Patents

Literature

80results about How to "Meet the quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bicomponent high-strength sprayed polyurethane waterproof paint

InactiveCN101608094AHigh solid contentFast curingLiquid surface applicatorsAntifouling/underwater paintsAlcoholPolyol

The invention provides bicomponent high-strength sprayed polyurethane waterproof paint. The paint consists of a component A and a component B according to the volume ratio of 1 to 1, wherein the component A is a semi-prepolymer synthesized by polyisocyanate with low functionality and polyether glycol; according to weight portion, the component A comprises 50 to 80 portions of the polyisocyanate with functionality of between 2.0 and 2.4 and 20 to 50 portions of the polyether glycol with functionality of between 2 and 4; and the component B comprises 40 to 84 portions of the polyether polyol or amino-terminated polyether or mixture of the polyether polyol and the amino-terminated polyether, 10 to 40 portions of amine chain extender or alcohol chain extender or mixture of the amine chain extender or the alcohol chain extender and 0 to 20 portions of pigment filler and additive. The bicomponent high-strength sprayed polyurethane waterproof paint has mechanical performance close to or even higher than that of a waterproof coiled material, adopts a spraying construction method, is convenient and high-efficient and greatly prolongs the service life of the waterproof material; and a solvent-free system also greatly ensures the environment-friendly requirement of the material, so that the performance is more reliable, high efficient and environment-friendly. Compared with a conventional waterproof material, the bicomponent high-strength sprayed polyurethane waterproof paint has high strength and elongation rate.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Chemical mechanical polishing solution for large-sized silicon wafers and preparation method thereof

ActiveCN101870852AImprove consistencyReduce hardnessPolishing compositions with abrasivesCompound (substance)Cleansing Agents

The invention relates to a chemical mechanical polishing solution for large-sized silicon wafers and a preparation method thereof, and the chemical mechanical polishing solution is mainly applied to the ultraprecision machining of large-sized semiconductor silicon substrate slices, and can obtain a nanometer-level ultrasmooth surface. The polishing solution consists of the following components inpercentage by weight: 5 to 50 percent of silicon dioxide abrasive, 1 to 10 percent of pH value regulator, 0.01 to 5 percent of surfactant, 0.01 to 0.05 percent of cleaning auxiliary, 0.01 to 2 percent of chelator and the balance of deionized water; and the silicon dioxide is added in the state of silicasol. Under proper polishing technological conditions, the polishing solution prepared with the components according to the contents can obtain a high-quality polished surface and meet the requirement of the semiconductor industry on the surface quality and removal rate of silicon substrate slices, and moreover, the invention has the advantages of low cost, easy cleaning, low corrosiveness and the like, and has a good application prospect.

Owner:BEIJING GRISH HITECH

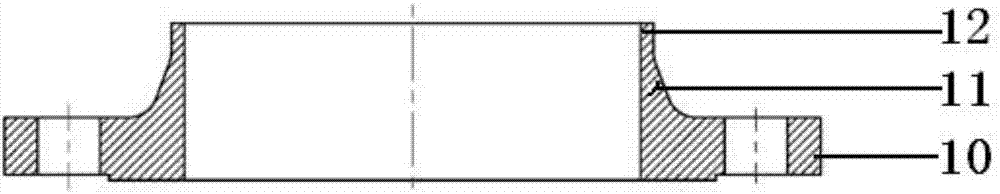

Electric arc additive manufacturing method for flange part

ActiveCN107470620AMeet the qualityFulfil requirementsAdditive manufacturing apparatusIncreasing energy efficiencyShielding gasWater cooling

The invention relates to an electric arc additive manufacturing method for a flange part. The electric arc additive manufacturing method for the flange part comprises the steps that a base plate, a wire, protective gas and equipment are selected; multi-layer and multi-pass accumulation is completed on the base plate from inside to outside along a spiral path through the electric arc additive manufacturing method, so that a bottom surface and a lower neck of the flange part are manufactured; multi-layer and single-pass accumulation is completed on the lower neck along a circular path, so that an upper neck of the flange part is manufactured, and the temperature, current, overlap rate and advancing speed between the layers and the passes are controlled; and redundant portions of the base plate are cut off, solid solution treatment is conducted, the temperature and the constant-temperature time are controlled, and water cooling is conducted. According to the electric arc additive manufacturing method for the flange part, restrains from complex tools, molds and special tools are avoided, only a small degree of finish machining needs to be conducted on a formed blank, the machining procedure is greatly simplified, the manufacturing cycle of products is shortened, and customized individual production can be achieved; and the nondestructive detection quality of the formed flange part is qualified, metal is pure, the structure, the plasticity and the toughness are optimized, the anisotropy phenomenon is improved, and the performance of the flange part can meet the quality and performance requirements for similar forged pieces.

Owner:SUZHOU NUCLEAR POWER RES INST +3

Leadless enamel blocks

A non-lead fritted glaze for ceramics is prepared from quartz, feldspar, borax, boric acid, barium carbonate, stalactite, zinc oxide, strontium carbonate, lithium carbonate, prepared talc, and aluminium hydroxide through proportionally mixing, fusing at 1300-1350 deg.C, quenching in water, and grinding. Its advantages are wide range of calcine temp, low calcine temp. high surface finish quality, no lead, and high antiwear performance.

Owner:SHANDONG JINLING MINING CO LTD

Hot rolling method for wide and thin size high-strength cold-rolled base plate for automobile

InactiveCN105478472AGuaranteed MicrostructureGuaranteed mechanical propertiesMetal rolling arrangementsStructure propertySheet steel

The invention discloses a hot rolling method for a wide and thin size high-strength cold-rolled base plate for an automobile. After continuous casting billets are assembled in a heating furnace in a hot state, the Cu accumulation amount of iron oxide scales and steel substrates is reduced by adopting high-temperature preheating and high-temperature rapid heating technologies; after rough rolling, the thickness of an intermediate billet is reduced, a heat holding cover is used for reducing temperature drop and temperature differences of all parts, so that the finish rolling entry temperature of the intermediate billet is increased; and loads of all racks for finish rolling are reduced, and the stability of finish rolling is improved. In the process from finish rolling to steel belt coiling, a controlled rolling and controlled cooling technology is adopted, so that the cold-rolled base plate has excellent uniformity between the shape and the structure property. According to the method, the cold-rolled base plate with the thickness of 1.5-2.5 mm and the width of 1650-2000 mm can be obtained; the convexity degree of a steel belt is controlled to be in a range between 45-15 mu m and 45+15 mu m; the straightness is controlled to be 30I; the thickness accuracy is in a range between -30 mu m and +30 mu m; the structure property of different edges of the head, the middle, the tail of the steel belt is uniform; and the yield and the production efficiency of the wide and thin size high-strength cold-rolled base plate can be increased and improved, so that the cold-rolled base plate meeting the requirements of the actual product quality and the performance is provided for steel plates with the grade of 450-590 MPa for automobile covering parts.

Owner:ANGANG STEEL CO LTD

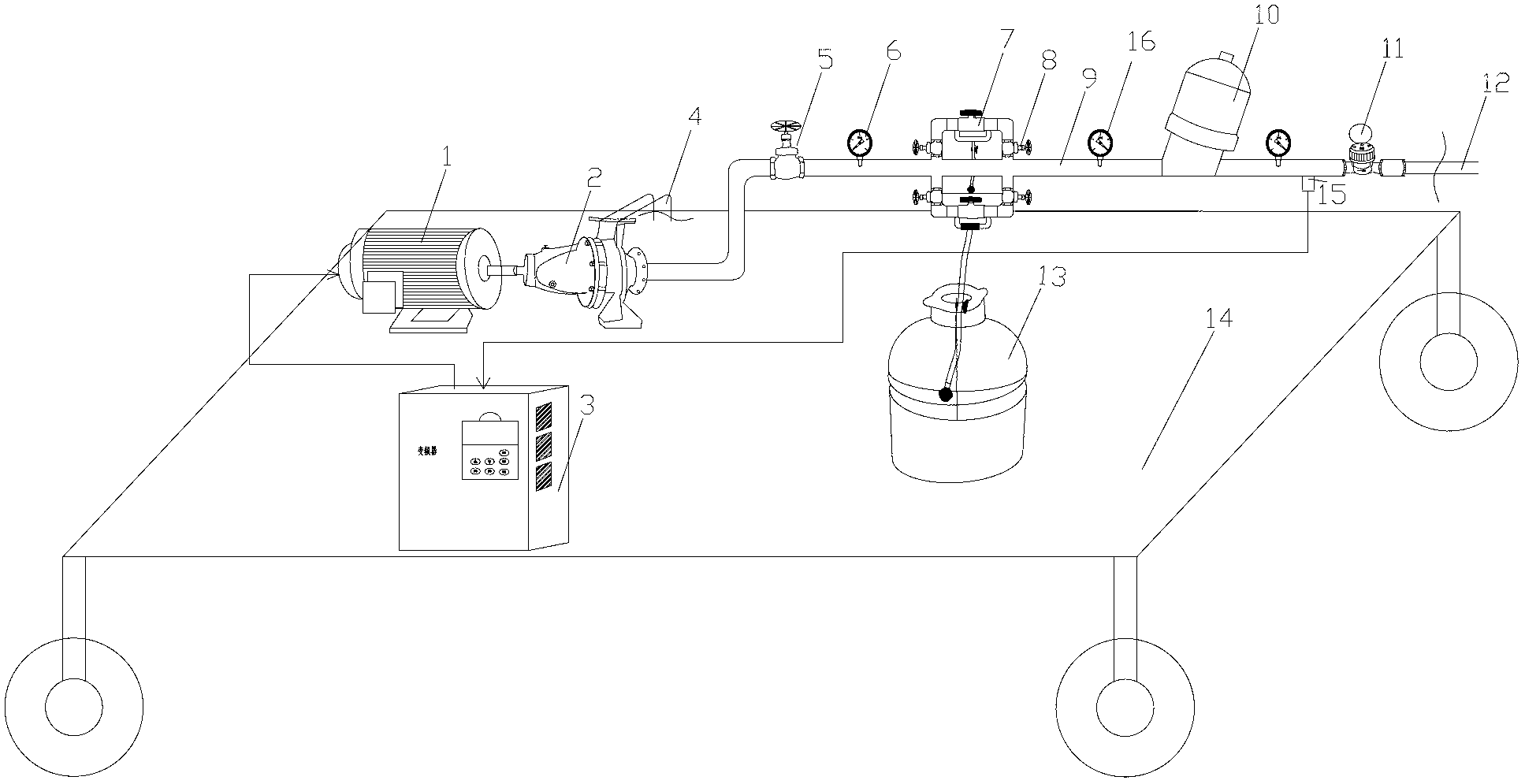

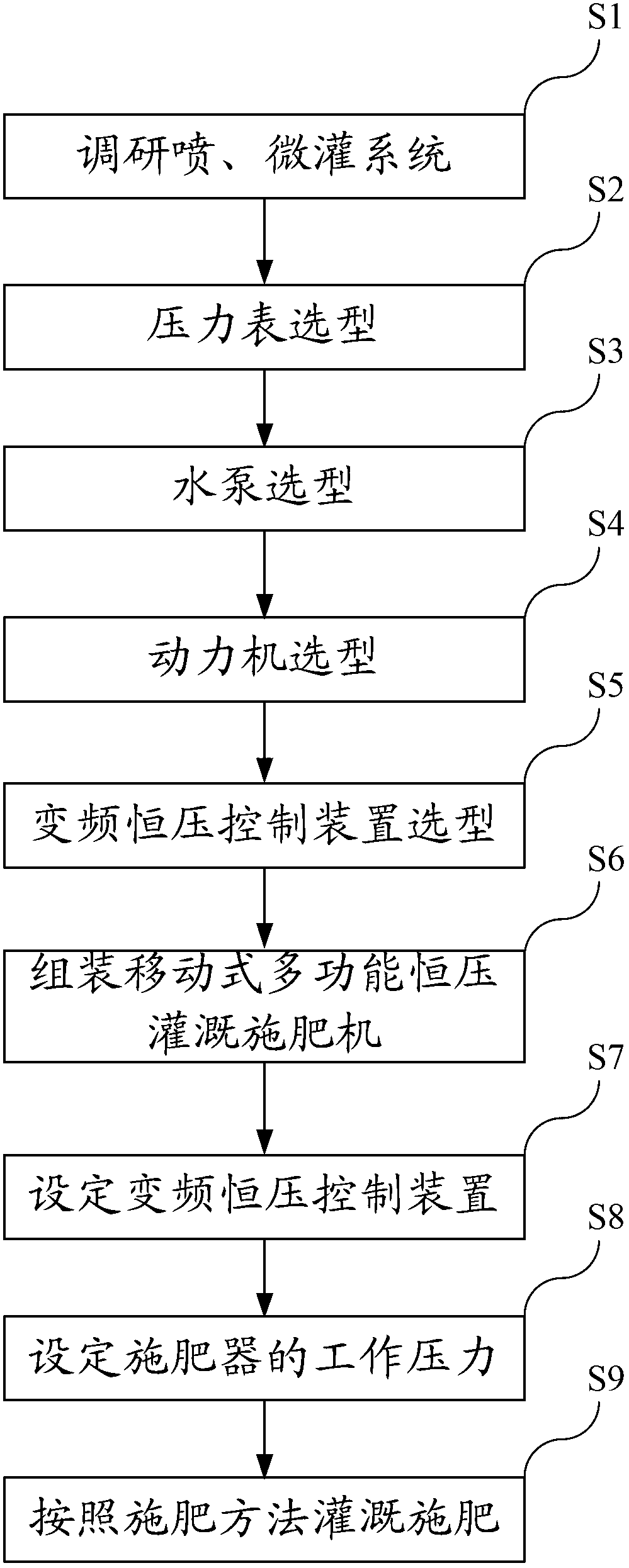

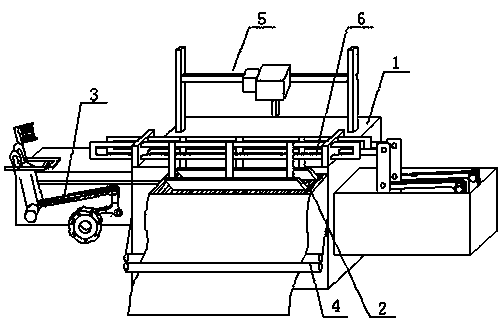

Mobile multifunctional constant-pressure irrigation fertilizer distributor and irrigation and fertilizer distribution method thereof

InactiveCN103053385ARealize the purpose of energy savingIncrease pressureWatering devicesPressurised distribution of liquid fertiliserDistribution methodNutrient solution

The invention belongs to the field of field irrigation and fertilizer distribution and discloses a mobile multifunctional constant-pressure irrigation fertilizer distributor and an irrigation and fertilizer distribution method thereof. The irrigation fertilizer distributor comprises a main pipeline, a water pump and a fertilizer applicator. The main pipeline is used for conveying water-fertilizer fixed liquid. The water pump is used for extracting irrigation water of the main pipeline and adjusting water inflow of the irrigation water. The water pump is controlled by a variable frequency constant-pressure control device to pressurize the irrigation water. The fertilizer applicator is used for conveying fertilizer and nutrient solution to the main pipeline. The variable frequency constant-pressure control device is connected with the main pipeline through a pressure sensor and used for receiving pressure signals acquired by the pressure sensor and controlling rotation speed of the water pump. By the irrigation fertilizer distributor and the irrigation and fertilizer distribution method thereof , irrigation pressure and flow can be controlled simultaneously, stable system fertilizer distribution concentration can be guaranteed while blocking and corrosion of the irrigation system can be prevented, the requirements for even and high-quality irrigation and fertilizer distribution can be satisfied, and energy conservation can be achieved.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

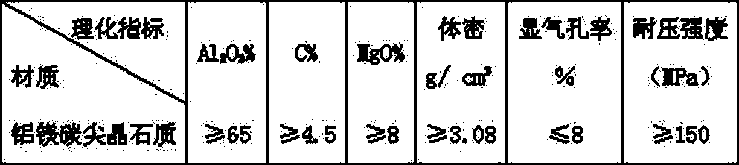

Novel slide plate brick for automatic slag-retaining slide gate of converter and preparation method of slide plate brick

The invention discloses a novel slide plate brick for an automatic slag-retaining slide gate of a converter and a preparation method of the slide plate brick. The slide plate brick is characterized by containing the following components in percentage by weight: 58%-68% of tabular corundum, 6%-8% of 98 magnesia, 8%-11% of electrically-fused spinel, 3%-5% of graphite, 4%-7% of a-aluminum oxide powder, 1%-2% of sintering agent, 2%-7% of aluminum-silicon alloy powder and 4%-5% of resin. The slide plate brick can be prepared from the components through the processes of mixing, shaping, drying, sintering, oil immersing, roasting, and machining. By virtue of adjustment on the formula of the slide gate brick and simplification on the production technology of the slide gate brick, the comprehensive performance of the slide gate brick is enhanced, the direct benefit of slag-free tapping with the slide plate brick is high, and beneficial conditions are provided for development of good-quality steel grades, so that the slide plate brick and the preparation method of the brick have a very wide application prospect and remarkable economic and social benefits.

Owner:无锡市南方耐材有限公司

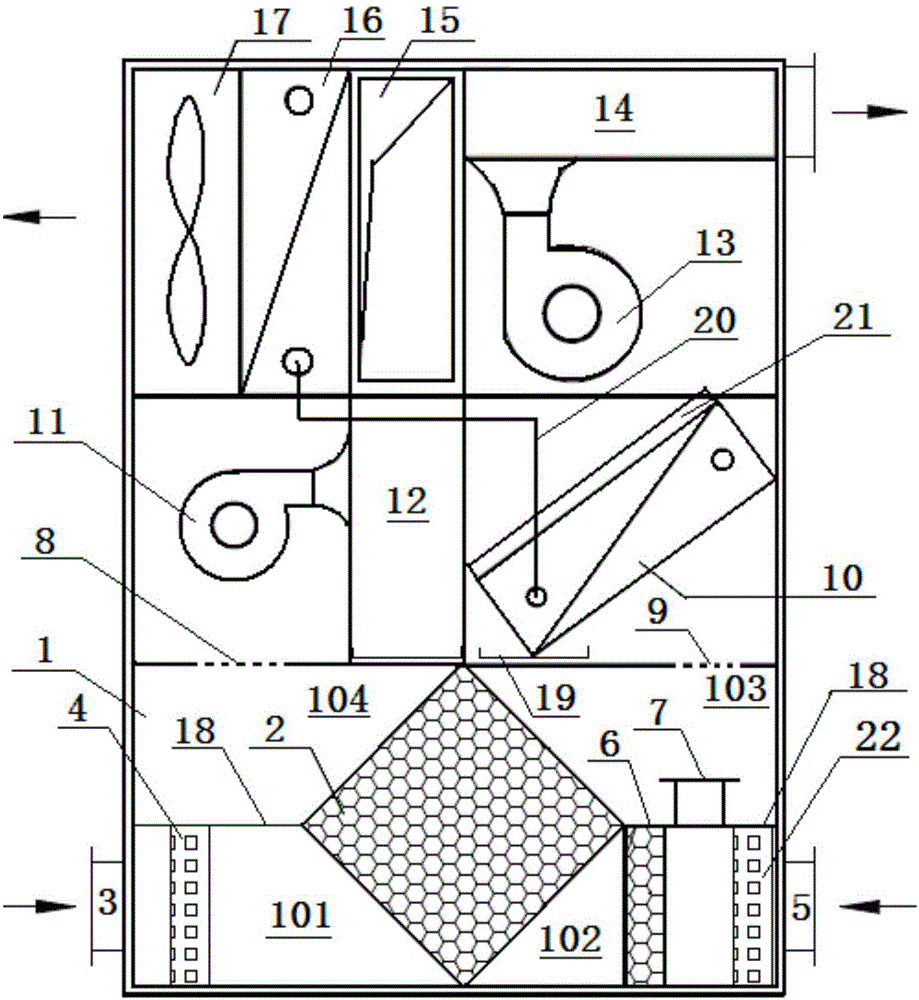

Air-freshening, ventilating, air-conditioning and purifying unit with heat recovery function

InactiveCN105674444AMeet the qualityMeet needsEnergy recovery in ventilation and heatingMechanical apparatusRecovery functionEngineering

An air-freshening, ventilating, air-conditioning and purifying unit with the heat recovery function comprises an air-conditioning indoor unit heat exchanger, an air-conditioning outdoor unit heat exchanger connected to the air-conditioning indoor unit heat exchanger through a connection pipe, a ventilating unit and an air and air heat exchanger arranged in the ventilating unit; the ventilating unit is provided with an air inlet communicating with the outdoor side, an internal air outlet guided to the outdoor side, an air return port communicating with the indoor side and an internal air supply port guided to the indoor side, gas subjected to heat exchange and output by the internal air supply port of the ventilating unit is guided into an air supply channel and conveyed into the indoor side after sequentially flowing through the air-conditioning indoor unit heat exchanger and an air supplier, and gas subjected to heat exchange and exhausted by the internal air outlet of the ventilating unit is exhausted to the outdoor side after sequentially flowing through an air exhaust channel, the air-conditioning outdoor unit heat exchanger and an exhaust fan. The air-freshening, ventilating, air-conditioning and purifying unit integrates the functions of air freshening, air ventilating, heat recovering, air conditioning and purifying and can be operated stably at the highest temperature in summer or at the lowest temperature in winter, and the energy is saved by more than 40%.

Owner:CHINA ACAD OF BUILDING RES

Production method for copper-clad steel double-metal wire

ActiveCN101763916AMeet the qualityFulfil requirementsSingle bars/rods/wires/strips conductorsFurnace typesCopper-clad steelSolution treatment

The invention discloses a production method for a copper-clad steel double-metal wire, which includes the steps as follows: straightening a steel core, then removing rust, cleaning and mechanically polishing; heating and melting electrolytic copper, heating the steel core, then horizontally and continuously casting a coating copper layer; heating the copper-clad steel and implementing quick solid solution treatment; continuously pulling the copper-clad steel wire for a plurality of times to lead the diameter of a product to reach 4mm-26mm; annealing the pulled copper-clad steel wire and pulling a die to a specification needed by a finished product. The steel and copper in the product are connected in a melting way by malleable metallurgy and an interface can be completely and firmly combined to become a single compound. The pulling of the double-metal wire is just like pulling of a single metal wire. The invention can coat any products with different materials and different copper layer thicknesses, can meet the requirements of relevant industries on product quality and performances, can produce products with large diameter and long length, and does not pollute the environment. The production method for the copper-clad steel double-metal wire has the advantages of less equipment investment, quick effect and stable performance; moreover, the production method for the copper-clad steel double-metal wire can meet the high requirements on industries like war industry, high-speed railway, communications, electron and electric power, etc.

Owner:GANSU TINTO METALLURGICAL SCI & TECH

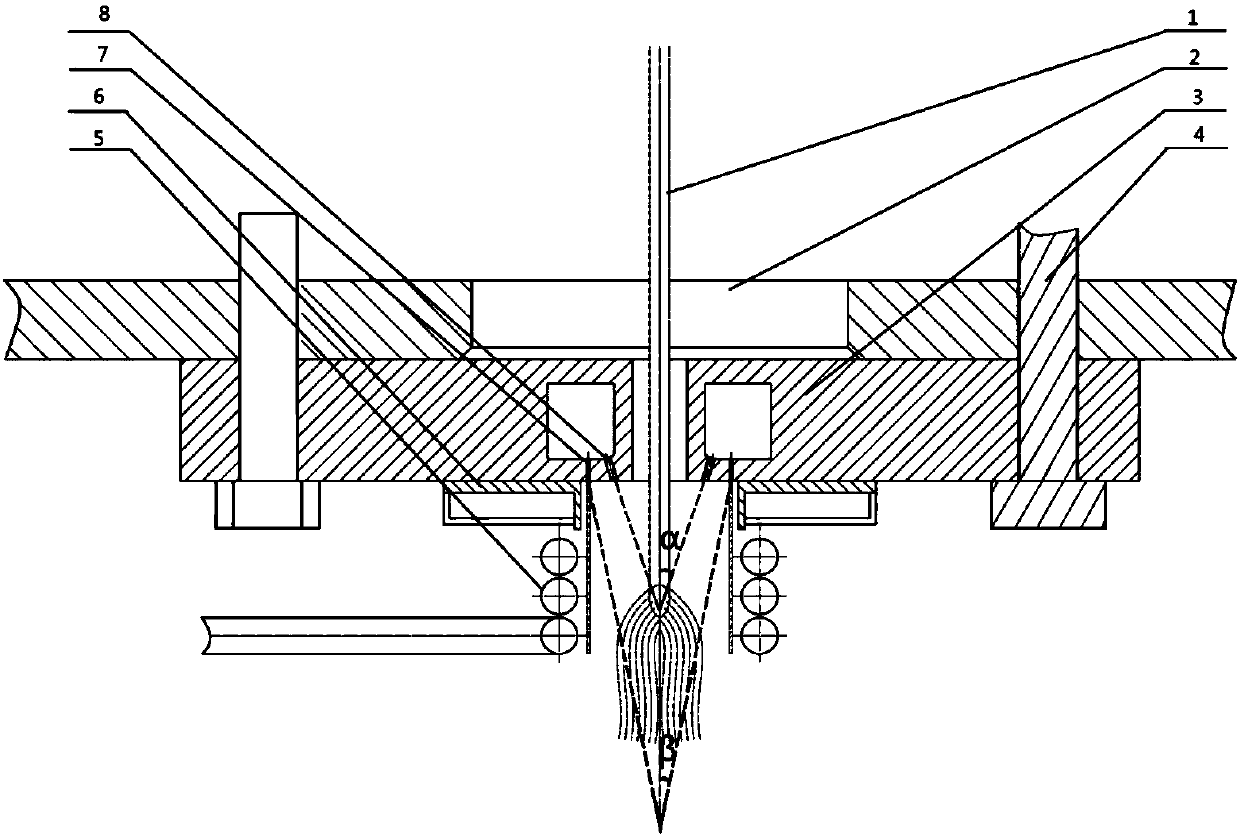

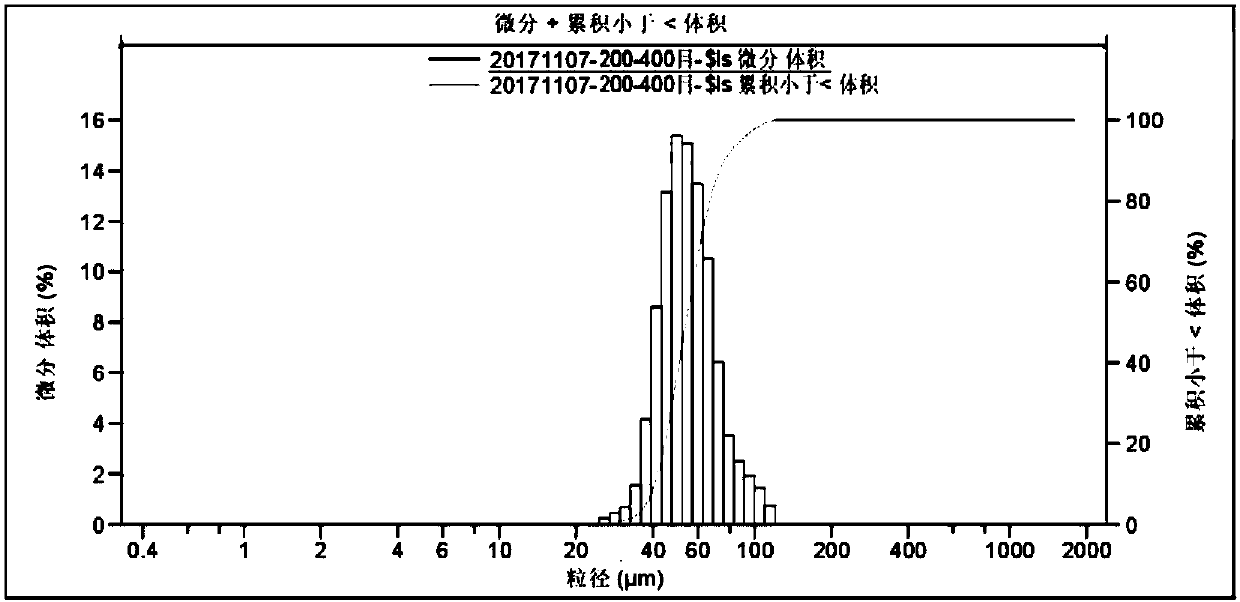

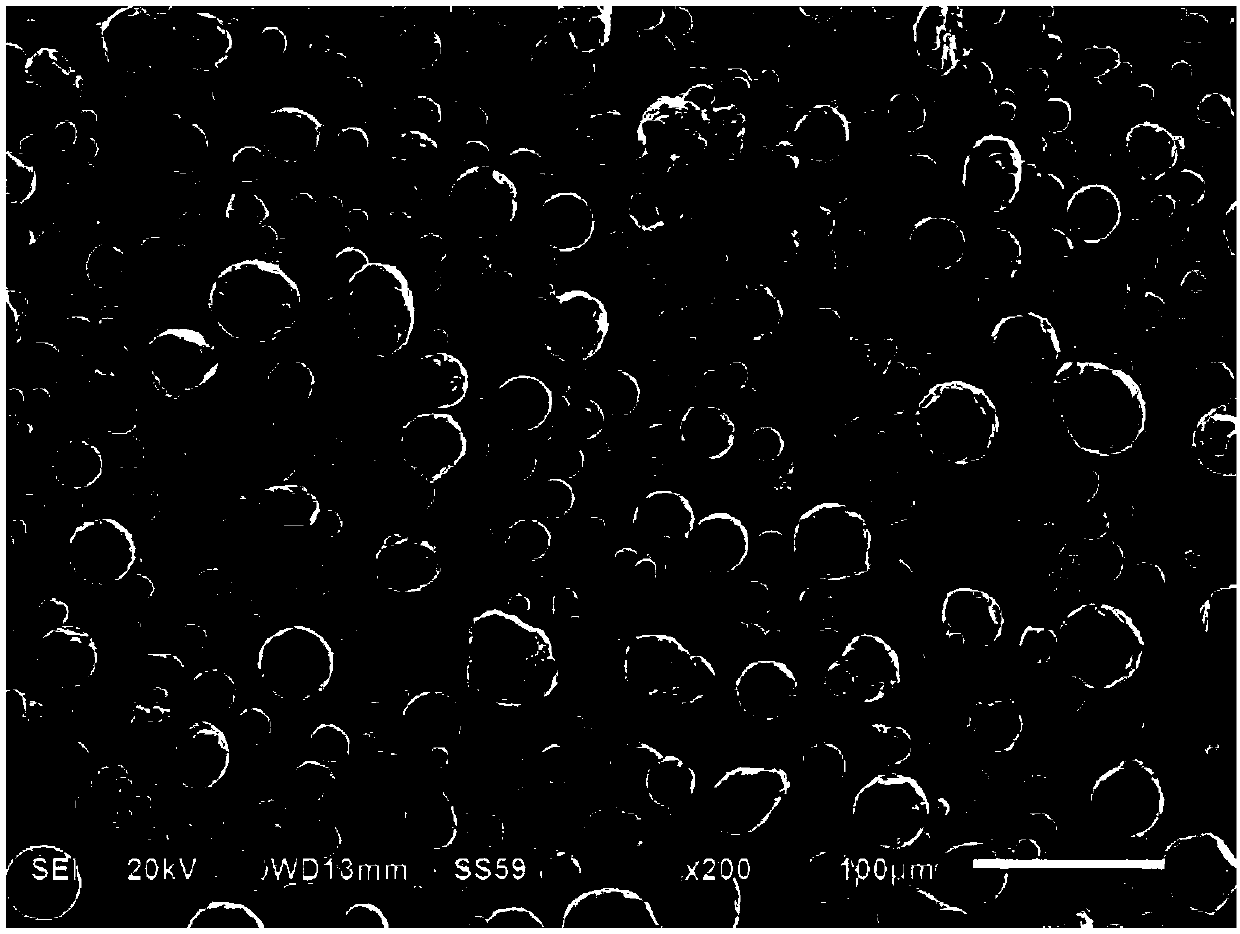

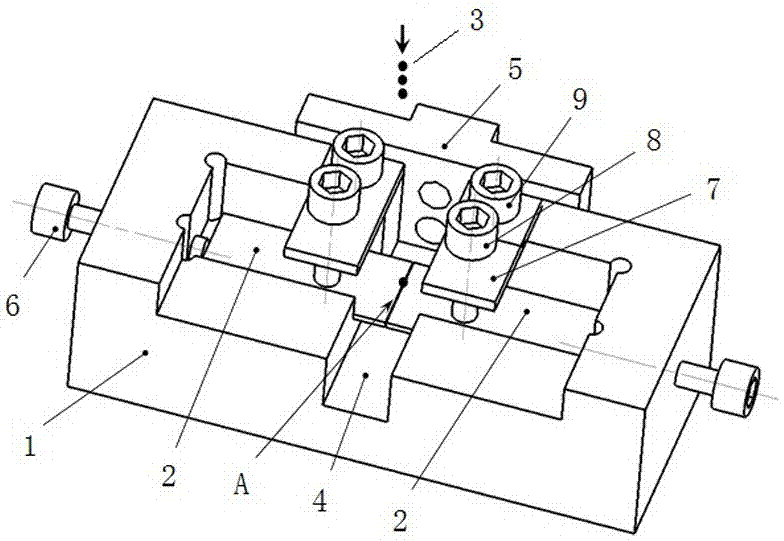

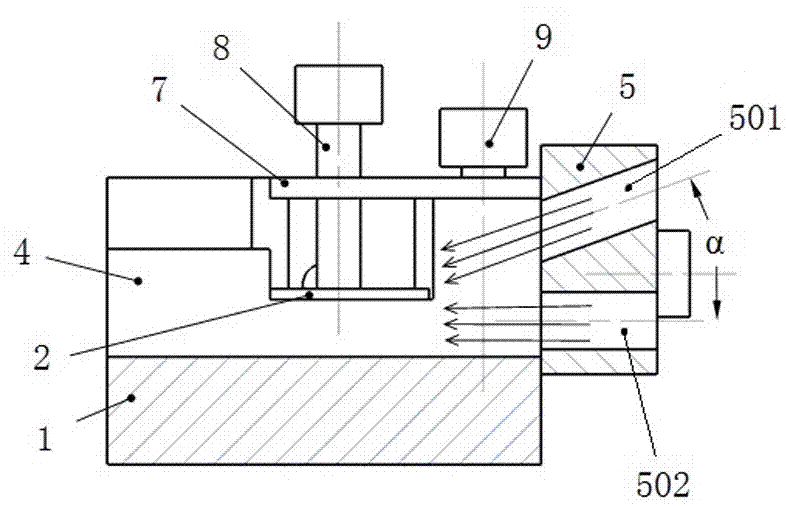

Device and method for continuously preparing titanium or titanium alloy powder for 3D printing through gas atomization

ActiveCN107900366AIncrease productivityReduce lossesAdditive manufacturing apparatusHeat lossesTitanium

The invention relates to a device and a method for continuously preparing a titanium or titanium alloy powder for 3D printing through gas atomization. The device comprises an atomization spray disc fixing top plate, an atomization spray disc, an electromagnetic shielding ring and a high-frequency induction coil from top to bottom, wherein the atomization spray disc and the fixing top plate are fixed through a fixing bolt; continuous conveying feeding holes for a titanium or titanium alloy wire material are formed in the central positions of the atomization spray disc fixing top plate and the atomization spray disc; the atomization spray disc and the electromagnetic shielding ring are coaxially installed about the axes of the conveying feeding holes; the atomization spray disc comprises a main atomization gas flow nozzle and auxiliary protection gas flow nozzles; and atomization gas flow sprayed out via the main atomization gas flow nozzle is collected on the wire material to form an atomization centre, and the atomization centre is superposed with a melting centre formed due to the heating of the high-frequency induction coil for the end part of the wire material. Therefore, melting flow is immediately limited and atomized by the main atomization gas flow after being generated, so that a superheating degree is furthest ensured, heat loss is reduced, and a high fine powder yieldof titanium or titanium alloy atomization is realized.

Owner:BEIJING COMPO ADVANCED TECH

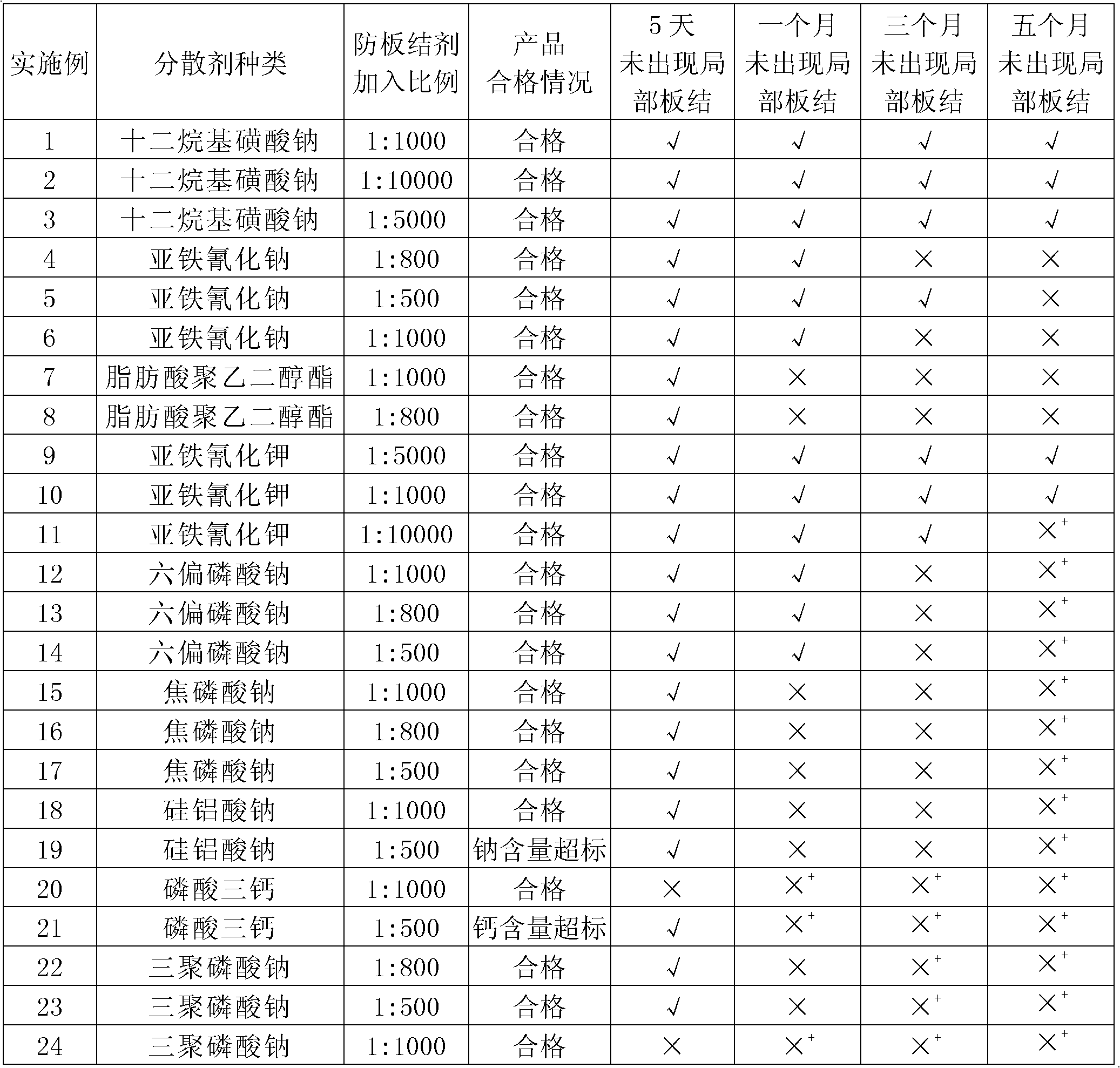

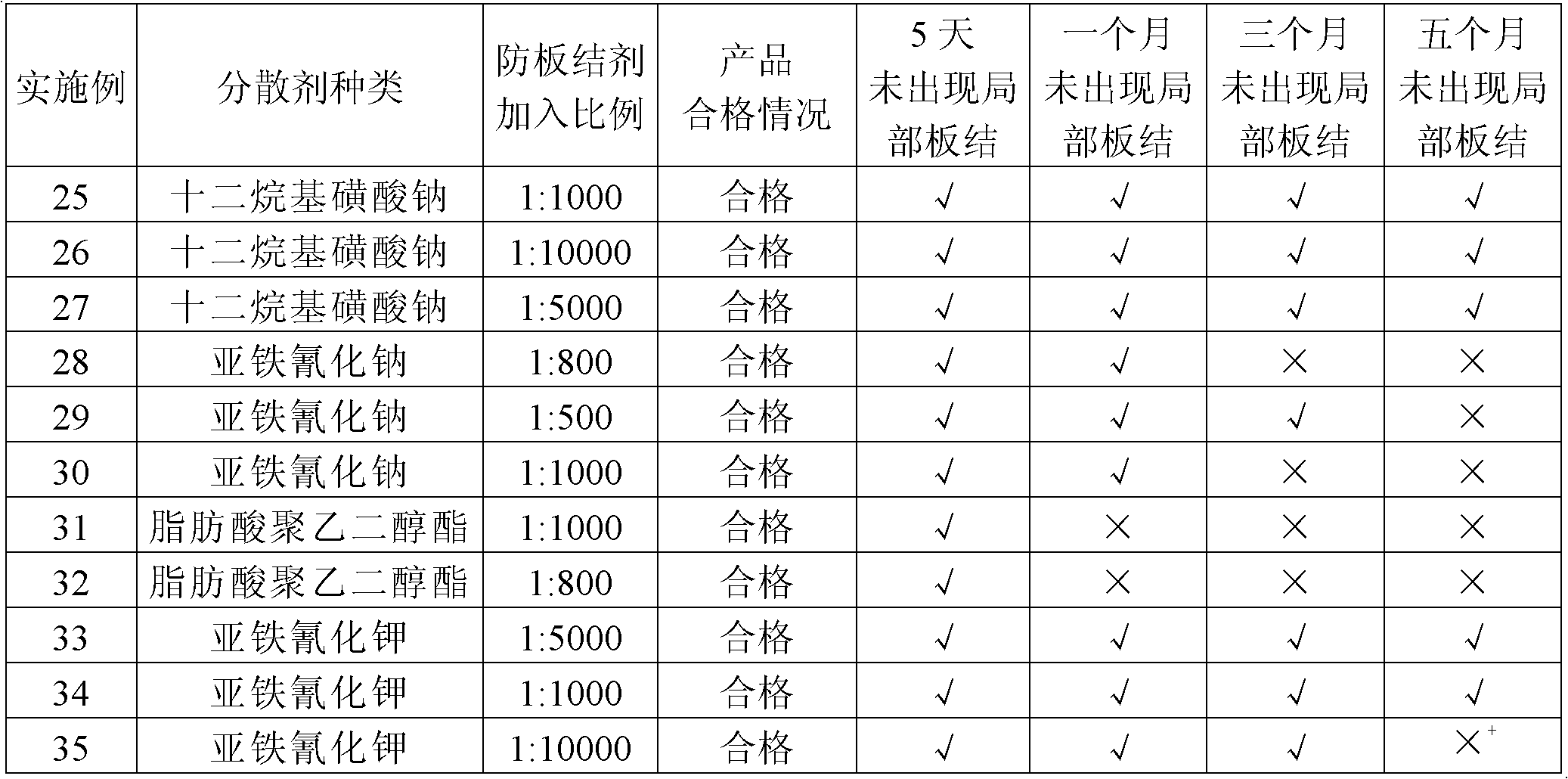

Lithium hydroxide monohydrate and preparation method thereof

ActiveCN102020294ANo flyingMeet the qualityTransportation and packagingLithium oxides/hydroxidesCalcium hydroxideDust explosion

The invention refers to a dust-free lithium hydroxide monohydrate and a preparation method thereof, belonging to the technical field of lithium hydroxide. The technical problems to be solved by the invention are that wet LiOH.H2O has a problem of hardening and dry LiOH.H2O has a problem of dust explosion in the prior art. The invention provides a novel LiOH.H2O, that is, dust-free lithium hydroxide monohydrate without hardening. The lithium hydroxide monohydrate is a loosened granular wet product, wherein the content of water is less than or equal to 3.5%, and the surface of the lithium hydroxide monohydrate is coated with a little anti-hardening agent. The dust-free lithium hydroxide monohydrate is prepared by the following methods: (1) preparing a LiOH solution having a Li2O concentration of 70+-5g / l, and the concentration of SO42- is less than or equal to 15g / l; (2) evaporating the LiOH solution obtained in the step (1) until the ratio of liquid to solid is 1: (0.8-1.5); adding a little anti-hardening agent; uniformly stirring; separating and washing the mixture to obtain dust-free wet LiOH.H2O; and carrying out vacuum seal and packing the wet product, wherein the obtained product is not hardened within 3-5 months.

Owner:TIANQI LITHIUM CORP

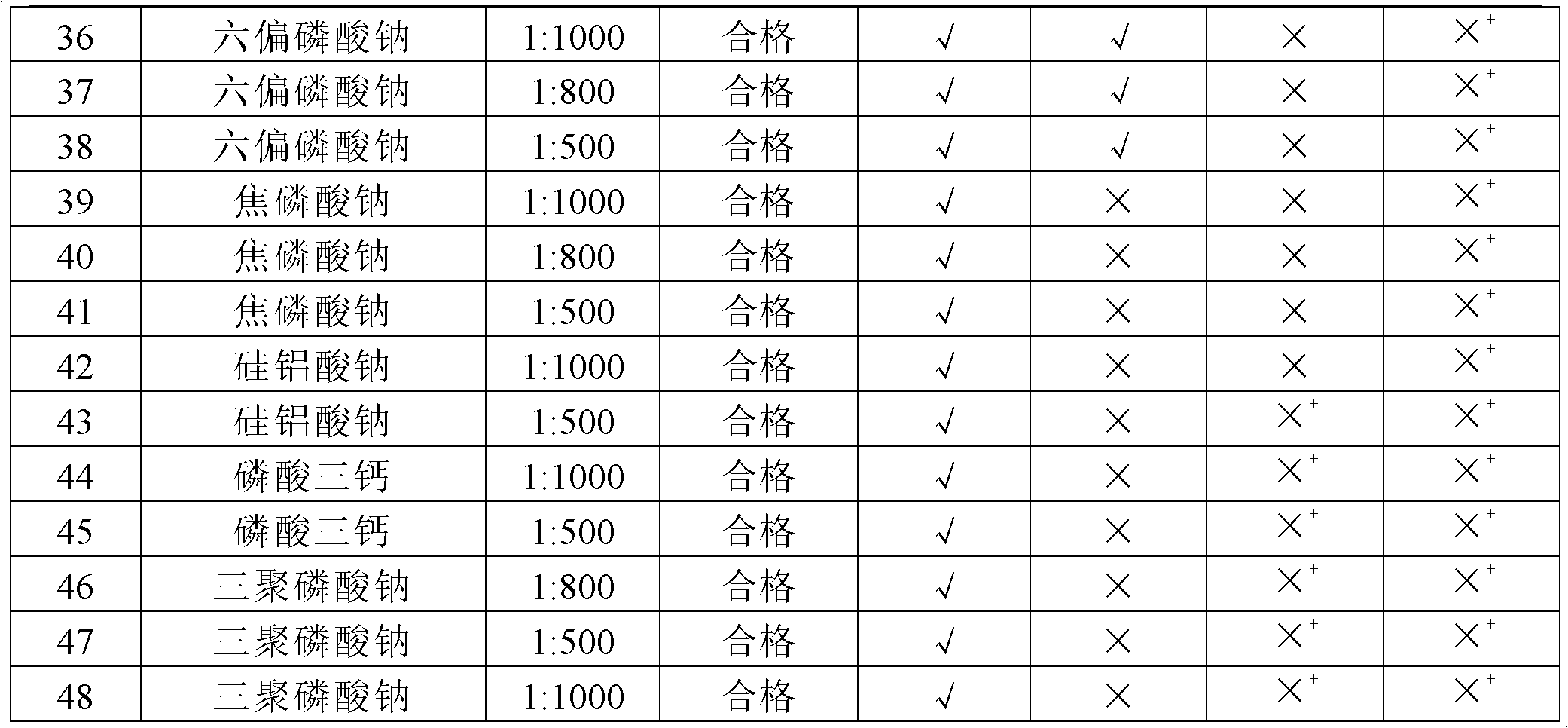

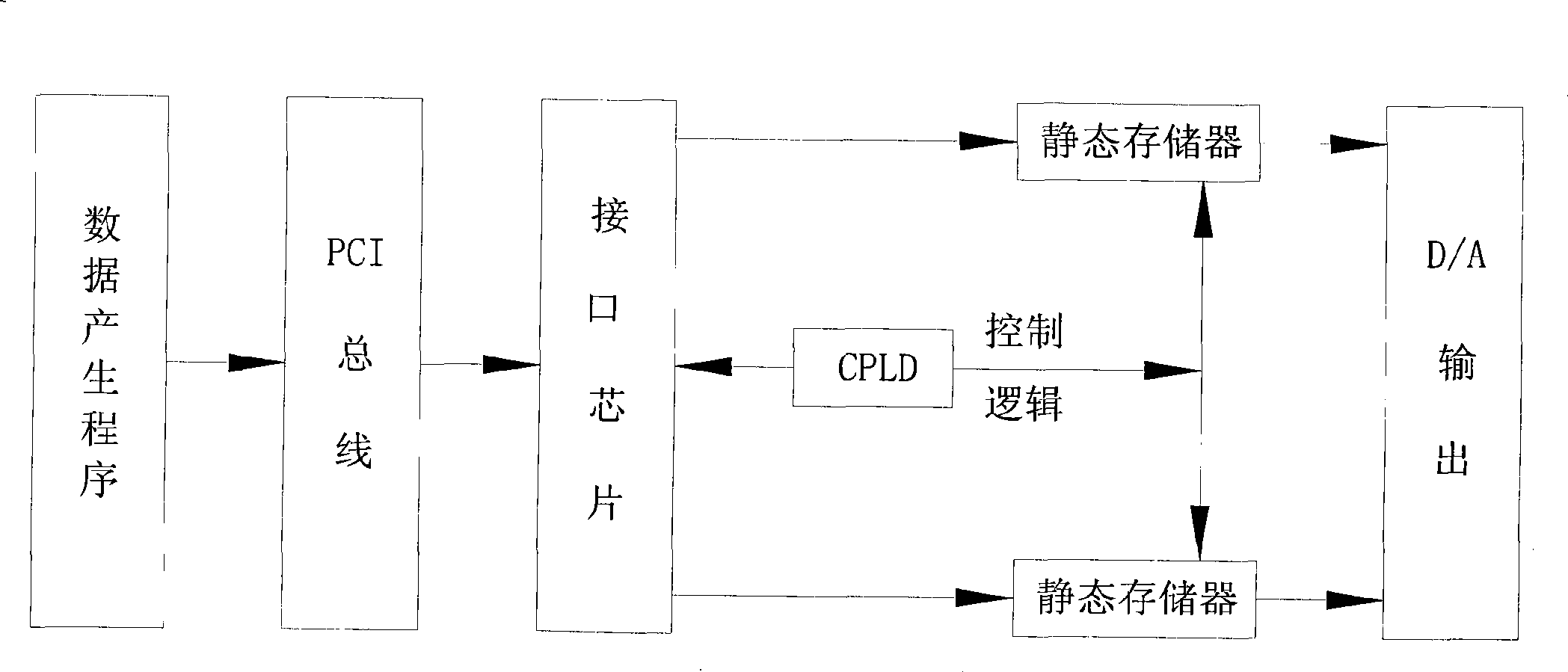

Optional waveform generator based on PCI bus

InactiveCN101425103AQuick switchGuaranteed continuitySpecial data processing applicationsParallel computingControllability

The invention relates to an arbitrary waveform generator based on a PCI bus, which comprises the PCI bus being a local bus not attached to some a concrete processor. Structurally, the PCI is a primary bus which is inserted between a CPU and an original system bus, management on the layer is concretely realized by a bridge circuit, and an interface between top and bottom is realized to coordinate data transportation. An application layer buffer zone can continuously exchange data. The process of the data transportation is sponsored by an application layer program, but is executed by a chip PLX9054 of a PCI bridge interface, application layer software can carry out data generation and allocation in the process, and the whole transportation process is completed by direct memory access (DMA) and interruption. By utilizing the buffer zone to fast exchange the data, the arbitrary waveform generator can fast carry out data exchange, efficiently ensures the continuity of space signals and the fast switch of multiple signals, and has the advantages in multiple aspects such as flexibility, rapidness, changeability, controllability, high accuracy, and the like.

Owner:成都飞机工业(集团)电子科技有限公司

Slitting striping method of PS aluminum base belt-material

The invention provides a longitudinal cutting striping method for a PS-edition aluminum-based strip. The method comprises: a PS-edition base aluminum coil which is rolled to have the thickness of a finished product is straightened and washed via a stretch-bending straightening machine series, and then is subdivided by a longitudinal cutting machine series; a circular-cutter assembly frame of the longitudinal cutting machine series adopts the following quantity of striping circular-blade strips: the ratio of an upper part to a lower part is 3:4 or 4:3; the longitudinal cutting machine series performs bilateral longitudinal cutting on the aluminum coil; and the edges of striping circular blades on two sides of the circular-cutter assembly frame are provided with rubber isolating rings respectively. As the method adopts bilateral longitudinal cutting PS-edition aluminum-based strip, production efficiency is improved by 50 percent, and the upper and lower surfaces of the stripped strip are free from scrapes or scratches, aluminum powder aggregation, depressions, protrusions and other quality defects. The method can obviously save energy, reduce consumption, improve yield and production efficiency, can meet the requirements of high-grade PS printing aluminum strip on high surface quality, strip shape and thickness difference, and can realize large-scale production.

Owner:CHINALCO RUIMIN

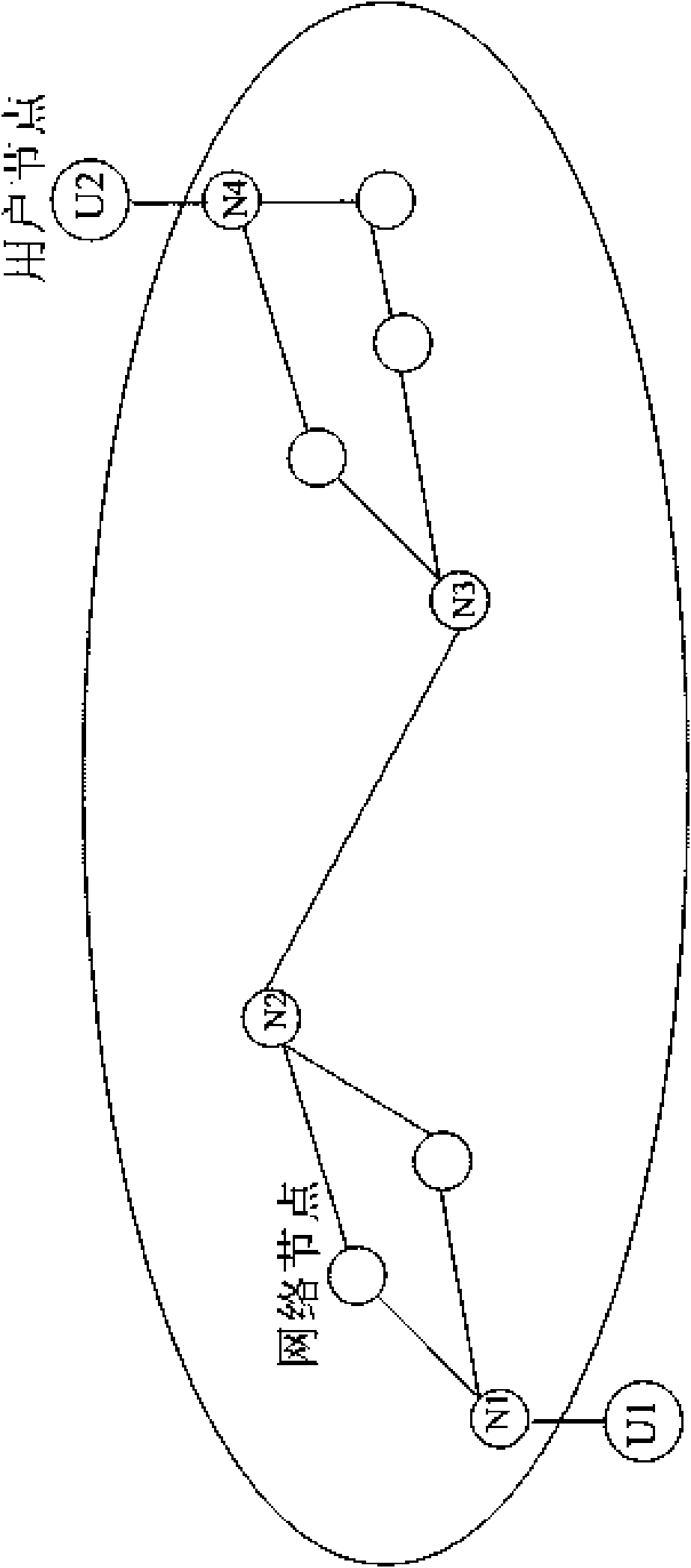

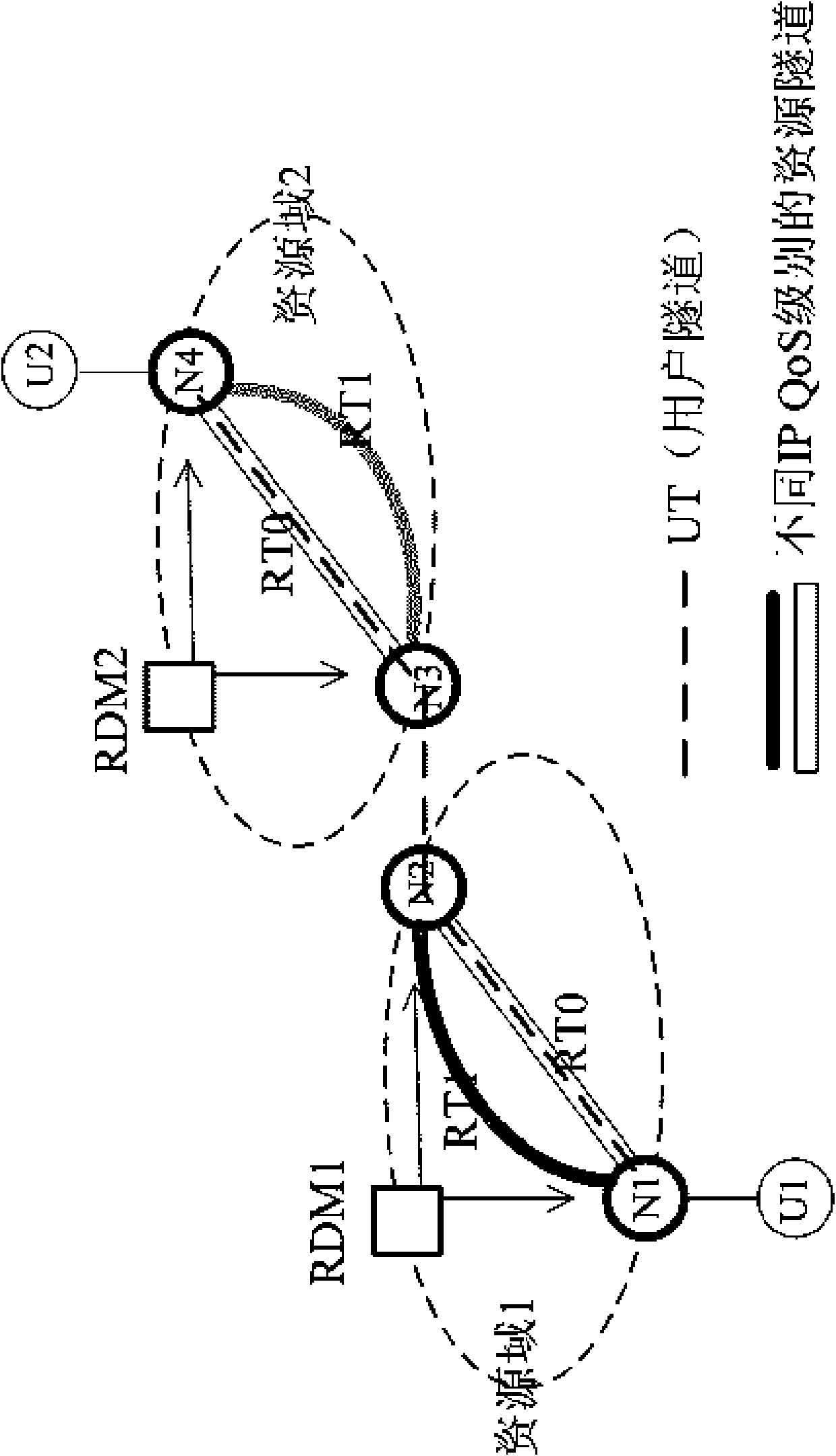

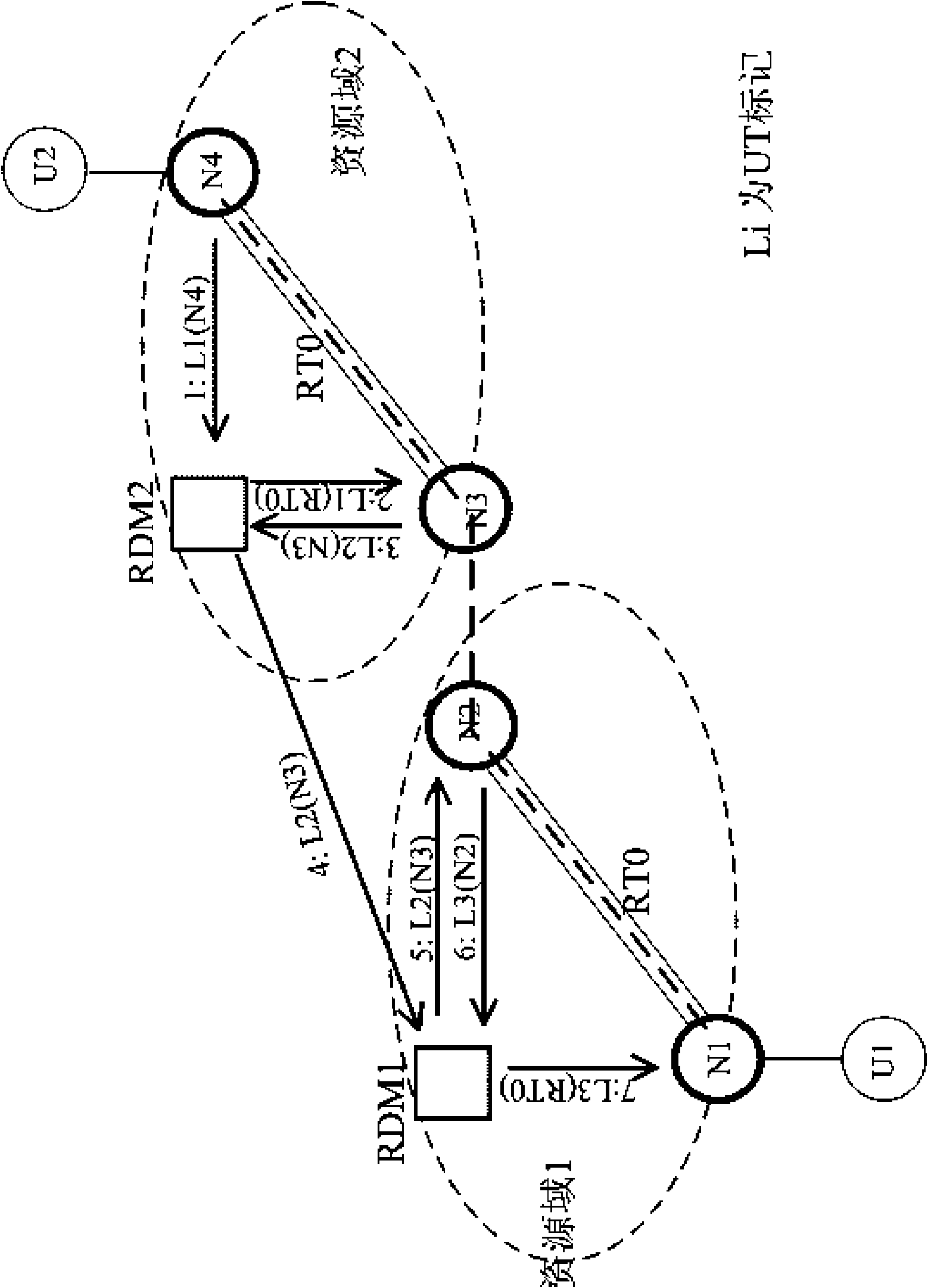

Method for realizing IP telecommunication network based on tunnel

ActiveCN101599979AImprove controllabilityImprove manageabilityNetworks interconnectionQuality of serviceTraffic capacity

The invention relates to technology of network communication, in particular to a method for realizing an IP telecommunication network based on a tunnel. Aiming at the defects in the prior art, the invention discloses the method for realizing the IP telecommunication network based on the tunnel, which smoothly transits under the condition of lower cost and not changing the prior network structure so as to realize end-to-end service quality guarantee for users and provide service of multiple IP QoS levels according to requirement for users. The invention adopts a technical proposal that: a plurality of independent resource domains are formed through planning a physical network. A resource tunnel of a domain is established in the resource domain, and data traffics with different service quality requirements are classified into different resource tunnels, thereby realizing that user data traffic can be transmitted in a resource tunnel in accordance with the user requirement on IP QoS level, and ensuring the QoS requirement of user service. For communication service for a specific user, a full range user tunnel is established inside the resource tunnel, and the user tunnel passes through the resource tunnel to form a multilayer tunnel.

Owner:MAIPU COMM TECH CO LTD

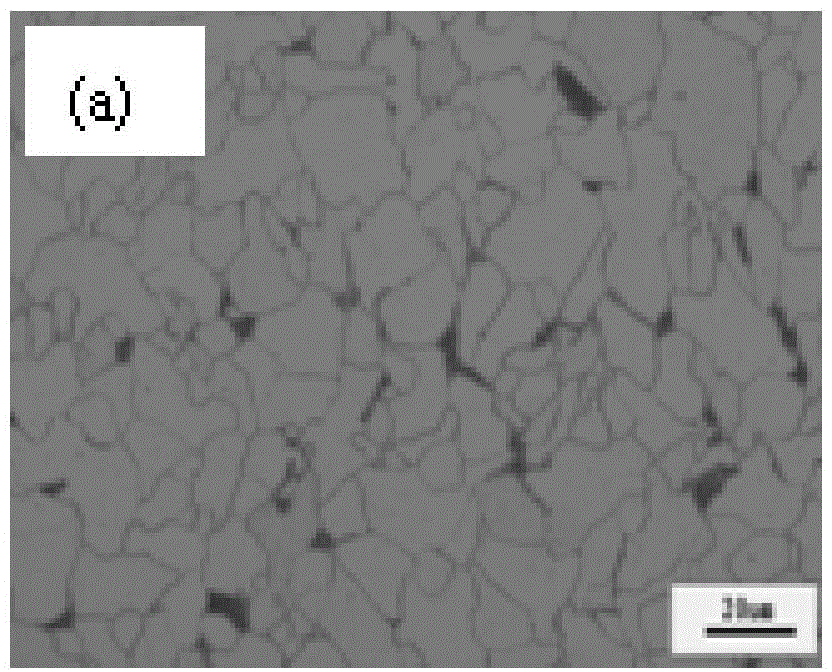

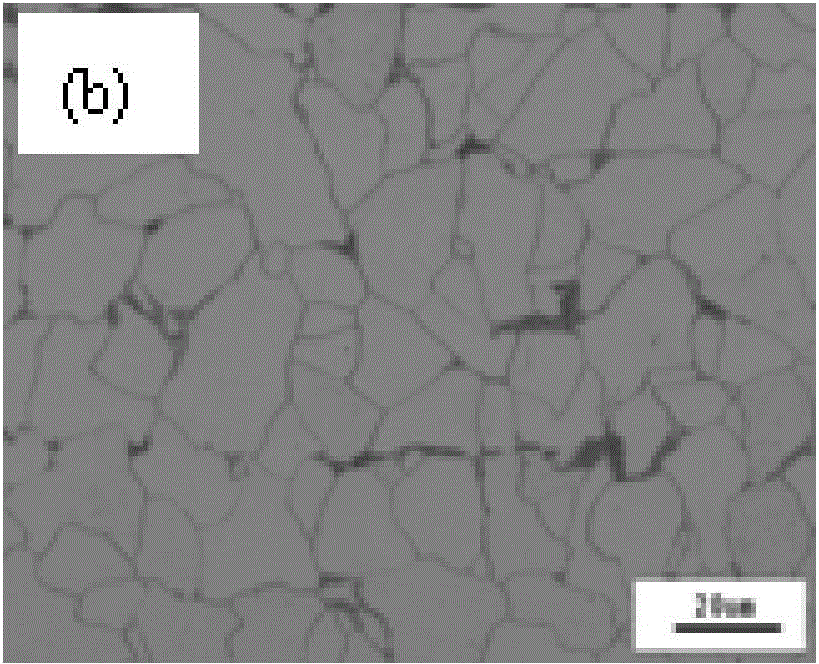

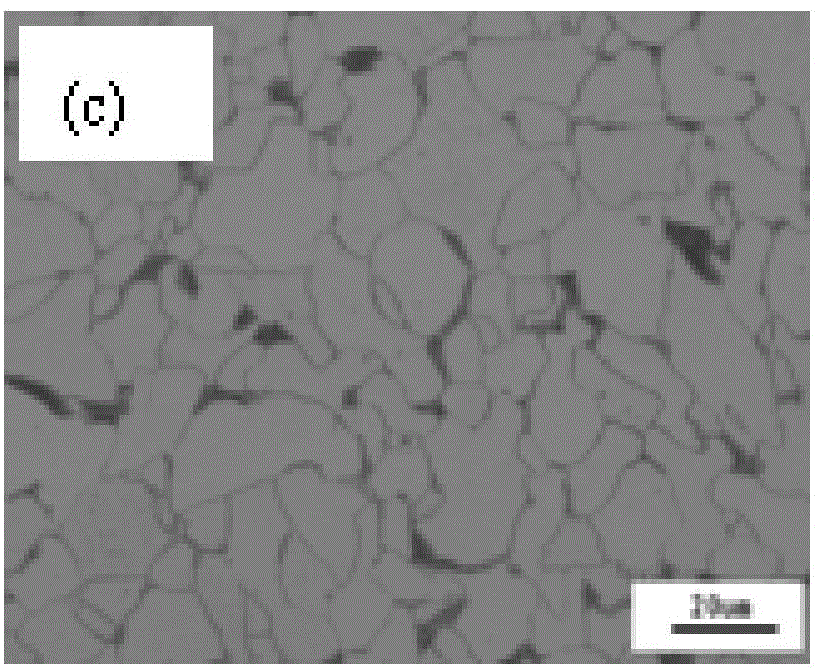

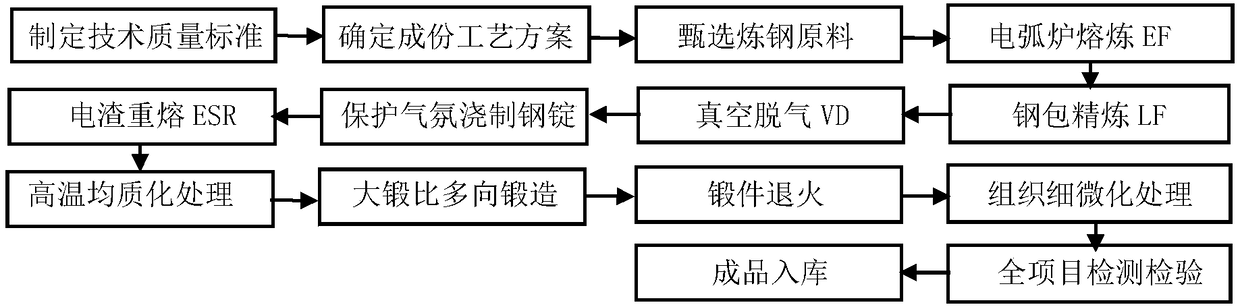

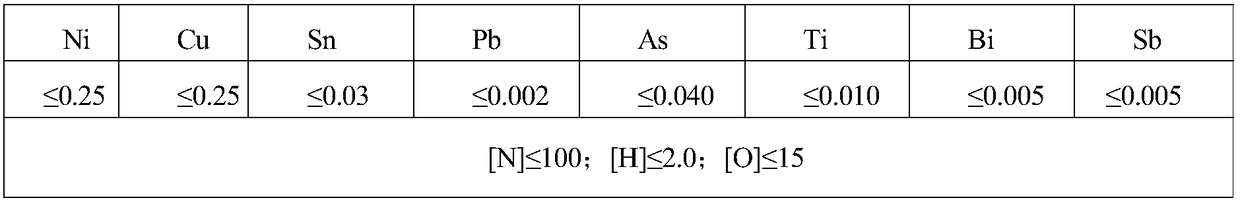

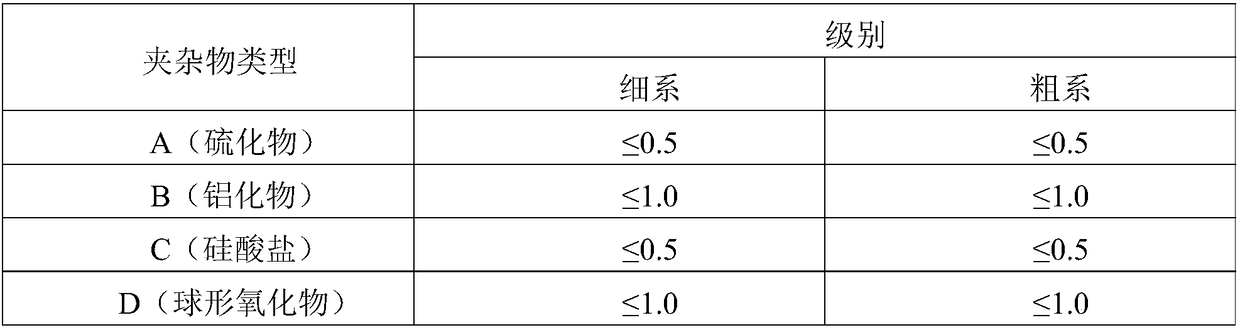

Special hot-stamping die steel HS7 and preparation method thereof

InactiveCN109402514AExcellent toughness and ductilityImprove performanceProcess efficiency improvementHot stampingCrack resistance

The invention discloses novel special hot-stamping die steel HS7 and relates to the technical field of die steel component formulas and manufacturing. The chemical components of the special hot-stamping die steel include, by weight, 0.41-0.45% of C, 0.45-0.55% of Si, 0.35-0.45% of Mn, 6.4-6.80% of Cr, 1.20-1.40% of Mo, 0.75-0.85% of V, 015% or below of P, 0.003% or below of S and the balance Fe and inevitable impurities and residual trace elements. The die steel adopts unique optimized alloy element proportion, the organization level of and purity degree of materials are greatly improved through refined smelting and multidirectional forging and combination with high temperature homogenizing, ultrafine processing and other processes, the key indicators of the hot-stamping die steel are obviously improved, including abrasion resistance, high temperature abrasion resistance, thermal fatigue cracking resistance, resistance to plastic deformation and the like. Therefore, improve the qualityof hot stamping dies can be obviously improved, the service life of the dies can be prolonged, and better economic benefits can be obtained.

Owner:上海合毓模具技术有限公司

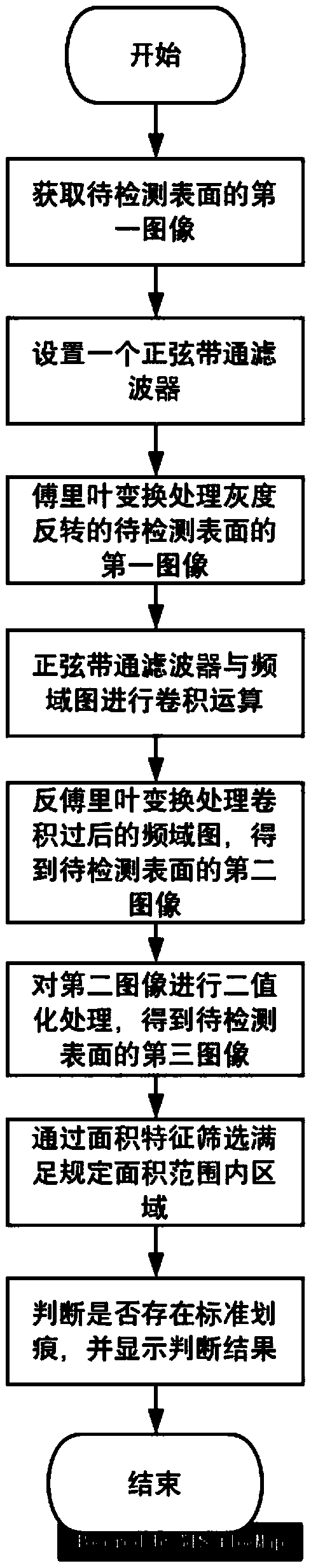

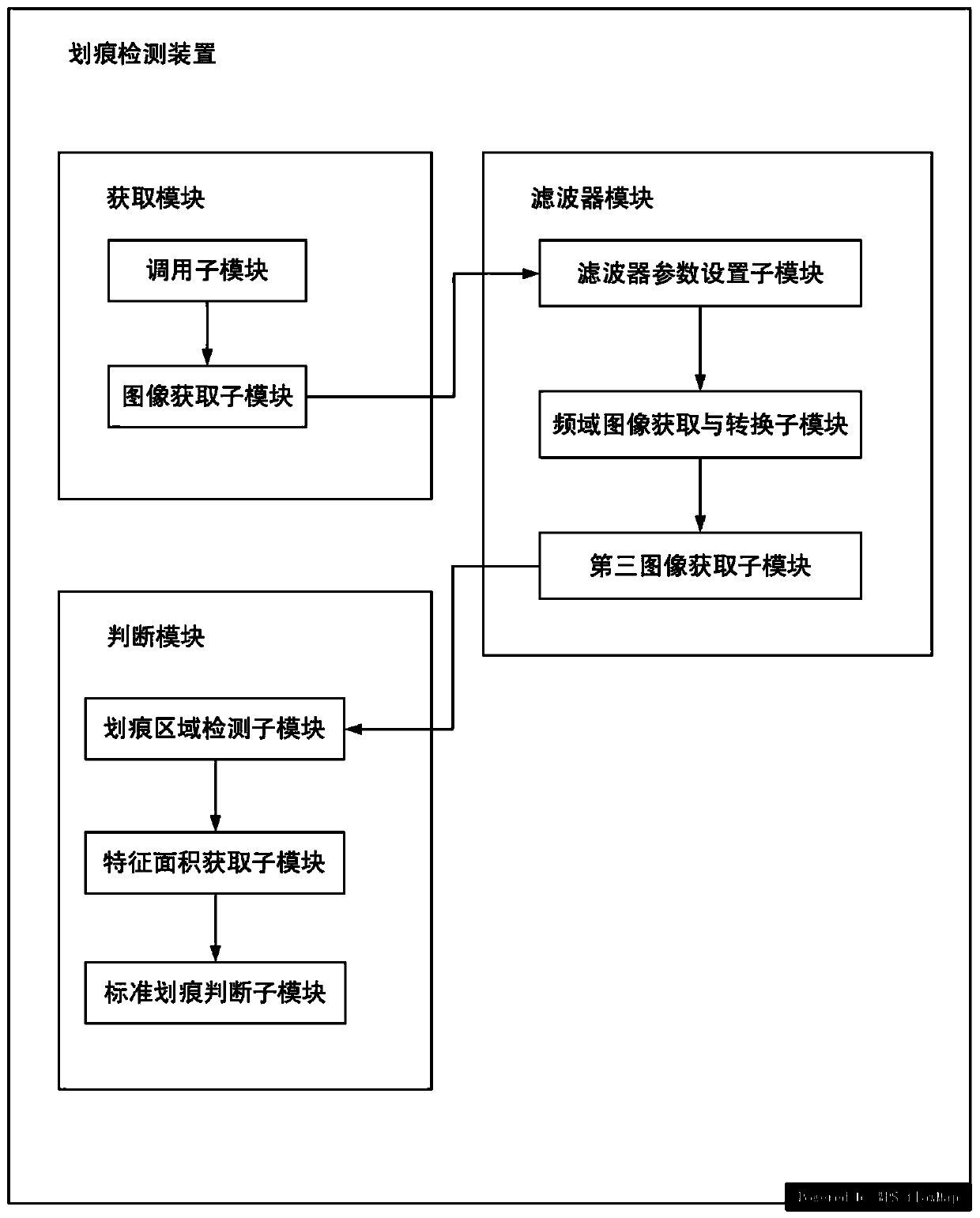

Metal surface scratch detection method and device

PendingCN110717909AAvoid Manual InspectionHigh precisionImage enhancementImage analysisImaging processingComputer graphics (images)

The invention relates to the field of image processing, in particular to a metal surface scratch detection method and device, and the method specifically comprises the steps: obtaining a first image of a to-be-detected surface; performing Fourier transform on the first image to obtain a frequency domain graph; processing the frequency domain graph through a filter, and removing high and low frequency parts in the frequency domain graph; performing inverse Fourier transform on the removed frequency domain image to obtain a second image of the to-be-detected surface; judging whether a standard scratch exists in the second image or not, and displaying a judgment result. The device specifically comprises an acquisition module, a filter module and a judgment module. The acquisition module is composed of a calling sub-module and an image acquisition sub-module, the filter module is composed of a filter parameter setting sub-module, a frequency domain image acquisition and conversion sub-module and a third image acquisition sub-module, and the judgment module is composed of a scratch area detection sub-module, a feature area acquisition sub-module and a standard scratch judgment sub-module.

Owner:JIANGSU UNIV OF SCI & TECH

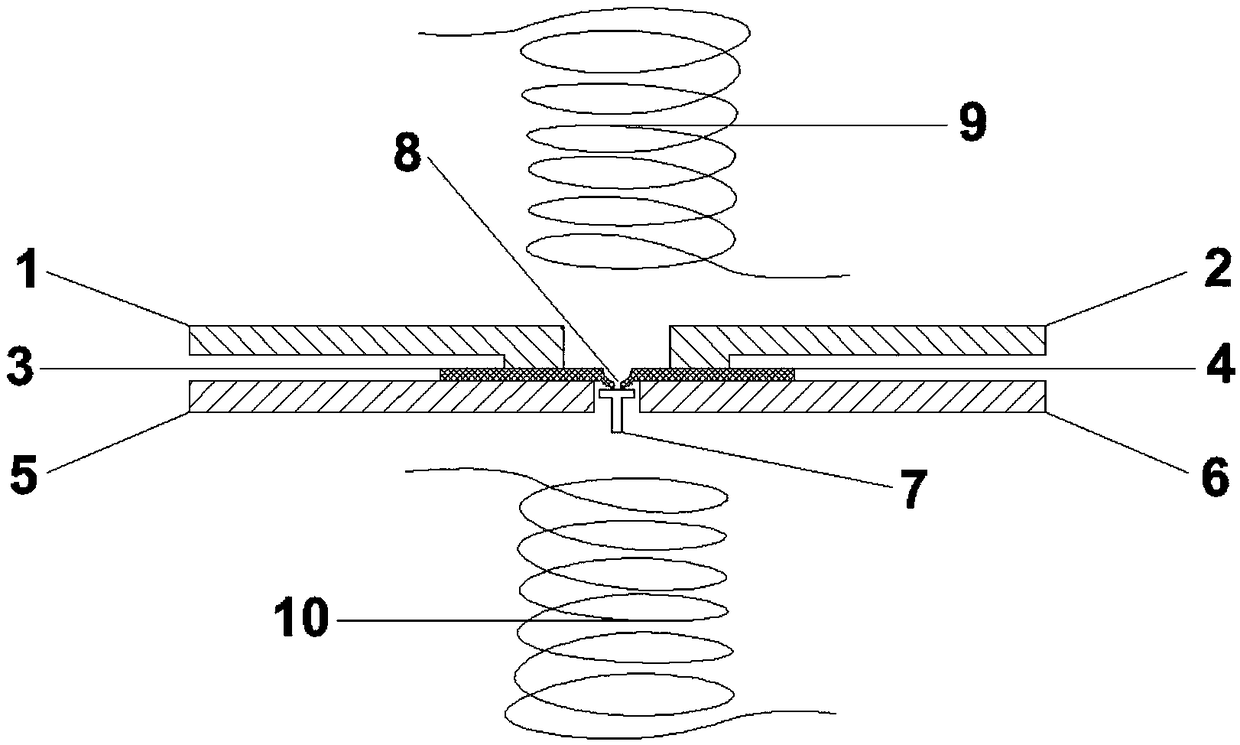

High-frequency induction heating brazing method of molybdenum-rhenium alloy foil

The invention belongs to the field of metal material welding, and relates to a welding method of refractory metal, in particular to a high-frequency induction heating brazing method of molybdenum-rhenium alloy foil with the thickness smaller than 0.2 mm. The method includes the steps that the molybdenum-rhenium alloy foil is cut, and a welded zone is machined into a downwards-bent butt joint structure. Ni-Cr-Si-B or Ni-Mn-Cu-Zr series blocky brazing filler metal is added into the welded zone and placed in the position between an up induction coil and a lower induction coil, and power-on welding is carried out, wherein the upper induction coil and the lower induction coil are formed through halving. According to welding process parameters, the power of a high-frequency generator is 5.5 kW,the power ratio ranges from 45% to 75%, the power-on time ranges from 15 s to 40 s, and the maximum induction heating temperature is controlled to be 1,050 DEG C. During welding, the molybdenum-rhenium alloy foil is in butt joint with downwards-bent zone metal through an upper ceramic push rod to achieve straight butt joint. By the adoption of the method, effective connection of the molybdenum-rhenium alloy foil can be achieved, brazing connectors without air holes or cracks and with the attractive appearance are obtained, and the quality of the connectors is stable. The method has the beneficial effects of being simple in process, high in welding speed, low in cost, convenient to popularize and the like.

Owner:SHANDONG JIANZHU UNIV

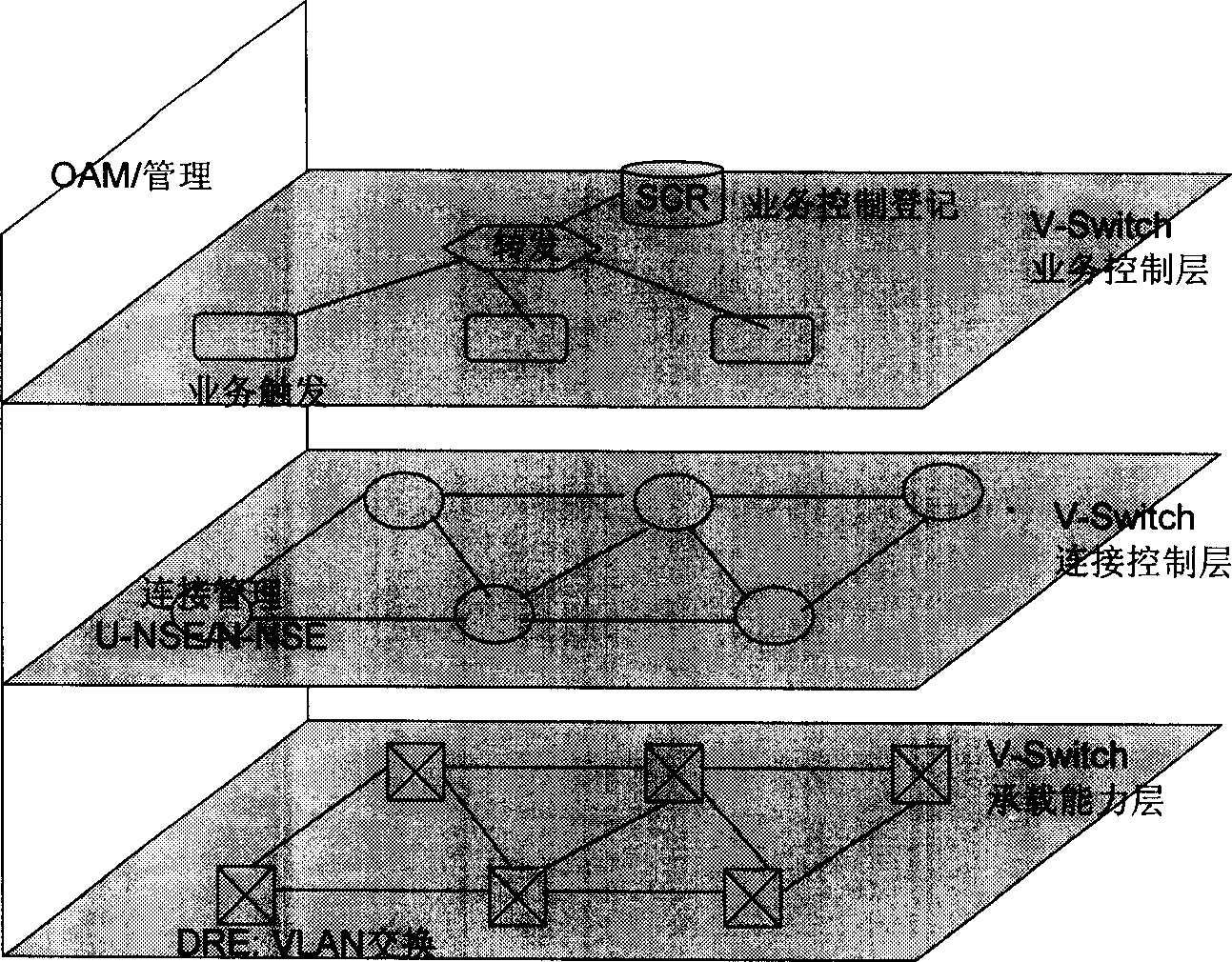

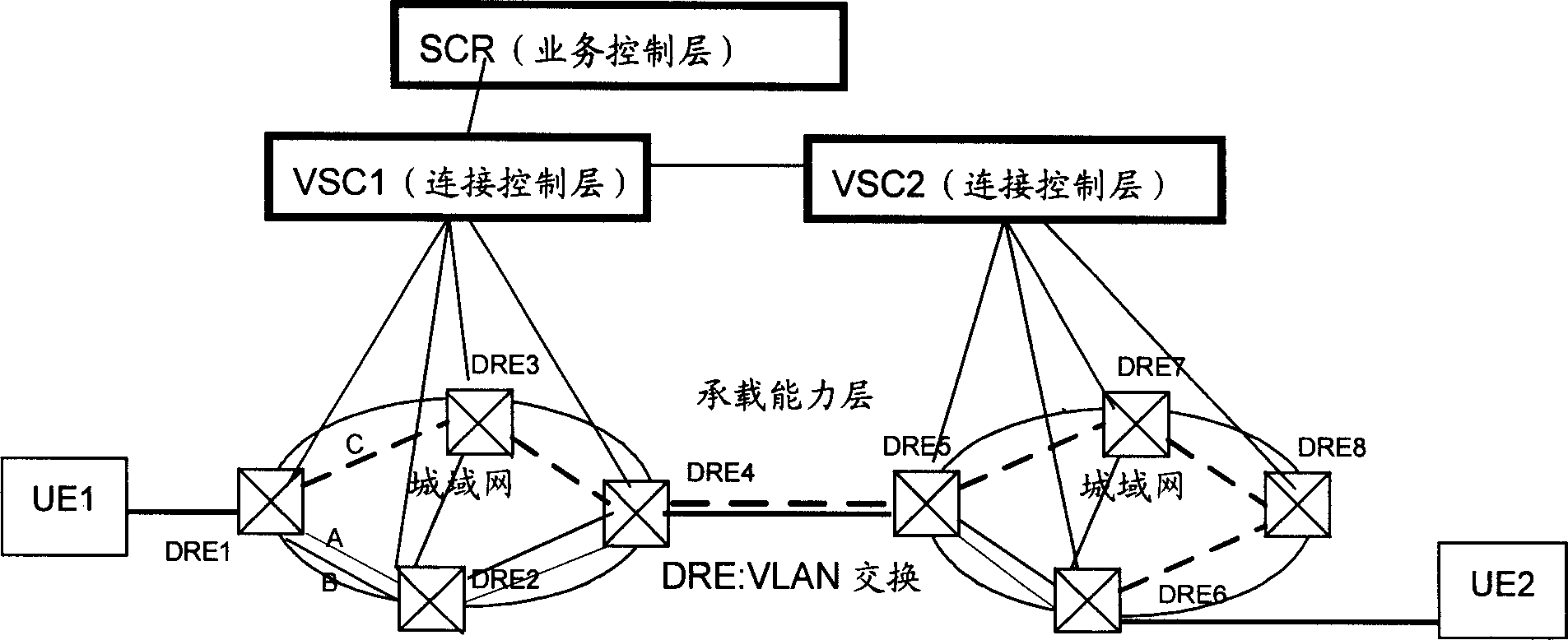

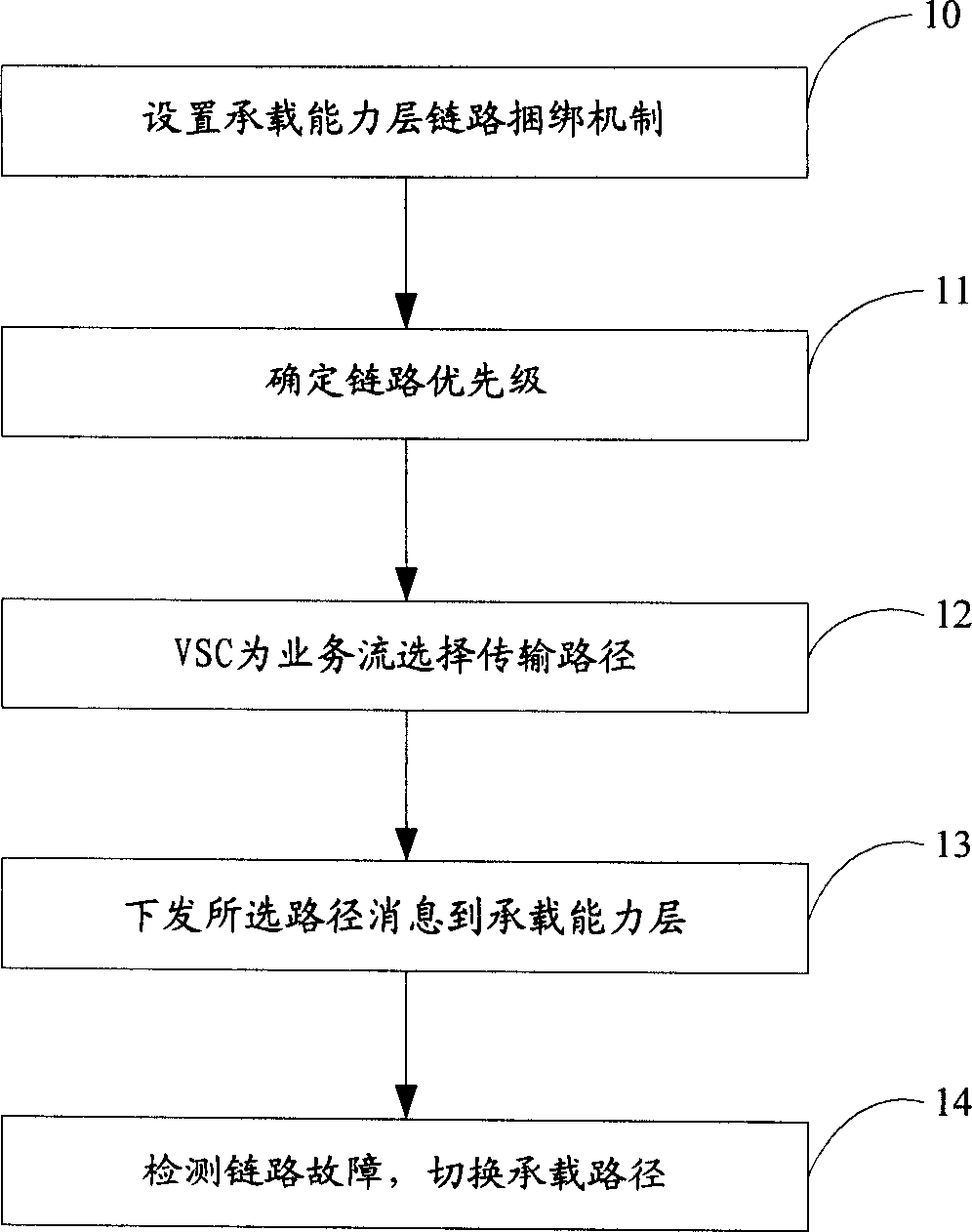

Method for raising transmission reliability in virtual exchange system

InactiveCN1870575ARealize failure recovery functionImprove reliabilityError preventionData switching networksVirtual switchConnection control

This invention relates to a method for increasing stability of transmission in a virtual switch system, which connects multiple physical links among the DRE of a load ability layer to be bound logically by software to become a logic link and sets priorities of the links on the connection control layer to select links based on the link priority, which realizes the faulty resuming function of the V-Switch, when a physical link among the DRE is faulty, the DRE will switch the V-Switch special line service to other bound physical links to continue the load.

Owner:HUAWEI TECH CO LTD

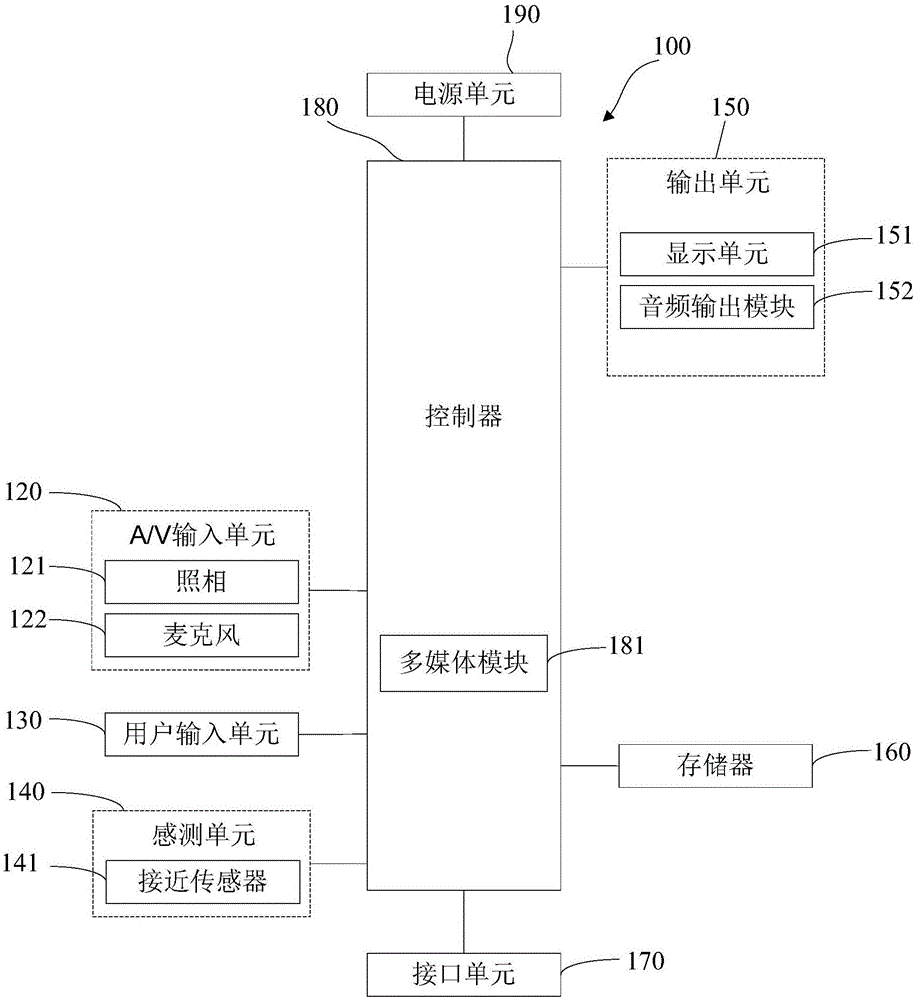

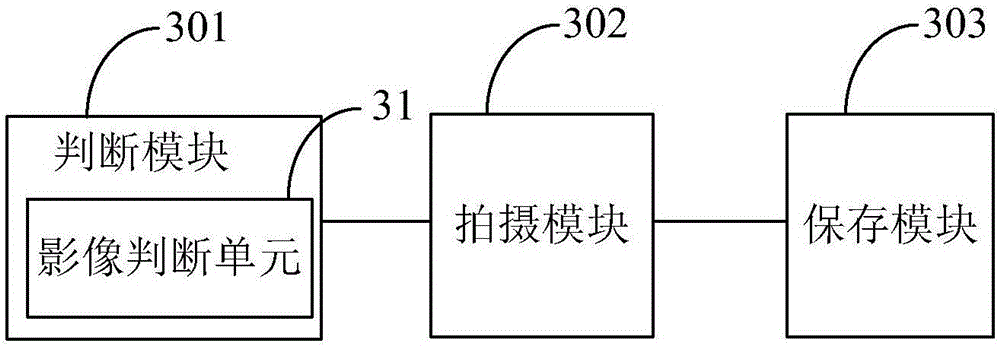

Photographing method and mobile terminal

ActiveCN106713656AImprove picture qualityImprove clarityTelevision system detailsColor television detailsComputer graphics (images)CLARITY

The present invention discloses a photographing method and a mobile terminal. The mobile terminal comprises a judgment module, a photographing module and a saving module; the judgment module is used for judging whether a photographing object is in a motion state; the photographing module is used for performing photographing by adopting at least two cameras when the photographing object is in the motion state; the periodic photographing operation of the cameras for image frames is not overlapped in the aspect of time; and the saving module is used for saving the image frames photographed by the at least two cameras according to a time sequence so as to obtain a video file. According to the photographing method and the mobile terminal of the invention, the state of the photographing object is judged, so that the working modes of the at least two cameras can be adjusted in real time, and therefore, the pursuit for high-quality images or videos in non-motion states can be satisfied, and the clarity of a video about a high-speed moving object can be improved; and the application conditions of terminals comprising at least two cameras can be enriched; and user experience can be enhanced.

Owner:NUBIA TECHNOLOGY CO LTD

Casting epoxy resin composition for part repair

The invention relates to a casting epoxy resin composition for part repair, aims at achieving the technical purpose that the requirements of rapid curing at room temperature and excellent properties can be met simultaneously, and belongs to technical field of high-molecular polymers. The composition is characterized in that a preparation method of the composition comprises the steps that 1, preheated bisphenol A type epoxy resin, toughening type epoxy resin and a diluent are added into a reaction kettle in sequence, the temperature inside a stirring tank is maintained to be 50-70 DEG C, a defoamer is added, stirring and defoaming are conducted simultaneously, and a resin mixture is obtained; 2, aliphatic amine is added into another reaction kettle, stirring is started, the temperature inside a tank is maintained to be about 25-40 DEG C, alicyclic amine and an amine type accelerator are added in sequence, mixing and stirring are conducted continuously for 15-30 min, and a curing agent mixture is obtained; 3, the resin mixture and the curing agent mixture are mixed to be uniform according to the ratio of 100:(15-17), and the epoxy resin composition for part repair is obtained. The comprehensive performance of the product is excellent, and the composition has low viscosity and rapid curing speed and can meet curing requirements in different temperature environments.

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

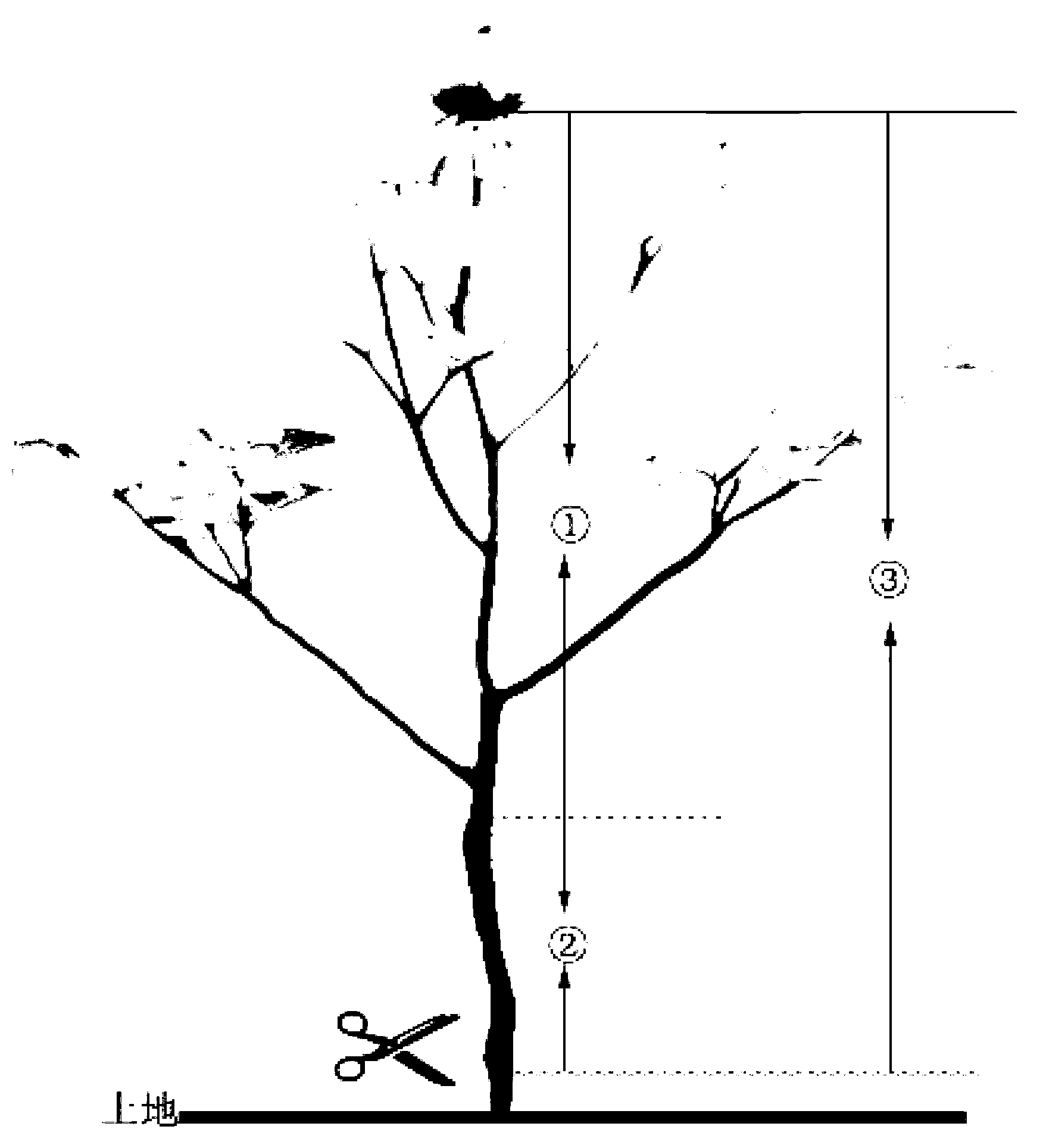

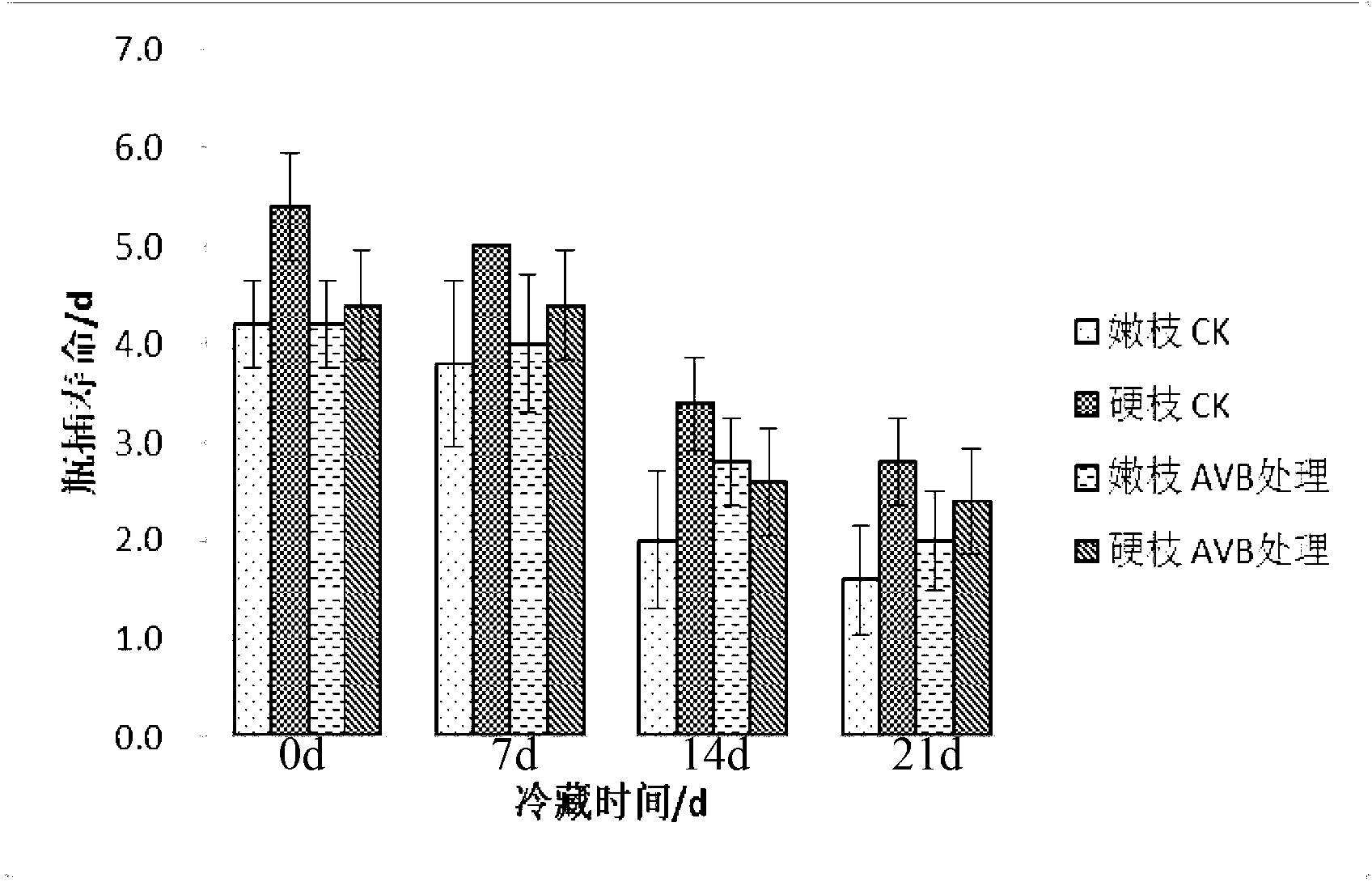

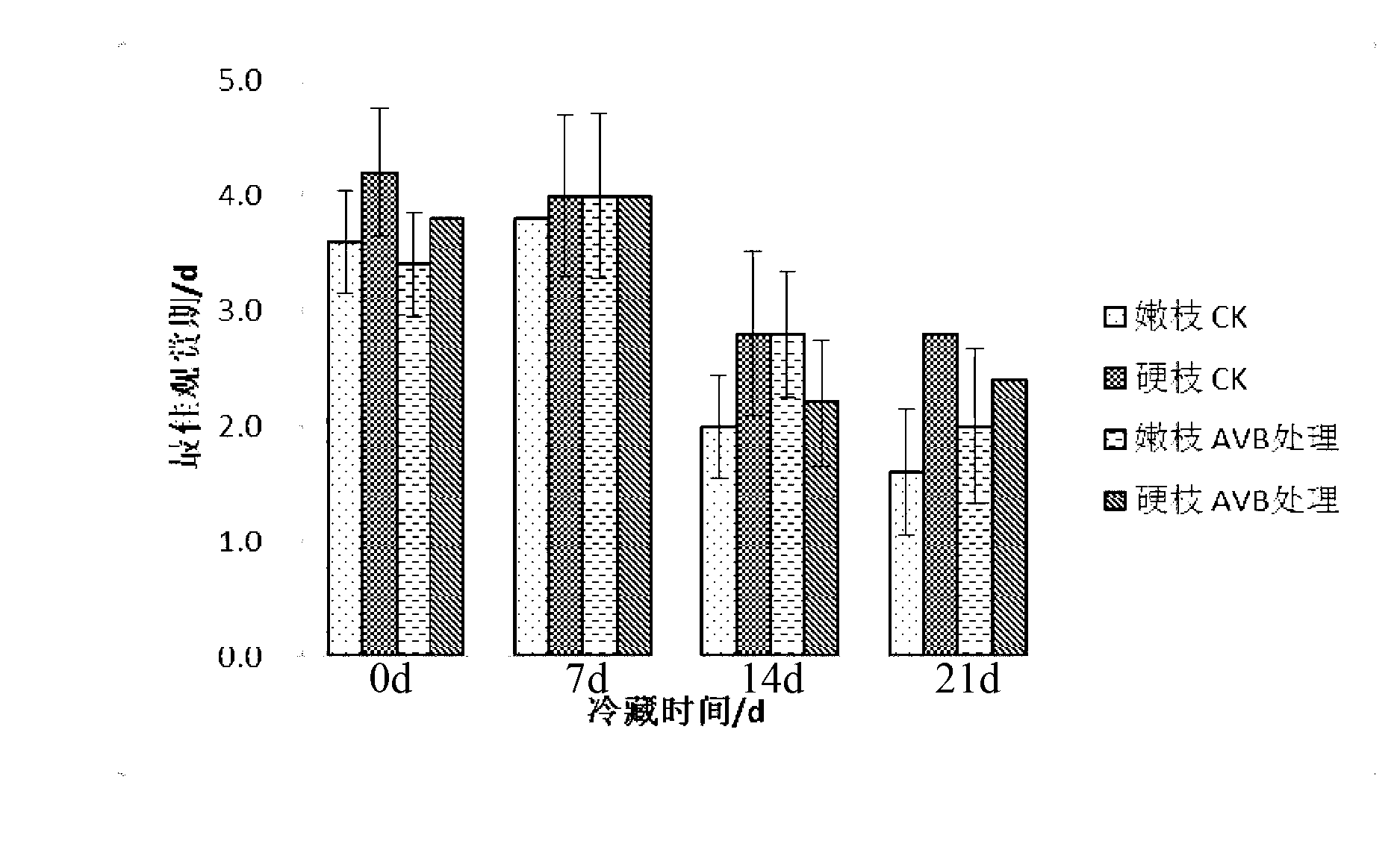

Peony stiff twig cut flower production method

InactiveCN103314742AIncrease the lengthOvercome shortcomingFloral handlingHorticulture methodsCut flowersTwig

The invention discloses a peony stiff twig cut flower production method which includes the steps of 1) peony plant preprocessing, 2) peony cut flower twig cultivating and picking and 3) repeating of step 2) each year. The step 1) includes conducting spring shearing or autumn shearing to achieve stumping and conducting hilling on the roots of plants subjected to stumping. The step 2) includes shearing other twigs from the root portions of cut flower twigs selected and retained in autumn shearing of the year or spring shearing of the next year and picking peony stiff twig cut flowers from the root portions in a flower period of the next year. By means of the method, a large amount of slips can be ensured to grow on peony plants in spring each year, the requirement for cut flower twig selection and cultivation can be met, the shortcoming of short twigs of peony is overcome, the requirements of flower markets for cut flower product quality and specification standard are met, and the peony cut flower twigs are improved qualitatively.

Owner:BEIJING FORESTRY UNIVERSITY

Tissue culture and rapid propagation method for dianthus caryophyllus L

InactiveCN104663461AReduce outputReduce qualityHorticulture methodsPlant tissue cultureCut flowersCarnation

The invention discloses a tissue culture and rapid propagation method for dianthus caryophyllus L. The dianthus caryophyllus L belongs to caryophyllaceae dianthus herbaceous perennial flowers, has the advantages of high productbility, good ornamental value, easiness in storage and transportation, and the like, and is one of main culture varieties of commercial cut-flowers cultured most widely in the present world. A large number of high-quality seedlings can be obtained by plant in-vitro culture, the propagation coefficient is greatly increased, viruses carried in a plant body are reduced, the stress resistance of the whole plant is improved, the limitations of environmental conditions of seasons are avoided, and the defects of conventional cutting propagation are made up through the breeding mode. A lateral bud of dianthus caryophyllus L is taken as an explant, and a dianthus caryophyllus L in-vitro replanting plant is successfully obtained by adventive bud induction culture, multiplication culture, rooting culture, acclimatization and transplantation, and the like, a dianthus caryophyllus L tissue culture and rapid propagation system is established, and the large-scale production of dianthus caryophyllus L tissue culture seedlings is promoted.

Owner:黎有辉

Knitting machine

ActiveCN103850048AThe surface is rich in fancyHas a sense of thicknessFlat warp knitting machinesYarnEngineering

The invention discloses a knitting machine which is used for knitting various types of textiles. The knitting machine comprises a machine frame, a needle bed, a warp yarn feeding device, a guide bar horizontally-moving mechanism, a dragging and winding mechanism and a transmission mechanism. The knitting machine further comprises a weft yarn feeding device which is arranged on the machine frame and used for providing weft yarn during a knitting process of the knitting machine, and a pattern weaving device which is arranged on the machine frame and used for weaving patterns of the textiles. According to the knitting machine, and through the arrangement of the weft yarn feeding device, looseness performance of the textiles is greatly reduced; and through the pattern weaving device, pattern types on the surfaces of the textiles are abundant, and meanwhile the textiles become thick and solid, whole quality is greatly improved, and different requirements on quality and appearance effect of consumers are fully met.

Owner:JIANGSU JINGMENG KNITTING

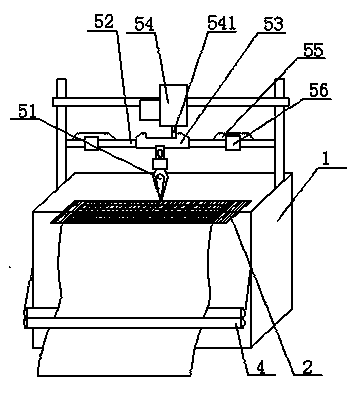

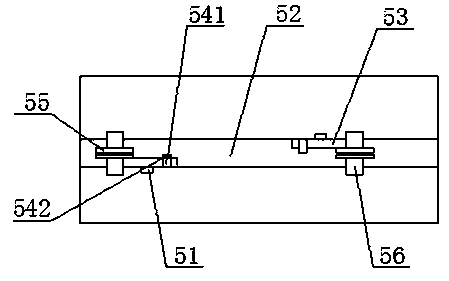

Double-sided gas-assisted device for pulse laser welding of metal sheets

InactiveCN106862761AAccelerate the cooling rate of high temperatureImproved surface oxidation qualityLaser beam welding apparatusSurface oxidationMetal sheet

The invention relates to a double-sided gas-assisted device for pulse laser welding of metal sheets. The double-sided gas-assisted device comprises a base. A cavity used for containing the at least two to-be-welded metal sheets in a flatly-lied manner is formed in the base. A pulse laser beam is arranged above the slicing seam of every two adjacent metal sheets. A through groove is formed below the slicing seam of every two adjacent metal sheets. A gas inlet insert is arranged on the portion, at one ends of the through grooves, of the base. An upper gas inlet hole facing the upper surfaces of the metal sheets and a lower gas inlet hole facing the lower surfaces of the metal sheets are formed in the gas inlet insert. The double-sided gas-assisted device is simple and reasonable in structural design, the problems that in the prior art, it is difficult to control the welding size precision of the metal sheets, surface oxidation is severe, the energy consumption is high, efficiency is low and safety is low are solved, and the defects in the prior art are overcome.

Owner:FUZHOU UNIV

Anionic nano wax emulsion as well as preparation method and application thereof

InactiveCN104330960AGood dispersionStable oil-in-water (O/W structure) uniform dispersionDevelopersEmulsionRoom temperature

The invention relates to a stable anionic nano wax emulsion as well as a preparation method and application thereof. The preparation process of the nano wax emulsion comprises the following steps: (1) heating wax and a surfactant until the temperature is greater than the melting point of the wax, and then stirring until the wax and the surfactant are uniformly mixed; (2) adding an aqueous solution of the surfactant into a system of the step (1), performing emulsification reaction, and continuously stirring after the reaction is ended until the system is cooled to room temperature so as to obtain the nano wax emulsion. The preparation process is safe, simple and environment-friendly; the prepared anionic nano wax emulsion can be stably stored; when the anionic nano wax emulsion is applied to a gathering and combining method, colored ink powder which is high in yield and can meet the requirement on high-quality laser printing or electrostatic copying (such as brightening and demolding) can be obtained.

Owner:INST OF CHEM CHINESE ACAD OF SCI

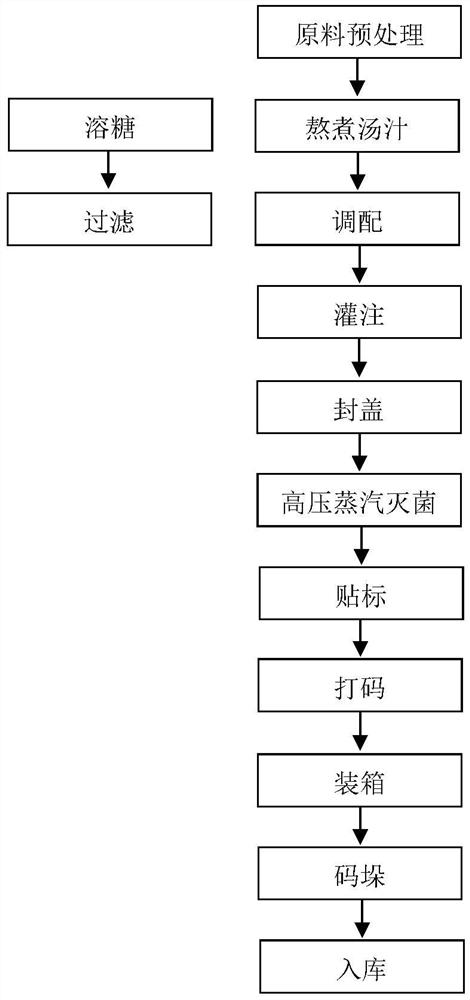

Tremella beverage and preparation method thereof

PendingCN114514968ARetain nutrientsKeep fresh tasteClimate change adaptationNatural extract food ingredientsBiotechnologyTremella

The invention belongs to an instant freeze-dried tremella thick soup beverage, and relates to the technical field of food processing, the instant freeze-dried tremella thick soup beverage comprises the following components: 400-800 parts of drinking water, 10-200 parts of tremella, 0-30 parts of red date, 0-20 parts of wolfberry, 0-30 parts of lotus seed, 0-15 parts of lily, 0-100 parts of rock sugar, 0-80 parts of xylitol, and 0-1.0 part of cubilose. The preparation method comprises the following steps: pretreating the raw materials, boiling, dissolving sugar, blending, sub-packaging, quickly freezing and freeze-drying. According to the invention, the high-pressure steam sterilization treatment is adopted in the tremella beverage food for the first time, so that the boiling time of the raw materials such as the tremella is shortened in the processing process of the tremella beverage, and the nutritional ingredients and fresh taste in the tremella are well reserved. Besides, the tremella beverage disclosed by the invention meets the increasing requirements of people on product quality and taste, forms a deeply processed product with relatively strong export foreign exchange earning, provides a new thought for a sterilization technology of tremella beverage products, and improves the deep processing level of agricultural products in China.

Owner:四川工大西南食品研究有限责任公司

Preparation method of high-nitrogen-content nitrified bamboo cellulose

The invention relates to a preparation method of high-nitrogen-content nitrified bamboo cellulose, and belongs to the field of nitrocellulose preparation. The method comprises the following steps: half-immersing a pressure-resistant three-opening device filled with nitric acid in a high-precision low-temperature constant-temperature tank, adding acetic anhydride into the nitric acid, stirring, adding a nitrification aid after complete dissolution, heating, and keeping the temperature to obtain a solution A; adding bamboo cellulose into the solution A, stirring for 20-40 minutes, sealing the reaction device, heating to 40-60 DEG C, keeping the temperature for 4-6 hours, filtering, and washing and drying filter residues to obtain a nitrified bamboo cellulose crude product; dissolving the crude product in water, and adding dilute sulfuric acid and a solution B; and filtering and drying to obtain the high-nitrogen-content nitrified bamboo cellulose. The preparation method disclosed by theinvention is simple in process, easily available in raw materials, low in waste acid discharge amount in the production process and suitable for factory operation; and the prepared product has high nitrogen content and meets the process parameter requirements of high-quality smokeless and sulfur-free pyrotechnic composition, propellant and explosive.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for industrially producing manganese-copper alloy

The invention discloses a method for industrially producing manganese-copper alloy. The method comprises the following steps that raw materials, comprising, by weight, 0-100 parts of copper oxide, 0-100 parts of 100-mesh manganese oxide, 0.3-0.7 part of zinc chloride, 0.3-0.7 part of ferrous sulfate and a sulfo chalcophile agent, 0.5-1.5 parts of oxyphile agents and 1.5-2.5 parts of binding agentsare uniformly mixed with water, wherein the total amount of the copper oxide and the manganese oxide is 100 parts, and the coefficient of the zinc chloride with carbon is 0.70-0.80; and 2, the mixture is pressed and uniformly mixed into a material block, and the material block is dried, calcined and cooled under the protection of nitrogen to obtain the product. The product prepared by the methodcan obviously improve the manganese and copper recovery rate when the copper alloy product is applied to iron and steel, and meanwhile, the raw material cost of the manganese-copper alloy in steel production is reduced, and the method has good economic and social benefits.

Owner:田长对

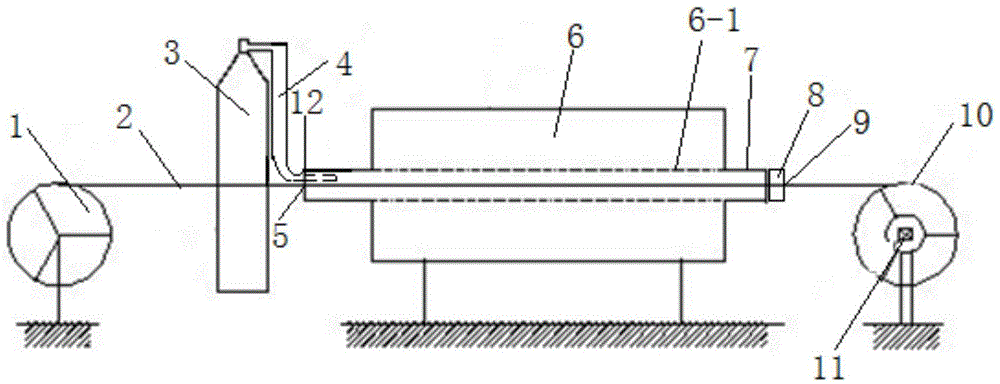

Titanium alloy irregular wire material straightening device and straightening method thereof

The invention discloses a titanium alloy irregular wire material straightening device and a straightening method thereof. The straightening device comprises a tube-type heating furnace which is placed horizontally, wherein a wire conveying pipe with one closed end is nested in a center hole of the tube-type heating furnace; the two ends of the wire conveying pipe respectively extend out of hole openings of the two ends of the center hole; a circular hole a is formed in the end face of the closed end of the wire conveying pipe; a pipe cover is mounted at an open end of the wire conveying pipe; a circular hole b is formed in the end face of the pipe cover; one end of a titanium alloy irregular wire material is connected to an unwinding wheel; the other end of the titanium alloy irregular wire material sequentially penetrates through the circular hole a and the circular hole b and then is connected to a winding wheel driven by a motor; a circular hole c is formed in the wire conveying pipe; an inert gas tank is communicated with the circular hole c through a gas transmission hose; the circular hole a and the circular hole b are coaxial, and the hole diameter of the circular hole a and the hole diameter of the circular hole b are the same and are 1 to 2 times the cross section size of the titanium alloy irregular wire material. According to the titanium alloy irregular wire material straightening device and the straightening method thereof, the problem that the existing straightening methods cannot be used for straightening materials of irregular cross sections is solved, and the requirements of titanium alloy irregular wire material straightening on surface quality and mass production are met.

Owner:西安赛特思迈钛业有限公司

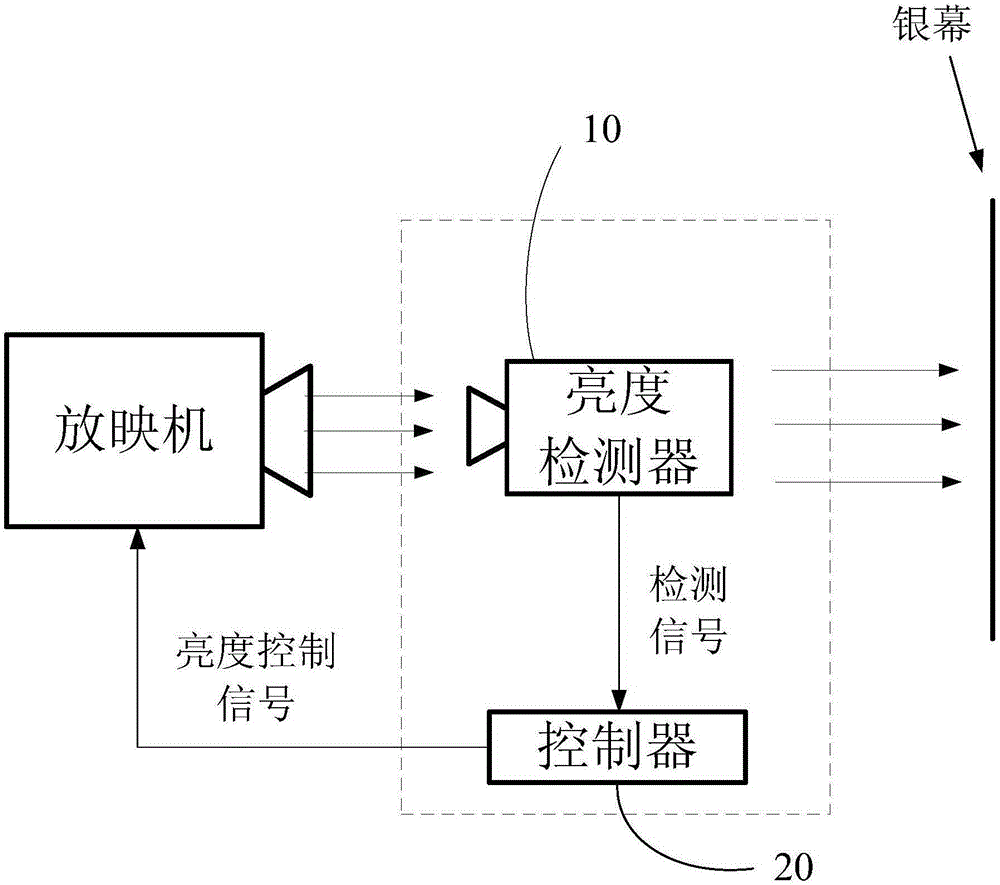

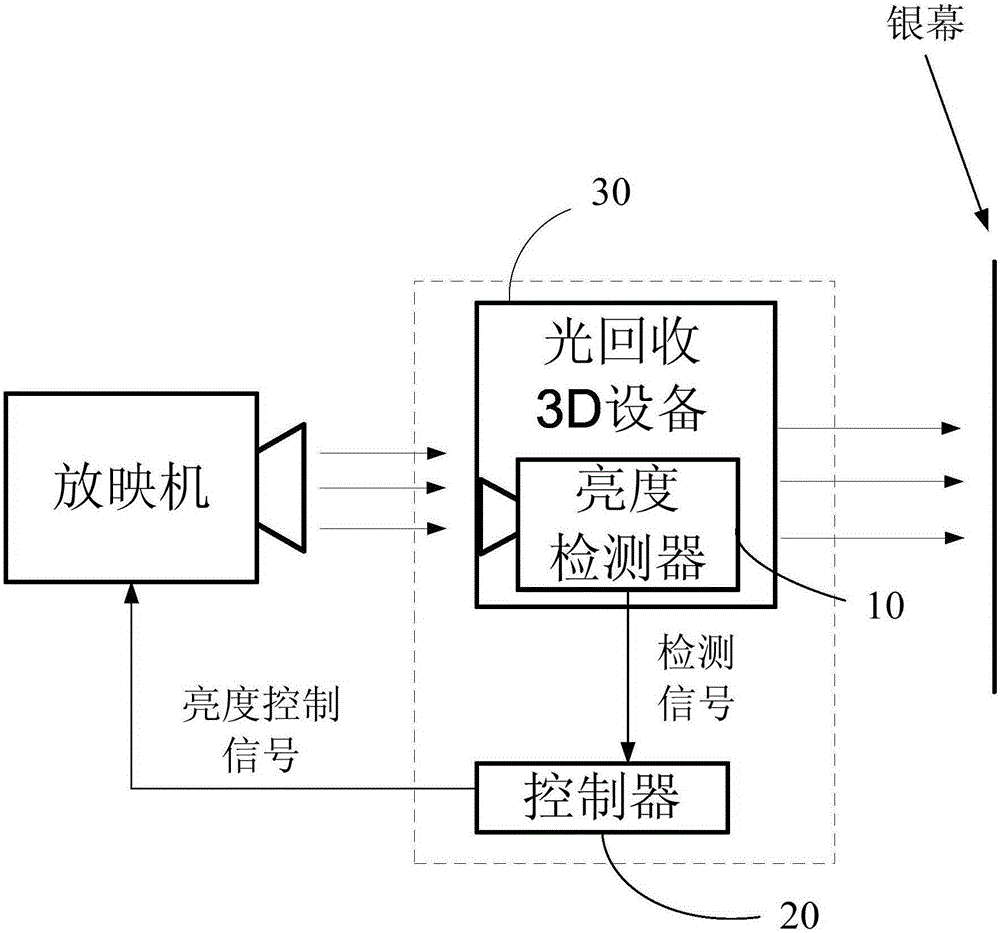

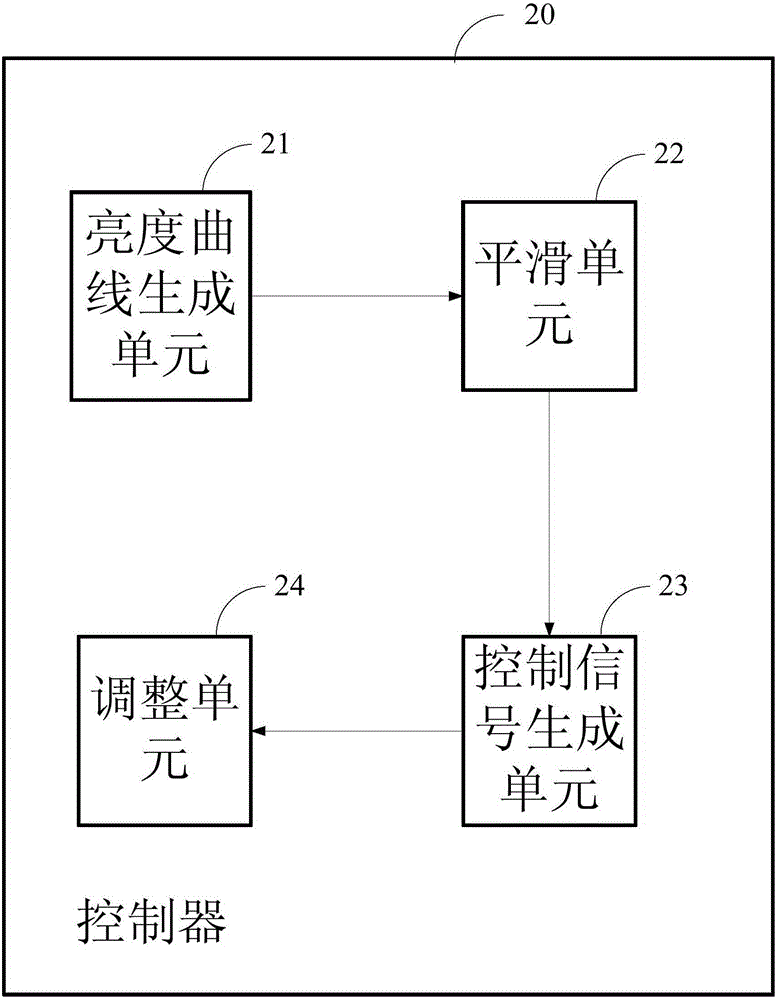

Brightness automatic equalization device and method used in light recovery 3D projection system

ActiveCN105223763AImprove experienceMeet the qualityProjectorsOptical elementsElectricityProjection screen

The invention provides a brightness automatic equalization device and method used in a light recovery 3D projection system. The brightness automatic equalization device includes: a brightness detector arranged between a projector and a projection screen and used for detecting brightness between the projector and the projection screen and generating a detection signal; and a controller electrically connected with the brightness detector and used for adjusting output brightness of the projector according to the detection signal. The brightness automatic equalization device used in the light recovery 3D projection system can prevent the output brightness of the projector from large fluctuation, thereby satisfying the specified projection quality.

Owner:雷欧尼斯(北京)信息技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com