Patents

Literature

1057 results about "Gas explosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A gas explosion is an explosion resulting from mixing a gas, typically from a gas leak, with air in the presence of an ignition source. In household accidents, the principal explosive gases are those used for heating or cooking purposes such as natural gas, methane, propane, butane.In industrial explosions many other gases, like hydrogen, as well as evaporated (gaseous) gasoline (American ...

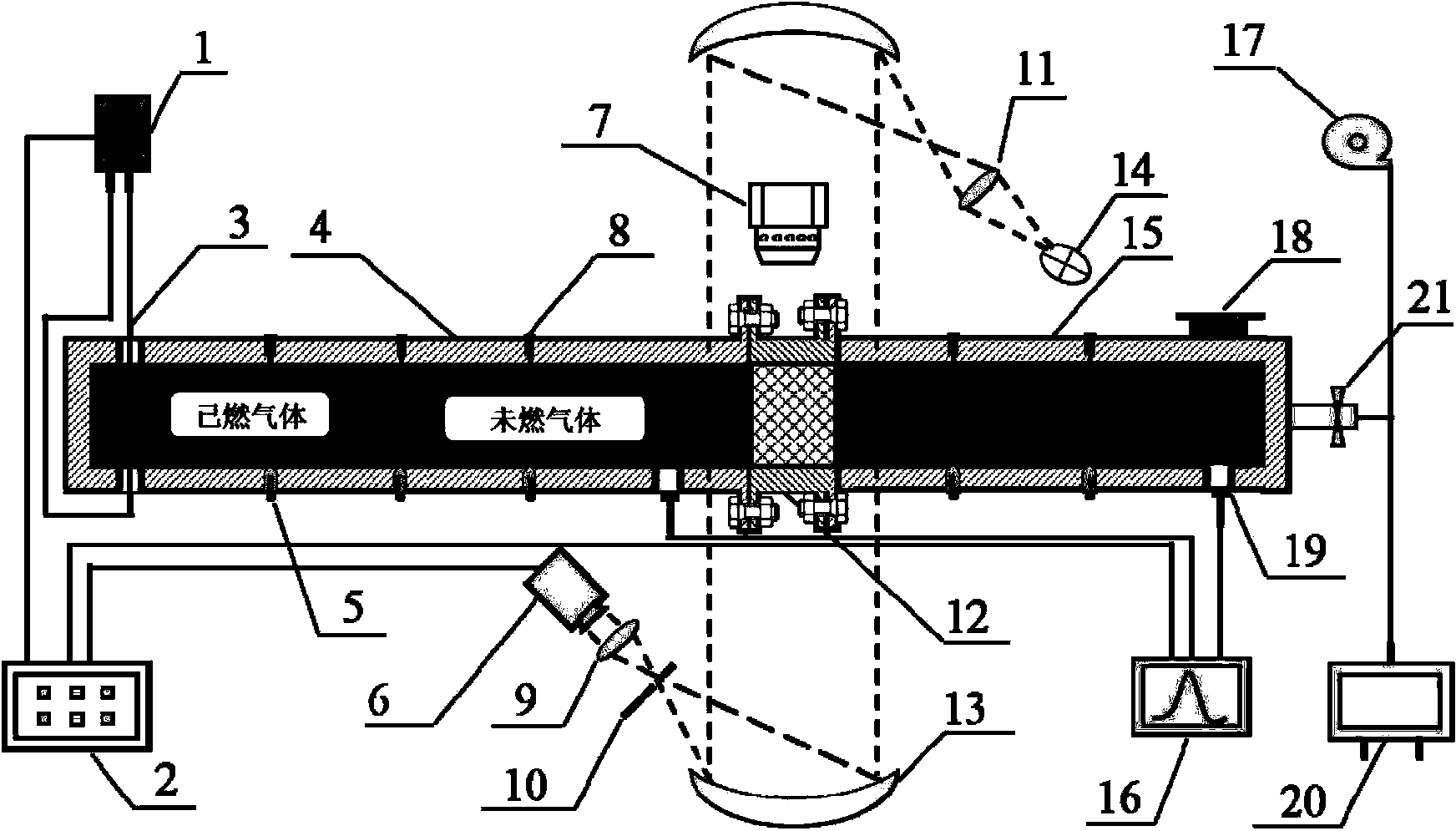

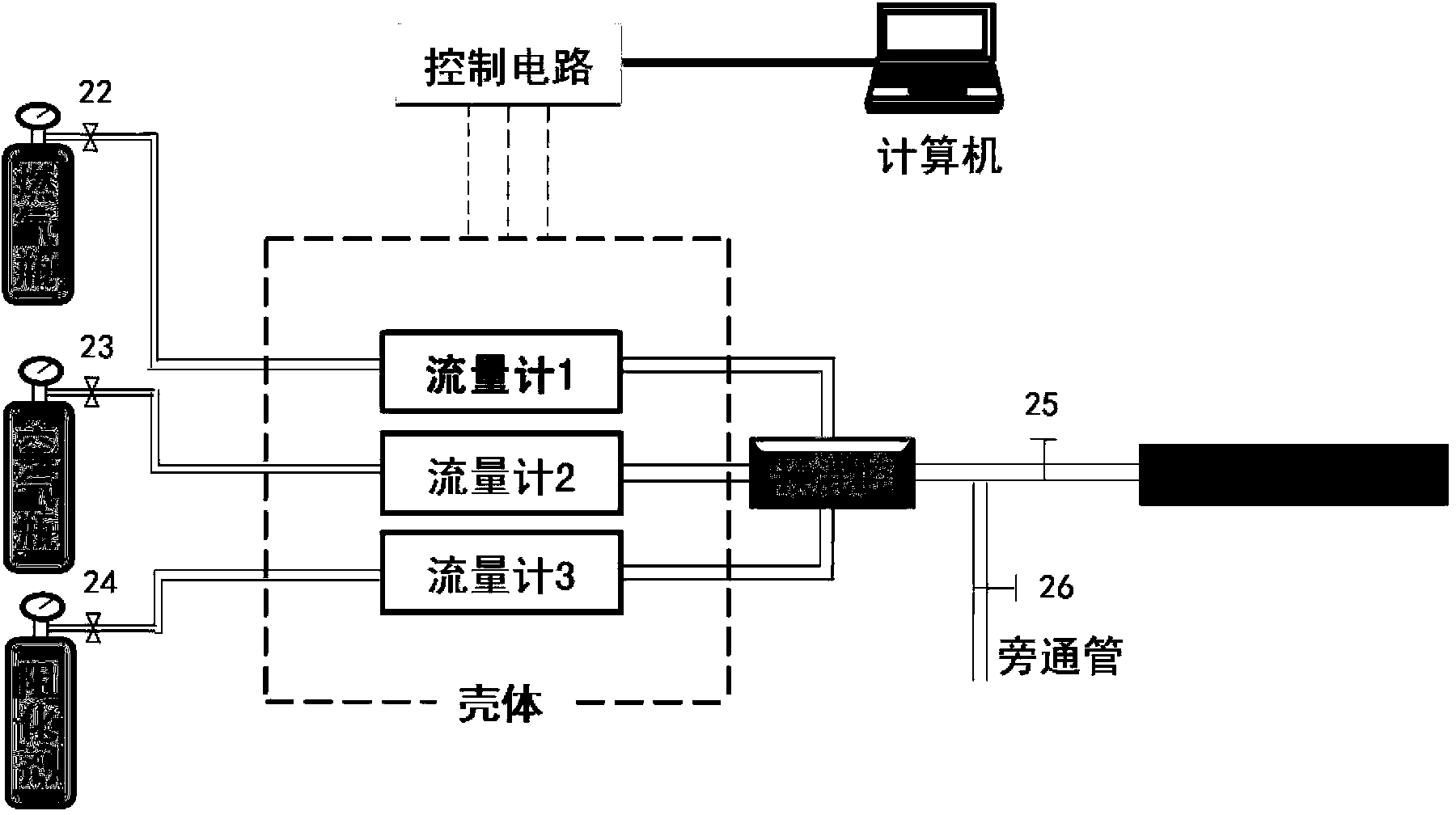

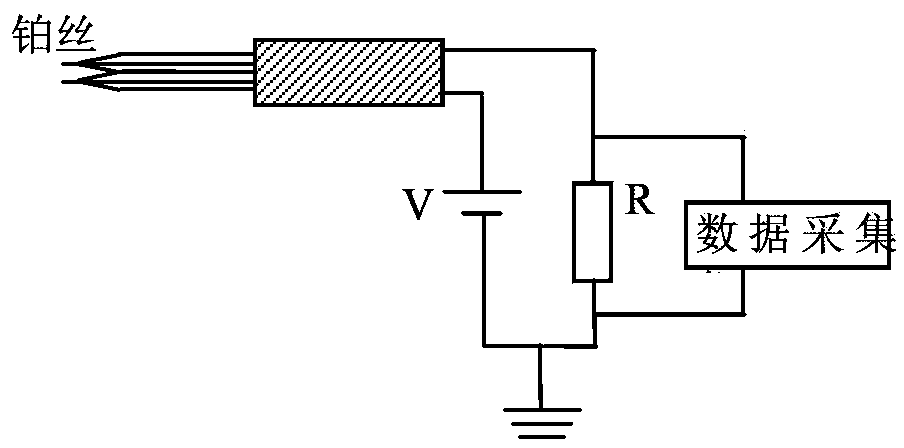

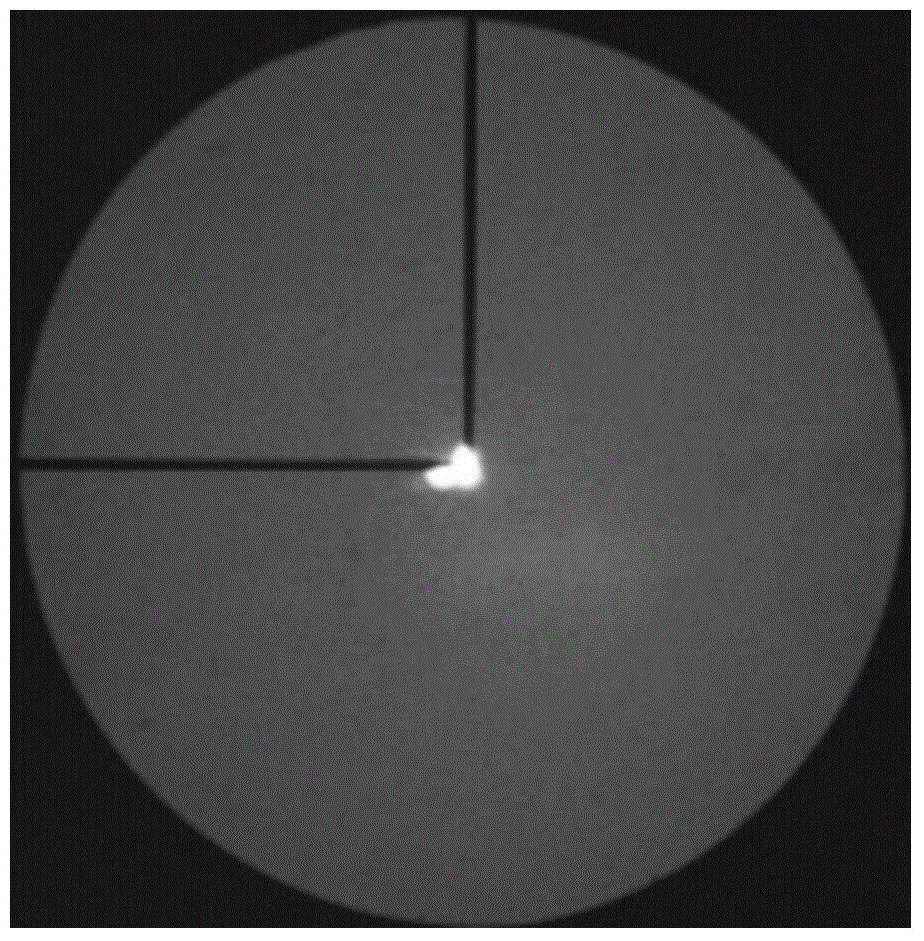

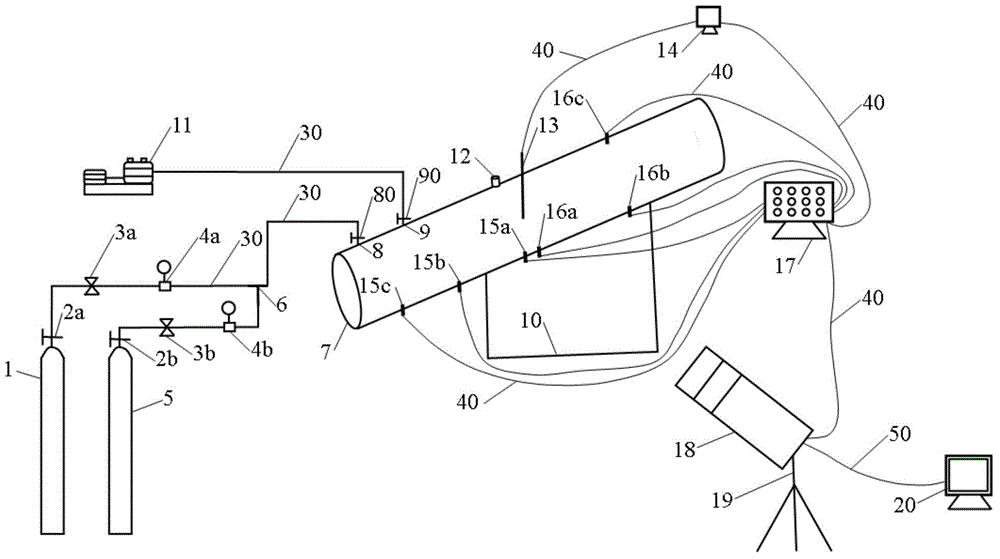

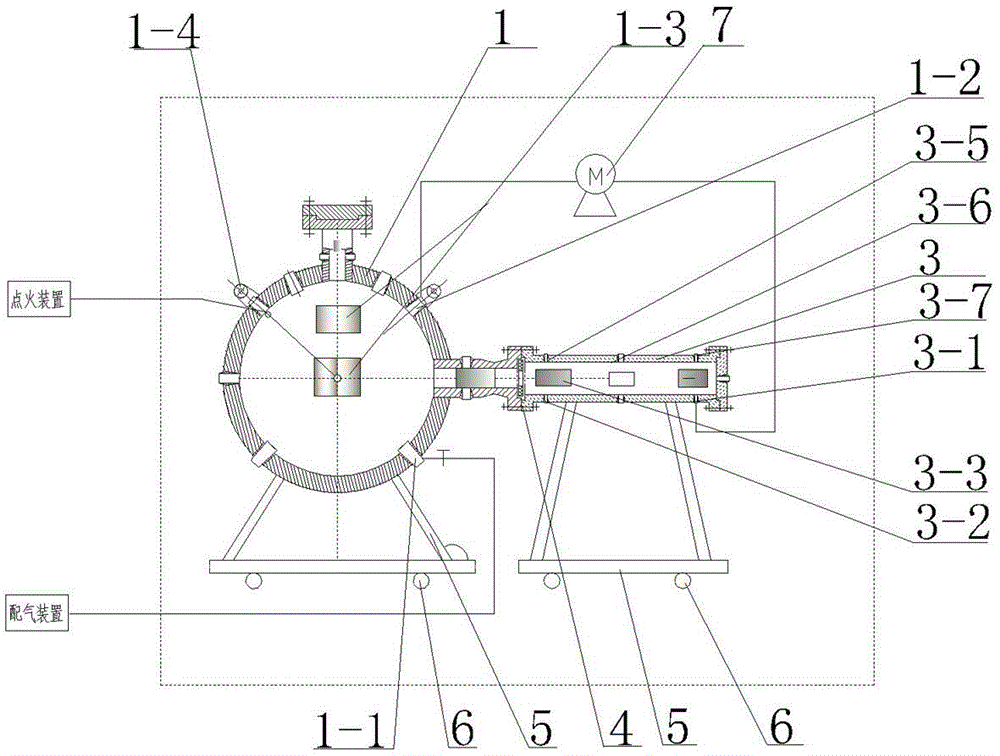

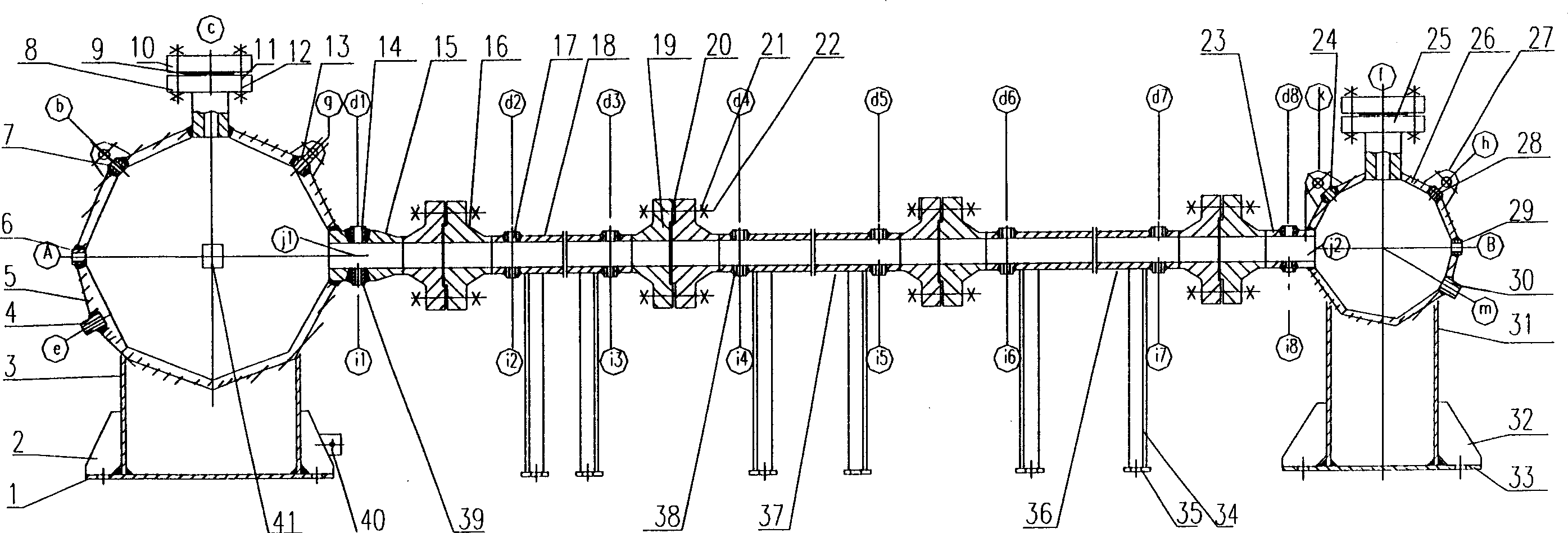

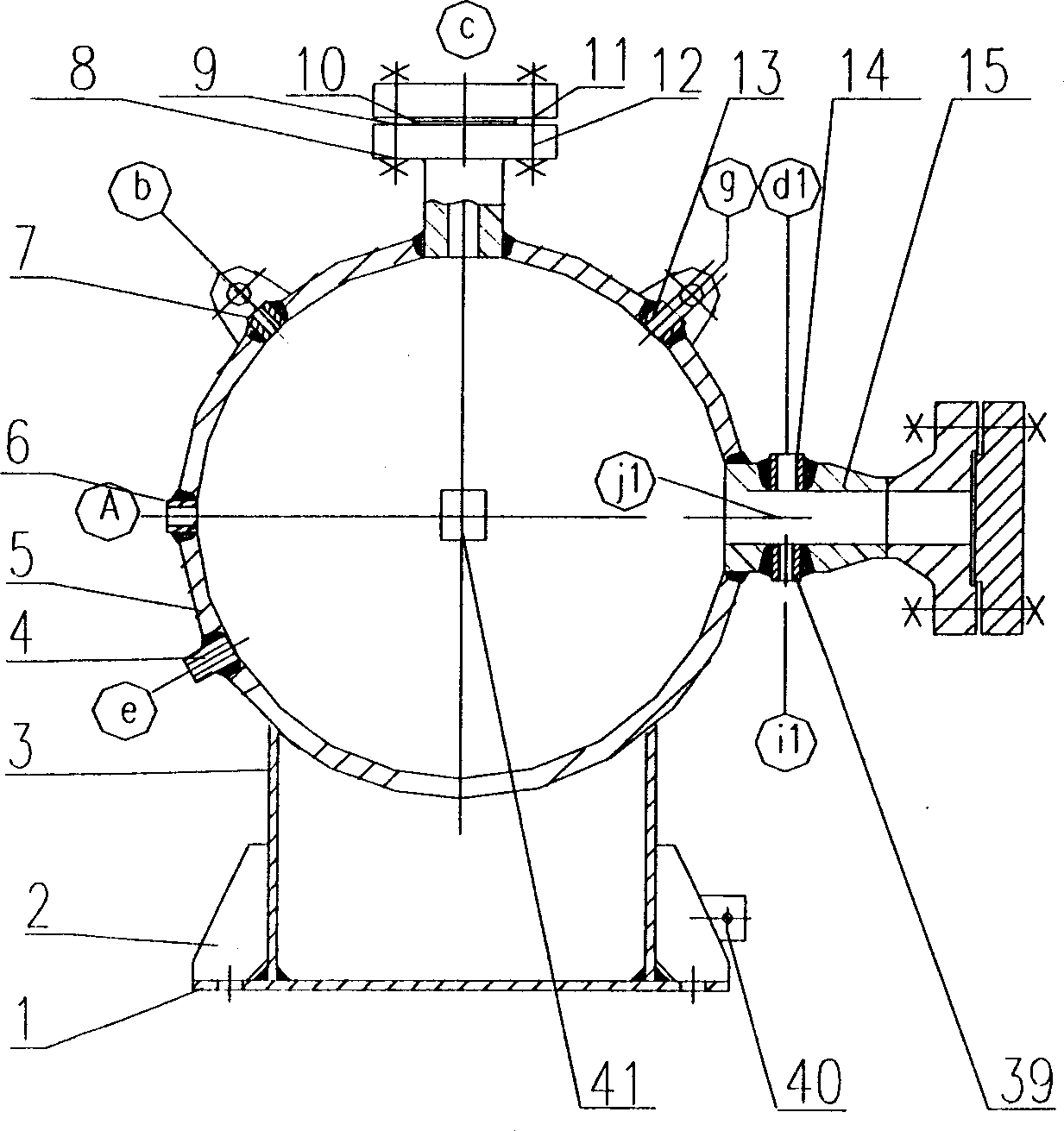

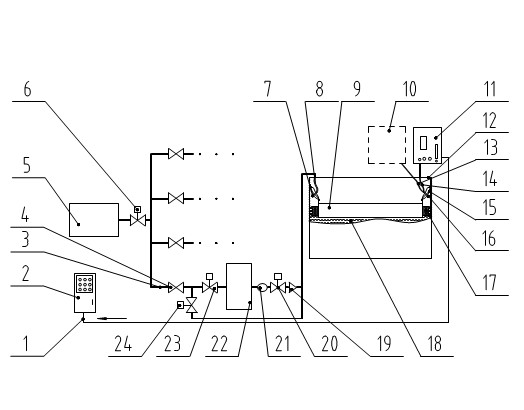

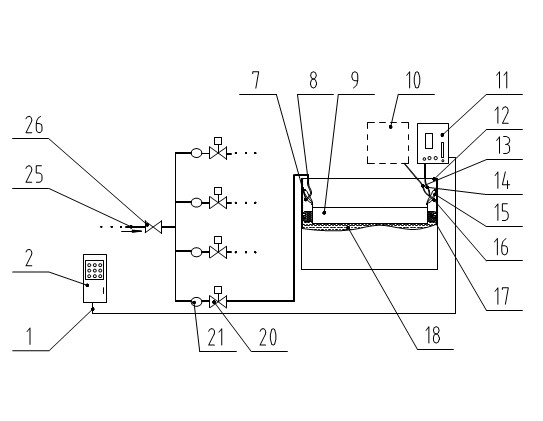

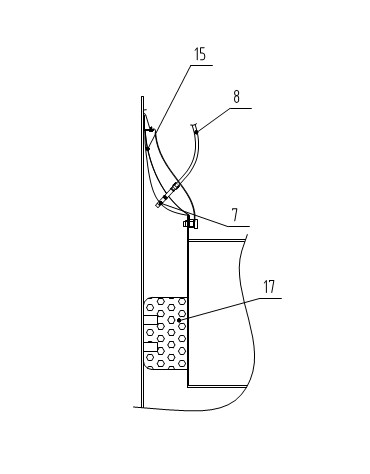

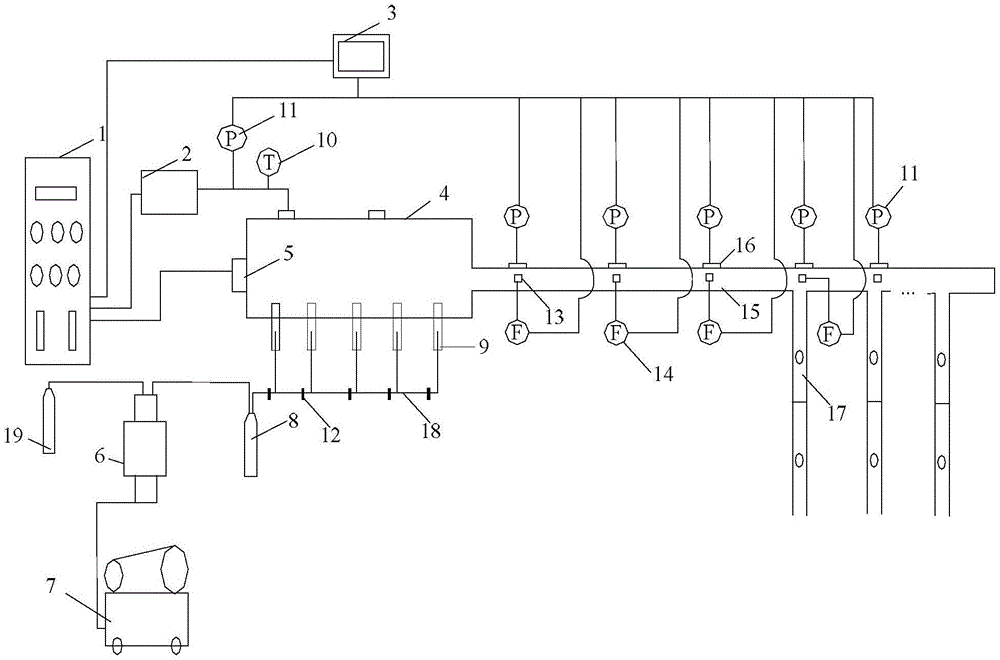

Apparatus for testing flame propagation and flame suppression in flammable gas and air premixed gas explosion process

ActiveCN103454308AAccurate and intuitive recordReveal inhibitionMaterial exposibilityData acquisitionInstability

The invention provides an apparatus for testing flame propagation and flame suppression in the flammable gas and air premixed gas explosion process. The whole apparatus comprises a combustion pipeline, a water mist generating device, a metal net fire retardance device, a high-speed camera, a schlieren system, a pressure testing system, an automatic gas distribution system, a temperature testing system, an ion probe detection system, a data acquisition instrument, a high-tension ignition system and a synchronous controller. Through the apparatus, flame propagation characteristics and flame propagation rules are researched in the premixed gas explosion process under the influences of factors such as different flammable gas components, different opening states, different ignition positions and different types of flame instability, the effects of stopping agents, fire-retardant metal nets, water mist and the like on controlling and restraining flame propagation are researched, a method and technology for restraining premixed gas flame propagation are developed under the physical-chemical coupling effect, and the inner mechanism of the apparatus is explained.

Owner:UNIV OF SCI & TECH OF CHINA

Gas explosion simulation test system and method

Owner:ANHUI UNIV OF SCI & TECH

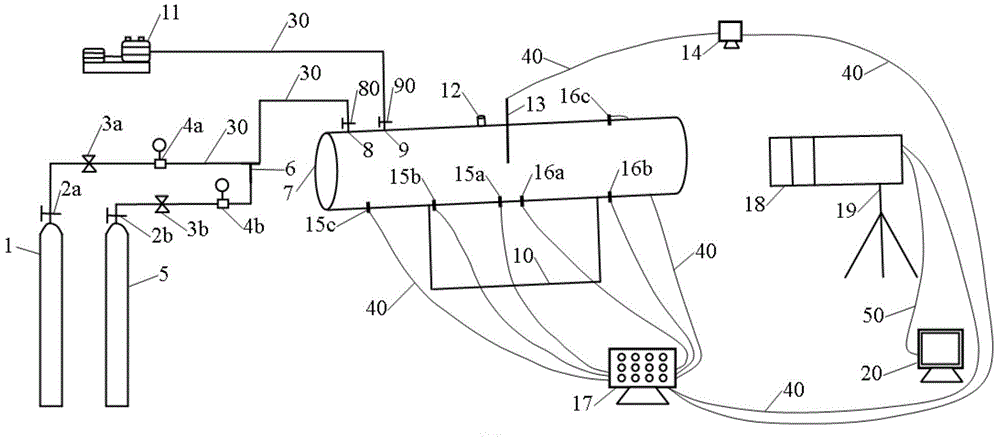

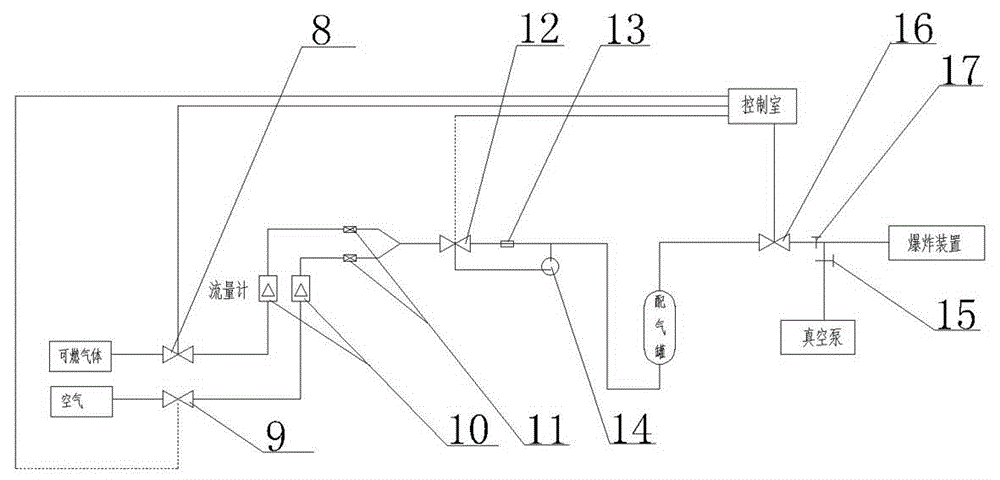

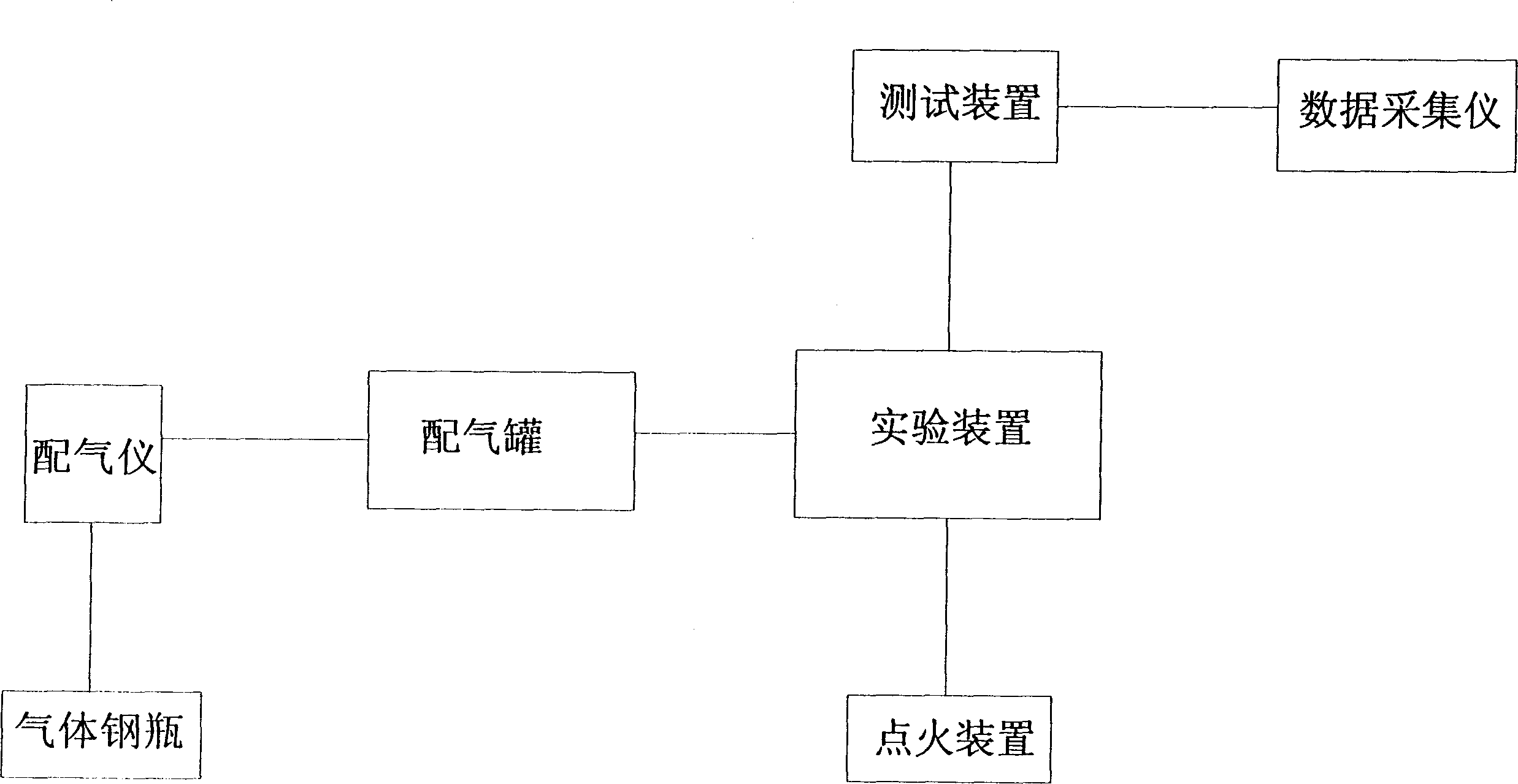

Testing system for gas explosion characteristic size effect

The invention discloses a testing system for a gas explosion characteristic size effect and relates to a testing system which studies on the gas explosion characteristic size effect. The device comprises a gas distribution device, an ignition device, an explosion device, a data collecting and processing device and a high-speed digital camera, wherein the gas distribution device comprises a combustible gas source, a distribution gas source and a gas distribution tank; the ignition device comprises a igniter, and the igniter is installed on the explosion device; the data collecting and processing device comprises a pressure sensor, a flame propagation rate sensor, a temperature sensor, a signal amplification circuit, a data collecting circuit and a computer, and the pressure sensor, the flame propagation rate sensor and the temperature sensor are installed on a spherical container, a cylindrical container and a pipeline; the explosion device is installed between the gas distribution device and the data collecting and processing device, and the explosion device comprises the spherical container, the cylindrical container and the pipeline; and the high-speed digital camera is used for shooting flames during explosion of the combustible gas inside the containers and the pipeline, and an output end of the high-speed digital camera is connected with the computer.

Owner:NANJING UNIV OF TECH

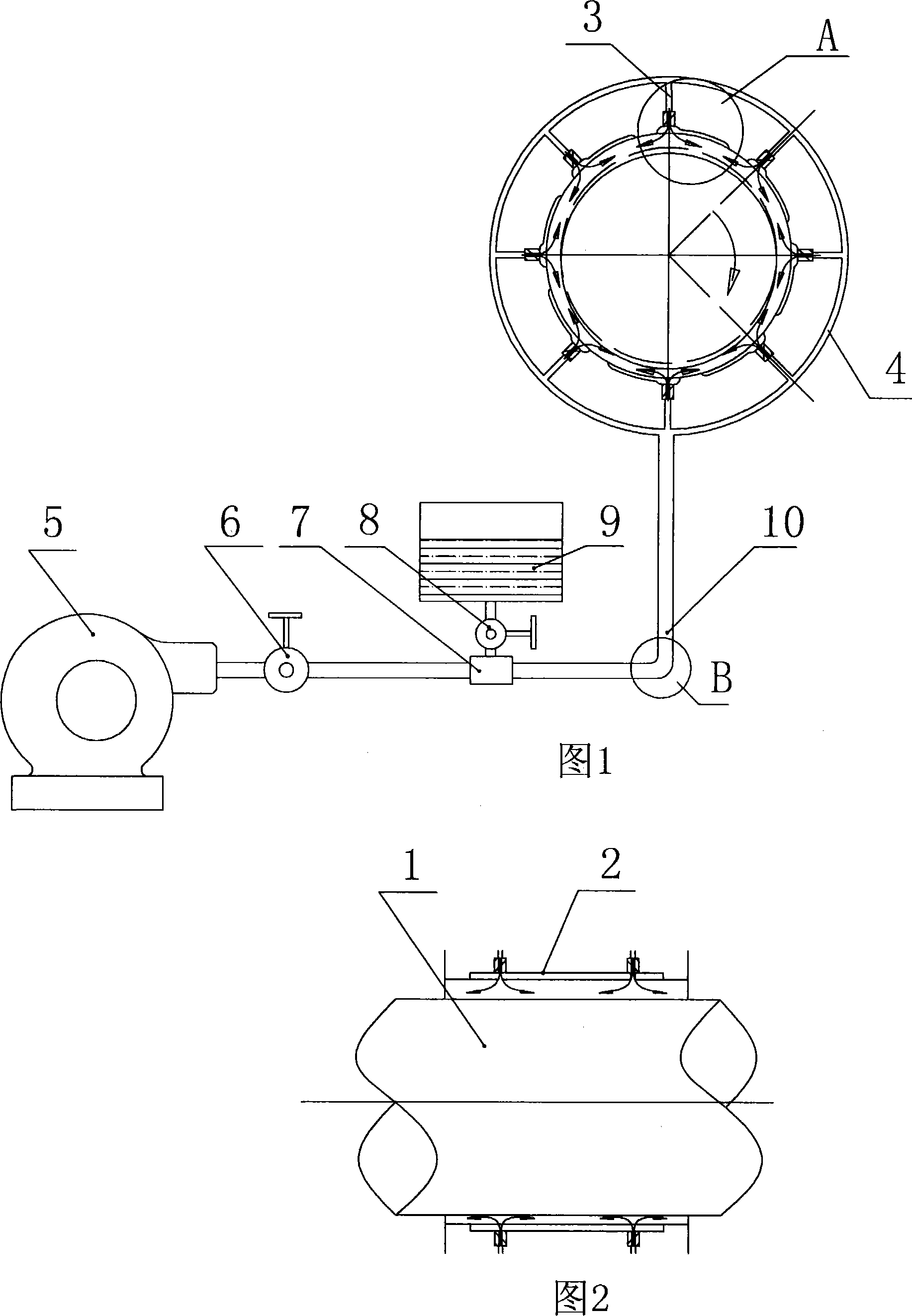

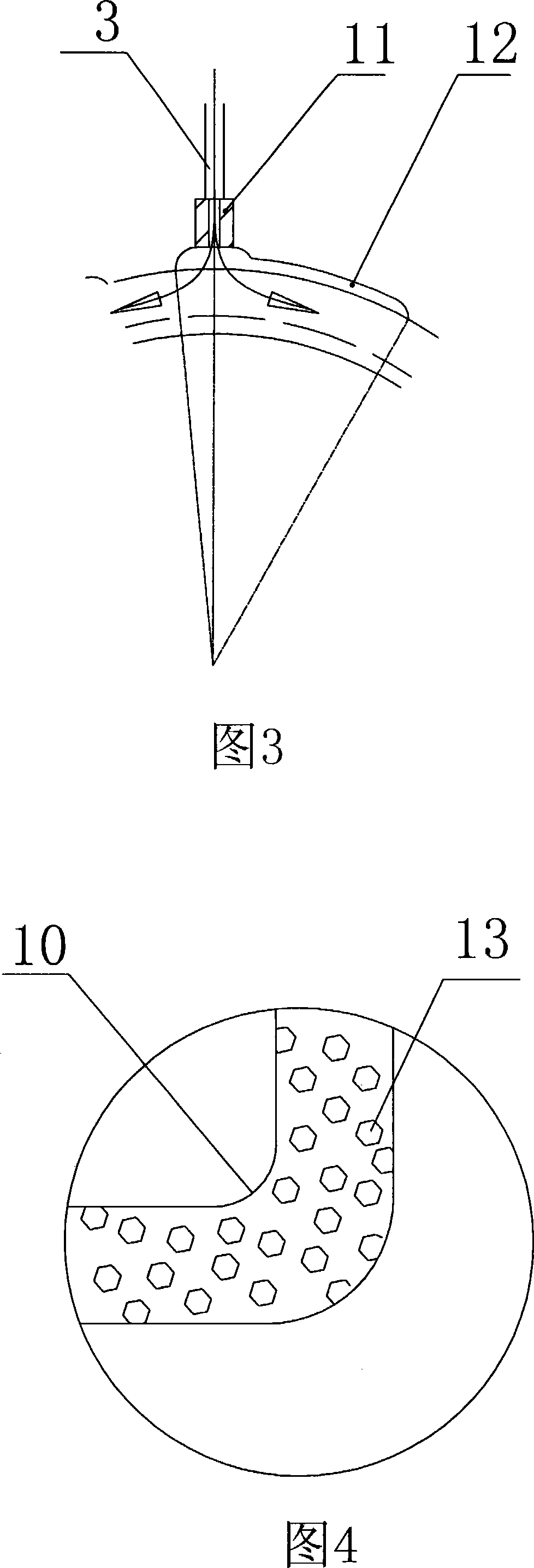

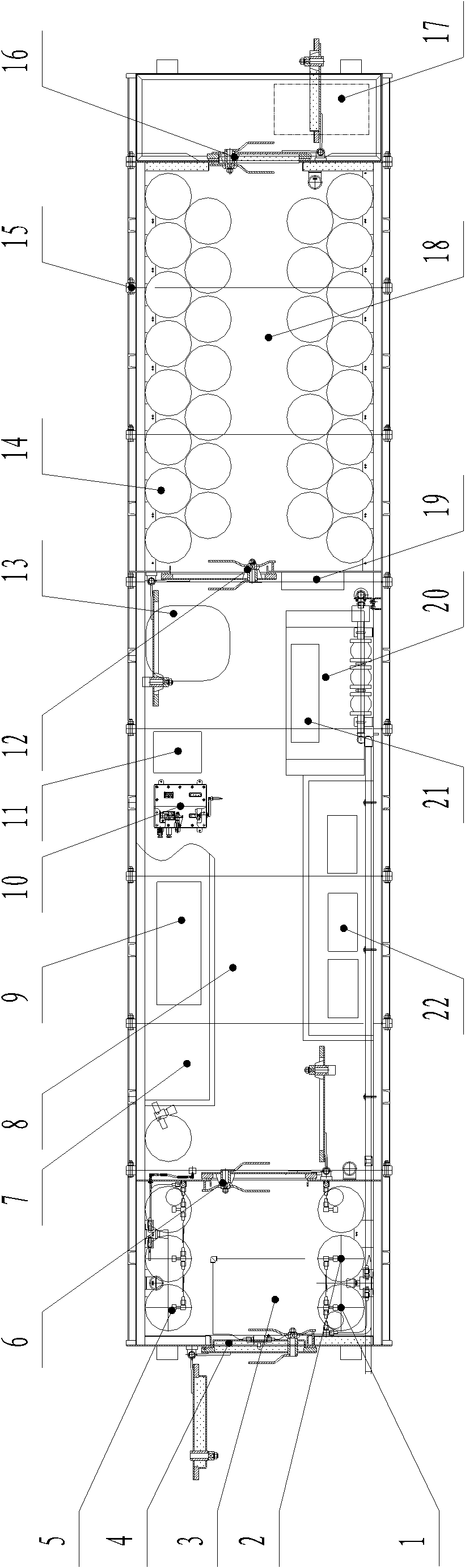

Multifunctional gas explosion experiment system

The related multifunction container-pipe gas blast experiment system comprises: an experiment device with two ball containers and pipe all arranged with sensor hole, gas in-out hole, vacuum-pressure gauge interface, discharging blast hole and an ignition hole; a gas distributing device with a steel bottle, a distribution meter, a tank and delivery pipe,; an ignition device with an electric spark generator, a spark plug and wire; a test device with a vacuum-pressure gauge, a pressure transmitter, a flame sensor and sensor wire; and a data acquisition and process part with multichannel data collector and software.

Owner:NANJING UNIV OF TECH

Carbon dioxide fracturing device

A carbon dioxide fracturing device comprises an energy relief head, a constant-pressure energy relief piece, a main pipe and a filling head, wherein the energy relief head and the filling head are respectively screwed with the two ends of the main pipe; a filling channel leading to a filling cavity of the main pipe and a thimble capable of opening and closing the filling channel are arranged on the filling head; an energy relief channel is arranged on the energy relief head; one end of the energy relief channel leads to the filling cavity of the main pipe, and the other end of the energy relief channel leads to the outside of the carbon dioxide fracturing device; the constant-pressure energy relief piece is arranged between the energy relief channel of the energy relief head and the filling cavity of the main pipe in a sealed manner; a heating device is arranged in the filling cavity of the main pipe; and the constant-pressure energy relief piece fractures when the heating device heats up and gasify liquid carbon dioxide in the filling cavity of the main pipe and the carbon dioxide gas expands to a certain pressure. The carbon dioxide fracturing device can replace detonators and explosives, which are frequently used in mine mining, avoids gas explosion caused by open fire to realize safety production of mines, can also enable coal to pre-split in the gas exhausting and mining process, effectively increases the air permeability of coal beds and improves the gas exhausting and mining efficiency of coal beds.

Owner:河北亿科金属制品有限公司

Carbon dioxide mining device

The invention discloses a carbon dioxide mining device. The carbon dioxide mining device comprises an energy release head, a fixed pressure energy release sheet, a main pipe and a filling head, wherein the energy release head and the filling head are respectively fastened at the two ends of the main pipe; a filling passage and an ejector pin are arranged on the filling head; the filling passage is led to a main pipe filling chamber, and the ejector pin is used for opening and closing the filling passage; an energy release passage is formed in the energy release head; one end of the energy release passage is led to the main pipe filling chamber; the other end of the energy release passage is led outside the carbon dioxide mining device; the fixed pressure energy release sheet is arranged between the energy release passage of the energy release head and the main pipe filling chamber in a sealed way; a heating device is arranged in the main pipe filling chamber; and the fixed pressure energy release sheet is fractured when liquid carbon dioxide filled into the main pipe filling chamber is heated, gasified and expanded to a certain pressure by the heating device. The carbon dioxide mining device disclosed by the invention can be used instead of common detonators and explosives in mine mining; gas explosion caused by fire explosion is avoided and safety production of the mine is also achieved; and a coal body can be also pre-cracked in the gas mining process, so that the air permeability of a coal layer is effectively improved, and the gas mining efficiency of the coal layer is increased.

Owner:CCTEG CHINA COAL RES INST

Method for preparing dietary fiber through solid-gas explosion

The invention belongs to the technical field of preparation of dietary fibers, and particularly relates to a method for preparing the dietary fibers by using grain seed husks, such as corn husks and the like as raw materials and utilizing a solid-gas explosion technology, which comprises the following steps of: regulating the water content of the grain seed husks to 50-300 percent, and then placing into a sealed gas explosion device; raising the pressure of the gas explosion device to 0.4-1.2Mpa within 5-25 minutes, and retaining the pressure for 10-120 seconds and then instantaneously depressurizing; and adding water into the processed grain seed husks for extraction, removing the starch and the protein therein, modifying, separating and removing impurities to obtain the dietary fibers. The method has the advantages of simple operation, convenient and rapid extraction, abundant raw material sources and low production cost and can simultaneously obtain two types of high-quality corn-husk dietary fiber products with high purity and large yield, and both the yield and the physiological activity of the products are markedly improved.

Owner:河南省农科院农副产品加工研究所

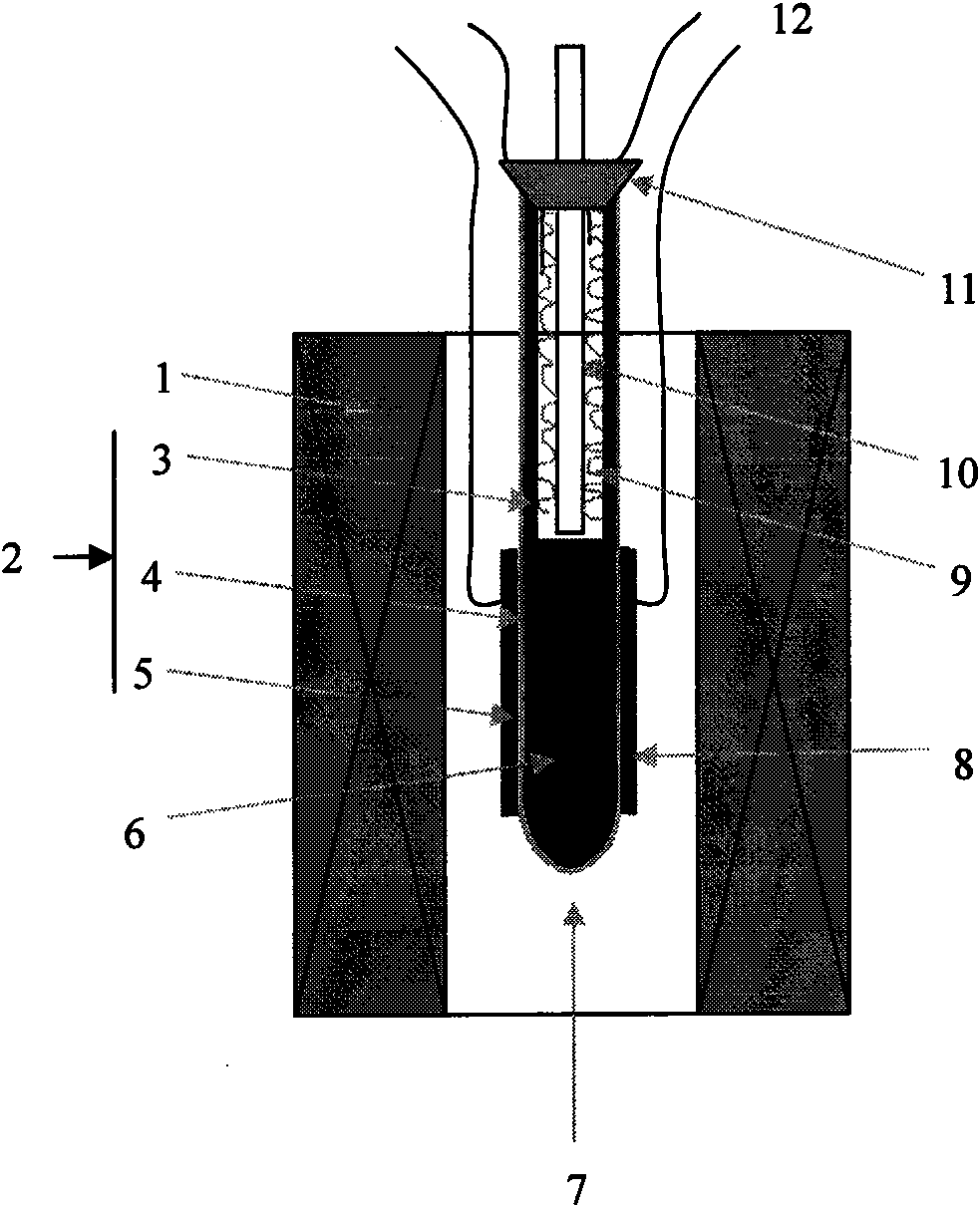

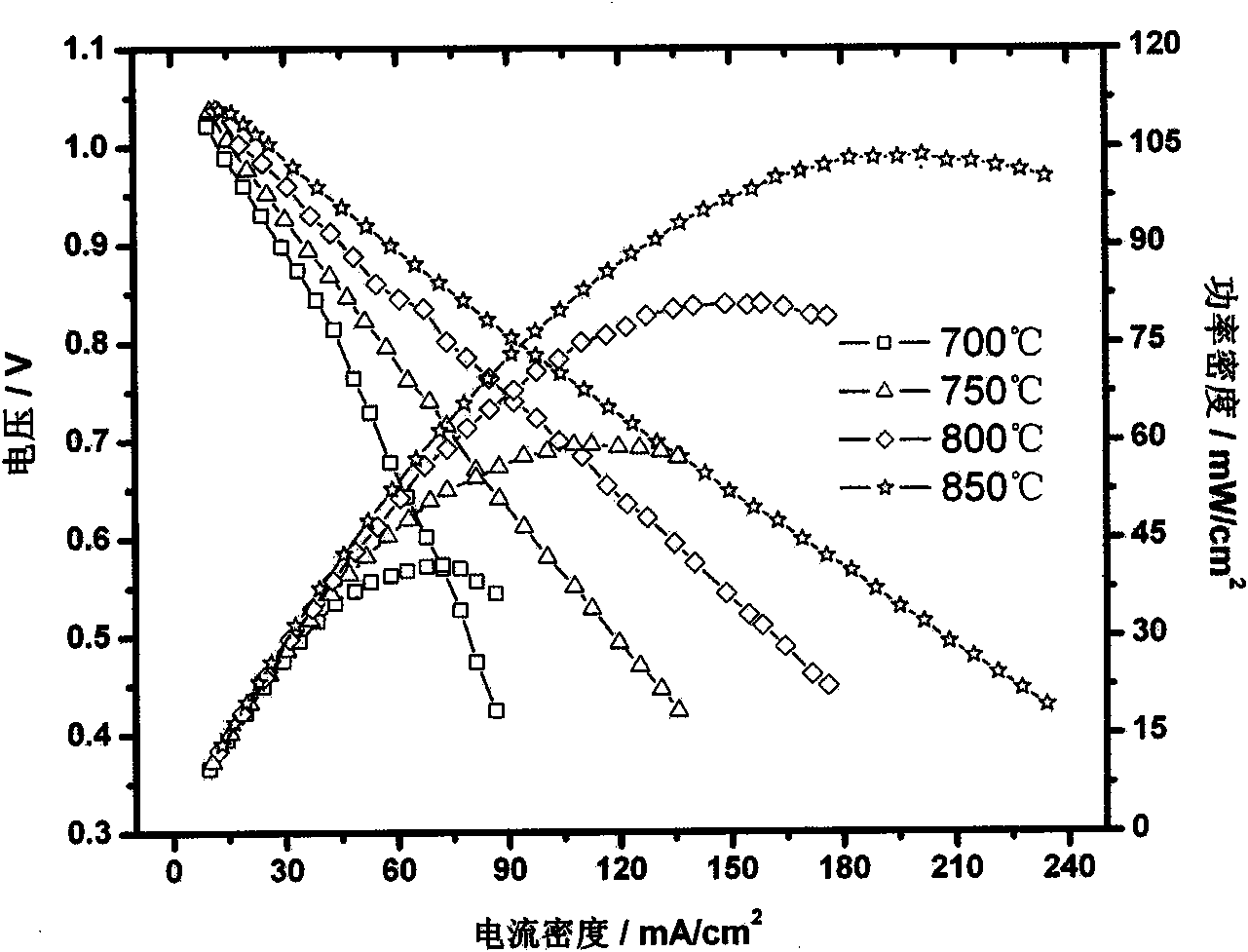

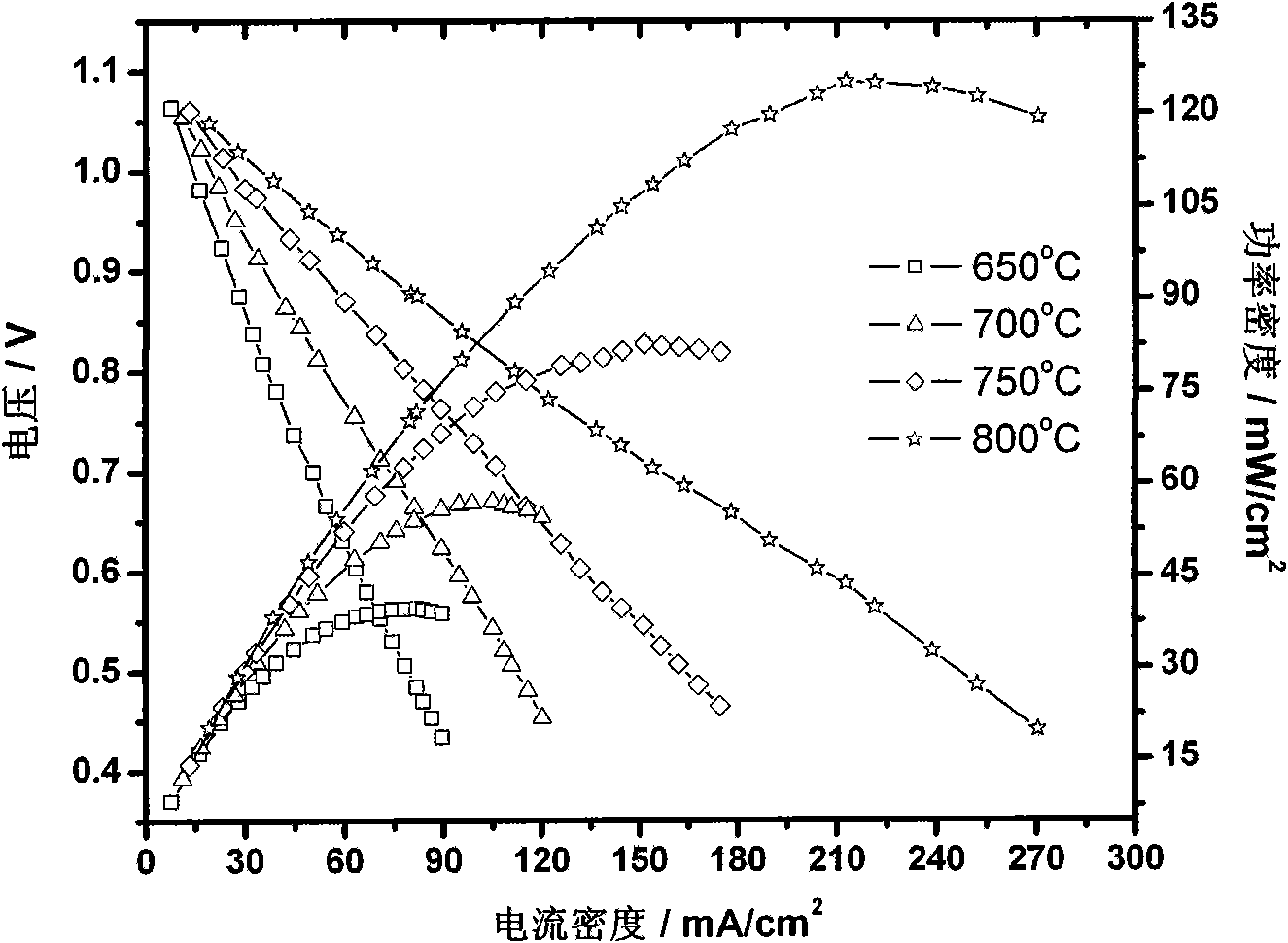

Solid electrolyte direct carbon fuel cell

InactiveCN101540411AEasy to operateImprove energy efficiencySolid electrolyte fuel cellsElectrochemical responseHigh energy

The invention relates to solid electrolyte direct carbon fuel cell. In the invention, tube-type batteries serve as the electrochemical reaction device, the inner layer of the batteries is anode, the intermediate layer is the electrolyte and the outer layer is cathode, carbon fuel is filled in the tube-type batteries. The carbon fuel cell of the invention features high energy efficiency, sound environmental protection property, a theoretic efficiency being 2-3 times of the generating efficiency of the existing coal power plants, reduction of discharge of greenhouse gas CO2, no generation of acidic gases such as nitrogen oxide and sulfide, no possible danger of liquid leakage and gas explosion and fine electrochemistry property.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

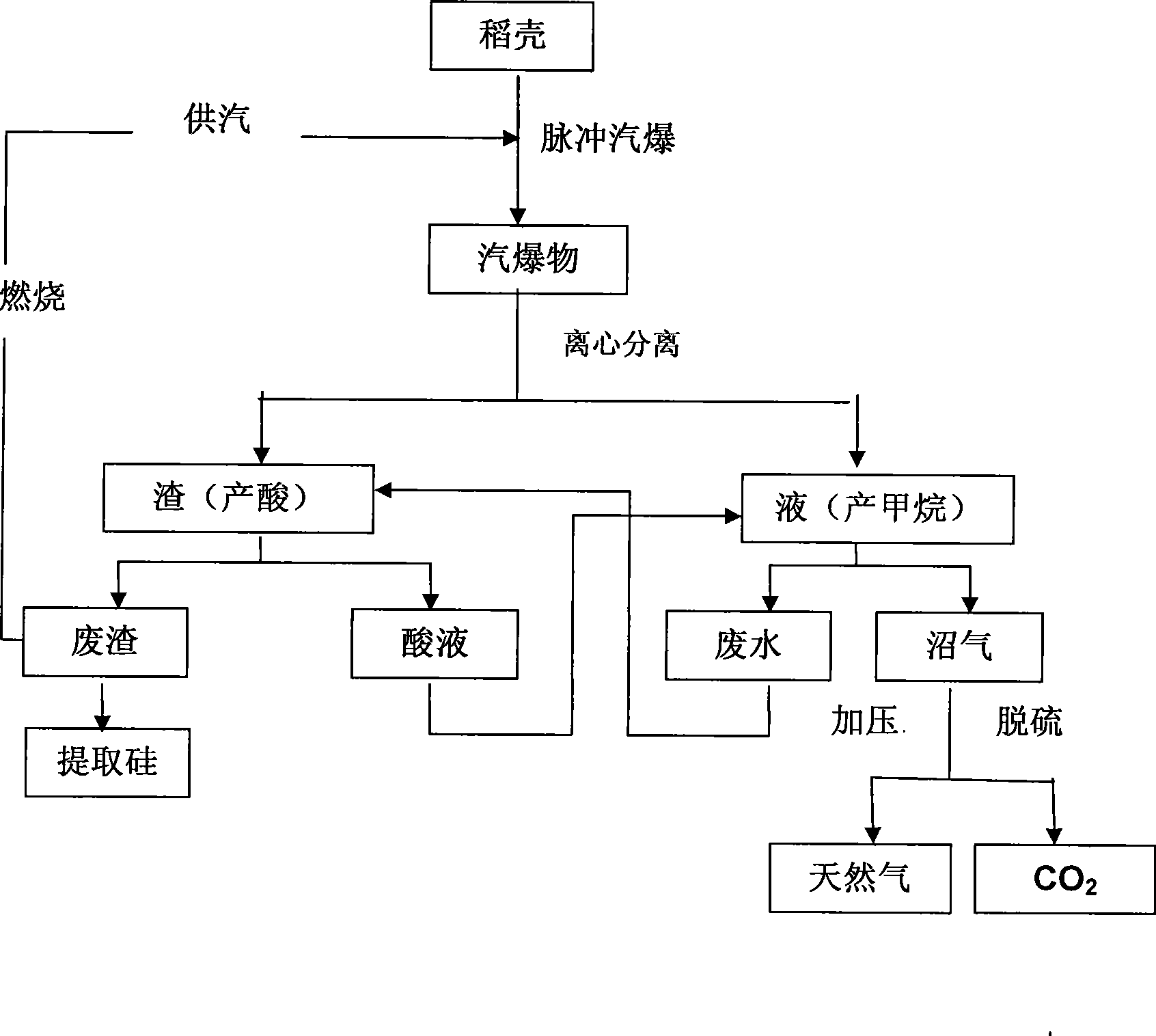

Production process of natural gas by using paddy hull

The invention relates to a production technique utilizing rice hulls to produce natural gas, which solves the problem of economically and effectively utilizing the rice hulls which are rich resources and biological materials. The technique of the invention essentially comprises the following steps: 1. Pulse gas explosion is carried out to the rice hulls and more than 90 percent of hemicelluloses in products of gas explosion are hydrolyzed while more than 85 percent of celluloses are isolated and puffed; 2. two-phase anaerobic fermentation is carried out to the products of gas explosion, thus respectively obtaining methane and acid liquor; and 3. desulfurization is carried out to the methane, thus obtaining the natural gas of the rice hulls. The technique of the invention pertains to anaerobic fermentation and has little manpower and low management cost; compared with the biomass heat energy transformation modes, such as cellulosic ethanol, biomass methanol, biological oil, pyrolytic bio-oil, biomass hydrogen production, wheat straw power generation, and the like, the transformable heat energy of biological natural gas is the highest; the technique of the invention pertains to a closed internal recycling system, which is environmentally friendly and has no pollution and high economic benefit.

Owner:浙江格义清洁能源技术有限公司

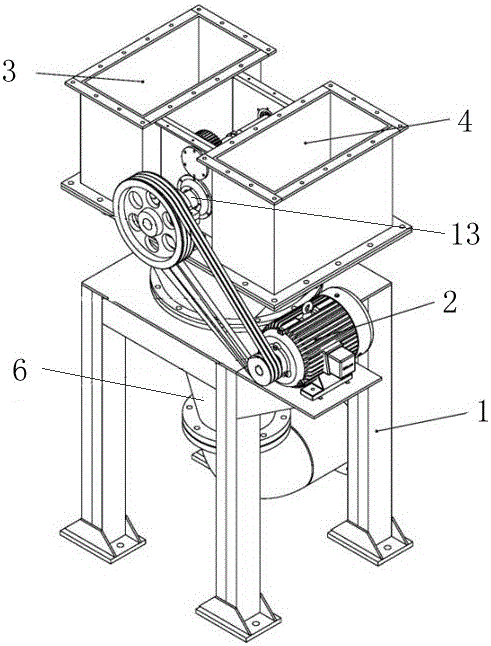

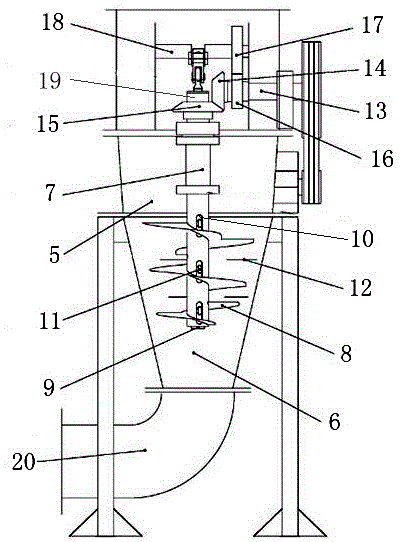

Pipeline transporting spiral crushing device for solid waste and household garbage

The invention belongs to the technical field of garbage disposal equipment and discloses a pipeline transporting spiral crushing device for solid waste and household garbage. The pipeline transporting spiral crushing device for the solid waste and the household garbage is used for solving the problems that because a direct recycling manner is adopted for scenic spots, stations, airports and other sites which are huge in waste amount and require instantaneous recycling in the prior art, a conveying pipeline can be blocked easily, and the gas explosion noise can be caused easily. The pipeline transporting spiral crushing device for the solid waste and the household garbage comprises a machine body which is provided with a feeding bin; the lower end of the feeding bin is communicated with a feeding channel; the lower end of the feeding channel is communicated with a spiral crushing barrel; the lower end of the spiral crushing barrel is communicated with a conveying pipeline of a matched pneumatic waste recycling system; a hollow rotating shaft is arranged in the spiral crushing barrel; spiral blades are arranged on the periphery of the hollow rotating shaft; a plurality of through grooves formed in the axial direction of the hollow rotating shaft are formed in the circumferential wall of the hollow rotating shaft; a core shaft capable of rotating along with the hollow rotating shaft and capable of moving up and down along the hollow rotating shaft is arranged in the hollow rotating shaft in a sleeved manner; and the core shaft is connected with a plurality of longitudinal cutters capable of sliding up and down in the through grooves.

Owner:浙江易顺通科技有限公司

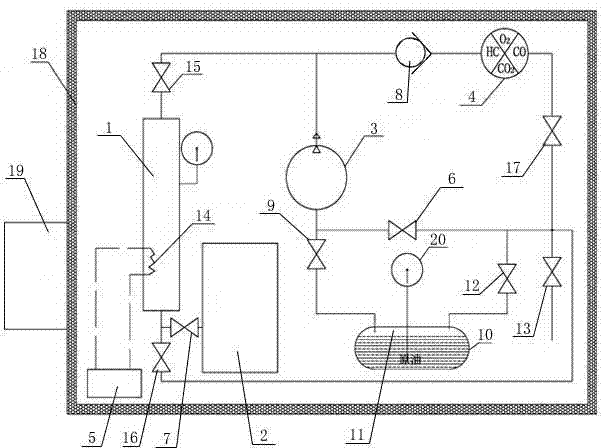

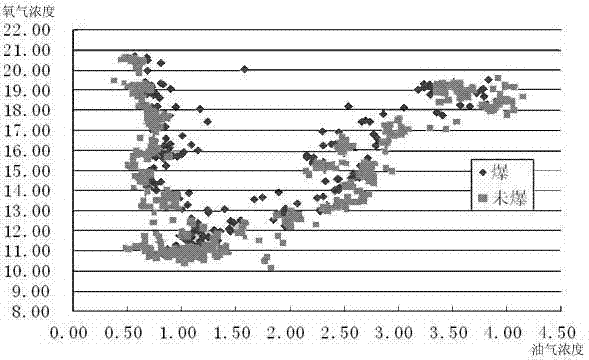

Oil-gas explosive critical parameter testing device and method

The invention discloses an oil-gas explosive critical parameter testing device. The oil-gas explosive critical parameter testing device comprises an explosion reaction pipe, an inert gas supply device, a vacuum pump, a gas analyzer and an ignition device. The invention provides the explosive critical parameter testing device with a high-energy ignition source, which is used for simulating an actual volatilization state of oil gas in an oil tank and uses the online gas analyzer to test an explosive critical parameter, aiming at the problems that the conventional explosive testing device is lack of guiding and practical values of detection data and the like. The oil-gas explosive critical parameter testing device uses a sealing pipeline with a cross section which has an area equivalent to an area between primary seal and secondary seal of the conventional oil storage tank with the volume of 100,000 cubic meters as an explosion reaction pipe; the oxygen concentration and an oil gas concentration of mixed gas inside the pipeline can be respectively controlled by introducing nitrogen and oil gas; an electric sparkle firing and igniting test is carried out; and the explosive strength of the mixed gas, and the oxygen concentration value and the oil gas concentration value before explosion can be tested, so that the upper limit and the lower limit of the oil gas explosions under different oxygen concentrations can be found out. Therefore, the safe section of the oil-gas mixed gas can be found out.

Owner:VITALONG FIRE SAFETY GRP

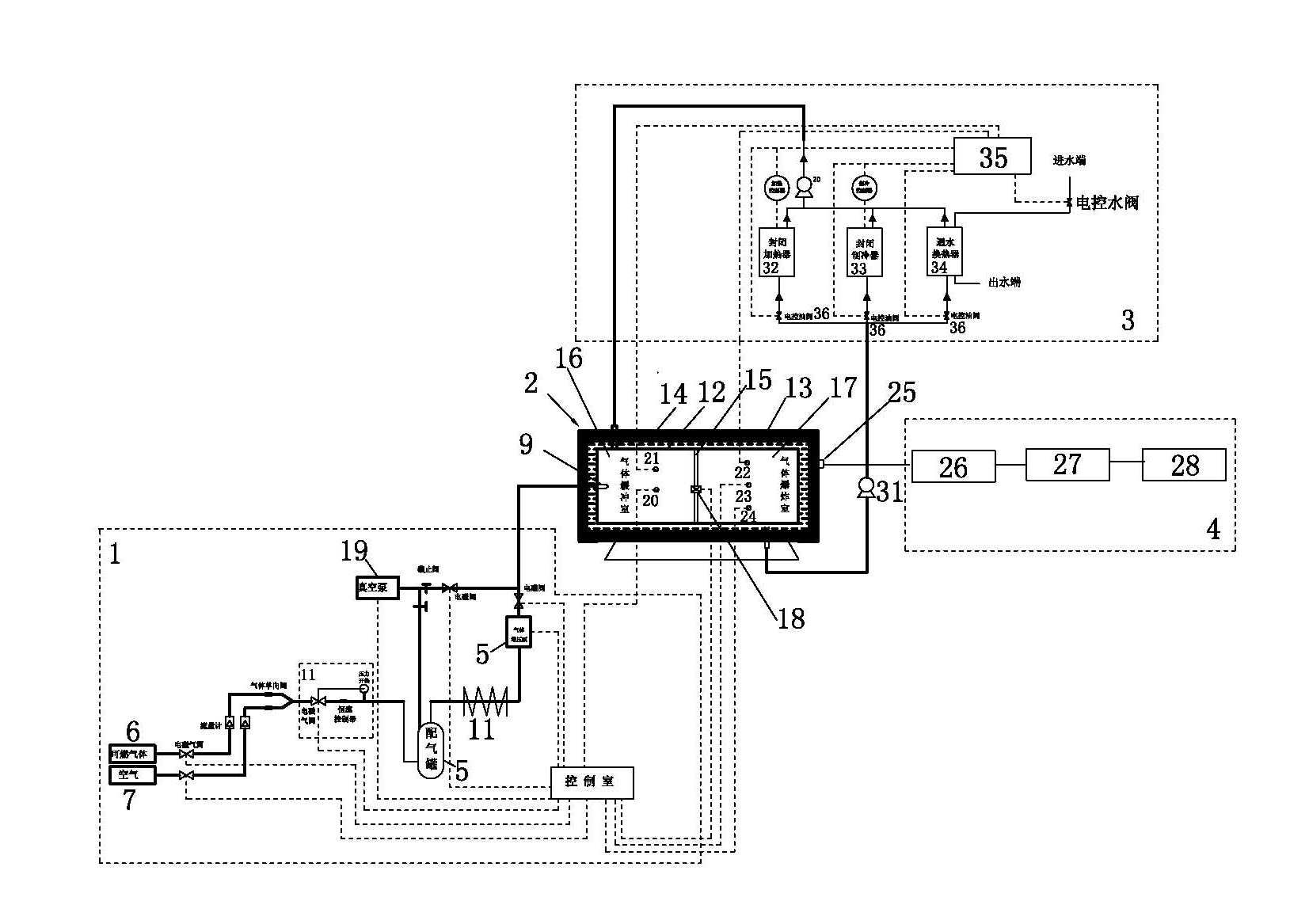

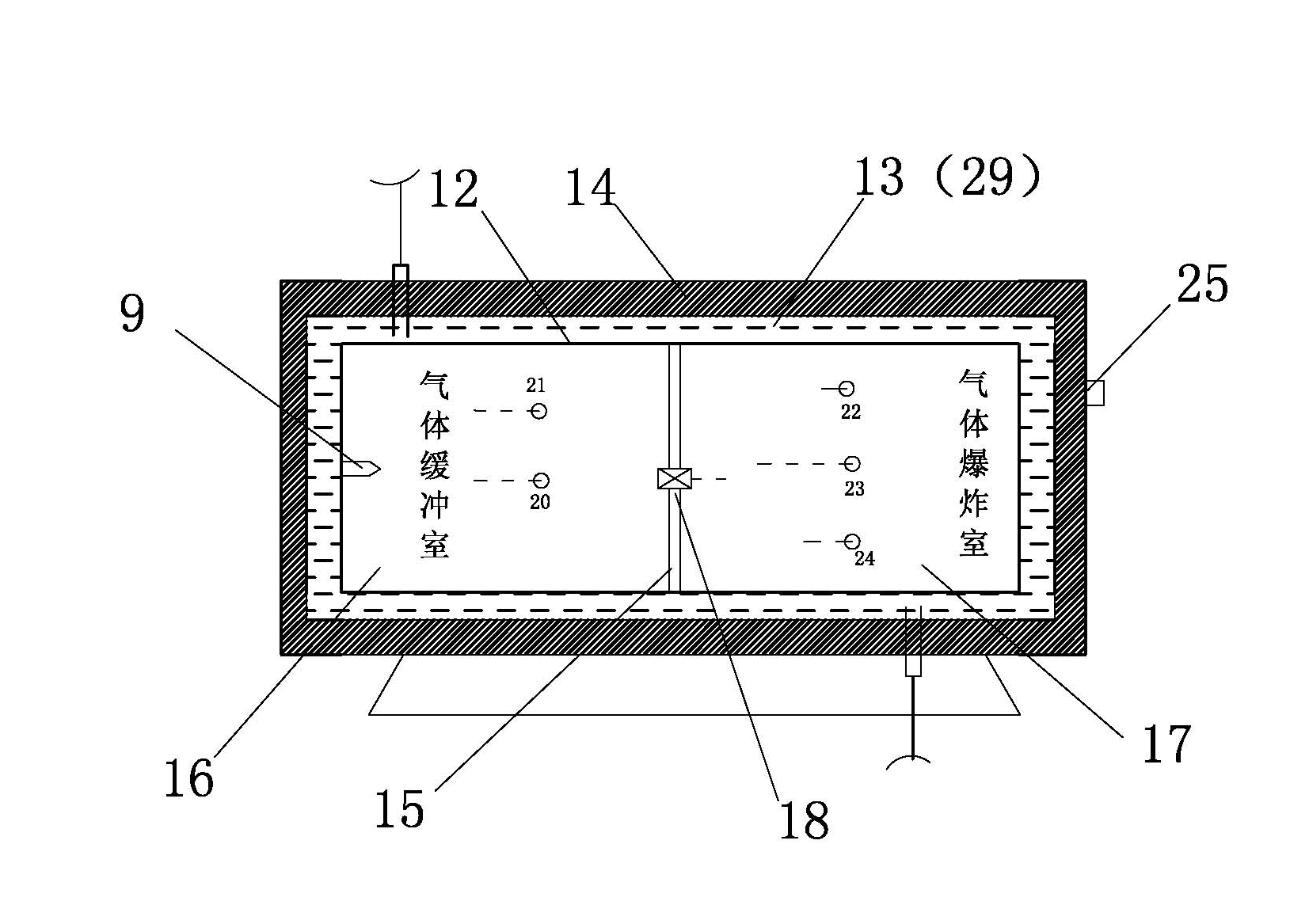

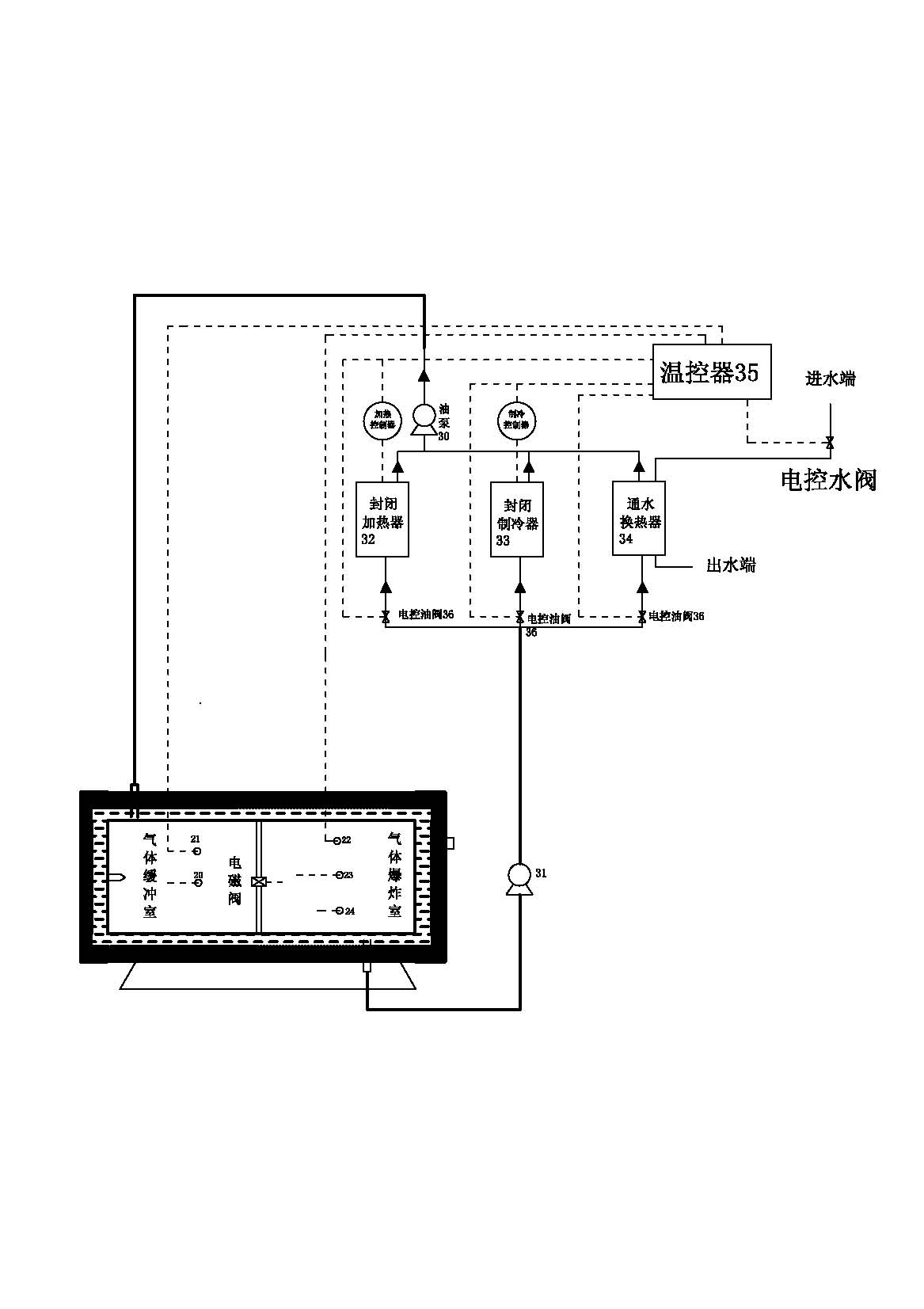

Combustible gas explosion limit test system in non-standard state

The invention provides a combustible gas explosion limit test system in a non-standard state, which is characterized by comprising a gas distribution device, an explosion device, a temperature control device and a data acquisition processing device. The explosion device comprises an anti-explosion tank and a heat preservation jacket; a heating element is arranged between the anti-explosion tank and the heat preservation jacket; a partition board is arranged in the anti-explosion tank and partitions the inner cavity of the anti-explosion tank into a gas buffer chamber and a gas explosion chamber; a solenoid valve communicating the gas buffer chamber with gas explosion chamber is arranged on the partition board; an input opening of the explosion device is communicated with the gas buffer chamber and in bypass connection with a vacuum pump; a buffer pressure sensor and a buffer temperature sensor are arranged in the gas buffer chamber; and an unexploded temperature sensor, an unexploded pressure sensor, an igniter and an explosion pressure sensor for the explosion test are arranged in the gas buffer chamber. The invention has the advantages of simple structure and good operability, and solves the difficulty of detecting the combustible gas explosion characteristics in the non-standard state, such as high temperature, high pressure and the like.

Owner:NANJING UNIV OF TECH

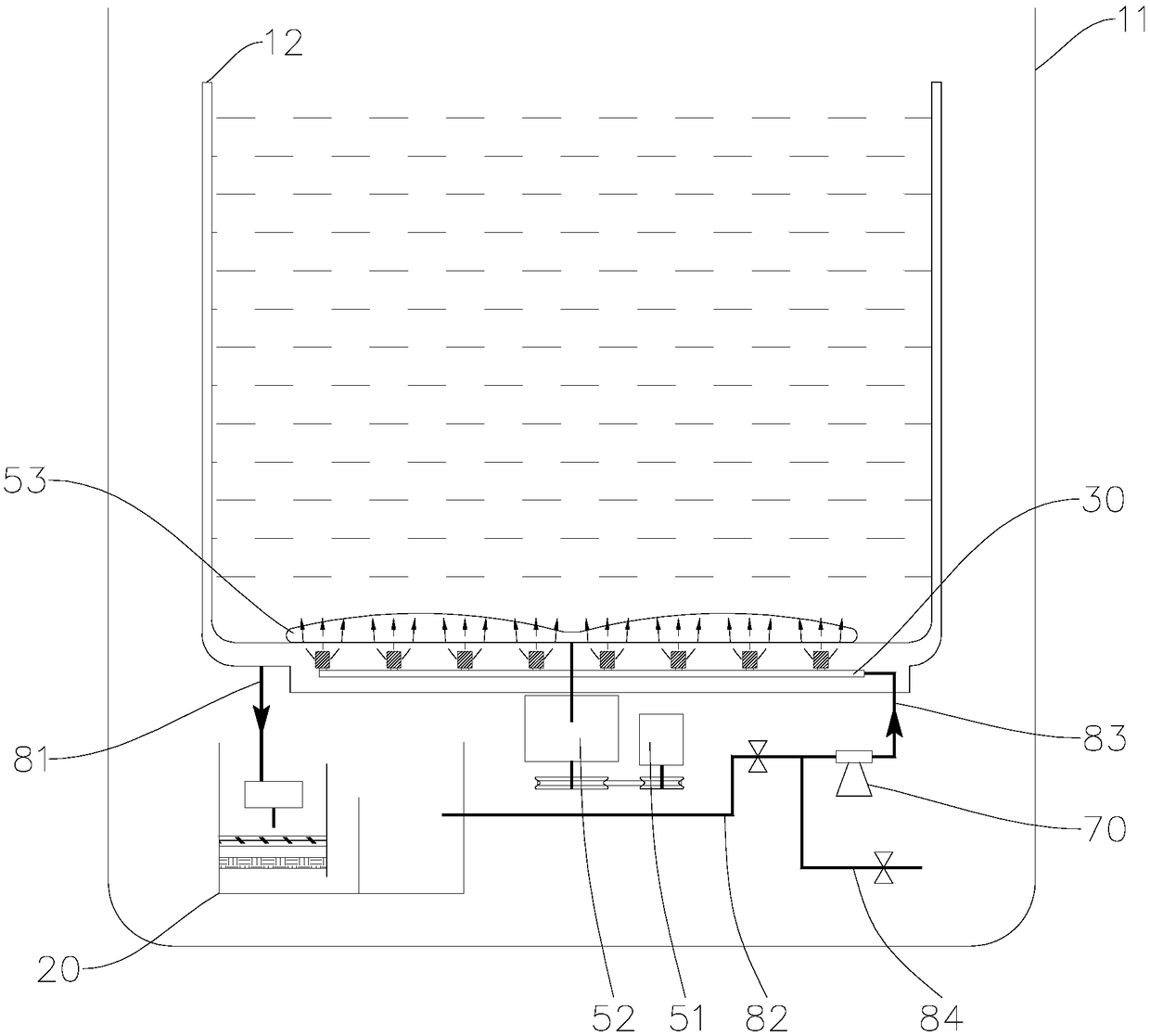

Active safeguard system and method for floating-roof oil tank

ActiveCN101985328AActive protectionReduce the possibilityLarge containersFire rescueLightning strikeCombustion

The invention discloses an active safeguard system and method for a floating-roof oil tank. Carbon dioxide gas serving as an inerting agent is filled into an annular spaced formed among the primary and secondary seals as well as tank walls of the floating-roof oil tank, the oxygen content and combustible mixed gas content in the annular space are controlled within a specified range, and the original dangerous space of fire disaster is turned into an inert safeguarding space which is prevented from explosion and combustion. The invention has the following advantage: the problem that the floating-roof oil tank is susceptible to oil gas explosion caused by lightning strike, static and the like in the annular space is solved.

Owner:VITALONG FIRE SAFETY GRP

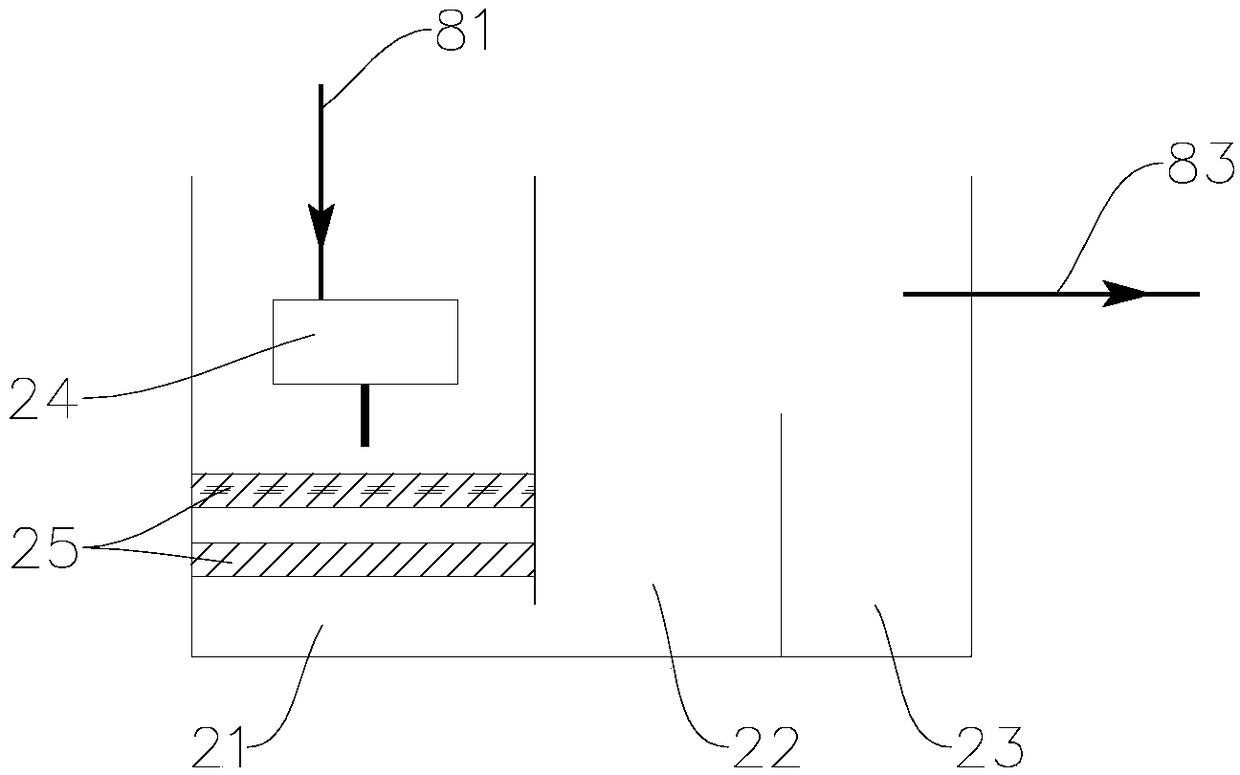

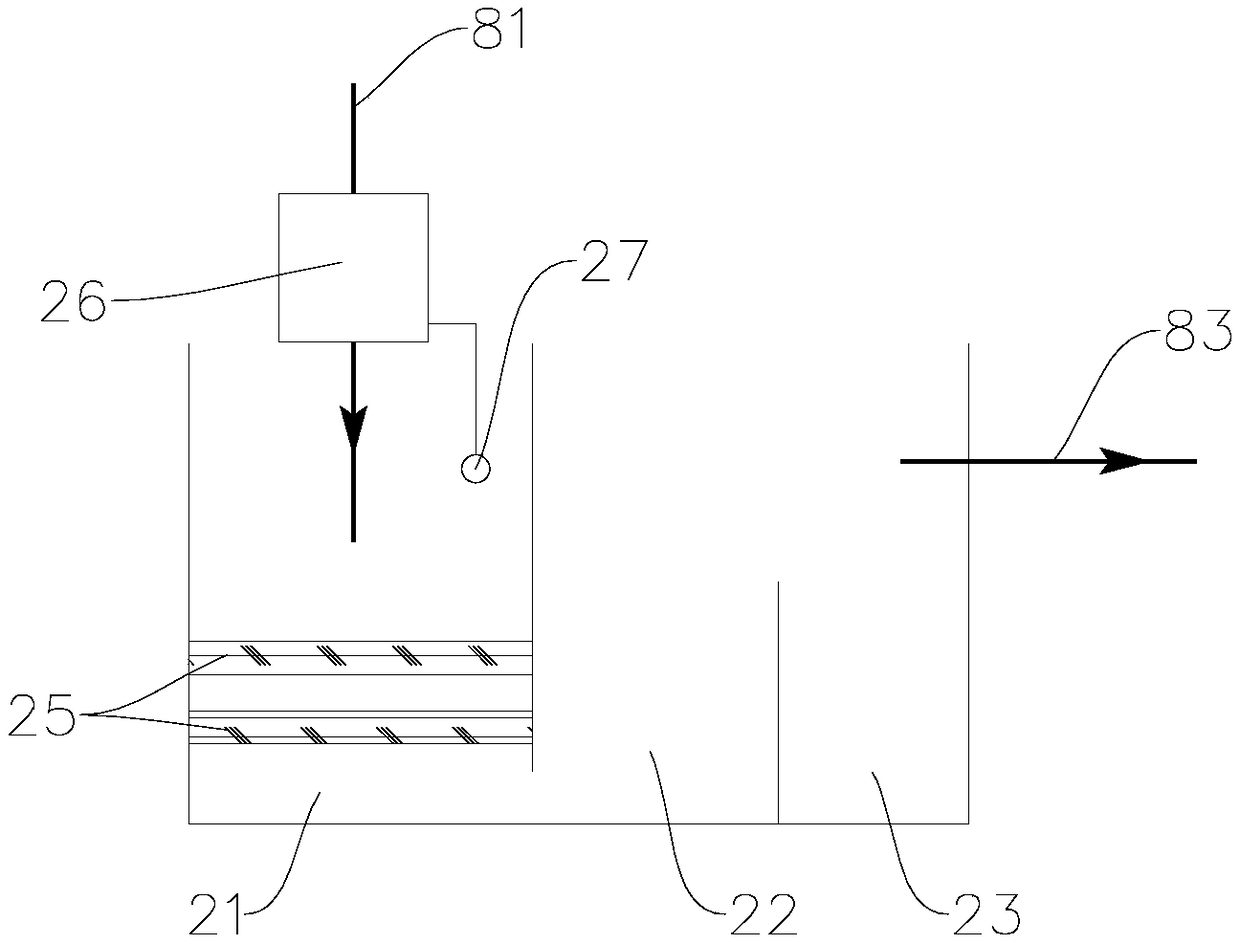

Washing machine filter device based on micro-nano gas explosion

InactiveCN108842384AReduce usageImprove washing effectOther washing machinesWashing machine with receptaclesMicro nanoGas explosion

The invention discloses a washing machine filter device based on micro-nano gas explosion, and relates to the technical field of washing machines. The device comprises a barrel body for containing washing water and a filter unit, the filter unit is communicated with an inner cavity of the barrel body through a water inlet pipe, the filter unit is connected with a micro-nano bubble generator through a connecting pipe, the micro-nano bubble generator is connected with a water outlet unit, the water outlet unit comprises a water outlet pipe connected with a water outlet of the micro-nano bubble generator, and the other end of the water outlet pipe is communicated with the inner cavity of the barrel body. Micro-nano bubbles can be introduced into filtered washing water and released in the barrel body, the washing effect can be enhanced, the consumption of a detergent is lowered, and the water consumption for rinsing and the rinsing frequency are lowered.

Owner:陈浩航

Coal mine gas explosion burst treatment method and its matched gas dissolving and elimineting agent

InactiveCN1624298AAvoid Explosion Prominent AccidentsGuarantee the safety of lifeDust removalFire preventionCoal dustCoal mine methane

This invention relates to a method and a gas dissolvant for the frequent gas explosions in coal mine. Its procedures are as following: the gas dissolvent and water are poured in turn into the coal seams containing gas. The gas dissolvent is a kind of water solution made up of acetum and yeast which selective weight ratio is 1000:5-15. The acetum is preferred to be replaced by vinegar of the same acetum. After the vinegar is added into the yeast, their dehydro-ratio is 2-8 times as heavy as the vinegar. The advantages are safety efficient, more feasible and harmless to human body.

Owner:洛阳保矿安矿山设备有限公司

Hydraulic cutting and gas explosion combined enhancing extraction method for fracturing coal body in drill hole

ActiveCN104314606ALower adsorption potentialFacilitate desorptionFluid removalGas removalHigh concentrationShock wave

The invention discloses a hydraulic cutting and gas explosion combined enhancing extraction method for fracturing a coal body in a drill hole. The hydraulic cutting and gas explosion combined enhancing extraction method is suitable for high-efficiency extraction of underground gas of a coal mine. The enhanced extraction method comprises the following steps: firstly, forming a slot by using a hydraulic cutting technology, relieving the pressure and increasing permeability, and desorbing and gushing gas; secondly, pressing air into a sealed drill hole by using an air pump, wherein the air and the gushed gas from the drill hole form gas mixed gas with the concentration of 9-10 percent; detonating the mixed gas by an ignition device to form an explosive shock wave; fracturing the coal body under the guiding action of the slot. The slot provides a greater explosion space, so that the power of explosion is enhanced and a fracture network in the coal body can be fully constructed; besides, the adsorption potential of gas can be remarkably reduced and the desorption and the flowing of the gas are promoted by the heat effect generated by explosion, so that the aim of enhancing the gas extraction of a coal bed with high-concentration gas and low permeability is achieved. The enhanced extraction method has the advantages of safety, reliability, low cost, simplicity, feasibility, time conservation and force conservation; the influence range of effective pressure relief of single holes can be remarkably widened, and the extraction rate of the gas in the coal bed is increased by over 80 percent.

Owner:CHINA UNIV OF MINING & TECH

Explosion limit determining device and determining method

InactiveCN102937604AEasy to measureEfficient determinationMaterial exposibilityFlammability limitGas explosion

The invention relates to an explosion limit determining device and an explosion limit determining method. The explosion limit determining device comprises an ignition device, a pressure-resistant vessel, a gas inlet, a temperature measuring port, a pressure measuring port, a vent port, and an observation port. The ignition device is embedded in the pressure-resistant vessel. The pressure-resistant vessel is provided with a heating and temperature-maintaining system, the gas inlet, the temperature measuring port, the pressure measuring port, the vent port, and the observation port. With the explosion limit determining device provided by the invention, gas explosion limit under various process conditions can be conveniently, highly efficiently, and truly determined. The device and the method provided by the invention have a great significance in ensuring industrial production safe operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

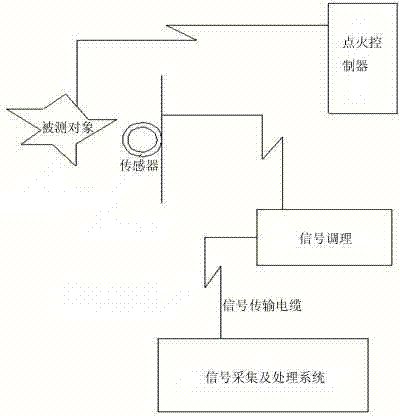

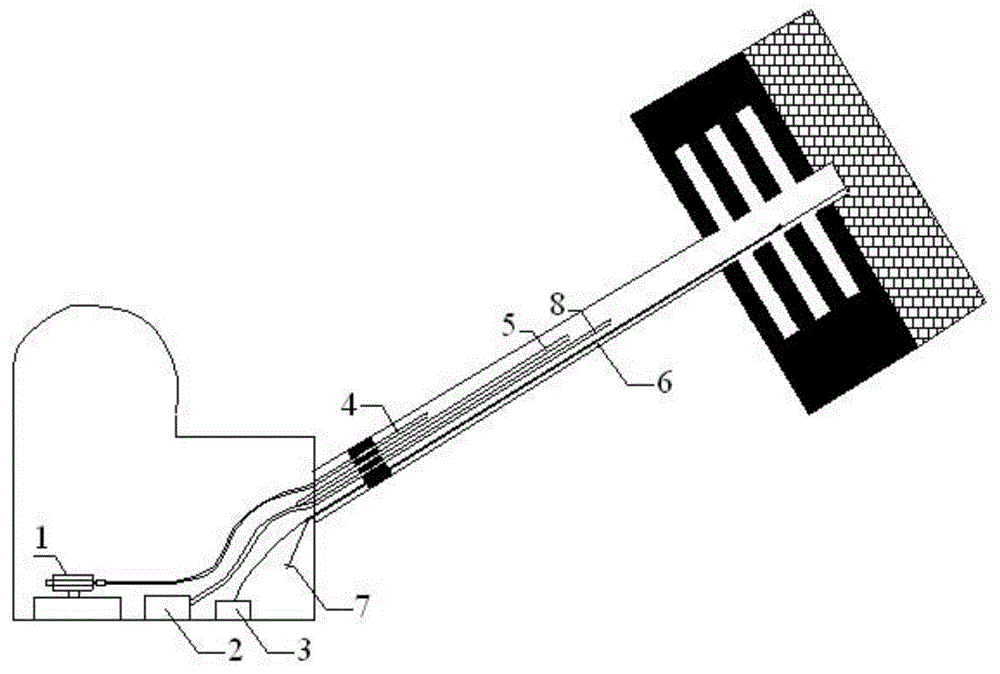

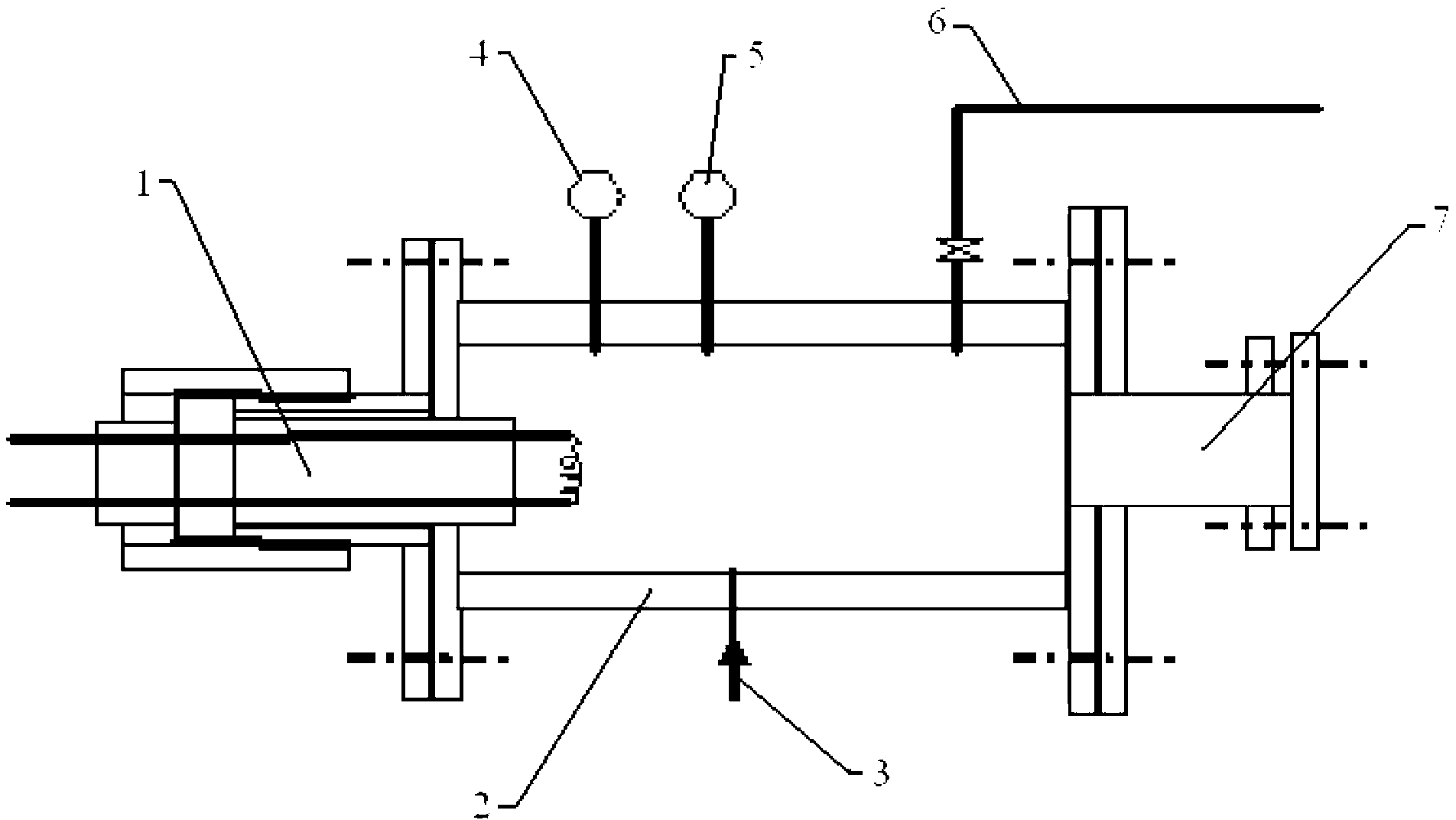

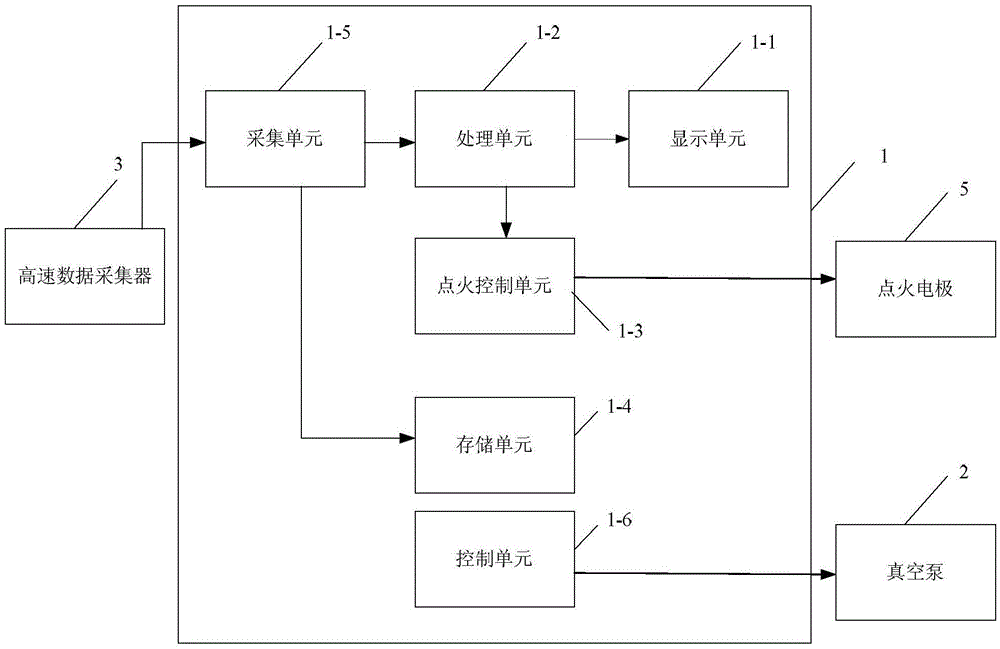

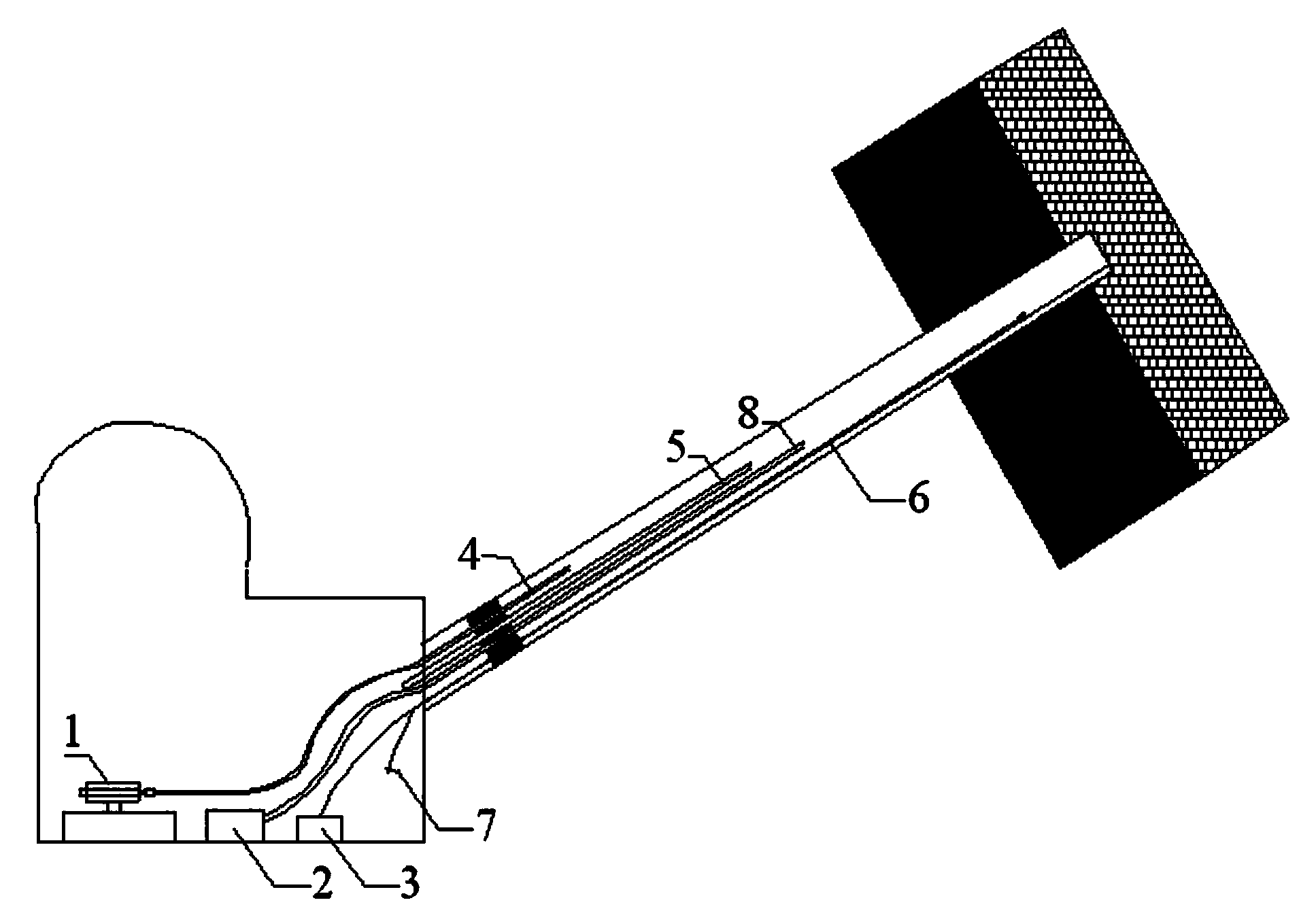

Experiment device and method for simulating gas-coal dust explosion in underworkings of coal mine

InactiveCN105548254ARich teaching effectGood demonstration simulation effectMaterial exposibilityHigh energyCoal mine methane

The invention relates to an experiment device and method for simulating gas-coal dust explosion in underworkings of a coal mine, and belongs to the technical field of safety engineering of the coal mine. Requirements on the experiment device and method for the gas-coal dust explosion in the underworkings of the coal mine are met. Gas-coal dust is poured into an explosion cavity, and when a pressure value in the explosion cavity is equal to that of outside atmospheric pressure, a high-energy ignition cabinet controls an ignition electrode on the explosion cavity to ignite, so that the explosion experiment of the gas-coal dust is realized, and exploded gas and the like are diffused through a gas explosion diffusion pipeline and gas explosion diffusion branches; pressure sensors and flame sensors are used for monitoring the pressure and the flame in the gas explosion diffusion pipeline during explosion in a real-time manner, and transmitting pressure data and flame data to a high-speed data acquisition unit, and the pressure data and the flame data are saved in an industrial computer. The experiment device and method disclosed by the invention are suitable for observing gas explosion of the coal mine.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

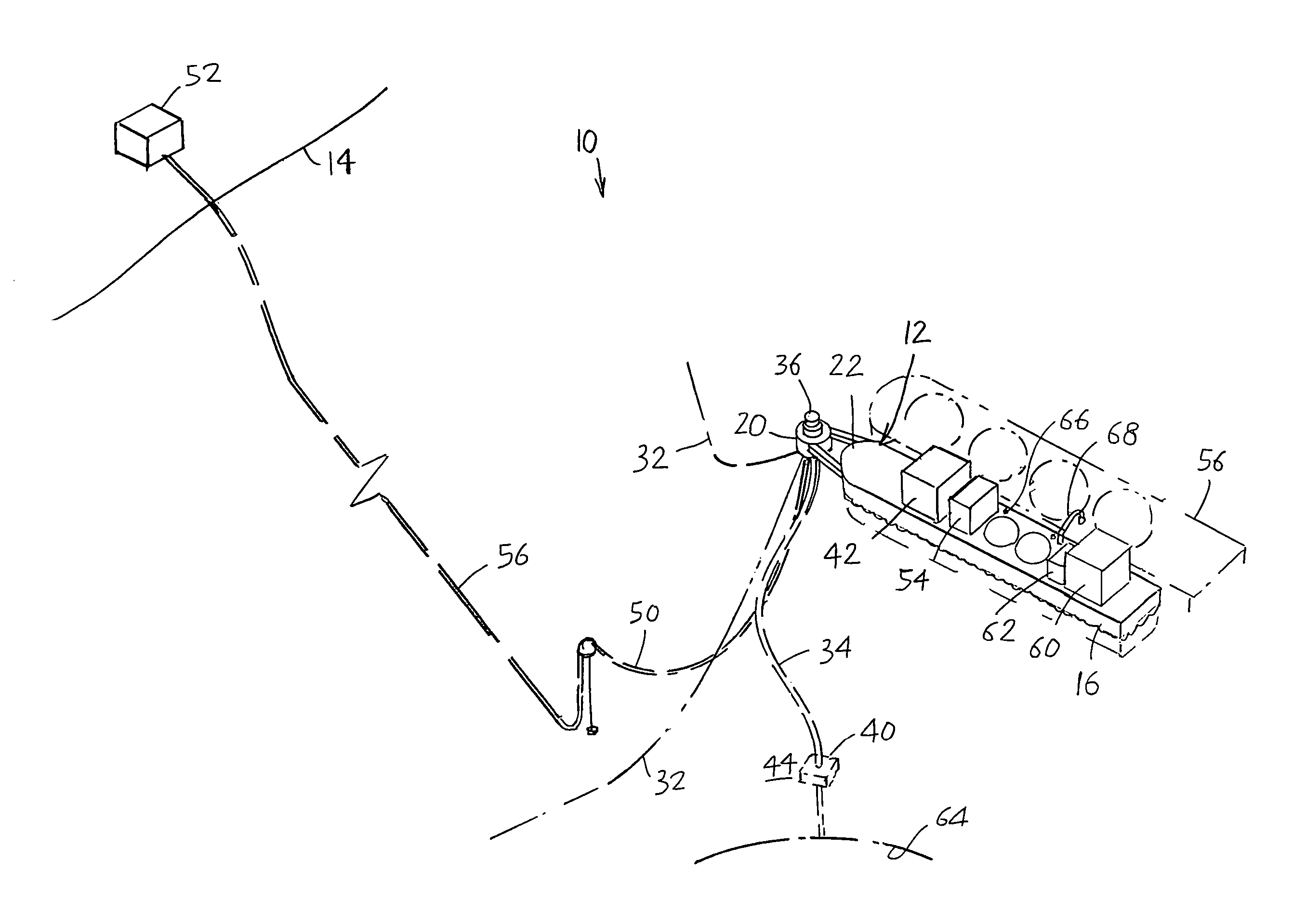

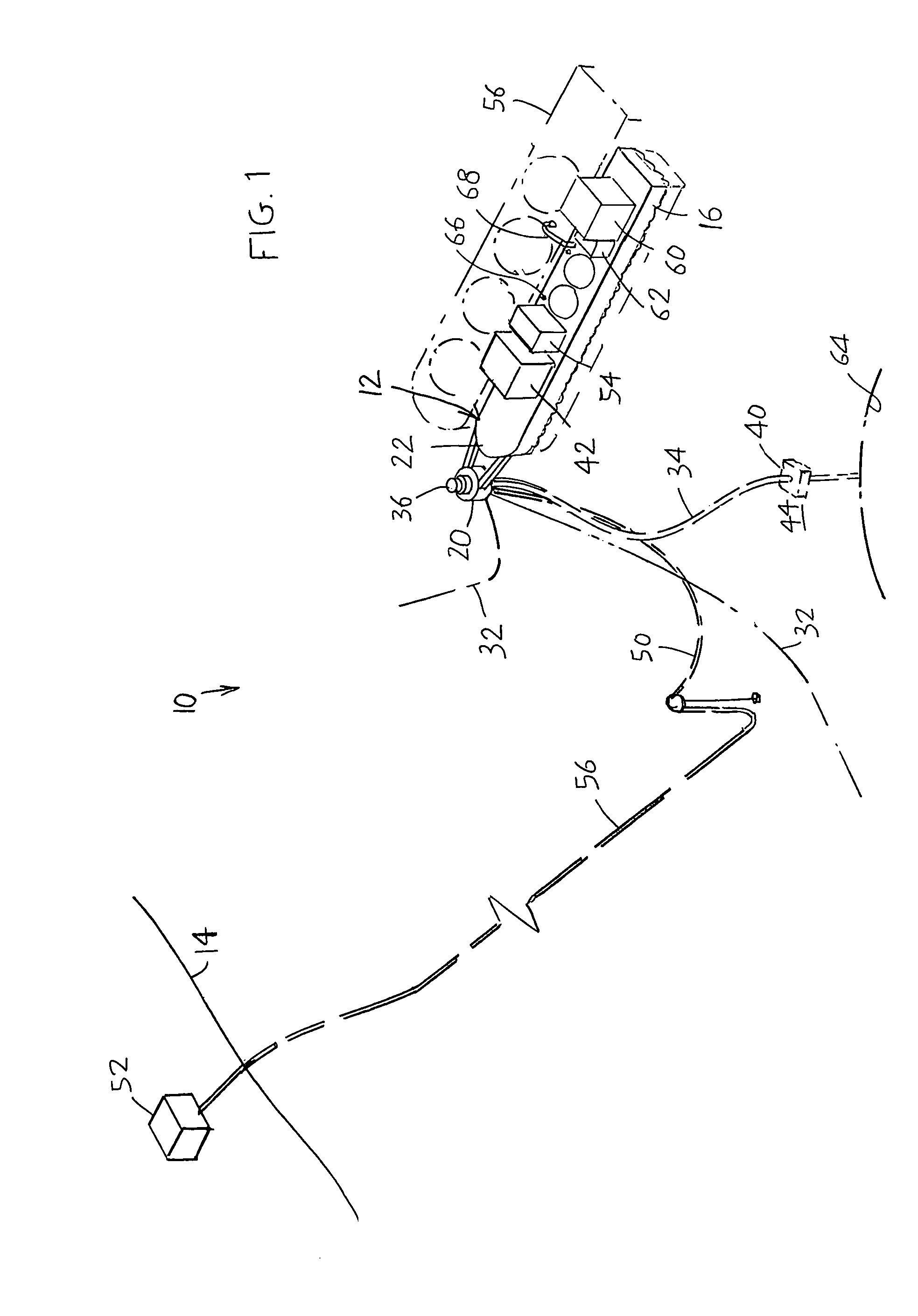

Floating power generation system

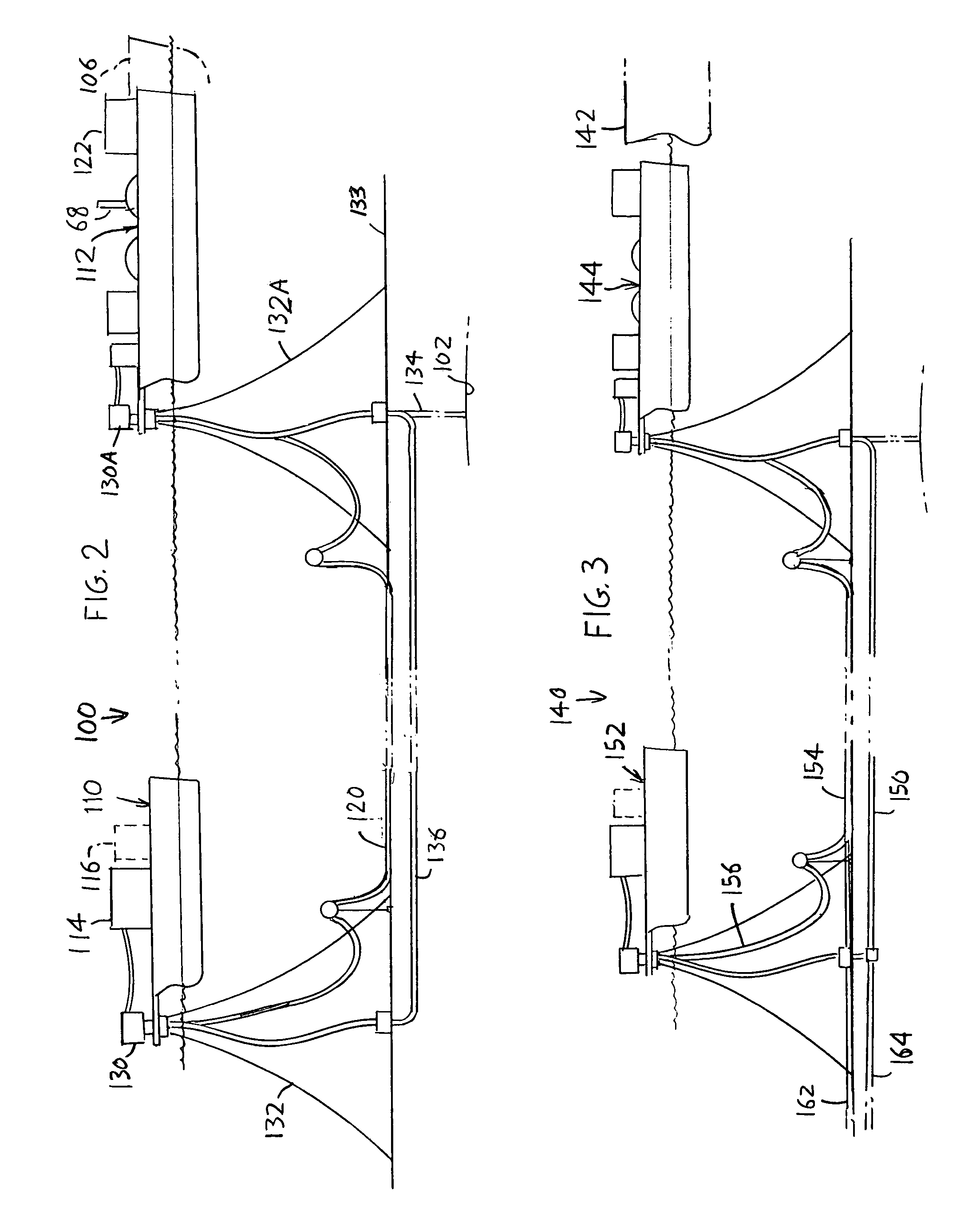

A system for using natural gas to safely provide large amounts (at least 30 megawatts) of electricity to consumers. The system includes a floating generating vessel (110) that lies offshore and carries one or more turbine-generator sets (114, 116) that use natural gas as fuel and whose electricity output is delivered though a power line (138) that extends at least partially in the sea to a consumer. One consumer is a process vessel (112) that processes natural gas and that has transfer facilities (68) that transfer liquified gas to or from a tanker (106) that holds over 10,000 tons of liquified gas. Some of the gas is transferred from the process vessel through a conduit (136) in the sea to the generating vessel (110) to provide fuel. Another consumer is an onshore facility (52). The generating and process vessels (110, 112) are widely separated (e.g. at least 0.2 kilometer) to protect personnel in the event of a gas explosion or fire. The separate generating and process vessels enable rapid acquisition of the vessels, which is especially useful to quickly supply large quantities of electricity in newly developed areas.

Owner:SINGLE BUOY MOORINGS INC

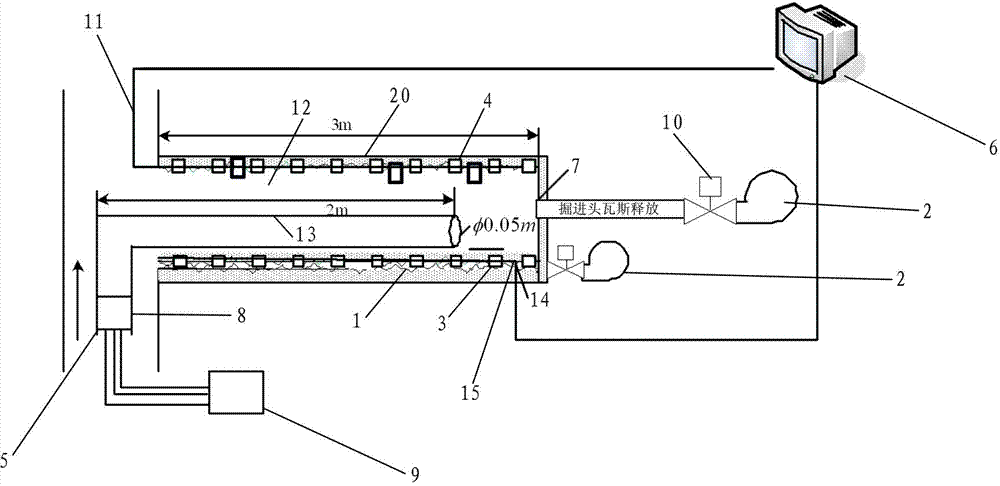

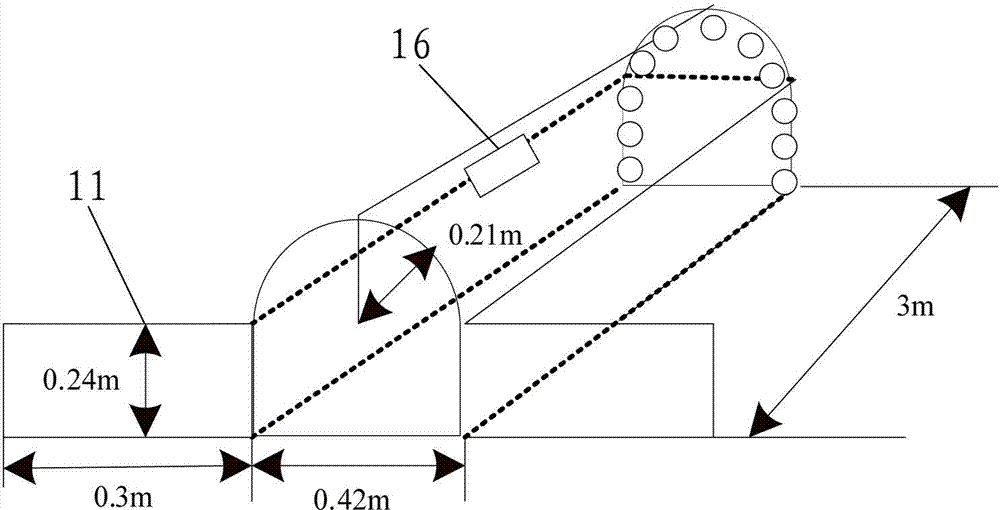

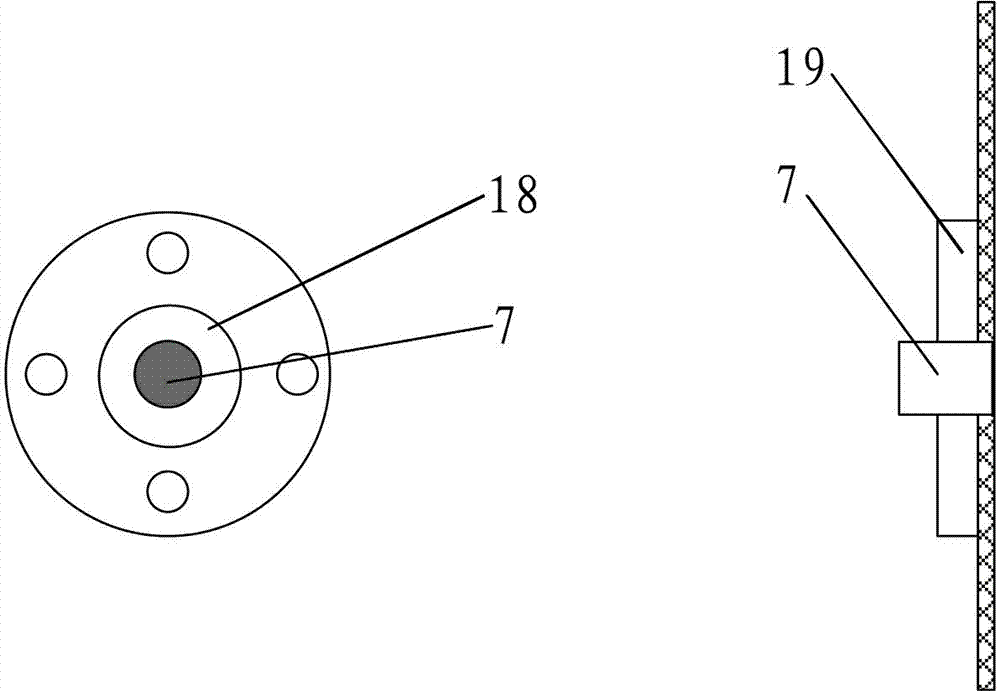

Method and experiment system for simulating tunneling gas migration rule of coal mine

InactiveCN102733843AIncrease authenticityImprove reliabilityGas removalQualitative analysisGas explosion

The invention relates to a method and an experiment system for simulating a tunneling gas migration rule of a coal mine, aiming at providing a theory basis for safely and fast discharging gas. The invention discloses the method and the experiment system for simulating tunneling gas migration rule, firstly the tunneling experiment system is built, and then gas migration rules under turbulent jet action can be deeply explored by using orientated and quantitative methods under semi-closed condition, wherein the qualitative method is of non-contact measurement, qualitative analysis is conducted on the basis of not interfering flow field running characteristic, and the analysis result can be used as a basis of sensor arrangement in quantitative experiments. The quantitative method comprises the steps of arranging various sensors through multifunctional operation holes on a tunnel model, and exploring the tunneling gas migration rules through data analysis. The method and the experiment system can provide theory and data bases for fan control strategy under the normal ventilation and gas emission condition of tunnels, and also can provide guidance for preventing the gas explosion accidents in the tunnels.

Owner:BEIJING UNION UNIVERSITY

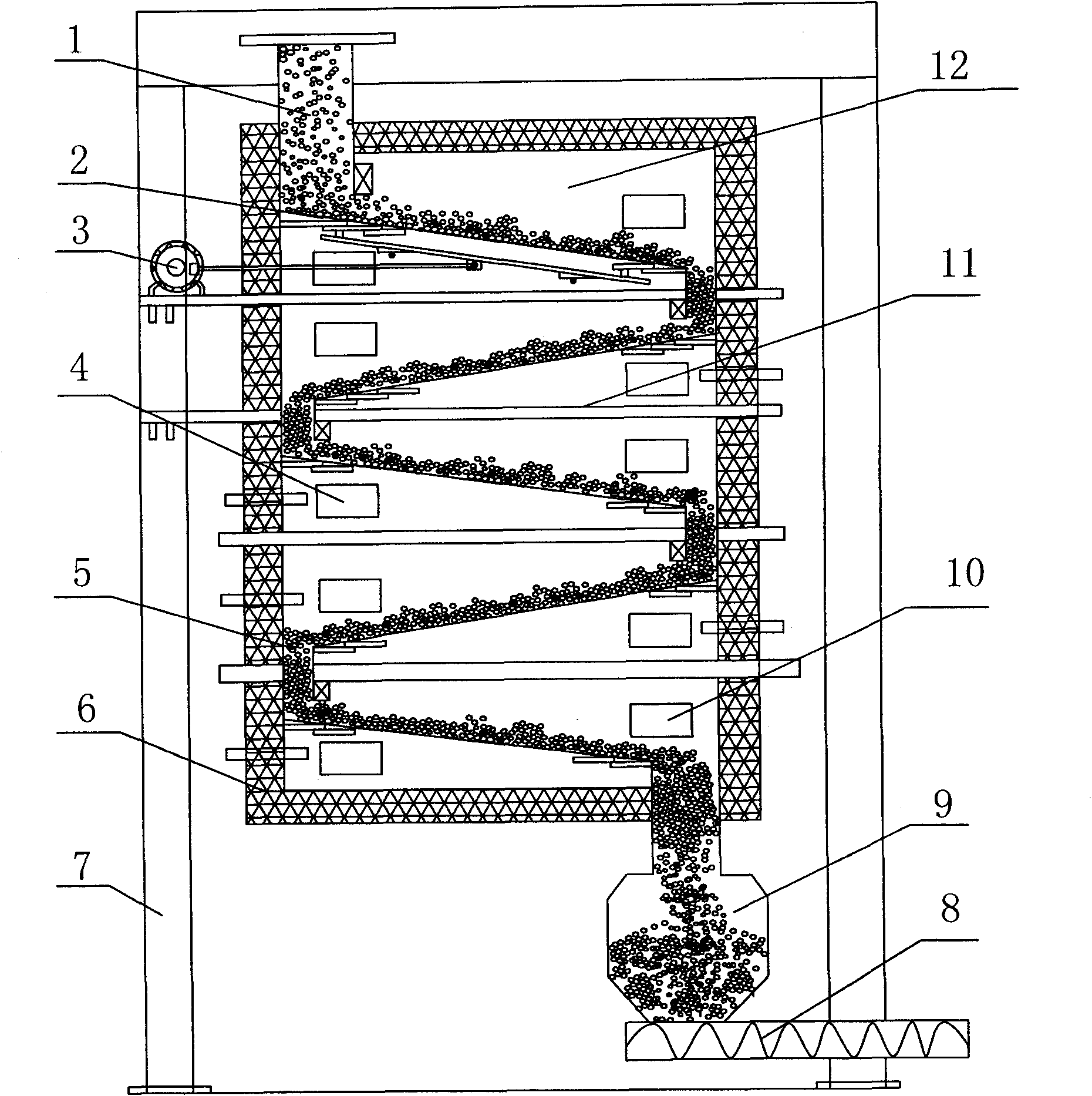

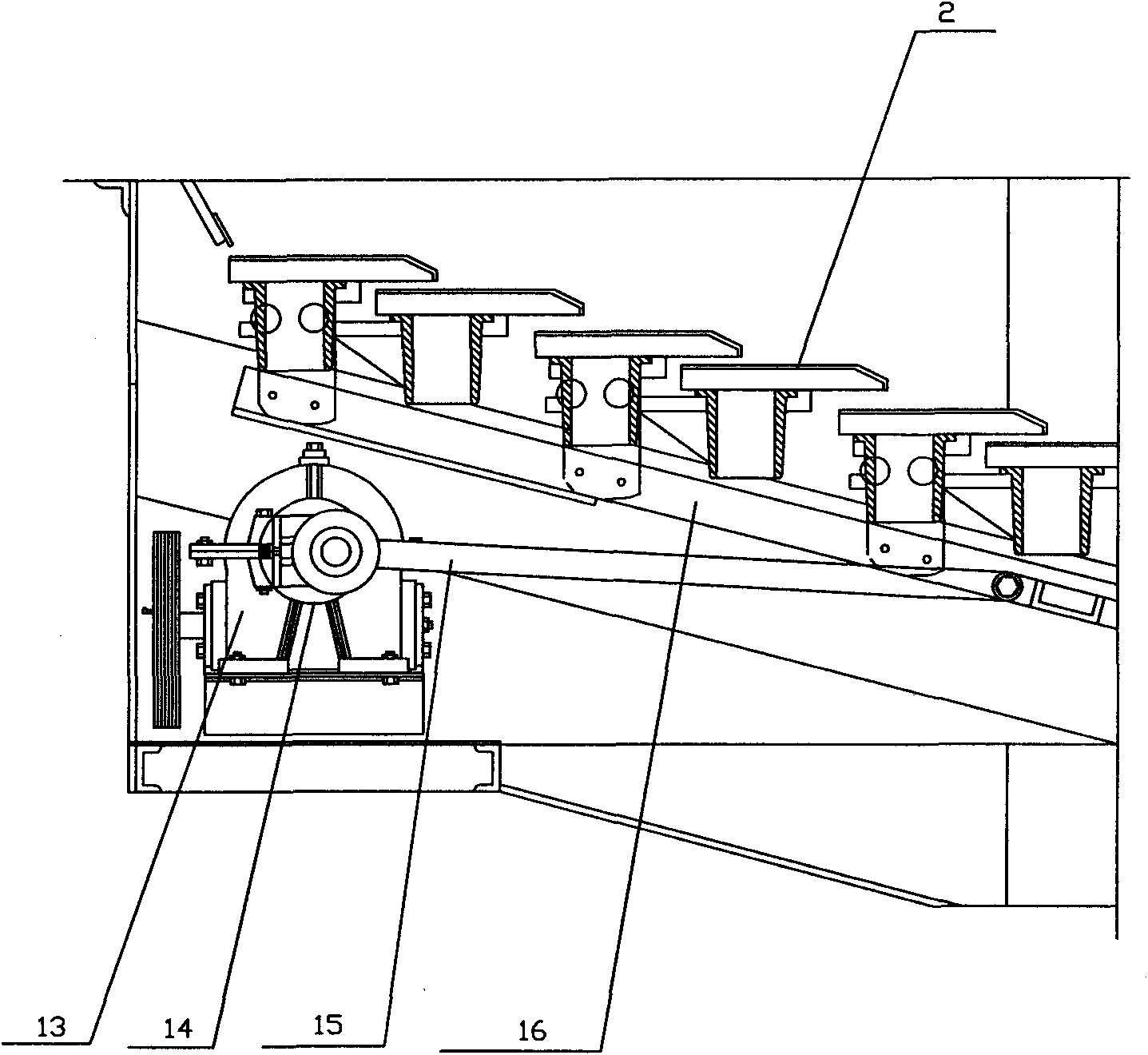

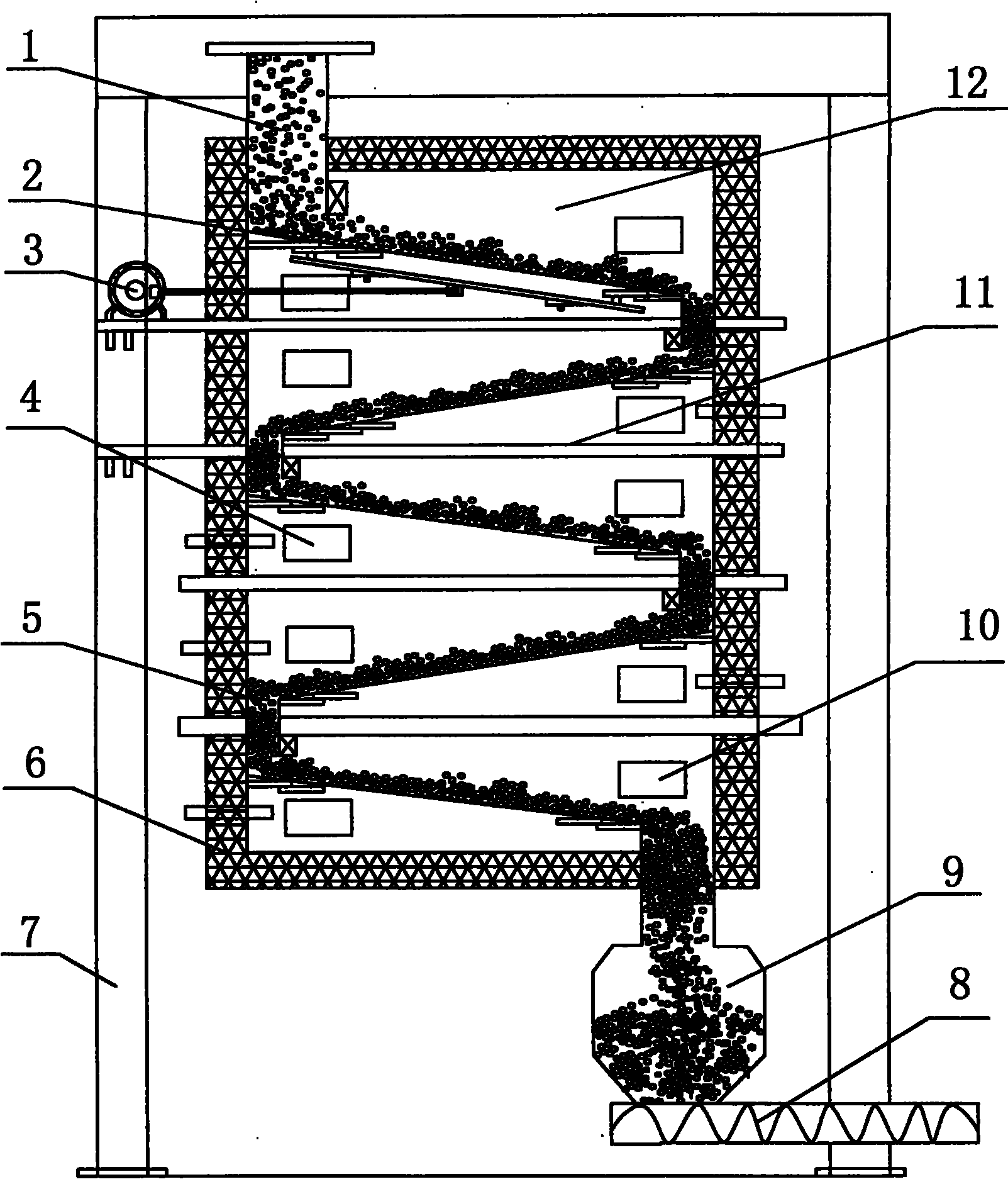

Lignite drying and carbonization quality-improving tower with reciprocating and turning-back rolling bed

InactiveCN101845312AReduce drying speedPrevent burstGearingSpecial form destructive distillationDesiccantCarbonization

The invention relates to a lignite drying and carbonization quality-improving device, in particular to a lignite drying and carbonization quality-improving tower with a reciprocating and turning-back rolling bed. In the quality-improving tower, a drying and carbonization reaction chamber is surrounded by a furnace lining; the top of the reaction chamber is provided with a coal conduit, and the inside of the reaction chamber is divided into multiple layers of drying chambers and multiple layers of carbonization chambers from top to bottom; each drying chamber and each carbonization chamber areprovided with an air inlet and an air outlet for introducing and discharging drier or carbonization agent; and each inclined reciprocating grate is installed in each drying chamber and each carbonization chamber, the inclination directions of the reciprocating grates form staggered arrangement from top to bottom, each reciprocating grate is provided with an eccentric drive device, an interlay barrier below the tail part of each reciprocating grate is provided with an interlayer coal seal, a coke quenching tank is connected to the lower part of the interlay coal seal of the carbonization chamber at the bottom layer, and a coal discharging screw conveyer is arranged at the bottom part of the coke quenching tank. The invention solves the problems of raised dust and gas explosion, poor coal layer air permeability, low gas-solid heat transfer efficiency, raw coal burst, nonuniform coal layer temperature and poor regulation and control maneuverability for different sections existing in the traditional lignite drying and carbonization device.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

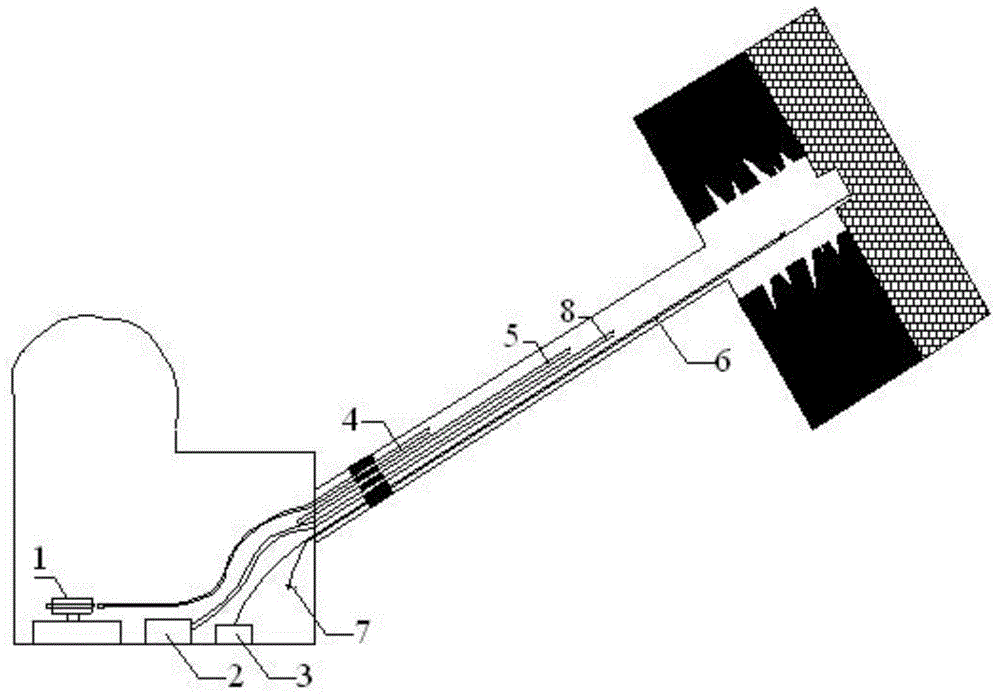

In-borehole gas explosion coal body cracking forced extraction method

The invention discloses an in-borehole gas explosion coal body cracking forced extraction method, and is applied to the efficient extraction of underground gas of a coal mine. An air pump is used for pressing air into a sealed borehole, the air and gas gushed from the borehole are premixed to form mixed gas at concentration of 9 to 10 percent, and the mixed gas is detonated by virtue of an ignition device to form explosion waves to crack a coal body to construct a fracture network; meanwhile, by thermal effects achieved by explosion, the adsorption potential of the gas can be remarkably lowered, and the desorption and the flowing of the gas can be promoted, so that the aim of forced gas extraction of a high-gas low-air-permeability coal seam is fulfilled. The method is low in cost, simple, easy, time-saving and labor-saving; the effective pressure relief influence scope of a single hole can be remarkably widened, and the gas extraction efficiency of the coal seam can be improved by over 40 percent.

Owner:CHINA UNIV OF MINING & TECH

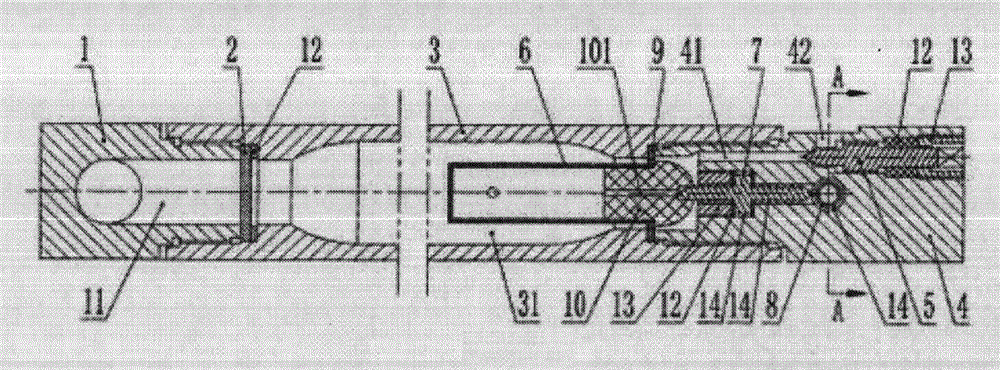

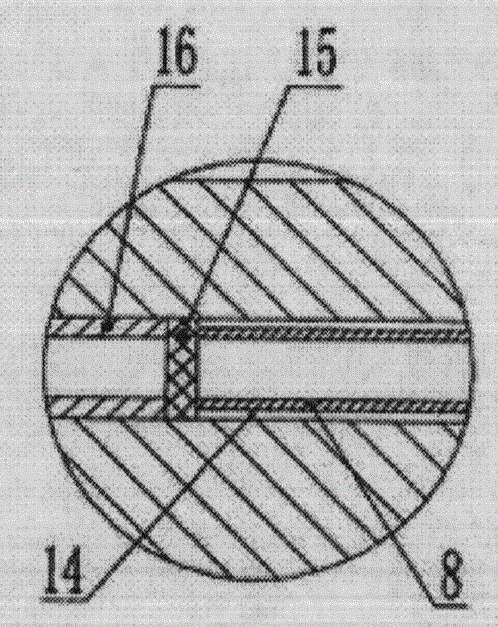

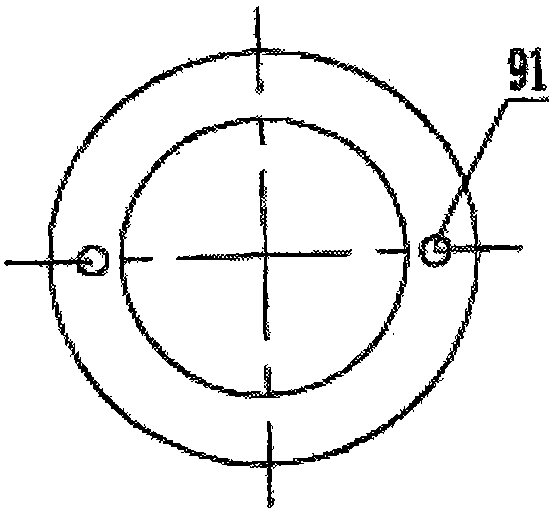

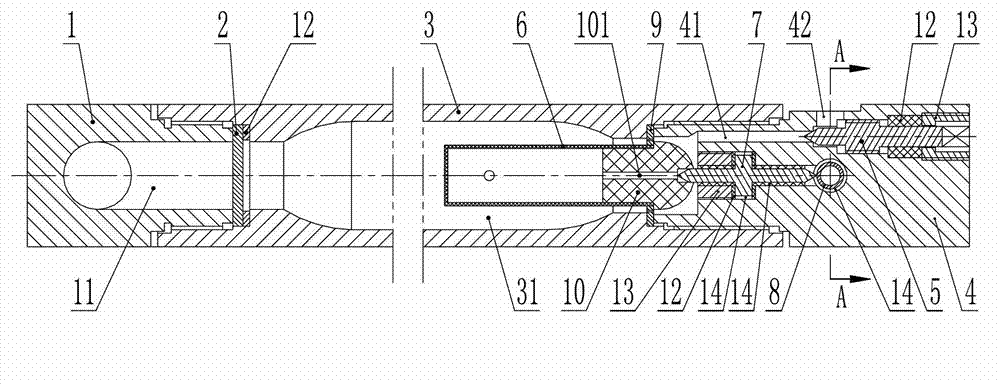

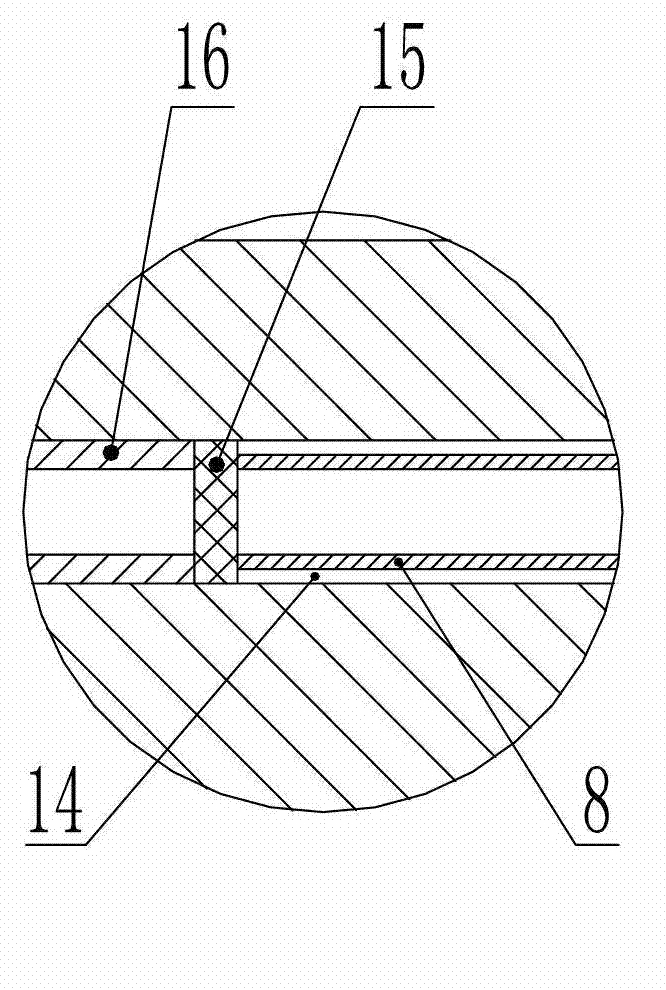

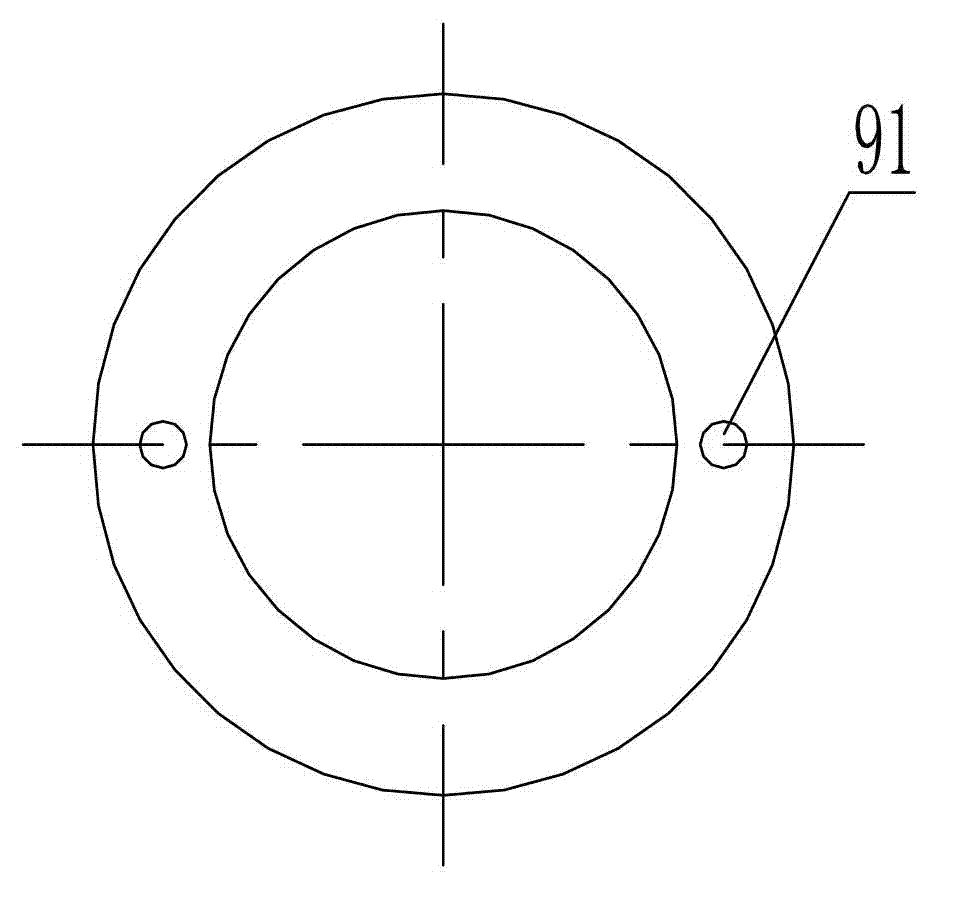

Static pressure, static pressure bearing used for high speed precision machine tool principal axis

InactiveCN101109409AIngenious designImprove performanceBearingsMaintainance and safety accessoriesCavitationEngineering

The invention relates to a hydrostatic and hydro-dynamic / -static bearing on a hi-speed precision spindle, which comprises a spindle (1), and a bearing (2). On the surface of the bearing (2) opposite to the spindle (1), a plurality of hydrostatic oil cavities (12) are arranged, each is connected with the pipeline of each lubricating point (3) through the throttle of the bearing (11); the pipeline of each lubricating point (3) is connected with the oil-air fluid lubricant supply system through a general pipeline (4) of the bearing. The lubrication way in the invention is different from mist lubrication and oil-air lubrication, is the so-called ''sub-oil-air lubrication''. The invention can avoid any cavitation and gas explosion in the bearing, and give full play to the advantage of oil-air lubrication. With the invention, novel bearings with high speed, rigidity and long service life can be developed, the application field of hydrostatic, hydro-dynamic / -static slide bearing can be further expanded, and a new form of oil-air compound lubricated hydrostatic, hydro-dynamic / -static bearing can be explored in between the prior ordinary gas lubricated and fluid lubricated bearings.

Owner:GUANGDONG UNIV OF TECH

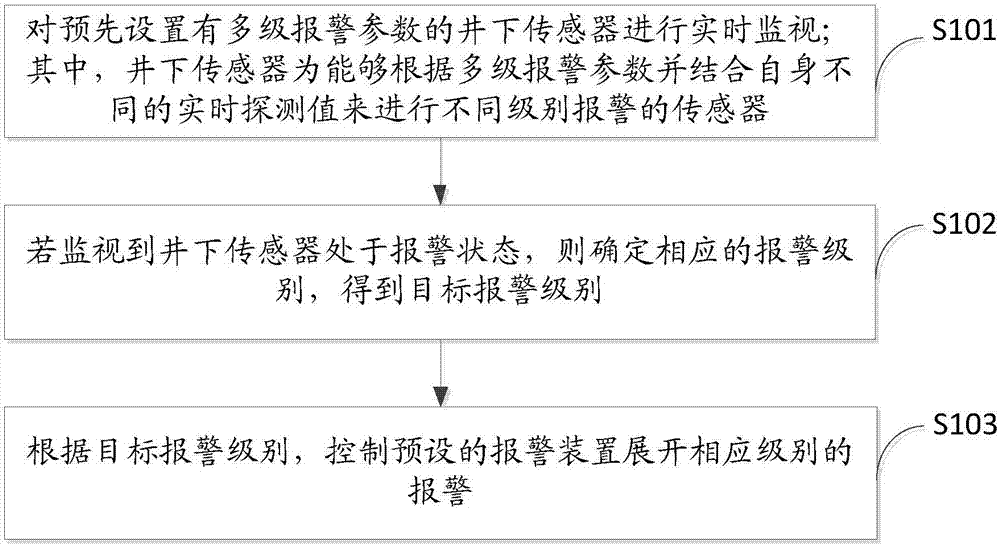

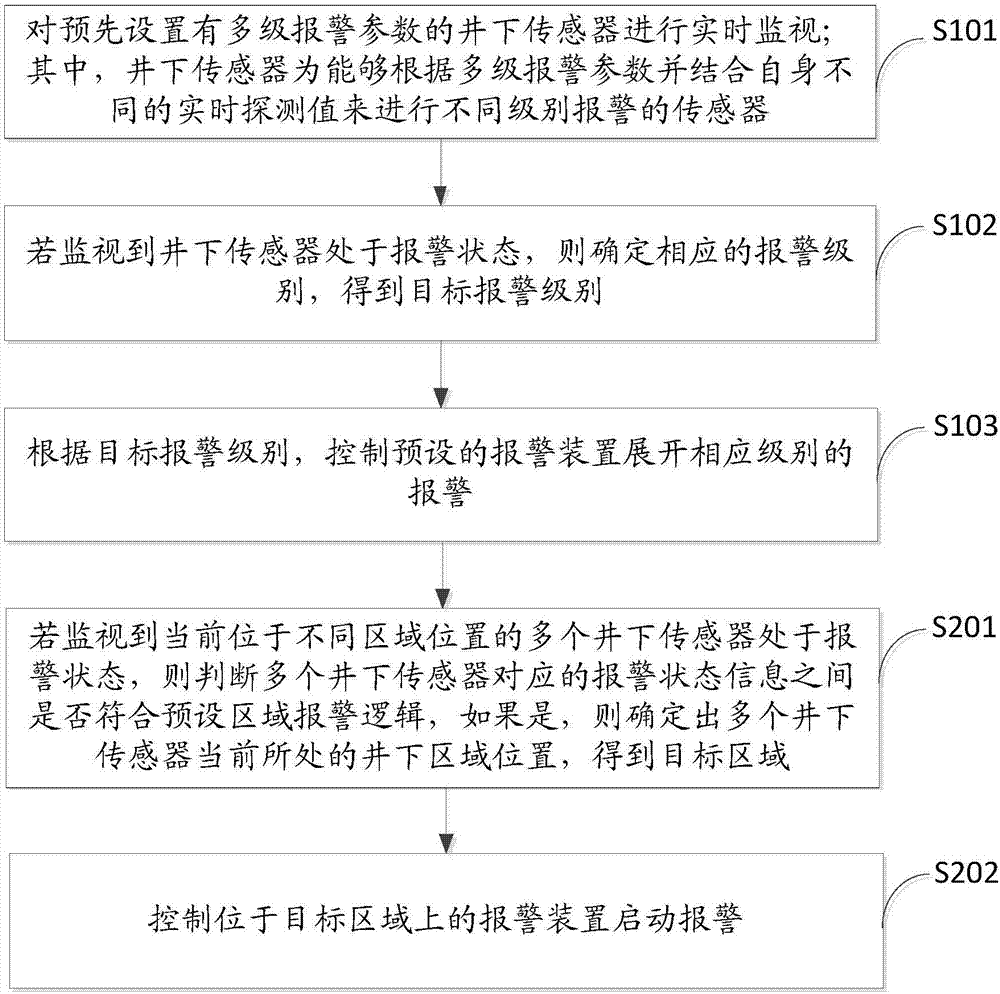

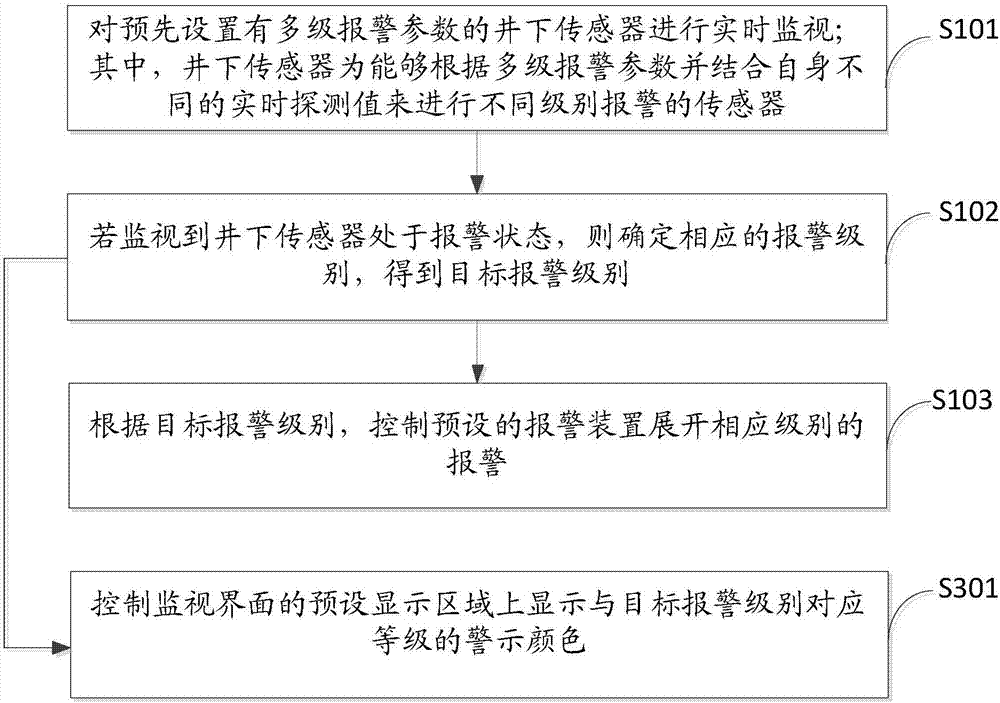

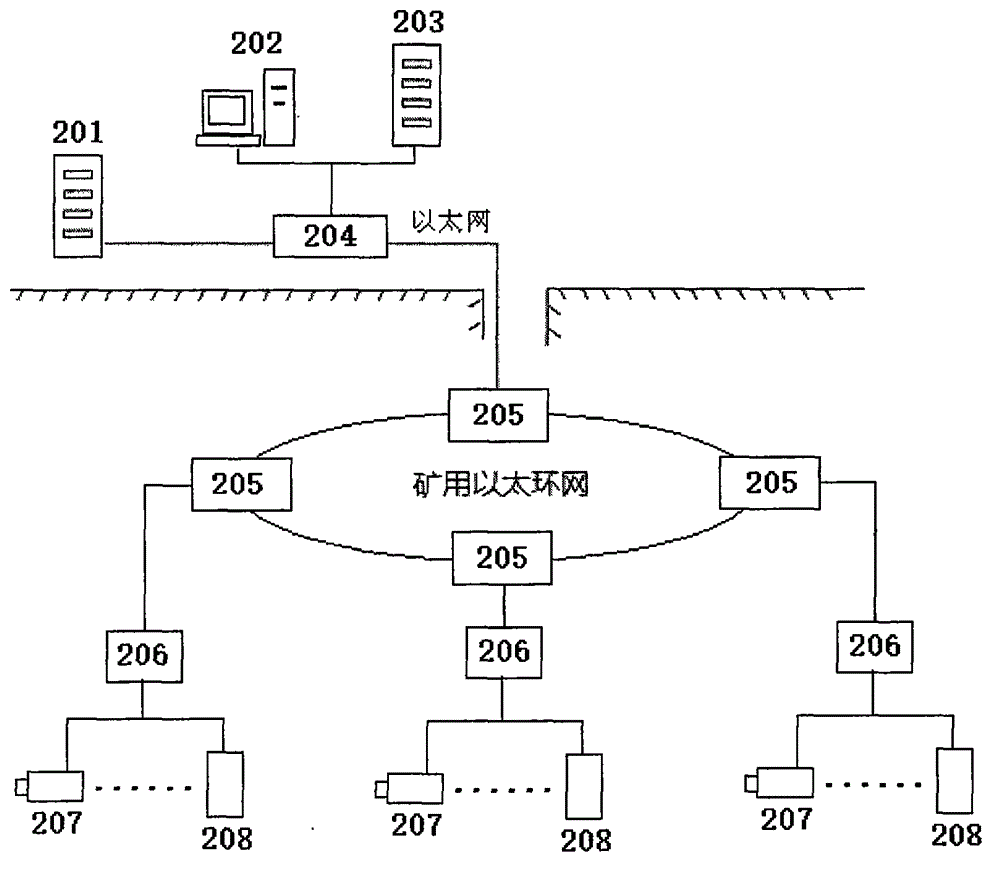

Underground classified alarm method, apparatus and system

InactiveCN107038847APrevent overrunningAvoid safety hazardsMining devicesAlarmsAlarm stateEngineering

The application discloses an underground classified alarm method, apparatus and system. The method comprises: an underground sensor with a preset multi-level alarm parameter is monitored in real time, wherein the underground sensor is one capable of carrying out alarming with different levels according to the multi-level alarm parameter and different real-time detection values of the sensor; if the underground sensor is monitored to be in an alarm state, a corresponding alarm level is determined to obtain a target alarm level; and according to the target alarm level, a preset alarm device is controlled to carry out alarming with a corresponding level. According to the method disclosed by the invention, alarming with different levels can be carried out, so that the potential safety hazard can be eliminated timely; a phenomenon of limit exceeding of underground gas of the mine can be avoided and thus occurrence of disaster events like mine gas explosion can be reduced, so that a safety warning effect can be realized.

Owner:TIANDI CHANGZHOU AUTOMATION +1

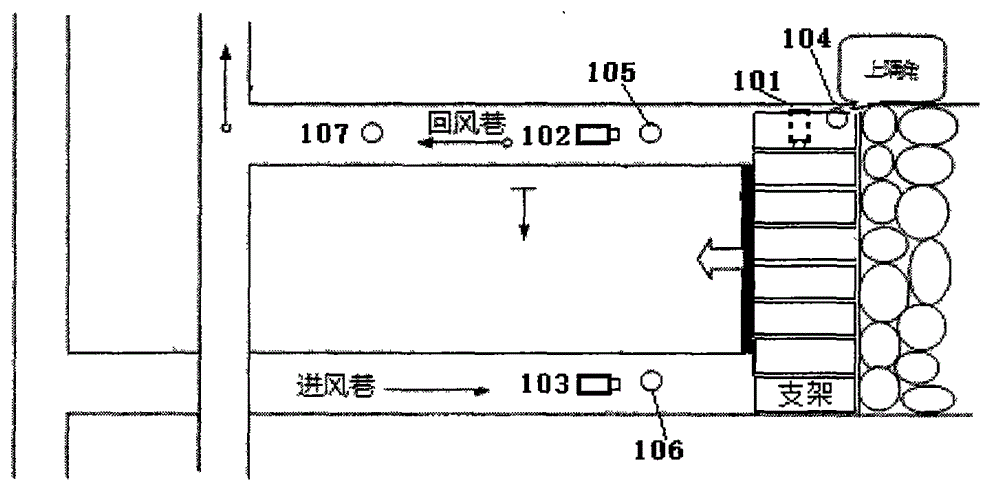

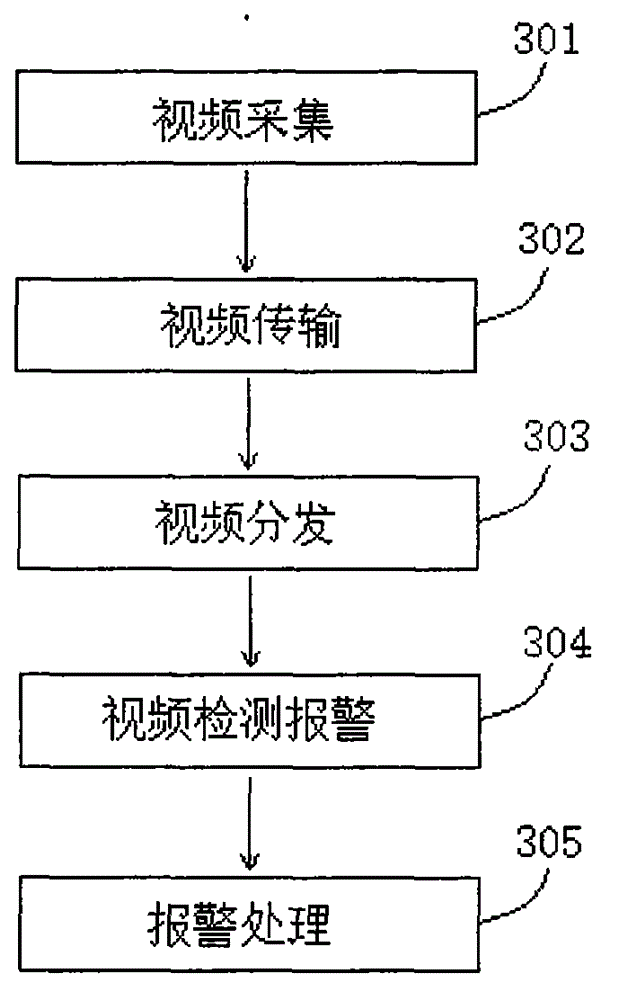

Coal face rock burst alarming method based on images

The invention discloses a coal face rock burst alarming method based on images. According to the alarming method, cameras are installed at the positions nearby related areas of a coal face, the video image data change and the device working situation are analyzed in real time, the abnormal data change in the monitored area is found, and if the combination situation of information abnormity conforms to the alarming condition, a rock burst alarm signal is given out. According to the alarming method, various features of coal mine coal face rock burst are fully taken into consideration, implementation is easy, the rock burst of the coal face can be accurately judged, the rescue efficiency can be effectively improved, managers can take corresponding measures in time, gas explosion and other serious accidents caused by roadway blocking and gas accumulation are avoided, and casualties are avoided or reduced.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

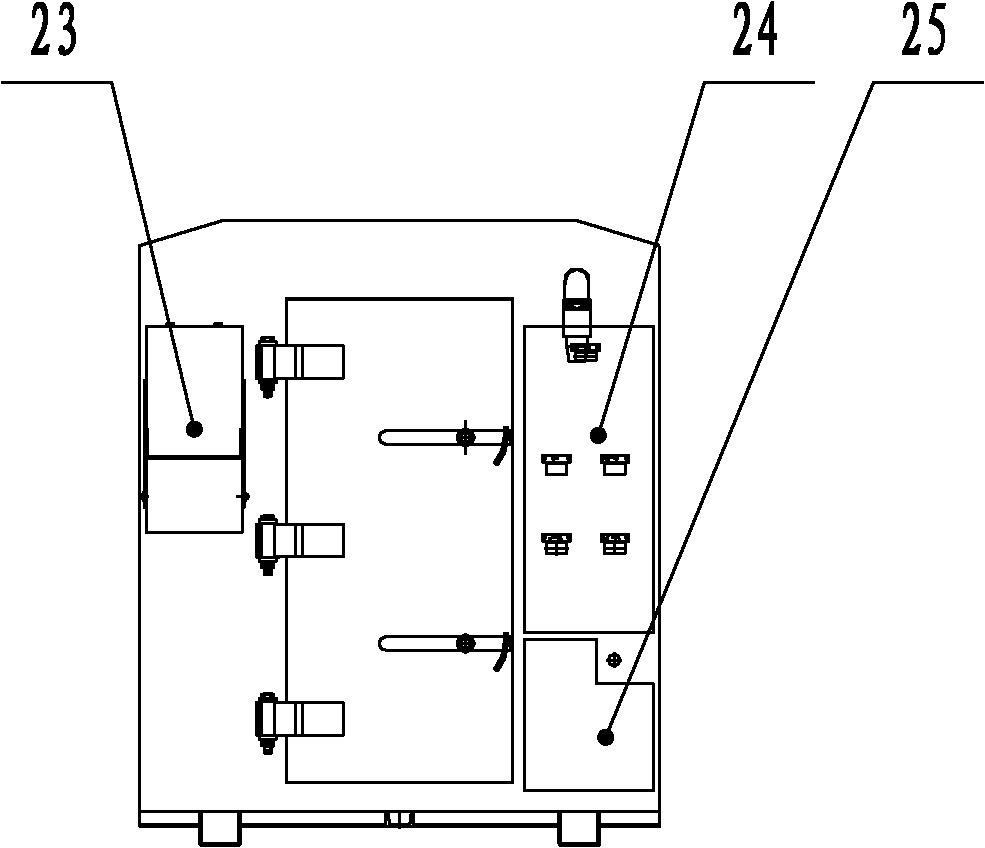

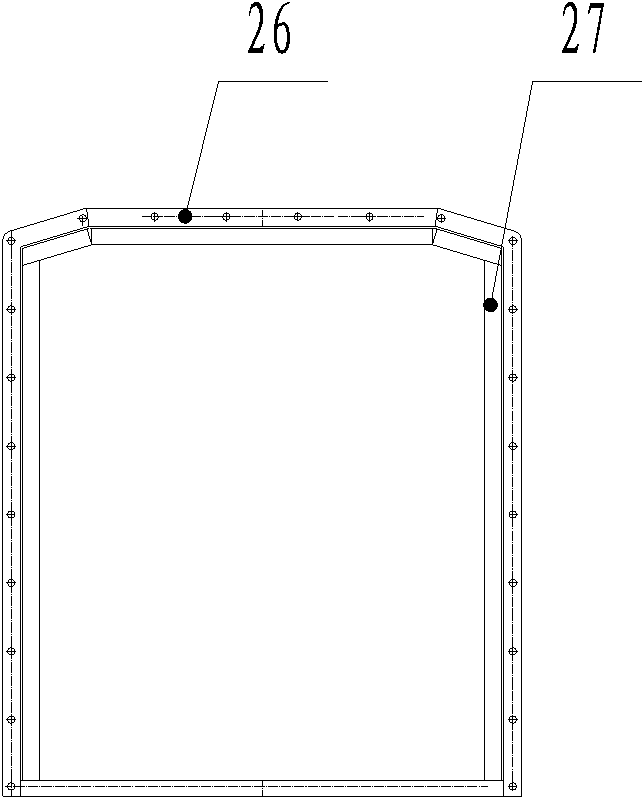

Movable split-type refuge chamber

InactiveCN102003206AAnti-collapseWith heating, drying and humidity adjustmentSafety equipmentsFood storageEngineering

The invention relates to a movable split-type refuge chamber, belonging to the technical field of life saving apparatus. The movable split-type refuge chamber is characterized by comprising a transfer chamber, a main chamber and an auxiliary chamber; the movable transfer chamber and the main chamber which are combined by sealing joints and the movable auxiliary chamber and the main chamber which are combined by sealing joints form the refuge chamber; a transfer chamber body is provided with a front chamber door, the main chamber body is provided with a side chamber door, and the auxiliary chamber is provided with a life saving chamber door; and the refuge chamber is provided with an environment monitoring device, a power supply, a communication telephone, an oxygen gas steel cylinder and / or a food storage device. The movable split-type refuge chamber has the advantages of collapse resistance, gas explosion resistance, sealing of the influx of underground noxious gas, adjustment of temperature and humidity, automatic oxygen supply, free arrangement and combination, favorable air tightness and heat insulation effect, simpleness of installation, convenience and flexibility, investment saving, and ability to provide a set of complete life assurance system for escaping persons on site, and the like.

Owner:天津市天矿电器设备有限公司

Enhanced extraction method for fracturing coal body by multistage gas explosion in drill hole

ActiveCN104314605ALower adsorption potentialFacilitate desorptionFluid removalGas removalSingle holeGas explosion

The invention discloses an enhanced extraction method for fracturing a coal body by multistage gas explosion in a drill hole. The enhanced extraction method is suitable for high-efficiency extraction of underground gas of a coal mine. Air is pressed in a sealed drill hole by using an air pump; the air and gas gushed from the drill hole form gas mixed gas with the concentration of 9-10 percent; the mixed gas is detonated by an ignition device to form an explosive shock wave for fracturing the coal body around the drill hole; the later-stage explosion is realized on the basis of the previous-stage explosion, so that cracks of the coal body around the drill hole are further expanded; besides, the shock wave compress the coal body to form a greater explosion space, and the power of explosion is enhanced. By multistage explosion, a fracture network in the coal body can be fully constructed; besides, the adsorption potential of gas can be remarkably reduced and the desorption and the flowing of the gas are promoted by the heat effect generated by explosion, so that the aim of enhancing the gas extraction of a coal bed with high-concentration gas and low permeability is achieved. The enhanced extraction method has the advantages of low cost, simplicity, feasibility, time conservation and force conservation; the influence range of effective pressure relief of single holes can be remarkably widened, and the extraction rate of the gas in the coal bed is increased by over 60 percent.

Owner:CHINA UNIV OF MINING & TECH

A raw material pretreatment method for improving the dissolution rate of active ingredients of medicinal plants

InactiveCN102274246AImprove dissolution efficiencyFast preprocessingPlant ingredientsPretreatment methodWater vapor

The invention discloses a raw material gas explosion pretreatment method for improving the dissolution rate of active ingredients of medicinal plants. The method comprises the following steps of: putting materials preimpregnated in water or aqueous solution into a high-pressure container, sealing, introducing a medium, keeping the temperature between 40 and 250 DEG C for 0.5 to 30 minutes, releasing pressure quickly, and discharging the materials in the high-pressure container to a normal-pressure container to obtain materials which are subjected to gas explosion pretreatment, wherein the medium is one or a combination of two of air, carbon dioxide, ozone, liquid nitrogen, nitrogen, water vapor and supercritical CO2. On the basis of the bioactivity of the active ingredients of the medicinal plants, various medium combination gas explosion modes in the low-temperature and high-pressure state are adopted selectively to ensure the treatment strength of the materials, and the dissolution rate of the active ingredients is improved on the premise that the active ingredients are not damaged to improve the utilization rate of raw materials; and the method is quick, simple, economic, high in adaptation degree and wide in selective range, and pollution is avoided, so the method is a significant path for realizing high-value utilization of the medicinal plants.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for pre-treating chitin raw material

The invention discloses a method for pre-treating a chitin raw material, which is characterized by comprising the following steps: 1), filling the chitin raw material in a gas explosion expansion tank and injecting a gas explosion expansion medium which may be vapor, water, aqueous ammonia or ethanol; and 2), relieving the pressure in the gas explosion expansion tank instantaneously and spraying the chitin raw material into a normal pressure container to obtain a chitin concentrate. Compared with the prior art, the method has the advantages of: 1), loosening the compact crystal structure of the chitin and increasing the exposure of active groups; 2), increasing the activity of chemical reaction to smoothly perform a main chemical reaction and increase the reaction speed; and 3), performing the main chemical reaction at a low temperature, inhibiting side reactions and improving product yield.

Owner:汪昔奇 +1

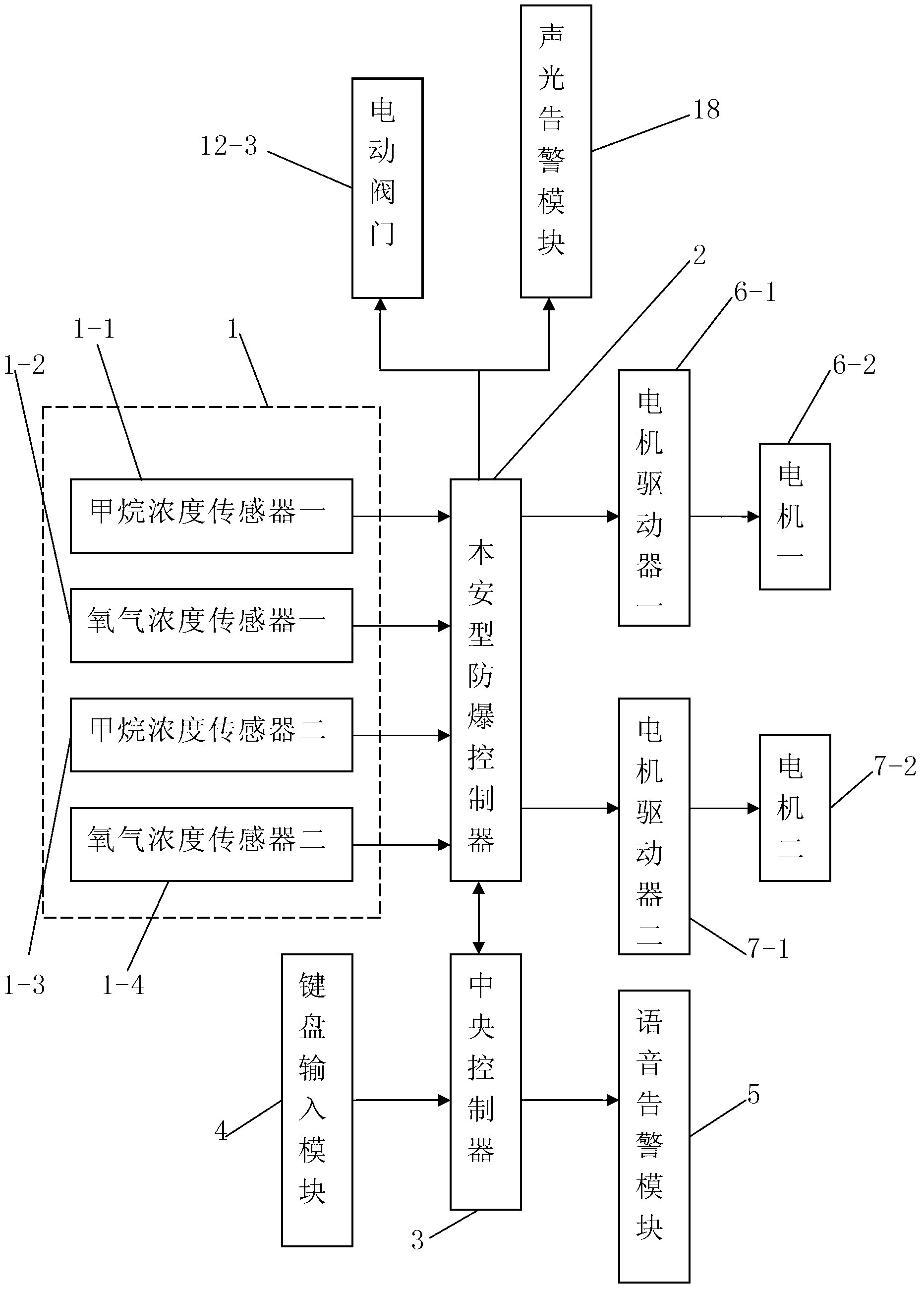

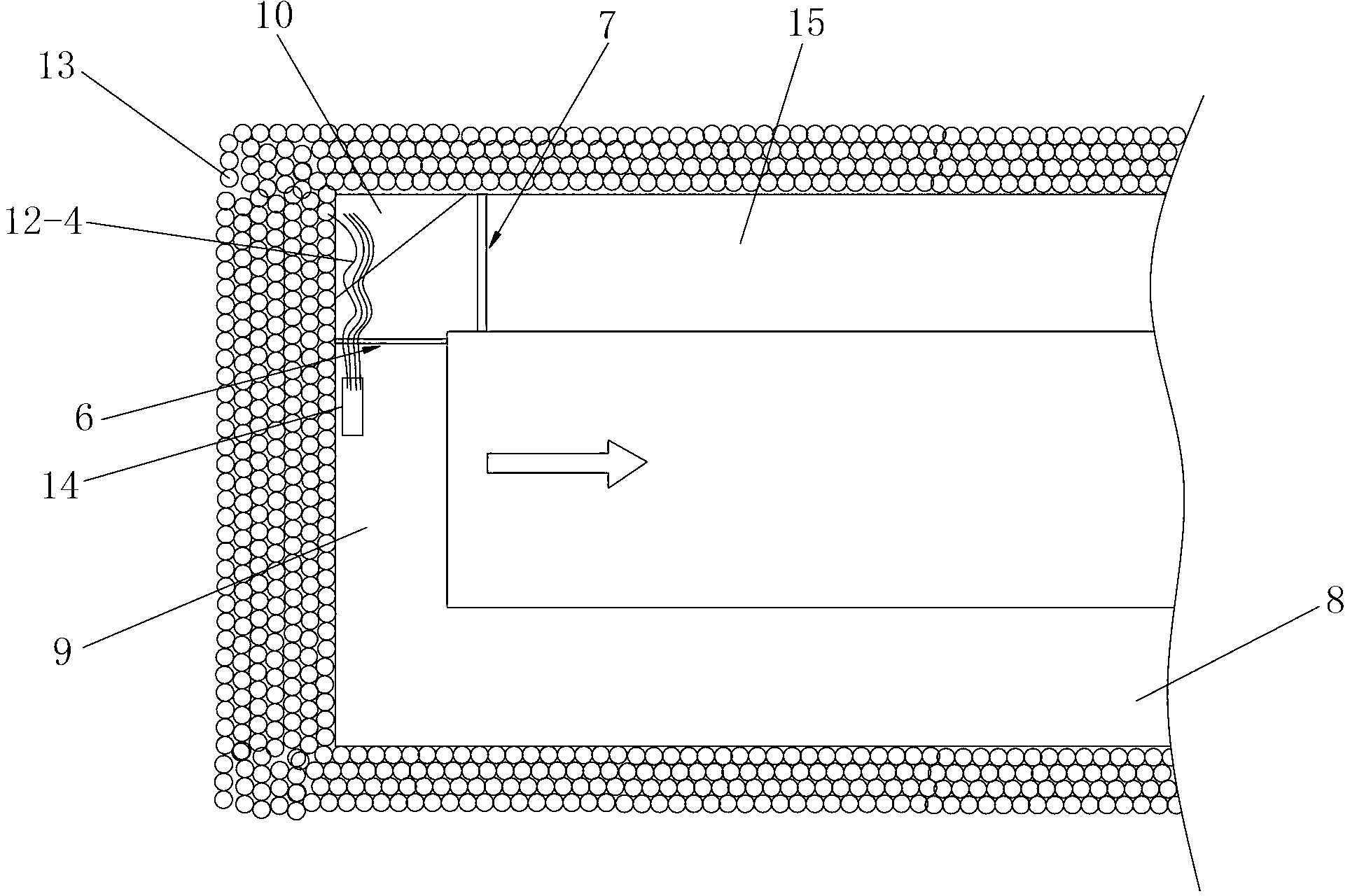

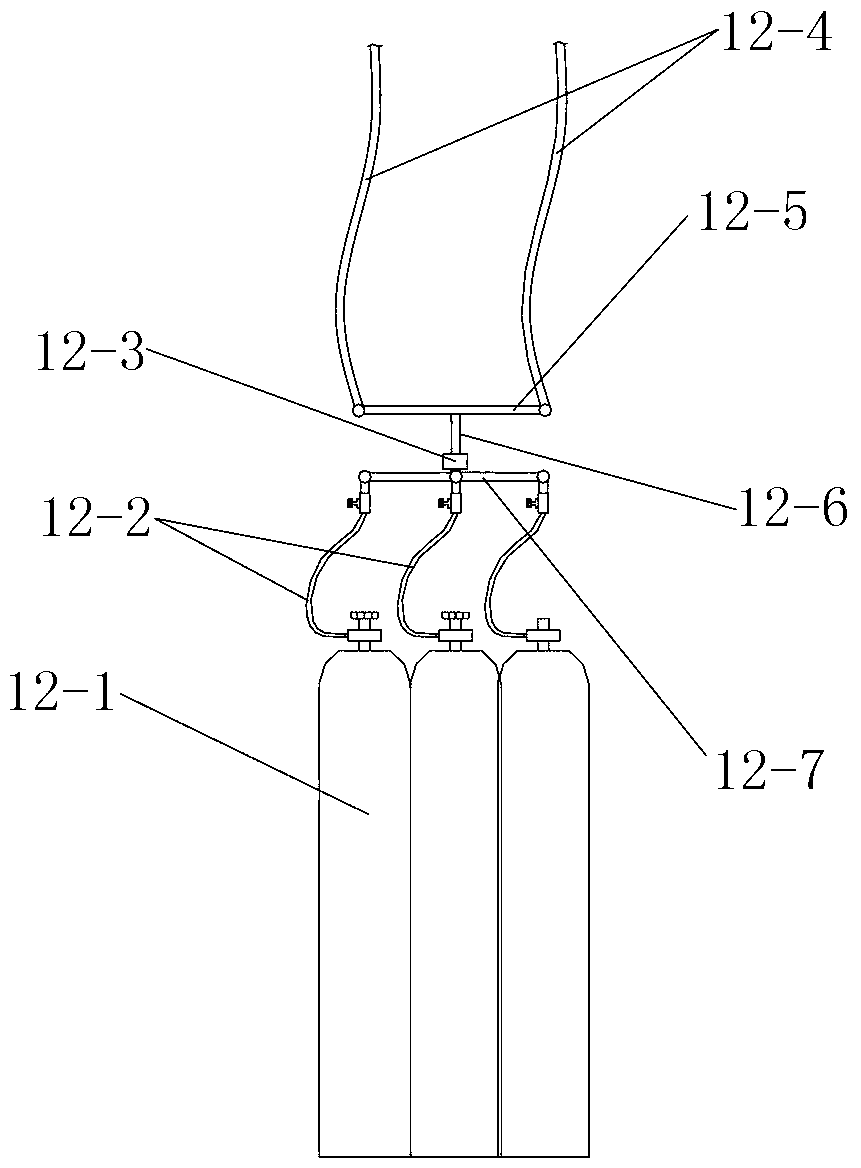

Gas explosion suppression system and method for coal mine

ActiveCN103075176AEliminate explosion hazardGood effectDust removalFire preventionIntrinsic safetyElectricity

The invention discloses a gas explosion suppression system and method for a coal mine. The system comprises a gas detection module for detecting concentrations of methane and oxygen at the corner of a coal mining working face and an intrinsic safety type anti-explosion control valve electrically connected with the gas detection module. The intrinsic safety type anti-explosion control valve is electrically connected with an inert gas releasing device for releasing inert gases to the corner of the coal mining working face so as to dilute concentrations of methane and oxygen as well as a wind shielding device I for preventing oxygen in an air way from entering into the corner of the coal mining working face. The explosion suppression method comprises the steps of: 1, detection of concentrations of methane and oxygen; 2, judgment of concentrations of methane and oxygen; 3, dilution of methane and oxygen; and 4, emission of diluted methane and oxygen. According to the invention, the work reliability is high, the underground gas explosion suppression purpose is realized, the coal mining safety is improved, the practicality is strong and the using effect is good, and the system and the method are convenient to popularize and apply.

Owner:哈尔滨誉进新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com