Testing system for gas explosion characteristic size effect

A technology of gas explosion and characteristic size, which is applied in the direction of material explosion, can solve the problems that cannot be applied, that the explosive characteristic test device cannot systematically study combustible gases, and the research results are not valid, etc., to achieve powerful functions, high degree of automation, comprehensive and reasonable layout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

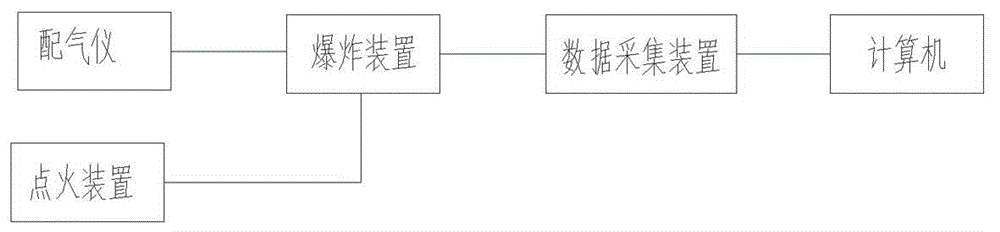

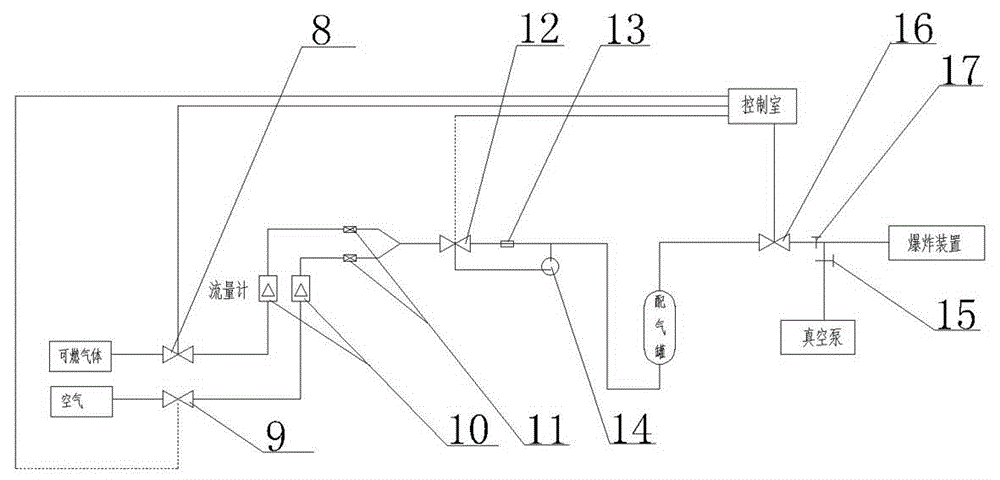

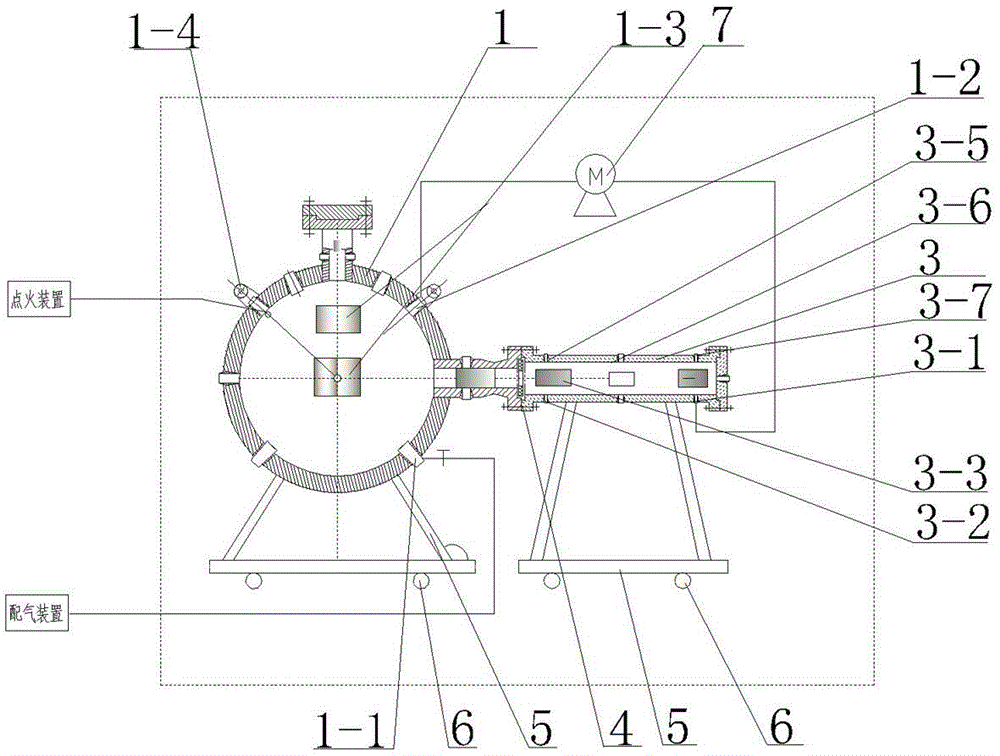

[0047] Refer to attached Figure 1-11 , The size effect test system of gas explosion characteristics includes gas distribution device, ignition device, explosive device, data acquisition and processing device and high-speed digital camera.

[0048] The gas distribution device includes a combustible gas source, a gas distribution gas source and a gas distribution tank. The input ends of the gas distribution tank are respectively connected to the combustible gas source and the gas distribution gas source, and the other output of the gas distribution tank is connected to the explosive device. The input ports are connected.

[0049] The ignition device includes an igniter installed on the explosive device, and the igniter adopts electric spark to ignite. Depending on the installation position of the igniter, ignition at different positions can be realized; according to the depth of entering the container, two types of ignition can be realized: wall ignition and center ignition of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com