Experiment device and method for simulating gas-coal dust explosion in underworkings of coal mine

A technology for underground tunnels and gas explosions, which is applied in the direction of explosive materials, etc., to improve safety awareness and enrich teaching effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

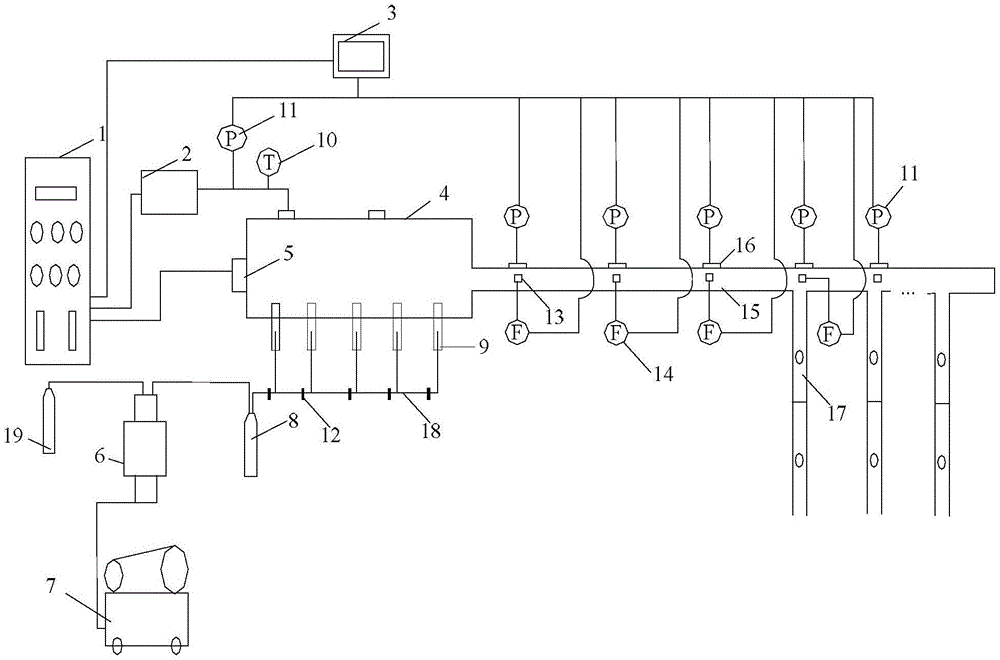

[0036] Specific implementation method 1. Refer to figure 1 To specifically describe this embodiment, an experimental device for simulating gas-coal dust explosion in a coal mine underground tunnel described in this embodiment includes a high-energy ignition cabinet 1, a vacuum pump 2, a high-speed data collector 3, an explosion cavity 4, an ignition Electrode 5, booster pump 6, air compressor 7, high pressure gas storage cylinder 8, t powder chambers 9, solenoid valve 10, m pressure sensors 11, stop valve 12, flame sensor installation port 13, n flame sensors 14 , gas explosion diffusion pipeline 15, pressure sensor installation port 16, gas explosion diffusion branch 17, connecting pipe 18 and gas cylinder 19; n, m and t are all positive integers;

[0037]One end of the explosion chamber 4 is provided with an ignition electrode 5; the ignition signal input end of the ignition electrode 5 is connected to the ignition signal output end of the high-energy ignition cabinet 1; the...

specific Embodiment approach 2

[0050] Specific embodiment 2. This embodiment is a further description of the experimental device for simulating gas-coal dust explosion in coal mine underground tunnels described in Embodiment 1. In this embodiment, the explosion chamber 4 and the gas explosion diffusion pipeline The junction of 15 is provided with a Teflon film, which is used for sealing.

[0051] The explosion cavity and the gas explosion diffusion pipeline are separated by a holder equipped with a PTFE film to ensure the relative sealing of the explosion cavity and the configuration requirements of a certain concentration of gas in the explosion cavity.

specific Embodiment approach 3

[0052] Specific embodiment 3. This embodiment is a further description of the experimental device for simulating gas-coal dust explosion in underground tunnels of coal mines described in Embodiment 1. In this embodiment,

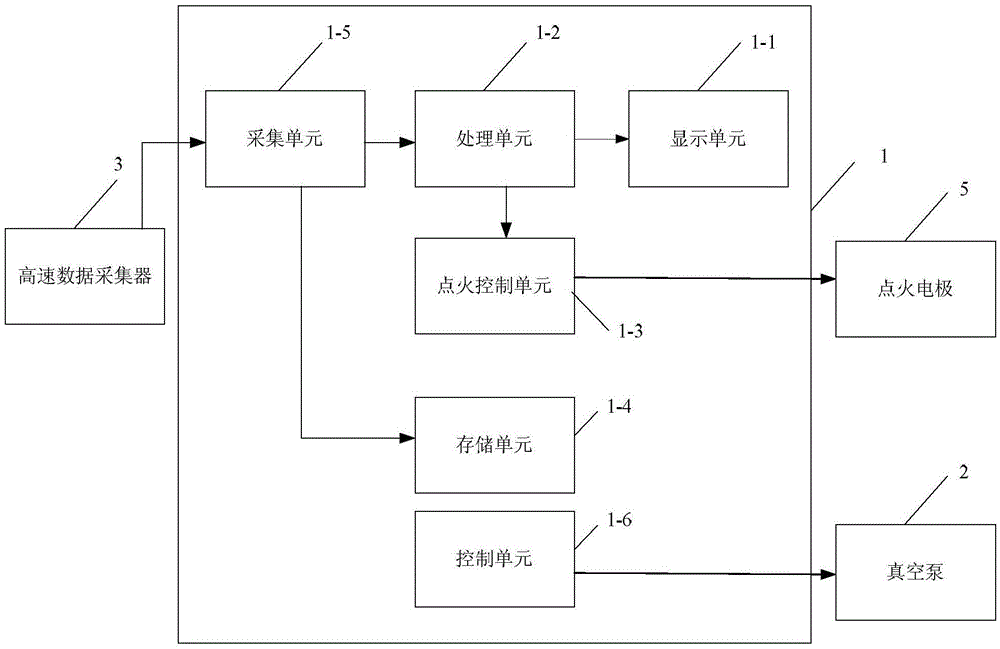

[0053] The high-energy ignition cabinet 1 includes a display unit 1-1, a processing unit 1-2, an ignition control unit 1-3, a storage unit 1-4, a collection unit 1-5 and a control unit 1-6;

[0054] The acquisition units 1-5 are used to collect the pressure signal and the flame signal sent by the high-speed data collector 3;

[0055] The processing unit 1-2 is used to compare the pressure value in the explosion chamber 4 collected by the collection unit 1-5 with the external atmospheric pressure value, and input the comparison result to the display unit 1-1; it is also used to control the vacuum pump 2 to start , close, control solenoid valve 10 to open, close and control solenoid valve opening delay;

[0056] The display unit 1-1 is used to display the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com