Patents

Literature

529 results about "Dust explosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A dust explosion is the rapid combustion of fine particles suspended in the air within an enclosed location. Dust explosions can occur where any dispersed powdered combustible material is present in high-enough concentrations in the atmosphere or other oxidizing gaseous medium, such as pure oxygen. In cases when fuel plays the role of a combustible material, the explosion is known as a fuel-air explosion.

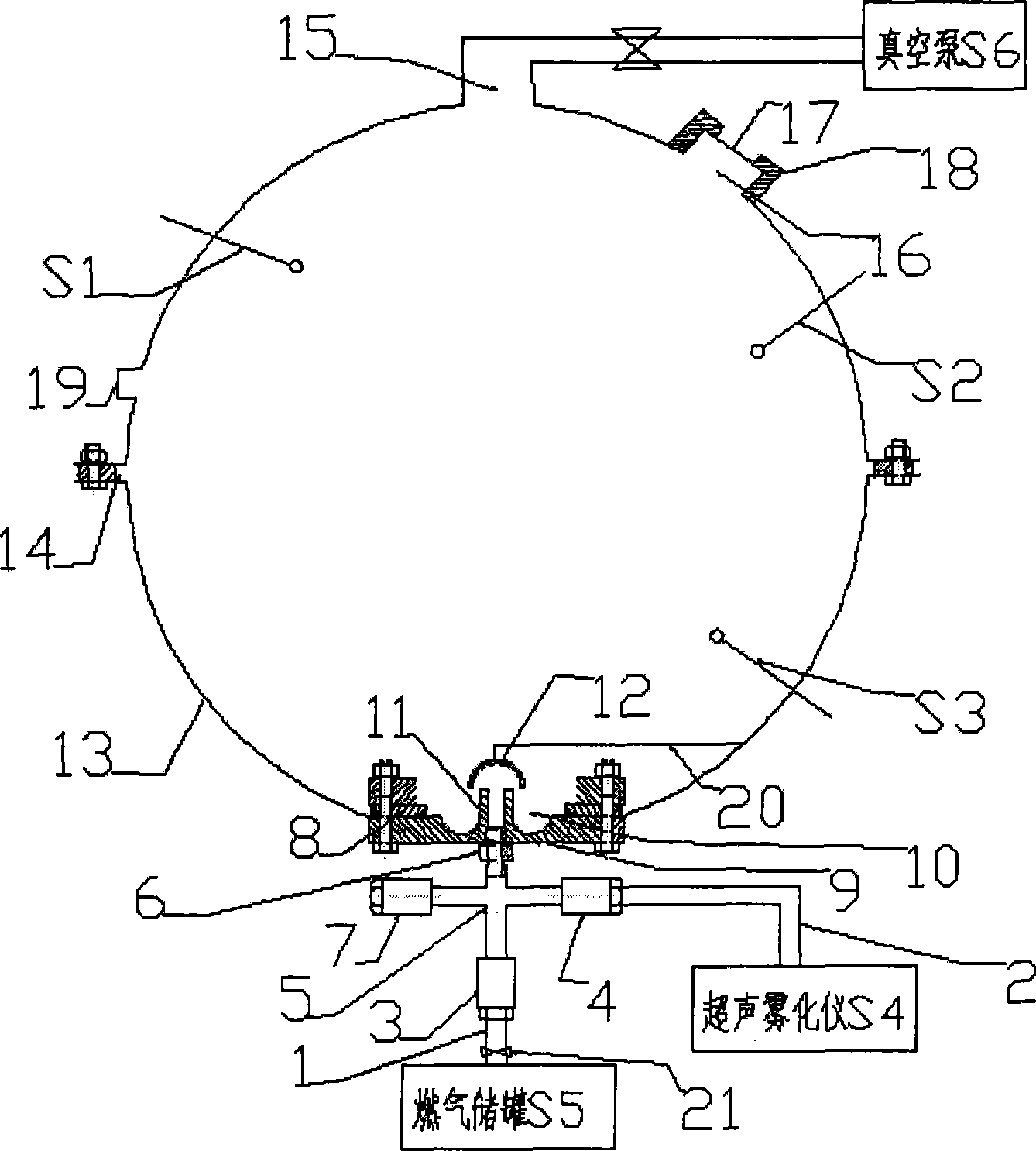

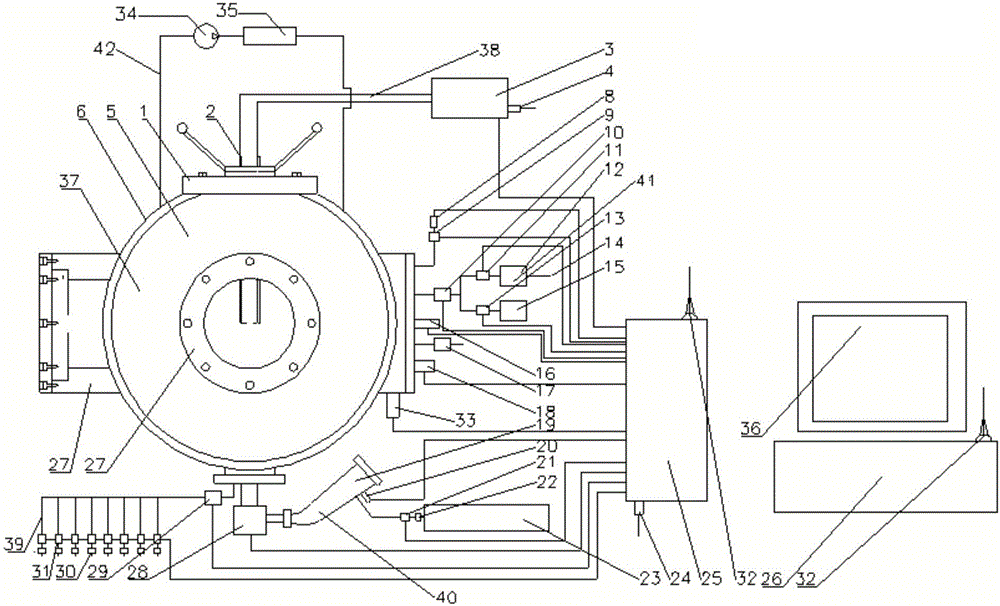

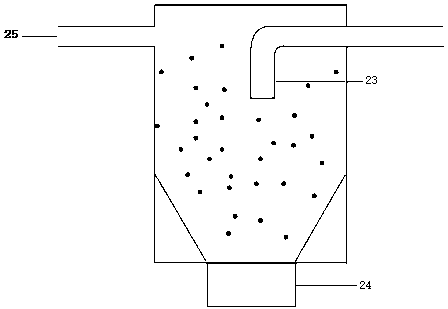

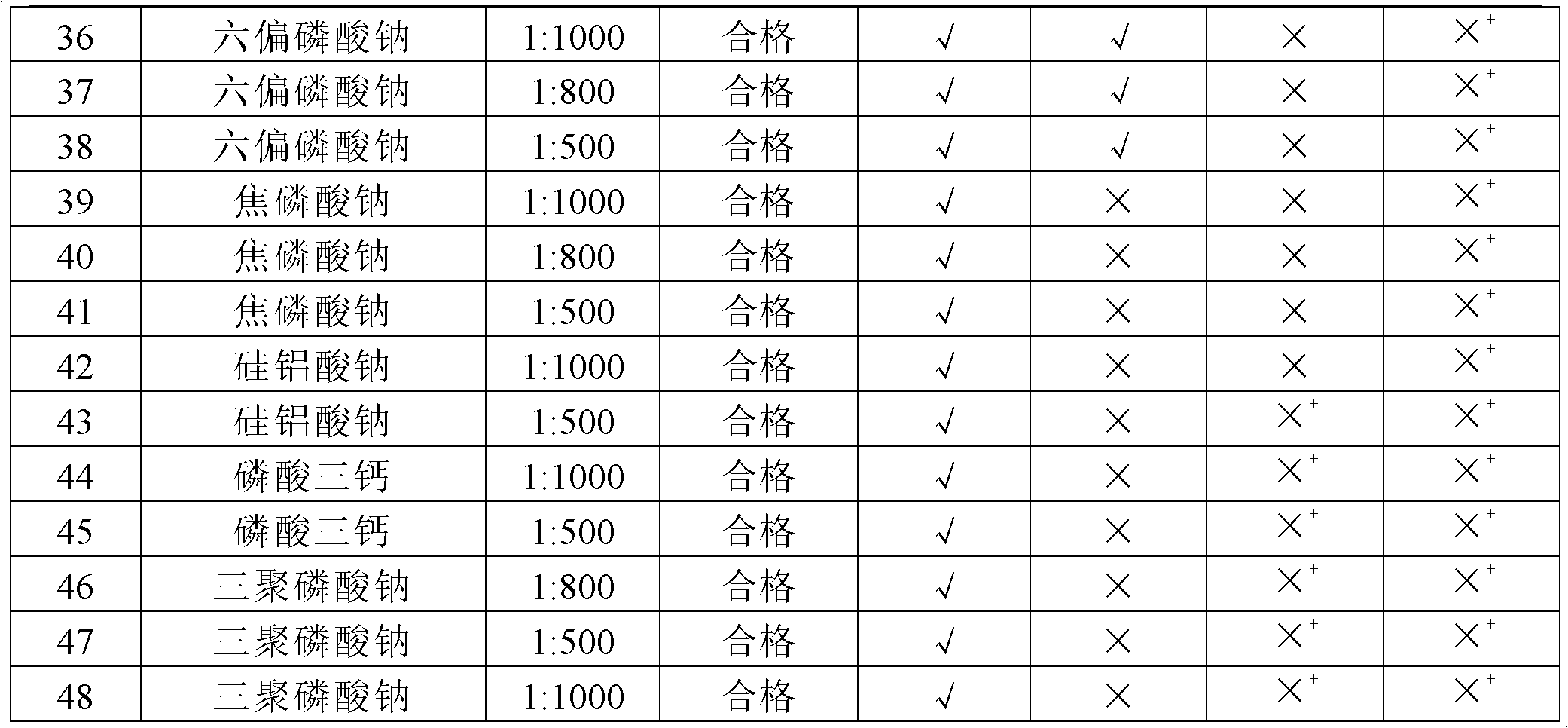

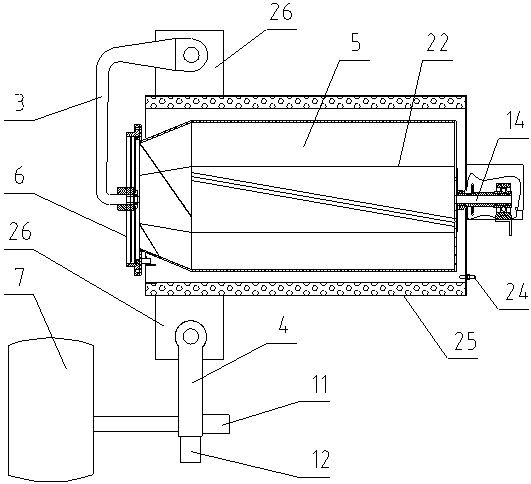

Experimental device for restraining gas and dust explosion by water mist

InactiveCN101477094AControl limit test pressureGood for optical observationChemical methods analysisAtmospheric airInlet pressure

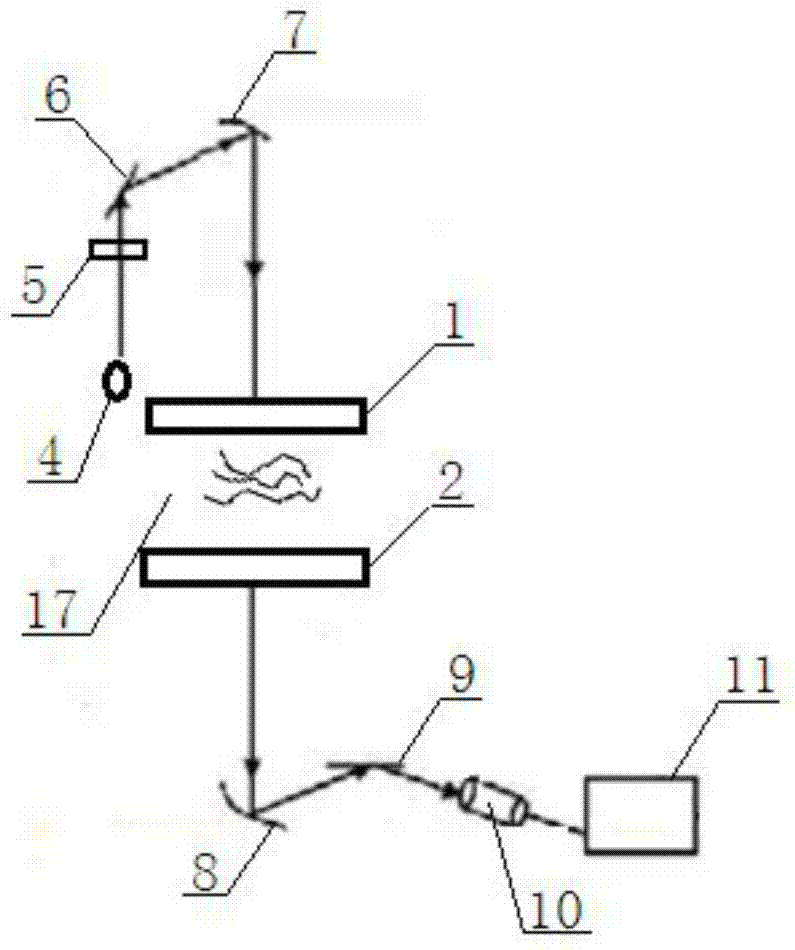

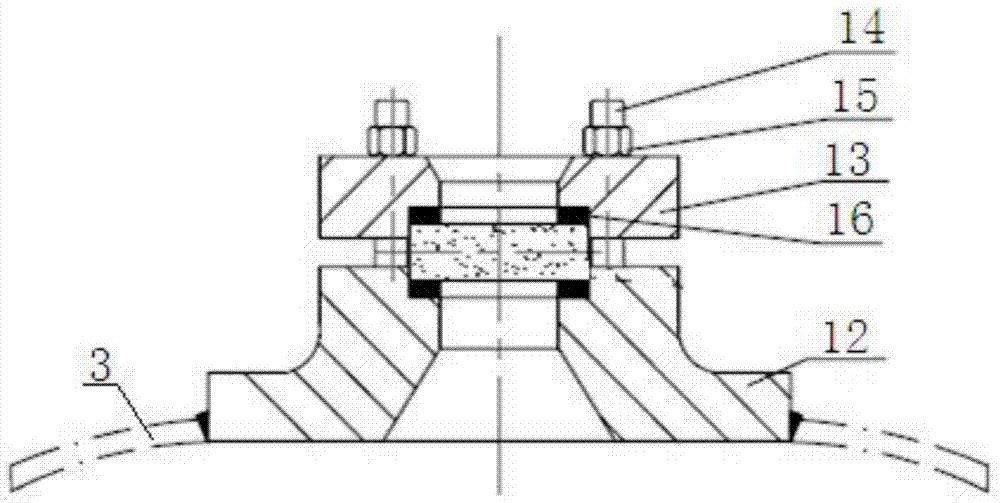

The invention discloses an experimental device adopting fine water mist to suppress gas and dust explosion. The experimental device is characterized in that a pressure-resisting airtight burner of the device is provided with a temperature sensor, a pressure sensor and an ignition device inside; the wall of the burner is provided with a transparent observation window and a pressure release hole pasted with an explosion-proof piece; the top of the burner is connected with a vacuum pump through a gas suction pipe with a valve; a flange base on the bottom of the burner is provided with a gas inlet pipe protruding inwards; a hollow hemispherical cover body with the spherical top protruding inwards is fixed above a nozzle of the gas inlet pipe; the flange base encircling the bottom of the outer wall of the gas inlet pipe is provided with an annular groove inside; the gas inlet pipe is respectively connected with a gas storage tank through a valve via an adjusting valve and an ultrasonic atomizer through a fine water mist inlet pipe, and is also communicated with the atmospheric environment; and dust inside the bottom flange groove is raised and suspended in the burner by means of inlet pressure. The experimental device can carry out explosion suppression experiment of gas, dust or gas-dust composite explosion and research on flame spreading rule and microstructure.

Owner:UNIV OF SCI & TECH OF CHINA

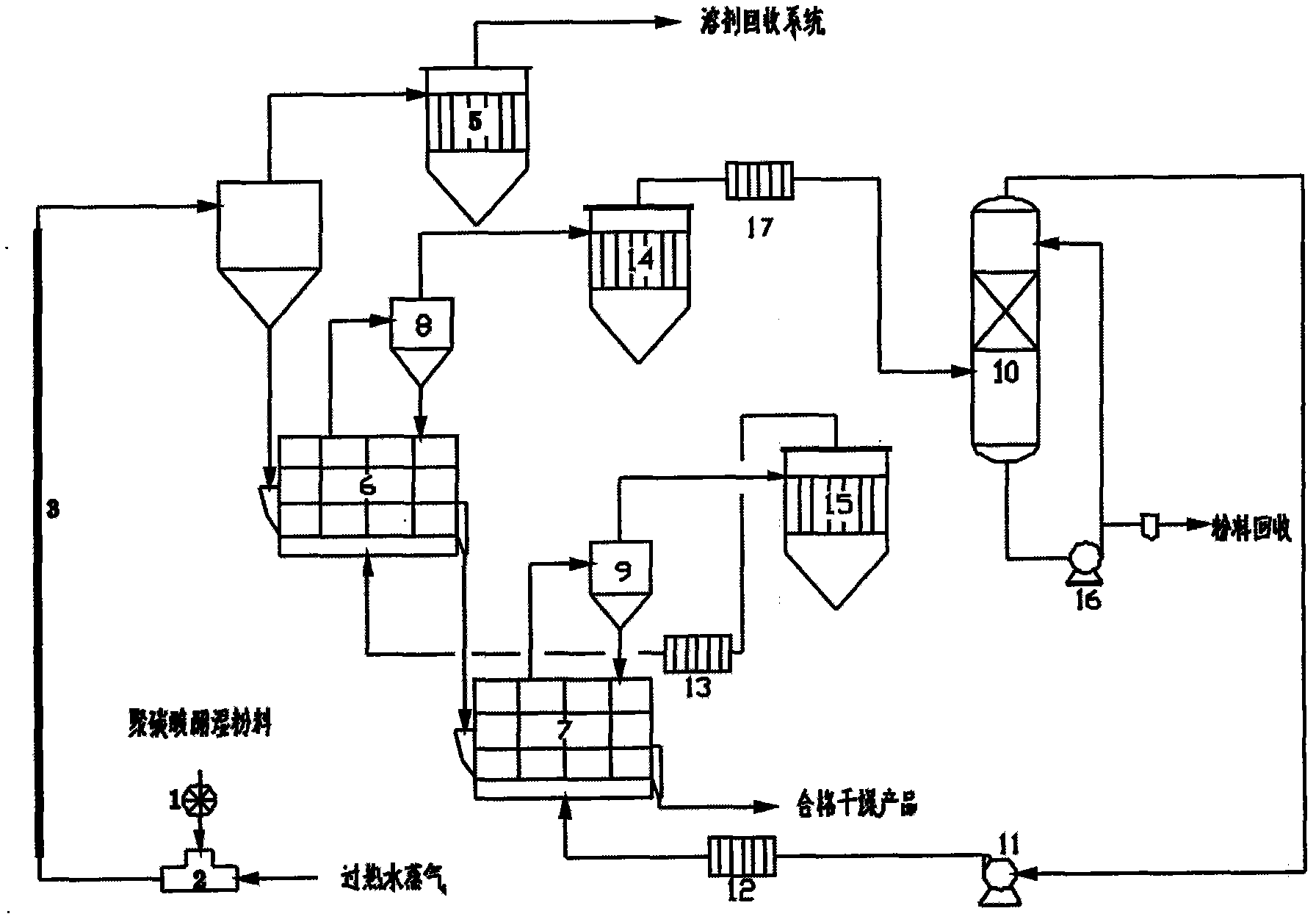

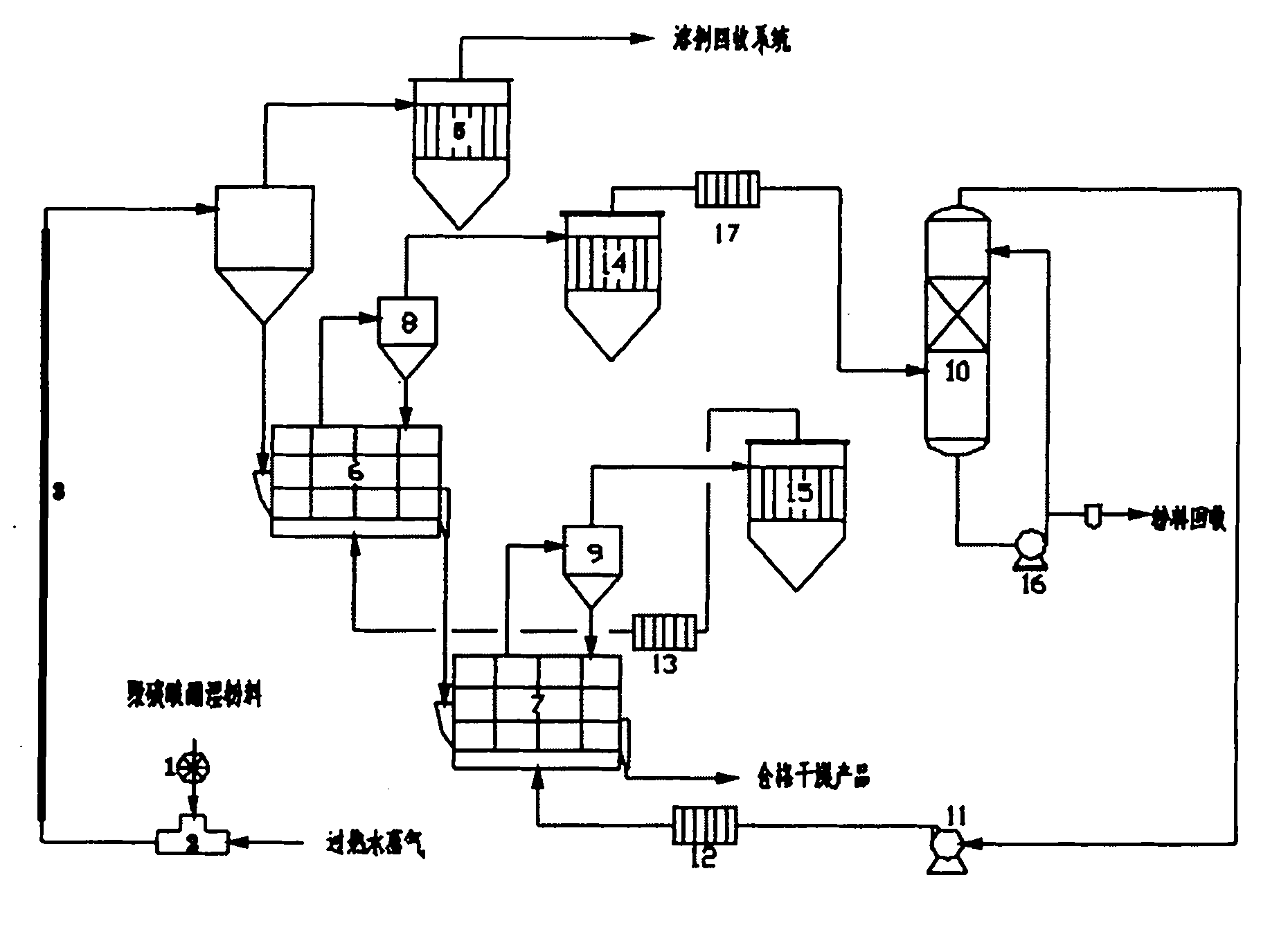

Method for drying poly carbonate (PC)

InactiveCN102620526ASolving Recycling ProblemsAvoid accident hazardsDrying solid materials with heatHearth type furnacesFluidized bed dryingThree stage

The invention relates to a method for drying polycarbonate (PC), which is characterized in that PC powder is subjected to drying treatment by adopting a one-stage pneumatic drying and two-stage fluid bed drying combined way, and overhot vapor is used as the drying medium in the one-stage drying process; and hot nitrogen gas is used as the drying medium in the fluid bed drying process, the nitrogen gas is recycled through processes such as washing, cooling, dehumidifying, pressurizing, heating and the like, and the PC powder in washing water is recycled. The water content of a product dried in the three-stage draying combined way can meet the later processing requirement, accident potentials such as dust explosion and the like caused in the drying process of the PC powder can be effectively solved, and the quality of the product can be improved.

Owner:甘肃银光聚银化工有限公司 +1

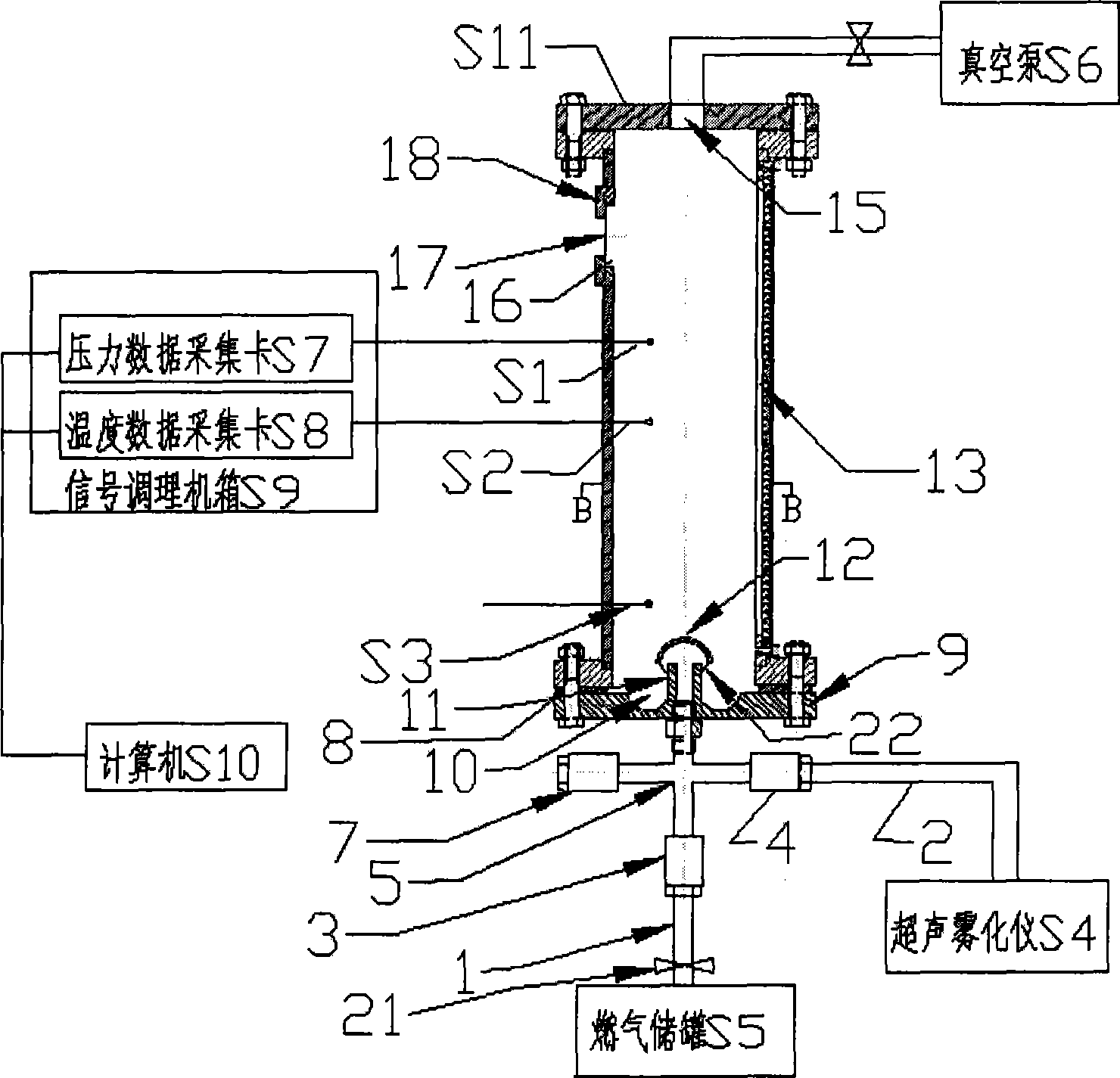

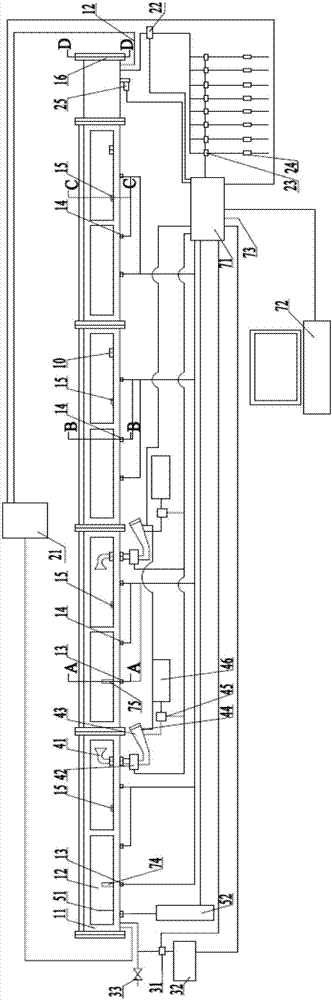

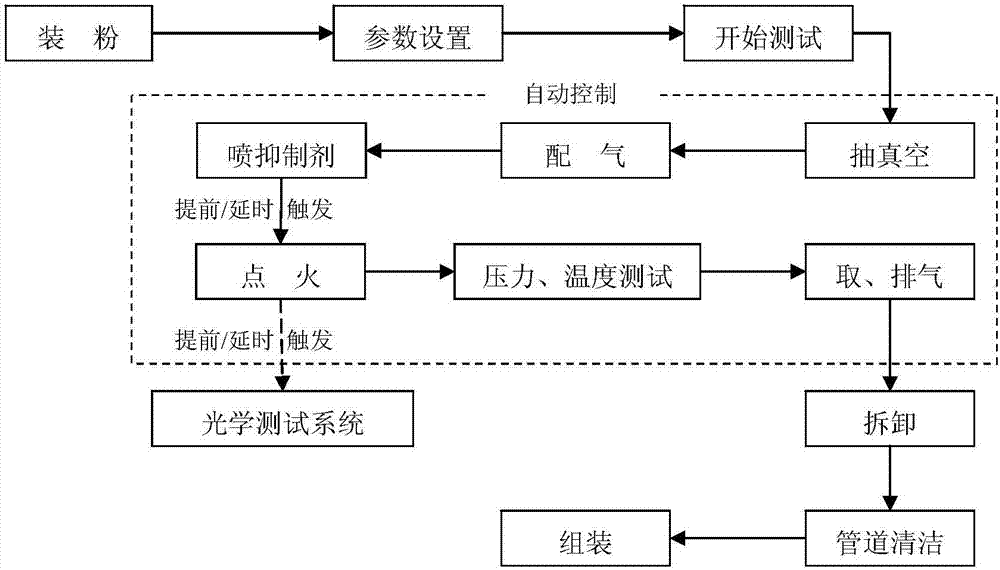

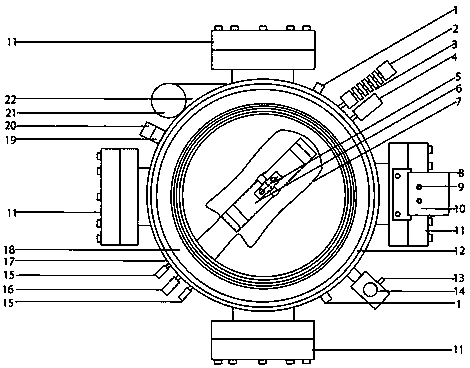

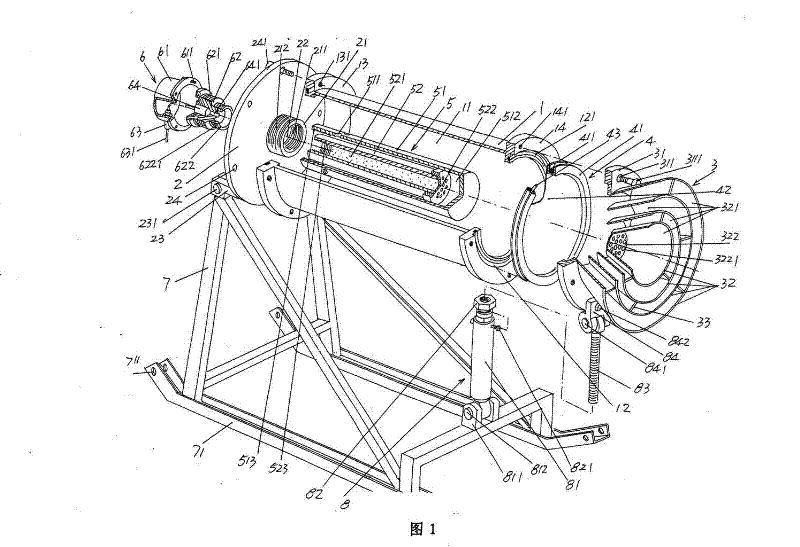

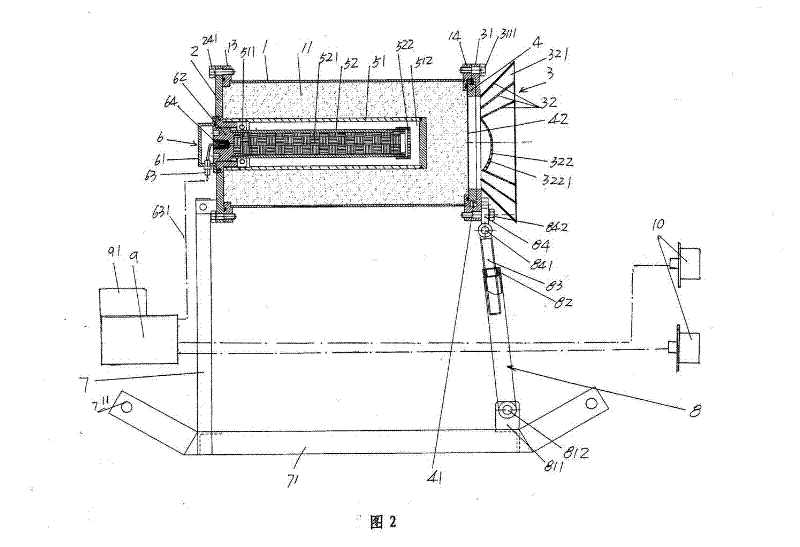

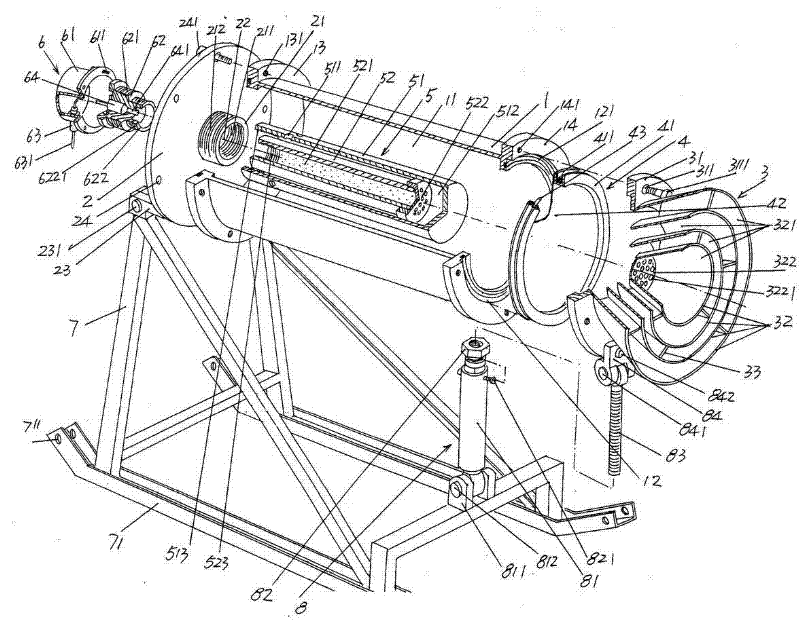

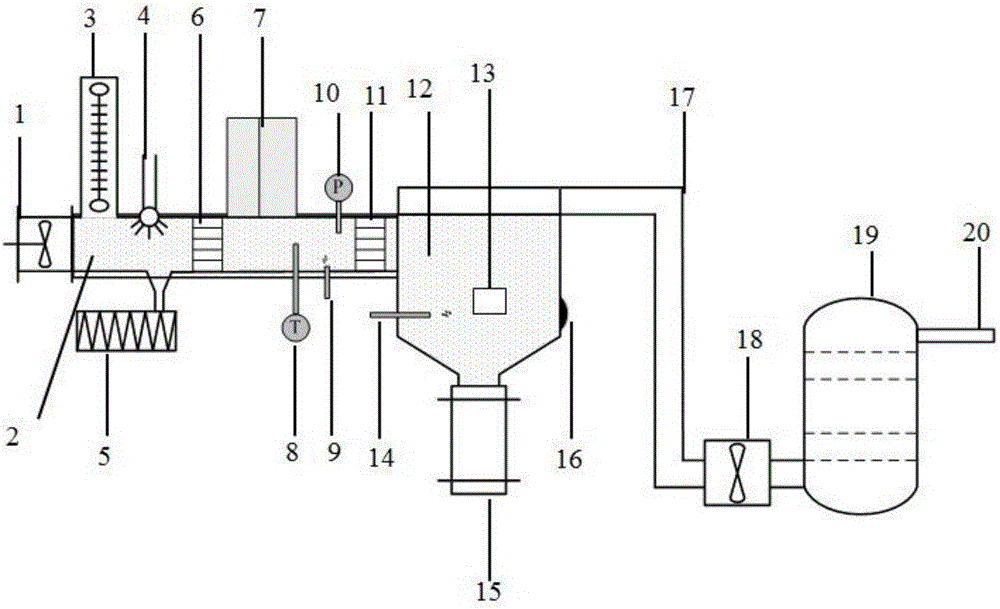

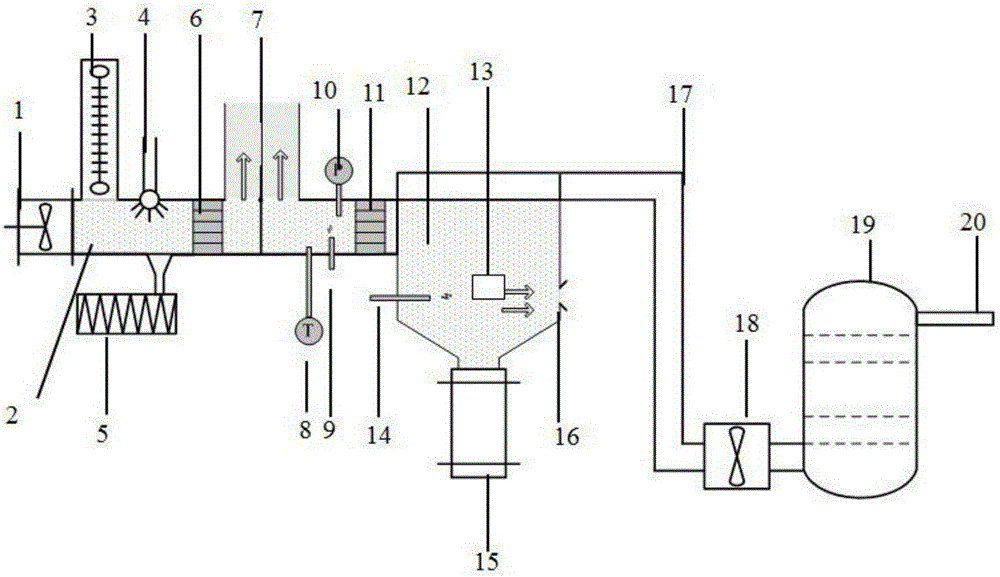

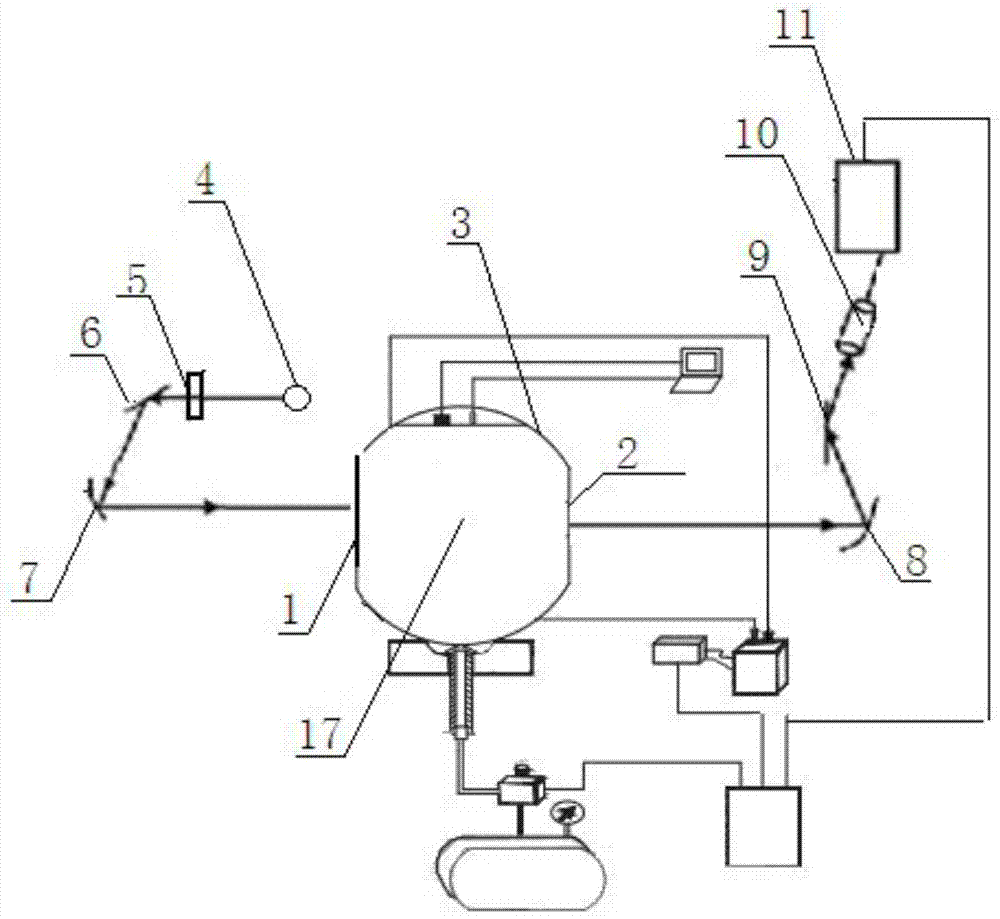

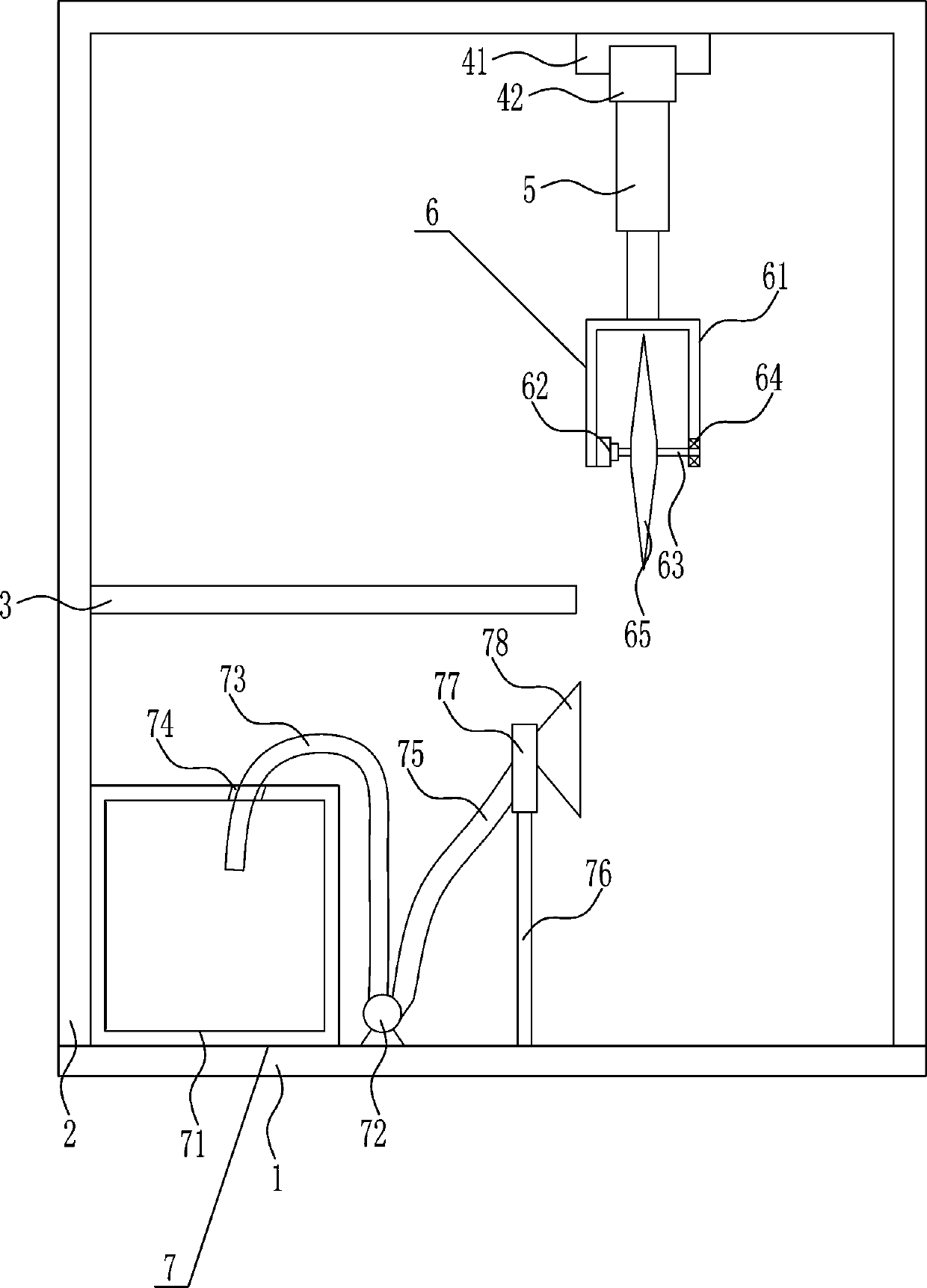

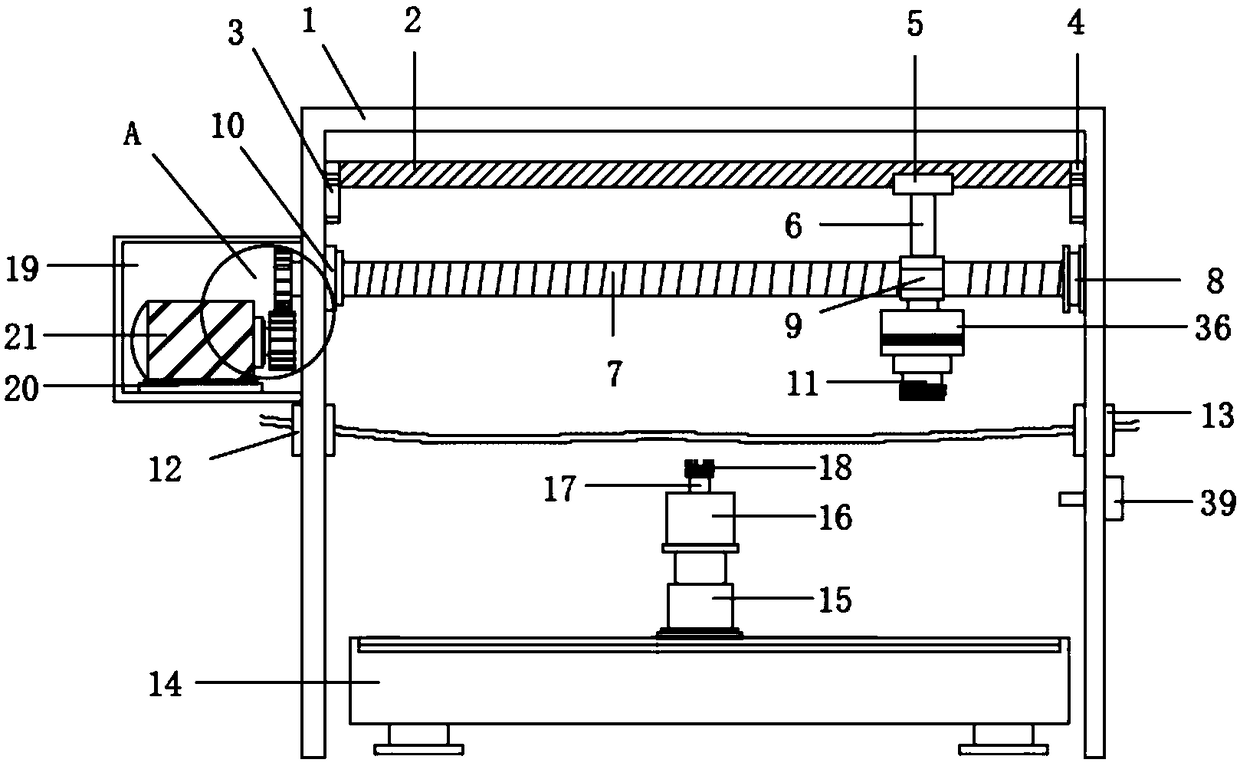

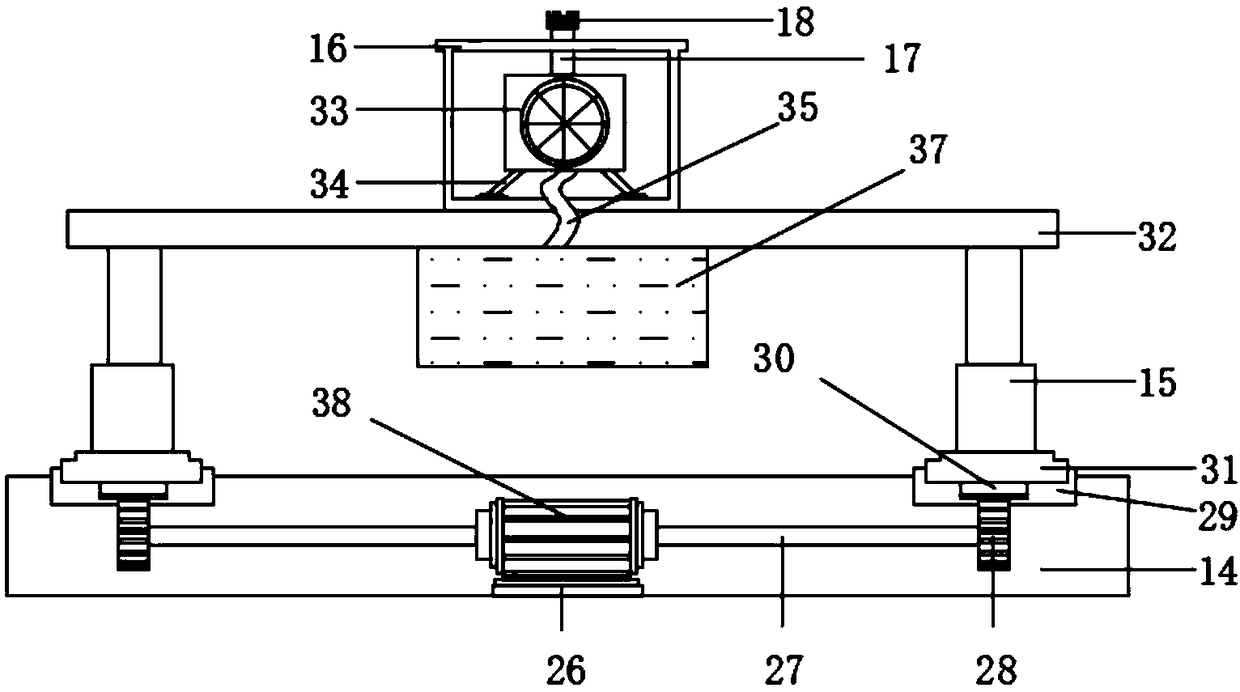

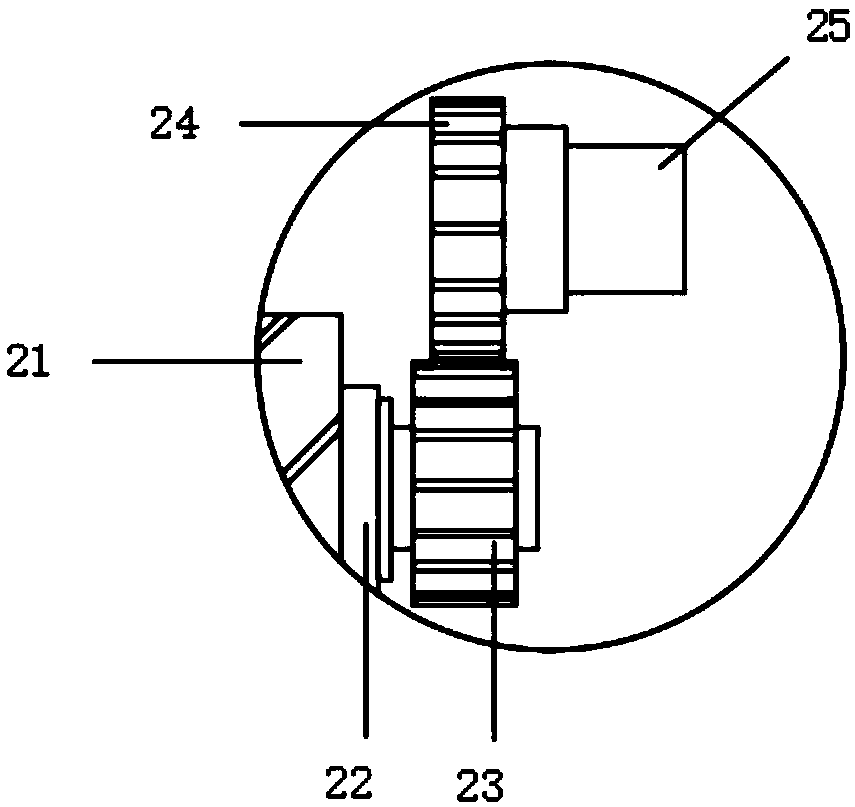

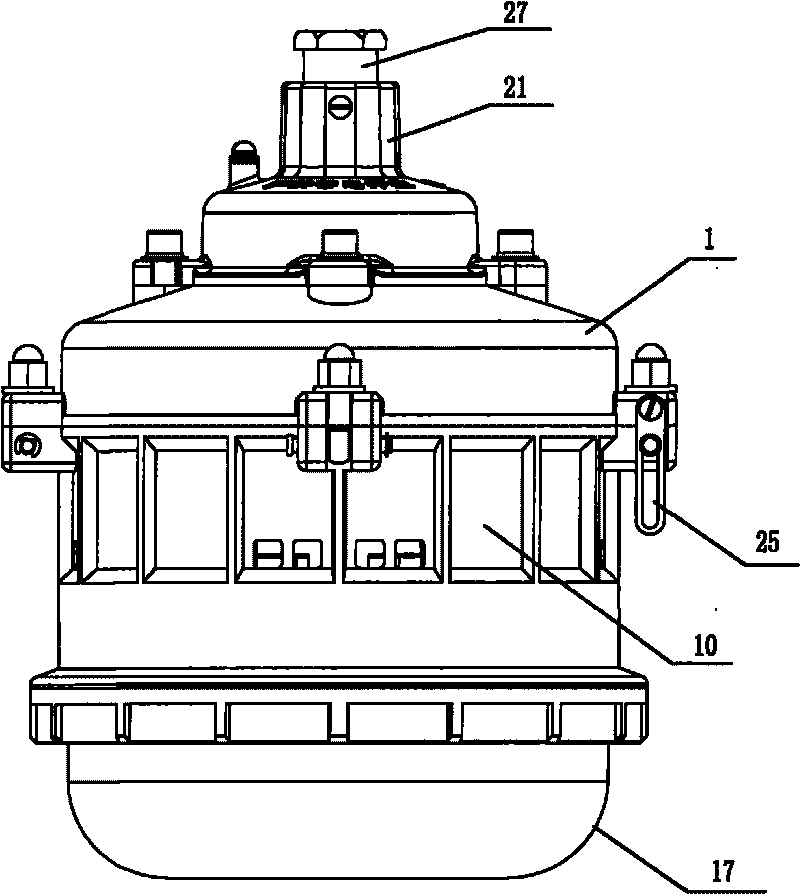

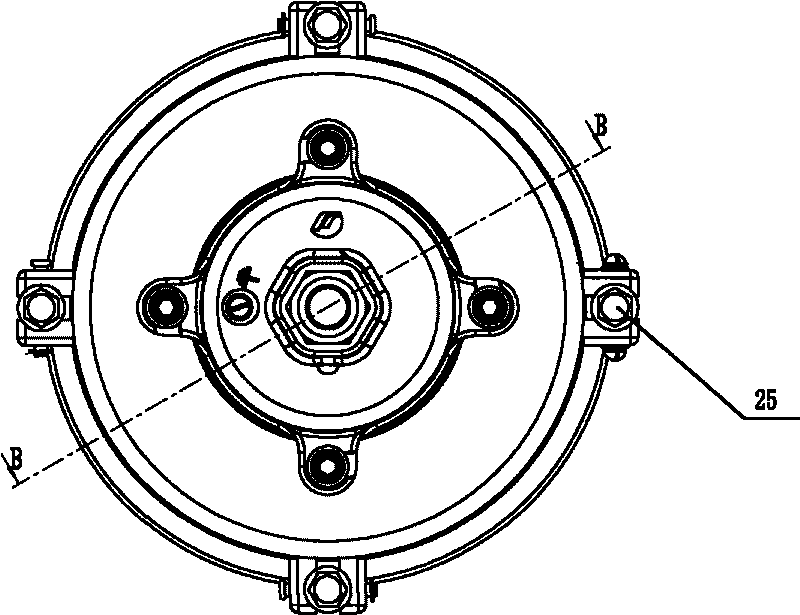

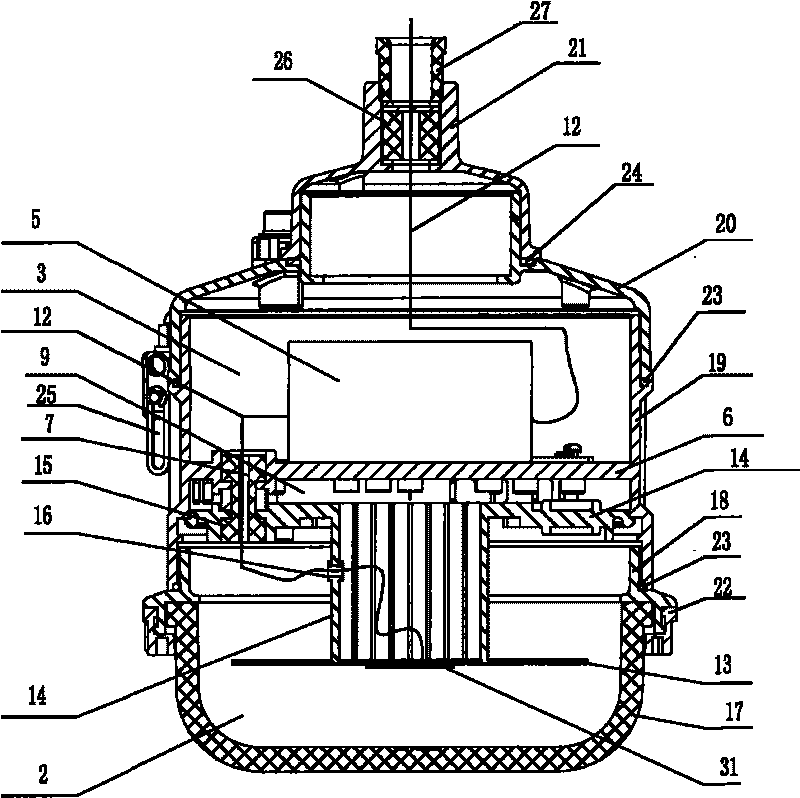

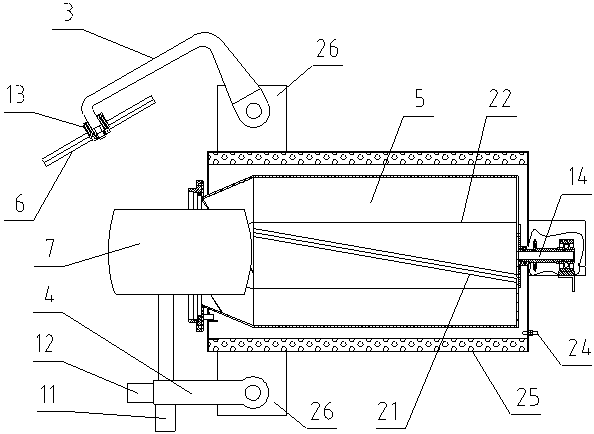

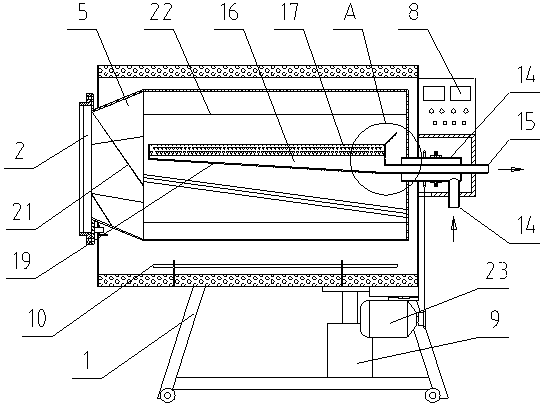

Multi-window multifunctional gas and dust explosion inhibition experiment system

ActiveCN106248733AMeet Synchronous ApplicationsSatisfy synchronous testing requirementsMaterial exposibilityEngineeringHigh pressure

The invention provides a multi-window multifunctional gas and dust explosion inhibition experiment system, and aims to meet a high-transparency quartz window characterized in that a plurality of external triggering connectors are available for externally connecting devices and a plurality of advanced optical testers are synchronously used, and to achieve a comprehensive explosion experiment testing system for preparing multiple gases. The multi-window multifunctional gas and dust explosion inhibition experiment system comprises a testing control system, an explosion container, an ignition system, a gas distribution system, a powder spraying system, a vacuuming system, a heating constant-temperature system as well as at least two optical diagnosis windows, an ignition external triggering connector and a powder spraying external triggering connector, wherein the ignition system is connected with the explosion container; the optical diagnosis windows are formed in side surfaces of the explosion container; the ignition external triggering connector is arranged on an energy-adjustable high-pressure pulse igniter; the powder spraying external triggering connector is arranged on a system testing and control main machine.

Owner:XIAN UNIV OF SCI & TECH +1

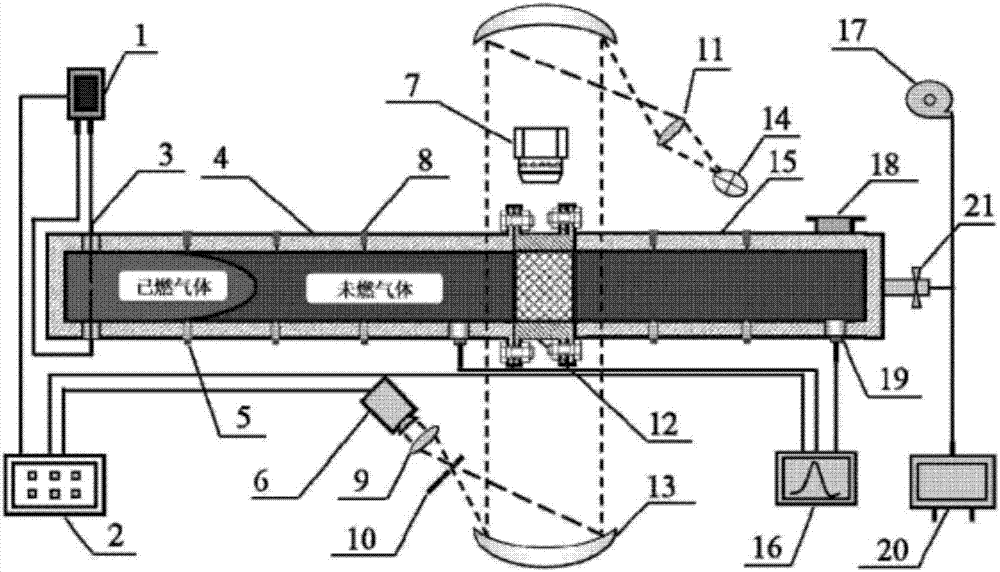

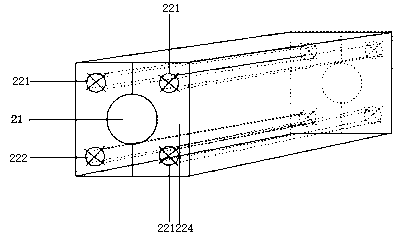

Gas, dust explosion and explosion suppression experiment system applicable to various optical diagnosis methods

ActiveCN107121453AReveal information about changes in microdynamic processesMaterial exposibilityPlanar laser-induced fluorescenceOptical measurements

Owner:XIAN UNIV OF SCI & TECH

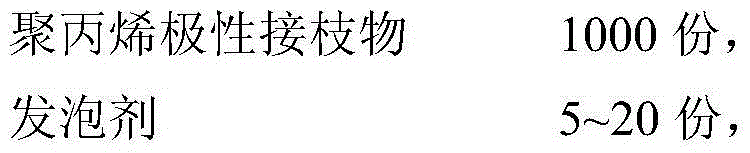

Polypropylene graft microcellular foaming material and preparation method thereof

InactiveCN104419101AMeet polar material requirementsMeets non-polar material requirementsLow-density polyethyleneMasterbatch

The invention belongs to the technical field of polymer materials, and relates to a polypropylene graft microcellular foaming material and a preparation method thereof. The foaming material comprises the following components by weight: 1000 parts of a polypropylene polar graft, 5-20 parts of a foaming agent, 2-10 parts of a foaming assistant agent, 10-35 parts of a nucleating agent, 20-70 parts of low density polyethylene, 15-50 parts of a thermoplastic elastomer and 1-5 parts of an antioxidant. The polypropylene graft microcellular foaming material using the polypropylene (PP) polar graft for foaming, the PP foaming material can not only meet the requirement of polar materials, but also can satisfy the requirements of non polarity materials, and the scope of application of the PP foaming material is expanded. In addition, by preparation of the foaming agent into foaming agent masterbatch, the problem of dispersion of the foaming agent can be solved, and the problems of dust explosion, metering error and the like can be solved.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

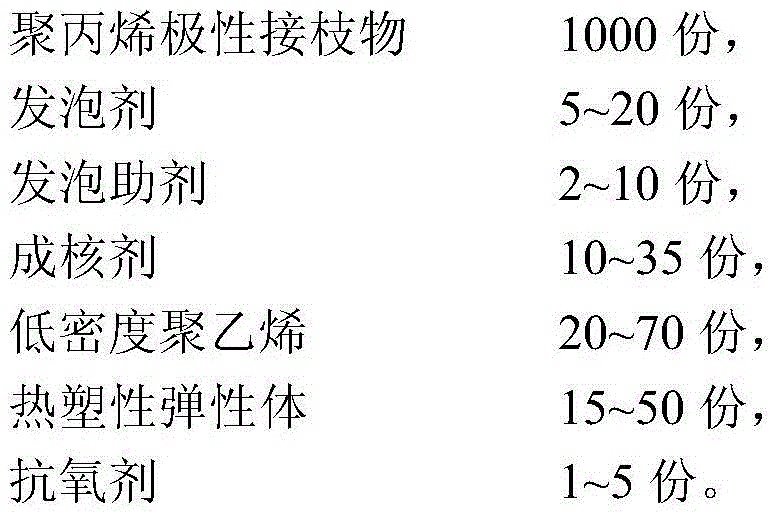

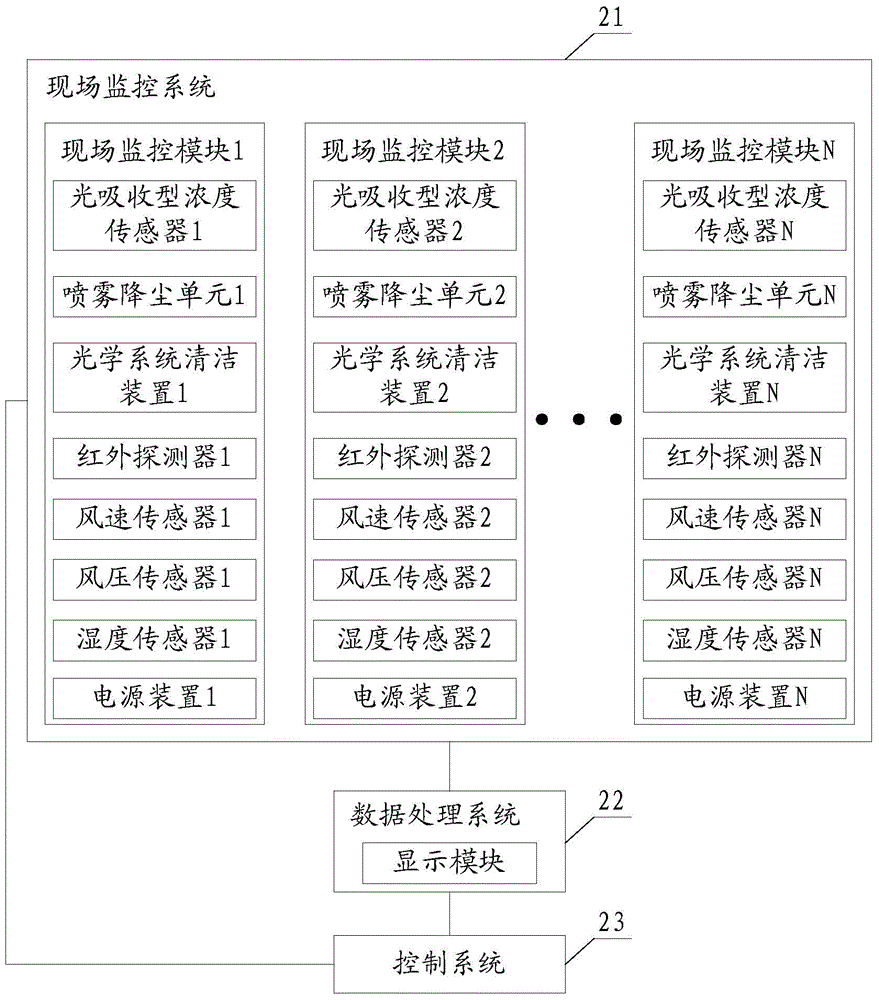

Coal mine dust monitoring system and method

InactiveCN104564156AAvoid explosive situationsReduce the likelihood of an explosionMining devicesDust removalDust explosionNormal values

The invention discloses a coal mine dust monitoring system and method. The system comprises a light absorption type concentration sensor, a data processing system and a control system, wherein the light absorption type concentration sensor is used for collecting real-time dust concentration data, when the real-time dust concentration data is an abnormal value, the data processing system generates warning eliminating signals, when the real-time dust concentration data is changed from an abnormal value to a normal value, the data processing system generates warning elimination signals, and the control system is used for controlling a spraying dust reducing unit to start or stop the spraying processing. In the system disclosed by the embodiment of the invention, the collected dust concentration data is real-time dust concentration data, the condition that the dust explosion can be caused since the real-time performance of the dust concentration data is poor in the prior art is avoided, and the dust explosion possibility is reduced; in addition, the control system can control the spraying dust reducing unit to stop the spraying processing, the condition that the spraying device is in the spraying state for a long time due to the personnel negligence in the prior art is avoided, and the utilization rate of water resources is improved.

Owner:浙江图讯科技股份有限公司

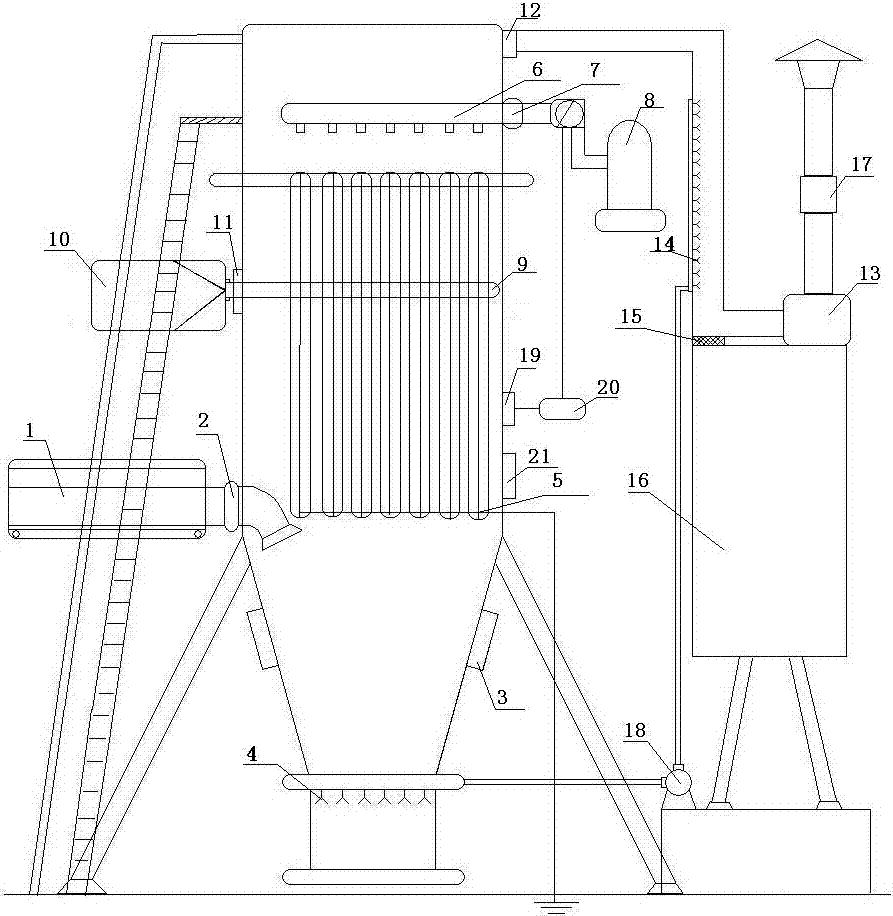

Dust removing and explosion preventing apparatus for wood dust explosion

InactiveCN106938162AGood cleaning effectNo cloggingCombination devicesDispersed particle filtrationSpray nozzleDust explosion

The present invention discloses a dust removing and explosion preventing apparatus for wood dust explosion. According to the present invention, during the process from wood dust transportation to dust removing, an electromagnetic iron removing device, a metal wire, an electric conduction coating material and a metal shell are synergistically used, such that the generation of static electricity is avoided, and the wood dust burning explosion caused by static spark is inhibited; through the synergetic effect of a temperature measurement device and a monitor, the temperature and the pressure during the dust removing process are real-timely monitored; by matching a water sprinkling head and a rapping device, the burning explosion caused by the clogging during the material discharging after the dust removing or the contact of the discharged material and air at the high temperature is avoided; through the synergetic effect of a polytetrafluoroethylene film, an electromagnetic pulse blowing device and a vibration rod, clogging and hardening cannot be caused during the dust removing process, the long-term operation can be achieved, the apparatus has advantages of high-temperature resistance and corrosion resistance, and it can be ensured that the dust collector does not produce the burning explosion after the long-term work at the high temperature; and by matching a fireproof ring and a spraying nozzle, the secondary burning explosion can be prevented, and the burning explosion of the discharged waste gas can be avoided.

Owner:NANJING FORESTRY UNIV

Gas-liquid-dust explosion experiment system for use under multiple working conditions

PendingCN108375604APerfect ignition and detonation prediction technologyAccurately measure the minimum ignition energy valueMaterial exposibilityMultiphysics couplingTemperature control

The invention discloses a gas-liquid-dust explosion experiment system for use under multiple working conditions. The system comprises a container main body as well as a material temperature control unit, an inner-layer container temperature control unit, a precise electric spark ignition energy generation unit, a gas concentration testing unit, a humidity control unit, a pressure sensor unit, a flame temperature sensor unit and an air inlet and vacuuming unit which are respectively arranged on the container main body. The system can be used for simulating a complex working condition in which multiple multi-physical fields including the temperature, pressure, impurities, humidity, leaking hole shapes, ignition positions and the like are coupled, determining accurate critical ignition energyvalues of explosion of gas, liquid and dust and finishing the measurement of relevant parameters and can be further used for evaluating the explosion suppression property of explosion suppression materials and verifying an explosion suppression method.

Owner:NANJING UNIV OF TECH +1

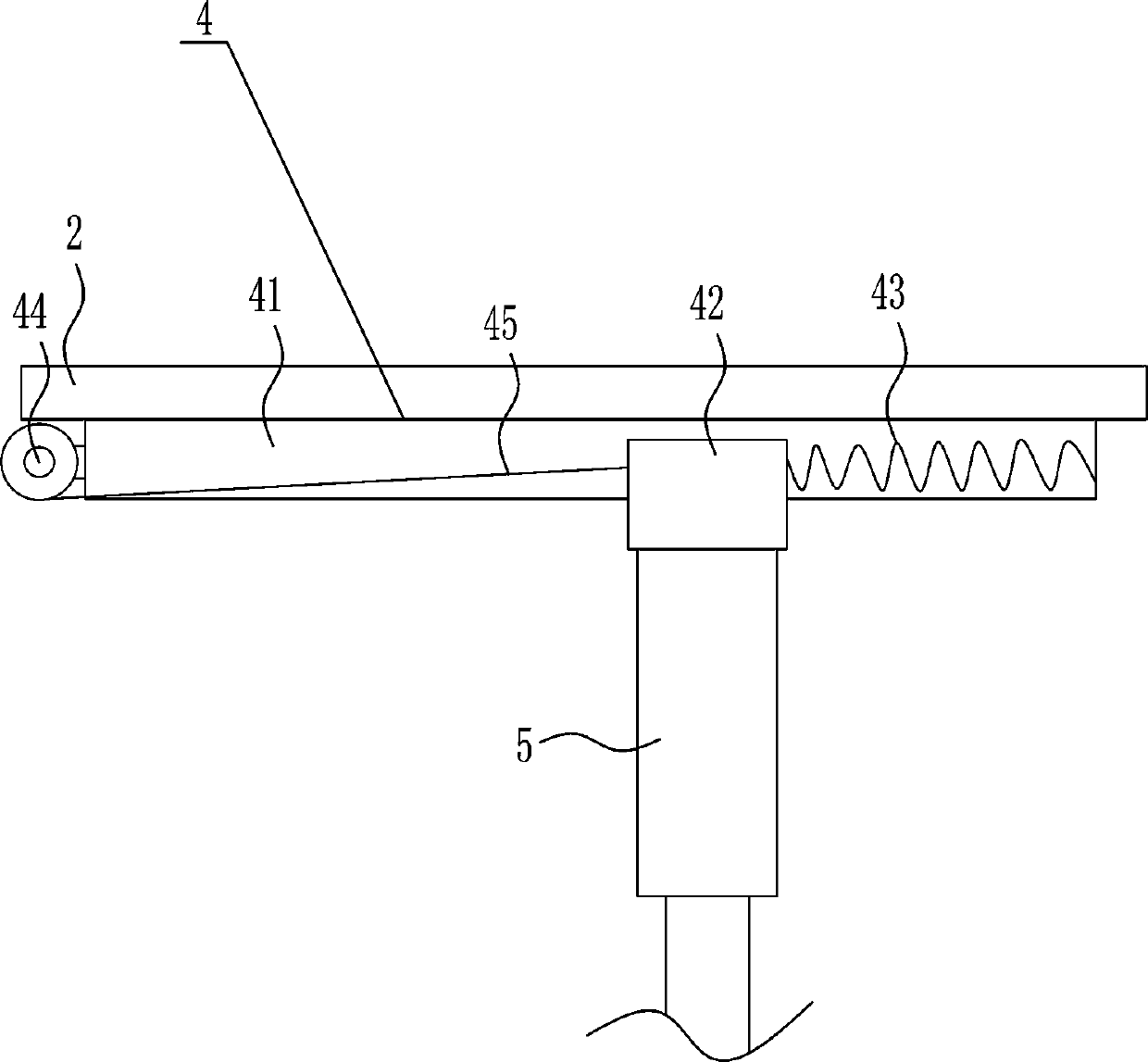

Dust explosion suppression device

InactiveCN102230389AAvoid idle wasteImprove mobilityDust removalFire preventionDust explosionEngineering

The invention discloses a dust explosion suppression device, belonging to the technical field of mine safety facilities. The dust explosion suppression device comprises a tank body, a tail cover, an adaptive seat, a nozzle, a seal disc, a gas generation mechanism and an ignition mechanism, wherein the tank body is provided with a powder extinguishing agent storage cavity; the tail cover is configured on the port part of one end of the tank body; the adaptive seat is arranged in the center of the tail cover and faces to one side of the powder extinguishing agent storage cavity; the nozzle is configured on the port part of the other end of the tank body and is gradually expanded from the tank body to the direction far away from the tank body to form a trumpet shape; the seal disc is arranged in a film disc cavity on the tank body; the gas generation mechanism is positioned in the powder extinguishing agent storage cavity and is fixed with the adaptive seat; and the ignition mechanism is also adaptive with the gas generation mechanism. The dust explosion suppression device is characterized by also comprising a moving rack; one end facing to the nozzle, of the moving rack is provided with a lifting regulation mechanism; the lifting regulation mechanism is connected with the tank body or the nozzle; and the tail cover is connected with the pivot of the moving rack. The dust explosion suppression device has the advantages that in-field setting requirements can be satisfied, the dust explosion suppression device has ideal maneuverability, idle and waste device resources can be prevented, an injection area can be enlarged, and gas and / or dust explosion flame can be quickly put out.

Owner:JIANGSU HUAKAI MINING TECH

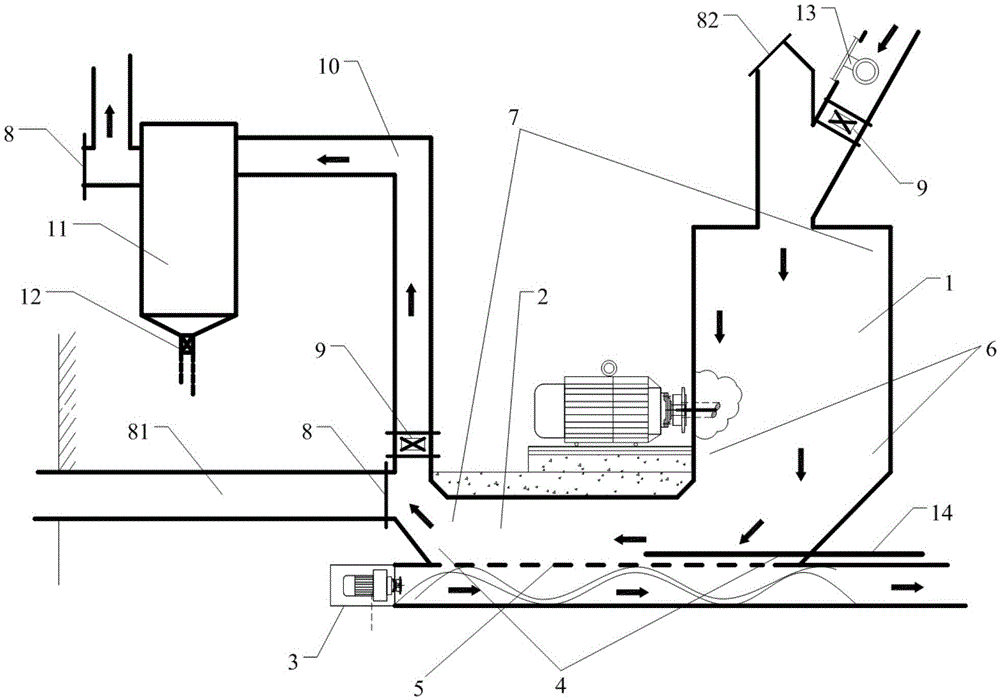

Air curtain and water mist linkage dust settling method for full mechanized workface

The invention provides an air curtain and water mist linkage dust settling method for a full mechanized workface, which is applicable to dust control in a full mechanized workface in an underground coal mine. According to the invention, an air curtain generator arranged in a no man's zone located between a head-on workface and a driver of a heading machine is started to form an air curtain, and an enclosed area is formed between the head-on workface and the air curtain, which prevents dust from spreading outwards; simultaneously, water mist is injected into the formed enclosed area, and the water mist rapidly disperses in the enclosed area to capture dust in a moistened settling enclosed zone, thereby realizing air curtain and water mist linkage dust settling for the full mechanized workface. The method has the advantages of a simple process, convenient operation, small water consumption, low utilization cost and high dust settling efficiency; the water mist injected into the enclosed area can wet the surface of coal rock mass in head-on full mechanized workface, which enables gas and dust explosion induced by sparks generated in cutting of coal rocks to be avoided; the invention has wide practicality.

Owner:CHINA UNIV OF MINING & TECH

Rizatriptan benzoate film agent

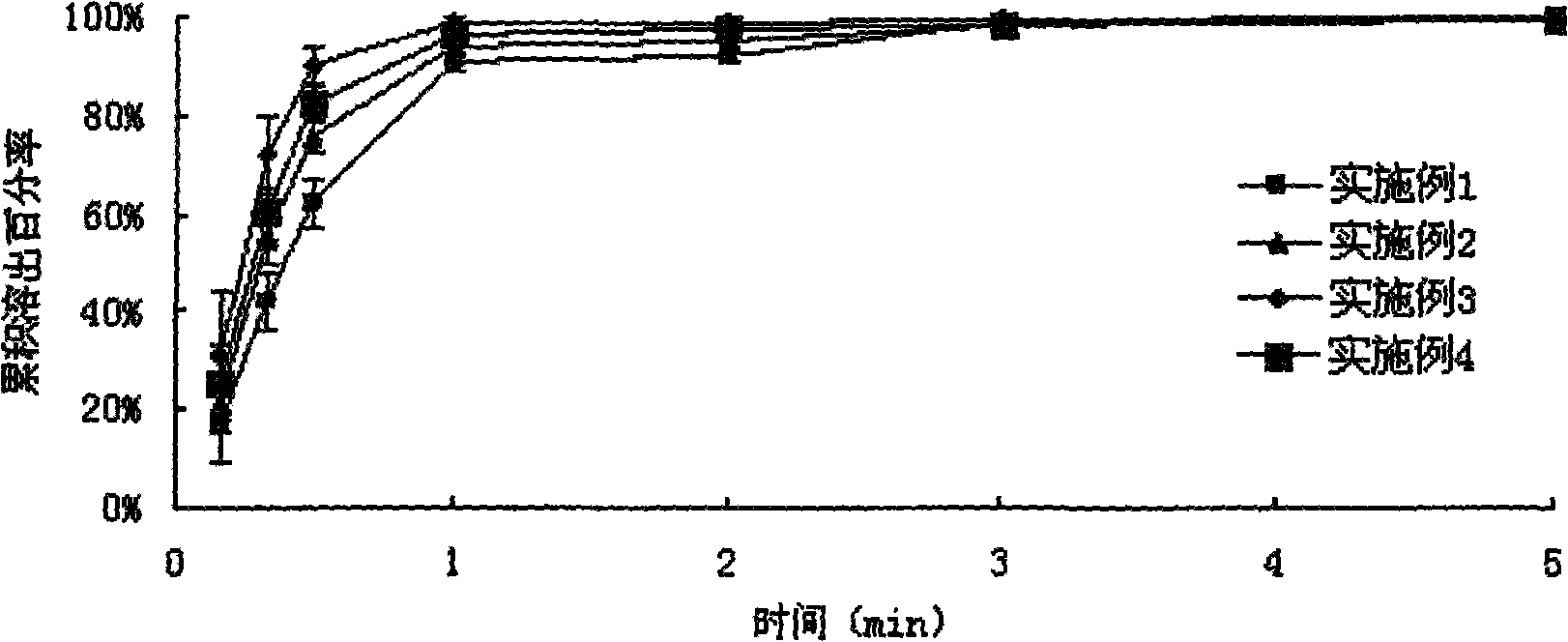

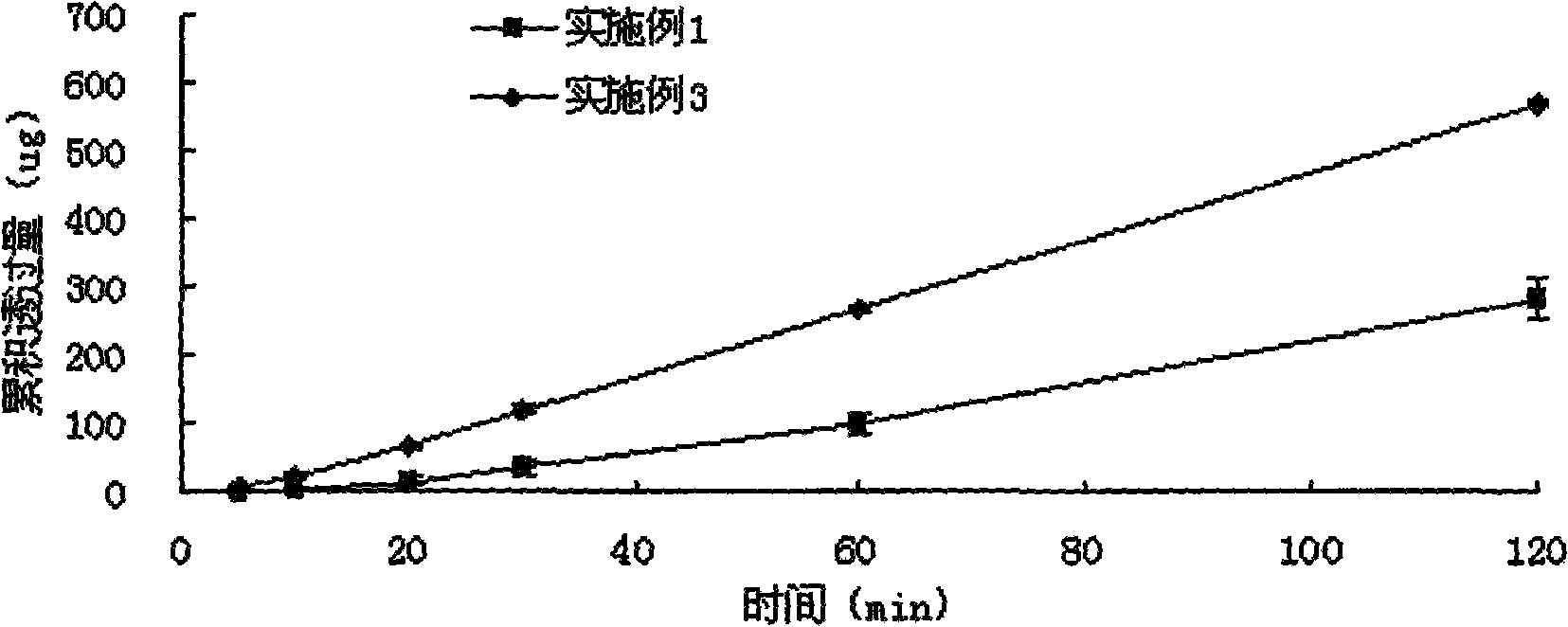

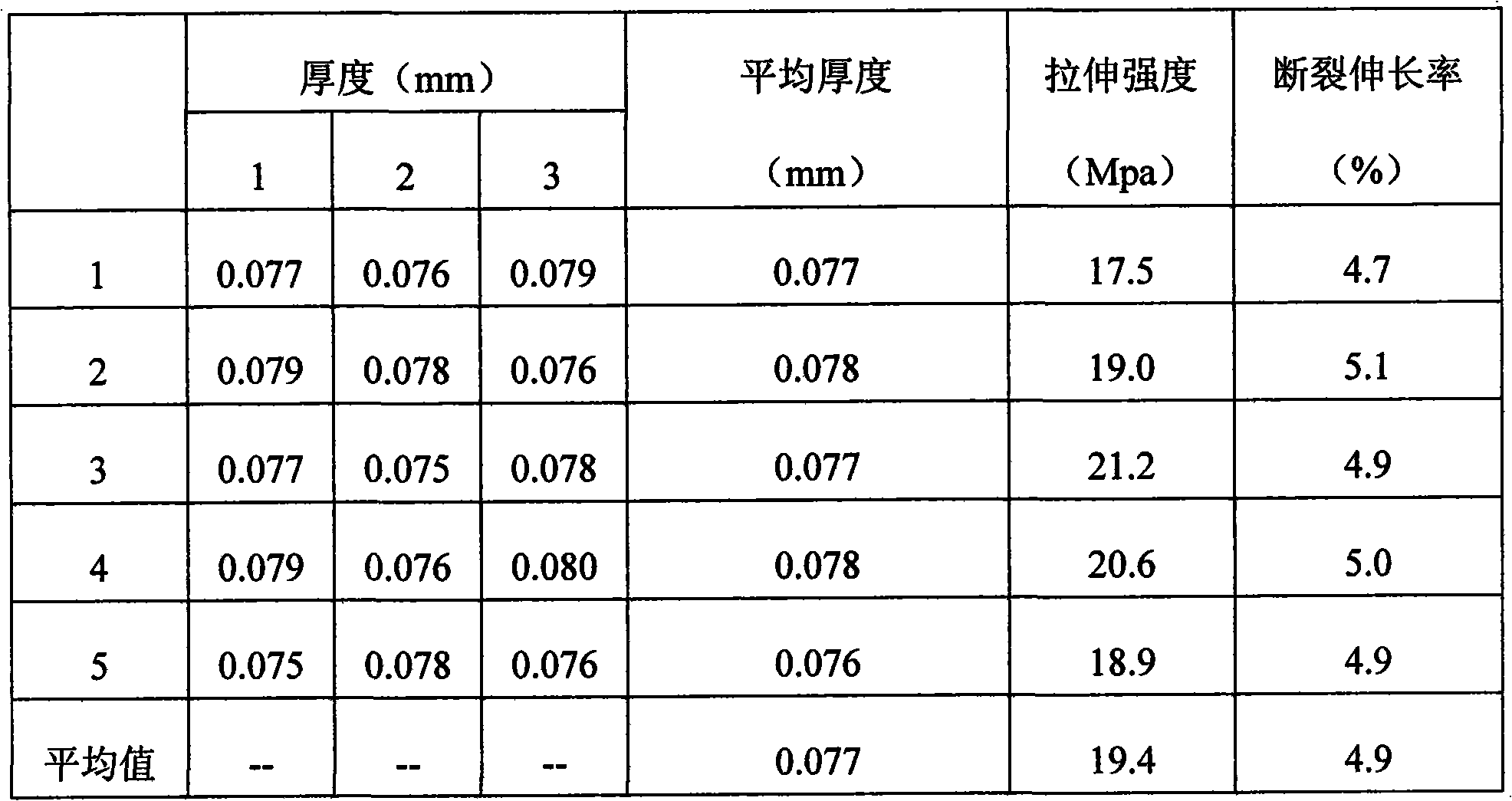

InactiveCN101574330ANice appearanceEasy to carryOrganic active ingredientsNervous disorderPolyvinyl alcoholDrug administration

The invention discloses a rizatriptan benzoate film agent. The film agent comprises the following components by weight percentage: 1-40 percent of rizatriptan benzoate, 40-98 percent of macromolecule film-forming material, 0-20 percent of plasticizer, 0-3 percent of titanium pigment, and 1-30 percent of flavoring agent. The high molecular film-forming material comprises more than one of the following components of hydroxypropyl methylcellulose, hydroxy propyl cellulose, polyvinyl alcohol, polyvinyl pyrrolidone, sodium alginate, polyoxyethylene, bletilla mucilage, cornstarch, or carrageenan. The film agent has rapid dissolving out, good stability and high bioavailability, can release medicaments on the surface of a mucosa, and absorb the medicaments quickly, is convenient in use, quick in effect, excellent in biological effectiveness, good in adaptability, popular by patients, has good formability, can be adhered at the drug administration position after drug administration, and keeps the drugs not to be dispersed, can keep the original state to release the drugs continuously, thus having accurate dosage; and no dust explosion occurs during the production process, thus being possible to solve the problems of labor security and environmental pollution.

Owner:SHANGHAI MODERN PHARMA ENG INVESTIGATION CENT

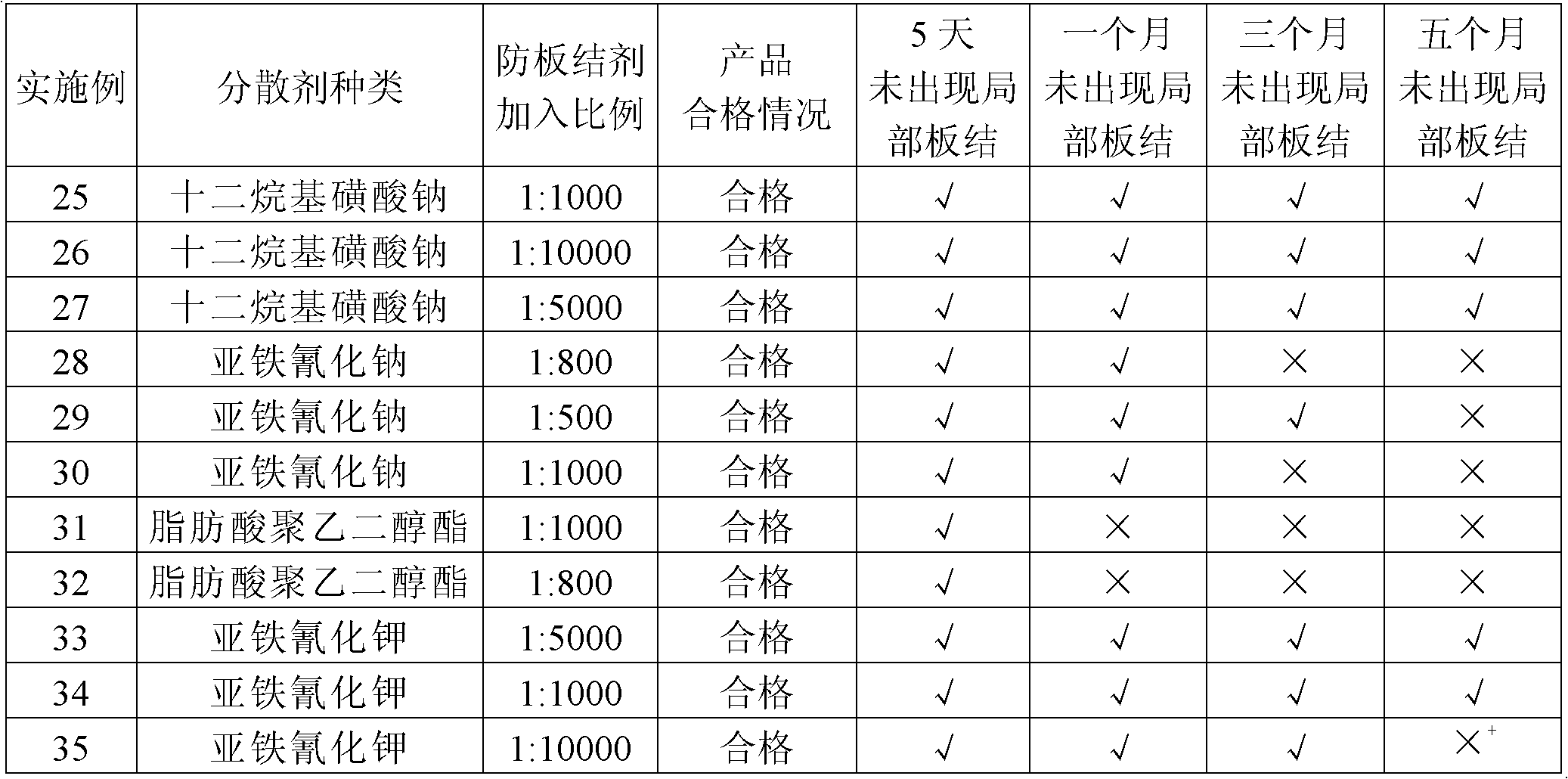

Lithium hydroxide monohydrate and preparation method thereof

ActiveCN102020294ANo flyingMeet the qualityTransportation and packagingLithium oxides/hydroxidesCalcium hydroxideDust explosion

The invention refers to a dust-free lithium hydroxide monohydrate and a preparation method thereof, belonging to the technical field of lithium hydroxide. The technical problems to be solved by the invention are that wet LiOH.H2O has a problem of hardening and dry LiOH.H2O has a problem of dust explosion in the prior art. The invention provides a novel LiOH.H2O, that is, dust-free lithium hydroxide monohydrate without hardening. The lithium hydroxide monohydrate is a loosened granular wet product, wherein the content of water is less than or equal to 3.5%, and the surface of the lithium hydroxide monohydrate is coated with a little anti-hardening agent. The dust-free lithium hydroxide monohydrate is prepared by the following methods: (1) preparing a LiOH solution having a Li2O concentration of 70+-5g / l, and the concentration of SO42- is less than or equal to 15g / l; (2) evaporating the LiOH solution obtained in the step (1) until the ratio of liquid to solid is 1: (0.8-1.5); adding a little anti-hardening agent; uniformly stirring; separating and washing the mixture to obtain dust-free wet LiOH.H2O; and carrying out vacuum seal and packing the wet product, wherein the obtained product is not hardened within 3-5 months.

Owner:TIANQI LITHIUM CORP

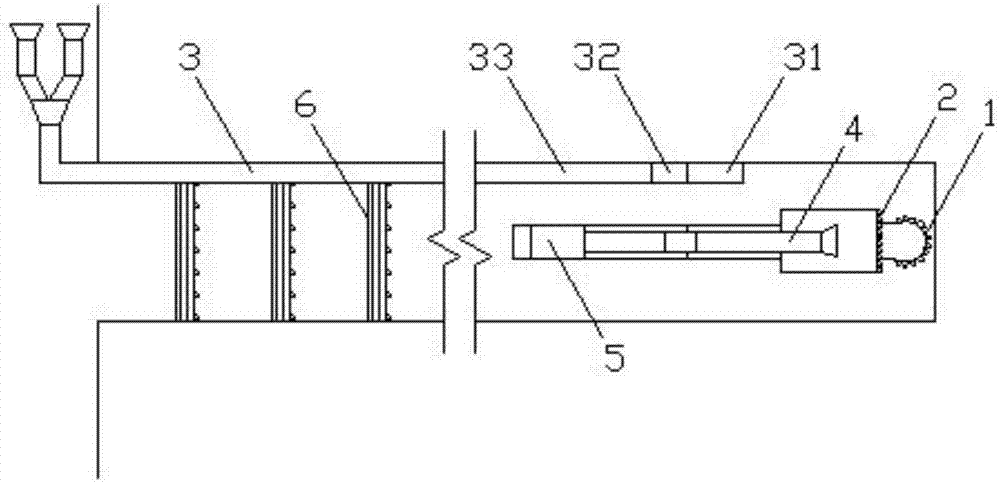

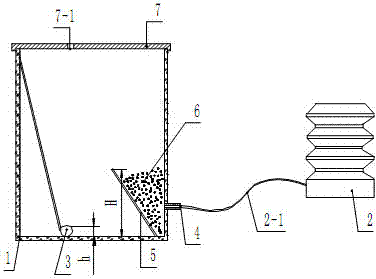

Combined type industrial dust explosion simulation demonstration system

ActiveCN106841300AImprove portabilityGood disassembly effectMaterial exposibilityElectronic controllerDust explosion

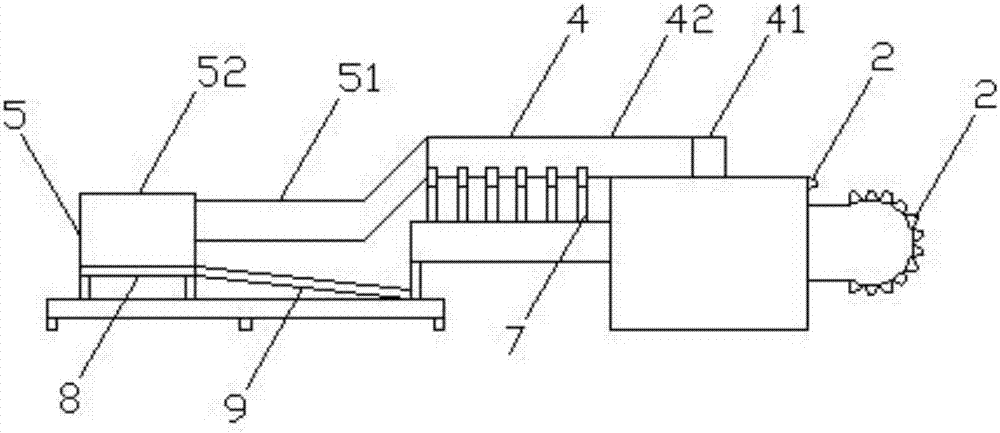

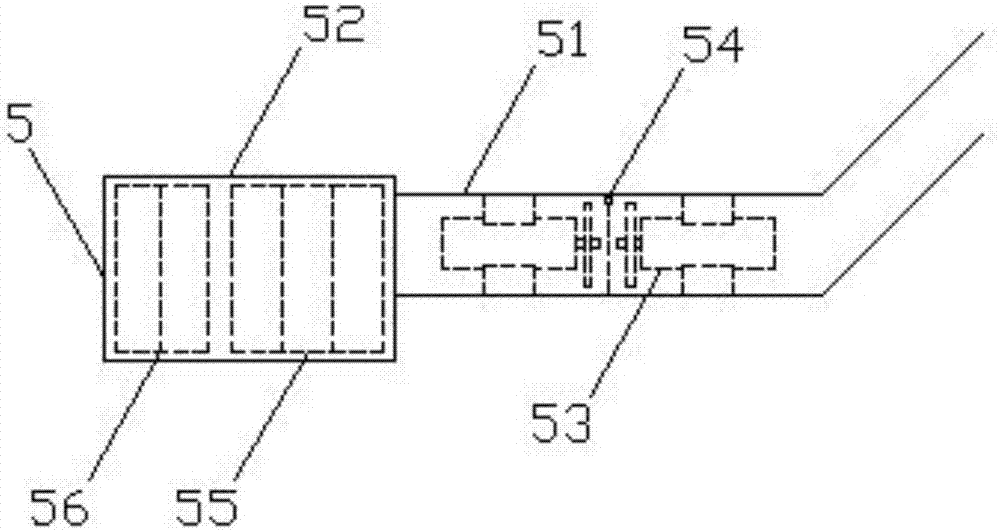

The invention relates to a combined type industrial dust explosion simulation demonstration system which comprises a dust explosion reaction observation pipeline, a variable frequency axial flow fan arranged at one end of the dust explosion reaction observation pipeline, a dust collector arranged at the other end of the dust explosion reaction observation pipeline and communicated with the dust explosion reaction observation pipeline, a dust conveying unit located between the variable frequency axial flow fan and the dust collector and communicated with the dust explosion reaction observation pipeline, an ignition detection control unit arranged on the dust explosion reaction observation pipeline, a dust collection box arranged at the bottom of the dust collector, a purified air pipeline communicated with the top of the dust collector, as well as a tail gas purifier and an electronic controller that are communicated with the purified air pipeline. Compared with the prior art, the system disclosed by the invention is maintained easily, is suitable for various conditions, has the characteristics of being carried conveniently, being simple in operation, good in an explosion display effect and high in cost performance and the like, and can be used for a dust explosion test and a practical training demonstration at any time everywhere.

Owner:SHANGHAI RES INST OF CHEM IND +1

Test device for dust explosion experiment

The invention discloses a test device for a dust explosion experiment. An explosion cavity is provided with photoscopes; focusing streak systems are arranged on both sides of the explosion cavity; the explosion flow field of a test zone in the explosion cavity is shot; light rays emitted from the light source are converted to be divergent light beams through a slot device; the divergent light beams are projected through a first reflecting mirror onto a first paraboloid mirror to be parallel light beams; the parallel light beams are projected on a second paraboloid mirror after penetrating through the first photoscope, the test zone and the second photoscope, and are converted to be convergent light beams through a second paraboloid mirror; and the convergent light beams are projected to a second reflecting mirror and reaches a digital imaging device through a blade system. The flow field structure for the dust explosion experiment inside the cavity can be observed through the photoscopes arranged on the explosion cavity, the first photoscope and the second photoscope symmetrically arranged ensure that light rays from the focusing streak system can pass through the test zone in the middle, and the dust explosion flow field image inside the test zone is projected onto a high-speed digital imaging device and recorded for study.

Owner:WUHAN UNIV OF TECH

Tunnel boring dust prevention system

PendingCN107514275AControlled explosionKeep healthyDust removalFire preventionVisibilityPositive pressure

The invention discloses a tunnel boring dust prevention system. The system comprises a roadheader spraying system, a dust removal system and a roadway spraying system; a water outlet of the roadheader spraying system is formed in a roadheader, and the roadheader spraying system is connected with a water supply pipeline; the dust removal system comprises a positive pressure air cylinder, a negative pressure air cylinder and a dust removal fan; one end of the positive pressure air cylinder faces a head-on part, and the other end of the positive pressure air cylinder is connected with an air supply pipeline; one end of the negative pressure air cylinder faces the head-on part, and the other end of the negative pressure air cylinder is connected with the dust removal fan; the roadway spraying system comprises a plurality of water curtains, the water curtains cover the whole section of a roadway, and the water curtains are arranged on the portions, behind the outlet of the dust removal fan, in the roadway at intervals. The system has the advantages that the comprehensive dust prevention system is used, the concentration of dust generated when the roadheader cuts rock is reduced, the visibility of a tunneling field is improved, the body health of workers is guaranteed, the working efficiency is improved, dust explosion can be effectively controlled, and safe production of a coal mine is ensured.

Owner:HUAINAN MINING IND GRP

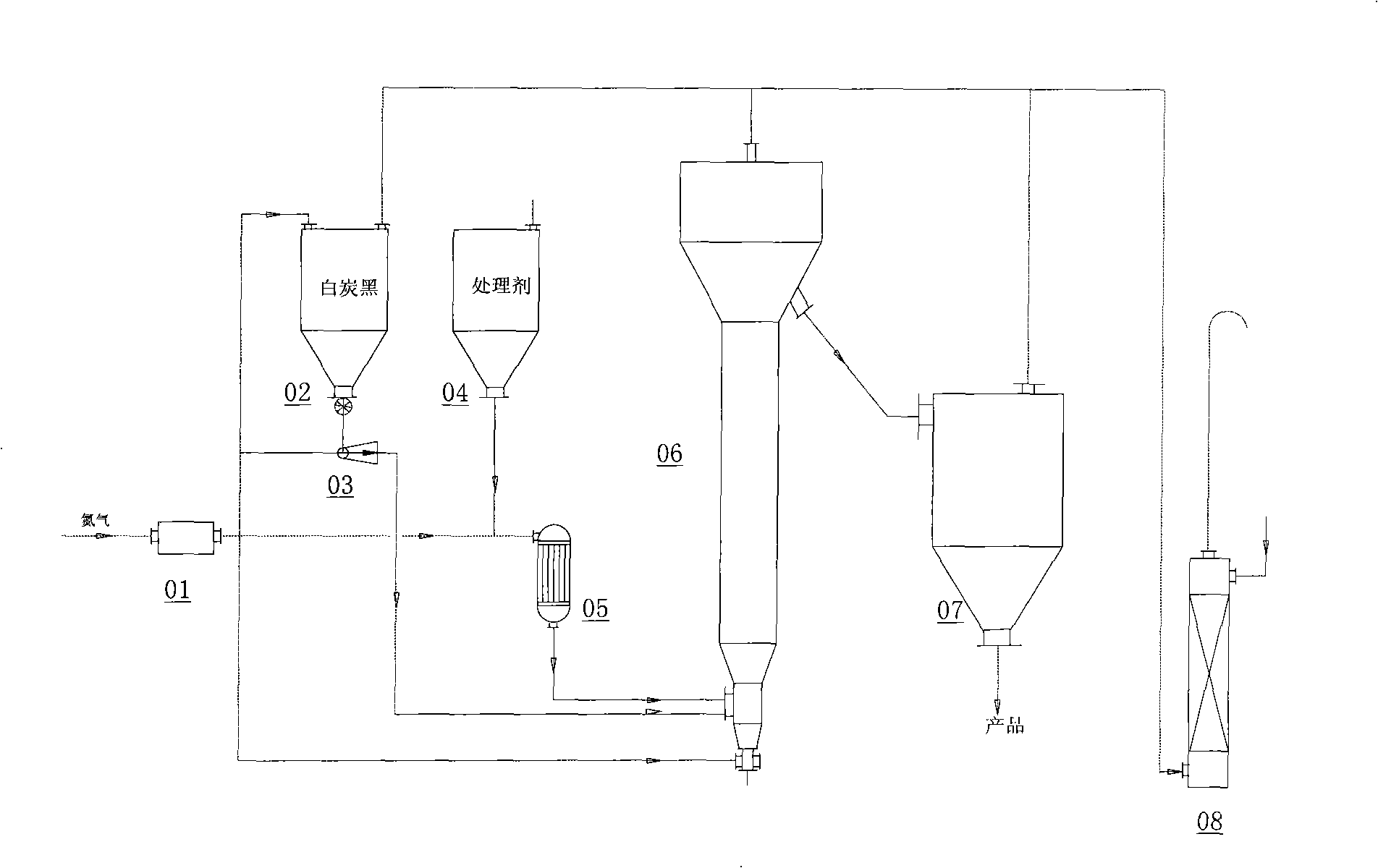

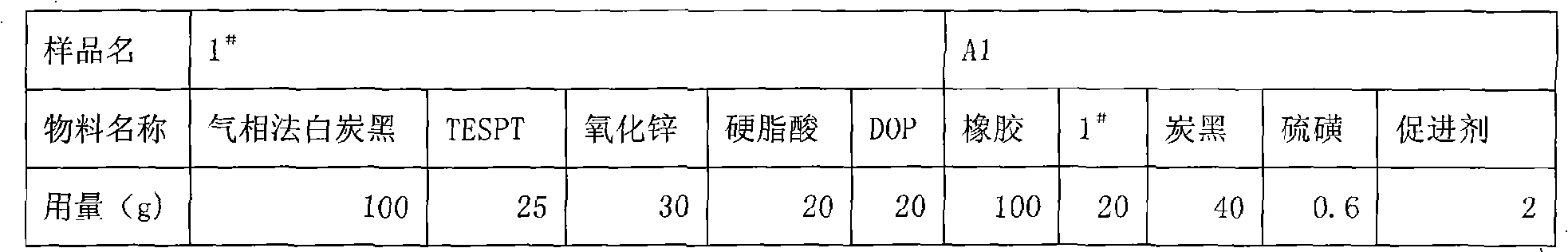

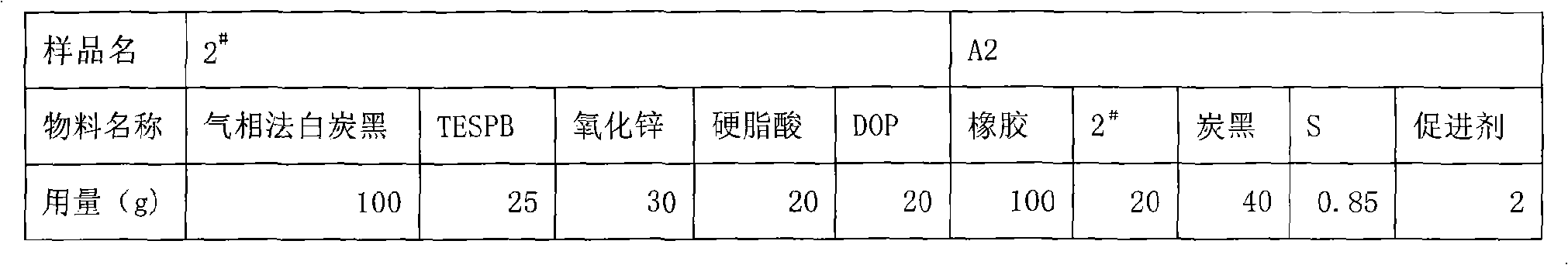

Method for preparing rubber packing containing white carbon black by gas-phase method

The invention discloses a method for preparing rubber filler which contains gas-phase white carbon black. The method comprises the following two steps that: silane coupling agent reacts with the gas-phase white carbon black, and surface treatment is performed on the gas-phase white carbon black; and the gas-phase white carbon black after surface treatment is mixed with rubber plasticizer and rubber processing aid. The stacking density of the gas-phase white carbon black after treatment is greatly improved, and dust explosion during the mixing process is overcome; simultaneously the dispersivity of the gas-phase white carbon black in rubber and the interreaction of the rubber are improved as well, and high-performance rubber materials can be obtained.

Owner:GUANGZHOU GBS HIGH TECH & IND

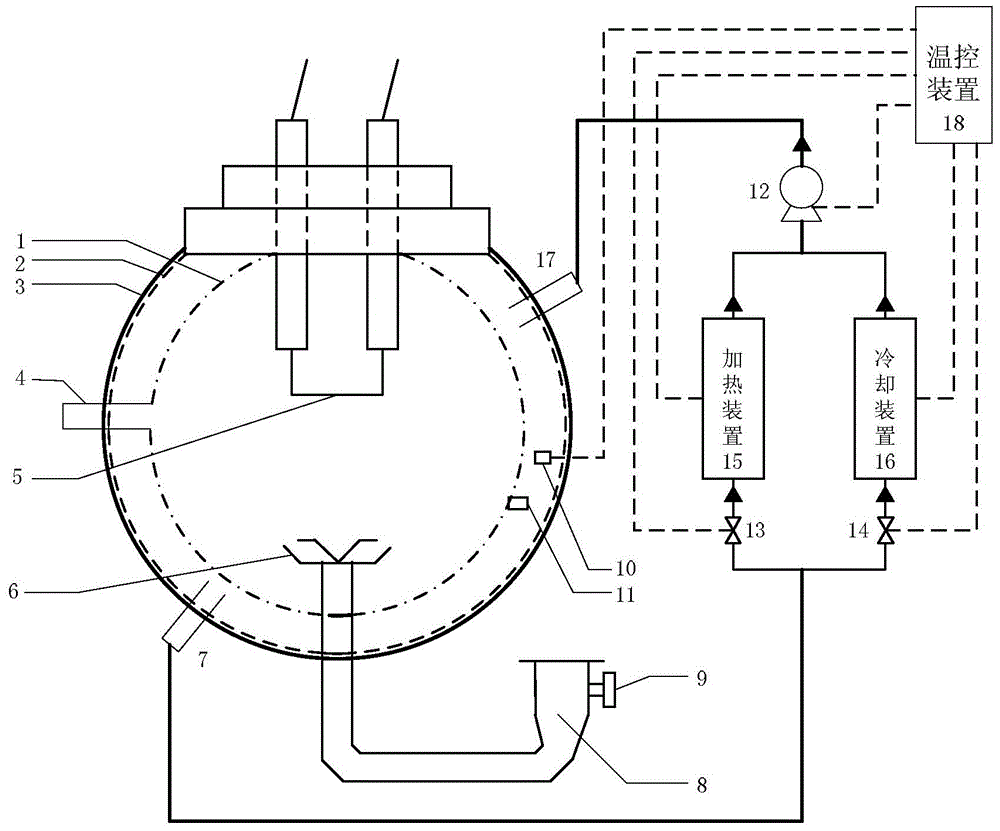

Dust explosion limit test device and test method thereof

The embodiment provides a dust explosion limit test device and a test method thereof. The test device comprises a spherical explosion tank, a heating device, a cooling device and a temperature control device, wherein the outer wall of the explosion tank adopts a double-layer structure with a cavity; the cavity is filled with heat transfer oil; the outer wall of the explosion tank is covered with a thermal insulation layer; a temperature sensor is arranged inside the cavity and used for measuring the temperature of the heat transfer oil; the temperature control device controls the heating device or the cooling device to heat or cool the heat transfer oil according to the temperature measured by the temperature sensor. The test device can not only achieve the dust explosion limit test in a standard condition, but also realize the dust explosion limit test in an abnormal temperature condition, thereby ensuring the carrying out of the research work of the dust explosion limit test under a non-standard condition, so as to guide the chemical powder practical production, and to provide a technical support for safety production.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

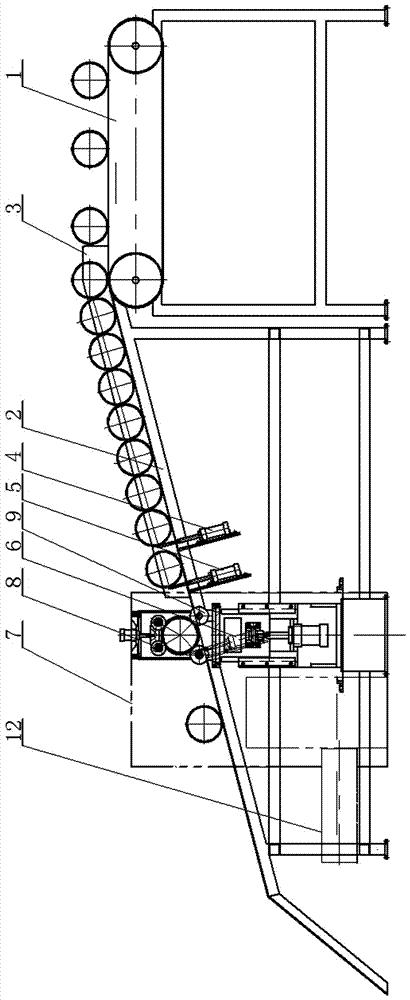

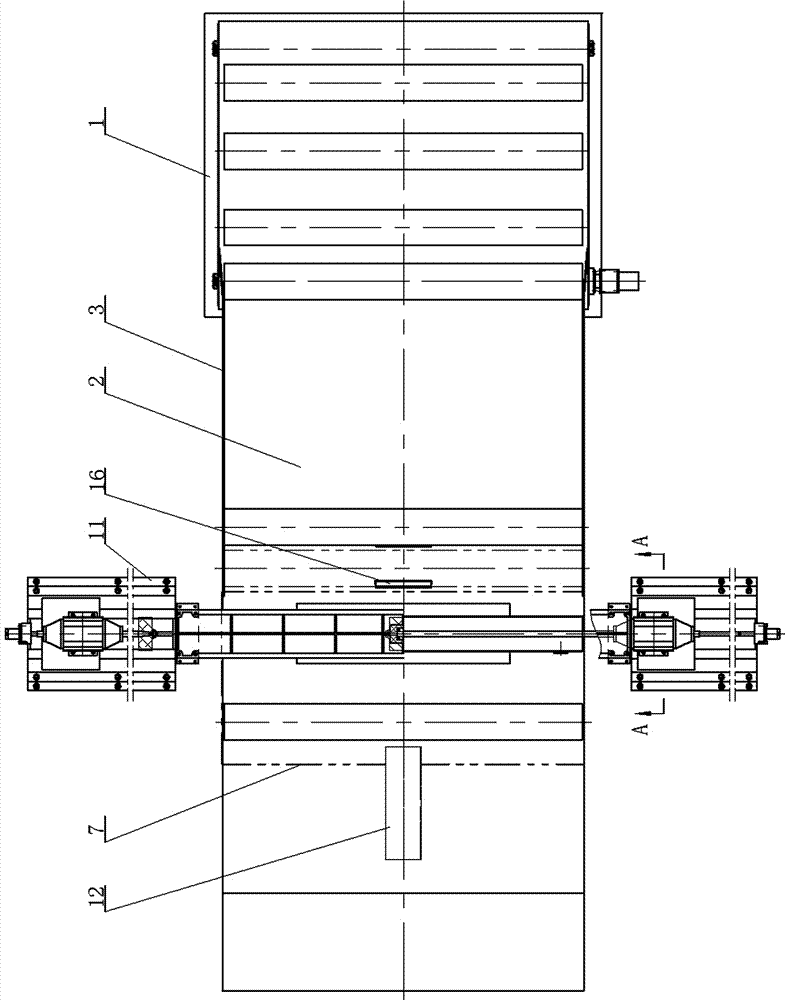

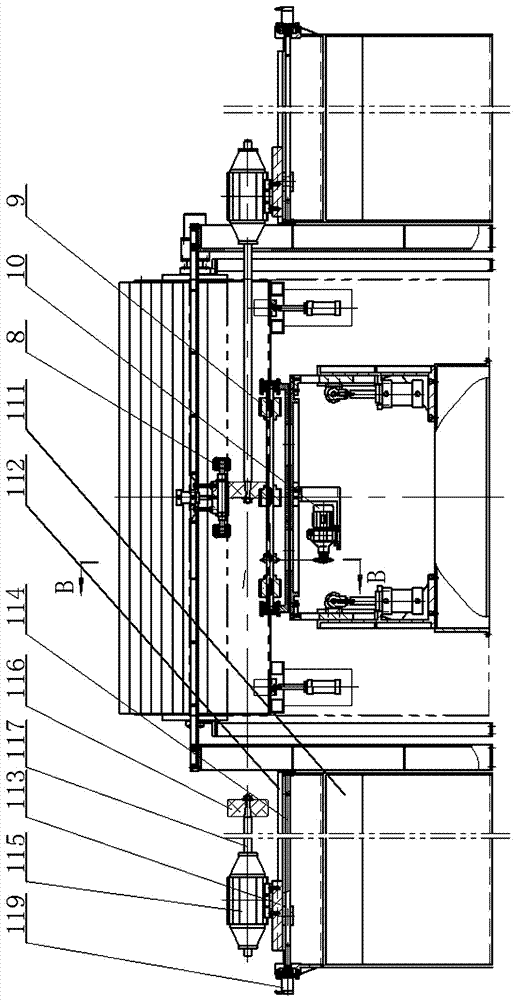

Automatic polishing and grinding equipment for inner hole of metal pipe

ActiveCN107571156AProtect your healthNo explosionGrinding/polishing safety devicesDust explosionEngineering

The invention relates to automatic polishing and grinding equipment for an inner hole of a metal pipe. According to the automatic polishing and grinding equipment for the inner hole of the metal pipe,the problems that when the inner wall of the metal pipe is polished and ground, the production efficiency is low, the workshop environment is polluted, and explosion is likely to occur are solved. The automatic polishing and grinding equipment is characterized in that a pressing wheel device (8) and a supporting wheel device (9) are arranged on the upper portion and the lower portion, at a thirdmaterial blocking device (6), of an inclined sliding table (2) correspondingly; polishing devices (11) are arranged on the two sides of a dustproof shell (7) correspondingly, and the dustproof shell (7) communicates with a draught fan through an air suction pipeline (12). The automatic polishing and grinding equipment can be controlled through a PLC, the automation degree is high, and the production efficiency is effectively improved; and a relatively-closed polishing space is formed in the dustproof shell, so that dust generated during polishing does not diffuse in a workshop, pollution to the workshop environment is avoided, dust explosion accidents are avoided, and the anti-explosion requirement is met.

Owner:山东鹤鹏技术有限公司

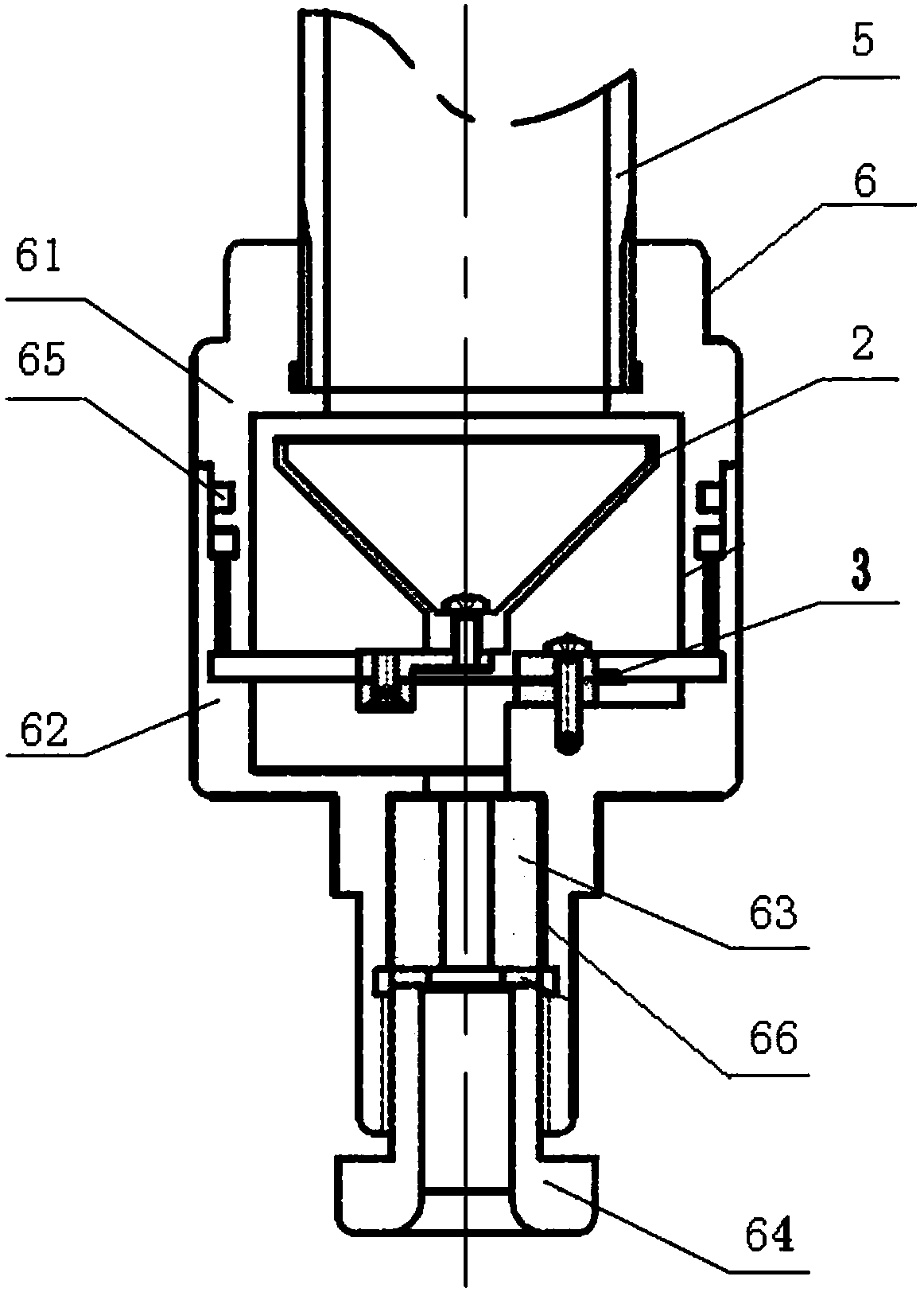

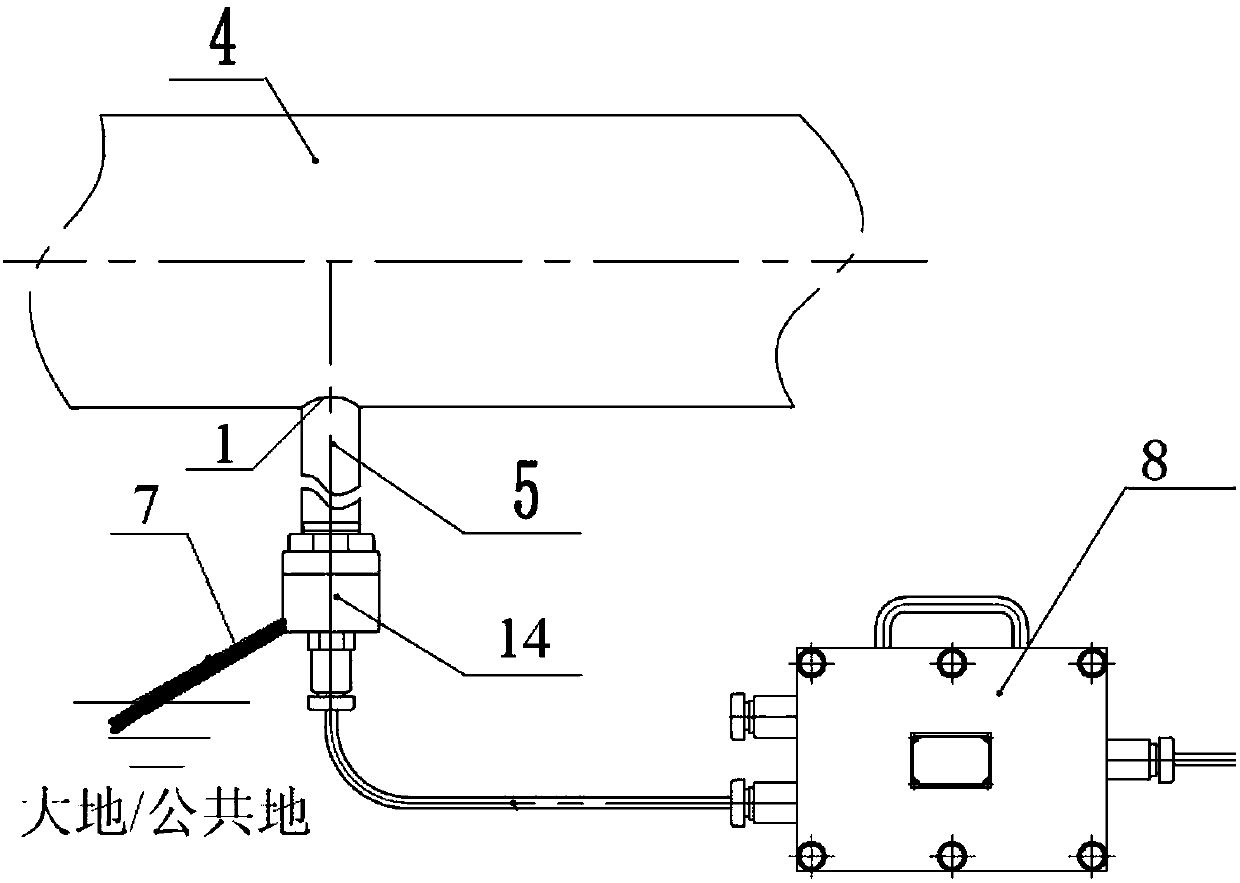

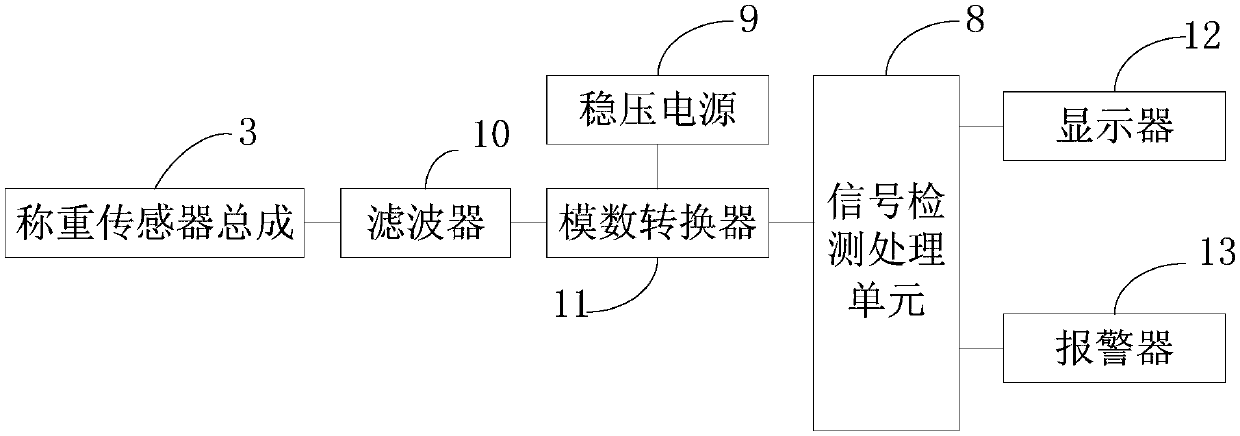

Dust deposition detecting and sensing unit, system and method

ActiveCN107741375AReal-time monitoring of dust thicknessReduce the impactElectrical/magnetic thickness measurementsWeighing by absorbing componentMoving averageDust explosion

The invention discloses a dust deposition detecting and sensing unit, system and method. The dust deposition detecting and sensing unit comprises a detecting hole, a dust accumulating hopper and a weighing sensor assembly, wherein the detecting hole is formed in the bottom of a dust collection pipeline; the dust accumulating hopper is used for accumulating the dust depositing at the bottom of thedust collection pipeline; the bottom of the dust accumulating hopper is in contact connection with a weighing surface of the weighing sensor assembly; the sensing unit can realize online continuous monitoring and does not require separate weight test after dust collection, so as to monitor the dust thickness on the dust collection pipeline in real time. Signals output by a weighing sensor are processed by filtering, analog-digital conversion, moving average, singular value removal, vibration interference removal and the like, thus the influence on the test result caused by the vibration interference from the complicated test environment and the creep property of the weighing sensor is reduced, average dust thickness of unit area in the dust collection pipeline can be tested accurately, andthe prediction of dust explosion can be realized.

Owner:CHINA COAL TECH ENG GRP CHONGQING RES INST

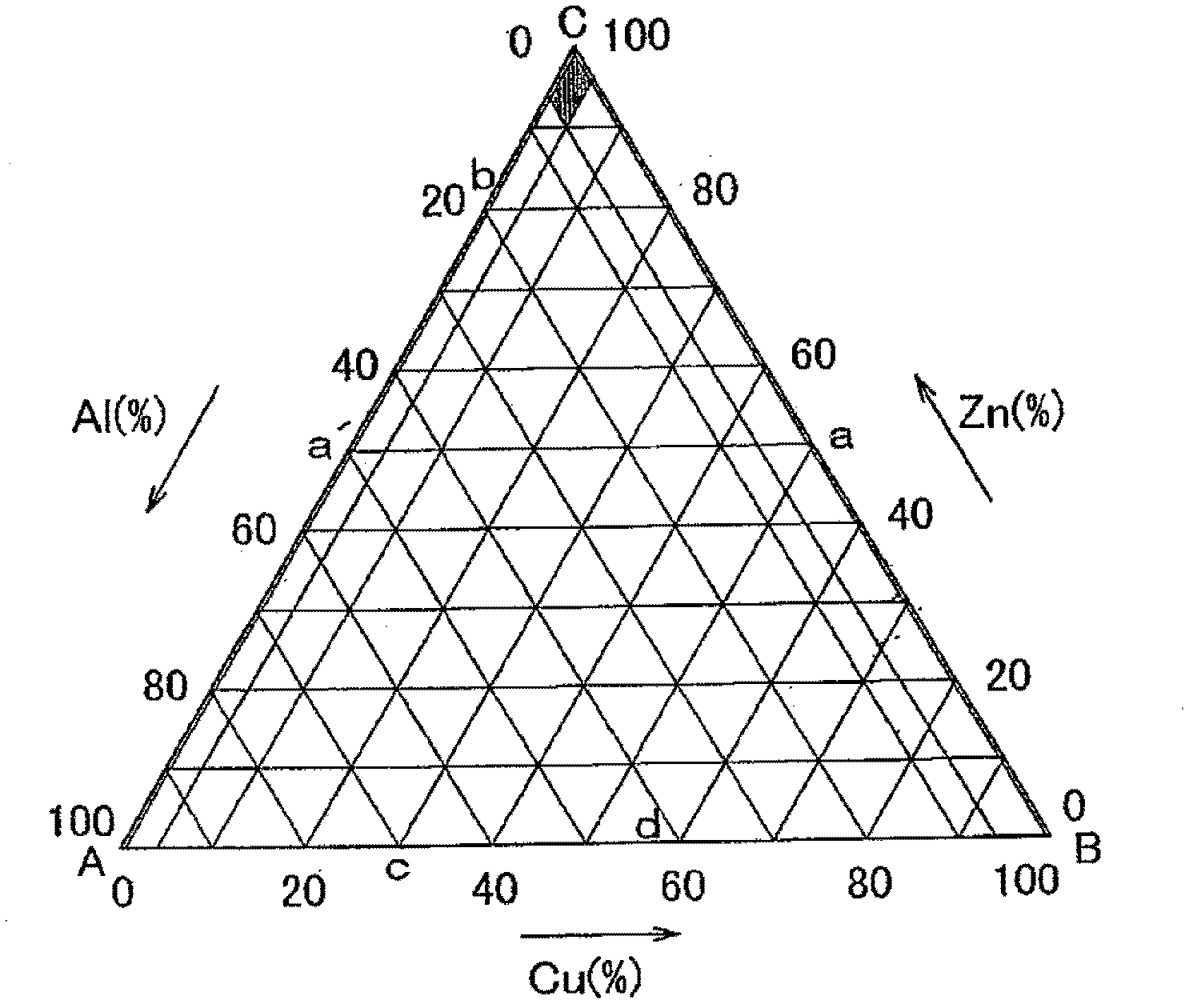

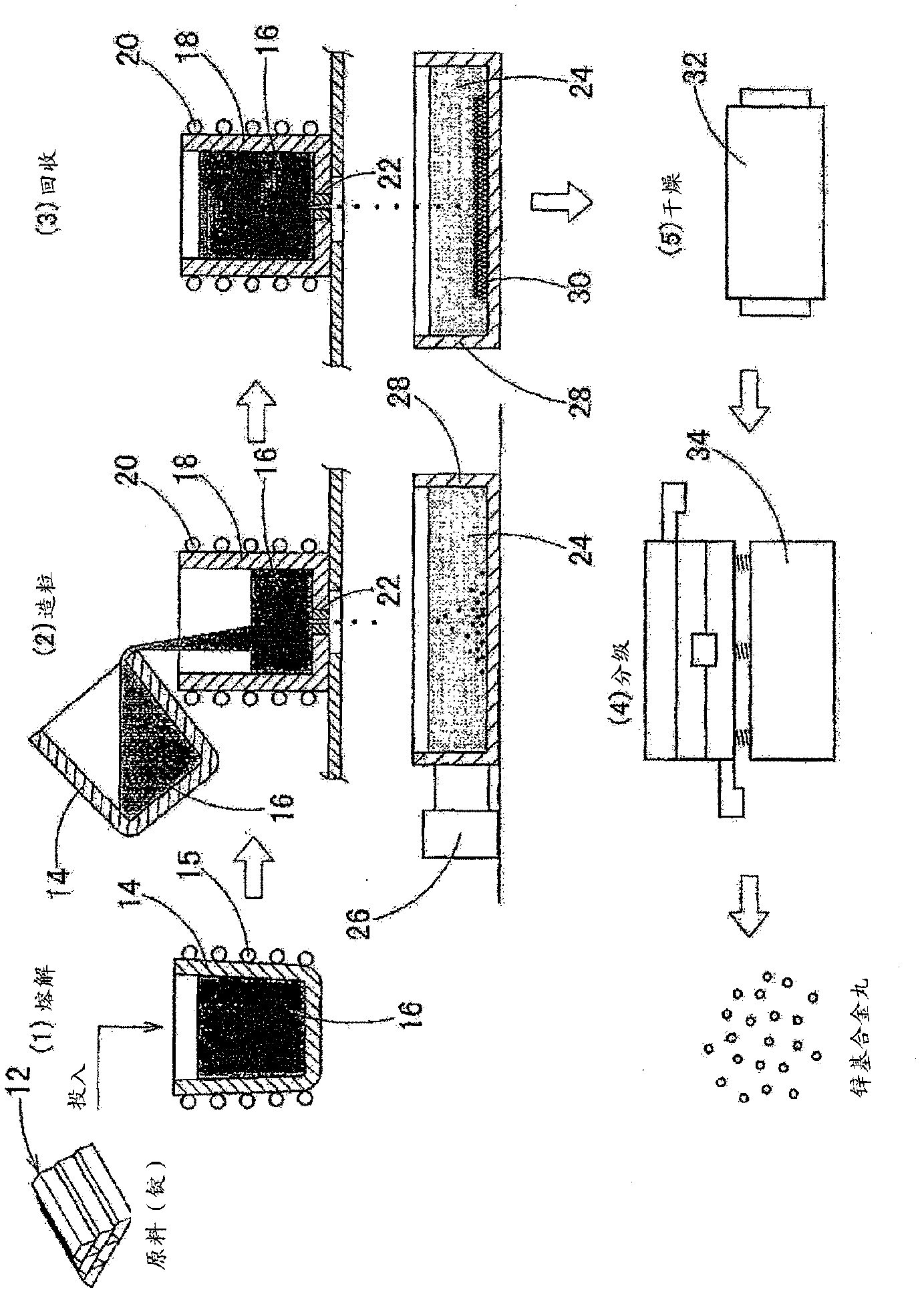

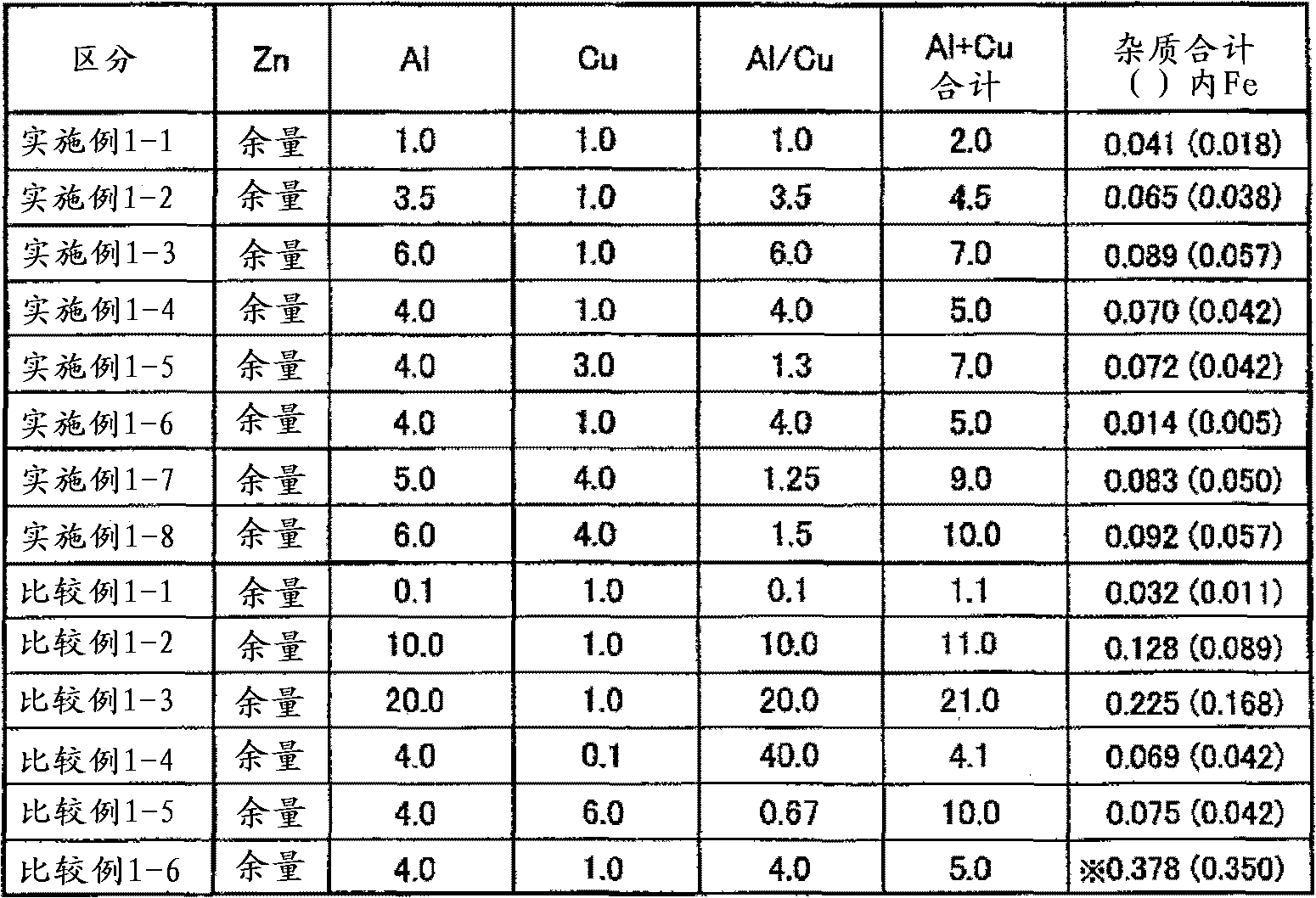

Zinc-based alloy shots

ActiveCN102574274AReduce consumptionReduce generationAbrasion apparatusMass compositionDust explosion

Provided are zinc-based alloy shots which, without risk of dust explosion, are capable of high performance deburring and abrasion cleaning through shot blasting and application of compressive residual stress through shot peening, with low quantities of shots consumed by shot projection. The zinc-based alloy shots include a three-component zinc-based alloy shot wherein 0.5 - 6.5 mass % Al, 0.5 - 4.5 mass % Cu are contained as additional elements, the mass composition ratio of Al to Cu (Al / Cu) is 1.0 - 13.0, the total amount (Al + Cu) is 1.5 - 10.5 mass %, and the Vickers hardness is 90 - 190 HV; and a four-component zinc-based alloy shot wherein 0.5 - 6.5 mass % Al, 0.5 - 4.5 mass % Cu, 0.01 - 0.2 mass % Mg are contained as additional elements, the mass composition ratio of Al to Cu (Al / Cu) is 1.0 - 13.0, the total additional amount (Al + Cu) is 1.5 - 8.0 mass %, and the Vickers hardness is 90 - 190 HV.

Owner:SINTOKOGIO LTD

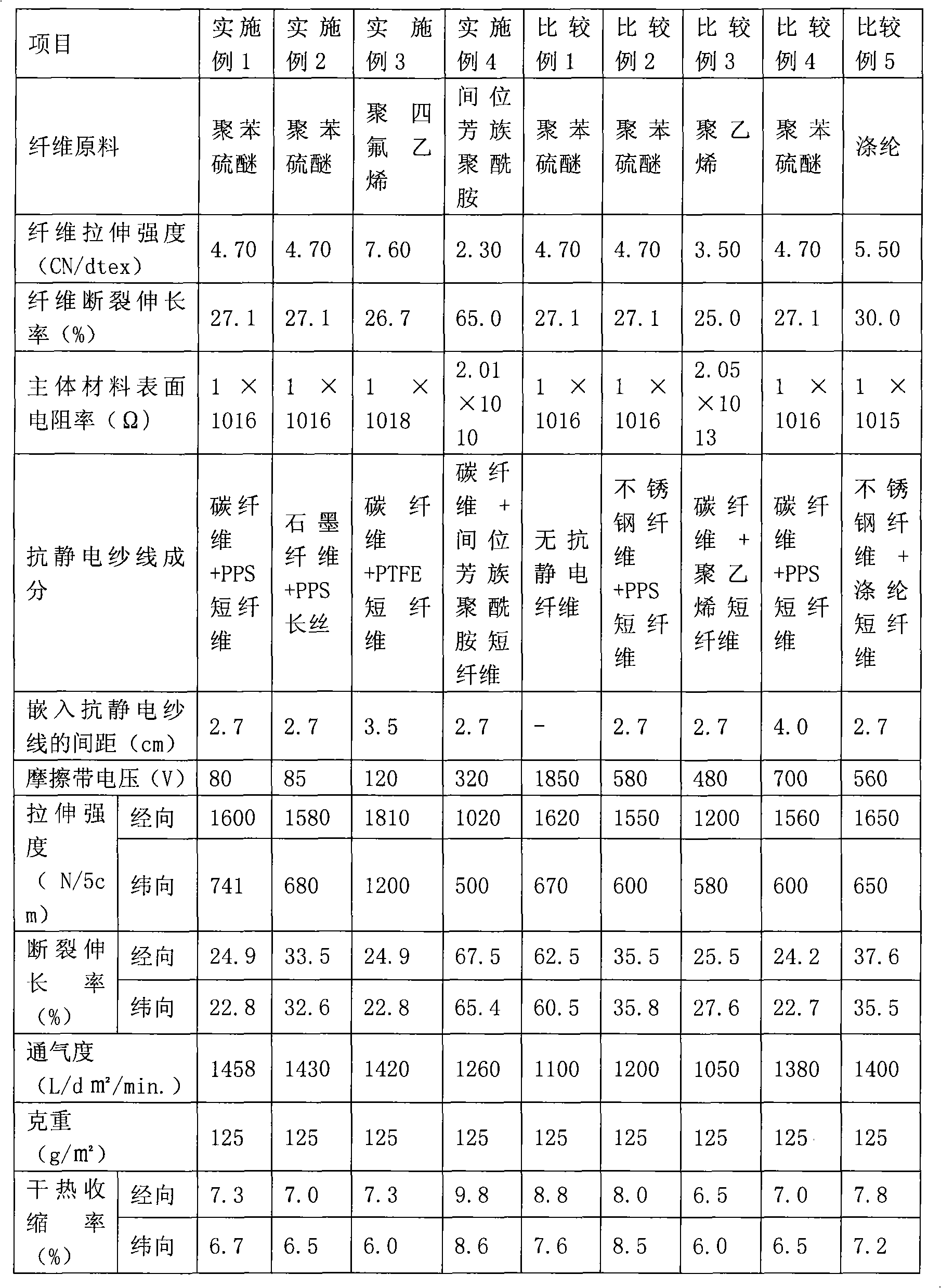

Anti-static base cloth for filter material and production method for anti-static base cloth

InactiveCN102337622AGood durability and antistatic performanceGood dimensional stabilityHeating/cooling textile fabricsWoven fabricsDust explosionGraphite

The invention discloses anti-static base cloth for a filter material and a production method for the anti-static base cloth. Warp and weft yarns forming the base cloth are high temperature heat-resistant fibers with the fineness of between 260 and 1,500 deniers, and are interwoven with a mixed anti-static yarn consisting of at least one of carbon black fiber and graphite fiber and a high temperature heat-resistant fiber and having the fineness of between 260 and 1,500 deniers at an interval of 2.7-3.5cm in the warp direction, the warp density is 120-180 / 10cm, the weft density is 20-80 / 10cm, and the base cloth is manufactured. The base cloth for the filter material has the characteristics of durable anti-static property, dust explosion resistant, high dimensional stability, higher tensile strength, high venting quality, and capacity of prolonging the service life of the filter material.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

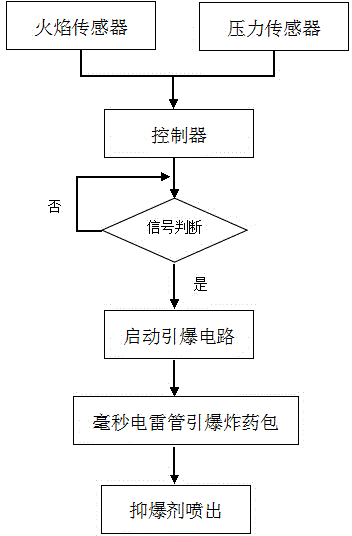

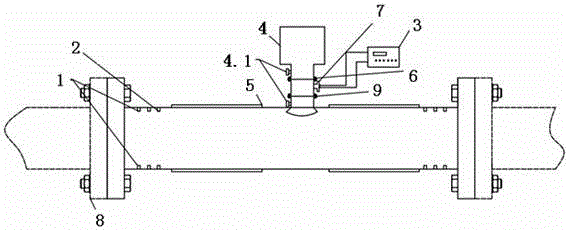

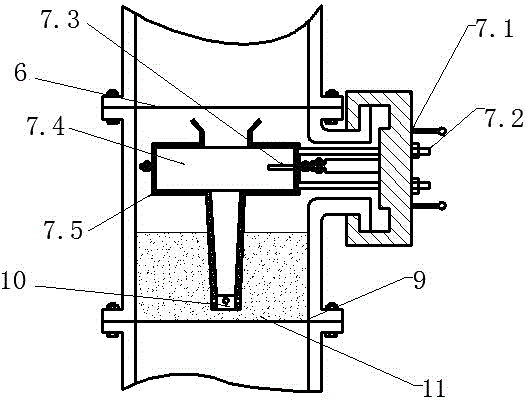

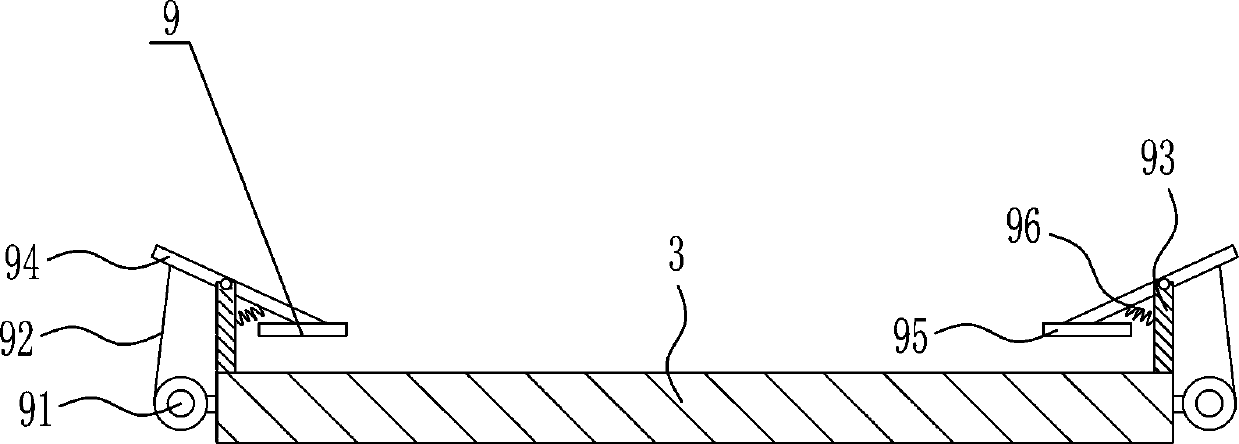

Automatic explosion suppressing device applicable to dust explosion in pipeline

The invention relates to an automatic explosion suppressing device applicable to dust explosion in a pipeline. The automatic explosion suppressing device comprises flame sensors, pressure sensors, a high-pressure explosion suppression agent container and a small-sized detonation device, wherein a carbonate powder explosion suppression agent is placed in the small-sized detonation device, the high-pressure explosion suppression agent container is filled with a high-pressure N2 gas explosion suppression agent, a rupture disc is arranged between the high-pressure explosion suppression agent container and the small-sized detonation device and is used for separating high-pressure N2 gas of the high-pressure explosion suppression agent container, a rupture disc diaphragm is arranged between the small-sized detonation device and a powder conveying pipeline and is used for supporting the carbonate powder explosion suppression agent, the flame sensors and the pressure sensors are connected with a controller, and the controller is connected with the small-sized detonation device and is used for controlling to trigger the small-sized detonation device, so that the high-pressure N2 gas explosion suppression agent in the high-pressure explosion suppression agent container and the carbonate powder explosion suppression agent enter the pipeline at high speed, and thus, explosion suppression is realized. According to the automatic explosion suppressing device applicable to the dust explosion in the pipeline, quick response to an explosion accident in the pipeline can be carried out, so that the occurrence of the explosion accident or the further expansion of harm is avoided.

Owner:SHANGHAI INST OF TECH

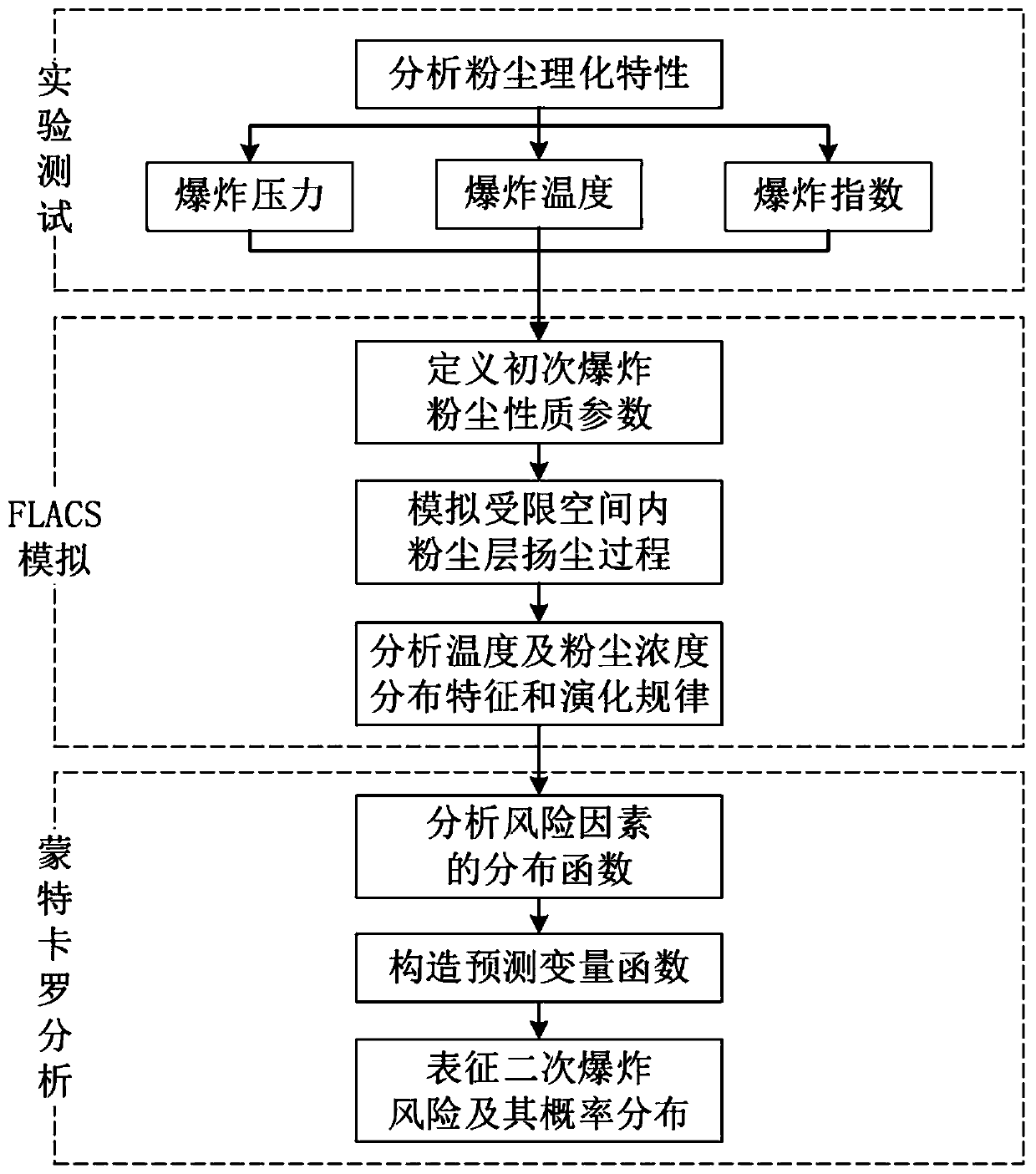

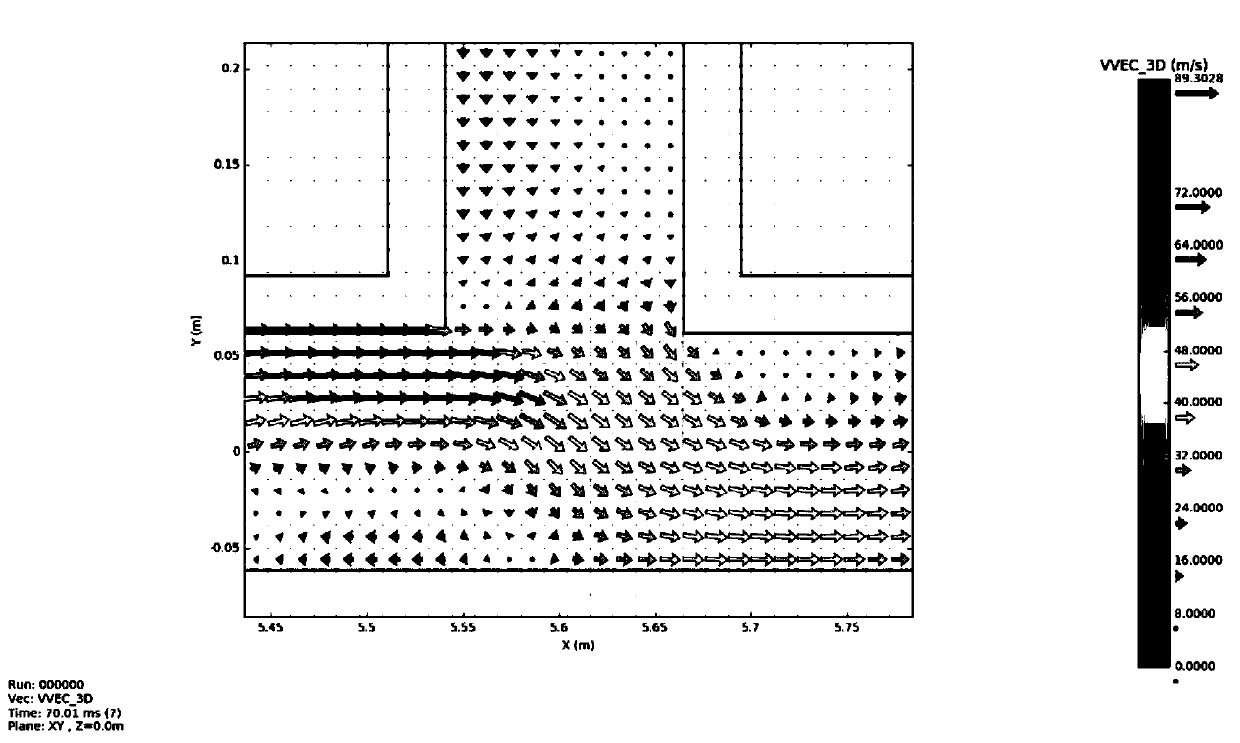

Monte Carlo simulation-based dust secondary explosion risk prediction method

ActiveCN109871640AAchieve continuous acquisitionWide coverageSpecial data processing applicationsPredictive methodsDust explosion

The invention discloses a Monte Carlo simulation-based dust secondary explosion risk prediction method, which specifically comprises the following steps of: testing and analyzing physicochemical characteristic parameters and dust explosion parameters of dust through an experiment, and then setting a FUEL file required by simulation; A dust explosion module of simulation software FLACS is used forsimulating the dynamic change of a flow field structure of dust explosion in a limited space, and the distribution condition of the temperature and the dust concentration of the dust explosion is analyzed in combination with dust ignition characteristic parameters, so that risk factor data is provided for risk characterization; Monte Carlo simulation is applied to carry out probability distribution fitting on risk factor data of dust explosion, uncertainty and sensitivity analysis is carried out on a risk result by constructing a prediction variable function, and the uncertainty risk of secondary explosion of dust and probability distribution of the uncertainty risk are predicted. And the establishment of the dust secondary explosion risk prediction model is of great significance to the control of dust explosion and explosion safety production.

Owner:CHANGZHOU UNIV

Dust explosion-proof protection system of grain/feed/granular powder grinding apparatus

ActiveCN105478217AAchieve forecastAchieve protectionFire rescueGrain treatmentsForeign matterEngineering

The invention discloses a dust explosion-proof protection system of a grain / feed / granular powder grinding apparatus in an embodiment to avoid the risk of dust explosion caused by dust cloud explosion in a grinding processing region due to generated sparks and induced combustion during grinding processing of the grain / feed / granular powder grinding apparatus. The dust explosion-proof protection system of the grain / feed / granular powder grinding apparatus in the embodiment of the dust explosion-proof protection system comprises a grinding apparatus emergency braking interlocking device mounted in dust explosion-proof association with the grinding apparatus, a powder falling settling chamber and a powder conveying system, a magnetic-absorption separation device for metal foreign bodies, the powder conveying system, an air exhausting system, a dust removing apparatus, a spark detection device, a gas fire-extinguishing device, an explosion-proof device, a temperature monitoring device, a fire-extinguishing water spraying device, an interlocking protector and an interlocking protector control system.

Owner:GUANGDONG JINFANGYUAN SAFETY TECH TESTING CO LTD

Cutting device for circuit board production

The invention relates to a circuit board cutting device, in particular to a cutting device for circuit board production. According to the cutting device for circuit board production cutting efficiencyis high, fixing can be conducted during cutting, and dust explosion does not exist during cutting. The cutting device includes a bottom plate and the like. The top of the bottom plate is provided with an n-shaped frame. The right side of the inner top part of the n-shaped frame is provided with a moving mechanism. A moving component of the moving mechanism is connected with an air cylinder. The bottom end of the air cylinder is connected with a cutting mechanism. The lower part of the inner left side of the n-shaped frame is provided with a horizontal plate. The left side of the top of the bottom plate is provided with a dust suction mechanism. According to the cutting device for circuit board production, the effects that cutting efficiency is high, fixing can be conducted during cutting,and dust explosion does not exist during cutting can be achieved; through interaction of the moving mechanism and the cutting mechanism, cutting is conducted to a circuit board; meanwhile, the dust suction mechanism can suck the dust produced during cutting, so that human health cannot be affected.

Owner:南昌安润科技有限公司

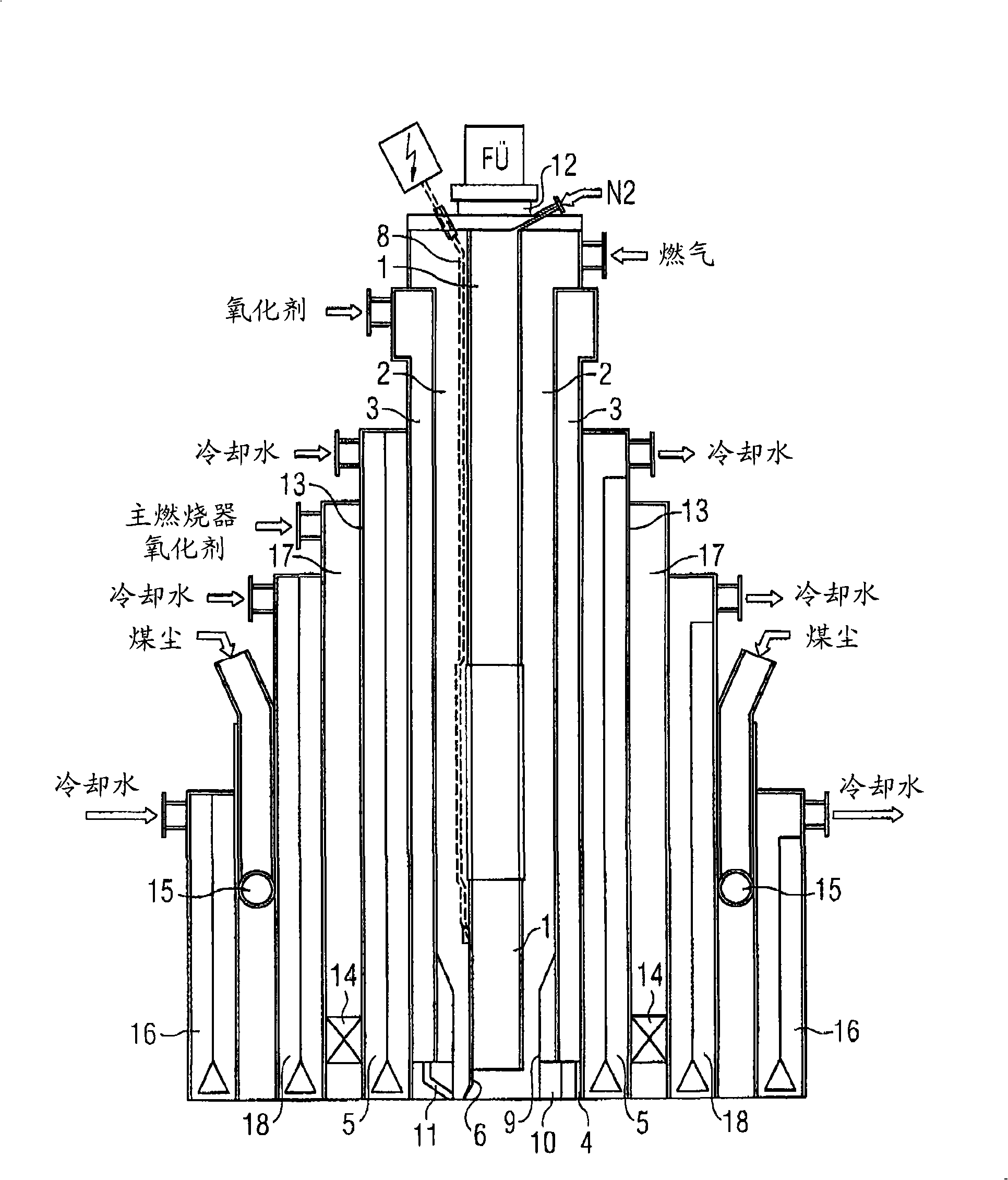

Combined pulverized coal burner comprising an integrated pilot burner

ActiveCN101403496AReliable functionRun without troubleBurner ignition devicsPulverulent fuel combustion burnersCombustorDust explosion

The invention comprises a combination burner for the gasification of pulverized fuels with an oxidation means containing free oxygen at ambient or higher pressures, as well as temperatures between 800-1800 DEG C., with the ignition device of the pilot burner with flame monitoring and the pulverized fuel burner being integrated as a combination burner and all operating channels being routed separately from each other up to the mouth of the burner and the media carried by the channels only being mixed at the mouth of the burner. When the pilot burner is dismantled the eddy bodies 14 attached to its sleeve in the main burner oxidation means supply 17 can be exchanged quickly and easily and thus the main burner flame adapted in the optimum way to the reaction chamber contour of the reactor.

Owner:西门子能源全球两合公司

Dust explosion experimenting device

The invention discloses a dust explosion experimenting device, and relates to the technical field of manufacturing of experiment teaching aids. The dust explosion experimenting device comprises a tank body with a cover body at a tank opening, and a dust container arranged inside the tank body and communicated with an air pump, wherein a partition board is arranged at the inner bottom of the tank body and at a position close to the tank wall; the partition board and the inner wall of the tank body surround the dust container; a combustion vessel is arranged on one side, with the dust container, of the tank body. Compared with the prior art, the dust explosion experimenting device has the advantage that the explosion experimenting device can solve the problem that the existing dust explosion experiment is low in success rate.

Owner:鹿寨县初级实验中学

Environment-friendly dust removal and humidification device for textile fabric

InactiveCN108867005AImprove work efficiencyAvoid explosionMechanical cleaningPressure cleaningDust explosionEngineering

The invention discloses an environment-friendly dust removal and humidification device for textile fabric. The device comprises a processing box, wherein a first linear guide rail is arranged at the inner top of the processing box. The two ends of the first linear guide rail are fixedly connected with the two sides of the processing box respectively, one end of the first linear guide rail is connected with a first limiting baffle plate, and the other end, away from the first limiting baffle plate, of the first linear guide rail is connected with a second limiting baffle plate. A servo motor box is connected to the one side outside the processing box, and a screw rod and a dust collector are arranged. When the cloth is processed and produced, dust generated in the production process can beabsorbed by the dust collector. Dust explosion is avoided. A water pump and a spray head are arranged at the bottom of environment-friendly textile fabric, humidification can be carried out in the processing box, so that the dust and the humidity in the box are controlled to be within a certain range by combining the dust collector, and the working efficiency is accelerated. The device is simple and novel in structure, the operation is easy, and the working use efficiency of the device is greatly improved.

Owner:南通布鲁斯纺织有限公司

LED anti-explosion lamp

InactiveCN101706050AAvoid explosionImprove cooling effectPoint-like light sourceElectric circuit arrangementsDust explosionEngineering

The invention relates to an LED anti-explosion lamp which comprises a shell, wherein the LED anti-explosion lamp consists of a front light source cavity, a rear electric appliance cavity and a heat radiating cavity positioned between the front light source cavity and the rear electric appliance cavity, the light source cavity and the electric appliance cavity are closed cavities and are capable of preventing electric sparks from leaking, heat radiating through holes are arranged on the circumferential wall of the heat radiating cavity, the light source cavity is internally provided with an LED module, the electric appliance cavity is internally provided with a power supply driver adapted with the LED module, an electric wire connected with the power supply driver and the LED module is led to the light source cavity from the electric appliance cavity after passing through a sealing sleeve membrane; and a heat radiating sheet is connected to the LED module in the light source cavity, and the rear end of the heat radiating sheet is communicated with the heat radiating cavity. The invention has the advantages of good heat radiation effect, dust explosion prevention, high safety and long service life of the LED lamp.

Owner:绍兴晶彩光电技术有限公司 +1

Drum-type automatic final-panning aroma raising machine and processing method thereof

InactiveCN102754705ACompact and smooth shapeColor emerald greenPre-extraction tea treatmentProduction lineAutomatic control

The invention discloses a drum-type automatic final-panning aroma raising machine. The drum-type automatic final-panning aroma raising machine comprises a frame, a drum, a drum heater and a drum dumping mechanism, wherein the drum, the drum heater and the drum dumping mechanism are disposed on the frame. One end of the drum is provided with a tea leaf access hole, and the other end of the drum isclosed and is connected with an air heating device through a hot air pipe. A door opening and closing manipulator and a feeding and discharging manipulator are arranged on two sides of the drum on the frame. A moving door is disposed at the tail end of the door opening and closing manipulator. A tea leaf chute is arranged at the tail end of the feeding and discharging manipulator. The drum-type automatic final-panning aroma raising machine is further provided with an automatic control system. By the drum-type automatic final-panning aroma raising machine, the problem that an existing drum-type tea leaf final-panning machine is unavailable for an automatic tea leaf production line is solved effectively, and the problem that dustiness of the drum-type tea leaf final-panning machine endangers physical health of workers and possibly causes dust explosion is also solved. The drum-type automatic final-panning aroma raising machine is ingenious in structure, suitable for automatic tea leaf production lines, clean and safe and has broad market prospect.

Owner:苏和生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com