Patents

Literature

2821results about How to "Reasonable arrangement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

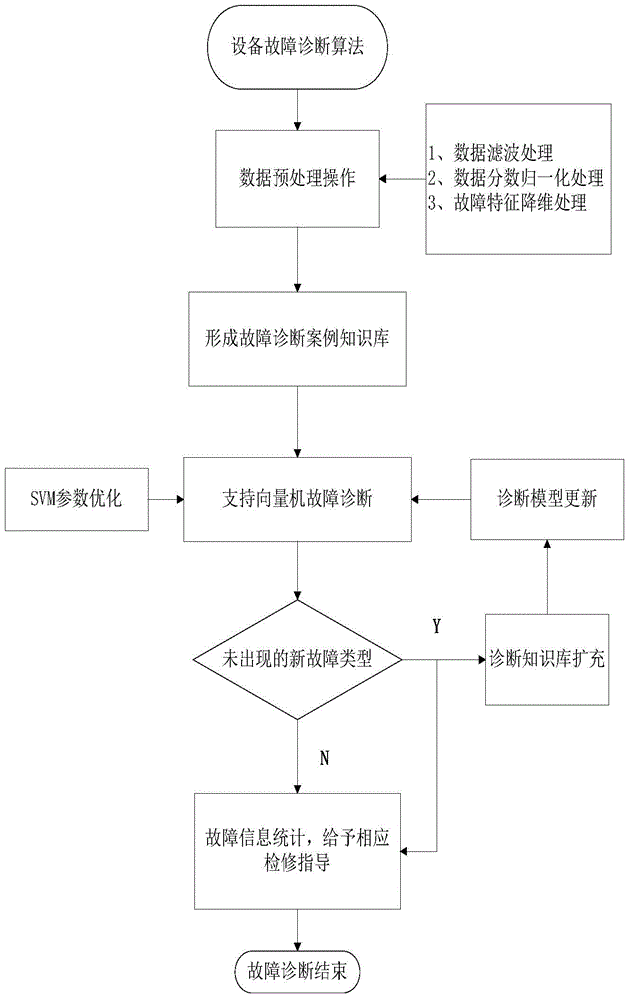

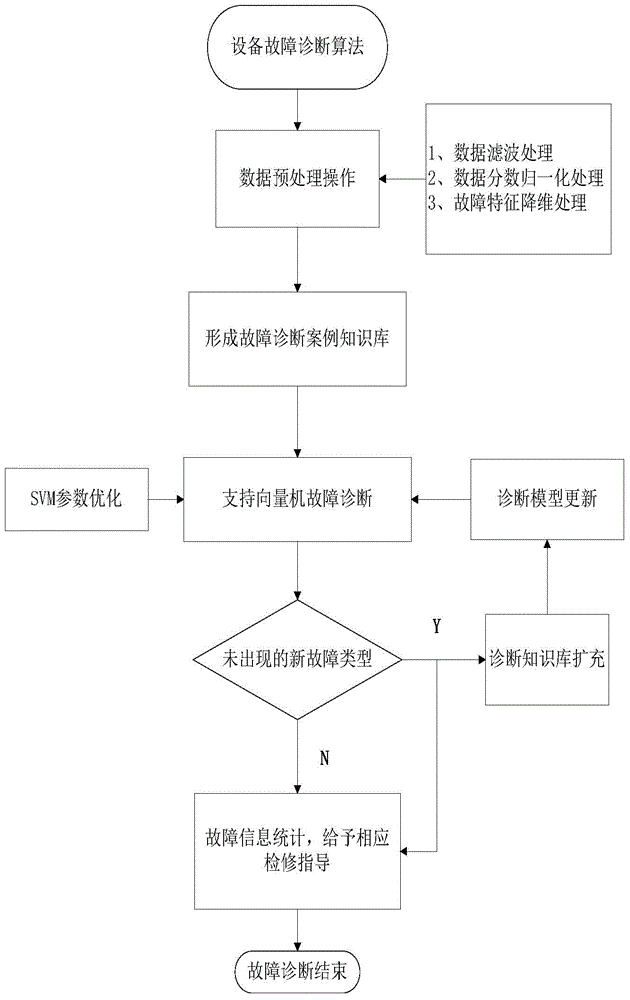

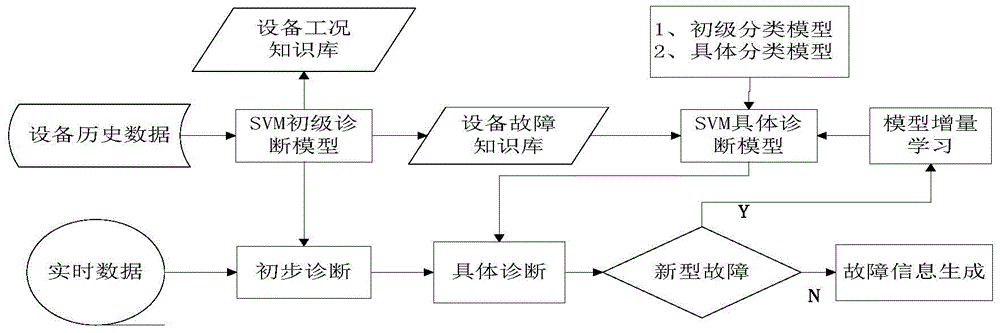

Intelligent device failure diagnosis method based on support vector machine

ActiveCN104462846AHigh speedHigh precisionSpecial data processing applicationsSupport vector machineKnowledge base

The invention provides an intelligent device failure diagnosis method based on a support vector machine. The method includes the steps that preprocessing operation is conducted on device data; a failure diagnosis case knowledge base is built; failure diagnosis is conducted on the support vector machine; the failure information is obtained, and troubleshooting guide is conducted. By means of the intelligent device failure diagnosis method based on the support vector machine, the failure feature of a device is highlighted to the maximum degree, the situations that the device data are incomplete and imprecise are reduced, the method provides the possibility for building a precise and reliable failure diagnosis model, the problem of aging of the diagnosis model along with the runtime of the device is solved, the misdiagnosis rate of the failure diagnosis model is reduced, and the correct rate and speed of the device failure diagnosis are increased to the maximum degree.

Owner:SHANDONG LUNENG SOFTWARE TECH

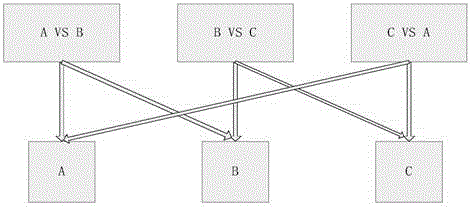

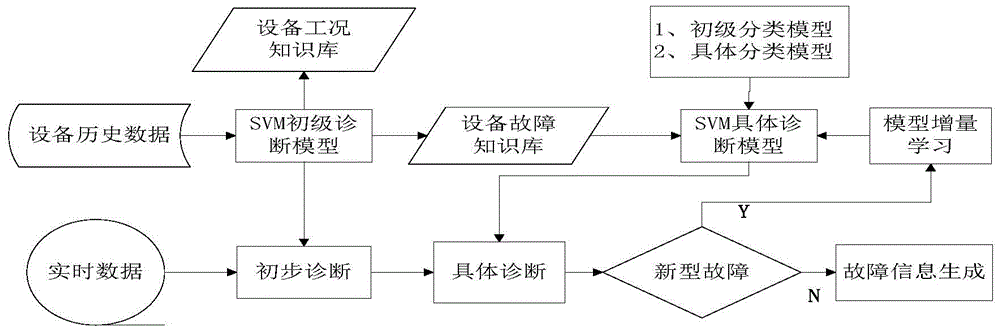

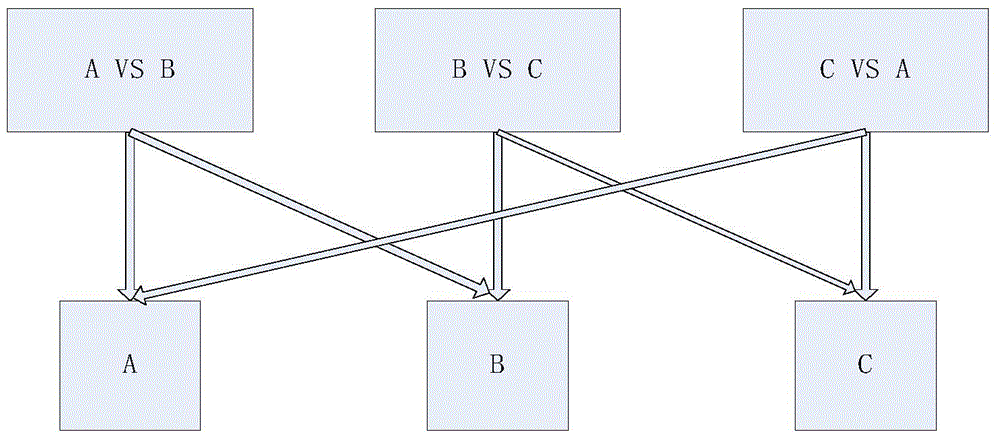

SVM classification model-based equipment fault diagnosing method

ActiveCN104573740AHigh speedHigh precisionDetecting faulty computer hardwareCharacter and pattern recognitionSupport vector machineDiagnosis methods

The invention discloses an SVM classification model-based equipment fault diagnosing method. The method comprises the following steps: performing a preprocessing operation on equipment data; constructing a fault diagnosis case knowledge base; performing fault diagnosis on a support vector machine on the basis of an SVM classification model; acquiring fault information and performing maintenance guide. According to the support vector machine-based intelligent equipment fault diagnosis method, the fault features of equipment are highlighted to the maximum degree; the situations that the equipment data are incomplete and inaccurate are reduced; the possibility is provided for constructing an accurate and reliable fault diagnosis model; the problem that the diagnosis model ages along with the operating time of the equipment is solved; the misdiagnosis rate of the fault diagnosis is reduced; the accuracy and the speed of the equipment fault diagnosis are greatly improved.

Owner:SHANDONG LUNENG SOFTWARE TECH

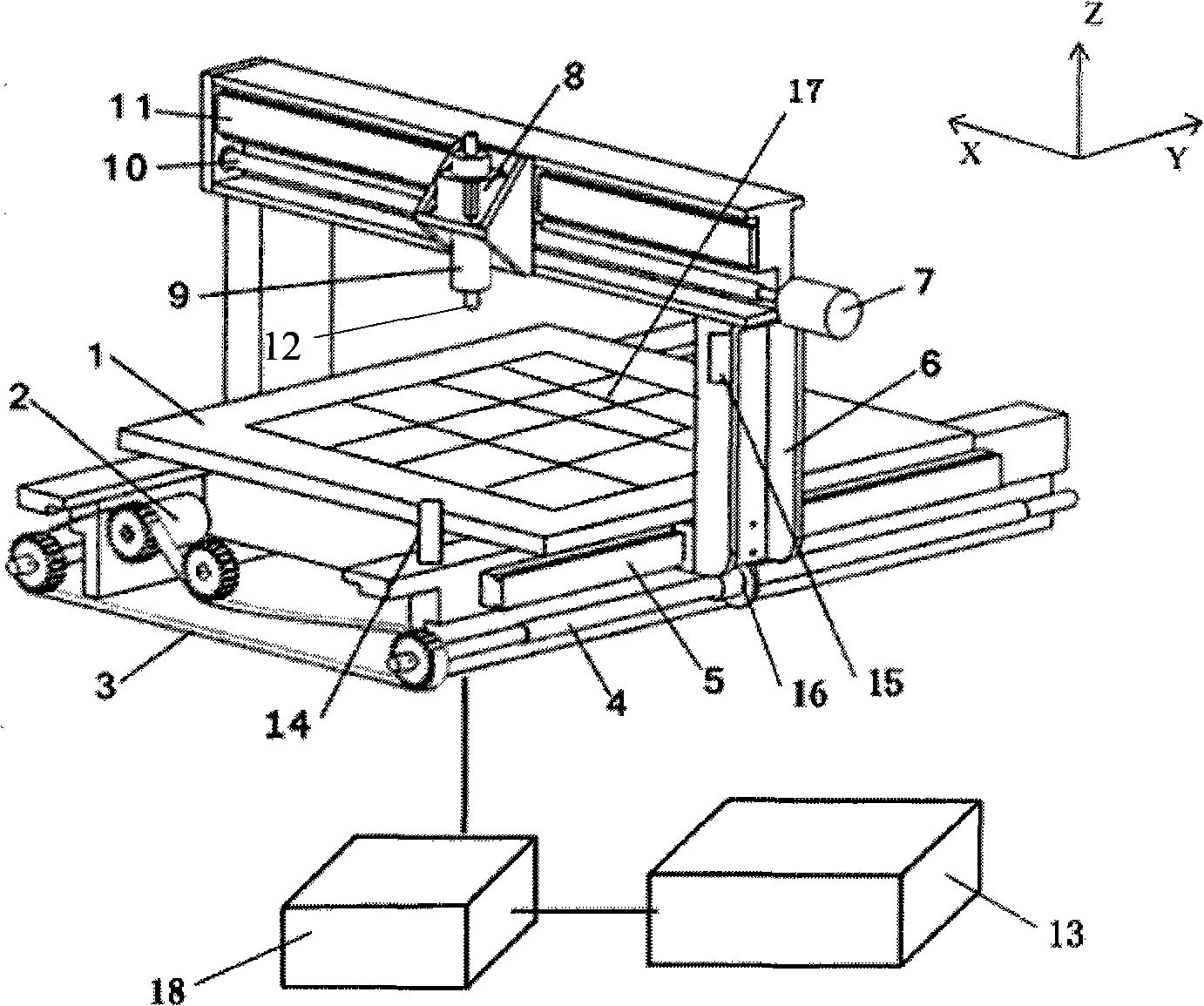

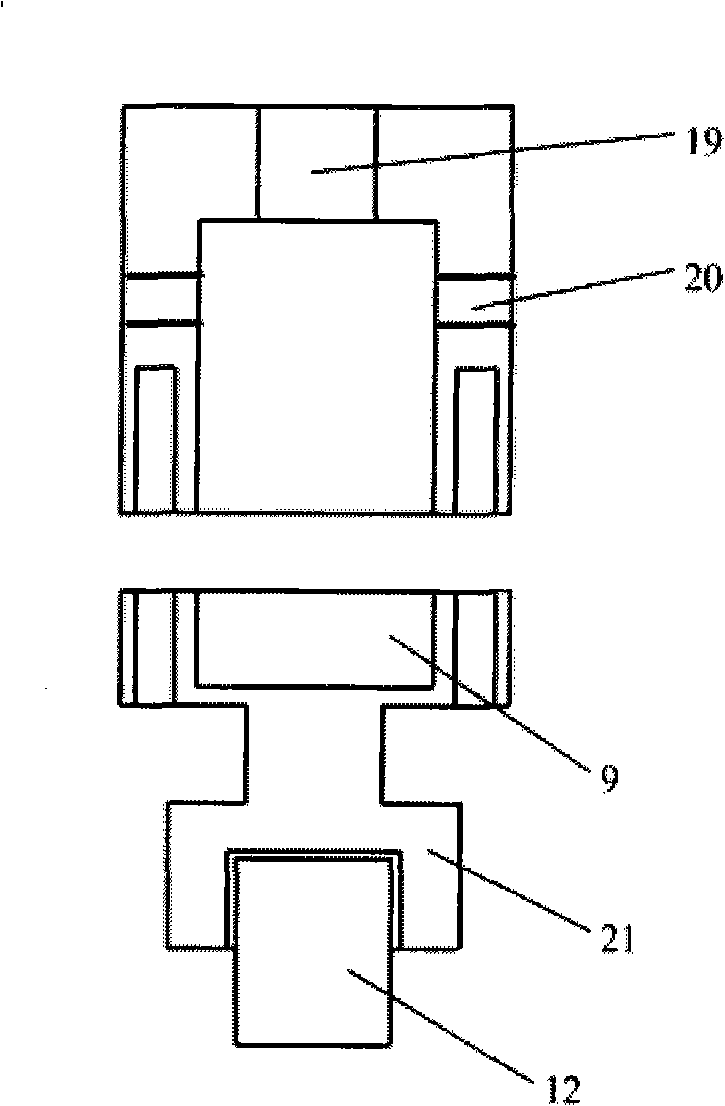

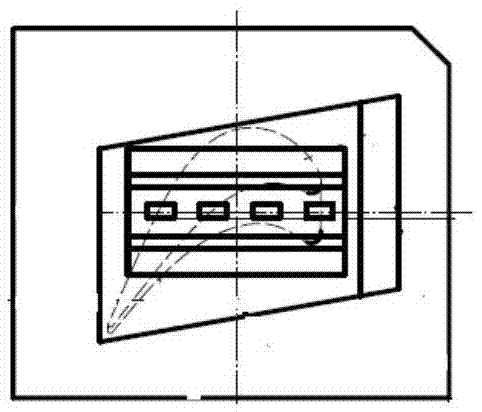

Mechanics sensor array calibrating apparatus and working method thereof

ActiveCN101281073APrecision mechanical designQuick start and stopForce/torque/work measurement apparatus calibration/testingSensor arrayElectricity

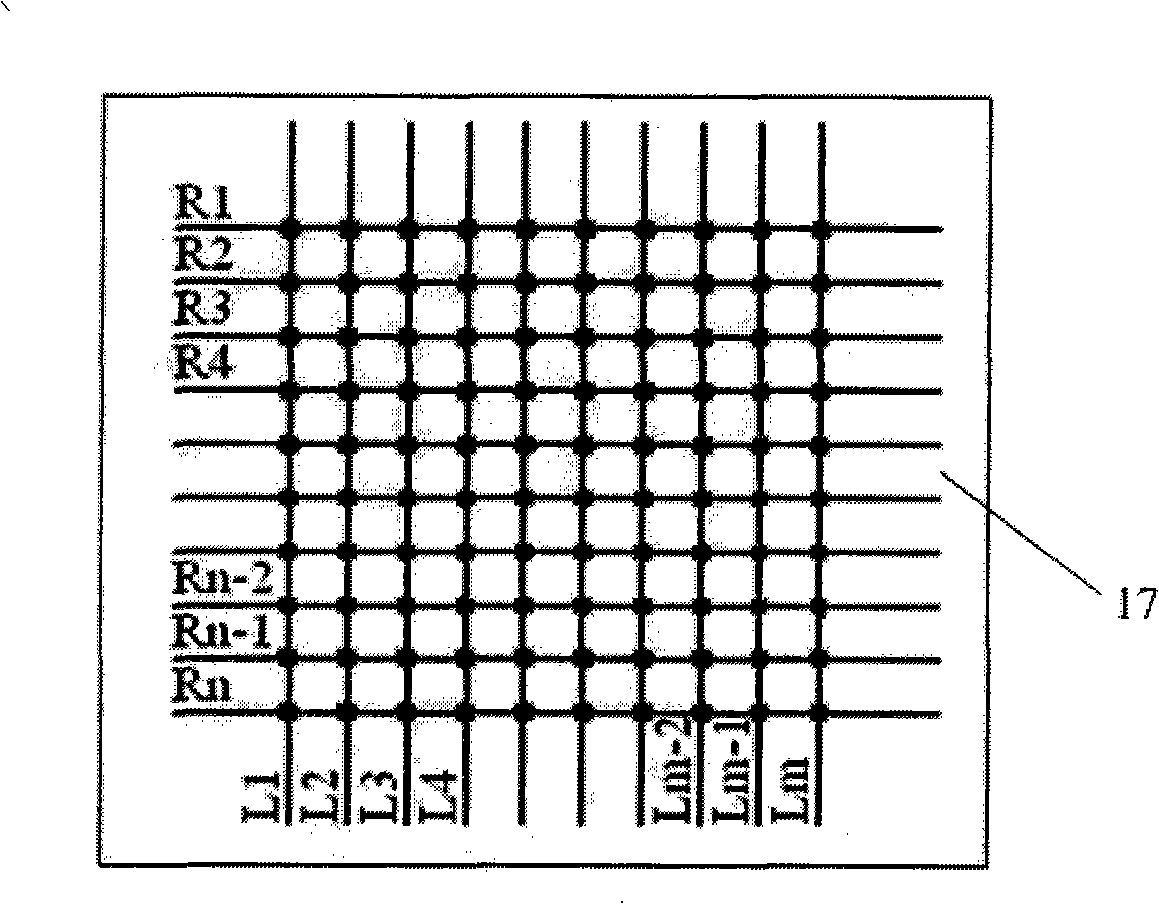

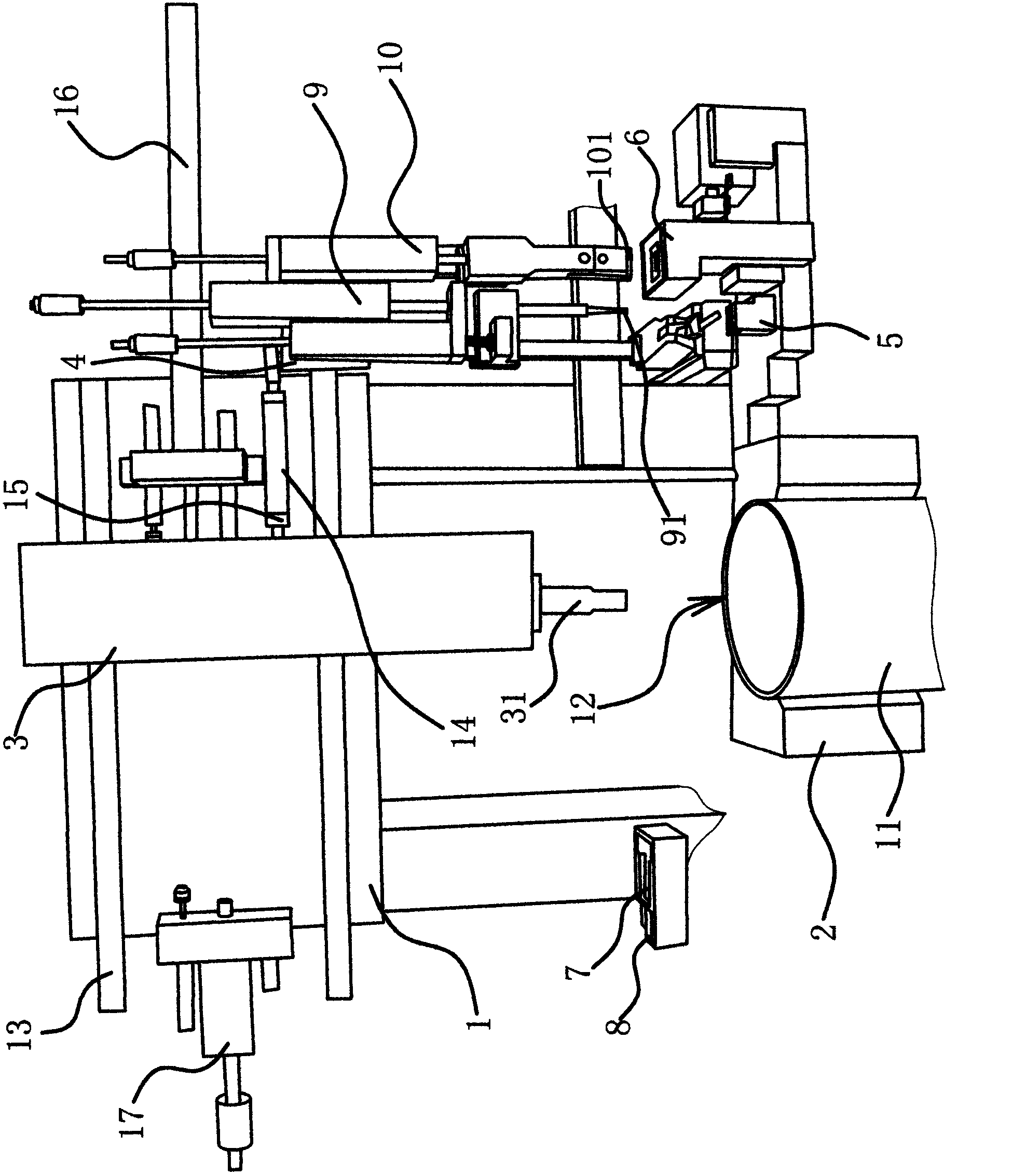

The present invention discloses a mechanical sensor array calibration device and the working method thereof. The device comprises locating transmission part and control part which is electrically connected with the locating transmission part; wherein, the locating transmission part comprises calibrated working platform and pressure head testing part; the pressure head testing part is connected with a force sensor through an extension head of a Z-directional linear stepper motor. Using the working method of the device adopts three stepper motors as the driving source; two stepper motors drive the coordinate motion of the slides on the guide rail to finish the location of coordinate point on the working platform; an extension of a linear stepper motor drives the pressure head to exert force on the tested sensor; when the force exerted by the pressure head achieves the set pressure valve, the singlechip collects the output of the tested sensor and the force sensor and the position coordinate of the tested sensor. The present invention is able to execute the choose and configuration of the calibrating mode and process according to the specific sensor array and the specific calibrating demand so as to enlarge the using range of the device.

Owner:ANHUI ZHONGKE BENYUAN INFORMATION TECH CO LTD

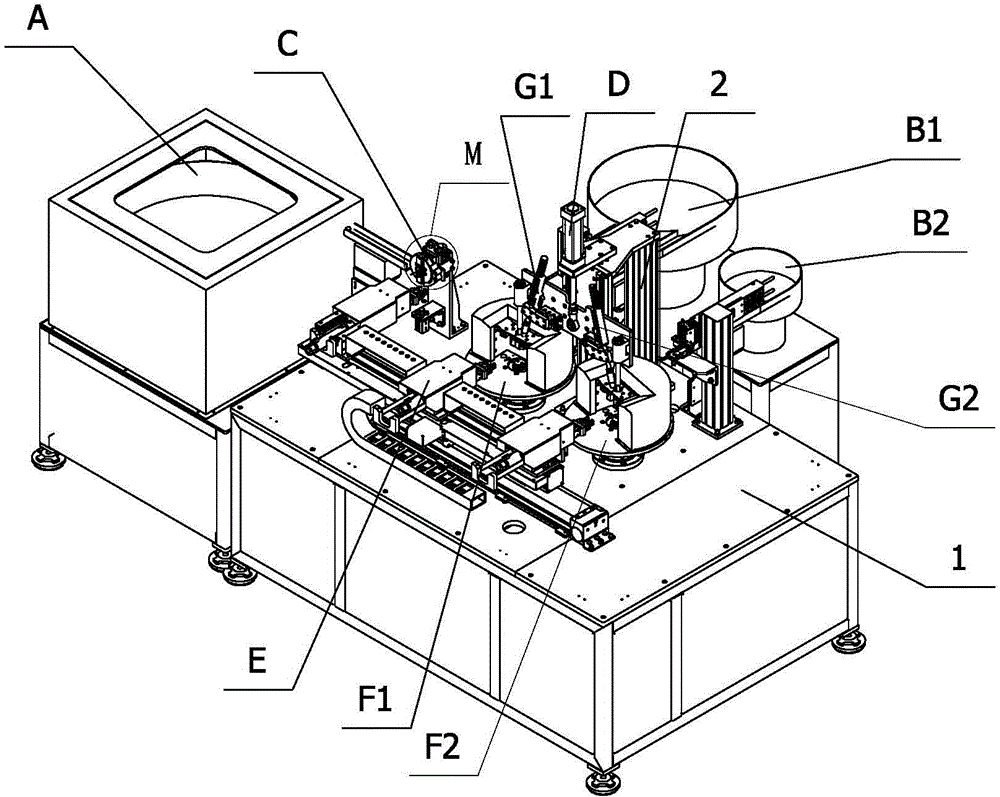

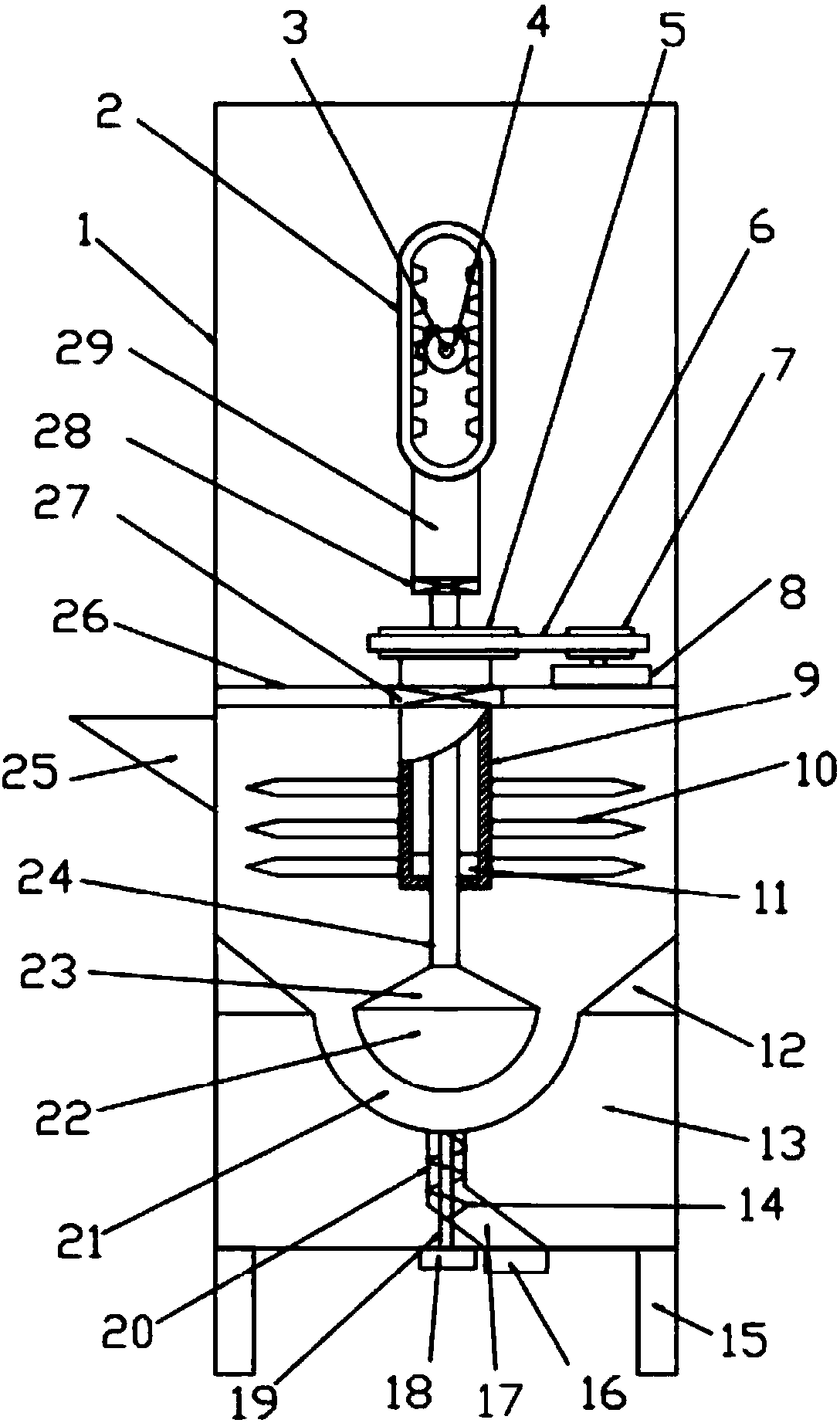

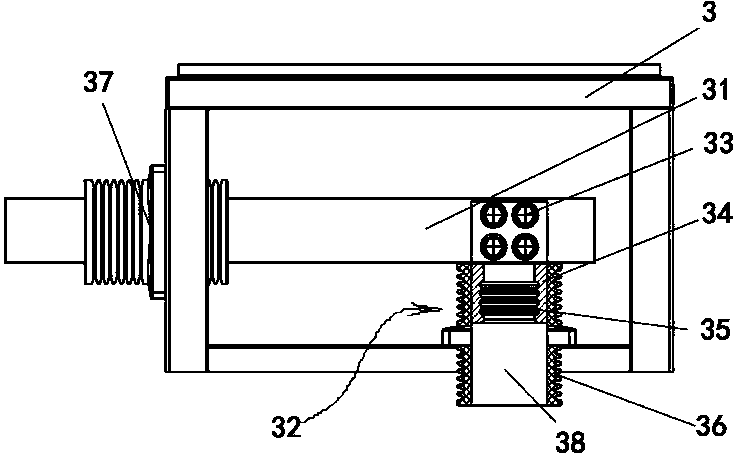

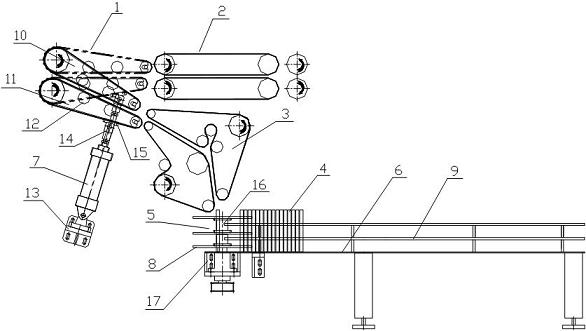

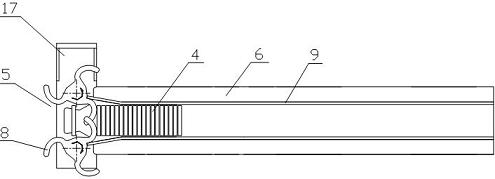

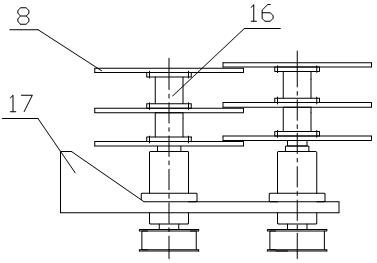

Diamond tool welding machine

ActiveCN103223538AReasonable arrangementSimple structureMetal working apparatusEngineeringMechanical engineering

The invention provides a diamond tool welding machine, and belongs to the technical field of operation. The welding machine solves the problem that the conventional brazing is low in automaticity. The welding machine comprises a machine frame and a positioning tooling fixed on the machine frame, wherein a tool bit clamping device is arranged above the positioning tooling, the tool bit clamping device is connected with the machine frame through linear guide components, and a driving part is arranged between the tool bit clamping device and the machine frame; a welding rod and a dipple glue station I are arranged on the motion trajectory of the tool bit clamping device corresponding to one side of the positioning tooling in sequence, and a dipple glue station two and a tool bit positioning base are arranged on the motion trajectory of the tool bit clamping device corresponding to the other side of the positioning tooling in sequence; a translational base is also arranged on the linear guide components, and a soldering lug sucking device corresponding to the welding rod and a dipple glue device corresponding to the dipple glue station I are arranged on the translational base; and the translational base is in rigid connection with the tool bit clamping device. The welding machine provided by the invention has the advantages that the welding machine is reasonable in arrangement, has a simple structure, and is convenient to operate and low in manufacturing cost.

Owner:项大清

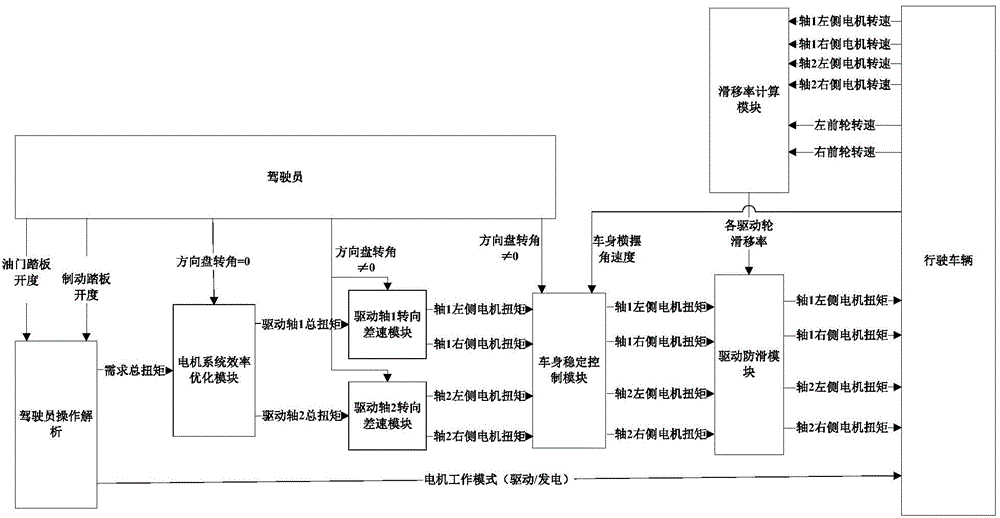

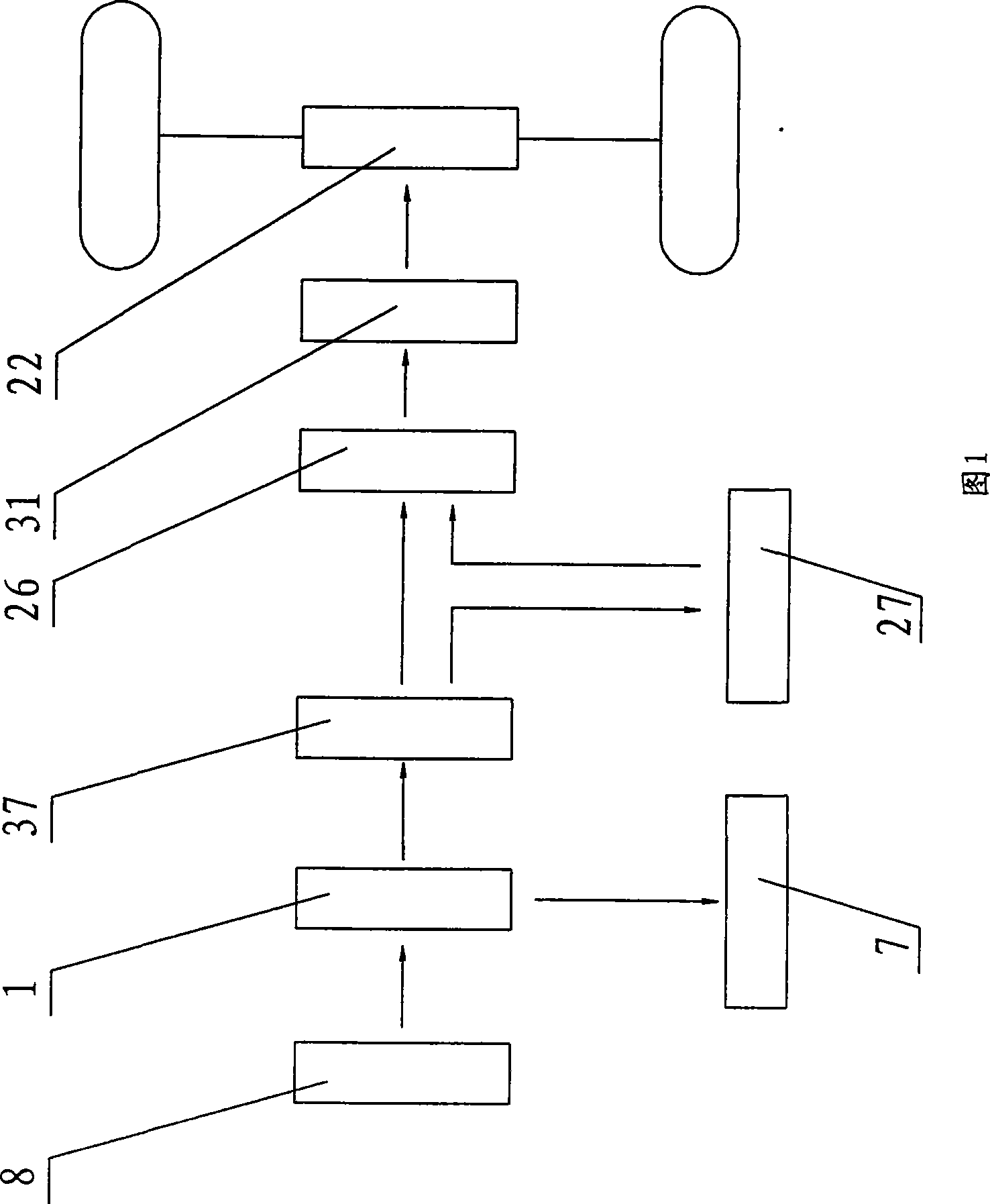

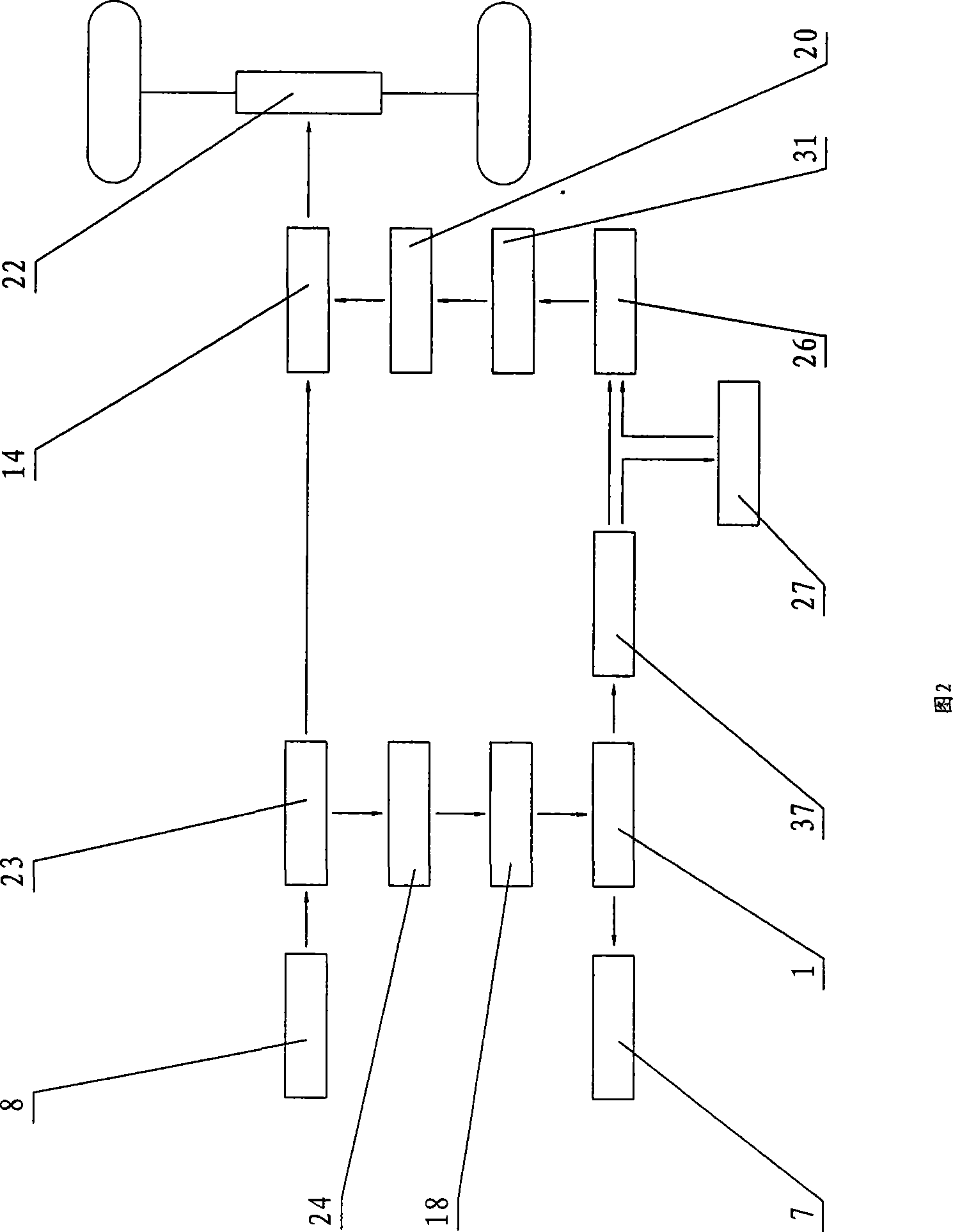

Vehicle and wheel edge drive system and wheel edge drive torque distributing method thereof

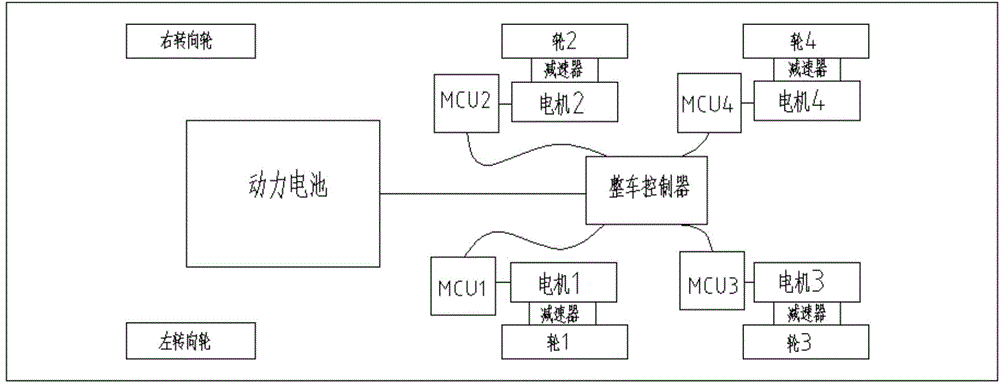

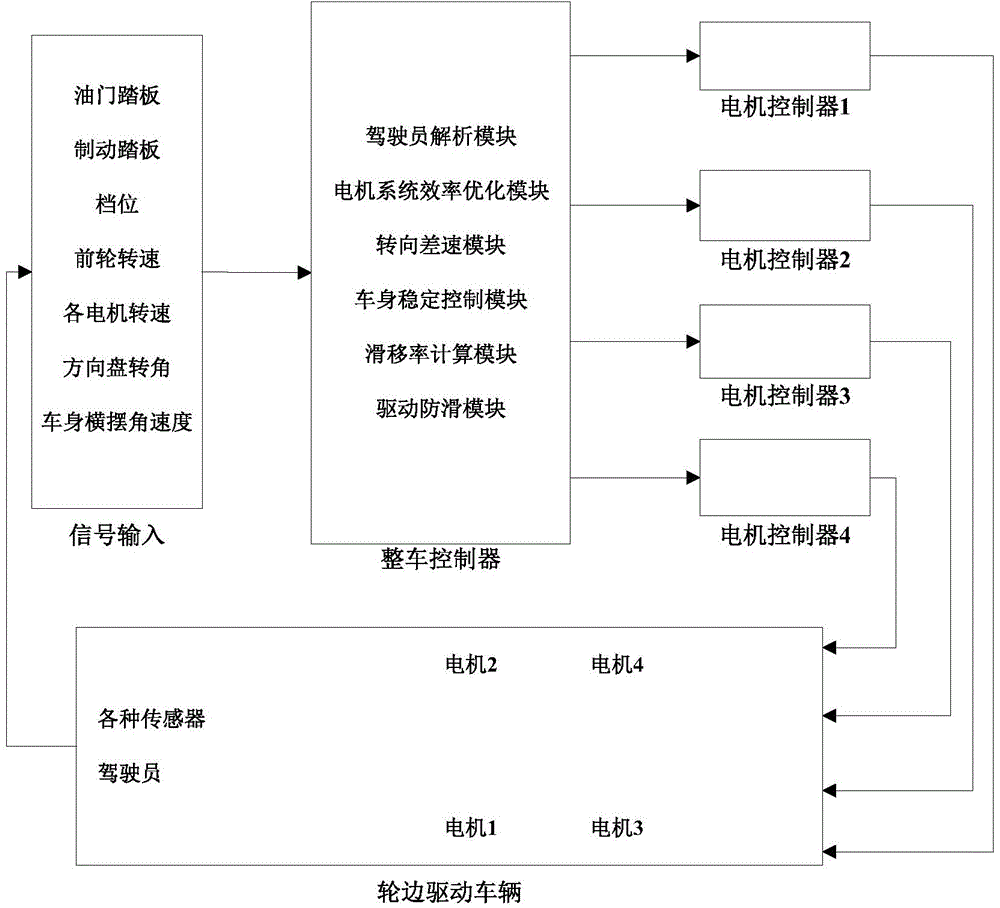

ActiveCN104786804AFlexible distribution of torqueImprove efficiencySpeed controllerElectric propulsion mountingPower batteryCarrying capacity

The invention relates to a vehicle and a wheel edge drive system and a wheel edge drive torque distributing method thereof. The number of drive shafts of the drive system is no less than two, vehicle internal space can be arranged more reasonably, the better dynamic property can be obtained, and the passenger carrying capacity and the climbing property are enhanced compared with those of a bus driven by a single motor; torque of the drive shafts can be distributed flexibly according to power needed by the vehicle, the high efficiency of the wheel edge drive system is obtained, and the power consumption of a power battery is saved to the greatest degree; the torque distribution between the shafts, the steering differential and other control modules are combined together to form a control method suitable for the multi-rear-shaft wheel edge drive system, energy optimization of the drive system and the functions of the advanced automobile electronic control systems such as an ASR, an ESP and an EBS can be achieved, and the whole vehicle can obtain a good balance in the aspects of the dynamic property, economy, comfort, safety and the like.

Owner:ZHENGZHOU YUTONG BUS CO LTD

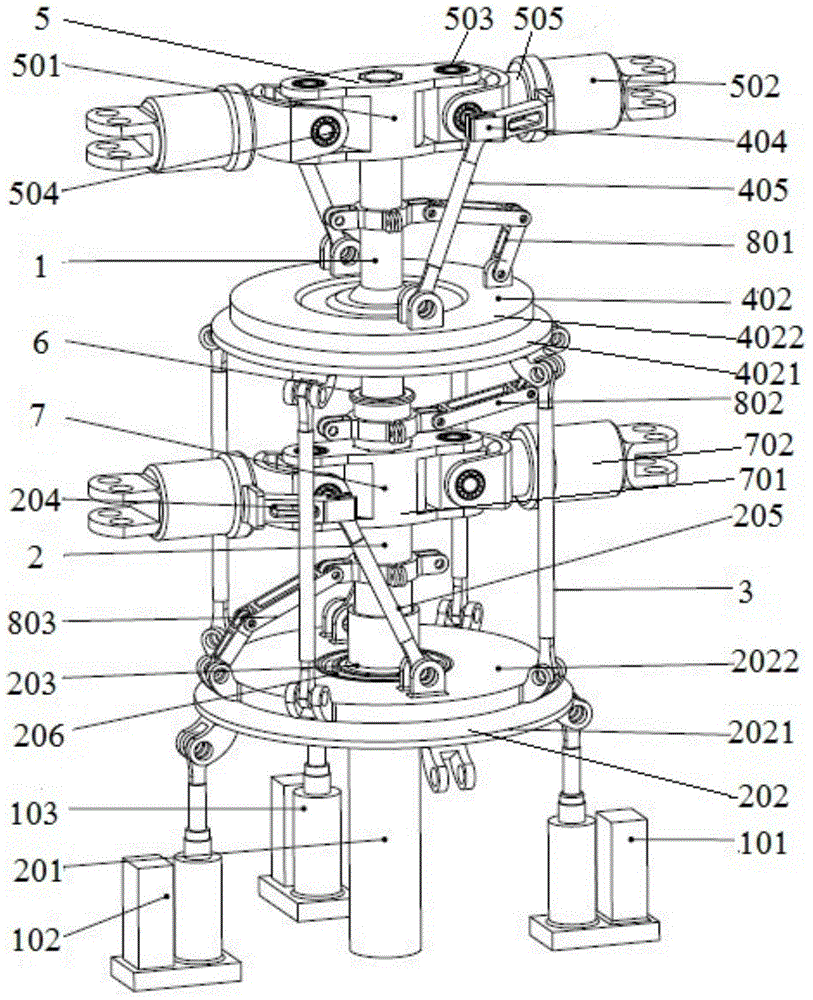

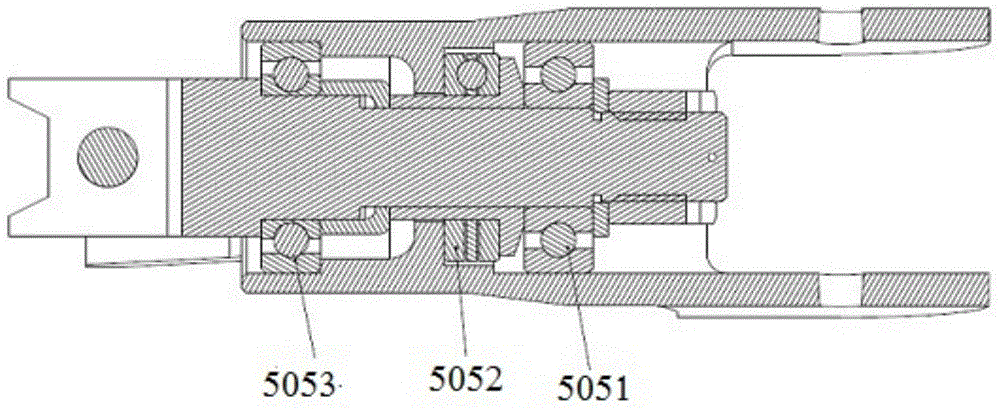

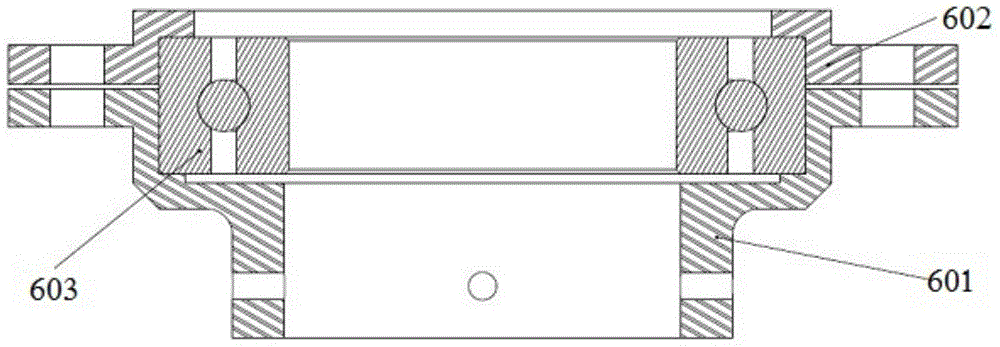

Simple rotor mechanism of coaxial dual-rotor helicopter test stand

InactiveCN104908976AAchieve collective controlRealization cycleStatic/dynamic balance measurementAircraft components testingControl systemPropeller

The invention relates to a simple rotor mechanism of a coaxial dual-rotor helicopter test stand. The rotor mechanism comprises an inner shaft, an outer shaft, an actuator group, a lower control system, an upper control system, an upper rotor propeller hub and a lower rotor propeller hub, wherein the upper rotor propeller hub comprises a first propeller hub seat, and a first paddle arm arranged on the first propeller hub seat in a full articulation manner; the lower rotor propeller hub comprises a second propeller hub seat and a second paddle arm arranged on the second propeller hub seat in a full articulation manner; the upper control system is connected with the first paddle arm; the lower control system is connected with the second paddle arm; the upper control system is connected with the lower control system via an intermediate draw bar; and the actuator group is connected with the lower control system to control synchronous motion of the first paddle arm and the second paddle arm. The mechanism can achieve collective pitch control and cyclic pitch change of coaxial dual rotors, and effectively achieves various dynamic tests of the helicopter such as upper and lower rotor aerodynamic characteristics of the coaxial dual rotors, dynamic stability of the rotors, and moving part loads of the rotors.

Owner:BEIHANG UNIV +1

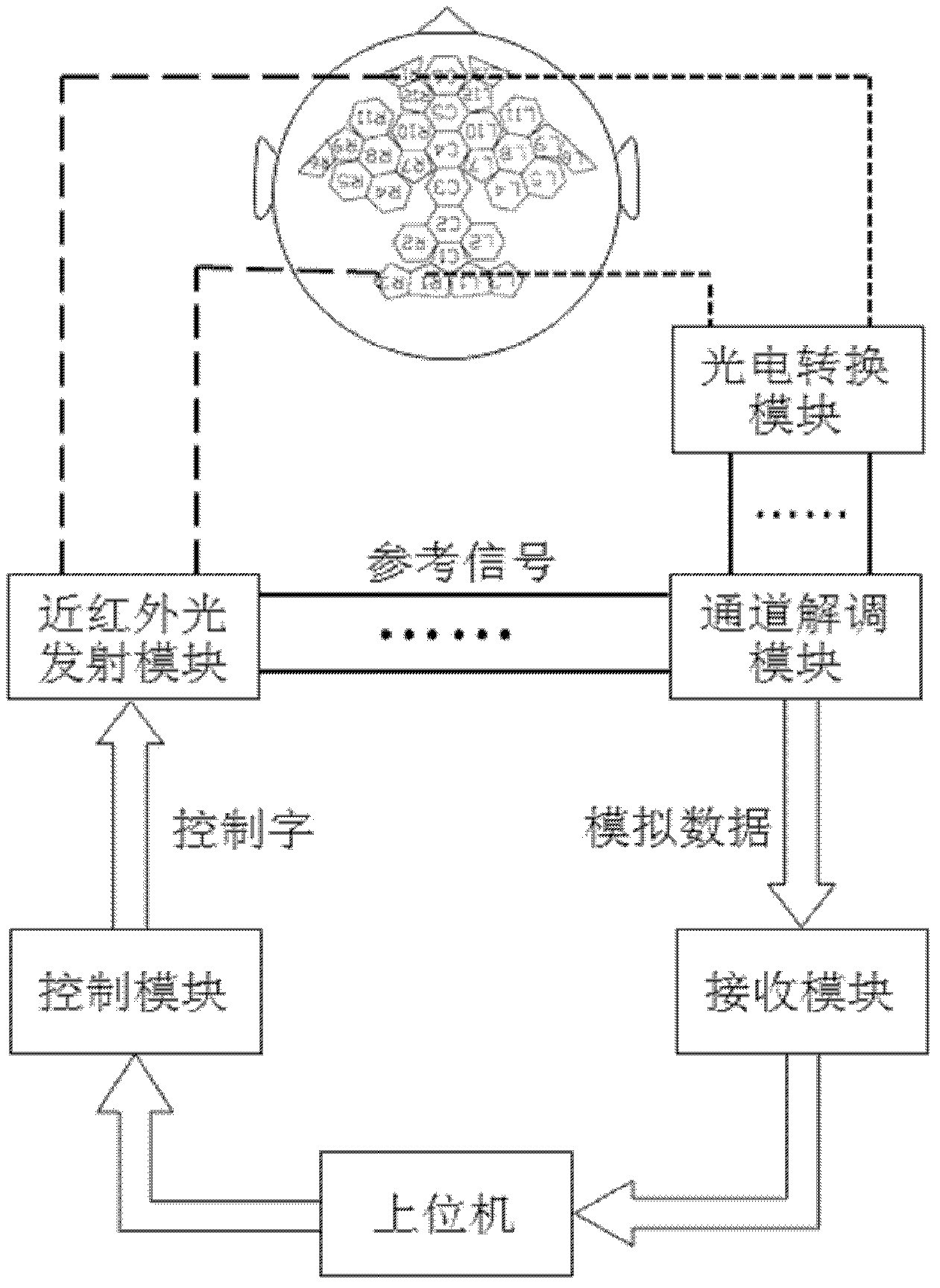

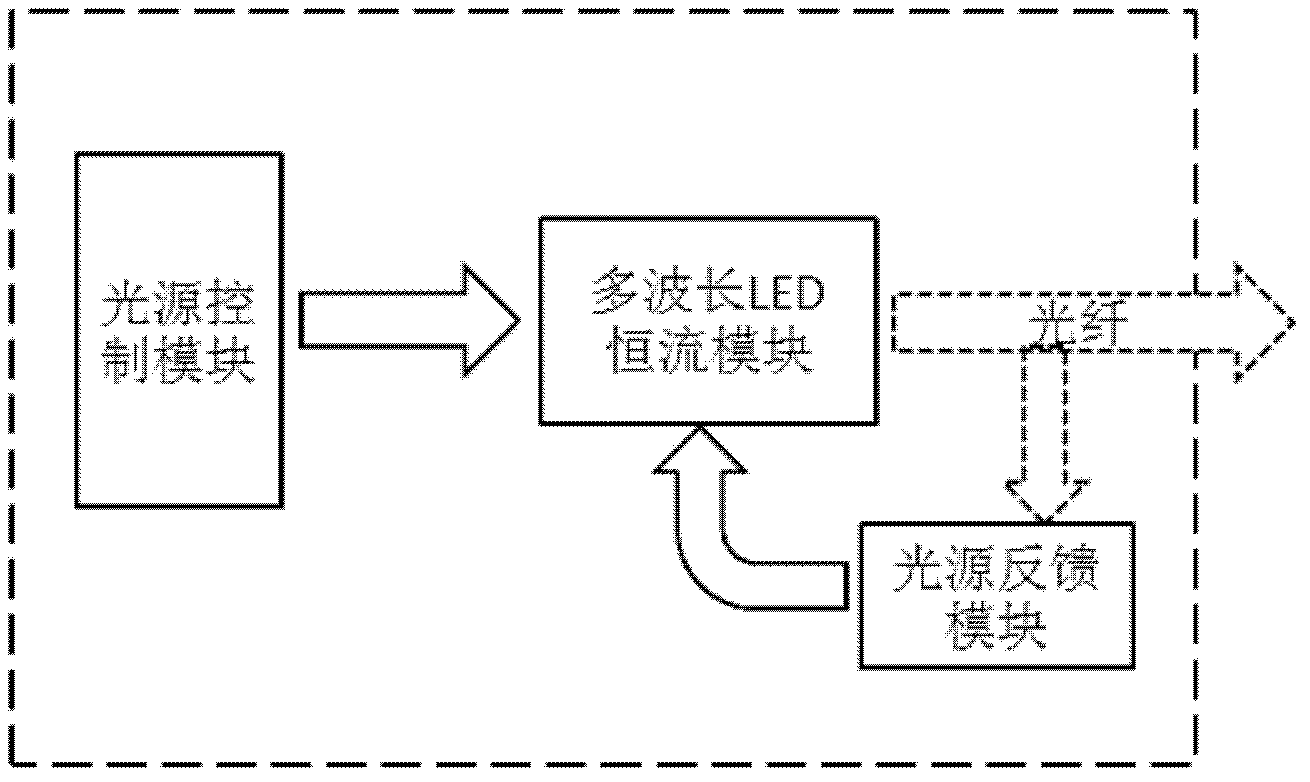

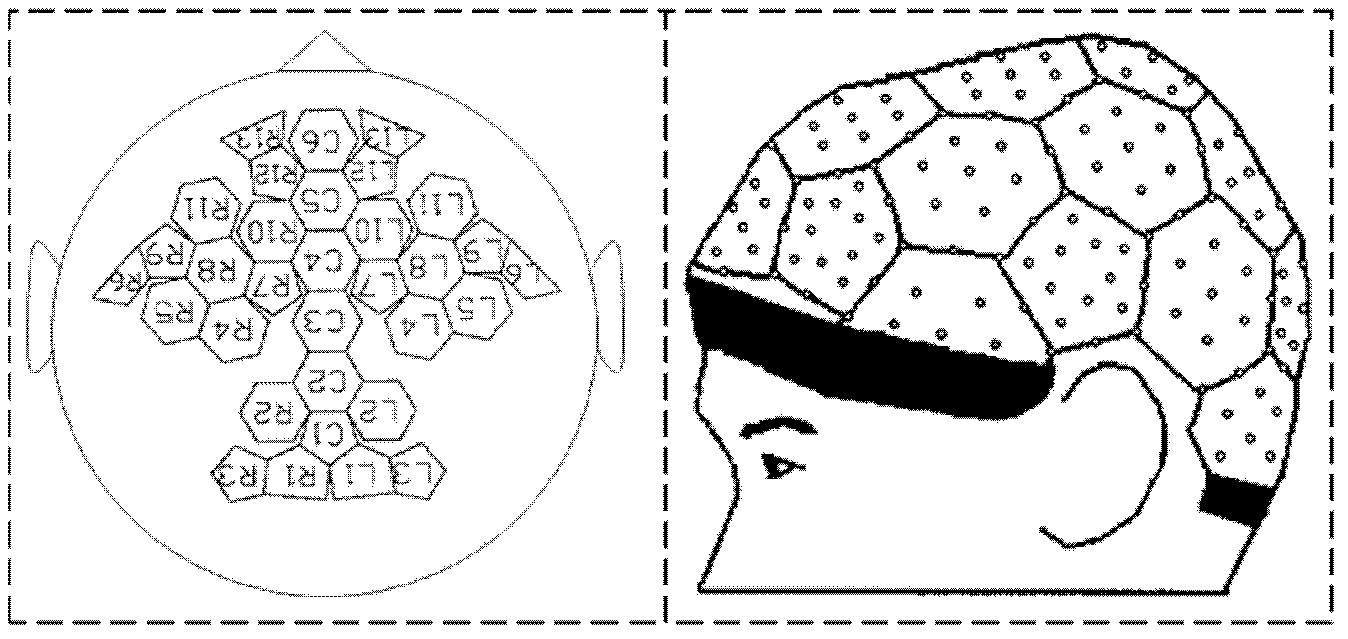

Multi-channel parallel near infrared spectrum imaging system

ActiveCN103156620ALow cost to manufacture and useHigh costDiagnostic recording/measuringSensorsMulti wavelengthInfrared

The invention discloses a multi-channel parallel near infrared spectrum imaging system. A multi-wavelength light emitting diode (LED) is applied to finishing emission of near-infrared light. An avalanche photodiode is used for detecting a weak optical signal, the simulating lock-in amplifier technology is used for achieving amplification of the signal, and a near infrared spectrum cerebral function imaging helmet disclosed in Chinese patent application CN200520002784.8 can be used for improving the partial unreasonable design of a self-adaptation head portion. The multi-channel parallel near infrared spectrum imaging system can achieve continuous rapid accurate detection and collection of cerebral blood oxygen signals, overcomes the defect of an existing functional near infrared system, and brings superiority of the near infrared spectrum imaging technology compared with other cerebral function imaging technologies into full play.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

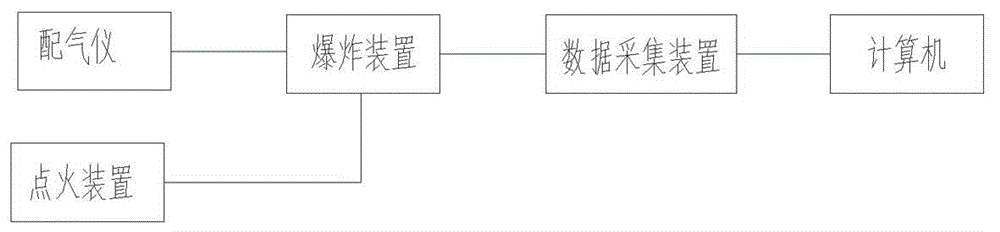

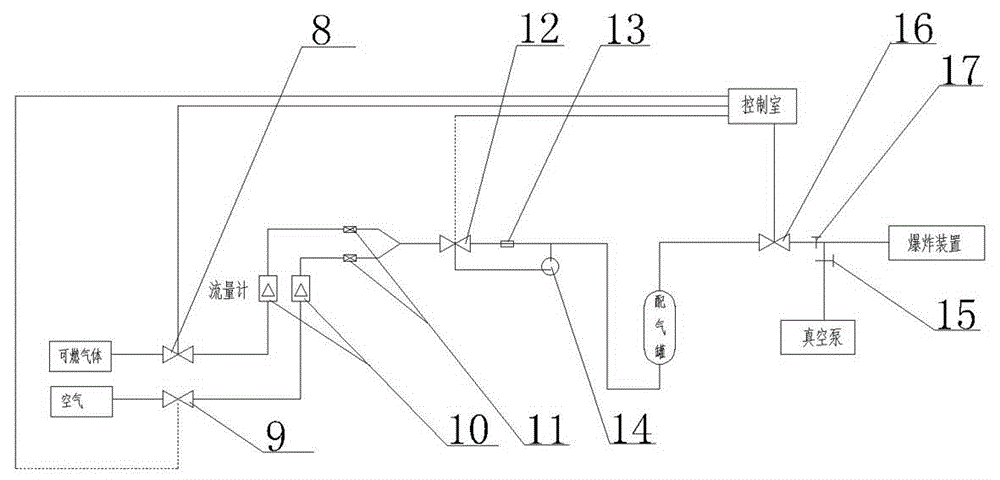

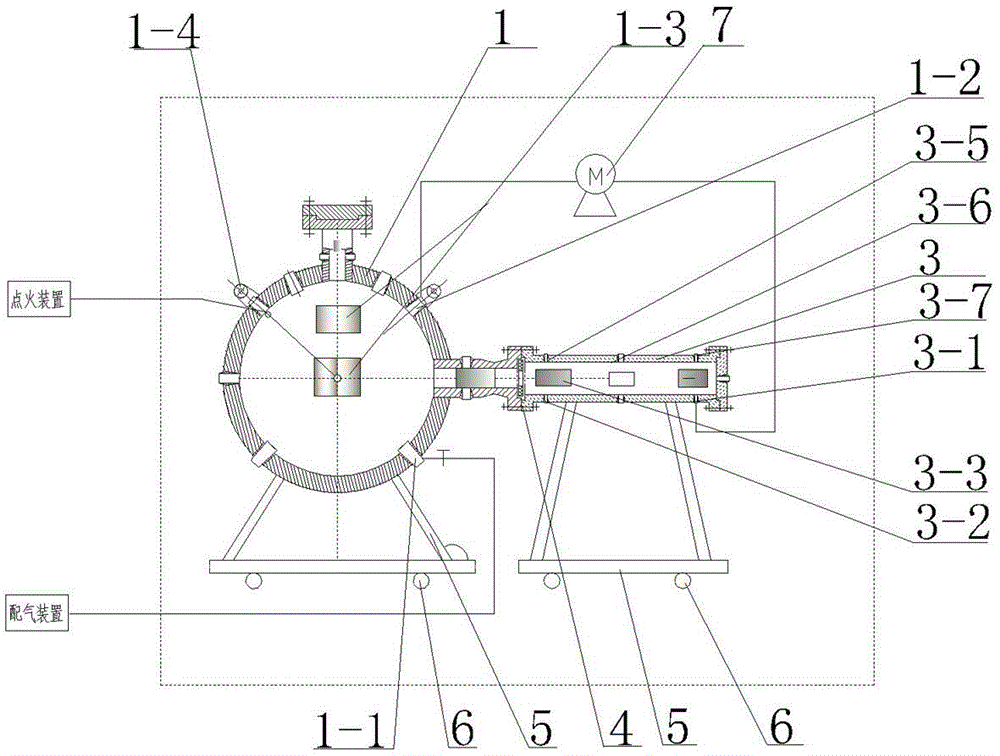

Testing system for gas explosion characteristic size effect

The invention discloses a testing system for a gas explosion characteristic size effect and relates to a testing system which studies on the gas explosion characteristic size effect. The device comprises a gas distribution device, an ignition device, an explosion device, a data collecting and processing device and a high-speed digital camera, wherein the gas distribution device comprises a combustible gas source, a distribution gas source and a gas distribution tank; the ignition device comprises a igniter, and the igniter is installed on the explosion device; the data collecting and processing device comprises a pressure sensor, a flame propagation rate sensor, a temperature sensor, a signal amplification circuit, a data collecting circuit and a computer, and the pressure sensor, the flame propagation rate sensor and the temperature sensor are installed on a spherical container, a cylindrical container and a pipeline; the explosion device is installed between the gas distribution device and the data collecting and processing device, and the explosion device comprises the spherical container, the cylindrical container and the pipeline; and the high-speed digital camera is used for shooting flames during explosion of the combustible gas inside the containers and the pipeline, and an output end of the high-speed digital camera is connected with the computer.

Owner:NANJING UNIV OF TECH

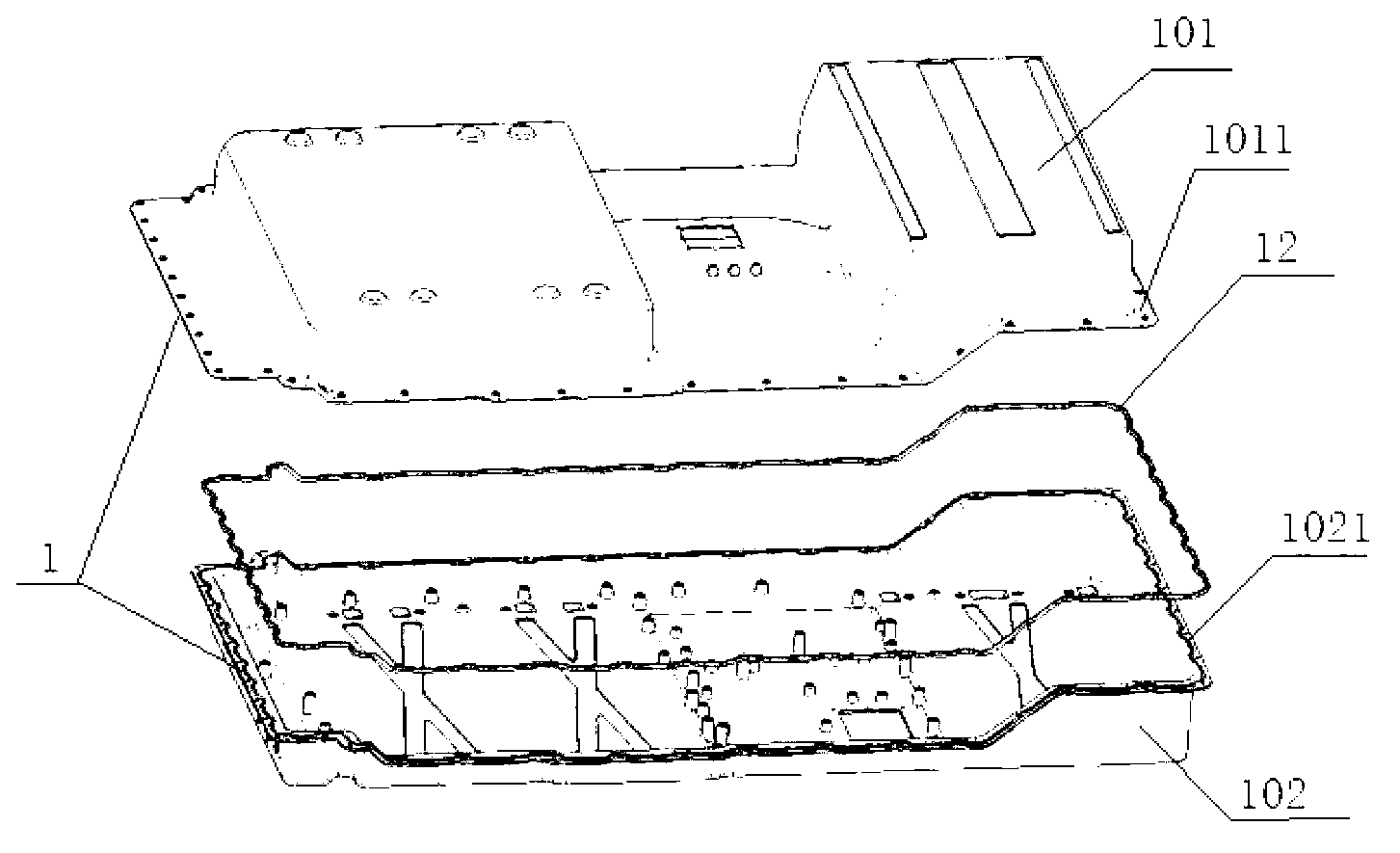

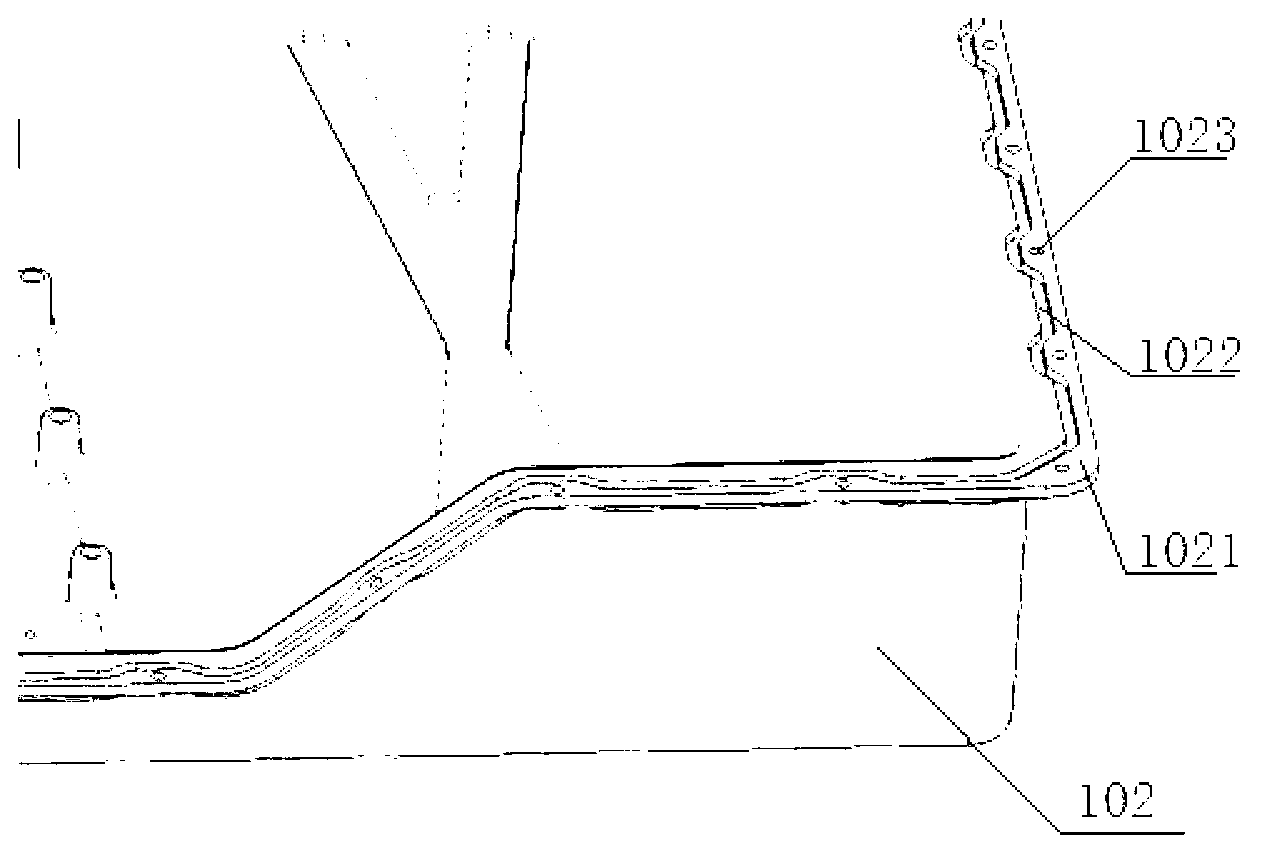

Power battery pack assembly structure of all-electric vehicle

ActiveCN103066225AGuaranteed to be fixed and stableReasonable arrangementSecondary cellsCell component detailsPower batteryElectrical battery

The invention discloses a power battery pack assembly structure of an all-electric vehicle. The power battery pack assembly structure comprises a shell; the outer side at the bottom of the shell is symmetrically provided with a battery pack fixing structure connected with a vehicle body floor board; the front part of the shell is positioned below the middle part of a front floor board; the middle part of the shell is positioned below a middle channel of the front floor board; the rear part of the shell is positioned below a middle floor board; the inner side at the bottom of the shell is provided with a battery cooling system; a front battery module is arranged at the front part above the battery cooling system; a rear batter module is arranged at the rear part above the battery cooling system; the front battery module and the rear battery module are respectively provided with battery module fixing structures connected with the battery pack fixing structure; and a battery management unit is arranged between the front battery module and the rear battery module. According to the invention, after a fuel oil tank is not installed on the electric vehicle, available spaces below a rear seat and below a front seat can be utilized fully, and the requirements on ground clearances of a riding space and a battery pack are met. The power battery pack assembly structure provided by the invention is reasonable in structural arrangement, extremely firm in fixation, and convenient to mount and dismount.

Owner:DONGFENG MOTOR CORP HUBEI

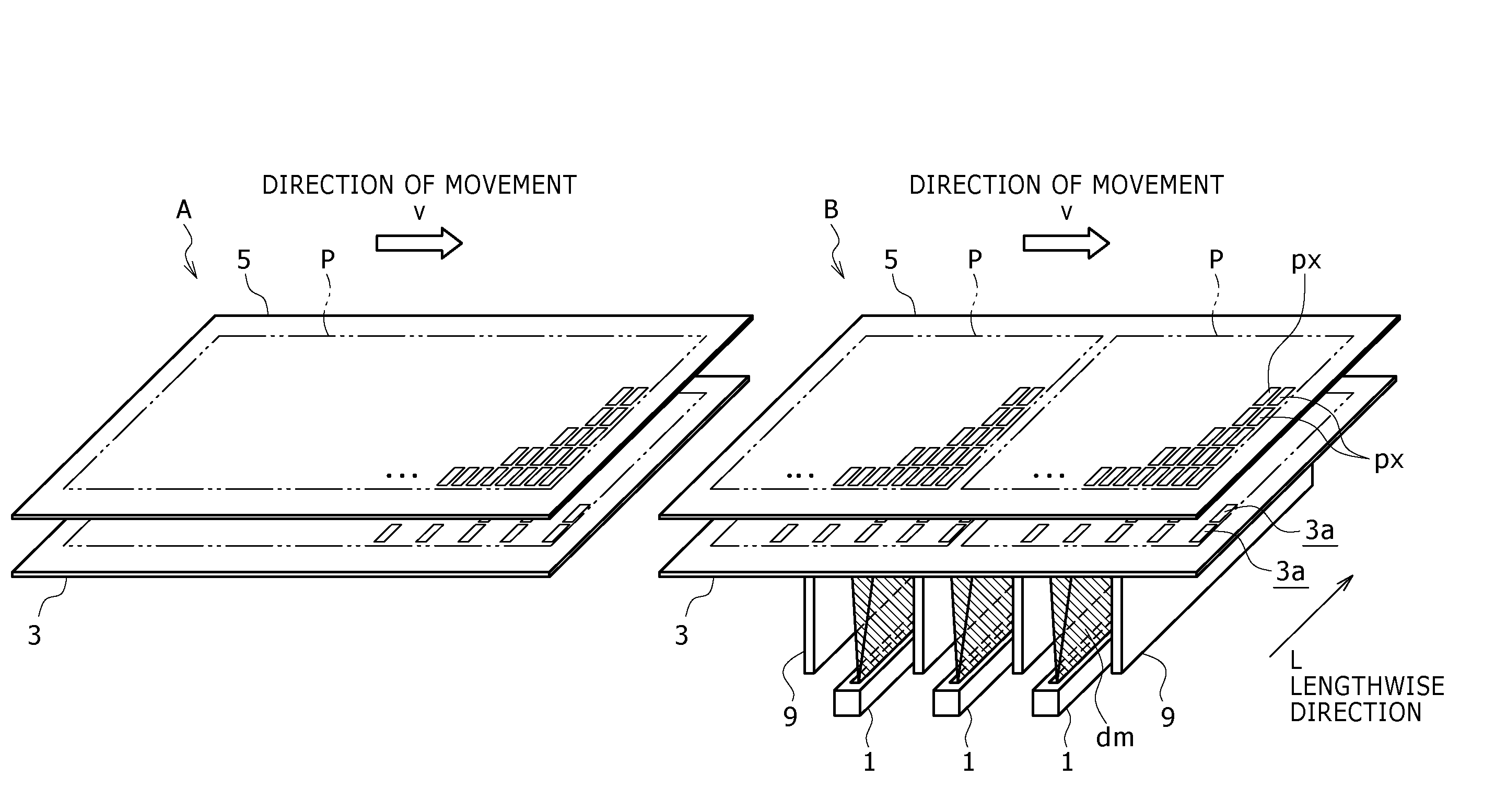

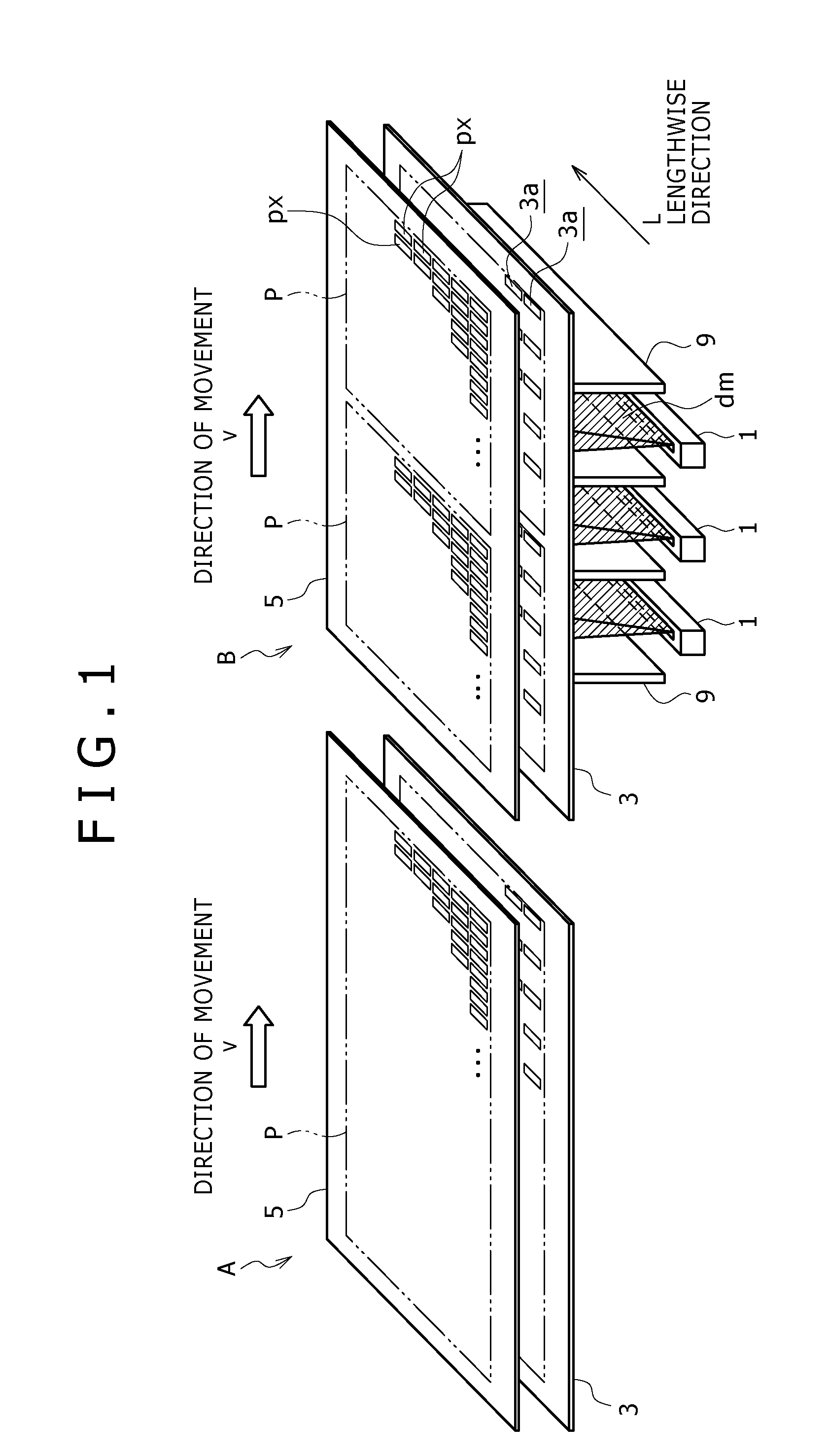

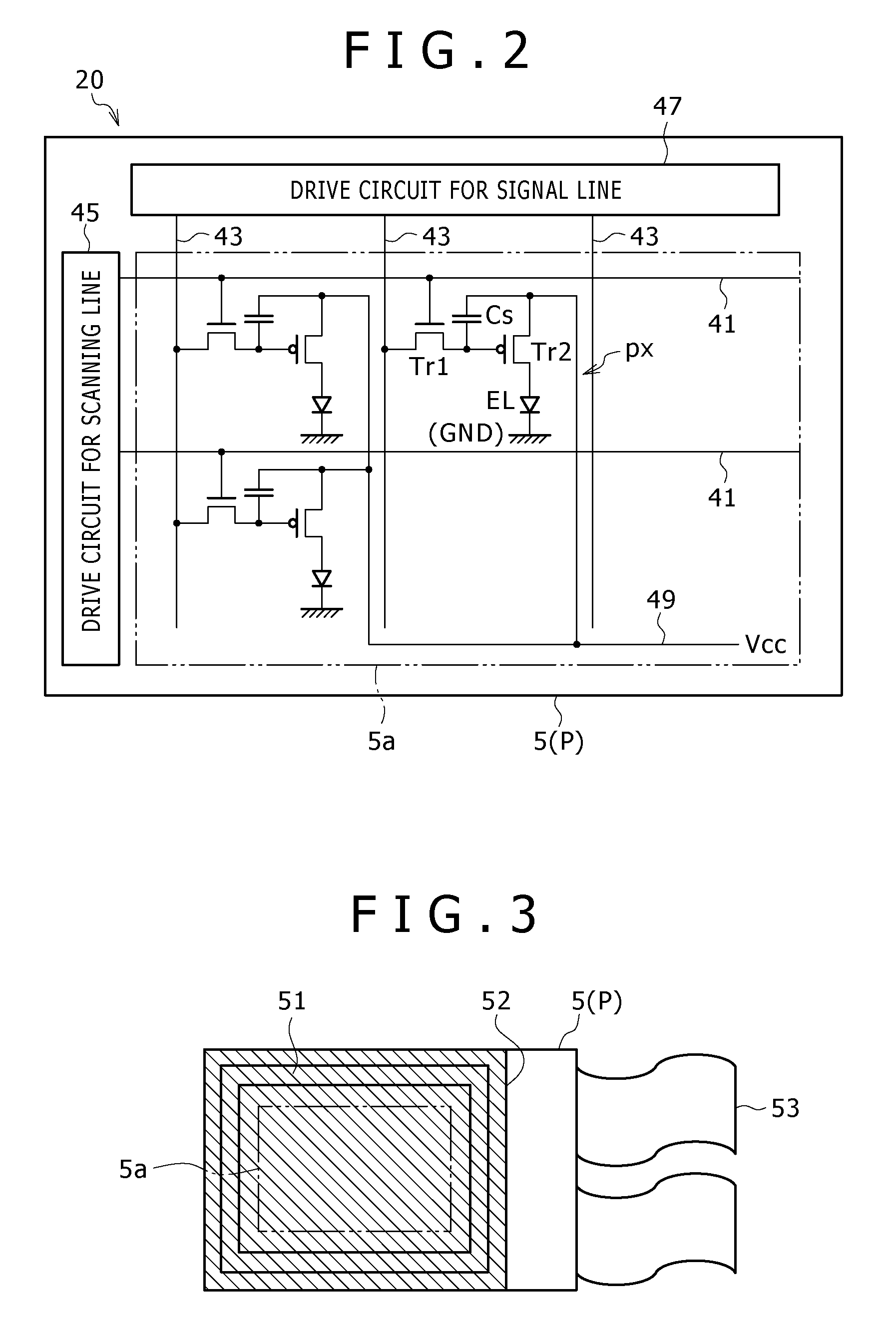

Method for producing display device

InactiveUS20090181163A1Produced economicallyReasonable arrangementVacuum evaporation coatingSolid-state devicesDisplay deviceEvaporation

Disclosed herein is a method for producing display devices for forming deposited patterns conforming to pixels on a substrate by means of elongated evaporation sources and a deposition mask having regularly arranged apertures, the method including the steps of arranging the deposition mask and the substrate in such a way that the long sides of the apertures and pixels are parallel to the lengthwise direction of the evaporation sources irrespective of the direction in which the display panel regions are arranged within the substrate; and moving the substrate and the deposition mask relative to the evaporation sources, thereby forming the deposited patterns conforming to the pixels on the substrate.

Owner:SONY CORP

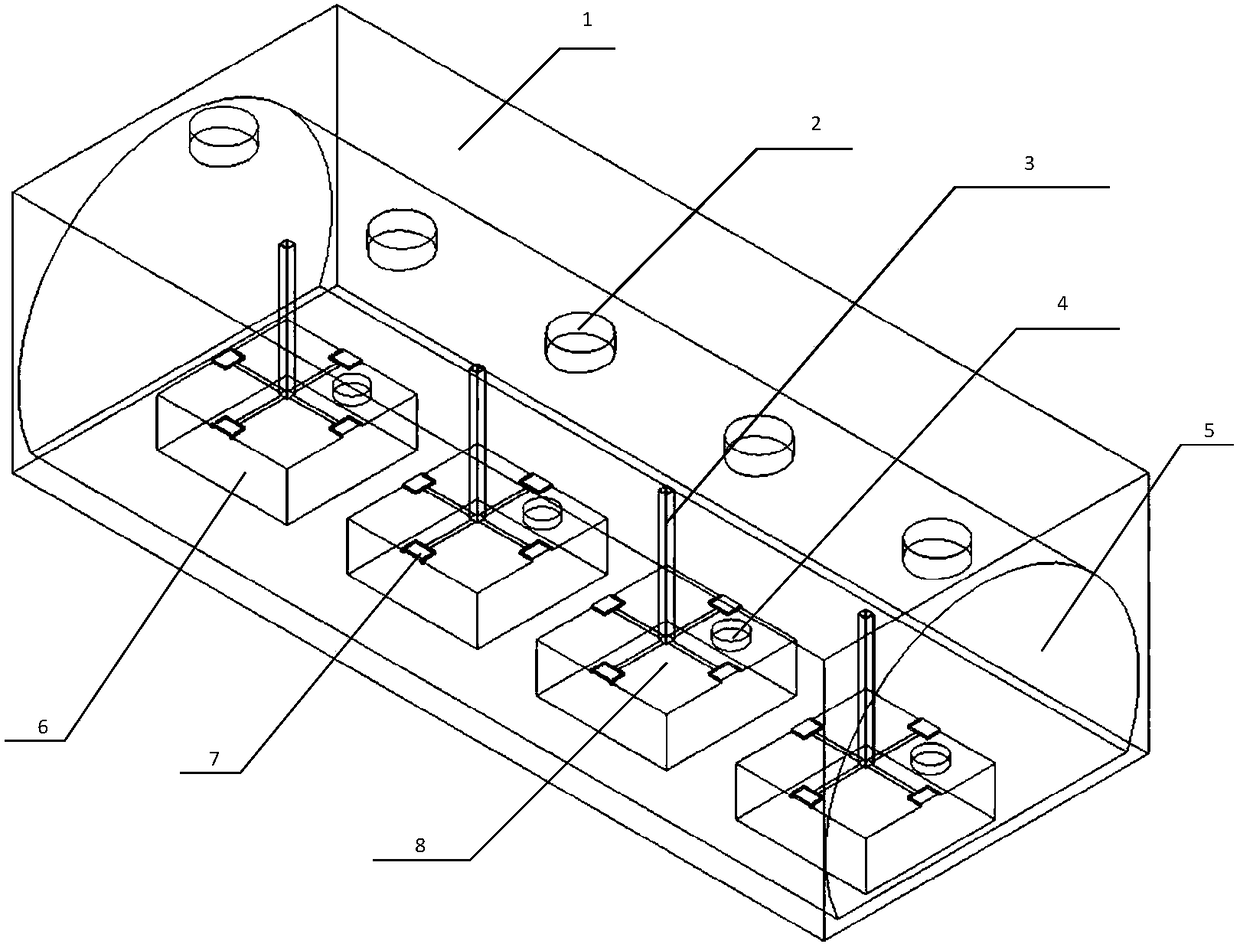

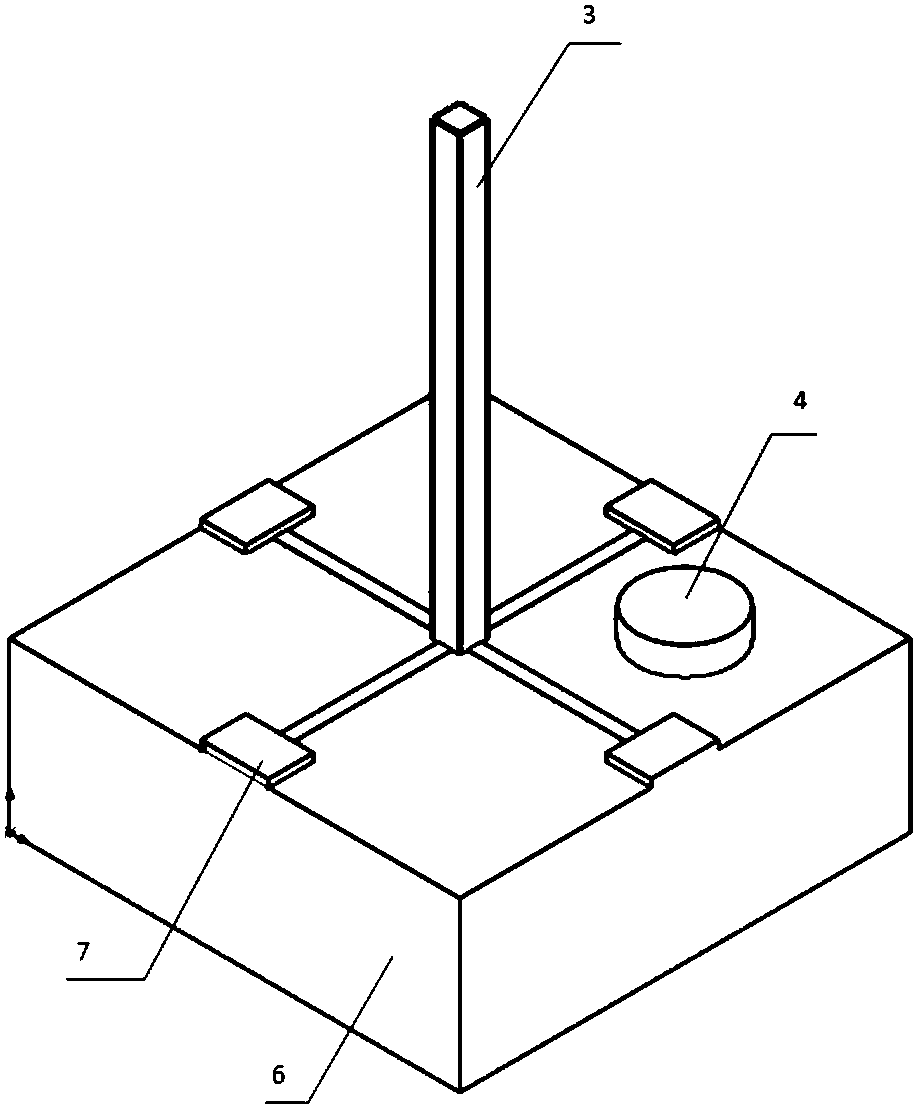

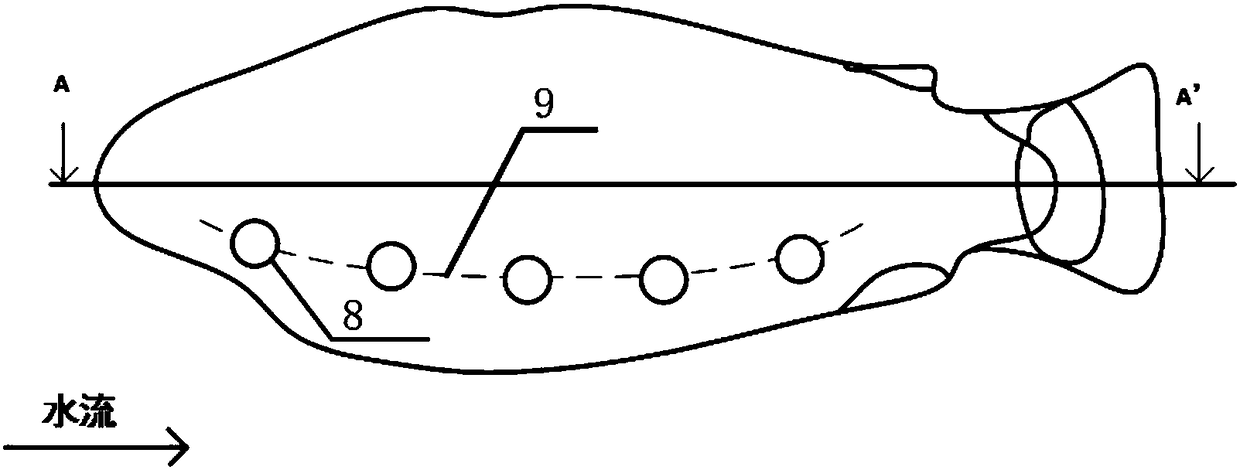

Underwater bionic lateral line sensing array

ActiveCN108362334AAvoid being affected by the surrounding large flow field environmentAccurate measurementHydrodynamic testingTransducerWater flow

An underwater bionic lateral line sensing array includes a bionic lateral line array structural body, runner water holes, an inner channel and a plurality of water current and water pressure compositesensors, wherein each water pressure composite sensor includes cilia made of electric reactive polymer smart material, a pressure transducer, electrodes and a pedestal. The bionic lateral line arraystructural body is therein provided with the inner channel in the length direction. The water current and water pressure composite sensors are arranged in the inner channel. The runner water holes communicating with the inner channel are arranged in one side of the bionic lateral line array structural body. The pedestals are arranged in the inner channel. Four electrodes are arranged on each pedestal. Each pedestal is provided with the cilia made of electric reactive polymer smart material and the pressure transducer is arranged on the pedestal. The underwater bionic lateral line sensing arrayhas a fish lateral line simulating system and senses water current and water pressure change at the same time, is high in anti-interference capability, high in sensibility and precision, and can provide measurement basis for accurate sensing of water environment change in the surrounding of a lateral line system.

Owner:XI AN JIAOTONG UNIV

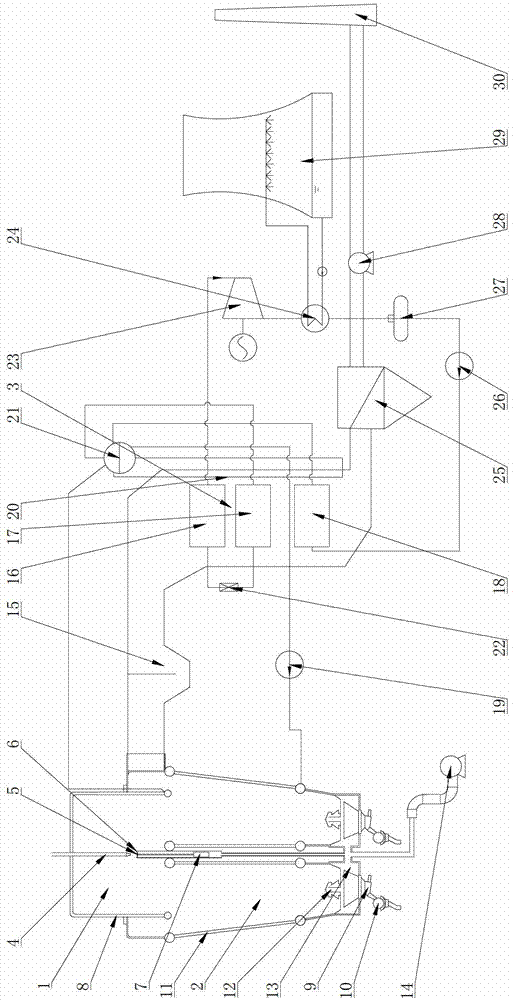

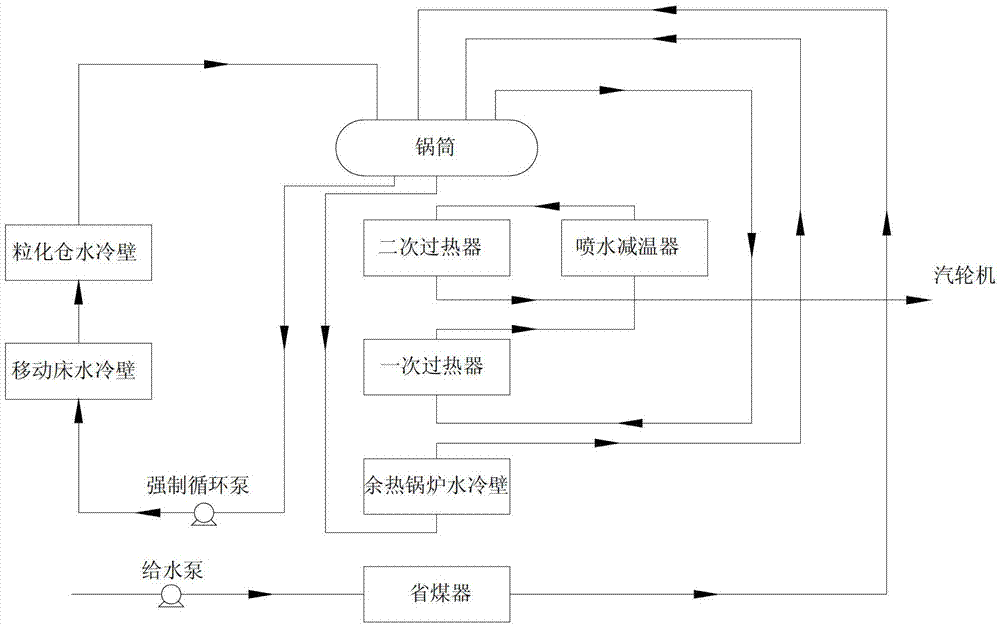

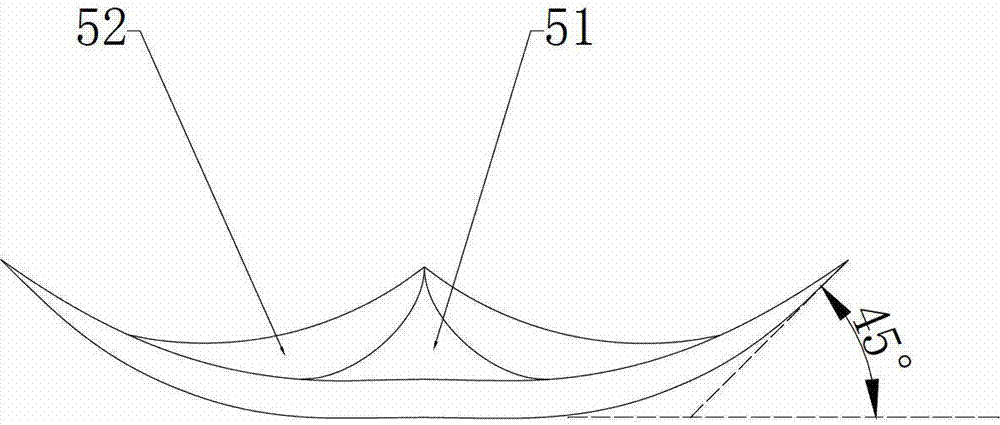

Afterheat recovery system and method of dry granulating liquid slag

ActiveCN102827969AEasy to diluteImprove granulation effectIncreasing energy efficiencyRecycling and recovery technologiesRecovery methodLiquid slag

The invention discloses an afterheat recovery system and an afterheat recovery method of dry granulating liquid slag. The system comprises a granulating cabin, a moving bed and an afterheat recovery system, the inner surface of the granulating cabin is provided with a granulating cabin water cooling wall, the center of the top of the granulating cabin is provided with a slag pipe, the slag pipe extends into the granulating cabin, the lower part of the tail end of the slag pipe is provided with a centrifugal granulator, the centrifugal granulator is connected with a motor arranged at the lower part of the centrifugal granulator, the lateral side of the centrifugal granulator is provided with an air supply pipeline, an annular air opening is formed between the centrifugal granulator and the air supply pipeline, the lower part of the granulating cabin is provided with the moving bed, the inner surface of the moving bed is provided with a moving bed water cooling wall, the top of the moving bed is provided with an air outlet, the bottom of the moving bed is provided with a slag discharge device, an air inlet device is arranged above the slag discharge device, the afterheat recovery system comprises a primary dust remover, an afterheat boiler, a secondary dust remover, an exhaust fan and a chimney which are connected in sequence, and the primary dust remover is connected with the air outlet arranged at the top of the moving bed. The system and the method effectively solve the problems of heat recovery and furnace slag granulation of equipment such as a blast furnace.

Owner:XI AN JIAOTONG UNIV +1

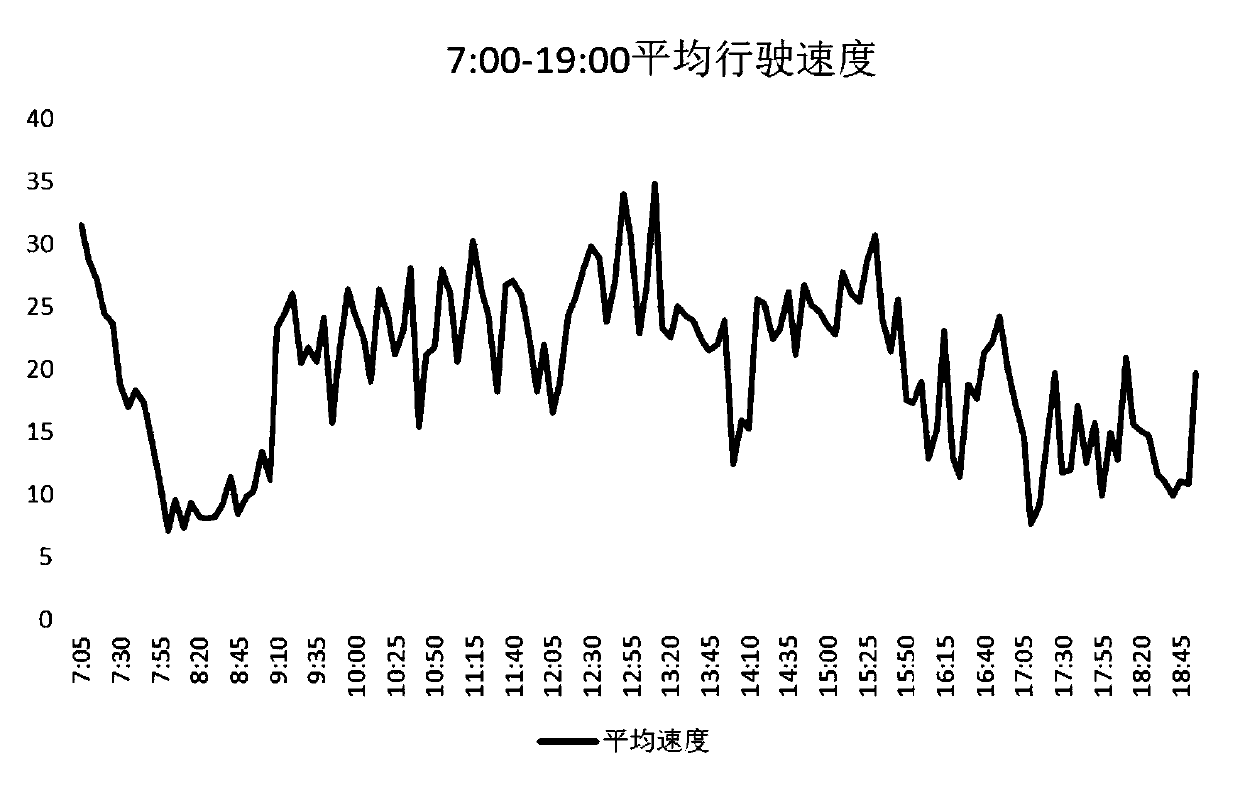

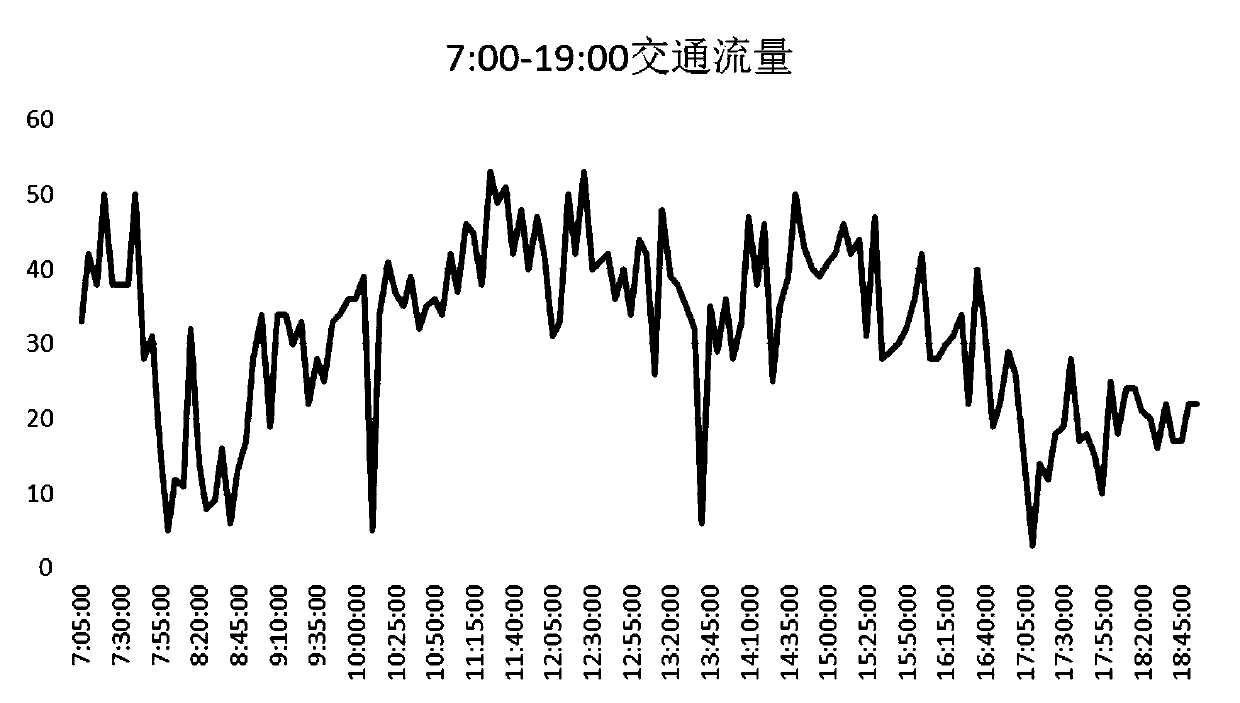

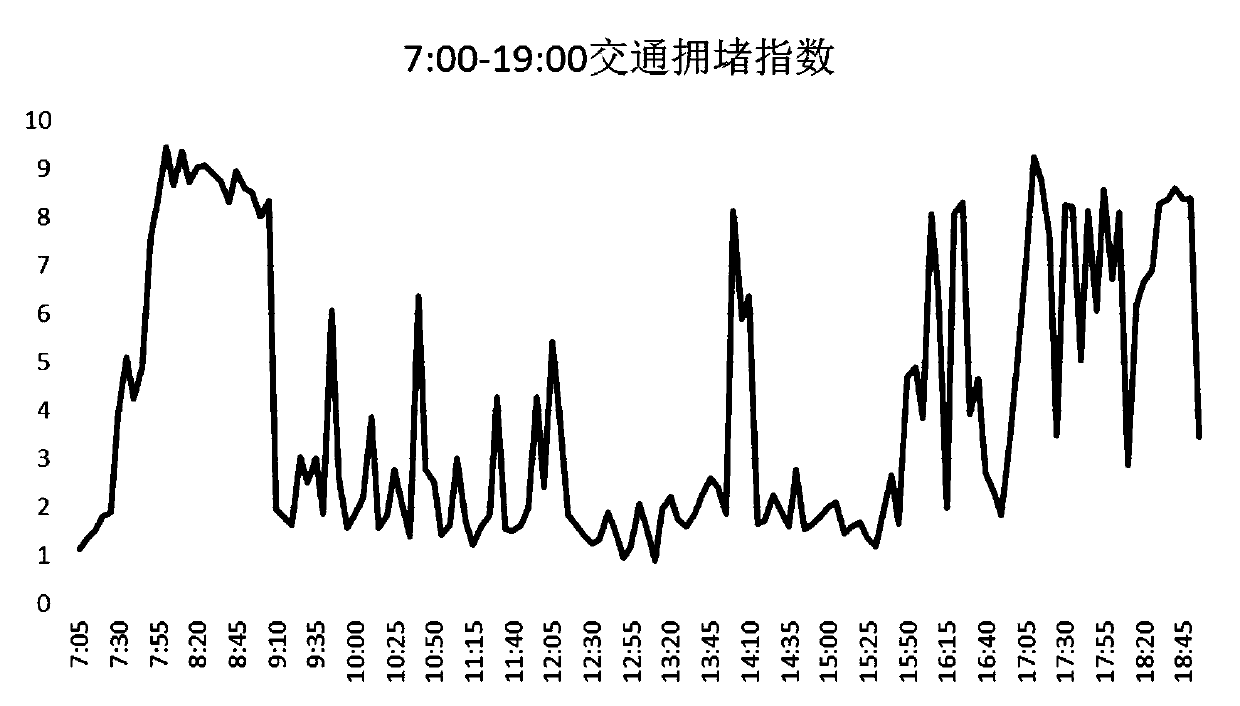

Road traffic congestion index calculation method based on fixed detection device

InactiveCN108629973AClose to congestionTraffic congestion indexDetection of traffic movementResourcesRoad trafficOperating speed

The invention discloses a road traffic congestion index calculation method based on a fixed detection device. The method comprises the steps that data collected by the fixed detection device are compared and processed by using a period of 5 to 10 minutes, so as to acquire a representative speed value and travel time of the road in a time period; and a congestion index calculation formula is used to convert the speed value and travel time into a road traffic congestion index to acquire the current traffic congestion of the road. According to the invention, the traffic congestion index of the road network is calculated through parameters such as the length of the road, the travel time, the speed, the number of lanes, the free travel speed, the occupancy rate and the flow rate; travel delay time is used to reflect the traffic congestion index, and the traffic congestion index is closer to the congestion feeling of a driver; the calculation of the road congestion index can provide automatic input parameters for an urban intelligent traffic light signal controller; automatic traffic light control is realized; and the road use efficiency and the work efficiency of a traffic management department are improved.

Owner:SICHUAN JIUZHOU VIDEO TECH

Digging laneway aerating and dust removing system arrangement method

InactiveCN101169041ADisadvantages of reducing open rateSolve the problem of poor ventilation and dust removal effectDust removalFire preventionCycloneHooping

The invention provides an arrangement method of a ventilating and dust-removing system for the excavation tunnel, and includes a boring machine, a belt feeding machine, a belt transshipment device, a dust-removing device, and a ventilating device. The boring machine is connected with the belt transshipment. The transshipment device is set on the belt feeding machine, and the negative pressure wind cylinder of the ventilating device is hung on the tunnel and connected with a fan in a hooping method. Two positive pressure wind cylinders are arranged on the ventilating device, one positive pressure wind cylinder is connected with a fan and a dust catcher in the hooping method; the other positive pressure wind cylinder is connected with a cyclone in the hooping method and is hung on the tunnel. The dust catcher of the dust-removing device is set up on a dust catcher supporting device. The dust-removing device is arranged on a position 20 to 40 meters behind the boring machine, and the negative pressure wind cylinder is connected at a position 3 to 5 meters apart from and opposing the drivage face, fresh air is pressed in by the positive pressure wind cylinder, and the outlet is 15 to 35 apart from and opposing the drivage face. The ventilation arrangement of the method is rational and safe, the movement is convenient, the operation is simple, the dust removing effect is good, the water consumption is low, and the cost is low.

Owner:TANGSHAN KAILUAN GUANGHUI EQUIP MFGCO

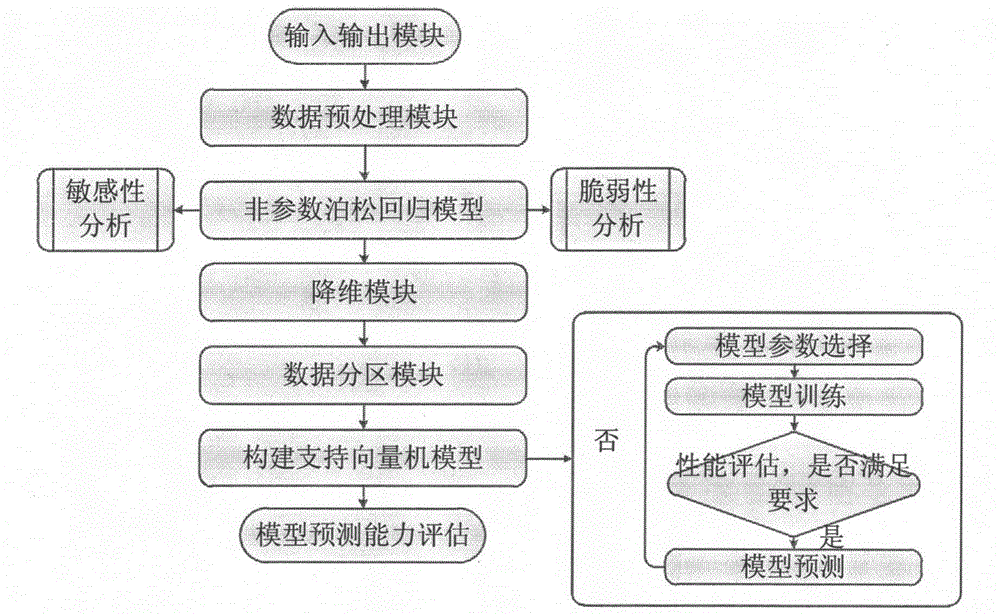

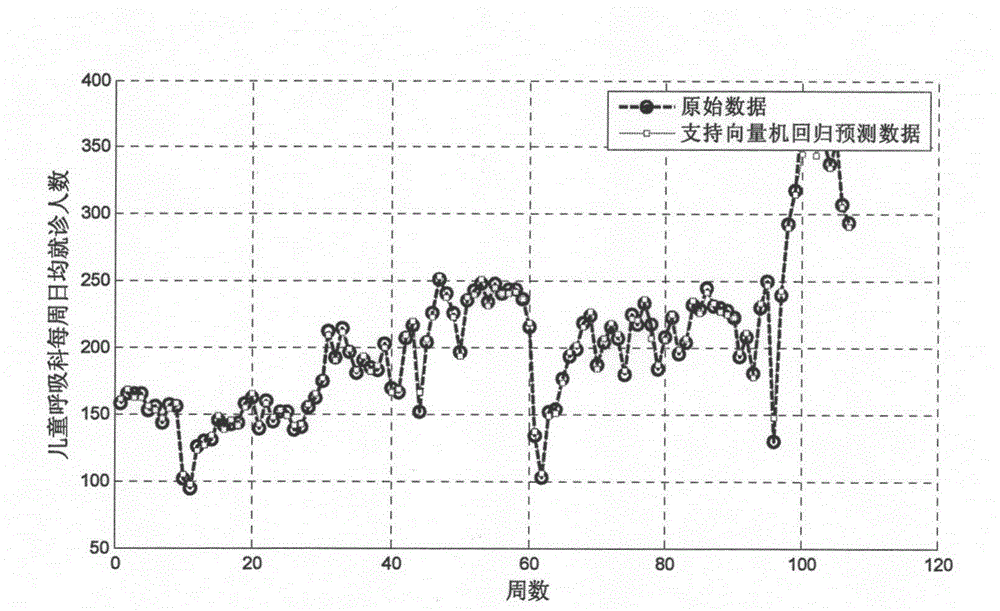

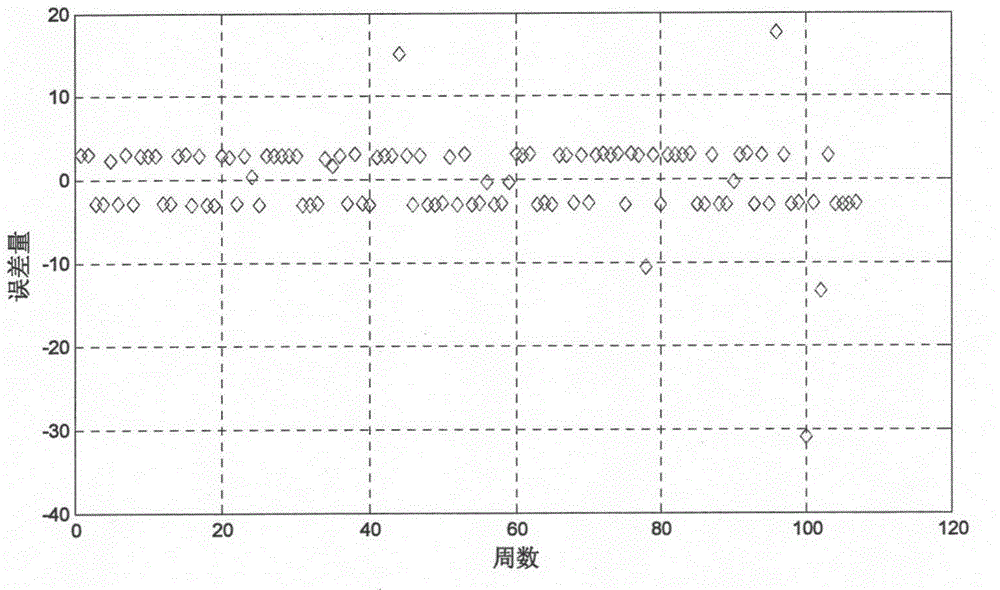

Analytical prediction module of disease incidence affected by environmental change

ActiveCN104809335AReduce morbidityImprove the quality of lifeSpecial data processing applicationsDiseasePublic health

The invention discloses an analytical prediction module of disease incidence affected by environmental change. An association condition between outpatient capacity data and meteorology change and environmental pollution data is analyzed, a quantitative analysis module is built based on the incidence of the disease incidence caused by the environment change of a non-parameter Poisson regression model, and a prediction module which affects the outpatient capacity based on support vector regression is built based on the quantitative analysis module, and the weekly outpatient capacity of each department of a hospital is predicted. Therefore, a patient can avoid the influence on bad weather conditions and environmental pollution factors in advance and arrange the daily activities reasonably; furthermore, a hospital can reasonably configure the medical resources and manpower of all departments aiming at top diseases; furthermore, the emergency preparation can be done by public hygiene departments in advance, and the special crowds can be intervened in advance, therefore the morbidity can be reduced and the human living quality can be improved.

Owner:上海卫生信息工程技术研究中心有限公司 +1

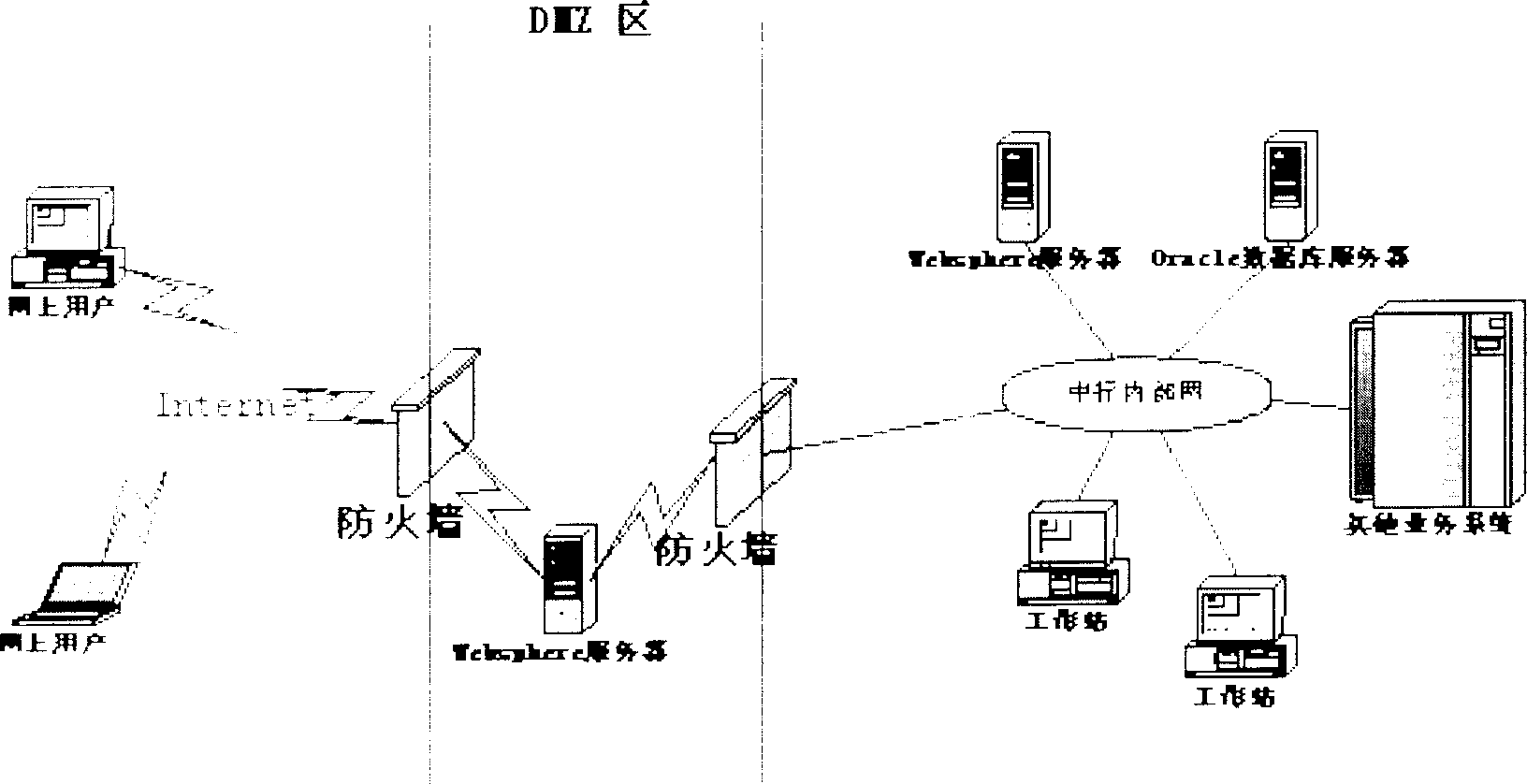

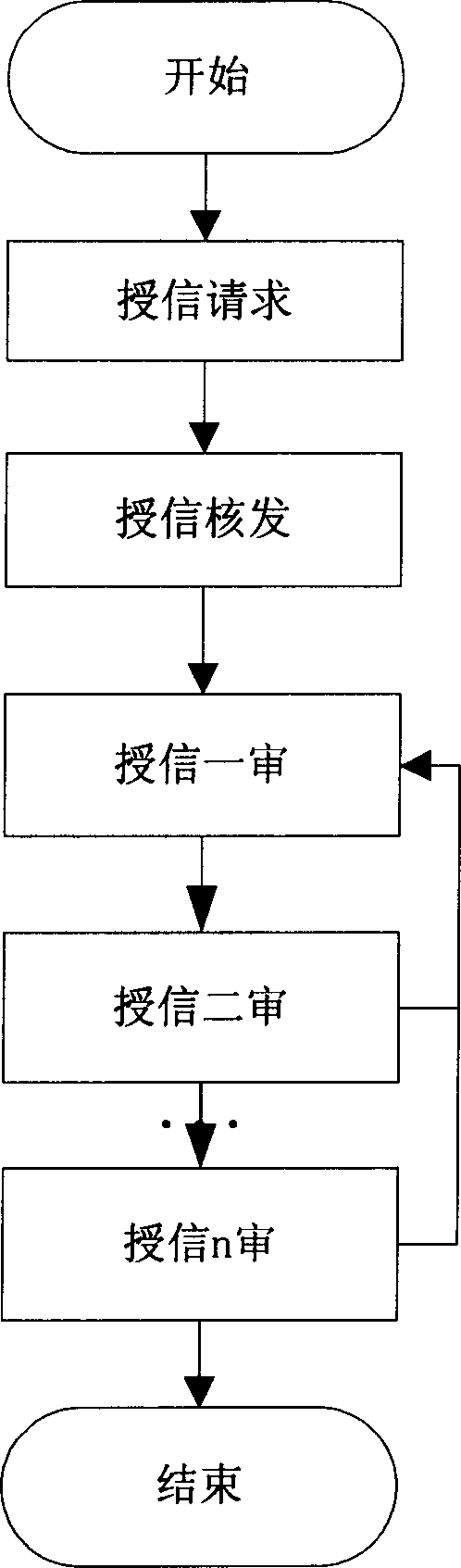

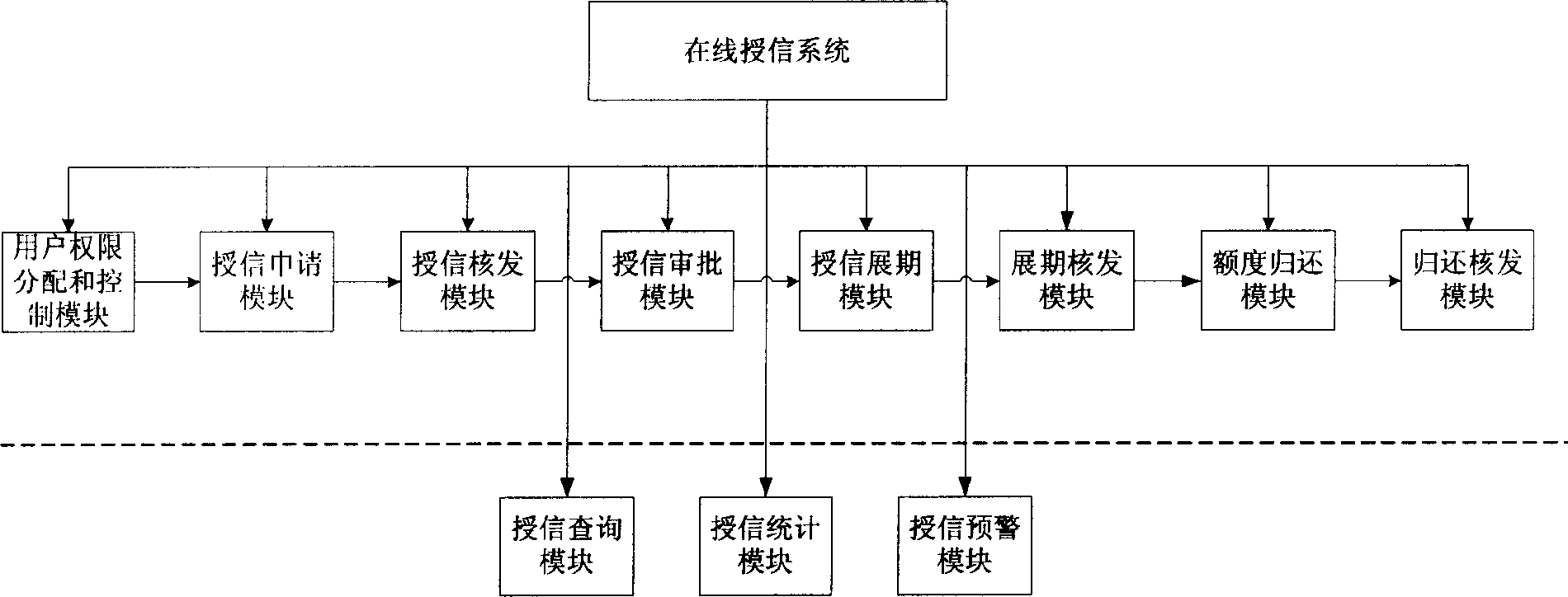

System and method for online user authorization for banks

A system of granting credit to the client on line by financial enterprise comprises user power distribution and control module, credit application module, credit checking and issuing module, credit approval module, credit extending module, extension period approval module, ceiling return module, return back checking and issuing module, credit inquiry module, credit statistic analysing module and credit prewarning module. The system can be used as control system of credit approval operation within financial enterprises.

Owner:BANK OF CHINA

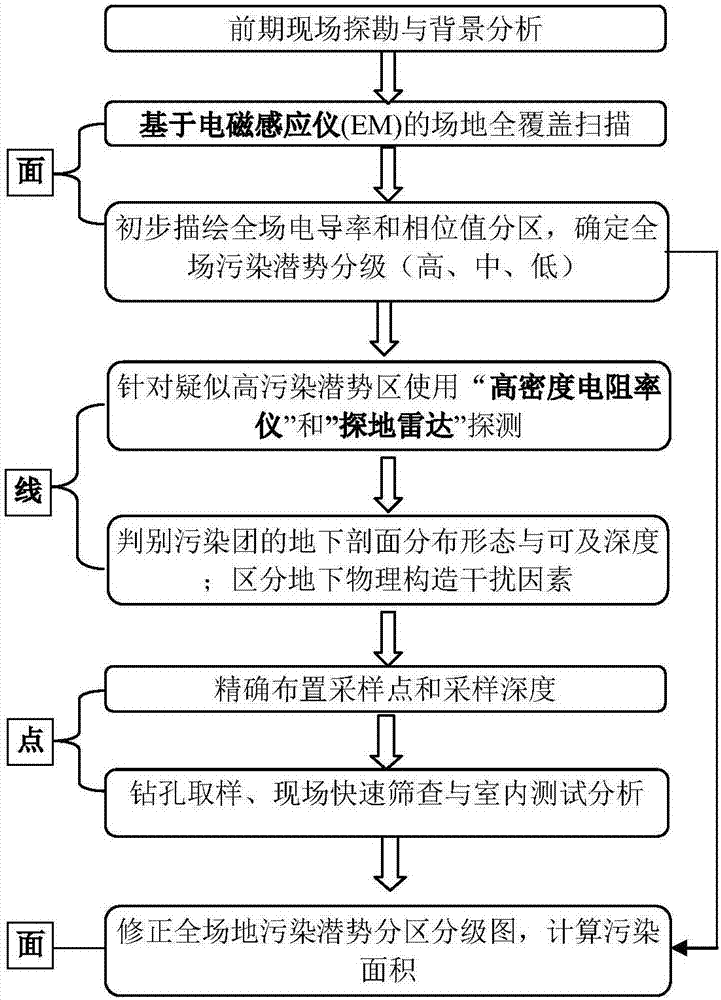

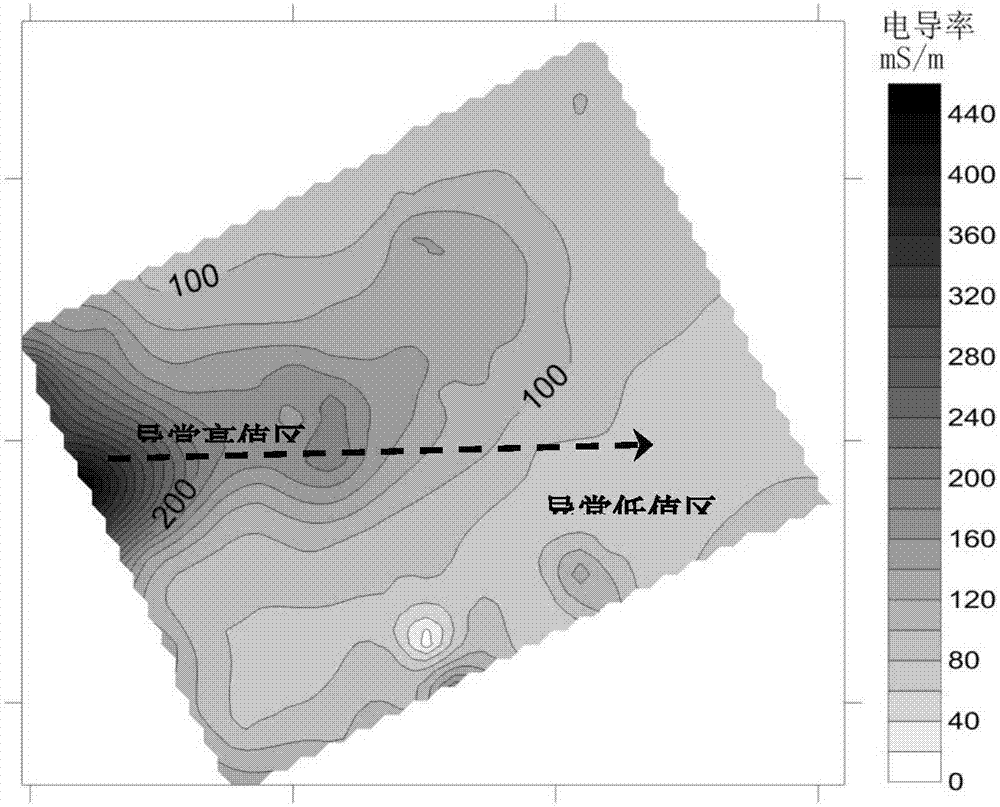

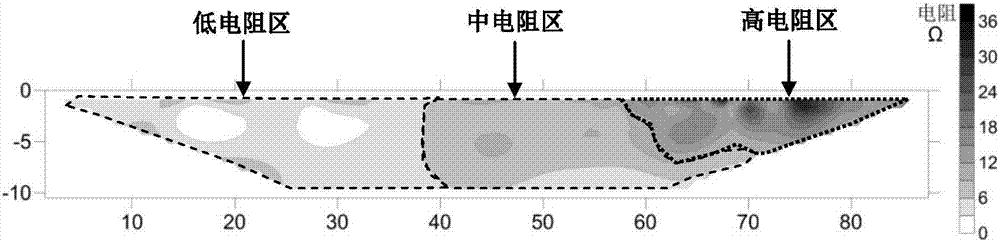

Method for accurately positioning soil contamination based on geophysical exploration and accurate estimation method

ActiveCN107544097APrecise positioningArrange sampling points reasonablyGeological measurementsHigh densitySoil science

The invention discloses a method for accurately positioning soil contamination based on geophysical exploration and an accurate estimation method. The method for accurately positioning soil contamination includes the following steps: on-site surveying, rapid exploration which covers entire site from the width perspective, further contamination body and availability positioning from the depth perspective, drilling sampling and analysis verification from specific point perspective, and accurate contamination level evaluation from the width perspective. In specific target sites or regions, the method herein adopts geophysical exploration technology which combines electromagnetic instruments, high density resistivity meters and ground penetrating radars in a step-by-step and targeted manner, can accurately position areas or points that are suspected to have soil contamination, arranges sapling points in a scientific manner, combines rapid site contamination pollution screening as well as drilling sampling, test and analysis, and establishes an entire set of soil pollution investigation procedures from the width perspective, the depth perspective and the specified point perspective. Themethod herein can rapidly and accurately position soil contamination, scientifically arrange sampling points, conducts soil contamination investigation that cover an entire region, and increases theprecision in estimating the contamination area.

Owner:SHANGHAI ACADEMY OF ENVIRONMENTAL SCIENCES

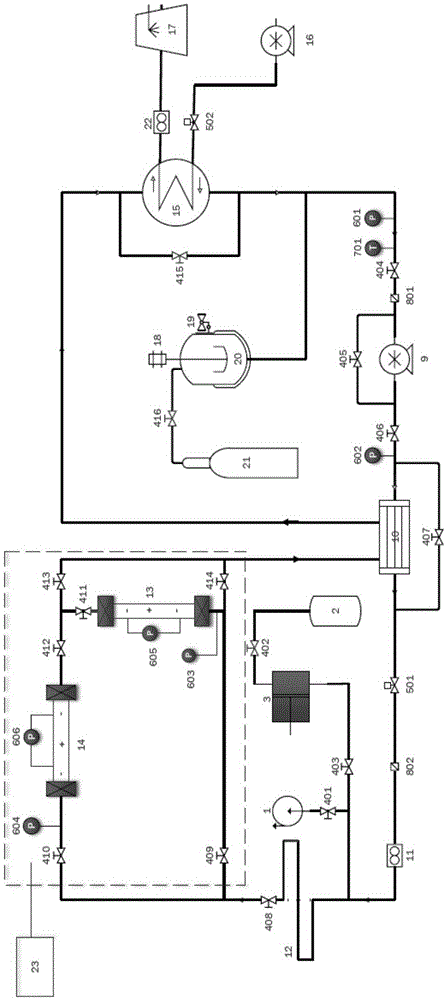

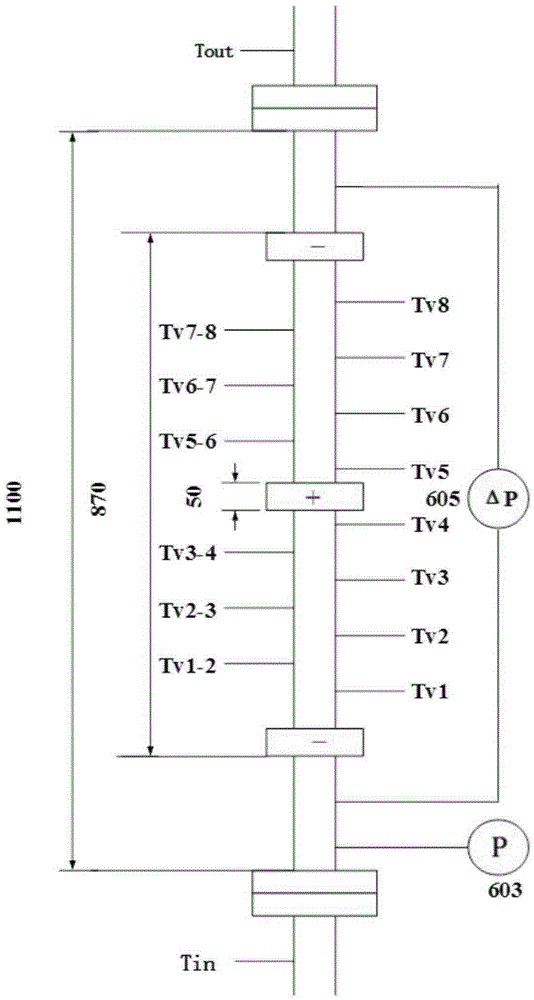

Supercritical Freon heat exchange experiment system and experiment method thereof

ActiveCN105301047AVersatileSimple and reliable structureMaterial heat developmentEngineeringHigh pressure

The invention discloses a supercritical Freon heat exchange experiment system and an experiment method thereof. The system comprises a vacuum and Freon injection module consisting of a vacuum pump, a coolant tank, a coolant recycling and injection machine, a valve and a pipeline connected to a main loop, a circulating module consisting of a shield pump and a closed type loop pipeline, a heat return module consisting of a heat regenerator and a bypass pipeline, a preheating module consisting of a snake-shaped preheating section and a direct current power supply, an experiment module consisting of an experiment section and a relevant valve, and a pressure adjustment module consisting of a high-pressure nitrogen bottle, a pressure stabilizer, a safety valve and a pressure reduction valve, wherein Freon flows into the experiment section after being subjected to heat regeneration and preheated from the outlet of the shield pump, and then finally returns to the inlet of the shield pump after being cooled by a condenser, thus forming a closed circulation. The invention further provides an experiment method of the system. The system can bear a higher-temperature working condition and a higher-pressure working condition, ensure that the Freon can run cyclically under a supercritical state, and also easily, conveniently and quickly adjust system parameters.

Owner:XI AN JIAOTONG UNIV

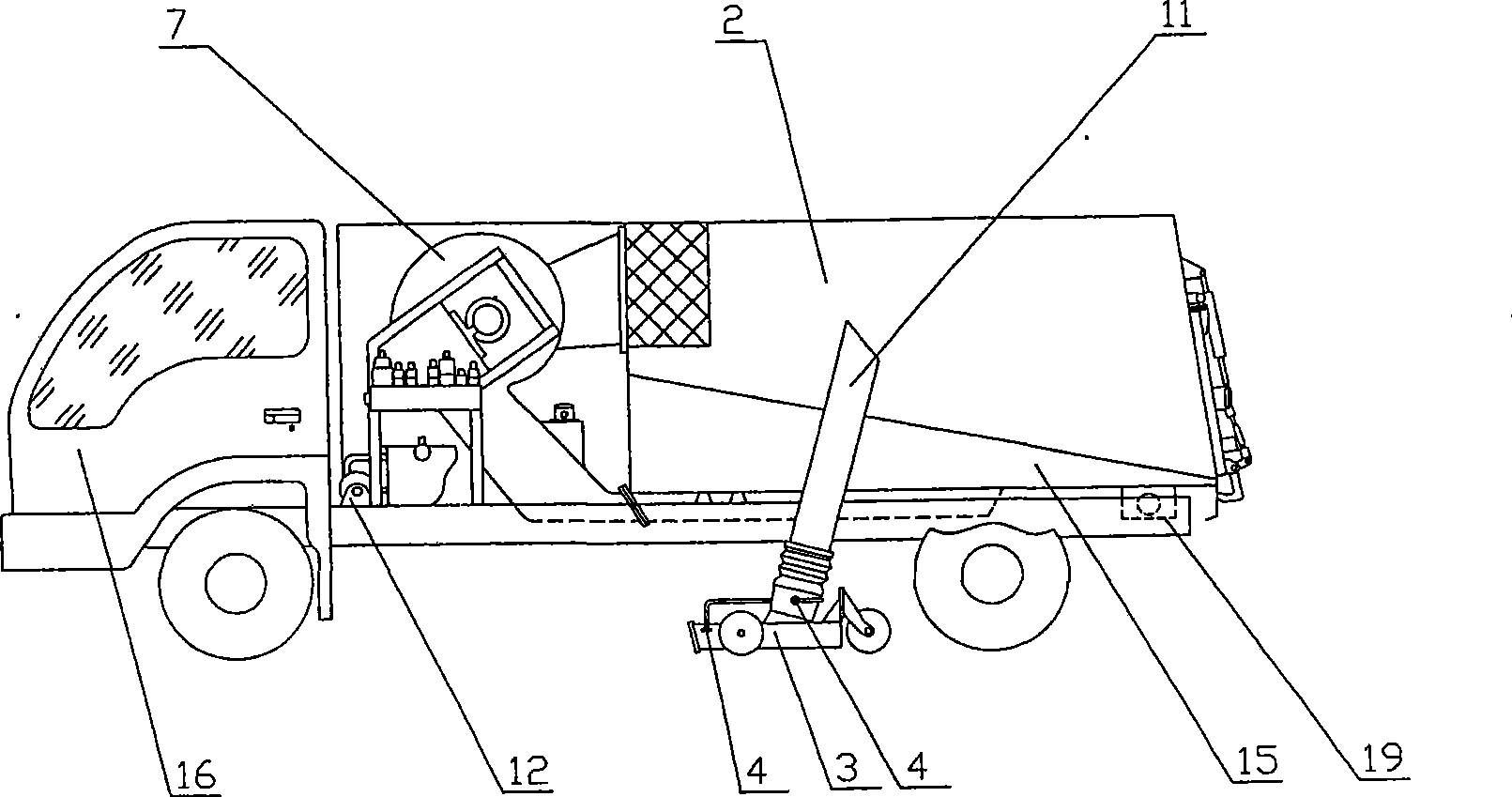

Hybrid dust absorption environmental sanitation vehicle and hybrid sweeping environmental sanitation vehicle

InactiveCN101392506AMeet the uncertain long-term continuous operation needsMeet power needsRoad cleaningTransfer caseVehicle frame

The invention relates to a hybrid vacuum sweeper. A chassis is provided with an engine, a gear transfer case, a silicon rectifying generator, a storage battery, a power converter, a motor, a dustbin, a suction tube, a suction cup, a fan, a water tank and a water pump. The engine drives the silicon rectifying generator and the fan respectively. The silicon rectifying generator is connected with the power converter and the storage battery to output generated electric current. The power converter is connected with the motor to drive a rear axle shaft to drive the vacuum sweeper to run. The fan sucks dust and garbage on the ground in front of the suction cup into the dustbin through the dustbin, the suction tube and the suction cup. The water pump pumps water from the water tank to control the dust in the suction tube and the suction cup by a wet method. In the invention, a hybrid drive technology is applied to a special urban environment sanitary vehicle with vehicle-mounted operating devices, and the special vehicle has an oil-saving effect due to the use of a single engine as well as good operation effects; and a hybrid drive mechanism continuously generates electricity and overcomes the drawback that an electrical vehicle can not work for a long time due to the limitation from the capacity of the storage battery.

Owner:赵国贵

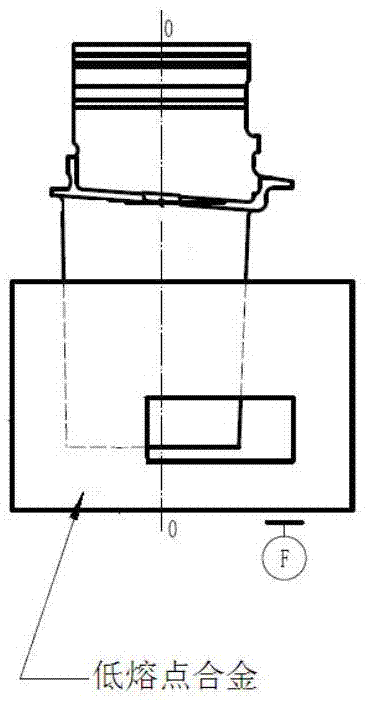

Machining method for turbine work blade

The invention discloses a machining method for a turbine work blade. The machining method for the turbine work blade aims to improve the production quality and production efficiency of the turbine blade and meet the machining and use requirements for the turbine work blade of an aero-engine. According to the technical scheme, the machining process comprises the steps of oil removing, precision positioning of the blade, wax filling, grinding of tenon teeth and the tooth exhaust side, wax removing, melting of low-melting-point alloy, pollutant removing, grinding of the bottoms of the tenon teeth, grinding of a marginal plate and the tooth air inlet lateral face, fluorescent inspection, comprehensive detection, machining of film holes, cleaning and storage. A five-axis numerical control creep feed grinder is adopted, the turbine work blade machining process with the advanced manufacturing technology is achieved, novelty, creativity and practicability are high, the process route is arranged reasonably, the production efficiency is high, the blade machining quality is high, the requirement for production of a large batch of turbine blades can be met, and the machining method can be widely used for machining turbine work blades of aero-engines.

Owner:AECC AVIATION POWER CO LTD

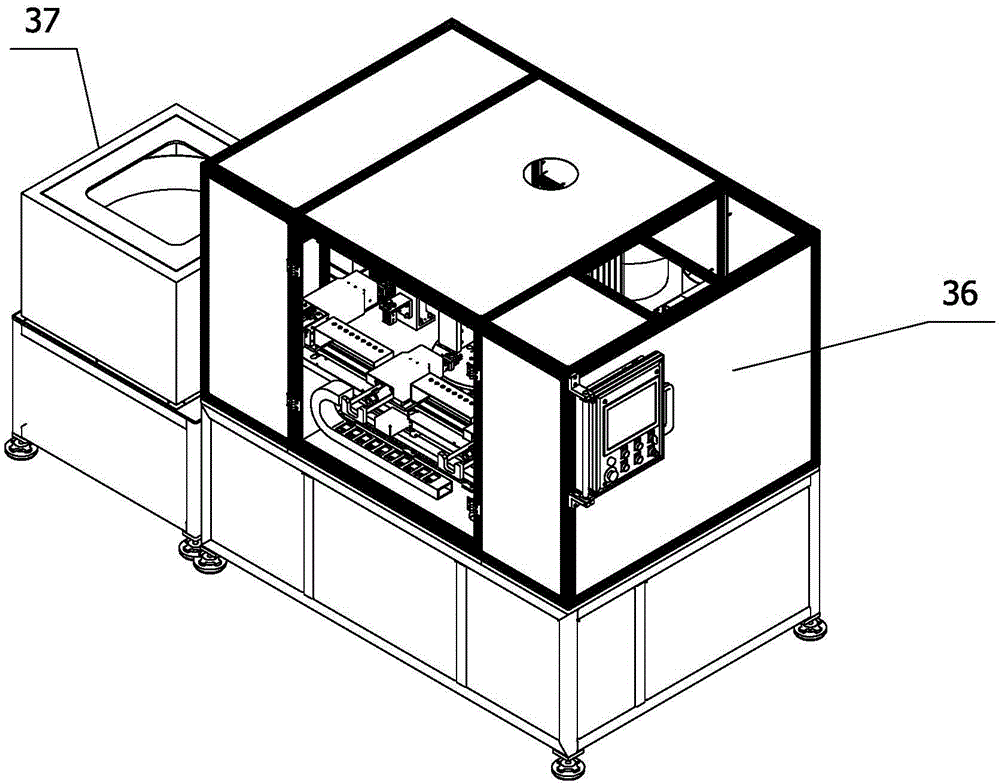

Automatic air impermeability helium detector for square power batteries

The invention discloses an automatic air impermeability helium detector for square power batteries. The automatic air impermeability helium detector can automatically complete on-line leakage detection of aluminum-shell battery cores, is high in efficient and avoids direct contact between the human hand and the aluminum-shell battery cores. The automatic air impermeability helium detector comprises a machine frame. The machine frame is provided with a feeding pull belt assembly, a helium detection testing assembly and a feeding and discharging mechanical arm assembly. The feeding and discharging mechanical arm assembly comprises a feeding mechanical arm assembly and a discharging mechanical arm assembly, wherein the feeding mechanical arm assembly and the discharging mechanical arm assembly are arranged in a back-to-back mode. The feeding pull belt assembly comprises an aluminum-shell battery core feeding position at the start end, an aluminum-shell battery core discharging position at the tail end and an aluminum-shell battery core detection position between the feeding position and the discharging position. The machine frame is further provided with a helium injection assembly connected with a helium injection port of the helium detection testing assembly, and a vacuumizing pipeline assembly connected with a vacuumizing port of the helium detection testing assembly. The vacuumizing pipeline assembly is connected with a vacuum pump assembly. The machine frame is further provided with a helium detection instrument.

Owner:SHENZHEN YUCHEN AUTOMATION EQUIP CO LTD

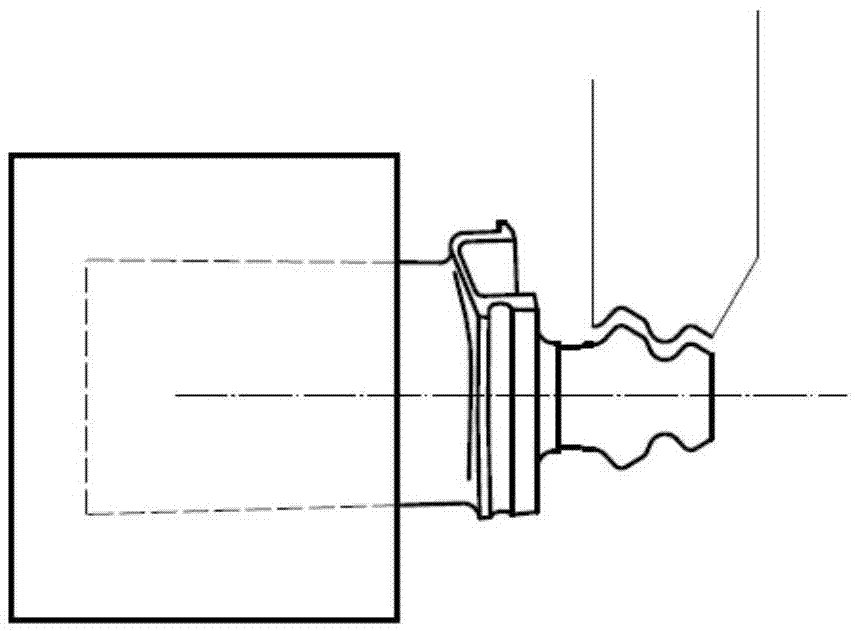

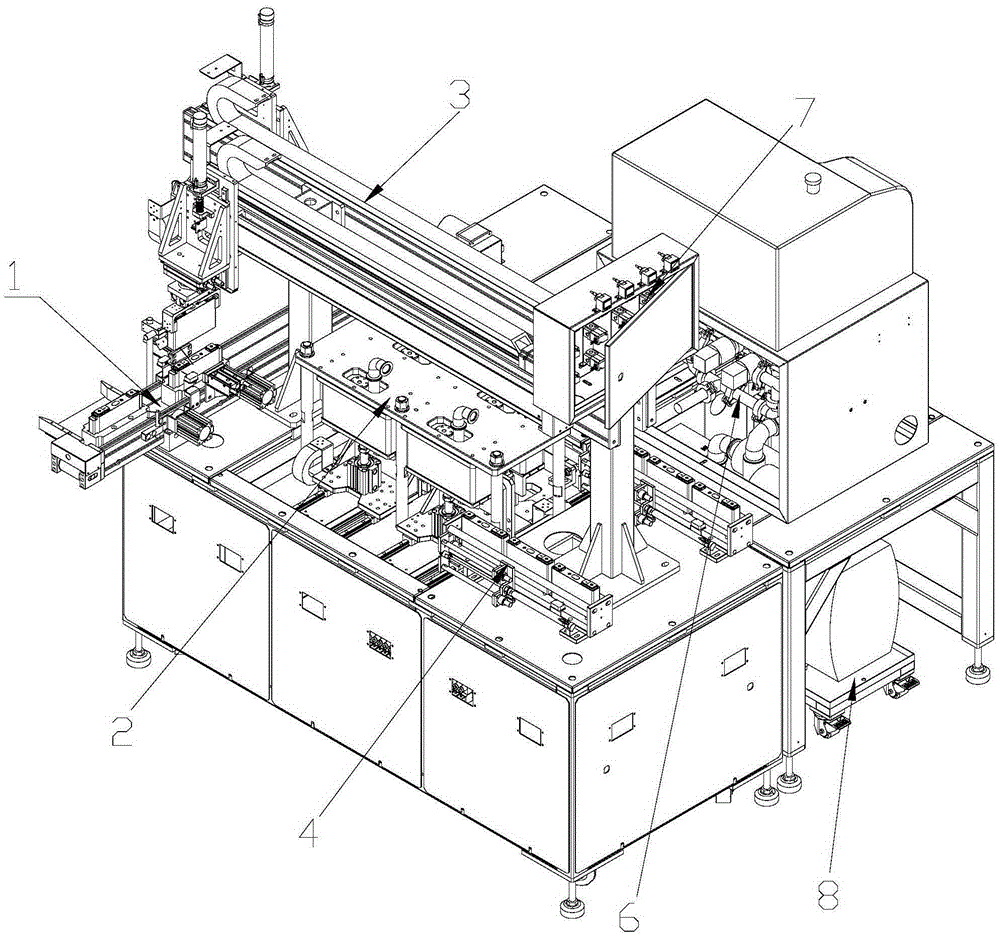

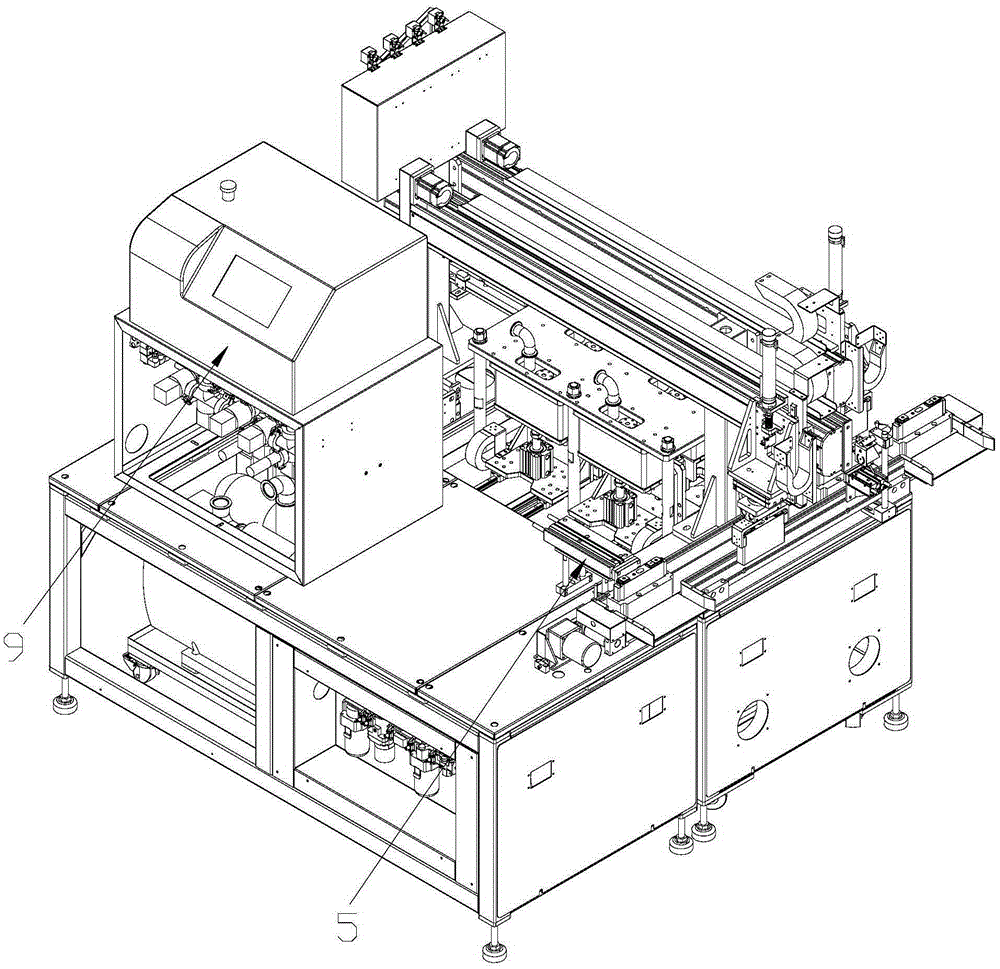

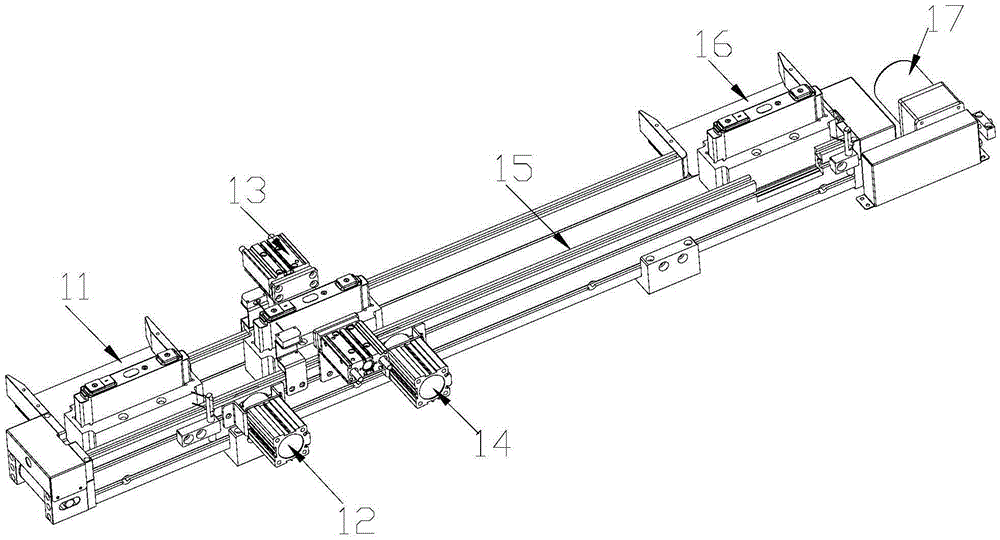

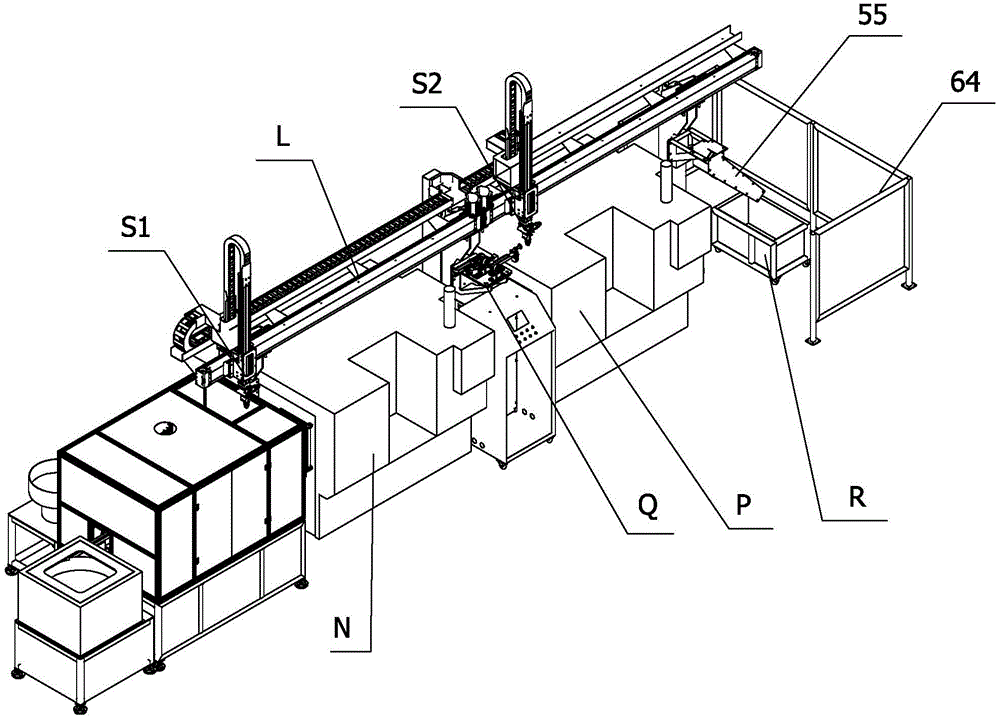

Integrated machine for welding and machining flange-type sleeve

ActiveCN104308545ACompact structureReasonable arrangementOther manufacturing equipments/toolsManipulatorFully automatic

The invention discloses an integrated machine for welding and machining a flange-type sleeve. The integrated machine comprises a welding station and a machining station, wherein the welding station comprises a pipe vibration charging machine, a first flange vibration charging machine, a second flange vibration charging machine, a turning charging mechanism, a welding gun supporting component, a workpiece clamping manipulator mechanism, a first workpiece welding rotation component and a second workpiece welding rotation component; the machining station comprises a truss robot, a first lathe, a second lathe, a transferring device and a material receiving device. The flange-type sleeve can be welded and machined in a fully-automatic manner, and the production efficiency is improved.

Owner:CHONGQING LANGZHENG TECH

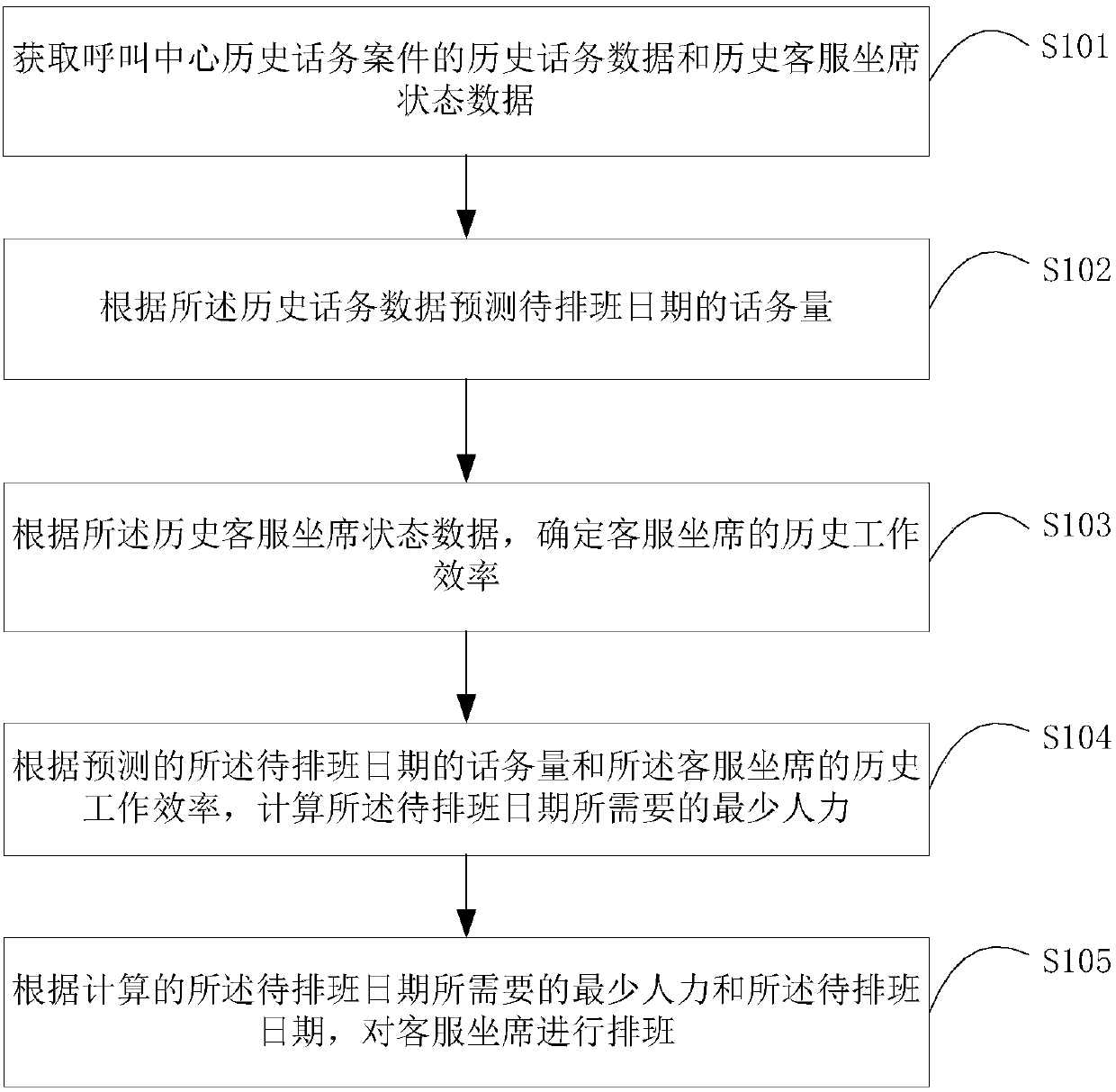

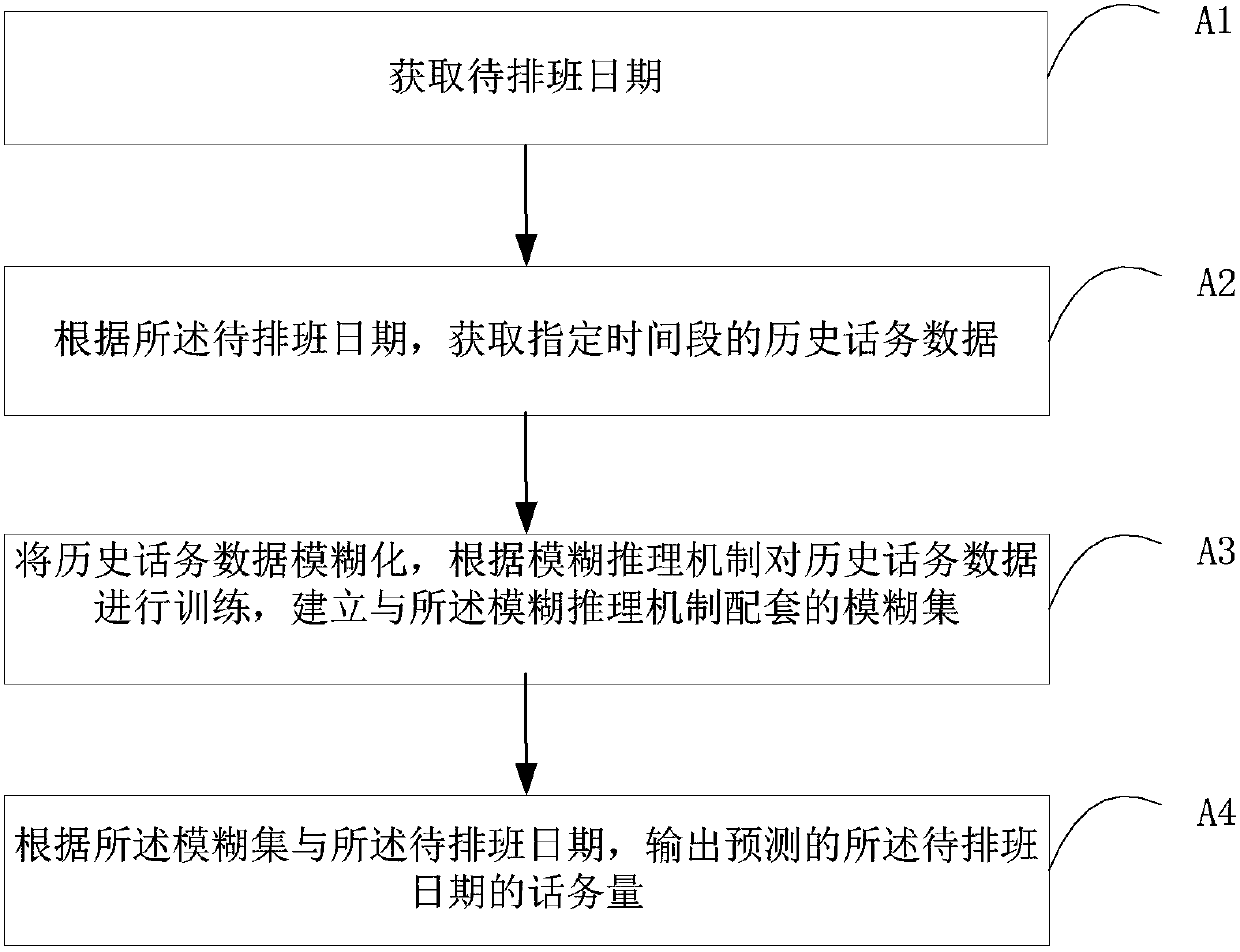

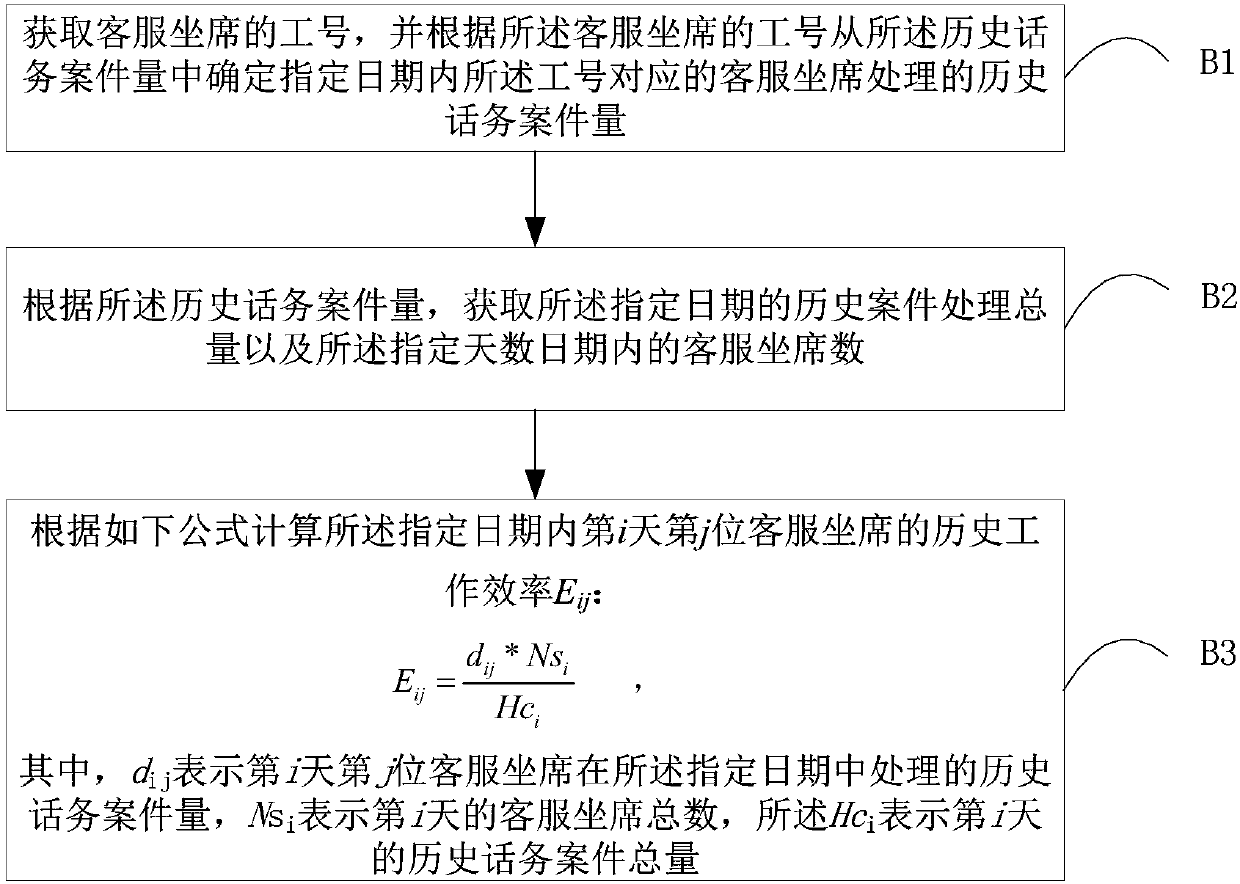

Scheduling method for customer service agent, storage medium and server

ActiveCN108551533AImprove the efficiency of automatic schedulingImprove effectivenessSpecial service for subscribersResourcesData predictionDistributed computing

The invention provides a scheduling method for a customer service agent, a storage medium and a server. The method comprises the steps of: acquiring historical traffic data and historical customer service agent status data of a call center historical traffic case; predicting the traffic volume of a to-be-scheduled date according to the historical traffic data; determining the historical work efficiency of the customer service agent according to the historical customer service agent status data; calculating the minimum manpower required for the to-be-scheduled date according to the predicted traffic volume of the to-be-arranged date and the historical work efficiency of the customer service agent; and scheduling the customer service agent according to the calculated minimum manpower required for the to-be-scheduled date and the to-be-scheduled date. The invention is capable of effectively and reasonably arranging the customer service agent to handle the traffic case and improving the effectiveness of the scheduling.

Owner:PINGAN PUHUI ENTERPRISE MANAGEMENT CO LTD

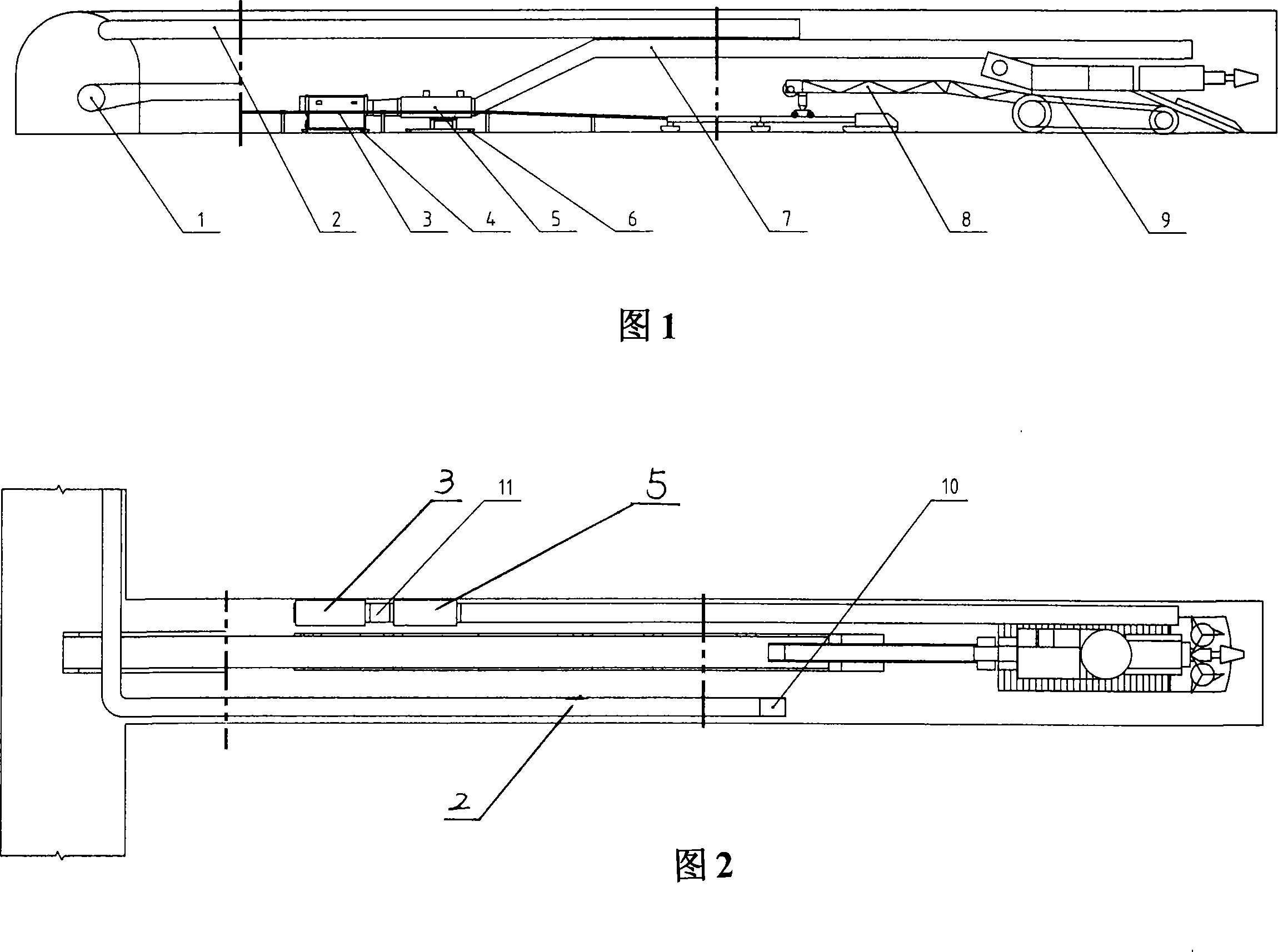

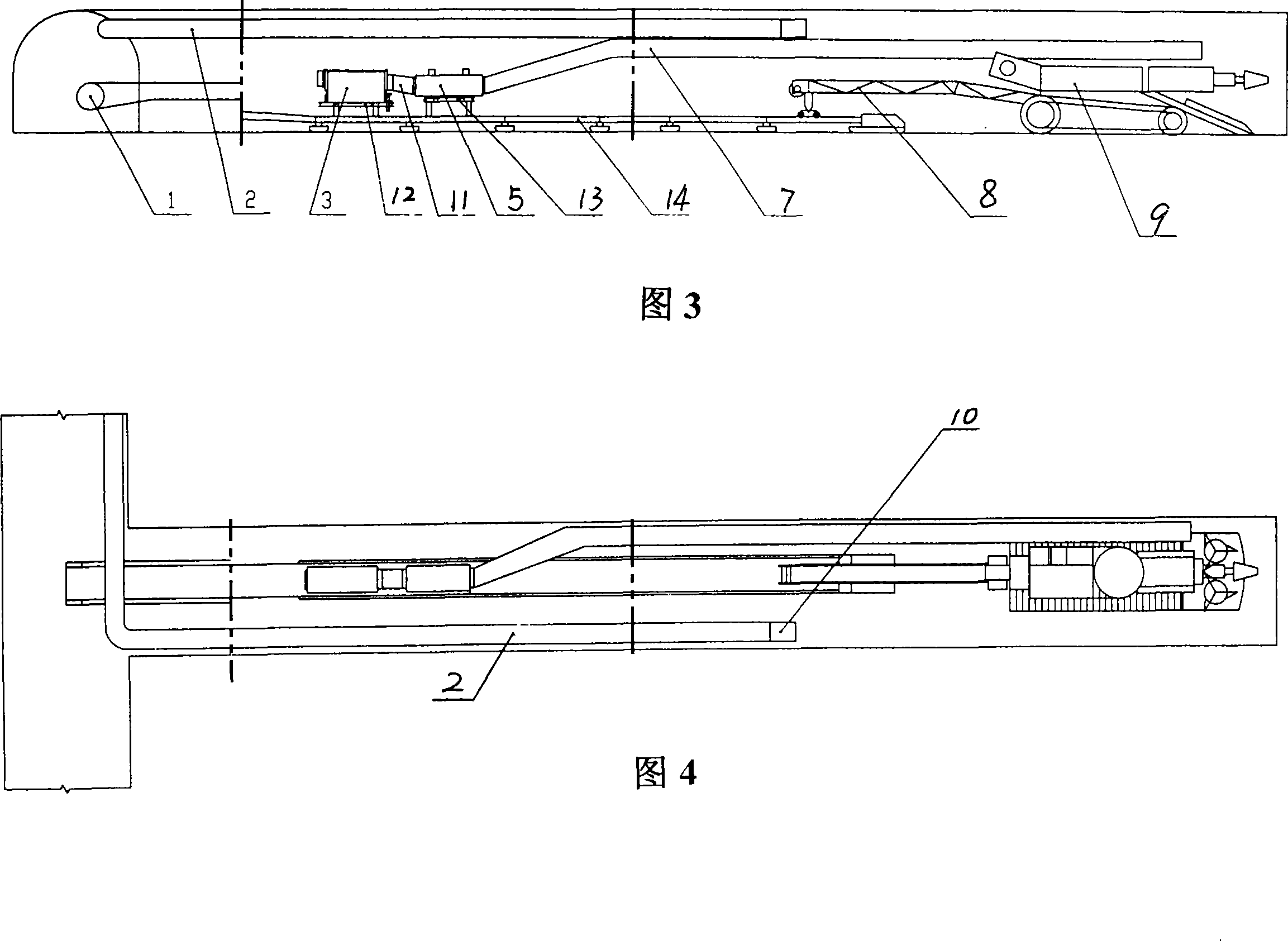

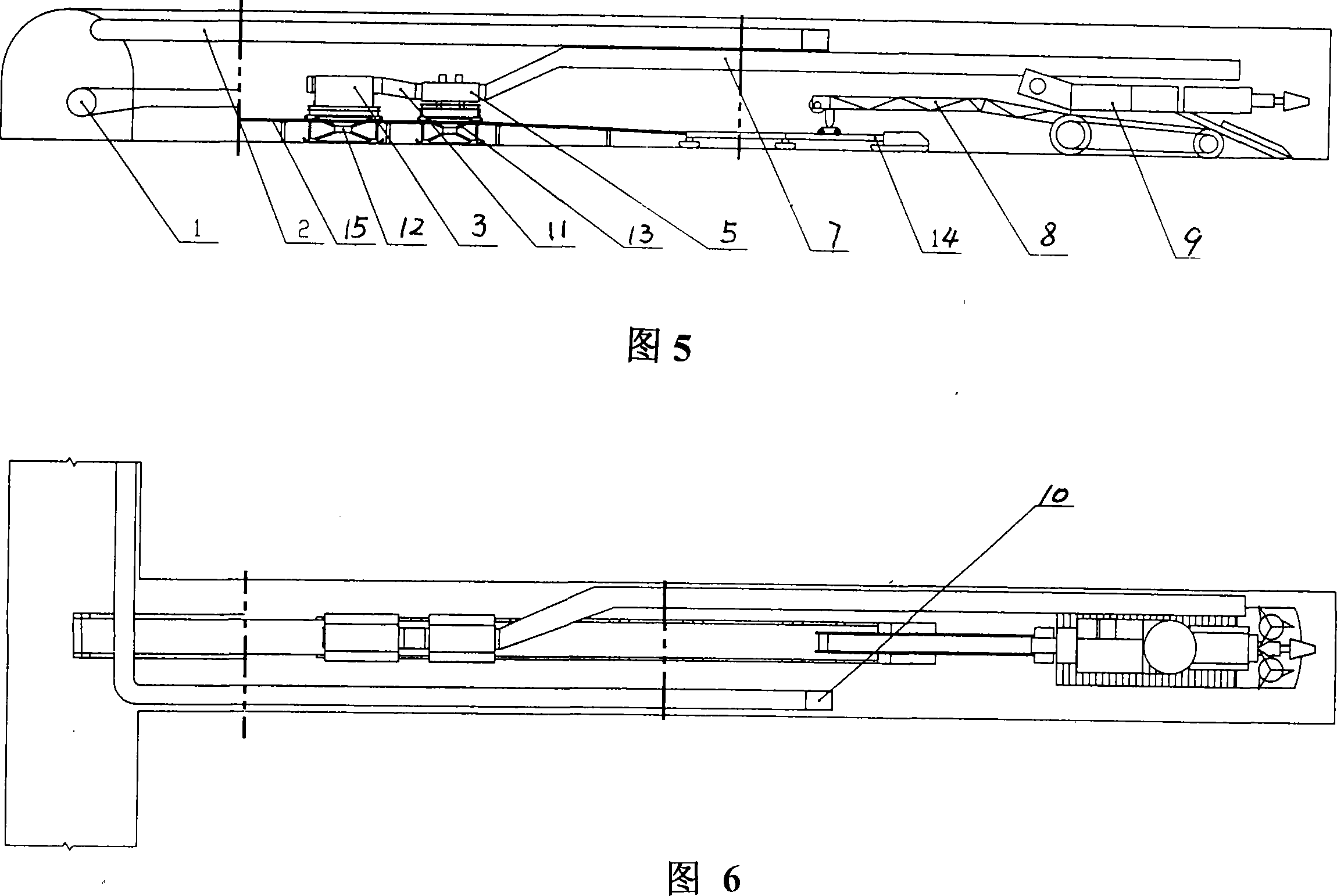

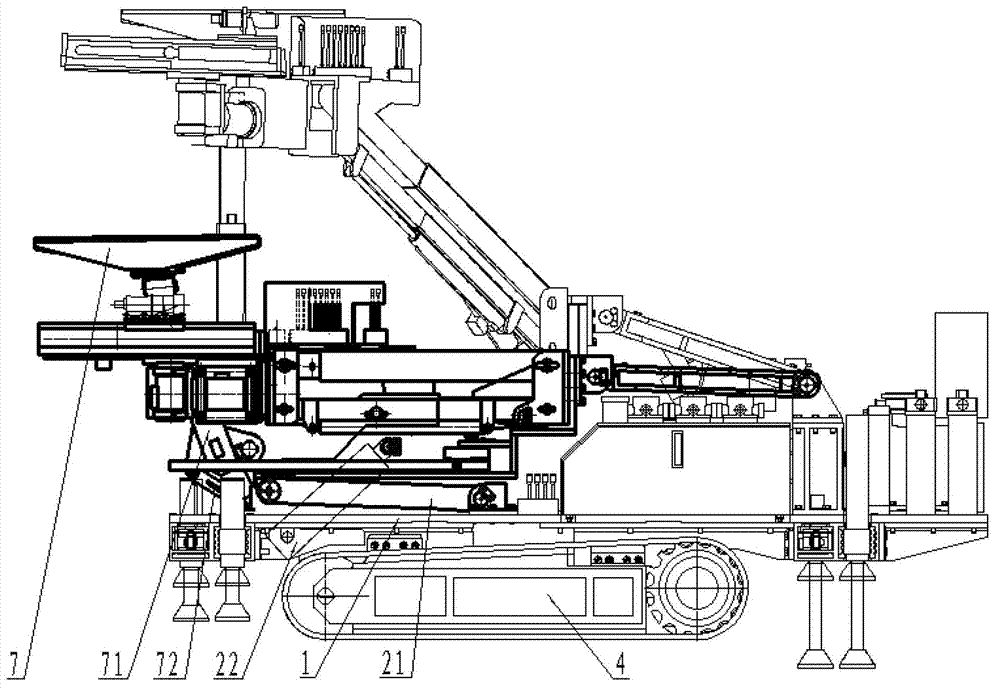

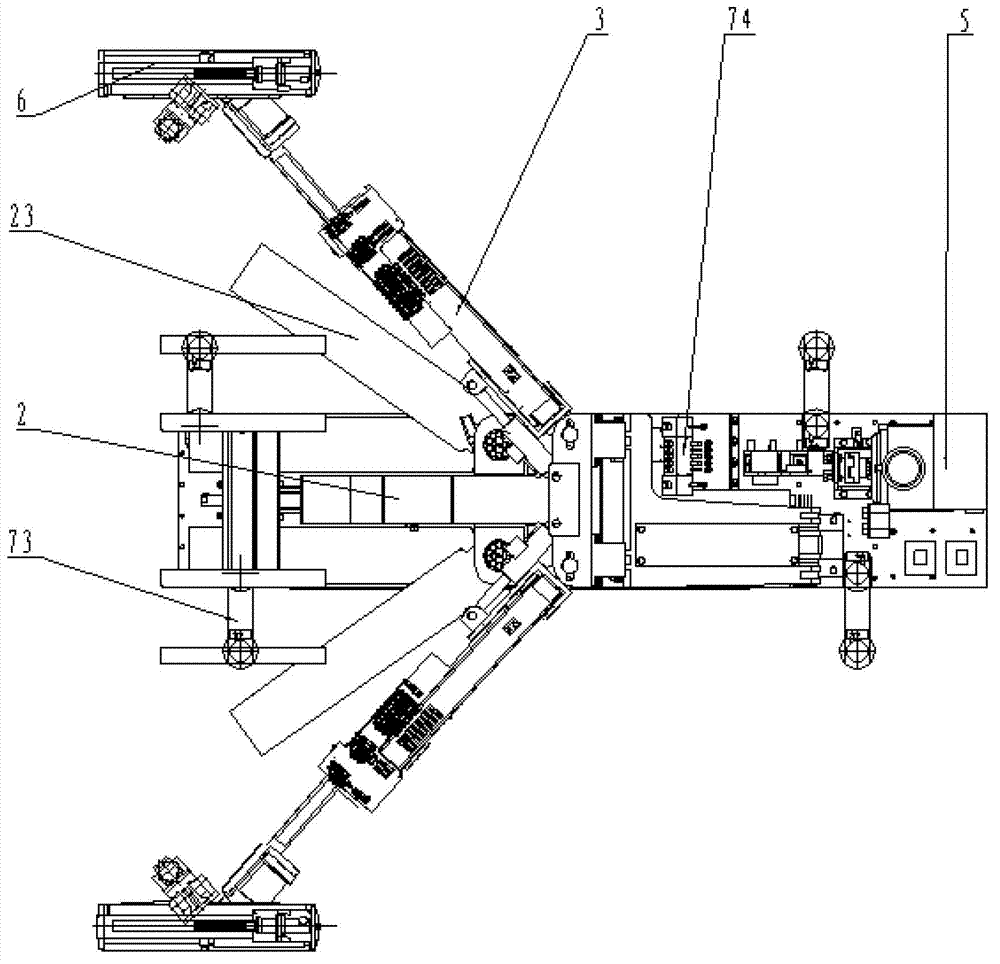

Narrow-machine-body full-hydraulic bolt and anchor cable drill carriage for coal mine tunnel

InactiveCN102900362AMechanizationIncrease the level of mechanized supportAnchoring boltsCutting machinesEngineeringRock bolt

The invention relates to a narrow-machine-body full-hydraulic bolt and anchor cable drill carriage for a coal mine tunnel. The narrow-machine-body full-hydraulic bolt and anchor cable drill carriage comprises a machine body part, a lifting platform, a drill boom mechanism, crawler-type walking mechanisms and an electric cabinet, wherein the lifting platform is arranged at the machine body part through a foldable connecting rod and a lifting oil cylinder; the drill boom mechanism is arranged on the lifting platform through a feeding mechanism; the crawler-type walking mechanisms are arranged on two sides of the machine body part; and the electric cabinet is used for controlling the lifting oil cylinder and the crawler-type walking mechanisms. According to the narrow-machine-body full-hydraulic bolt and anchor cable drill carriage disclosed by the invention, the support of an anchor rod is completely mechanized, the support efficiency and the support quality of the bolt and anchor cable are greatly improved, the standardization degree is improved, the better stabilizing action is realized and the reliable use of the drill carriage and the safe operation of operators are fully ensured.

Owner:LANG FANG JING LONG GRAND IND MACHINERY CO LTD

Planting technology of agriculture wheat

The invention relates to a planting technology of agriculture wheat. The planting technology includes first time insecticide spraying, exposure to the sun, rotary tillage, fertilization, second time insecticide spraying, seed sowing and regular fertilization. The planting technology is reasonable in arrangement, remarkable in pest killing effect, timely in nutrition supply, and capable of guaranteeing the growth of the wheat effectively and guaranteeing the harvest of the wheat.

Owner:张芝仁

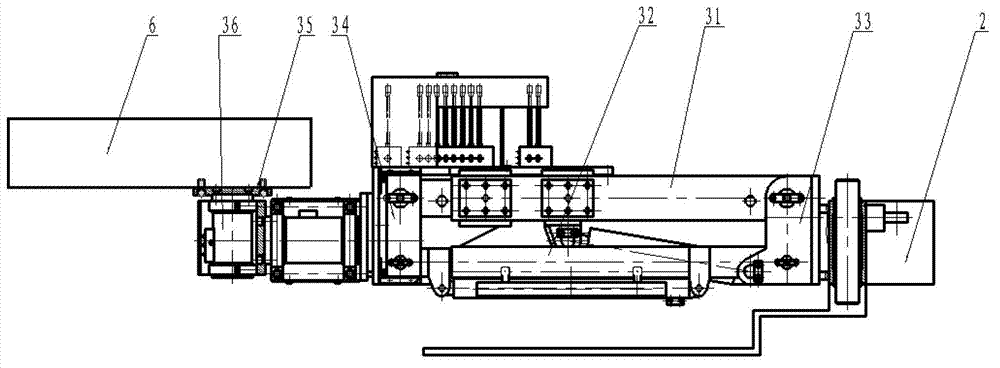

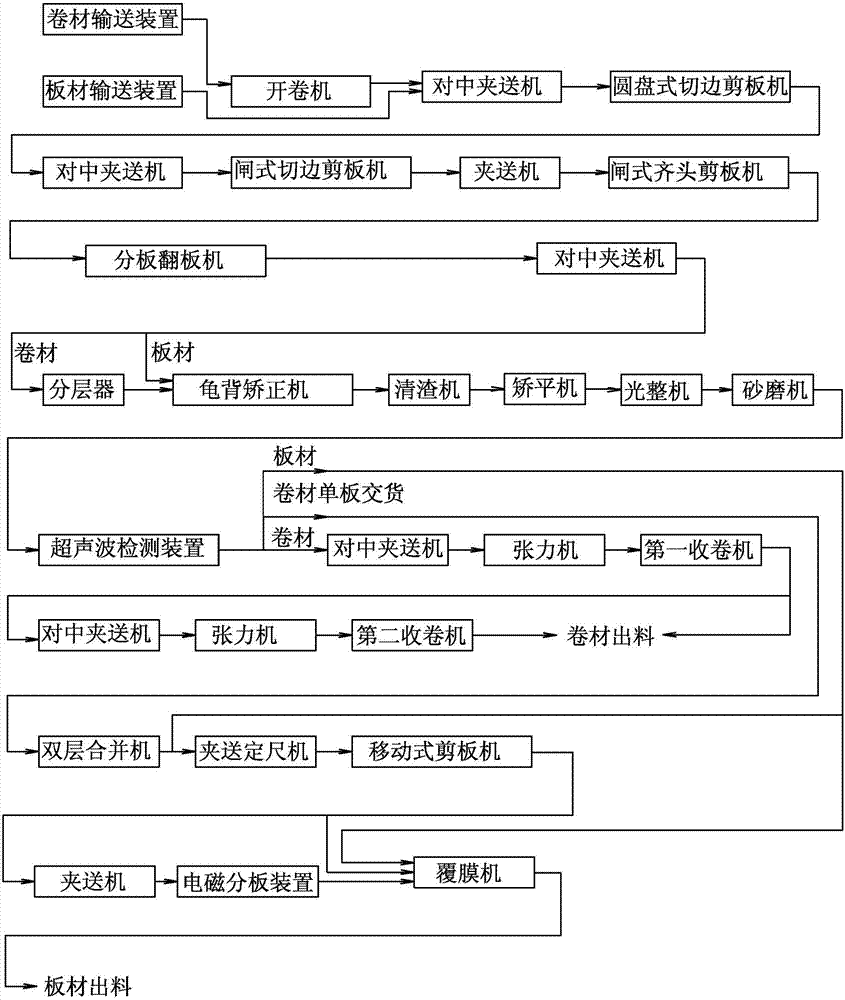

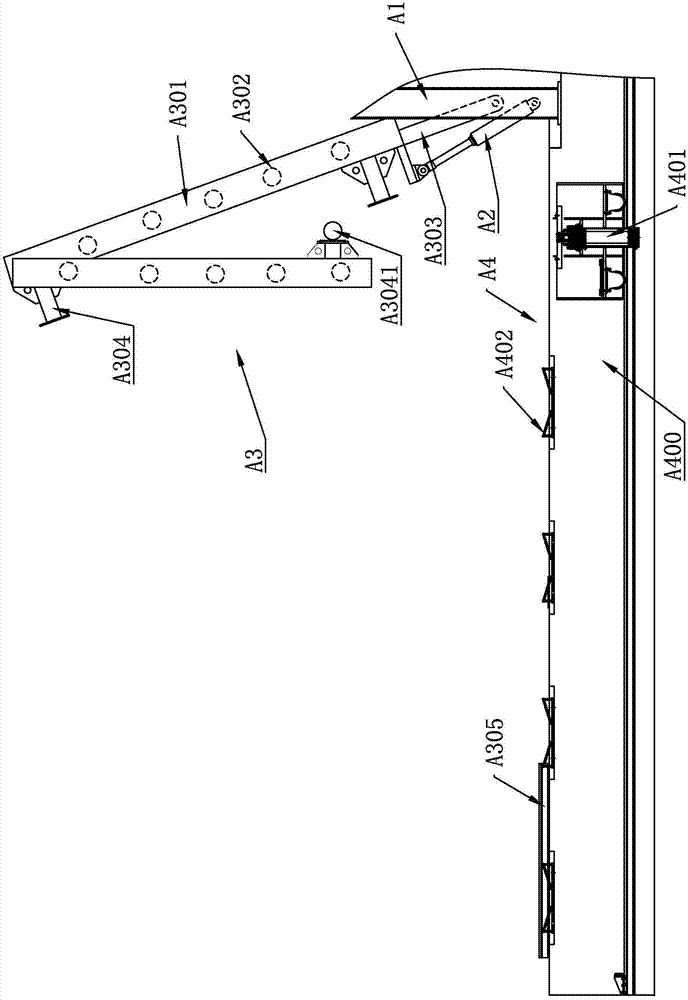

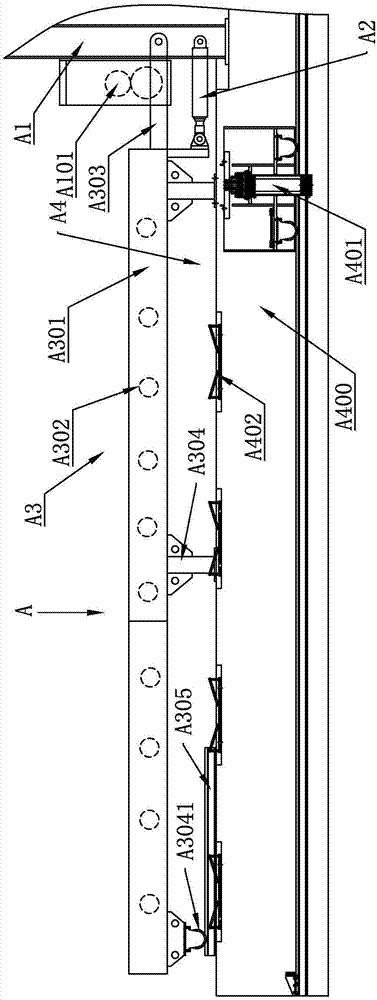

Hot rolling double-layer thermometal composite coiled material/plate finishing production line

ActiveCN107052820AReduce investmentReduce space occupancyShearing machinesOther manufacturing equipments/toolsProduction lineComposite plate

The invention discloses a hot rolling double-layer thermometal composite coiled material / plate finishing production line. The hot rolling double-layer thermometal composite coiled material / plate finishing production line comprises a feeding device, an uncoiler, a centring clamping machine, a disk type edge cutting plate shearing machine, a brake type edge cutting plate shearing machine, a brake type flushing plate shearing machine, a plate separating and turnover machine, a layering device, a turtle back straightening machine, a residue cleaning machine, a leveller, a temper mill, a sand mill, an ultrasonic detecting device, a tensioner, a first rolling machine, a second rolling machine, a double-layer combining machine, a clamping shear gauge, a movable plate shearing machine, a plate dividing machine and a film laminating machine all of which are sequentially arranged according to the advancing direction of a plate or a coiled material. The production can machine the double-layer thermometal composite coiled material and can also machine the double-layer thermometal composite plate, one machine has two functions, the production line integrates high rigidity, high precision, high stability and high efficiency of a machine tool, the working procedures are arranged reasonably, the structural design is compact, the production efficiency is high, running is stable and reliable, the investment and the energy consumption are low, operation is safe, and debugging is convenient.

Owner:山东易川新材料科技股份有限公司

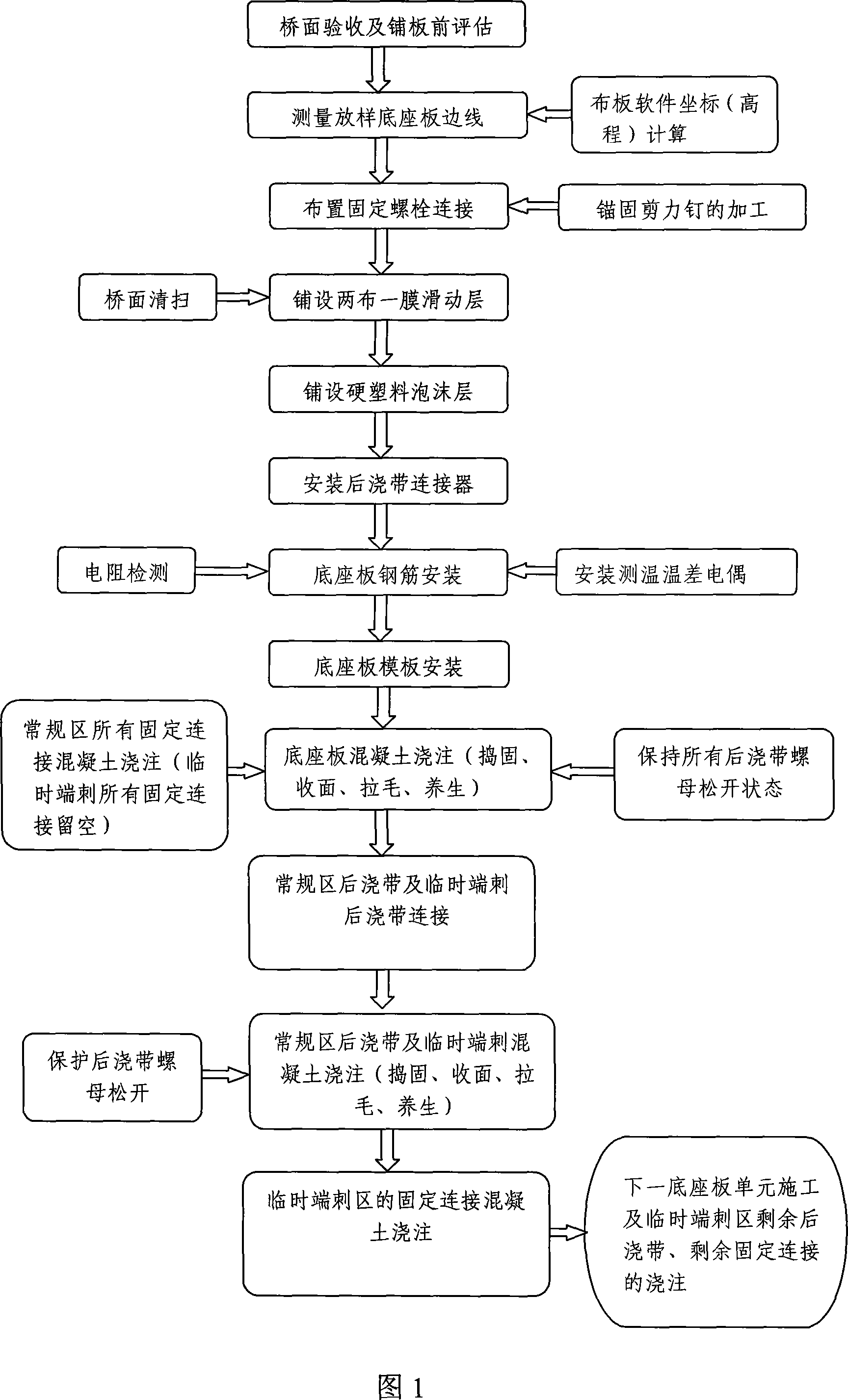

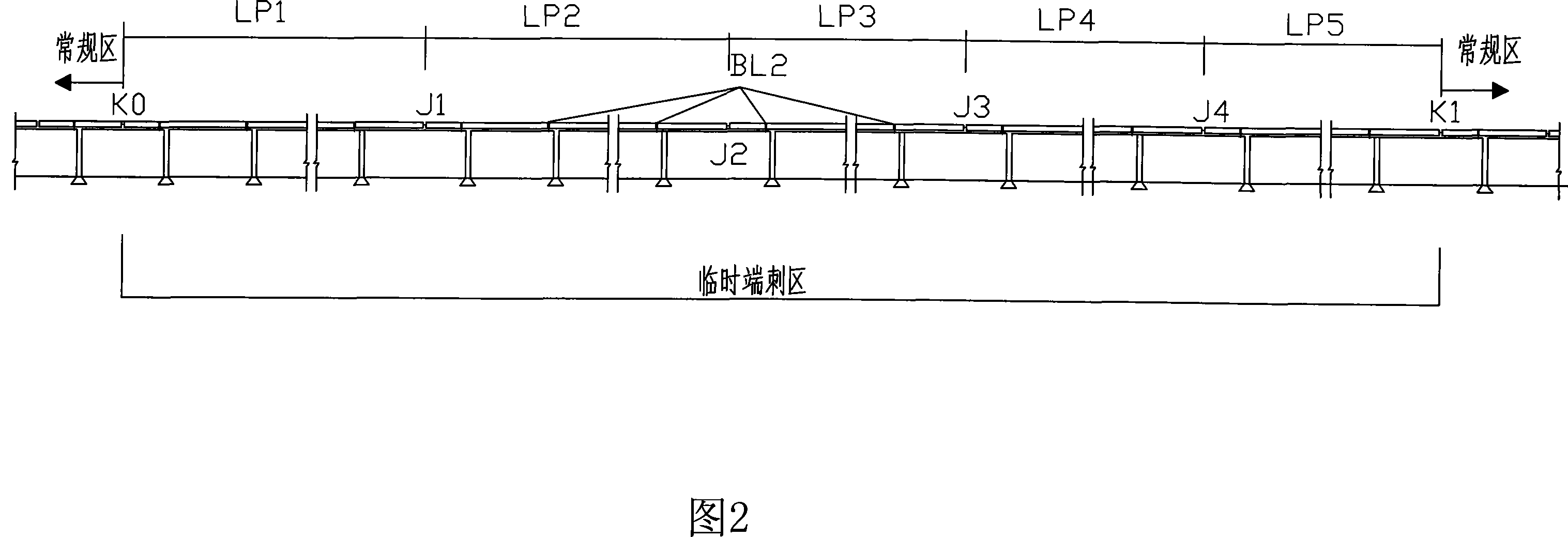

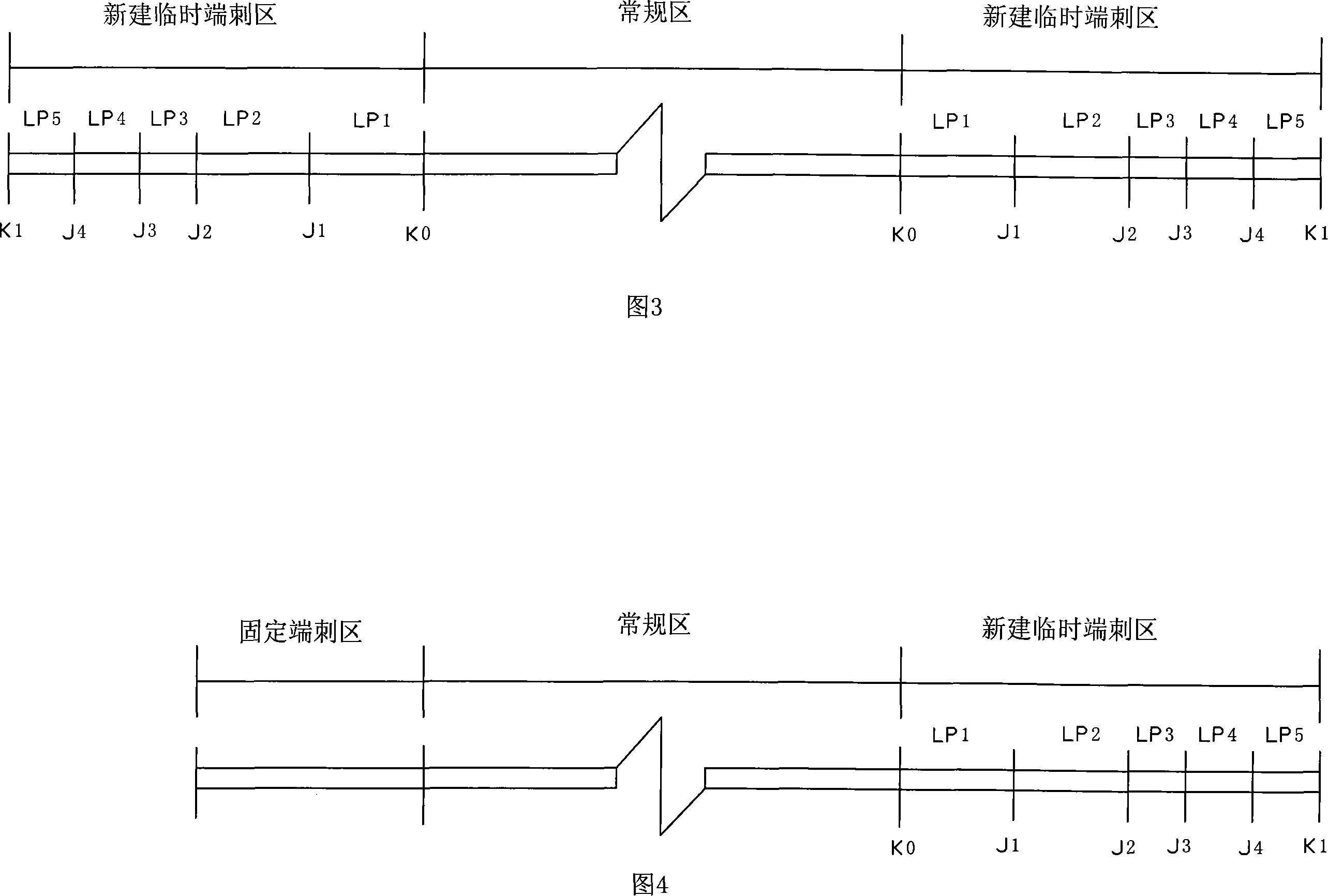

Unballasted track bed plate construction method

ActiveCN101195983ASolve technical difficulties in constructionImprove construction qualityRailway track constructionArchitectural engineeringBridge deck

The invention relates to a construction method of the bottom seat plate of the ballastless track, which belongs to a construction process method of tracks. The purpose of the invention is to provide a reliable construction method of the bottom seat plate of the ballastless track on bridges to meet the quality and accuracy requirement of the bottom seat plate of the ballastless track. The construction method comprises the following steps: step one, firstly, the bridge floor is checked and accepted and assessed before planking; secondly, the stakingout connecting line of the bottom seat plate is measured; thirdly, the connection of the fixed bolt is arranged; fourthly, a sliding layer with two cloth and one film is laid on the bridge floor of the box-beam bridge; step two, a hard plastics foam layer is laid on the two ends of the beam slot; step three, a post casting strip connector is installed; step four, firstly, tooth socket welding studs are installed; secondly, bottom seat plate reinforcing bars are installed; step five, bottom seat plate mould plates are installed; step six, the concrete of the bottom seat plate is cast; step seven, the cast post casting strip and the welding stud tooth socket are fixedly connected, and the connection of the bottom seat plates is completed.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD

High efficiency pounding device for processing traditional Chinese medicinal materials

The invention discloses a high efficiency pounding device for processing traditional Chinese medicinal materials. The device comprises a shell; support legs are symmetrically arranged at the left andright of the bottom of the shell; a medicine pounding base is arranged at the bottom in the shell; a medicine pounding groove is formed in the top of the medicine pounding base and is in an arc shape;the medicine pounding groove is internally provided with a medicine pounding head in a sleeving manner; a spacer plate is arranged at the upper part in the shell; a vertical rotary barrel is arrangedin the middle of the spacer plate in a sleeving way; the vertical rotary barrel vertically passes through the spacer plate and extends into the bottom of the shell; the top of the vertical rotary barrel is arranged, in a sleeving way, on a fixed bearing positioned at the corresponding position of the spacer plate; an axial rotation driving mechanism of the vertical rotary barrel is arranged in the shell at the upper side of the spacer plate; the middle part of the vertical rotary barrel sleeves a piston rod; a movable sleeve is arranged on the piston rod in the vertical rotary barrel; the piston rod is connected with the vertical rotary barrel in a transmission way by means of the movable sleeve. The high efficiency pounding device, provided by the invention, for processing the traditional Chinese medicinal materials is ingenious in structure and reasonable in arrangement, and realizes high efficiency pounding of the traditional Chinese medicinal materials, and the discharging is convenient.

Owner:新宁县永鑫药材开发有限公司

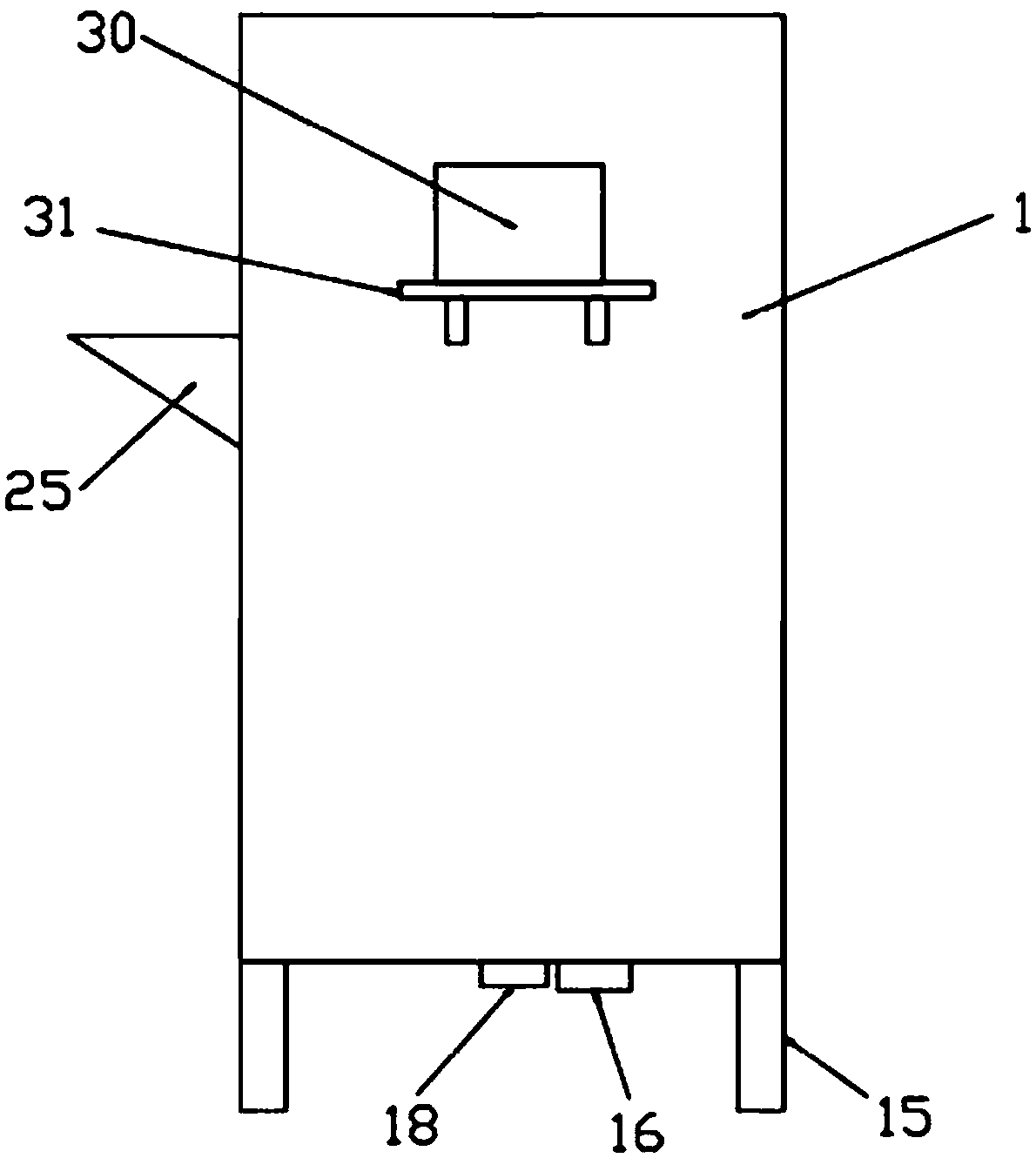

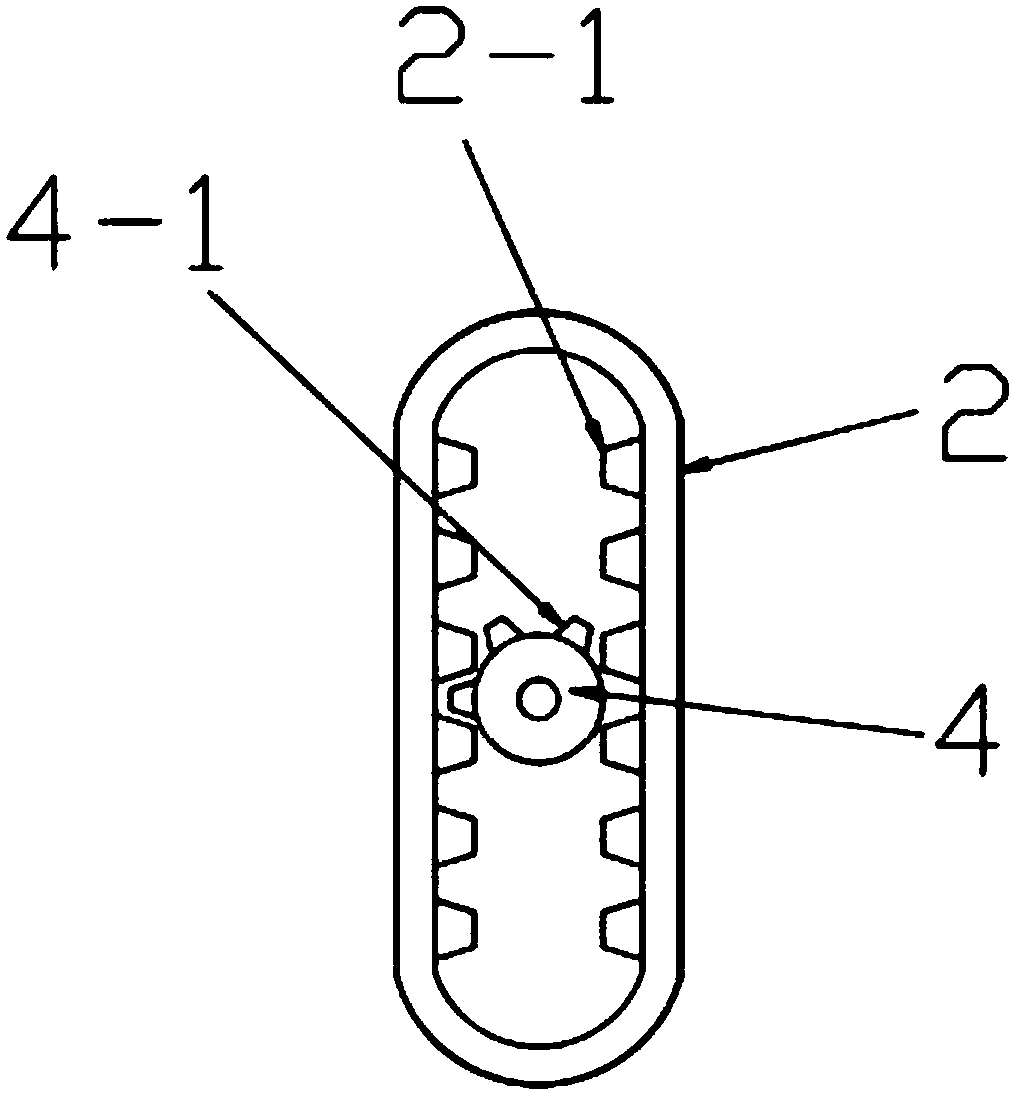

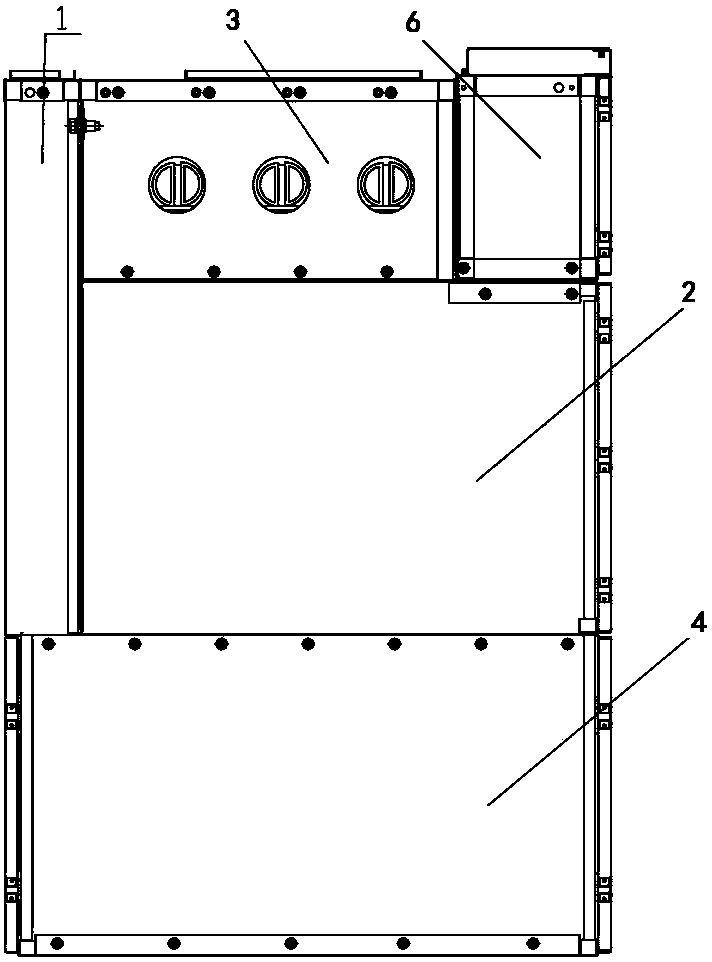

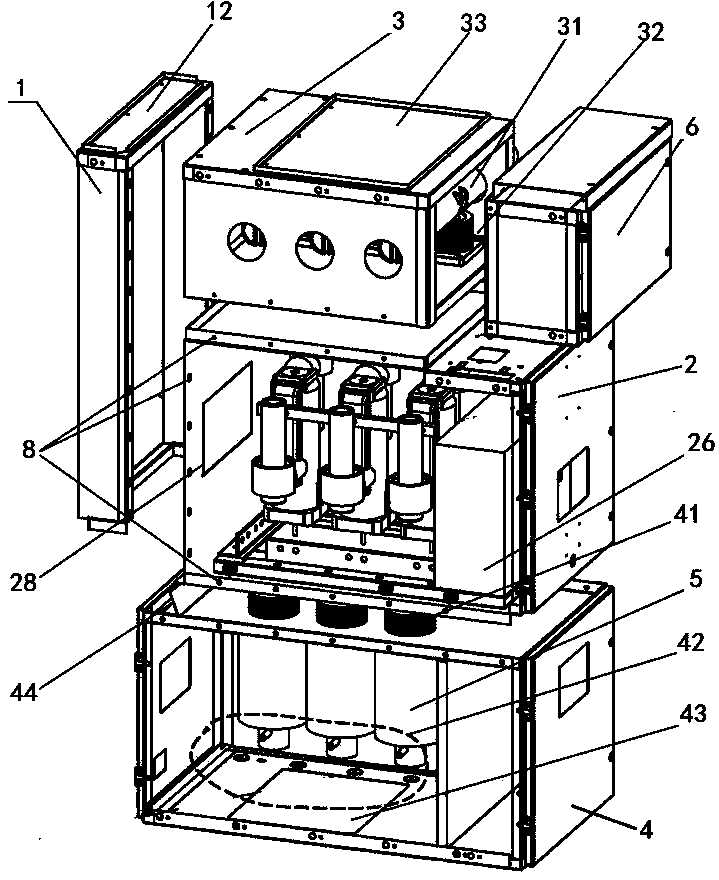

Modular stacked switch cabinet

ActiveCN103683016AReasonable arrangementImprove interchangeabilitySwitchgear with horizontal withdrawalSubstation/switching arrangement casingsModularitySwitchgear

The invention discloses a modular stacked switch cabinet which comprises a cable chamber module, a circuit breaker chamber module and a bus chamber module. The various modules are provided with module shells, the module shells are of case structures, the shell of the cable chamber module is adjacently connected with the shell of the circuit breaker chamber module, and the shell of the bus chamber module is adjacently connected with the shell of the circuit breaker chamber module, so that the cable chamber module, the circuit breaker chamber module and the bus chamber module are assembled with one another in a stacked manner and are detachably fixedly connected with one another; holes are formed in corresponding surfaces of each two module shells which are adjacently connected with each other, and isolation movable contacts or isolation fixed contacts can penetrate the holes so as to be connected with one another or isolated from one another. The module stacked switch cabinet has the advantages that various function units can be assembled while the various branch modules of a cabinet body are assembled, and accordingly the difficulty in assembling components inside the cabinet body can be greatly reduced.

Owner:STATE GRID CORP OF CHINA +1

Non-woven fabric napkin arrangement and output device and transportation method

The invention is related to a non-woven fabric napkin arrangement and output device and a transportation method. The non-woven fabric napkin arrangement and output device comprises a top transportation mechanism with a swing arm transportation mechanism on the left, a bottom transportation mechanism is arranged below top transportation mechanism, a wheel fork mechanism is arranged below the bottom transportation mechanism and a products output platform is arranged on the right of the wheel fork mechanism. The mechanism is suitable for high-speed arrangement and output of napkins and some soft package products. For some production lines with docking and automatic packaging, products enter an automatic docking and packaging mechanism via the top transportation mechanism in normal situation, and while the automatic docking and packaging mechanism has faults, products are switched to the bottom transportation mechanism rapidly and automatically, arranged and outputted via the wheel fork mechanism rapidly and returned to the top mechanism automatically when the automatic docking and packaging mechanism has no fault, thus simultaneous fault-solving and high-speed production are realized without decreasing the speed and stopping a host machine when the automatic docking and packaging mechanism has faults.

Owner:ZHEJIANG YONGCHUANG MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com