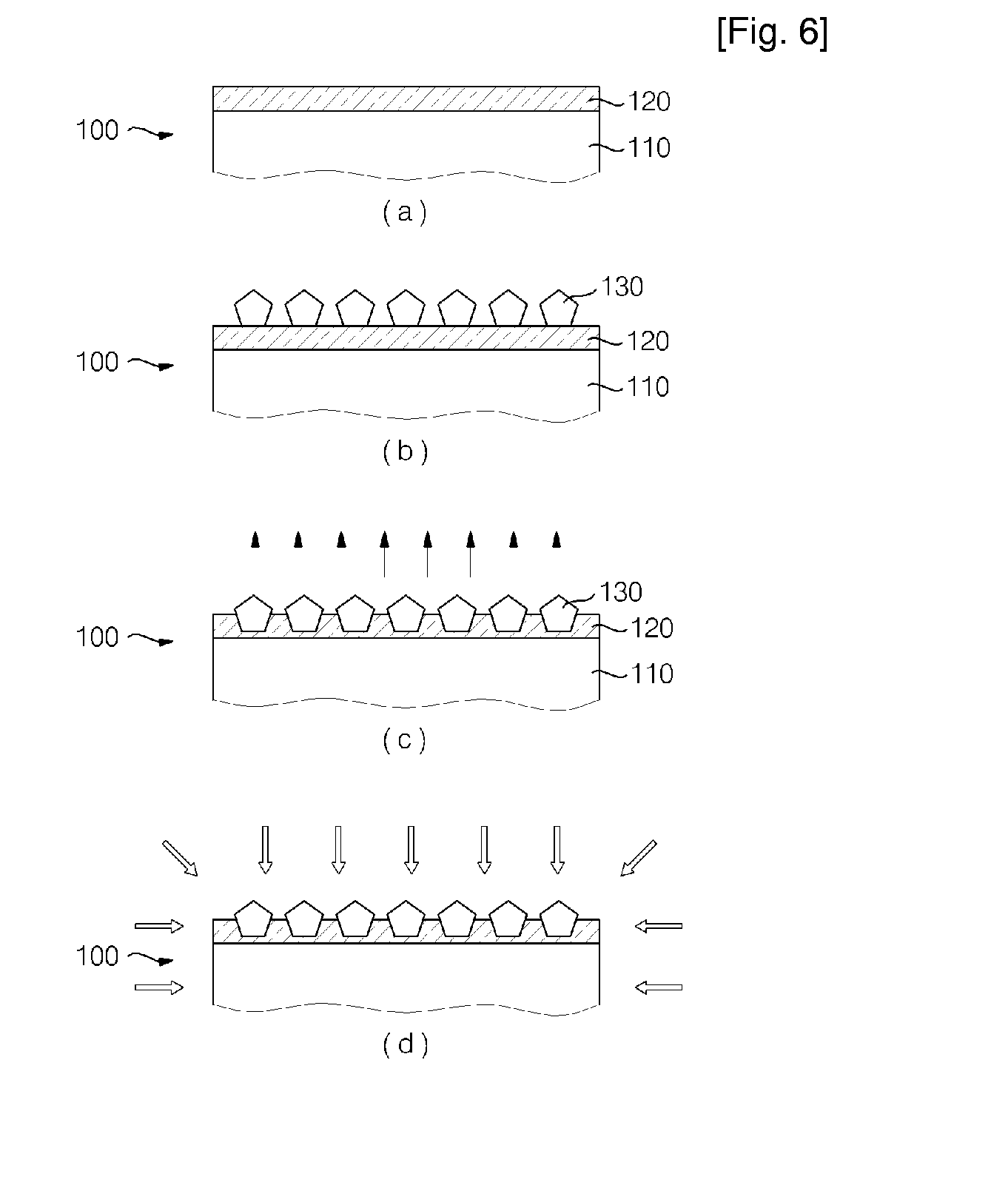

Diamond tools with multilayers of abrasive grain and method for manufacturing the same

ActiveUS20070151554A1Evenly distributedUniform thicknessBonded abrasive wheelsGrinding devicesElectroplatingHeat treated

The present invention relates to a diamond tool and a method of manufacturing the same, wherein multiple abrasive layers are formed through a brazing or electroplating method, thereby improving the performance and service life of the tool. According to the method of the present invention, a plurality of concave portions are formed in a surface of the shank. A bonding paste is coated into the concave portions and abrasives are dispersed in the bonding paste to thereby form a lower abrasive layer. Again, a bonding material is coated on the lower abrasive layer and abrasives are dispersed in the bonding material to thereby form an upper abrasive layer. Then, a heat treatment is executed to fusion-bond the bonding material and abrasives onto the surface of the shank. Therefore, the diamond tools manufactured through a multiple brazing or electroplating method according to the invention can significantly extend the service life thereof, which has been a detrimental weakness of the conventional diamond tools having a single abrasive layer, in spite of various advantages of the brazing and electroplating methods. Furthermore, multiple abrasive layers can be formed inside the concave portions having a desired spacing, width and depth, thereby significantly improving the service life and the cutting performance of diamond tools.

Owner:SHINHAN DIAMOND IND

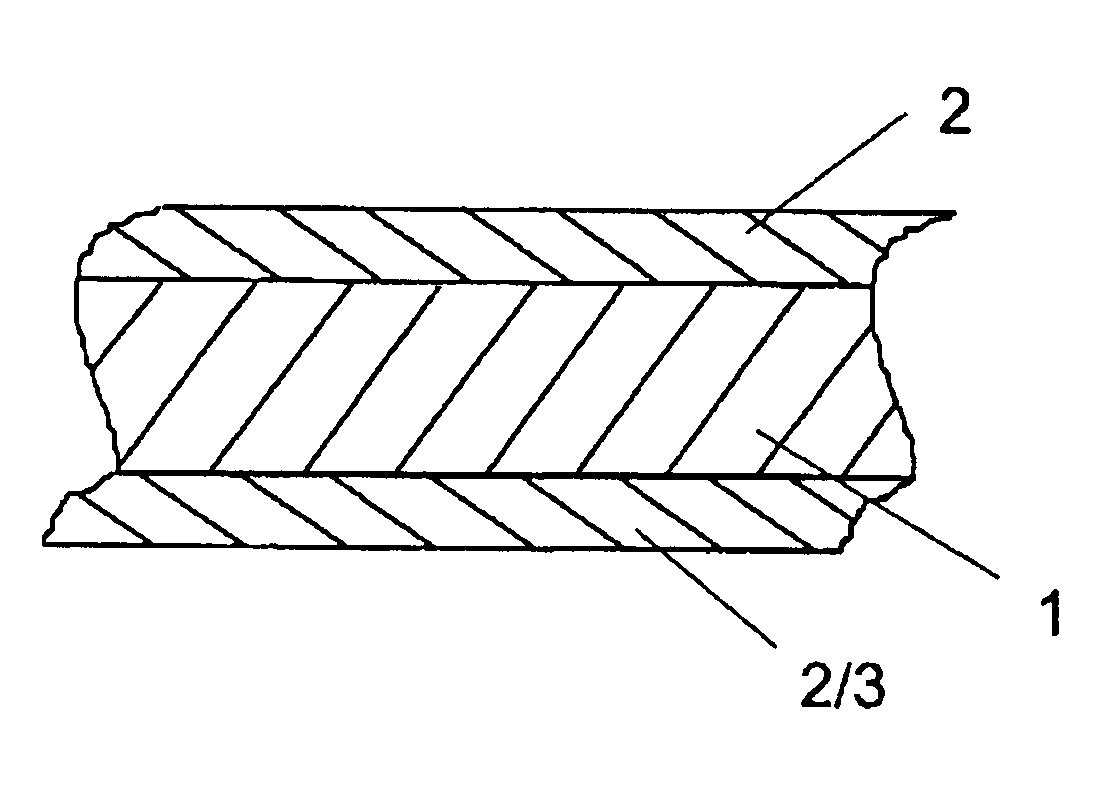

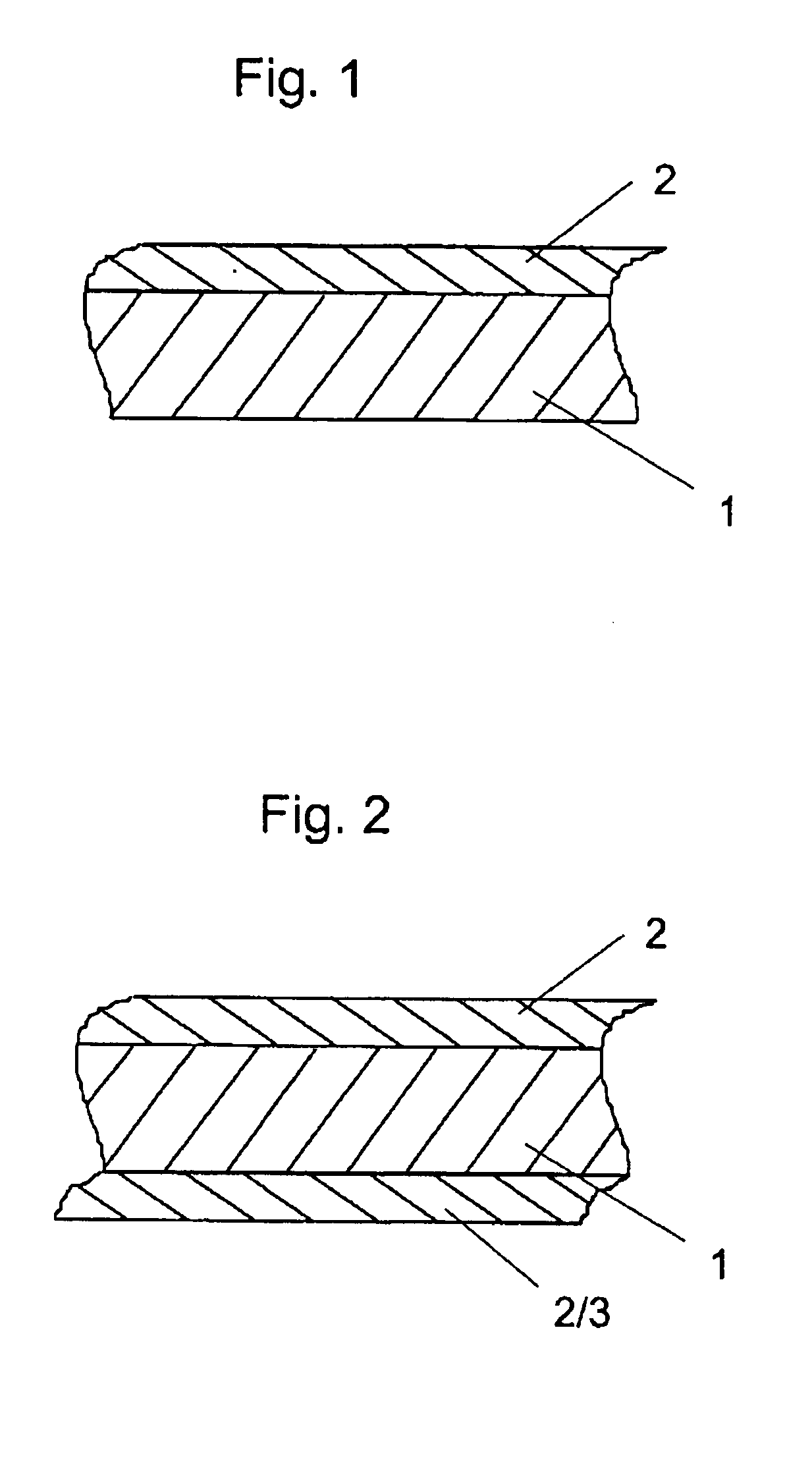

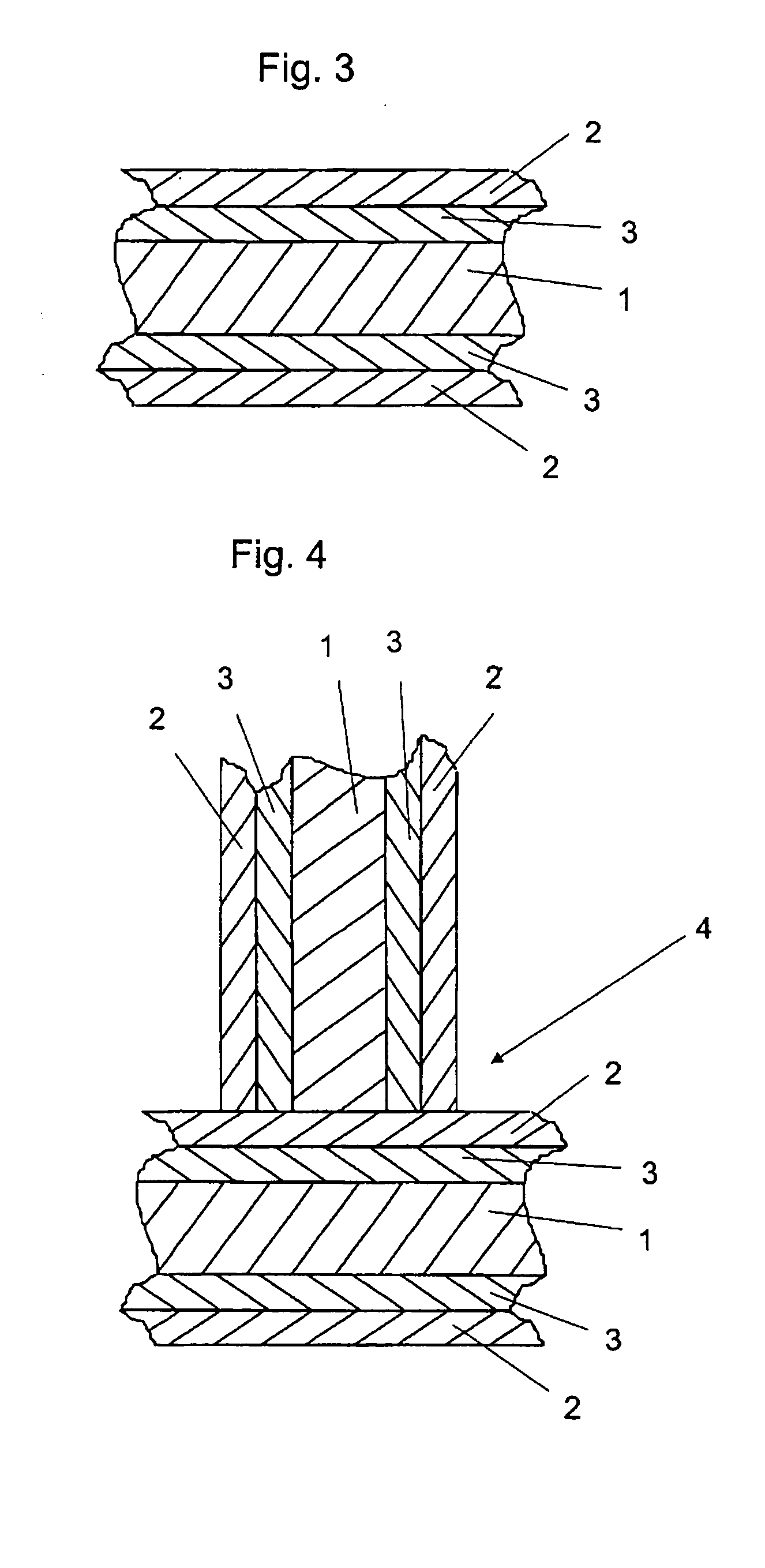

Multilayer braze-able sheet

InactiveUS20070246509A1Increased post braze strengthShorten aging timeCooking-vessel materialsWelding/cutting media/materialsManganeseCopper

A multi-layer aluminum brazing sheet including a core layer, interliner, braze clad layer and a sacrificial layer, in which the post-braze strength of the brazing sheet is optimized by controlling the manganese (Mn), silicon (Si), copper (Cu) and magnesium (Mg) contents of the core layer and the Mn, Si and Cu content of the interliner and the Mn, Si and Zn content of the sacrificial layer and the specifics of the braze thermal cycle. The brazing sheet maintains corrosion resistance, while optimizing post-braze strength, by utilizing 0.5 wt. % to 1.2 wt. % Cu in the interliner. Further, the interliner and sacrificial layer of the brazing sheet contain low or no magnesium to maintain the brazing sheet's braze-ability.

Owner:ARCONIC TECH LLC +1

C/C and C/SiC composite material and metal connecting method

ActiveCN101143397AFirmly connectedSoldering apparatusWelding/soldering/cutting articlesParticulatesMetal fibers

The invention is a method of binding compound materials of the C / SiC and C / C, which belongs to the technology field of binding heterogeneous materials. The processing procedures are as following: 1. The surface of the e compound materials of the C / SiC and C / Cis pretreated, which comprise the surface of the connecting are grinding, cleaning, vacuum biscuit firing, preparation of double-layer metal film and microvacum heat treatment and so on. 2. The transition layer of the connecting area surface gradient of the compound materials of the C / SiC is coated and sintered. 3. The compound materials with the gradient transition layer as the felted phase is brazed with the metal in vacuum. The invention is characterized in that the gradient transition layer is directly used as the materials that bind the compound materials with the metal; the gradient transition layer is double-layered or multilayered (sub-layered) structure; from the inner basal body to the outer part of the compound materials, the melting points of active brazing alloy adopted by each sub-layer gradually lower, the coefficient of heat expansion that adjust volume percentage composition gradually lower and the coefficient of heat expansion of the sub-layers gradually rise. The brazing ceramic metal connecting piece of the invention has good strength, air tightness and wide application field, which is suitable for various non-metallic fibers, such as ceramics of SiC, Si3N4, Al2O3, AlN and so on and applicable for connecting the ceramic matrix compound materials with particulate reinforced with the metal.

Owner:GRIMAT ENG INST CO LTD

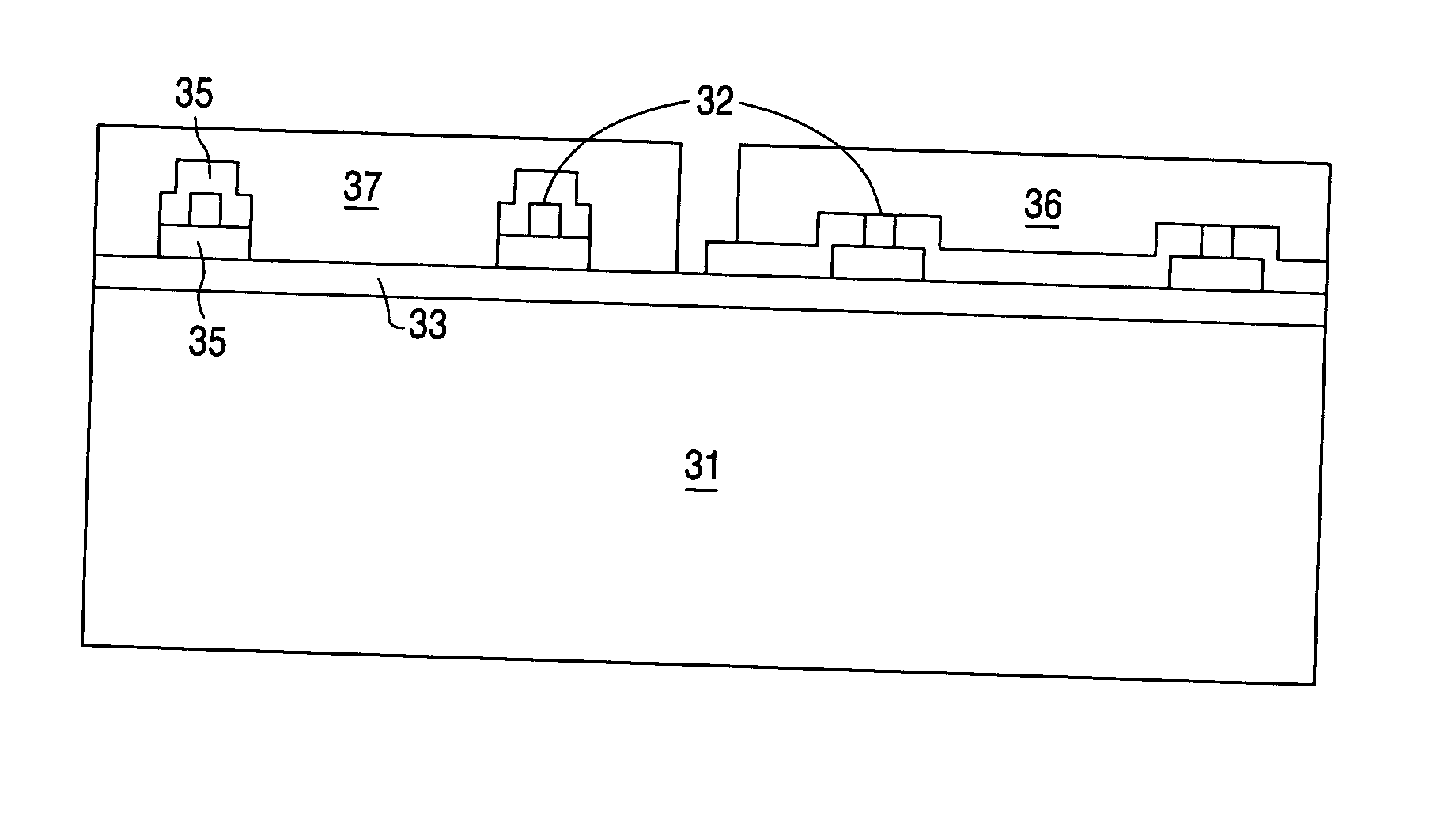

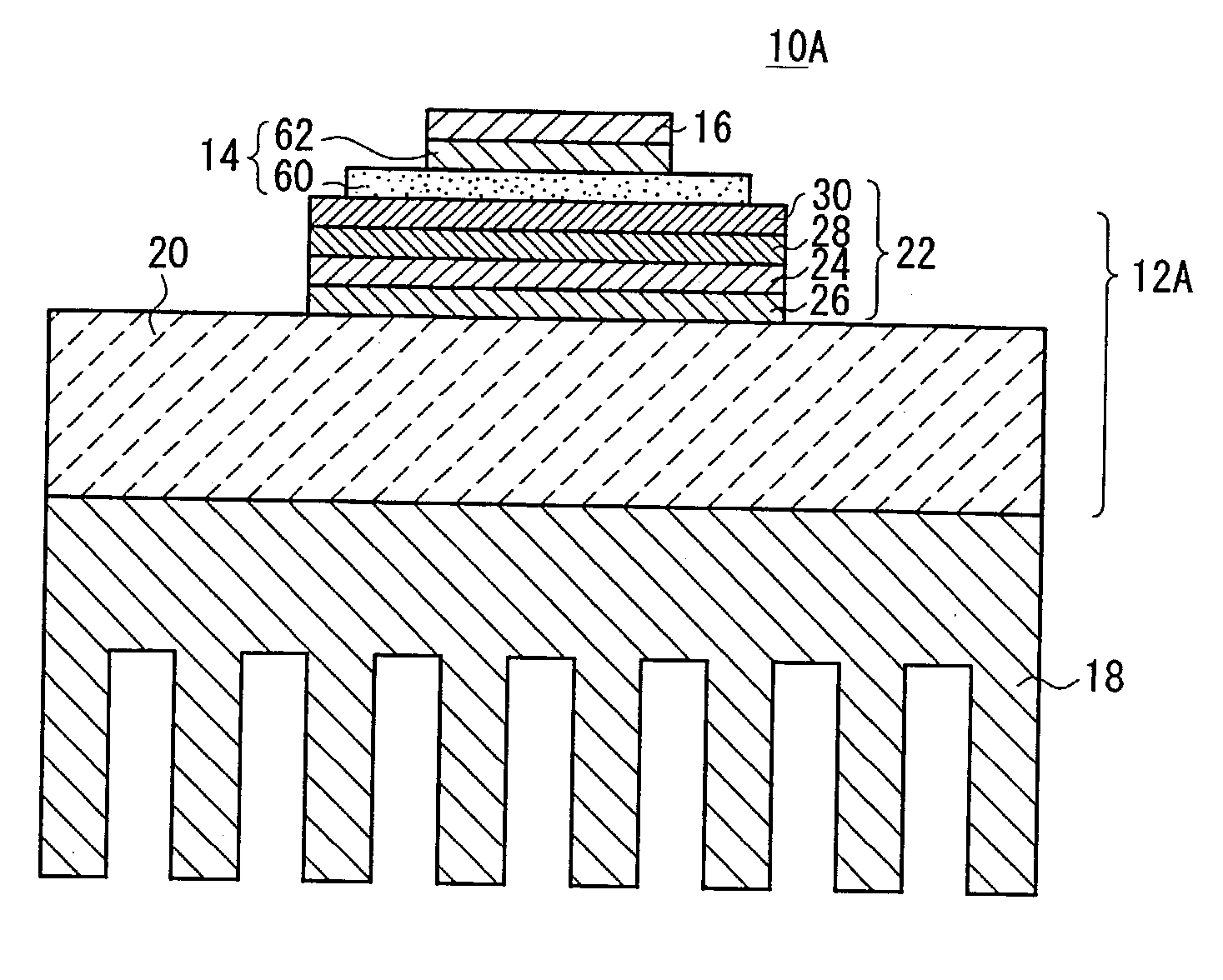

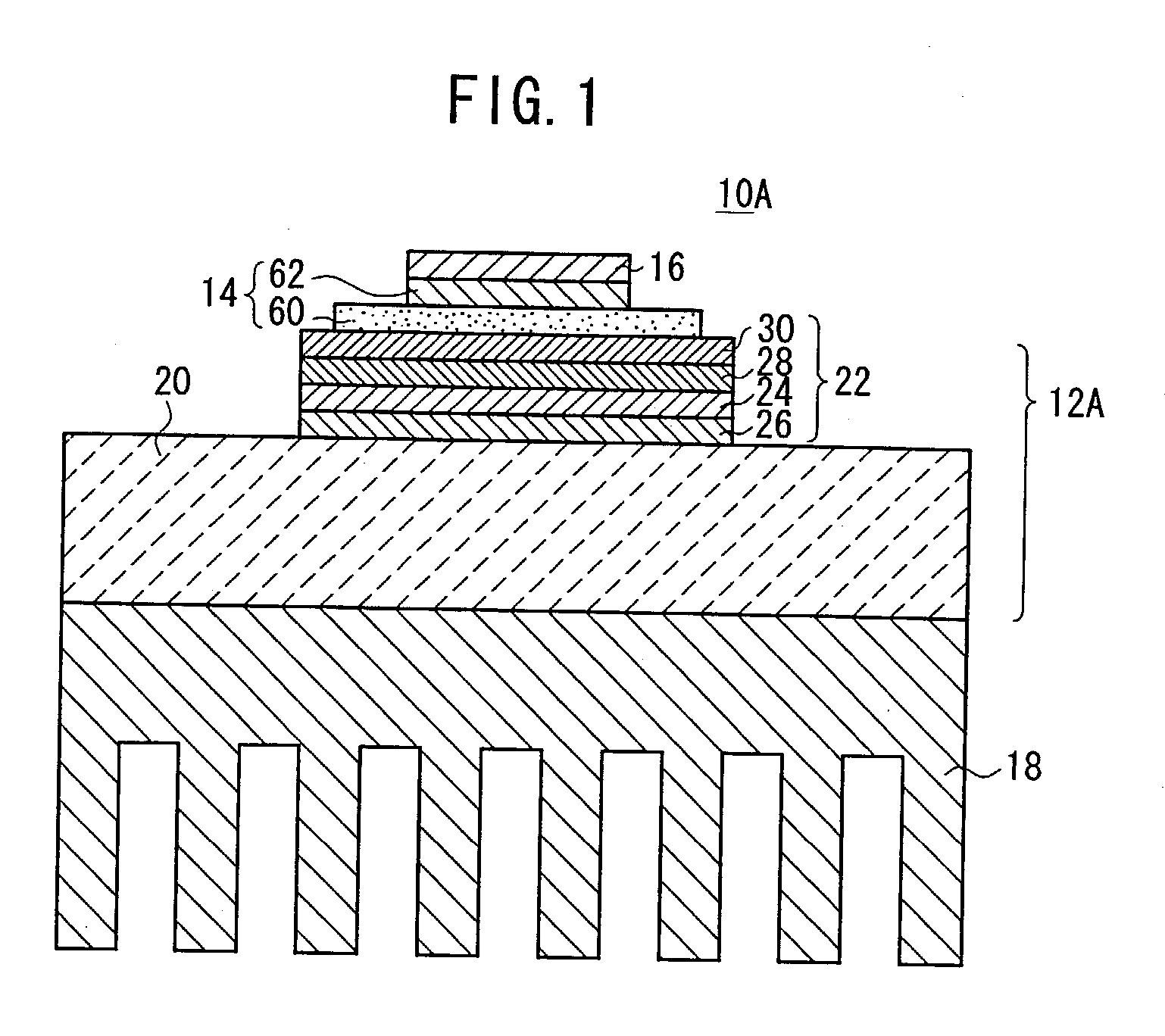

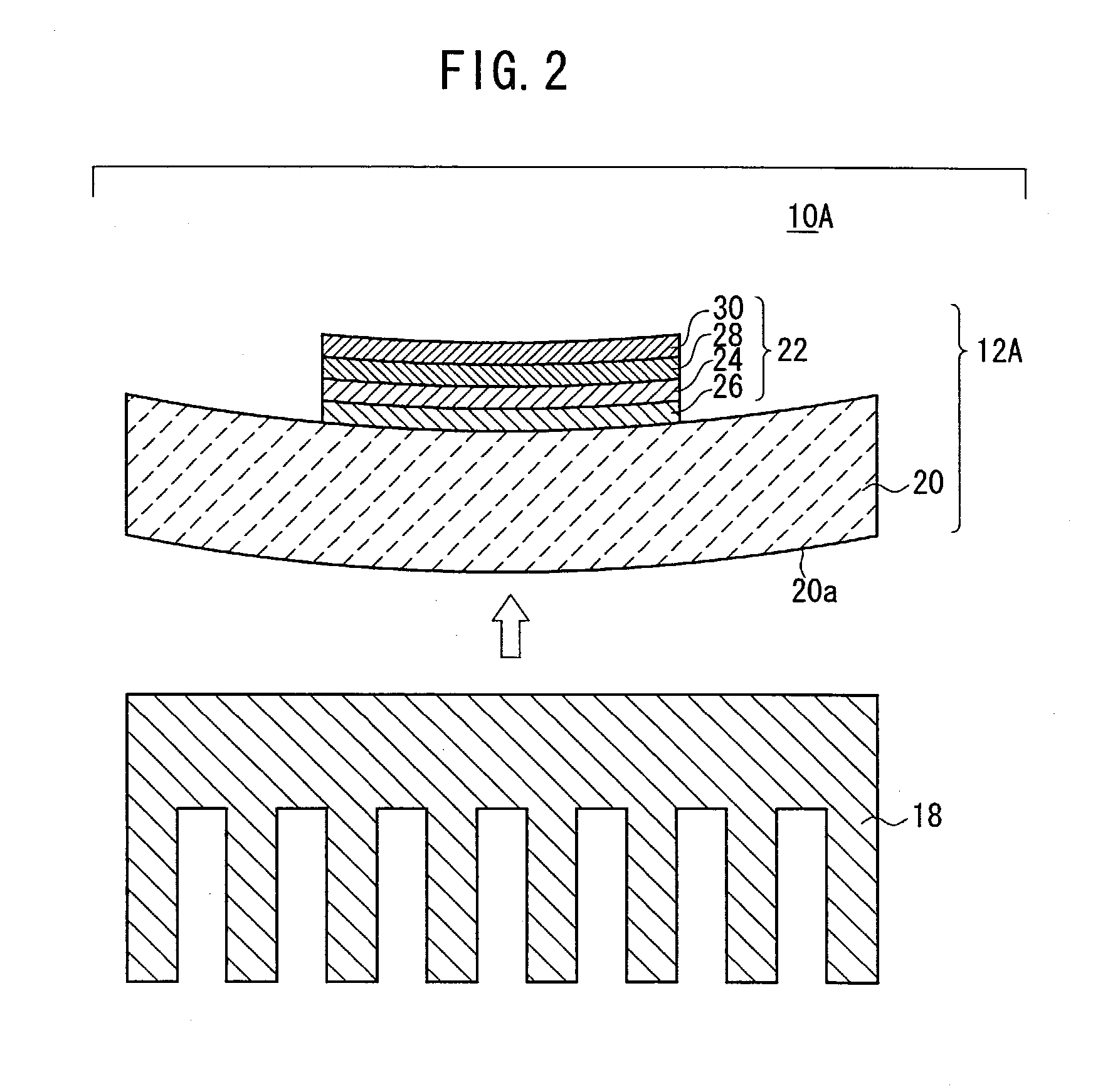

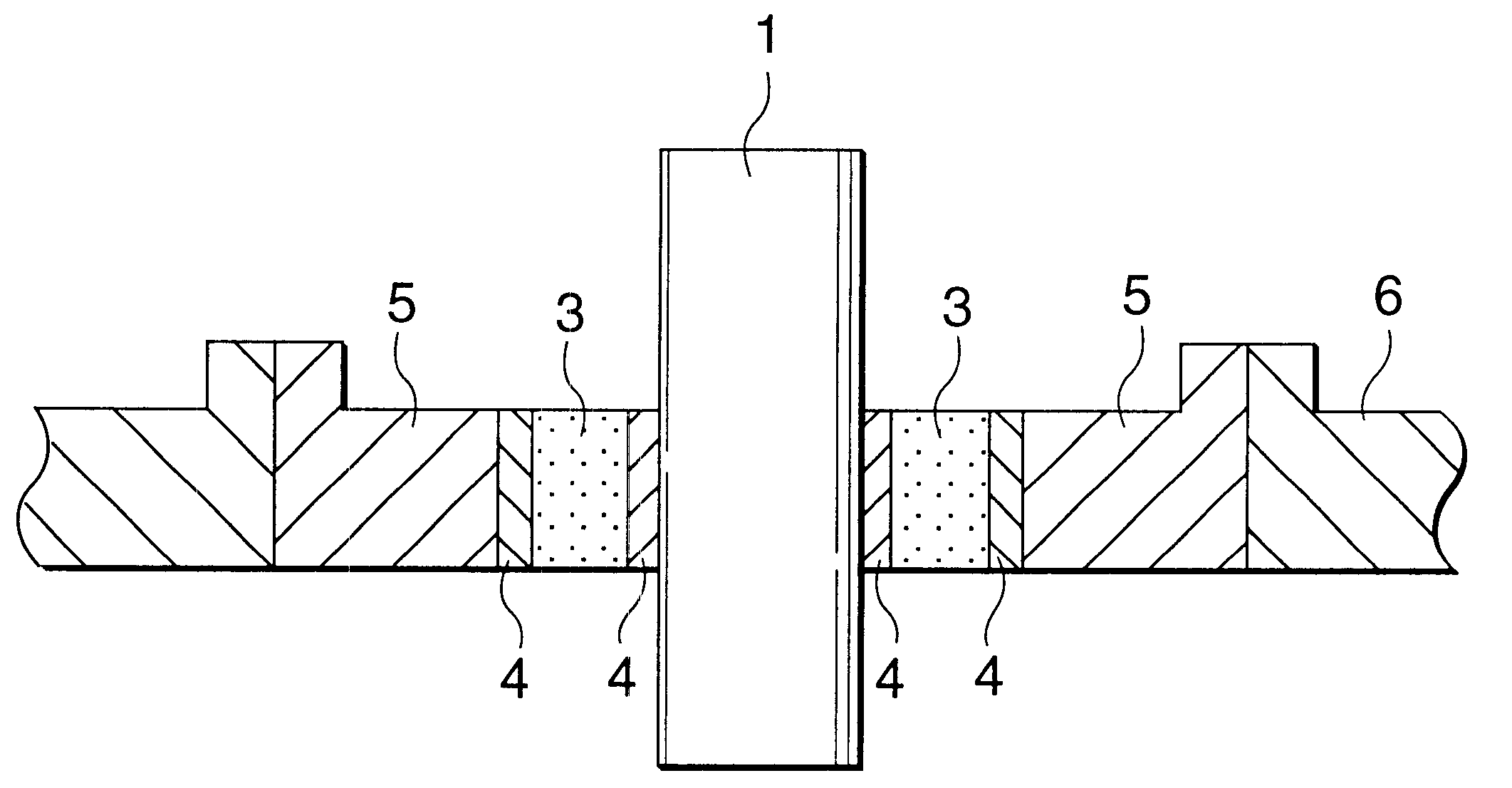

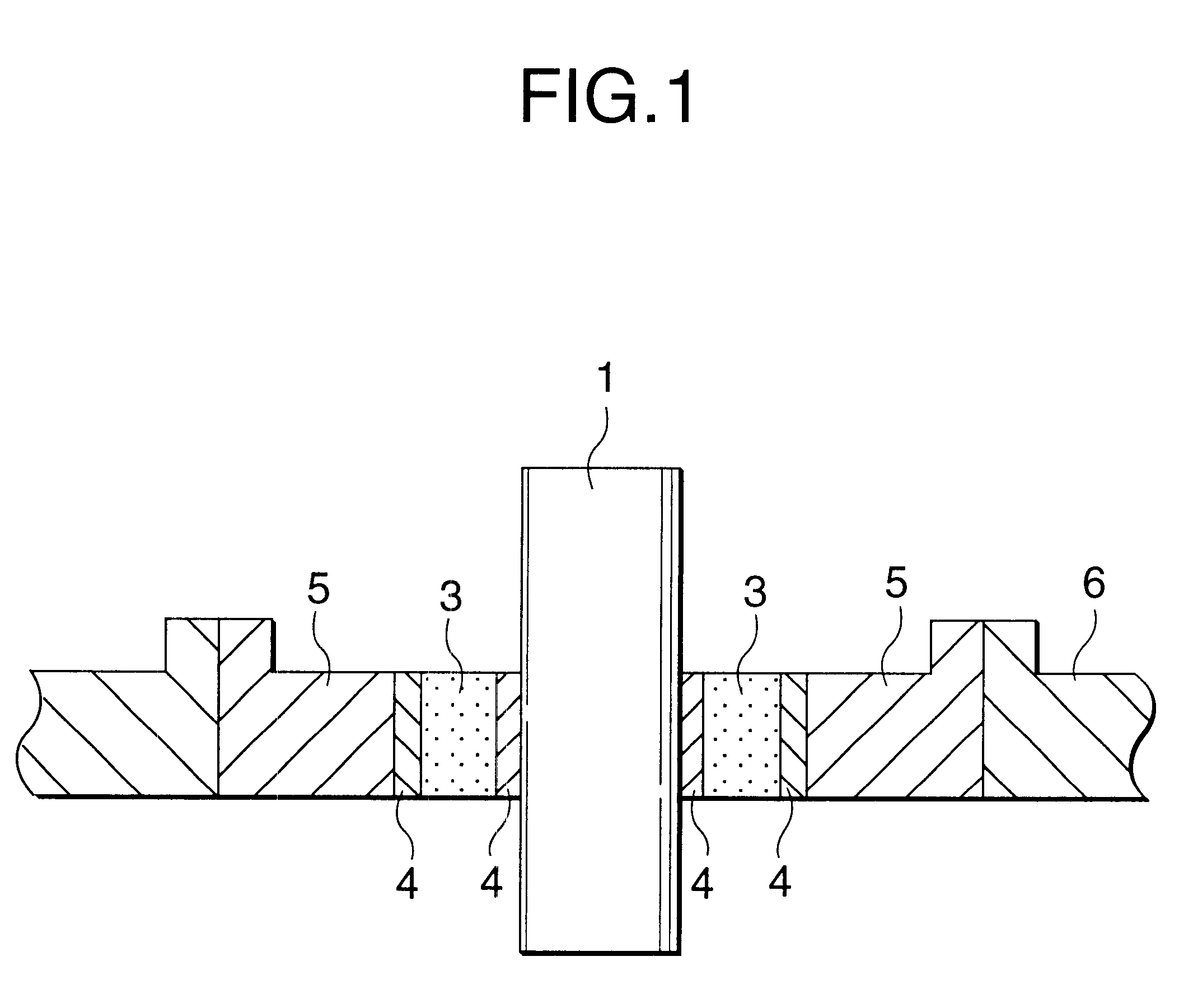

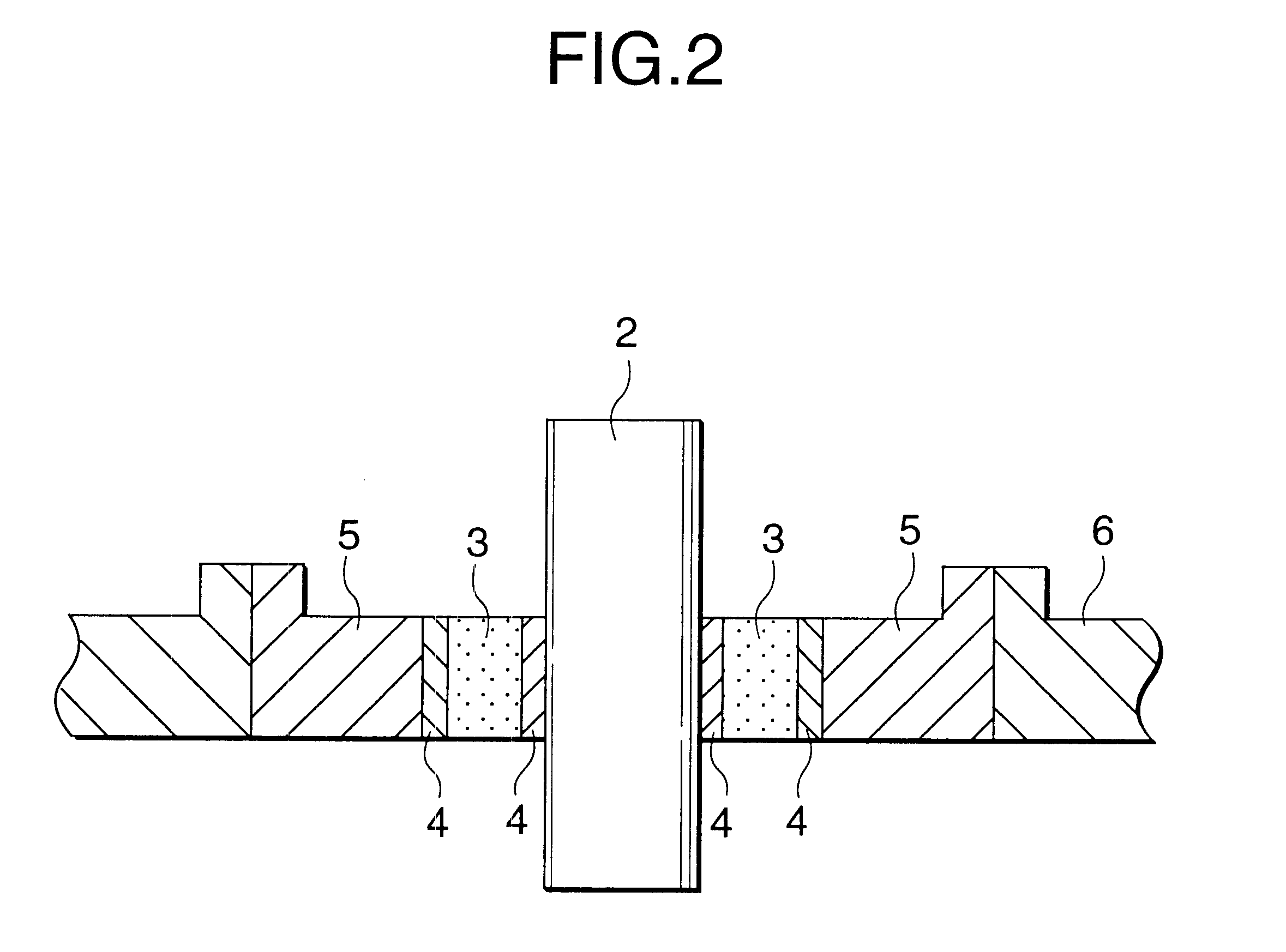

Member for electronic circuit, method for manufacturing the member, and electronic part

InactiveUS20030102553A1Reduce manufacturing stepsReduce manufacturing costInsulating substrate metal adhesion improvementSemiconductor/solid-state device detailsJoint componentEngineering

A member (12A) for use in an electronic circuit has a thermally conductive layer (22) mounted on a heat sink (20). The thermally conductive layer (22) comprises an insulating substrate (24), a first joint member (26) joining the insulating substrate (24) to the heat sink (20) and containing an active element, a second joint member (28) disposed on the insulating substrate (24), and an electrode (30) disposed on the second joint member (28). The insulating substrate (24) comprises an AlN layer or an Si3N4 layer. Each of the first and second joint members (26, 28) is made of a hard brazing material containing an active element. The heat sink (20) is made of an SiC / Cu composite material or a C / Cu composite material.

Owner:NGK INSULATORS LTD

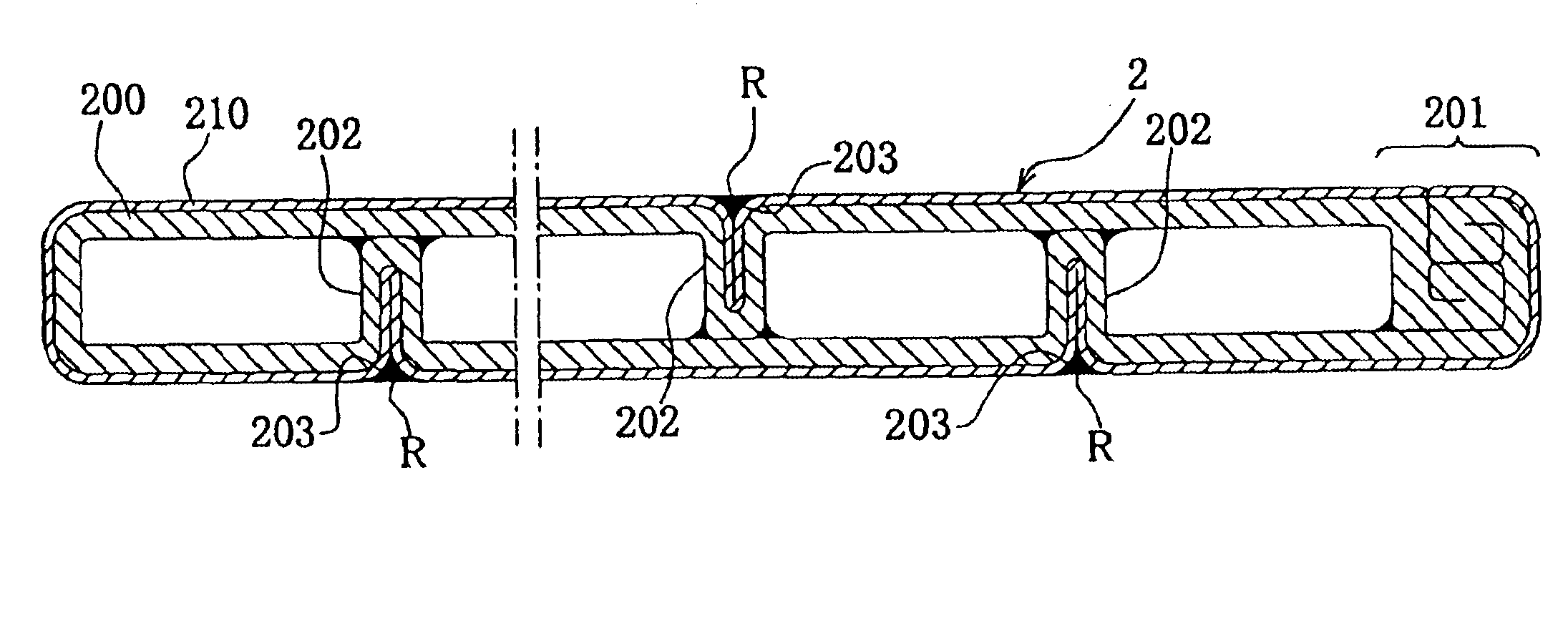

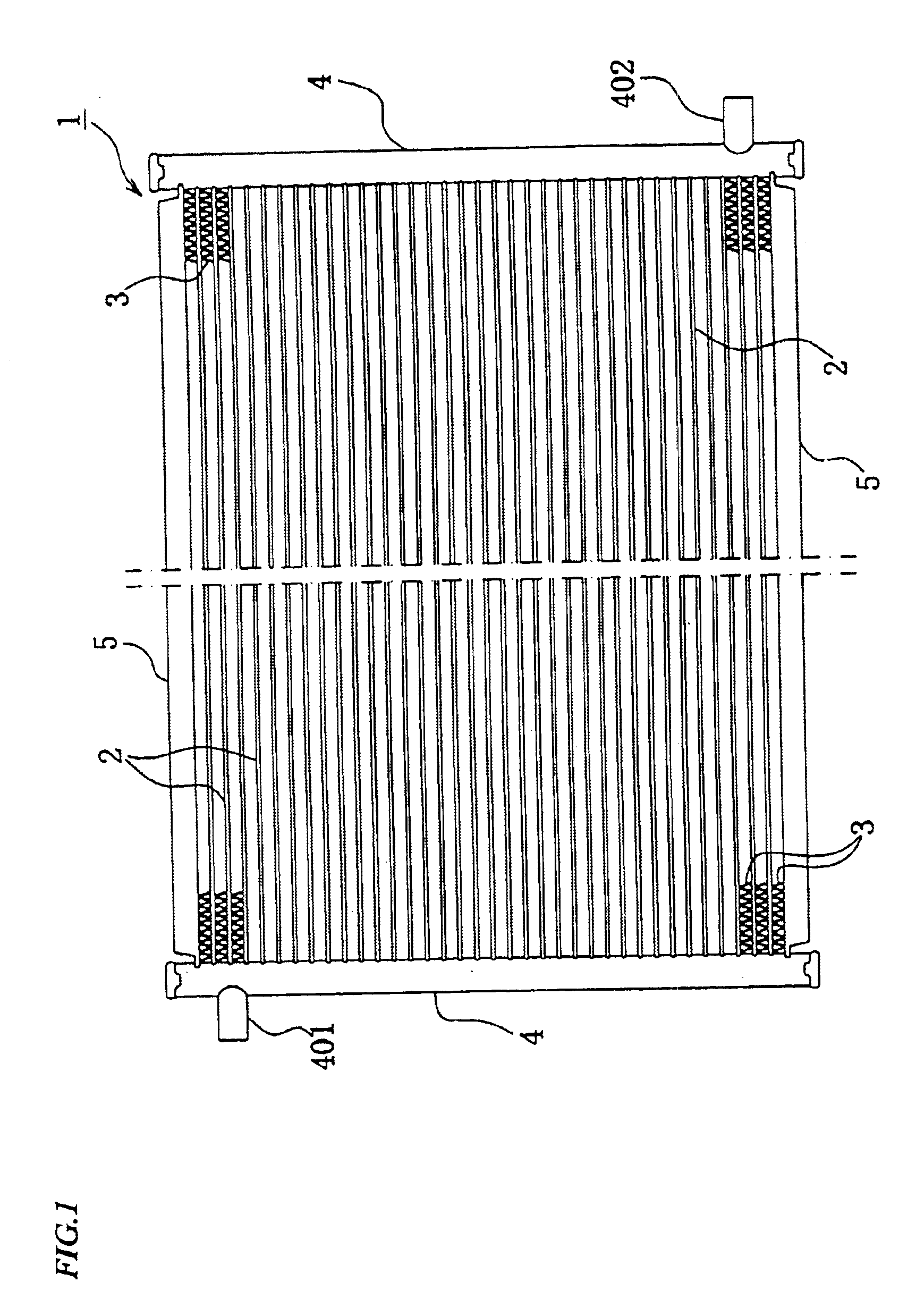

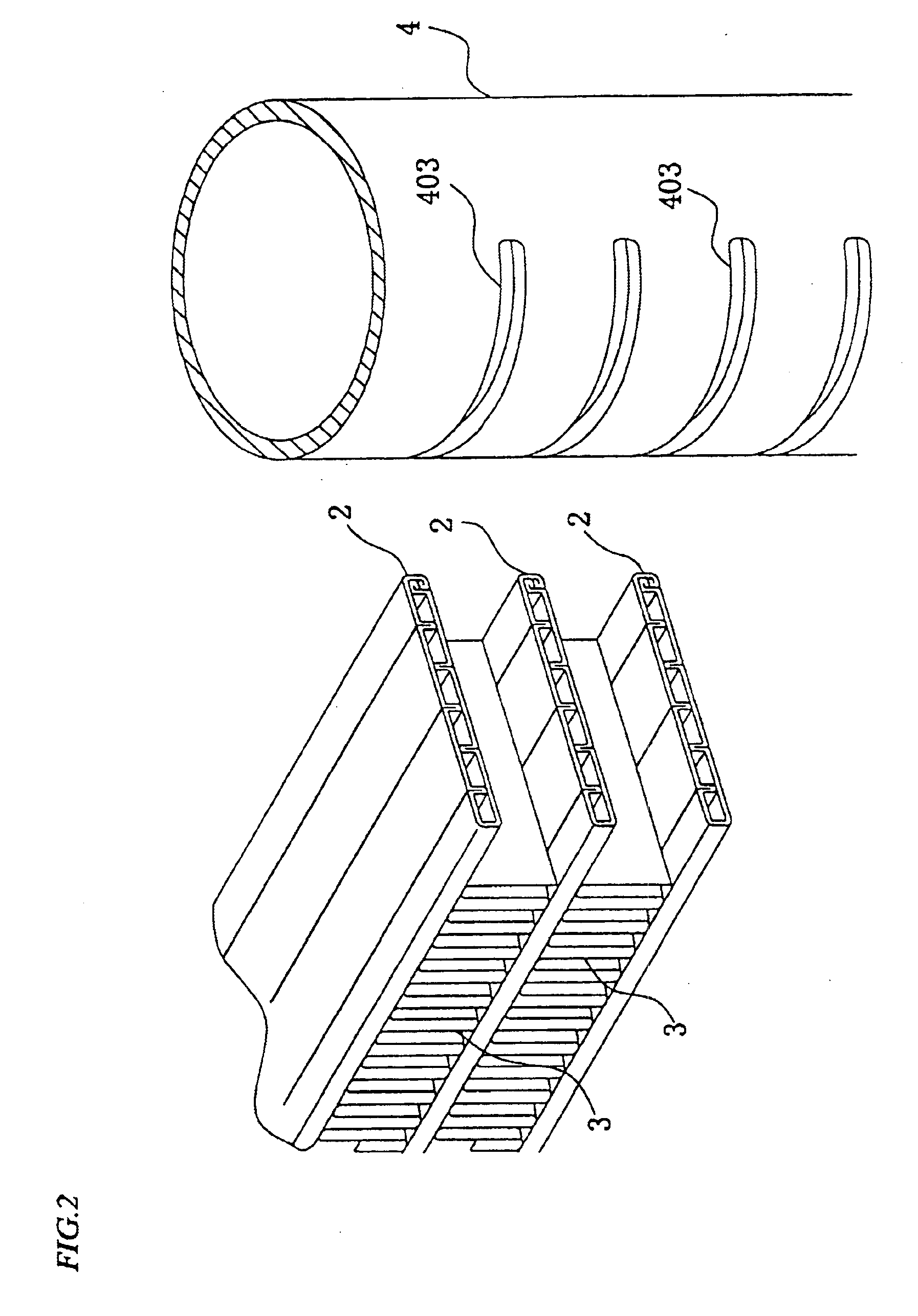

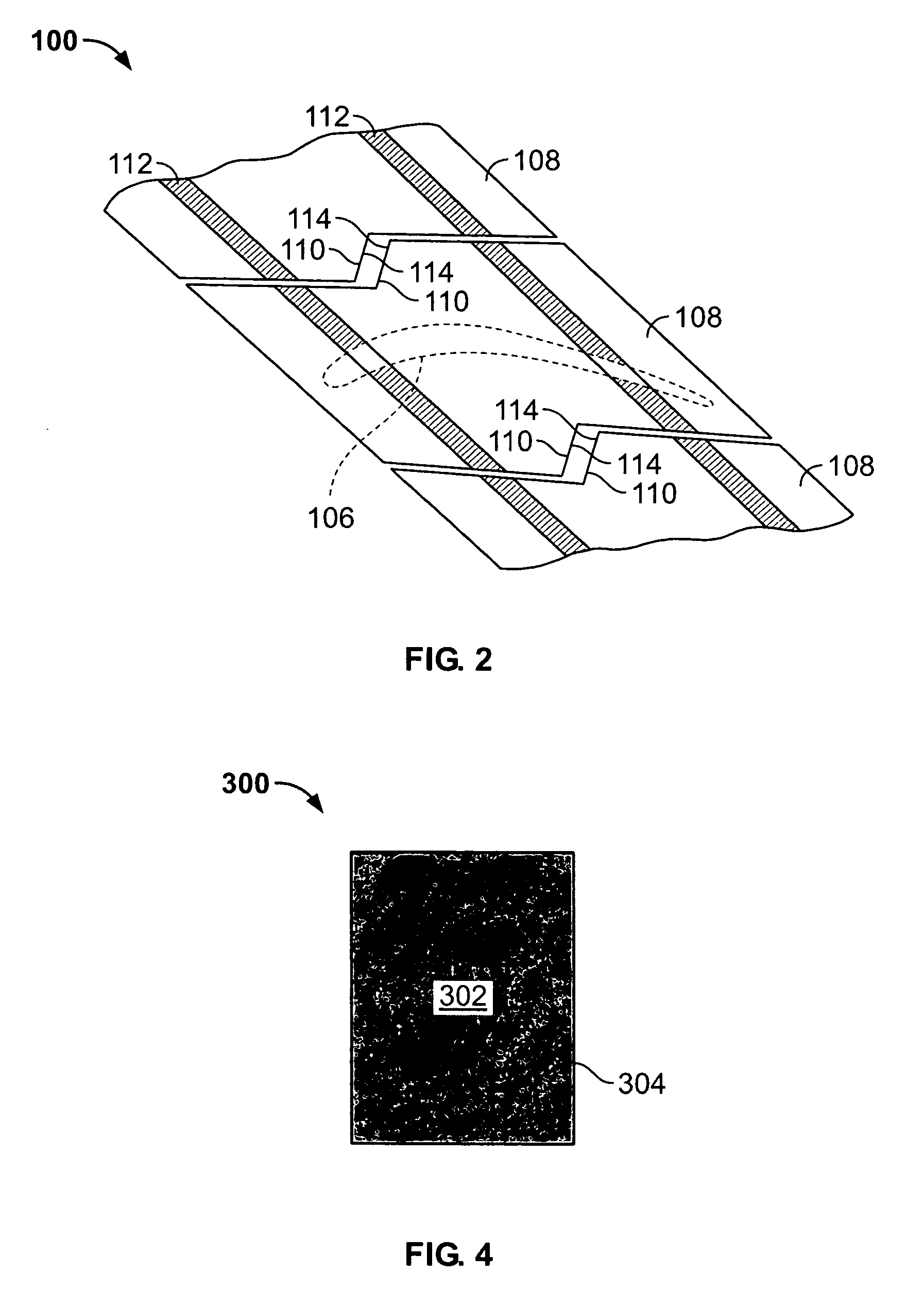

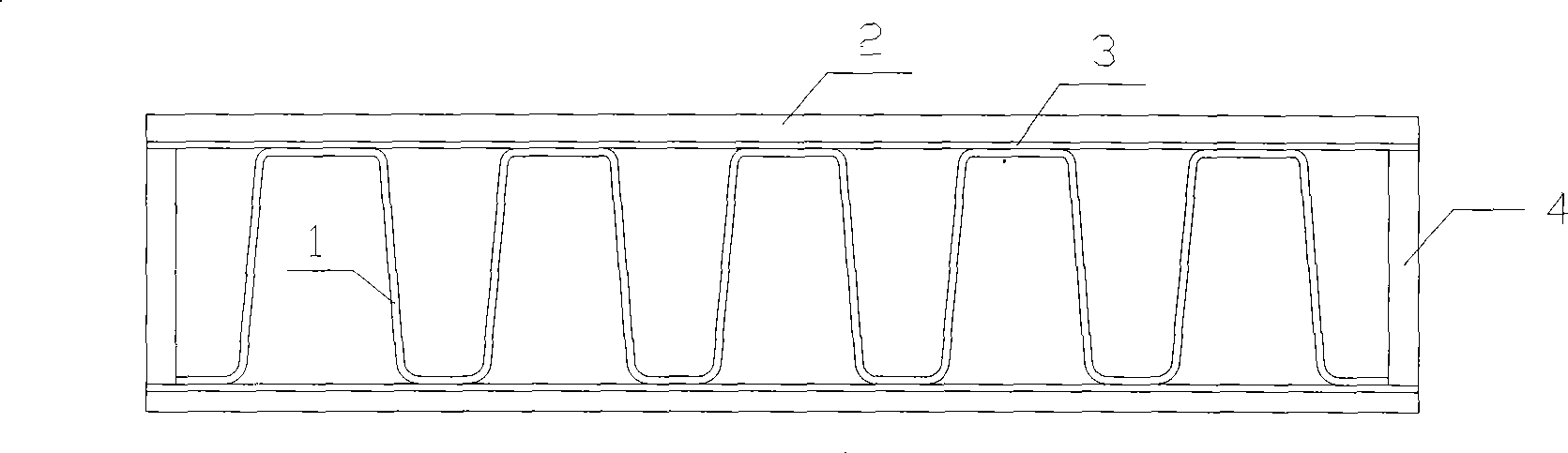

Heat exchanger

InactiveUS6988539B2Accelerated corrosionCorrosion resistanceSoldering apparatusCorrosion preventionPlate heat exchangerEngineering

A heat exchanger comprising a heat exchange core (1) including a plurality of tubes (2) flowing a medium for heat exchange and a pair of tanks (4) to which ends of said tubes are connected, each tube formed by shaping a plate member (200) not clad with a row laminated brazing material and having a sacrifice layer (210) on an outer surface thereof and a plurality of recessed portions (203) formed on an outer surface of said sacrifice layer and filled with a brazing material (R).

Owner:ZEXEL VALEO CLIMATE CONTROL CORP SAITAMA

Nonaqueous electrolyte battery having hermetically sealed terminals

In a nonaqueous electrolyte battery, a negative electrode terminal is fixed to an insulating ceramic material with filler materials for brazing mainly composed of copper and insulation-sealed to an opening of a metallic exterior member with the ceramic material being provided interposed therebetween. A positive electrode terminal fixed to an insulating ceramic material with an aluminum alloy-based filler materials for brazing and insulation-sealed to the opening in the metallic exterior member.

Owner:GS YUASA INT LTD

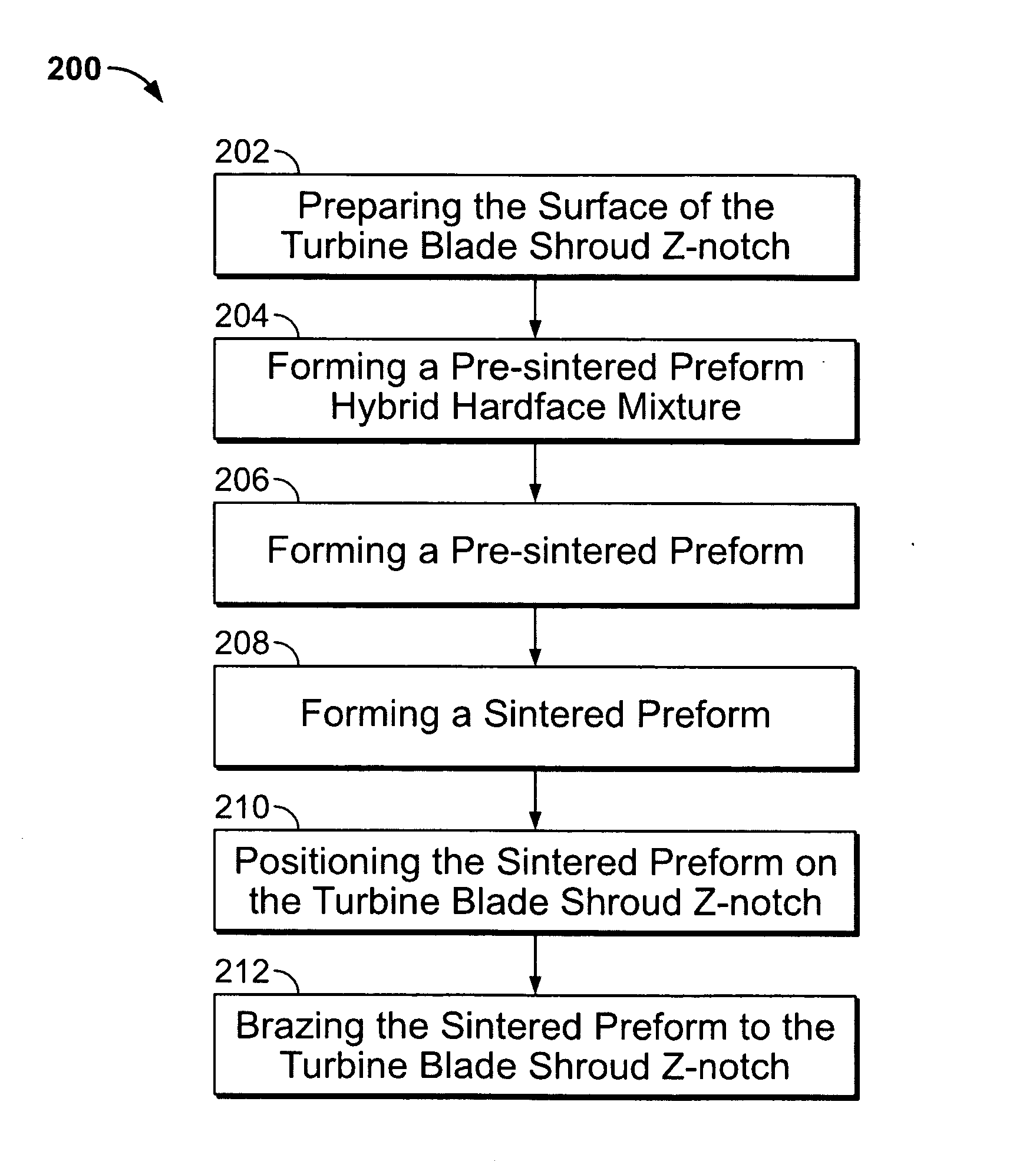

Machine components and methods of fabricating and repairing

A method of fabricating a machine component is provided. The method includes preparing at least a portion of a surface of a machine component for receiving a sintered preform. The method also includes forming a pre-sintered preform hybrid hardface mixture that includes combining a predetermined portion of at least one hardfacing material with a predetermined portion of at least one brazing material. The method further includes forming a pre-sintered preform. The pre-sintered preform has predetermined dimensions. The method also includes forming the sintered preform and positioning the sintered preform on the machine component. The method further includes fixedly coupling the sintered preform to at least a portion of the machine component via brazing.

Owner:GENERAL ELECTRIC CO

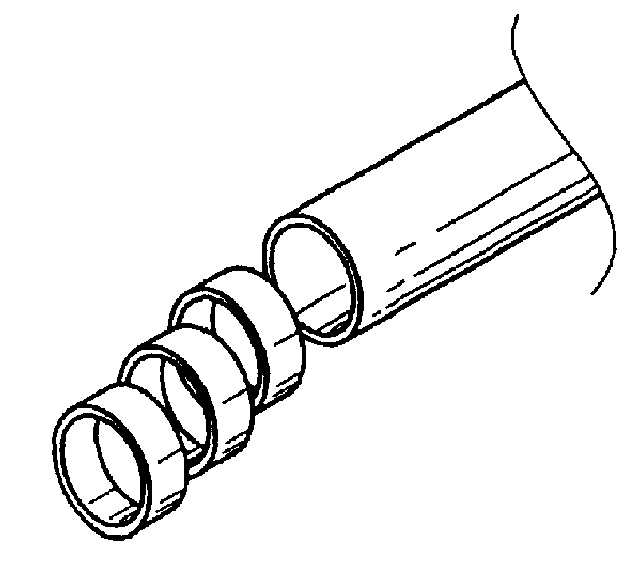

Seamless, ring-shaped brazing material and method for producing same

InactiveUS6164517AReduce necessityWelding/cutting auxillary devicesAuxillary welding devicesNonferrous metalMetal powder

The seamless, ring-shaped brazing material comprises a brazing metal and a flux uniformly dispersed in the brazing metal for brazing nonferrous metal members and has a relative density of 0.90 or more. The seamless, ring-shaped brazing material is produced by (a) mixing brazing metal powder and flux powder uniformly; (b) pressing the resultant mixture to a powder compact billet; (c) forming the billet into a pipe by hot extrusion; and (d) slicing the pipe into rings.

Owner:SUN KWANG BRAZING FILLER METAL +2

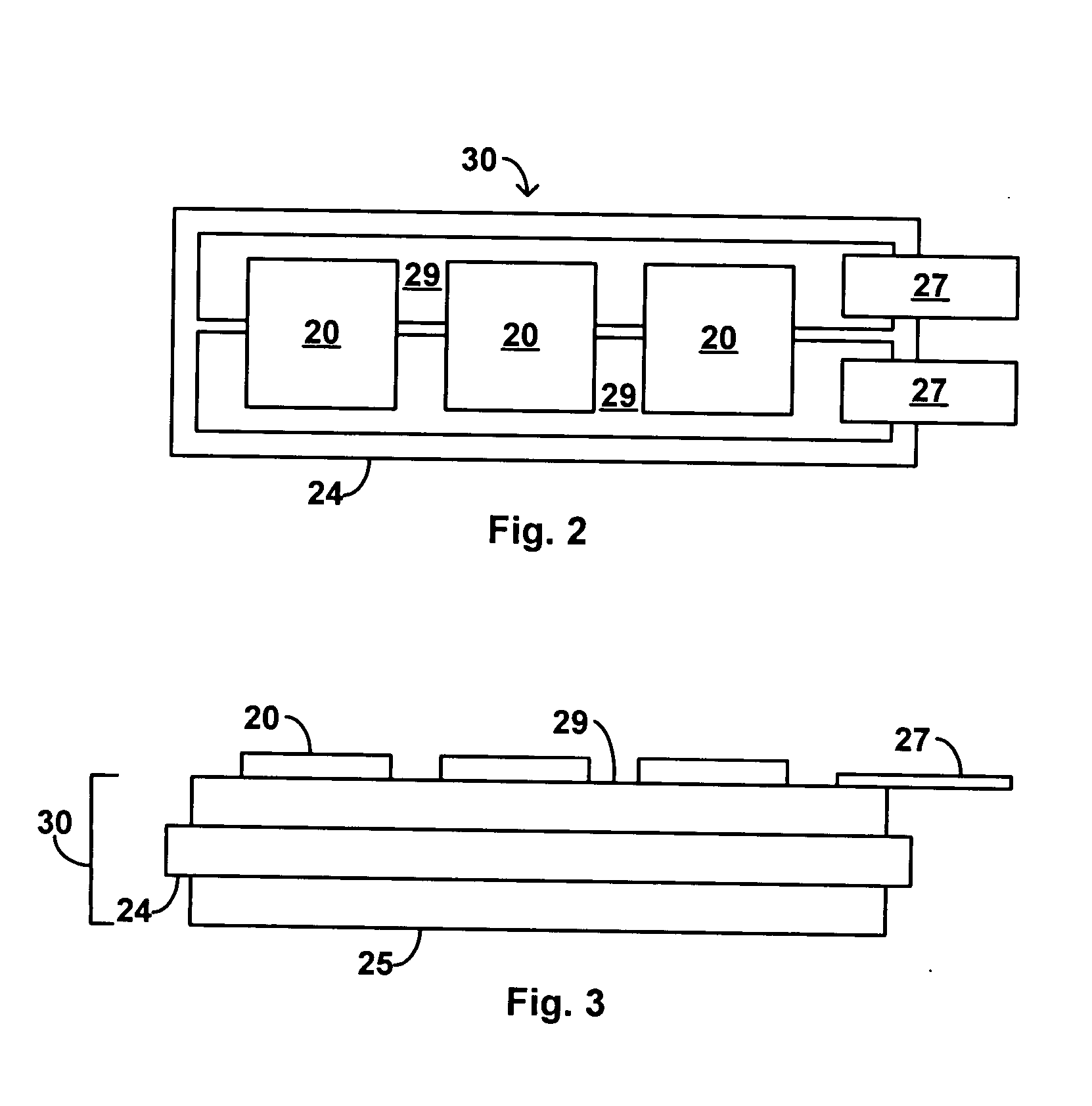

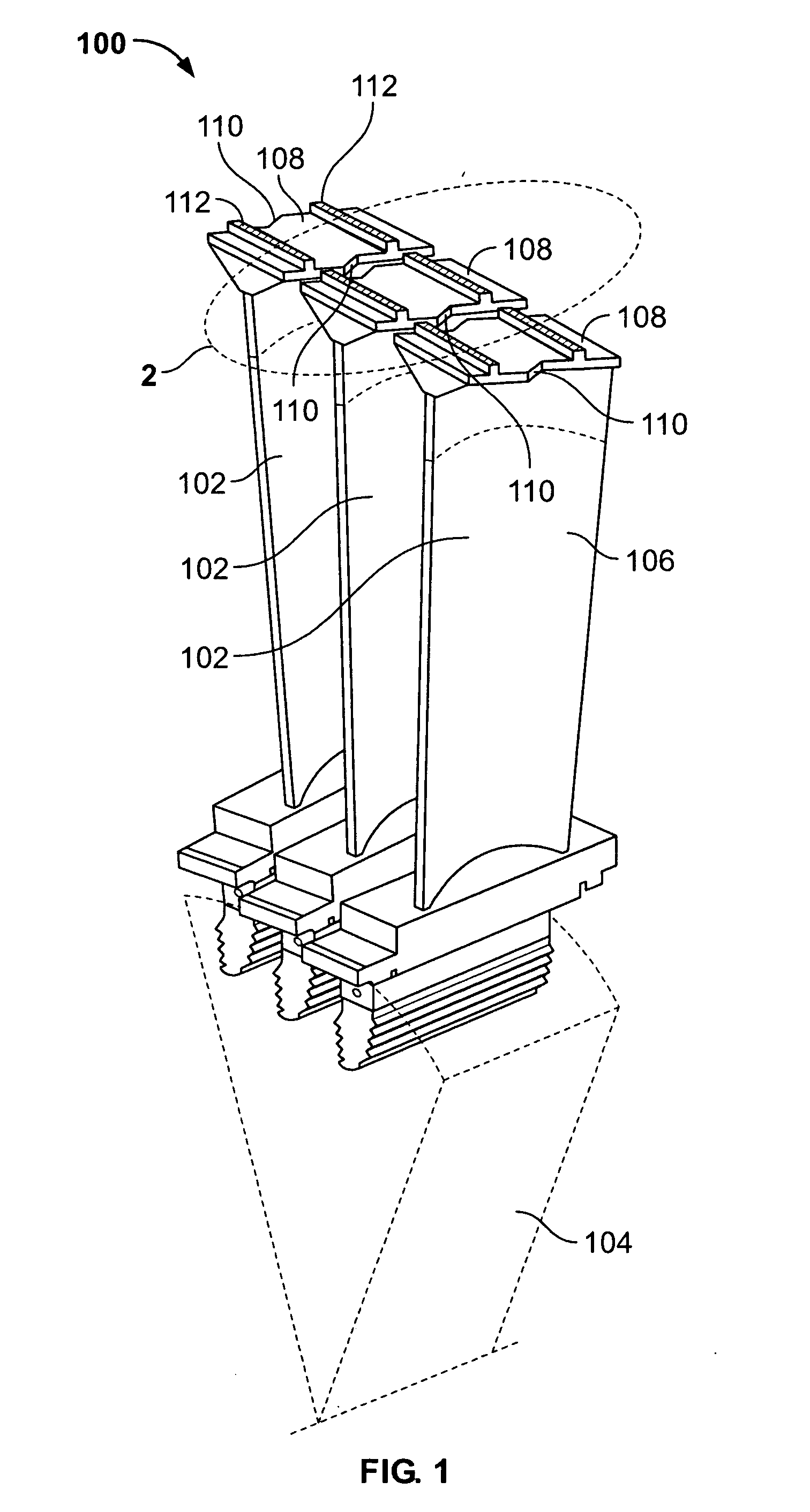

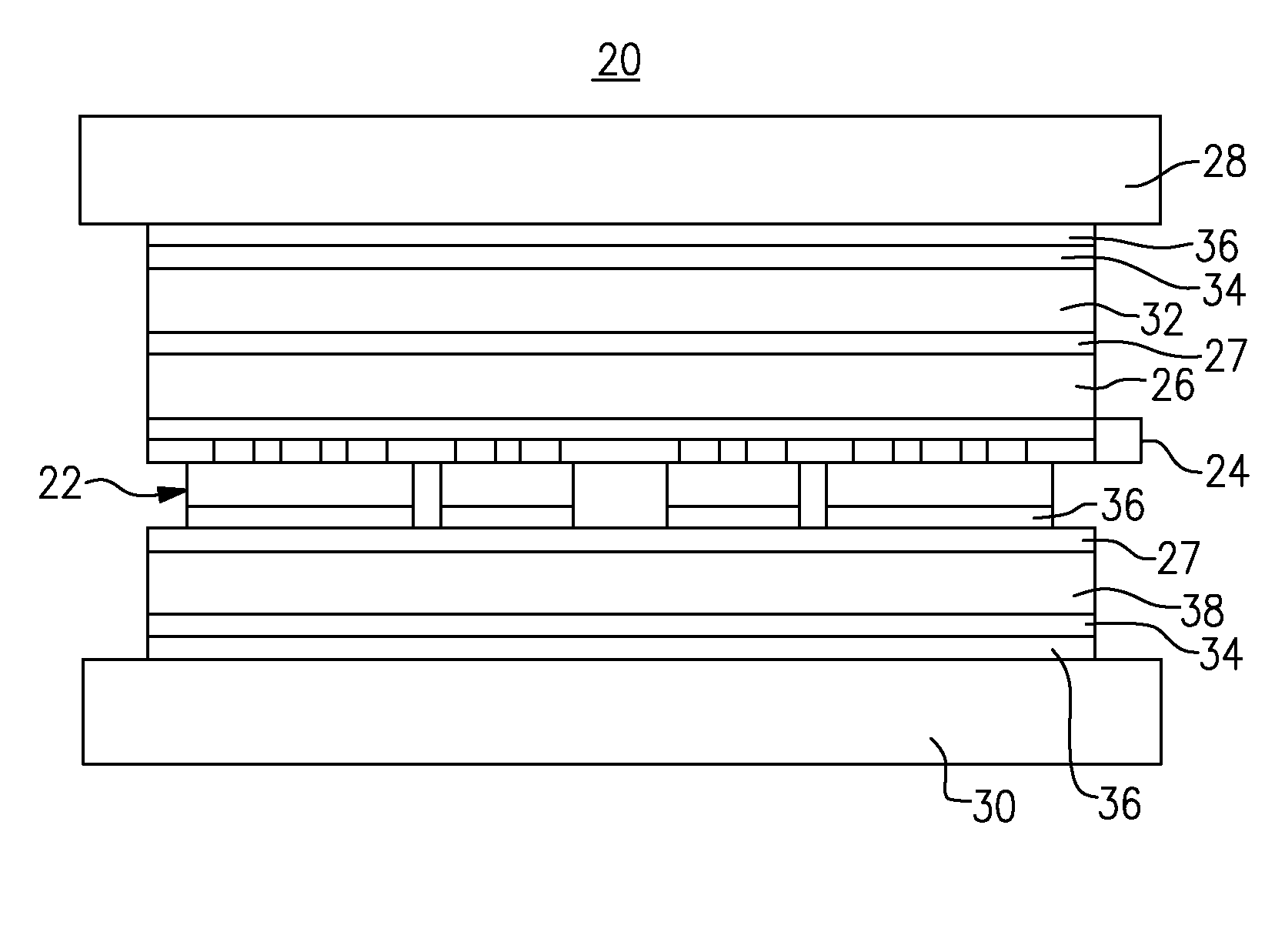

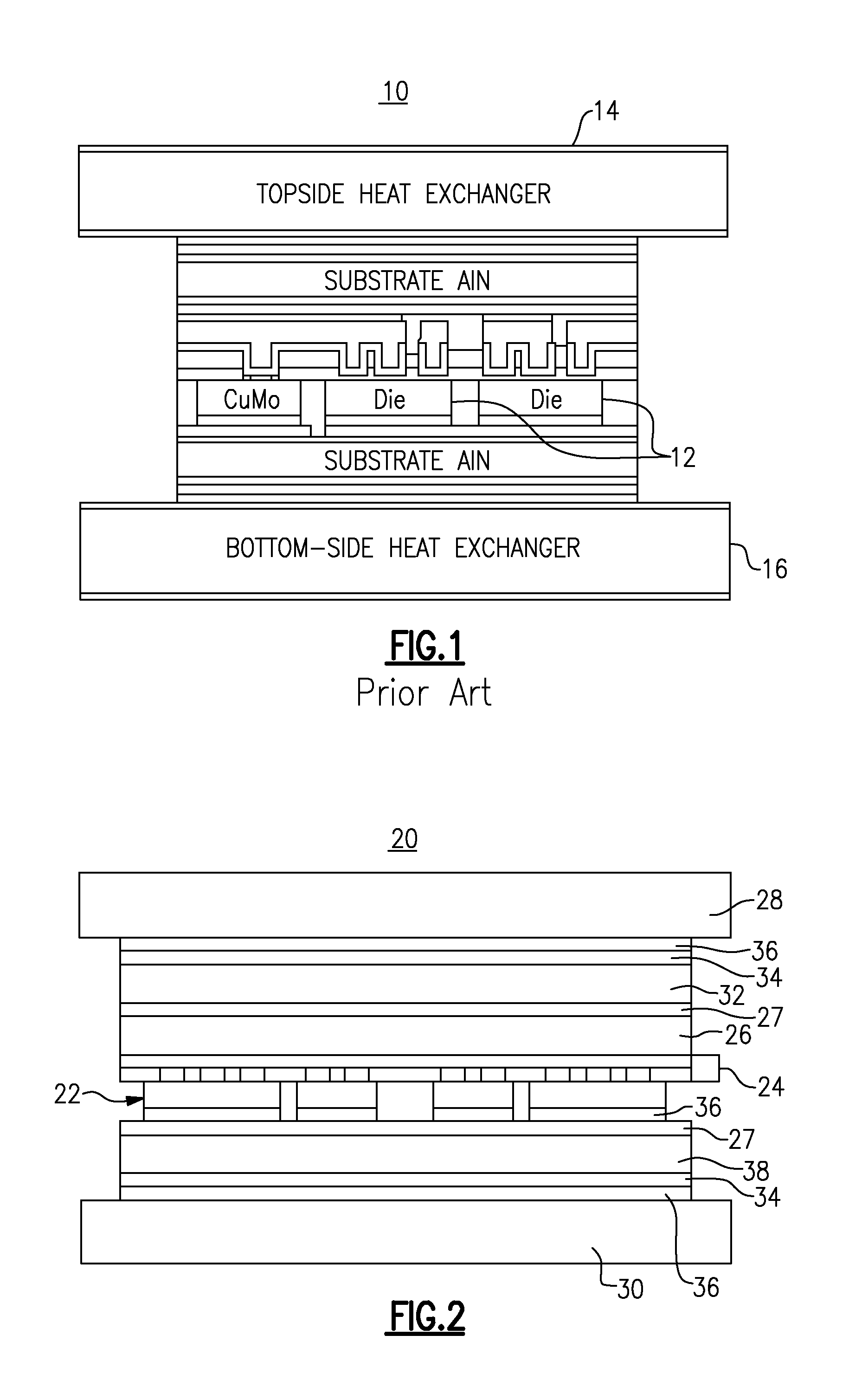

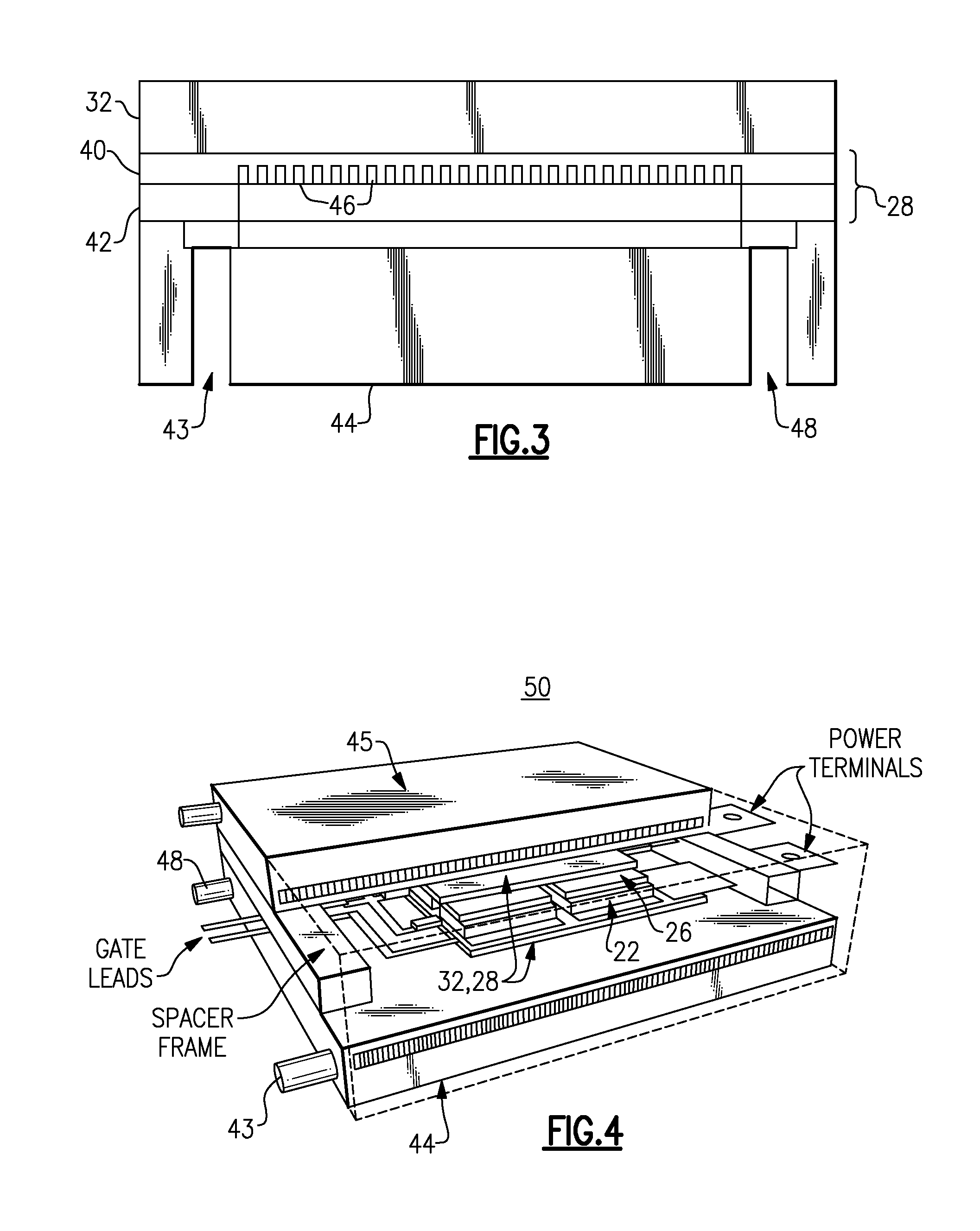

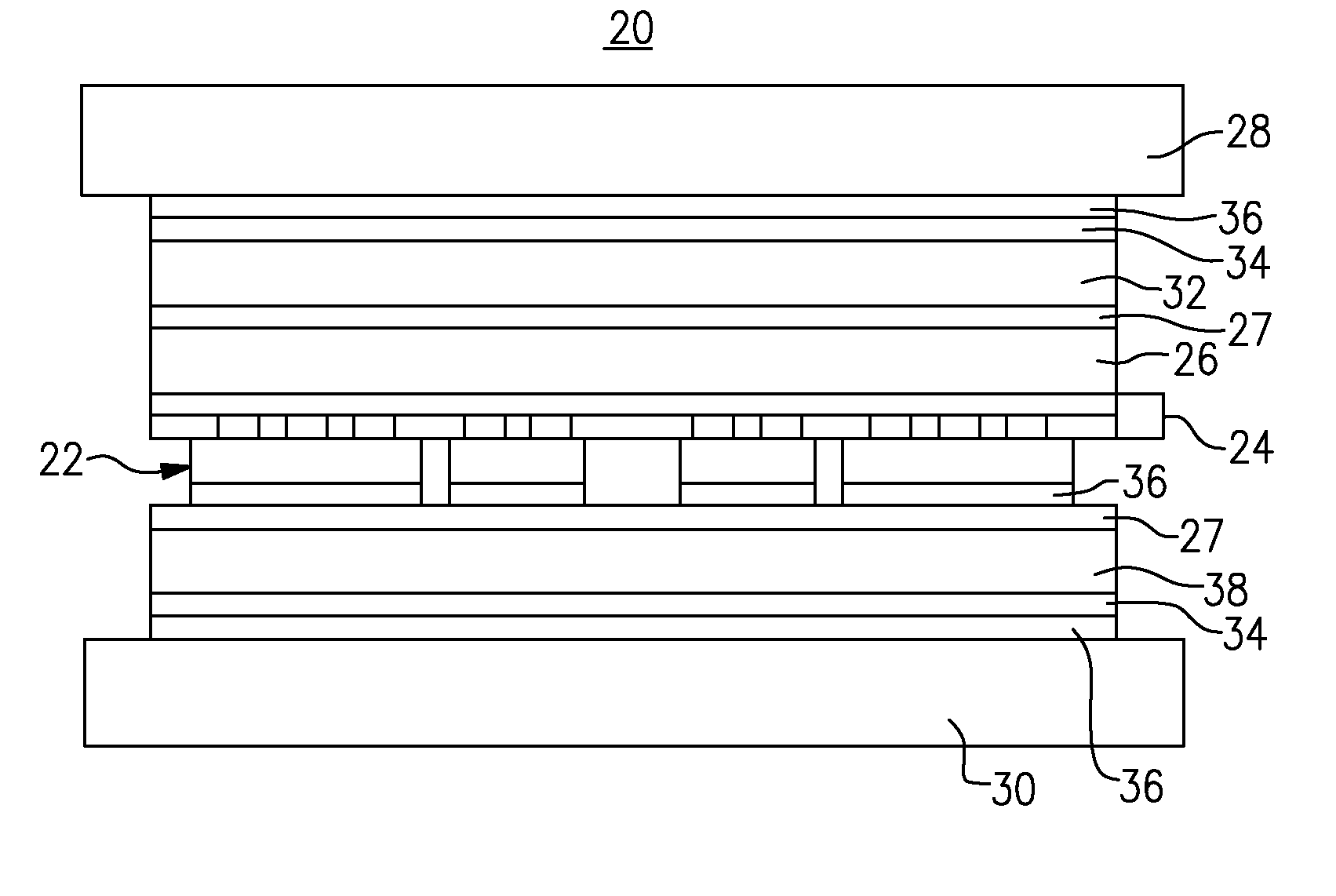

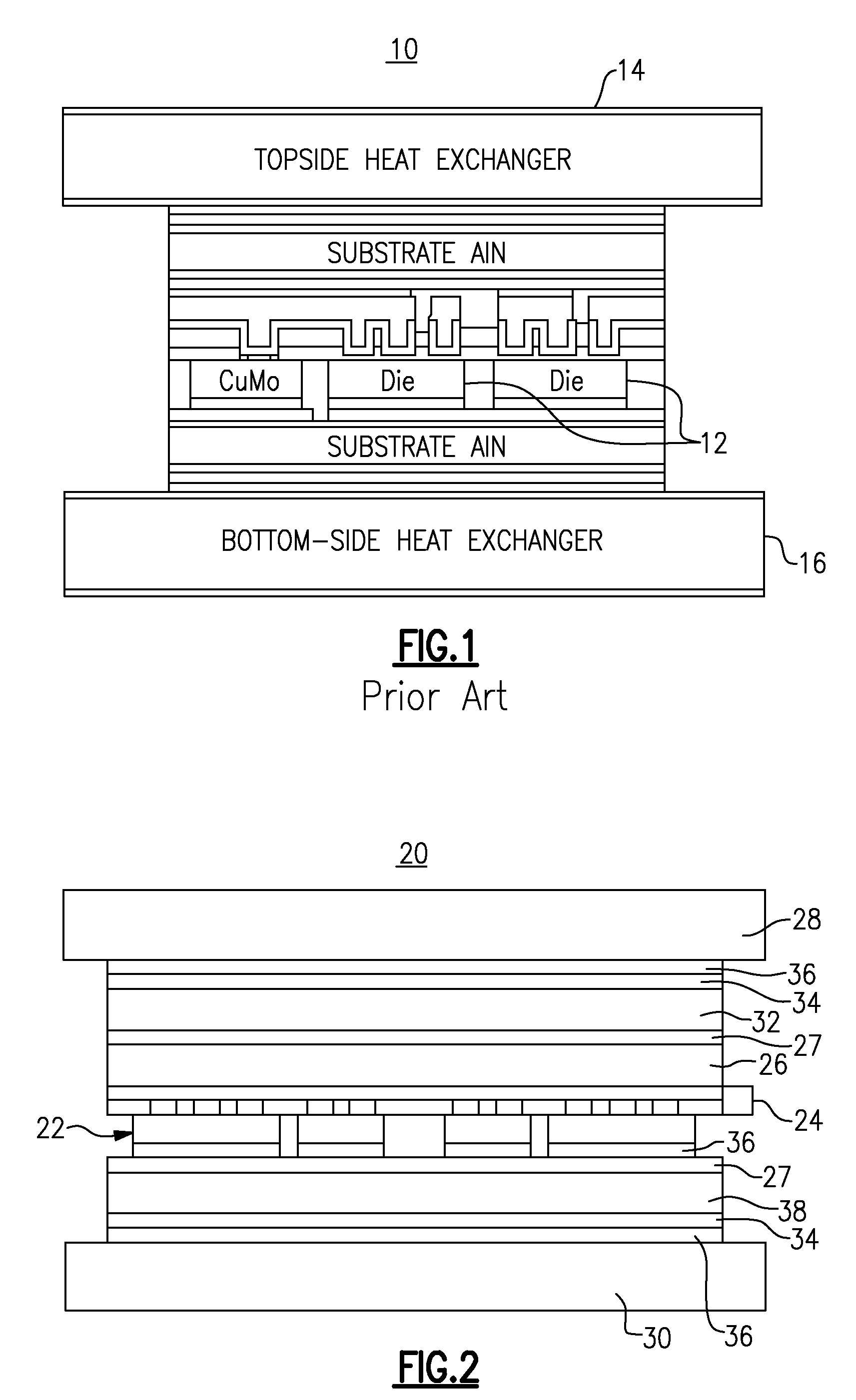

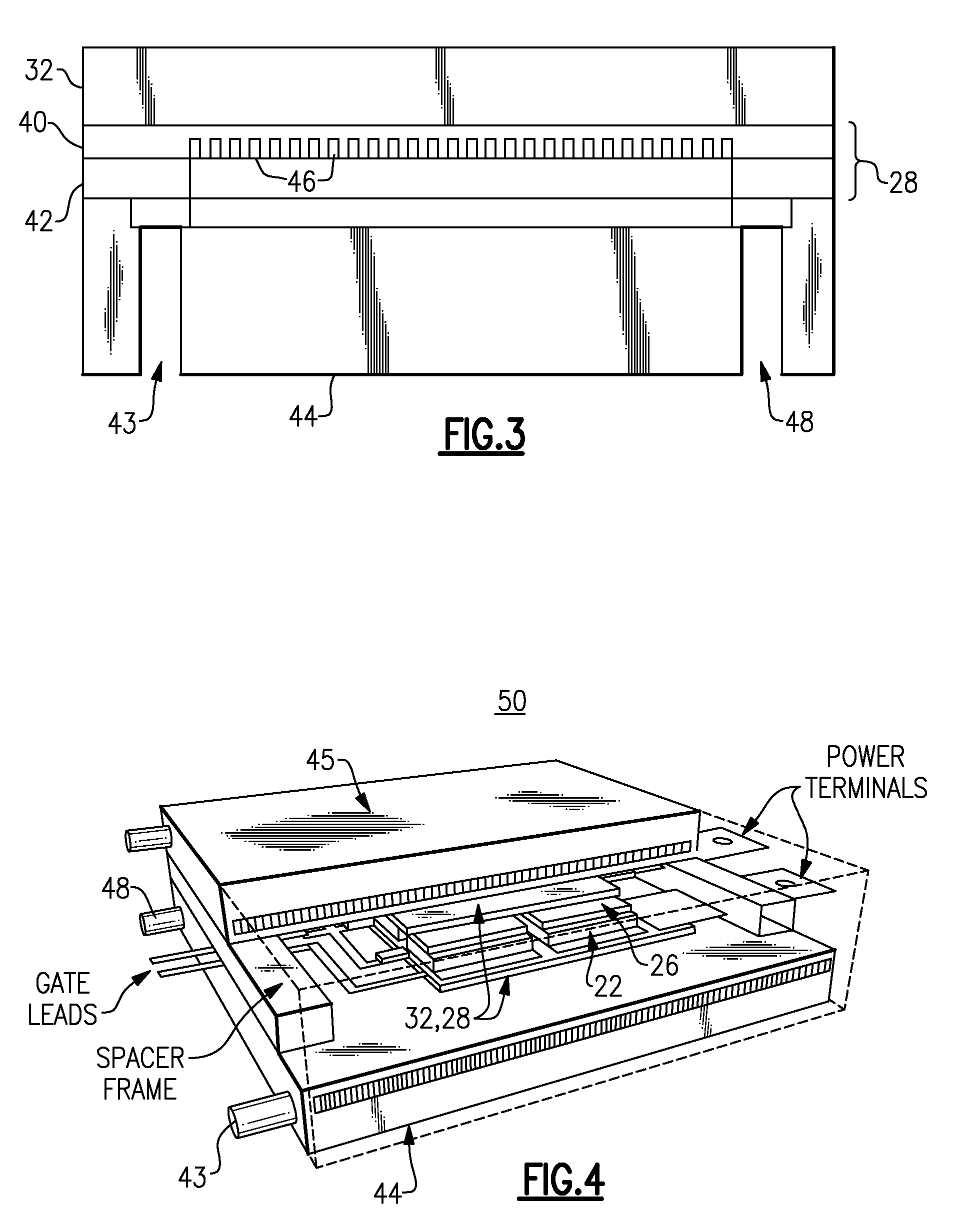

Double side cooled power module with power overlay

ActiveUS20100230800A1Semiconductor/solid-state device detailsSolid-state devicesEngineeringCooling power

A power module includes one or more semiconductor power devices having a power overlay (POL) bonded thereto. A first heat sink is bonded to the semiconductor power devices on a side opposite the POL. A second heat sink is bonded to the POL opposite the side of the POL bonded to the semiconductor power devices. The semiconductor power devices, POL, first channel heat sink, and second channel heat sink together form a double side cooled power overlay module. The second channel heat sink is bonded to the POL solely via a compliant thermal interface material without the need for planarizing, brazing or metallurgical bonding.

Owner:GENERAL ELECTRIC CO

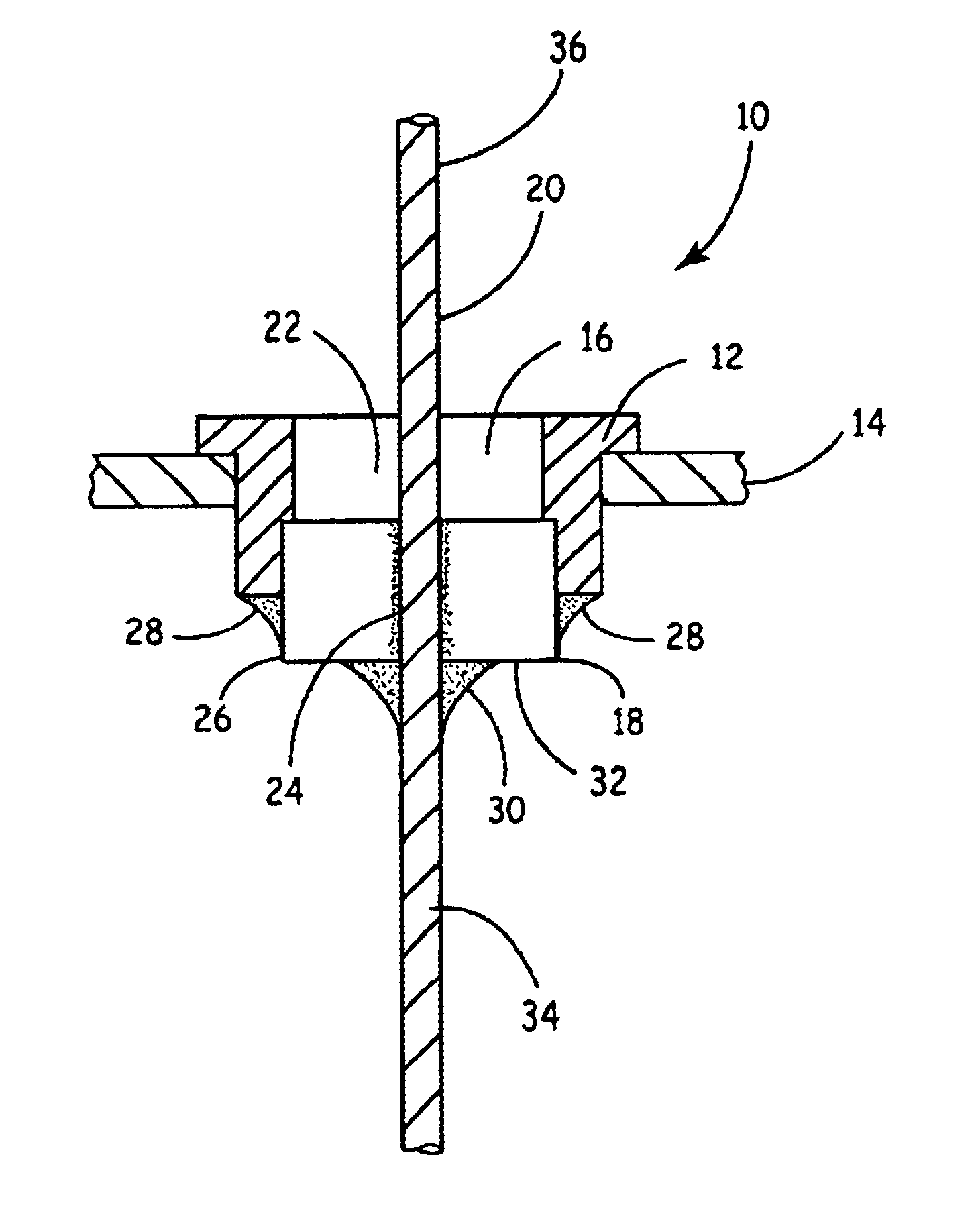

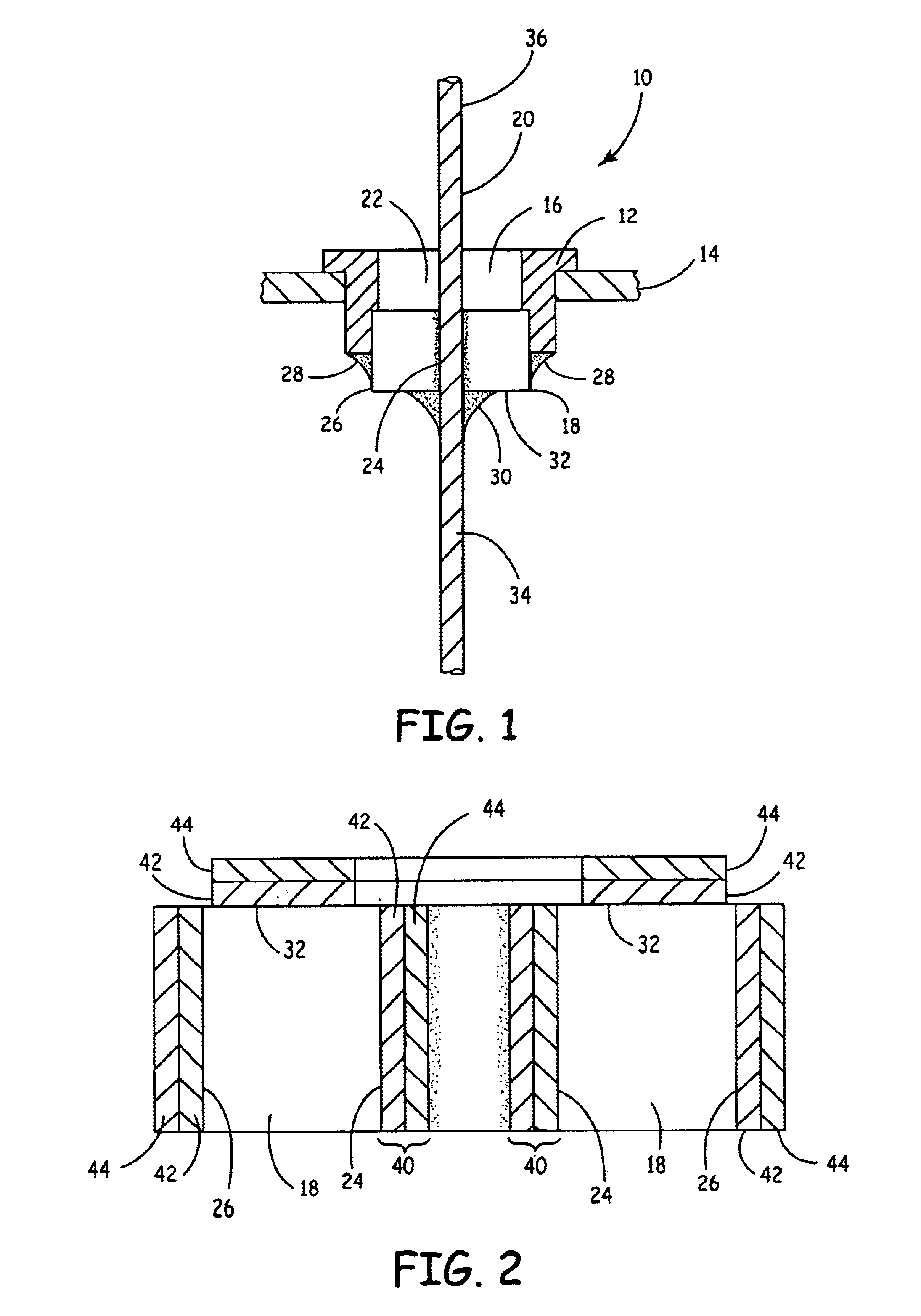

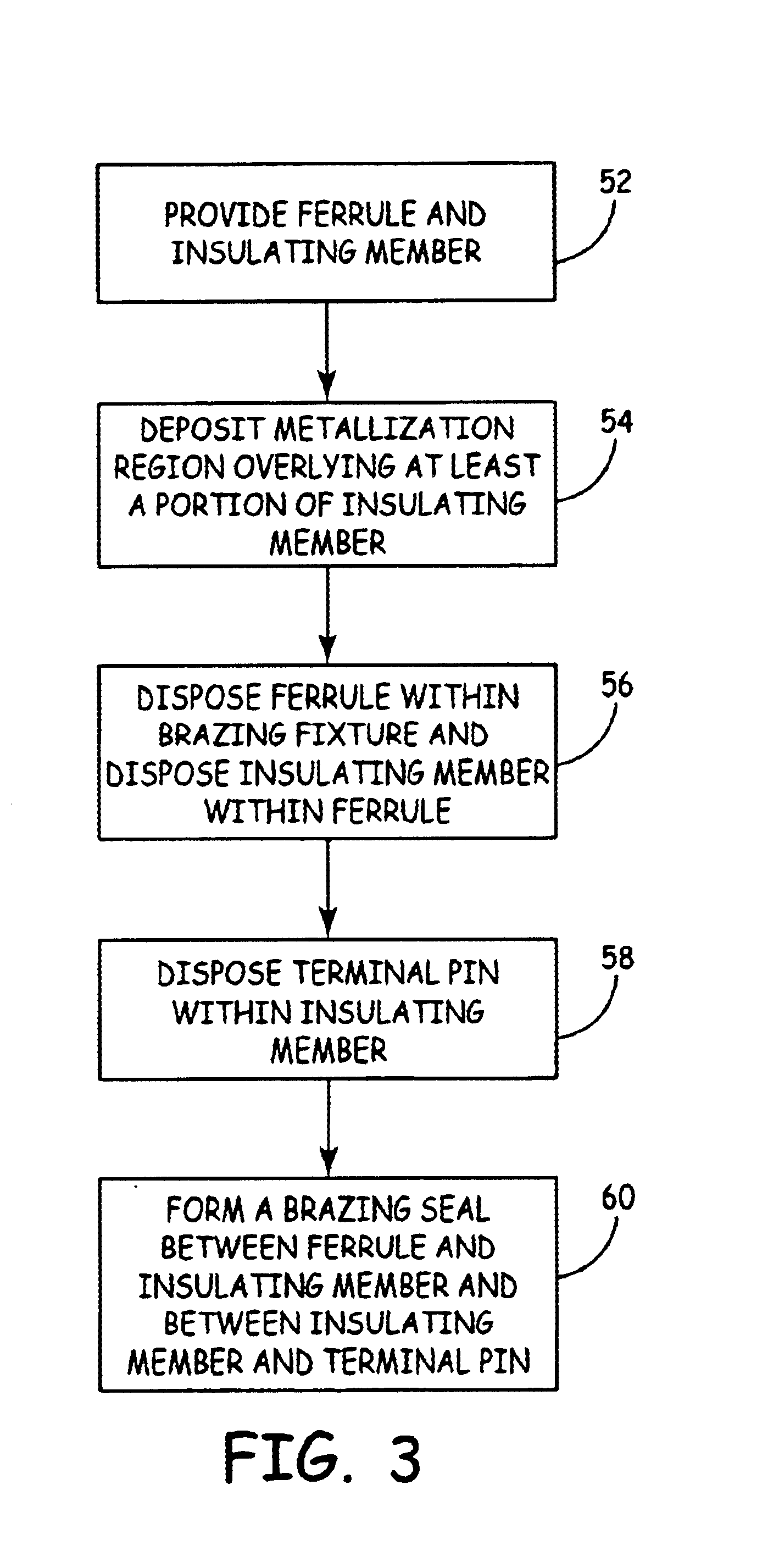

Feed-through assemblies having terminal pins comprising platinum and methods for fabricating same

A feed-through assembly for an IMD and a method for fabricating the same are provided. The feed-through assembly has a ferrule having a first aperture disposed therethrough. An insulating member is disposed at least partially within the first aperture. The insulating member has a second aperture, an inside surface and an outside surface. A metallization region overlies at least a portion of the inside surface and at least a portion of the outside surface of the insulating member. The metallization region is formed of a first layer of titanium and a second layer of niobium. A portion of a terminal pin of platinum is disposed through the second aperture. A first brazing seal is disposed between the insulating member and the ferrule and a second brazing seal is disposed between the insulating member and the terminal pin. The first and second brazing seals are formed of gold.

Owner:MEDTRONIC INC

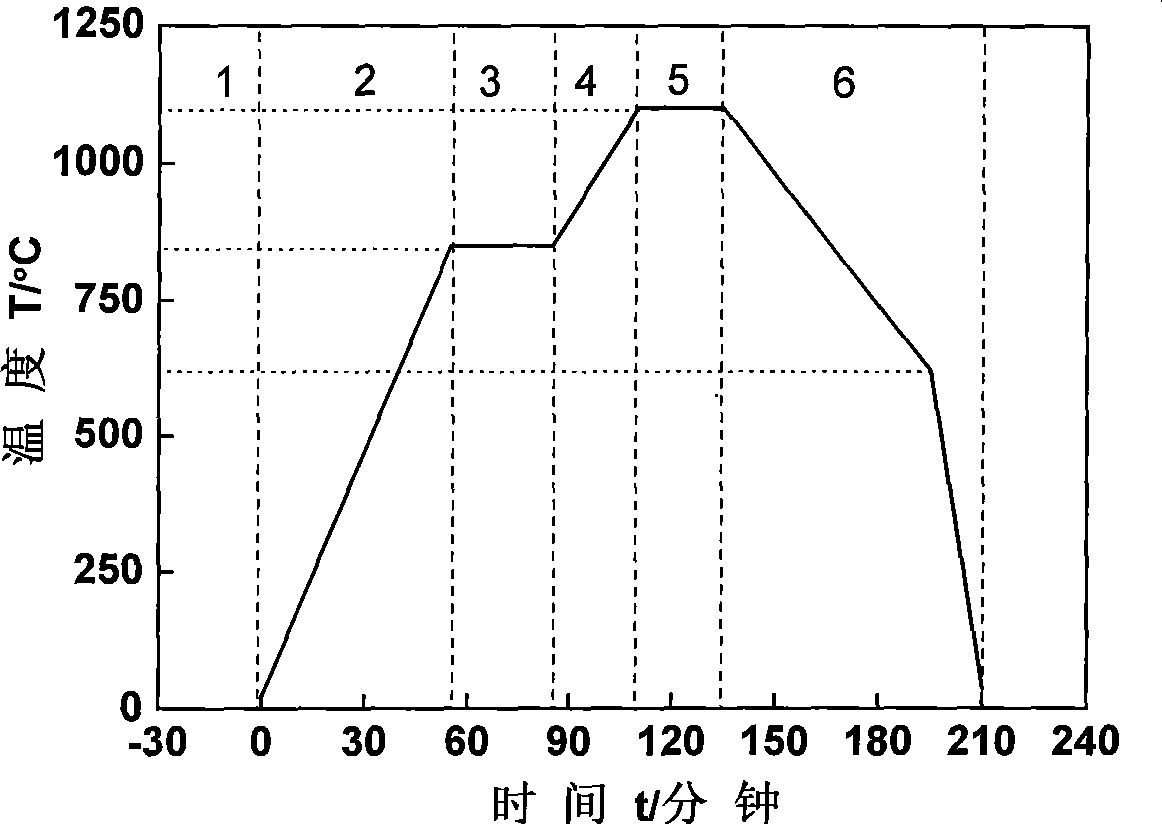

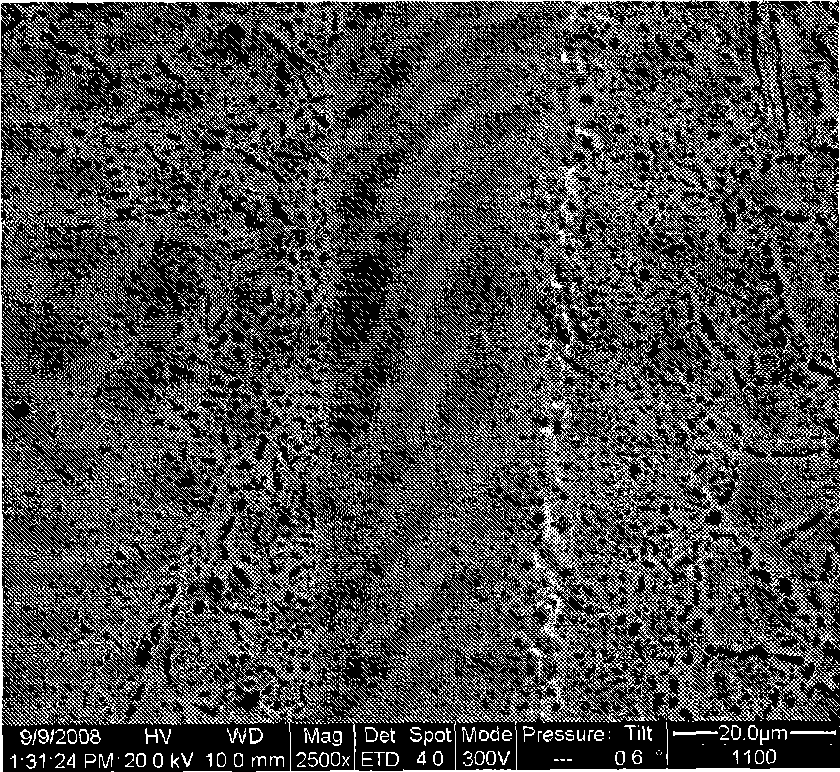

Vacuum brazing technique of stainless steel plate fin structure

InactiveCN101391329AOptimizing the Vacuum Brazing ProcessHigh strengthSoldering apparatusNitrogenNitrogen gas

The invention discloses a vacuum brazing process of a stainless steel plate-fin structure, comprising: firstly placing a fin on a baffle and then placing a baffle thereon, placing a solder foil between the fin and the baffles, and then sealing the two sides by edge sealing tapes to form an elementary unit; stacking up a plurality of elementary units according to the design requirements, then using a special jig to clamp and firm the units and exerting pressure on the units, and placing the units in a vacuum brazing furnace; vacuumizing the brazing furnace firstly; then heating the stainless steel plate-fin structure to 850 to 870DEG C and then preserving the heat; and again heating the stainless steel plate-fin structure to the brazing temperature of 1070 to 1100DEG C and then preserving the heat; and then self-cooling the structure slowly in vacuum from the brazing temperature of 1070 to 1100DEG C to 620 to 640DEG C, then filling nitrogen into the furnace, starting up a fan to cool the structure to 40 to 60DEG C so as to take out the structure, and finally obtaining the stainless steel plate-fin structure. The stainless steel plate-fin structure acquired through the brazing process has excellent microstructures and rather high strength.

Owner:NANJING UNIV OF TECH

Double side cooled power module with power overlay

ActiveUS8358000B2Semiconductor/solid-state device detailsSolid-state devicesEngineeringCooling power

A power module includes one or more semiconductor power devices having a power overlay (POL) bonded thereto. A first heat sink is bonded to the semiconductor power devices on a side opposite the POL. A second heat sink is bonded to the POL opposite the side of the POL bonded to the semiconductor power devices. The semiconductor power devices, POL, first channel heat sink, and second channel heat sink together form a double side cooled power overlay module. The second channel heat sink is bonded to the POL solely via a compliant thermal interface material without the need for planarizing, brazing or metallurgical bonding.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com